Patents

Literature

1099 results about "Reactive distillation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reactive distillation is a process where the chemical reactor is also the still. Separation of the product from the reaction mixture does not need a separate distillation step, which saves energy (for heating) and materials. This technique can be useful for equilibrium-limited reactions such as esterification and ester hydrolysis reactions. Conversion can be increased beyond what is expected by the equilibrium due to the continuous removal of reaction products from the reactive zone. This approach can also reduce capital and investment costs. Typically, reactive distillation equipment comprises a reactive column, with the feed input, with directly attached stripping and enriching columns with the outputs.

Recovery of organic acids

InactiveUS20090281354A1Promote recoveryOvercome consumptionPreparation from carboxylic acid saltsOrganic compound preparationOrganic acidReactive distillation

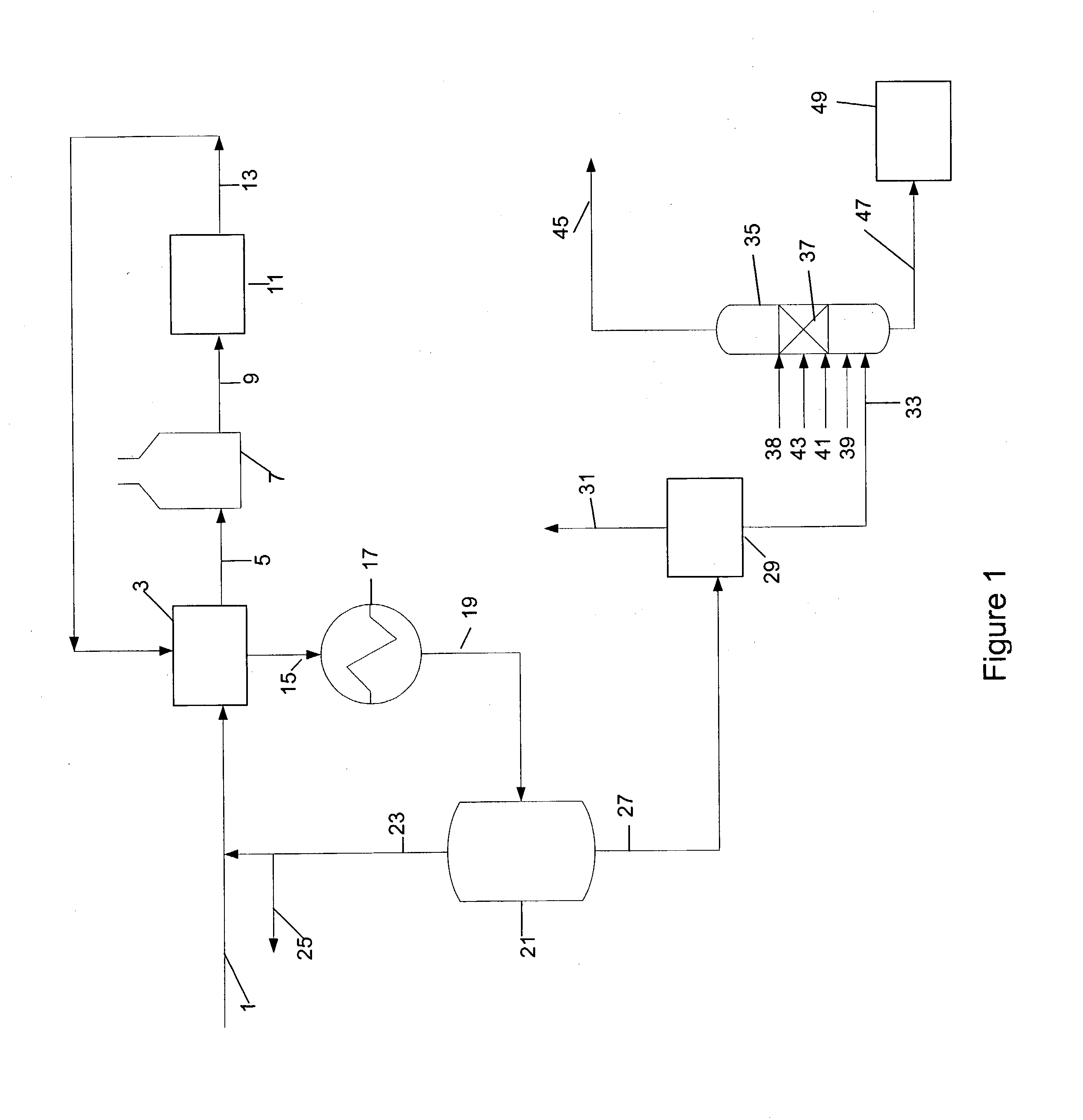

A method is disclosed for the recovery of an organic acid from a dilute salt solution in which the cation of the salt forms an insoluble carbonate salt. An amine and CO2 are introduced to the solution to form the insoluble carbonate salt and a complex between the acid and the amine. The acid / amine complex is thermally dissociated, or “cracked”, in the presence of a water immiscible solvent in which the amine is selectively soluble and in which the acid is not appreciably soluble. The organic acid may then be recovered from the water by any suitable means such as distillation, reactive distillation, extraction, or reactive extraction.

Owner:ZEACHEM

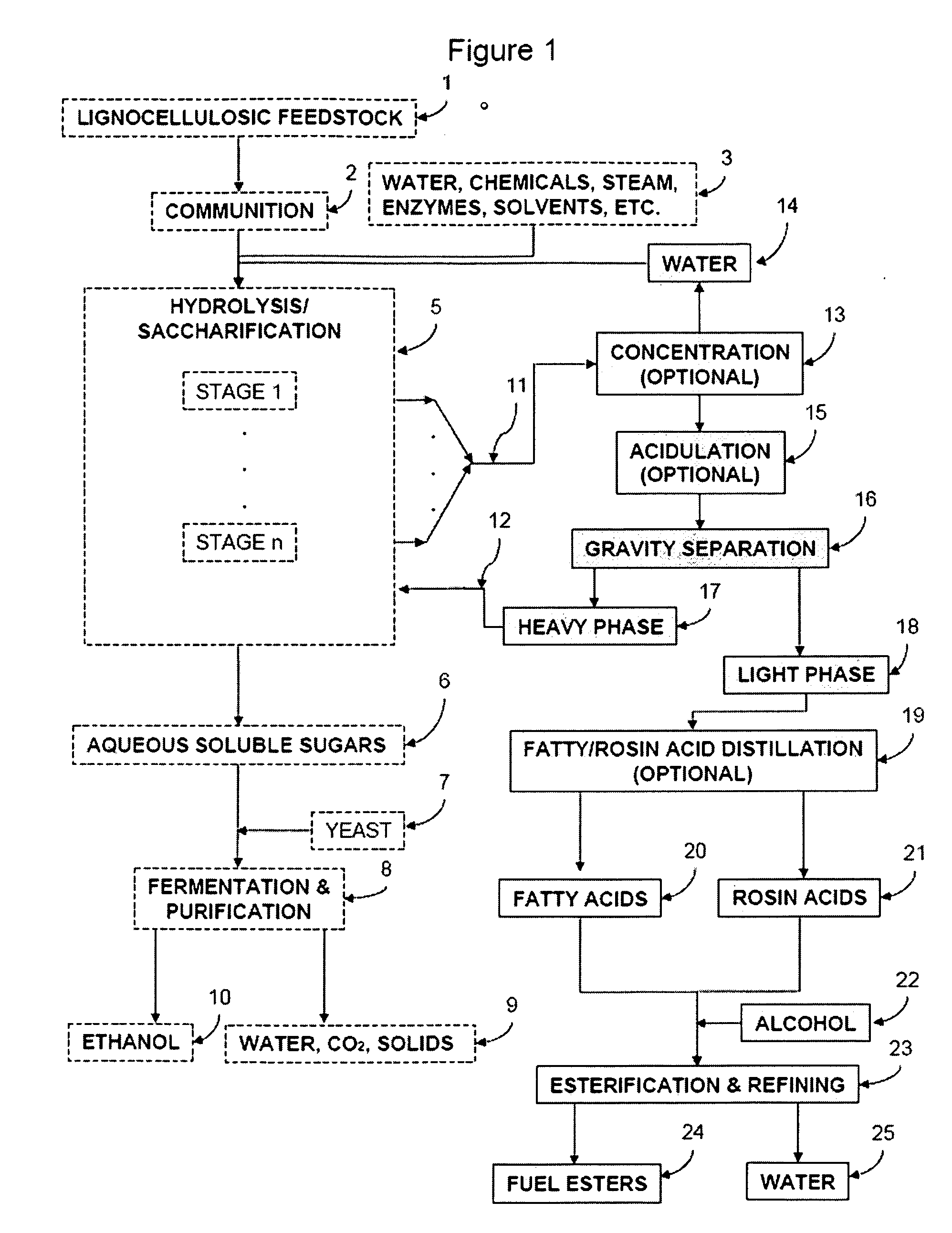

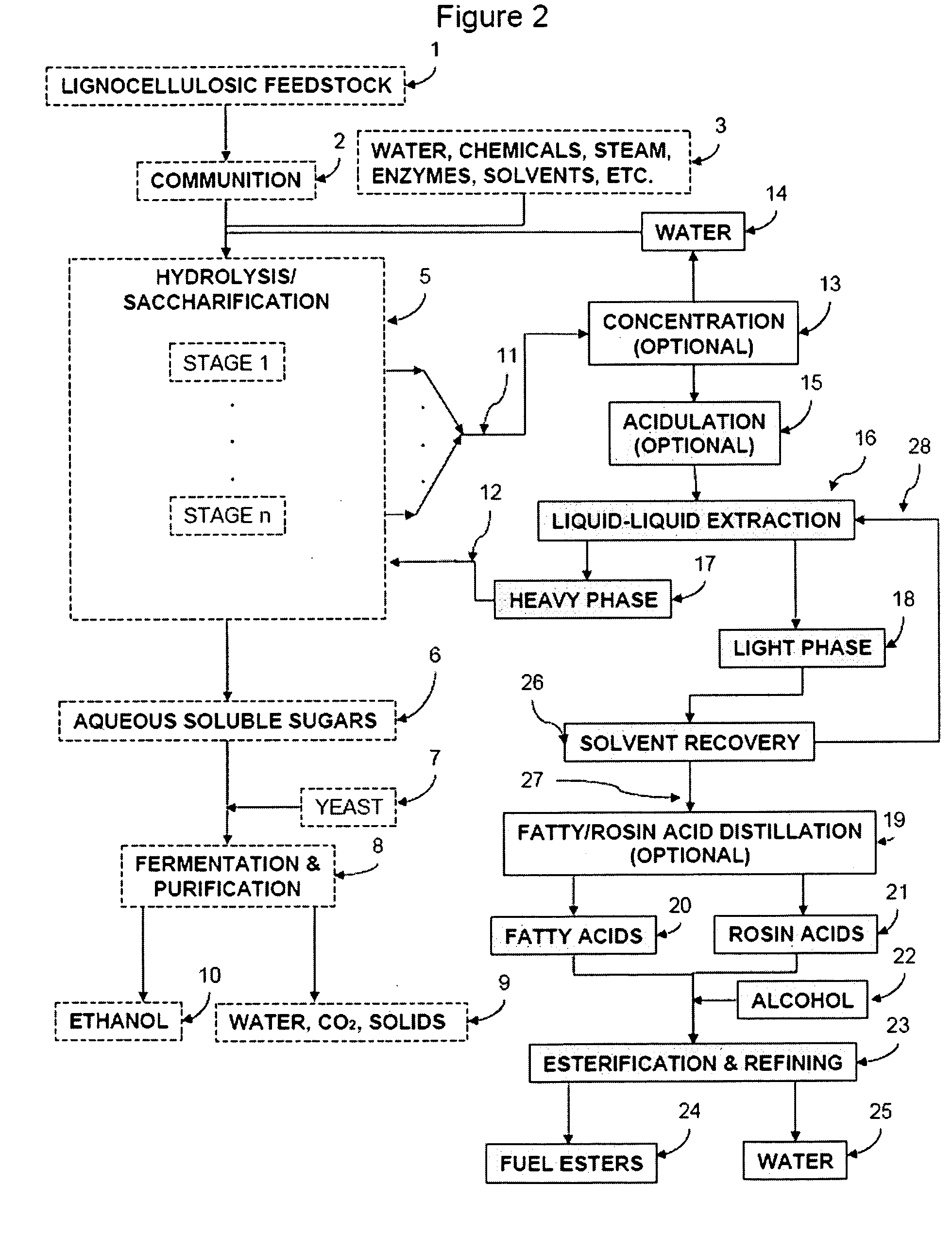

Production of Ester-based Fuels Such As Biodiesel From Renewable Starting Materials

ActiveUS20090056201A1Fatty oils/acids recovery from wasteFatty acid esterificationCelluloseBiodiesel

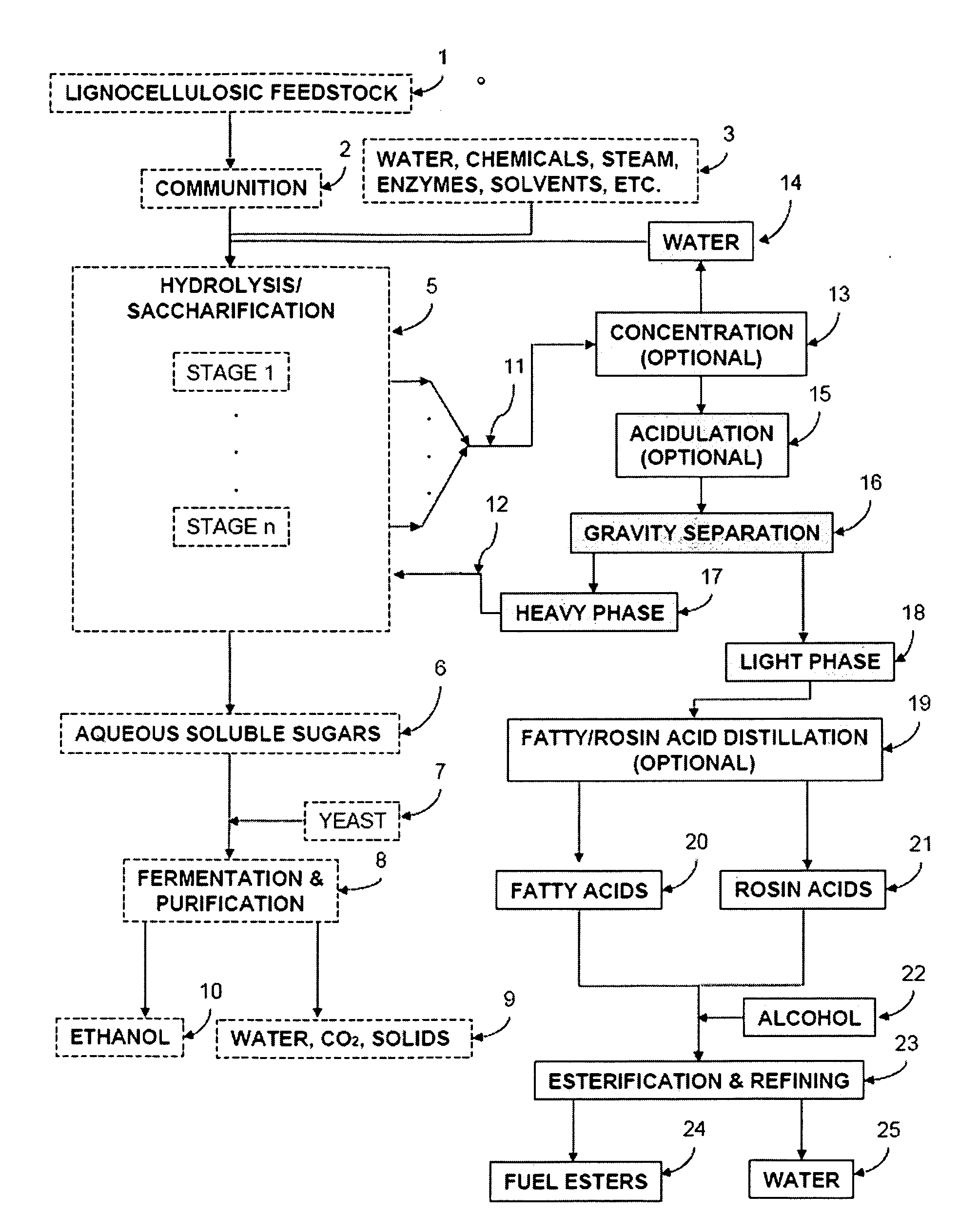

Production of ester-based fuels such as biodiesel or jet fuel from renewable starting materials such as lignocellulosic material or algae is disclosed. Pulping and saccharification of the renewable starting materials produces carboxylic acids such as fatty acids or rosin acids, which are esterified via a gas sparged, slurry form of heterogeneous reactive distillation to yield ester-based fuels.

Owner:ENDICOTT BIOFUELS II

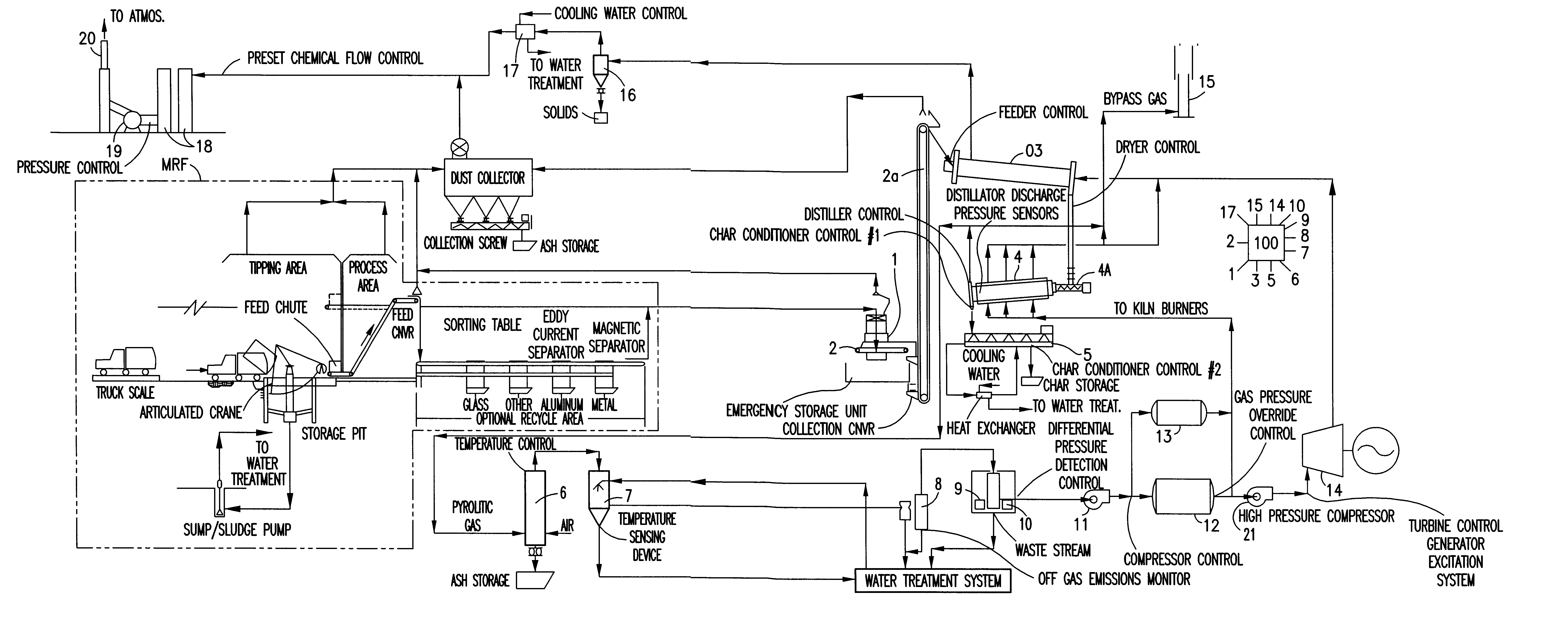

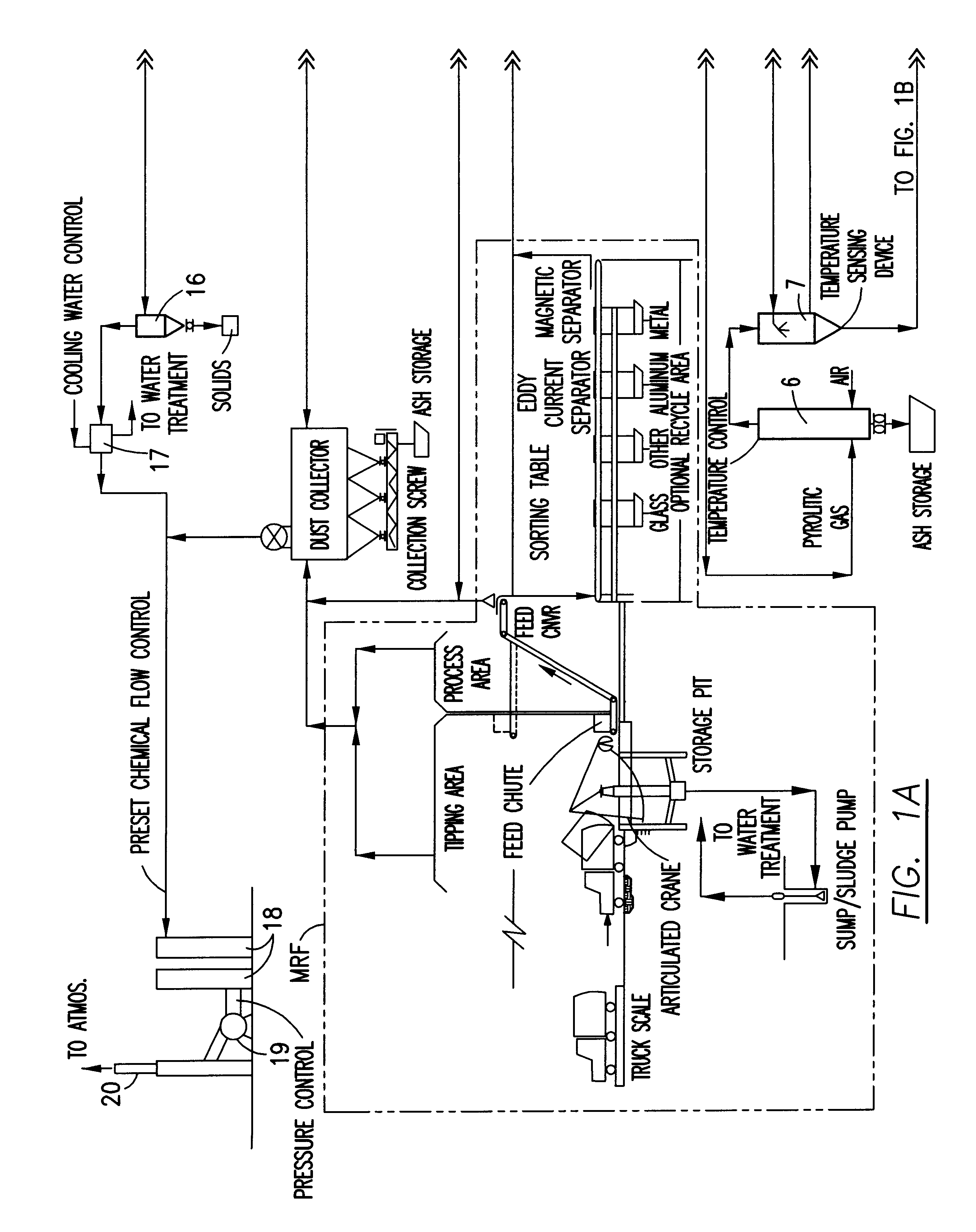

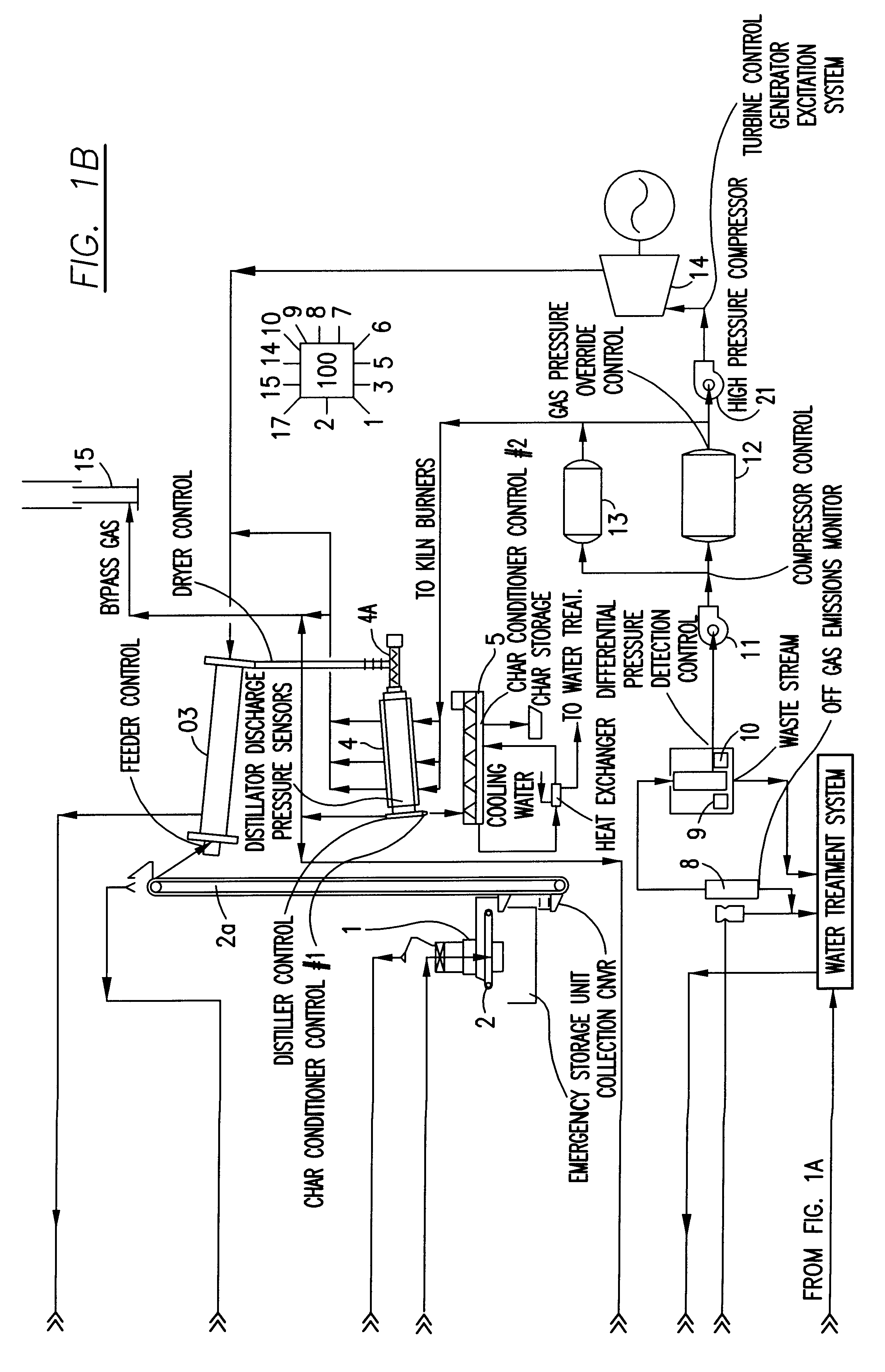

Integrated control and destructive distillation of carbonaceous waste

InactiveUS6182584B1High quantity and qualityEnhanced yield quantity and qualityHorizontal chamber coke ovensEmission preventionComputer control systemWaste stream

A system and process to provide integrated control for the pyrolytic composition of organic (biomass) waste products especially for municipal solid waste systems. The system includes integrated control that monitors biomass waste stream throughout the entire system and the products produced therefrom and includes presorting, controlling the amount of material processed in a continuous manner, shredding, removing moisture in a continuous process that is controlled and providing the waste stream to the distillation unit for pyrolytic action where it is converted into gaseous fuel and a char residue. The gaseous fuel is scrubbed clean and monitored and stored and reused to provide heat to the system. The entire system may be self-sustaining and continuous with very little or no human intervention. An integrated real time computer control system includes sensors and measuring devices with all the major components to ensure integrated efficiency.

