Patents

Literature

65 results about "Chain propagation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chain propagation (sometimes referred to as propagation) is a process in which a reactive intermediate is continuously regenerated during the course of a chemical chain reaction.

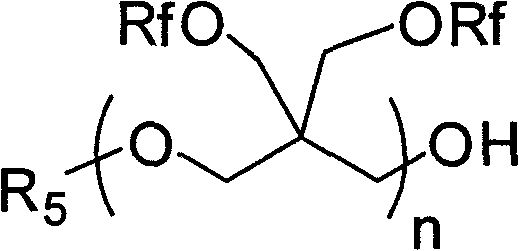

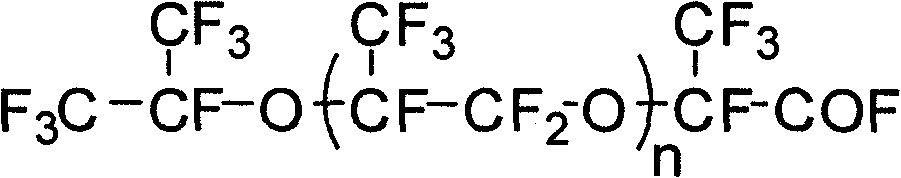

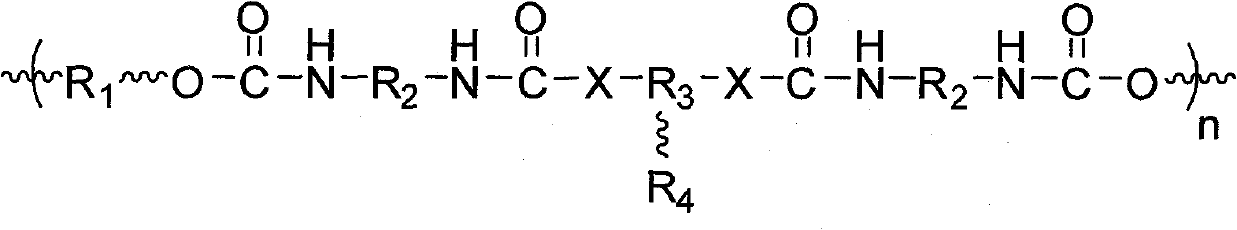

Fluorine-containing polyether graft modified aqueous polyurethane and preparation and application thereof

InactiveCN101157750AGood water repellencyGood weather resistanceOther chemical processesSolventBioaccumulation

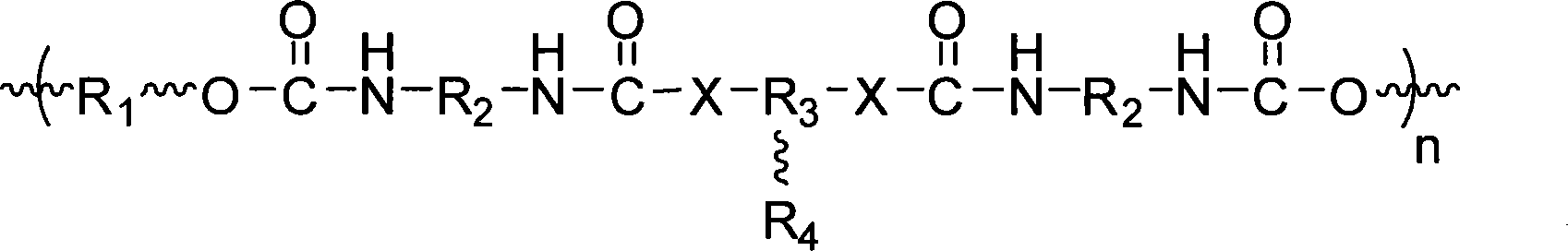

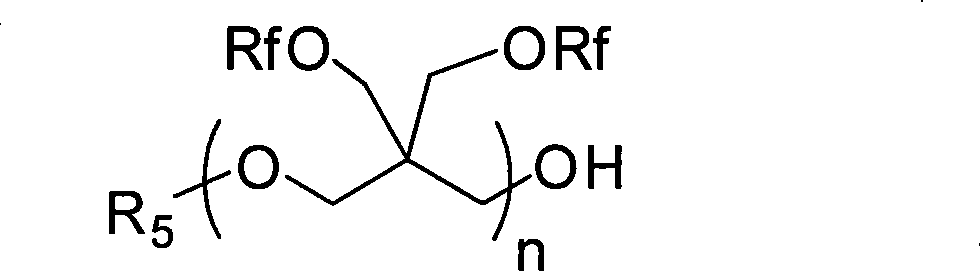

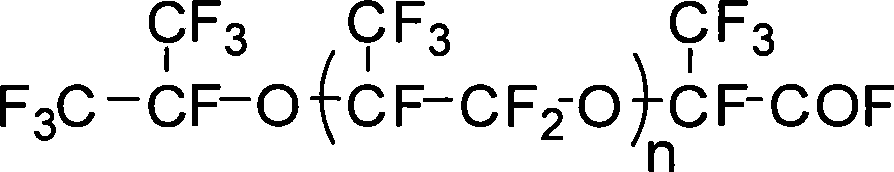

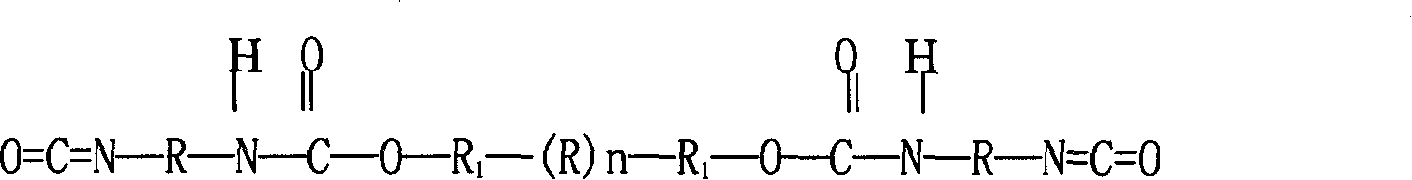

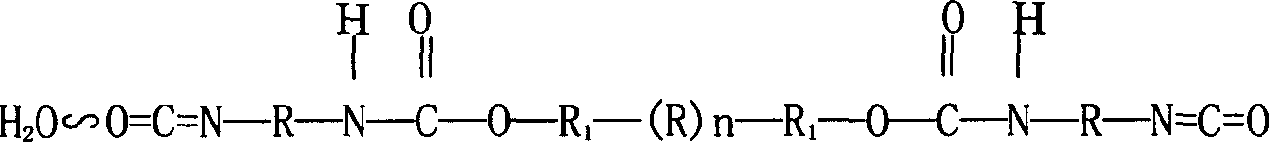

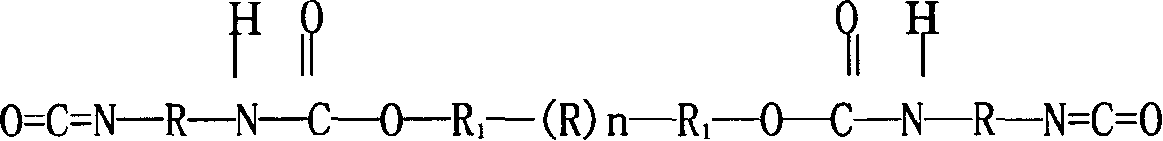

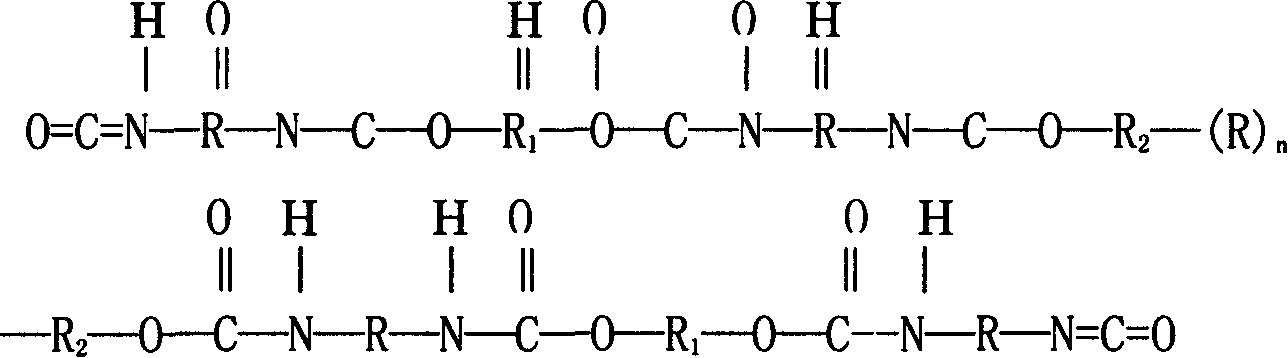

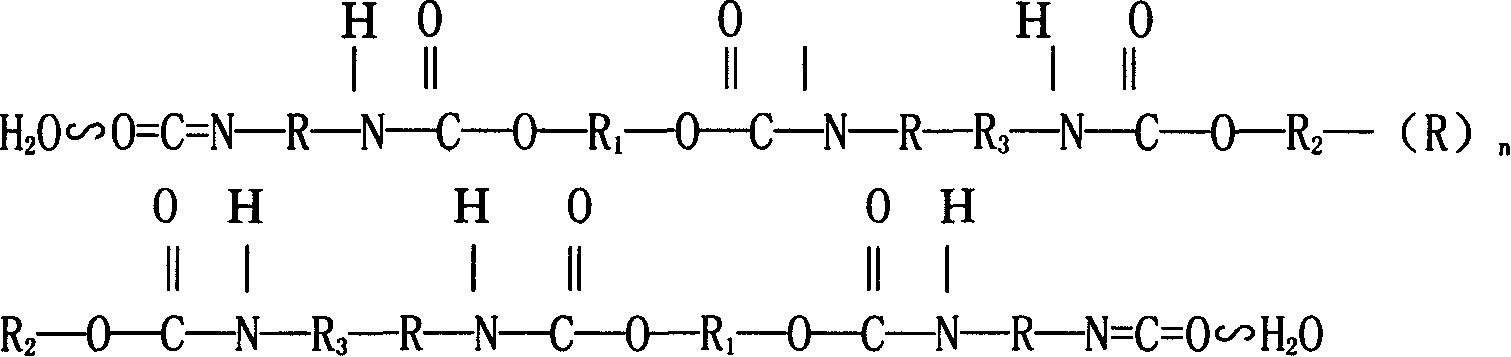

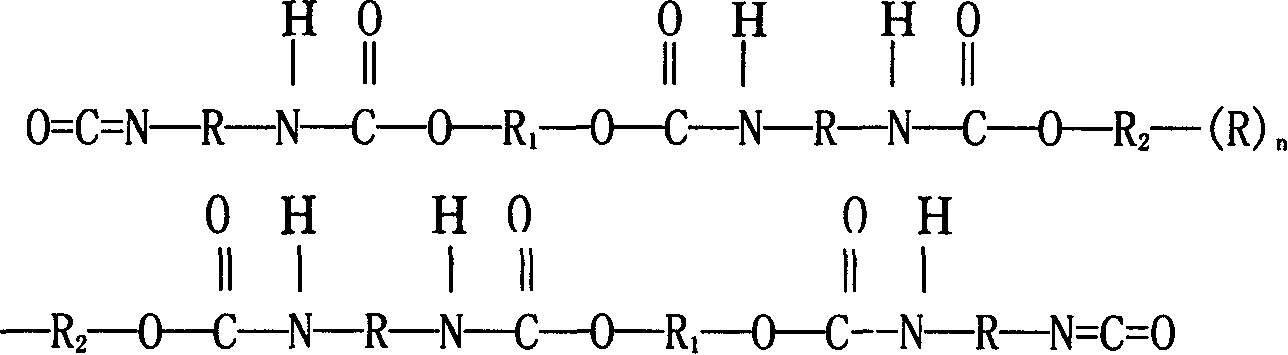

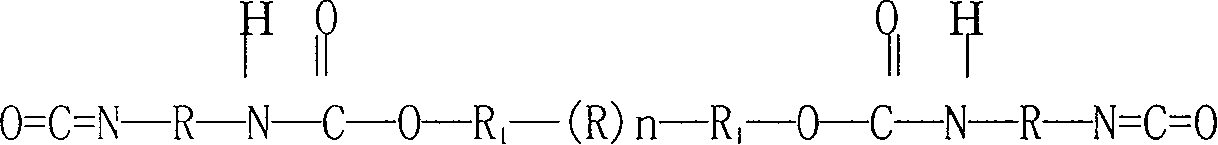

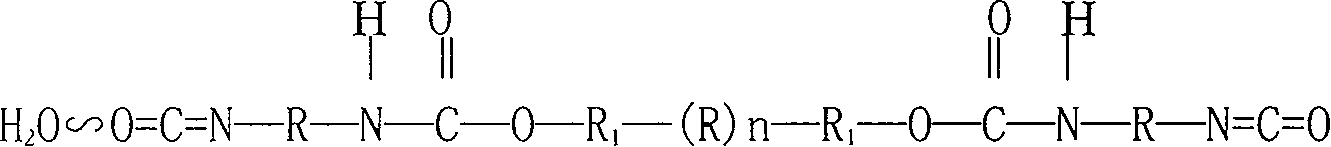

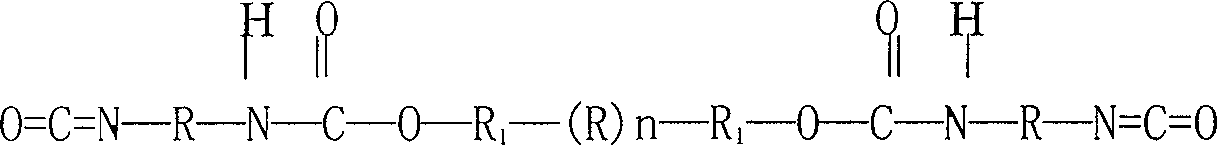

The present invention relates to a fluorine-containing polyether grafting modified waterborne polyurethane, the preparation and the application thereof, a structural general formula of polyurethane is as the formula, wherein, R1 is equal to a polyurethane soft-segment polyol structure, R2 is equal to a polyurethane hard-segment isocyanate structure, R3 is equal to a polyurethane hard-segment chain extender structure, R4 is equal to the fluorine-containing polyether; X is equal to NH and O; the preparation is that: the polyol and the isocyanate react to compound the polyurethane prepolymer, then the waterborne polyurethane are obtained through the chain propagation of a chain extender, then the waterborne polyurethane and the fluorine-containing polyether are carried out a grafting reaction in the big molecules, so as to synthesize the fluorine-containing polyether grafting modified waterborne polyurethane; the application is that: the present invention can be applied to aerospace, aviation, automobiles, electronics, textiles, carpets, leathers, paper making, packaging, washing, machinery, construction and other fields. The present invention adopts the water as the solvent and has no formaldehyde, no or low VOC emission, no bioaccumulation and no toxicity, which is a multifunctional, green, environment protective, water-proof and dirt-proof coating layer and fabric finishing agent.

Owner:DONGHUA UNIV

Enzymatic antioxidant of allene oxide for lipid peroxidation in biological systems

InactiveUS6132711ABeneficial antioxidativeExtend effective lifeSugar derivativesPeptide/protein ingredientsLipid formationFatty acid

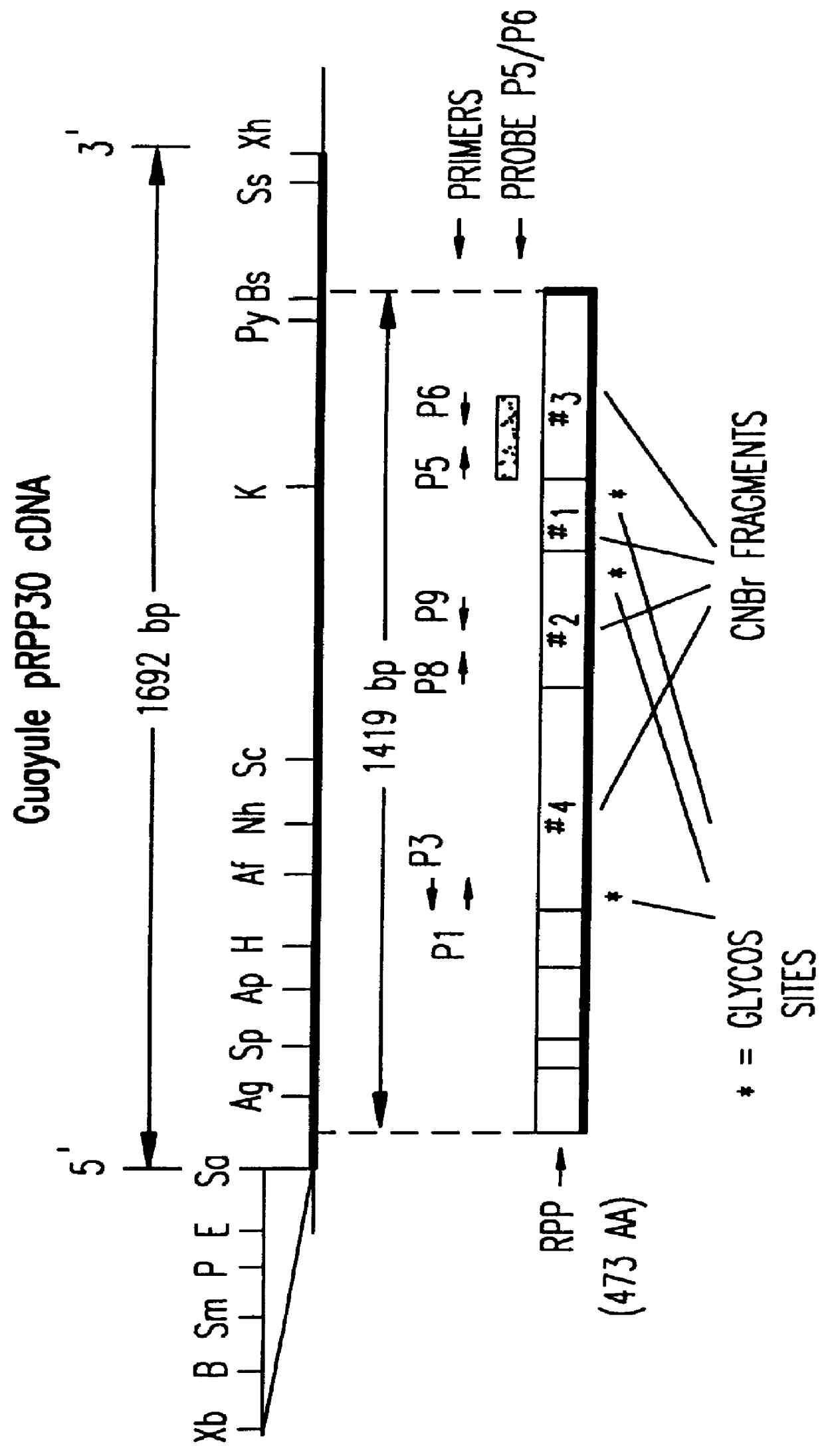

The present invention relates to the isolation and use of an allene oxide synthase enzyme as an antioxidant of lipid peroxides in biological systems. It is based, at least in part, on the discovery that antioxidation is accomplished enzymatically by RPP, a species of allene oxide synthase, in guayule, and on the discovery that the allene oxide synthase RPP disrupts the chain reaction and propagation steps of lipid peroxidation. The present further invention relates to the use of an allene oxide synthase to result in a time-dependent disappearance of conjugated dienes (i.e. lipid hydroperoxides). The allene oxide synthase rapidly converts free or esterified fatty acid peroxides or hydroperoxides into their corresponding epoxides, which, in turn are converted to ketols. The lipid peroxide and hydroperoxide substrates for this enzyme are known to be toxic to biological organisms and can generate additional peroxides by chain propagation reactions. In the presence of an allene oxide synthase these compounds are rapidly and effectively converted to allene oxides (the epoxide), thus breaking the chain reaction.

