Patents

Literature

546results about "Single layer graphene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

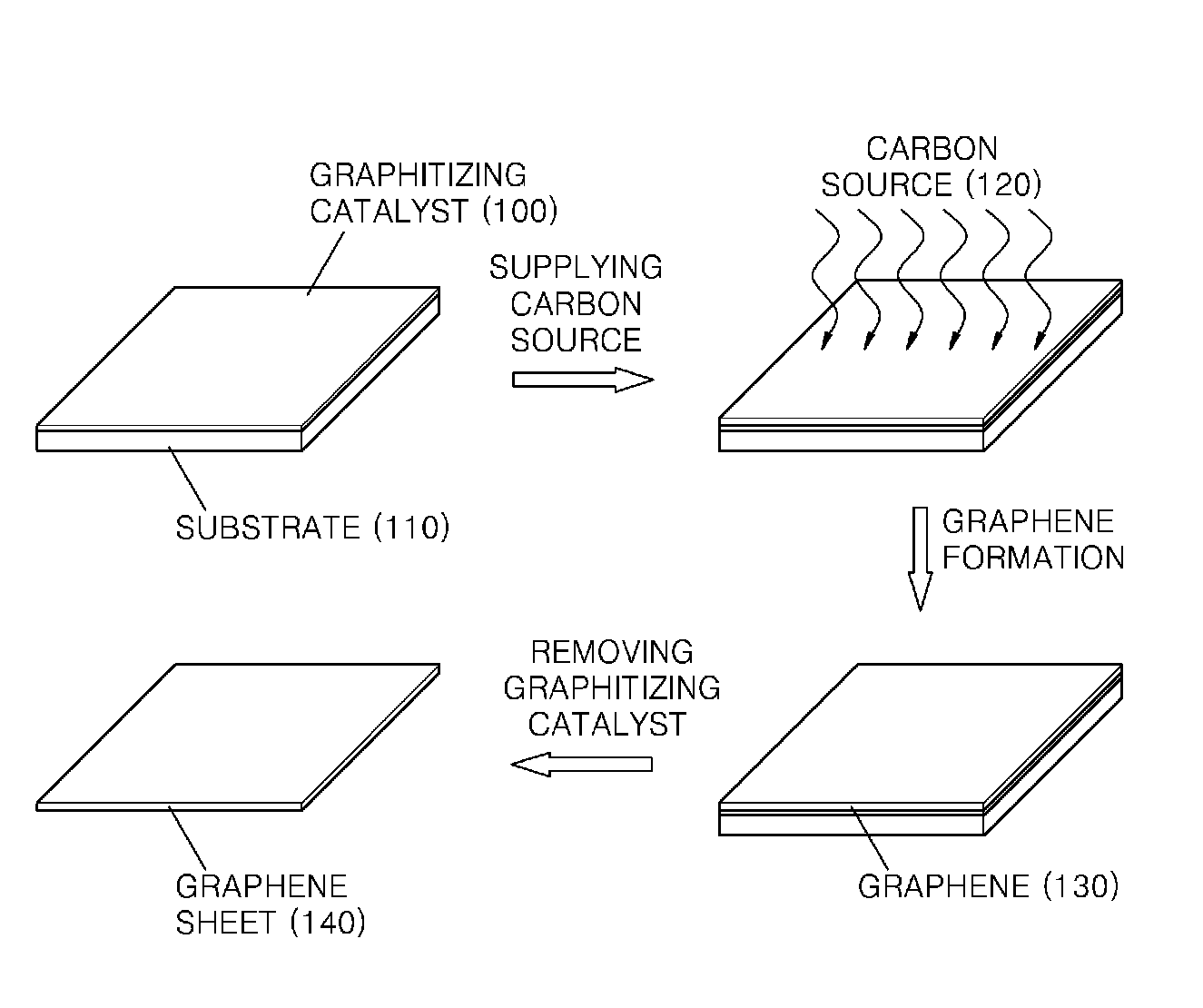

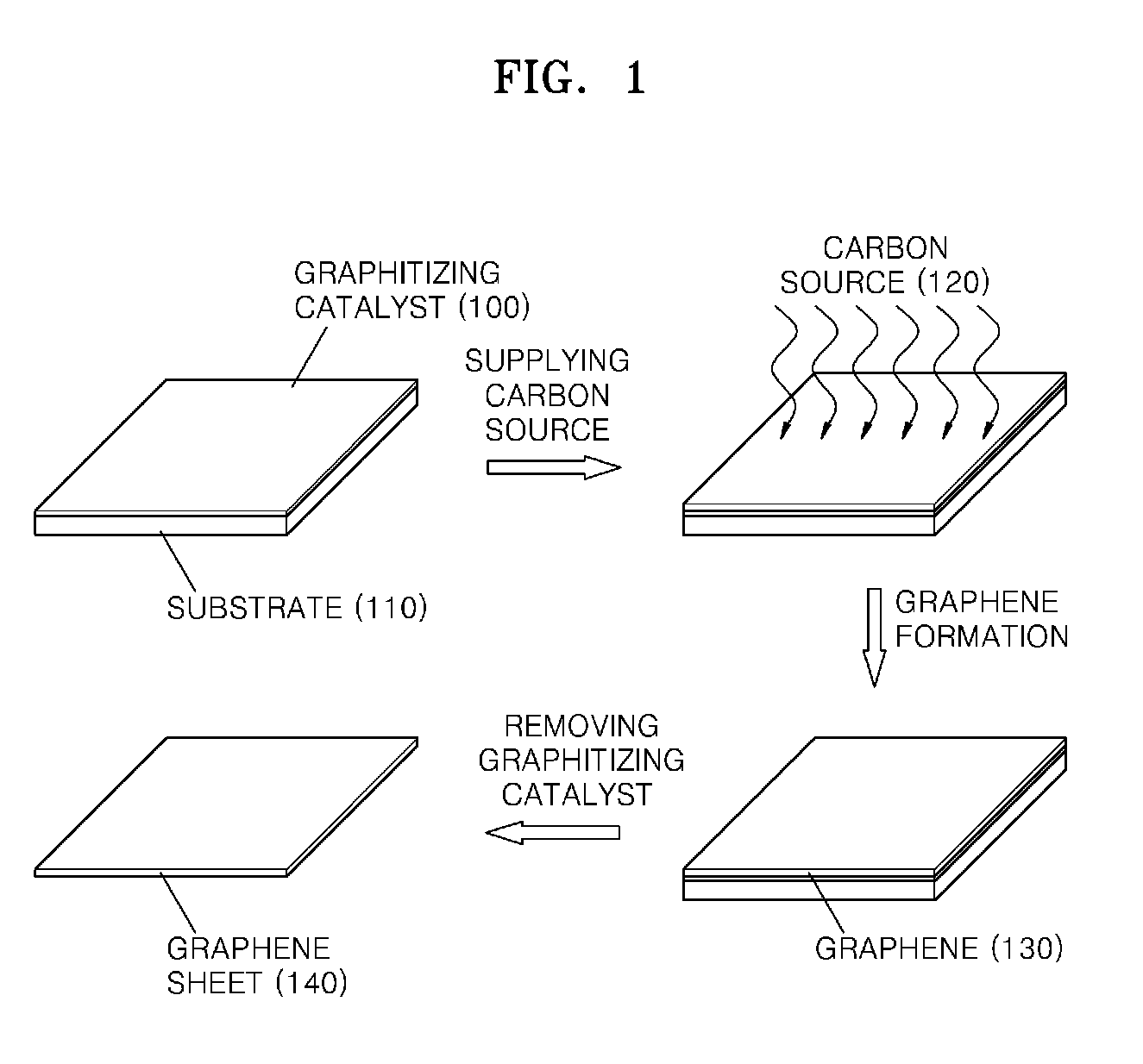

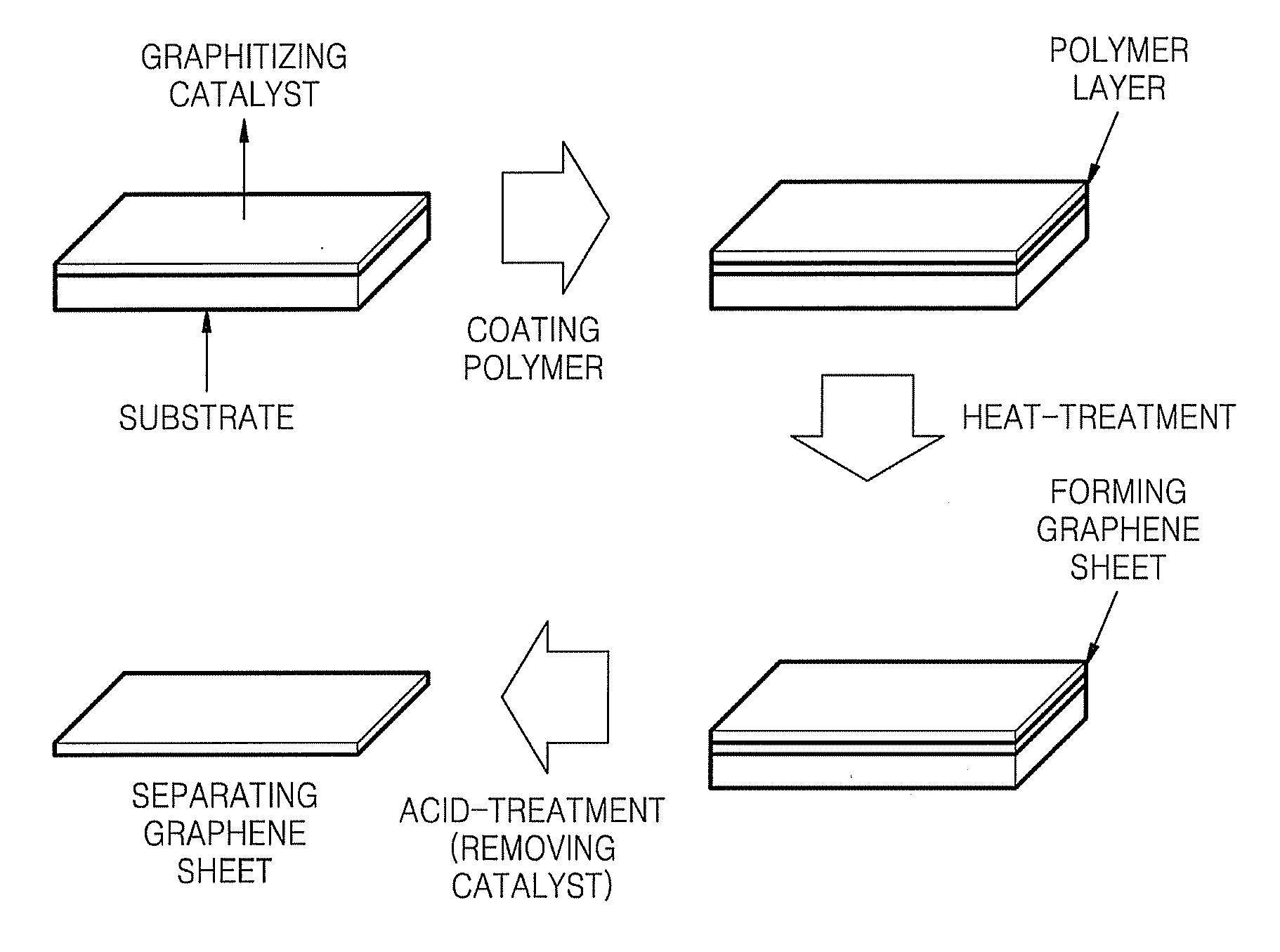

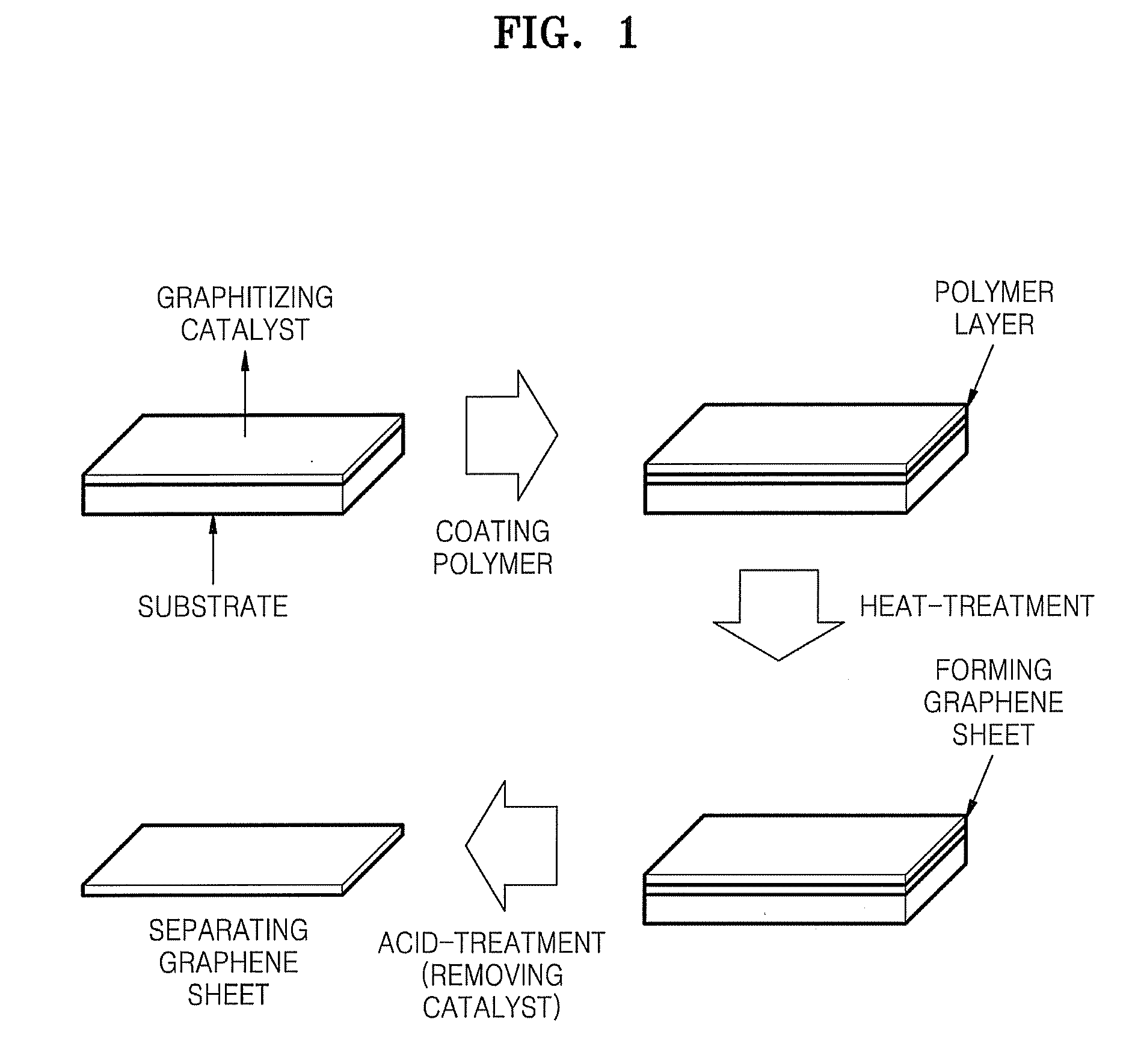

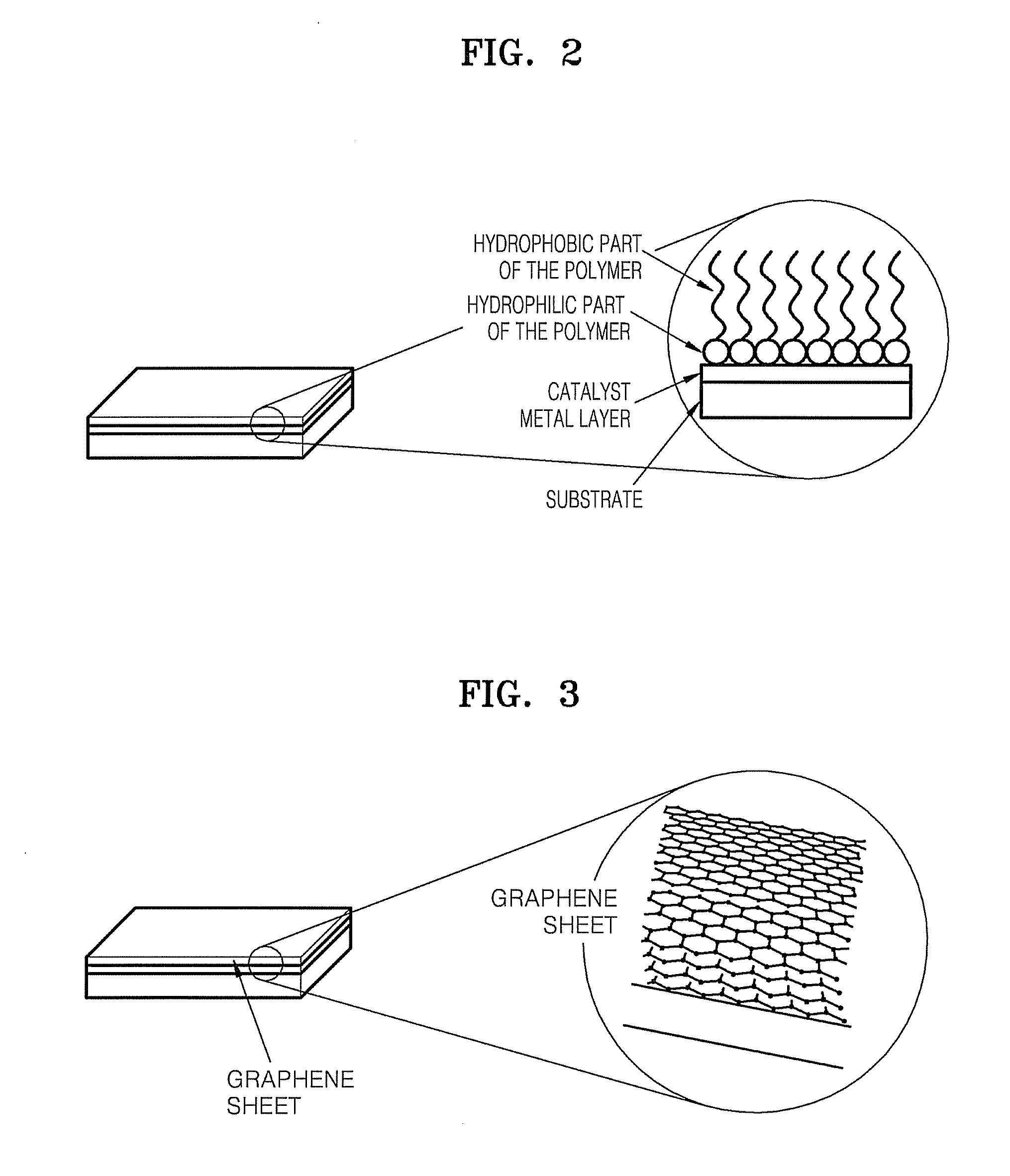

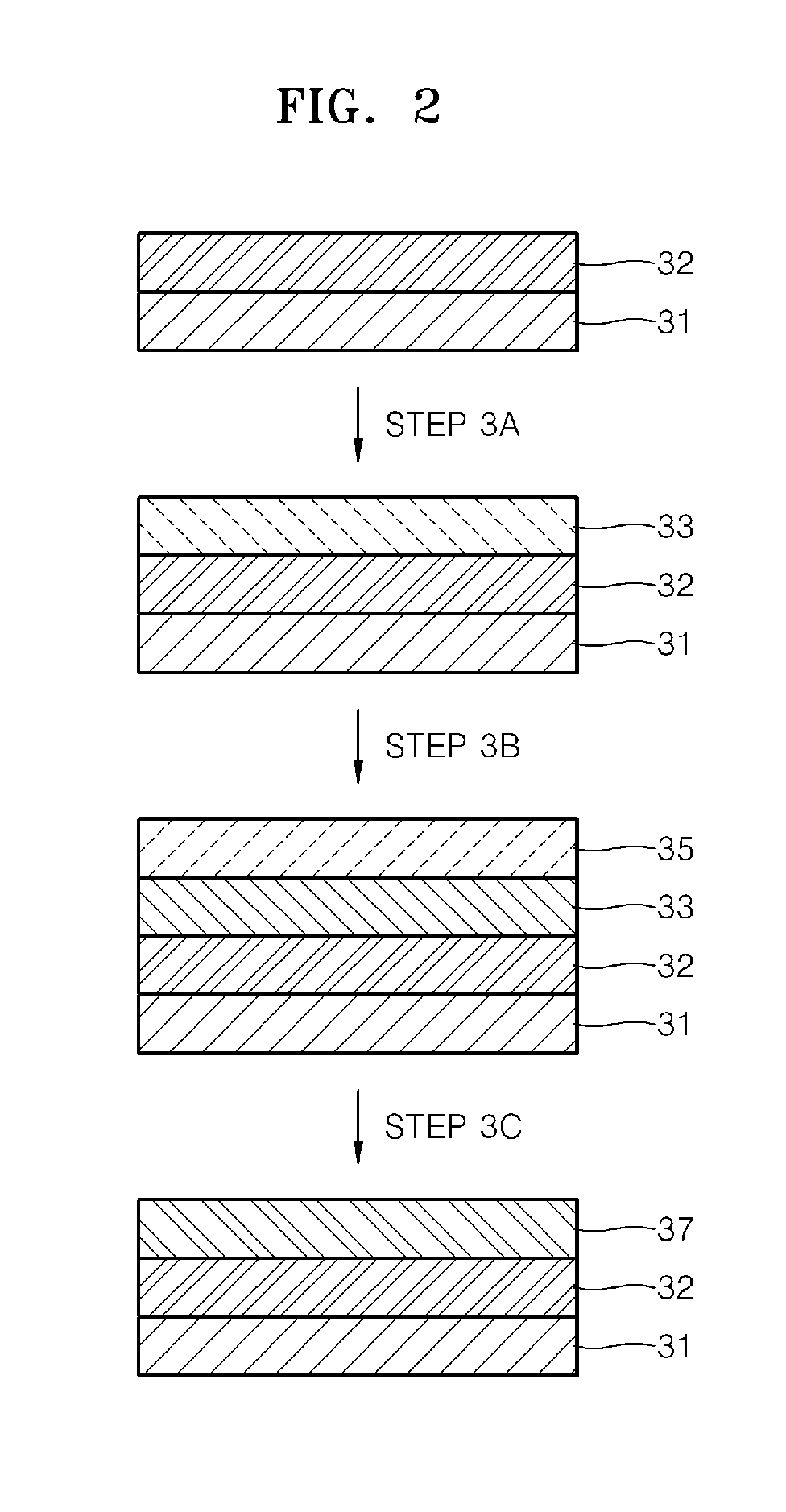

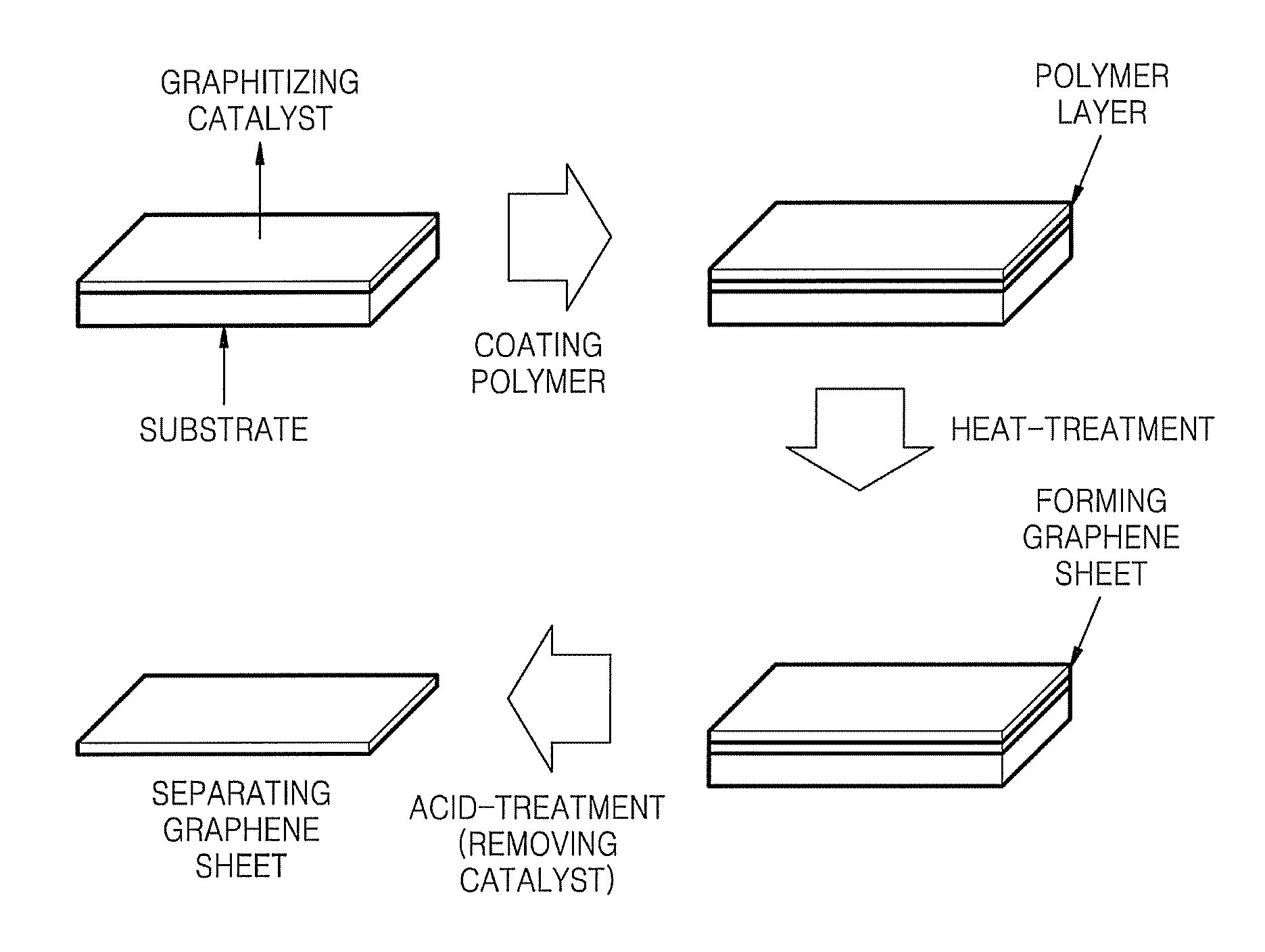

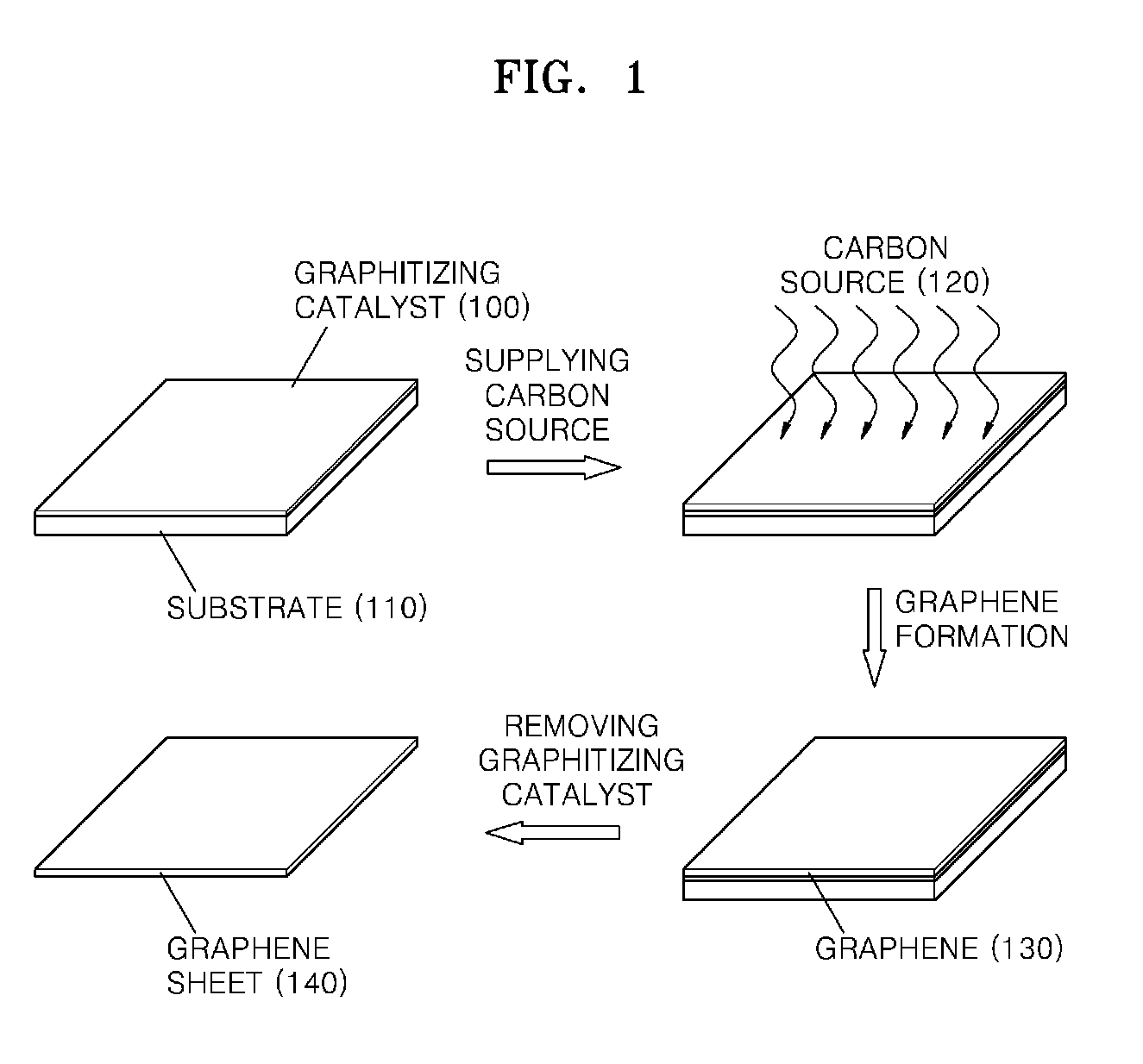

Graphene sheet and method of preparing the same

An economical method of preparing a large-sized graphene sheet having a desired thickness includes forming a film, the film comprising a graphitizing catalyst; heat-treating a gaseous carbon source in the presence of the graphitizing catalyst to form graphene; and cooling the graphene to form a graphene sheet. A graphene sheet prepared according to the disclosed method is also described.

