Preparation method of large-size graphene oxide or graphene

A graphene, large-scale technology, which is applied in the field of large-scale graphene oxide or graphene preparation, can solve the difficulty of solid-liquid separation of graphene oxide suspension, cannot be solved, and the radial size of graphene sheets is small, reducing Graphene size and other issues, to achieve the effect of facilitating large-scale industrial production, low production cost, and avoiding uneven expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

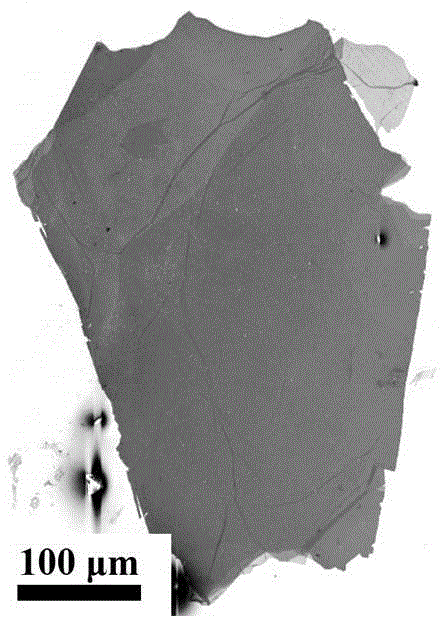

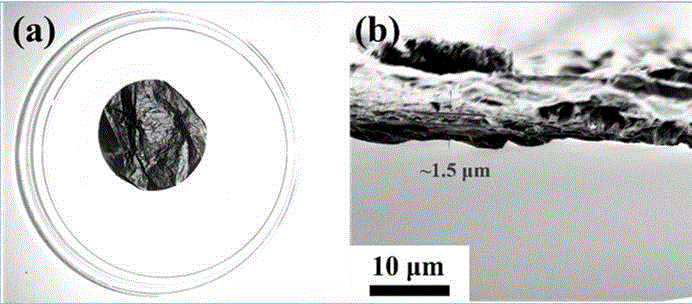

Embodiment 1

[0032] 50 mL of concentrated sulfuric acid and 5 g of ammonium persulfate were mixed and stirred at 5 °C for 10 min, and 1 g of flake graphite was added, and stirred continuously in a water bath at 20 °C for 10 h to obtain intercalated graphite (GICs). Then slowly put into 200mL 0.1mol / L oxalic acid solution, react rapidly at room temperature for 2 days, filter and wash with water to obtain graphene aggregates. Next, slowly pour into a mixture of 40 mL of concentrated sulfuric acid and 2 g of potassium permanganate, let stand at 35° C. for 6 h, and then filter and wash with water. Add 1L of deionized water, and vibrate for 10 min under an oscillating bed at 500 rpm to obtain a uniform graphene dispersion. Microscopic results show that the average radial size of the obtained graphene oxide can reach more than 100 microns, and more than 90% are single layers. figure 1 is the SEM image of the obtained graphene oxide flakes, with radial dimensions up to 450 μm. figure 2 The appea...

Embodiment 2

[0034] After the graphene oxide suspension obtained in Example 1 was filtered to form a film, it was heat-treated at 800°C for 60 minutes, and pressed for 5 minutes at a pressure of 20MPa. The four-probe measurement results showed that the conductivity of the film could reach 600S / cm above.

Embodiment 3

[0036] Mix 30 mL of concentrated sulfuric acid and 10 mL of concentrated nitric acid in an ice-water bath at 5°C and stir for 10 min, add 1 g of graphite flakes, stir continuously in a water bath at 20°C for 6 h, and then filter to obtain GICs. Then, slowly put into 200mL0.1mol / L oxalic acid solution, react at room temperature for 1d, filter and wash with water to obtain graphene aggregates. Next, slowly pour into a mixture of 40 mL of concentrated sulfuric acid and 2 g of potassium permanganate, let stand at 35° C. for 6 h, and then filter and wash with water. Add 1L of deionized water, and vibrate under an oscillating bed at 500rpm for 10min. The obtained graphene oxide has an average radial size of more than 100 microns, and more than 90% of it is a single layer. It is reduced by hydriodic acid solution (57%) at 60°C for 2h After that, the conductivity reaches above 600S / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com