Patents

Literature

306results about How to "Controlled heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

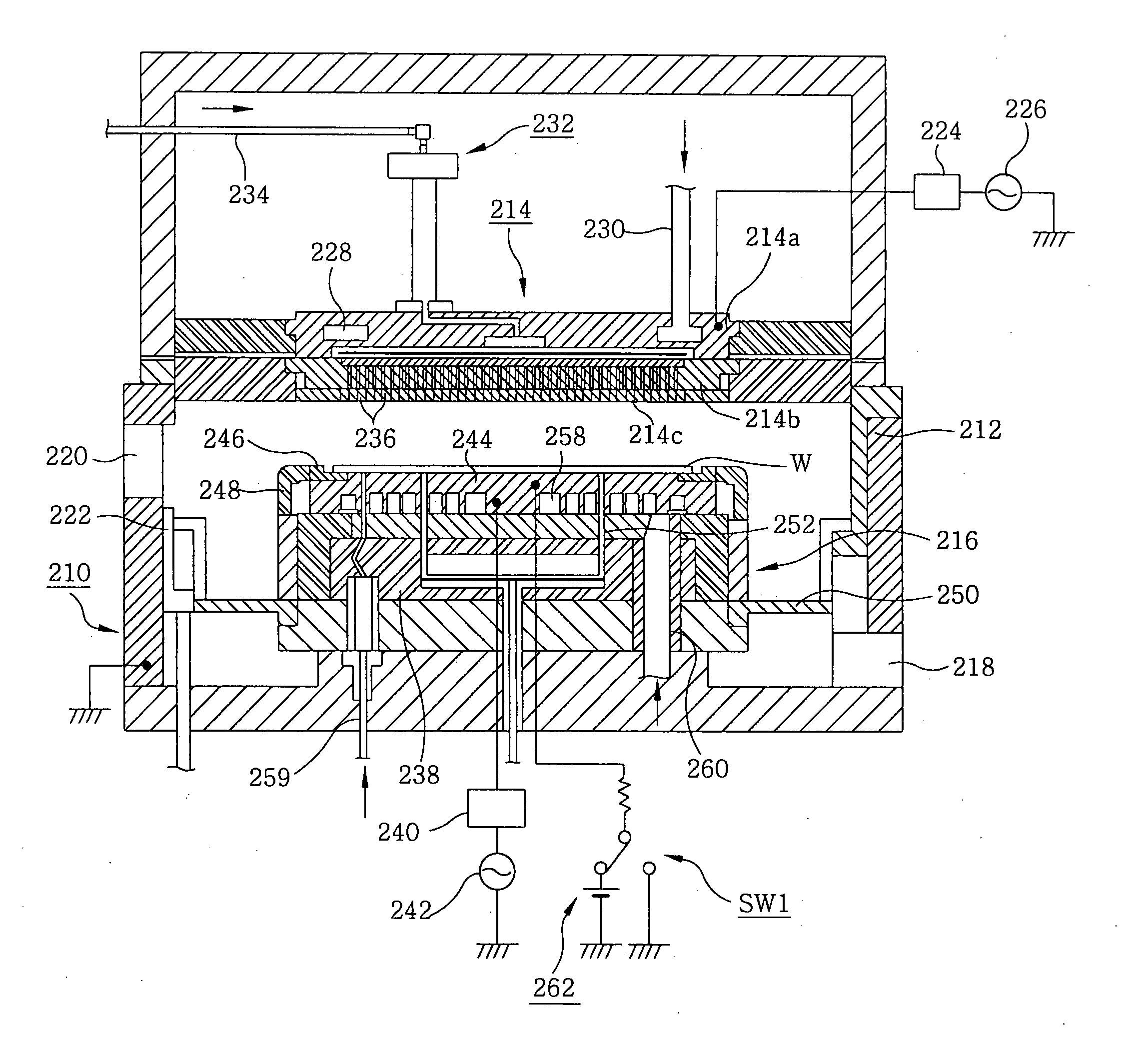

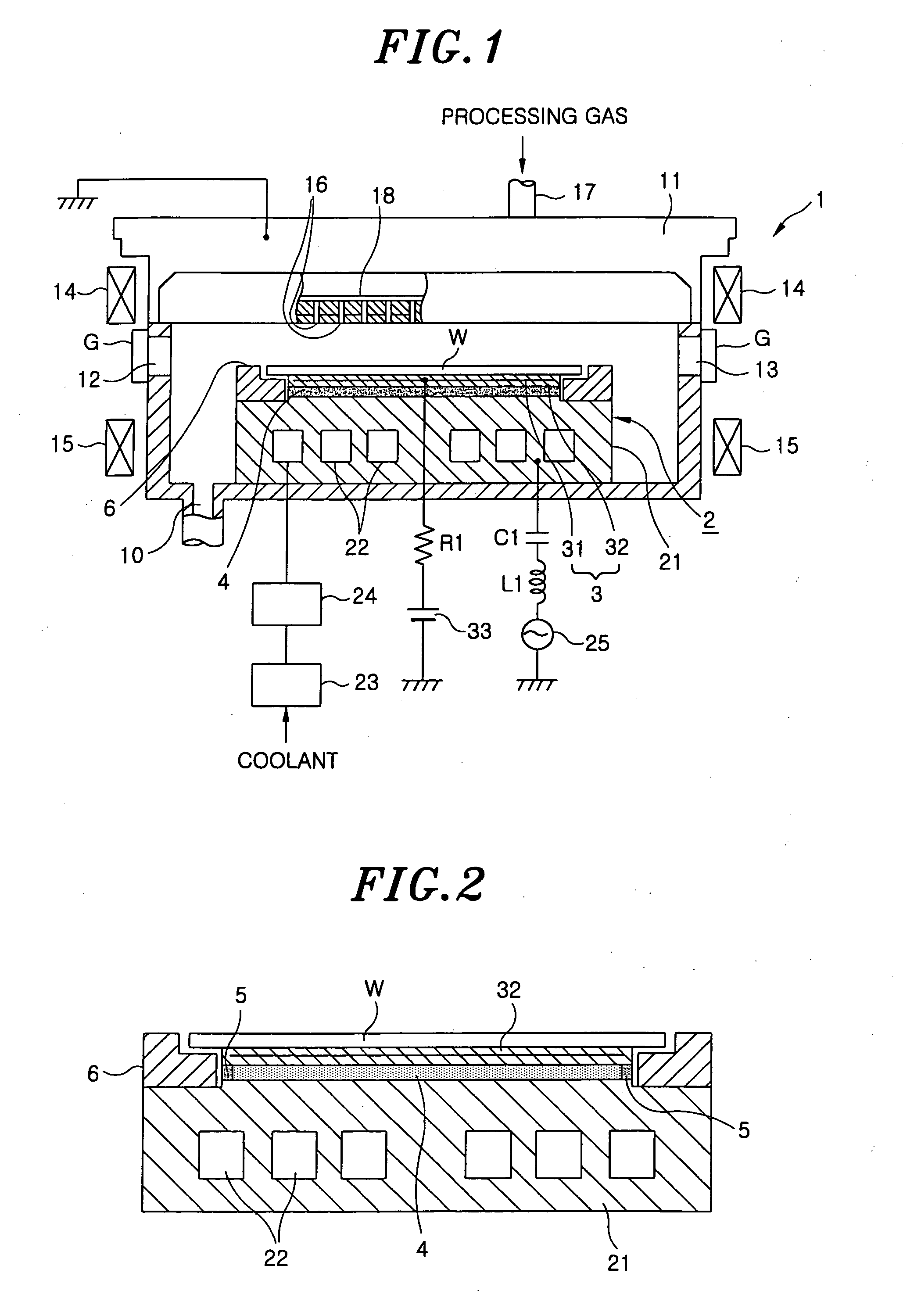

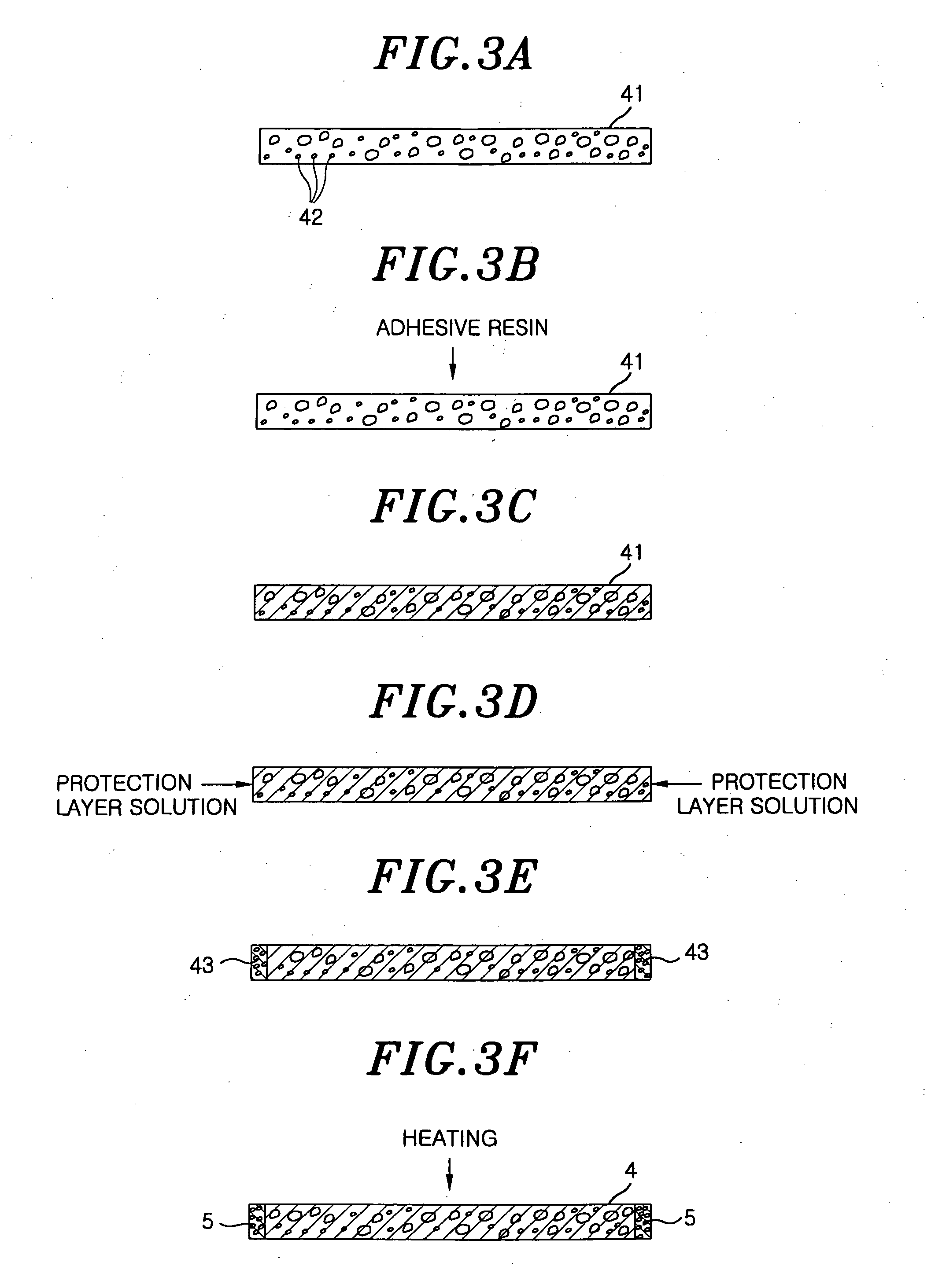

Processing apparatus

InactiveUS20050042881A1Improve thermal conductivityShorten the timeSemiconductor/solid-state device manufacturingThermal conductivityTungsten

The time period during which a wafer is stabilized to a predetermined temperature by increasing a thermal conductivity of a junction layer for bonding an electrostatic chuck layer and a support together, and the deterioration of the junction layer that is caused by active species generated by plasma is suppressed. Between the electrostatic chuck layer formed by sintering together a chuck electrode made of tungsten and an insulating layer made of alumina and the support, made of aluminum, for supporting the electrostatic chuck layer, the junction layer is provided to bond the electrostatic chuck layer and the support together. The junction layer is formed by impregnating a porous ceramic with a silicone-based adhesive resin. Further, rubber or a heat shrink tube made of a fluoric resin such as PFA is provided as a soft coating member so as to coat a side circumferential surface of the junction layer and the side circumferential surfaces of the electrostatic chuck layer and the support come into a tight contact with the heat shrink tube or rubber.

Owner:TOKYO ELECTRON LTD

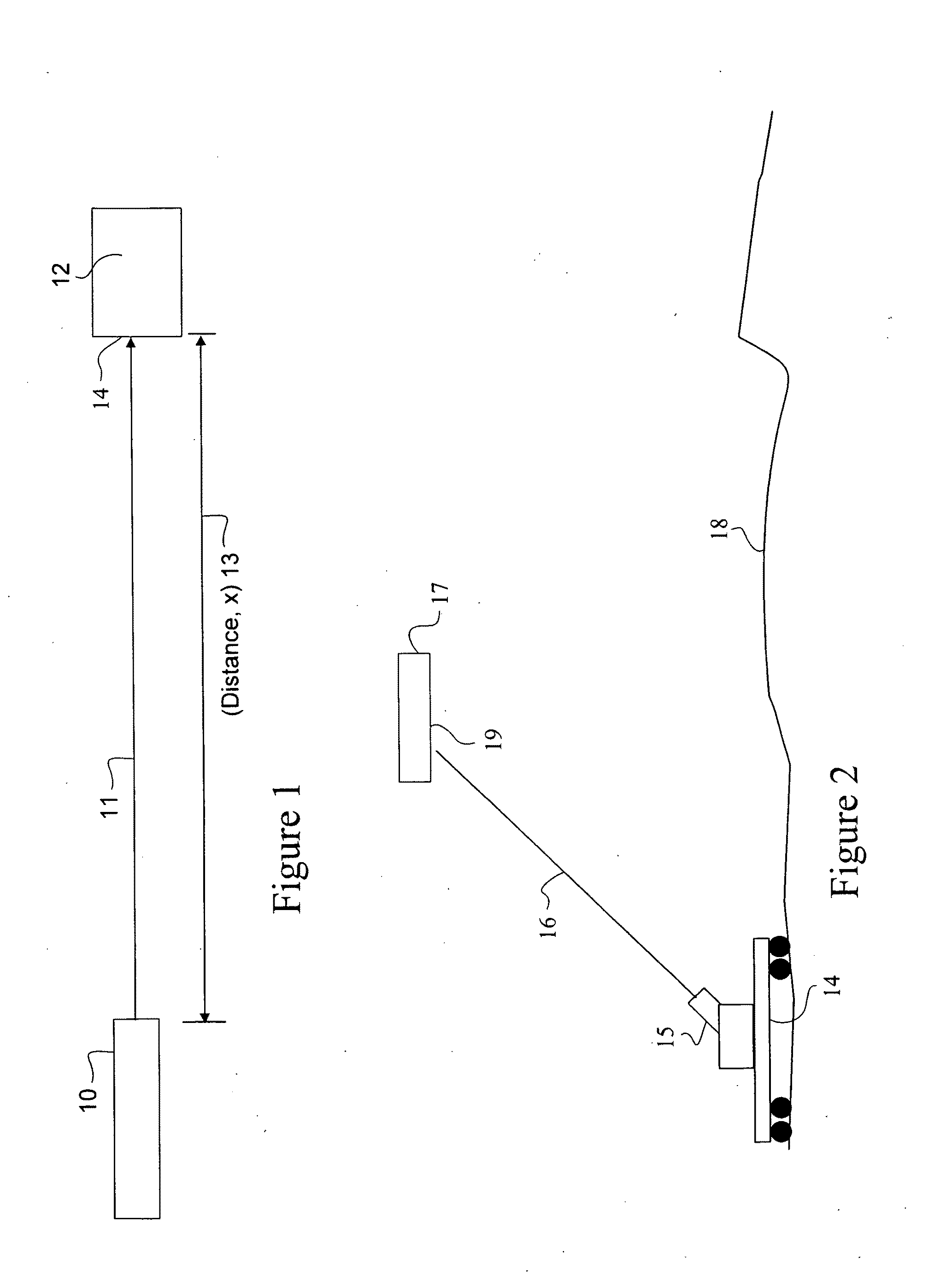

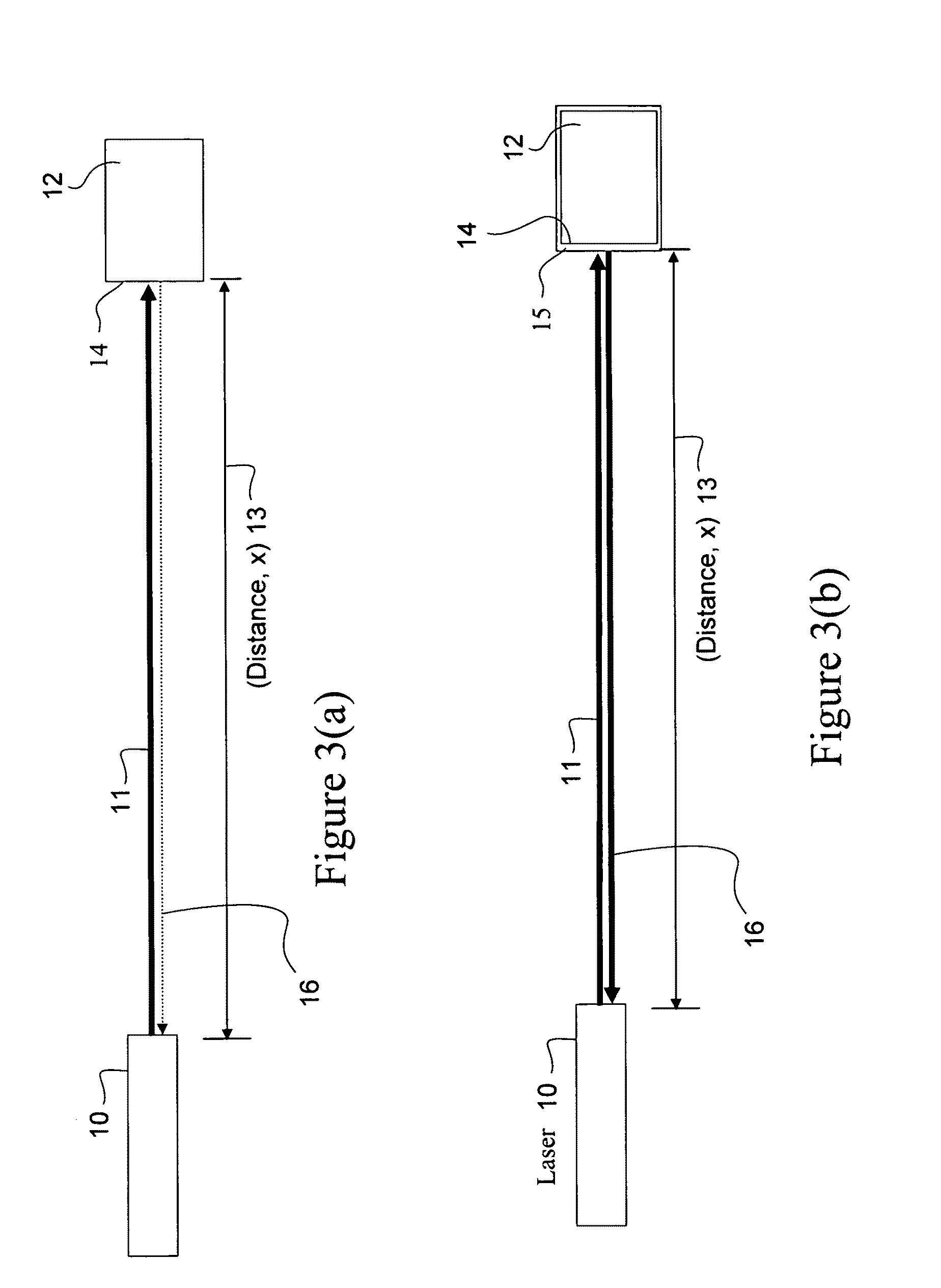

Microbial decontamination of food

InactiveUS6165526AShorten treatment timeEliminate areaMilk preparationDough treatmentMicroorganismEngineering

PCT No. PCT / GB98 / 02840 Sec. 371 Date Jul. 14, 1999 Sec. 102(e) Date Jul. 14, 1999 PCT Filed Sep. 18, 1998 PCT Pub. No. WO99 / 13741 PCT Pub. Date Mar. 25, 1999Food is rendered sterile by UV irradiation, preferably with UV at 265+ / -15 nm. A sterilization unit may include UV sources (90, 100, 110, 120) and a heat source, which may be a broad band UV source, a source of IR or microwave radiation. A combined microwave / UV unit can be used to defrost frozen food and simultaneously sterilize it or maintain sterility. Heating prior to UV irradiation can enhance the sterilization, as can rapid cooling after irradiation. Irradiation can also be enhanced by displacing the food during irradiation e.g. by supporting it on a rotatable support (135) and / or by displacing it relative to the support surface.

Owner:NEWMAN PAUL BERNARD

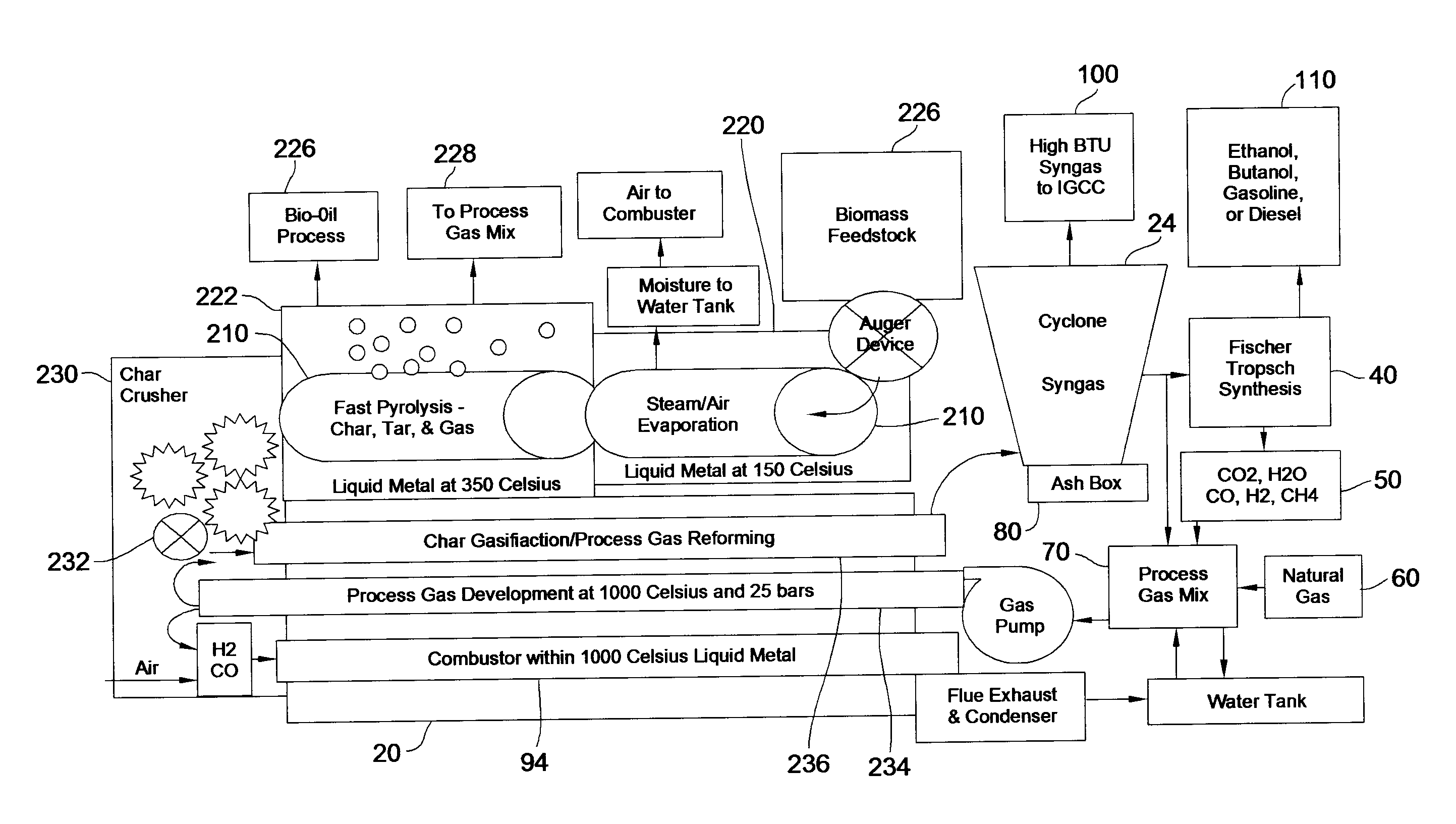

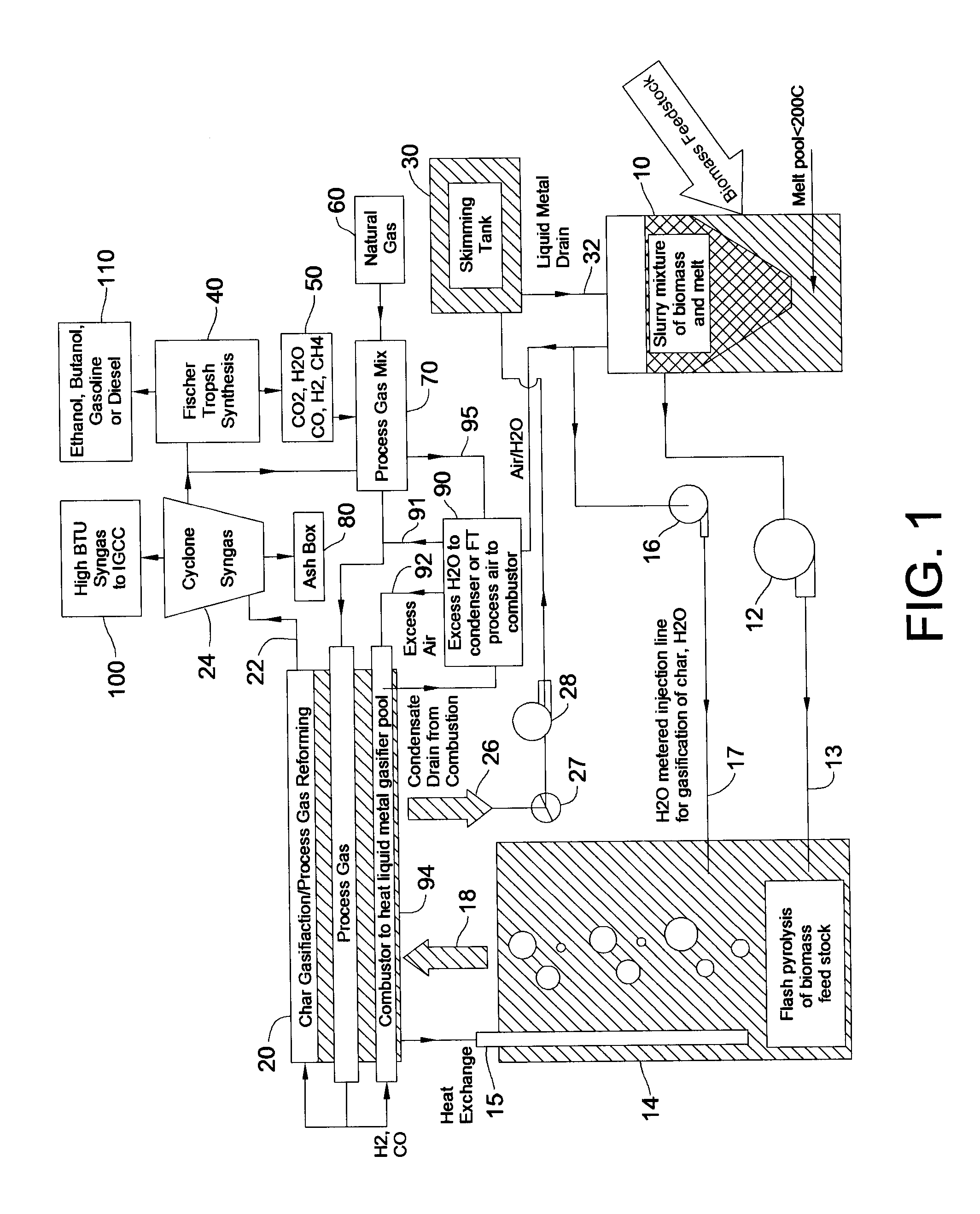

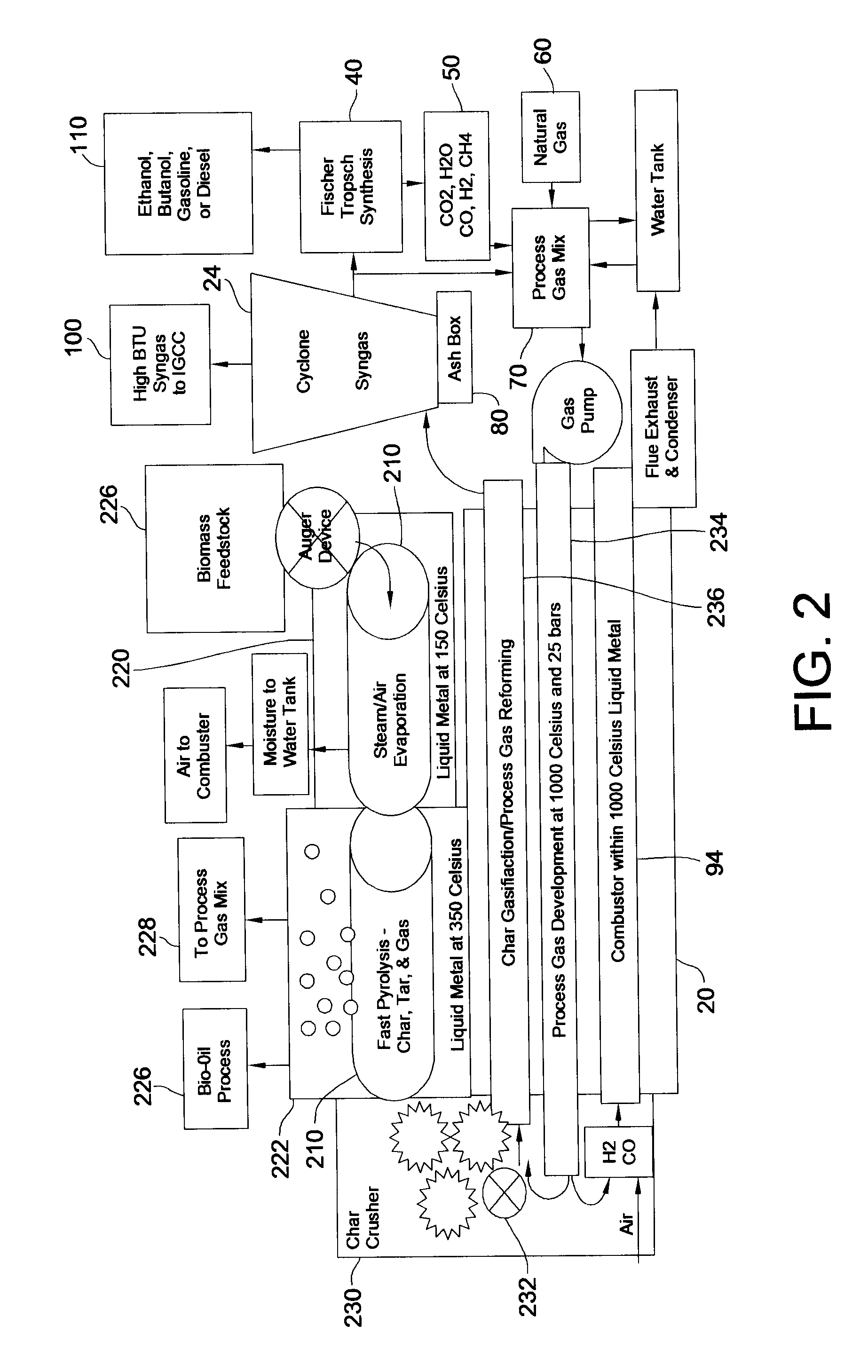

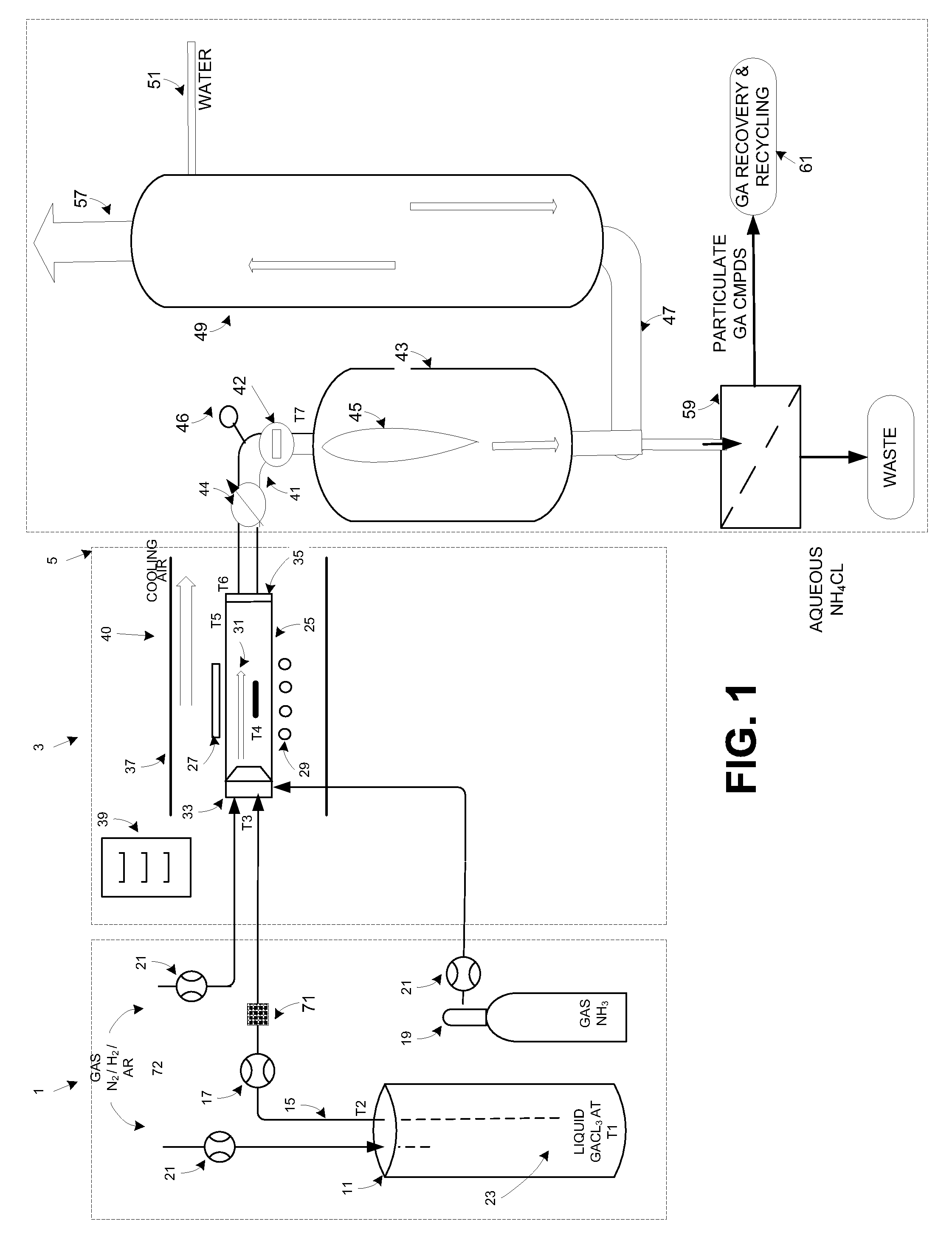

Method and apparatus to protect synthesis gas via flash pyrolysis and gasification in a molten liquid

InactiveUS20080307703A1Improve efficiencyLittle heating lossWaste based fuelRetortsSyngasThermodynamics

Disclosed are a method and a corresponding apparatus for converting a biomass reactant into synthesis gas. The method includes the steps of (1) heating biomass in a first molten liquid bath at a first temperature, wherein the first temperature is at least about 100° C., but less than the decomposition temperature of the biomass, wherein gas comprising water is evaporated and air is pressed from the biomass, thereby yielding dried biomass with minimal air content. (2) Recapturing the moisture evaporated from the biomass in step 1 for use in the process gas. (3) Heating the dried biomass in a second molten liquid bath at a second temperature, wherein the second temperature is sufficiently high to cause flash pyrolysis of the dried biomass, thereby yielding product gases, tar, and char. (4) Inserting recaptured steam into the process gas, which may optionally include external natural gas or hydrogen gas or recycled syngas for mixing and reforming with tar and non-condensable gases. (5) Further reacting the product gases, tar, and char with the process gas within a third molten liquid bath at a third temperature which is equal to or greater than the second temperature within the second molten liquid bath, thereby yielding high quality and relatively clean synthesis gas after a relatively long residence time needed for char gasification. A portion of the synthesis gas so formed is combusted to heat the first, second, and third molten liquid baths, unless external natural or hydrogen gas is available for this use.

