Patents

Literature

14547results about How to "Improve mobility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Amorphous Oxide And Thin Film Transistor

InactiveUS20070194379A1High ionicityGeneration of oxygen defects is less frequentTransistorVacuum evaporation coatingCharge carrierElectron

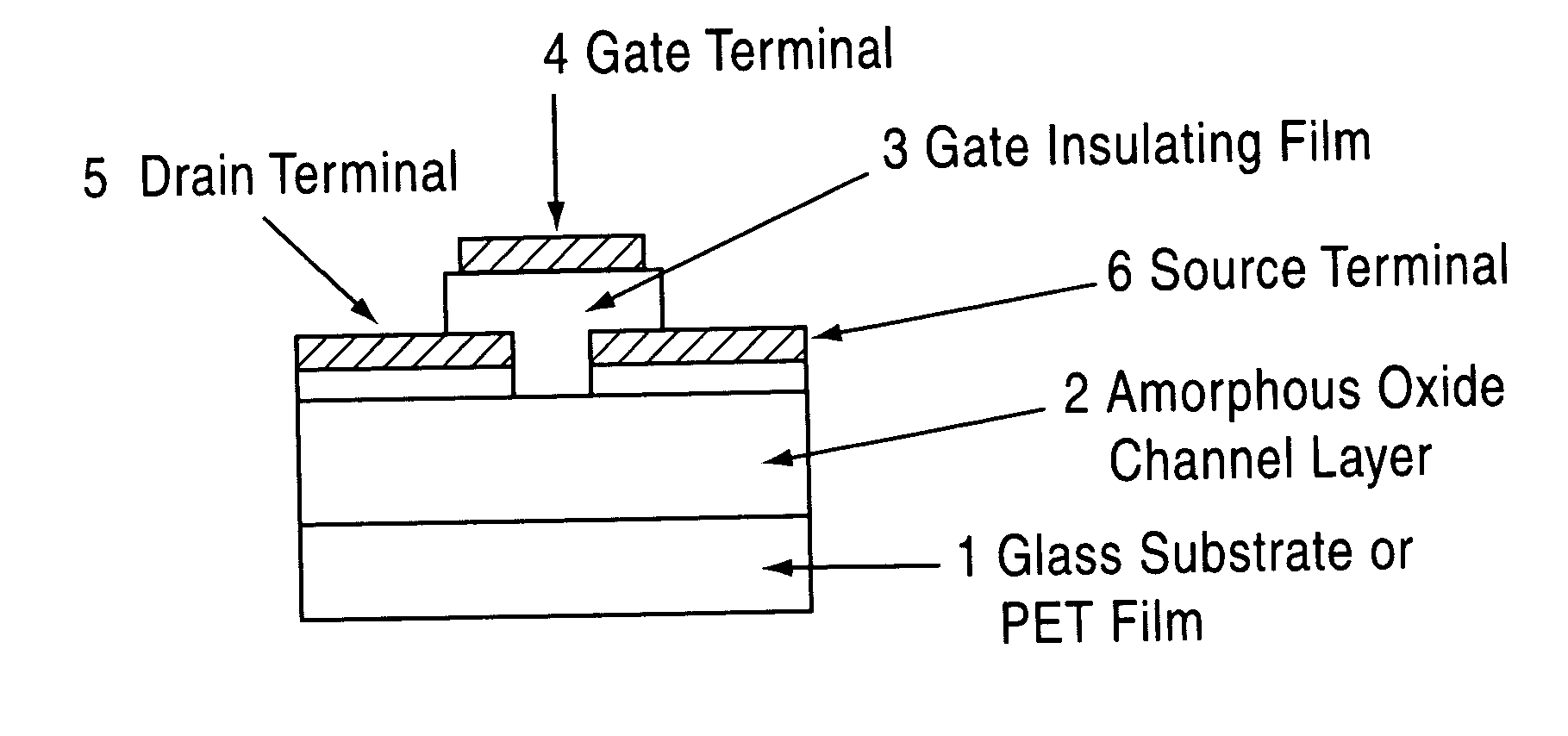

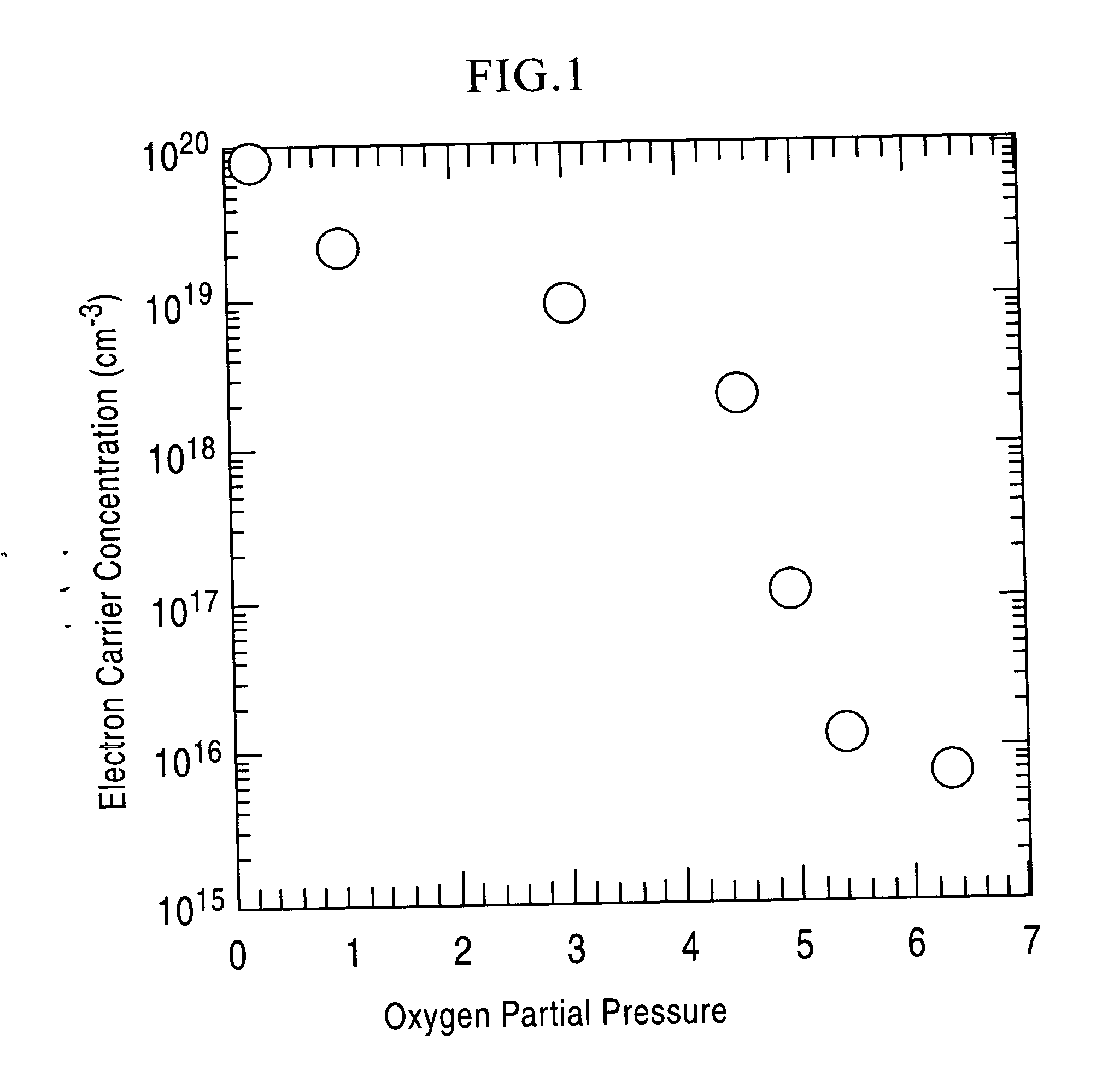

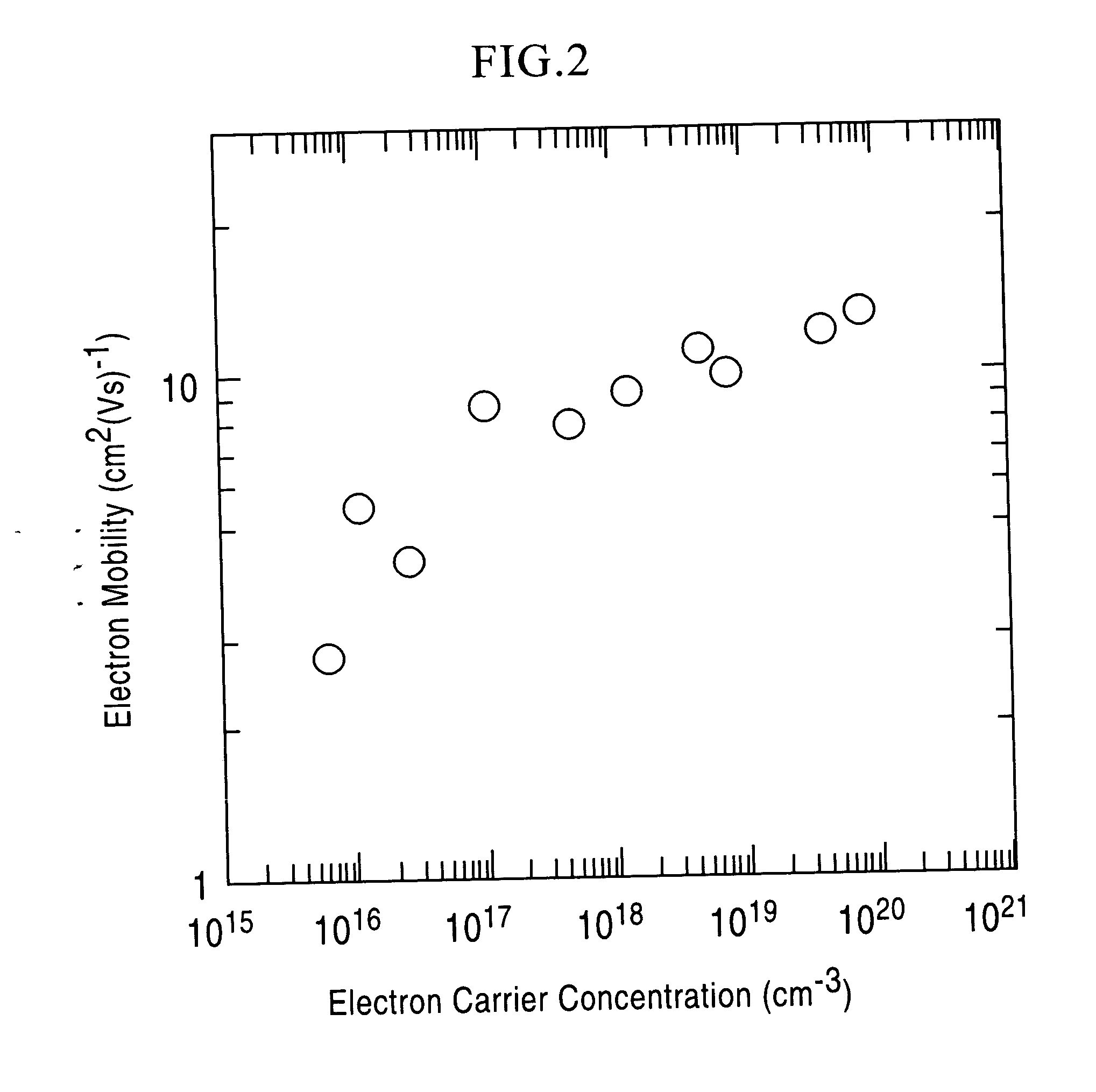

The present invention relates to an amorphous oxide and a thin film transistor using the amorphous oxide. In particular, the present invention provides an amorphous oxide having an electron carrier concentration less than 1018 / cm3, and a thin film transistor using such an amorphous oxide. In a thin film transistor having a source electrode 6, a drain electrode 5, a gate electrode 4, a gate insulating film 3, and a channel layer 2, an amorphous oxide having an electron carrier concentration less than 1018 / cm3 is used in the channel layer 2.

Owner:JAPAN SCI & TECH CORP

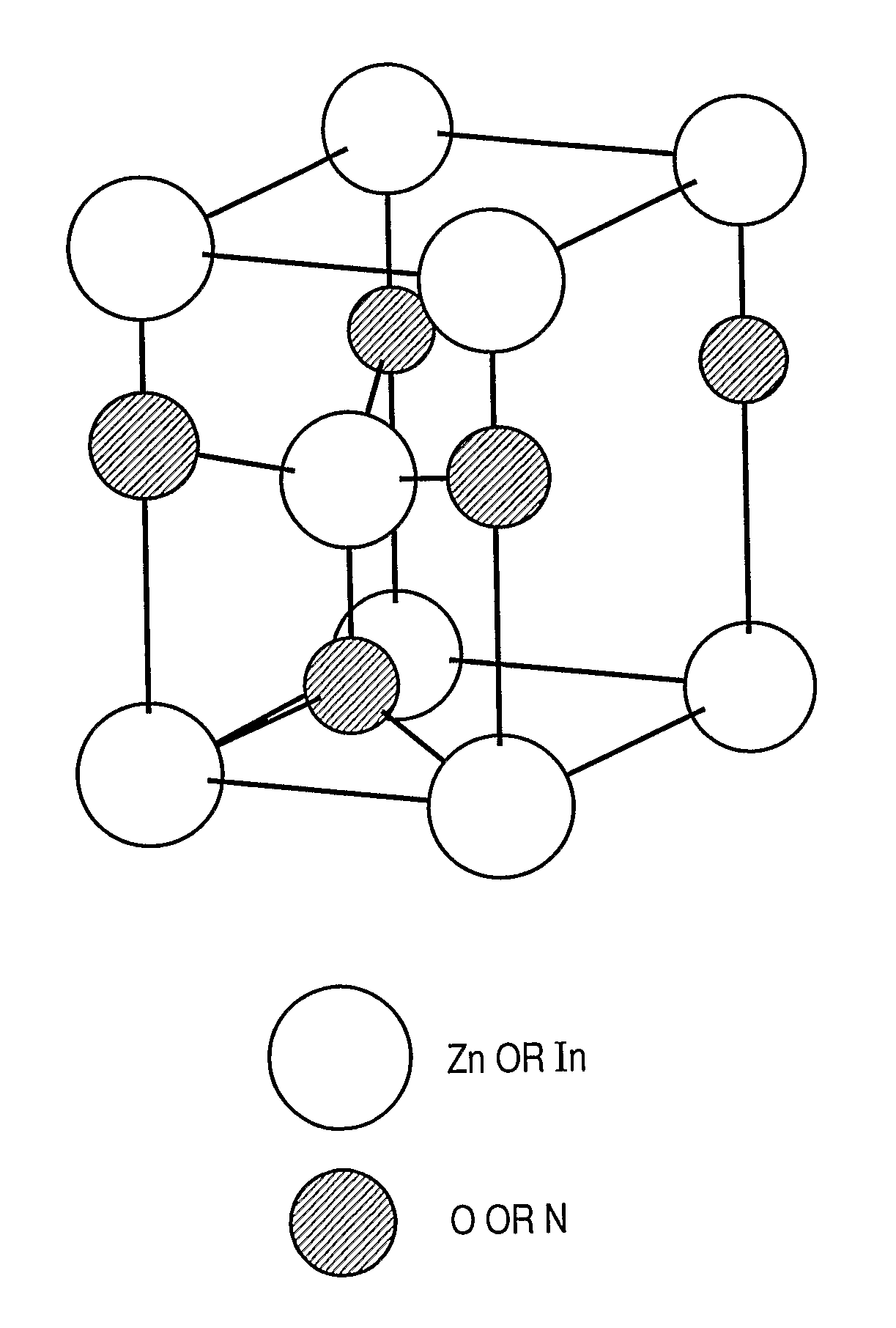

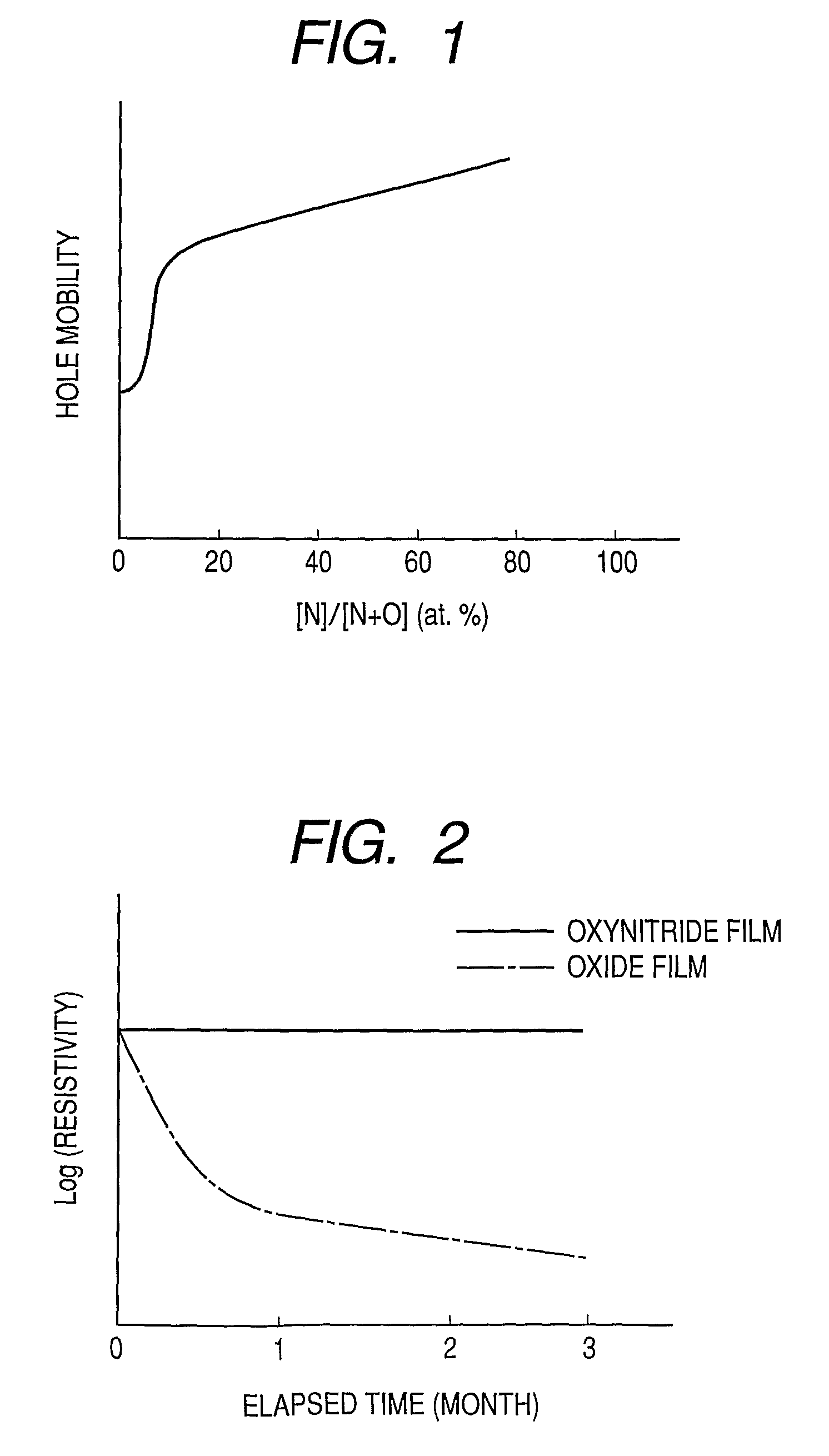

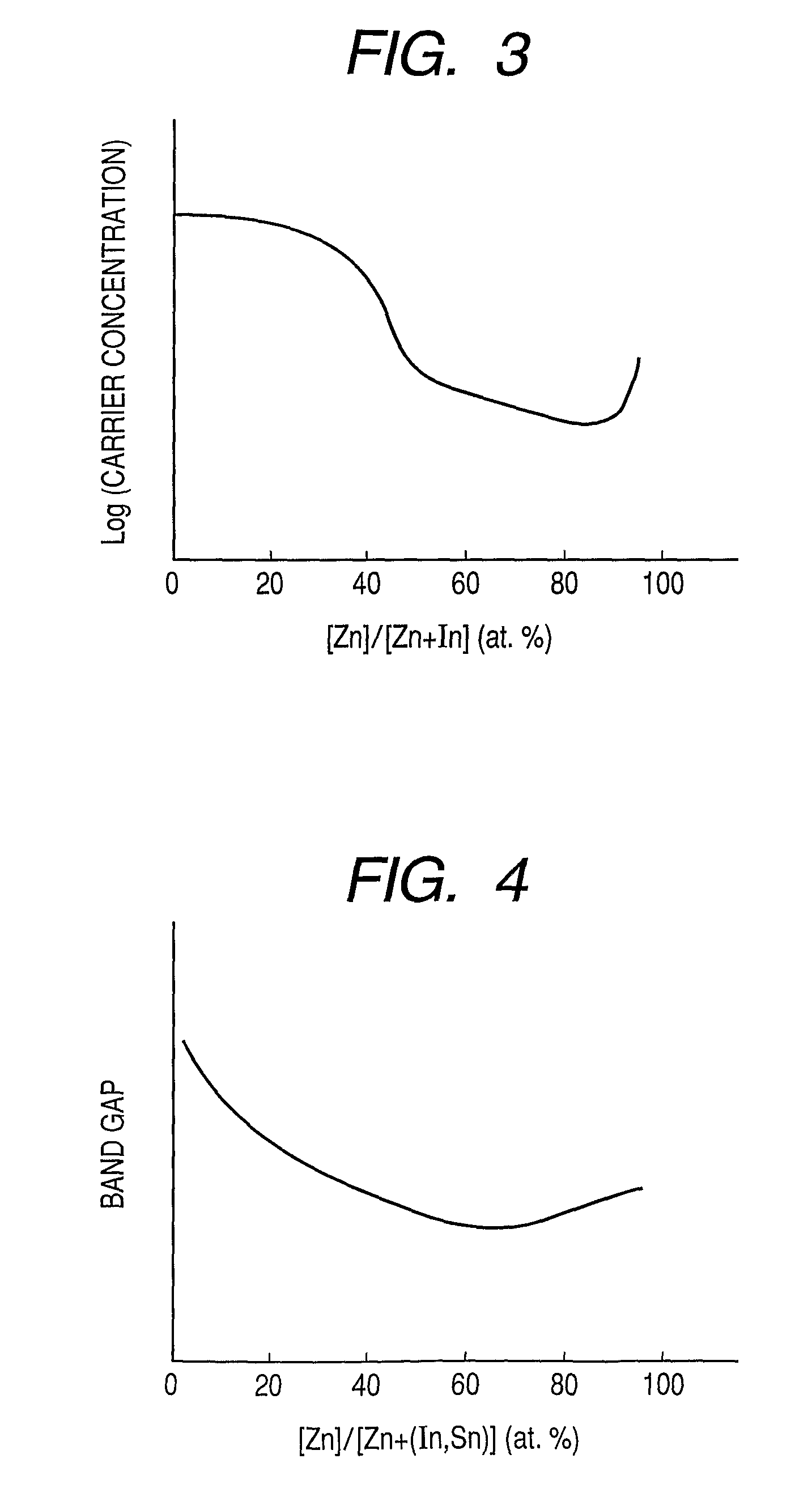

Oxynitride semiconductor

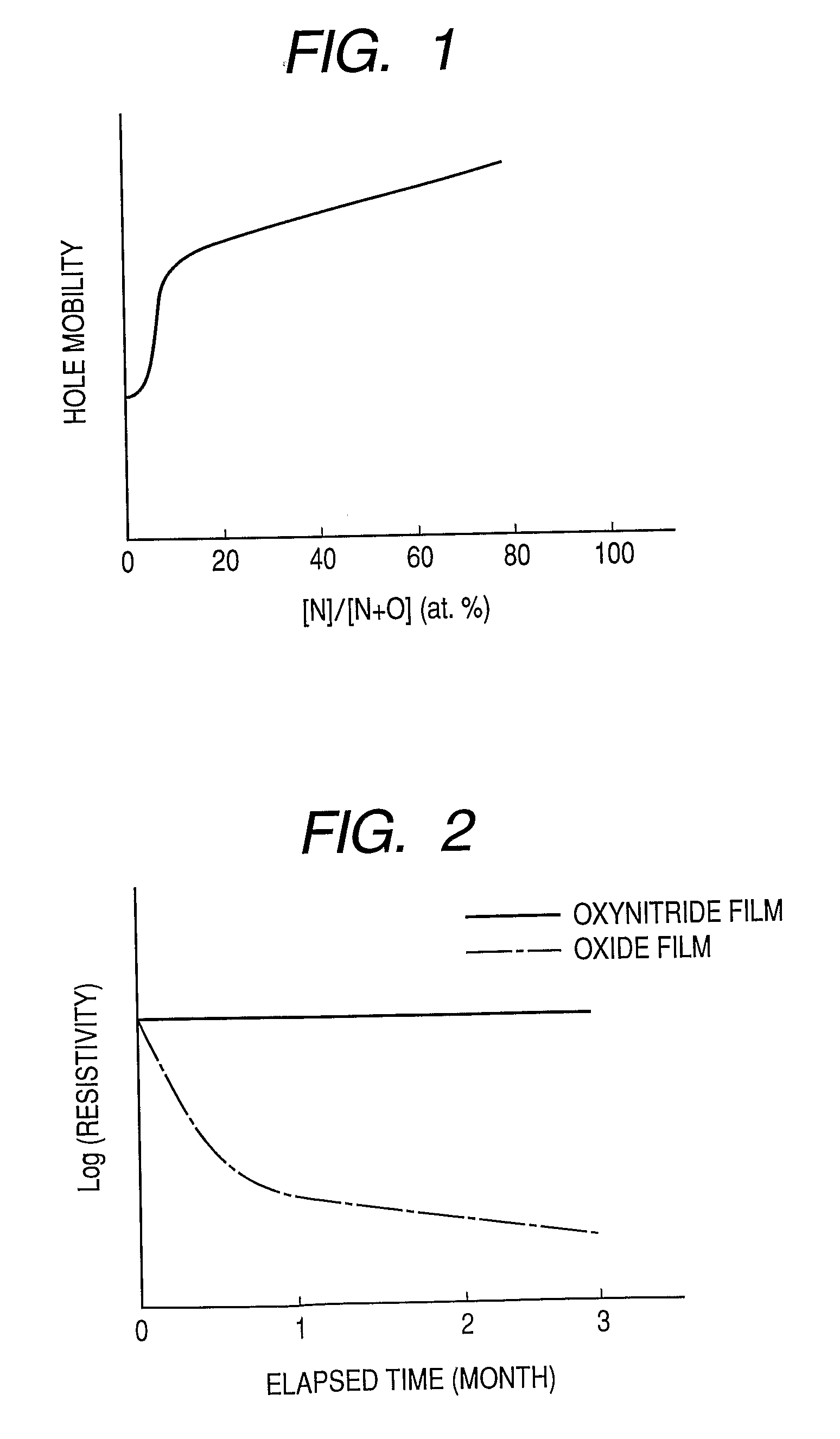

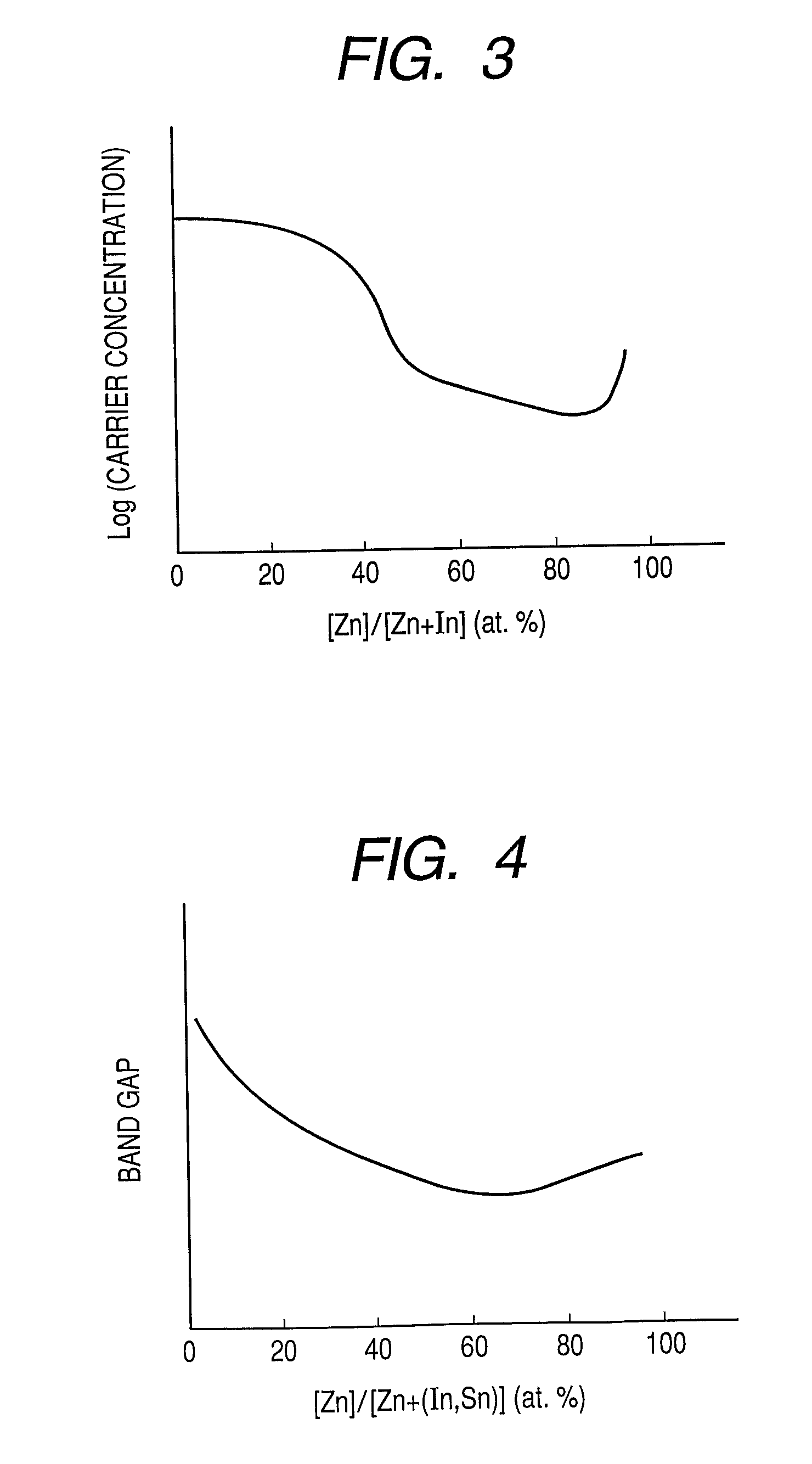

ActiveUS20100109002A1High mobility and environmental stabilityImprove mobilitySemiconductor devicesNitrogen oxideOxygen

Provided is an oxynitride semiconductor comprising a metal oxynitride. The metal oxynitride contains Zn and at least one element selected from the group consisting of In, Ga, Sn, Mg, Si, Ge, Y, Ti, Mo, W, and Al. The metal oxynitride has an atomic composition ratio of N, N / (N+O), of 7 atomic percent or more to 80 atomic percent or less.

