Reactive distillation process device and method for synthesis of PODEn (polyoxymethylene dimethyl ethers)

A polymethoxy dimethyl ether, process method technology, applied in chemical instruments and methods, preparation of organic compounds, chemical industry and other directions, can solve the problem of high manufacturing cost, large circulating flow rate, and anhydrous trioxane market. high price problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

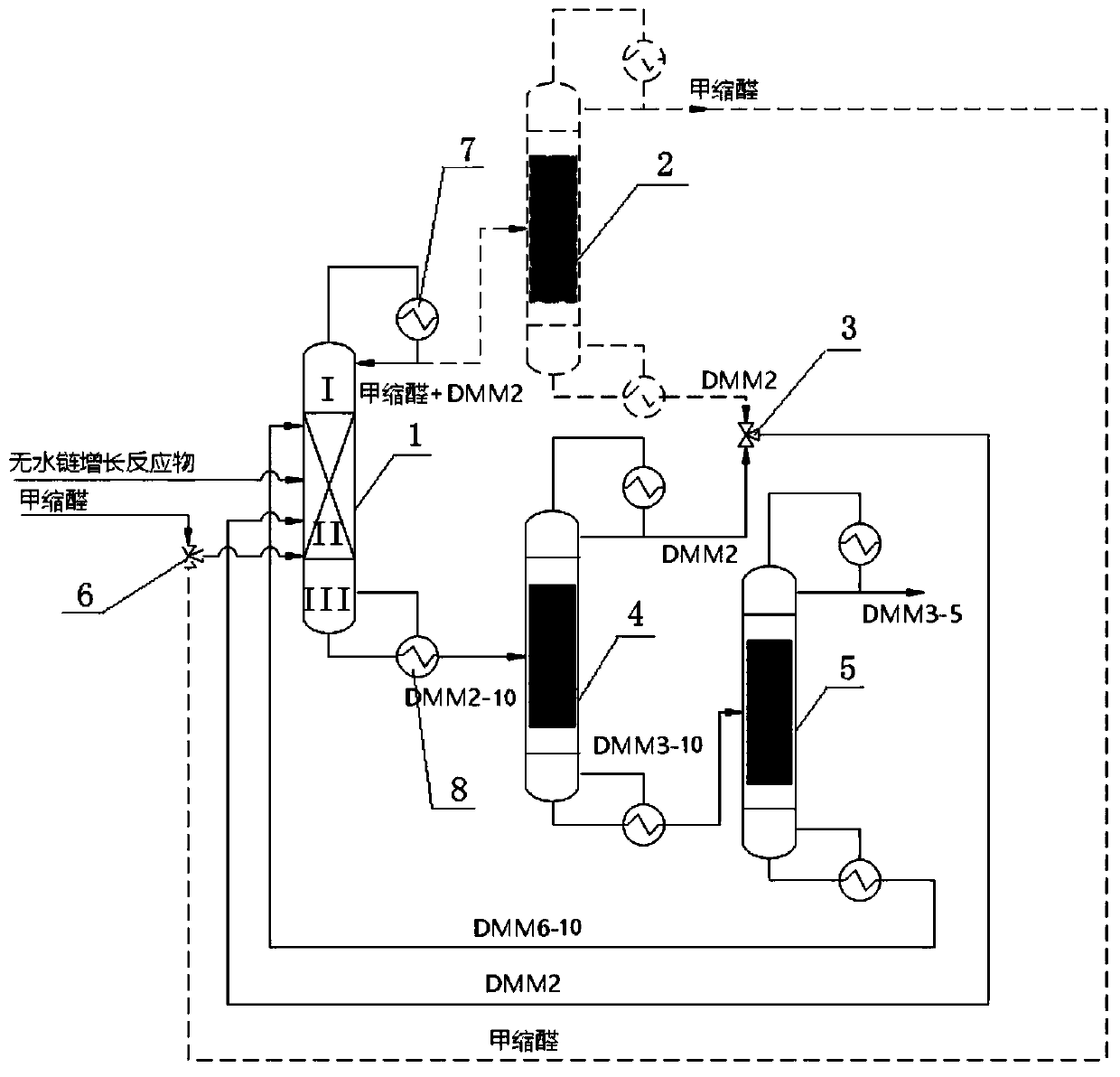

[0059] The method of the present invention is used for the reaction system polyoxymethylene dimethyl ether process of methylal and paraformaldehyde under acidic conditions, which is the same as the process described in the present invention, including a polyoxymethylene dimethyl ether reactive distillation tower, a Class product refining tower, secondary product refining tower, light component separation tower, methylal mixer, DMM2 mixer. Methylal and paraformaldehyde enter the polyoxymethylene dimethyl ether reactive distillation column from the two liquid-phase feed ports on the reaction section respectively, and the methylal feed port is below the paraformaldehyde feed port . The mass ratio of polyoxymethylene dimethyl ether reactive distillation column raw material paraformaldehyde to methylal is 4.5, the working pressure of polyoxymethylene dimethyl ether reactive distillation column is absolute pressure 4atm, and the top reflux ratio is 0.5, The catalyst is an acidic re...

Embodiment 2

[0062] The method of the present invention is used for the polyoxymethylene dimethyl ether process of methylal and paraformaldehyde reaction under acidic conditions, is identical with the flow process described in the present invention, comprises polyoxymethylene dimethyl ether reactive rectification tower, a Class product refining tower, secondary product refining tower, light component separation tower, methylal mixer, DMM2 mixer. Methylal and paraformaldehyde enter the polyoxymethylene dimethyl ether reactive distillation column from two liquid-phase feed ports on the reaction section respectively, and the methylal feed port is below the paraformaldehyde feed port . The mass ratio of polyoxymethylene dimethyl ether reactive distillation column raw material paraformaldehyde to methylal is 2, the working pressure of polyoxymethylene dimethyl ether reactive distillation column is absolute pressure 2atm, and the top reflux ratio is total reflux , the catalyst is an acidic mole...

