Patents

Literature

86results about How to "Enhanced heat transfer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

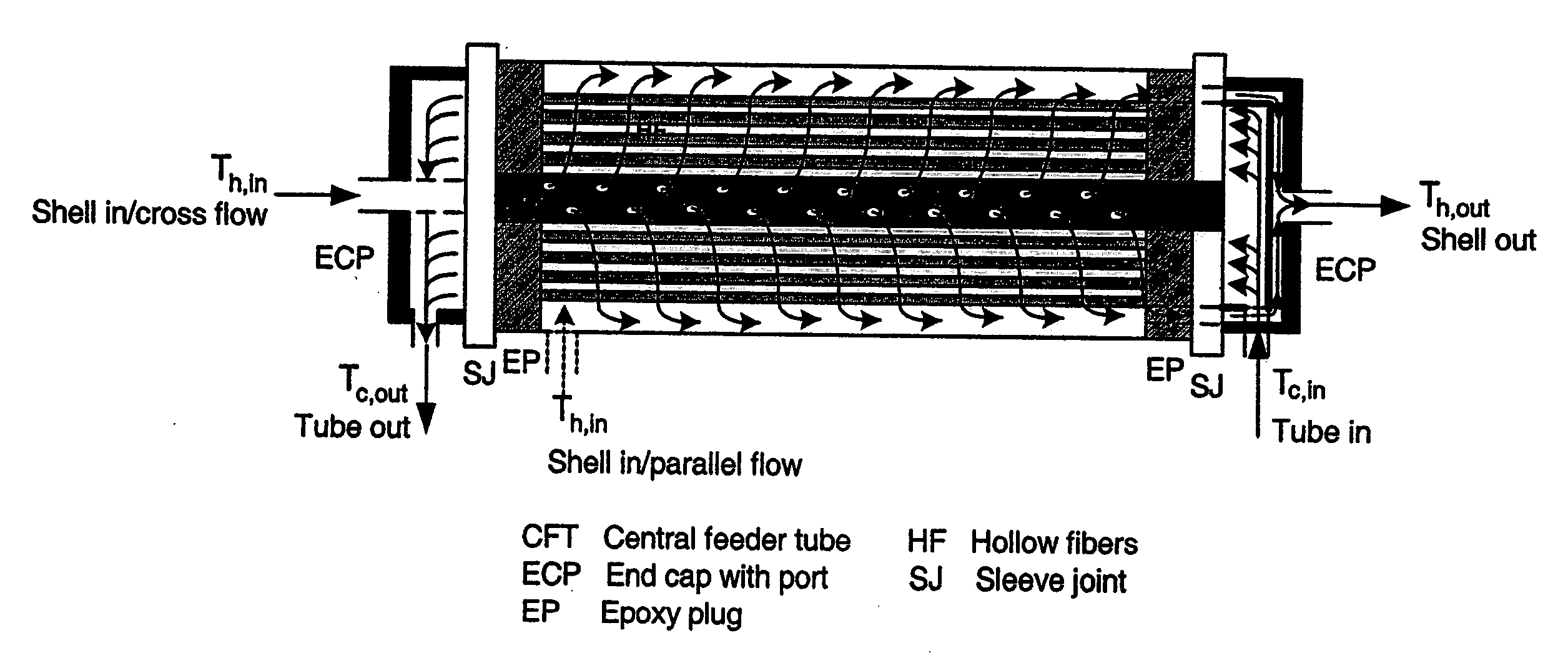

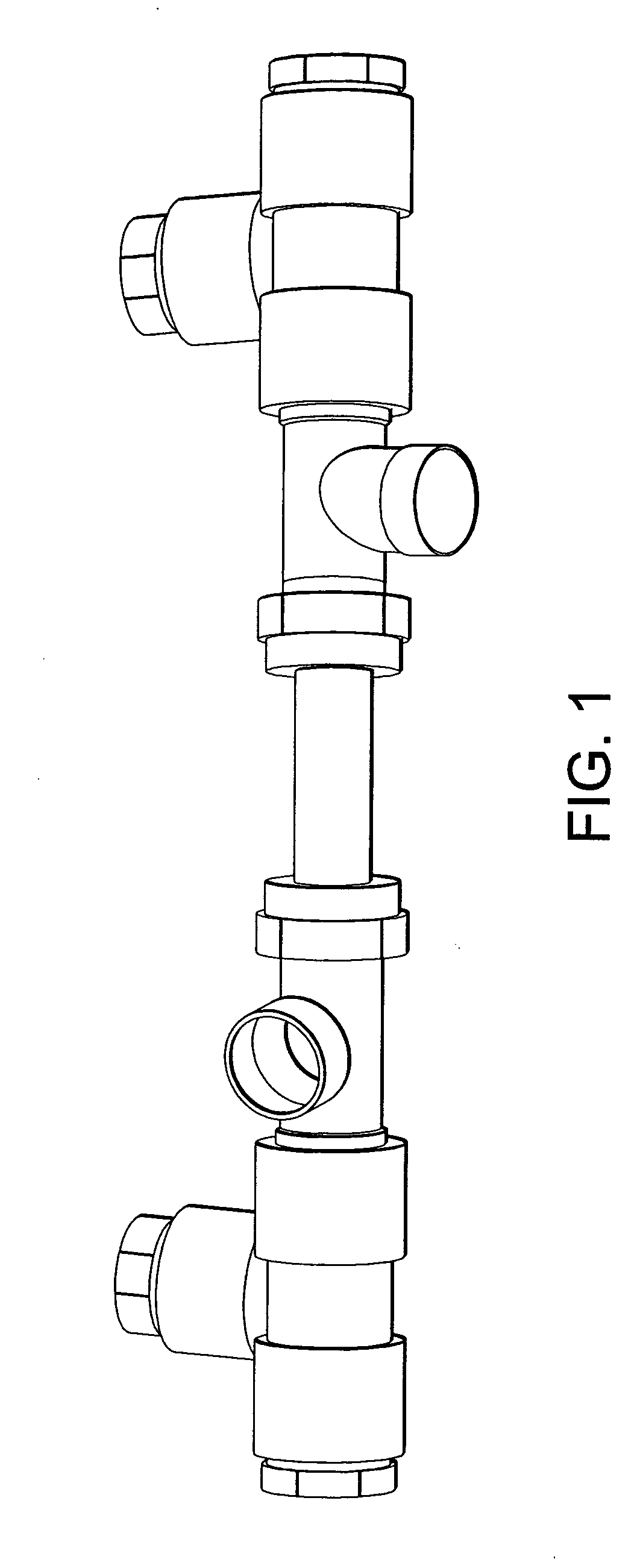

Polymeric hollow fiber heat exchange systems

InactiveUS20070107884A1Preventing liquid transmission and contaminationEnhanced heat transferCorrosion preventionHeat exchanger casingsChemical industrySolvent

Heat exchange systems are provided that include one or more polymeric hollow fibers. Exemplary hollow fibers are asymmetric and include a microporous wall and a dense skin formed thereon, thereby preventing liquid transmission and / or contamination through the wall of the hollow fiber while simultaneously enhancing heat transfer based on the presence of liquid molecules within the porous substructure of the hollow fiber. The hollow fibers may be employed in a variety of heat transfer-related commercial / industrial applications, including solvent-aqueous systems, organic-aqueous systems, organic-organic systems, desalination applications, solar heating applications, applications in the chemical industry, applications in the biomedical industry, and applications in the biotechnology or pharmaceutical industry, e.g., extracorporeal blood oxygenation systems. Heat transfer systems wherein steam is advantageously condensed on a first side of a polymeric, hollow fiber-based heat exchanger are also provided. The condensed steam provides energy that may be used to heat water and / or other liquids that flow on a second side of the polymeric, hollow fibers.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

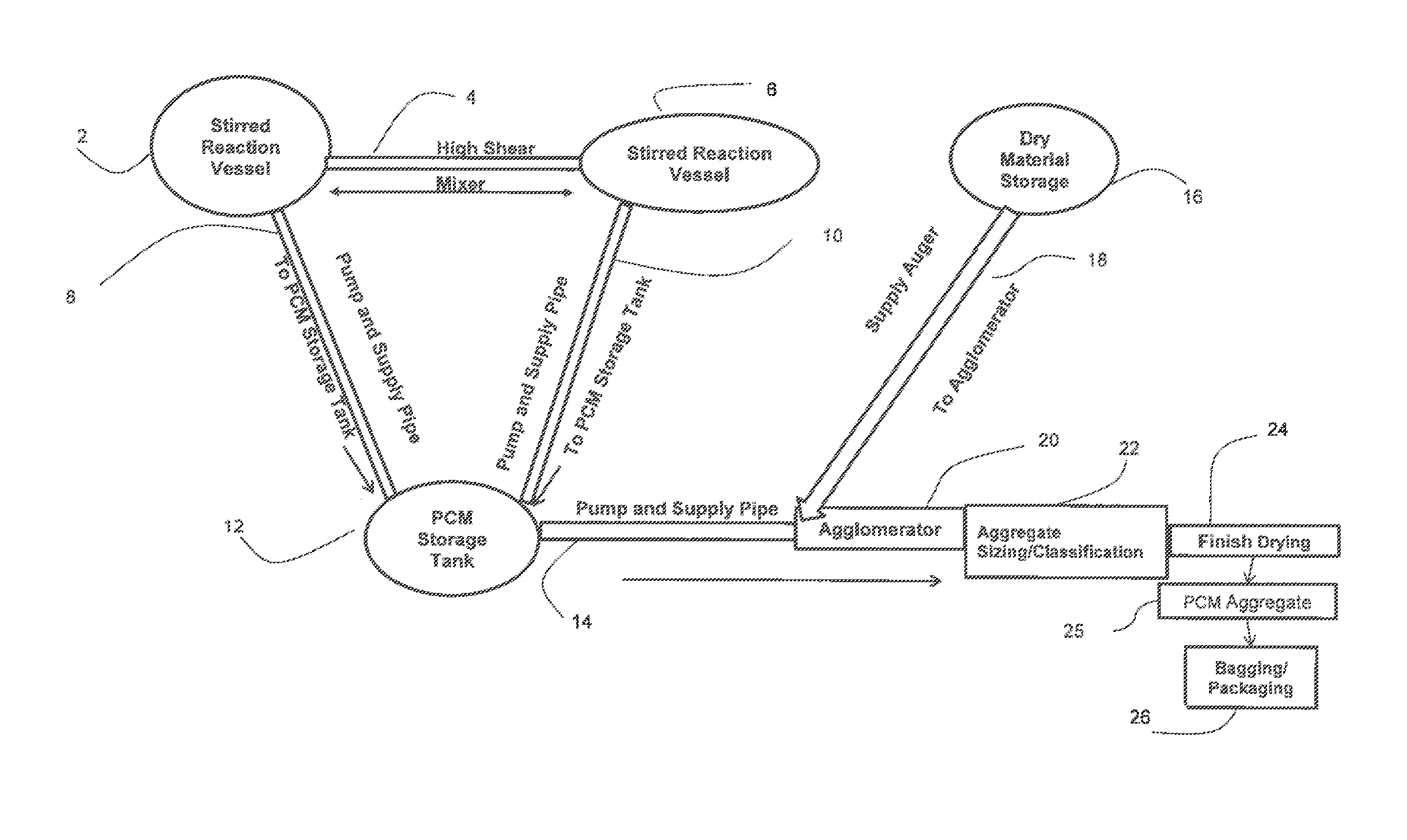

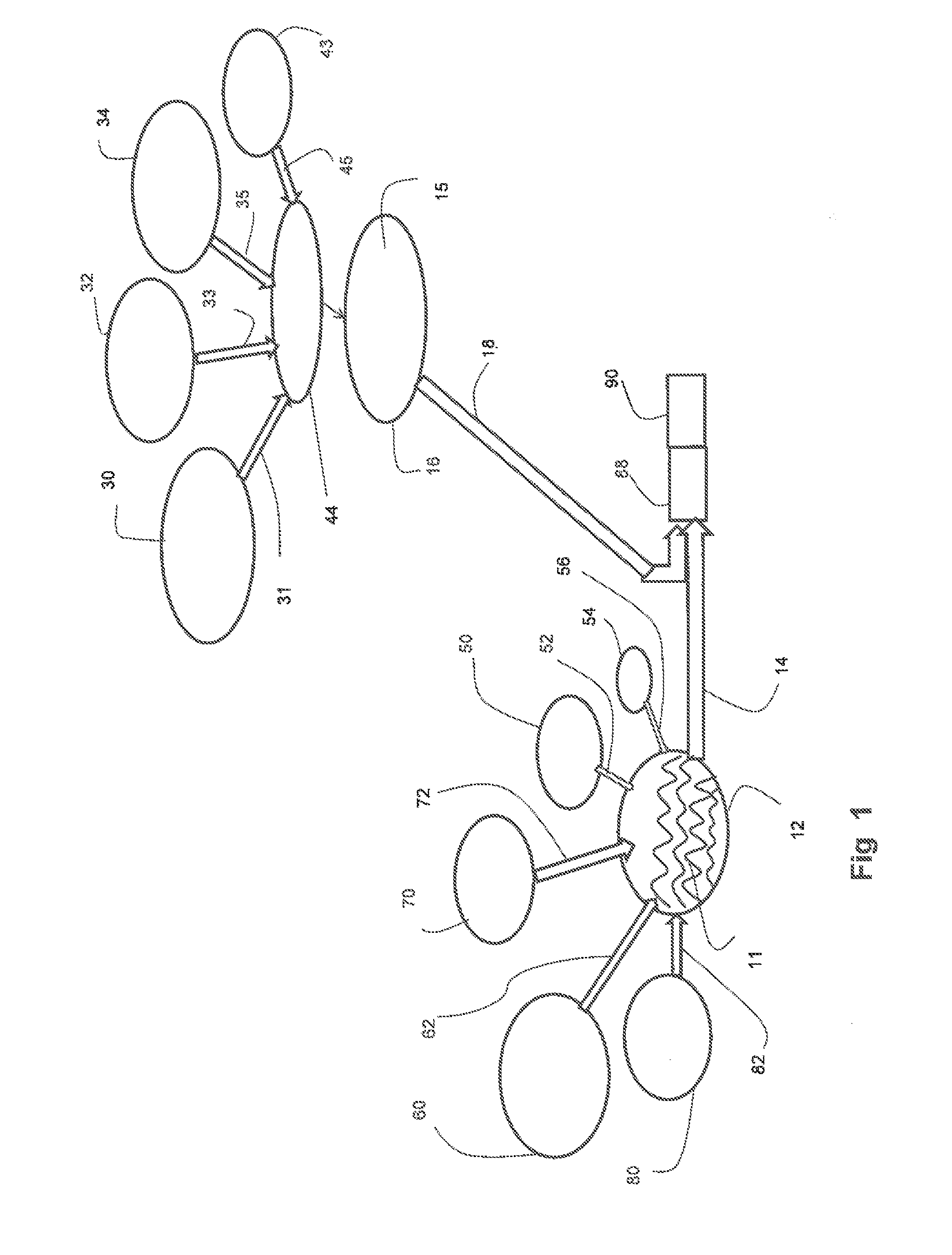

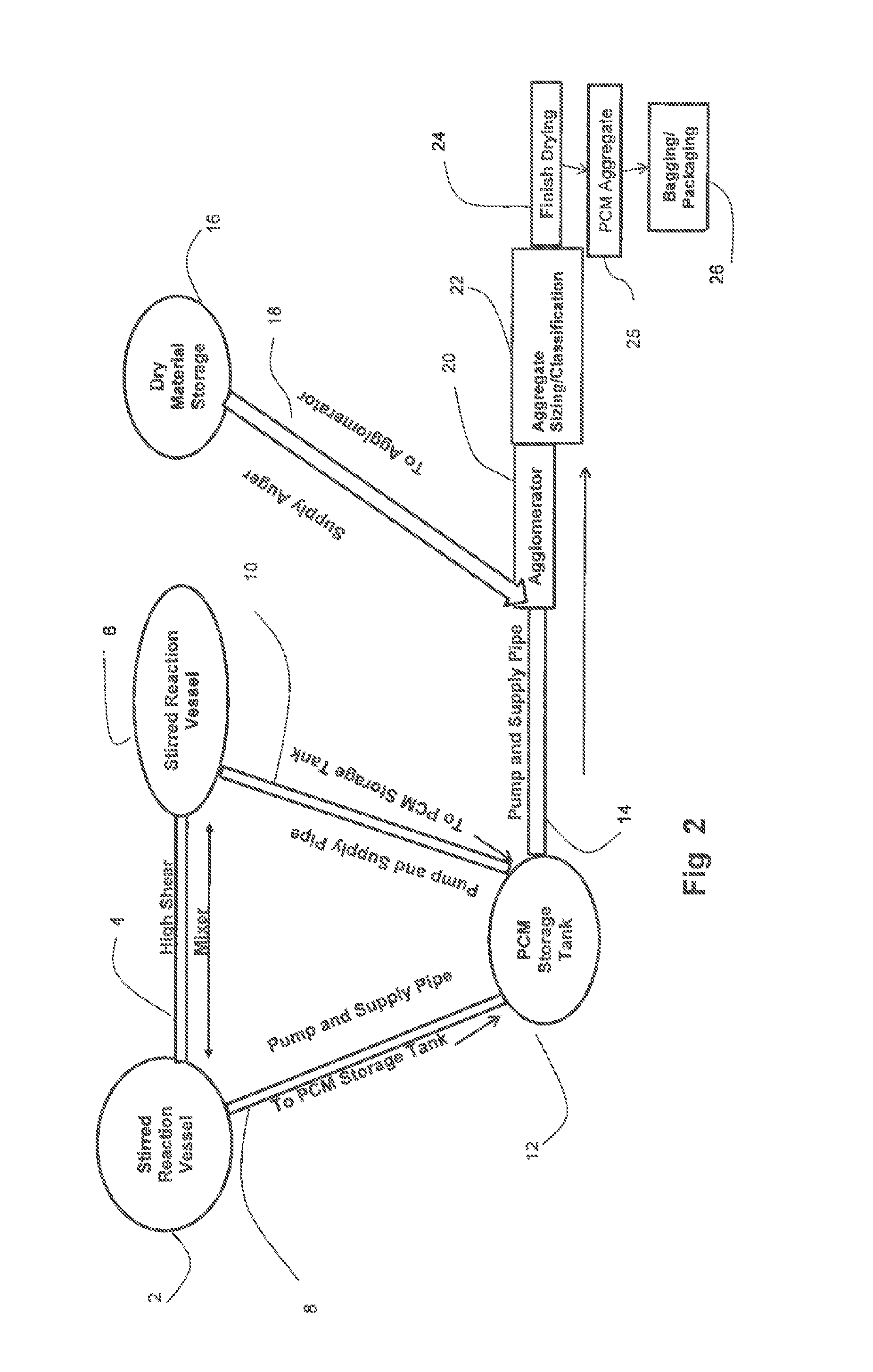

Phase change aggregates including particulate phase change material

InactiveUS20130298991A1Highly fire-resistantEnhanced heat transferSolid waste managementSynthetic resin layered productsEmulsionPhase-change material

The present invention provides methods of producing manufactured aggregates and other compositions from a particulate PCM slurry, suspension or emulsion by combining a cementitious binder and a adsorbent and / or absorbent with the PCM slurry. The PCM-containing composition can be produced in an agglomeration process. The ingredients can also be mixed to form a viscous mass which can be extruded or otherwise formed to produce useful products.

Owner:SMART PCM PATENT HOLDCO

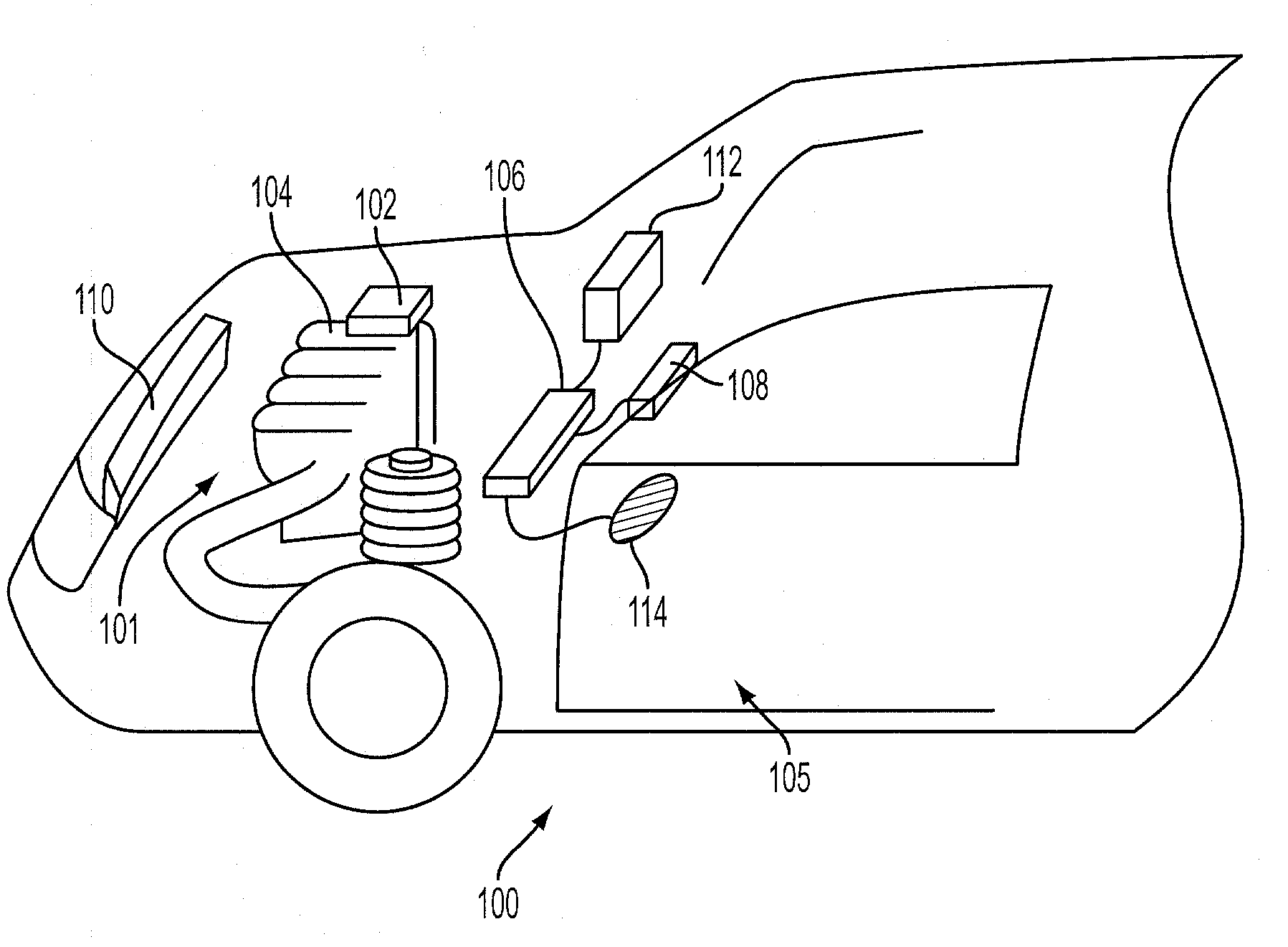

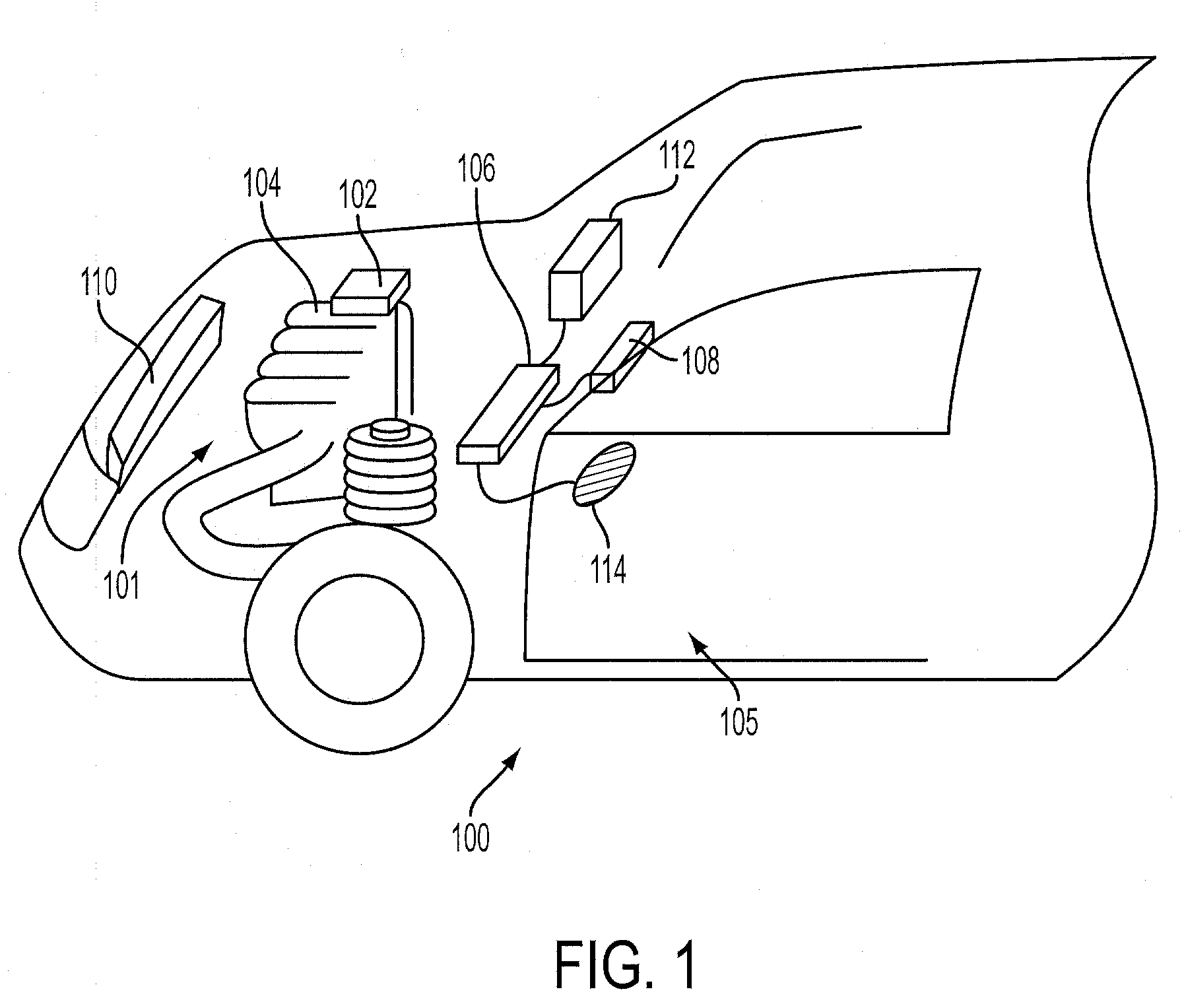

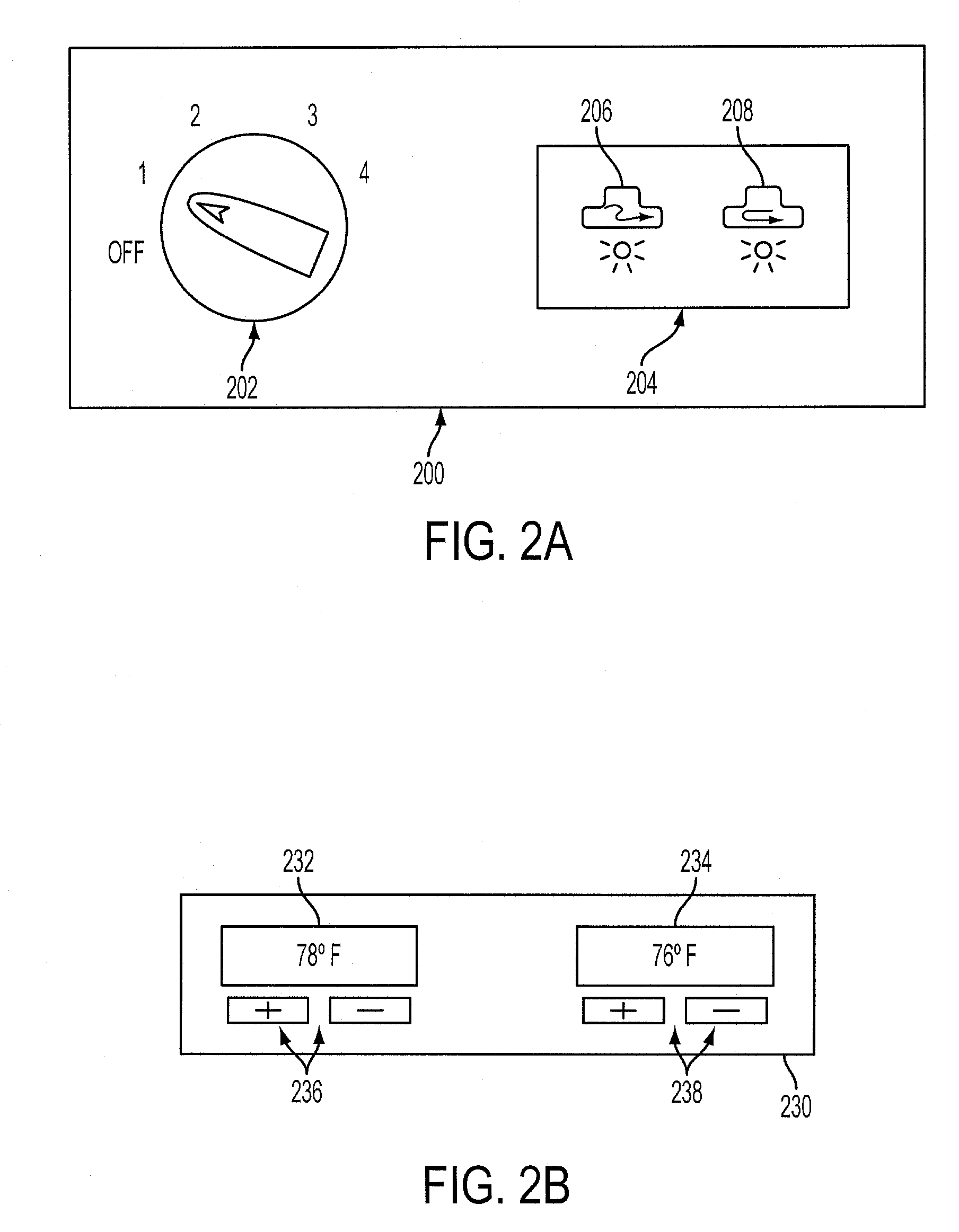

Control Unit Heat Management

ActiveUS20080076342A1Enhanced heat transferImprove heat transfer performanceAir-treating devicesRailway heating/coolingAutomotive engineeringControl set

A method of cooling an engine control unit (ECU) coupled to an engine in a vehicle having a cabin climate control system, comprising of operating the vehicle cabin climate control system according to a customer-based climate control setting during a first operating condition, and overriding said customer-based setting during a second operating condition including an ECU over-temperature condition.