Owner:CANON KK

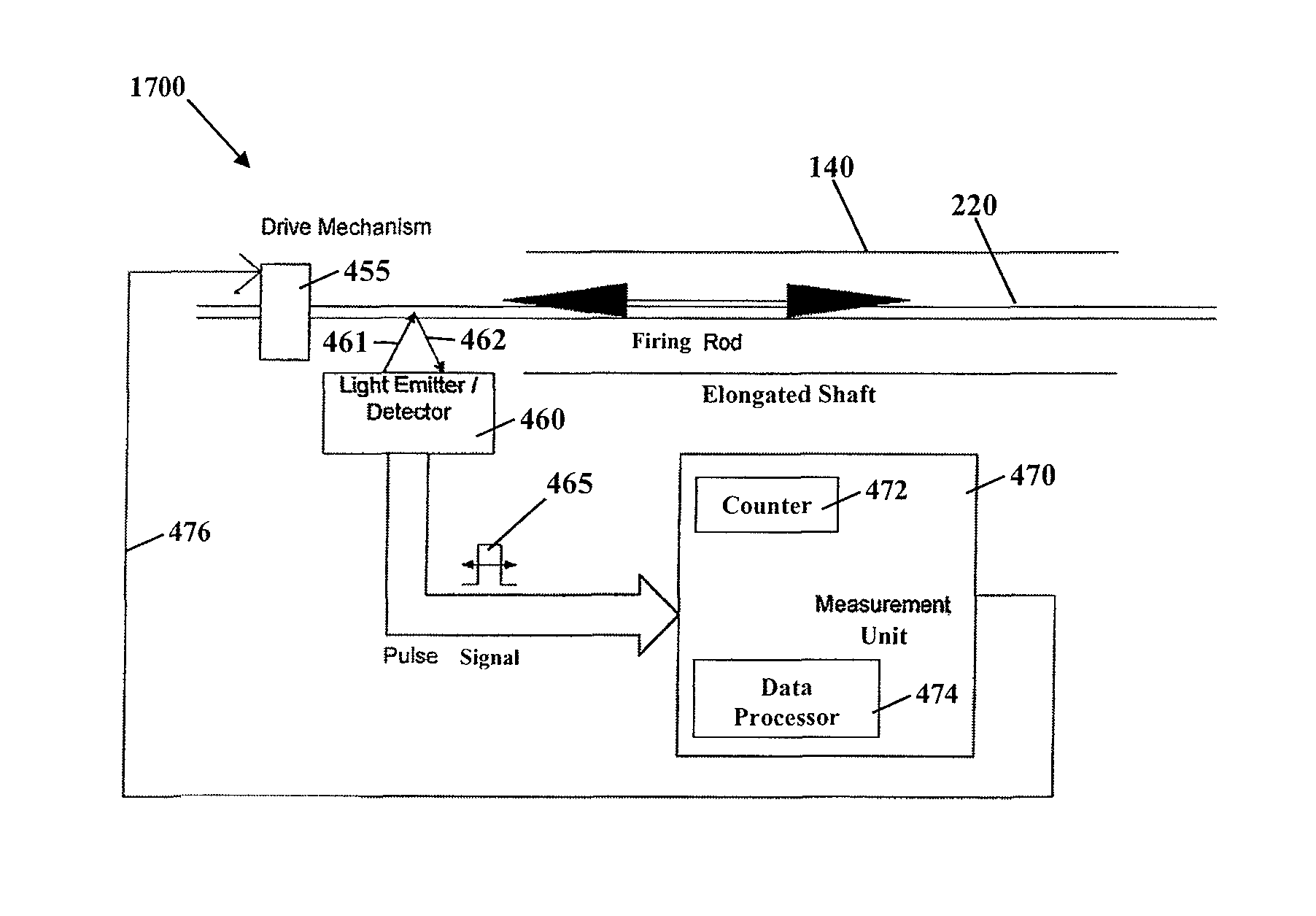

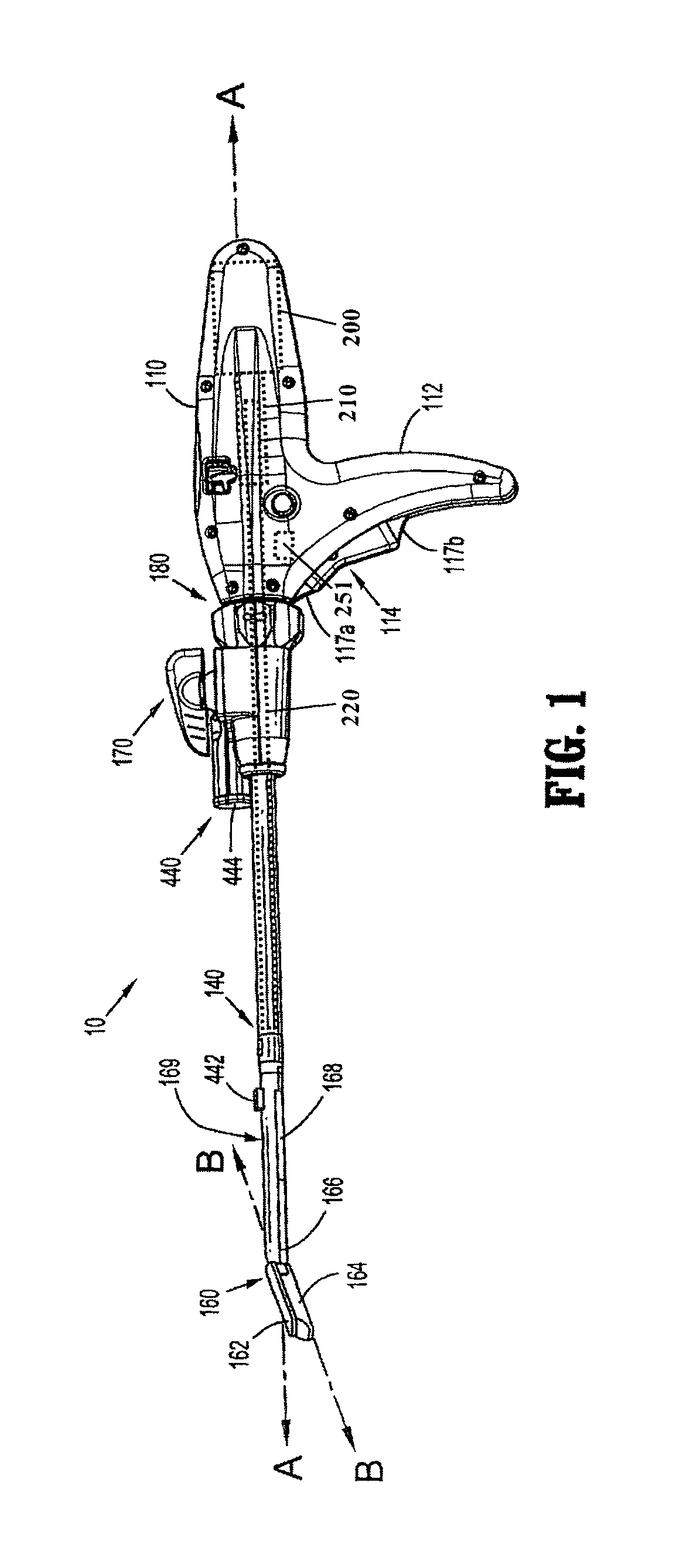

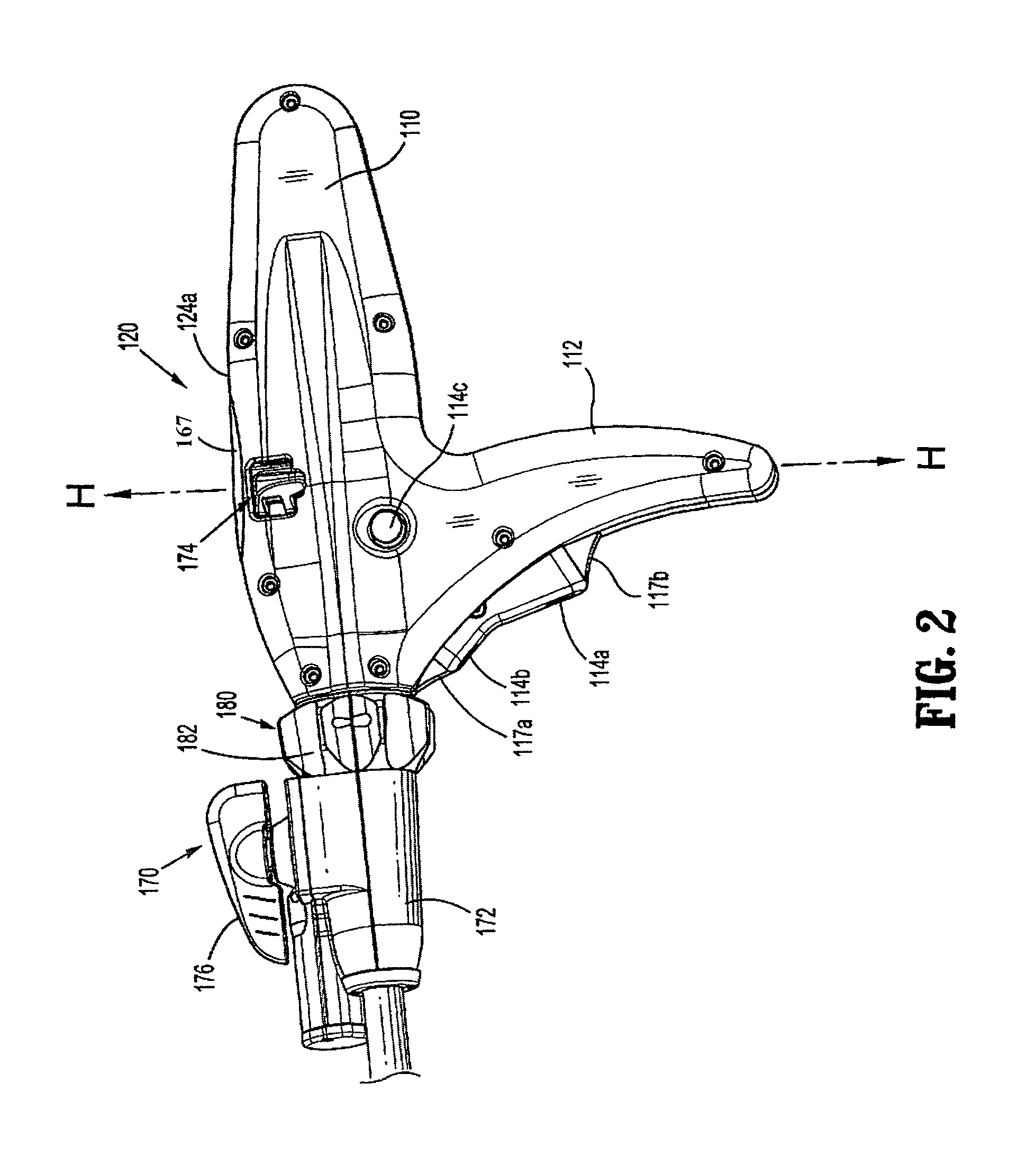

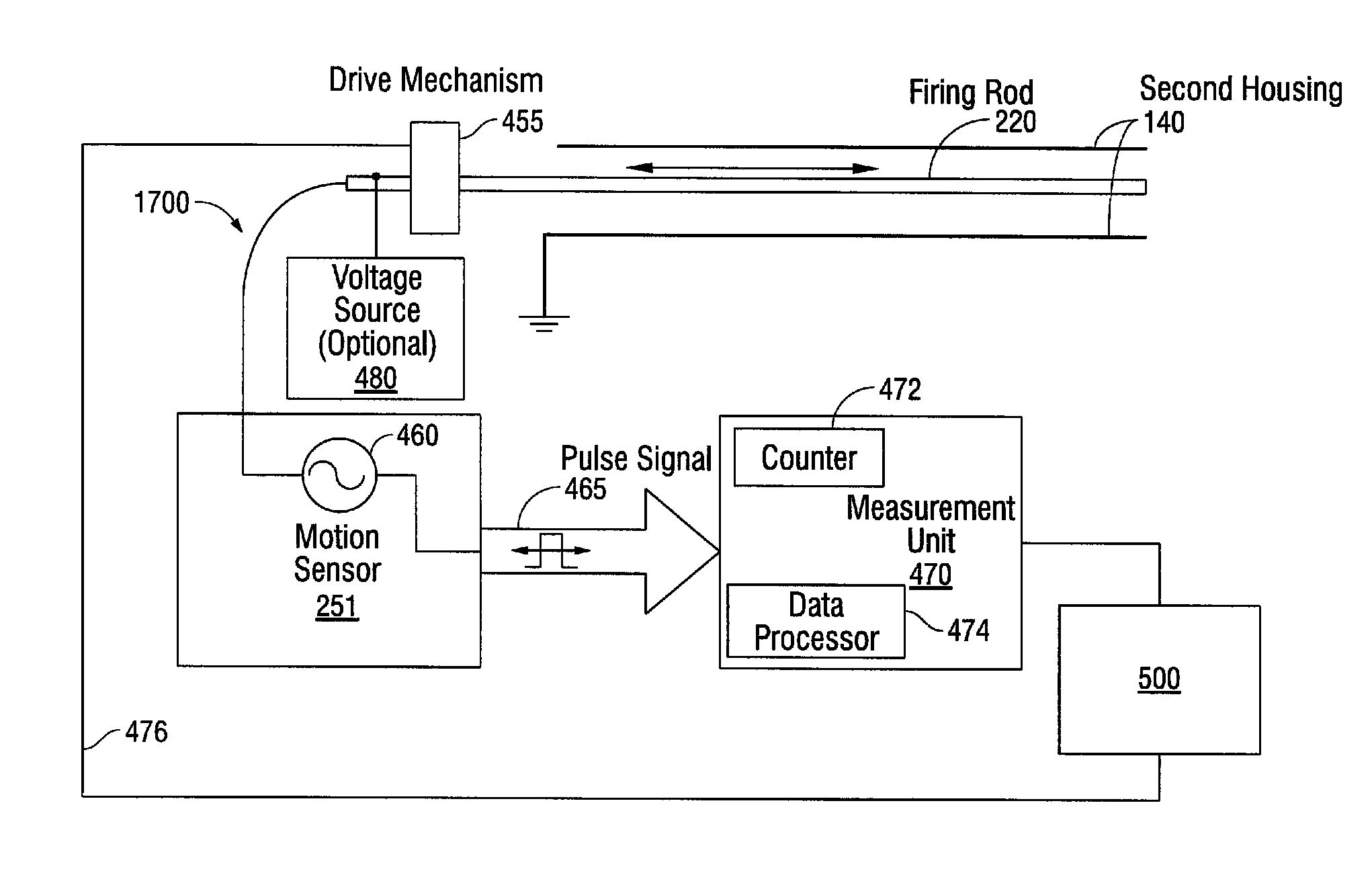

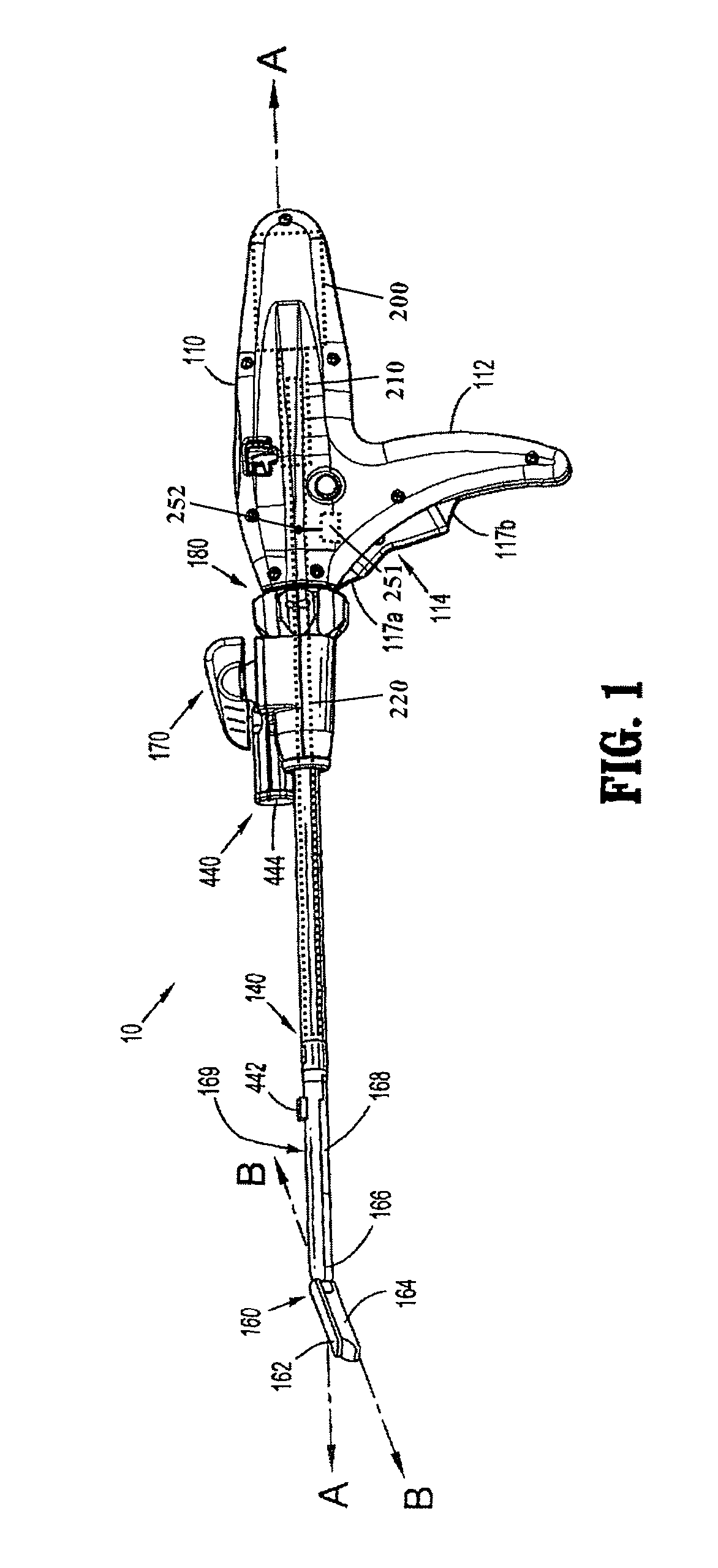

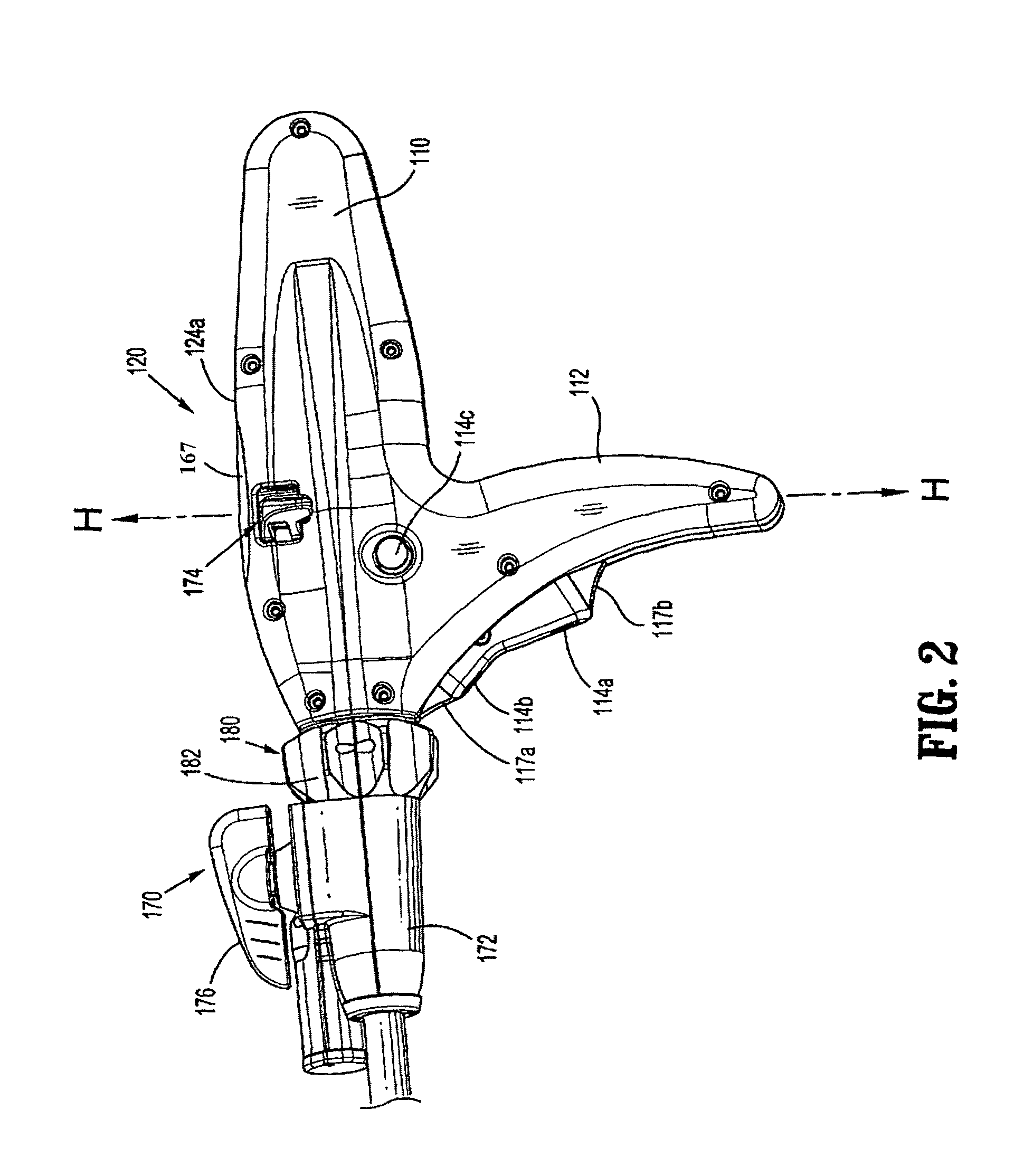

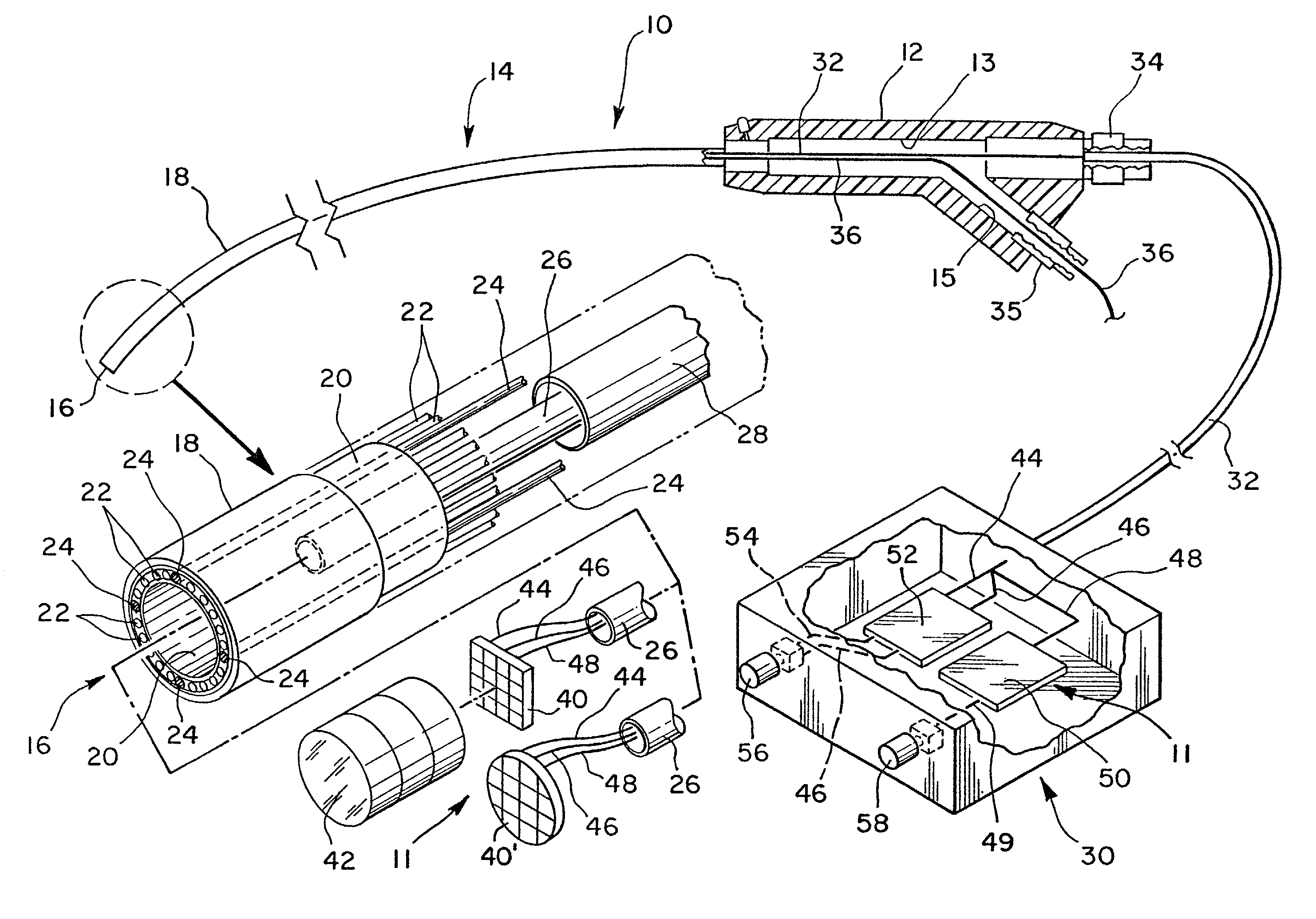

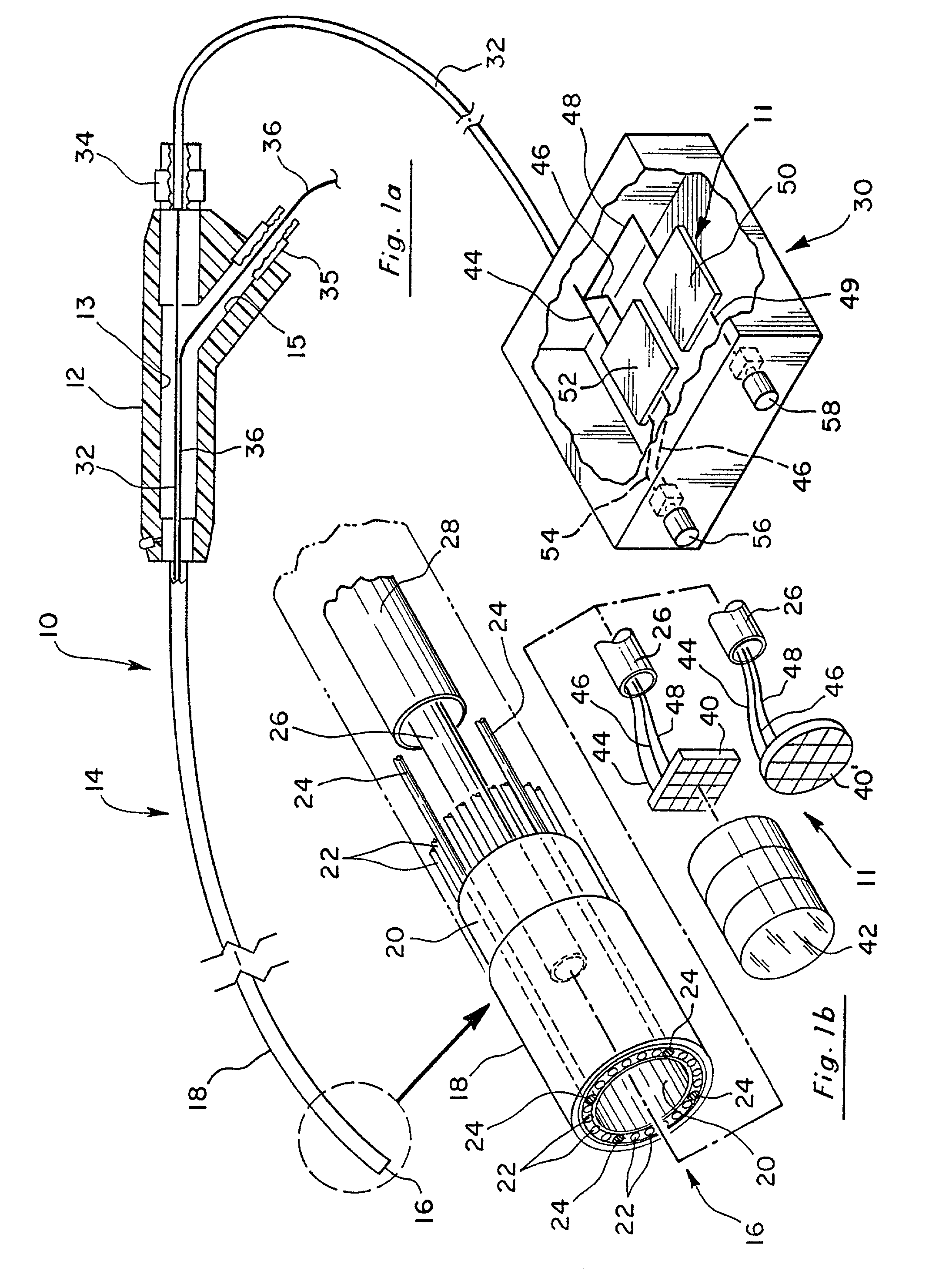

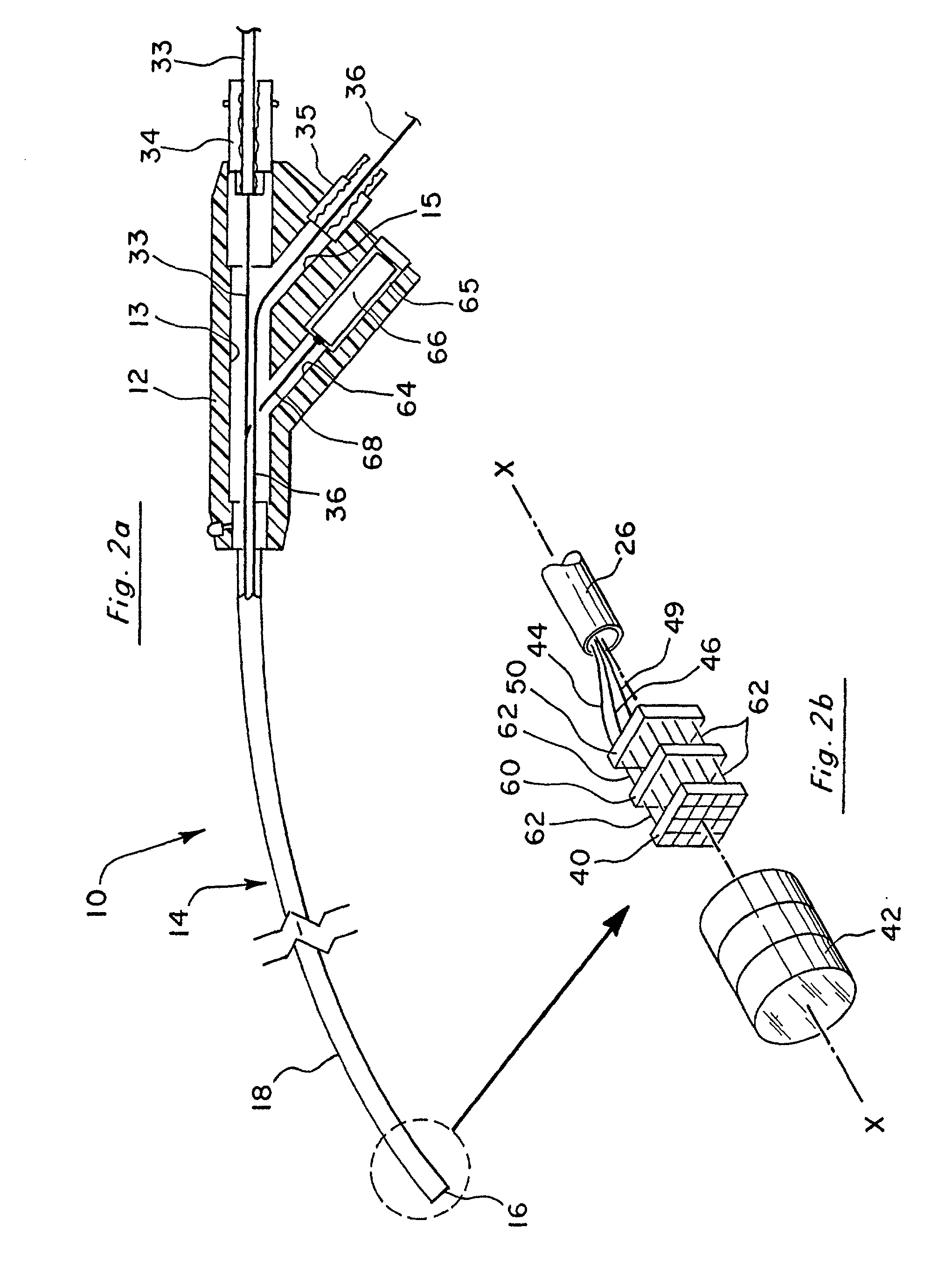

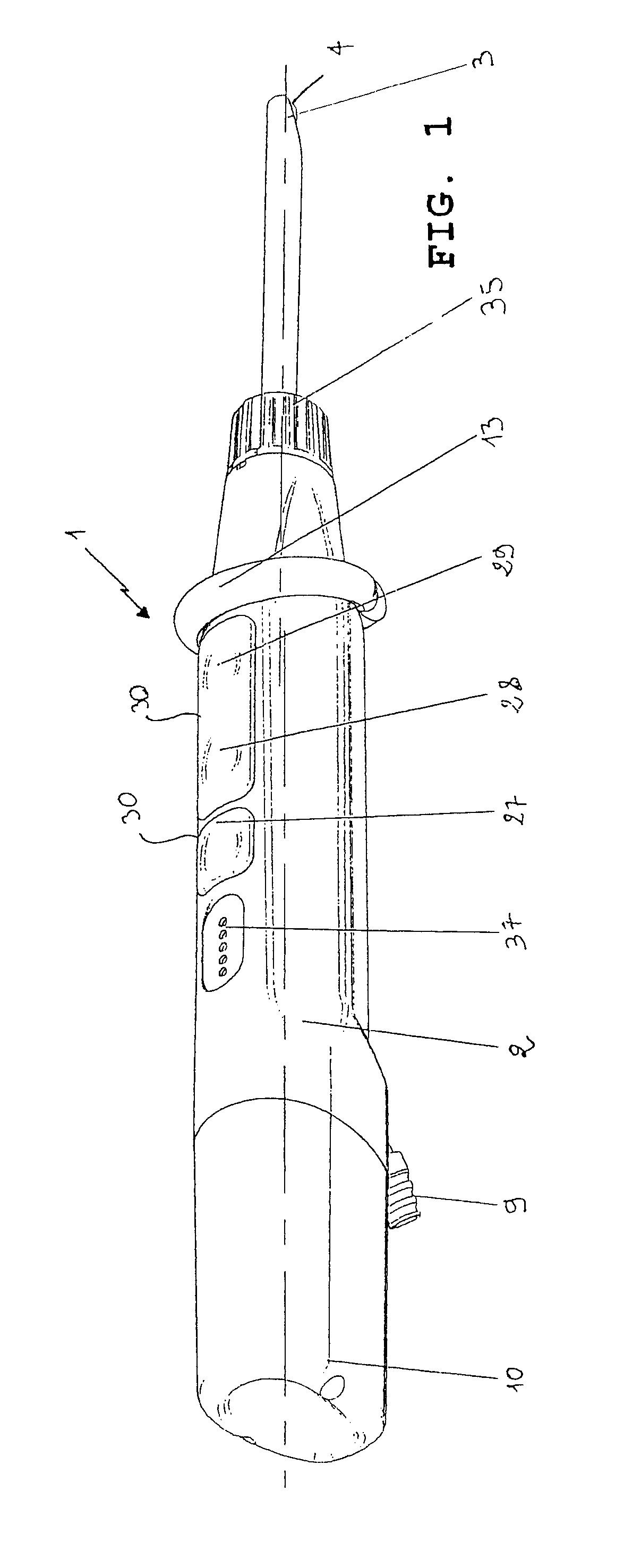

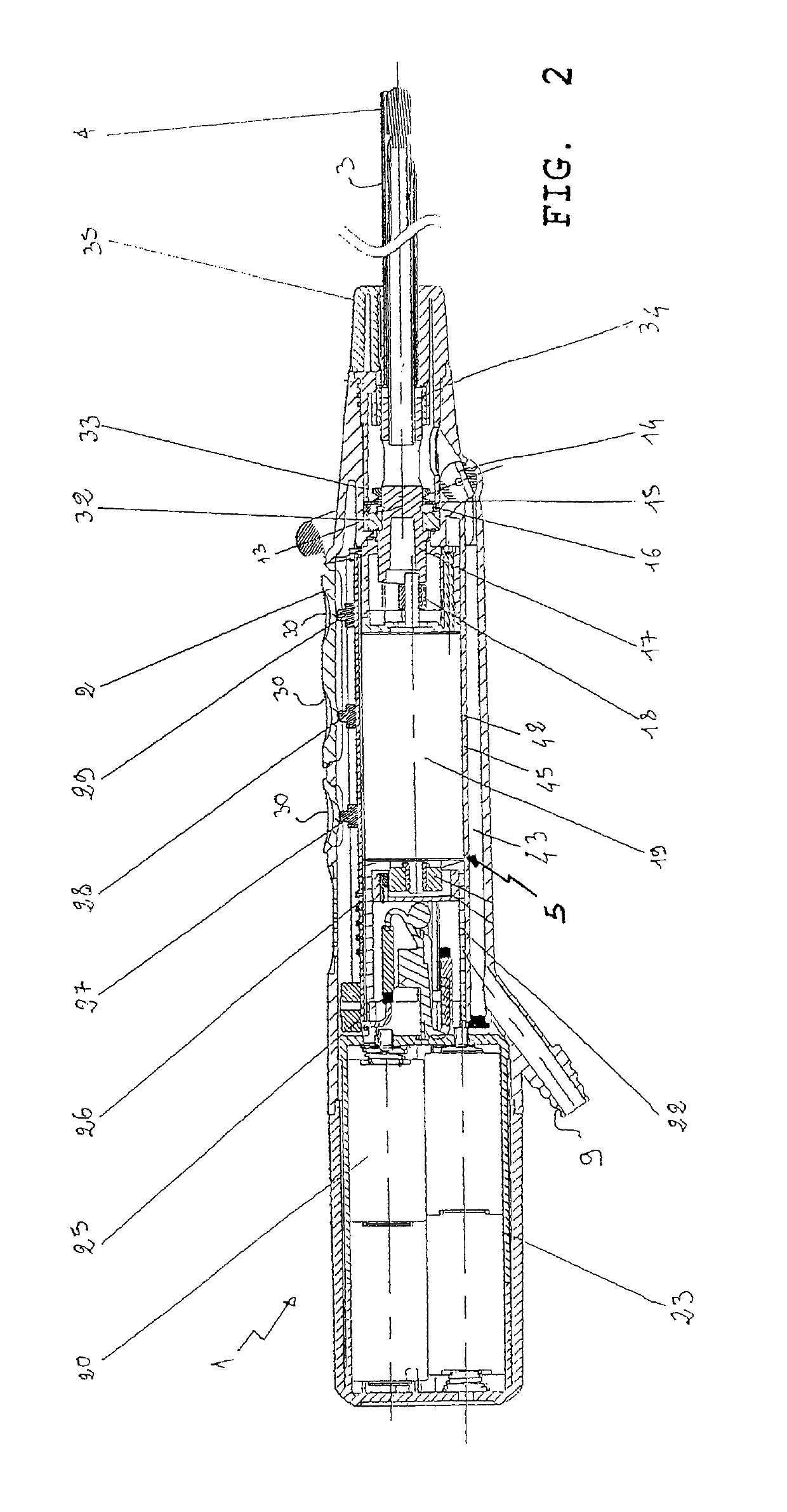

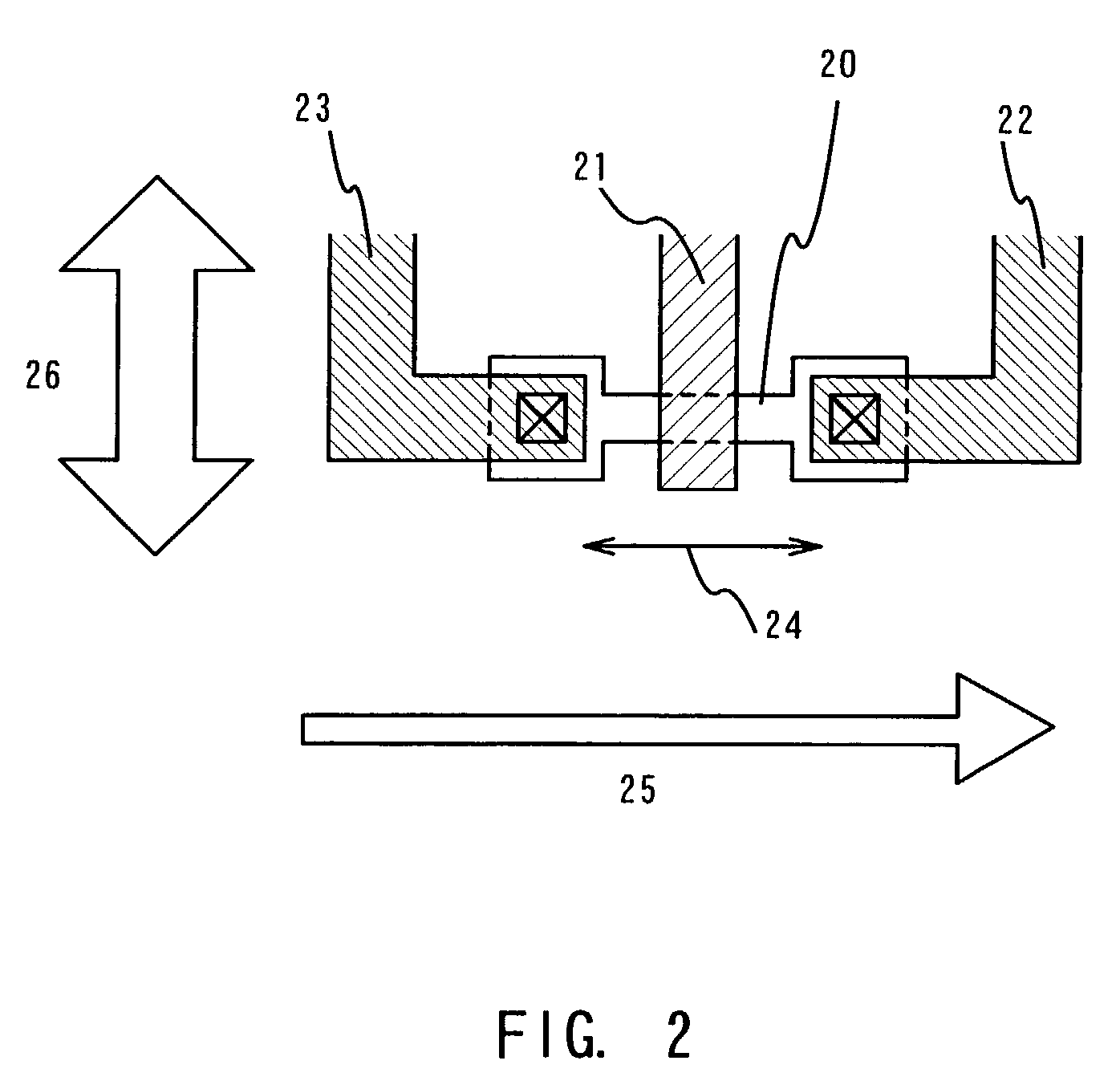

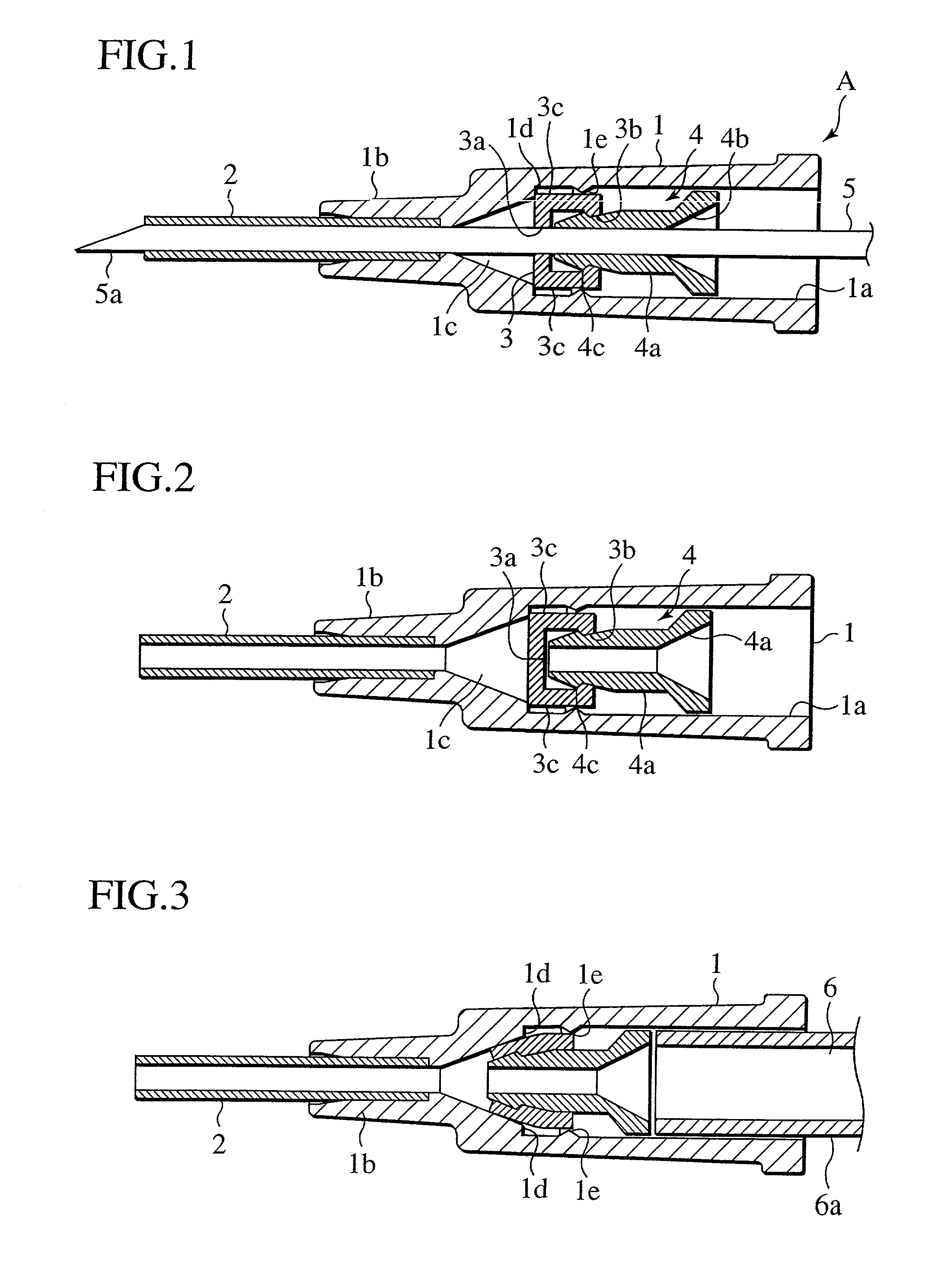

Method and apparatus for determining parameters of linear motion in a surgical instrument

ActiveUS8967443B2Reduce mechanical wearMinimized in sizeSuture equipmentsStapling toolsLinear motionMotion parameter

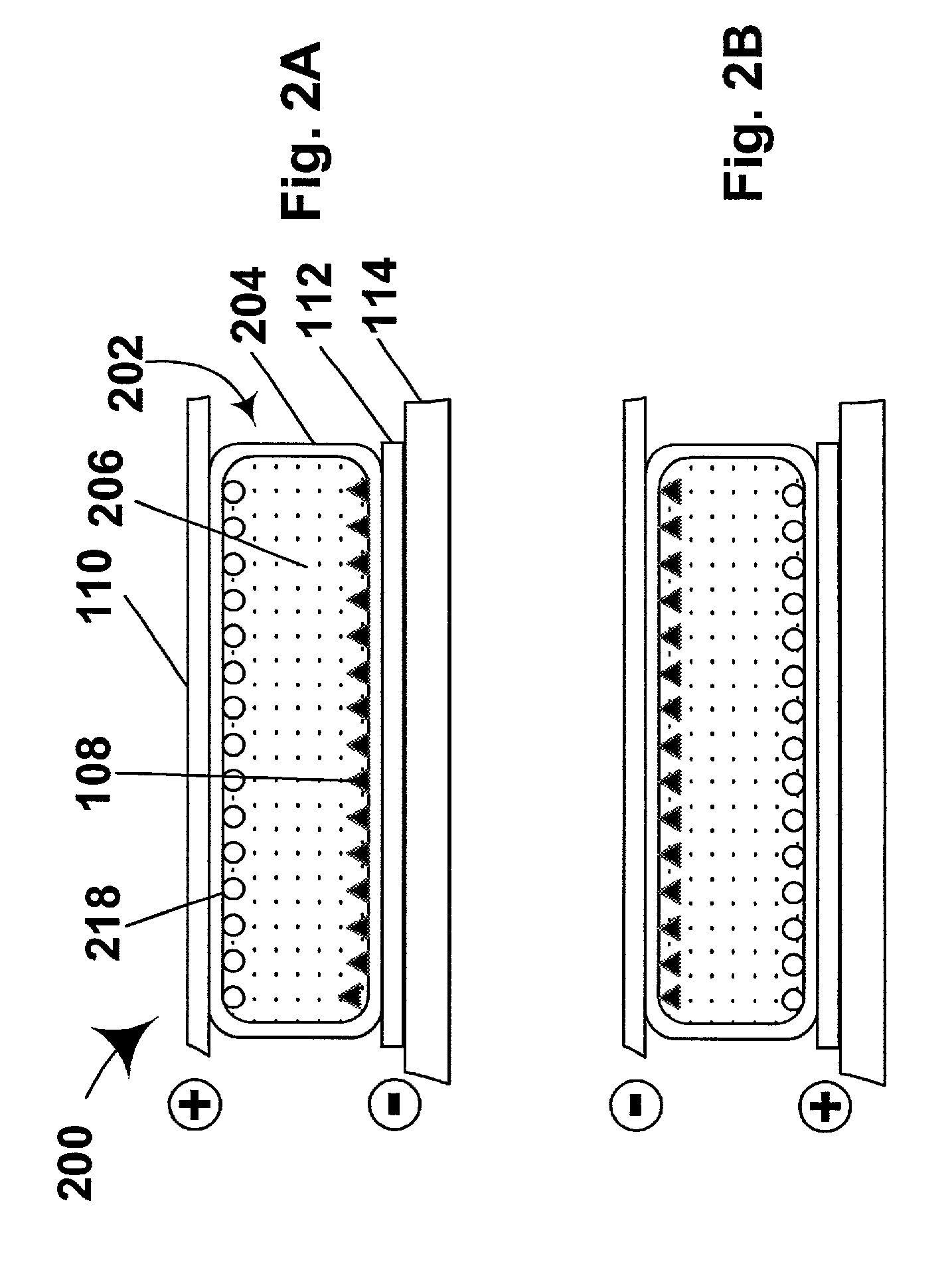

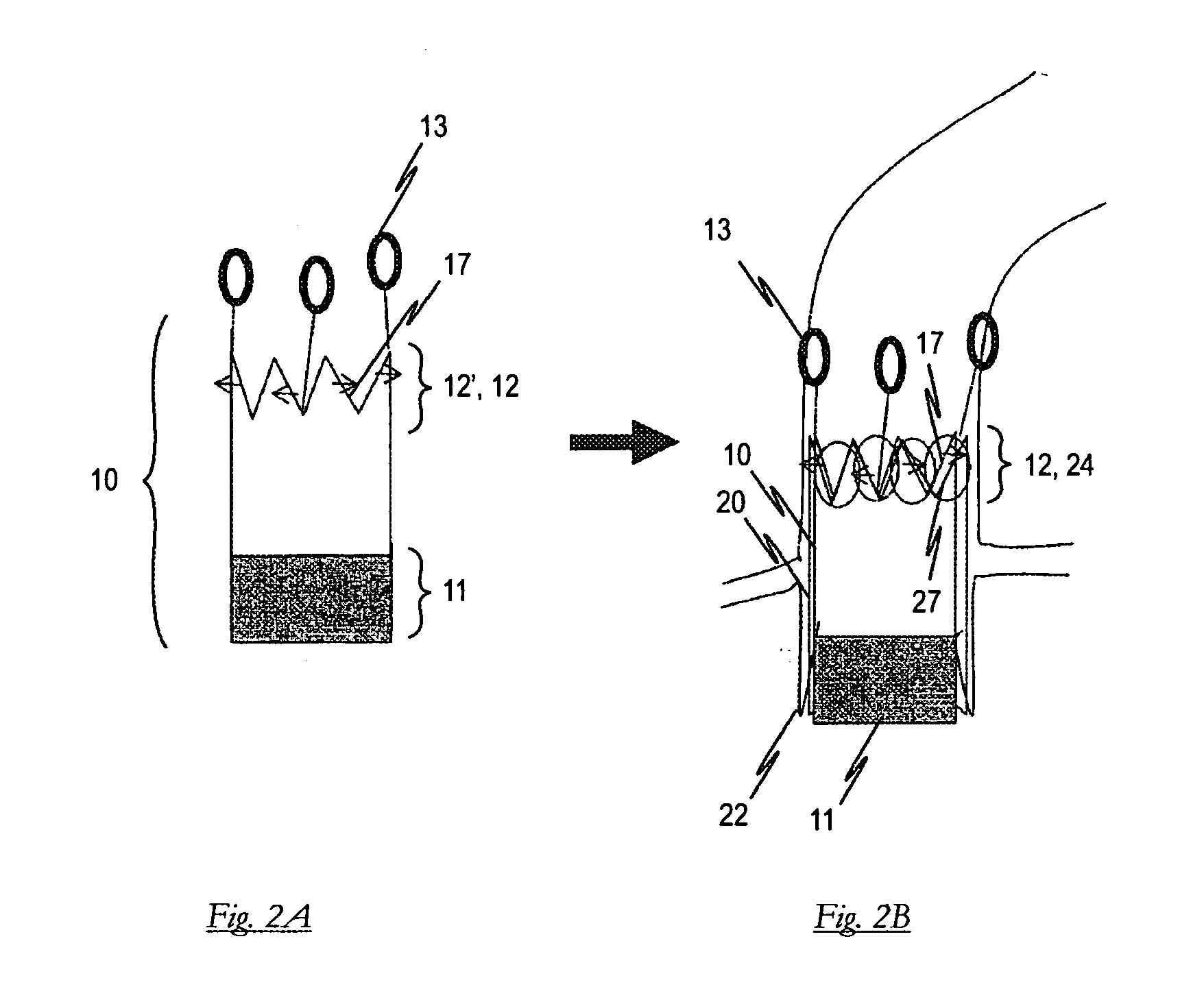

A surgical instrument and method of controlling the surgical instrument are disclosed. The surgical instrument includes a housing and an elongated shaft that extends distally from the housing and defines a first longitudinal axis. The surgical instrument also includes a firing rod disposed in the elongated shaft and a drive mechanism disposed at least partially within the housing. The drive mechanism mechanically cooperates with the firing rod to move the firing rod. A sensor senses a parameter of light reflected from the surface of the firing rod, which includes markings that change the reflectivity of the firing rod. The measurement unit determines a parameter of the motion of the firing rod, such as the position and speed of the firing rod, based on the sensed parameter of the light reflected from the surface of the firing rod.