Owner:SAMSUNG ELECTRONICS CO LTD

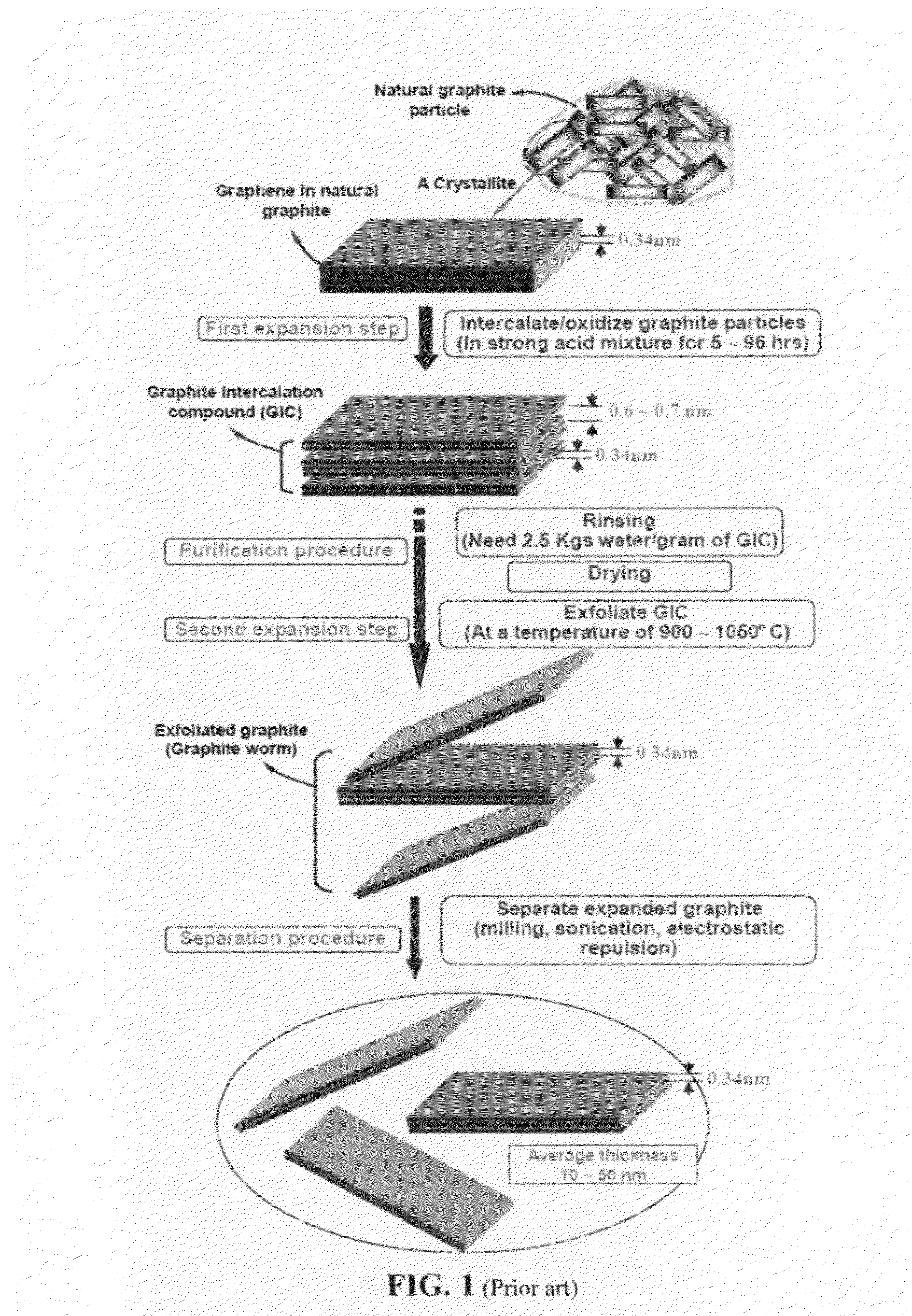

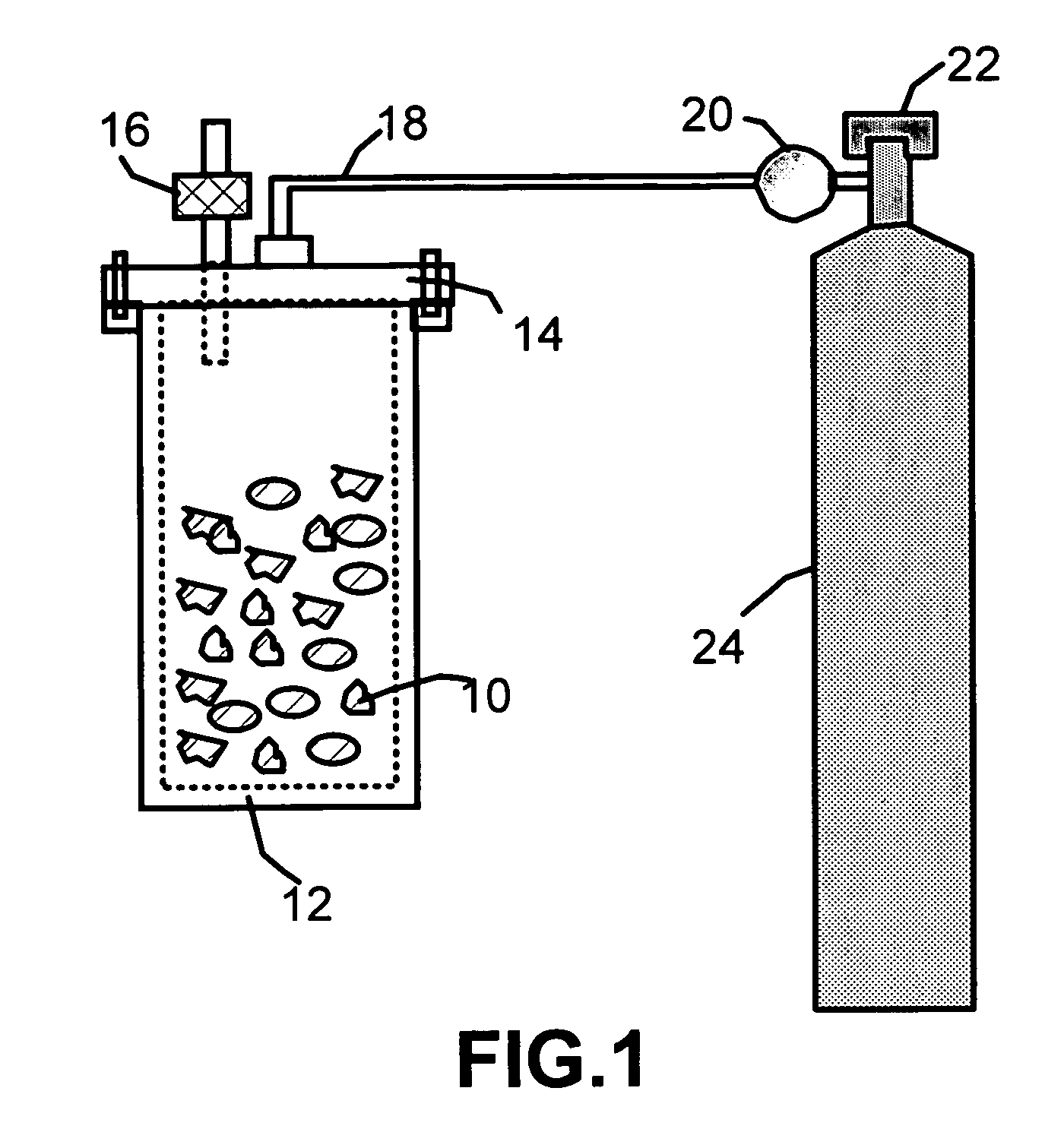

Process for producing nano-scaled platelets and nanocompsites

Disclosed is a process for exfoliating a layered material to produce nano-scaled platelets having a thickness smaller than 100 nm, typically smaller than 10 nm, and often between 0.34 nm and 1.02 nm. The process comprises: (a) subjecting a layered material to a gaseous environment at a first temperature and first pressure sufficient to cause gas species to penetrate between layers of the layered material, forming a gas-intercalated layered material; and (b) subjecting the gas-intercalated layered material to a second pressure, or a second pressure and a second temperature, allowing gas species to partially or completely escape from the layered material and thereby exfoliating the layered material to produce partially delaminated or totally separated platelets. The gaseous environment preferably contains only environmentally benign gases that are reactive (e.g., oxygen) or non-reactive (e.g., noble gases) with the layered material. The process can also include dispersing the platelets in a matrix material to form a nanocomposite.