Owner:US SEC AGRI +1

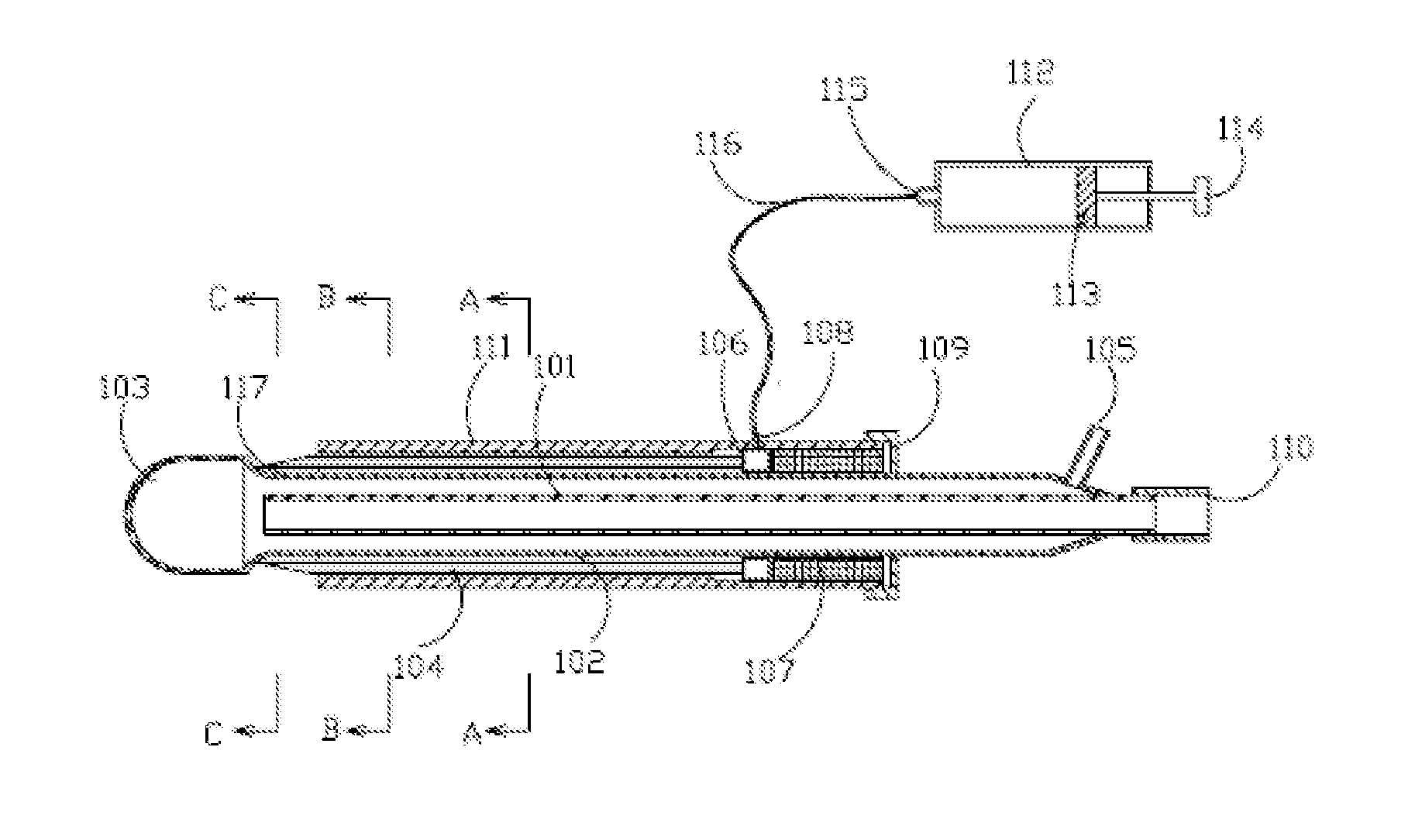

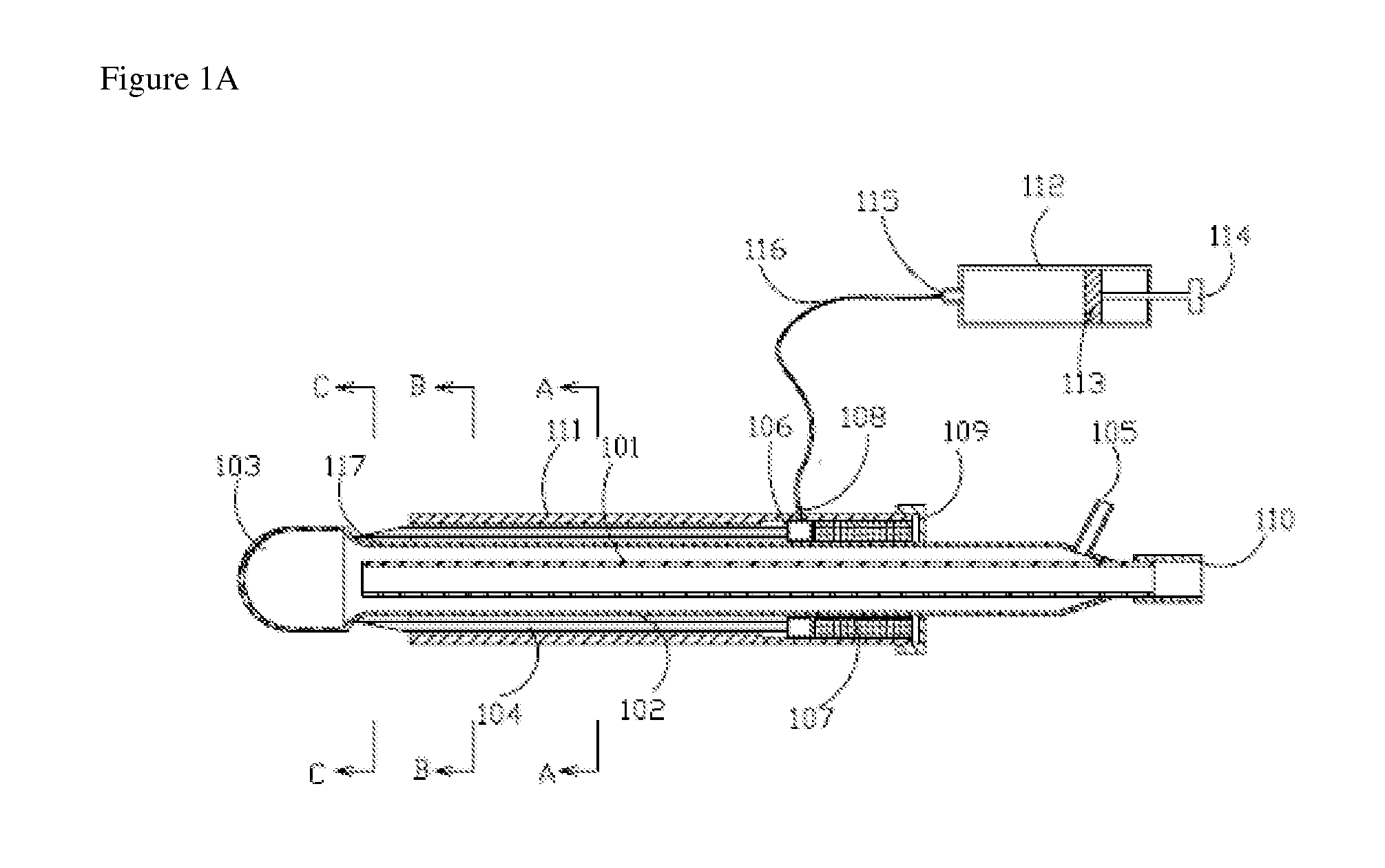

Method And Device For Combined Treatment

InactiveUS20080140061A1Efficient deliveryShort timeInfusion needlesSurgical instruments for coolingActive agentCryogenic treatment

A cryoprobe supports administration of an active agent to a location of cryogenic treatment. The cryoprobe may optionally be combined with a syringe to form a cryoprobe system; alternatively and optionally, the syringe may be external to the cryoprobe.

Owner:ICECURE MEDICAL

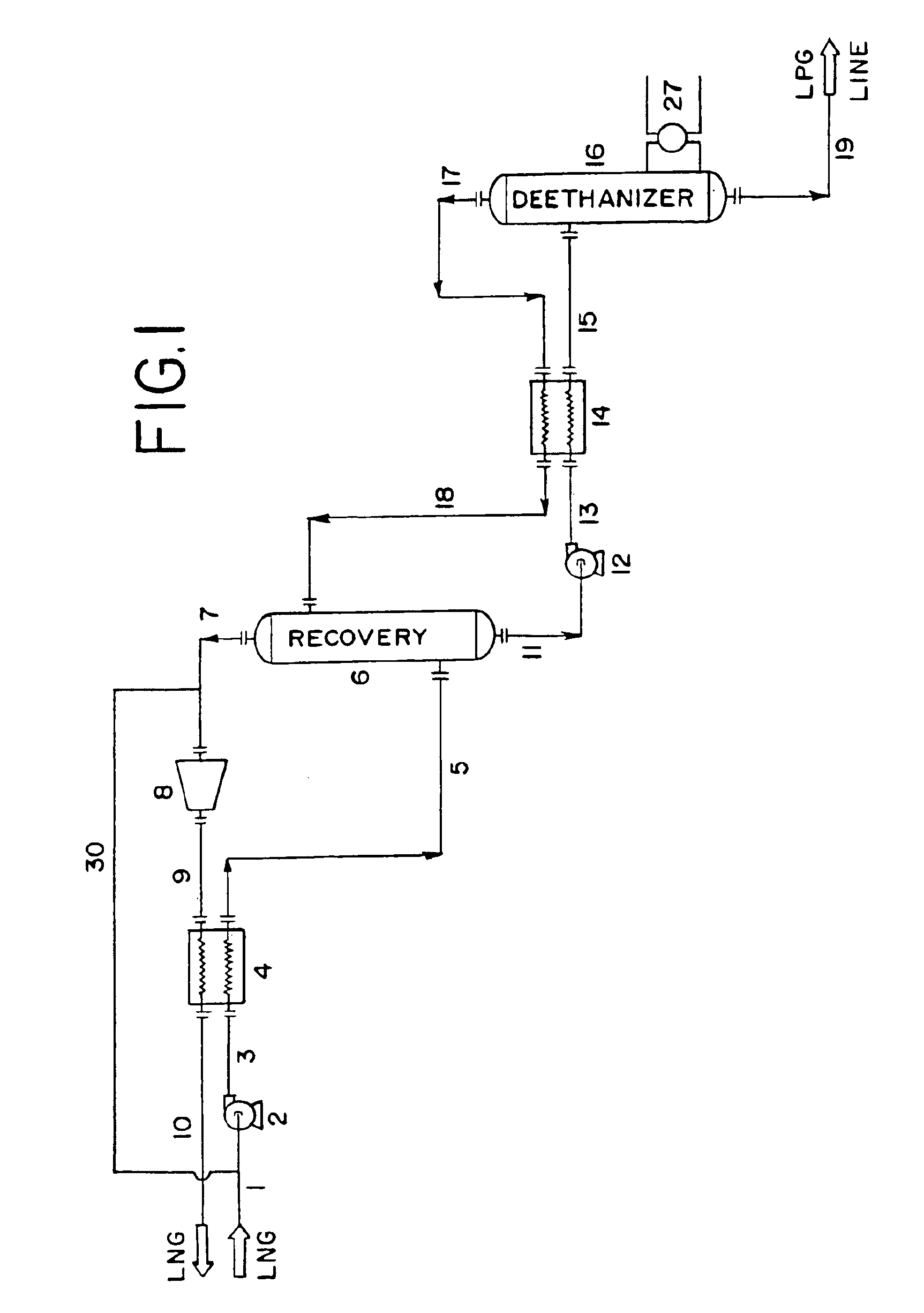

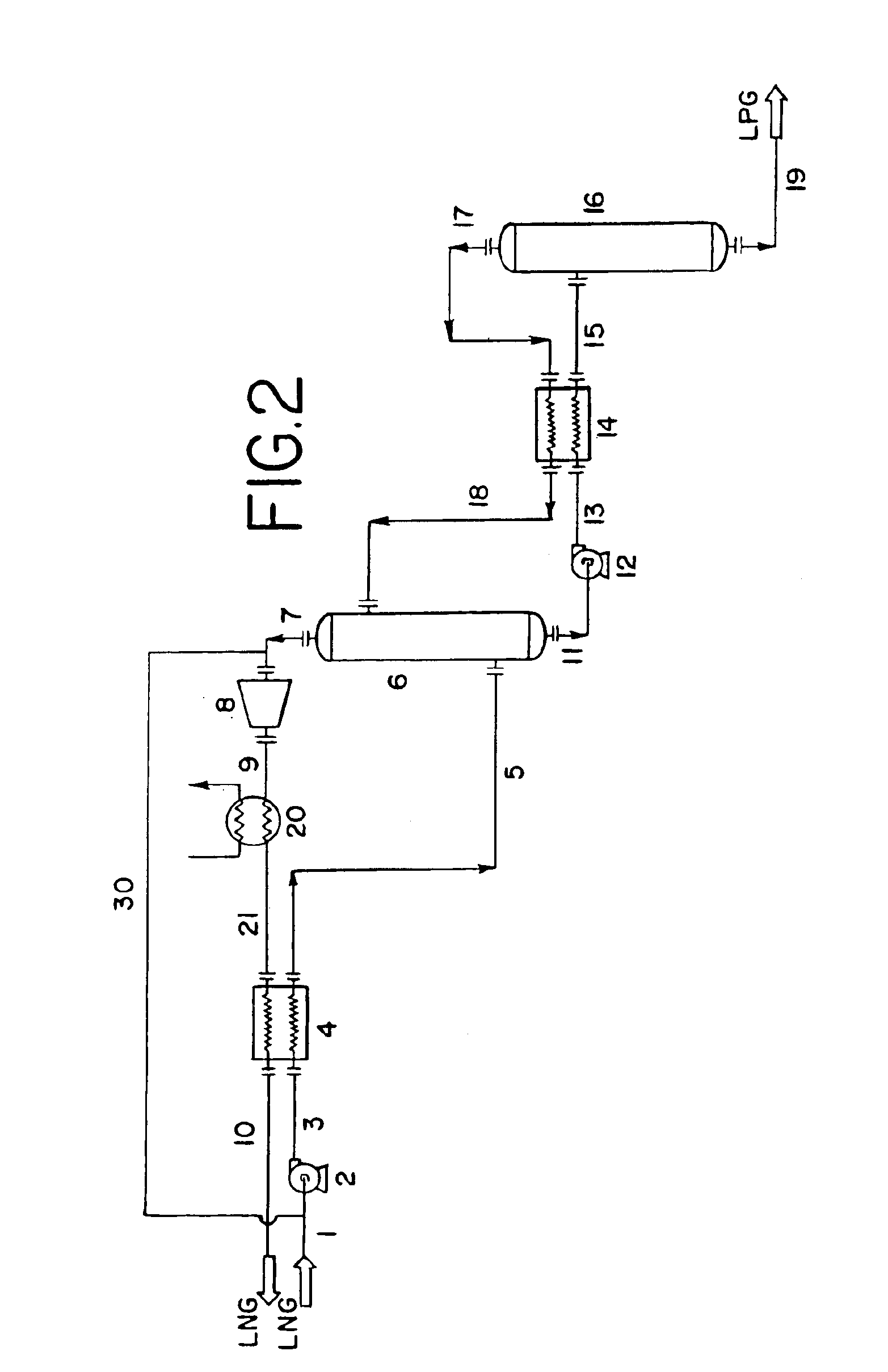

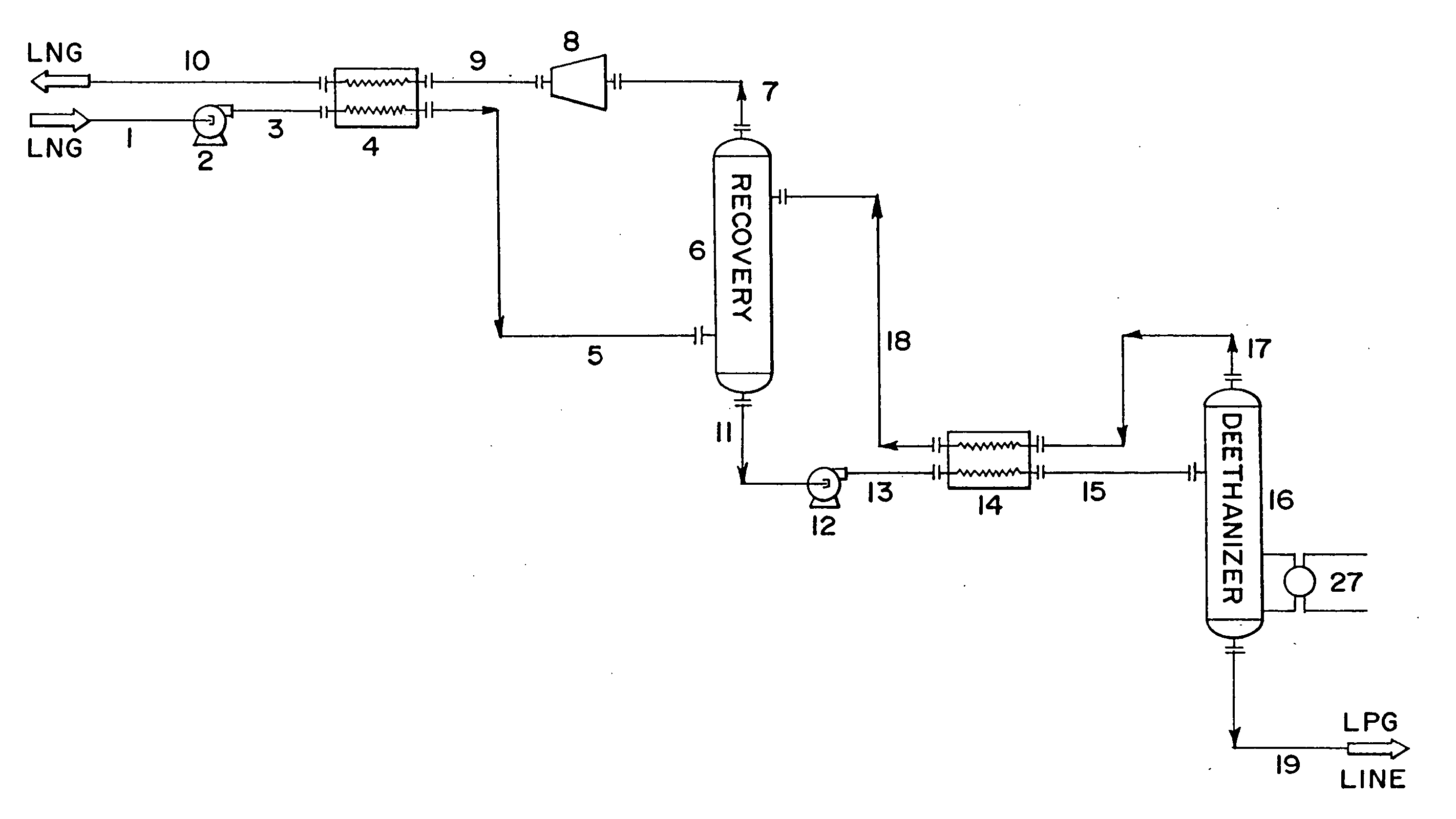

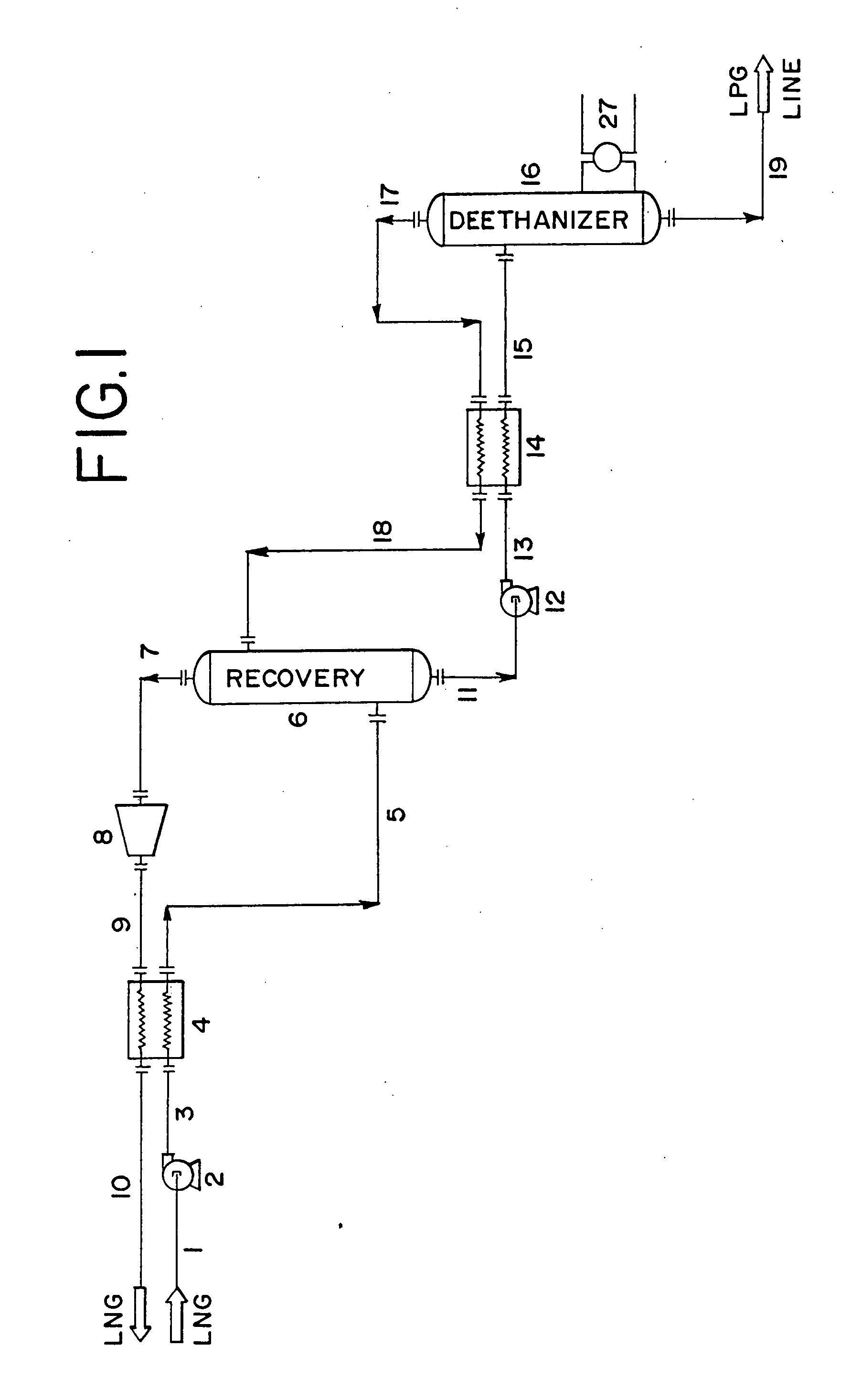

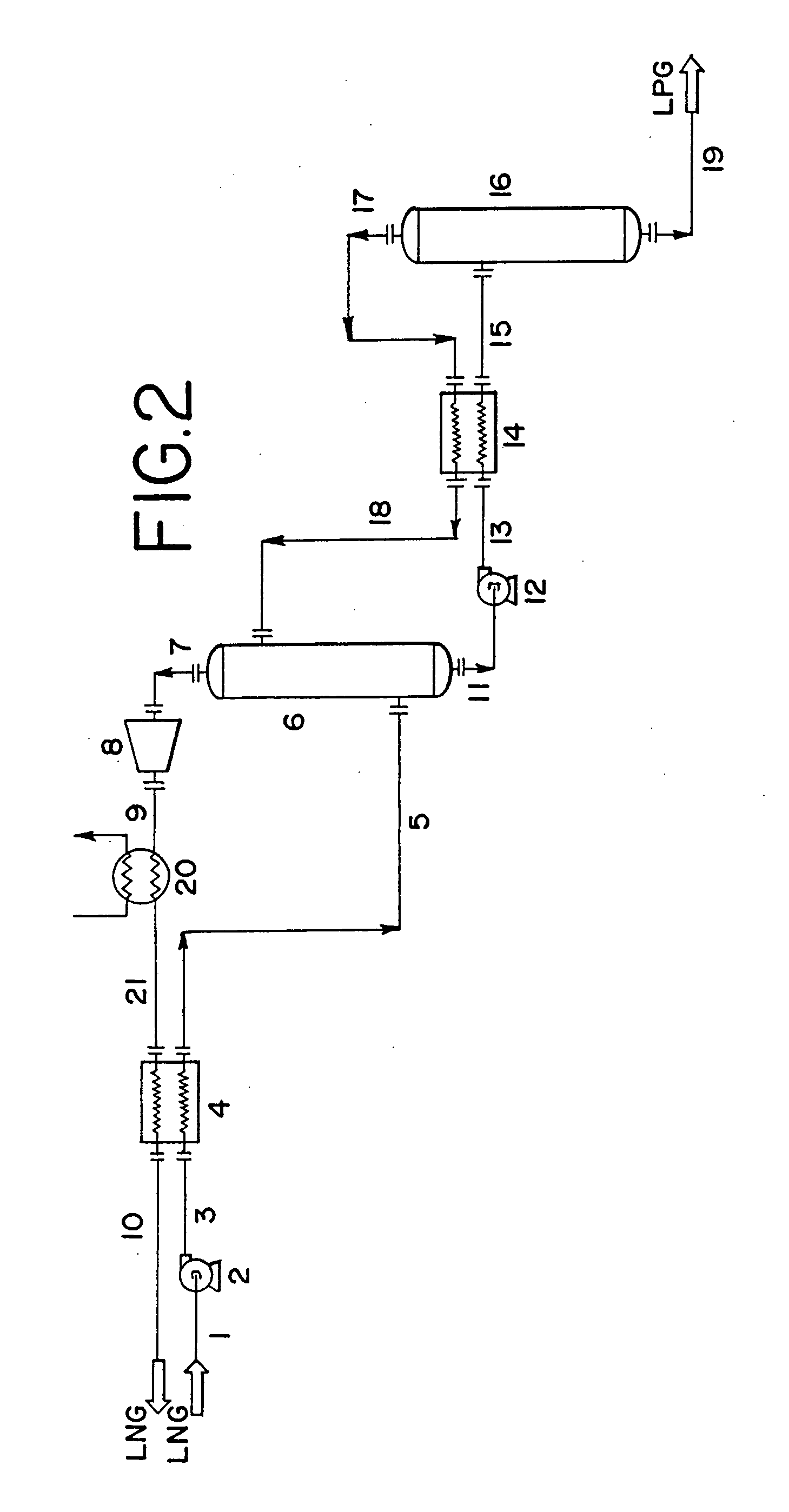

Cryogenic liquid natural gas recovery process

A process for the recovery of natural gas liquids (NGL) (ethane, ethylene, propane, propylene and heavier hydrocarbons) from liquefied natural gas (LNG) is disclosed. The LNG feed stream is split with at least one portion used as an external reflux, without prior treatment, to improve the separation and recovery of the natural gas liquids (NGL).

Owner:HOWE BAKER ENGINEERS LTD

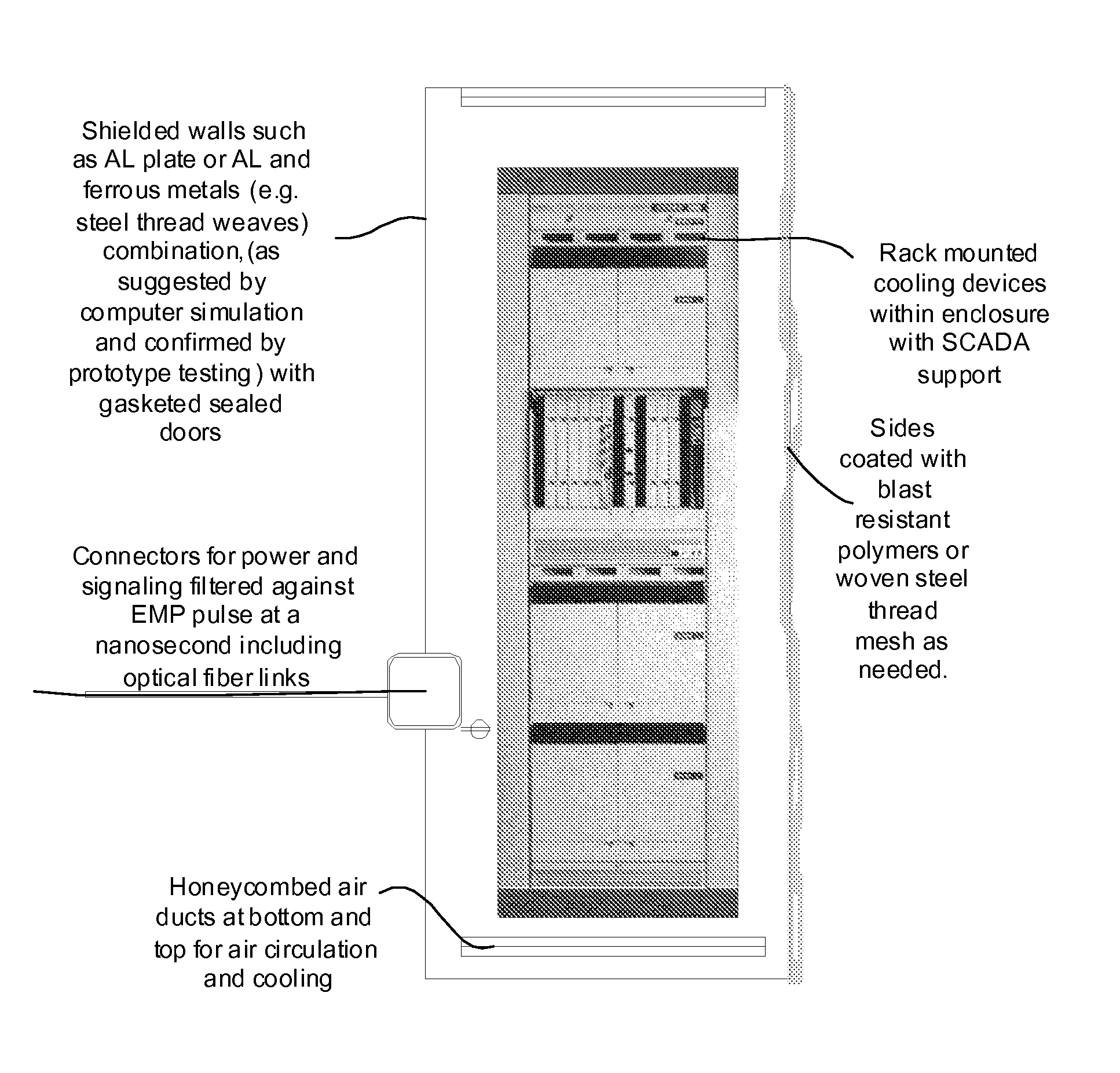

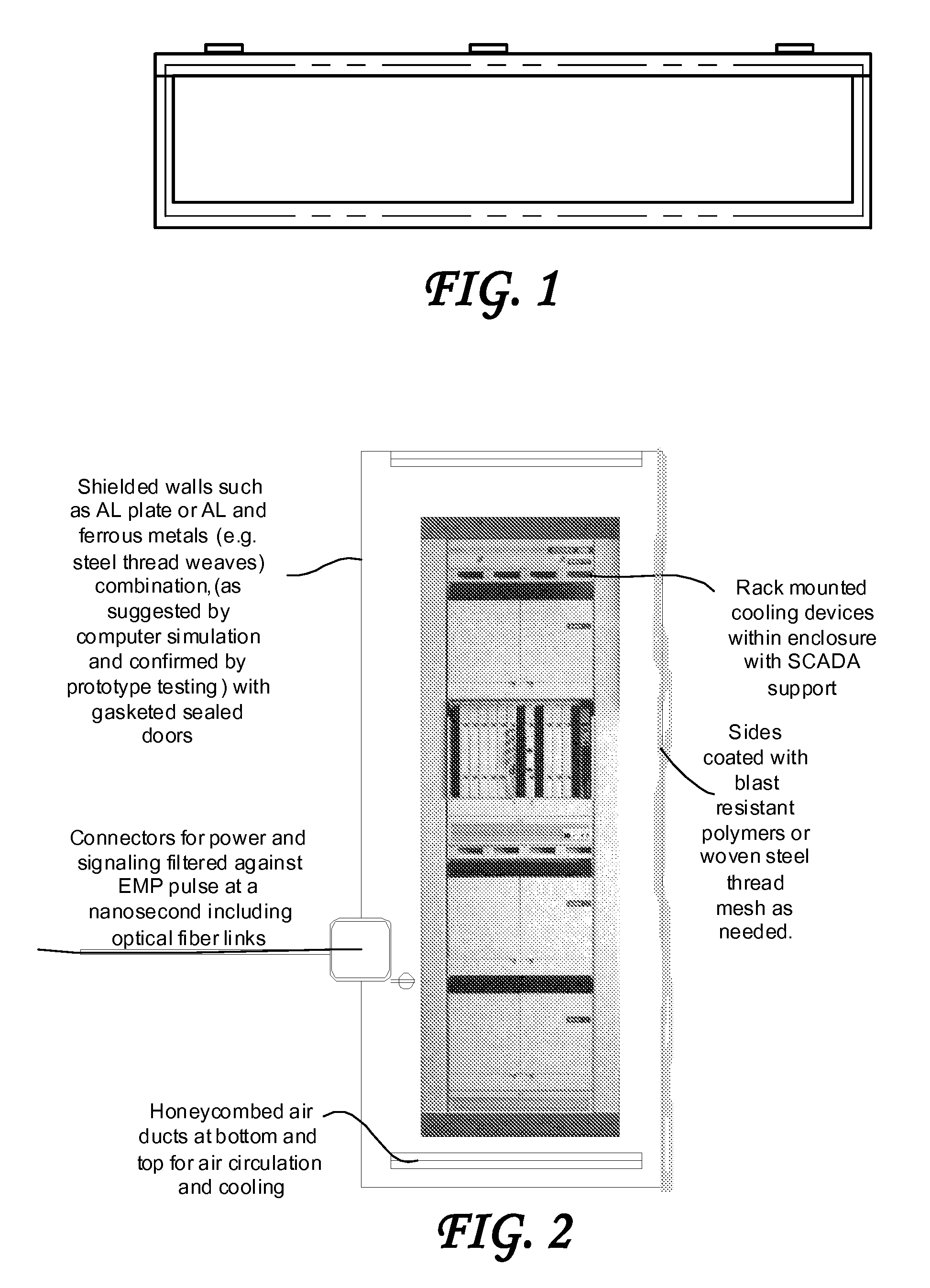

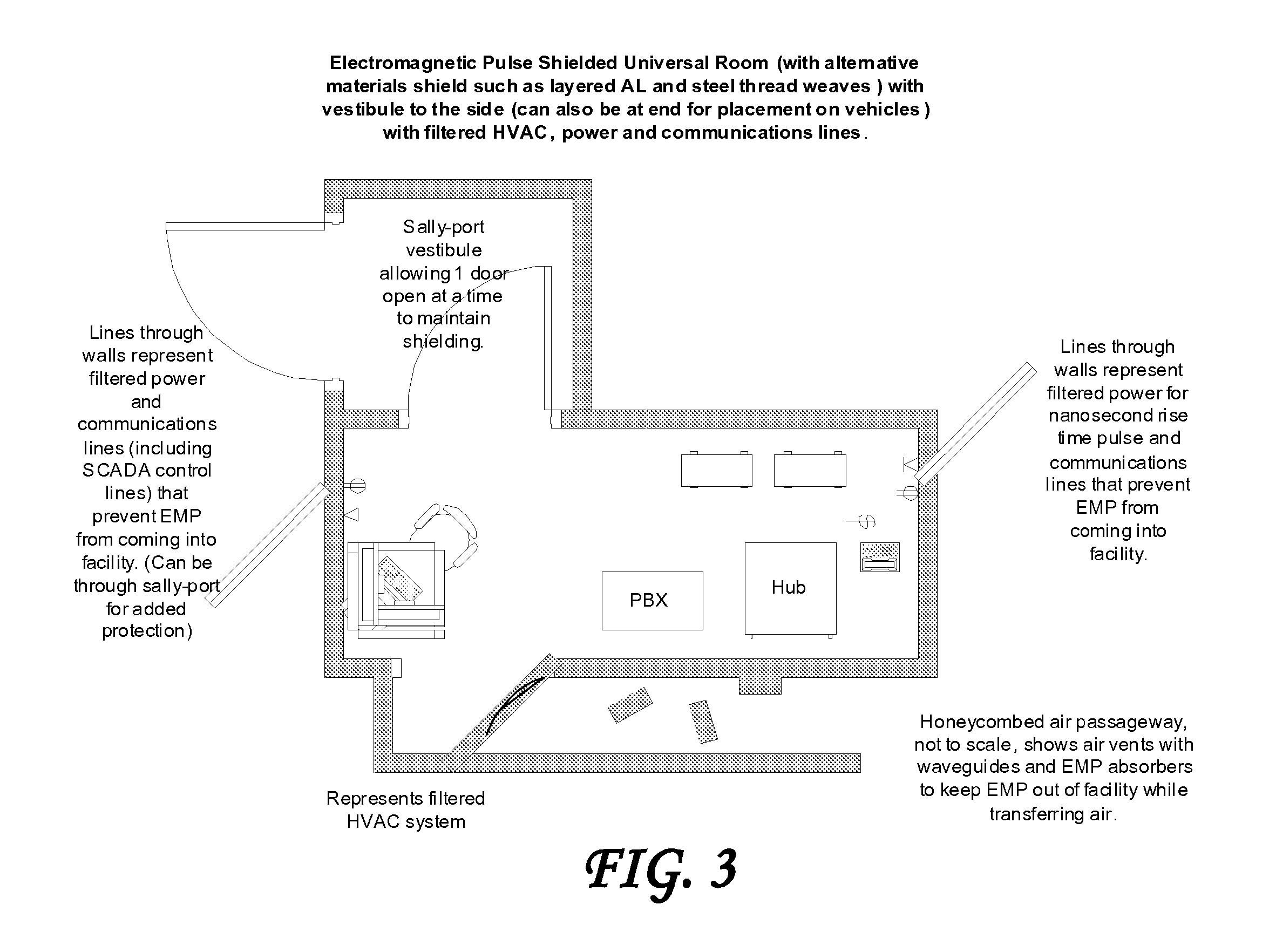

System and method for providing certifiable electromagnetic pulse and rfi protection through mass-produced shielded containers and rooms

InactiveUS20070105445A1Light weightControlled heatingScreening rooms/chambersShielding materialsElectricitySCADA

Disclosed are a system and method for providing certifiable shielded cabinets and rooms, or pods, to protect devices, equipment and people from electromagnetic interference such as electromagnetic pulse, and directed energy attack. The method simulates the separate electric and magnetic shield requirements and capabilities of each type of materials, simulating them separately and together to form a combined set of materials layered for an enhanced electromagnetic shield that is lighter weight and less expensive. Further disclosed is a system and method for SCADA, RFID, and OID monitoring and controls to enable initial and ongoing testing and control.