Owner:TYCO HEALTHCARE GRP LP

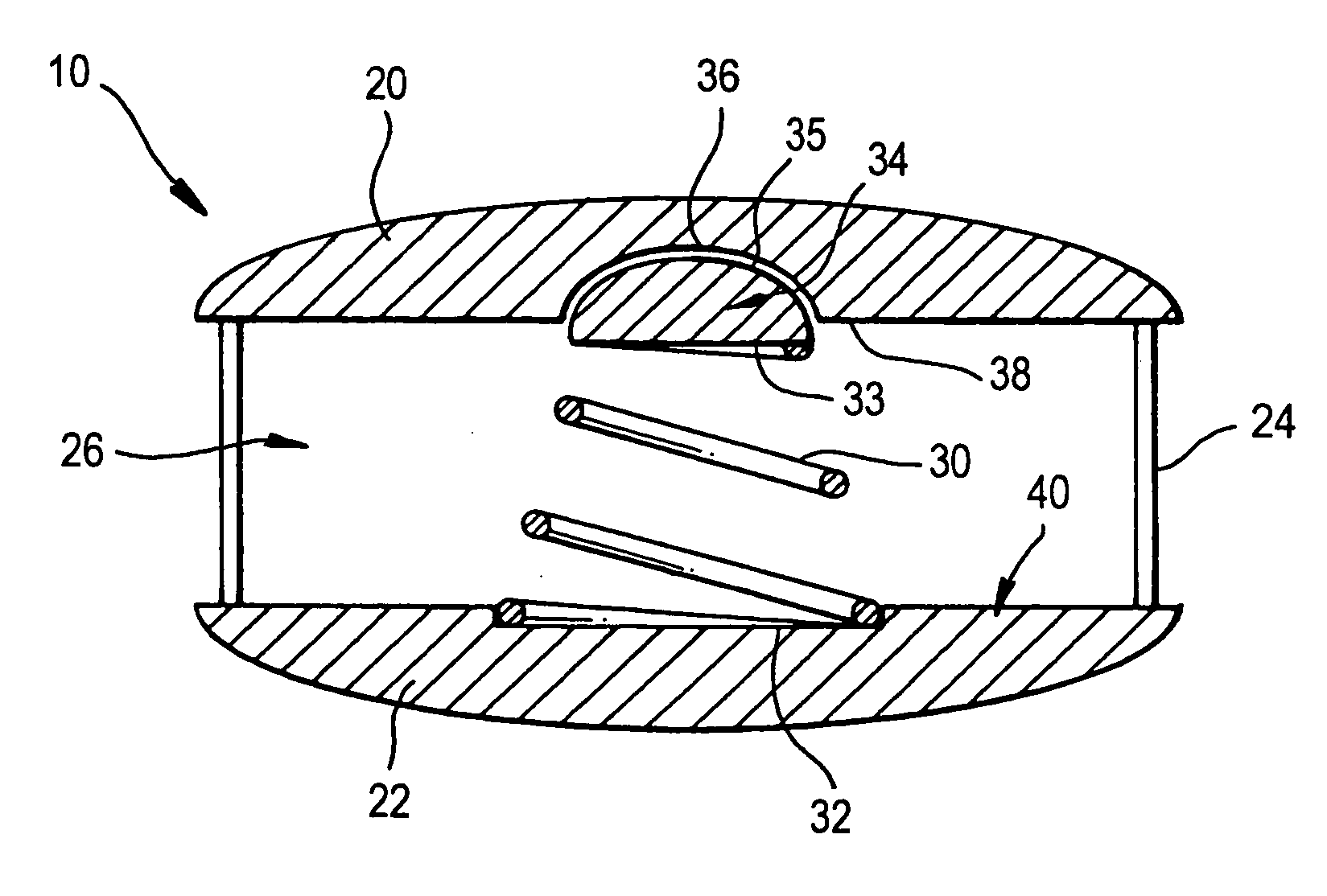

Method and apparatus for determining parameters of linear motion in a surgical instrument

ActiveUS8960520B2Reduce mechanical wearMinimized in sizeSuture equipmentsStapling toolsCapacitanceLinear motion

A surgical instrument and method of controlling the surgical instrument are disclosed. The surgical instrument includes a housing and an elongated shaft that extends distally from the housing and defines a first longitudinal axis. The surgical instrument also includes a firing rod disposed in the elongated shaft and a drive mechanism disposed at least partially within the housing. The drive mechanism mechanically cooperates with the firing rod to move the firing rod. A motion sensor senses a change in the electric field (e.g., capacitance, impedance, or admittance) between the firing rod and the elongated shaft. The measurement unit determines a parameter of the motion of the firing rod, such as the position, speed, and direction of the firing rod, based on the sensed change in the electric field. A controller uses the measured parameter of the motion of the firing rod to control the drive mechanism.

Owner:TYCO HEALTHCARE GRP LP

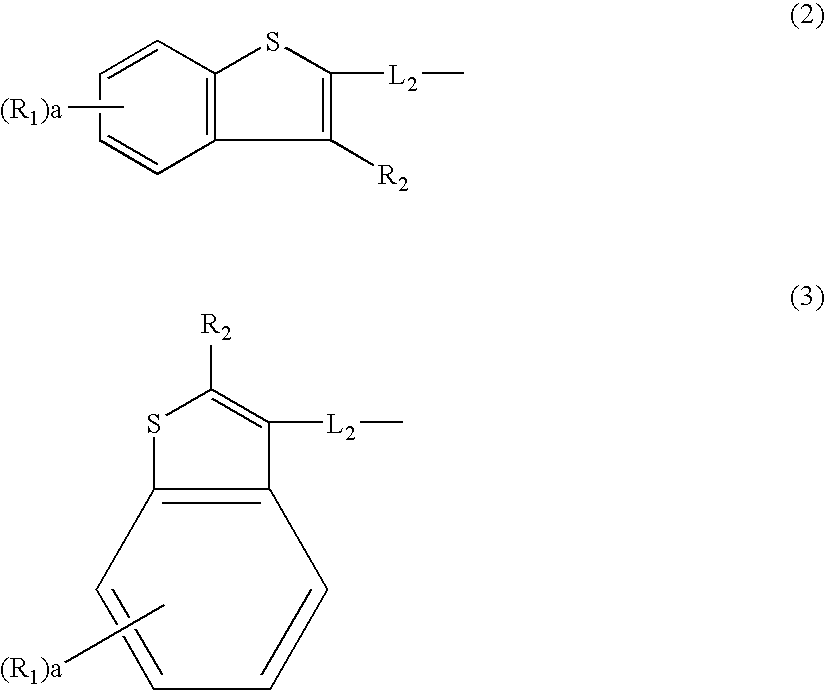

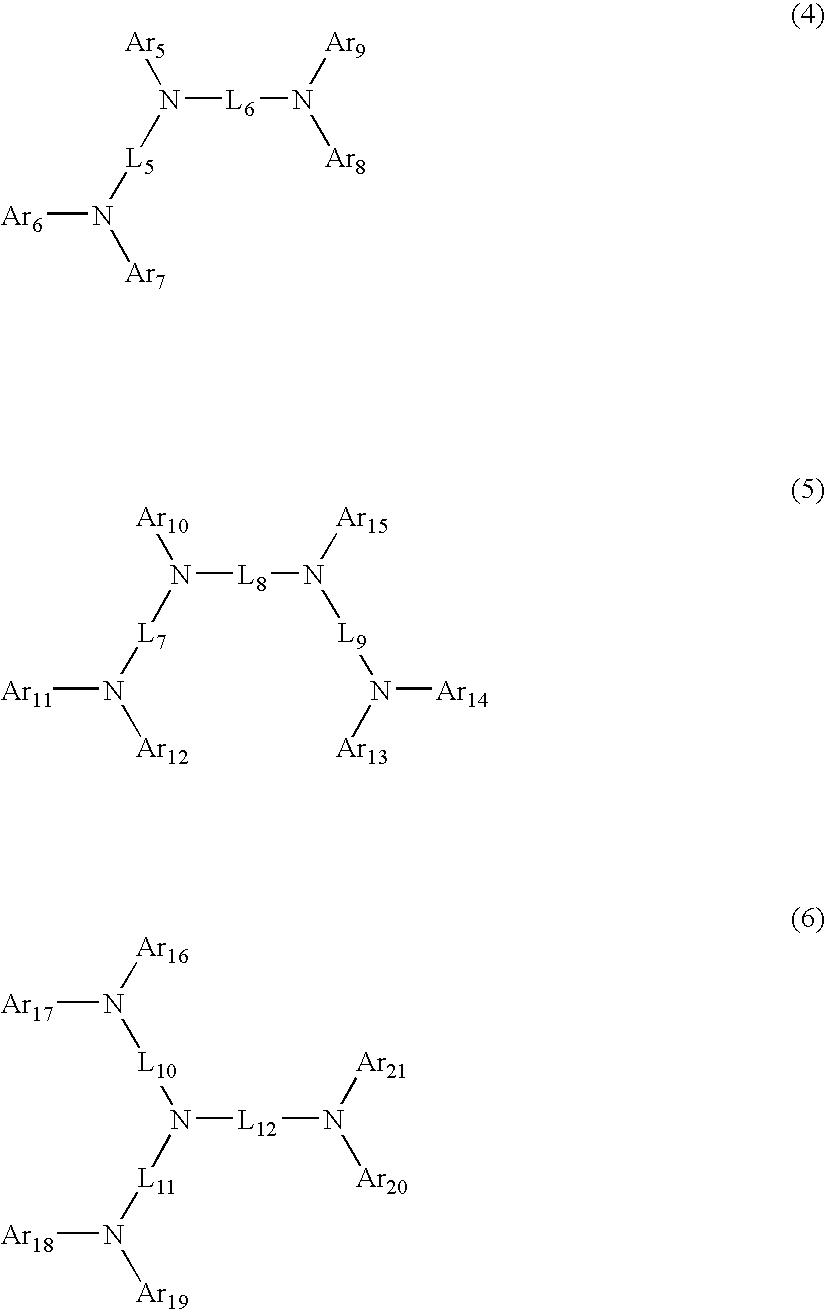

Aromatic amine derivatives and organic electroluminescent device using same

InactiveUS20080106190A1Less liableImproved in yield in producingOrganic chemistryDischarge tube luminescnet screensHole transport layerOrganic electroluminescence

The present invention provides a novel aromatic amine derivative having a specific structure and an organic electroluminescence device in which an organic thin film layer comprising a single layer or plural layers including at least a light emitting layer is interposed between a cathode and an anode, wherein at least one layer in the above organic thin film layer, particularly a hole transporting layer contains the aromatic amine derivative described above in the form of a single component or a mixed component. Use of the aromatic amine derivative described above materialize an organic electroluminescence device which reduces a driving voltage and makes molecules less liable to be crystallized and which enhances a yield in producing the organic EL device and has a long lifetime.

Owner:IDEMITSU KOSAN CO LTD

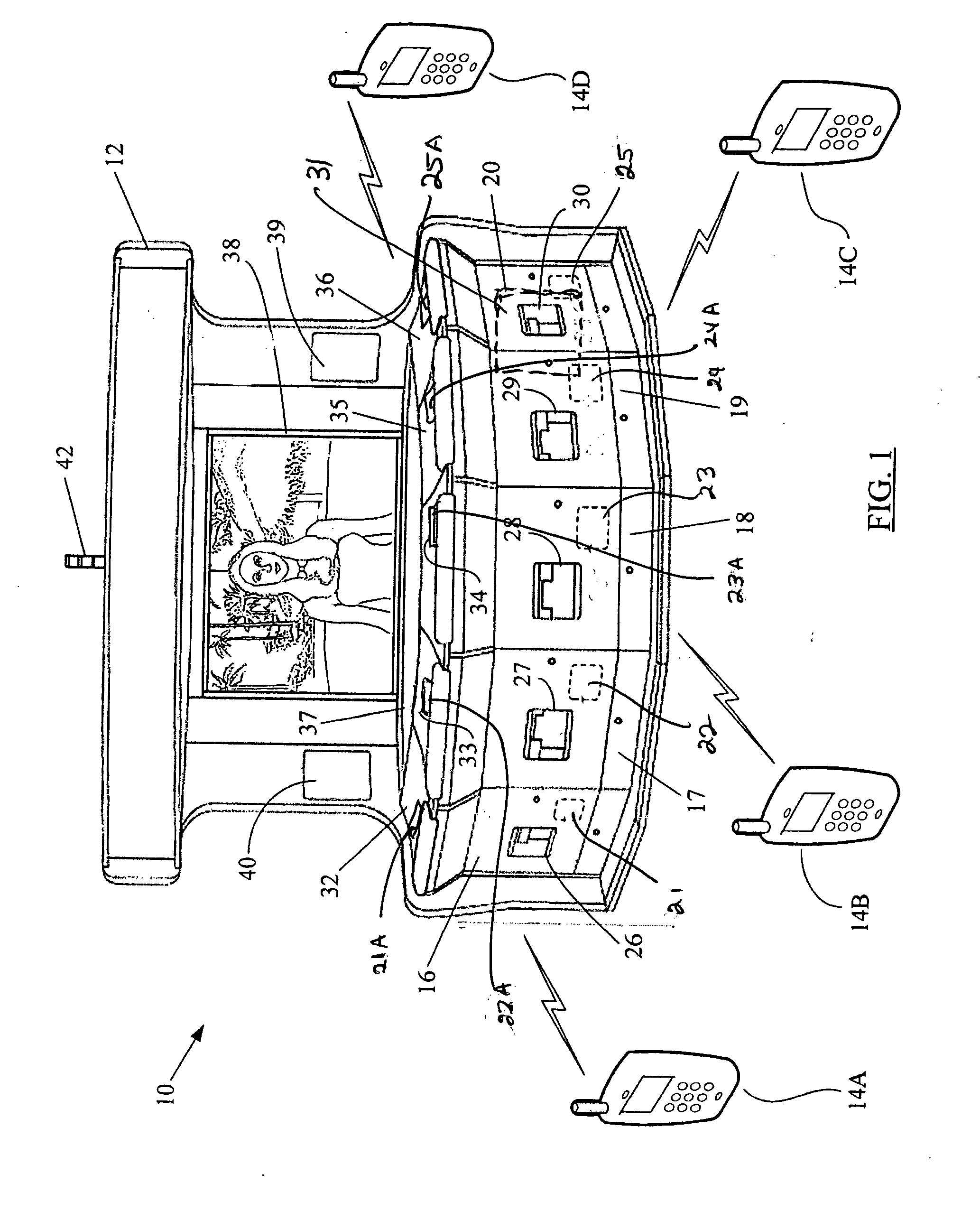

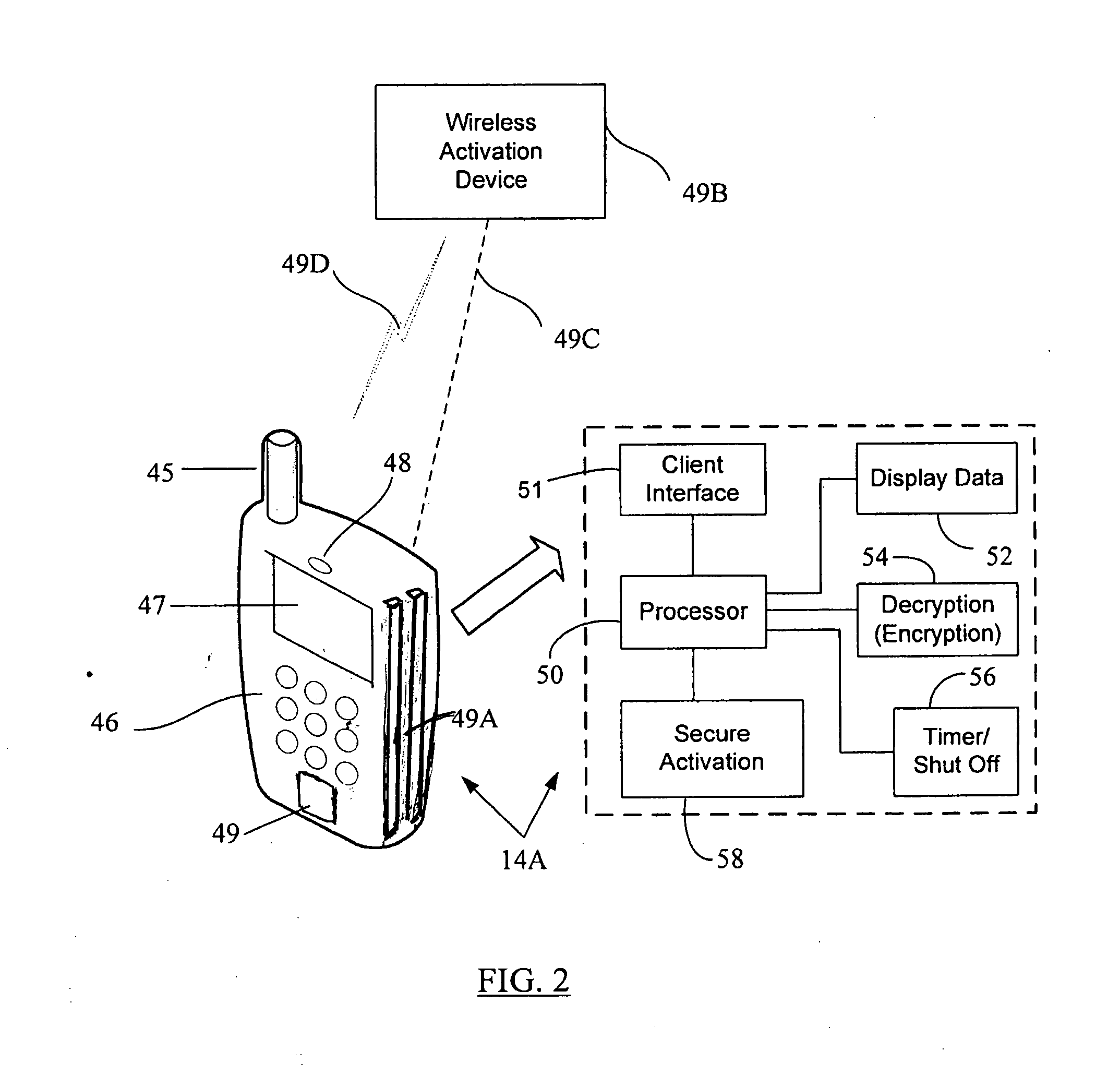

Reduced area imaging device incorporated within wireless endoscopic devices

InactiveUS7030904B2Improve usabilityImprove mobilityTelevision system detailsDigital data processing detailsDental instrumentsWireless transmission

A reduced area imaging device is provided for use in medical or dental instruments such as an endoscope. In a first embodiment of the endoscope, connections between imaging device elements and between a video display is achieved by hard-wired connections. In a second embodiment of the endoscope, wireless transmission is used for communications between imaging device components, and / or for transferring video ready signals to a video display. In one configuration of the imaging device, the image sensor is placed remote from the remaining circuitry. In another configuration, all of the circuitry to include the image sensor is placed in a stacked fashion at the same location. The entire imaging device can be placed at the distal tip of an endoscope. Alternatively, the image sensor can be placed remote from the remaining circuitry according to the first configuration, and control box is used which communicates with the image sensor and is placed remotely from the endoscope. Further alternatively, the imaging device can be incorporated in the housing of a standard medical camera which is adapted for use with traditional rod lens endoscopes. In any of the configurations or arrangements, the image sensor may be placed alone on a first circuit board, or timing and control circuits may be included on the first circuit board containing the image sensor. The timing and control circuits and one or more video processing boards can be placed adjacent the image sensor in a tubular portion of the endoscope, in other areas within the endoscope, in the control box, or in combinations of these location.

Owner:MICRO IMAGING SOLUTIONS

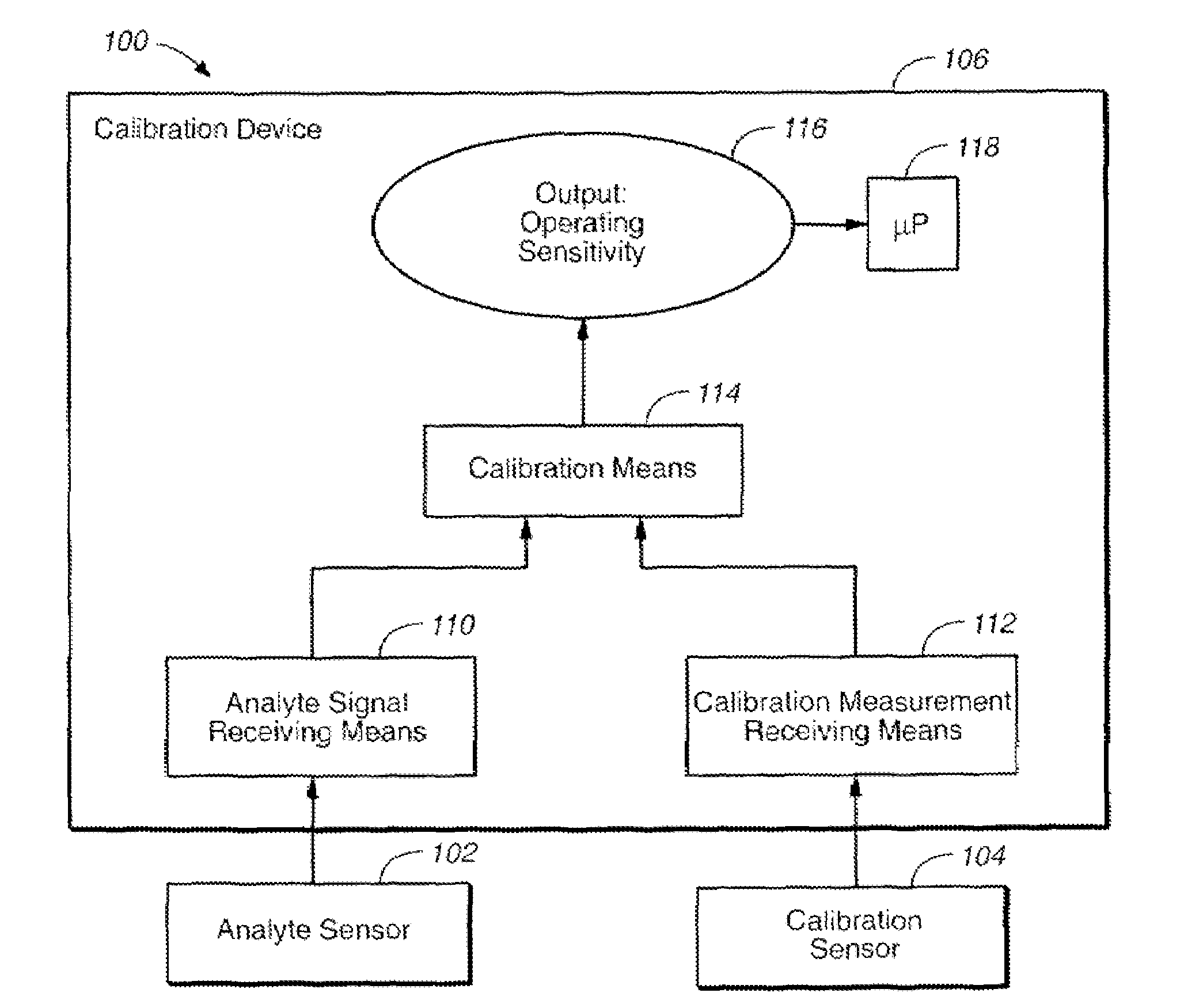

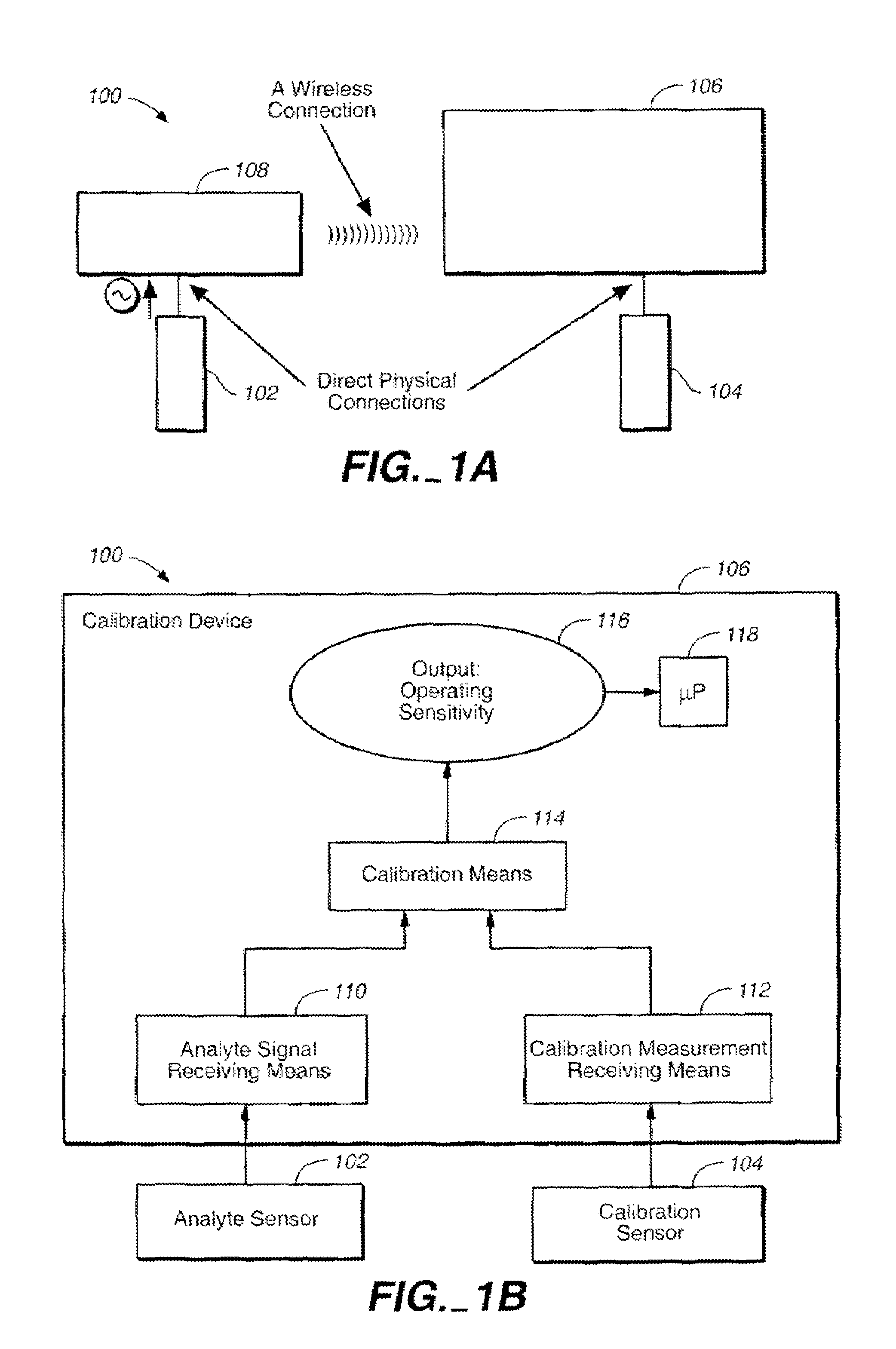

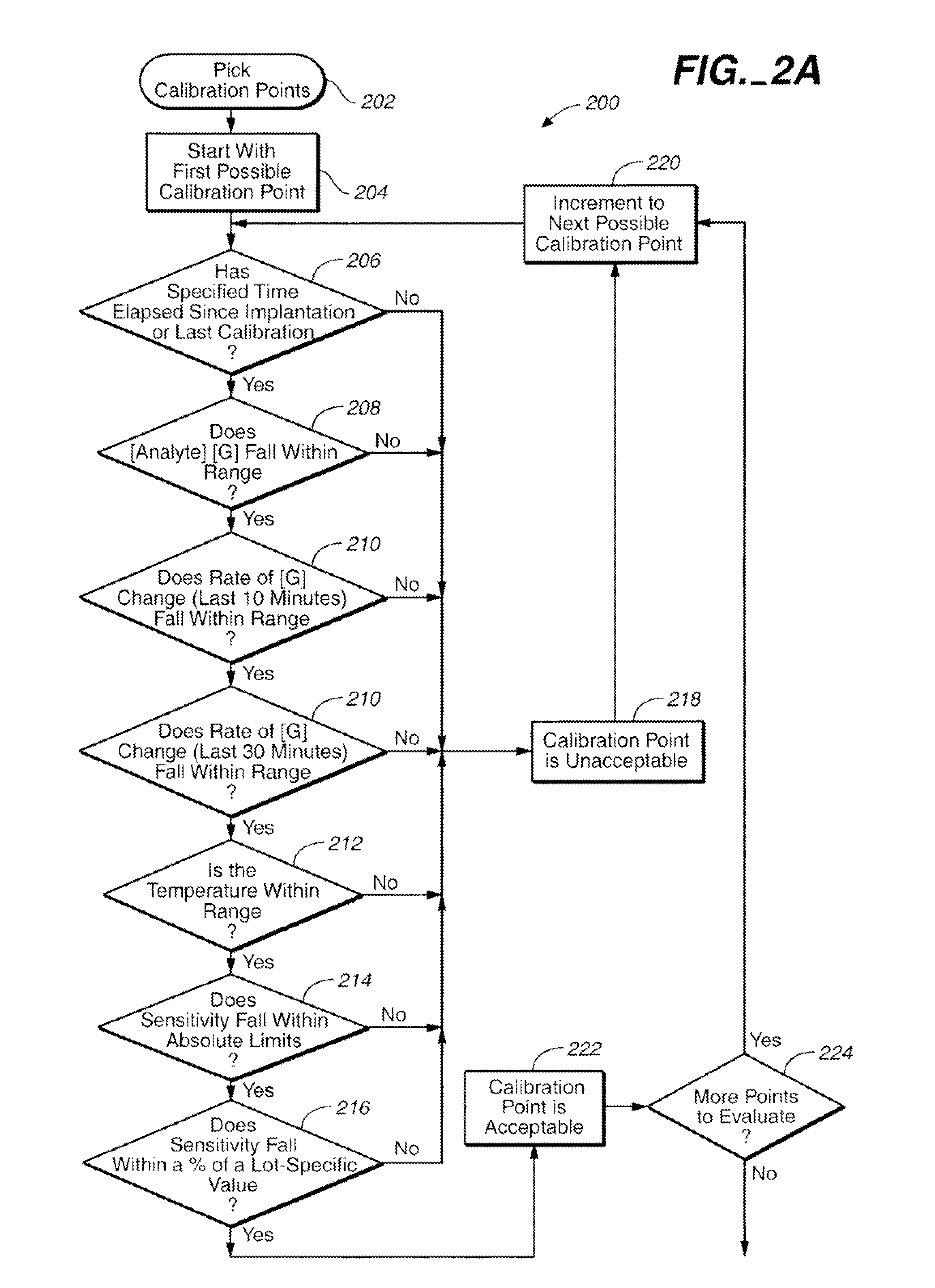

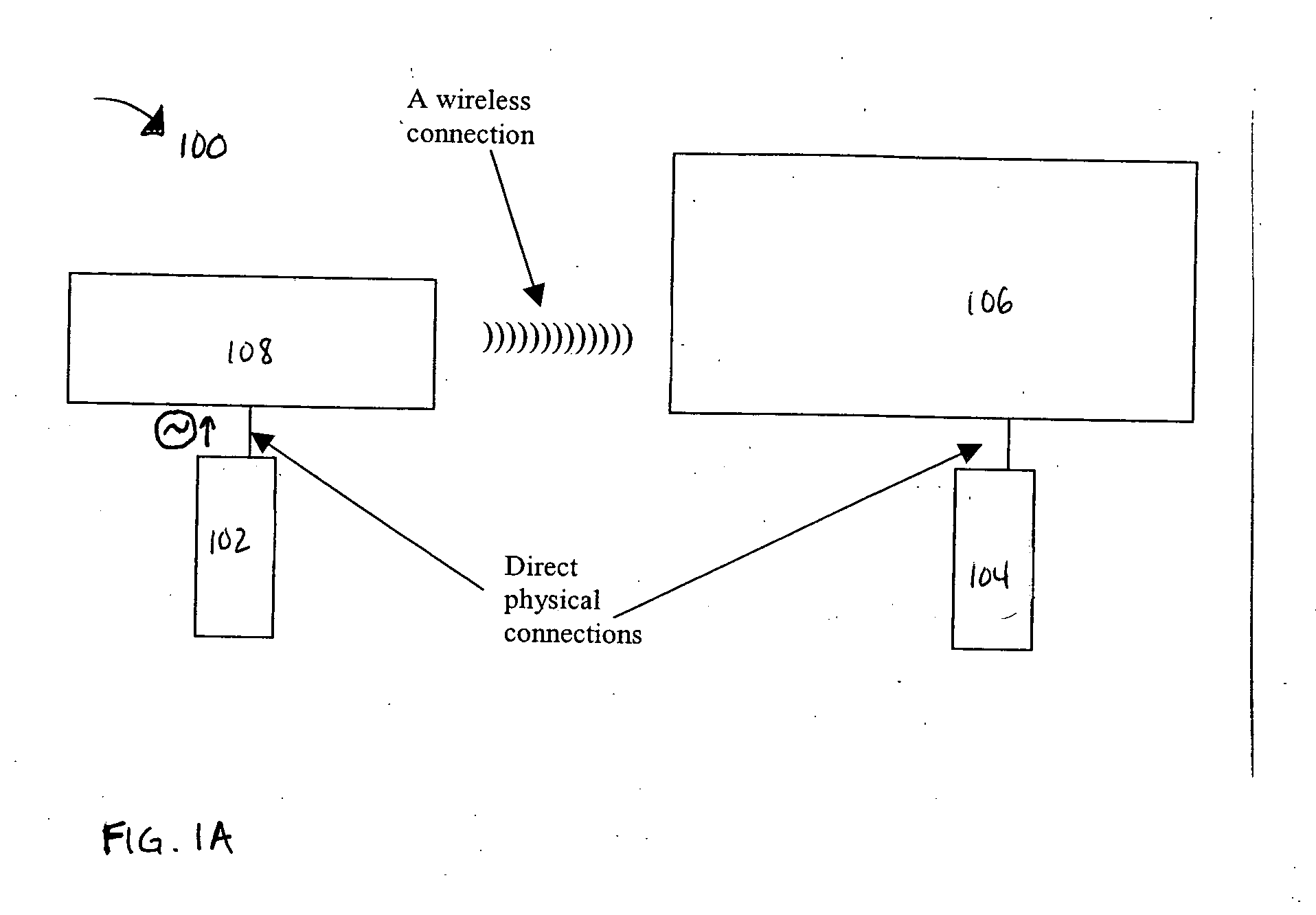

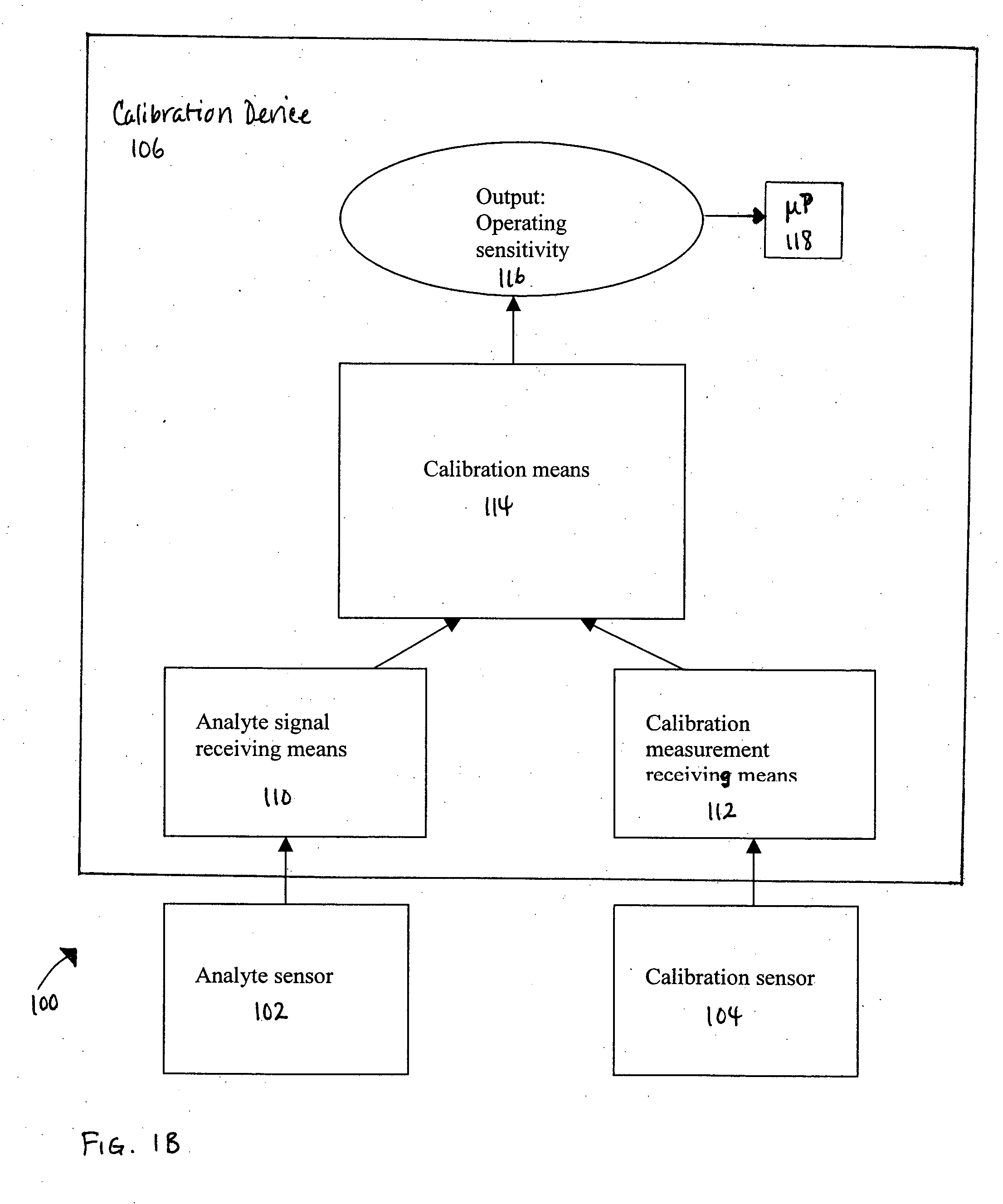

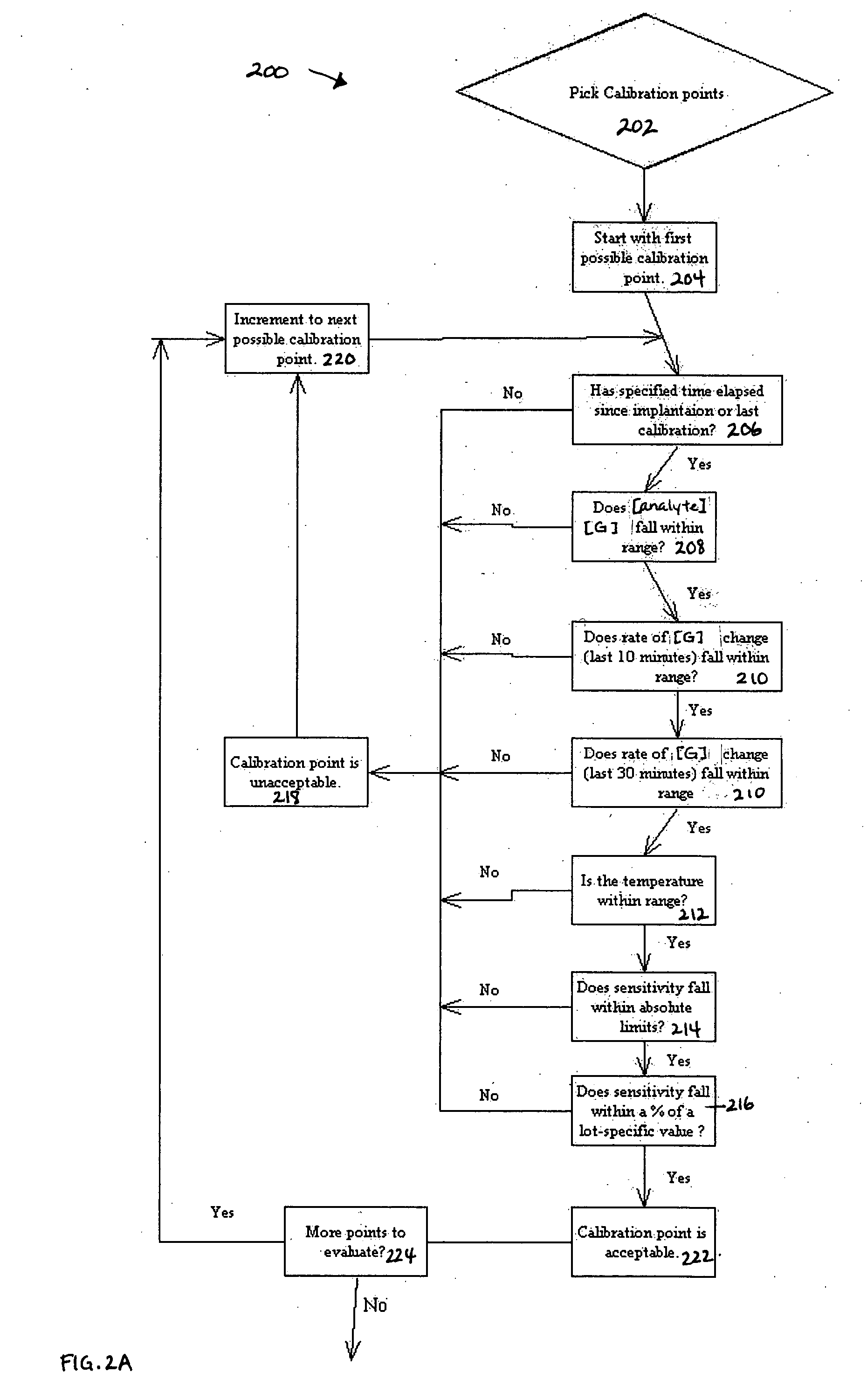

Method of calibrating an analyte-measurement device, and associated methods, devices and systems

ActiveUS7299082B2Improve mobilityAvoid high pressureMicrobiological testing/measurementCatheterMeasurement deviceAnalyte

Owner:ABBOTT DIABETES CARE INC

A method of calibrating an analyte-measurement device, and associated methods, devices and systems

ActiveUS20050239154A1Improve mobilityAvoid high pressureMicrobiological testing/measurementCatheterMeasurement deviceAnalyte

The invention relates to a method for calibrating an analyte-measurement device that is used to evaluate a concentration of analyte in bodily fluid at or from a measurement site in a body. The method involves measuring a concentration, or calibration concentration, of an analyte in blood from an “off-finger” calibration site, and calibrating the analyte-measurement device based on that calibration concentration. The invention also relates to a device, system, or kit for measuring a concentration of an analyte in a body, which employs a calibration device for adjusting analyte concentration measured in bodily fluid based on an analyte concentration measured in blood from an “off-finger” calibration site.