Owner:GLOBAL GRAPHENE GRP INC

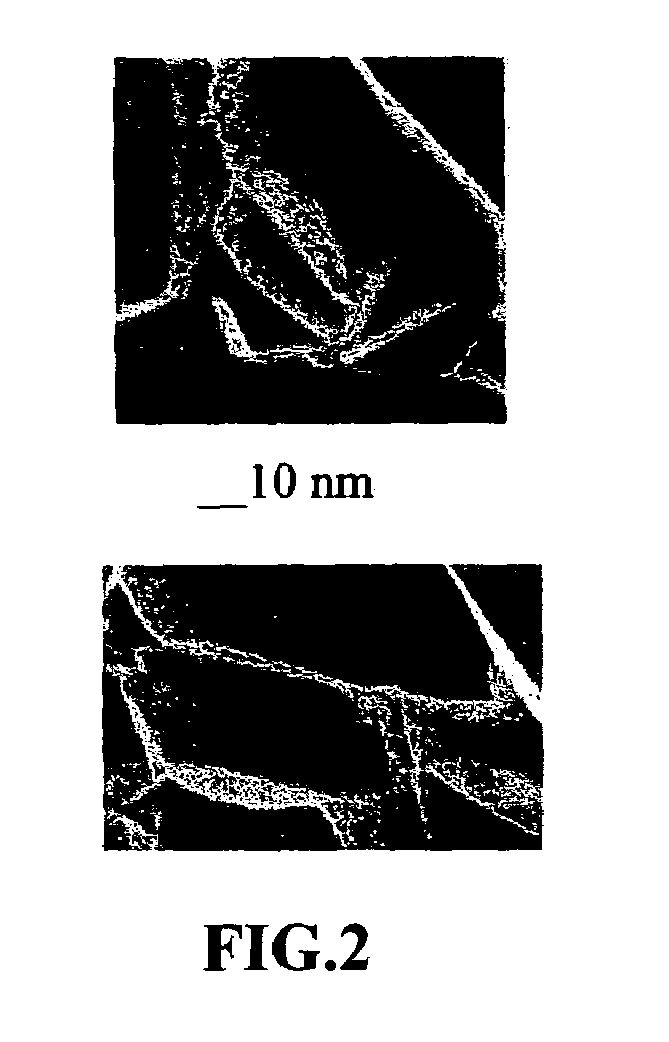

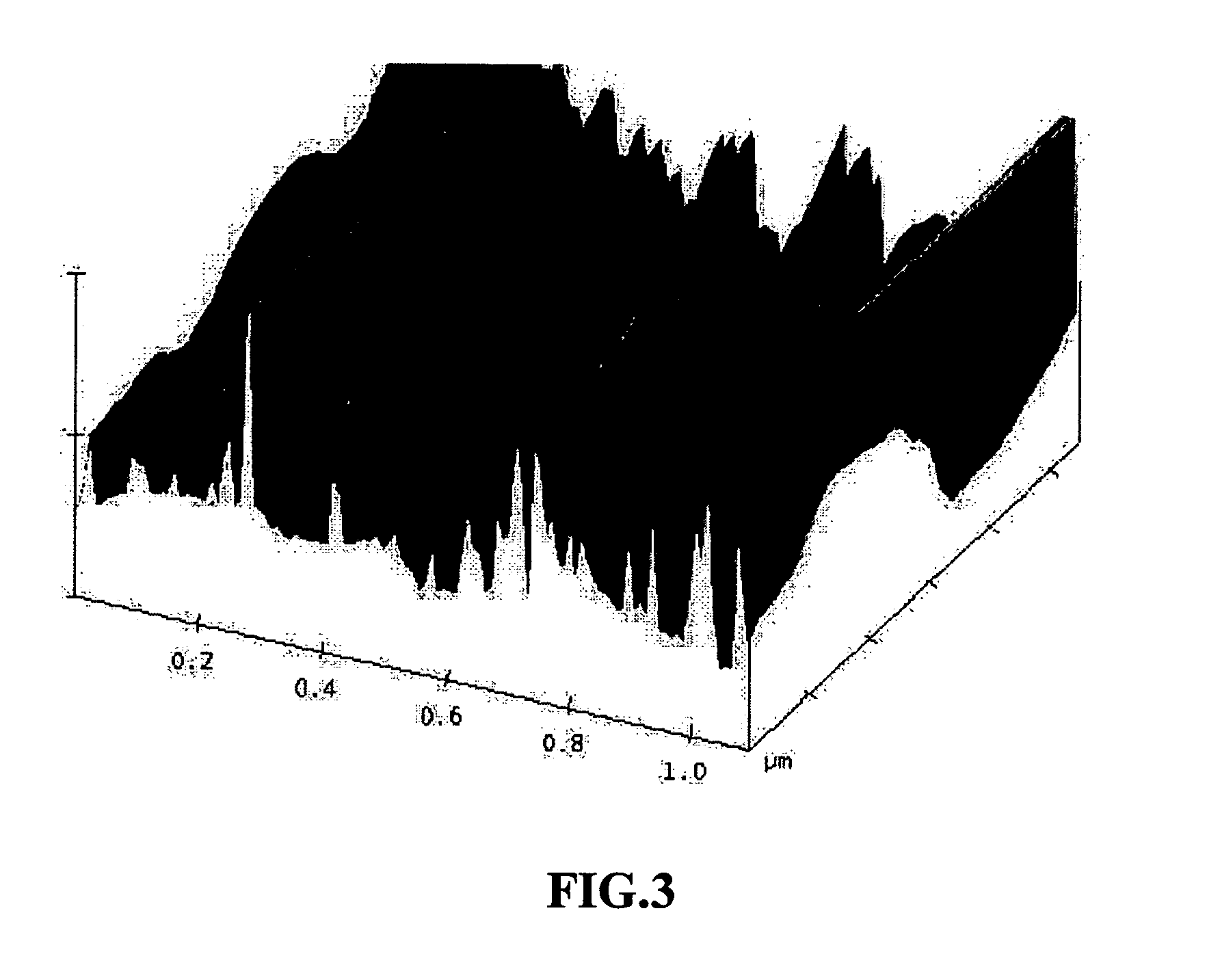

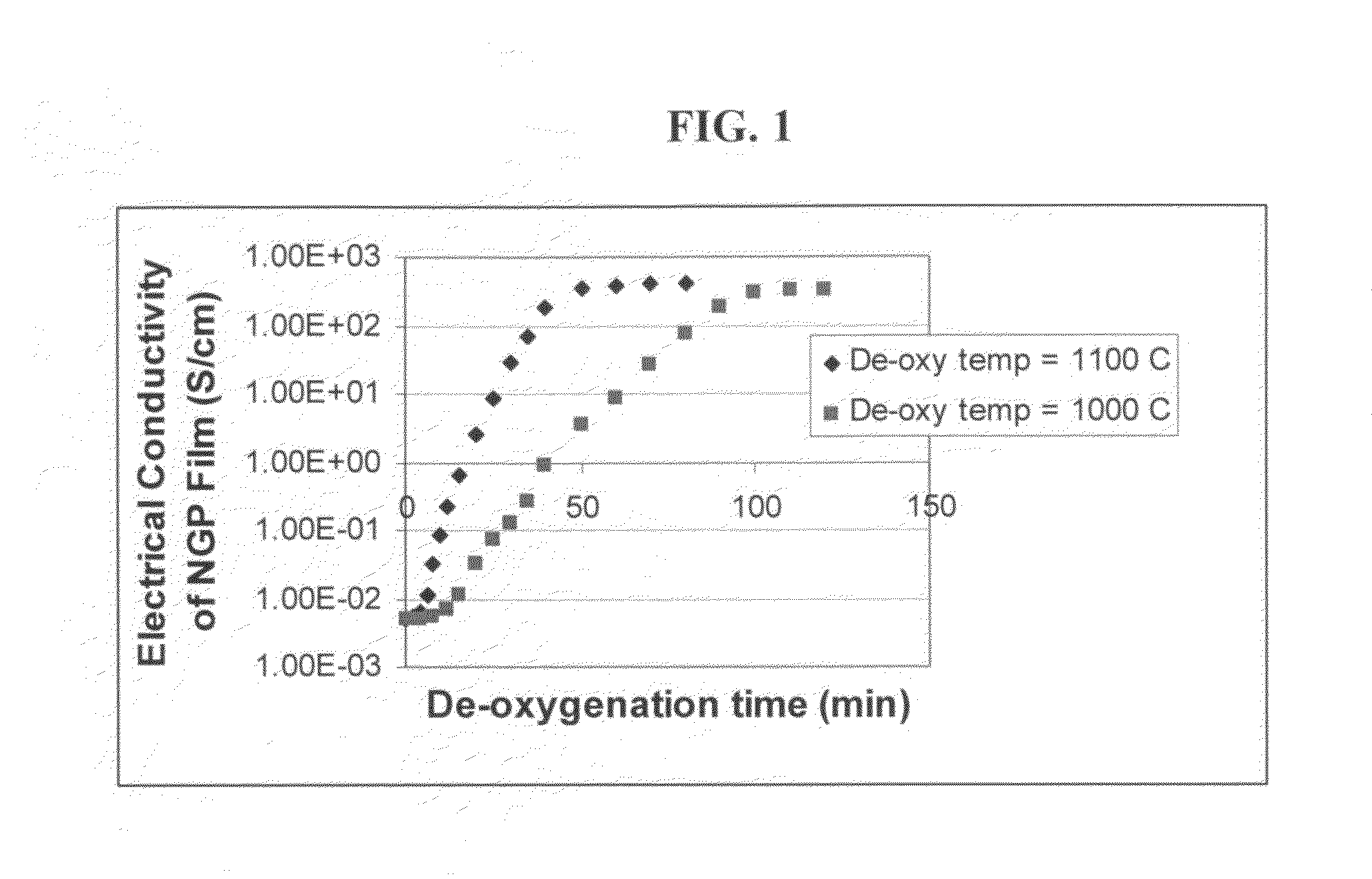

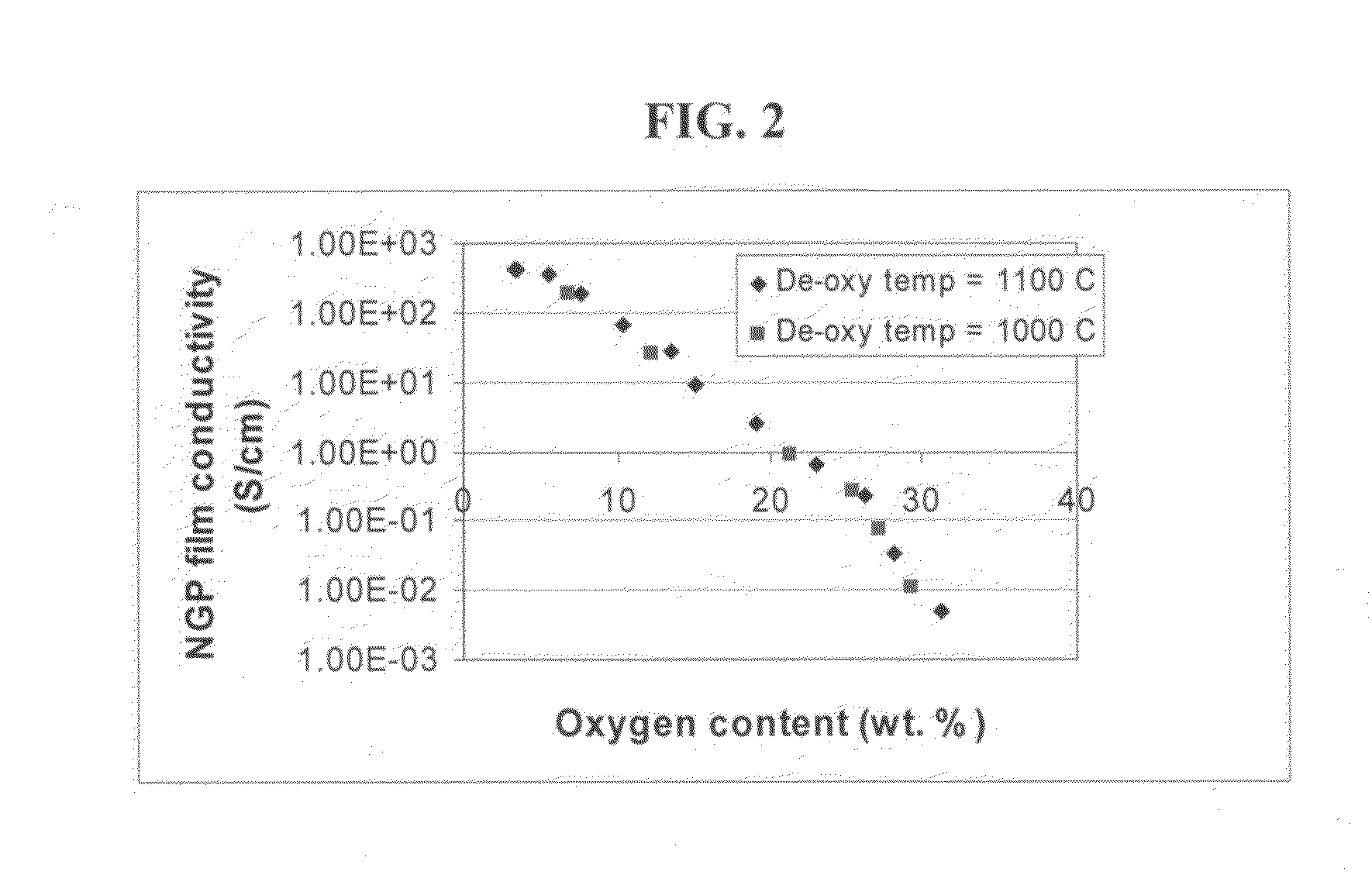

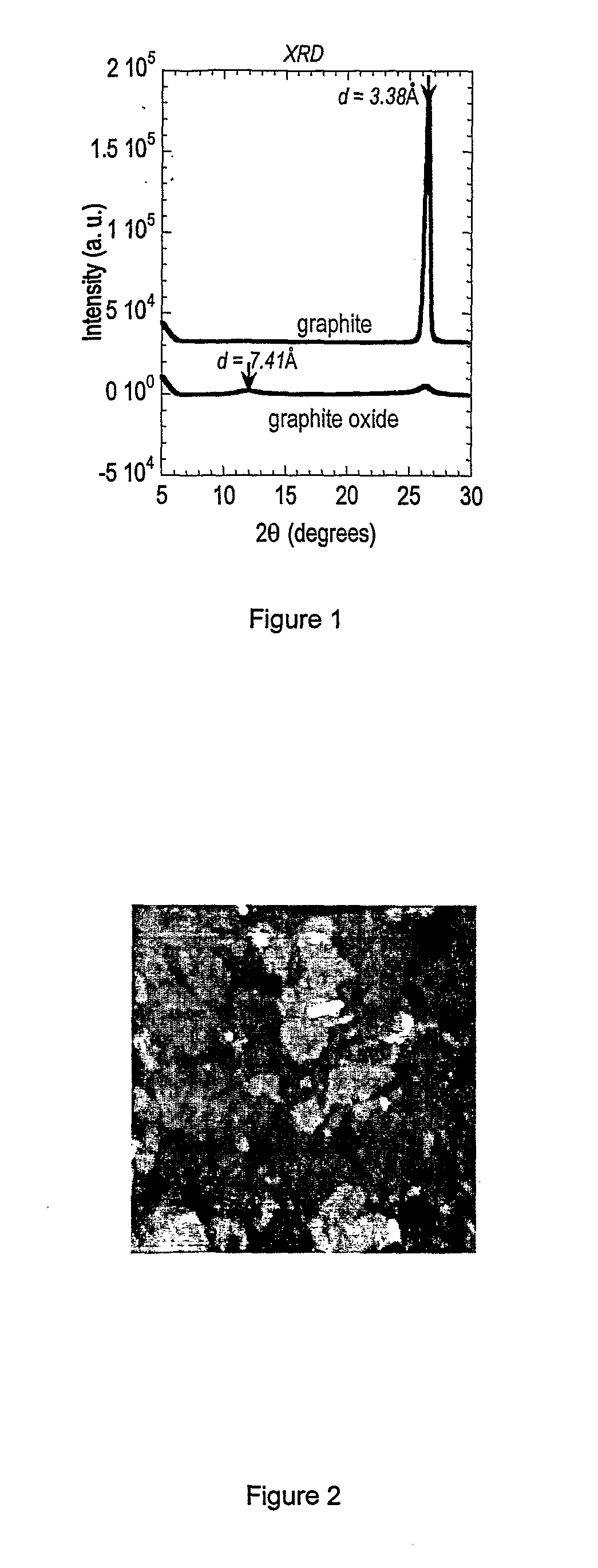

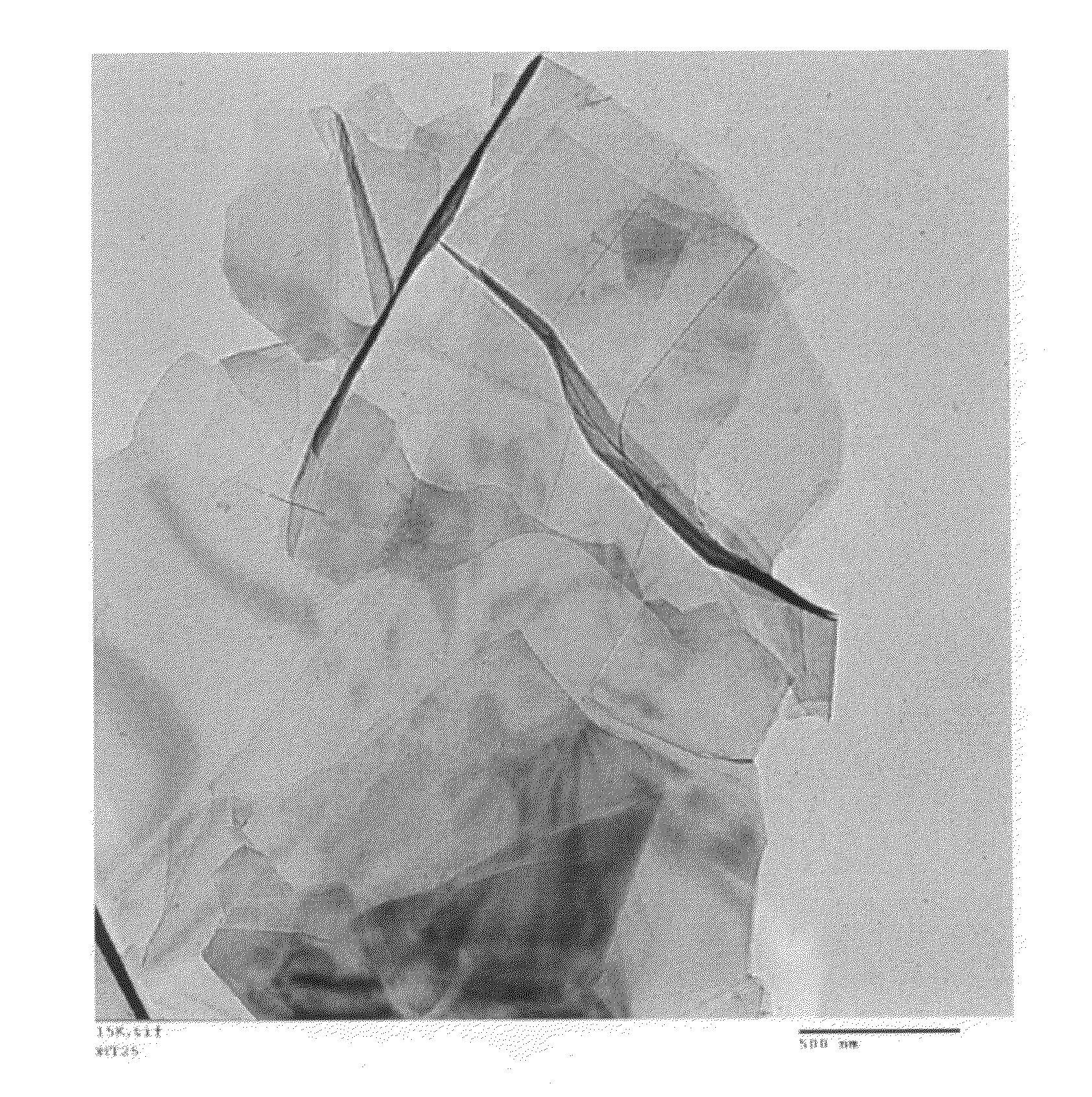

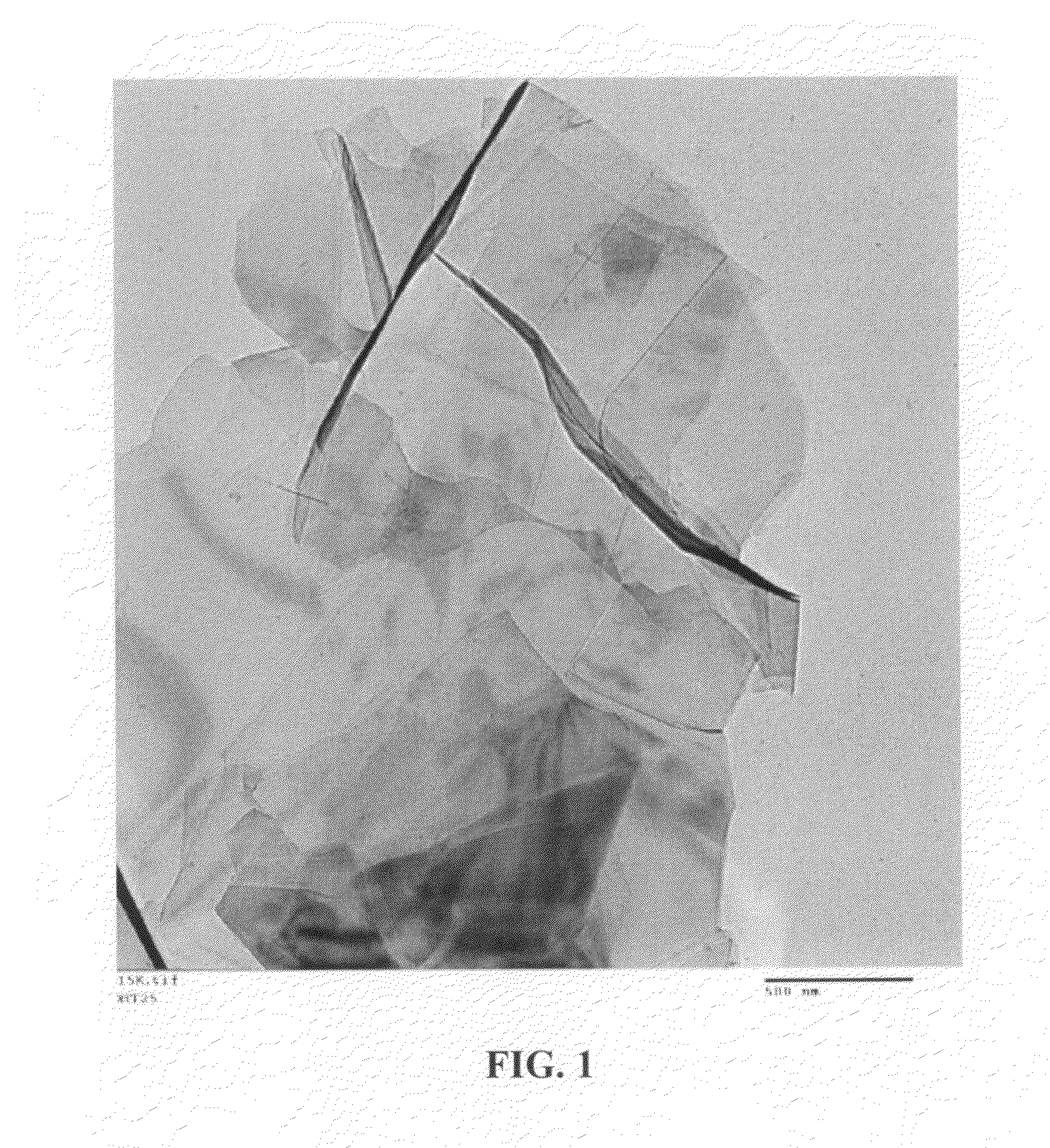

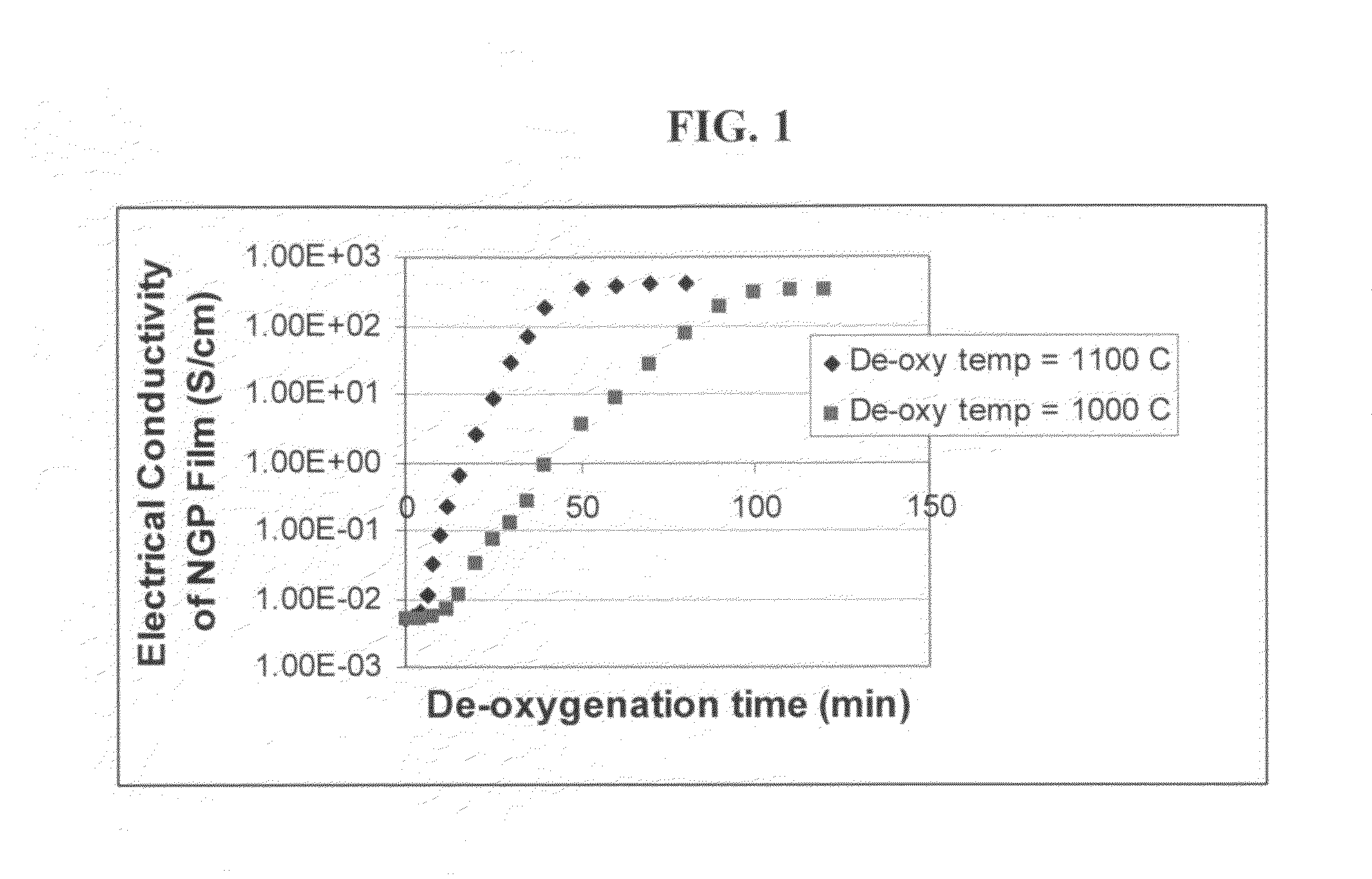

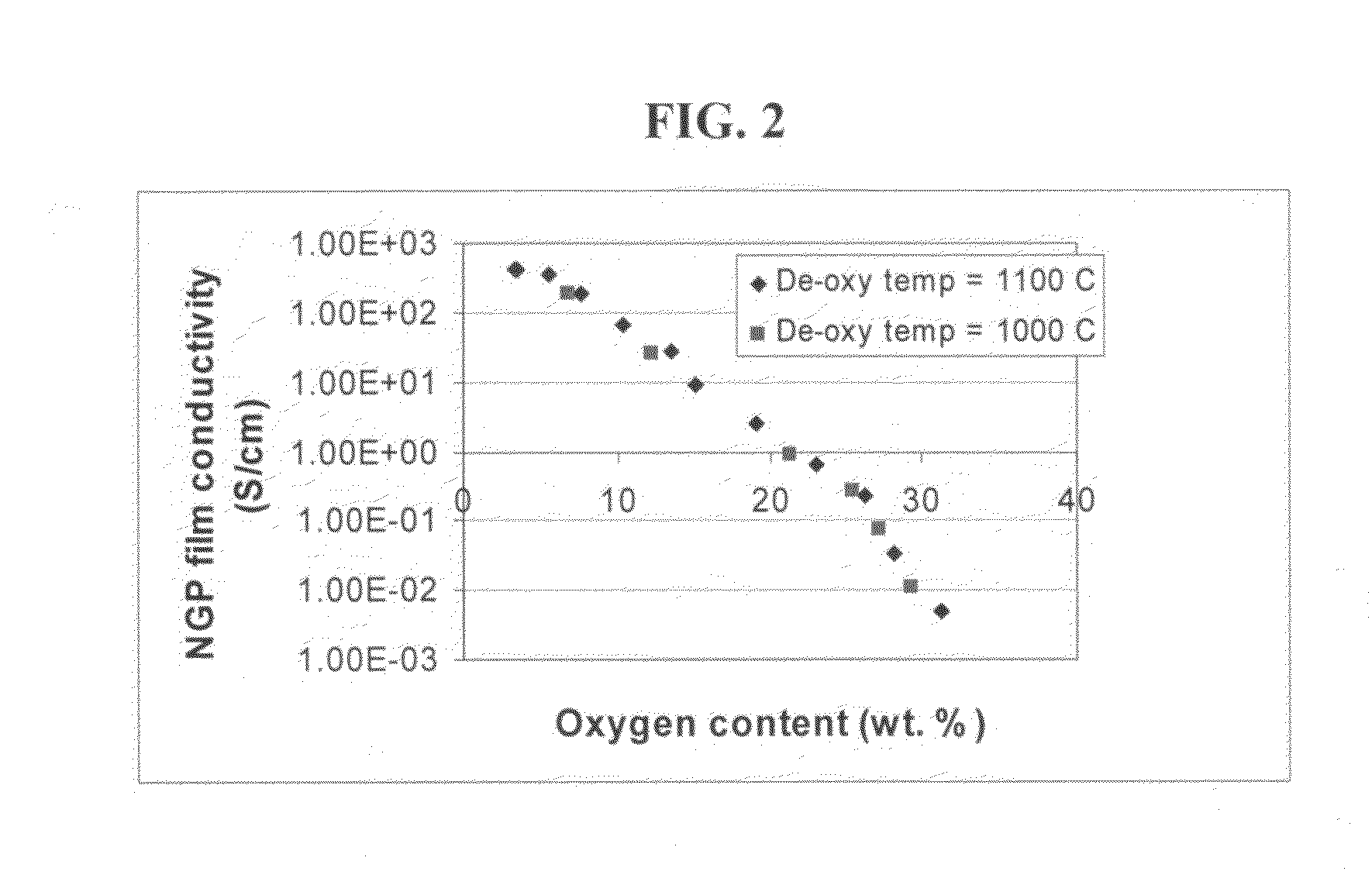

Process for producing dispersible Nano Graphene Platelets from oxidized graphite

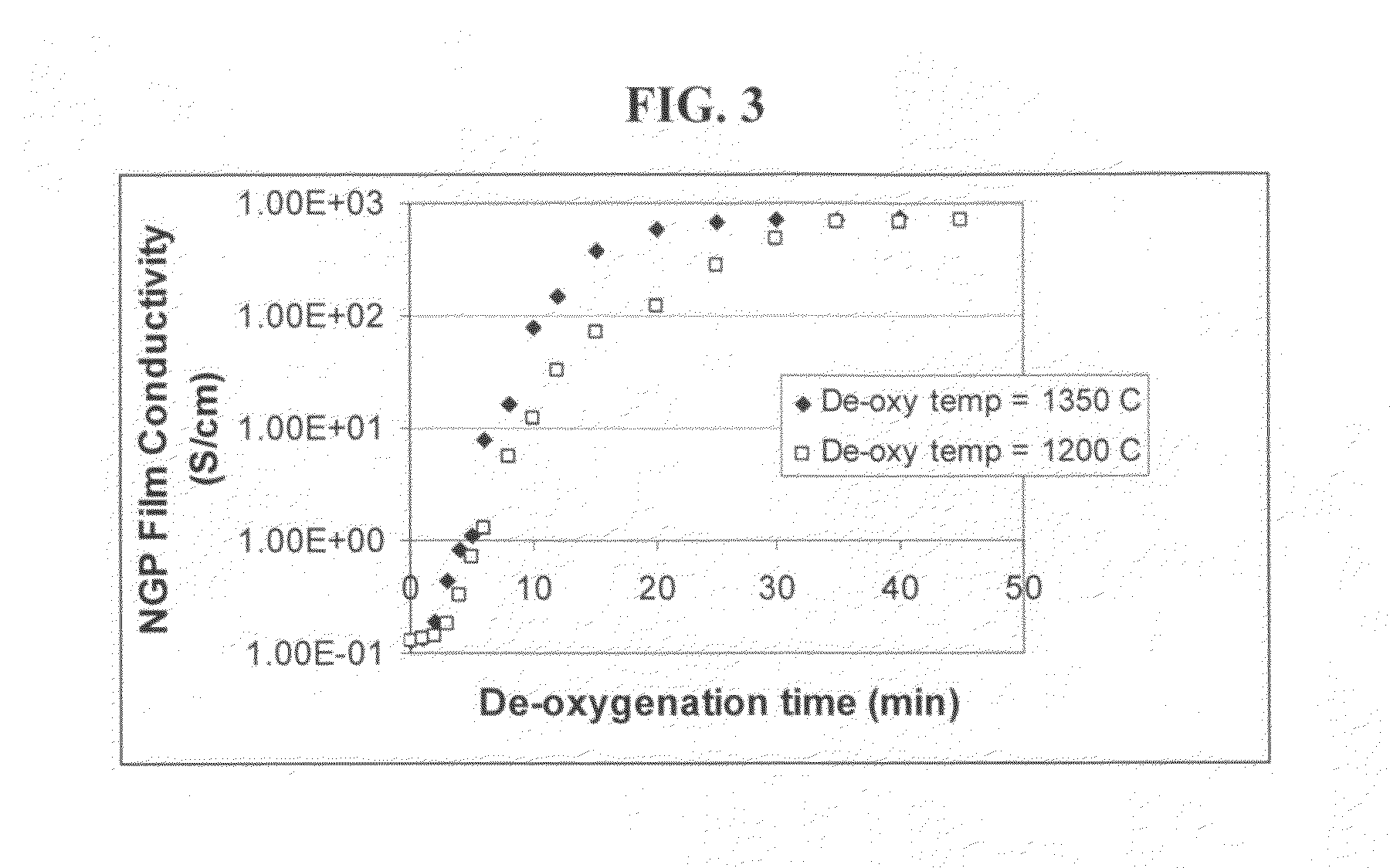

The present invention provides a process for producing nano graphene platelets (NGPs) that are dispersible and conducting. The process comprises: (a) preparing a graphite intercalation compound (GIC) or graphite oxide (GO) from a laminar graphite material; (b) exposing the GIC or GO to a first temperature for a first period of time to obtain exfoliated graphite; and (c) exposing the exfoliated graphite to a second temperature in a protective atmosphere for a second period of time to obtain the desired dispersible nano graphene platelet with an oxygen content no greater than 25% by weight, preferably below 20% by weight, further preferably between 5% and 20% by weight. Conductive NGPs can find applications in transparent electrodes for solar cells or flat panel displays, additives for battery and supercapacitor electrodes, conductive nanocomposite for electromagnetic wave interference (EMI) shielding and static charge dissipation, etc.

Owner:GLOBAL GRAPHENE GRP INC

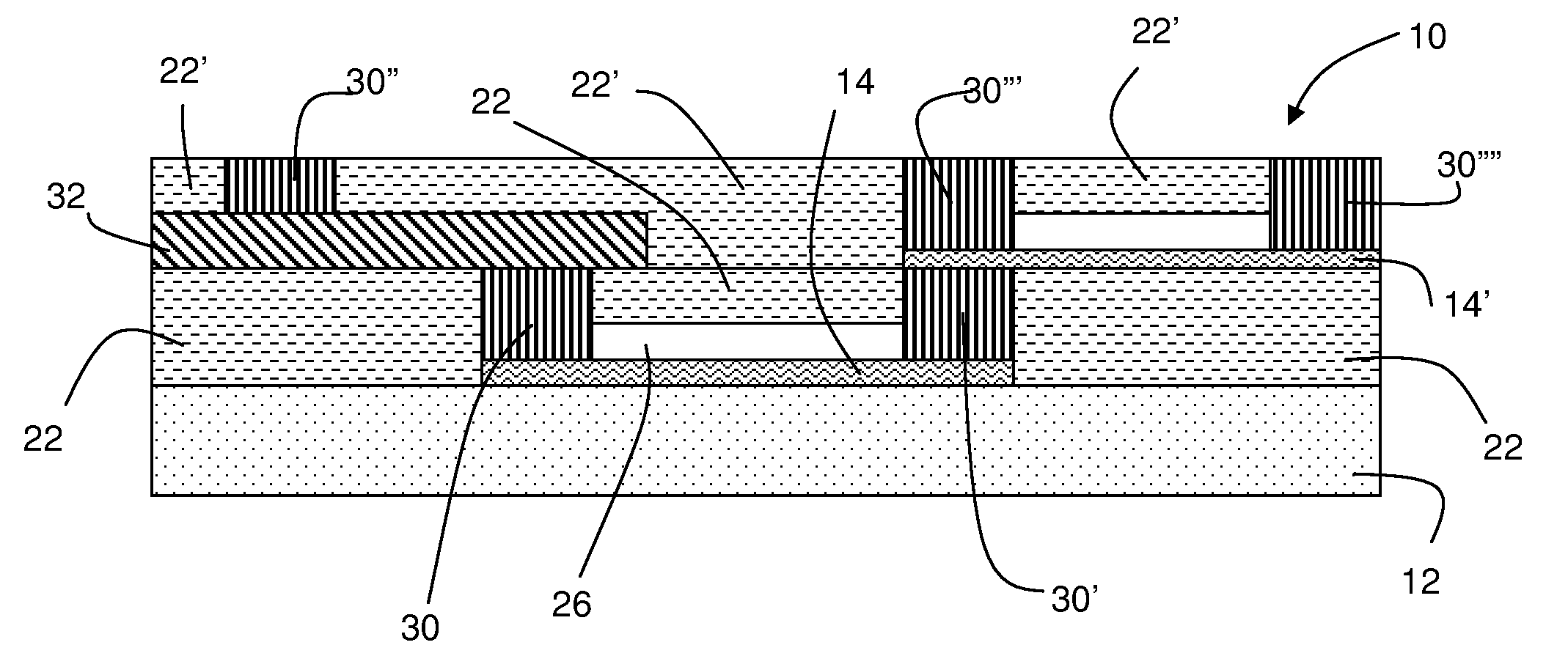

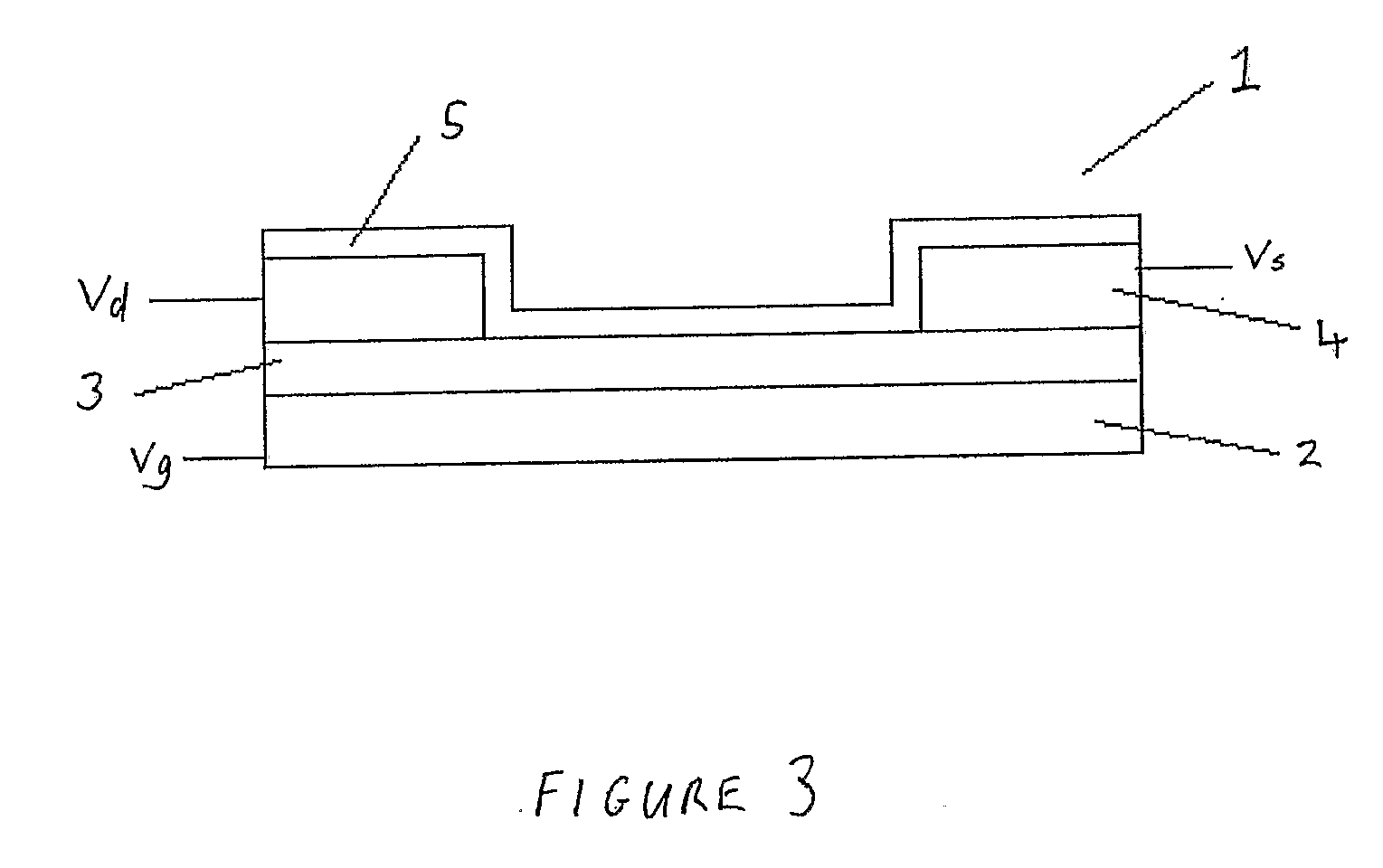

Graphene Nanoelectric Device Fabrication

Embodiments of the present invention provide methods for fabricating graphene nanoelectronic devices with semiconductor compatible processes, which allow wafer scale fabrication of graphene nanoelectronic devices. Embodiments of the present invention also provide methods for passivating graphene nanoelectronic devices, which enable stacking of multiple graphene devices and the creation of high density graphene based circuits. Other embodiments provide methods for producing devices with graphene layer segments having multiple thicknesses.

Owner:LOCKHEED MARTIN CORP

Functionalised graphene oxide

ActiveUS20110052813A1Good dispersionReadily deoxidised to grapheneMaterial nanotechnologyOrganic chemistryHigh concentrationRoom temperature

A functionalised graphene oxide and a method of making a functionalised graphene oxide comprising: (i) oxidizing graphite to form graphite oxide wherein the graphene sheets which make up the graphite independently of each other have a basal plane fraction of carbon atoms in the sp2-hybridised state between 0.1 and 0.9, wherein the remainder fraction comprises sp3-hybridised carbon atoms which are bonded to oxygen groups selected from hydroxyl and / or epoxy and / or carboxylic acid; and (ii) exfoliating and in-situ functionalizing the graphite oxide surface with one or more functional groups such that functionalisation of the surface is effected at a concentration greater than one functional group per 100 carbon atoms and less than one functional group per six carbon atoms. The functionalised graphene oxide is dispersible at high concentrations in appropriate solvents without aggregating or precipitating over extended periods at room temperature.

Owner:NAT UNIV OF SINGAPORE

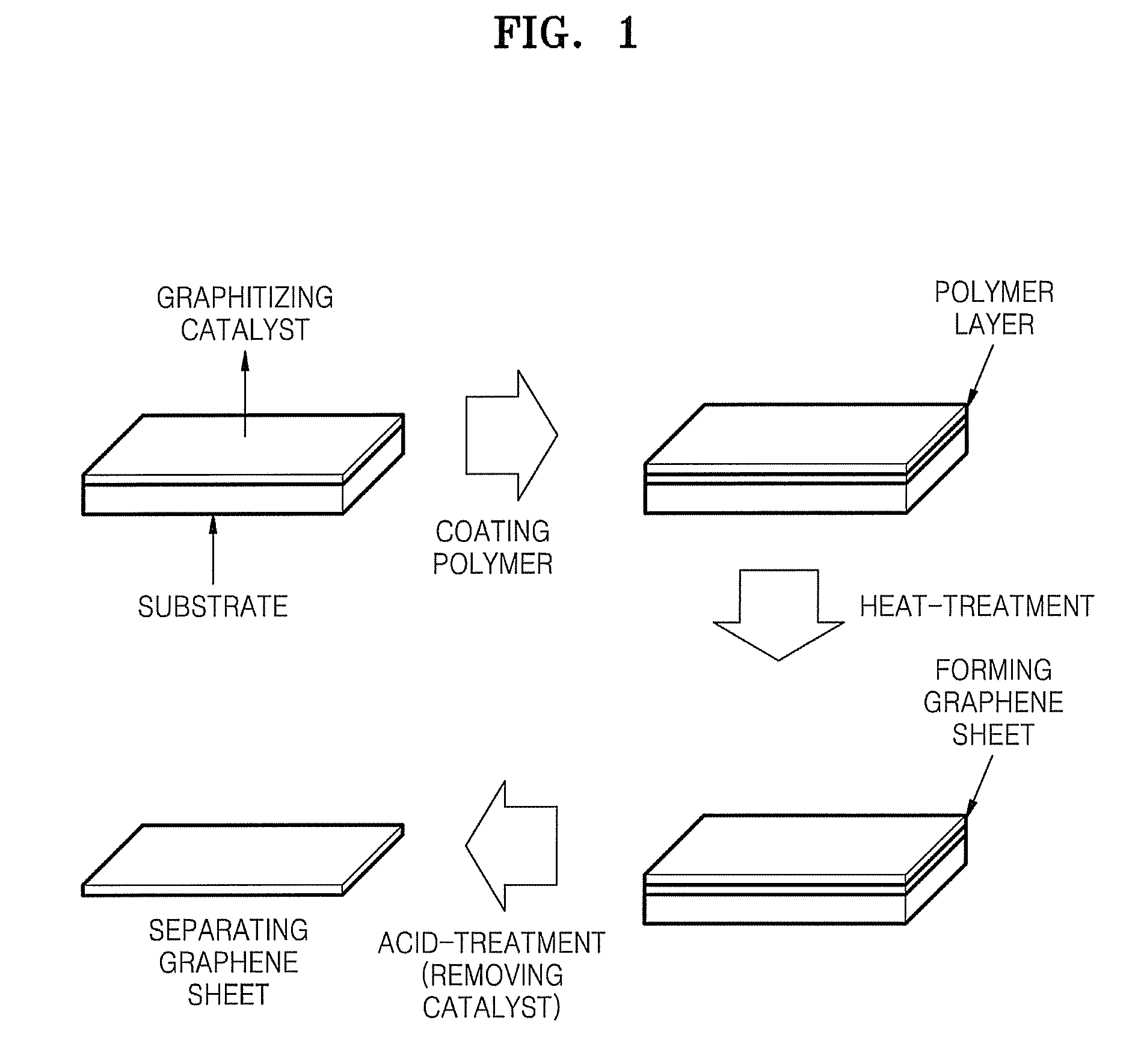

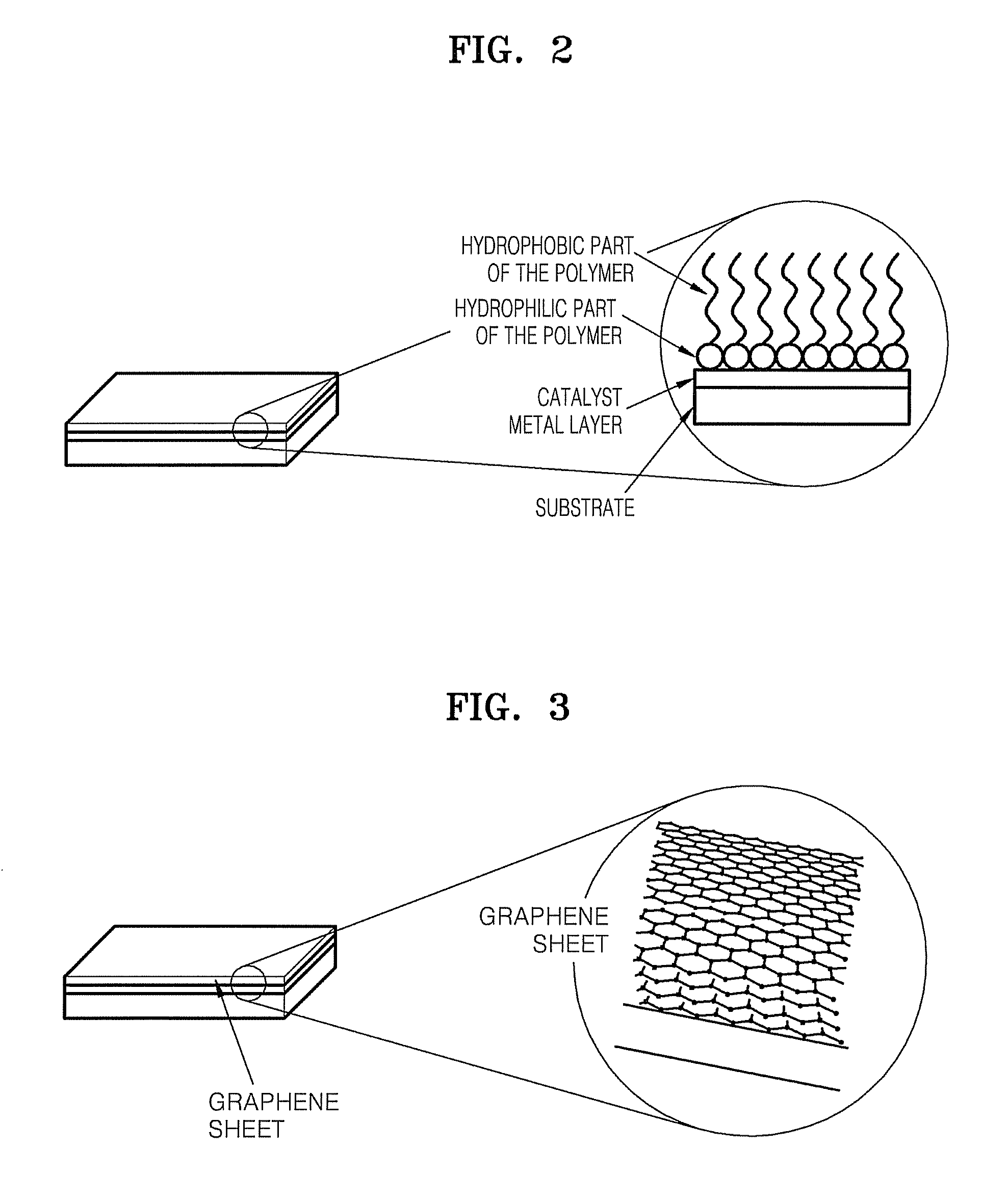

Graphene sheet and process of preparing the same

ActiveUS20090068471A1Prepared economicallyMaterial nanotechnologyPhysical/chemical process catalystsPolymer scienceGraphene

Owner:SAMSUNG ELECTRONICS CO LTD

Graphene protective film serving as a gas and moisture barrier, method for forming same, and use thereof

ActiveUS20120282419A1Improve featuresImprove electrical characteristicsMaterial nanotechnologyDecorative surface effectsTectorial membraneGraphene

The present invention relates to a method for forming a graphene protective film having gas and moisture barrier properties, to a graphene protective film formed by the method, and to the use thereof. A single-layer or multi-layer graphene protective film can be used as a material for a barrier coating or bags, and improves the gas and moisture barrier properties of a variety of devices in a wide array of industrial fields to thereby maintain the electrical characteristics of devices over a long period of time.

Owner:GRAPHENE SQUARE

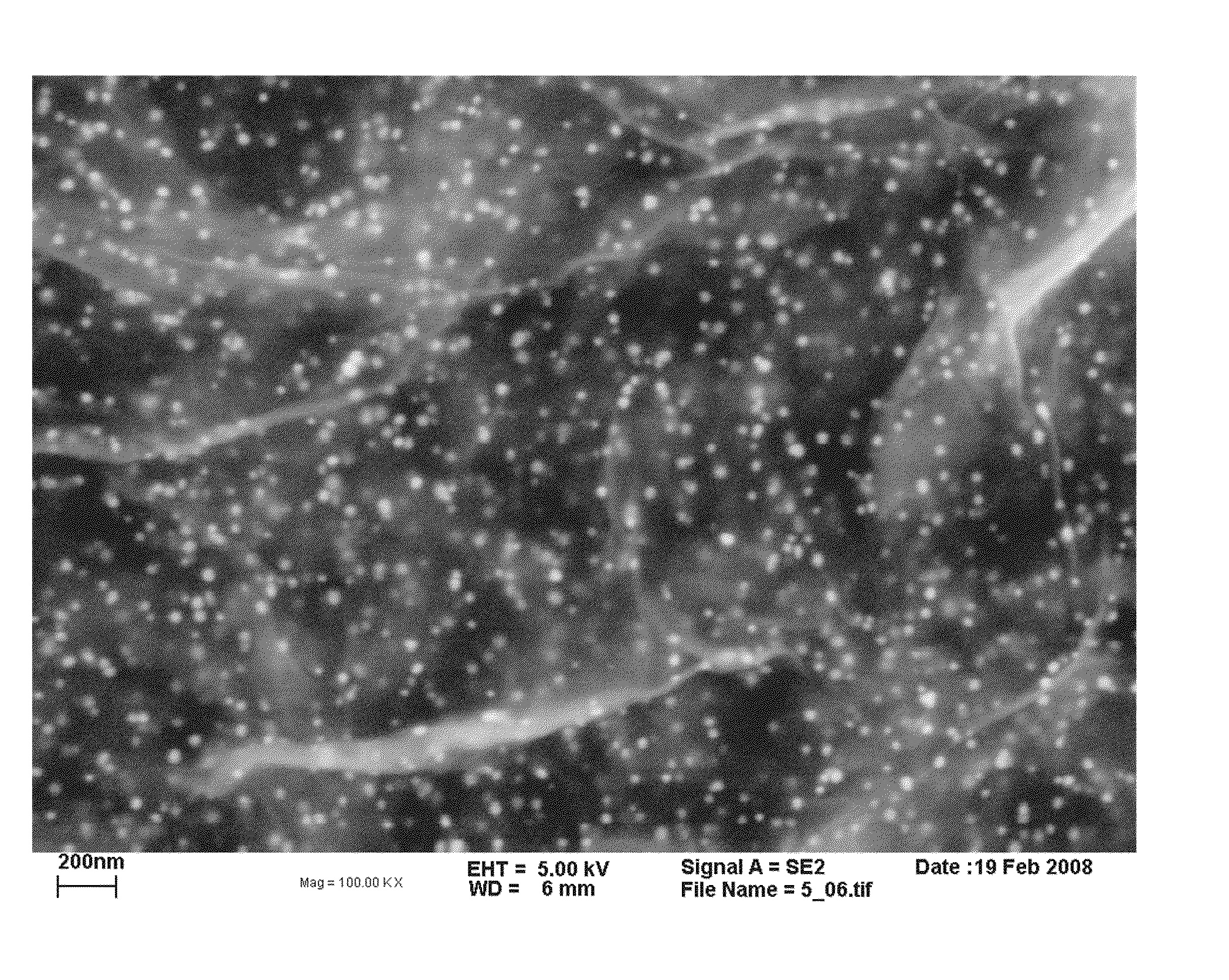

Spacer-modified nano graphene electrodes for supercapacitors

ActiveUS20110157772A1Increase surface areaMaterial nanotechnologyLiquid electrolytic capacitorsCapacitanceSupercapacitor

A surface-modified nano graphene platelet (NGP), comprising: (a) a nano graphene platelet having a thickness smaller than 10 nm; and (b) discrete, non-continuous, and non-metallic bumps or nodules bonded to a surface of the graphene platelet to serve as a spacer. When multiple surface-modified NGP sheets are stacked together to form an electrode, large numbers of electrolyte-accessible pores are formed, enabling the formation of large amounts of double layer charges in a supercapacitor, which exhibits an exceptionally high specific capacitance.

Owner:NANOTEK INSTR GRP LLC

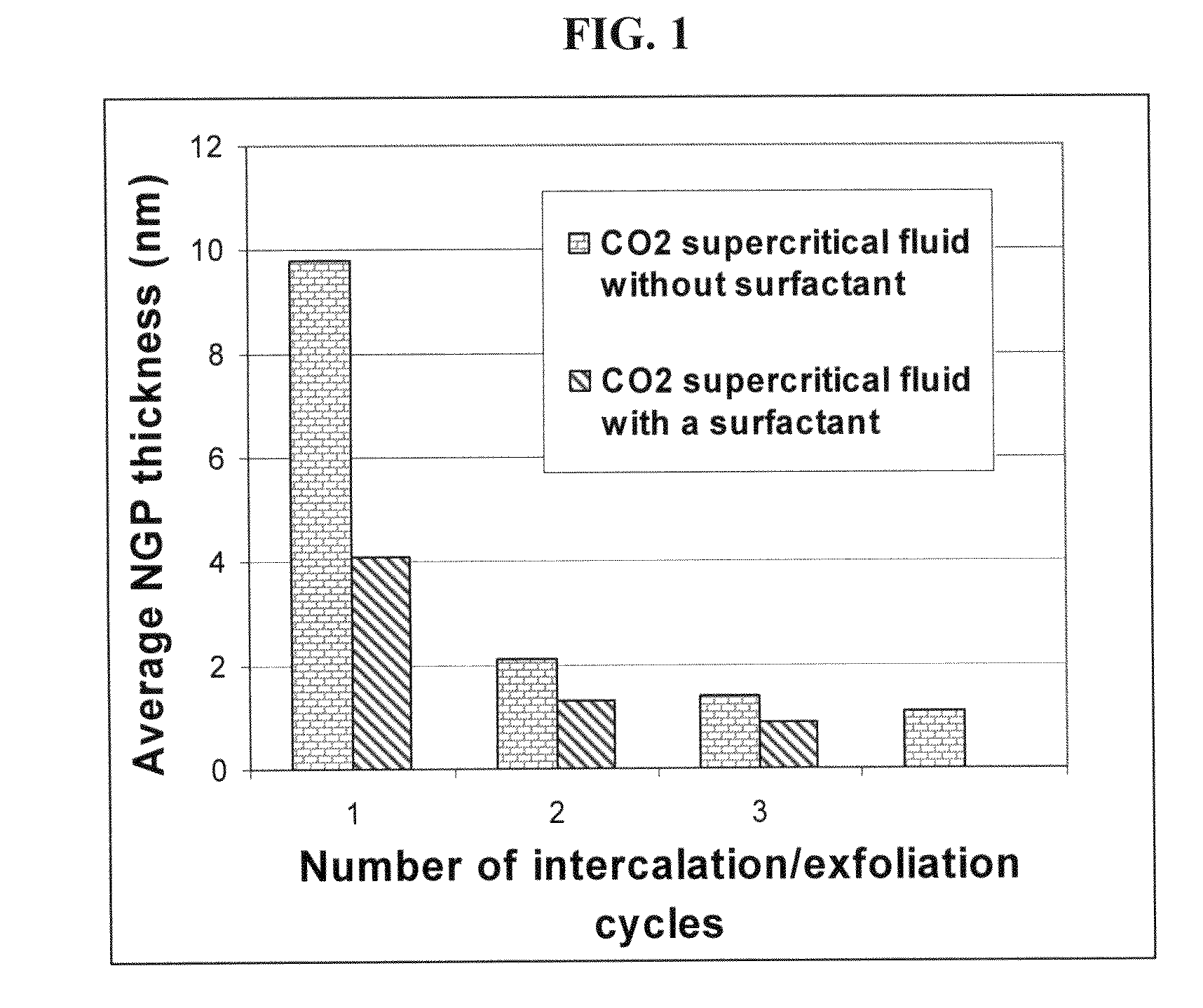

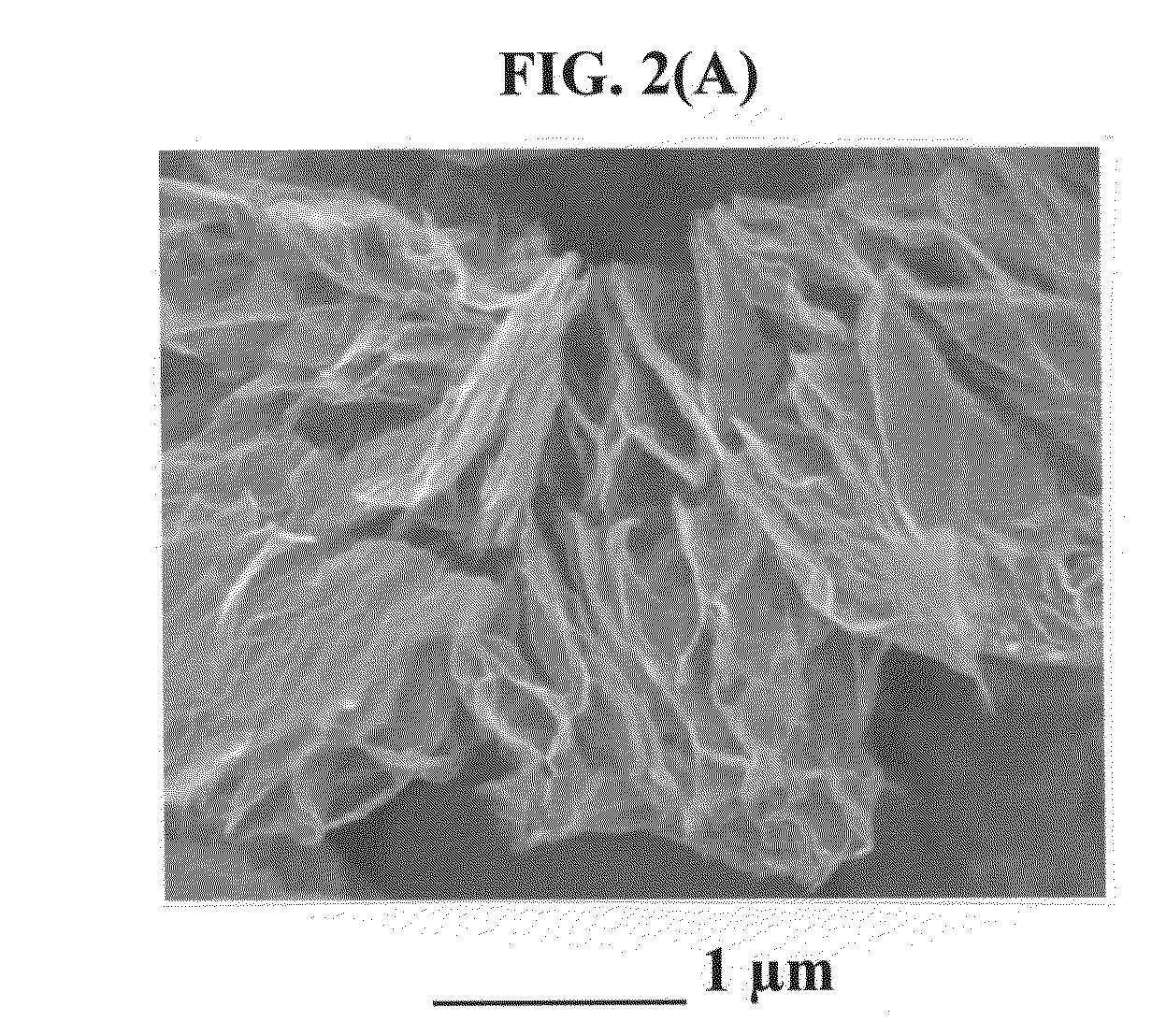

Supercritical fluid process for producing nano graphene platelets

ActiveUS20100044646A1Improve conductivityPigmenting treatmentNon-metal conductorsDisplay deviceSolar cell

The present invention provides a process for producing pristine or non-oxidized nano graphene platelets (NGPs) that are highly conductive. The process comprises: (i) subjecting a graphitic material to a supercritical fluid at a first temperature and a first pressure for a first period of time in a pressure vessel and then (ii) rapidly depressurizing the fluid at a fluid release rate sufficient for effecting exfoliation of the graphitic material to obtain the NGP material. Conductive NGPs can be used as a conductive additive in transparent electrodes for solar cells or flat panel displays (e.g., to replace expensive indium-tin oxide), battery and supercapacitor electrodes, and nanocomposite for electromagnetic wave interference (EMI) shielding and static charge dissipation, etc.

