Patents

Literature

76931 results about "Liquid-crystal display" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

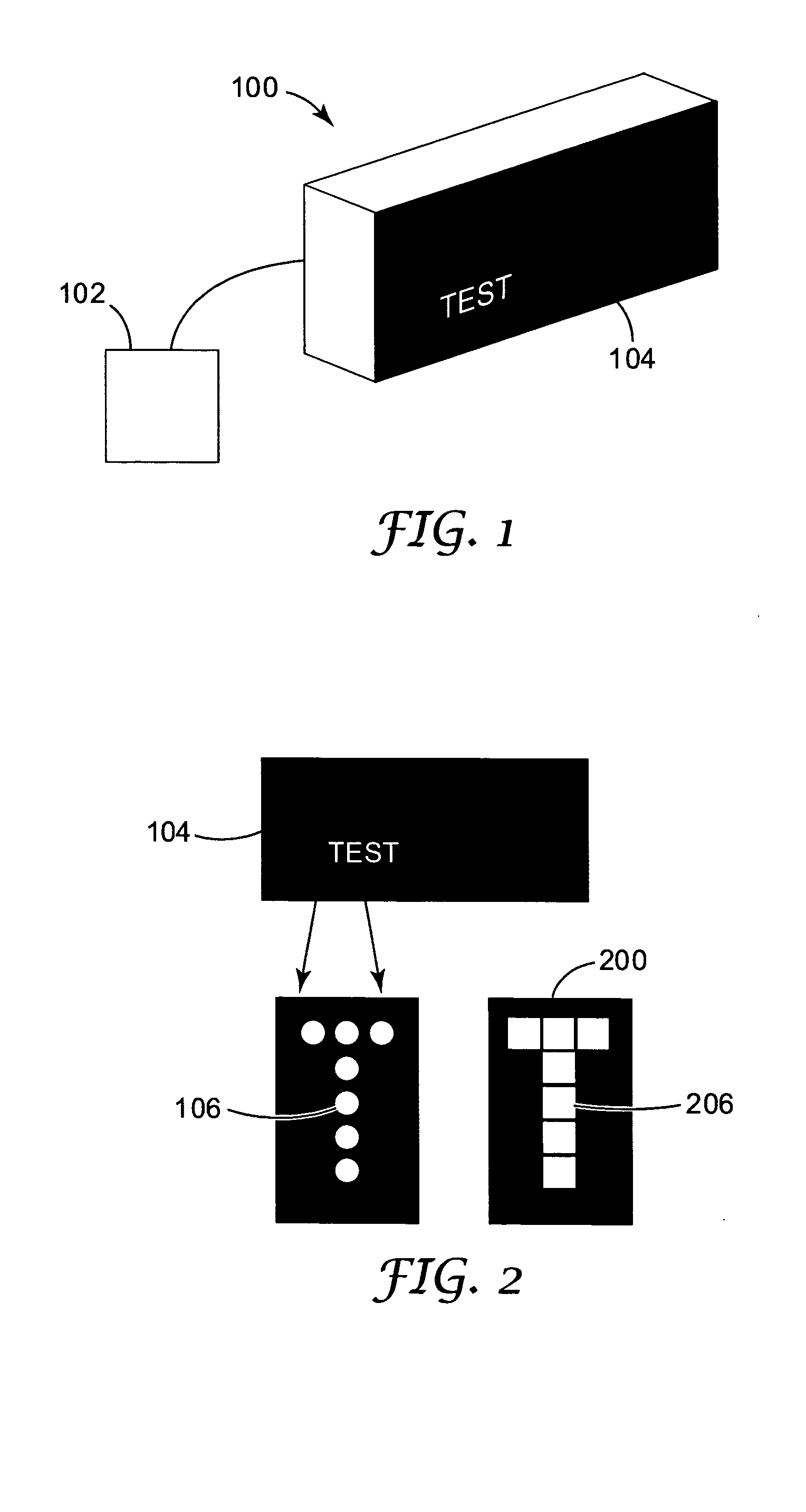

A liquid-crystal display (LCD) is a flat-panel display or other electronically modulated optical device that uses the light-modulating properties of liquid crystals. Liquid crystals do not emit light directly, instead using a backlight or reflector to produce images in color or monochrome. LCDs are available to display arbitrary images (as in a general-purpose computer display) or fixed images with low information content, which can be displayed or hidden, such as preset words, digits, and seven-segment displays, as in a digital clock. They use the same basic technology, except that arbitrary images are made up of many small pixels, while other displays have larger elements. LCDs can either be normally on (positive) or off (negative), depending on the polarizer arrangement. For example, a character positive LCD with a backlight will have black lettering on a background that is the color of the backlight, and a character negative LCD will have a black background with the letters being of the same color as the backlight. Optical filters are added to white on blue LCDs to give them their characteristic appearance.

Structure, transmission type liquid crystal display, reflection type display and manufacturing method thereof

A method of manufacturing a transmission type liquid crystal display is disclosed including preparing a color filter; forming a substantially transparent semiconductor circuit on a surface of the color filter while position adjustment between the color filter and the semiconductor circuit is performed; and forming a transmission type liquid crystal display element on one side of the substantially transparent semiconductor circuit, wherein there is no color filter on the one side.

Owner:TOPPAN PRINTING CO LTD

Structure with transistor

ActiveUS20080258139A1Improve mobilityOn/off ratio highSemiconductor/solid-state device manufacturingSemiconductor devicesLiquid-crystal displayDisplay device

A structure with a transistor is disclosed comprising a substrate, a gas barrier layer on the substrate, and a transistor on the gas barrier layer. The transistor can include an oxide semiconductor layer. The oxide semiconductor layers can comprise In—Ga—Zn—O. A display, such as a liquid crystal display, can have such a structure.

Owner:TOPPAN PRINTING CO LTD

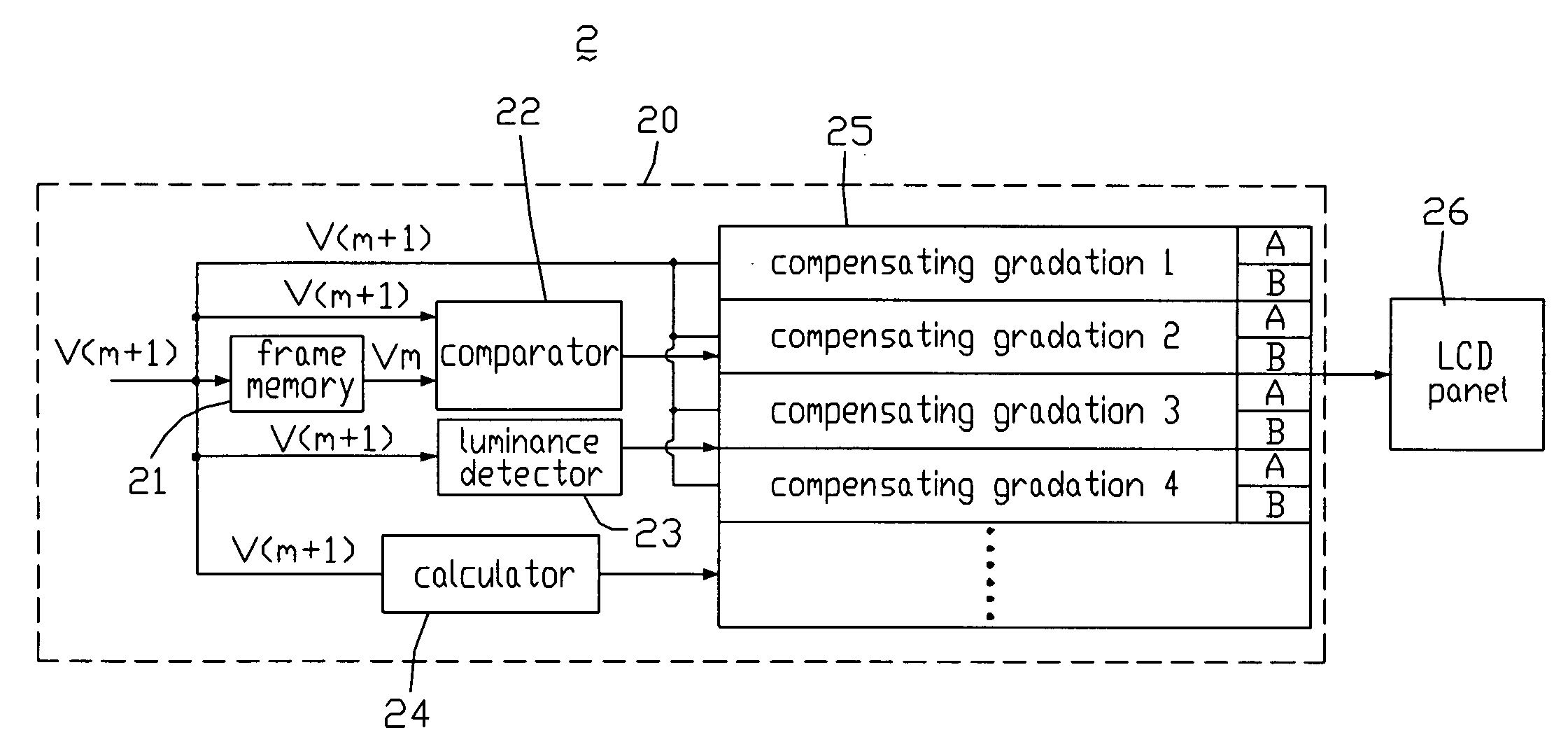

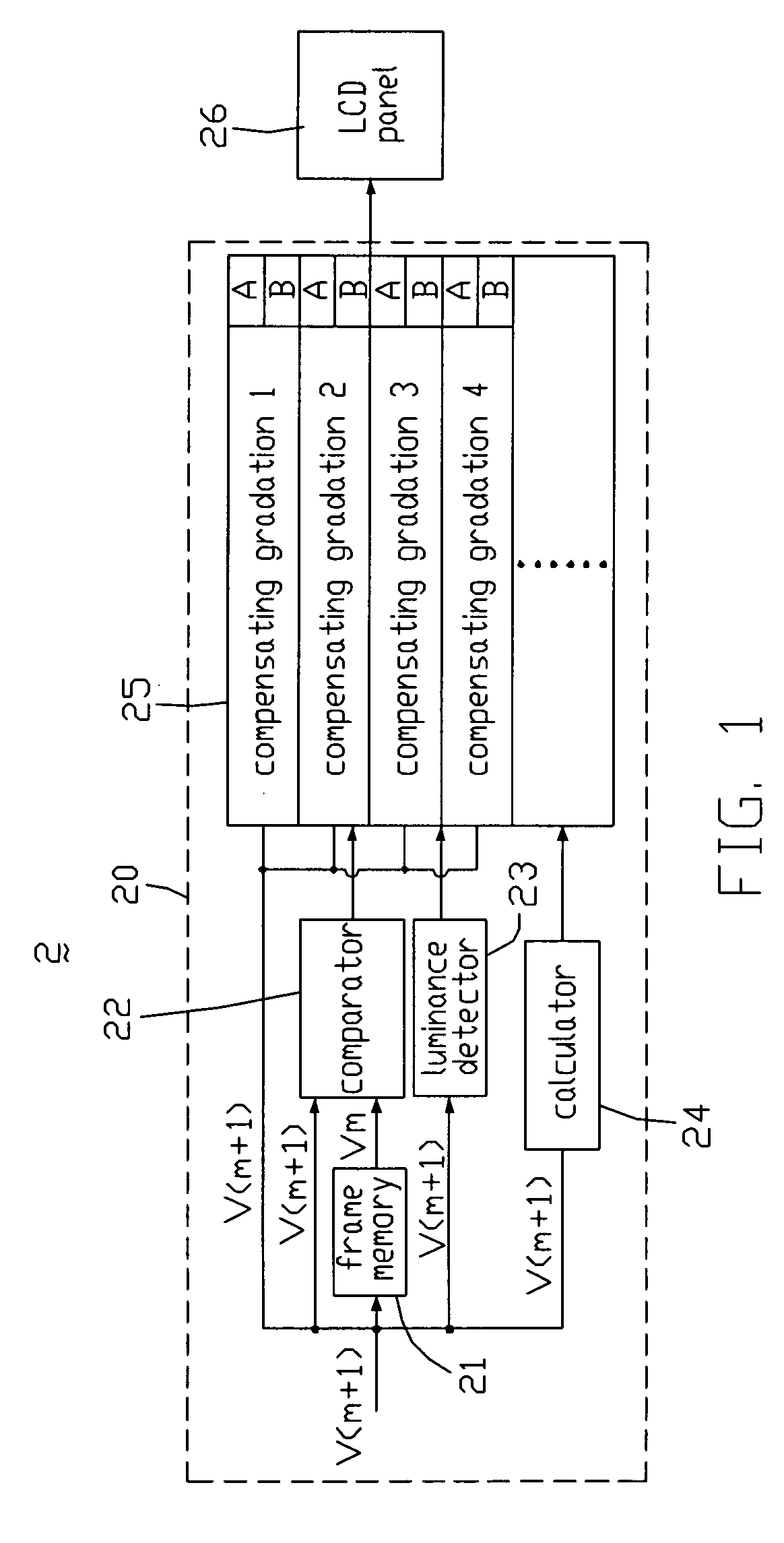

Liquid crystal display device and method for driving same

ActiveUS20090002360A1Cathode-ray tube indicatorsInput/output processes for data processingLiquid-crystal displayComputer science

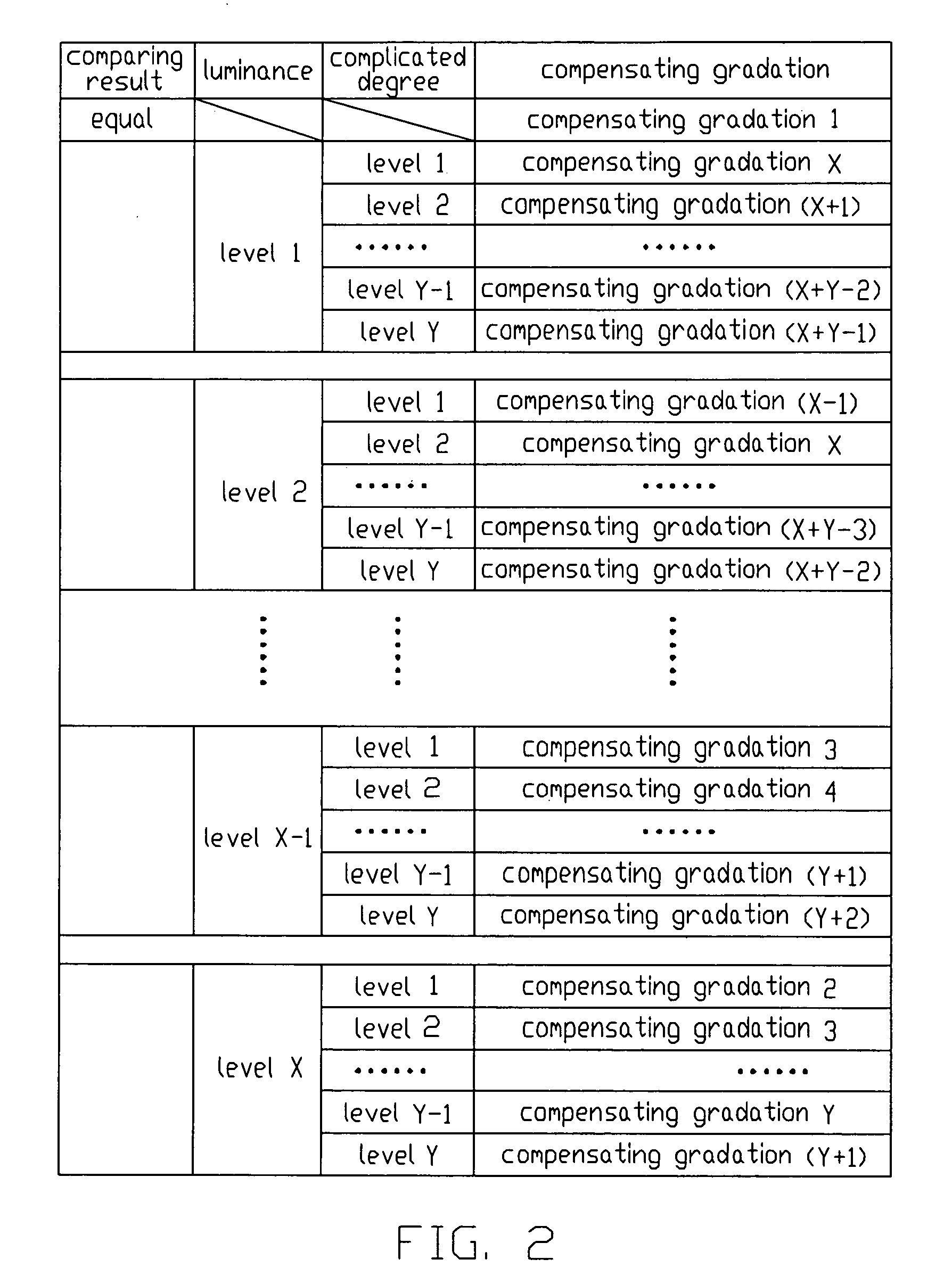

An exemplary LCD includes a frame memory configured for receiving a plurality of first gradations of current frame and outputting a plurality of second gradations of preceding frame pre-stored therein; a comparator configured for receiving, comparing the first gradations with the second gradation to generate a comparison result; a luminance detector configured for detecting a luminance degree of each of pixel according to the gradations of current frame; a calculator configured for calculating a complication degree of a picture to be displayed in current frame; and a gradation processor configured for receiving the first gradations of current frame to be displayed on the LCD panel, generating a plurality of pairs of compensating gradations according to the gradation of each pixel, and selecting one pair of the compensating gradations to be outputted to the LCD panel according to a received comparison result, a received luminance degree, and a received complication degree.

Owner:INNOLUX CORP

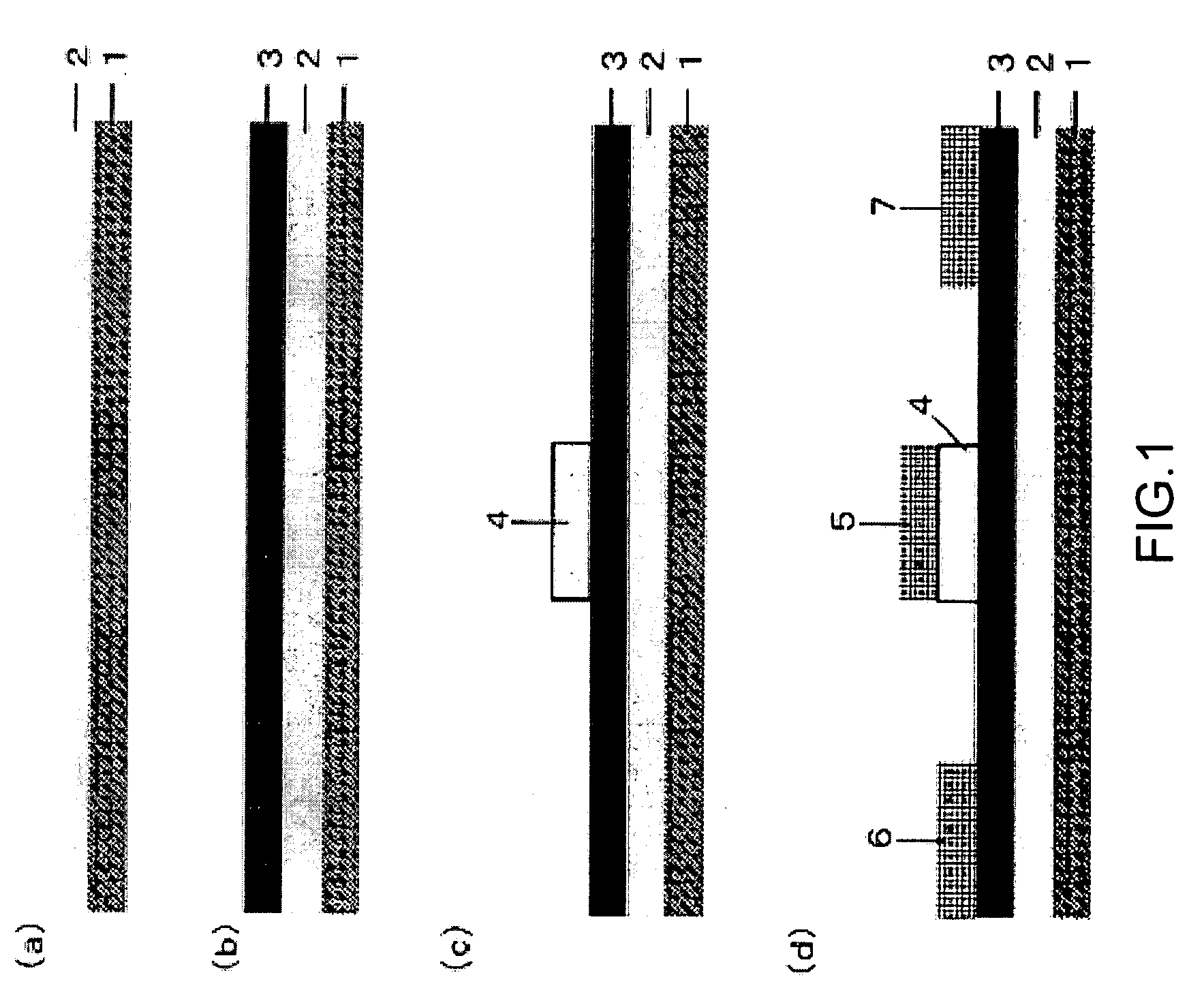

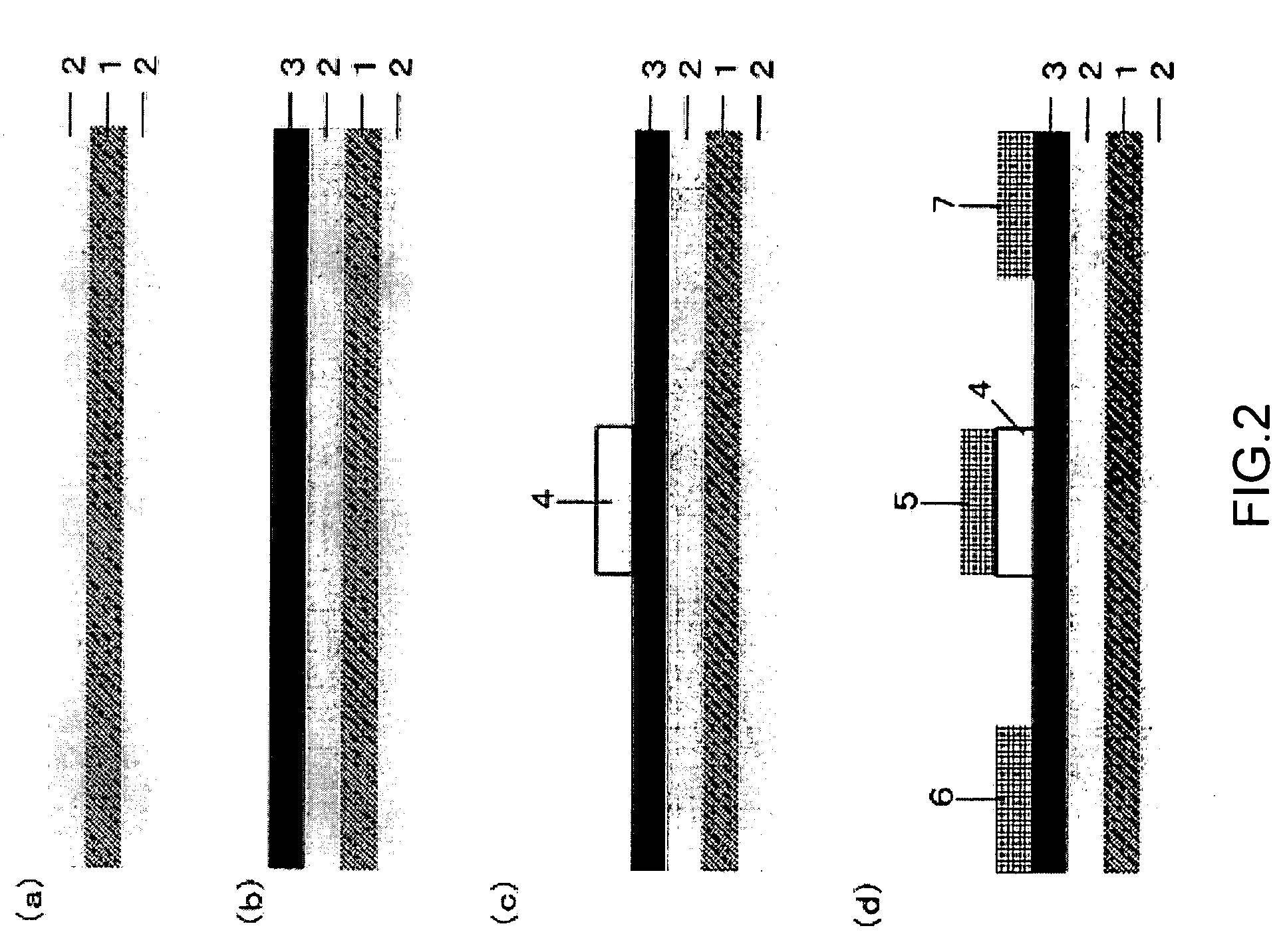

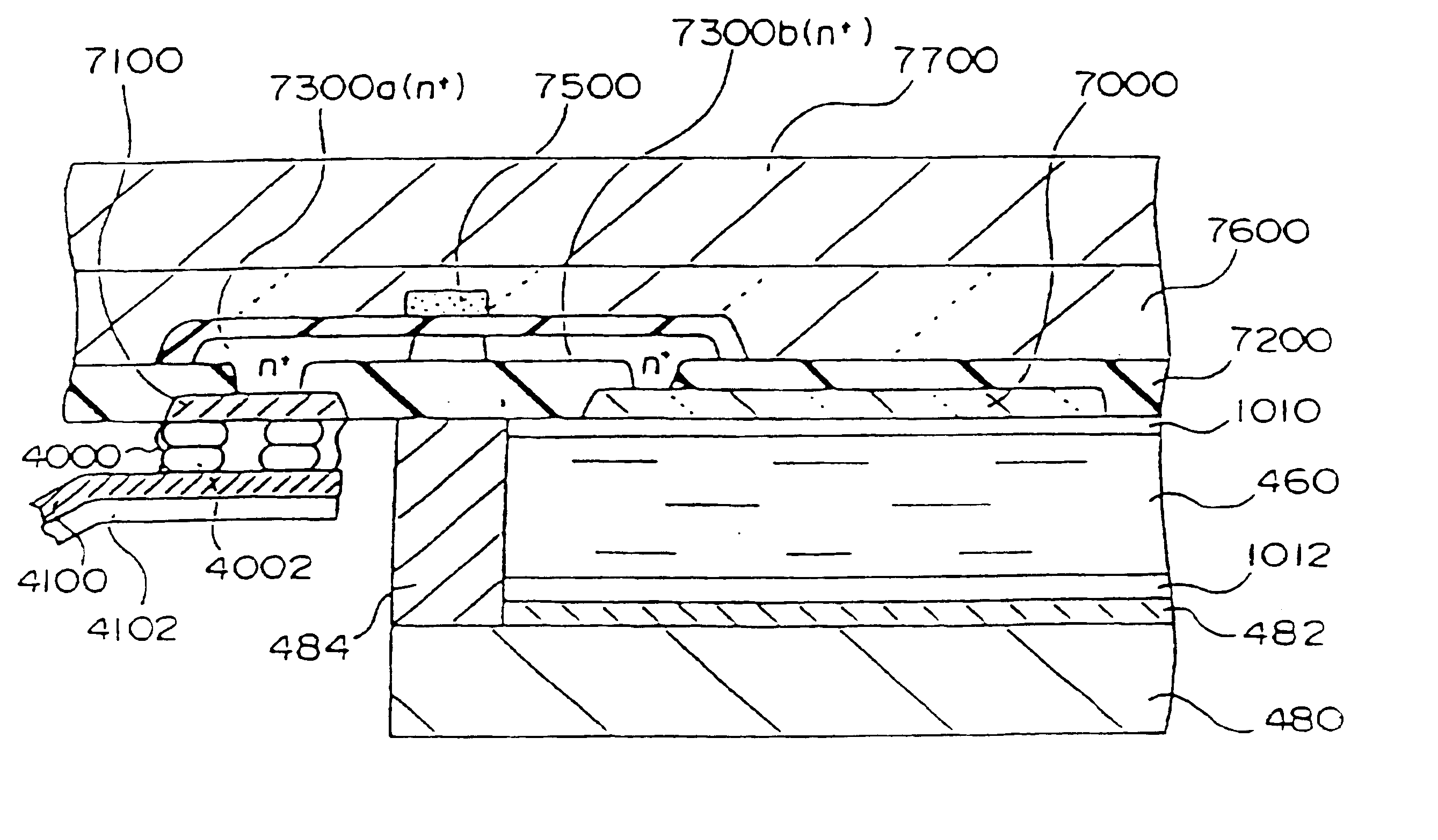

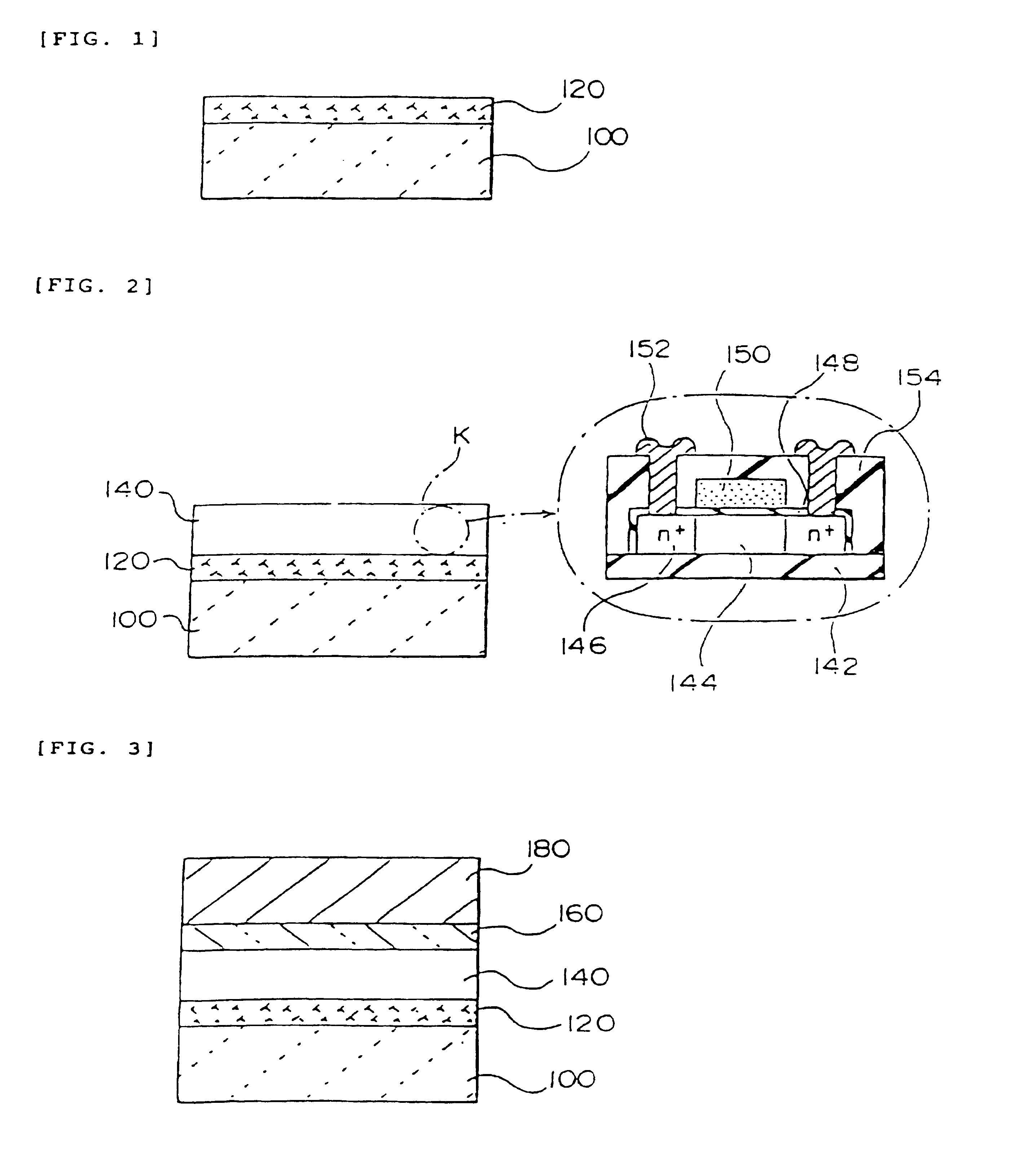

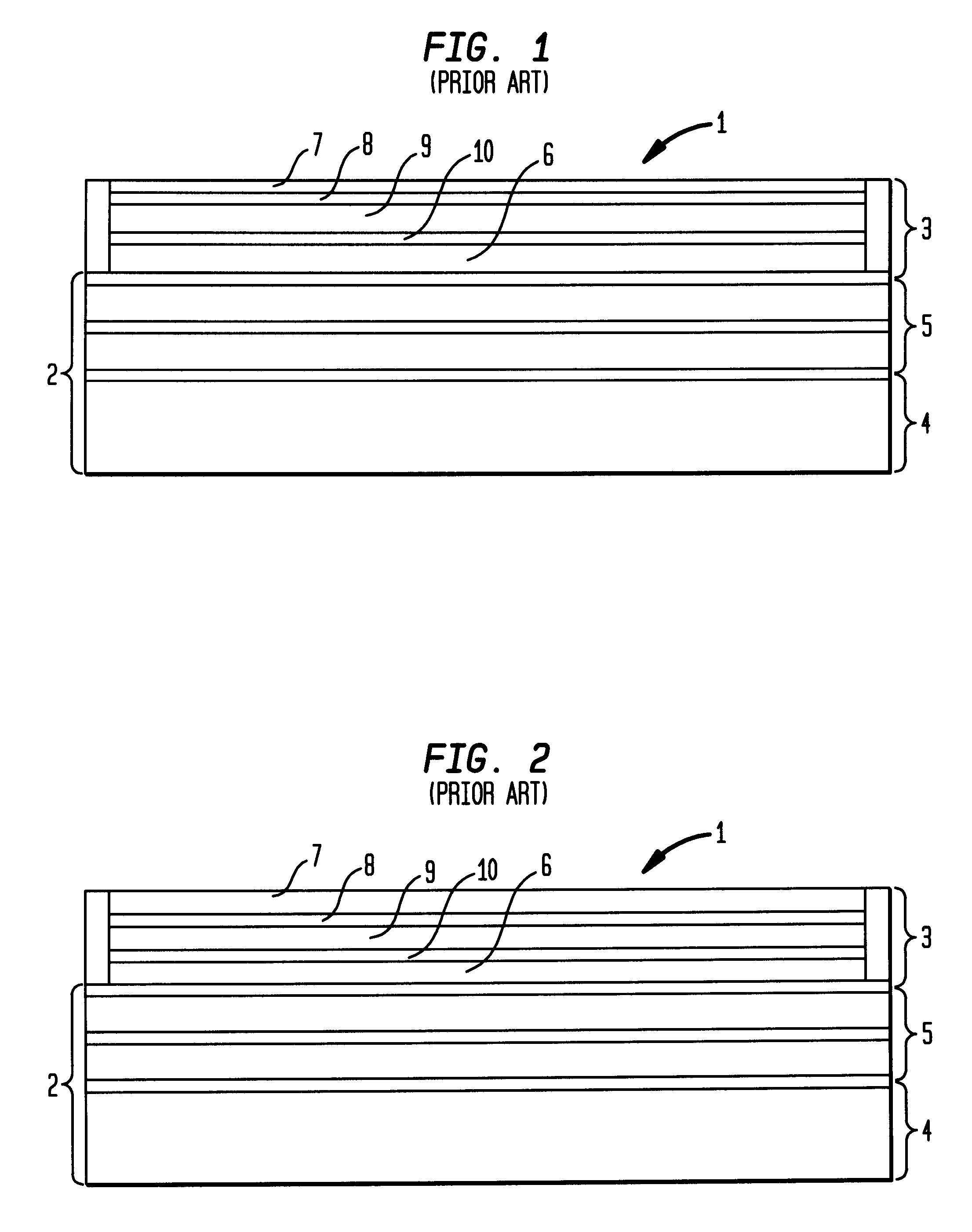

Exfoliating method, transferring method of thin film device, and thin film device, thin film integrated circuit device and liquid crystal display device produced by the same

InactiveUS6645830B2Improve reliabilityReduce adhesionSolid-state devicesSemiconductor/solid-state device manufacturingLiquid-crystal displayPellicle membrane