Owner:FORD GLOBAL TECH LLC

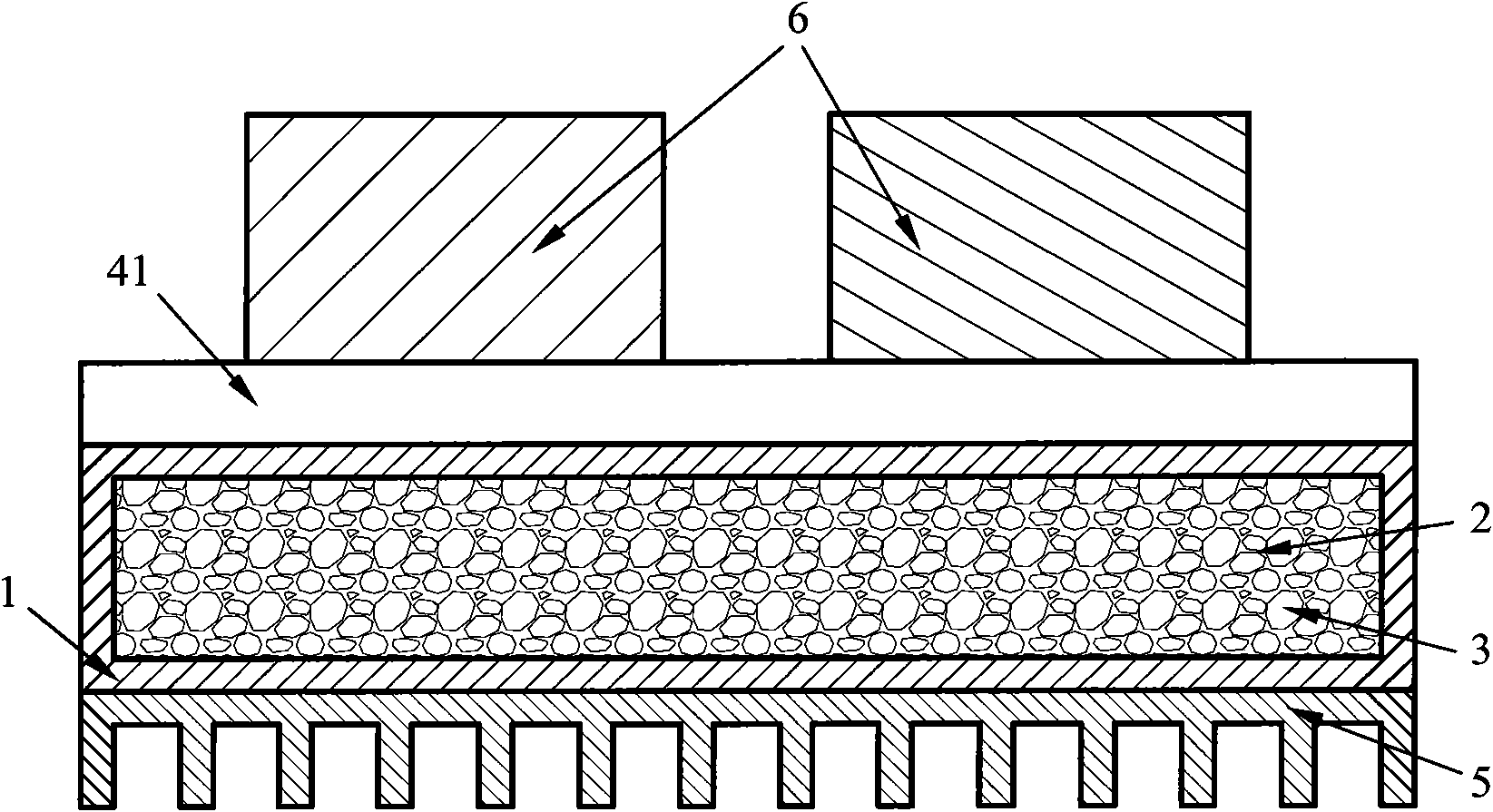

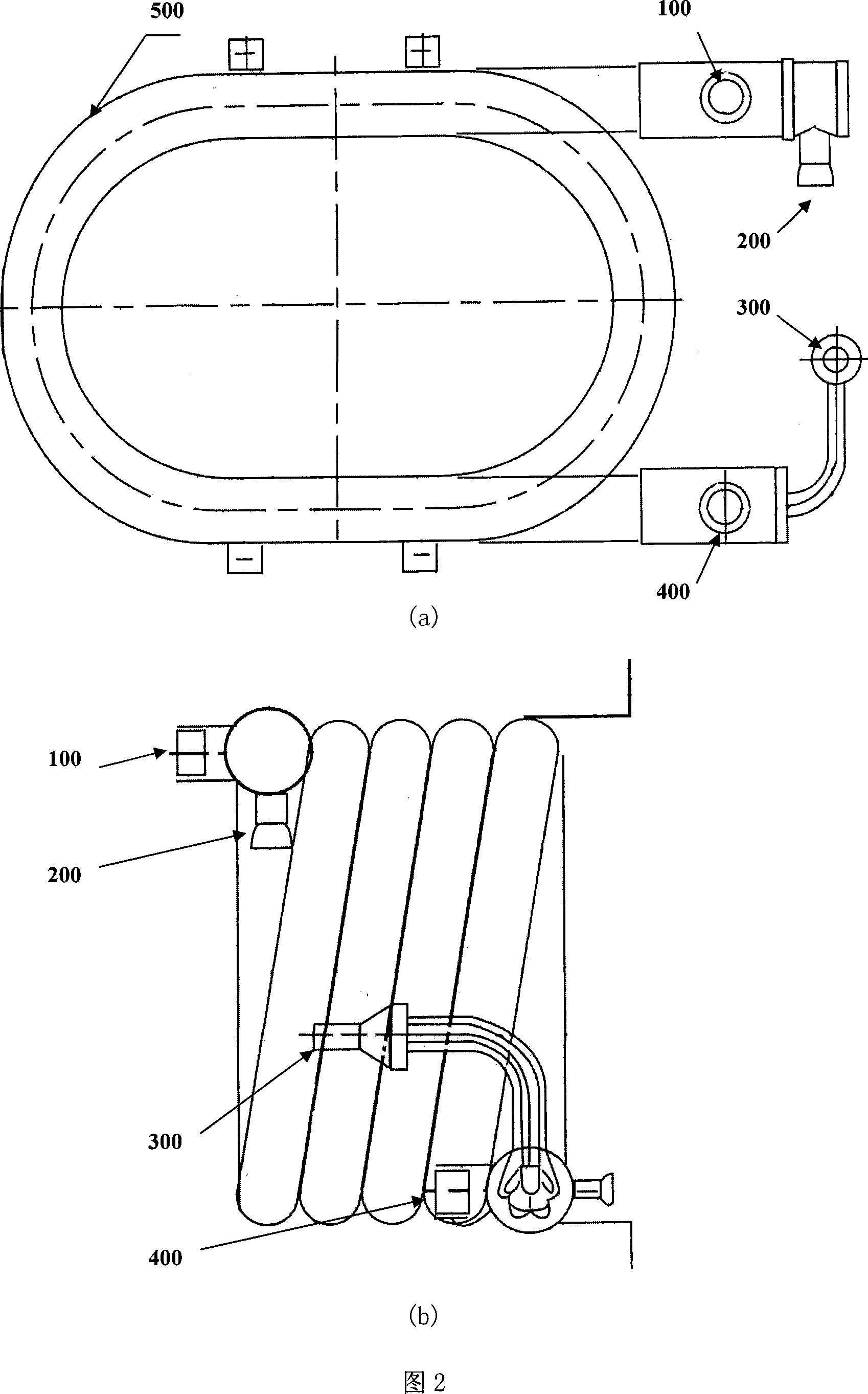

Phase-change temperature control device integrating heat pipe and foam metal core body

InactiveCN101578029AImprove thermal conductivityEnhanced heat transferSemiconductor/solid-state device detailsSolid-state devicesPhase change temperatureHeat conducting

The invention relates to a temperature control system of electronic equipment, which adopts phase-change materials and integrates a heat pipe and a foam metal core body. The temperature control system comprises a container, at least one heat pipe and a radiating fin, wherein the container is filled with the foam metal core body and the phase-change materials, and the at least one heat pipe can be a flat-plate type heat pipe or at least one axial non-conventional type heat pipe or at least one axial rectangle heat pipe arranged in the phase-change material container. The phase-change temperature control device integrating the heat pipe and the foam metal core body has better heat conducting property, higher effective utilization rate of the phase-change materials and more uniform temperature distribution and solves the problem that partial high temperature and concentrated heat stress generated by cavities intensively distributed in the prior phase-change temperature control device affect the reliability of the phase-change material container, thereby more effectively controlling the temperature of the electronic equipment or an electronic element.

Owner:BEIHANG UNIV

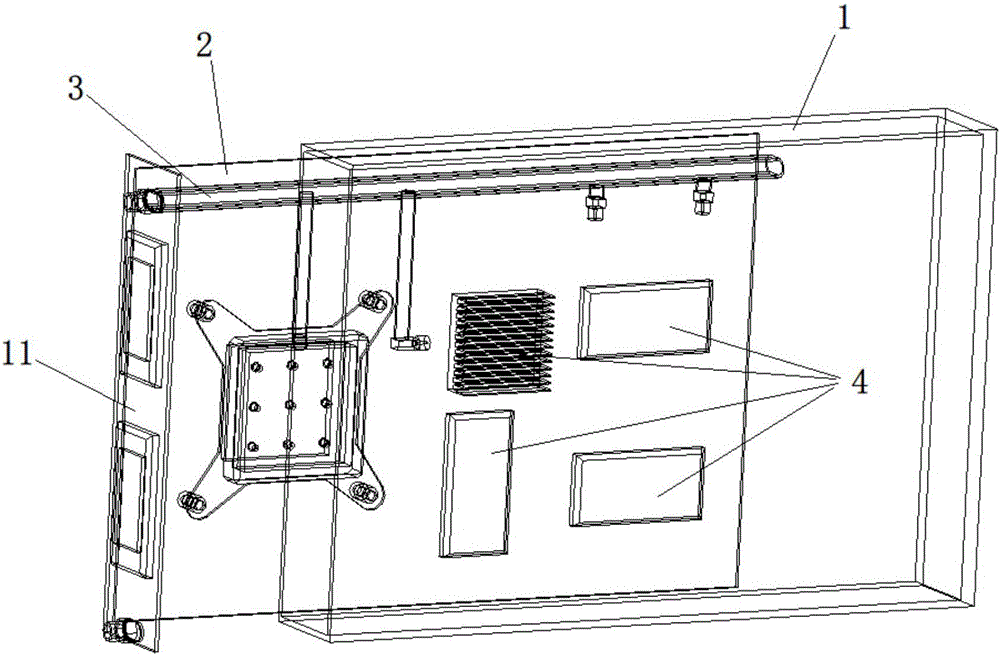

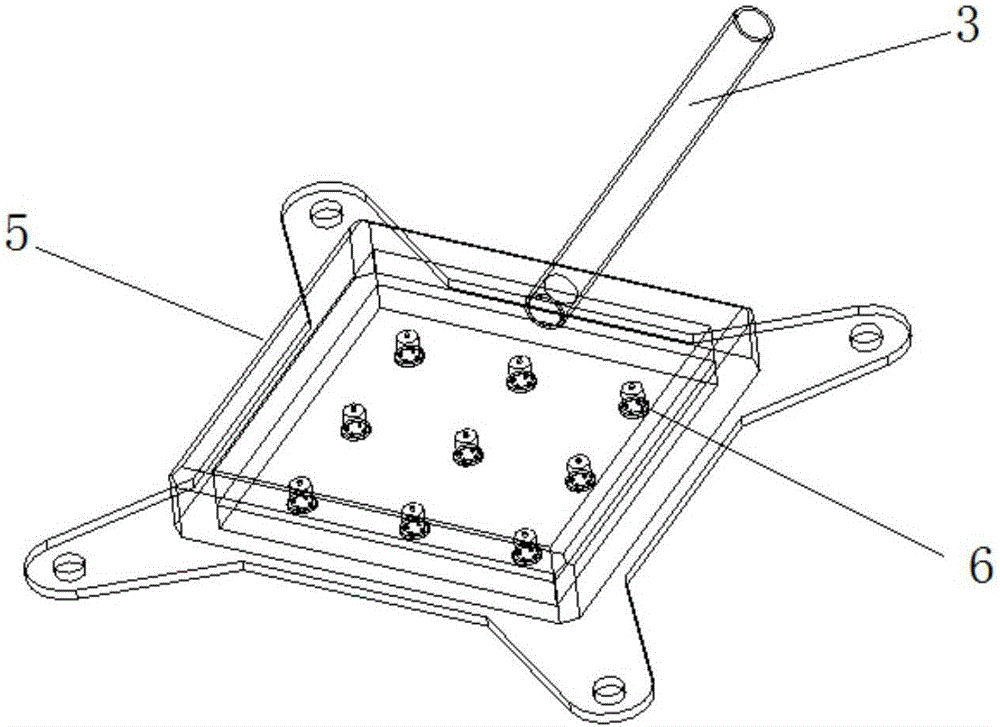

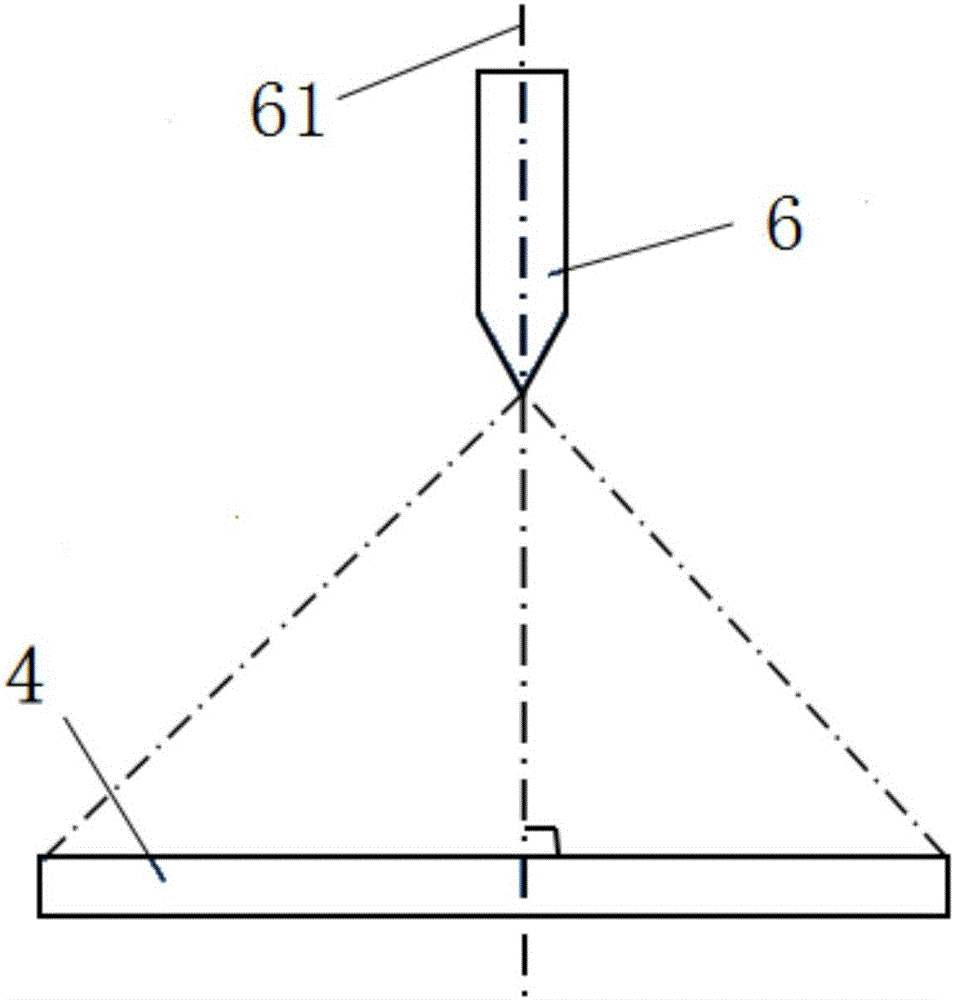

Electronic device and heat radiation device utilizing liquid cooling heat radiation and cooling method thereof

ActiveCN105025691AEnhanced heat transferImprove cooling efficiencyDigital data processing detailsCooling/ventilation/heating modificationsSystem structureNuclear engineering

The invention provides an electronic device utilizing liquid cooling heat radiation. The electronic device comprises a shell, a circuit board and a liquid cooling heat radiation module. The circuit board and the liquid cooling heat radiation module are arranged in the shell. The circuit board is provided with one or multiple heating devices. The liquid cooling heat radiation module comprises a liquid inlet pipeline and nozzles which are arranged on the liquid inlet pipeline. Cooling liquid is conducted into the shell from the outside of the shell by the liquid inlet pipeline. Cooling liquid is sprayed in a space formed by the shell by the nozzles to cool the heating devices. Cooling liquid steam after heat exchange is mixed with cooling liquid sprayed by the nozzles so that the cooling liquid steam is enabled to be condensed. Compared with an existing direct liquid cooling heat radiation device, the electronic device utilizing liquid cooling heat radiation has advantages of being low in demand for cooling liquid, low in weight, simple in system structure, high in heat exchange capability and high in environmental adaptability and has quite high application potential.

Owner:沈珂

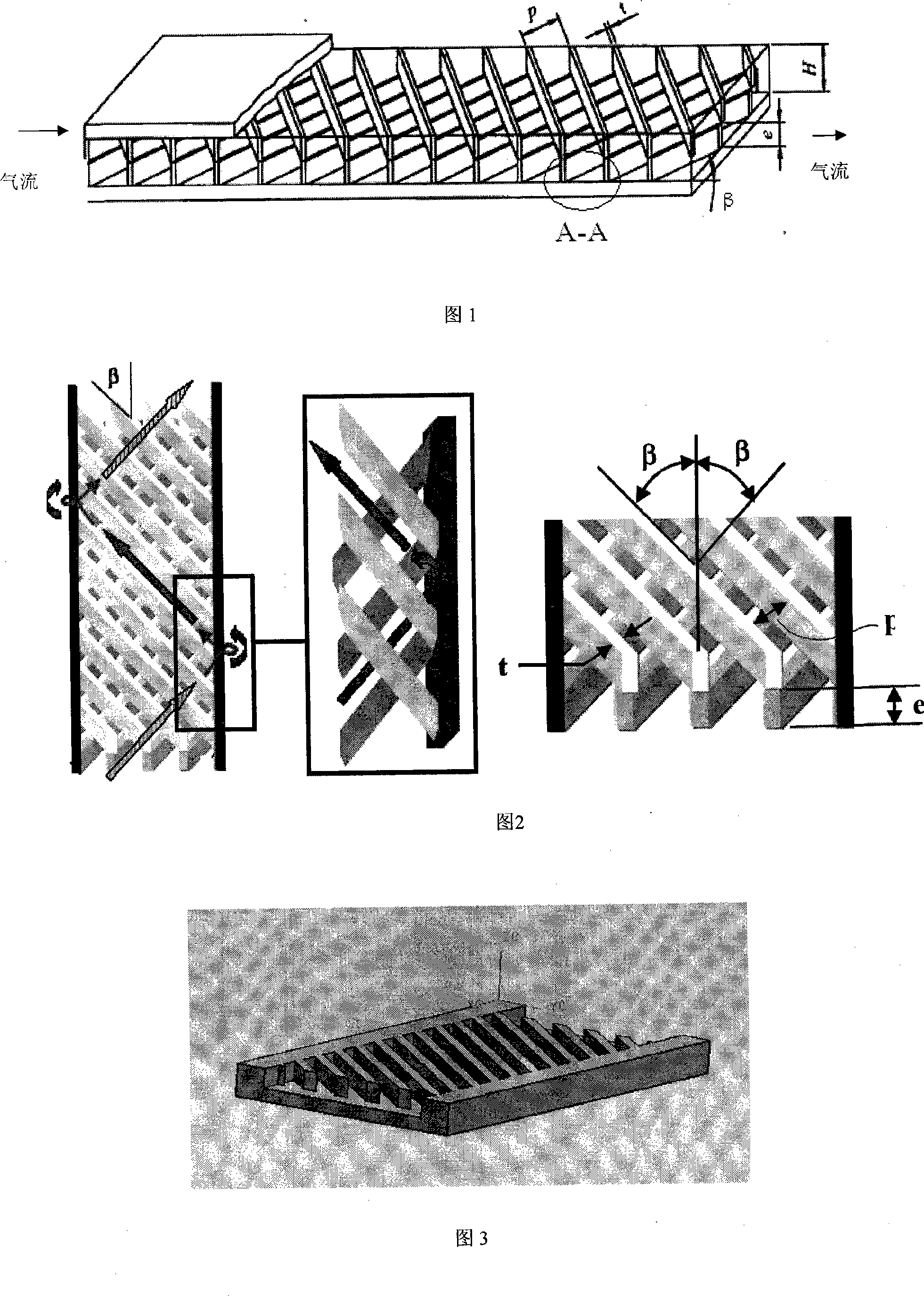

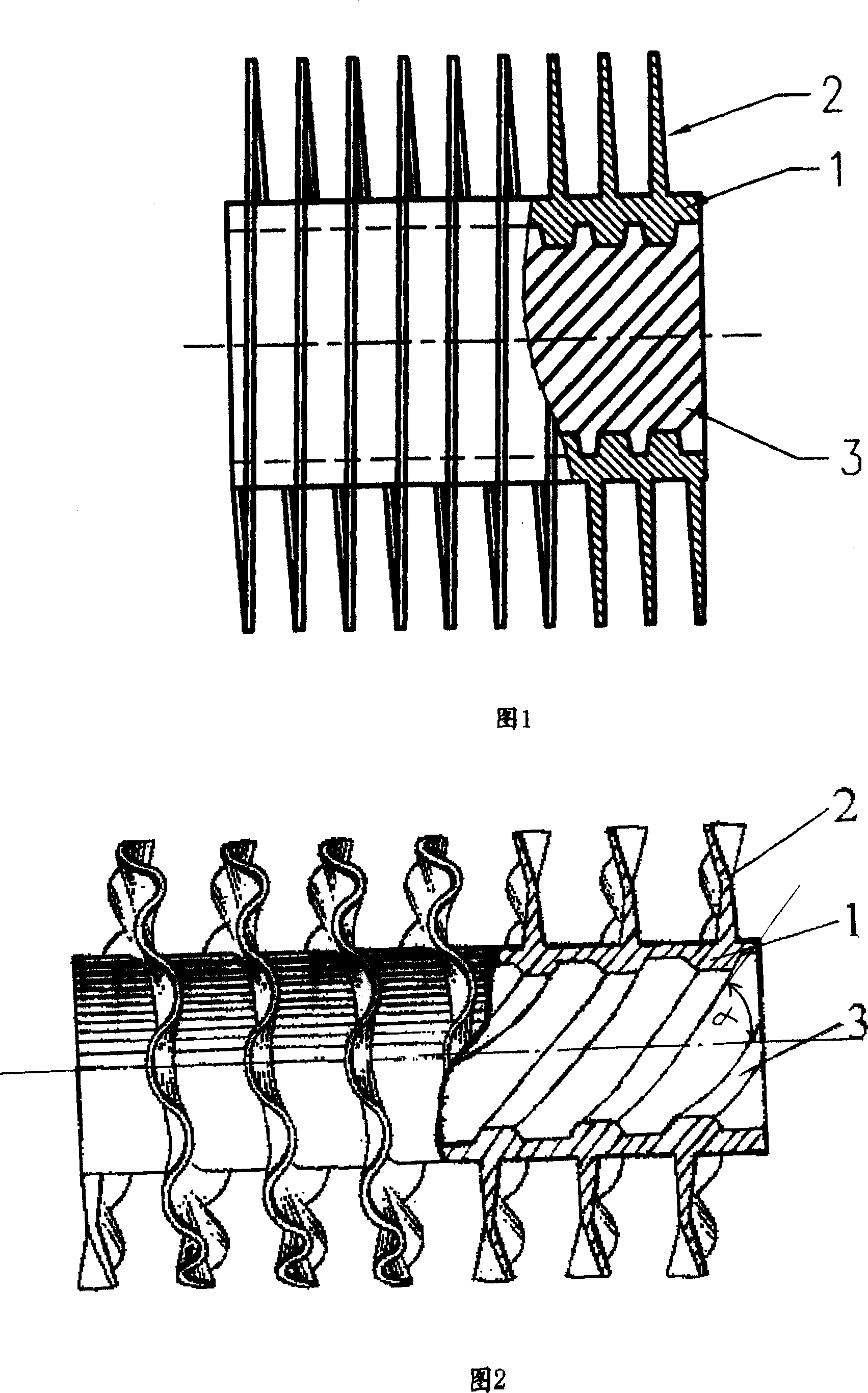

Gradually widened slot staggered rib passage suitable for internal cooling member as turbine blade

InactiveCN101100951AEnhanced heat transferLow flow resistanceBlade accessoriesMachines/enginesAerospace engineeringTurbine blade

This invention is a turbine blade internal cooling structure. This cooling structure is a notched crossed-rib channel, which groove width increases gradually along from channel inlet to outlet. For the crossed-rib channel that is long along the flow direction, the inner fluid flow resistance will decrease when both sides of channel have micro pass way with the best width. Thus, the heat exchanging ability of inter-fluid will increase. This invention realizes the optimizing design of turbine blade cooling structure.