Owner:GLOBAL GRAPHENE GRP INC

Stable dispersions of single and multiple graphene layers in solution

ActiveUS20100301279A1Improved propertyInhibition formationMaterial nanotechnologyCell electrodesColloidCvd graphene

Disclosed is a method for producing colloidal graphene dispersions comprising the steps of(i) dispersing graphite oxide in a dispersion medium to form a colloidal graphene oxide or multi-graphene oxide dispersion(ii) thermally reducing the graphene oxide or multi-graphene oxide in dispersion.Dependent on the method used for the preparation of the starting dispersion a graphene or a multi-graphene dispersion is obtained that can be further processed to multi-graphene with larger inter-planar distances than graphite. Such dispersions and multi-graphenes are for example suitable materials in the manufacturing of rechargeable lithium ion batteries.

Owner:BELENOS CLEAN POWER HLDG

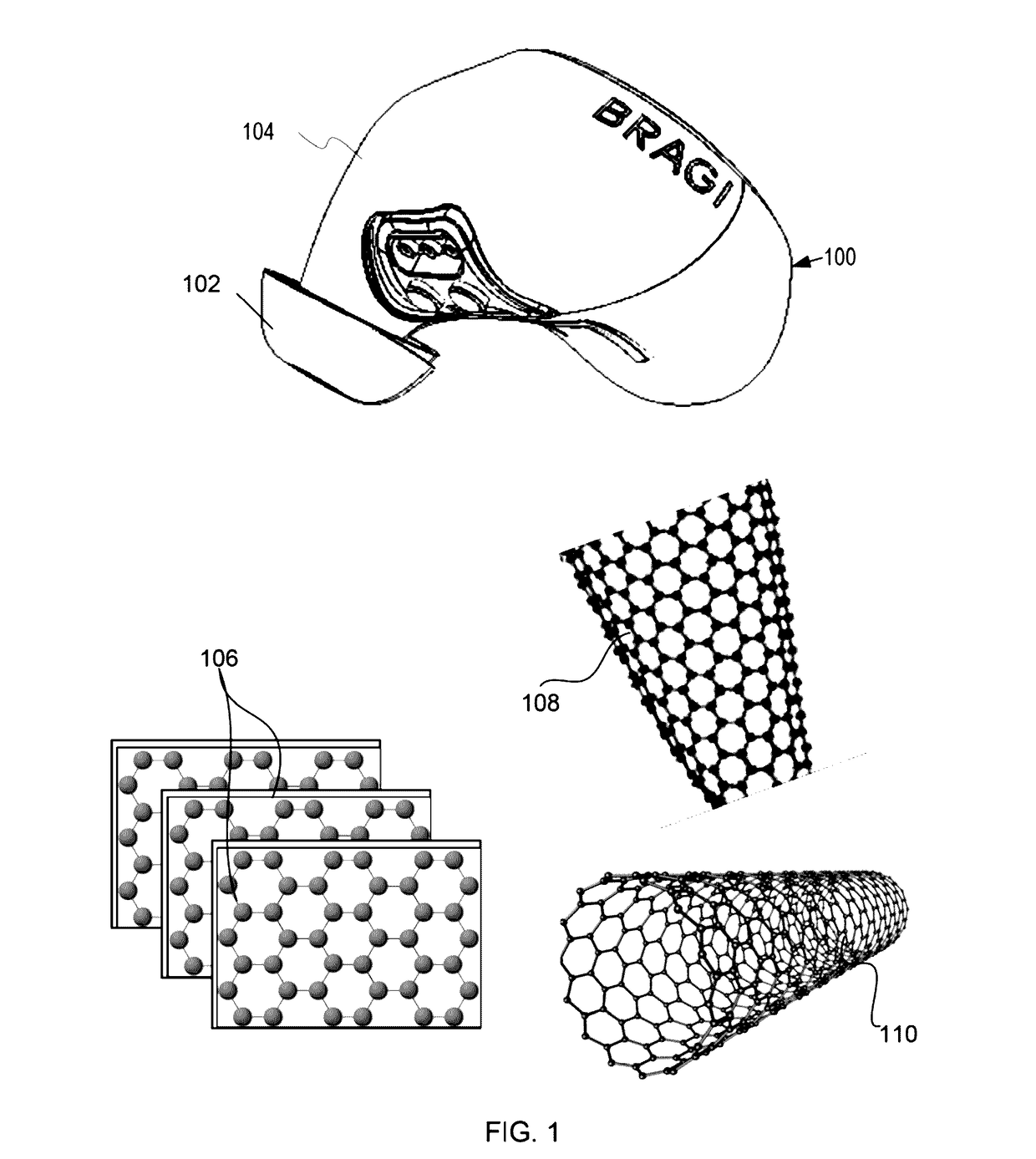

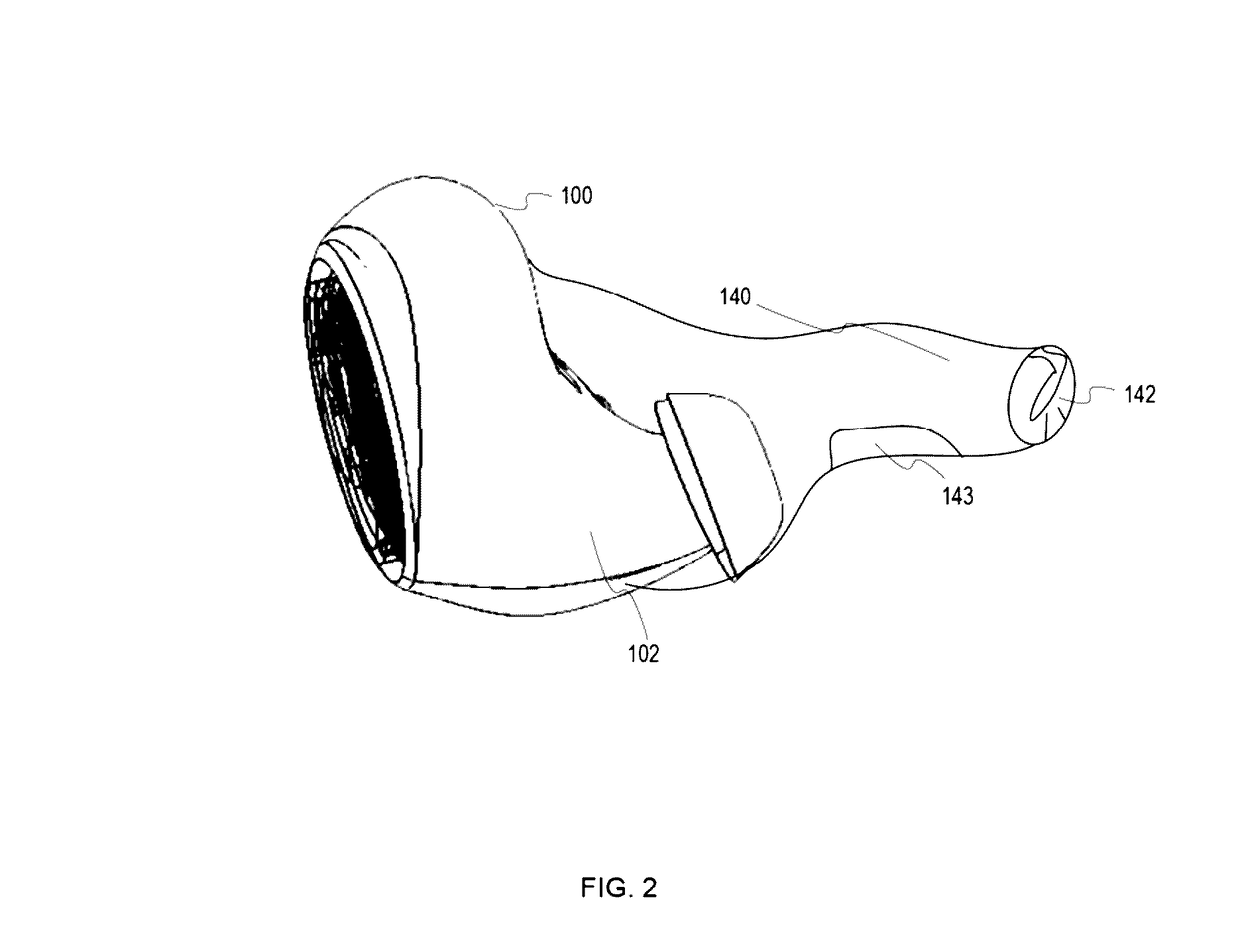

Graphene Based Mesh for Use in Portable Electronic Devices

A system, method, and wireless earpiece. The wireless earpiece includes a frame supporting circuitry of the wireless earpiece The frame includes an extension composed of graphene shaped to fit in to an ear canal of a user. The wireless earpiece includes a sleeve fitted over the frame to fit in to the ear canal of the user.

Owner:BRAGI

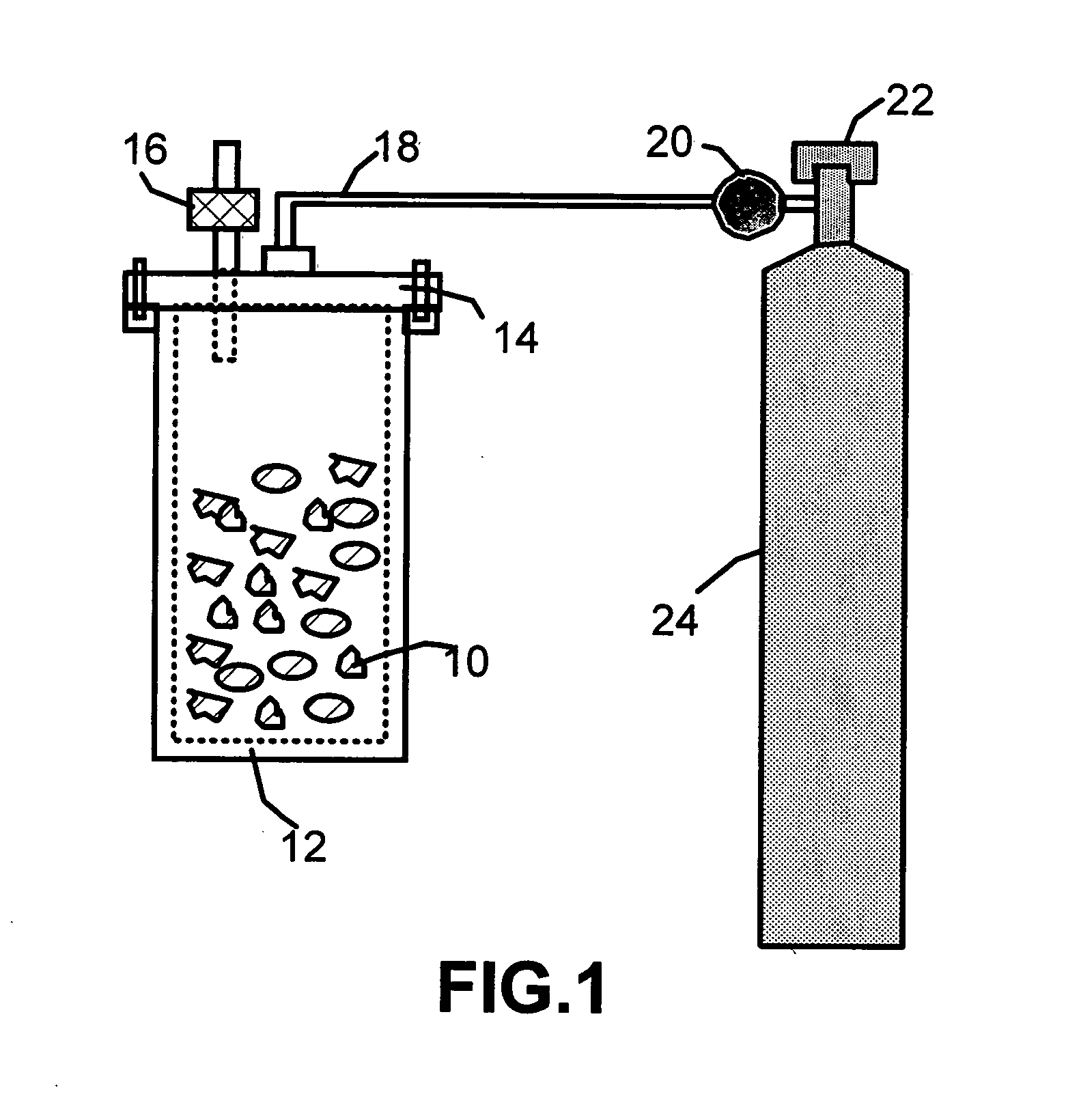

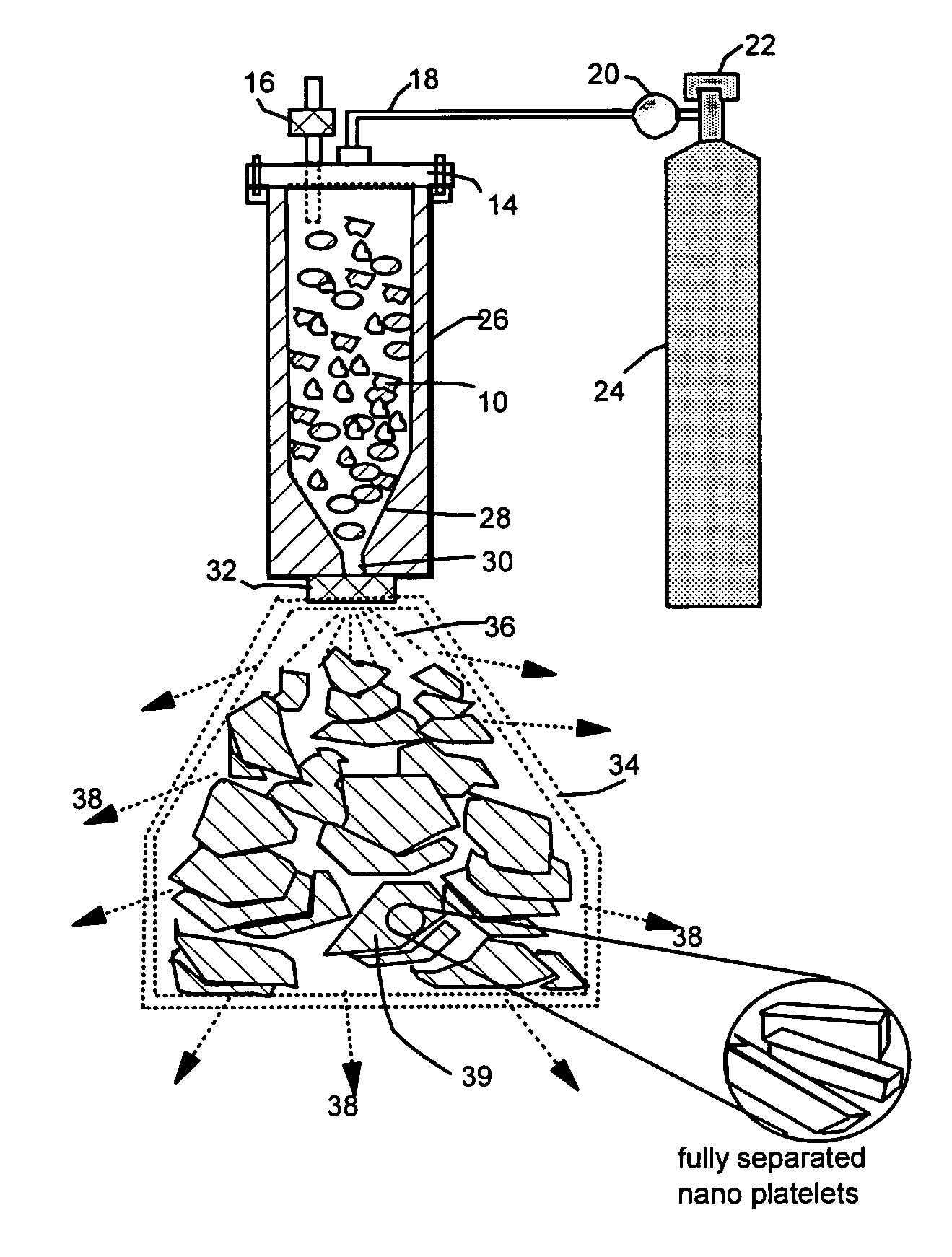

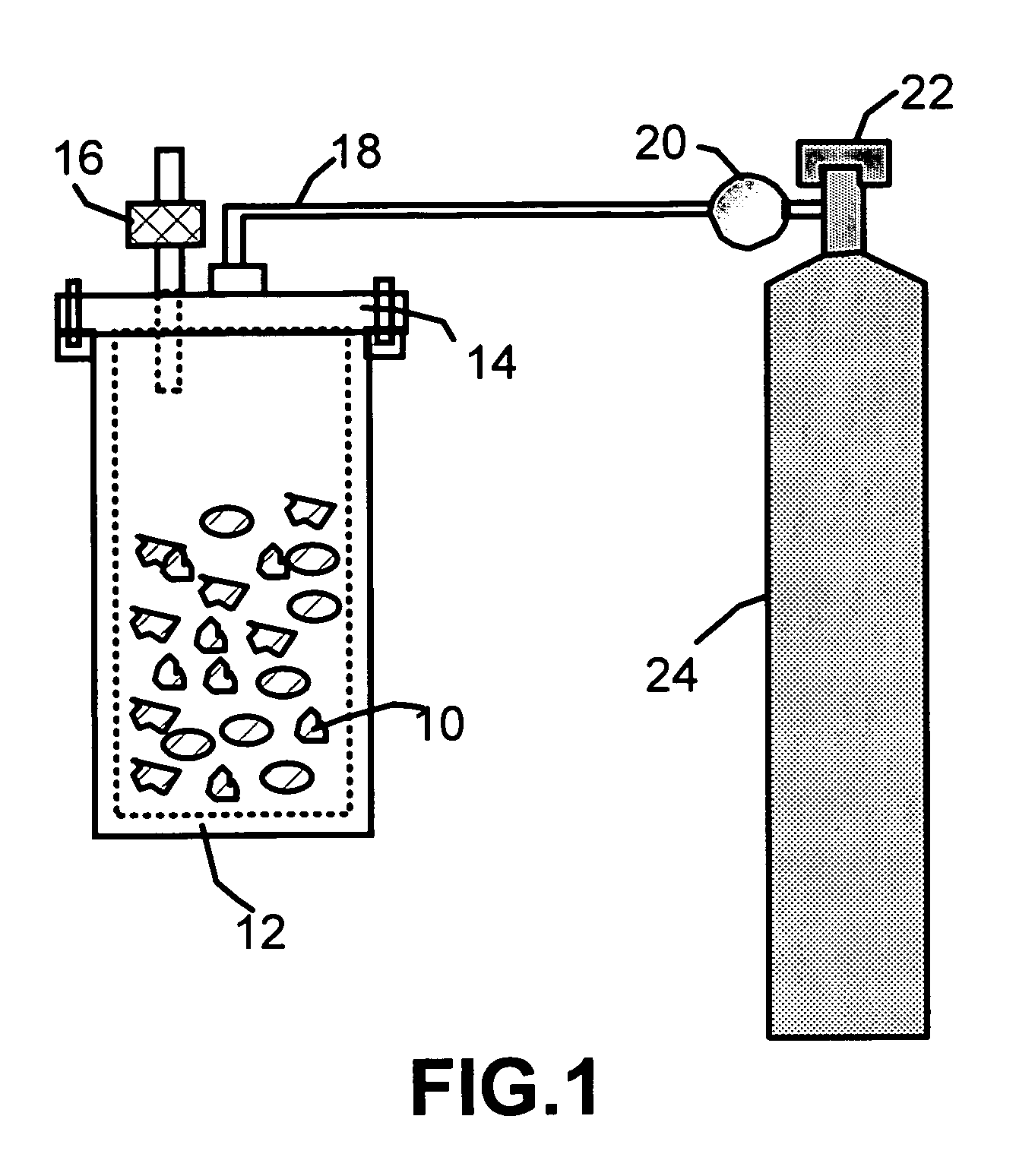

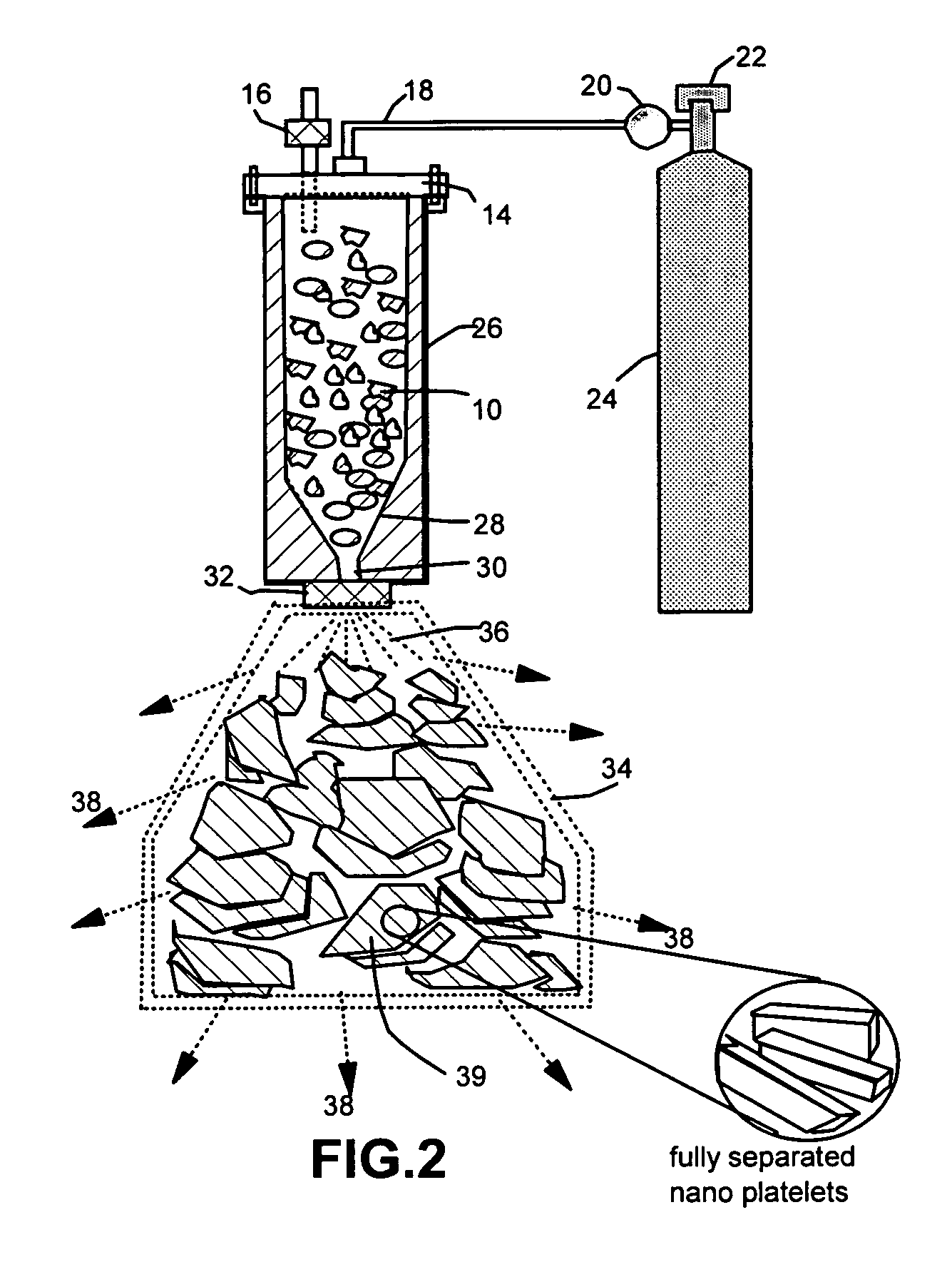

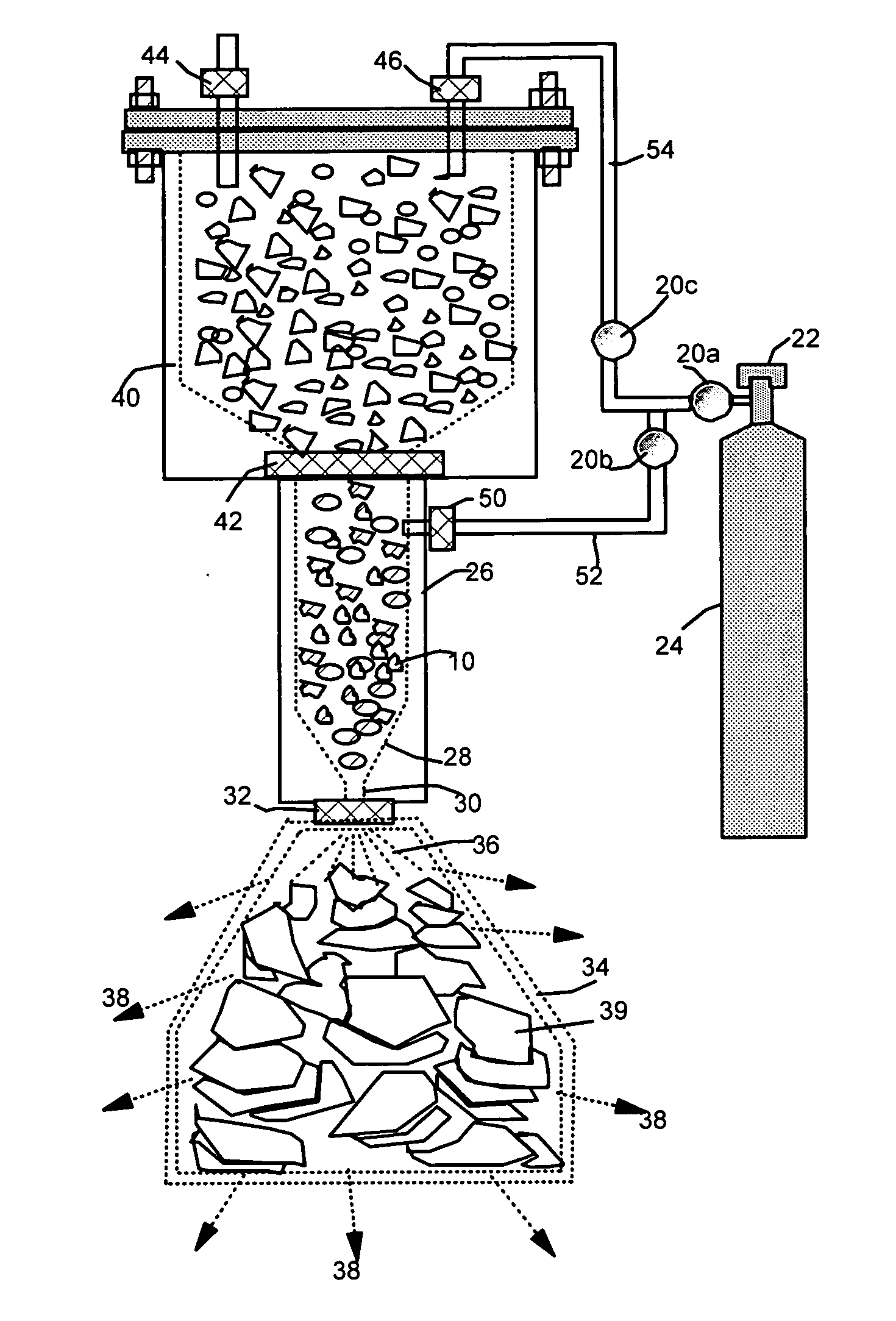

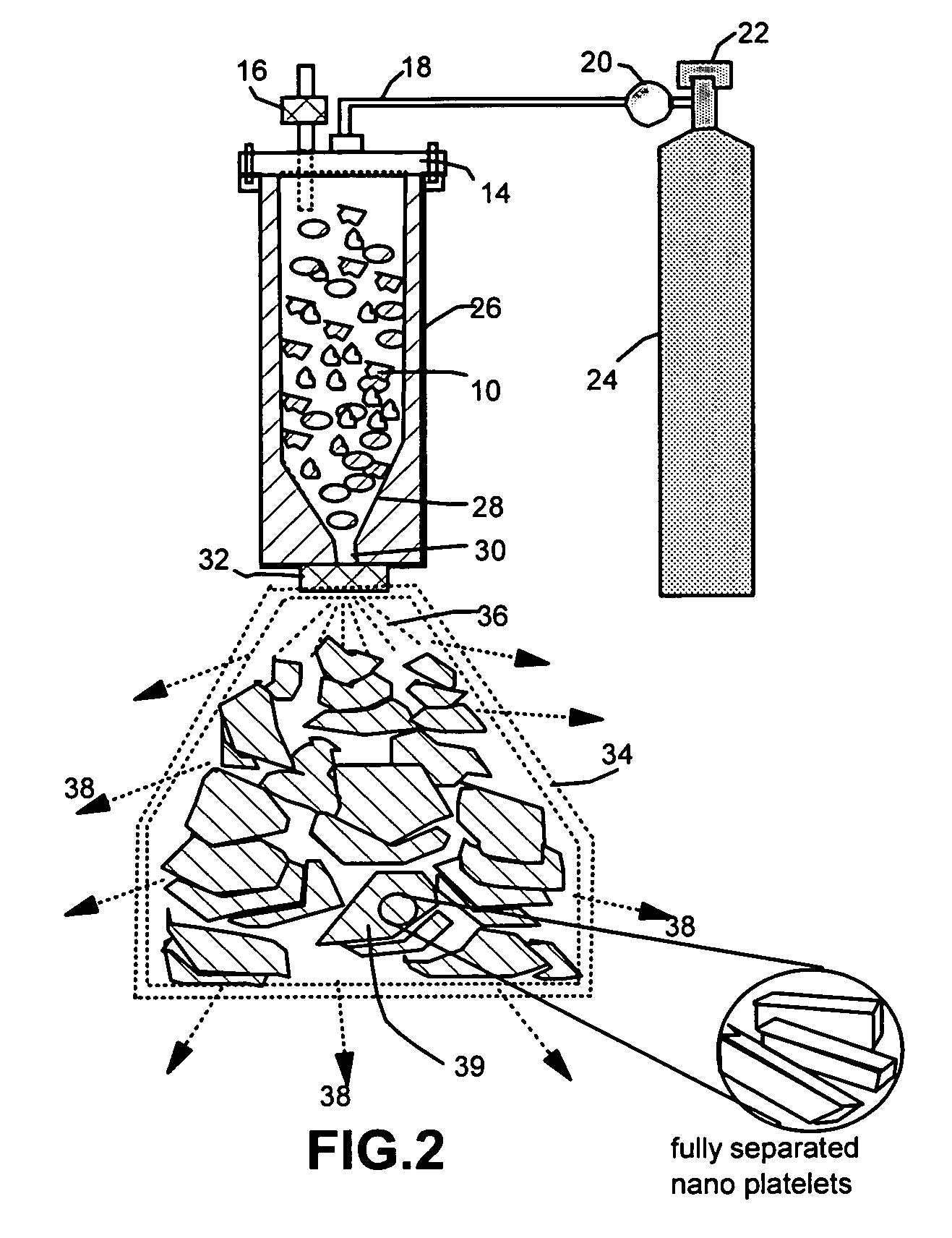

Mass production of nano-scaled platelets and products

ActiveUS7785492B1Reduce necessary intercalation timeSmall thicknessMaterial nanotechnologyGraphiteNoble gasGraphite

Disclosed is a process for exfoliating a layered material to produce nano-scaled platelets having a thickness smaller than 100 nm, typically smaller than 10 nm, and often between 0.34 nm and 1.02 nm. The process comprises: (a) charging a layered material to an intercalation chamber comprising a gaseous environment at a first temperature and a first pressure sufficient to cause gas species to penetrate into the interstitial space between layers of the layered material, forming a gas-intercalated layered material; and (b) operating a discharge valve to rapidly eject the gas-intercalated layered material through a nozzle into an exfoliation zone at a second pressure and a second temperature, allowing gas species residing in the interstitial space to exfoliate the layered material to produce the platelets. The gaseous environment preferably contains only environmentally benign gases that are reactive (e.g., oxygen) or non-reactive (e.g., noble gases) with the layered material. The process can additionally include dispersing the platelets in a matrix material to form a nanocomposite. The process also can include an additional process of re-compressing the nana-scaled platelets into a product such as a flexible graphite sheet.