Owner:ABBOTT DIABETES CARE INC

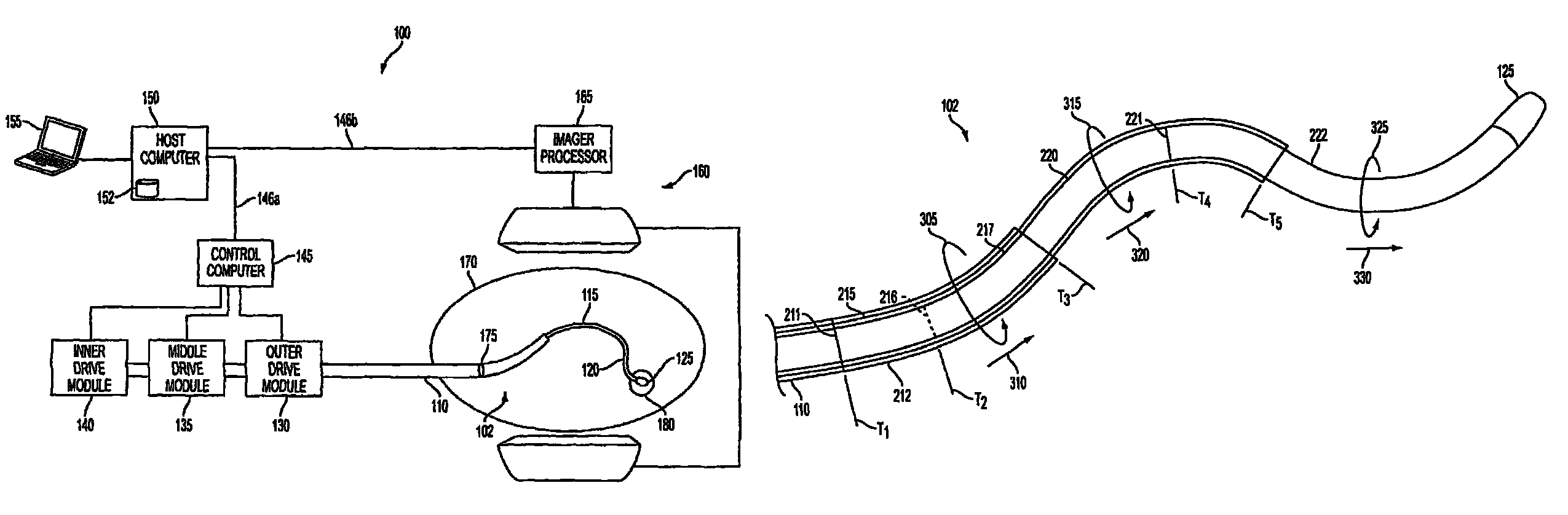

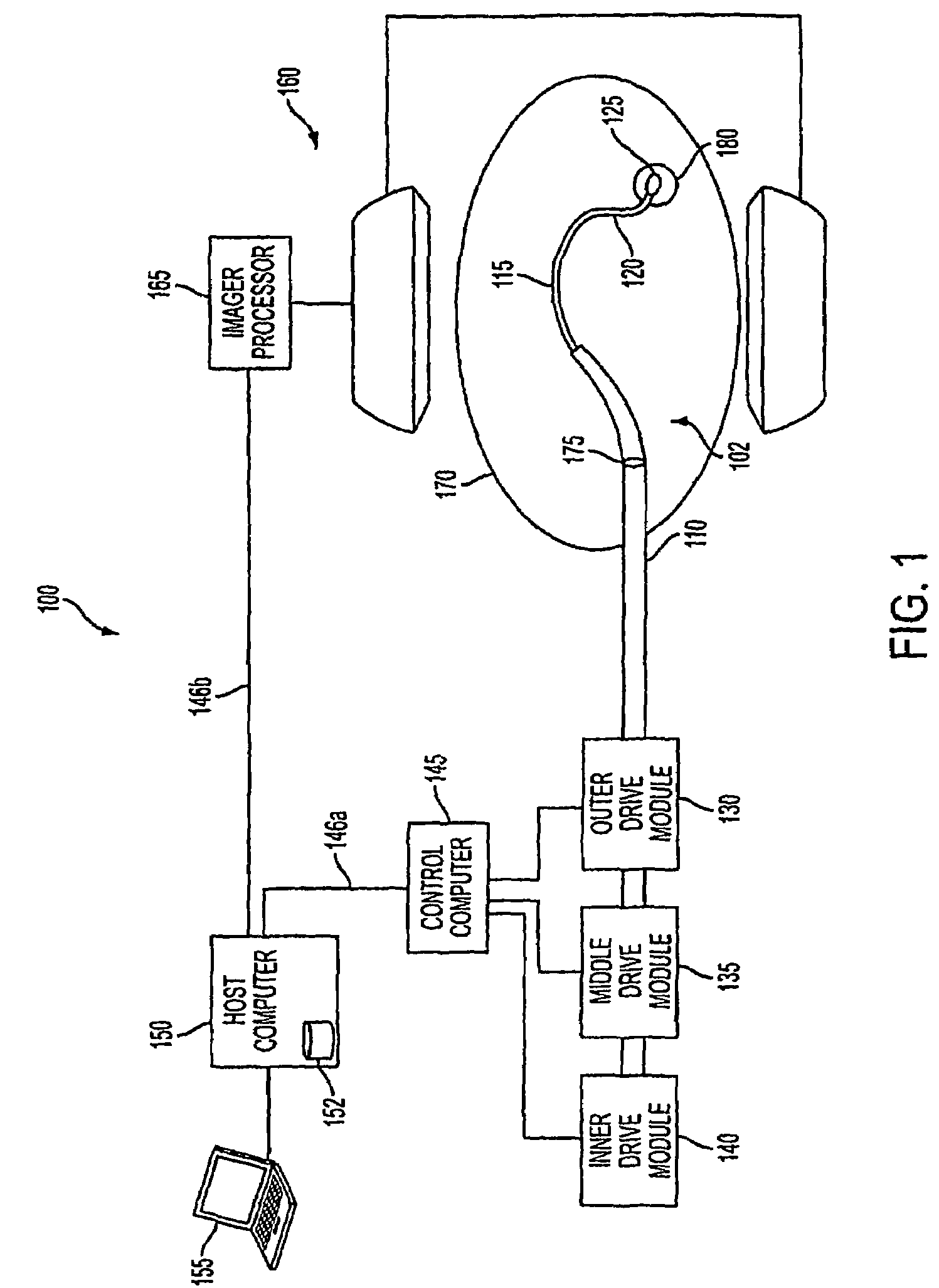

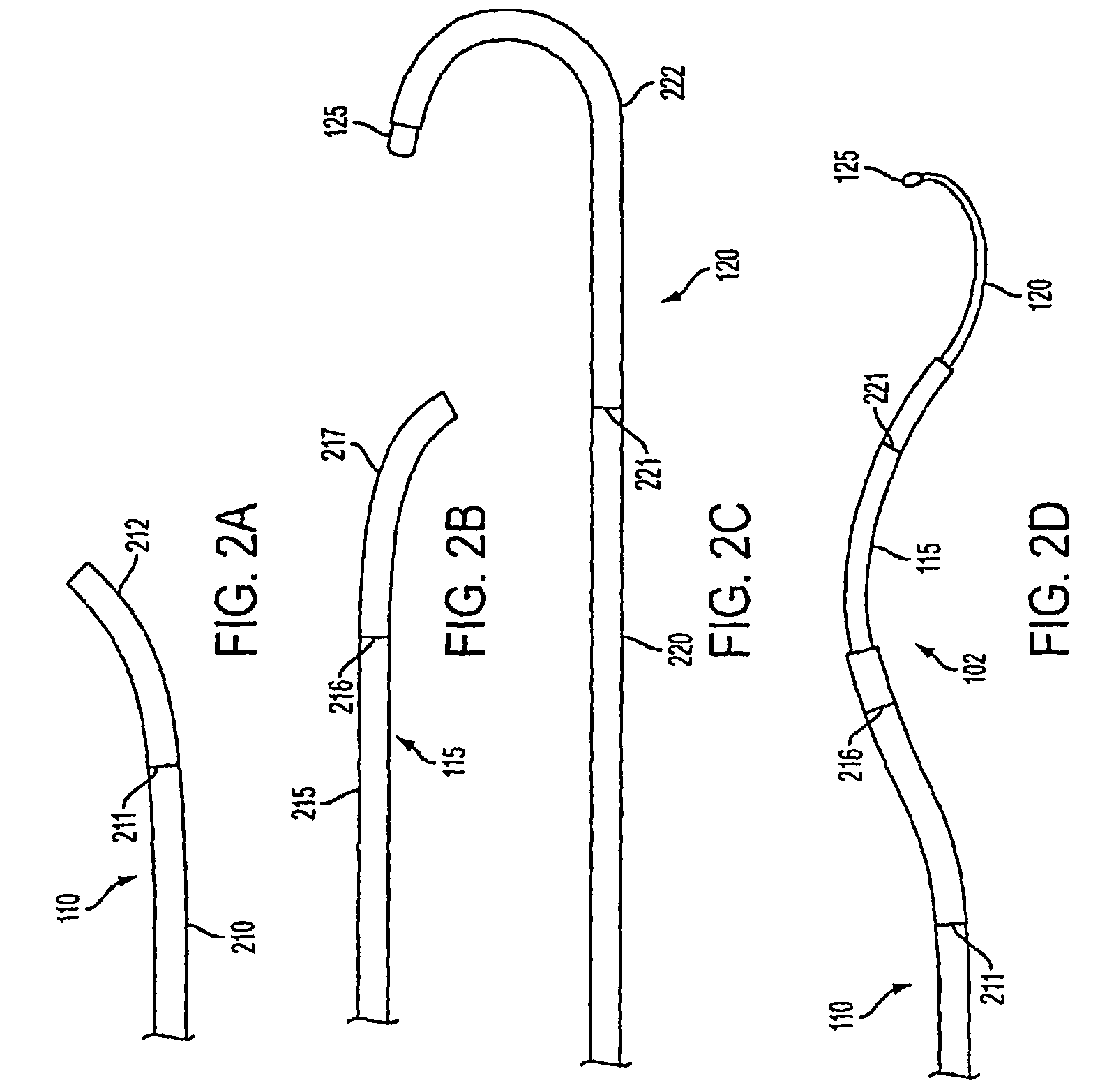

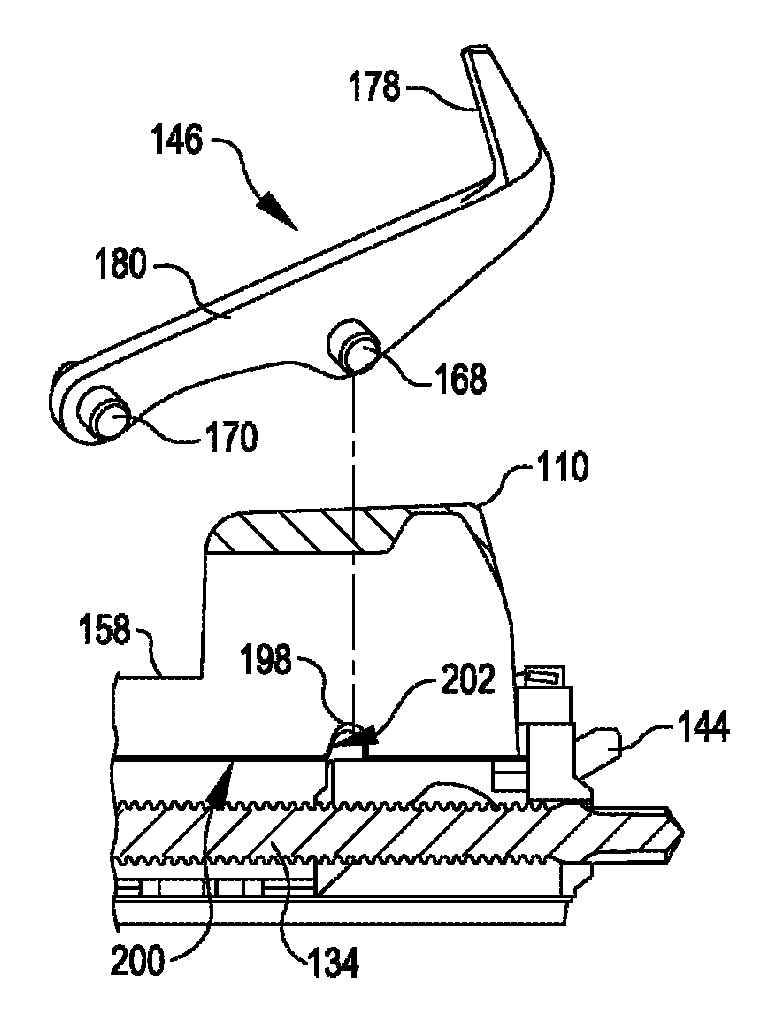

Active cannula for bio-sensing and surgical intervention

ActiveUS8152756B2Easy accessReduces the collateral trauma imposedCannulasSurgical needlesSurgical operationAnatomical structures

Disclosed is a surgical needle, or active cannula, that is capable of following a complex path through cavities and tissue within a patient's anatomy. The needle has a plurality of overlapping flexible tubes, each of which has a pre-formed curvature and a pre-determined flexibility. Each of the plurality of flexible tubes is selected based on their respective preformed curvature and flexibility so that a given overlap configuration causes the combination of overlapping flexible tubes to form a predetermined shape that substantially matches a desired path through the anatomy. By individually controlling the translation and angular orientation of each of the flexible tubes, the surgical needle may be guided through the anatomy according to the desired path.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

Surgical instrument with integral knife blade

ActiveUS9924941B2Reduce the possibilityShorten the lengthSurgical furnitureDiagnosticsEngineeringKnife blades

A cartridge of a surgical instrument includes a housing, a lead screw mounted for rotation in the housing, a drive member operatively coupled with the lead screw, and a knife member. The knife member is driven distally by the drive member and is configured to cut when moved distally. During an initial distal movement of the drive member, the knife member is coupled with the housing to restrain the knife member from moving distally. Subsequent to the initial distal movement of the drive member, the drive member drives the knife member toward the distal end.

Owner:INTUITIVE SURGICAL OPERATIONS INC

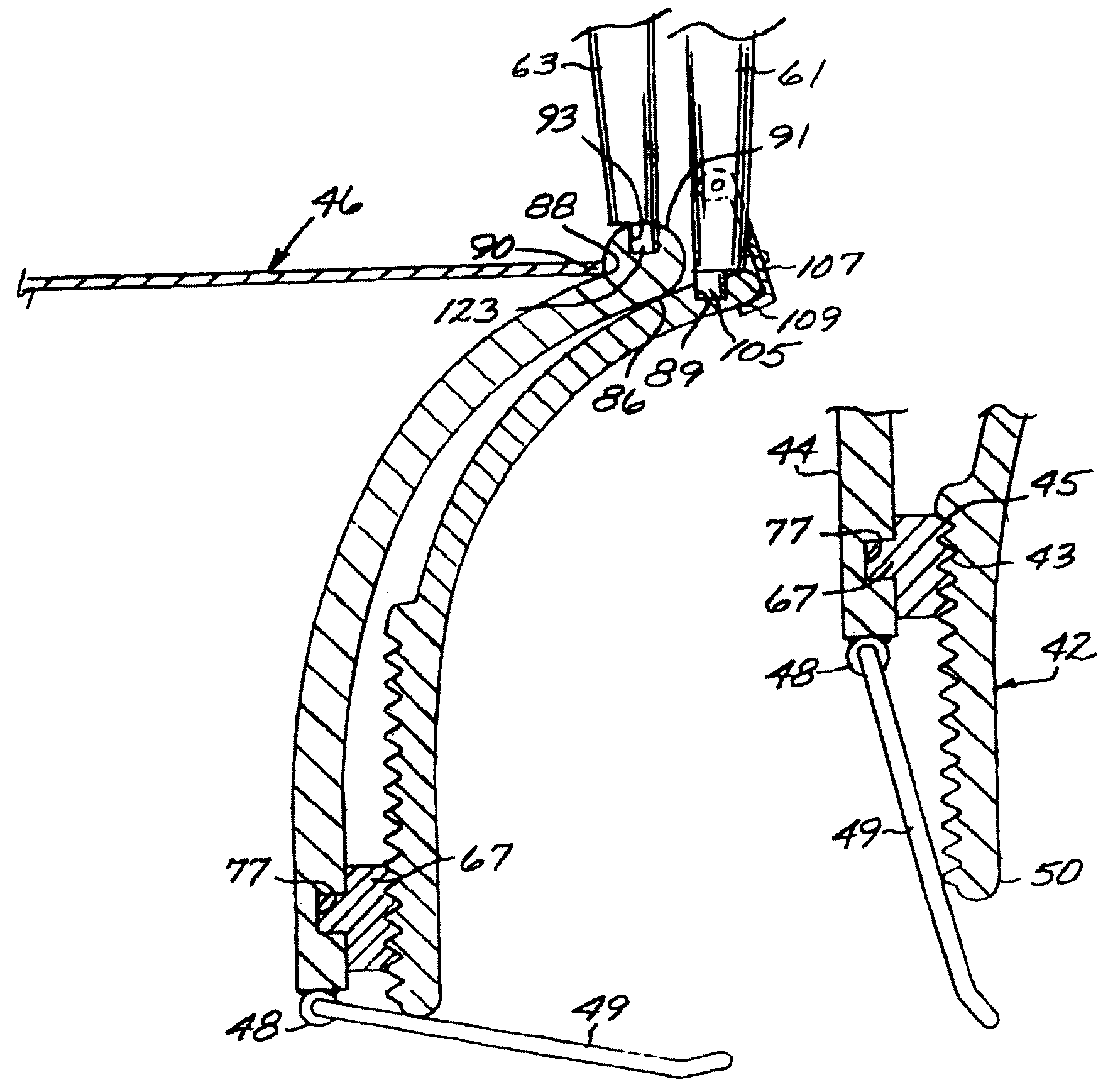

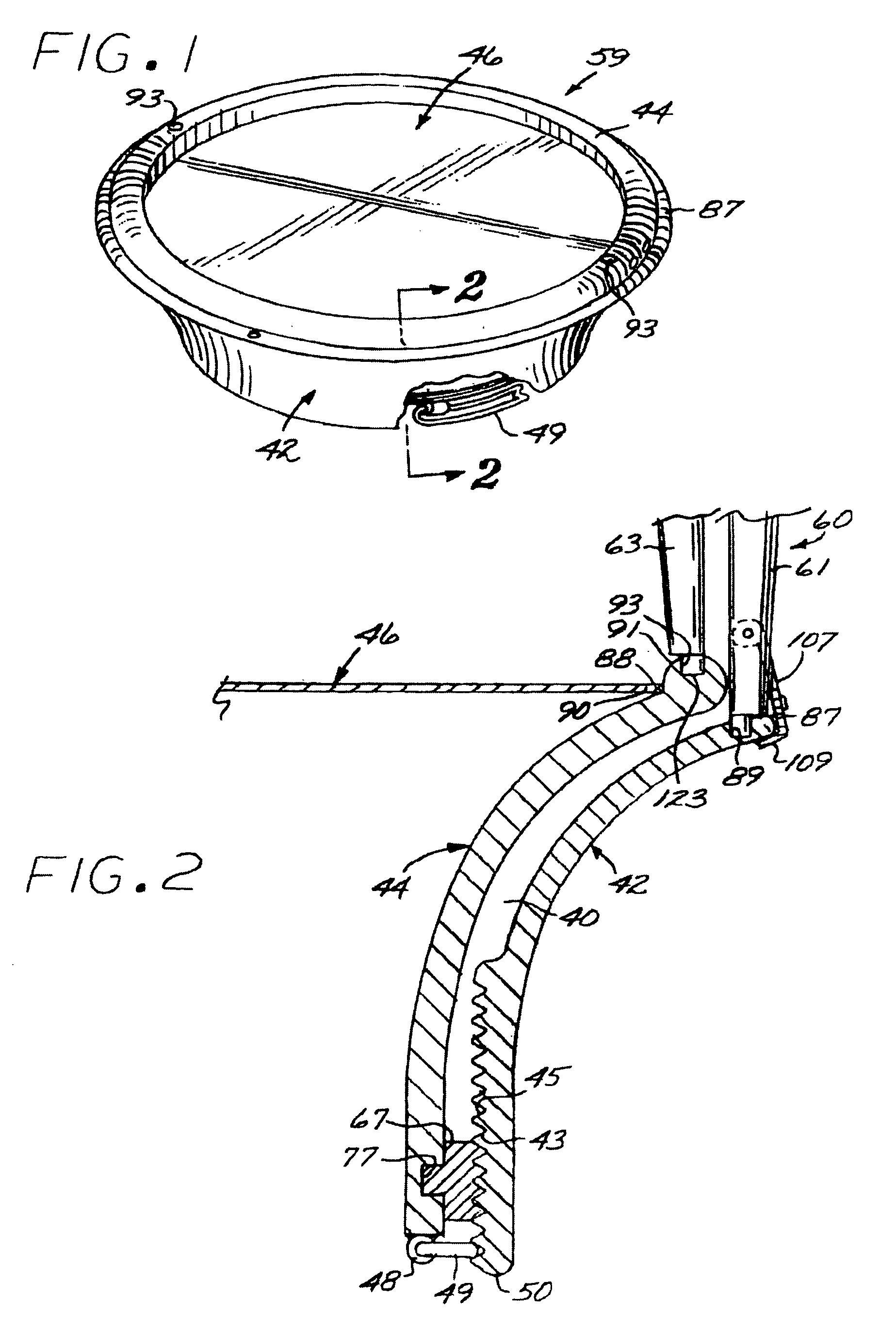

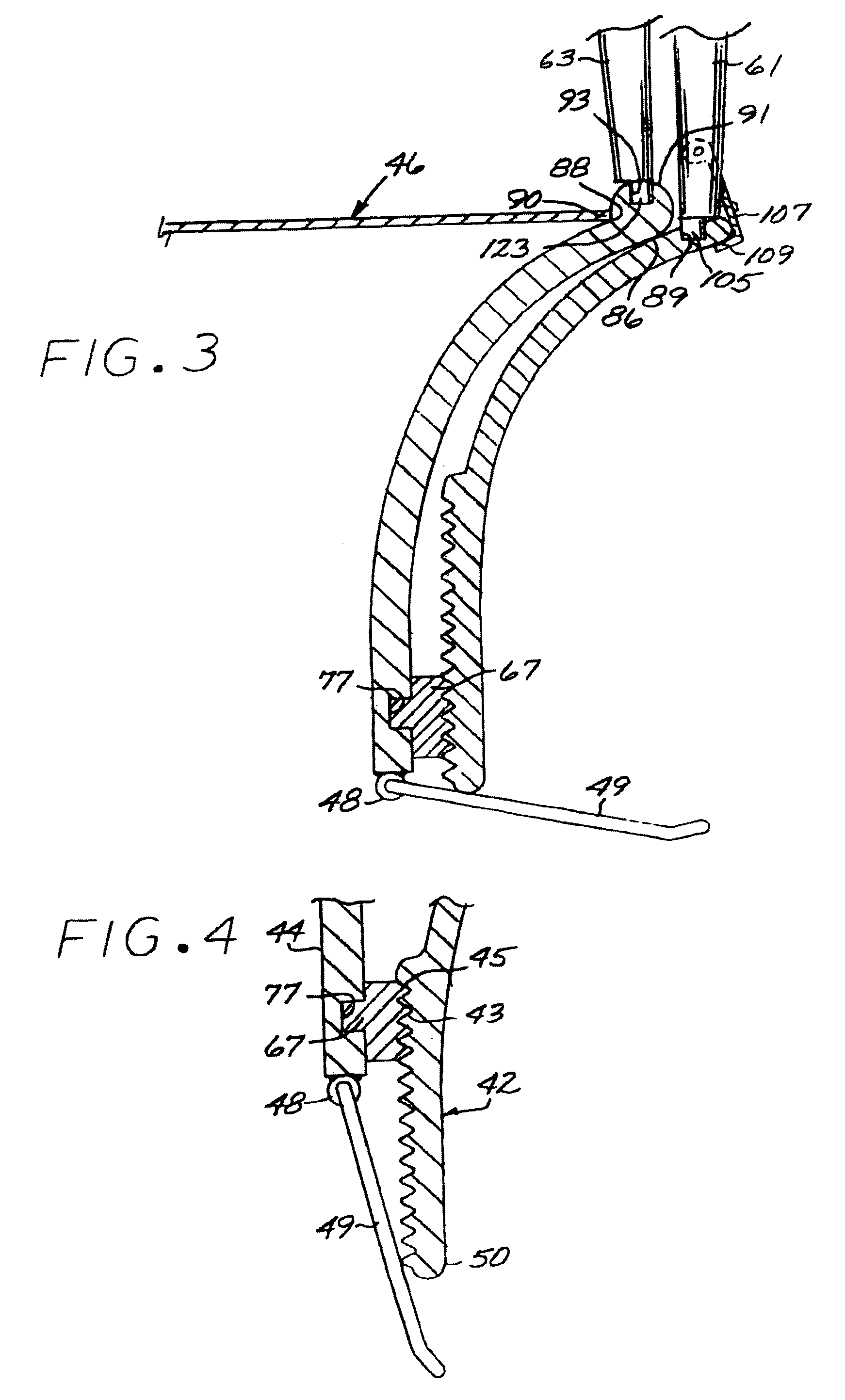

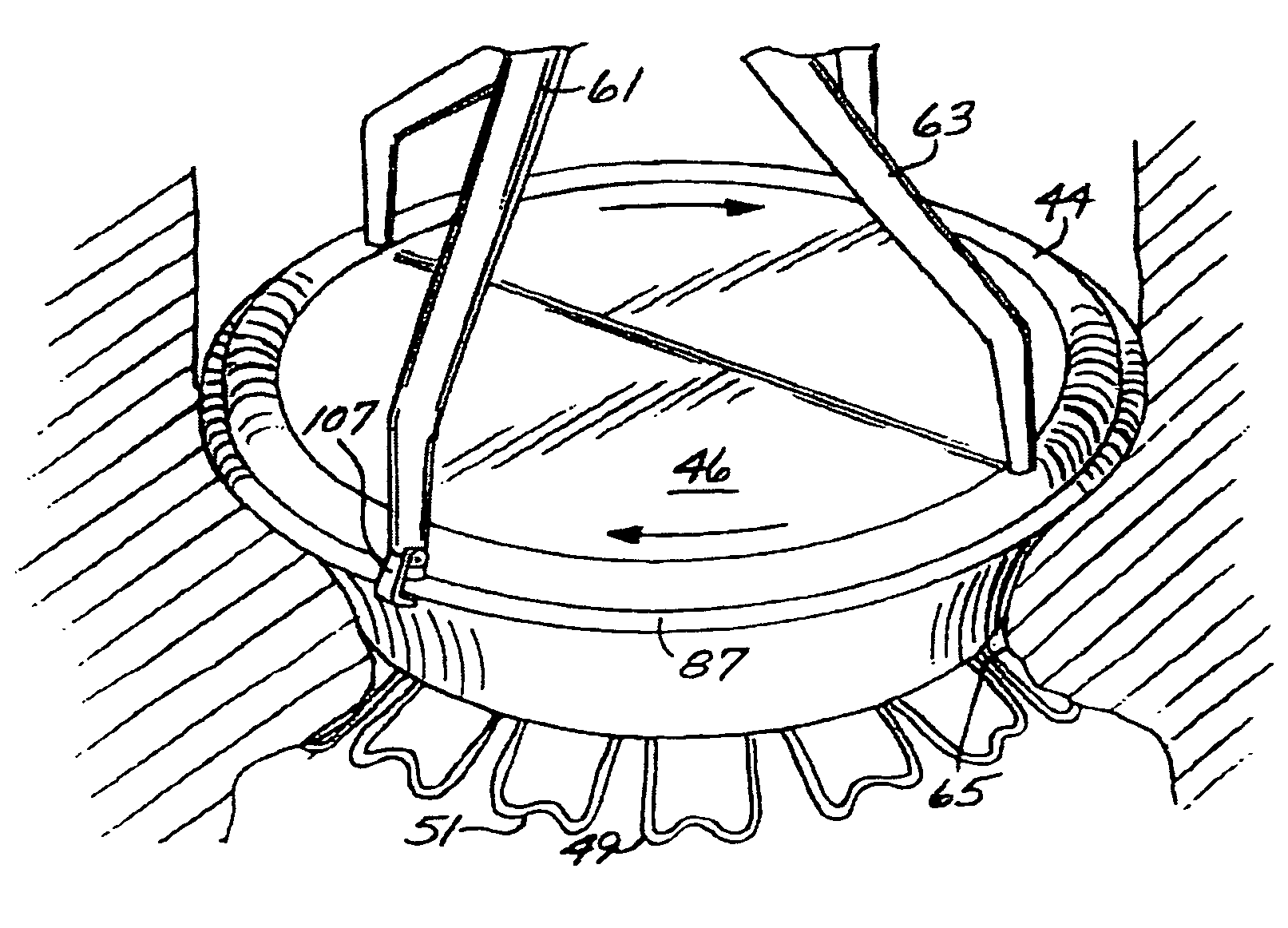

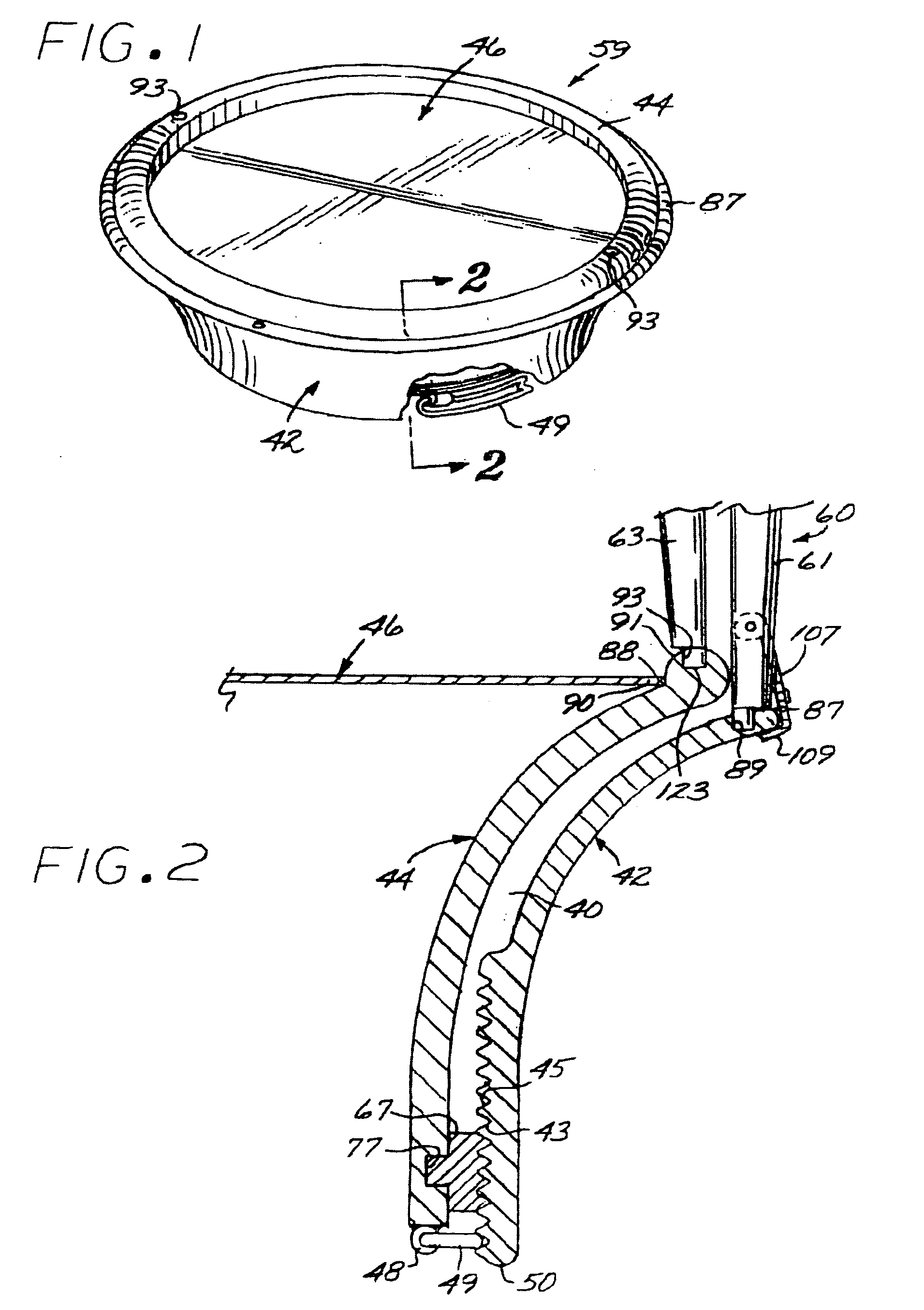

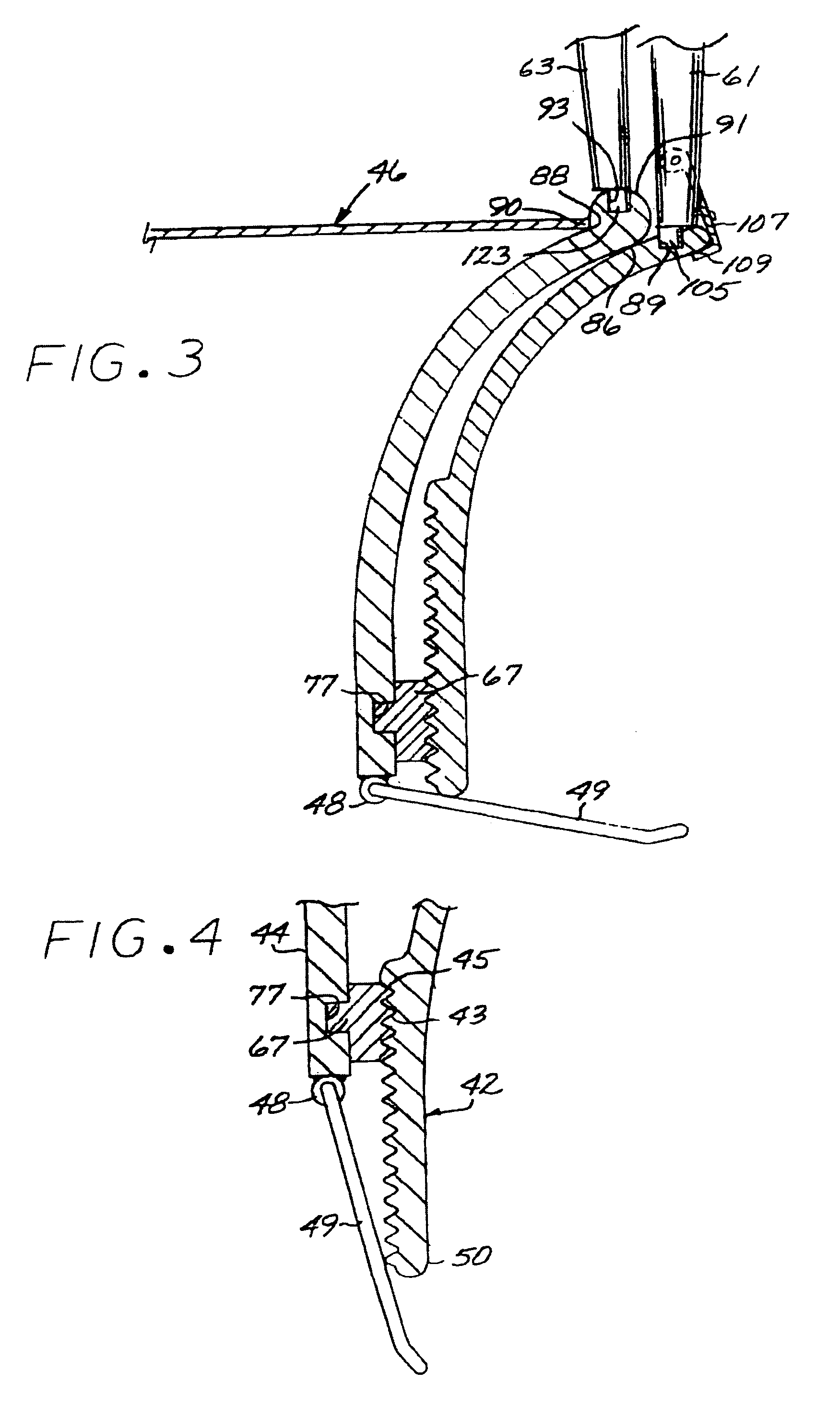

Heart valve annulus device and method of using same

InactiveUS6893459B1Minimize time-consume processShorten the timeHeart valvesProsthesisCardiac muscle

A method of implanting a universal heart valve prosthetic anchor device for receipt of a mating occluder. The anchor device includes a pair of rings axially shiftable from a retracted to a deployed position. The anchor device further formed with a plurality of flexible retaining elements received within the anchor rings and which are capable of laterally downwardly outward movement upon deployment of the rings. The deployment tool includes an elongated tubular housing mounted at its distal end with radially outwardly diverging tines for reversible engagement with the anchoring rings. A wire is telescoped through the tines for actuation of the fork thereby causing deployment of the anchoring rings. Once placed at the desired location within the heart muscle, the deployment tool is actuated causing the anchor device to shift axially thereby causing the retainers to deploy outwardly and upwardly to secure the valve anchor in place at the heart valve annulus shelf.

Owner:VENTURE LENDING & LEASING IV

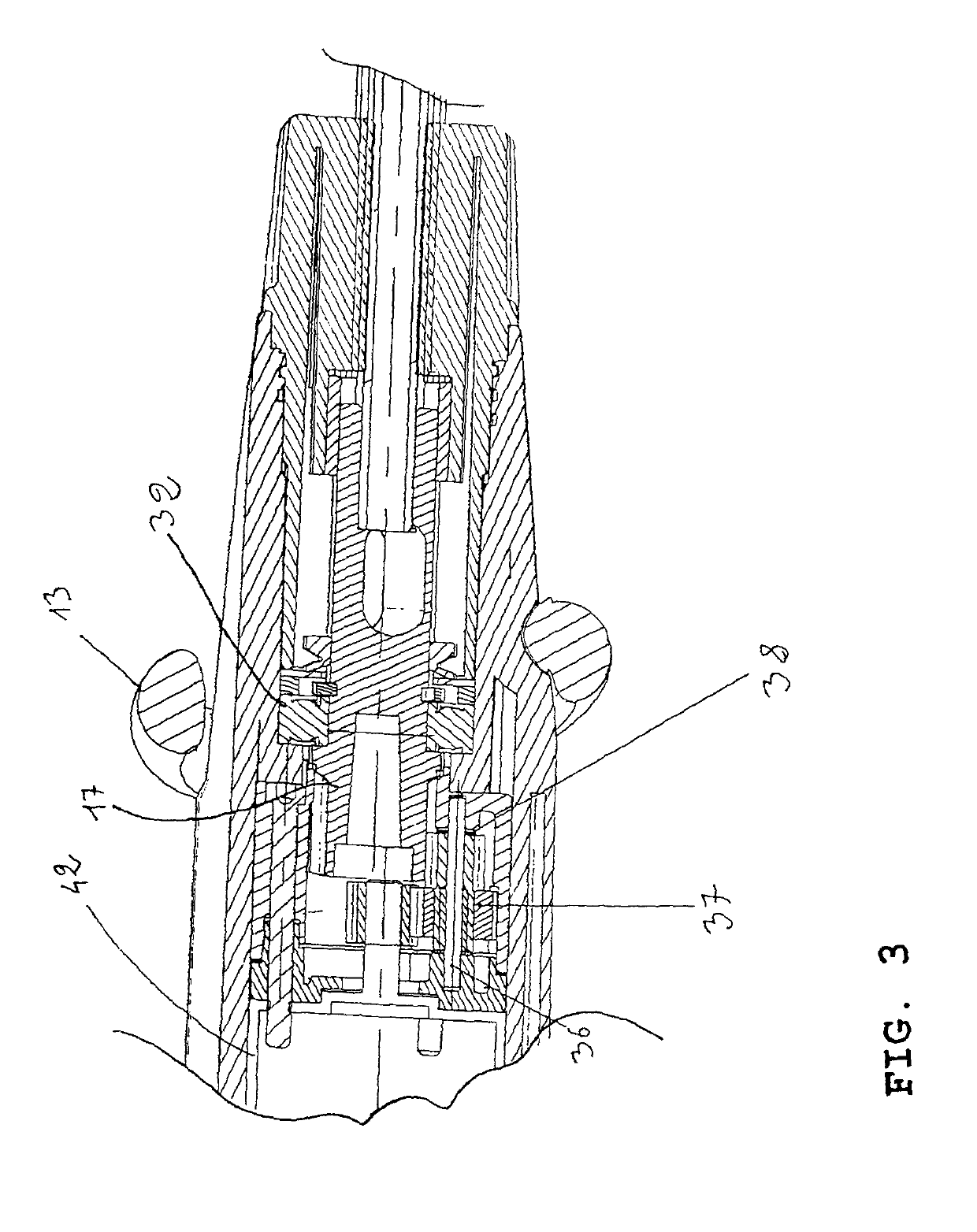

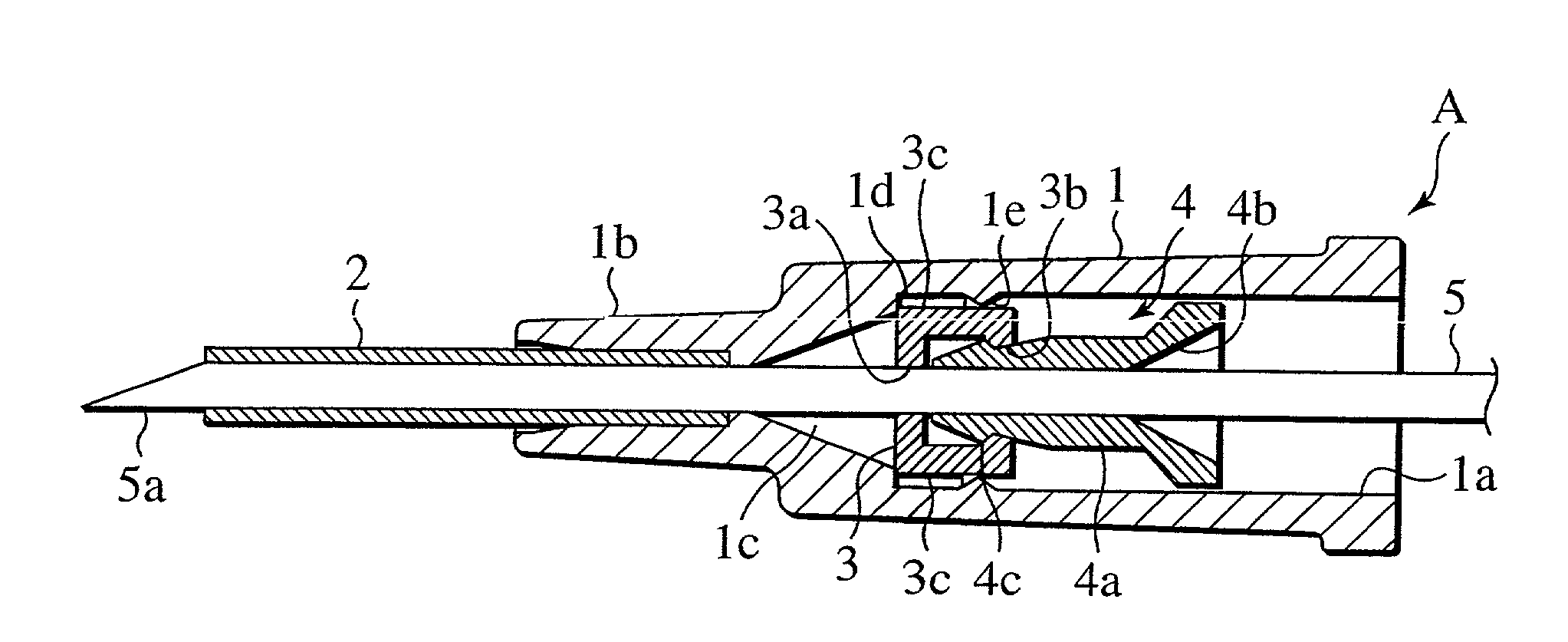

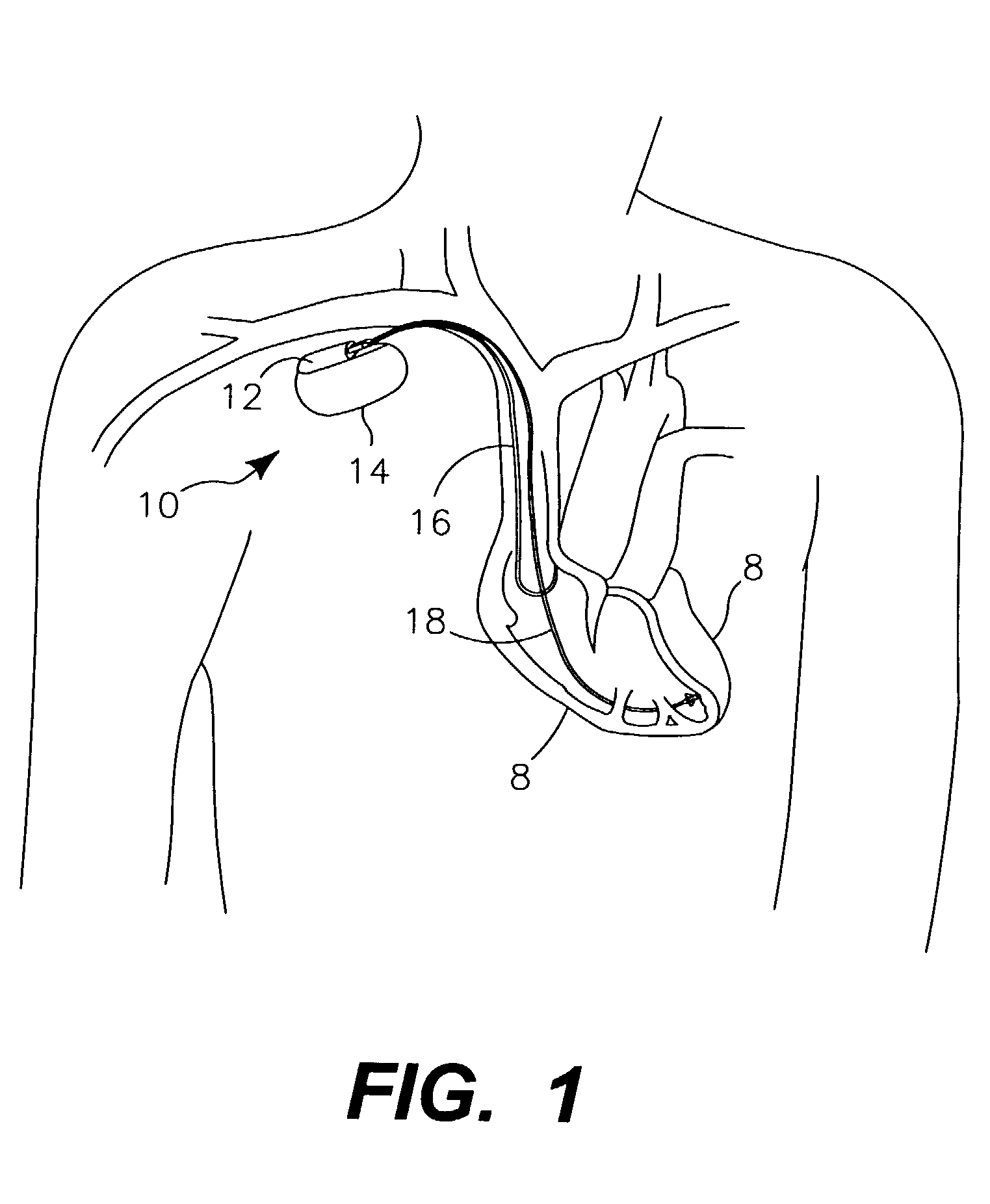

Device for treatments of endoscopic resection/removal of tissues

ActiveUS10299818B2Improve ergonomicsControlled heatingEndoscopesPortable power-driven toolsEndoscopic resectionBiomedical engineering

A device (1) for treatments of endoscopic resection / removal of tissues, includes: a handpiece apt to be held by an user; an external tubular element (3) having a proximal end, a distal end and a cutting aperture disposed at the distal end; an internal tubular element (4) apt to be pivotally housed in the external tubular element (3) and having a proximal end, a distal end and a cutting tip at its distal end. The device also includes guide elements (5) for rotating and / or oscillating the internal tubular element (4) with respect to the external tubular element (3). The guide elements (5) include an electric motor (19) and electric feeding element for the electric motor (19) and are contained completely inside the handpiece (2).

