Patents

Literature

1559results about "Inflatable tyres" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

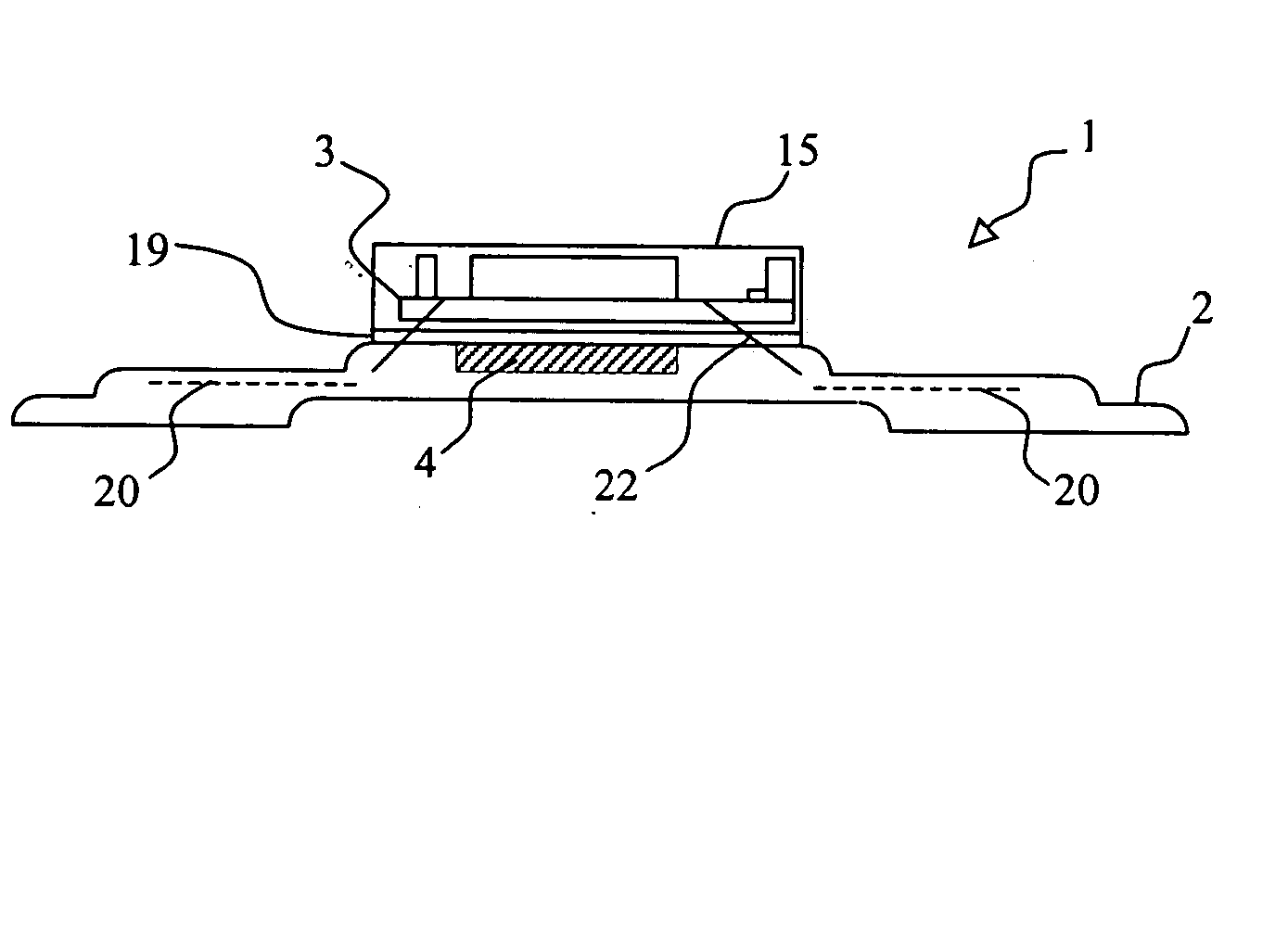

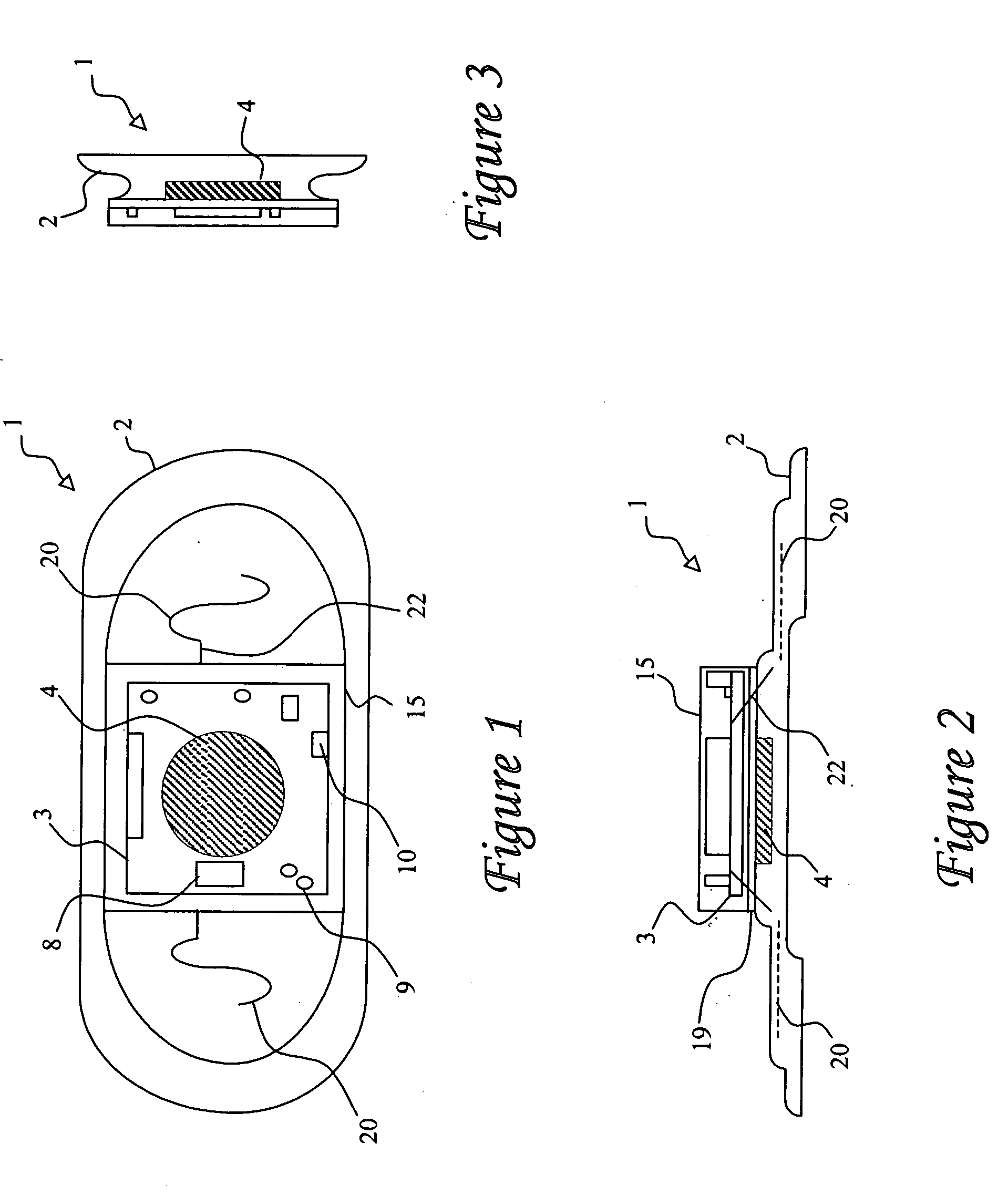

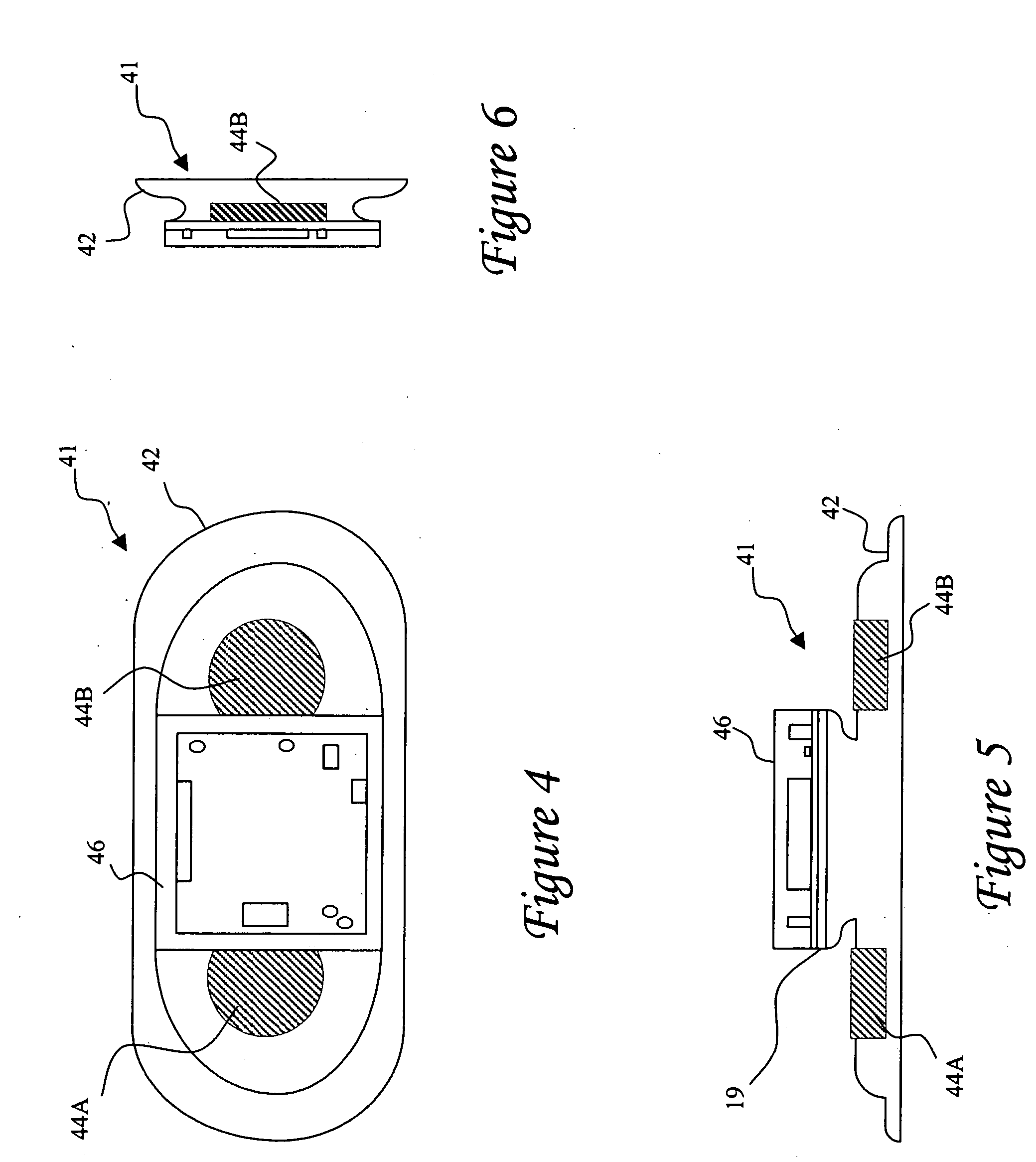

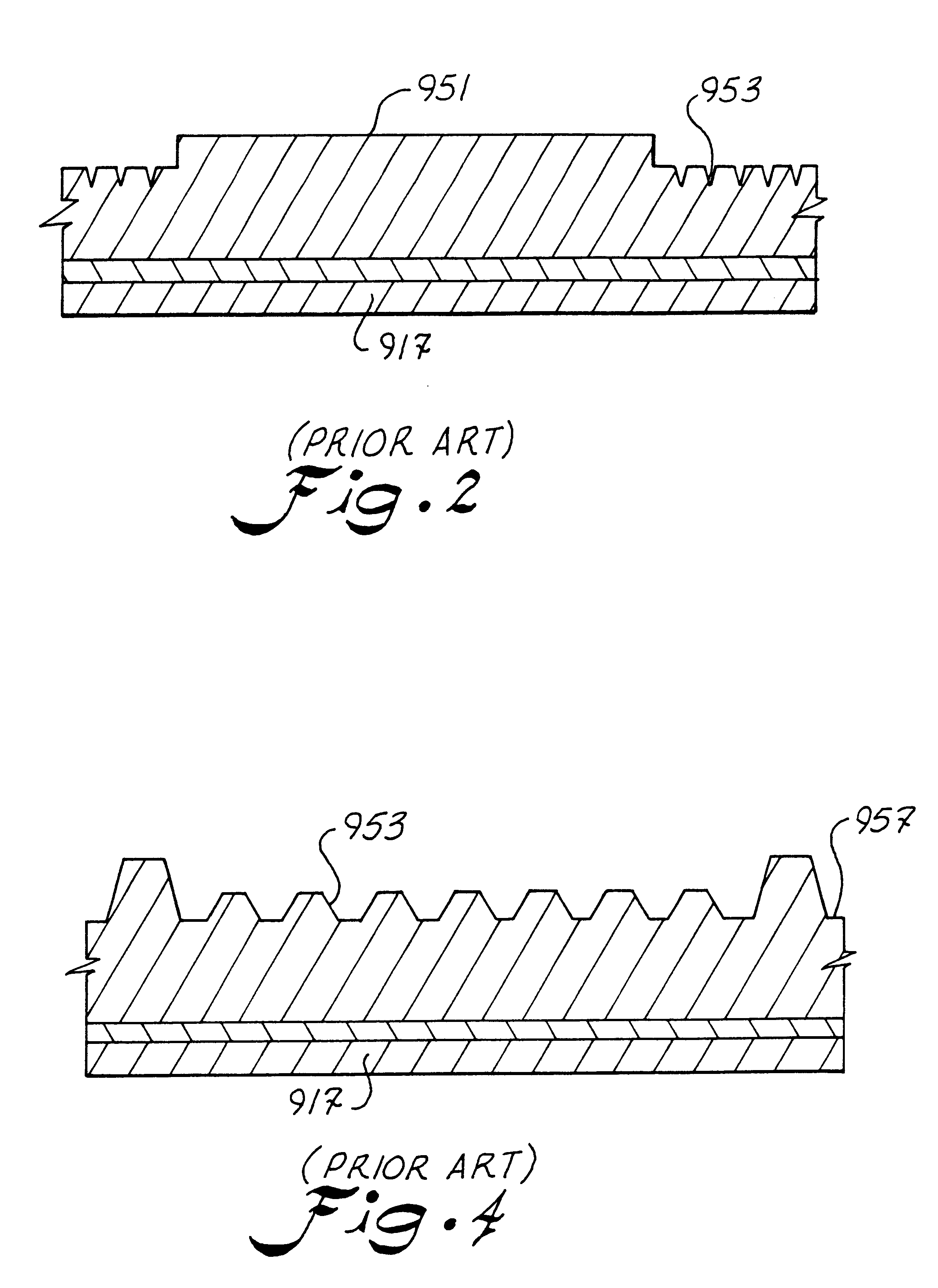

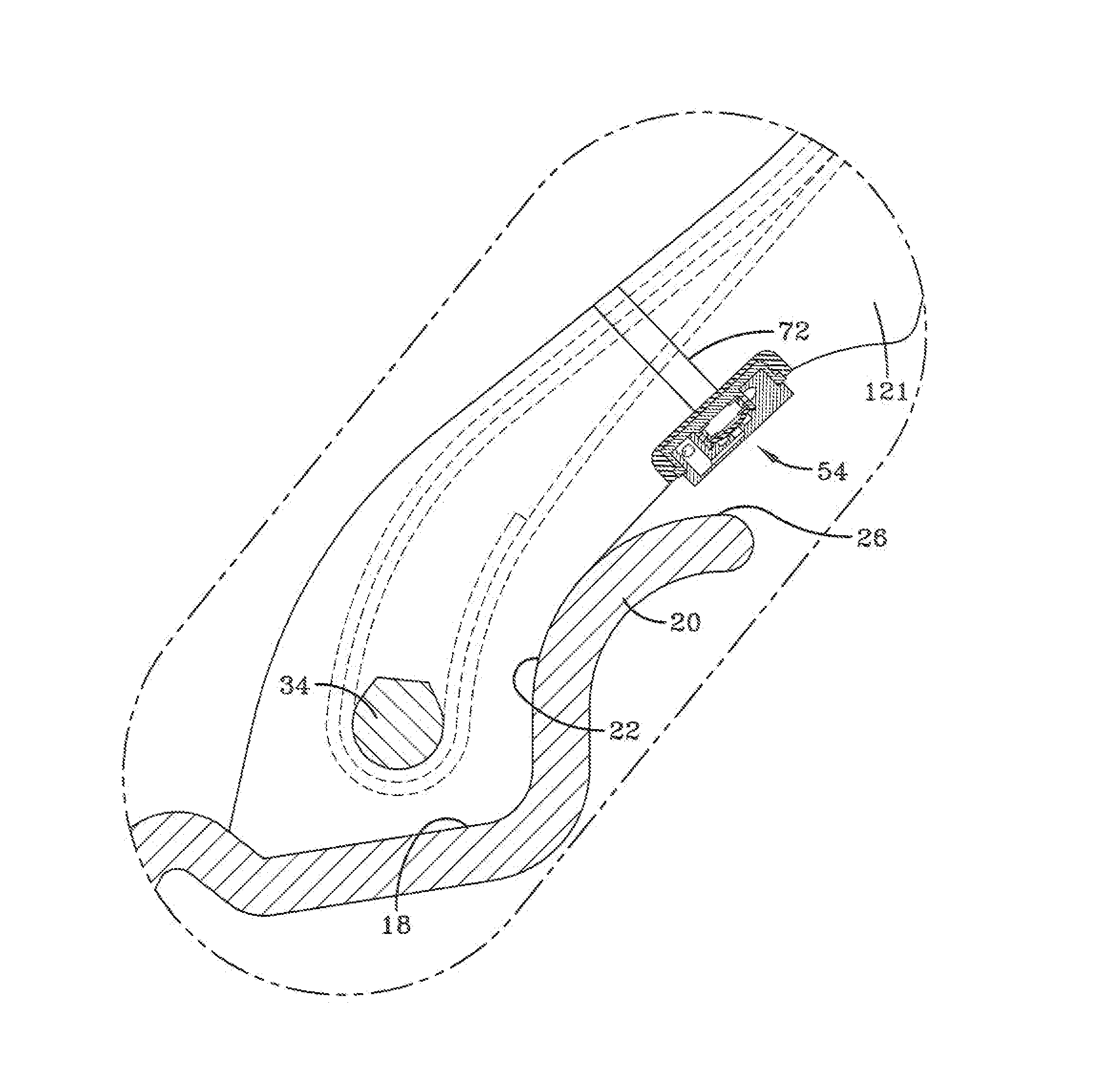

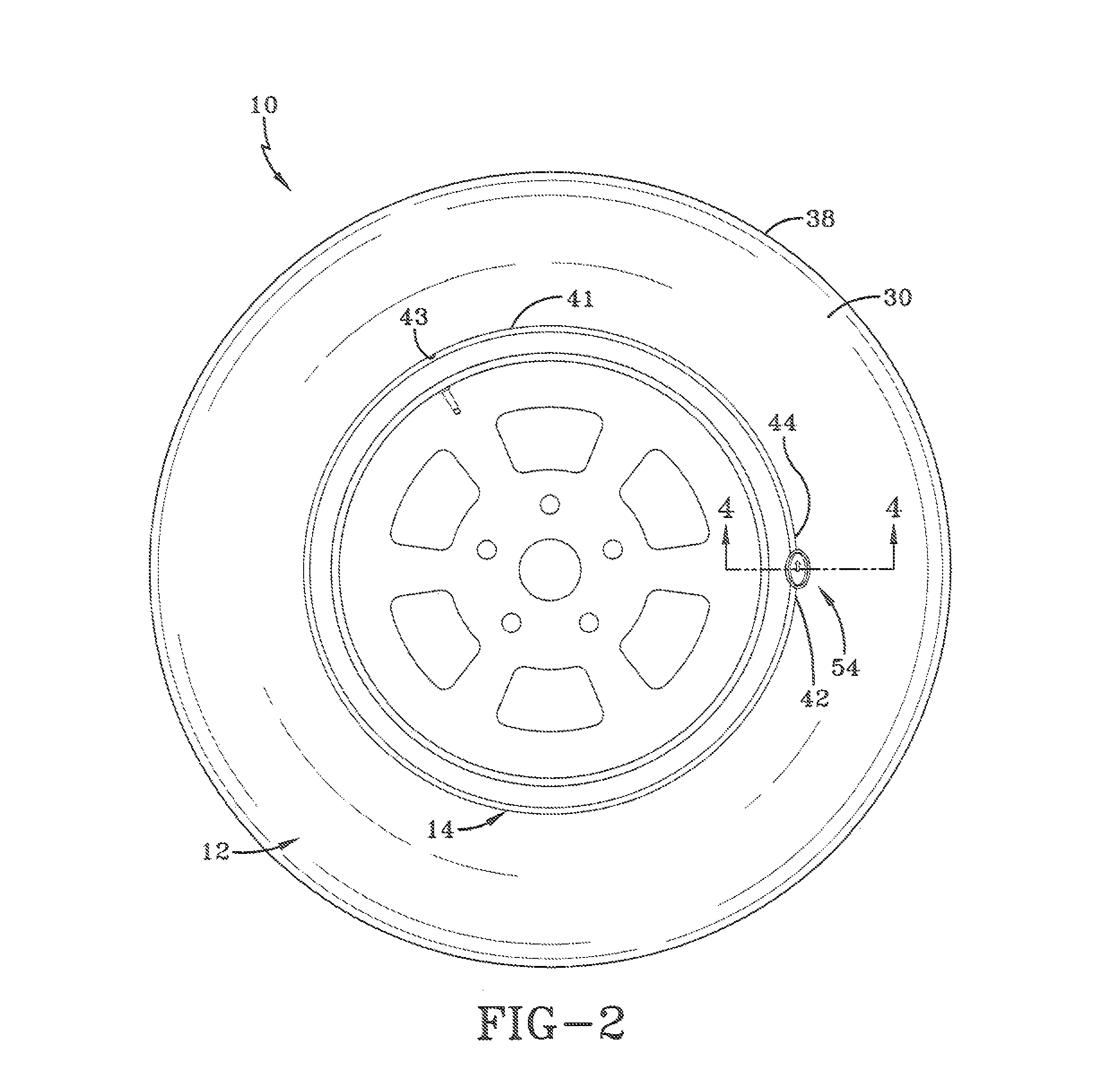

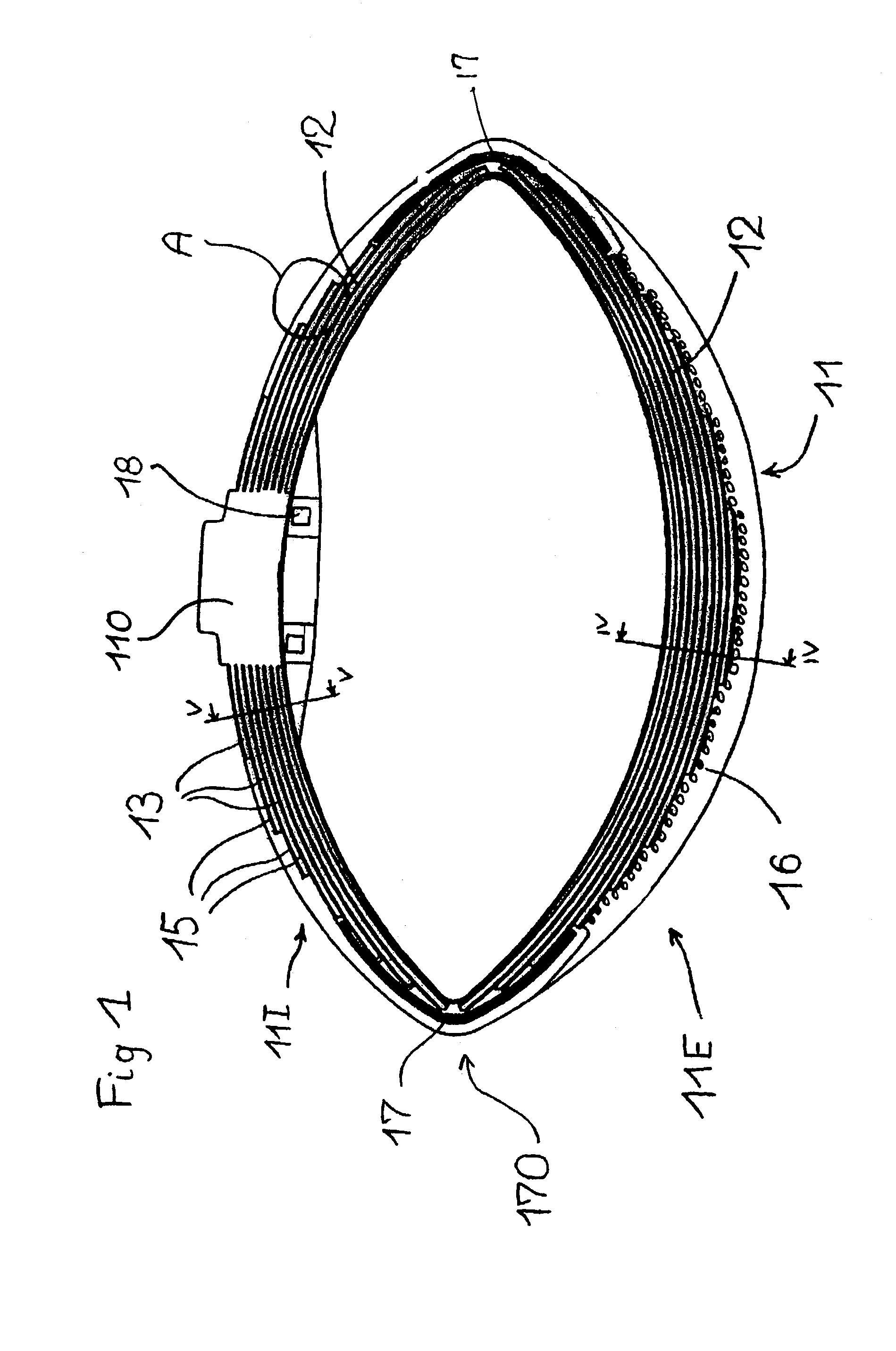

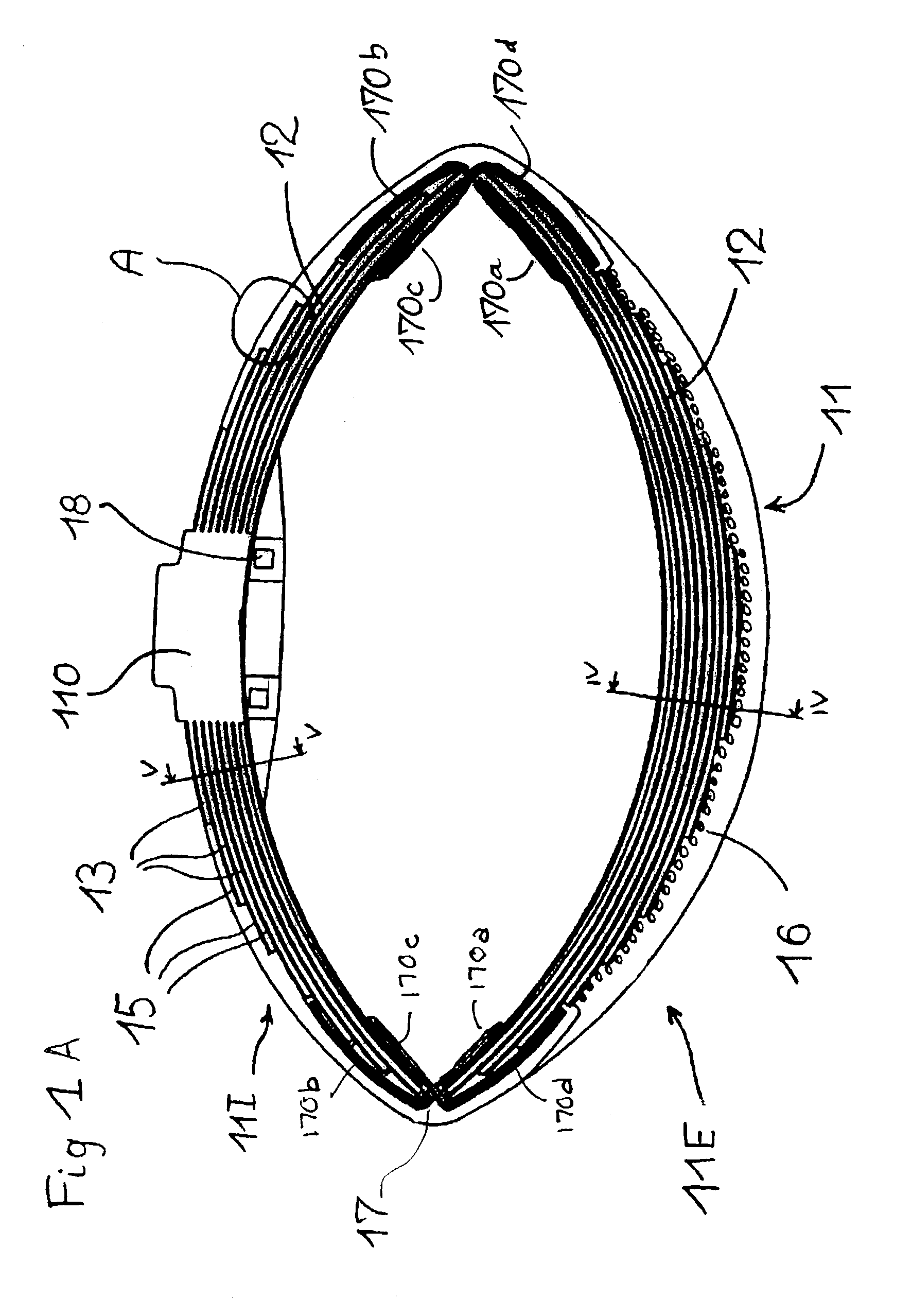

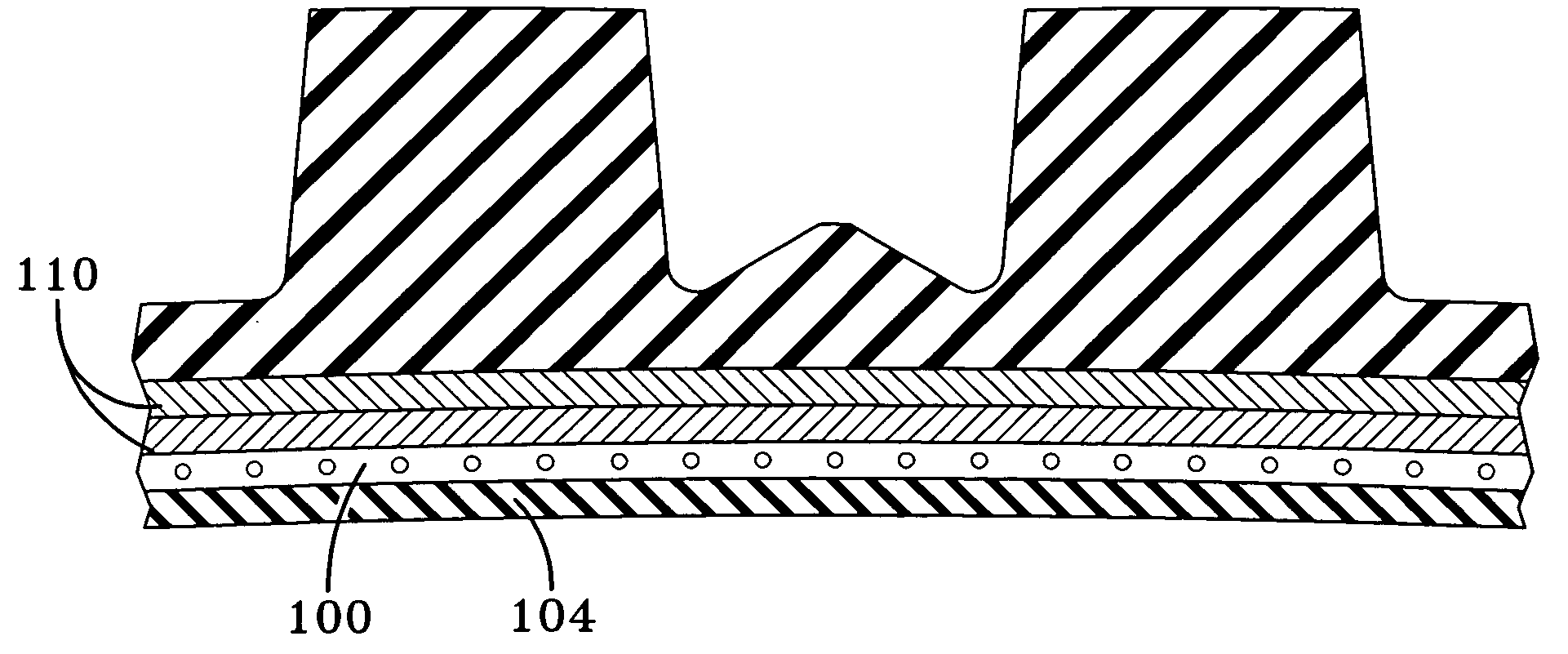

Post patch assembly for mounting devices in a tire interior

InactiveUS20050076982A1Lower center of gravityImprove mechanical stabilityInflatable tyresOptical signallingElastomerSurvivability

A modular electronic assembly for integration with a pneumatic tire includes a mounting patch, a power source, and at least one electronic device supported by a substrate. The mounting patch is preferably adapted for positioning on the inner liner of a pneumatic tire, and the power source is at least partially embedded in the mounting patch. Such embedded positioning of the battery results in an overall structure with a lower center of gravity than previous tire electronics assemblies, thus having increased mechanical stability and survivability in a tire environment. Electronic device(s) supported on the substrate may receive power from the power source, which in some embodiments corresponds to one or more batteries. The substrate supporting the at least one electronic device may be attached to the mounting patch by a variety of fashions. Exemplary attachment configurations may correspond to an adhesive layer, a hook and loop tape combination, or physical interconnection via terminals extending from the power source through the support substrate. Exemplary electronic devices may include such components as condition-responsive devices including transducers, acoustic devices, sensors, etc. for sensing certain environmental conditions such as temperature and / or pressure, tire revolution counters, vehicle speed sensors, sidewall deflection sensors, tire displacement sensors, microprocessors, memory modules, RFID transponders, light assemblies, data transmitters and / or receivers, and power, supply components. Selected of the electronic devices (including one or more antennas associated with any RF devices) may be encapsulated by a non-conductive rubber or elastic material to facilitate effective transmission characteristics. Conductive springs, flexible conductive elastomer or fatigue-resistance metal may be used to interconnect various electronic components (such as an RF device to an antenna).

