Patents

Literature

2228 results about "Graft reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for obtaining a grafted elastomer having functional groups along the chain and a rubber composition

A process for obtaining a grafted diene elastomer having functional groups along the chain, a rubber composition containing this grafted elastomer and having in particular improved hysteresis properties in the cross-linked state, a preparation process for this composition, a tire tread made from this composition and a tire of reduced rolling resistance which incorporates this tread. A process for obtaining this grafted elastomer includes a radical grafting reaction carried out in solution or without a solvent by means of a reagent of the mercaptan type to graft functional groups on to the chain of a starting elastomer. The starting elastomer is treated with an antioxidant having at least one aromatic amine function before the grafting reaction, so that the grafted elastomer has a macrostructure which is practically identical to that of the starting elastomer. A rubber composition containing the grafted diene elastomer includes a reinforcing inorganic filler, and the grafted elastomer preferably has a molar ratio of units originating from conjugated dienes greater than 30%.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

Hyaluronan and biodegradable high polymer modified material and preparation method

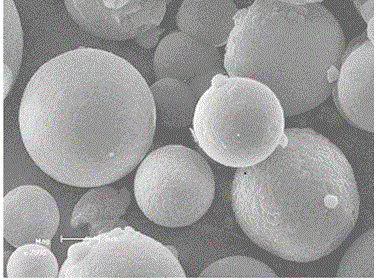

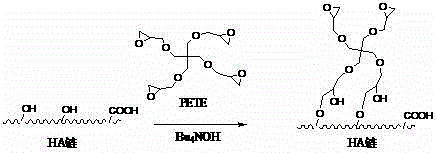

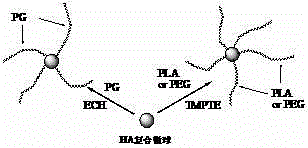

The invention relates to a hyaluronan and biodegradable high polymer modified material and a preparation method, in particular to a method for complex crosslinking and grafting of the hyaluronan and a derivative thereof with a biodegradable high polymer with active functional groups through a crosslinking agent. The method comprises the steps of taking the hyaluronan and the biodegradable high polymer as raw materials, conducting complex crosslinking or grafting reaction of a hyaluronan aqueous solution and at least one biodegradable high polymer solution with the presence of the crosslinking agent, and removing a solvent. According to the method, plural gel, an amphiphilic polymer, a graft polymer, a star polymer and a microsphere can be prepared. The method has the advantages that the reaction condition is simple, the utilization ratio of the crosslinking agent is high, the residual quantity of the crosslinking agent is small, and the gel is higher in thermostability and good in biological compatibility. The method is applicable to the fields of cosmetics, tissue filling and repair, biological stents, ophthalmonogy, sustained-release delivery and targeted drug delivery and the like, and has a wider application prospect.

Owner:IMEIK TECH DEV CO LTD

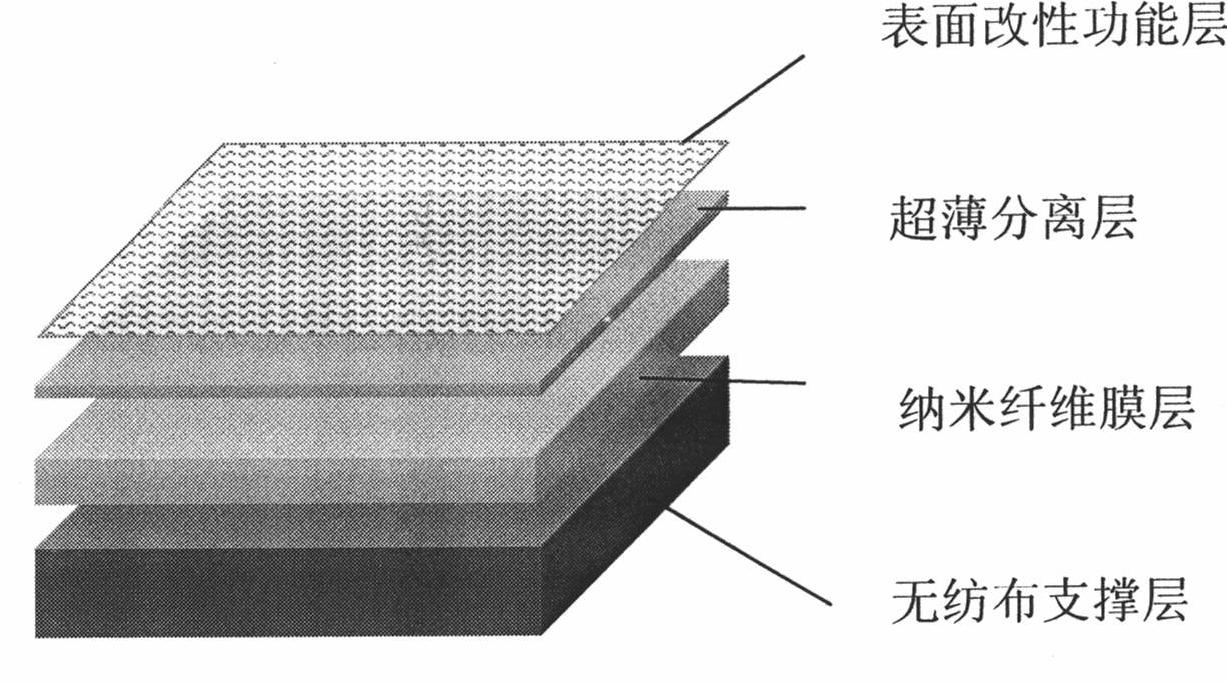

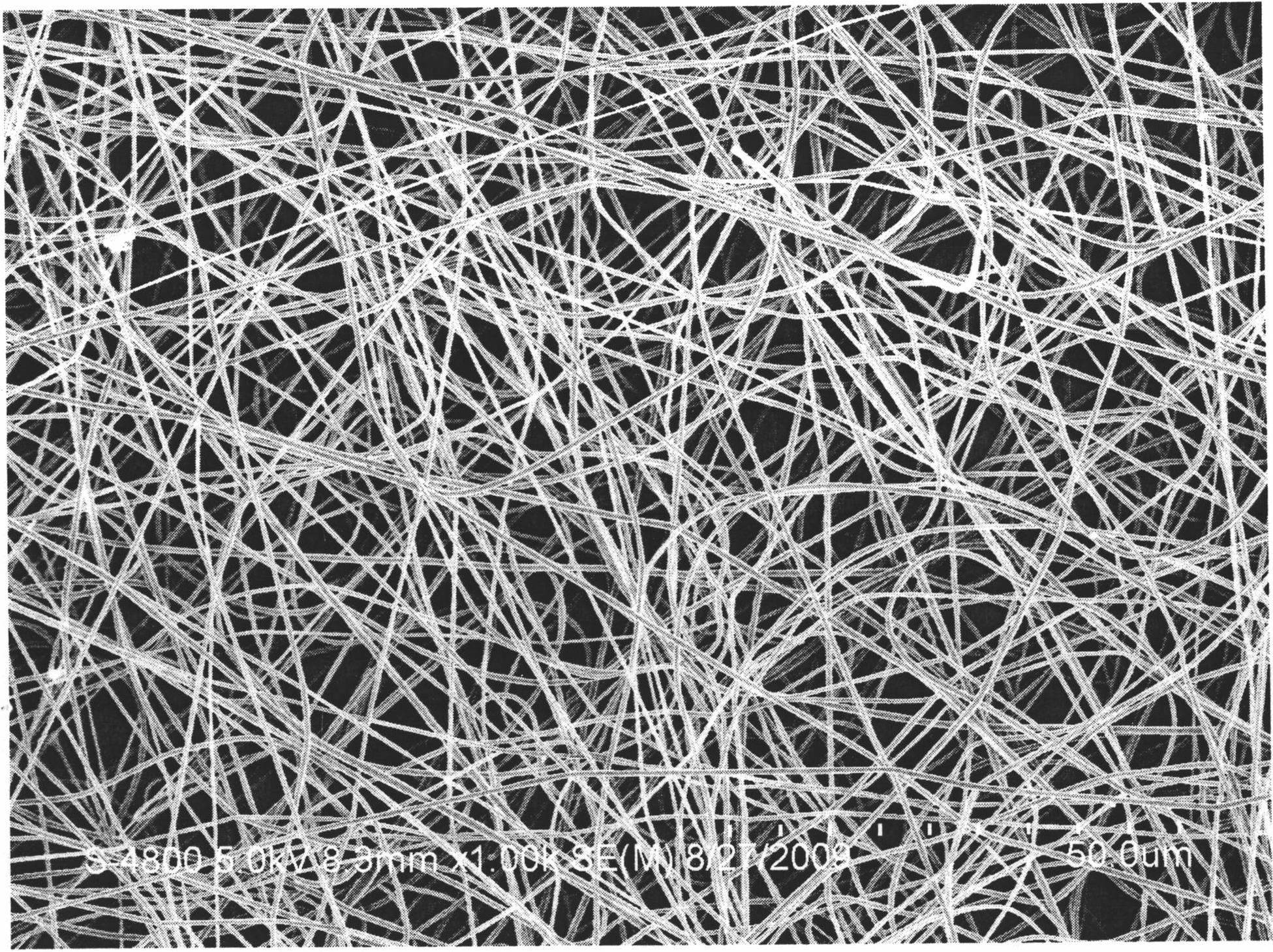

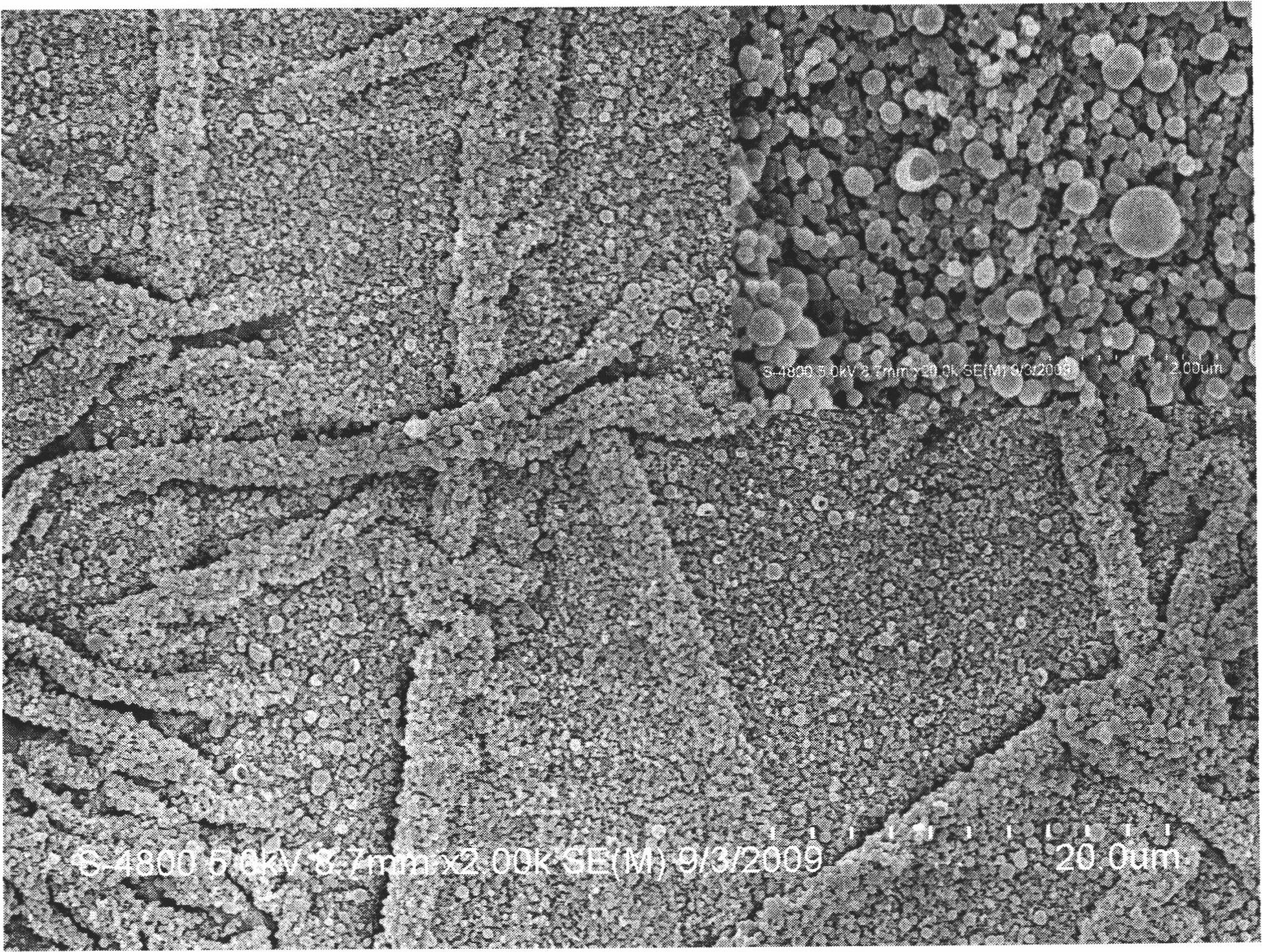

Hyperfiltration membrane or nanofiltration membrane with multi-layered composite structure and preparation method thereof

InactiveCN102139187AIncrease water fluxHigh retention rateSemi-permeable membranesEnvironmental resistanceHydrophilic polymers

