Method for manufacturing heat sink body

A manufacturing method and heat sink technology, applied in the direction of improving process efficiency and energy efficiency, can solve problems such as difficult to process structures and simplicity, and achieve the effects of increasing heat transfer efficiency, saving heat sink space, and improving heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

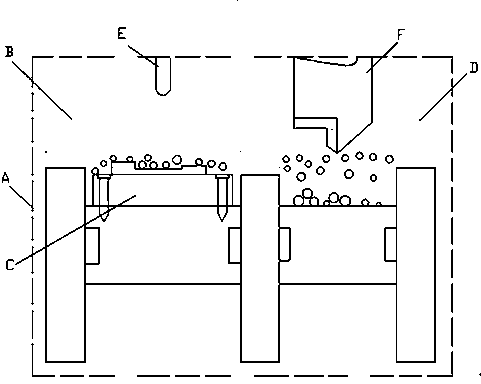

[0041] A heat sink 3D printing manufacturing method, its additive manufacturing equipment adopts EOSM270, supporting software is PSW3.5, the customer needs to prepare a narrow channel heat sink, and the material is chromium.

[0042] Step 1. Use proE, solidworks, UG, CATIA and other 3D graphics software to design the overall 3D shape of the heat sink, including the microchannel structure inside the heat sink and the external positioning holes, etc. The support cannot be removed after the internal channel is formed, so the design is appropriate The shape and size avoid adding internal support that is difficult to remove;

[0043] Step 2. Fill the chrome powder into the powder spreading cylinder of the additive manufacturing equipment;

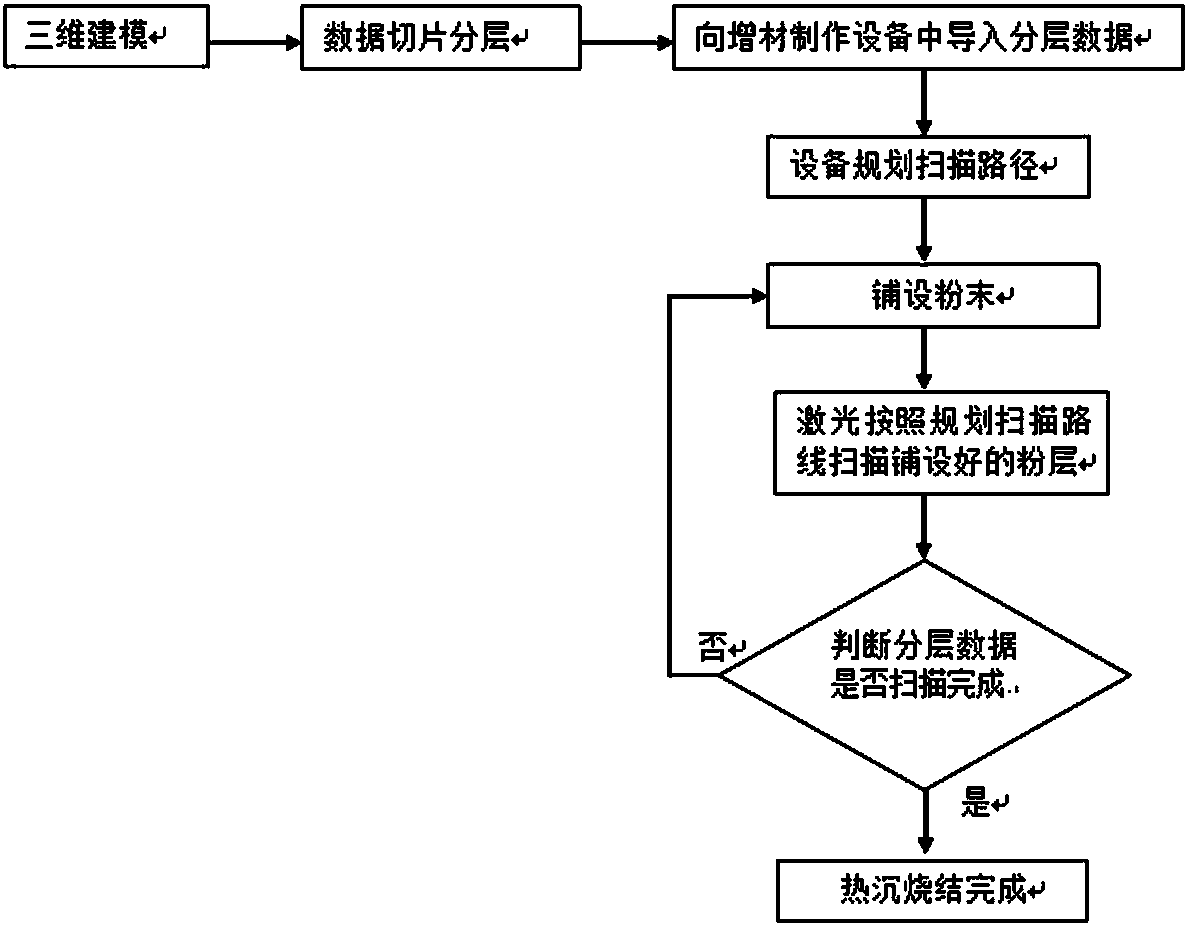

[0044] Step 3. Use the software RP-Tools to slice and layer the heat sink three-dimensional graphics: cut the heat sink three-dimensional graphics along the z-axis direction into a series of two-dimensional graphic slices with a layer thickness...

Embodiment 2

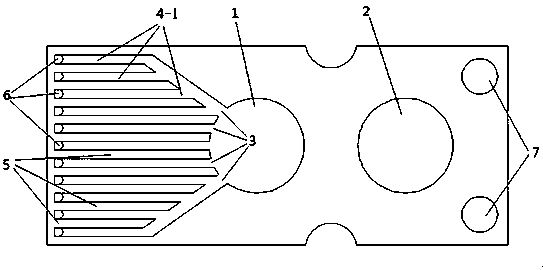

[0052] The manufacturing method of the structure in this example is a narrow channel heat sink integrally formed by additive manufacturing technology. The cooling water enters the water inlet channel 4 between the channel walls 5 sequentially from the water inlet hole 1 through the water inlet channel hole 3, the water inlet channel, and then The bonding front end of the heat sink chip enters the water outlet channel 9 through the reverse water hole 6, and finally enters the two wide water outlet channels after summarization, and enters the water outlet hole 2 through the water outlet channel hole 8, thereby completing a cycle of refrigeration. The reasons for increasing the narrow water inlet and outlet channels and making the channel walls as long as possible are to increase the heat transfer area as much as possible, reduce the liquid movement speed, and improve the heat transfer efficiency. The channel height h3 at the reverse water hole 6 of the water outlet channel 9 is g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Oxygen content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com