Patents

Literature

3651 results about "Conjugated diene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

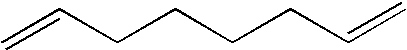

Conjugated diene. [′kän·jə‚gād·əd ′dī‚ēn] (organic chemistry) An acyclic hydrocarbon with a molecular structure containing two carbon-carbon double bonds separated by a single bond.

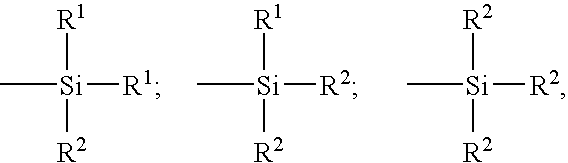

Process for obtaining a grafted elastomer having functional groups along the chain and a rubber composition

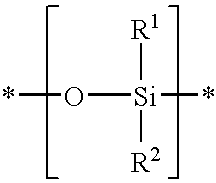

A process for obtaining a grafted diene elastomer having functional groups along the chain, a rubber composition containing this grafted elastomer and having in particular improved hysteresis properties in the cross-linked state, a preparation process for this composition, a tire tread made from this composition and a tire of reduced rolling resistance which incorporates this tread. A process for obtaining this grafted elastomer includes a radical grafting reaction carried out in solution or without a solvent by means of a reagent of the mercaptan type to graft functional groups on to the chain of a starting elastomer. The starting elastomer is treated with an antioxidant having at least one aromatic amine function before the grafting reaction, so that the grafted elastomer has a macrostructure which is practically identical to that of the starting elastomer. A rubber composition containing the grafted diene elastomer includes a reinforcing inorganic filler, and the grafted elastomer preferably has a molar ratio of units originating from conjugated dienes greater than 30%.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

Modified polymers prepared with lanthanide-based catalysts

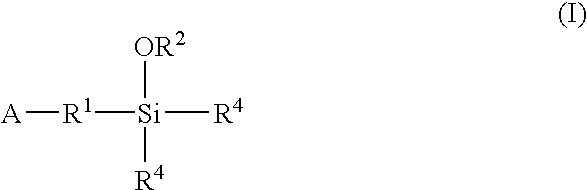

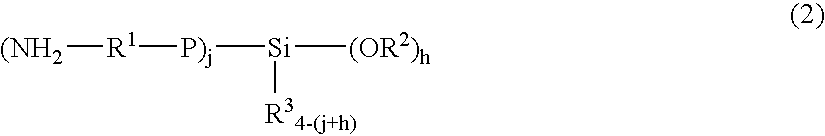

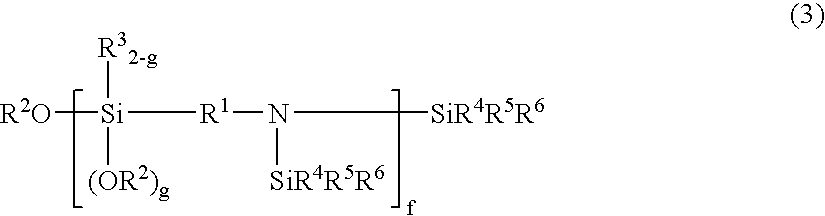

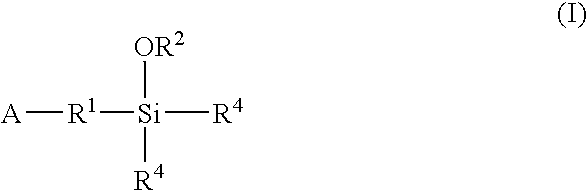

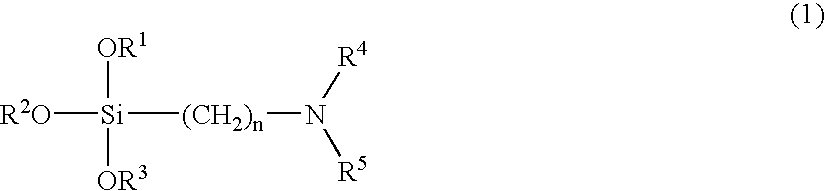

A method for preparing a functionalized polymer comprising the steps of preparing a pseudo-living polymer by polymerizing conjugated diene monomer with a lanthanide-based catalyst, and reacting the pseudo-living polymer with at least one functionalizing agent defined by the formula (I) where A is a substituent that will undergo an addition reaction with a pseudo-living polymer, R1 is a divalent organic group, R2 is a monovalent organic group, and each R4, which may be the same or different, is a monovalent organic group or a substituent defined by —OR5 where R5 is a monovalent organic group, with the proviso that A, R1, R2, R4, and R5 are substituents that will not protonate a pseudo-living polymer. Also, the functionalized polymer and a vulcanizable composition containing the polymer.

Owner:BRIDGESTONE CORP

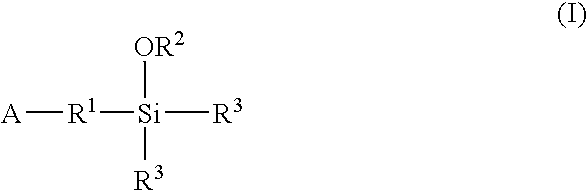

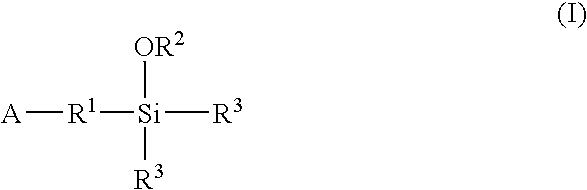

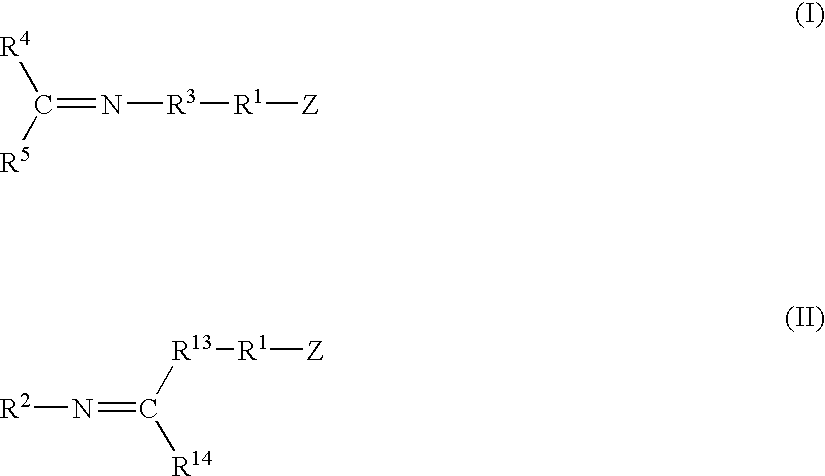

Modified polymers prepared with lanthanide-based catalysts

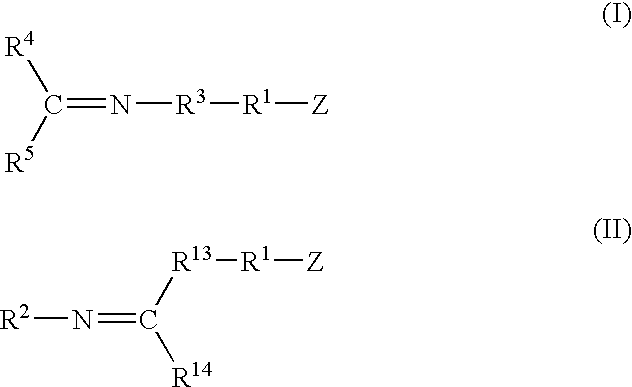

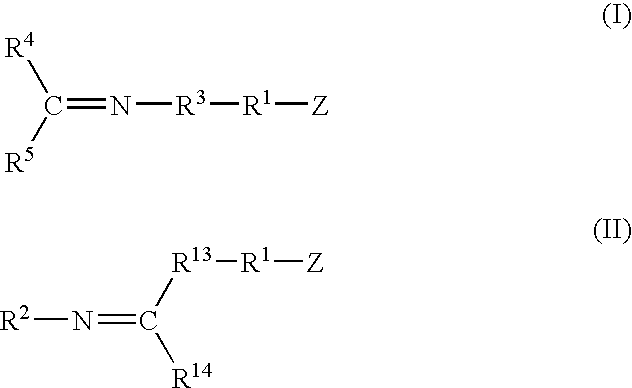

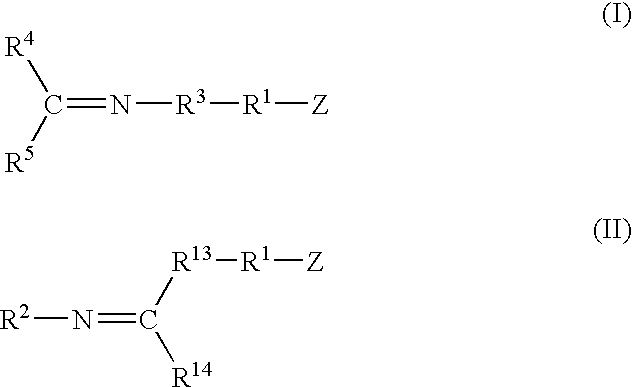

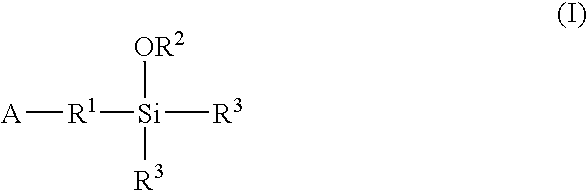

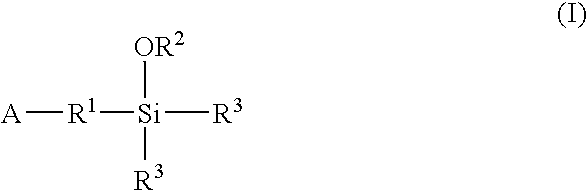

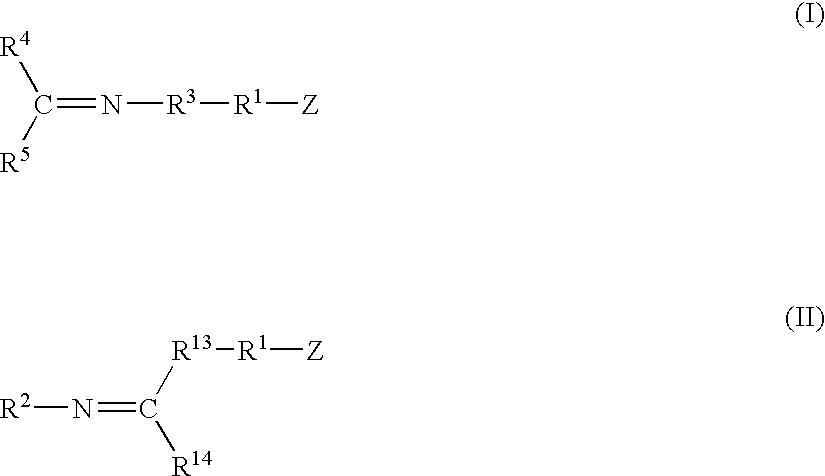

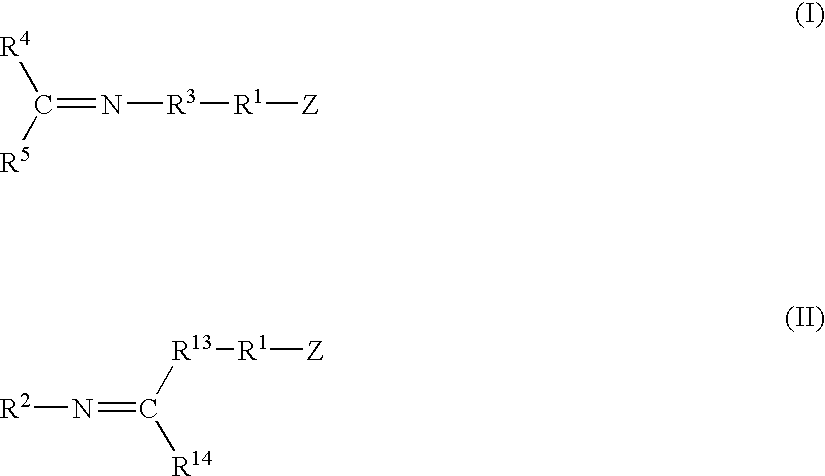

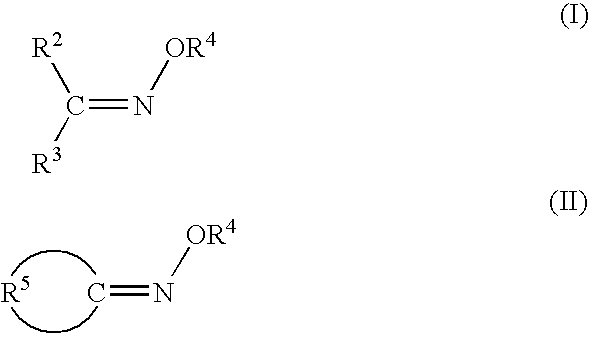

A method for preparing a functionalized polymer comprising the steps of preparing a pseudo-living polymer by polymerizing conjugated diene monomer with a lanthanide-based catalyst, where said pseudo-living polymer is characterized by having greater than about 85 percent of the polymer in the cis microstructure and less than about 3 percent of the polymer is in the 1,2- or 3,4-microstructure, and reacting the pseudo-living polymer with at least one functionalizing agent defined by the formula (I) or (II) where Z is a substituent that will react or interact with organic or inorganic fillers; R1 is a single bond or a divalent organic group; R2 is a monovalent organic group or a divalent organic group that forms a cyclic organic group with R13 or R14; R3 is a single bond, a divalent organic group, or a trivalent organic group that forms a cyclic organic group with R4 or R5; R13 is a single bond, a divalent organic group, or a trivalent organic group that forms a cyclic organic group with R2 or R14; R4 is a monovalent organic group or a divalent organic group that forms a cyclic organic group with R3 or R5; R14 is a monovalent organic group or a divalent organic group that forms a cyclic organic group with R2 or R13; and R5 is a monovalent organic group or a divalent organic group that forms a cyclic organic group with R3 or R4; with the proviso that each group attached to the imino carbon is attached via a carbon atom and R1, R2, R3, R4, R5, R13, R14 and Z are substituents that will not protonate a pseudo-living polymer.