Owner:INSTANT ACCESS NETWORKS

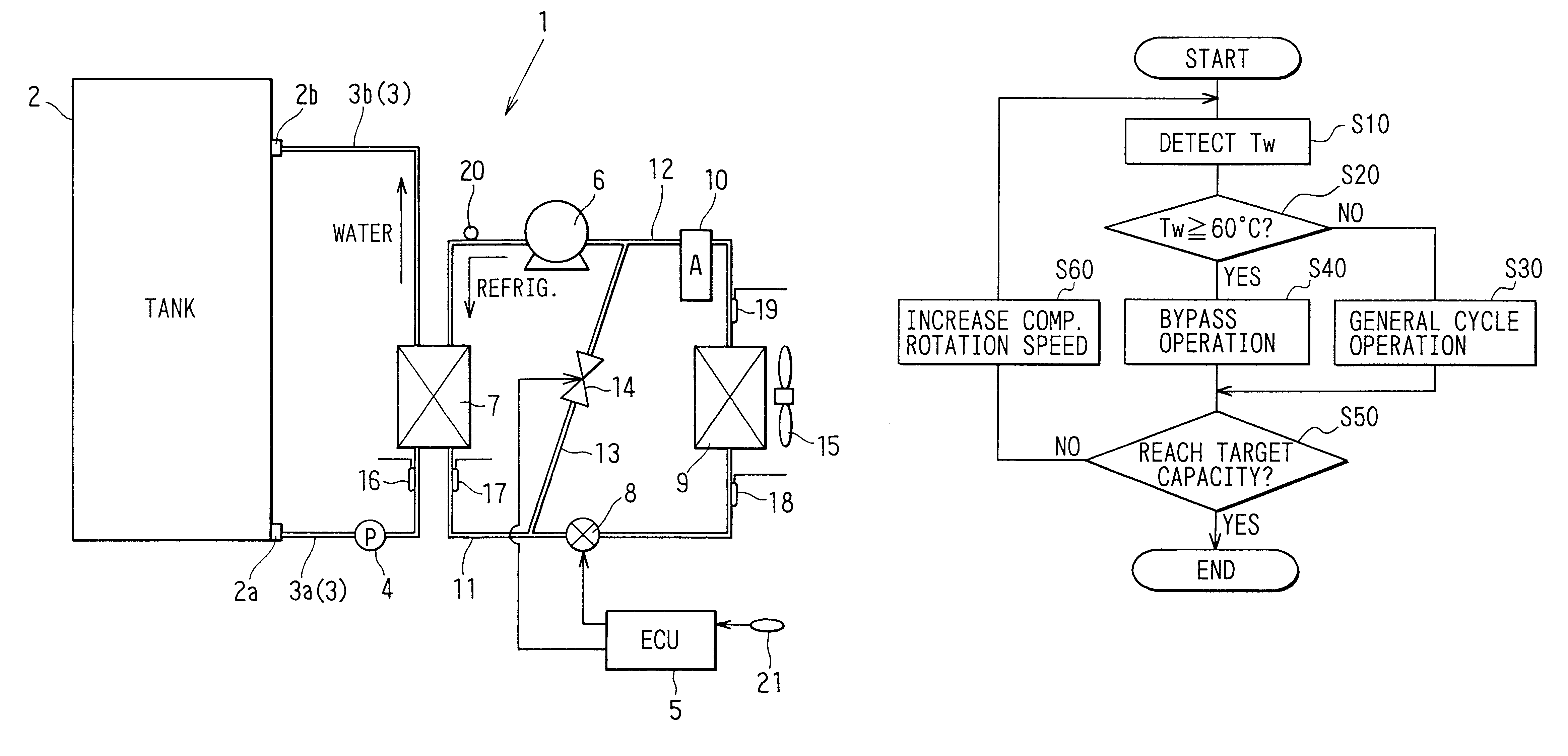

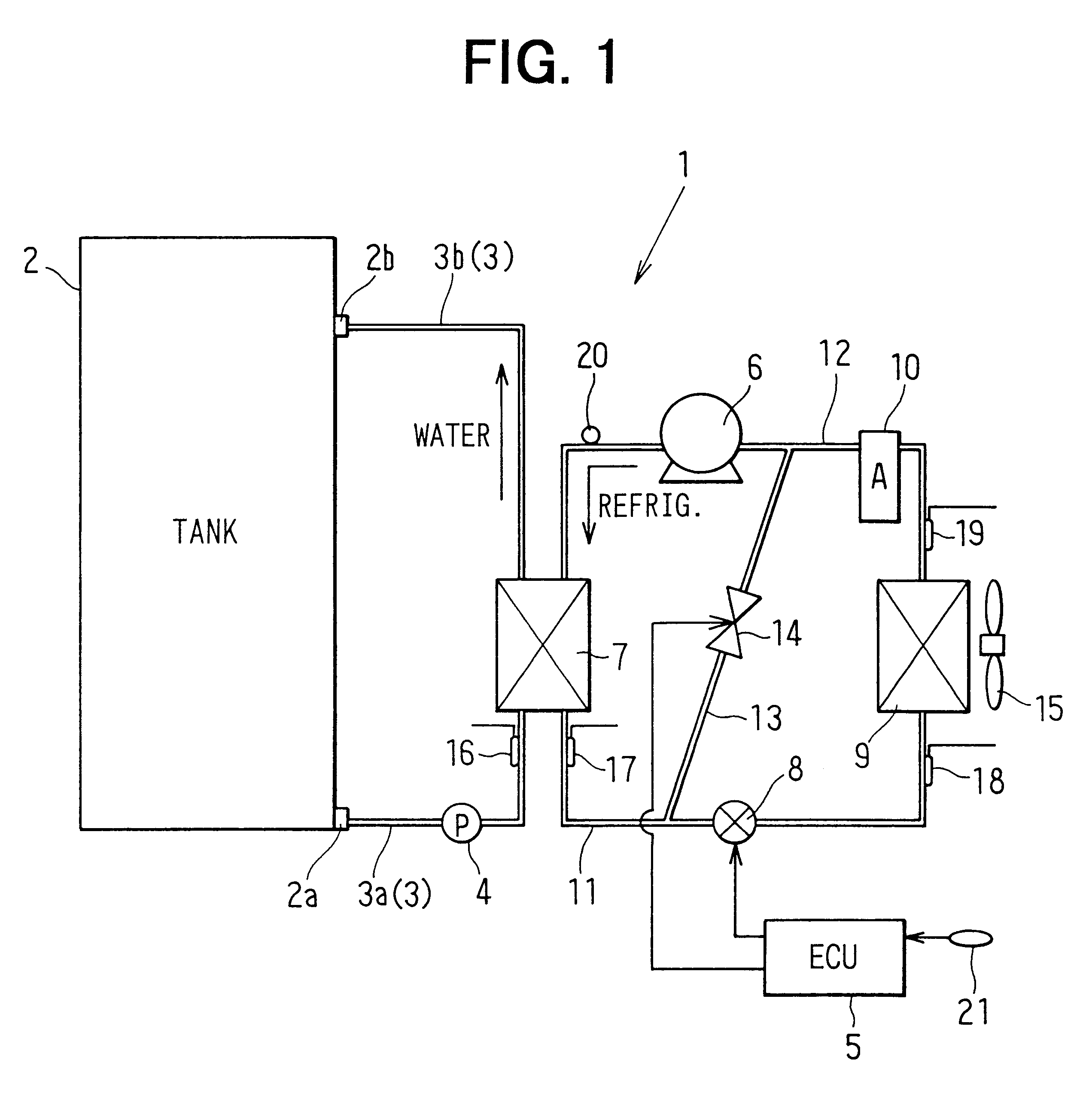

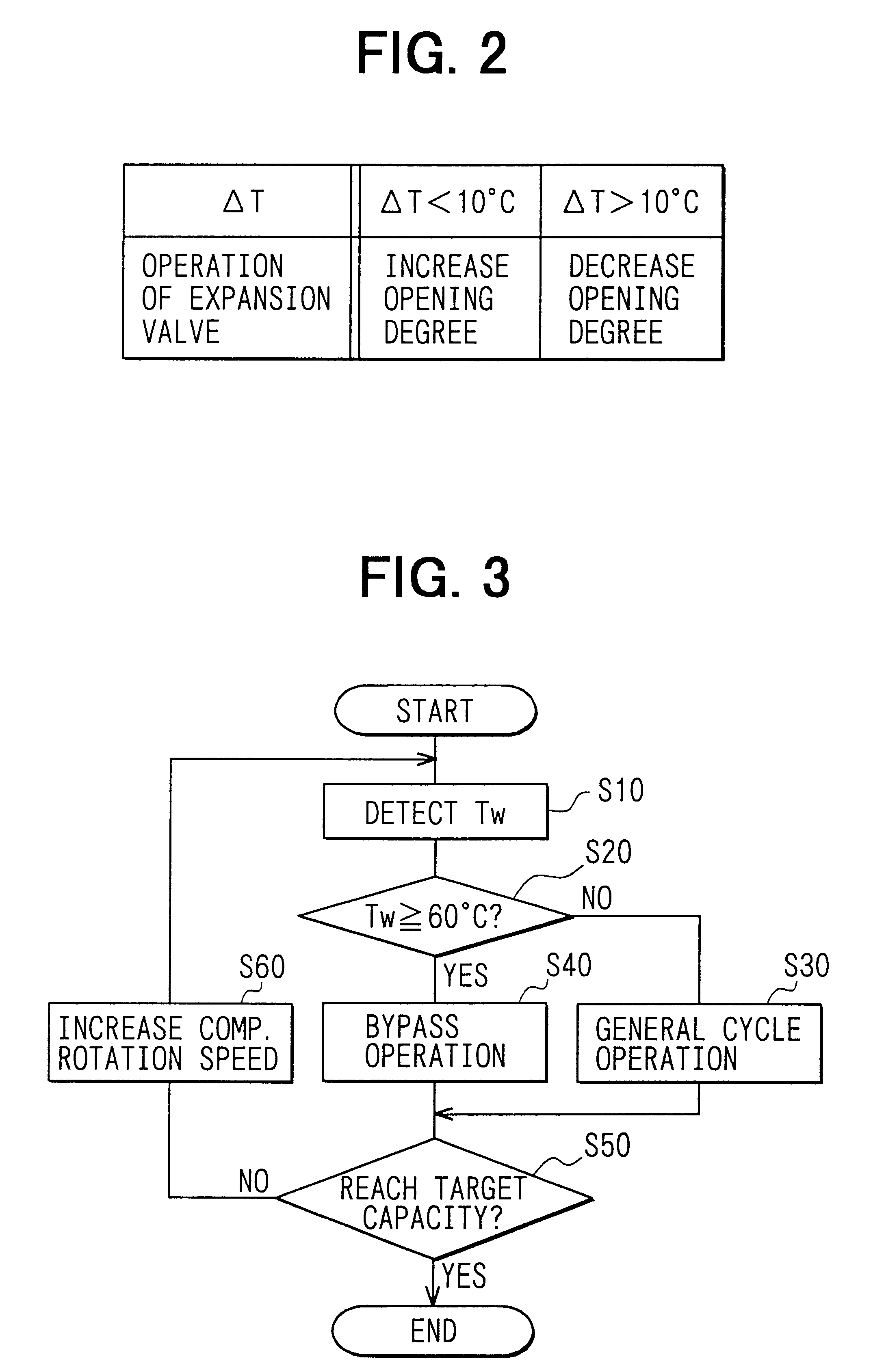

Heat-pump water heater

InactiveUS6467288B2Controlled heatingImprove heat pump efficiencyMechanical apparatusHeat pumpsEngineeringRefrigerant

In a heat-pump water heater, a control unit has a heat-radiation determining means for determining a heat radiation from refrigerant to outside air in an air heat exchanger based on a water temperature flowing into a water heat exchanger, and the control unit selectively performs a general cycle operation and a bypass operation in accordance with a determination result of the heat-radiation determining means. That is, when the water temperature flowing into the water heat exchanger is lower than 60° C., the general cycle operation is performed. On the other hand, when the water temperature is equal to or higher than 60° C., the bypass operation is performed.

Owner:DENSO CORP +2

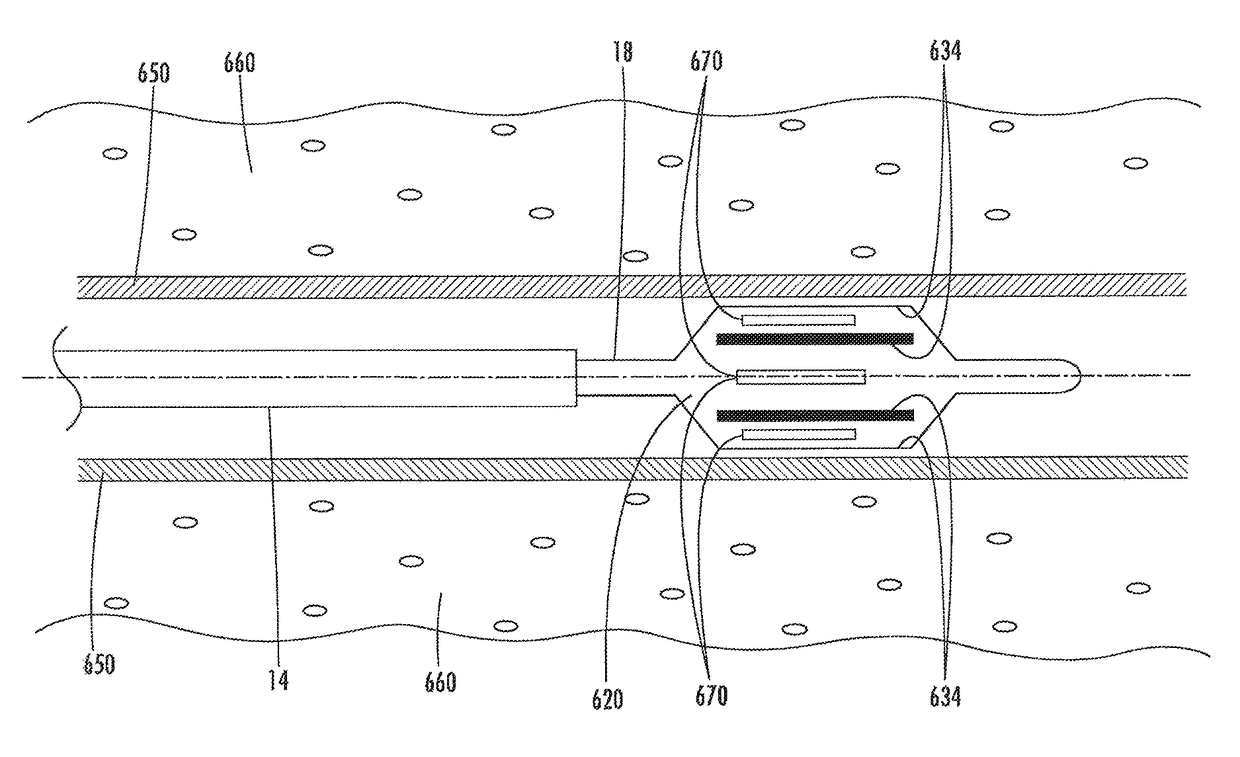

Apparatus and method for treatment of in-stent restenosis

ActiveUS9713730B2Avoid injuryGood curative effectSurgical instruments for heatingLight therapyProximateBlood vessel

A catheter and catheter system can use energy tailored for remodeling and / or removal of target material proximate to a body lumen, often of stenotic material or tissue in the luminal wall of a blood vessel of a patient. An elongate flexible catheter body with a radially expandable structure may have a plurality of electrodes or other electrosurgical energy delivery surfaces to radially engage the luminal wall when the structure expands. Feedback using one or parameters of voltage, current, power, temperature, impedance magnitude, impedance phase angle, and frequency may be used to selectively control the delivery of energy.

Owner:BOSTON SCI SCIMED INC

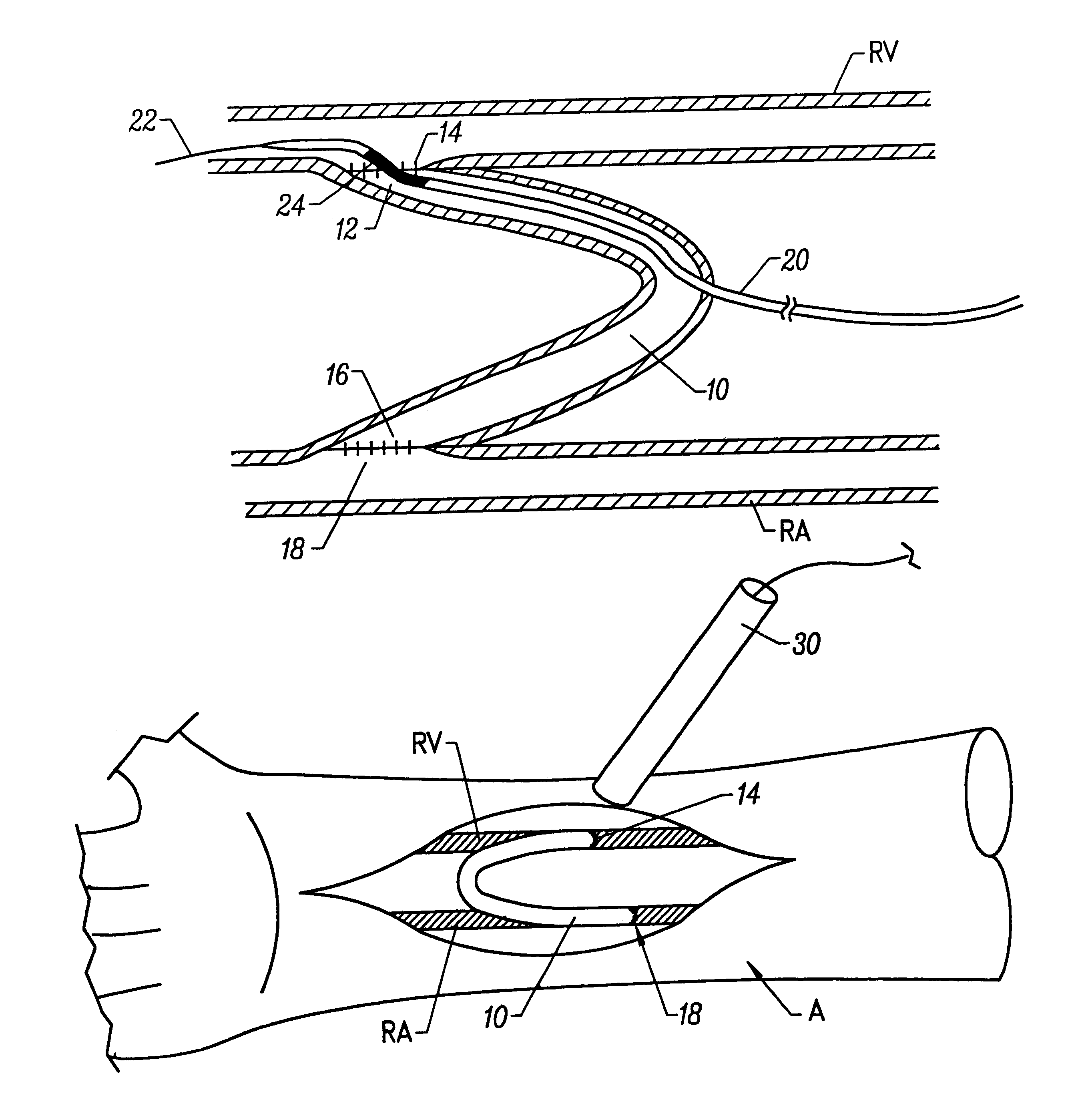

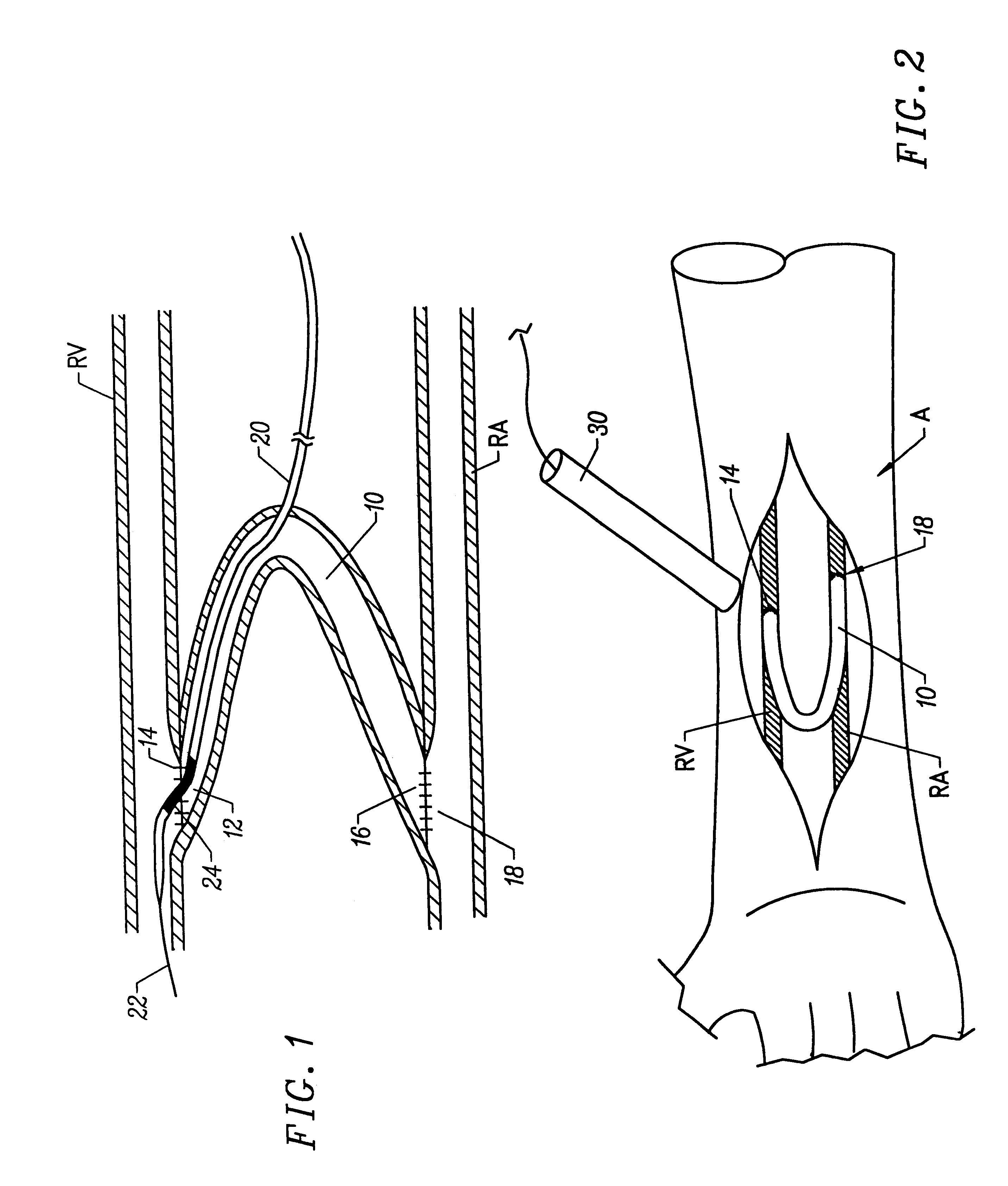

Methods and kits for the inhibition of hyperplasia in vascular fistulas and grafts

InactiveUS6387116B1Inhibit hyperplasiaInhibition is effectiveSurgeryBlood vesselsHaemodialysis machineMechanical index

A method for inhibiting hyperplasia at an anastomotic junction of a vascular fistula or vascular graft comprises exposing the anastomotic junction to vibrational energy at a mechanical index and for a time sufficient to inhibit hyperplasia. Kits are described comprising the catheter or a probe suitable for performing the methods together with instructions for use setting forth the methods. The methods and kits are particularly suitable for treating anastomotic junctions formed to provide vascular access for hemodialysis, hemofiltration, and the like. The methods and kits are also suitable for treating other vascular grafts, such as those formed during cardiac bypass graft surgery, vascular repair, and the like.

Owner:PHARMASONICS

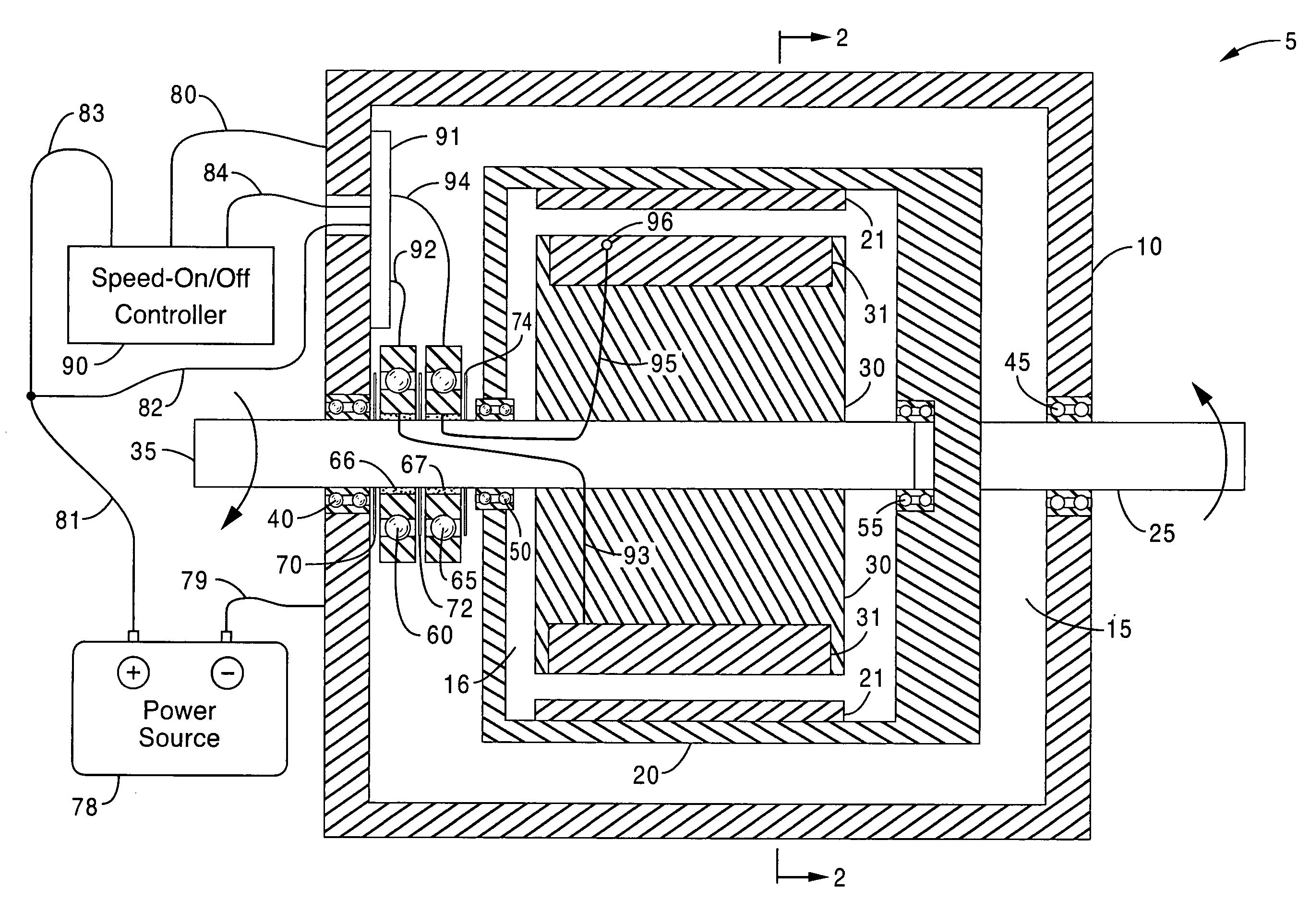

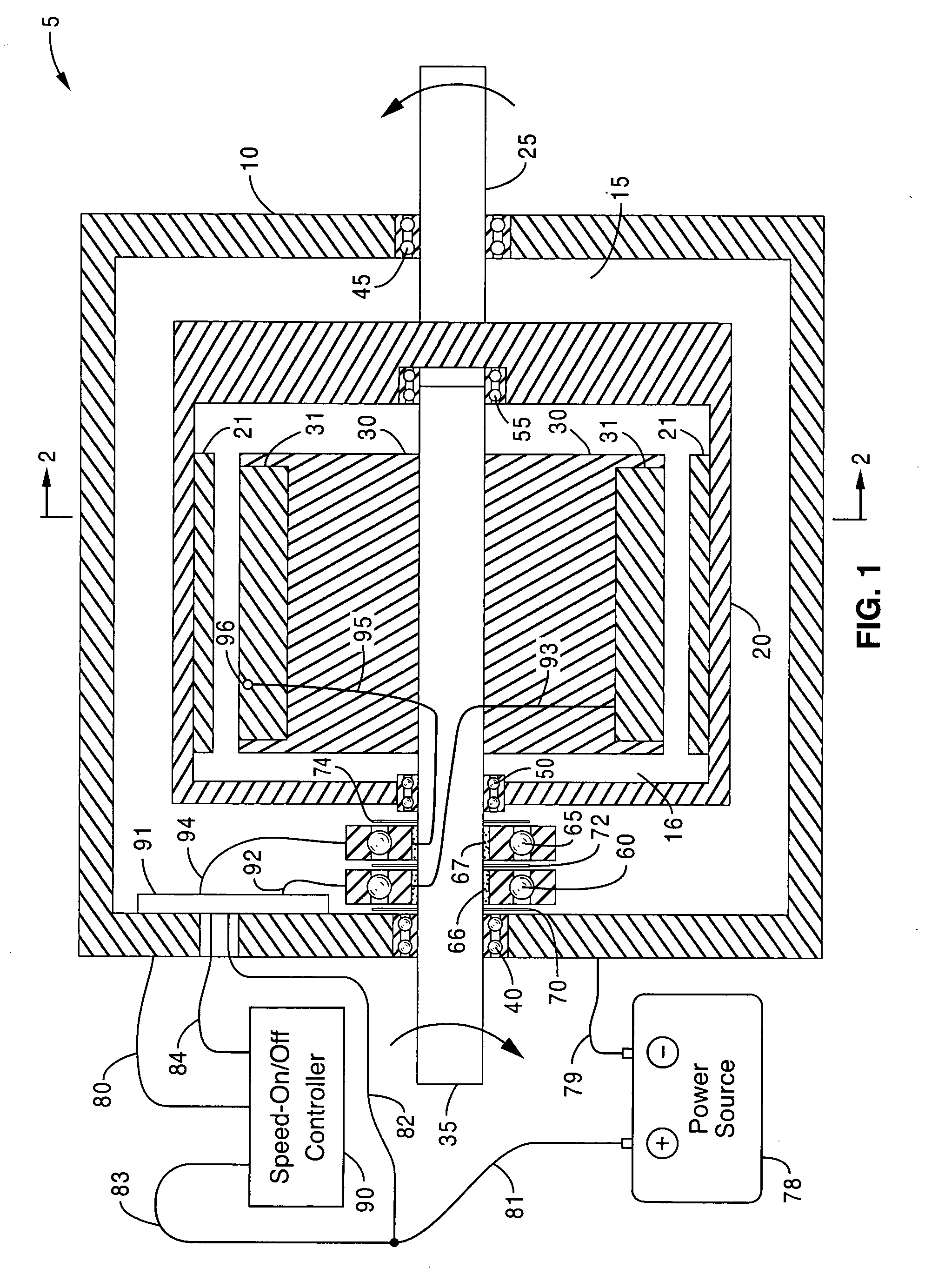

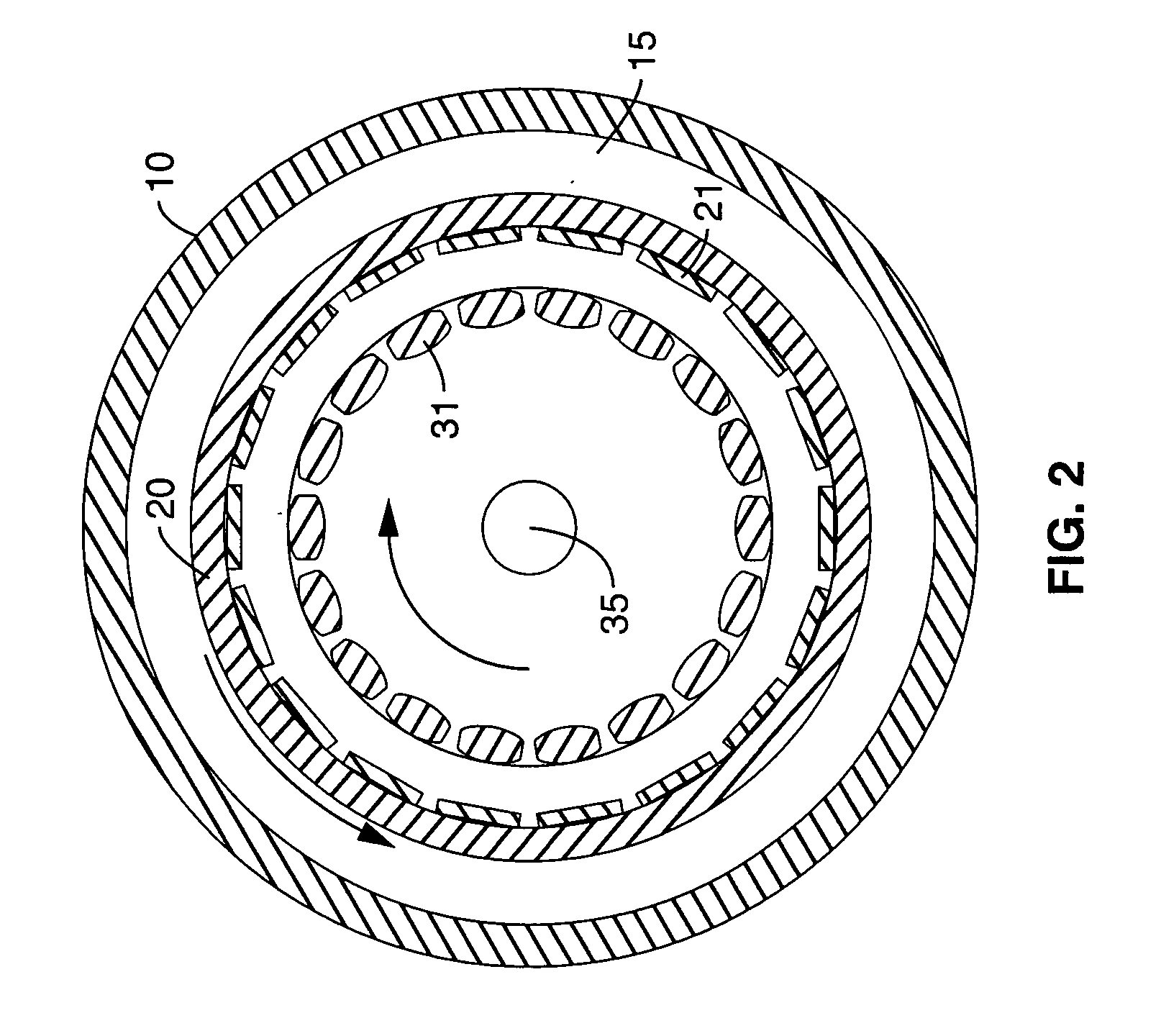

Brushless counter-rotating electric apparatus and system

InactiveUS20100236849A1Improve efficiencyControlled heatingMotor depositionPropulsion by batteries/cellsPortable powerEngineering

A brushless counter-rotating electric apparatus, motor, wheel hub motor, and associated vehicle includes a brushless counter-rotating electric motor that has oppositely rotating armature and stator components, oppositely rotating armature and stator output drives and, when associated with a vehicle, a control assembly for speed-on / off control of the motor and a portable electric power supply.

Owner:E WISH TECH

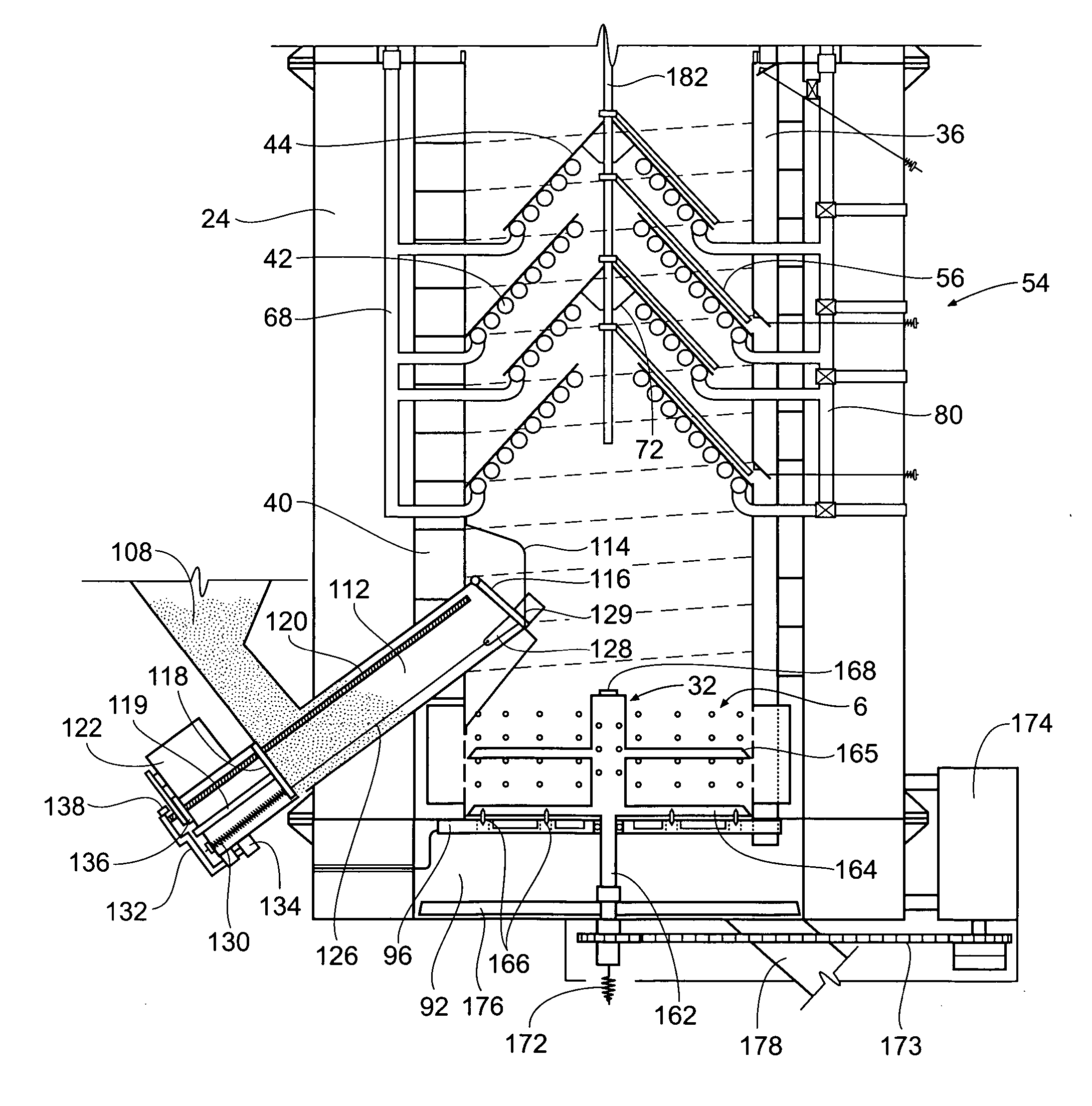

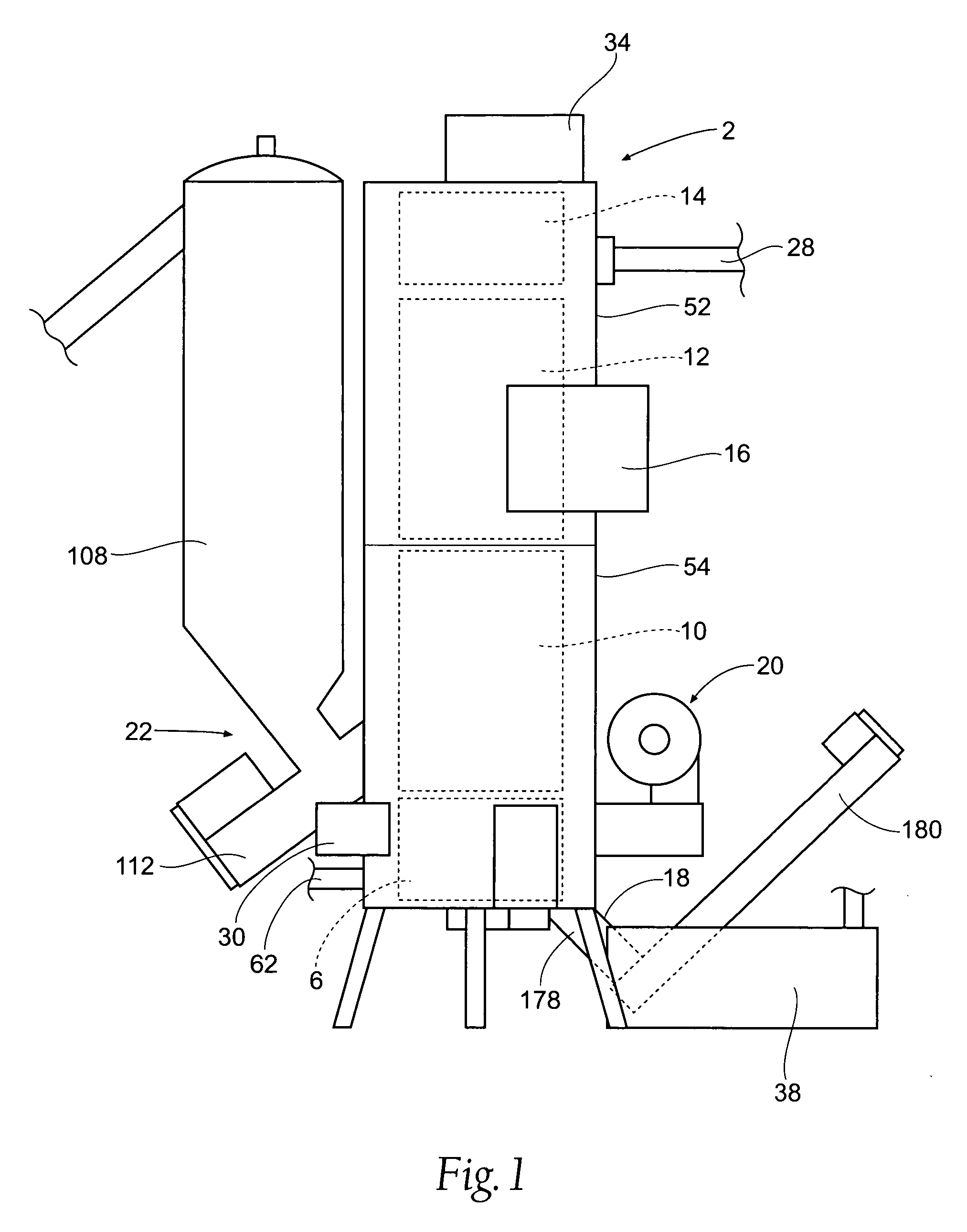

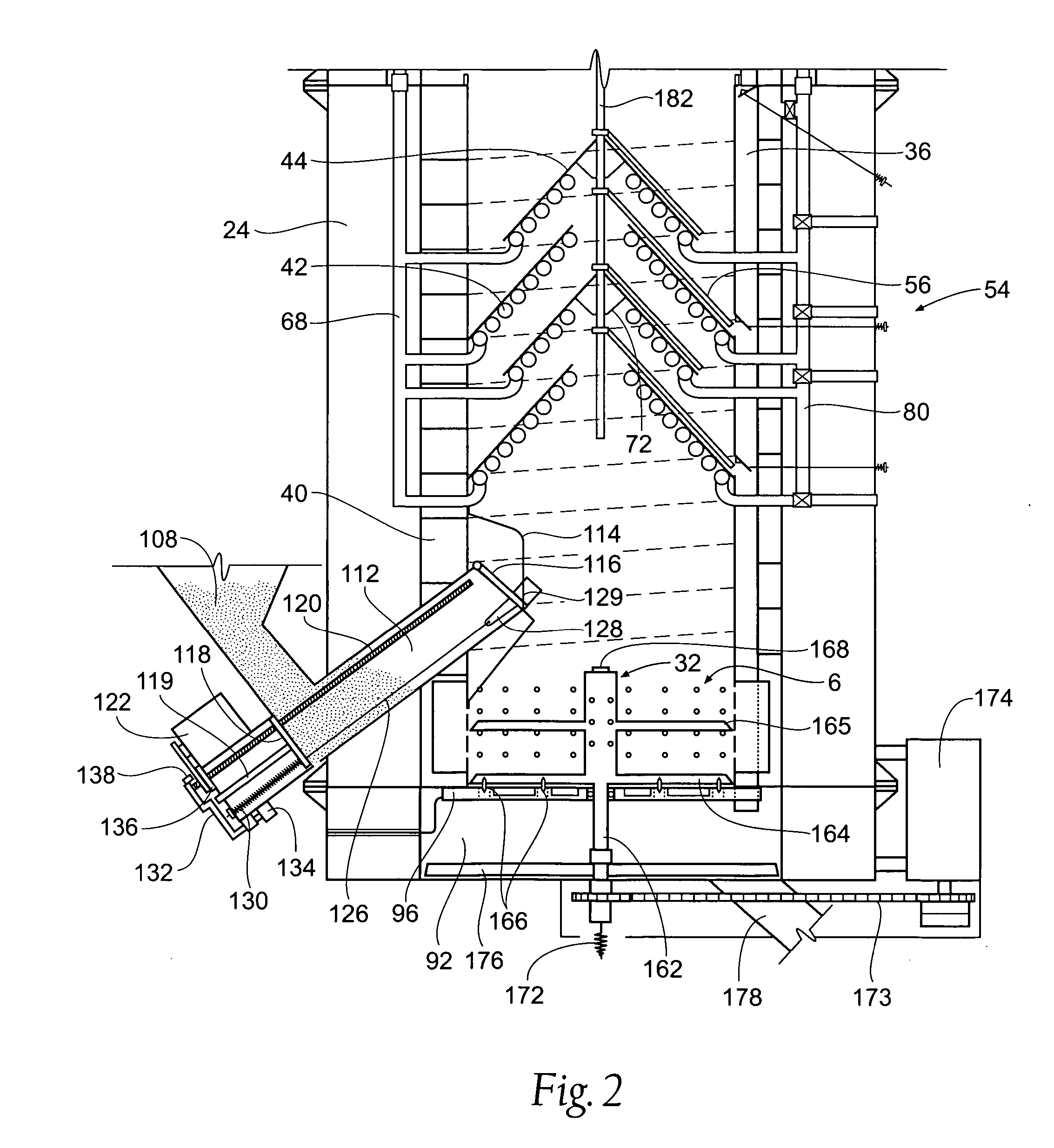

Granular biomass burning heating system

InactiveUS20070137538A1Improve unit efficiencyReduce lag timeAir supply regulationStirring devicesInformation controlProcess engineering

A granular biomass burning furnace for use with any appropriate granular biomass, such as grains, cherry pits, etc. The furnace includes a three stage heat exchanger, a fuel injector, a fuel stirrer, an ash ejector, a wash down system, a three stage air inducer, a fuel igniter, and supporting components. The unit includes a computer controller which controls all aspects of the operation of the unit based on information from sensors located throughout the unit. The unit includes a smart logic thermal controller to adjust the output heat of the unit via a variable speed air inducer. The three stage heat exchanger system includes a spiral water jacket surrounding the burn pot, a plurality of heat exchanger baffles in the unit, and a fine finned heat exchanger at the top of the unit. The air inducer provides air to the burn pot from three directions to promote complete combustion.