Owner:FRII

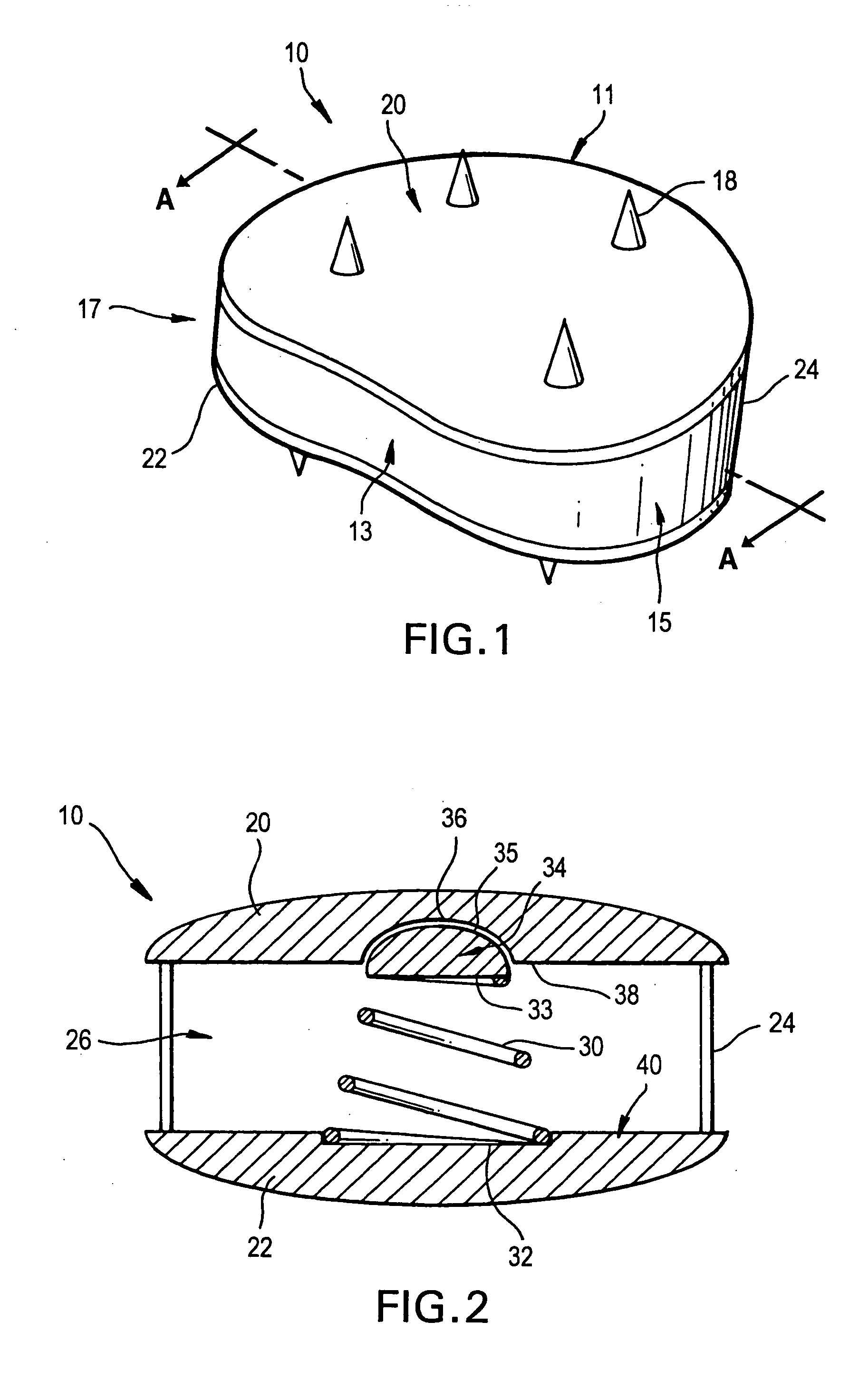

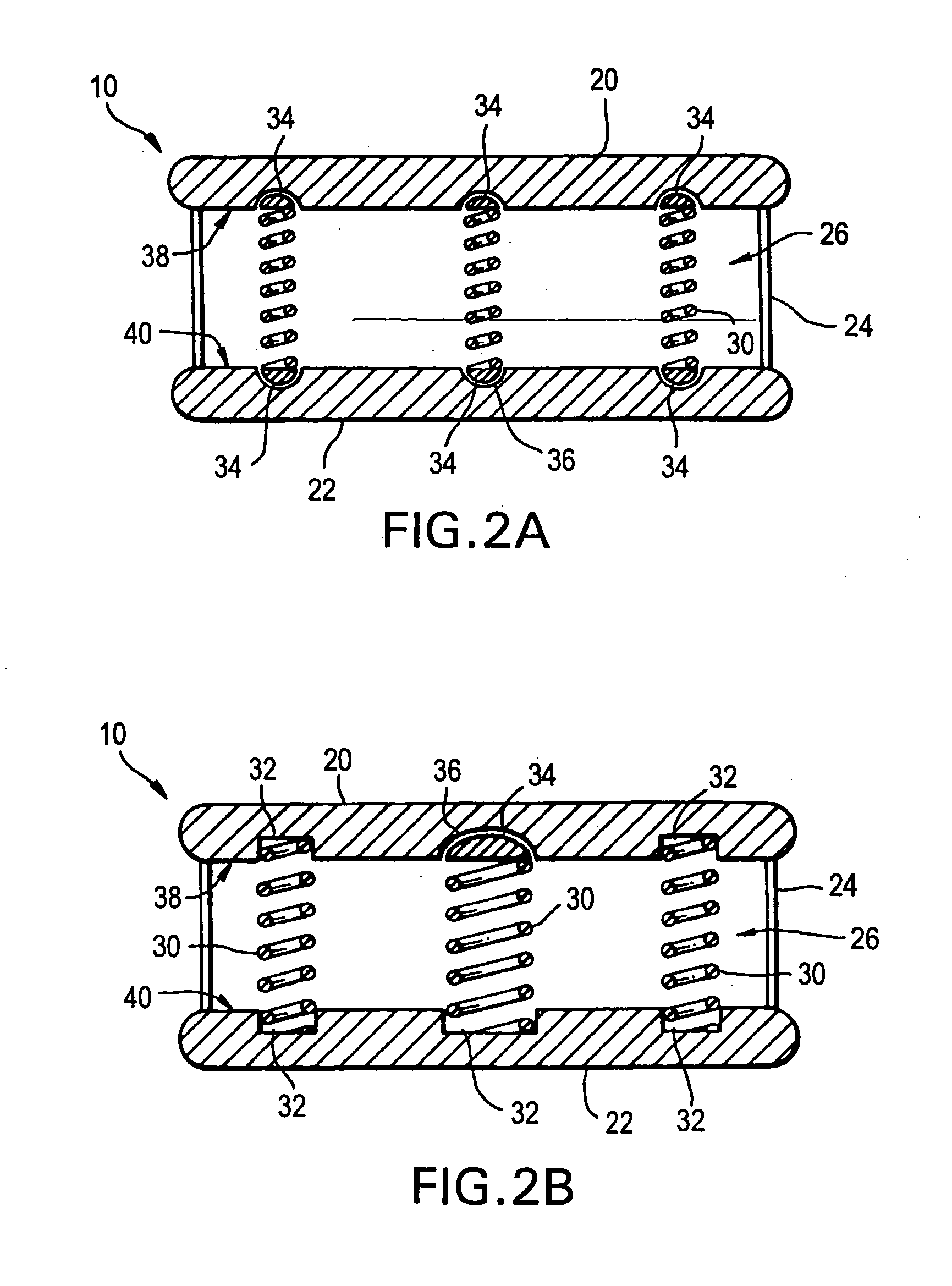

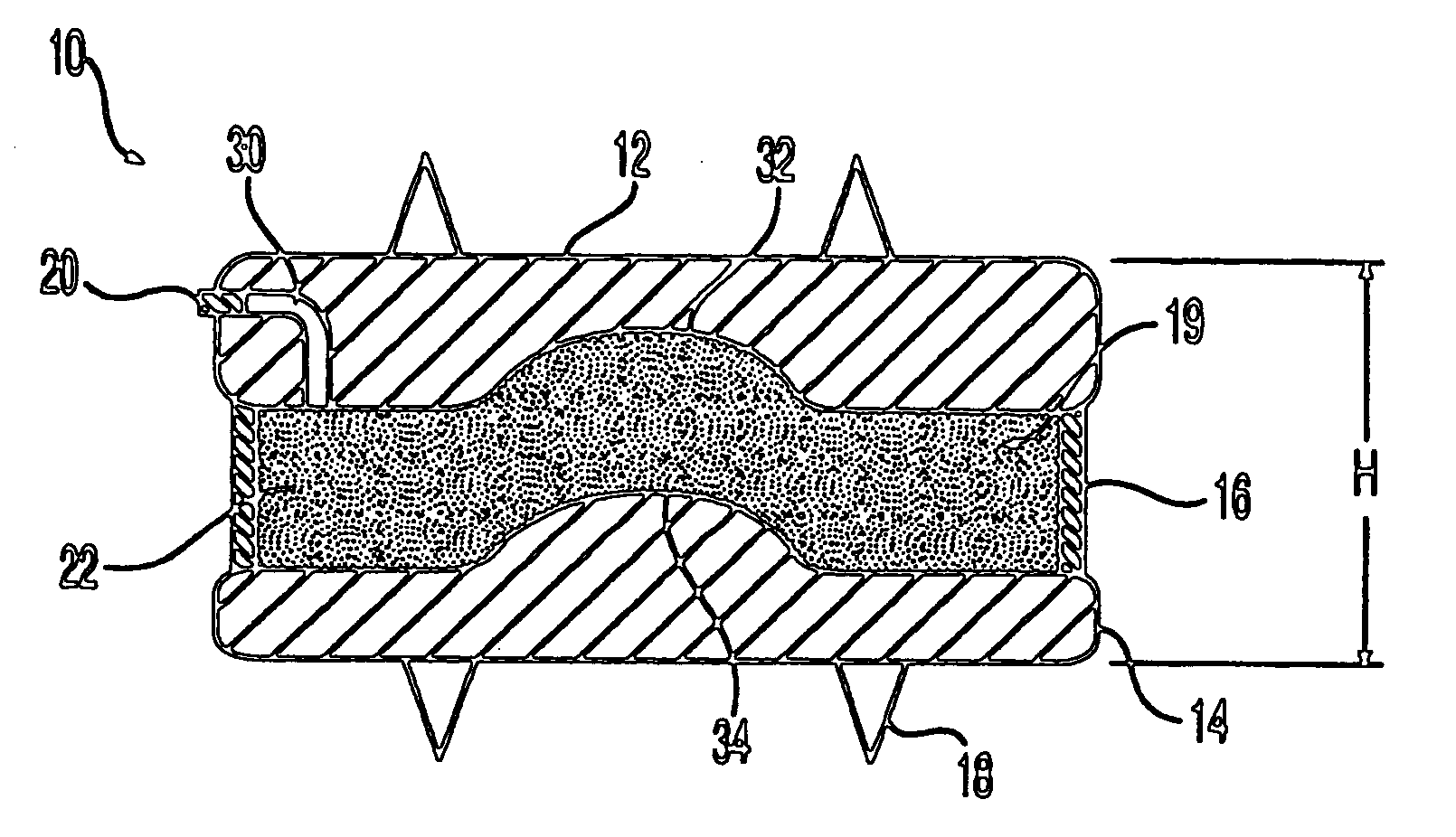

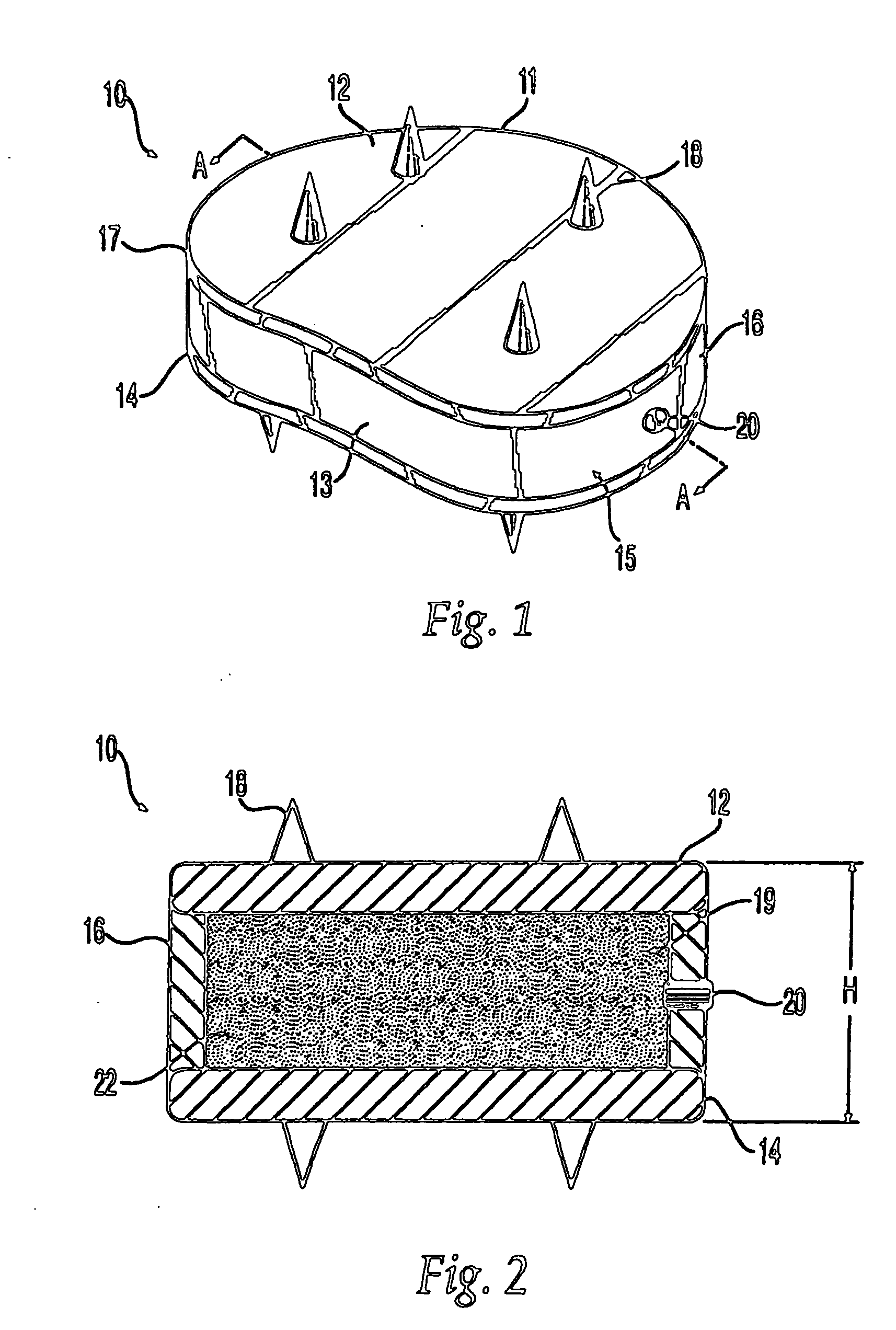

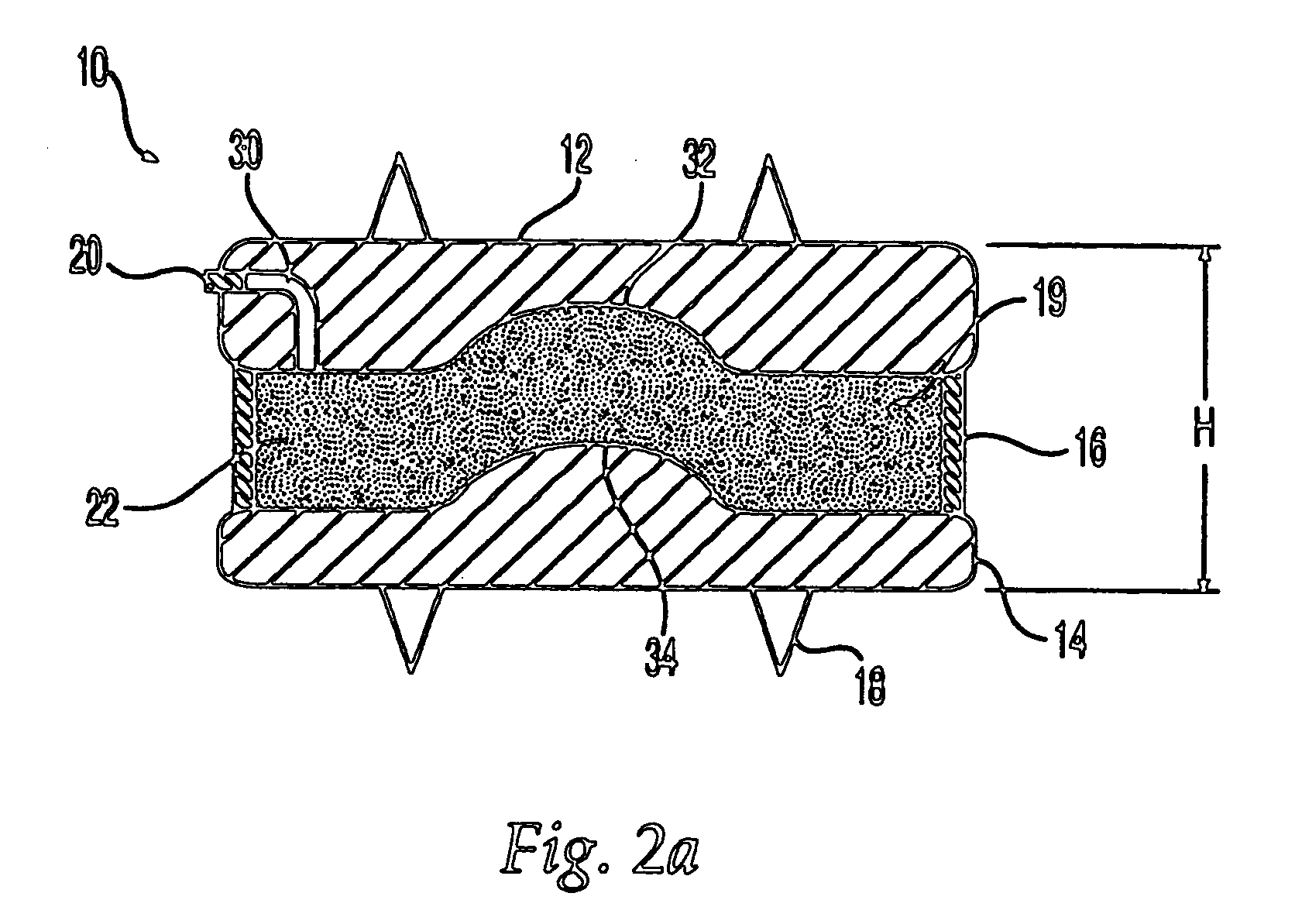

Controlled artificial intervertebral disc implant

ActiveUS20050251260A1Reduce the amount requiredProlong lifeBone implantJoint implantsMedicineAxial compression

The invention relates to an artificial intervertebral disc for placement between adjacent vertebrae. The artificial intervertebral disc is preferably designed to restore disc height and natural disc curvature, allow for a natural range of motion, absorb shock and provide resistance to motion and axial compression. Furthermore, the intervertebral disc may be used in the cervical, the thoracic, or the lumbar regions of the spine. The artificial intervertebral disc may include either singularly or in combination: an interior including at least one spring member preferably incorporating a arcuate surface member, a flexible core, the flexible core preferably being a slotted core, a ring spring, a winged leaf spring, or a leaf spring, or The articulating member preferably being attached to one of the endplate by an intermediate shock absorbing element.

Owner:SYNTHES USA

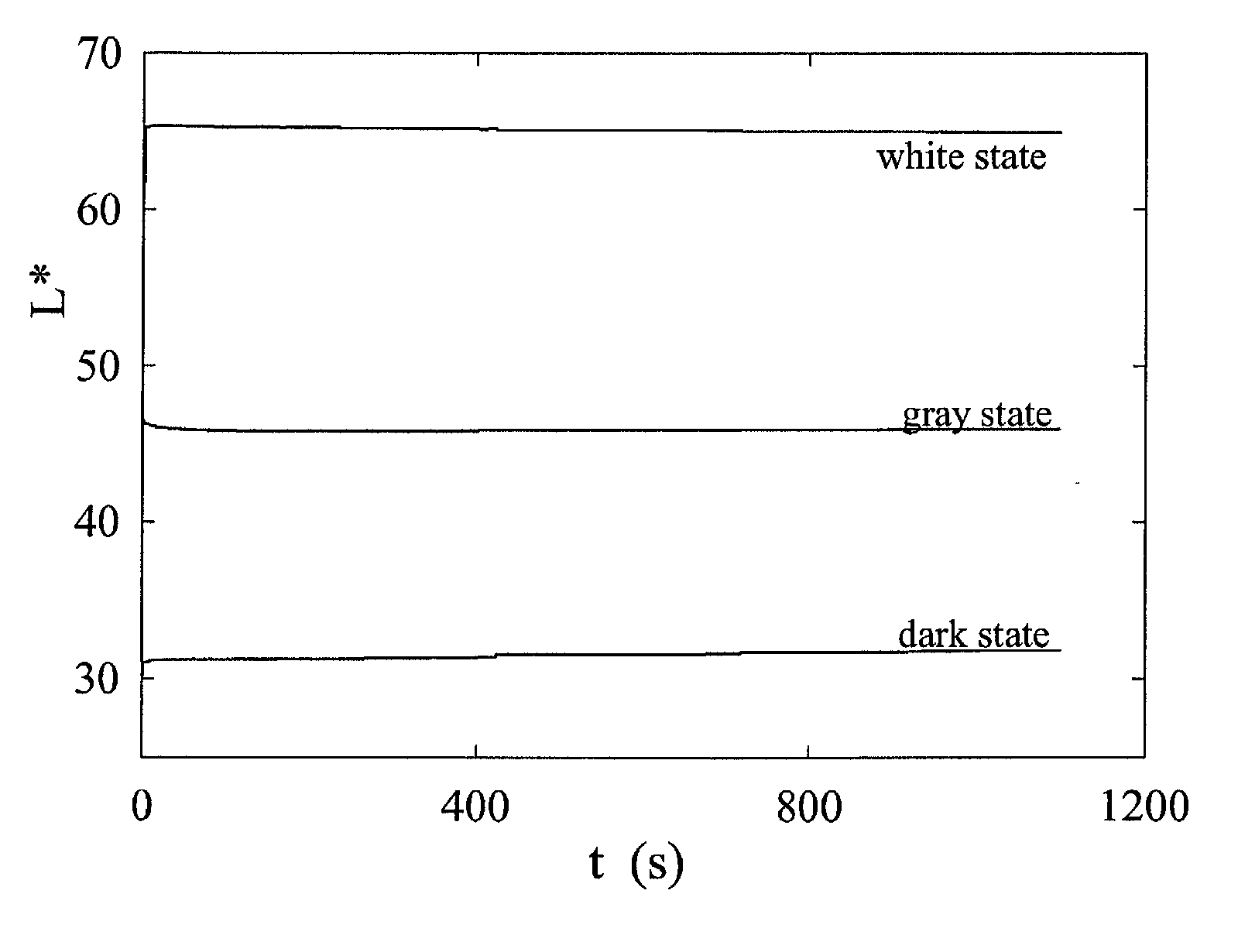

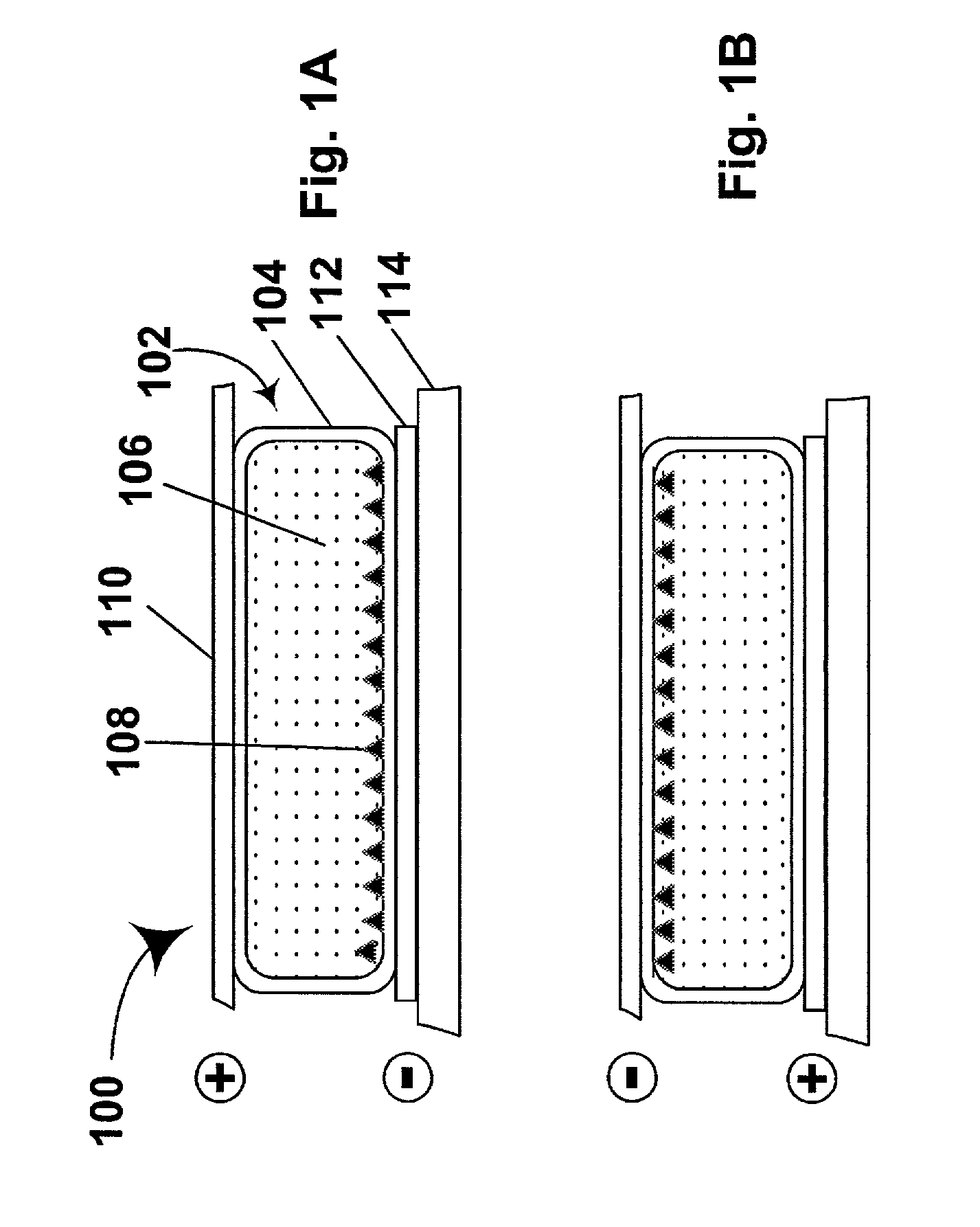

Electrophoretic medium and display with improved image stability

InactiveUS20020180687A1Improve imaging stabilityExtend switching timeStatic indicating devicesNon-linear opticsPolymer scienceElectrophoresis

An electrophoretic medium comprises a plurality of particles suspended in a suspending fluid, the particles being capable of moving through the fluid upon application of an electric field to the medium, the fluid having dissolved or dispersed therein a polymer having a number average molecular weight in excess of about 20,000, the polymer being essentially non-absorbing on the particles. The polymer improves the bistability of the display (i.e., the period for which a written image persist without the display being refreshed) but does not greatly increase the viscosity of the suspending fluid, thus keeping the switching time of the display within reasonable limits. The medium may be encapsulated, or may be in the form a polymer-dispersed electrophoretic medium.

Owner:E INK CORPORATION

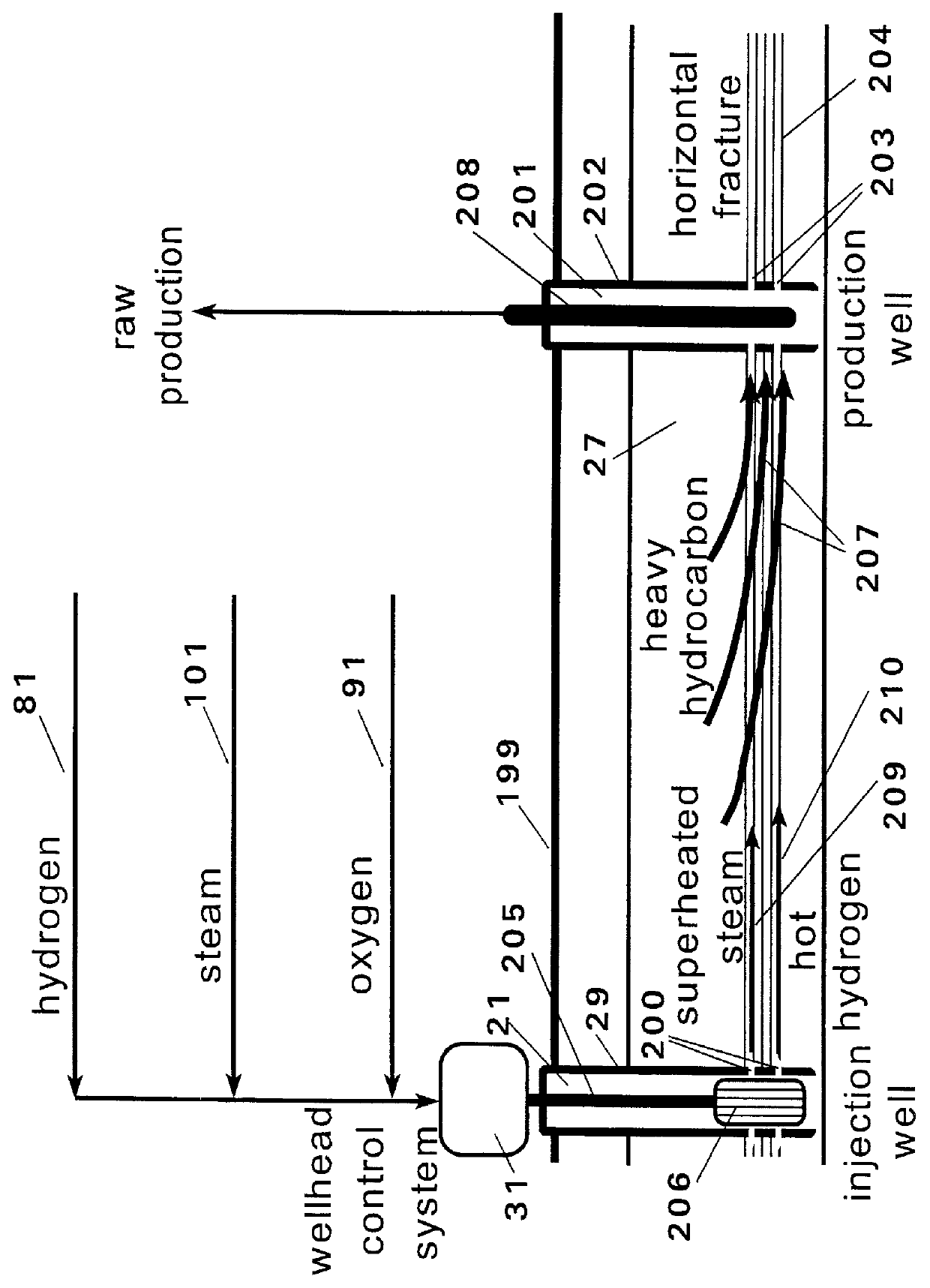

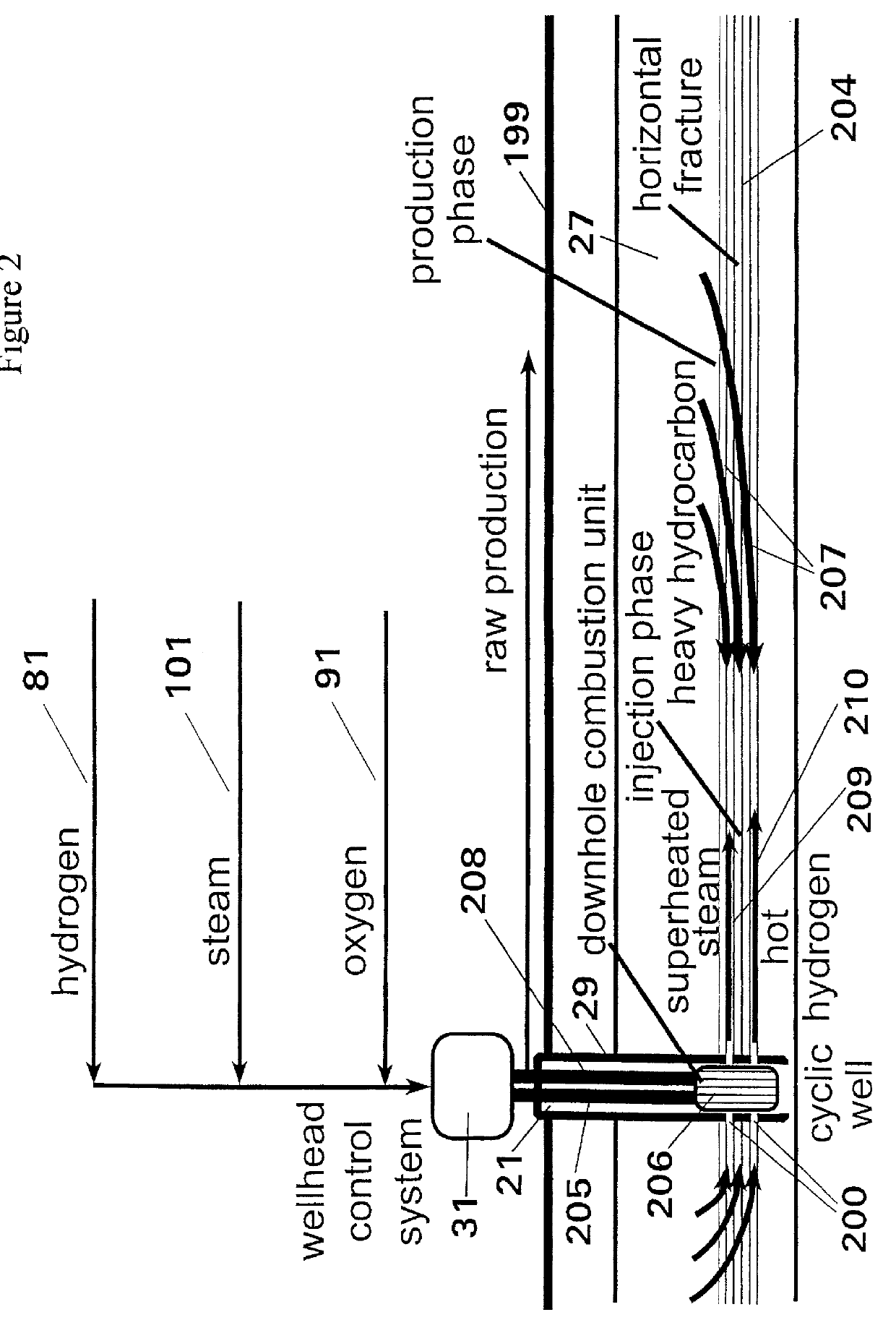

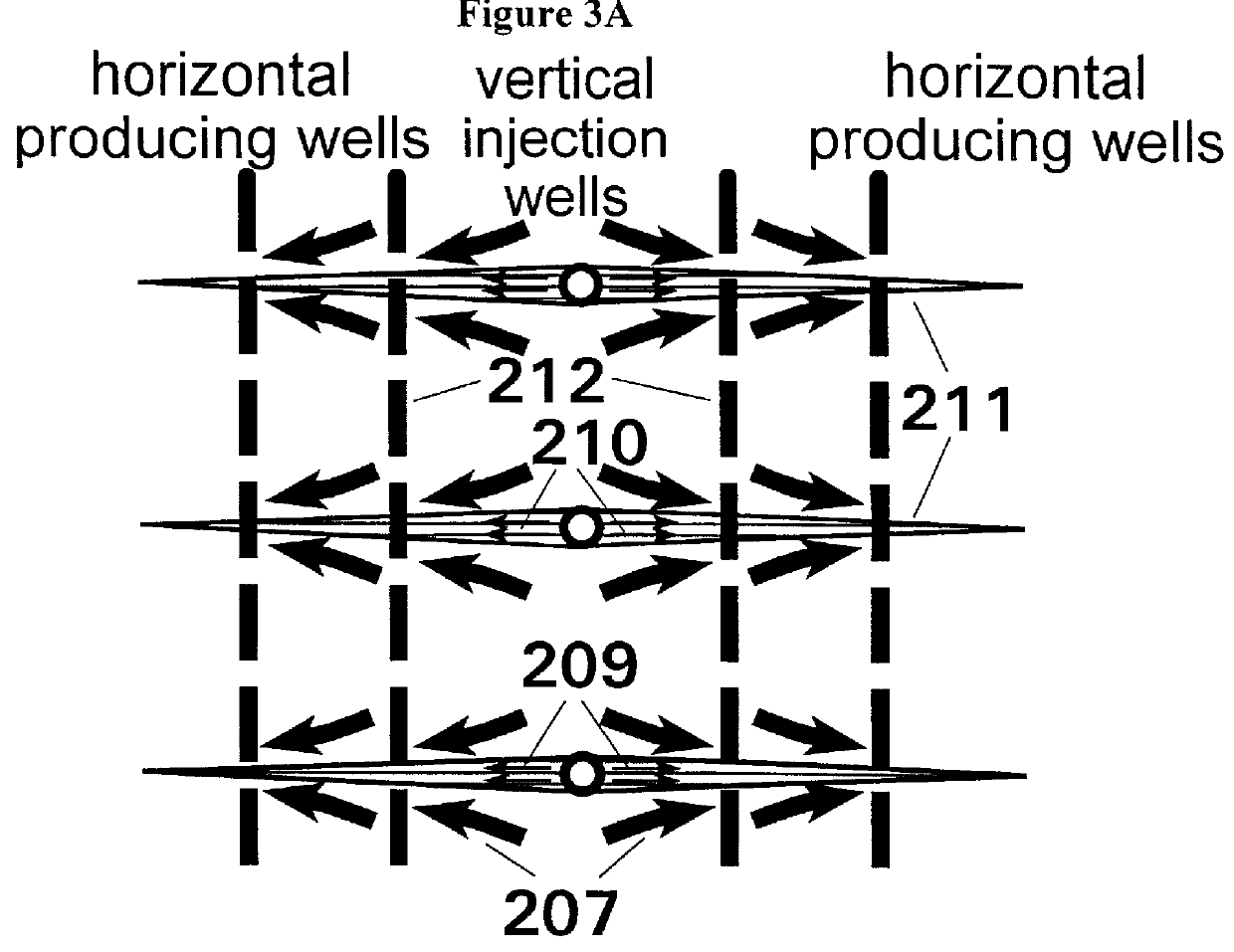

Upgrading and recovery of heavy crude oils and natural bitumens by in situ hydrovisbreaking

A process is disclosed for the in situ conversion and recovery of heavy crude oils and natural bitumens from subsurface formations using either a continuous operation with one or more injection and production boreholes, which may include horizontal boreholes, or a cyclic operation whereby both injection and production occur in the same boreholes. A mixture of reducing gases, oxidizing gases, and steam are fed to downhole combustion devices located in the injection boreholes. Combustion of the reducing gas-oxidizing gas mixture is carried out to produce superheated steam and hot reducing gases for injection into the formation to convert and upgrade the heavy crude or bitumen into lighter hydrocarbons. Communication between the injection and production boreholes in the continuous operation and fluid mobility within the formation in the cyclic operation is induced by fracturing or related methods. In the continuous mode, the injected steam and reducing gases drive upgraded hydrocarbons and virgin hydrocarbons to the production boreholes for recovery. In the cyclic operation, wellhead pressure is reduced after a period of injection causing injected fluids, upgraded hydrocarbons, and virgin hydrocarbons in the vicinity of the boreholes to be produced. Injection and production are then repeated for additional cycles. In both operations, the hydrocarbons produced are collected at the surface for further processing.