Owner:BEIHANG UNIV

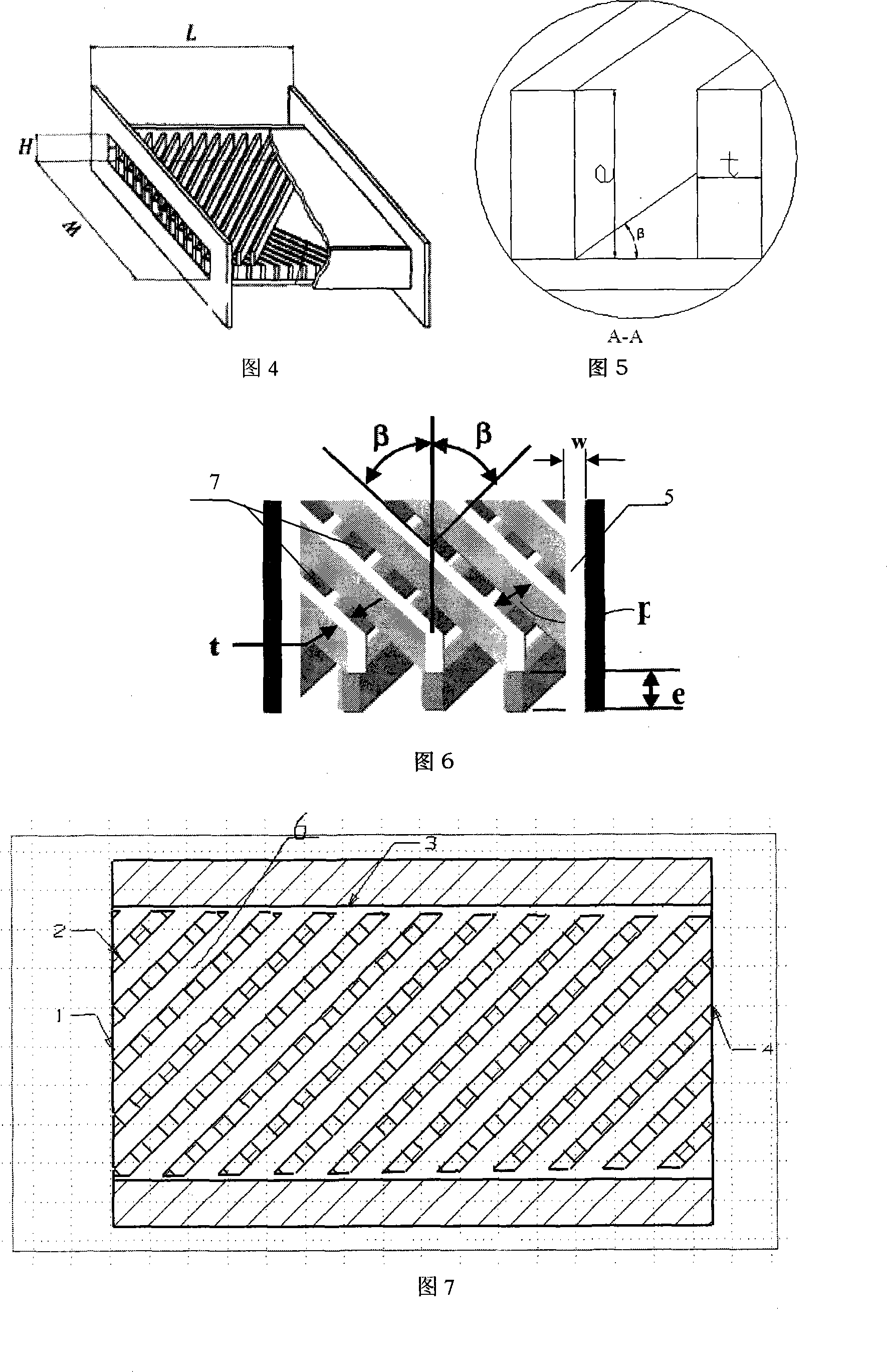

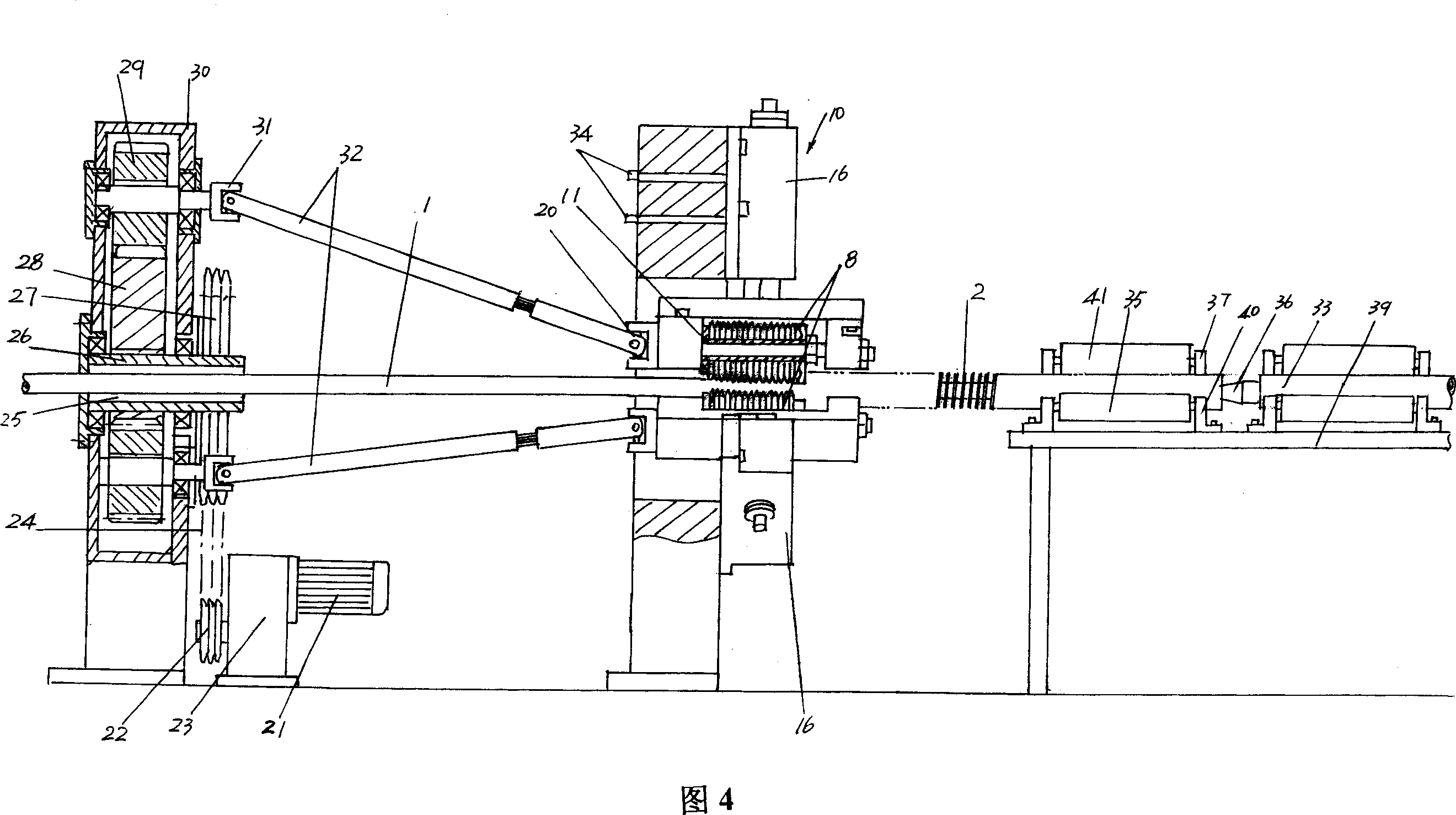

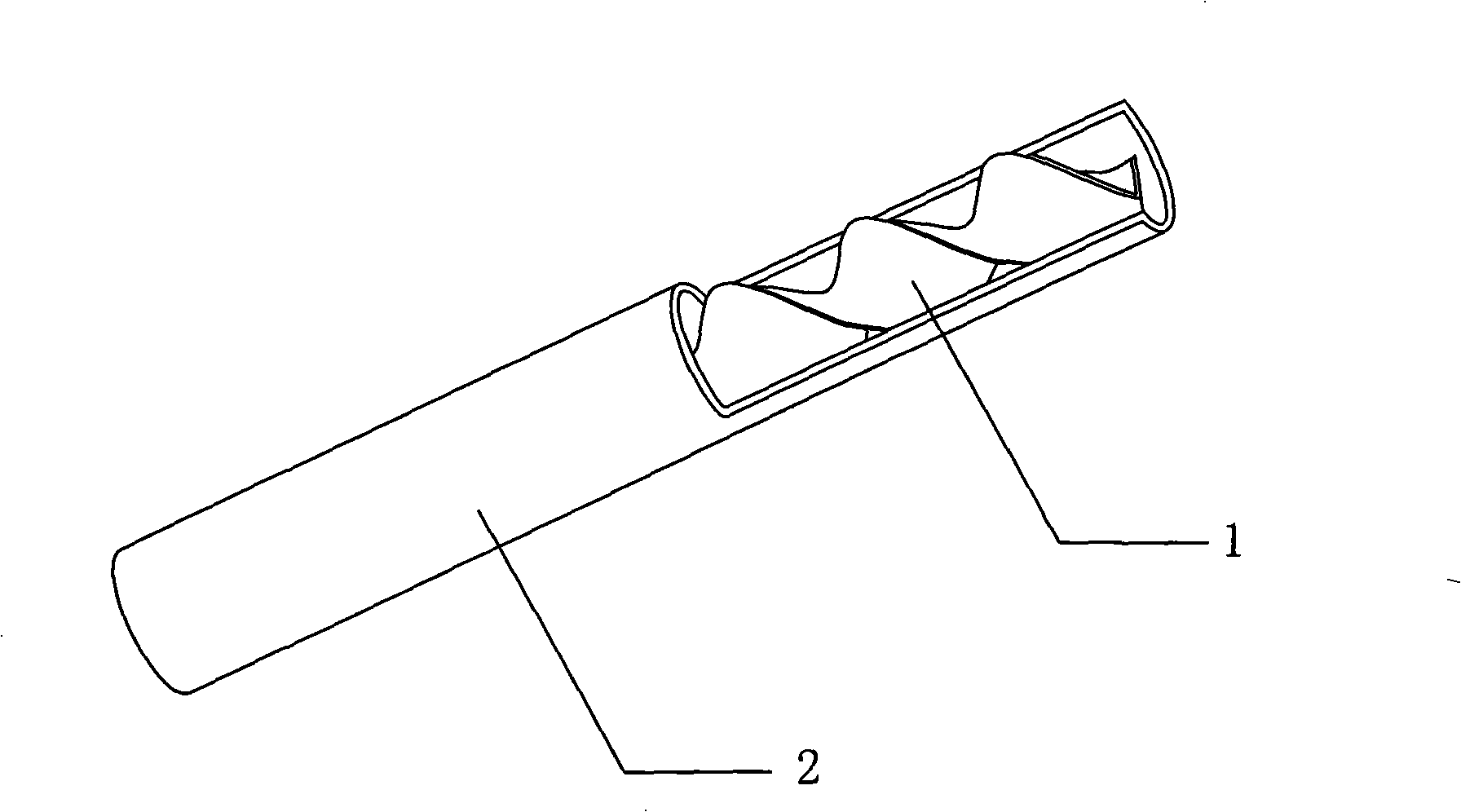

High finned heat-exchange tube and processing method thereof

ActiveCN101013013AEnhanced heat transferImprove heat transfer coefficientShaping toolsTubular elementsThermal conductivityWave shape

A high-fin heat exchange tube comprises a tube and external fins combined on the outer wall of tube. The external fins are extended along the axle of tube in screw shape on the outer wall of tube. The fins are shifted to two sides to form wave shape. The invention has the advantages that the outer wall of tube is formed by wave high fins, to strengthen the heat exchange and improve 10% of thermal conductivity. Compared with prior coiled-fin tube, the invention can eliminate the contact thermal resistance between the tube and fin root, the wave shape of high-fin is decided by the fins and the fin mould, to induce the airflow towards to the tube and backwards the tube along the radius of tube, with high horizontal interference on the airflow. The invention only arranges relative wave fin mould based on present technique.

Owner:JIANGSU CUILONG PRECISION COPPER TUBE CORP

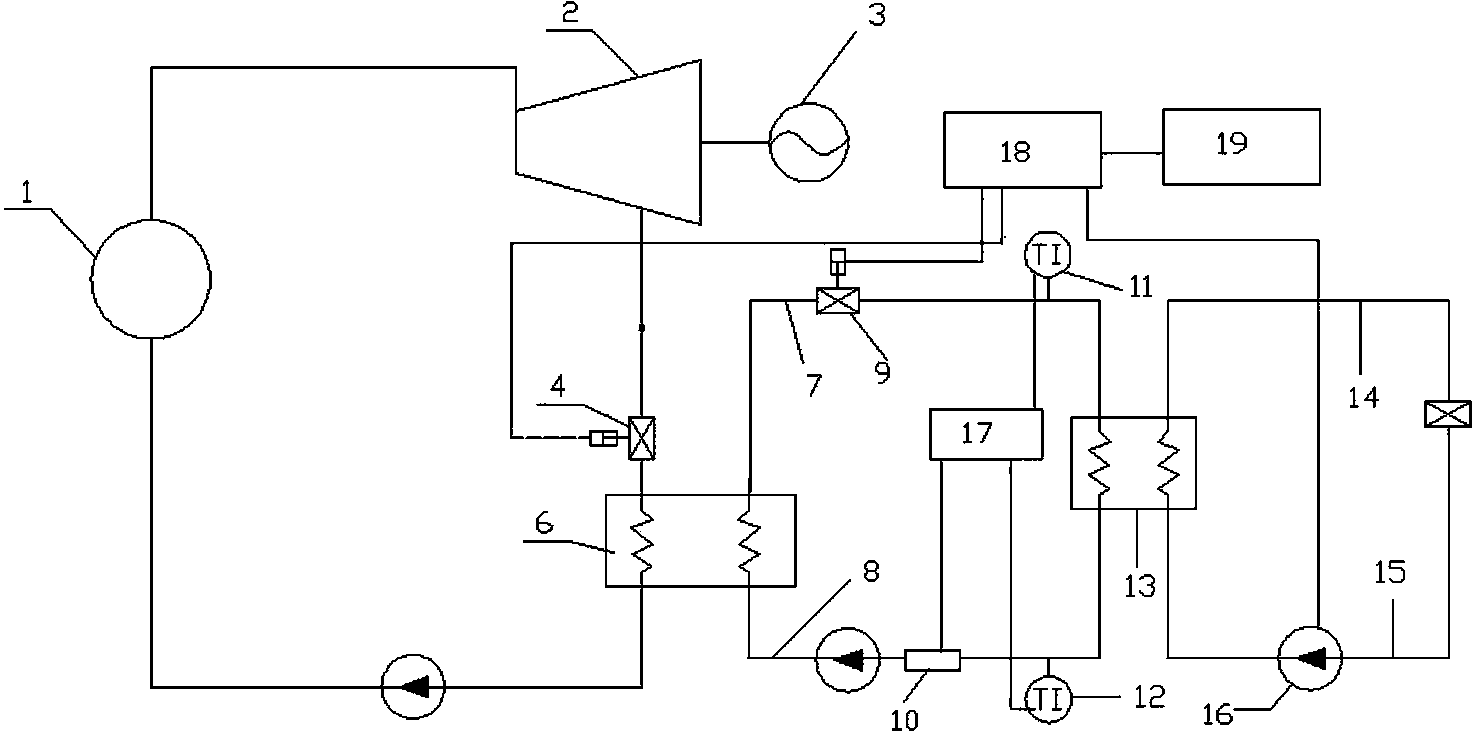

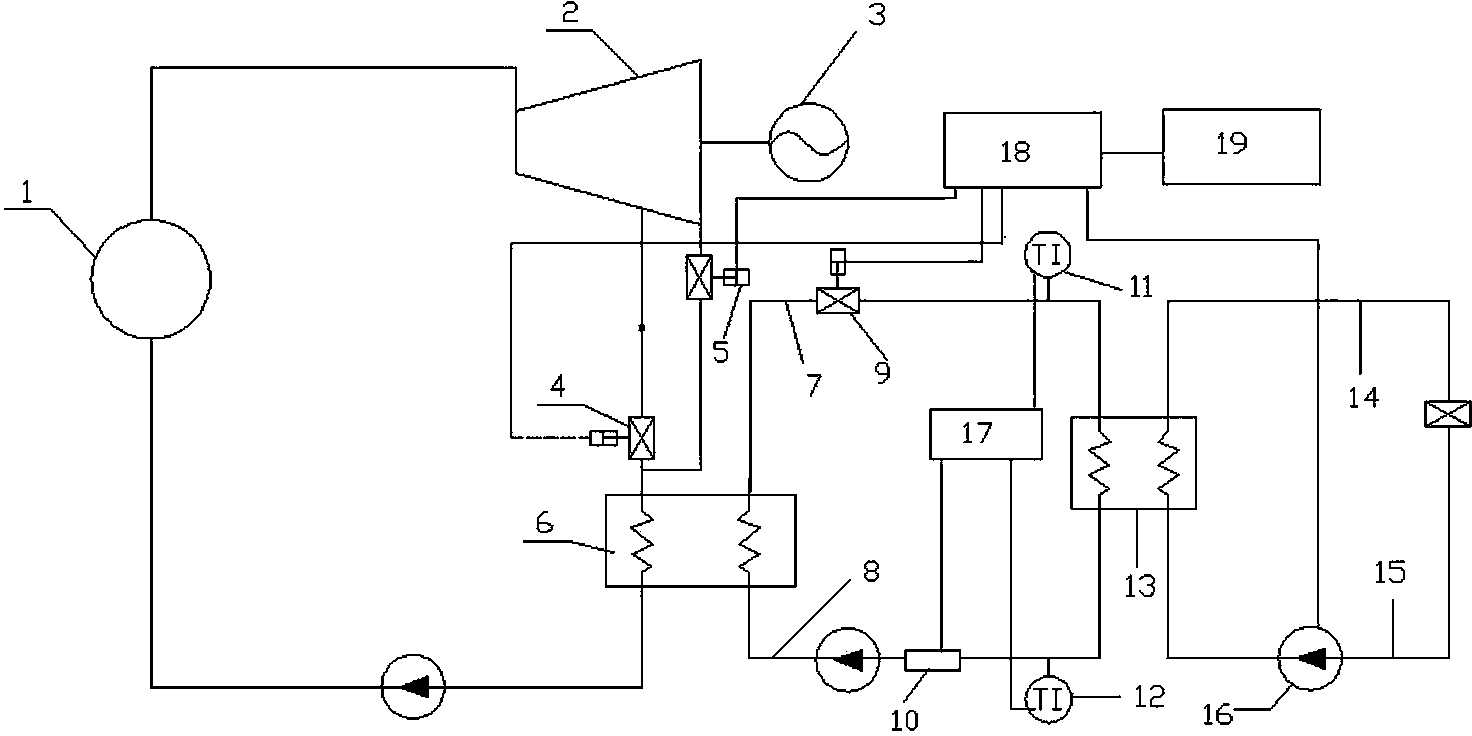

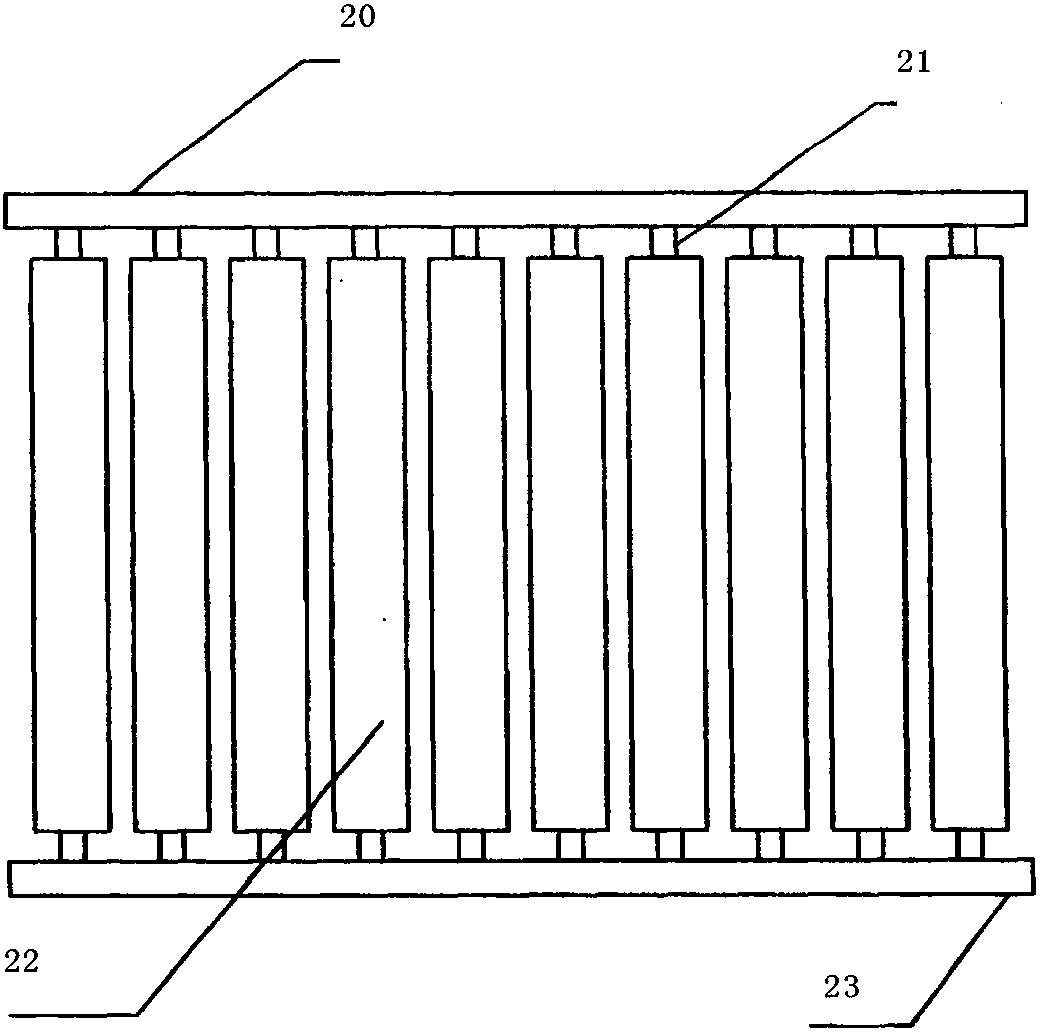

Heat radiator and combined heat and power generation system including same

InactiveCN103939979AEnhanced heat transferEnhanced chimney effectSteam useEnergy industryCogenerationHeat transfer efficiency

The invention provides a heat radiator and a combined heat and power generation system including the same. The heat radiator comprises a base tube and external fins, the external fins are sealed, the sealed external fins comprise fins and a sealing sheet for sealing the fins, and the distance between the sealing sheet and the base tube gets closer from the lower portion of the base tube to the upper portion of the base tube. According to the heat radiator and the combined heat and power generation system, the structure of the heat radiator is optimized, heat transfer efficiency of the heat radiator is maximized, energy is saved, and the purposes of environmental protection and energy saving are achieved.