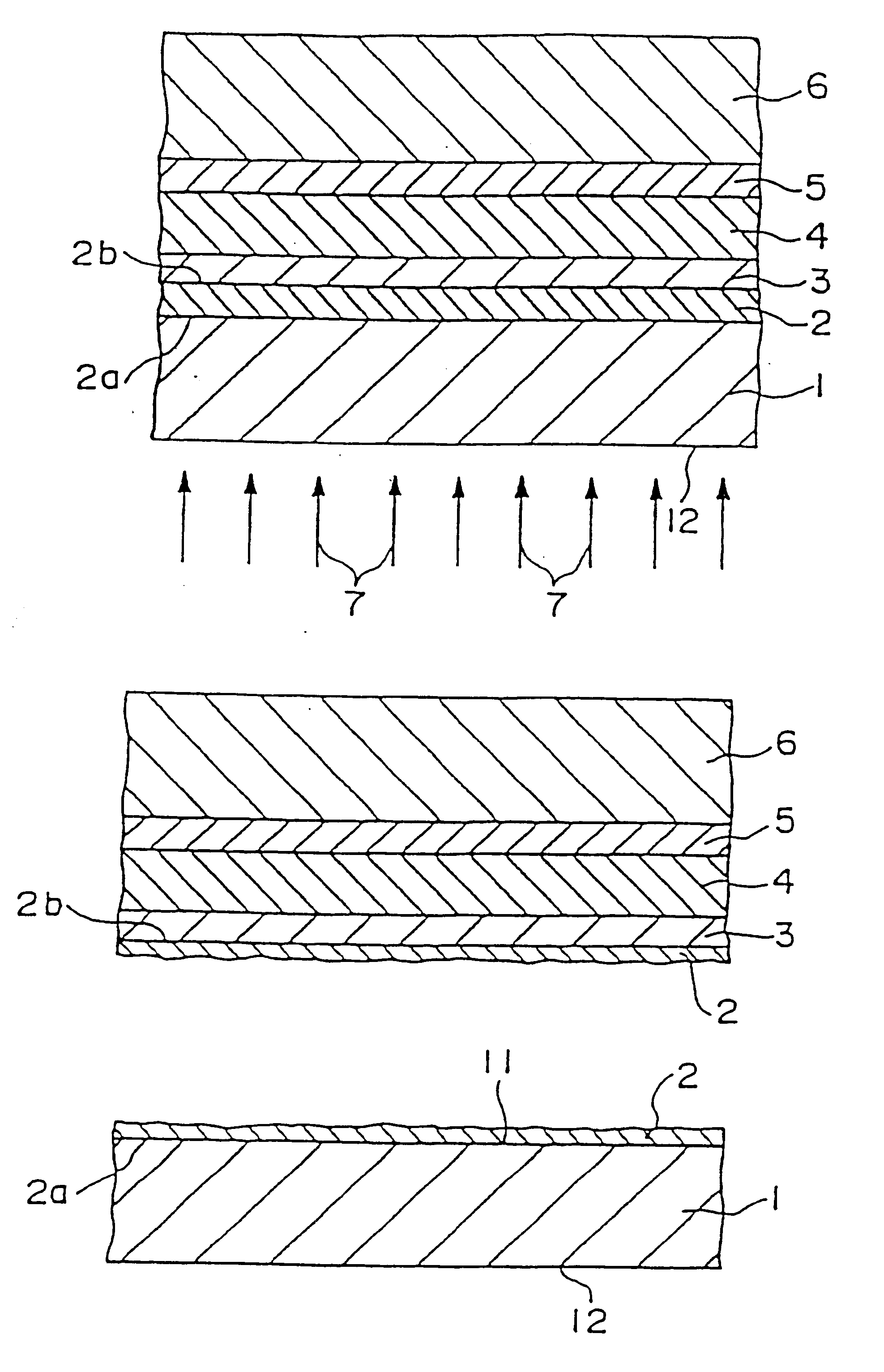

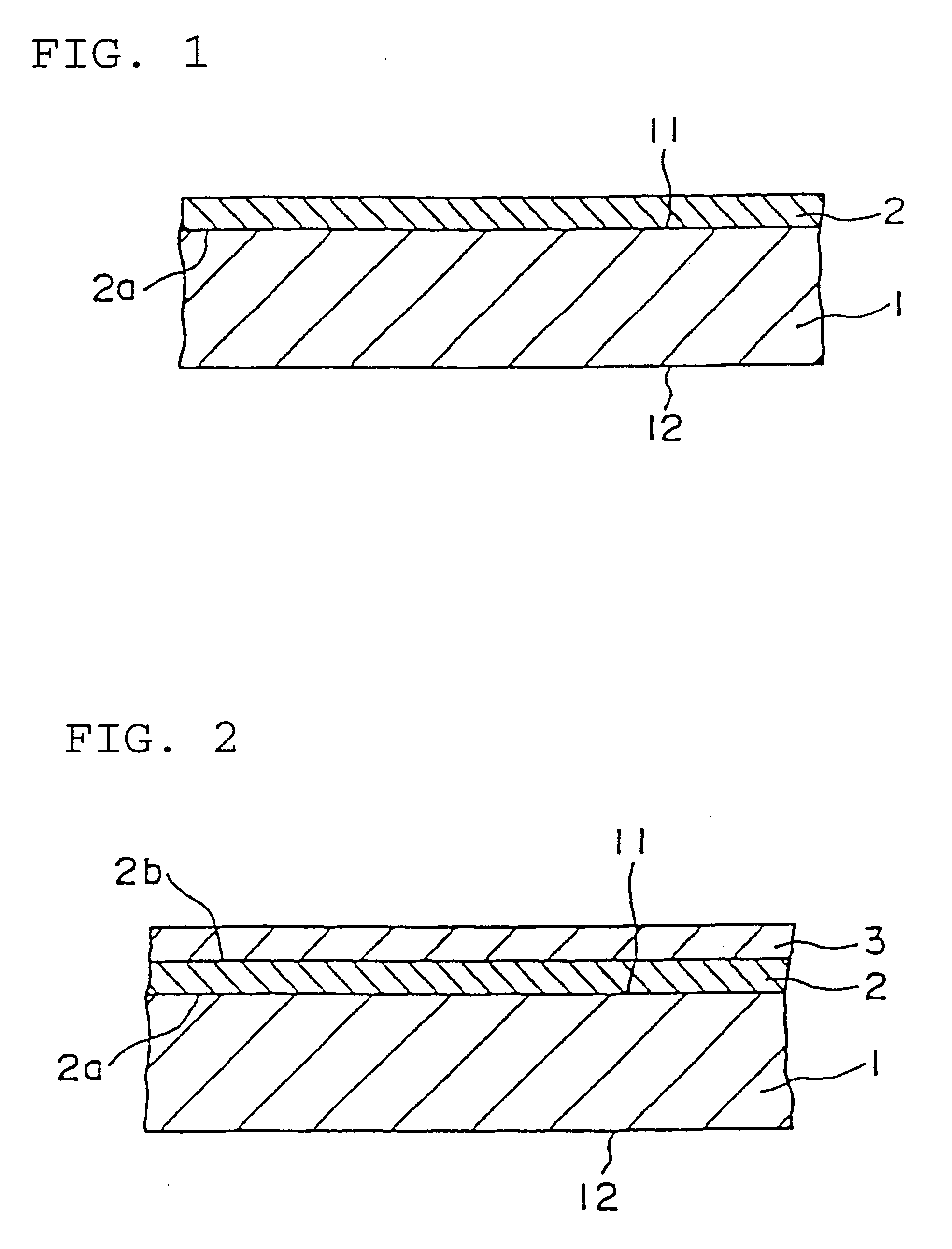

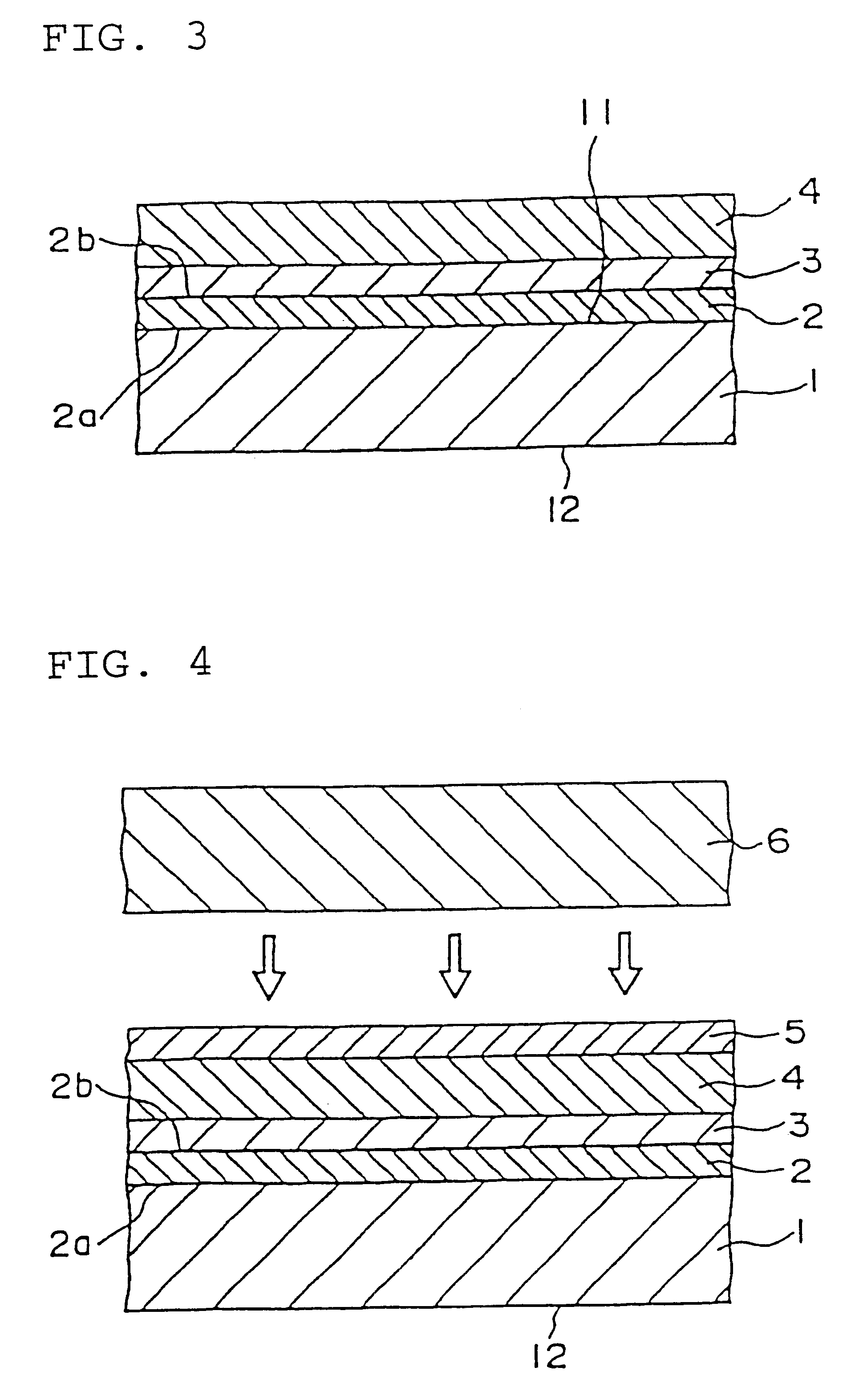

A method for transferring a thin film device on a substrate onto a transfer member, includes a step for forming a separation layer on the substrate, a step for forming a transferred layer including the thin film device on the separation layer, a step for adhering the transferred layer including the thin film device to the transfer member with an adhesive layer therebetween, a step for irradiating the separation layer with light so as to form internal and / or interfacial exfoliation of the separation layer, and a step for detaching the substrate from the separation layer.

Owner:SAMSUNG ELECTRONICS CO LTD

Double-sided touch-sensitive panel with shield and drive combined layer

ActiveUS7920129B2Small sizeArea minimizationTransmission systemsDigital data processing detailsCapacitanceLiquid-crystal display

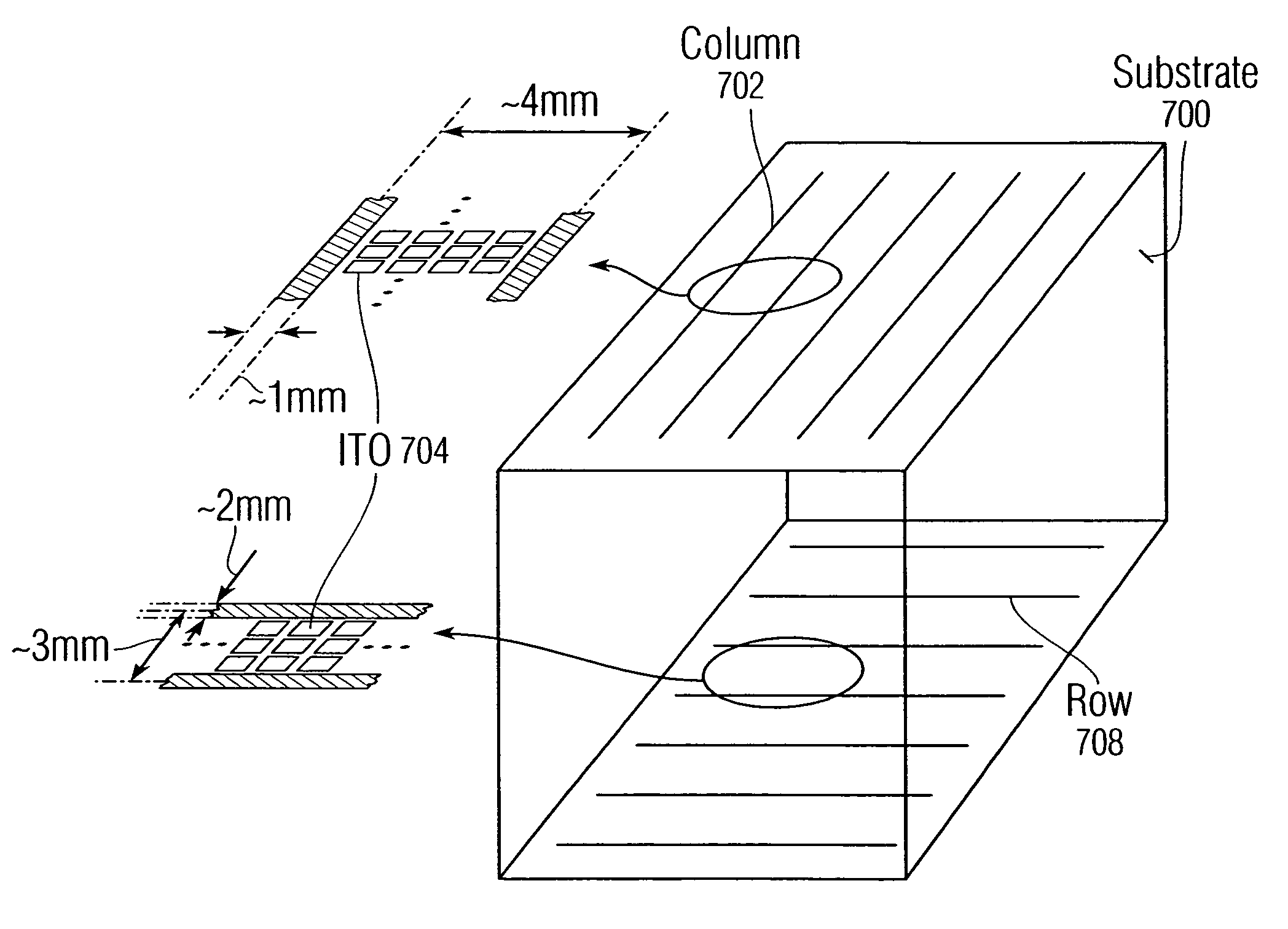

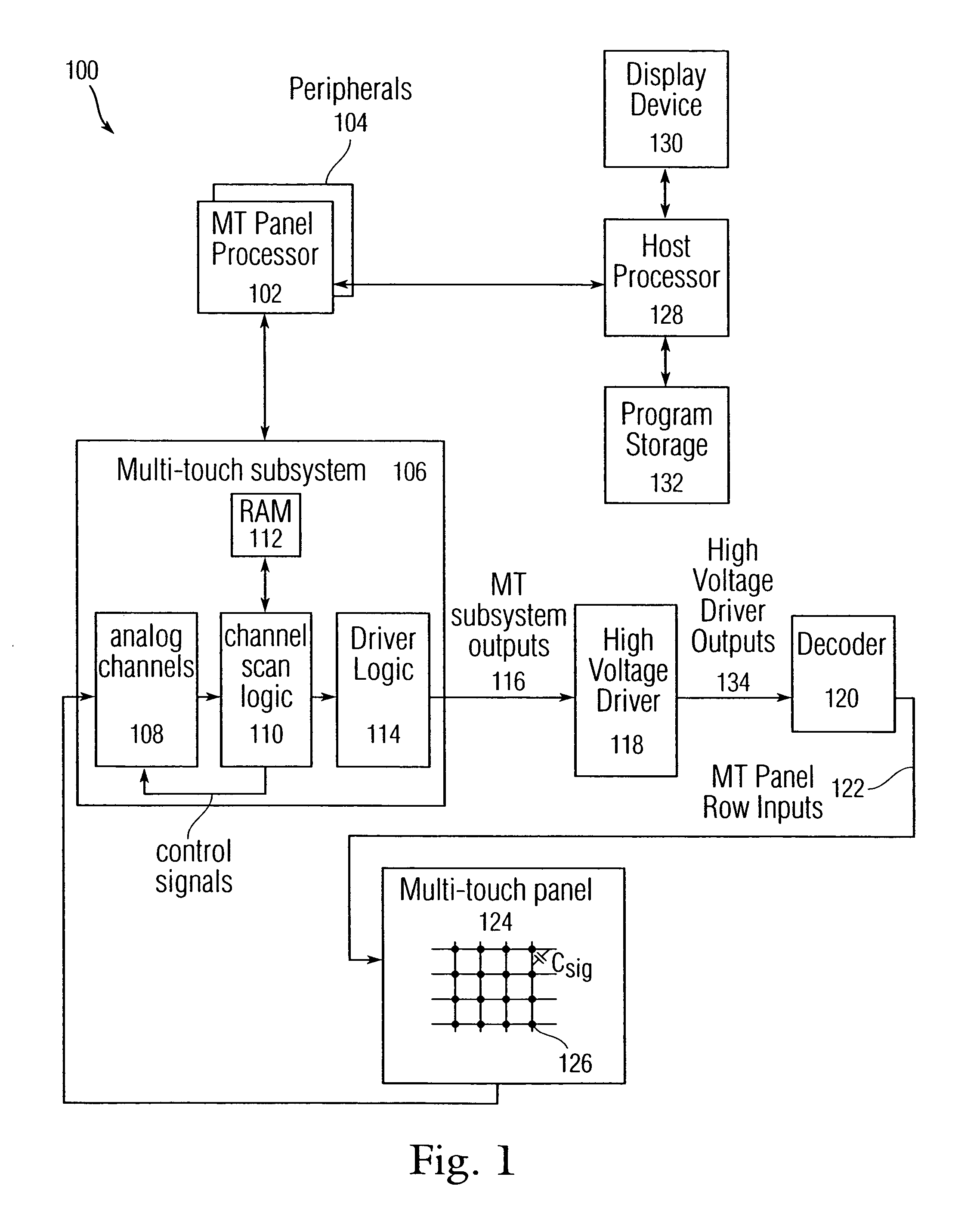

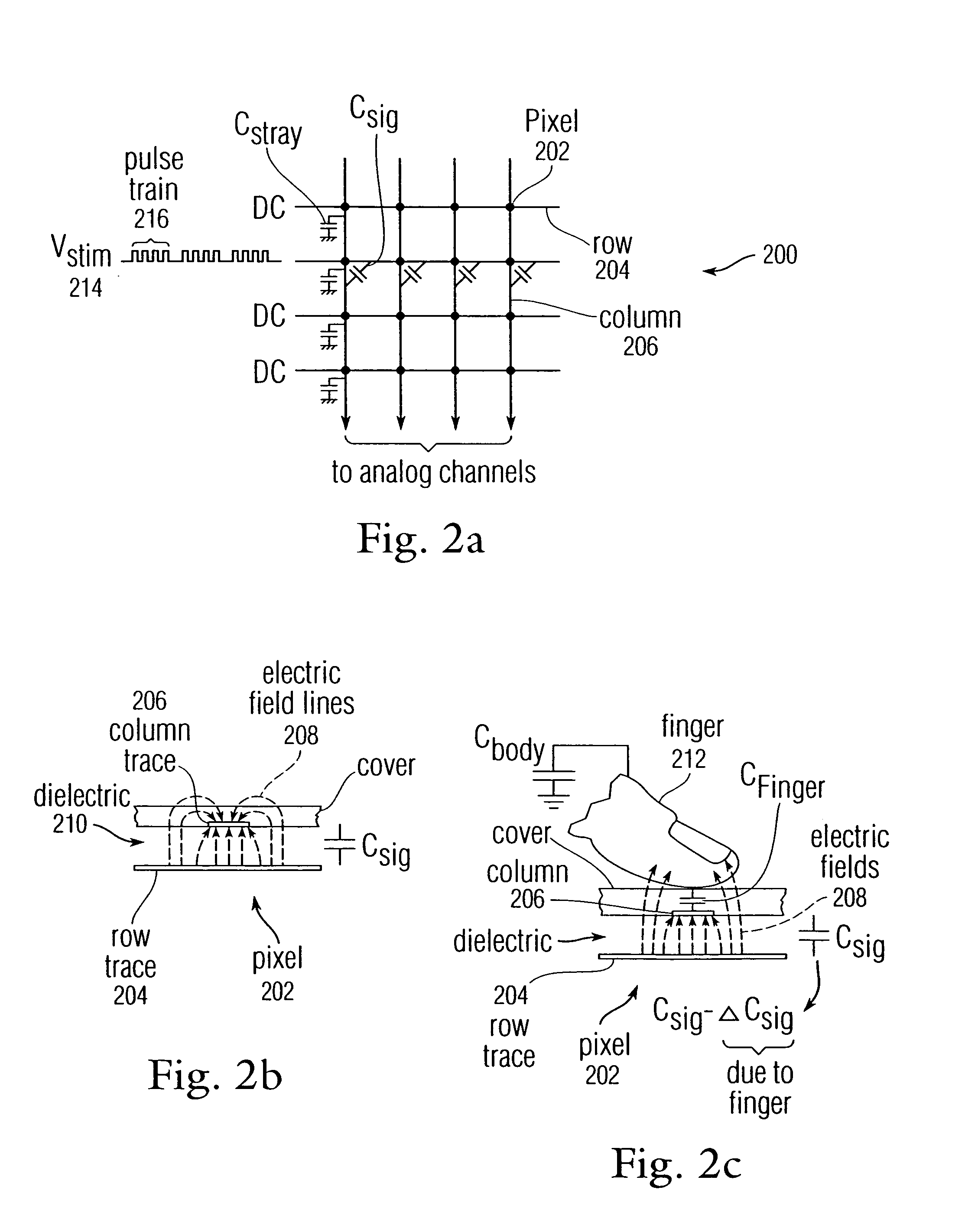

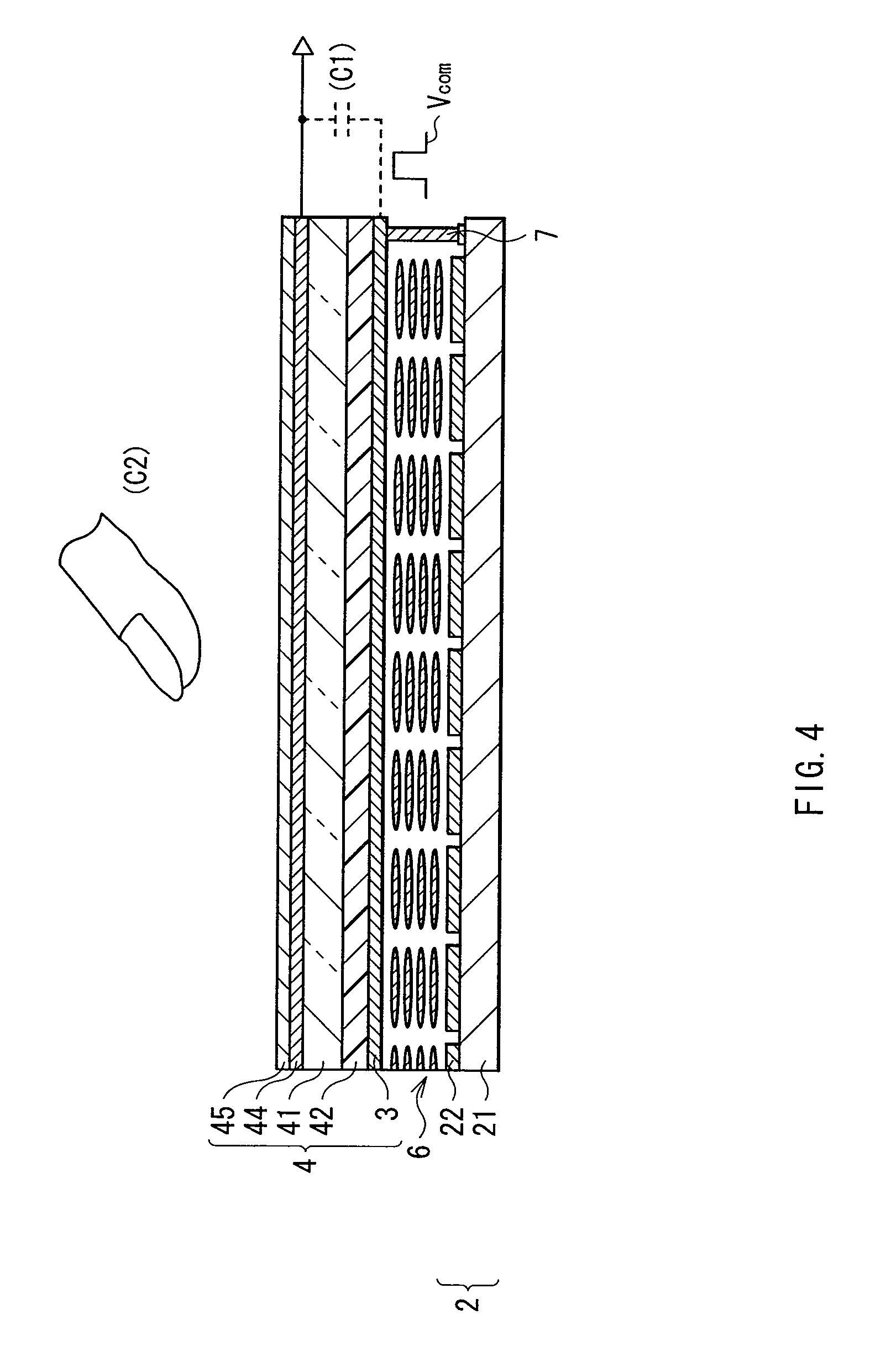

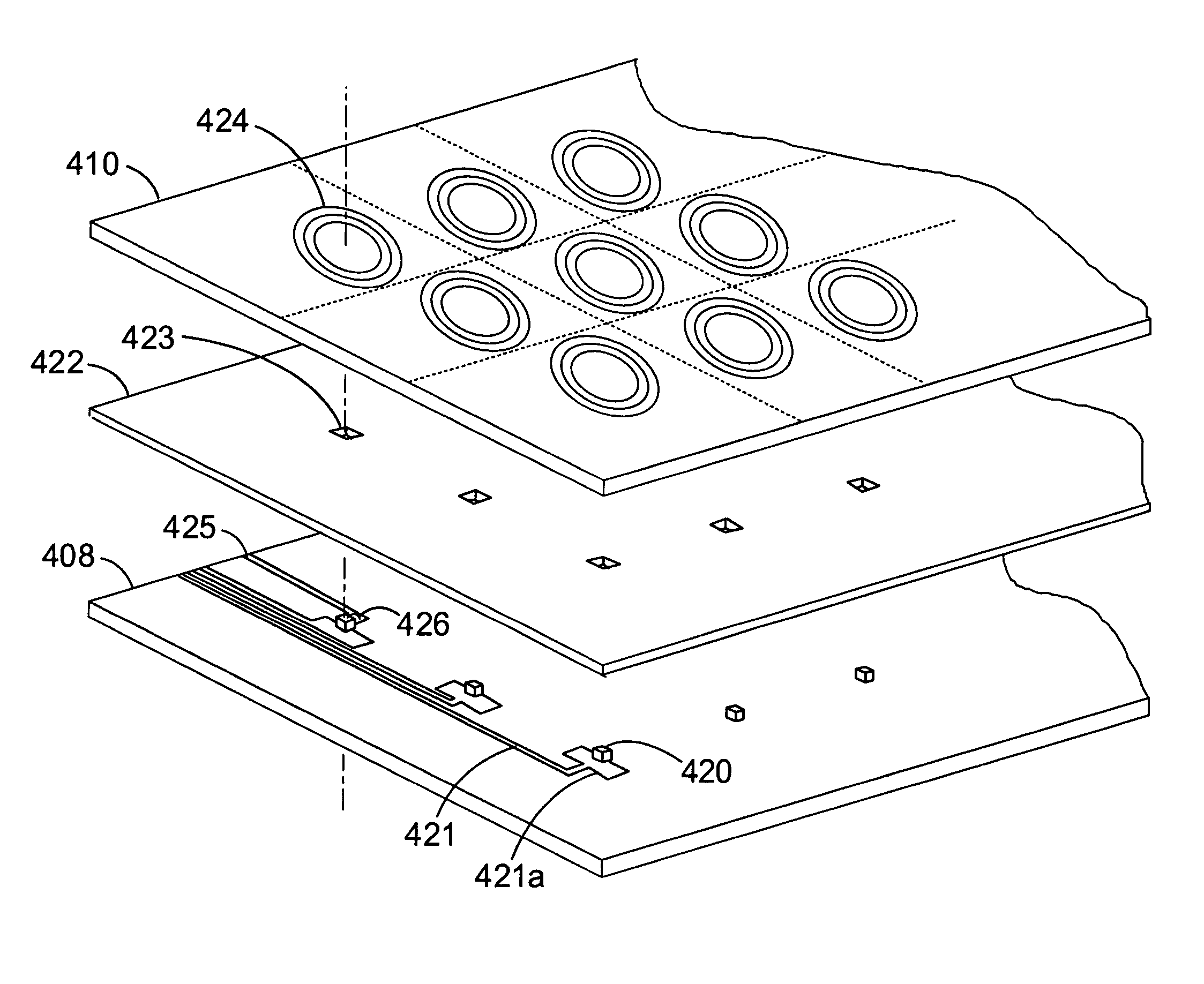

A multi-touch capacitive touch sensor panel can be created using a substrate with column and row traces formed on either side of the substrate. To shield the column (sense) traces from the effects of capacitive coupling from a modulated Vcom layer in an adjacent liquid crystal display (LCD) or any source of capacitive coupling, the row traces can be widened to shield the column traces, and the row traces can be placed closer to the LCD. In particular, the rows can be widened so that there is spacing of about 30 microns between adjacent row traces. In this manner, the row traces can serve the dual functions of driving the touch sensor panel, and also the function of shielding the more sensitive column (sense) traces from the effects of capacitive coupling.

Owner:APPLE INC

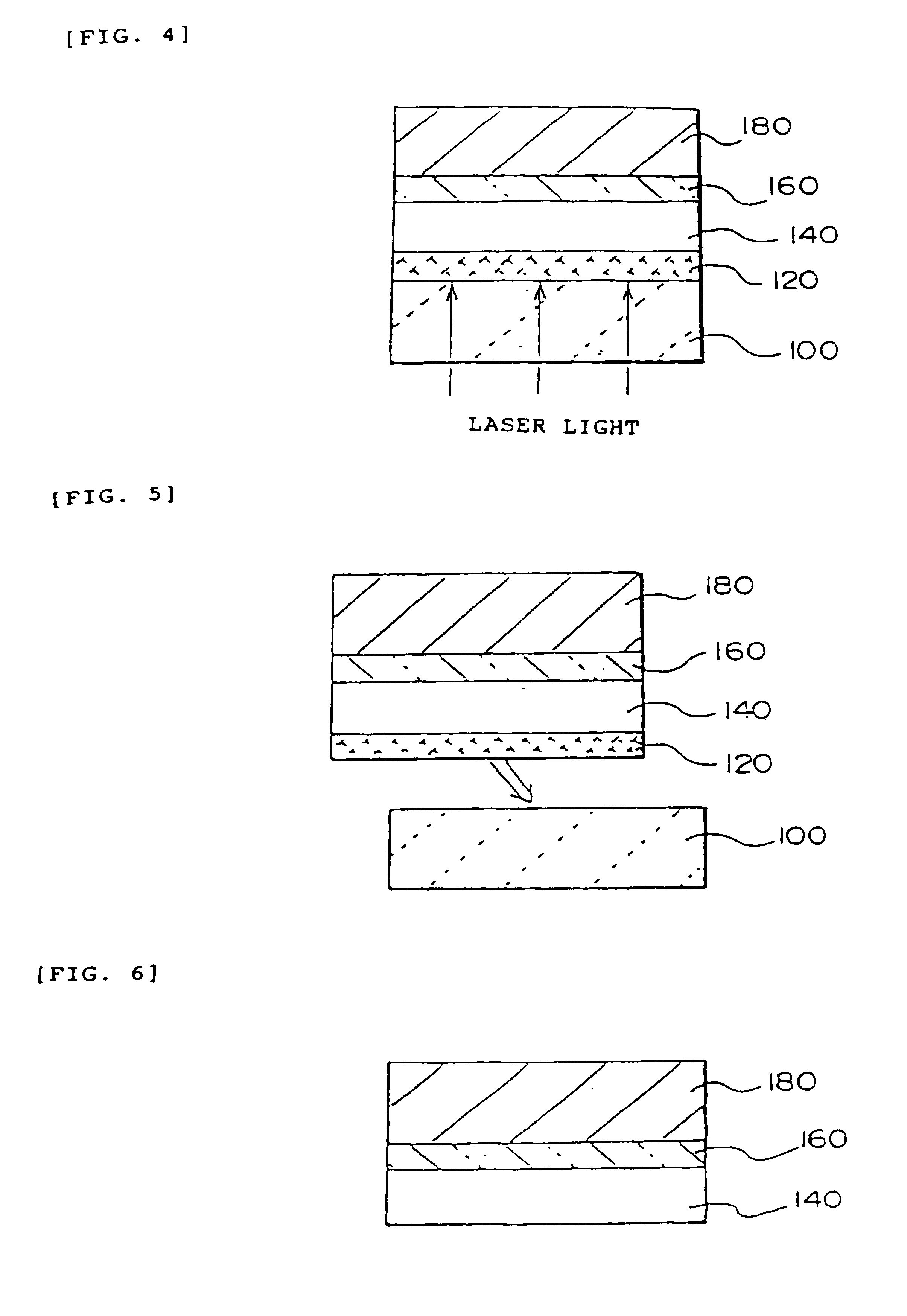

Manufacturing method of active matrix substrate, active matrix substrate and liquid crystal display device

InactiveUSRE38466E1Property for applicationMaintain good propertiesSolid-state devicesSemiconductor/solid-state device manufacturingLiquid-crystal displayActive matrix

A method of manufacturing an active matrix substrate is provided that uses a technique of transferring a thin film device. In forming thin film transistors and pixel electrodes on an original substrate before transfer, an insulator film such as an interlayer insulation film or the like, is previously removed before the pixel electrodes are formed. Further, the original substrate is separated by exfoliation to transfer the device to a transfer material to cause the pixel electrodes to partially appear in the surface or the vicinity of the surface of the device. This portion permits application of a voltage to a liquid crystal through the pixel electrode.

Owner:SAMSUNG ELECTRONICS CO LTD

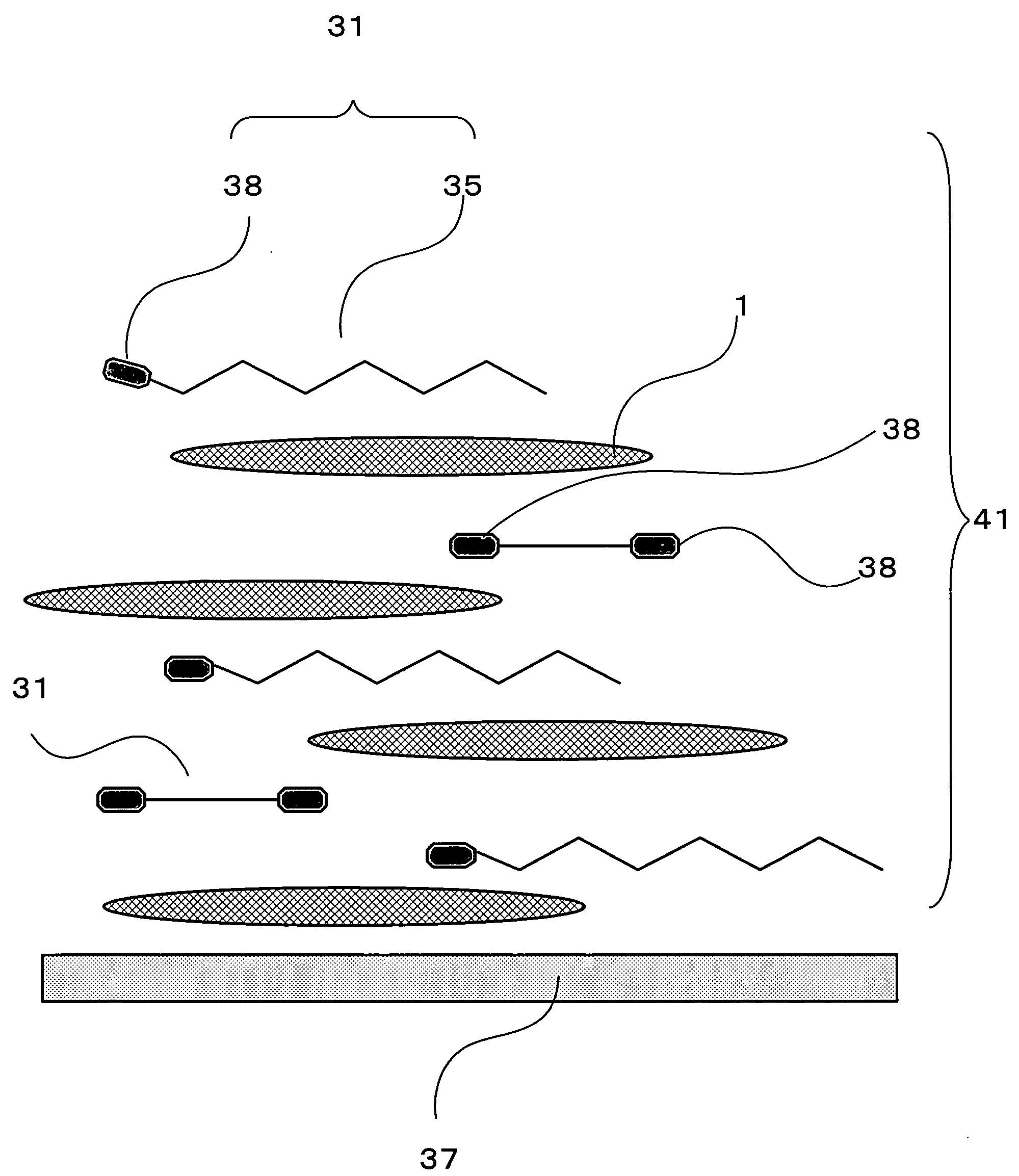

Liquid crystal display device and method of manufacture of the same

InactiveUS20060103804A1Improve reliabilityLittle and no tendency to exhibit white lineLiquid crystal compositionsNon-linear opticsLiquid-crystal displayReduced contrast volume

A liquid crystal composition, comprising a liquid crystal and a polymerizable compound capable of polymerization by means of light, heat, or a combination thereof, is placed in the gap between two parallel substrates on which are formed a pair of electrodes, and the polymerizable compound is polymerized to form a liquid crystal layer and a resin film. A liquid crystal display device is manufactured accordingly. The polymerizable compound comprises a monofunctional polymerizable compound, and the dipole moment of the monofunctional polymerizable compound is 4 debyes or lower. Thus, a liquid crystal display device, with high reliability, and of excellent quality with little or no contrast reduction due to white lines, is provided.

Owner:SHARP KK

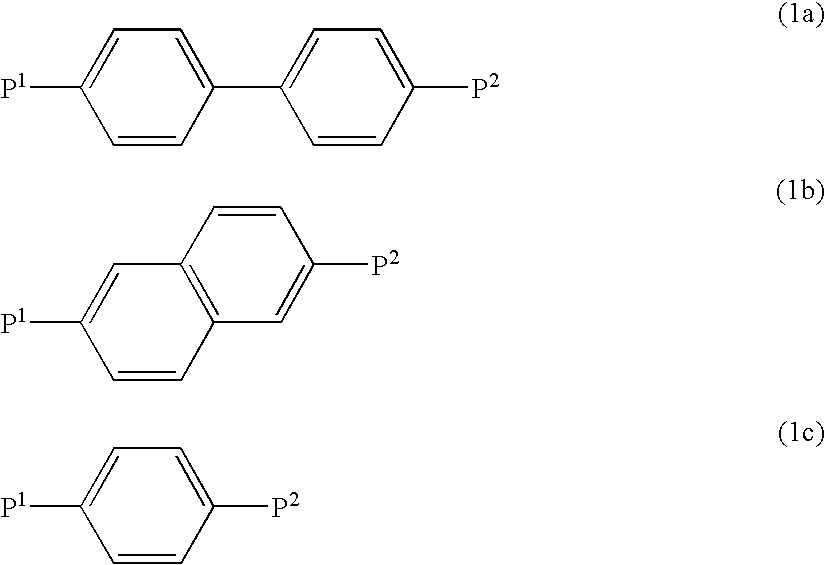

Liquid crystal display device

InactiveUS7169449B2Reduced in image burnLiquid crystal compositionsThin material handlingCrystallographyLiquid-crystal display

A liquid crystal display device produced through the steps of injecting a polymerizable monomer-containing liquid crystal composition between two substrates and, while applying a voltage between opposing transparent electrodes of the substrates, polymerizing the monomer, wherein the polymerizable monomer contained in the liquid crystal composition has one or more ring or condensed ring structures and functional groups bonded directly to the ring or condensed ring structure.The monomer is preferably represented by the following general formula:P1-A1-(Z1-A2)n-P2wherein P1 and P2 are acrylates or the like, A1 and A2 are 1,4-phenylenes or the like, Z1 is —COO— or the like, and n is 0 to 2.