Owner:BRIDGESTONE CORP

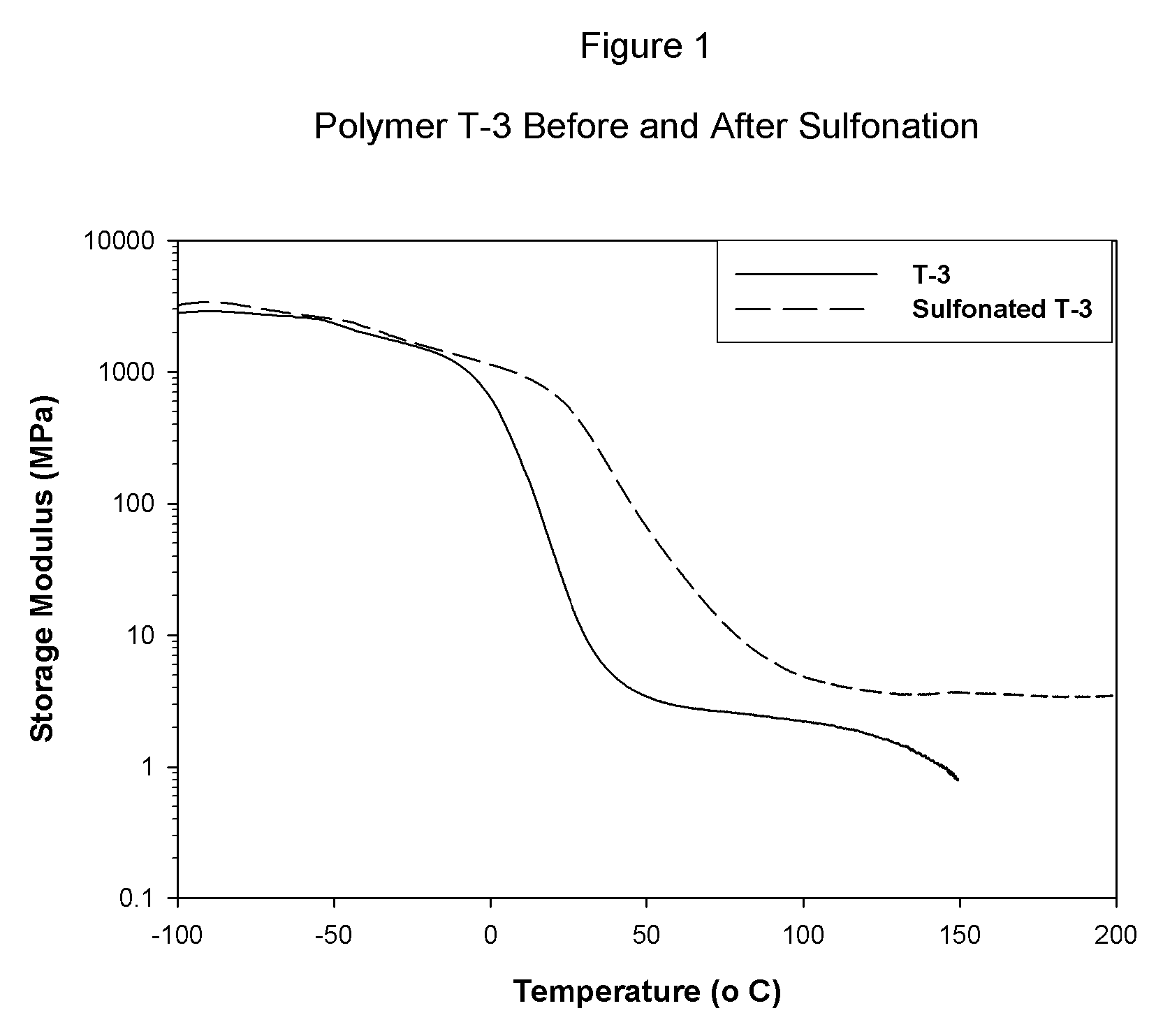

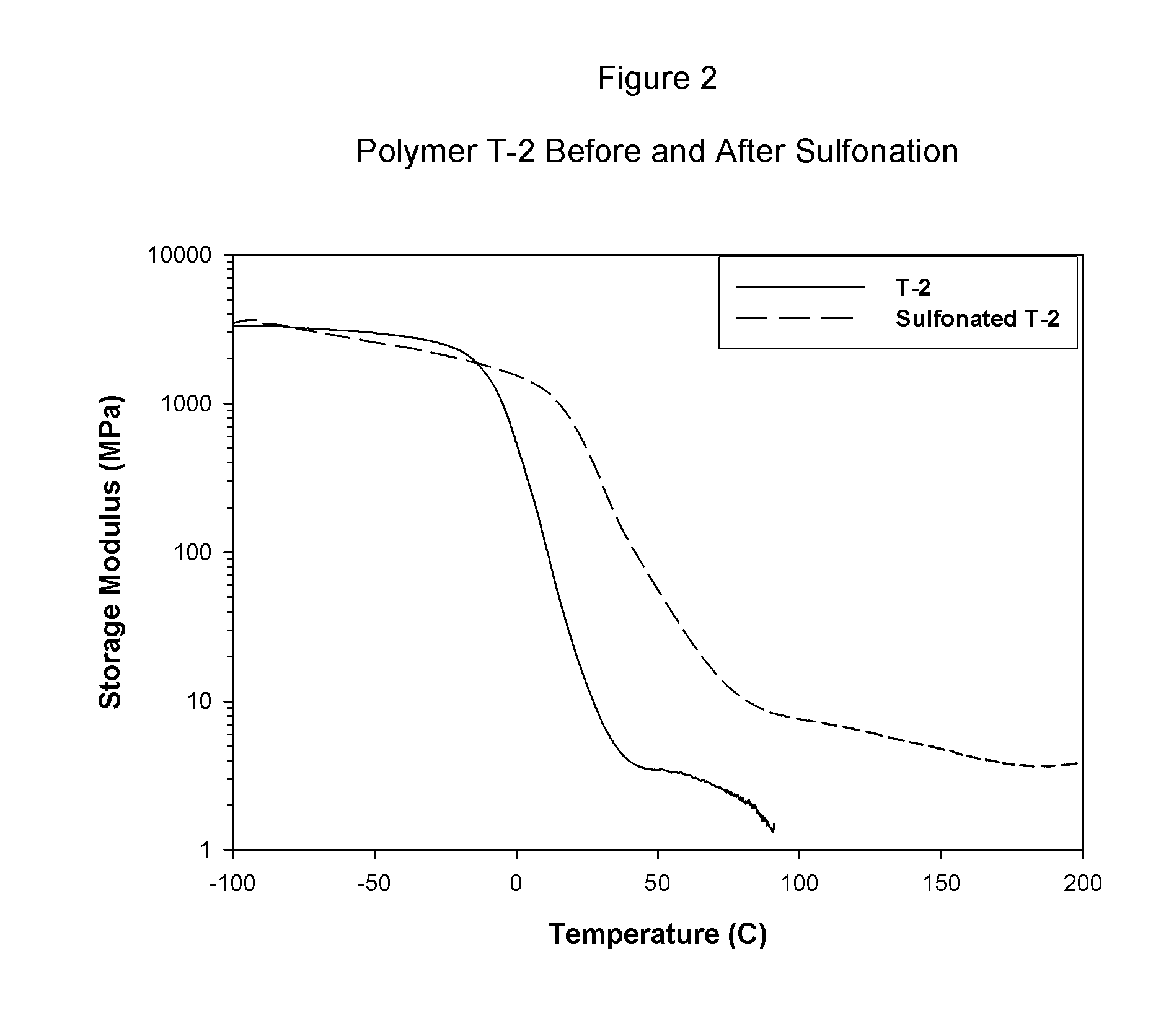

Sulfonated block copolymers, method for making same, and various uses for such block copolymers