The invention relates to a hyperfiltration membrane or nanofiltration membrane with a multi-layered composite structure and a preparation method thereof. The hyperfiltration membrane or nanofiltration membrane is a polymer electrostatic spinning nanofiber membrane layer characterized in strong chemical resistance prepared through an electrostatic spinning method, a hydrophilic polymer ultra-thin separation layer obtained through interfacial polymerization, and a functional group surface modification functional layer formed through the grafting reaction of reactant gases on the surfaces of hydrophilic polymers, or a long-chain polymer surface modification functional layer formed through the grafting reaction of the reaction gases on the surfaces of the hydrophilic polymers, or a functionalgroup-containing long-chain polymer surface modification functional layer through the grafting reaction of the reaction gases with the functional groups on the surfaces of the hydrophilic polymers. The hyperfiltration membrane or nanofiltration membrane with the multi-layered composite structure has the advantages of high water flux, high cutting rate and stable chemical performances. The filtration membrane can be used for the production of domestic water, drinking water or water in special conditions, and is suitable for the medical field, food field, environmental protection field and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

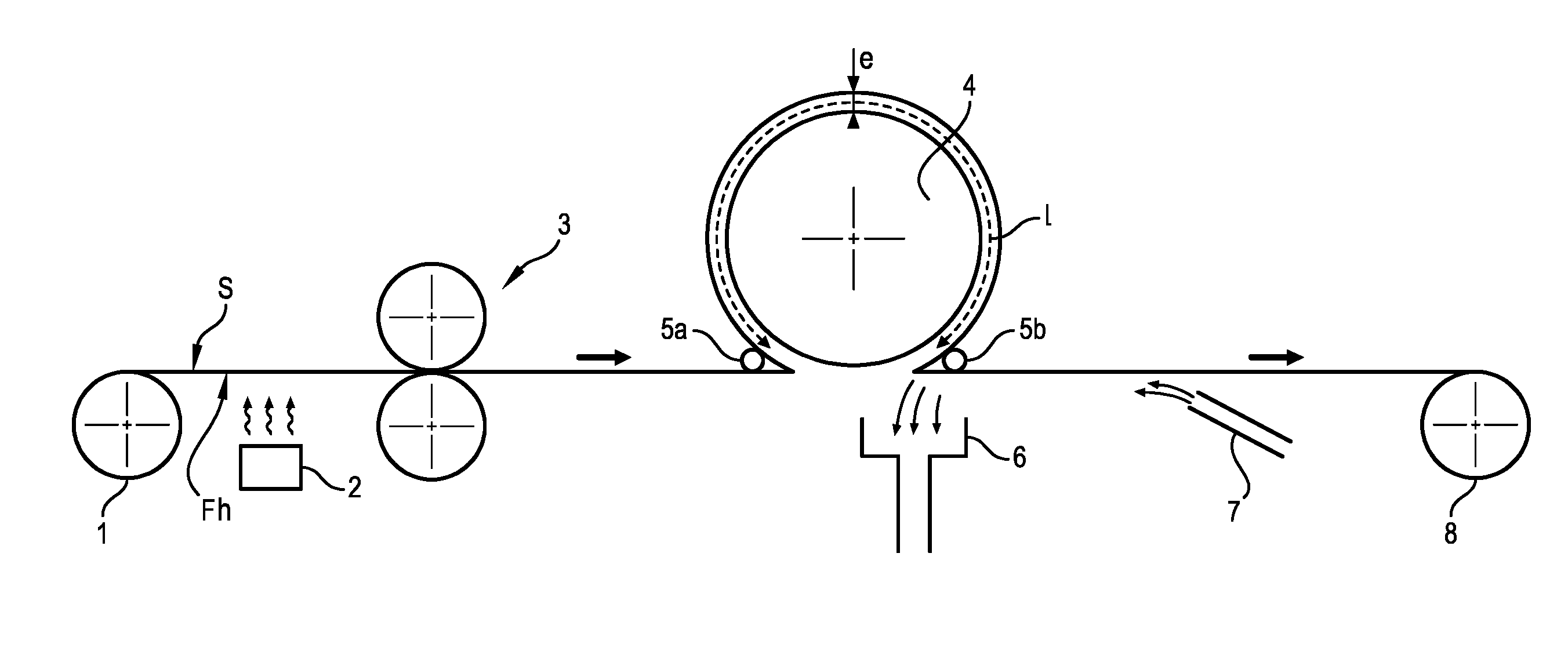

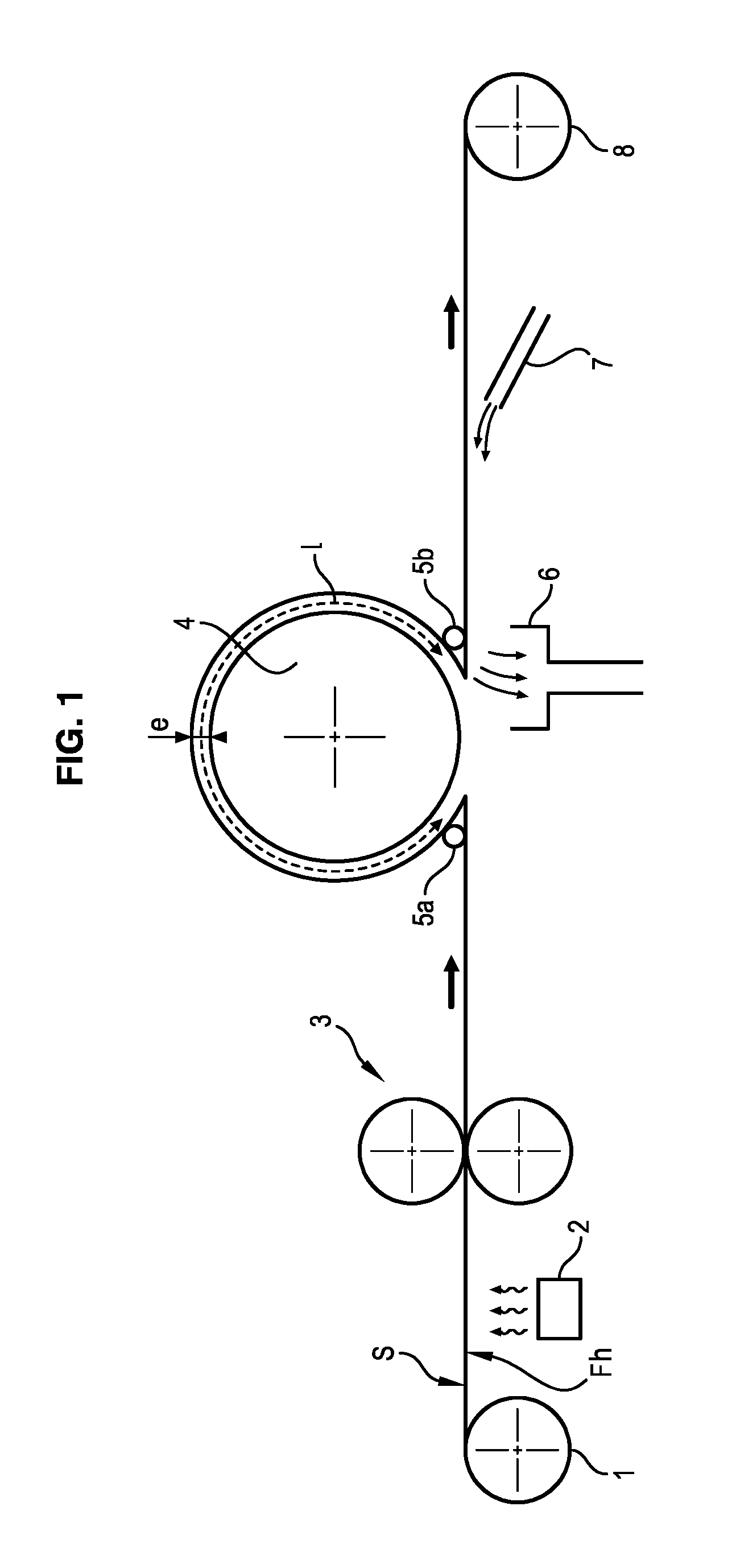

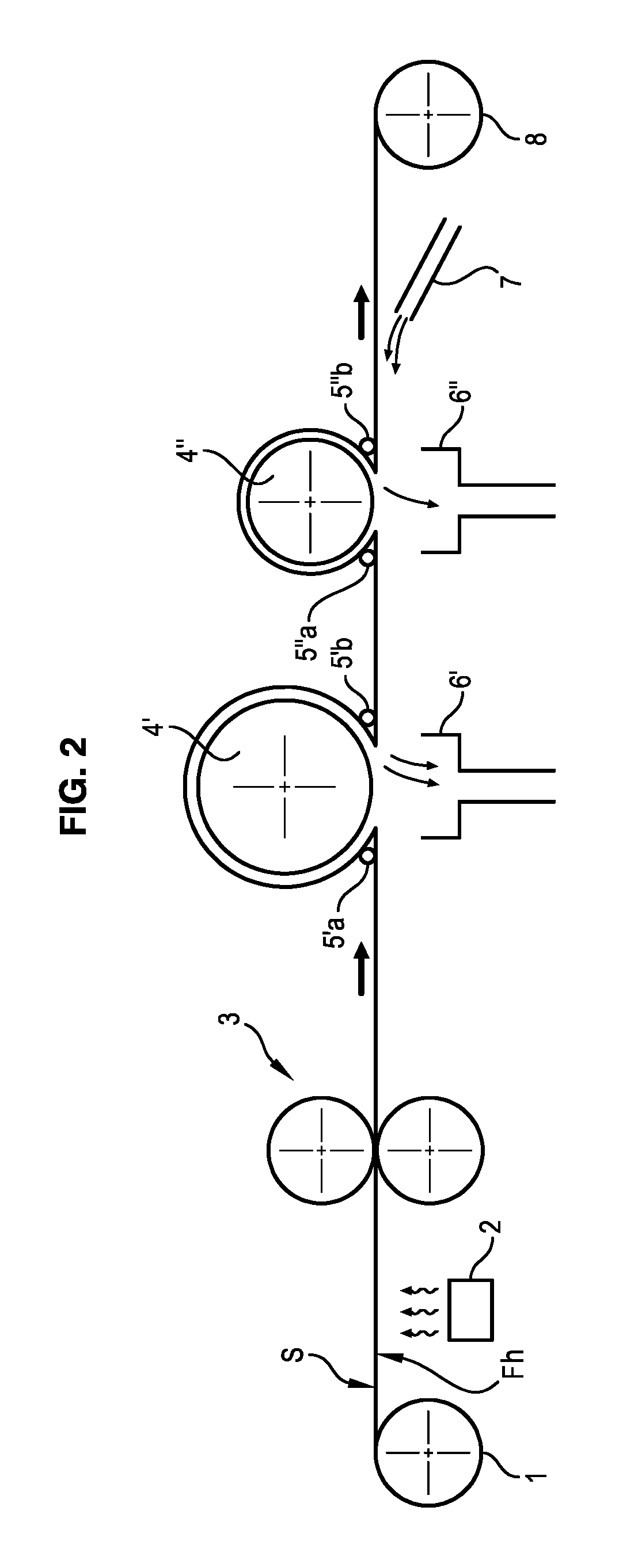

Machine and treatment process via chromatogenous grafting of a hydroxylated substrate

ActiveUS20130236647A1DissipationWater-repelling agents additionNon-macromolecular organic additionGraft reactionPulp and paper industry

The invention relates to a machine for chromatogenous grafting treatment of a scrolling substrate (S) having a hydroxylated face (Fh), comprising:an application device (3) of a grafting reagent on the hydroxylated face (Fh) of the substrate,a heating roller (4) for the development of the grafting reaction on the hydroxylated face (Fh) of the substrate, said roller (4) being provided with a bar-end system (5a, 5b) for applying a face of the substrate (S) against said heating roller (4),an extraction device (6) of the hydrochloric acid produced during the grafting reaction,an application device (7) of an air knife on the treated face of the substrate for eliminating the residual grafting reagent.The invention also relates to a chromatogenous grafting process used in said machine.