Owner:MICHELIN RECH & TECH SA

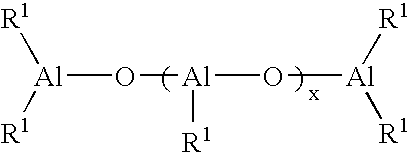

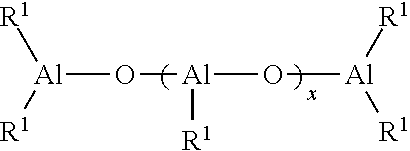

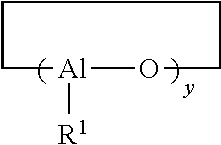

Method for producing functionalized cis-1,4-polydienes having high cis-1,4-linkage content and high functionality

This invention relates to a method for producing functionalized cis-1,4-polydienes having a combination of a high cis-1,4-linkage content and a high functionality, the resulting polymers and the vulcanized products containing the polymers. The functionalized cis-1,4-polydienes of the present invention are produced by a method comprising the steps of: (1) preparing a reactive polymer by polymerizing conjugated diene monomer with a lanthanide-based catalyst in the presence of less than 20% by weight of organic solvent based on the total weight of monomer, organic solvent, and resulting polymer, where the lanthanide-based catalyst is the combination of or reaction product of (a) a lanthanide compound, (b) an aluminoxane, (c) an organoaluminum compound other than an aluminoxane, and (d) a halogen-containing compound; and (2) contacting the reactive polymer with a functionalizing agent.

Owner:BRIDGESTONE CORP

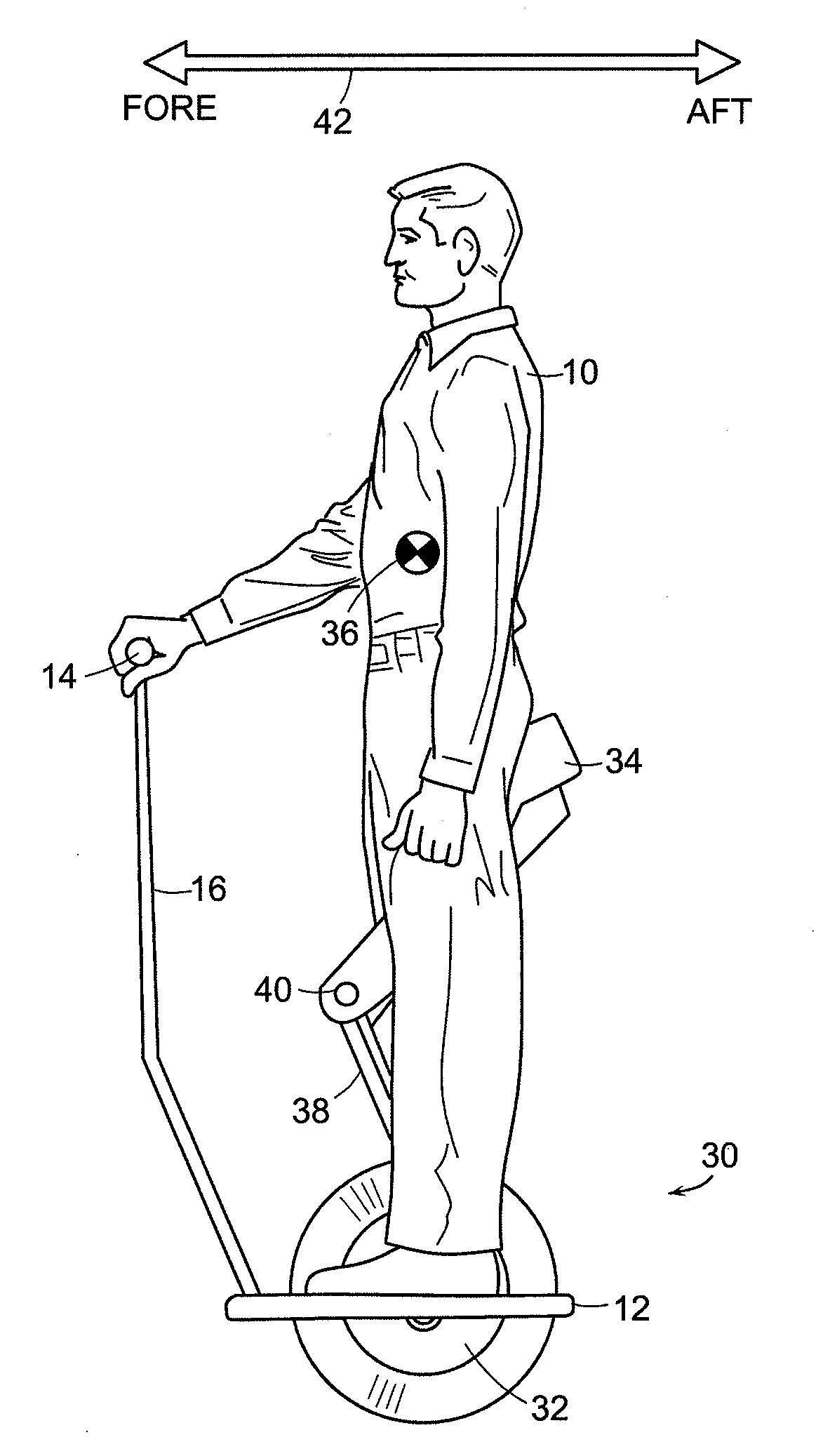

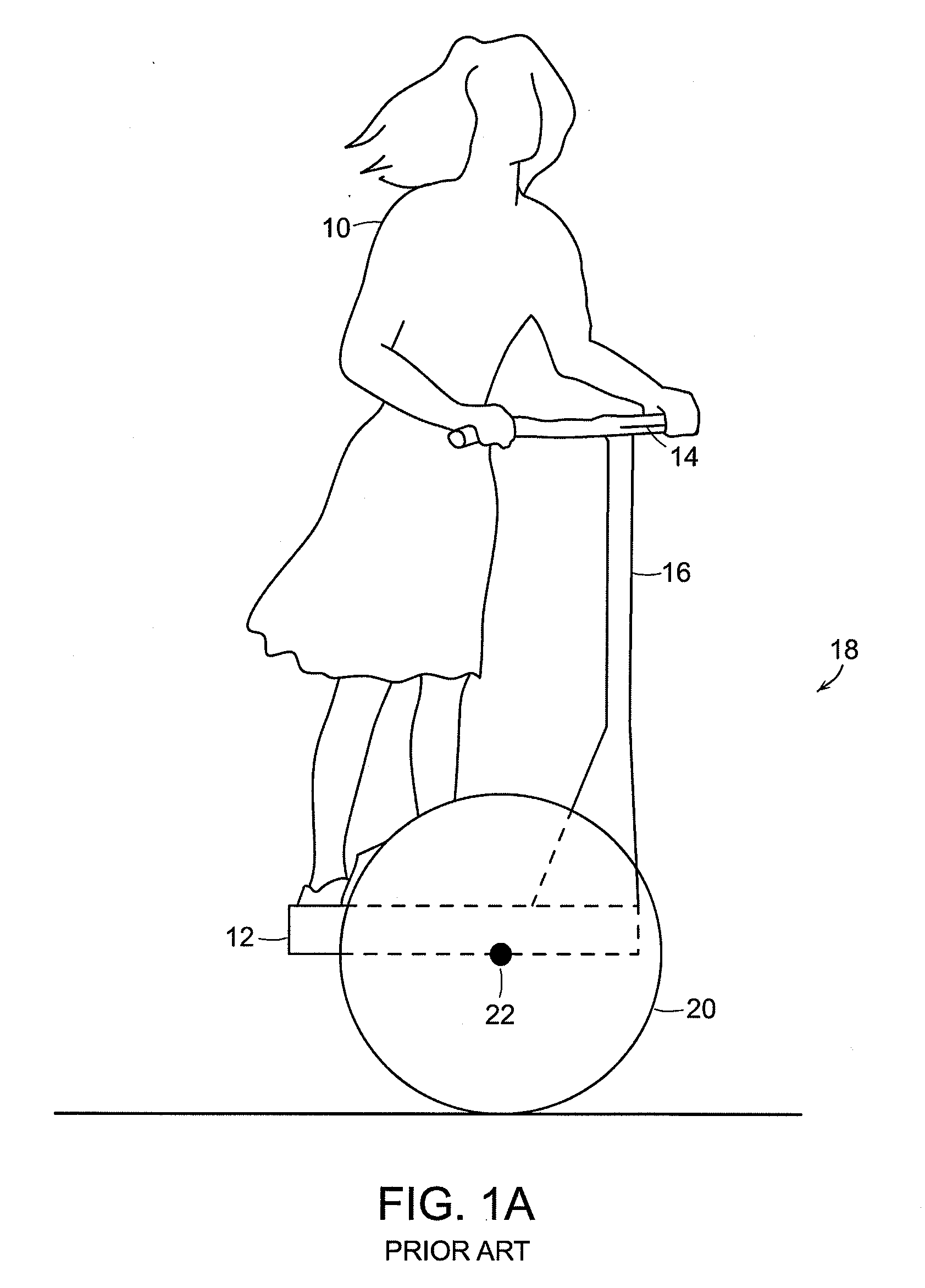

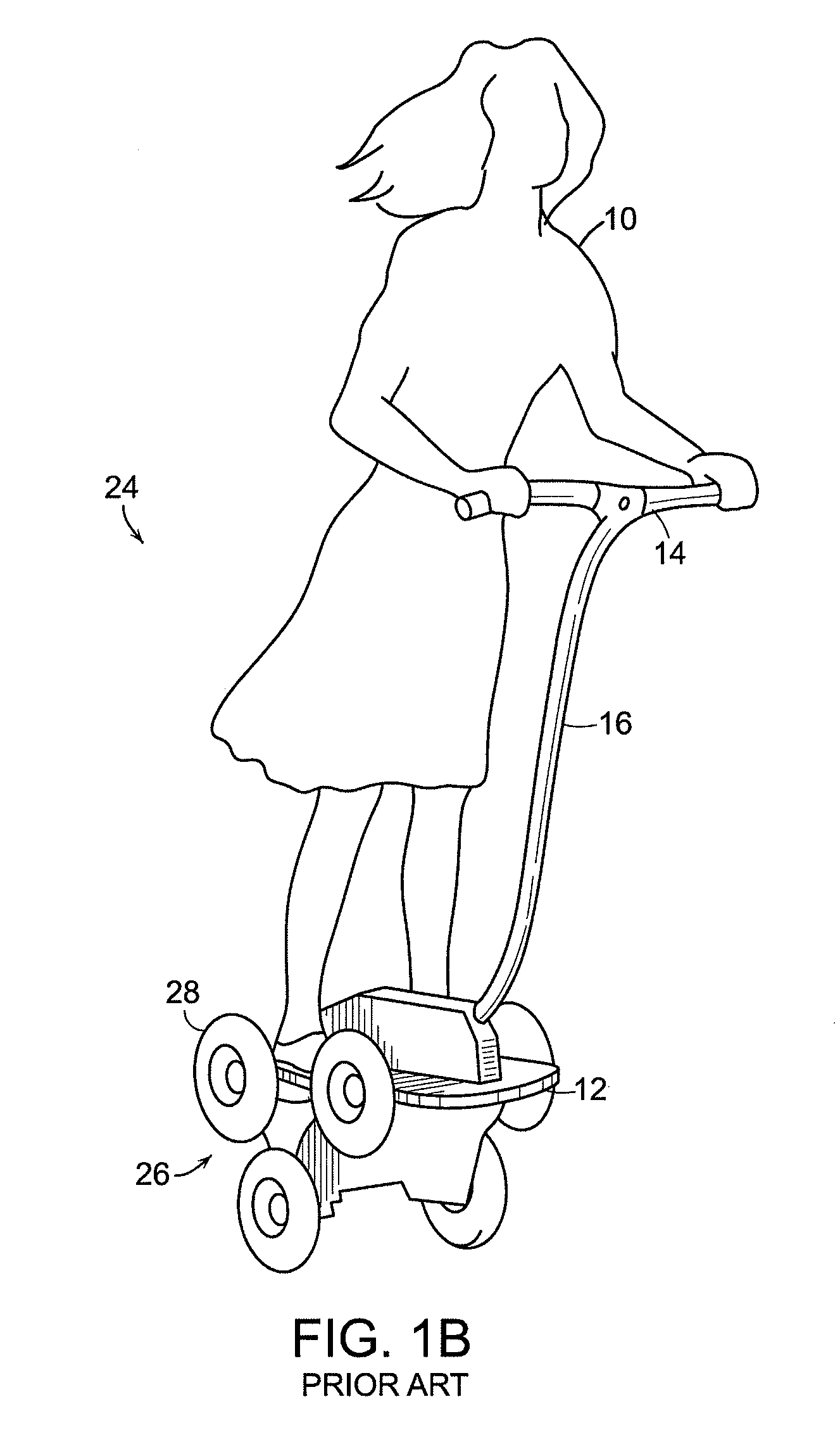

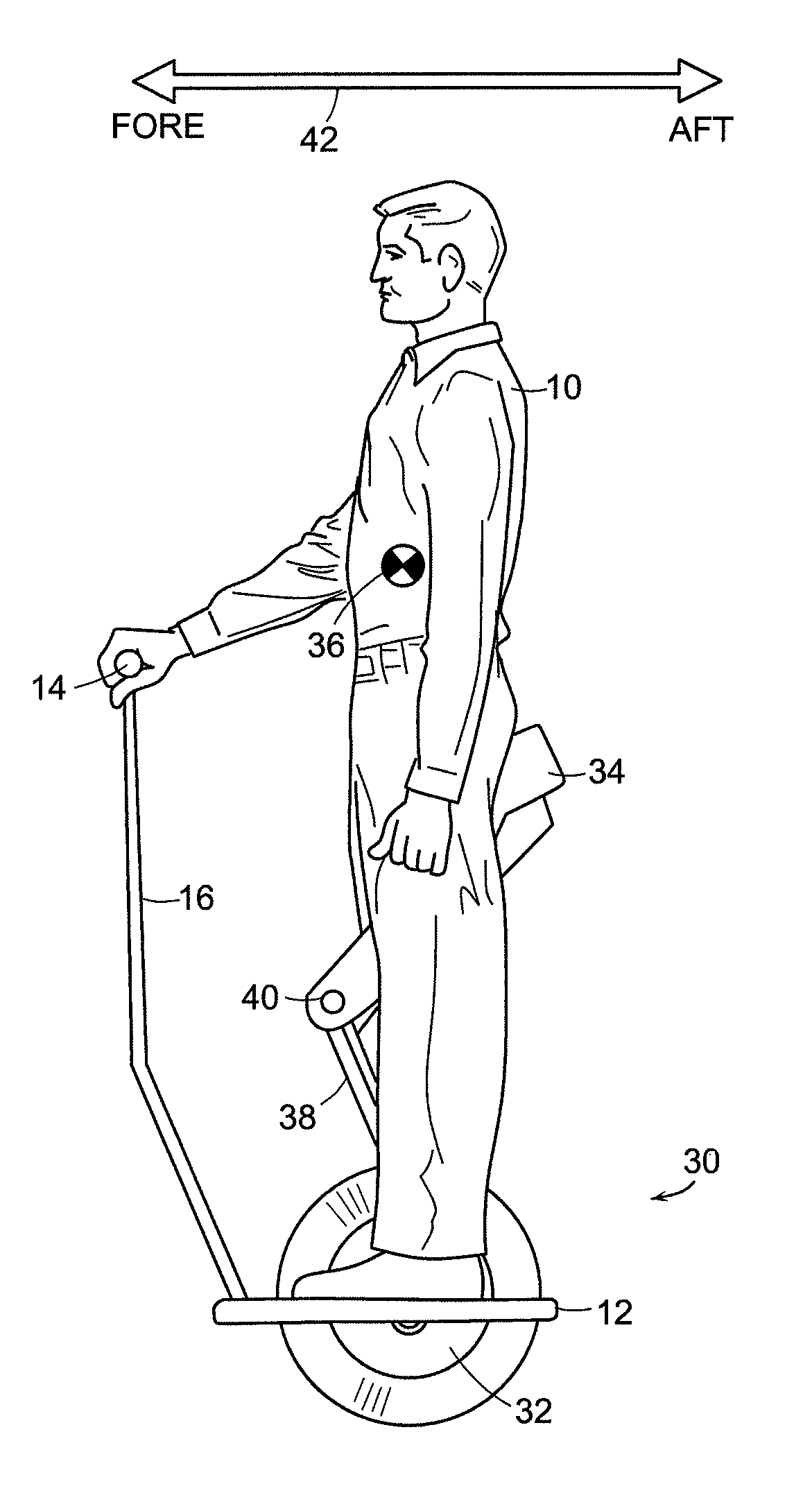

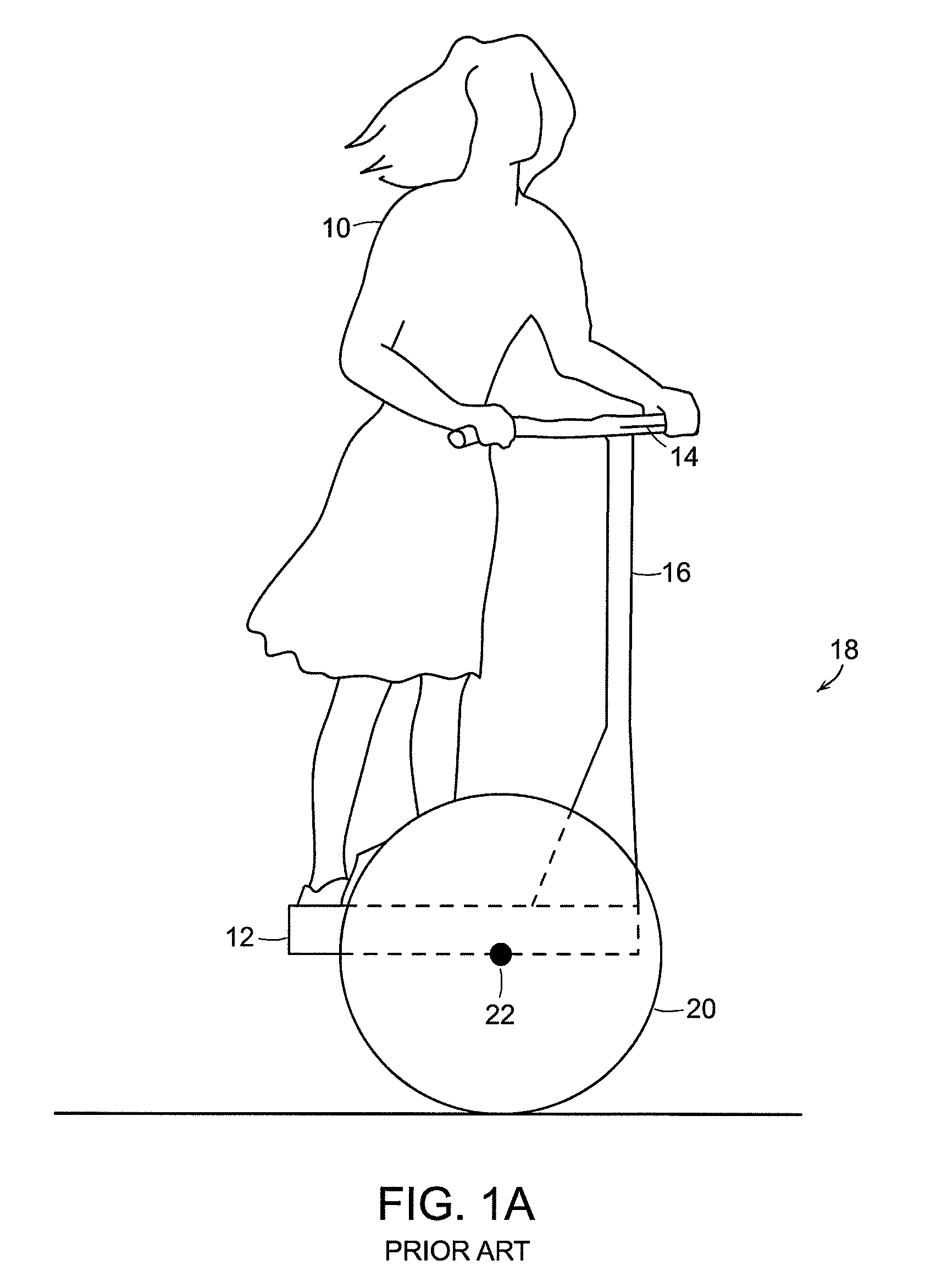

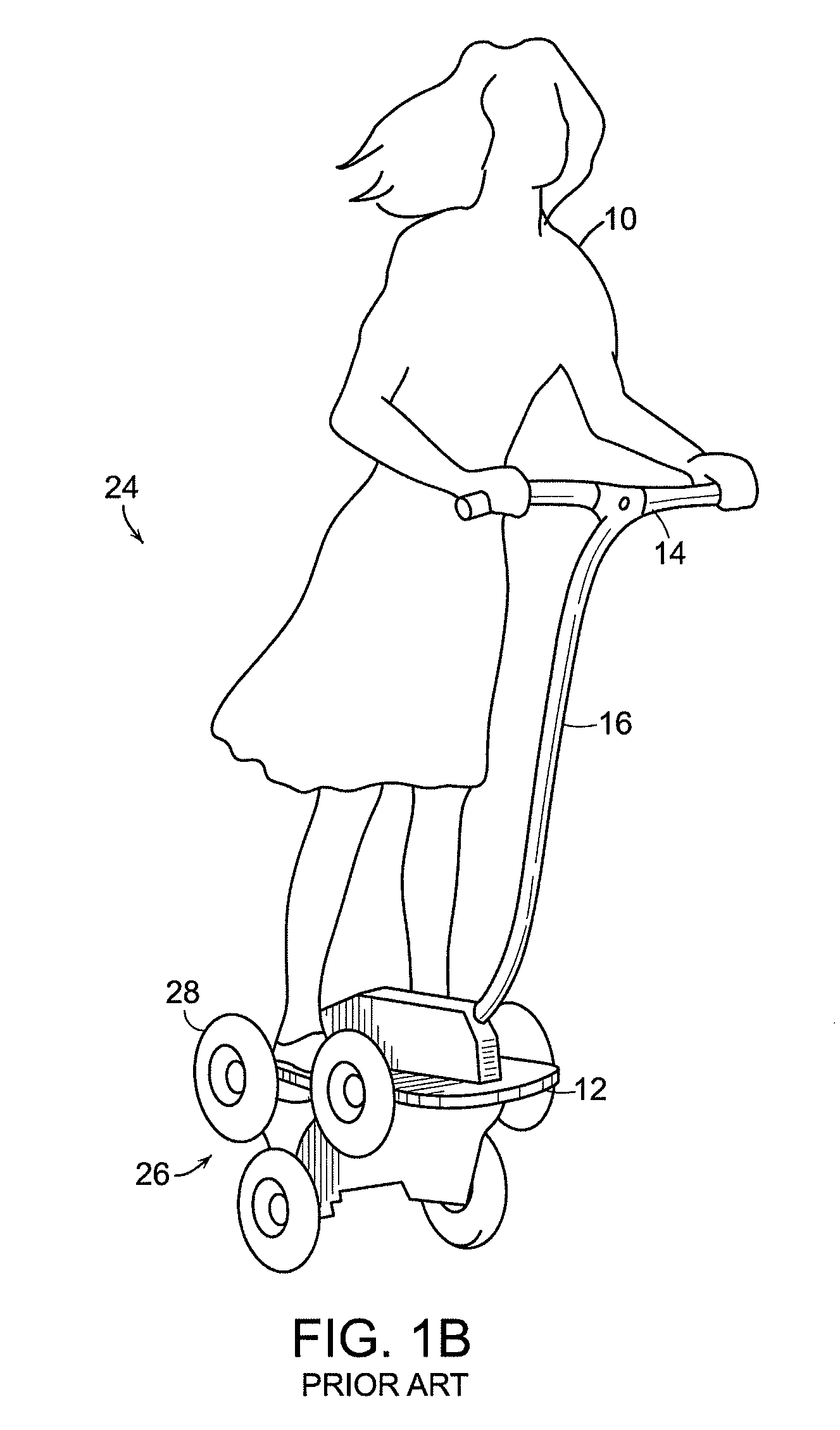

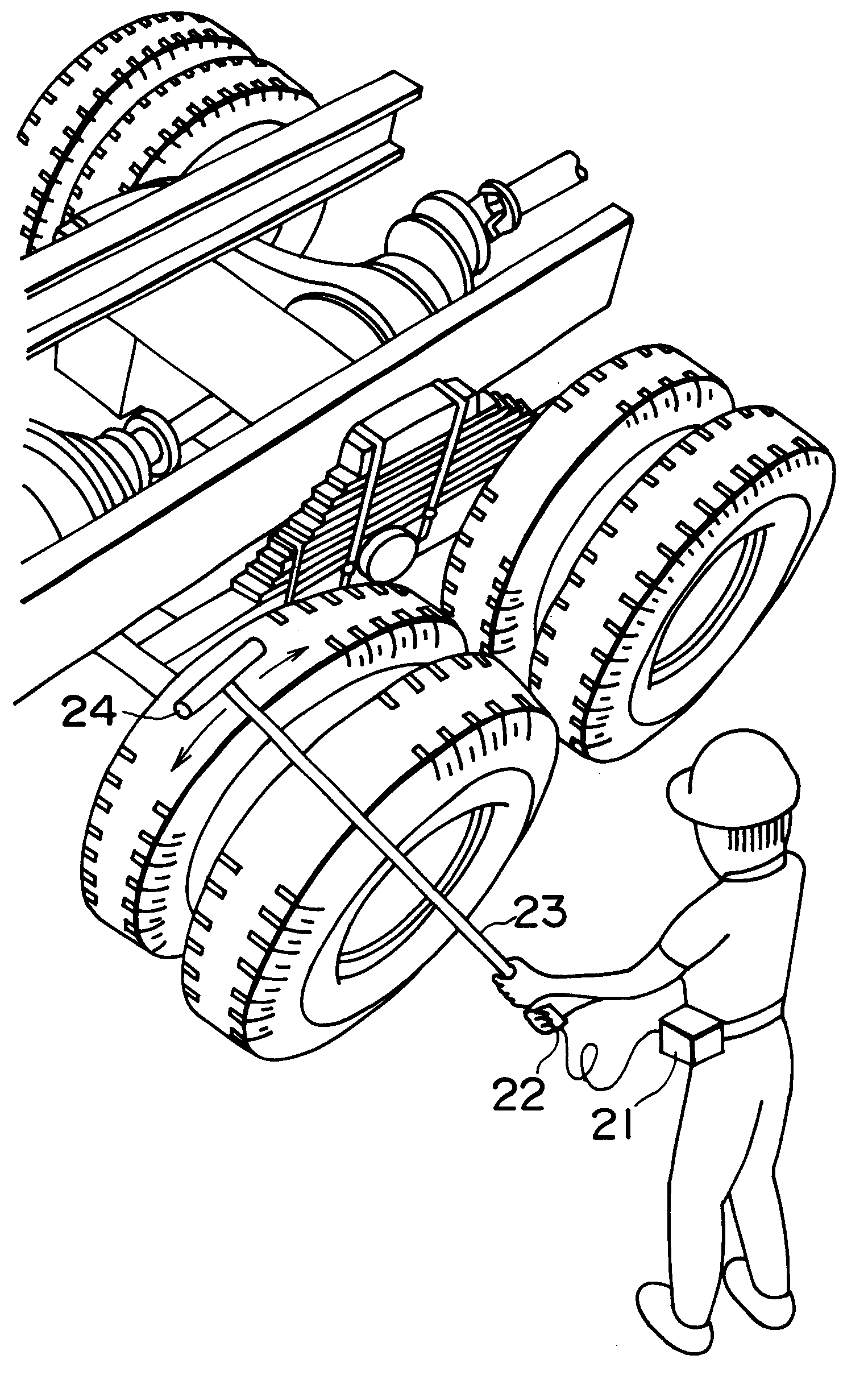

Apparatus and method for control of a vehicle

An apparatus and method for transporting a payload over a surface is provided. A vehicle supports a payload with a support partially enclosed by an enclosure. Two laterally disposed ground-contacting elements are coupled to at least one of the enclosure or support. A motorized drive is coupled to the ground-contacting elements. A controller coupled to the drive governs the operation of the drive at least in response to the position of the center of gravity of the vehicle to dynamically control balancing of the vehicle.