Owner:STERR KEVIN K

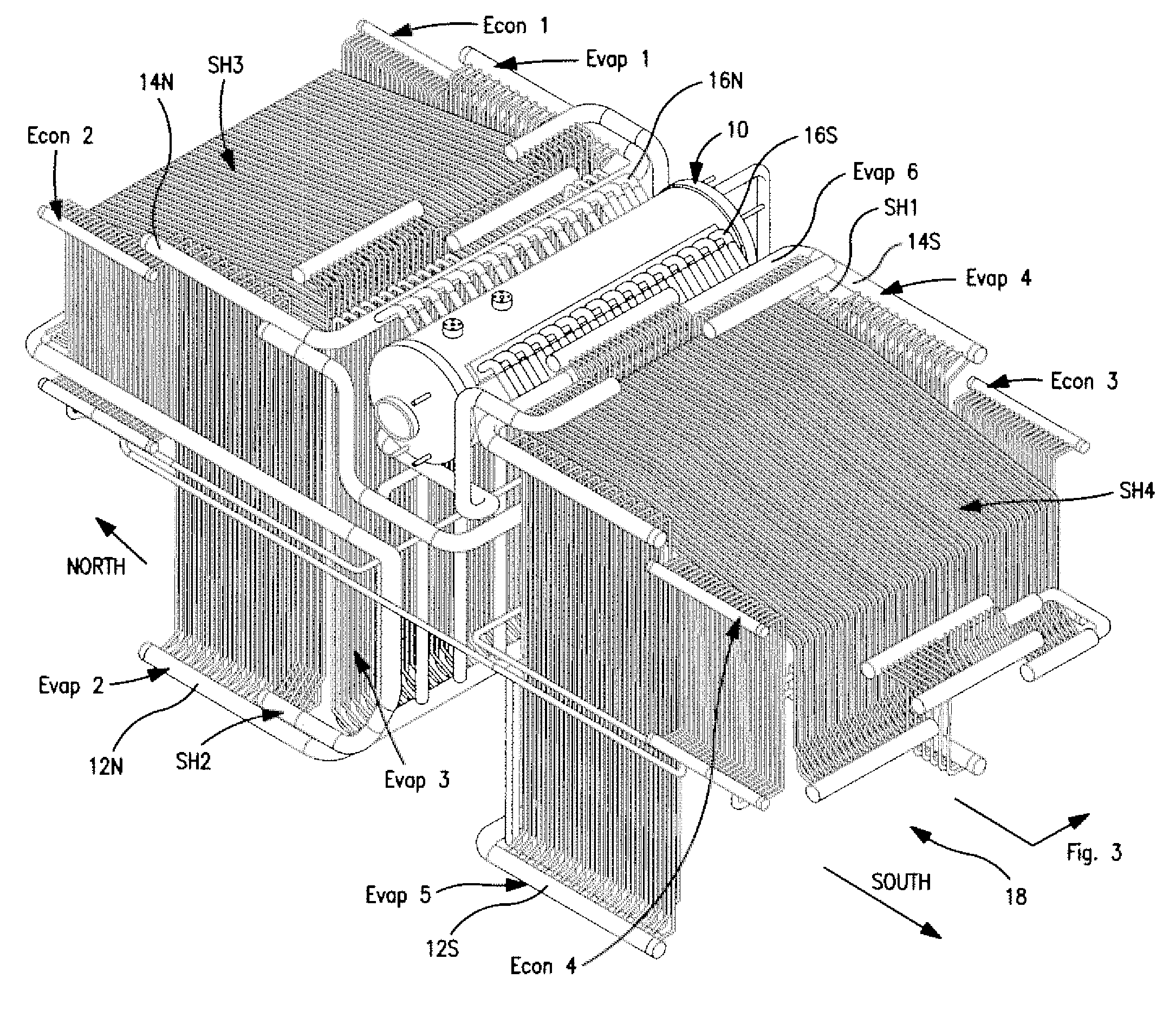

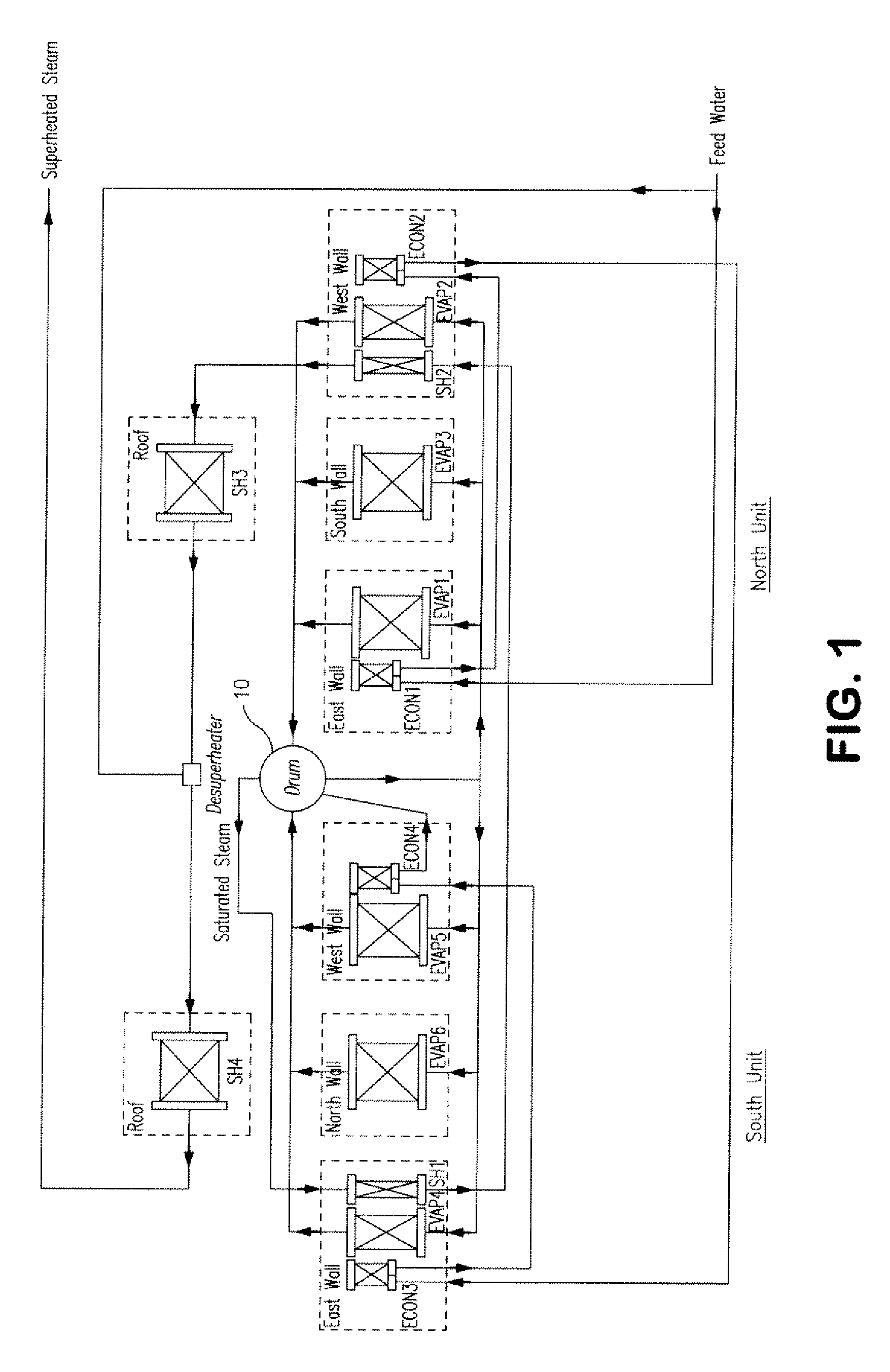

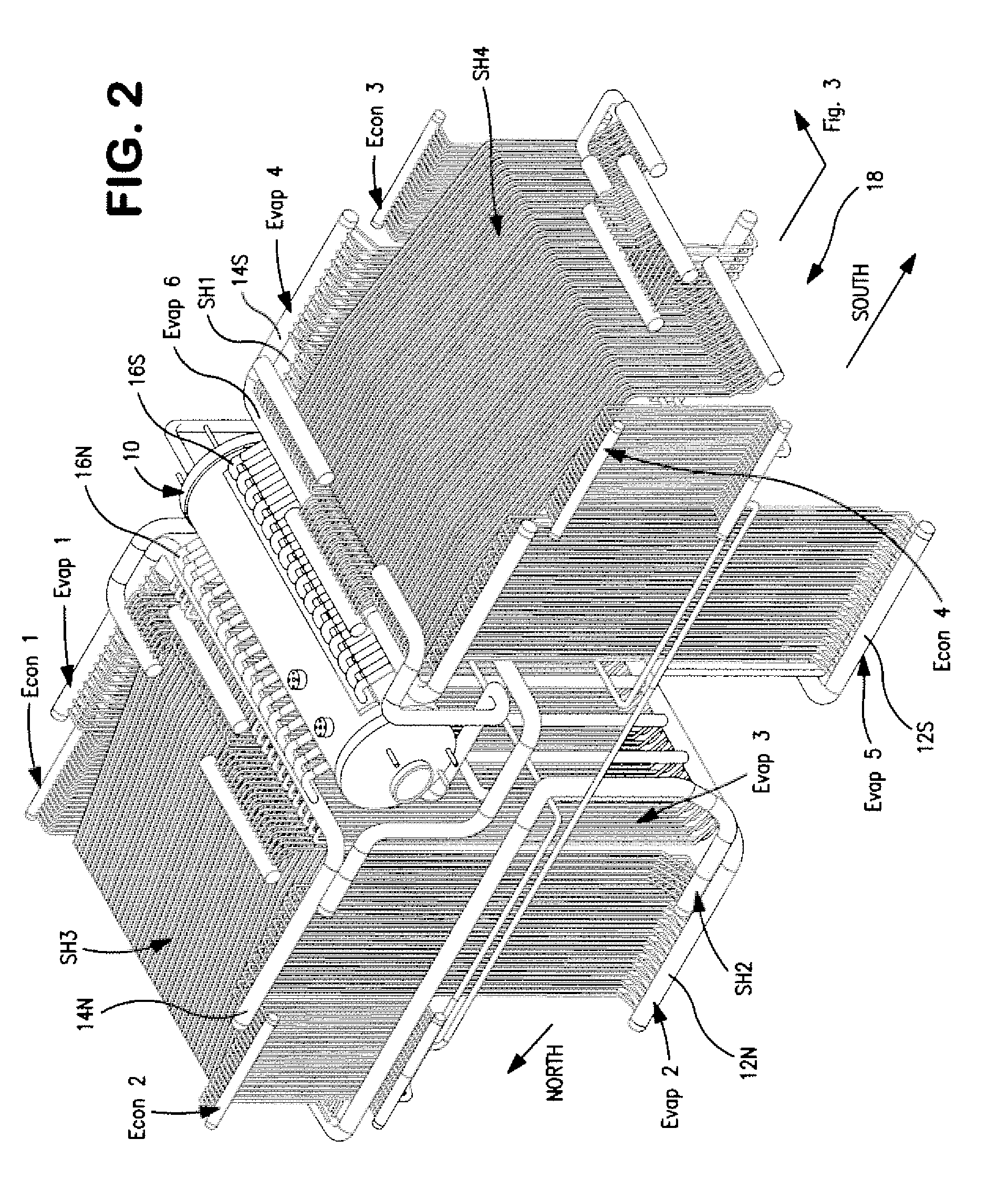

Generation of steam from solar energy

InactiveUS20100258112A1Control heat lossControlled heatingSolar heating energySolar heat devicesEngineeringHigh pressure

A cavity-type solar energy receiver for generating high pressure steam, which includes panels of tubes defining a cavity within an outer enclosure. Concentrated solar energy provided by a heliostat enters the cavity opening in the enclosure and evaporates water within some of the tube panels. The evaporating tubes receive hot water from a steam drum by natural circulation and return a mixture of steam and hot water to the steam drum. Additional tube panels are positioned to receive reflected solar energy, which is used to preheat feed water and to superheat steam.

Owner:VICTORY ENERGY OPERATIONS

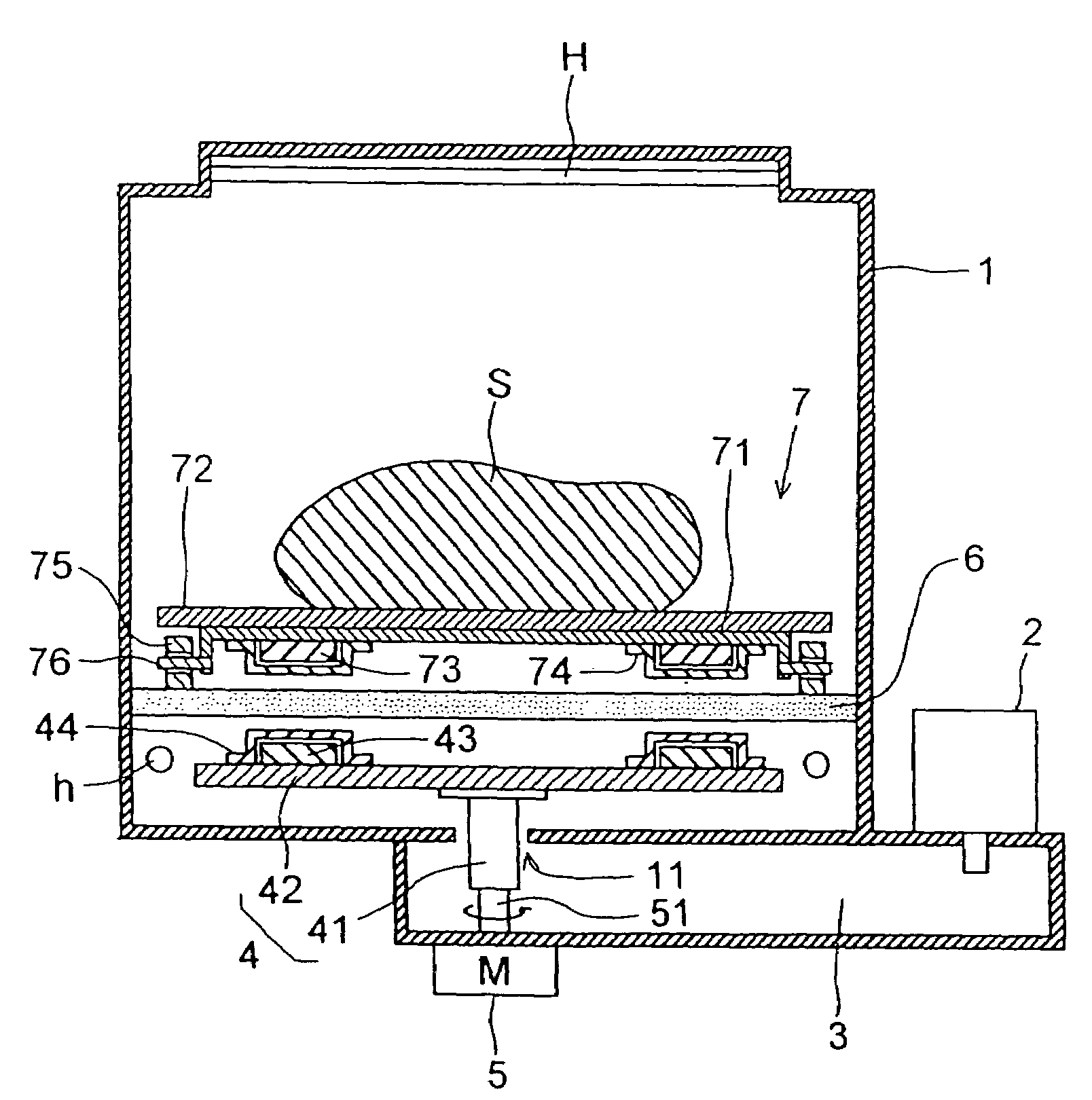

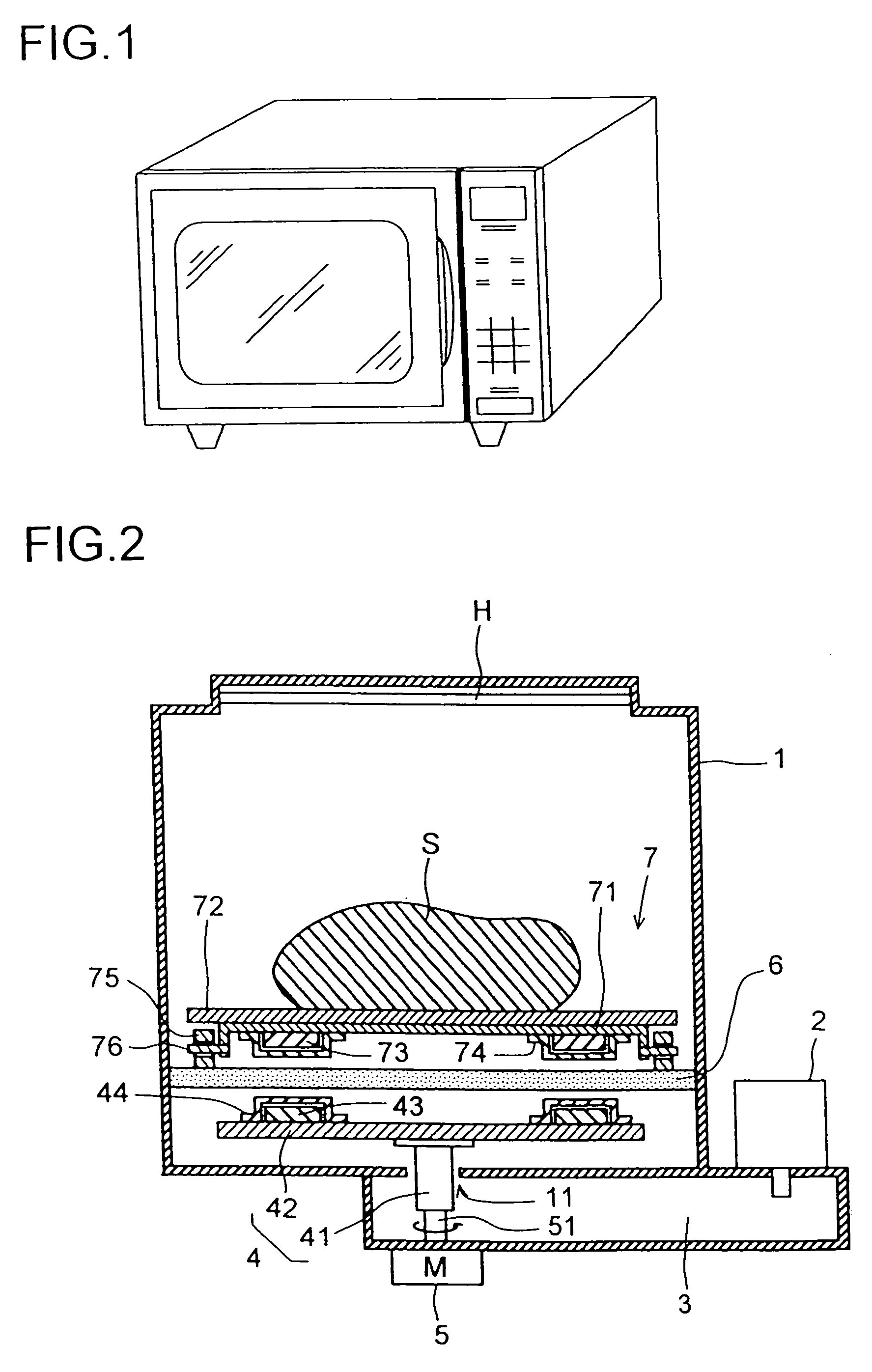

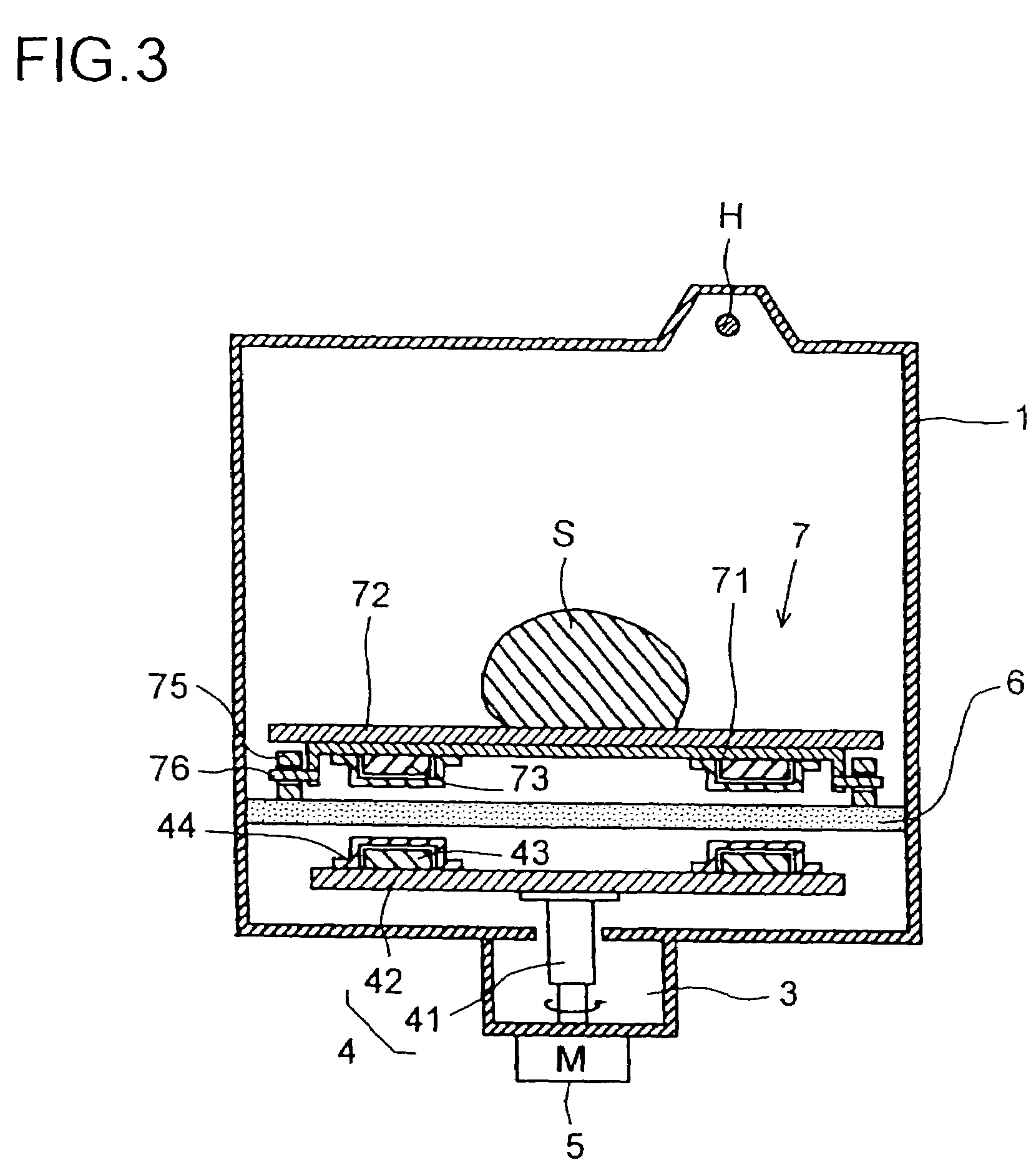

High-frequency heating apparatus

A high-frequency heating apparatus comprises a heating chamber, a high-frequency generator, a waveguide, an antenna, a motor for rotating the antenna, and a stage (6) provided above and near the antenna to partition the heating chamber and made of dielectric. A rotary base on which an object to be heated is mounted is provided on the stage. A first magnet is provided to the antenna. A second magnet is provided on the rotary base at a place corresponding to the first magnet on the rotary base. By utilizing the magnetic coupling between the first and second magnets, the rotary base is rotated in synchronism with the rotation of the antenna. While maintaining the advantages of conventional antenna high-frequency heating apparatuses, the heating efficiency by grill heating or oven heating is enhanced, and minute heating uniformness is achieved.

Owner:SHARP KK

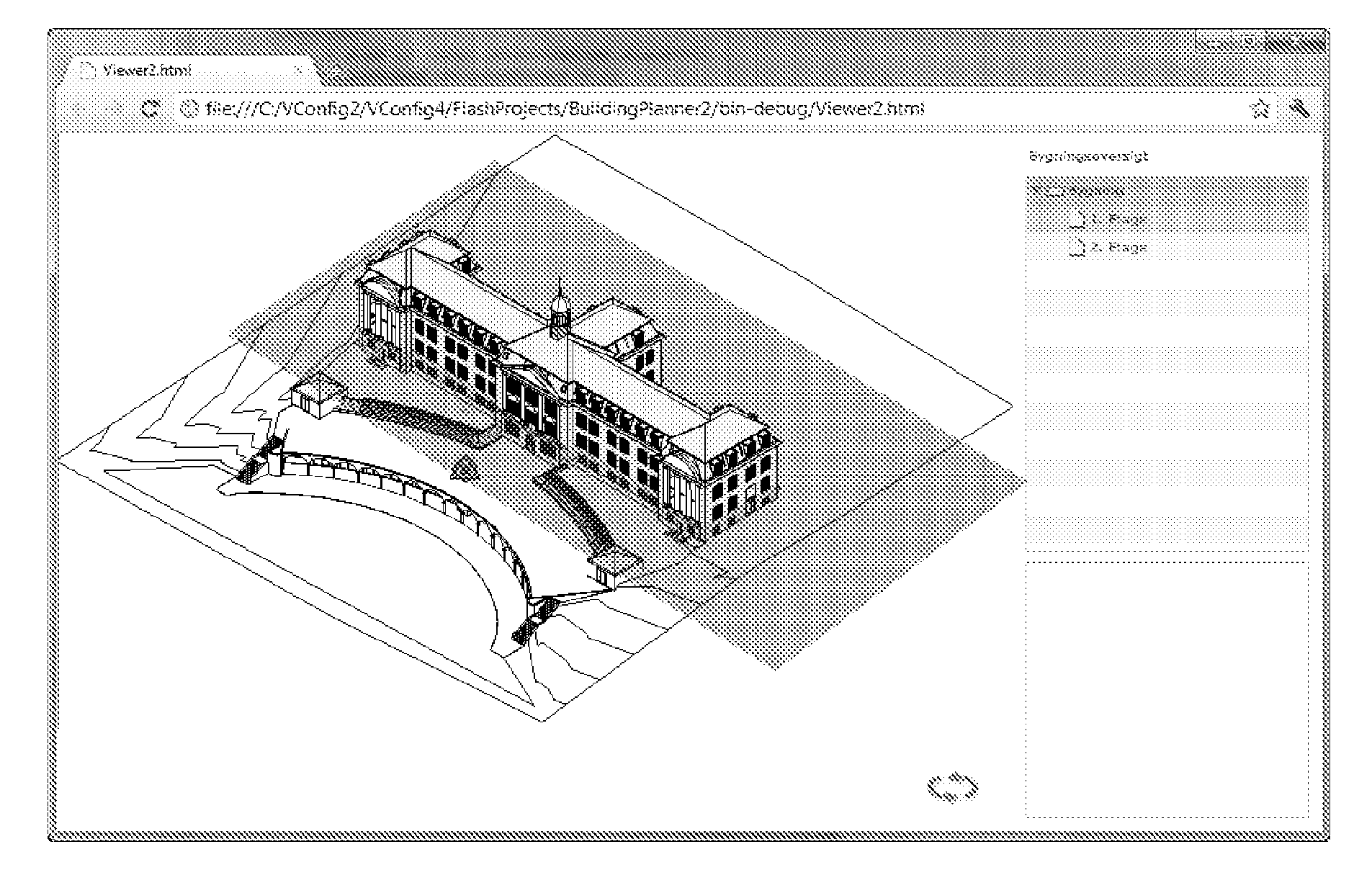

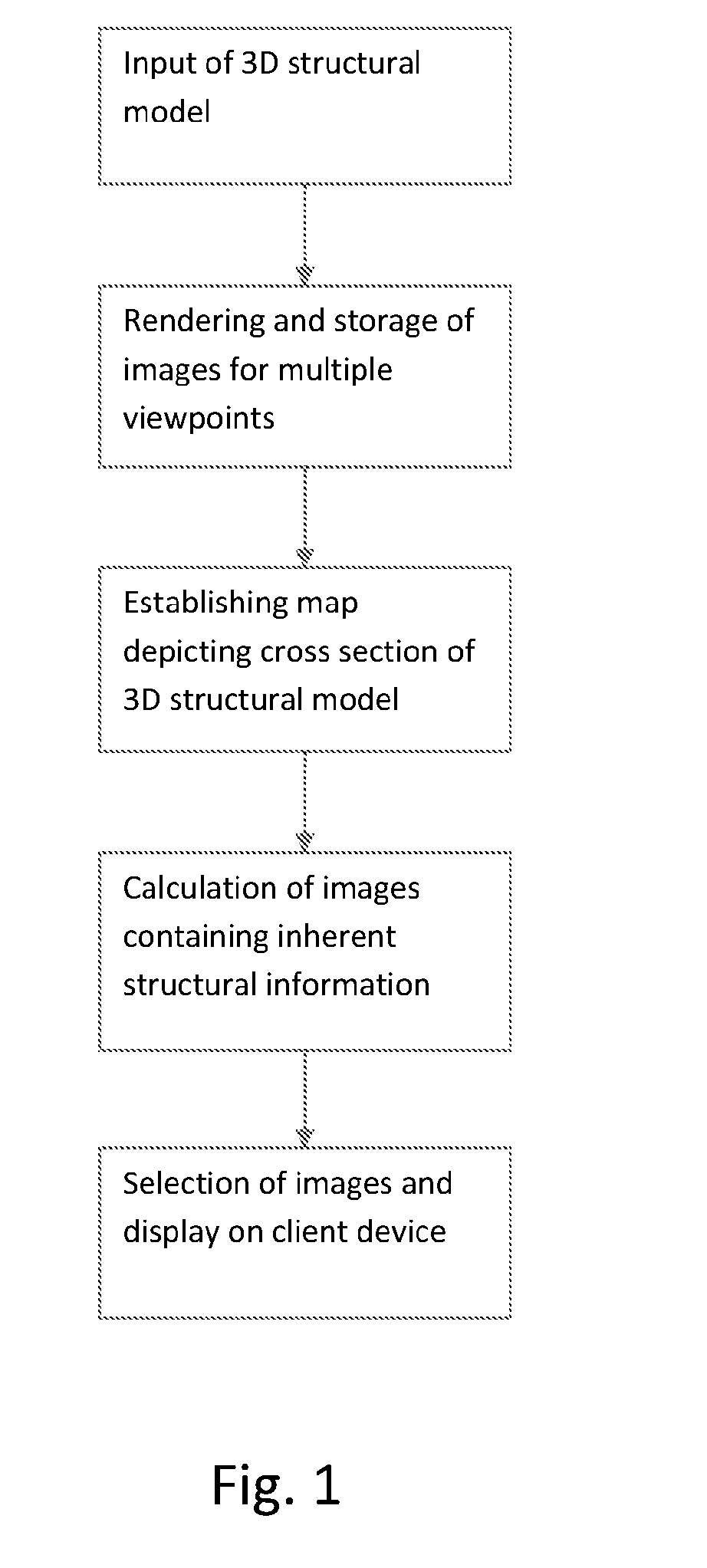

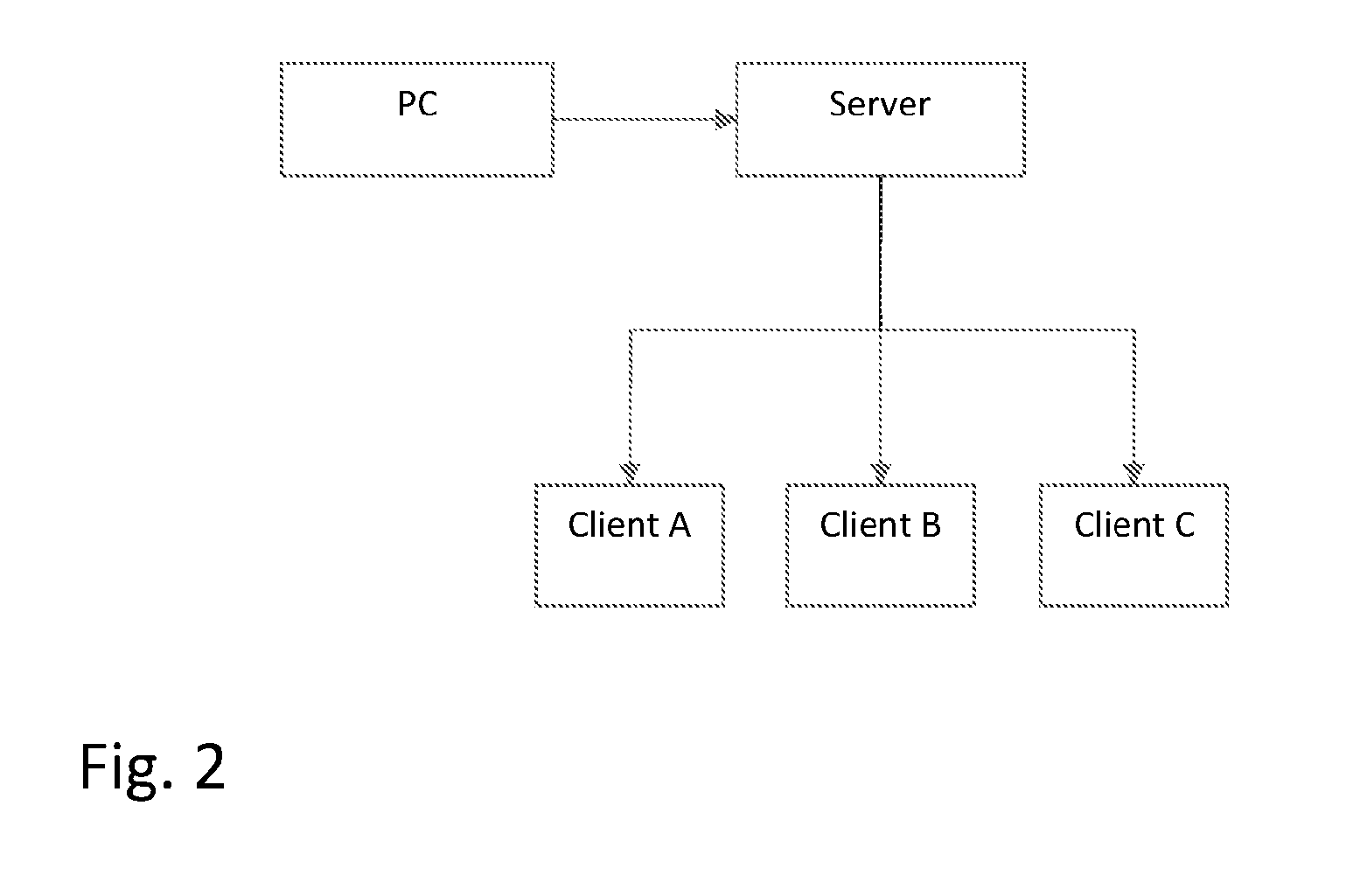

BIM and display of 3D models on client devices

InactiveUS20140218360A1Work fasterControl power consumptionCAD network environmentSpecial data processing applicationsComputer graphics (images)2d images

The invention relates to the calculation of 2D images from a 3D model, wherein the 2D images may be generated on a computer device and stored on a server for subsequent display on a client device.