Owner:ARIZONA STATE UNIVERSITY

Epoxy end group hyperbranched poly (amide-ester) and preparation method

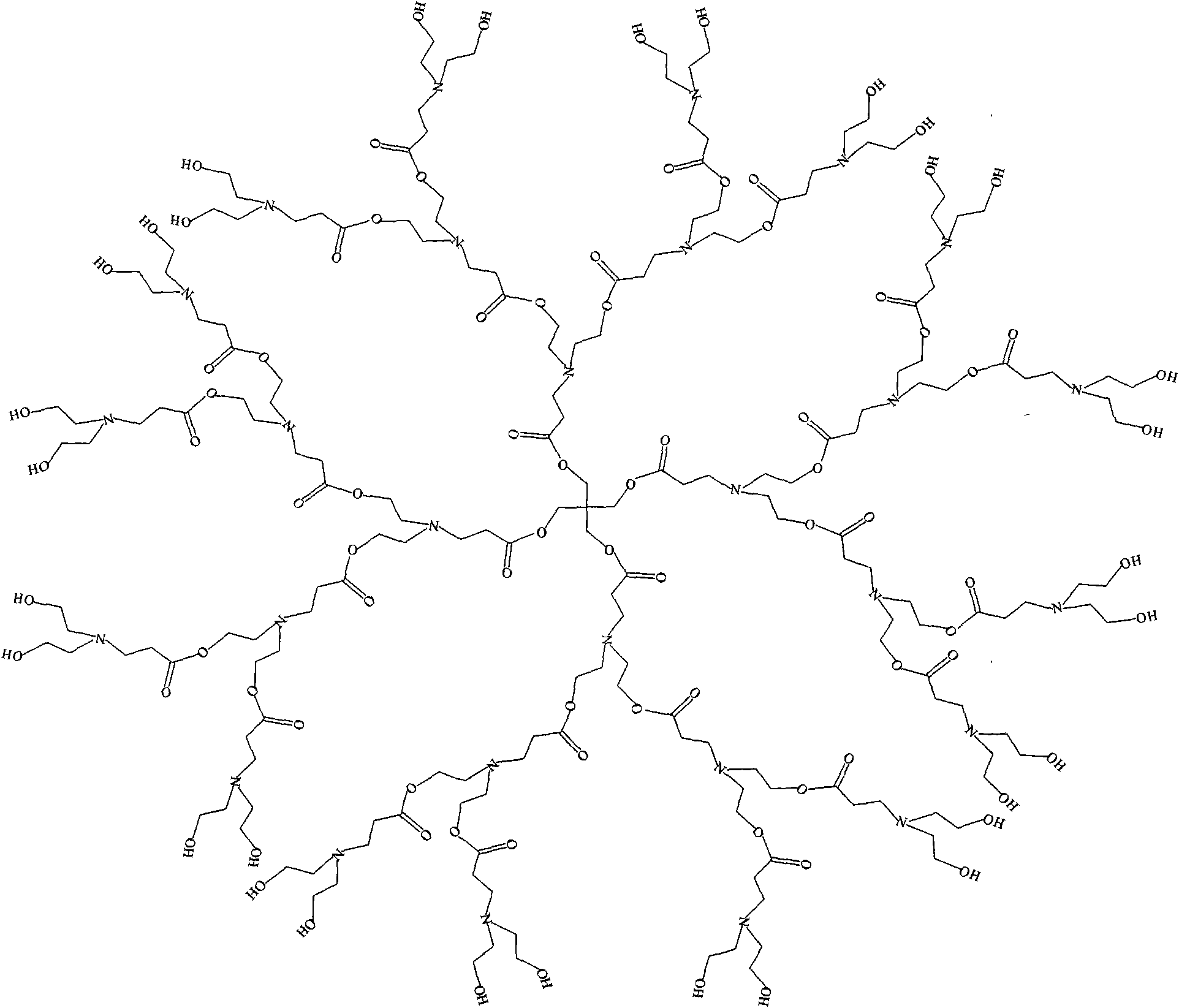

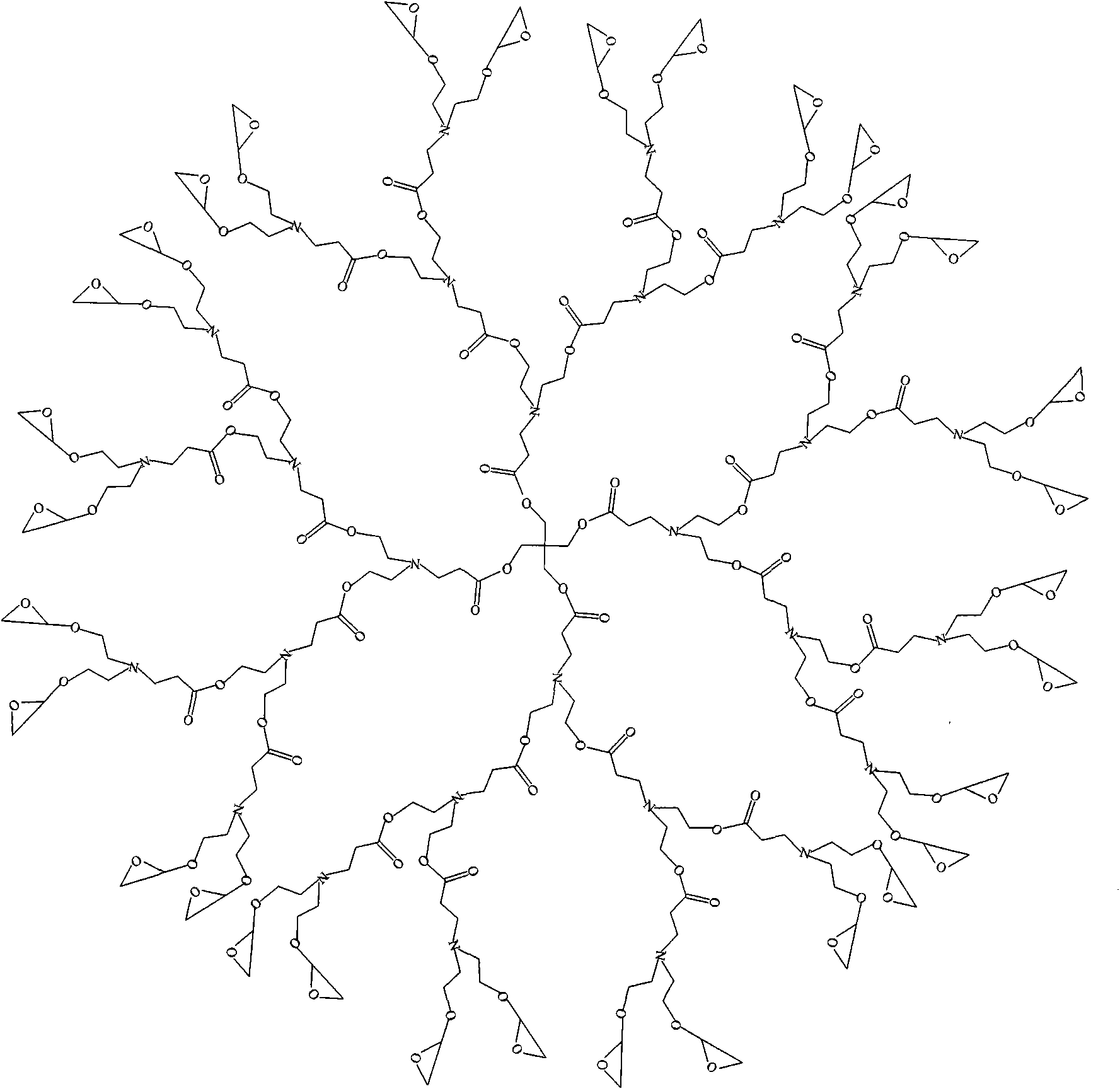

The invention provides an epoxy end group hyperbranched poly (amide-ester) and a preparation method. The preparation method comprises the following steps: taking dihydroxy amide ester as a chain propagation monomer, adding multifunctionalmolecule polylol as a core, reacting in the presence of a catalyst and inert gases to obtain hydroxyl end group amido hyperbranched poly (amide-ester); and then enabling a hydroxyl end group to react with epoxy chloropropane to generate the epoxy end group hyperbranched poly (amide-ester). The epoxy end group hyperbranched poly (amide-ester) is in an approximately sphere symmetrical three-dimensional structure with high functionality, has the relatively molecular weight as high as 10,000-20,000 and the molecular weight distribution coefficient as much as 1.02-1.35, can be used as a rheologicalproperty regulator or polymer rheological processing modifier, can improve the compatibility when being blended with a polymer containing an epoxy group, improvethe tensile strength by 40 percent compared with a pure polymer, improve the breaking strength by 60 percent compared with the pure polymer and achieve the functions of toughening and strengthening.

Owner:CHANGCHUN UNIV OF TECH

Polysiloxane-polyether copolymer modified aqueous polyurethane preparation method

InactiveCN1884335AImprove heat resistanceImprove low temperature resistanceLiquid surface applicatorsFibre treatmentCarbamateSolvent

The invention relates to a method for preparing aqueous polyurethane. It comprises following steps: employing polyisocyanates bridging agent, proceeding copolymerization with excess aqueous polyether, liquid ploydimethyl oxosilane ternary block and getting ployoxosilane-polyether polymer, introducing polyurethane and organic silicon when generating carbamate with carbamate to main chain, adding chain propagation agent for chain propagation reaction and getting preploymer containing hydrophilic group; adding mixture of polyhydroxy compound and dissolvent into reaction system for second chain propagation reaction; neutralizing by adding neutralization agent, adding water for emulsification, adding polyamine for chain propagation; distilling to remove dissolvent after reaction and getting aqueous polyurethane modified with aqueous polyurethane-polyether polymer. The product possesses characteristics of polyurethane and polysiloxane, the storage stability, mechanics property and comprehensive performance is increased and it mainly is used as pigmentum and aqueous industrial coating material.

Owner:山东圣光化工集团有限公司

High molecular weight cationic polyacrylamide preparation method

The invention discloses a high molecular weight cationic polyacrylamide preparation method and the method adopts the inverse suspension polymerization method. The invention is characterized in that the method comprises the following steps: mixing acrylamide, cationic ethyl monomer and composite initiator evenly to form the dispersed phase, adding the dispersed phase in oil-soluble dispersion medium under a certain temperature to disperse to aqueous phase droplets under the action of suspension dispersant and to initiate the polymerization; and after finishing the reaction, obtaining the bead product of high molecular weight cationic polyacrylamide by filtrating and drying the suspension. The invention adopts inverse suspension polymerization method so that the polymerization can be performed steadily at a certain temperature, thus benefiting the chain propagation and providing conditions for the preparation of high molecular weight cationic polyacrylamide; better polymerization effect can be realized by selecting proper composite initiator and using a small amount of initiator so that the high molecular weight product can be obtained and the intrinsic viscosity of the product is not less than 6.0dl / g.

Owner:SOUTH CHINA NORMAL UNIVERSITY

High molecular weight aliphatic-aromatic copolyester and preparation method thereof

The invention relates to the technical field of polymer materials, and especially relates to high molecular weight aliphatic-aromatic copolyester and a preparation method thereof. The preparation method of high molecular weight aliphatic-aromatic copolyester comprises following steps: (1) adding aromatic monomers, 1,4-butanediol, hexanedioic acid, and a catalyst into an intermittent reactor, carrying out esterification reactions under the protection of inert gas, and carrying out condensation polymerization reactions after the esterification reactions are over so as to obtain a PBAT prepolymer; (2) subjecting the obtained PBAT prepolymer to a chain propagation treatment with a double screw extruder when adopting a chain extender so as to obtain a PBAT copolyester with a number-average molecular weight Mn of 10000 to 100000. Compared to the prior art, the preparation method of PBAT copolyester is capable of simplifying the production technology, and has the advantages of controllable operation, realization of continuous production, and reduction on production cost.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Acrylic acid-epoxy resin modified aqueous polyurethane preparation method

The invention relates to a method for producing acroleic acid / epoxide resin modified aqueous polyurethane, which employs processes of interpenetrating polymer network and grafting which comprises following steps: (1) pre-polymerization for polyatomic alcohol and polyisocyanates, adding hydrophilic chain propagation agent chain propagation reaction and getting preploymer containing hydrophilic group; (2) adding mixture of polyhydroxy compound, acroleic acid modified epoxide resin and acrylic ester monomer containing dissolvent into reaction system for second chain propagation reaction; (3) neutralizing by adding neutralization agent, adding water for emulsification, adding polyamine for chain propagation; (4) polymerization for free radical emulsion; (5) distilling to remove dissolvent after reaction and getting polyurethane hybrid water dispersion which taking acrylic resin as nucleus and acroleic acid / epoxide resin modified aqueous polyurethane as shell. The product is characterized by strong weatherability, good chemical product resistance and water resistance, excellent hardness, glossiness, storage stability, mechanics performance and comprehensive property.

Owner:山东圣光化工集团有限公司

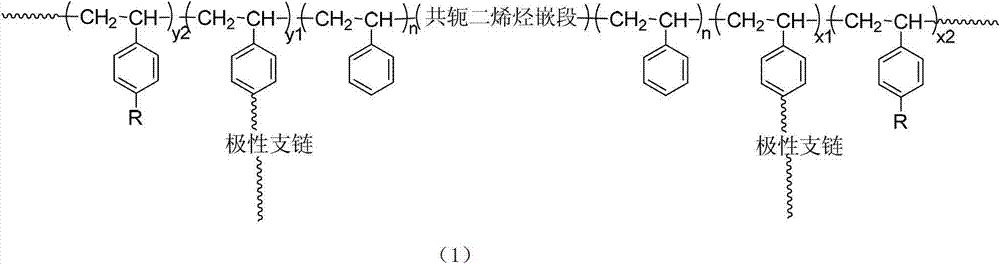

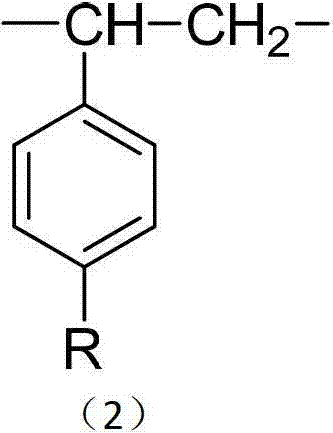

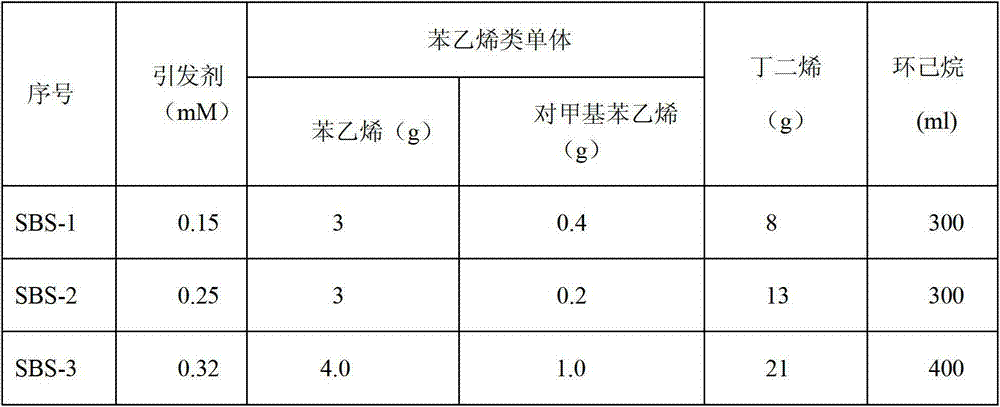

Thermoplastic elastomer containing polar styrene block and preparation method thereof

The invention discloses a thermoplastic elastomer containing polar styrene block and a preparation method thereof. The elastomer is characterized by being a polymer which adopts a linear styrene elastomer polymer as a main chain and is connected with a polar branch chain at the styrene block. The preparation method of the elastomer comprises the following steps of: synthesizing the main chain containing a lithiation unit by virtue of an anionic coupling technology; carrying out lithiation reaction on the main chain; and adding the polar monomer and carrying out chain propagation reaction of the ethylene oxide side chain by utilizing generated lithiation points. The polarity of the thermoplastic elastomer is increased by the polar branch chain; and the defect that the bonding effect of an adhesive using SBC (Polyethylene Polypropylene Fiber) as a substrate is non-ideal is solved.