Owner:ENVIRONMENTAL SOLUTIONS & TECH

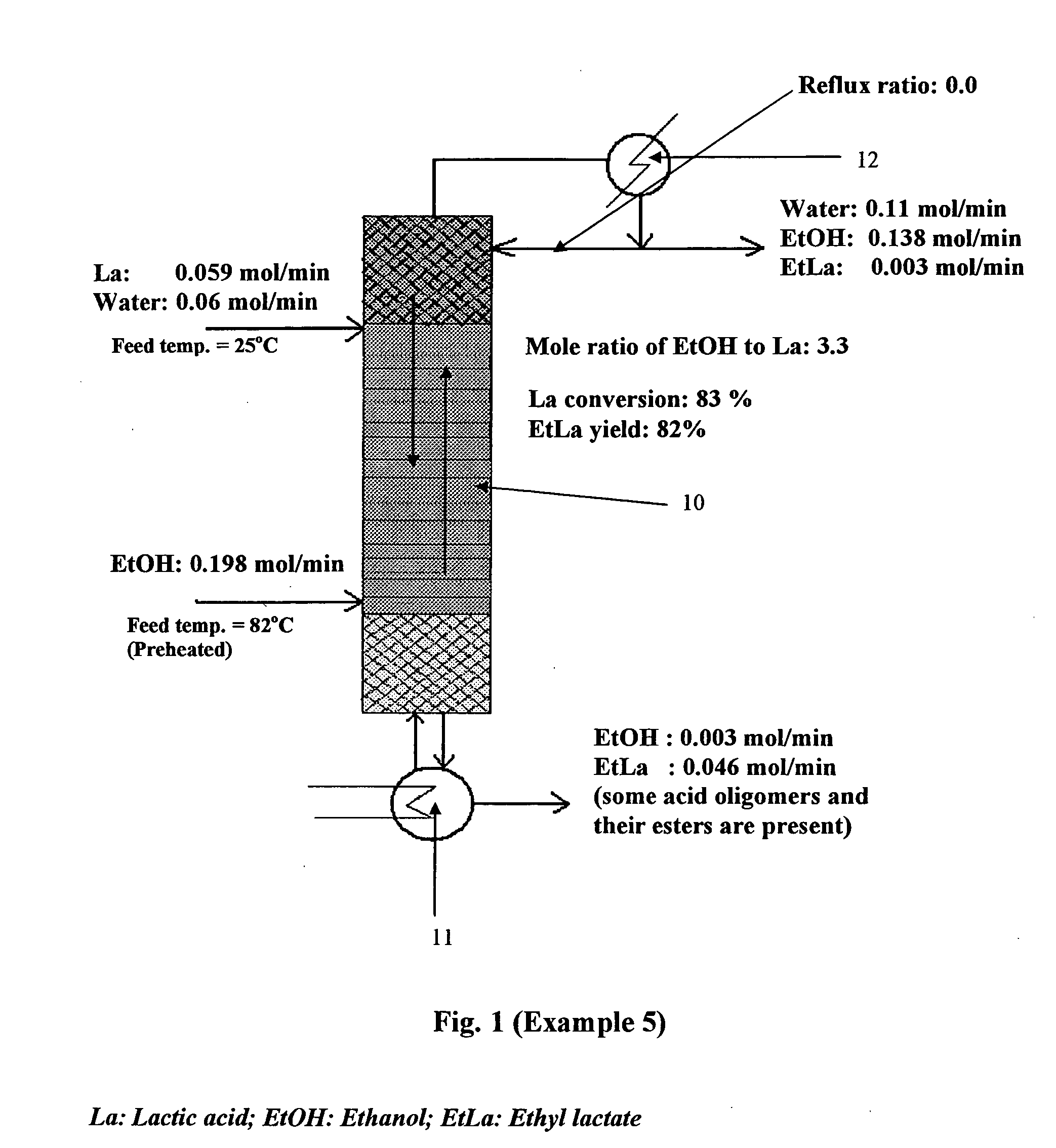

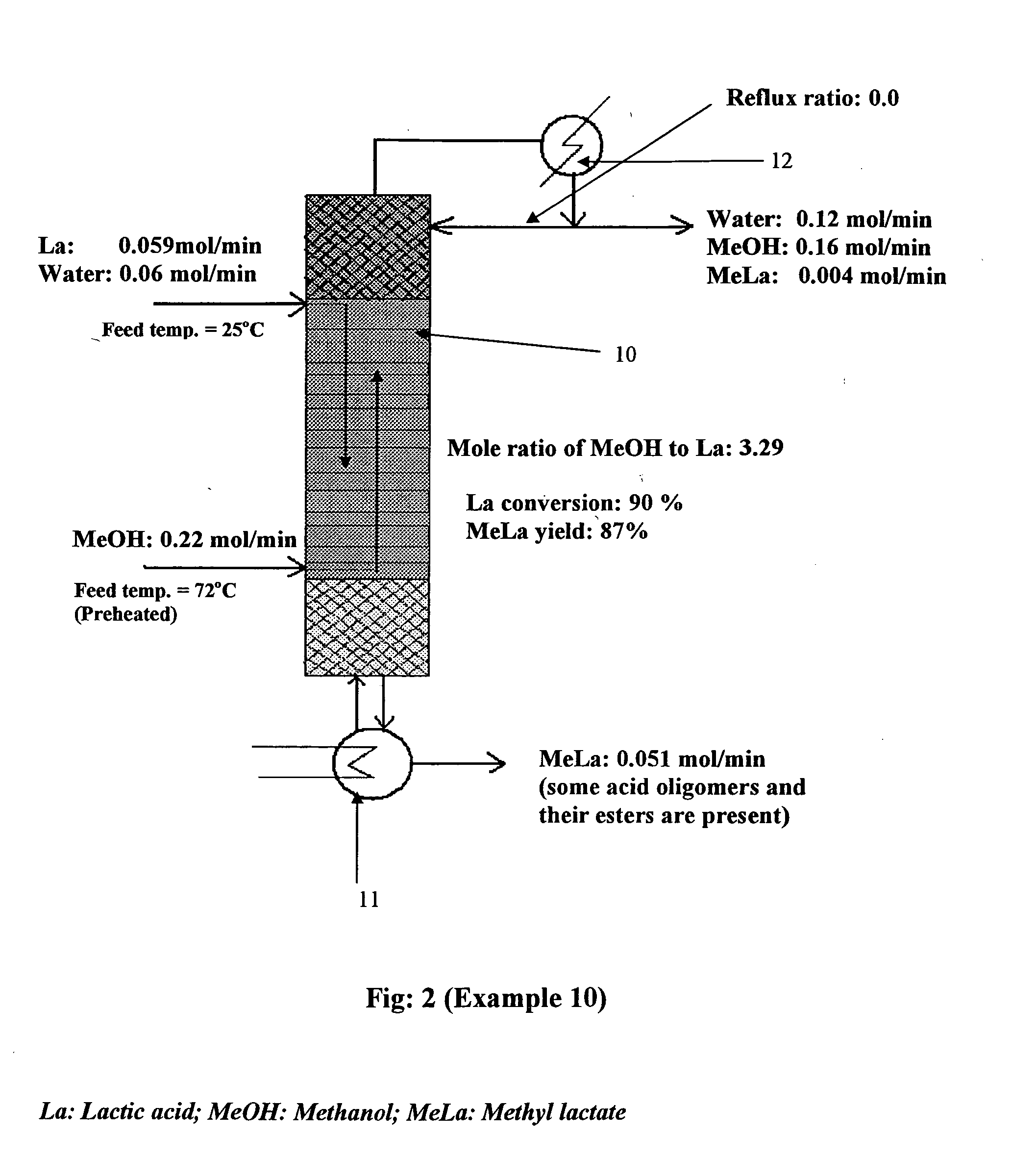

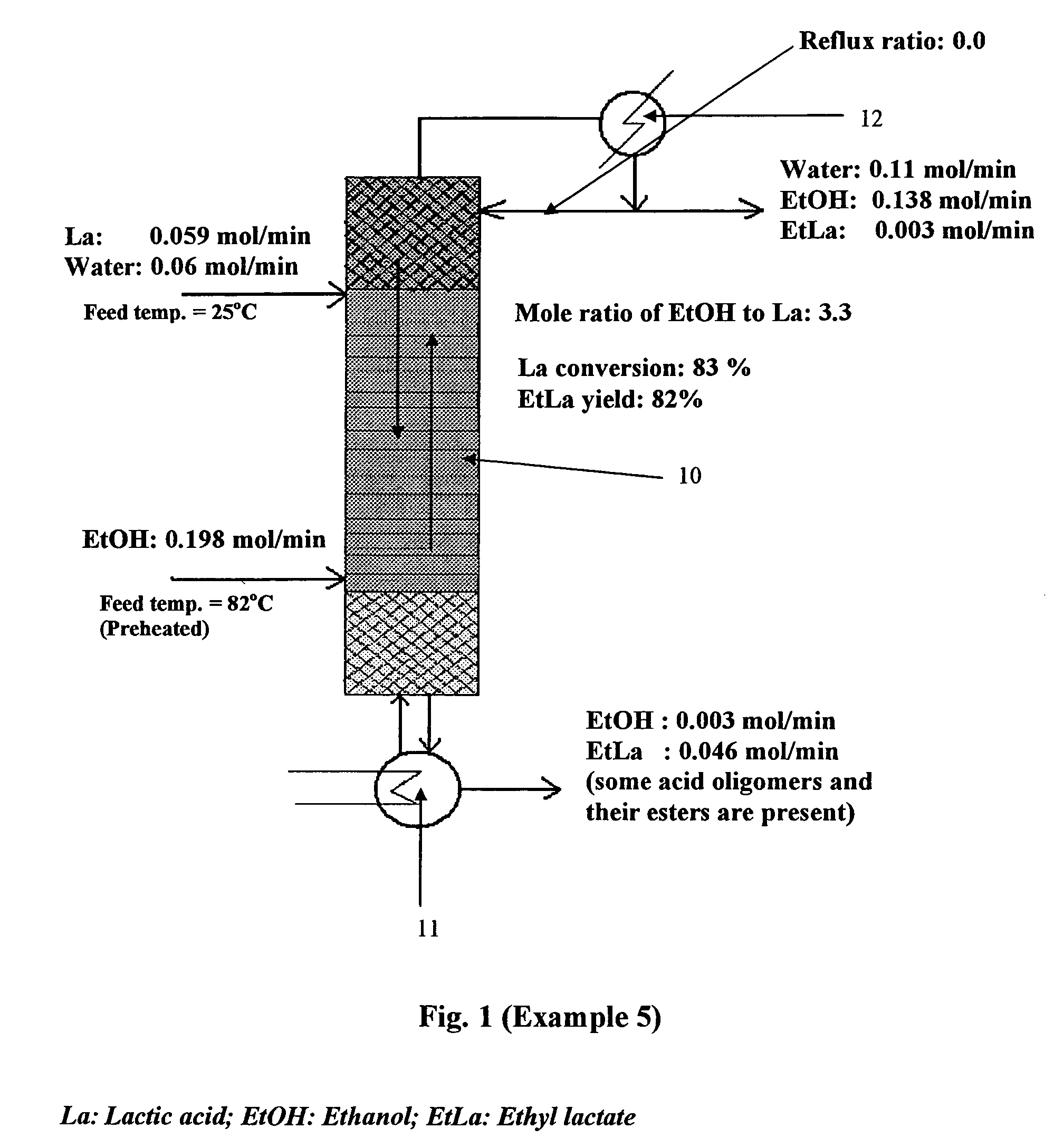

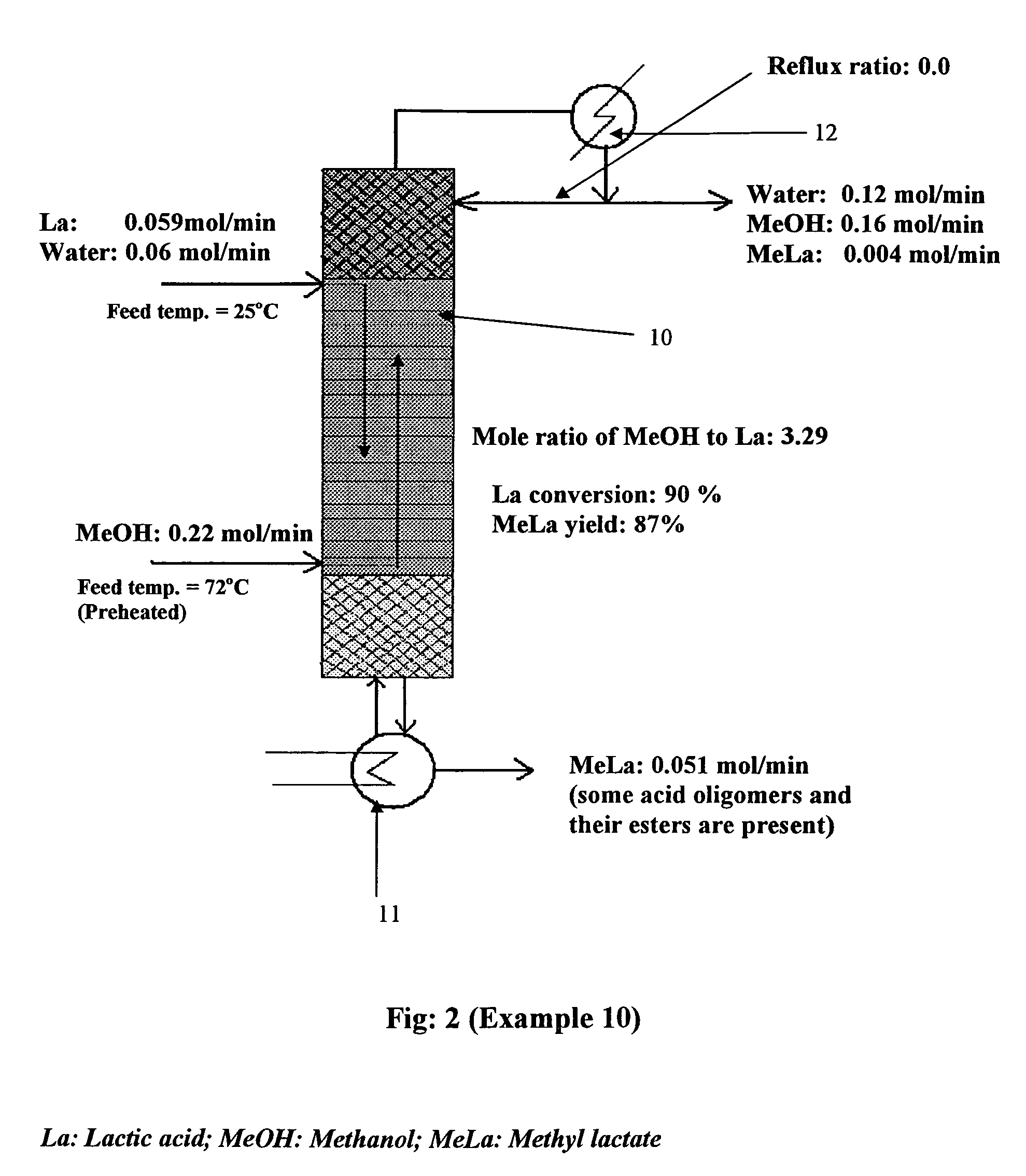

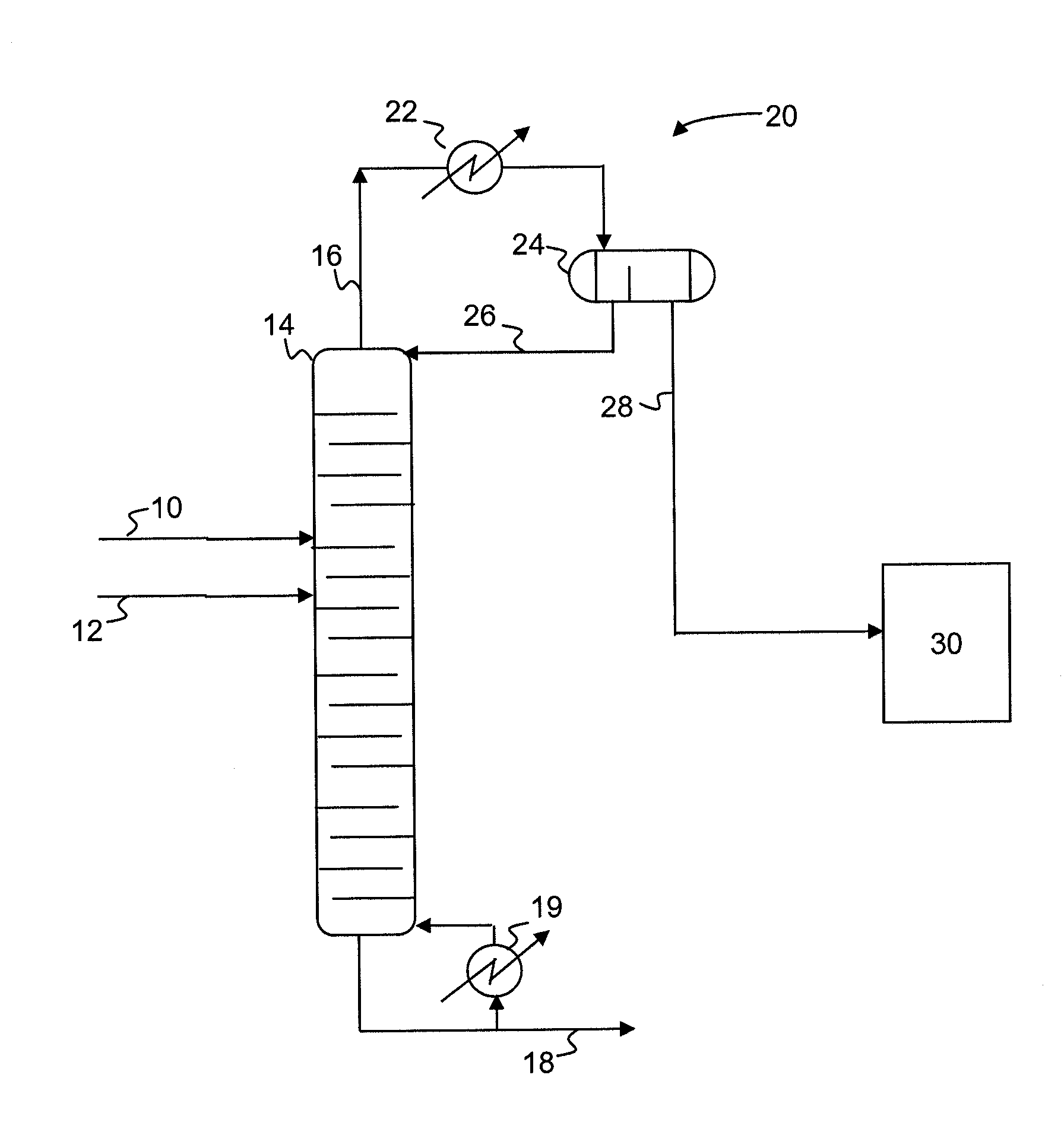

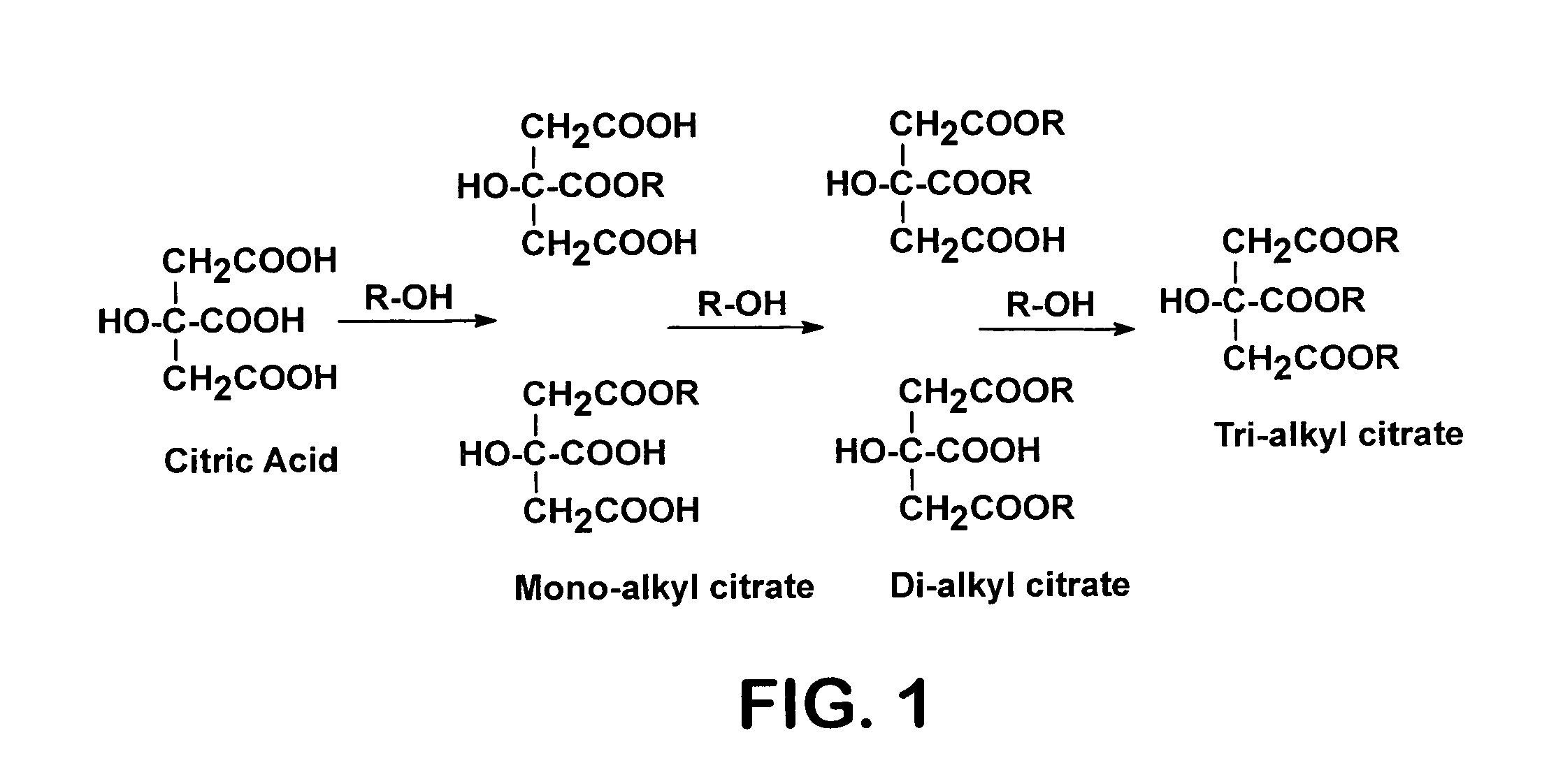

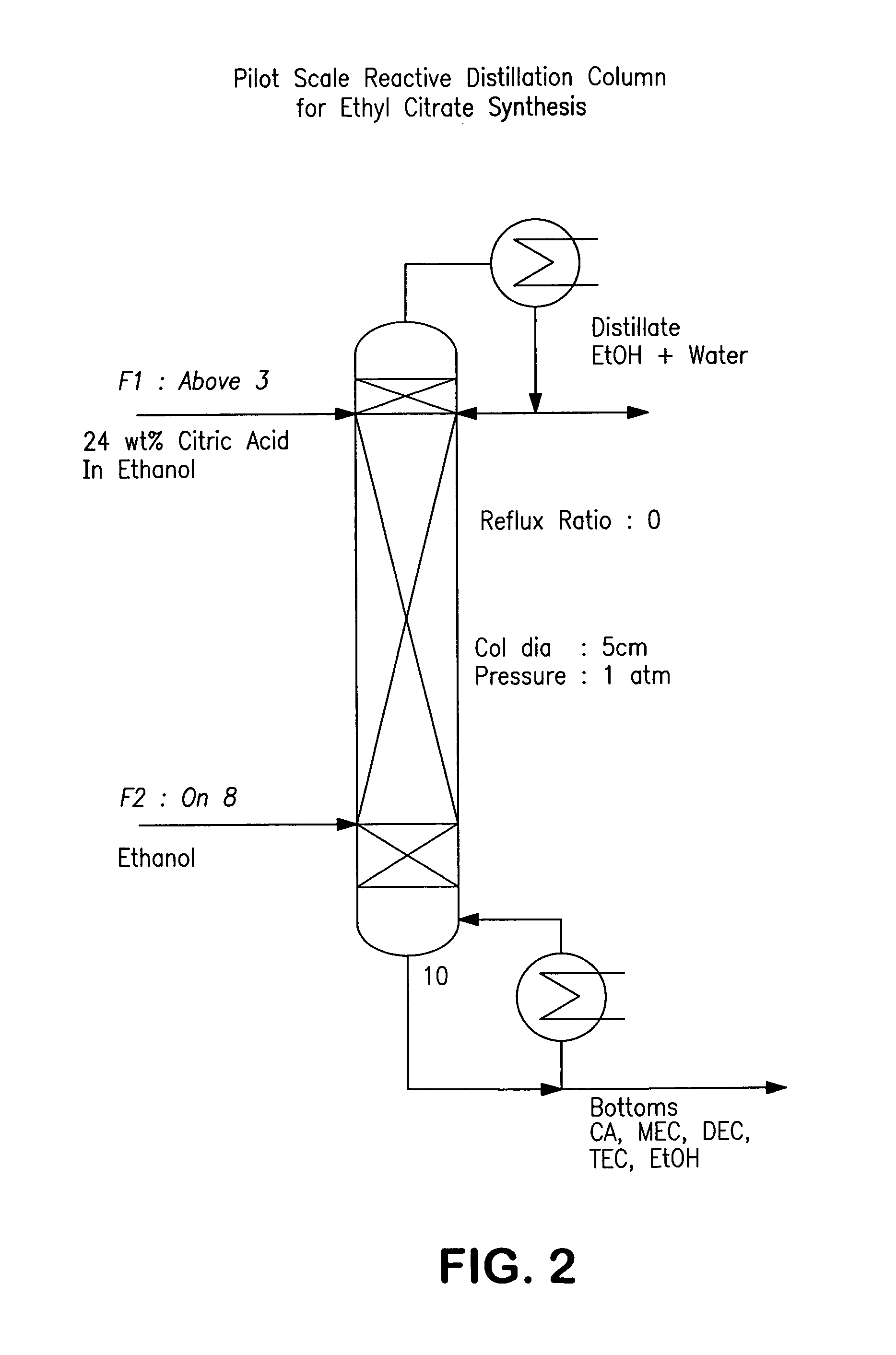

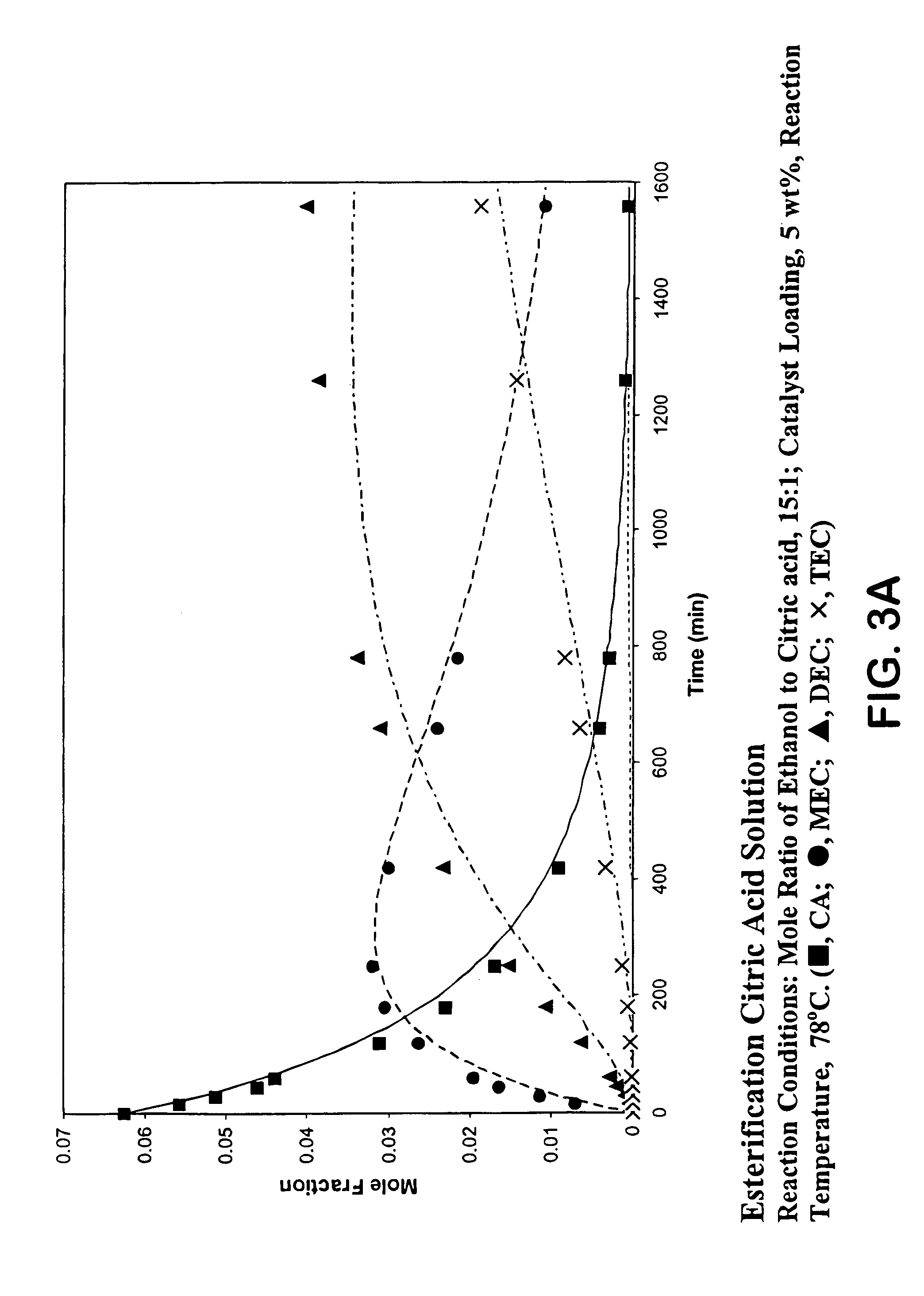

Process for production of organic acid esters

InactiveUS20060014977A1Speed up the processPreparation by ester-hydroxy reactionOrganic compound preparationOrganic acidChemical reaction