Owner:GLOBAL GRAPHENE GRP INC

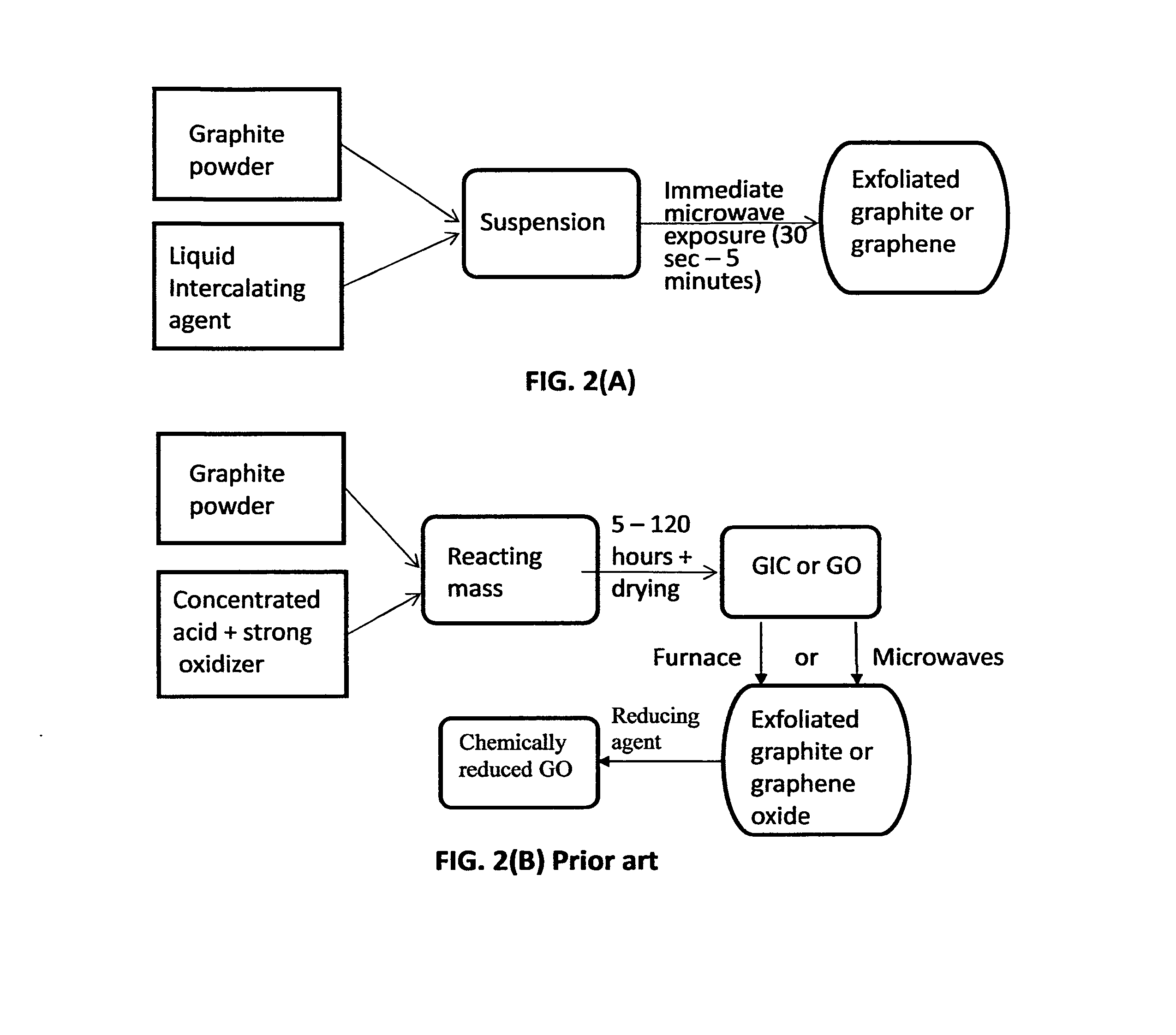

One-step production of graphene materials

InactiveUS20130087446A1Simple and short processSimply replace furnace heatingMaterial nanotechnologyGraphiteMicrowaveGraphite

A method of producing exfoliated graphite or graphene from a graphitic or carbonaceous material. The method includes: (a) dispersing a graphitic material in a liquid intercalating agent to form a suspension; and (b) subjecting the suspension to microwave or radio frequency irradiation for a length of time sufficient for producing the exfoliated graphite or graphene. In one preferred embodiment, the intercalating agent is an acid or an oxidizer, or a combination of both. The method enables production of more electrically conducting graphene sheets directly from a graphitic material without going through the chemical intercalation or oxidation procedure. The process is fast (minutes as opposed to hours or days of conventional processes), environmentally benign, and highly scalable.

Owner:GLOBAL GRAPHENE GRP INC

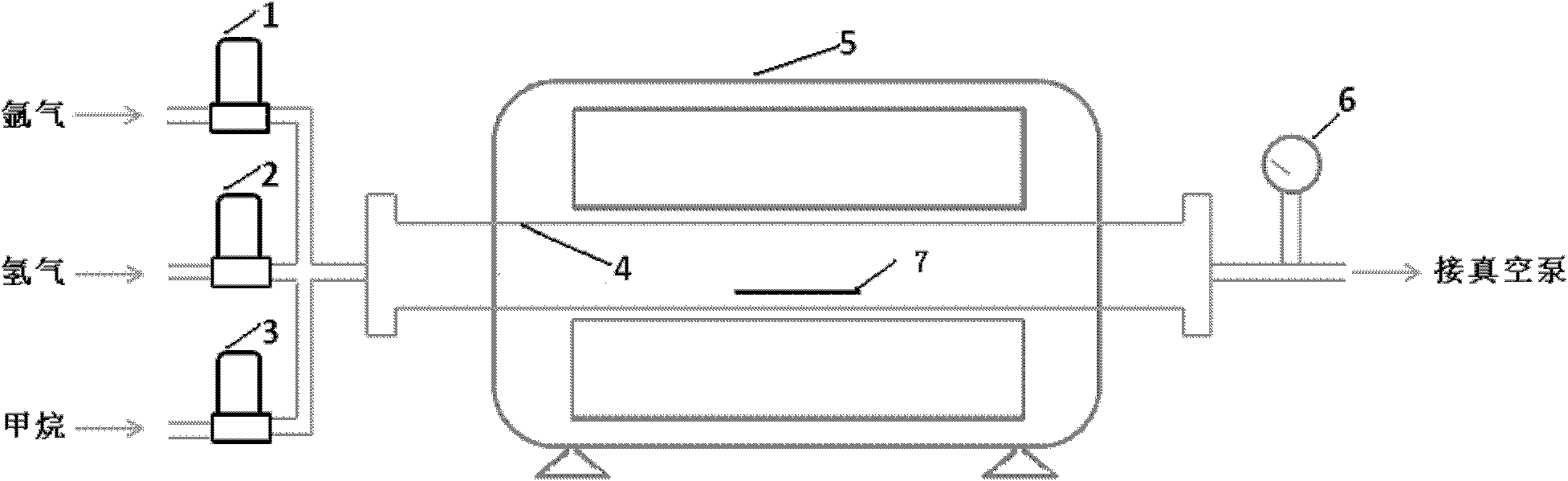

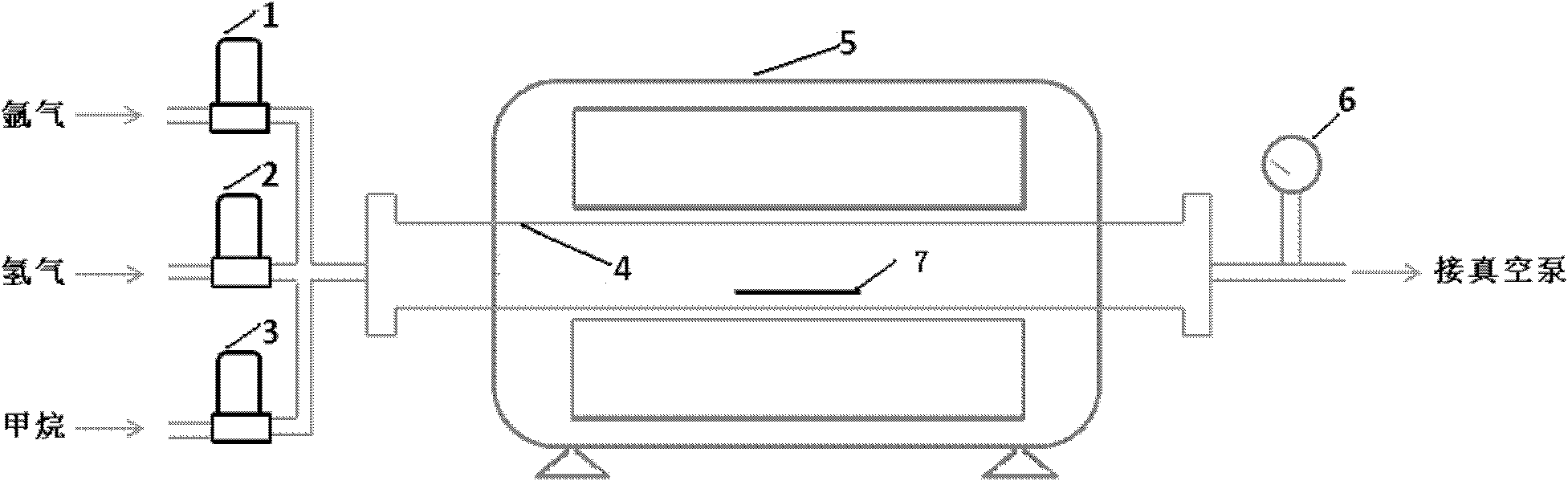

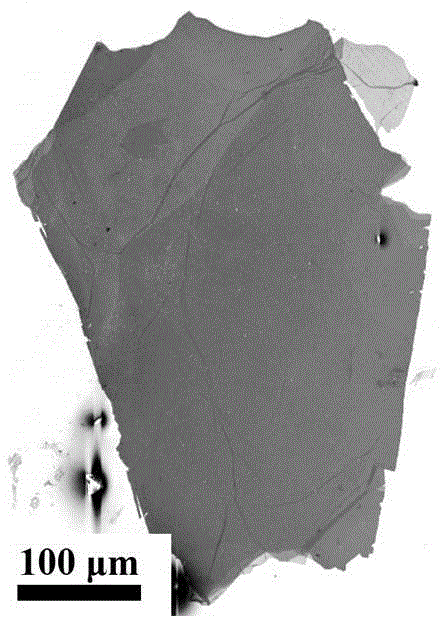

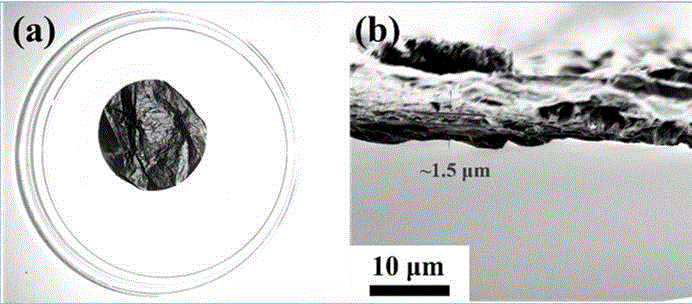

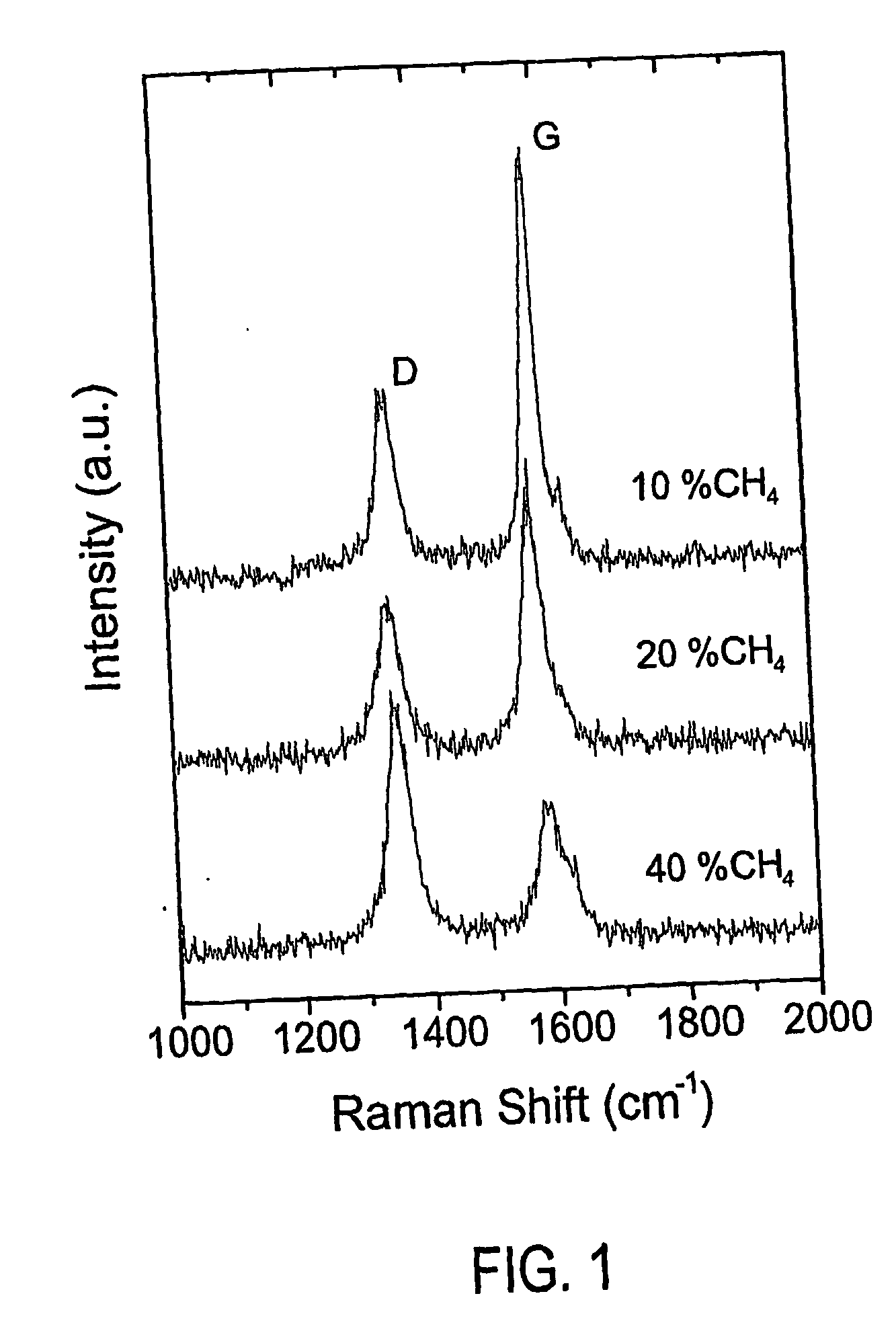

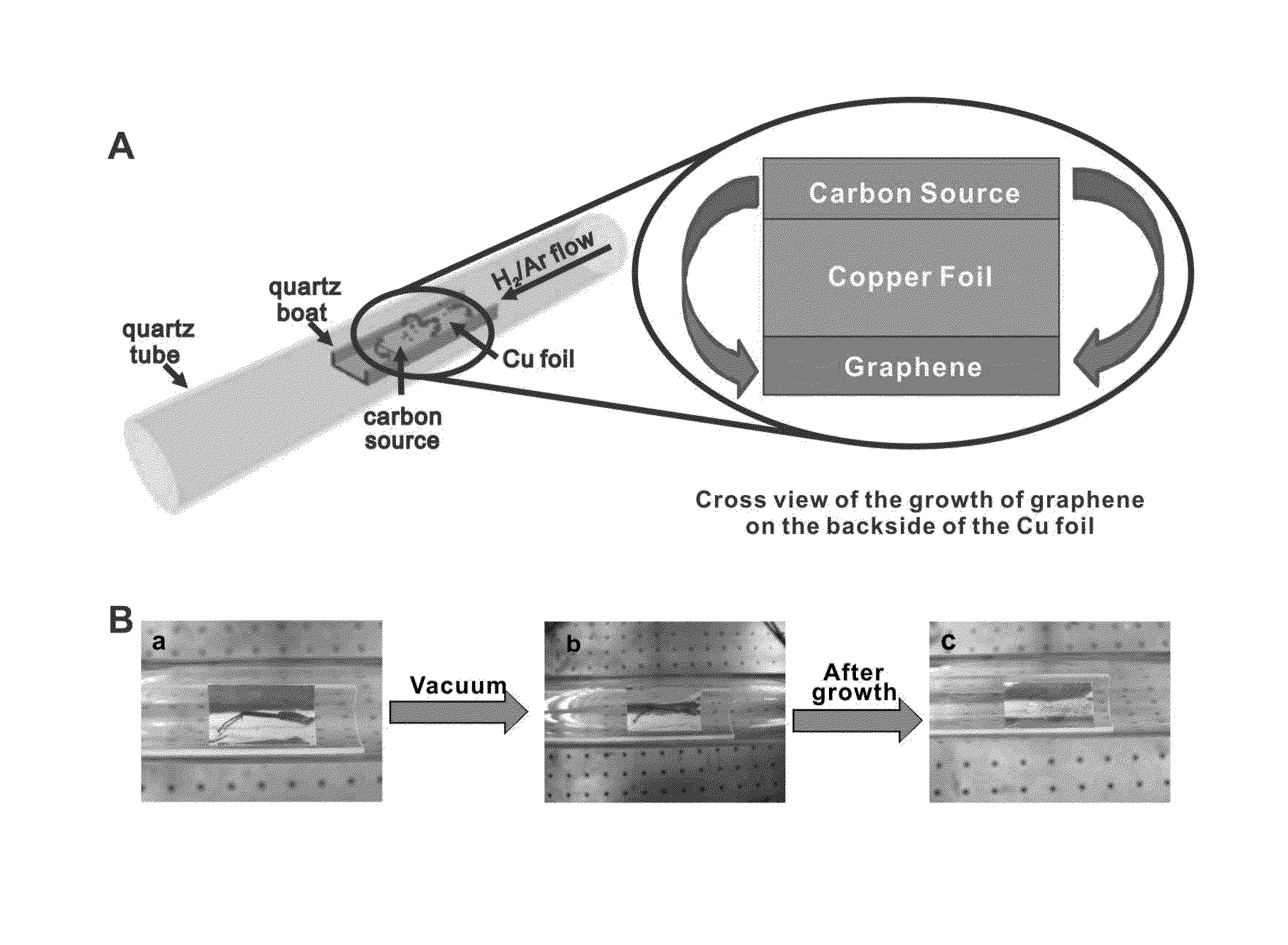

Method for preparing single-layer or multi-layer graphene through chemical vapor deposition

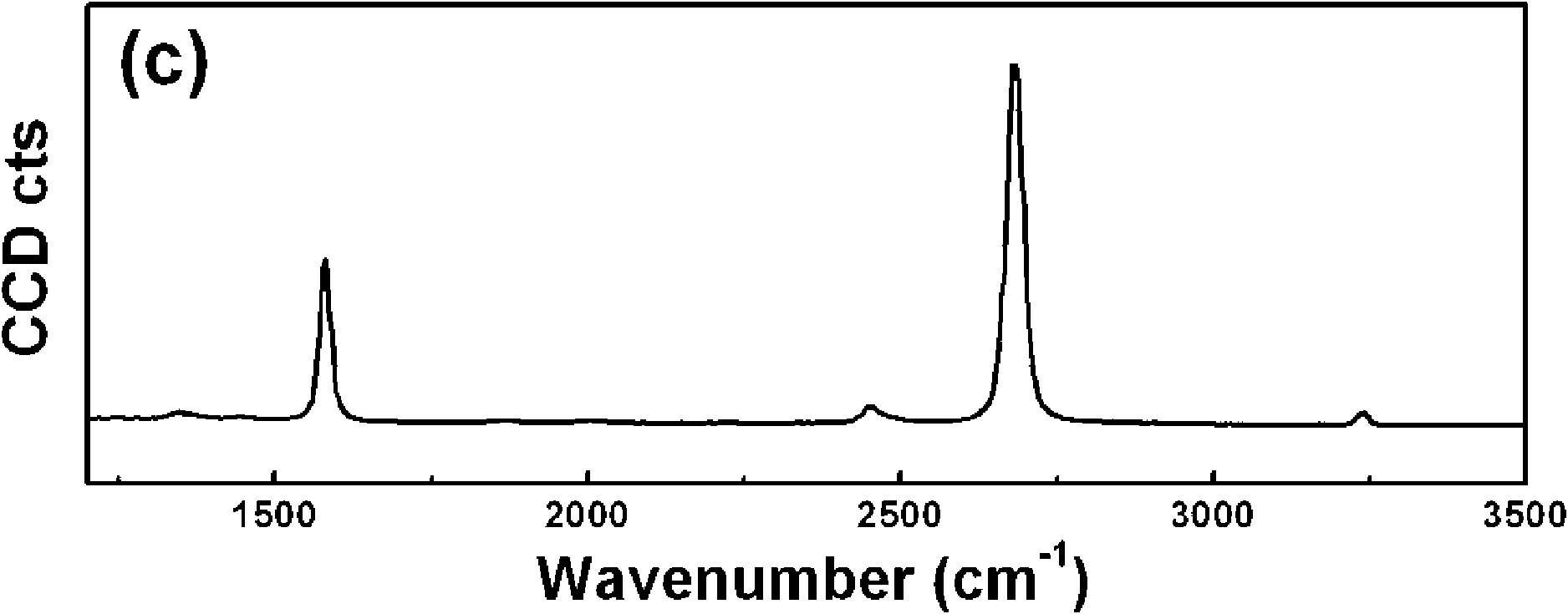

InactiveCN102220566ADefect peak lowImprove crystal qualityMaterial nanotechnologySingle layer grapheneGas phaseCopper foil

The invention discloses a method for preparing single-layer or multi-layer graphene through chemical vapor deposition, and relates to a method for preparing a graphene material. The method comprises the following steps of: placing a metal substrate in a vacuum tubular furnace or a vacuum atmosphere furnace; injecting hydrogen into a vacuum cavity under the situation of removing the oxygen in the vacuum cavity; heating to 800-1,100 DEG C; and injecting a carbon source gas into the vacuum cavity to obtain the metal substrate for depositing graphene. According to the method disclosed by the invention, a graphene film is deposited by cracking methane or other carbon source gases on the metal substrate (such as a copper foil or a nickel foil and the like) at a high temperature by using the chemical vapor deposition method; and therefore, the invention provides a method for preparing the single-layer or multi-layer graphene with an ultra-large area.

Owner:无锡第六元素高科技发展有限公司

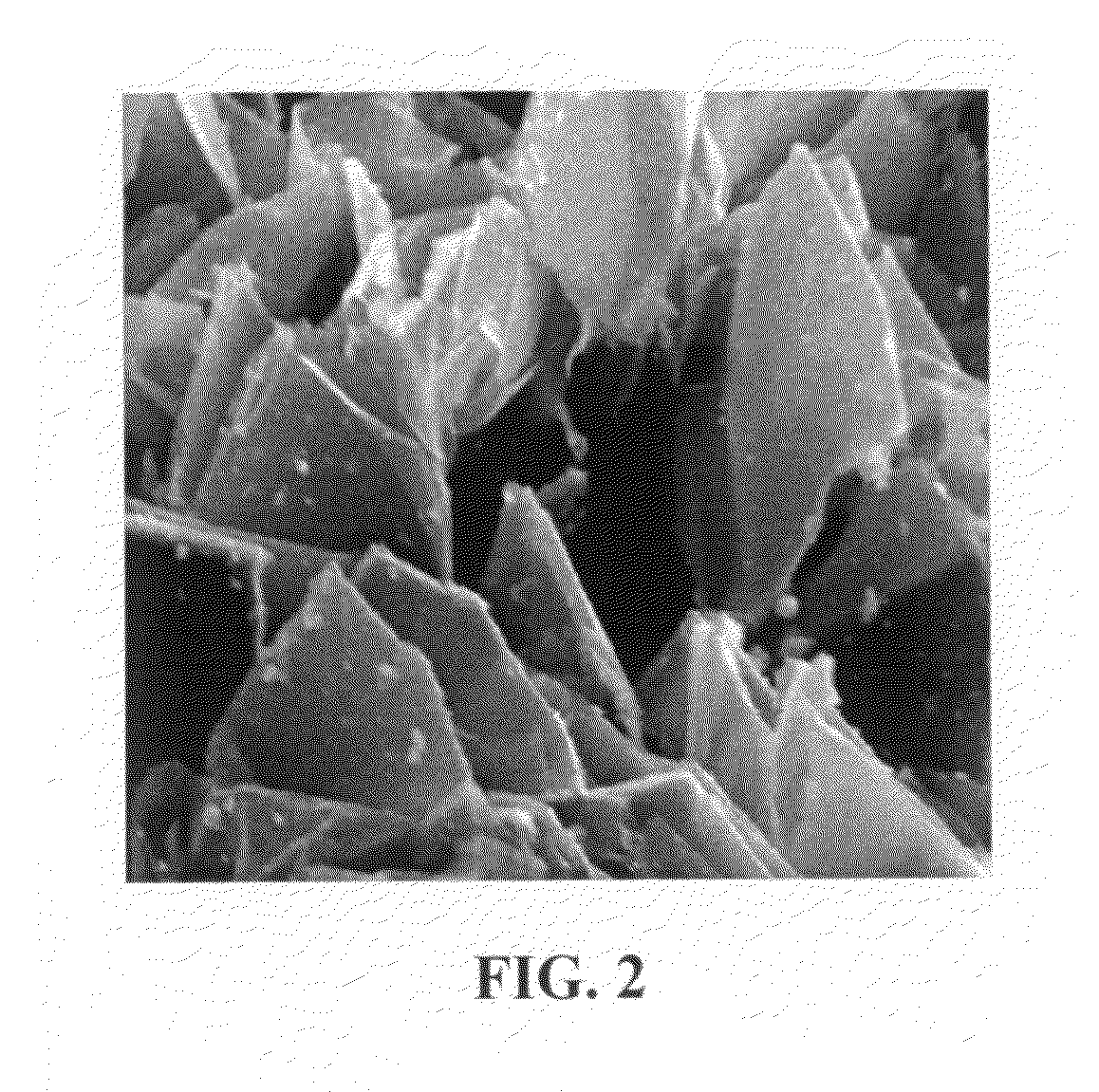

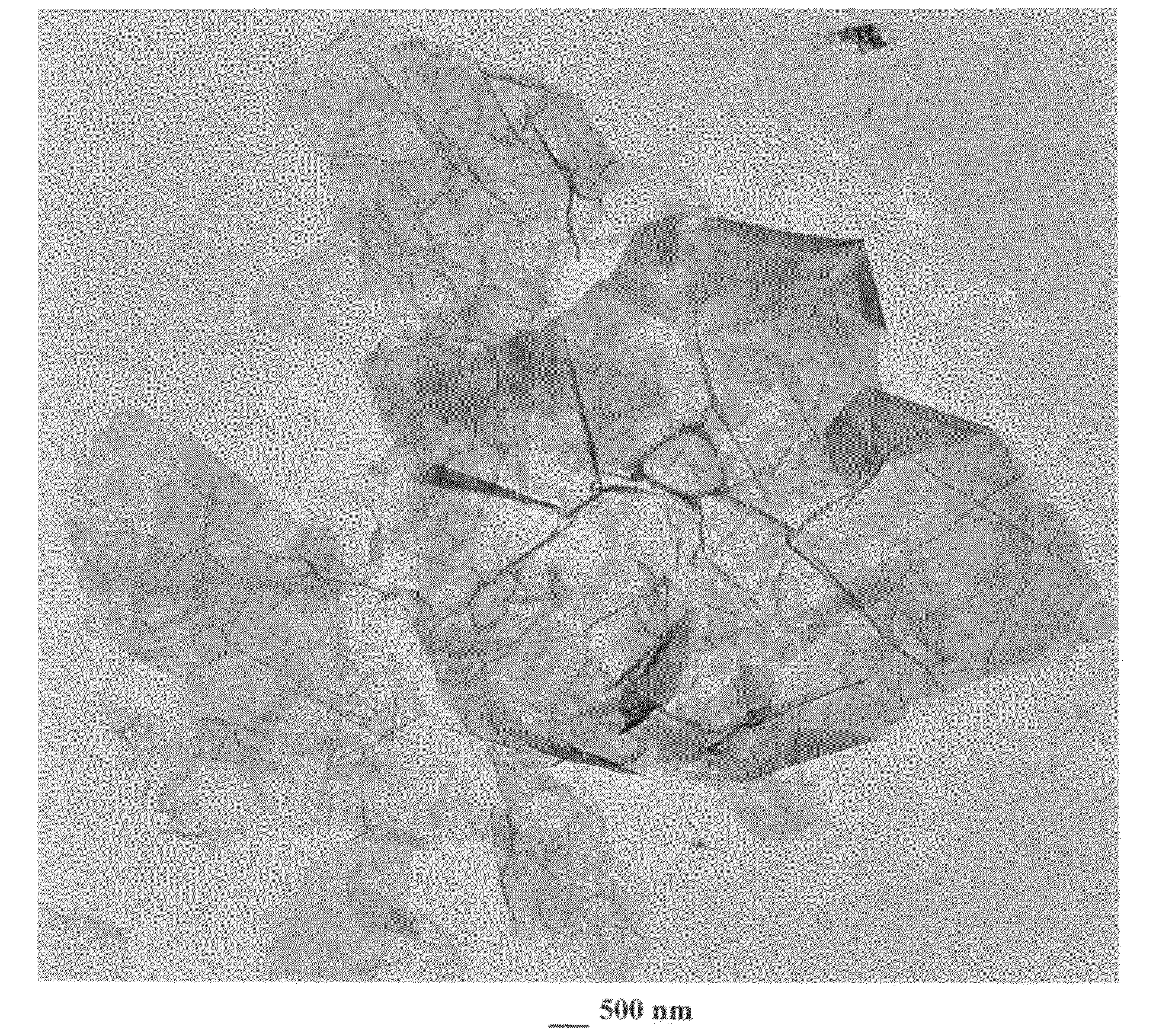

Preparation method of large-size graphene oxide or graphene

ActiveCN105293476ASmall sizeQuality improvementMaterial nanotechnologySingle layer grapheneHigh energyReducing agent

The invention discloses a preparation method of large-size graphene oxide or graphene. The preparation method mainly utilizes graphite as a raw material and comprises that 1, under the action of an intercalator and an expanding agent, graphite fully releases interlayer spaces so that interlayer interaction is reduced and a graphene aggregate is obtained, 2, the graphene aggregate is oxidized by an oxidizing agent, and then the oxidized graphene aggregate is peeled in water under gentle mechanical action so that a large area of a dispersion liquid of graphene oxide is obtained, and 3, the peeled graphene oxide is reduced by a reducer or heat treatment so that high conductivity graphene is obtained. The preparation method utilizes cheap raw materials, has a simple process, can be controlled easily, realizes fast and high efficiency solid-liquid separation, is convenient for industrial large scale production, prevents graphene crystal structure destroy caused by high energy supersonic wave, high speed shearing or fluid crushing. The obtained graphene has a large size and high conductivity and can be popularized and used in fields of high efficiency heat management, flexible display, energy conversion and storage.