Owner:MERCK PATENT GMBH

Liquid crystal display apparatus

ActiveUS20050184952A1Increase contrastLess irregularityStatic indicating devicesNon-linear opticsLiquid-crystal displayEffect light

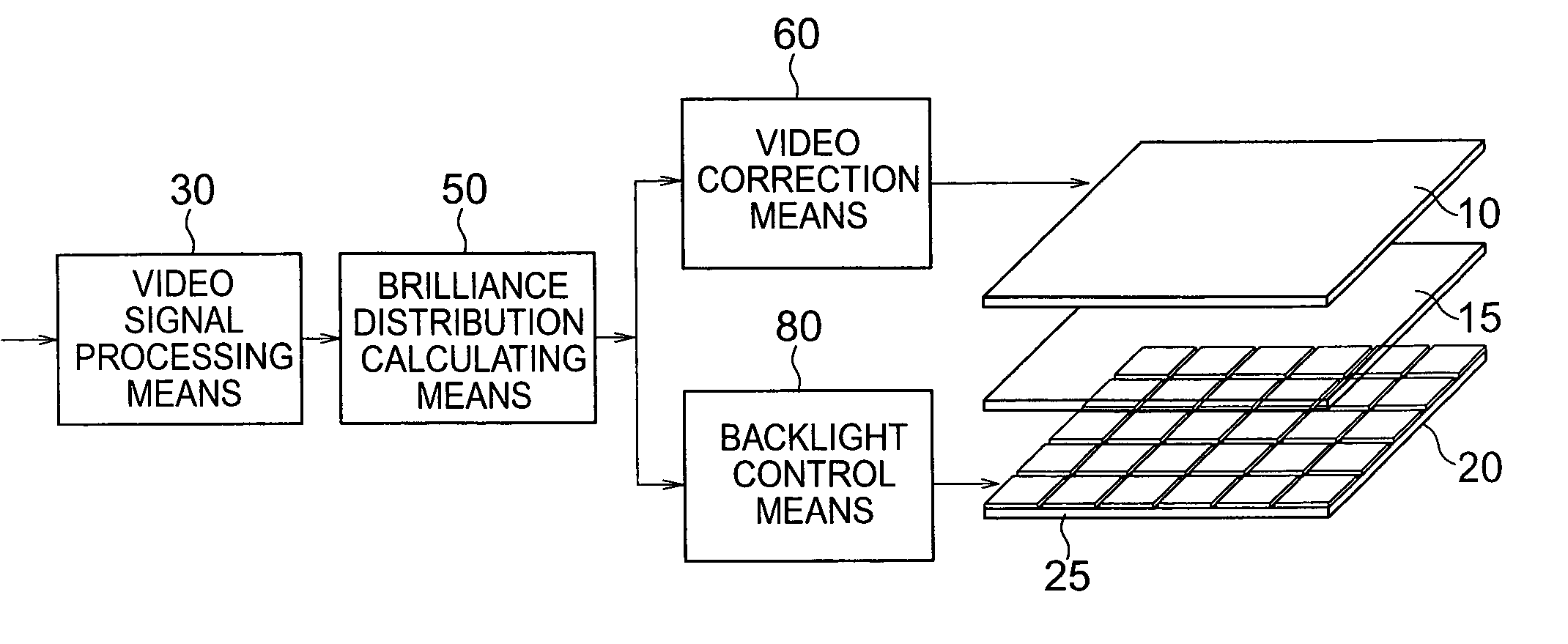

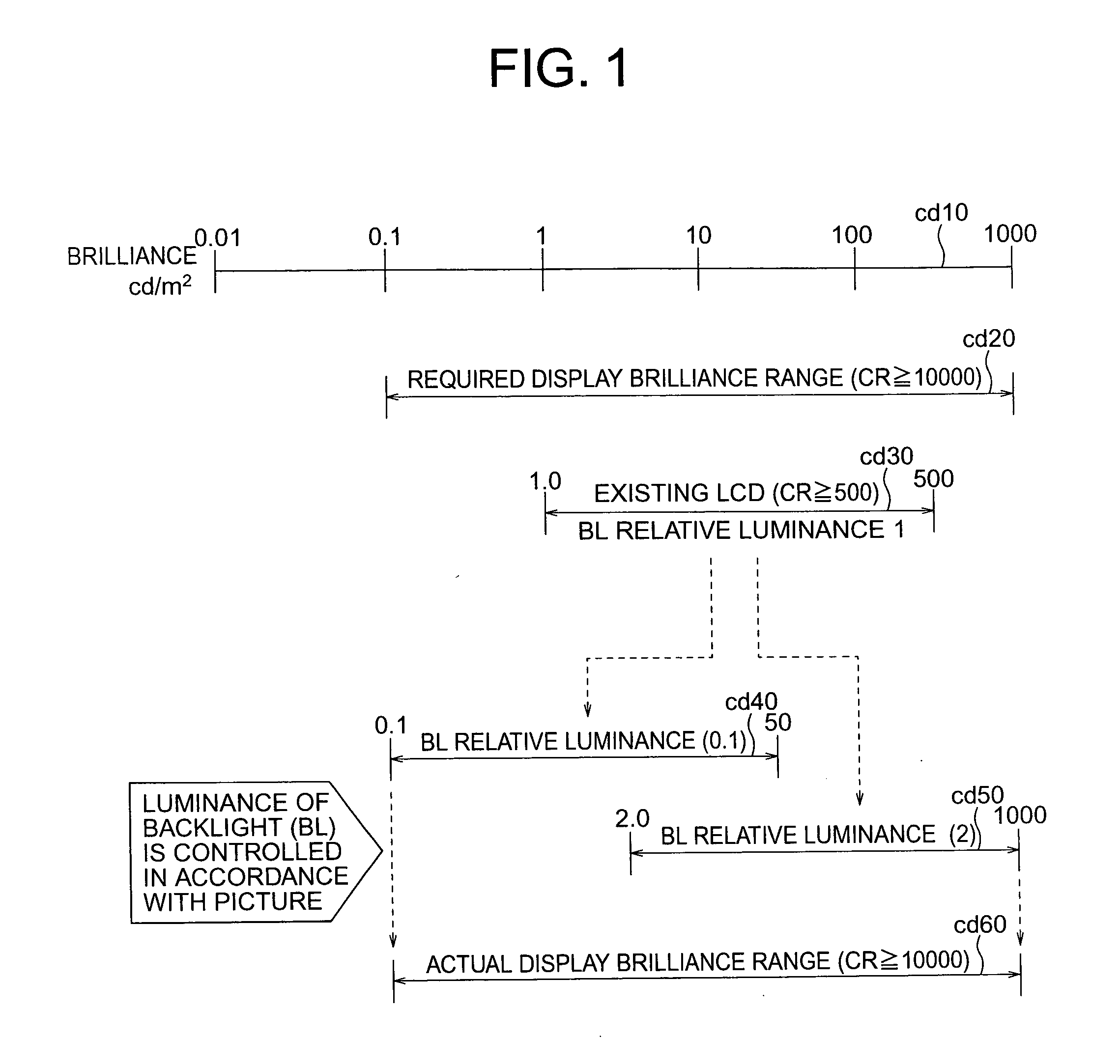

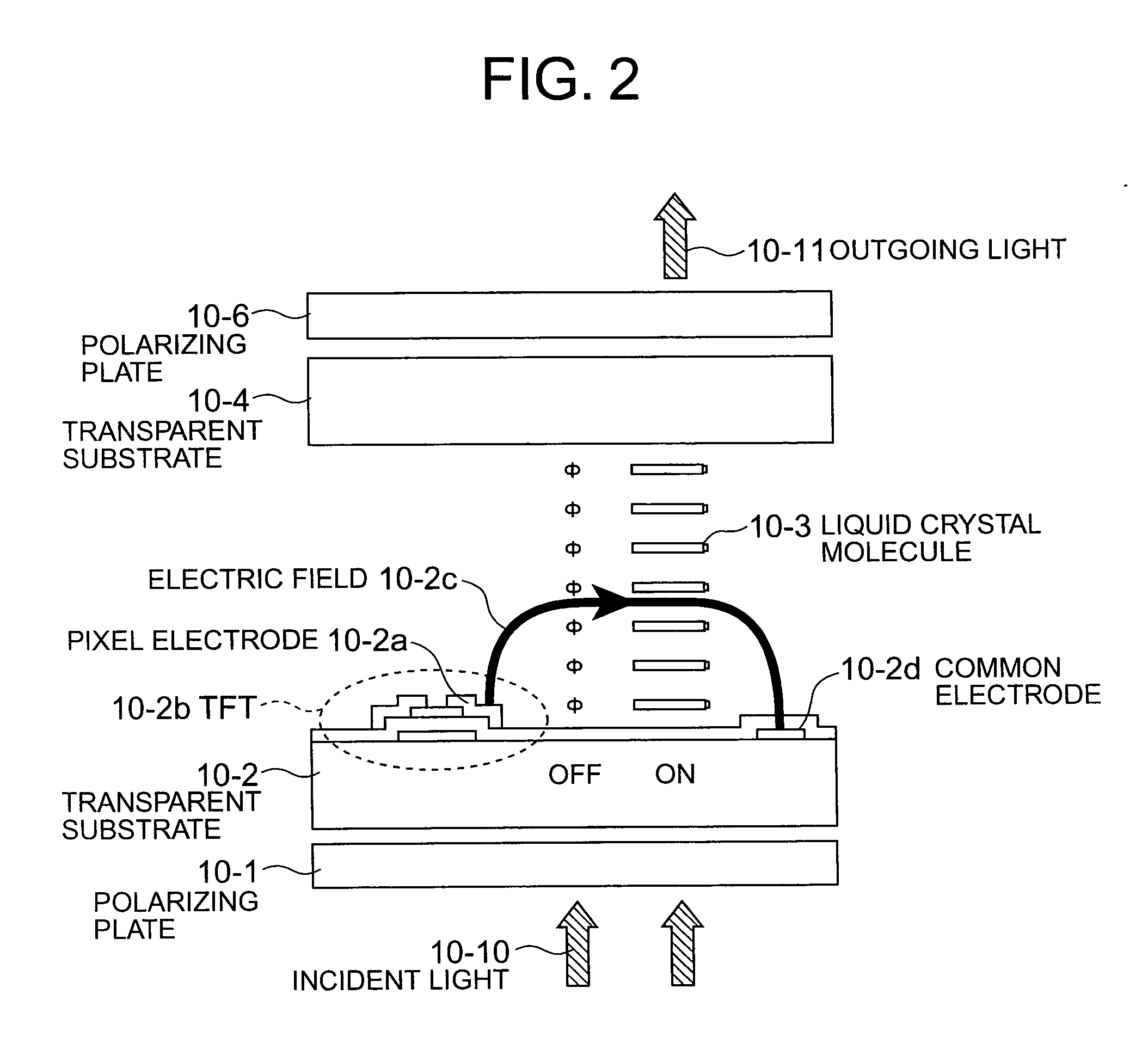

The video display apparatus has a light modulation device for forming a picture in accordance with a video signal and a lighting unit for irradiating, on the light modulation device, illumination light necessary to cause it to display the picture. In the apparatus, the lighting unit irradiates the illumination light in sequence of individual plural illumination light source partitive areas, a luminance distribution calculating unit calculates luminance distributions of video signals corresponding to the plural partitive areas to determine illumination light luminance levels of the individual partitive areas, an illumination controller controls rays of the illumination light of individual areas of the lighting unit on the basis of determination by the luminance distribution calculating unit, and a video corrector corrects the video signal inputted to the light modulation device on the basis of the determination by the luminance distribution calculating unit.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

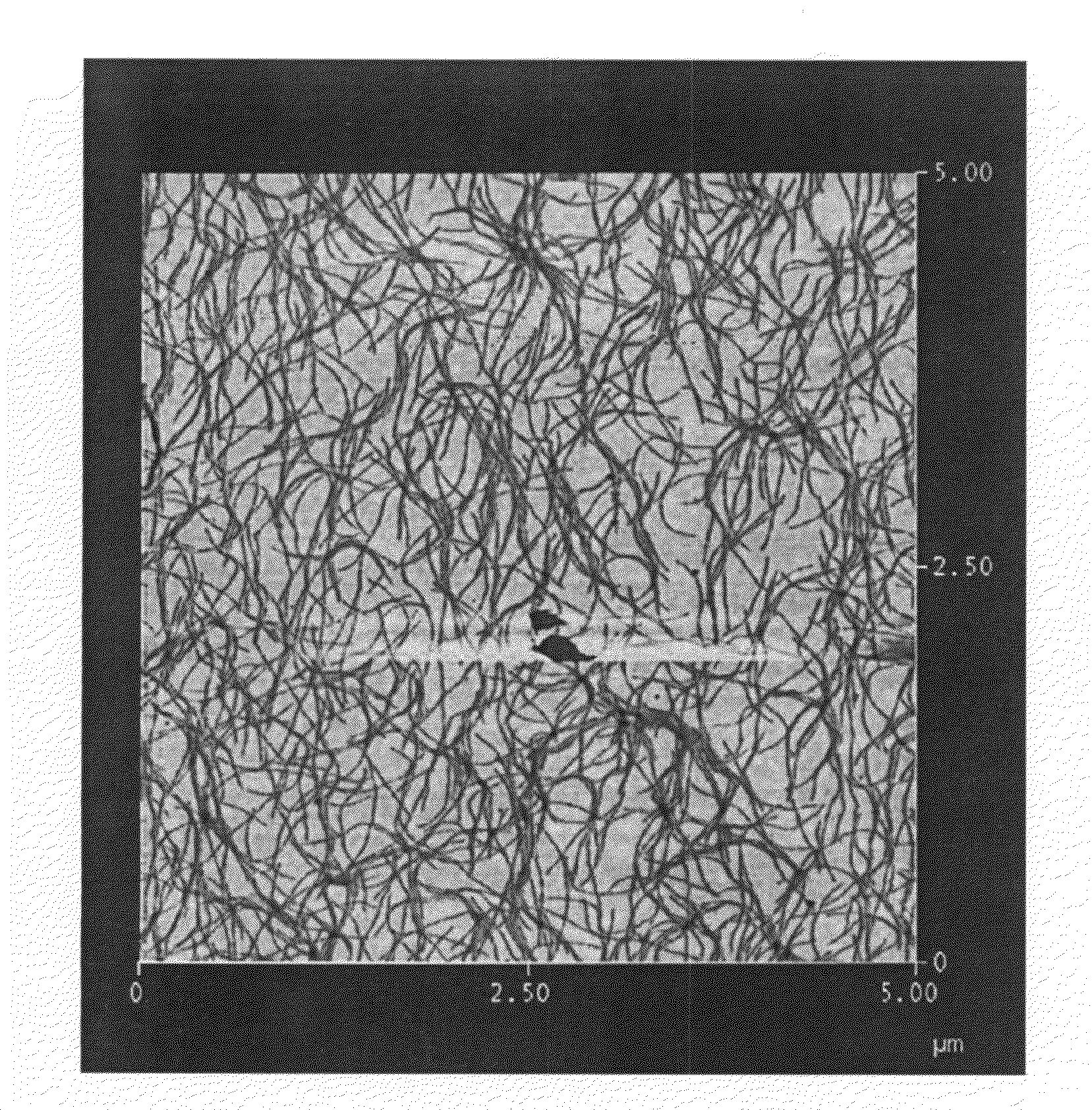

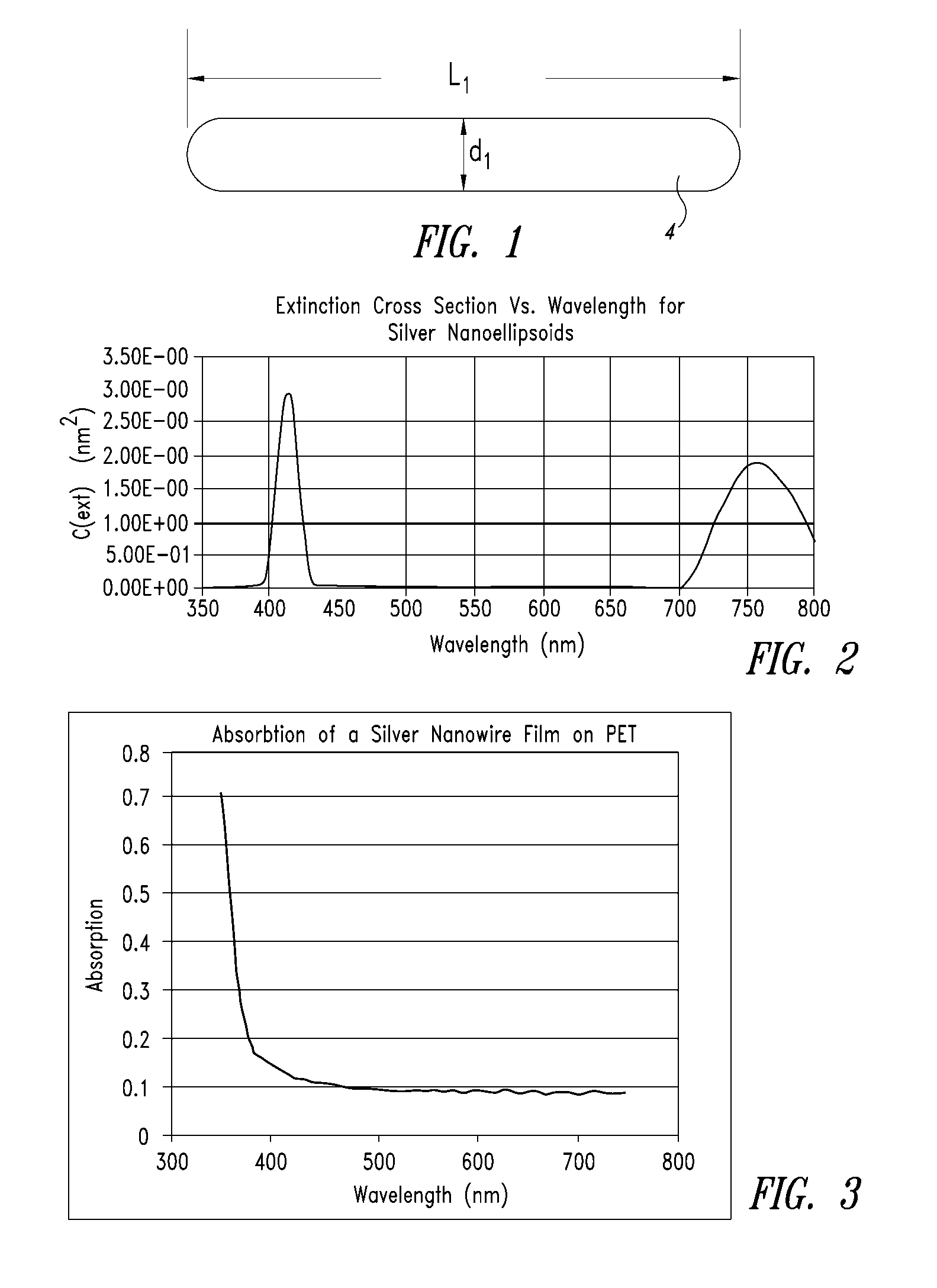

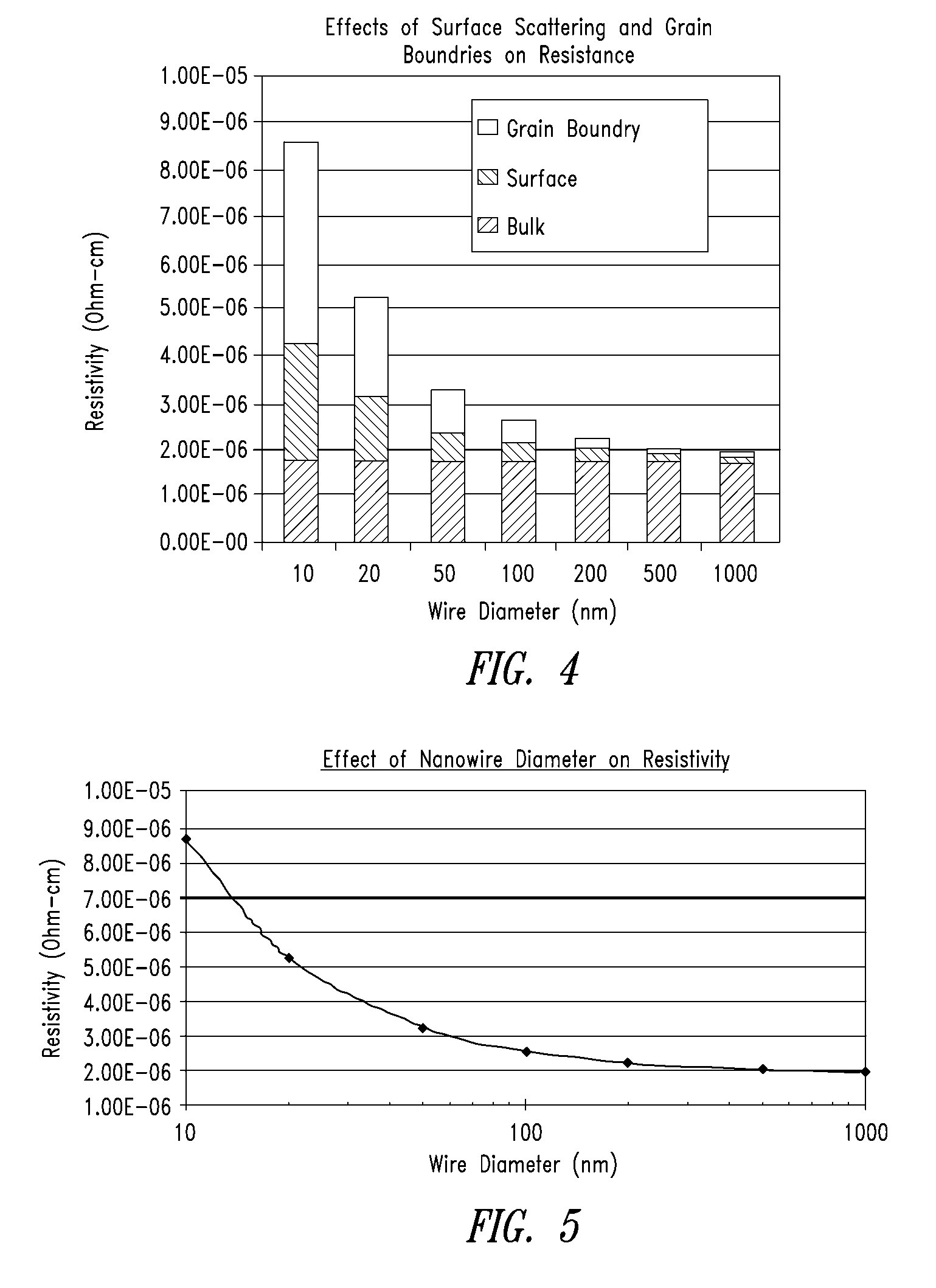

Nanowire-based transparent conductors and applications thereof

A transparent conductor including a conductive layer coated on a substrate is described. More specifically, the conductive layer comprises a network of nanowires that may be embedded in a matrix. The conductive layer is optically clear, patternable and is suitable as a transparent electrode in visual display devices such as touch screens, liquid crystal displays, plasma display panels and the like.

Owner:CHAMP GREAT INTL

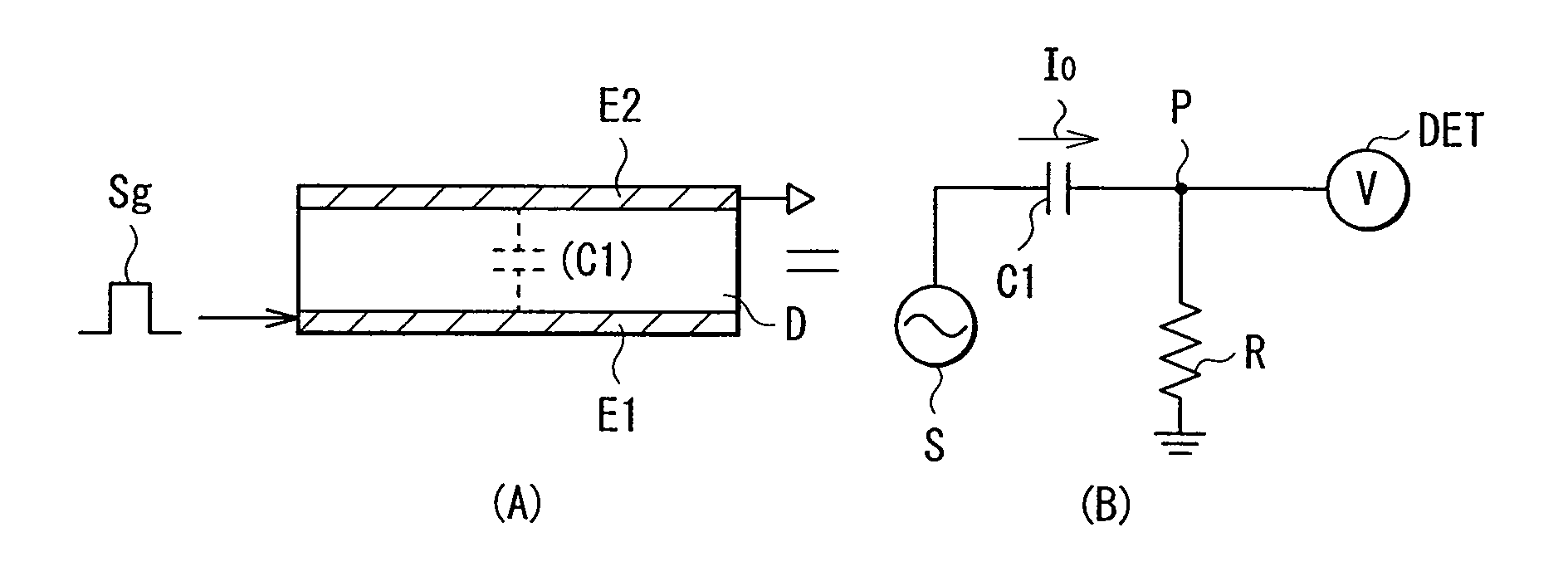

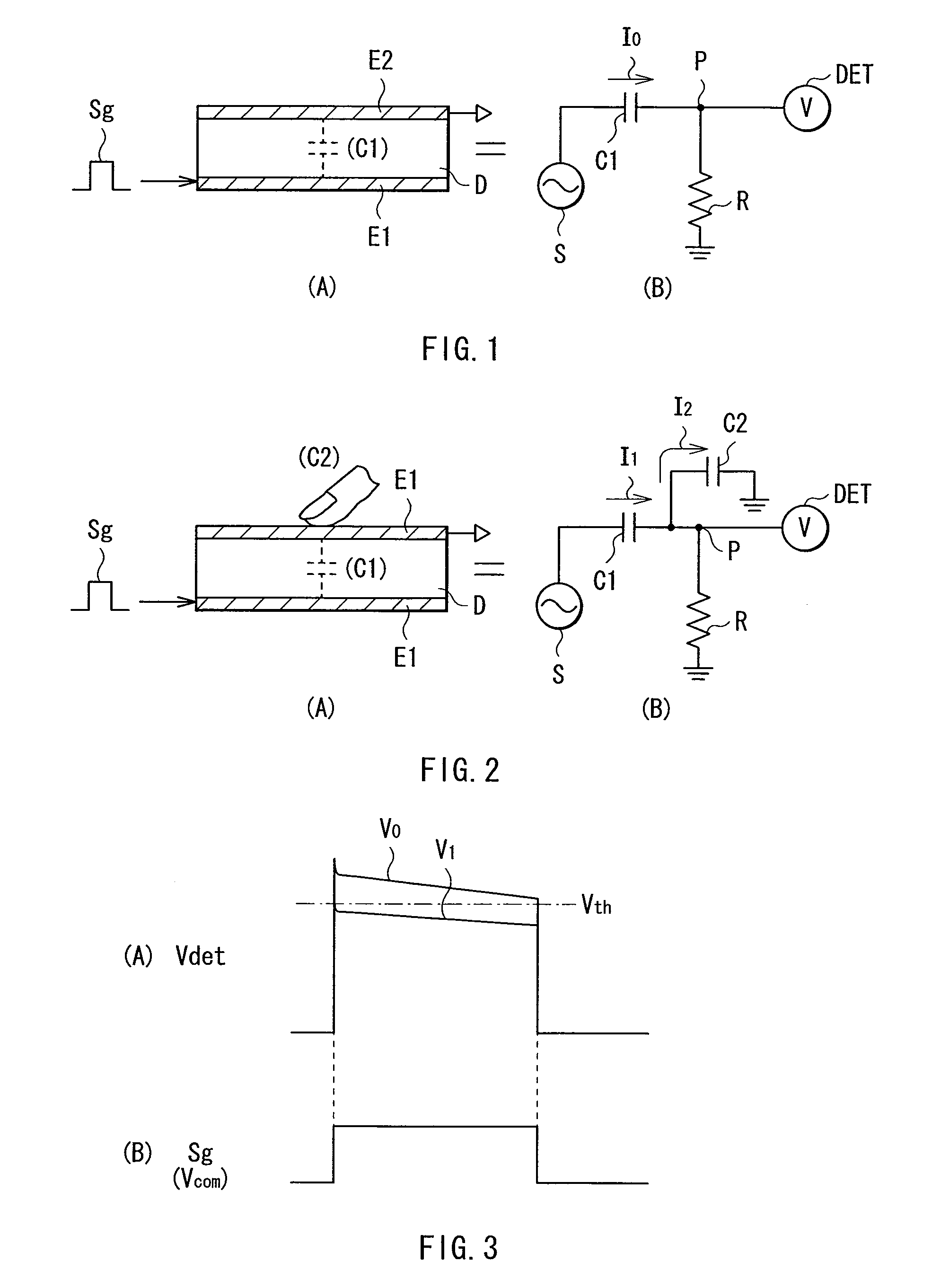

Display device with touch sensor

ActiveUS20100182273A1Improve design flexibilityEasy to integrateStatic indicating devicesNon-linear opticsCapacitanceLiquid-crystal display

A common electrode 43 for display, which is originally provided in a liquid crystal display element, is also used as one (drive electrode) of a pair of electrodes for a touch sensor, and the other (detection-electrode-for-the-sensor 44) of the pair of electrodes is newly formed. An existing common drive signal Vcom as a drive signal for display is used in common for a drive signal for the touch sensor. A capacitance is formed between the common electrode 43 and the detection-electrode-for-the-sensor 44, and touch detection is performed by utilizing a change of this capacitance caused by a finger touch of a user. Thus, a display device with a touch sensor is also applicable to a mobile device in which electric potential of the user is inconstant in many cases. The newly-provided electrode is only the detection-electrode-for-the-sensor 44, and it is unnecessary to newly prepare a drive signal for the touch sensor. Therefore, the configuration is simple.

Owner:JAPAN DISPLAY INC

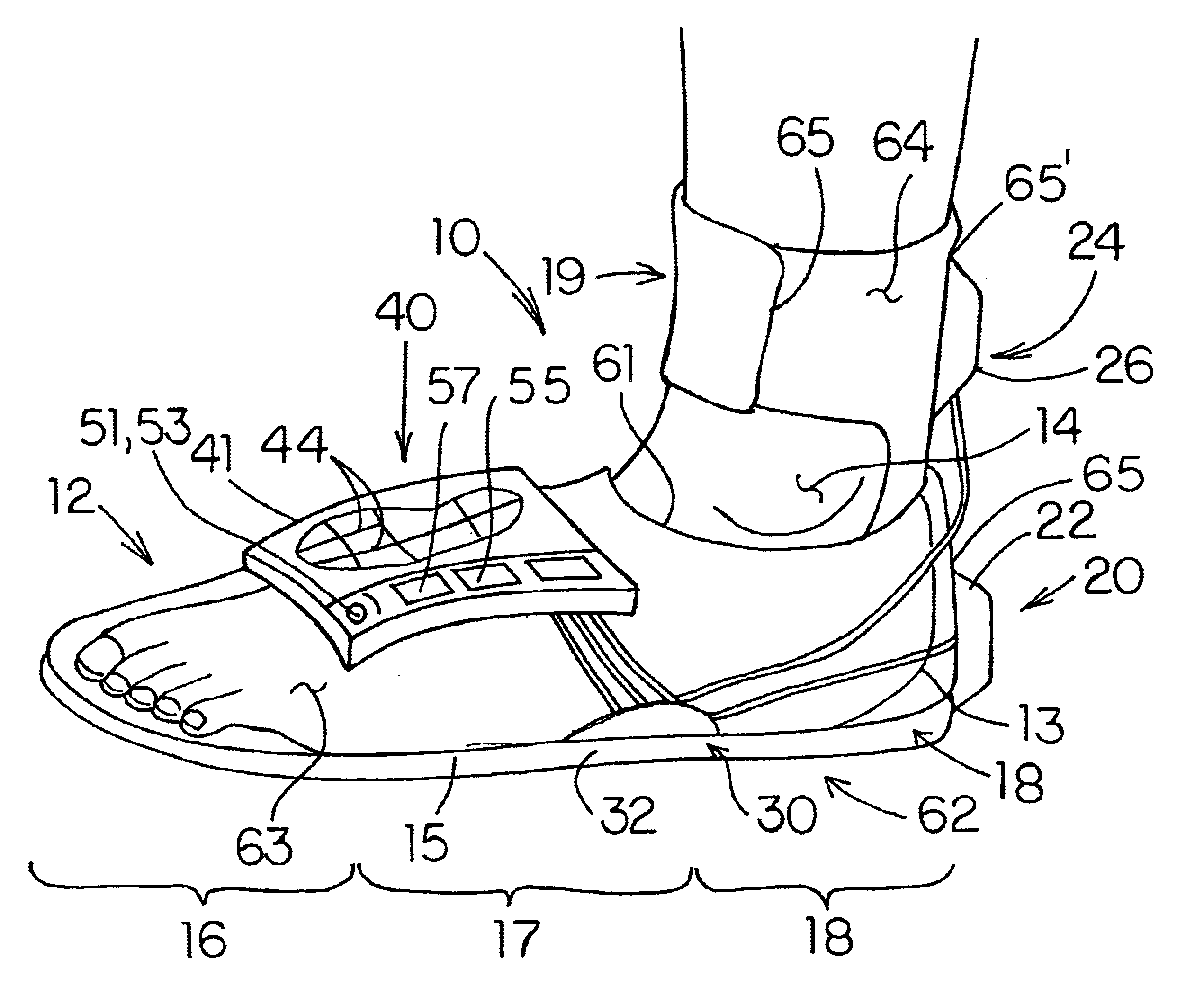

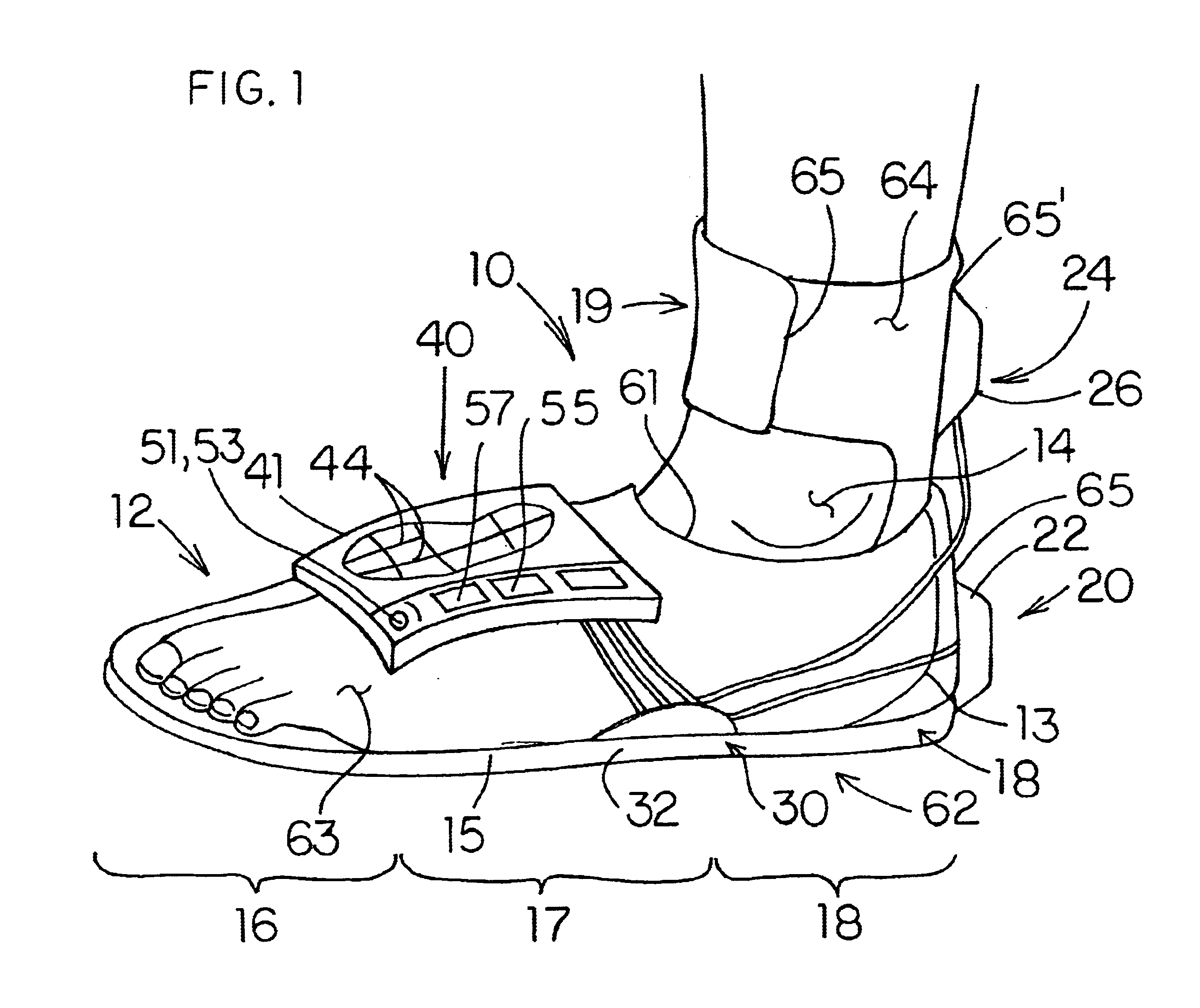

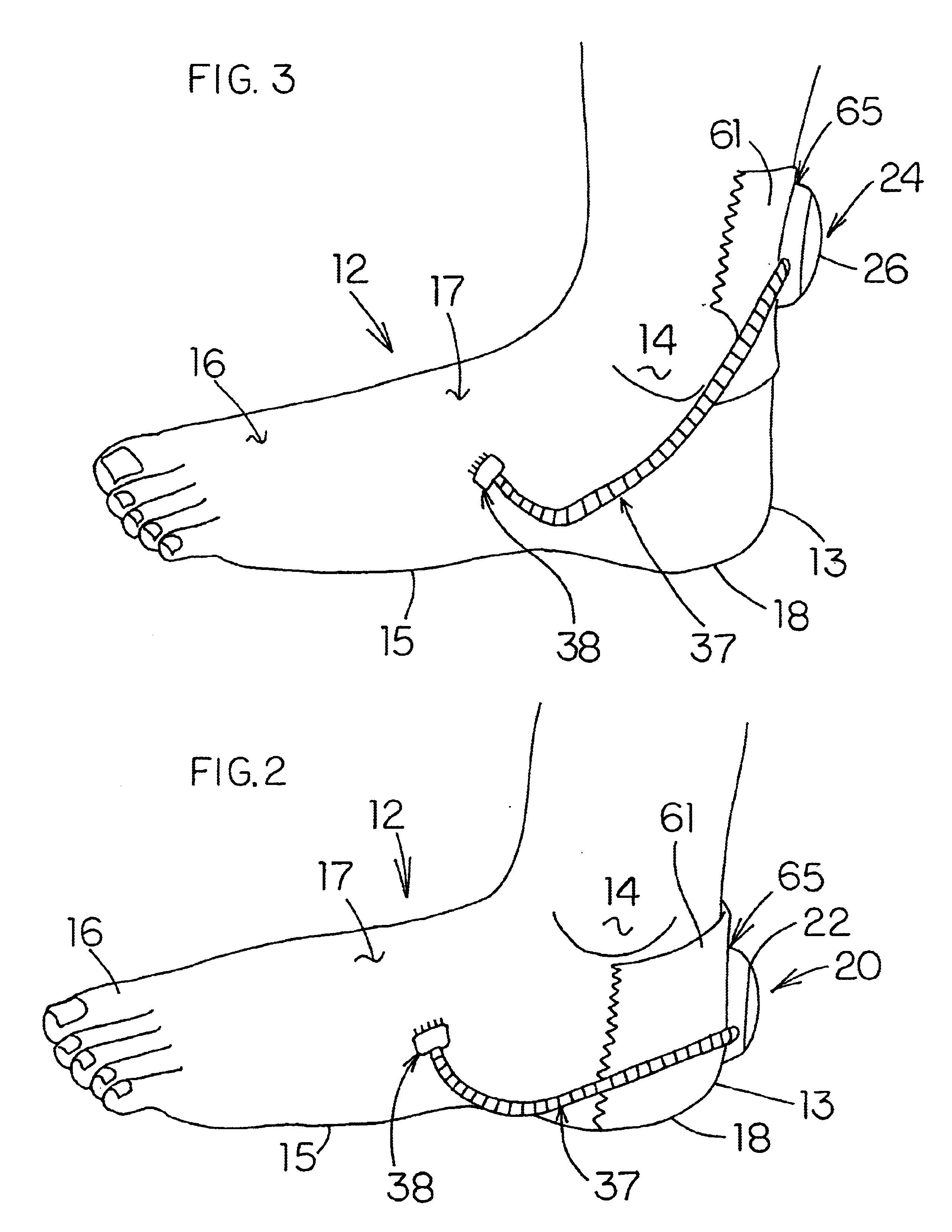

Portable system for analyzing human gait

InactiveUS6836744B1Input/output for user-computer interactionInertial sensorsAccelerometerAngular velocity

The invention is a portable gait analyzer comprising of at least one independent rear foot motion collection unit, at least one independent lower shank motion collection unit, plantar pressure collection unit, at least one processing and display unit, and a soft casing unit. A plurality of accelerometers, rate sensors, force sensor resistors, and pressure sensors provide for the acquisition of acceleration signals, angular velocity signals, foot force signals, and foot pressure signals to be processed. At least one central processing unit, a plurality of memory components, input / output components and ports, telemetry components, calibration components, liquid crystal displays components for the processing and outputting of three dimensional acceleration, angular velocity, tilt, and position. The rearfoot motion collection unit and lower shank motion collection unit interact with the processing and display unit to calculate rear foot kinematic data crucial to identify the motions of pronation and supination. The plantar pressure collection unit interacts with the processing and display unit to calculate plantar pressure data crucial to identify the center of pressure line and excessive and abnormal loads on the sole of the foot. These factors of rear-foot kinematics and plantar pressure lead to gait style identification.