Owner:CENT NAT DE LA RECHERCHE SCI +1

Process for obtaining a grafted elastomer having functional groups along the chain and a rubber composition

A process for obtaining a grafted diene elastomer having functional groups along the chain, a rubber composition containing this grafted elastomer and having in particular improved hysteresis properties in the cross-linked state, a preparation process for this composition, a tire tread made from this composition and a tire of reduced rolling resistance which incorporates this tread. A process for obtaining this grafted elastomer includes a radical grafting reaction carried out in solution or without a solvent by means of a reagent of the mercaptan type to graft functional groups on to the chain of a starting elastomer. The starting elastomer is treated with an antioxidant having at least one aromatic amine function before the grafting reaction, so that the grafted elastomer has a macrostructure which is practically identical to that of the starting elastomer. A rubber composition containing the grafted diene elastomer includes a reinforcing inorganic filler, and the grafted elastomer preferably has a molar ratio of units originating from conjugated dienes greater than 30%.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

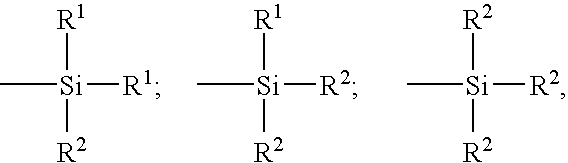

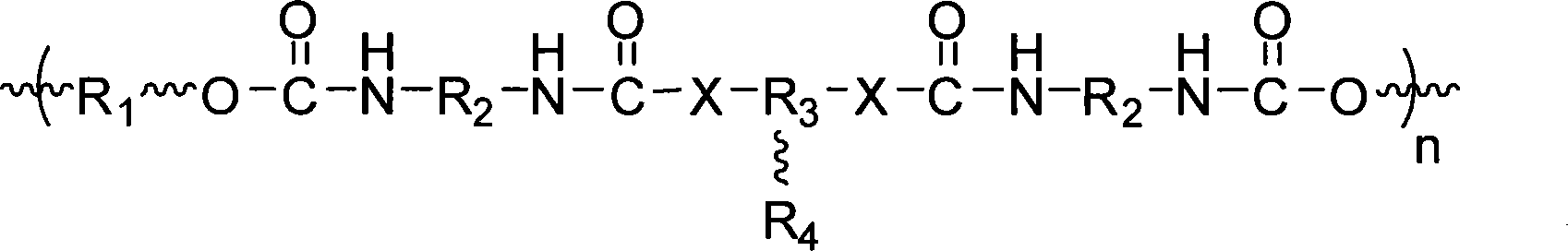

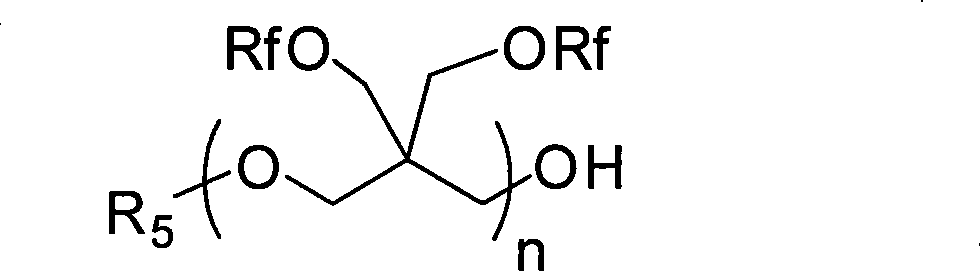

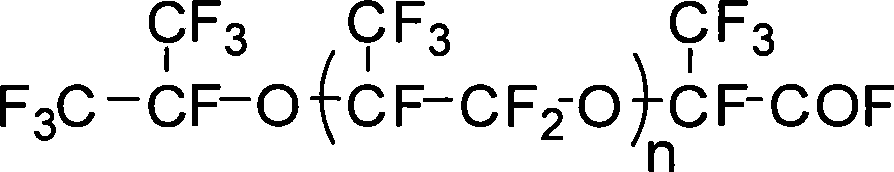

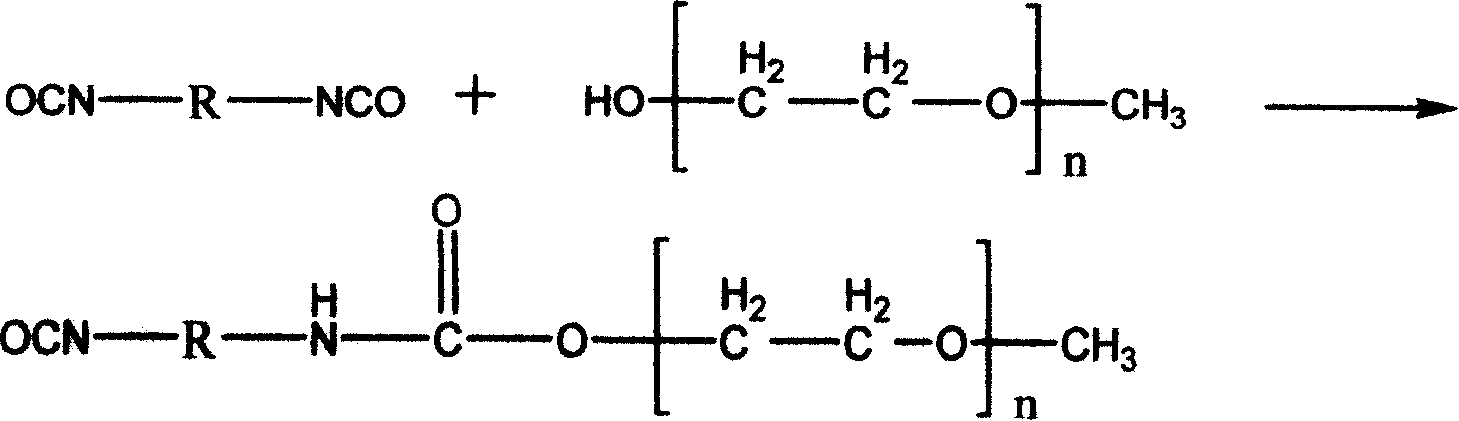

Fluorine-containing polyether graft modified aqueous polyurethane and preparation and application thereof

InactiveCN101157750AGood water repellencyGood weather resistanceOther chemical processesSolventBioaccumulation

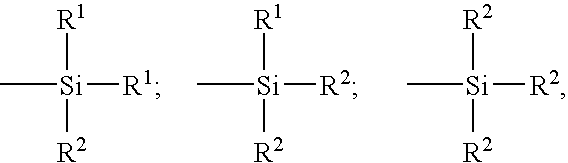

The present invention relates to a fluorine-containing polyether grafting modified waterborne polyurethane, the preparation and the application thereof, a structural general formula of polyurethane is as the formula, wherein, R1 is equal to a polyurethane soft-segment polyol structure, R2 is equal to a polyurethane hard-segment isocyanate structure, R3 is equal to a polyurethane hard-segment chain extender structure, R4 is equal to the fluorine-containing polyether; X is equal to NH and O; the preparation is that: the polyol and the isocyanate react to compound the polyurethane prepolymer, then the waterborne polyurethane are obtained through the chain propagation of a chain extender, then the waterborne polyurethane and the fluorine-containing polyether are carried out a grafting reaction in the big molecules, so as to synthesize the fluorine-containing polyether grafting modified waterborne polyurethane; the application is that: the present invention can be applied to aerospace, aviation, automobiles, electronics, textiles, carpets, leathers, paper making, packaging, washing, machinery, construction and other fields. The present invention adopts the water as the solvent and has no formaldehyde, no or low VOC emission, no bioaccumulation and no toxicity, which is a multifunctional, green, environment protective, water-proof and dirt-proof coating layer and fabric finishing agent.

Owner:DONGHUA UNIV

Lubricity coatings preparation method on the medical catheter polymers surface

InactiveCN101455861AImprove surface physicochemical propertiesChange adsorption stateCatheterCoatingsPolymer scienceGraft reaction

The invention discloses a method for preparing a lubricant coating on the surface of polymer materials of a medical catheter, which comprises the following steps: (A), pretreating the surface of the polymer materials of the medical catheter, so as to obtain hydrophilic adsorption active sites; (B), soaking the pretreated polymer materials of the medical catheter in step (A) into a prepared precursor solution of the lubricant coating for adsorption; and (C), performing grafting reaction on the soaked polymer materials of the medical catheter in step (B), and washing and drying the polymer materials of the medical catheter. The method can be widely used for preparing medical polymer materials and coating materials on the surface of a medical apparatus.

Owner:SOUTHEAST UNIV

Method of preparing low temperature solidifying environment protection type cathode electrophoresis coating

InactiveCN101054487AImprove stabilityLow curing temperaturePaints for electrolytic applicationsPolyamide coatingsEpoxyLow temperature curing

The invention discloses an environment-friendly cathode electrophoretic coating with a low heating loss and low solvent content which can be cold cured. The method includes following steps and craft conditions: (1) preparation of curing agent and modification of mainbody resin. The curing agent is prepared by reaction of isocyanate, ketoximes solvent and trimethylolpropane so as to produce multifunctional group for closing the isocyanate curing agent. The whole reaction of mainbody resin modification includes chain extension reaction of epoxide resin, ring-opening reaction of amine and polyamide to the epoxide resin, the preparation of semi enclosed isocyanate and grafting reaction steps; (2) preparation of the catalytic curing agent slurry; (3) preparation of cathode electrophoretic coating latex and color paste. The invention improves the epoxide resin stability, reduces the resin curing temperature, and declines the heating loss of the dope and the discharge of the solvent. It applies extracting method in the latex producing process to reduce the solvent content so as to produce a environment-friendly cathode electrophoretic coating which can be cold cured.

Owner:佛山科富科技有限公司

Natural fibre reinforced polylactic acid composite material and method for making same

The present invention belongs to the macromolecular material technical field and concretely relates to natural fibre enhanced polylactic acid composite material and a preparation method thereof. The composite material consists of graft modified polylactic acid and the natural fibre. A concrete preparation step is that a polylactic acid matrix is processed for the graft modification, so as to improve the interface combined degree of the natural fibre and the polylactic acid matrix. Firstly, the polylactic acid is processed for the graft reaction with maleic anhydride under the action of an initiator to prepare the graft modified polylactic acid matrix; then the modified polylactic acid and the natural fibre are compounded to obtain biological full-degraded natural fibre enhanced polylactic acid composite material. Compared with pure polylactic acid, the mechanical performance and the thermal performance of the composite material are all improved, and the composite material can be used for preparing the project plastic with rigorous condition requirement. The composite material of the present invention can be degraded completely in the natural environment after being used and wasted and belongs to environmental friendly material.

Owner:TONGJI UNIV

Method for modifying fly ash

ActiveCN101700491ASolve the problem of biological growth and foulingReduce time to chemical modificationOther chemical processesWater/sewage treatment by sorptionUltrasound - actionHigh absorption

The invention relates to a method for carrying out surface modification on waste fly ash and leading the waste fly ash to become an absorbing material with high absorption capacity and sterilization performance, and the method comprises the following steps: mixing the fly ash of 20 meshes with solution of an inorganic acid modifier (mixed solution that HCl: H2SO4 is equal to 1:3) according to the solution-ash ratio of 3: 1, and obtaining the partially modified fly ash under the ultrasonic action; and using a silane coupling agent for processing the surface of the fly ash, and further utilizing the reaction activity of the silane coupling agent for carrying out the further graft reaction, thereby preparing the absorbing material with immobilized polyquaternary ammonium salt sterilization performance and higher absorption capacity.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Preparation method of star branched polyisobutylene or butyl rubber

The invention relates to a preparation method of star-shaped branched polyisobutylene or butyl rubber, which uses polystyrene / isoprene block copolymers containing silicon chloride groups at the end or polystyrene / isoprene block copolymers containing silicon chloride groups at the end. As the initiator-grafting agent of cationic polymerization, the diene block copolymer directly participates in cationic polymerisation; through the initiation of cationic polymerisation by silicon chloride group, the star-branched polymer is prepared by participating in the grafting reaction through unsaturated bonds. Isobutylene and butyl rubber products; the advantages of the present invention are: the synthesized branched polymer exhibits different processing properties from the original linear branched polymer molecule in terms of colloidal strength and stress relaxation balance, and has excellent performance, involving thermoplastic elasticity body more.

Owner:CHINA PETROLEUM & CHEM CORP +1

Nitrogen-doped carbon nanotube-loaded nitrogen-doped carbon-coated iron-cobalt alloy bifunctional catalyst and preparation method and application thereof

InactiveCN110783582ALarge specific surface areaMany active sitesMaterial nanotechnologyFuel and secondary cellsCarbon layerPtru catalyst

The invention discloses a nitrogen-doped carbon nanotube-loaded nitrogen-doped carbon-coated iron-cobalt alloy bifunctional catalyst and a preparation method and an application thereof. The catalyst is characterized in that for a structural unit, nitrogen-doped carbon nanotubes (NCNTs) are utilized as a conductive network, and iron-cobalt alloy nanoparticles wrapped by a nitrogen-doped ultrathin carbon layer are loaded on the nitrogen-doped ultrathin carbon layer. The preparation method comprises steps of pretreatment of carbon nanotubes, removing impurities on surfaces of the carbon nanotubesthrough cleaning, and generating a large number of defects and oxygen-containing surface functional groups on the surfaces of the carbon nanotubes through acid treatment; carrying out grafting reaction of an iron-cobalt organic ligand and melamine on the surfaces of the functionalized carbon nanotubes; calcining the iron-cobalt organic ligand and the melamine-grafted functionalized carbon nanotubes under a high-temperature condition to obtain the nitrogen-doped carbon nanotube-loaded nitrogen-doped carbon-coated iron-cobalt alloy bifunctional catalyst.

Owner:ZHEJIANG SCI-TECH UNIV

Maleic anhydride grafted polypropylene preparation method

The invention discloses a maleic anhydride grafted polypropylene preparation method, which comprises: uniformly mixing maleic anhydride, an activator and polypropylene powder in a high-speed mixer; and feeding into a multifunctional rubber-plastic processing device, and carrying out a grafting reaction on the maleic anhydride and the polypropylene powder under the co-action of microwaves and the activator to prepare the maleic anhydride grafted polypropylene. According to the present invention, by introducing the activator, the microwave reaction efficiency is promoted, and the grafting ratioof the maleic anhydride grafted polypropylene is increased, such that the compatibility, the toughness and the impact strength of the maleic anhydride grafted polypropylene product are substantially improved.

