Patents

Literature

2458results about How to "Small pressure drop" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

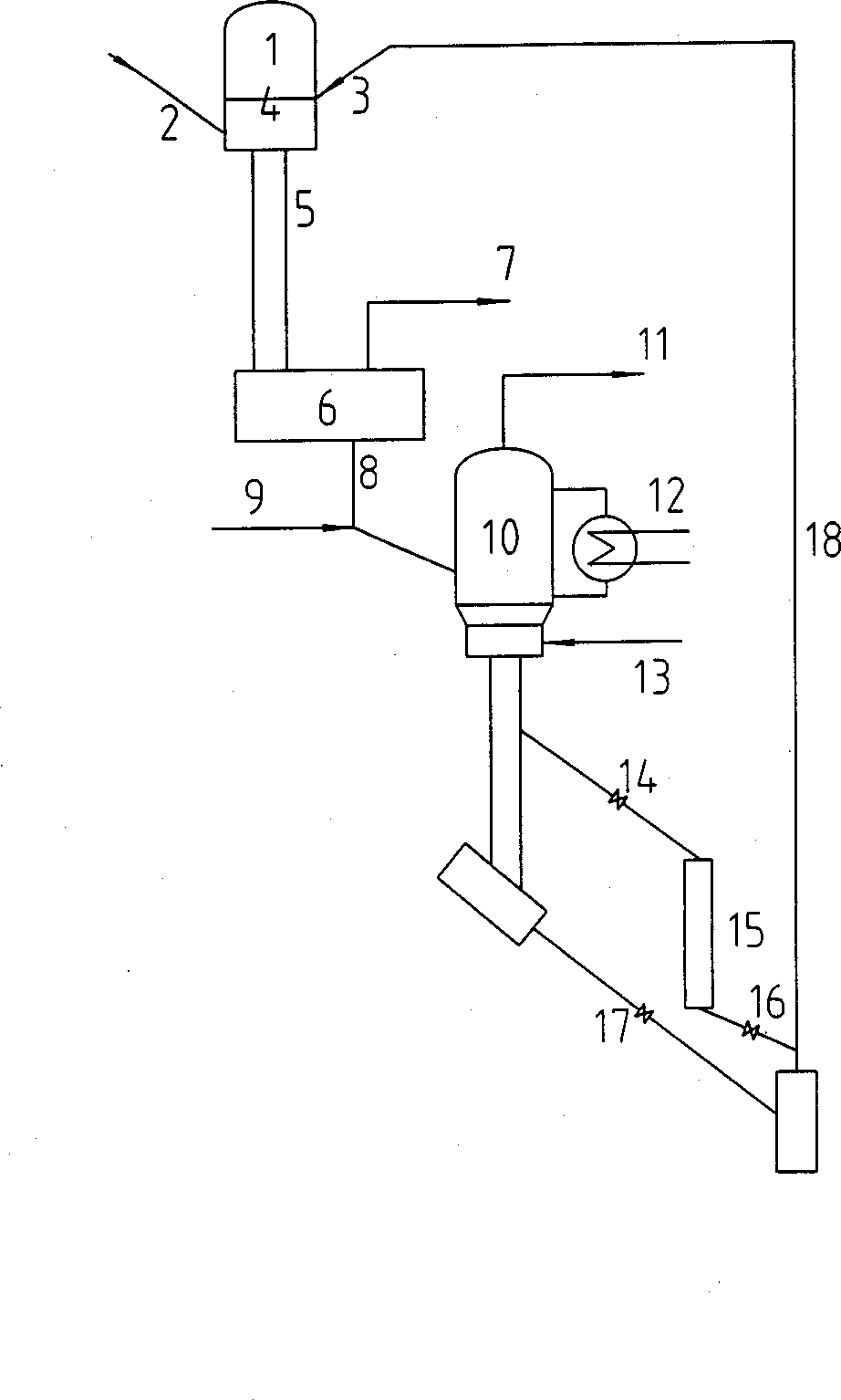

Process and system for preparing low-carbon olefin from methanol or dimethylether

InactiveCN1356299AReduce wearReduce aggregationHydrocarbon from oxygen organic compoundsChemical recyclingAlkaneGas solid

A process for preparing low-carbon olefin from methanol or dimethyl ether includes loading its raw material and silicon aluminium phosphate (SAPO34) molecular sieve as catalyst into gas-solid parallel down-flowing fluidized bed reactor, super-short contact, reaction, fast gas-solid separation to separating resultant from catalyst to prevent secondary reaction, and regerating catalyst for cyclic use. Its advantages include high output rate (93%), high conversion rate of raw material, and less by-product.

Owner:TSINGHUA UNIV

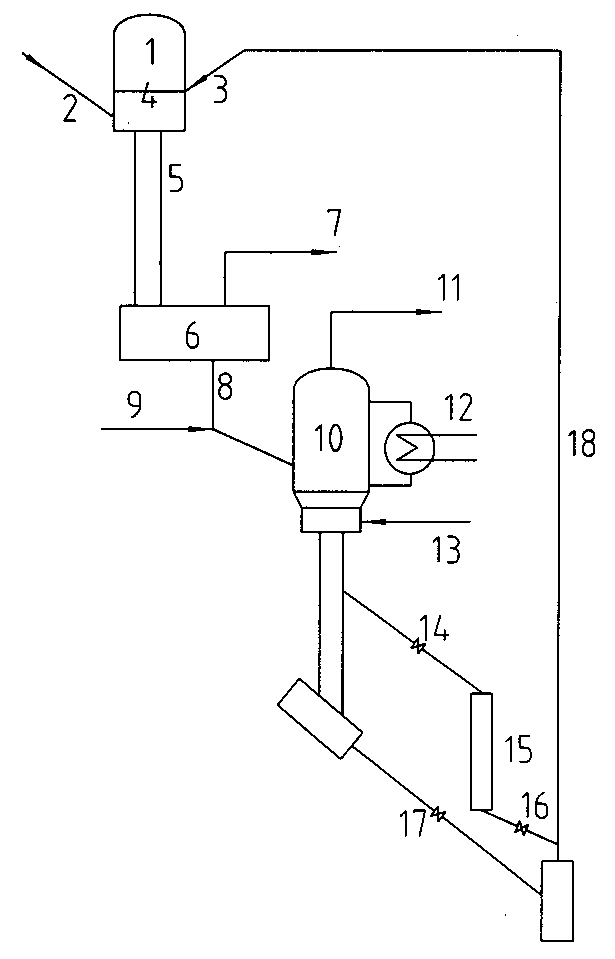

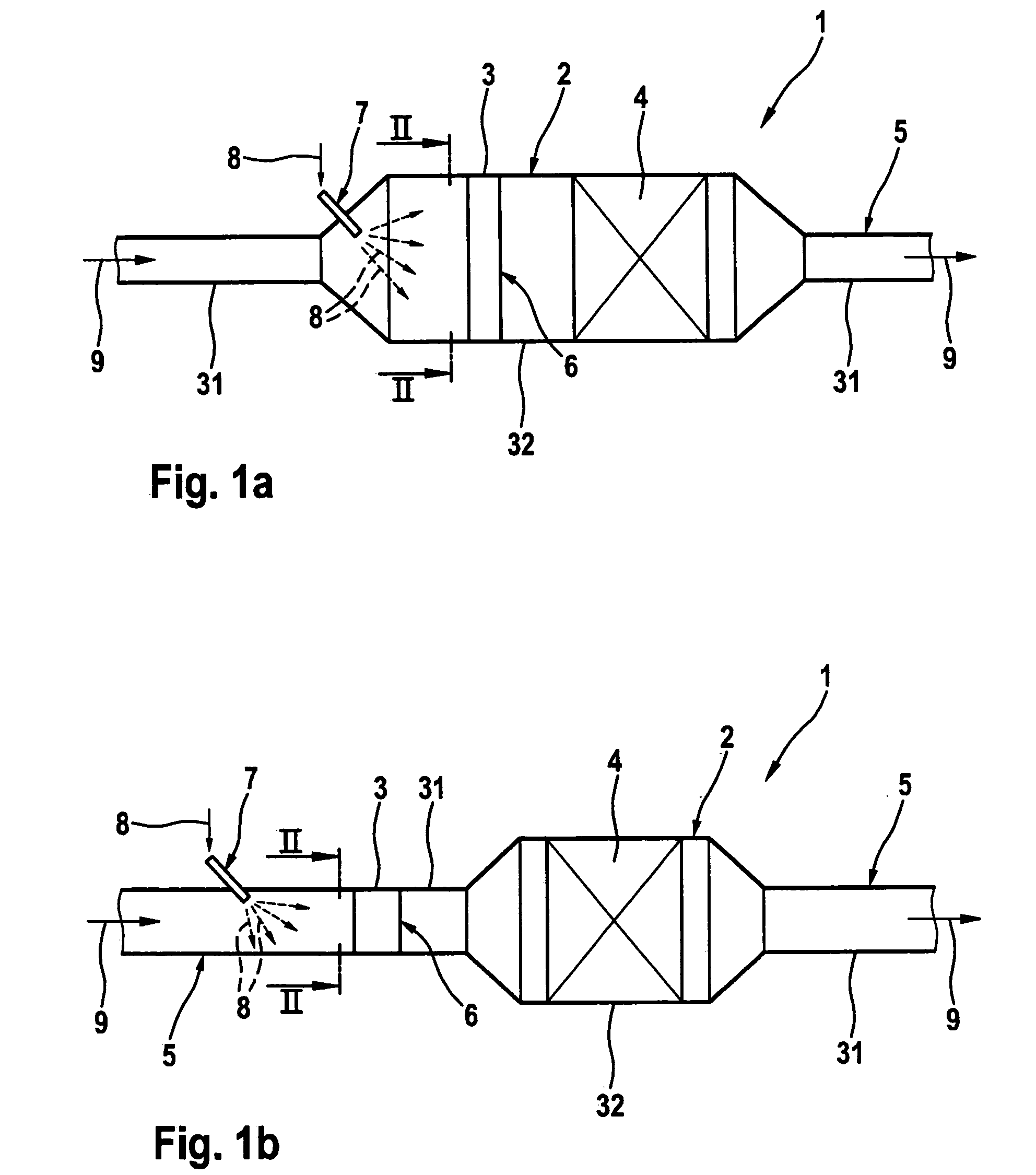

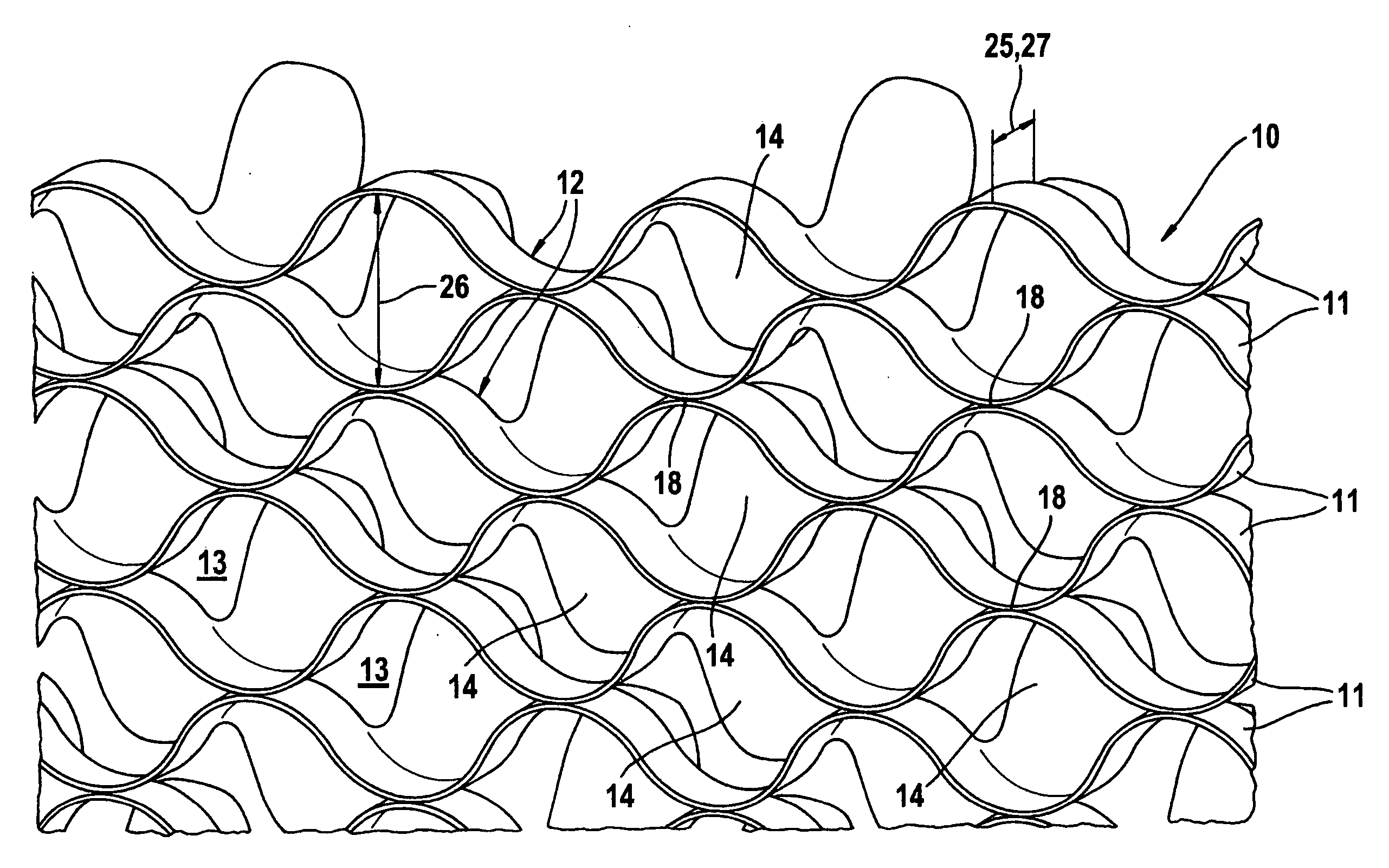

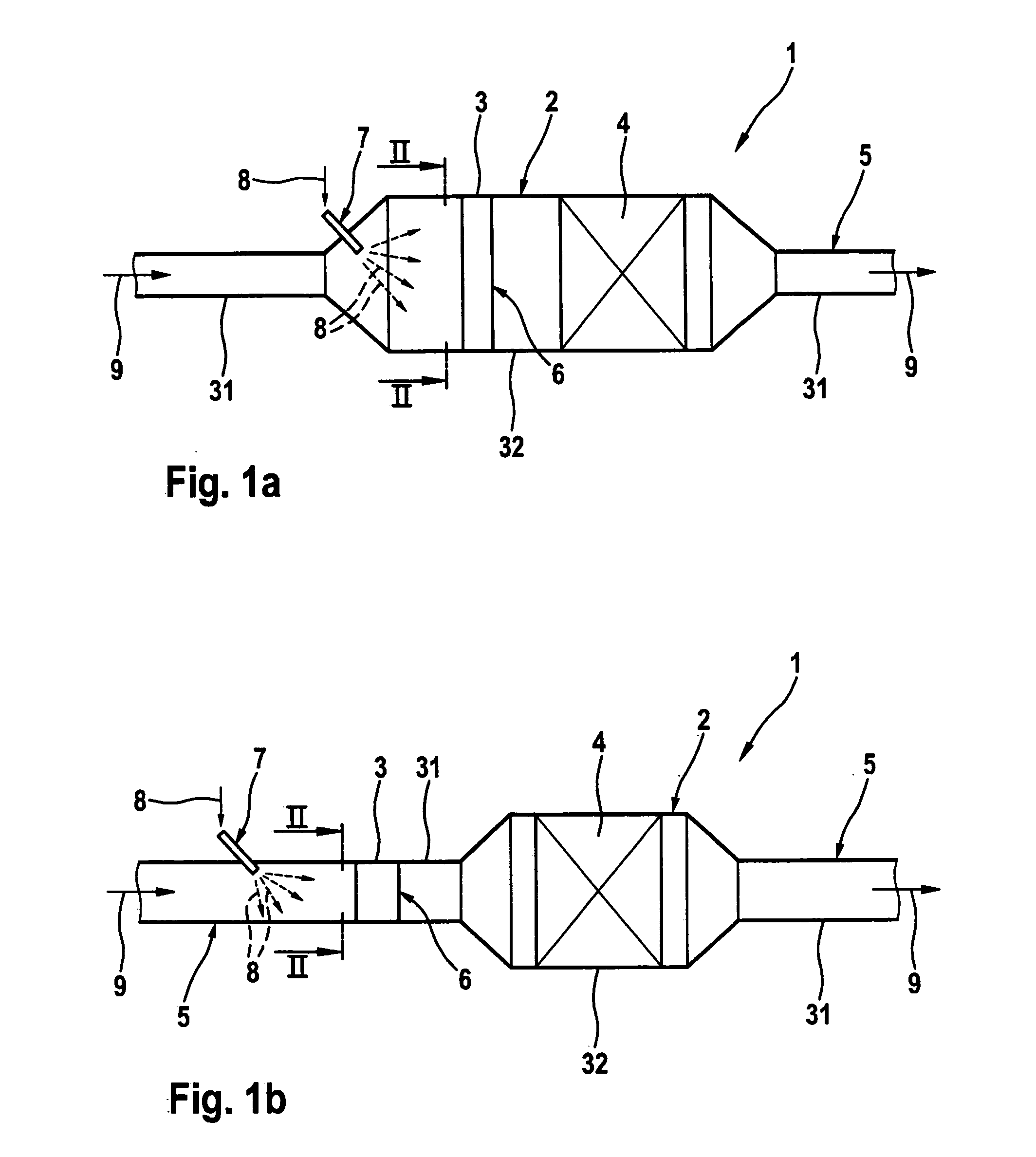

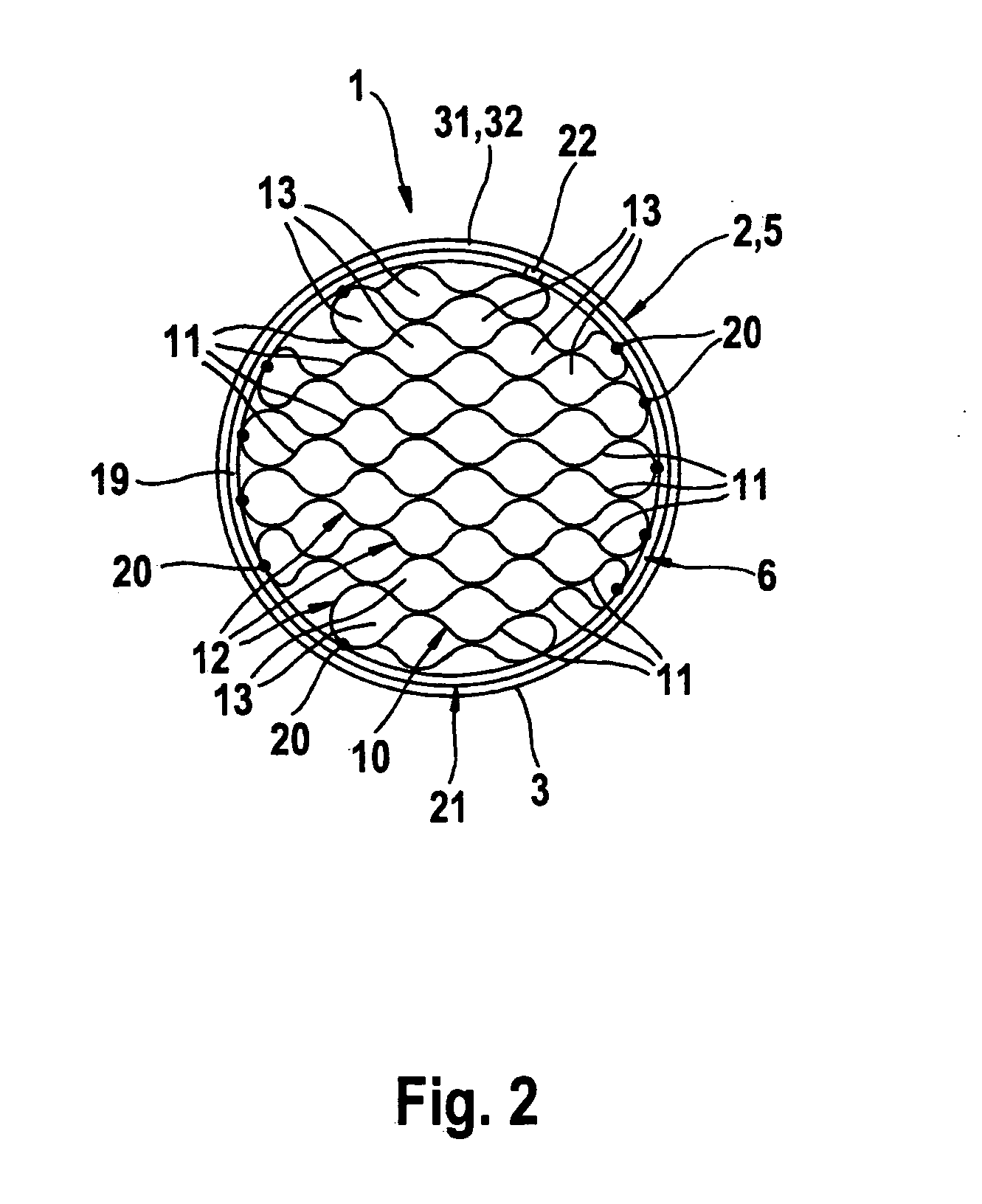

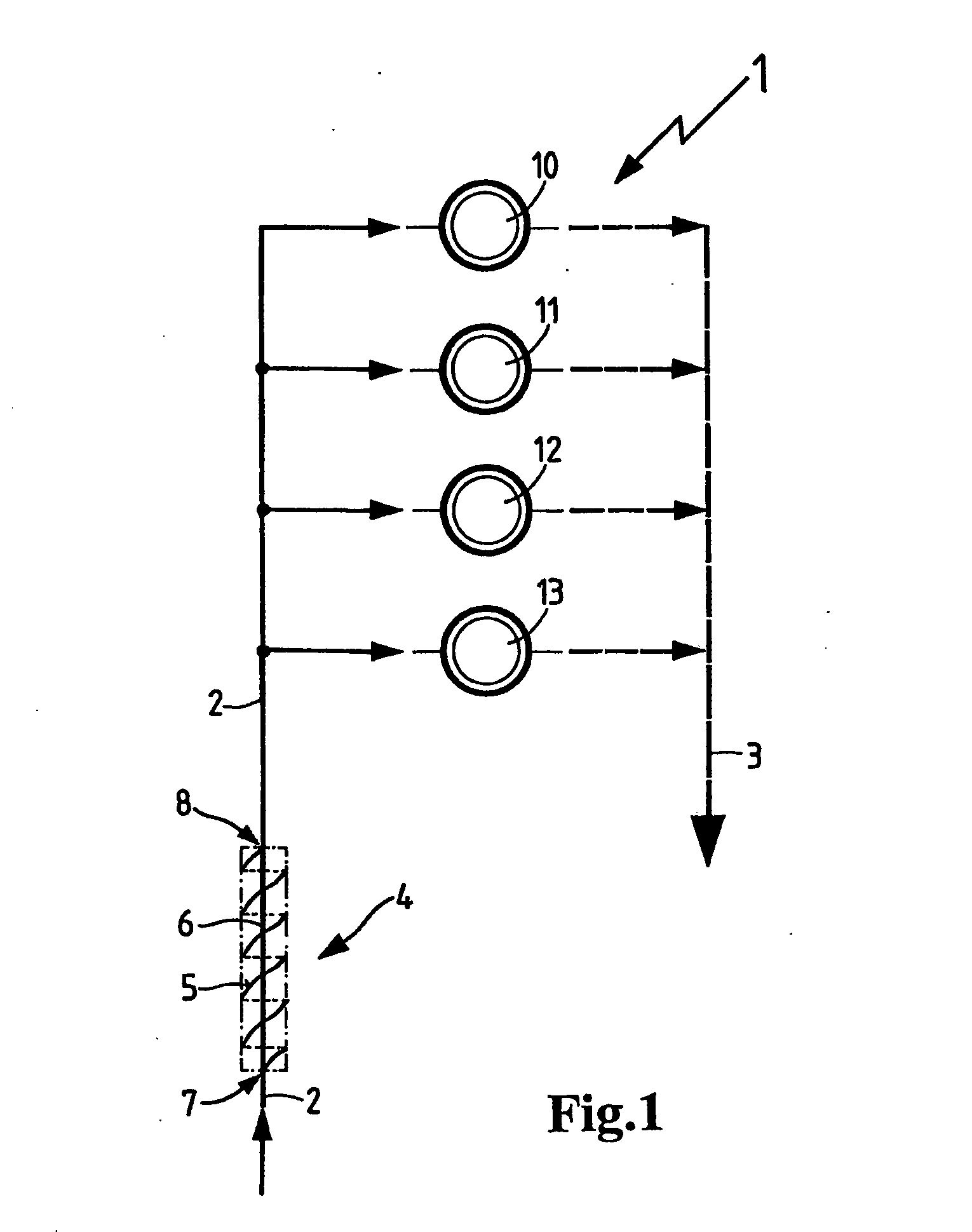

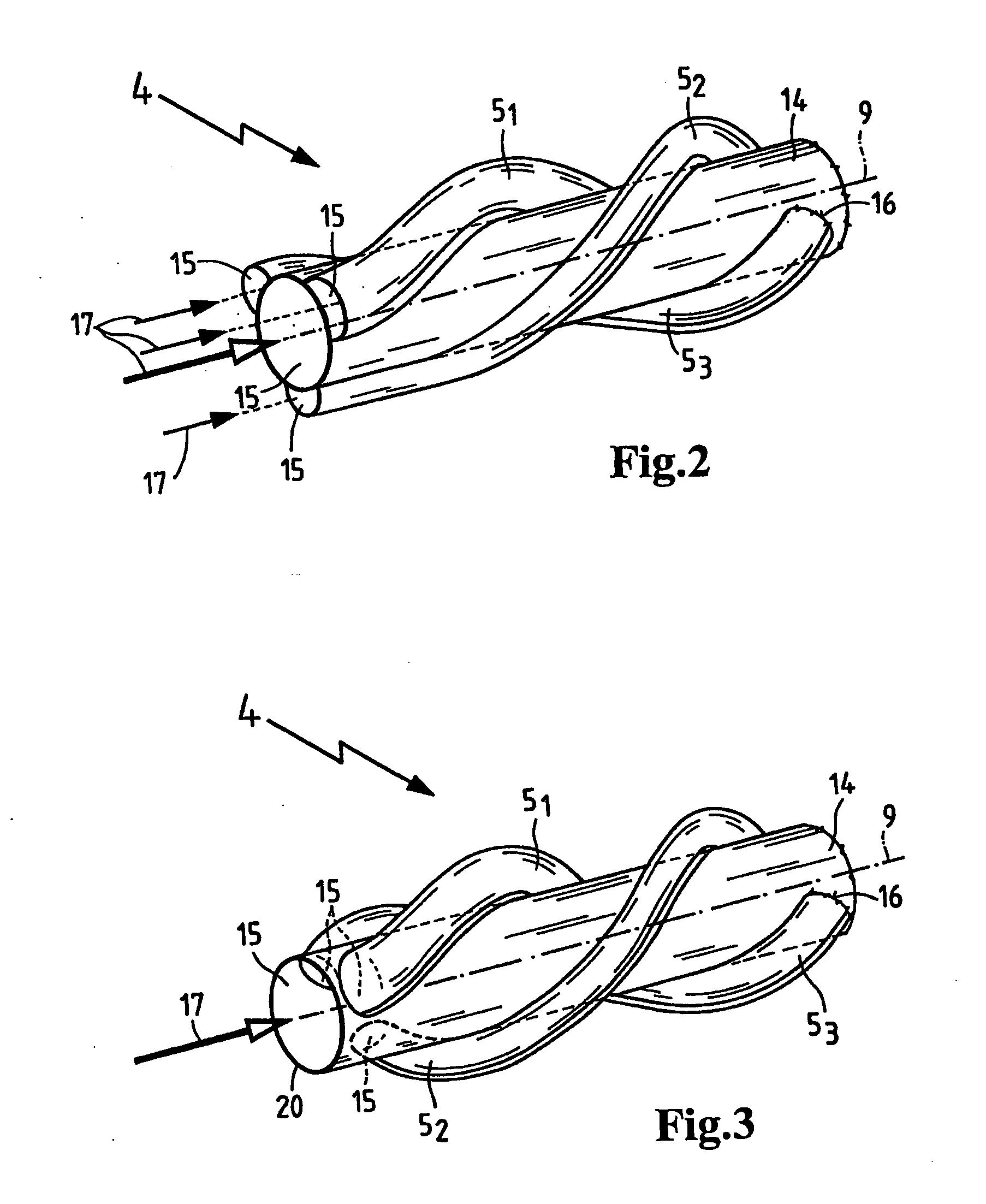

Static mixer and exhaust gas treatment device

InactiveUS7793494B2Design economyIntense mixing effect and vaporization effectInternal combustion piston enginesFlow mixersExhaust fumesEngineering

The invention relates to a static mixer for an exhaust system of an internal combustion engine. The mixer has a wall structure that is arranged across the directional of flow in a pipe and has several layers of a corrugated sheeting material laying across one another in the direction of flow. The cells through which the flow can pass in the direction of flow are provided between the sheeting material of neighboring layers. The sheeting material has baffles for all or several of the cells. The baffles are arranged on the sheeting material so that they are arranged on their outgoing flow side in the case of said cells and extend in the direction of flow and across it.