Owner:ADVANCED MOTION TECH INC

Led array systems

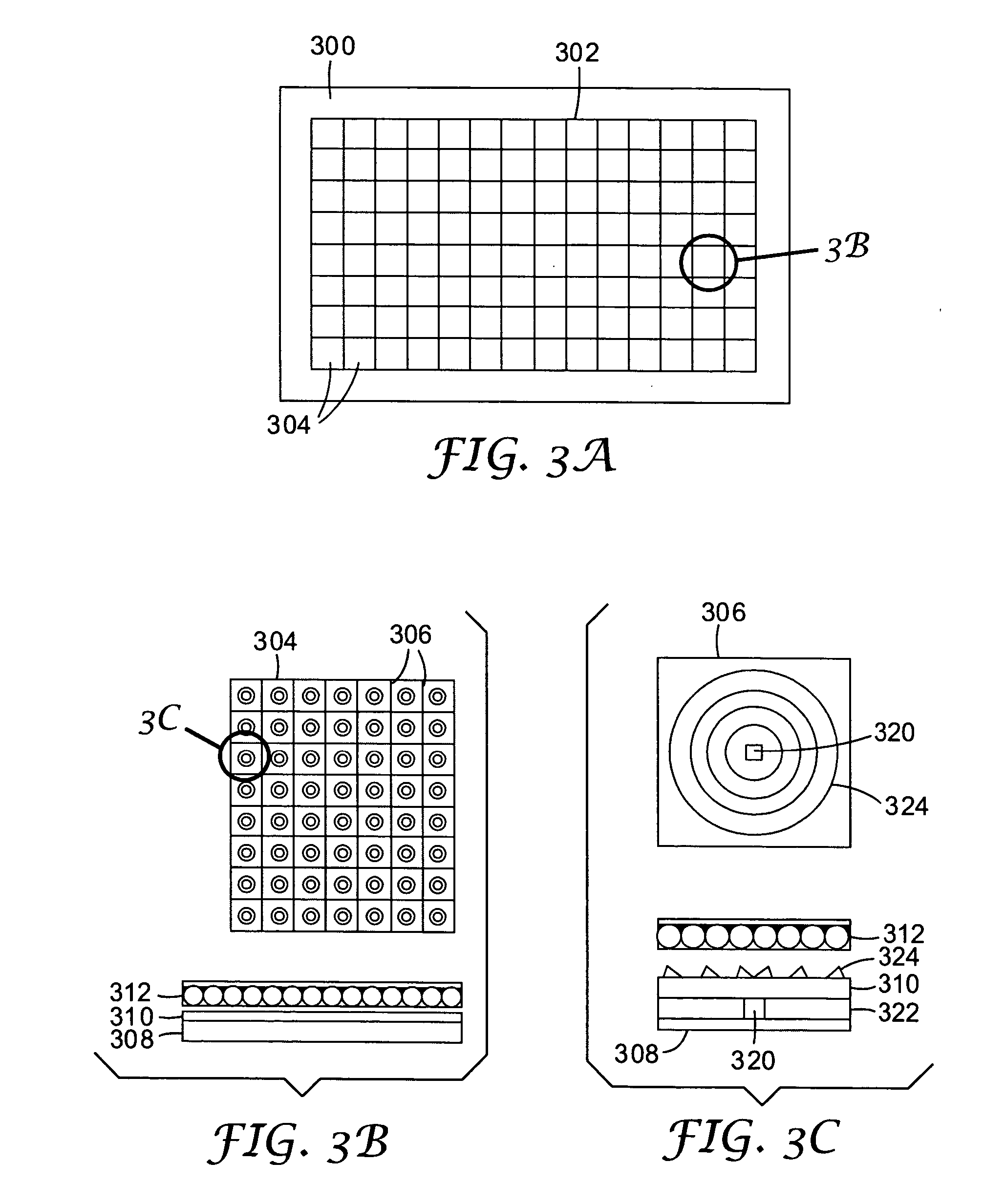

A light emitting diode (LED) array comprises an array of LEDs mounted to a substrate. The LEDs emit light in a direction generally perpendicular to the substrate. An optical sheet is disposed over the LEDs. At least a portion of light entering one side of the optical sheet from the LEDs is guided within the optical sheet in a direction generally parallel to the substrate. Light extraction features direct light from the optical sheet in a generally forward direction. Such an array is useful for several applications, including space lighting, direct information display and backlighting of liquid crystal displays. The light spreading effect of the optical sheet reduces the amount of black space between LED pixels.

Owner:3M INNOVATIVE PROPERTIES CO

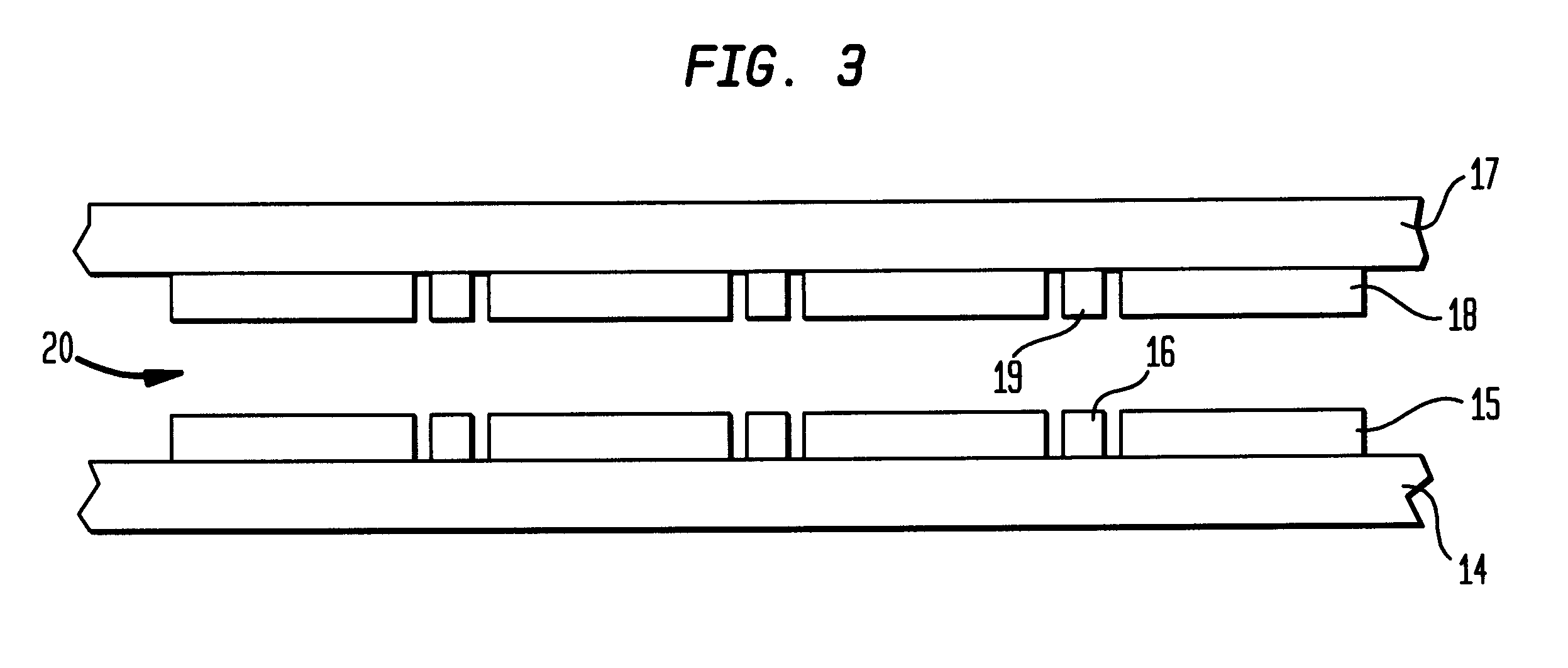

Method and apparatus for filling liquid crystal display (LCD) panels

InactiveUS6055035AElectroluminescent light sourcesVessels or leading-in conductors manufactureLiquid-crystal displayEngineering

A system, apparatus, and method for filling a display panel having first and second plates, with liquid crystal material, includes a nozzle for depositing a layer of liquid crystal material over a surface of a first plate of the panel, a scanning arm, coupled to the nozzle, for uniformly forming the layer of liquid crystal material over the surface of the first plate of the panel, and an attachment mechanism for placing the second plate over the first plate having the liquid crystal material thereover, thereby to form the display panel.

Owner:AU OPTRONICS CORP

Liquid crystal display element integrated with a touch sensor

The present invention provides a newly constituted liquid crystal display element incorporating a touch sensor unit.In a liquid crystal display element where a liquid crystal layer is inserted between a first substrate and a second substrate, a display electrode for displaying an image and a touch electrode for detecting a touch position are provided on the surfaces of the first substrate and the second substrate opposing with each other. The display electrode may be used as the touch electrode. A pillar-shaped spacer may be formed to support the first substrate and the second substrate. Additionally, the touch electrode may be provided on a convex-shaped part formed on the substrate.

Owner:AU OPTRONICS CORP

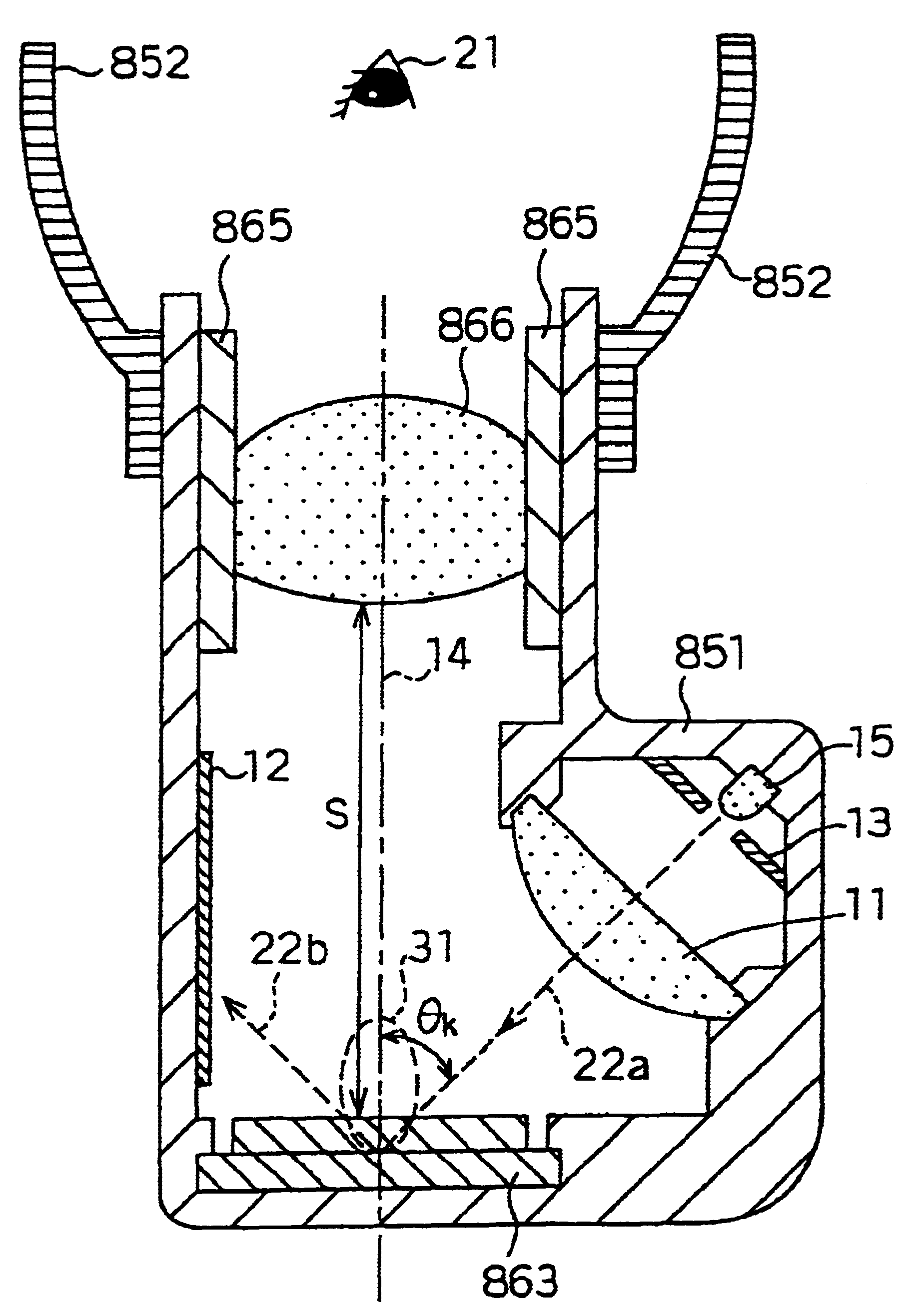

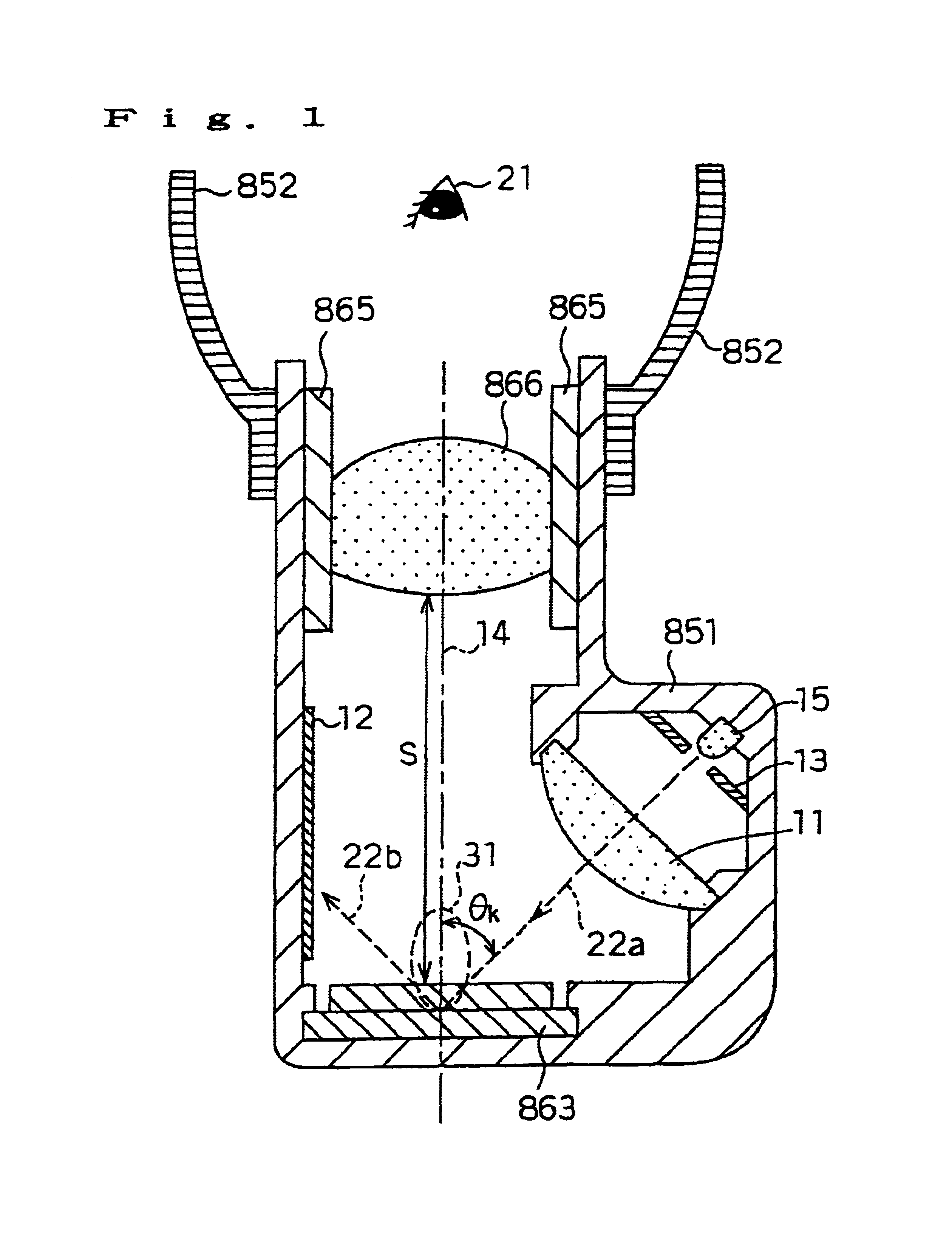

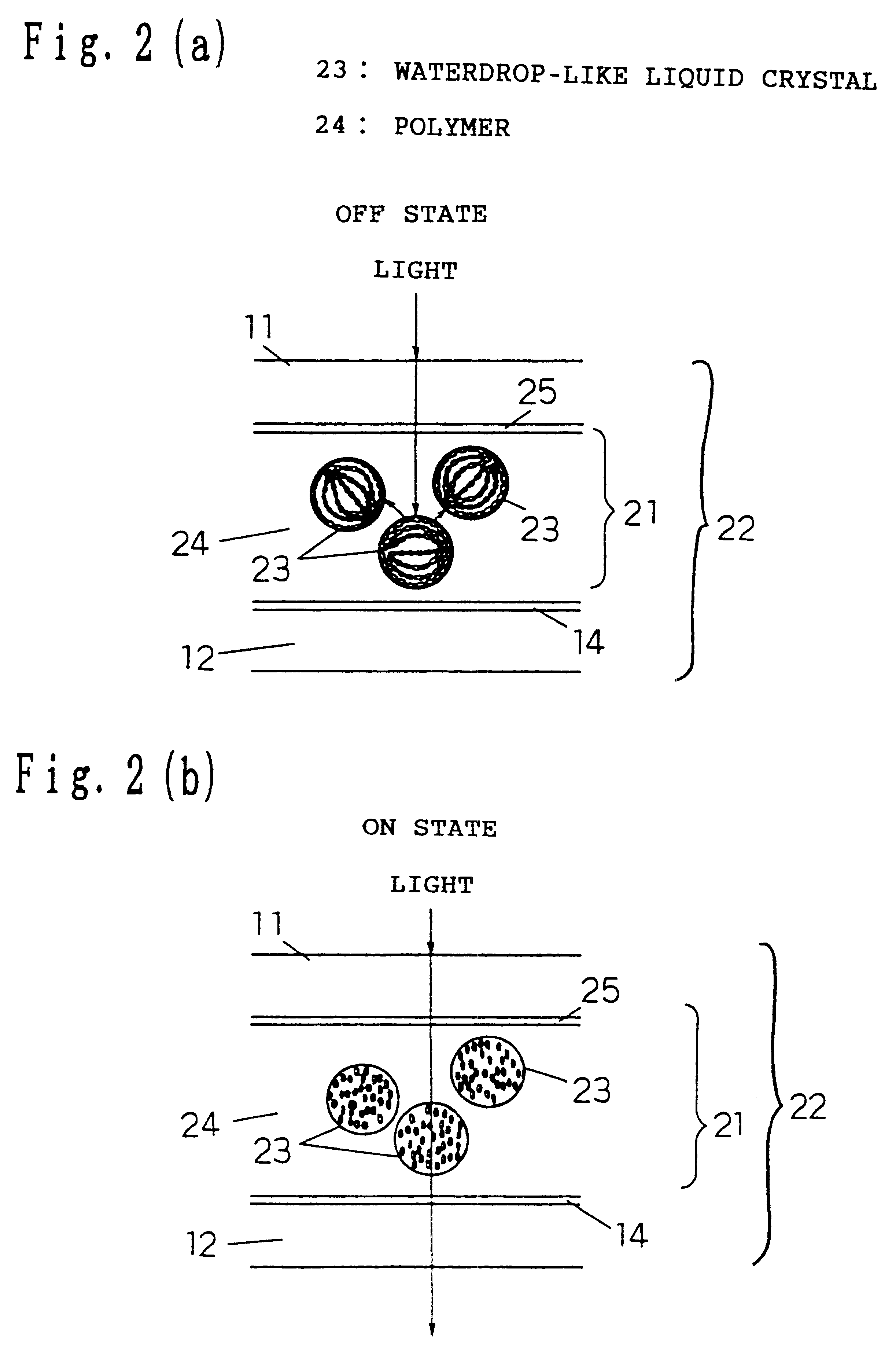

Illuminating apparatus, display panel, view finder, video display apparatus, and video camera mounting the elements

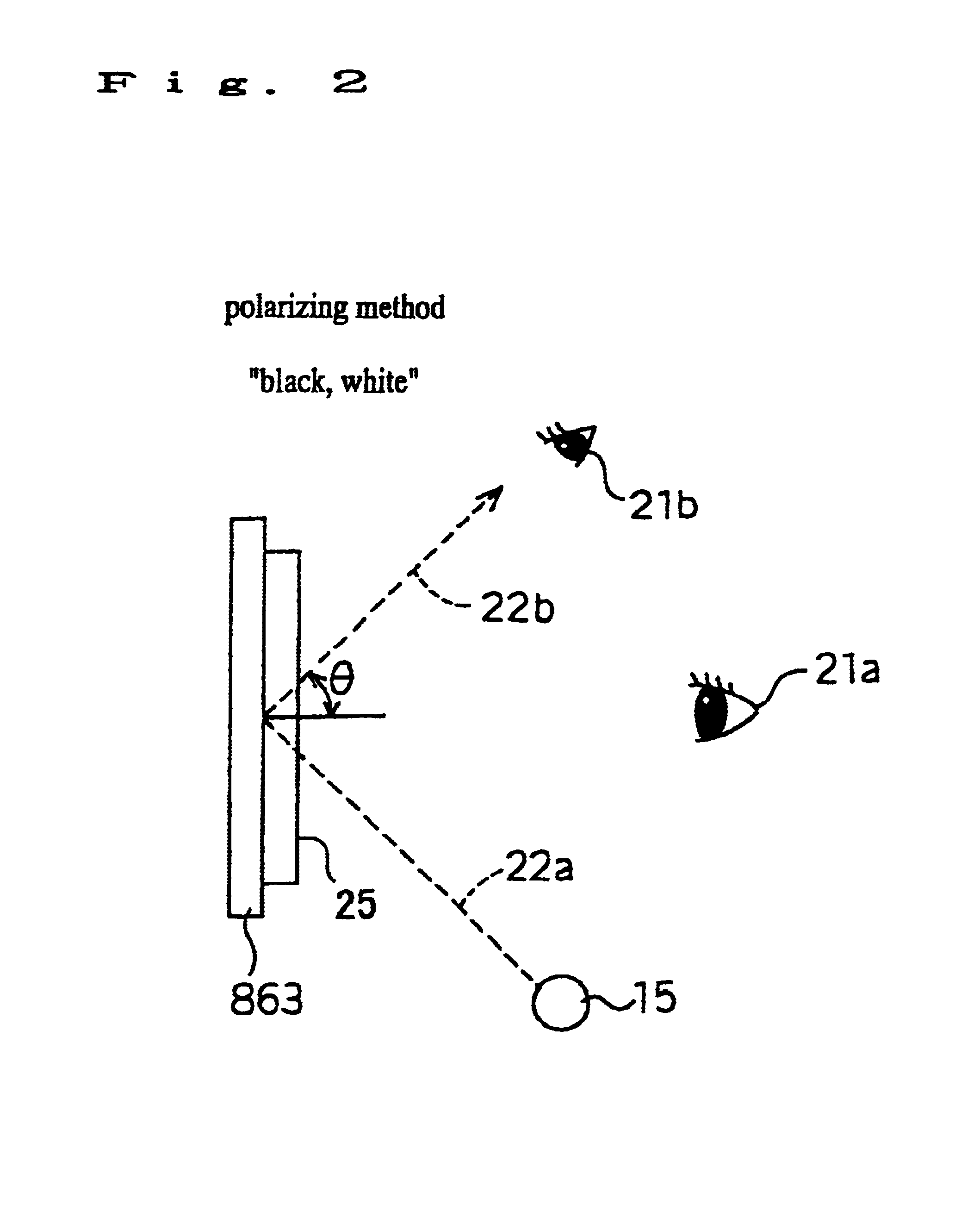

InactiveUS6992718B1Easy to watchEnlargedly observedTelevision system detailsColor television detailsEyepieceLiquid-crystal display

Light emitted from a white LED 15 is converted by a lens 11 into light having an excellent directionality. The light illuminates a display panel 863 from the direction of an angle θk. The display panel 863 is a polymer dispersed liquid crystal display panel in a normally white mode. The display panel 863 modulates incident light by scattering it, the scattered light is incident on a magnification lens 866, and light from the magnification lens reaches an eye 21 of the observer. Light which passes straight through a liquid crystal layer in the display panel 863 is absorbed by an optical absorbing film 12. The observer fixedly positions his / her eye 21 to an eyepiece cover 852 and observes the displayed image.

Owner:PANASONIC CORP

System for heat treatment of semiconductor device

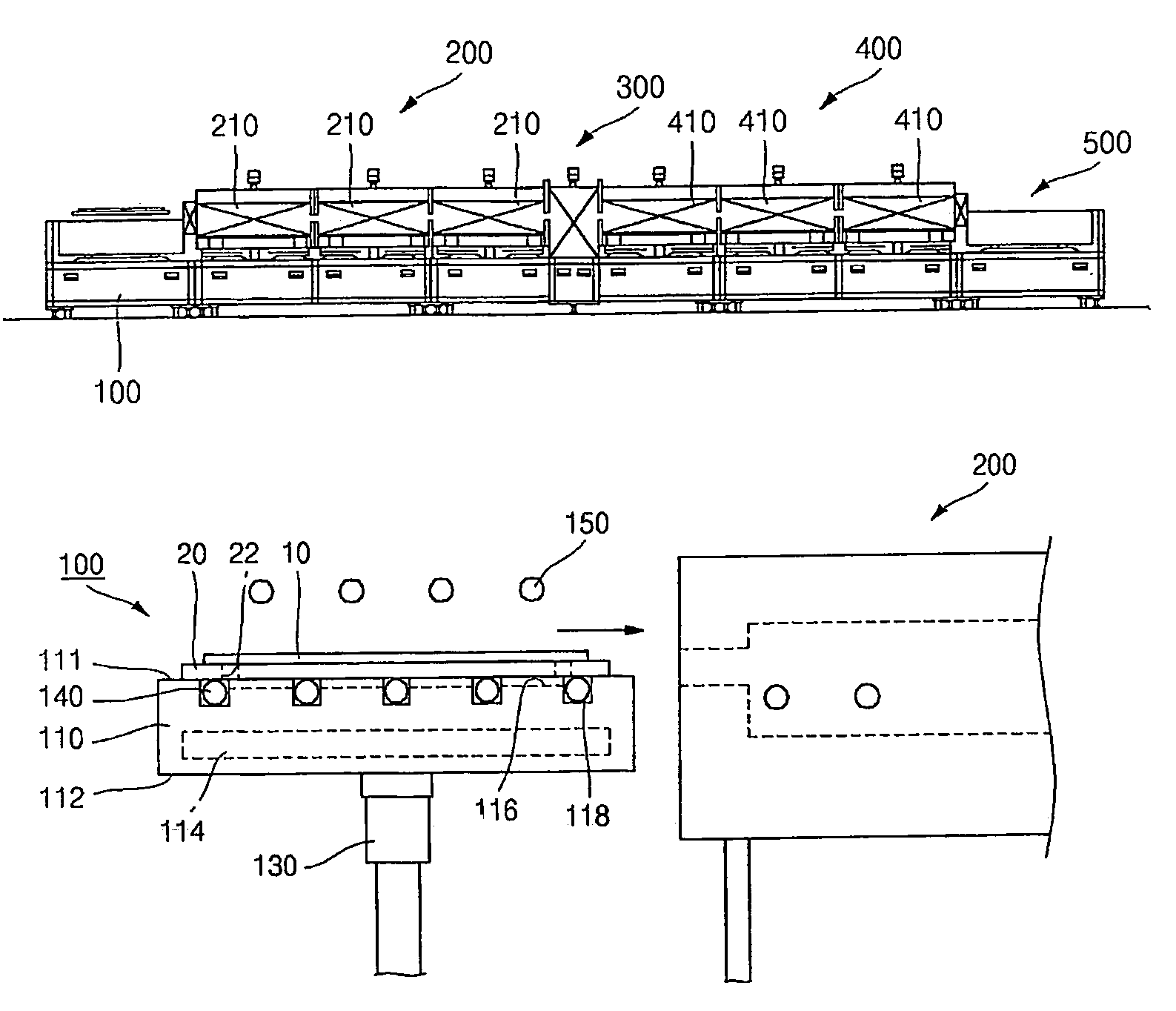

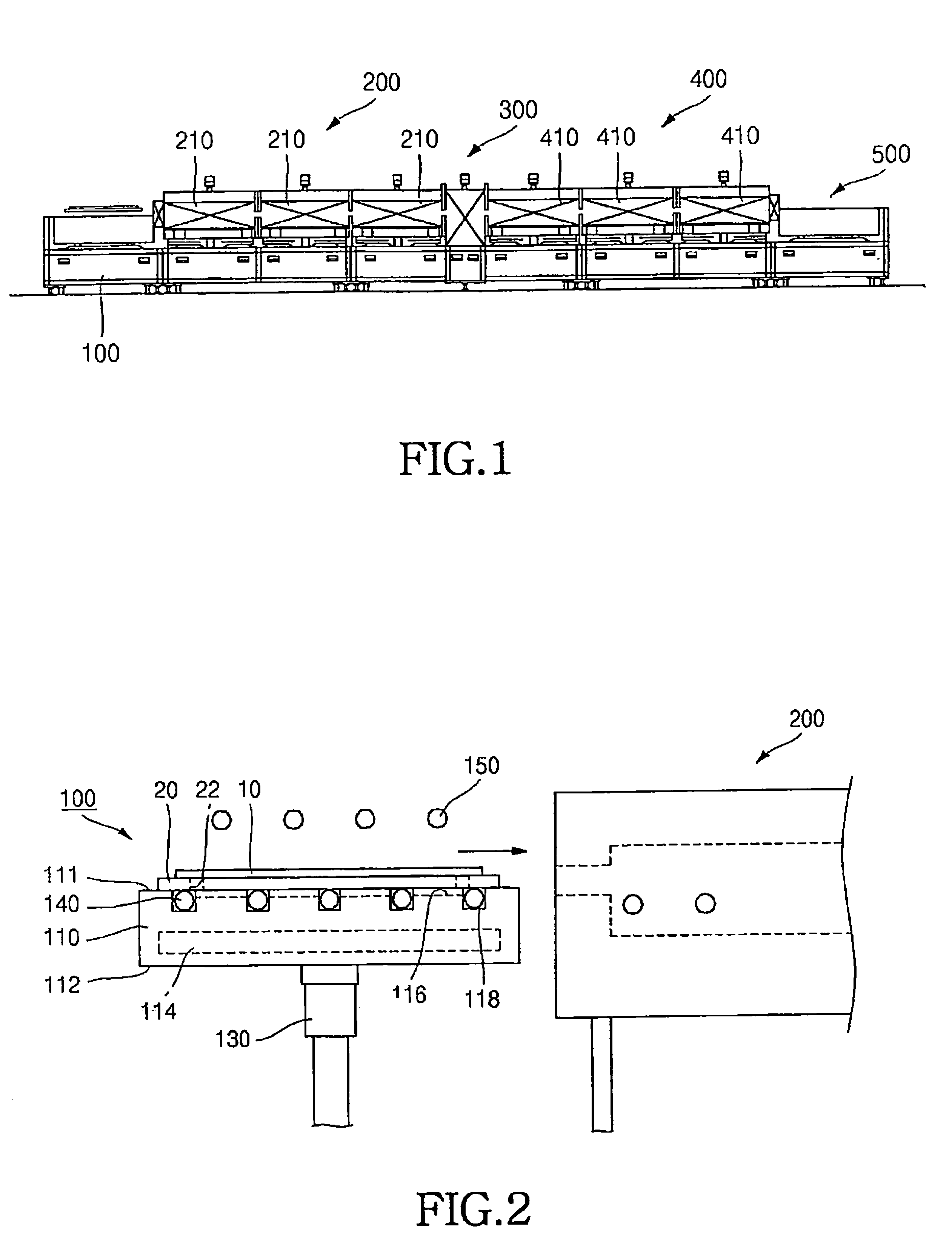

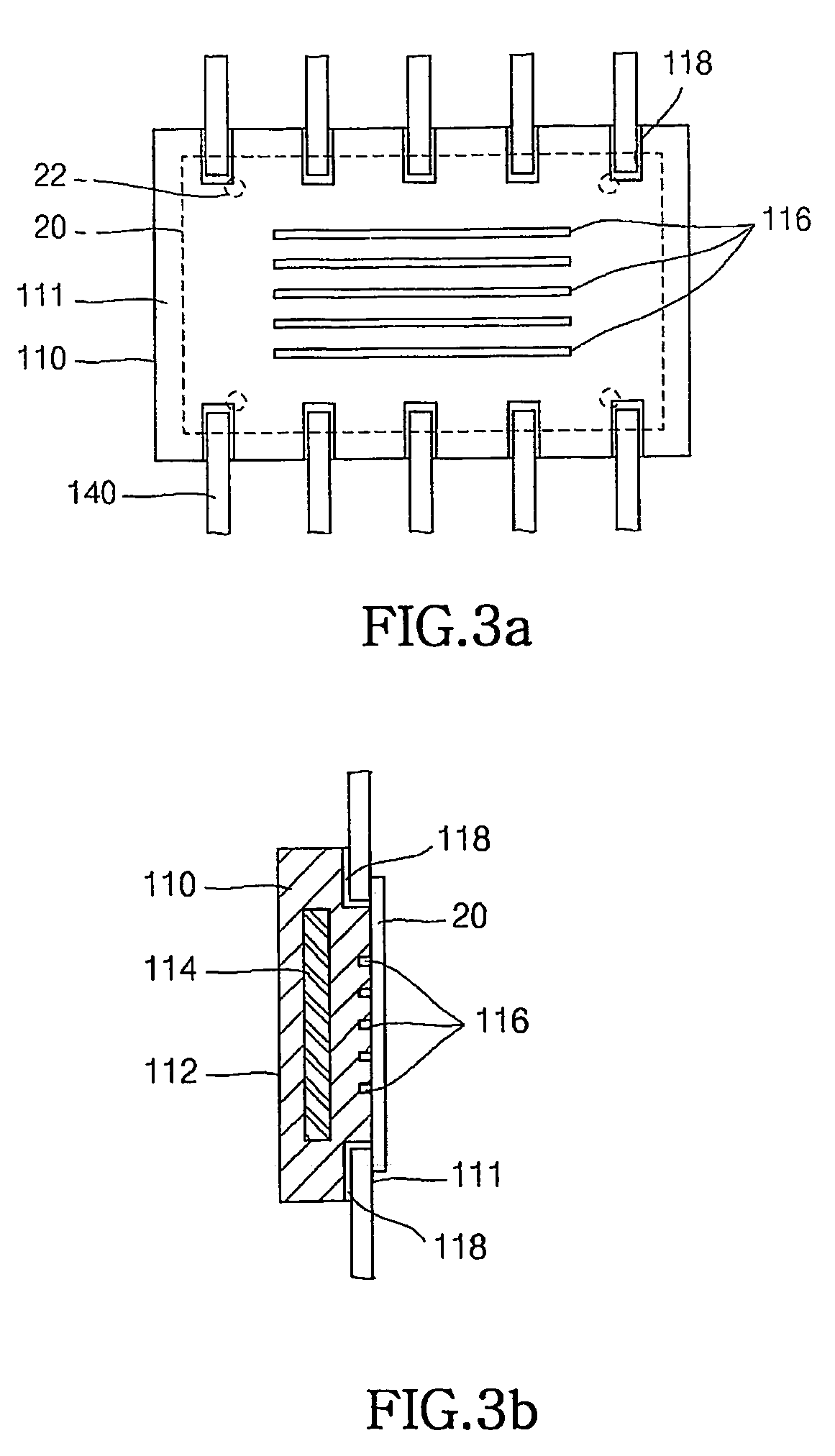

InactiveUS7989736B2Avoid damageIncrease temperatureFurnaces without endless coreSemiconductor/solid-state device manufacturingElectromotive forceSilicon thin film

Disclosed is a heat treatment system for semiconductor devices. The heat treatment system is used in a heat treatment process for semiconductor devices, such as a crystallization process for an amorphous silicon thin film or a dopant activation process for a poly-crystalline silicon thin film formed on a surface of a glass substrate of a flat display panel including a liquid crystal display (LCD) or an organic light emitting device (OLED). The heat treatment system transfers a semiconductor device after uniformly preheating the semiconductor device in order to prevent deformation of the semiconductor device during the heat treatment process, rapidly performs the heat treatment process under the high temperature condition by heating the semiconductor device using a lamp heater and induction heat derived from induced electromotive force, and unloads the semiconductor device after uniformly cooling the semiconductor device such that the semiconductor device is prevented from being deformed when the heat treatment process has been finished. The heat treatment system rapidly performs the heat treatment process while preventing deformation of the semiconductor device by gradually heating or cooling the semiconductor device.