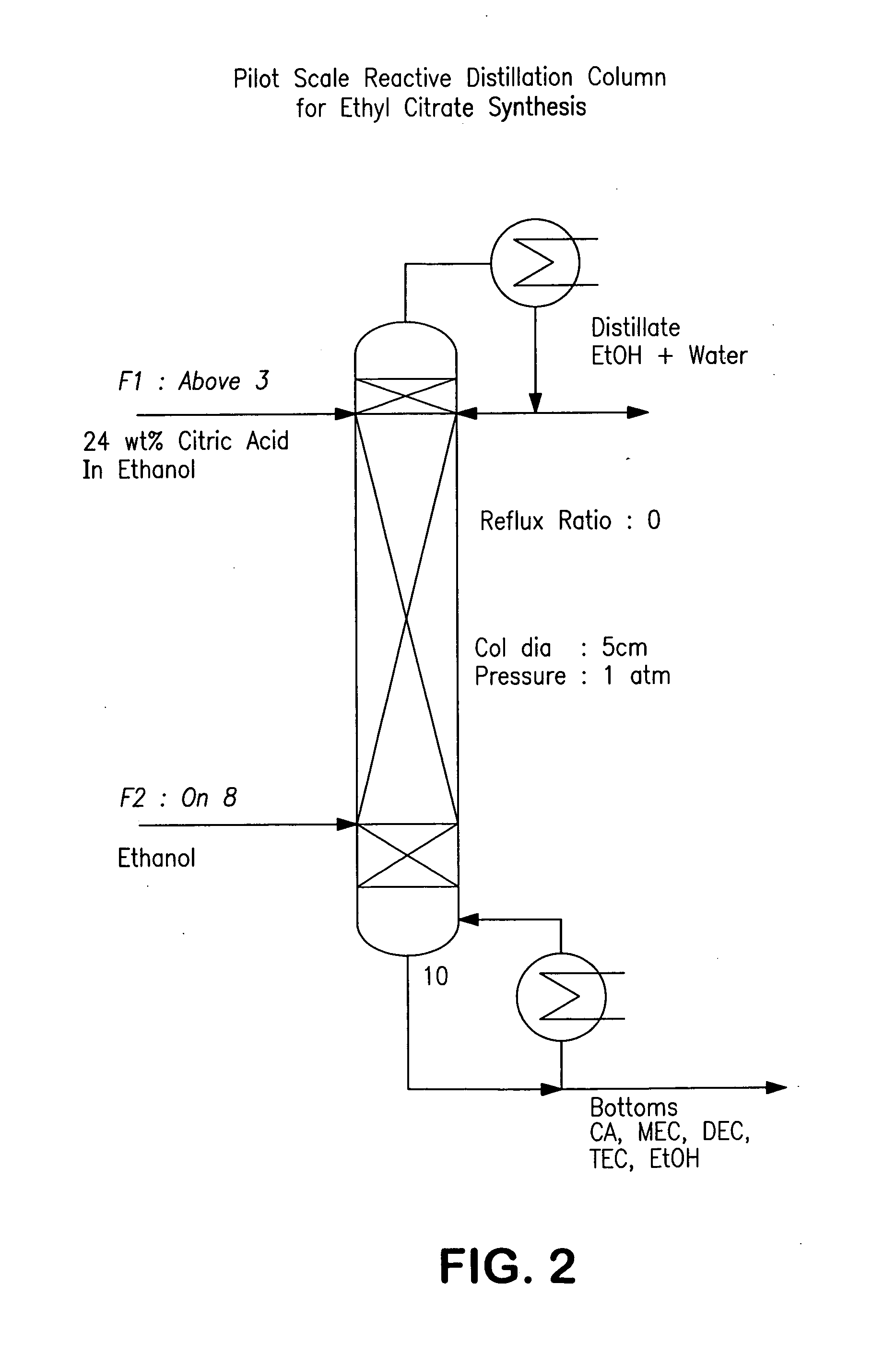

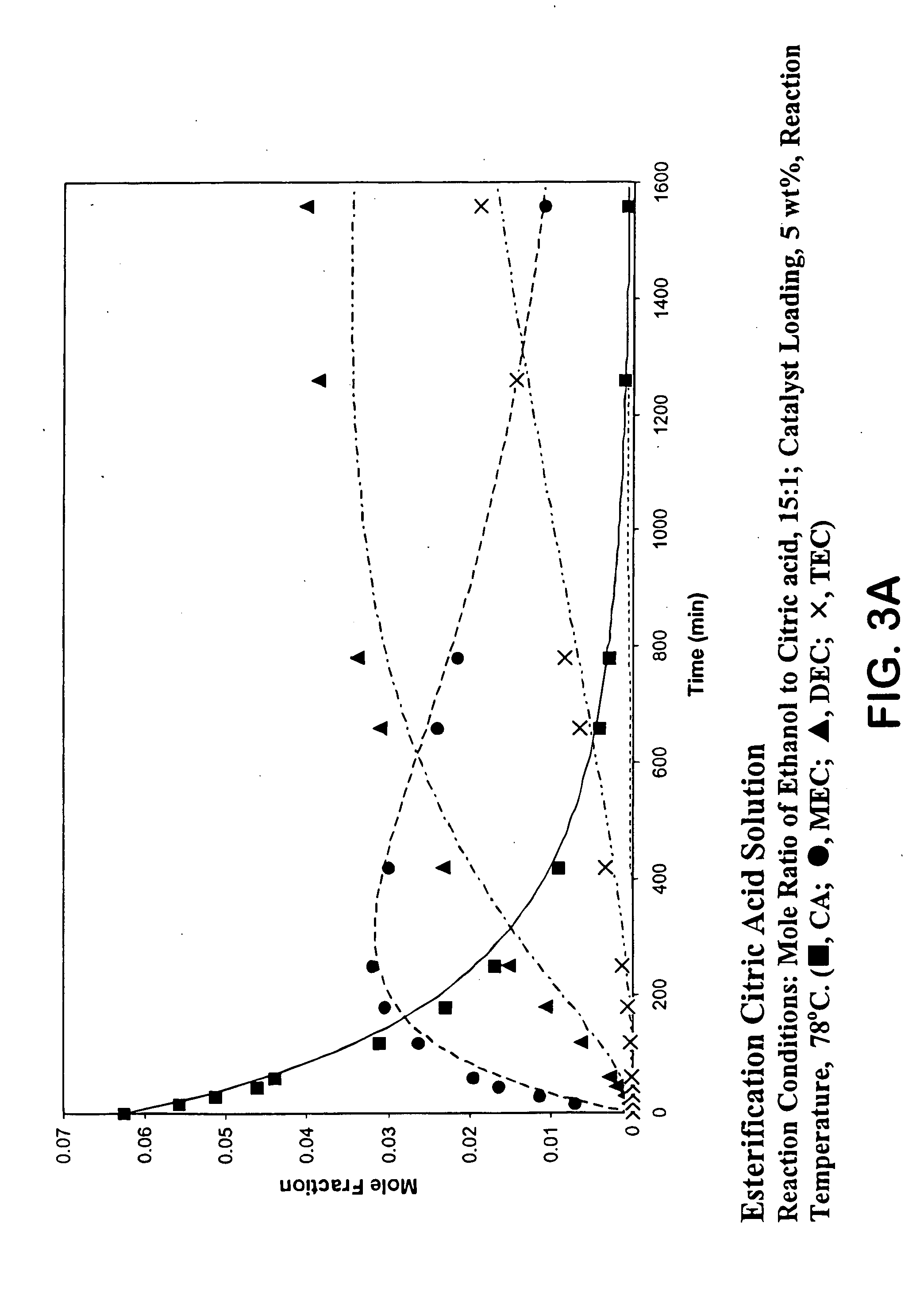

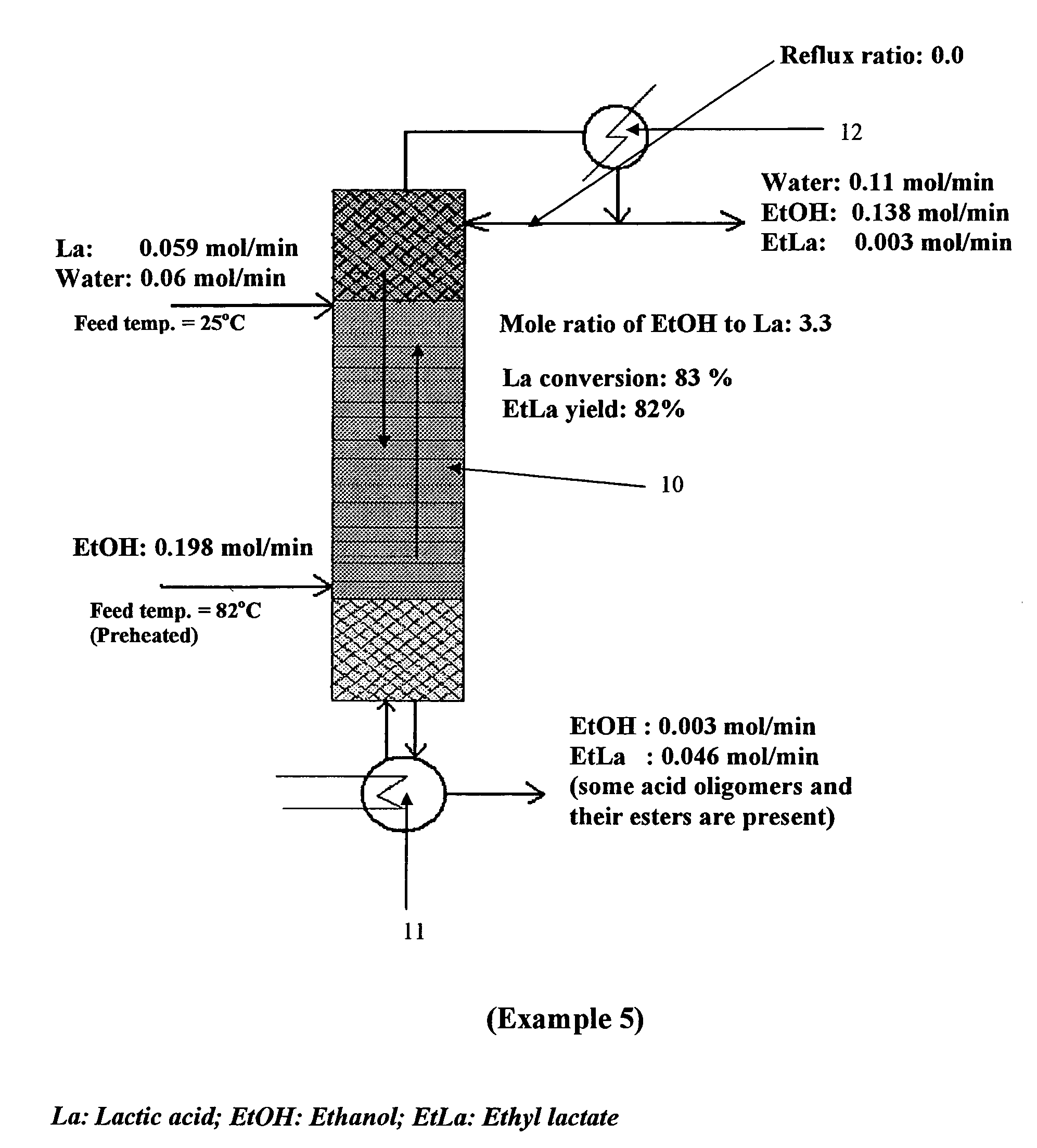

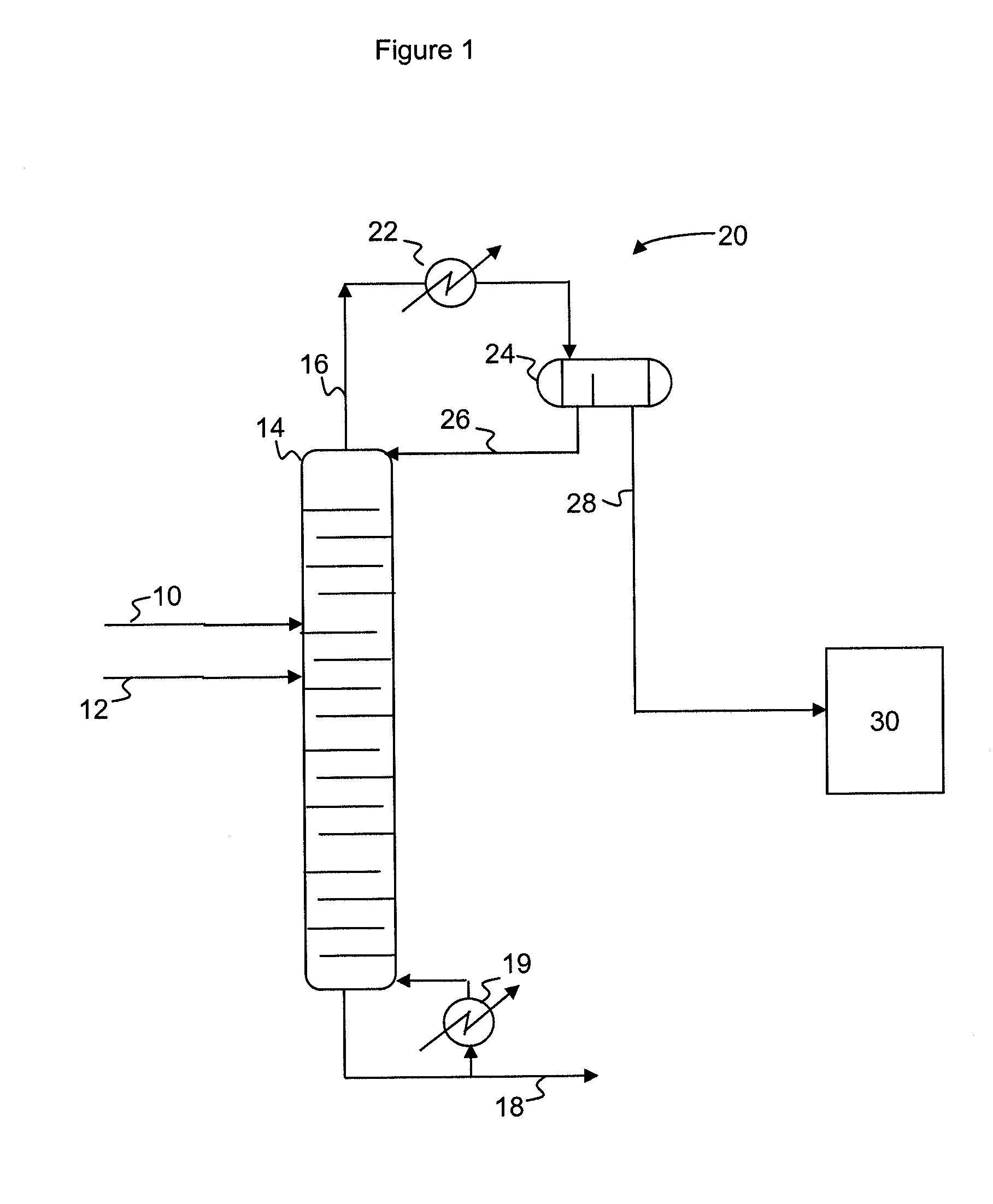

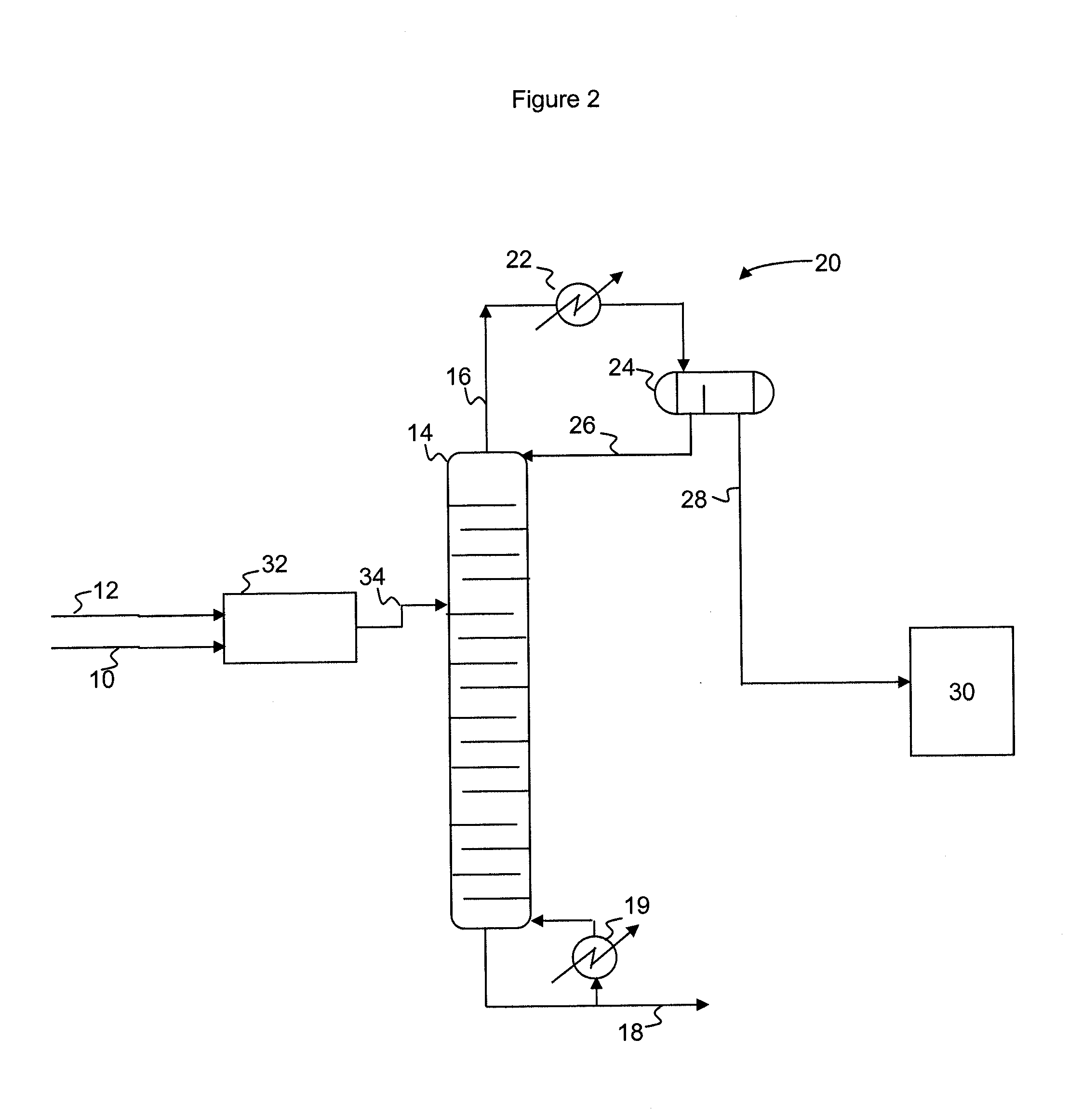

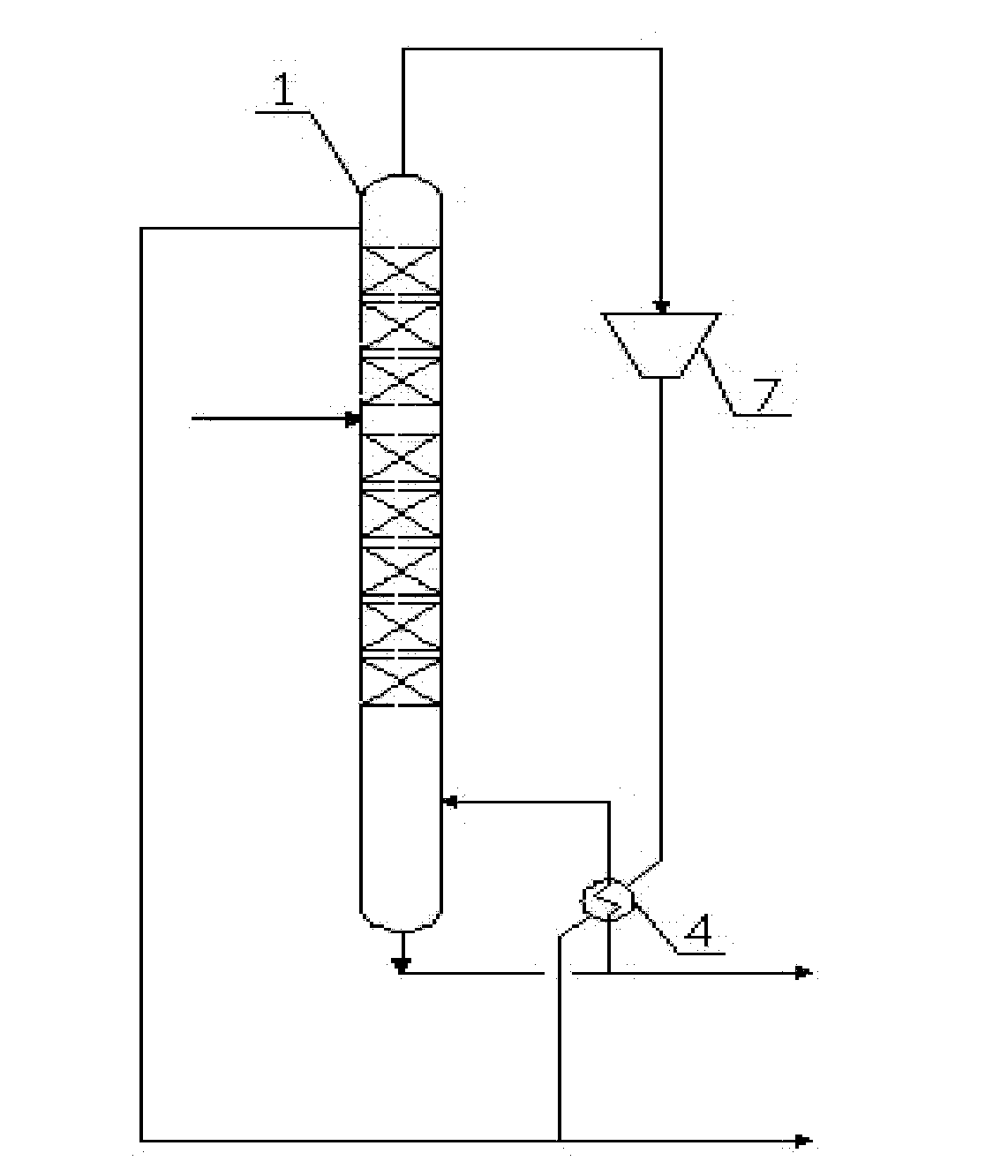

A process for producing organic acid esters using continuous countercurrent reactive distillation using acid catalysts in a structured packing in a single column (10) is described. In the reactive distillation an organic acid ester is formed by chemical reaction and can be purified to its final state within the single column. Organic acid esters are produced at relatively low cost, with less waste production, and in a less complicated manner than prior processes. Organic acid ester have uses as solvents, as intermediate chemicals, and in consumer products.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

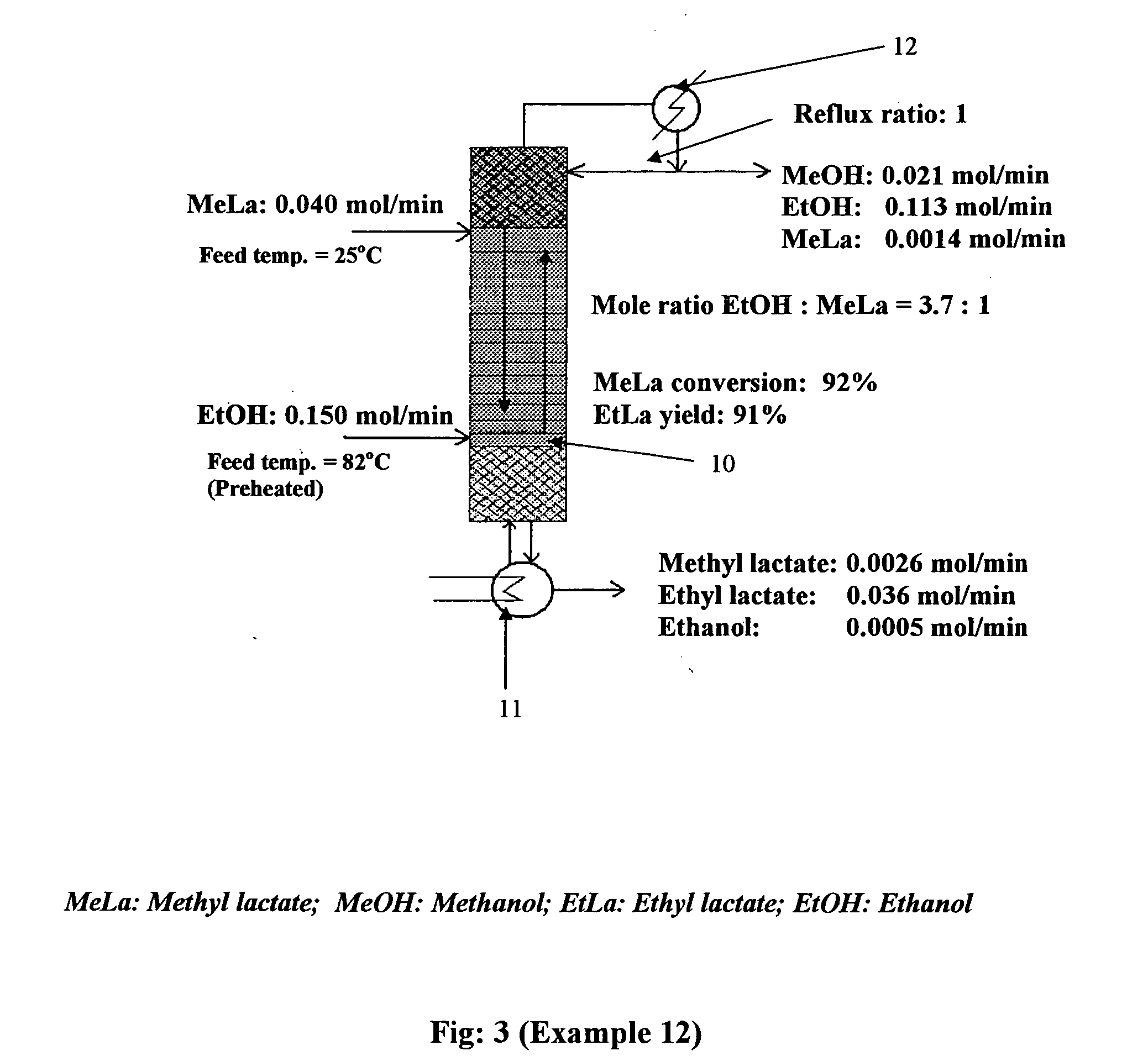

Process for reactive esterification distillation

ActiveUS20060252956A1Preparation by ester-hydroxy reactionOrganic compound preparationOrganic acidChemical reaction

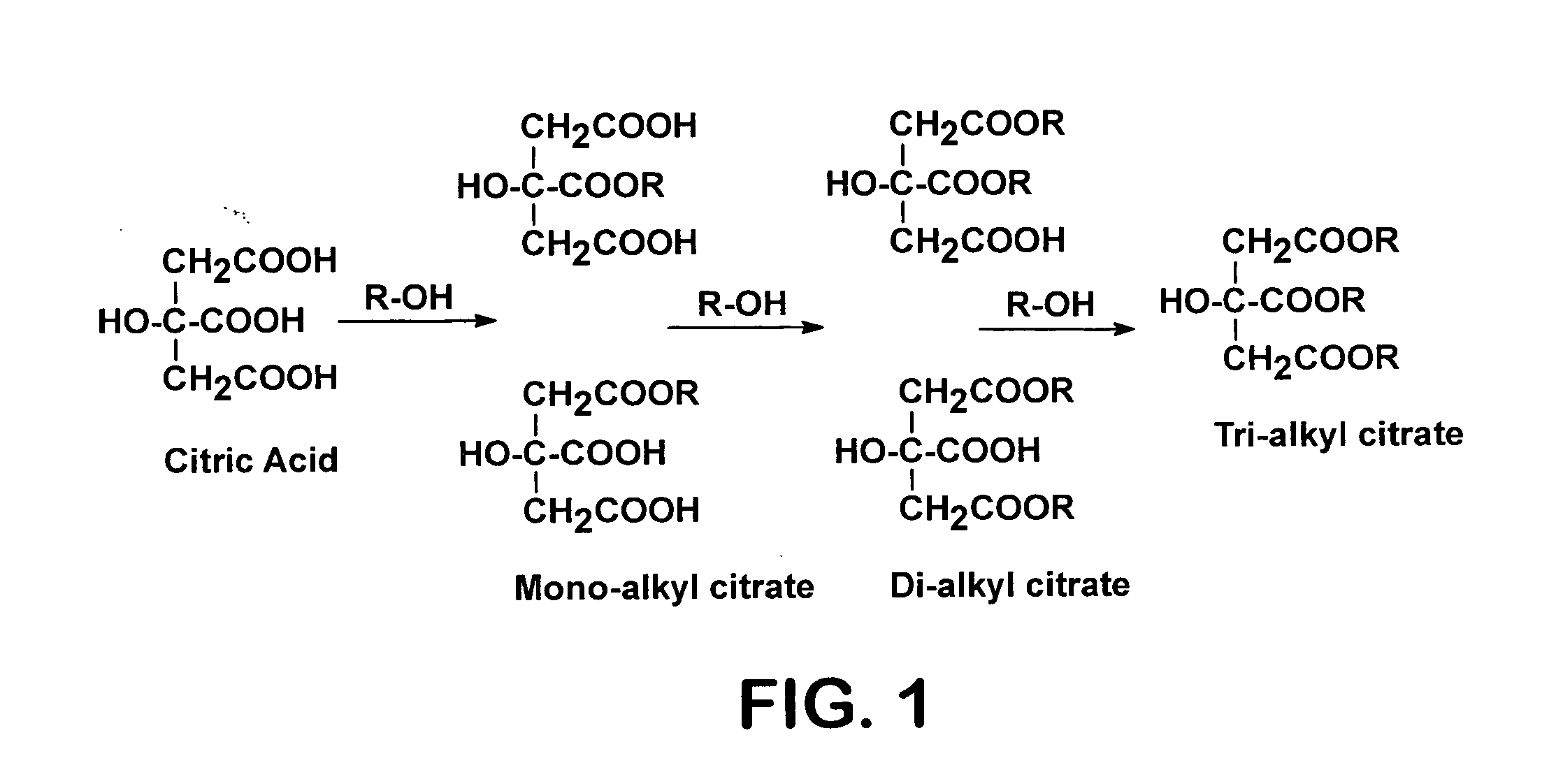

A process for producing organic acid di- or tri-esters, particularly citric acid tri-esters, with the available acid groups esterified using countercurrent reactive distillation using acid catalysts in a structured packing is described. In the reactive distillation an organic acid di- or tri-ester is formed by chemical reaction and purified to its final state within the single column. Organic acid di- or tri-esters are produced at relatively low cost, with less waste production in by-products of the reaction, and in a less complicated manner than prior processes. Organic acid di- and tri-esters have uses as solvents, as plasticizers and in conversion products.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

Process for production of organic acid esters

InactiveUS7652167B2Speed up the processPreparation by ester-hydroxy reactionOrganic compound preparationOrganic acidChemical reaction