Owner:FUDAN UNIV

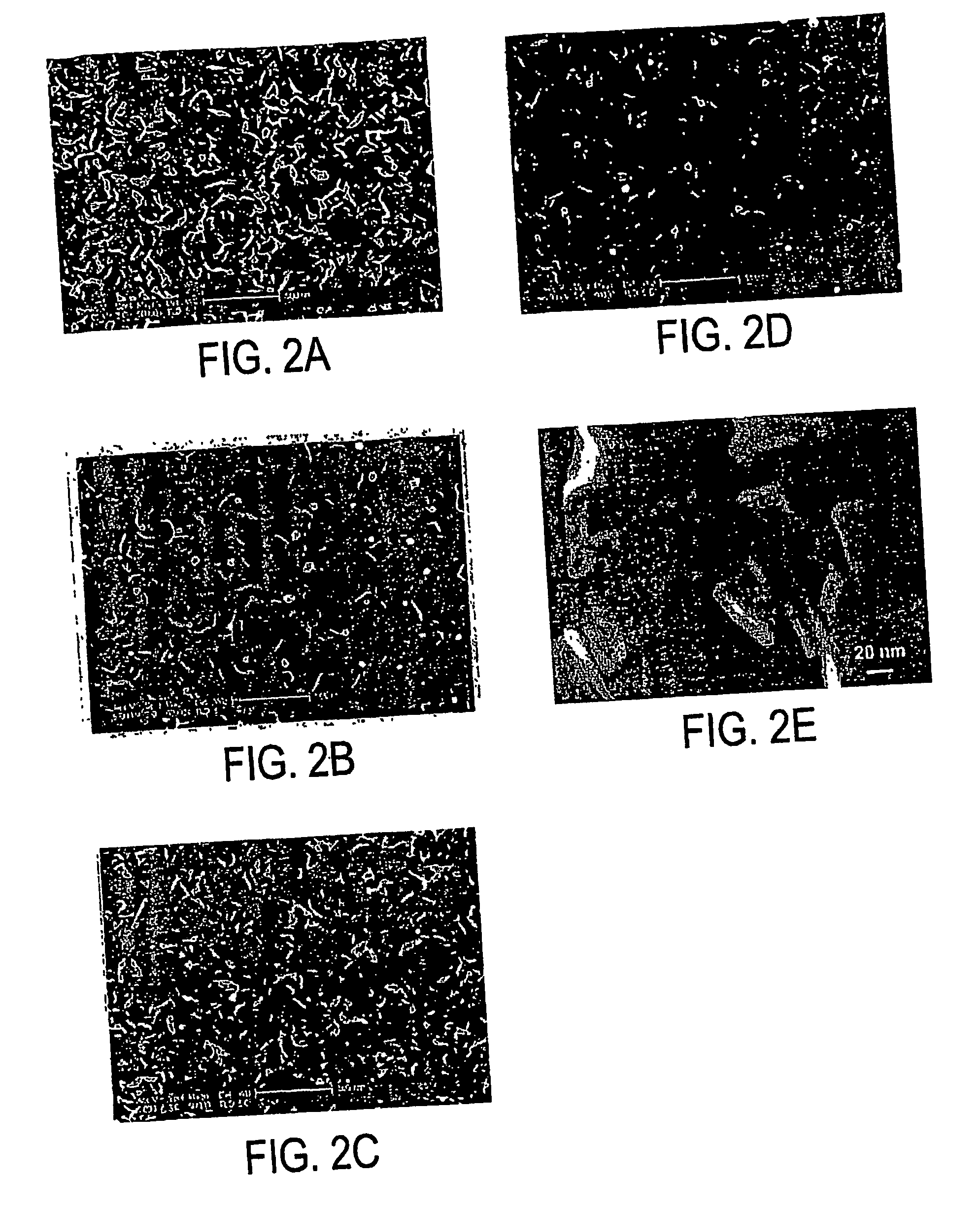

Carbon nanostructures and methods of making and using the same

ActiveUS20090011204A1Material nanotechnologySingle layer grapheneCatalyst supportCarbon nanostructures

Carbon nanoflakes, methods of making the nanoflakes, and applications of the carbon nanoflakes are provided. In some embodiments, the carbon nanoflakes are carbon nanosheets, which are less than 2 nm thick. The carbon nanoflakes may be made using RF-PECVD. Carbon nanoflakes may be useful as field emitters, for hydrogen storage applications, for sensors, and as catalyst supports.

Owner:WILLIAM & MARY COLLEGE OF

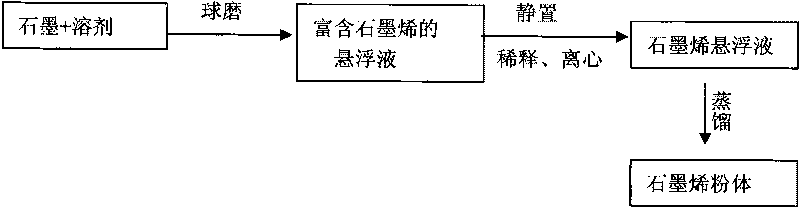

Method for producing graphene

ActiveCN101704520AAvoid damageIncrease frictionMaterial nanotechnologySingle layer grapheneState of artOrganic solvent

The invention discloses a method for producing graphene, which comprises the step that: graphite powder is subjected to wet ball milling in organic solvent, wherein the surface tension of the organic solvent is 30 to 45 mNm-1; and the surface of a milling ball used for the wet ball milling is wrapped with soft polymer. After adopting the scheme, the method selects and uses a ball milling process widely applied in the actual production to peel off graphite. Compared with the prior art, the method has the following advantages that: 1) the damage of rigid collision between the milling balls to the graphite crystal structure is effectively reduced by adopting the soft polymer to wrap the hard milling balls, meanwhile, the soft polymer has stronger friction force with the graphite so as to greatly improve the milling and peeling effects, and the yield of the graphene can reach 30 to 50 weight percent; 2) the adopted ball milling process is easier to expand the scale and implement industrialized production; 3) except little defect at the edge part, the graphene crystal structure is kept intact; and 4) the graphene product has even thickness which is kept between 1 and 2 carbon atom layers.

Owner:HUAQIAO UNIVERSITY +1

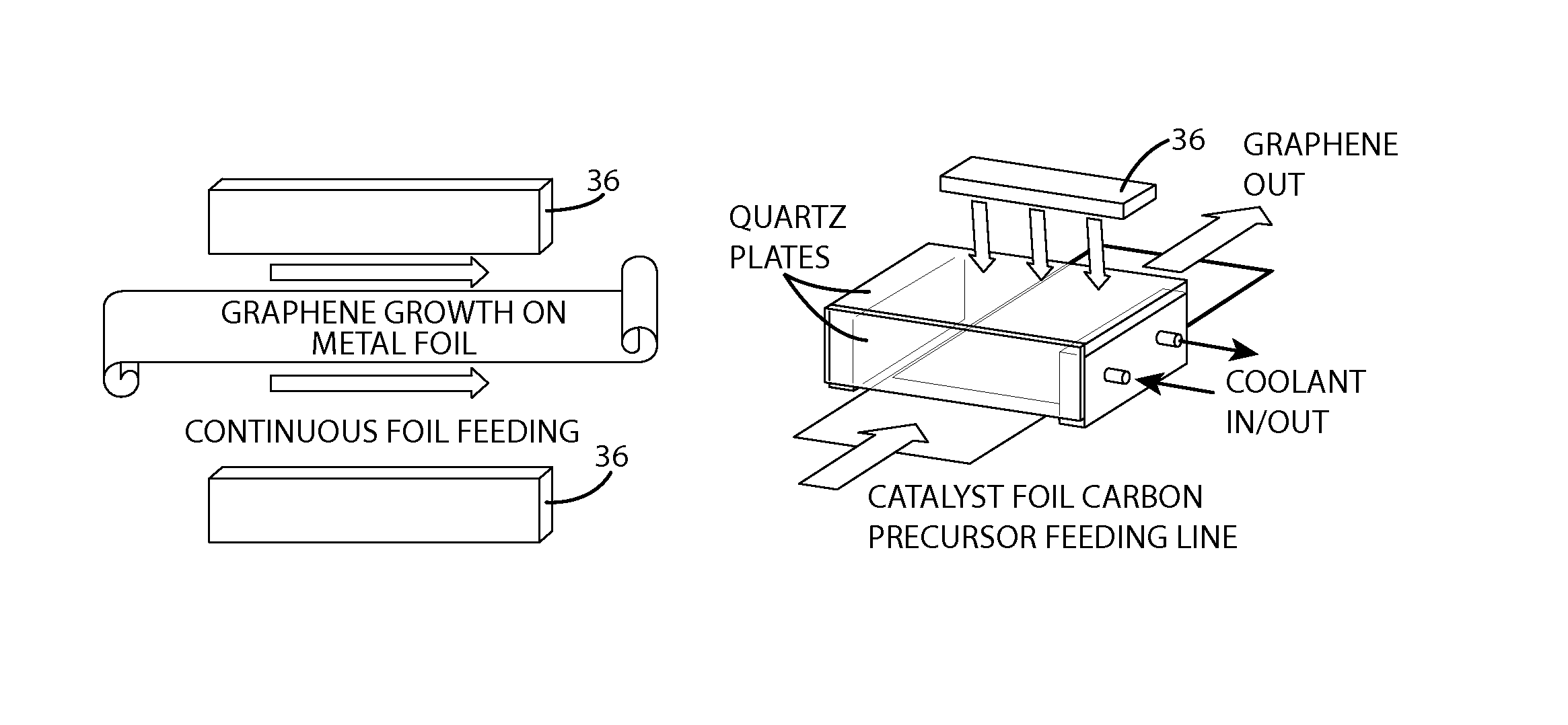

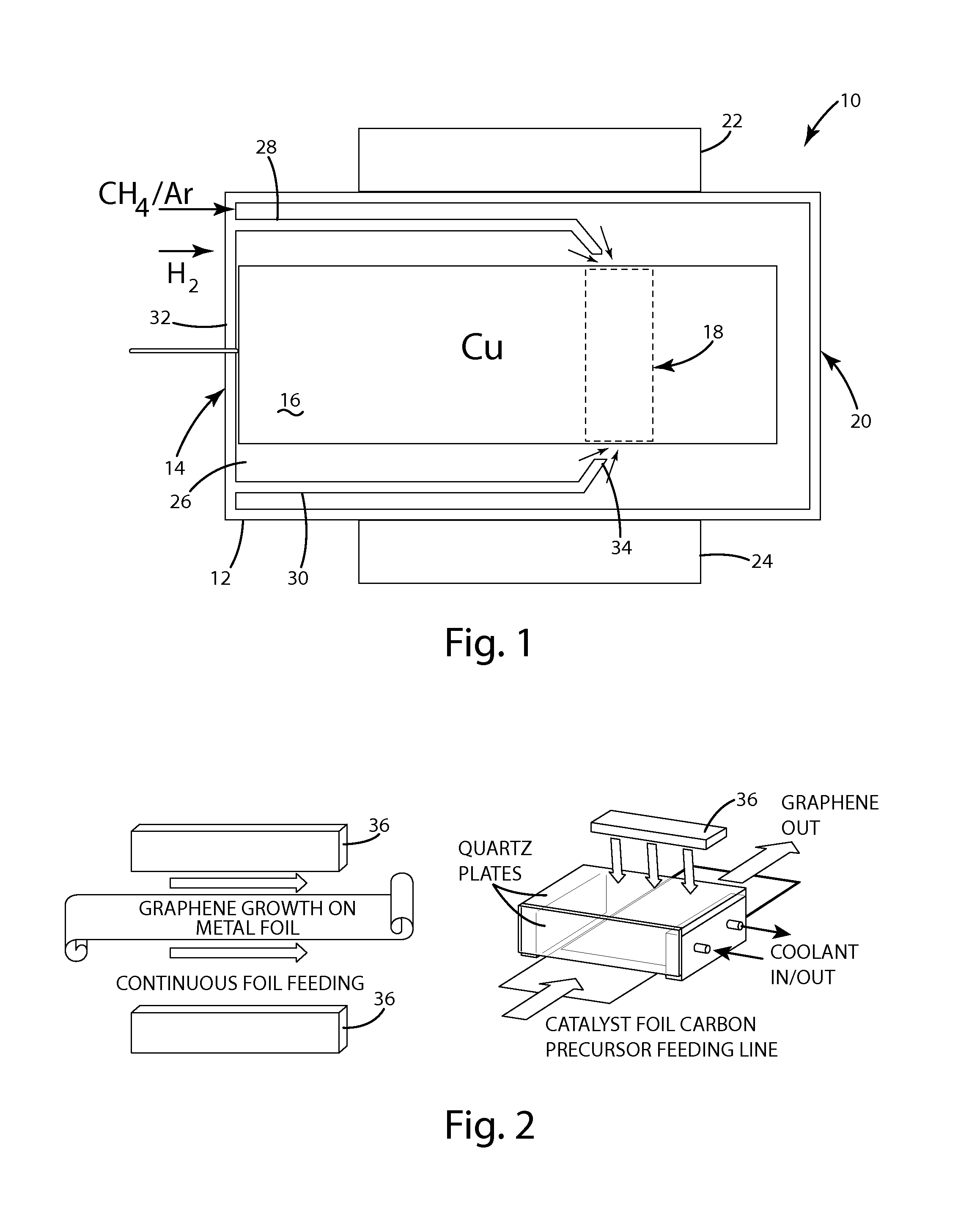

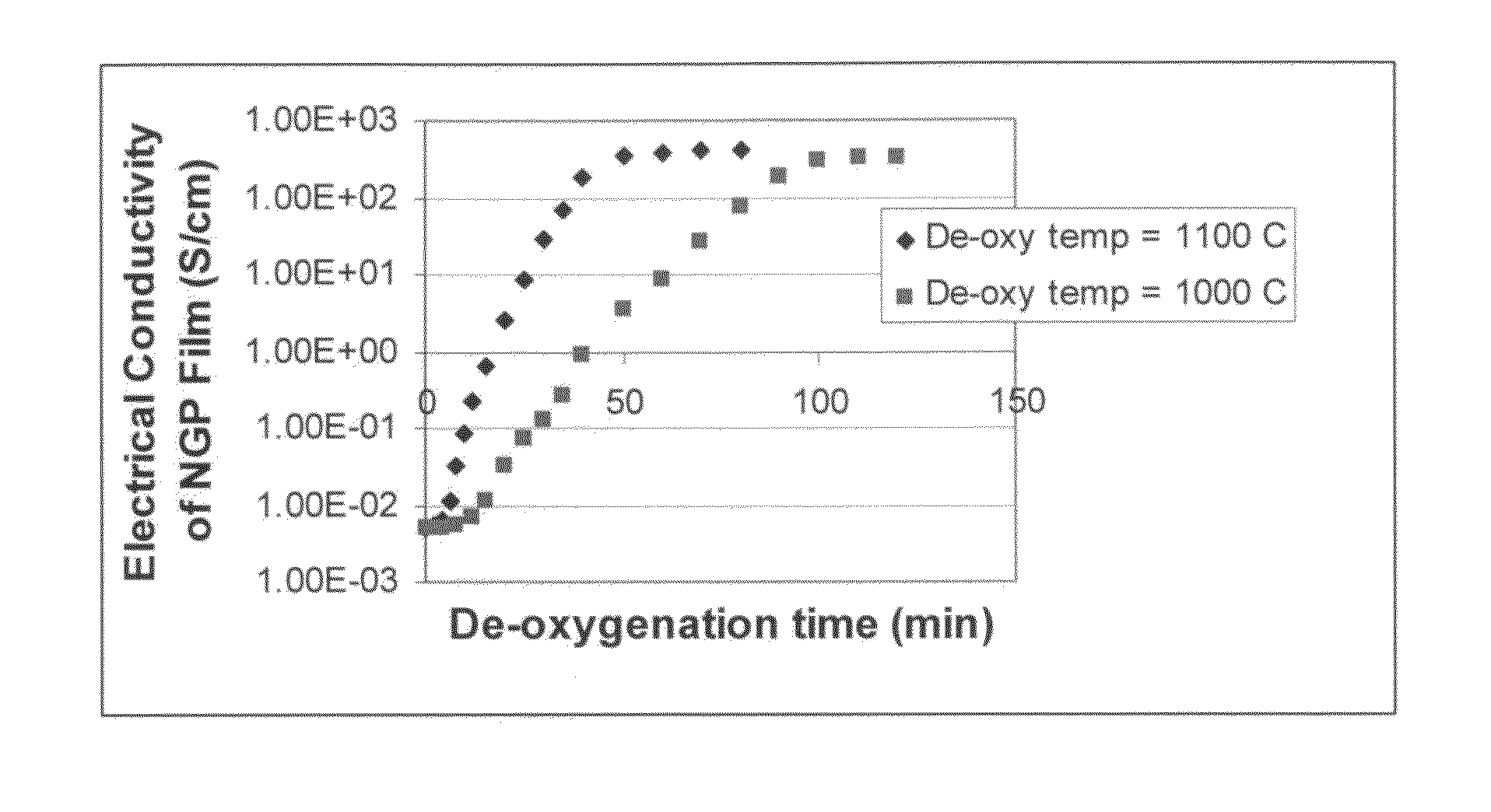

High quality large scale single and multilayer graphene production by chemical vapor deposition

ActiveUS20130174968A1Reduce manufacturing costShorten production timeMaterial nanotechnologySingle layer grapheneNoble gasGas phase

Systems and methods for synthesizing continuous graphene sheets are provided. The systems and methods include passing a catalyst substrate through a heated chemical vapor deposition chamber and exposing the substrate to a reaction gas mixture of hydrogen and hydrocarbon at a preselected location within the chamber. The reaction gas mixture can include hydrogen having a partial pressure of between about 0 Torr and 20 Torr, hydrocarbon having a partial pressure of between about 20 mTorr and about 10 Torr, and one or more buffer gases. The buffer gases can include argon or other noble gases to maintain atmospheric pressure within the chemical deposition chamber. The resulting graphene can be made with continuous mono and multilayers (up to six layers) and have single crystalline hexagonal grains with a preselected nucleation density and domain size for a range of applications.

Owner:UT BATTELLE LLC

Process for producing dispersible nano graphene platelets from oxidized graphite

The present invention provides a process for producing nano graphene platelets (NGPs) that are dispersible and conducting. The process comprises: (a) preparing a graphite intercalation compound (GIC) or graphite oxide (GO) from a laminar graphite material; (b) exposing the GIC or GO to a first temperature for a first period of time to obtain exfoliated graphite; and (c) exposing the exfoliated graphite to a second temperature in a protective atmosphere for a second period of time to obtain the desired dispersible nano graphene platelet with an oxygen content no greater than 25% by weight, preferably below 20% by weight, further preferably between 5% and 20% by weight. Conductive NGPs can find applications in transparent electrodes for solar cells or flat panel displays, additives for battery and supercapacitor electrodes, conductive nanocomposite for electromagnetic wave interference (EMI) shielding and static charge dissipation, etc.

Owner:GLOBAL GRAPHENE GRP INC

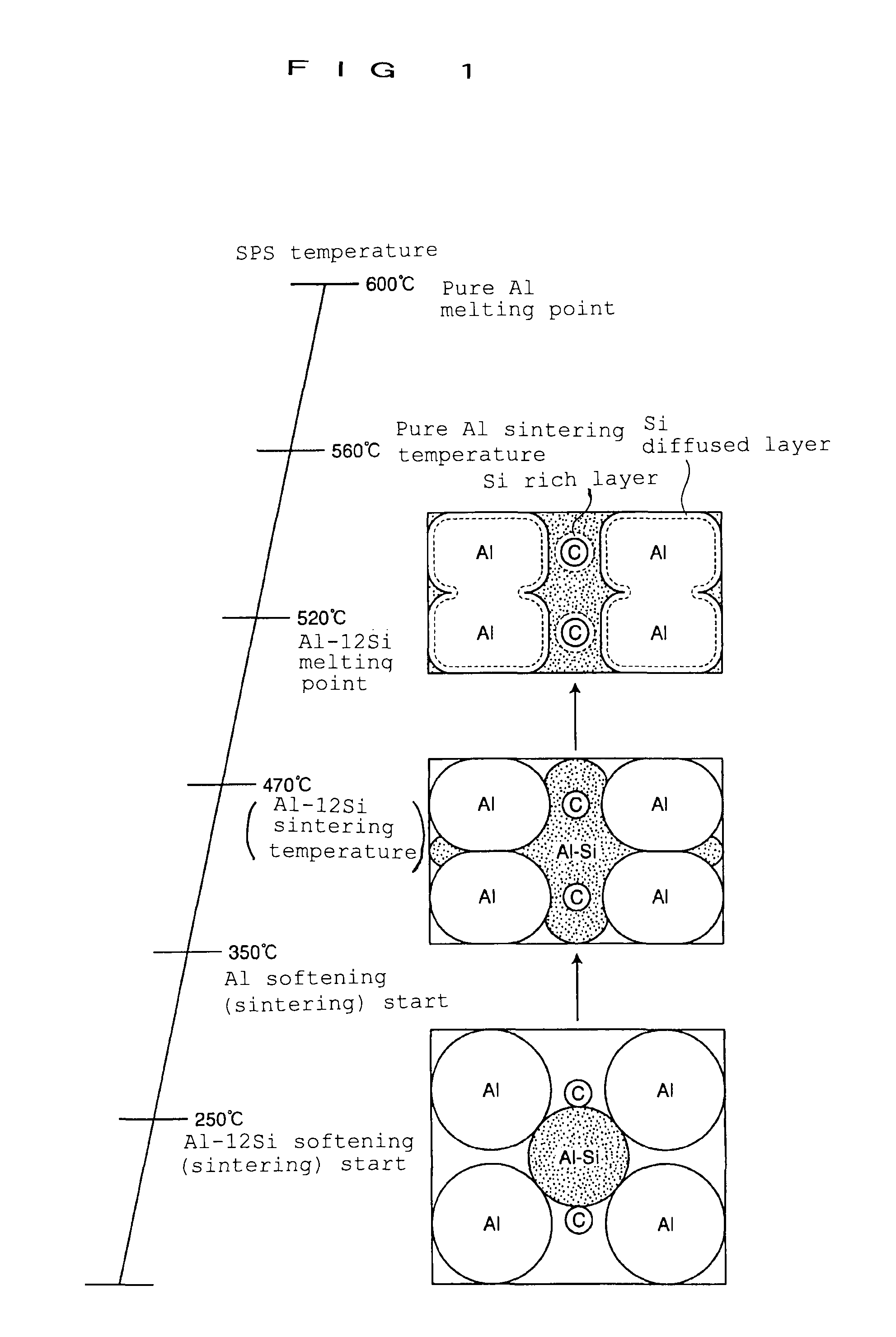

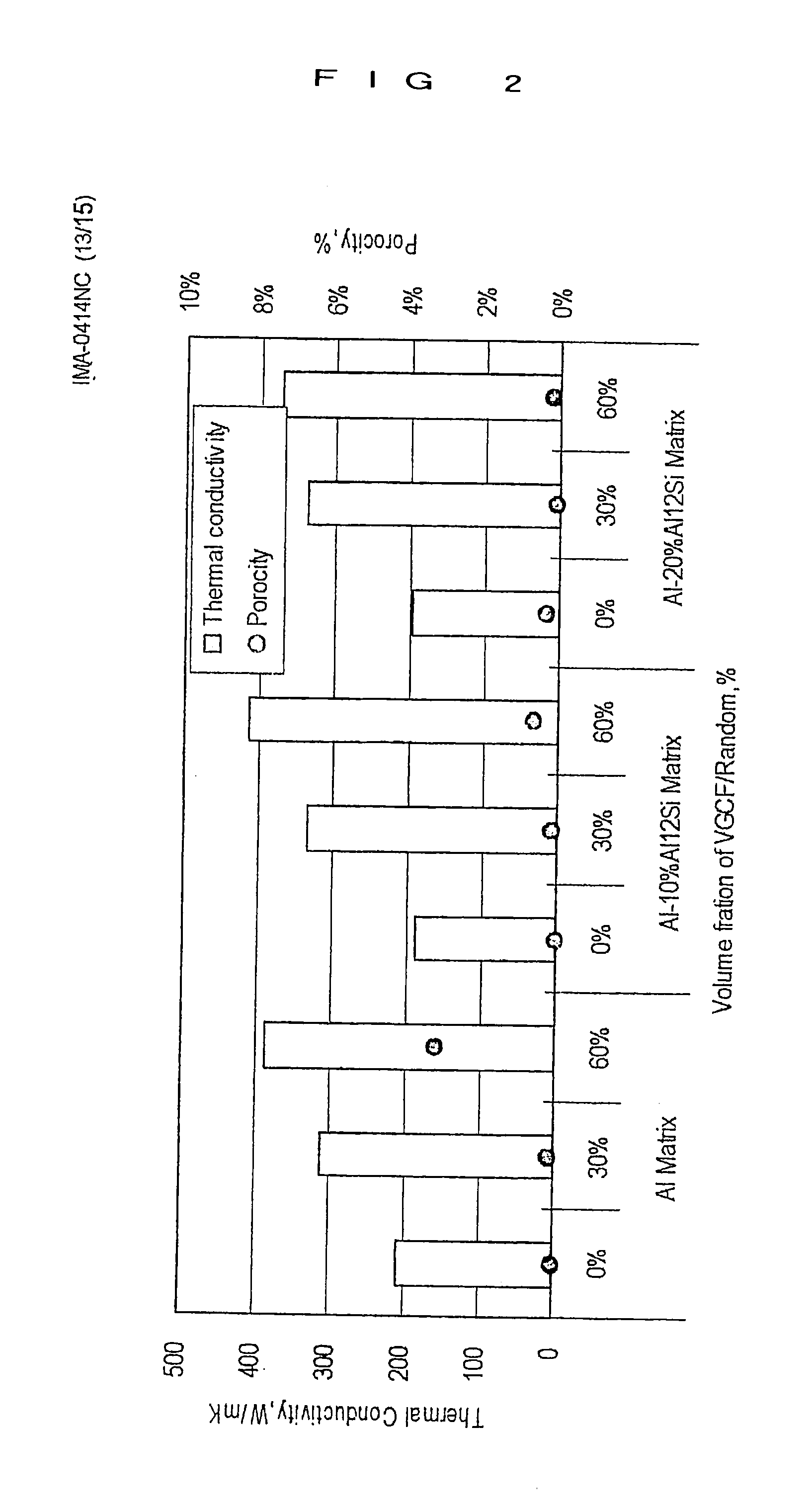

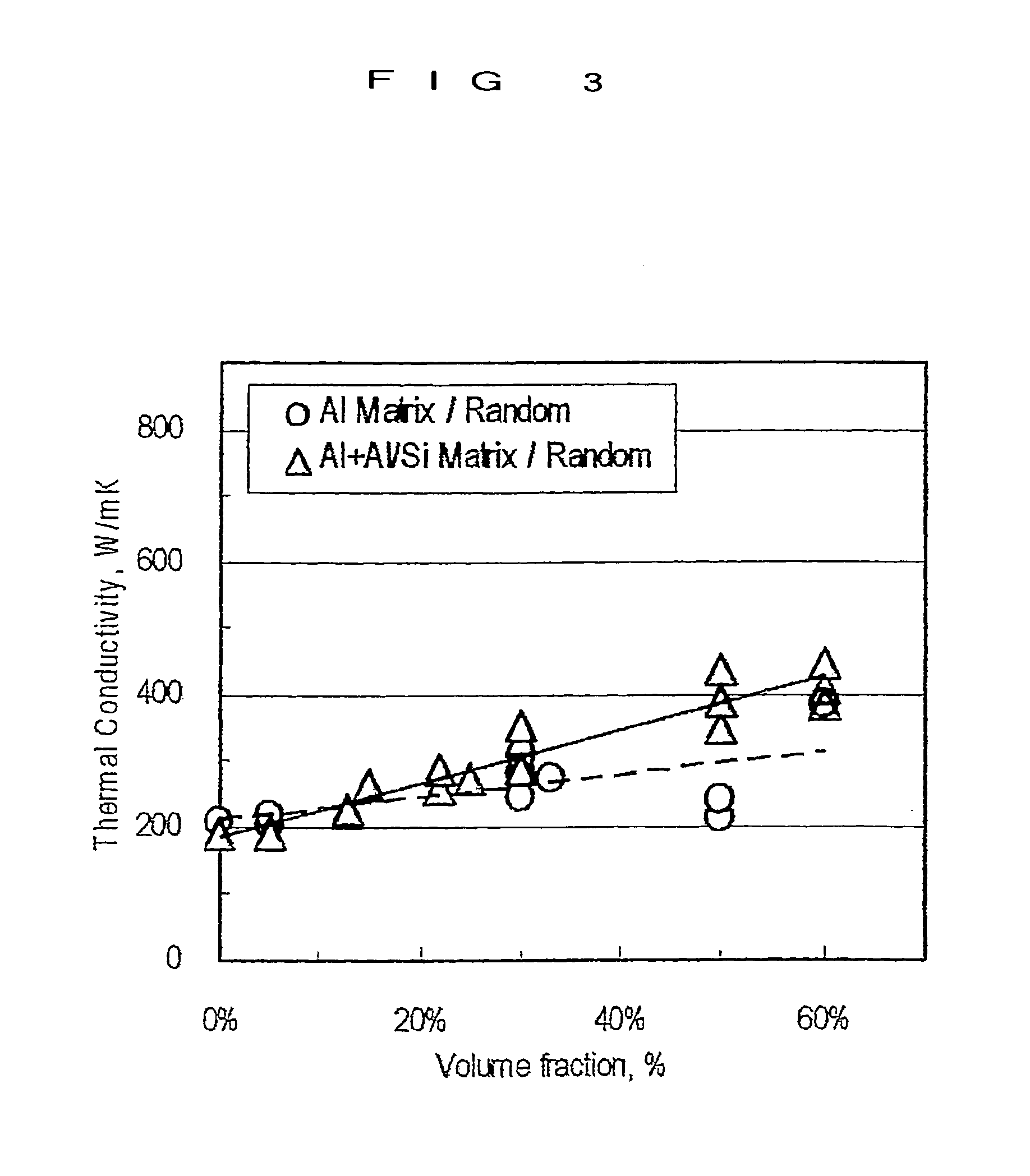

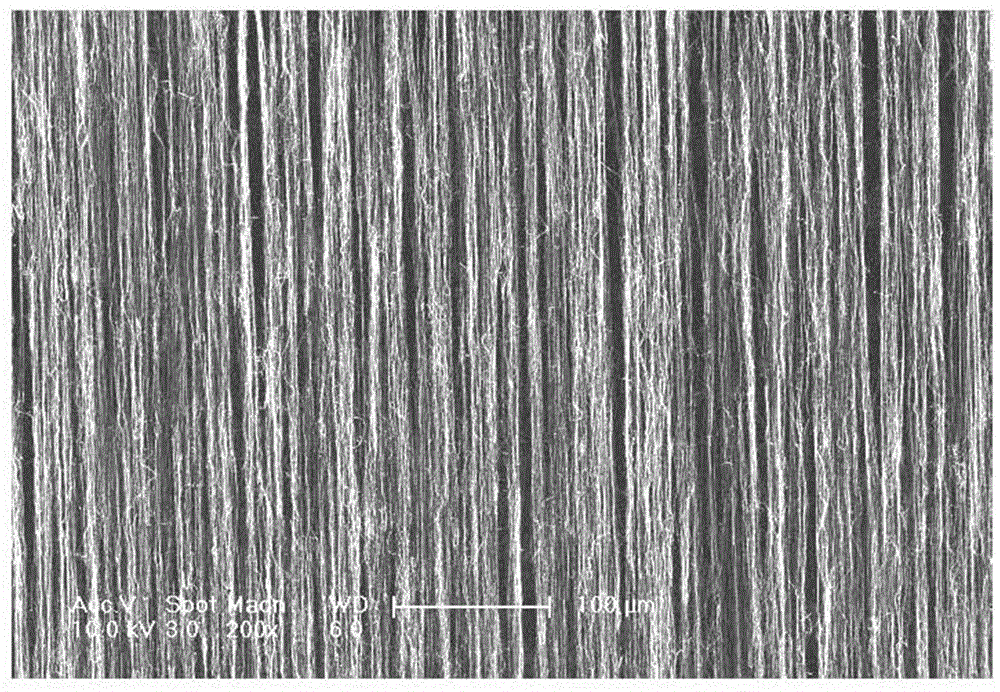

Highly heat-conductive composite material

InactiveUS8163060B2Improve the heating effectIncrease resistanceSingle layer grapheneAluminium powderAlloy

The heat conductivity of an aluminum composite material containing a fibrous carbon material is enhanced. In order to realize this, a spark plasma sintered body having a fibrous carbon material compounded in a metal matrix powder of aluminum or the like is fabricated. At the time of fabrication, an aluminum powder serving as a matrix mother material is compounded with an Al alloy powder such as an Al-12Si powder having a melting point lower than the sintering temperature of the mother material. During the process of sintering the aluminum powder, the Al alloy powder is melted, whereby the heat conductivity between the aluminum powder particles and between the aluminum powder particle and the fibrous carbon material is improved.