Owner:SEGWAY INC

Apparatus and method for control of a vehicle

Owner:SEGWAY INC

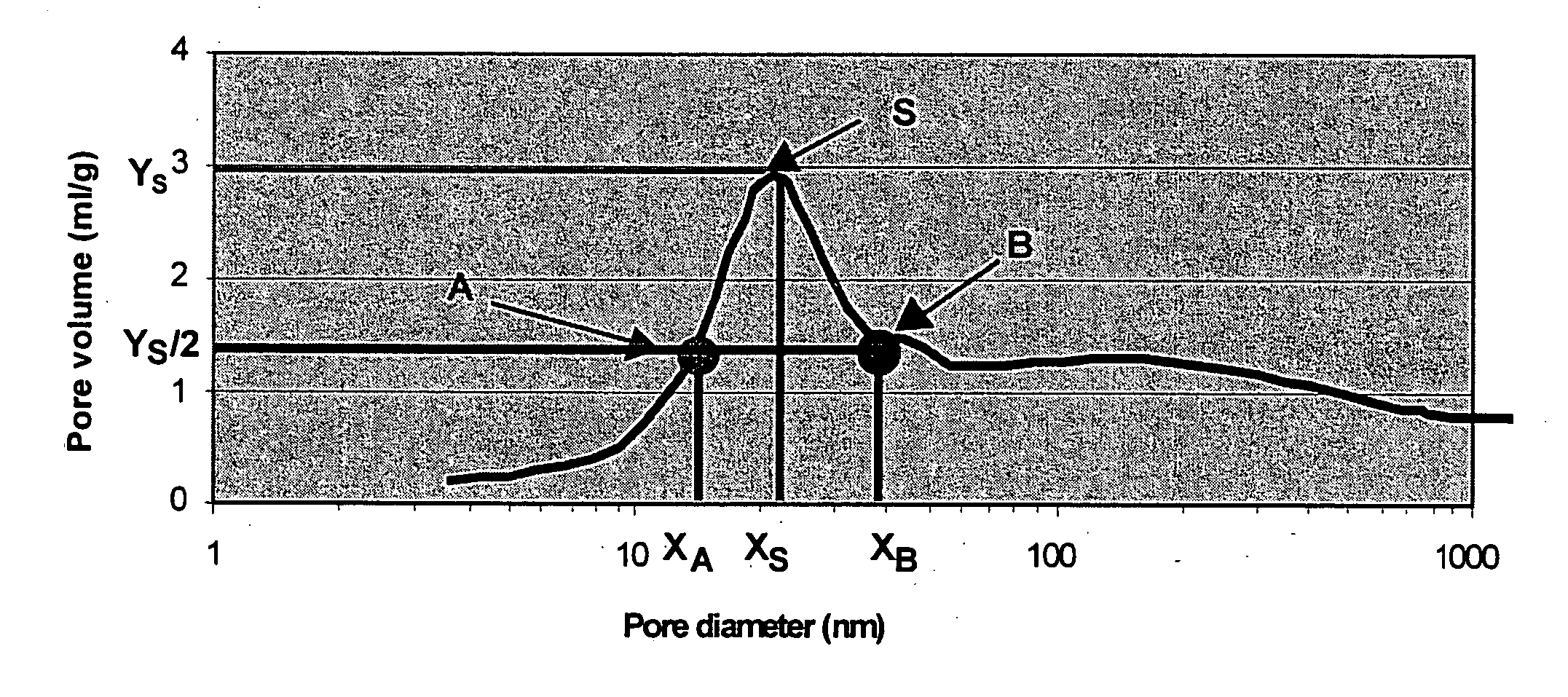

Diene rubber composition for tire comprising a specific silica as reinforcing filler

InactiveUS20050004297A1Less-difficult to processReduce hysteresisMaterial nanotechnologySpecial tyresElastomerPorosity

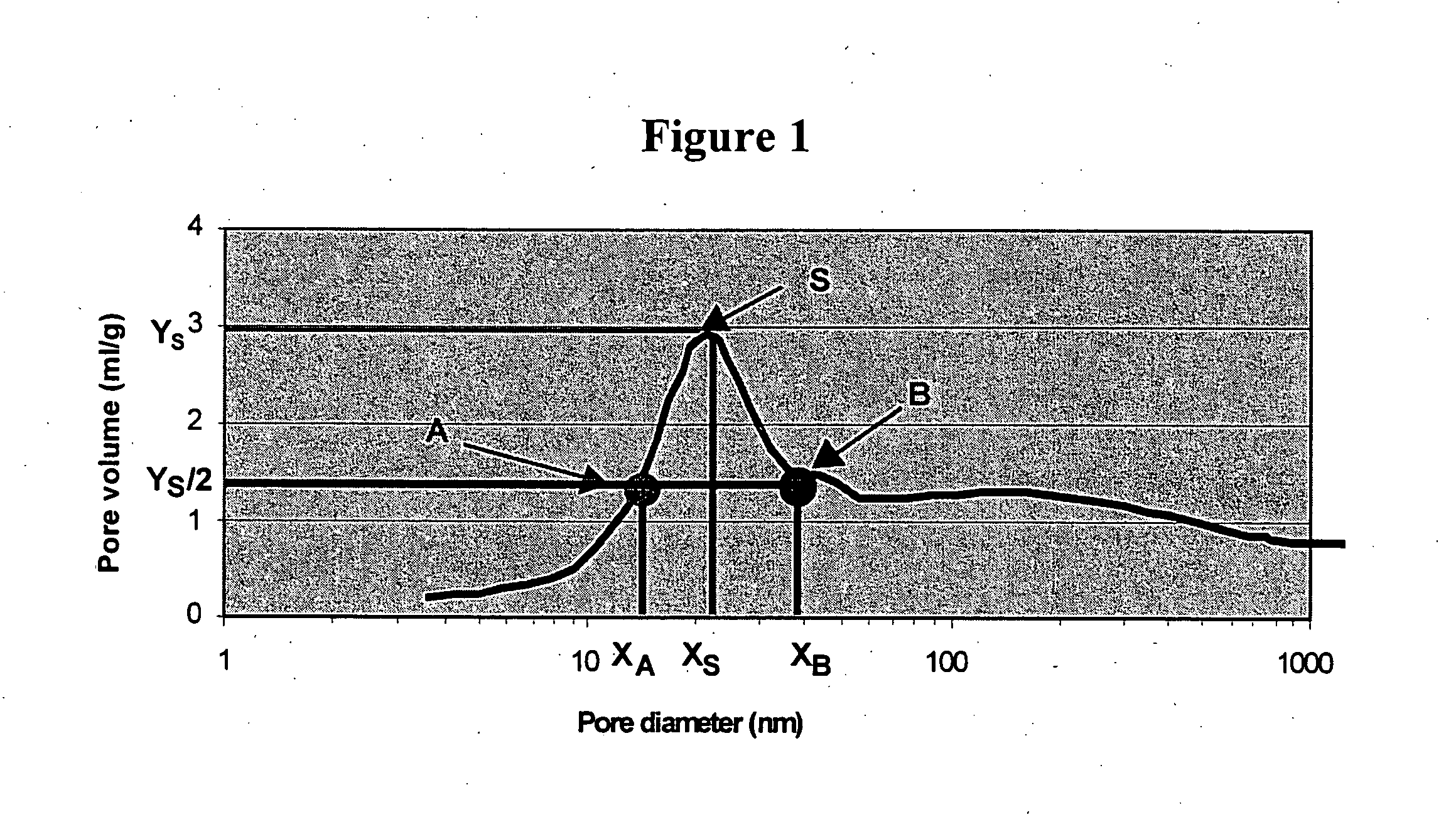

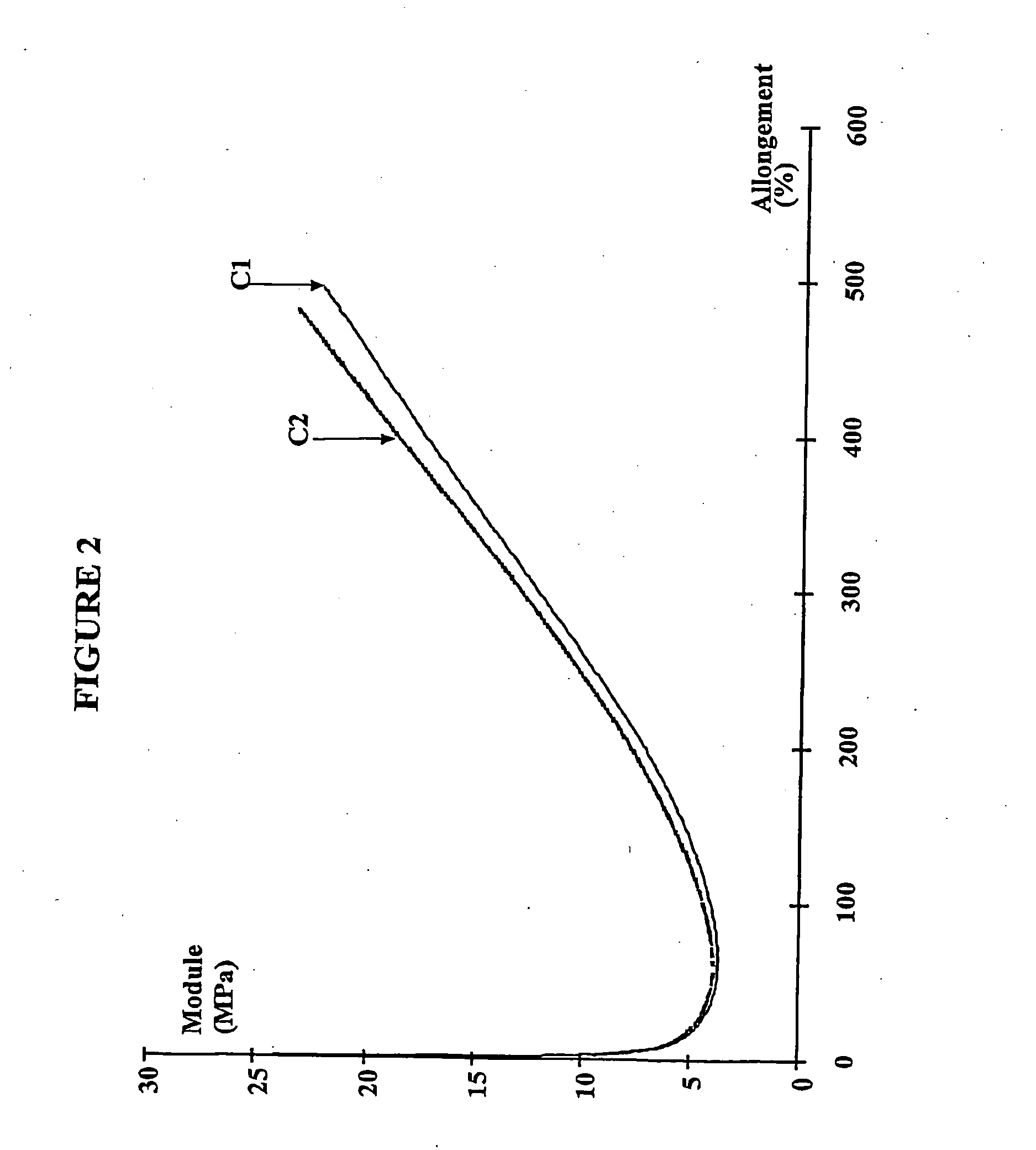

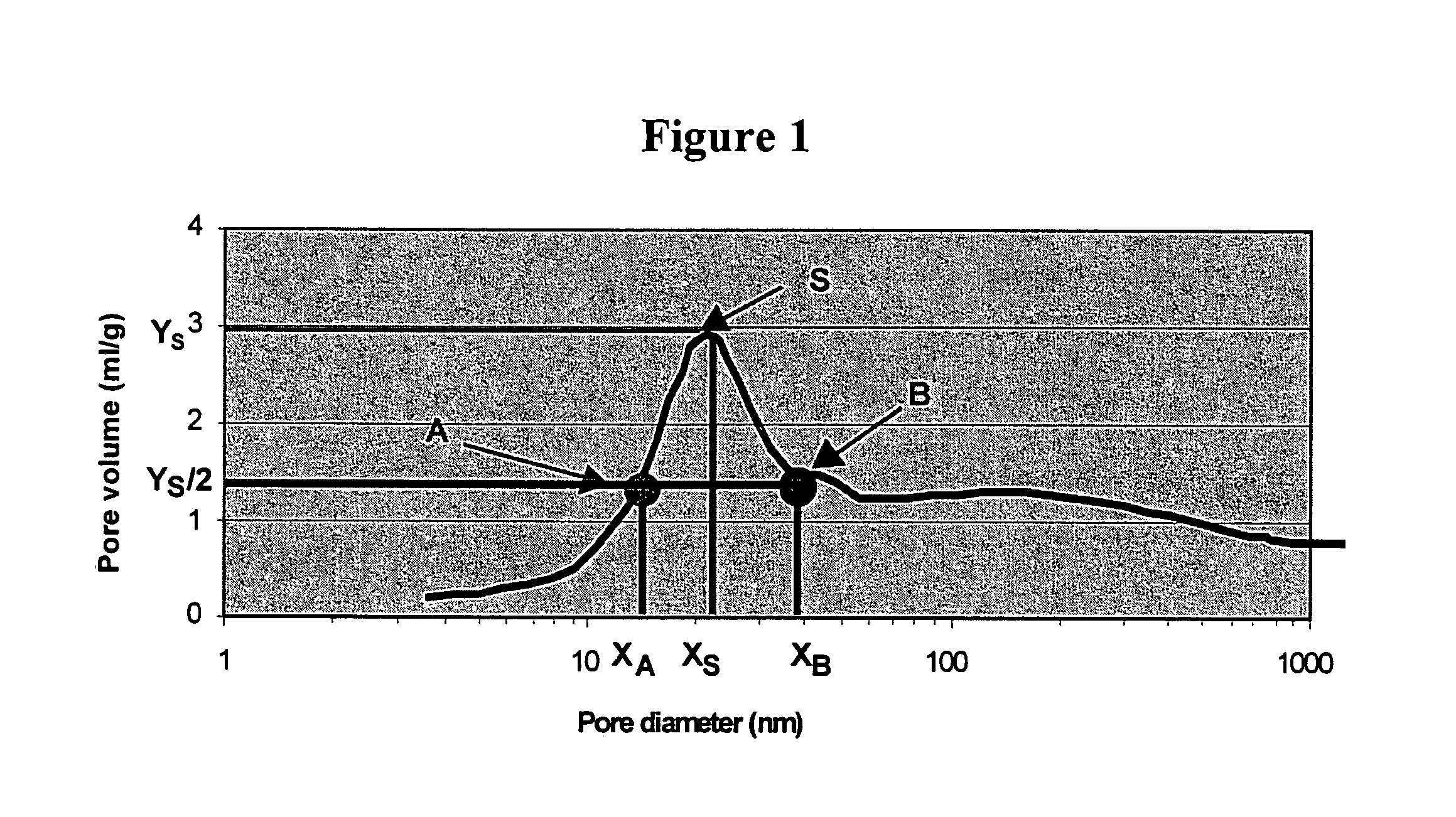

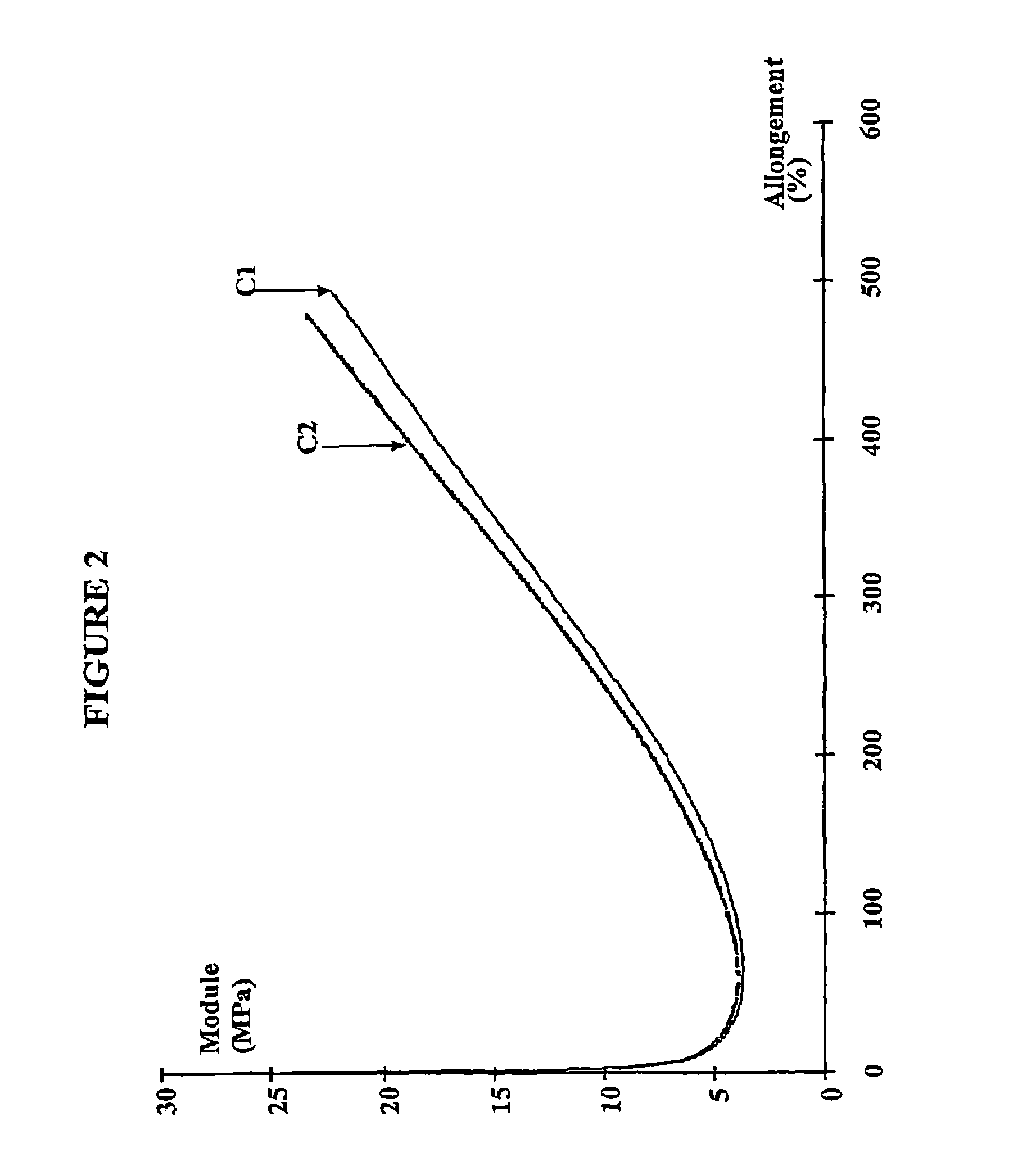

Diene rubber compositions are described containing a diene elastomer, a reinforcing inorganic filler, and a coupling agent wherein the inorganic filler includes a silica having the following characteristics: (a) a BET specific surface area between 45 and 400 m2 / g; (b) a CTAB specific surface area between 40 and 380 m2 / g; (c) an average particle size (by mass), dw, of 20 to 300 nm; and at least one of the following characteristics, preferably two and more preferably all three: (d) a particle size distribution such that dw≧ / CTAB)−30; (e) a porosity which meets the criterion L / FI≧−0.0025 CTAB+0.85; (f) an amount of silanols per unit of surface area, NSiOH / nm2; NSiOH / nm2≦−0.027 CTAB+10.5. These diene rubber compositions can be used for the manufacture of tires or of semi-finished products intended for tires.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

Diene rubber composition for tire comprising a specific silica as reinforcing filler

InactiveUS7250463B2Less-difficult to processReduce hysteresisMaterial nanotechnologySpecial tyresPorosityElastomer