Owner:DALUX APS

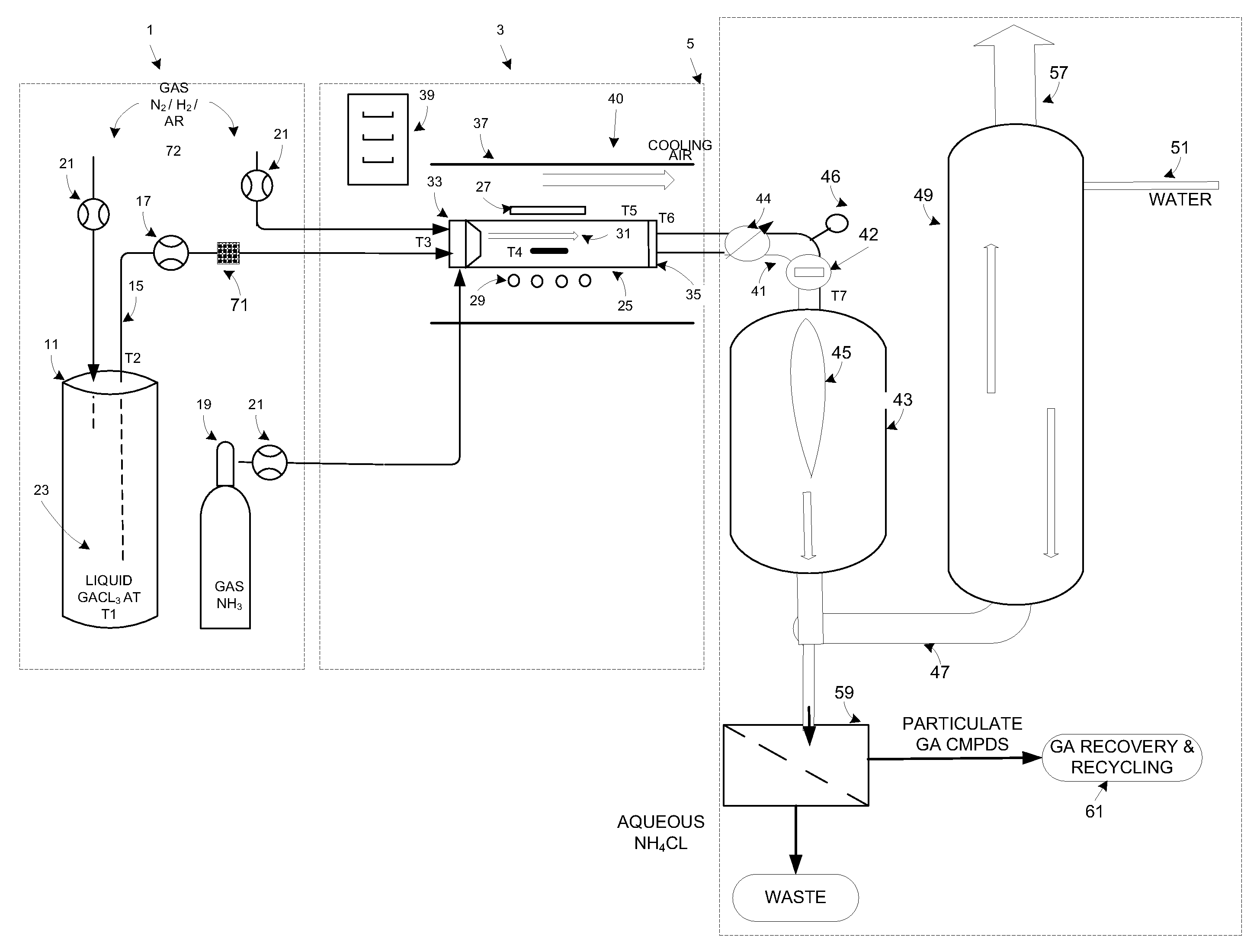

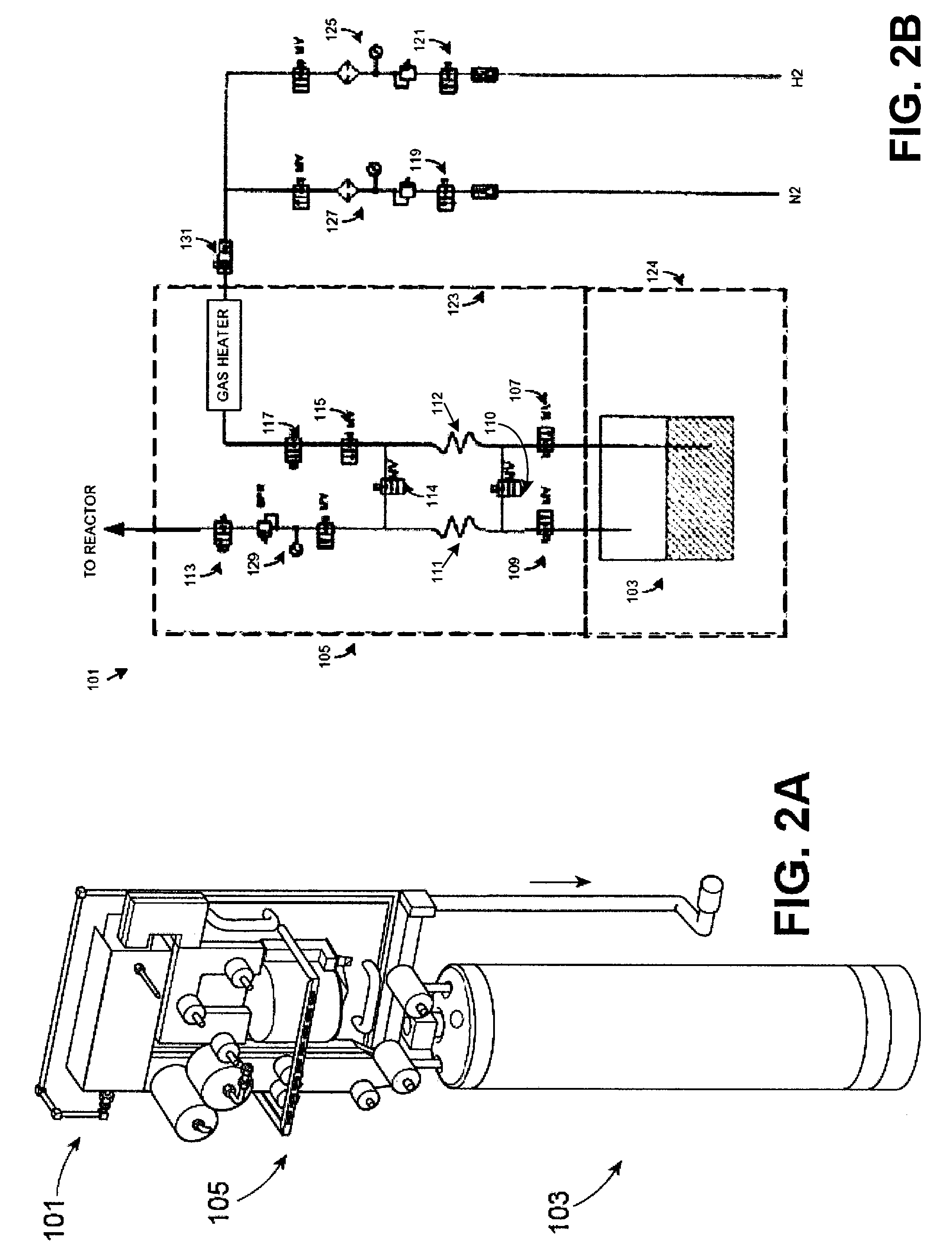

Temperature-controlled purge gate valve for chemical vapor deposition chamber

ActiveUS20090205563A1Efficiently formedEasy to depositAfter-treatment apparatusPolycrystalline material growthTemperature controlIsolation valve

The present invention relates to methods and apparatus that are optimized for producing Group III-N (nitrogen) compound semiconductor wafers and specifically for producing GaN wafers. Specifically, the methods relate to substantially preventing the formation of unwanted materials on an isolation valve fixture within a chemical vapor deposition (CVD) reactor. In particular, the invention provides apparatus and methods for limiting deposition / condensation of GaCl3 and reaction by-products on an isolation valve that is used in the system and method for forming a monocrystalline Group III-V semiconductor material by reacting an amount of a gaseous Group III precursor as one reactant with an amount of a gaseous Group V component as another reactant in a reaction chamber.

Owner:S O I TEC SILICON ON INSULATOR THECHNOLOGIES

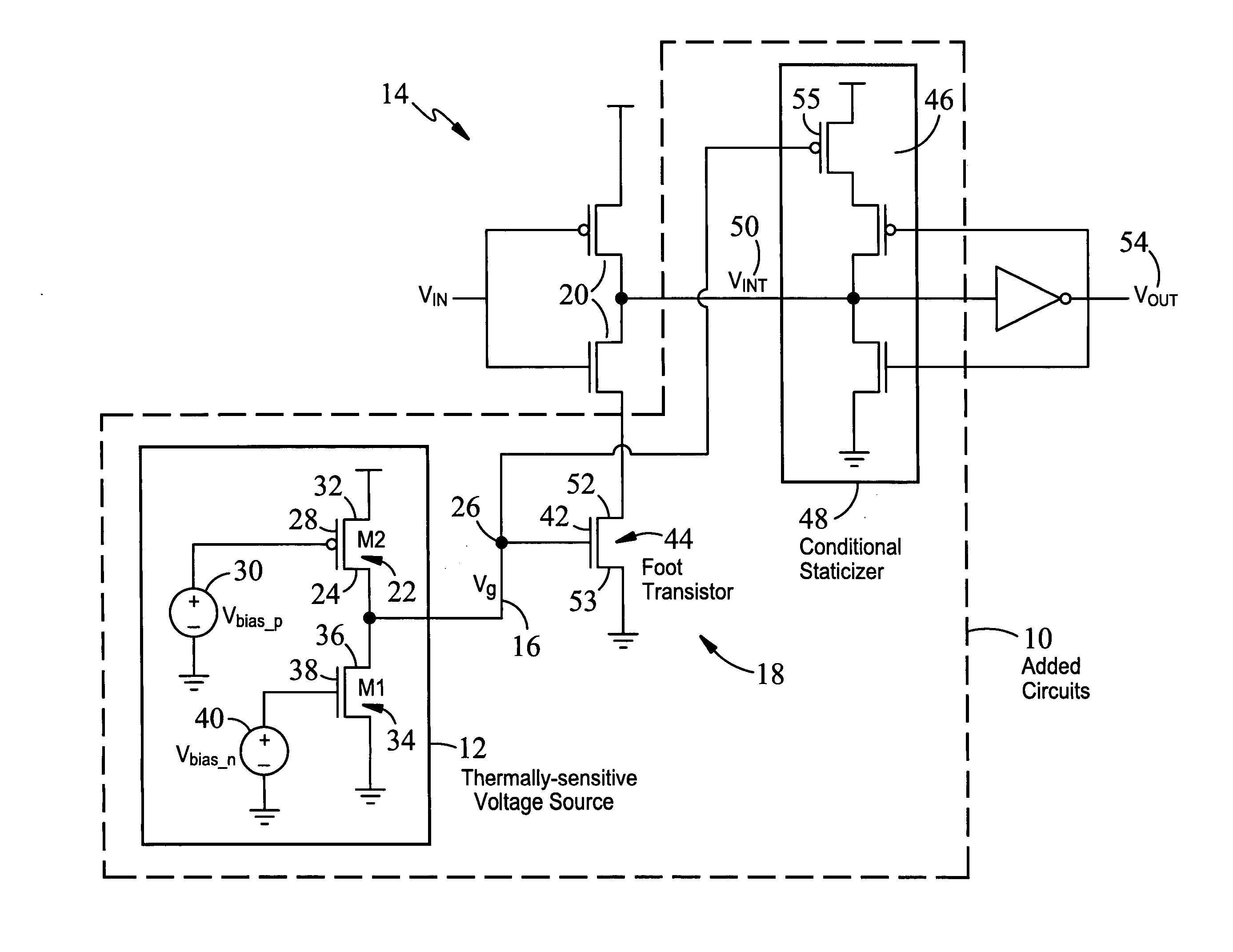

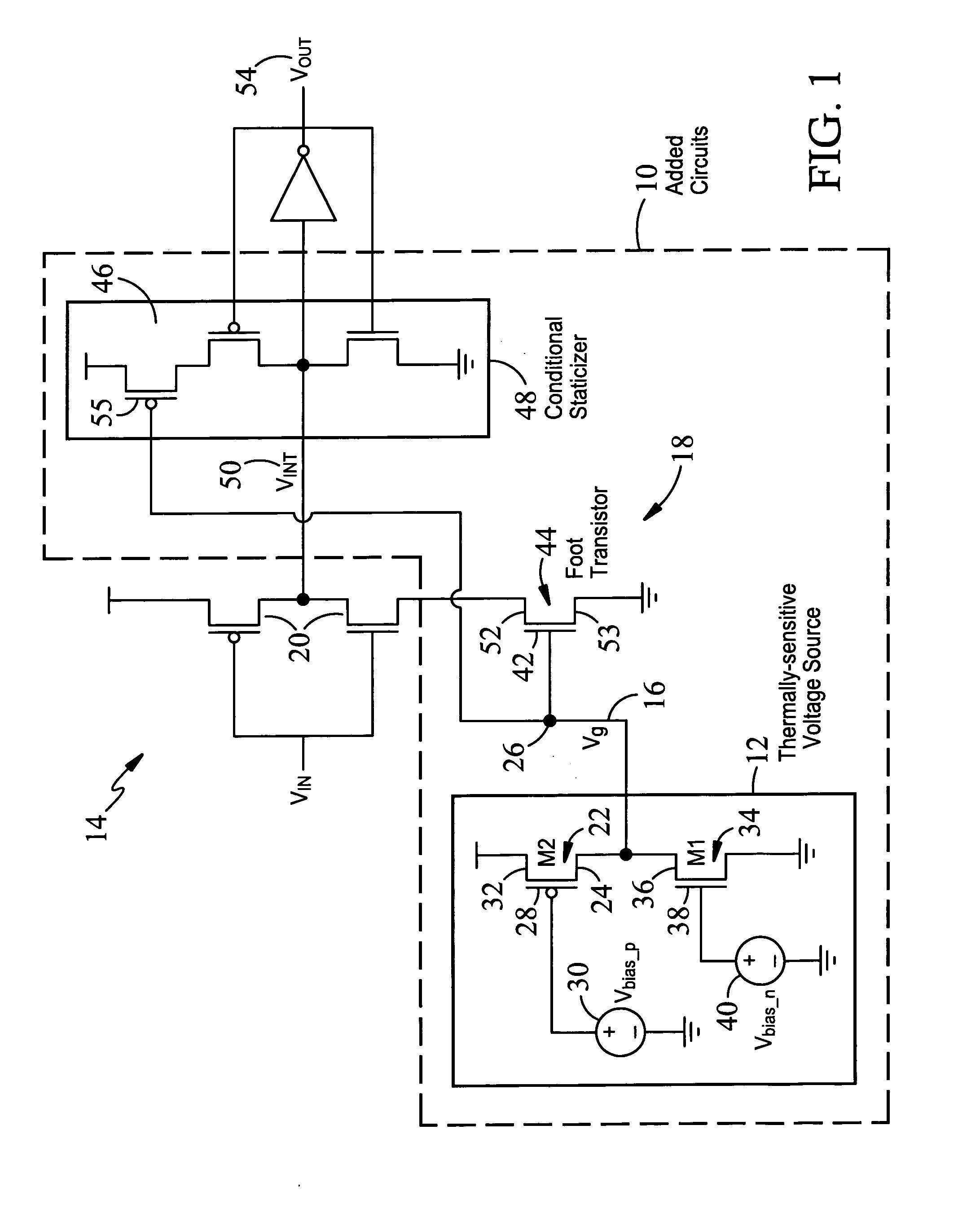

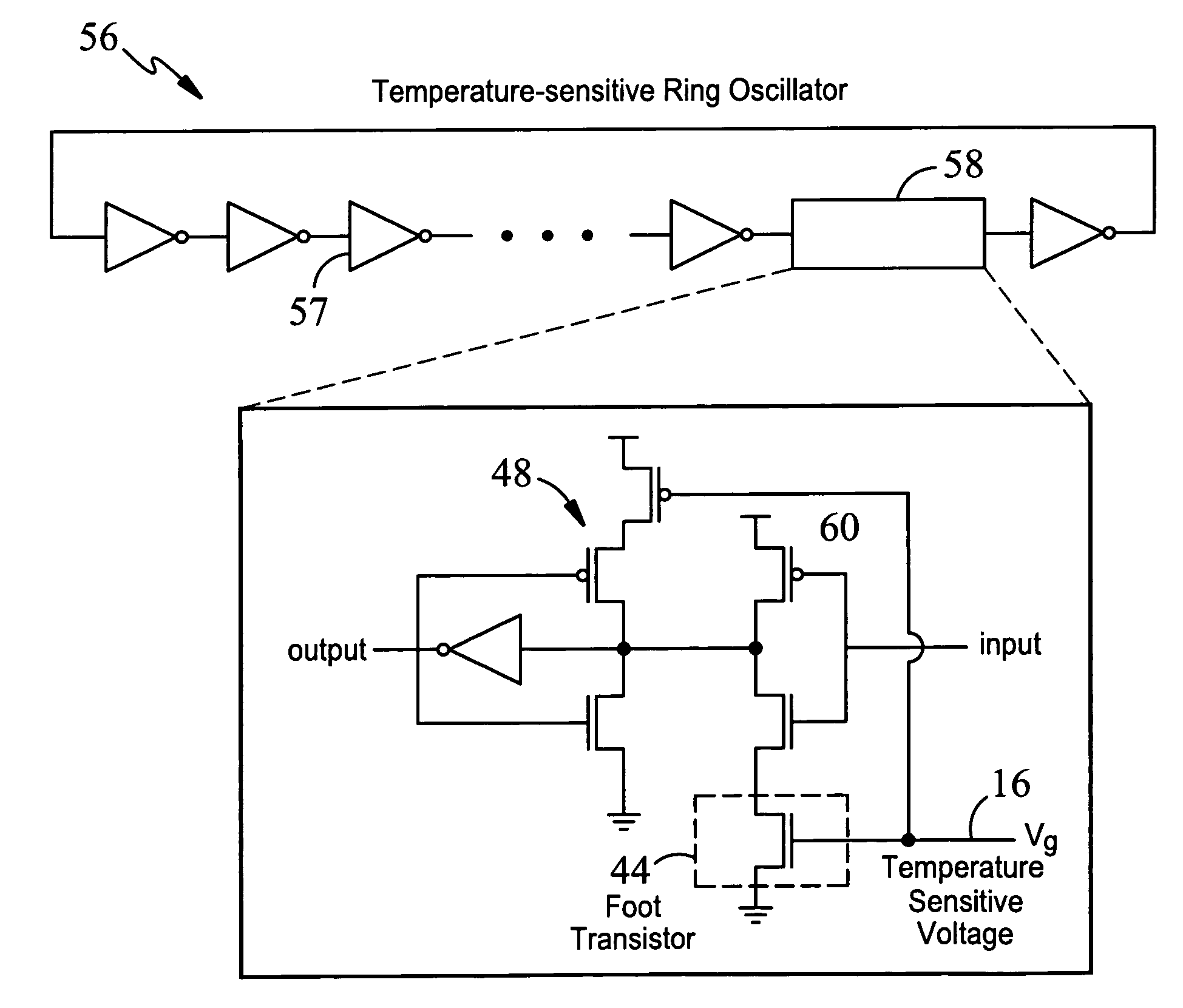

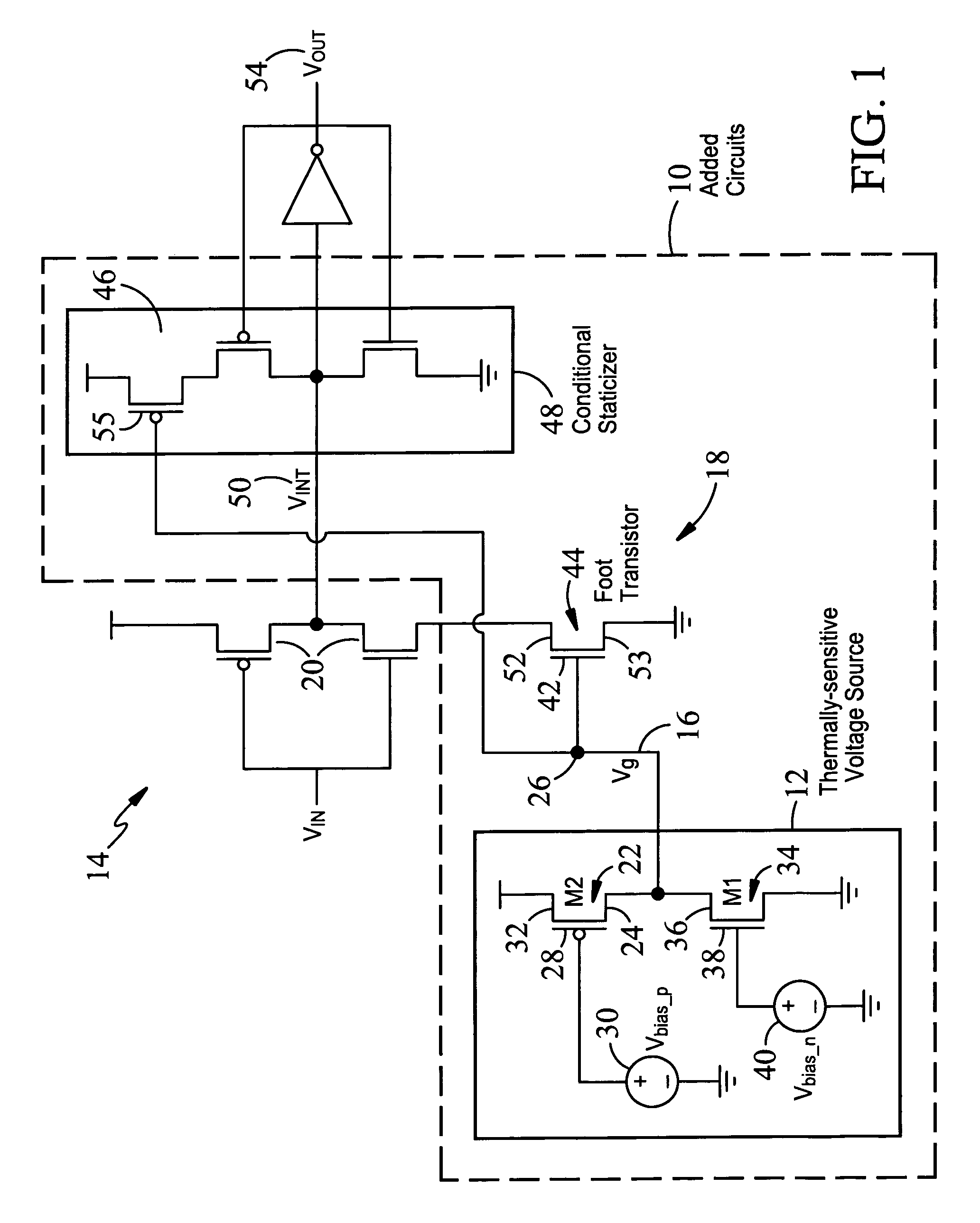

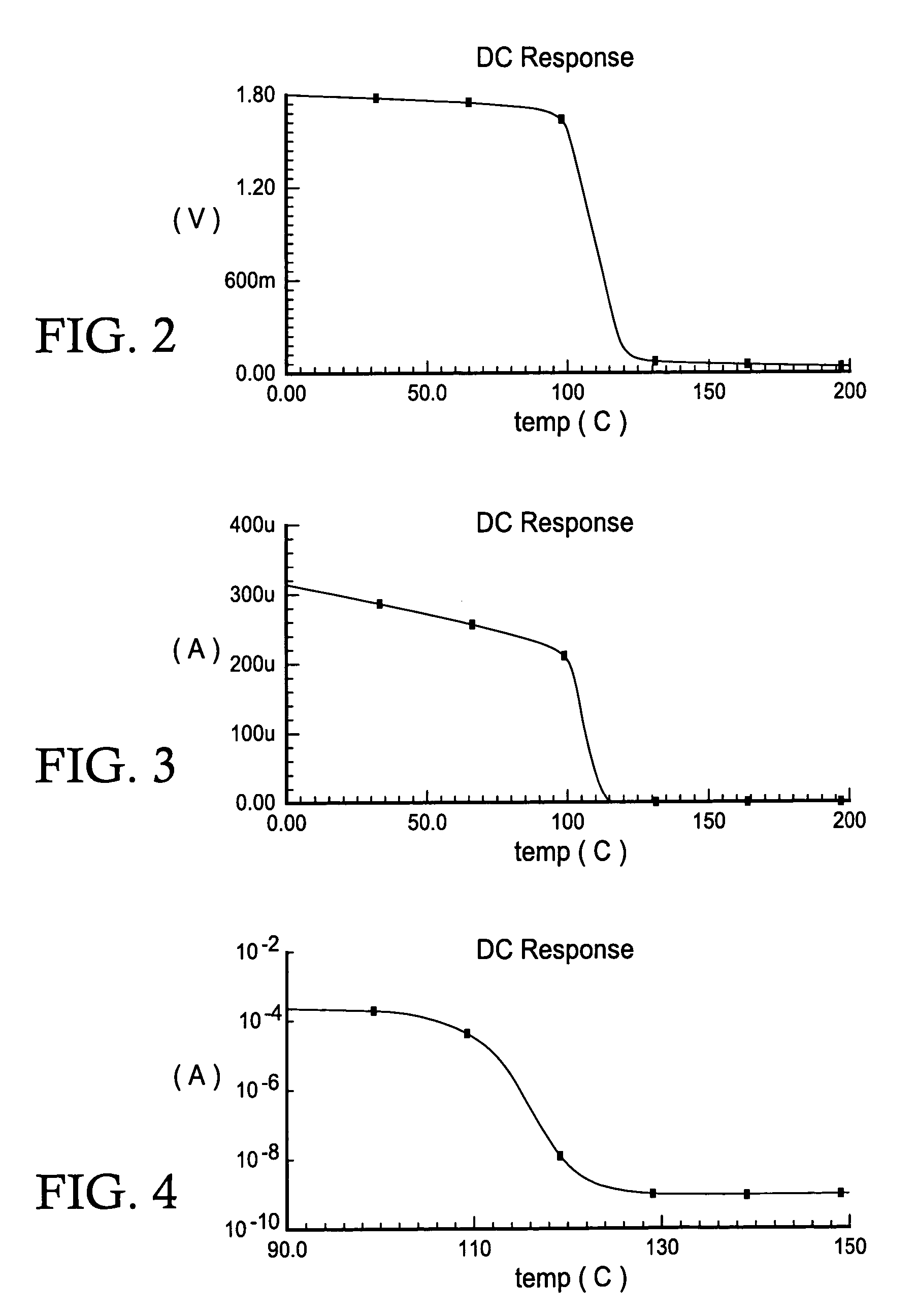

Self-timed thermally-aware circuits and methods of use thereof

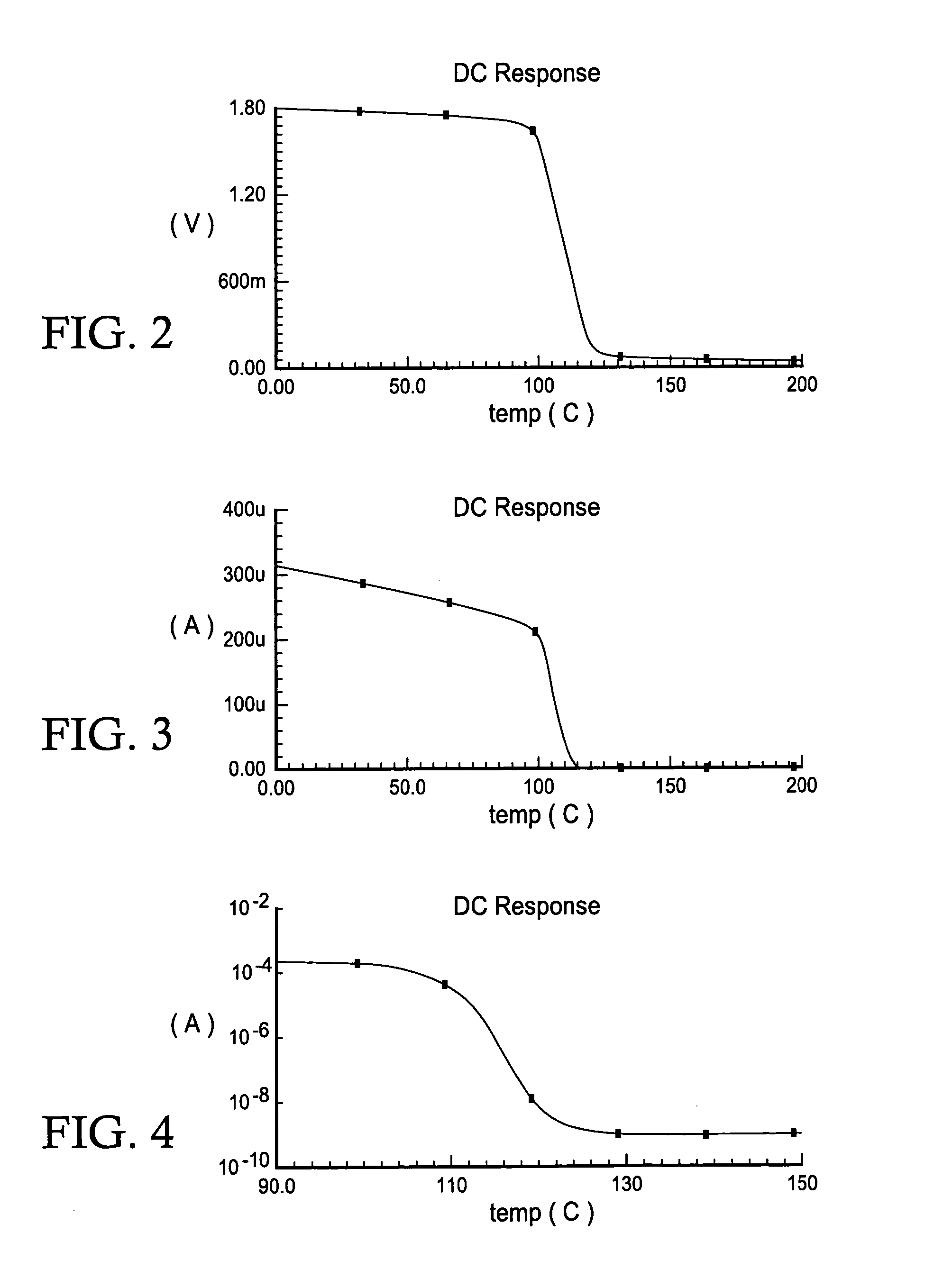

InactiveUS20070200608A1Without imposing significant implementation overheadStall-free performance-throttlingElectronic switchingNetwork modifications to reduce temperatureVoltage sourceThreshold temperature

Apparatus and methods for regulating gate delays of synchronous and asynchronous digital circuits. Thermally-sensitive circuits include, generally, temperature sensitive voltage sources outputting a voltage signal indicative of the temperature of the digital circuit, where the voltage signal reflects non-linear temperature sensitivity above a predetermined threshold temperature, and delay mechanisms receiving said temperature sensitive voltage signal(s) as input and being configured to automatically continuously modulate the speed of signal propagation through the circuit in response to said voltage signal, thereby causing circuit elements within the circuits to switch less frequently and consequently causing the circuit elements to generate less heat with increasing circuit temperature.

Owner:CORNELL RES FOUNDATION INC

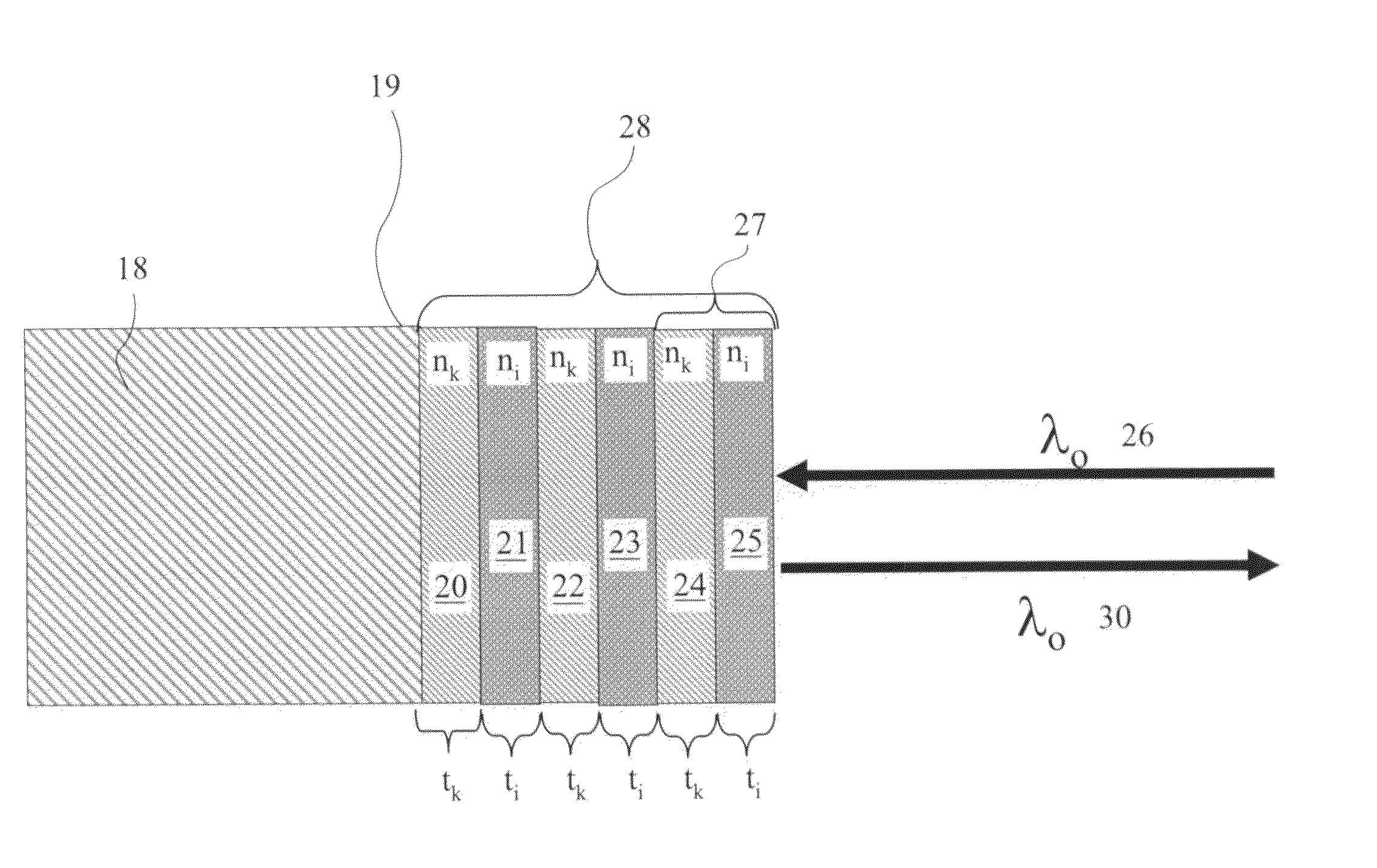

Method of reflecting impinging electromagnetic radiation and limiting heating caused by absorbed electromagnetic radiation using engineered surfaces on macro-scale objects

ActiveUS20100118407A1Reduce heat transferReduce transportationMirrorsOptical filtersRefractive indexElectromagnetic radiation

A method of reflecting impinging electromagnetic radiation by using engineered surfaces of alternating layers of materials having different indices of refraction is described. These layers can be fabrication or applied onto the surfaces of macro-scale objects. Also, a method of limiting the heating within the interior of an object being impinged upon by electromagnetic radiation is described.