Owner:EBERSPACHER EXHAUST TECH GMBH & CO KG

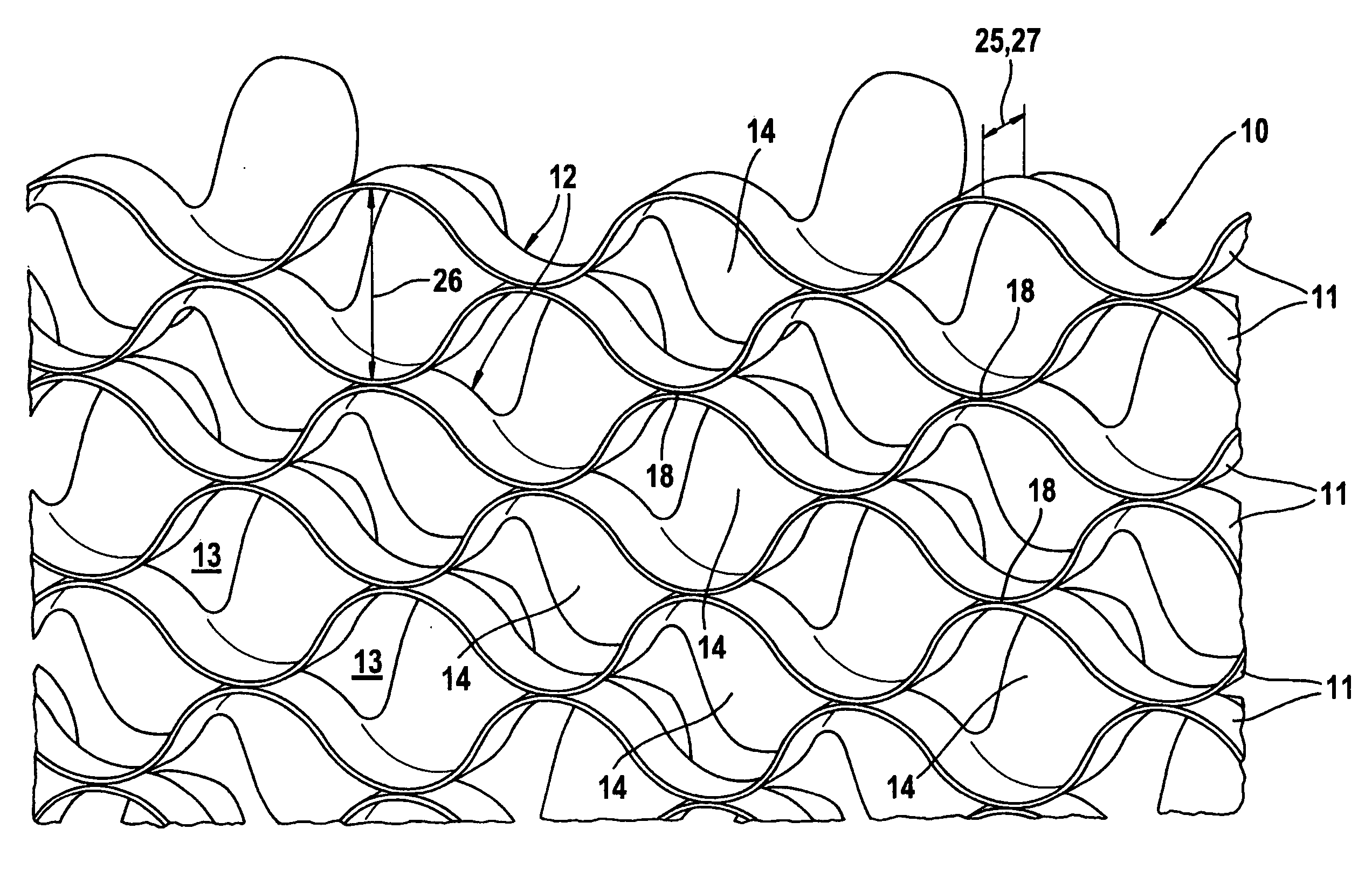

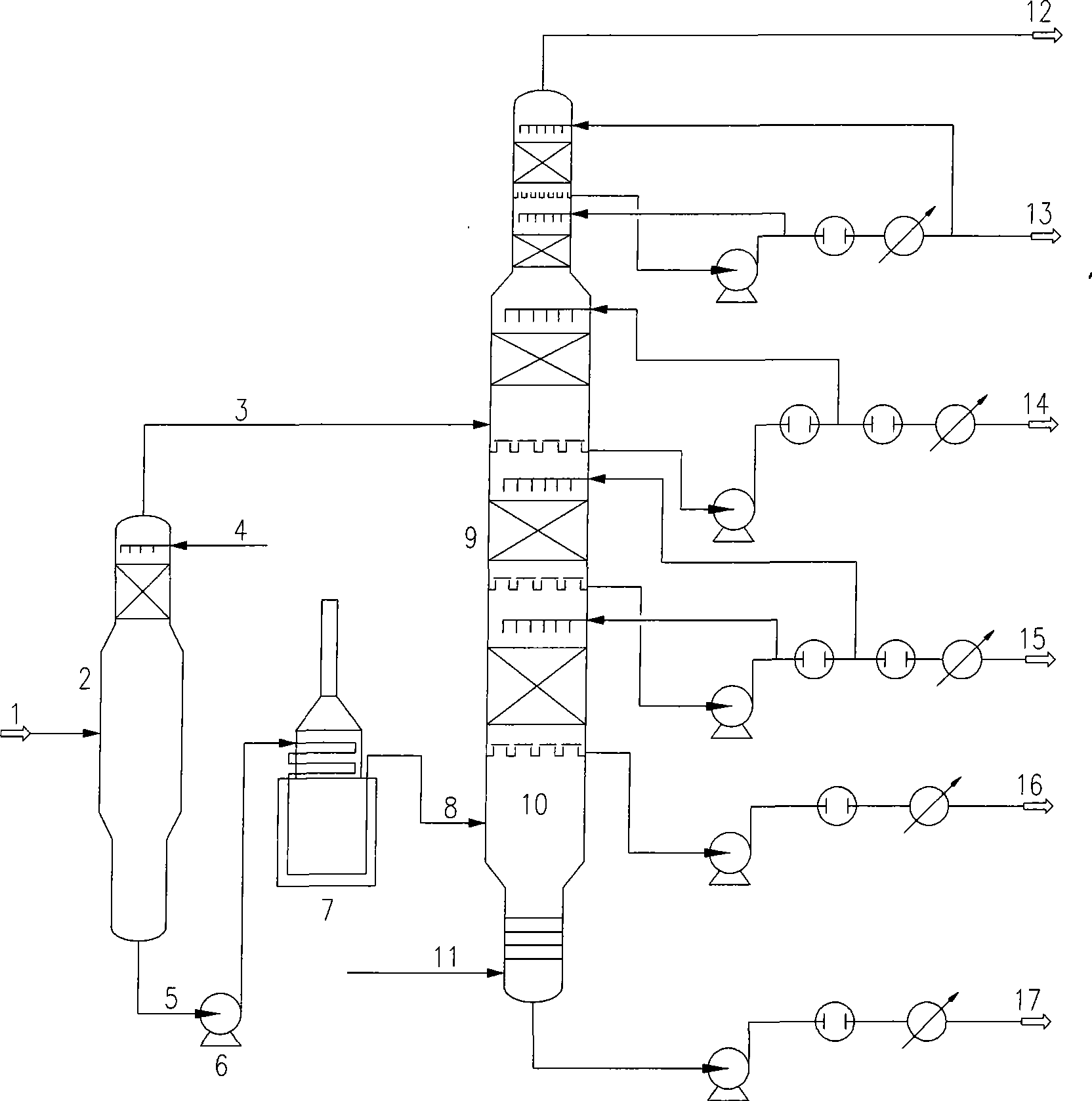

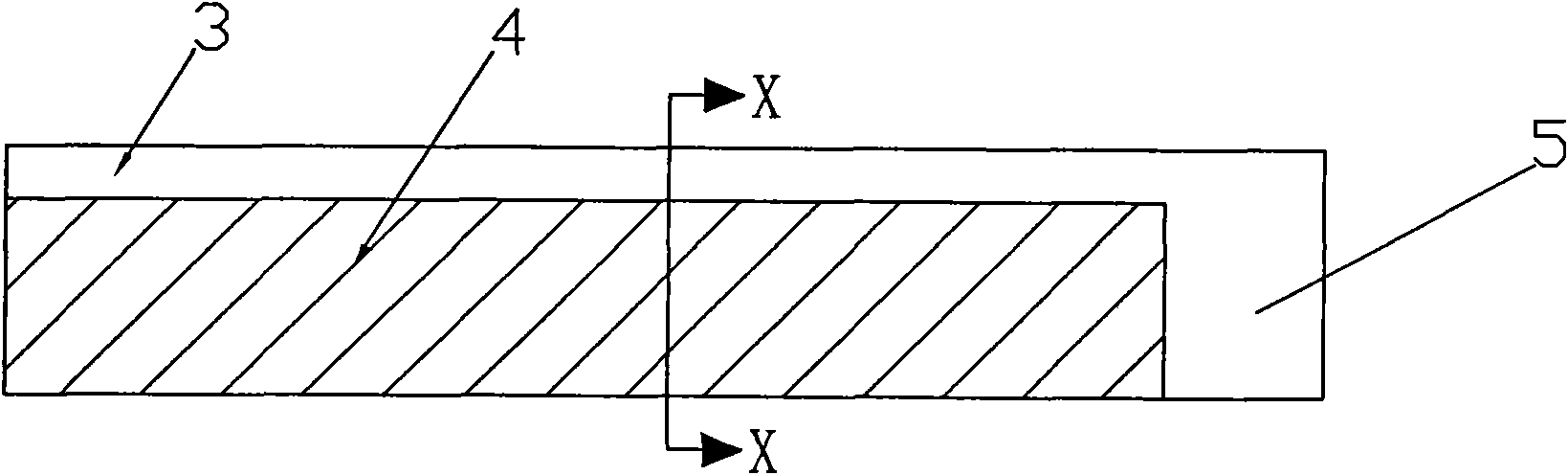

Atmospheric vacuum distillation method and apparatus with vacuum flash vaporizer

InactiveCN101376068AReduce the amount of feedEasy to handleVacuum distillation separationVacuum distillationVaporizationPulp and paper industry

The invention relates to an atmospheric and vacuum distillation device with a vacuum flash tower and a method thereof. The atmospheric and vacuum distillation device with a vacuum flash tower is characterized in that the vacuum flash tower arranged in front of a vacuum furnace is connected with the vacuum furnace and a vacuum tower through a pump and a pipeline. Constant bottom oil (1) is introduced into the vacuum flash tower (2)at first, and the operation pressure at the top part of the vacuum flash tower is higher than the operation pressure at the top part of the vacuum tower (9) by10 to 200mmHg; Flash cap gas (3) is introduced into the upper part or the lower part of an outlet for a side product which is similar to Flash cap gas fraction; flash bottom oil (5) is introduced into the vacuum furnace (7) through a flash bottom oil pump (6); when the flash bottom oil is heated to 350 to 430 degrees, air-liquid mixing vacuum tower feed material is obtained through partial vaporization and is introduced into a flash evaporation segment (10) of the vacuum tower through a transfer line (8); and products with different fractions are drawn from the side of the vacuum tower and vacuum residue is drawn from the bottom of the vacuum tower. Through adding the vacuum flash tower to improve the working process of the atmospheric and vacuum distillation device, the invention achieves the advantages of increasing treatment capacity, increasing vacuum distillation yield, and reducing energy consumption.

Owner:TIANJIN UNIV +2

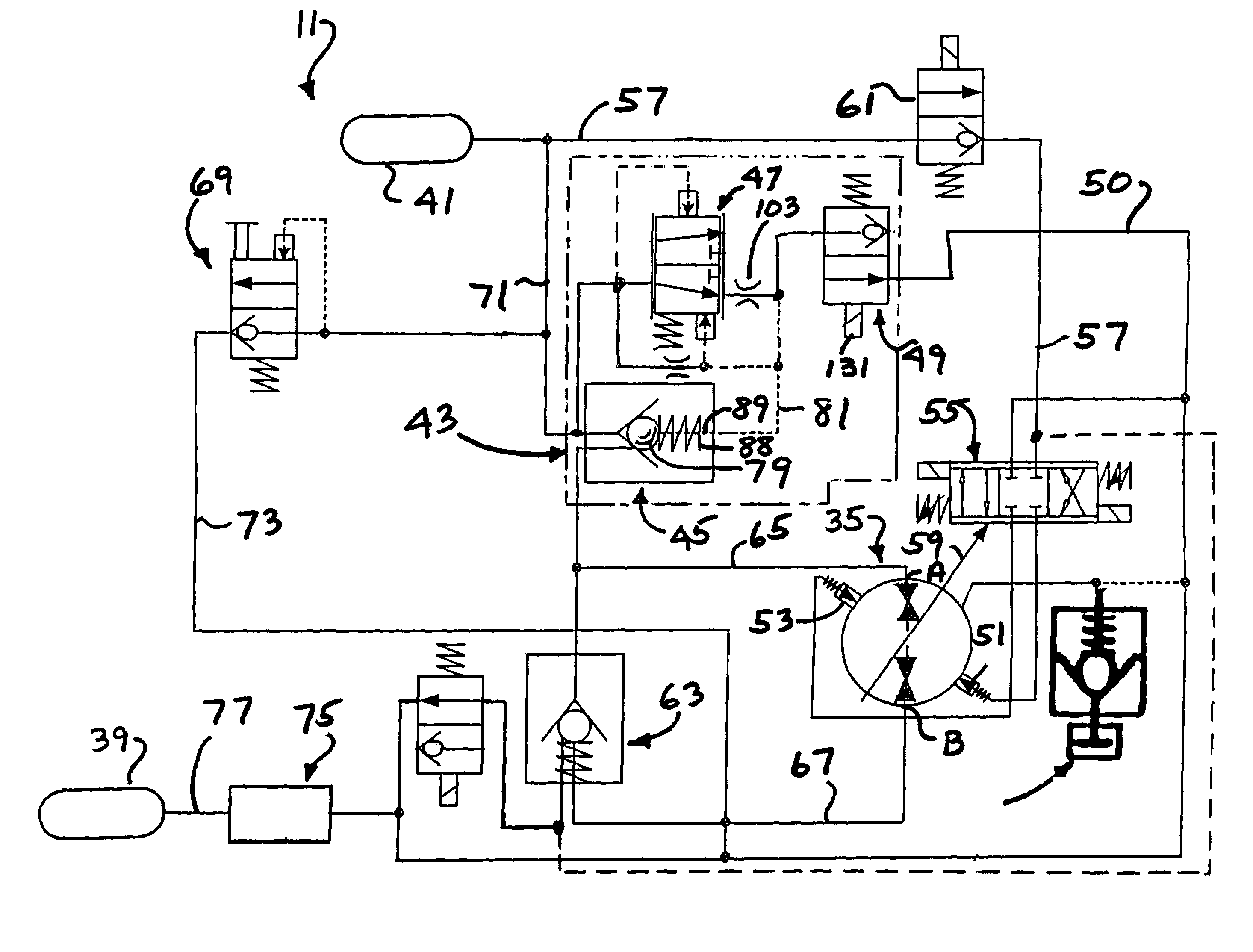

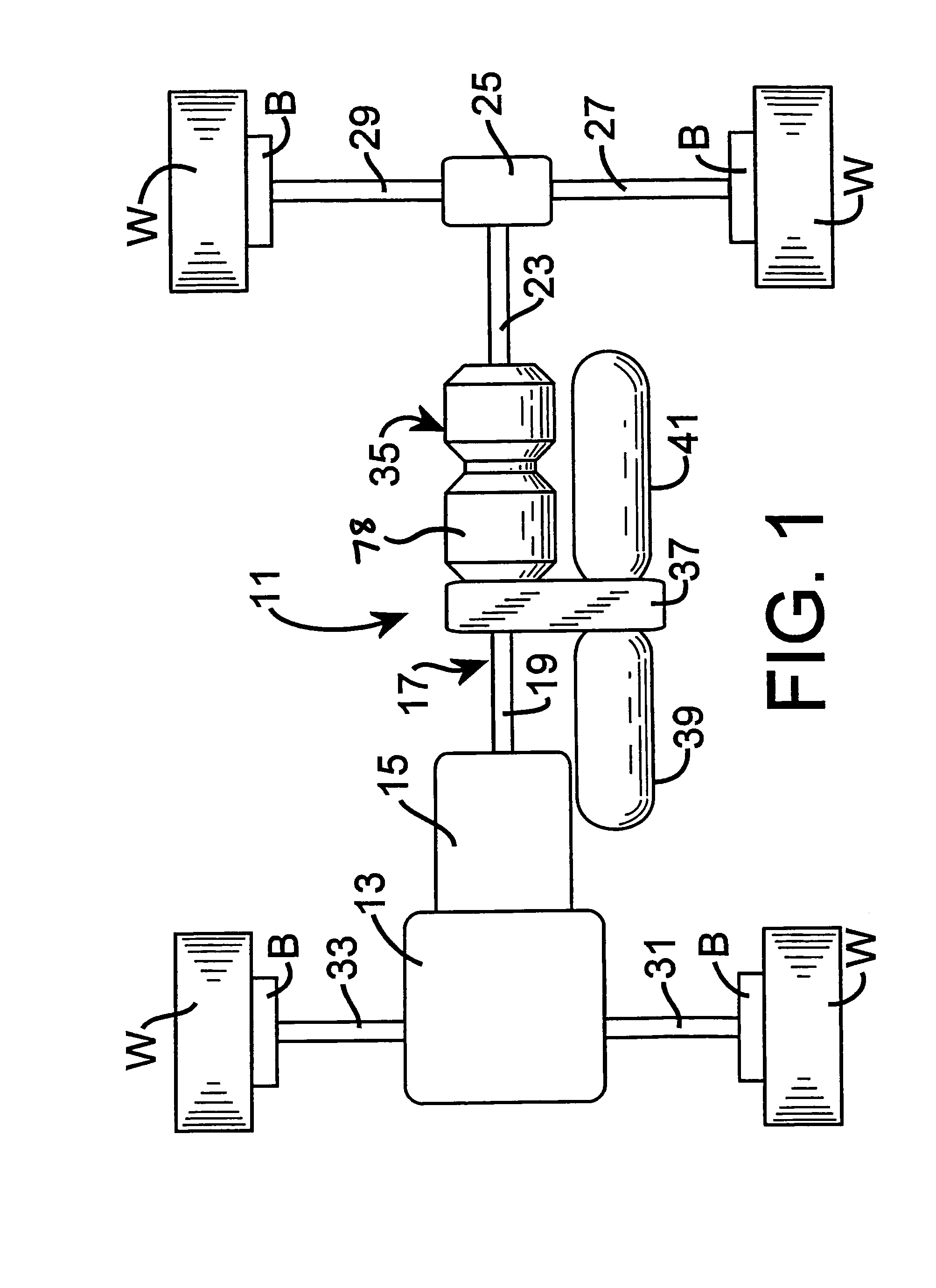

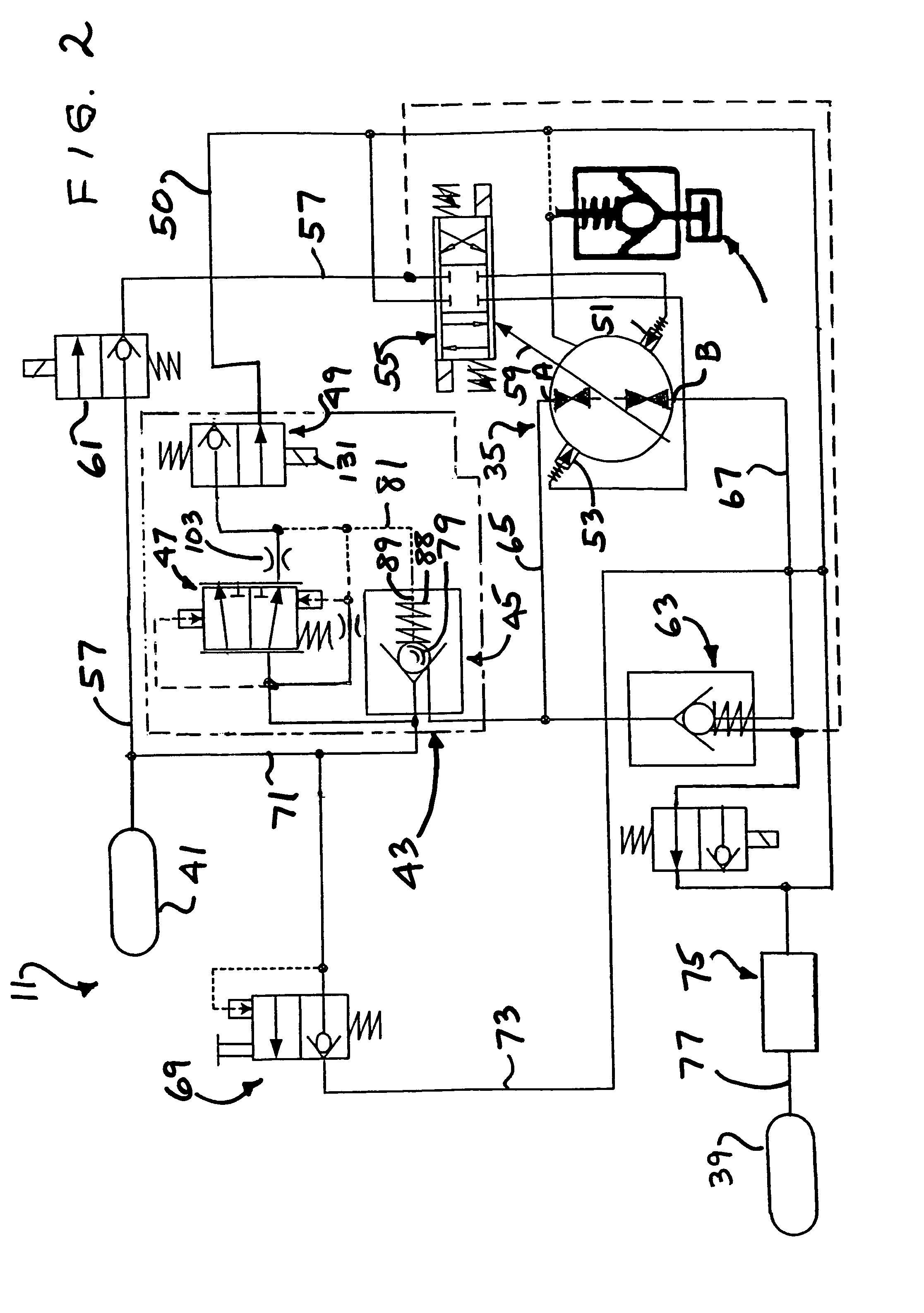

Hydraulic drive system and improved control valve assembly therefor

InactiveUS6971232B2Fast response timeSmall pressure dropBraking element arrangementsServomotor componentsEngineeringHigh pressure

A control valve assembly (43) for use in a system in which a pump-motor unit (35) can either receive drive torque from a drive-line (17) or transmit torque thereto. The system includes a high pressure accumulator (41) and the control valve assembly is disposed between the pump-motor unit and the accumulator, and includes a mode valve (45) normally biased closed by pressure in a control cavity (89), the fluid pressure in which is controlled by a pilot valve assembly (49) in response to an electrical signal (133). A step-orifice valve (47) associated with the mode valve poppet member (79) provides a relatively larger orifice (115) into the control cavity (89) when pressure therein is high, and a relatively smaller orifice (119) into the control cavity when pressure therein is low, i.e., when the pilot valve assembly (49) is open. Thus, a large volume of flow can occur from the accumulator to the unit (35) in a motoring mode, with a relatively low pressure drop, while the poppet member is able to have softer, relatively longer opening time, but a relatively faster closing time.

Owner:EATON CORP

Static mixer and exhaust gas treatment device

InactiveUS20070204751A1Design economyIntense mixing effect and vaporization effectInternal combustion piston enginesFlow mixersExhaust fumesEngineering

The invention relates to a static mixer for an exhaust system of an internal combustion engine. The mixer has a wall structure that is arranged across the directional of flow in a pipe and has several layers of a corrugated sheeting material laying across one another in the direction of flow. The cells through which the flow can pass in the direction of flow are provided between the sheeting material of neighboring layers. The sheeting material has baffles for all or several of the cells. The baffles are arranged on the sheeting material so that they are arranged on their outgoing flow side in the case of said cells and extend in the direction of flow and across it.

Owner:EBERSPACHER EXHAUST TECH GMBH & CO KG

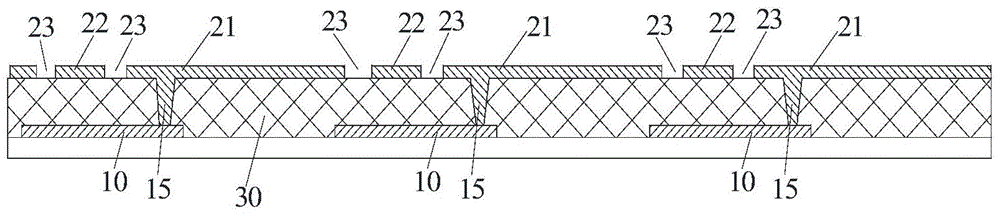

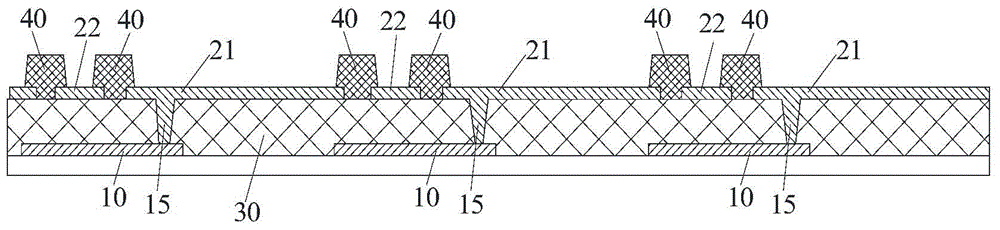

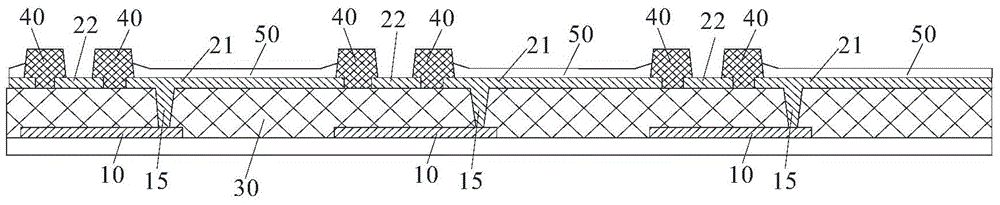

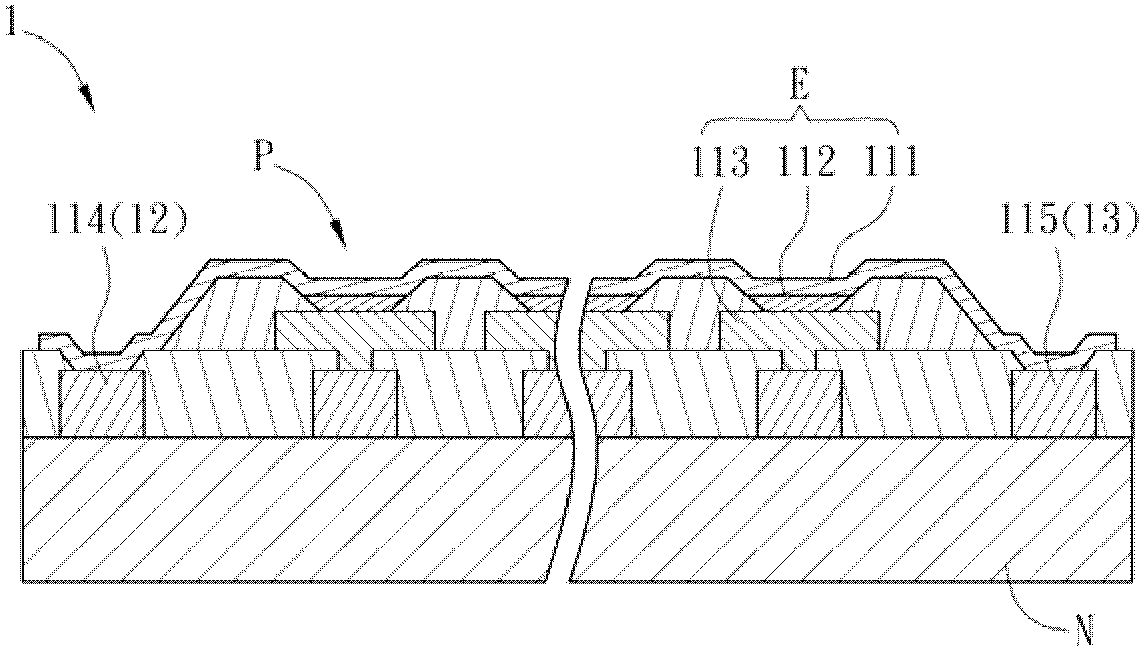

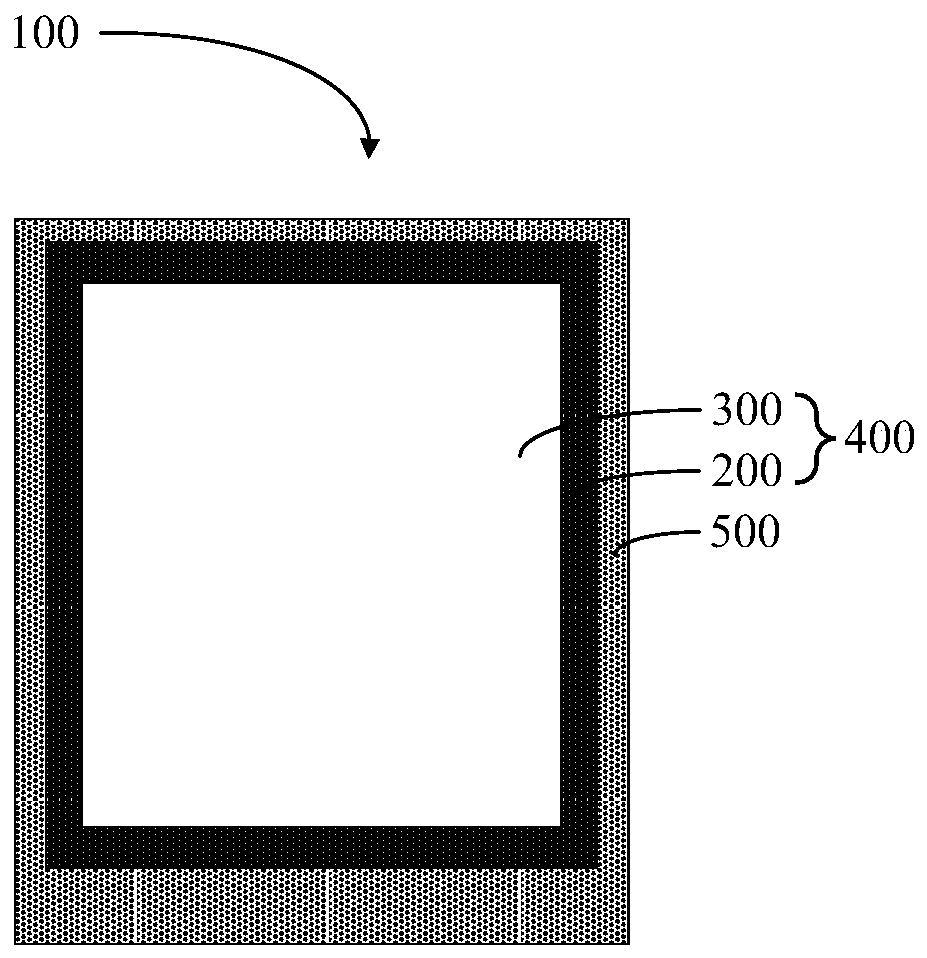

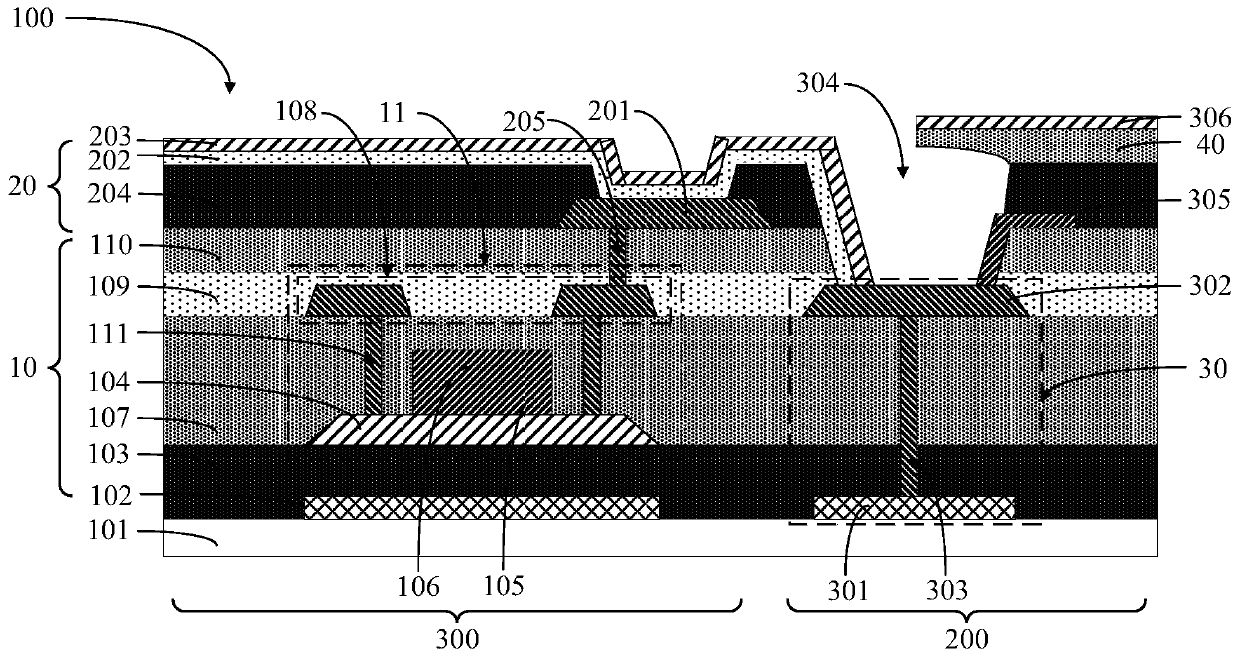

Display substrate, manufacture method thereof, display panel and mask plate

InactiveCN104659063ASmall pressure dropReduce lossesVacuum evaporation coatingSolid-state devicesElectrical resistance and conductanceImaging quality

The invention provides a display substrate. The display substrate comprises an anode layer, a cathode layer, and a luminous layer arranged between the anode layer and the cathode layer, wherein the anode layer comprises a plurality of anodes; the display substrate further comprises at least one auxiliary electrode; the auxiliary electrode and the anodes are formed at intervals in an insulated way; the auxiliary electrode is in contact with the cathode layer in a parallel connection way, so that the overall resistance formed after the auxiliary electrode is connected with the cathode layer in parallel is smaller than the resistance of the cathode layer. The invention further provides a display panel, a manufacture method of the display substrate, and a mask plate. The cathode resistance voltage drop (namely IR drop) of the display substrate is small, so that loss of electrical signals cathode layer in the cathode layer and the auxiliary electrode is small, and relatively higher image quality can be obtained.