Owner:LUOYANG HEMENG TECH CO LTD

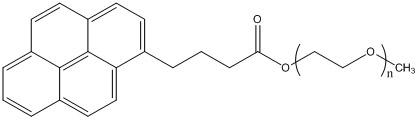

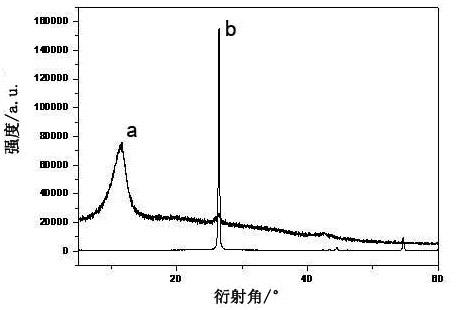

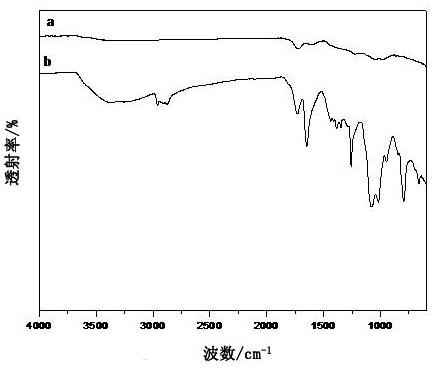

Method for functionalizing polymer on surface of nano graphene oxide

InactiveCN102320599AWide variety of sourcesImprove developmentMaterial nanotechnologySolubilityEnd-group

The invention relates to a method for functionalizing a polymer on the surface of nano graphene oxide. The method comprises the following specific steps: preparing graphene oxide from natural graphite powder by an improved Hummers method, utilizing methoxy polyethylene glycol and pyrene acids to carry out esterification to generate polyethylene glycol with pyrenyl as the terminal group, and finally grafting the polyethylene glycol with pyrenyl as the terminal group on the surface of graphene oxide through pi-pi interaction between pyrenyl and the surface of graphene oxide, thus obtaining the graphene oxide with the functionalized polymer on the surface. The solubility of the prepared graphene oxide with the functionalized polymer on the surface is greatly improved. The method has the following advantages: a main process adopted in the experiment is as follows: a polymer with a complex structure is designed and prepared in advance and then is grafted on the graphene oxide, and the grafting reaction can be carried out at normal temperature and pressure, so the whole experiment process is very simple and convenient. Therefore, the study provides a direct method for modifying the graphene oxide and preparing the functionalized graphene oxide-polymer complex to form a new inorganic-organic hybrid material, thereby promoting the development and application of graphene oxide-based materials.

Owner:TONGJI UNIV

Adsorbent for adsorbing six-valent chromium ion and its prepn process

InactiveCN101088597AEvenly distributedEasy to operateOther chemical processesSorbentMesoporous silica

The present invention is adsorbent for adsorbing six-valent chromium ion and its preparation process. The adsorbent includes silicon-base porous carrier and functional heterocyclic compound group supported through grafting reaction onto the surface of the silicon-base porous carrier. The silicon-base porous carrier is porous silica gel or ordered mesoporous silica; and the heterocyclic compound is nitrogen-containing piperidine, imidazole, triazole, triazo sodium or their salt. The preparation process includes the steps of: adding silicon-base porous material into toluene, adding organosilane coupler to react under the protection of N2, filtering and washing. The adsorbent is suitable for adsorption, separation and elimination of six-valent chromium ion in chromium containing solution.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for modifying hydroophilicity of highly active separation membrane made from polymer

InactiveCN1539550AImprove hydrophilicityGood biocompatibilitySemi-permeable membranesChemical LinkagePolymer science

A process for hydrophilic modification of efficient separating polymer membrane includes coating the grafting monomer containing glycosyl compound on the surface of polymer membrane, evaporating solvent, and radiating said monomer for triggering graft reaction to modify said polymer membrane. Its advantages are high hydrophilic effect, and easy washing.

Owner:ZHEJIANG UNIV

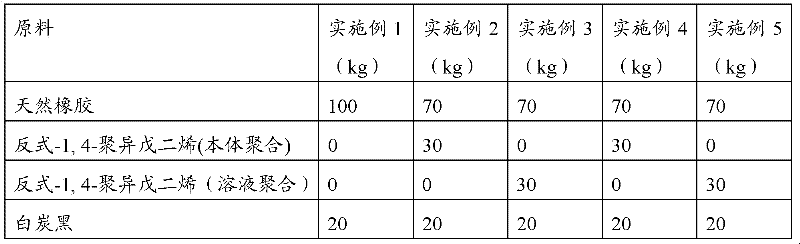

Isoprene rubber blend and its preparation method

InactiveCN102382338AImprove fatigue resistanceGood resistance to flex crackingPolymer scienceCrack resistance

The invention discloses an isoprene rubber blend and its preparation method, the isoprene rubber blend comprises the following raw materials: 60-100 parts of isoprene rubber, 5-50 parts of trans-1,4-polyisoprene, 5-100 parts of reinforcing filler, 1-25 parts of in-situ grafted modification additive, 0-40 parts of cooperated rubber and 0-25 parts of first additive. Compared with the prior art, the in-situ grafted modification additive is performed chemical reaction with the reinforcing filler, and is simultaneously performed grafting reaction with function groups like double bond of a rubber molecular chain, so that the interface bonding strength between the organic polymer and the reinforcing filler as well as the dispersion level of the reinforcing filler in rubber can be substantially enhanced, and the fatigue resistance performance of the isoprene rubber blend is increased. The test results indicate that the isoprene rubber blend of the invention has favorable flex cracking resistance and excellent general mechanical performance.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