Owner:ZHONGBEI UNIV

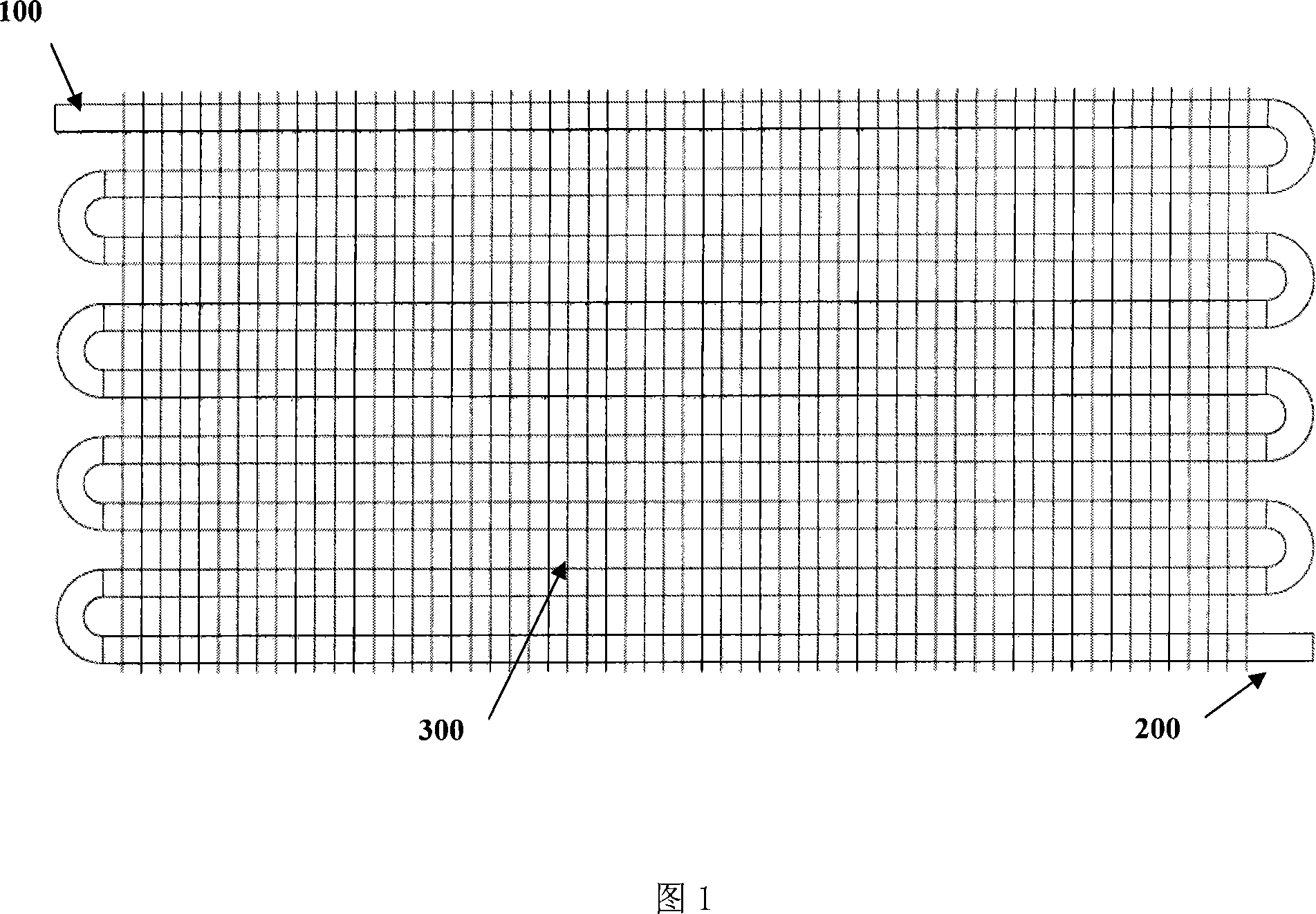

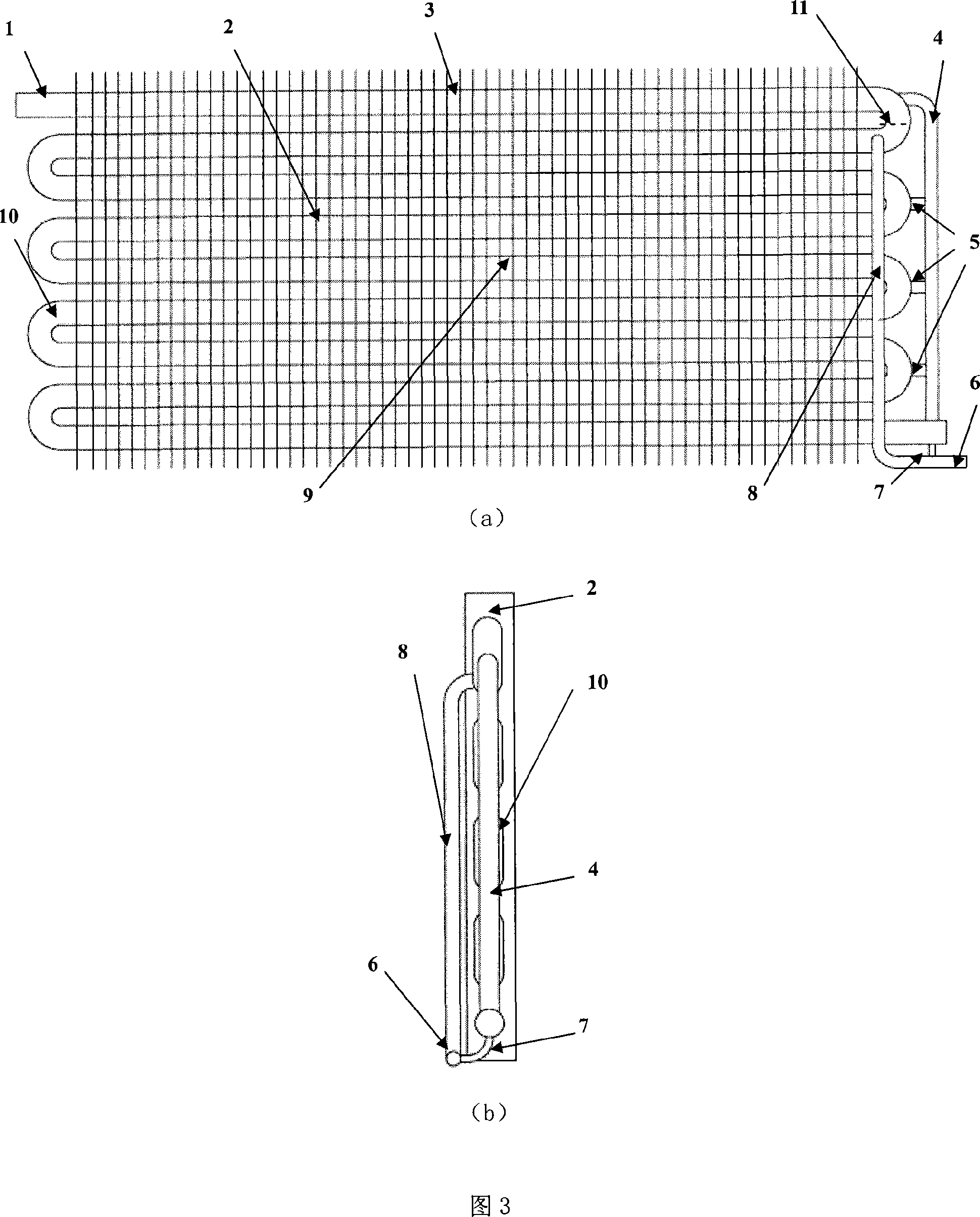

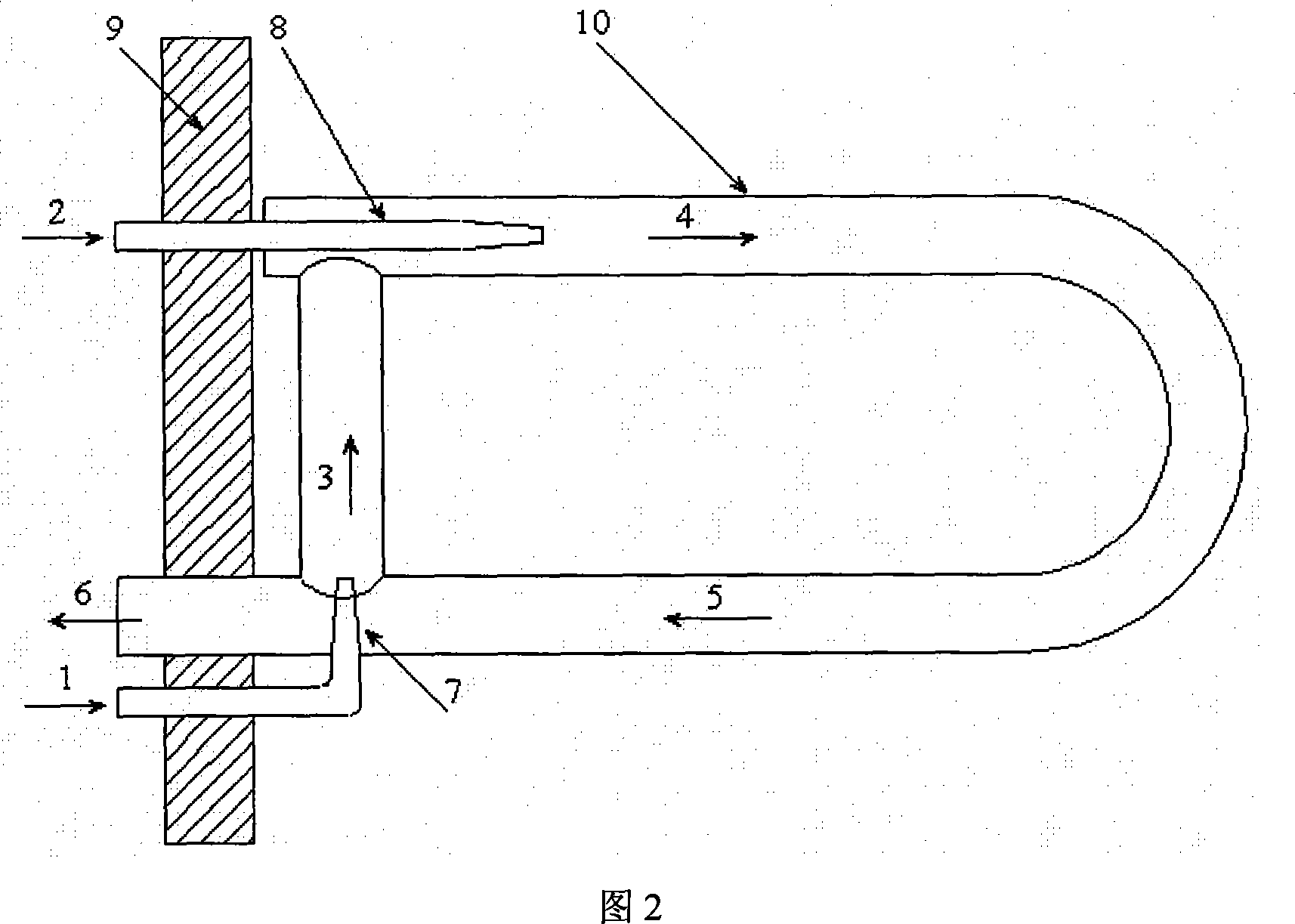

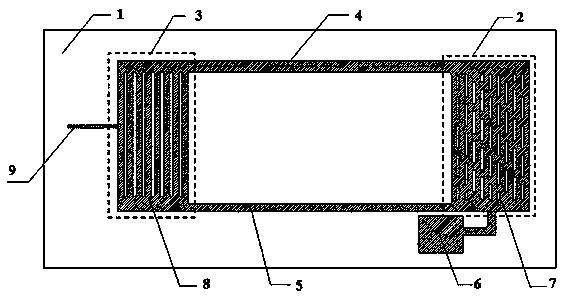

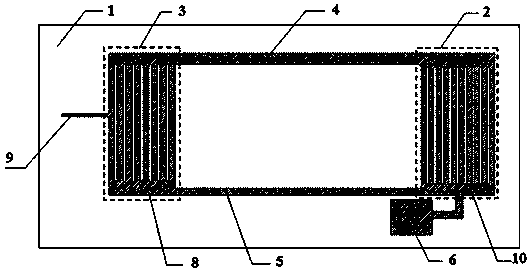

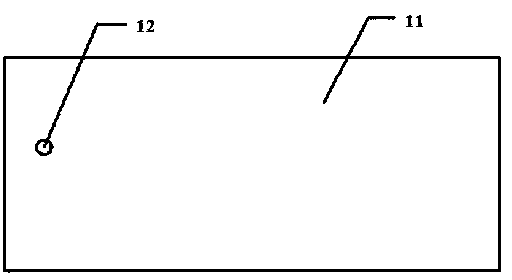

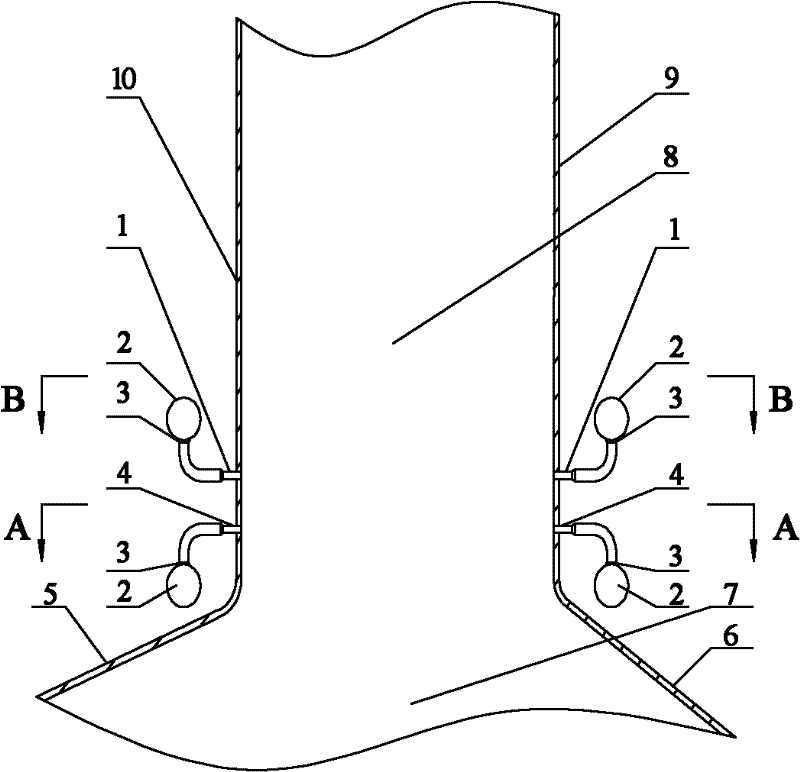

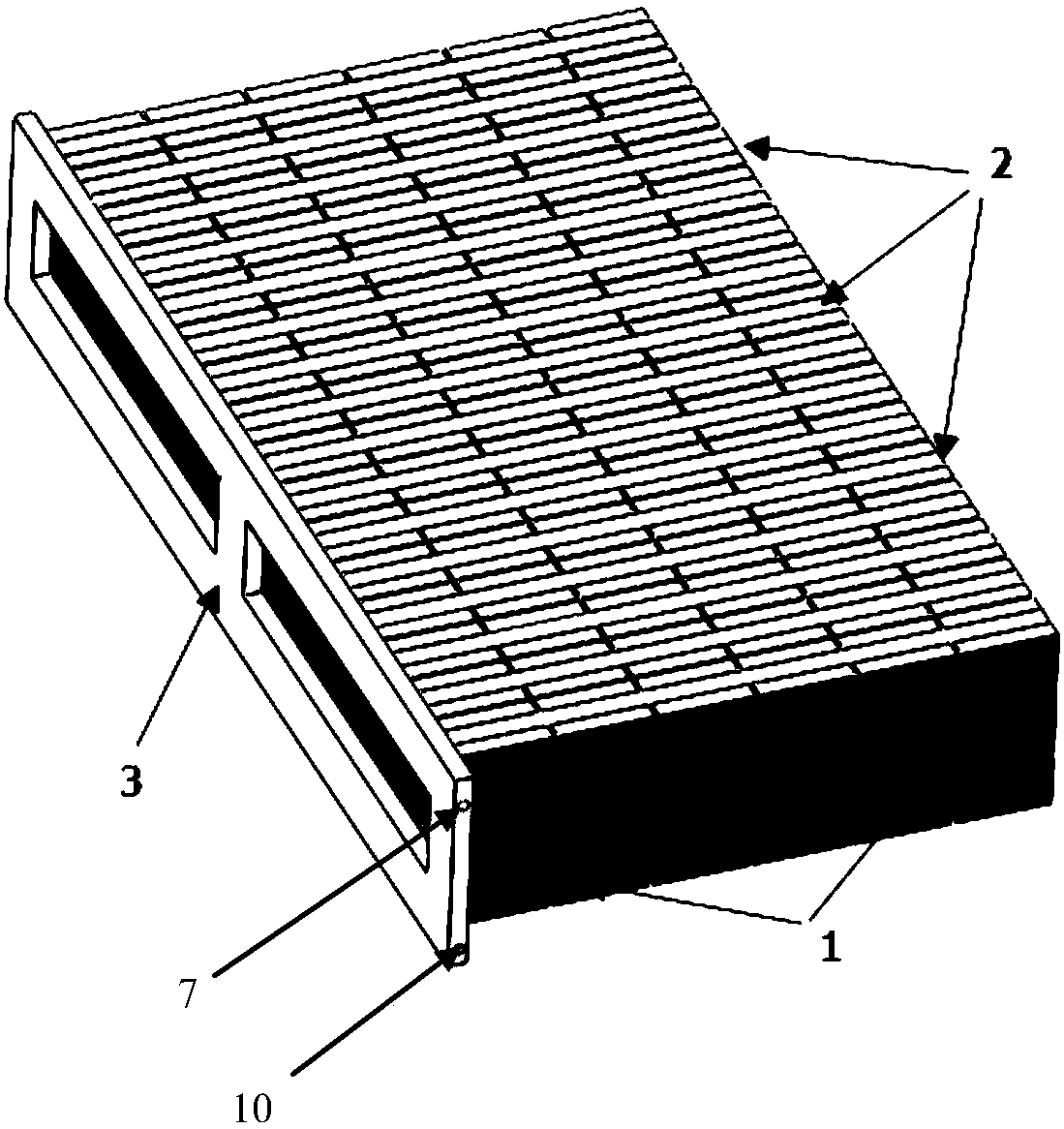

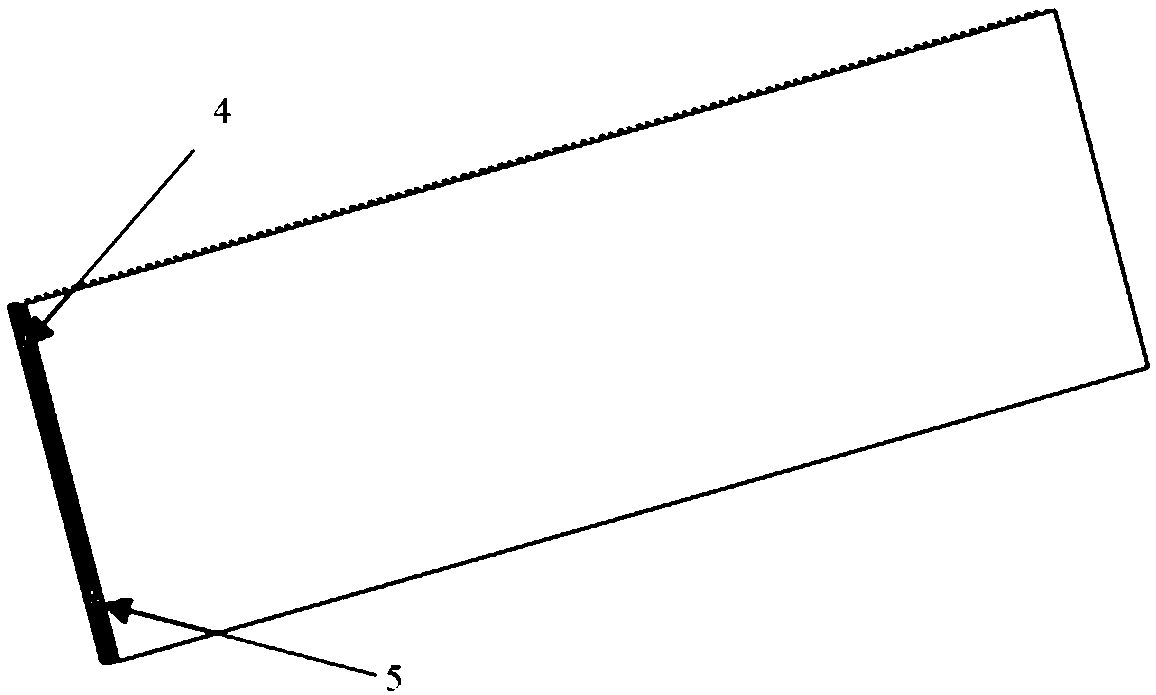

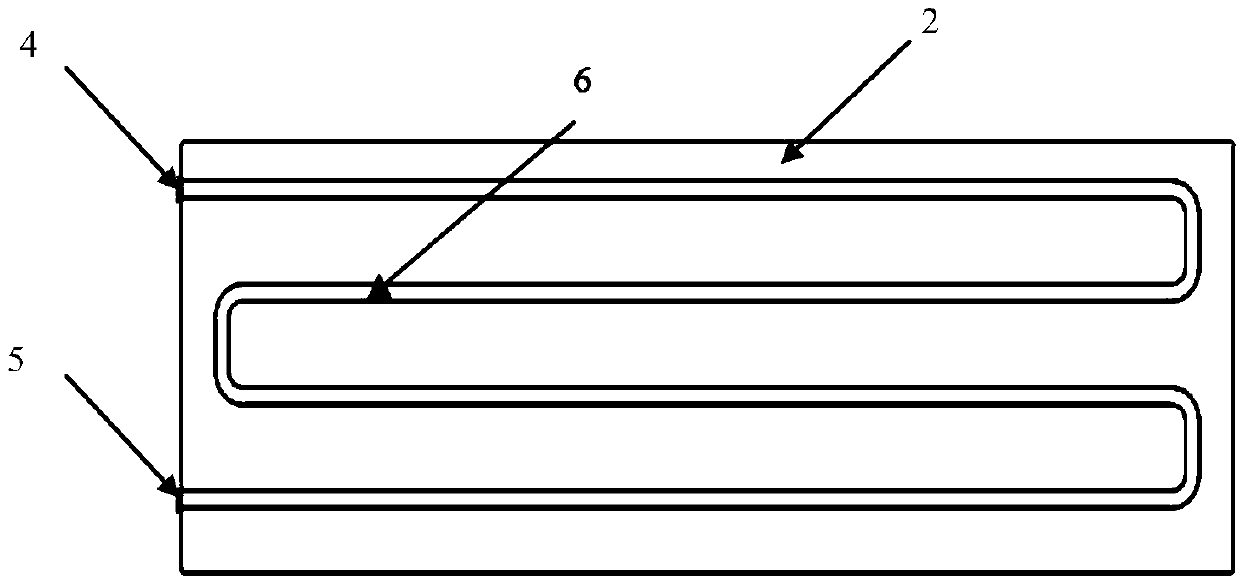

Canal evaporator

InactiveCN101101177AEnhanced heat transferImprove performanceEvaporators/condensersStationary conduit assembliesExhaust gasEvaporator

The invention relates to a tube evaporator, belongs to the thermal equipment technical area. The air heating tube evaporator includes the evaporator export of the liquid vapor (1), fin (2), overheating segment (3), gas collection and exhaust port (5), the evaporator import of liquid (6), snake heat exchange segment( 9), snake heat tube (10), divider (11). The one end of the snake heat tube (10) is sealed by another end of the evaporator export of liquid vapor (1), it is divided into overheating segment (3) and the snake heat exchange segment (9) by the divider (11), and in the tube has the porous layer; the top pf the exhaust-gas tube and the gas collection tube (4) in the snake tube connect the top of the divider (11) which is located in the overheating segment (3). The remaining liquid of the evaporation returns to the evaporator import of liquid (6) and cycles evaporation; the invention also provides a fluid heat-pipe evaporator. The invention has high- heat exchange performance, is conducive to maintain the efficient evaporation process; simple processing, enhanced the work efficiency and the adapt ability of the evaporator.

Owner:TSINGHUA UNIV

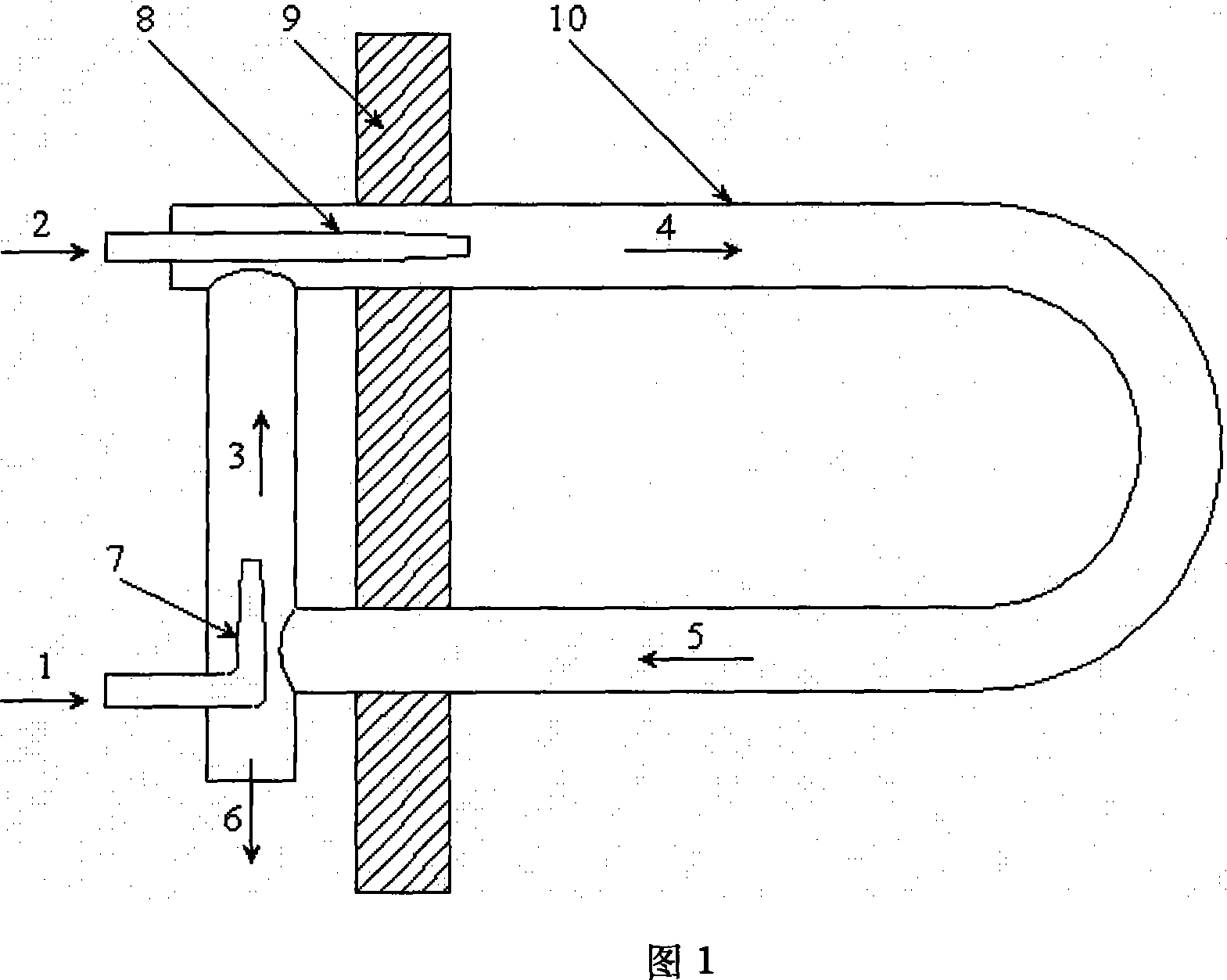

Oxygen-enriched combustion radiant tube heaters

InactiveCN101063525ALower combustion temperatureEnhanced heat transferFurnace typesIndirect carbon-dioxide mitigationInjectorProcess engineering

A radiant-tube heater of oxygen-enriched combustion belonging to the field of environmental protection relates to a new method of oxygen-enriched combustion technology applicable to radiant-tube heater, to develop a combustion system of novel industrial radiant tube that combusts the low-calorific value gas (or other fuel gas) to increase the heat utilization, which is characterized in that the heater comprises oxygen or oxygen-enriched air (1), fuel (2), mixed gas (3) of oxygen or oxygen-enriched air and smoke gas, fuel gas (4), smoke gas (5) in the radiant tube, smoke gas (6) discharged from the radiant tube, a smoke gas injector (7), a combustor (8), a boiler wall (9) and a radiant tube (10). The heater has low combusting temperature, low content of harmful gas like NOx in the smoke gas and high heat efficiency, and is good for collecting the smoke, in particular to CO2 and increases the stability and reliability of the system.

Owner:UNIV OF SCI & TECH BEIJING

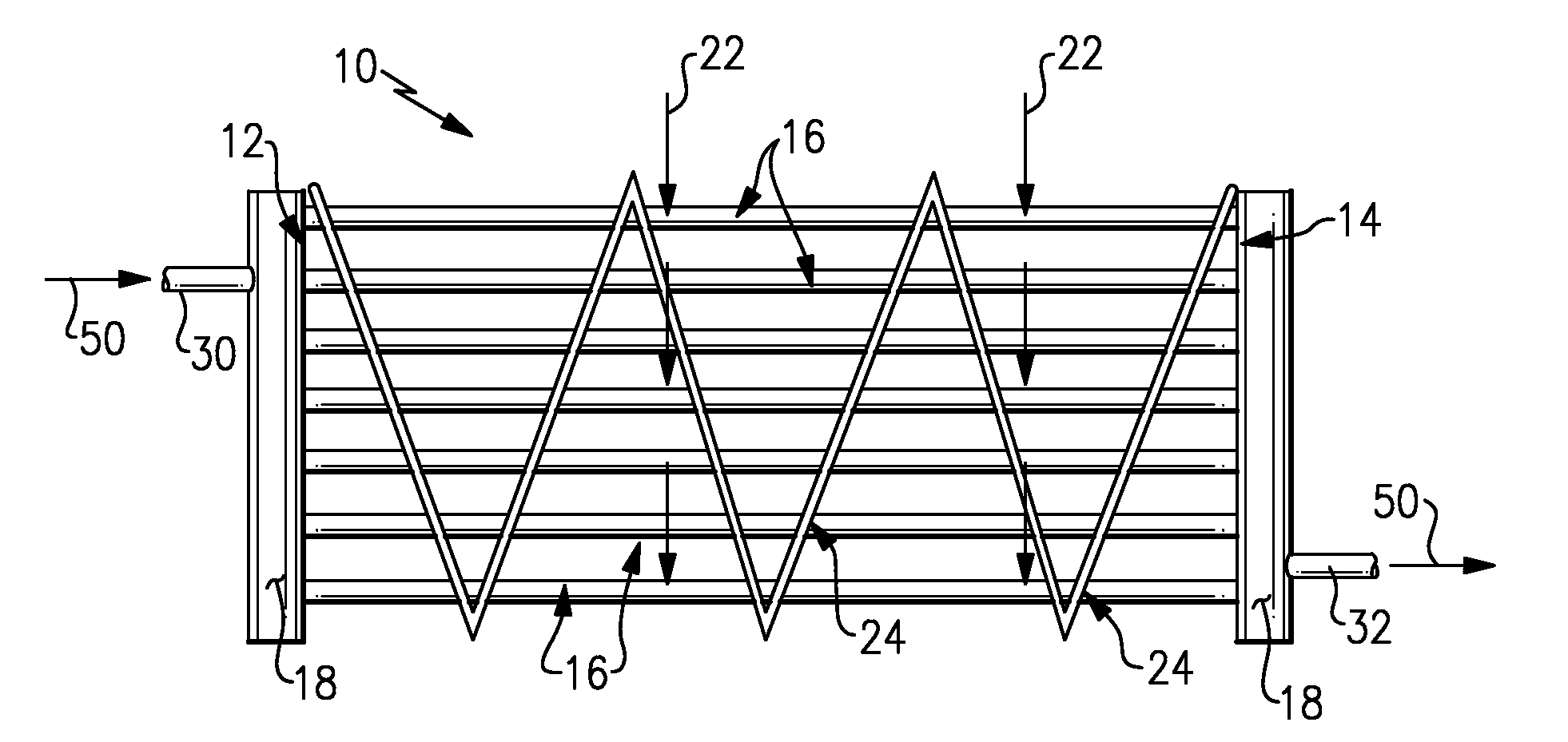

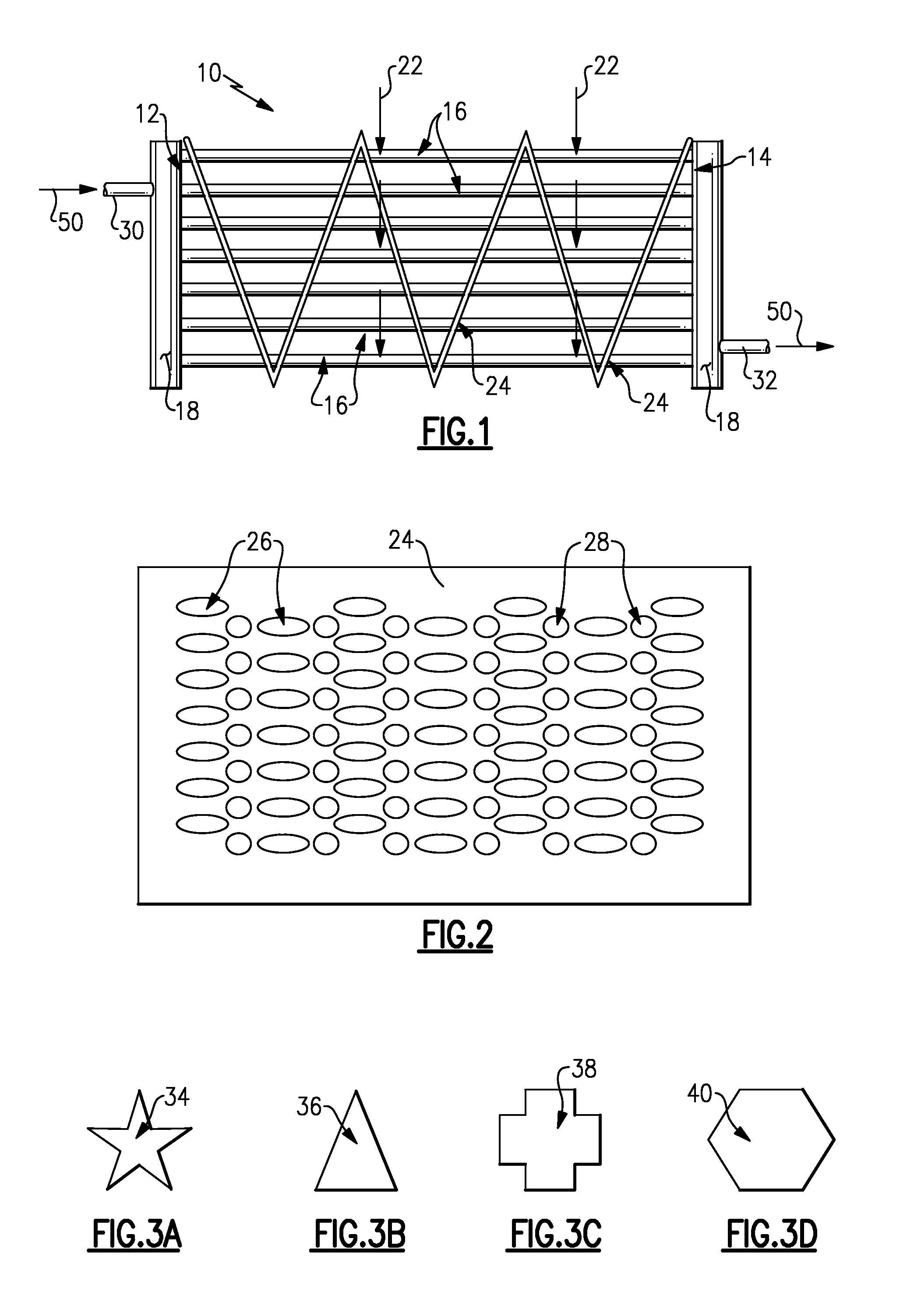

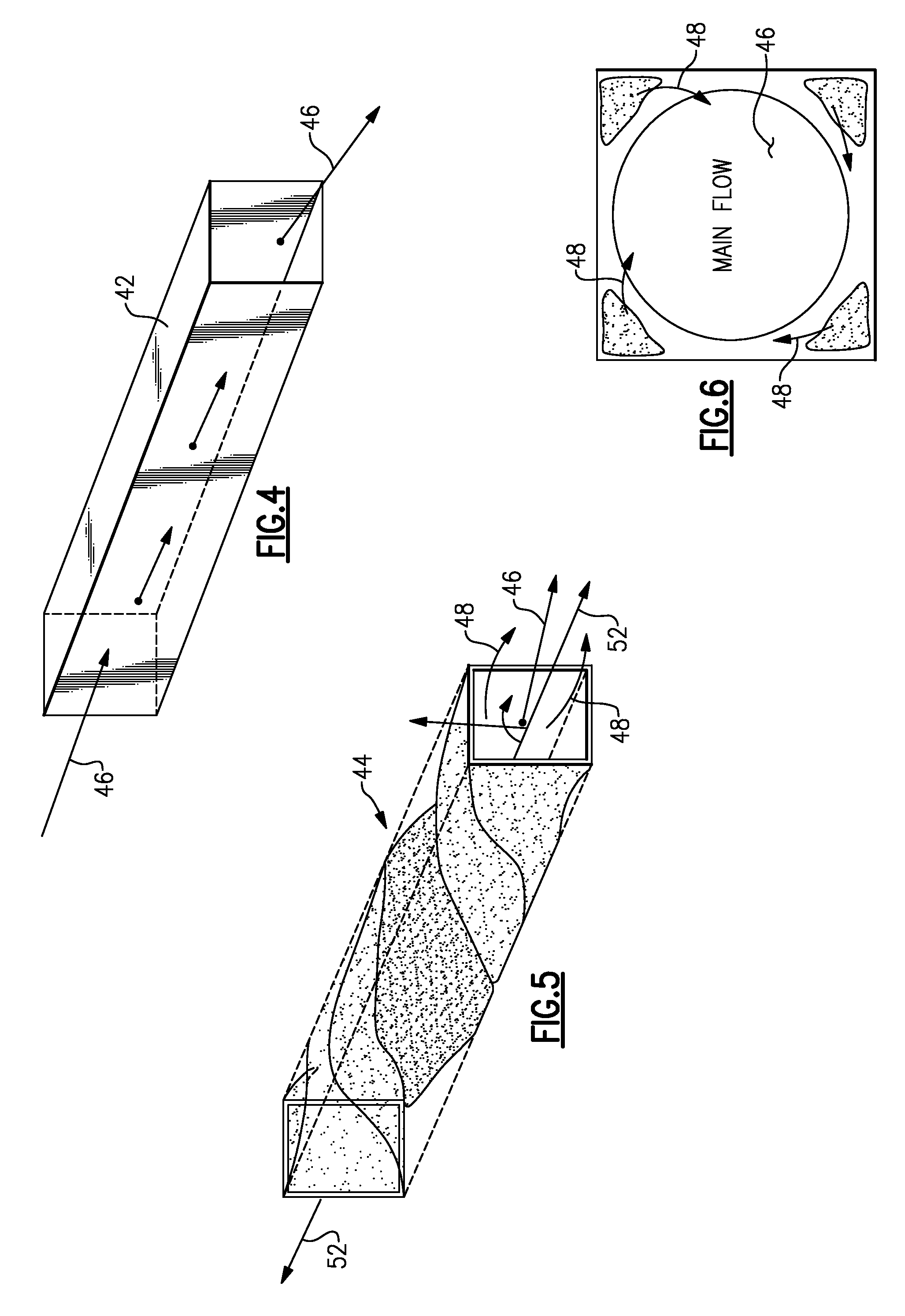

Plastic intercooler

InactiveUS20080173436A1Heat transferEnhanced heat transferInternal combustion piston enginesHeat exchanger casingsPhysicsIntercooler

An intercooler comprises a plurality of plastic cooling tubes extending between a first end plate and a second end plate and a baffle arranged in the intercooler and extending at least partially between the first end plate and the second end plate. The baffle comprises a plurality of first openings for receiving a respective plastic cooling tube, the baffle further comprising a plurality of second openings arranged between the first openings. The second openings permit air to flow through the intercooler whilst creating turbulence in the air flow which increase the thermal transfer between the air and the tubes increasing the efficiency of the intercooler.