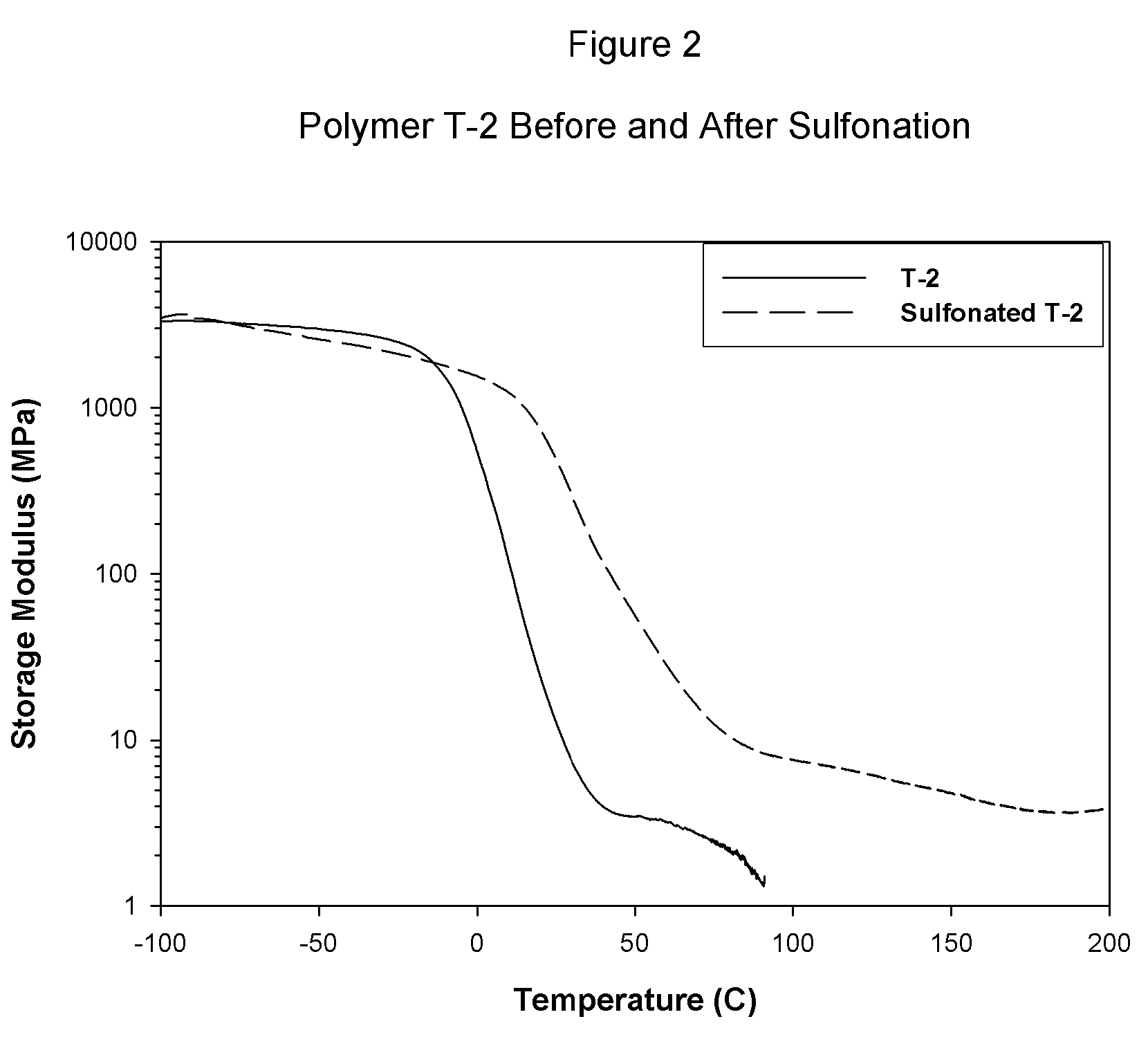

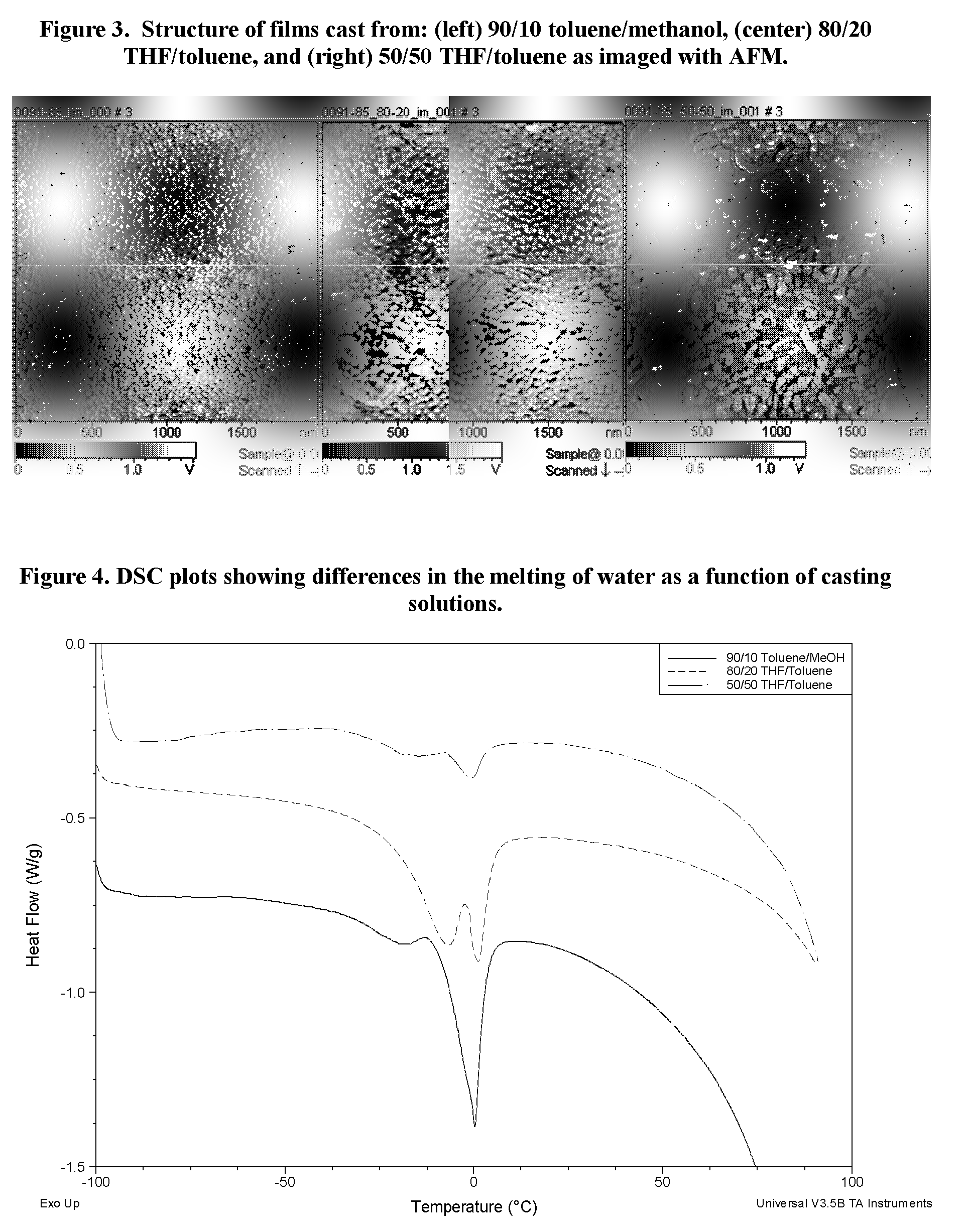

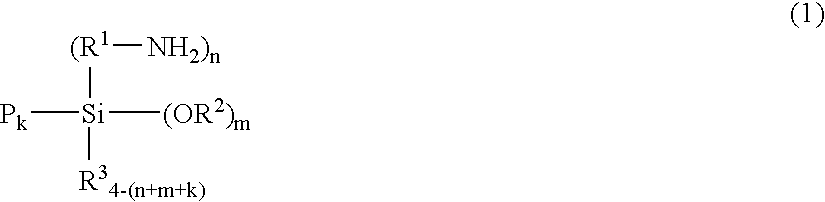

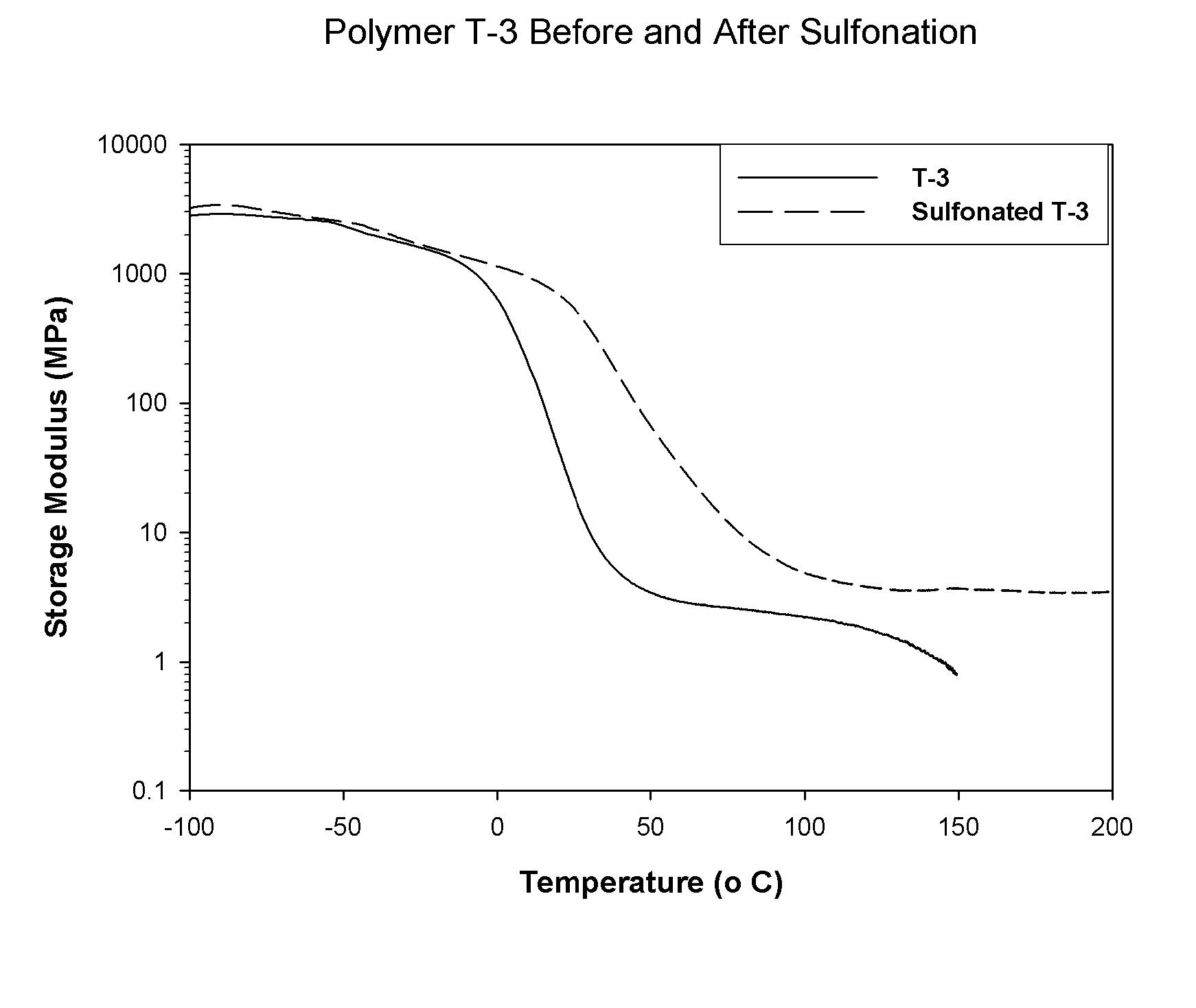

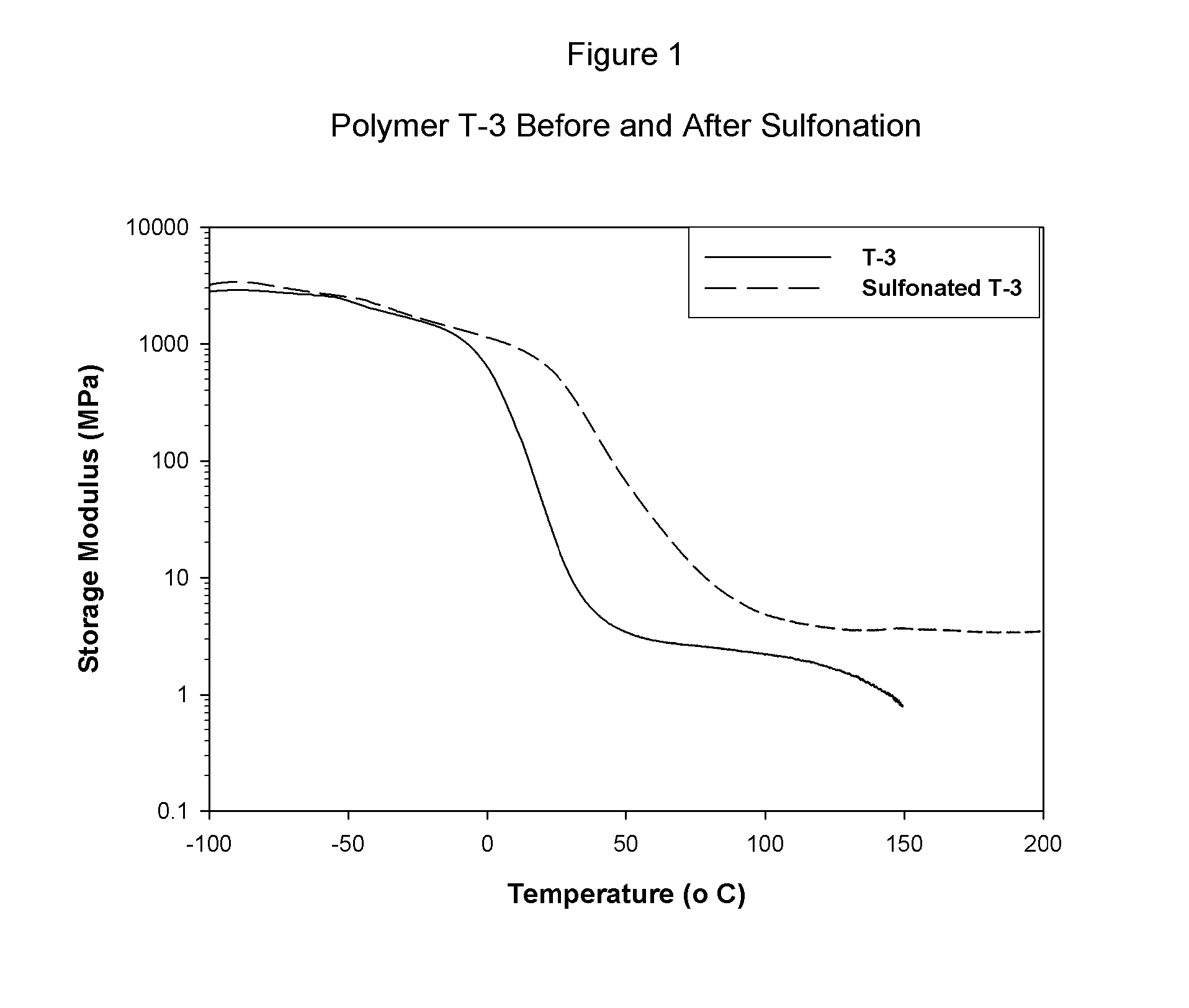

ActiveUS7737224B2Reduced responseHigh propertySemi-permeable membranesNegative electrodesMethacrylatePolymer science

The present invention is a, solid block copolymer comprising at least two polymer end blocks A and at least one polymer interior block B wherein each A block is a polymer block resistant to sulfonation and each B block is a polymer block susceptible to sulfonation, and wherein said A and B blocks do not contain any significant levels of olefinic unsaturation. Preferably, each A block comprising one or more segments selected from polymerized (i) para-substituted styrene monomers, (ii) ethylene, (iii) alpha olefins of 3 to 18 carbon atoms; (iv) hydrogenated 1,3-cyclodiene monomers, (v) hydrogenated monomers of conjugated dienes having a vinyl content less than 35 mol percent prior to hydrogenation, (vi) acrylic esters, (vii) methacrylic esters, and (viii) mixtures thereof; and each B block comprising segments of one or more polymerized vinyl aromatic monomers selected from (i) unsubstituted styrene monomers, (ii) ortho-substituted styrene monomers, (iii) meta-substituted styrene monomers, (iv) alpha-methylstyrene, (v) 1,1-diphenylethylene, (vi) 1,2-diphenylethylene and (vii) mixtures thereof. Also claimed are processes for making such block copolymers, and the various end uses and applications for such block copolymers.

Owner:KRATON POLYMERS US LLC

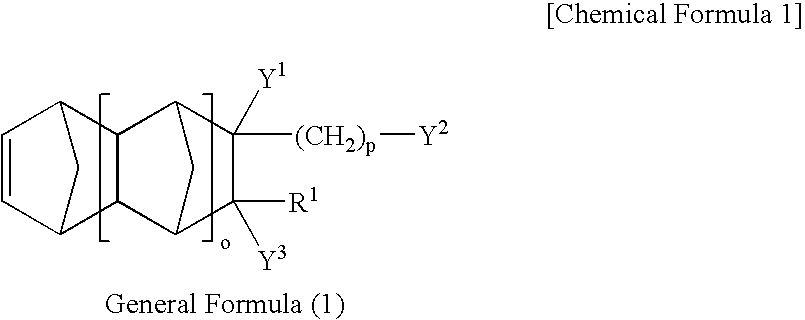

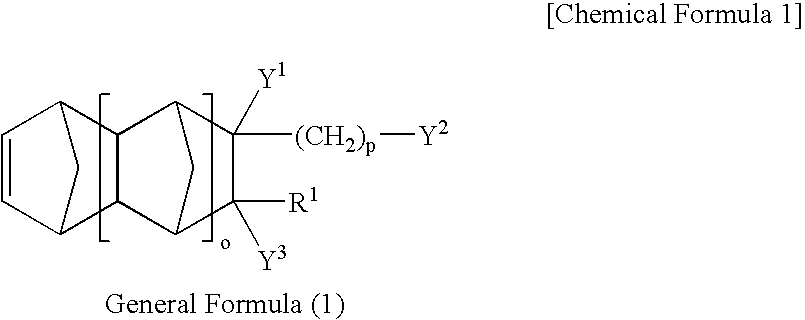

Conjugated diolefin (co)polymer rubber, process for producing (co)polymer rubber, rubber composition, composite, and tire

ActiveUS7342070B2Reduce fuel consumptionImprove performanceSpecial tyresRolling resistance optimizationHysteresisPolymer science

Disclosed are a conjugated diolefin (co) polymer rubber formed from either a conjugated diolefin or a conjugated diolefin and an aromatic vinyl compound, wherein the (co) polymer rubber has a primary amino group and an alkoxysilyl group which are bonded to a (co) polymer chain; a process for producing the same; a rubber composition; a composite; and a tire. The (co) polymer rubber has satisfactory processability, and can give an automotive tire tread having a balance among wear resistance, failure characteristics, low hysteresis loss and wet-skid characteristics.

Owner:ENEOS MATERIALS CORP

Modified polymers prepared with lanthanide-based catalysts

A method for preparing a functionalized polymer comprising the steps of preparing a pseudo-living polymer by polymerizing conjugated diene monomer with a lanthanide-based catalyst, and reacting the pseudo-living polymer with at least one functionalizing agent defined by the formula (I) where A is a substituent that will undergo an addition reaction with a pseudo-living polymer, R1 is a divalent organic group, R2 is a monovalent organic group, and each R4, which may be the same or different, is a monovalent organic group or a substituent defined by —OR5 where R5 is a monovalent organic group, with the proviso that A, R1, R2, R4, and R5 are substituents that will not protonate a pseudo-living polymer. Also, the functionalized polymer and a vulcanizable composition containing the polymer.

Owner:ENEOS MATERIALS CORP

Thermoplastic Elastomer Composition, Method for Producing Same and Formed Article

The invention provides a thermoplastic elastomer composition having mechanical properties equivalent or superior to those of conventional thermoplastic elastomer compositions and having excellent heat resistance and oil resistance and a preparation process thereof, and molded or formed products making use of this thermoplastic elastomer composition. The thermoplastic elastomer composition according to the present invention contains a thermoplastic resin having a polar group and an ethylene•α-olefin elastomer having a functional group. The ethylene•α-olefin elastomer having the functional group is preferably a random copolymer obtained by copolymerizing ethylene, an α-olefin having 3 to 10 carbon atoms, an unsaturated monomer having the functional group and an optional non-conjugated diene.

Owner:JSR CORPORATIOON

Modified polymers prepared with lanthanide-based catalysts

A method for preparing a functionalized polymer comprising the steps of preparing a pseudo-living polymer by polymerizing conjugated diene monomer with a lanthanide-based catalyst, where said pseudo-living polymer is characterized by having greater than about 85 percent of the polymer in the cis microstructure and less than about 3 percent of the polymer is in the 1,2- or 3,4-microstructure, and reacting the pseudo-living polymer with at least one functionalizing agent defined by the formula (I) or (II) where Z is a substituent that will react or interact with organic or inorganic fillers; R1 is a single bond or a divalent organic group; R2 is a monovalent organic group or a divalent organic group that forms a cyclic organic group with R13 or R14; R3 is a single bond, a divalent organic group, or a trivalent organic group that forms a cyclic organic group with R4 or R5; R13 is a single bond, a divalent organic group, or a trivalent organic group that forms a cyclic organic group with R2 or R14; R4 is a monovalent organic group or a divalent organic group that forms a cyclic organic group with R3 or R5; R14 is a monovalent organic group or a divalent organic group that forms a cyclic organic group with R2 or R13; and R5 is a monovalent organic group or a divalent organic group that forms a cyclic organic group with R3 or R4; with the proviso that each group attached to the imino carbon is attached via a carbon atom and R1, R2 R3, R4, R5, R13, R14 and Z are substituents that will not protonate a pseudo-living polymer.

Owner:BRIDGESTONE CORP

Sulfonated block copolymers, method for making same, and various uses for such block copolymers

ActiveUS20070021569A1High water transport propertyImprove wet strengthSemi-permeable membranesNegative electrodesMethacrylatePolymer science

The present invention is a, solid block copolymer comprising at least two polymer end blocks A and at least one polymer interior block B wherein each A block is a polymer block resistant to sulfonation and each B block is a polymer block susceptible to sulfonation, and wherein said A and B blocks do not contain any significant levels of olefinic unsaturation. Preferably, each A block comprising one or more segments selected from polymerized (i) para-substituted styrene monomers, (ii) ethylene, (iii) alpha olefins of 3 to 18 carbon atoms; (iv) hydrogenated 1,3-cyclodiene monomers, (v) hydrogenated monomers of conjugated dienes having a vinyl content less than 35 mol percent prior to hydrogenation, (vi) acrylic esters, (vii) methacrylic esters, and (viii) mixtures thereof; and each B block comprising segments of one or more polymerized vinyl aromatic monomers selected from (i) unsubstituted styrene monomers, (ii) ortho-substituted styrene monomers, (iii) meta-substituted styrene monomers, (iv) alpha-methylstyrene, (v) 1,1-diphenylethylene, (vi) 1,2-diphenylethylene and (vii) mixtures thereof. Also claimed are processes for making such block copolymers, and the various end uses and applications for such block copolymers.

Owner:KRATON POLYMERS US LLC

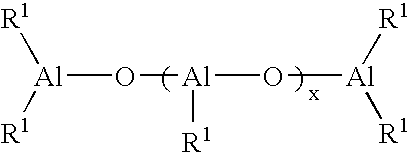

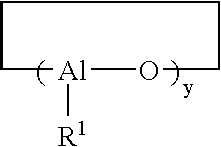

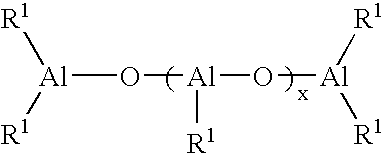

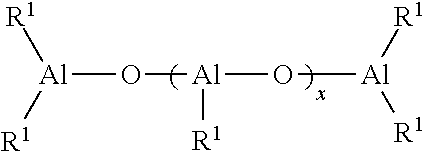

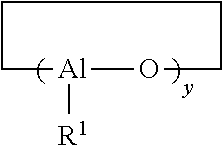

Method for producing functionalized cis-1,4-polydienes having high cis-1,4-linkage content and high functionality

This invention relates to a method for producing functionalized cis-1,4-polydienes having a combination of a high cis-1,4-linkage content and a high functionality, the resulting polymers and the vulcanized products containing the polymers. The functionalized cis-1,4-polydienes of the present invention are produced by a method comprising the steps of: (1) preparing a reactive polymer by polymerizing conjugated diene monomer with a lanthanide-based catalyst in the presence of less than 20% by weight of organic solvent based on the total weight of monomer, organic solvent, and resulting polymer, where the lanthanide-based catalyst is the combination of or reaction product of (a) a lanthanide compound, (b) an aluminoxane, (c) an organoaluminum compound other than an aluminoxane, and (d) a halogen-containing compound; and (2) contacting the reactive polymer with a functionalizing agent.

Owner:BRIDGESTONE CORP

Method of producing conjugated diene polymers with narrow molecular weight distribution and polymer produced

Conjugated diene polymers having good wear resistance, mechanical properties, storage stability, processability and a reduced cold flow are produced by polymerizing a conjugated diene compound with a catalyst of rare earth element compound, a compound containing at least one halogen atom, an aluminoxane, and an organoaluminum compound in an organic solvent and reacting the resulting polymer just after the polymerization with at least one compound selected from the group consisting of a halogenated organometallic compound, a halogenated metal compound, an organometallic compound, a heterocumulene compound, a hetero three-membered-ring containing compound, a halogenated isocyano compound, a carboxylic acid, an acid halide, an ester compound, a carbonic ester compound, an acid anhydride and a metal salt of a carboxylic acid as a modifying agent.