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

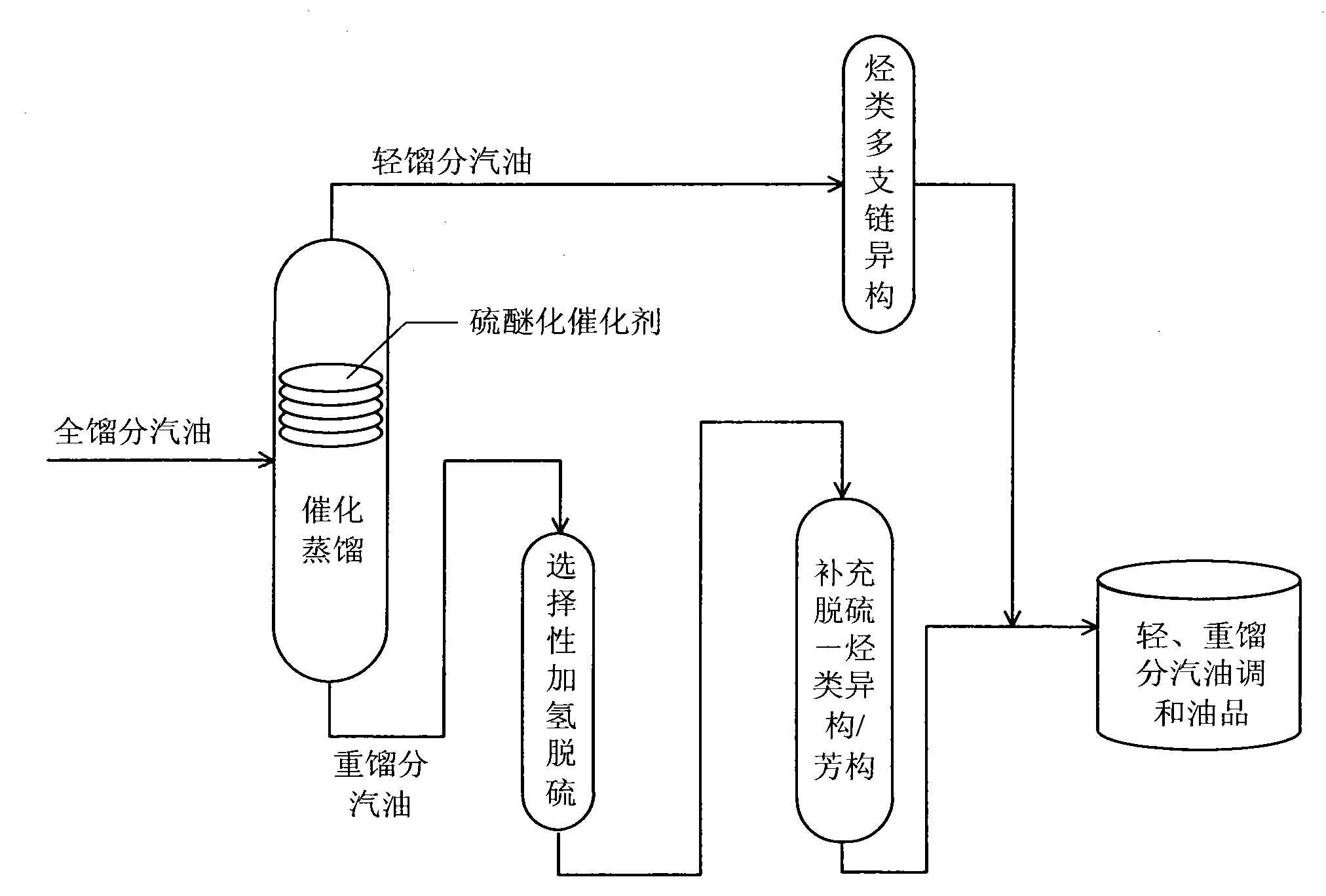

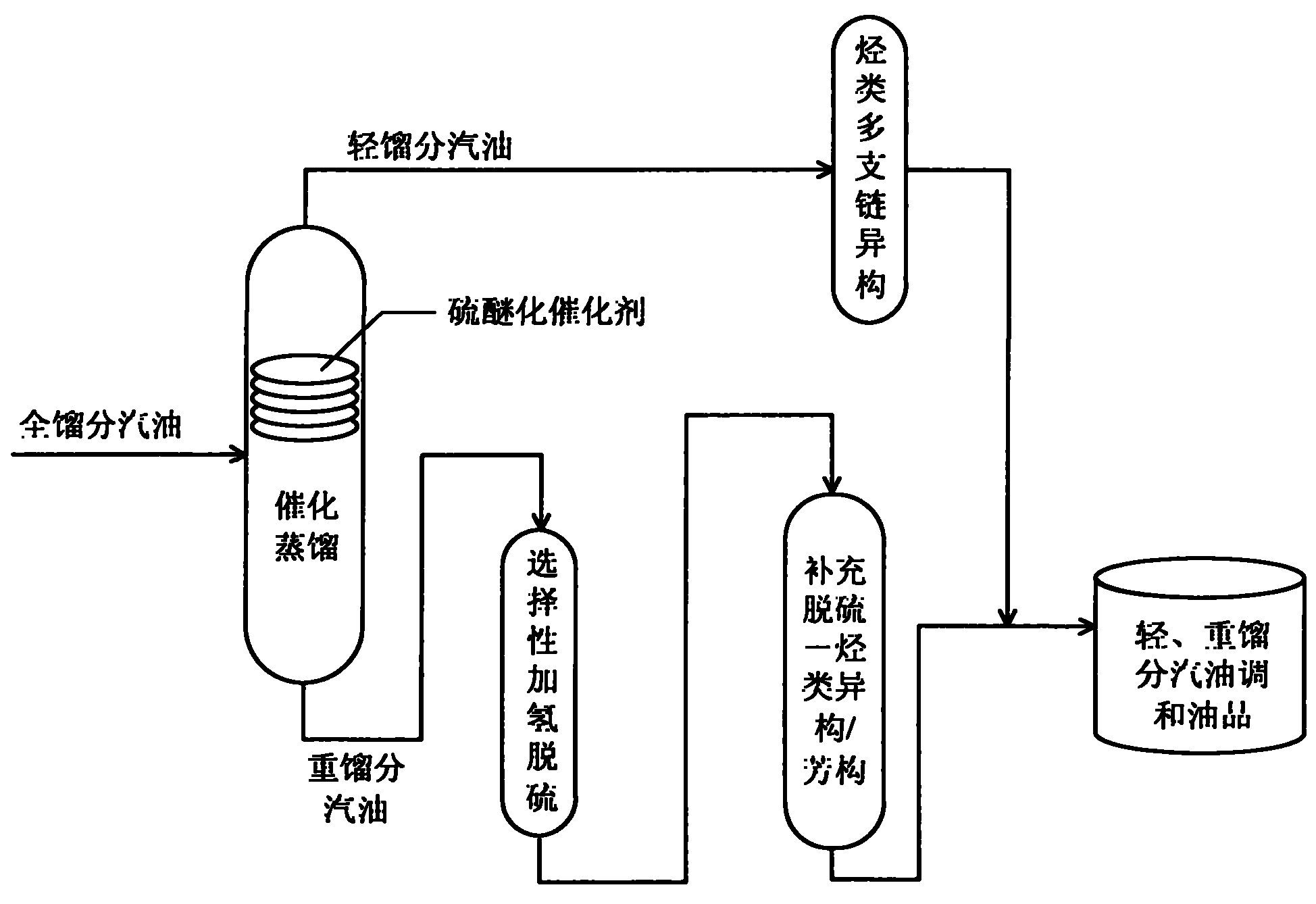

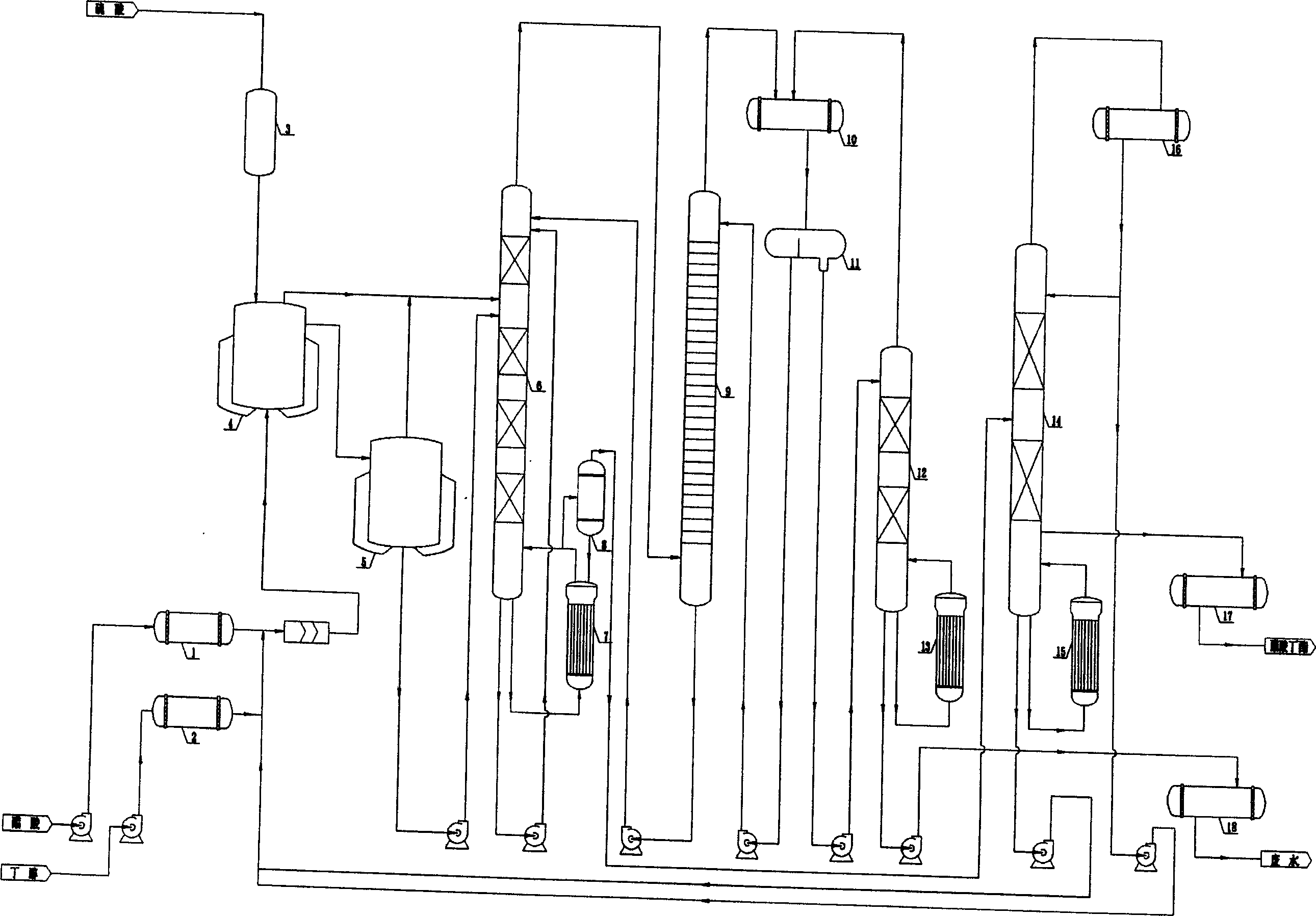

Production method for ultra-low sulfur and high-octane number gasoline

ActiveCN101885985ATake advantage ofIncrease temperatureTreatment with hydrotreatment processesIsomerizationHydrodesulfurization

The invention relates to a production method for ultra-low sulfur and high-octane number gasoline. The method comprises the following steps of: filling a poor-quality full range gasoline raw material in a reaction distillation column to contact the material with a sulfoether catalyst to perform a sulfur ether reaction and fraction cutting so that low-boiling point sulfides, such as thiol and thiophene, are converted into high-boiling point sulfoether which is then transferred into heavy fraction gasoline, wherein the cutting fractionation temperature of light fraction gasoline and the heavy fraction gasoline is 50 to 90 DEG C; contacting the light fraction gasoline with a hydrocarbon highly branched isomerization catalyst; contacting the heavy fraction gasoline with a selective hydrodesulfurization catalyst and a desulfurization-hydrocarbon isomerization / aromatization catalyst; and mixing the treated light fraction gasoline and the heavy fraction gasoline to obtain the ultra-low sulfur and high-octane number gasoline. The method is suitable for modifying poor-quality gasoline, can reach better desulfurization and olefin reduction effects on ultra-high sulfur and high-olefin poor-quality catalytic gasoline, and can maintain or increase the octane number of the product and keep a higher product yield after reaction.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

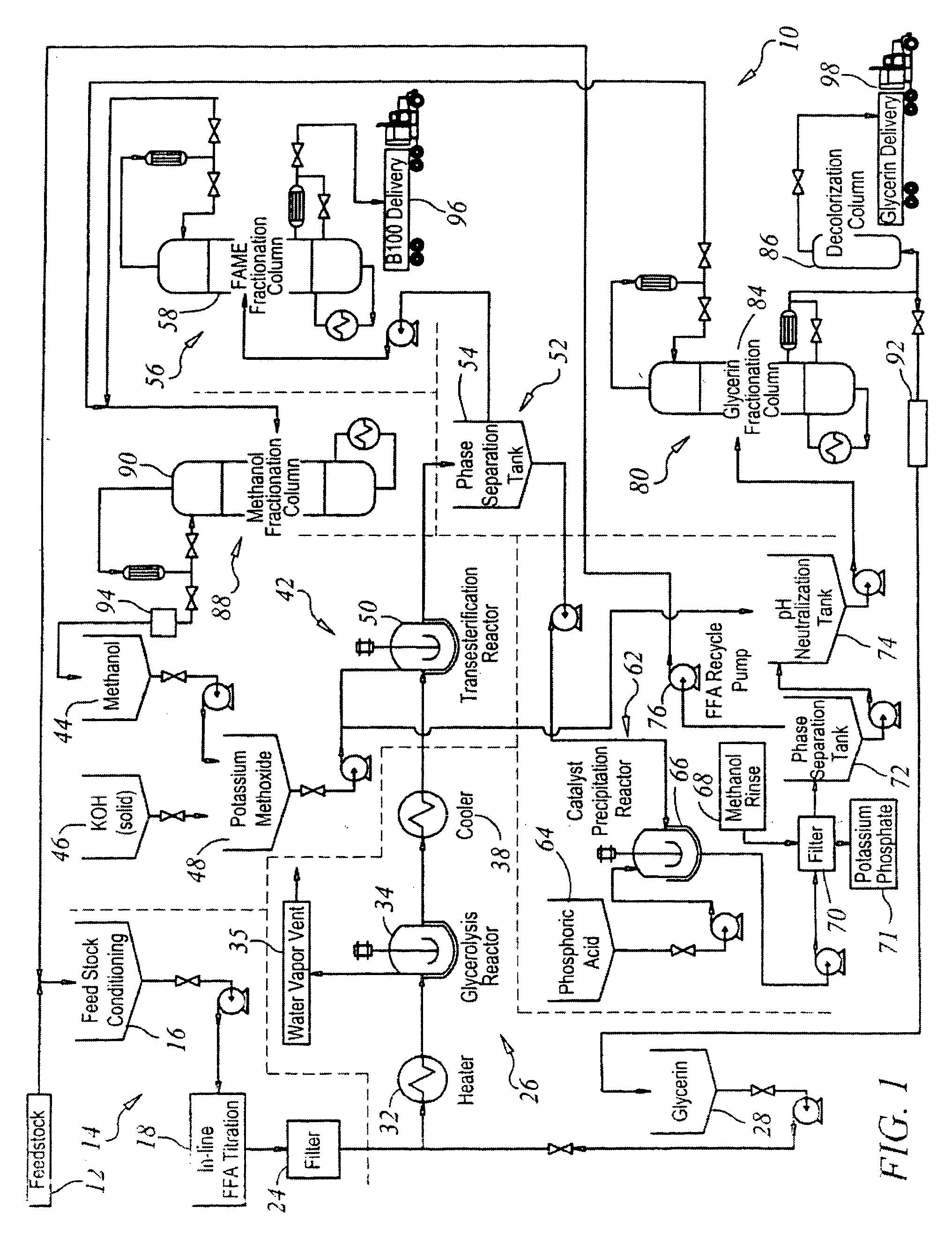

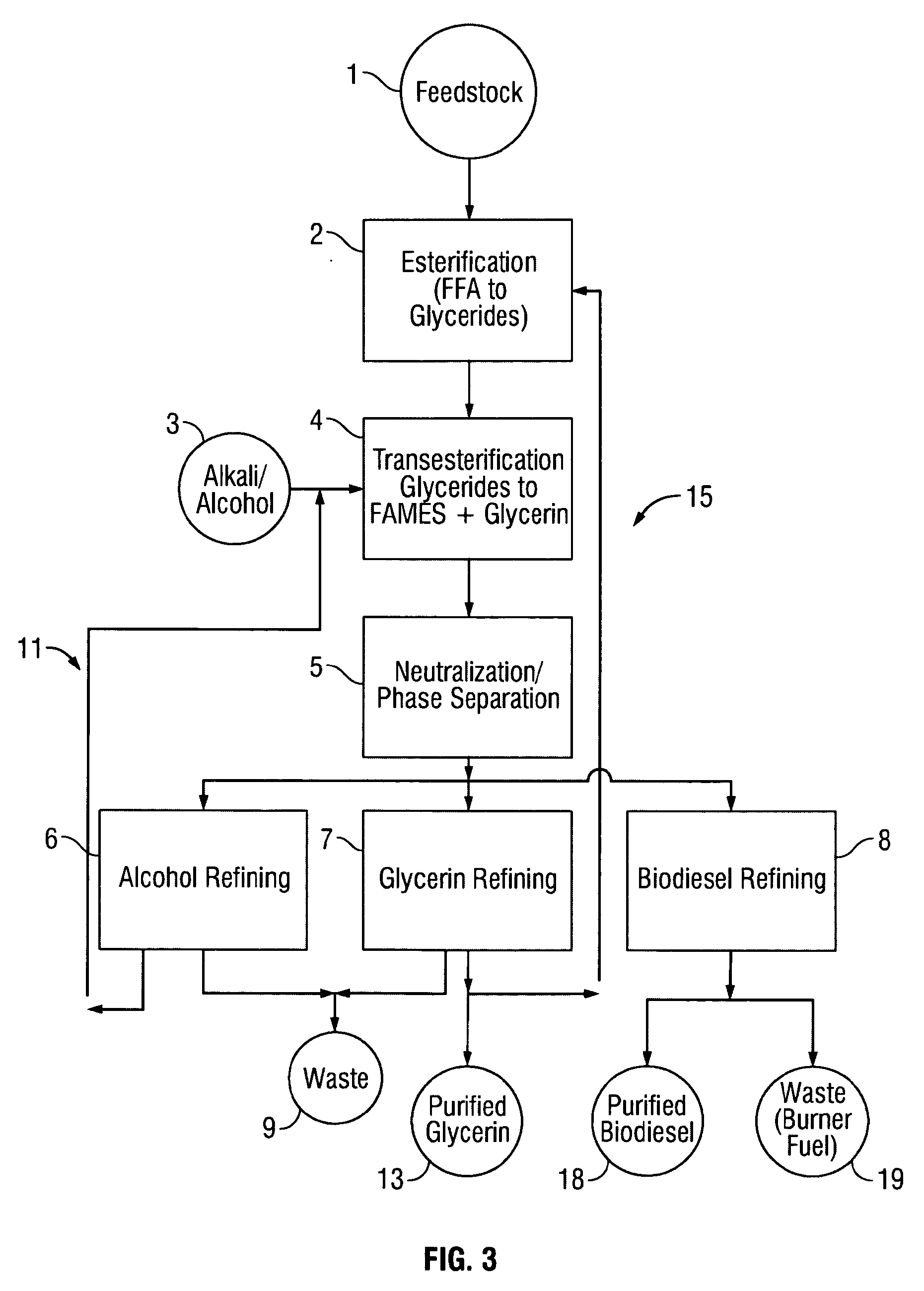

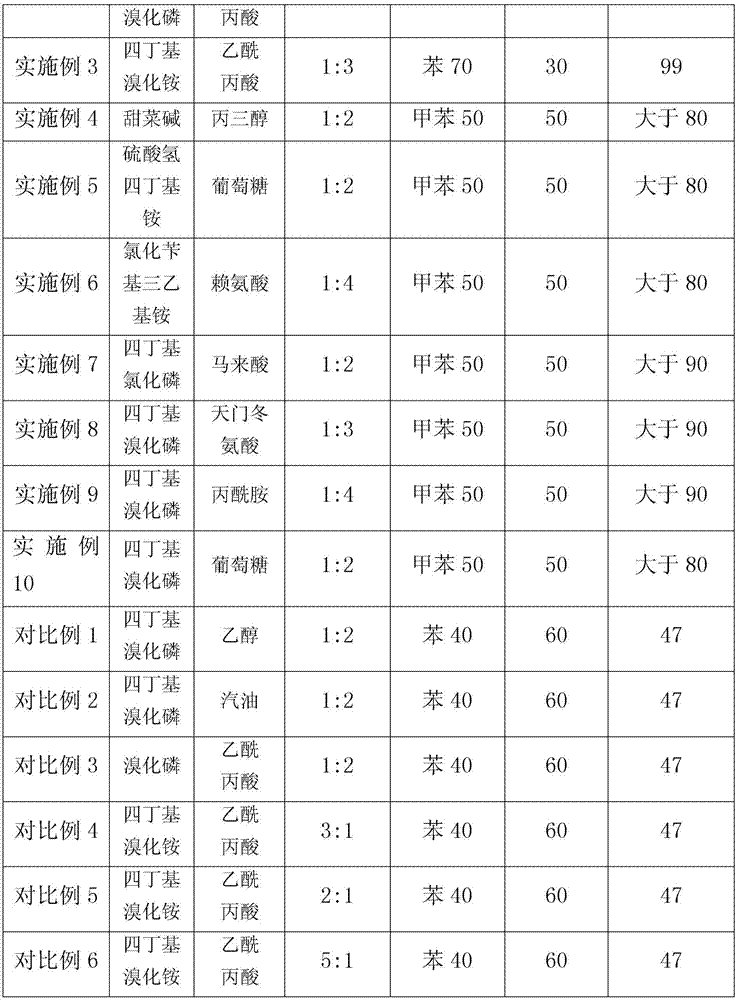

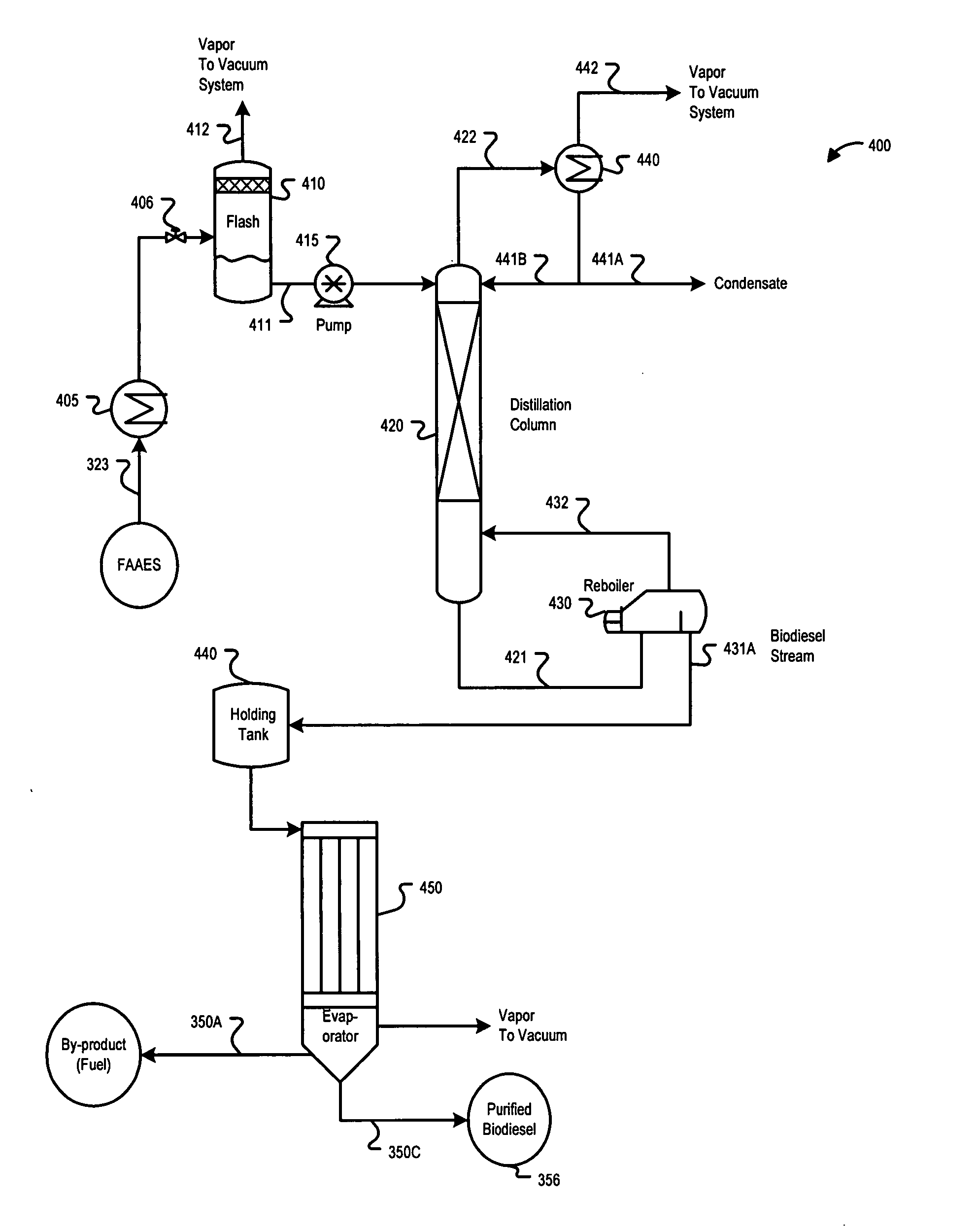

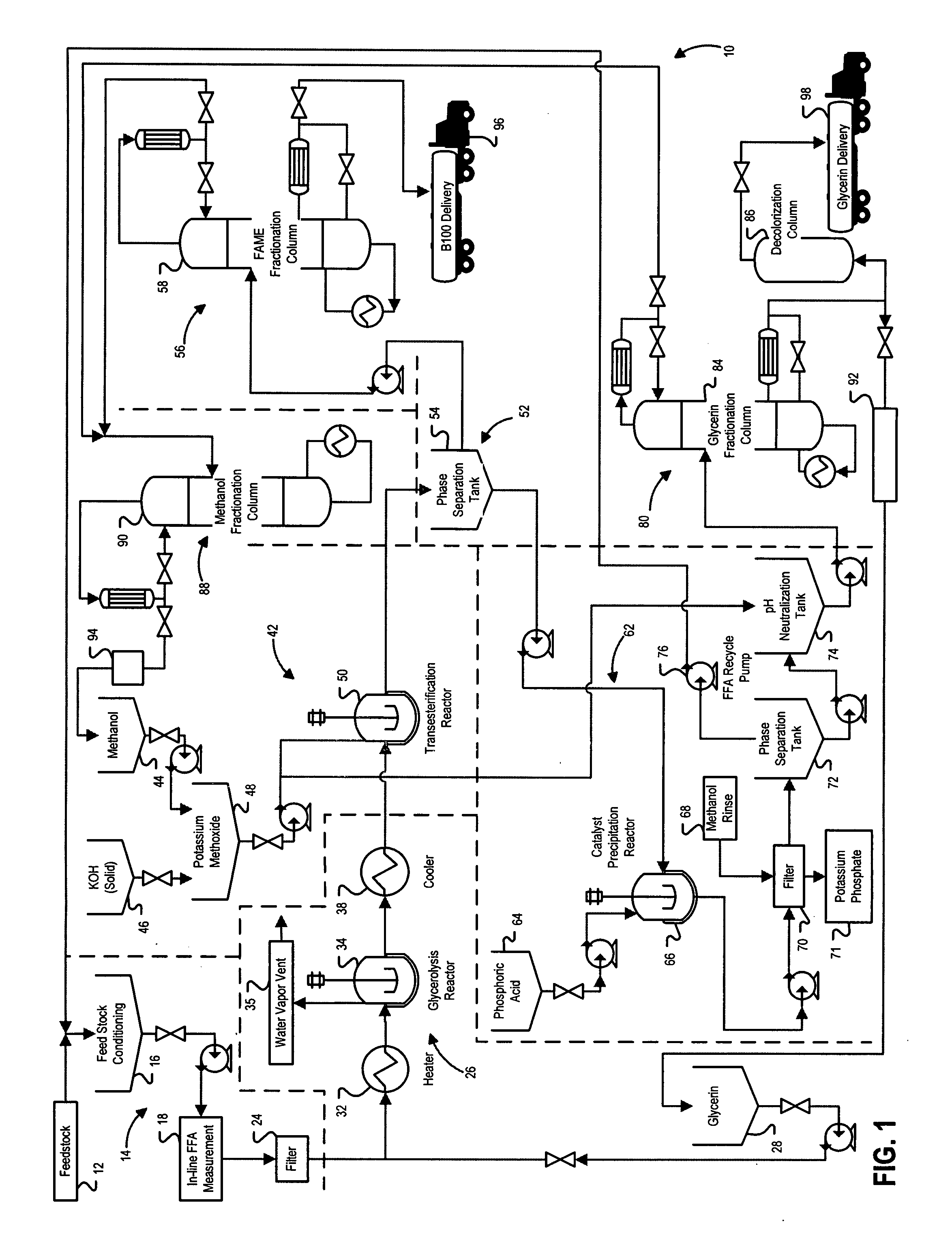

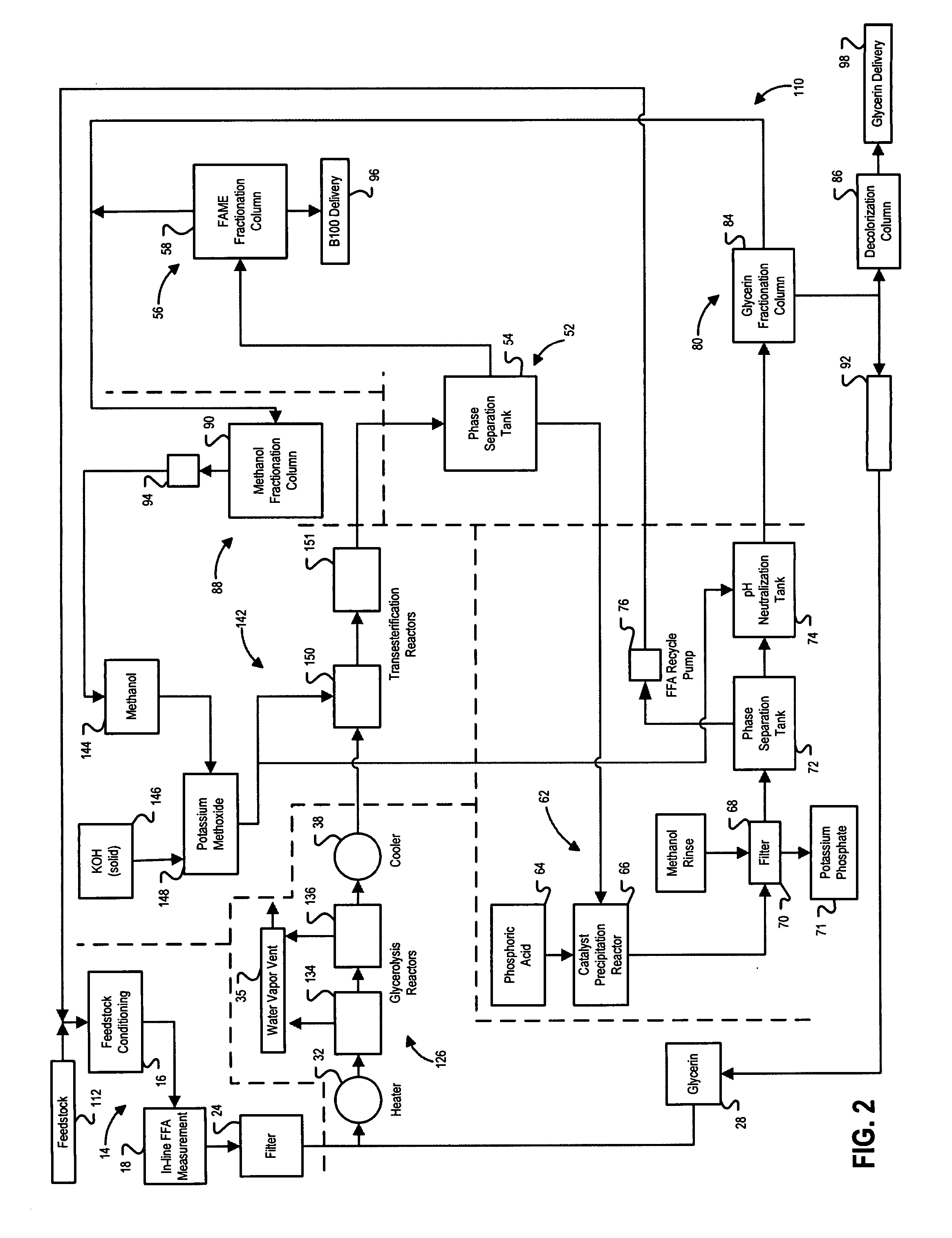

Production of biodiesel and glycerin from high free fatty acid feedstocks

ActiveUS20070277430A1Increase productionHigh purityFatty acid esterificationPreparation by ester-hydroxy reactionOrganic acidChemical reaction

A system and method for the conversion of free fatty acids to glycerides and the subsequent conversion of glycerides to glycerin and biodiesel includes the transesterification of a glyceride stream with an alcohol. The fatty acid alkyl esters are separated from the glycerin to produce a first liquid phase containing a fatty acid alkyl ester rich (concentrated) stream and a second liquid phase containing a glycerin rich (concentrated) stream. The fatty acid alkyl ester rich stream is then subjected to distillation, preferably reactive distillation, wherein the stream undergoes both physical separation and chemical reaction. The fatty acid alkyl ester rich stream is then purified to produce a purified biodiesel product and a glyceride rich residue stream. The glycerin rich second liquid phase stream may further be purified to produce a purified glycerin product and a (second) wet alcohol stream. Neutralization of the alkaline stream, formed during the alkali-catalyzed transesterfication process, may proceed by the addition of a mineral or an organic acid.