Owner:WORLD ENERGY SYST

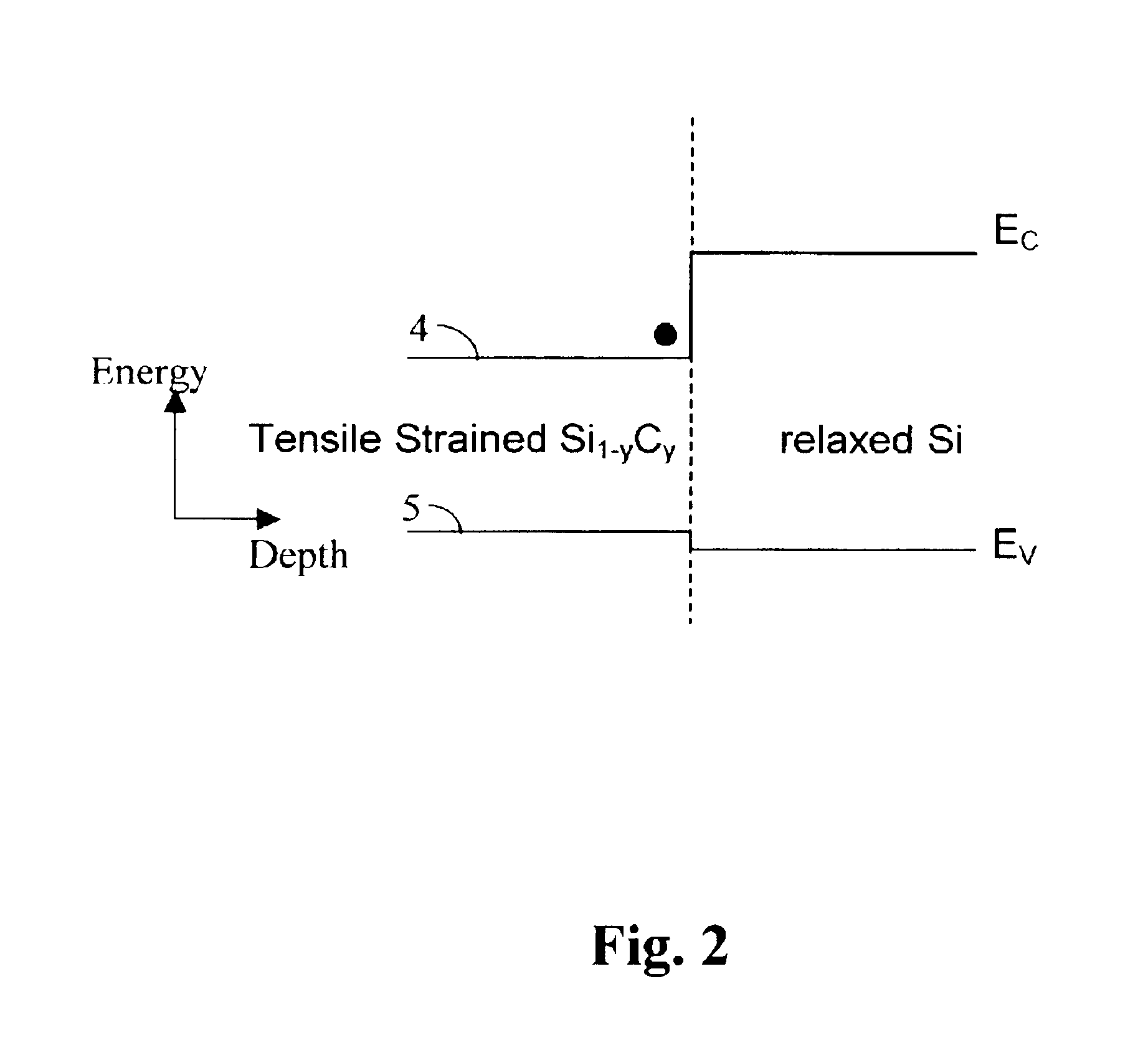

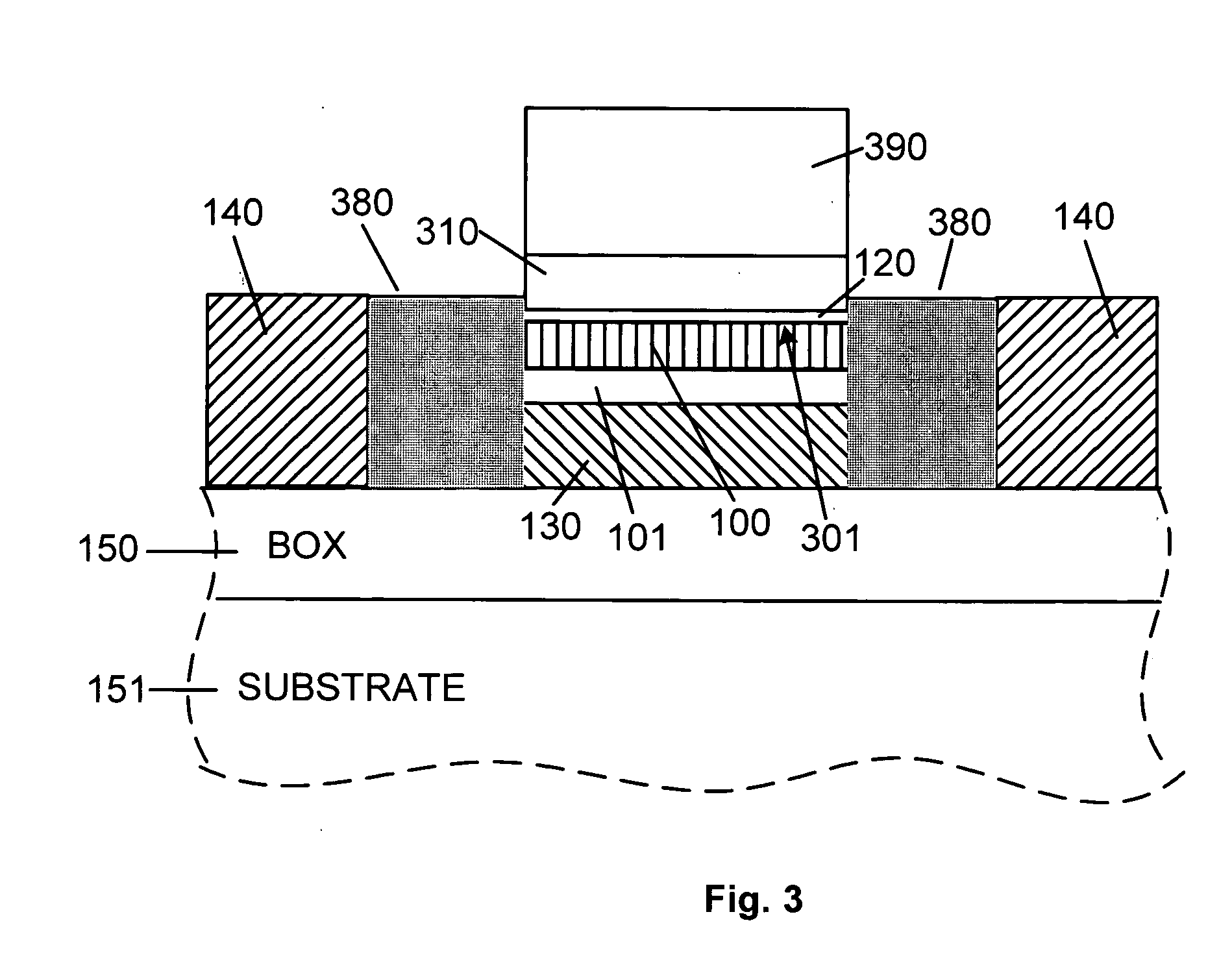

Low leakage heterojunction vertical transistors and high performance devices thereof

InactiveUS6943407B2Superb performanceSuperb scalabilityTransistorSolid-state devicesReverse short-channel effectHeterojunction

A method for forming and the structure of a vertical channel of a field effect transistor, a field effect transistor and CMOS circuitry are described incorporating a drain, body and source region on a sidewall of a vertical single crystal semiconductor structure wherein a hetero-junction is formed between the source and body of the transistor, wherein the source region and channel are independently lattice strained with respect the body region and wherein the drain region contains a carbon doped region to prevent the diffusion of dopants (i.e., B and P) into the body. The invention reduces the problem of short channel effects such as drain induced barrier lowering and the leakage current from the source to drain regions via the hetero-junction and while independently permitting lattice strain in the channel region for increased mobility via choice of the semiconductor materials. The problem of scalability of the gate length below 100 nm is overcome by the heterojunction between the source and body regions.

Owner:GLOBALFOUNDRIES INC

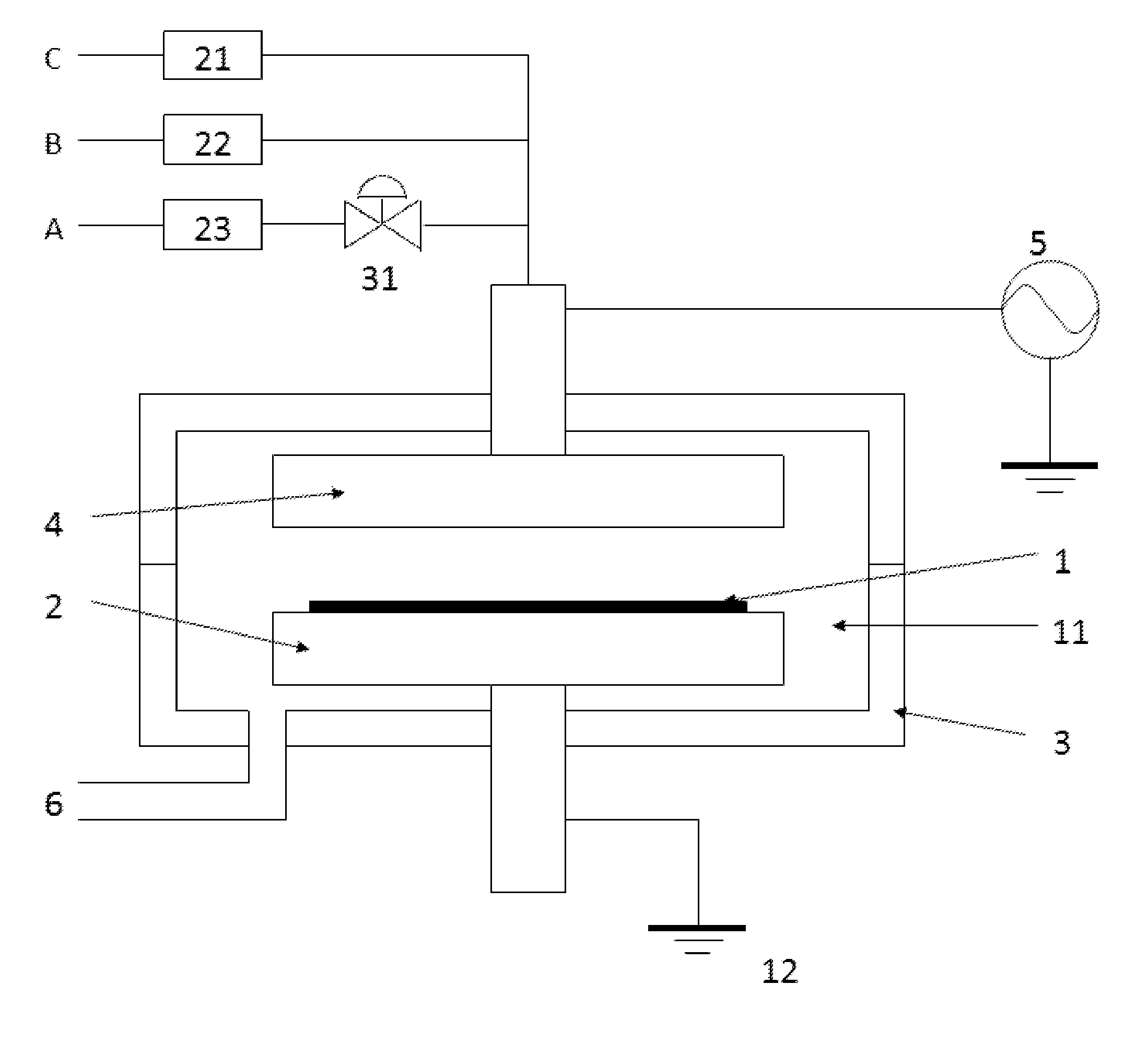

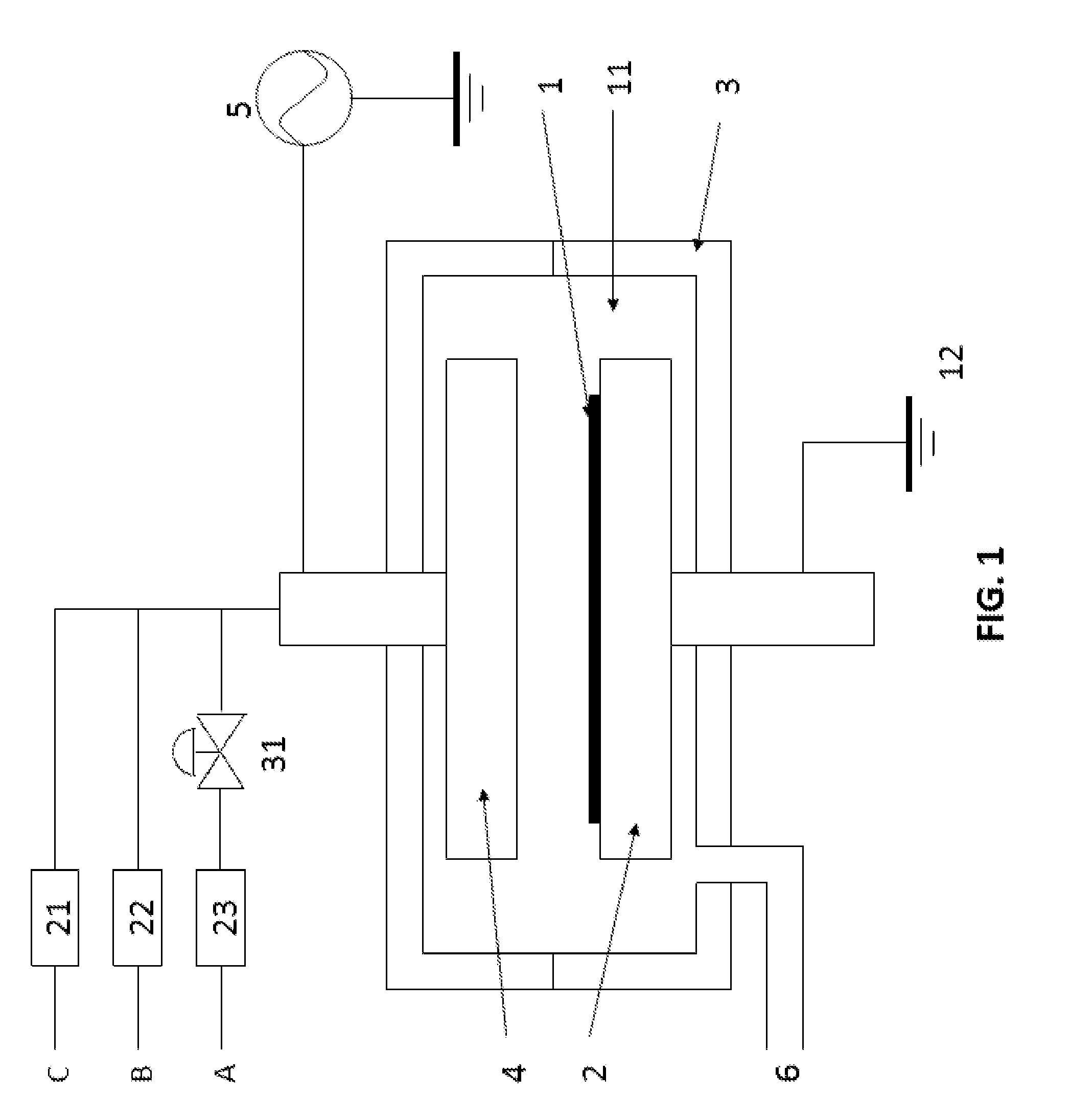

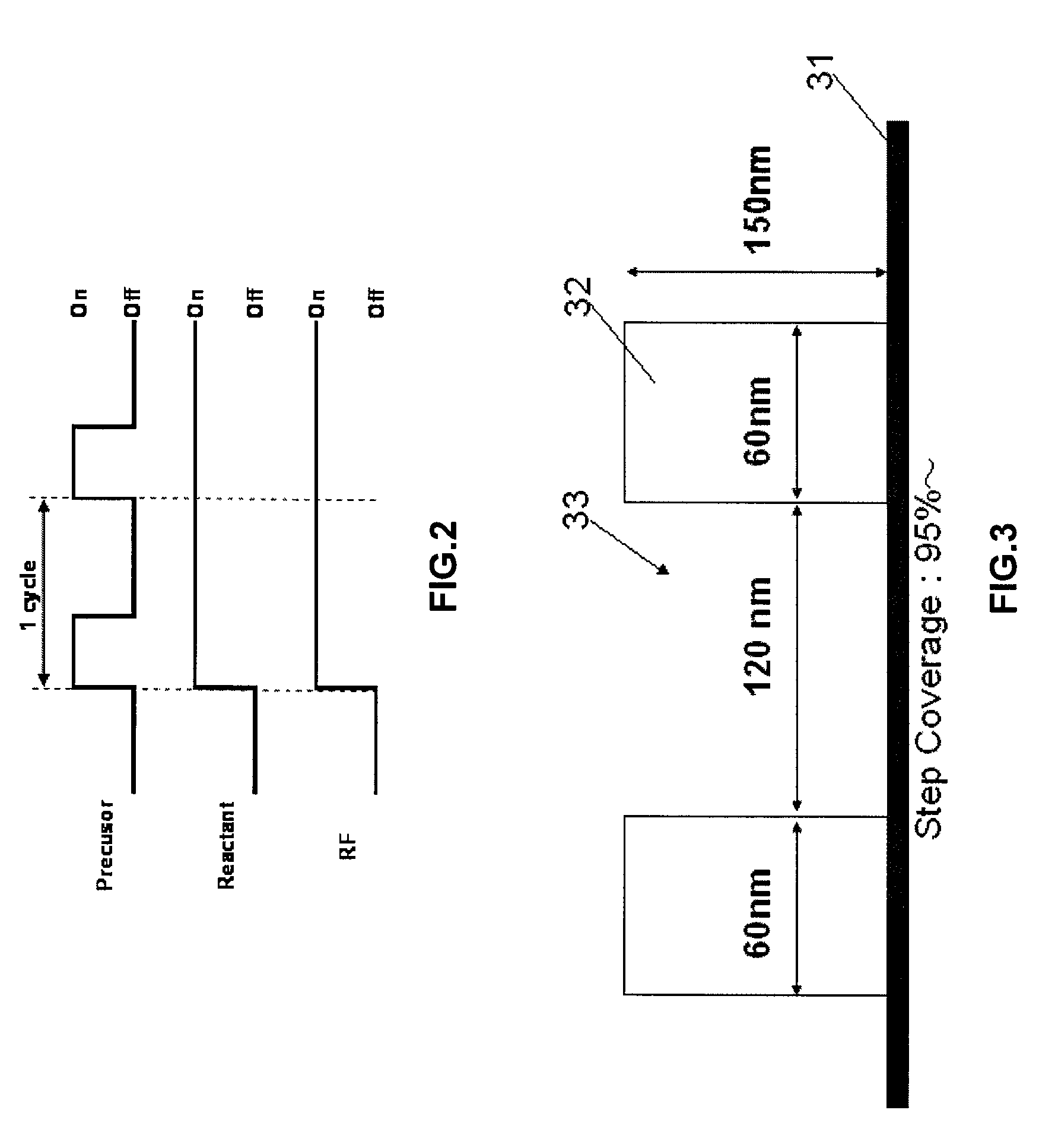

Method of forming conformal film having si-N bonds on high-aspect ratio pattern

ActiveUS8394466B2Increasing mobilityIncreasing diffusivitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingSiliconConformal map

Owner:ASM JAPAN

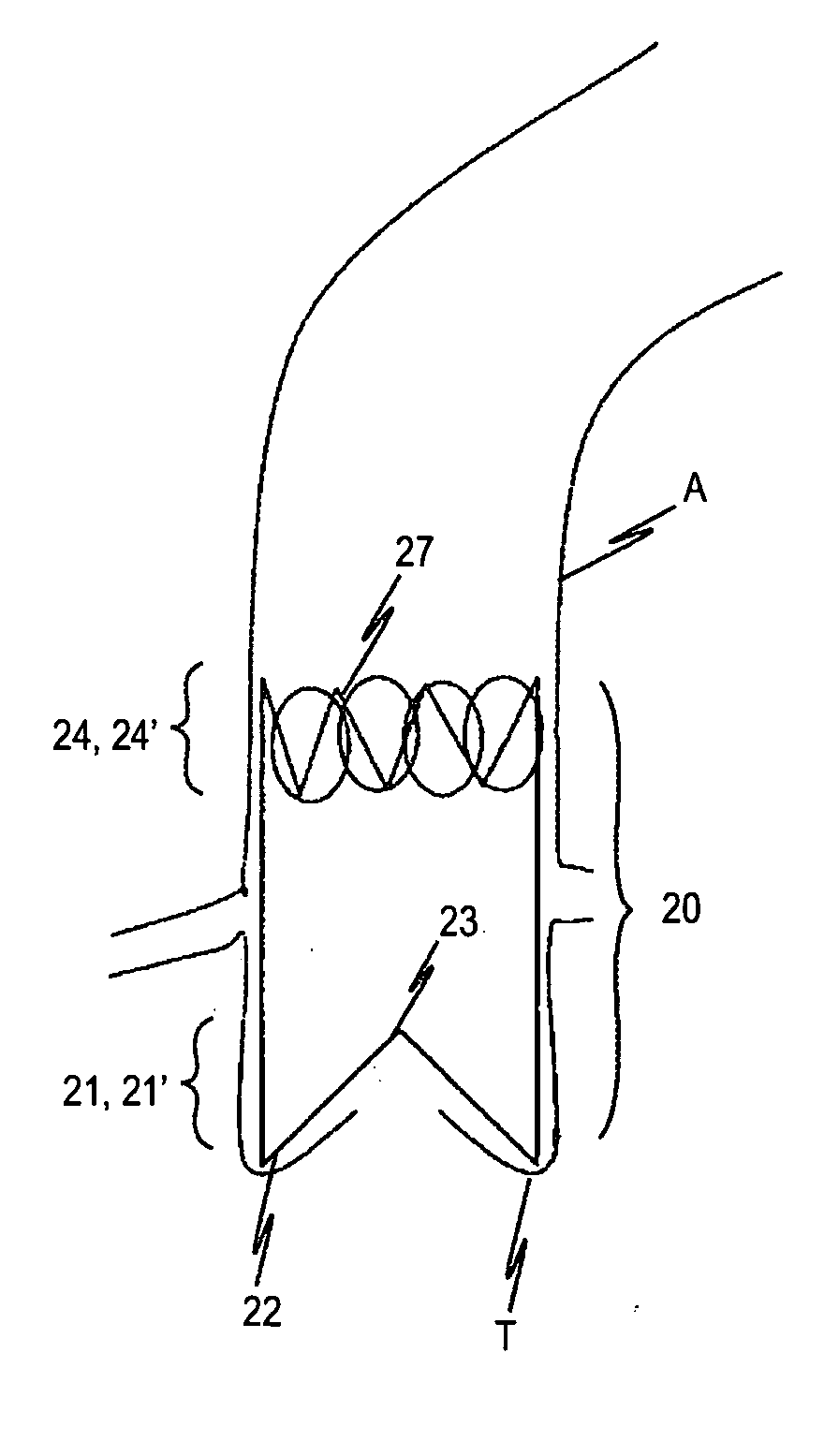

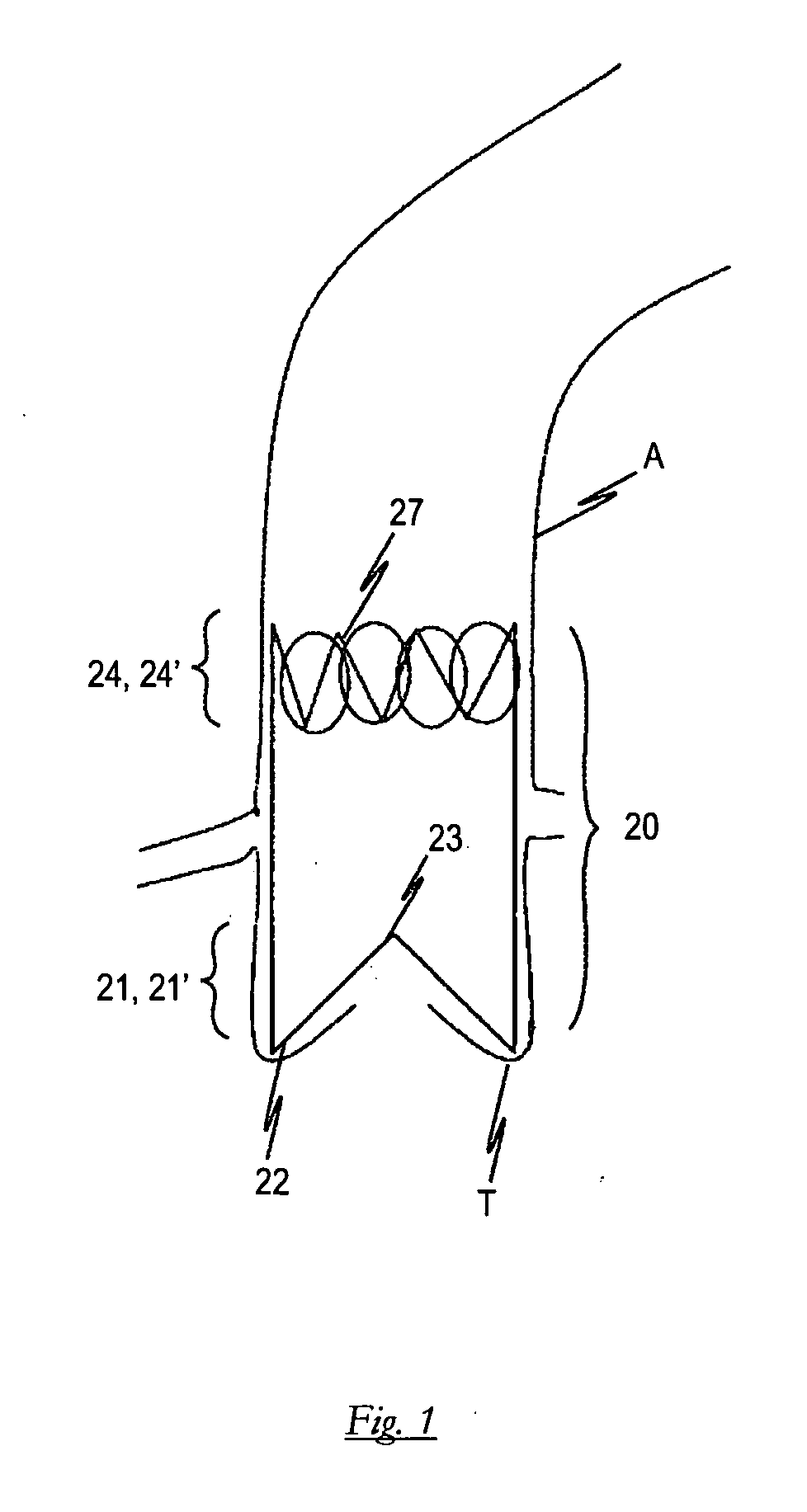

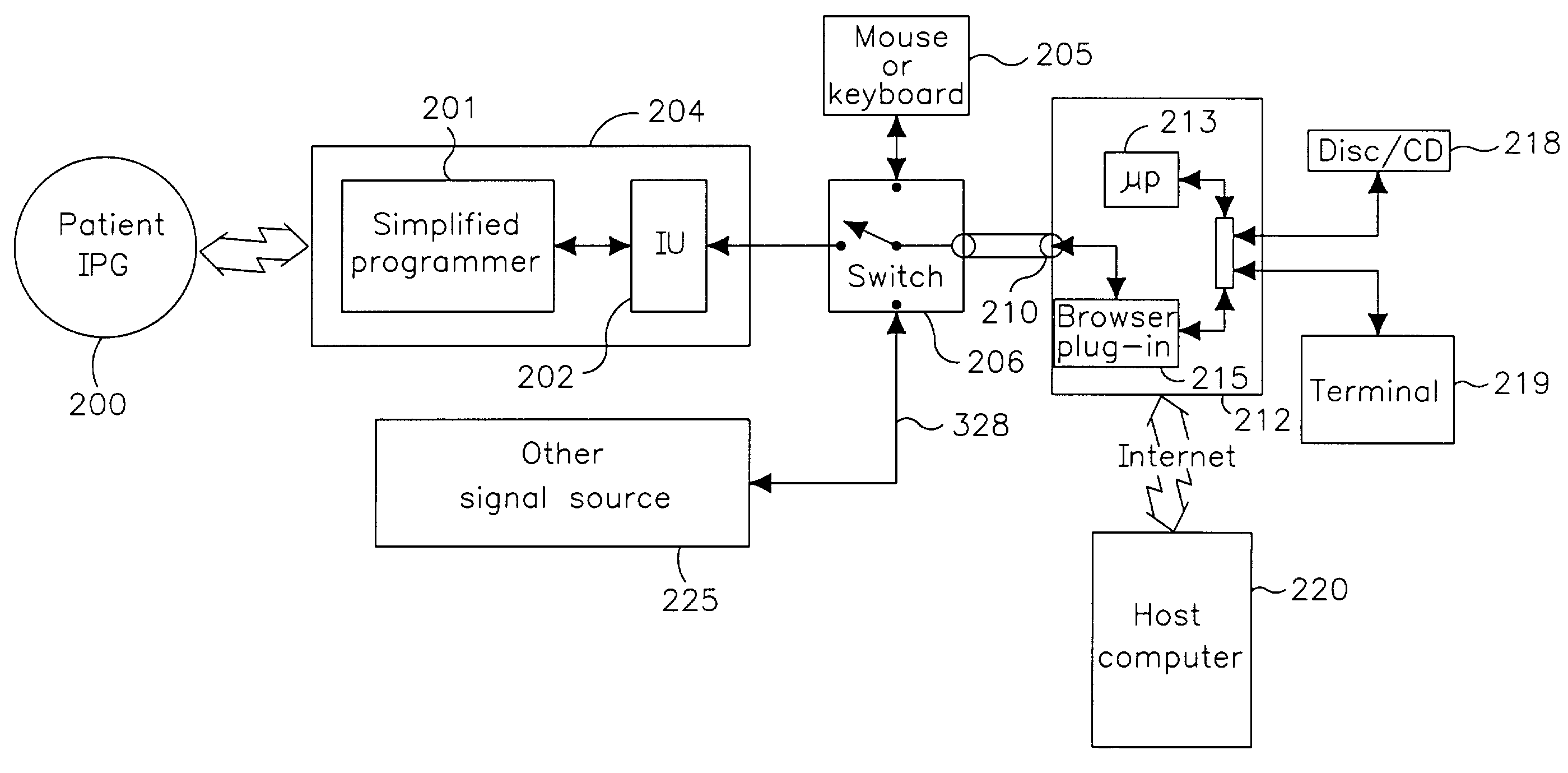

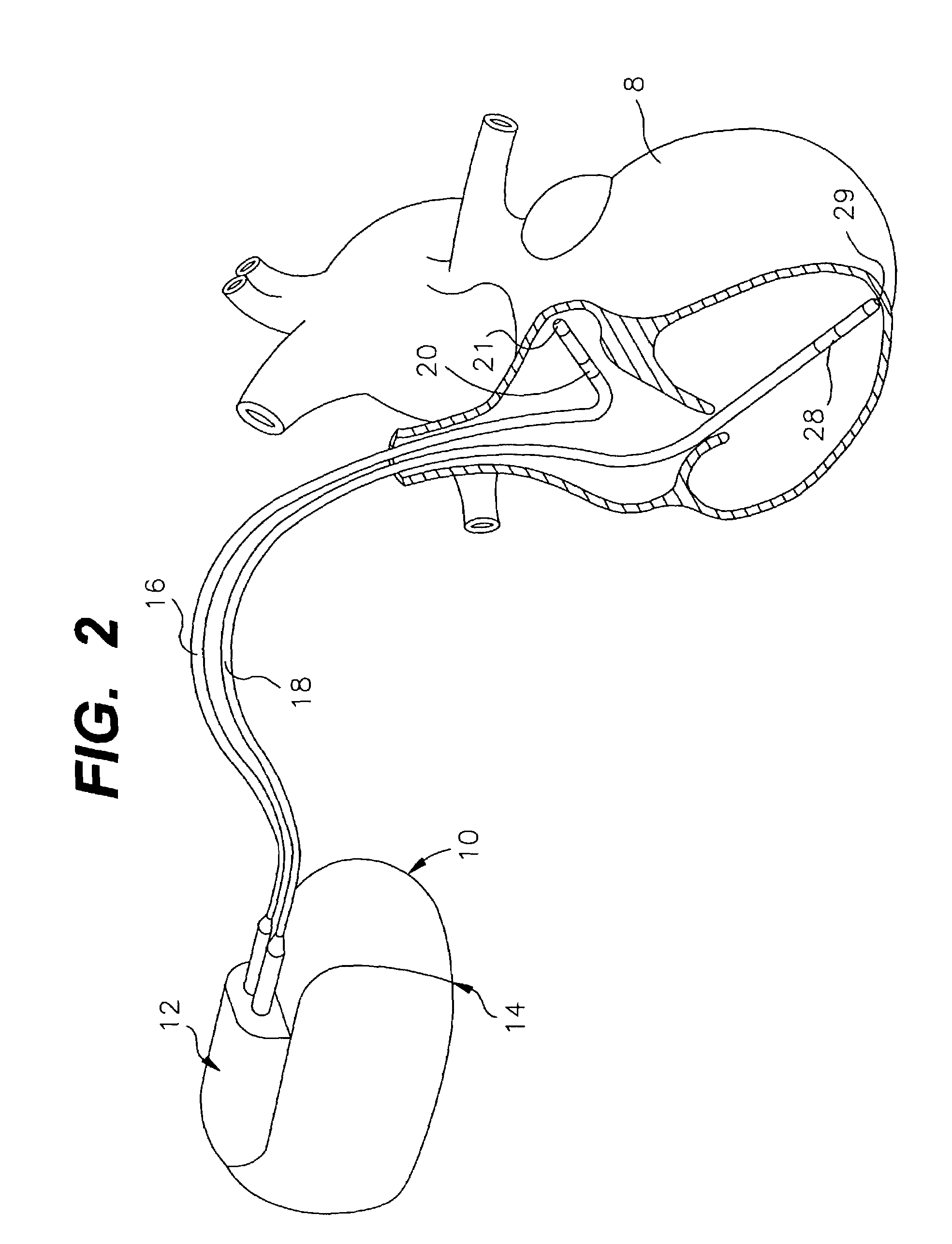

Device for the implantation and fixation of prosthetic valves

ActiveUS20070100440A1High positioning accuracyImprove mobilityStentsBalloon catheterProsthetic valveProsthetic heart

A device for the transvascular implantation and fixation of prosthetic heart valves having a self-expanding heart valve stent (10) with a prosthetic heart valve (11) at its proximal end is introducible into a patient's main artery. With the objective of optimizing such a device to the extent that the prosthetic heart valve (11) can be implanted into a patient in a minimally-invasive procedure, to ensure optimal positioning accuracy of the prosthesis (11) in the patient's ventricle, the device includes a self-expanding positioning stent (20) introducible into an aortic valve positioned within a patient. The positioning stent is configured separately from the heart valve stent (10) so that the two stents respectively interact in their expanded states such that the heart valve stent (10) is held by the positioning stent (20) in a position in the patient's aorta relative the heart valve predefinable by the positioning stent (20).