Owner:BOE TECHNOLOGY GROUP CO LTD

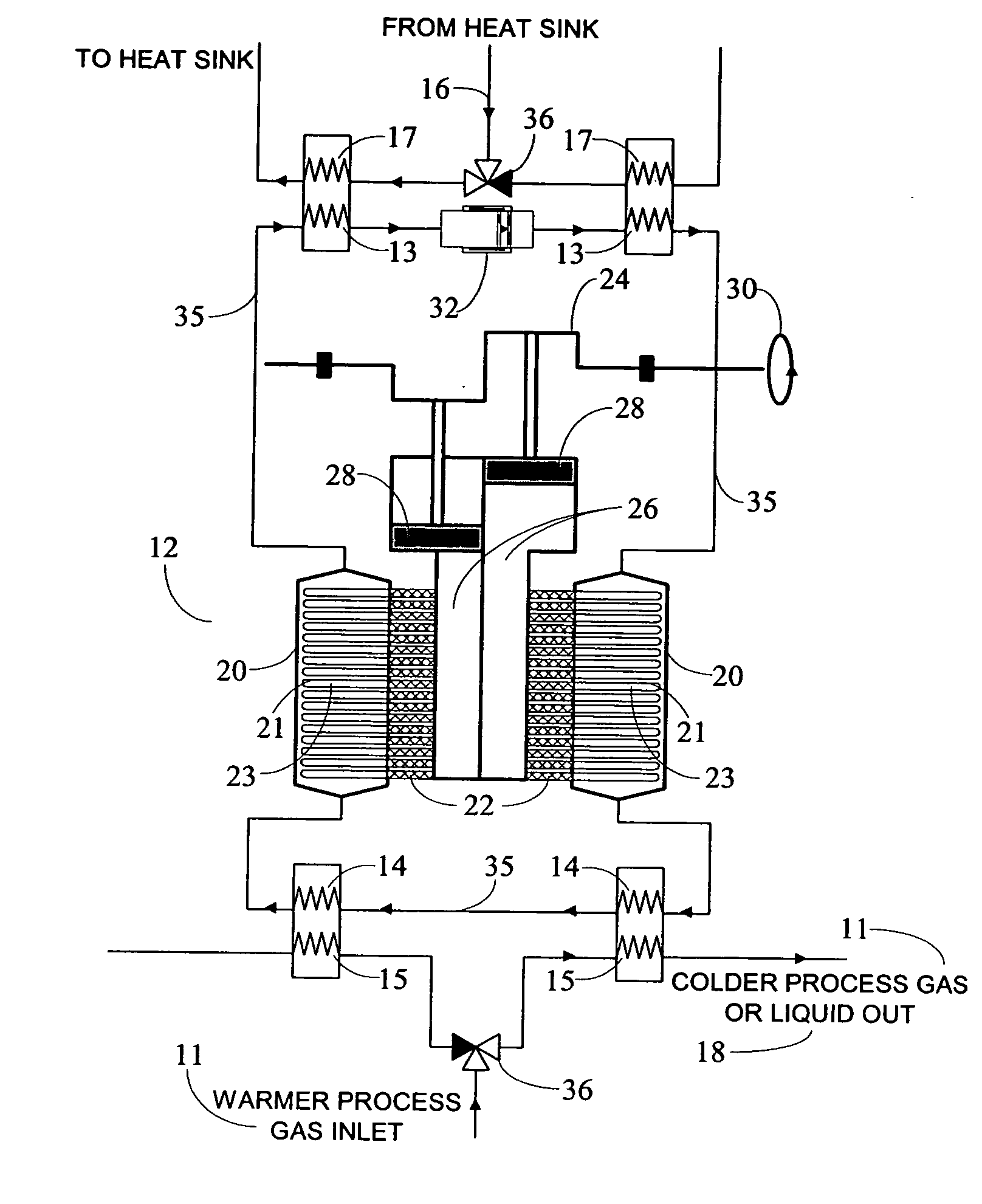

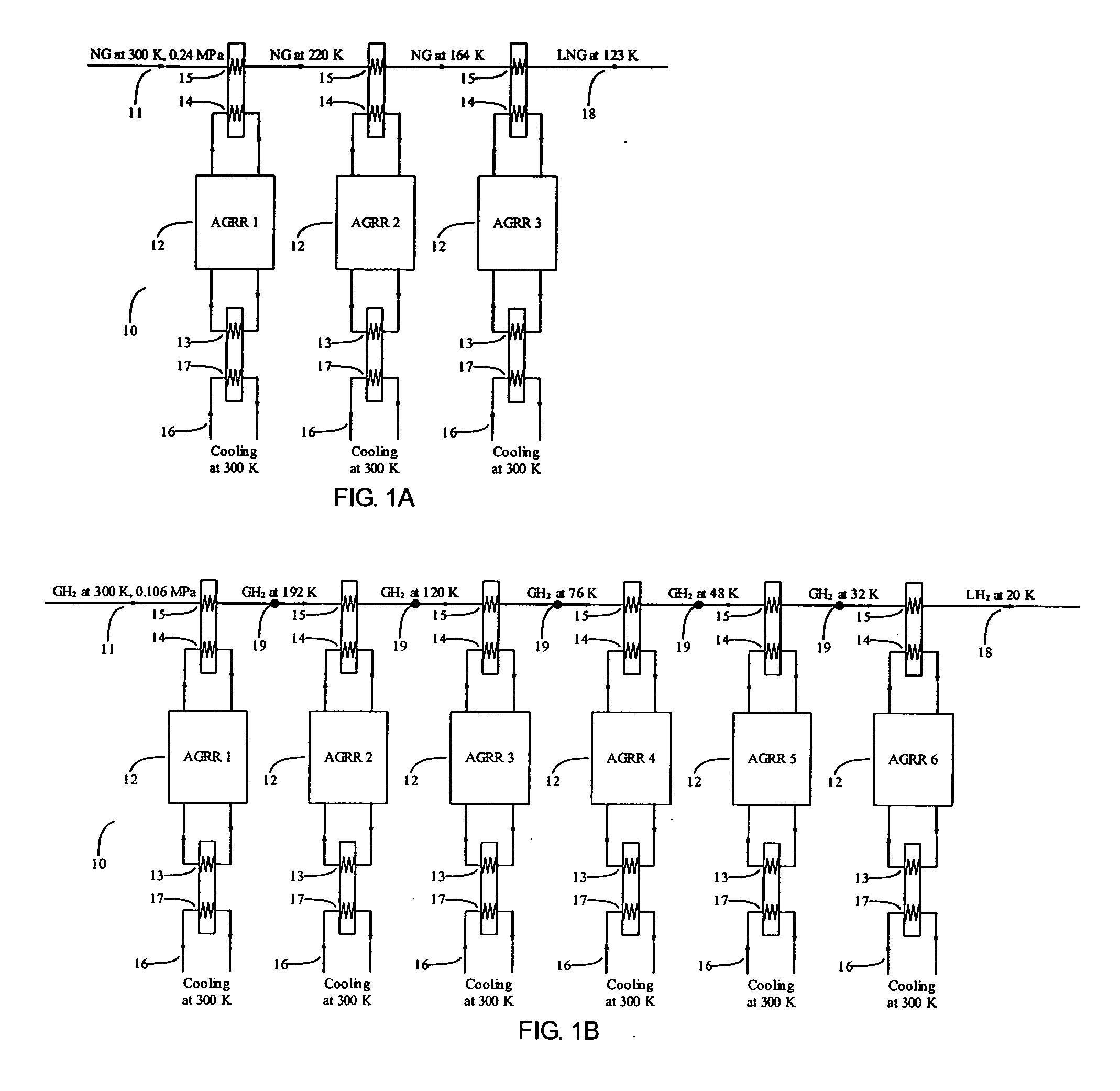

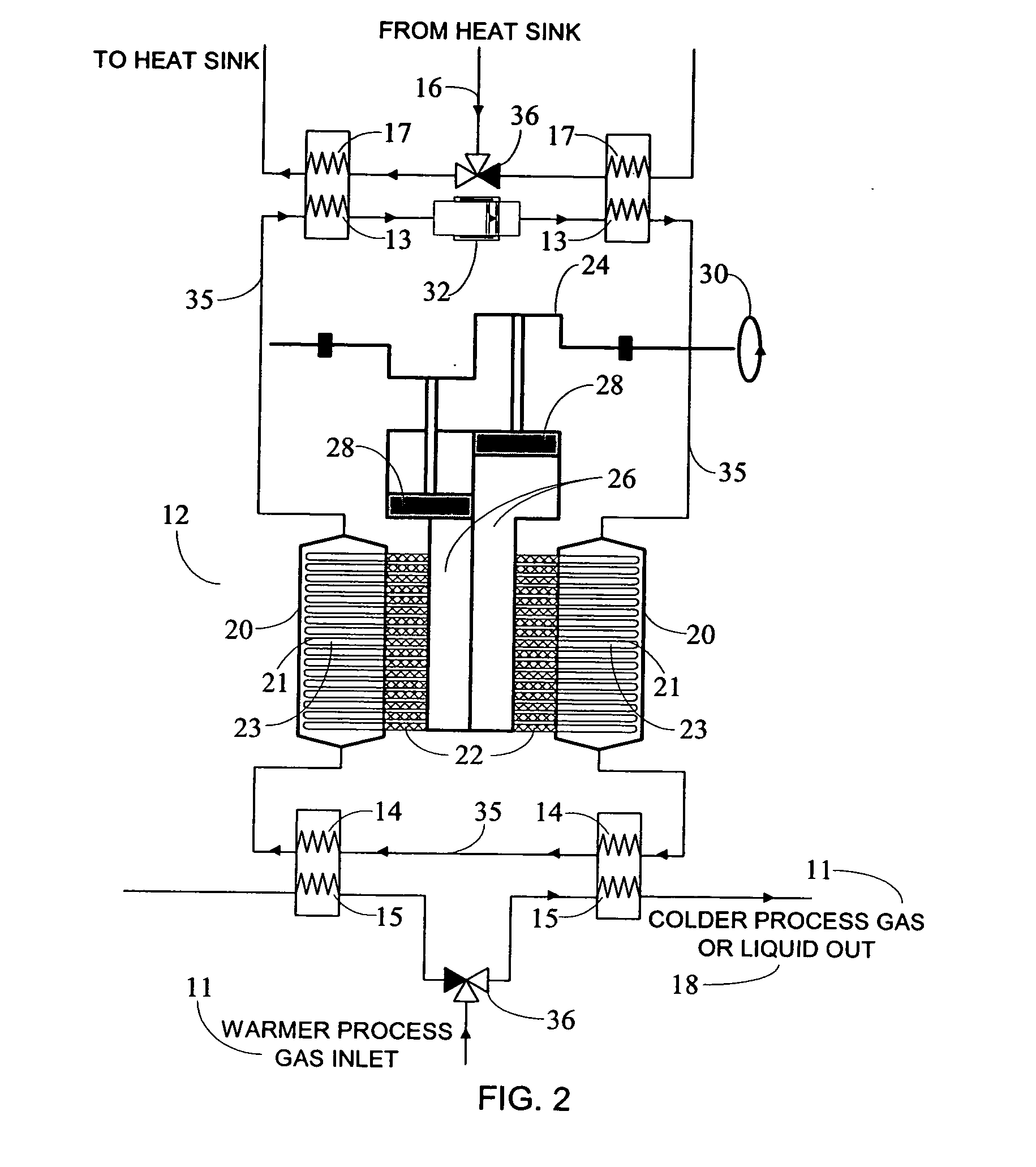

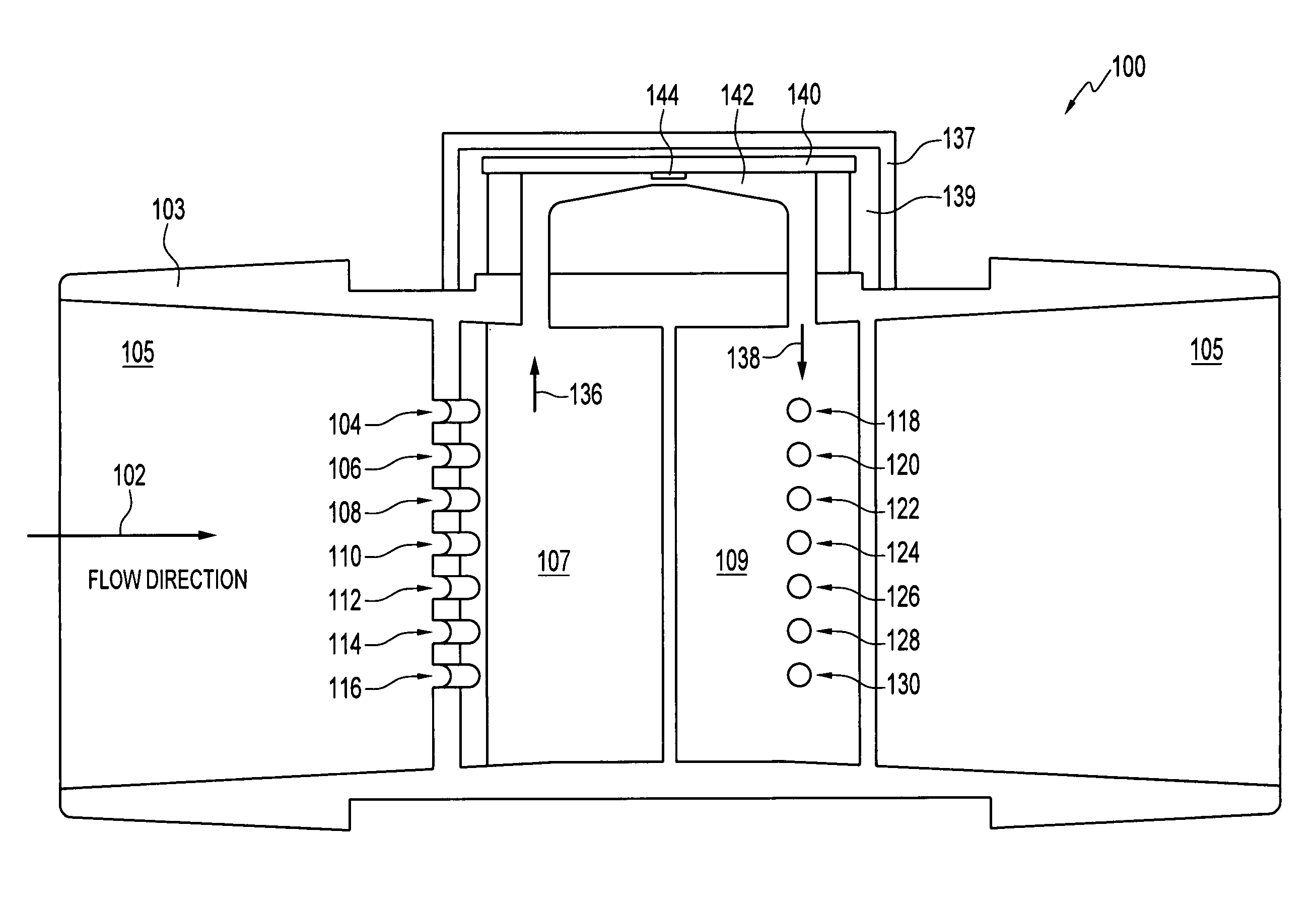

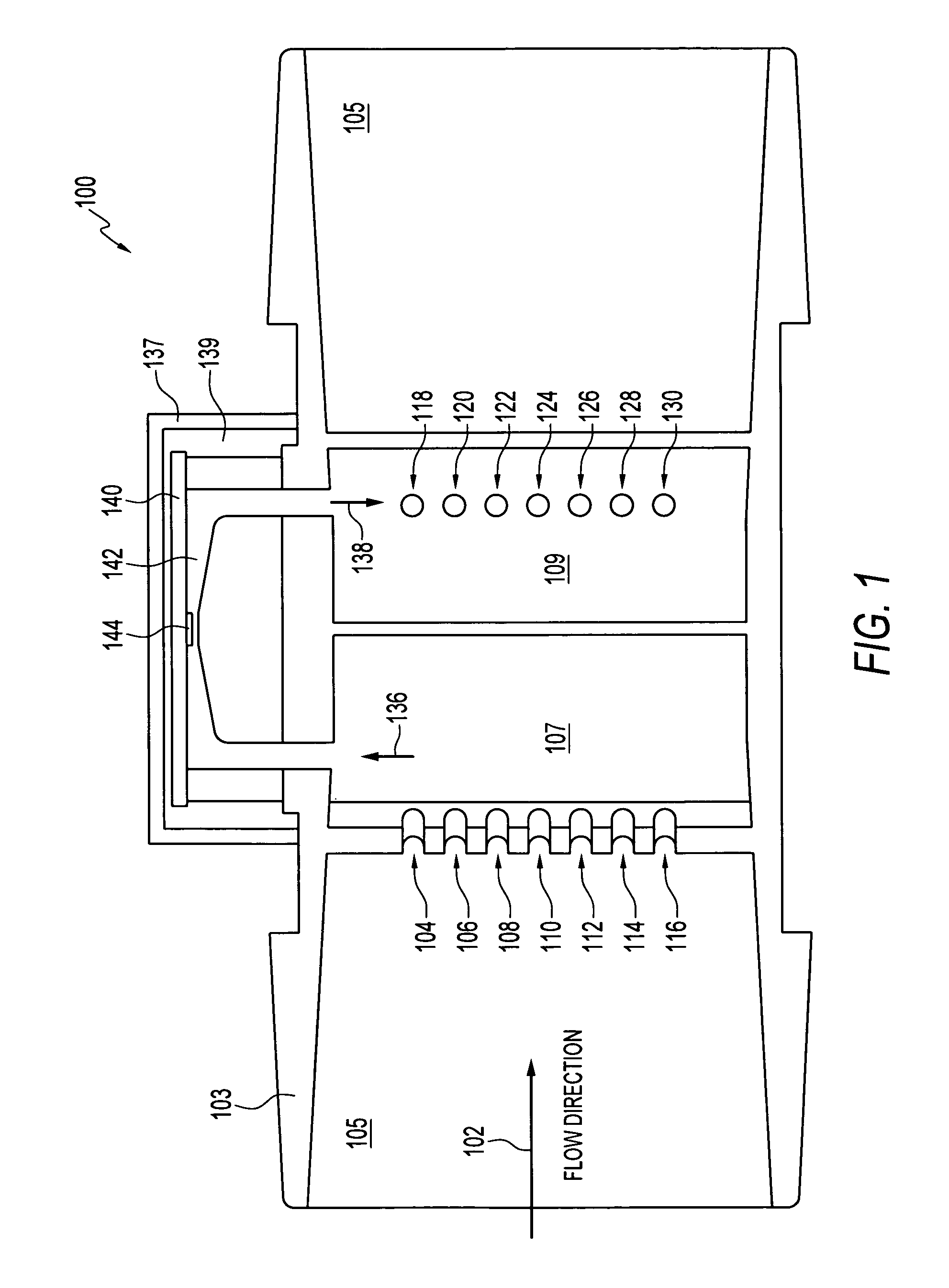

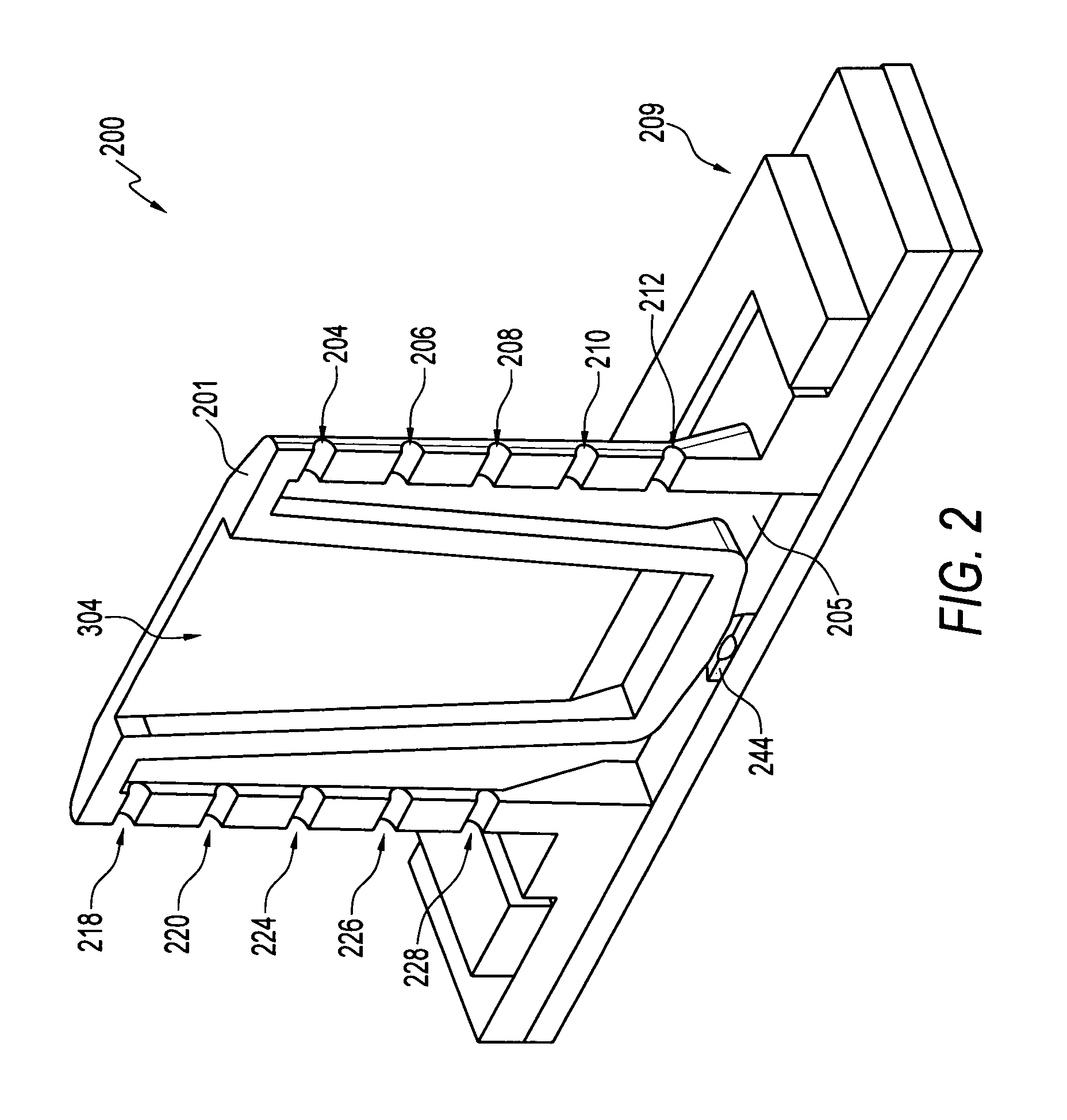

Active gas regenerative liquefier system and method

InactiveUS20080016907A1Improve efficiencyMinimize irreversible entropy creationSolidificationLiquefactionHydrogenProduct gas

The present invention provides an active gas regenerative liquefier (AGRL) for efficiently cooling and liquefying a process stream based on the combination of several active gas regenerative refrigerator (AGRR) stages configured to sequentially cool and liquefy the process stream, e.g. natural gas or hydrogen. In specific embodiments, the individual AGRR stages include heat exchangers, dual active regenerators, and a compressor / expander assembly, configured to recover a portion of the work of compression of a refrigerant by simultaneously expanding a refrigerant in one portion of the device while compressing the refrigerant in another portion to effect cooling of a heat transfer fluid, and ultimately the process stream.