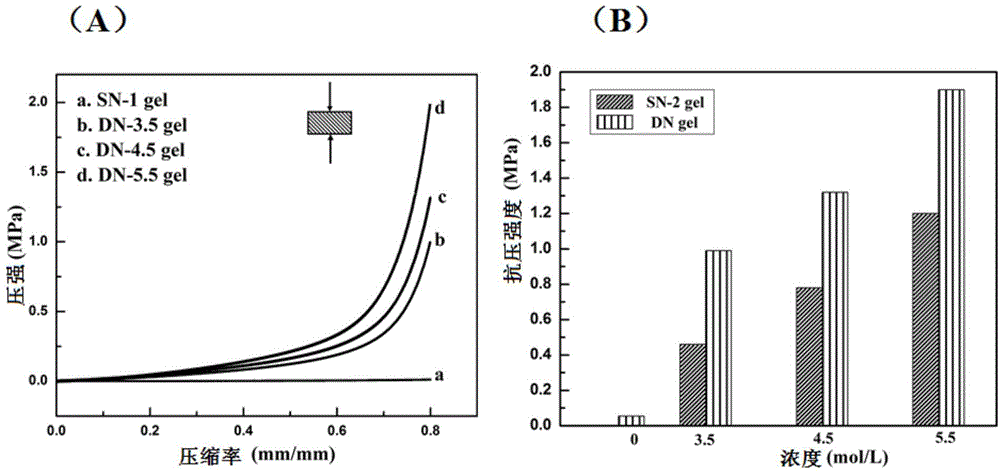

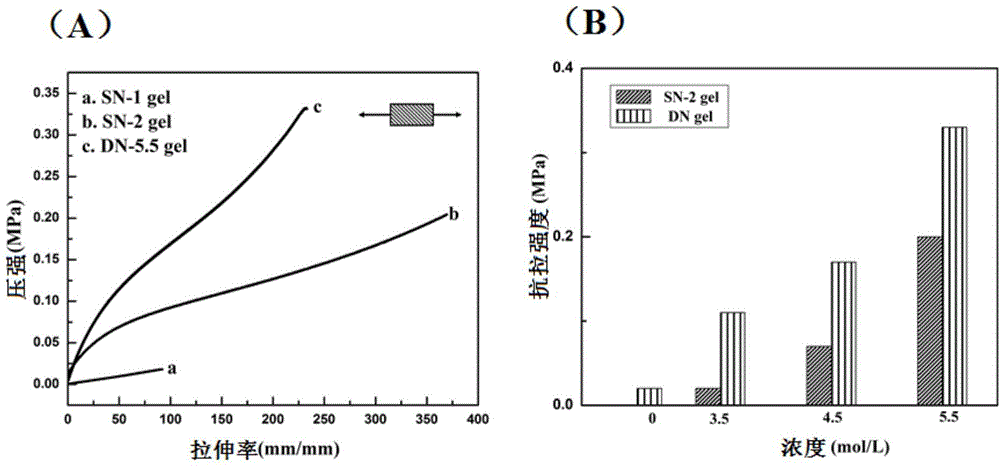

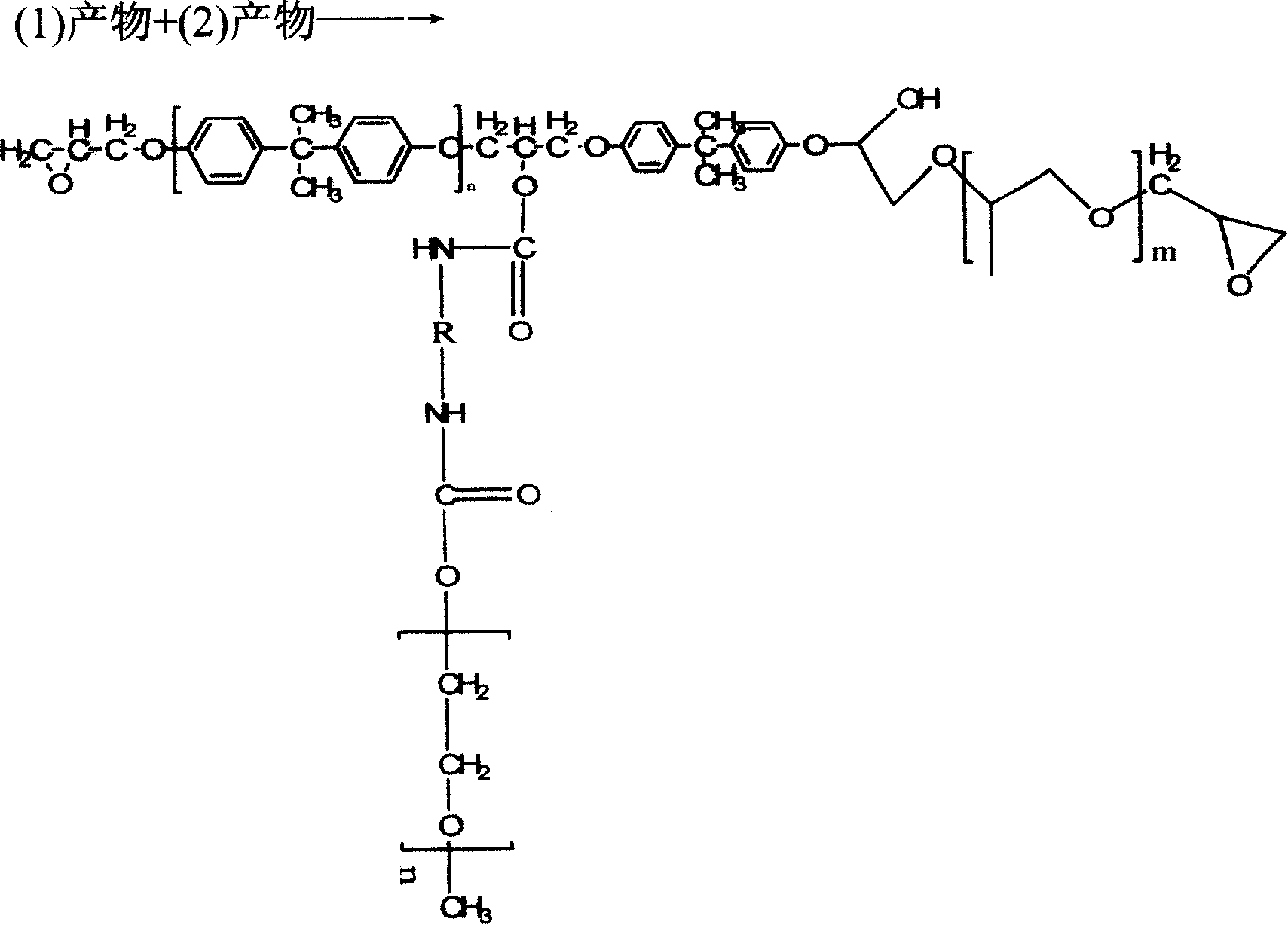

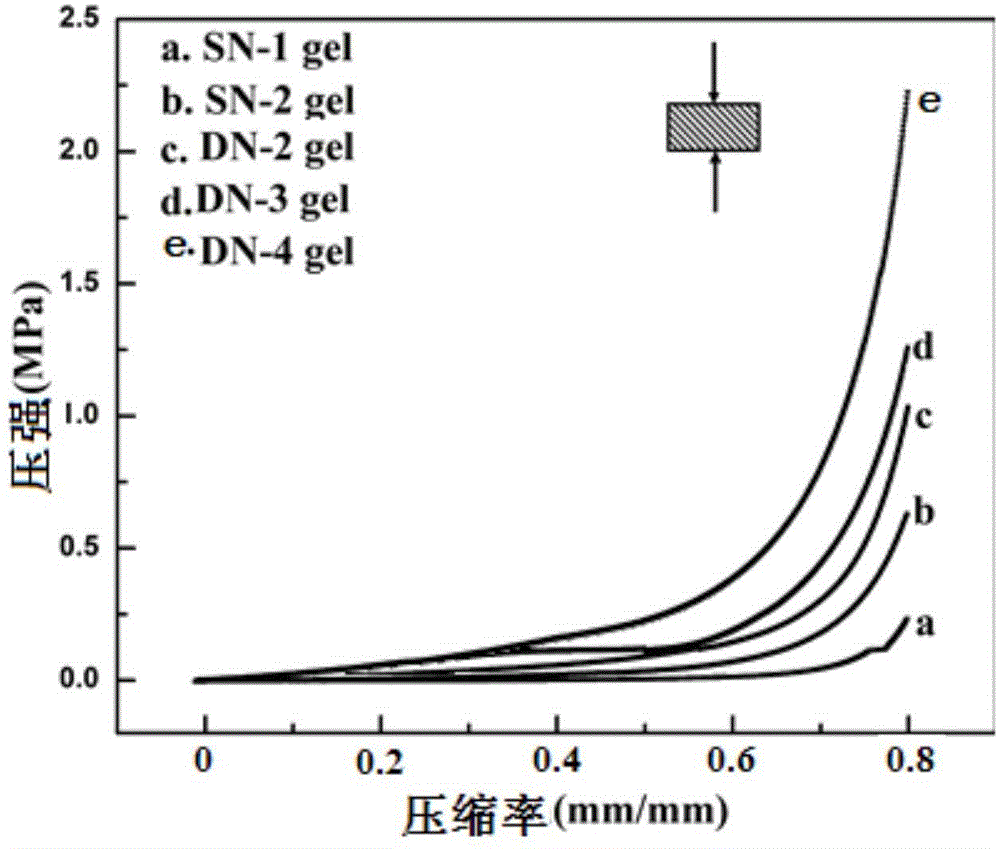

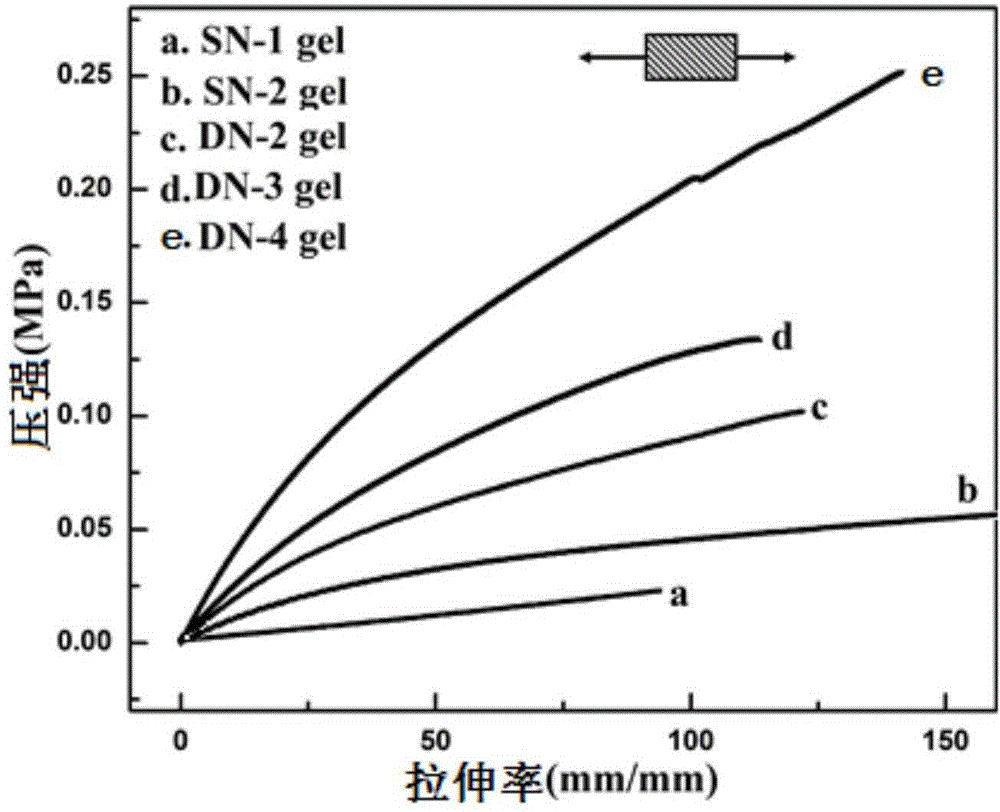

Chitosan-based double-network hydrogel and preparation method thereof

The invention provides chitosan-based double-network hydrogel. The hydrogel is of a double-network structure. A first network is chitosan graft hydrogel, and the chitosan graft hydrogel is formed by chitosan liquid, an initiator, a first single body and a cross-linking agent through grafting reaction. A second network is inserted inside the first network, and the second network is hydrogel which is formed by polymerization of a second single body, a cross-linking agent and a photo-initiator under the radiation of ultraviolet light and has high compression strength and tensile strength. Due to the introduction of chitosan, the biocompatibility of the hydrogel is improved. Thus, application of the double-network hydrogel in the fields such as biological medicine, the construction industry, the chemical industry and the mining industry is improved. The invention further provides a preparation method for preparing the chitosan-based double-network hydrogel. The method is simple in technology and enables industrialization to be easy.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Modified coupling agent and its preparing process and use

The present invention provides one kind of coupler for stuffing modification of organic polymer and its preparation process. The coupler maleic anhydride grafted polyisobutylene polymer with grafting rate controlled in 1-80 % and prepared the grafting reaction with maleic anhydride and polyisobutylene with or without initiator. The polyisobutylene is common polyisobutylene or high activity polyisobutylene of molecular weight 800-10000, and the grafting reaction has reaction temperature 120-250 deg.c and reaction time of 30-240 min. The coupler can improve the compatibility and adherence between the polymer and the inorganic stuffing, and has the features of no pollution, precisely controlled grafting rate, wide application range, etc.

Owner:PETROCHINA CO LTD

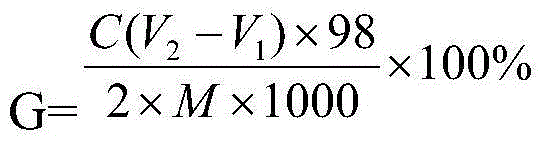

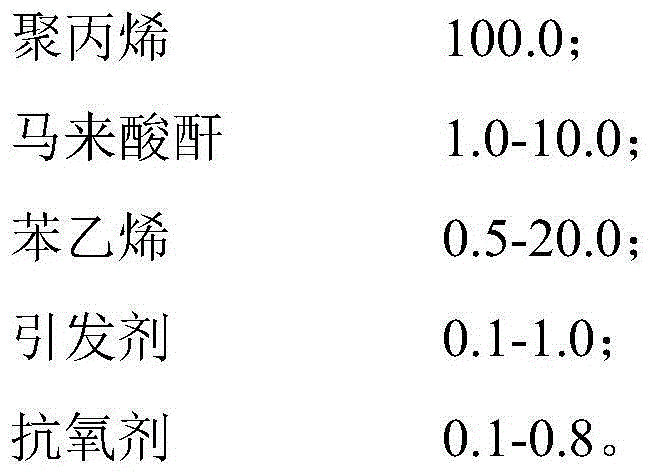

Preparation method of maleic anhydride grafted polypropylene

The invention provides a preparation method of maleic anhydride grafted polypropylene. According to the method, maleic anhydride is grafted to a polypropylene molecular chain through melting free radical grafting reaction. In the melting grafting reaction initiated by a peroxide initiator, the initiator and auxiliary monomer styrene are prepared into a solution, and the solution is continuously metered and input to a plurality of positions of different screw barrel sections of a double-screw extruder. The adopted extruder is the double-screw extruder of which the draw ratio is greater than or equal to 48: 1 or a double-order double-screw extruder. The usage of the maleic anhydride in raw materials is 1.0-10.0 weight percent of that of polypropylene. According to the preparation method, the functional maleic anhydride grafted polypropylene which is high in grafting rate can be obtained, and the molecular weight of the functional maleic anhydride grafted polypropylene is not obviously reduced compared with the molecular weight of the polypropylene in the raw materials.

Owner:EAST CHINA UNIV OF SCI & TECH

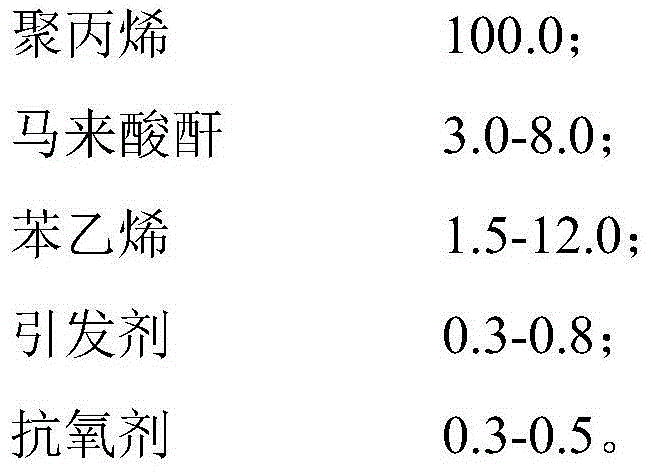

Method for preparing self-emulsification aqueous epoxy resin emulsion

The invention relates to a method for preparing self-emulsifying aqueous epoxy resin emulsion, which is characterized in that the emulsion is made through the following two steps: (1) introducing hydrophilic groups to both ends of the main chain and the side chain through chain extending and grafting reaction to form aqueous epoxy resin; (2) Adding water to the produced aqueous epoxy resin and aqueous epoxy resin emulsion is obtained through self-emulsifying reaction. The self-emulsifying aqueous epoxy resin emulsion has excellent water dispersibility and processability. After film-forming by the firming agent, the self-emulsifying aqueous epoxy resin emulsion has excellent decoration effect and certain flexibility.

Owner:上海华谊涂料有限公司

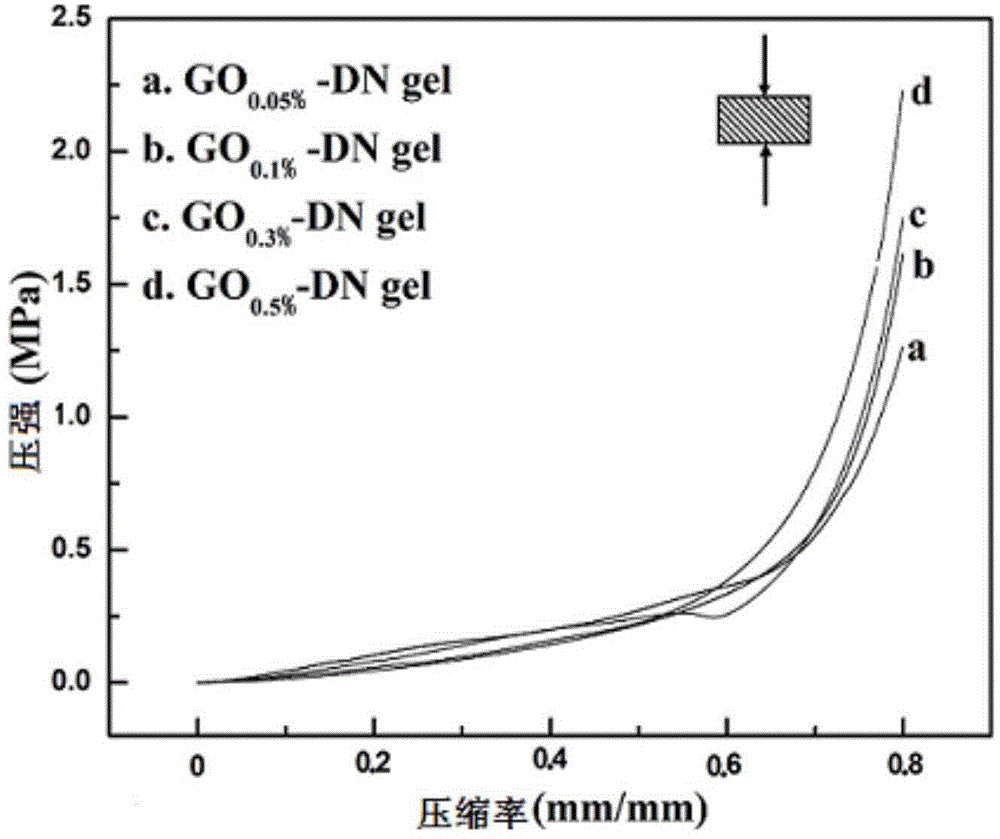

Graphene oxide/chitosan grafted type double-network hydrogel and preparation method thereof

The invention provides graphene oxide / chitosan grafted type double-network hydrogel. The graphene oxide / chitosan grafted type double-network hydrogel is of a double-network structure, wherein the first network is graphene oxide / chitosan grafted hydrogel which is formed by a graphene oxide solution, a chitosan solution, an initiator, a first monomer and a cross-linking agent through grafting reaction, the second network is inserted in the first network in a penetrating mode, and the second network is hydrogel which is formed by a second monomer, a cross-linking agent and a photo-initiator through polymerization under ultraviolet irradiation. The graphene oxide / chitosan grafted type double-network hydrogel has high compression strength and tensile strength. Due to the fact that the chitosan is introduced, biocompatibility of the hydrogel is improved, and then the double-network hydrogel can be better applied to the fields of biological medicine, construction industry, chemical industry, mining industry and the like. The invention further provides a preparation method for preparing the graphene oxide / chitosan grafted type double-network hydrogel. The method is simple in process, and industrialization can be easily achieved.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