Owner:JENAVALVE TECH INC

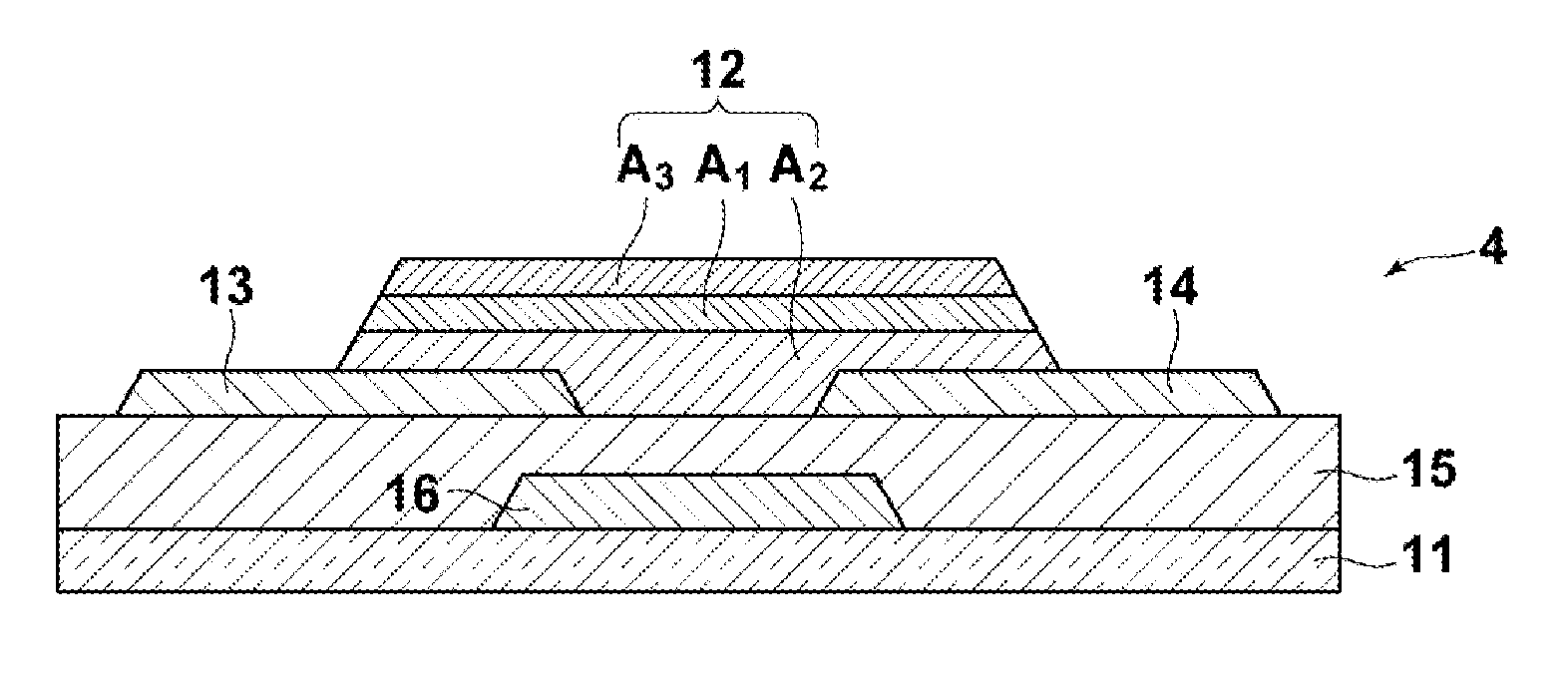

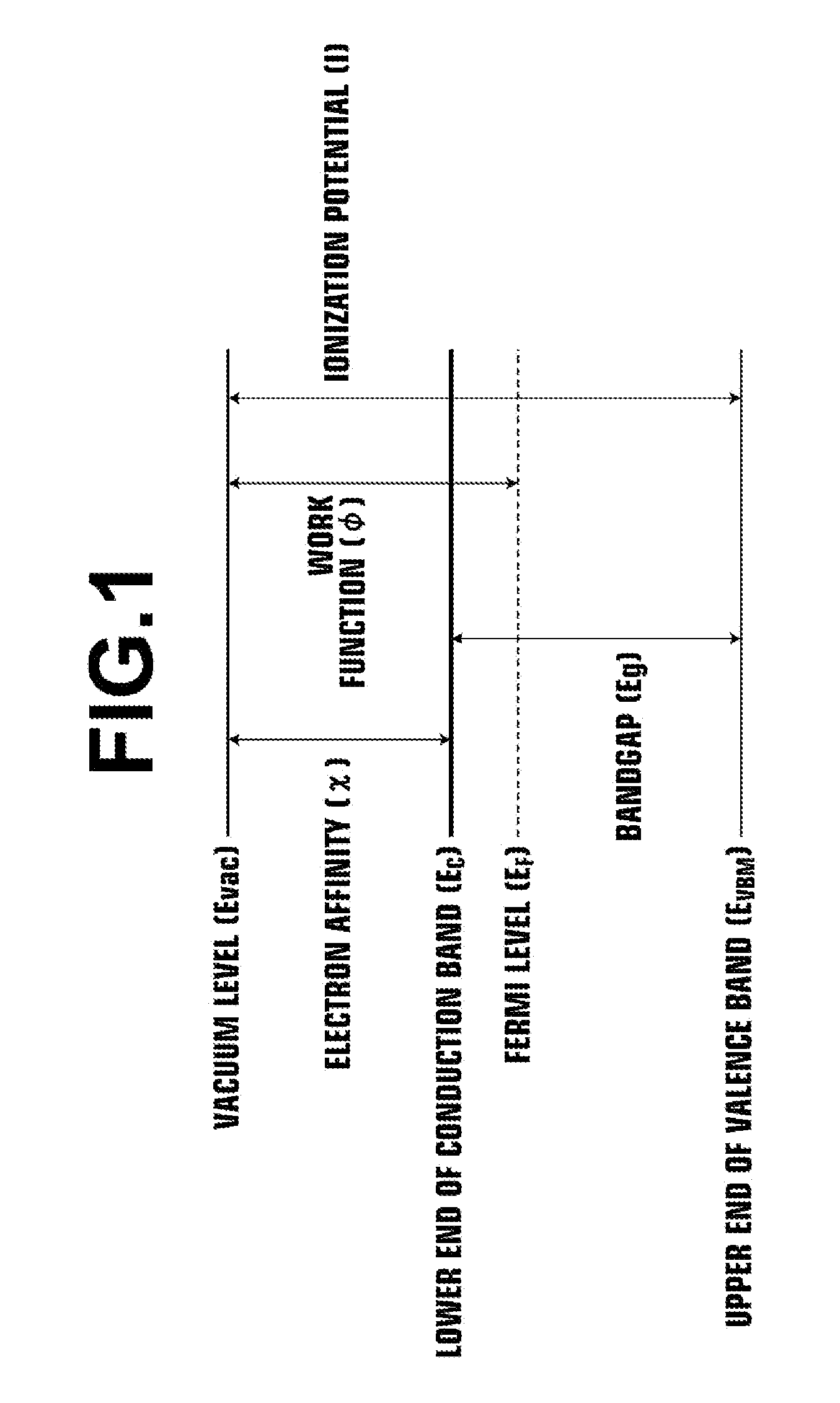

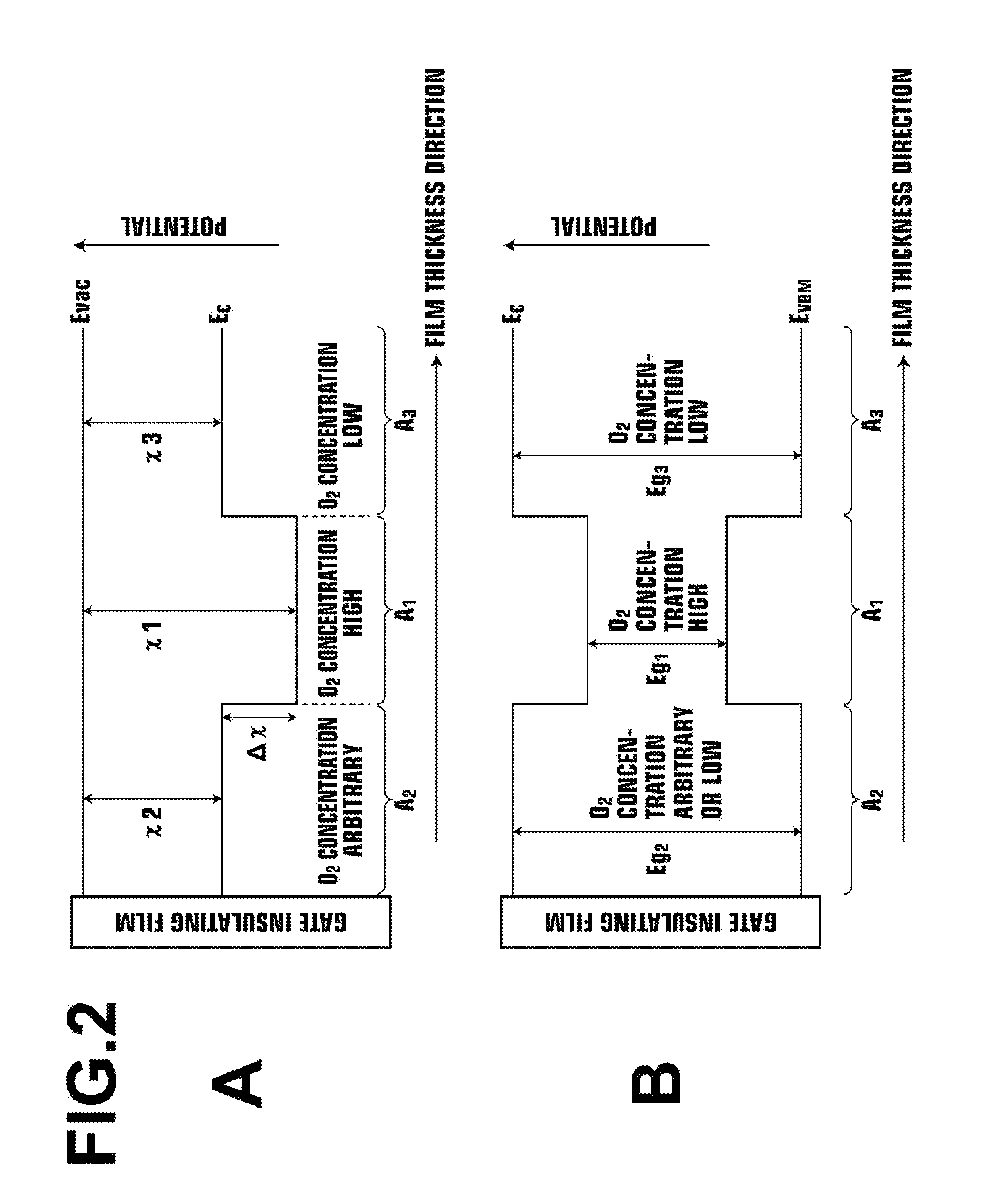

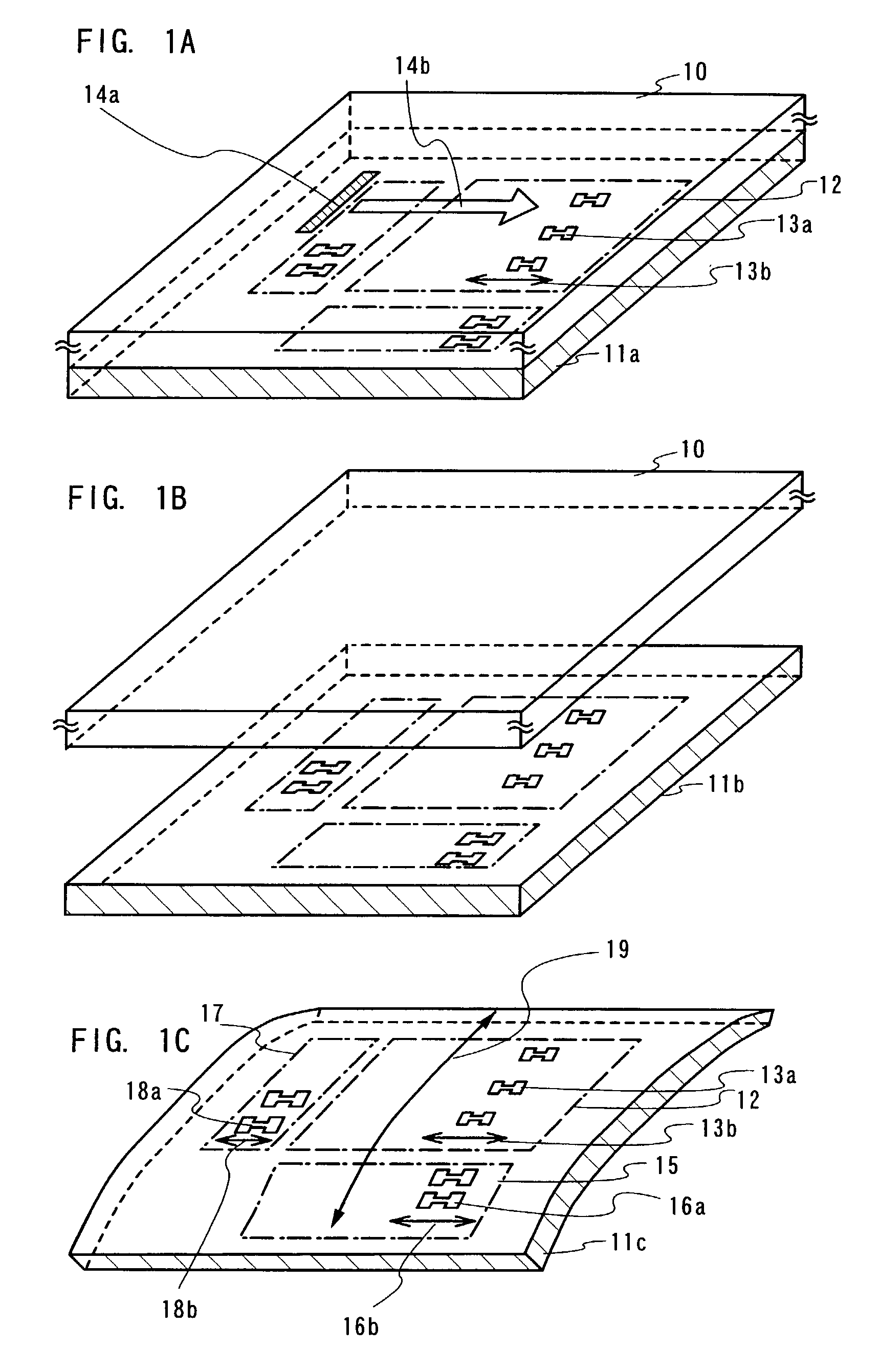

Thin-film transistor, method of producing the same, and devices provided with the same

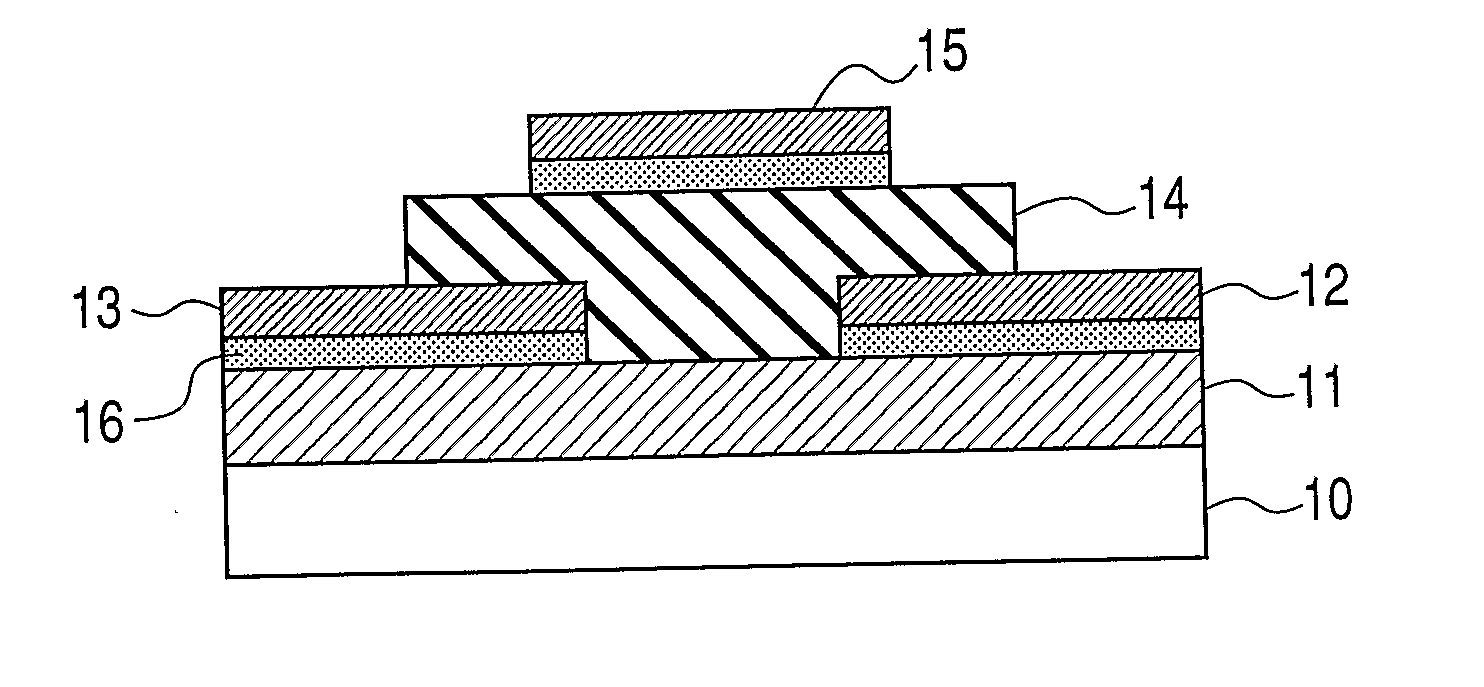

ActiveUS20110140100A1Low mobilityIncrease carrier densityTransistorSemiconductor/solid-state device manufacturingOxygenSemiconductor

A thin-film transistor including an oxide semiconductor layer is disclosed. The oxide semiconductor layer includes a first area, a second area and a third area forming a well-type potential in the film-thickness direction. The first area forms a well of the well-type potential and has a first electron affinity. The second area is disposed nearer to the gate electrode than the first area and has a second electron affinity smaller than the first electron affinity. The third area is disposed farther from the gate electrode than the first area and has a third electron affinity smaller than the first electron affinity. At least an oxygen concentration at the third area is lower than an oxygen concentration at the first area.

Owner:SAMSUNG DISPLAY CO LTD

Heart valve annulus device and method of using same

InactiveUS20050216079A1Reduce morbidityMinimize time-consume processHeart valvesWound clampsBiomedical engineeringCardiac valve annulus

A heart valve implant has a body sized and configured to rest near or within a heart valve annulus. A plurality of spaced-apart retainers extend outwardly from the body to contact tissue near or within the heart valve annulus. The retainers are sized and configured to secure the body to the heart valve annulus. The implant can be secured, e.g., without the use of sutures.

Owner:VENTURE LENDING & LEASING IV

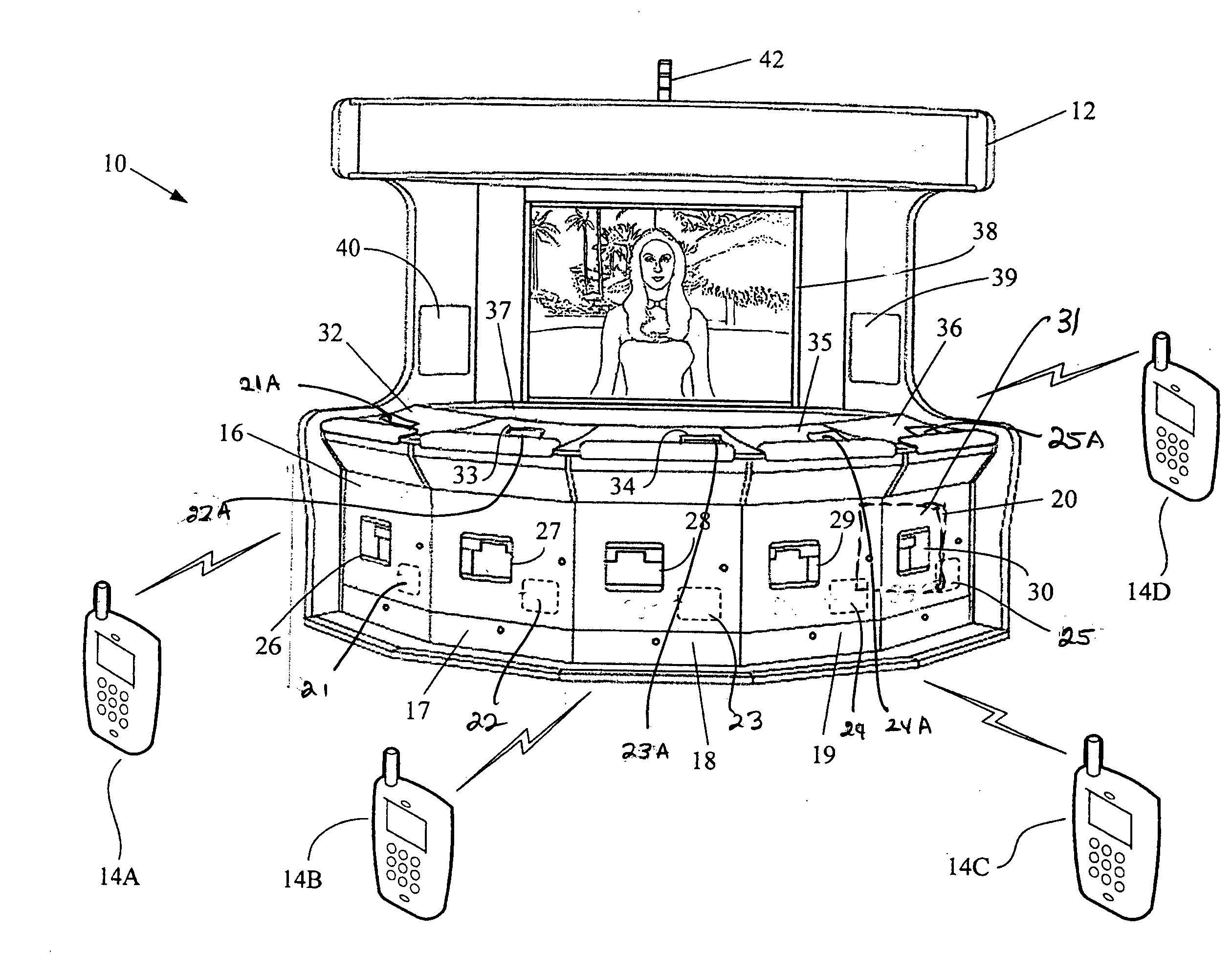

Wireless communal gaming system

InactiveUS20080096659A1Increase capacityReduce and eliminate needApparatus for meter-controlled dispensingVideo gamesDisplay deviceGame server

A system and method for wireless communal gaming in a casino environment. The system includes one or more wireless gaming devices each equipped with a display, one or more gaming servers configured to communicate wirelessly with the wireless gaming devices, and one or more financial servers configured to record financial transactions for players playing communal games of chance on the handheld gaming devices. The wireless approach to communal gaming allows greater player mobility within the casino establishment and also allows a large number of players (players playing wirelessly as well as players playing traditionally at a physical player station) to participate in a common game, thereby increasing the capacity of existing communal game tables. When the wireless game-playing option is available, a player can participate in the communal game regardless of whether there is a physical player station available. Thus, flexible game-playing options can be provided to casino patrons participating in a communal game.

Owner:SHUFFLE MASTER

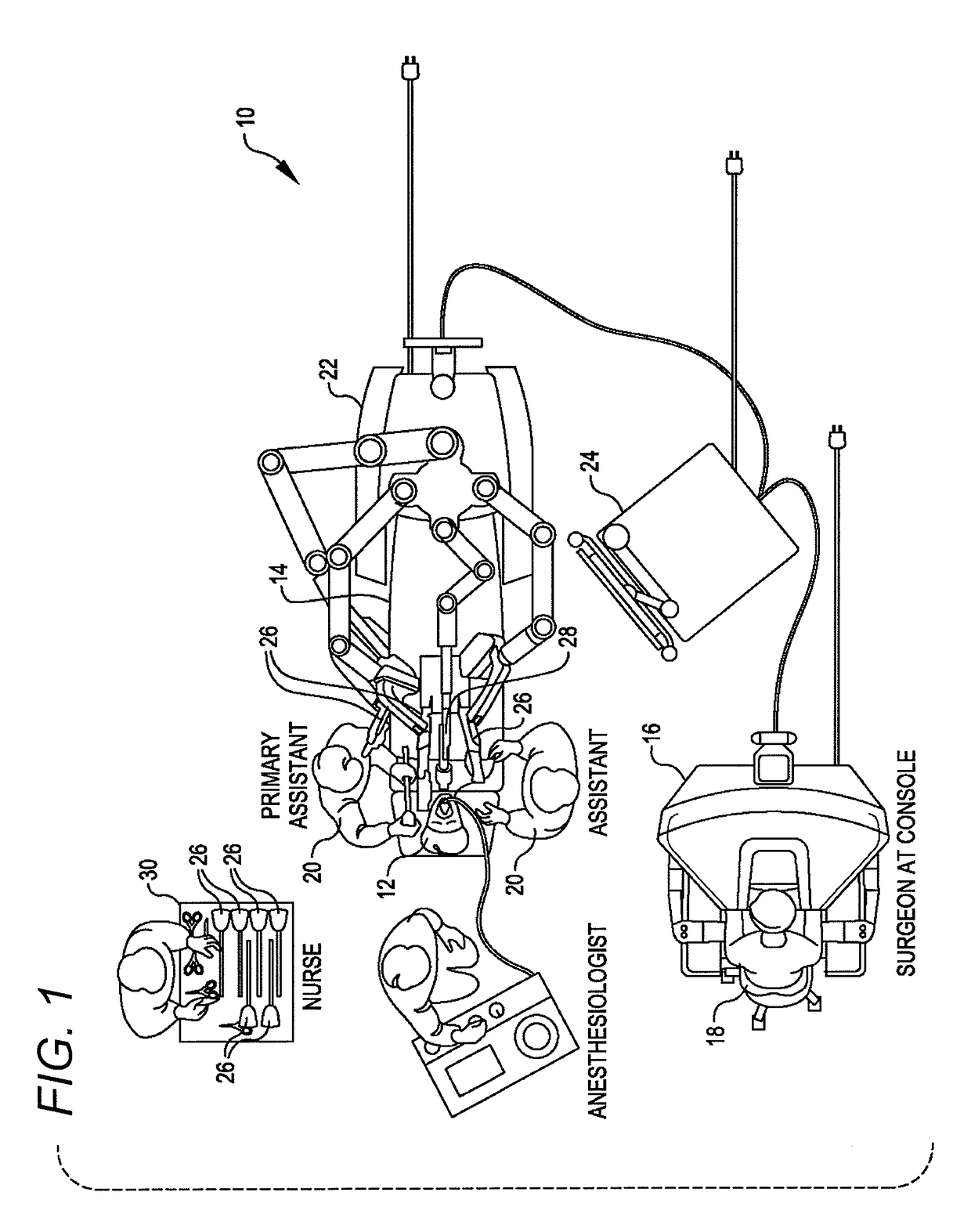

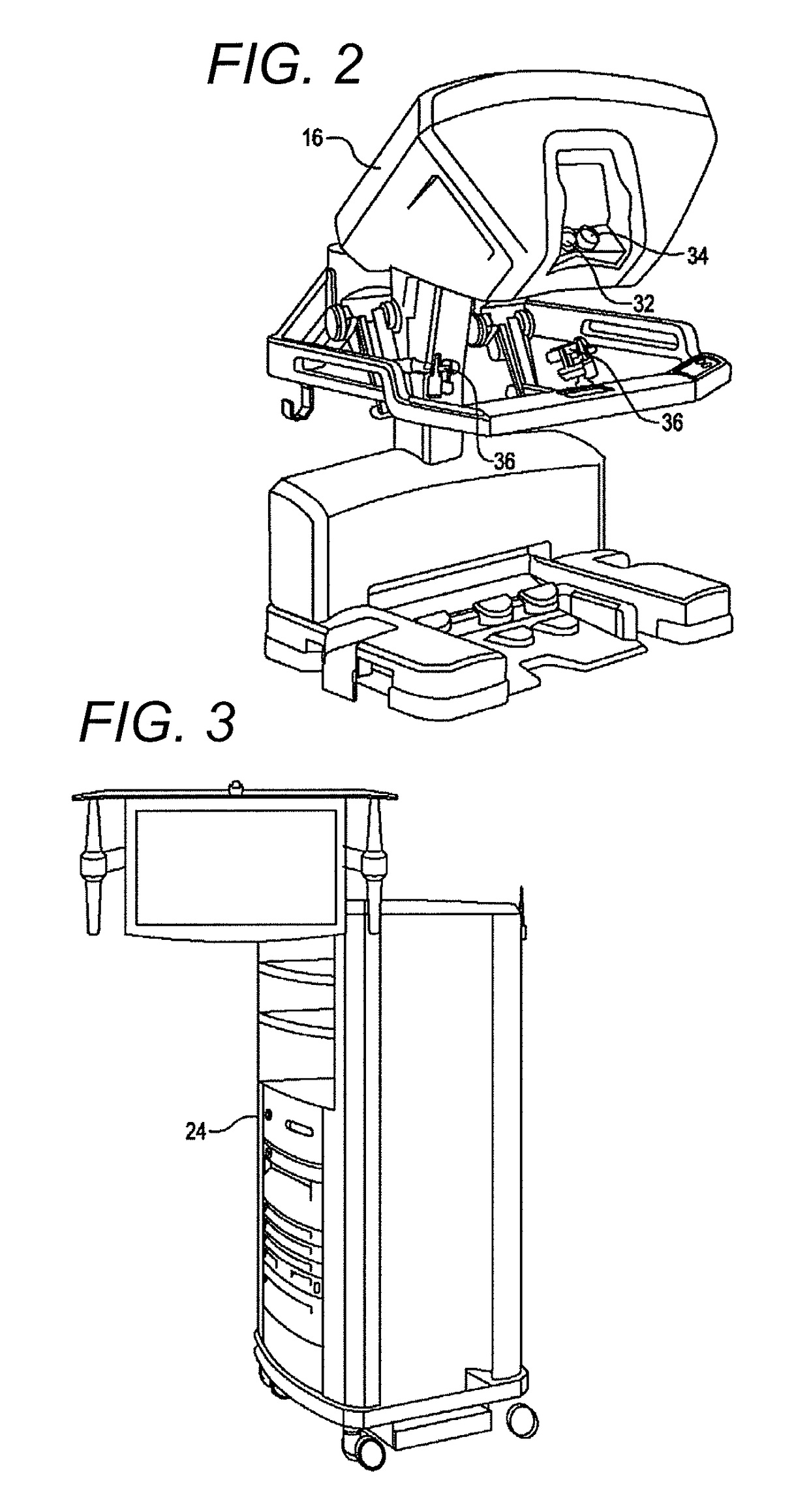

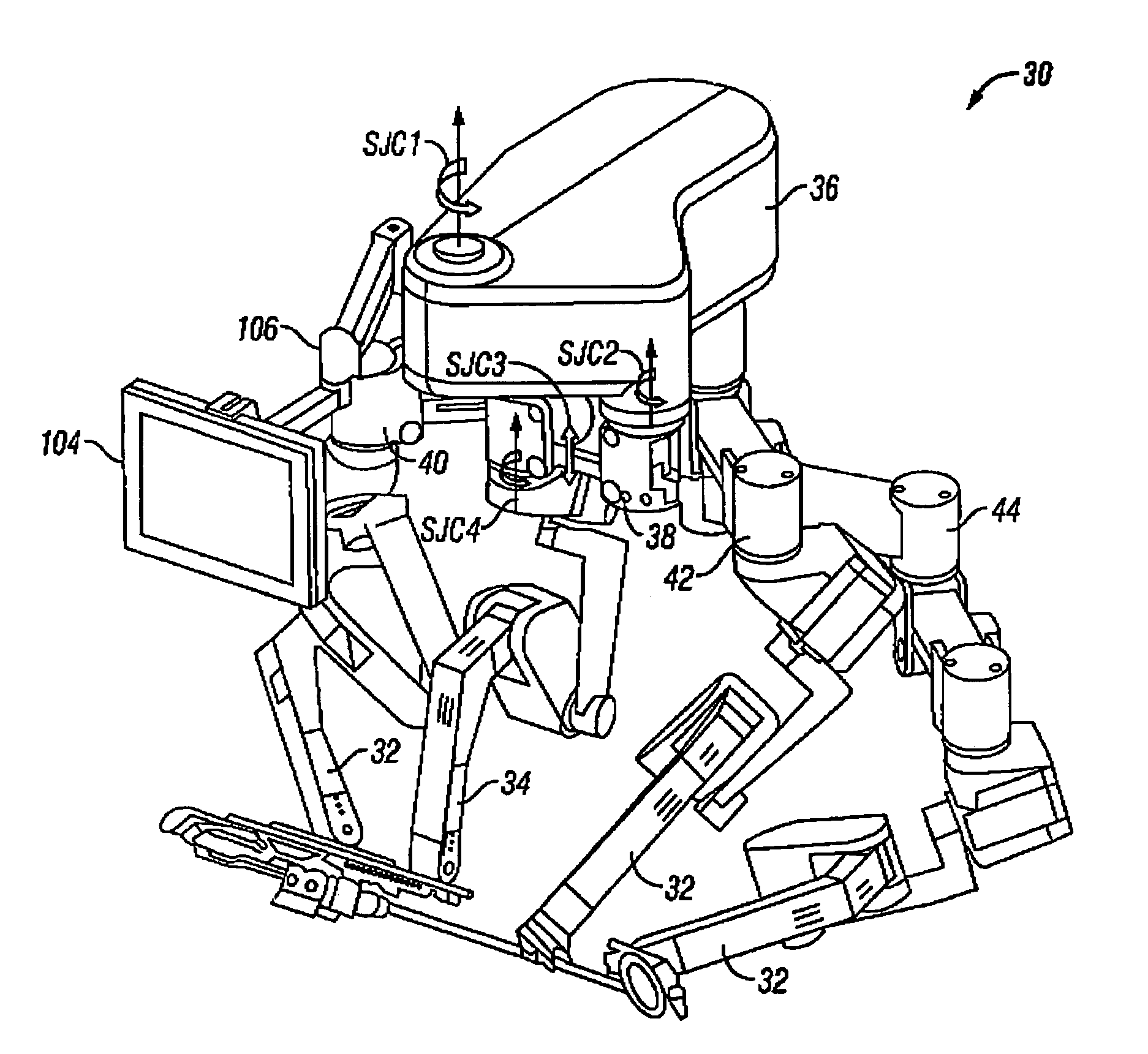

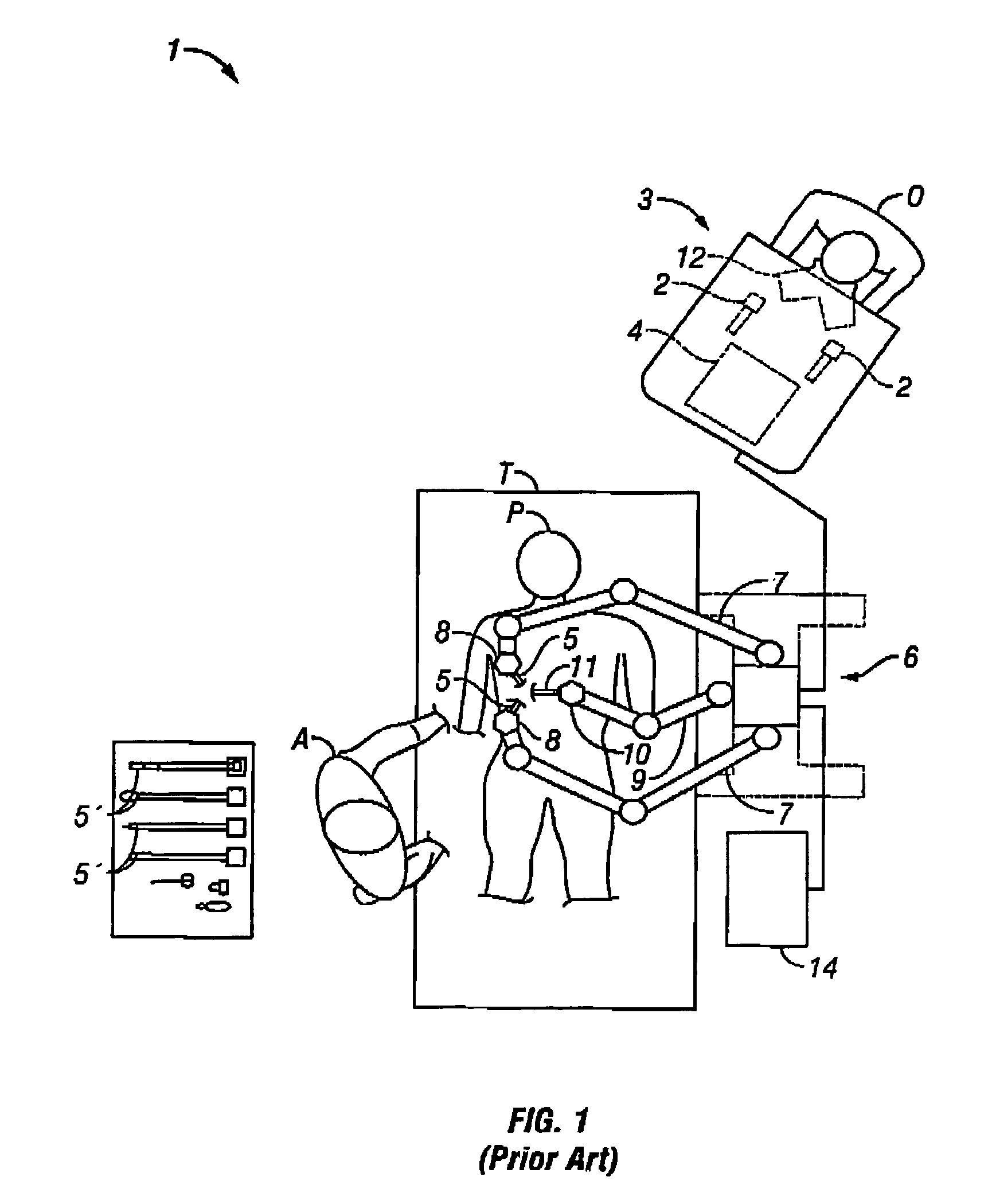

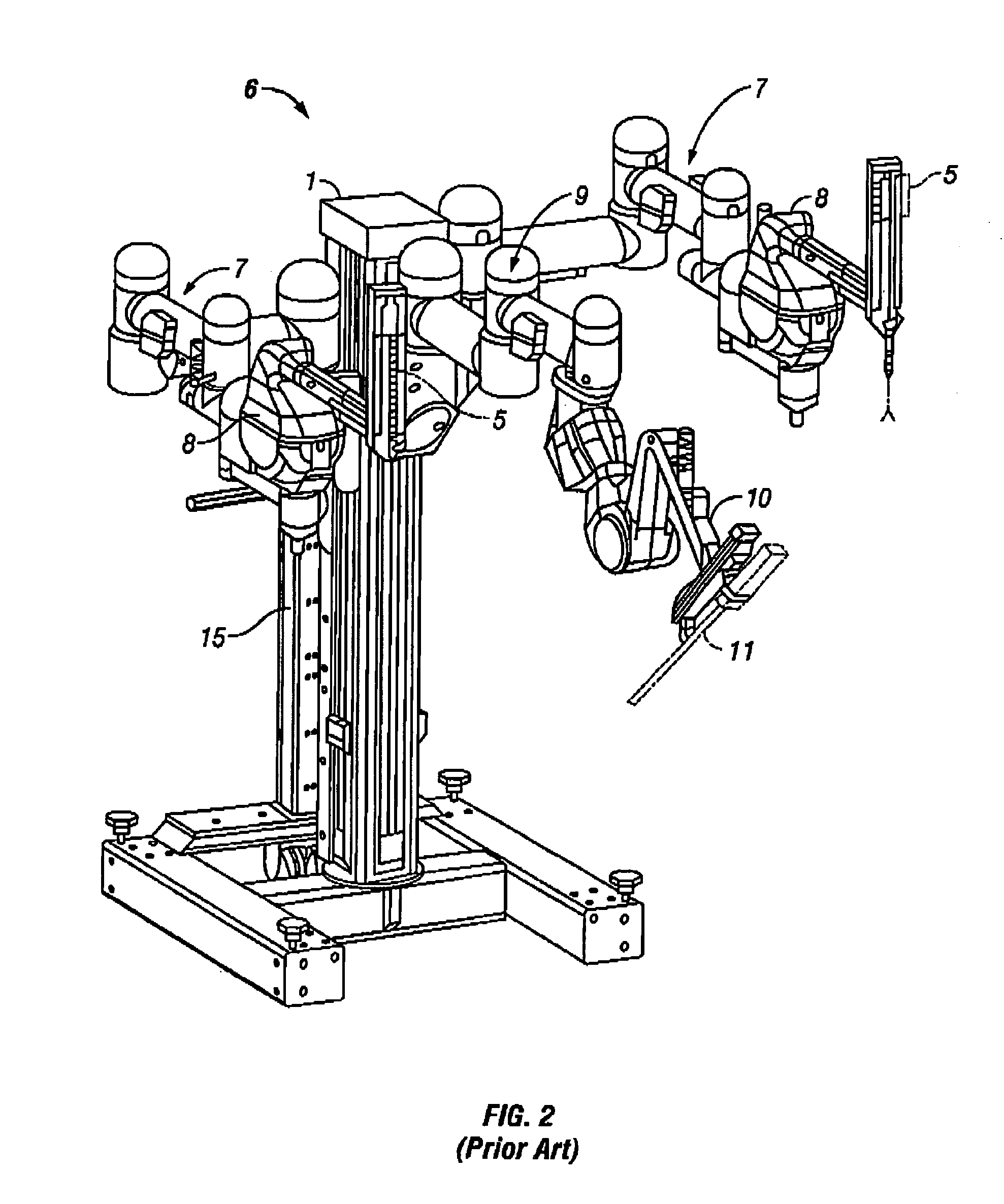

Modular manipulator support for robotic surgery

InactiveUS7763015B2Simple structureReduce complexityDiagnosticsRobotSurgical instrumentationModularity

A robotic surgery system comprises a mounting base, a plurality of surgical instruments, and an articulate support assembly. Each instrument is insertable into a patient through an associated minimally invasive aperture to a desired internal surgical site. The articulate support assembly movably supports the instruments relative to the base. The support generally comprises an orienting platform, a platform linkage movably supporting the orienting platform relative to the base, and a plurality of manipulators mounted to the orienting platform, wherein each manipulator movably supports an associated instrument.

Owner:INTUITIVE SURGICAL OPERATIONS INC

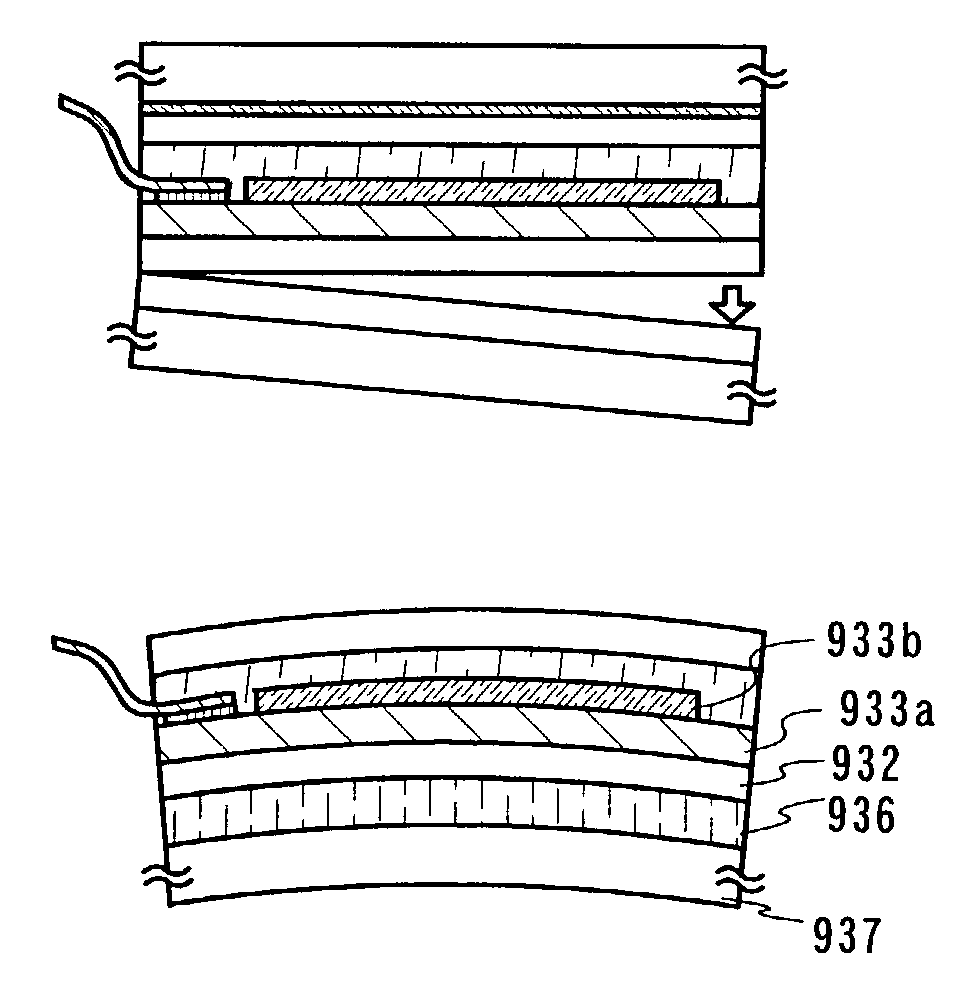

Vehicle, display device and manufacturing method for a semiconductor device

InactiveUS7335573B2Simple processBroad visionFinal product manufactureSemiconductor/solid-state device detailsDisplay deviceLight emitting device

To provide a semiconductor device in which a layer to be peeled is attached to a base having a curved surface, and a method of manufacturing the same, and more particularly, a display having a curved surface, and more specifically a light-emitting device having a light emitting element attached to a base with a curved surface. A layer to be peeled, which contains a light emitting element furnished to a substrate using a laminate of a first material layer which is a metallic layer or nitride layer, and a second material layer which is an oxide layer, is transferred onto a film, and then the film and the layer to be peeled are curved, to thereby produce a display having a curved surface.

Owner:SEMICON ENERGY LAB CO LTD

Intervertebral disc implant

ActiveUS20050197702A1Reduce the amount requiredProlong lifeBone implantLigamentsCircular discAxial compression

The invention relates to an artificial intervertebral disc for placement between adjacent vertebrae. The artificial intervertebral disc is preferably designed to restore disc height and lordosis, allow for a natural range of motion, absorb shock and provide resistance to motion and axial compression. Furthermore, the intervertebral disc may be used in the cervical, the thoracic, or the lumber regions of the spine. The artificial intervertebral disc may include either singularly or in combination: an interior at least partially filled with a fluid; a valve for injecting fluid into the interior of the disk; a central region having a stiffness that is preferably greater than the stiffness of the outer regions thus enabling the disc to pivot about the central region. The central pivot may be formed by a center opening, a central chamber, an inner core or a central cable.