Owner:VIATRON TECH INC

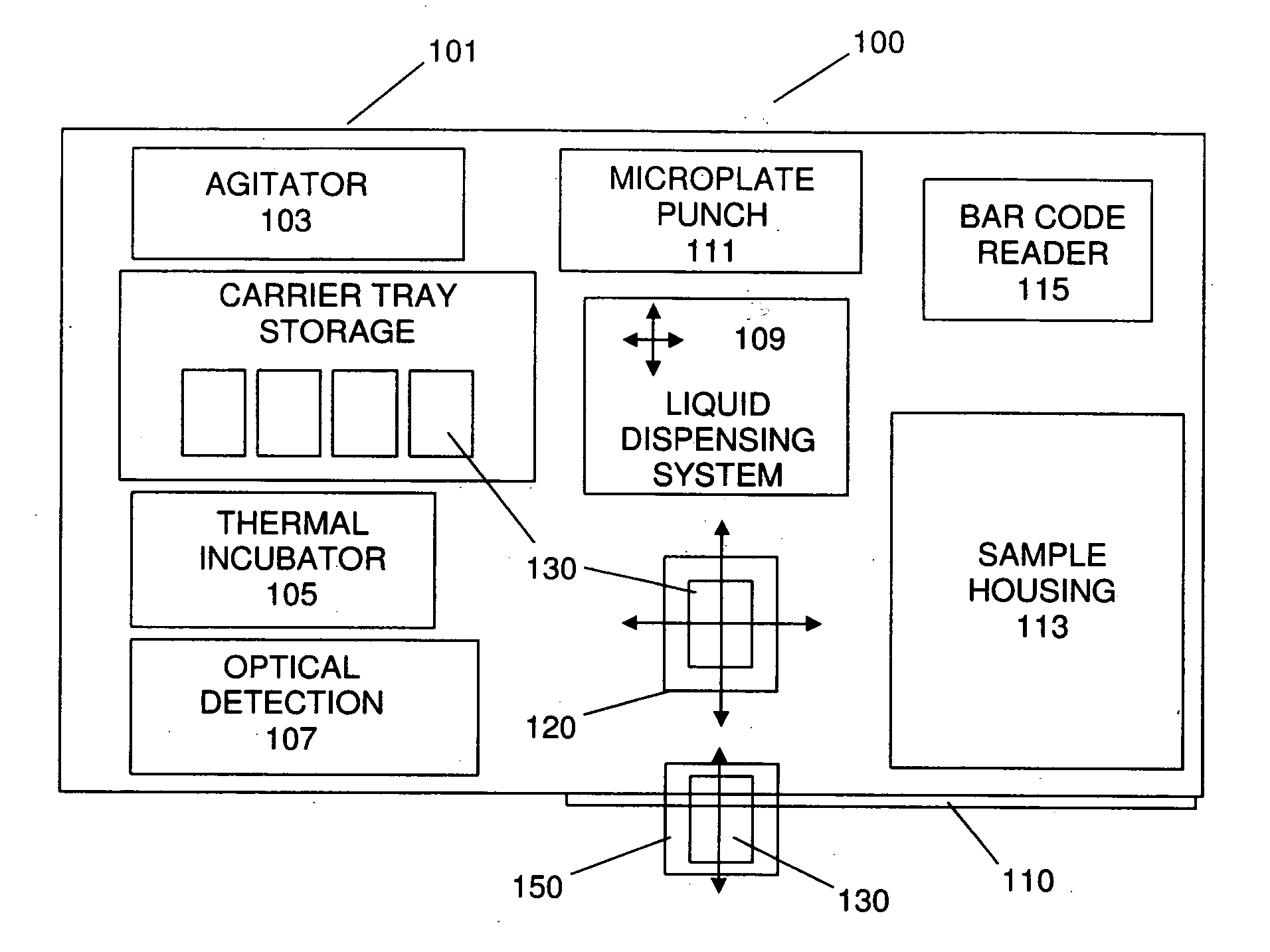

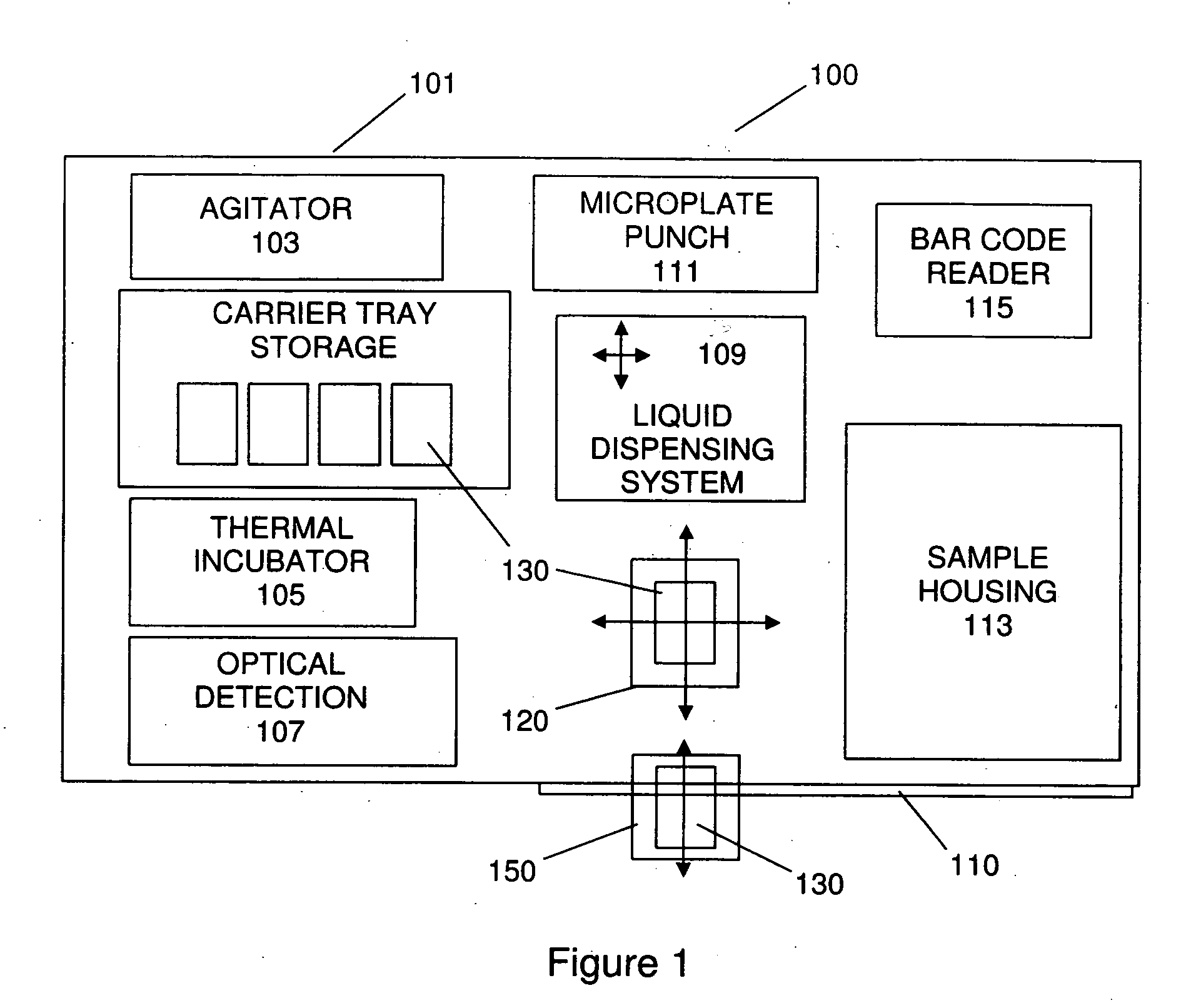

Automated analyzer

InactiveUS20060210435A1Minimal operator involvementEasy loadingBioreactor/fermenter combinationsBiological substance pretreatmentsLiquid-crystal displayBarcode

The present invention provides a bar-code driven, completely automated, microplate-based analyzer system for performing chemical, biochemical or biological assays. The analyzer is a modular, bench-top instrument that compactly integrates subsystems for sample dispensing, liquid handling, microplate transport, thermal incubation, vortexing, solid phase separation and optical reading. An internal processor is included for automating the instrument, and a user interface to facilitate communication with the operator via a touch-sensitive liquid-crystal display (LCD), and communicating with a remote network via multiple protocols. The analyzer includes firmware resident within the processing system and the user interface allows the operator to select pre-defined assay batch protocols and the user interface is configured in such as way so as to restrict an operator from programming the firmware.

Owner:NOVX SYST CANADA

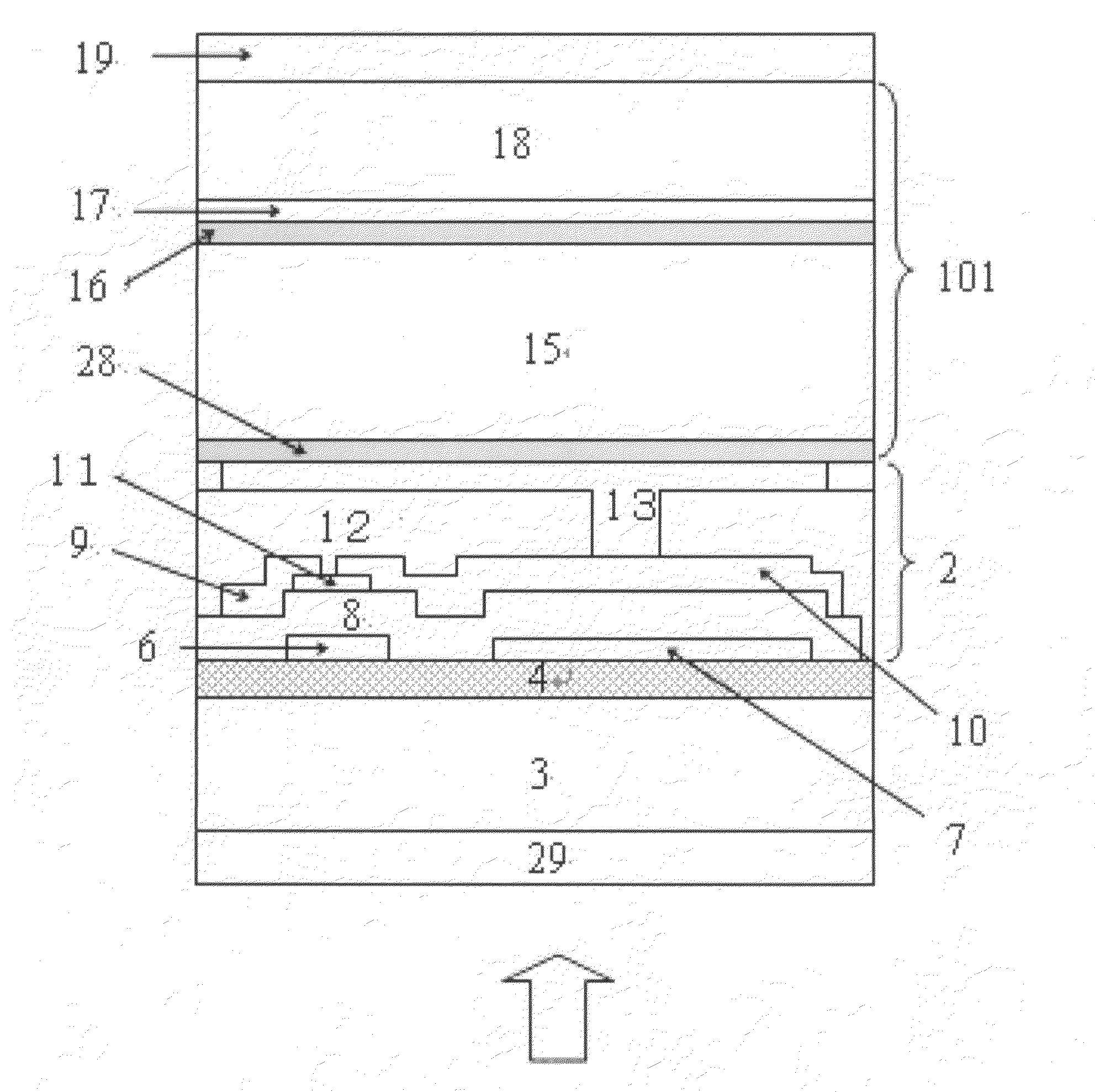

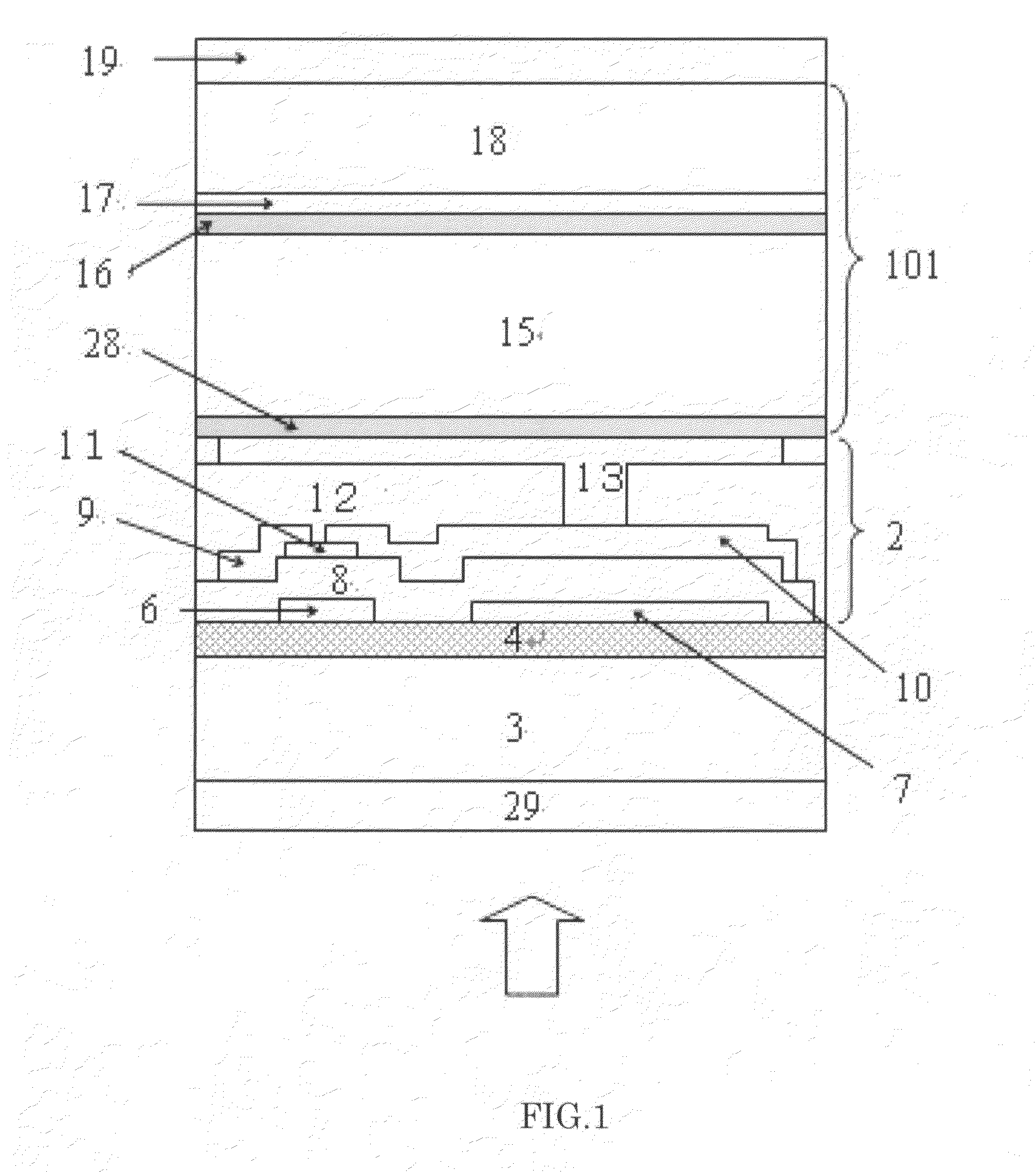

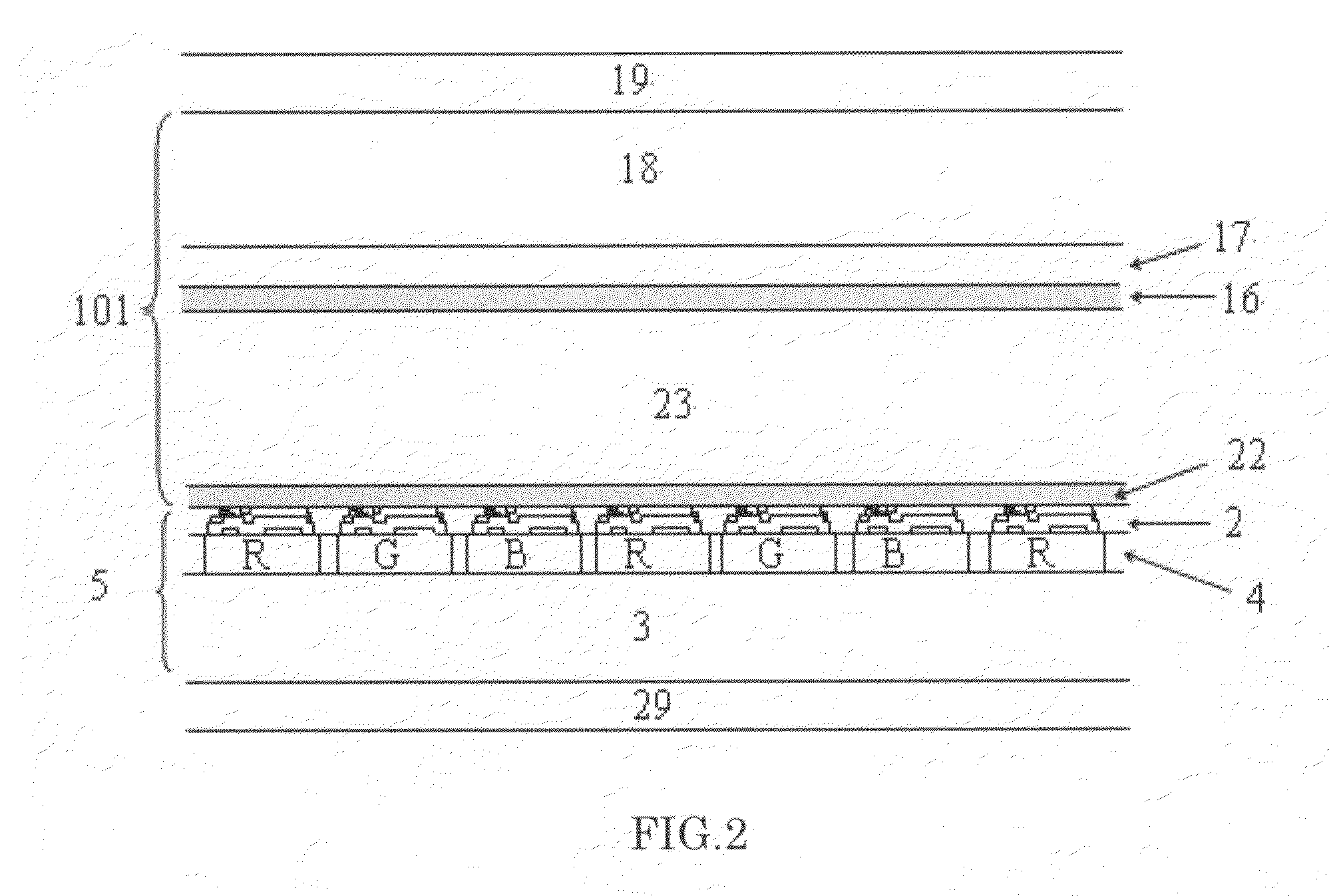

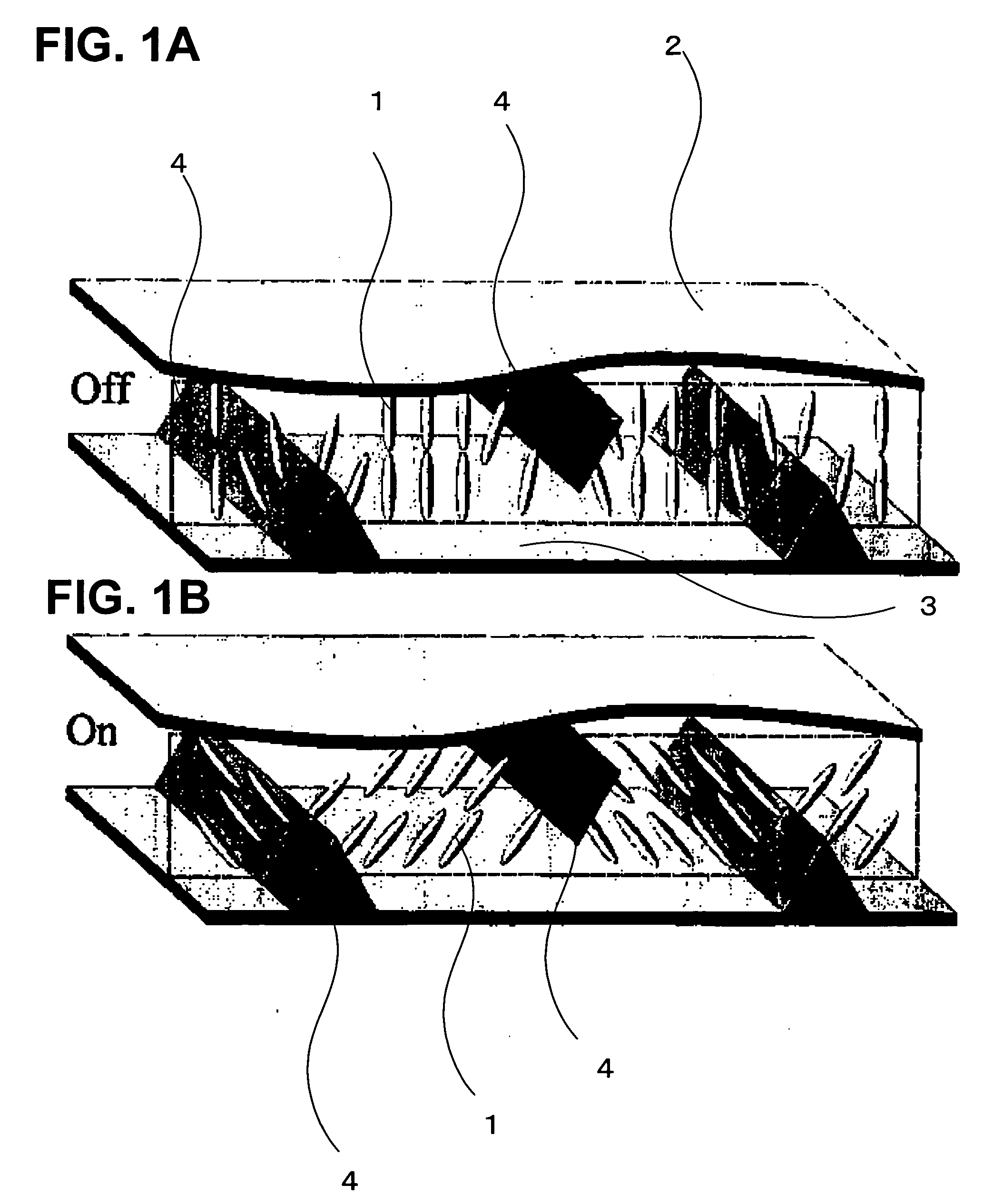

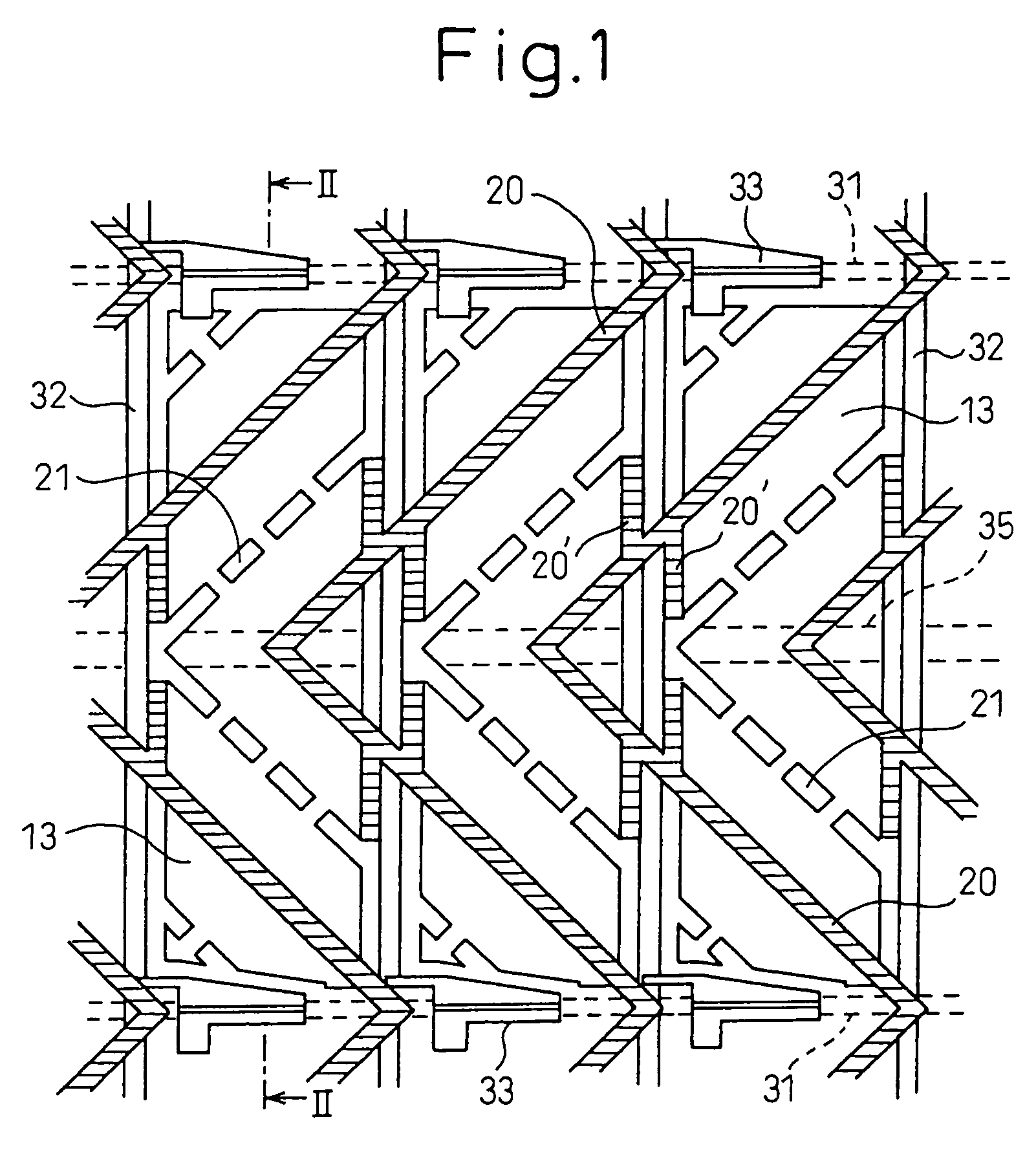

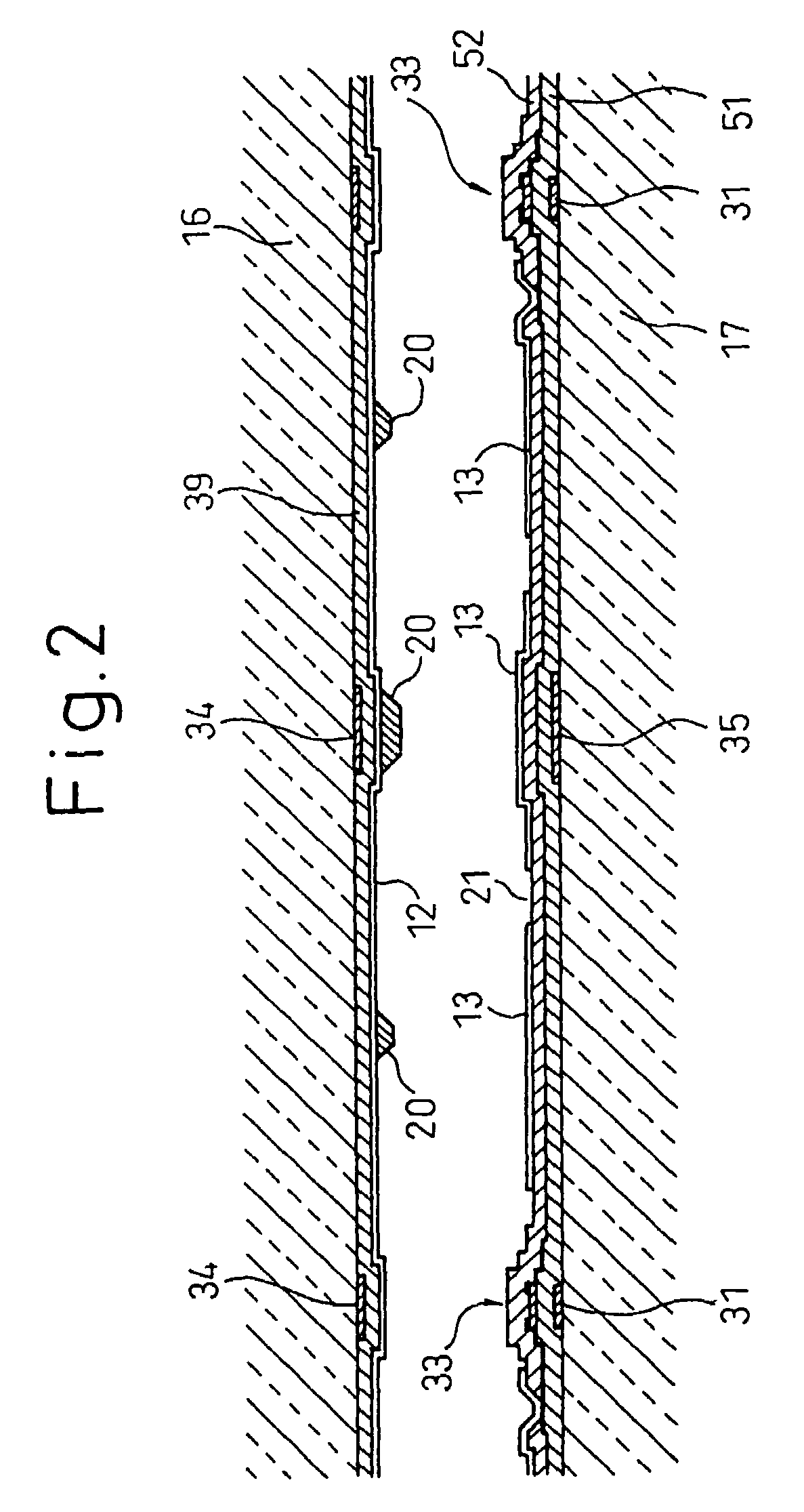

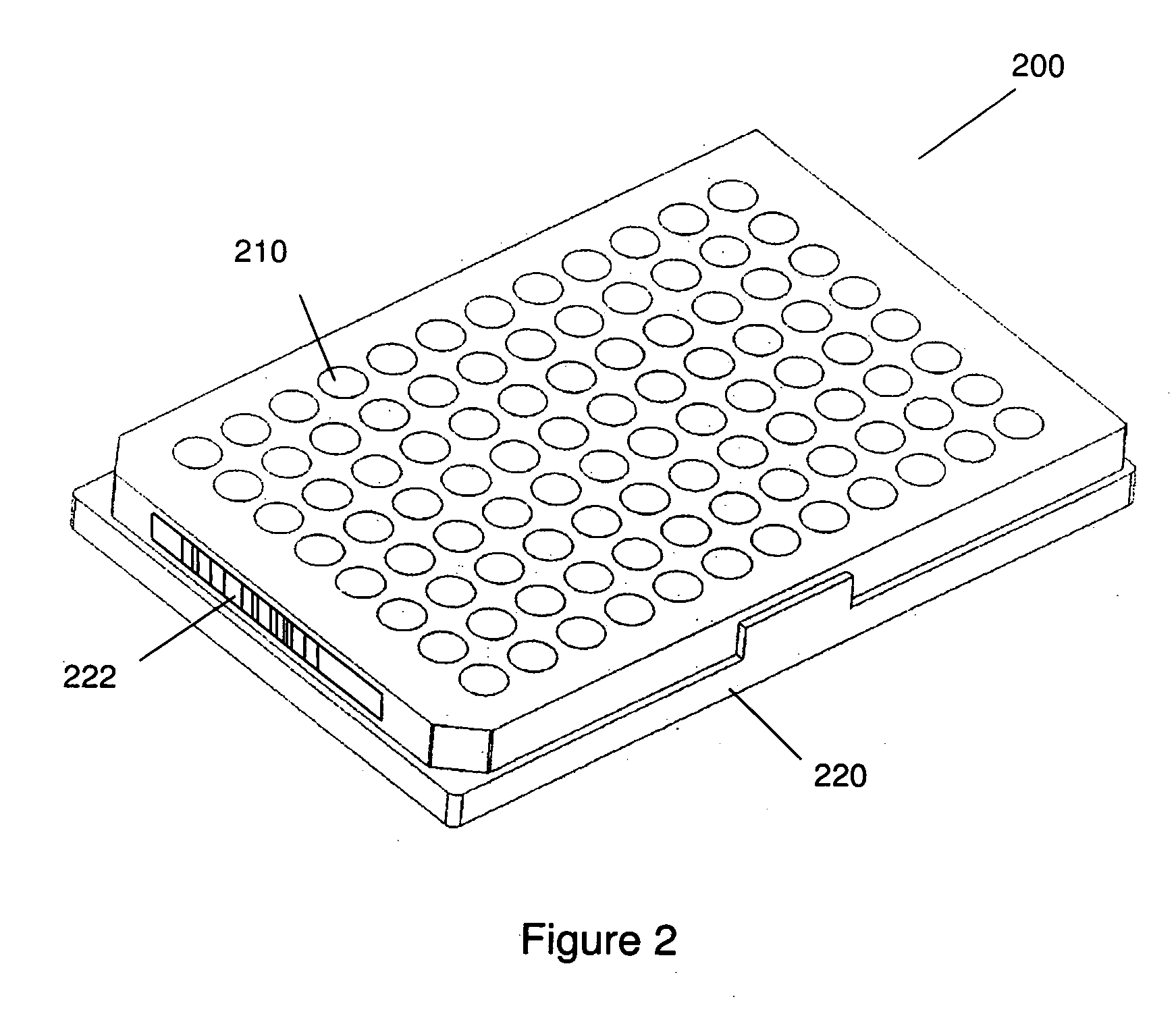

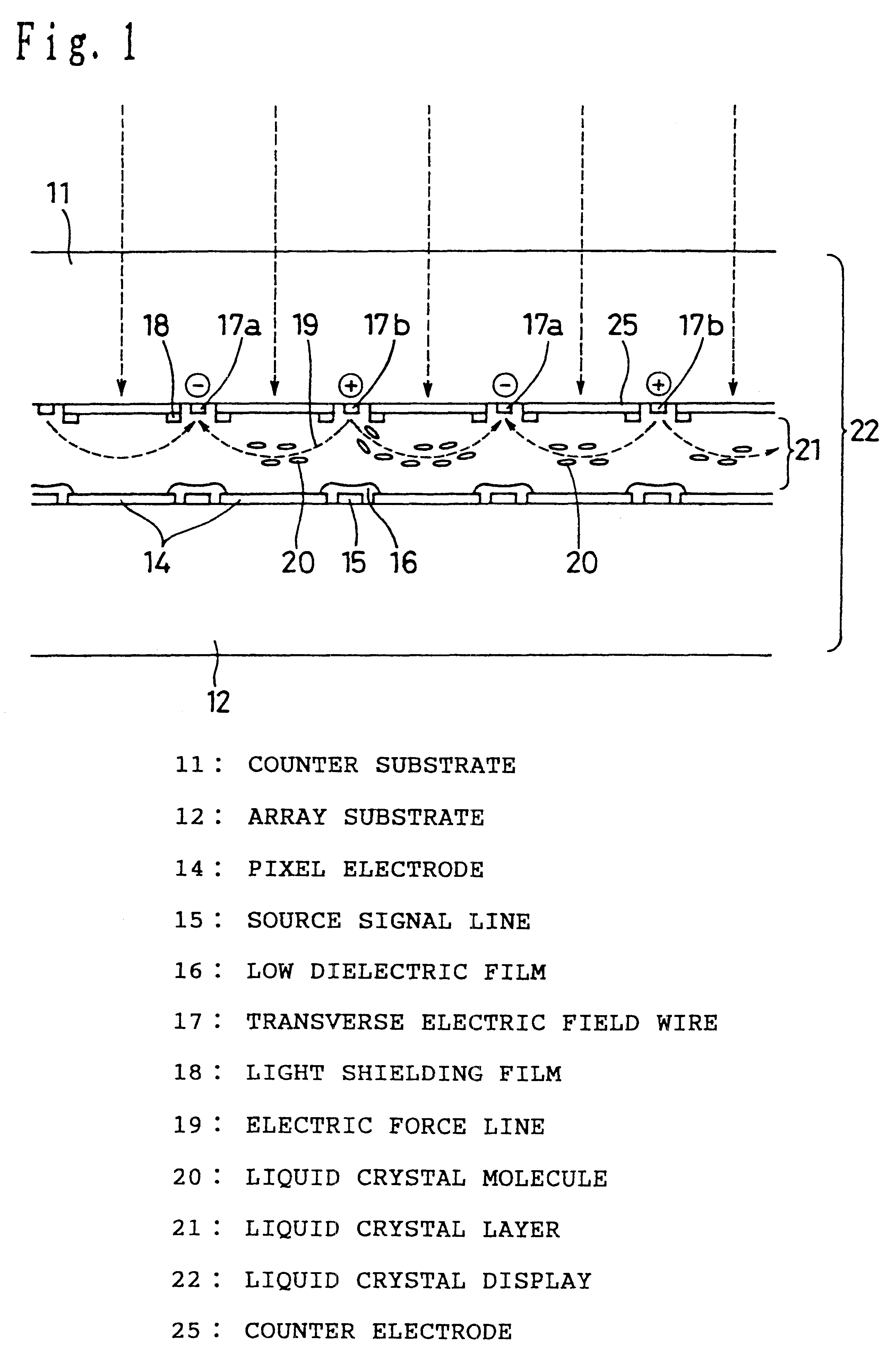

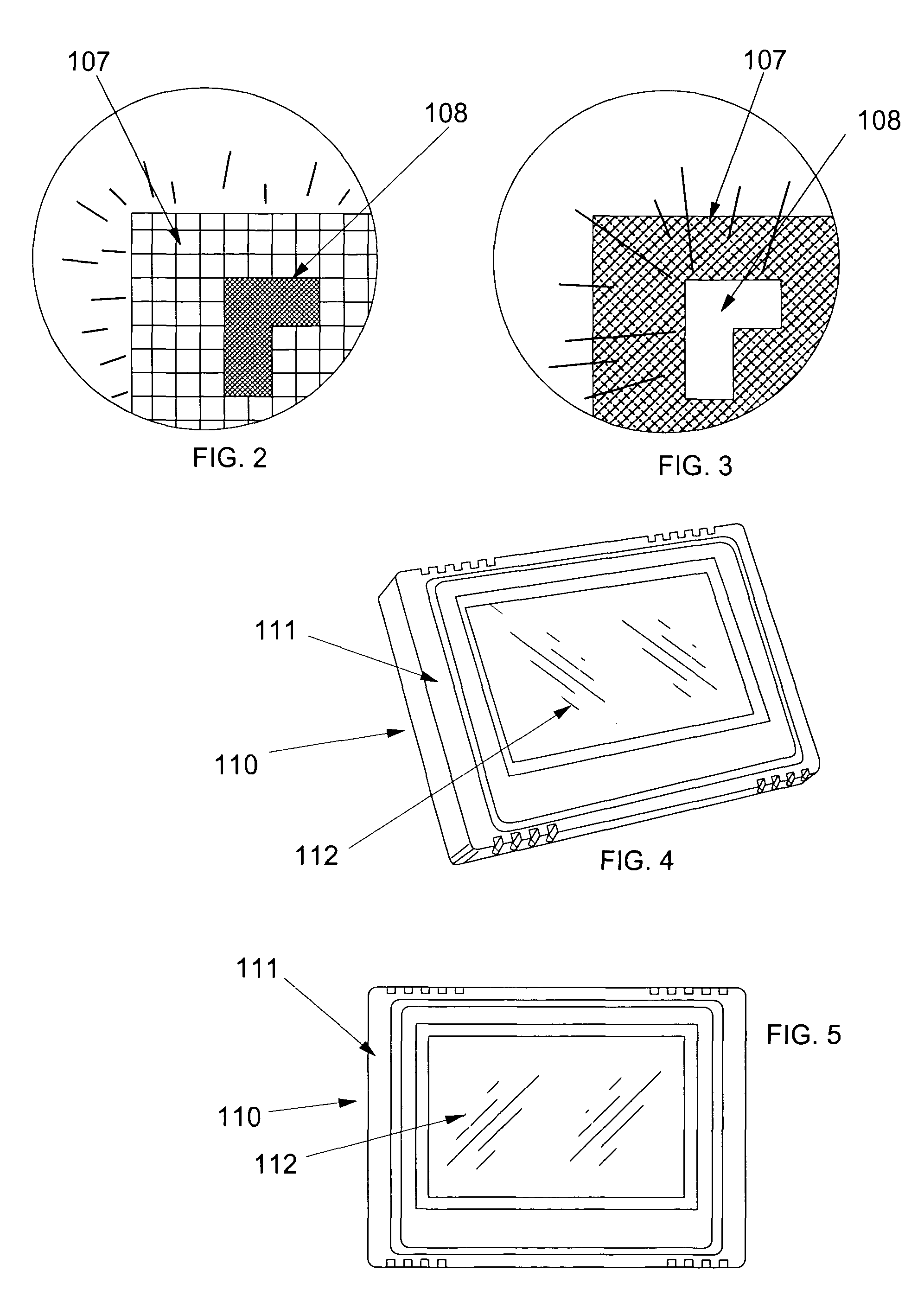

Liquid crystal display panel including a light shielding film to control incident light