Owner:PROMETHEUS TECH

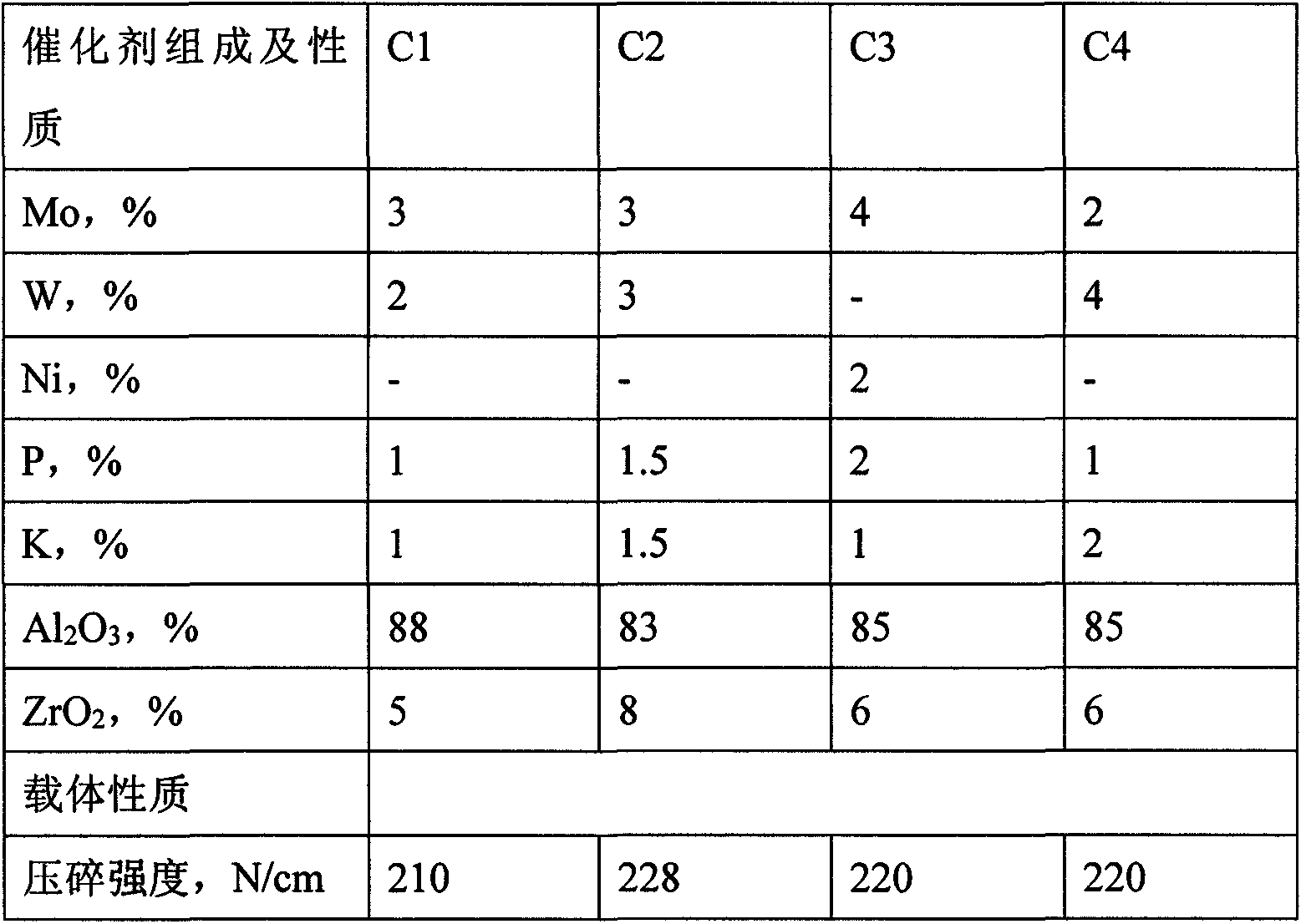

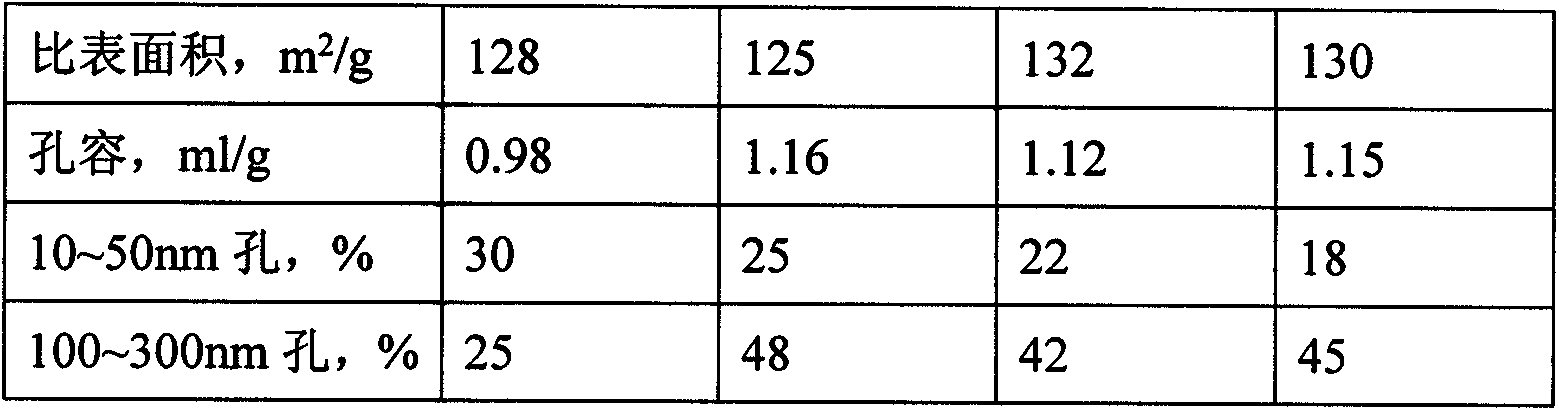

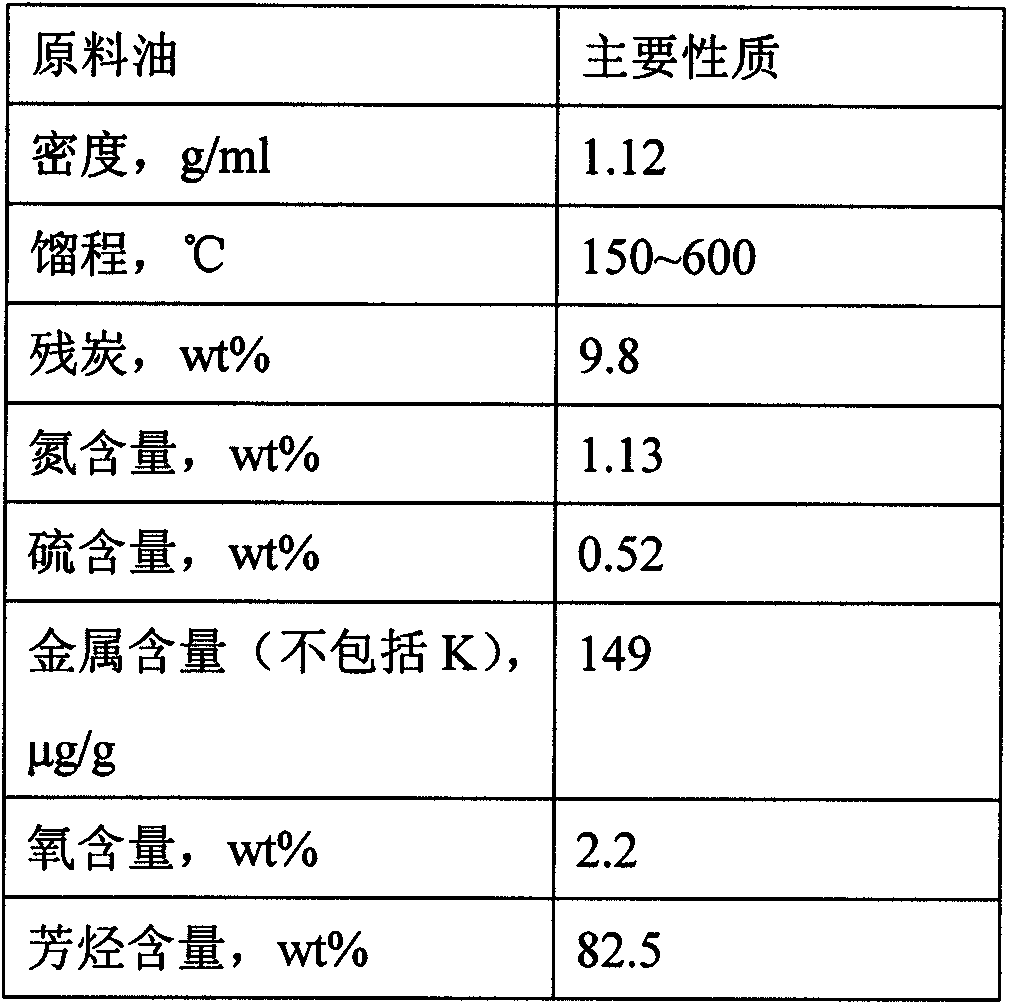

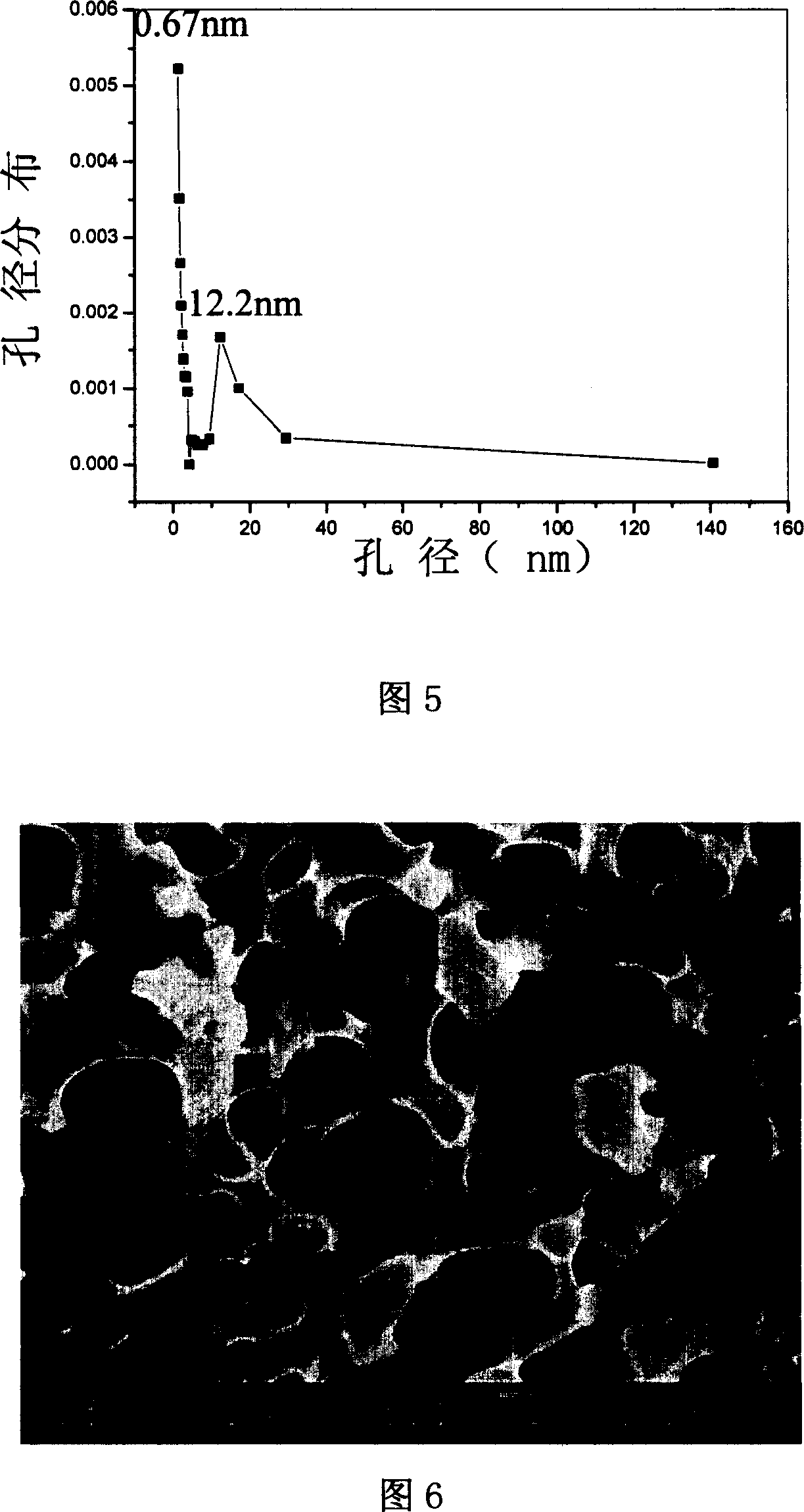

Protective agent of coal tar hydrogenation catalyst and preparation method of protective agent

ActiveCN103706408ASmall pressure dropHigh activityCatalyst protectionHydrocarbon oil crackingPotassiumMetal impurities

The invention discloses a protective agent of a coal tar hydrogenation catalyst and a preparation method of the protective agent. The protective agent is composed of three parts, namely carriers, active components and assistants, wherein the carriers include aluminium oxide and zirconium oxide in common; the active components include oxides of molybdenum, nickel or tungsten in common and account for 1-10% of total mass of the catalyst; the assistants include potassium and phosphorus in common, and account for 0.5-6% of total mass of the catalyst, and the balance is the carriers. The preparation method comprises preparation of the carrier and preparation of the protective agent. The protective agent has the advantages that the carrier comprises fine holes and thick holes, of which the apertures are relatively concentrated, wherein the thick holes are beneficial to containing metal impurities and carbon residue; a pressure drop of a catalyst bed is reduced, the hydrogenation catalyst is protected, removal of metal impurities such as vanadium is facilitated by the thin holes, the demetallization activity of the protective agent is properly improved, and different pore volumes and hole distribution of carriers can be prepared by adjusting the ratio of two pore forming materials. In addition, the preparation method of the protective agent is simple in technology, and convenient and stable to fabricate.

Owner:NINGBO JINYUANDONG PETROCHEM ENG TECH +1

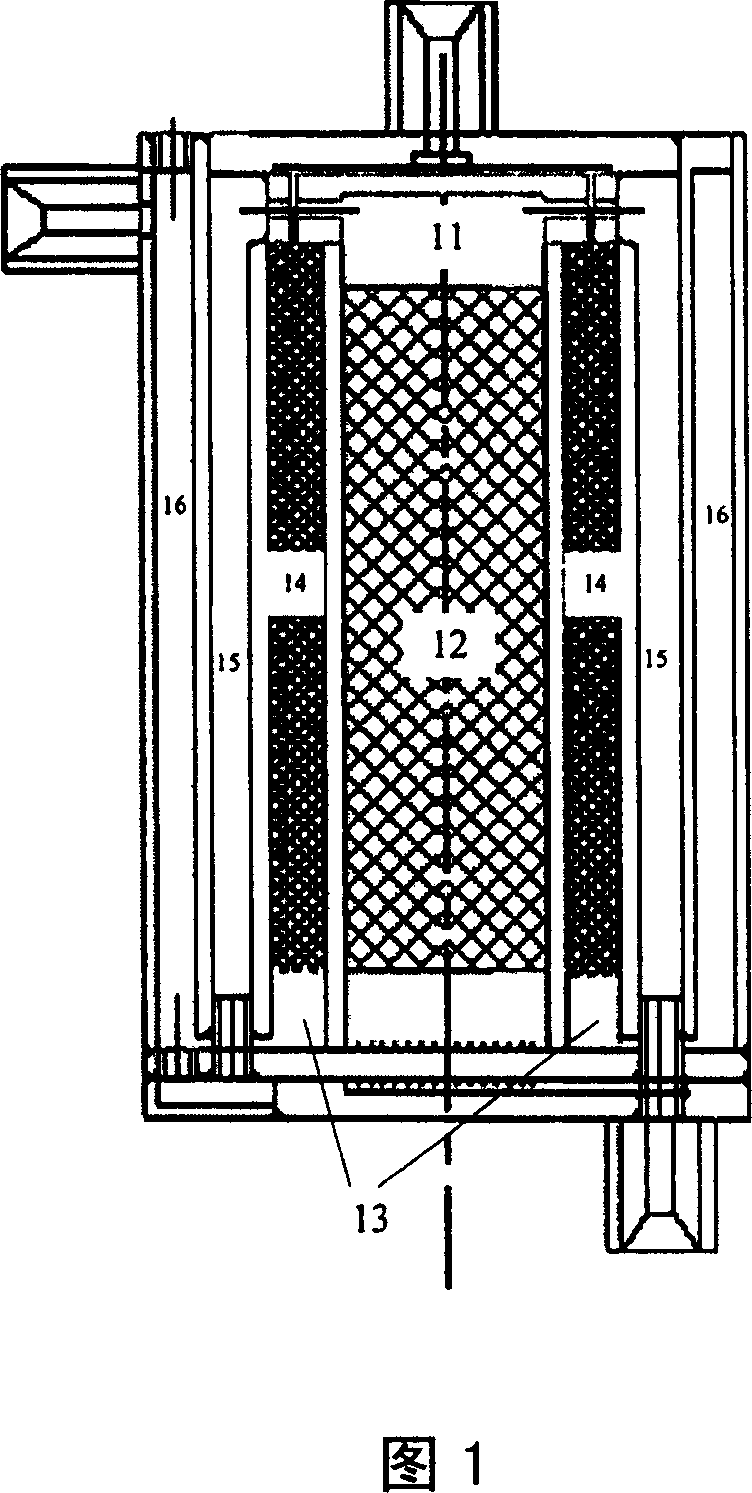

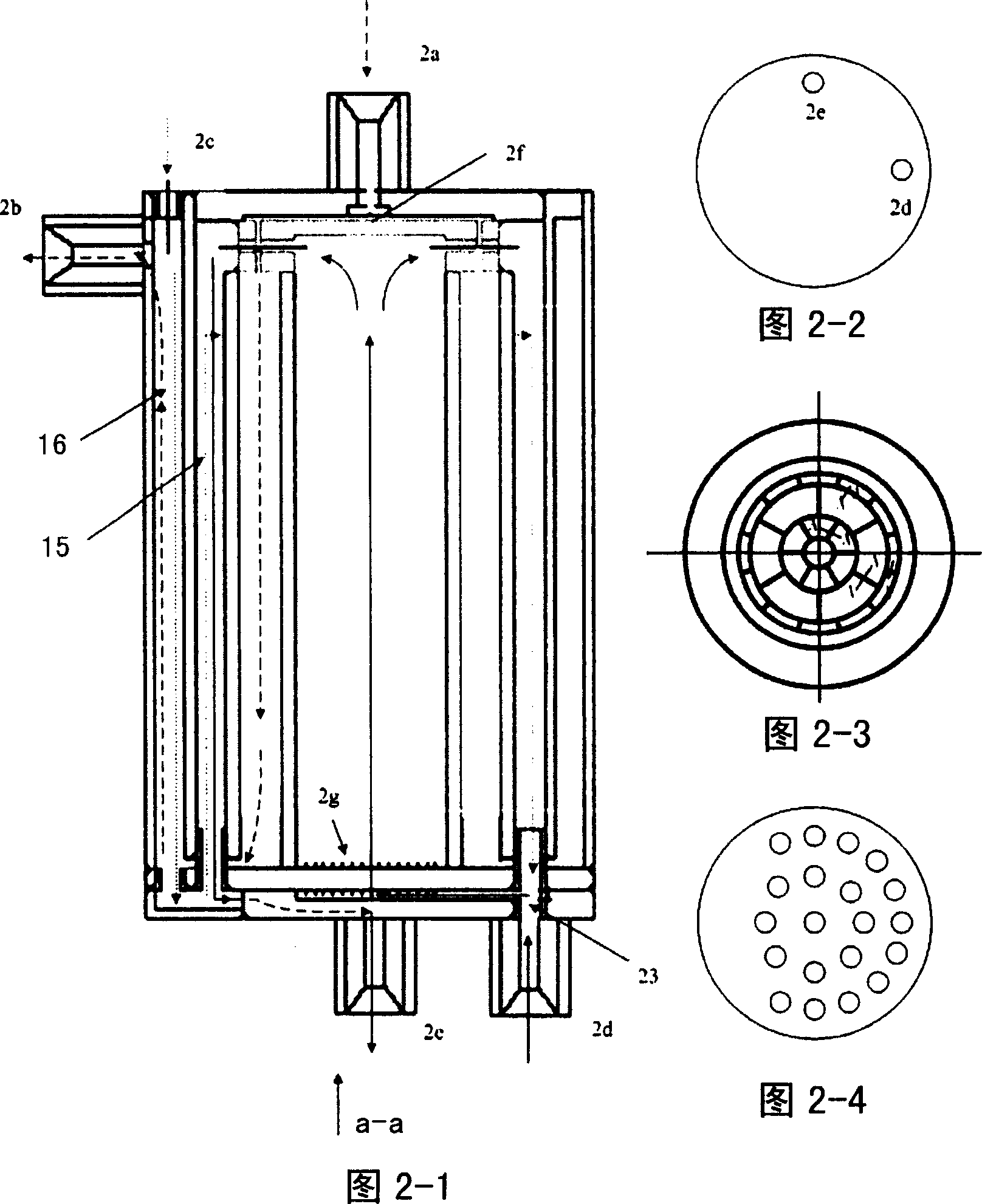

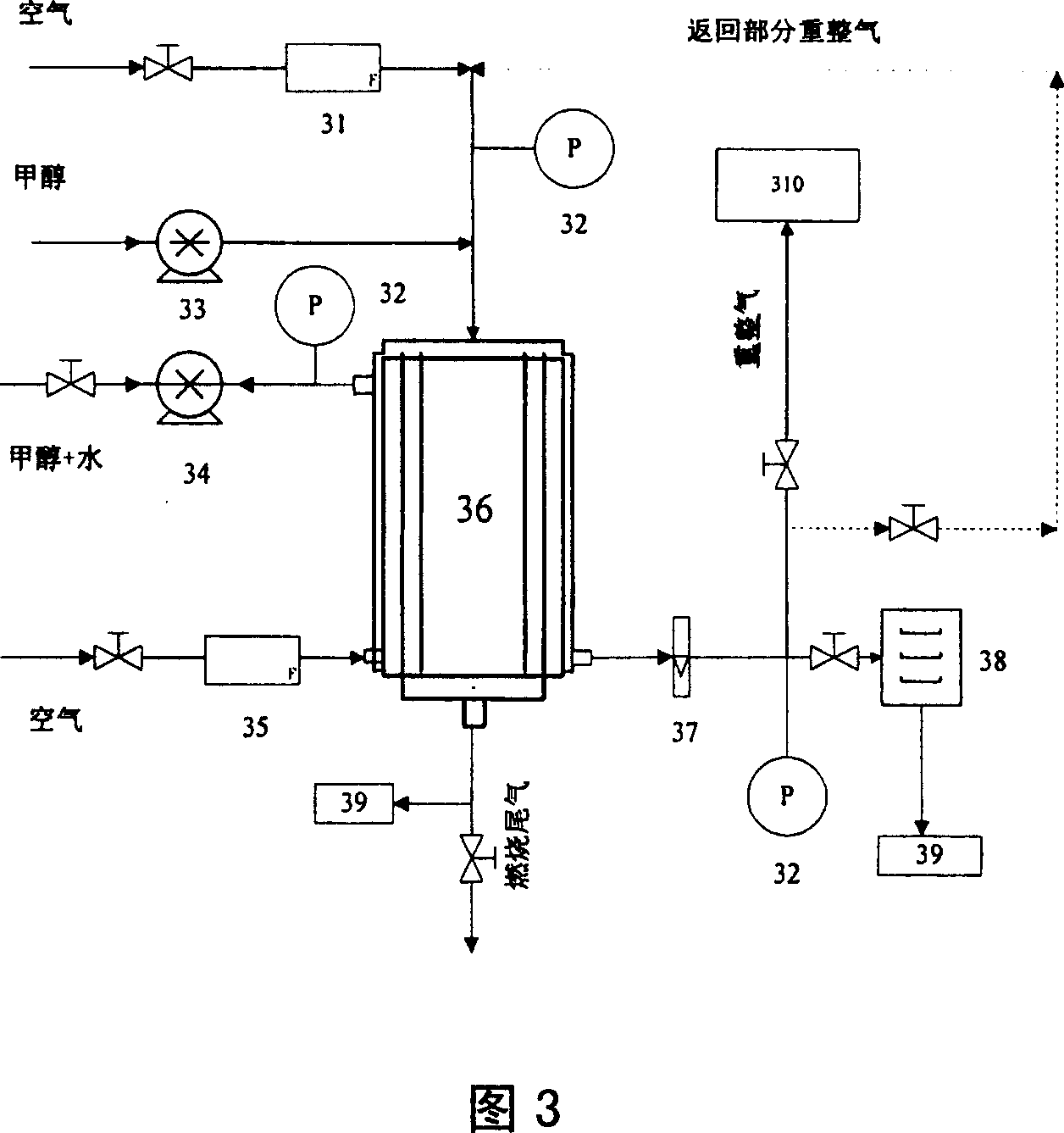

Mini reforming hydrogen-preparation reactor

InactiveCN101054160ARapid reforming hydrogen production reactionEven air distributionHydrogenHydrogenFuel cells

A minitype reactor for reforming hydrogen, which main part has telescopefeed structure, comprising a burning offgas heat exchange cavity, a reforming offgas heat exchange cavity, a burning cavity and a reforming cavity in sequence from outside; a fuel inlet is arranged communicating with the burning cavity; a reforming material inlet is arranged communicating with a built-in cavity of the burning offgas heat exchange cavity; reforming material liquid is preheated in the built-in cavity of the burning offgas heat exchange cavity then supplied into a built-in cavity of the reforming offgas heat exchange cavity; reforming material liquid flows in built-in cavities, burning offgas and reforming offgas exchange heat via tube wall of built-in cavities and flow oppose to reforming material liquid; a reforming air inlet is arranged, mixture gas of reforming air mixing with gas phase vaporized in the reforming offgas heat exchange cavity is supplied into the reforming cavity to process reforming hydrogen reaction. The catalytic burning reaction and reforming reaction of the invention has advantages of temperature easy to be control, stable running, easy operation; compact structure; the invention is suit for hydrogen source system of 10-500 W fuel cell minitype electrical source.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

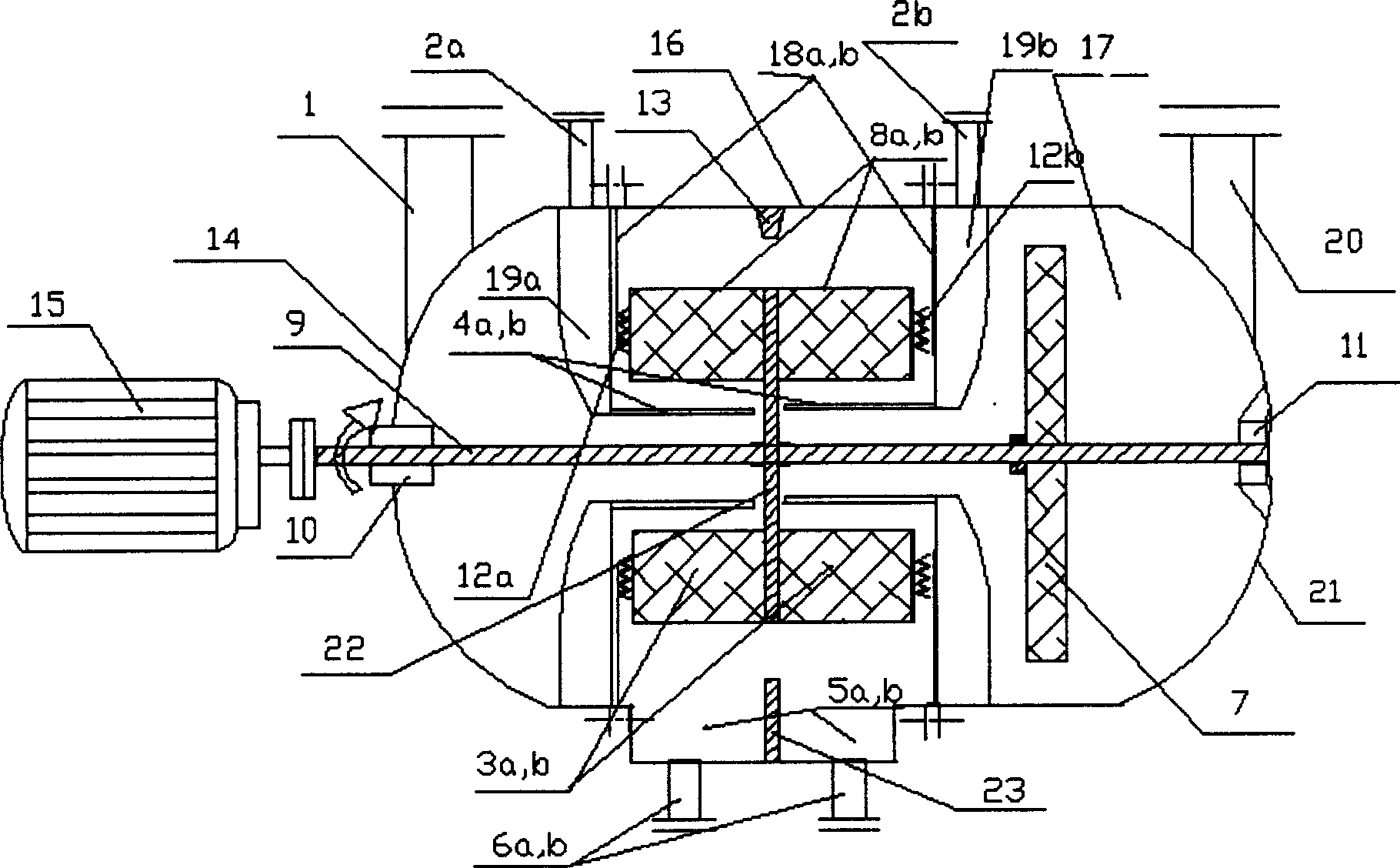

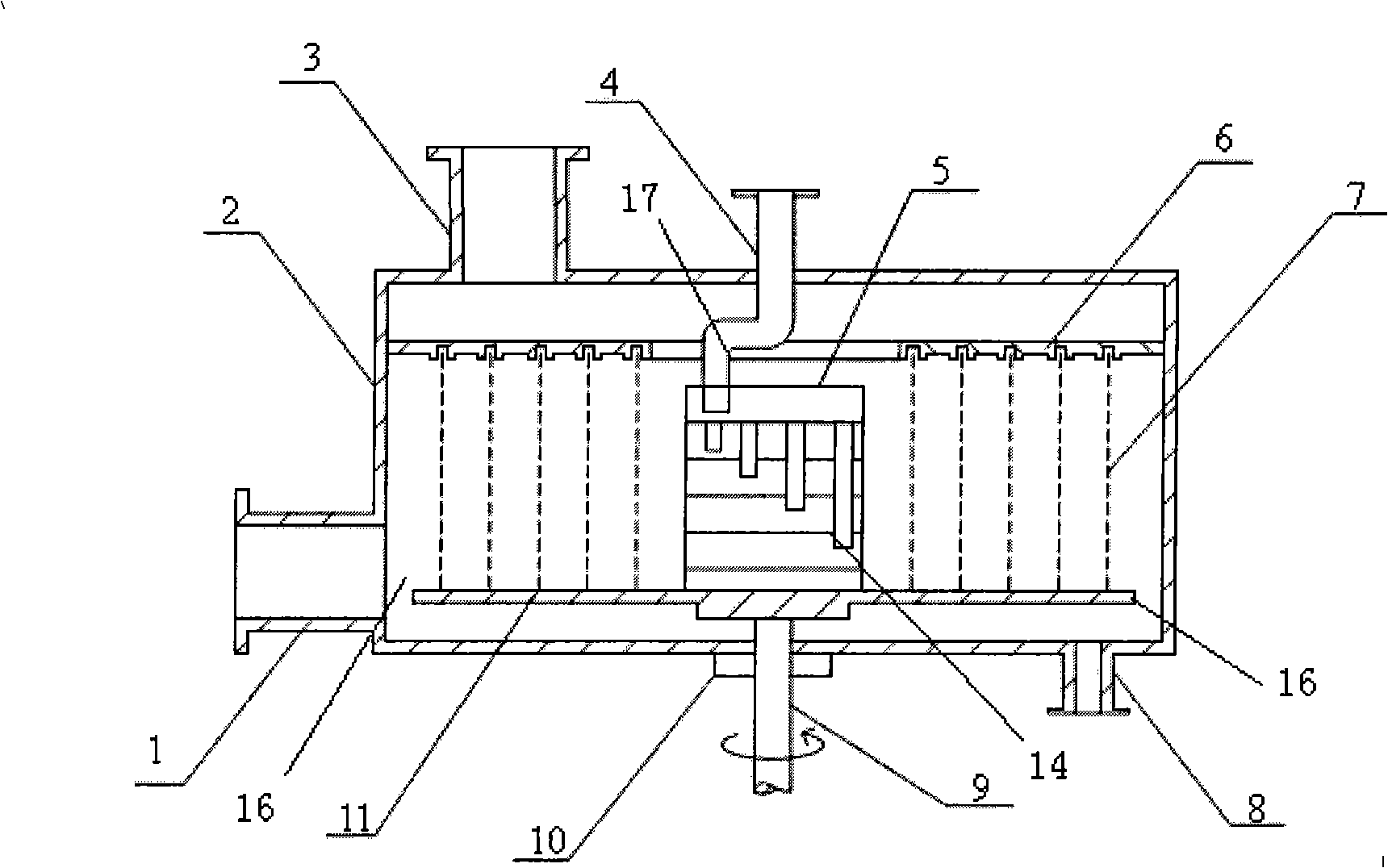

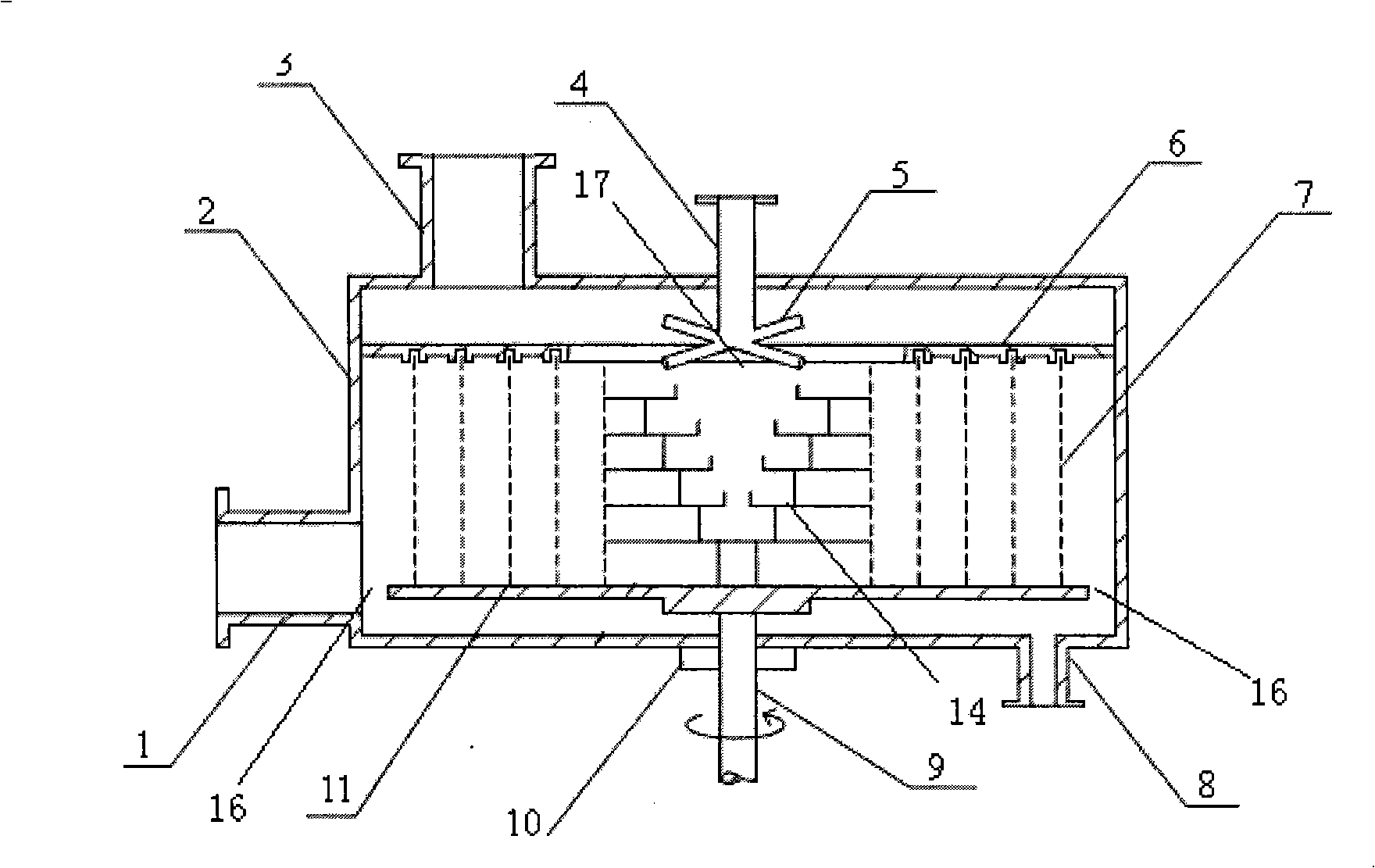

Ultragravity field rotary bed mass transfer and conversion unit

ActiveCN1611293ASmall sizeSmall footprintChemical/physical/physico-chemical moving reactorsFractional distillationLine tubingMetal

The present invention discloses an ultragravitational field rotation bed mass transfer and reaction equipment. Said equipment comprises machine shell, rotor, rotary foam-catching device and transmission device. The described machine shell comprises gas inlet end cover, straight cylinder section and gas outlet end cover; the described transmission device is formed from motor, transmission shaft, supporting bearing and seal system, and the described rotor is formed from dual rotors, and is consisted of two metal frames with shared bottom plate, two phases of gas and liquid can be parallelly-flowed and contacted on one rotor, and on another rotor they are counter-current-wise contacted, and the rotors are fixed on the shaft by means of shared bottom plate. Said invented equipment can be extensively used in the mass transfer and reaction process of multiphase material system of gas-liquid, gas-liquid-solid and gas-liquid-liquid.