Owner:FOR NAT RES INITIATIVES

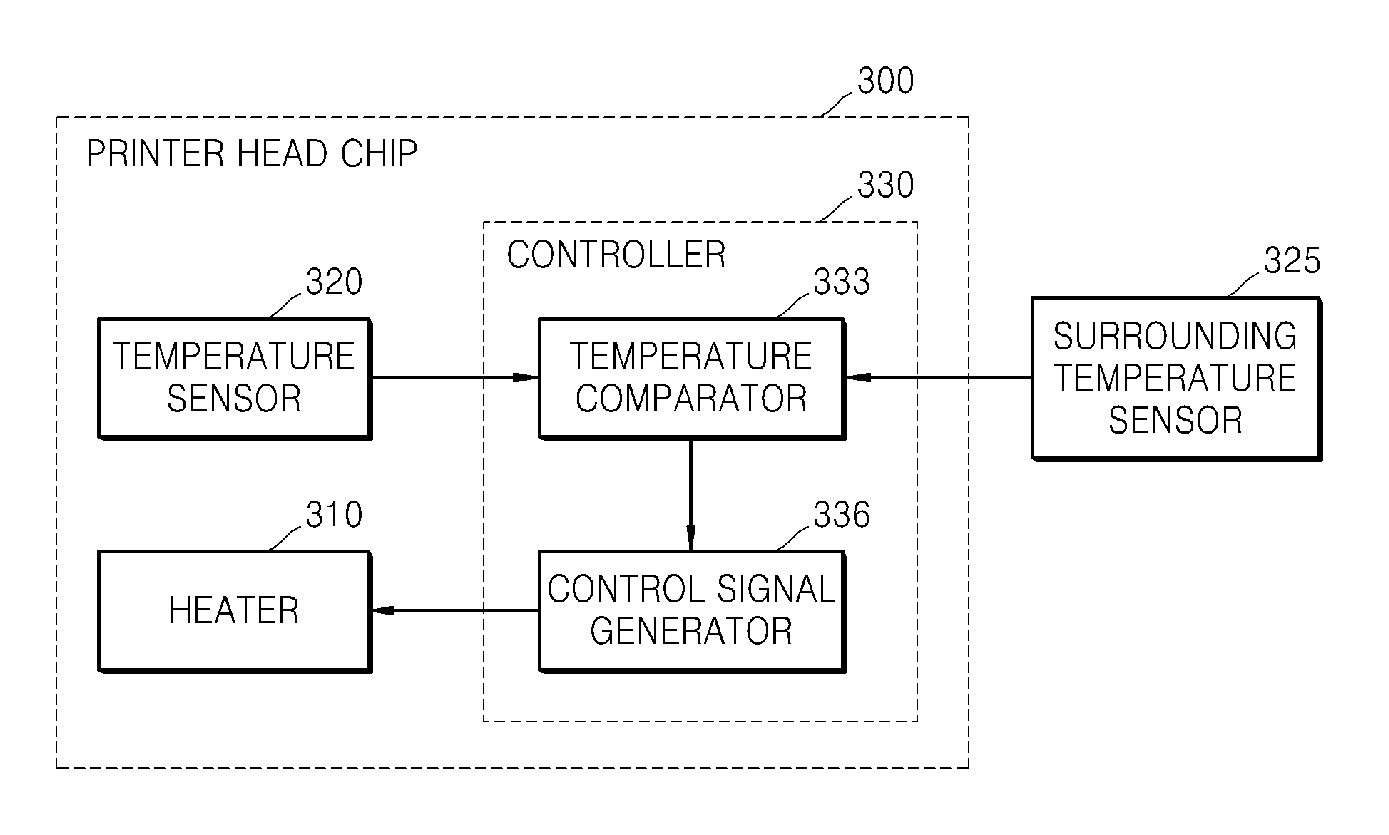

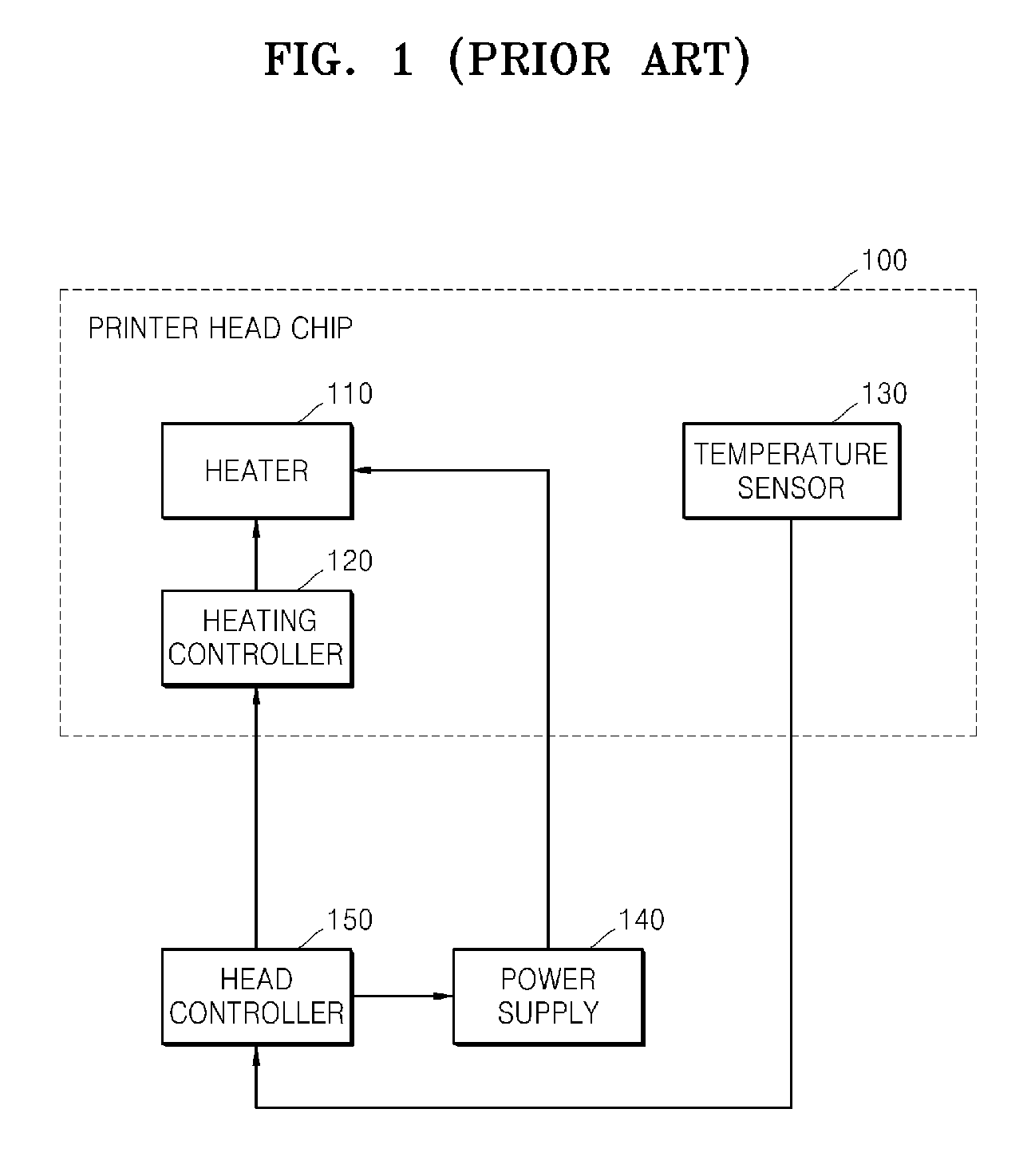

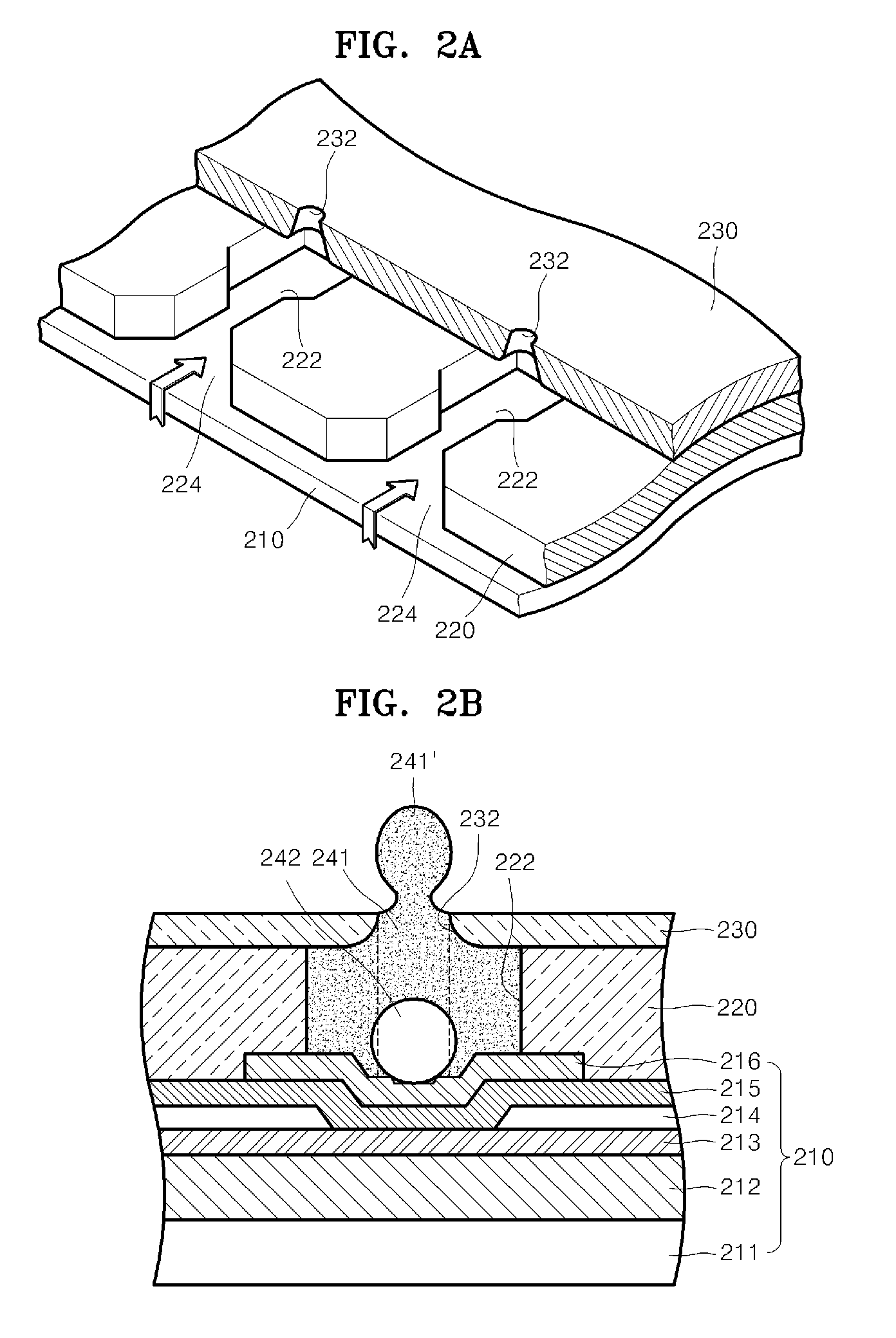

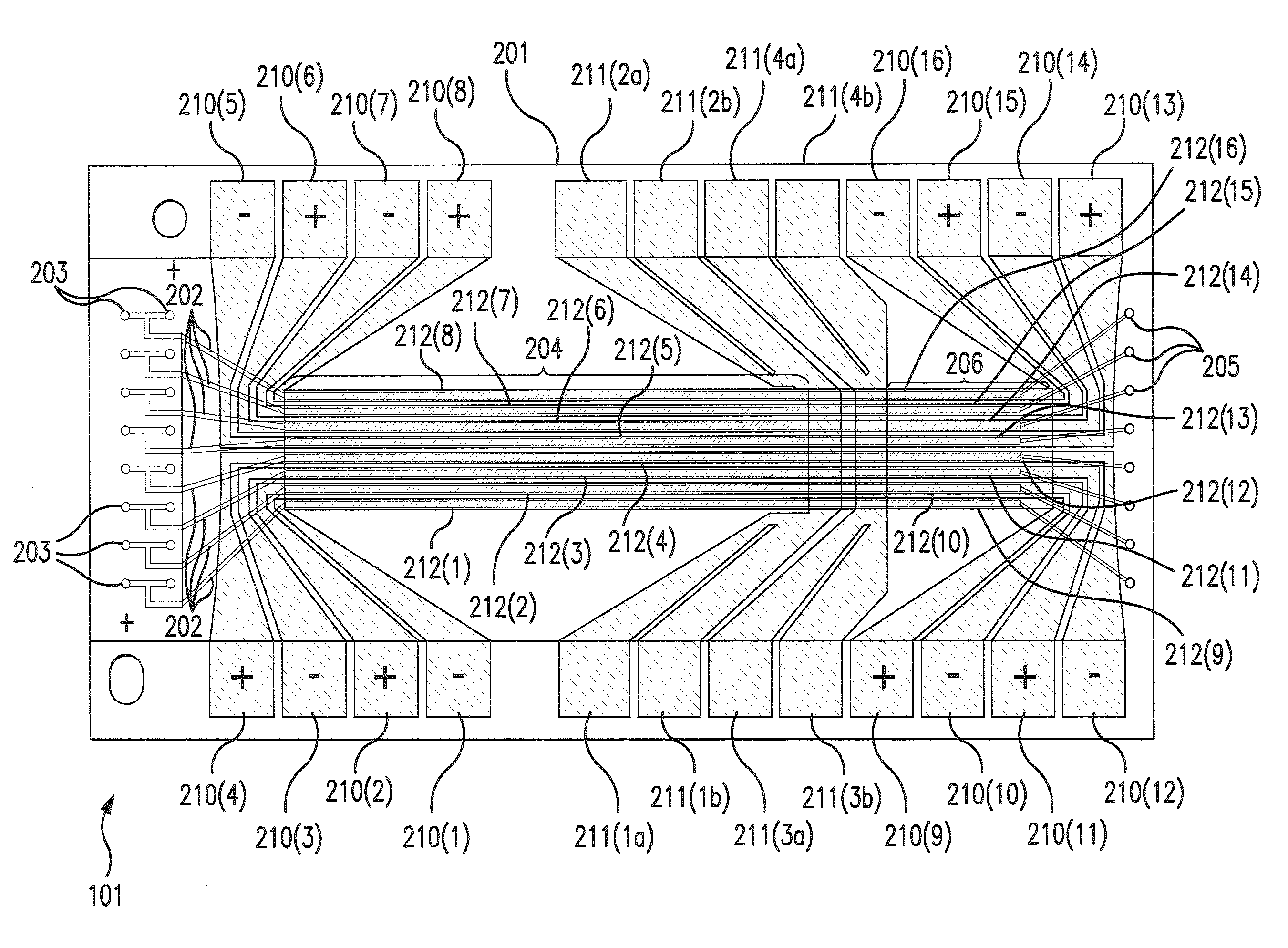

Method and apparatus to control a temperature of a printer head chip

A method and an apparatus to control a temperature of a printer head chip. The temperature control apparatus includes a heater, a temperature sensor, and a controller. The heater heats a predetermine portion of the printer head chip. The temperature sensor senses the temperature of the printer head chip. The controller is provided in the printer head chip and provides a control signal to the heater according to the sensed temperature. Accordingly, damage to the printer head chip can be prevented and safety in using the printer can be guaranteed. Also, ink droplets can be accurately ejected from the printer head chip such that printing quality is improved and a life span of the heater is extended.

Owner:SAMSUNG ELECTRONICS CO LTD

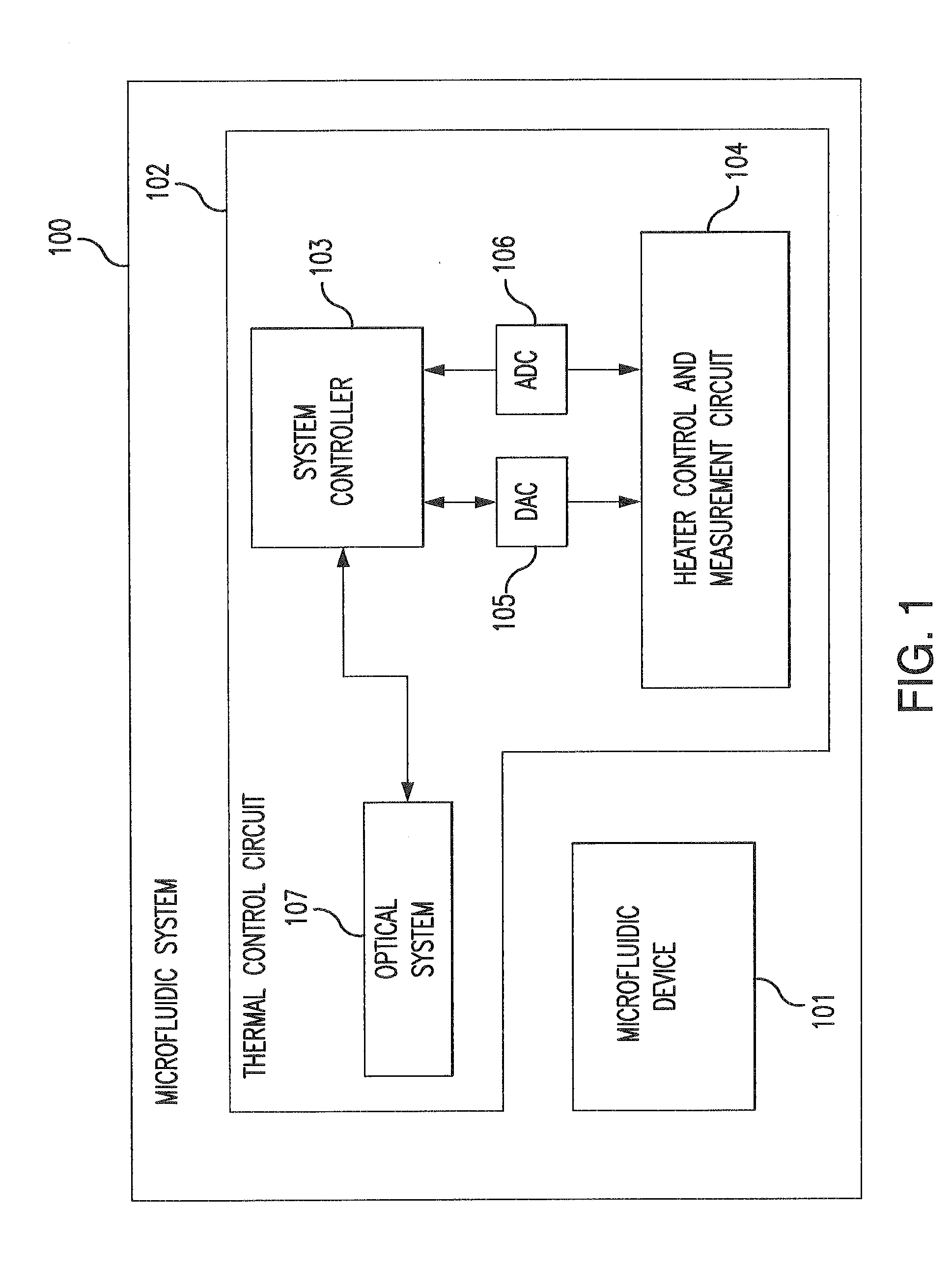

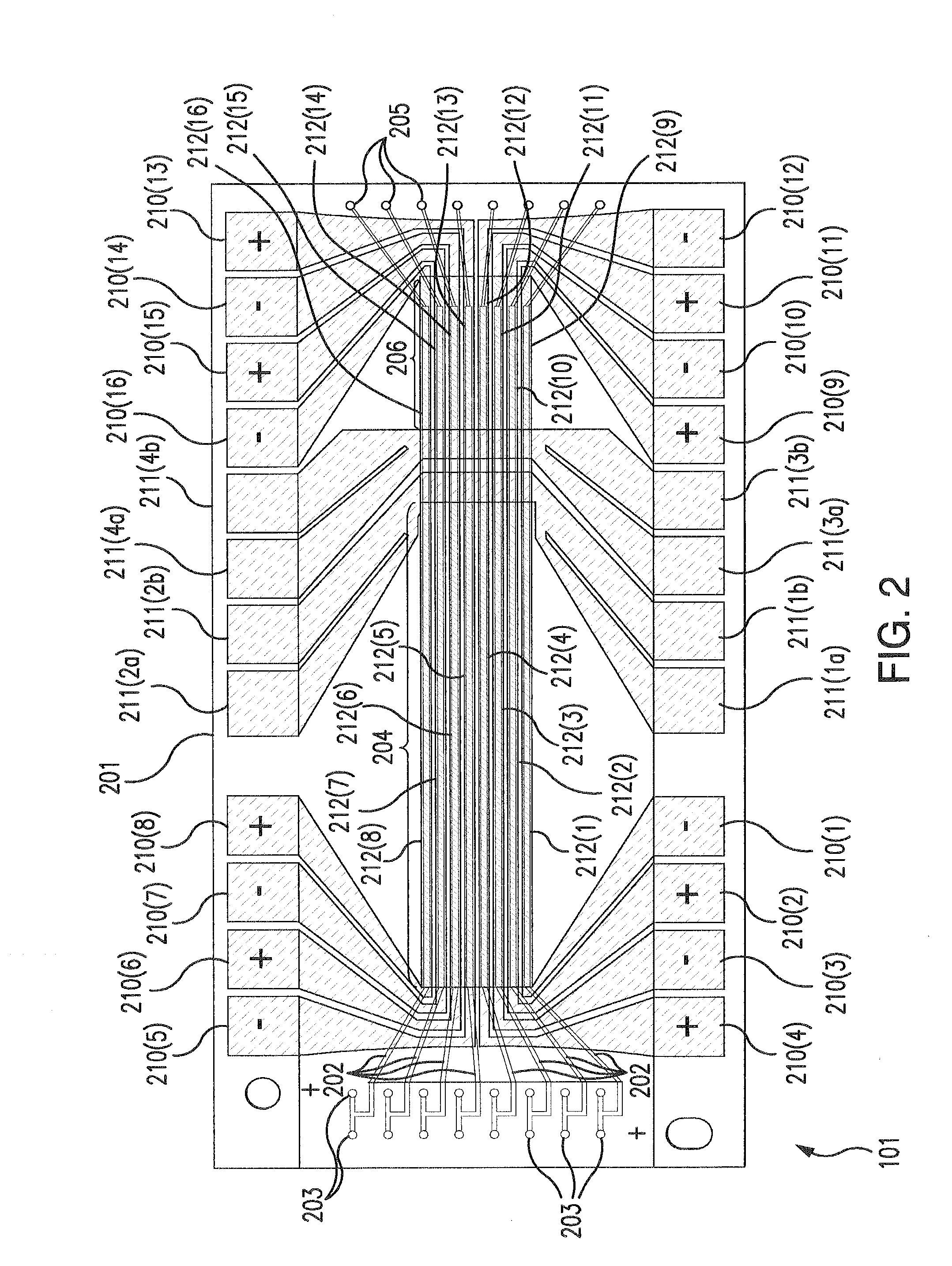

Systems and Methods Using External Heater Systems in Microfluidic Devices

ActiveUS20130157271A1Control heat lossImprove temperature uniformityBioreactor/fermenter combinationsBiological substance pretreatmentsHot meltEngineering

The present invention relates to methods and systems that result in high quality, reproducible, thermal melt analysis on a microfluidic platform. The present invention relates to methods and systems using thermal systems including heat spreading devices, including interconnection methods and materials developed to connect heat spreaders to microfluidic devices. The present invention also relates to methods and systems for controlling, measuring, and calibrating the thermal systems of the present invention.

Owner:CANON USA

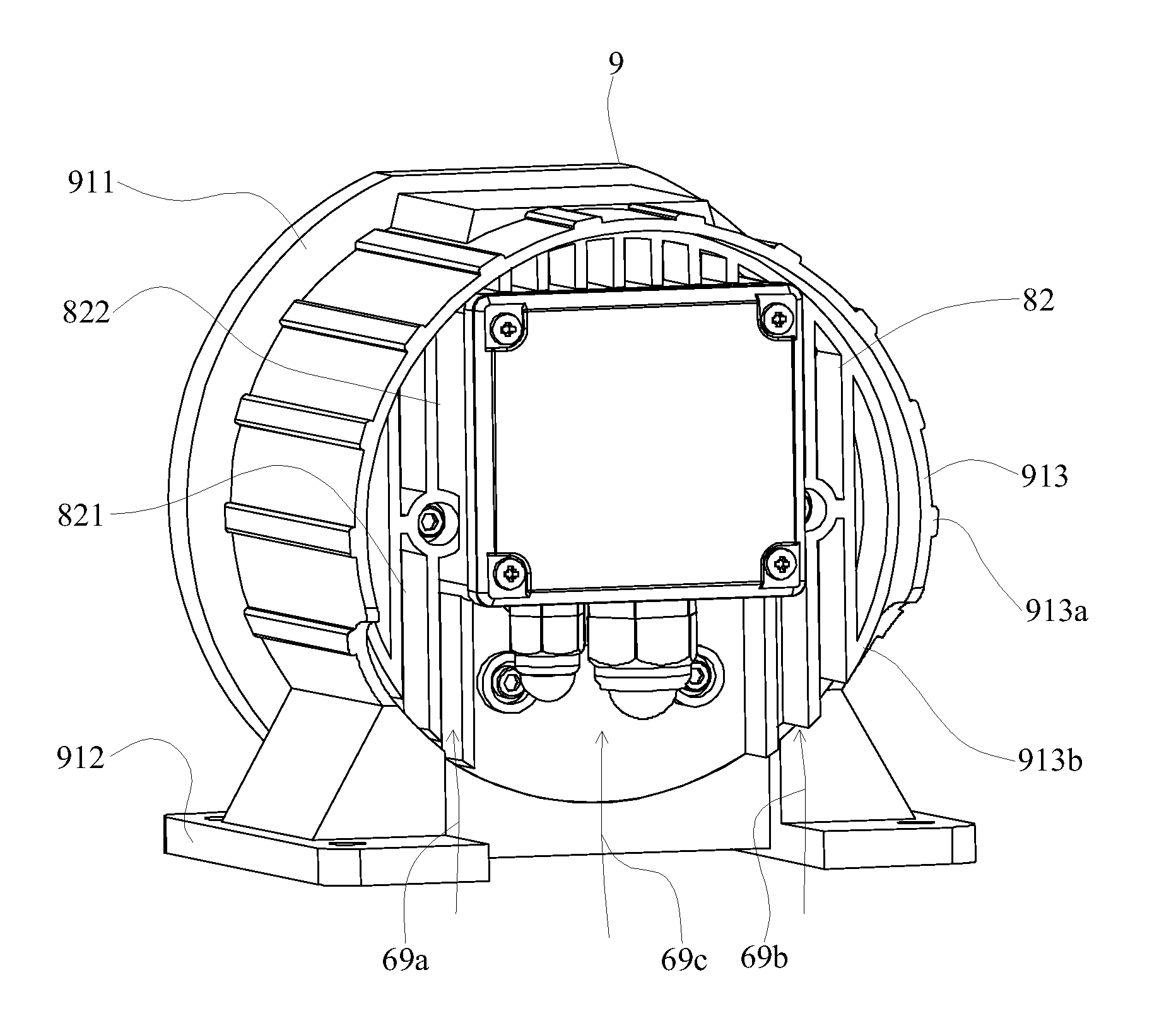

Permanent magnet canned motor pump with corrosion-protection housing

ActiveUS20130115118A1Avoid corrosionPrevent leakagePump componentsEngine fuctionsCompound (substance)Engineering

A permanent magnet canned motor pump features in its corrosion-protection housing which comprises a reinforced bracket, motor casing and a motor rear casing. The reinforced bracket is made of corrosion-resistance plastic and the motor casing and the motor rear casing are made of aluminum alloy. Accordingly, the corrosion-protection housing is capable of preventing the corrosion of the chemical liquid to the aluminum alloy components. Beside, the permanent magnet canned motor pump provides a heat dissipation mechanism while meets the structural need of the corrosion-protection housing, so that the motor can dissipate heat in a sufficient rate.