Owner:DALIAN UNIV OF TECH

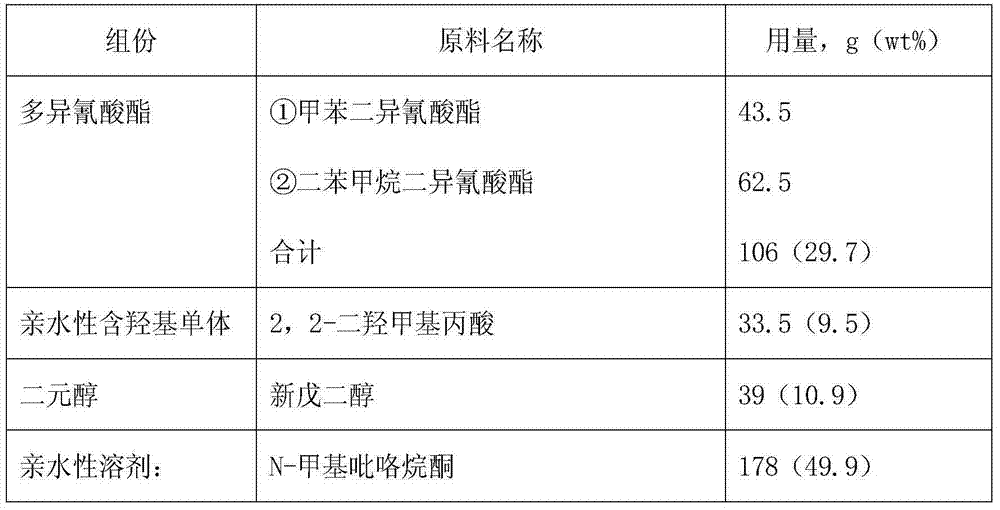

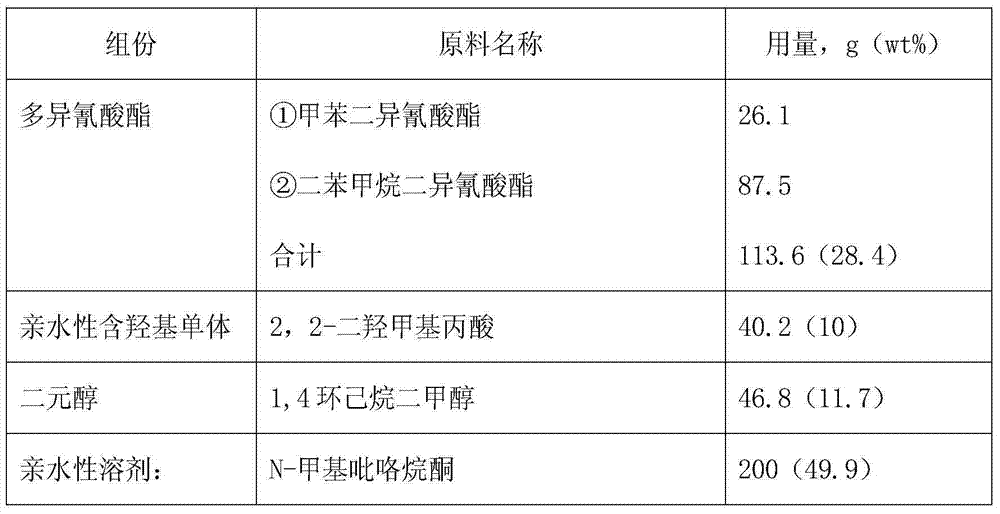

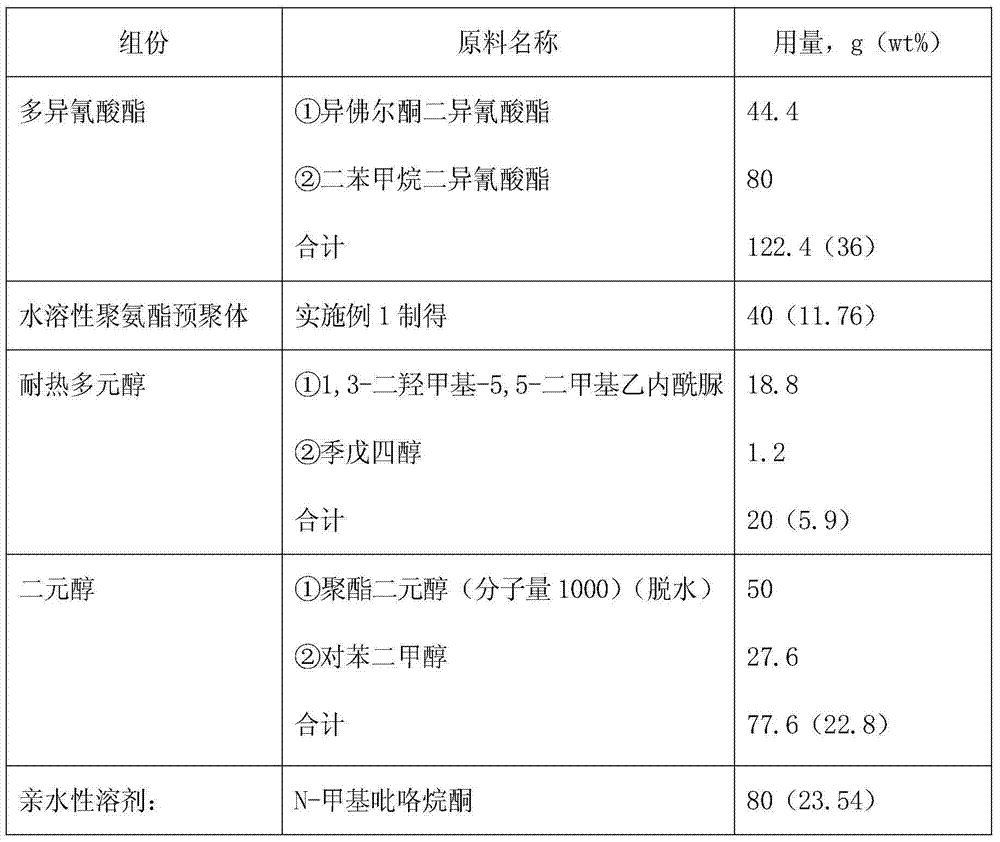

Water-based heat-resistant polyurethane resin and preparation method of same

ActiveCN103539914AGood water solubilityGood dispersionPolyurea/polyurethane coatingsWater basedSolvent

The invention relates to water-base heat-resistant polyurethane resin and a preparation method of the same. The resin is an addition polymerization product of polyisocyanates, dihydric alcohol, heat-resistant polyhydric alcohol, hydrophilic solvent and water-soluble polyurethane prepolymer, and is prepared by neutralization, dispersing, chain propagation and solid content regulation; according to percentage by weight, dosage of each constituent is shown as follows: 1-40% of polyisocyanates, 1-30% of dihydric alcohol, 1-10% of heat-resistant polyhydric alcohol, 1-30% of hydrophilic solvent, and 1-15% of water-soluble polyurethane prepolymer; the water-soluble polyurethane prepolymer is prepared from 5-20wt% of hydrophilic hydroxyl-containing monomer, 20-40wt% of polyisocyanates, 5-20wt% of dihydric alcohol and 30-60wt% of hydrophilic solvent through the addition polymerization under the condition of 50-100 DEG C. For the resin provided by the invention, weight loss at 200 DEG C is not more than 3wt%, and the paint film is unchanged after the resin is dipped for 168 hours at 25 DEG C, so that the application range of the water-base polyurethane resin is expanded.

Owner:CHINA NAT OFFSHORE OIL CORP +3

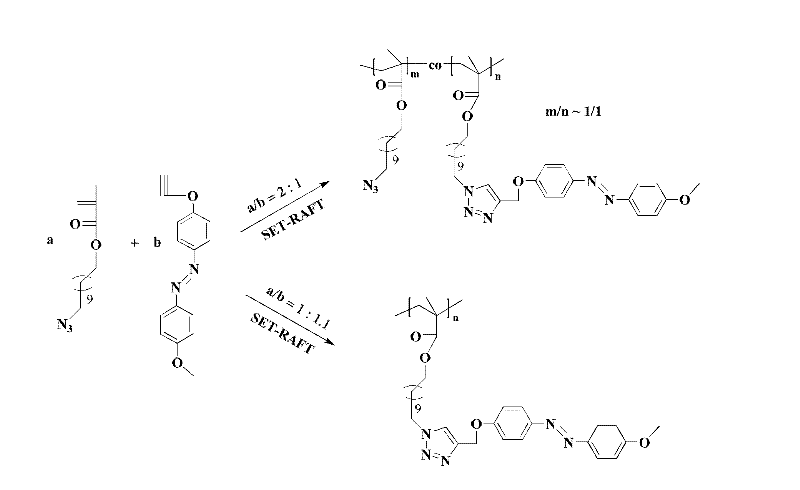

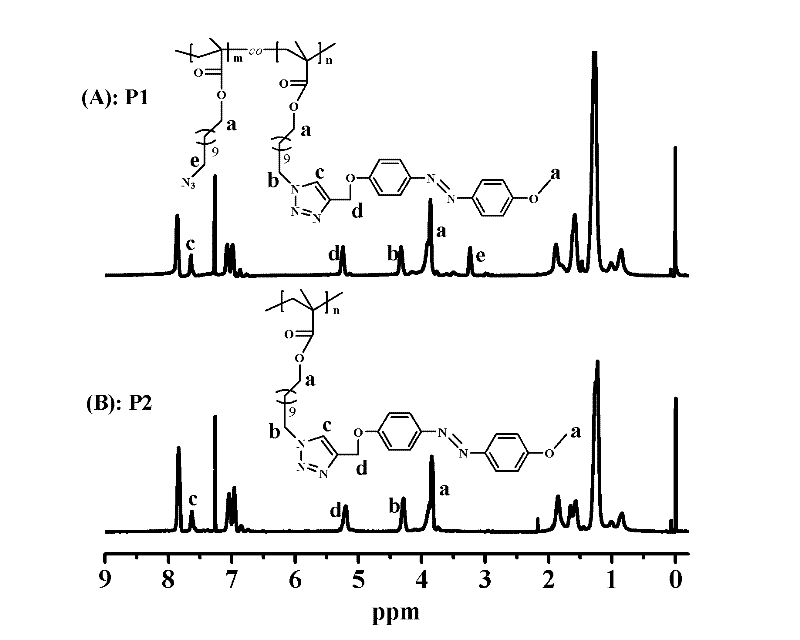

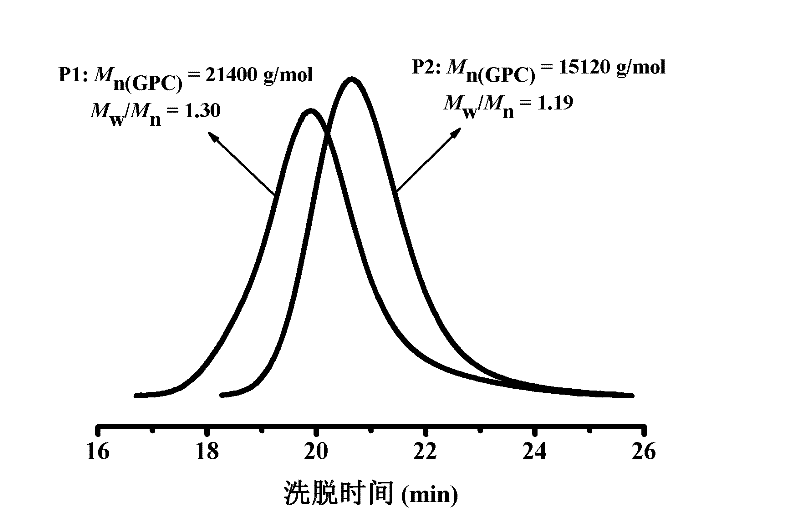

Side chain functional polymer and preparation method thereof

The invention discloses a side chain functional polymer and a preparation method thereof. A polymerization system consists of a monomer, an initiator, a chain transfer agent, a catalyst, a coordination agent and a coupling component, wherein the monomer is undecyl azidomethacrylic ester; the catalyst is copper; the coordination agent is N,N,N',N'',N''-pentamethyldiethylenetriamine; the coupling component is 4-methyoxyl-4'-propynyloxy azobenzene; single electron transfer (SET) is adopted for initiation to produce a free radical; polymerization reaction of the monomer is performed by a method for performing chain propagation in a reversible addition fragmentation chain transfer (RAFT) mode; meanwhile, click chemical reaction is performed; and monovalent copper is used for catalyzing an azide group and an alkynyl group in the coupling component to perform cycloaddition reaction so as to obtain the side chain functional polymer. Since the SET-RAFT method and the click chemical method are combined, the side chain functional polymer can be obtained by only one-step reaction; and thus, the reaction steps are reduced, the waste rate of the raw materials is reduced, rational utilization ofthe resources is realized, side reaction is basically avoided, and troublesome purification operation is avoided.

Owner:SUZHOU UNIV

Solid catalyst component for preparing ultra-high molecular weight polyethylene

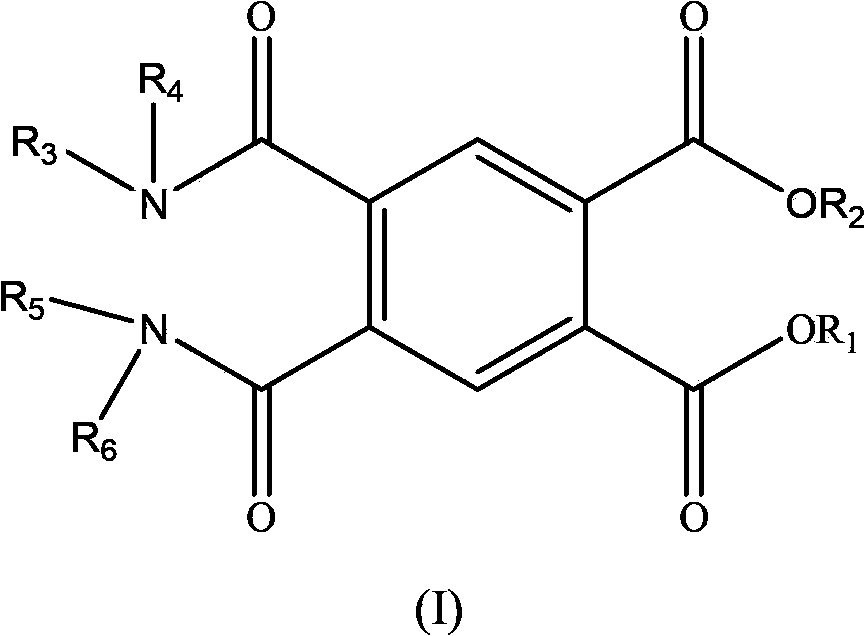

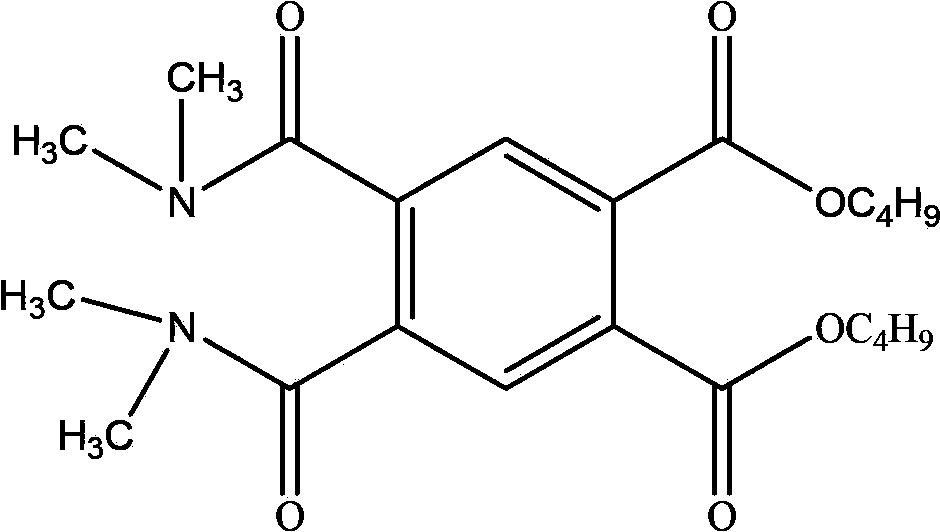

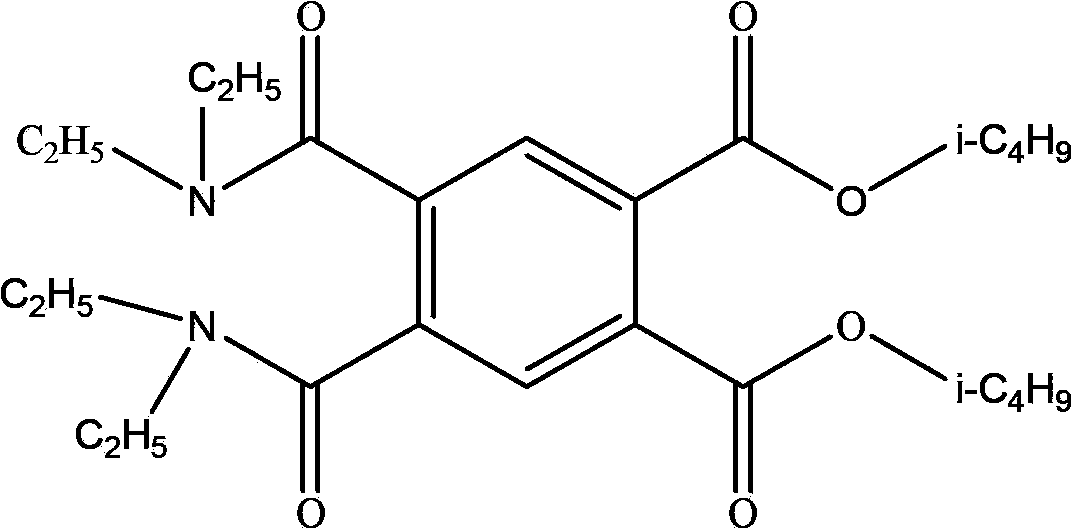

The invention discloses a solid catalyst component for preparing ultra-high molecular weight polyethylene. The solid catalyst component is mainly composed of anhydrous magnesium compound, alcohol, halogenated titanium, a titanate compound and a diester compound and is characterized in that the diester compound satisfies the structure represented by a general formula (I), the mol ratio of magnesium to diester in the catalyst is (100: 1)-(20: 1), and the mol ratio of the magnesium to titanium is (50: 1)-(1: 1). The diester compound with a specific structure is used as an internal electron donor so as to increase reaction capacity of active centre of chain propagation of the catalyst in the polymerization process and increase the chain length; the catalyst can be used for preparing the ultra-high molecular weight polyethylene, the catalytic activity is high, and the powder form stacking density of the polymerisate is good. The invention further discloses a preparation method of the catalyst component.