Owner:CHINA PETROLEUM & CHEM CORP +2

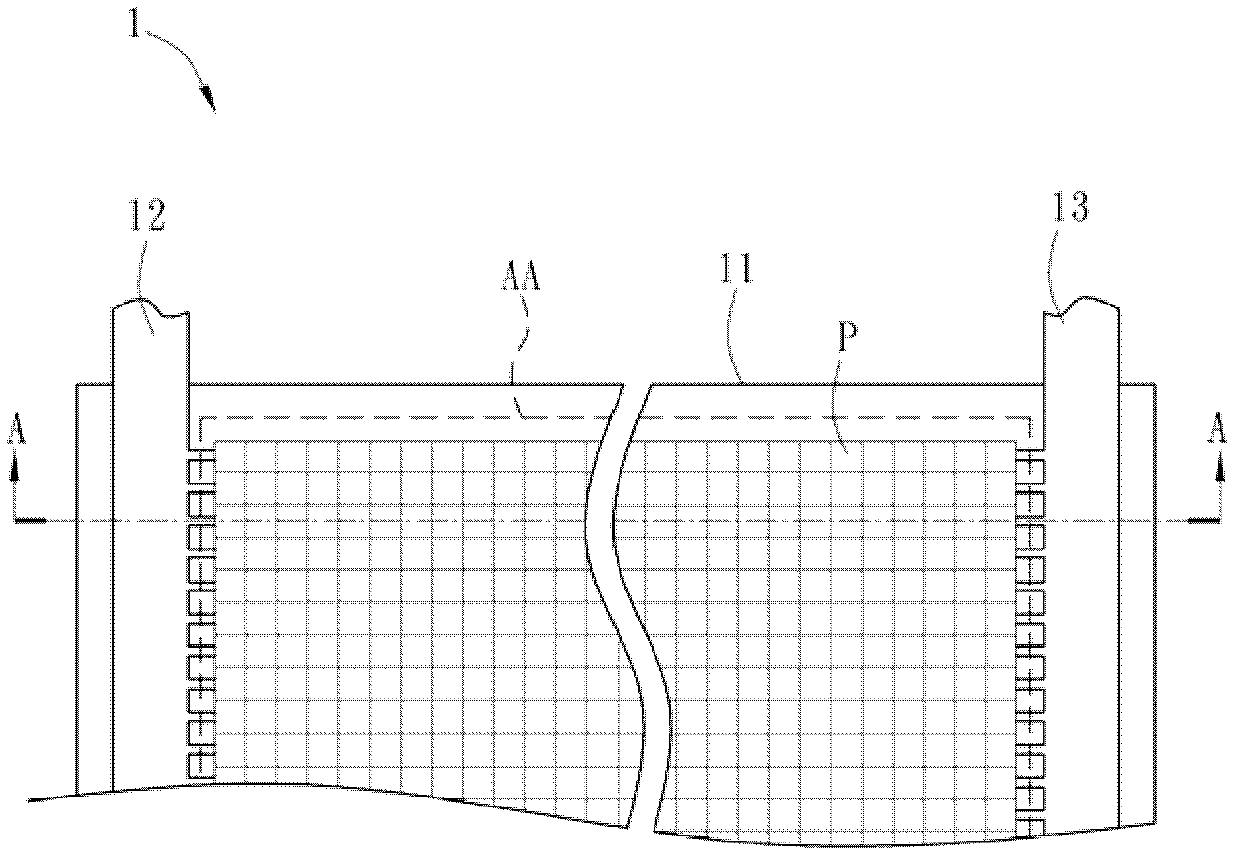

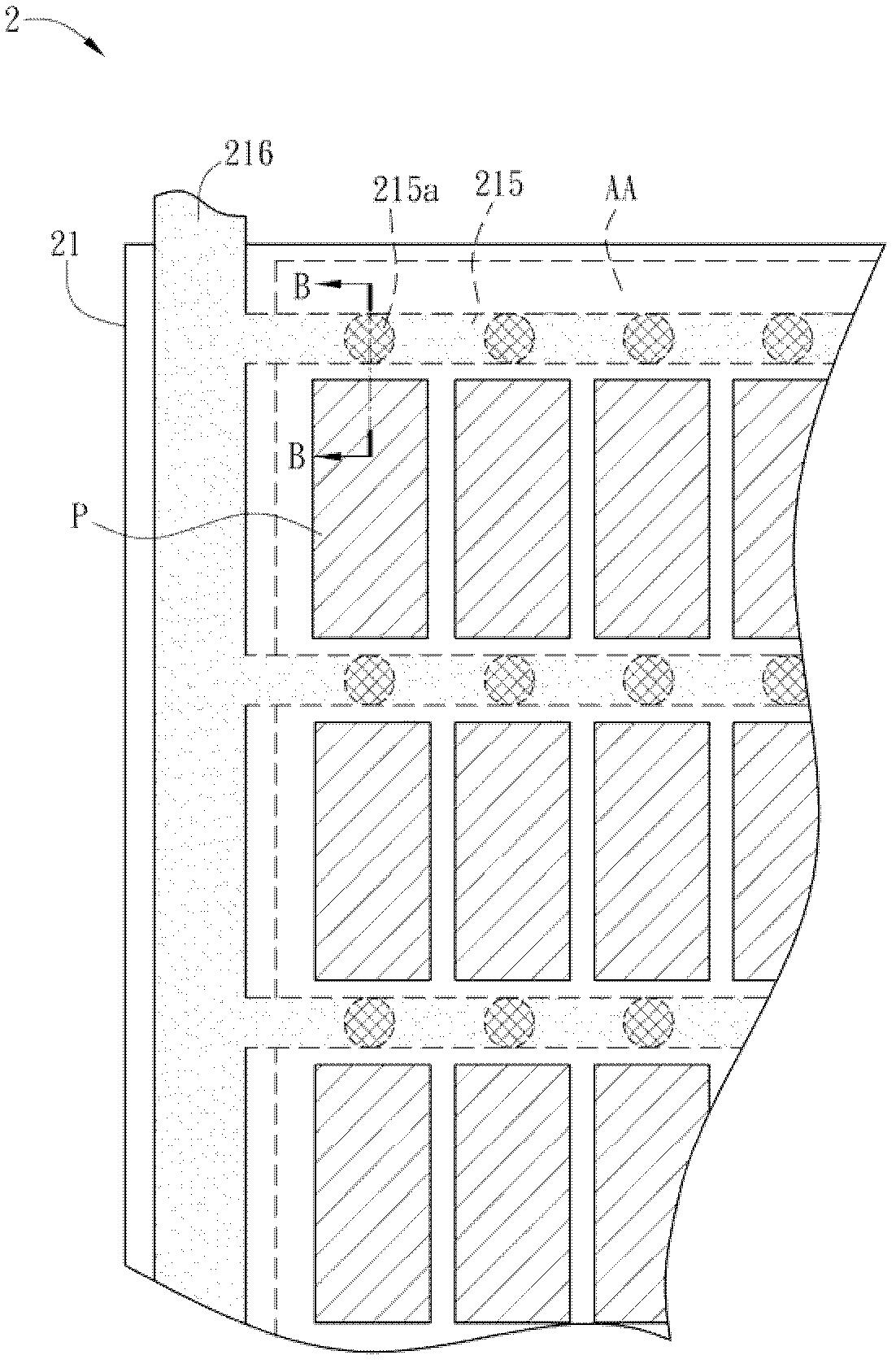

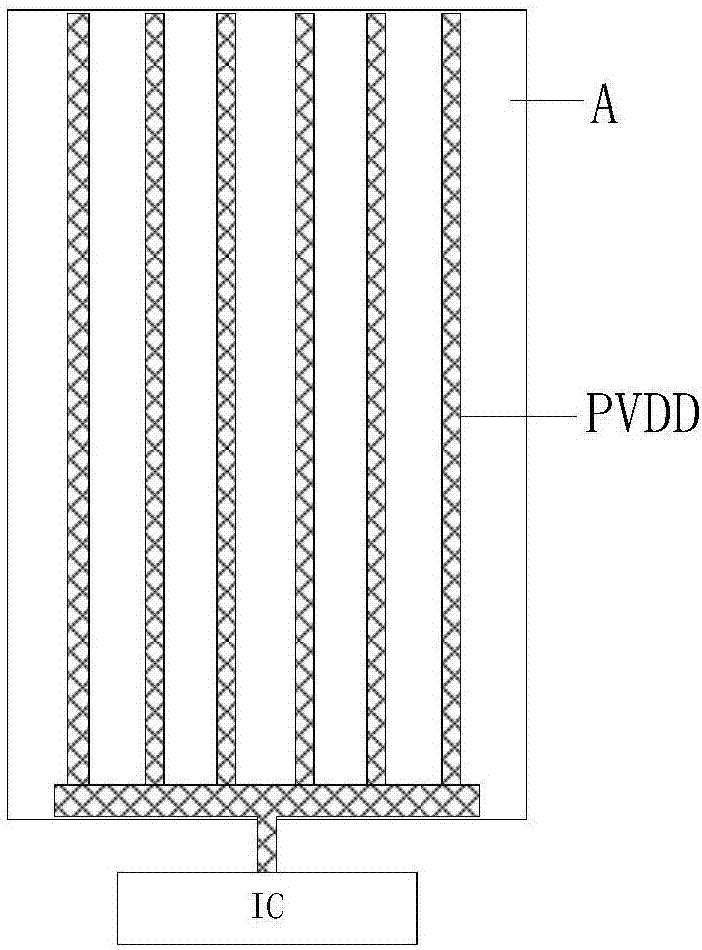

Display panel and display device

ActiveCN103296052AImprove brightness unevennessSmall pressure dropSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceAuxiliary electrode

The invention provides a display panel and a display device. The display panel comprises at least one pixel, an auxiliary electrode layer and a first organic material layer. The pixel comprises an organic light-emitting component which is provided with a first electrode layer. The auxiliary electrode layer is arranged adjacent to the pixel, and is provided with a through hole arranged corresponding to the pixel, the through hole is defined by a side wall of the auxiliary electrode layer, and the first electrode layer is electrically connected with the auxiliary electrode layer through the side wall. The first organic material layer is arranged in the through hole. The invention further discloses a display device with the display panel.

Owner:INNOCOM TECH SHENZHEN +1

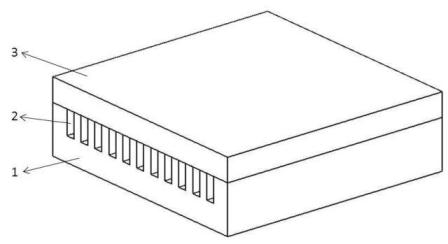

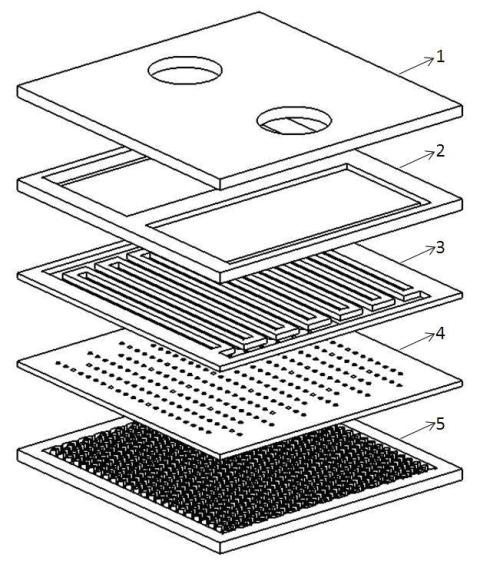

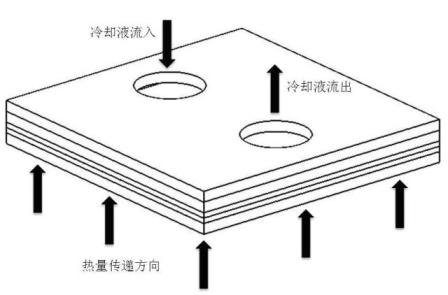

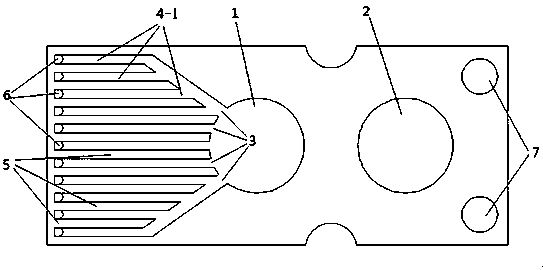

Prism-array jet micro-channel radiator

InactiveCN102014598AReduce temperature gradientFull heat exchangeCooling/ventilation/heating modificationsJet flowPrism

The invention relates to a prism-array jet micro-channel radiator. The radiator comprises a prism-array structure, a jet structure, an outlet-inlet cross structure, a liquid separating structure and an outlet-inlet arrangement structure. In the invention, cooling liquid enters the radiator via an inlet and then is led to side clearance through the liquid separating structure so as not to be mixedwith cooling liquid at an outlet; the distance between the outlet and the inlet is shortened by means of the comb-shaped outlet-inlet cross structure so as to reduce pressure drop; after reaching themultihole jet flow structure, the cooling liquid can be uniformly introduced onto a heated silicon substrate so that the temperature of the substrate is more uniform, heat is more easily taken away by the generated turbulent flow and meanwhile the pressure drop is also reduced by the jet structure; and finally the cooling liquid easily forms turbulent flow by means of the prism-array structure sothat the heat transferred to the prism structure from the substrate is more easily taken away, thus increasing the heat exchange efficiency. The prism-array radiator can be used in a cooler for microstructures such as an electronic chip, an LED and the like.

Owner:SHANGHAI UNIV

Ultra low pressure drop flow sensor

InactiveUS7343823B2Easy to moveSmall pressure dropVolume flow proportion measurementVolume/mass flow by differential pressureEngineeringStreamflow

Owner:HONEYWELL INT INC

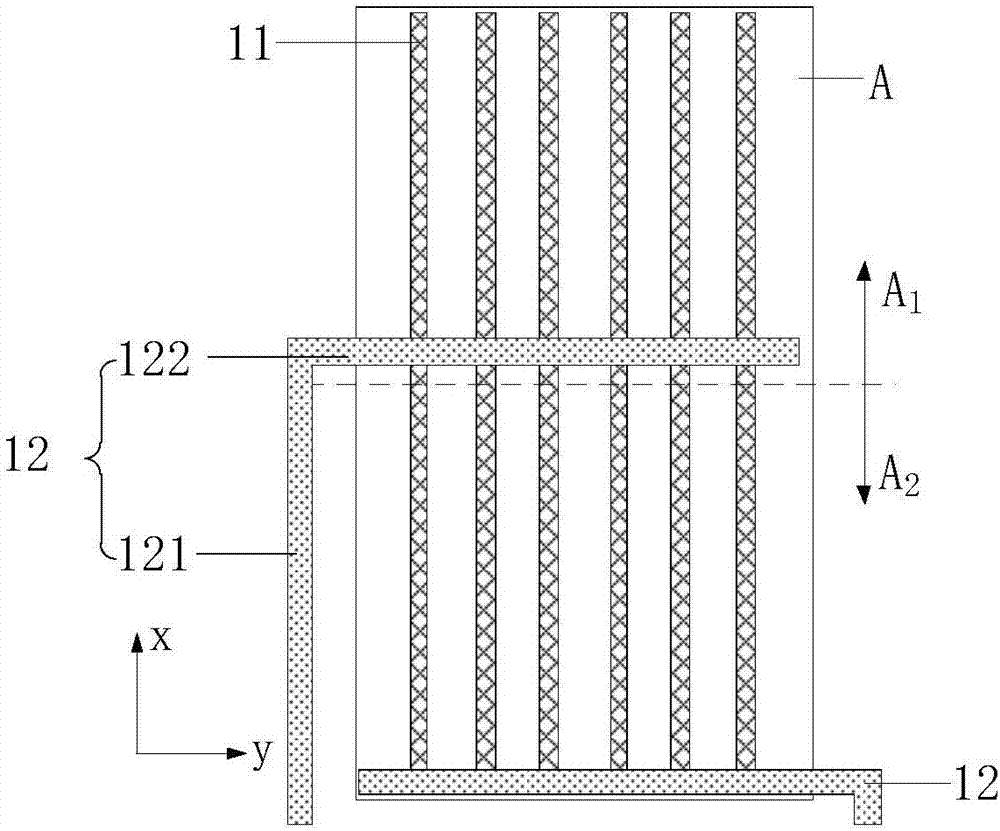

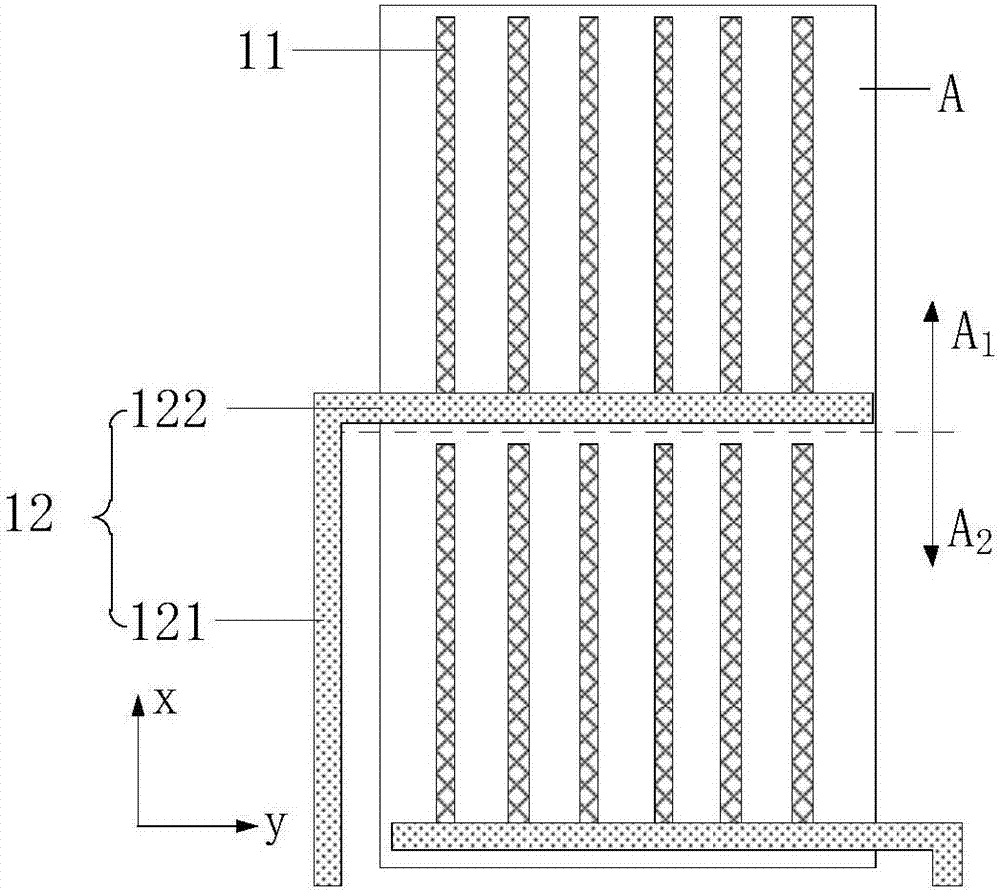

Display panel and display device

ActiveCN107887421AImprove display uniformitySmall pressure dropSolid-state devicesSemiconductor devicesLow voltageVoltage drop

The invention discloses a display panel and a display device. The display panel comprises a display area and a non-display area. The display area comprises at least two sub-display areas in the firstdirection of the display panel. The display panel also comprises multiple power voltage signal lines extending along the first direction and signal wiring lines which are arranged in different layersfrom the power voltage signal lines. Each signal wiring line is electrically connected with each power voltage signal line in each sub-display area. The linewidth of the signal wiring lines is greaterthan that of the power voltage signal lines. According to the display panel, the power voltage is inputted to the power voltage signal lines through the area division mode so that the voltage drop onthe power voltage signal lines can be reduced. Besides, the linewidth of the signal wiring lines is greater than that of the power voltage signal lines so that the voltage drop on the power voltage signal lines can be further reduced and the display homogeneity of the display panel can be enhanced.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

Lithium battery and manufacturing method thereof

InactiveCN101593849AImprove cycle lifeGuaranteed to workElectrode manufacturing processesFinal product manufactureInternal resistancePole piece

The invention discloses a lithium battery and a manufacturing method thereof, which belong to the field of batteries. The lithium battery comprises a positive pole, a negative pole and a diaphragm arranged between the positive pole and the negative pole. The manufacturing method comprises the following steps: making active matters into a mixed paste; preserving blank positions on the front and back sides of an edge in the lengthwise direction of a positive pole piece, coating the paste on other parts of the positive pole piece completely, preserving blank positions on the front and back sides of an edge in the lengthwise direction of a negative pole piece, and coating the paste on other parts of the negative pole piece completely; covering the pasted positions of the negative pole piece with the diaphragm, placing the positive pole piece, and staggering the blank positions of the positive pole piece and the blank positions of the negative pole piece at two ends respectively to arrange the positive pole with blanks at one end and the negative pole with blanks at the other end; welding the blanks of the positive pole with a positive pole tab and the blanks of the negative pole with a negative pole tab; and placing a battery cell welded with the pole tabs in a packaging shell, packaging the shell, drying the shell under vacuum, filling liquid, sealing the shell, and obtaining the battery after formation, capacity grading and examination. The lithium battery and the method have the advantages of reducing the distance from the pole pieces to pole terminals, internal resistance and heat generated during charge and improving safety, reducing pressure drop caused by internal resistance and discharge platform.

Owner:GUANGZHOU FULLRIVER BATTERY NEW TECH

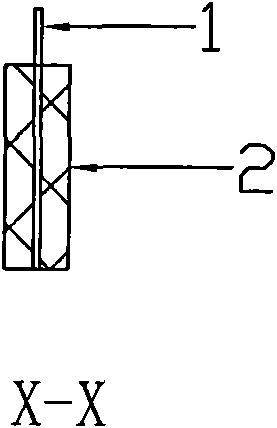

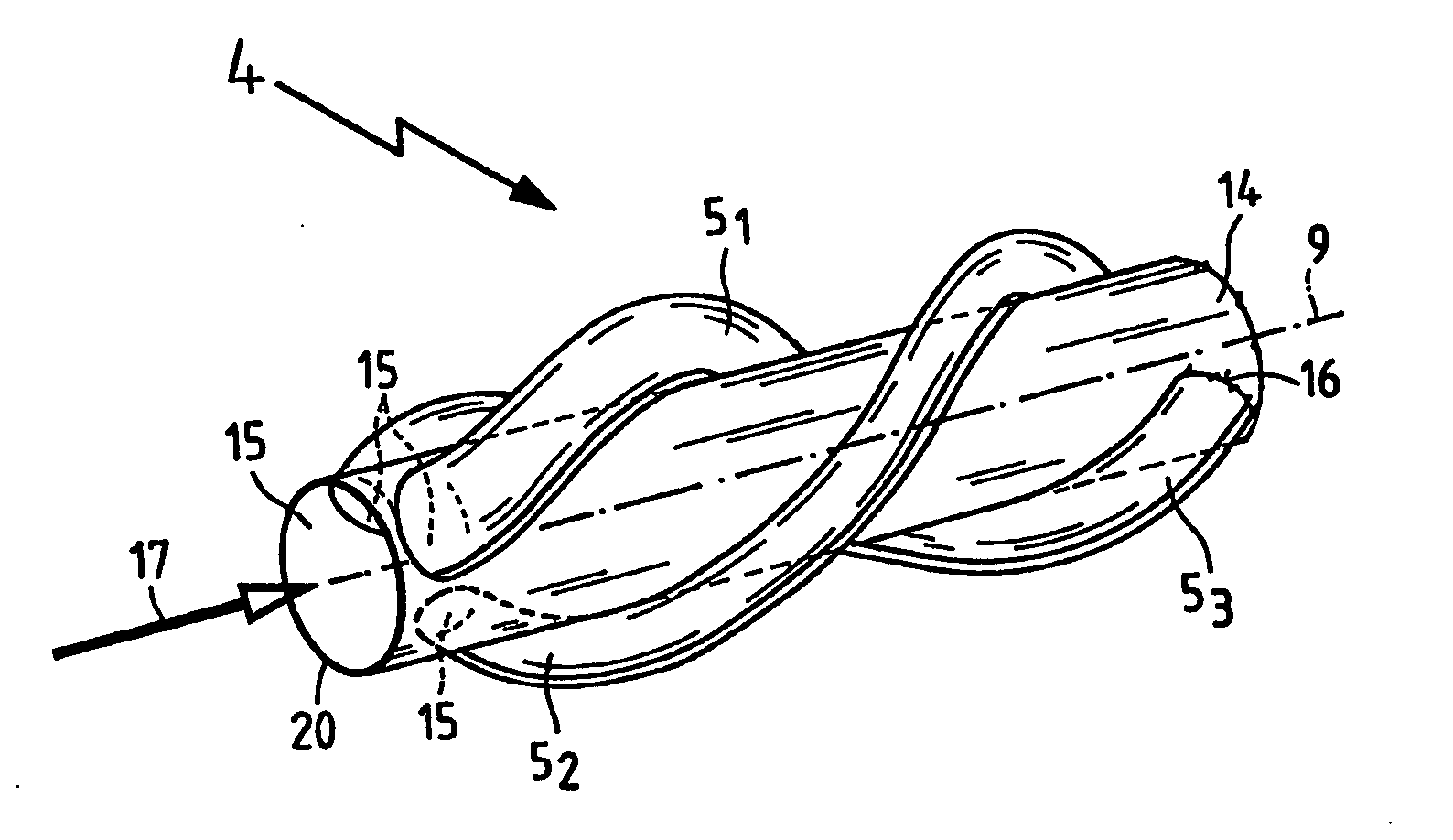

Noise suppressor apparatus for a gas duct

A sound damping device (4) for a tubular duct (2), particularly a gas transporting tract of an internal combustion engine (1) having a least one bypass channel (5) running parallel to a main duct (6) in a section of the duct (2). The bypass channel (5) is longer than the main duct (6) between a branching off point (7) and a re-entry inlet (8). The bypass duct according to the invention is configured as a spiral duct (5) which winds around the centrally disposed main duct (6) in order to decrease the installation space requirements for the noise suppressor (4).

Owner:MANN HUMMEL GMBH

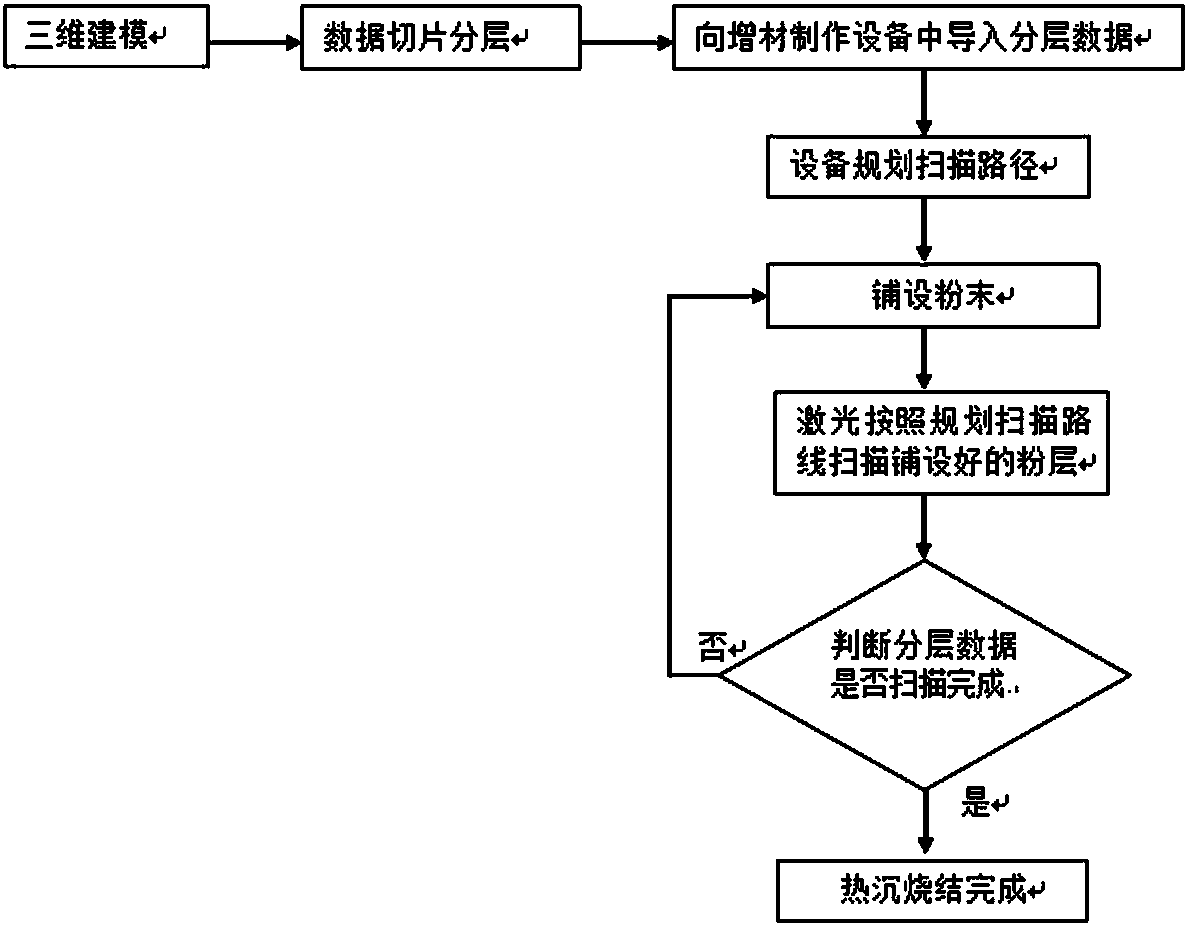

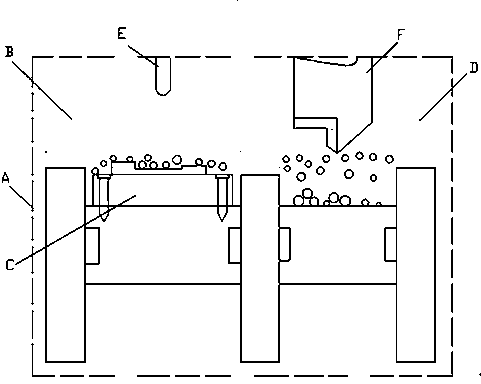

Method for manufacturing heat sink body

ActiveCN104028758AReduced time for structural optimization and product manufacturingImprove thermal performanceIncreasing energy efficiencyThree dimensional modelHeat sink

The invention discloses a method for manufacturing a heat sink body. The method aims at solving the problems that in the traditional heat sink manufacturing process, heat resistance is increased due to multilayer welding, and a heat sink body needs to be manufactured through multiple processes and is short in service life. The method includes the steps that three-dimensional modeling is conducted on the whole structure of the heat sink body; a three-dimensional model is guided to a workbench computer, and the printing angle and positions are set according to the structure of a three-dimensional pattern; a powder layer laid on a base plate of a workbench in advance is sintered into two-dimensional shapes corresponding to the powder layer through high-energy laser beams according to the scanning path; powder as thick as the powder layer is laid on the workbench on which one layer of pattern is sintered, and lasers scan the powder according to the scanning path of the layer until the whole three-dimensional pattern is finished. Through the structure, the heat sink body has the advantages that pressure distribution is uniform and the service life of the heat sink body is prolonged.