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

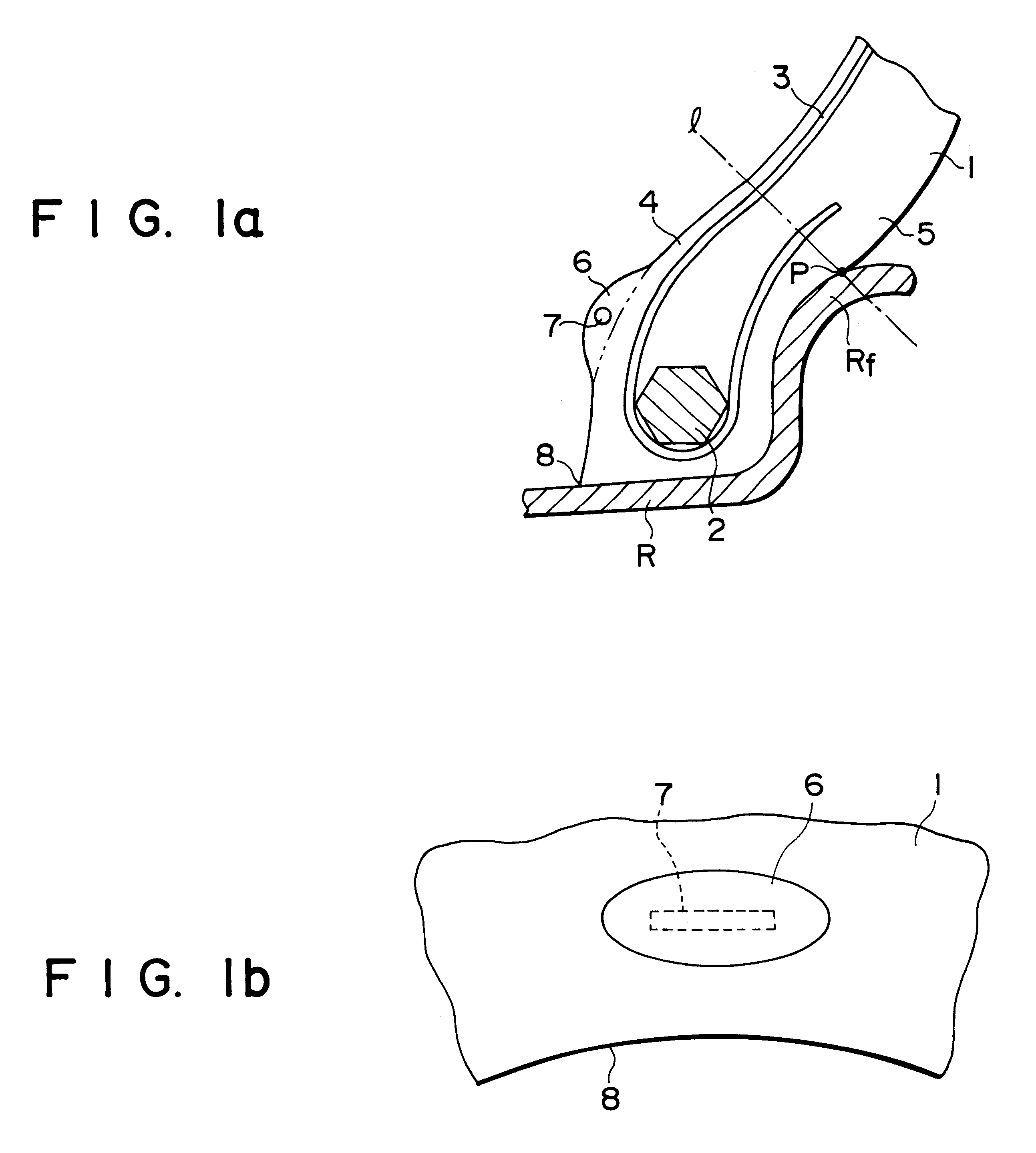

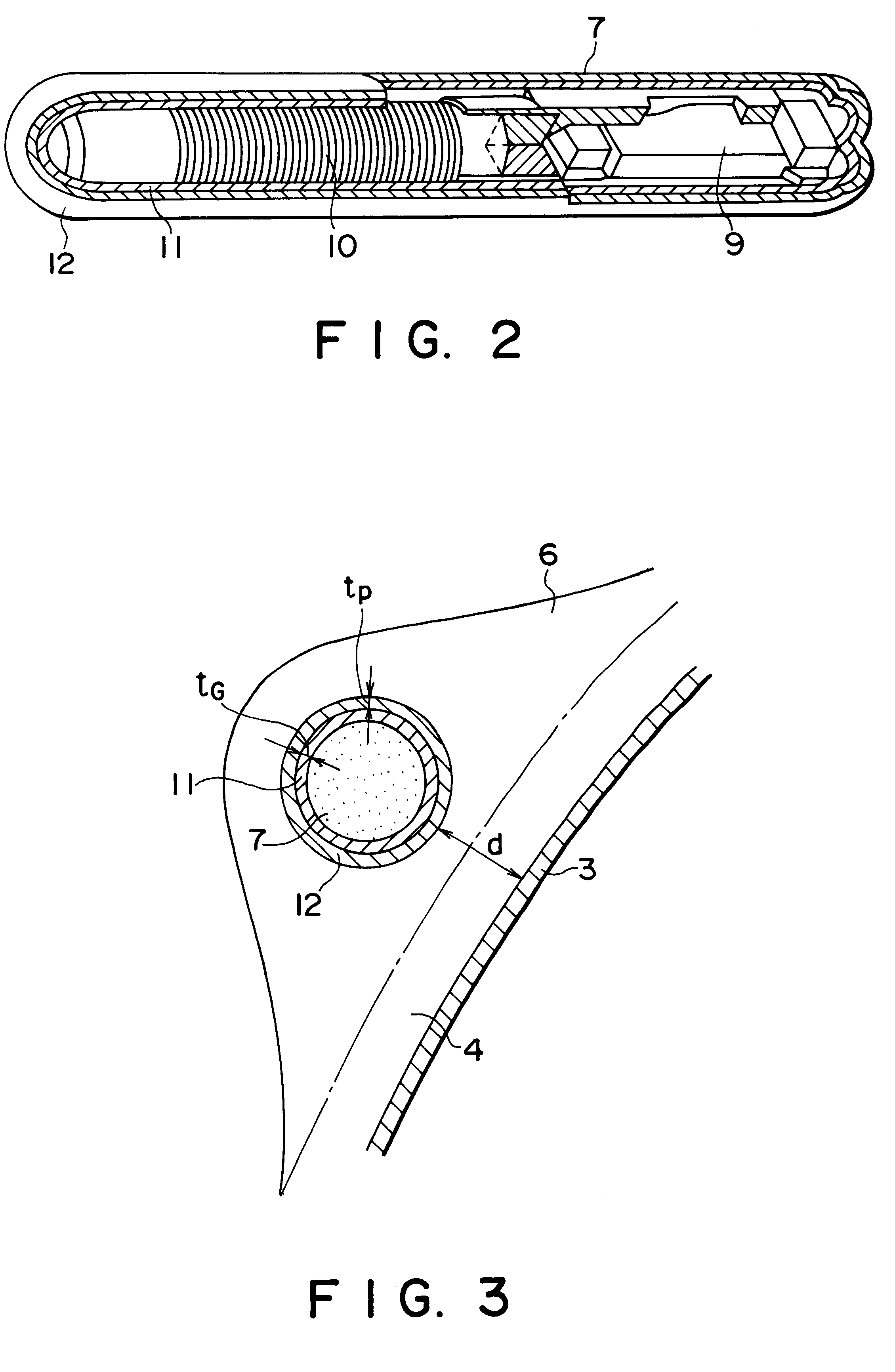

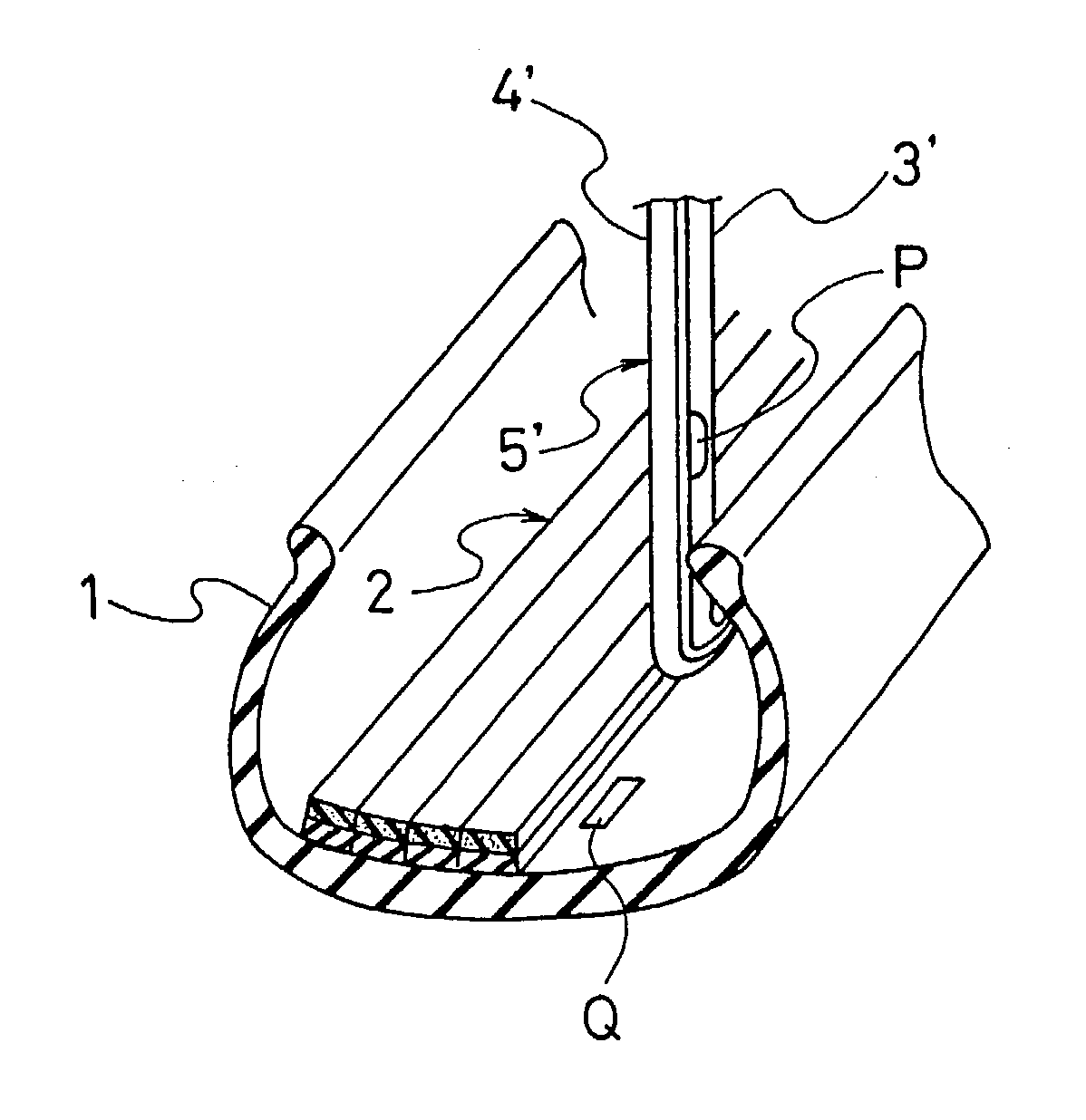

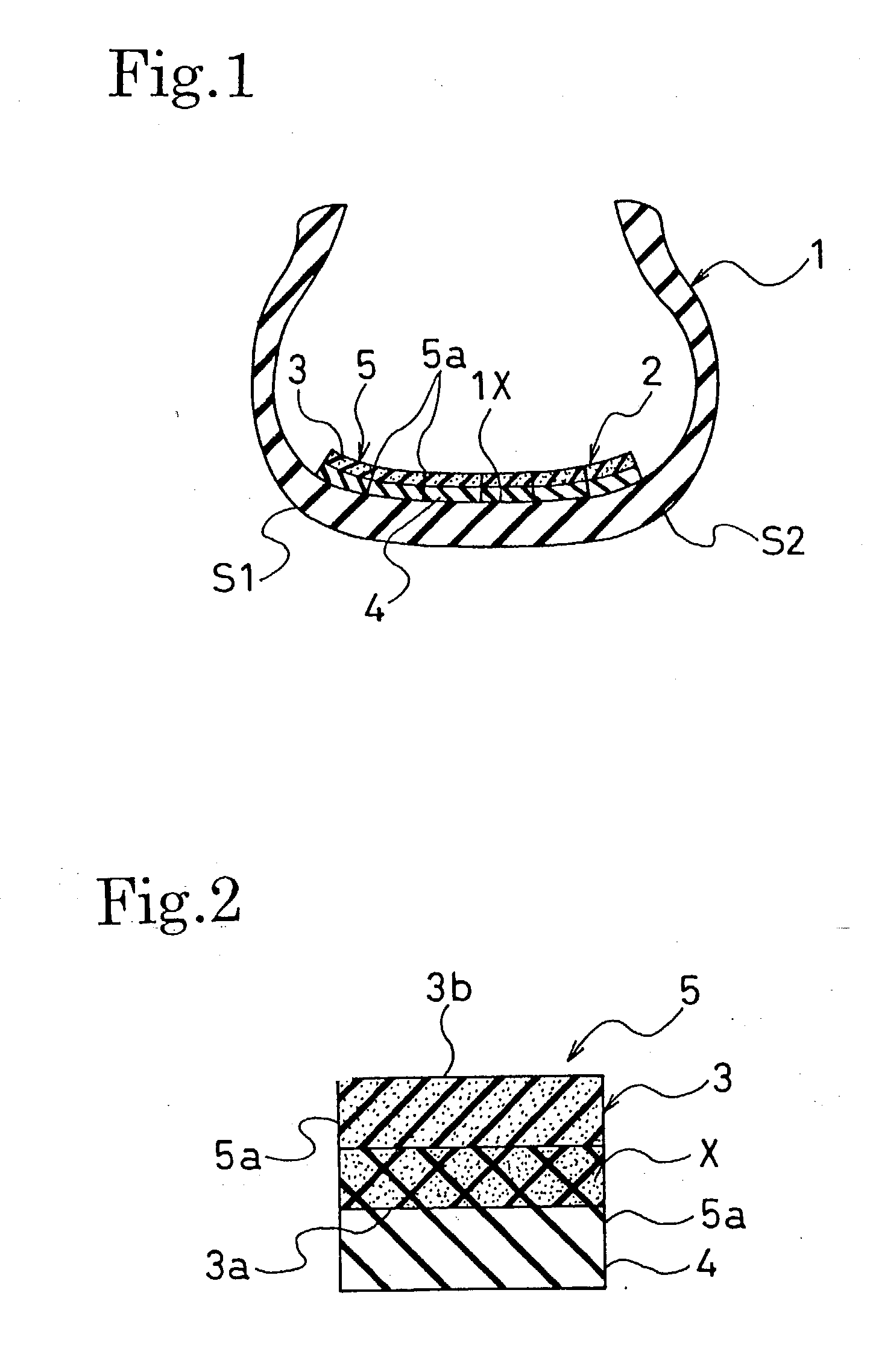

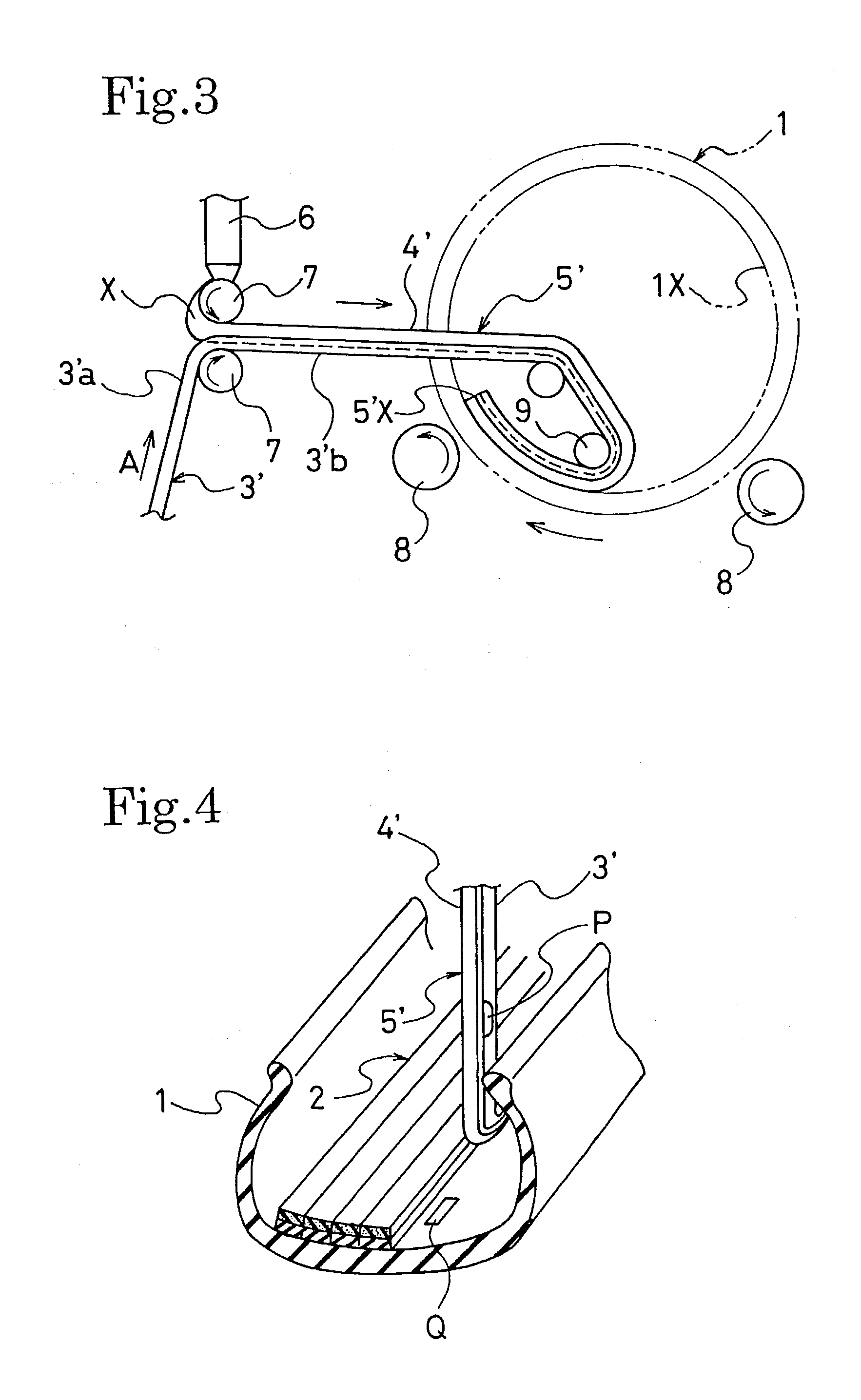

Pneumatic tire having a transponder therein, and a method of and a device for reading and writing of a transponder

A pneumatic tire having a transponder therein comprises a pair of sidewall portions and a crown portion toroidally arranged between a pair of bead cores, and a method of reading and writing of the transponder buried in the tire, wherein the transponder is buried in a projected portion at the inner surface of a bead portion of the tire, and the axial direction of the transponder is along the circumferential direction of the tire, and a rod antenna used for receiving and transmission for the transponder is moved as an axial line of the rod antenna along the circumferential direction of the tire when the reading and writing is done from outside of the tire.

Owner:BRIDGESTONE CORP

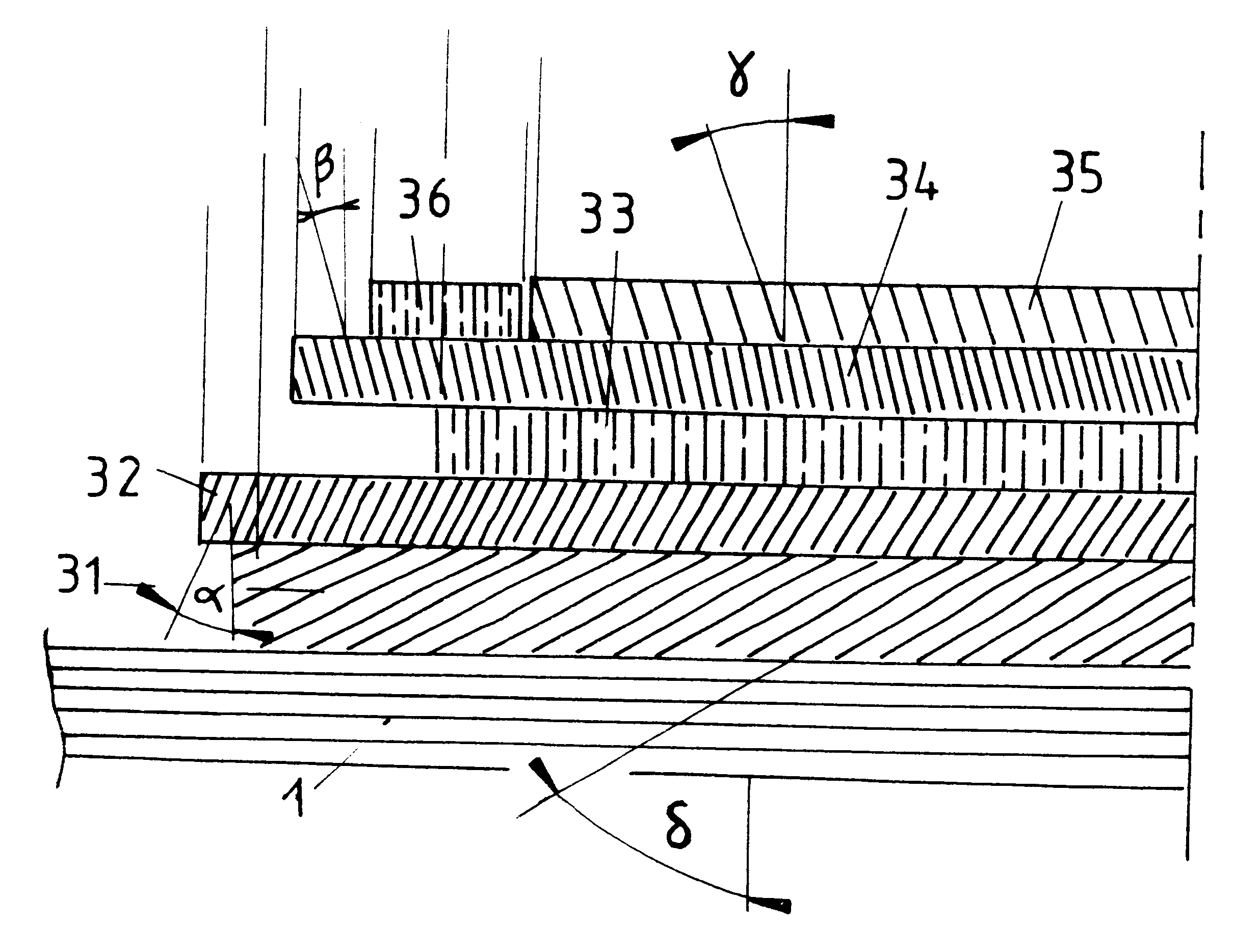

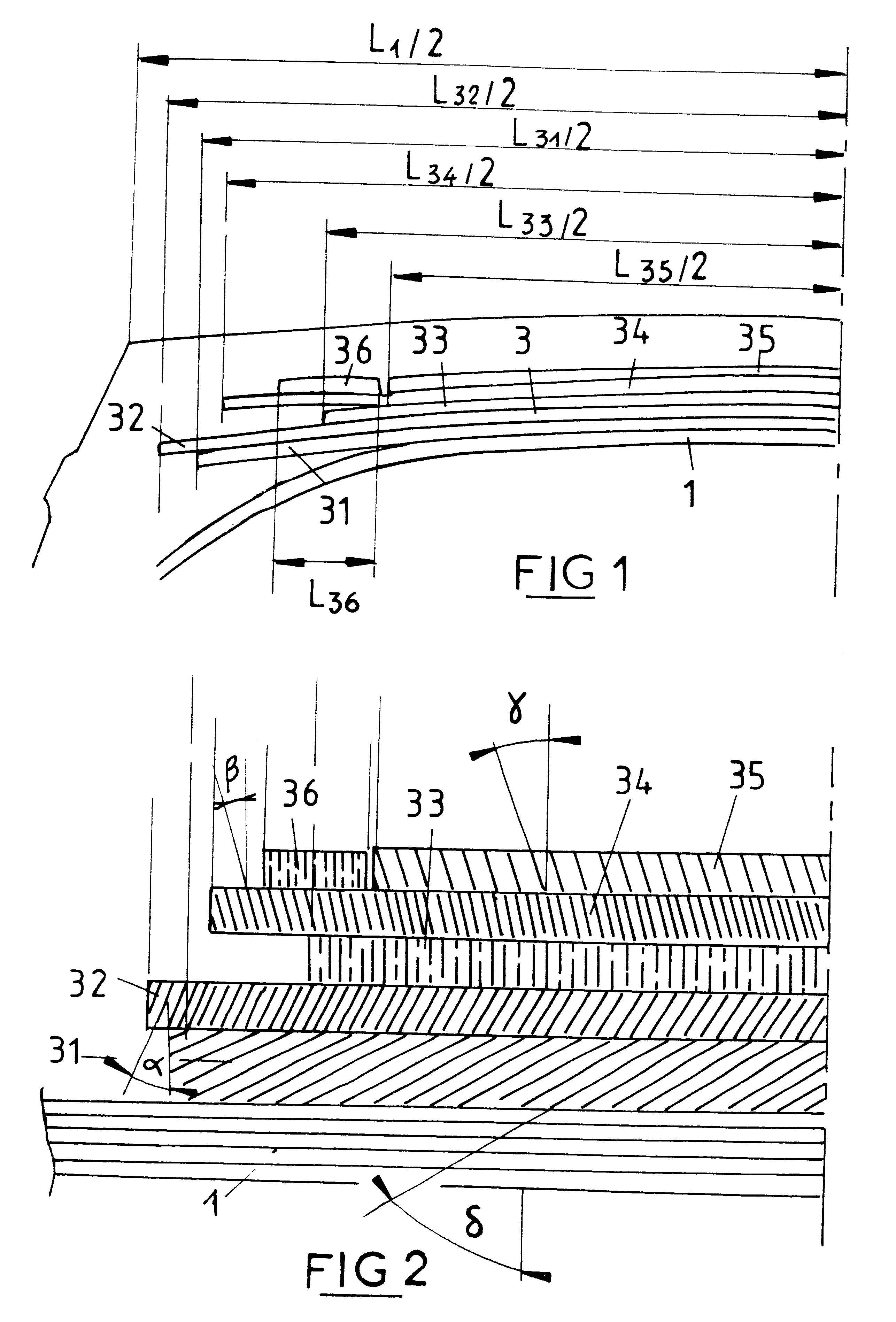

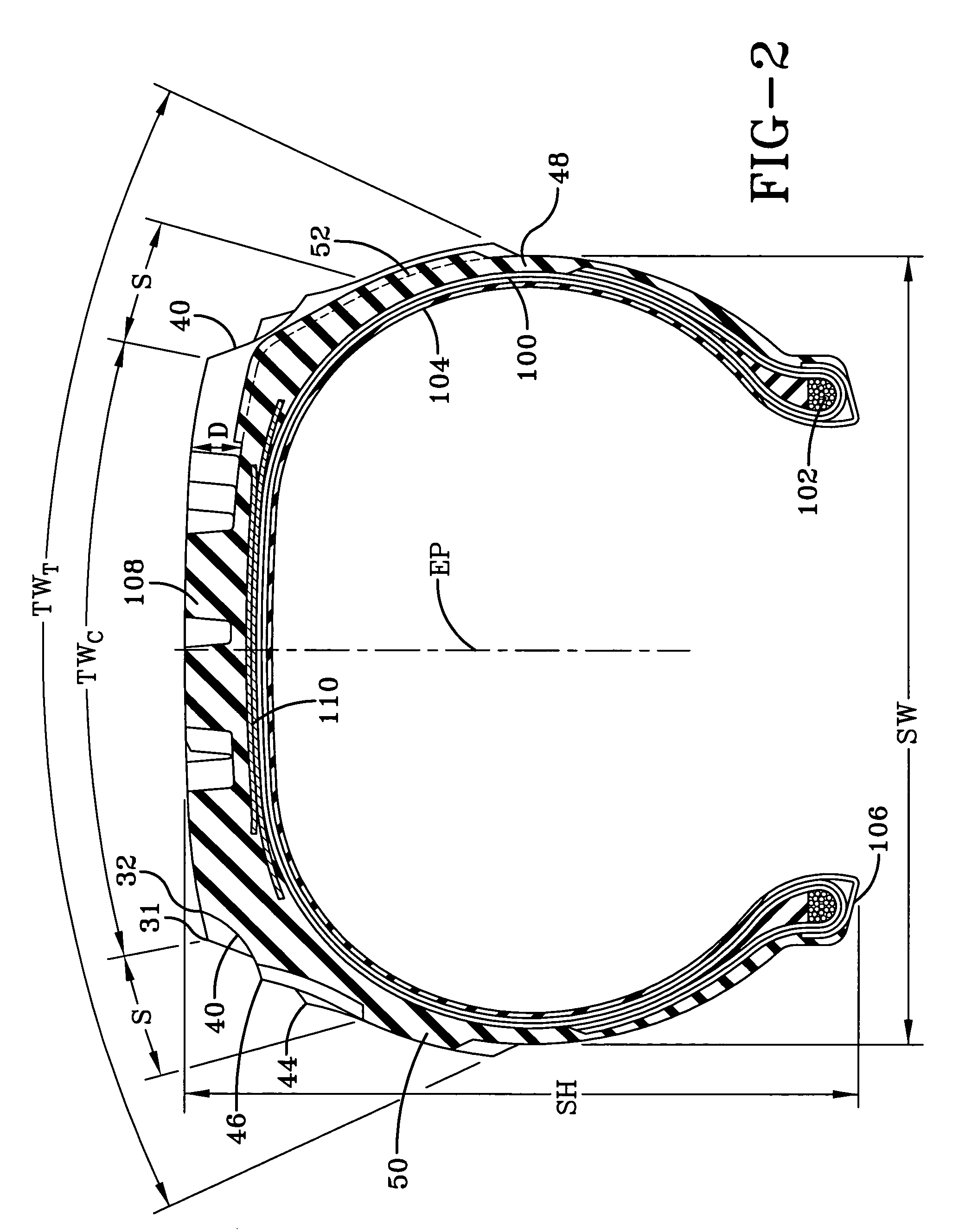

Tire having an H/S form ratio of <0.6

InactiveUS6367527B1Special tyresPneumatic tyre reinforcementsTriangulationElectrical and Electronics engineering

A tire, the H / S form ratio of which is at most 0.6, formed radially from the inside to the outside by a triangulation ply of metal cables oriented at least 60°, two working crown plies formed of inextensible metal cables oriented at angles of between 10° and 45°, between which there is inserted a first additional ply of metallic elements which are oriented substantially parallel to the circumferential direction of the tire, a second additional ply being arranged, on either side of the tire, radially above the outermost working ply and substantially centered on the end of the first additional ply.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

Tire with low hydrocarbon emission rubber combination of tread and sidewall components with compositional limitations

InactiveUS7214731B2Eliminate emissionsEmission reductionSpecial tyresInflatable tyresElastomerHydrophobic silica

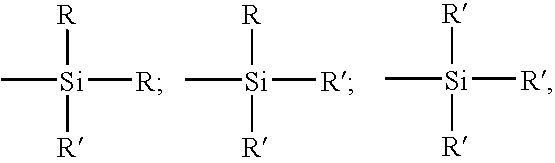

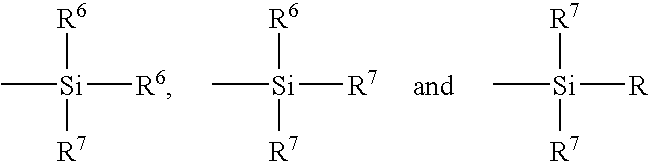

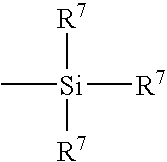

The invention relates to a tire of a structural combination of tire tread and sidewall components with compositional limitations containing minimal, if any, of in situ formed alcohol and methyl isobutyl ketone byproducts. The tread component rubber composition contains pre-hydrophobated silica reinforcement. The sidewall component contains low unsaturation EPDM or brominated copolymer of isobutylene and p-methylstyrene and may contain pre-hydrophobated silica reinforcement. The silica reinforcement for said tread and sidewall components is a pre-hydrophobated precipitated silica. The pre-hydrophobated silica is prepared, prior to mixing with the elastomer(s), by reacting hydroxyl groups (e.g. silanol groups) contained on the surface of a precipitated silica with an alkoxyorganomercaptosilane or a combination of an alkoxyorganomercaptosilane and a substituted alkylsilane or with a bis-3(trialkoxysilylalkyl) polysulfide which contains an average of from 2 to 4 connecting sulfur atoms in its polysulfidic bridge to form a composite thereof. The alcohol byproduct therefrom is removed from the composite prior to its introduction into the rubber composition(s). In another aspect of the invention, the connecting sidewall rubber composition, and optionally the tread composition is free of N-(1,3-dimethylbutyl)-N′-phenyl-p-phenylenediamine antidegradant (referred herein to as 6PPD) in order to prevent in situ formation of methyl isobutyl ketone byproduct from the reaction of 6PPD with atmospheric oxygen and / or ozone.