Owner:REG SENECA LLC +3

Process for producing epoxides

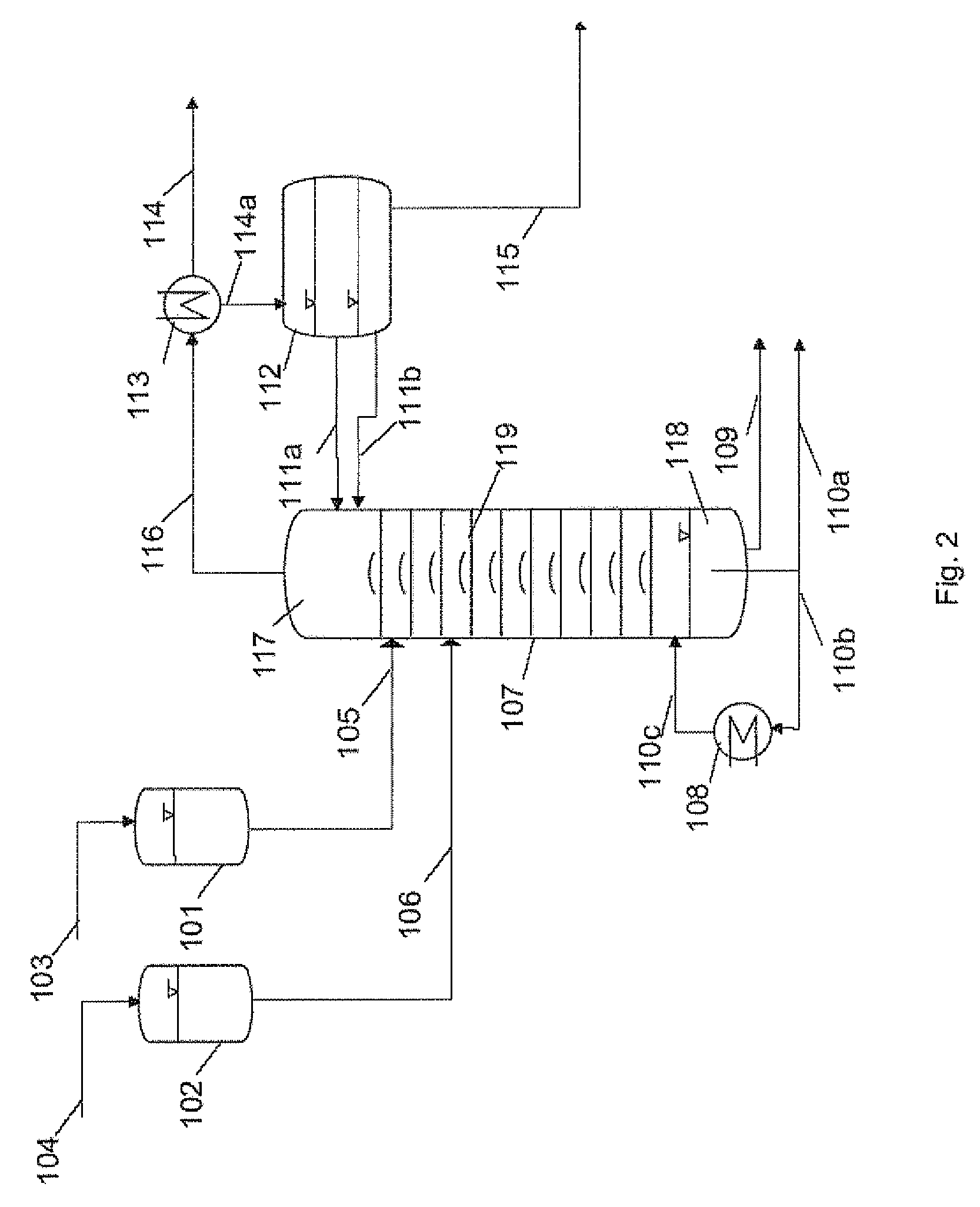

A process for producing epoxides, the process including: (a) feeding at least one aqueous alkali and at least one halohydrin to a reactive distillation column, wherein the reactive distillation column includes a feed zone, a top zone disposed above the feed zone, and a bottom zone disposed below the feed zone; (b) concurrently in the reactive distillation column: (i) reacting at least a portion of the halohydrin with the alkali to form an epoxide; and (ii) stripping water and the epoxide from a basic aqueous residue; (c) recovering the water and the epoxide from the reactive distillation column as an overheads fraction; (d) condensing and phase separating the overheads fraction to form an organic overheads fraction including the epoxide and an aqueous overheads fraction including water; and (e) maintaining a liquid holdup per plate in the feed zone at a residence time of 10 seconds or less.

Owner:BLUE CUBE IP

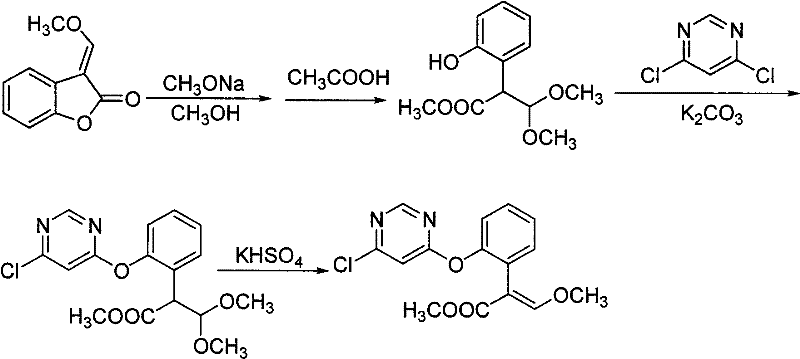

Synthetic method of azoxystrobin and special intermediate for synthesis

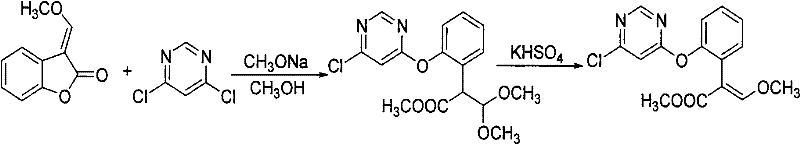

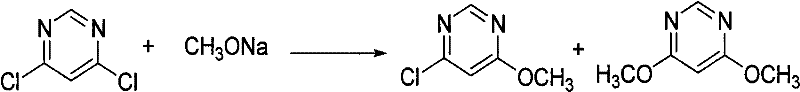

The invention relates to a synthetic process of a chemical substance, and particularly relates to a synthetic method for synthesizing (E)-2-[2-(6-chloro pyrimidine-4-yloxy)phenyl]-3-methoxy methacrylate and azoxystrobin; the method comprises the following steps: mixing a raw material of 3-(alpha-methoxy)methylene benzofuran-2-(3H)-ketone and potassium carbonate in a toluene solvent, cooling to 0-10 DEG C, adding sodium methoxide, reacting for 0.4-0.6 hours; adding 4,6-dichloropyrimidine and a catalyst of DABCO, reacting for 1-2 hours, filtering to remove inorganic salts, washing the filtrate with water, performing distillation to recover toluene; adding a catalyst of potassium bisulfate into the distillation residues of the above reaction, heating to 132-145 DEG C in a reduced-pressure condition for reaction; directly adding salicylonitrile to synthesize azoxystrobin or performing toluene dissolution, water washing, solvent recovery, recrystallization and filtration to obtain an intermediate. The production and synthesis of (E)-2-[2-(6-chloro pyrimidine-4-yloxy)phenyl]-3-methoxy methacrylate by the production process of the invention has high yield, and simple operations, and the used raw materials and processes are routine reagents and methods.

Owner:CHONGQING UNISPLENDOUR CHEM

Process for reactive esterification distillation

ActiveUS7667068B2Organic compound preparationPreparation by ester-hydroxy reactionOrganic acidChemical reaction

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

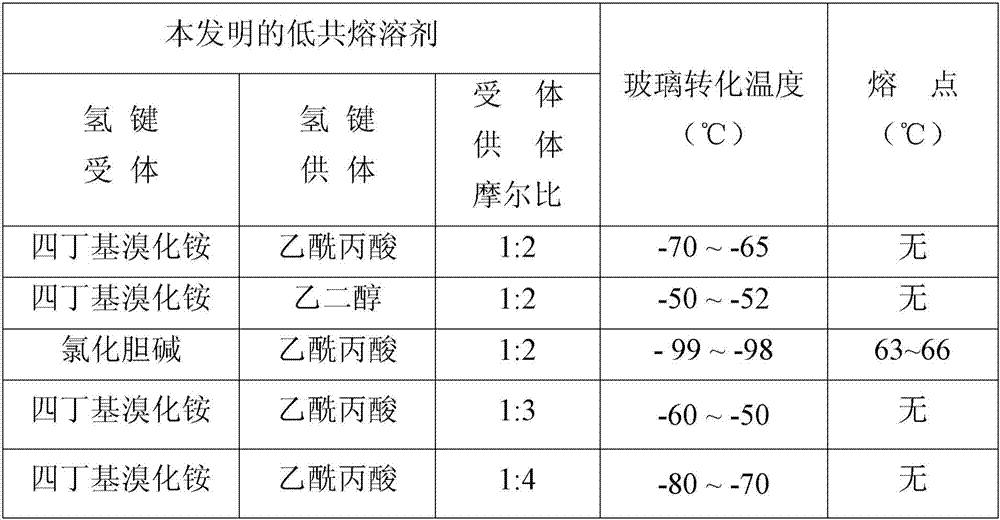

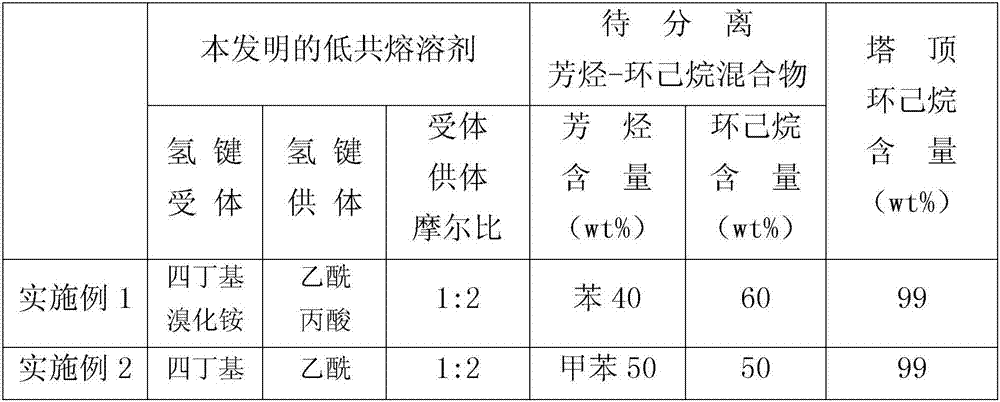

Low eutectic solvent for aromatic hydrocarbon separation and application thereof to extractive distillation

ActiveCN107311833AOvercome dosageOvercoming a large amountDistillation purification/separationExtractive distillationExtractive distillationReactive distillation

The invention discloses a low eutectic solvent for aromatic hydrocarbon separation. The low eutectic solvent is obtained by mixing hydrogen bond receptors and hydrogen bond donors according to a certain ratio (the molar ratio of 1: 1 to 1:10), and stirring till being in a uniform transparent state at 70-100 DEG C. The low eutectic solvent is low in toxicity, environment-friendly and high in efficiency, and can be applied to the process of separating aromatic hydrocarbons from non-aromatic hydrocarbons in coal tar and petroleum oil.

Owner:烟台中科恩吉科创新产业园管理有限公司

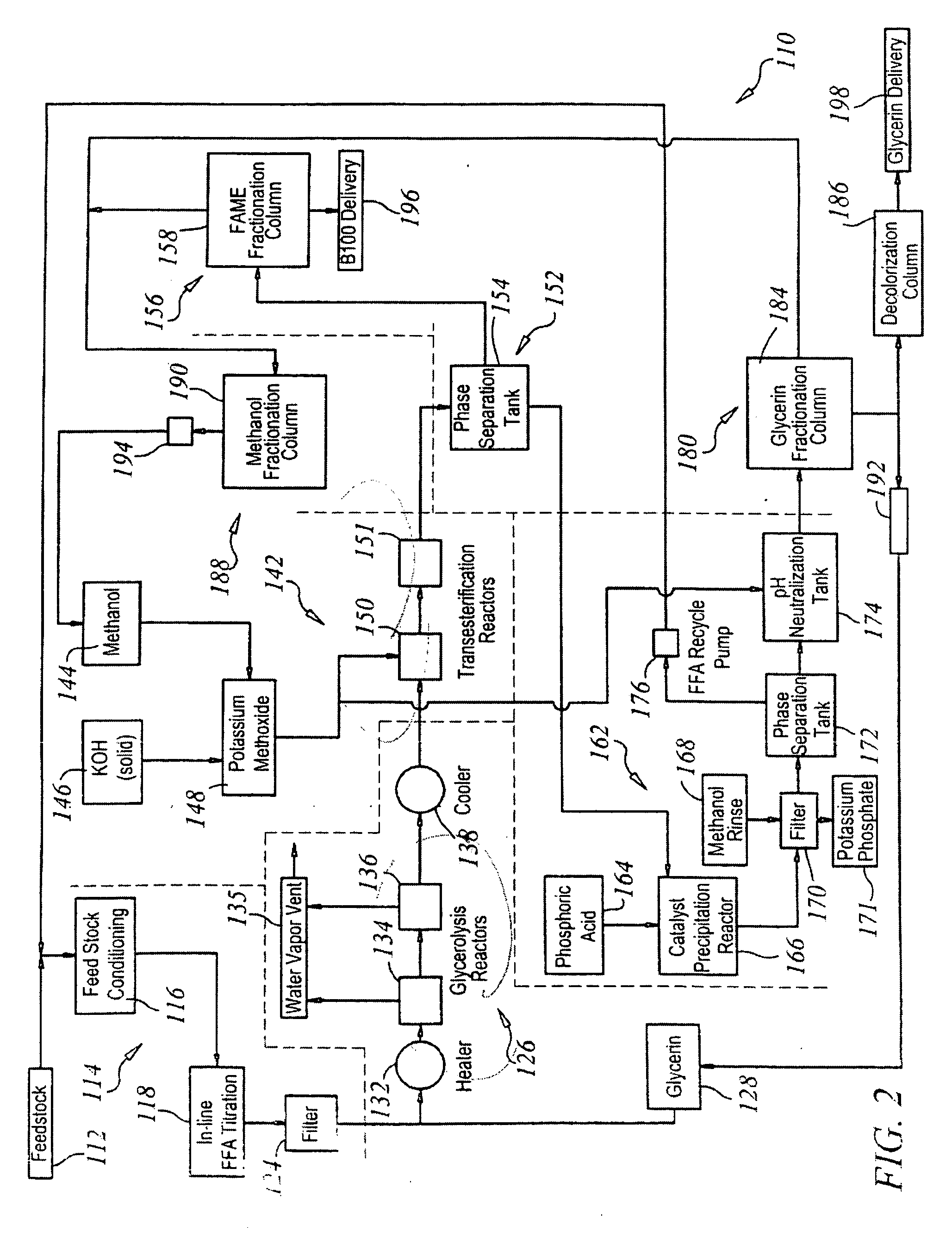

Production of biodiesel and glycerin from high free fatty acid feedstocks

ActiveUS20070277432A1Maximize recoveryQuality improvementFatty acid chemical modificationOrganic compound preparationOrganic acidChemical reaction

A system and method for the conversion of free fatty acids to glycerides and the subsequent conversion of glycerides to glycerin and biodiesel includes the transesterification of a glyceride stream with an alcohol. The fatty acid alkyl esters are separated from the glycerin to produce a first liquid phase containing a fatty acid alkyl ester rich (concentrated) stream and a second liquid phase containing a glycerin rich (concentrated) stream. The fatty acid alkyl ester rich stream is then subjected to distillation, preferably reactive distillation, wherein the stream undergoes both physical separation and chemical reaction. The fatty acid alkyl ester rich stream is then purified to produce a purified biodiesel product and a glyceride rich residue stream. Biodiesel may be further recovered from the glyceride rich residue stream, by further separation of and / or processing of glycerides / free fatty acids contained therein. The glycerin rich second liquid phase stream may further be purified to produce a purified glycerin product and a (second) wet alcohol stream. Neutralization of the alkaline stream, formed during the alkali-catalyzed transesterification process, may proceed by the addition of a mineral or an organic acid.

Owner:REG SENECA LLC

Method of producing a carboxylic alkyl ester

ActiveUS20090137825A1Increase productionHigh purityOrganic compound preparationChemical industryCarboxylic saltReactive distillation

The present invention relates to a novel process for preparing alkyl polycarboxylates from an aqueous solution of an ammonium salt of the polycarboxylic acid by reactive distillation, and to a process for hydrogenating the alkyl carboxylates prepared in this way.

Owner:BASF AG

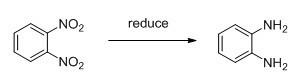

Method for preparing o-phenylenediamine by catalytic hydrogenation of o-nitrophenylamine

InactiveCN102633653ASolve the problem of impuritiesReduce the presence of impuritiesOrganic compound preparationAmino compound preparationPtru catalystHydrogen pressure

The invention discloses a method for preparing o-phenylenediamine by catalytic hydrogenation of o-nitrophenylamine. The method is characterized in that: in the hydrogenation reaction of o-nitrophenylamine, alcohol is used as a solvent, nickel is used as a catalyst, reduction reaction is performed for 2 to 10 hours under the hydrogen pressure of 1.0 to 6 MPa at the temperature of between 40 and 80 DEG C, and the reaction product is rectified to form the while o-phenylenediamine. The method has the advantages that the alcohol is used as the solvent in the catalytic hydrogenation for producing o-phenylenediamine, the alcohol can be reclaimed and directly used for next reaction, and the waste residue produced by distillation can be used as an organic fuel, so that the problem that a large amount of waste water containing organic substances is produced in reduction of iron powder or sodium sulfide in the conventional process is solved; and thick acid and thick alkali used in the conventional process are avoided in the hydrogenation process, so that corrosion of equipment is greatly reduced, pollution is reduced, and almost zero pollution is realized. In addition, compared with the conventional iron powder or sodium sulfide reduction, the catalytic hydrogenation process has the advantages of low pollution, high yield, high quality, short production period and low energy consumption.

Owner:JIANGSU KANGHENG CHEM

Manufacture of xylenes by reactive distillation of reformate

InactiveUS20050075524A1Formation of undesirable can be reducedReduce formationMolecular sieve catalystChemical industryReactive distillationXylene

A process is provided for the production of xylenes from reformate by reactive distillation. The process is carried out by methylating the benzene / toluene present in the reformate in a reactive distillation zone and under reactive distillation conditions to produce a resulting product having a higher xylenes content than the reformate. Greater than equilibrium amounts of para-xylene can be produced by the process.

Owner:EXXONMOBIL CHEM PAT INC

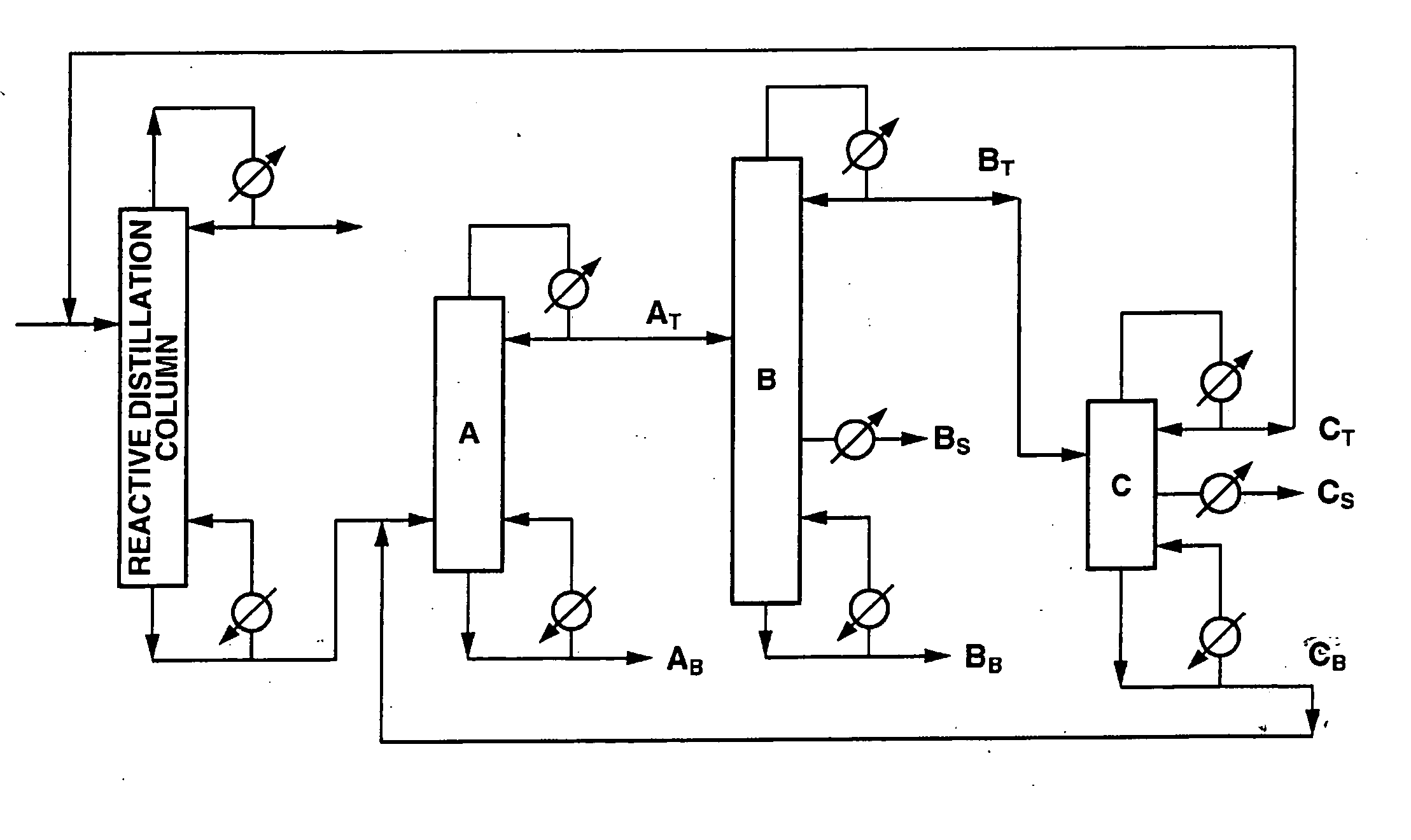

Transesterification process of methyl acetate

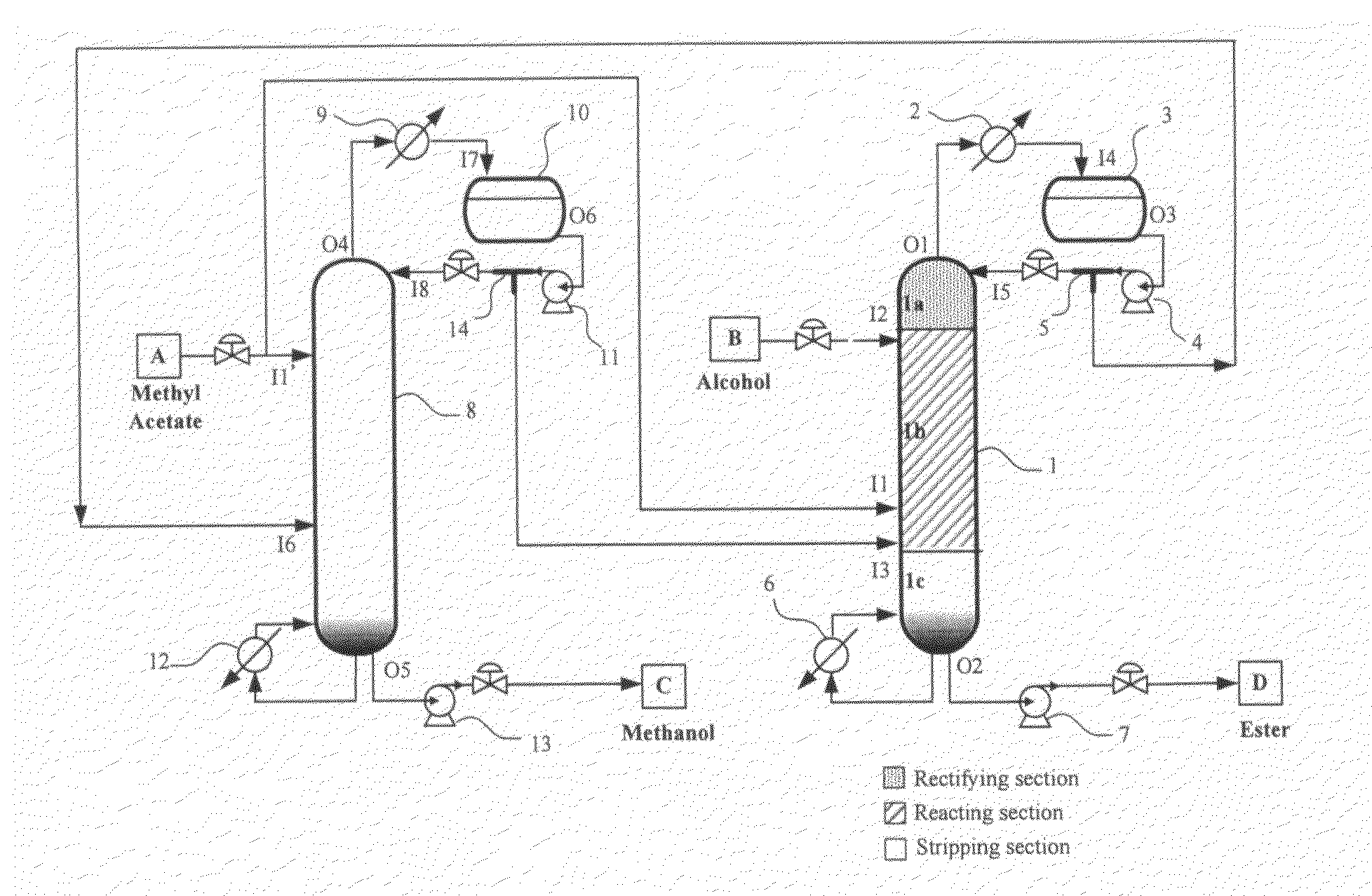

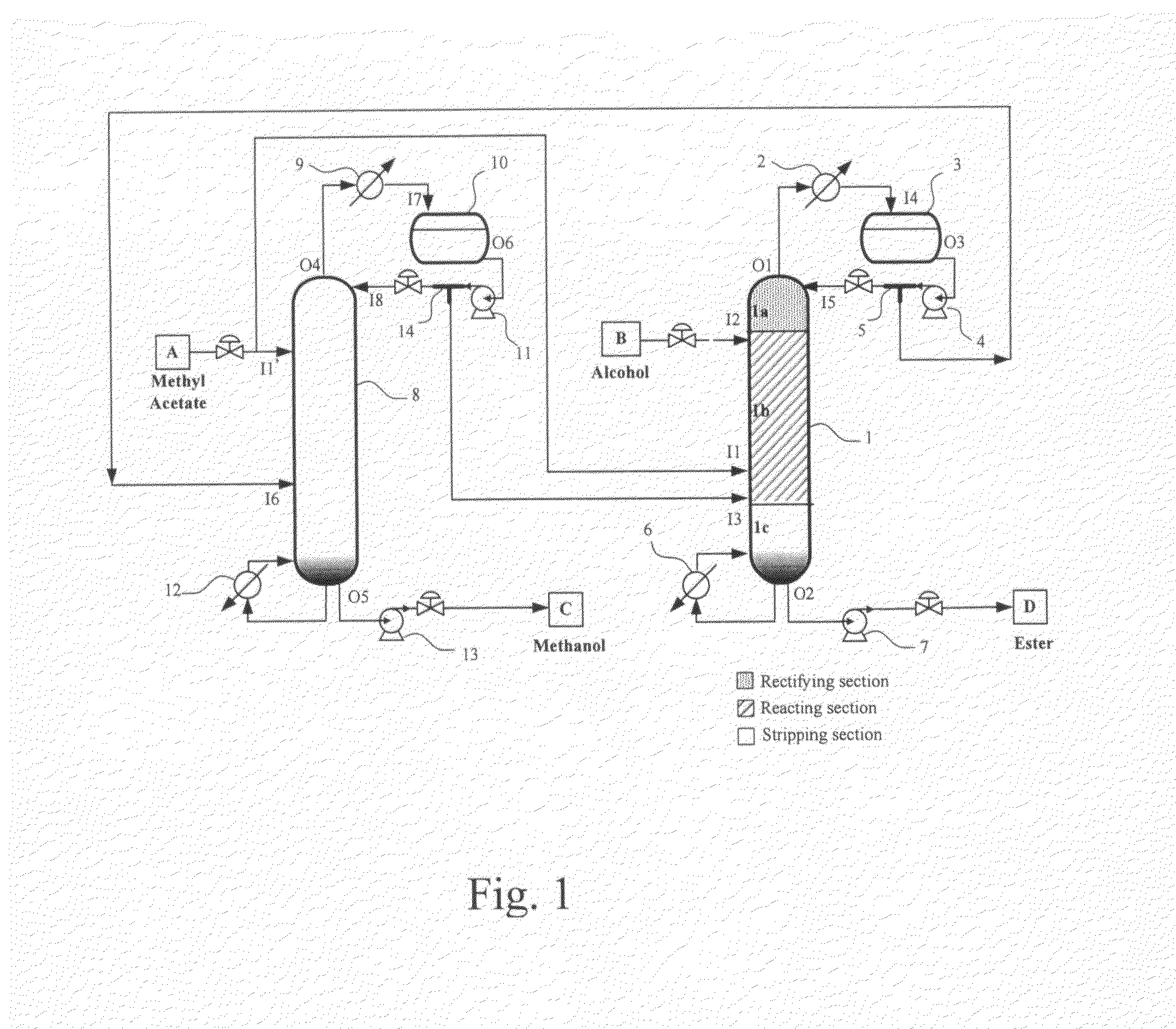

ActiveUS20080161595A1Economical and efficient operationOrganic compound preparationPreparation by ester-hydroxy reactionAlcoholTransesterification

A transesterification process of methyl acetate is provided. The process comprises: (a) performing a first reactive distillation of a methyl acetate solution and a first alcohol to generate a first ester and a first mixture; (b) performing a first distillation of a first part of the first mixture to generate a second mixture; and (c) performing a second reactive distillation of a first part of the second mixture and a second alcohol to generate a second ester; wherein the respective one of the first and second alcohols is a limiting reagent. The transesterification process provided in the present invention could highly reduce the investing production cost of the transesterification of the by-product, methyl acetate, in the conventional polyvinyl alcohol plants.