Embodiment 3

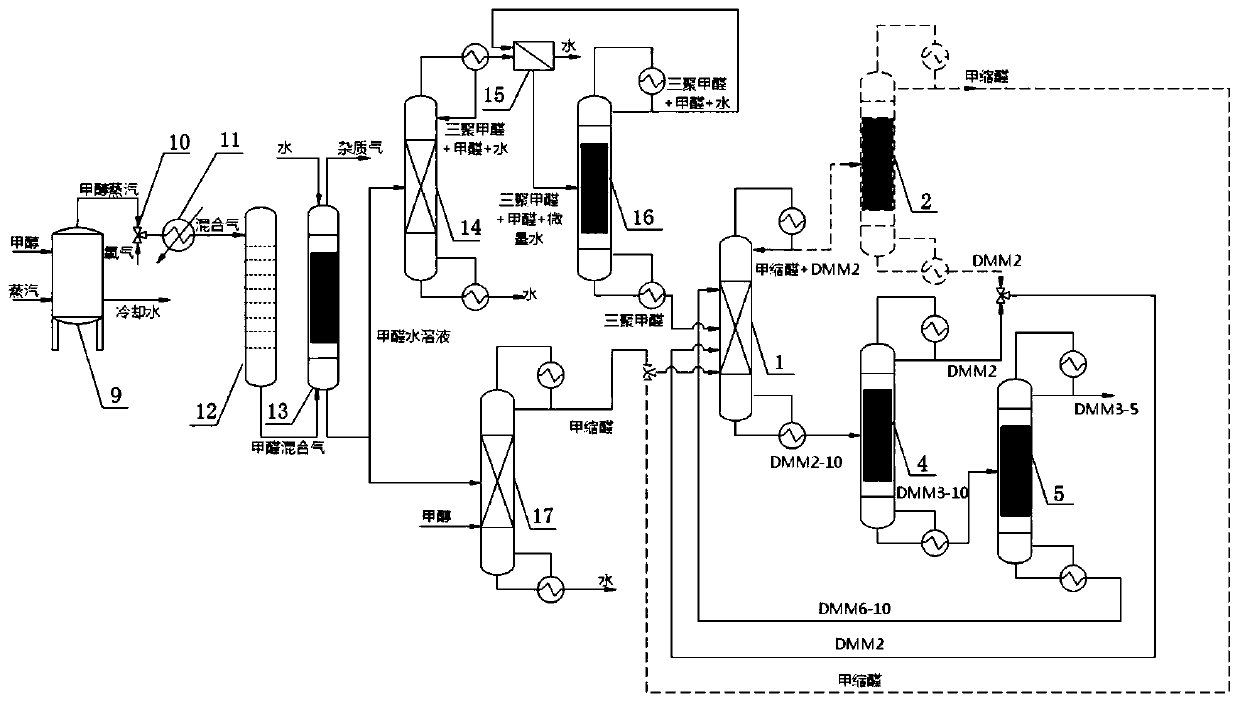

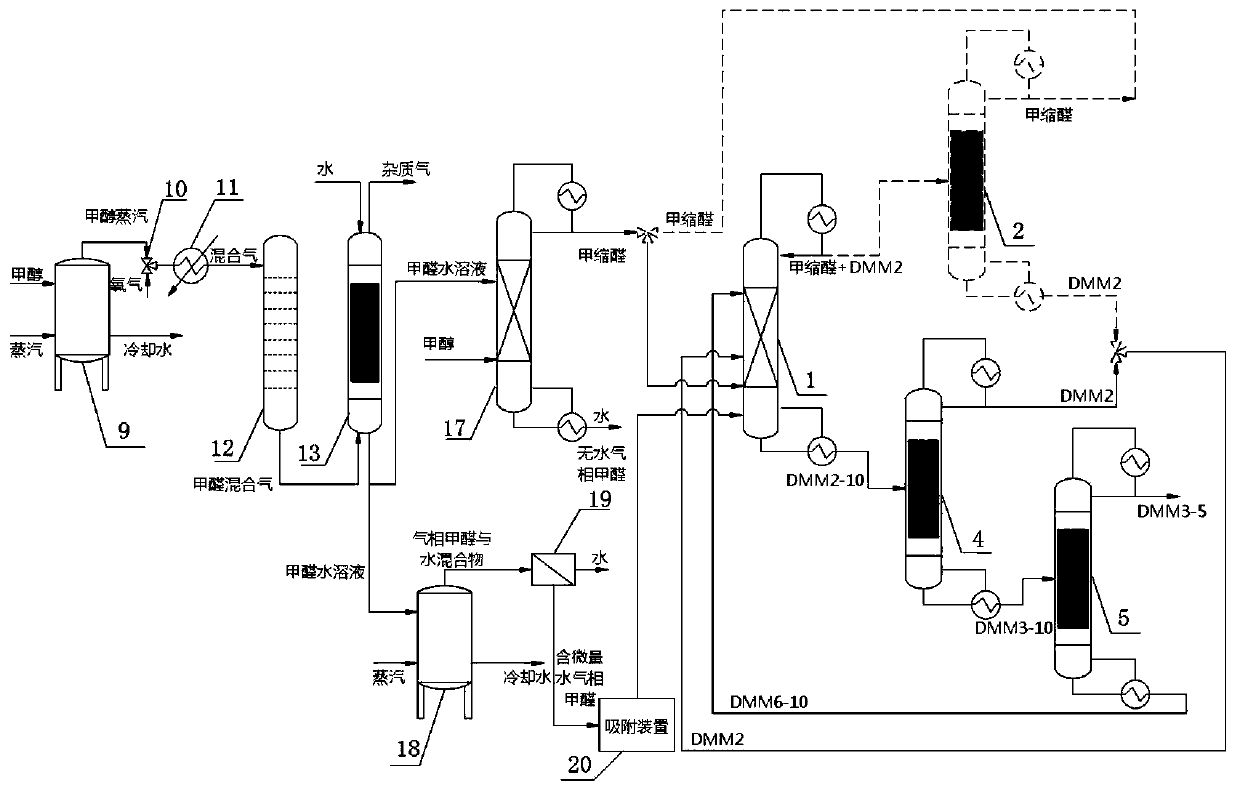

[0065] The process of using the method of the present invention for the reaction of methylal and gas-phase formaldehyde under acidic conditions to prepare polyoxymethylene dimethyl ether is the same as the process described in the present invention, including a polyoxymethylene dimethyl ether reactive distillation column, a first-stage Product refining tower, secondary product refining tower, light component separation tower, methylal mixer, DMM2 mixer. Methylal and gas-phase formaldehyde enter into the polyoxymethylene dimethyl ether reactive distillation column respectively from the liquid-phase feed port on the reaction section and the gas-phase feed port of the stripping section, and the methylal feed port is at Above the gas phase formaldehyde feed port. The mass ratio of gaseous formaldehyde and methylal in the polyoxymethylene dimethyl ether reactive distillation column raw material is 0.6, the working pressure of the polyoxymethylene dimethyl ether reactive distillatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com