Owner:PETROCHINA CO LTD

Method for preparing emulsion acrylic pressure-sensitive adhesive for high-speed coating machine

ActiveCN102504091AReduce surface tensionLow viscosityEster polymer adhesivesCross-linkPolymer science

The invention discloses preparation of an emulsion acrylic pressure-sensitive adhesive for a high-speed coating machine, which comprises the following steps of: preparation of pre-emulsion, i.e. adding a reactive monomer, an emulsifier, a wetting agent, a cross-linking agent and deionized water into a high-level emulsification tank to prepare the pre-emulsion for later use; preparation of seed emulsion and primary nucleation, i.e. performing the primary nucleation reaction for 1 to 4 hours; secondary nucleation, i.e. adding a functional monomer and a small amount of deionized water into the residual pre-emulsion and continuously dropwise adding an initiator with stirring; and chain propagation and partial cross-linking polymerization of a polymer, i.e. after totally dropwise adding the raw materials in the emulsification tank and the initiator, carrying out chain propagation and partial cross-linking polymerization for 1 to 4 hours. The emulsion acrylic pressure-sensitive adhesive has low raw material cost, high bonding strength, good adhesive application performance on the premise of the same solid content, and high curing speed.

Owner:CHANGZHOU BAOLI ADHESIVE

Synthesis technology of single-component water-based polyurethane finishing agent

ActiveCN102050936AReduce manufacturing costSimple application processPolyurea/polyurethane coatingsLeather surface finishingPolymer scienceToluene diisocyanate

The invention discloses a synthesis technology of single-component water-based polyurethane finishing agent, which is characterized in that polyether glycol, toluene diisocyanate, cross-linking agent and the like are taken as the main row material and are prepared into stable self cross-linking and self-emulsifying type -component water-based polyurethane finishing agent through prepolymerization, chain propagation, quaternization, emulsification and the like. By adopting the invention, the film is water-resistant and has good the heat resistance, and the coating is abrasion and dry resistant and has good wet rubbing fastness, so that the finishing requirements of high-grade leather such as sofa leather and the like can be satisfied.

Owner:温州市登达化工有限公司

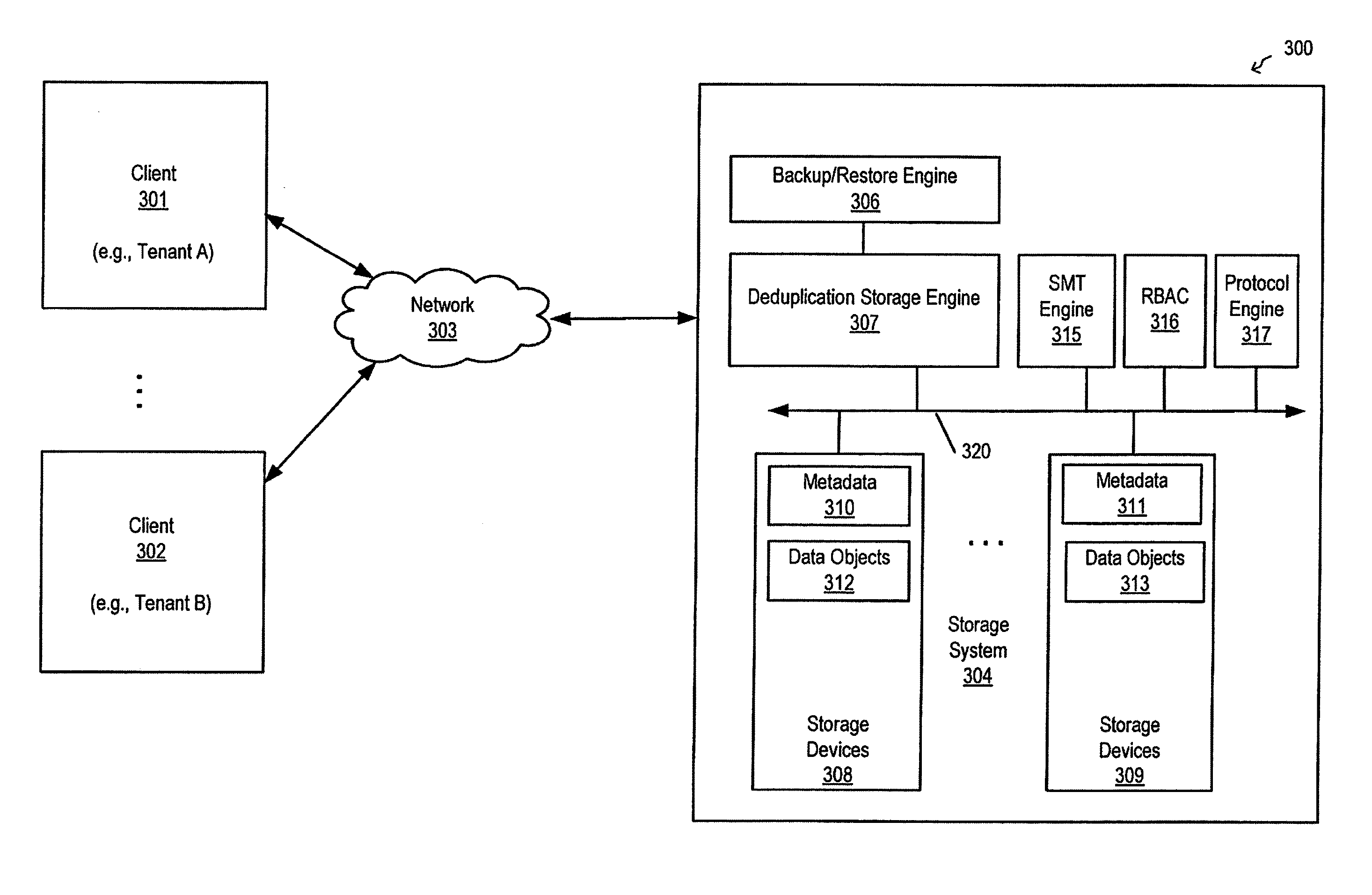

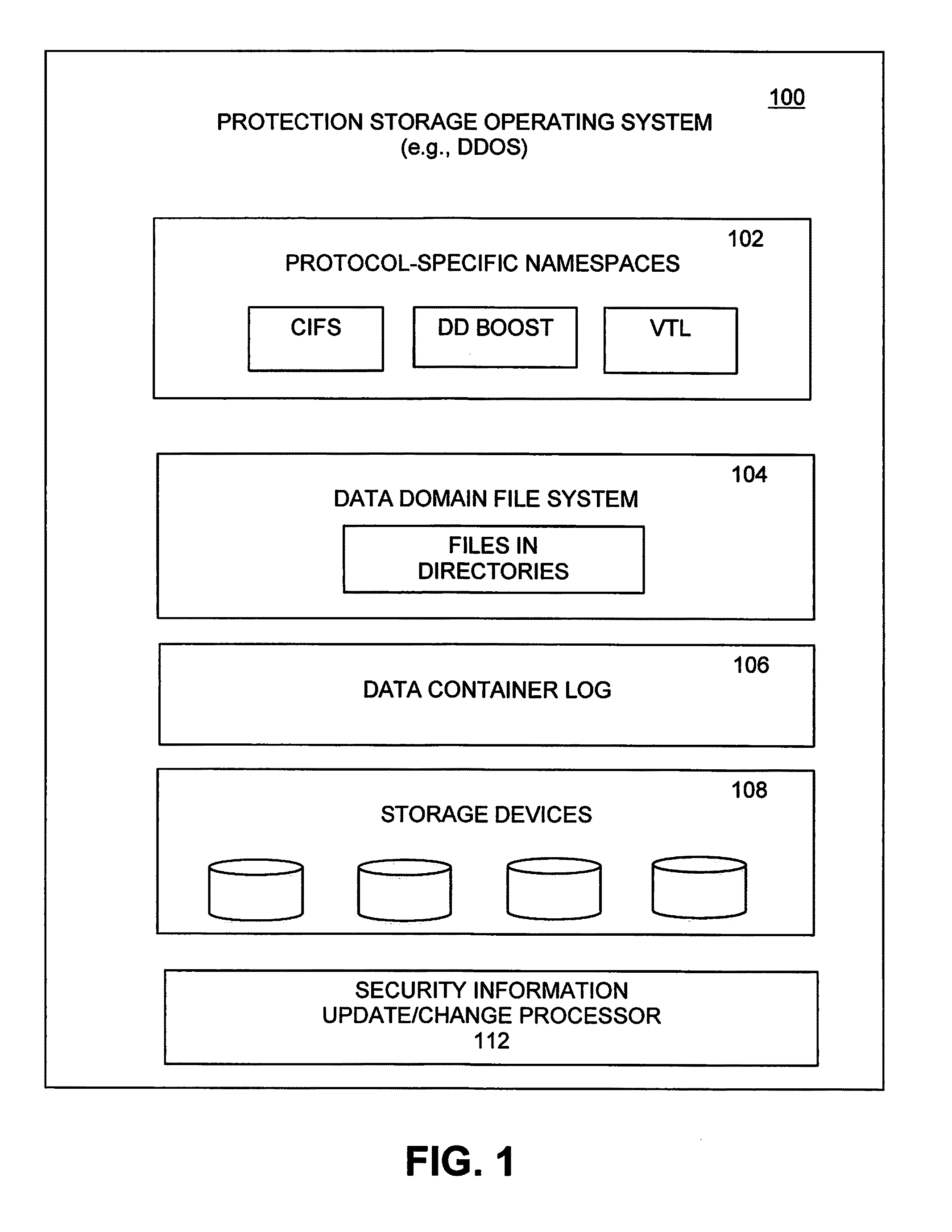

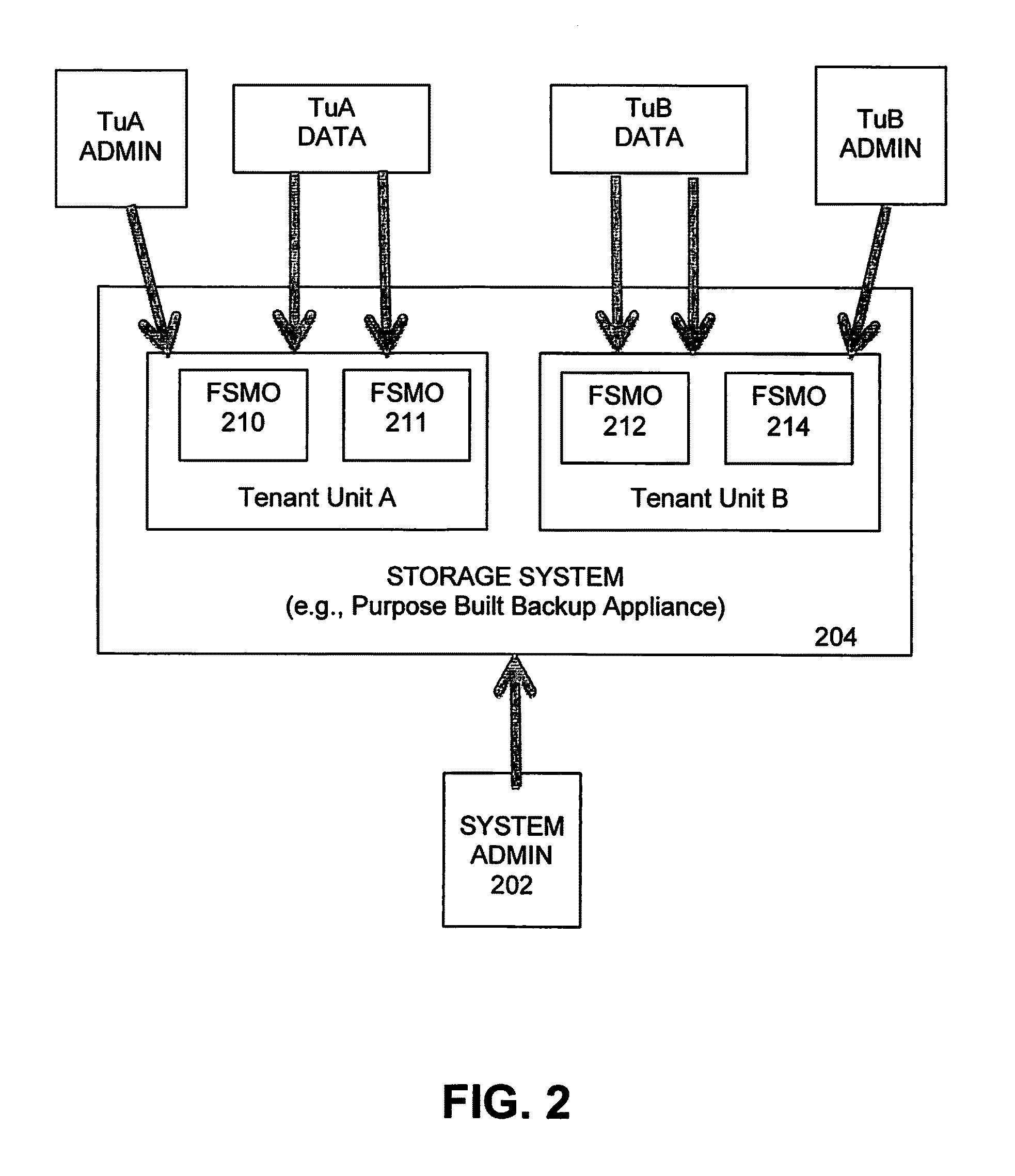

Cache-free and lock-free handling of security information for multiple distributed objects in protection storage systems

A native protection storage operating system (PSOS) process receives a request specifying an operation having security related implications for elements in the PSOS having a first set of components handling data transfer operations and a second set of components handling configuration operations. A security component stores an identifier of the requester and a security related information element locally within a storage location of the first or second set of components, and accesses, upon receiving the request, the security related information element and requester identifier to match other elements of the network impacted by the request, and performs a security condition specific check to determine whether or not the request is to be allowed or denied. The native process eliminates a need for caching, locking, and chain propagation of the security related information through the PSOS.

Owner:EMC IP HLDG CO LLC

Biodegradable spandex for paper diaper, and preparation method thereof

ActiveCN104630929AFast biodegradationImprove adhesionMonocomponent synthetic polymer artificial filamentArtifical filament manufactureAntioxidantPhosphate

The invention relates to a biodegradable spandex for paper diaper, which comprises biodegradation promotion composition and spandex for paper diaper, wherein the biodegradation promotion composition includes potassium dodecyl phosphate, sodium lauroyl glutamate and UV-320. The preparation method of the biodegradable spandex for paper diaper comprises the following steps: 1) enabling oligomer diol to react with diisocyanate to generate prepolymer; 2) performing chain propagation reaction to the prepolymer through amine chain extender, to obtain polymer stock solution; 3) adding the biodegradation promotion composition to the polymer stock solution, and adding an antioxidant, a delustering agent and a lubricant, fully stirring, to obtain spinning stoack solution; and 4) performing dry-process spinning to the spinning stock solution to prepare the biodegradable spandex for paper diaper. The biodegradable spandex for paper diaper has high biodegradation speed, excellent adhesion effect with base materials, and smooth unwinding property.