Owner:THE GOODYEAR TIRE & RUBBER CO

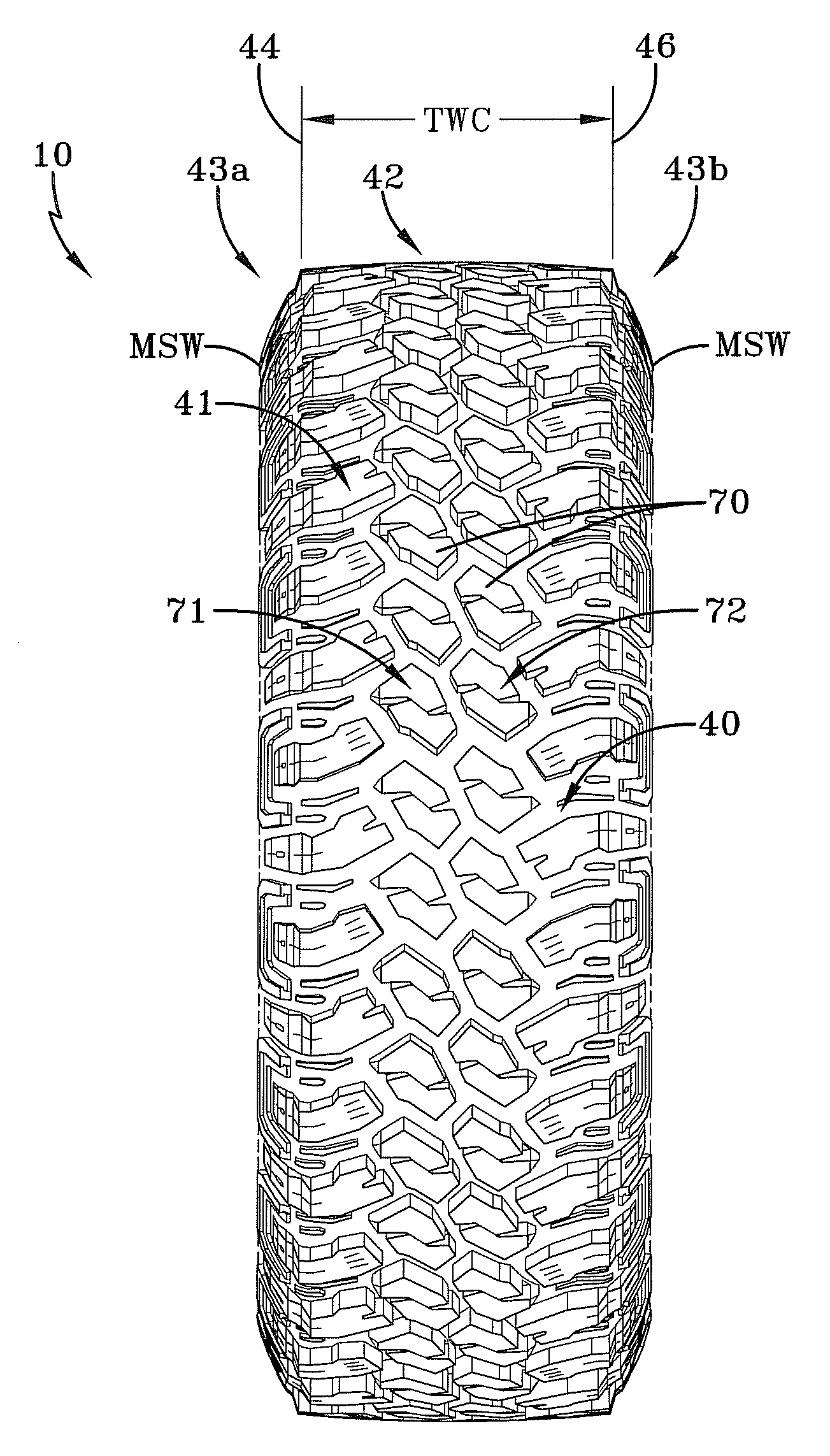

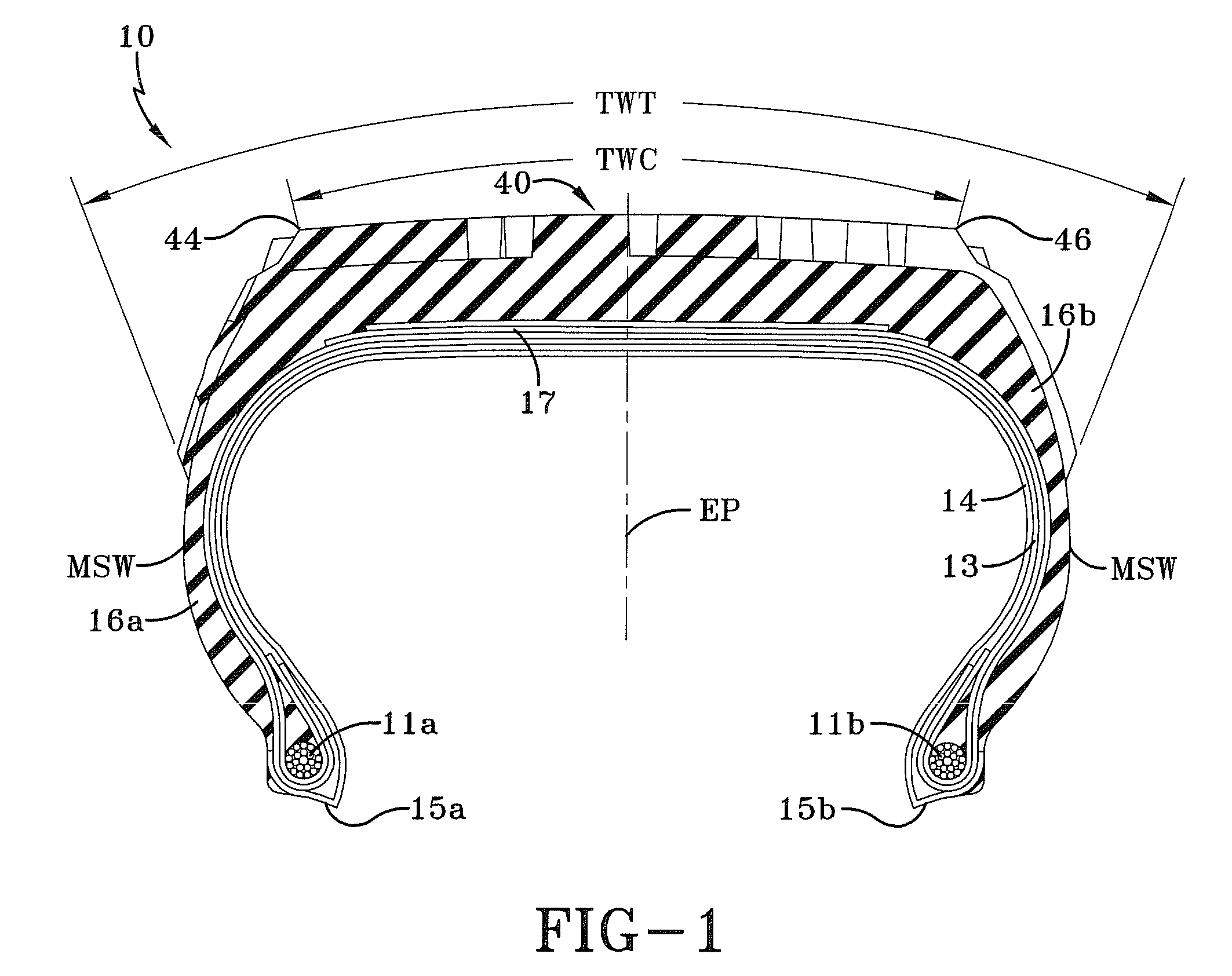

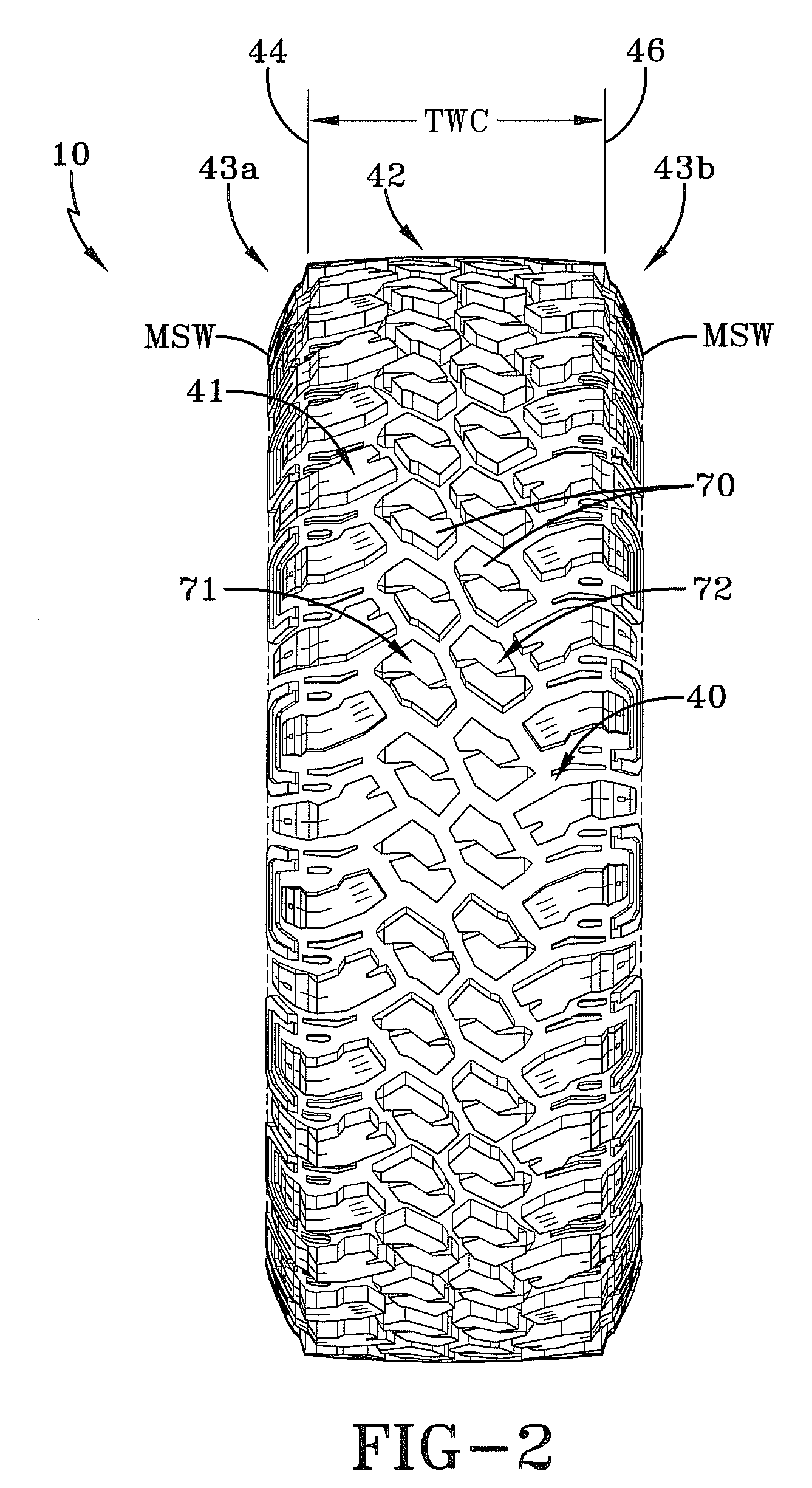

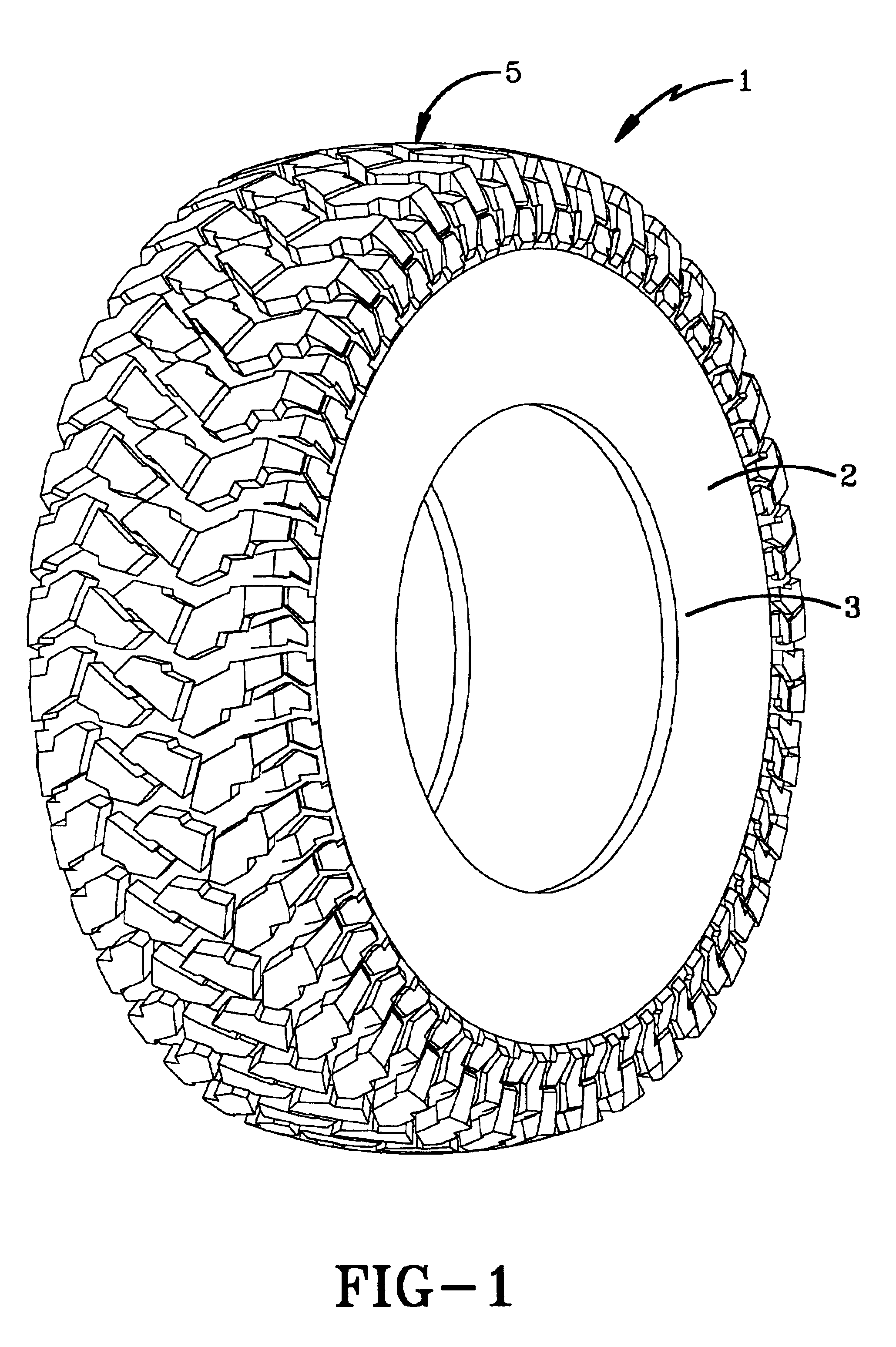

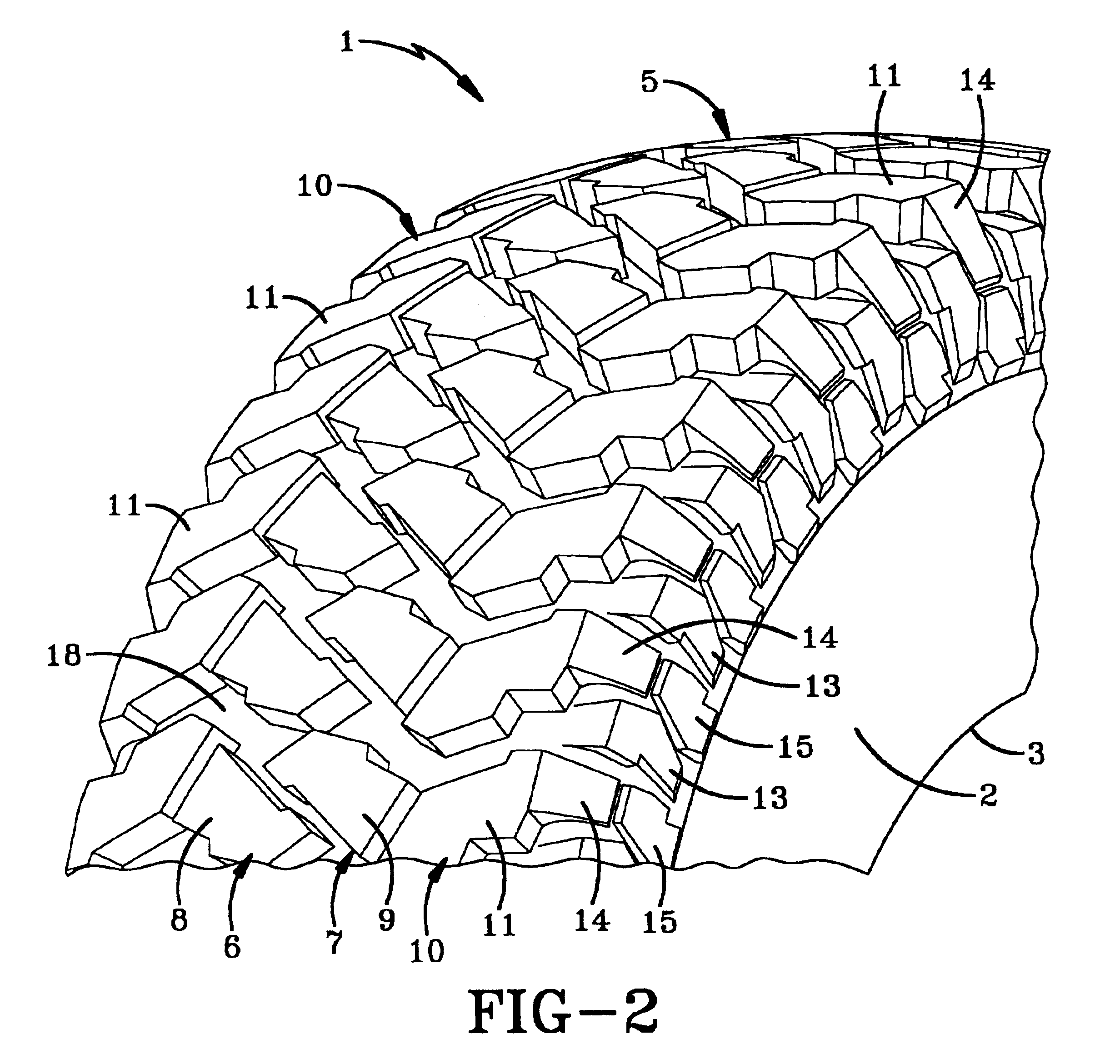

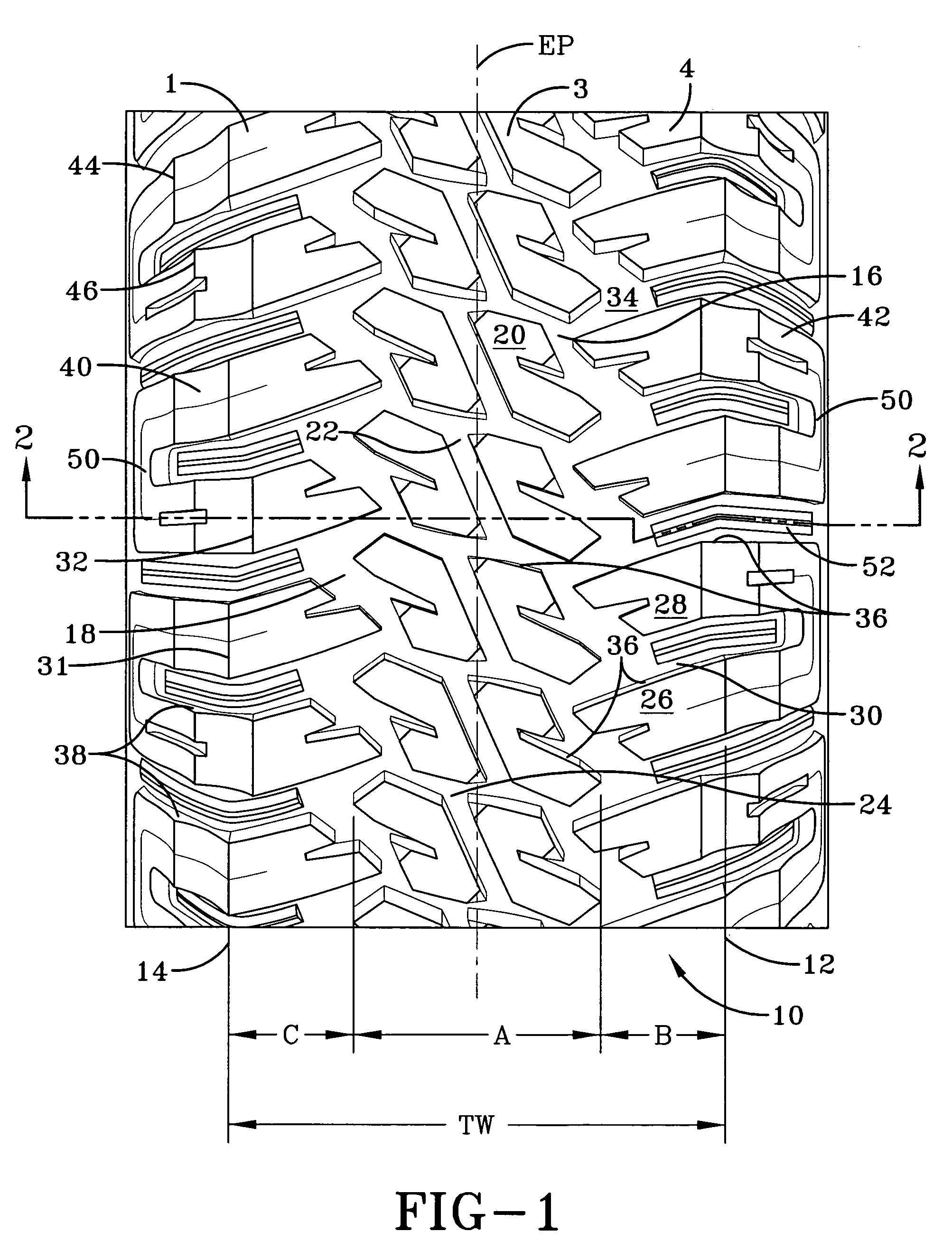

Grip tire with added puncture protection

InactiveUS20090107600A1Improve protectionWeight increaseInflatable tyresTyre tread bands/patternsTruckTread

A lightweight truck and passenger vehicle tire having an improved tread design that provides numerous biting edges for increased grip in mud, snow, loose debris, and when climbing rocks as well as providing increased protection from punctures and cuts to the tire's shoulder and upper sidewall regions.