Owner:JSR CORPORATIOON

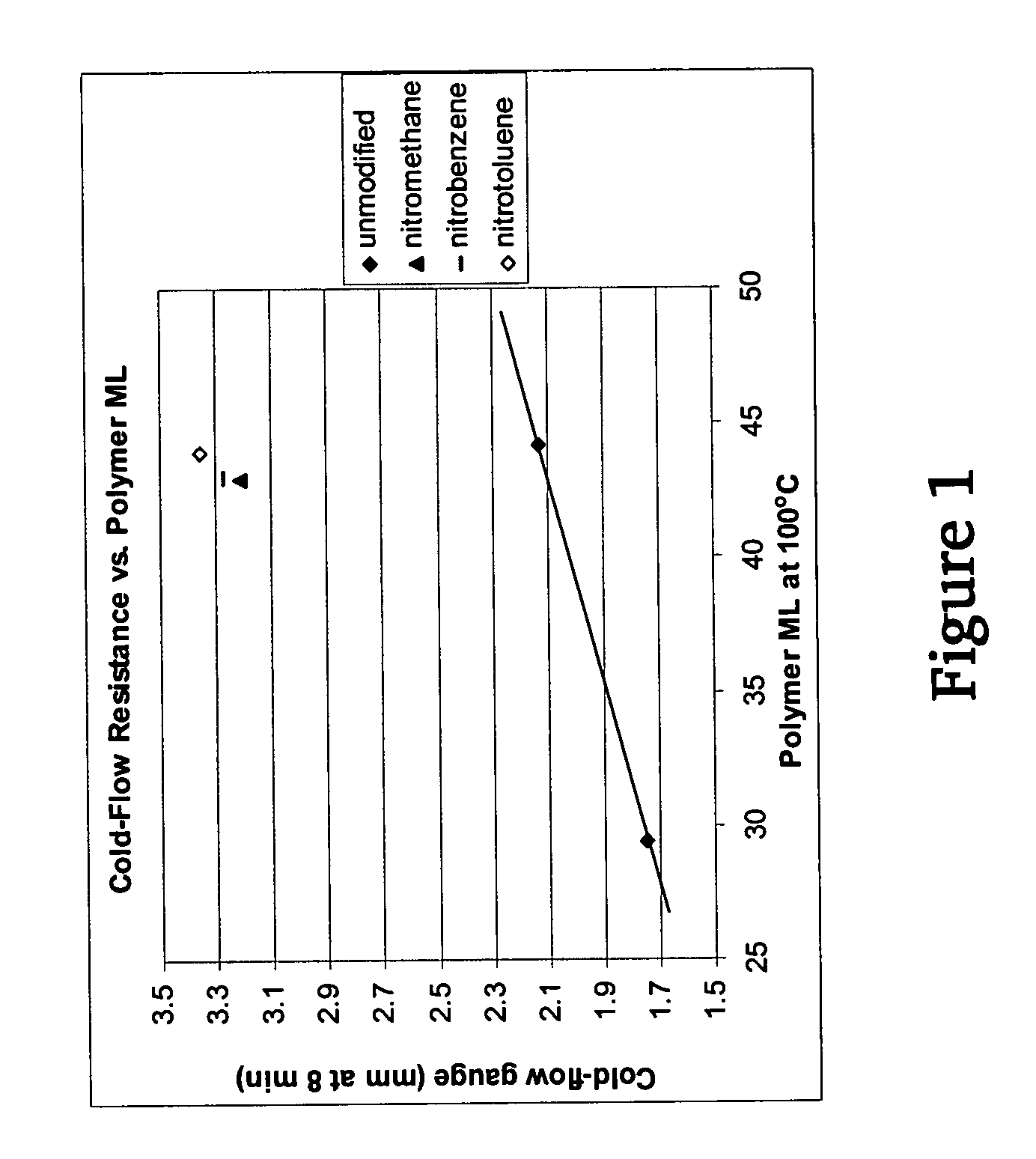

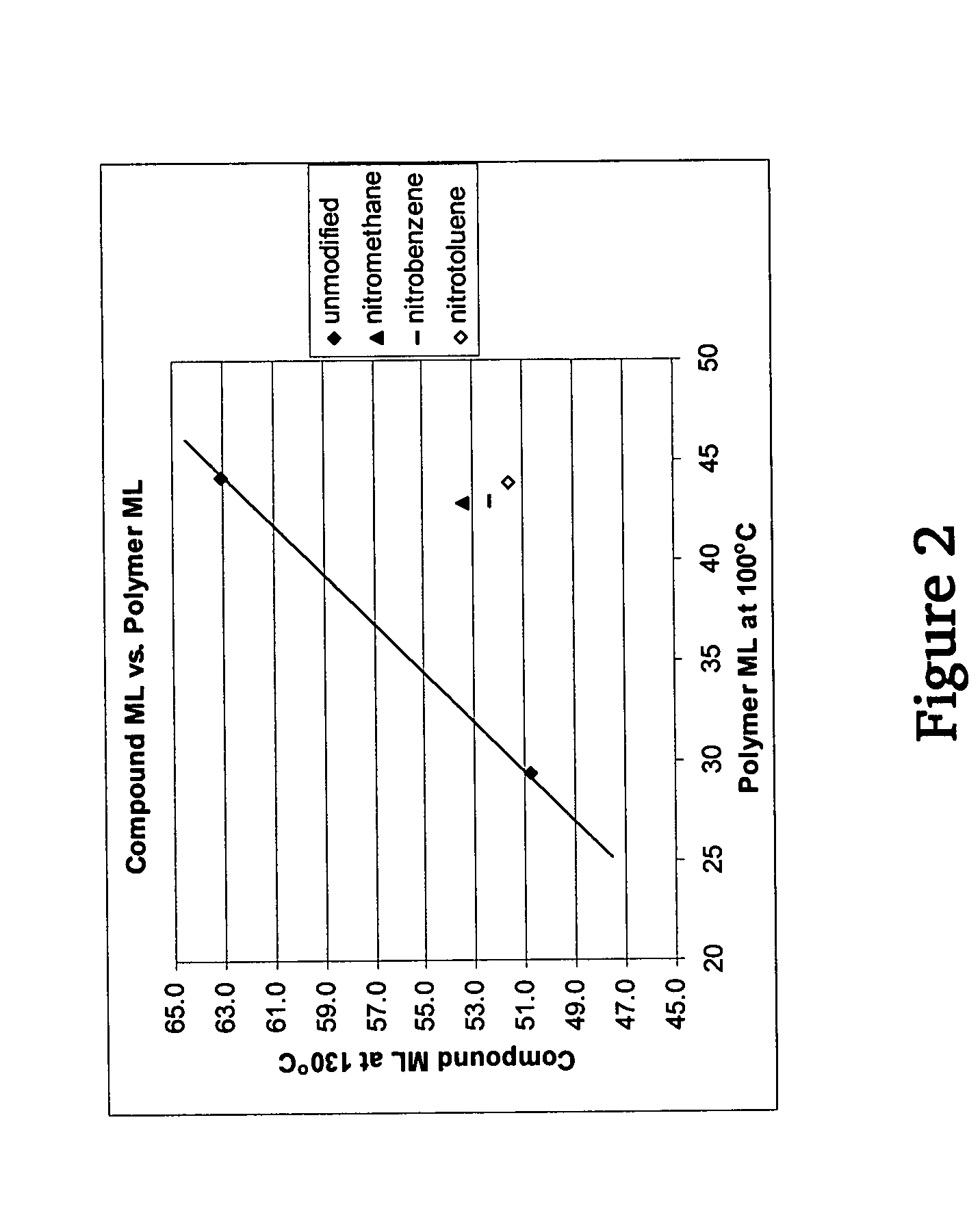

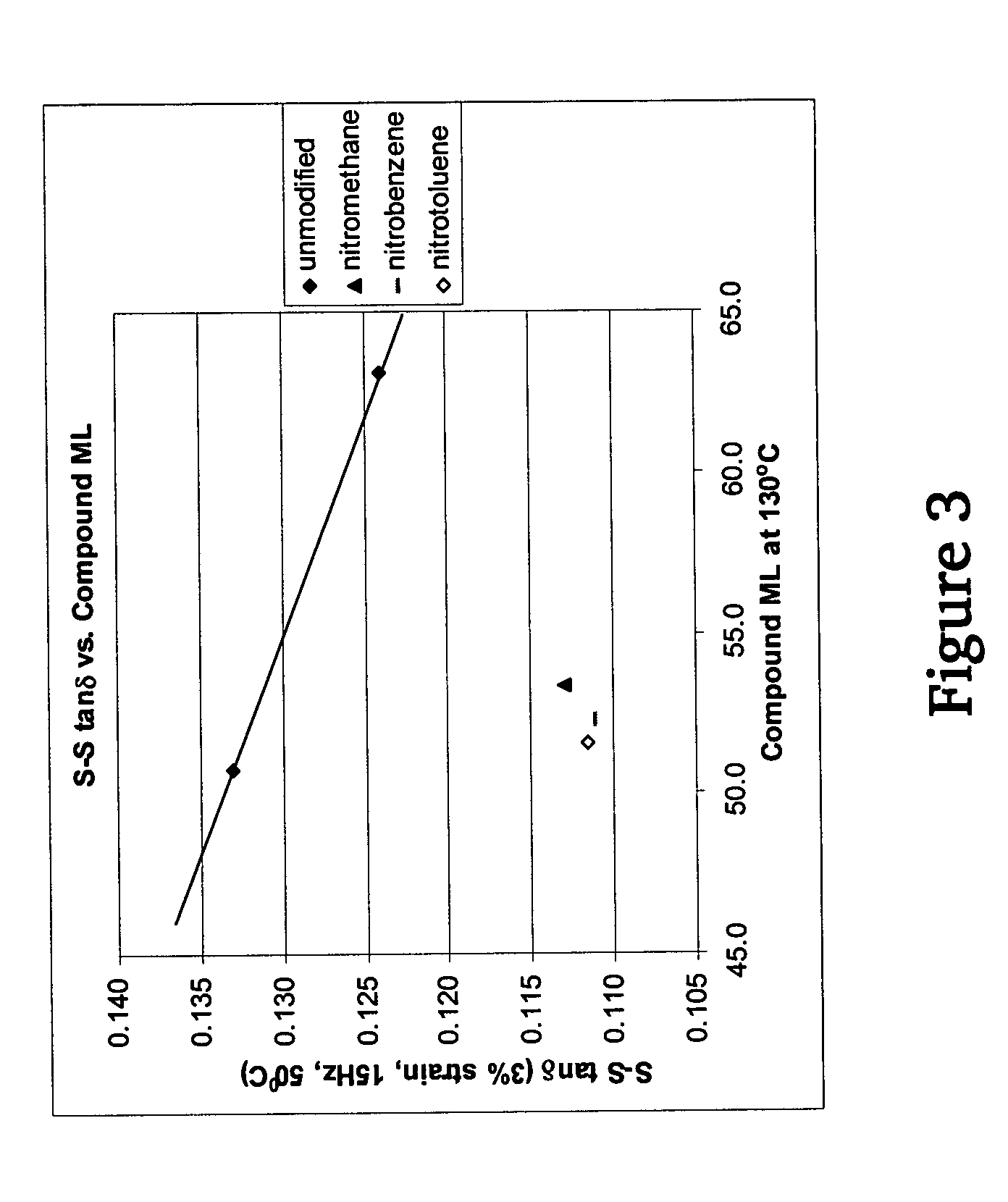

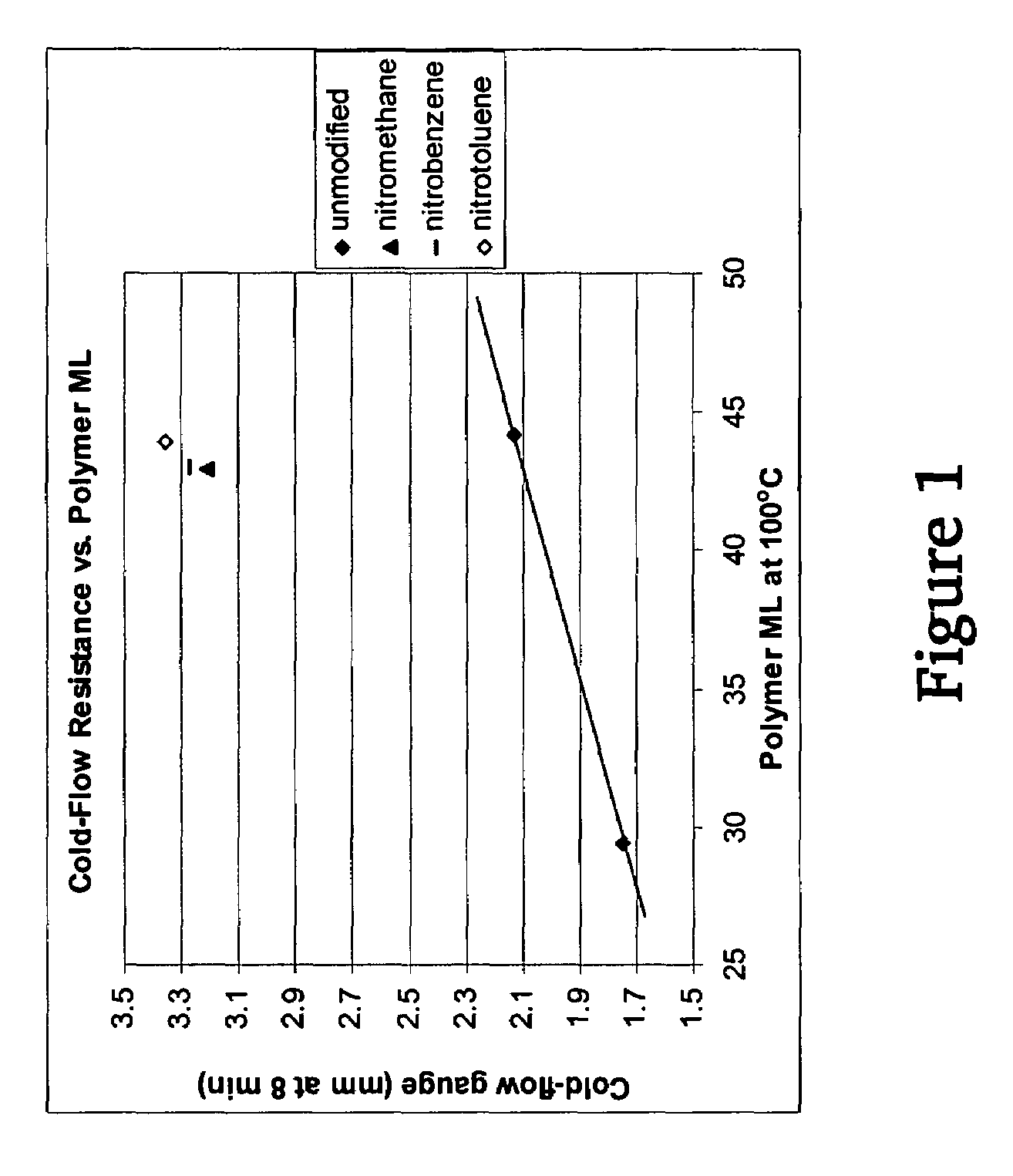

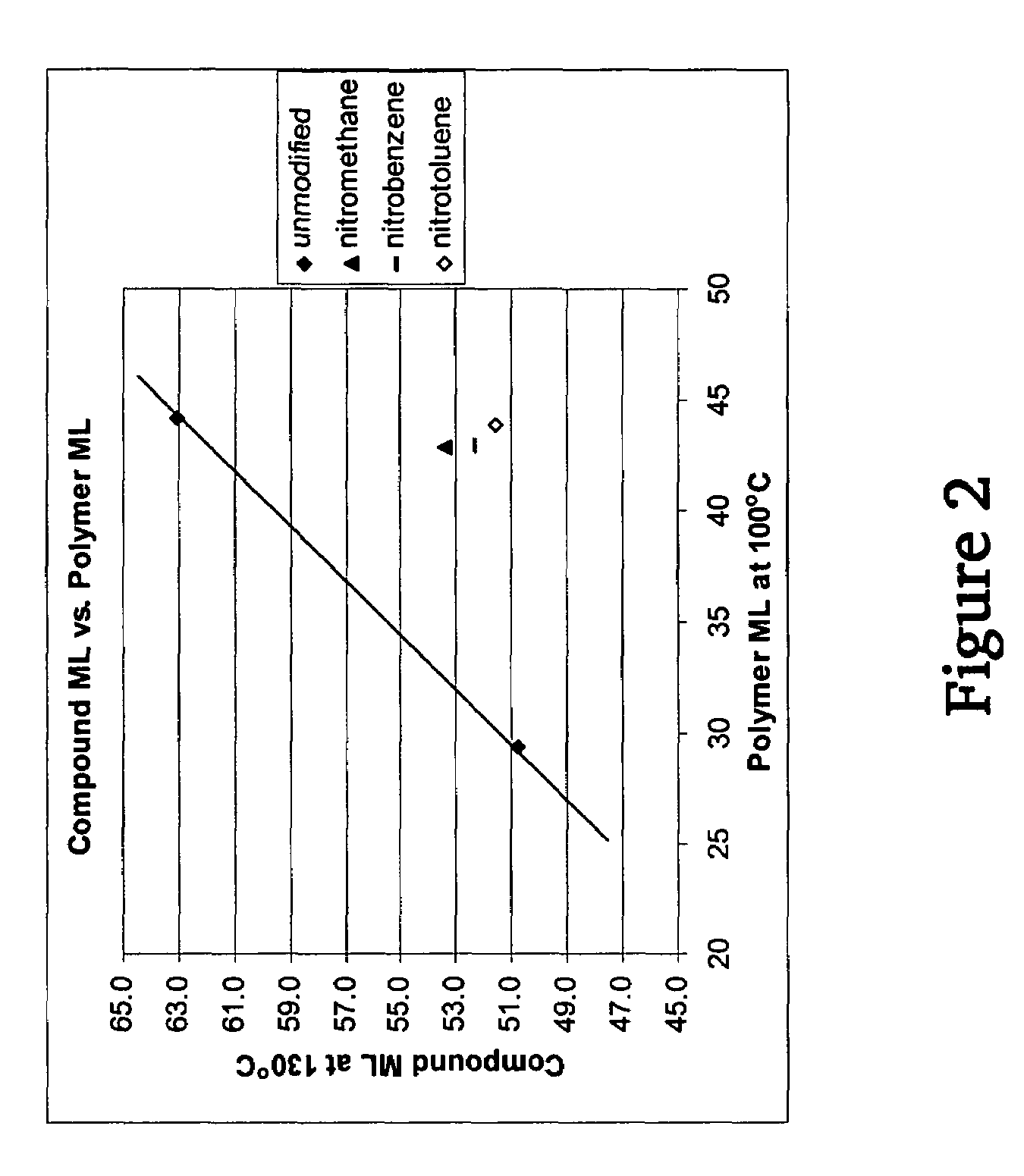

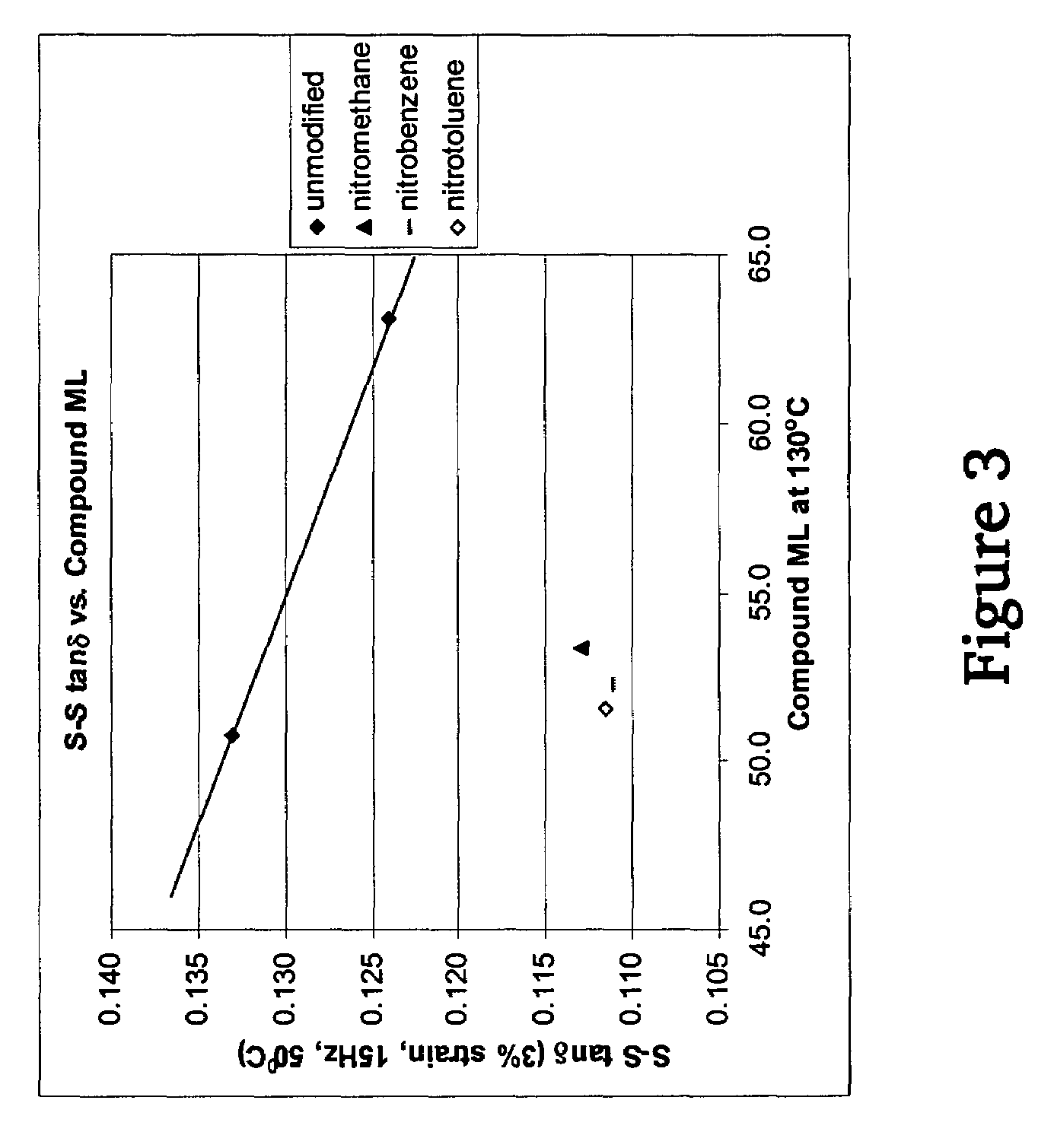

Polymers functionalized with nitro compounds

A method for preparing a functionalized polymer, the method comprising the steps of (i) polymerizing conjugated diene monomer by employing a lanthanide-based catalyst to form a reactive polymer, and (ii) reacting the reactive polymer with a nitro compound.

Owner:BRIDGESTONE CORP

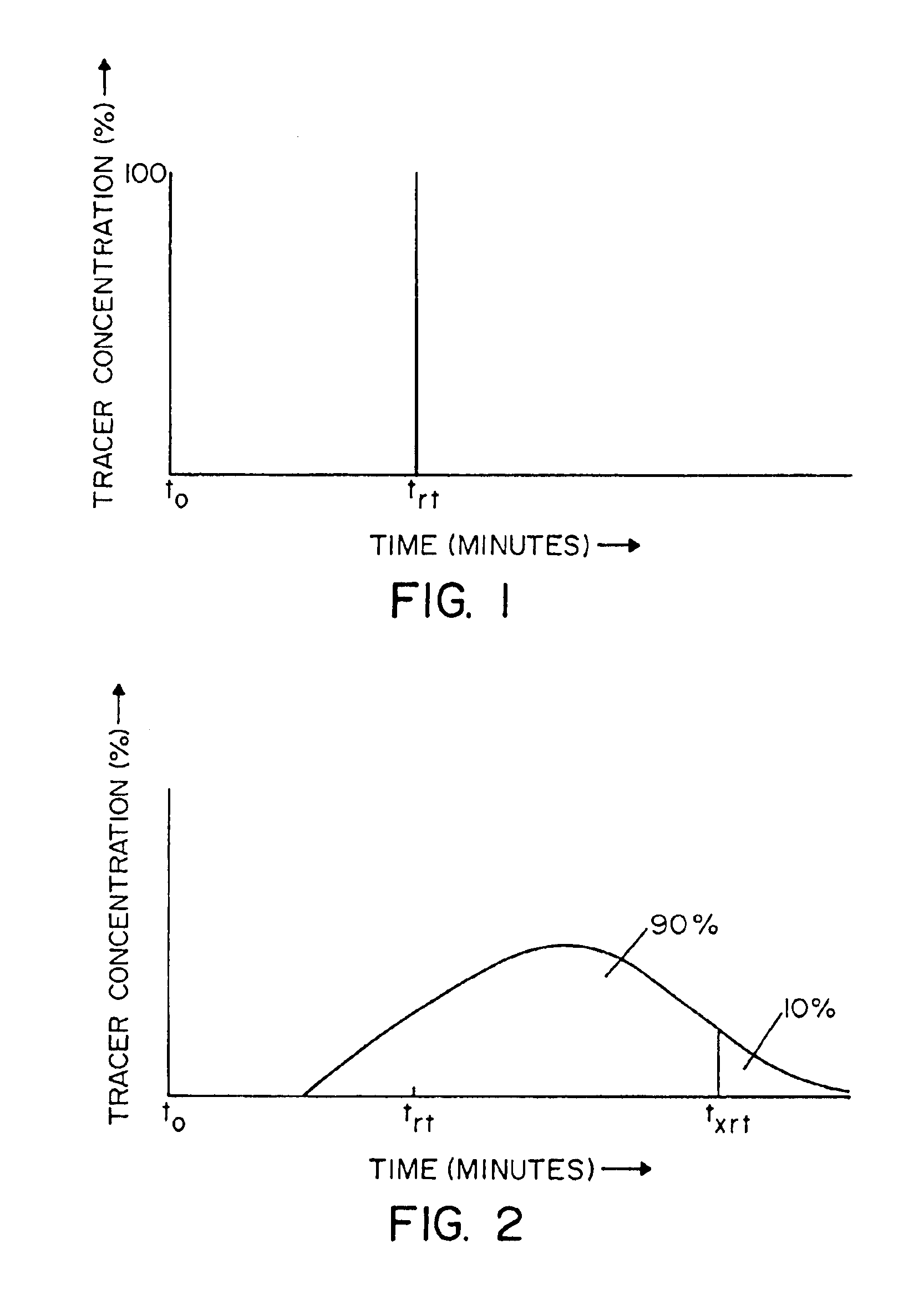

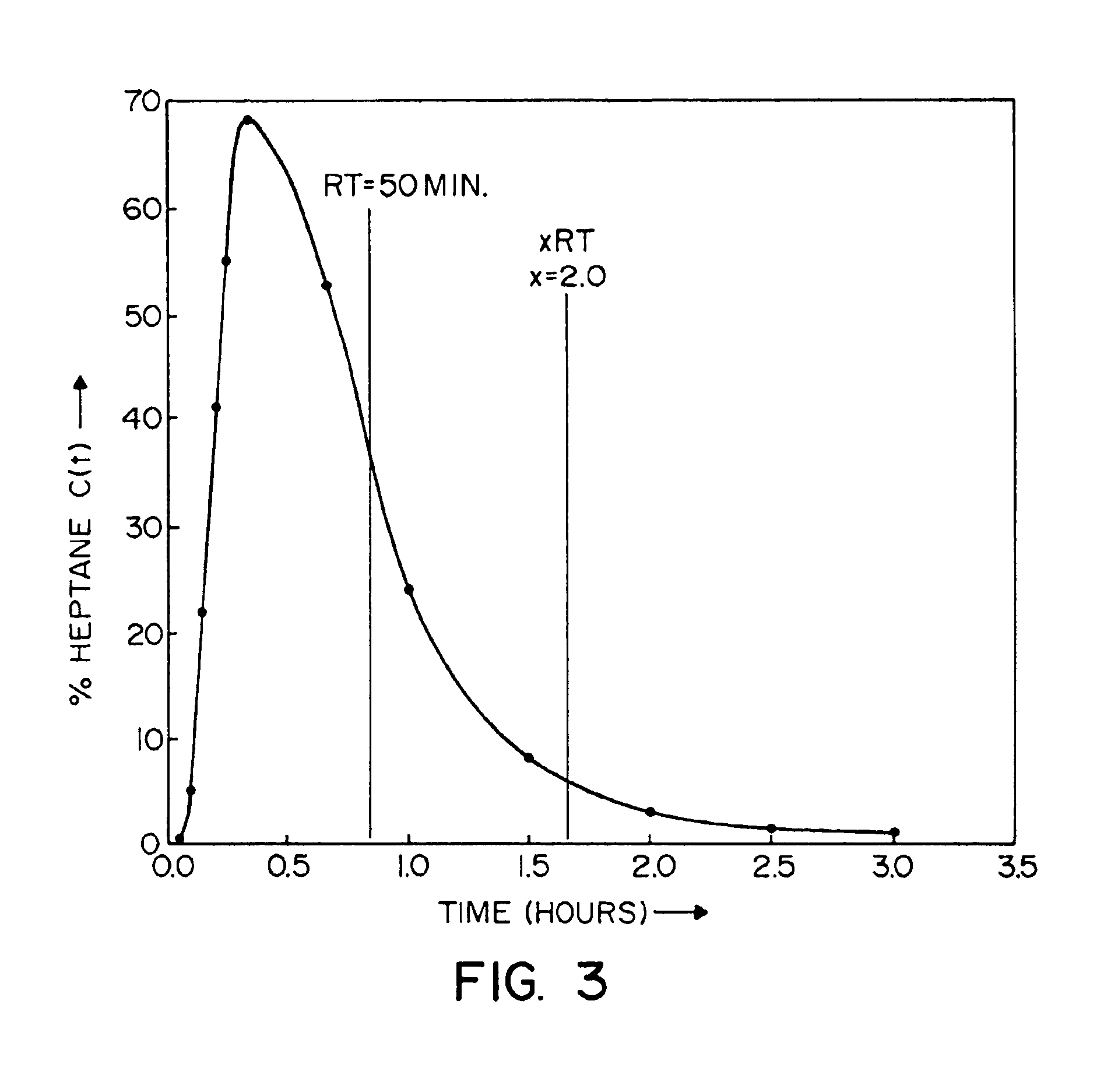

Continuous process for the production of conjugated diene polymers having narrow molecular weight distribution and products therefrom

InactiveUS6897270B2Narrow molecular weight distributionImprove responseHydrocarbon solventsContinuous reactor

A continuous process for producing conjugated diene polymers comprising the steps of contacting, within an hydrocarbon solvent and within a continuous reactor, conjugated diene monomer and a catalyst composition prepared by combining: (a) a lanthanide compound, (b) an alkylating agent, and (c) a halogen-containing compound, and maintaining a non-ideal flow pattern within the continuous reactor so that 10% of the reagents entering the reactor at a reference time t0 are still present within the continuous reactor at a time t0+xtrt, where trt is the residence time corresponding to ideal flow within the continuous reactor and x is a numeral greater than 1.5.

Owner:BRIDGESTONE CORP

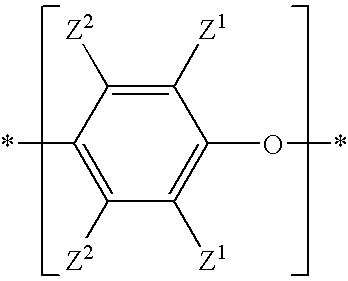

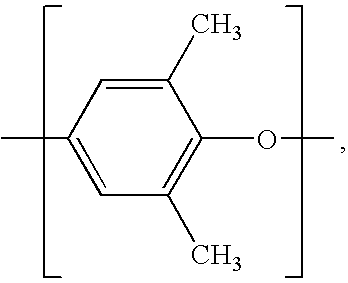

Poly(arylene ether) composition and extruded articles derived therefrom