Owner:ZHEJIANG HUAFENG SPANDEX

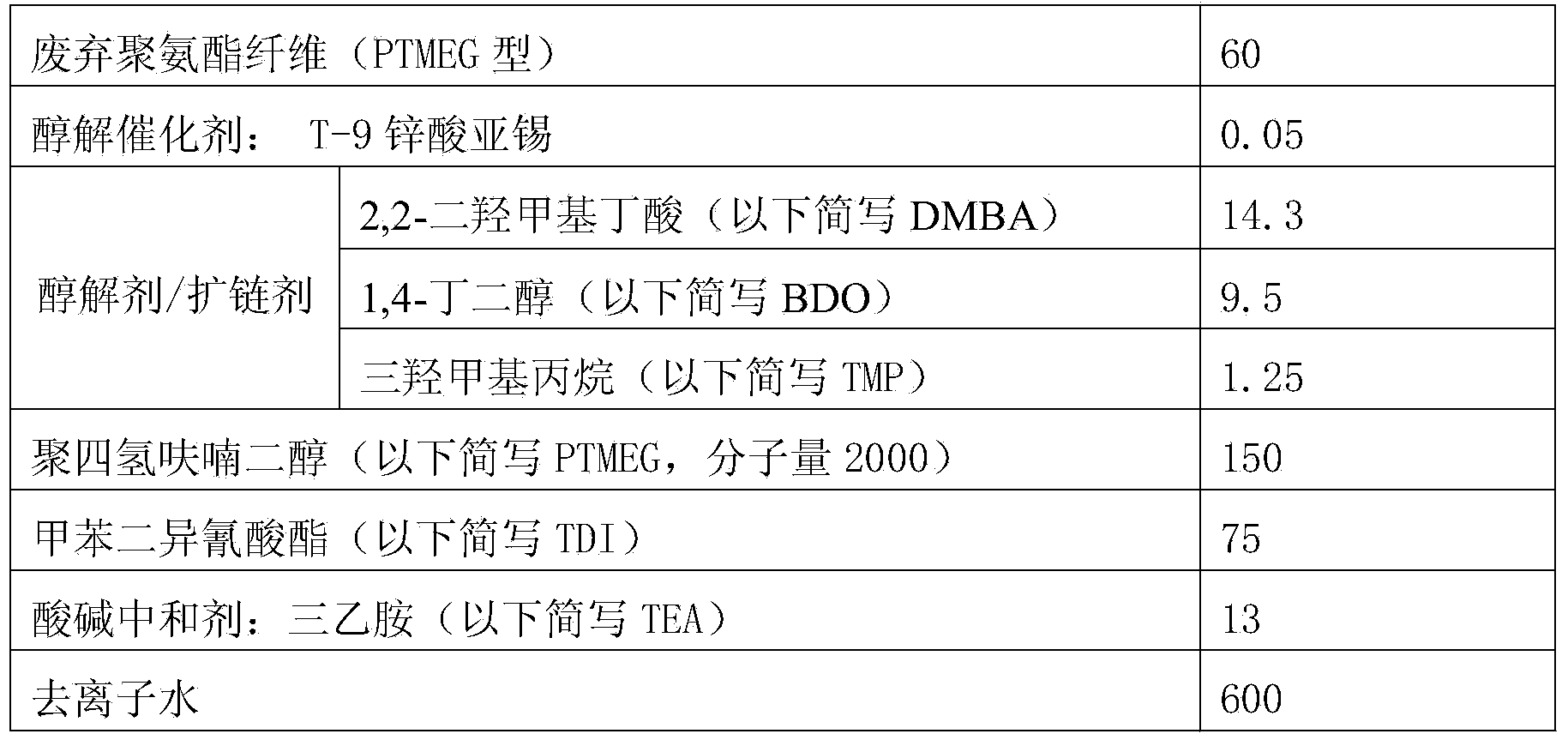

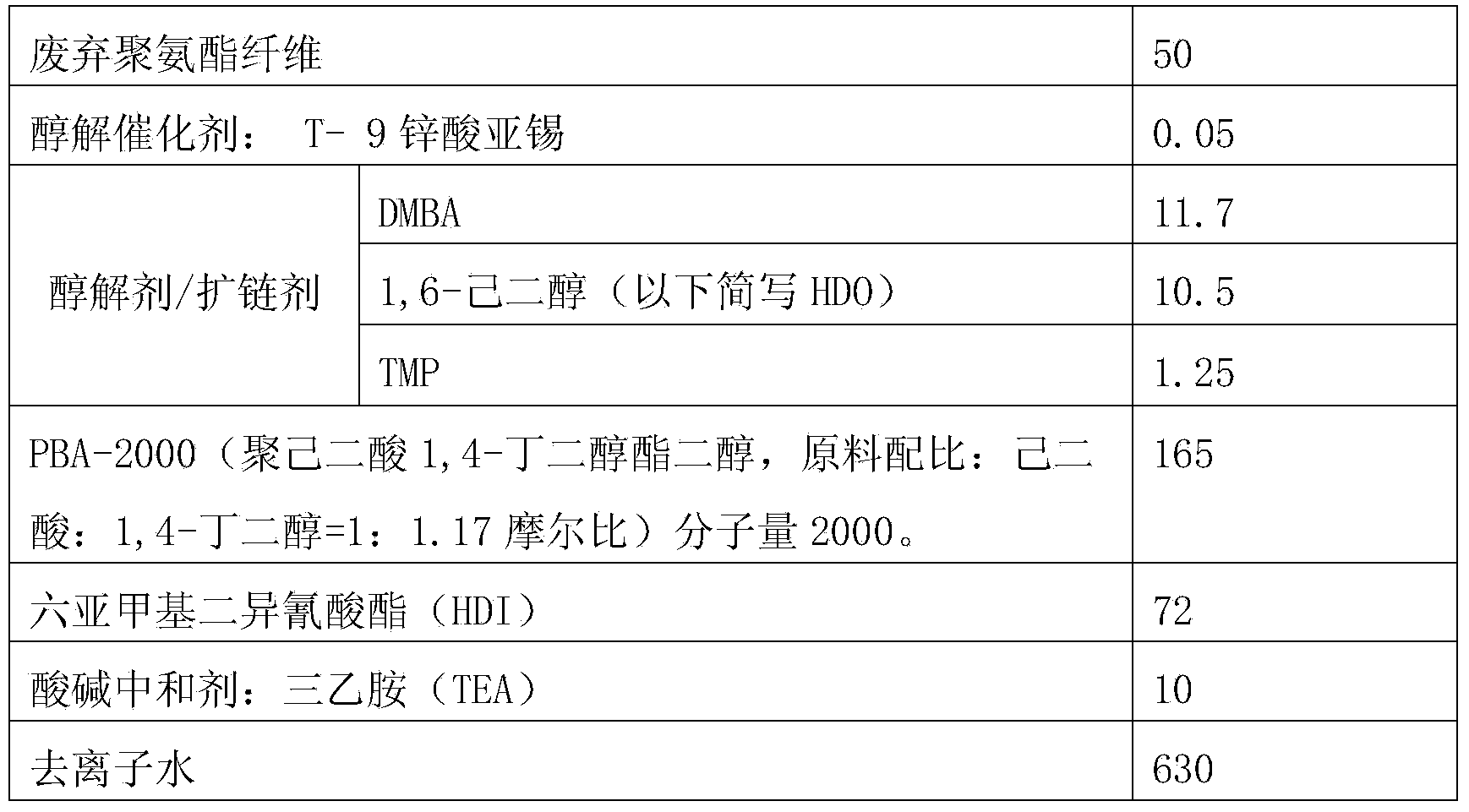

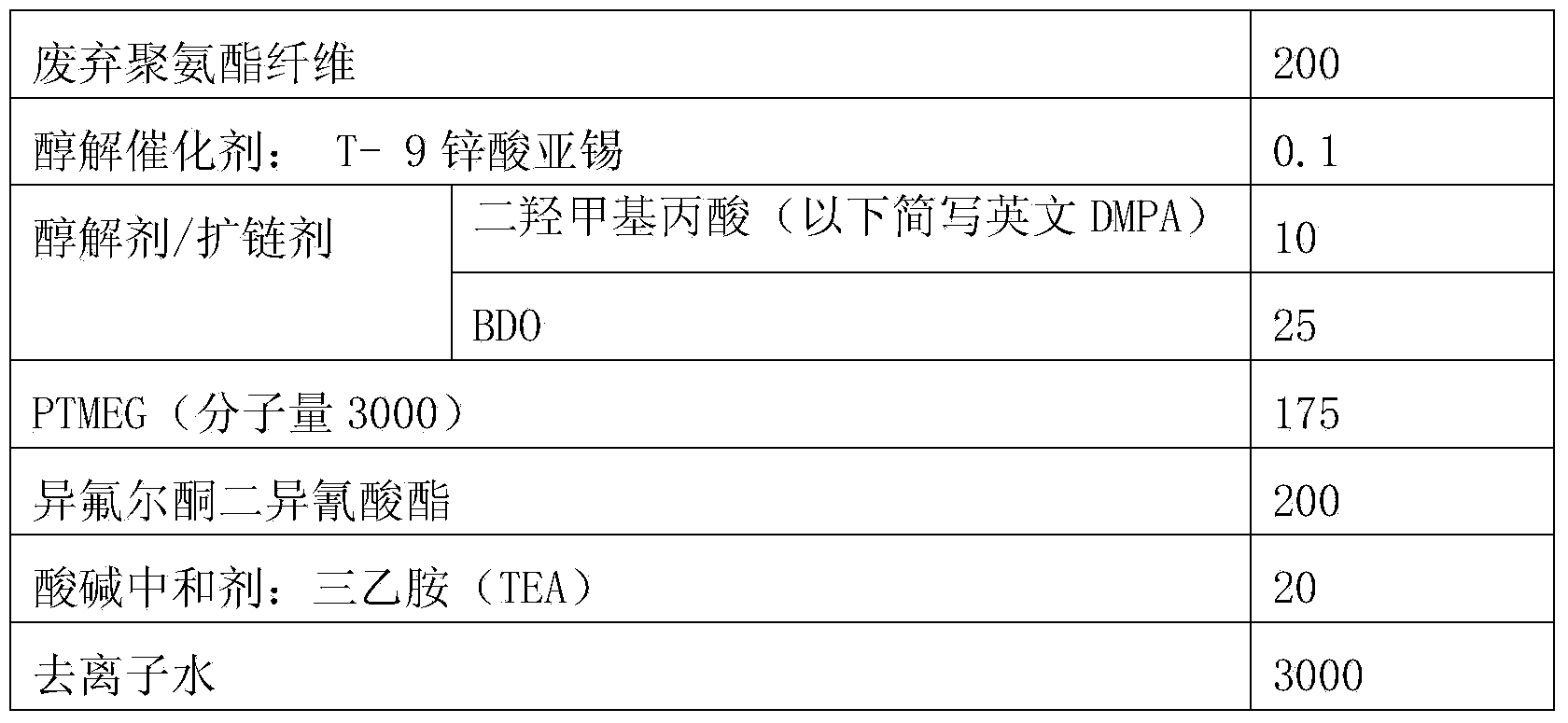

Preparation method of aqueous polyurethane emulsion and aqueous polyurethane emulsion prepared thereby

InactiveCN103641974AReduce manufacturing costPromote technological developmentPolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsFiberPolyol

The invention provides an aqueous polyurethane emulsion preparation method. The preparation method comprises the following steps: subjecting waste polyurethane fibers to an alcoholysis treatment so as to obtain a mixture of hydroxyl terminated polyurethane with a molecular weight of 5000 to 10000 and polyol, and directly subjecting the mixture to processes of pre-polymerization, chain propagation, and emulsification so as to one-step obtain aqueous polyurethane emulsion; wherein the waste polyurethane fiber is preferably selected from waste polyether type polyurethane fiber and / or polycarbonate type polyurethane fiber generated by dry spinning or wet spinning; more preferably, the waste polyurethane fiber is selected from waste polytetramethylene glycol type polyurethane fiber and / or polycarbonate diol type polyurethane fiber whose soft section ratio is 85% or more; and most preferably, the waste polyurethane fiber is waste polytetramethylene glycol type polyurethane fiber whose soft section ratio is 85% or more. The preparation method provided a more reasonable reutilization method with a more additional value for waste high-grade polyurethane fibers.

Owner:高松文

Fluorine-containing polyether graft modified aqueous polyurethane and preparation and application thereof

InactiveCN101157750BHas self-emulsifying propertiesNo emissionsOther chemical processesPolymer sciencePolyol

The present invention relates to a fluorine-containing polyether grafting modified waterborne polyurethane, the preparation and the application thereof, a structural general formula of polyurethane is as the formula, wherein, R1 is equal to a polyurethane soft-segment polyol structure, R2 is equal to a polyurethane hard-segment isocyanate structure, R3 is equal to a polyurethane hard-segment chain extender structure, R4 is equal to the fluorine-containing polyether; X is equal to NH and O; the preparation is that: the polyol and the isocyanate react to compound the polyurethane prepolymer, then the waterborne polyurethane are obtained through the chain propagation of a chain extender, then the waterborne polyurethane and the fluorine-containing polyether are carried out a grafting reaction in the big molecules, so as to synthesize the fluorine-containing polyether grafting modified waterborne polyurethane; the application is that: the present invention can be applied to aerospace, aviation, automobiles, electronics, textiles, carpets, leathers, paper making, packaging, washing, machinery, construction and other fields. The present invention adopts the water as the solvent and has no formaldehyde, no or low VOC emission, no bioaccumulation and no toxicity, which is a multifunctional, green, environment protective, water-proof and dirt-proof coating layer and fabric finishing agent.

Owner:DONGHUA UNIV

Preparation method of flesh-colored spandex

InactiveCN104278354AEvenly dispersedReduce reunionMonocomponent synthetic polymer artificial filamentPigment addition to spinning solutionPolymer scienceAntioxidant

The invention relates to a preparation method of flesh-colored spandex. The preparation method comprises the following steps: in a pre-polymerization tank, sequentially adding DMAC and polytetramethylene ether glycol PTMG, then adding 4,4-diphenylmethane diisocyanate 4,4-MDI according to the set NCO / OH ratio, and performing full pre-polymerization reaction; after the reaction is over, adding the prepared pigment solution, and stirring to obtain a low-polymer solution in which pigment is uniformly distributed; and transferring a polymerized product into a chain extension tank, stirring to be even, controlling to dropwise add a mixed amine DMAC solution at low temperature so as to perform chain propagation and chain termination to finally obtain polyurethane urea solution, wherein the mixed amine DMAC contains a diamine chain extender and a monoamines termination agent; then adding an antioxidant, a lubricant, a delustrant, an ultraviolet absorbent and the like, stirring and dispersing; and finally, by virtue of dry spinning system, performing spinneret drawing, high-temperature drying, oiling of an oil agent, winding and forming to pigment-containing polyurethane urea stock solution, so as to obtain flesh-colored spandex.

Owner:ZHEJIANG HUAFENG SPANDEX

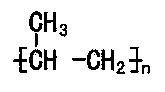

Weather-proof polypropylene material

InactiveCN103509244AImprovement and improvement of mechanical propertiesSimple production methodThermoplasticPolymer science

The invention belongs to the technical field of polypropylene (PP) material production, and aims at improving the disadvantages of polypropylene and producing products accord with social demands. Polypropylene resin belongs to hemicrystalline thermoplastic plastic, possesses relatively high impact resistance and strong mechanical property, is capable of resisting multiple organic solvents and resisting acid / base corrosion, is widely applicable to industries, and belongs to one of common high-molecular materials. Because of a large amount of unstable tertiary carbon atoms existed in the polypropylene chain, in the presence of oxygen, only extremely small energy is needed for removing of hydrogen atoms of the tertiary carbon atoms and further for forming of tertiary carbon free radicals. The tertiary carbon free radicals are extremely active, and can cause generation of various reactions comprising chain propagation and chain degradation on the molecular chain, and thus the PP material loses original performances and is aged. PP is extremely easy to age, and the basic physical performances of PP are all lost if PP is placed outdoors without an added antioxidant for one month, and therefore if PP is applied outdoors, a method must be found for improving the aging resistance of PP.