Owner:NAT TAIWAN UNIV

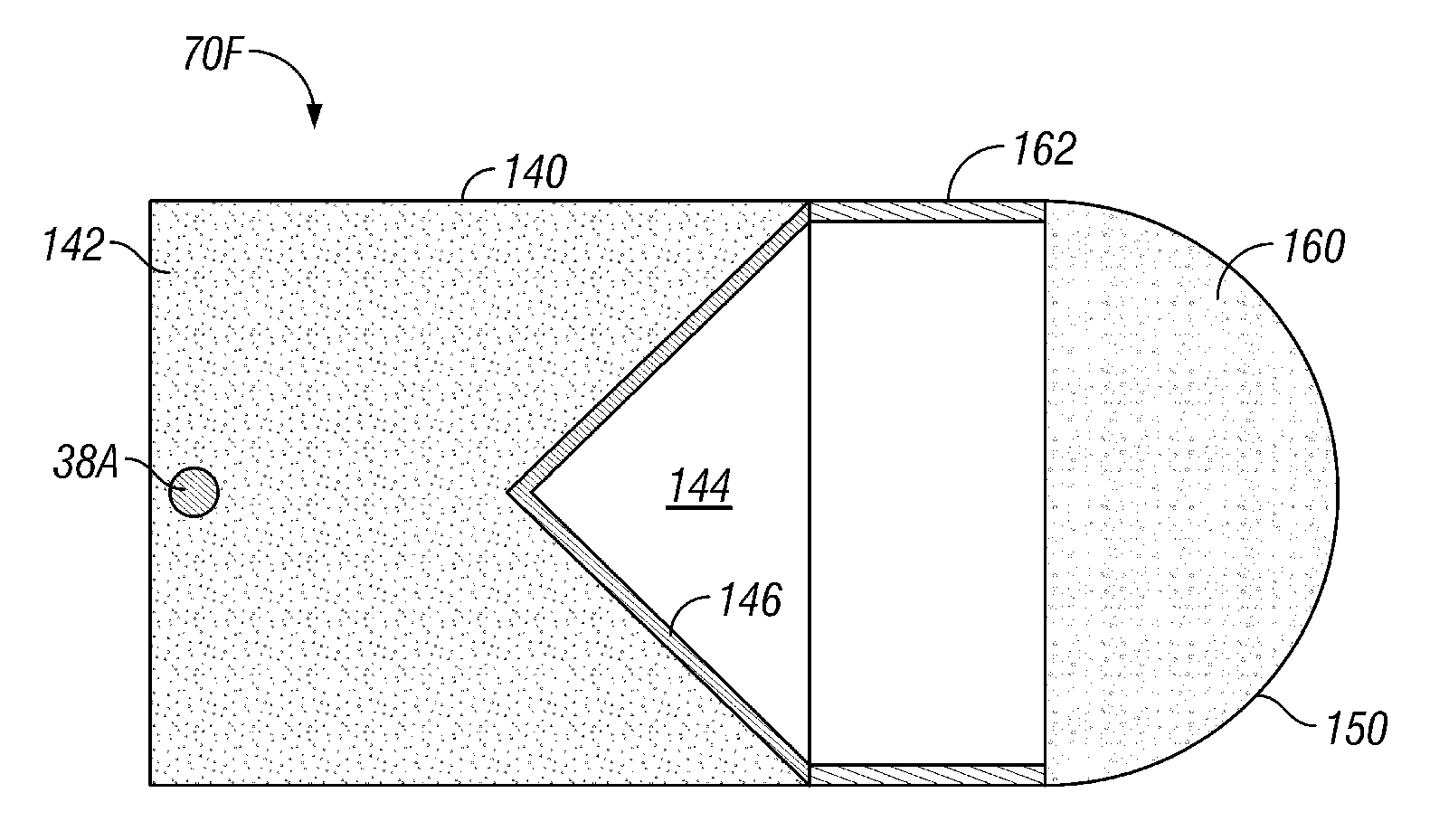

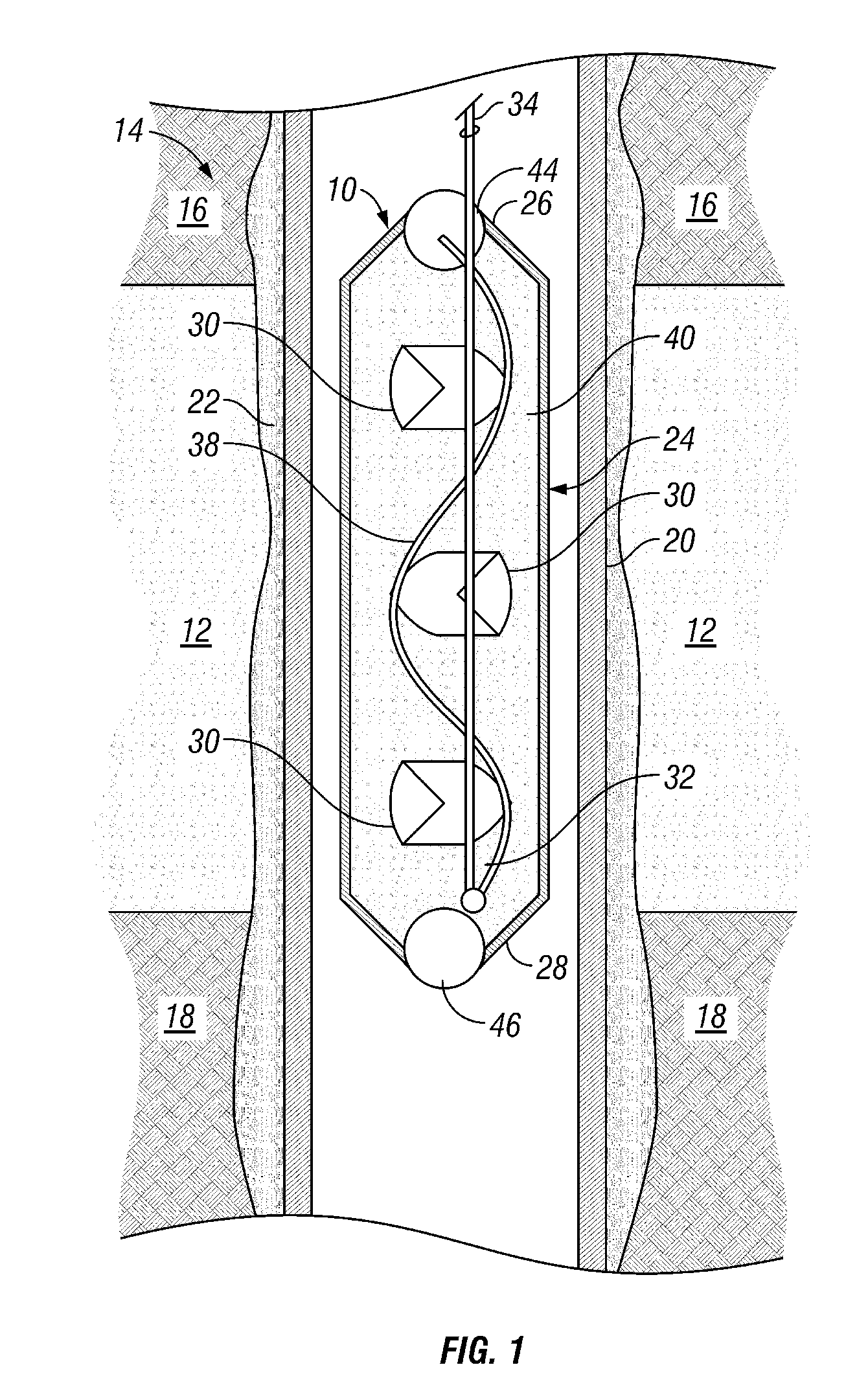

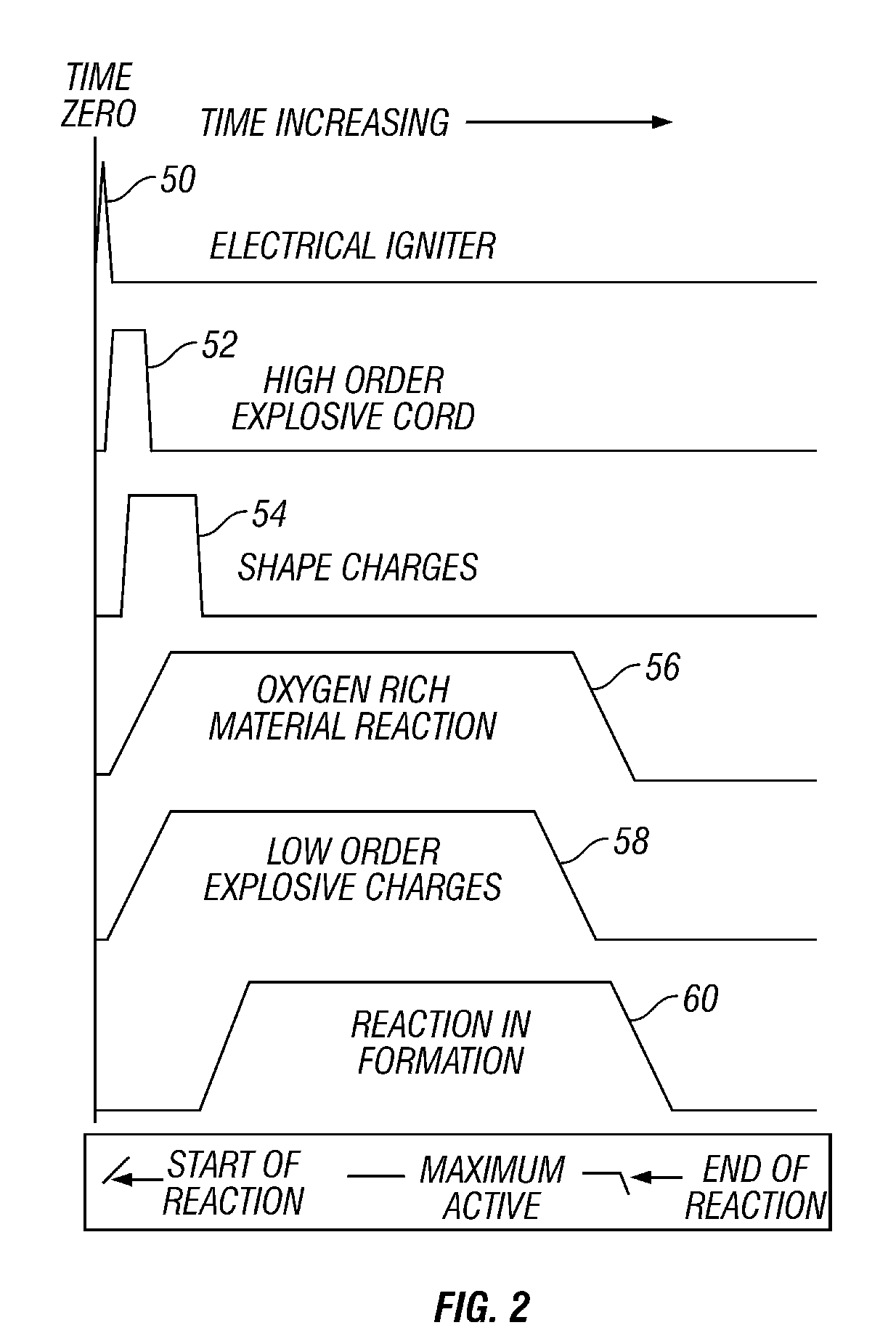

Reactive stimulation of oil and gas wells

InactiveUS7165614B1Improve burnsBurn of the hydrocarbons is enhancedNuclear explosivesFluid removalShaped chargeReactive distillation

A method and apparatus for stimulating producing strata in oil or gas wells. The formation is penetrated using shaped charges, and an oxygen-rich material then is introduced into the producing formation. Thus, oxygen is available within the formation to sustain an explosive reaction with the existing formation hydrocarbons acting as fuel. This explosive reaction will cause fracturing of the formation and will counteract plugging that often results from the use of conventional shaped charges. In one embodiment, a container encloses shaped charges surrounded by oxygen-rich material. Alternately, the oxygen can be a part of the shaped charge and projected into the formation with the shaped charge to accomplish the same results. Still further, oxygen-rich material can be pumped into the well in bulk in a liquid or paste form.

Owner:SUPERIOR ENERGY SERVICES LLC

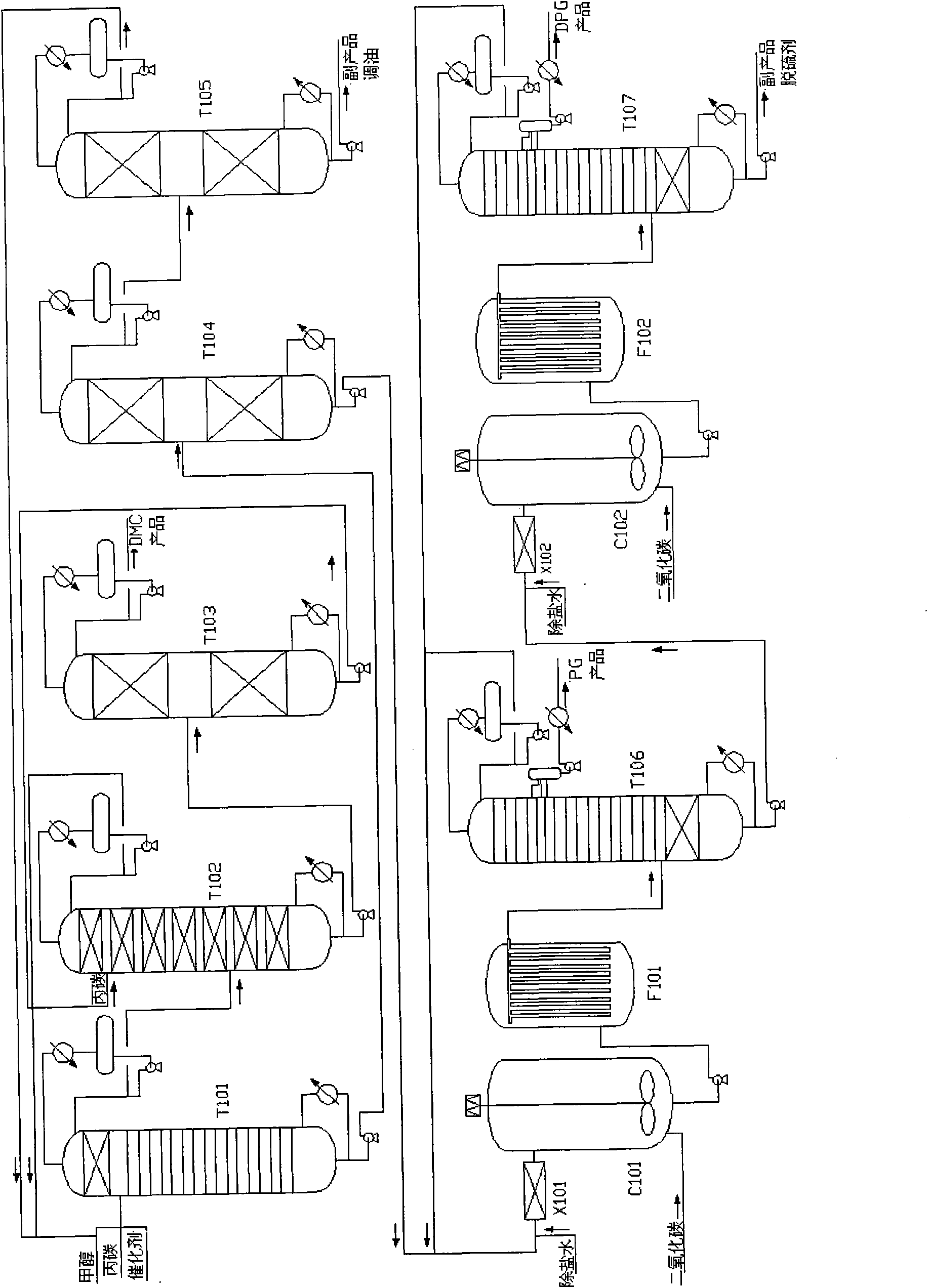

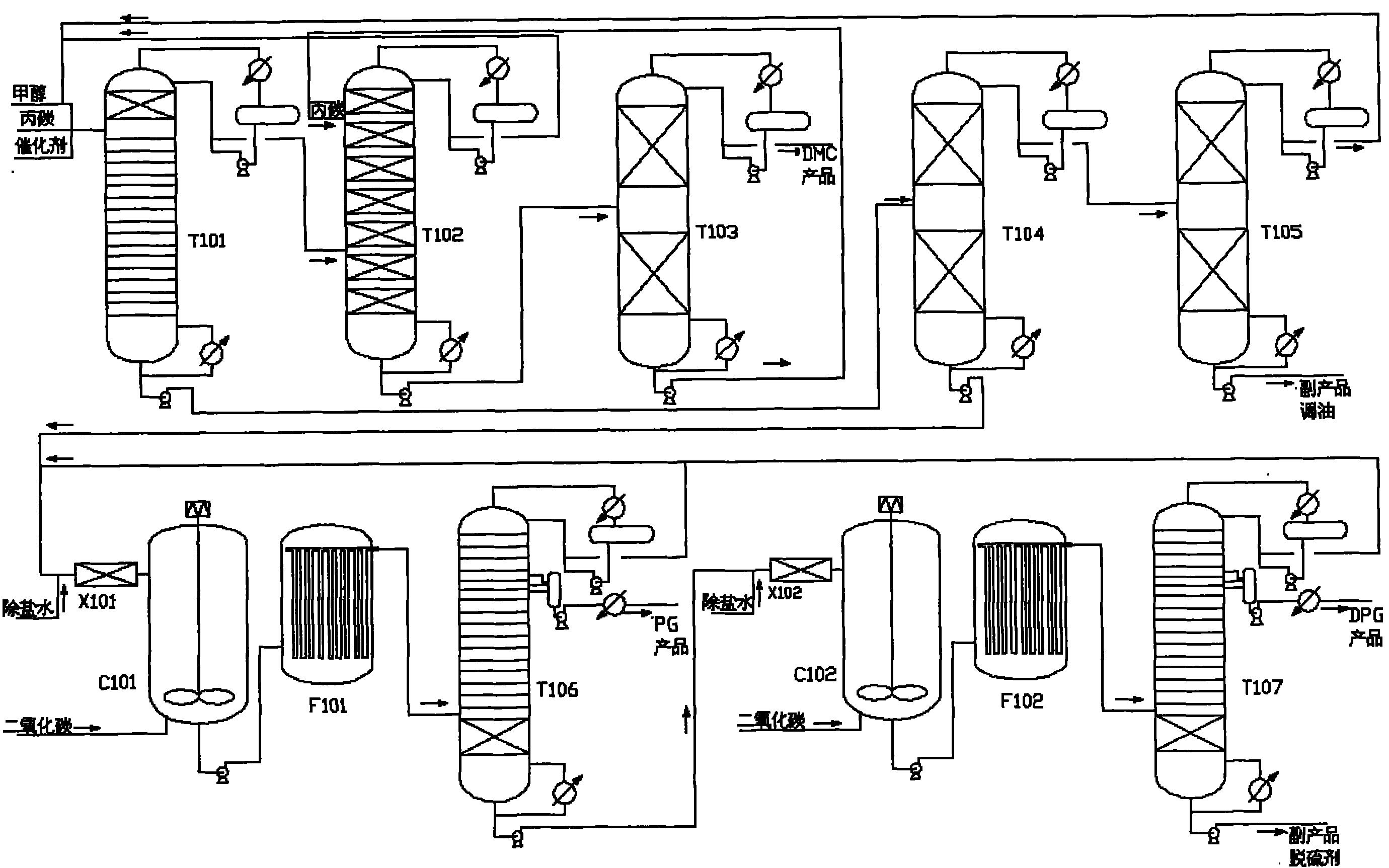

Novel technique for purifying high-quality propylene glycol in production process of dimethyl carbonate

ActiveCN101774888AHigh yieldSolve the emission problemChemical industryHydroxy compound separation/purificationFiltrationExtractive distillation

The invention relates to a technique for coproduction of dimethyl carbonate and propylene glycol, in particular to a novel technique for purifying high-quality propylene glycol in the production process of dimethyl carbonate. The technical scheme includes the steps of reactive distillation, extractive distillation, separation of the dimethyl carbonate, the recovery and refining of carbinol, primary carbonization, first filtration of sodium carbonate crystals and refining of the propylene glycol. The invention solves the problem of low recovery rate of the propylene glycol, and the recovery rate of the propylene glycol can be above 95%. Meanwhile, the propylene glycol has more stable quality, with the purity reaching 99.99% and the chroma less than 10, thereby the propylene glycol totally meets the requirements for medical auxiliary material, daily cosmetics, top grade unsaturated resin and polyether. Meanwhile, the purity of the byproduct dipropylene glycol can be above 99.50%, thus improving the benefit of the equipment.

Owner:DONGYING HI TECH SPRING CHEM IND

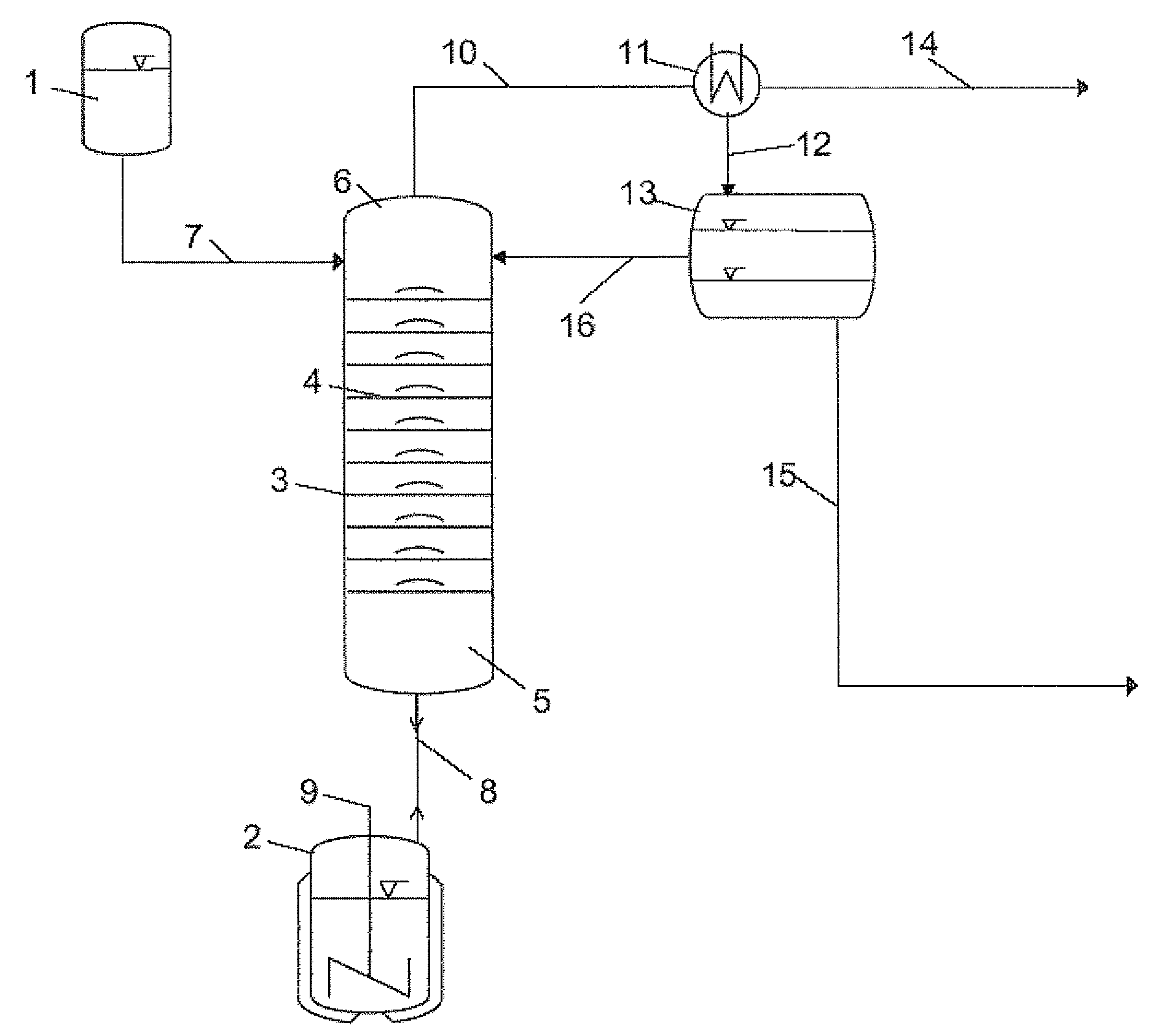

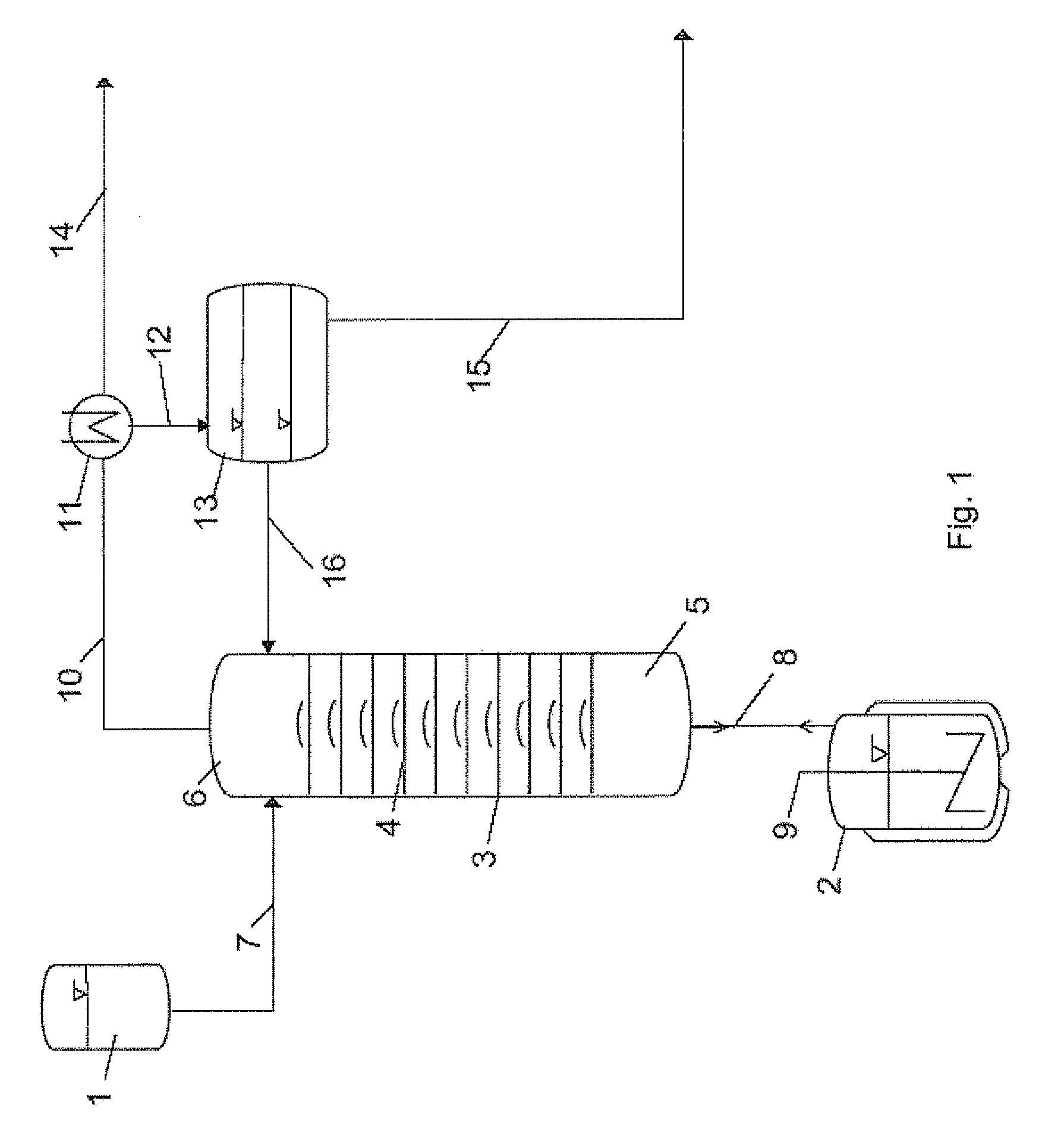

Process for reactive distillation of a carboxylic acid

InactiveUS7718039B2Speed up the conversion processLower energy requirementsOrganic compound preparationChemical industryAlcoholReactive distillation

A process for reactive distillation wherein a carboxylic acid is reacted in a reaction section of a reactive distillation column with an alcohol under esterifying conditions in the presence of a catalyst to form an ester, wherein a first supply stream comprising the carboxylic acid, a second supply stream comprising the alcohol and a third supply stream comprising an inert entrainer are supplied to the reactive distillation column, wherein the first supply stream is supplied to the column at a first entry level located just above or at the top of the reaction section, the second supply stream is supplied to the column at a second entry level located in or just below the reaction section and below the first entry level, and the third supply stream is supplied to the column at a third entry level located in or below the reaction section and not above the second entry level and wherein a bottom stream comprising the ester formed and unreacted carboxylic acid is obtained and a top stream comprising unreacted alcohol, water and entrainer is obtained.