InactiveUS6628355B1Improve featuresPreventing mechanical raptureStatic indicating devicesPicture reproducers using projection devicesDielectricLiquid-crystal display

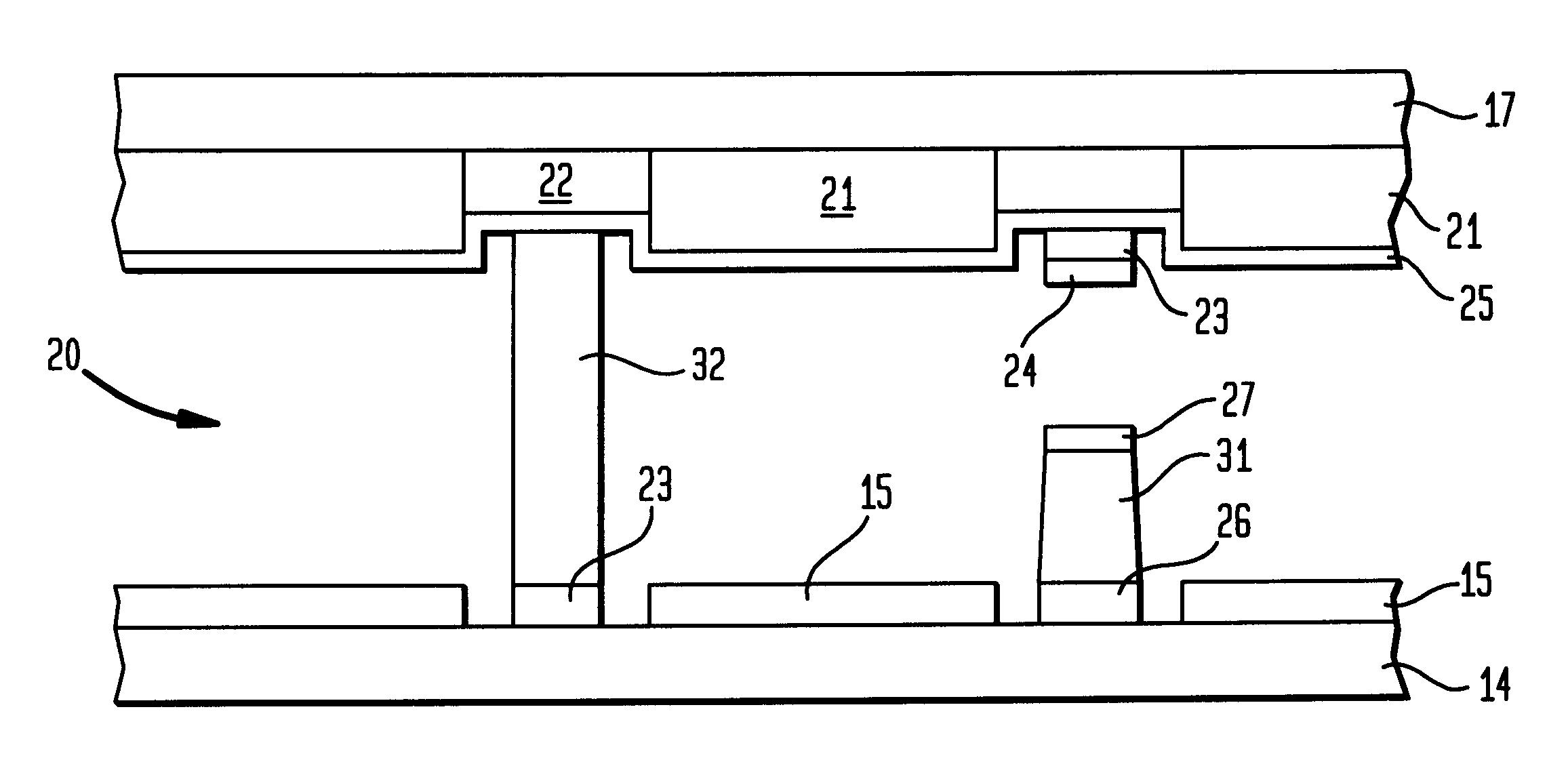

An array substrate 12 is formed with pixel electrodes 14 in the form of a matrix. The pixel electrode 14 is connected to a thin film transistor 155. The thin film transistor 155 is formed with a light shielding film 152 consisting of resin for preventing an entry of light into the thin film transistor 155. A polymer dispersion liquid crystal layer 21 is interposed between a counter electrode 25 and the pixel electrode 14. A substrate 11 is formed with a color filter 151 having red (R), green (G), and blue (B). The color filter 151 is formed from dielectric multilayer film or organic material. The counter electrode 25 is formed above the color filter 155, and the counter electrode 25 and the liquid crystal layer 21 are bonded together by an adhesive layer 371.

Owner:PANASONIC CORP

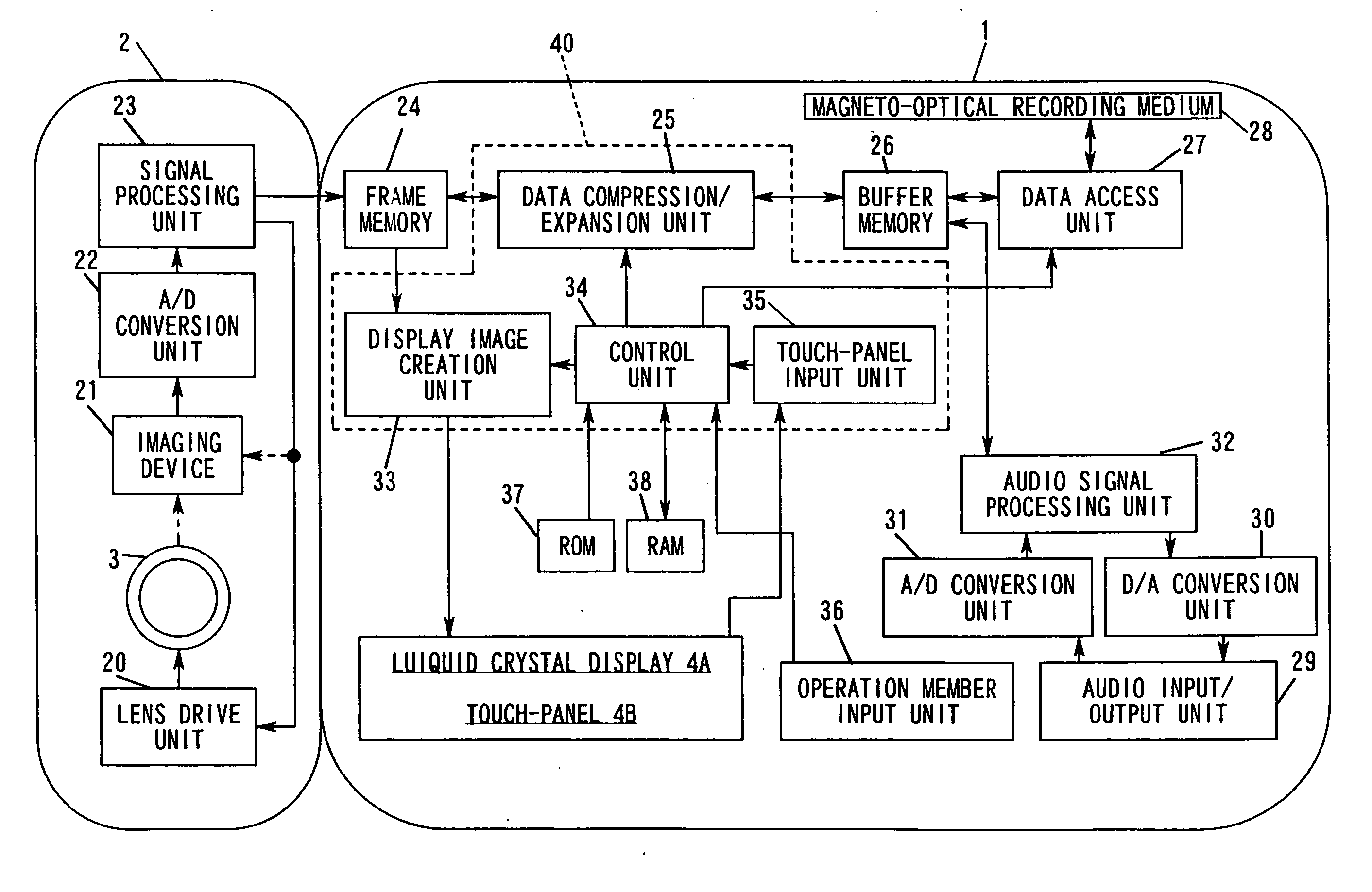

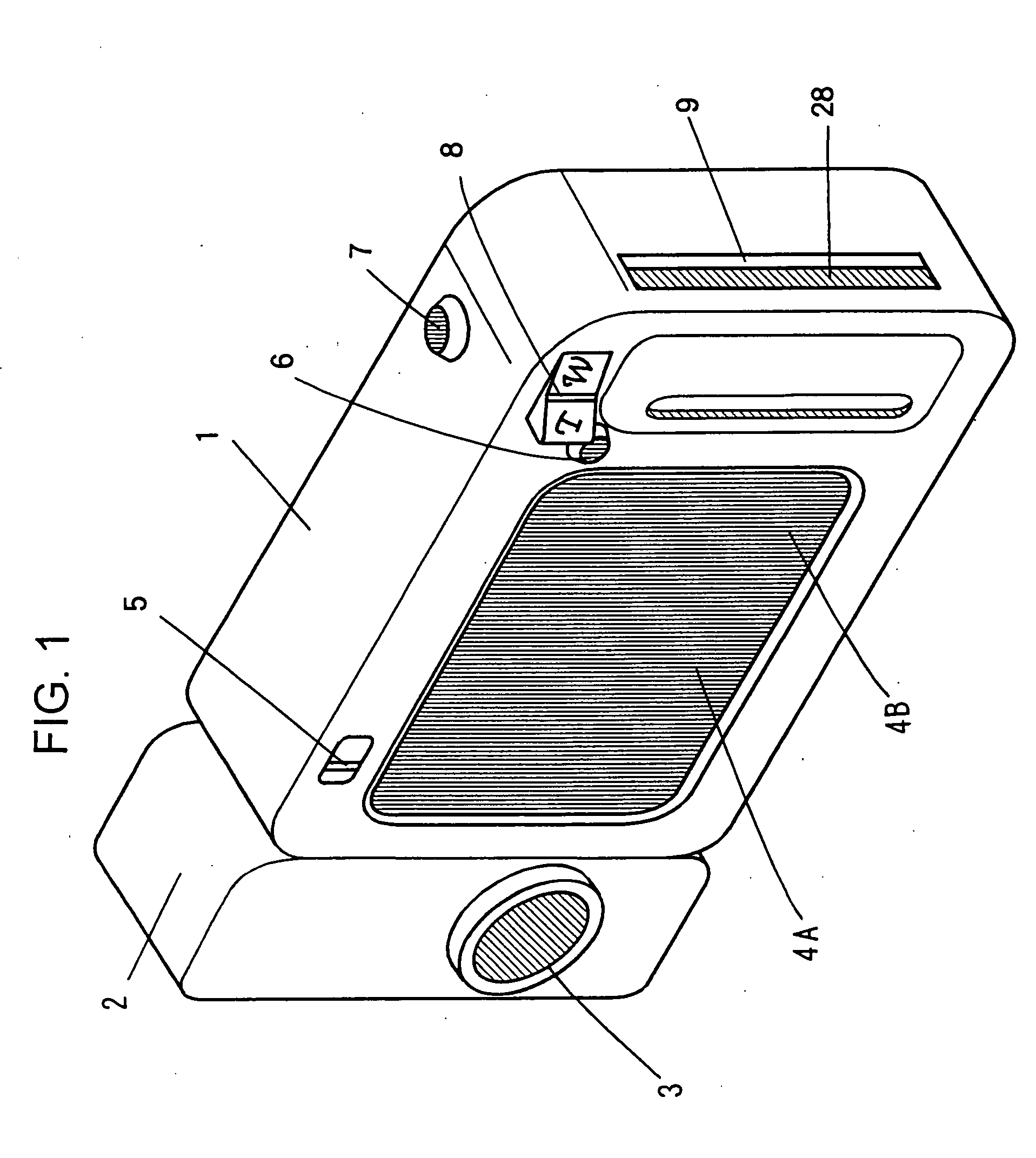

Image signal recording/reproduction apparatus, method employed therein, and image signal recording apparatus

InactiveUS20080025701A1Television system detailsColor television signals processingComputer hardwareLiquid-crystal display

A dynamic image recording button and a still image recording button are provided at the main unit of a movie camera. A magneto-optical recording medium is loaded in a slot. If the dynamic image recording button or the still image recording button is operated during a reproduction operation, the reproduction operation is interrupted in a state in which the mechanical drive (rotation) of the magneto-optical recording medium is sustained. At this point, a dynamic image signal or a still image signal obtained through a photographing operation performed at the camera unit is temporarily recorded in a buffer memory, and is written in the magneto-optical recording medium when a write in the magneto-optical recording medium becomes enabled. Instructions to record dynamic images and to record still images can be issued to the movie camera through a touch-panel provided on the screen of a liquid crystal display unit. Even when operation cannot be performed through the touch-panel, the instructions can be issued through the dynamic image recording button or the still image recording button.

Owner:NIKON CORP

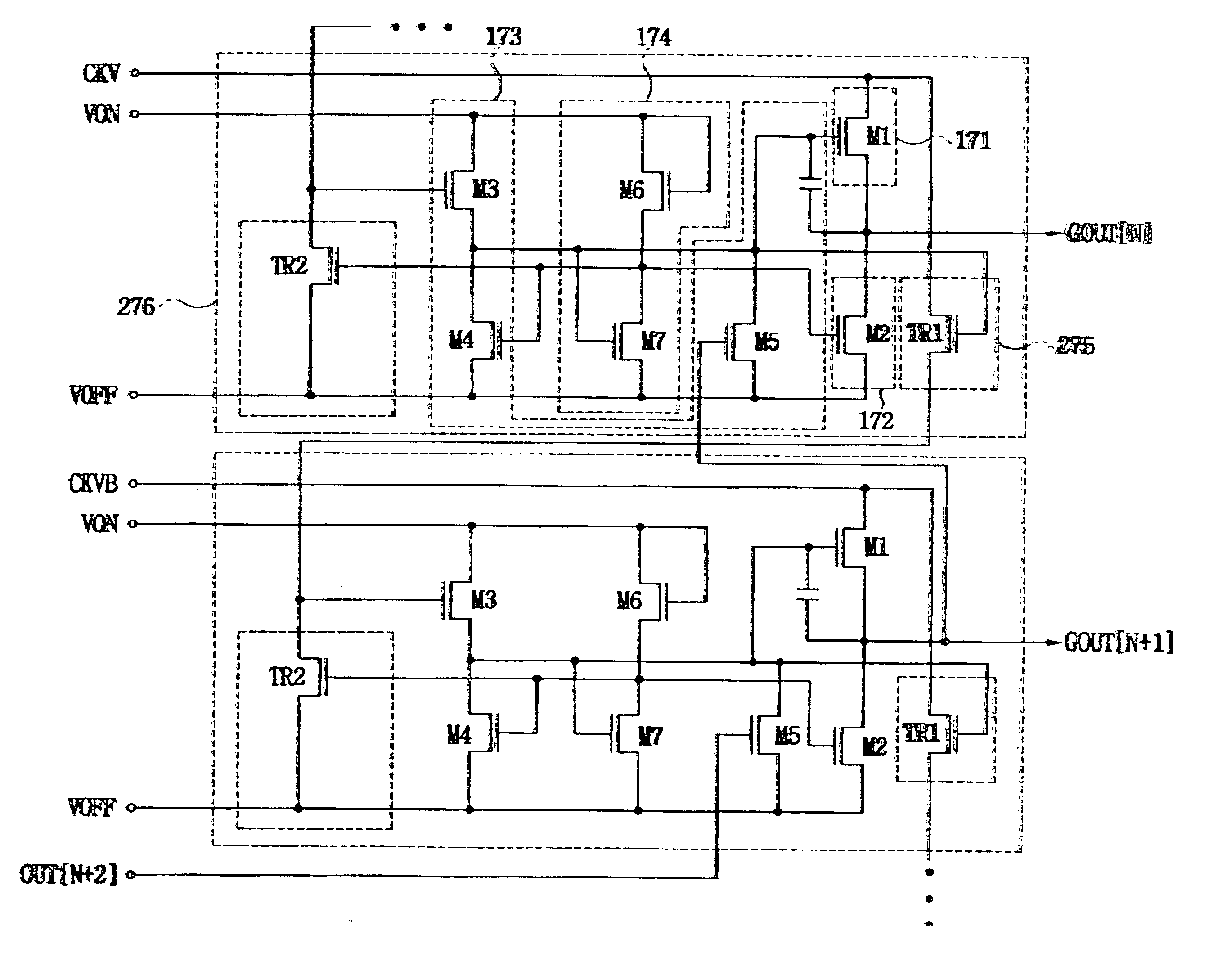

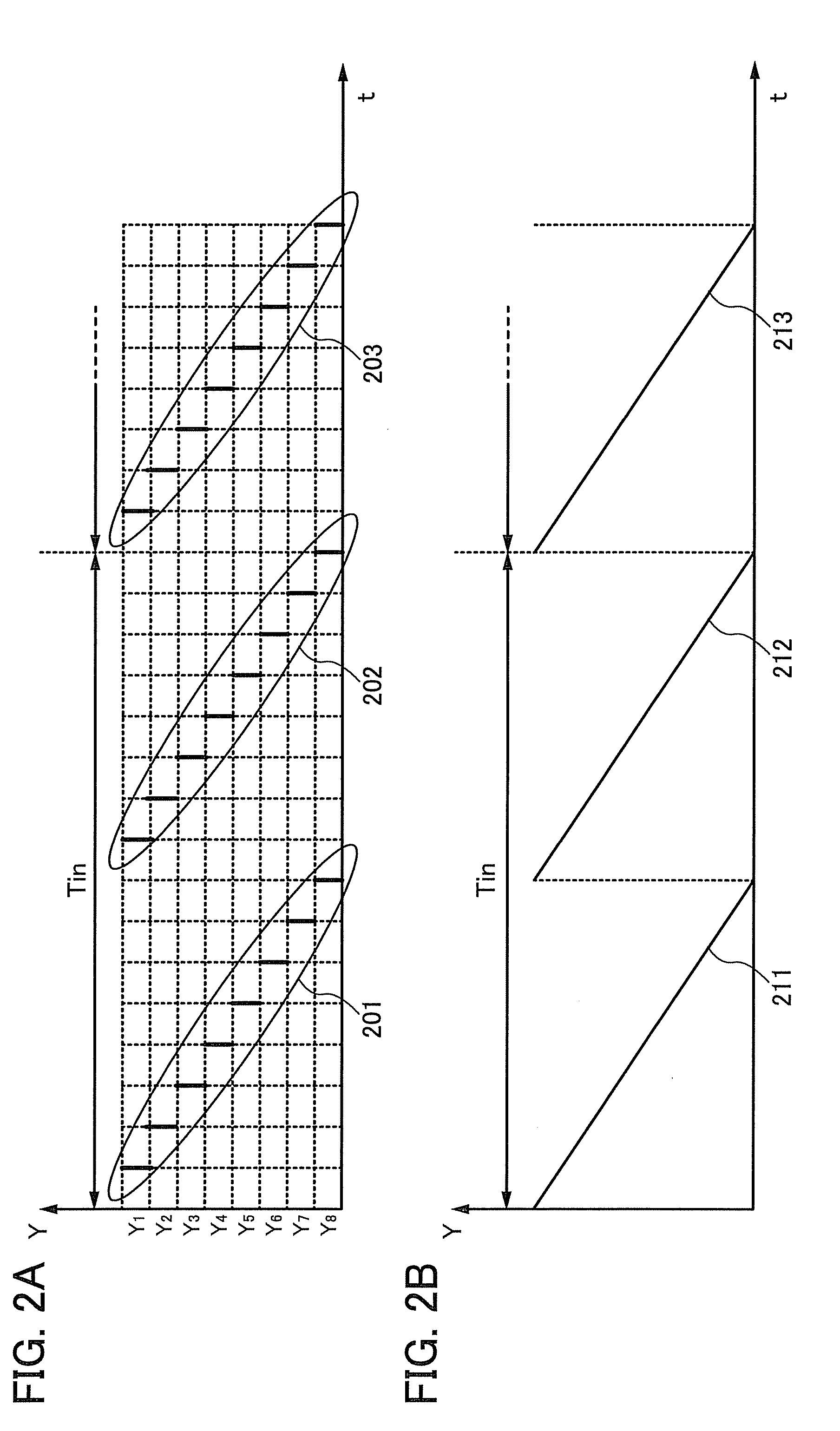

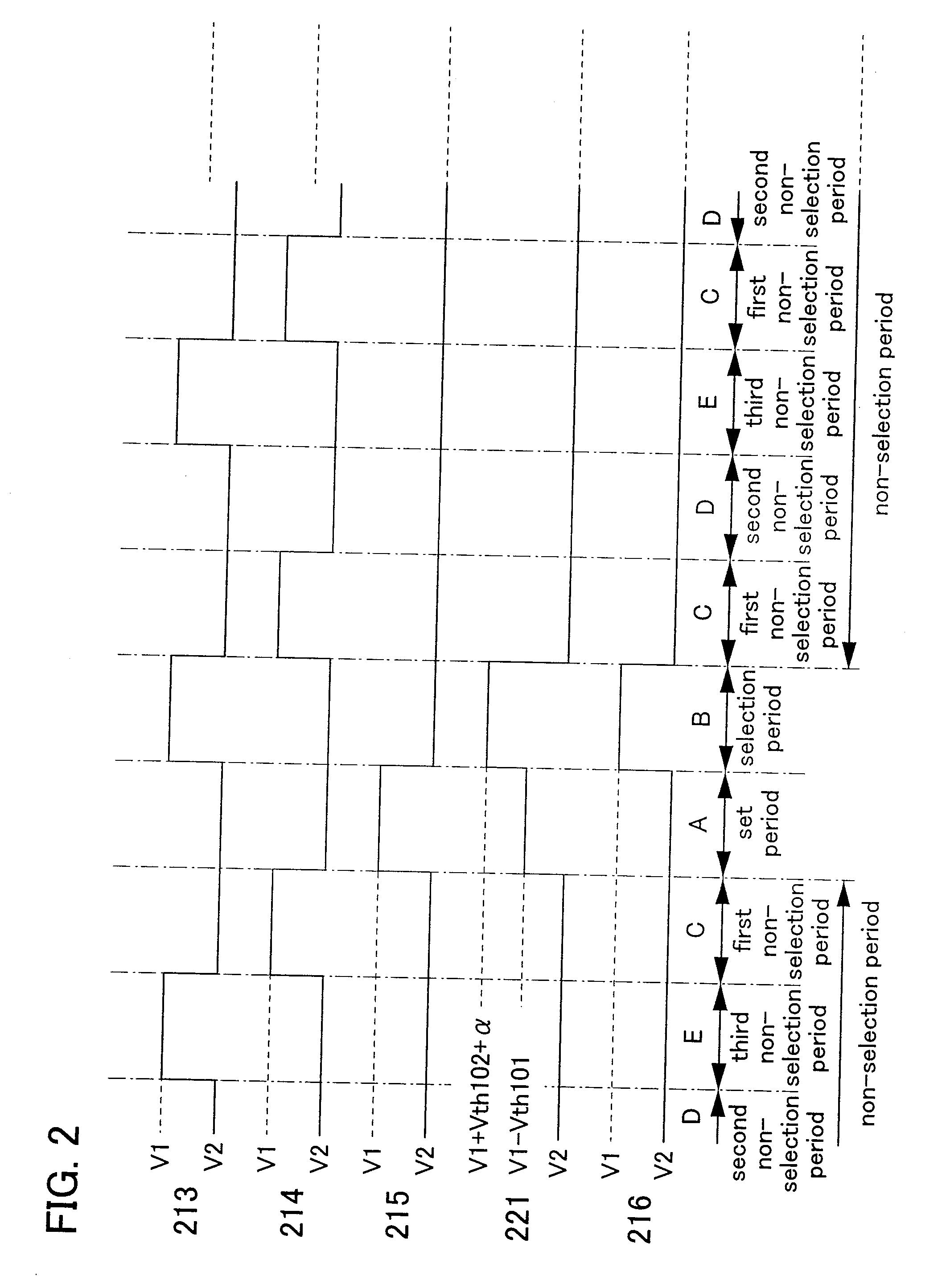

Method of driving a shift register, a shift register, a liquid crystal display device having the shift register

InactiveUS6845140B2InhibitionQuality improvementStatic indicating devicesDigital storageShift registerLiquid-crystal display

In a shift register and LCD device having the shift register that may be employed in the liquid crystal display device having a large screen size and a large resolution, the shift register includes stages cascade-connected with each other and each of the stages have a carry buffer for generating a carry signal. The pull-down transistor of each of the stages of the shift register is divided into a first pull-down transistor and a second pull-down transistor. A power voltage Vona larger than the power voltage Von applied to a clock generator is applied to the shift register. A signal delay due to the RC delay of the gate lines may be minimized, the shift register is independent of the variation of the threshold voltage of the TFTs, and image display quality may not be deteriorated.

Owner:SAMSUNG DISPLAY CO LTD

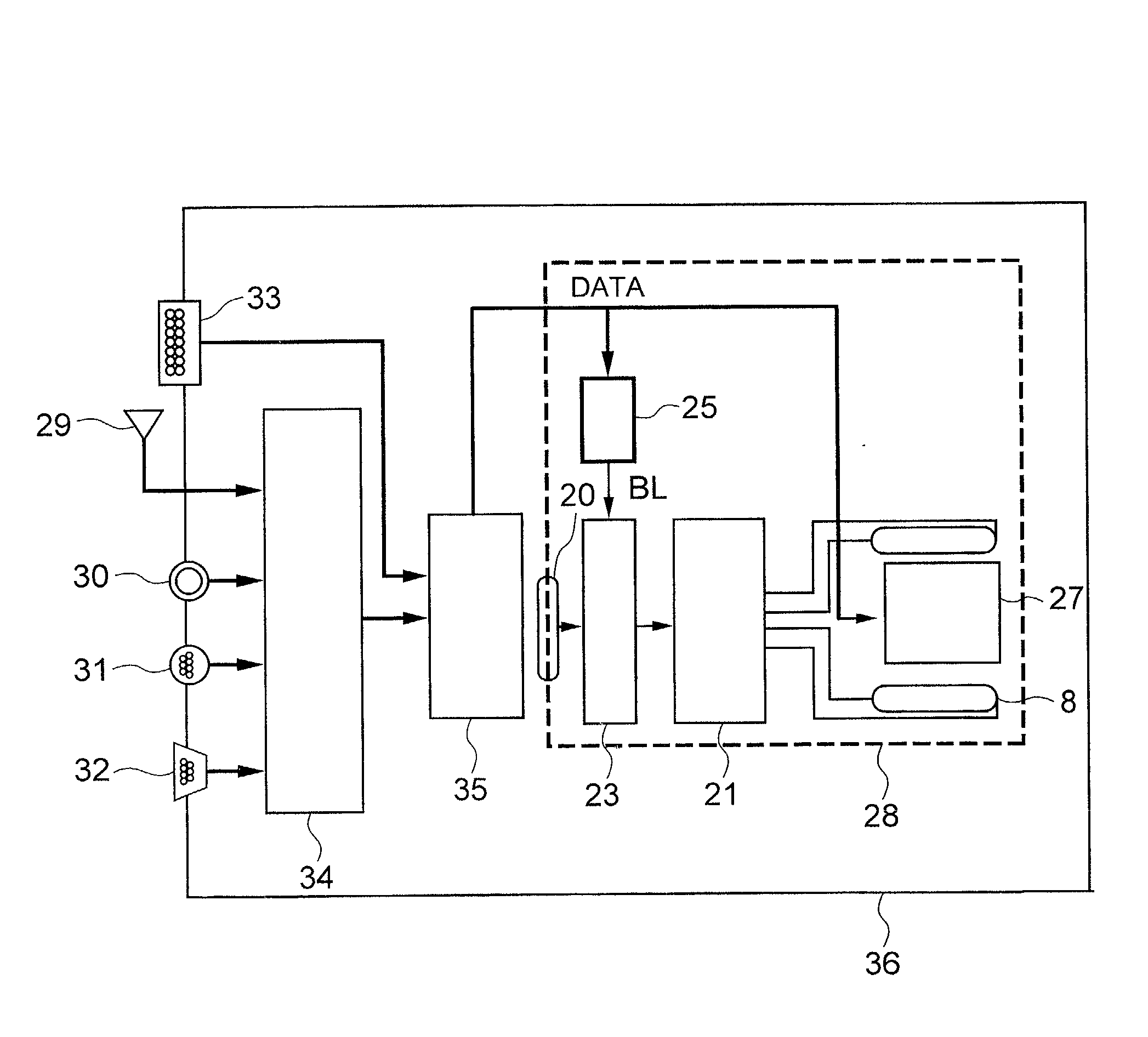

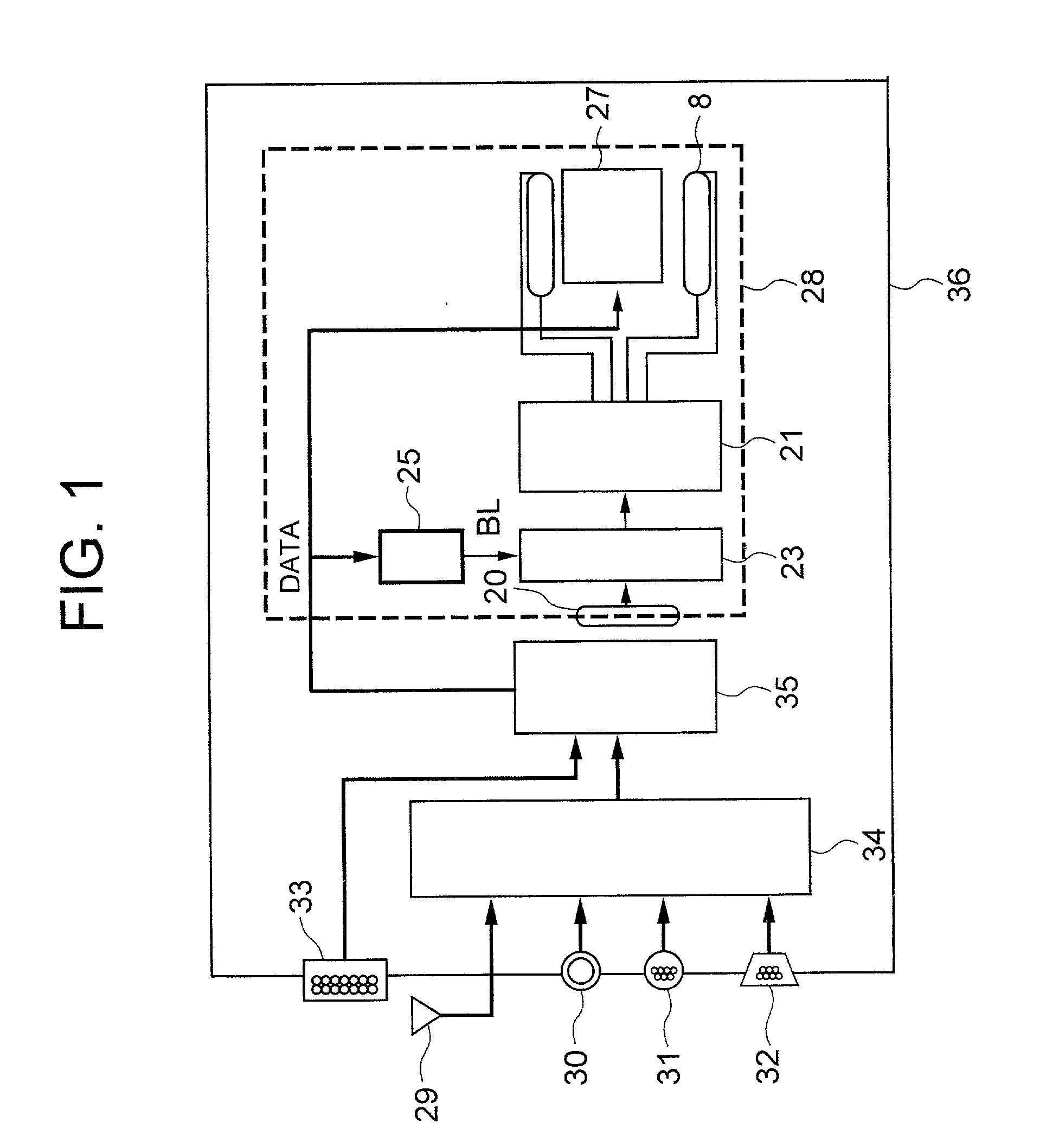

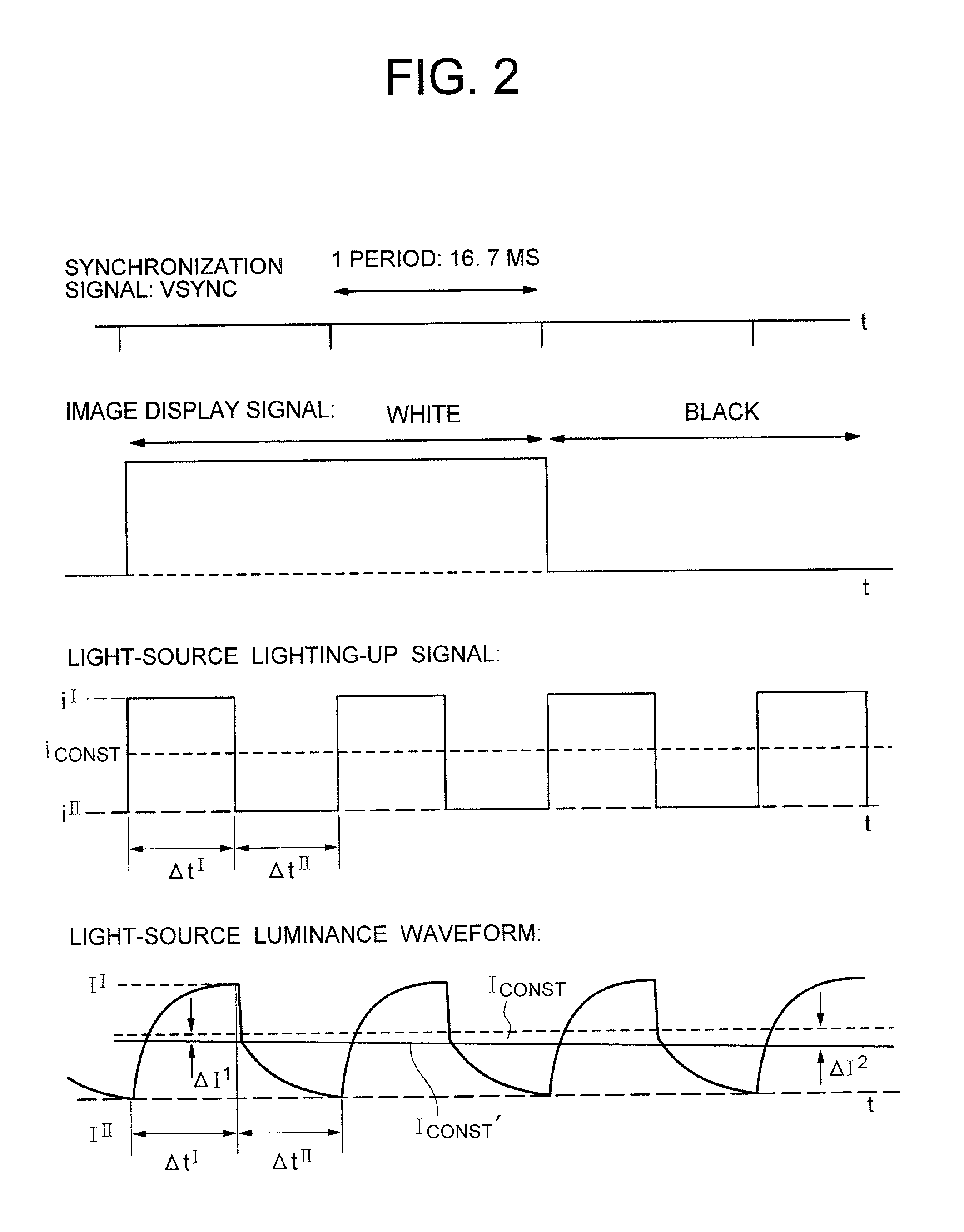

Liquid crystal display apparatus

InactiveUS20020057238A1Static indicating devicesNon-linear opticsLiquid-crystal displayControl circuit

The present invention includes a panel on which a plurality of pixels are located, a light-source for visualizing an image displayed on the plurality of pixels, a controlling circuit for controlling the light-source, and an image-signal tone characteristic controlling circuit. Moreover, the light-source controlling circuit has a function of repeating a period. Here, the period includes a 1st time-period during which an electric current having a 1st intensity is fed to the light-source, and a 2nd time-period during which an electric current having a 2nd intensity differing from the 1st intensity is fed to the light-source. The light-source controlling circuit controls the 1st time-period and the 2nd time-period in accordance with display information. Also, in accordance with the display information as well, the tone characteristic controlling circuit is controlled so that the excellent contrast will be always available.