Owner:QINGDAO YISHIBAO PLASTIC

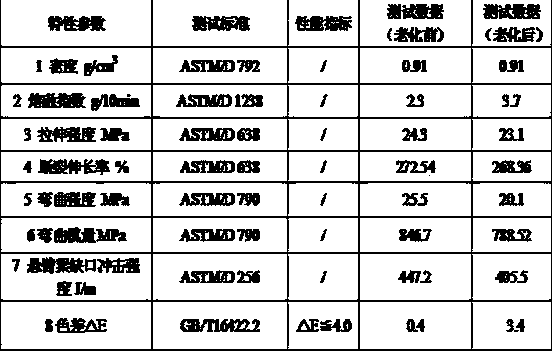

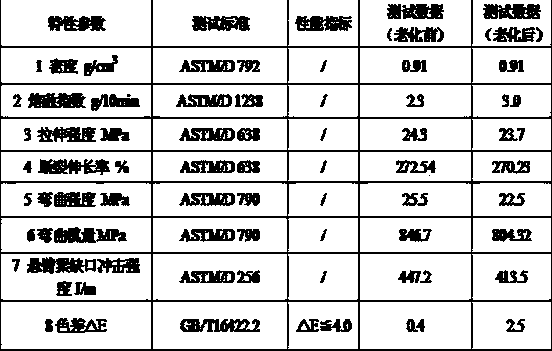

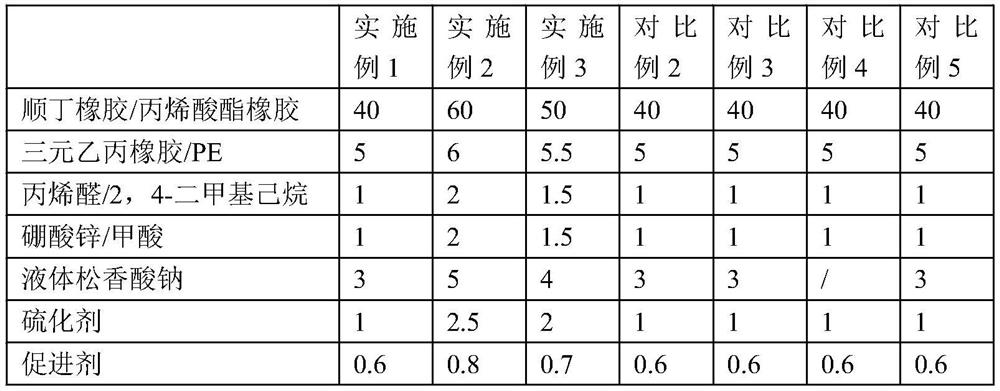

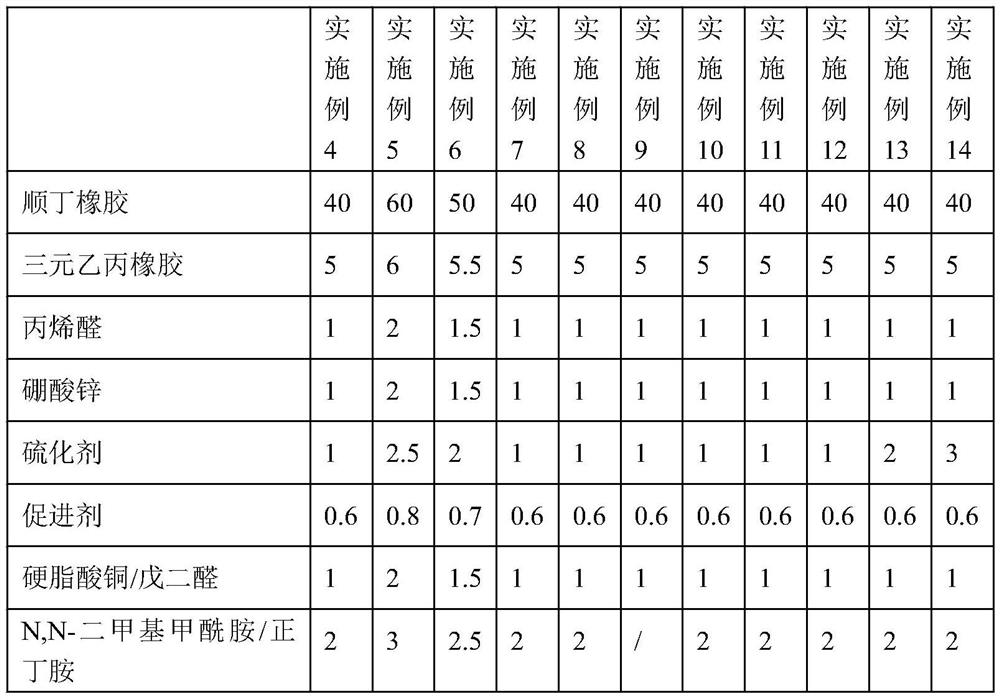

Female shoe with anti-aging sole and preparation process thereof

PendingCN112266508AIncrease connection densityImprove aging resistanceSolesDomestic footwearPolymer scienceVulcanization

The invention relates to the field of shoes, and discloses a female shoe with an anti-aging sole and a preparation process thereof. Thefemale shoe with an anti-aging sole comprises a vamp and a sole,wherein the sole comprises the following raw materials in parts by weight: 40-60 parts of butadiene rubber, 5-6 parts of ethylene propylene diene monomer, 1-2 parts of acrolein, 1-2 parts of zinc borate, 3-5 parts of liquid sodium abietate, 1-2.5 parts of a vulcanizing agent, and 0.6-0.8 part of an accelerant. The preparation process comprises the following steps of mixing raw materials, conducting vulcanization, and forming a female shoe. The process has the following advantages and effects that the blended ethylene propylene diene monomer and butadiene rubber have good weather resistance, heat resistance and acid and alkali resistance; butadiene rubber containing double bonds is easily subjected to chain propagation reaction with acrolein, ethylene propylene diene monomer and the like, so that the bonding density among the components is improved, and the anti-aging performance is improved; after zinc borate and liquid sodium abietate are mixed, the problems that the content of doublebonds is increased due to addition of butadiene rubber and acrolein, the shoe sole is easily eroded by oxygen in air, and the mechanical property is reduced can be solved, and the aging resistance ofthe shoe sole is improved.

Owner:WENZHOU BAILIDUO SHOES CO LTD

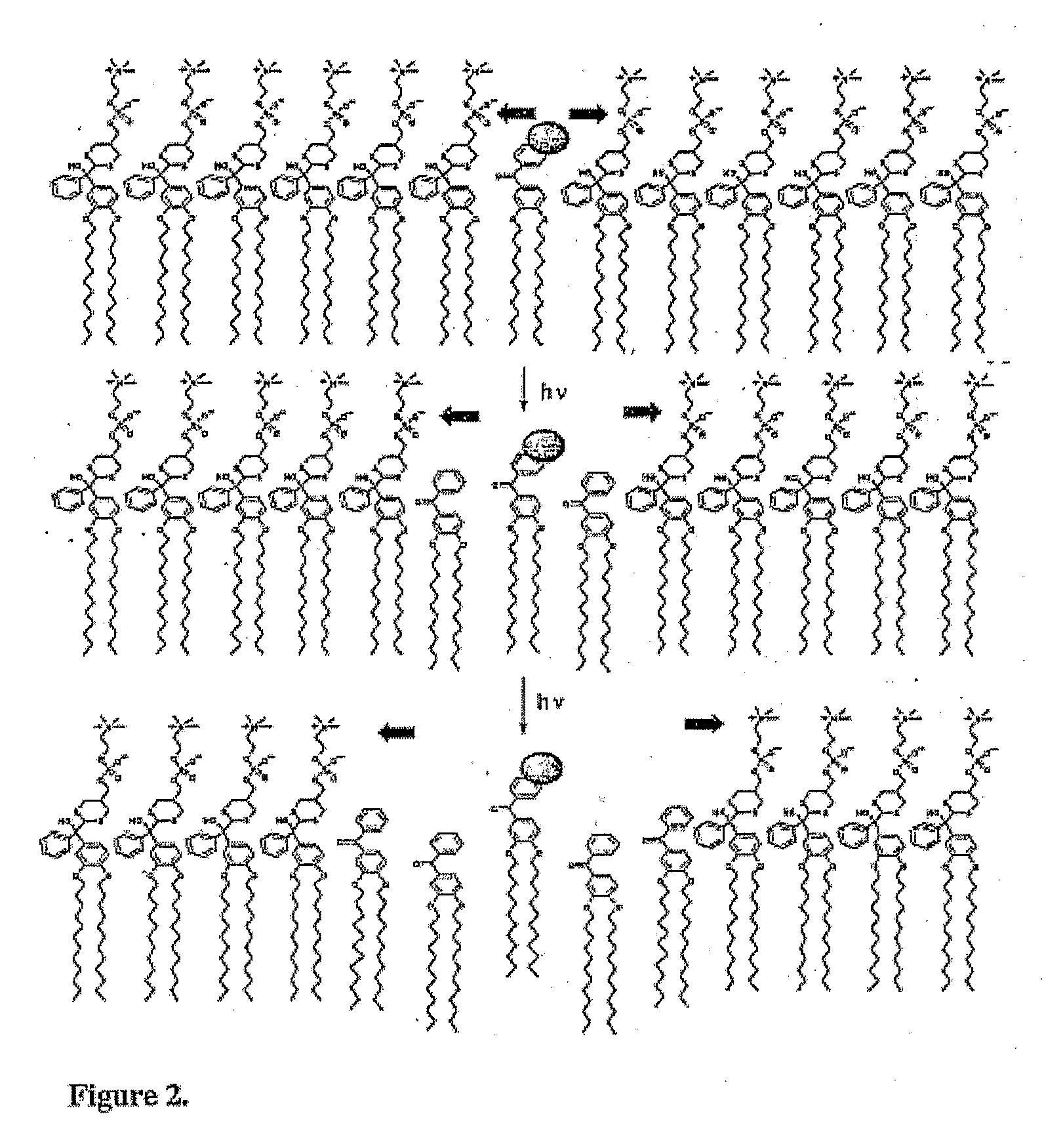

Photoinduced Signal Amplification Through Externally Sensitized Photofragmentation in Masked Photosensitizers

InactiveUS20080312092A1Not exactHigh quantum yieldChemiluminescene/bioluminescenceLibrary screeningLeaving groupPhotosensitizer

A method of photochemically amplifying the chemical signal associated with unmasking a photosensitizer and releasing a radical leaving group when a photochemical chain reaction is initiated by a sensitizer attached to a molecule of interest is provided. More specifically, provided is a method of photoinduced amplification comprising: providing a plurality of masked photosensitizers, each masked photosensitizer having a masking group bonded to a photosensitizer through a releasable covalent bond which disrupts the conjugation of the photosensitizer; providing a reaction photosensitizer in releasing proximity to a first masked photosensitizer; exciting the reaction photosensitizer with photoradiation, whereby the reaction photosensitizer induces release of the masking group from the first masked photosensitizer, producing a first unmasked photosensitizer which induces release of the masking group from a second masked photosensitizer in releasing proximity to the first masked photosensitizer, and so on. The release of the masking group from masked photosensitizer continues as long as masked photosensitizers are in releasing proximity to the reaction photosensitizer, or until a side reaction occurs which stops the chain propagation, or until the source of light is turned off.

Owner:COLORADO SEMINARY

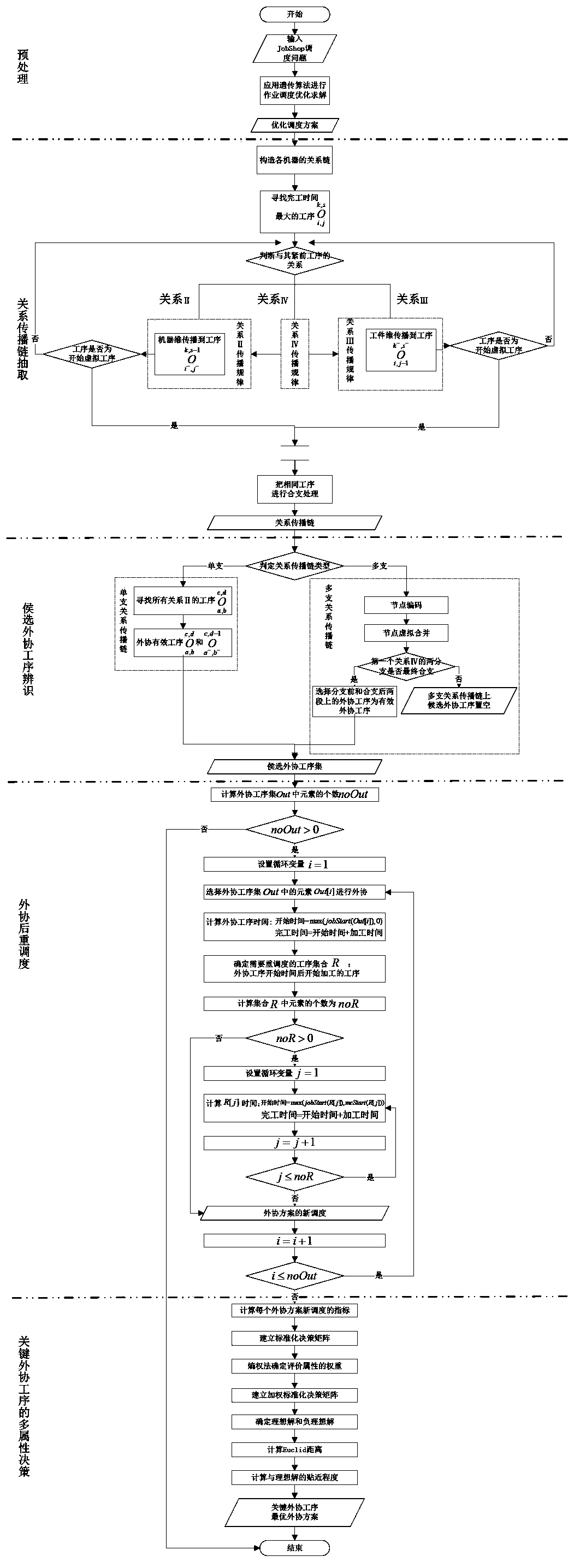

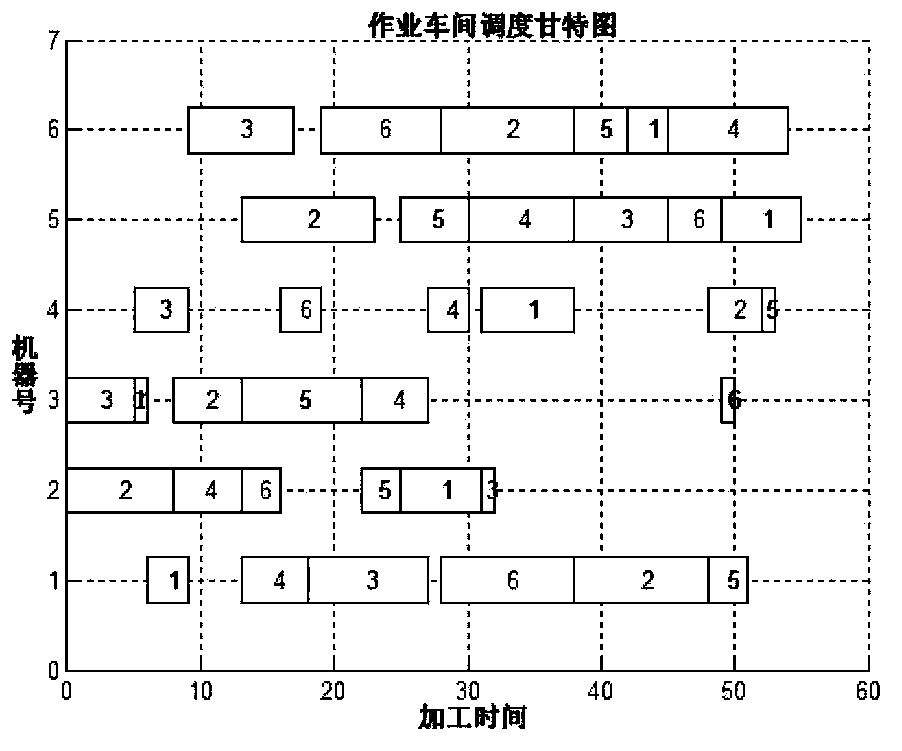

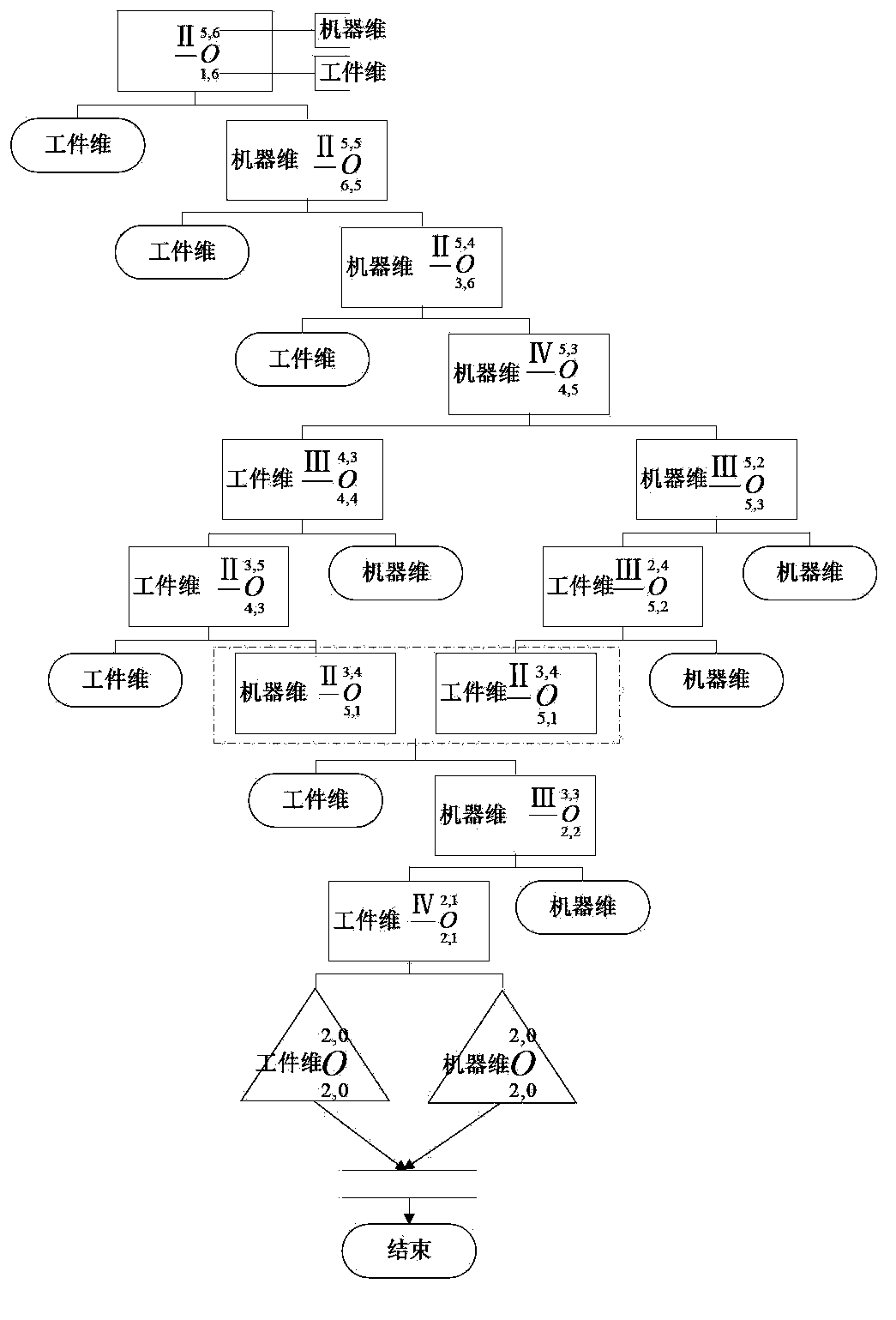

Improved relation chain-based job shop scheduling key outsourcing process identification method