Owner:CHENGDU 3D CHANGE TECH

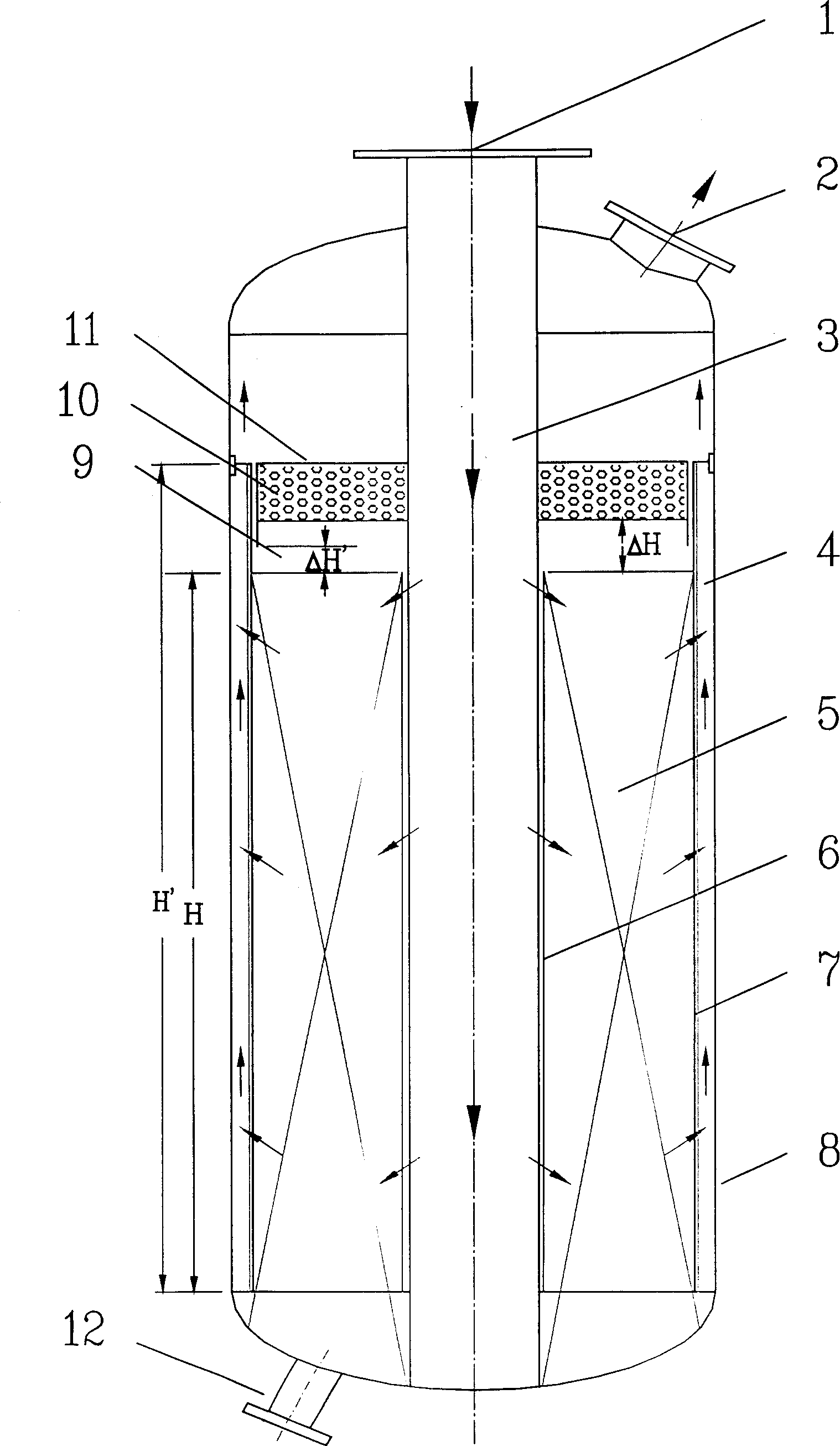

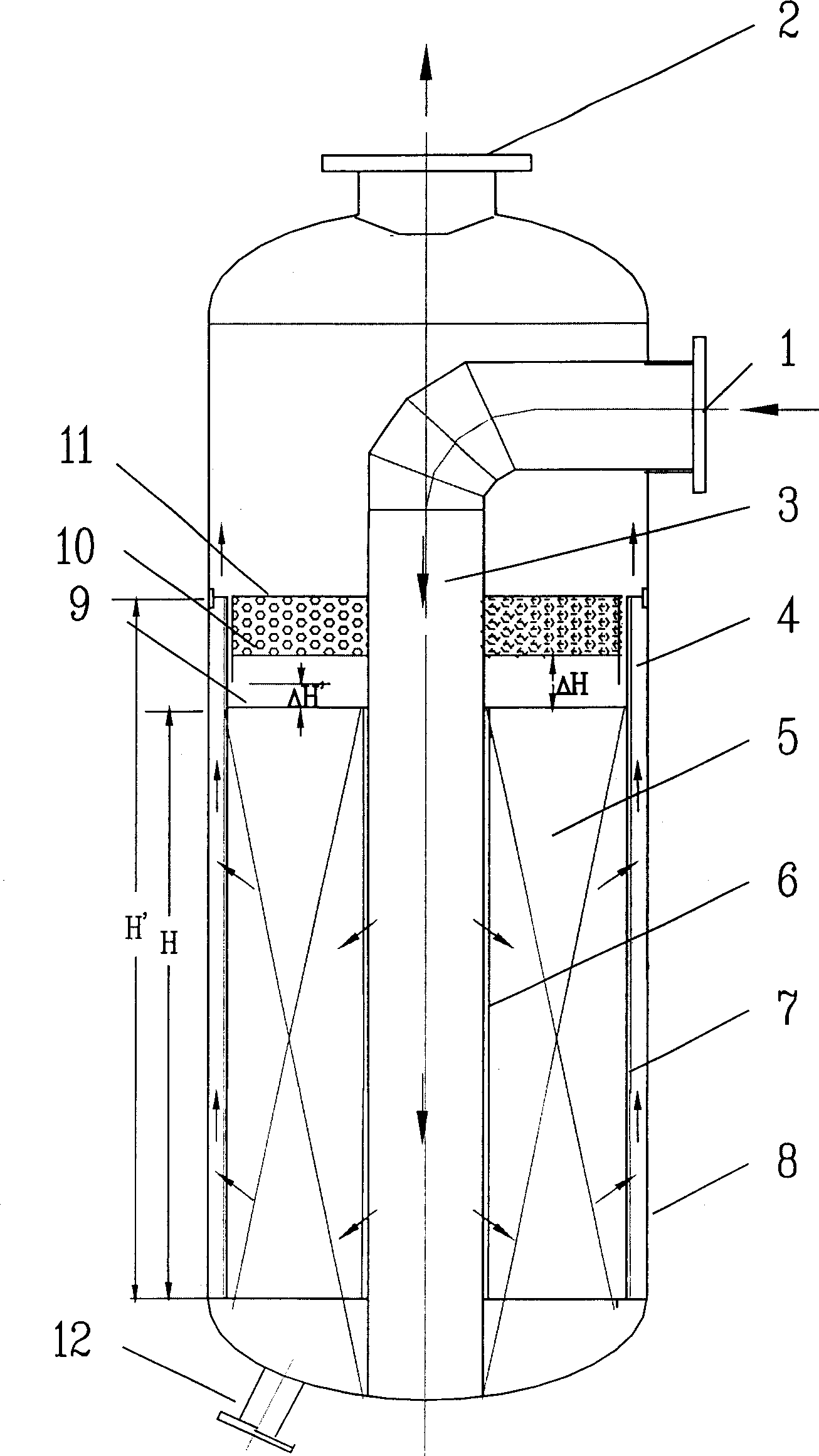

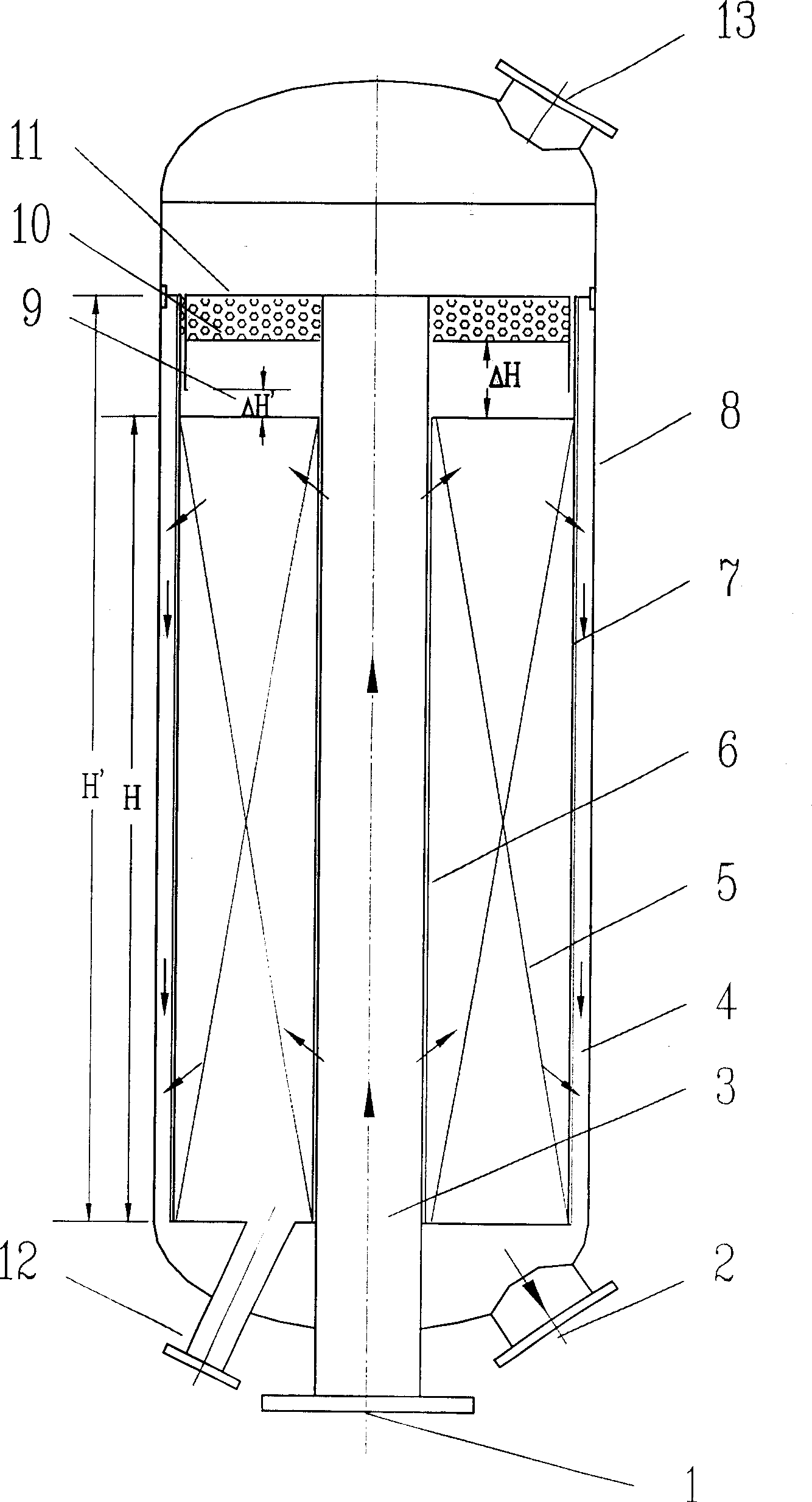

Catalytic reforming and catalytic dehydrogenation centrifugal type fixed bed radial reactor

InactiveCN1546217AAvoid heat lossUniform axial temperatureCatalytic crackingChemical/physical processesCatalytic reformingFixed bed

The invention discloses a kind of fixed bed reactor for catalytic reforming and dehydrogenation, the reactor uses a round pressure container which has a catalytic bed. The inlet and the outlet is at one side of the container, the catalytic bed is made up of outer multi-hole wall and round inner multi-hole wall, catalyst is filled in them, there has a cover sealing structure on the catalyst, the round inner multi-hole wall can uses variable hole-rate or zone structure. The reacting gas in the device flows centrifugally, the gas in the centre inner barrel and multi-hole outer barrel flow reversely.

Owner:EAST CHINA UNIV OF SCI & TECH

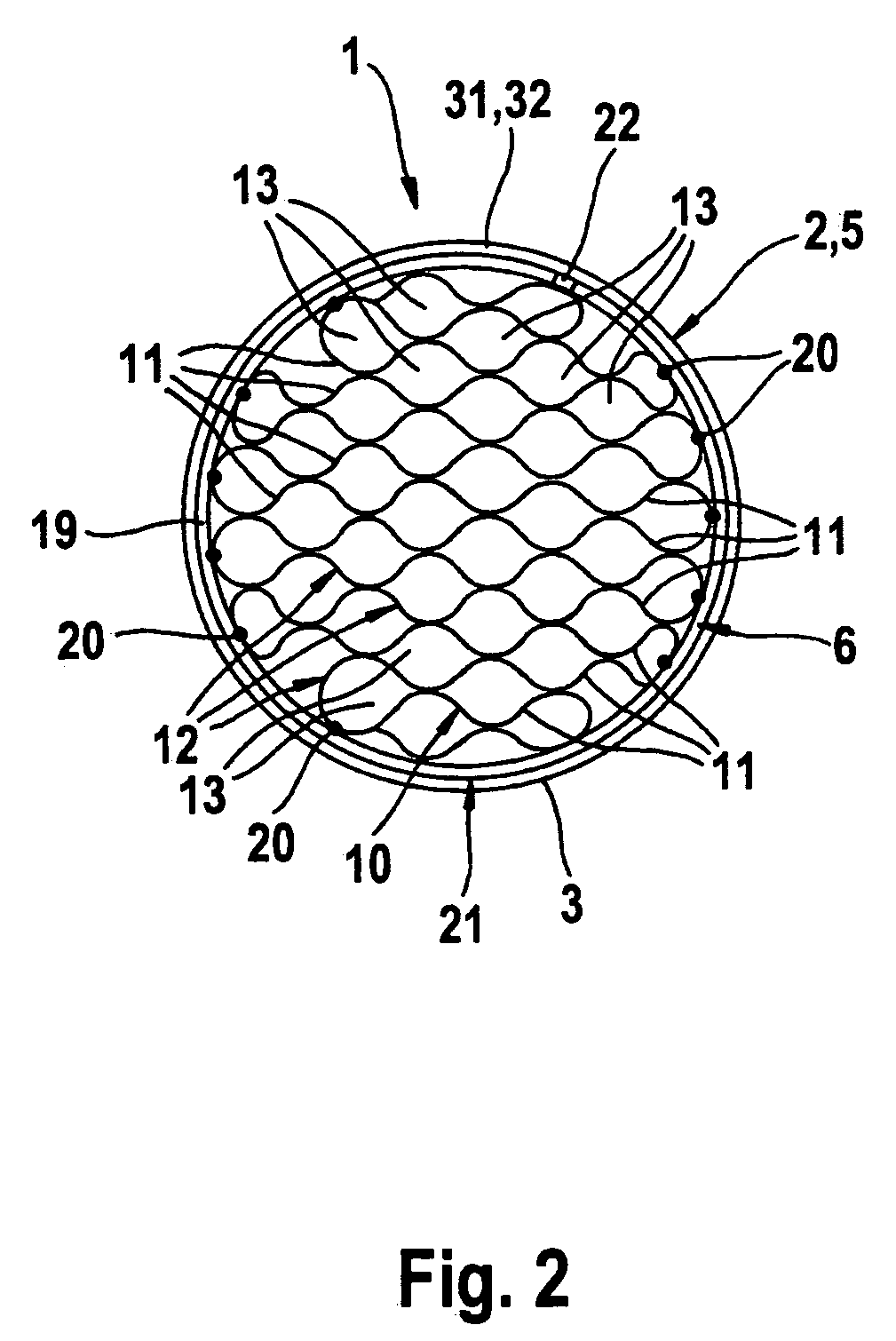

Concentric ring adverse current type hypergravity swinging bed device

ActiveCN101254356ASmall pressure dropGood contact spaceDispersed particle separationChemical/physical/physico-chemical stationary reactorsCounter flowHypergravity

The invention provides a concentric circularity counter-flow type super-gravity rotating packed bed, which comprises a shell, a liquid-phase inlet and a gas-phase outlet arranged on the upper end surface of the shell, a gas-phase inlet and a liquid-phase outlet arranged on the lower end of the shell, a rotating body arranged on the center of the shell, and a rotor connected with the rotating body, wherein the rotor comprises a rotating disc permanently connected with the rotating body and a static disc permanently connected with the shell, the two sides of the lower end of the rotor are provided with first access points, the center of the upper end of the rotor is provided with a second access point, the second access point is communicated with the gas-phase outlet and the liquid-phase inlet, and the first access points are communicated with the gas-phase inlet and the liquid-phase outlet; the rotor also comprises a concentric mesh moving coil, the concentric mesh moving coil is composed of a group of rotating coils which are concentric with different diameters and have meshes, the bottom end thereof is permanently connected on the rotating disc, the upper end is rotationally connected with the static disc, and the first access points and the second access point are communicated with the channel of the concentric mesh moving coil. The invention proposes the concentric circularity counter-flow type super-gravity rotating packed bed with low pressure drop, small rotor liquid holdup and better application effect.

Owner:ZHEJIANG UNIV OF TECH

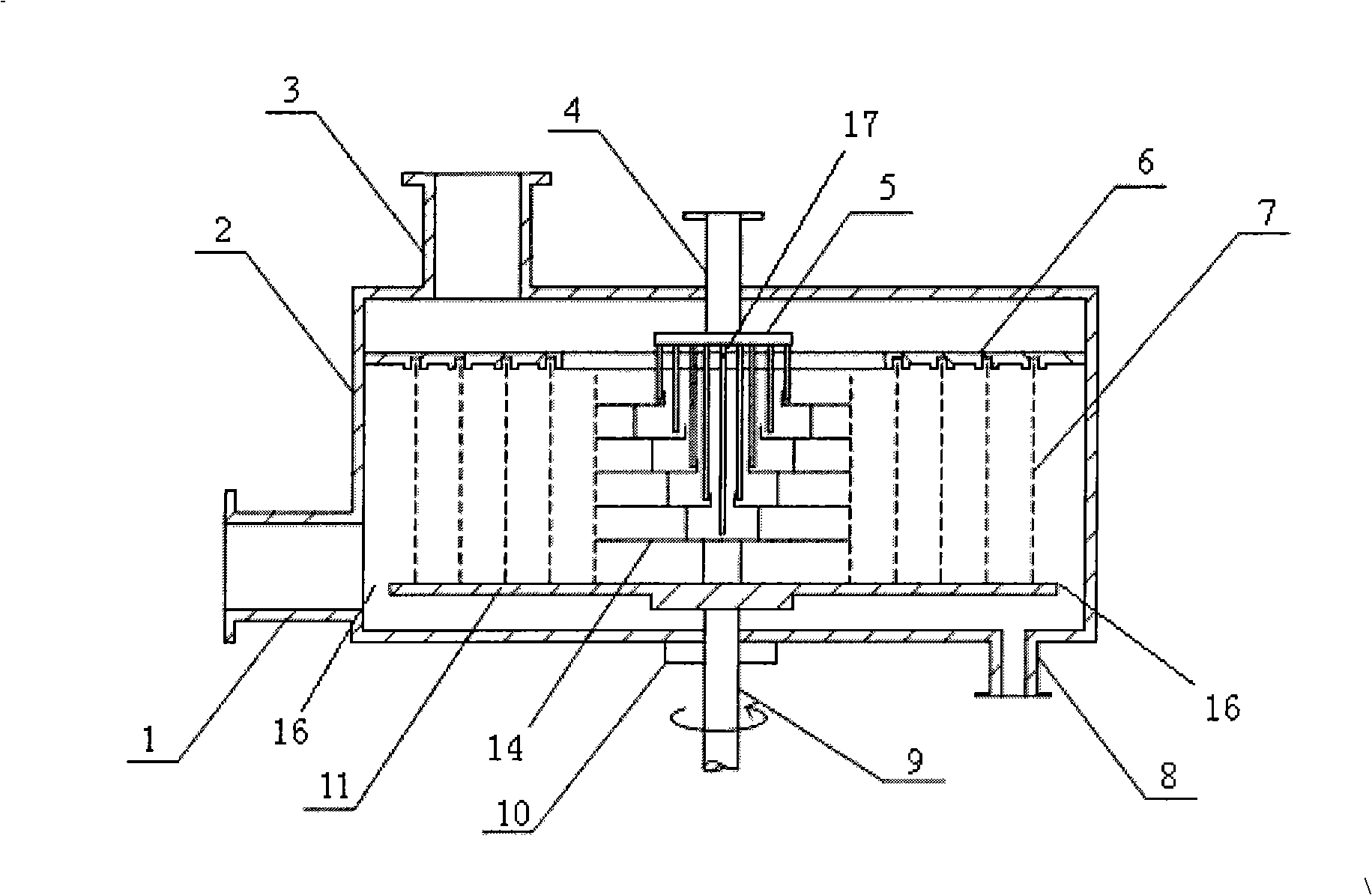

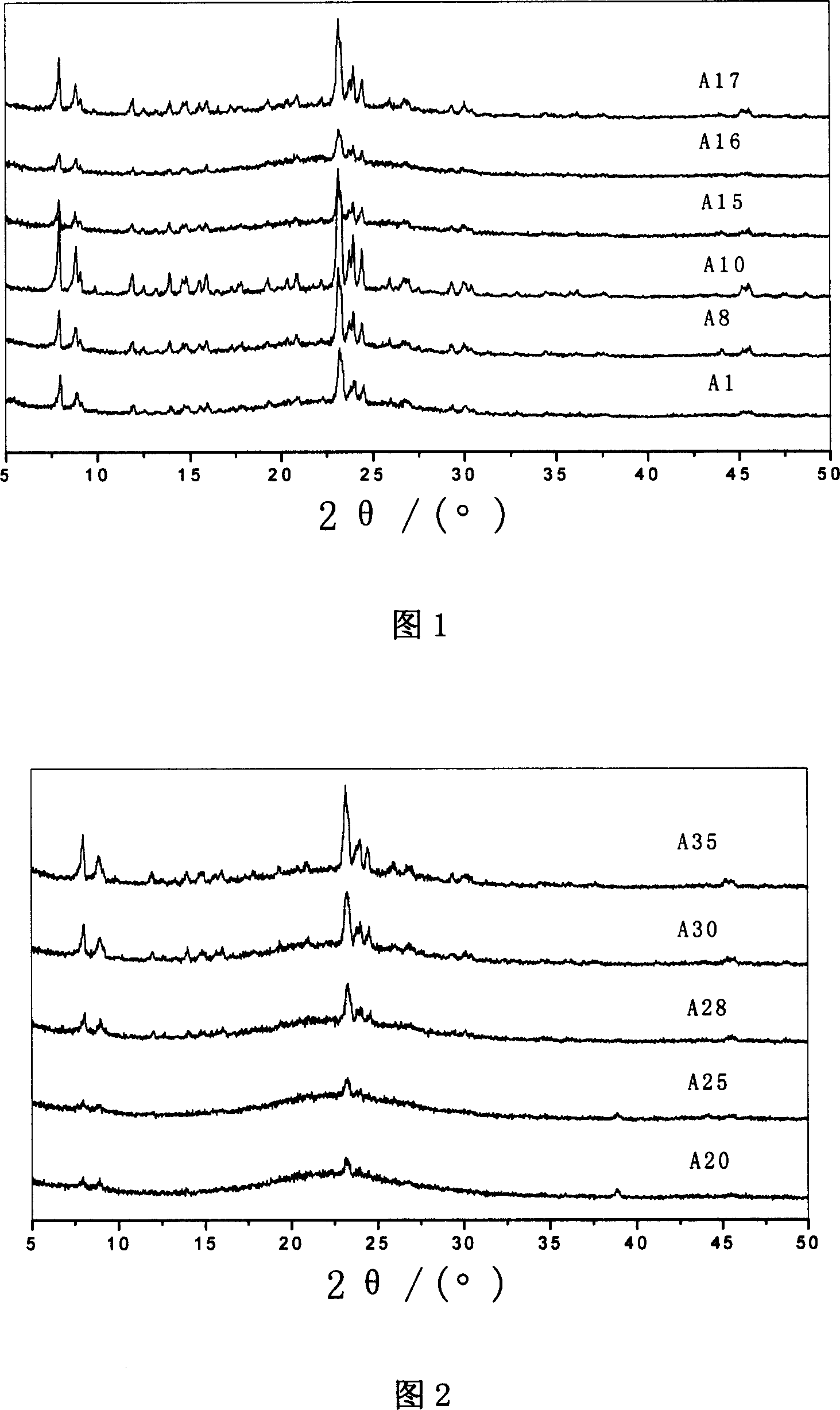

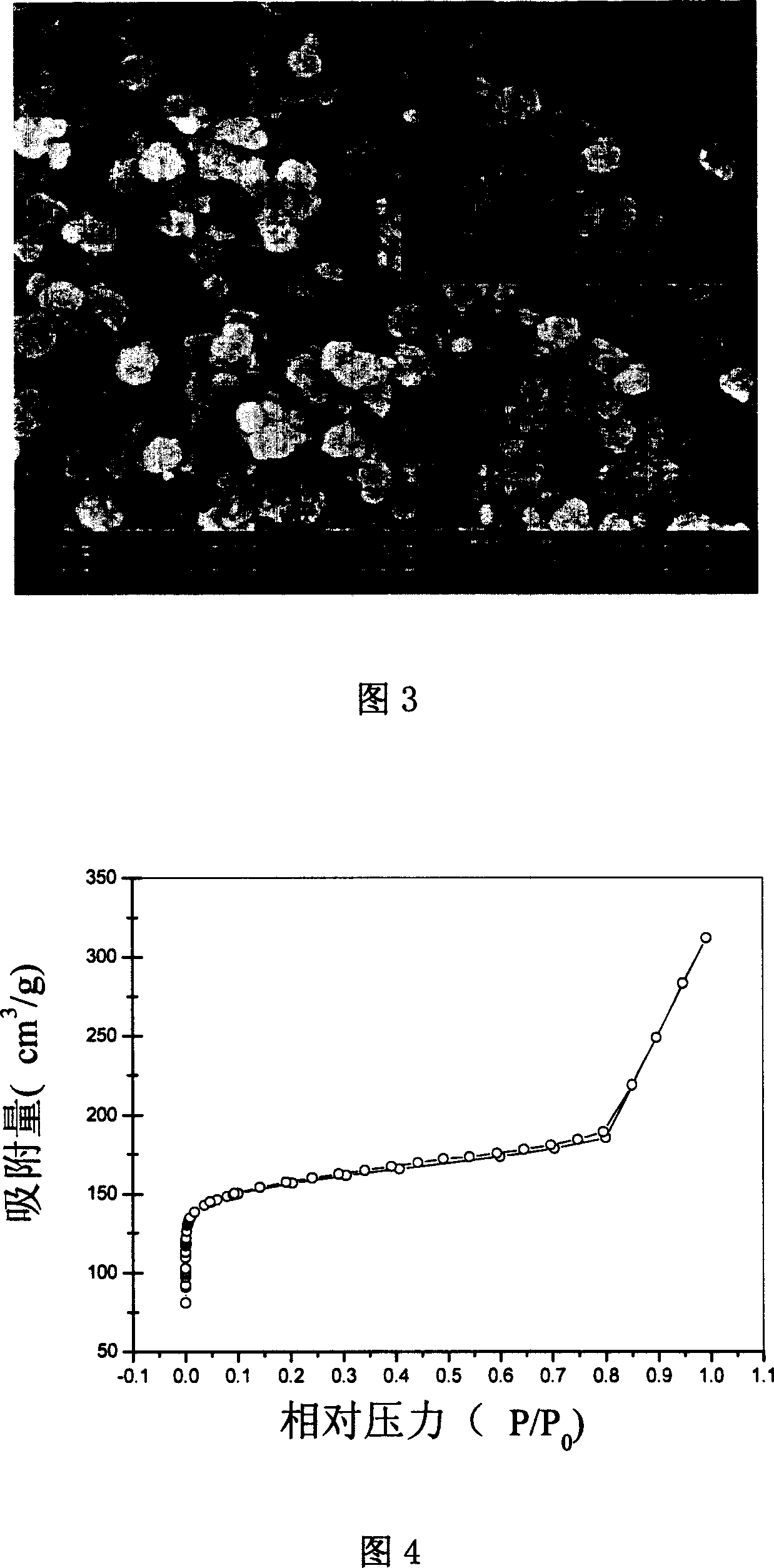

Method for synthesizing ZSM-5 zeolite with multilevel pore canals

ActiveCN101003380AThe operation process is simpleReduce manufacturing costMolecular sieve catalystsPentasil aluminosilicate zeoliteSucrose solutionChemistry

This invention discloses a method for synthesizing multi-level porous ZSM-5 zeolite. The method comprises: soaking monolithic silica gel column in sucrose solution, drying, polymerizing, carbonizing to obtain C-Si composite, wetting the C-Si composite with a mixed solution of Al source, inorganic alkali, organic amine and water, crystallizing, and recovering the product. The obtained ZSM-5 zeolite has multi-level pores, including micrometer-scale macropores, mesopores and micropores. The macropores can shorten the diffusion distances of reactive molecules, reduce the pressure decrease of the equipment, raise the unit processing capacity of the equipment, and make the adjustment and control of the product selectivity easier. The mesopores can provide large inner specific surface area, which is meaningful to the catalytic reaction of macromolecules.