Owner:ASSOMA

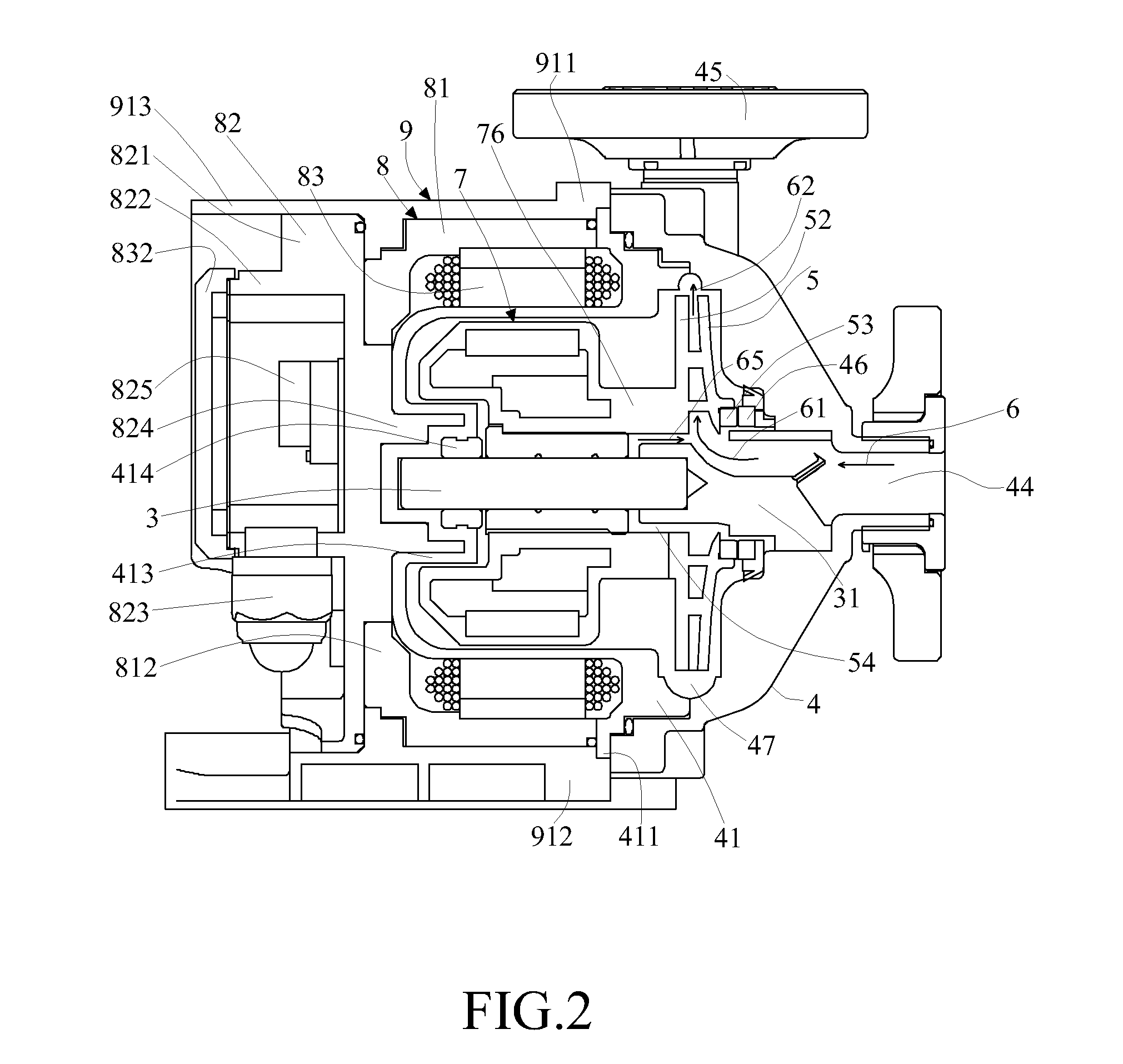

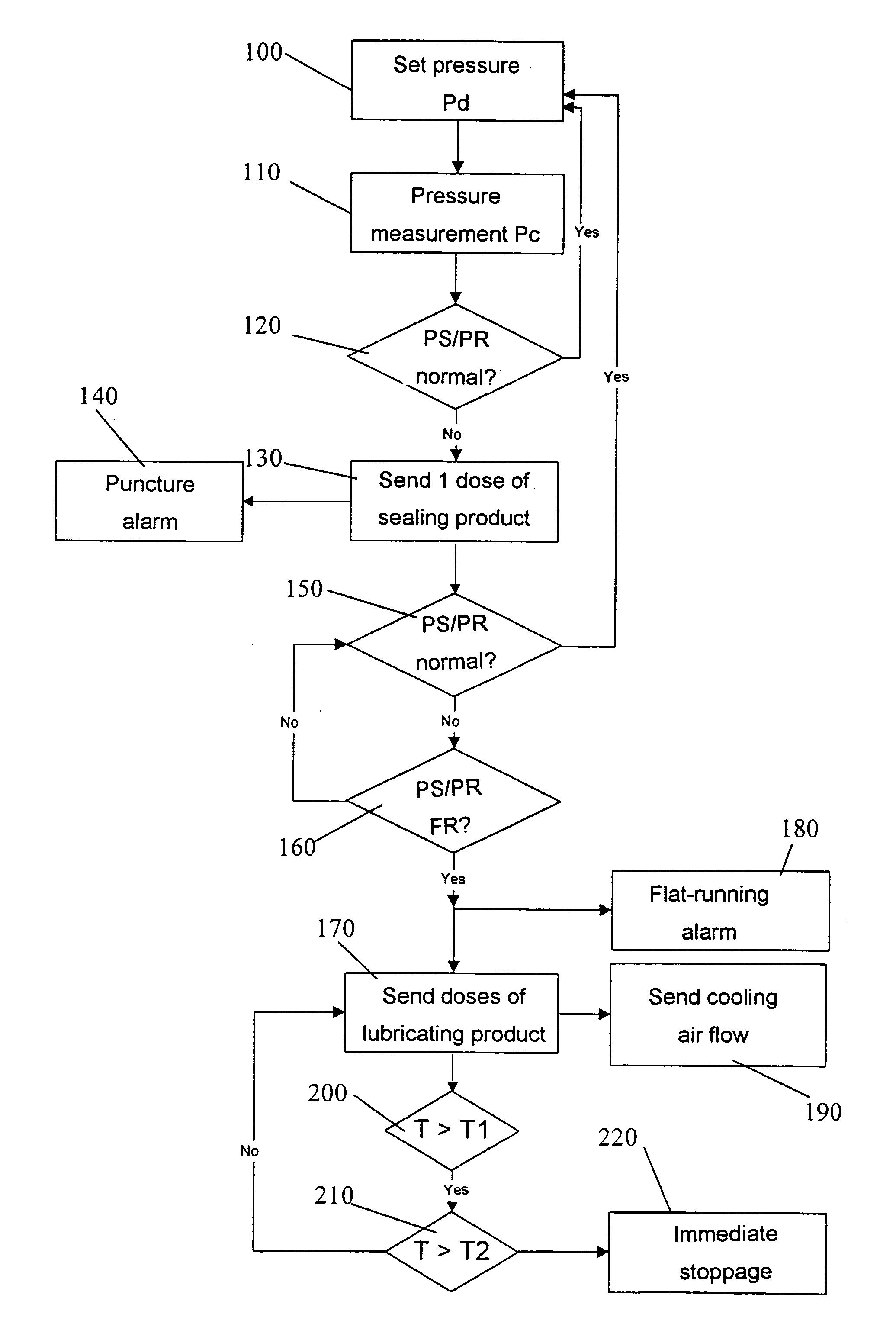

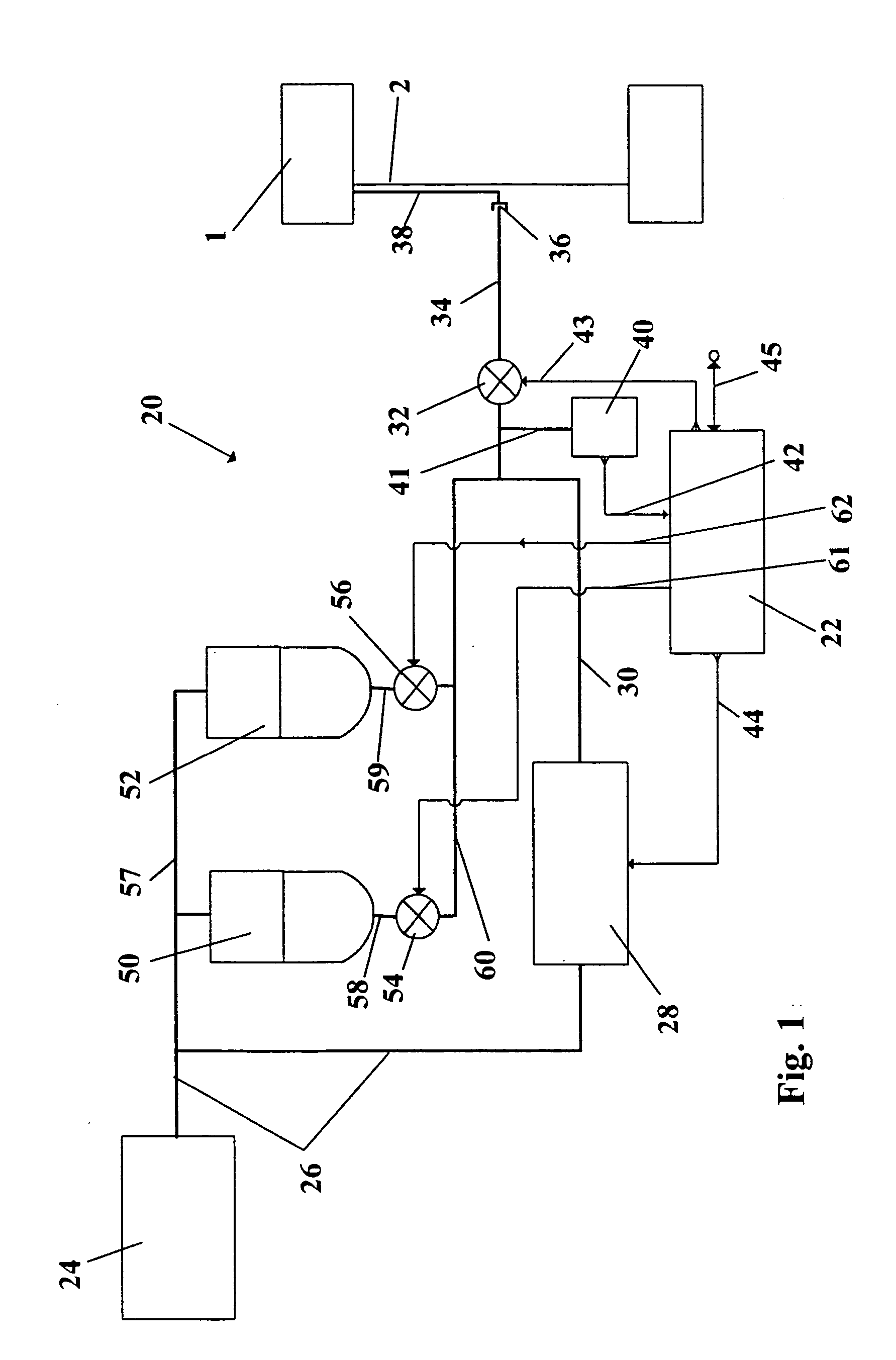

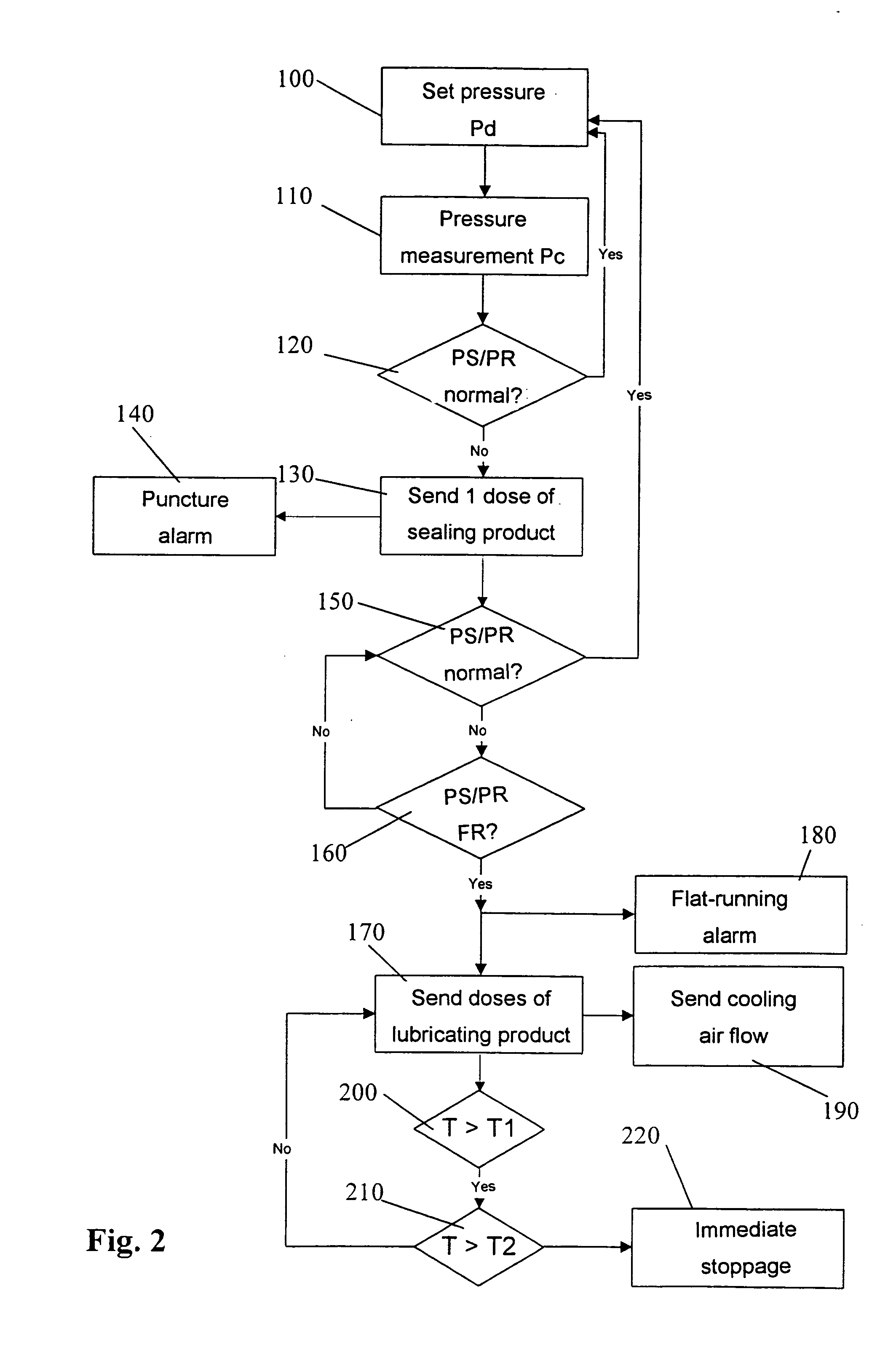

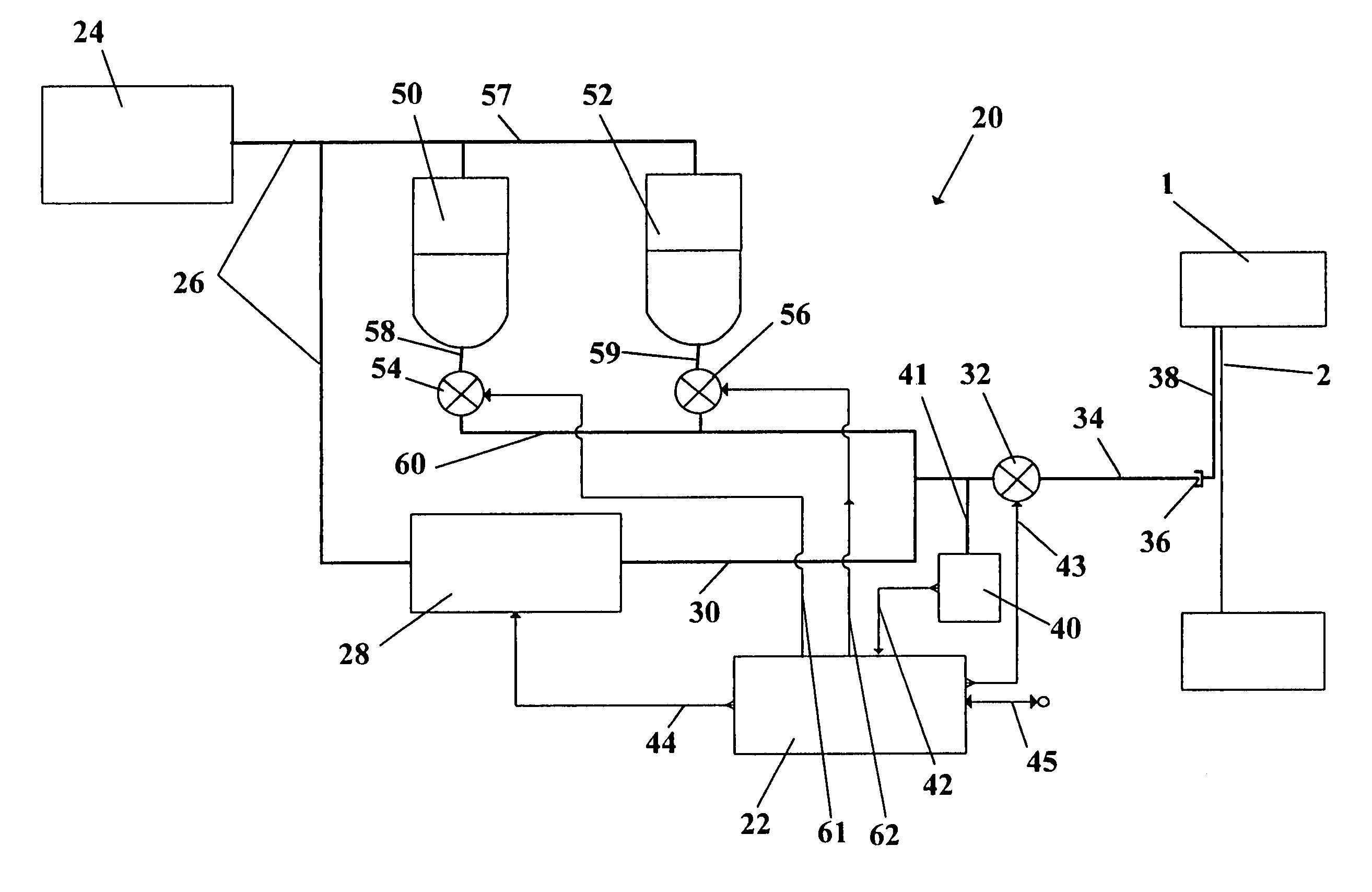

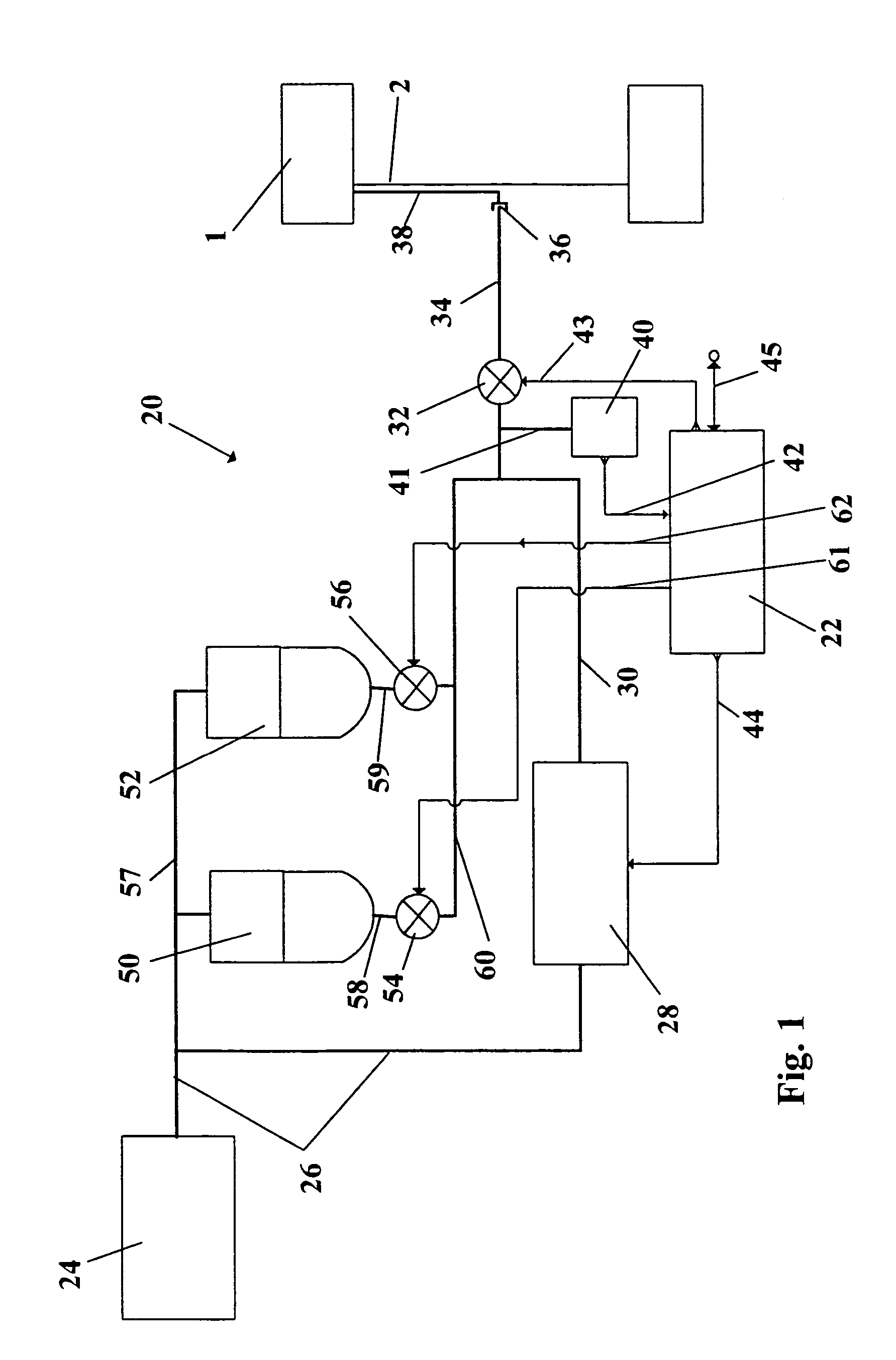

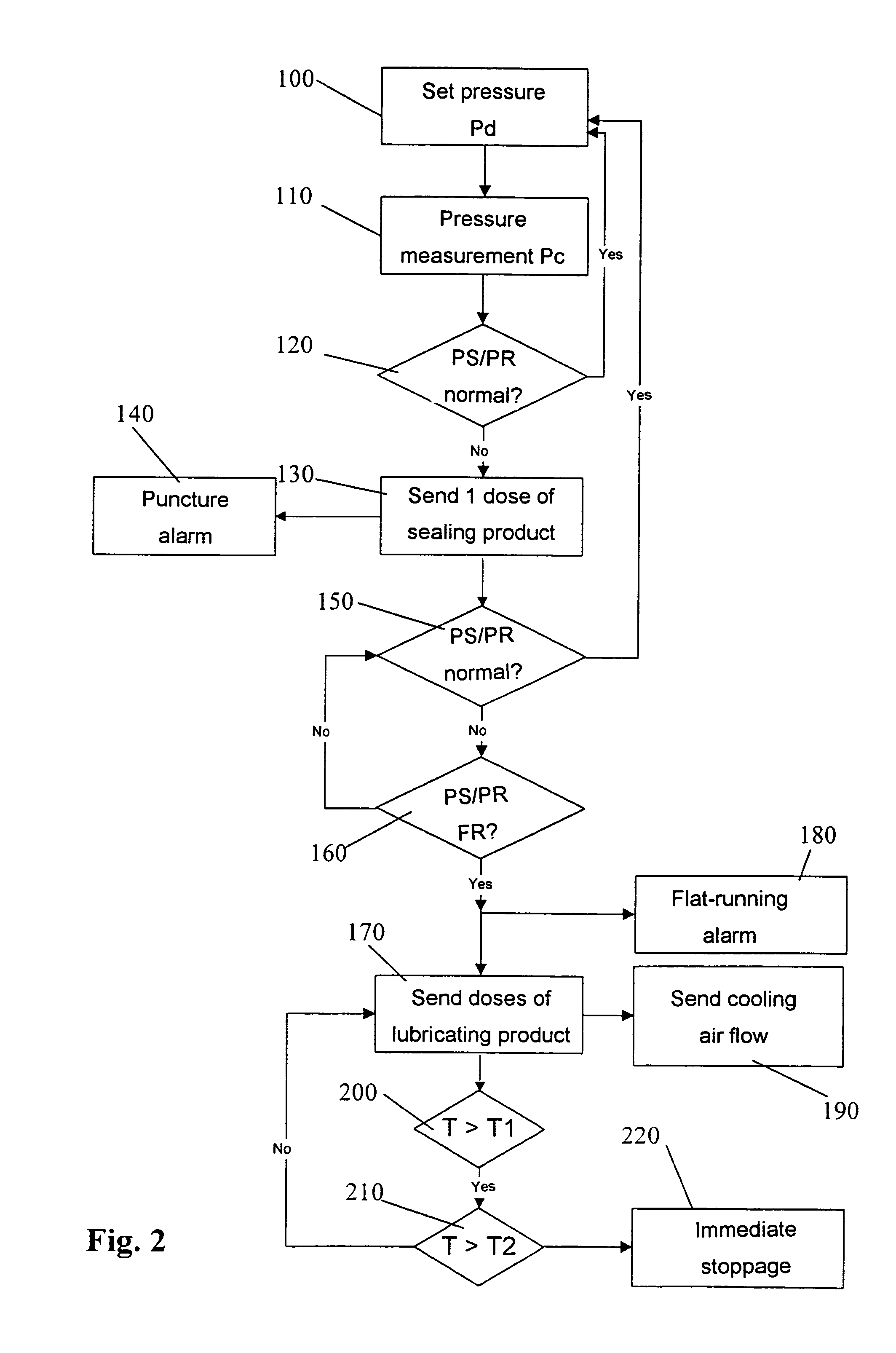

Device and method for dealing with phenomena of loss of pressure and running flat with vehicle tires

InactiveUS20050045259A1Heating be limitedRelieve friction forceRimsInflatable tyresInternal cavityAerospace engineering

A centralized device for dealing with the phenomena of loss of pressure and running flat with a vehicle tire, comprising a means external to the mounted assembly, permanently fixed to the vehicle and able to inject or otherwise bring into the internal cavity of the tire at least one active product, also external to the mounted assembly, and able to treat the phenomena of loss of pressure and ultimately running flat.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

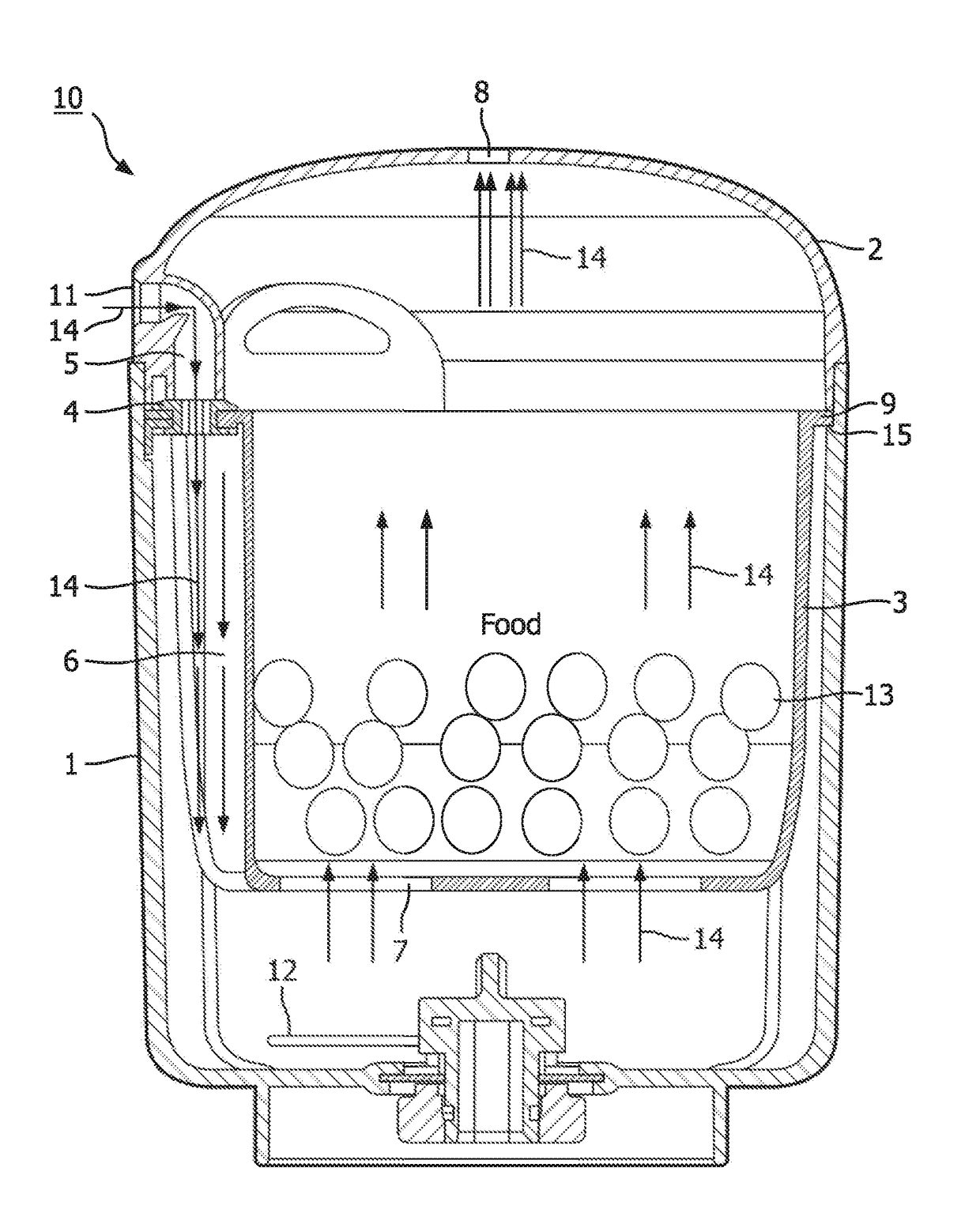

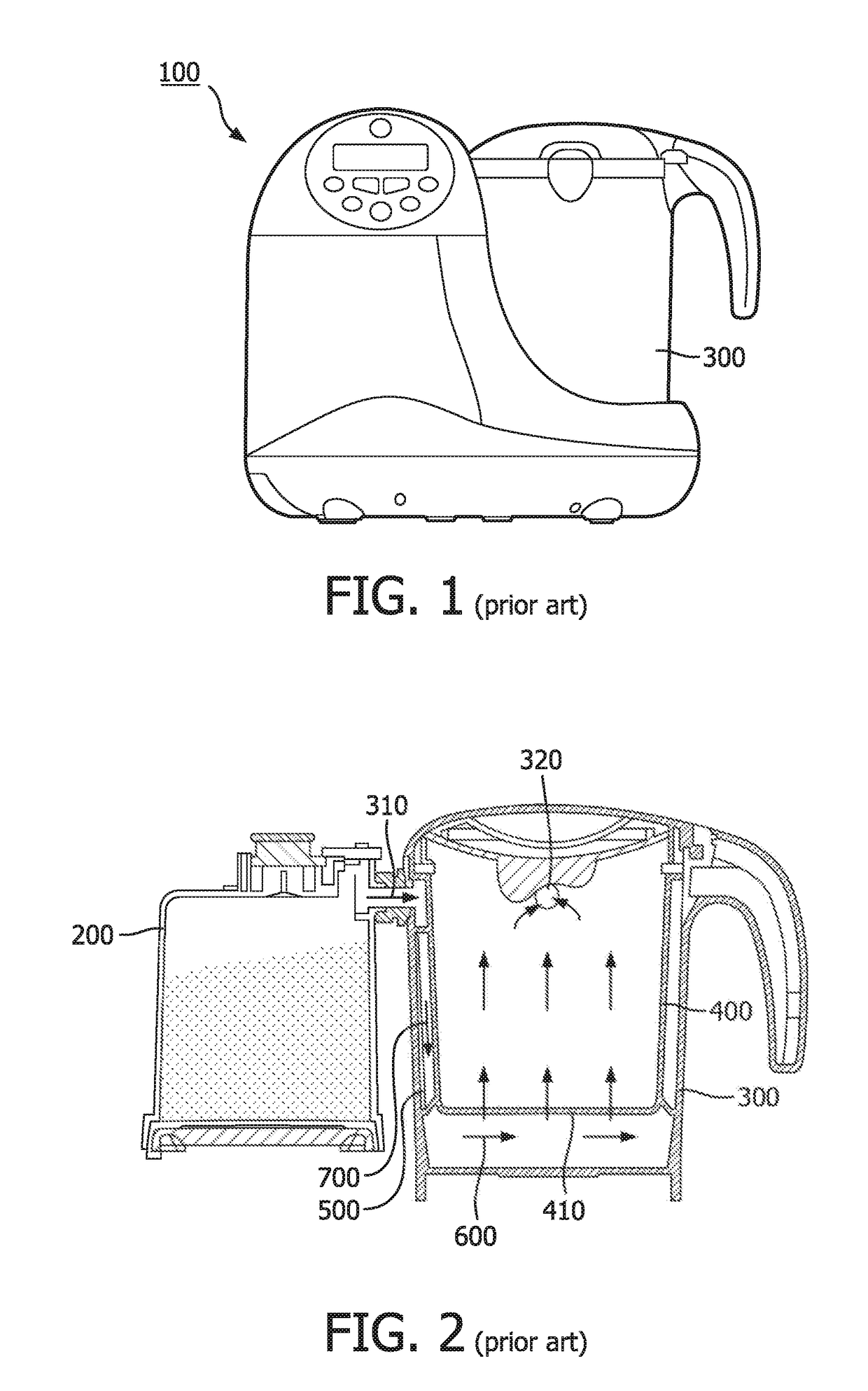

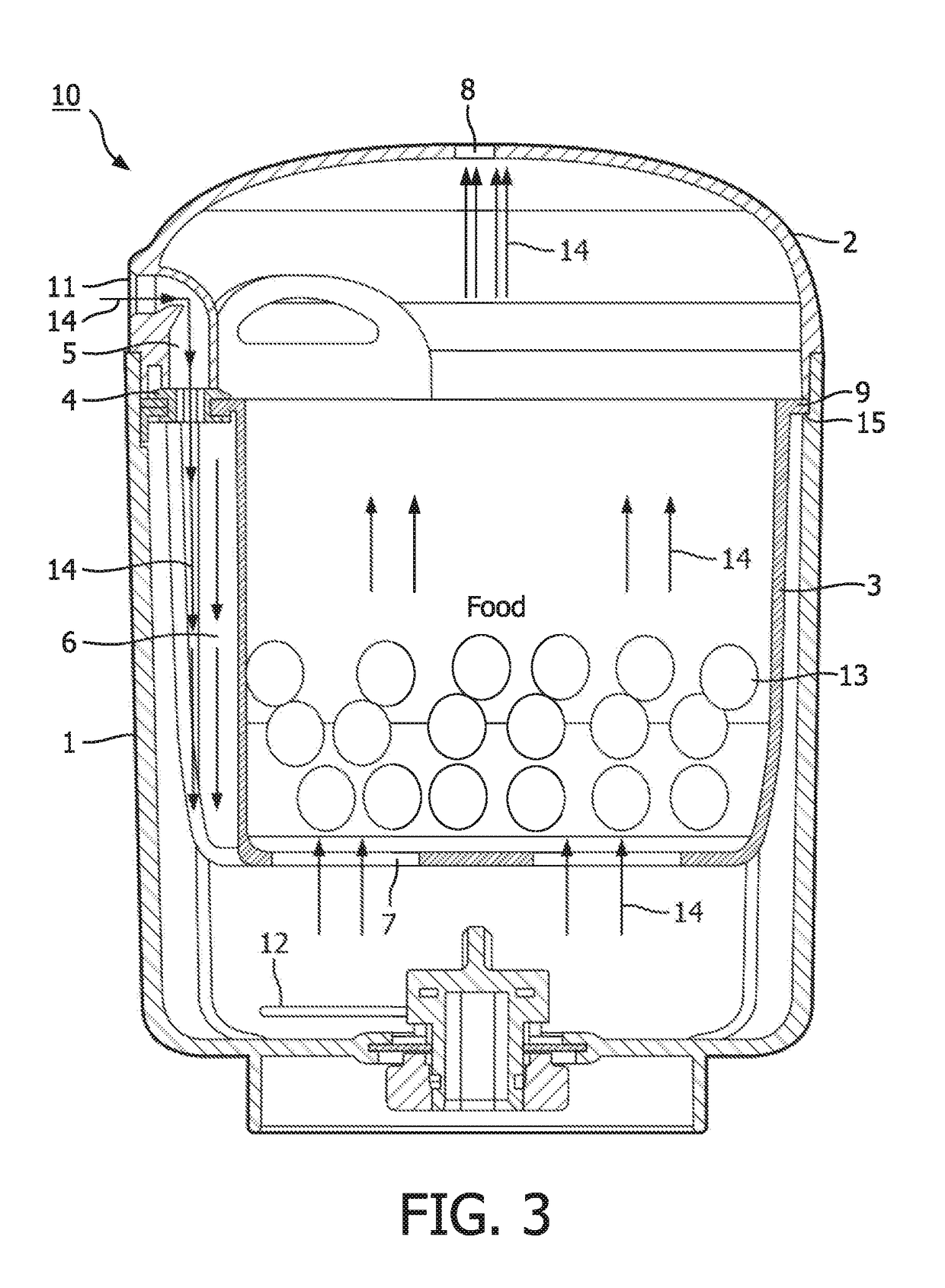

Food processor with improved steam channel structure

The invention relates to a food processor comprising a steam generator and a heating cup, wherein the heating cup comprises a container and a removable lid for sealing the container, the steam generator being coupled to the heating cup via a steam inlet arranged in the lid, the steam inlet being an opening of a steam pipe arranged in the lid and configured to dispense steam in the container when the lid seals the container.

Owner:KONINKLJIJKE PHILIPS NV

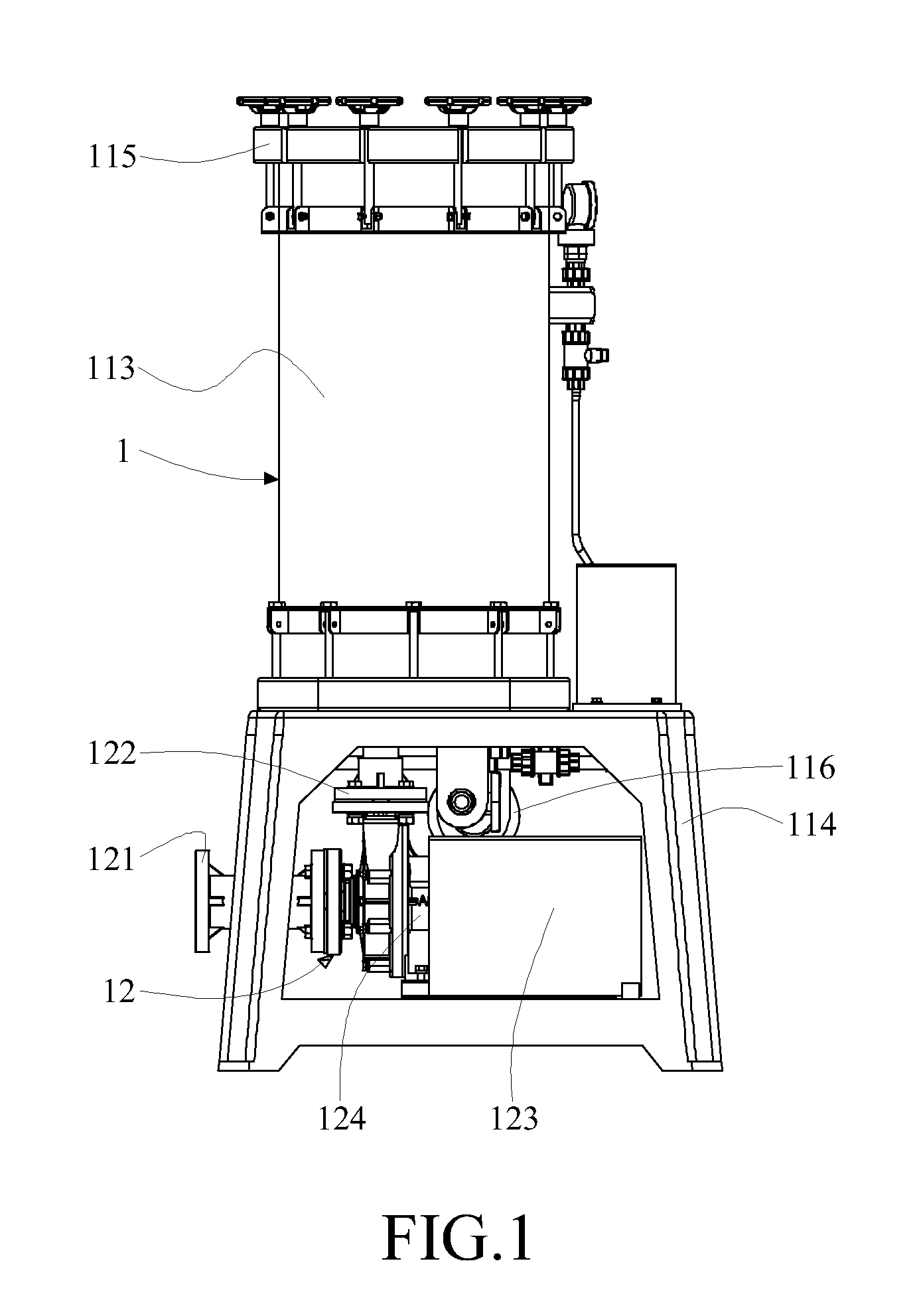

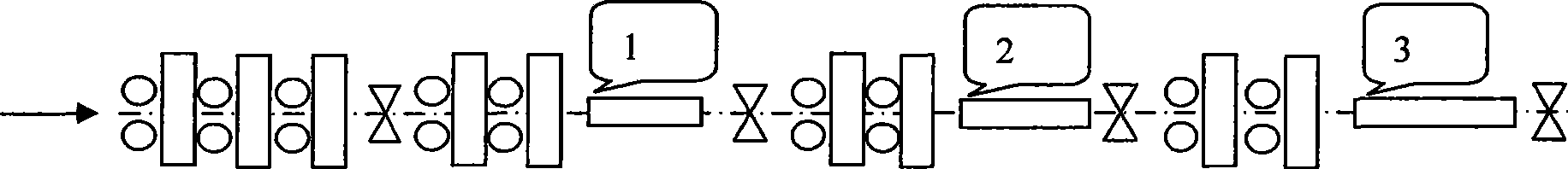

Millarray for producing ultra-fine crystal bar and milling method thereof

InactiveCN101518781AControlled heatingReasonable distributionWork treatment devicesMetal rolling arrangementsTemperature controlMetallic materials

The invention belongs to the field of metal material molding and processing, in particular relates to a mill array for producing an ultra-fine crystal bar and a milling method thereof. The milling method comprises the following steps: a coarse milling section, a middle milling section and a finish milling section with a water penetration cooling section at the rear are continuously milled without twist, mills are horizontally and alternately arranged, wherein a post finish milling section is arranged in front of the finish milling section, and water penetration cooling sections are respectively arranged at the rear of the middle milling section and / or the finish milling section. The mill array has strong temperature control capability and effectively solves the problem that the temperature control capability of the prior bar milling lines is insufficient; an ultra-fine crystal bar is milled at low temperature, can be controlled to be cooled after being milled in the middle middling section and the preliminary finish milling section and can be controlled above a transformation point in the finish milling section; heavy draught cumulation deformation is adopted to induce the phase change of ferrite, after being milled, the ultra-fine crystal bar mill can be controlled to be cooled to keep fine crystal left, and organizations which are fined into 3 mu m and use the ferrite as a base body are obtained, thus the strength of the steel can be increased by at least one level through the effects of fine crystal reinforcement and phase change reinforcement without the necessity of adding an alloying element.

Owner:CHINA IRON & STEEL RES INST GRP +1

Device and method for dealing with phenomena of loss of pressure and running flat with vehicle tires

InactiveUS7287565B2Easily vaporizable coolingGuaranteed uptimeRimsTyre measurementsHandling stressInternal cavity

A centralized device for dealing with the phenomena of loss of pressure and running flat with a vehicle tire, including a means external to the mounted assembly, permanently fixed to the vehicle and able to inject or otherwise bring into the internal cavity of the tire at least one active product, also external to the mounted assembly, and able to treat the phenomena of loss of pressure and ultimately running flat.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

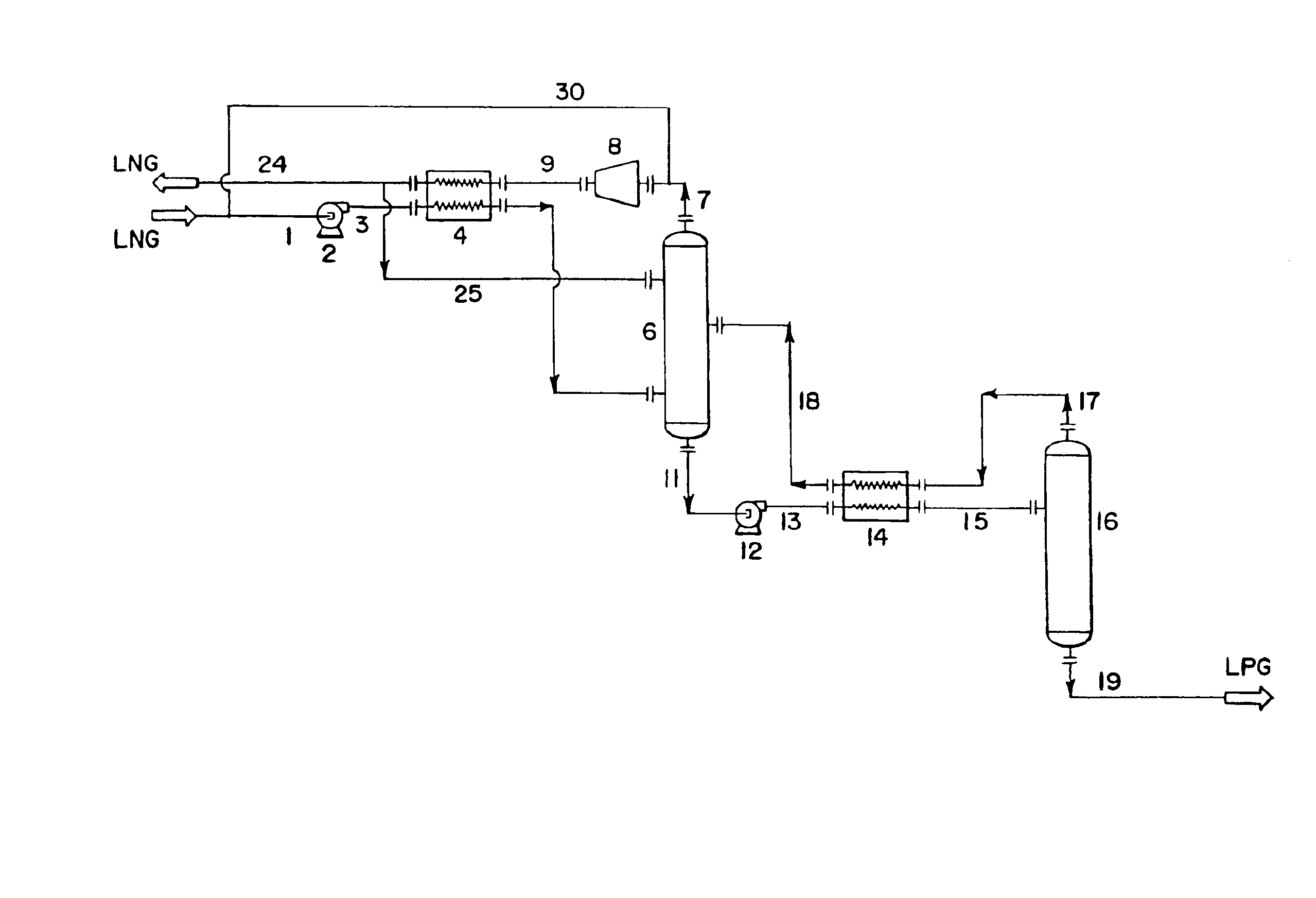

Cryogenic liquid natural gas recovery process

InactiveUS20050005636A1Avoid the needLower energy requirementsSolidificationLiquefactionRefluxPropane

A process for the recovery of natural gas liquids (NGL) (ethane, ethylene, propane, propylene and heavier hydrocarbons) from liquefied natural gas (LNG) is disclosed. The LNG feed stream is split with at least one portion used as an external reflux, without prior treatment, to improve the separation and recovery of the natural gas liquids (NGL).

Owner:HOWE BAKER ENGINEERS LTD

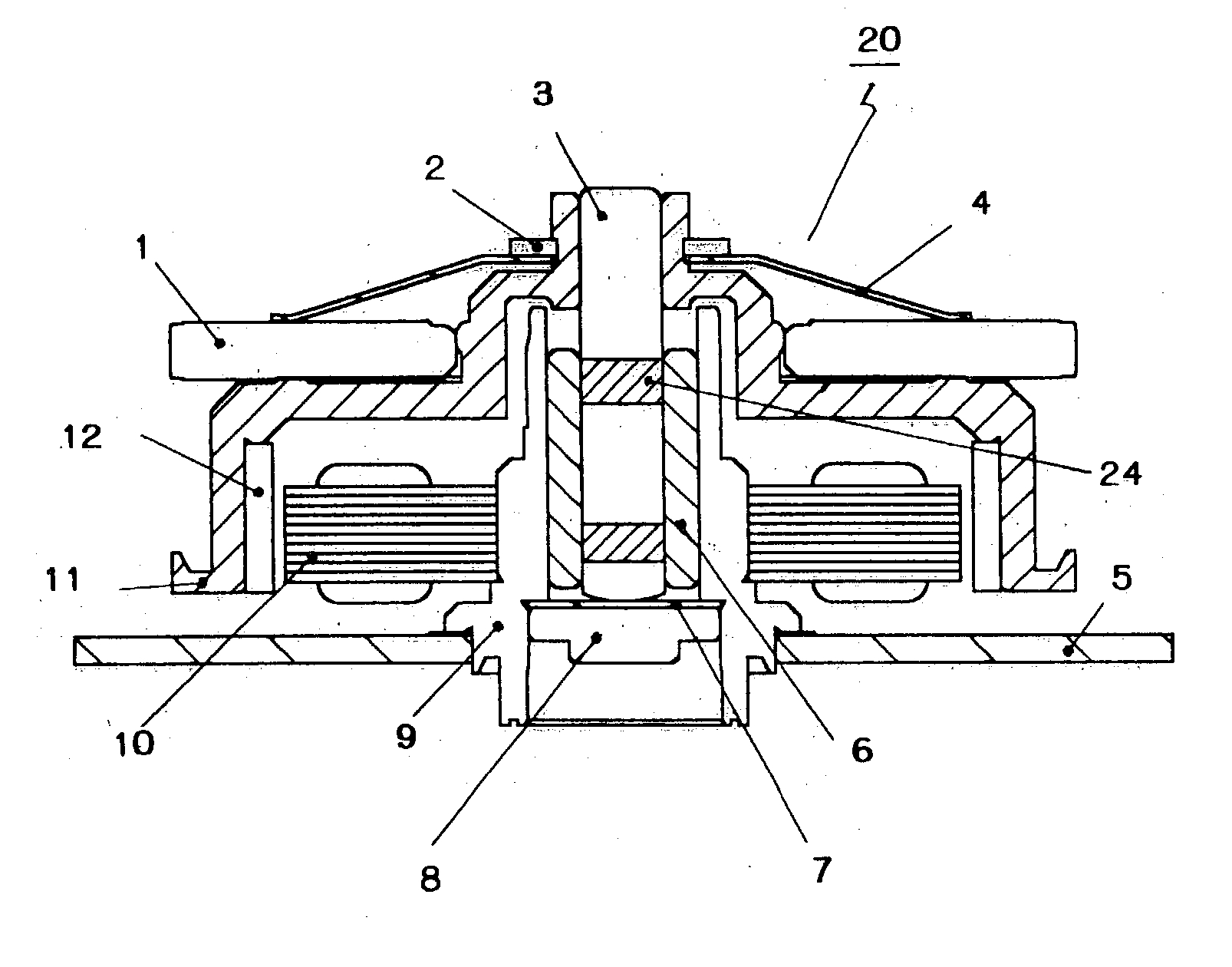

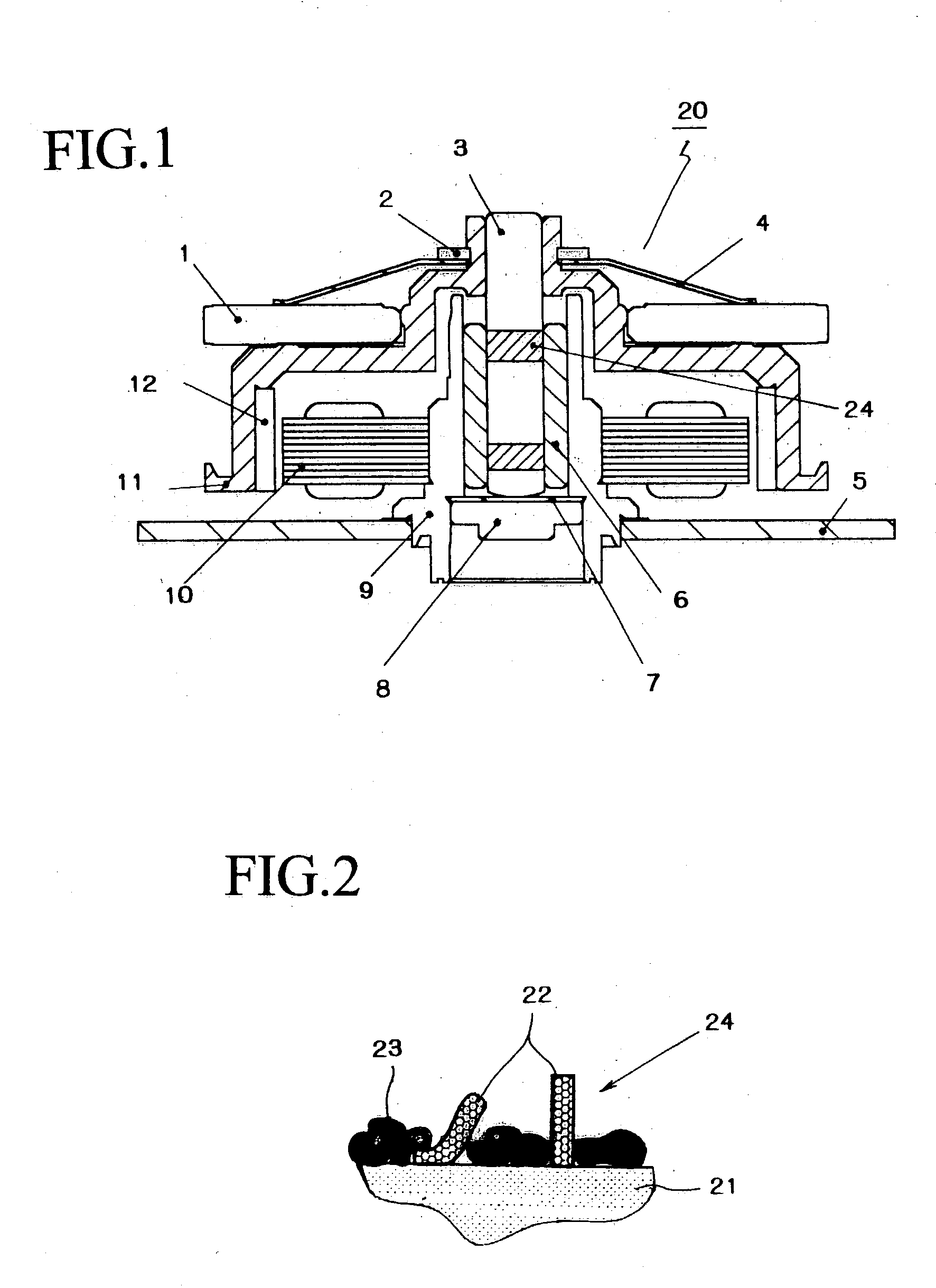

Shaft, bearing and motor

InactiveUS20050052088A1Reducing vibration and noiseSuppress feverPump componentsNanoinformaticsFiberCarbon nanofiber

The shaft and the bearing are capable of reducing vibration and noise of a motor. The shaft comprises: a shaft proper; and a sliding section provided to the shaft proper, the sliding section including carbon nano fibers or carbon nano tubes. On the other hand, the bearing comprises: a bearing proper; and a sliding section provided to the bearing proper, the sliding section including carbon nano fibers or carbon nano tubes.