Owner:MAHLE INT GMBH

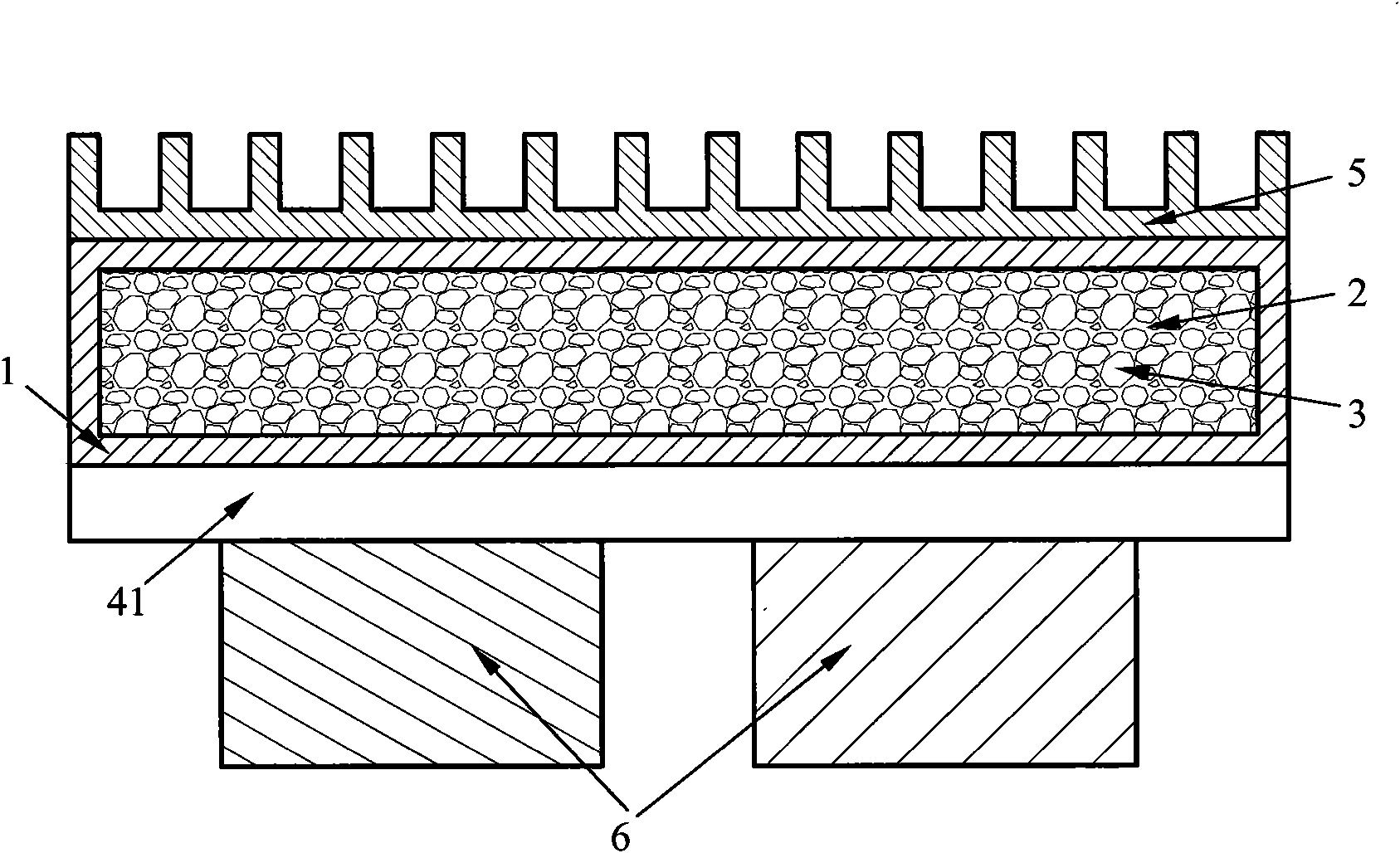

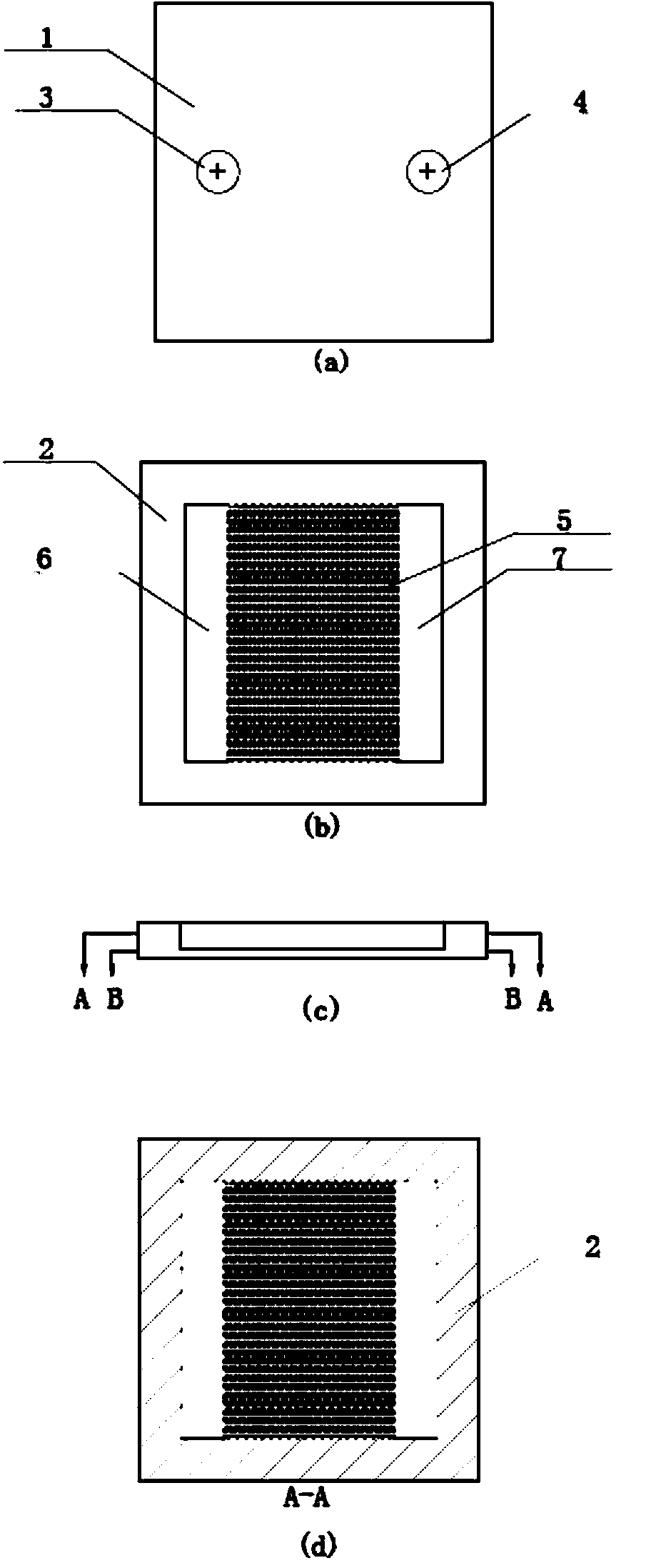

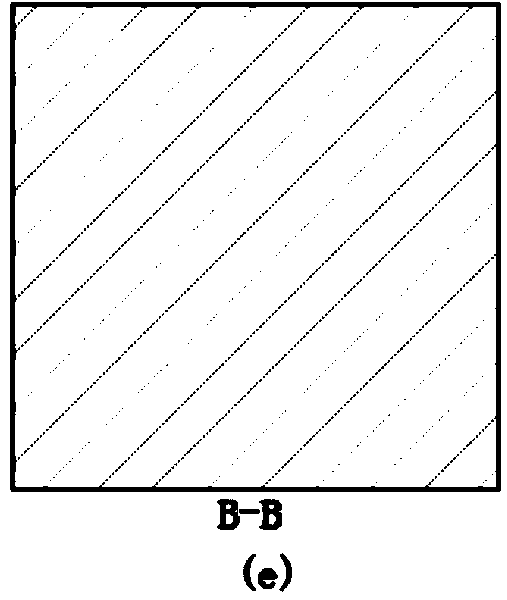

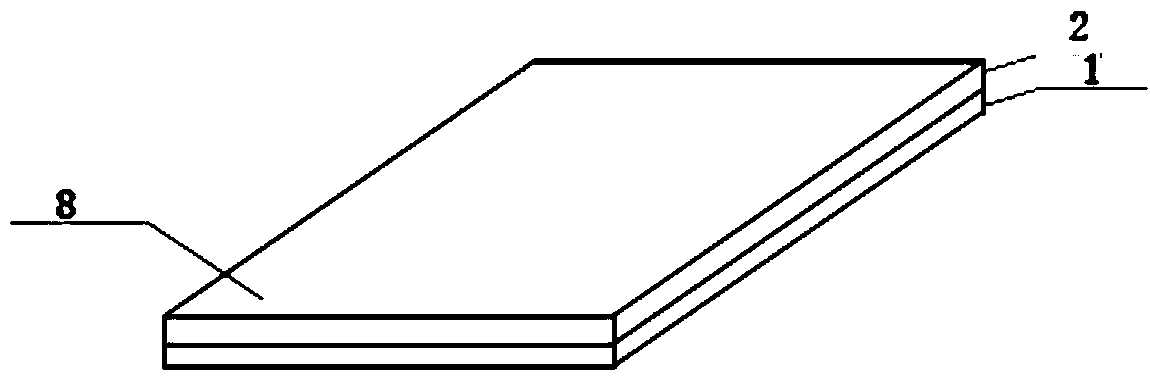

Staggered complex micro-channel miniature heat exchanger

ActiveCN104167399AEasy installation and integrationEnhanced heat transferSemiconductor/solid-state device detailsSolid-state devicesEngineeringRadiation

A staggered complicated micro-channel miniature heat exchanger belongs to the technical field of microelectronic heat exchangers. The staggered complex micro-channel miniature heat exchanger includes a packaging sheet (1) formed by packaging, and a substrate (2); the packaging sheet is provided with a fluid inlet (3) and a fluid outlet (4) which are connected with an external pipeline; and staggered complex micro channels (5), a liquid storage groove (6) at the inlet and a liquid storage groove (7) at the outlet are etched on the front side of the substrate. The device satisfies a heat radiation requirement of a large power electronic chip, and makes up the defects that application of an efficient metal micro-radiator is limited since the thermal expansion coefficient thereof is not matched with that of the electronic chip, and temperature distribution of a cooled surface (i.e., the electronic chip) is nonuniform.

Owner:BEIJING UNIV OF TECH

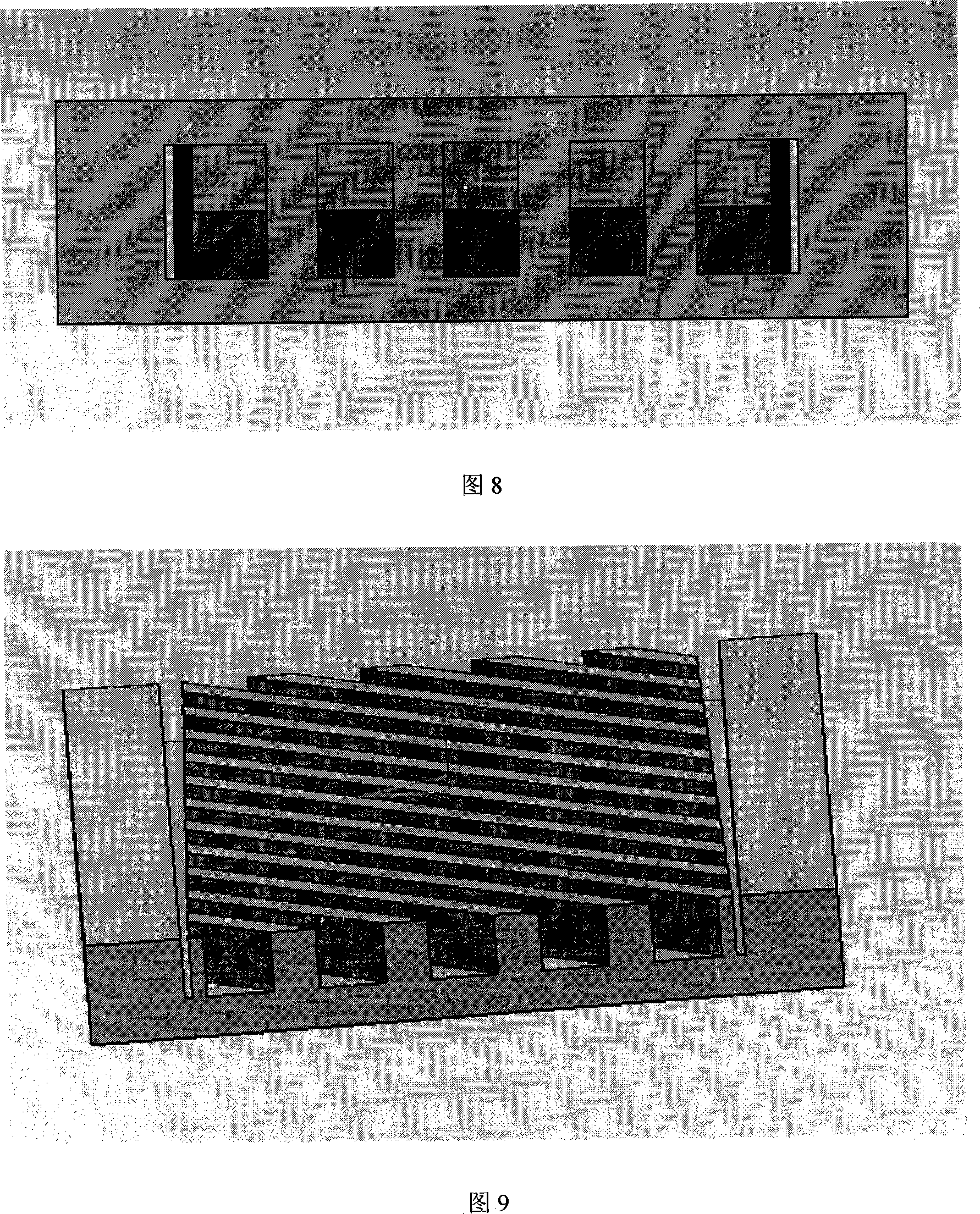

Strengthened heat exchange tube

ActiveCN101799252AIncrease the heat exchange areaEnhanced heat transferCorrosion preventionTubular elementsHeat transfer tubeMicro nano

The invention provides a strengthened heat exchange tube comprising a heat exchange tube and a strap-type metal slice, wherein one surface of the strap-type metal slice is a smooth plane, and the other surface of the strap-type metal slice obtains a super hydrophobic surface by advanced manufacturing methods, such as precise rolling, chemical, electrochemical methods and the like; the super hydrophobic surface is burr bulge with a micro-nano structure; the strap-type metal slice is tightly and spirally coiled on the outer surface of the heat exchange tube; the smooth surface of the strap-type metal slice and the outer surface of the heat exchange tube are tightly laminated, and the coiled strap-type metal slice is fixed on the heat exchange tube; before the strap-type metal slice is coiled, the outer surface of the heat exchange tube is covered with heat conduction filler, and the strap-type metal slice is coiled and fixed on the heat exchange tube covered with heat conduction filler. The heat transfer tube of the invention has simple production, convenient installation, favorable adaptability and small possibility of scaling and has the effect on strengthening heat transfer.

Owner:BEIJING UNIV OF CHEM TECH

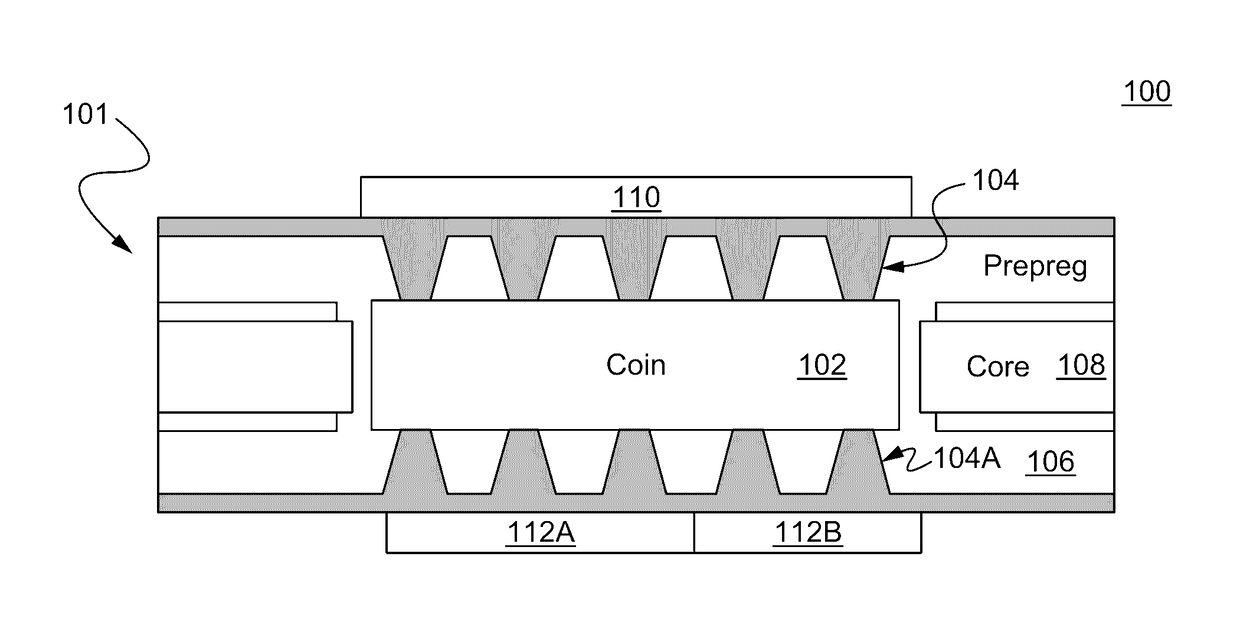

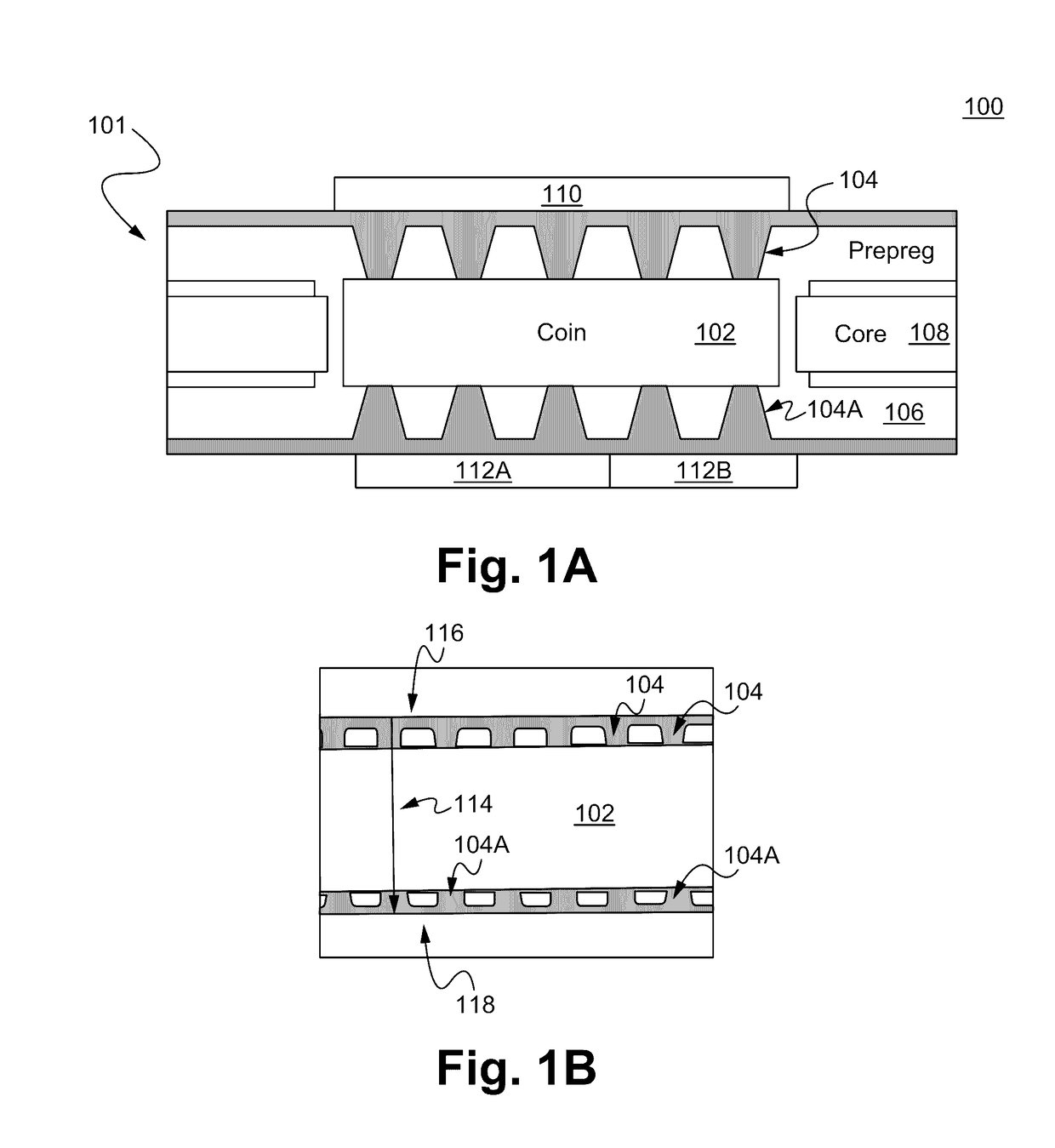

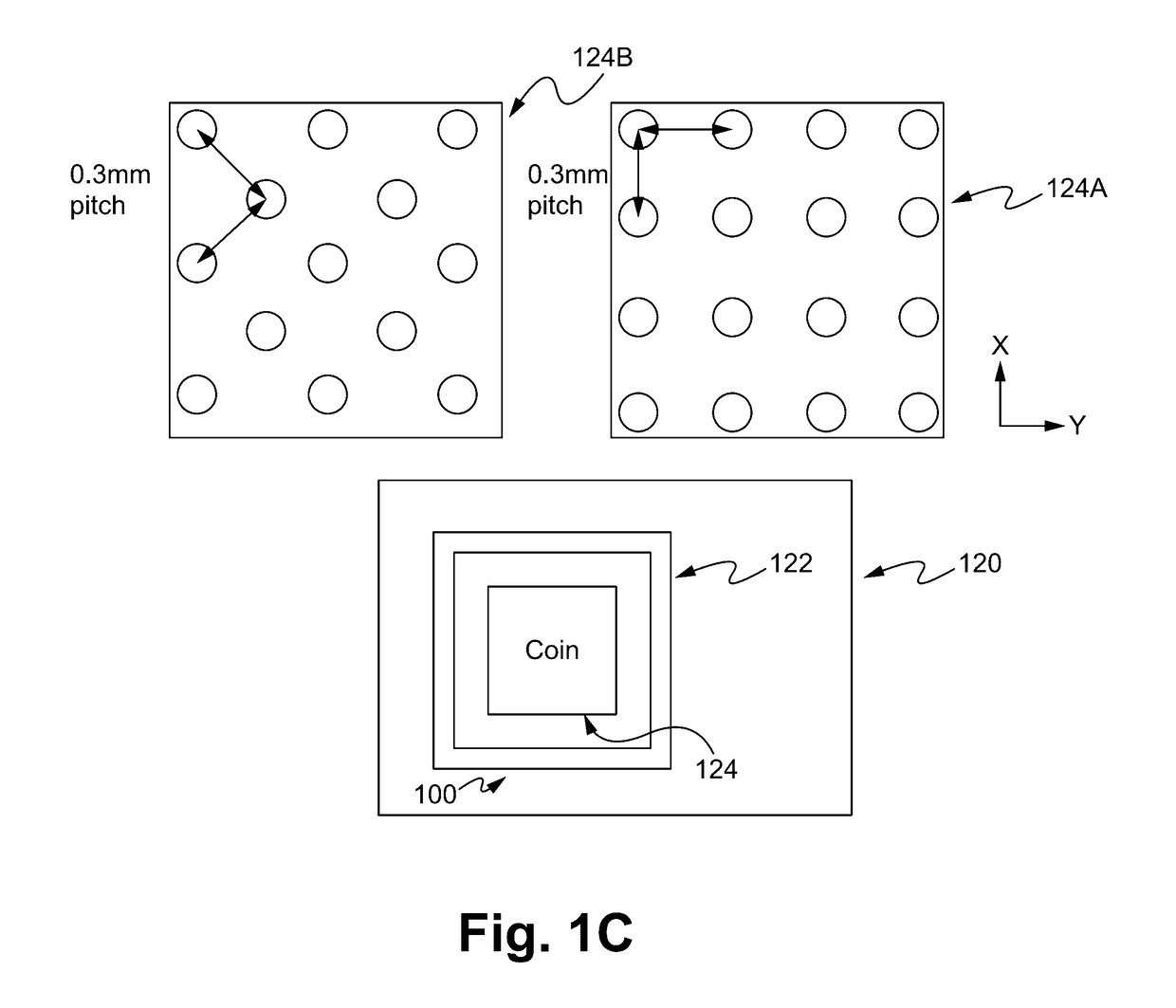

Embedded coins for HDI or SEQ laminations

ActiveUS9661738B1Enhanced heat transferHigh heat transfer efficiencyPrinted circuit aspectsSolid-state devicesEmbedded systemHigh density

A method of and a device for dissipating / transferring heat through one or more solid vias and embedded coins are disclosed. The method and device disclosed herein can be used to transfer heat for a High Density Interconnect (HDI) board.

Owner:FLEX LTD

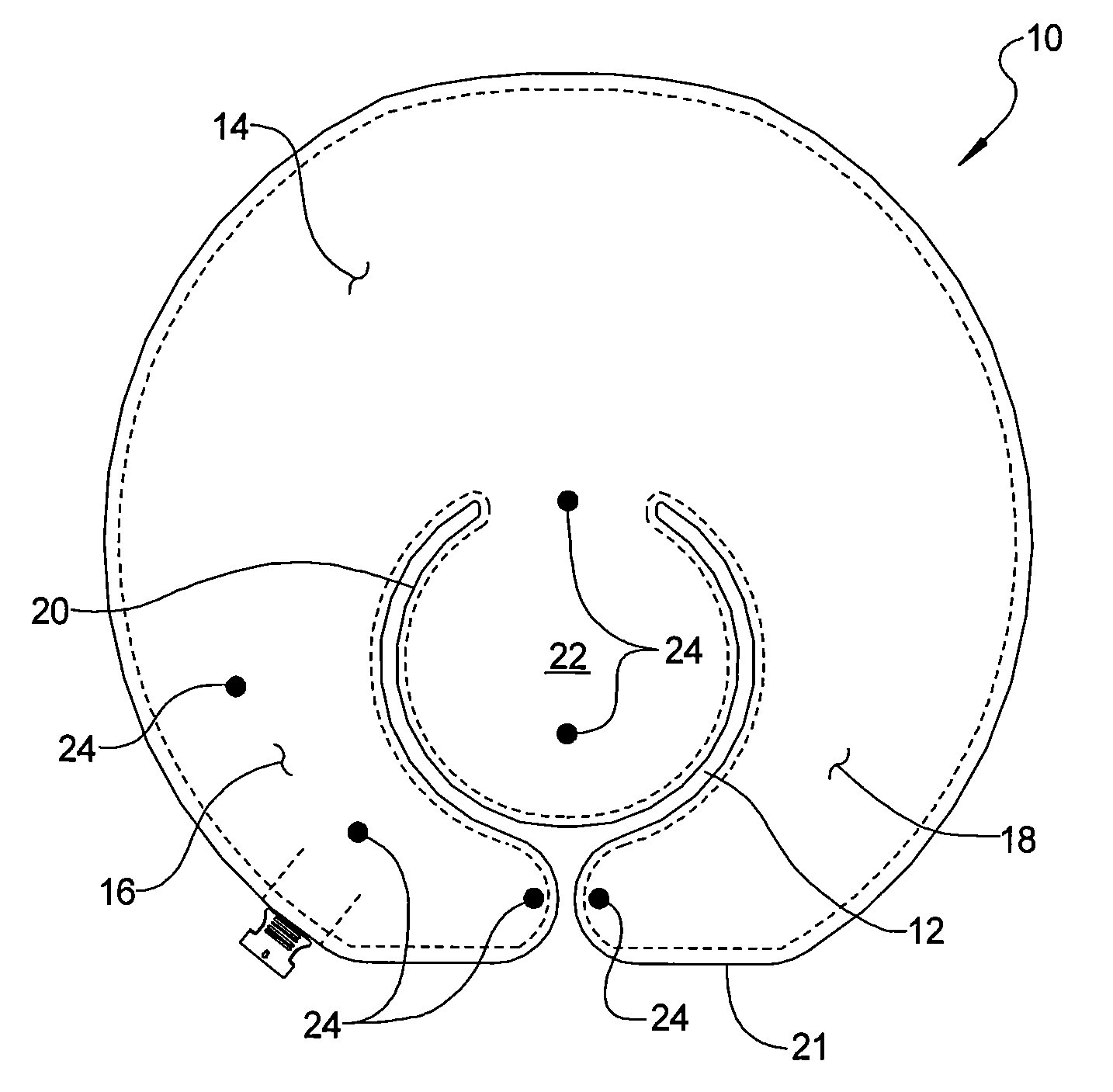

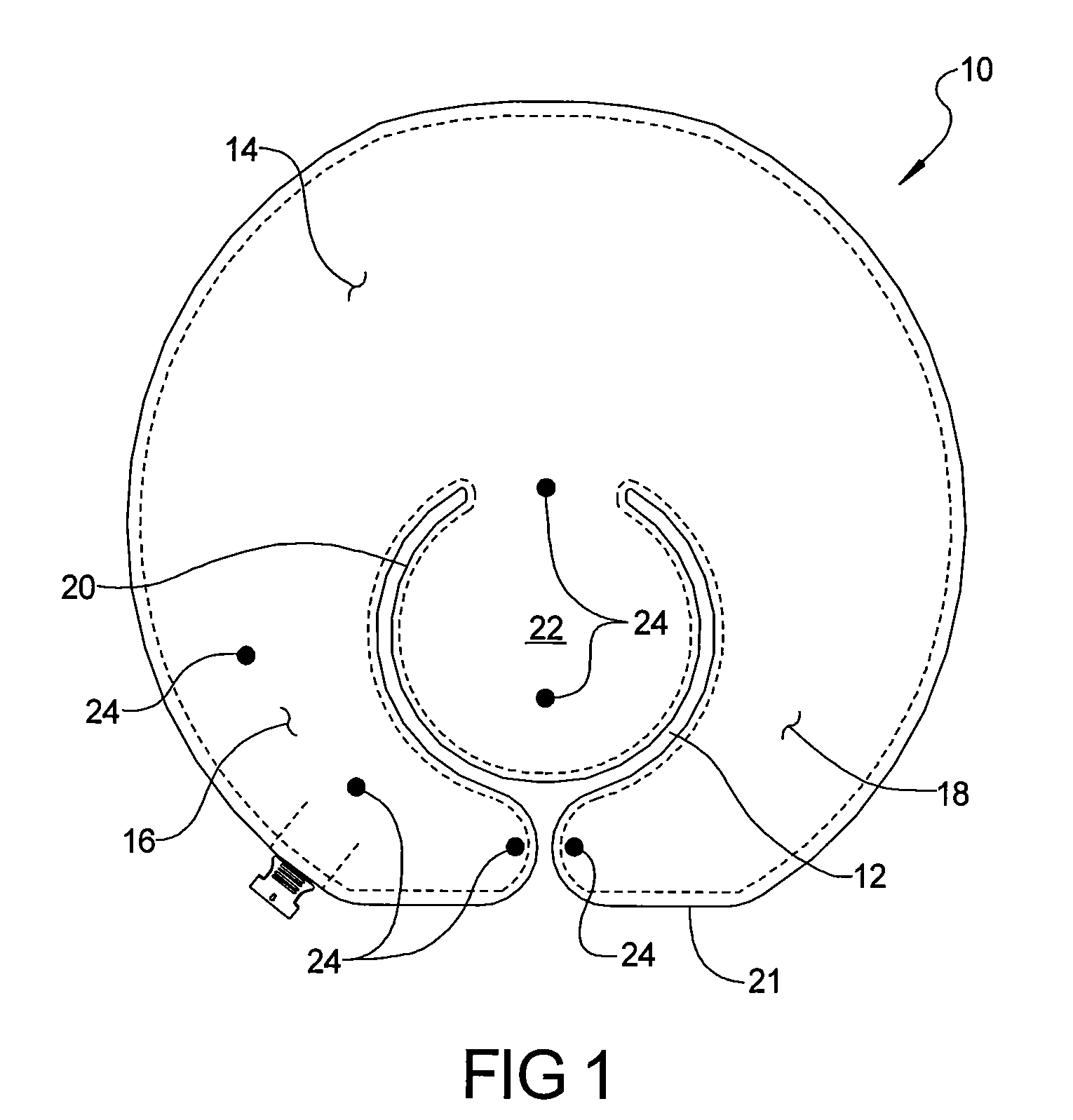

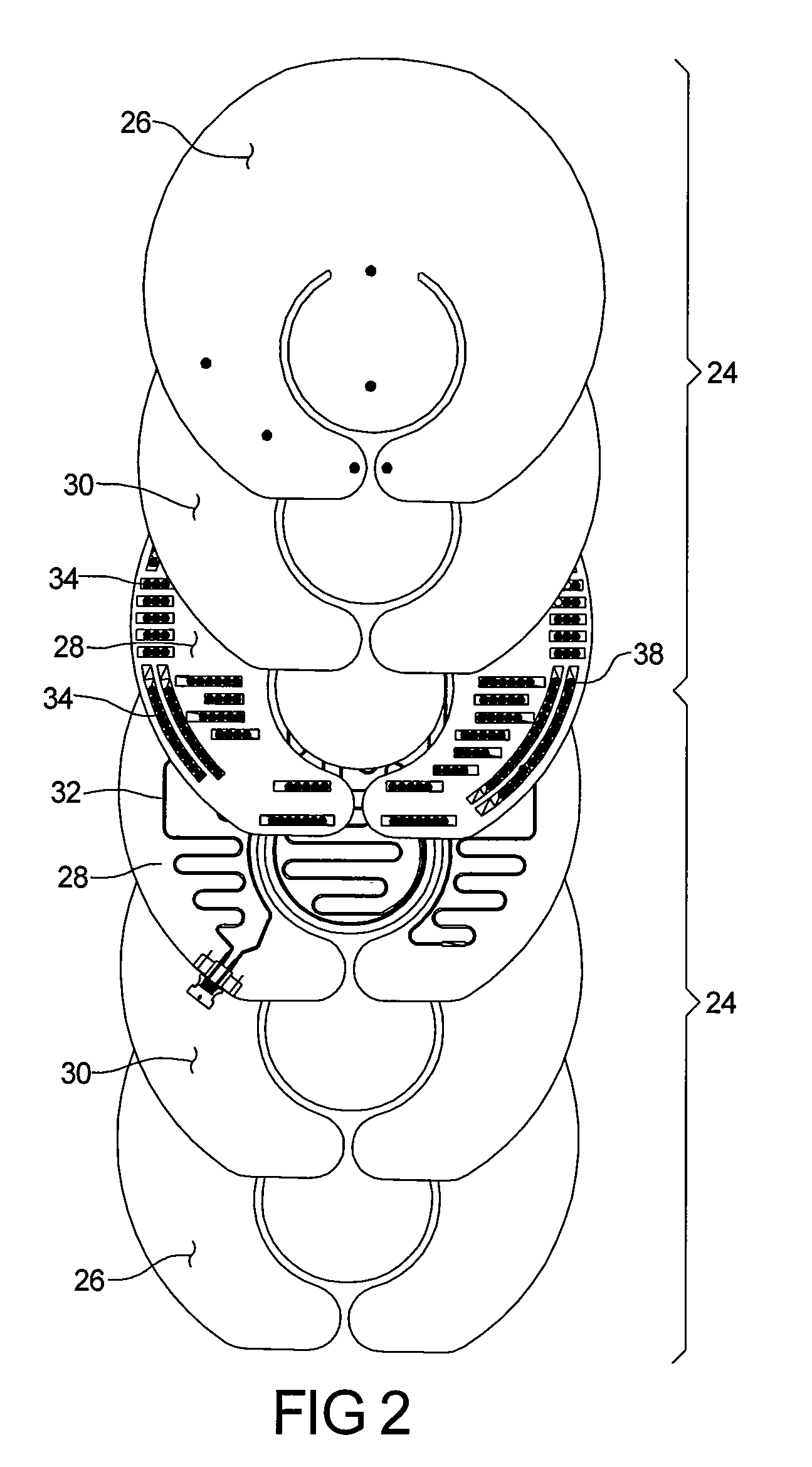

Conformable heating pad

InactiveUS20090032523A1Improve conformityEnhanced heat transferHeating element shapesEngineeringWing section

A conforming heating pad having a curvilinear Y-shaped recess has a pair of opposed curved wing sections surrounding a centralized opening occupied by a central flap portion created by the Y-shaped recess. A pair-of opposed multi-layer constructions housing a resistive NTC sensing wire and a plurality of individual weights serve to enhance the conformity of the heating pad. The heating pad is operable in at least two modes, including a constant heating level mode at various user-selectable temperature levels and a timed mode that offers user-selectable temperature levels over a user-selectable period of time. The heating pad can be wetted to offer a moist heat therapy.