Owner:CHINA PETROLEUM & CHEM CORP +2

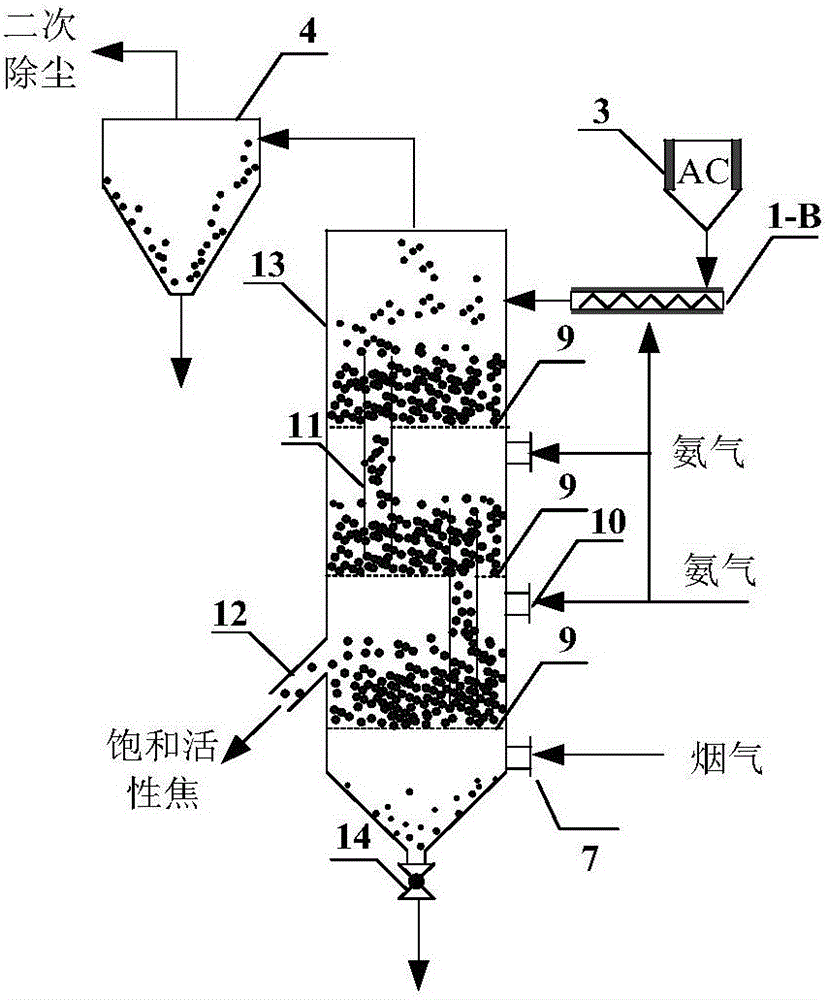

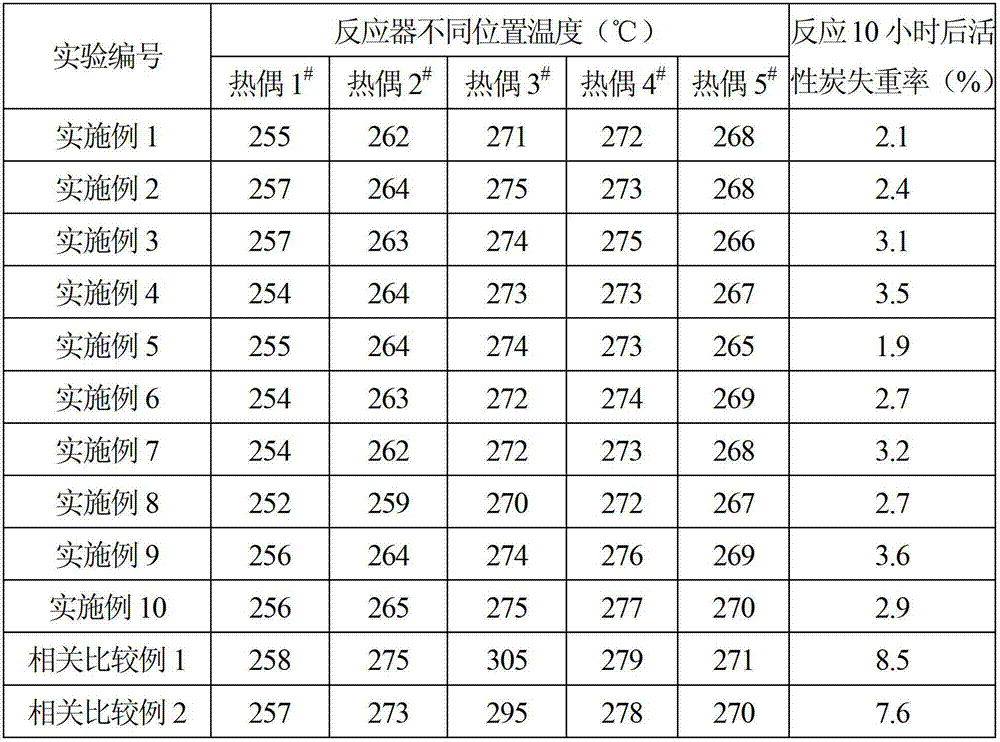

Cellular activated carbon-based denitration catalyst as well as preparation and application thereof

InactiveCN102078753ALarge specific surface areaWell-developed pore structureCatalyst carriersDispersed particle separationMANGANESE ACETATEActivated carbon

The invention discloses a catalyst for smoke denitration. The catalyst comprises the following components in percentage by weight: 77-96% of cellular activated carbon carrier, 1.3-6.5% of MnO and 2.4-18.8% of CeO2, wherein the mixture of the MnO and the CeO2 serves as an active component. The preparation method is as follows: mixing activated carbon with an organic binder, a forming auxiliary and water, carrying out vacuum extrusion molding, drying, and carbonizing, thus obtaining the cellular activated carbon carrier; and preparing the catalyst by using an isopknic impregnation method based on a mixed liquid of magnganous nitrate or manganese acetate and cerous nitrate, wherein the mixed liquid serves as an impregnation liquid. The cellular activated carbon-based denitration catalyst has the advantages of high specific surface area of cellular activated carbon, developed pore structure and small bed pressure drop, and when being used in smoke denitration, the cellular activated carbon-based denitration catalyst has high denitration activity at the wide temperature range of 80-200 DEG C.

Owner:EAST CHINA UNIV OF SCI & TECH

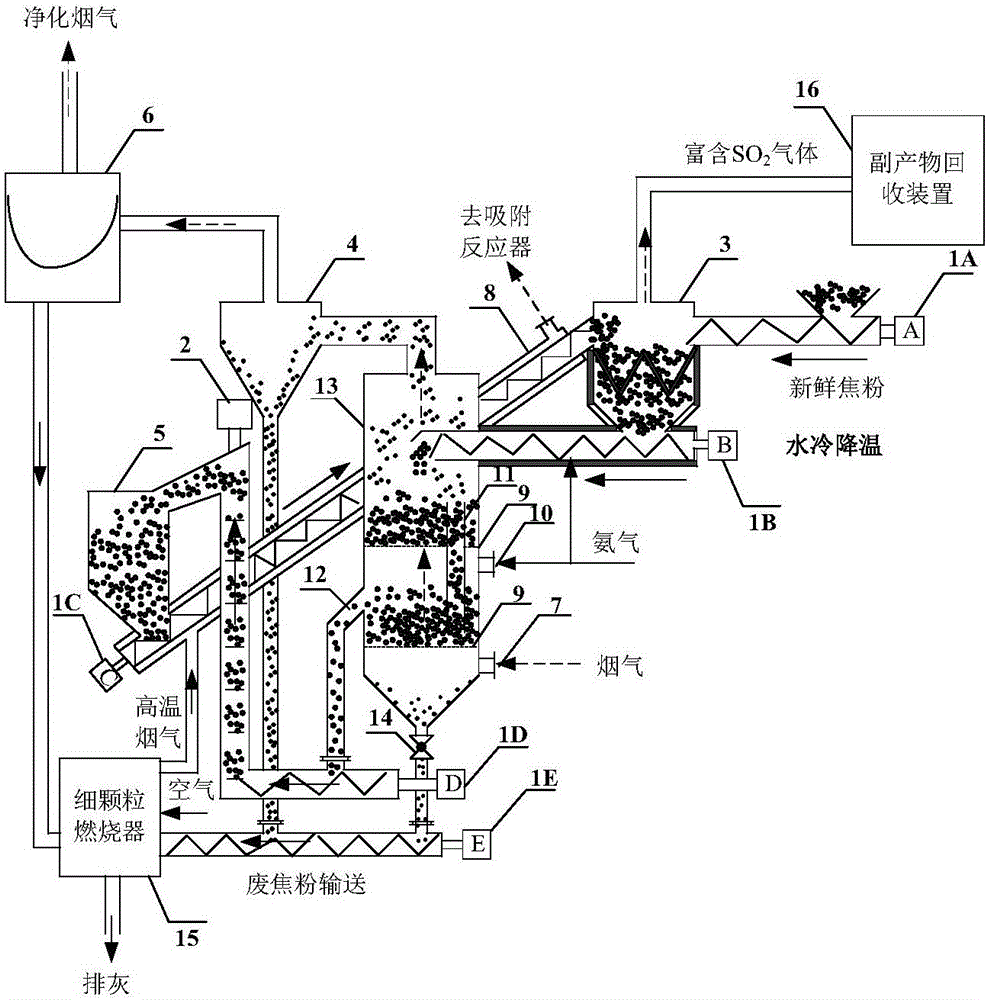

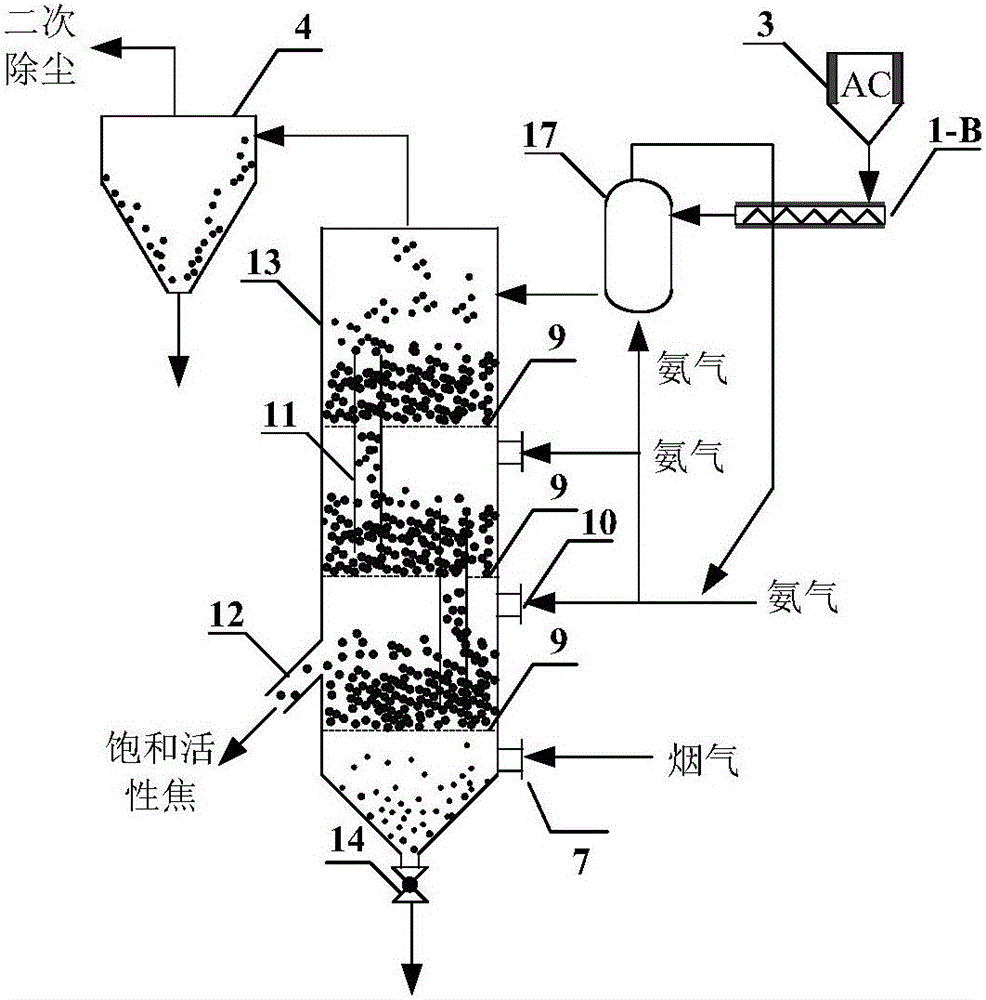

Multi-layer fluidized bed two-stage activated carbon/coke flue gas simultaneous-desulfurization and denitrification system and method

ActiveCN105727708ASave spaceEfficient use ofGas treatmentDispersed particle separationInjection portFluidized bed

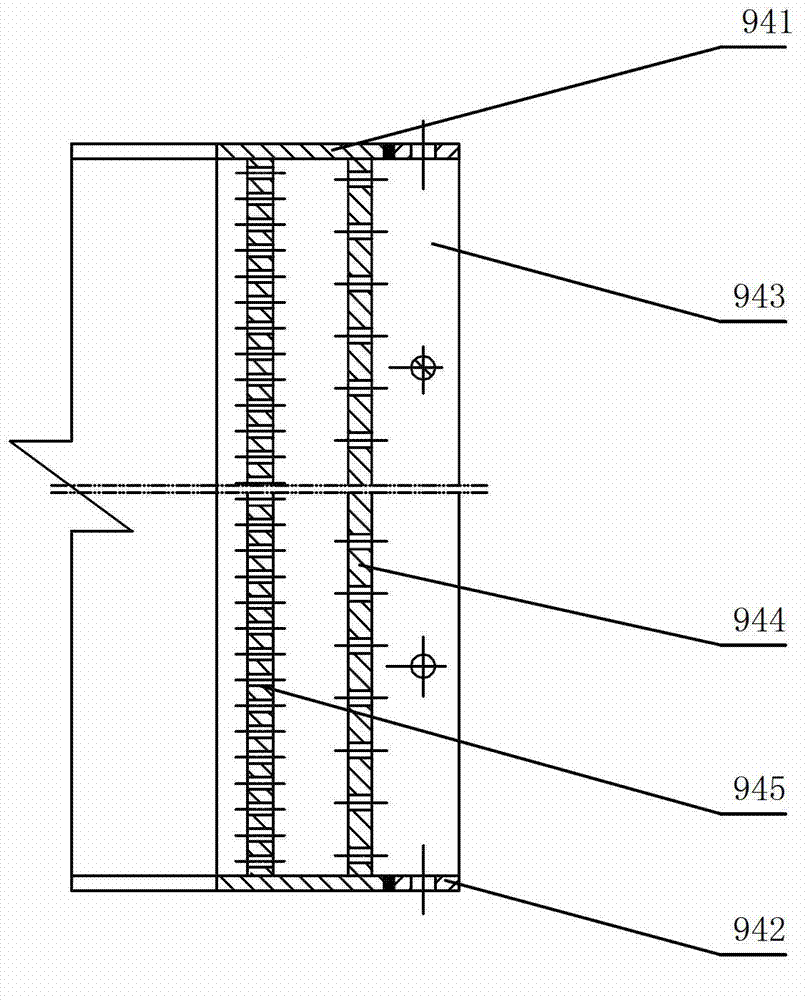

The invention relates to the field of industrial flue gas pollution control. A multi-layer fluidized bed two-stage activated carbon / coke flue gas simultaneous-desulfurization and denitrification system of the invention comprises a dust removal device (4) and further comprises a desulfurization and denitrification multi-layer fluidized bed reactor (13), wherein a feed port of the dust removal device (4) is communicated with the top of the desulfurization and denitrification multi-layer fluidized bed reactor (13); the desulfurization and denitrification multi-layer fluidized bed reactor (13) is divided into an upper denitrification section and a lower desulfurization section; the denitrification section comprises several layers of fluidized beds; an ammonia gas injection port (10) is formed in a side wall corresponding to a position below the bottom of each layer of fluidized bed; the desulfurization section comprises several layers of fluidized beds; a flue gas inlet (7) is formed in the side wall corresponding to the position below the bottom of a lowest layer of fluidized bed. The system provided by the invention can enhance the mass transfer and heat transfer, improve the efficiency of desulfurization and denitrification, replace high-cost formed activated carbon / coke with fine granular activated carbon / coke to reduce the costs for desulfurization and denitrification, and is suitable for the flue gas purification of power plant boilers, industrial boilers, heating boilers and coking industry.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

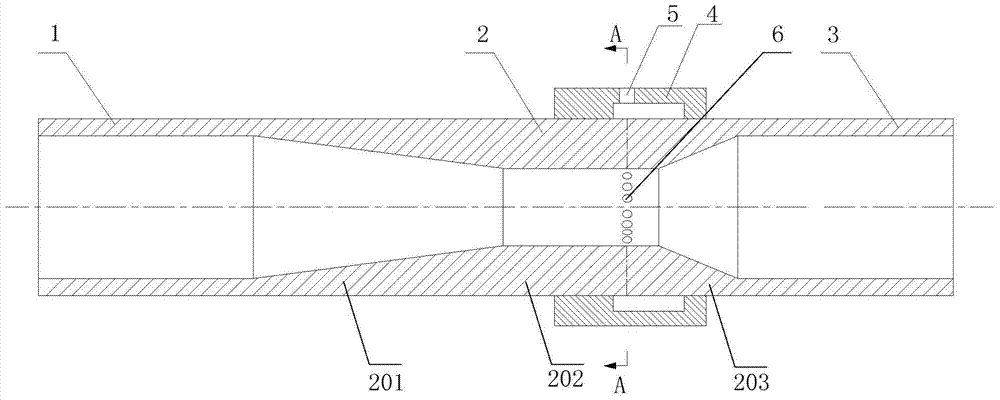

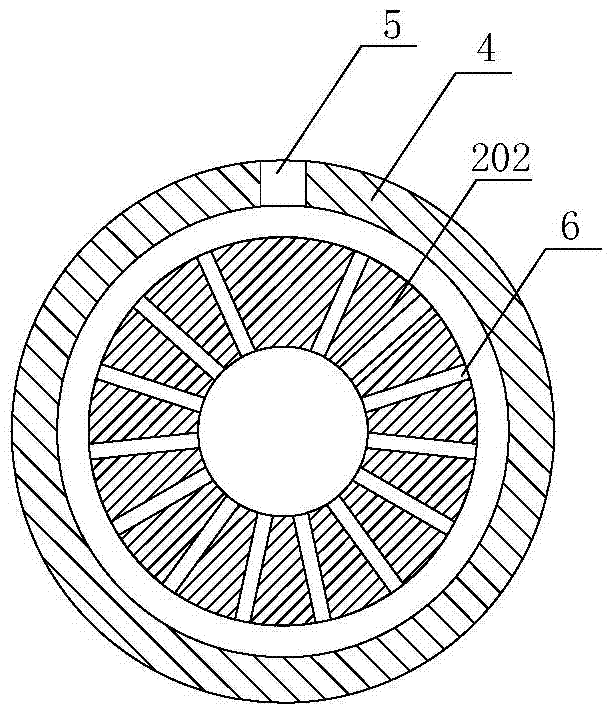

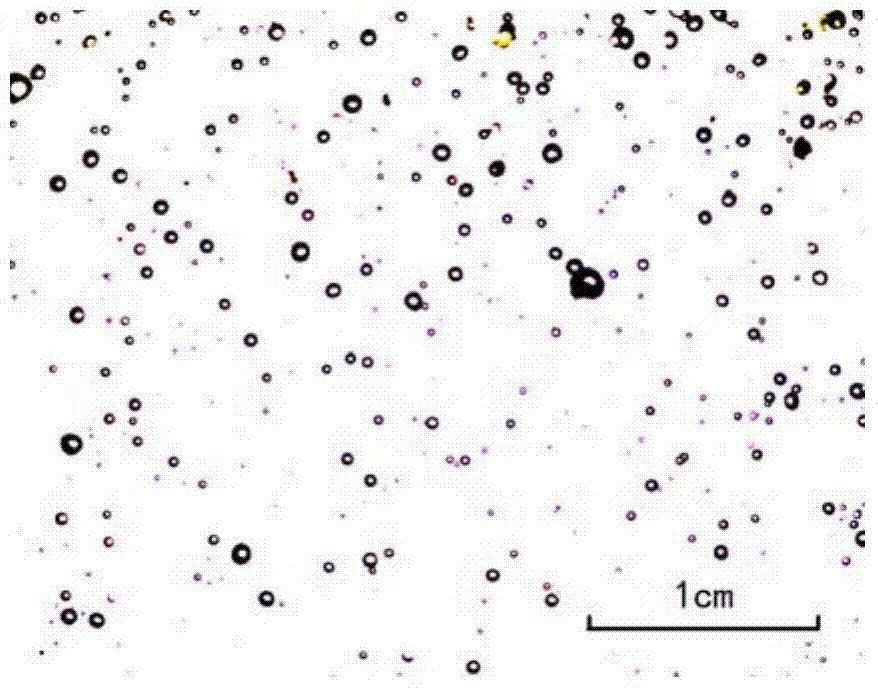

Microbubble generation device and use thereof

The invention discloses a microbubble generation device and a use thereof. The microbubble generation device comprises an input pipe, a Venturi tube and an output pipe, and the three parts are orderly communicated. The input pipe, the Venturi tube and the output pipe are arranged on the same straight line. The Venturi tube comprises a contraction section, a throat section and an expansion section, and the three parts of orderly communicated. The outer pipe wall of the throat section is provided with a ventilation ring. The ventilation ring is a hollow columnar sealed chamber. The columnar body of the hollow columnar sealed chamber is provided with a gas inlet. The pipe wall of the throat section is provided with thorough vents symmetrically distributed along the axle center of the Venturi tube. The cross section formed from the vents is perpendicular to the axis of the Venturi tube. The vents are located in the hollow columnar sealed chamber. The device can uniformly feed gas into a liquid so that micro-bubbles are produced in the liquid. The ventilatory capacity and the number and sizes of the bubbles can be adjusted and effectively controlled by device structure adjustment.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

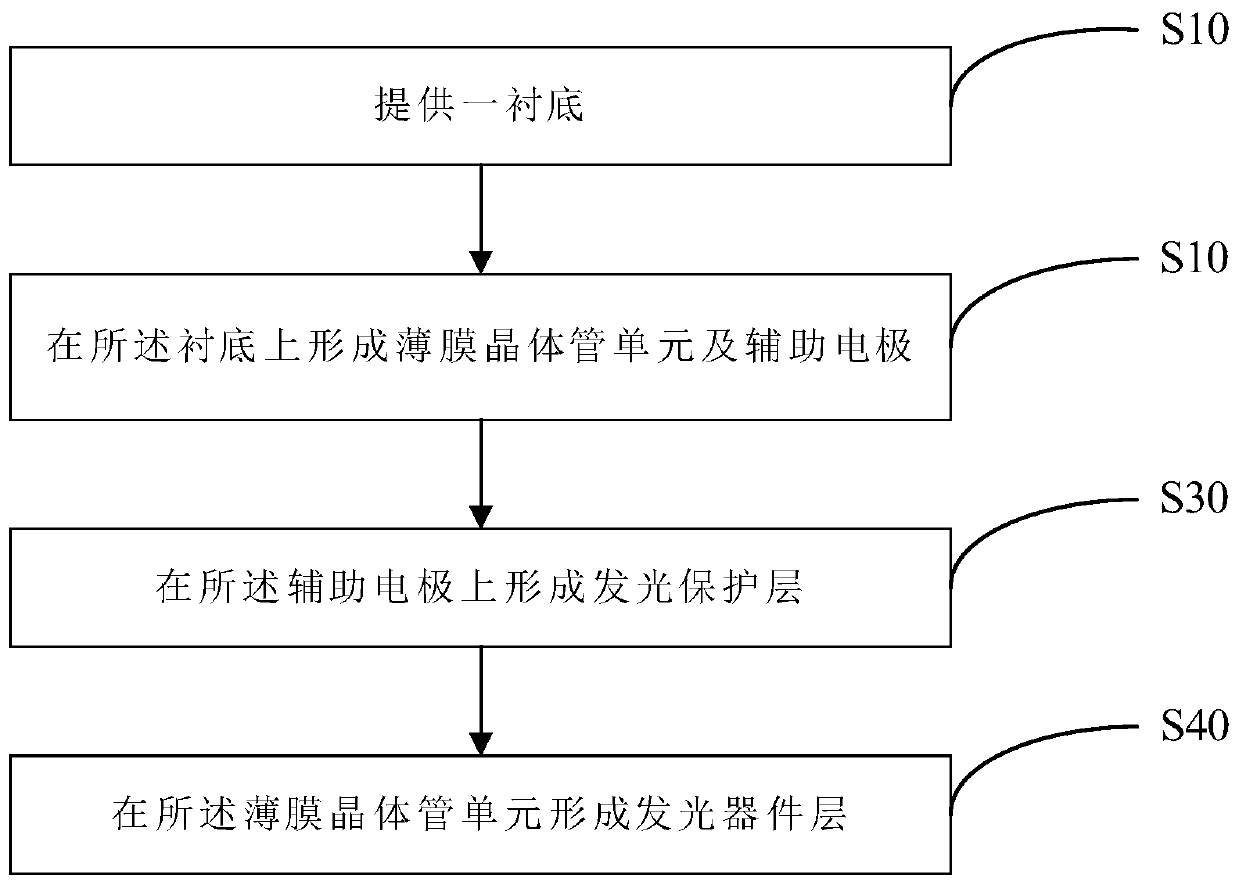

Display panel and manufacturing method

InactiveCN110071225AIncrease brightnessRaise the potentialSolid-state devicesSemiconductor/solid-state device manufacturingVoltage dropLap joint

The invention provides a display panel and a manufacturing method thereof, wherein a display area of the display panel comprises a first area positioned at the edge of the display area; and an auxiliary electrode and a light-emitting protection layer positioned on the auxiliary electrode are arranged in the first area, and orthographic projection of the light-emitting protection layer on the auxiliary electrode is partially overlapped with the auxiliary electrode. According to the invention, an auxiliary electrode is arranged in the edge area of a display panel, and cathode layer is in lap joint with the auxiliary electrode, so that the potential of the cathode layer is increased, the voltage drop of the cathode layer is slowed down, and the brightness uniformity of the display panel is improved.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Activated carbon coating/foam silicon carbide structural catalyst and preparation method thereof

ActiveCN102814188AUniform temperature distributionSufficiently chemically inertCatalyst activation/preparationChemical reactionHeat inactivation

The invention relates to the field of structural catalysts, in particular to an activated carbon coating / foam silicon carbide catalyst with a three-dimensional communicated structure and a preparation method for the catalyst. The invention aims to solve the problems that hole opening is discontinuous, the catalyst and reaction products are separated, a heat transfer and mass transfer effect is poor and the like in the prior art. By taking foam silicon carbide as a catalyst carrier, an activated carbon coating covers on the surface of the foam silicon carbide, wherein the activated carbon coating is between 0.1 micron and 500 microns thick, and a metal catalysis active component is loaded on the activated carbon coating. The activated carbon coating is prepared on the surface of the foam silicon carbide with the three-dimensional communicated structure, then, the metal catalysis active component is loaded, and activating treatment is performed on the metal catalysis active component to obtain the catalyst. According to the activated carbon coating / foam silicon carbide catalyst, holes in the catalyst carrier are totally communicated, thus, an enclosure space does not exist, and a heat transfer and mass transfer process of the chemical reaction can be strengthened. The activated carbon coating / foam silicon carbide catalyst has the characteristics that the temperature field distribution of the catalytic reaction is uniform, the heat inactivation rate is low, the pressure drop is low and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

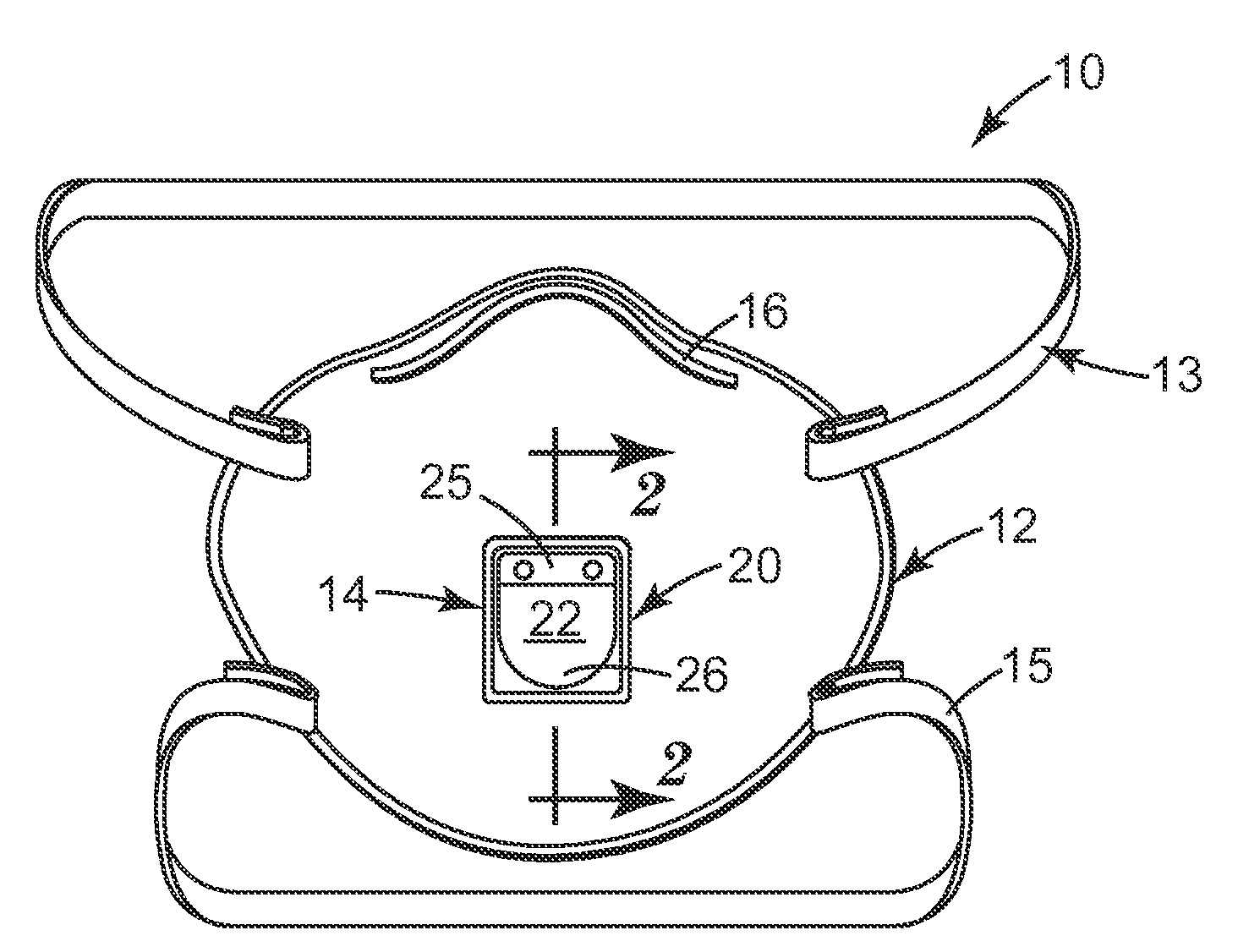

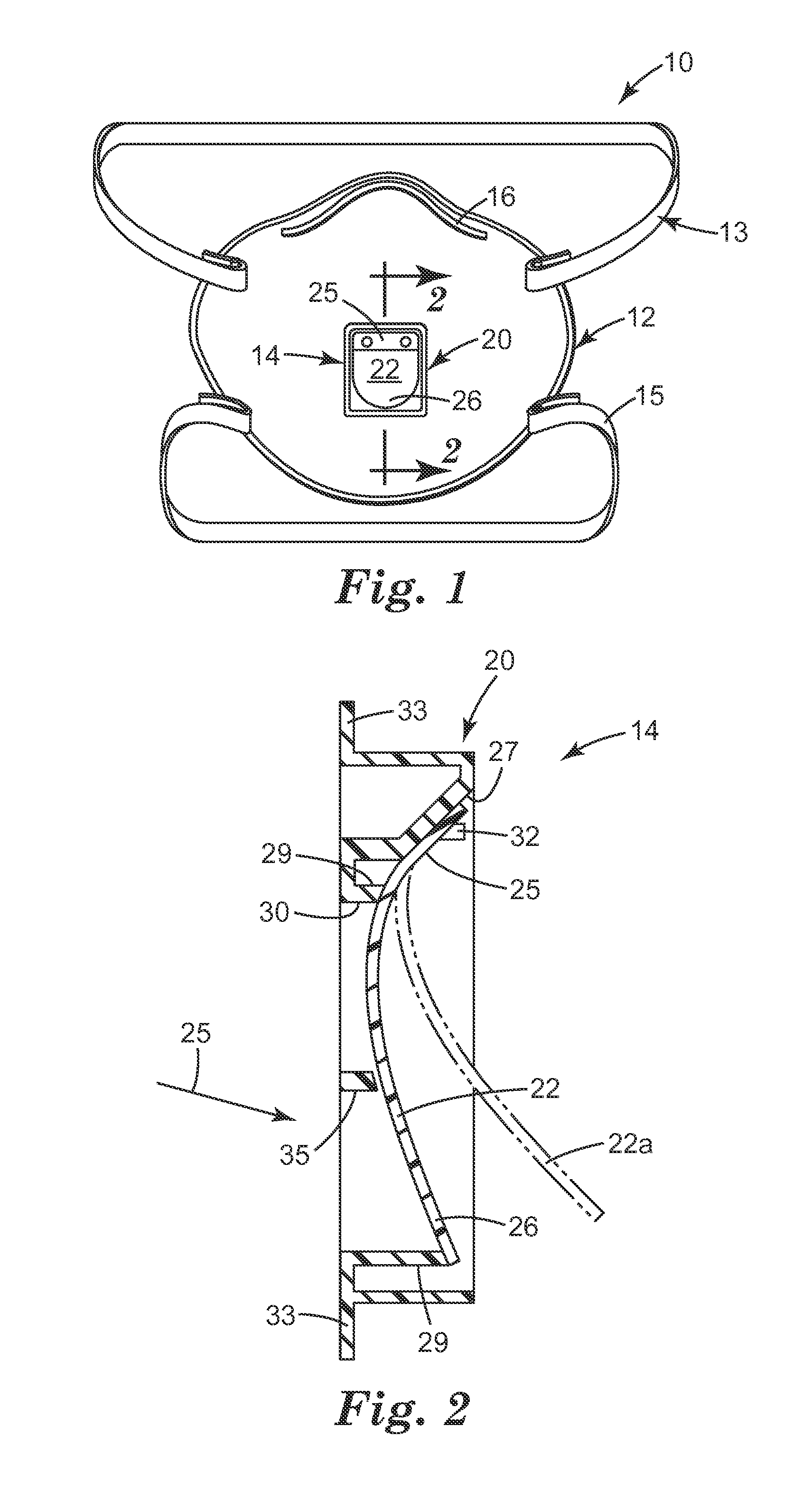

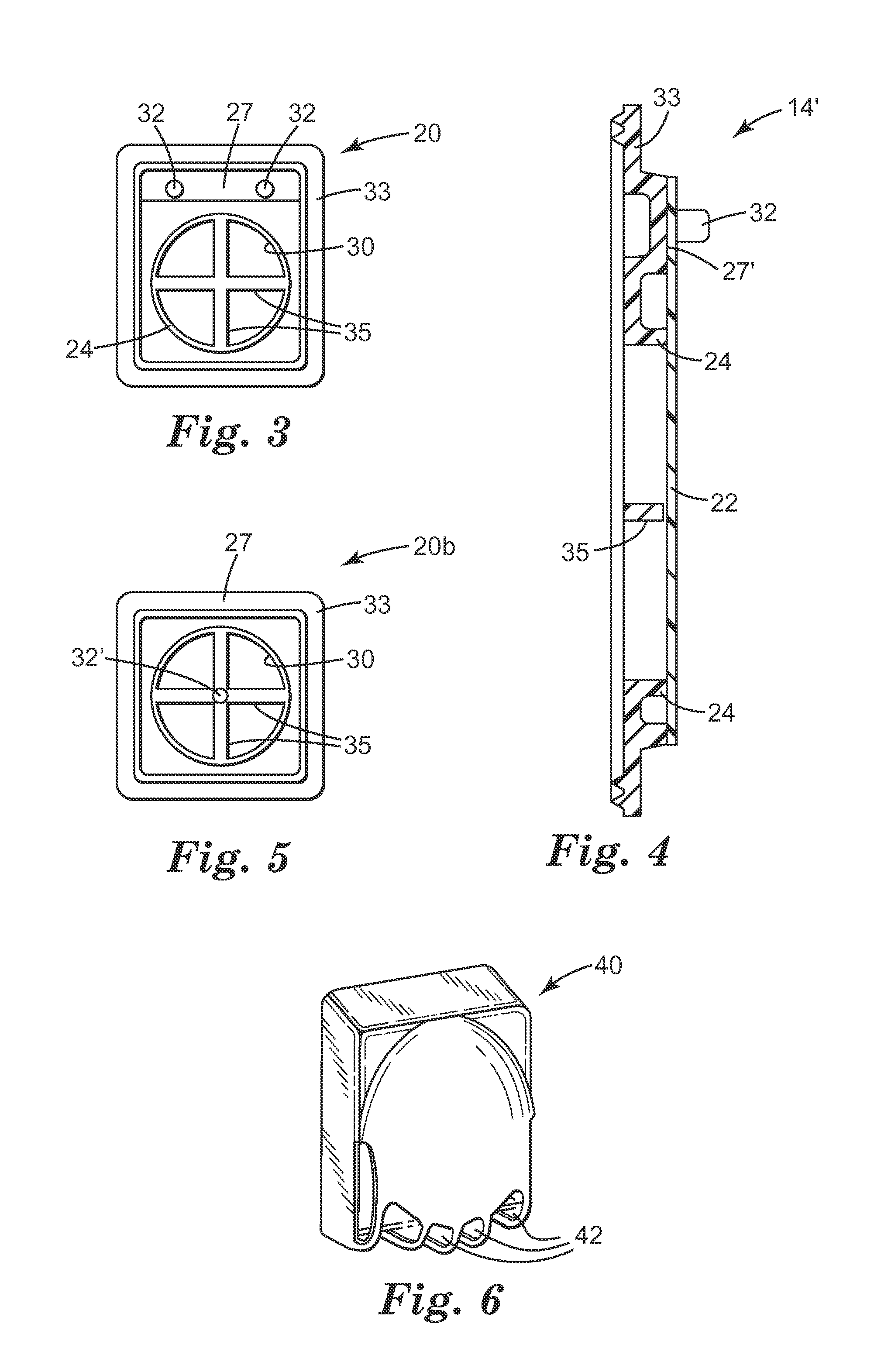

Respirator having valve with an ablated flap

InactiveUS20120167890A1Small pressure dropLess energyRespiratory device testingBreathing filtersRespiratorEngineering