Owner:SUMITOMO PRECISION PROD CO LTD +1

Mass production of nano-scaled platelets and products

ActiveUS20100222482A1Time necessarySmall thicknessMaterial nanotechnologyGraphiteNoble gasProduct gas

Owner:GLOBAL GRAPHENE GRP INC

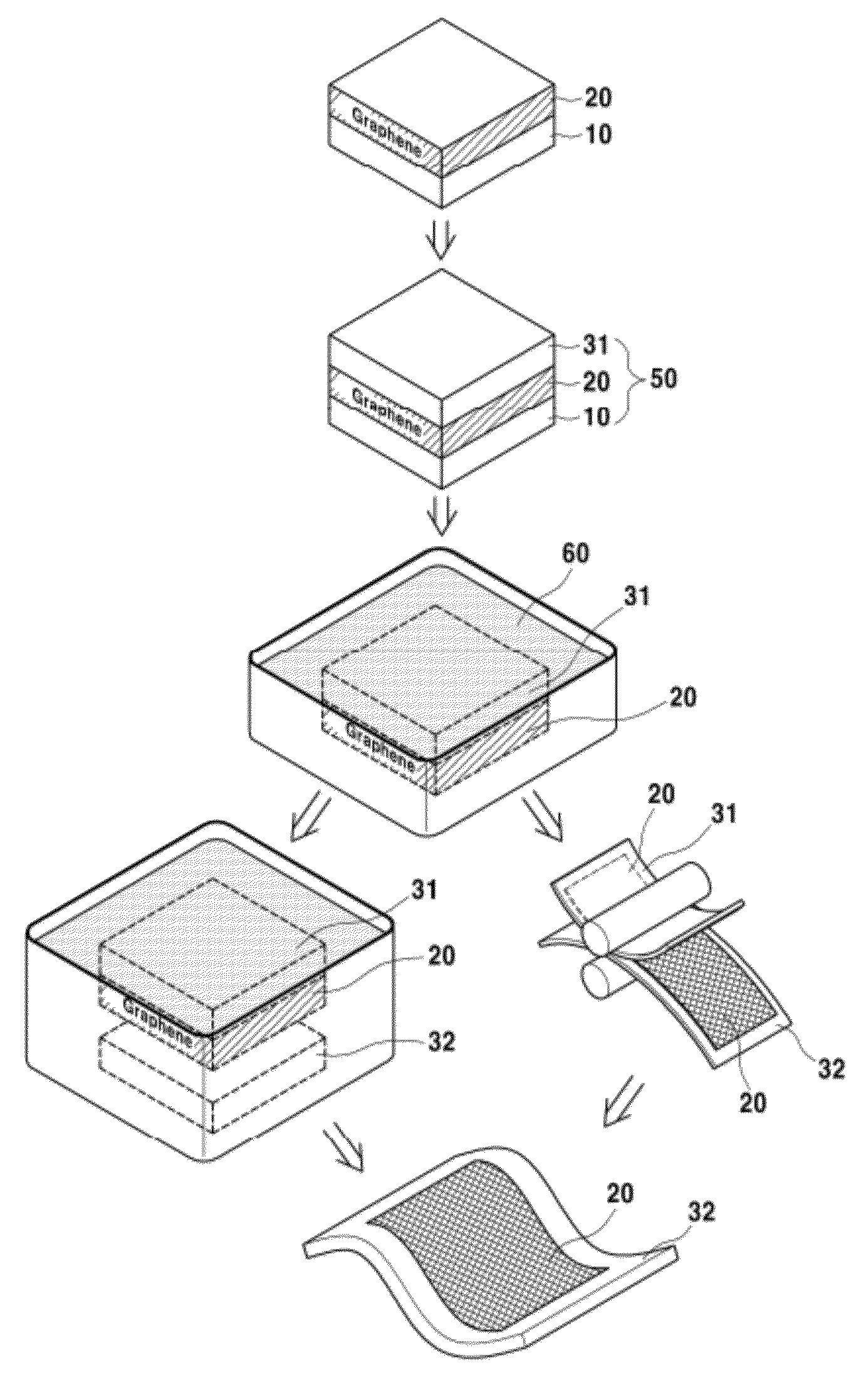

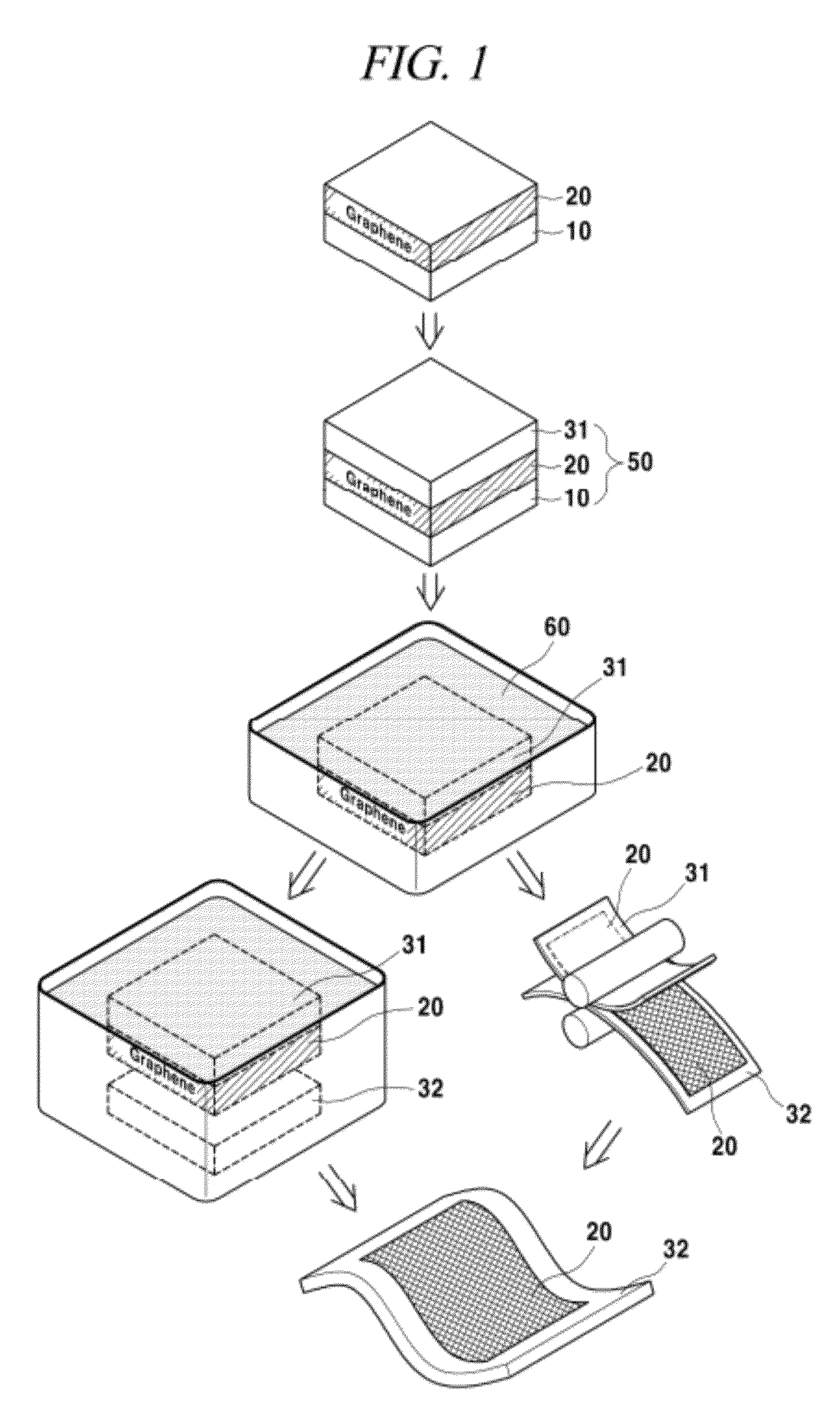

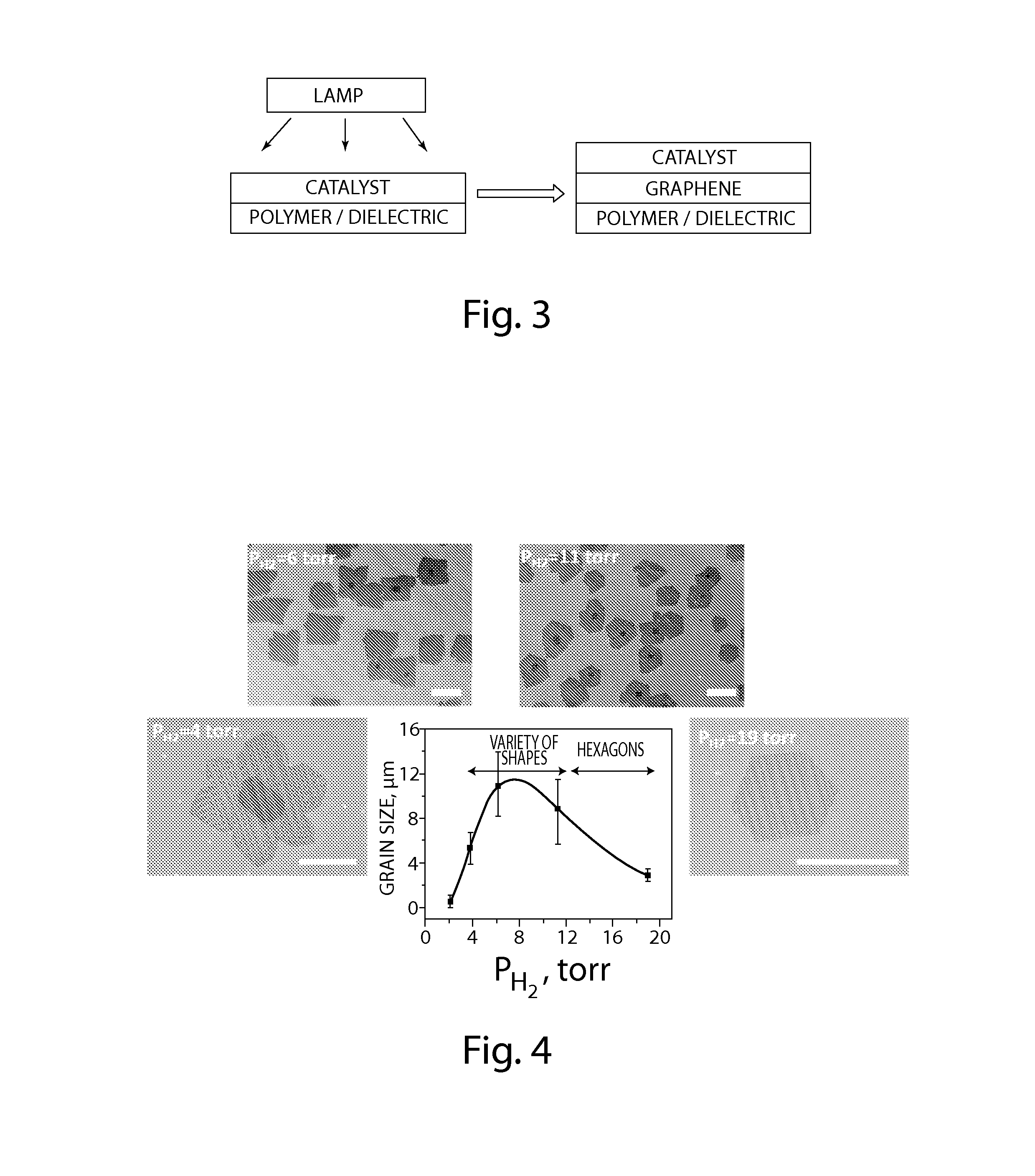

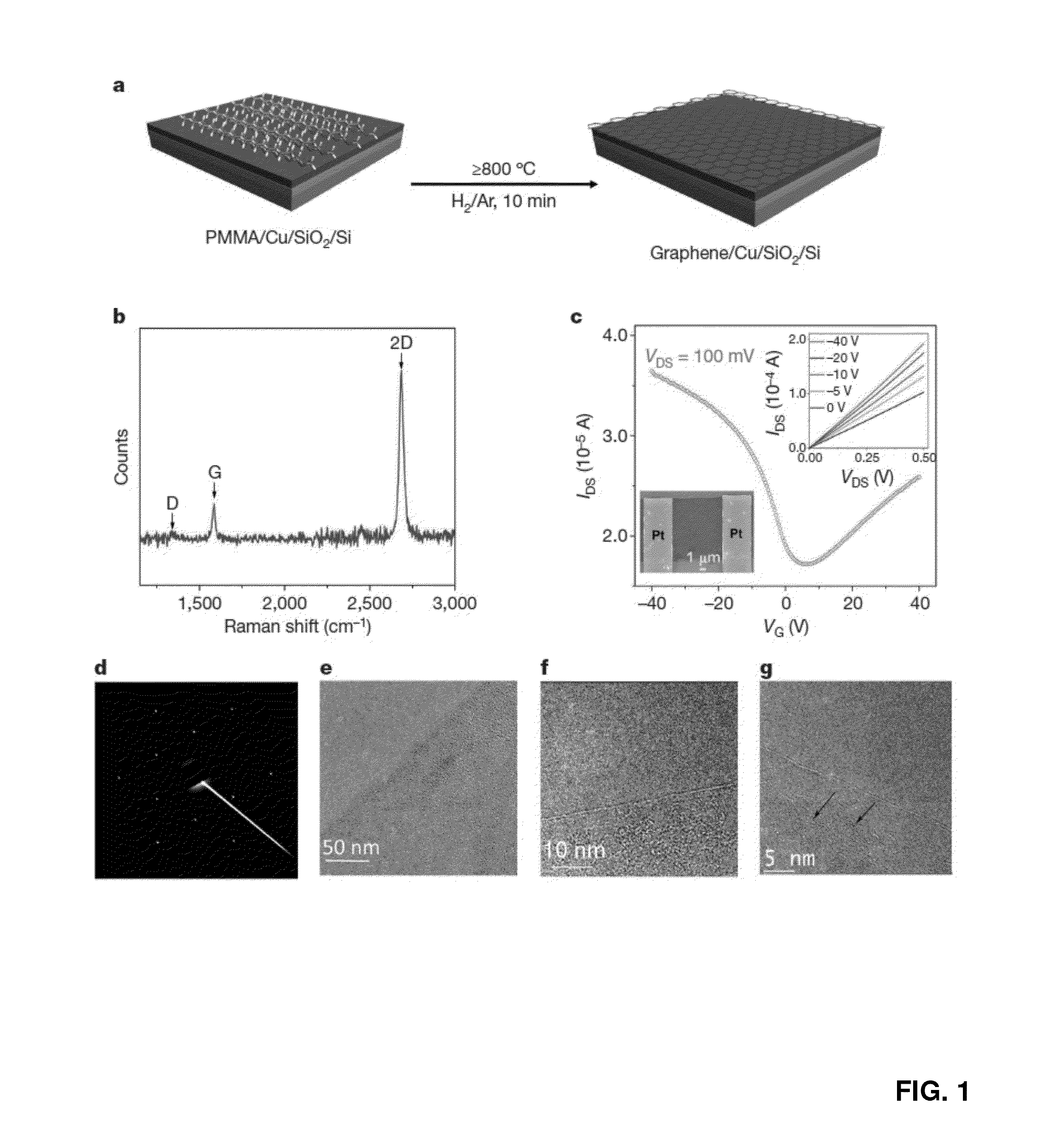

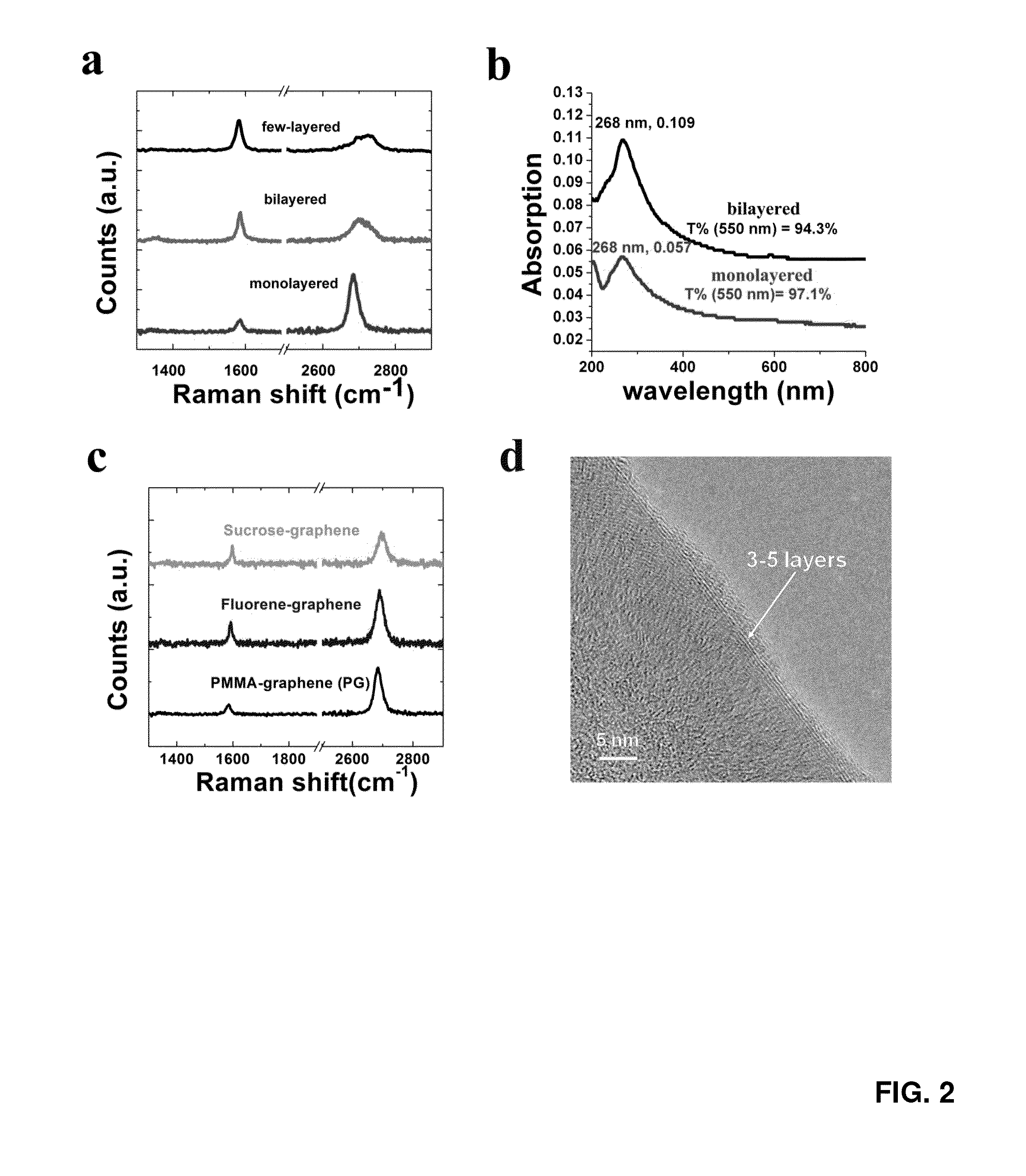

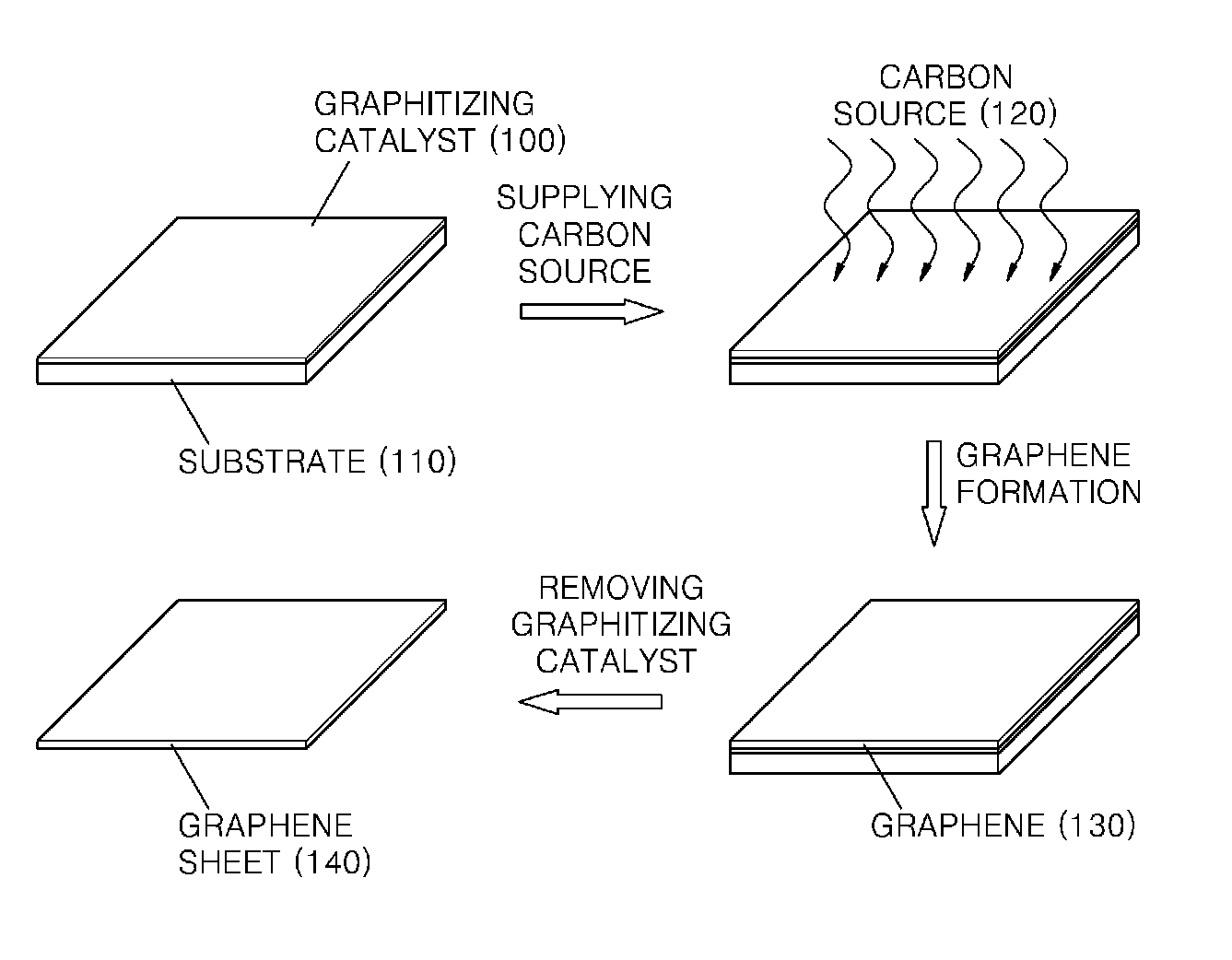

Growth of graphene films from non-gaseous carbon sources

ActiveUS20140234200A1Reduce defectsReduce sheet resistanceSingle layer grapheneGrapheneCarbon source

In various embodiments, the present disclosure provides methods of forming graphene films by: (1) depositing a non-gaseous carbon source onto a catalyst surface; (2) exposing the non-gaseous carbon source to at least one gas with a flow rate; and (3) initiating the conversion of the non-gaseous carbon source to the graphene film, where the thickness of the graphene film is controllable by the gas flow rate. Additional embodiments of the present disclosure pertain to graphene films made in accordance with the methods of the present disclosure.

Owner:RICE UNIV

Method of preparing carbon thin film, electronics comprising carbon thin film, and electrochemical device comprising carbon thin film

Owner:POSTECH ACAD IND FOUND

High-throughput solution processing of large scale graphene and device applications

A method of producing carbon macro-molecular structures includes dissolving a graphitic material in a solvent to provide a suspension of carbon-based macro-molecular structures in the solvent, and obtaining a plurality of the carbon macro-molecular structures from the suspension. The plurality of carbon macro-molecular structures obtained from the suspension each consists essentially of carbon. A material according to some embodiments of the current invention is produced according to the method of producing carbon macro-molecular structures. An electrical, electronic or electro-optic device includes material produced according to the methods of the current invention. A composite material according to some embodiments of the current invention has carbon macro-molecular structures produced according to methods of producing carbon macro-molecular structures according to some embodiments of the current invention. A hydrogen storage device according to some embodiments of the current invention has carbon macro-molecular structures produced according to methods of producing carbon macro-molecular structures according to some embodiments of the current invention. An electrode according to some embodiments of the current invention has carbon macro-molecular structures produced according to methods of producing carbon macro-molecular structures according to some embodiments of the current invention.

Owner:RGT UNIV OF CALIFORNIA

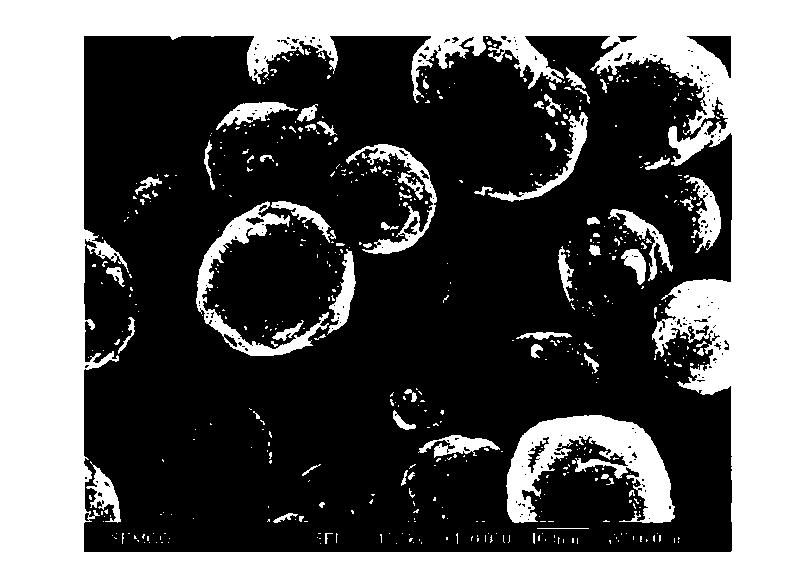

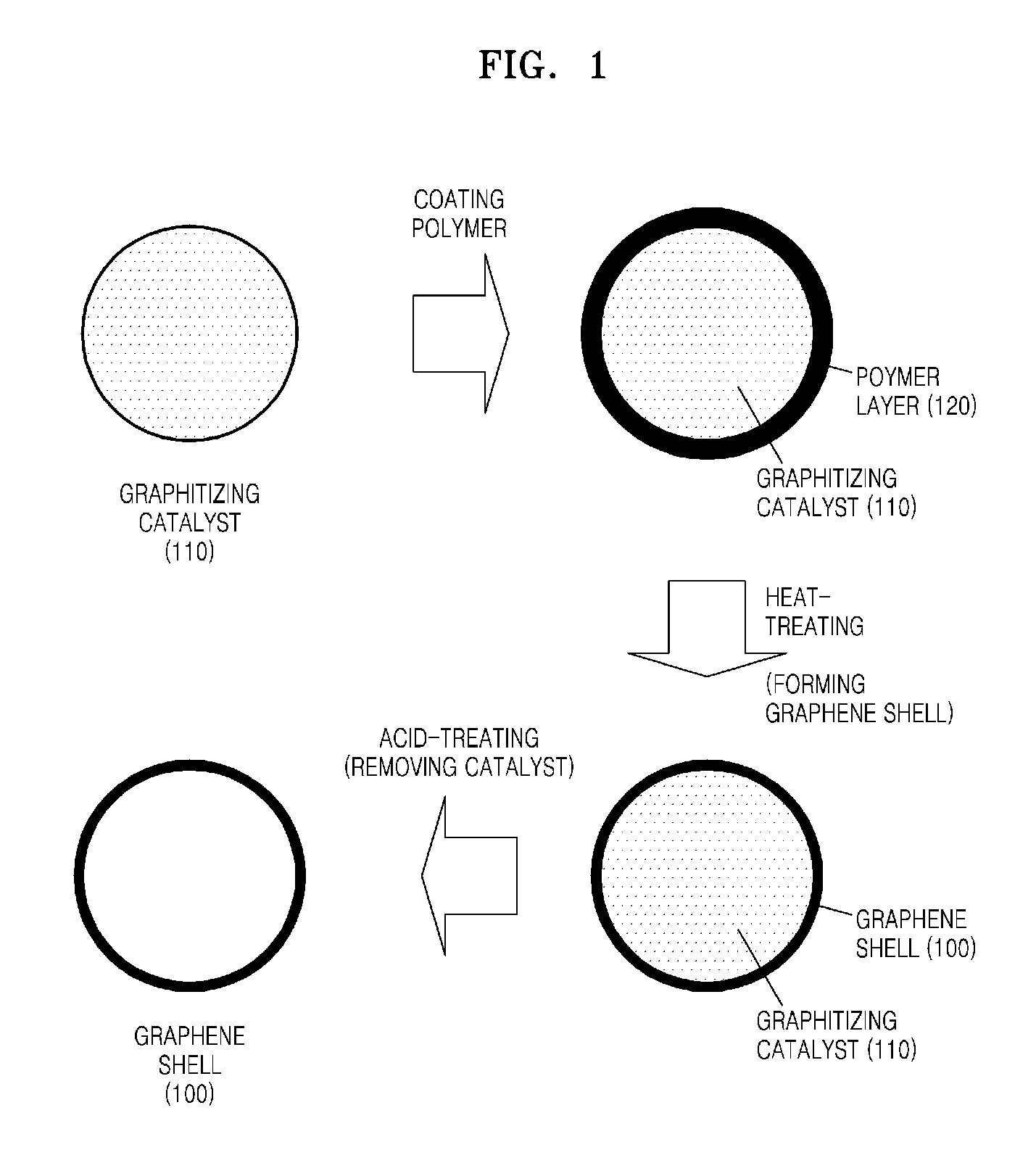

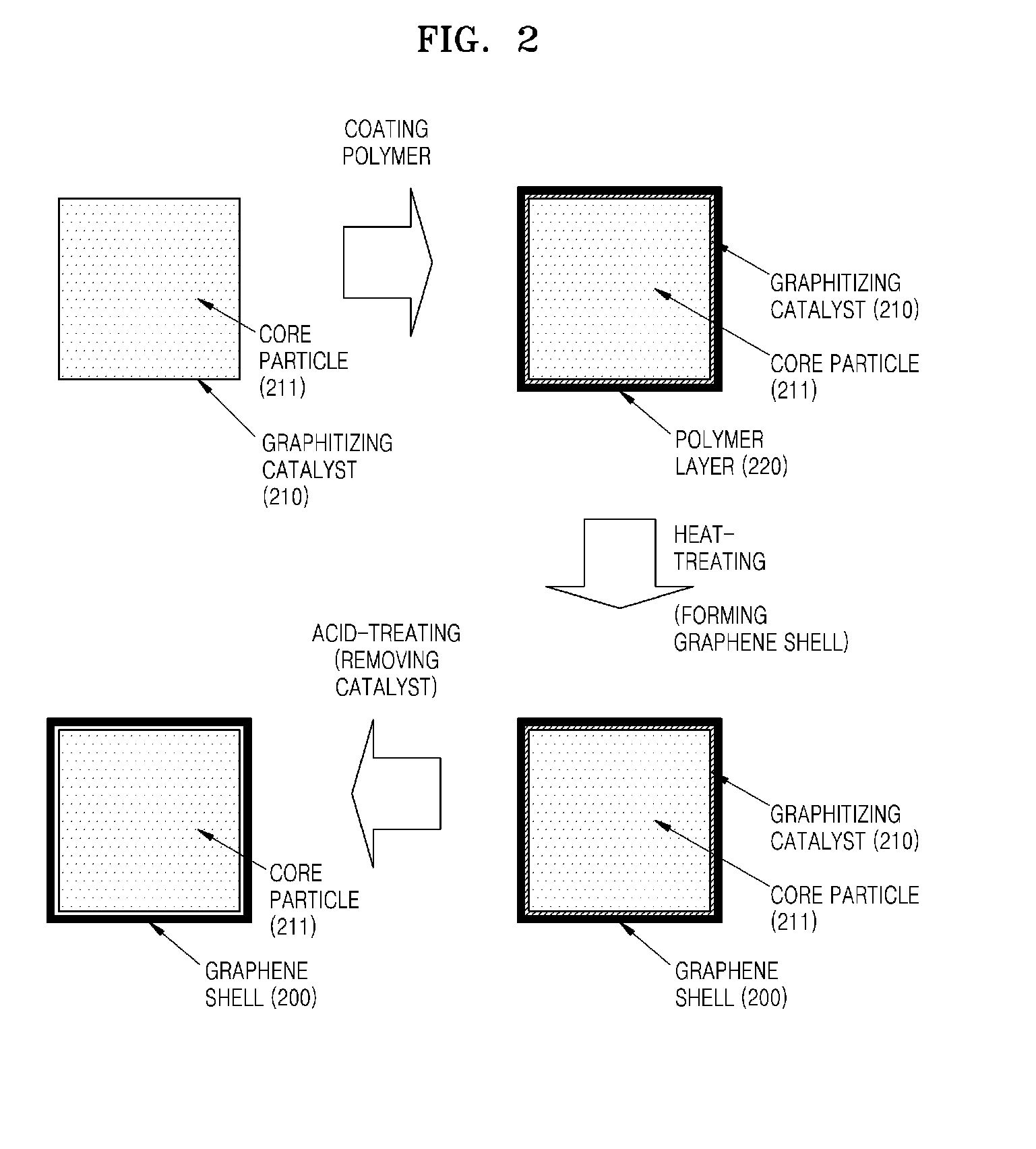

Graphene shell and process of preparing the same

ActiveUS20090068470A1Control thicknessMaterial nanotechnologySingle layer graphenePolymer scienceGraphene