Owner:HITACHI DISPLAYS +1

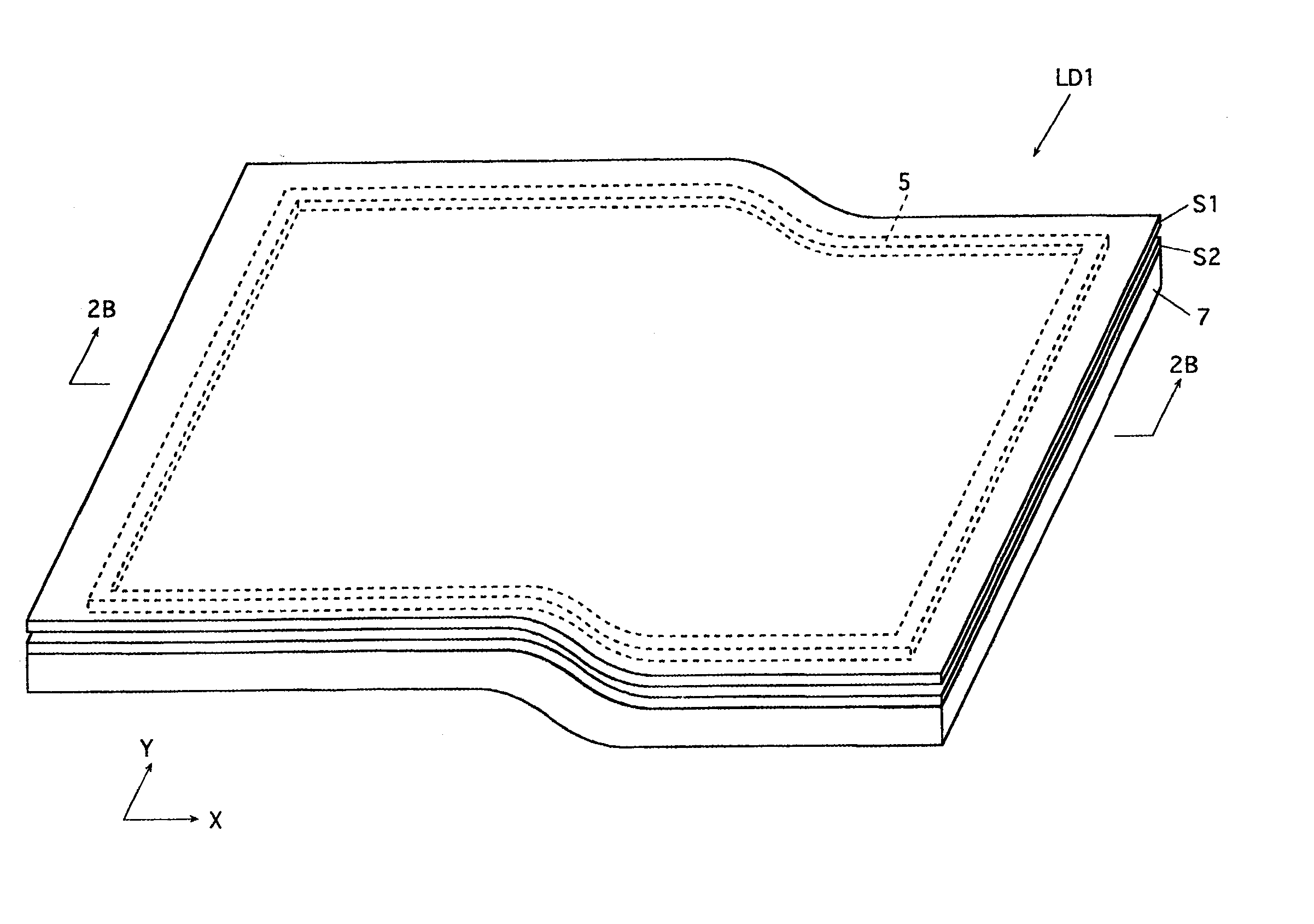

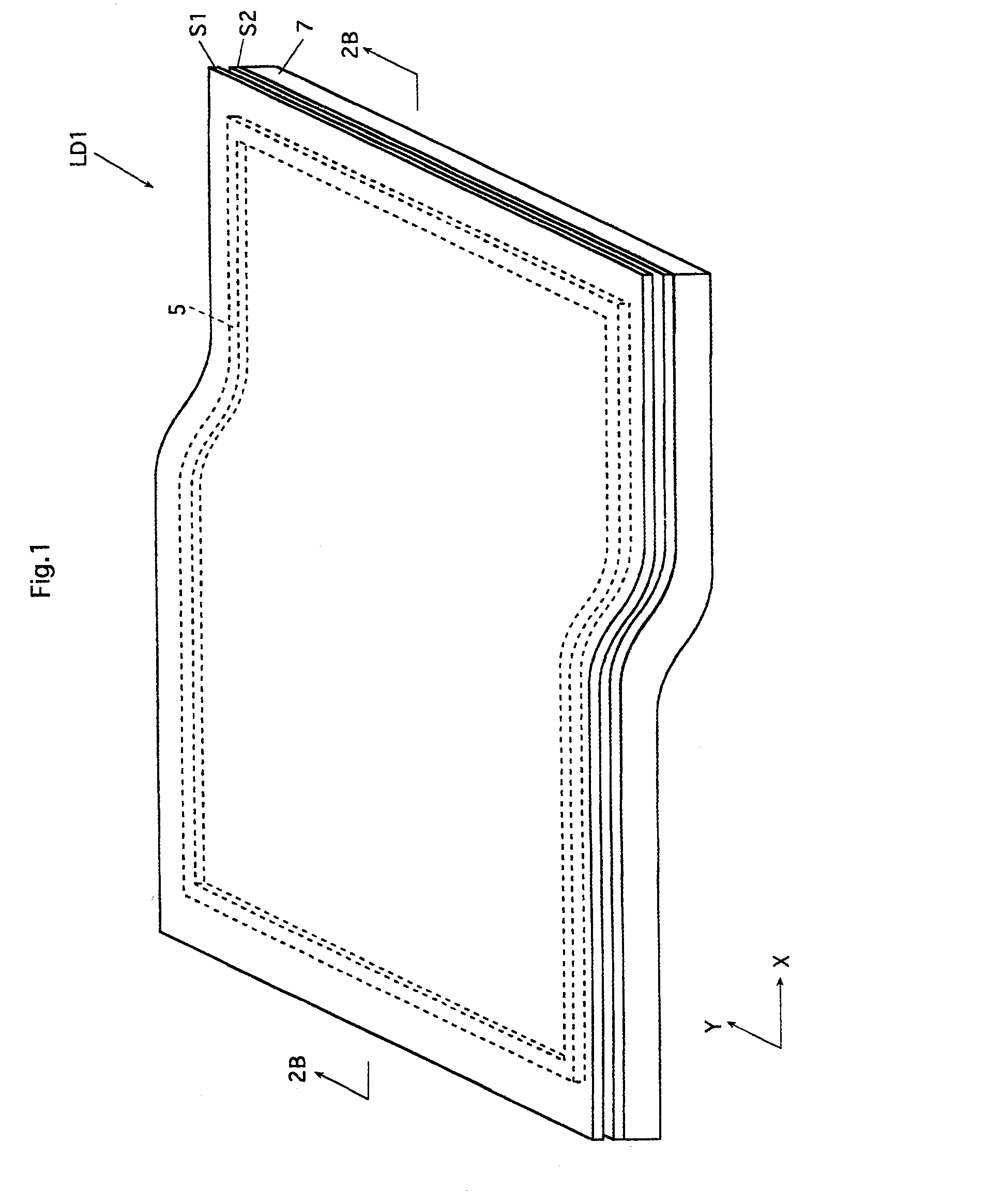

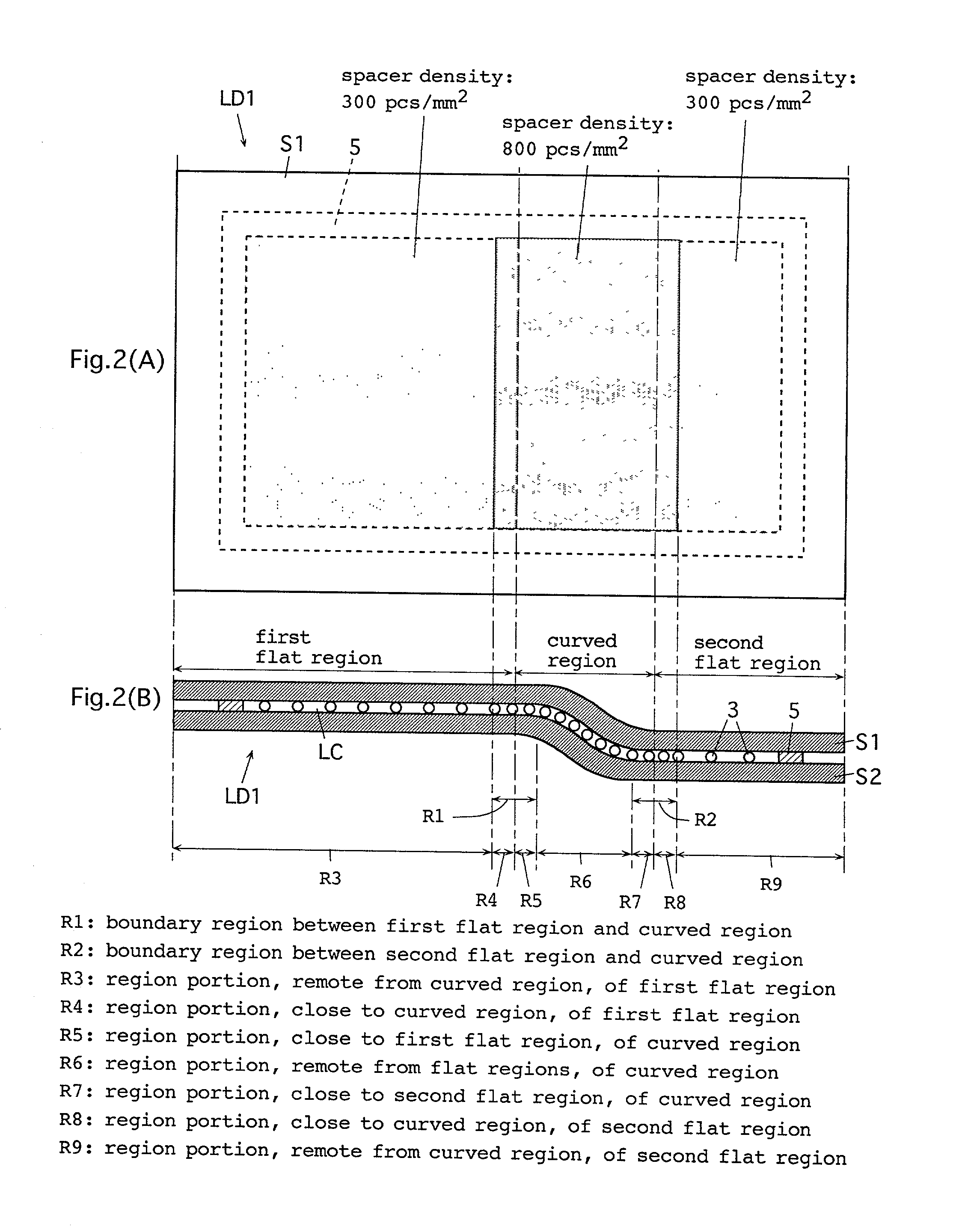

Non-flat liquid crystal display element and method of producing the same

InactiveUS20020027636A1High uniformity in gapEasy to displayVisible signalling systemsNon-linear opticsLiquid-crystal displayEngineering

Disclosed is a non-flat liquid crystal display (LCD) element having a liquid crystal, a sealing wall and paired substrates opposed to each other such that a major surface of the LCD element has a non-flat form. In an aspect, spacers are disposed between the substrates, and a spacer density in a predetermined region is different from that in at least a portion of the other region. In another aspect, resin structures are disposed between the substrates and are adhered to the substrates, and a resin structure adhesion area, per unit area of the substrate, with respect to the substrate in a predetermined region is different from that in at least a portion of the other region. In further another aspect, at least one of pixel form, size and arrangement pitch in a predetermined region is different from that in at least a portion of the other region. In further another aspect, the resin structures are disposed between the substrates, and at least one of resin structure form, size and arrangement pitch in a predetermined region is different from that in at least a portion of the other region. Also disclosed is a method of producing a non-flat LCD element. The method includes the steps of: holding a liquid crystal between paired flat substrates to produce a flat LCD element having an entirely flat form; and deforming the flat LCD element into a predetermined non-flat form.

Owner:MINOLTA CO LTD

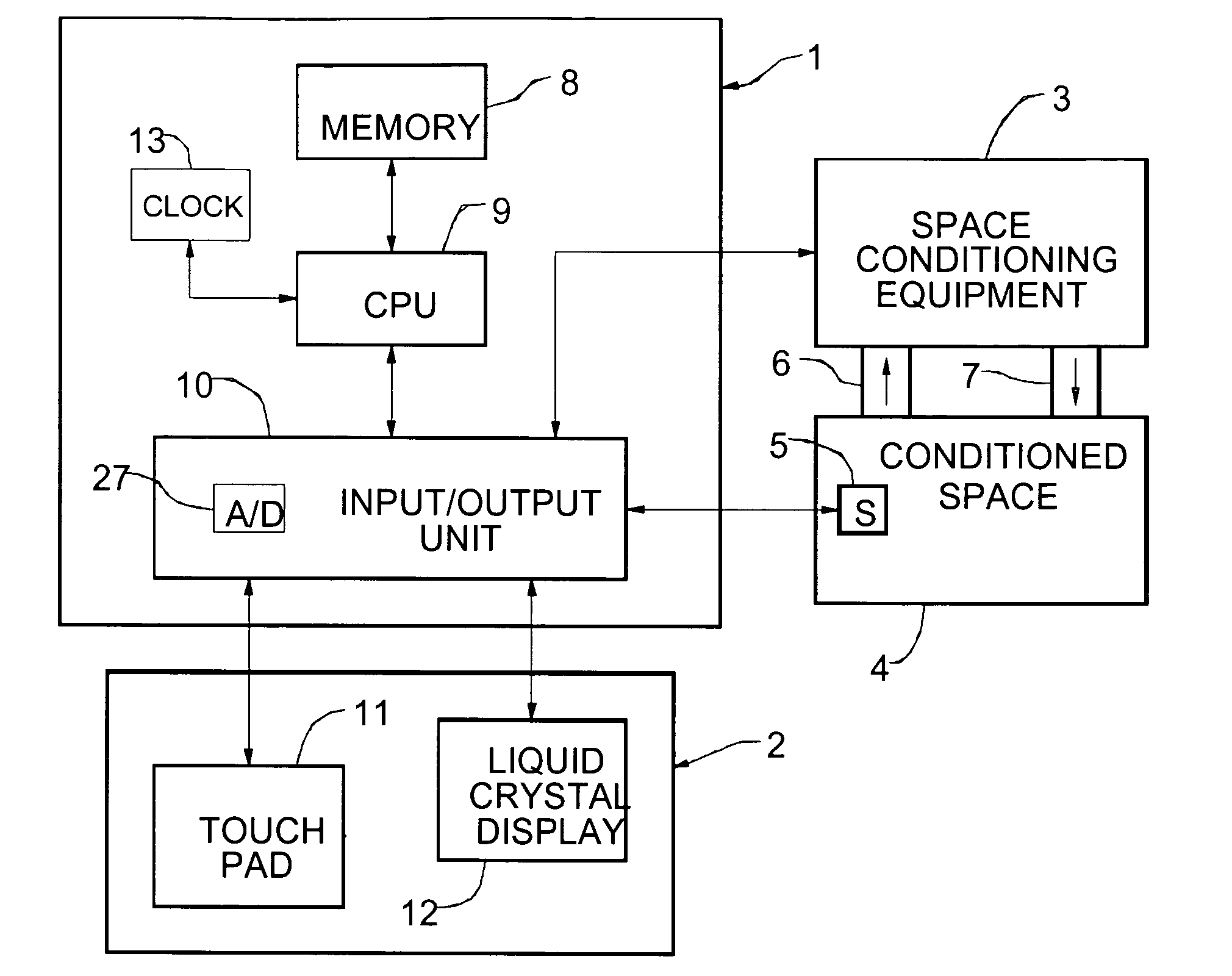

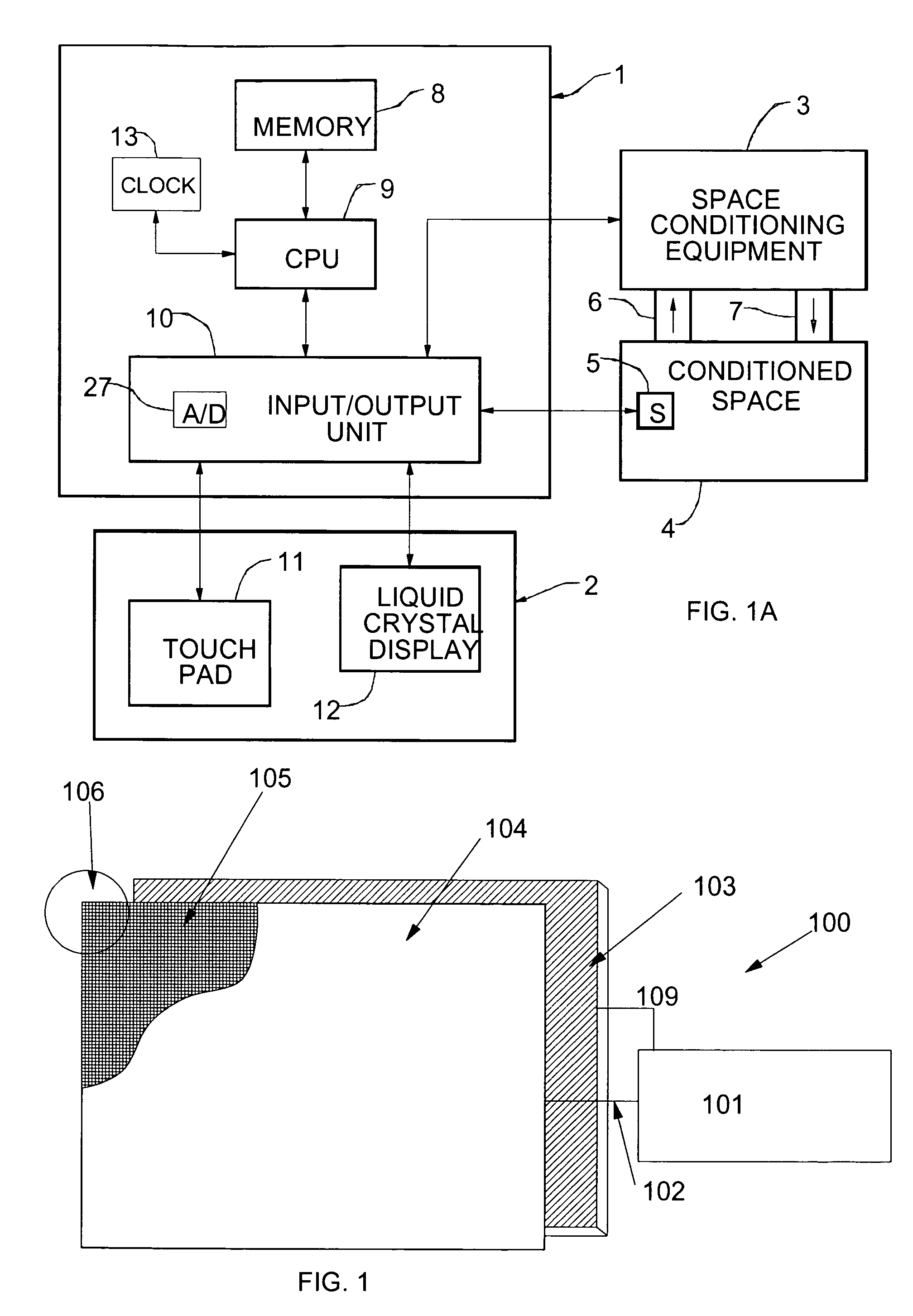

Programmable thermostat incorporating a liquid crystal display selectively presenting adaptable system menus including changeable interactive virtual buttons

ActiveUS7156318B1Easy for a user to programFacilitate intuitive programmingSampled-variable control systemsAir-treating devicesLiquid-crystal displayDisplay device

A programmable thermostat, with a touch screen liquid crystal display having the capability to add to or remove virtual buttons to the display depending on the items of space conditioning equipment connected with and controlled by the thermostat.

Owner:ROSEN TECH LLC

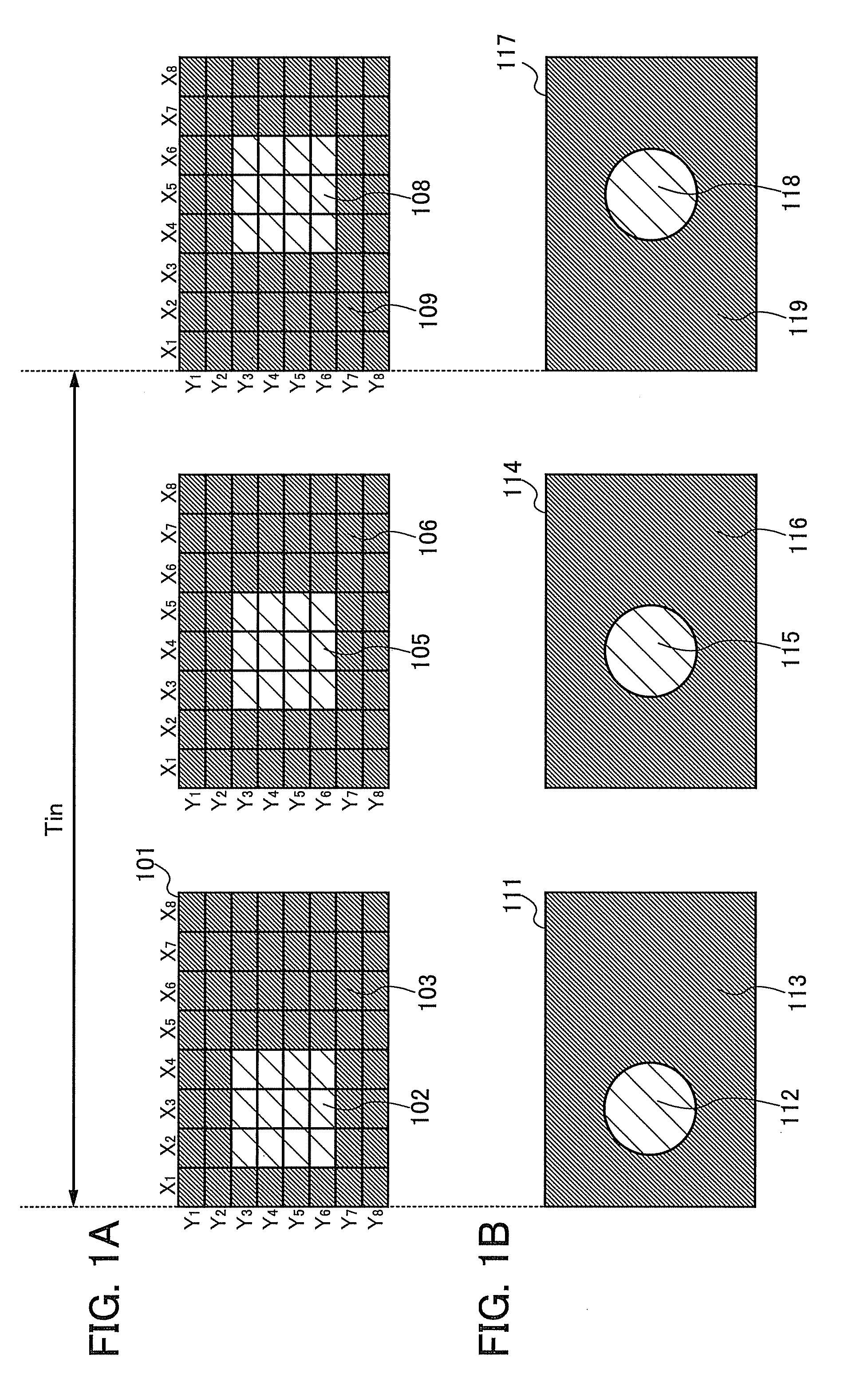

Liquid Crystal Display Device and Driving Method Thereof

ActiveUS20080284719A1Increase contrastImprove image qualityStatic indicating devicesSolid-state devicesLiquid-crystal displayDisplay device

In a display device including a backlight and a display panel, the area of the backlight is divided into a plurality of unit regions; the display panel includes pixels which are larger in number than the unit regions; a frame rate of image data input to the device is converted to perform display while part of the unit regions in which black is displayed is in a non-light emission state; and the driving frequency of the backlight is converted in accordance with the display.

Owner:SEMICON ENERGY LAB CO LTD

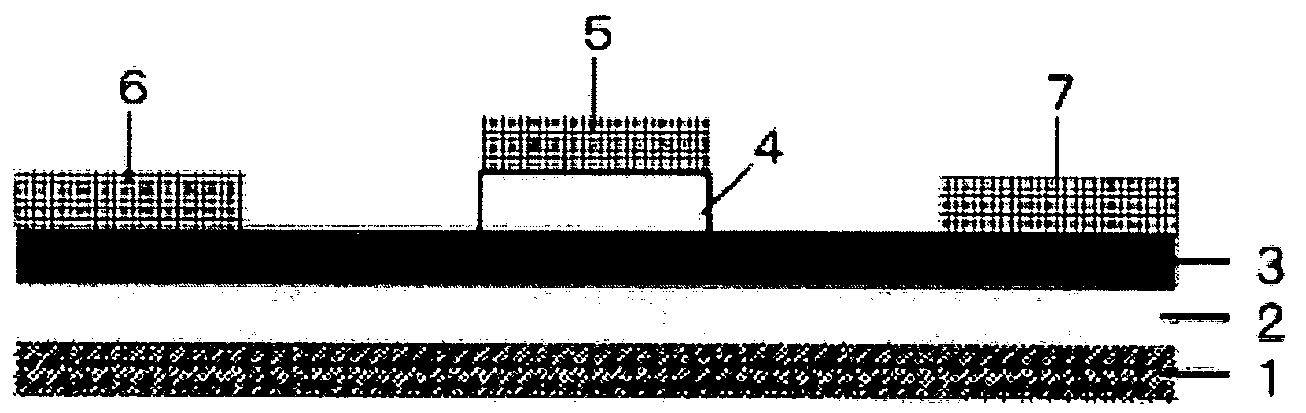

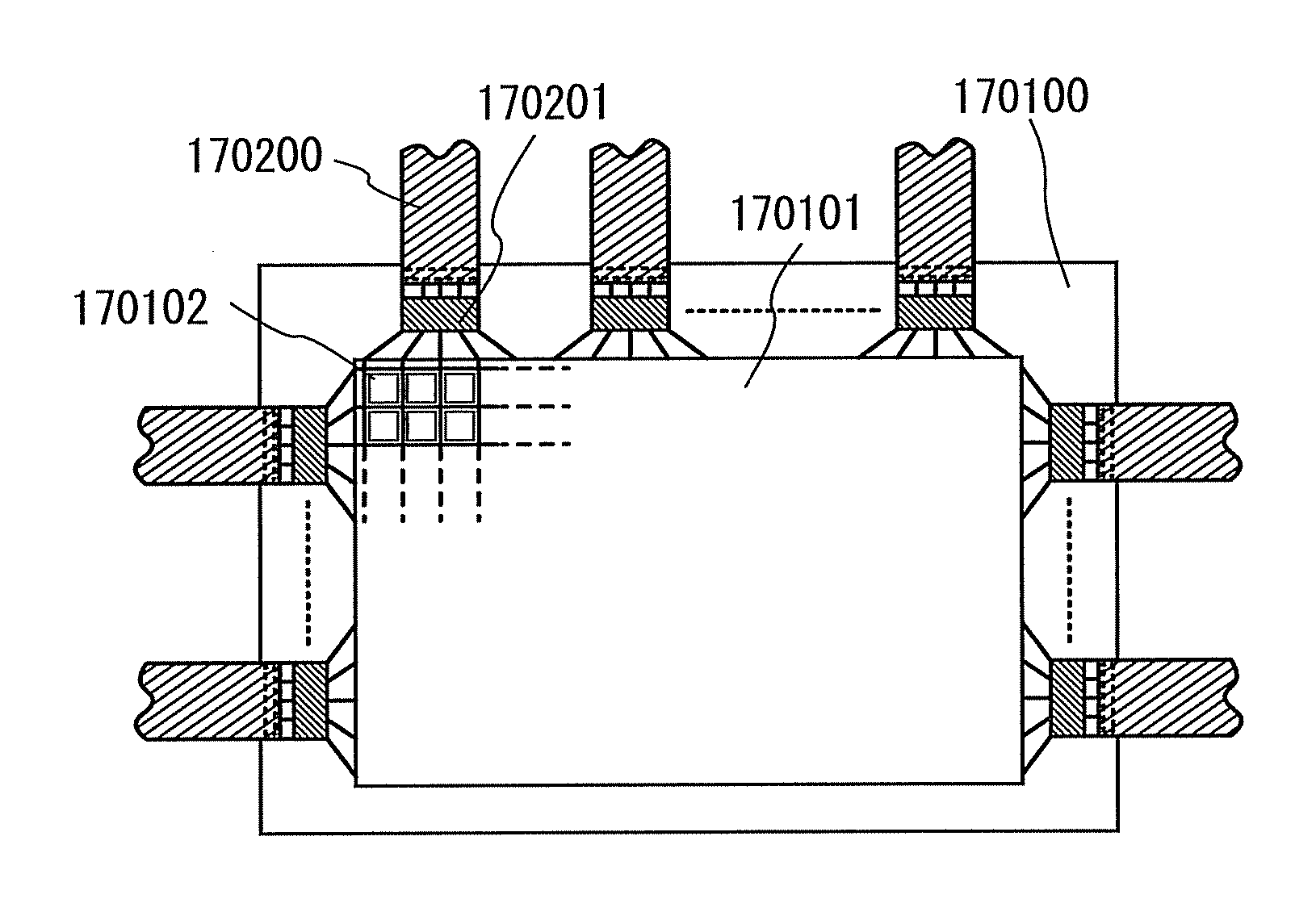

Thin film device transfer method, thin film device, thin film integrated circuit device, active matrix board, liquid crystal display, and electronic apparatus

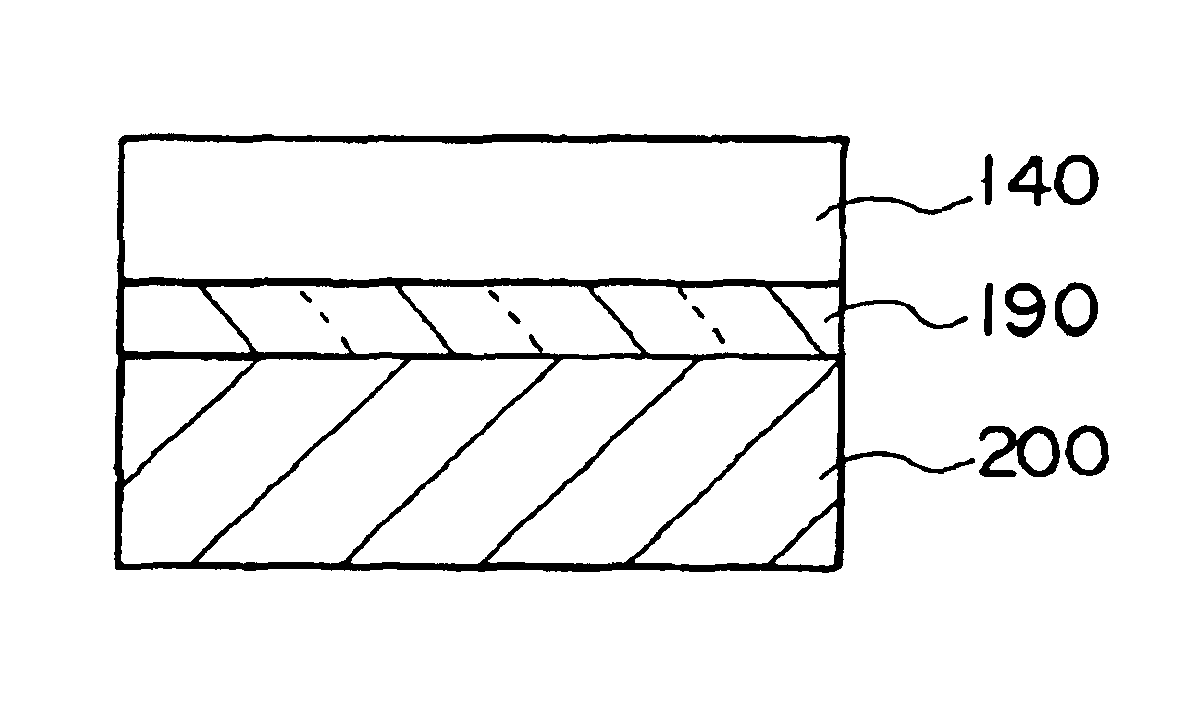

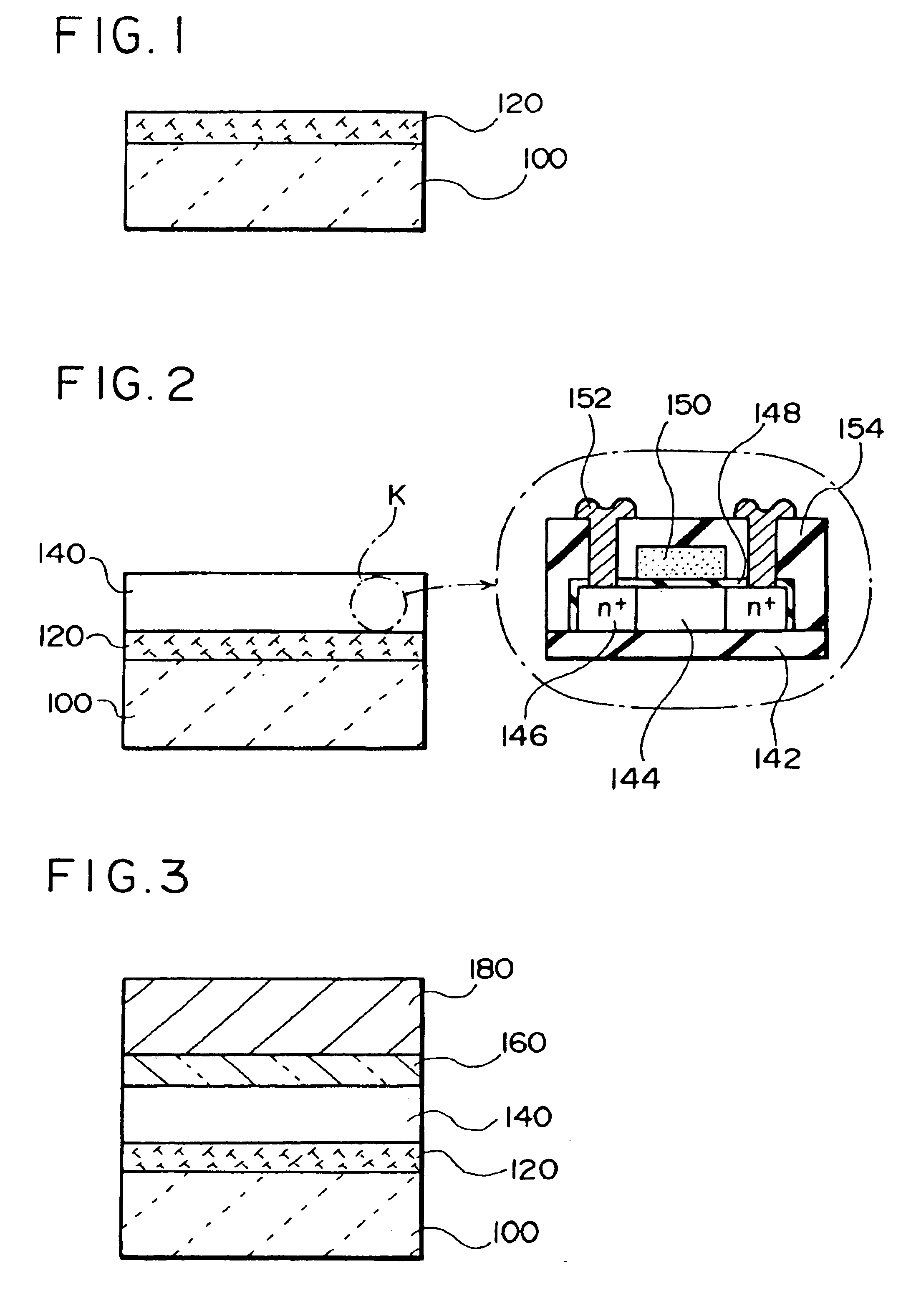

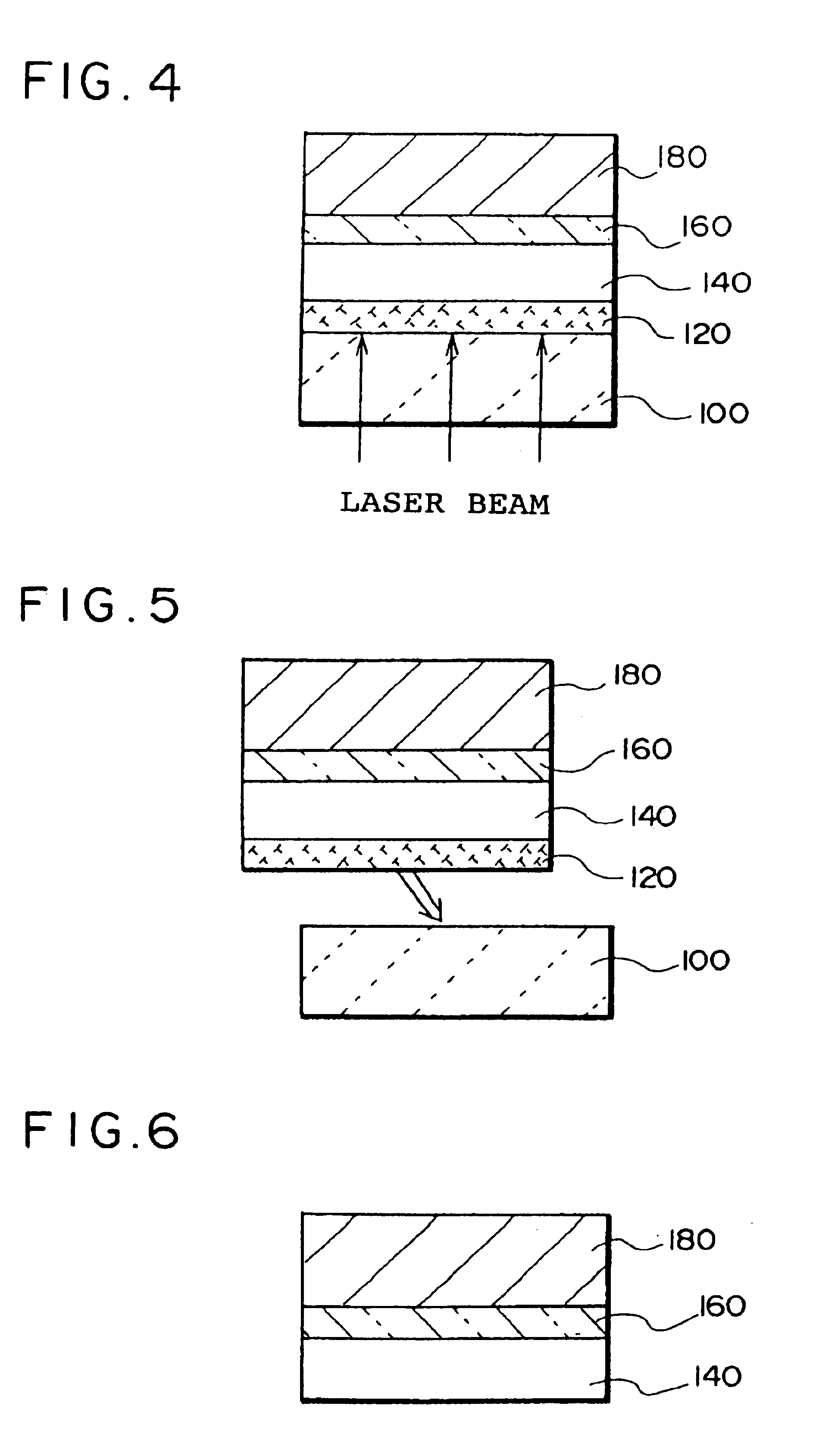

A thin film device fabrication method in which a thin film device formed on a substrate are transferred to a primary destination-of-transfer part and then the thin film device is transferred to a secondary destination-of-transfer part. A first separation layer (120) made of such a material as amorphous silicon is provided on a substrate (100) which allows passage of laser. A thin film device (140) such as TFTs are formed on the substrate (100). Further, a second separation layer (160) such as a hot-melt adhesive layer is formed on the thin film devices (140), and a primary destination-of-transfer part (180) is mounted thereon. The bonding strength of the first separation layer is weakened by irradiation with light, and the substrate (100) is removed. Thus, the thin film device (140) is transferred to the primary destination-of-transfer part. Then, a secondary destination-of-transfer part (200) is attached onto the bottom of an exposed part of the thin film device (140) via an adhesive layer (190). Thereafter, the bonding strength of the second separation layer is weakened by such means as thermal fusion, and the primary destination-of-transfer part is removed. In this manner, the thin film device (140) can be transferred to the secondary destination-of-transfer part (200) while maintaining layering relationship with respect to the substrate (100).