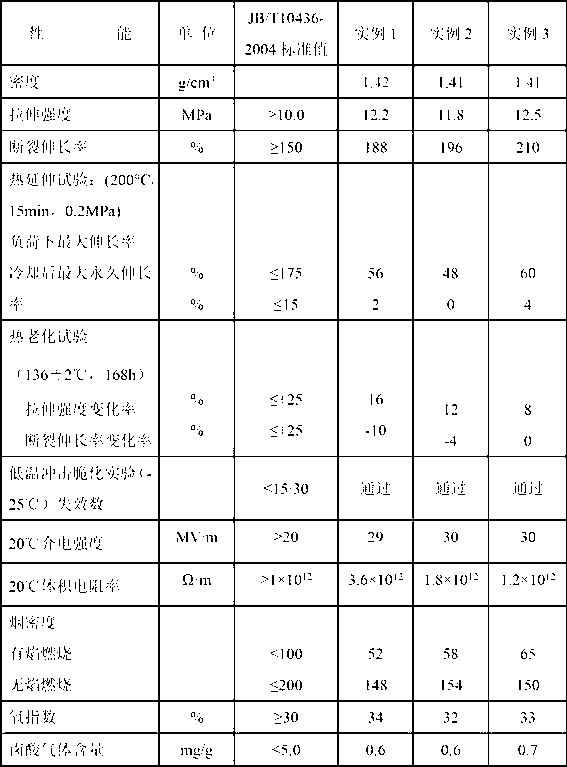

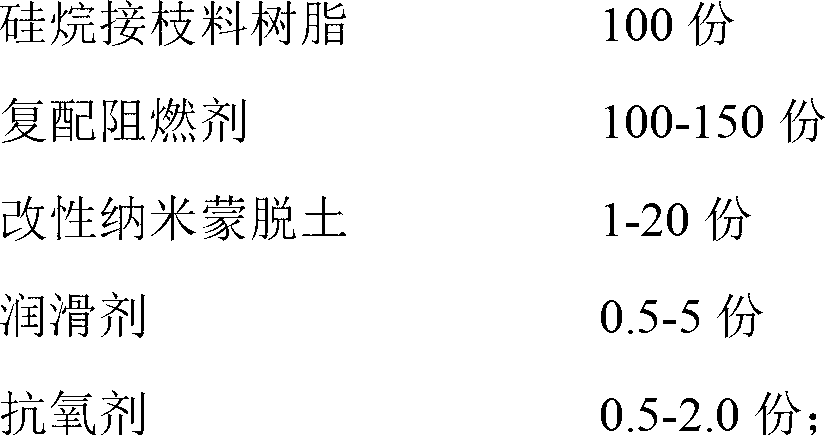

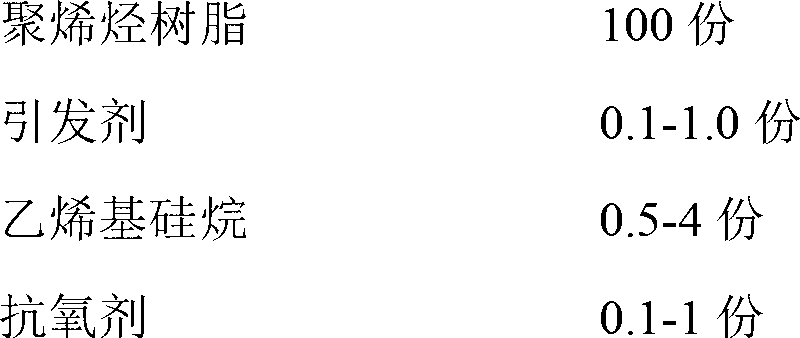

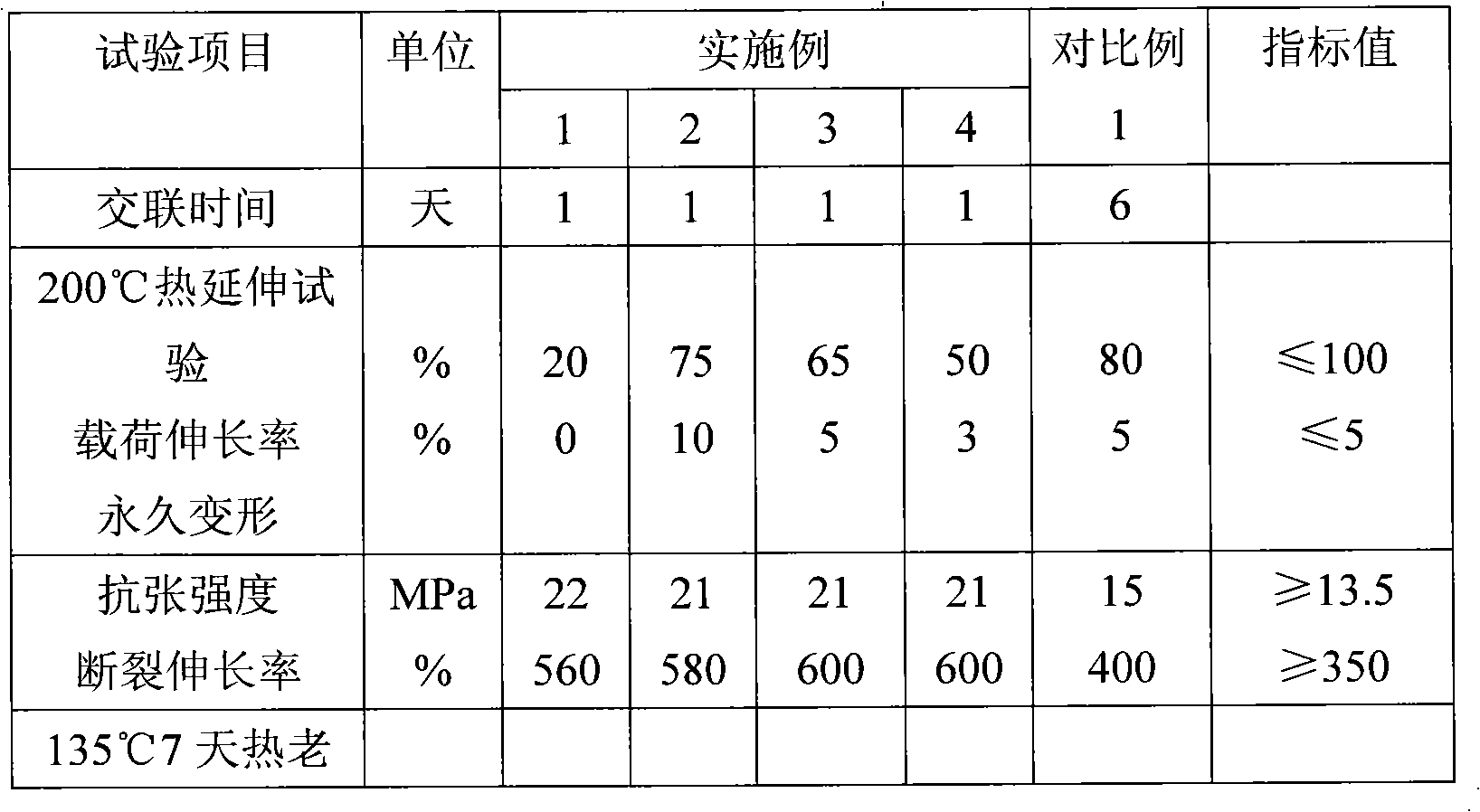

Natural silane cross-linking LSOH (Low Smoke Zero Halogen) flame-retardant polyolefin cable material and preparation method thereof

InactiveCN103013020ACrosslink GuaranteeNatural Crosslinking GuaranteePlastic/resin/waxes insulatorsInsulated cablesGraftingAntioxidant

The invention discloses a natural silane cross-linking LSOH (Low Smoke Zero Halogen) flame-retardant polyolefin cable material and a preparation method thereof. The natural silane cross-linking LSOH flame-retardant polyolefin cable material comprises a siliane grafted flame-retardant blend A and a catalyst flame-retardant master batch B; the blend A comprises the following ingredients in parts by weight: 100 parts of silane grafted resin, 100-150 parts of compound flame retardant, 1-20 parts of modified nano-montmorillonite, 0.5-5 parts of lubricant, and 0.5-2.0 parts of antioxidant, the master batch B comprises the following ingredients in parts by weight: 100 parts of polyolefin resin, 100-150 parts of compound flame retardant, 1-5 parts of catalyst and 0.5-3 parts of copper inhibitor. According to the natural silane cross-linking LSOH flame-retardant polyolefin cable material and the preparation method thereof, the siliane grafting reaction is completed separately, the natural effective crosslinking of the resin matrixes can be ensured, and side reaction produced in the follow-up process can be avoided. Through optimizing the compound flame retardants and adding the modified nano-montmorillonite, the product has the characteristics of being easy to process and LSOH high flame-retardant under relatively lower compactedness.