Owner:SHELL OIL CO

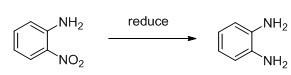

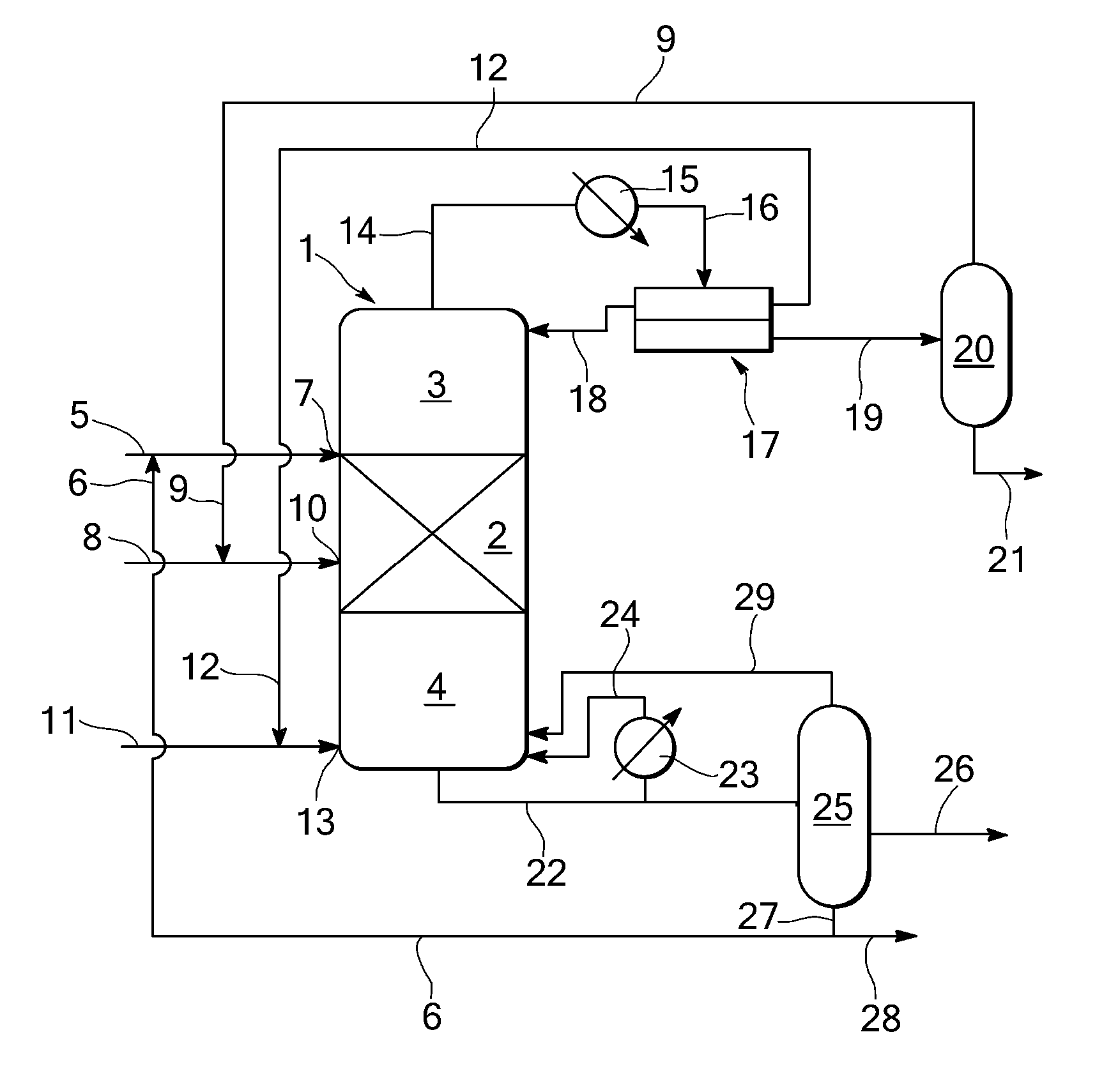

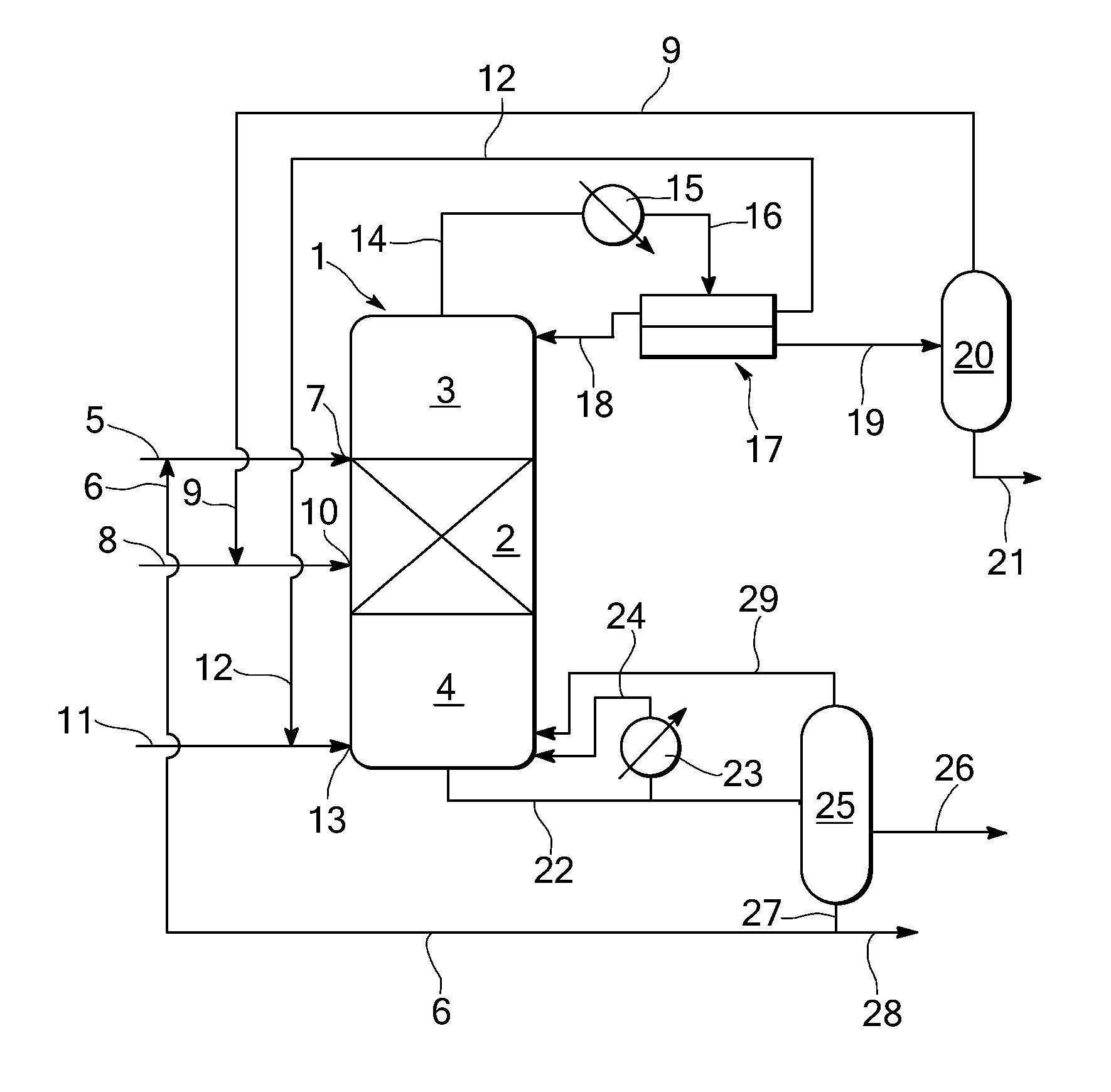

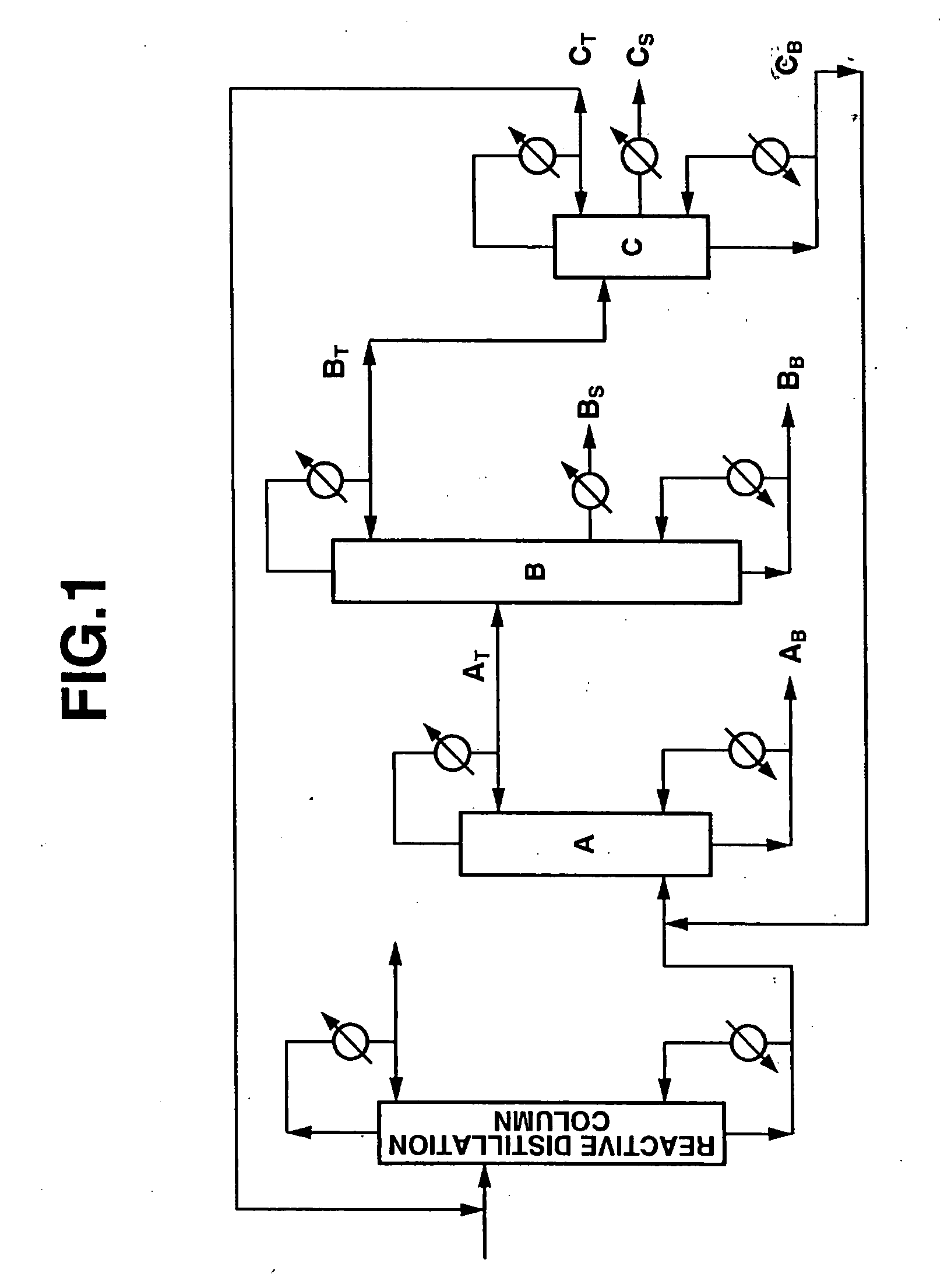

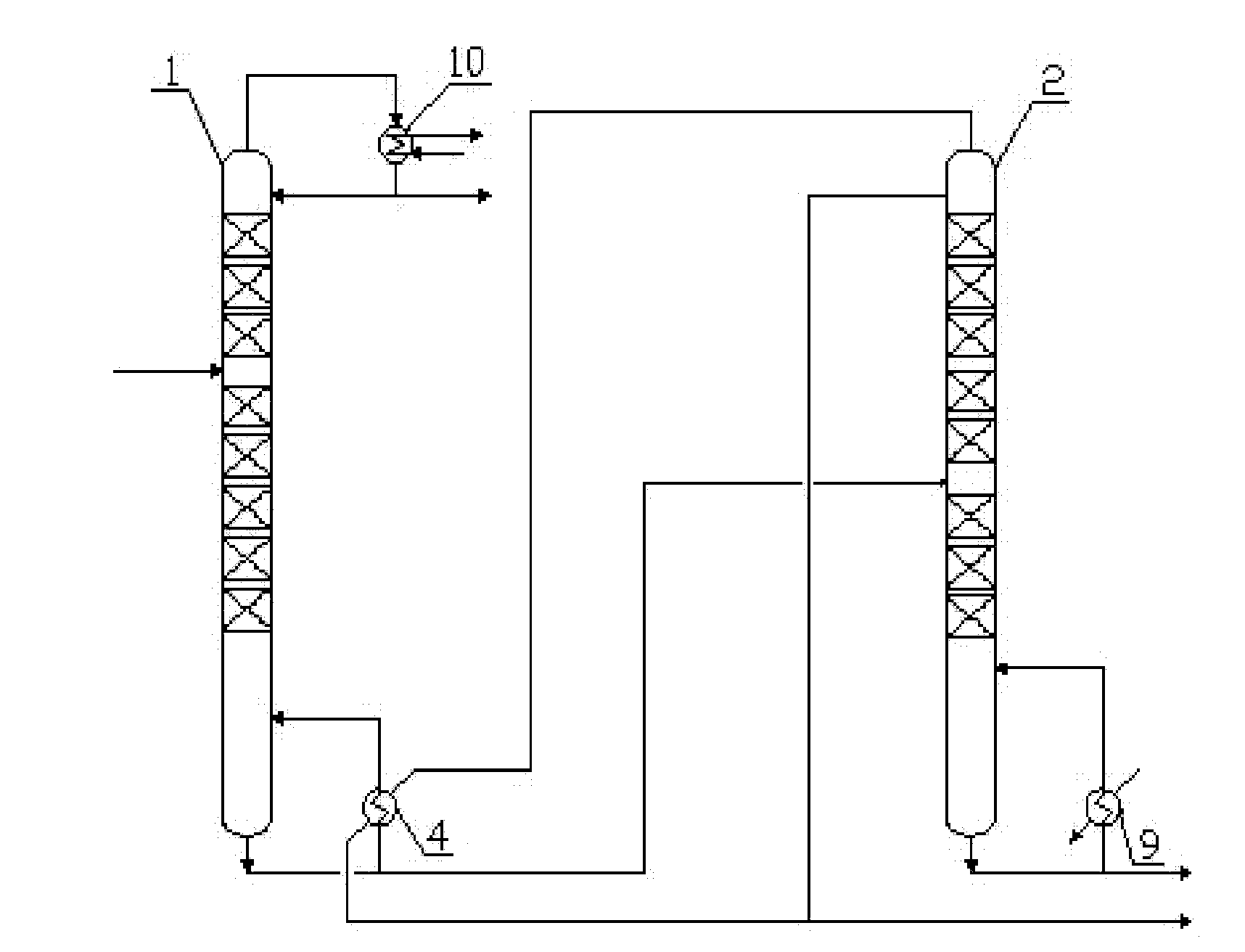

Process for Production of High-Purity Diaryl Carbonate

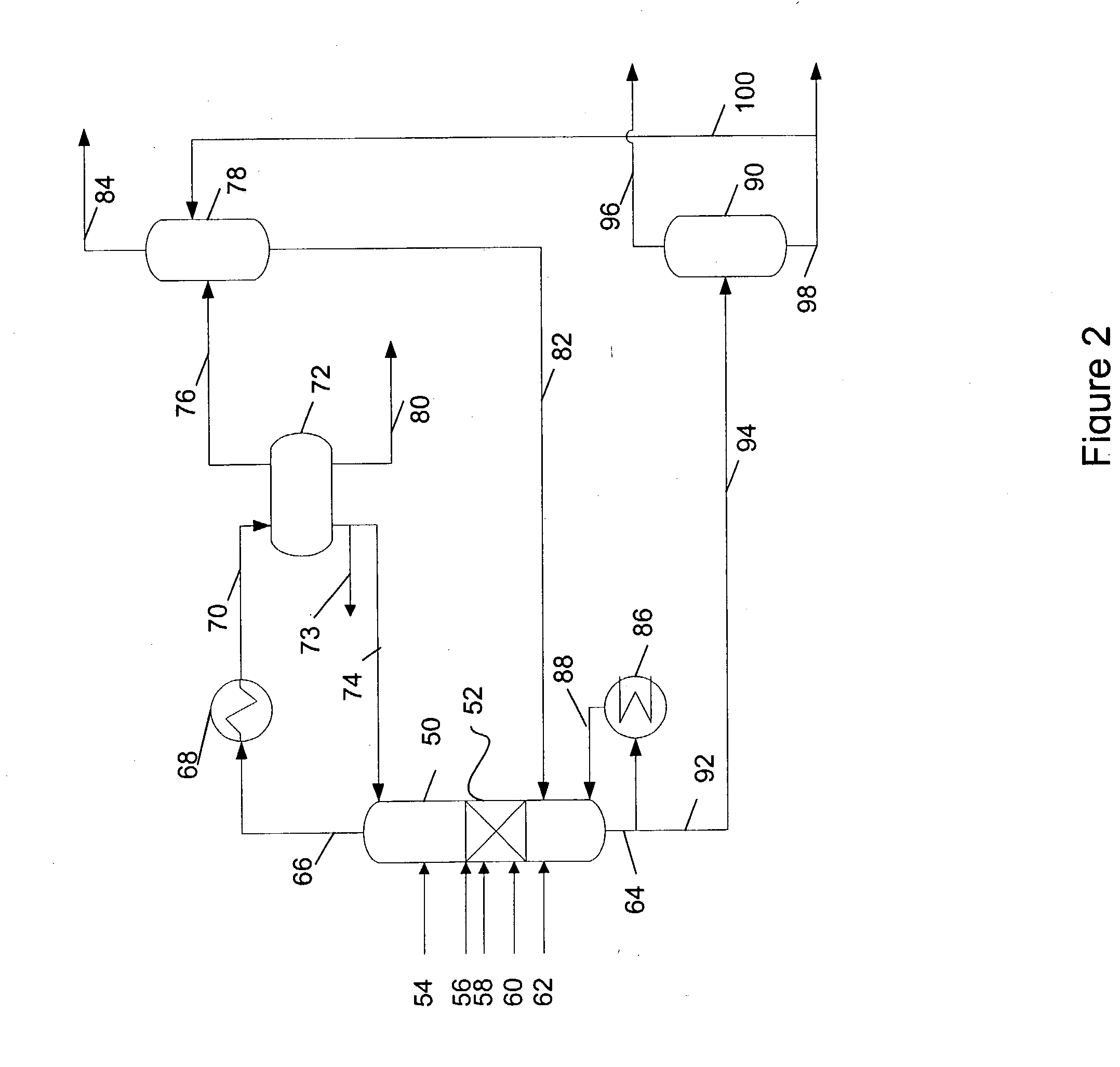

ActiveUS20070270604A1Stable productionChemical recyclingPreparation from organic carbonatesArylBoiling point

It is an object of the present invention to provide a specific industrially useful process that enables a high-purity diaryl carbonate having low contents of intermediate boiling point and high boiling point impurities as required for producing a high-quality and high-performance polycarbonate to be produced stably for a prolonged period of time using as a starting material a reaction mixture containing an alkyl aryl carbonate obtained through a transesterification reaction between a dialkyl carbonate and an aromatic monohydroxy compound. There have been various proposals regarding processes for the production of reaction mixtures containing aromatic carbonates by means of a reactive distillation method. The present inventors have now carried out studies aimed at discovering a specific process enabling a high-purity diaryl carbonate that can be used as a raw material of a high-quality and high-performance polycarbonate to be continuously produced stably for a prolonged period of time from such a reaction mixture. As a result, the present inventors have reached to the present invention after discovering that the above object can be attained through a process in which separation by distillation is carried out using three distillation columns in a specified order. Moreover, the present inventors have discovered that it is particularly preferable if a reactive distillation column and the three distillation columns, each of which has a specified structure, and the three distillation columns are each operated under specified distillation conditions.

Owner:ASAHI KASEI KK

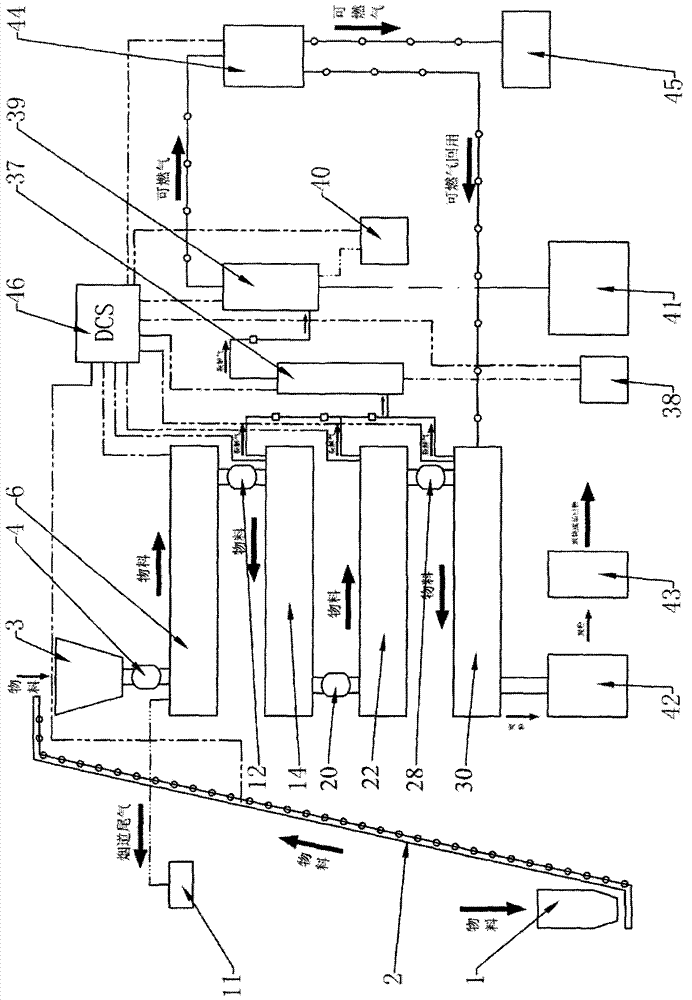

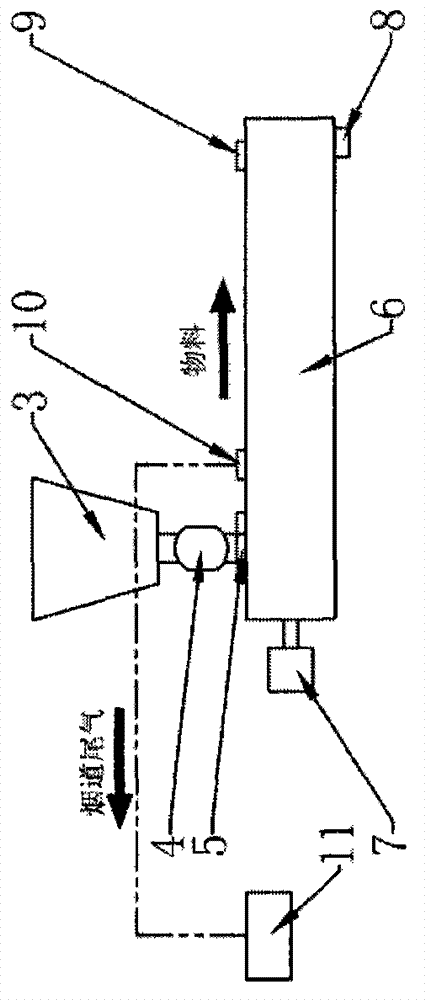

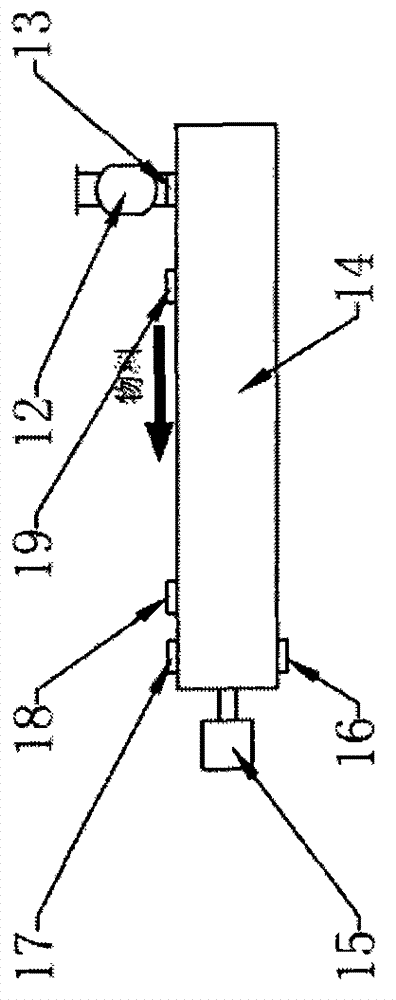

Apparatus and process for destructive distillation and cracking of biomass

ActiveCN102816575AShort processReduce energy consumptionMechanical conveying coke ovensCombustible gas coke oven heatingReactive distillationProcess engineering

The invention discloses an apparatus and a process for destructive distillation and cracking of biomass, belonging to the technical field of industrial processing apparatus structures and processes for mechanical products. The apparatus comprises an input part, a reaction vessel part, a control part and a processing output part. Self-balancing of energy in the process of production is realized through utilization of the destructive distillation and cracking process for biological garbage. According to the invention, the destructive distillation and cracking process for biomass has the advantages of short process flow, little equipment and low energy consumption, and the apparatus has the advantages of safe and convenient operation, easy maintenance and repair, etc.

Owner:上海清平环保科技有限公司

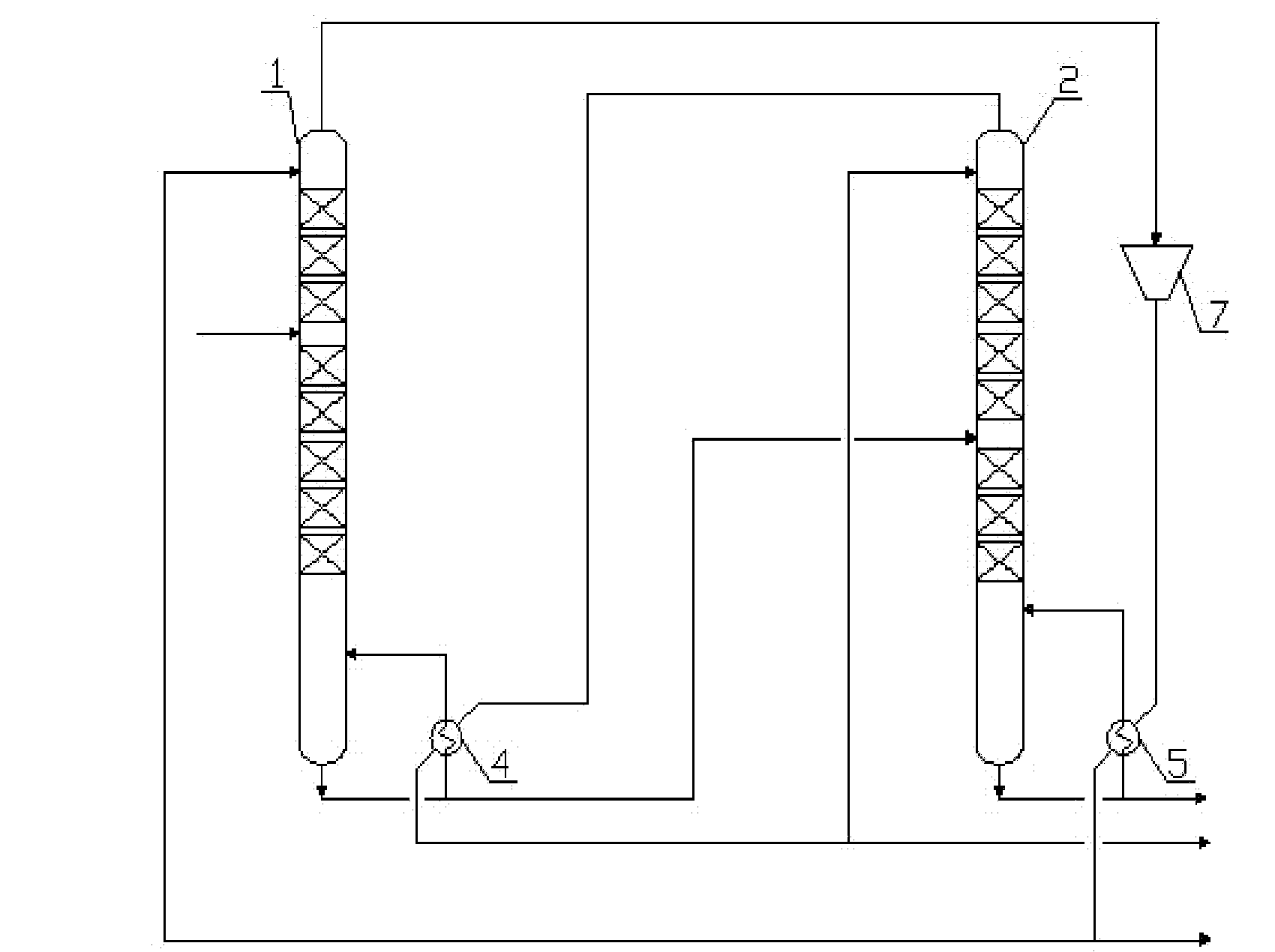

Heat pump distillation and multi-effect distillation integrated device and process for purifying trichlorosilane

InactiveCN102153092AReduce energy consumptionIncrease power consumptionEnergy inputHalogenated silanesElectricityReboiler

The invention discloses a heat pump distillation and multi-effect distillation integrated device and process for purifying trichlorosilane. The steam at the top of a high-pressure tower which is a high-boiling-fraction removal column is used to heat liquid at the bottom of a low-pressure tower which is a low-boiling-fraction removal column, the steam at the top of the high-boiling-fraction removal column is condensed, and the process is a multi-effect distillation process; meanwhile, the steam at the top of the low-boiling-fraction removal column is subjected to pressure and temperature rise through a compressor and then is used for heating the liquid at the bottom of the high-boiling-fraction removal column, the steam at the top of the low-boiling-fraction removal column is condensed, and the process is a heat pump distillation process; and the integration of the heat pump distillation and multi-effect distillation can be realized in the whole process. In the whole process flow, one compressor is additionally arranged, the heat exchange process inside a rectification system is realized by two heat exchangers and condensers and reboilers are saved simultaneously, that is to say, small amount of electricity consumption of one compressor is added and a large amount of cold energy and heat public works are saved, and thereby the energy consumption for the whole rectification and purification process of the trichlorosilane is greatly reduced.

Owner:TIANJIN UNIV

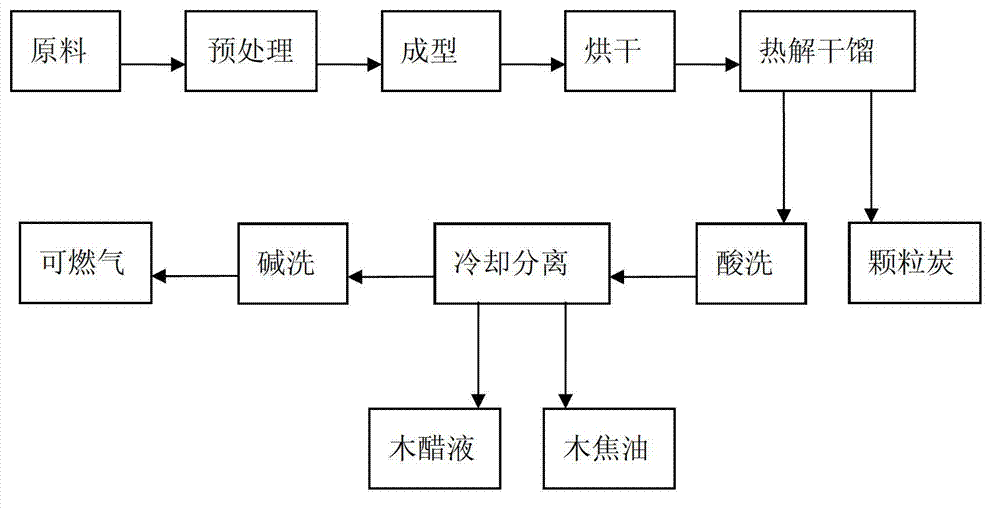

Process for industrially producing carbon, gas, oil and electricity through biomass energy forming and destructive distillation

ActiveCN102776009AReduce the chance of crackingExtended service lifeBiofuelsPyroligneous acid productionAcid washingMoisture

The invention discloses a process for industrially producing carbon, gas, oil and electricity through biomass energy forming and destructive distillation. The process comprises the following steps of: raw material pretreatment: crushing raw materials; forming: pressing the crushed raw materials into formed particles in a certain shape; drying: controlling the moisture content in the formed particles at 3%-5%; destructive distillation: thermo-chemically converting the dried formed particles into granular carbon, gas and liquid under the condition of air isolation or in the presence of little air; acid washing: performing acid washing on the gas produced through the destructive distillation; cooling and separation: cooling the acid-washed gas and performing gas-liquid separation on the gas and the condensed liquid, and then performing wood tar-pyroligneous separation on the cooled liquid; and alkali washing: performing alkali washing on the cooled gas. The process is capable of converting the biomass raw materials into high-grade good-quality fuels and industrial raw materials.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

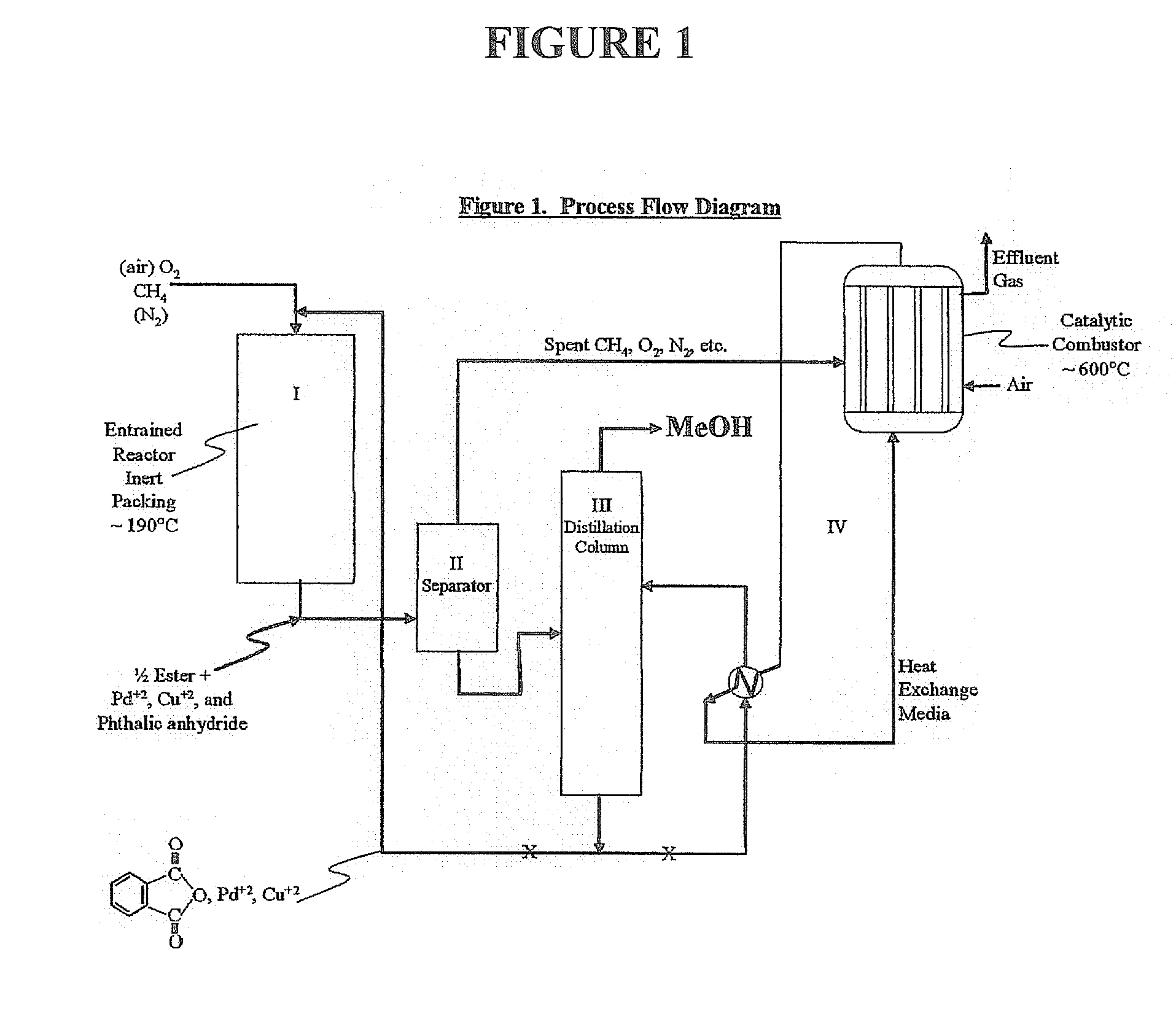

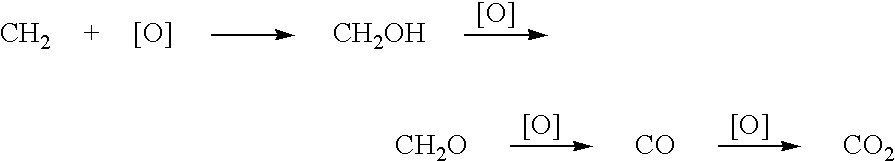

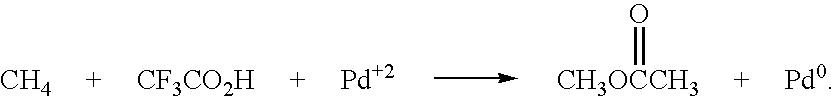

Method for deriving methanol from waste generated methane and structured product formulated therefrom

InactiveUS20060264683A1Less capitolInexpensively separatedPreparation by oxidation reactionsOrganic compound preparationPtru catalystReactive distillation

Methanol is produced from bacterially oxidized waste methane by reaction with Pd+2, Cu+2 air, and molten phthalic anhydride in an entrained oxidizer generating half ester of methyl phthalate which is reaction distilled to prodtice methanol and recycle phthalic anliydride containing the Pd+2,Cu+2 phthalate catalyst.