Owner:SYNTHES USA

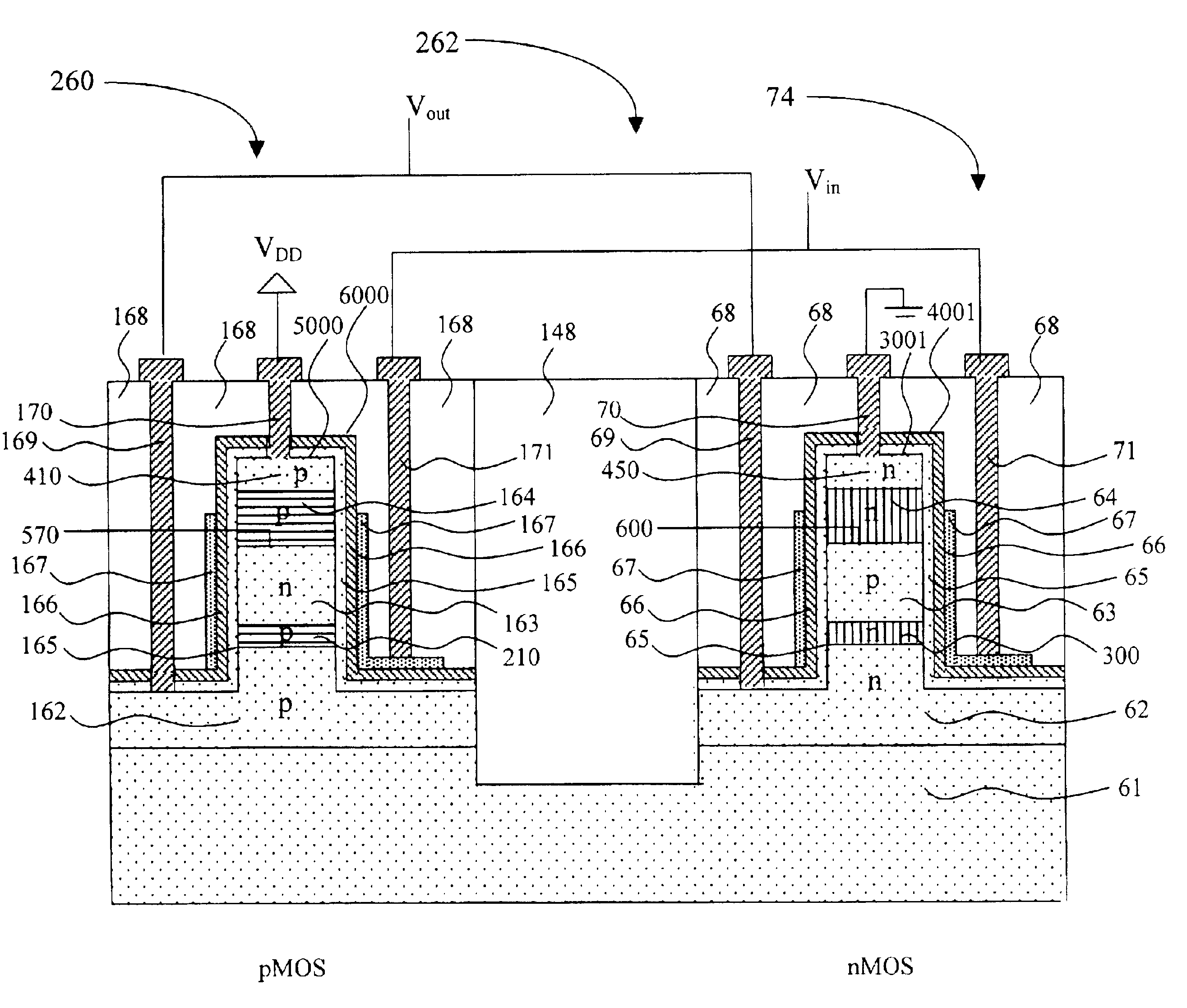

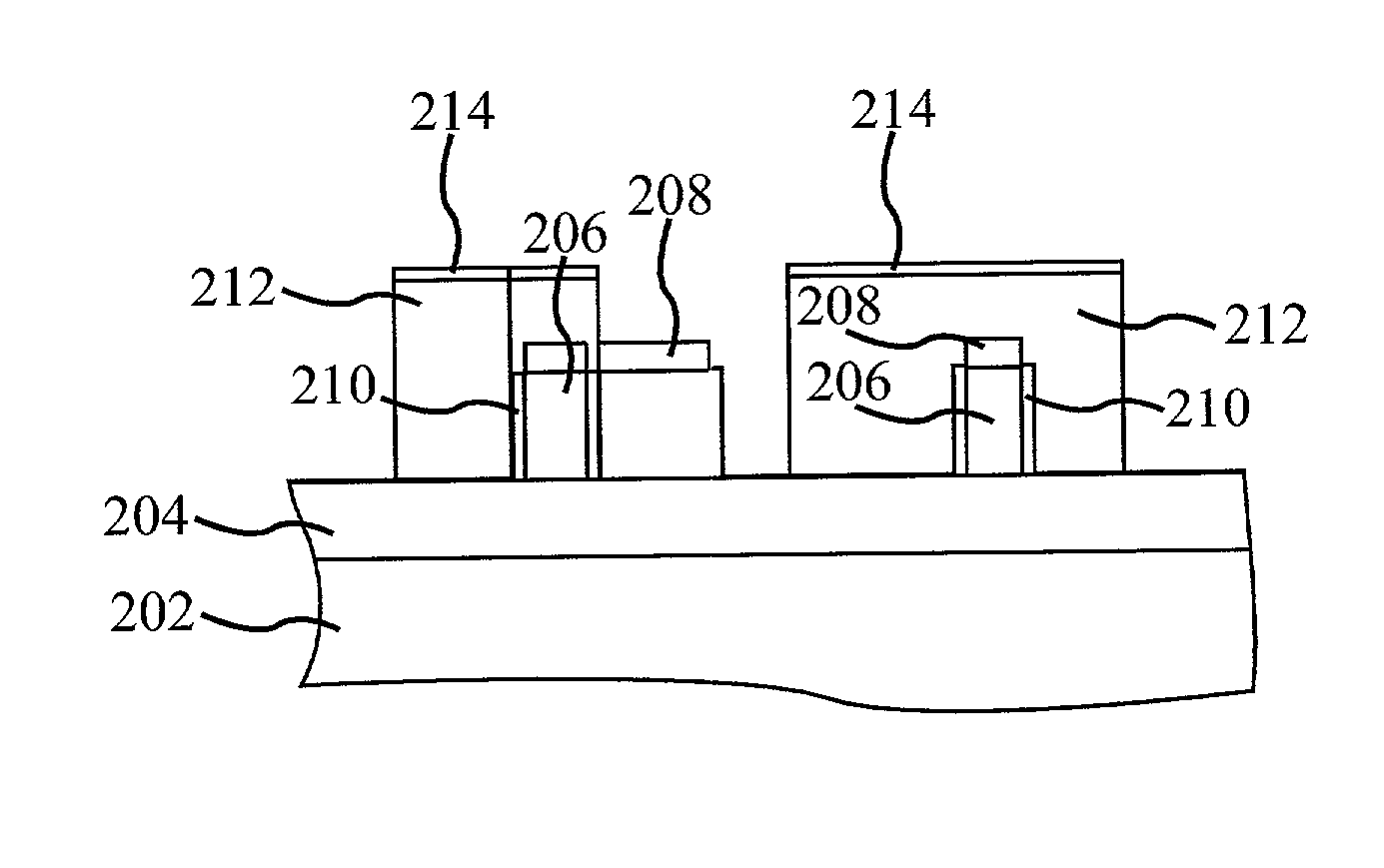

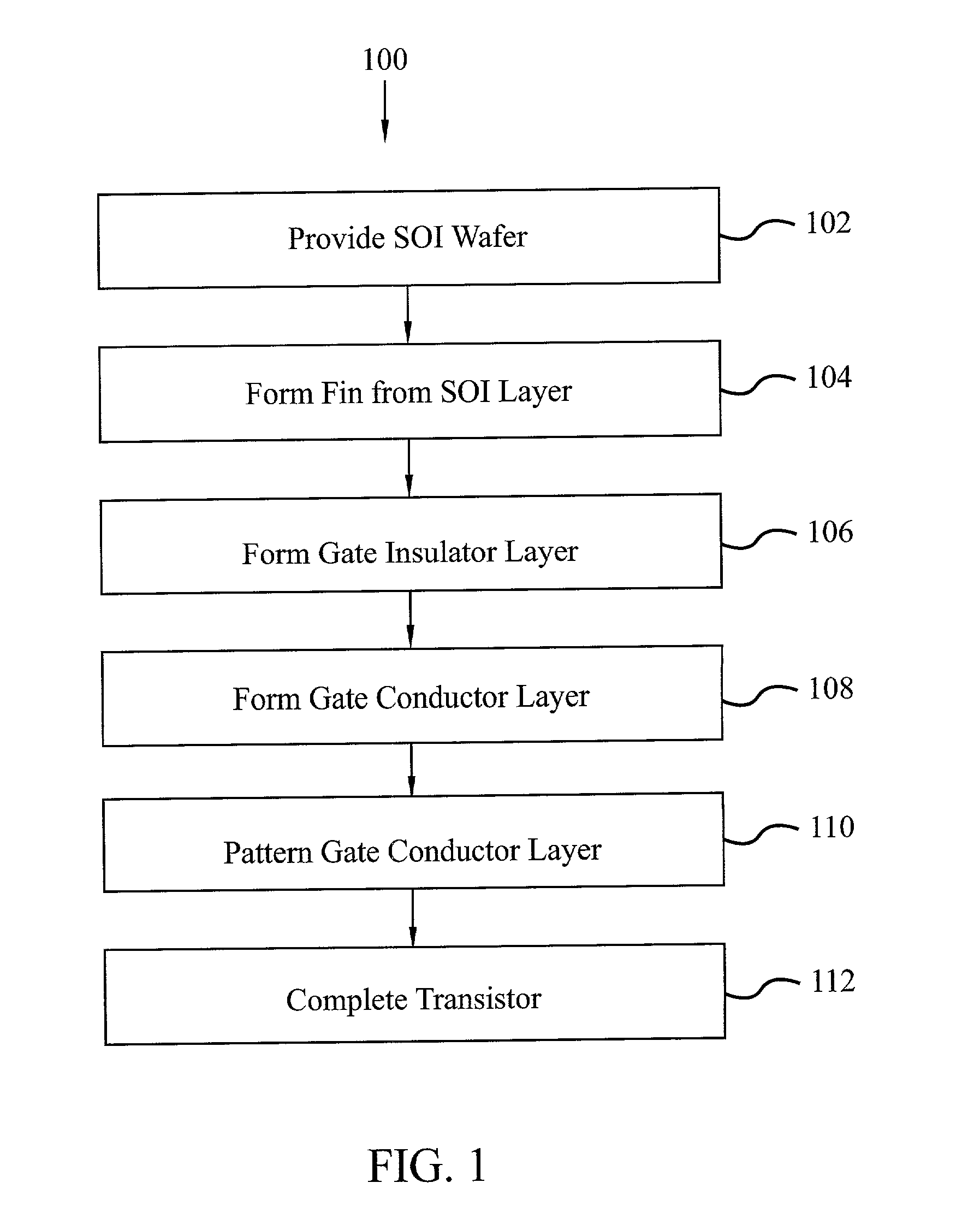

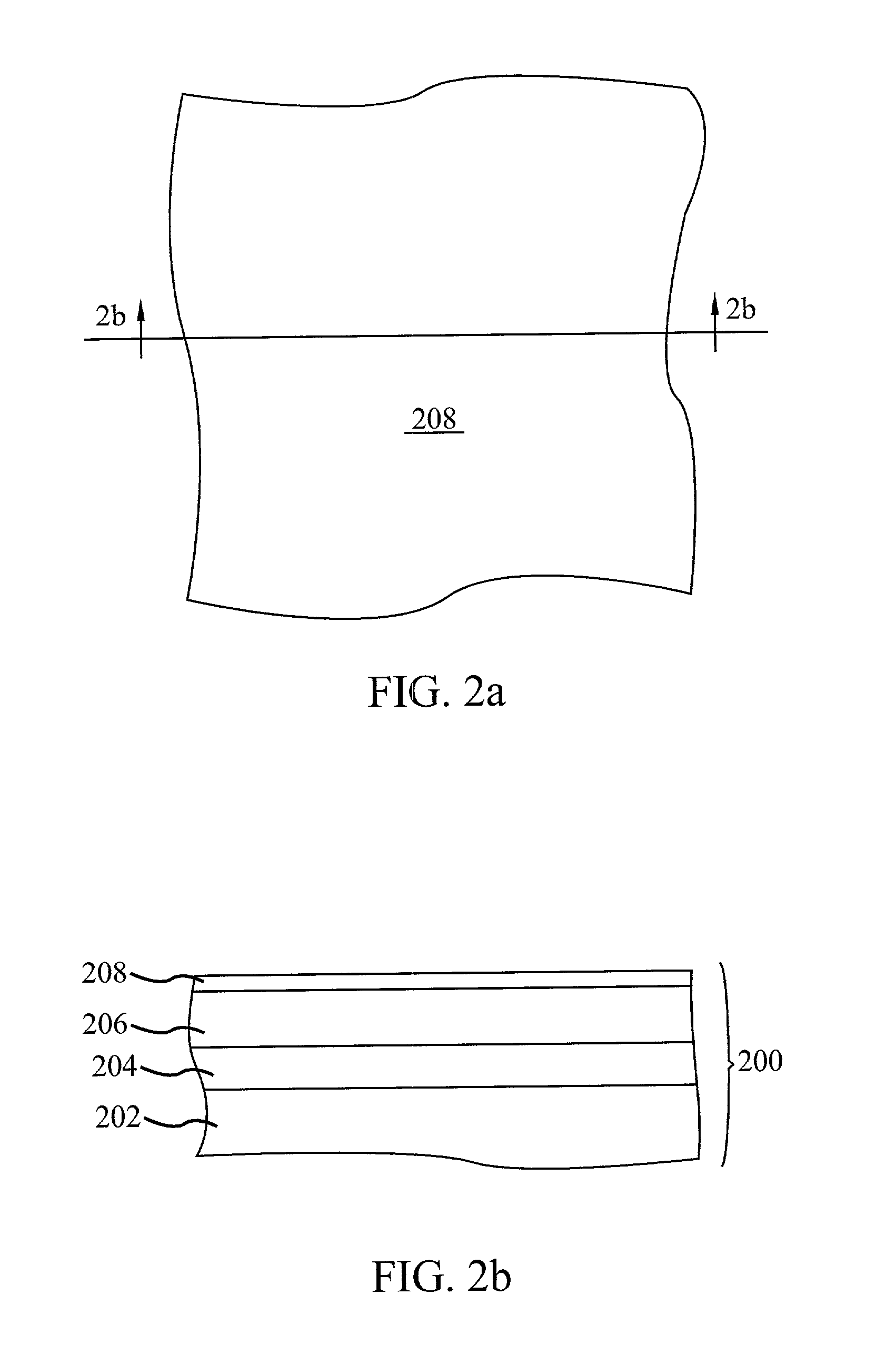

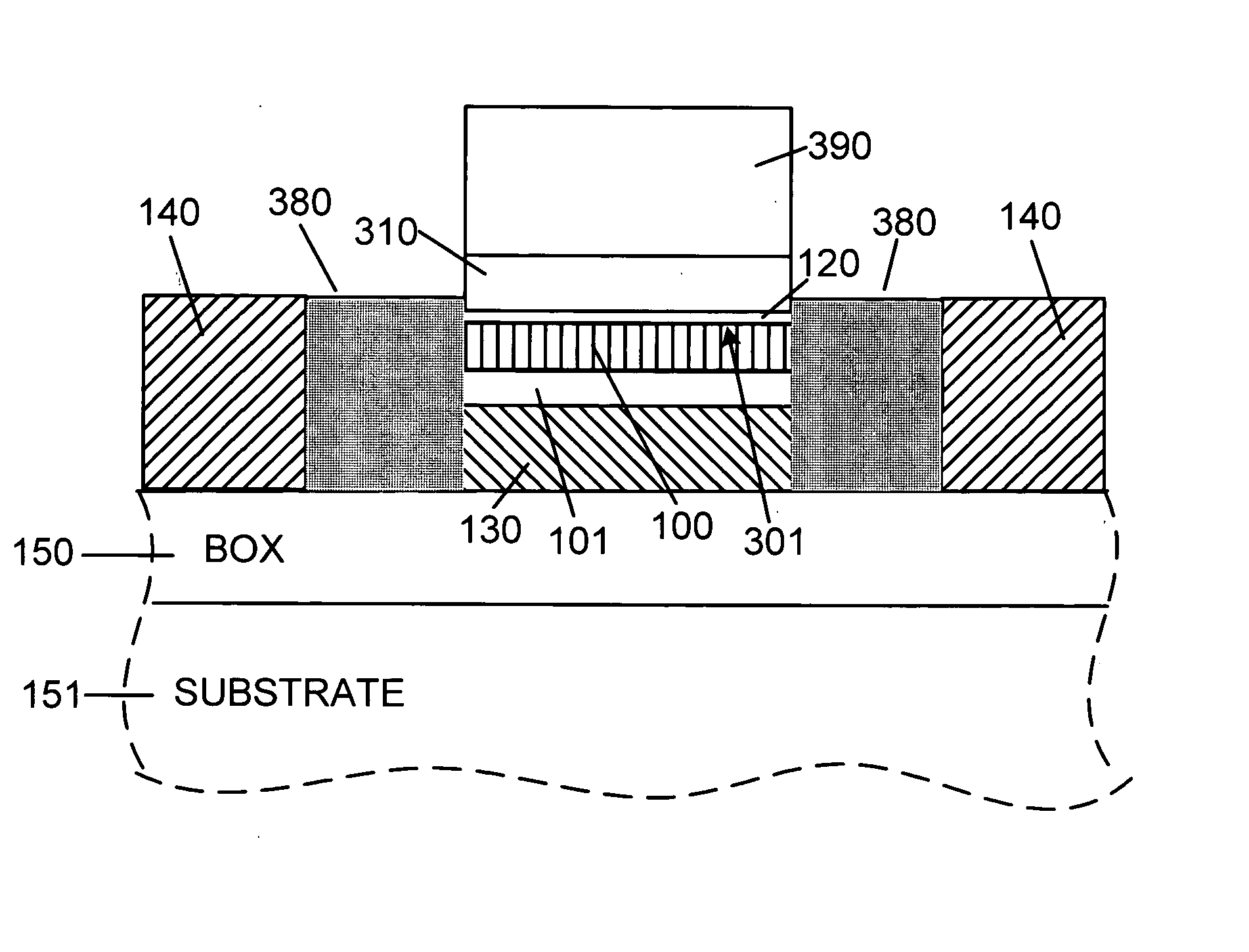

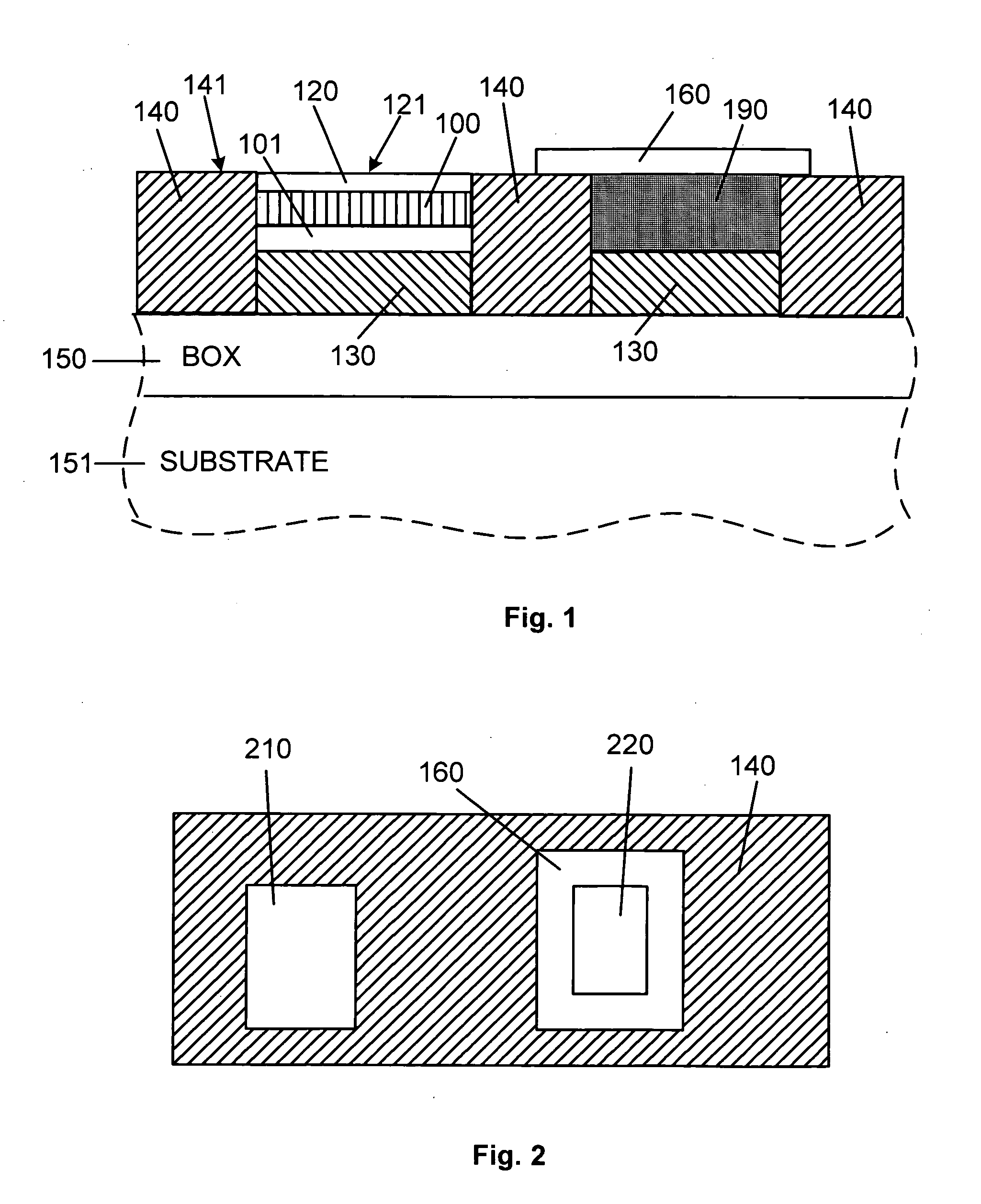

Multiple-plane finFET CMOS

InactiveUS20030102497A1Improve mobilityReduced carrier mobilityTransistorSolid-state devicesCMOSCrystal plane

The present invention provides FinFETs on the same substrate utilizing various crystal planes for FET current channels in order to optimize mobility and / or to reduce mobility. An embodiment of the present invention provides a substrate having a surface oriented on a first crystal plane that enables subsequent crystal planes for channels to be utilized. A first transistor is also provided having a first fin body. The first fin body has a sidewall forming a first channel, the sidewall oriented on a second crystal plane to provide a first carrier mobility. A second transistor is also provided having a second fin body. The second fin body has a sidewall forming a second channel, the sidewall oriented on a third crystal plane to provide a second carrier mobility that is different from the first carrier mobility.

Owner:GLOBALFOUNDRIES US INC

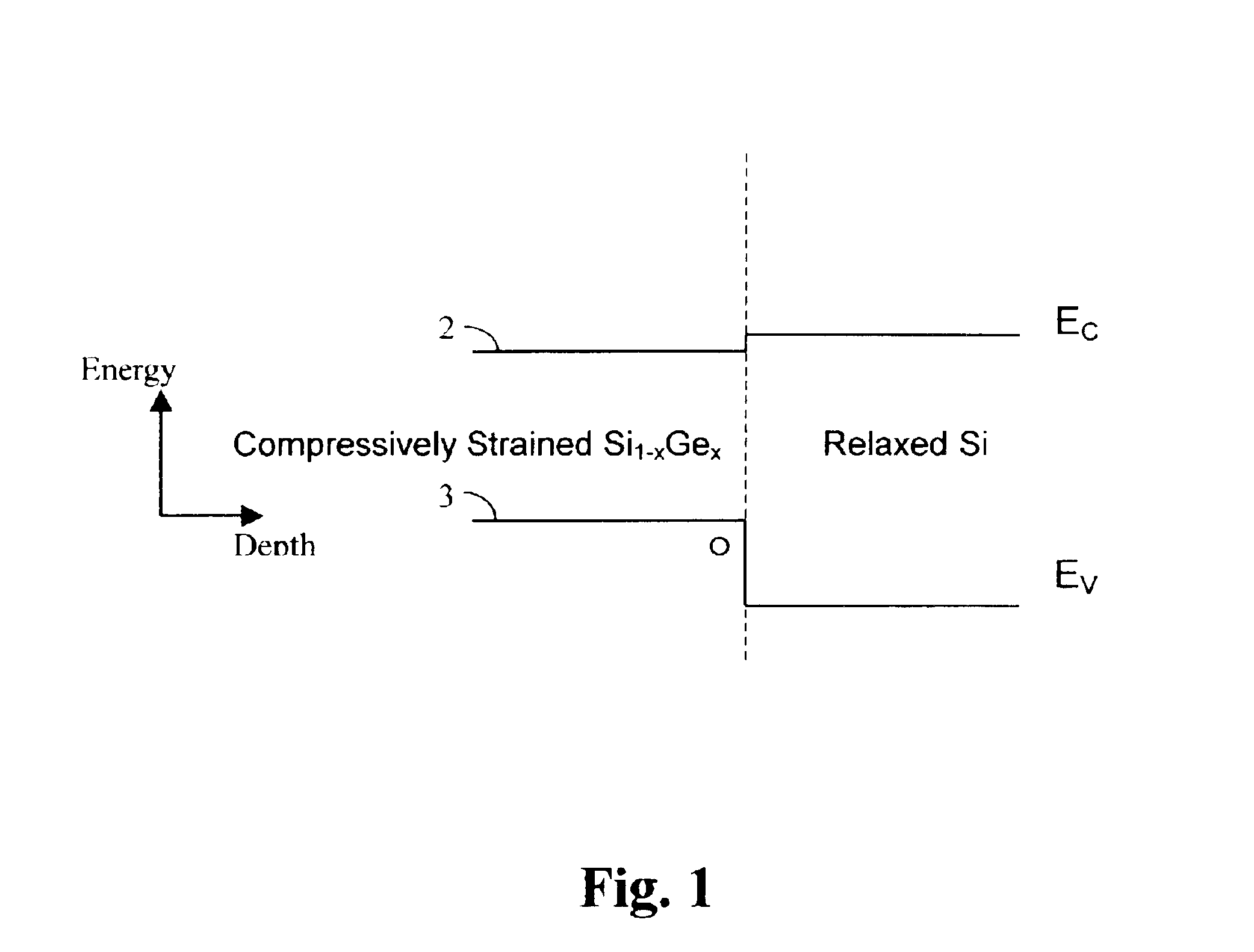

Integration of strained Ge into advanced CMOS technology

InactiveUS20050285097A1Improve mobilityImprove scalabilitySolid-state devicesSemiconductor/solid-state device manufacturingCMOSEngineering

A structure and method of fabrication for PFET devices in a compressively strained Ge layer is disclosed. The fabrication method of such devices is compatible with standard CMOS technology and it is fully scalable. The processing includes selective epitaxial depositions of an over 50% Ge content buffer layer, a pure Ge layer, and a SiGe top layer. Fabricated buried channel PMOS devices hosted in the compressively strained Ge layer show superior device characteristics relative to similar Si devices.

Owner:GLOBALFOUNDRIES INC

Metal oxynitride semiconductor containing zinc

ActiveUS8274078B2High mobility and environmental stabilityImprove mobilityPhotovoltaic energy generationSemiconductor devicesNitrogen oxideOxygen

Provided is an oxynitride semiconductor comprising a metal oxynitride. The metal oxynitride contains Zn and In and at least one element selected from the group consisting of Ga, Sn, Mg, Si, Ge, Y, Ti, Mo, W, and Al. The metal oxynitride has an atomic composition ratio of N, N / (N+O), of 7 atomic percent or more to 80 atomic percent or less.

Owner:CANON KK

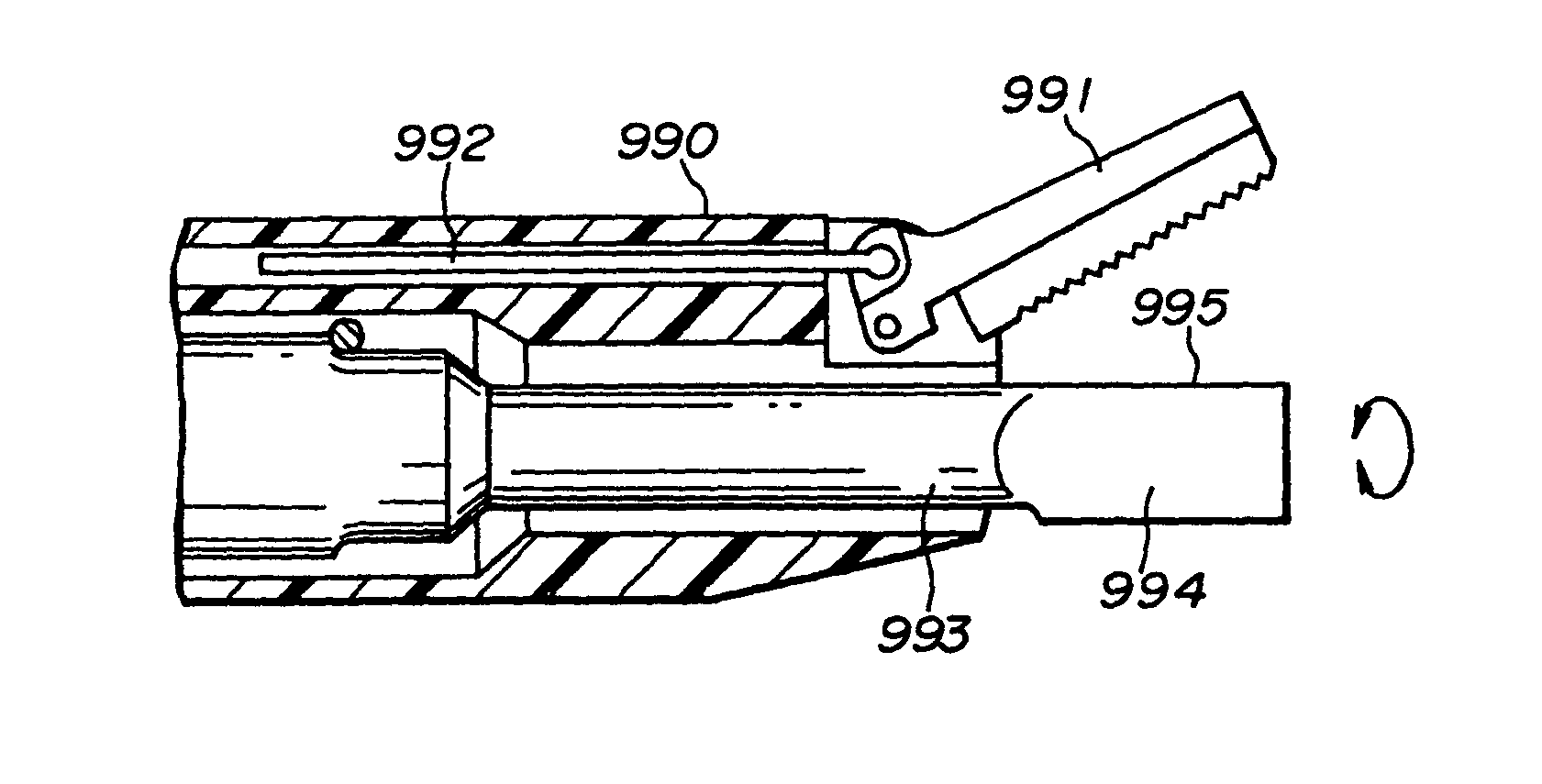

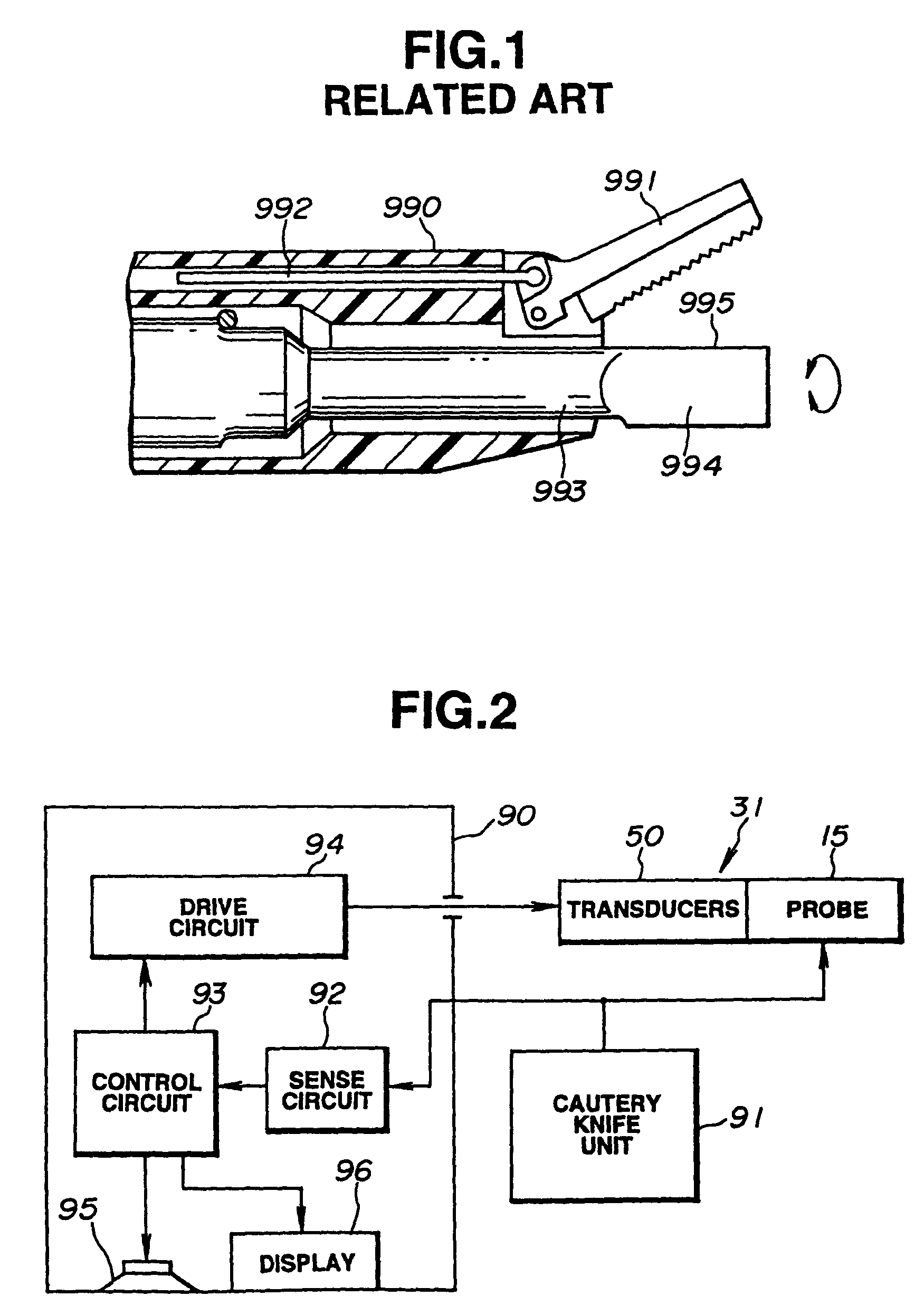

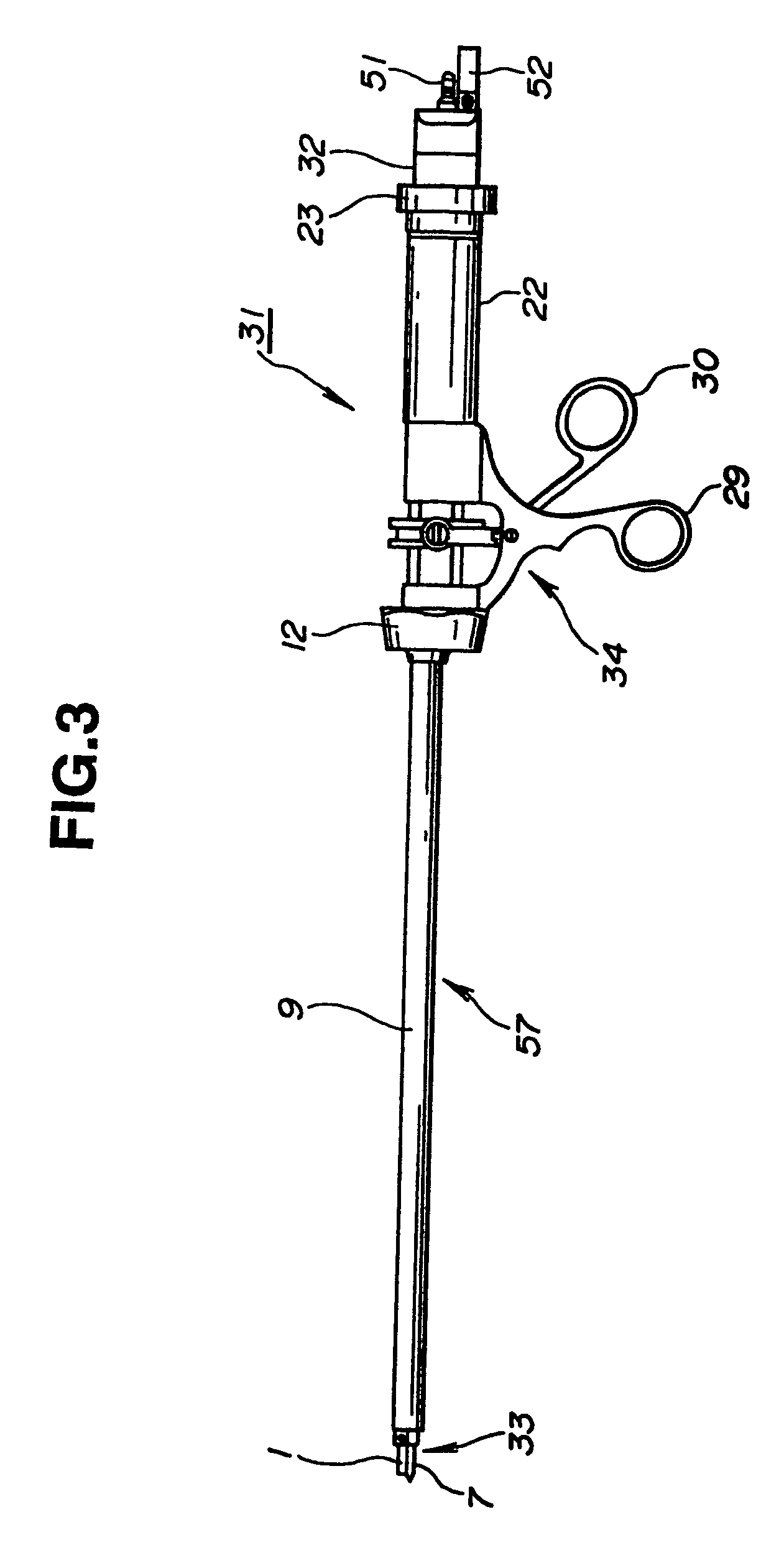

Ultrasound treatment system

InactiveUS7780659B2Improve mobilityShorten the timeSurgical instruments for heatingArtificial legsUltrasonic vibrationPerfusion

An ultrasound treatment system in accordance with the present invention comprises an ultrasonic transducer, a handpiece, a probe, a sheath, a clamping member, an operation unit, an operating member, a suction base, and a perfusion base. The ultrasonic transducer generates ultrasonic vibrations. The handpiece has the ultrasonic transducer incorporated therein and serves as an operation unit. The probe is connected to the ultrasonic transducer, and serves as a vibration transmitting member for transmitting ultrasonic vibrations to a distal member realizing a stationary portion that is a treatment portion for treating a living tissue. The sheath serves as a protecting member for shielding the probe. The clamping member is opposed to the distal member at the distal end of the sheath, and realizes a movable portion that is another treatment portion for clamping a living tissue in cooperation with the distal member. The operation unit is manipulated for clamping a living tissue with the clamping member and distal member or freeing the living tissue therefrom.

Owner:OLYMPUS CORP

Indwelling catheter

InactiveUS7008404B2Facilitate communicationImprove mobilityInfusion syringesCatheterIndwelling catheterCatheter device

An indwelling catheter has a hollow catheter body, a catheter tube fitted to a front end of the catheter body, an elastic valve fitted inside the catheter body, and a hollow plug slidably fitted inside the catheter body. The catheter tube, the elastic valve, and the plug are aligned in this order. A connector inserted from a proximal end of the catheter pushes the plug, and the plug presses the elastic valve open.

Owner:MEDIKIT CO LTD

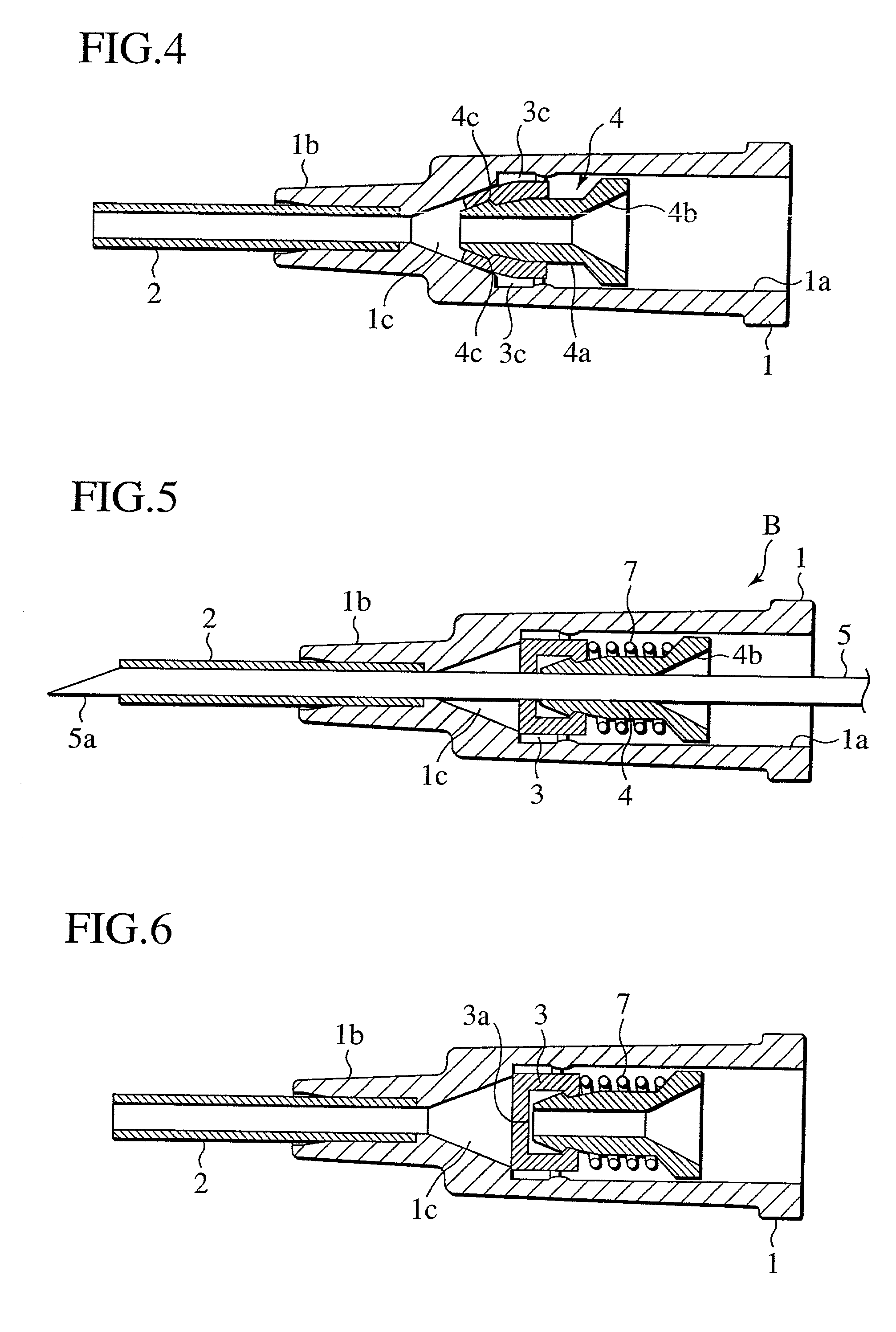

System and method for transmission of medical and like data from a patient to a dedicated internet website

InactiveUS7082334B2Improve mobilitySafe interconnectionElectrotherapyArtificial respirationWeb siteImplanted pacemaker

The invention provides a system and method for easy and reliable connection of patient-originated medical data through a simple port of a computer to a dedicated web site. A device originating medical data, such as an implanted pacemaker, downloads data into a transmit / receive device, and the data is then transformed in an interface unit to be accepted by a simple port of a computer, e.g. a keyboard port or a mouse port. The patient logs on to a dedicated web site, and transfers the data along with typed input to the web site for analysis. Following analysis, a reply message is sent back to the patient, which may include a control instruction for modifying or reprogramming the operation of the device that is used to originate the medical data. For a pacemaker application, the data transformation is done at a simple interface unit that is portable and easily manipulated by the patient. For other applications such as monitoring data from a diabetic, the data is transformed by the interface unit, and may be stored daily in the PC and transmitted to the web site after collection of a predetermined number of days of data.

Owner:MEDTRONIC INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com