A poly(arylene ether) composition includes a hydrogenated block copolymer of an alkenyl aromatic compound and a conjugated diene, a flame retardant, and a poly(arylene ether)-polysiloxane block copolymer reaction product that itself includes a poly(arylene ether)-polysiloxane block copolymer. The composition is useful for forming extruded articles, including insulation for wire and cable. The poly(arylene ether)-polysiloxane block copolymer contributes improved flame retardancy and, in many cases, improved physical properties to the composition.

Owner:SHPP GLOBAL TECH BV

Bulk polymerization process for producing polydienes

ActiveUS7094849B2Organic-compounds/hydrides/coordination-complexes catalystsHalogenBulk polymerization

A method of producing cis-1,4-polydienes, the method comprising the step of contacting conjugated diene monomer with a lanthanide-based catalyst system in the presence of less than 20% by weight of organic solvent based on the total weight of monomer, organic solvent, and resulting polymer, where the lanthanide-based catalyst system is the combination of or reaction product of (a) a lanthanide compound, (b) an organoaluminum hydride, (c) a trihydrocarbylaluminum, and (d) a halogen-containing compound.

Owner:BRIDGESTONE CORP

Oil extended rubber and composition containing low PCA oil

The invention is directed to an oil extended rubber and composition comprising: a solution-polymerized elastomer derived from at least one conjugated diene monomer and at least one vinyl aromatic monomer, the elastomer coupled with at least one metal selected from the group consisting of silicon and tin; and from about 5 to about 70 parts by weight, per 100 parts by weight of elastomer (phr), of a process oil having a glass transition temperature of from about −80° C. to about −40° C., a polycyclic aromatic content of less than 3 percent by weight as determined by the IP346 method, and an aromatic content of less than 20 percent by weight as measured by ASTM D2140.