Owner:SAMSUNG ELECTRONICS CO LTD

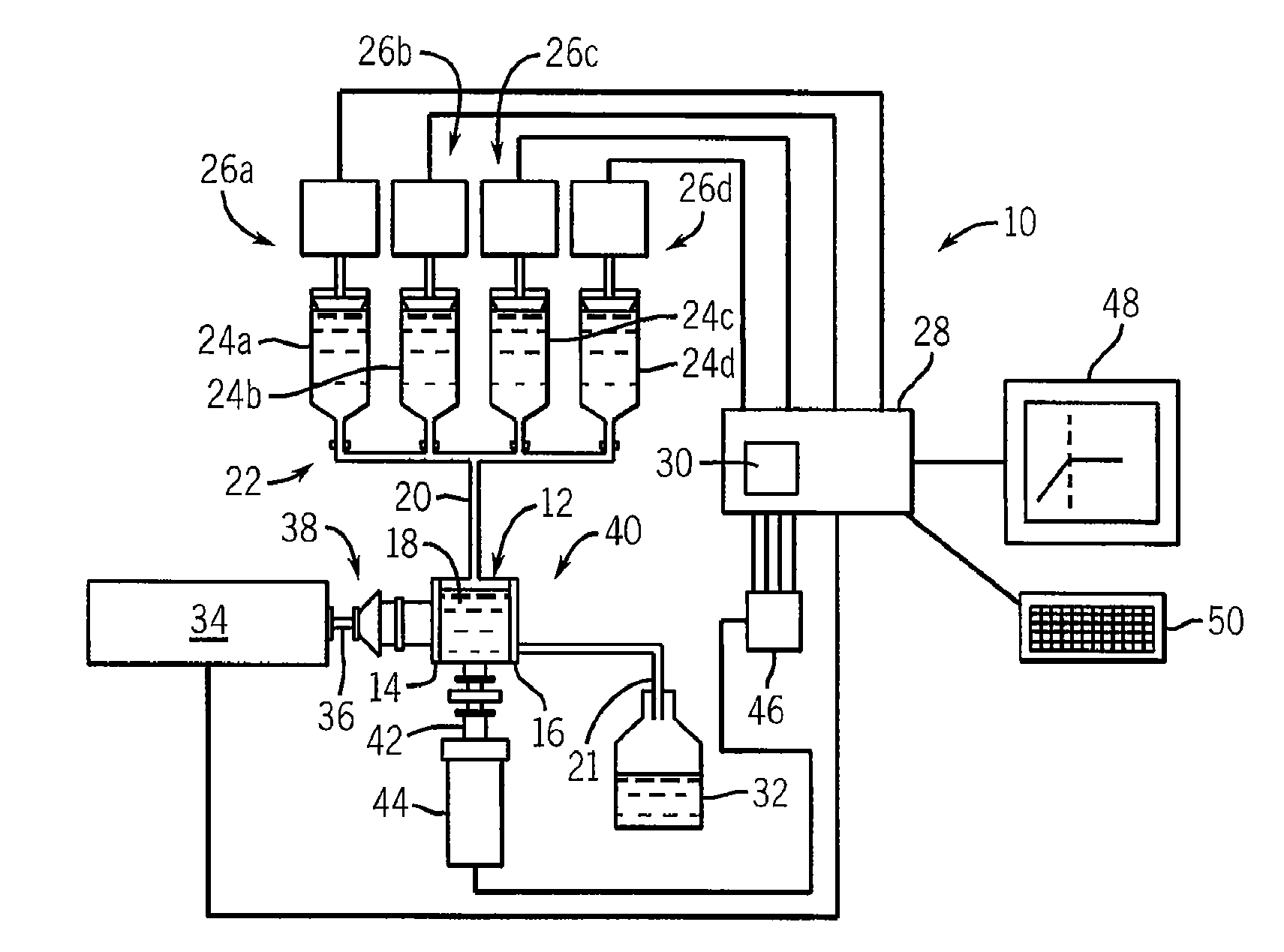

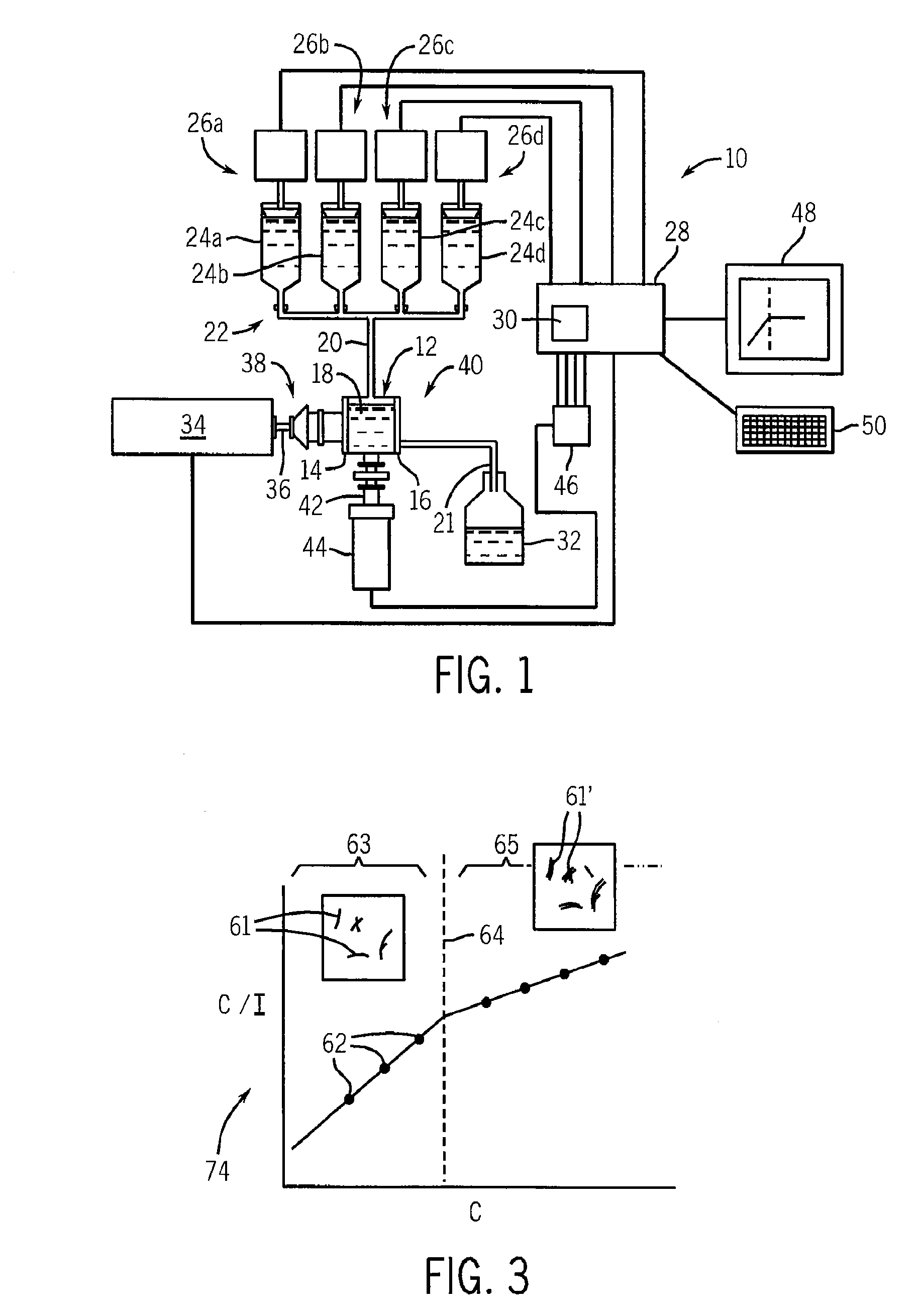

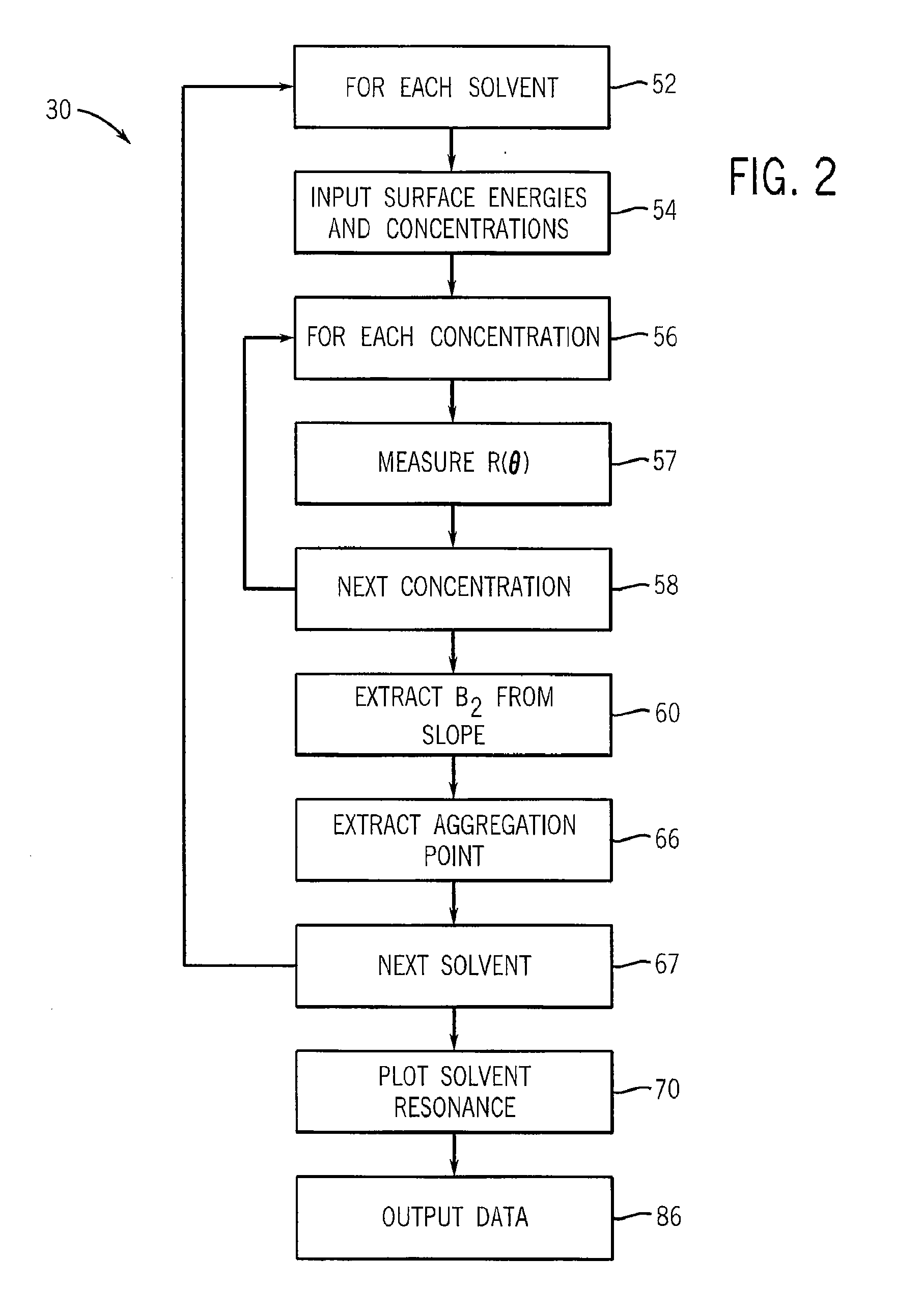

Method And Apparatus For Identifying And Characterizing Material Solvents And Composited Matrices And Methods Of Using Same

ActiveUS20110117361A1High composite strengthMaterial nanotechnologyElectrode manufacturing processesRayleigh scatteringRayleigh Light Scattering

Solvents for macromolecules generally believed to be insoluble in their pristine form are identified by generation of a ‘solvent resonance’ in the relationship between solvent quality (deduced by Rayleigh scattering) and an intrinsic property of solvents. A local extreme of the solvent resonance identifies the ideal intrinsic property of an ideal solvent which may then be used to select a particular solvent or solvent combination. A solvent for graphene is used in the production of transparent conductive electrodes.

Owner:WISYS TECH FOUND

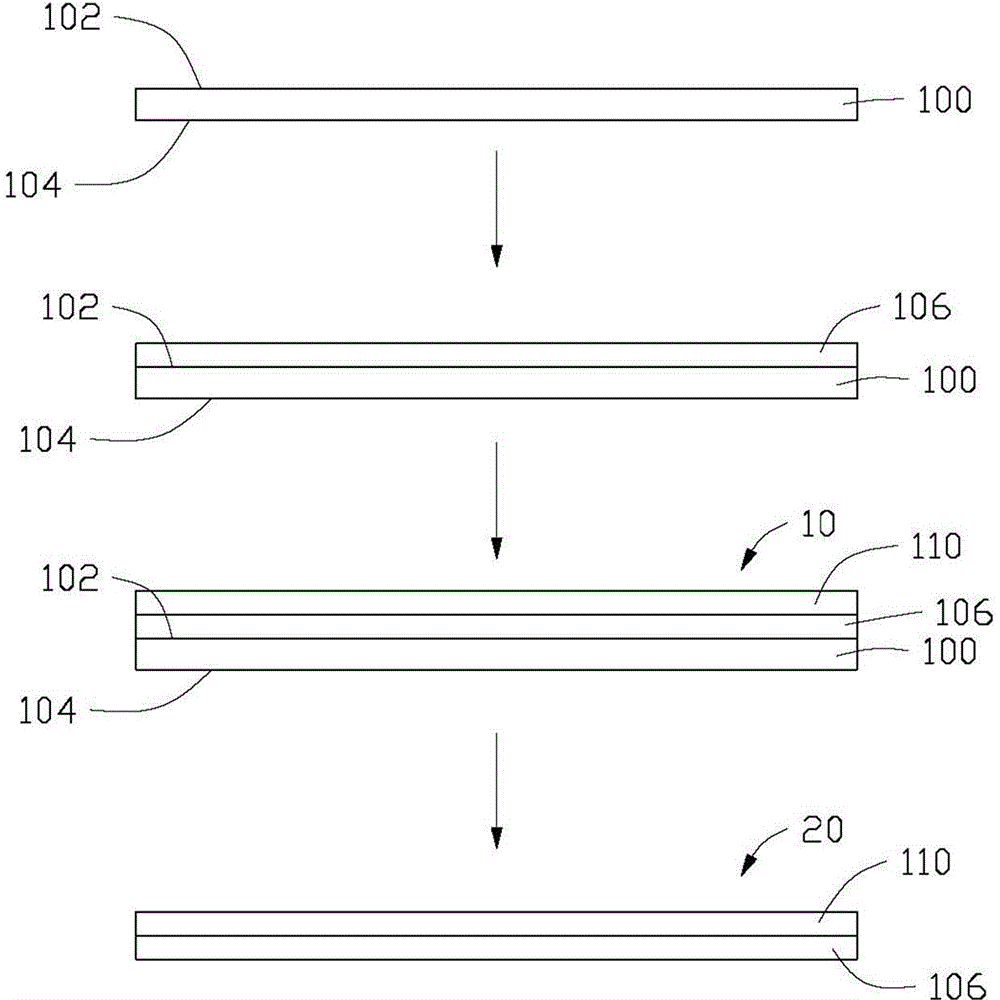

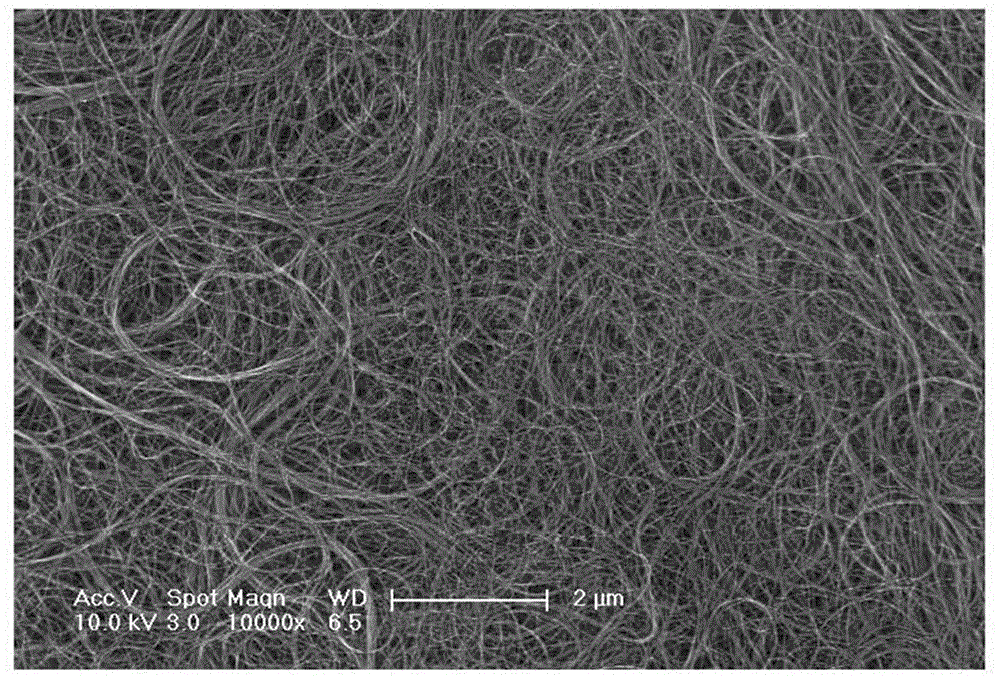

Preparation method of graphene-carbon nano tube composite structure

ActiveCN102795613AImprove conductivityImprove toughnessMaterial nanotechnologySingle layer grapheneCarbon nanotubeCvd graphene

The invention provides a preparation method of a graphene-carbon nano tube composite structure, comprising the following steps of: providing a substrate, wherein the substrate is provided with a first surface and a second surface which is opposite to the first surface; providing at least one graphene membrane, wherein the graphene membrane is formed or arranged on the first surface of the substrate; providing at least one carbon nano tube layer; compounding the substrate and the graphene membrane with the carbon nano tube layer; contacting the graphene membrane with the carbon nano tube layer to obtain a substrate-graphene-carbon nano tube composite structure; and removing the substrate to obtain the graphene-carbon nano tube composite structure.

Owner:TSINGHUA UNIV +1

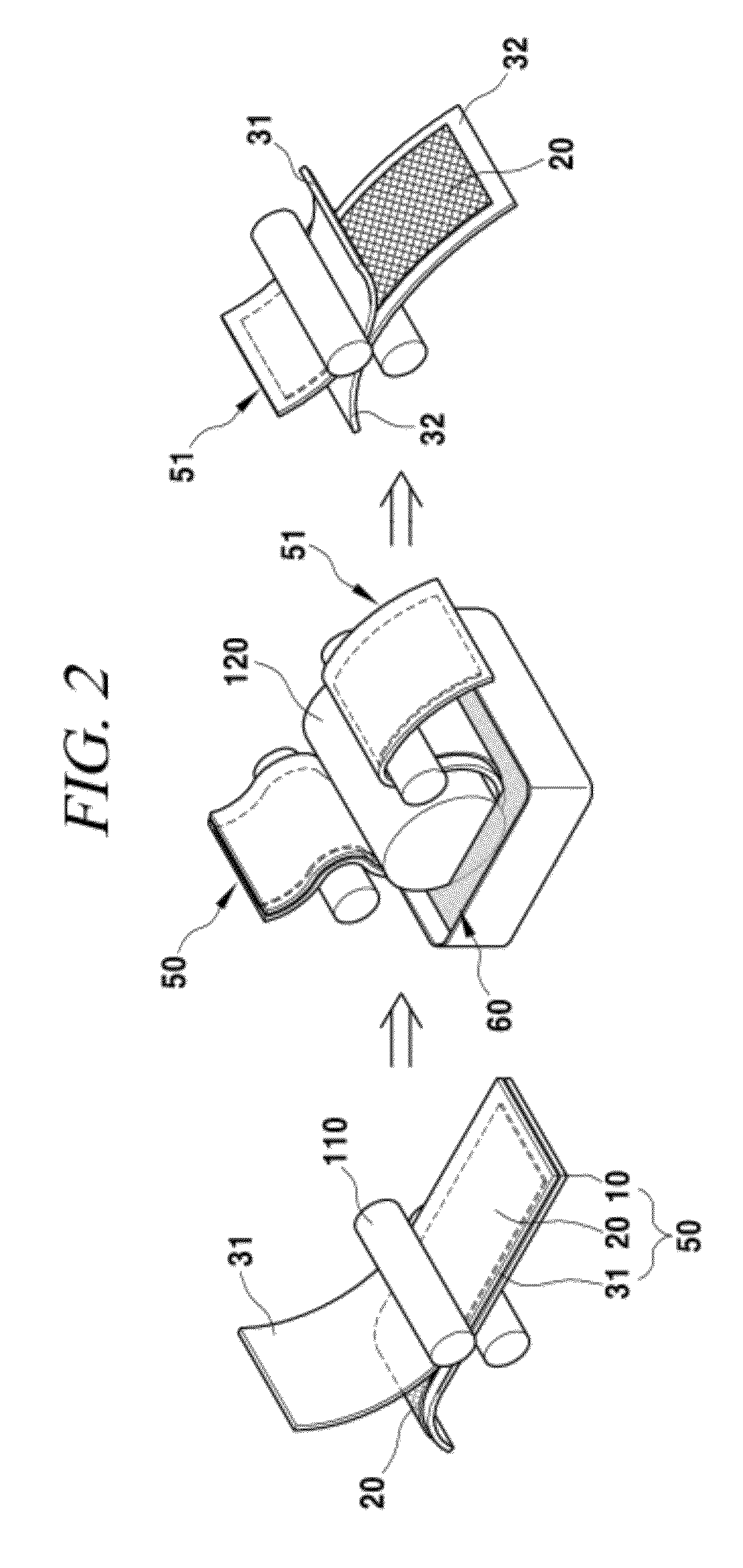

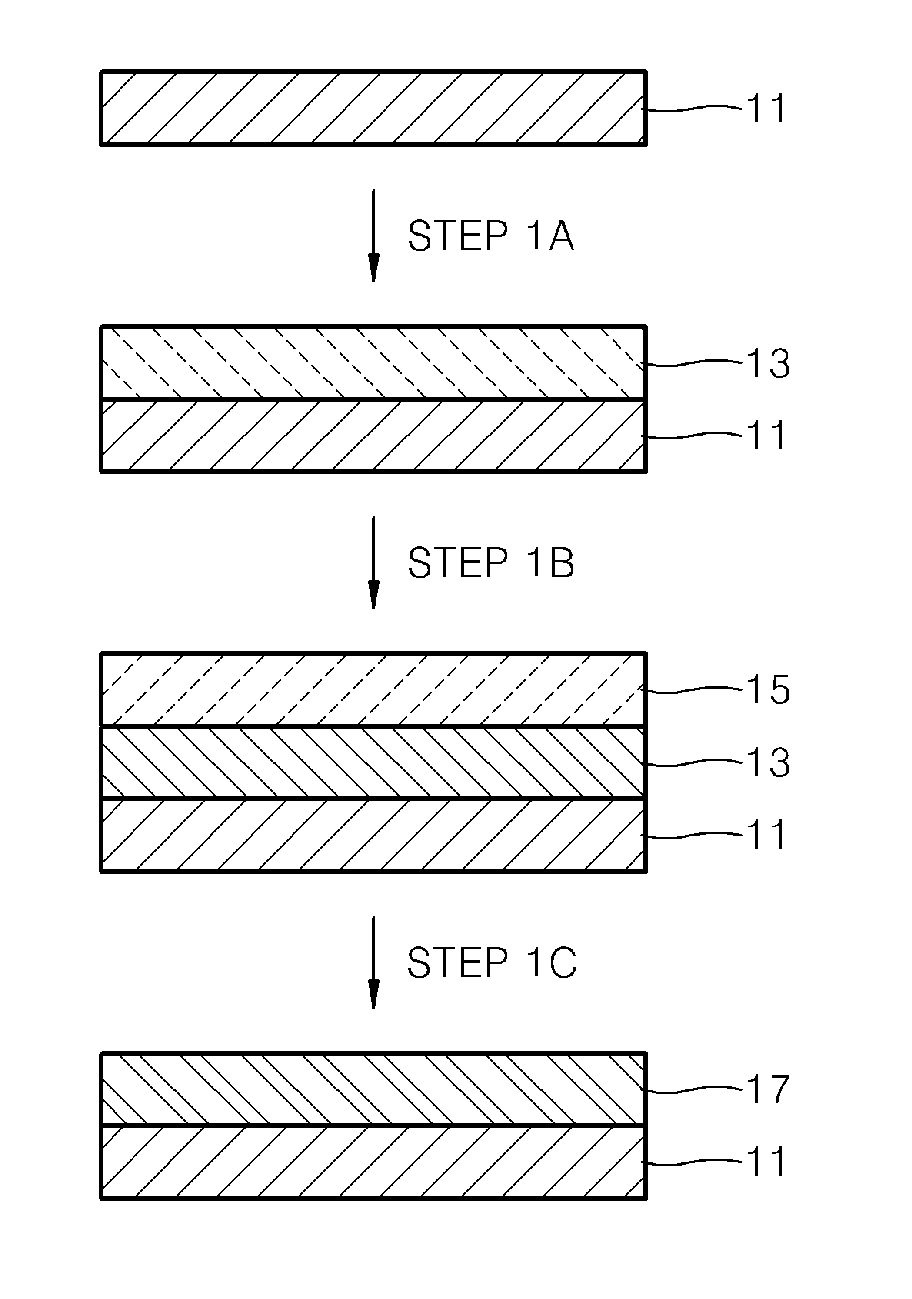

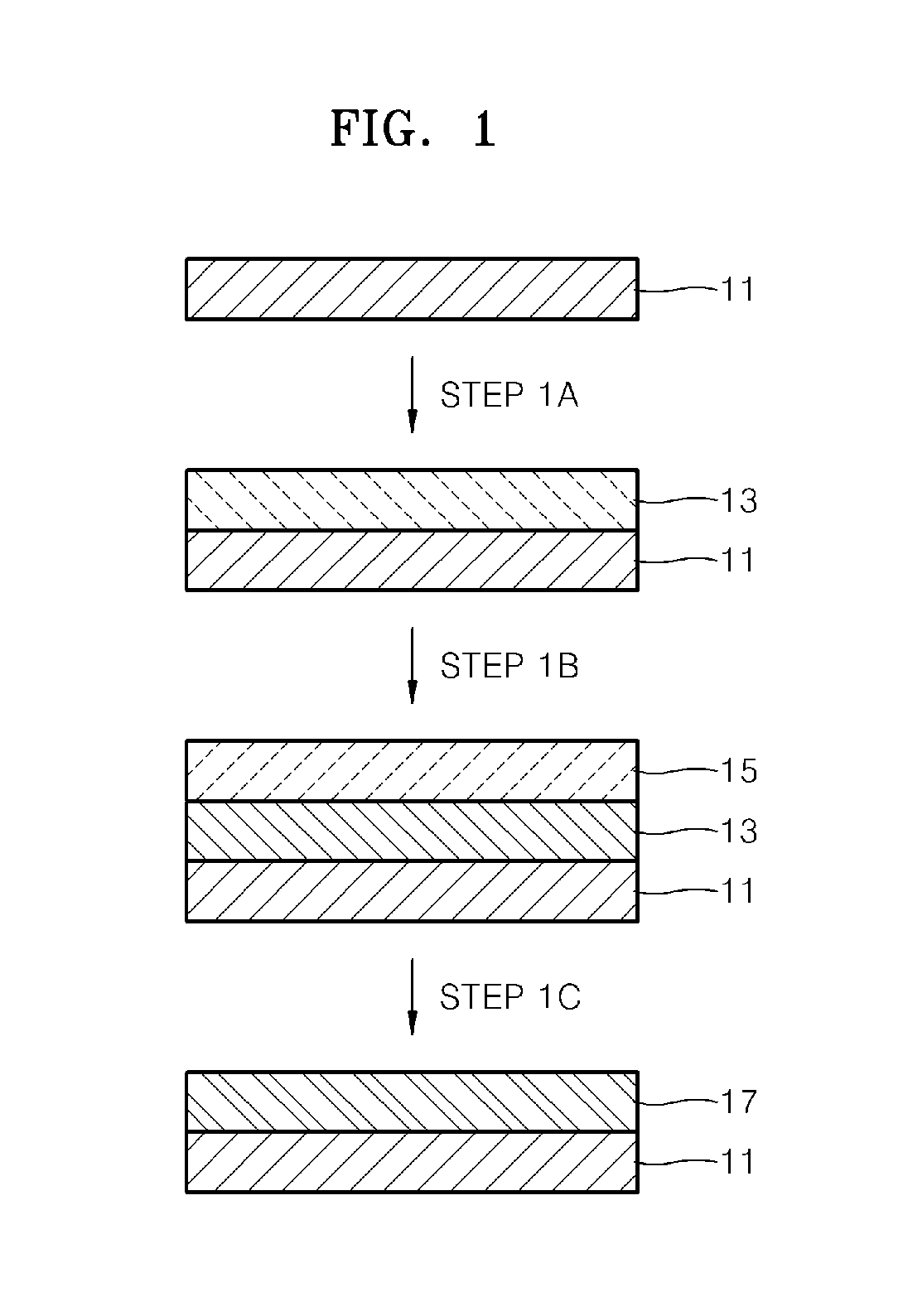

Graphene sheet and method of preparing the same

An economical method of preparing a large-sized graphene sheet having a desired thickness includes forming a film, the film comprising a graphitizing catalyst; heat-treating a gaseous carbon source in the presence of the graphitizing catalyst to form graphene; and cooling the graphene to form a graphene sheet. A graphene sheet prepared according to the disclosed method is also described.

Owner:SAMSUNG ELECTRONICS CO LTD

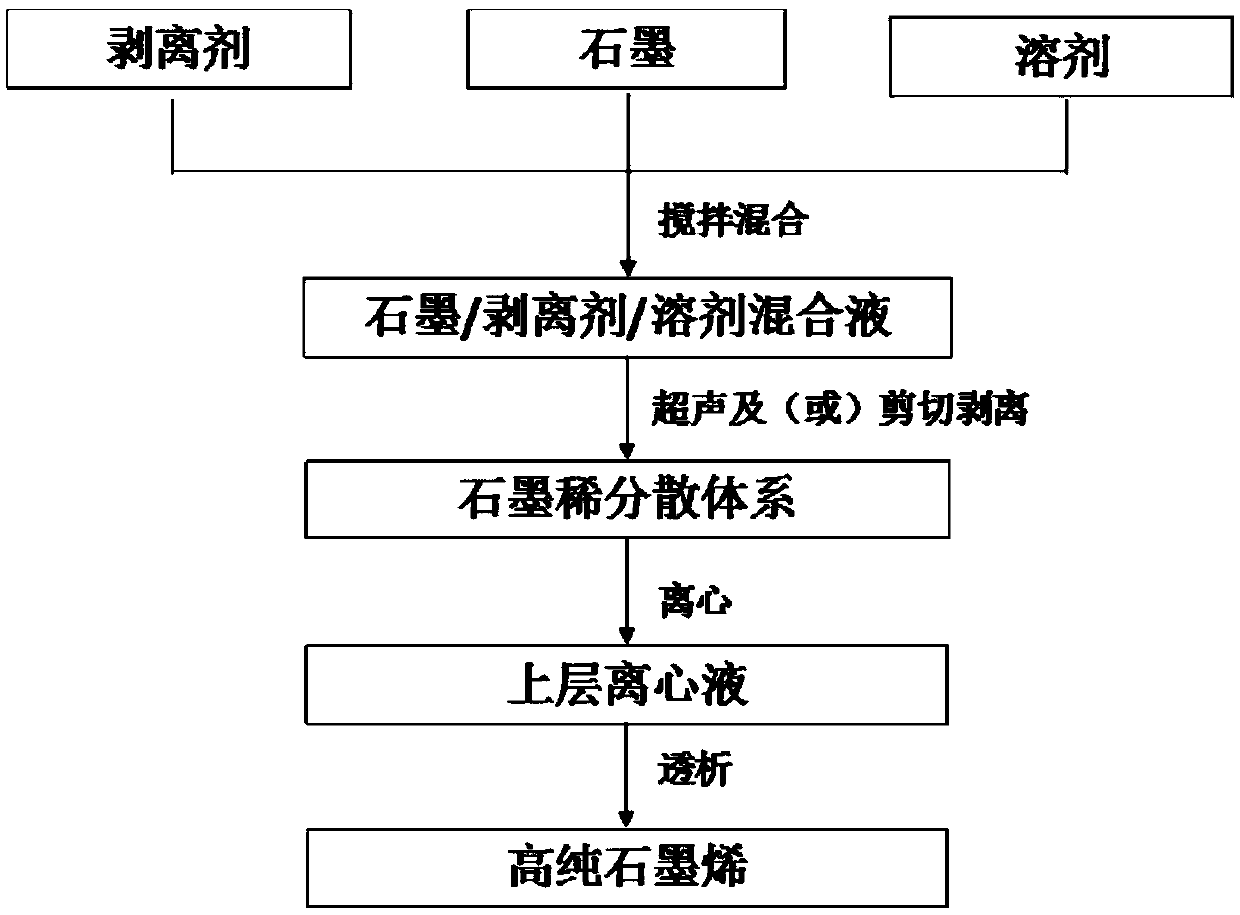

Liquid-phase stripping preparation method of graphene

ActiveCN105502371AReduce the number of layersHigh monolayer ratioSingle layer grapheneGraphiteCvd graphene

The invention provides a liquid-phase stripping preparation method of graphene. The liquid-phase stripping preparation method comprises the steps that first, an aromatic compound is used as a stripping agent to prepare a stripping agent solution, graphite powder is added, and graphite pre-stripping dispersion liquid is obtained after sufficient stirring; second, the graphite pre-stripping dispersion liquid obtained in the first step is subjected to stripping dispersion through ultrasonic and / or mechanical shear to obtain a graphene mixed dispersion system; third, the graphene mixed dispersion system obtained in the second step is centrifuged, the upper-layer solution can be taken for dialysis, and impurities are remove to obtain a pure graphene product. The liquid-phase stripping preparation method can effectively separate graphite flake layers, a large amount of graphene is obtained within a short period of time, and the prepared graphene is single-layer or double-layer graphene and is good in conductive / thermal performance and excellent in comprehensive performances. The liquid-phase stripping preparation method has the advantages of being simple in operation, high in efficiency and green, being environmentally-friendly and the like, and achievement of industrialized graphene preparation is hopeful.

Owner:SHANGHAI HIWAVE COMPOSITE MATERIALS CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com