Owner:SUNBEAN PROD INC

Micro cooling device of silicon-substrate capillary pump loop

InactiveCN103442541AEnhanced heat transferLow flow resistanceDigital data processing detailsSemiconductor/solid-state device detailsPhysicsHeat flow

The invention discloses a micro cooling device of a silicon-substrate capillary pump loop and belongs to the temperature-control field of microelectronic chips. The micro cooling device of the silicon-substrate capillary pump loop is formed by bonding a pair of semi-conductor silicon wafers and a heat-resistant boron silicic acid glass piece. An evaporator, a condenser, a vapor phase channel, a liquid phase channel, a liquid storing cavity and a pumping or liquid filling channel are formed in the contact surface between the silicon wafers and the heat-resistant boron silicic acid glass piece in an etching mode. The evaporator and the condenser are connected through the vapor phase channel and the liquid phase channel to form a closed circuit. The evaporator comprises a micro conduit. The condenser comprises a condensing micro channel. A pumping or liquid filling hole is machined in the silicic acid glass piece. The liquid storing cavity is connected with the evaporator. The micro cooling device of the silicon-substrate silicon substrate loop can be directly integrated with a semi-conductor microelectronic chip so as to effectively reduce the temperature and the temperature gradient of the chip. The problems of hot spots caused by local high heat flow are reduced and relieved. Safe and reliable operation of the chip is ensured.

Owner:JIANGSU UNIV

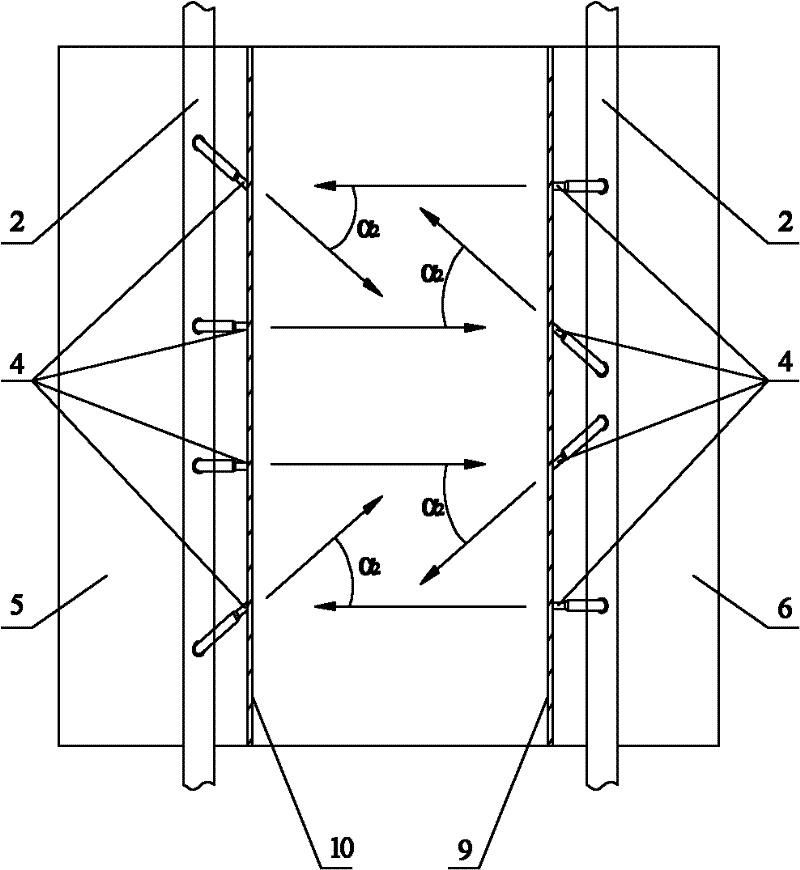

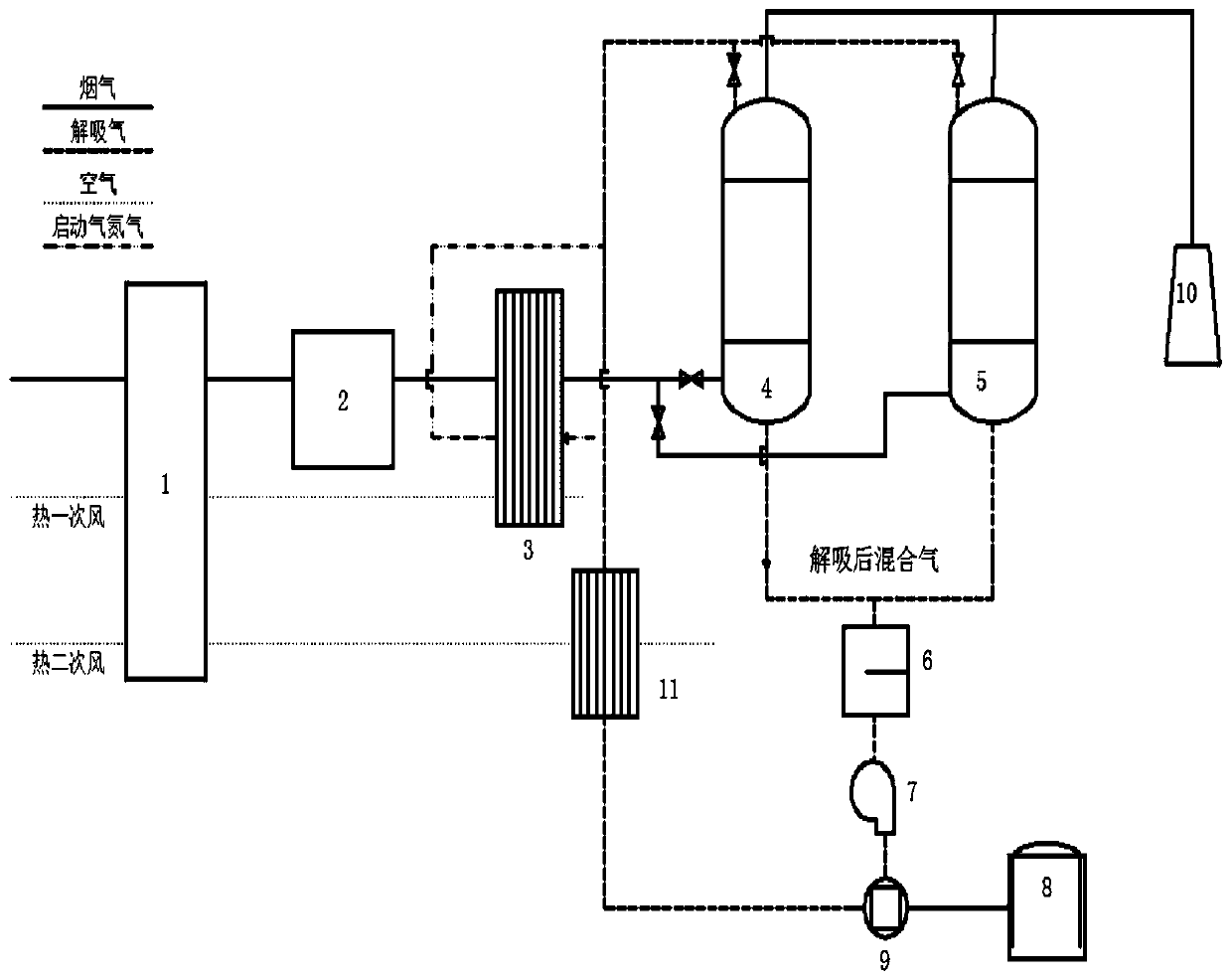

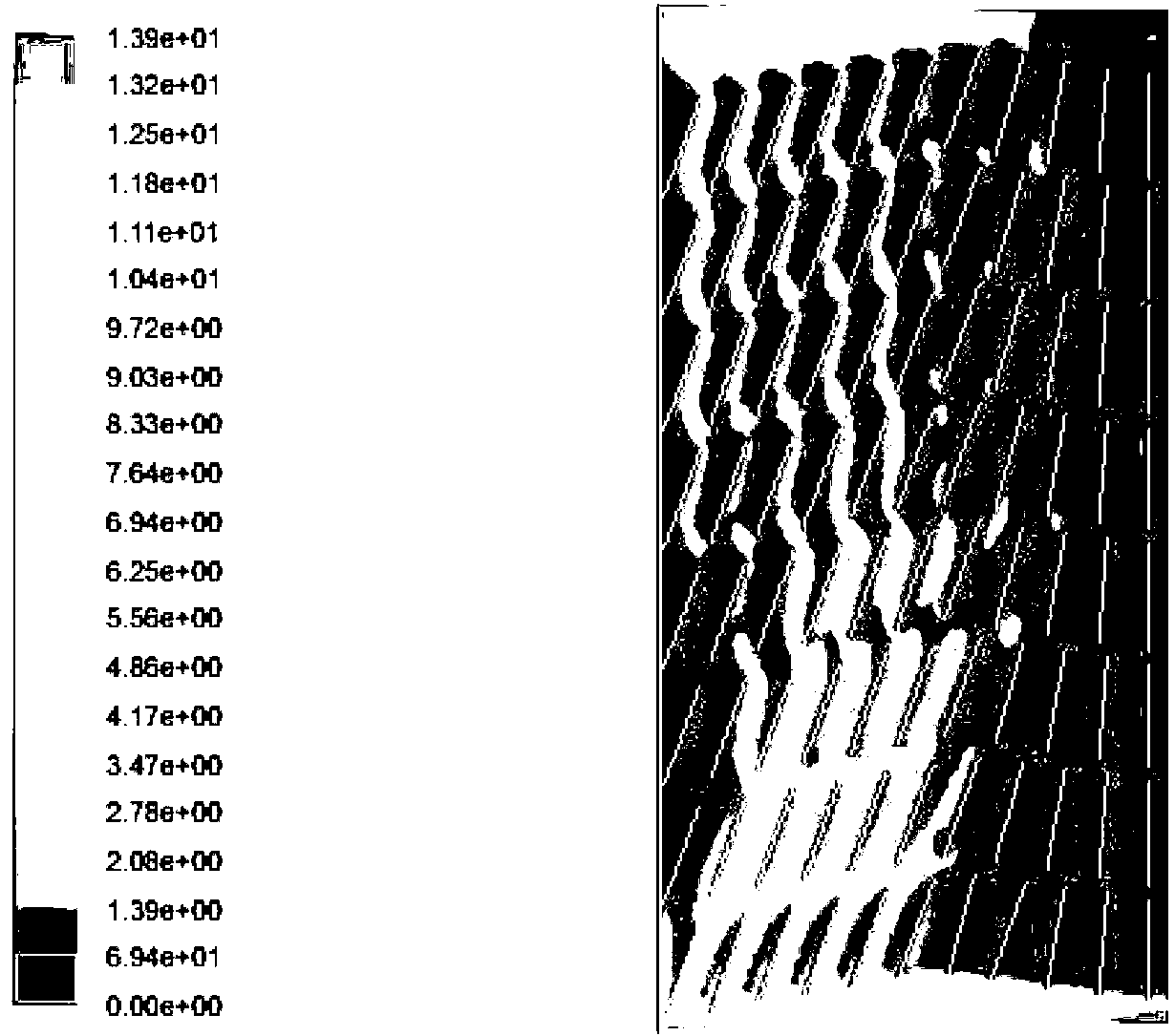

Arrangement device for double-layer swirl burn-off air of garbage incinerator

ActiveCN102269413AIncreased turbulenceEnhanced heat transferIncinerator apparatusDecompositionAir door

The invention provides a garbage incinerator double-layer rational flow over-fire air arranging device which comprises a first-layer over-fire air nozzle, a second-layer over-fire air nozzle, an over-fire air pipe and an over-fire air door, wherein the two layers of over-fire air nozzles are arranged on the bottom positions of front and back walls of the furnace hearth, the over-fire air nozzles are horizontally arranged, half of the nozzles are arranged vertical to the furnace hearth and half nozzles are deflected by a designed angle, so that the leading and driving effect of high-speed jet flow can be utilized, flue gas can be impelled to generate spiral ascending air flow, air flow disturbance in the furnace hearth can be strengthened, and flue gas route and residence time of flue gas can be effectively prolonged and full decomposition of harmful gases such as dioxins and the like can be ensured. The application of the over-fire air also aims at distributing air on a basis of classification, improving burn-off rate and reducing the generation amount of NOx. The invention can solve the problems of insufficient flue gas residence time, high fly ash combustible content and low burn-off rate and the like existing in the garbage incinerator which is not installed with the over-fire air device or only adopts vertical furnace wall injection as an over-fire air arrangement mode.

Owner:GUANGZHOU WEIGANG ENVIRONMENT TECH CO LTD

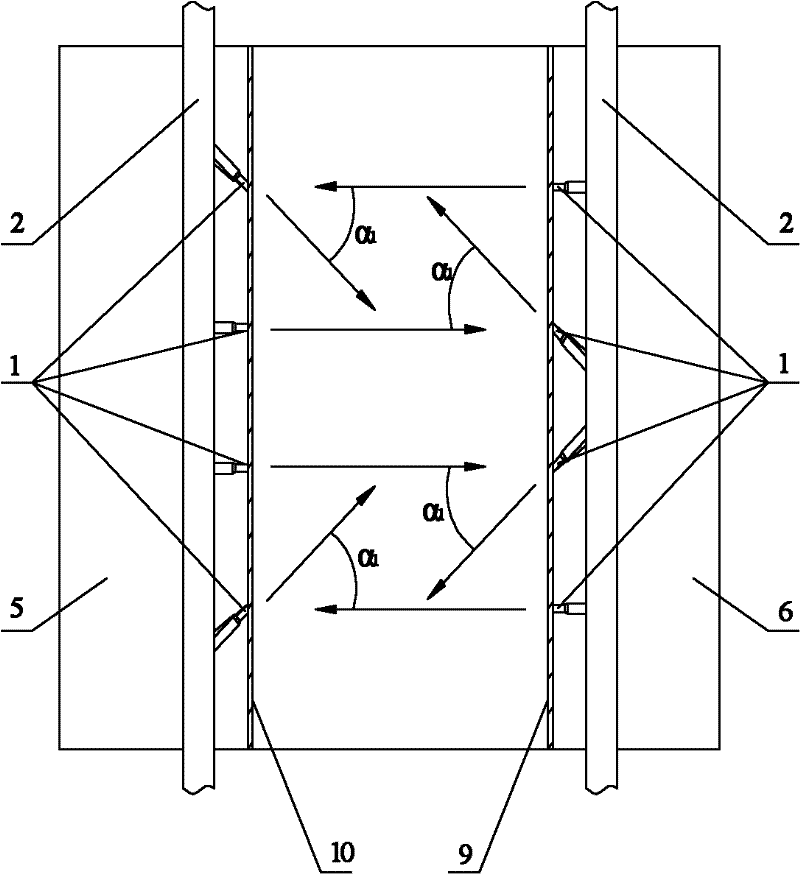

Double-wall small bent pipe structure for backflow combustion chamber and backflow combustion chamber

ActiveCN111928296AEnhanced heat transferImprove cooling efficiencyContinuous combustion chamberCombustion chamberCold air

The invention discloses a double-wall small bent pipe structure for a backflow combustion chamber and the backflow combustion chamber. The double-wall small bent pipe structure comprises a bent pipe inner wall and a bent pipe outer wall which are arranged at intervals, wherein the bent pipe outer wall is arranged on the outer side of the bent pipe inner wall, and a middle cavity is formed betweenthe bent pipe outer wall and the bent pipe inner wall, first impact holes are formed in the bent pipe inner wall, an air film hole which penetrates through the bent pipe outer wall to be used for communicating the outer side of the bent pipe outer wall with the middle cavity is formed in the wall body of the first side of the bent pipe outer wall, and a part of cold air flow flowing into the middle cavity flows out of the air film hole and is attached to the outer wall surface of the bent pipe outer wall to flow under the combined action of the flow guide effect of the bent pipe outer wall andthe impact effect of high-temperature fuel gas flow on the outer side of the bent pipe outer wall so as to form a cold air protective film on the outer surface of the bent pipe outer wall; and meanwhile, the other part of cold air flow flowing into the middle cavity flows out towards a bend pipe outlet in the second side of the bend pipe outer wall along the middle cavity. The double-wall small bent pipe structure for the backflow combustion chamber is not prone to ablation.

Owner:AECC HUNAN AVIATION POWERPLANT RES INST

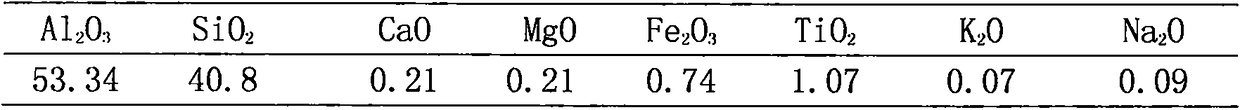

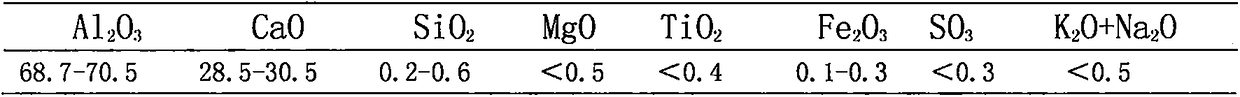

Boiler water cooling wall high-temperature anti-corrosion anti-staining anti-slagging ceramic coating material

The invention provides a boiler water cooling wall high-temperature anti-corrosion anti-staining anti-slagging ceramic coating material, a preparation method and applications thereof, and belongs to the technical field of special coating materials, wherein the ceramic coating material comprises, by mass, 45-51.2% of a filler, 35% of a binder, 5.22% of an additive, 1.22% of an auxiliary agent, andthe balance of water, and the filler comprises 27.5% of synthetic mullite, 9.9% of corundum powder, 1.5-2.7% of pure calcium aluminate micro-powder, 1.9-4.5% of active alumina micro-powder, 1.8-3.6 ofsilicon micro-powder, and 3% of a rare earth oxide. The preparation method comprises: adding water to a binder, mixing to obtain a binder liquid, carrying out grinding refining treatment on a fillerto achieve a particle size of less than or equal to 5 [mu]m, adding the treated filler into the binder liquid, adding an auxiliary agent, uniformly stirring, filtering, and encapsulating. According tothe present invention, the outer surfaces of boiler water cooling wall furnace pipes and heating furnace pipes can be coated with the obtained coating material to form ceramic coatings.

Owner:北京泽马新技术有限公司

Liquid cooling heat management device for power battery pack of vehicle

PendingCN109599639AEnhanced heat transferImprove compactnessSecondary cellsVehicular energy storageNew energyHeat transfer

The invention discloses a liquid cooling heat management device for a power battery pack of a vehicle. The device comprises a cooling liquid distributor, a plurality of liquid cooling plates and the battery pack; channels are formed in the liquid cooling plates; a liquid inlet and a liquid outlet are formed at the same time; and the battery pack is located between the two adjacent liquid cooling plates. The channels in the liquid cooling plates can be set according to a heat generating characteristic and temperature distribution of a power battery individual during working, so that heat generated during charging and discharging of the power battery pack of the new energy vehicle can be taken away efficiently; batteries can be heated by introducing a heat fluid into a heat management structure under the condition that heating is needed, so that the battery of the electric vehicle can work at a proper working temperature for a long time; and meanwhile, due to the fact that the liquid cooling capacity is strong, a reasonable cooling plate internal channel structure can be arranged as needed to reinforce heat transfer, so that the compactness of the battery pack can be improved.