Owner:THE GOODYEAR TIRE & RUBBER CO

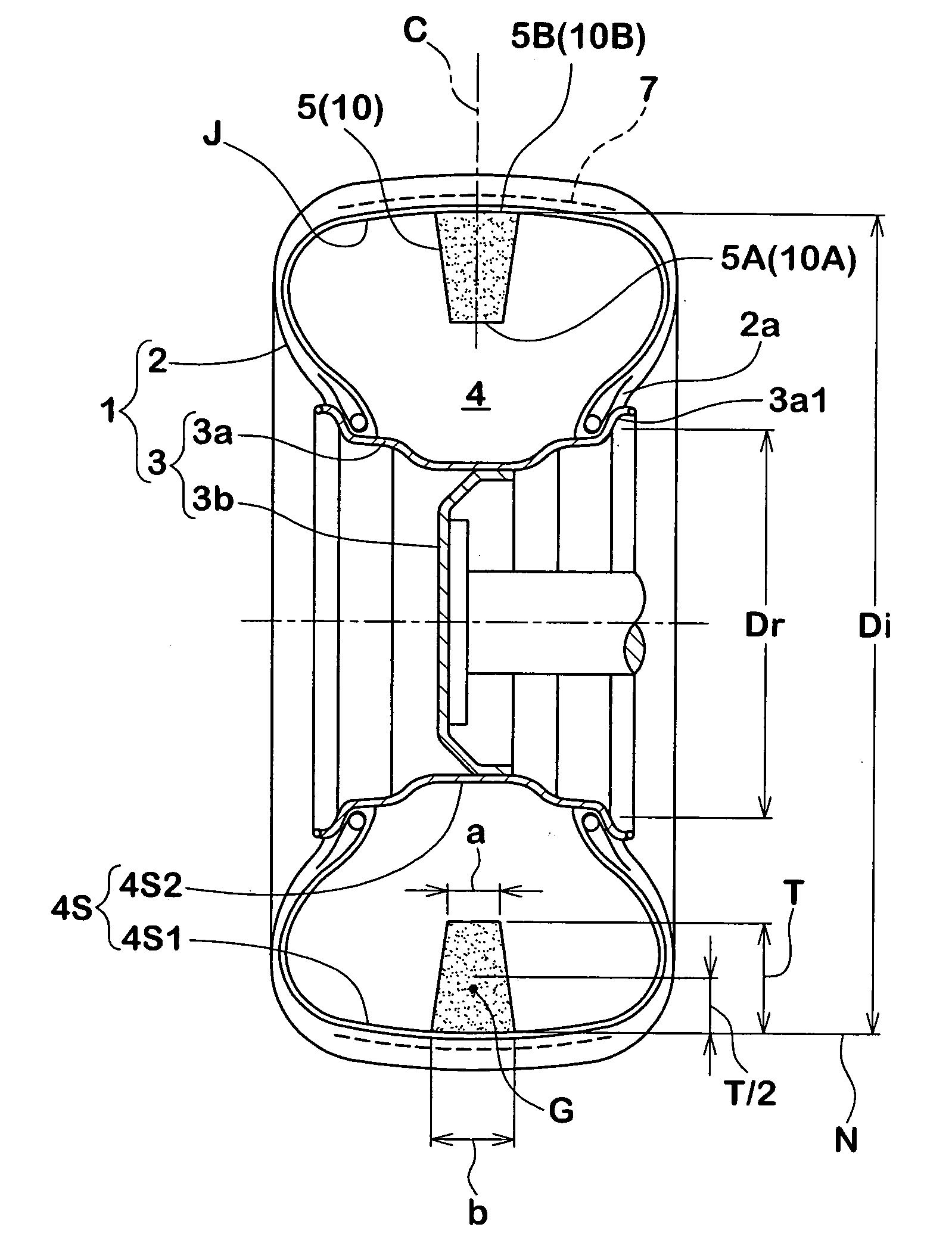

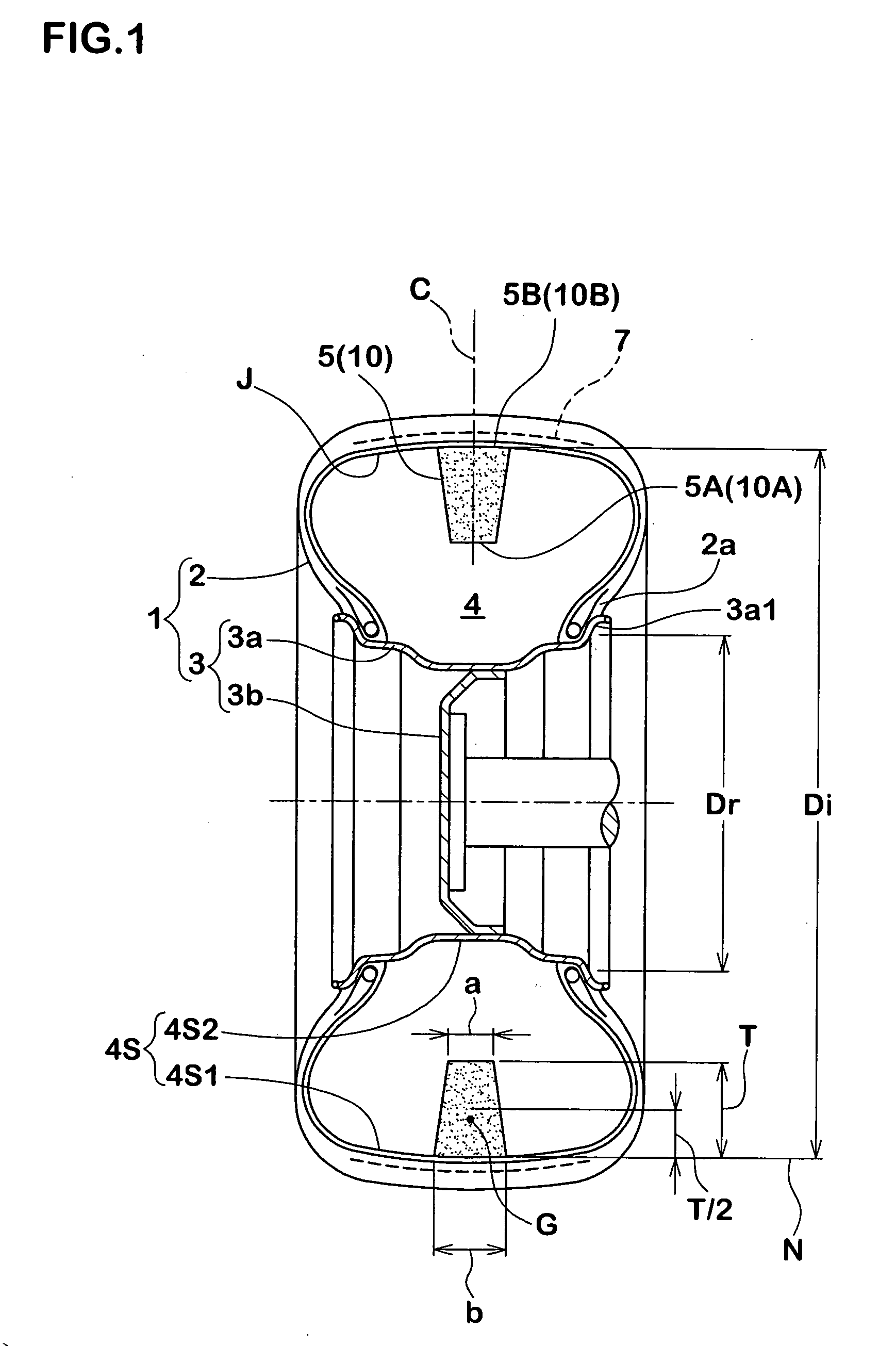

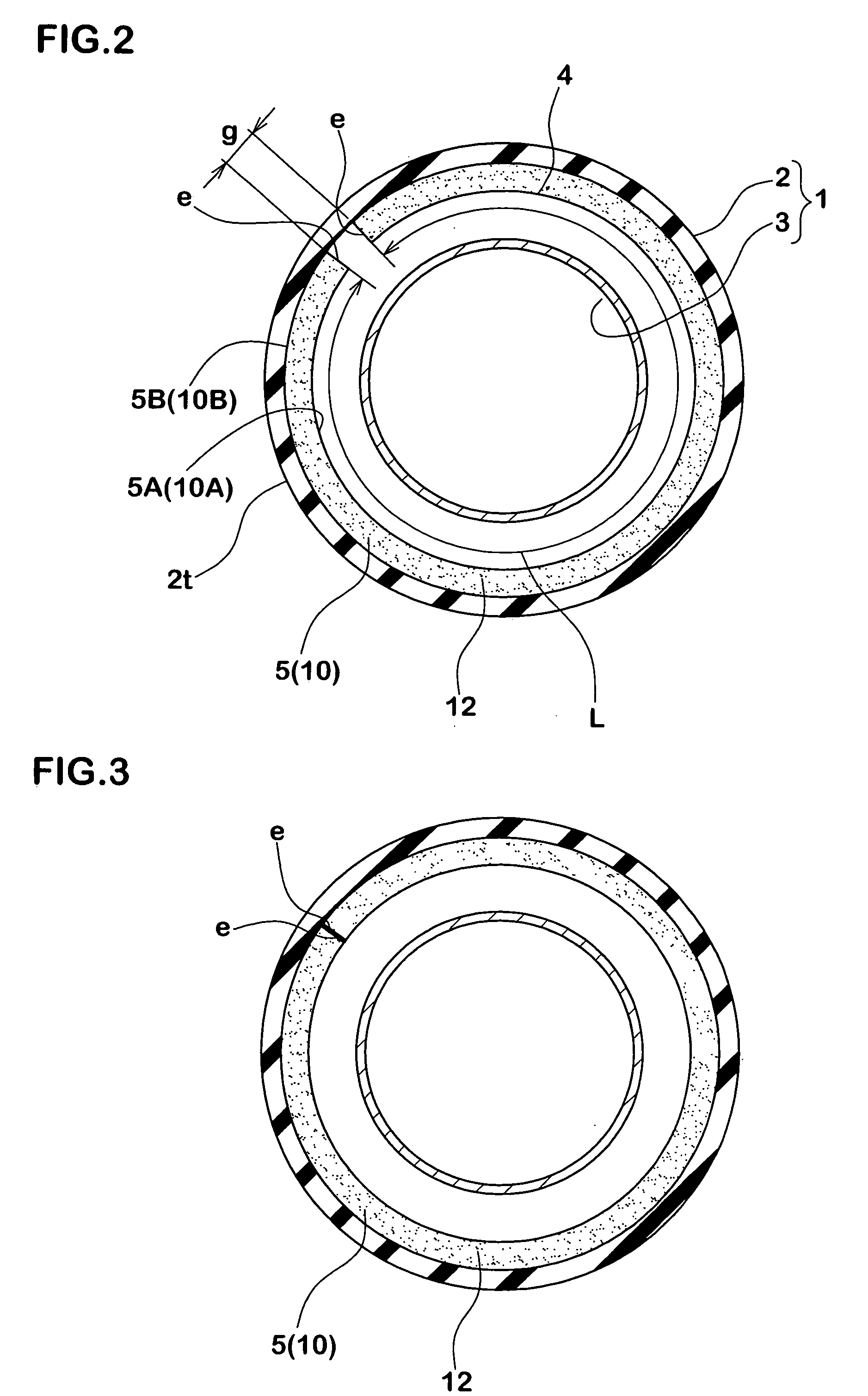

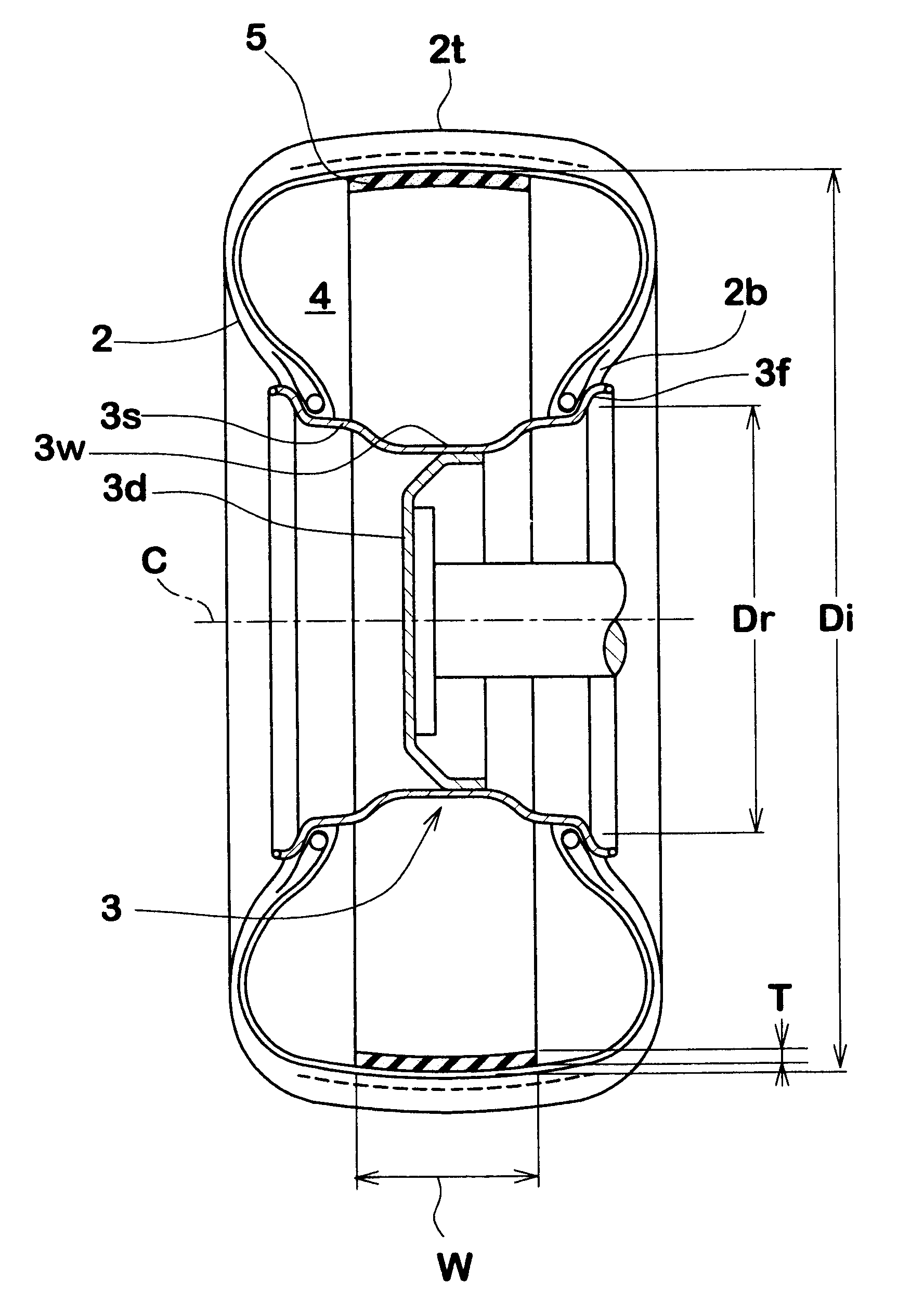

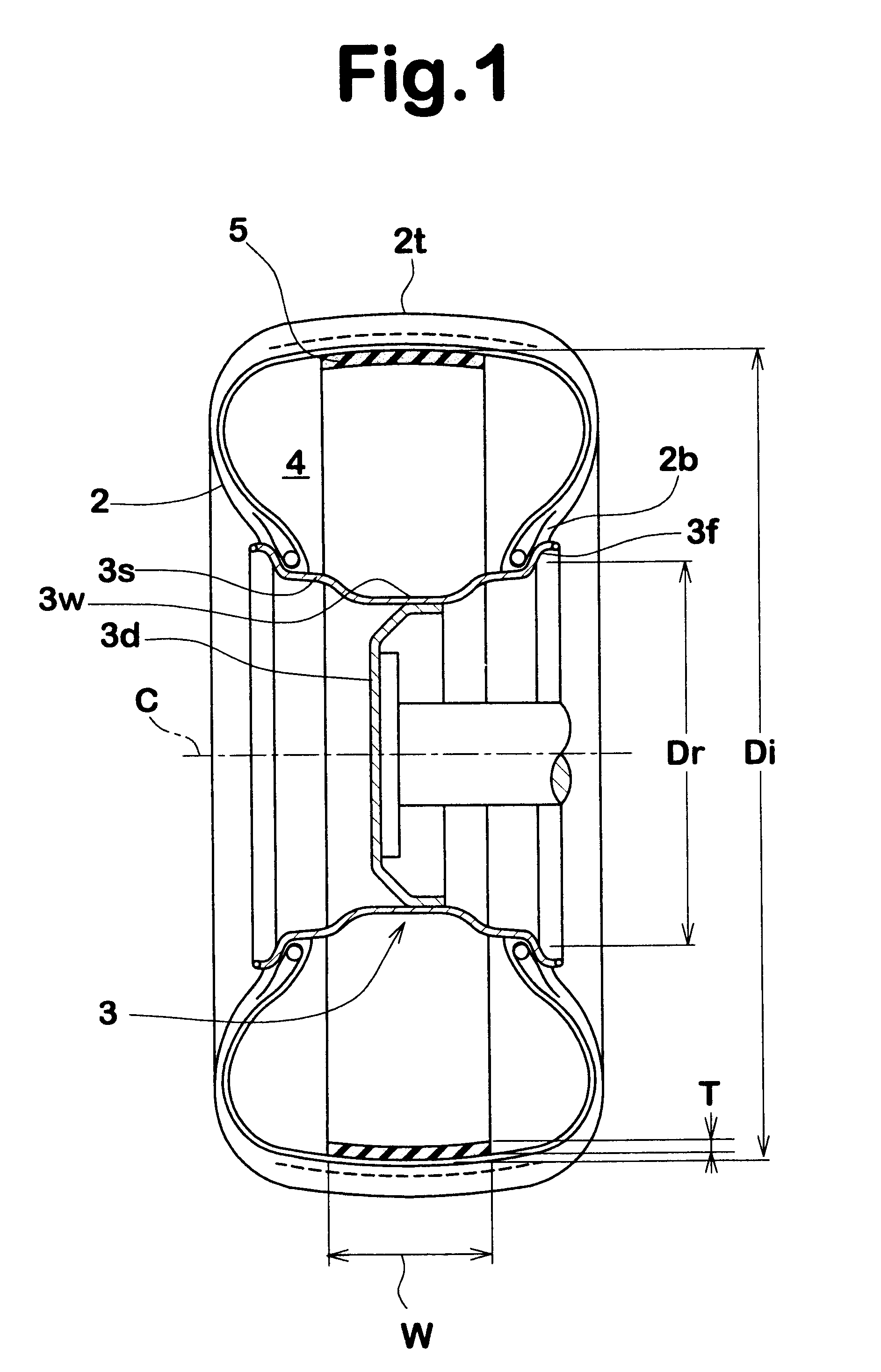

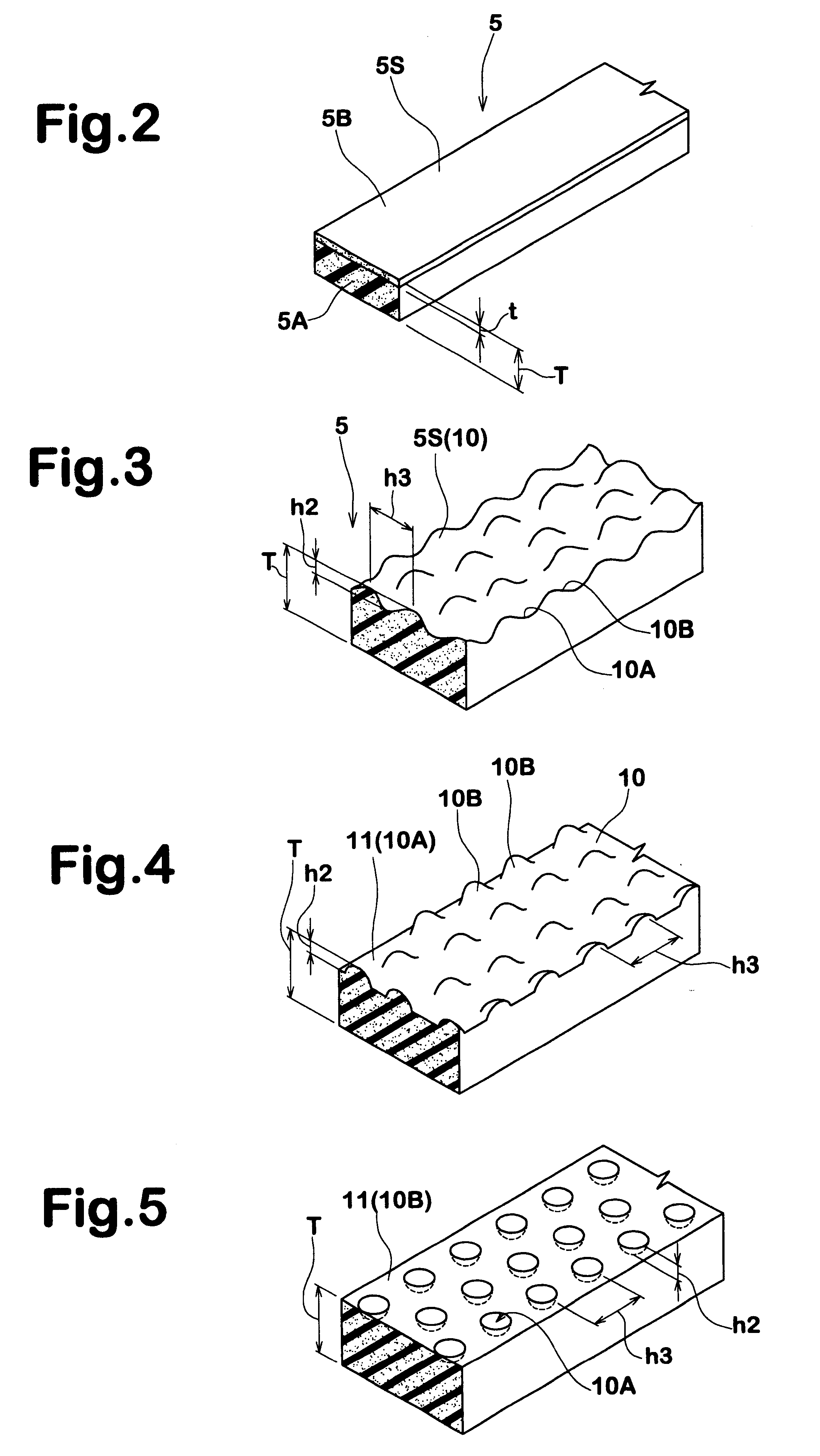

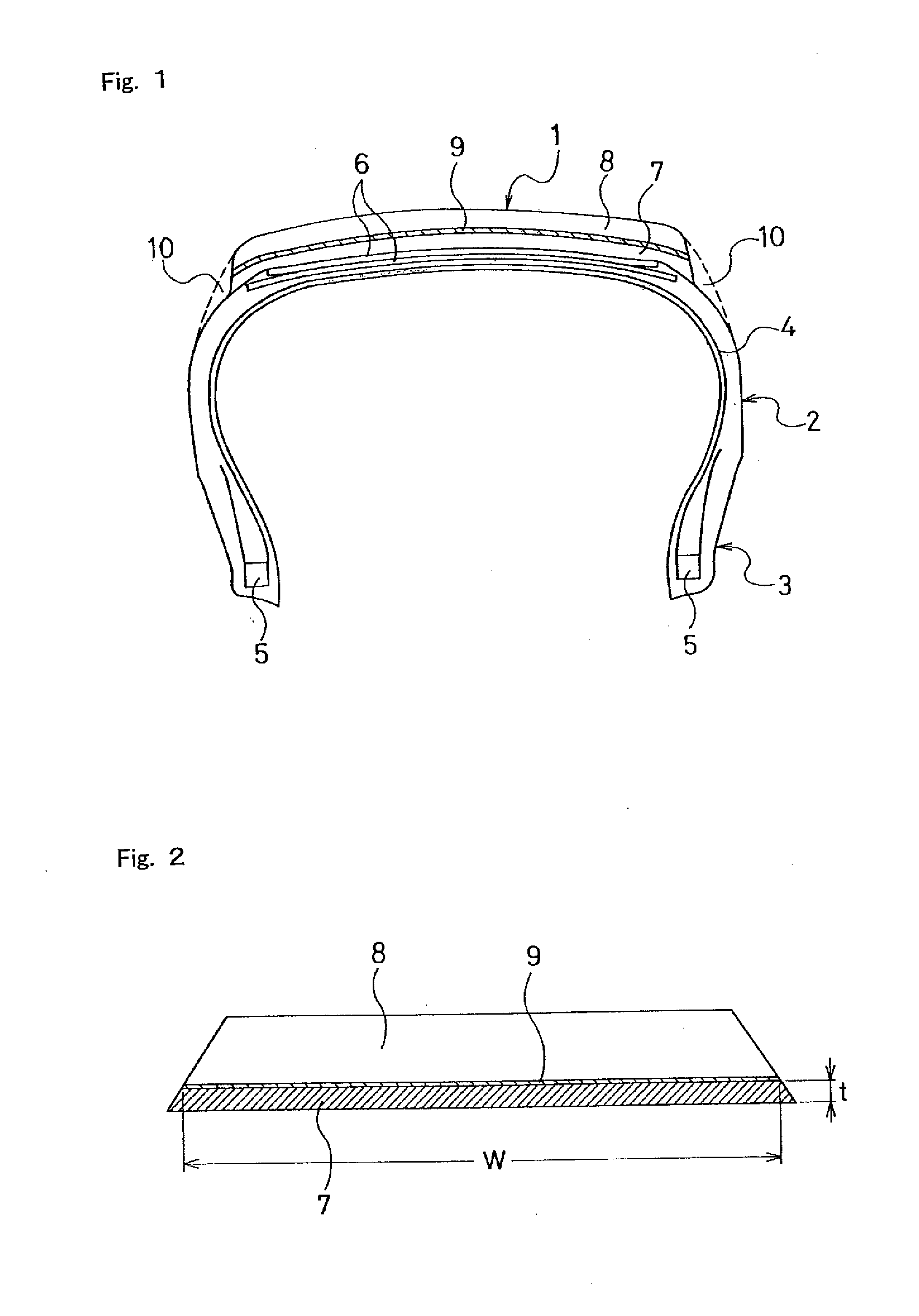

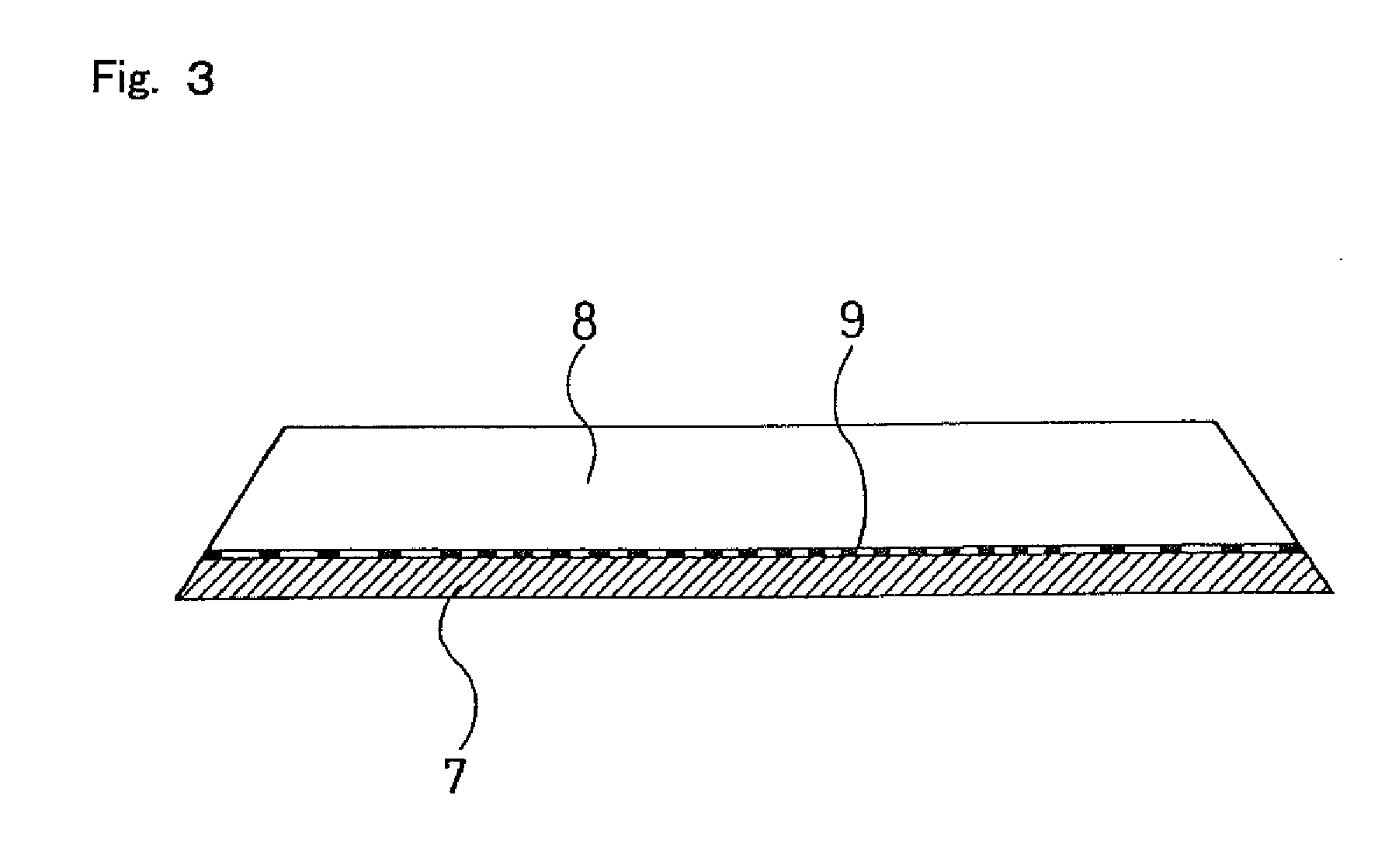

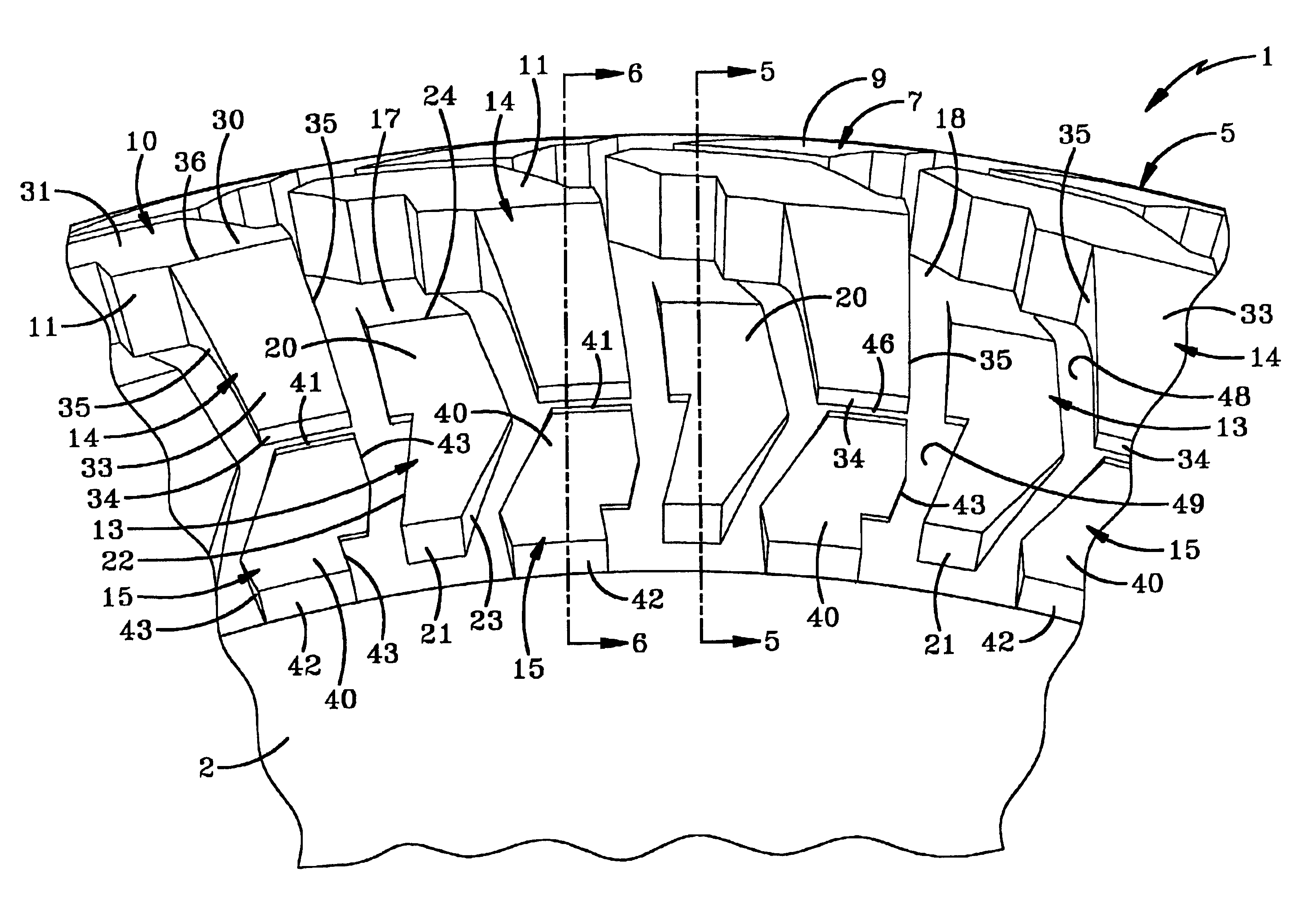

Assembly of pneumatic tire and rim, sound suppressing body used for the assembly and pneumatic tire storage method

An Assembly of a pneumatic tire and a rim and a sound suppressing body used for the assembly, the assembly wherein the sound suppressing body having a volume (V2) of 0.4 to 20% of the total volume (V1) of a tire inside hollow and formed of a sponge material extending in circumferential direction is installed in the tire inside hollow formed by the tire and the rim; the sound suppressing body comprising a tire side sound suppressing body having a bottom face fixed to the tire or a rim side sound suppressing body having a bottom face fixed to the rim, wherein the area gravity of the tire side sound suppressing body main part exceeding the bead base line of the rim side sound suppressing body is positioned in an area ranging form the middle point of a height form a reference plane to the trip of the sound suppressing body to the reference plane.

Owner:SUMITOMO RUBBER IND LTD

Pneumatic tire

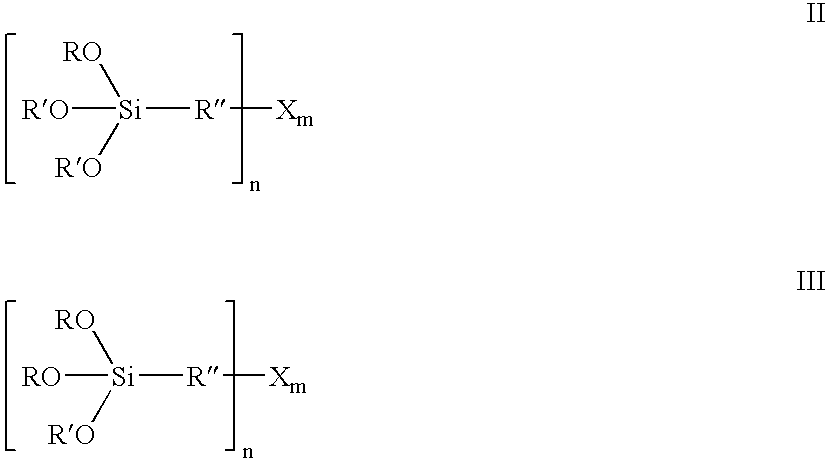

The invention is directed to a pneumatic tire having a tread including a vulcanizable rubber composition including, expressed as parts by weight per 100 parts by weight of elastomer (phr),(A) 60 to 95 phr of solution-polymerized styrene-butadiene rubber with a bound styrene content of from 20 to 30 percent by weight, a vinyl 1,2 content of from 50 to 70 percent by weight based on the butadiene content, and a Tg of from about −40° C. to about −20° C.;(B) 5 to 15 phr of cis-1,4 polybutadiene having a Tg of from −95° C. to −105° C.;(C) 10 to 20 phr of 3,4-polyisoprene;(D) 30 to 70 phr of processing oil;(E) 10 to 30 phr of carbon black having an Iodine absorption ranging from 192 to 212 g / kg according to ASTM D-1510 and an oil absorption ranging from 126 to 142 cc / 100 g according to ASTM D-2414;(F) 90 to 110 phr of silica;(G) 0.5 to 20 phr of a sulfur containing organosilicon compound; and(H) 10 to 20 phr of resin.

Owner:THE GOODYEAR TIRE & RUBBER CO

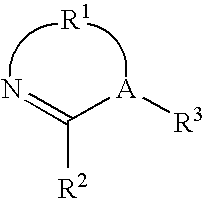

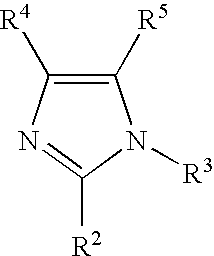

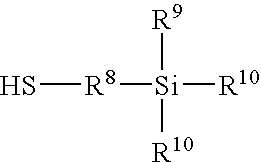

Method of producing a tire composition having improved silica reinforcement

Vulcanizable elastomeric compositions and vulcanizates are prepared by employing a nitrogen-containing heterocycle. The nitrogen-containing heterocycle is believed to enhance interaction between a silica particle and a silica-interactive compound.

Owner:BRIDGESTONE CORP

Method for producing functionalized cis-1,4-polydienes having high cis-1,4-linkage content and high functionality

This invention relates to a method for producing functionalized cis-1,4-polydienes having a combination of a high cis-1,4-linkage content and a high functionality, the resulting polymers and the vulcanized products containing the polymers. The functionalized cis-1,4-polydienes of the present invention are produced by a method comprising the steps of: (1) preparing a reactive polymer by polymerizing conjugated diene monomer with a lanthanide-based catalyst in the presence of less than 20% by weight of organic solvent based on the total weight of monomer, organic solvent, and resulting polymer, where the lanthanide-based catalyst is the combination of or reaction product of (a) a lanthanide compound, (b) an aluminoxane, (c) an organoaluminum compound other than an aluminoxane, and (d) a halogen-containing compound; and (2) contacting the reactive polymer with a functionalizing agent.

Owner:BRIDGESTONE CORP

Rubber composition containing resinous nanoparticle

InactiveUS7347237B2Deteriorate controllabilityDeteriorate stabilitySpecial tyresInflatable tyresElastomerEngineering

Owner:THE GOODYEAR TIRE & RUBBER CO

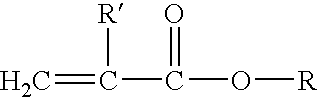

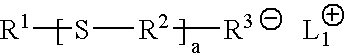

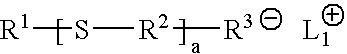

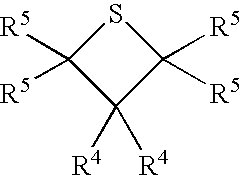

Functional polymers prepared with sulfur-containing initiators

A method for forming a polymer including a sulfur-containing functional group, the method comprising introducing a sulfur-containing initiator defined by the formulawith conjugated diene monomer and optionally copolymerizable monomer within a polymerization medium and allowing the sulfur-containing initiator to initiate the polymerization of the conjugated diene monomer and the optional copolymerizable monomer, where R1 is a monovalent organic group, R2 is a divalent organic group, R3 is a divalent organic group or a bond, and a is an integer from 1 to about 5.

Owner:BRIDGESTONE CORP

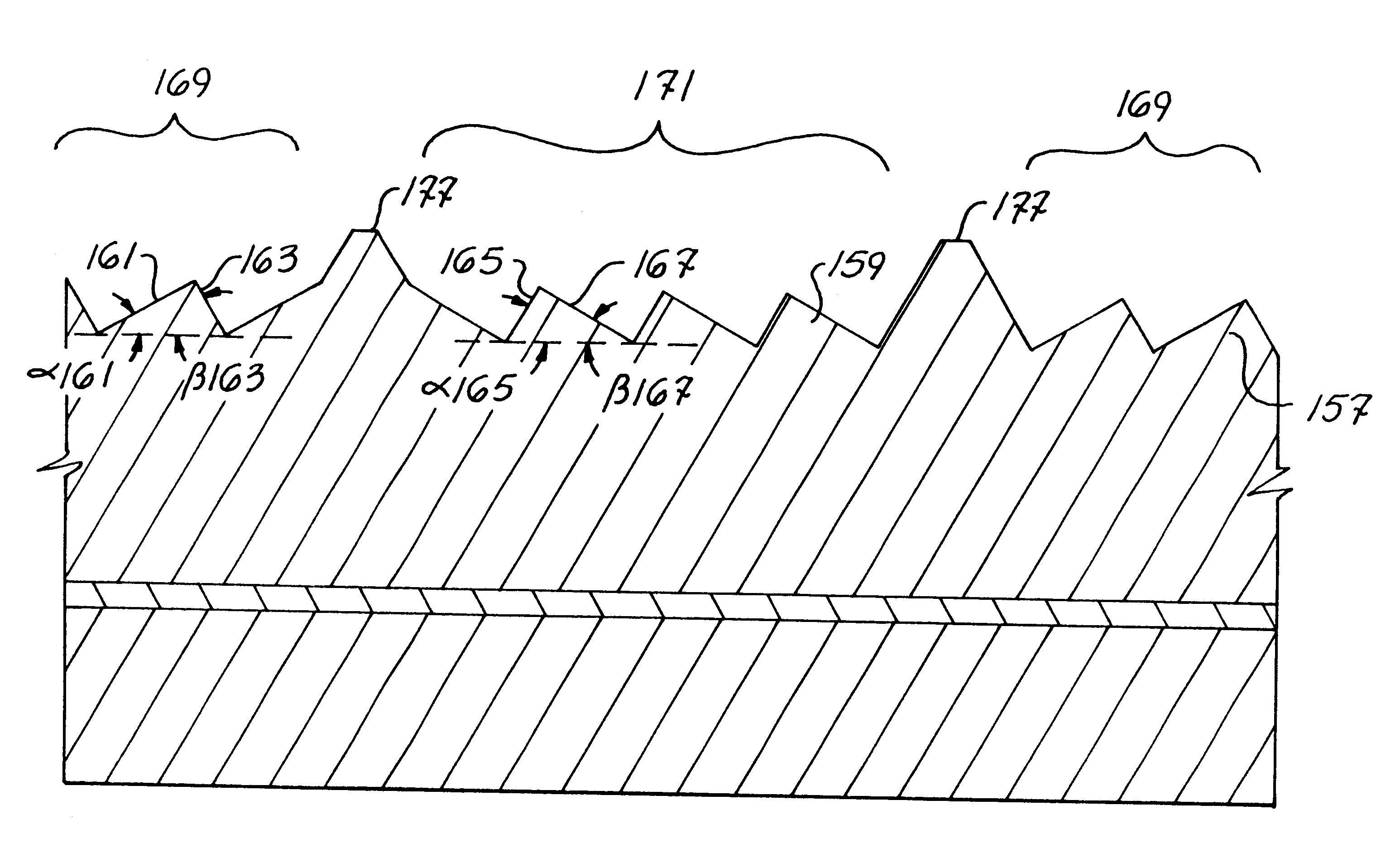

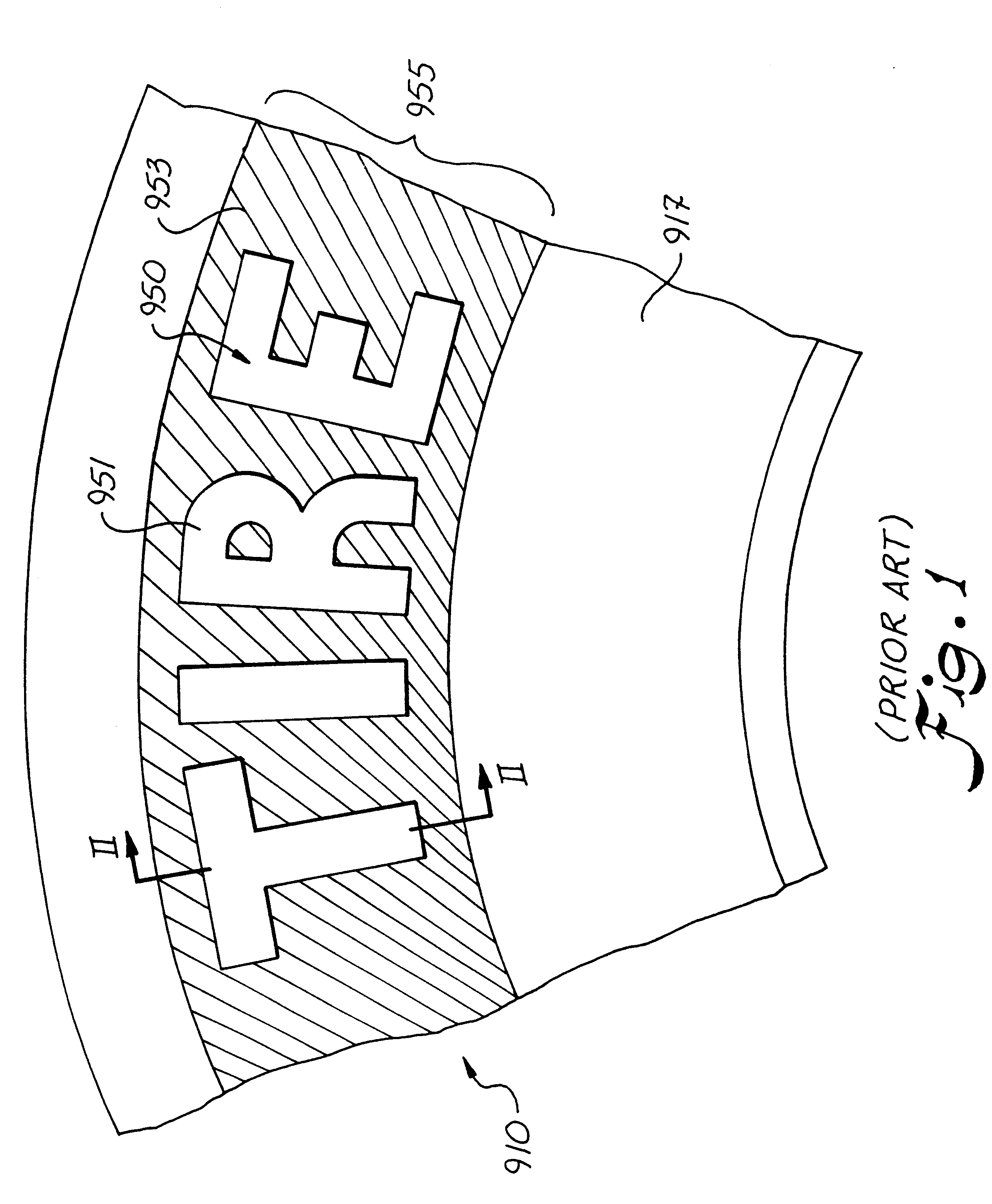

Design pattern for a tire

InactiveUS6253815B1Wider illumination angleLight effect designsInflatable tyresEngineeringOptical contrast

An opaque article having a surface and substantially asymmetric striae extending along the surface. A portion of the striae reside in a first area and have an orientation. Another portion of the striae reside in a second area and have an orientation substantially opposite the striae in the first area. The first area striae and the second area striae create an optical contrast therebetween at a wide range of viewing angles and illumination angles. The opaque article can be a tire. The striae can reside at numerous locations on the tire, including, for example, the sidewall, tread ribs or blocks, and stone ejectors.

Owner:MICHELIN RECH & TECH SA

Pneumatic tire

A tire has a tread and a pair of opposing shoulders. In the first sidewall, a series of extension blocks creates a pair of concentric rings. In the second sidewall, a different configuration of extension blocks may be present. The second sidewall has alternating extension blocks where one of the blocks has a portion that is located radially inward of the other block.

Owner:THE GOODYEAR TIRE & RUBBER CO

Tire noise reducing system

Owner:SUMITOMO RUBBER IND LTD

Rubber containing starch reinforcement and tire having component thereof

InactiveUS6269858B1Enhance tire rolling resistanceImprove lagPaper coatingSpecial tyresPlasticizerTread

The present invention relates to a rubber composition containing a combination of starch, modified starch and / or starch / plasticizer composite together with selected methylene donor and / or methylene acceptor compounds. The invention also relates to tires having at least one component comprised of such rubber composition. Such tire component can be, for example, its circumferential tread or other component of the tire.

Owner:THE GOODYEAR TIRE & RUBBER CO

Pneumatic radial tire and process for producing retreaded tire

InactiveUS20110056603A1Easy to separateImprove productivityTyresInflatable tyresElastomerThermoplastic elastomer

A pneumatic radial tire includes: at least one carcass layer suspended across left and right bead parts; a belt layer arranged on an outer circumferential side of the carcass layer; and a tread arranged on an outer circumferential side of the belt layer. The tread has a laminated structure in which a thermoplastic film layer of a thermoplastic resin or a thermoplastic elastomer composition is interposed between a tread-side rubber layer and a belt layer-side rubber layer. The thermoplastic elastomer composition is obtained by blending an elastomer in a thermoplastic resin. A process for producing a retreaded tire includes the steps of: forming a base tire from the pneumatic radial tire by softening the thermoplastic film layer through heating so as to separate and remove the tread-side rubber layer, the pneumatic radial tire having the tread worn away; and subsequently bonding a new tread-side rubber layer onto the base tire.

Owner:YOKOHAMA RUBBER CO LTD

Self-inflating tire and pressure regulator

A self-inflating tire assembly includes an air tube connected to a tire and defining an air passageway, the air tube being composed of a flexible material operative to allow an air tube segment opposite a tire footprint to flatten, closing the passageway, and resiliently unflatten into an original configuration. The air tube is sequentially flattened by the tire footprint in a direction opposite to a tire direction of rotation to pump air along the passageway to a regulator device. The regulator device regulates the inlet air flow to the air tube and the outlet air flow to the tire cavity.