Owner:THE GOODYEAR TIRE & RUBBER CO

Method for the selective hydrogenation of polymer containing conjugated diene

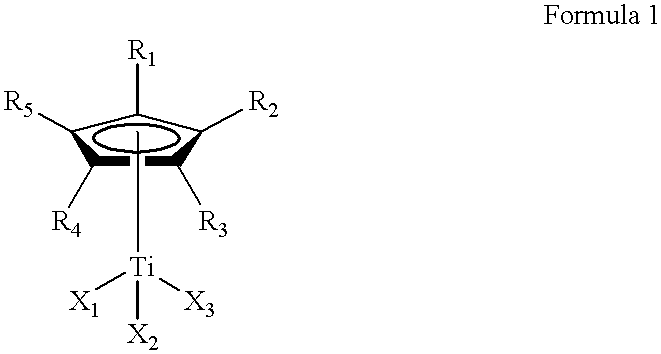

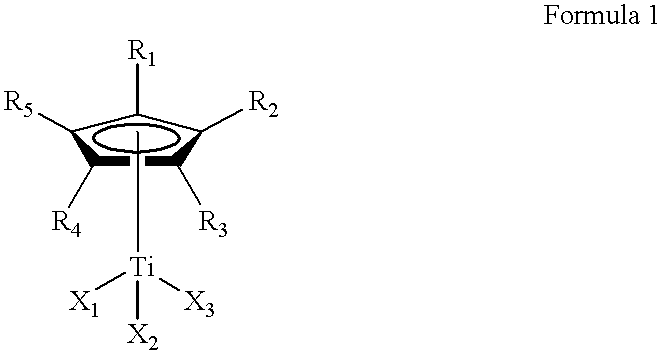

This invention relates to a method for the selective hydrogenation of the unsaturated double bonds in the conjugated diene units of a homopolymer or copolymer in the presence of a novel homogeneous organotitanium-based catalyst. Also, the process of this invention can demonstrate a high yield of hydrogenation and hydrogenation reproducibility using a novel catalyst, so prepared from a mixture consisting of a substituted or unsubstituted monocyclopentadienyl titanium compound expressed by the following formula 1 and lithium hydride derived from a reaction of both alkyl lithium and hydrogen in solution. In particular, this invention also relates to a novel method for the selective hydrogenation of unsaturated double bonds in the conjugated diene units of a conjugated diene polymer or copolymer, so prepared via the reaction between a conjugated diene monomer and vinyl-substituted aromatic monomerwherein, R1, R2, R3, R4 and R5, which may be same or different, are selected from hydrogen atoms and alkyl groups of 1~5 carbon atoms; X1, X2 and X3, which may be same or different, are selected from halogen atoms.

Owner:KOREA KUMHO PETROCHEMICAL CO LTD

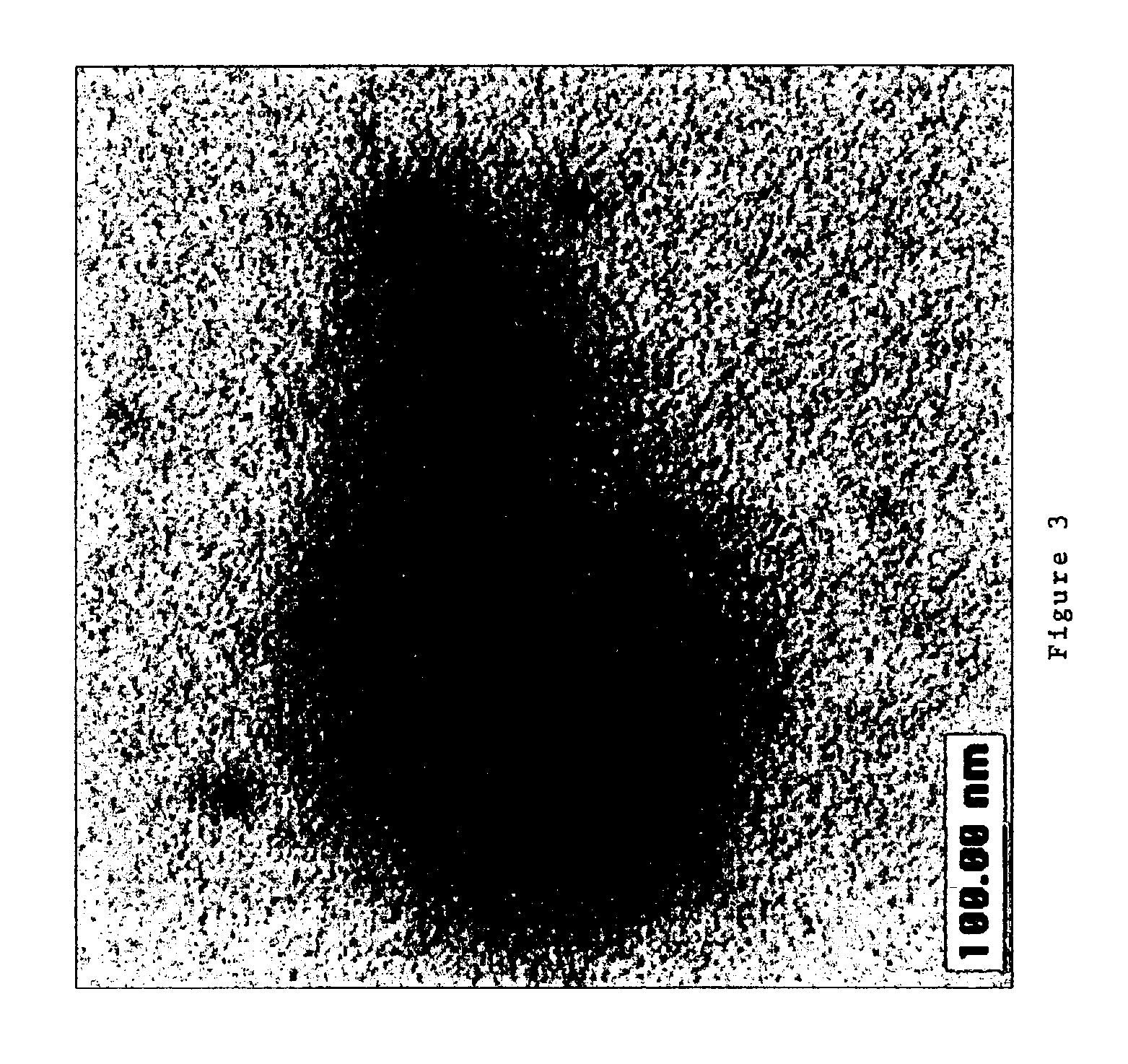

Nano-sized polymer-metal composites

A polymer nanoparticle is provided. The nanoparticle includes an inner layer having alkenylbenzene monomer units. The nanoparticle further includes an outer layer having monomer units selected from conjugated dienes, alkylenes, alkenylbenzenes, and mixtures thereof. The nanoparticle has at least one functional group associated with the outer layer. The nanoparticle further has at least one metal complexed with said functional group. The nanoparticles can be used as a templates for preparation of nano-sized metal crystals and polymer-metal nanocomposite.

Owner:BRIDGESTONE CORP

Process for producing modified diene polymer rubber

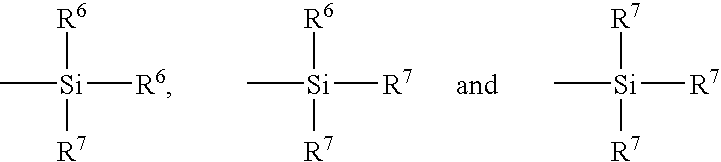

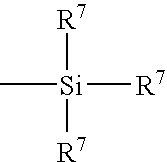

There is provided a process for producing a modified diene polymer rubber comprising the steps of: (1) polymerizing a conjugated diene monomer or a combination thereof with an aromatic vinyl monomer in a hydrocarbon solvent, in the presence of an alkali metal catalyst, to form an alkali metal end-carrying active polymer, and (2) reacting the alkali metal end-carrying active polymer with a silane compound defined by a specific formula.

Owner:SUMITOMO CHEM CO LTD

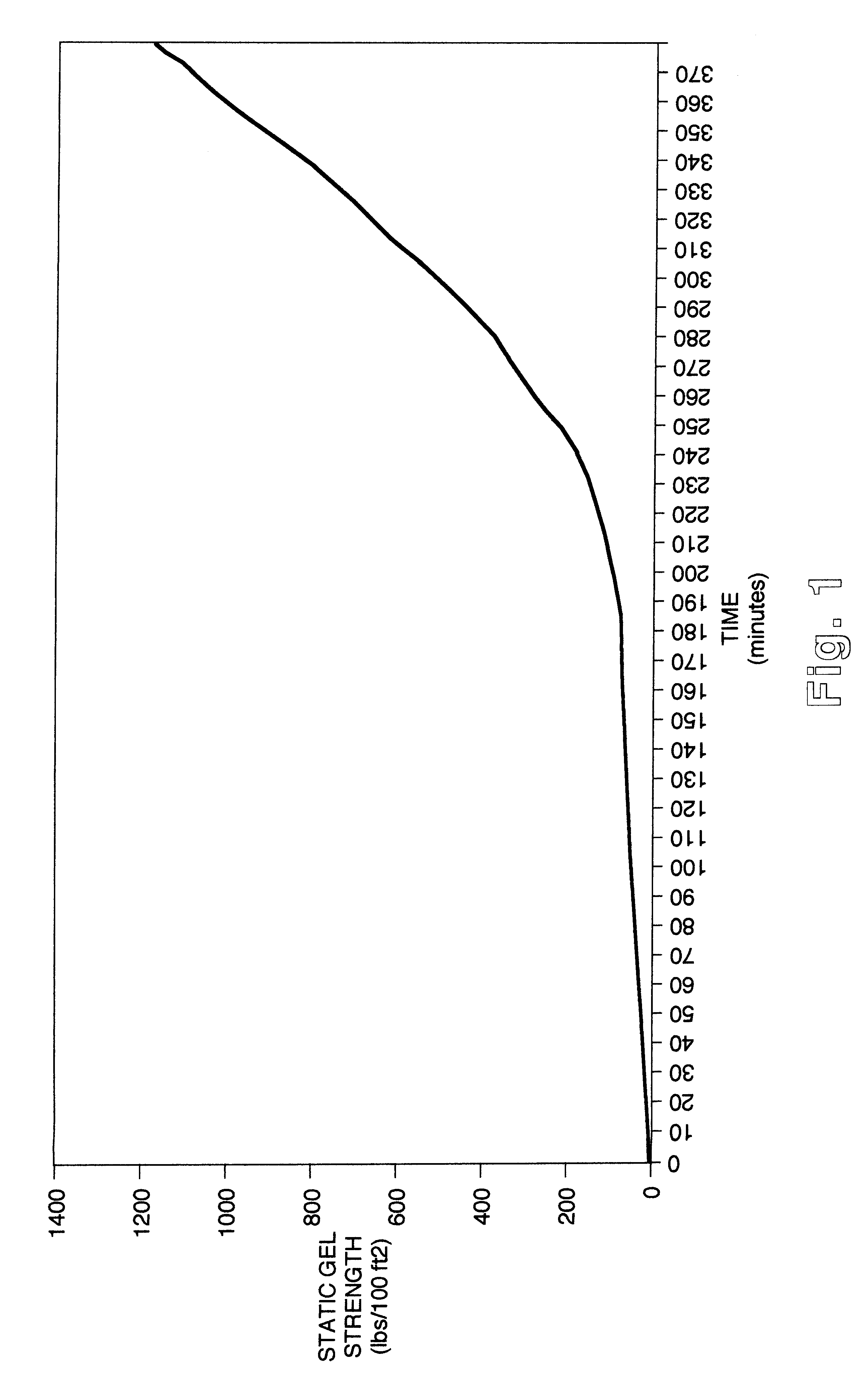

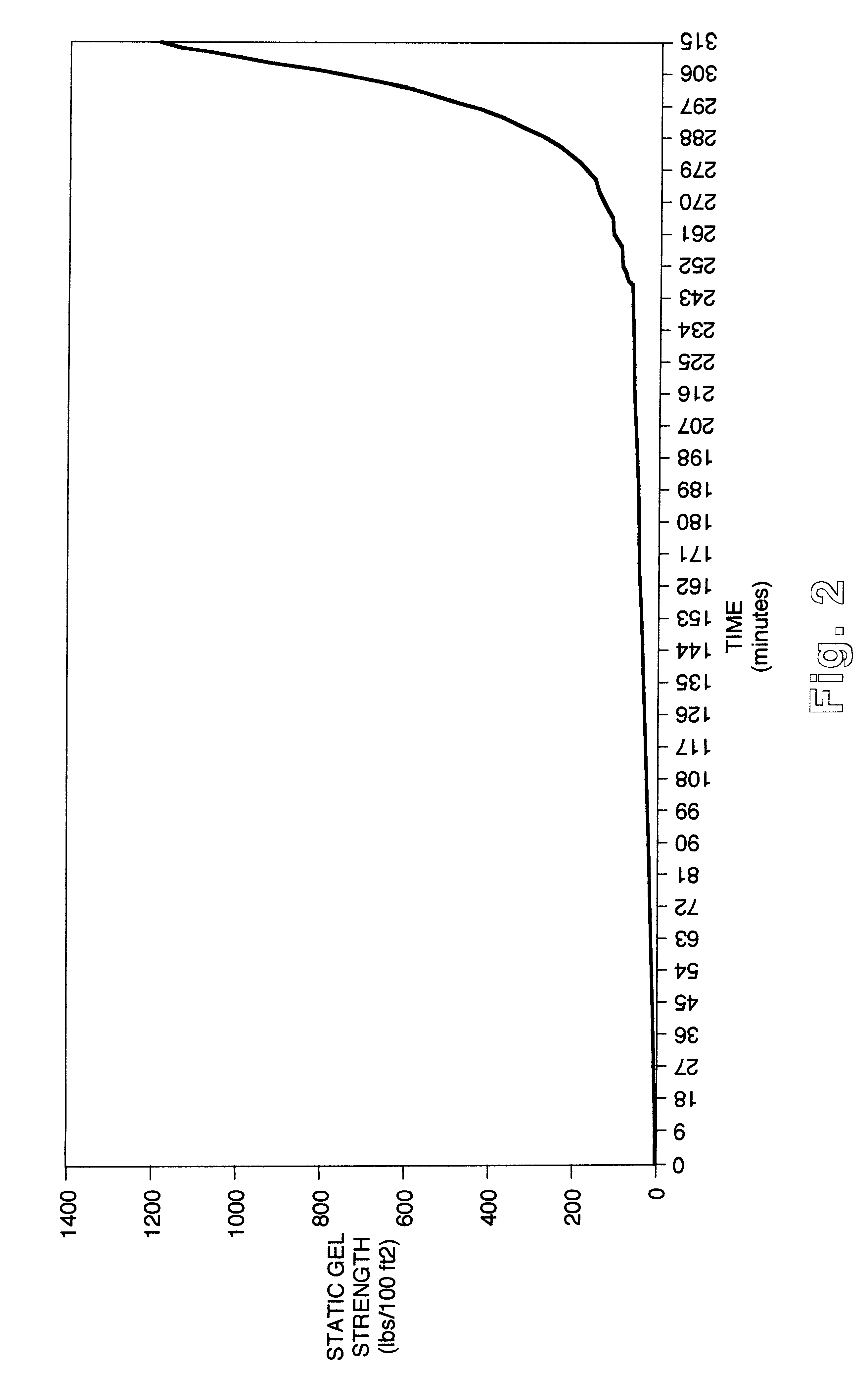

Cementing compositions, a method of making therefor, and a method for cementing wells

A cement composition includes cement, water in an amount from about 30% to 200% by weight of cement, and an interpolymer latex in an amount from about 10% to 50% by weight of cement. The interpolymer latex includes at least one conjugated diene monomer having 4 to 8 carbon atoms in an amount from about 5% to 95% by weight of the interpolymer latex, at least one vinyl aromatic monomer having 8 to 12 carbon atoms in an amount from about 5% to 95% by weight of the interpolymer latex, and a copolymerizable functional monomer in an amount from about 0.5% to 50% by weight of the interpolymer latex. A method of making a cement composition involves placing the above ingredients in a suitable mixer well known to those of ordinary skill in the art and mixing the ingredients until they form the cement composition. A method for cementing a subterranean zone penetrated by a wellbore involves forming a cement composition according to the above method, pumping the cement composition into the subterranean zone to be cemented by way of the wellbore, and allowing the cement composition to set within the subterranean zone.

Owner:BENCHMARK RES TECH

Polymers functionalized with nitro compounds

A method for preparing a functionalized polymer, the method comprising the steps of (i) polymerizing conjugated diene monomer by employing a lanthanide-based catalyst to form a reactive polymer, and (ii) reacting the reactive polymer with a nitro compound.