The invention provides an improved relation chain-based job shop scheduling key outsourcing process identification method. The method comprises the following steps of: firstly, initial scheduling is obtained according to a scheduling problem; secondly, a relation propagation chain is extracted according to processing rules of relation chains; thirdly, a candidate key outsourcing process is identified; fourthly, an affected process is rescheduled after outsourcing; and finally, multi-attribute decision making is performed according to the situation of a production site, and an optimal key outsourcing process and a corresponding production scheduling scheme can be outputted. With the method of the invention adopted, a relation chain propagation extraction functional module and a candidate outsourcing process identification functional module can be separated, and therefore, follow-up improvement and replacement of respective function methods can be facilitated, and stronger portability can be realized; and when a relation 4 identification candidate outsourcing process exists in relation propagation chains, the candidate outsourcing process can be directly identified through using rules, and the amount of calculation of testing and rescheduling can be reduced.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

High-strength low-stretch chinlon 6 short fiber and preparation method thereof

ActiveCN109402764AEvenly dispersedImprove mechanical propertiesArtifical filament manufactureMonocomponent polyamides artificial filamentBreaking strengthFiber

The invention relates to a high-strength low-stretch chinlon 6 short fiber and a preparation method thereof. The method includes: spinning high-strength low-stretch chinlon 6 melt to prepare the high-strength low-stretch chinlon 6 short fiber, wherein the high-strength low-stretch chinlon 6 is produced through a reinforcing powder surface chain propagation reaction, a ring-opening pre-polycondensation reaction, a final polycondensation reaction, and a tackifying reaction from a mixture, which is mainly composed of: caprolactam, the reinforcing powder coated with a catalyst, and water. The produced high-strength low-stretch chinlon 6 short fiber is 0.89-2.22 dtex in linear density, not less than 6.0 cN / dtex in breaking strength and not more than 45% in breaking elongation. The reinforcing powder can enhance mechanical performances of the chinlon 6 short fiber; by means of the reinforcing powder surface chain propagation reaction, the reinforcing powder can be dispersed completely in thefiber, so that the chinlon 6 short fiber has good mechanical performances, uniform strength distribution and high quality.

Owner:江苏恒创园区管理服务有限公司

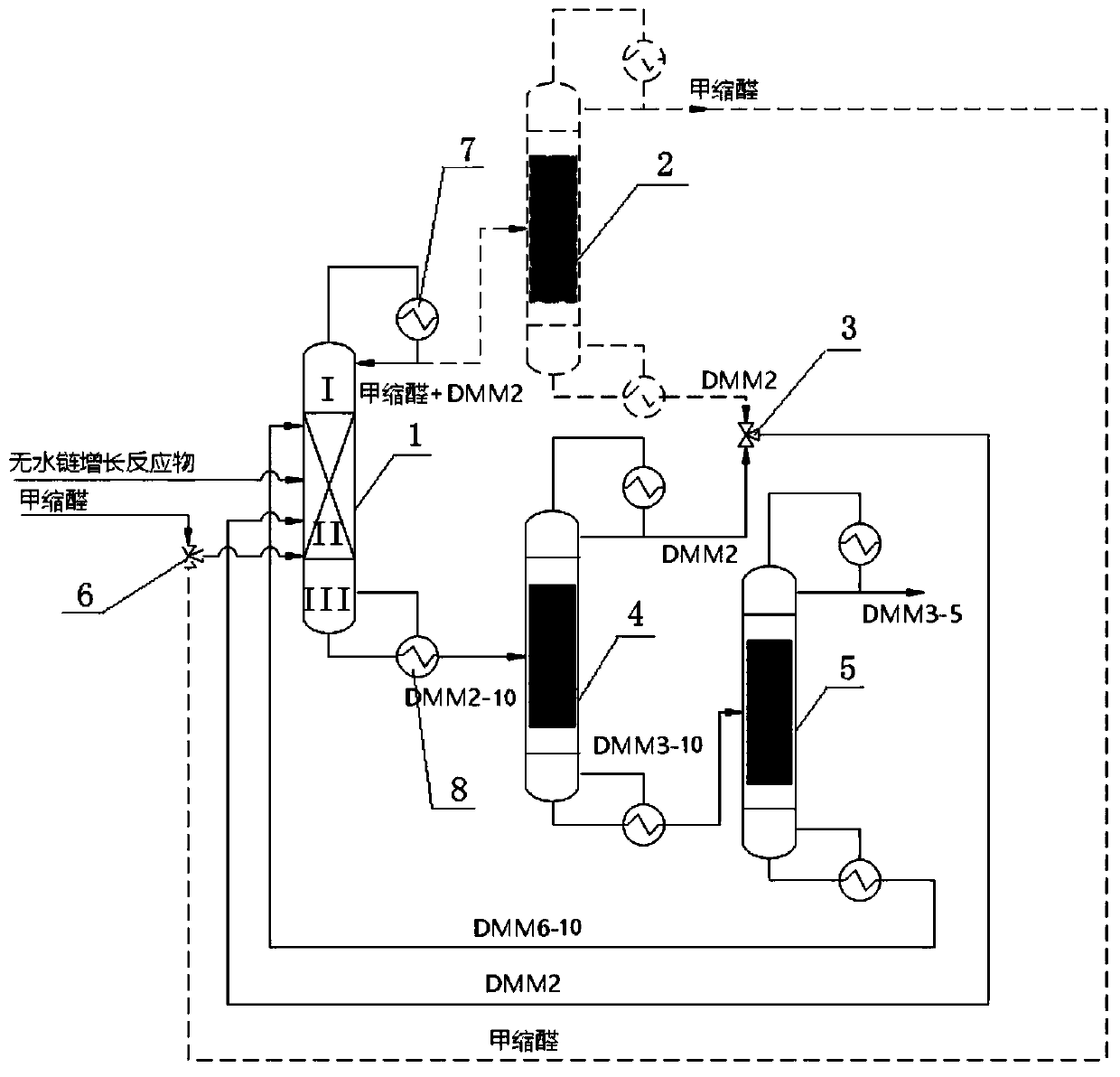

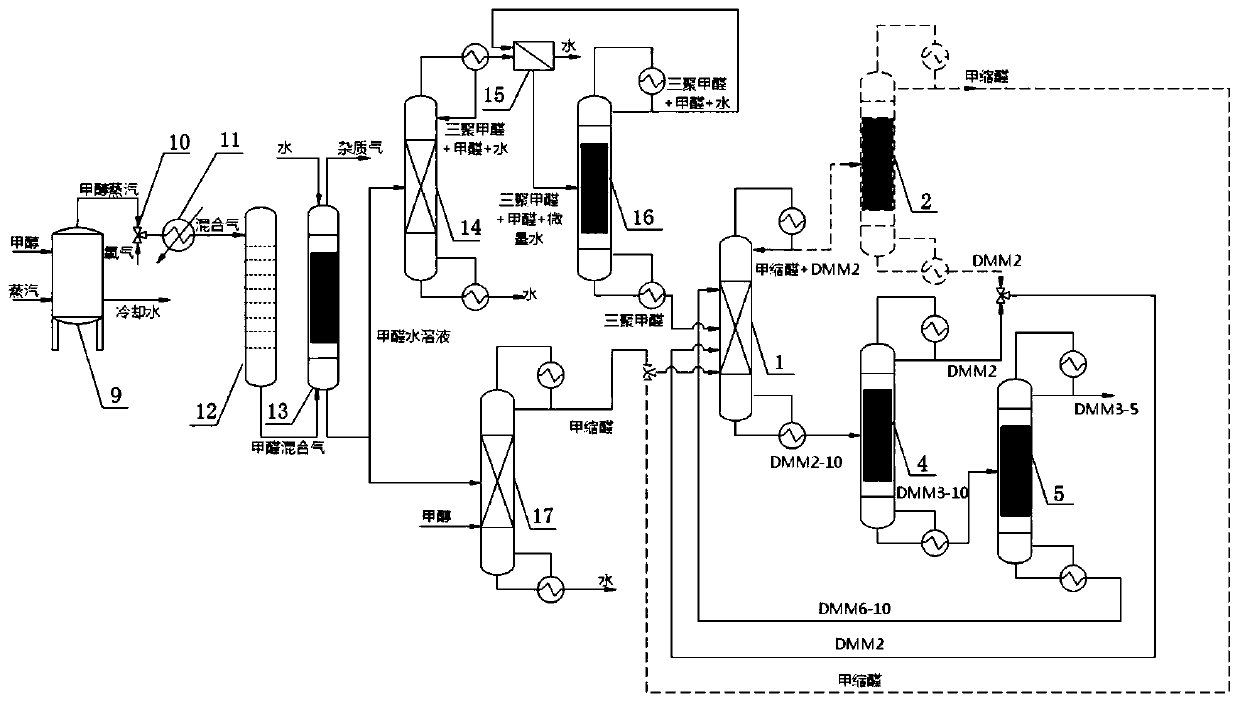

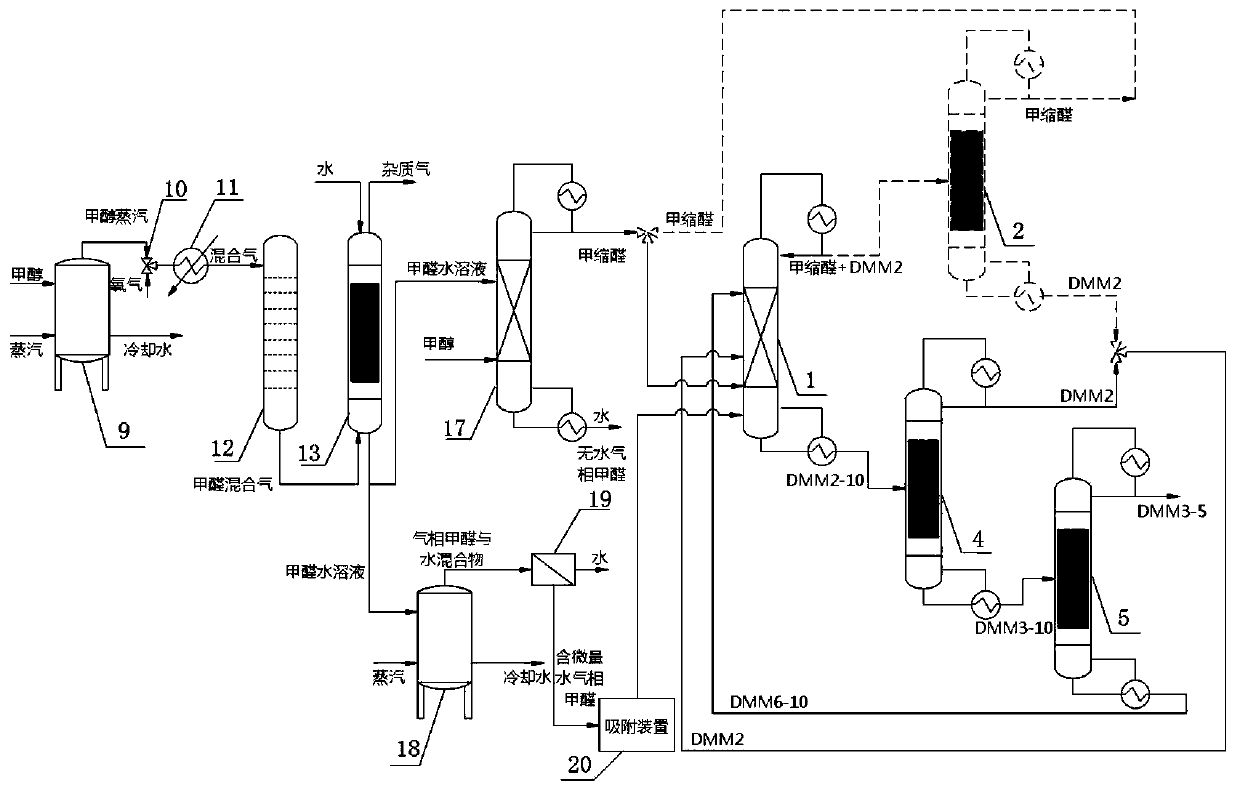

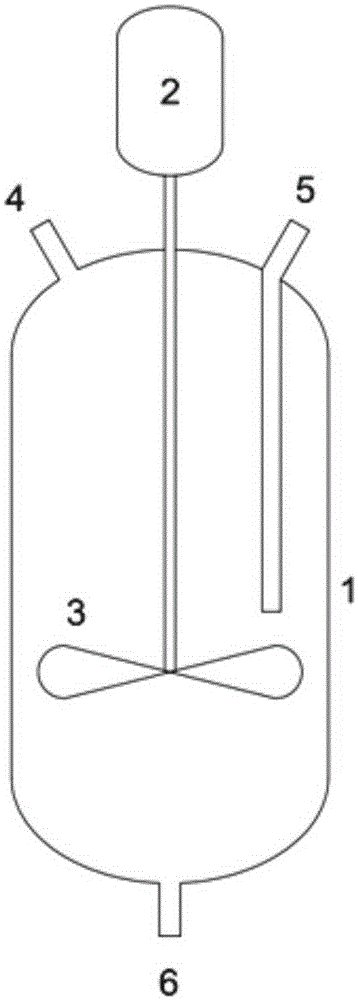

Reactive distillation process device and method for synthesis of PODEn (polyoxymethylene dimethyl ethers)

ActiveCN110078600AImprove conversion rateHigh yieldOrganic chemistryOrganic compound preparationGas phaseParaformaldehyde

The invention provides a reactive distillation process device and method for synthesis of PODEn (polyoxymethylene dimethyl ethers). According to the method, industrial methylal for product chain termination and one or a mixture of two or more of trioxymethylene, paraformaldehyde and gas-phase formaldehyde for product chain propagation are taken as raw materials, no water exits in a reaction system, a PODEn mixed product with multiple degrees of polymerization is obtained through a reaction under the action of an acidic catalyst, a reaction product with the degree of polymerization higher than2 is recovered from the column bottom under the separation action of a PODEn reactive distillation reaction column, and DMM2 with low degree of polymerization and incompletely reacted methylal are recovered from the column top; a product recovered from the column bottom is separated by a production refinery column, a target product DMM3-5 is obtained, DMM2 with low degree of polymerization and DMM6-10 with high degree of polymerization are returned to the PODEn reactive distillation reaction column; incompletely reacted methylal is recycled as a raw material. By use of the characteristic of reactive distillation, excessive methylal is adopted in the reaction process, the conversion rate of formaldehyde substances is substantially increased, and the selectivity and the yield of DMM3-5 are increased.

Owner:TIANJIN UNIV

Antistatic and biodegradable aliphatic-aromatic copolyester nano composite material and preparation method thereof

InactiveCN110776624APromote degradationImprove mechanical propertiesFlexible coversWrappersPolymer scienceIn situ polymerization

The invention discloses an antistatic and biodegradable aliphatic-aromatic copolyester nano composite material and a preparation method thereof. In the esterification process, hydroxylation modified carbon nanotubes are sufficiently mixed with 1,4-butanediol, adipic acid and terephthalic acid are added to the system for in-situ polymerization, and finally a polycondensation reaction is carried outto prepare the antistatic and biodegradable aliphatic-aromatic copolyester nano composite material. Compared with a method that a nano filler is directly added in the polyester processing process andcommixing is performed in the prior art, the preparation method adopts a mode of in-situ polymerization, so that a copolyester is subjected to chain propagation on the surfaces of the hydroxylation modified carbon nanotubes, and the carbon nanotubes have dispersibility of a nano scale in the copolyester. After 0.5-5% of the carbon nanotubes with dispersibility of the nano scale are added to a reinforcement, the composite material has good antistatic performance and mechanical properties, and meanwhile, due to biodegradability of a polyadipic acid / terephthalic acid / butanediol copolyester matrix of the composite material, the composite material has broad application prospects in environment-friendly degradable toys, antistatic packaging films and other fields.

Owner:RACHEM CHINA CO LTD +1

Preparation method of EVA elastomer

The invention discloses a preparation method of an EVA elastomer. In a single polymerization kettle, ethylene and vinyl acetate carry out free radical copolymerization in a solvent in the presence of an initiator; the free radical copolymerization comprises a pre-polymerization phase, a chain propagation phase, and a chain termination phase; and the controlled pre-polymerization phase, the chain propagation phase, and the chain termination phase are performed at different temperatures to prepare the EVA elastomer. According to the method, the controlled pre-polymerization phase, the chain propagation phase, and the chain termination phase are performed at different temperatures, thus the chance of implosion is largely reduced; the temperature runaway of polymerization and initiator loss caused by once heating are relieved, the reactions of polymerization monomers carry out completely, higher monomer conversion rate and copolymerization yield can be obtained; the copolymerization speed is guaranteed, at the same time, the solid content of products is increased, and the VAc content of polymerization products is adjusted to produce EVA elastomer products for satisfying different needs.