Owner:THE GOODYEAR TIRE & RUBBER CO

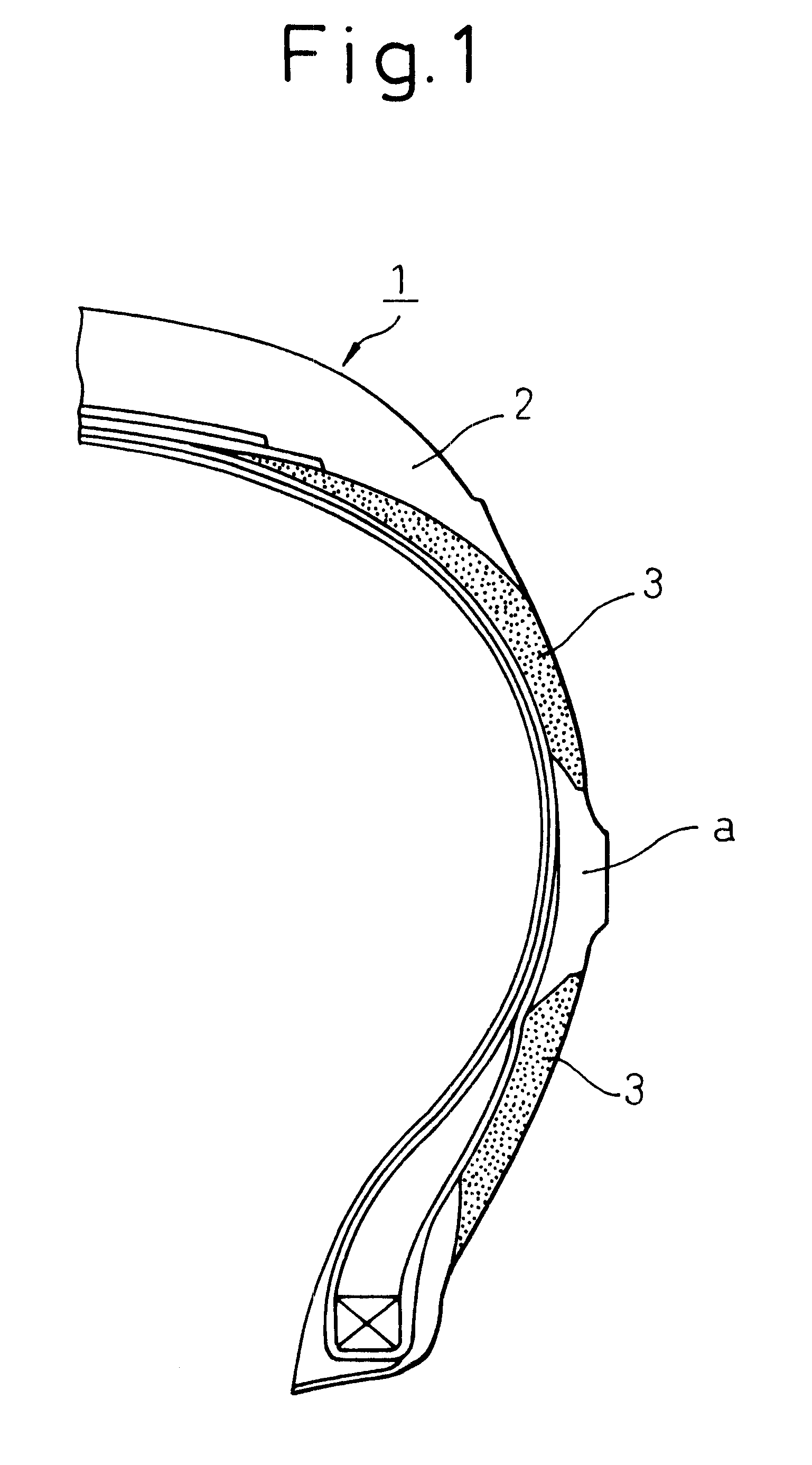

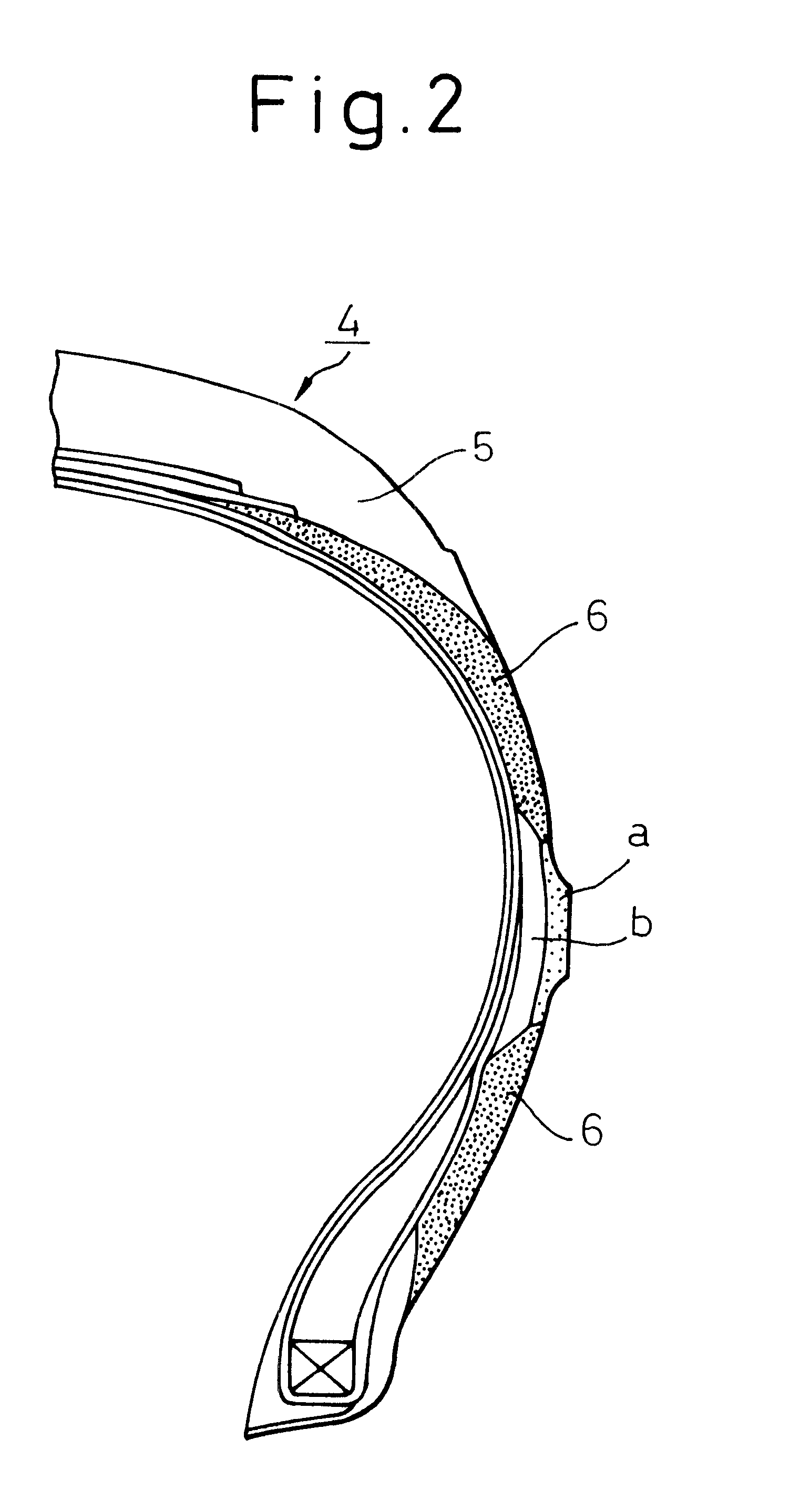

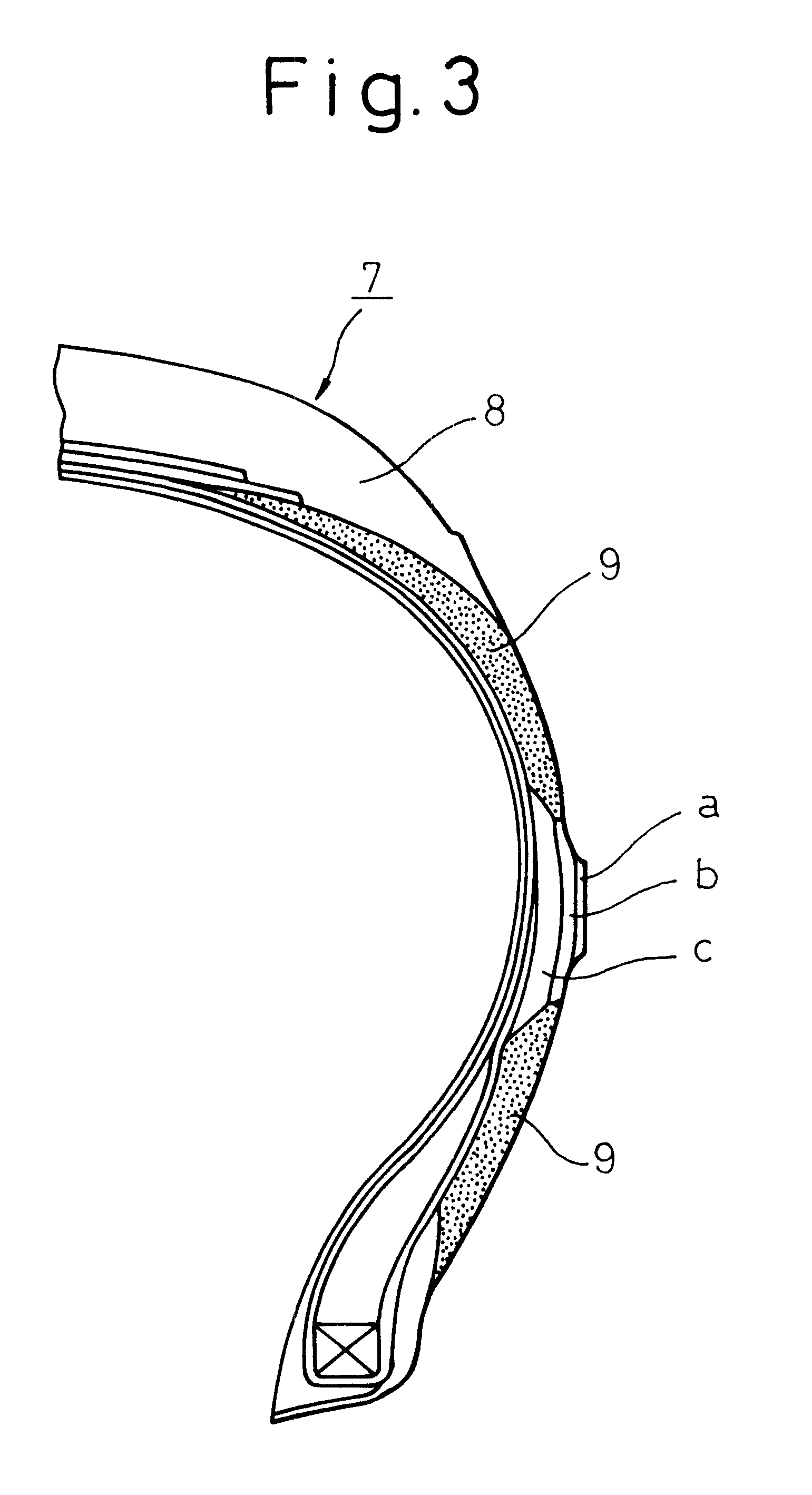

Self-seal tire and method of producing the same

A self-seal tire according to the present invention has a puncture sealing layer located all over a tire inner wall surface from one shoulder portion to the other shoulder portion of a pneumatic tire. The puncture sealing layer comprises at least one band-shape seal layer, which includes a band-shape sponge layer and a bonding layer, the band-shape sponge layer being impregnated with an adhesive so that it is exposed on a tier wall surface side face of the band-shape sponge layer and spaced apart from a tire counter wall surface side face thereof, and the bonding layer being made of adhesive and provided on the tire wall surface side face. The band-shape seal layer is bonded through the bonding layer on the tire inner wall surface with the band-shape seal layer being wound in a circumferential direction of the tire.

Owner:THE YOKOHAMA RUBBER CO LTD

Pneumatic tire using long afterglow phosphorescent rubber composition

InactiveUS6431236B1Improve fatigue resistanceMinimizes strainSpecial tyresInflatable tyresPolymer scienceSurface layer

Owner:YOKOHAMA RUBBER CO LTD

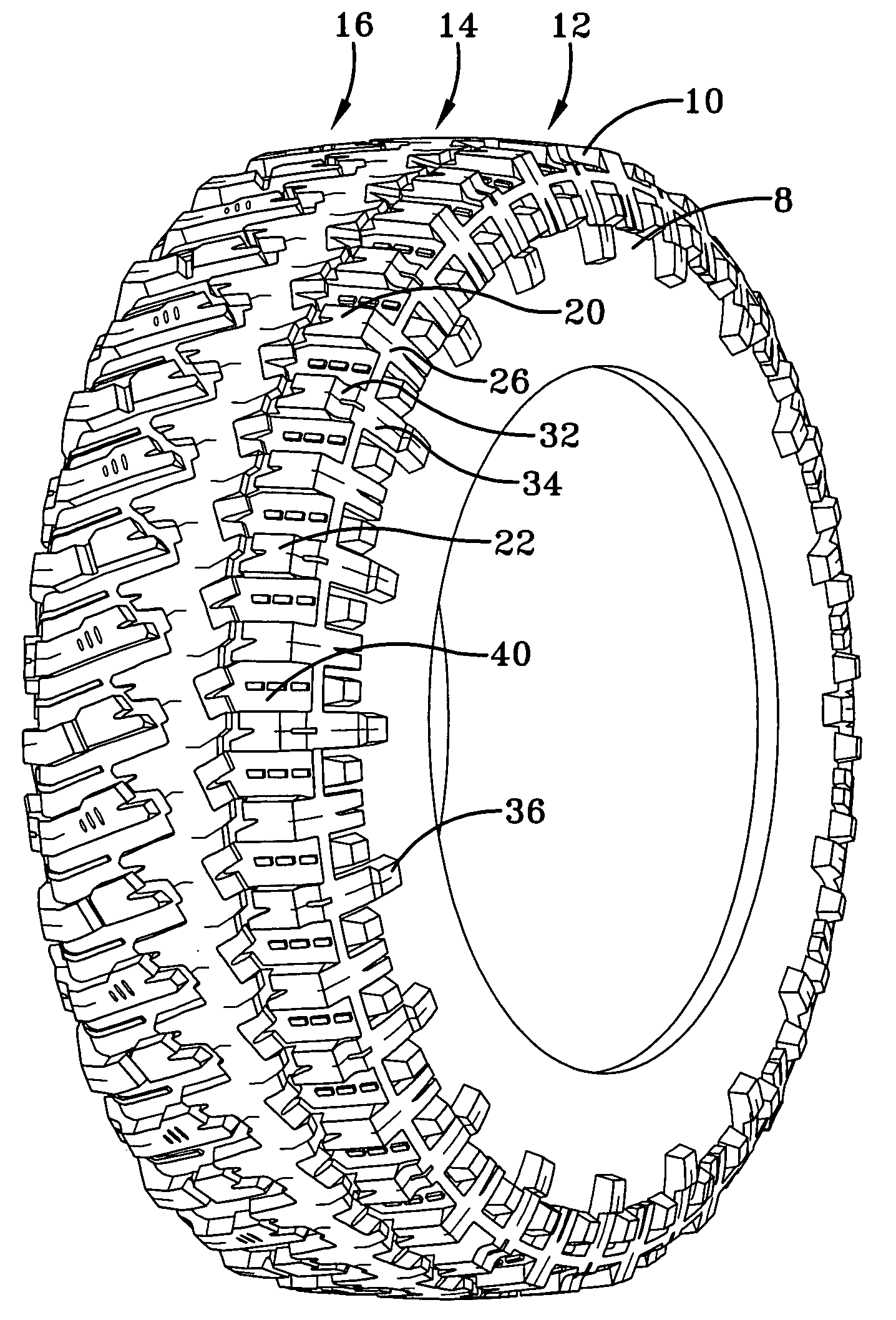

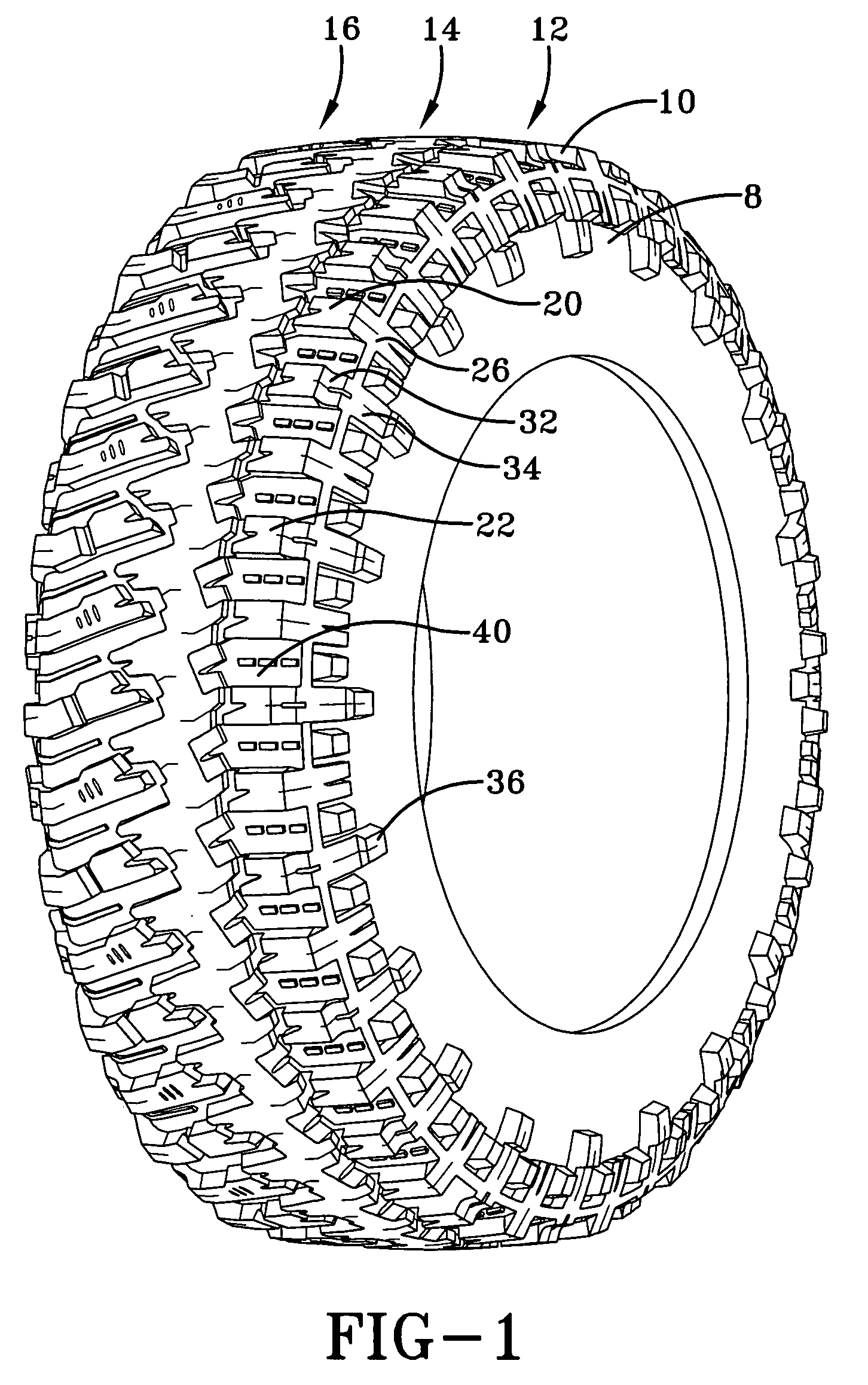

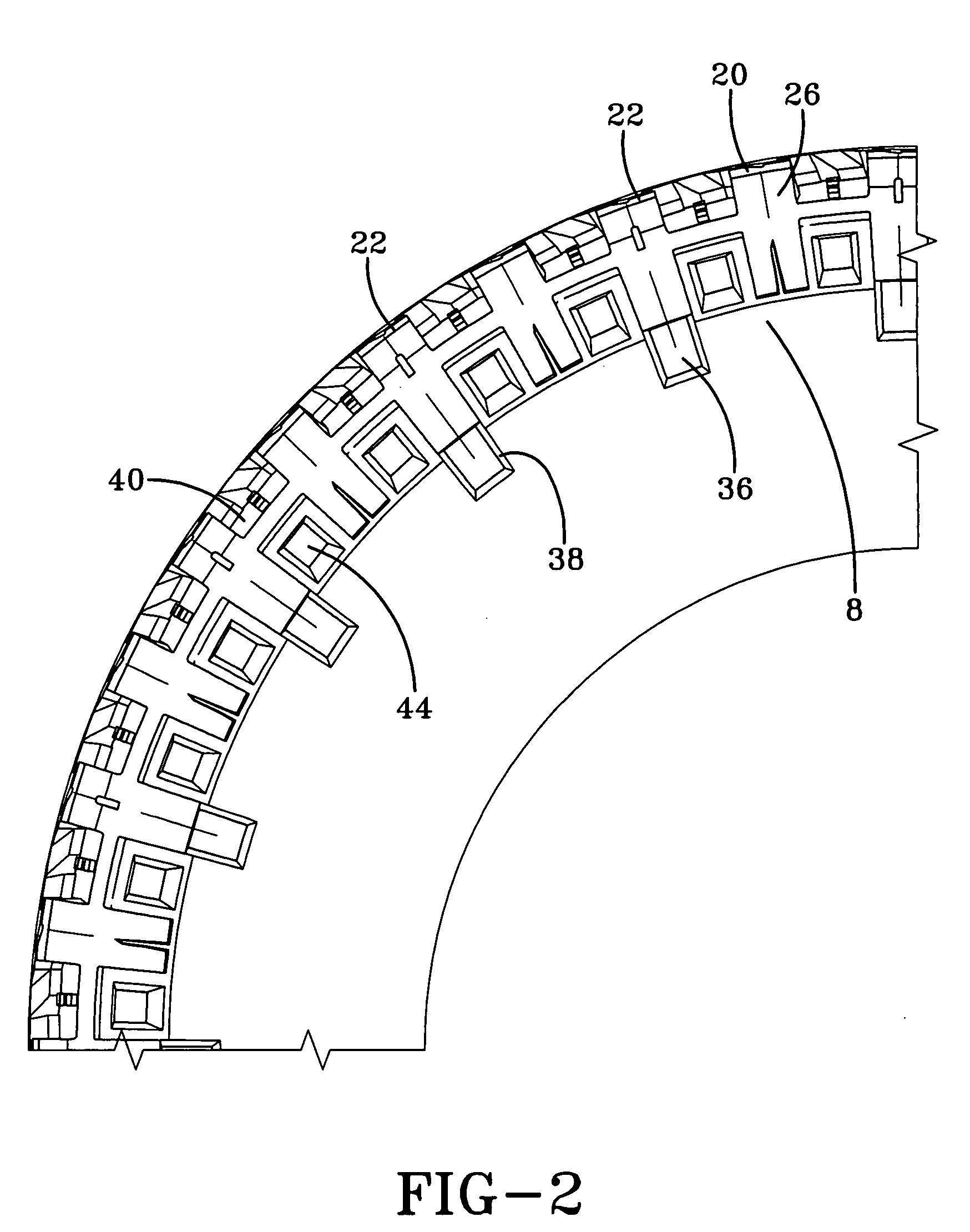

Pneumatic tire with sidewall projections

InactiveUS6920906B2Great tractionReduce accumulationOff-road vehicle tyresInflatable tyresMechanical engineeringTread

A pneumatic tire has an aggressive tread pattern for use on both on-road and off-road vehicles having at least a pair of intermediate ribs and a pair of shoulder ribs providing the ground engaging tread lugs. A plurality of circumferentially extending lug groups are formed on and extend outwardly from and along the sidewalls of the tire. Each lug group preferably includes three separate lugs, each lug having a substantially flat outer surface lying in a different plane than the outer surfaces of the other two lugs. Two of the lugs are radially aligned with each other along the sidewall of the tire with the third lug lying intermediate spaced pairs of these aligned lugs. The lugs are formed with sharp corners offset from each other which extend outwardly from the sidewall to different levels. A top surface of one of the lugs aligns with the ground engaging surface of an adjacent shoulder rib tread lug and the top surface of the intermediate lug aligns with the inner tread surface of the road engaging tread pattern.

Owner:BRIDGESTONE AMERICAS TIRE OPERATIONS LLC

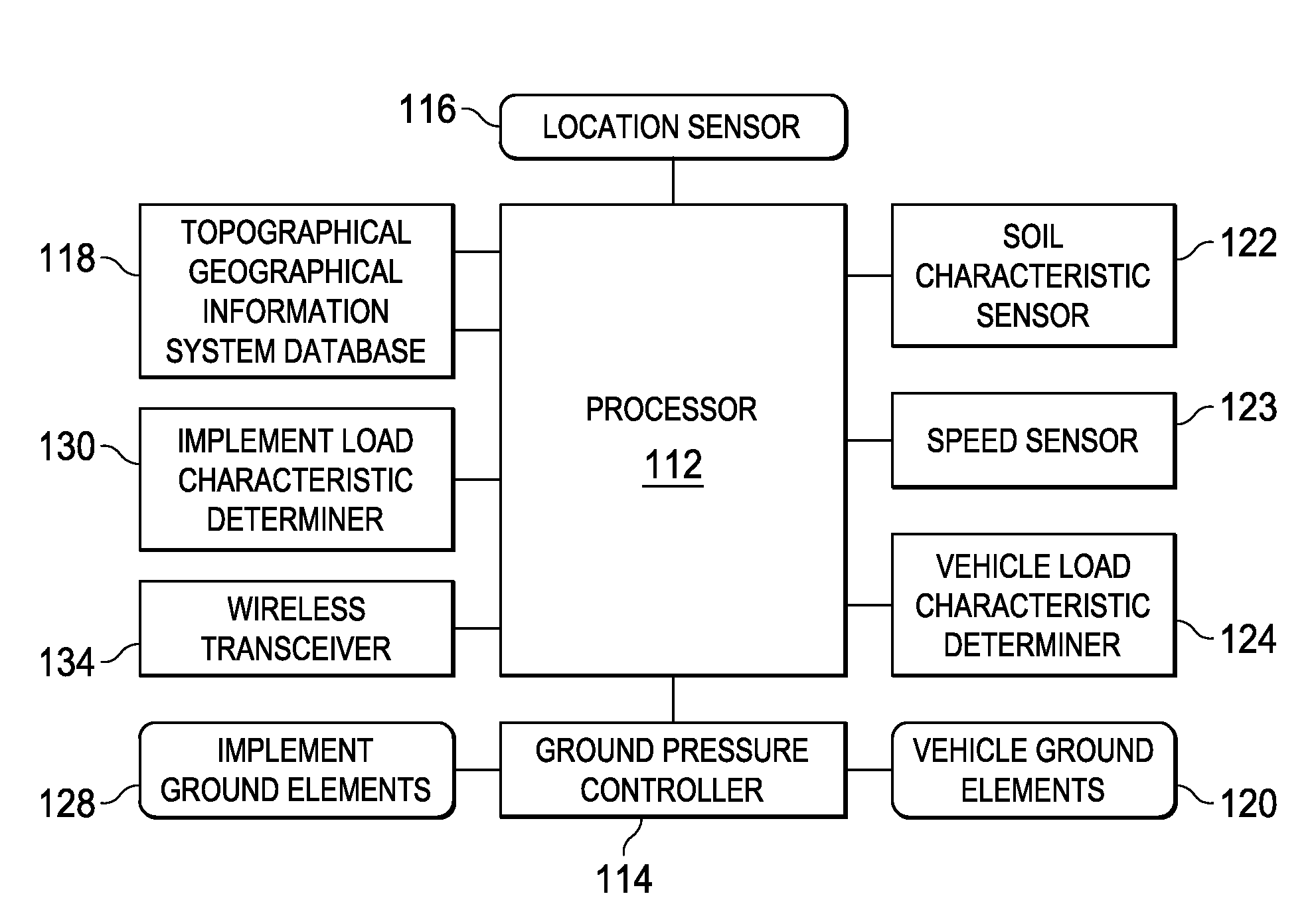

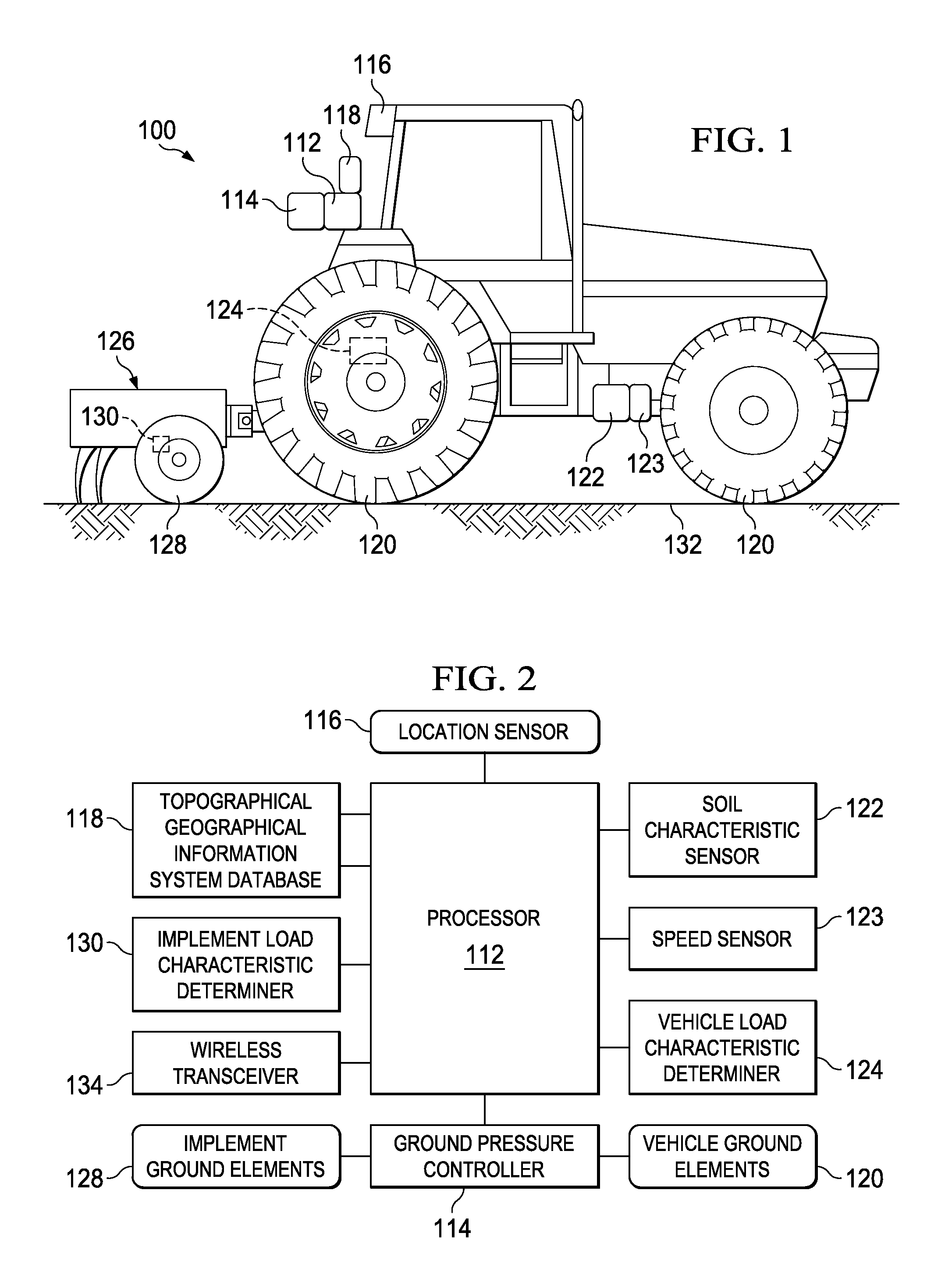

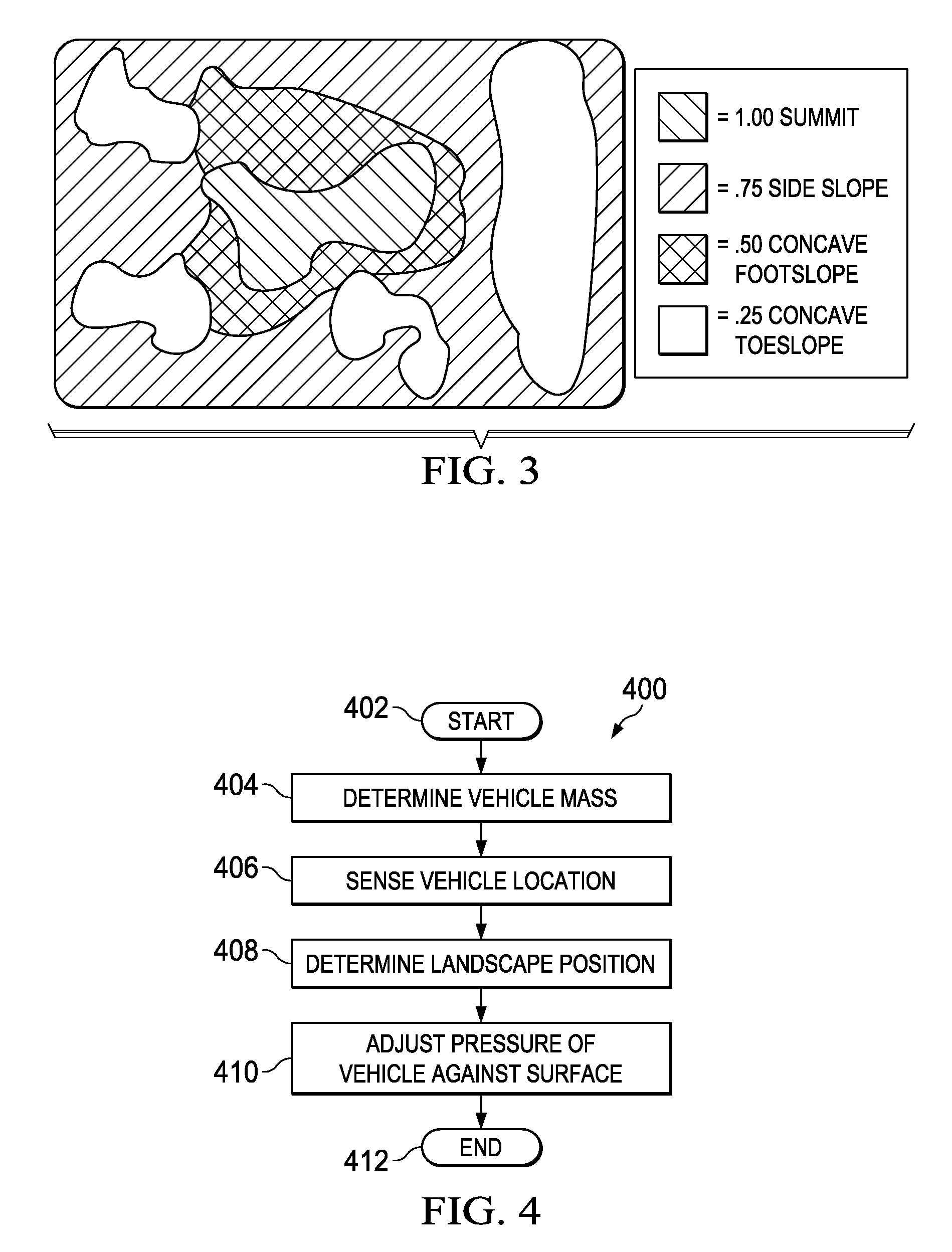

Vehicle soil pressure management based on topography

Systems and techniques are provided for managing an interface between a machine or work vehicle and a surface that the machine / work vehicle travels on in order to provide an optimum work performance level that balances fuel efficiency and surface adversity. Fleet management and reporting capabilities pertaining to such interface management are also provided.