Owner:SHINANO KENSHI

Self-timed thermally-aware circuits and methods of use thereof

InactiveUS7411436B2Without imposing significant implementation overheadStall-free performance-throttlingElectronic switchingNetwork modifications to reduce temperatureAsynchronous circuitEngineering

Apparatus and methods for regulating gate delays of synchronous and asynchronous digital circuits. Thermally-sensitive circuits include, generally, temperature sensitive voltage sources outputting a voltage signal indicative of the temperature of the digital circuit, where the voltage signal reflects non-linear temperature sensitivity above a predetermined threshold temperature, and delay mechanisms receiving said temperature sensitive voltage signal(s) as input and being configured to automatically continuously modulate the speed of signal propagation through the circuit in response to said voltage signal, thereby causing circuit elements within the circuits to switch less frequently and consequently causing the circuit elements to generate less heat with increasing circuit temperature.

Owner:CORNELL RES FOUNDATION INC

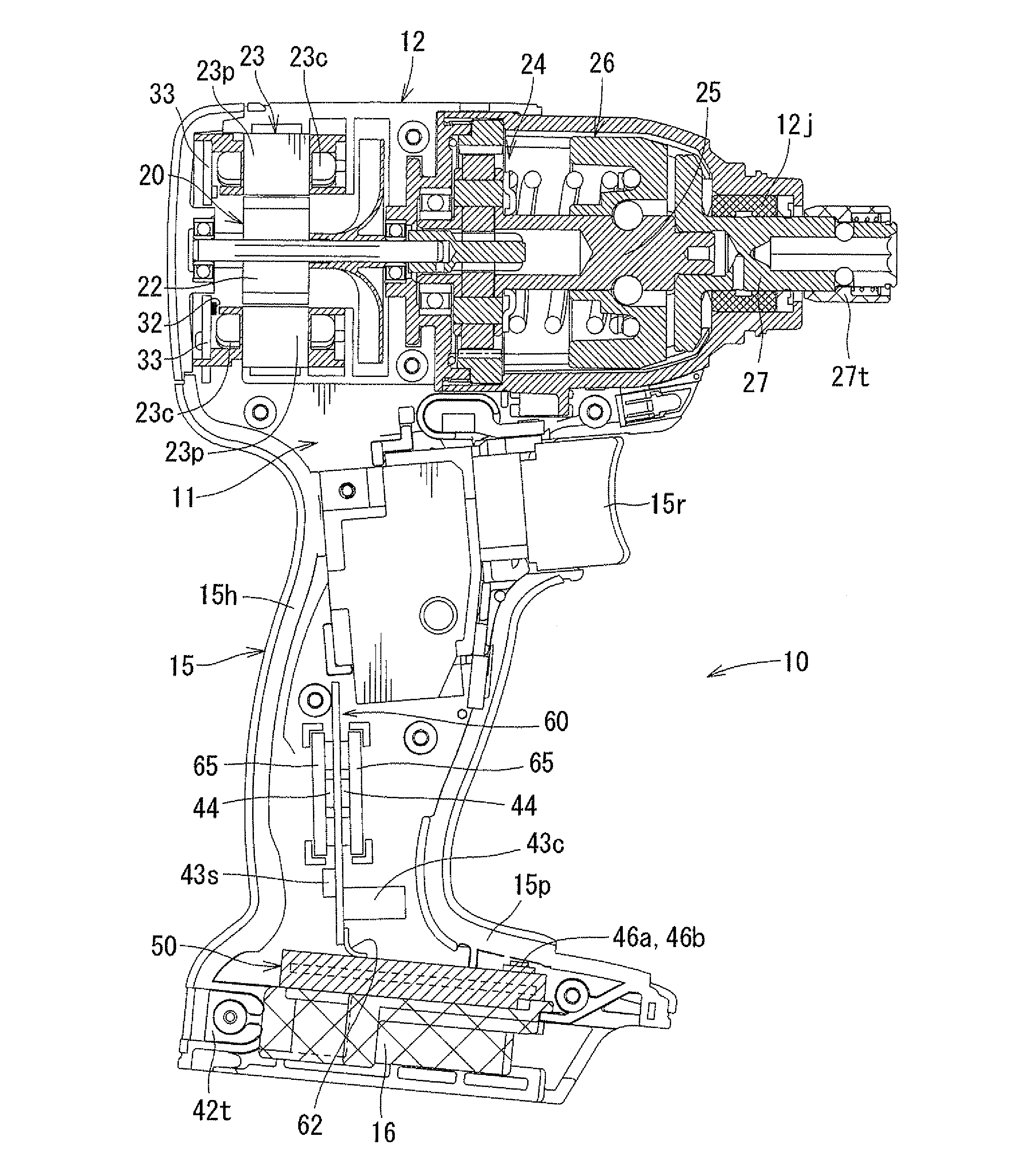

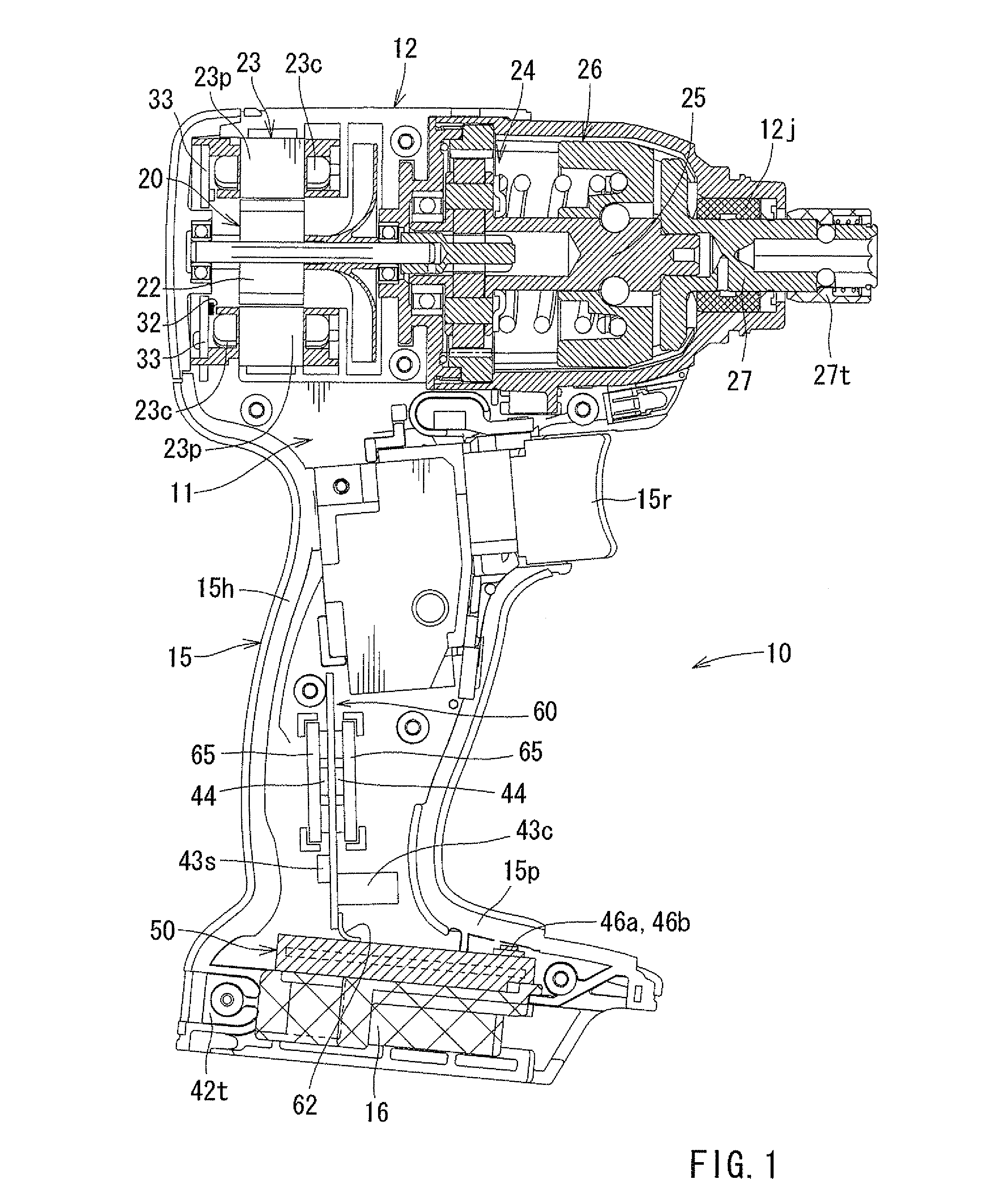

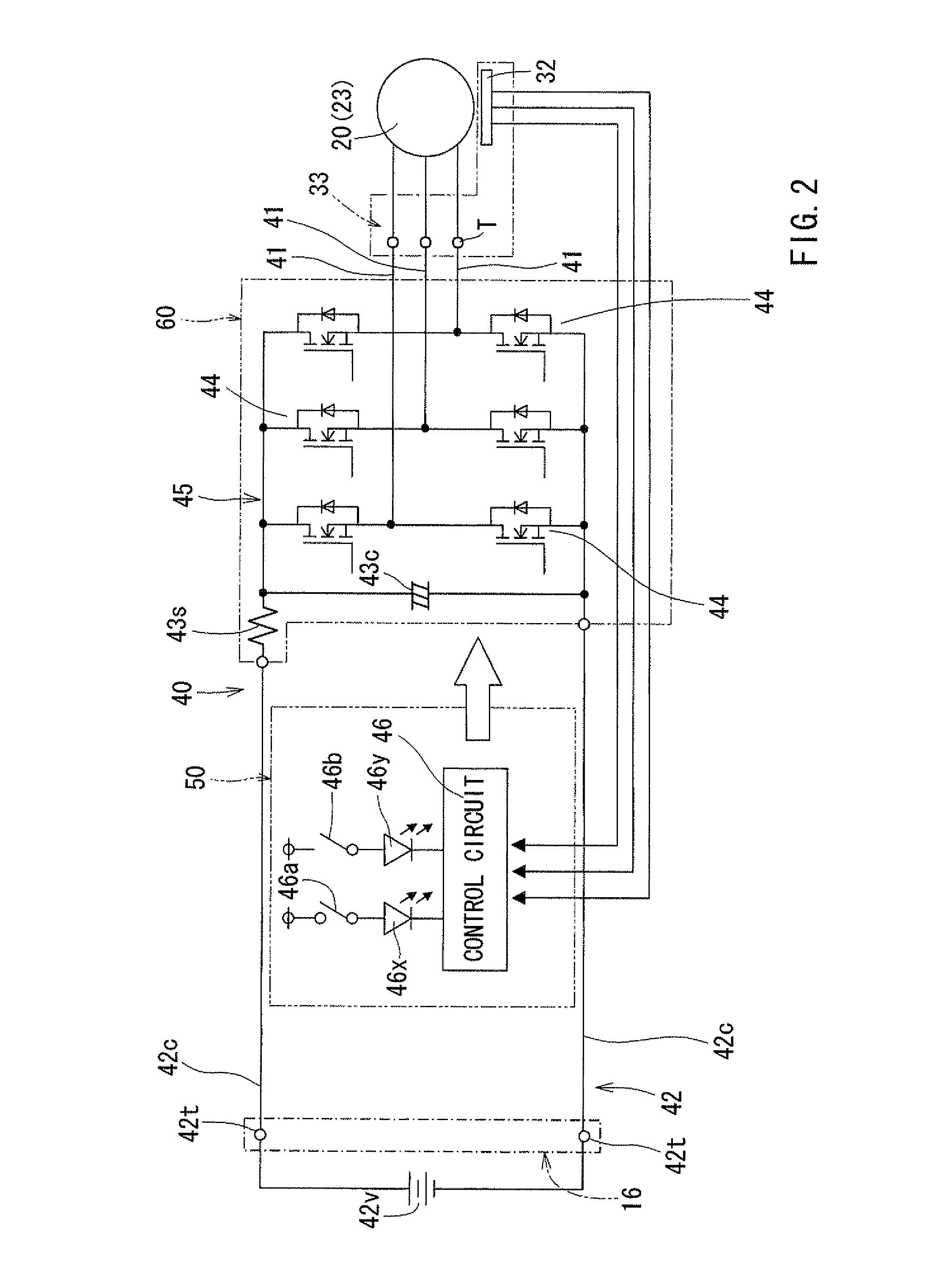

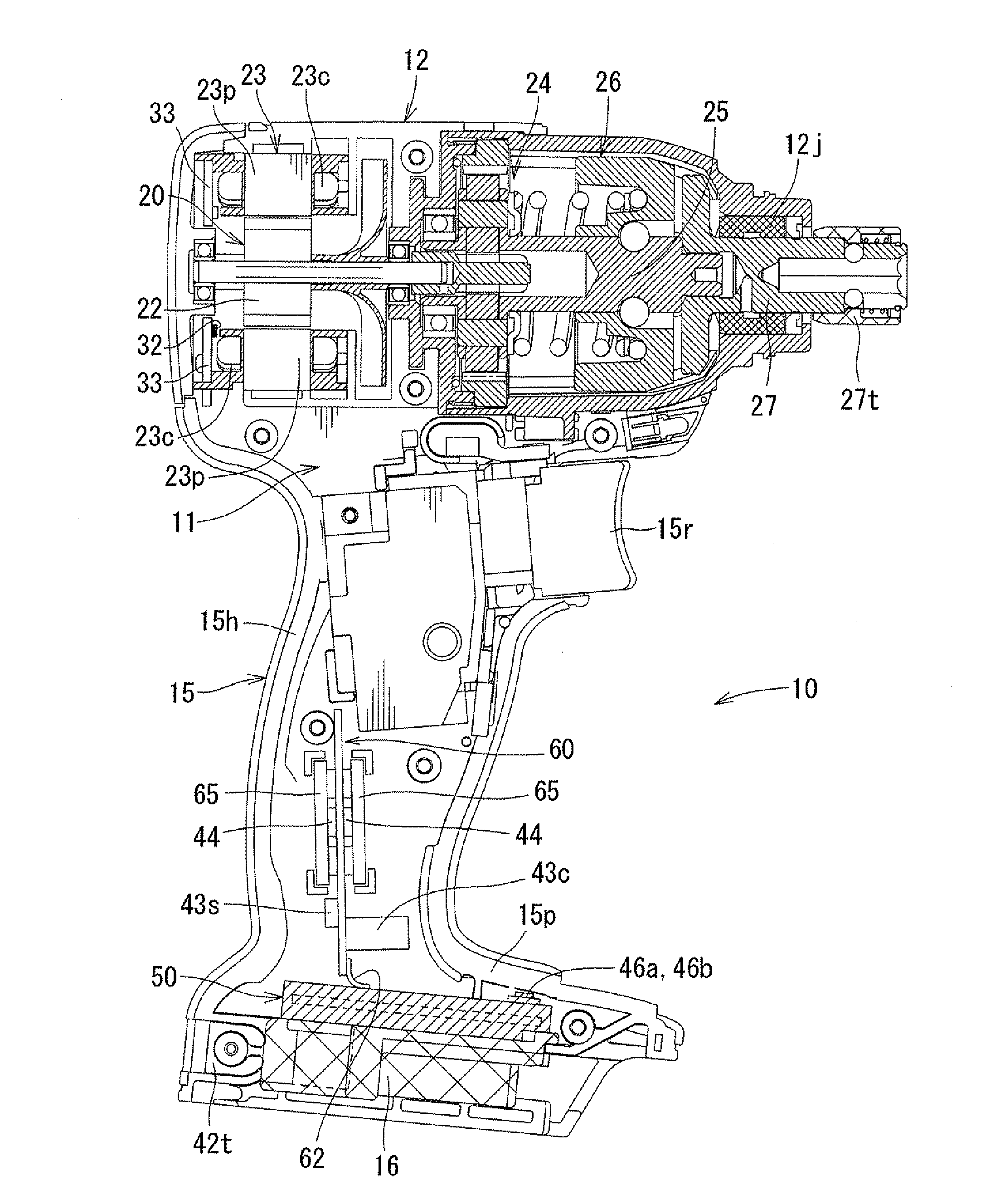

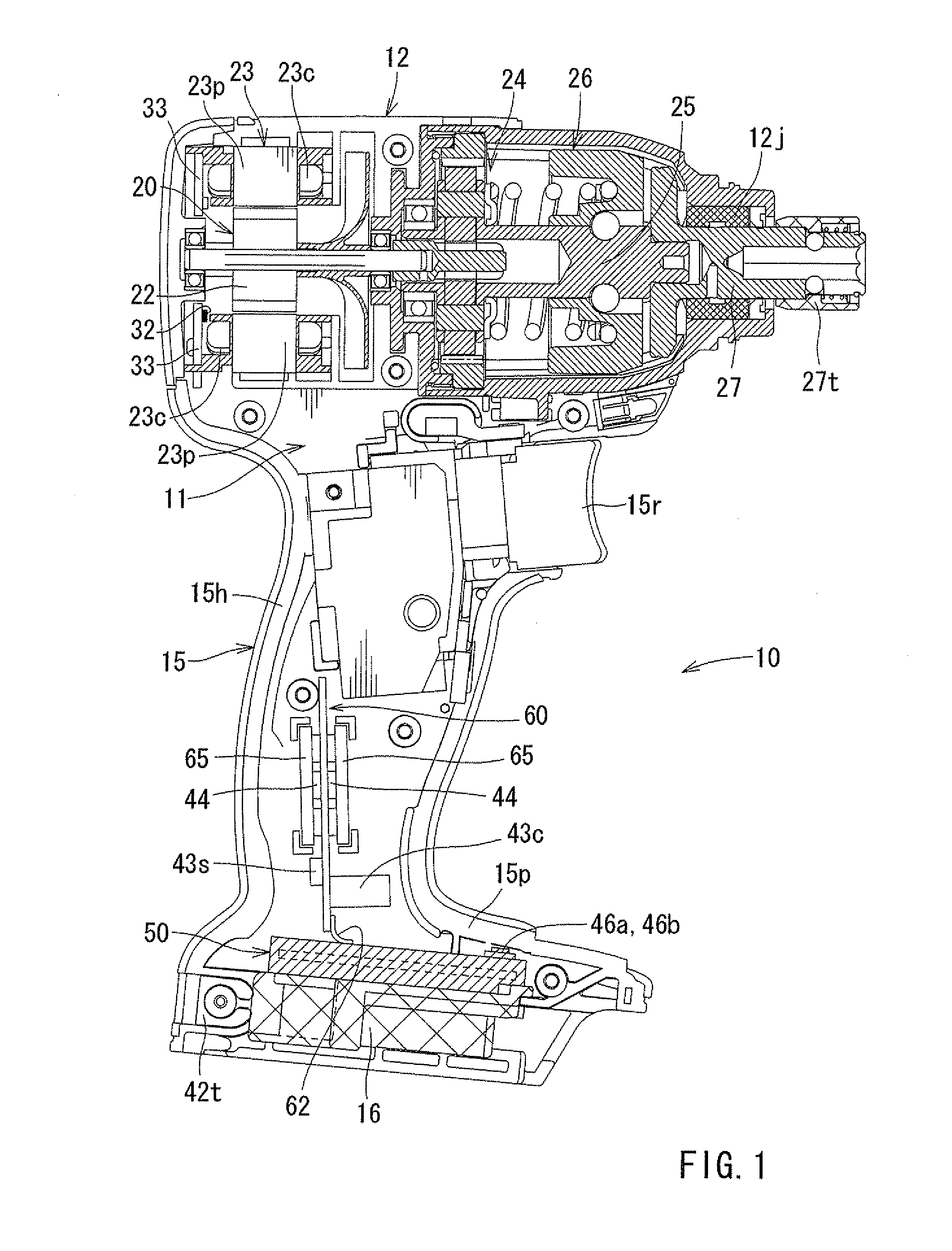

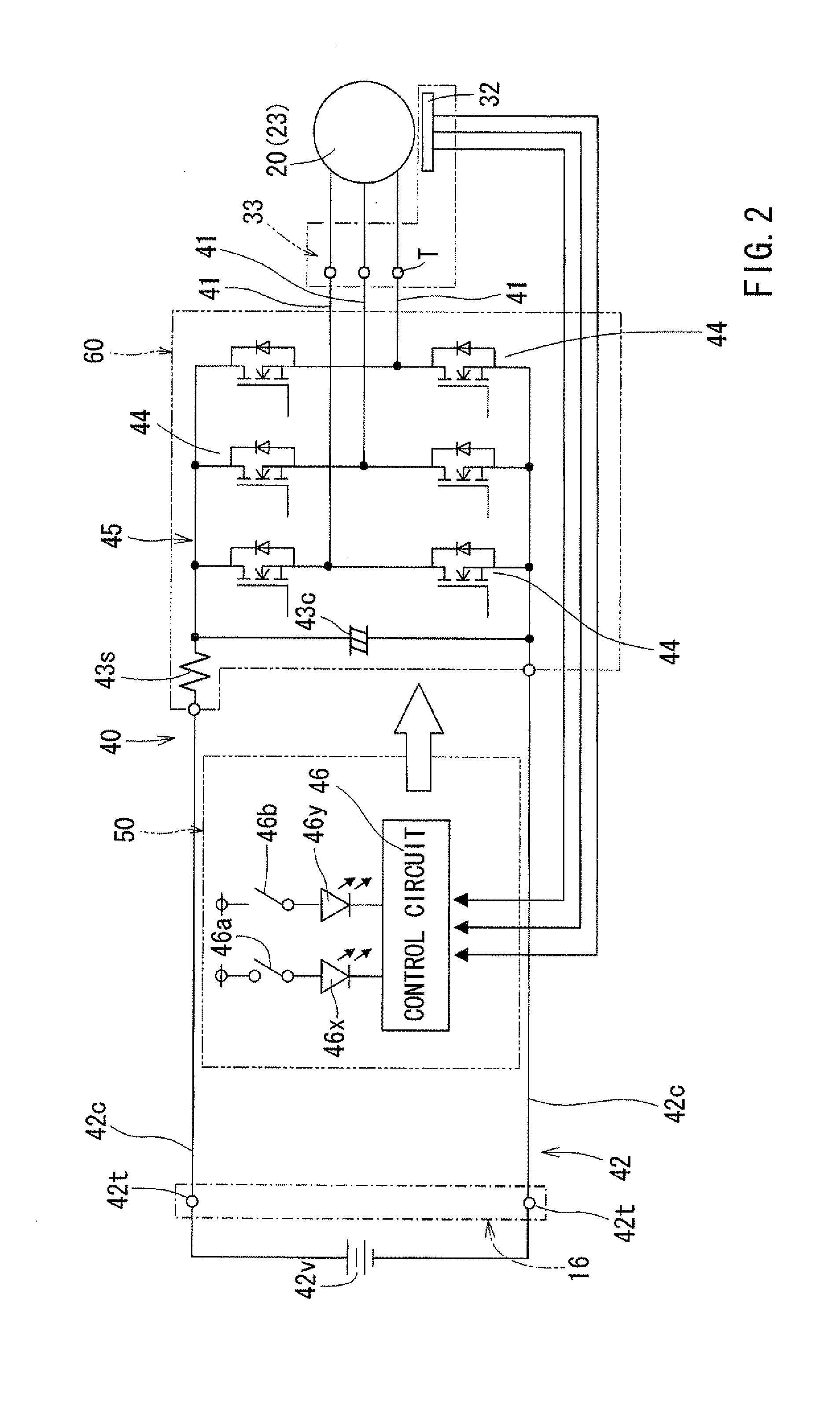

Electric power tool including a plurality of circuit boards

ActiveUS8810085B2Reduce measurementIncrease the lengthAssociation with control/drive circuitsDrilling rodsBrushless motorsElectric power system

An electric power tool, which uses a DC brushless motor as a drive source and controls the DC brushless motor by a switching element, can include a tubular housing main body portion accommodating the DC brushless motor, and a grip portion protruding from a side portion of the housing main body portion. The switching element is arranged inside the grip portion, and is spaced apart from an electronic circuit board for an electronic component for operating the switching element.

Owner:MAKITA CORP

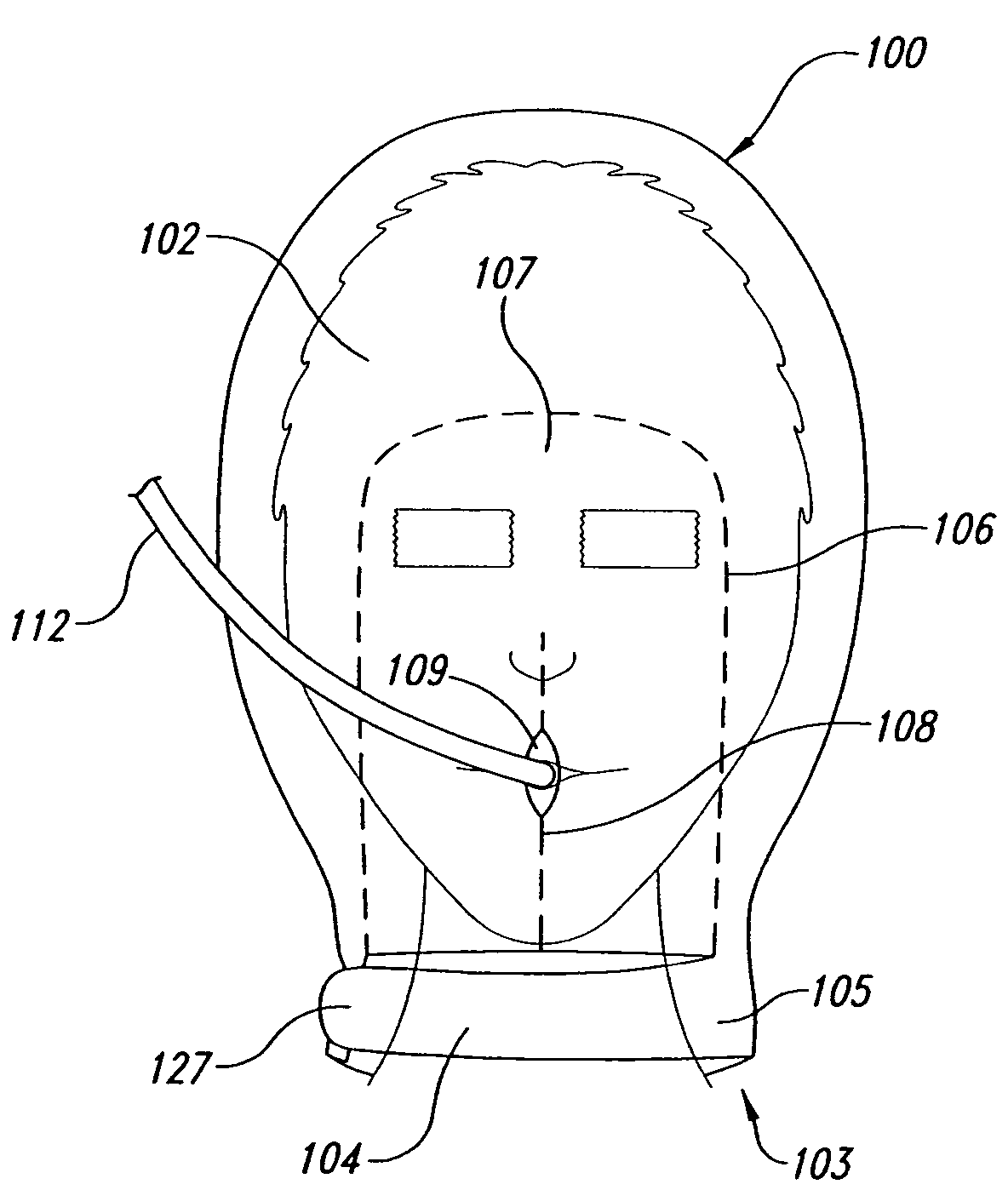

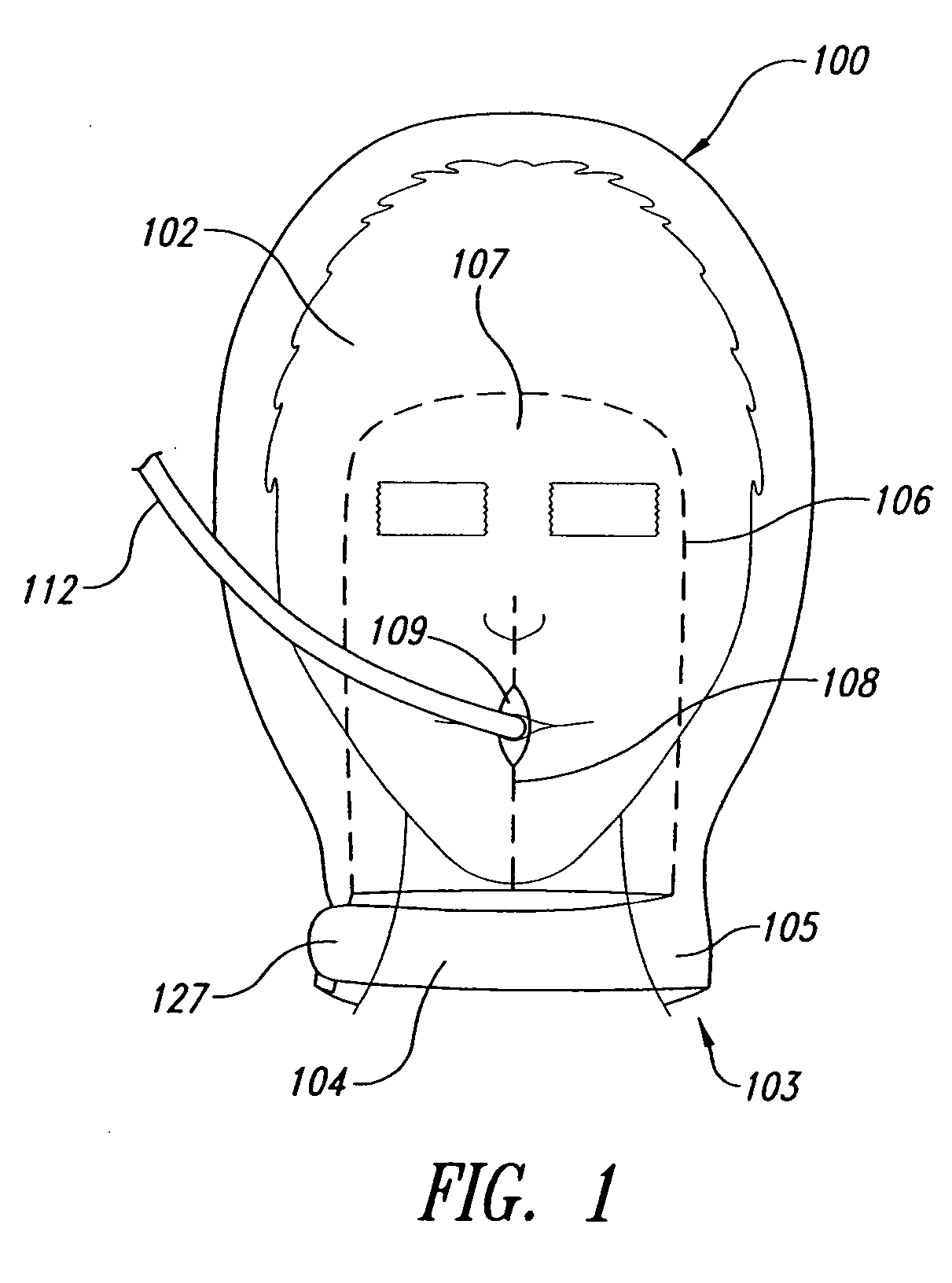

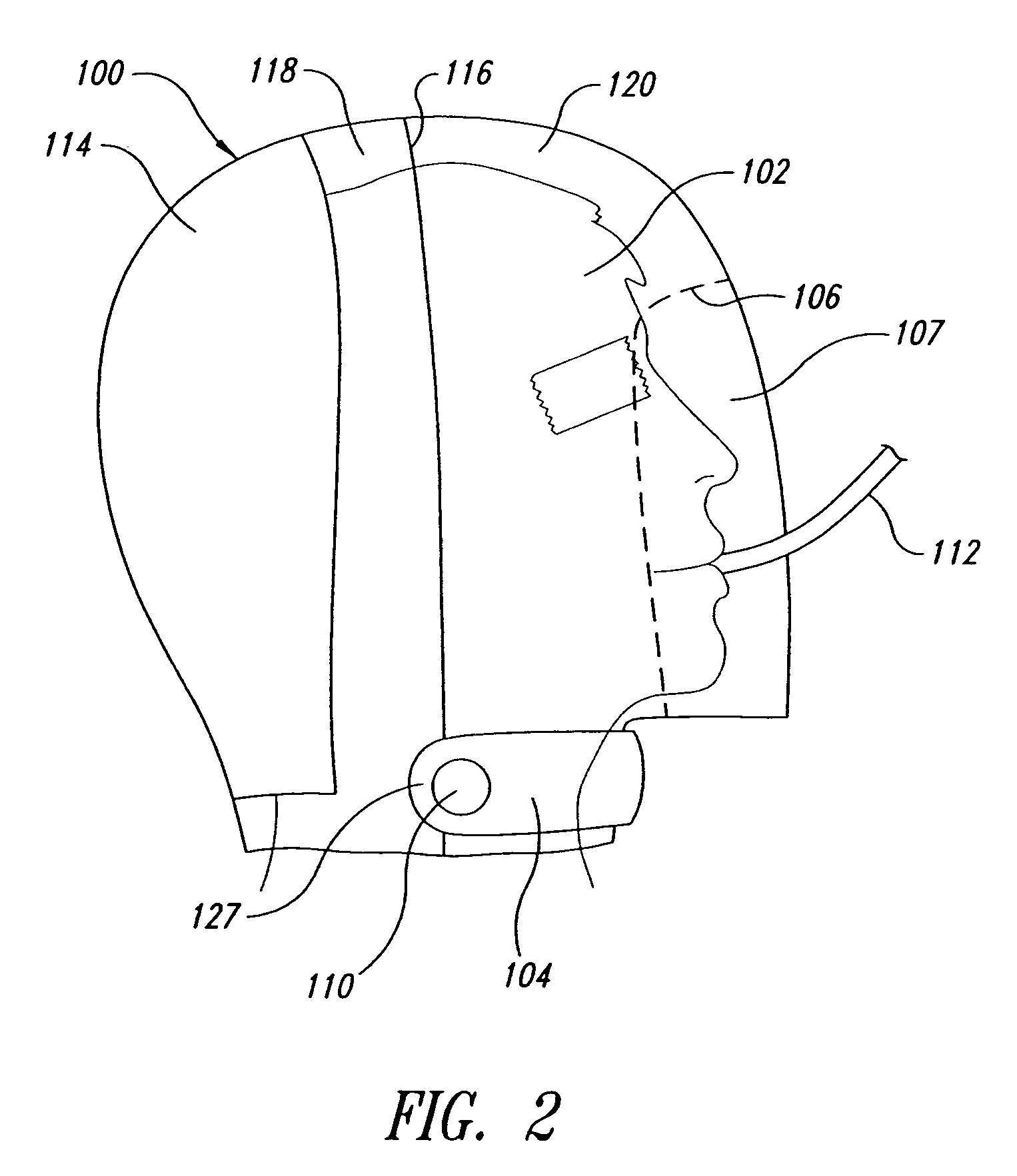

Thermal retention patient hood

InactiveUS7296570B2Reduced form requirementsRetain heatChemical protectionTracheal tubesNoseMedicine

A thermal retention hood for reducing heat loss from a patient's head during and following surgery includes an enclosure configured to cover the face and head of the patient, and configured to retain heat within the enclosure. The enclosure is at least partially transparent, to give a practitioner visual access to a patient's face. The hood further includes a scored line in the enclosure in a position corresponding to the patient's nose and mouth, a second scored line surrounding a region of the enclosure corresponding to the location of the patient's face, and a strap configured to secure an open end of the enclosure around the patient's neck. The hood may also include an absorbent pad within the enclosure, positioned to cover a portion of the back of the patient's head to absorb excess moisture.

Owner:HUTCHINSON CHAD H

Electric power tool

ActiveUS20110187211A1Reduce heat protection measureIncrease in entire lengthAssociation with control/drive circuitsPortable power-driven toolsBrushless motorsElectric power system

An electric power tool, which uses a DC brushless motor as a drive source and controls the DC brushless motor by a switching element, can include a tubular housing main body portion accommodating the DC brushless motor, and a grip portion protruding from a side portion of the housing main body portion. The switching element is arranged inside the grip portion, and is spaced apart from an electronic circuit board for an electronic component for operating the switching element.

Owner:MAKITA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com