Owner:NANJING FORESTRY UNIV

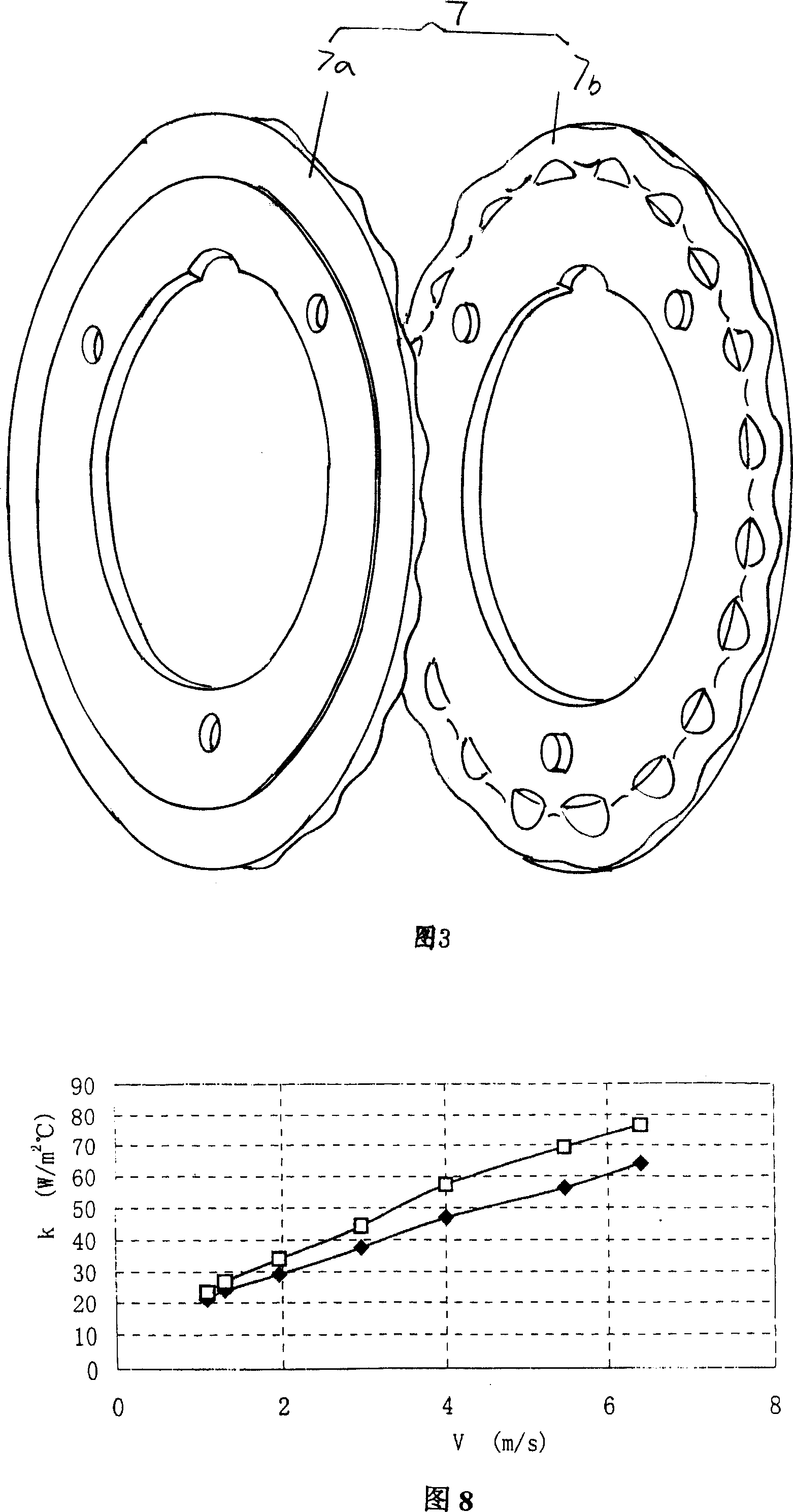

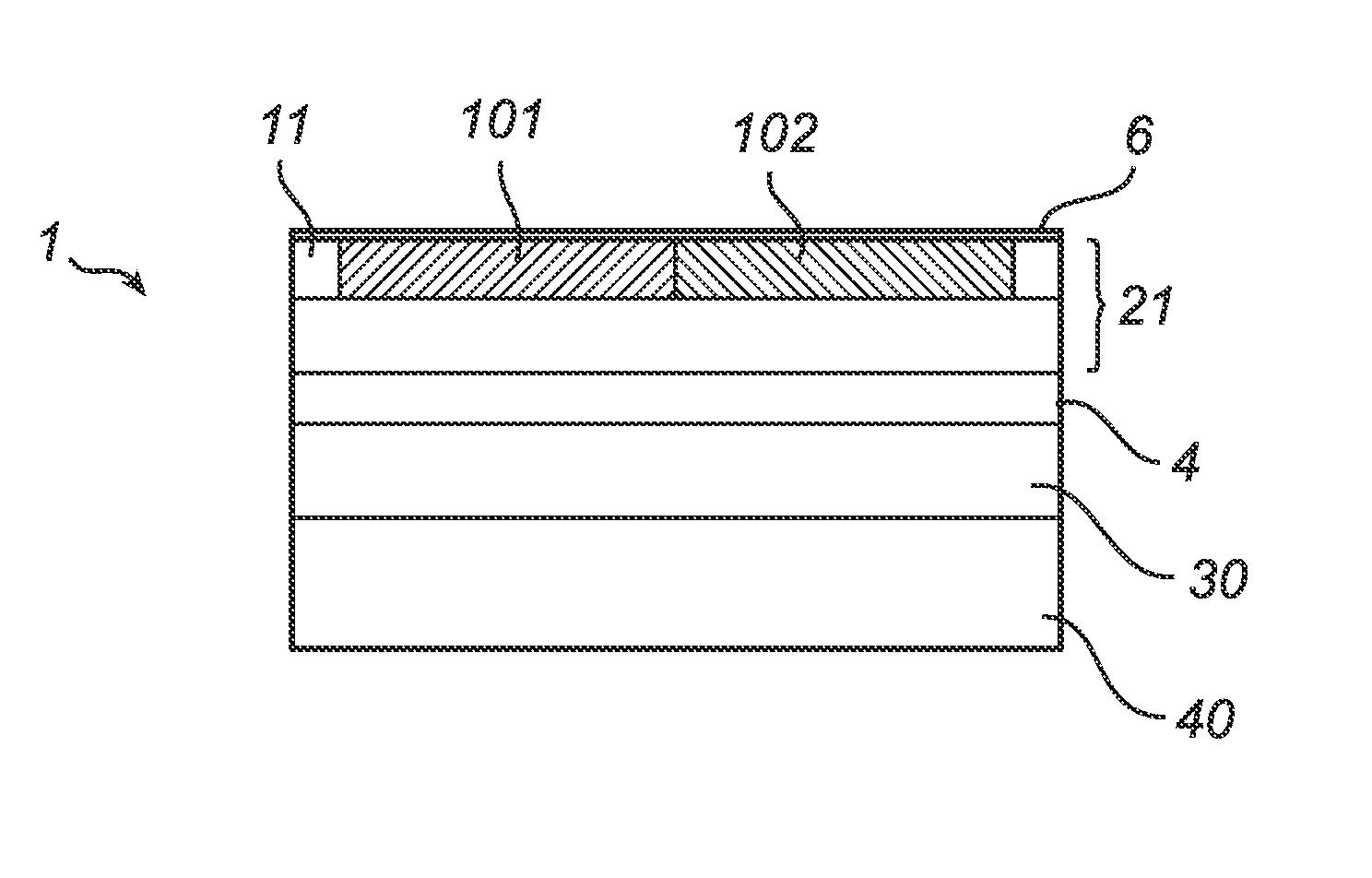

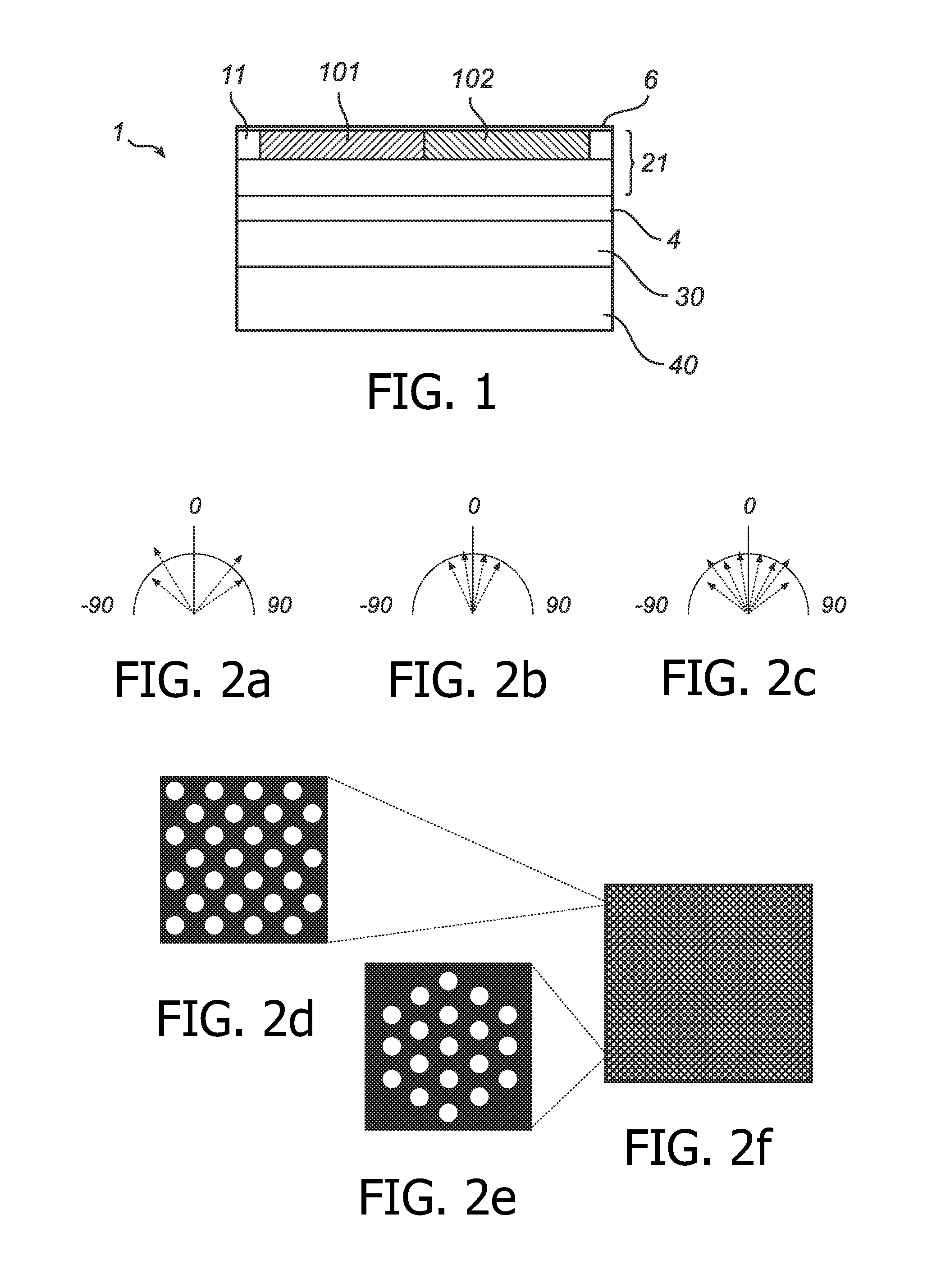

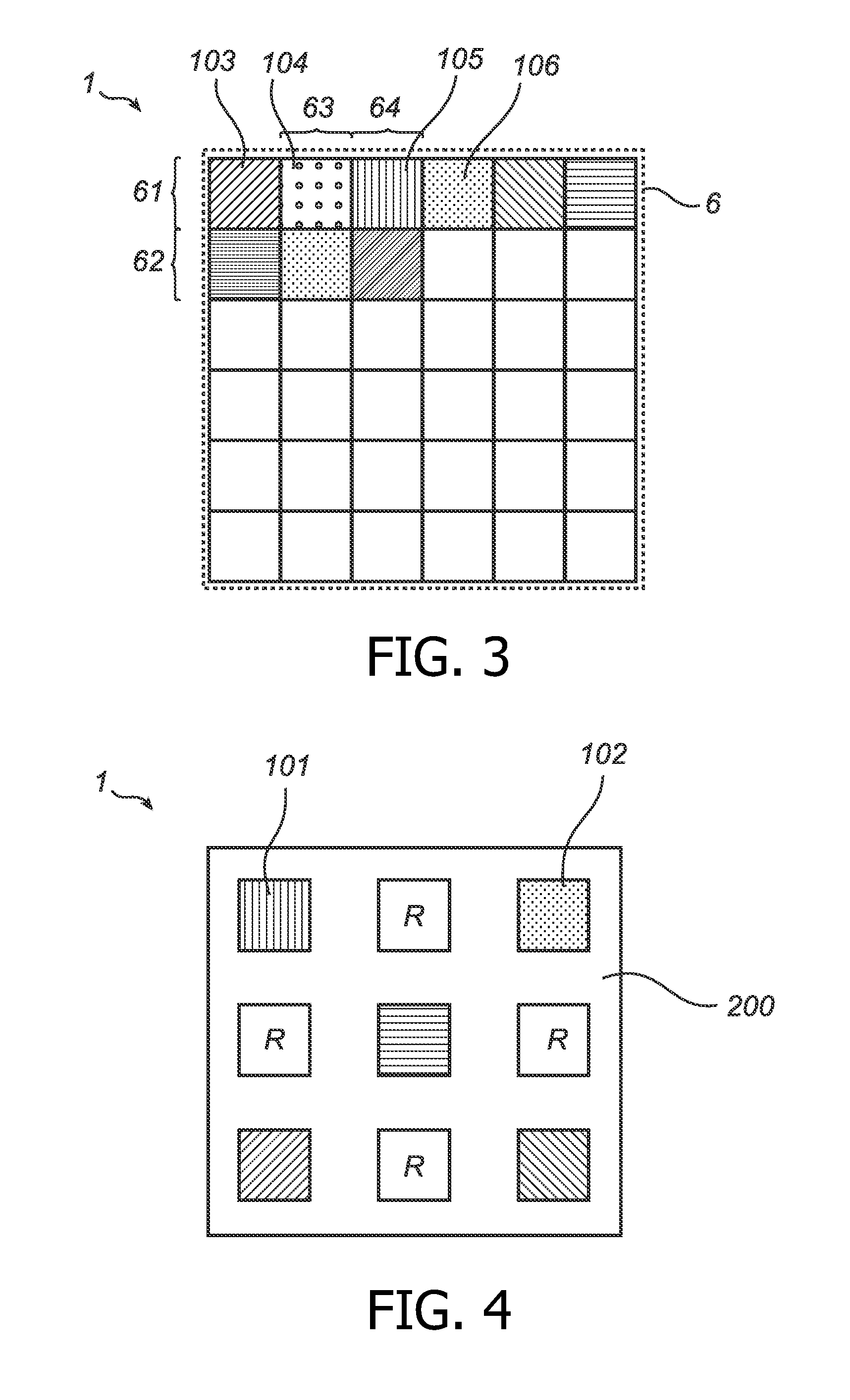

Photonic crystal LED

ActiveUS20100270572A1Easy and more predictable controlEnhanced heat transferSemiconductor devicesPhysicsVoltage

A semiconductor light emitting diode (1, LED), comprising a first and a second electrode (40, 11) for applying a voltage across an active region (4) for generation of light, a light emitting surface (6), and a plurality of photonic crystals (101, 102). Further, at least two photonic crystals (101, 102) of a first and a second type are adapted to extract light from the active region (4) and differ from each other with respect to at least one lattice parameter. Each of said at least two photonic crystals (101, 102) are associated with a respective far field pattern, wherein an arrangement of said plurality of photonic crystals (101, 102) is provided to arrange said at least two photonic crystals (101, 102). In this manner, a far field pattern is created by combining the respective far field patterns associated with each of said at least two photonic crystals (101, 102).

Owner:LUMILEDS

Preparation method of heat exchanger with efficient heat exchange and corrosion resistance and provided with graphene protective membrane

InactiveCN106802106AGuaranteed thermal conductivityEnhanced heat transferSingle layer grapheneChemical industryCvd grapheneBatch production

The invention discloses a preparation method of a heat exchanger with efficient heat exchange and corrosion resistance and provided with a graphene protective membrane. The preparation method is characterized by comprising the following steps: (1) firstly cleaning a copper pipe; (2) growing graphene on the surface of the copper pipe: setting the growth temperature at 800 to 1,200 DEG C, feeding protective gas into a reaction chamber, quickly heating the reaction chamber to the growth temperature of the graphene, then feeding methane gas, keeping feeding the methane gas for 8 to 15 minutes, then quickly cooling the reaction chamber, and cutting the feeding of all types of gas, wherein the growth time of the graphene is equal to the methane feeding time; and (3) controlling the pressure of the reaction chamber at 8 to 15 mbar in a graphene preparation process, thus the high-quality graphene protective membrane is prepared on the surface of the copper pipe, and covers copper to prevent corrosion. The preparation method disclosed by the invention is proper in cost, suitable for large-batch production and relatively high in membrane forming quality.

Owner:GUANGDONG MACRO GAS APPLIANCE

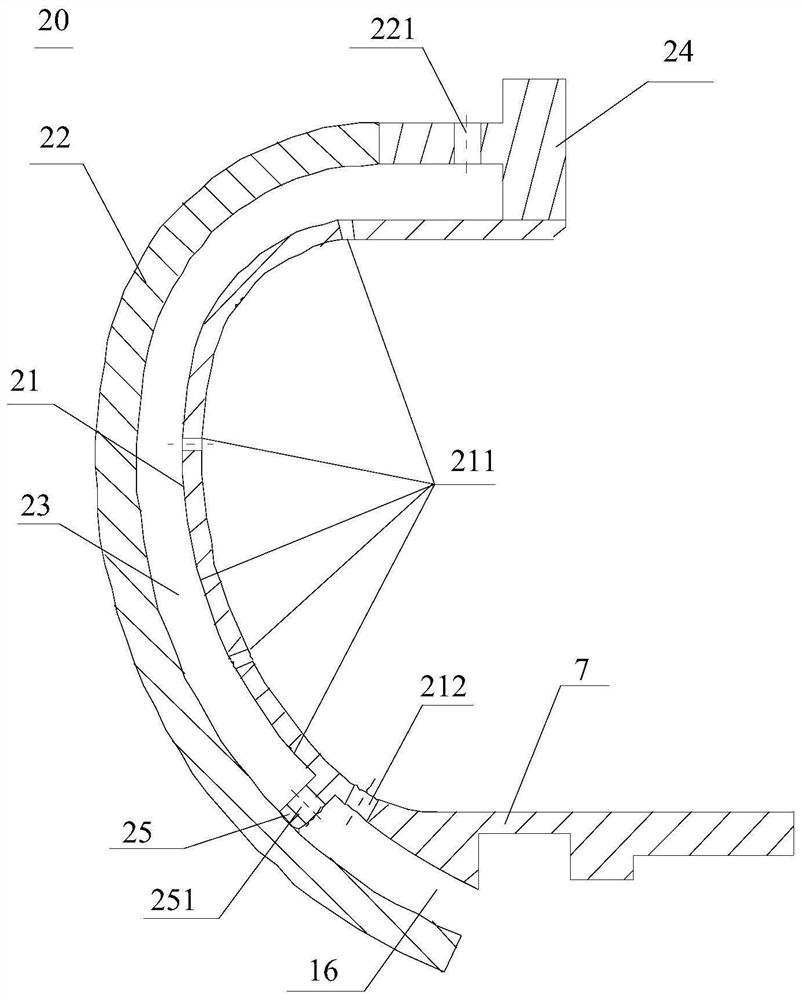

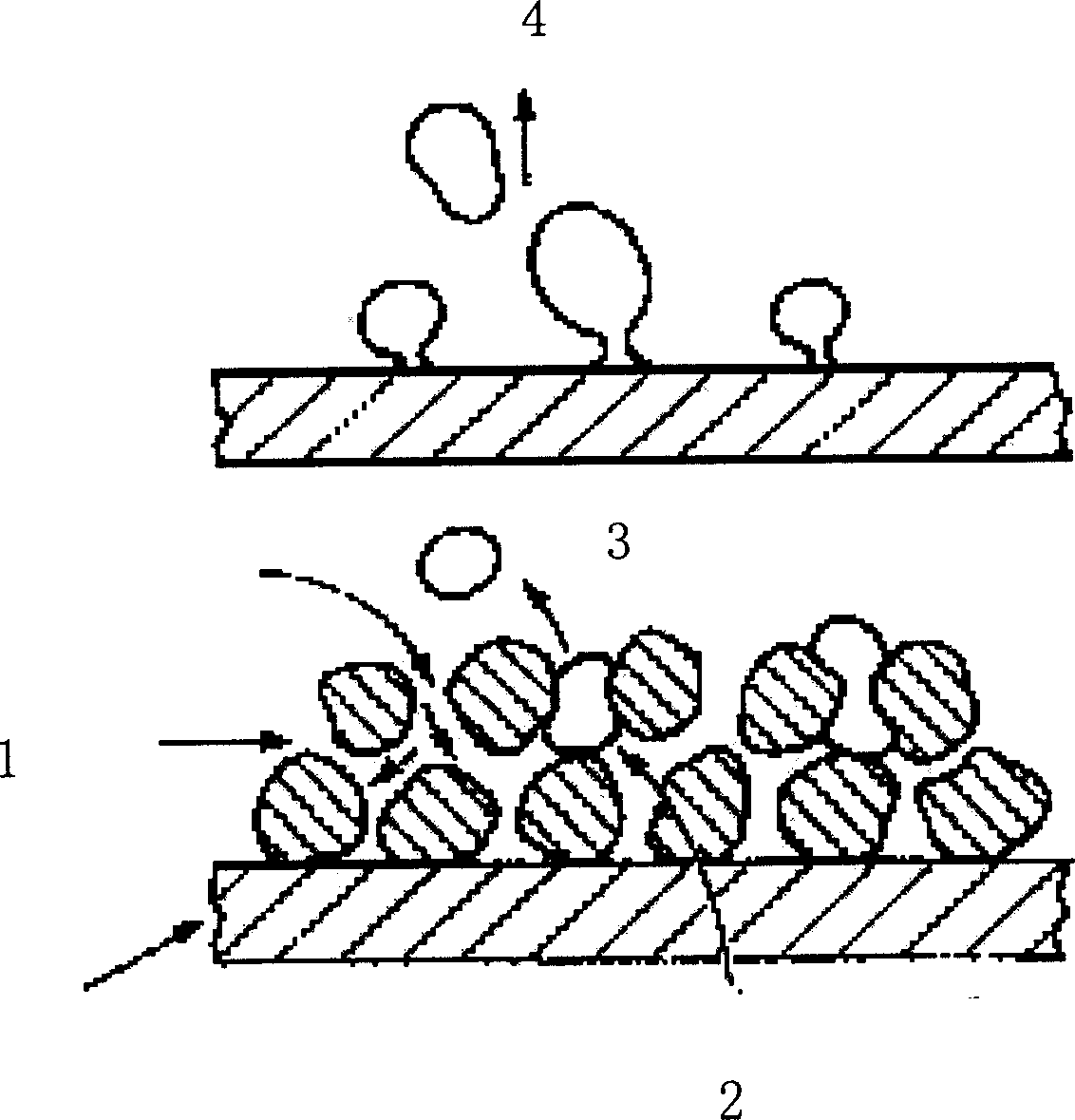

Delayed falling type solid particle heat absorber for solar thermal power generation

ActiveCN108592419AControllable flow trajectoryEnhanced heat transferSolar heating energySolar heat storageEngineeringRadiant energy

The invention discloses a delayed falling type solid particle heat absorber for solar thermal power generation. The heat absorber comprises a spiral quartz glass tube assembly (1), solid particles (2)which are located in the quartz glass tube assembly (1), an outer heat preservation layer (3) which surrounds the periphery of the quartz glass tube assembly (1), an inlet flow guide section (19) which is installed at the upper part of the quartz glass tube assembly (1), an outlet flow guide section (20) which is installed at the lower part of the quartz glass tube assembly (1), a particle distributor (17) which is arranged above the inlet flow guide section (19), a particle collector (18) which is arranged below the outlet flow guide section (20), a low-temperature particle storage tank (5)which is arranged above the particle distributor (17), a high-temperature particle storage tank (10) which is arranged below the particle collector (18), a low-temperature particle storage tank outletvalve (7) which is located between the low-temperature particle storage tank (5) and the particle distributor (17), a high-temperature particle storage tank inlet valve (8) which is installed betweenthe particle collector (18) and the high-temperature particle storage tank (10), low-temperature solid particles (6) which are stored in the low-temperature particle storage tank (5) and high-temperature solid particles (9) which are stored in the high-temperature particle storage tank (10); and the quartz glass tube assembly (1) faces radiant energy flows (4).

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

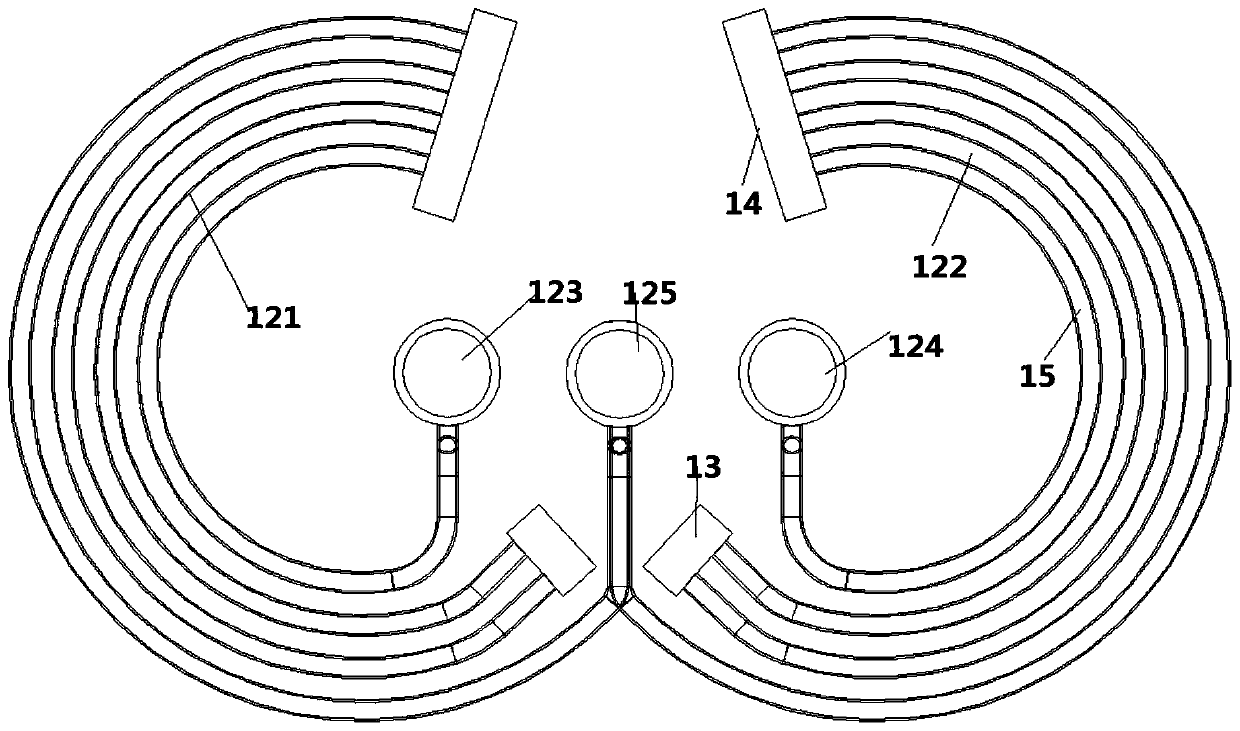

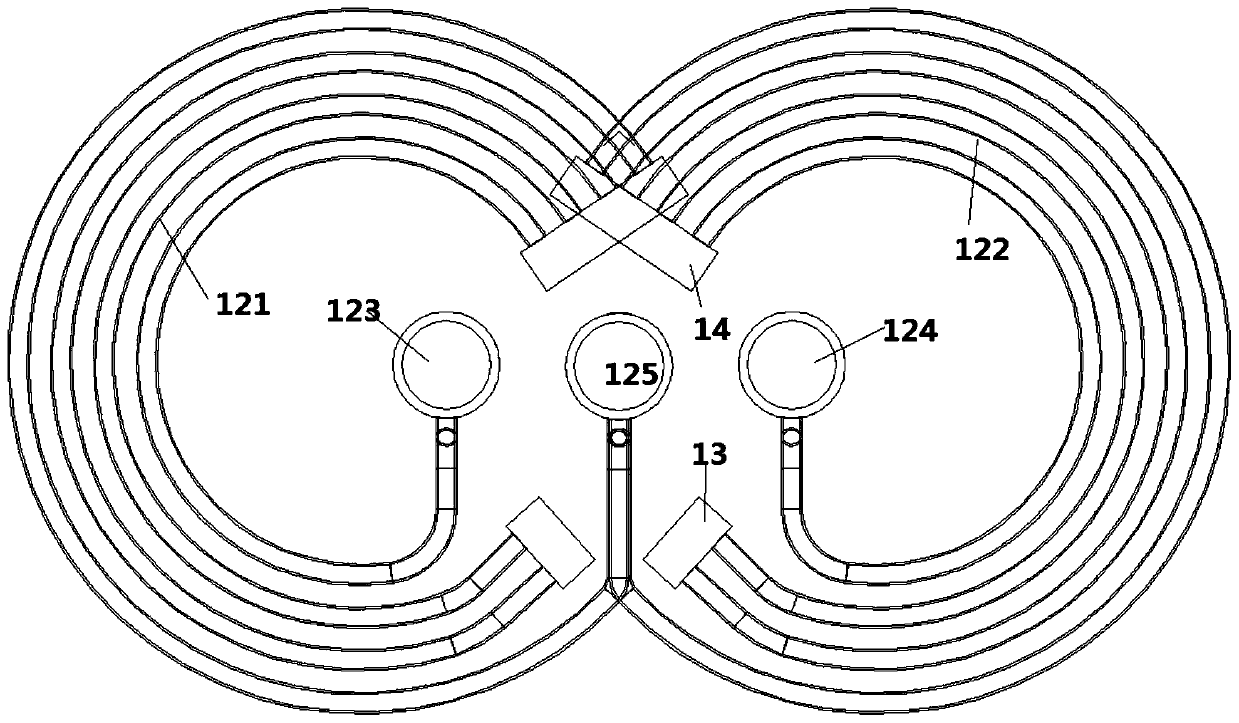

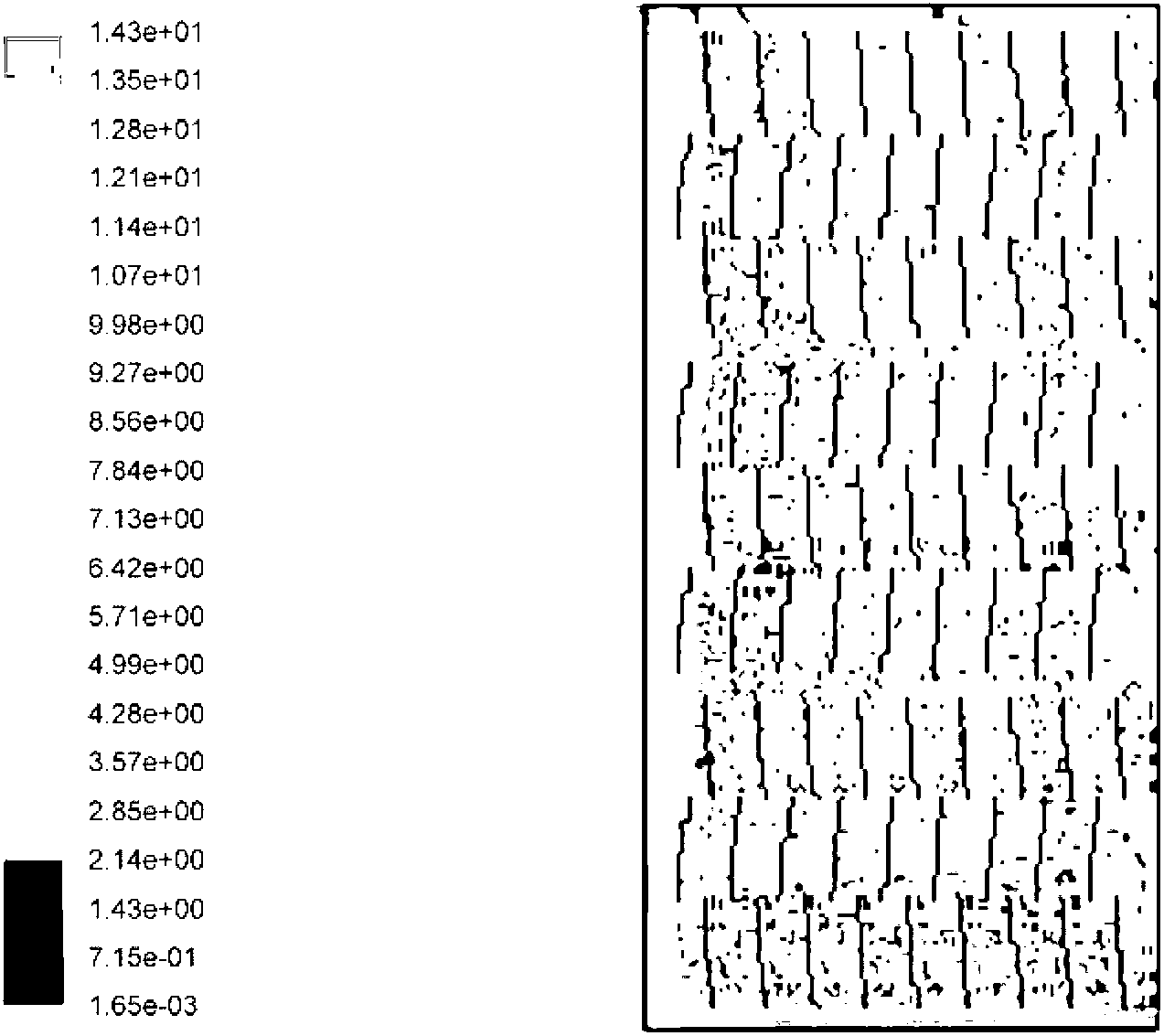

Asymmetrically-arranged heat exchanger

ActiveCN110174020AEnhanced heat transferStrengthen the dust removal effectEmission preventionIndirect heat exchangersEngineeringPlate heat exchanger

The invention provides an asymmetrically-arranged heat exchanger. The heat exchanger comprises a collecting pipe, left coil pipes and right coil pipes are distributed on the left side and the right side of the collecting pipe respectively; the heat exchanger is characterized in that the left coil pipes and the right coil pipes are arranged at intervals, one right coil pipe is arranged between every two adjacent left coil pipes, and one left coil pipe is arranged between every two adjacent right coil pipes. The heat exchanger can be used for carrying out reinforcing heat exchange and soot removal at different heights, and the effects of reinforcing heat exchange and removing accumulated dust are achieved.