Owner:DEERE & CO

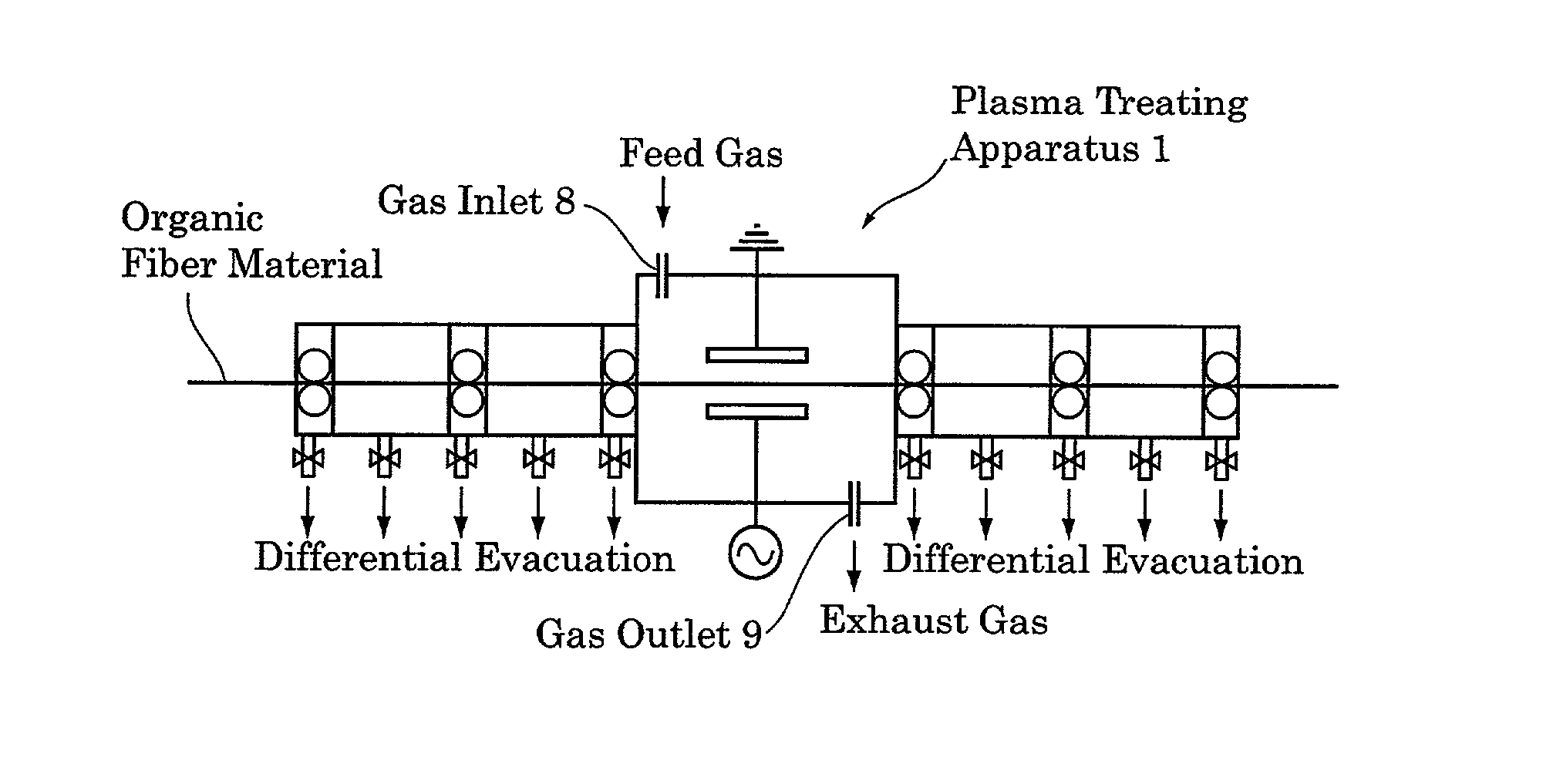

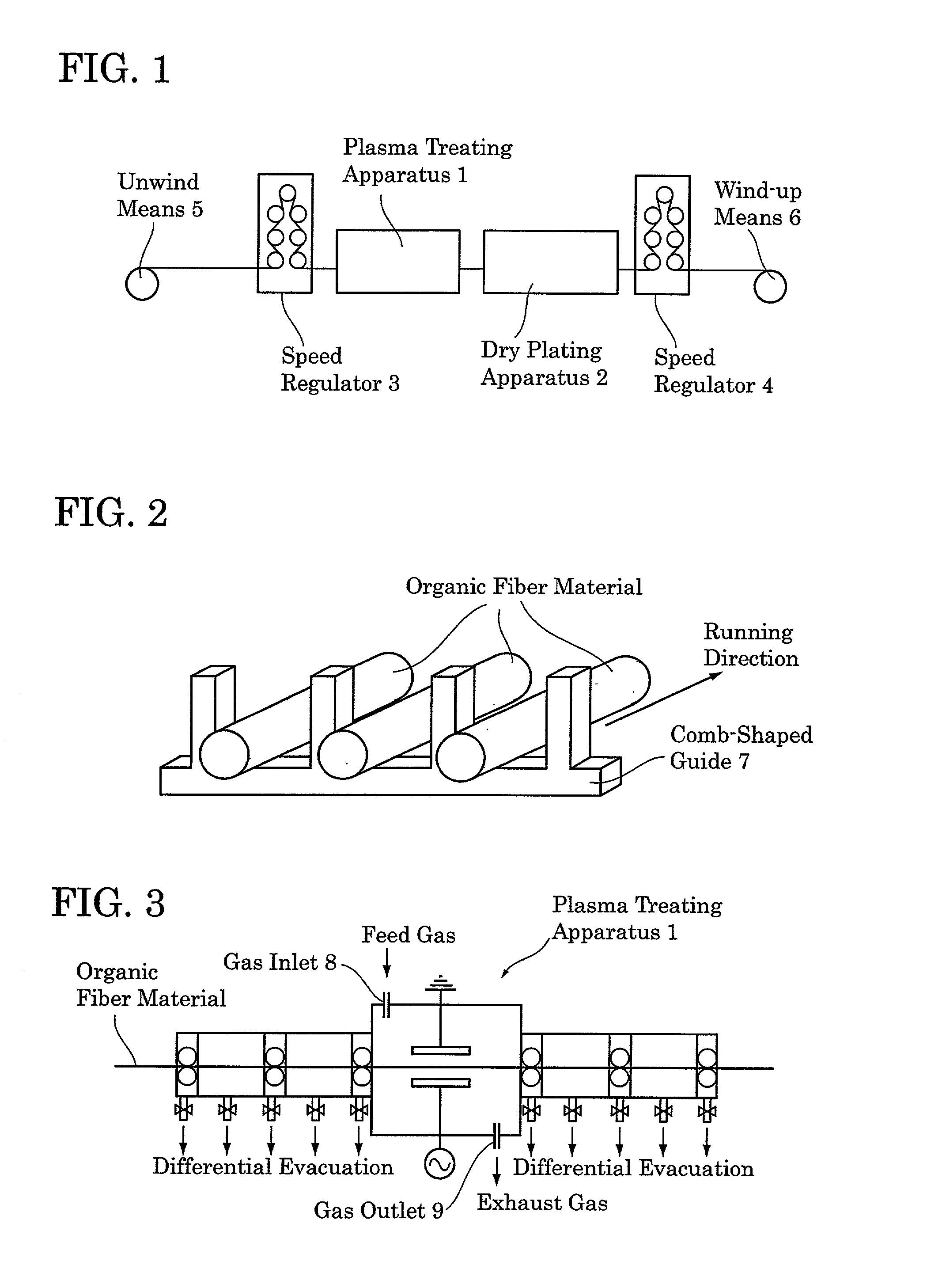

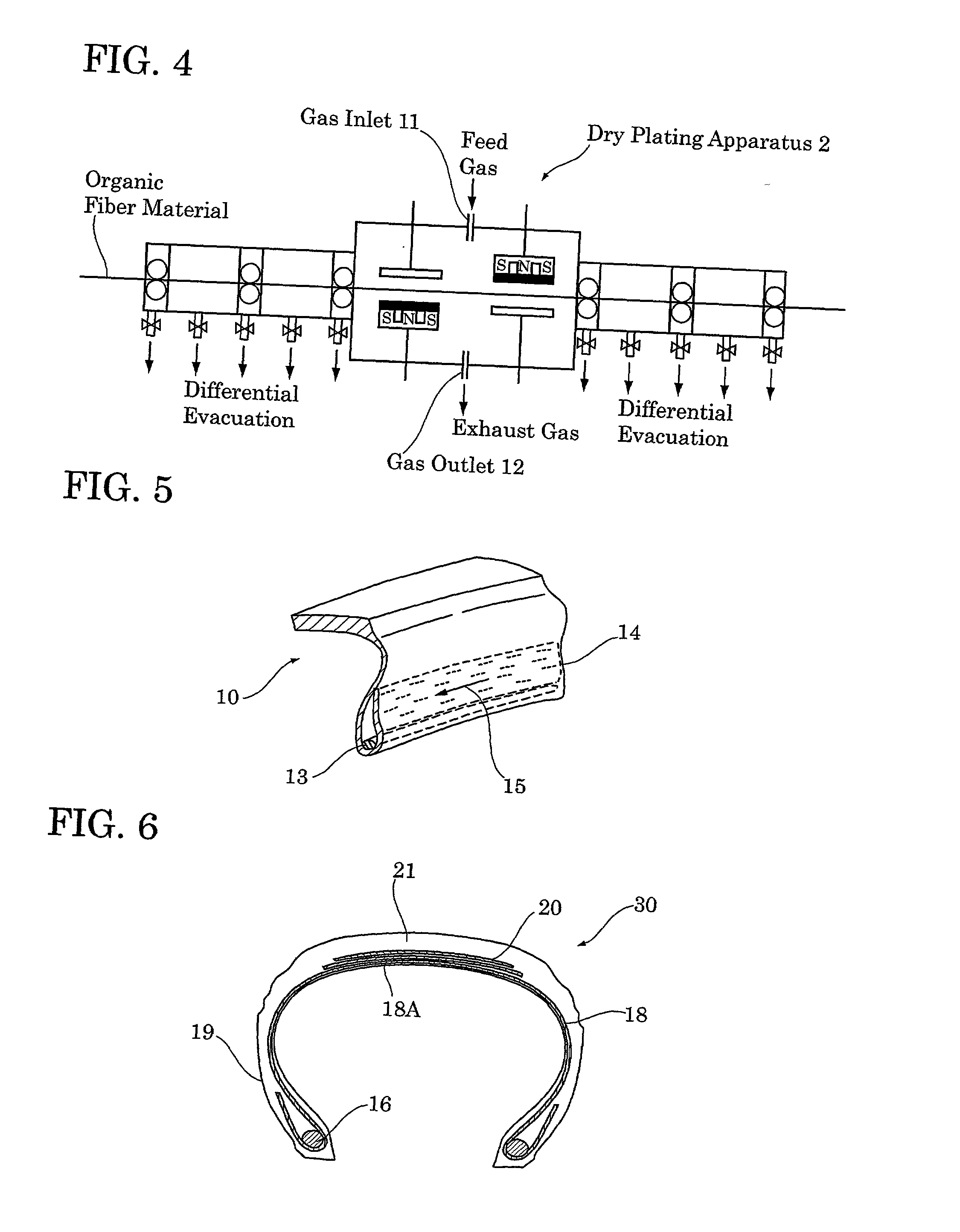

Rubber-reinforcing fiber, process for producing the same, and rubber product and pneumatic tire each made with the same

InactiveUS20030000619A1Sufficient fatigue resistanceSolve the lack of resistanceLiquid surface applicatorsTyresFiberTitanium

The rubber-reinforcing fiber of the present invention is provided with a coating layer of a thickness of 10 Å to 40 mum. The coating layer is formed by dry plating and contains at least one metal and / or metal compound selected from the group consisting of cobalt, zinc, copper, titanium, silver, nickel and compounds of the aforesaid metals. With such a coating layer, the rubber-reinforcing fiber of the present invention forms a firm adhesion to a rubber component and drastically improves the fatigue resistance and durability of a rubber article, particularly, a pneumatic tire.

Owner:BRIDGESTONE CORP

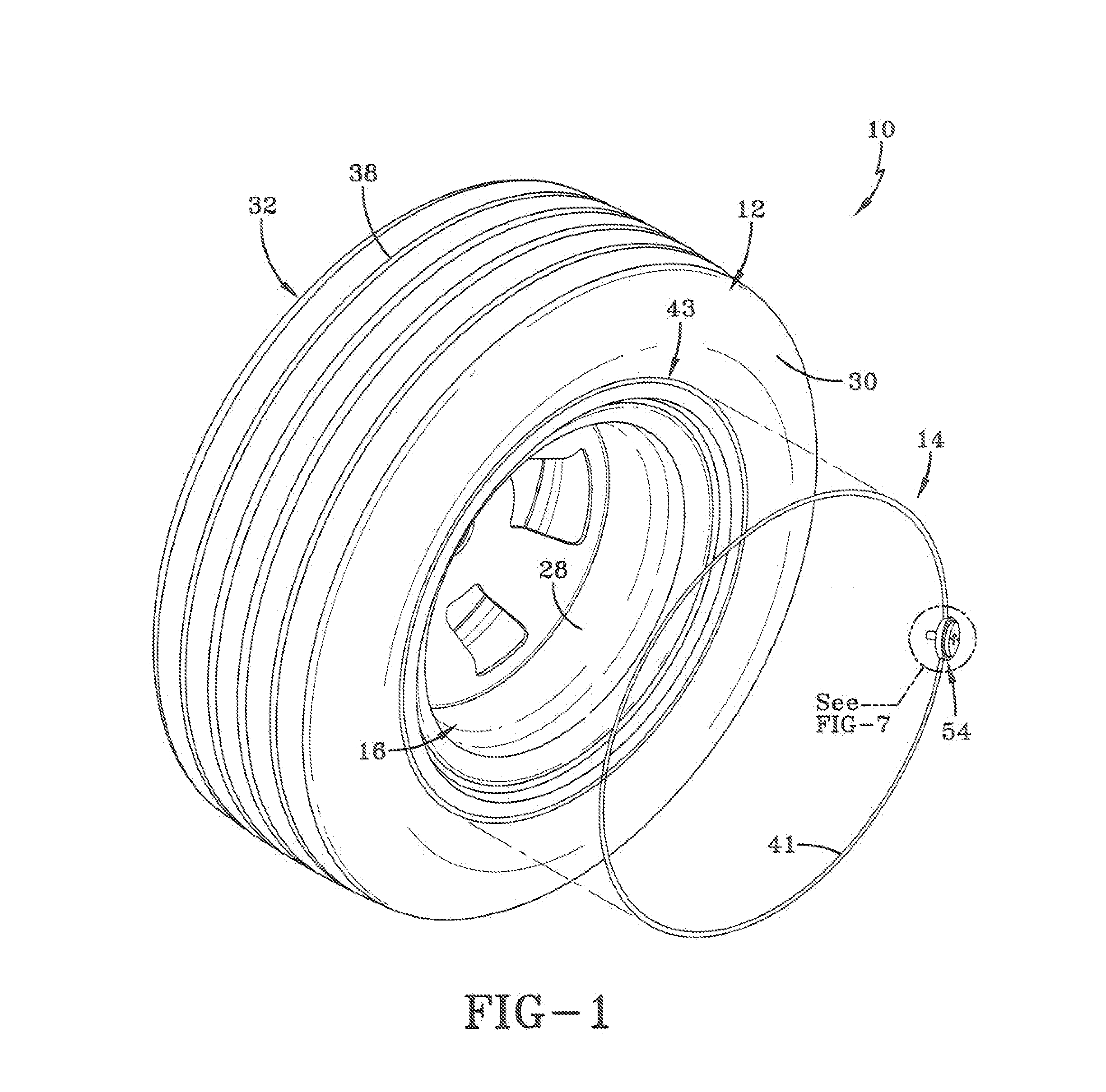

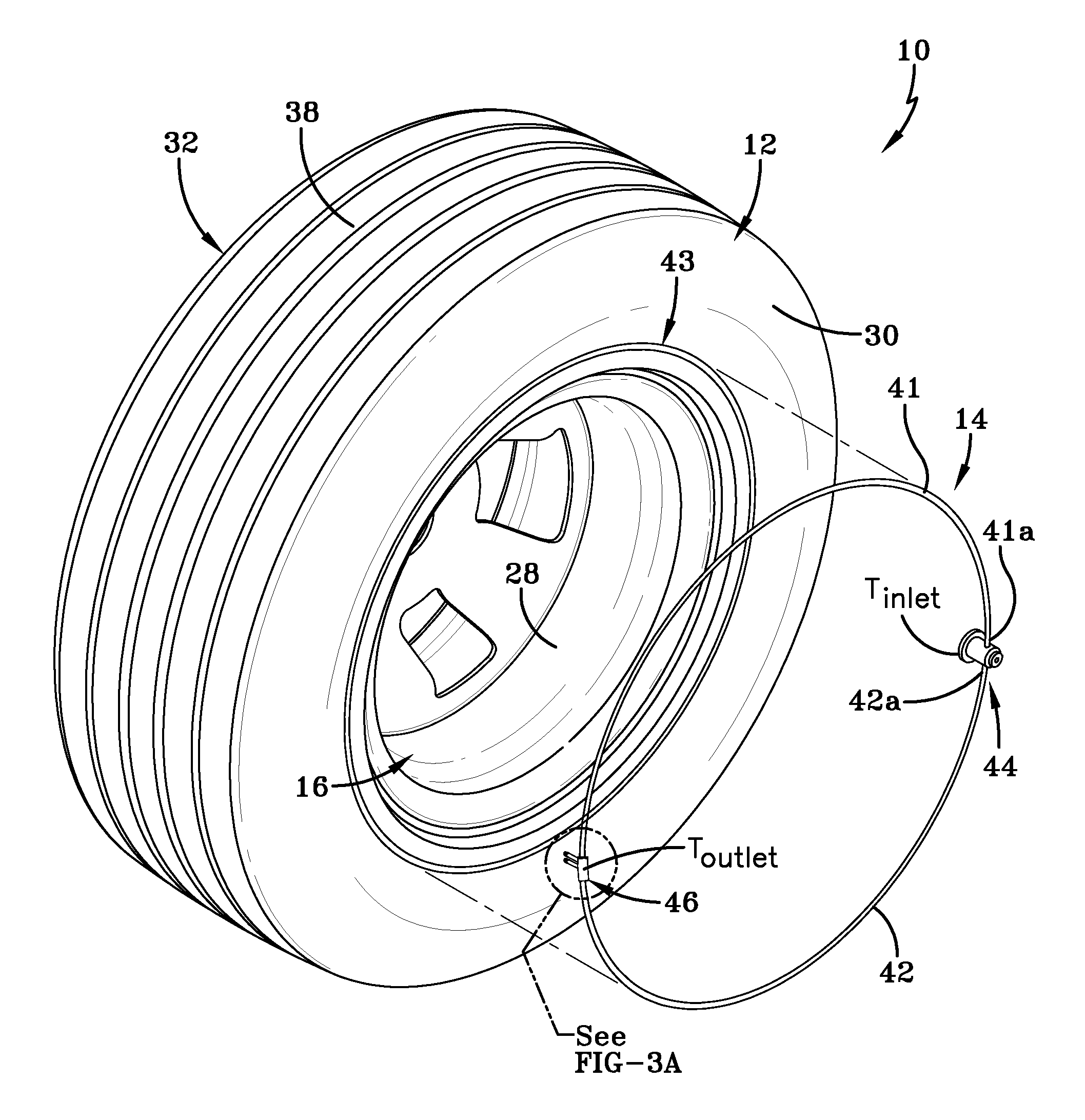

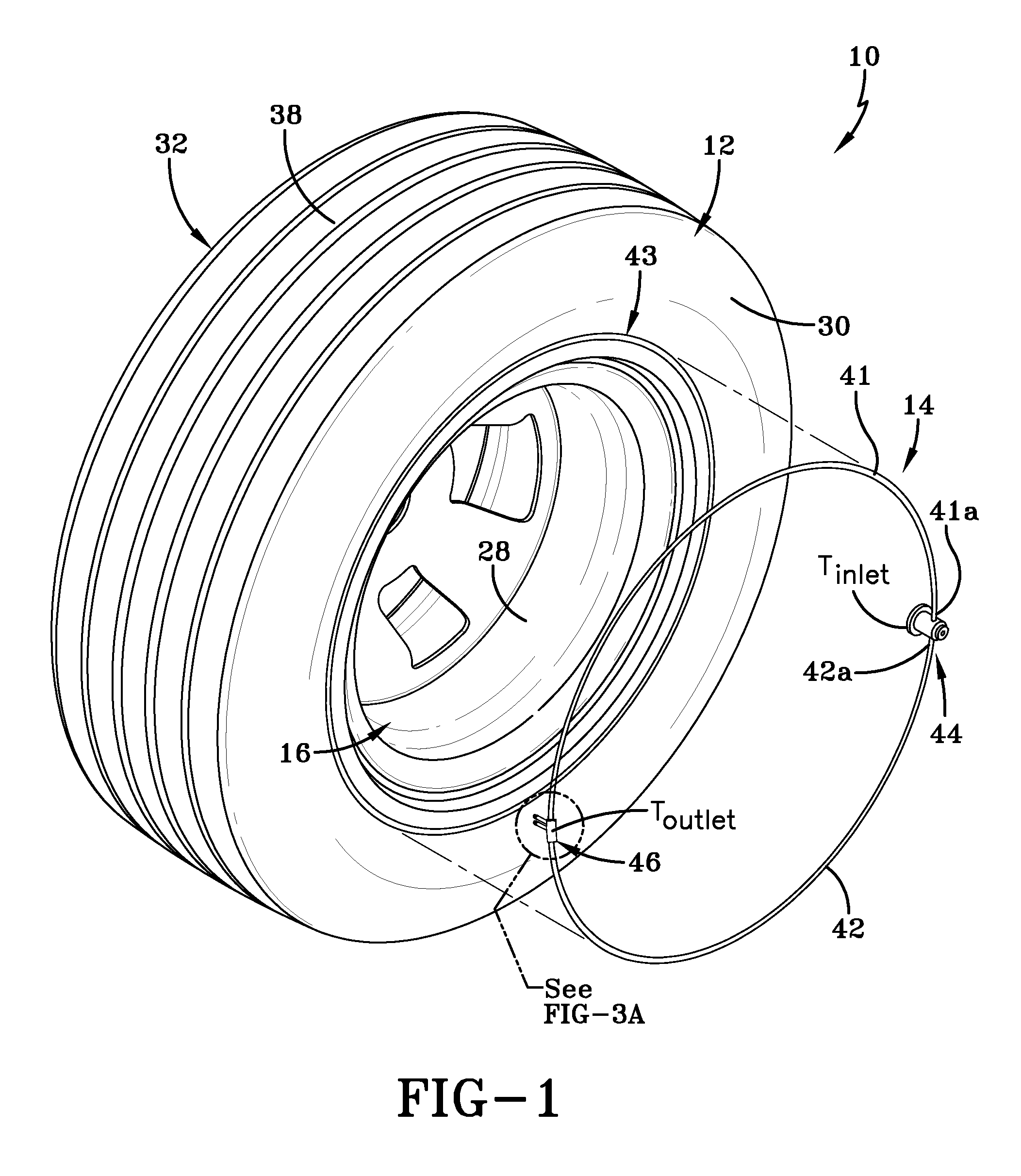

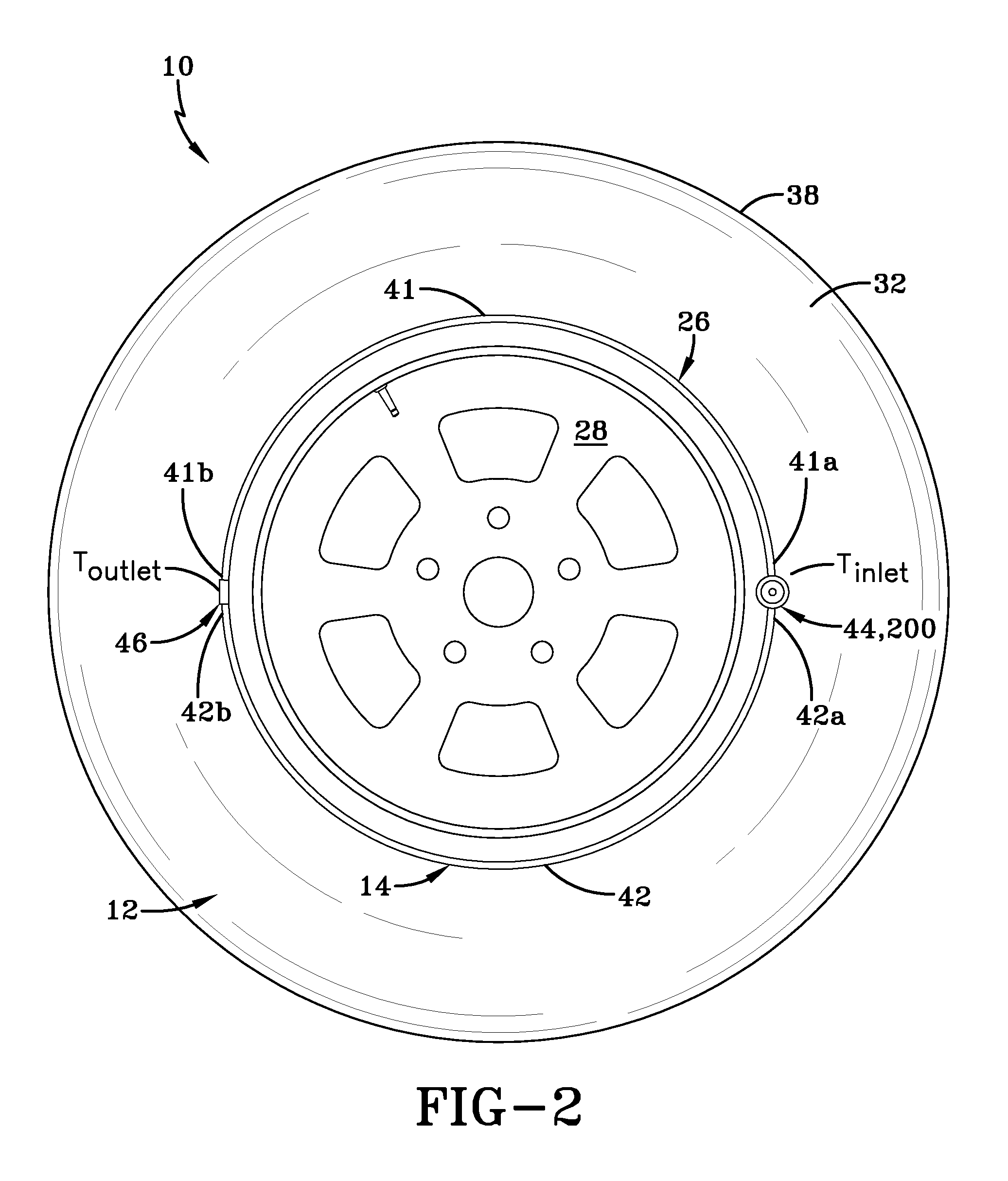

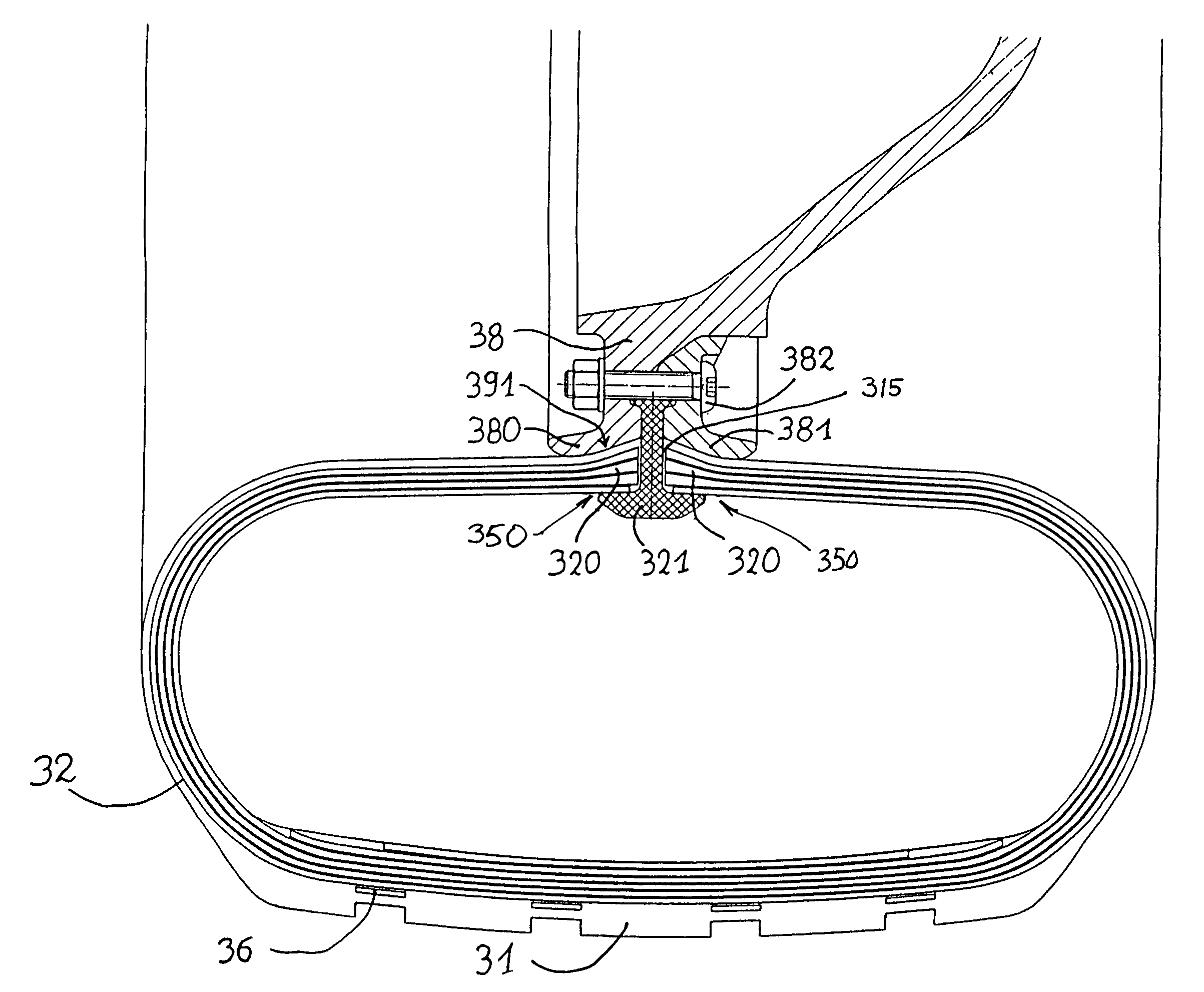

Self-inflating tire

A self-inflating tire assembly includes an air tube connected to a tire and defining an air passageway, the air tube being composed of a flexible material operative to allow an air tube segment opposite a tire footprint to flatten, closing the passageway, and resiliently unflatten into an original configuration. The air tube is sequentially flattened by the tire footprint in a direction opposite to a tire direction of rotation to pump air along the passageway to an inlet device for exhaust from the passageway or to an outlet device for direction into the tire cavity. The inlet device is positioned within the annular passageway 180 degrees opposite the outlet device such that sequential flattening of the air tube by the tire footprint effects pumping of air along the air passageway with the tire rotating in either a forward or reverse direction of rotation. The invention further includes an inlet device for regulating the inlet flow of the air tube pump.

Owner:THE GOODYEAR TIRE & RUBBER CO

Non-pneumatic resilient tire

InactiveUS7032634B2Improve comfortImprove adhesionNon-inflatable tyresSpecial tyresEngineeringMechanical engineering

Owner:CONCEPTION & DEV MICHELIN SA

Tire tread with anti-puncture pads

ActiveUS20050103416A1Improve puncture resistanceMinimal increaseOff-road vehicle tyresInflatable tyresShoulder regionEngineering

A pneumatic tire has a tread designed primarily for off-road activities, comprising large lugs. The tread can be defined as having a central tread width that is divided into a central tread zone and opposing lateral tread zones. The tire also has shoulder regions extending from each lateral tread zone. The tread itself has a plurality of tread elements separated by lateral grooves in the lateral tread zones. The lateral grooves in the lateral tread zones are protected by elongated pads, the pads extending from between a pair of the tread elements and into a shoulder region of the tire. Each pad has a radial height less than the adjacent tread elements and has a base width greater than 50% of the width of the lateral grooves.

Owner:THE GOODYEAR TIRE & RUBBER CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com