Owner:上海新上化高分子材料有限公司

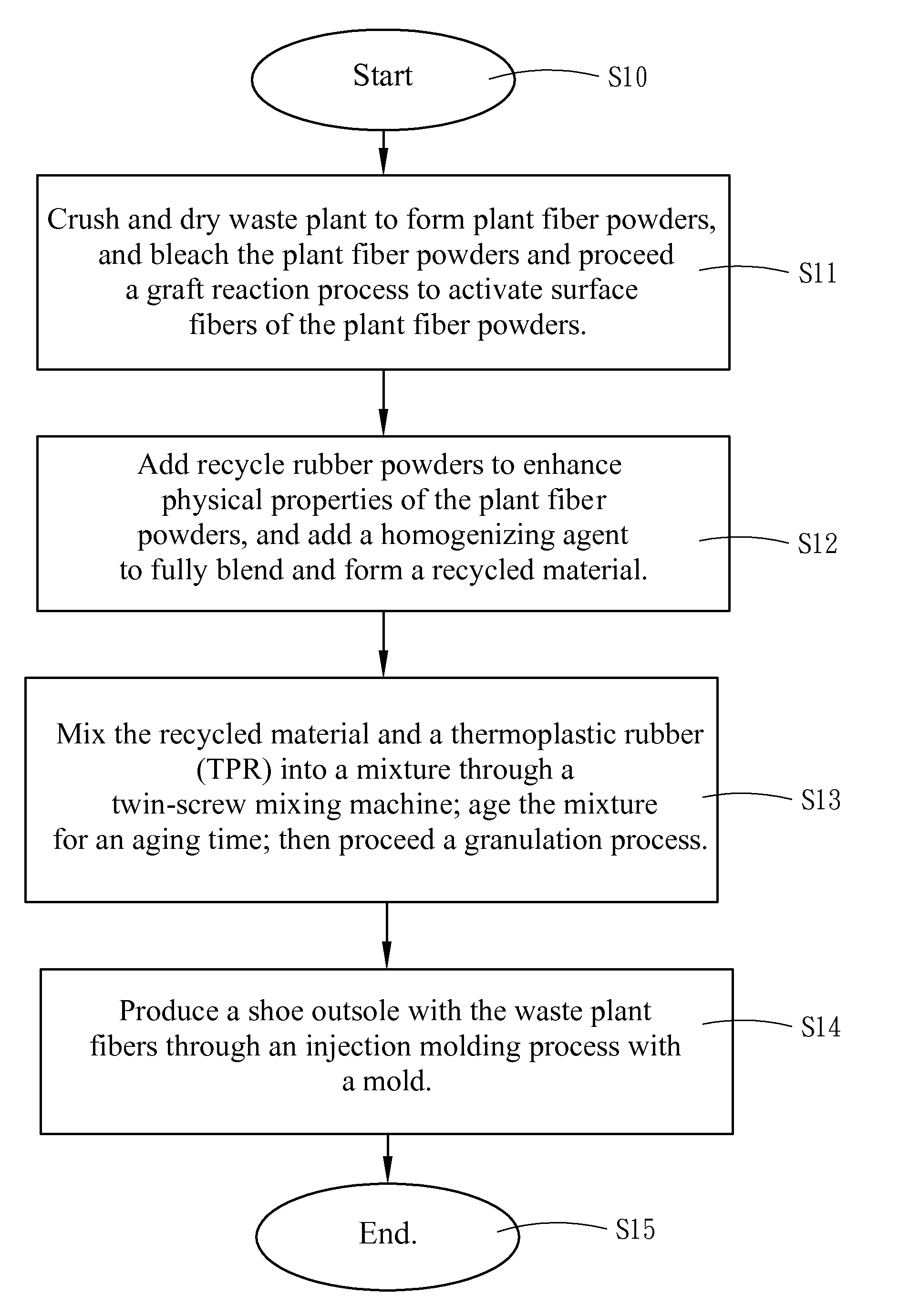

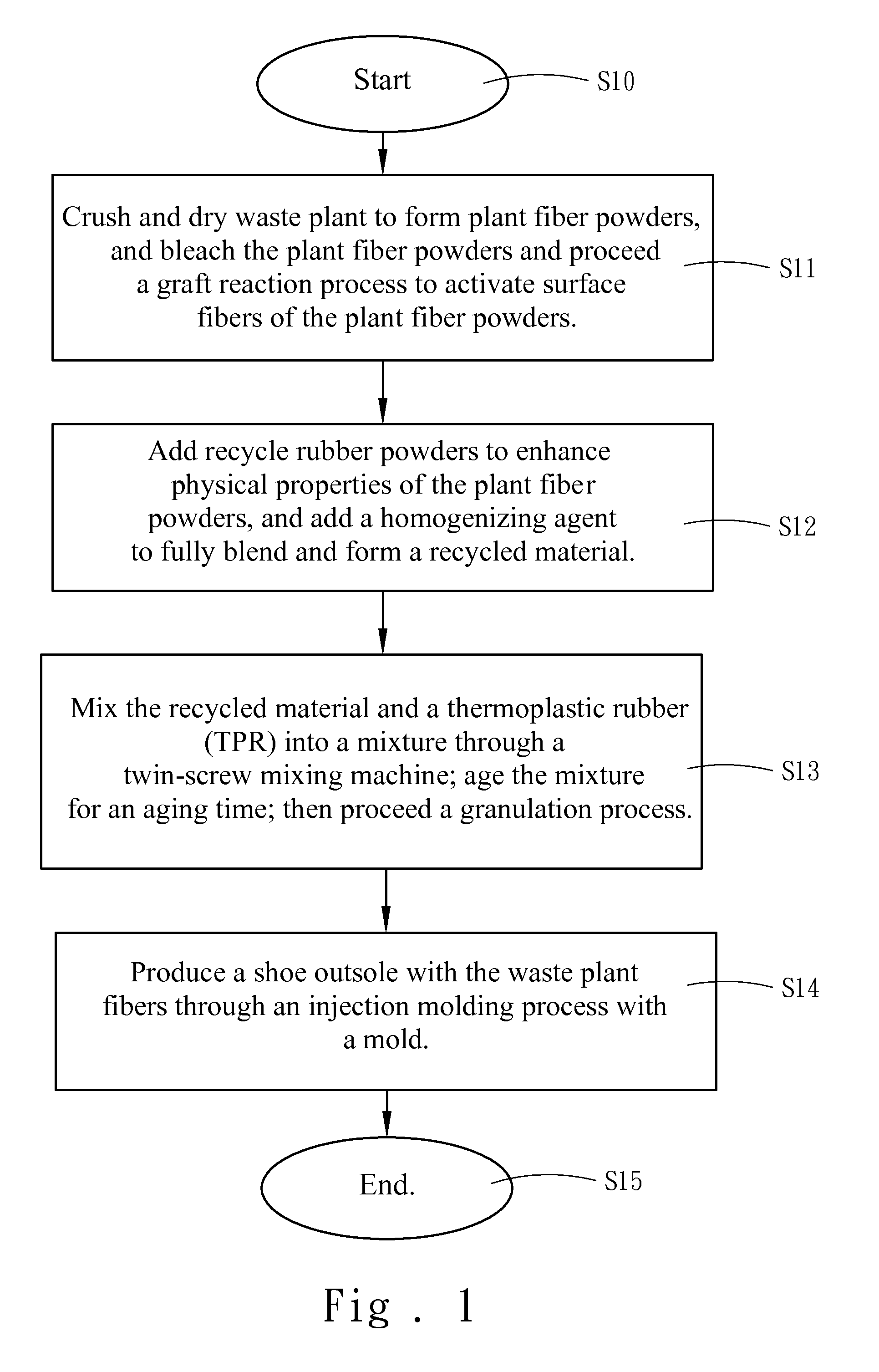

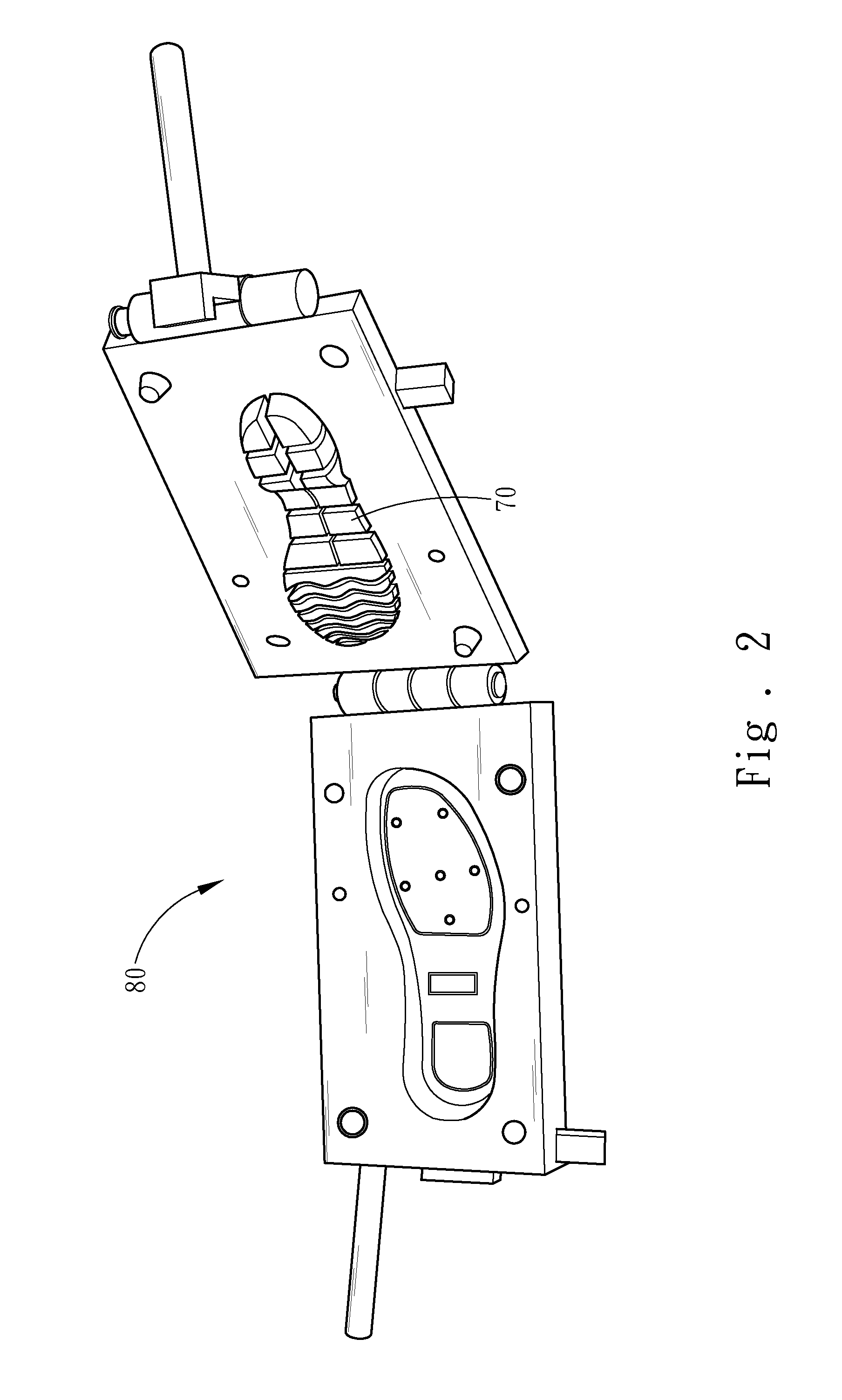

Method of manufacturing shoe outsoles from waste plant fibers

InactiveUS7785521B1Good physical propertiesUndesirable physical propertySolesPlastic recyclingGraft reactionPlant fibre

A method of manufacturing shoe outsoles from waste plant fibers includes steps of: bleaching plant fiber powders; activating the plant fiber powders through a graft reaction process; mixing the plant fiber powders and recycle rubber powders to enhance physical properties of the plant fiber powders; adding a homogenizing agent to fully blend the hydrophilic plant fiber powders and the lipophilic recycle rubber powders to form a recycled material; mixing the recycled material and thermoplastic rubber into a mixture; aging the mixture for an aging time; granulating the mixture; and producing a shoe outsole through an injection molding process. Thus a novel approach is provided to produce shoe products. Waste plants or rubber can be recycled to improve environmental conservation and protection.

Owner:CHEN SUNG HO

Lignin based polyoxyethylene ether, preparation method and application thereof

ActiveCN103709409AAvoid damageEasy to operate and controlBiocideAnimal repellantsEnvironmental resistanceSolubility

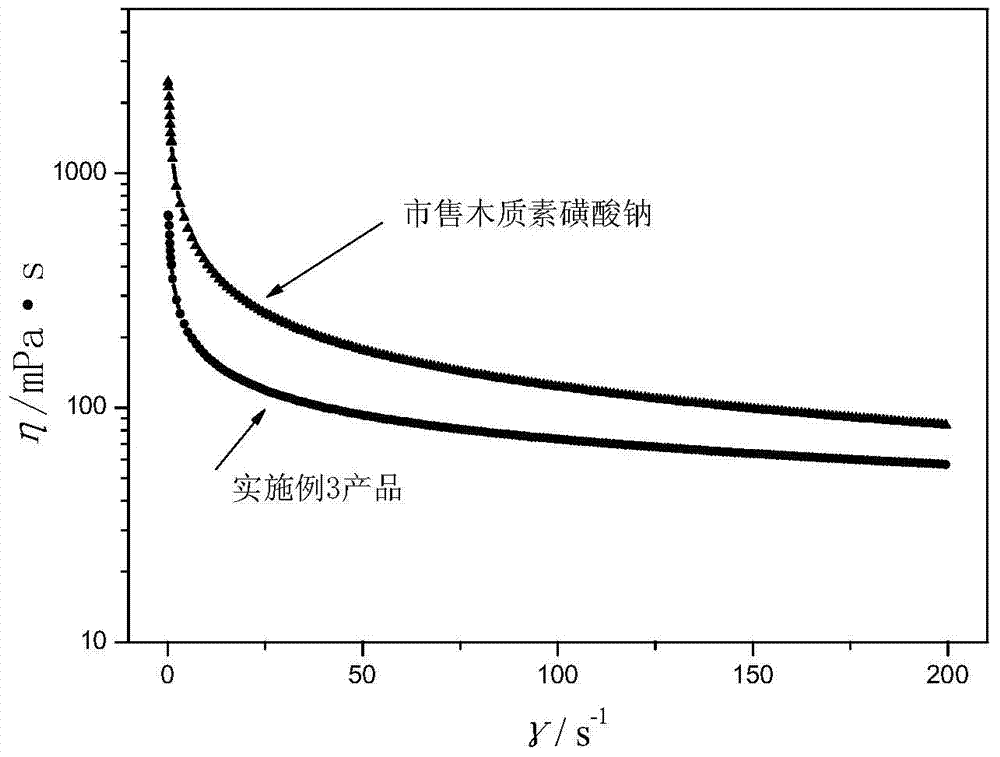

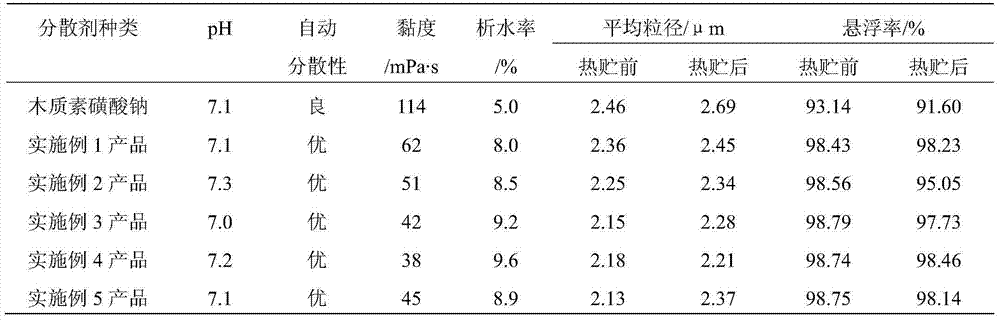

The invention discloses a lignin based polyoxyethylene ether, a preparation method and application thereof. The preparation method comprises the steps of: heating and fusing polyethylene glycol, adding catalysts, then slowly adding epichlorohydrin in a dropwise manner to undergo reaction, thus obtaining a modified polyethylene glycol intermediate; heating alkali lignin to 60-80DEG C, and adding the modified polyethylene glycol intermediate dropwise to undergo reaction, thus obtaining the lignin based polyoxyethylene ether. The preparation method provided by the invention is carried out under normal pressure and low temperature, and is easy to operate and control. Due to direct introduction of a polyoxyethylene ether hydrophilic group into an alkali lignin molecule through grafting reaction, the side reaction is fewer, and the damage to the lignin structure is very small. Only two-step reaction is needed, and the reaction time is short. The product has good water solubility, is environmental friendly and non-toxic. The lignin based polyoxyethylene ether provided by the invention can be used as a dispersing agent of a pesticide suspension individually, and has the advantages of excellent dispersion and viscosity reduction performance, crystal growth inhibition, and high heat storage suspension rate.