Owner:CHINA PETROLEUM & CHEM CORP +1

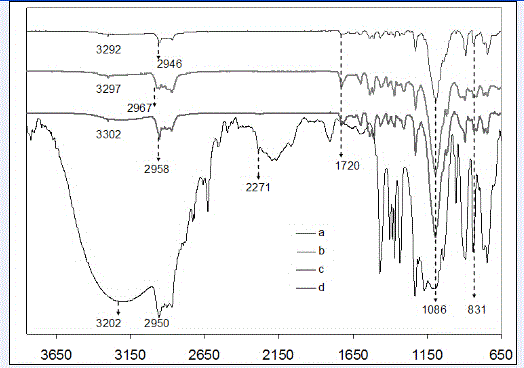

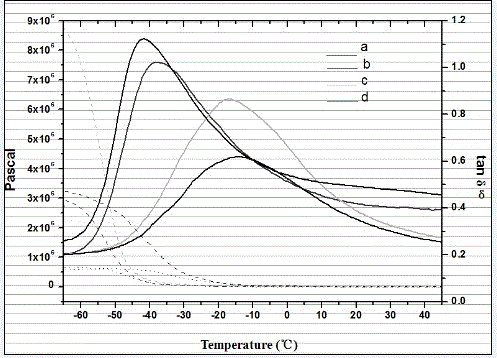

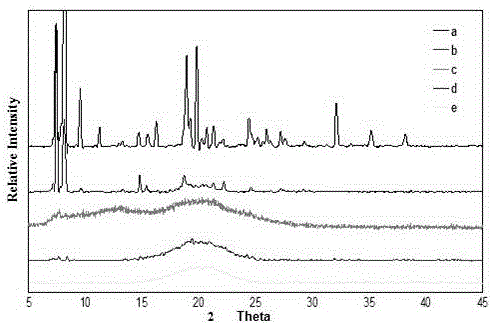

Preparation method of isobutyl cage type polysilsesquioxane modified polyurethane

The invention discloses a preparation method of isobutyl cage polysilsesquioxane modified polyurethane. First, the isobutyl cage polysilsesquioxane is pretreated in a vacuum oven, and then mixed with xylene Diisocyanate is reacted to prepare prepolymer, and then polyether polyol VORANOL 3010 is added for chain extension reaction, and modified by chemical bonding to prepare nano-organic-inorganic hybrid modified polyurethane. When the content of isobutyl cage polysilsesquioxane increased from 0% to 22%, the glass transition temperature of the modified polyurethane increased from ‑44.3 to ‑13.9°C, an increase of 30.4°C. The mechanical properties have been significantly improved. At the same time, with the increase of isobutyl cage polysilsesquioxane content, some sharp diffraction peaks appeared in the X-ray diffraction pattern of the modified polyurethane. Compared with the X-ray diffraction patterns of pure polyurethane, it can be concluded that the increase of the content of isobutyl cage polysilsesquioxane promotes the formation of crystal clusters and the obvious hard segment-soft segment microphase separation in the modified polyurethane structure Phenomenon, to a certain extent, improve the shaping of modified polyurethane.

Owner:SICHUAN NORMAL UNIVERSITY

Sponge capable of changing colors according to ambient temperatures and production technology of sponge

The invention discloses a sponge capable of changing colors according to ambient temperatures and a production technology of the sponge, which solve the technical problem that the conventional sponge cannot change colors according to the ambient temperatures. According to the technical scheme, homogeneous thermochromic powders are uniformly distributed inside a sponge body and are capable of changing colors under different temperature difference conditions. The production technology comprises the following steps of: in a technology of producing the sponge by a box foaming method, agitating raw materials for producing the sponge at a high speed, adding the thermochromic powders into the raw materials, and then agitating the mixture at a high speed until he thermochromic powders are uniformly distributed in the raw materials of the sponge; putting the raw materials, in which the thermochromic powders are uniformly distributed, of the sponge into a sponge forming box, and performing the procedures of chain propagation, forming, crosslinking and curing on the raw materials to obtain the formed sponge; and slitting the formed sponge according to actual sizes, wherein the thermochromic powders are ensured to be uniformly distributed on each slit surface of the sponge. The sponge has the beneficial effects that the technology is simple, the production cost is low, and the sponge is convenient to produce on the basis of not changing the production devices and the production technology.

Owner:HUIZHOU HUIDEBAO IND

Polysiloxane-polyether copolymer modified aqueous polyurethane preparation method

InactiveCN100402574CImprove heat resistanceImprove low temperature resistanceLiquid surface applicatorsFibre treatmentCarbamateSolvent

The invention relates to a method for preparing aqueous polyurethane. It comprises following steps: employing polyisocyanates bridging agent, proceeding copolymerization with excess aqueous polyether, liquid ploydimethyl oxosilane ternary block and getting ployoxosilane-polyether polymer, introducing polyurethane and organic silicon when generating carbamate with carbamate to main chain, adding chain propagation agent for chain propagation reaction and getting preploymer containing hydrophilic group; adding mixture of polyhydroxy compound and dissolvent into reaction system for second chain propagation reaction; neutralizing by adding neutralization agent, adding water for emulsification, adding polyamine for chain propagation; distilling to remove dissolvent after reaction and getting aqueous polyurethane modified with aqueous polyurethane-polyether polymer. The product possesses characteristics of polyurethane and polysiloxane, the storage stability, mechanics property and comprehensive performance is increased and it mainly is used as pigmentum and aqueous industrial coating material.

Owner:山东圣光化工集团有限公司

Parallel self-timer adder (PASTA)

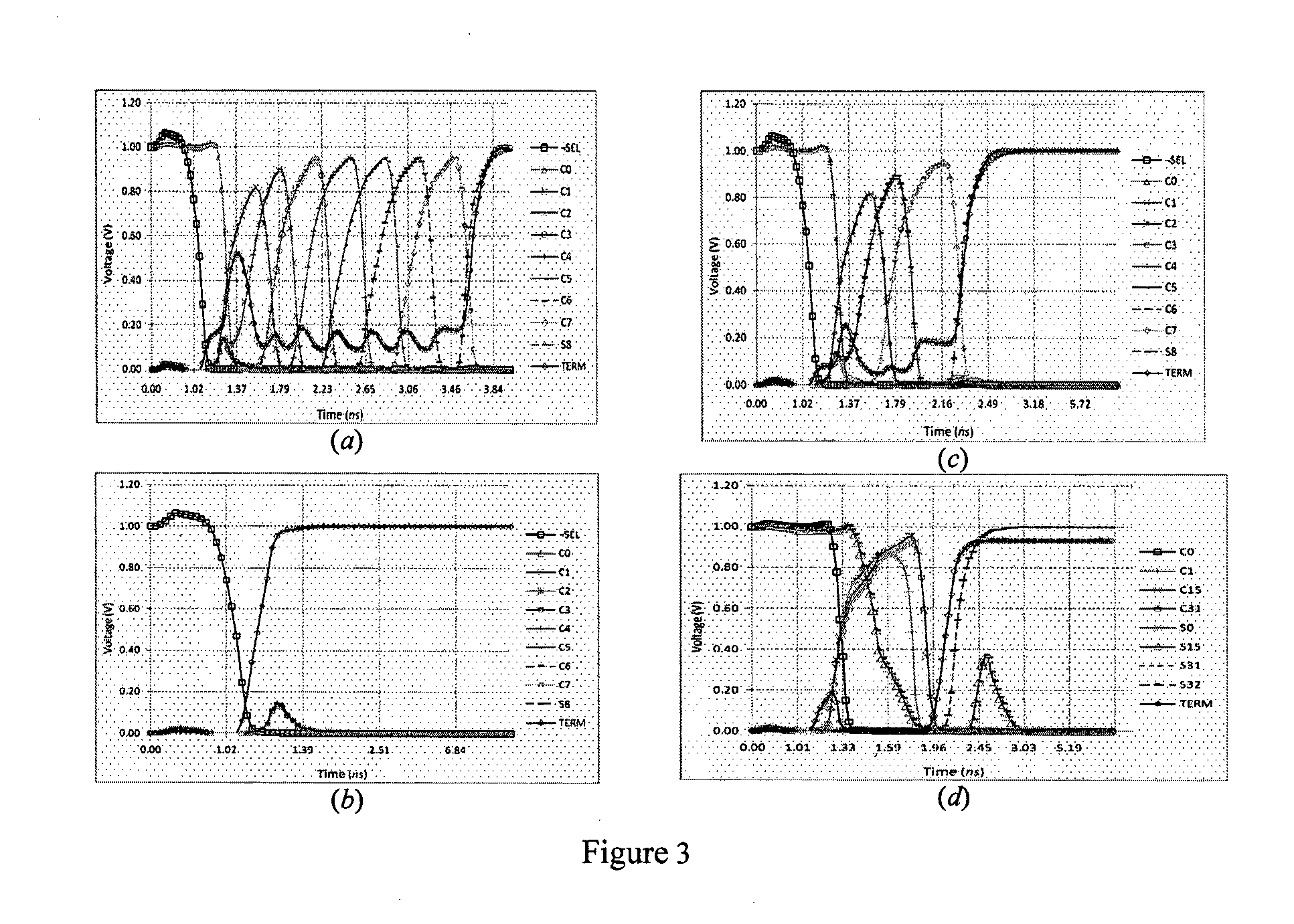

InactiveUS20130117345A1Fast and area/interconnection efficient parallel adderComputation using non-contact making devicesComplex mathematical operationsComputational scienceCMOS

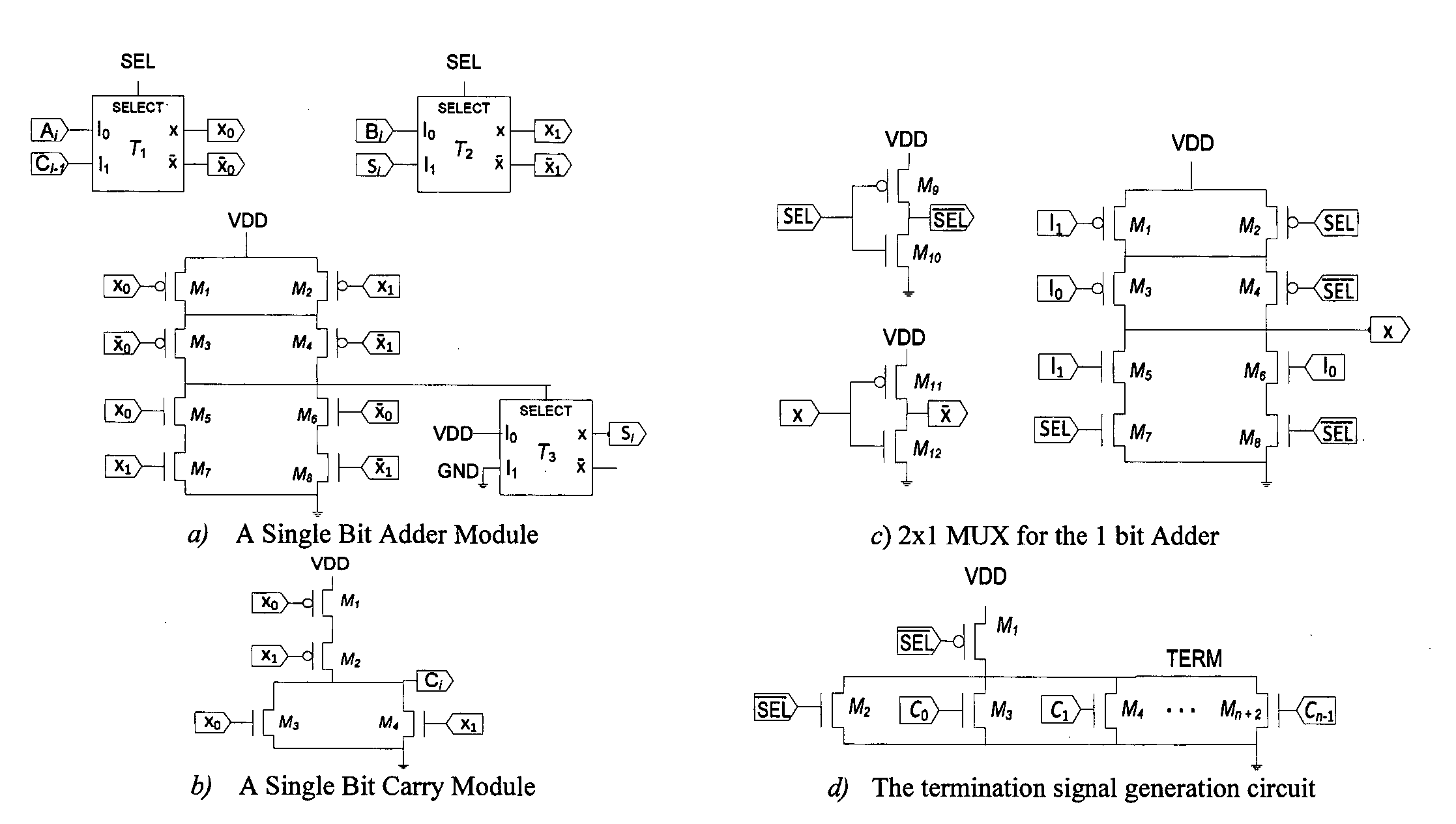

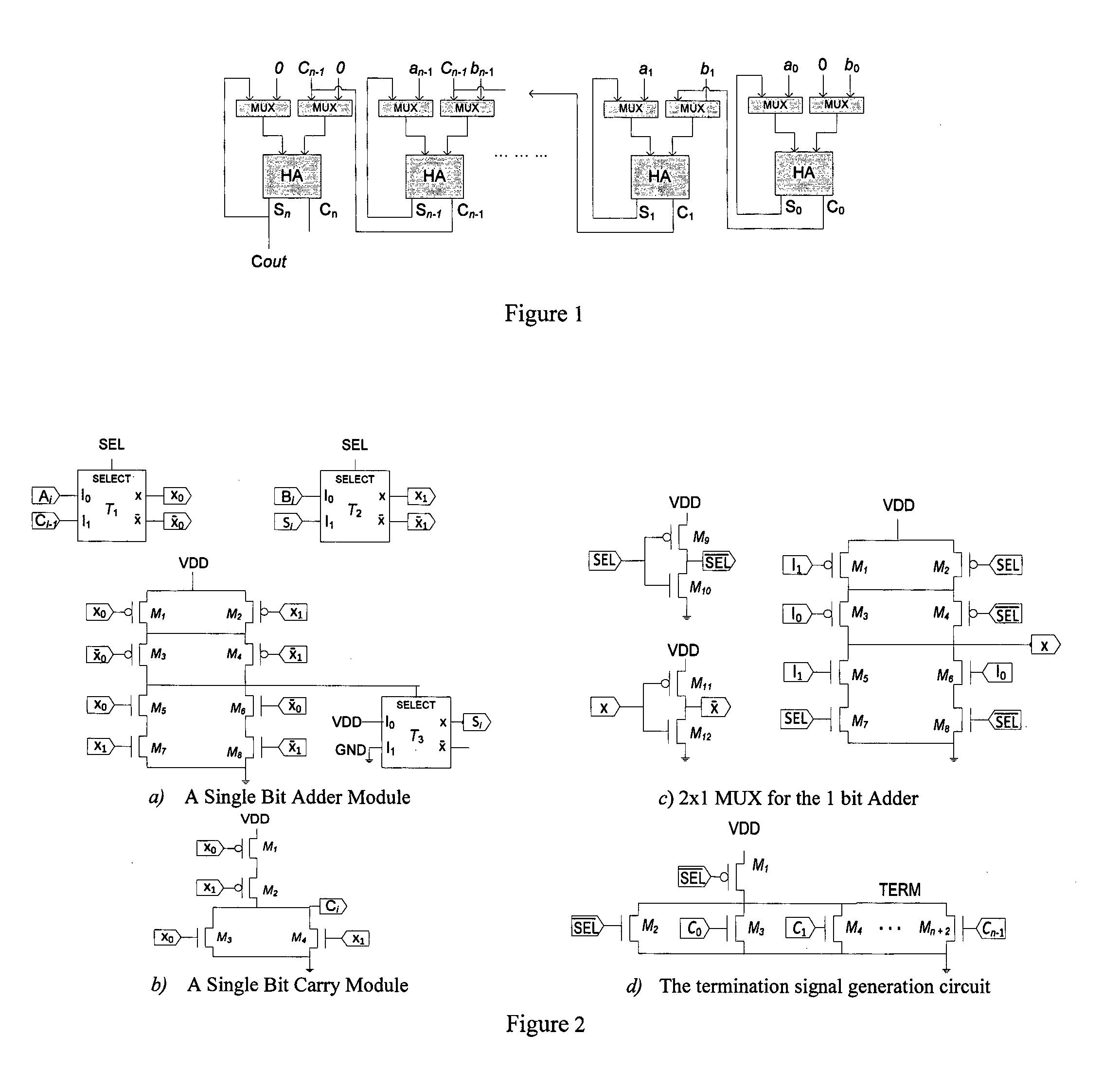

A parallel self-timed adder (PASTA) is disclosed. It is based on recursive formulation and uses only half adders for performing multi-bit binary addition. Theoretically the operation is parallel for those bits that do not need any carry chain propagation. Thus the new approach attains logarithmic performance without any special speed-up circuitry or look-ahead schema. The corresponding CMOS implementation of the design along with completion detection unit is also presented. The design is regular and does not have any practical limitations of fan-ins or fan-outs or complex interconnections. Thus it is more suitable for adoption in fast adder implementation in high-performance processors. The performance of the implementation is tested using SPICE circuit simulation tool by linear technology. Simulation results show its superiority over cascaded circuit adders. A constant time carry propagation is also achieved using the proposed implementation by tuning the CMOS parameters.

Owner:UNIVERSITI MALAYA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com