Owner:SHANDONG UNIV

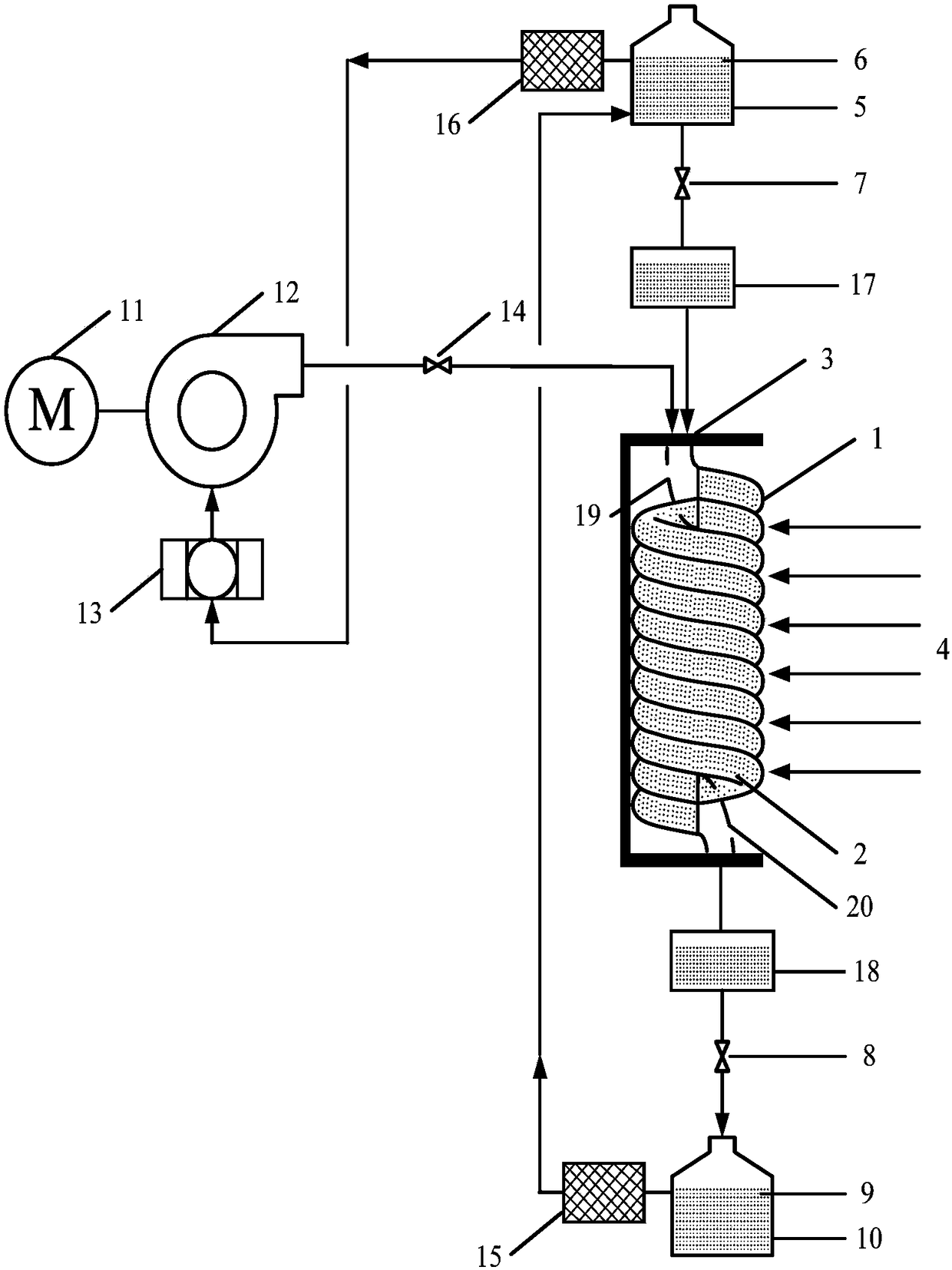

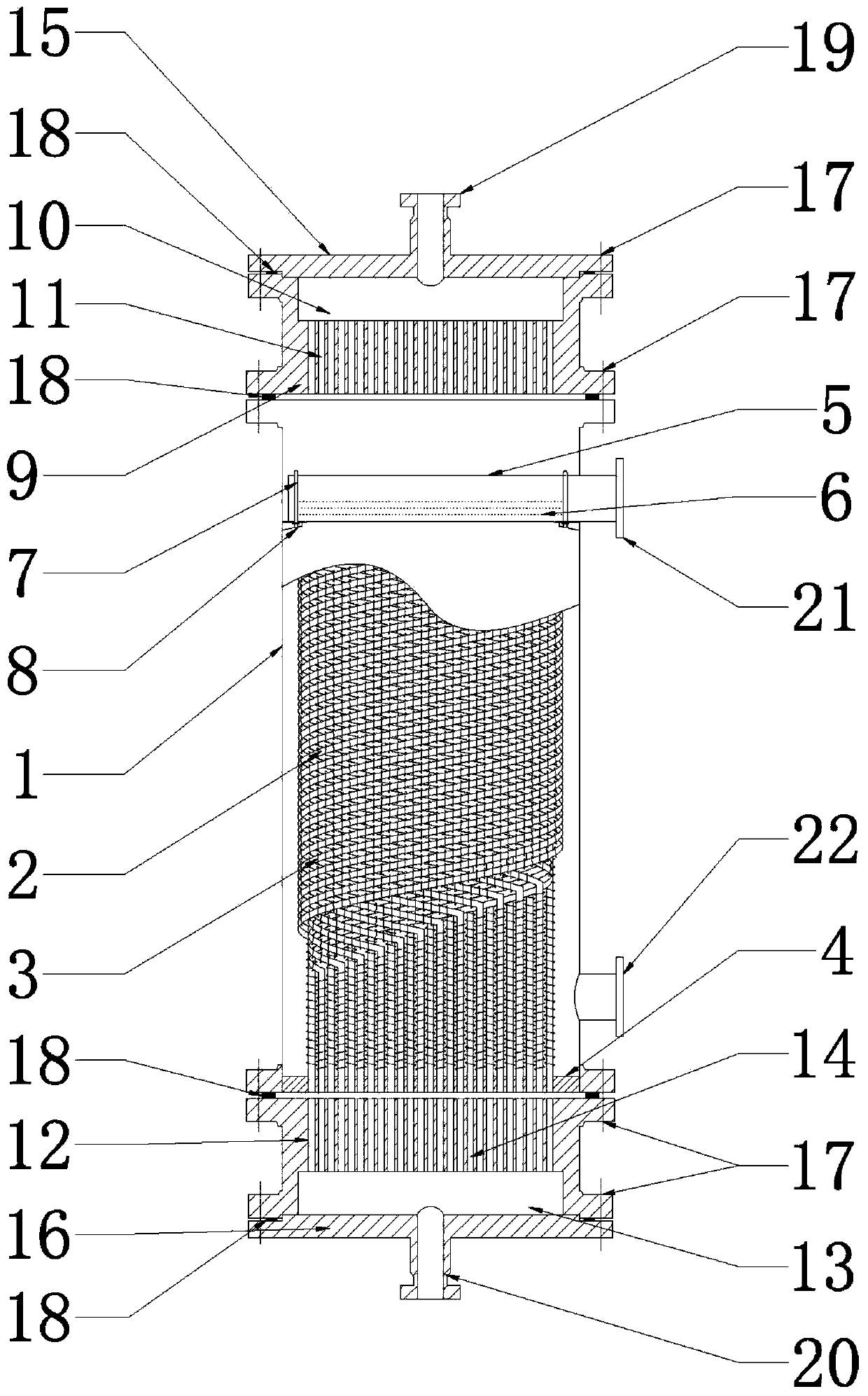

Spirally wound type quencher used for supercritical hydrothermal synthesis of nano powder

InactiveCN111521038ASmall footprintEnhanced heat transferStationary conduit assembliesHeat exchanger casingsPhysicsEngineering

The invention provides a spirally wound type quencher used for supercritical hydrothermal synthesis of nano powder. The spiral wound type quencher used for the supercritical hydrothermal synthesis ofthe nano powder comprises a cylinder, a plurality of layers of spirally wound heat exchange tubes are arranged in the cylinder, a spray pipe with a downward spray hole is arranged on the upper portionin the cylinder, the bottom end of each heat exchange tube communicates with a hot fluid inlet, the top end of each heat exchange tube communicates with a hot fluid outlet, the spray pipe is connected with a cooling water inlet, and the lower portion of the cylinder is provided with a cooling water outlet. Each layer of heat exchange tubes consists of a plurality of pipelines which are wound upwards or downwards in an inclined mode, the inclined directions of every two adjacent layers of heat exchange tubes are opposite, and spirals formed by winding are coaxial with the cylinder. Fins of a spiral structure can be arranged on the heat exchange tubes, a diversion collection box can be arranged at the bottom end of the cylinder, and a gathering collection box can be arranged at the top endof the cylinder. A spirally wound type heat exchanger structure is adopted, a spray structure is additionally arranged, heat exchange is enhanced, and the cooling efficiency of the quencher is improved. The heat exchange area is fully utilized, the occupied area of the quencher is greatly reduced, and the quenching requirement of the supercritical hydrothermal synthesis of the nano powder is met.

Owner:XI AN JIAOTONG UNIV

Column plate with porous surface

ActiveCN1754605AEnhanced heat transferIncrease the gas-liquid contact areaFractional distillationEngineeringHeat transmission

This invention discloses one tower panel with multiple hole surface, which uses tower surface of gas liquid tower panel with one layer of multiple hole with gap rate of15-45% and with even hole radium of 10 to 200 micro meter with even thickness of 0.2 to 0.8 mm. The tower in this invention can keep effect core boiling status in small temperature difference to strengthen the heat transmission quality and to improve fine stilling rate at 8 percent.

Owner:CHINA PETROLEUM & CHEM CORP +1

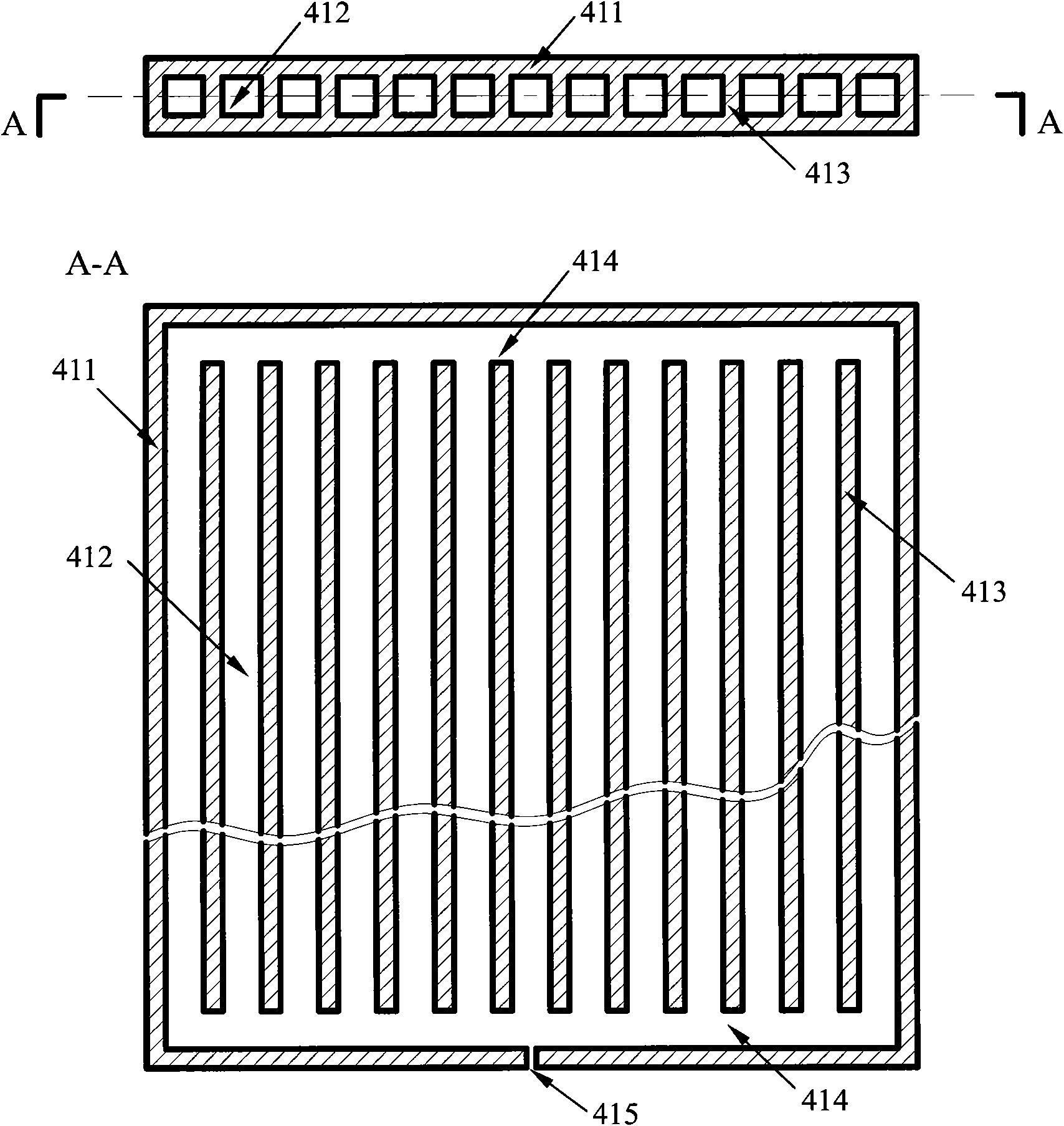

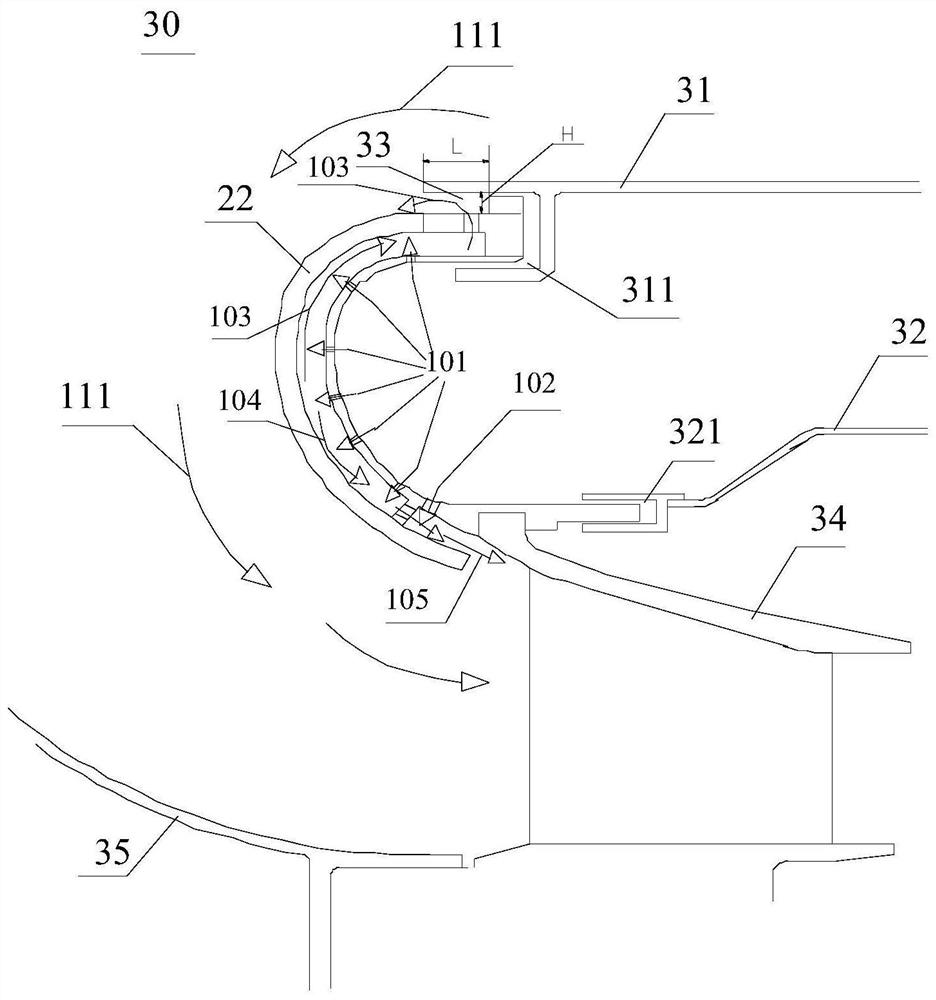

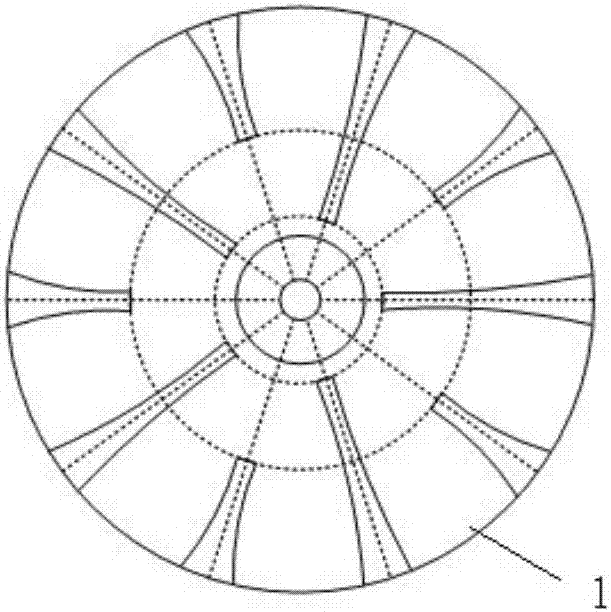

Absorber plate core for flat plate solar thermal collector and solar thermal collector

InactiveCN102706016AEnhanced heat transferImprove efficiencySolar heating energySolar heat devicesCollector deviceSolar thermal collector

Aiming at the defect in the prior art that as reinforced heat exchange is adopted to improve the flow of a working medium for heat exchange of the plate core as far as possible, the higher flow resistance reduces the energy input-output ratio of the thermal collector, the invention discloses an absorber plate core suitable for a solar thermal collector, and provides an absorber plate core capableof remarkably improving the heat exchange effect without obviously increasing the flow resistance. The product includes a plate core cavity and streaming fins arranged in M rows and N lines, wherein in each row, the first streaming fin is parallel to the inlet frame of the plate core cavity, and the second streaming fin to the No. N streaming fin are rotated by the rotation angle alpha to the frame of the outlet side of the plate core cavity and take the peaks of the second streaming fin to the No. N streaming fin as centers; and in each line, the second streaming fin to the No. 5n streaming fin are lifted equidistantly, and the No. 5n+1 streaming fin to the No. N streaming fin are lowered equidistantly. The invention further provides a flat plate solar thermal collector installed with the absorber plate core. The absorber plate core improves the heat exchange efficiency of the thermal collector through uniformly distributing flow rates of the heat exchange working medium in differentrunners of the absorber plate core.

Owner:西藏自治区能源研究示范中心

Aluminum spiral radiator

InactiveCN101266114AIncrease disturbanceEnhanced heat transferTubular elementsHeat transfer tubeAluminium

Provided is an aluminum spiral radiating pipe having the advantages of simple structure, long service life, low flow contact thermal resistance and excellent heat-transfer capability. The radiating pipe includes heat transfer tube and spiral fin, characterized in that the spiral fin and the heat transfer tube are to become integrated by hot-extrusion.

Owner:许雪峰

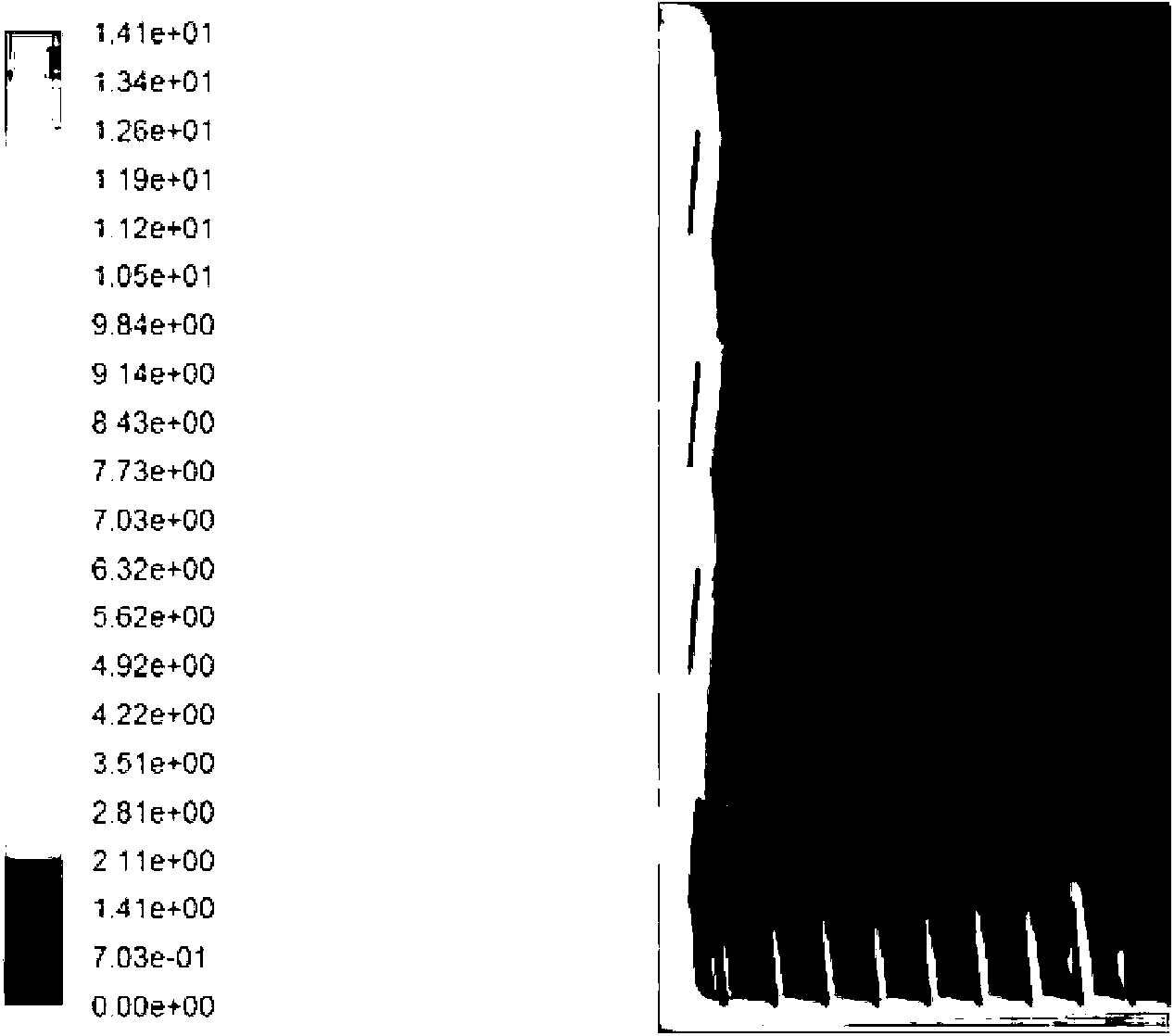

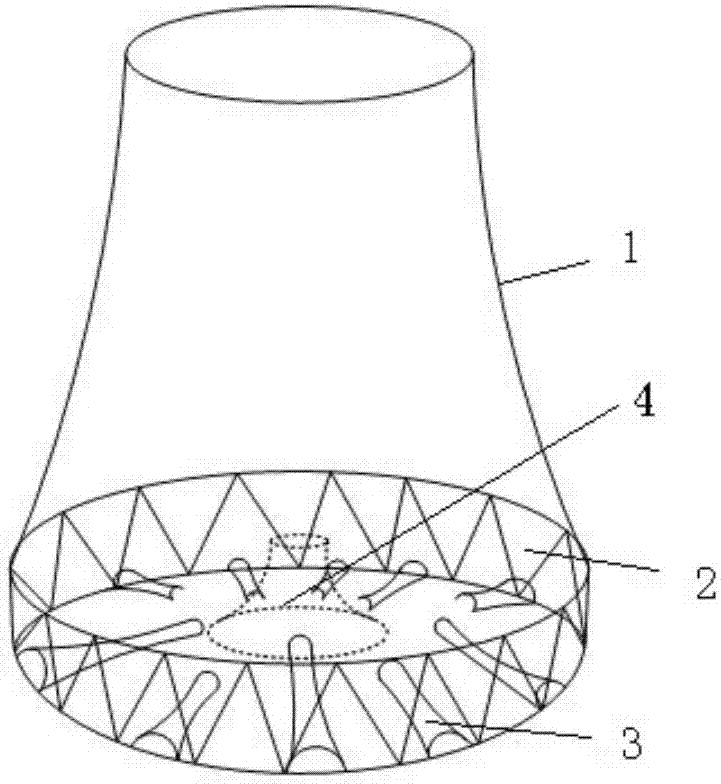

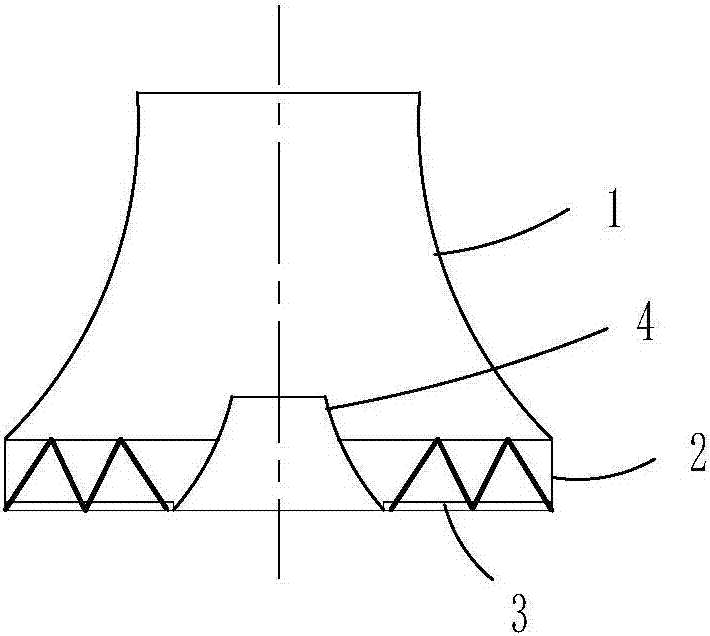

Natural ventilation wet type cooling tower ventilation device

PendingCN107543447AIncrease wind speed and volumeEnhanced heat transferTrickle coolersEngineeringWind speed

The invention provides a natural ventilation wet type cooling tower ventilation device, and belongs to the technical field of heat exchange devices. The device comprises a plurality of ventilation channels. The ventilation channels are evenly distributed in the radial direction of the circumference of an air inlet of a cooling tower, the cross sections of the ventilation channels are in an arch shape, and the cross sections of the ventilation channels are decreased from the exterior to the center of the air inlet. According to the natural ventilation wet type cooling tower ventilation device,a ventilation duct is additionally arranged inside the cooling tower, cold air can be directly fed into the center of the cooling tower, the blast capacity and the air speed of heat exchange in the center of the cooling tower are increased, the heat transfer of the central region of the cooling tower is effectively enhanced, the outlet water temperature is lowered, and the efficiency and economical efficiency are improved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Ternary refrigerant mixture for pulsating heat pipe

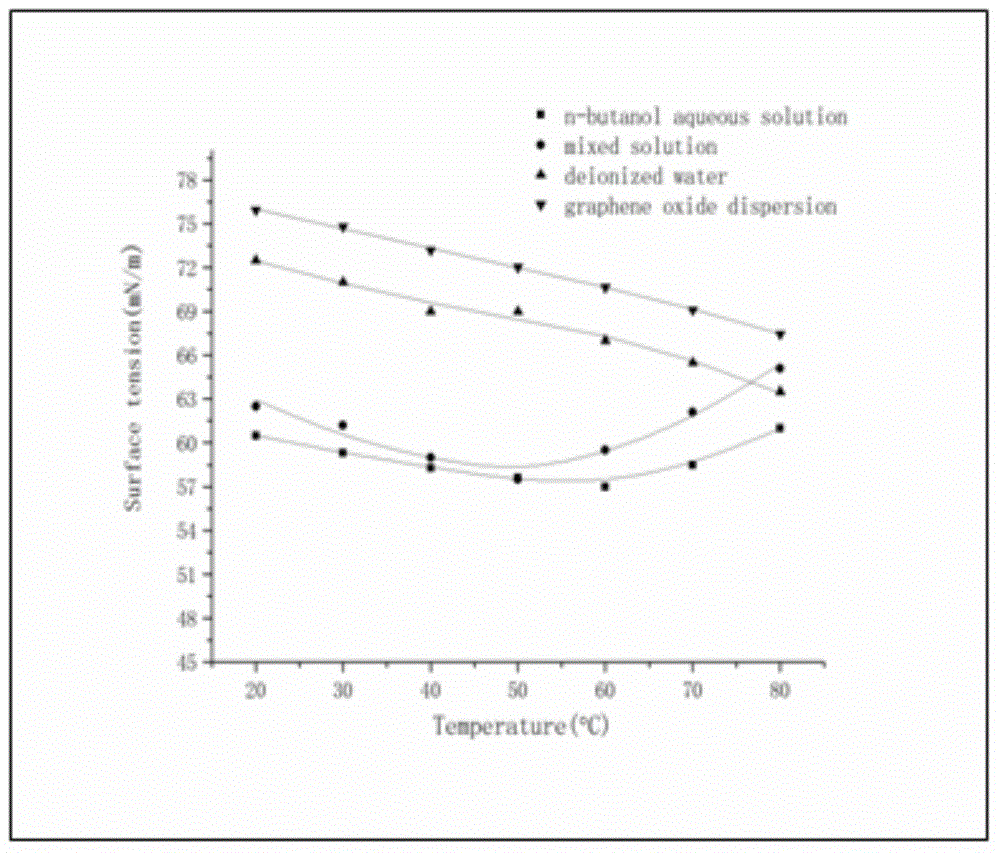

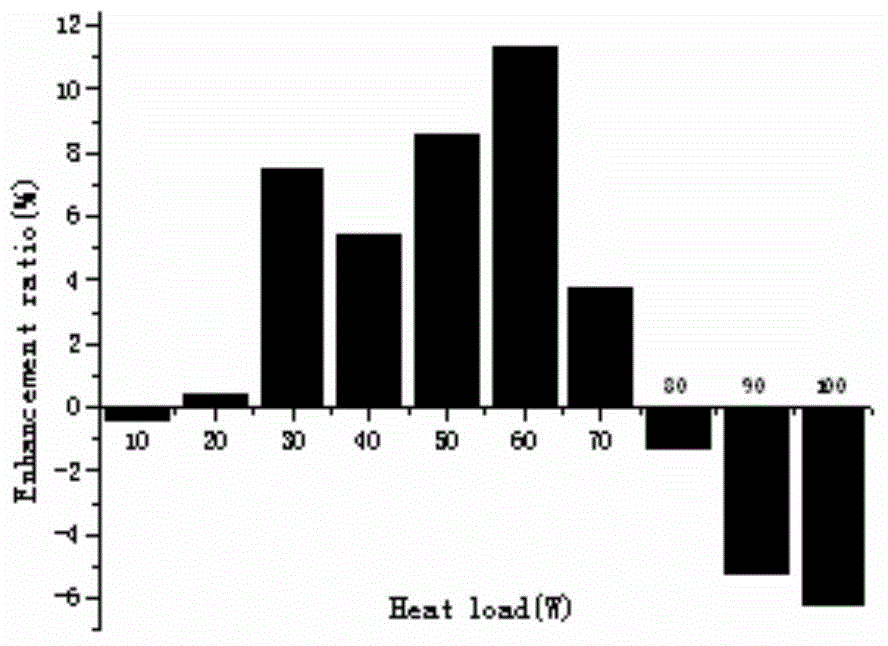

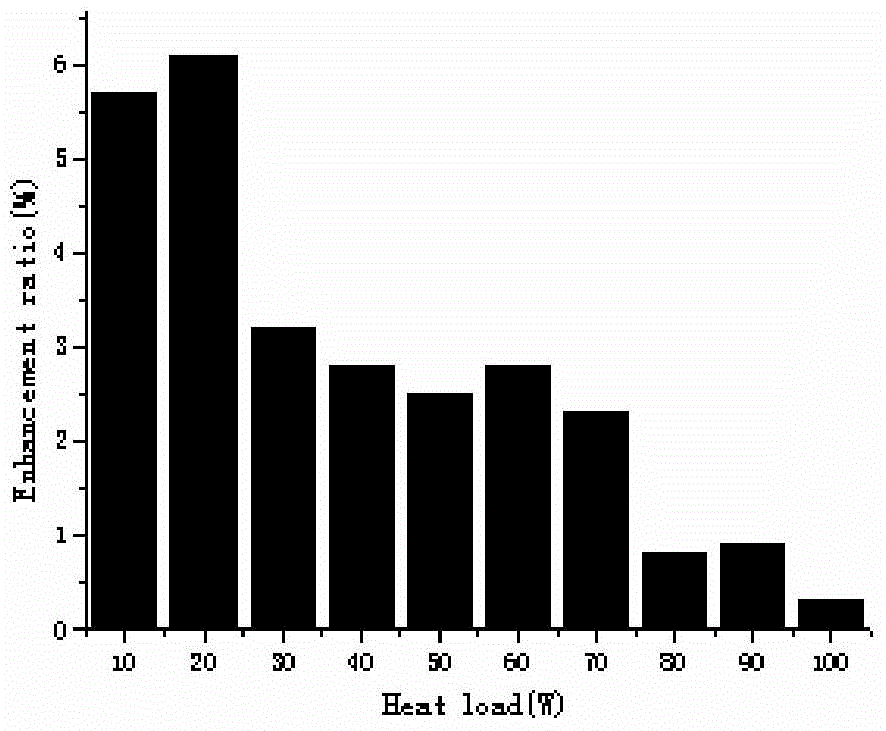

InactiveCN104818000AEnhanced heat transferLow starting heat loadHeat-exchange elementsWorking rangeAqueous solution

The invention discloses a ternary refrigerant mixture for a pulsating heat pipe. The ternary refrigerant mixture is prepared by evenly mixing a binary working medium graphene oxide dispersion liquid with a binary working medium normal butanol water solution, wherein the concentration of the binary working medium graphene oxide dispersion liquid is 0.5mg / ml; the mass percent of the binary working medium normal butanol water solution is 0.5%; and the binary working medium graphene oxide dispersion liquid and the binary working medium normal butanol water solution are evenly mixed at a volume ratio of 2 to 5. The pulsating heat pipe employing the ternary refrigerant mixture can be started under relatively small thermal load; and the heat transfer property of the pulsating heat pipe can be strengthened within the overall work range, so that the pulsating heat pipe employing the mixed solution as a working medium is relatively small in size and relatively light in weight under the same thermal load, and has a relatively wide application prospect in the field of heat dissipation of electronic parts and components and aviation and aerospace.

Owner:TIANJIN UNIV OF COMMERCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com