Owner:BRIDGESTONE CORP

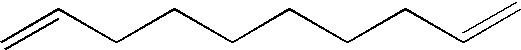

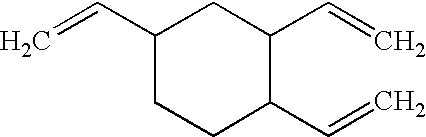

Golf ball

ActiveUS20060135287A1Improved combination of characteristicEasy to compressGolf ballsSolid ballsElastomerEnd-group

An elastomeric composition for forming a golf ball or a component thereof is disclosed that includes the use of a non-conjugated diene monomer having two or more vinyl (CH2═CH—) terminal end groups. The composition produces a molded product exhibiting an enhanced combination of increased compression (i.e., softness) and resilience (C.O.R.).

Owner:TOPGOLF CALLAWAY BRANDS CORP

Polymers functionalized with protected oxime compounds

A method for preparing a functionalized polymer, the method comprising the steps of (i) polymerizing conjugated diene monomer by employing a lanthanide-based catalyst to form a reactive polymer, and (ii) reacting the reactive polymer with a protected oxime compound.

Owner:BRIDGESTONE CORP

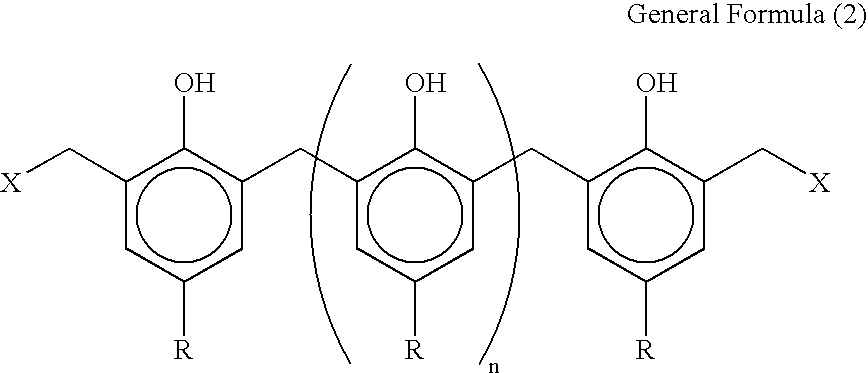

Unsaturated copolymers, processes for preparing the same, and compositions containing the same

InactiveUS6310164B1Improve compatibilityLower glass transition temperatureSpecial tyresArylPolymer science

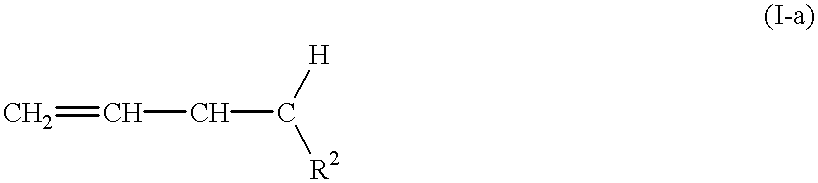

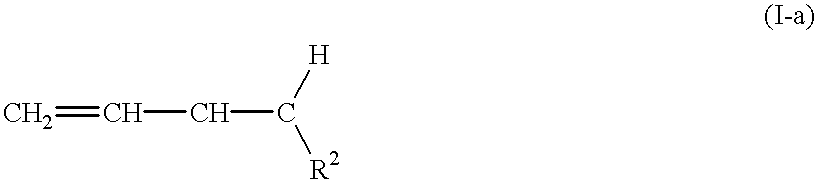

Unsaturated copolymer which is a copolymer of an alphaolefin of 2 to 12 carbon atoms and a conjugated diene monomer represented by the following formula (I-a) and has the properties: (a) in said copolymer, 1,2-addition units (including 3,4-addition units) derived from the conjugated diene monomer (I-a) form double bonds in the side chain of the copolymer, 1,4-addition units derived from the conjugated diene monomer (I-a) form double bonds in the main chain of the copolymer, and the quantity ratio of the double bonds of the side chain derived from the 1,2-addition units to the double bonds of the main chain derived from the 1,4-addition units (side chain double bonds derived from 1,2-addition units / main chain double bonds derived from 1,4-addition units) is in the range of 10 / 90 to 99 / 1 (b) five-membered rings are present in the main chain of said copolymer; and (c) the quantity ratio of the double bonds from all of the addition units to the five-membered rings (total of double bonds from all addition units / five-membered rings) is in the range of 20 / 80 to 90 / 10;wherein R2 is a hydrogen atom, an alkyl group of 1 to 8 carbon atoms or an aryl group.

Owner:MITSUI CHEM INC

Conjugated diene polymer, conjugated diene polymer composition, and method for producing conjugated diene polymer

A conjugated diene polymer is provided that comprises a conjugated diene-based constituent unit and a constituent unit of formula (I) below, at least one terminus of the polymer being modified by a compound of formula (II):wherein X1, X2, and X3 independently denote a group of formula (Ia) below, a hydroxy group, a hydrocarbyl group, or a substituted hydrocarbyl group, and at least one of X1, X2, and X3 is a group of formula (Ia) below or a hydroxy group,wherein R1 and R2 independently denote a hydrocarbyl group having 1 to 6 carbon atoms, a substituted hydrocarbyl group having 1 to 6 carbon atoms, a silyl group, or a substituted silyl group, and R1 and R2 may be bonded so as to form, together with the nitrogen atom, a ring structure,wherein n denotes an integer of 1 to 10, R3, R4, and R5 independently denote a hydrocarbyl group having 1 to 4 carbon atoms or a hydrocarbyloxy group having 1 to 4 carbon atoms, at least one of R3, R4, and R5 is a hydrocarbyloxy group, and A denotes a nitrogen atom-containing functional group.

Owner:SUMITOMO CHEM CO LTD

Conjugated diene polymer, conjugated diene polymer composition, and method for producing conjugated diene polymer

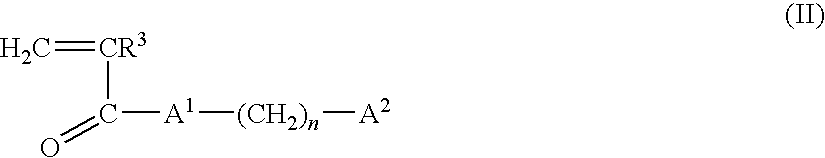

A conjugated diene polymer is provided that comprises a conjugated diene-based constituent unit and a constituent unit of formula (I) below, at least one terminus of the polymer being modified by a compound of formula (II):X1, X2, and X3 independently denote a group of formula (Ia) below, a hydroxy group, a hydrocarbyl group, or a substituted hydrocarbyl group, and at least one of X1, X2, and X3 is a group of formula (Ia) below or a hydroxy group.wherein R1 and R2 independently denote a hydrocarbyl group having 1 to 6 carbon atoms, a substituted hydrocarbyl group having 1 to 6 carbon atoms, a silyl group, or a substituted silyl group, and R1 and R2 may be bonded so as to form, together with the nitrogen atom, a ring structure,wherein n denotes an integer of 1 to 10, R3 denotes a hydrogen atom, a hydrocarbyl group having 1 to 6 carbon atoms, or a substituted hydrocarbyl group having 1 to 6 carbon atoms, A1 denotes an oxygen atom or an —NR4— group, wherein R4 denotes a hydrogen atom or a hydrocarbyl group having 1 to 10 carbon atoms, and A2 denotes a nitrogen atom- and / or oxygen atom-containing functional group.

Owner:SUMITOMO CHEM CO LTD

Golf Ball

ActiveUS20070173607A1Improved combination of characteristicEasy to compressGolf ballsSolid ballsElastomerEnd-group

An elastomeric composition for forming a golf ball or a component thereof is disclosed that includes the use of a non-conjugated diene monomer having two or more vinyl (CH2═CH—) terminal end groups. The composition produces a molded product exhibiting an enhanced combination of increased compression (i.e., softness) and resilience (C.O.R.).

Owner:TOPGOLF CALLAWAY BRANDS CORP

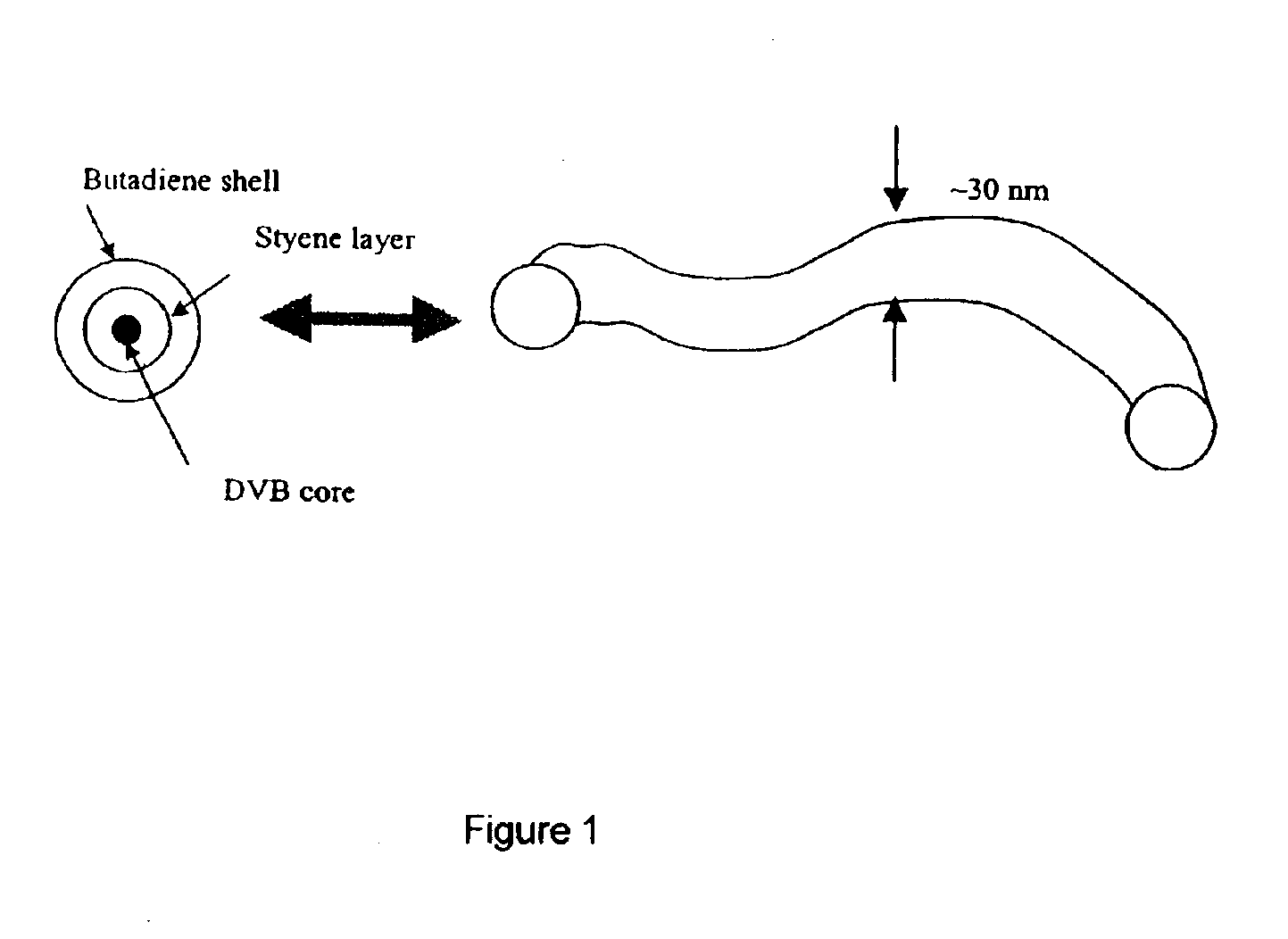

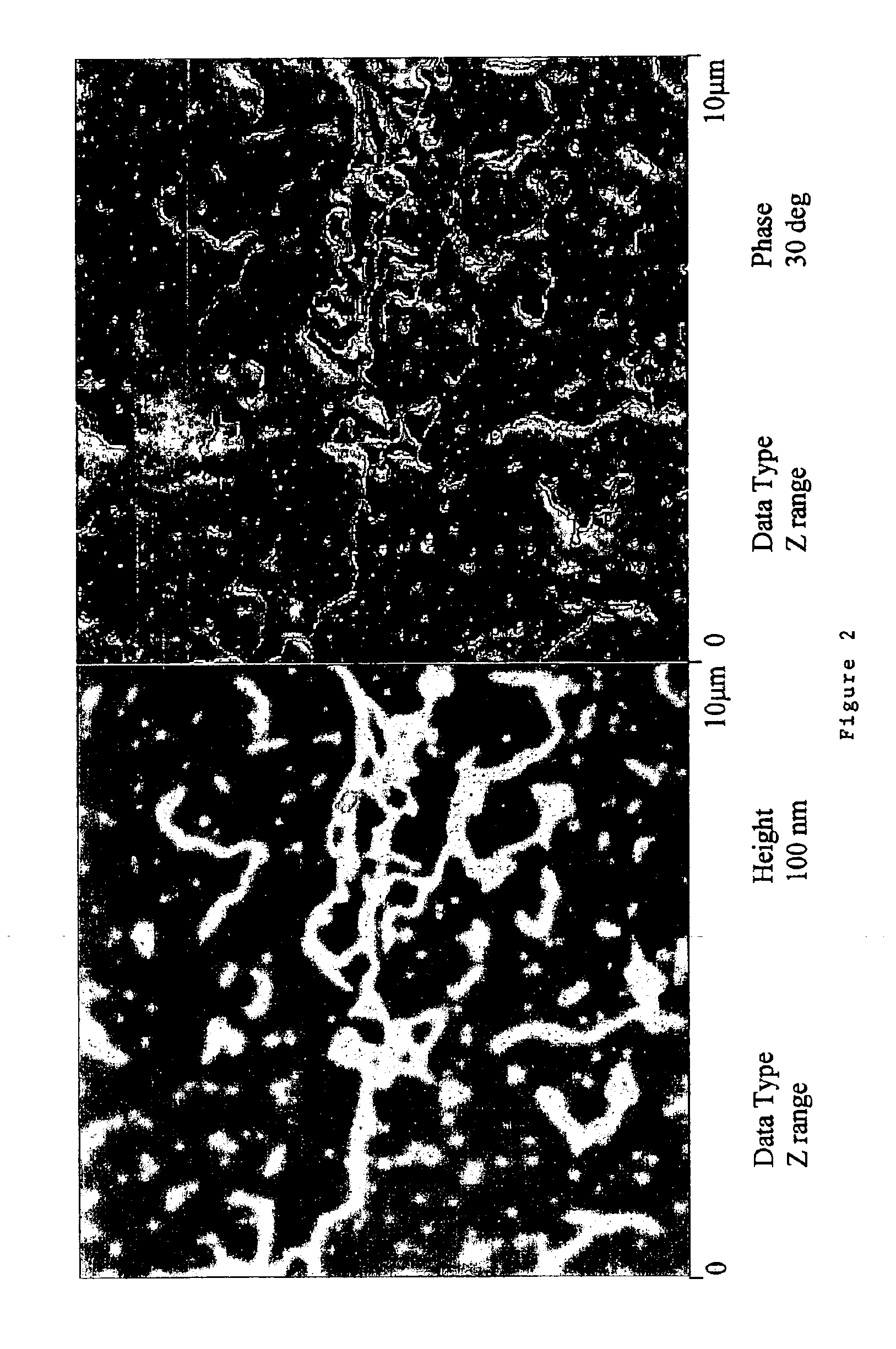

Polymer nano-strings

A polymer nano-string composition is provided. The polymer nano-strings can include a poly(alkenylbenzene) core, and a surface layer comprising poly(conjugated diene). The nano-strings have a mean average diameter of less than about 100 nm and a length of greater than about 1 μm.

Owner:BRIDGESTONE CORP

Monovinylarene/conjugated diene copolymers having lower glass transition temperatures

ActiveUS20050101743A1Low TgReduction of processibilityRolling resistance optimizationPolymer scienceGlass transition

We disclose a monovinylarene / conjugated diene block copolymer, comprising: (i) a random (conjugated dienex / monovinylareney)m block, wherein x is about 2.5 wt % to about 10 wt %, y is from about 90 wt % to about 97.5 wt %, and x+y is about 97.5 wt % to 100 wt %; and (ii) a (conjugated diene)n block; wherein n is from about 20 wt % to about 30 wt %, m is from about 70 wt % to about 80 wt %, and m+n is from about 90 wt % to 100 wt %. We also disclose a method of forming the block copolymer and a method for fabricating an article from the block copolymer. The block copolymer typically exhibits a Tg at least about 10° C. less than the Tg of a reference polymer differing only in that x is about 0 wt % and y is about 100 wt %.