A respirator 10 that has a mask body 12, a harness 13, and an exhalation valve 14. Both the harness 13 and the exhalation valve 14 are secured to the mask body 12. The exhalation valve 14 comprises a valve seat 20 and a flap 22 that has a surface 57 that has been ablated. Through use of an ablated flap, the flap characteristics can be better fashioned to achieve desired valve performance. The valve flap can be fashioned to remain closed under any orientation but also to open with minimal force or pressure from the wearer's exhaled air. A valve having these qualities provides a respirator that is more comfortable for a person to wear, which can be particularly beneficial to workers who wear respirators for extended time periods.

Owner:3M INNOVATIVE PROPERTIES CO

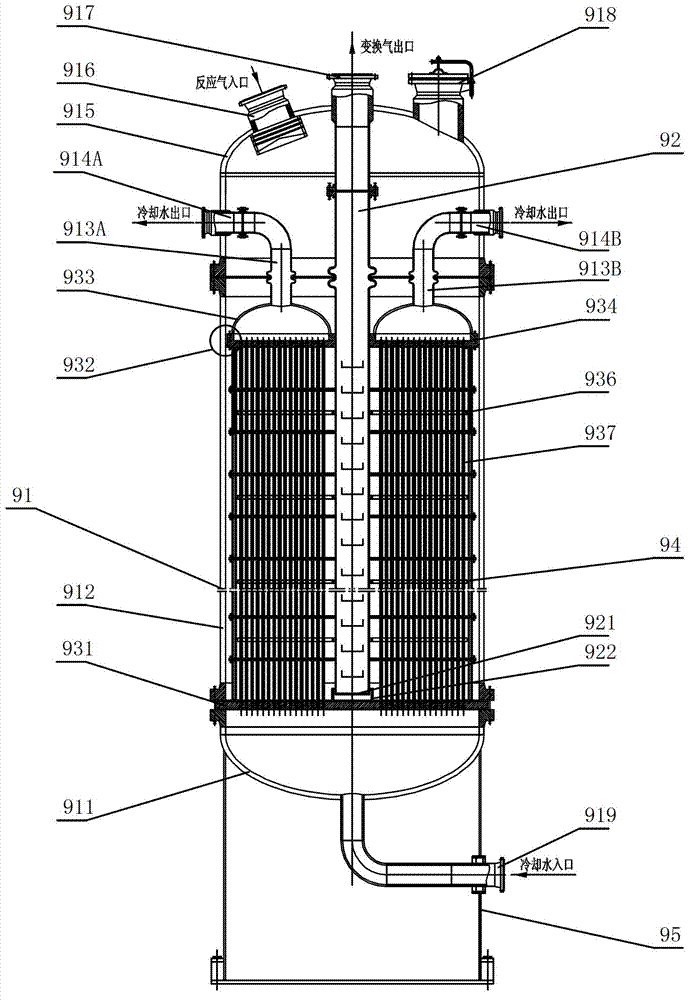

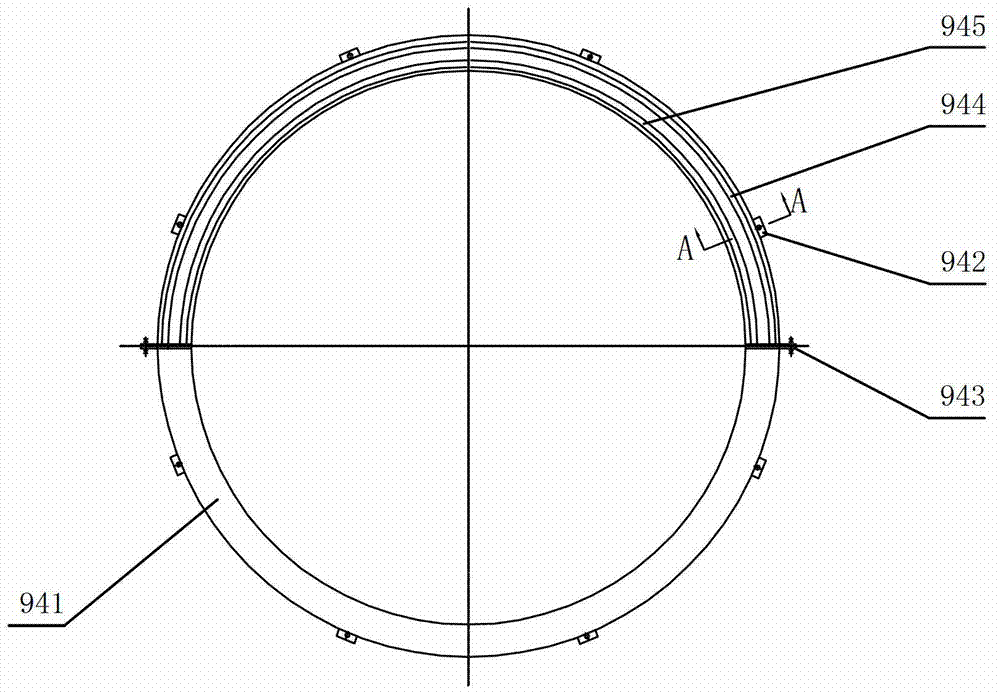

Low-moisture low-variable serial saturation tower thermal CO transformation technology

ActiveCN102888253AShort transformation processReduce resistanceHydrogenCombustible gas catalytic treatmentDry gasMoisture

Owner:CHINA PETROCHEMICAL CORP +2

Flexible display panel and preparation method thereof

InactiveCN109686758AImprove bending performanceImprove display uniformityStatic indicating devicesDigital data processing detailsVoltage dropEngineering

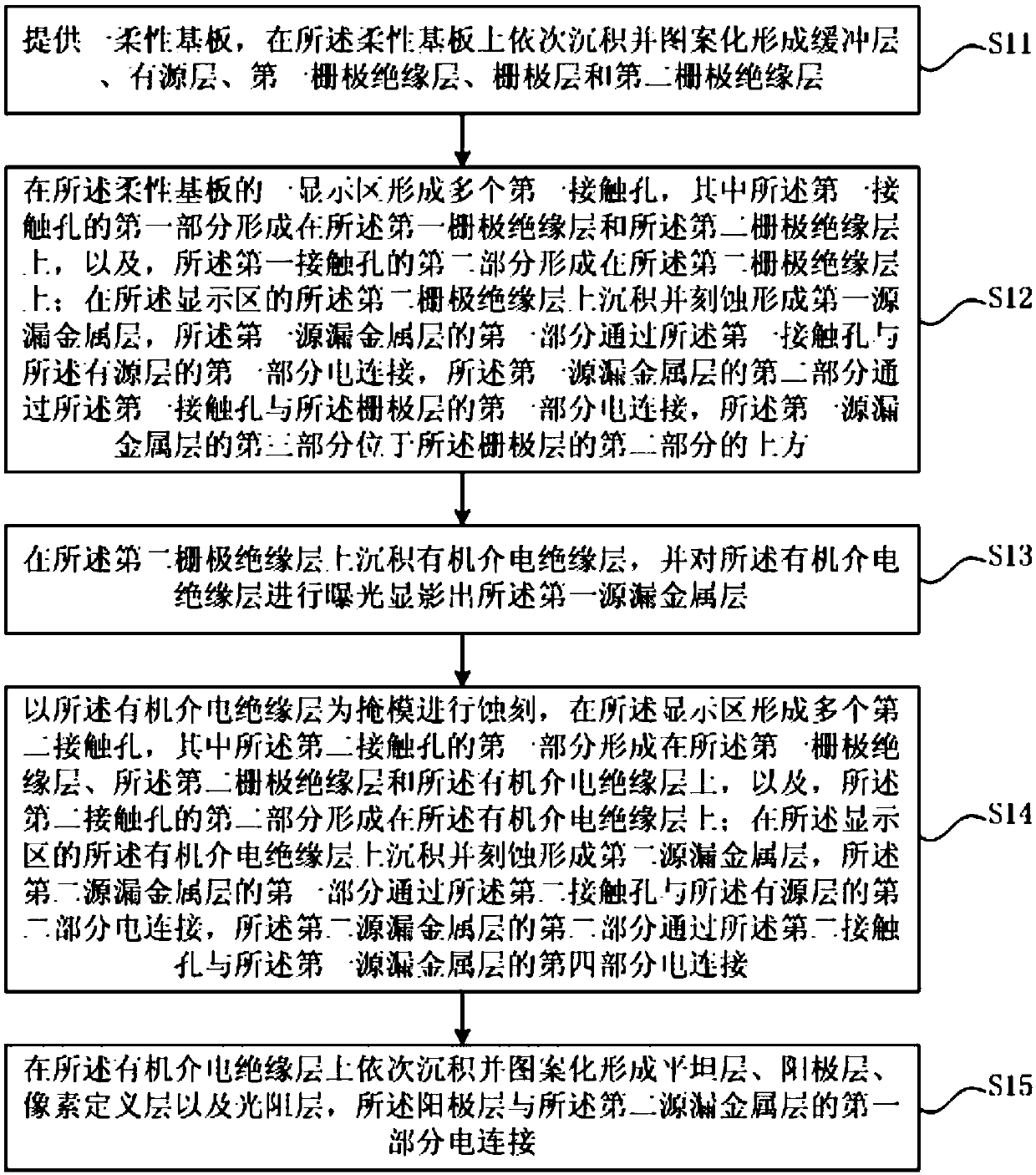

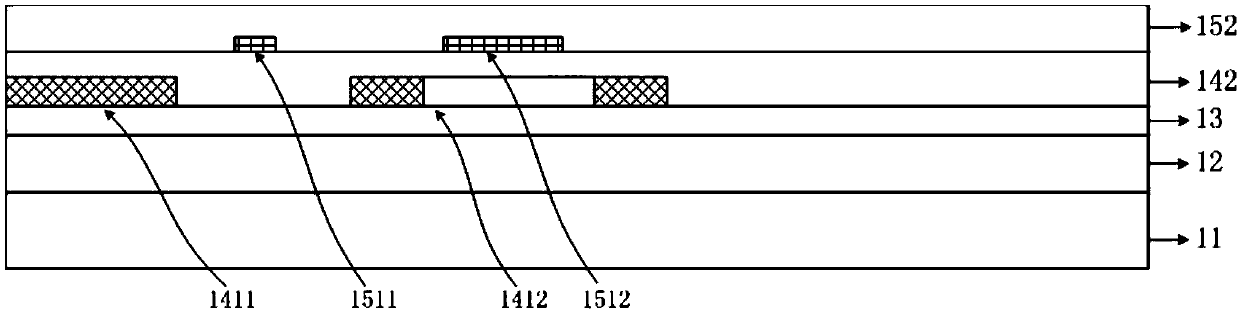

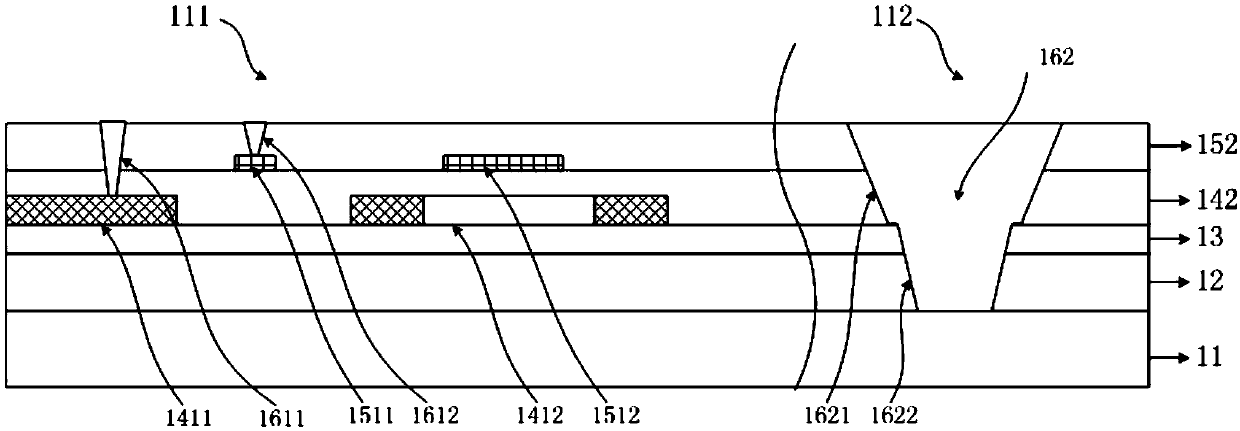

The invention discloses a flexible display panel and a preparation method thereof. The bending performance of the flexible display panel is improved by adopting an organic material with better bendingperformance as a dielectric insulating layer; contact holes in a display area and deep holes in a bending area are dug behind an insulating layer of a second grid electrode, so that a part of the contact holes are completed in a first source drain metal layer to reduce the density of hole digging of a second source drain metal layer, and the high PPI is ensured while the bending performance of the panel is improved; double-layer SD structural processing is adopted, so that IR voltage drop can be reduced, and the display uniformity of the panel can be improved; wiring of the bending area is designed to be double-layer metal wiring, so that the IR voltage drop can be further reduced, and the processing risk is reduced.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

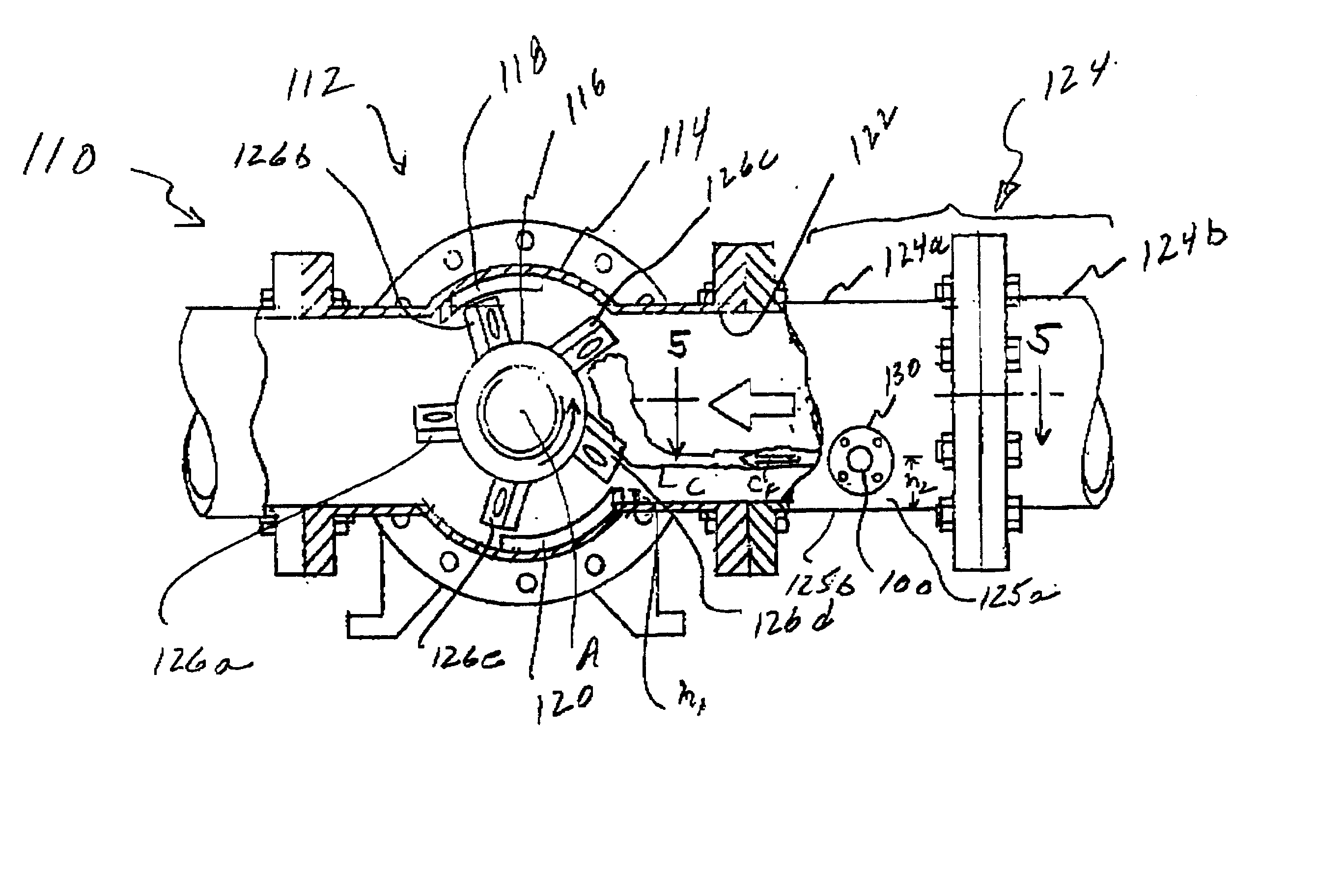

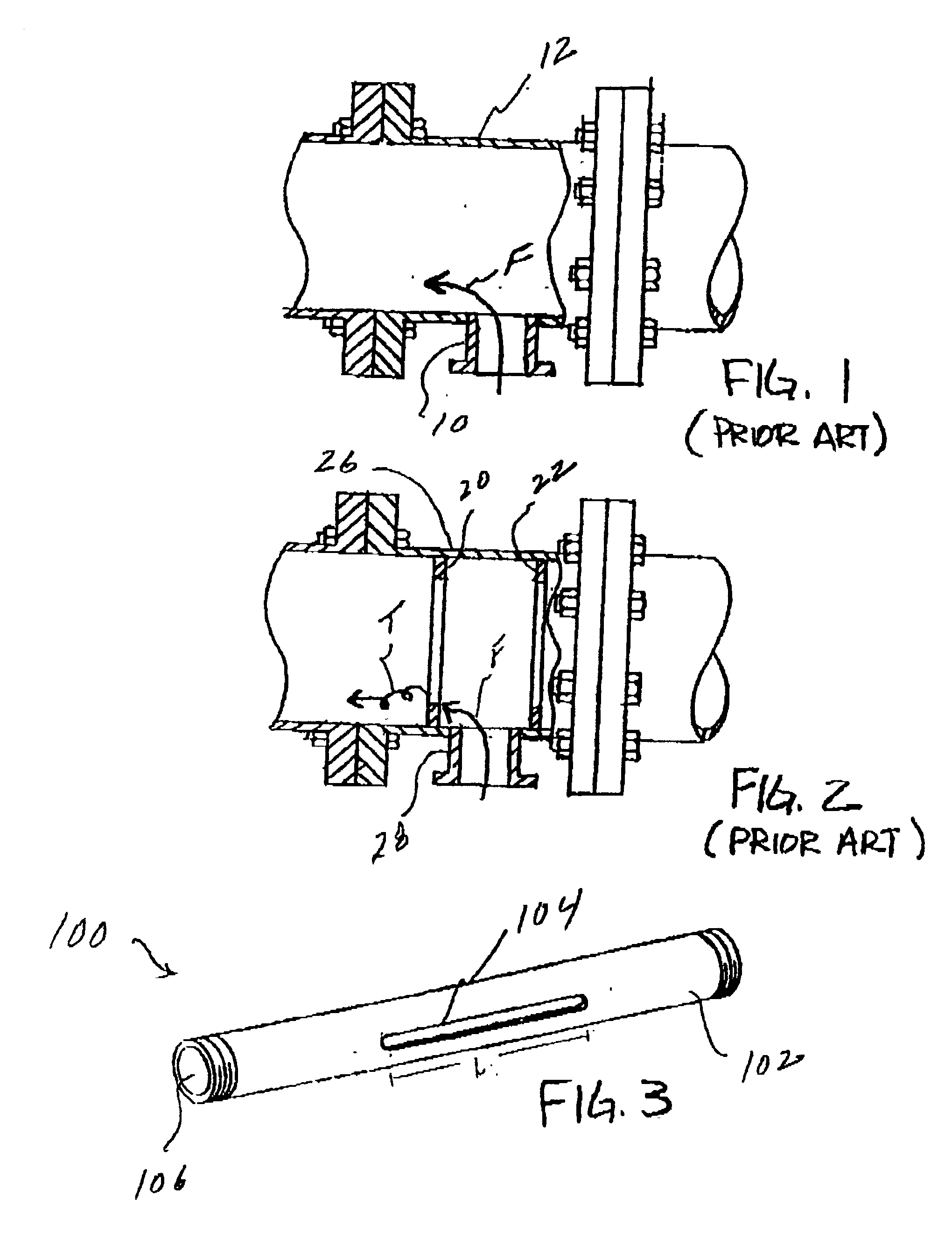

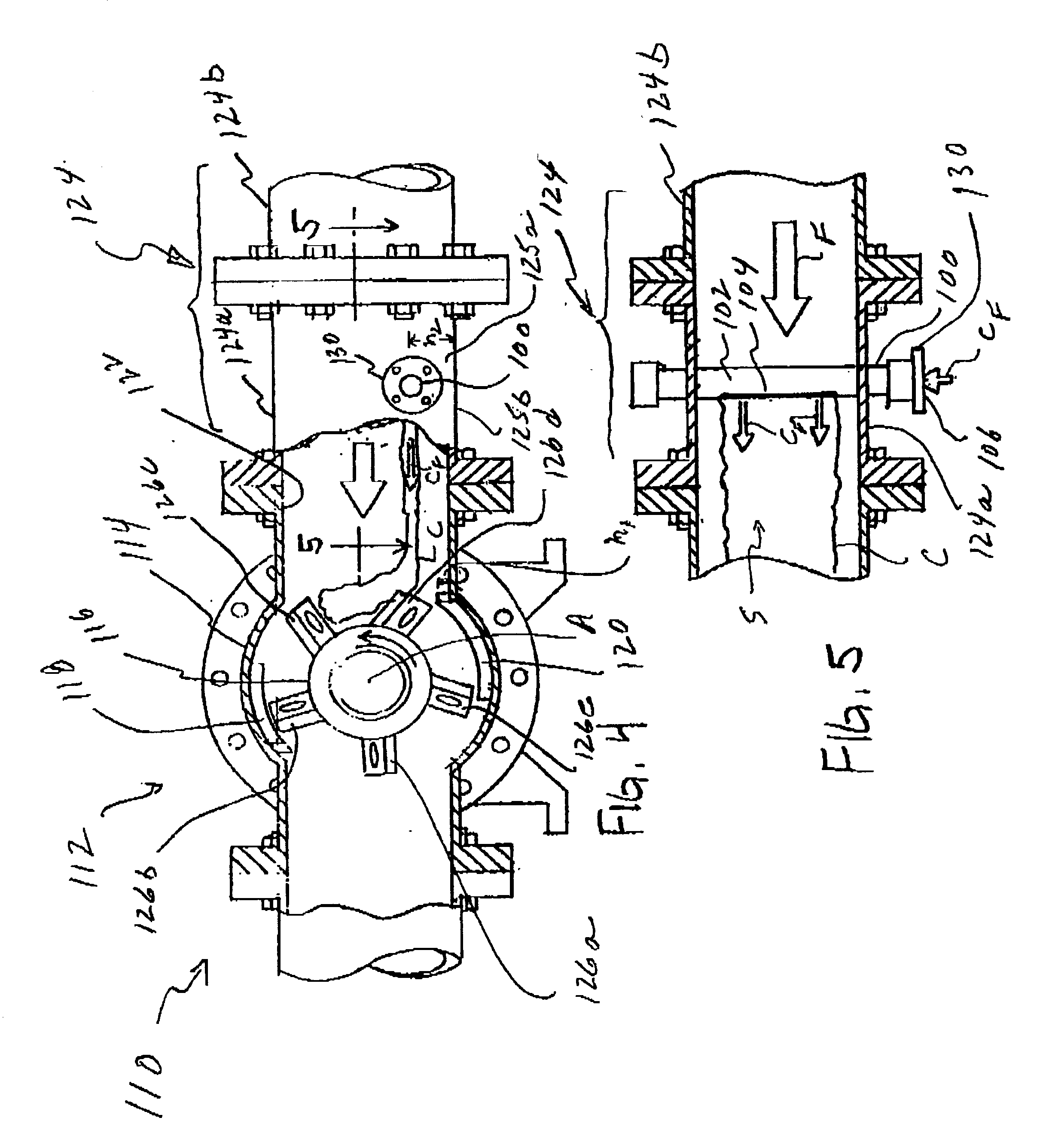

Method and apparatus for injecting a chemical into a process upstream of an inline mixer

InactiveUS20040013032A1Sufficient widthOptimize locationFlow mixersRotary stirring mixersEngineeringMechanical engineering

A new and unique inline mixer and process pipe combination includes an inline mixer with a casing and a rotor arranged therein. The casing has one or more stationary vanes and an inlet connected to a process pipe configuration. The rotor has one or more rotary vanes that rotate on an axis of rotation in the casing. The process pipe configuration includes a chemical injection pipe having a slotted injection pipe arranged therein having an outer surface with a long narrow slot therein oriented substantially parallel to the axis of rotation of the rotor for injecting a chemical into a process flow media flowing in the process pipe configuration. The long narrow slot is located on a downstream side of the outer surface and oriented in a plane parallel to the direction of flow of the process media.

Owner:ITT MFG ENTERPRISES LLC

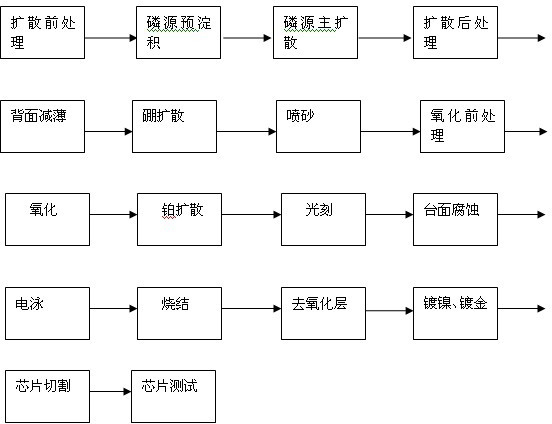

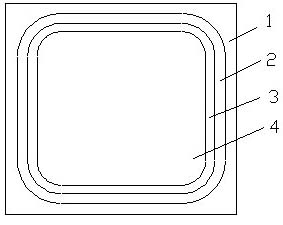

Fast recovery diode (FRD) chip and production process thereof

ActiveCN102087976AImprove anti-surge performanceImprove switching performanceSemiconductor/solid-state device manufacturingSemiconductor devicesElectrophoresesEtching

The invention relates to a fast recovery diode (FRD) chip and a production process thereof. A diode with a P+NN+ structure is produced by adopting the process steps of diffusion pretreatment, double diffusion of a liquid source, back thinning, oxidization, platinum diffusion, photoetching, mesa etching, electrophoresis, sintering, scribing and the like. In the chip production process, a method of carrying out deep junction diffusion by carrying a liquid phosphorous source is adopted, so that the flatness of a diffusion junction is improved and the homogeneity and the stability of a breakdown voltage are strengthened; a method of reducing the concentration of a boron diffusion source and improving the purity of the boron diffusion source is adopted, so that the surge resistance capacity of an FRD is improved; and an electrophoresis glassivation process is adopted, so that the voltage withstanding stability and reliability of a bidirectional voltage stabilizing diode are improved. In addition, the production process has the advantages that the reverse recovery time is shortened, the switching speed is improved, the voltage drop is reduced, the power consumption is reduced, the voltage withstanding stability is improved, and the reliability of the diode is improved.

Owner:TIANJIN ZHONGHUAN SEMICON CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com