Owner:SAMSUNG ELECTRONICS CO LTD

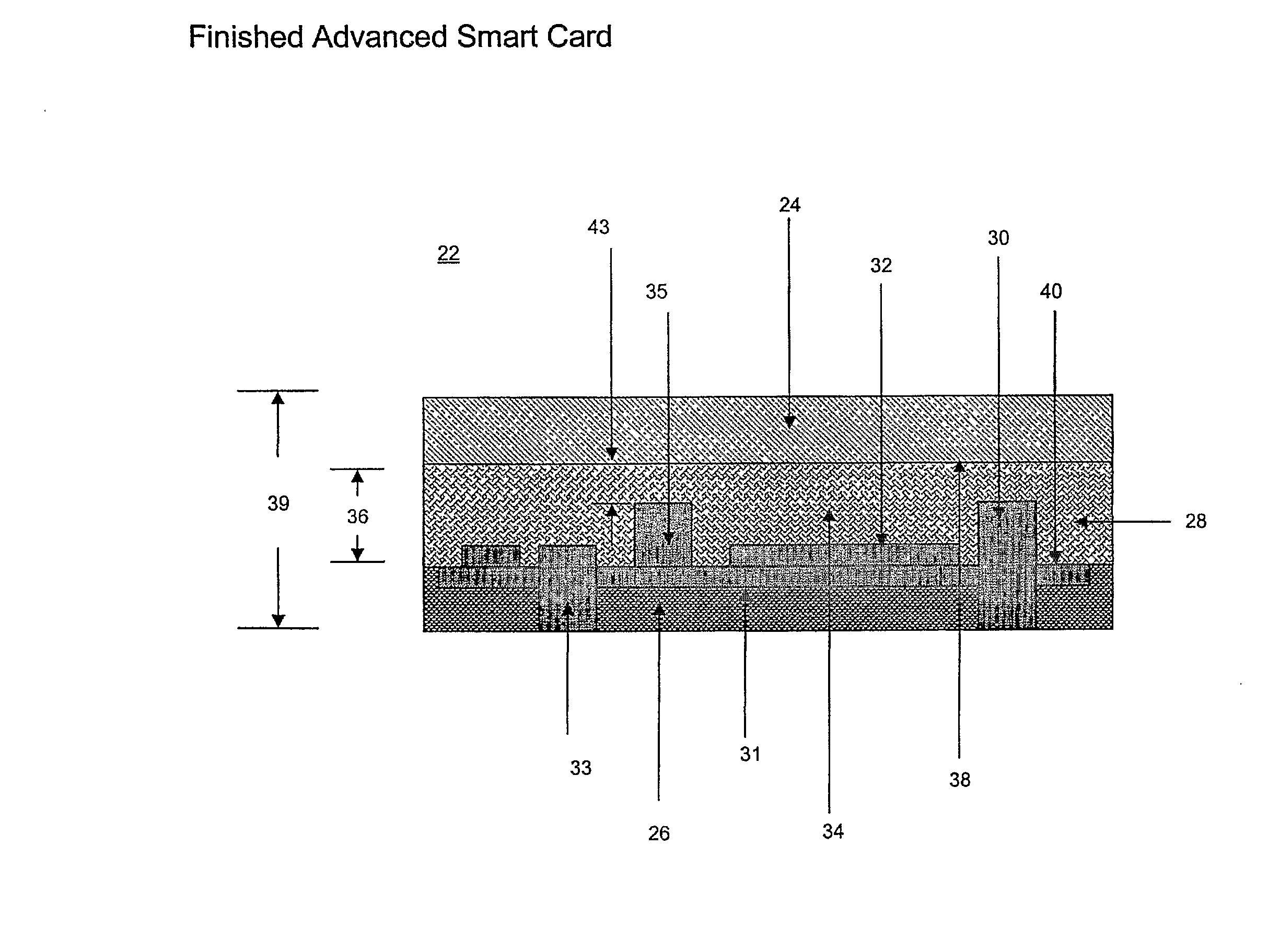

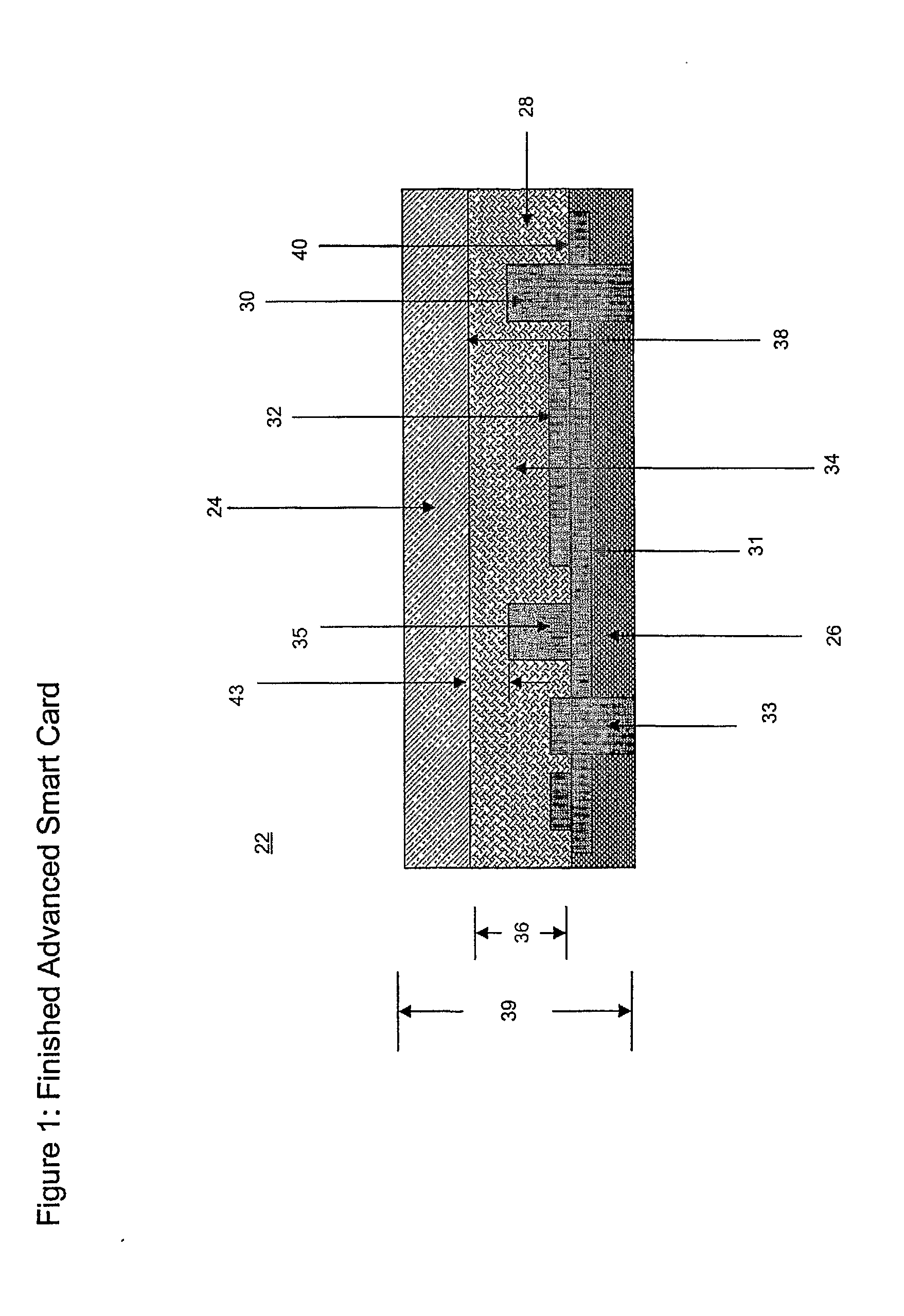

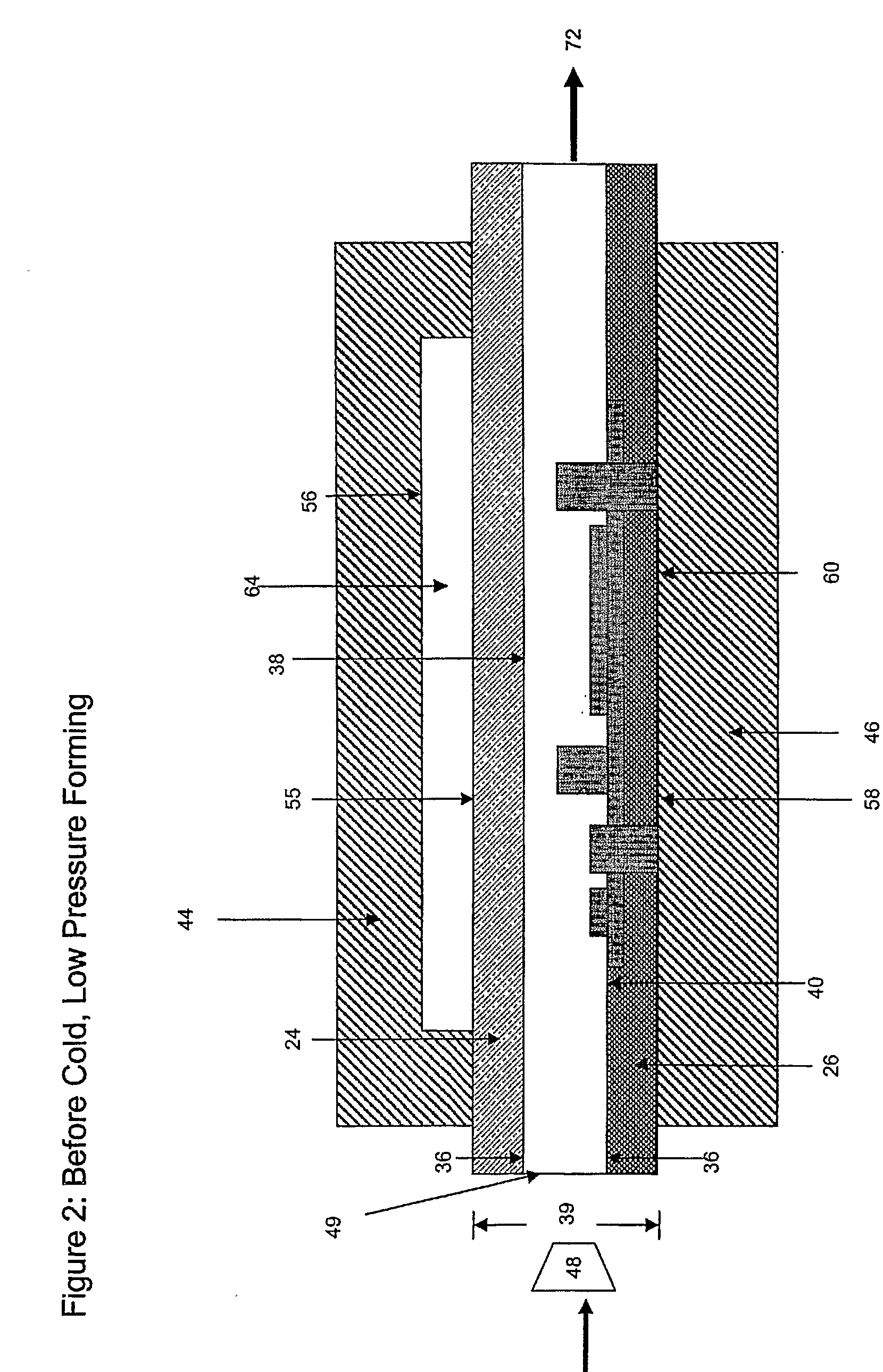

Method for Making Advanced Smart Cards With Integrated Electronics Using Isotropic Thermoset Adhesive Materials With High Quality Exterior Surfaces

InactiveUS20080096326A1Speed up the flowPrinted circuit assemblingLine/current collector detailsIntegrated electronicsSmart card

Advanced Smart Cards and similar form factors (e.g. documents, tags) having high quality external surfaces of Polyvinylchloride (PVC), Polycarbonate (PC), synthetic paper or other suitable material can be made with highly sophisticated electronic components (e.g. Integrated Circuit chips, batteries, microprocessors, Light Emitting Diodes, Liquid Crystal Displays, polymer dome switches, and antennae), integrated in the bottom layer of the card structure, through use of injection molded thermosetting or thermoplastic material that becomes the core layer of said Advanced Smart Cards. A lamination finishing process can provide a high quality lower surface, and the encapsulation of the electronic components in the thermosetting or thermoplastic material provides protection from the lamination heat and pressure.

Owner:CARDXX

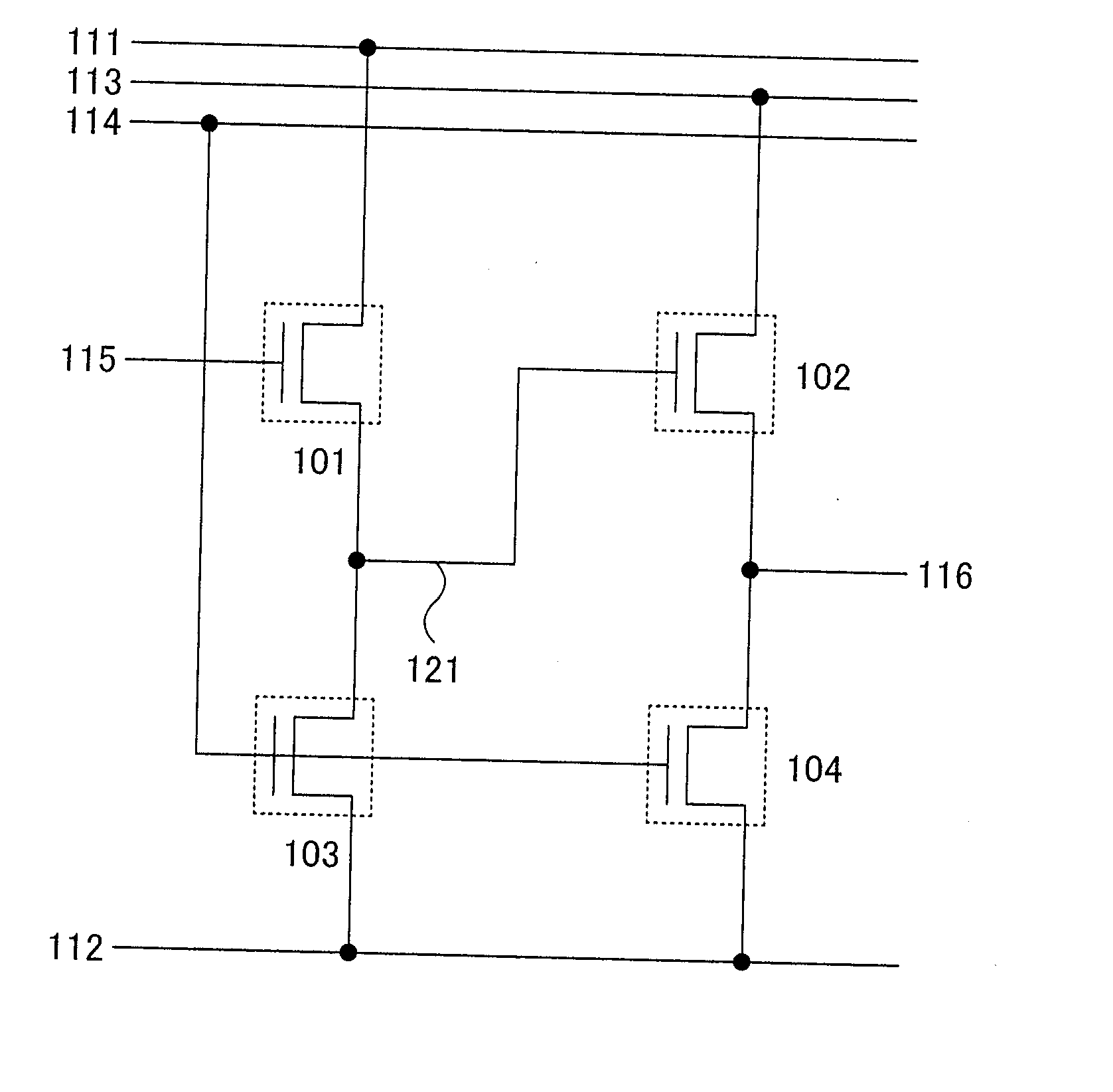

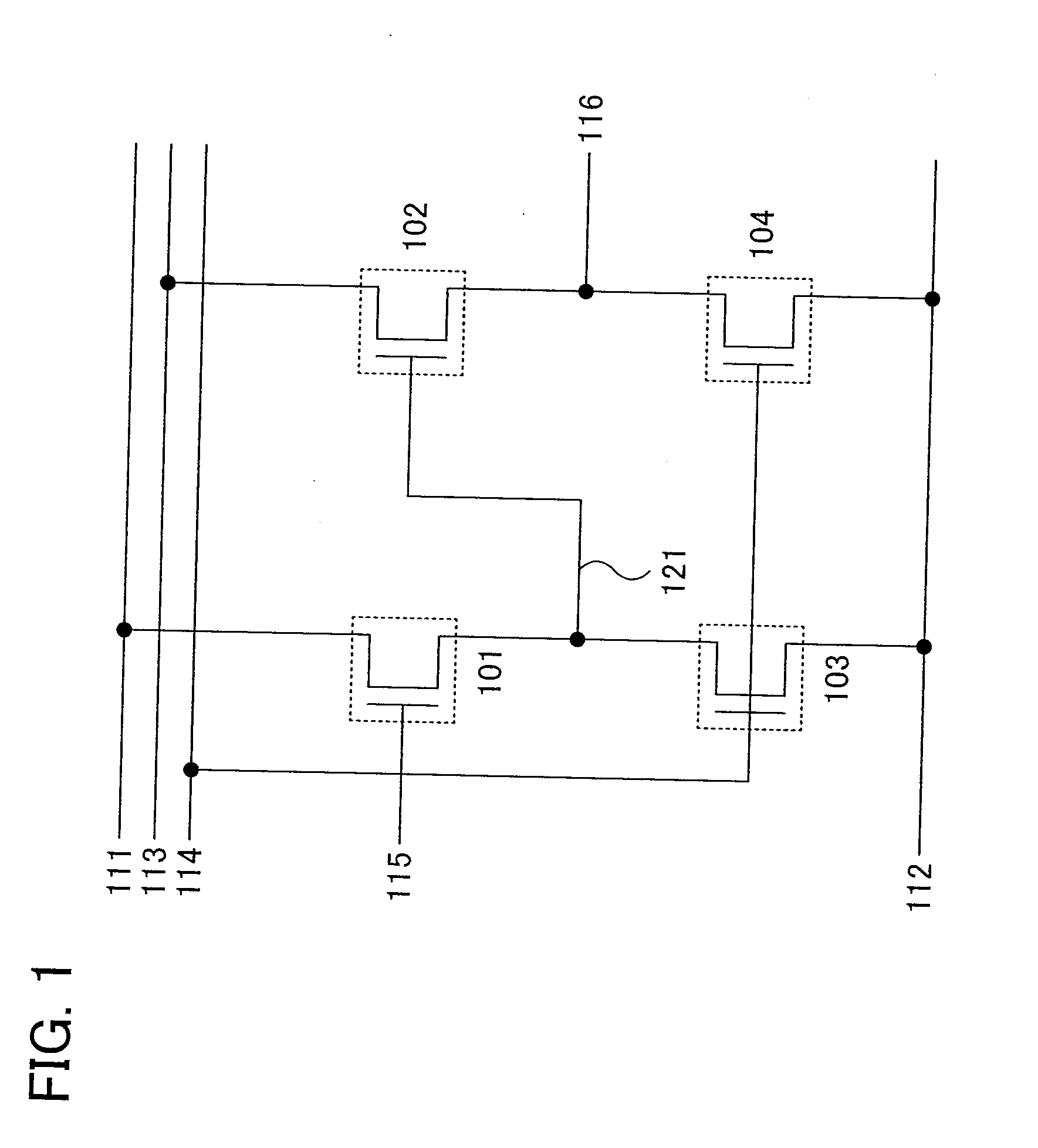

Liquid crystal display device

InactiveUS20080062112A1Deterioration in characteristic can be suppressedDeterioration of characteristicStatic indicating devicesSolid-state devicesLiquid-crystal displayTransistor

A first transistor, a second transistor, a third transistor, a fourth transistor are provided. In the first transistor, a first terminal is electrically connected to a first wiring; a second terminal is electrically connected to a gate terminal of the second transistor; a gate terminal is electrically connected to a fifth wiring. In the second transistor, a first terminal is electrically connected to a third wiring; a second terminal is electrically connected to a sixth wiring. In the third transistor, a first terminal is electrically connected to a second wiring; a second terminal is electrically connected to the gate terminal of the second transistor; a gate terminal is electrically connected to a fourth wiring. In the fourth transistor, a first terminal is electrically connected to the second wiring; a second terminal is electrically connected to the sixth wiring; a gate terminal is connected to the fourth wiring.

Owner:SEMICON ENERGY LAB CO LTD

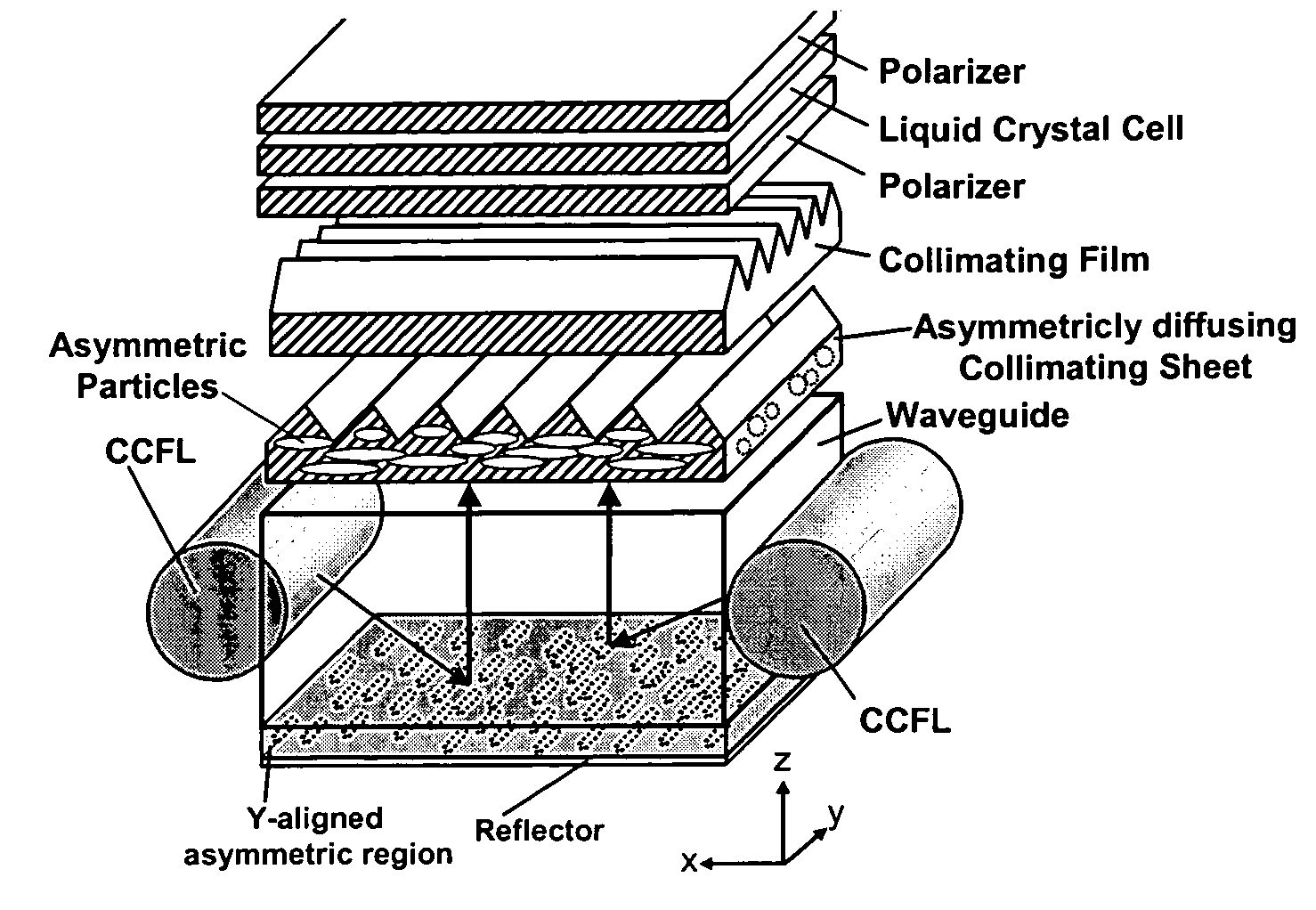

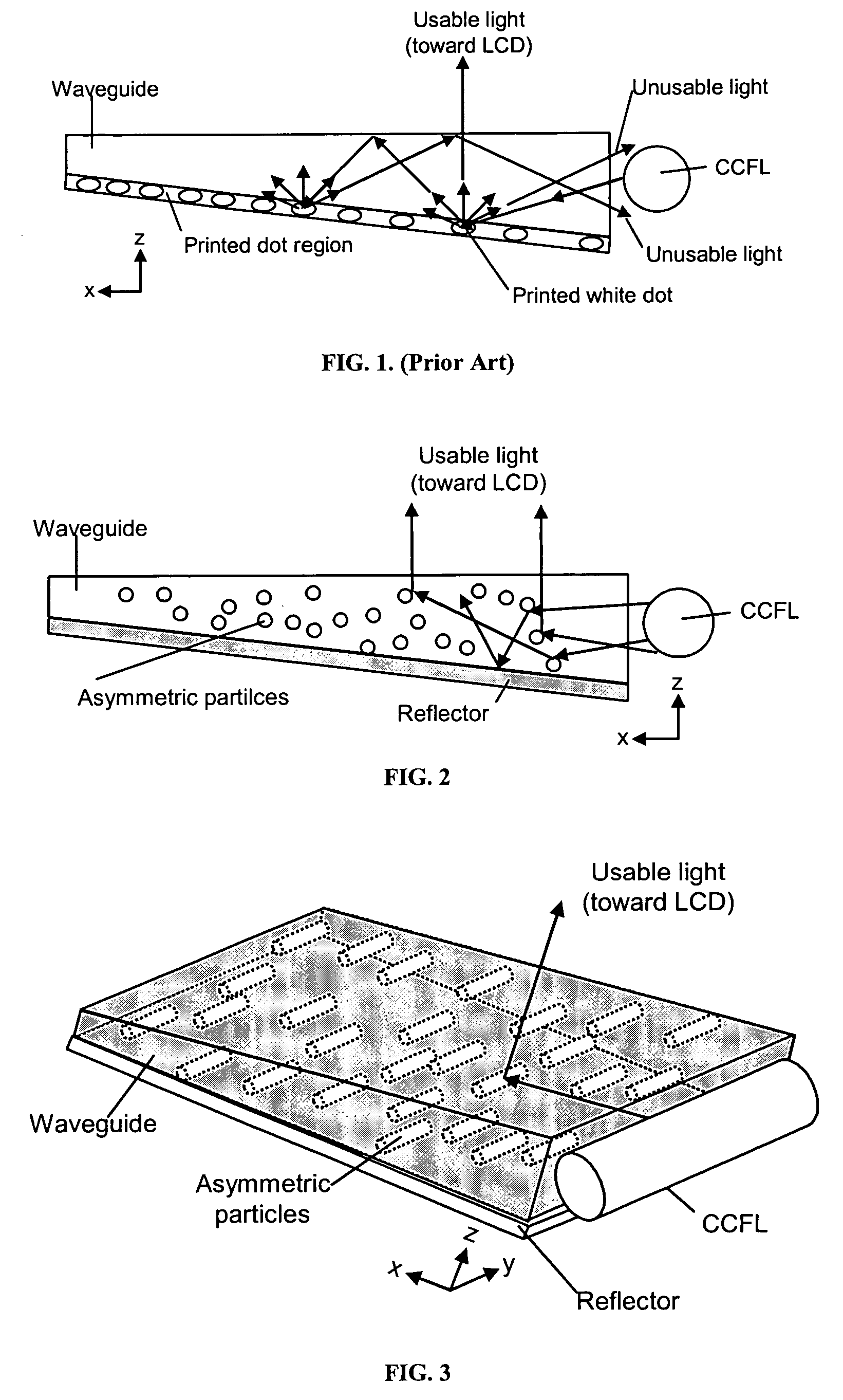

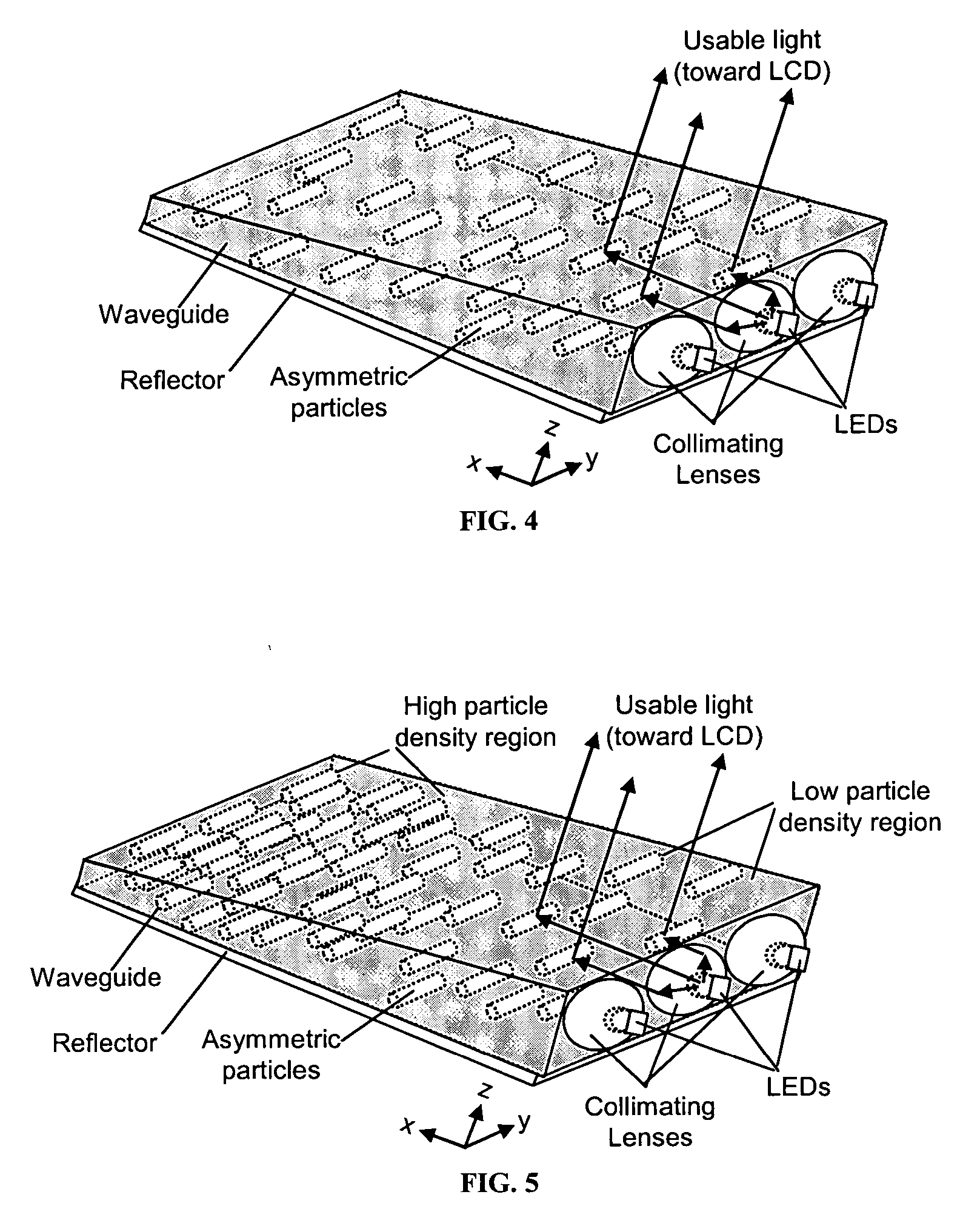

Enhanced LCD backlight

ActiveUS20060056166A1Improved backlight assemblyAvoid less flexibilityElectric discharge tubesDiffusing elementsCompression moldingEllipsoidal particle

The present invention provides an improved light guide with inherently more flexibility for display system designers and higher optical efficiency. By using a light guide containing substantially aligned non-spherical particles, more efficient control of the light scattering can be achieved. One or more regions containing ellipsoidal particles may be used and the particle sizes may vary between 2 and 100 microns in the smaller dimension. The light scattering regions may be substantially orthogonal in their axis of alignment. Alternatively, one or more asymmetrically scattering films can be used in combination with a backlight light guide and a reflector to produce an efficient backlight system. The light guides may be manufactured by embossing, stamping, or compression molding a light guide in a suitable light guide material containing asymmetric particles substantially aligned in one direction. The light scattering light guide or non-scattering light guide may be used with one or more light sources, collimating films or symmetric or asymmetric scattering films to produce an efficient backlight that can be combined with a liquid crystal display or other transmissive display. By maintaining more control over the scattering, the efficiency of the recycling of light by using reflective polarizers can also be increased.

Owner:MASSACHUSETTS DEV FINANCE AGENCY

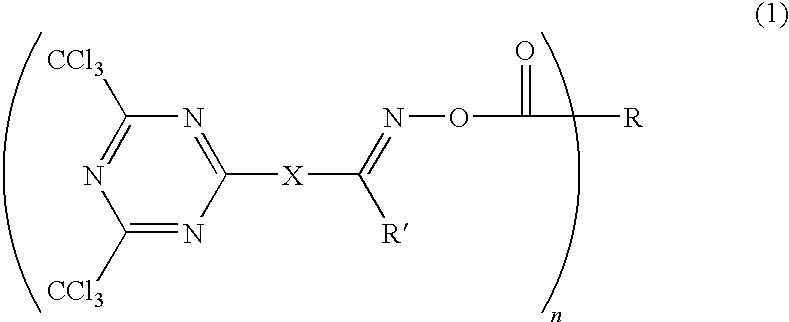

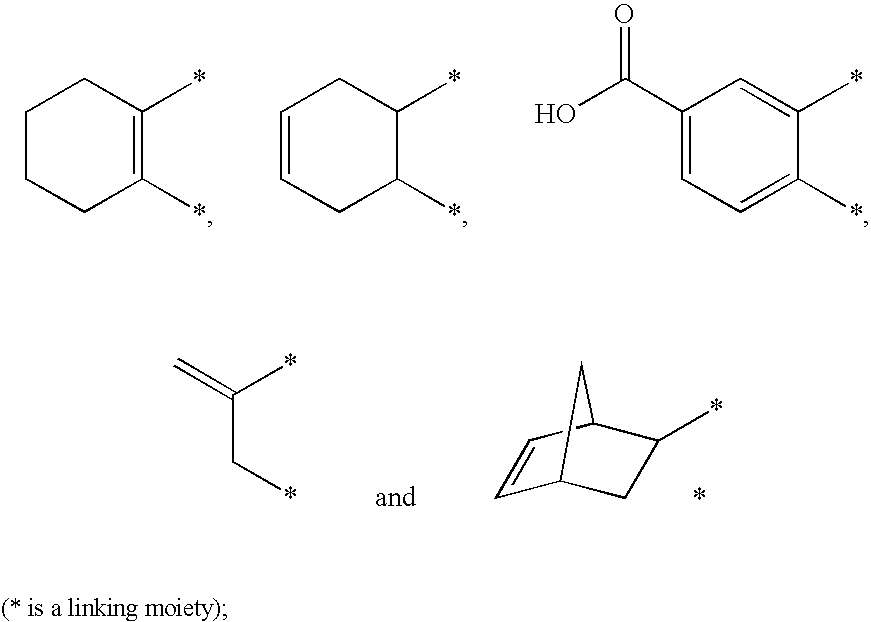

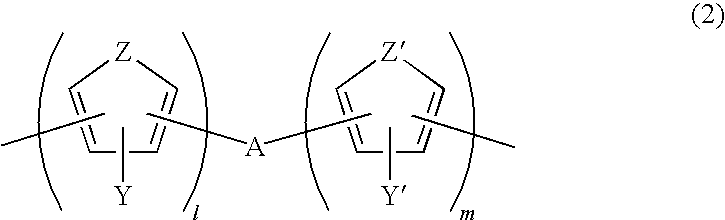

Photosensitive composition comprising triazine-based photoactive compound containing oxime ester

ActiveUS7556910B2Effective absorptionDevelopment durabilityOrganic chemistryPhotosensitive materialsOximePhotochemistry

The present invention relates to a photosensitive composition comprising a triazine-based photoactive compound containing oxime ester. The photosensitive composition according to the present invention has good sensitivity, retention rate, mechanical strength, heat resistance, chemical resistance and developing durability since it contains, as photopolymerization initiator, a compound having an oxime ester group and a triazine group in one molecule and thus effectively absorbs UV radiation. Therefore, the photosensitive composition according to the present invention is advantageous not only in curing of materials for color filters, resin black matrixes, column spacers, overcoats and passivation films of liquid crystal displays, but also in high temperature process characteristics.

Owner:LG CHEM LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com