Owner:INEOS STYROLUTION GRP GMBH

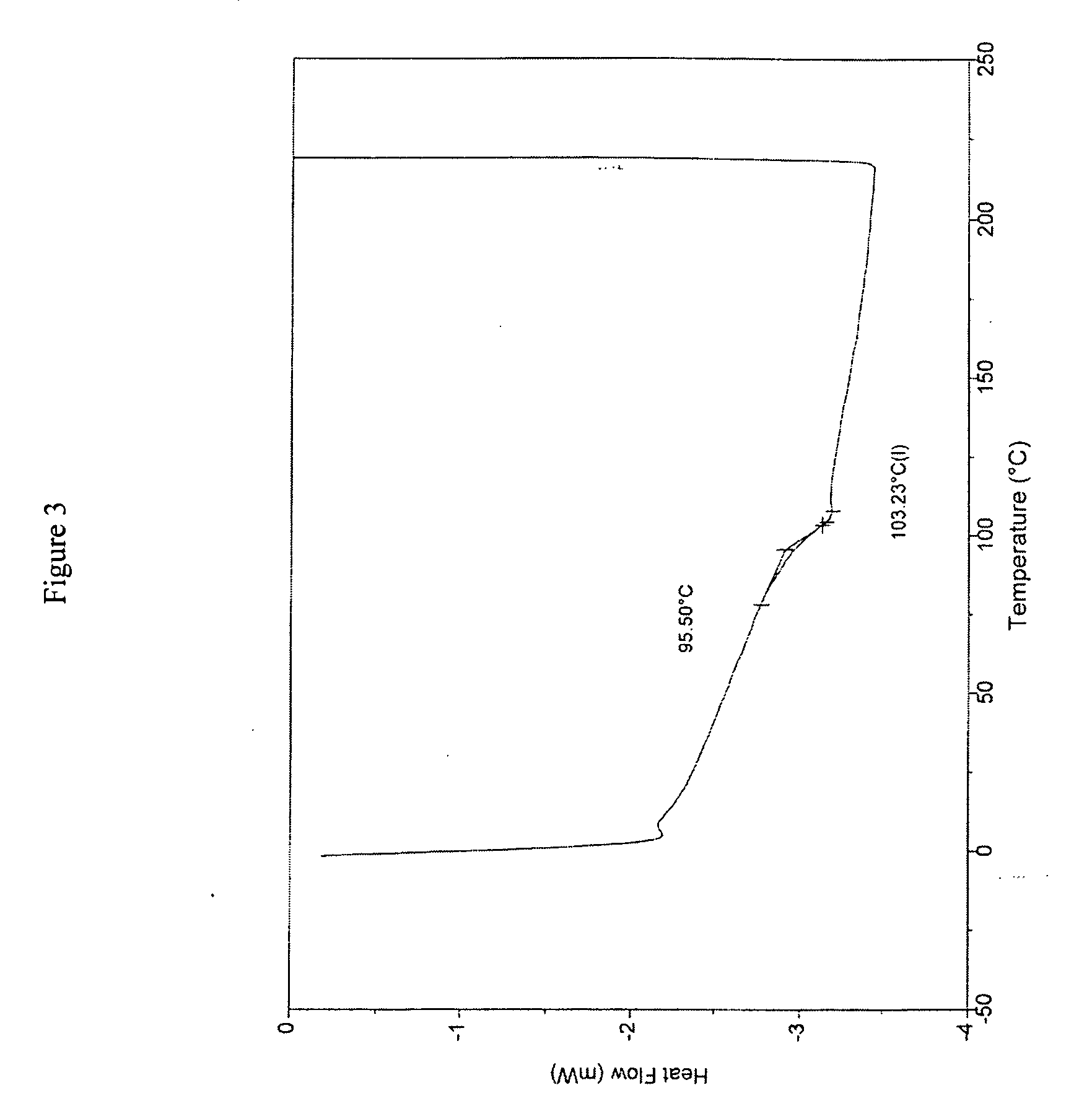

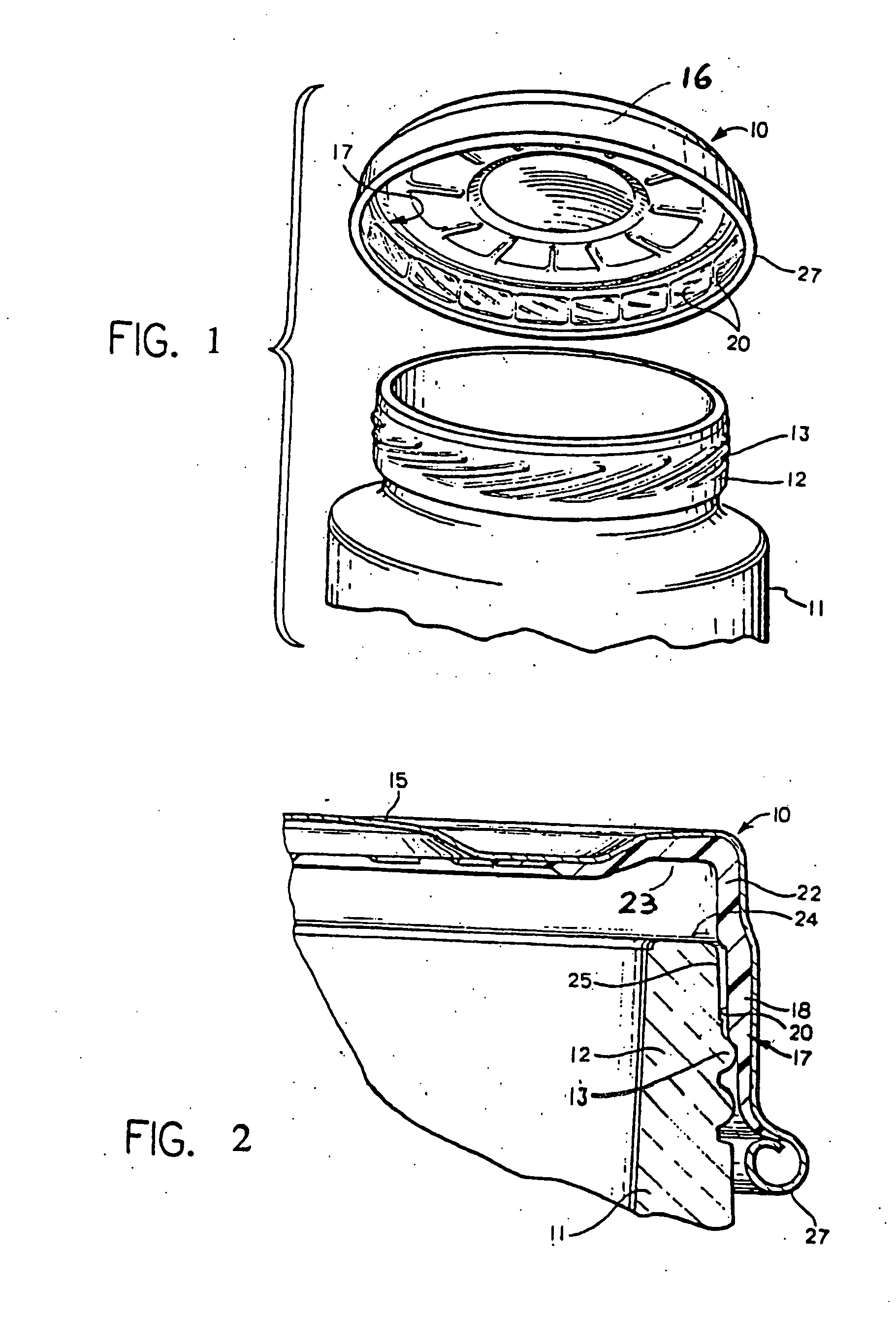

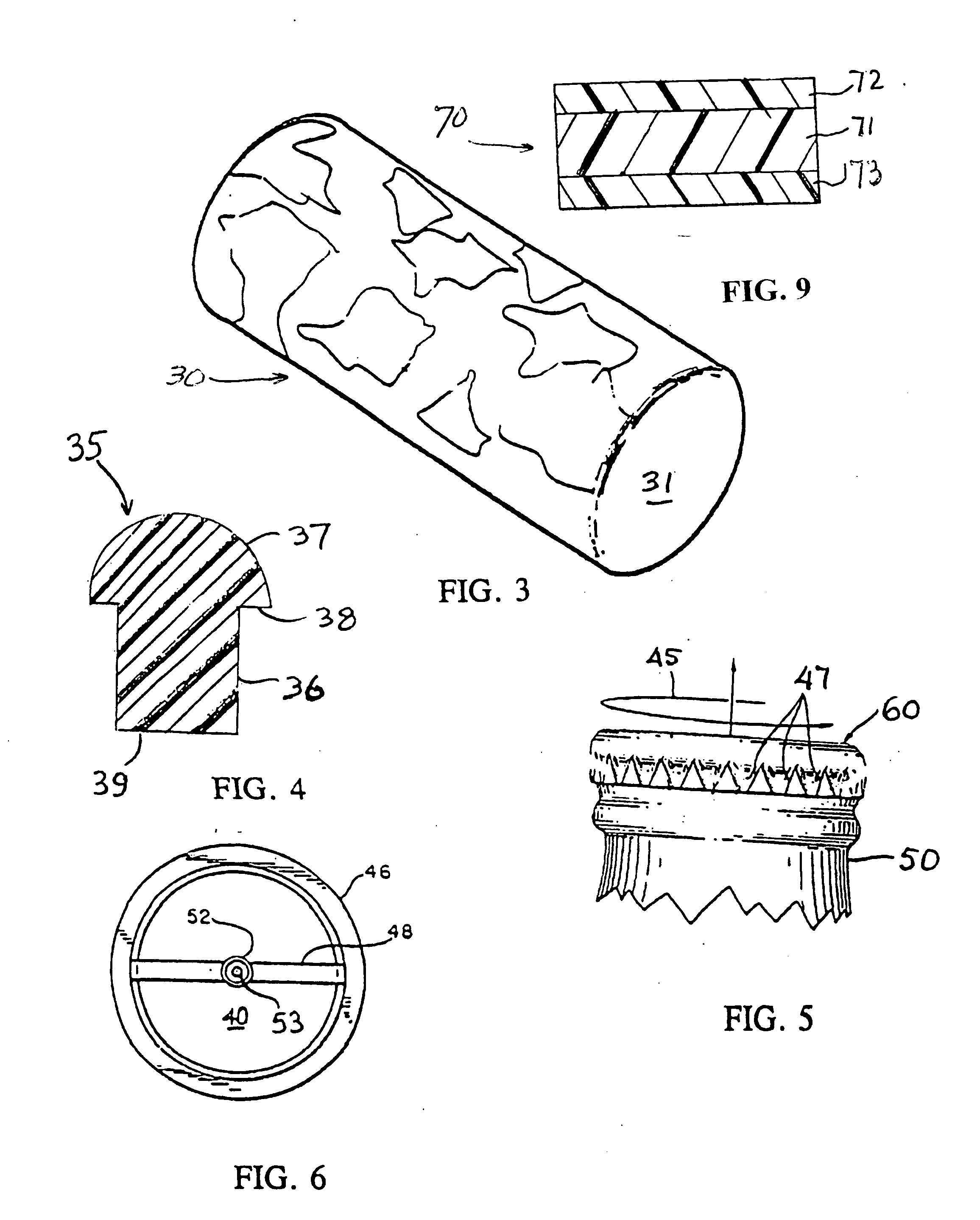

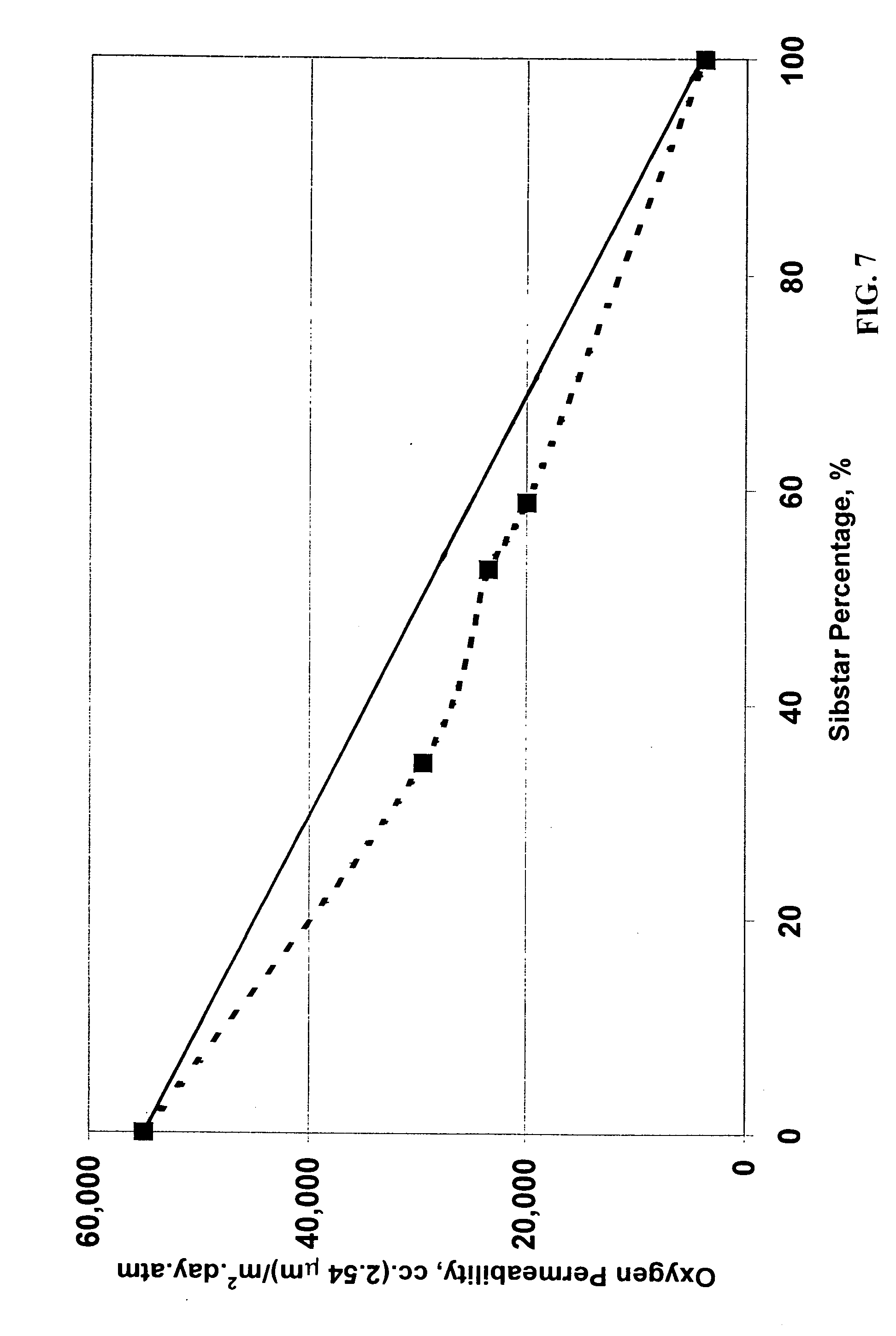

Essentially gas-impermeable thermoplastic sealant

InactiveUS20060229402A1Improve barrier propertiesExtended shelf lifeCapsClosure using stoppersThermoplasticPolymer science

A thermoplastic essentially oxygen-impermeable plasticized sealant is formed by melt-blending a hydrogenated styrene-conjugated diene-styrene (SMS) block copolymer rubber with a polystyrene-polyisobutylene-polystyrene (SIBS) block copolymer rubber and a polyolefin plastic with a liquid polyisobutylene (PIB) oil plasticizer provided the PIB oil is present (i) in the range from 5% to less than 50% by weight of the sealant and (ii) in relation to total rubber, in the range from 0.3 to 0.8. The required minor amount of PIB oil, relative to total rubber, in combination with SIBS present in a minor amount relative to the amount of plasticized sealant, provides the sealant with unexpectedly better oxygen barrier properties and load bearing at 82° C. (180 ° F.) than a comparable blend of SIBS with mineral oil; the sealant is also essentially free of tack, adhesive properties and oil-bleed, with essentially no detackifier present. The PIB-oil plasticized SIBS sealant has a haze of less than 15%; a composite made by melt-bonding a core layer between polyC2-C3olefin sheets, maintains a haze less than 14%. The plasticised sealant is particularly useful for sealing elements for containers in which foods, beverages and medical products must be preserved for a long period.

Owner:GLS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com