Owner:SOUTH CHINA UNIV OF TECH

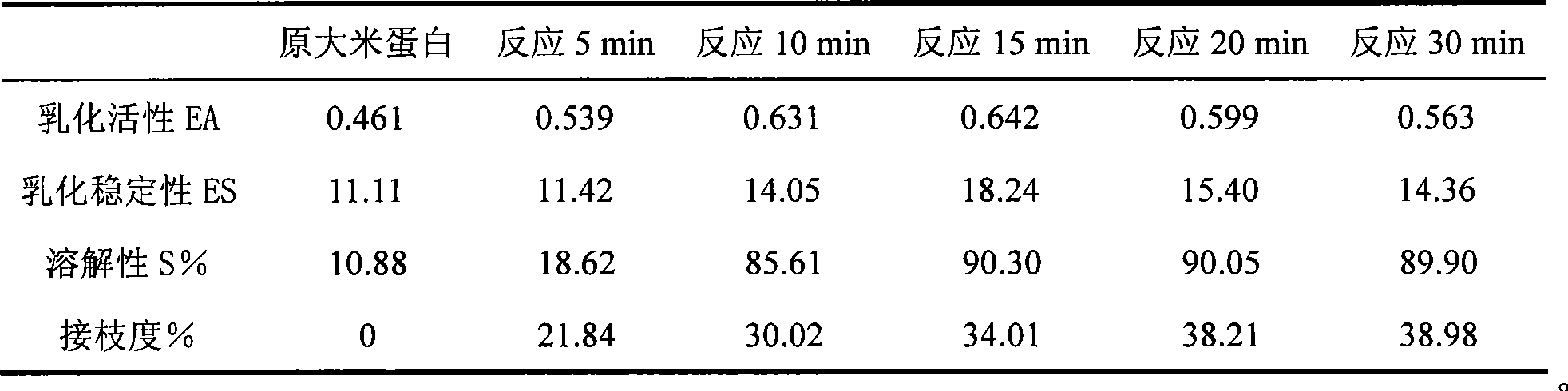

Method for improving rice protein functional property with protein-polysaccharide graft coupling technology

InactiveCN101429226AImprove functional propertiesImprove the level of comprehensive utilizationPeptide preparation methodsPhosphorylationRice protein

The invention provides a method for improving functional property of rice protein by protein-polyoses graft coupling technology, which belongs to the technical field of hydrophobicity vegetable protein modification. The method is to carry out glycosylation modification on a side product of producing rice starch and rice syrup, namely the rice protein as a raw material by different glycosyl donors through a wet method. Dissolvability, emulsibility, foamability and other functional properties of the rice protein are effectively improved and sufficiently utilized through the graft reaction of the rice protein and sugar. Compared with methods chemically modifying the vegetable protein, such as alkylation, phosphorylation, deamidization and the like, the method is safe and environment friendly, a rice protein-polyoses graft coupling product can be used as a natural macromolecular emulsifying agent or a protein nutritional reinforcing agent to sufficiently reflect and exert low sensitivity and high nutritive characteristic of the rice protein, thereby effectively expanding the application field of the rice protein. Meanwhile, the method provides theoretical reference for deep research and development of the hydrophobicity vegetable protein.

Owner:JIANGNAN UNIV

Hydroxyalkyl cationic guar gum and its preparation method and application

InactiveCN1757827ASolve forming problemsImprove adsorption capacityPaper/cardboardRetention agents additionAlcoholGraft reaction

A process for preparing the cationic hydroxyalkyl guar gum includes such steps as dispersing the raw powder of guar gum in the aqueous solution of low-carbon alcohol, adding high-alkaline catalyst, immersing, adding cationic etherifying agent, cationic graft reaction, adding phase-transfer catalyst and alkoxy etherifying agent, hydro-xyalkylating reaction, neutralizing and filtering. It can be used as the retention aid or filter aid of paper pulp.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing crosslinkable polyethylene cable material

The invention discloses a preparation method of crosslinkable polyethylene cable material, which includes the steps and the following components are represented in proportion by weight: throwing polyethylene 75-95 proportion by weight, ethylene-vinyl acetate copolymer 0-20 proportion by weight, unsaturated silicone hydride 1.0-5 proportion by weight, free radical evocating agent 0.1-0.5 proportion by weight, organotin catalyst 0.1-1 proportion by weight, organic acid compound 0.1-1 proportion by weight, anti-oxidant 0.1-0.5 proportion by weight, anti-copper agent 0.1-0.5 proportion by weight, and lubricant 0.5-2 proportion by weight into the high speed mixing machine with rotary speed at 80-120 rpm for mixing 15-25 minutes, and then adding the mixture into the double-screw extruder, melting and prilling for obtaining crosslinkable polyethylene cable material. The method provided by the invention mixes all the material and dispersing uniformly, and then executes grafting reaction, thereby realizing more uniform grafting reaction and guaranteeing homogeneity of the crosslinking process, in addition, the invention uses organic acid compound which remarkably improves catalysis function of organotin catalyst, and improves crosslinking speed of silicone hydride, and overcomes the defect that the conventional silicone hydride crosslinked plastic can be linked only in warm water or steam environment with long time cooking, thereby saving production cost for manufacturer considerably. The crosslinkable polyethylene cable material obtained according to the invention is extruded by plastic cable extrusion machine unit for obtaining cable insulation layer, and is placed under the condition of 23 DEG C. with 50% humidity for one day naturally, then the crosslinking process is finished, moreover the product can pass performance indexes of hot extension performance test, dynamics test and aging characteristic test according to the national standard request.

Owner:SHANGHAI JIAO TONG UNIV

Method for preparing polyethylene-based thermoplastic wood-plastic composite material

The invention relates to a preparation method of polyethylene base thermoplastic wood and plastic composite material. Firstly, liquid monomers which have good appetence with wood powder and have grafting reaction with polyethylene are directly compounded with wood powder to form activated wood powder; secondly, the reaction extrusion is performed to polyethylene, initiator, catalyst, activated wood powder, lubricant, plasticizer and stabilizer by adopting a double screw extruder, to prepare the polyethylene base thermoplastic wood and plastic composite material which has advantages that the integrated performance is superior, the surface is smooth, and the material can be extruded, die-pressed and molded by injection, etc. The method of the invention is simple, in which the process that the graft copolymer is firstly prepared in the past is omitted, simultaneously, because the liquid monomer can be adsorbed by the wood powder, the volume of the wood powder is reduced, which is convenient for blending and processing.

Owner:SHANGHAI JIAO TONG UNIV

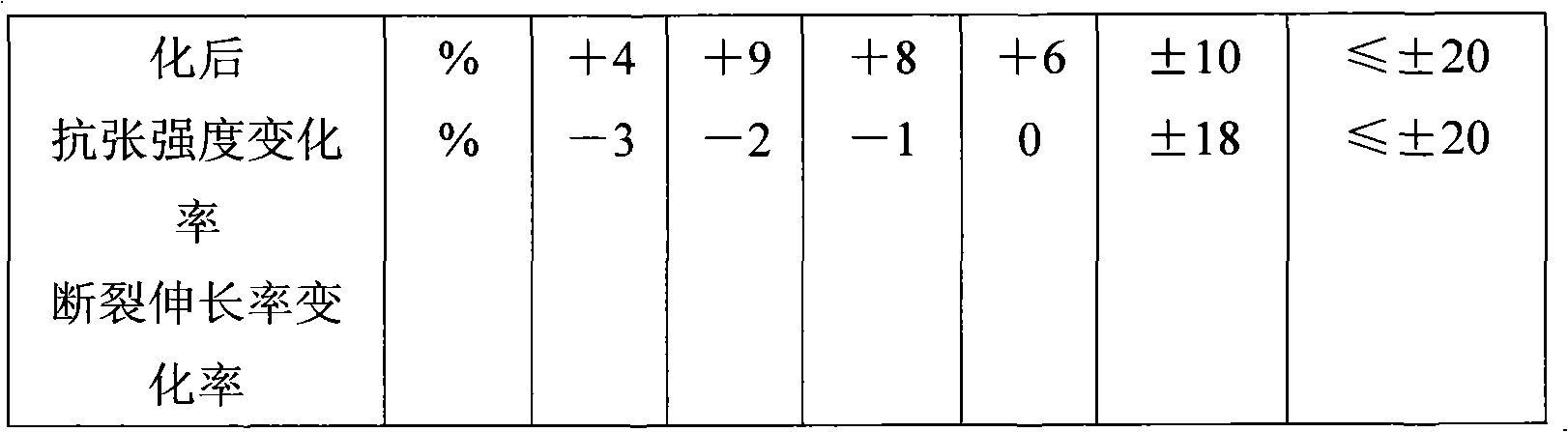

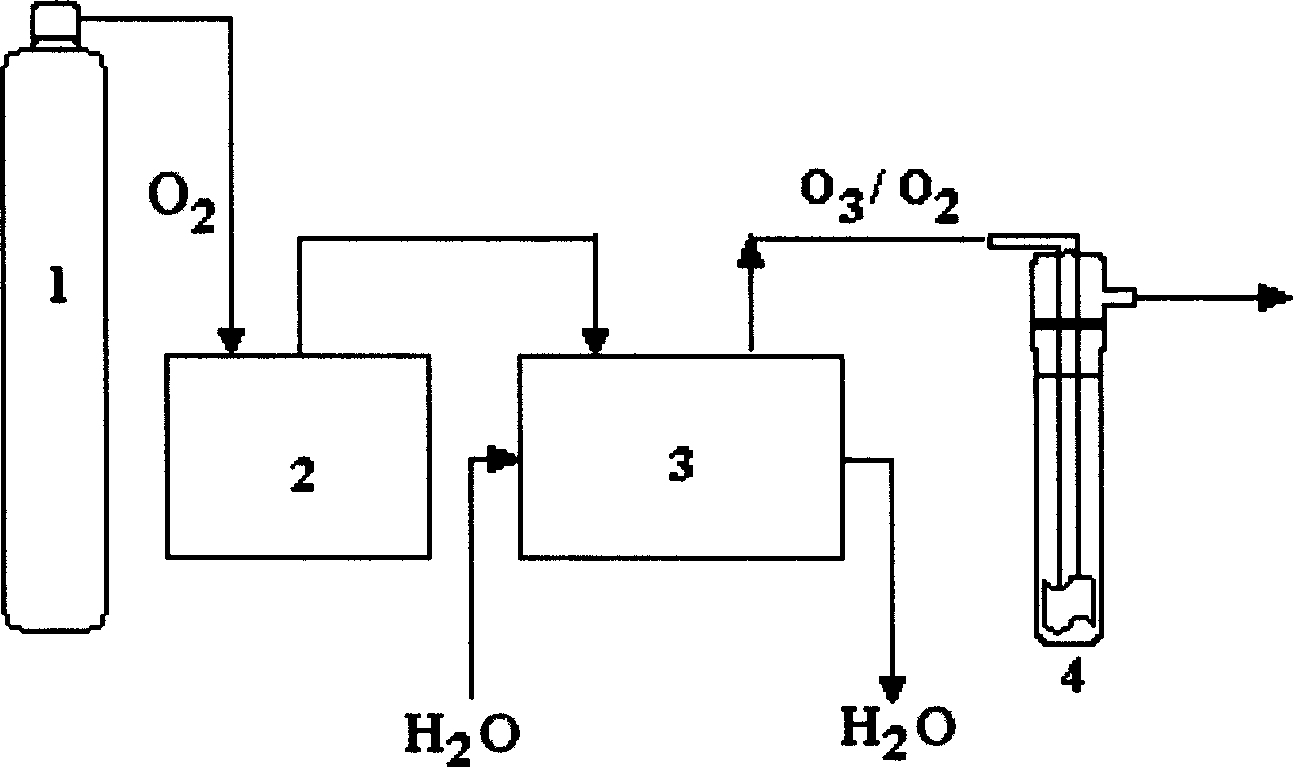

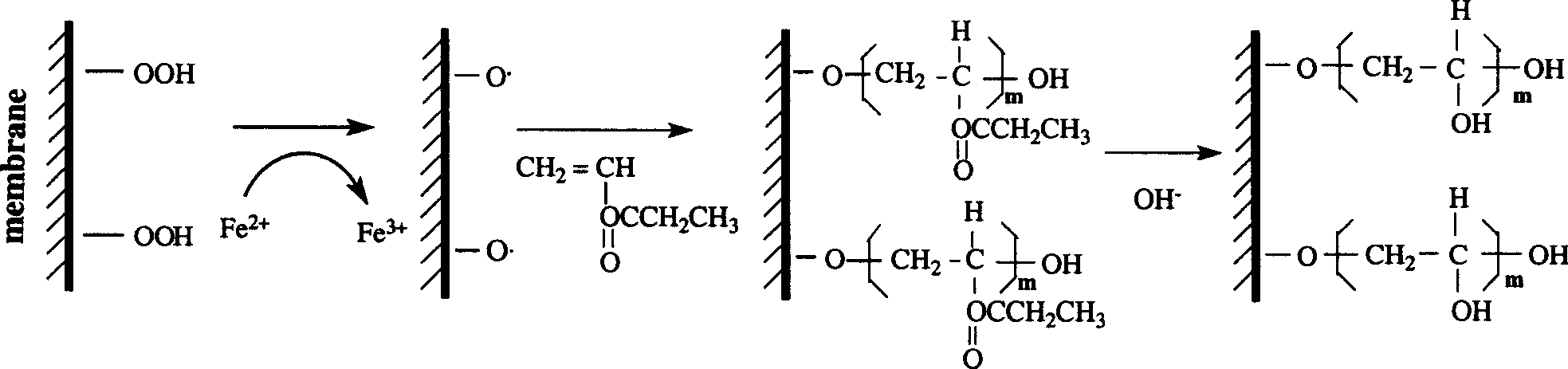

Method for hydrophilic modification of ultrahigh molecular weight polyethylene microporous membrane surface

The hydrophilic modification method of surface of ultrahigh molecular weight polyethylene microporous filtering membrane belongs to the field of ozone grafted ultrahigh molecular weight polyethylene microporous filtering membrane preparation technology. It is characterized by that it utilizes ozone to initiate graft reaction on the surface of microporous filtering membrane, it selects vinyl-acetic ester (VAc) as graft monomer, after graft reaction makes saponification hydrolysis to form polyvinyl alcohol (PVA) hydrophilic group. The obtained microporous filtering membrane has good hydrophilic property and moisture absorbability.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com