Owner:RINNOVI

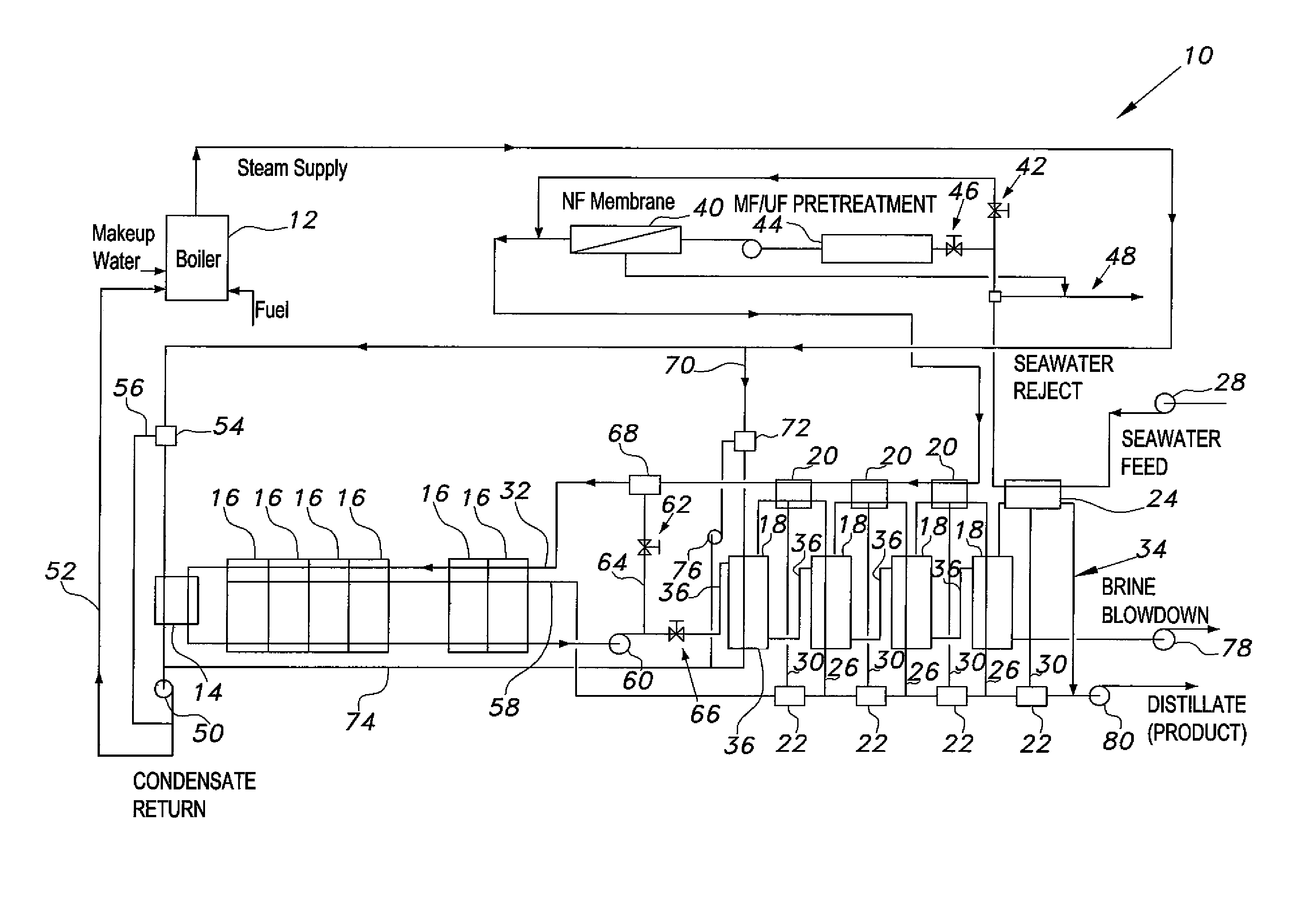

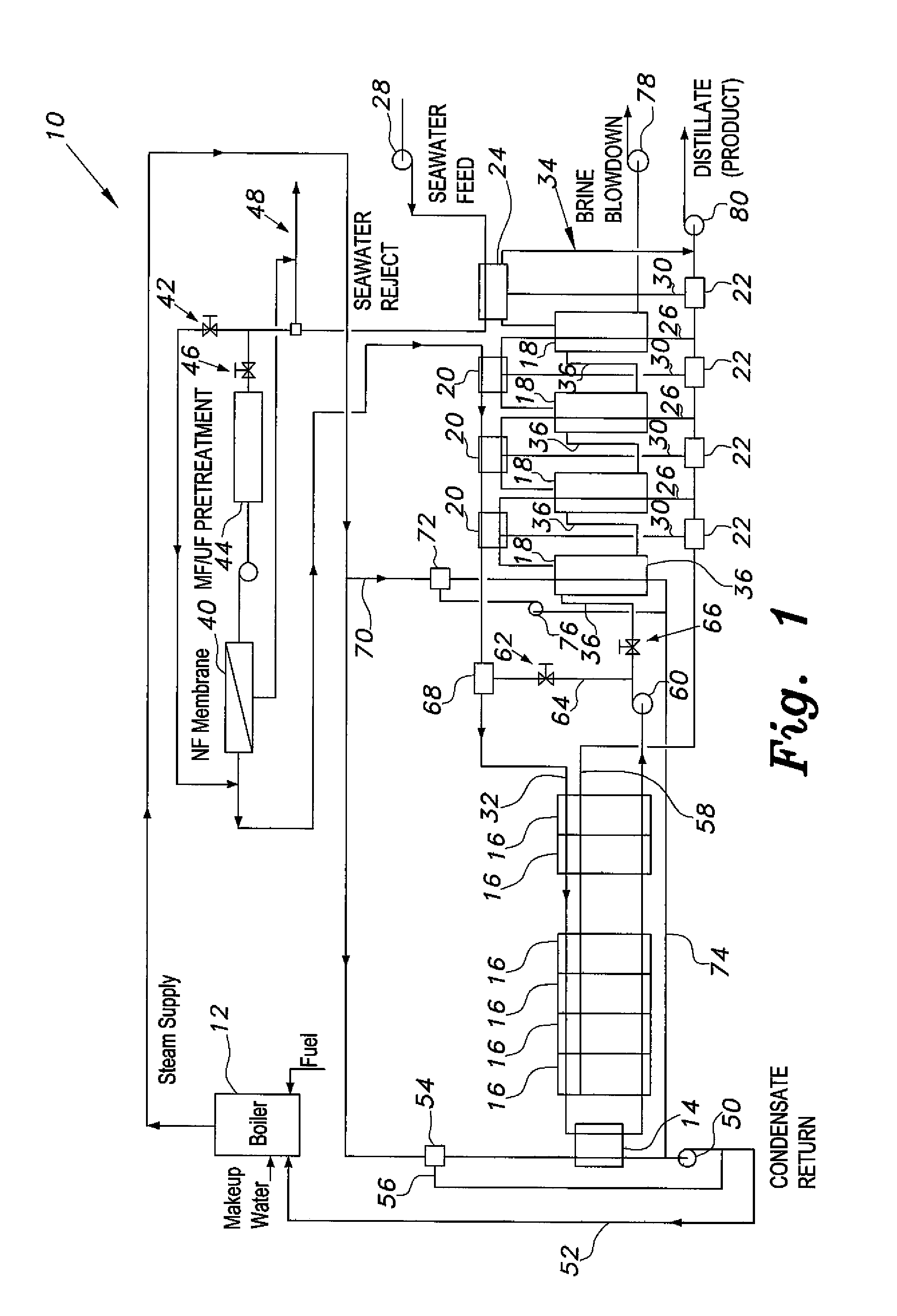

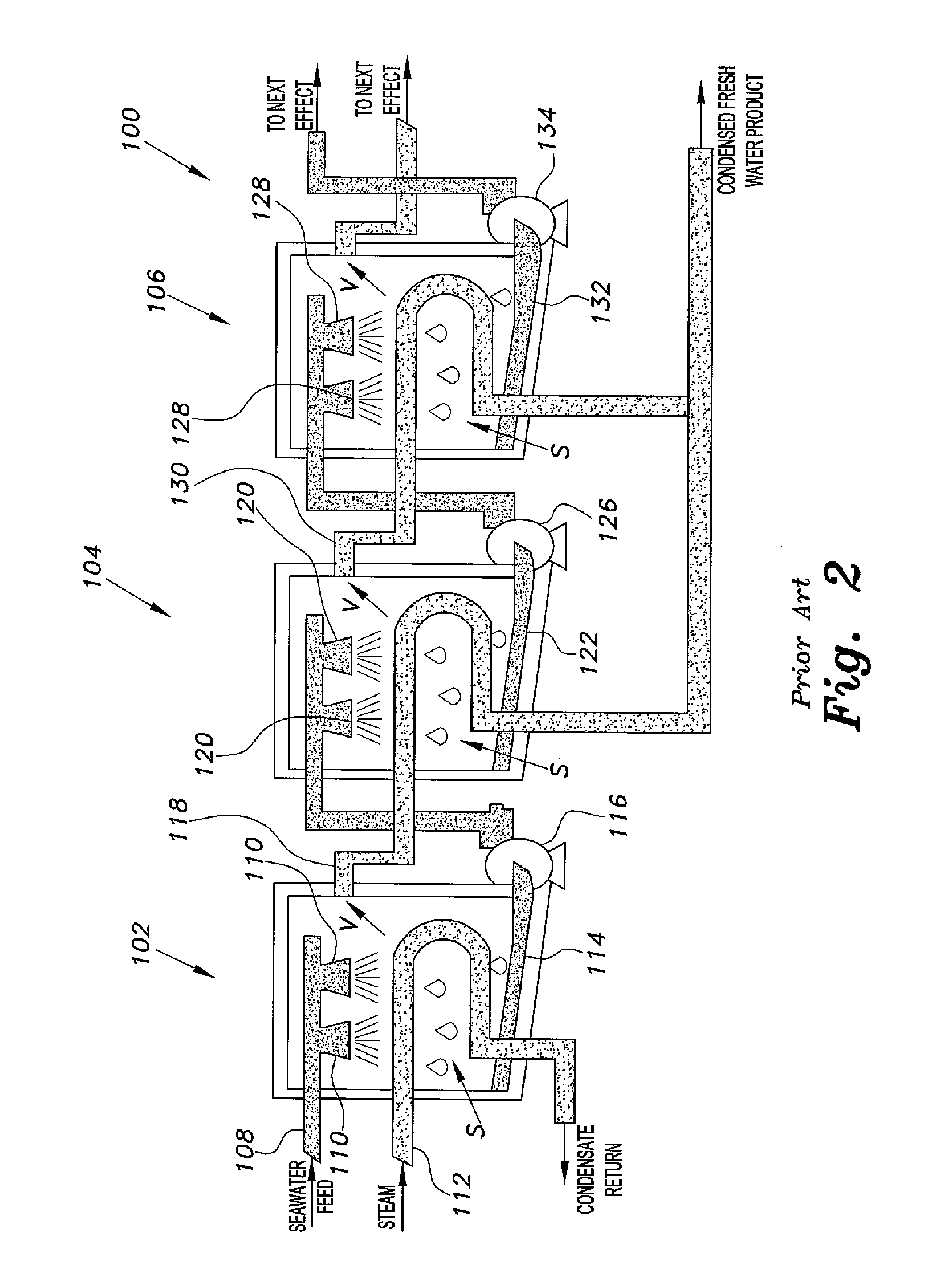

Combination multi-effect distillation and multi-stage flash evaporation system

ActiveUS9539522B1Readily apparentSemi-permeable membranesMembranesMulti-stage flash distillationReactive distillation

The combination multi-effect distillation and multi-stage flash evaporation system integrates a multi-stage flash (MSF) evaporation system with a multi-effect distillation (MED) system such that the flashing temperature range of the MSF process is shifted upward on the temperature scale, while the MED distillation process operates in the lower temperature range. The multi-stage flash evaporation system includes a plurality of flash evaporation / condensation stages, such that the multi-stage flash evaporation system receives a volume of seawater or brine from an external source and produces distilled water. The multi-effect distillation system includes a plurality of condensation / evaporation effects, such that the multi-effect distillation system receives concentrated brine from the multi-stage flash desalination system and produces distilled water.

Owner:KUWAIT INST FOR SCI RES

Method for mass producing butyl acetate by reactive distillation method and using sulfuric acid as catalyst

ActiveCN1844076AEasy to separateAvoid corrosionPhysical/chemical process catalystsOrganic compound preparationAcetic acidAlcohol

The refers to a mass production method of isobutyl acetate which uses hydric sulphate as accelerant by reaction fractional distillation, using ethyl acetate and butyl alcohol as raw material, concentrated sulfuric acid as accelerant, continue producing isobutyl acetate by reaction fractional distillation, the whole production system contains three towers, reaction fractionating tower, azeotropy tower and eater fractionating tower, the reaction fractionating tower, azeotropy tower are setted side by side. The ethyl acetate, butyl alcohol and concentrated sulfuric acid are drived into feeder column plate of reaction fractionating tower after esterification prereaction, the gas phase of prereactor going into feeding phase of reaction fractionating tower, the gas phase on top of reaction fractionating tower going into column plate of cellar of azeotropy towder, the liquid phase of towder bottom going into mesomere of eater fractionating tower, the butyl product is continue discharged from side tower. This invention combines the technique which using sulfuric as accelerant by mean improvement of reaction fractional distillation technique, not only ustilizing the advanced technology of reaction fractional distillation, but also making the liquid accelerant's characters of convenience to operate, easy to enlarge production scale getted adequate use.

Owner:NANTONG BAICHUAN NEW MATERIAL CO LTD +1

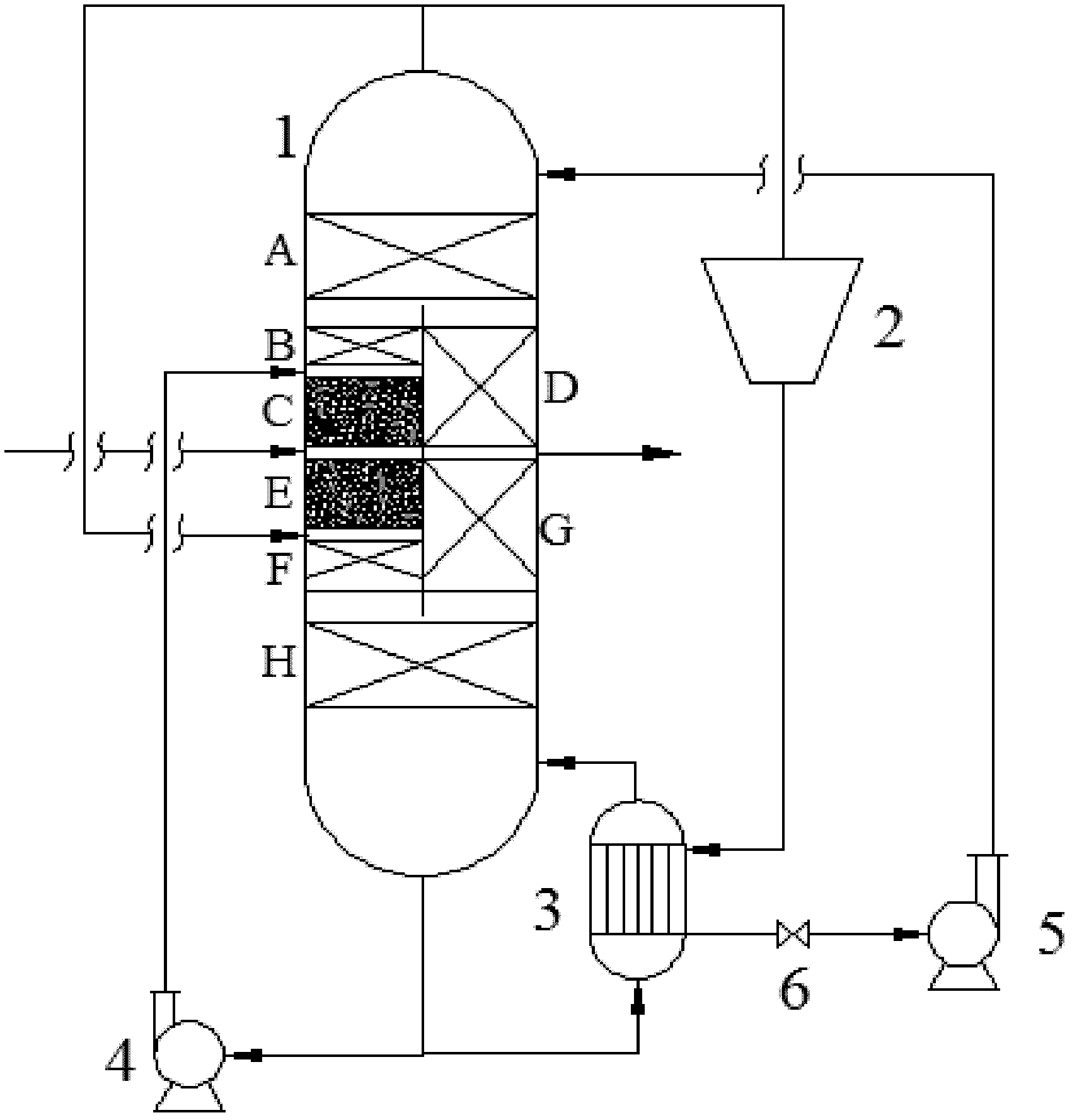

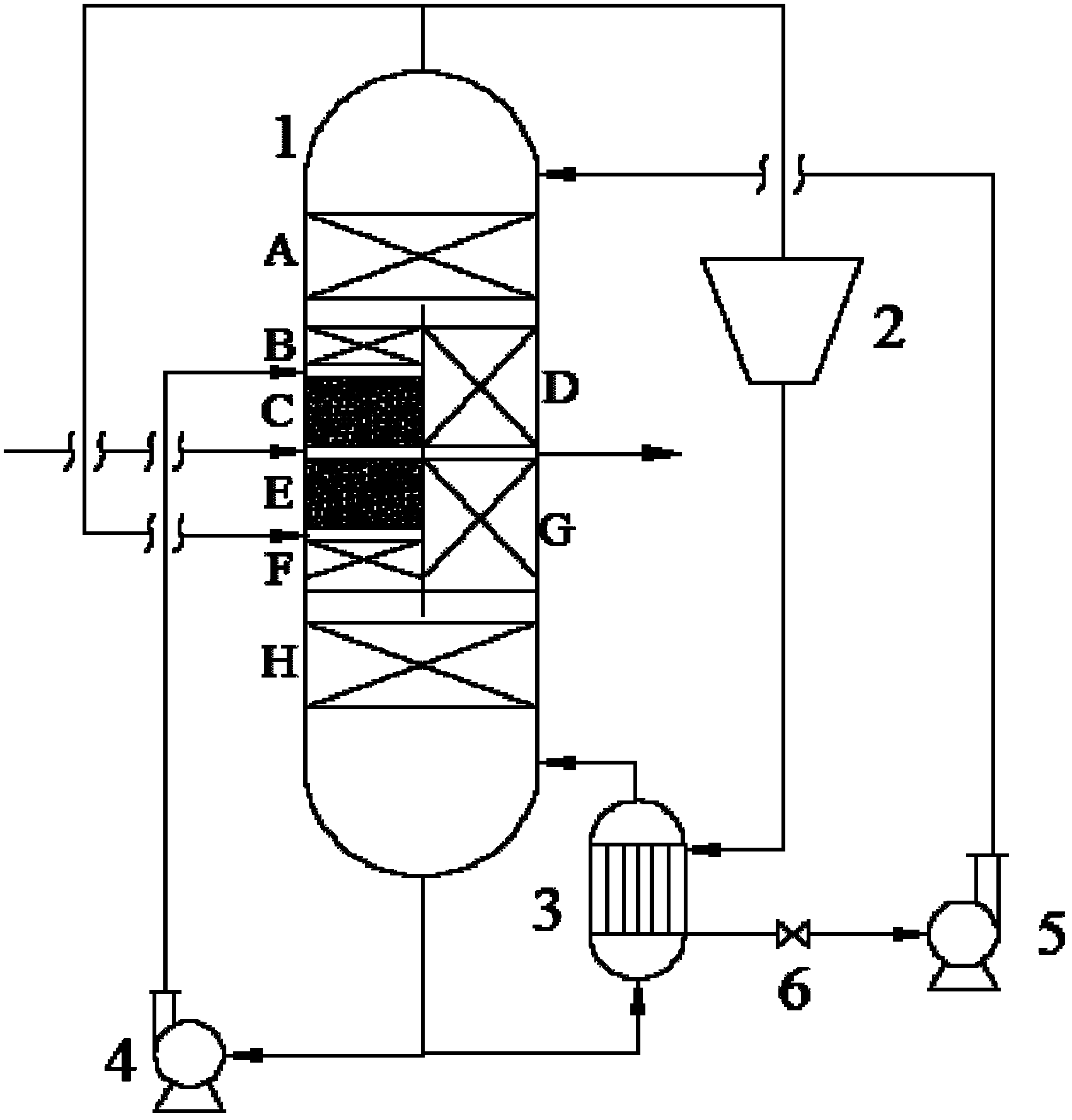

Reactive distillation device for preparing trichlorosilane from mixed chlorosilane and method for device

InactiveCN102491341AIncrease profitResolve enrichmentChemical industryHalogenated silanesPartial gravityReactive distillation

The invention relates to a reactive distillation device preparing trichlorosilane from mixed chlorosilane and a method for the reactive distillation device. The method comprises the following steps of: feeding mixed chlorosilane raw materials at a middle position of an upper reaction section C and a lower reaction section E, obtaining dichlorosilane on the top of a tower, and making partial dichlorosilane return to the lower part of the lower reaction section E under the gravity and serve as a feed to enter the tower; obtaining silicon tetrachloride at the bottom of the tower, and returning partial silicon tetrachloride serving as a feed to the tower through the upper part of the upper reaction section C by using a feed liquid circulating pump at the bottom of the tower; extracting a trichlorosilane product in the middle of the tower; pressurizing and heating the partial dichlorosilane extracted on the top of the tower through a compressor, performing heat exchange with the partial silicon tetrachloride extracted at the bottom of the tower, returning the heated silicon tetrachloride to the bottom of the tower for refluxing, and returning the cooled dichlorosilane to the top of the tower for refluxing through a throttling valve and the feed liquid circulating pump on the top of the tower. The traditional reactive distillation equipment and subsequent separation and purification equipment are integrated in a dividing-wall tower, the process flow is simplified, the equipment investment is saved, and energy consumption is reduced.

Owner:TIANJIN UNIV

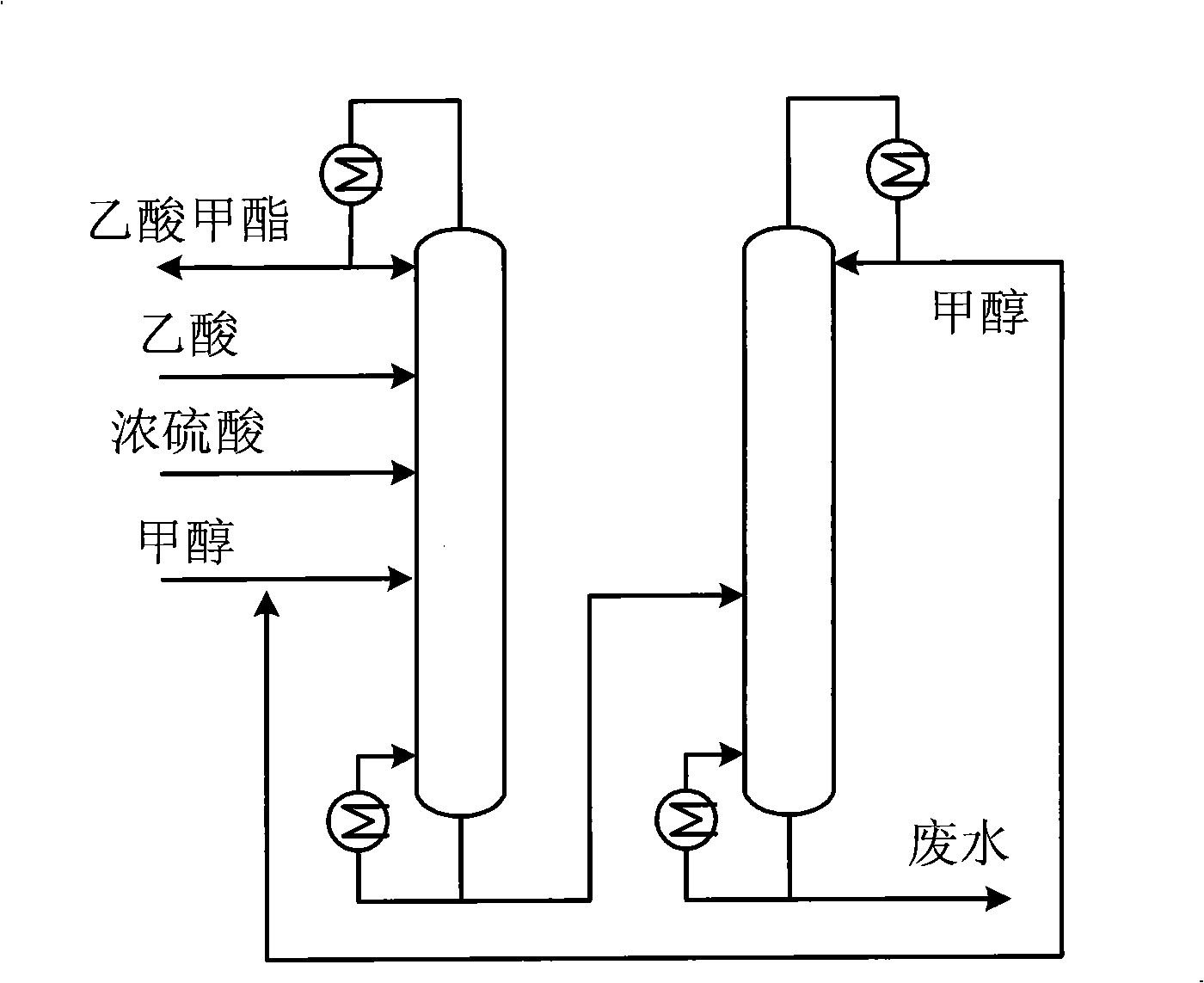

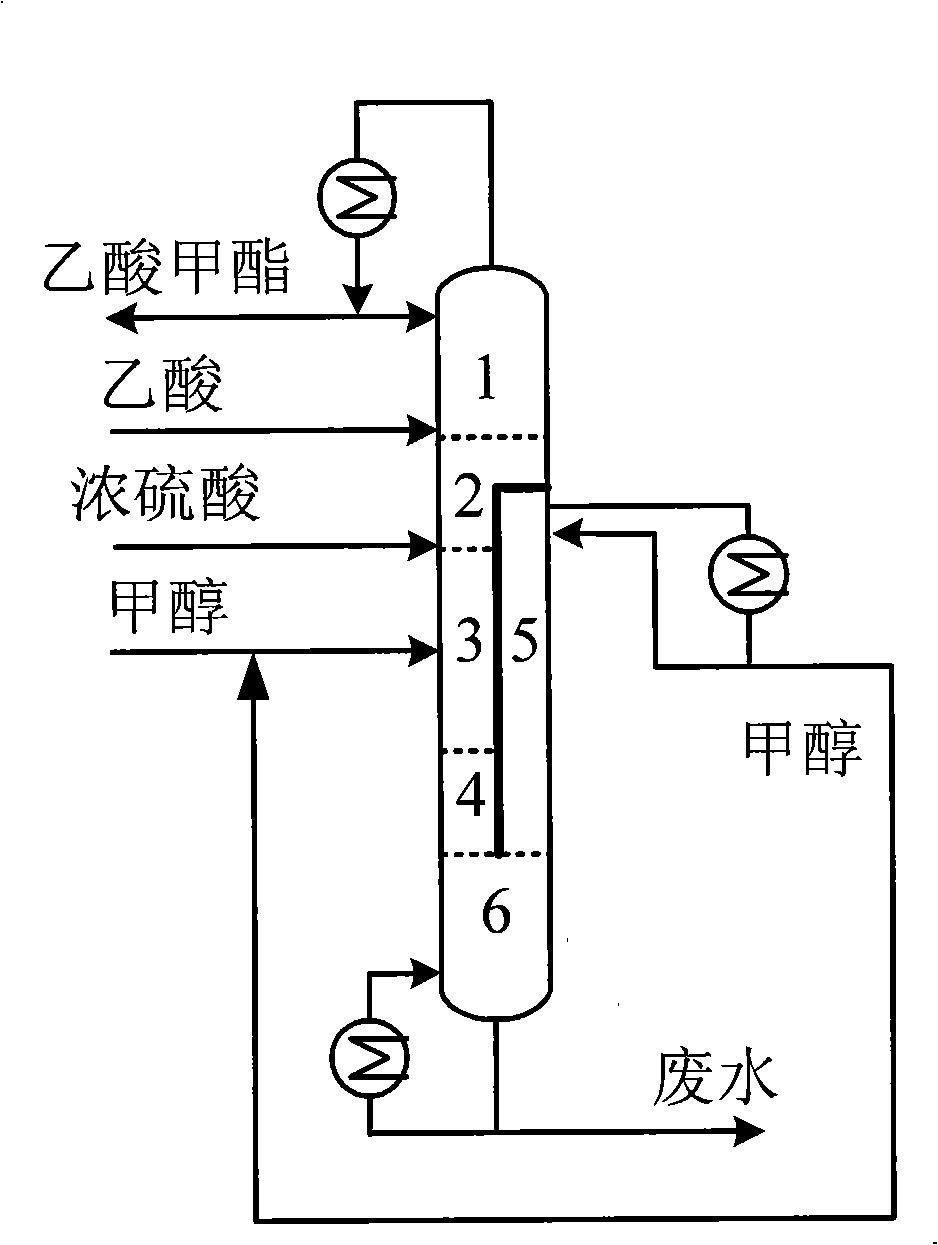

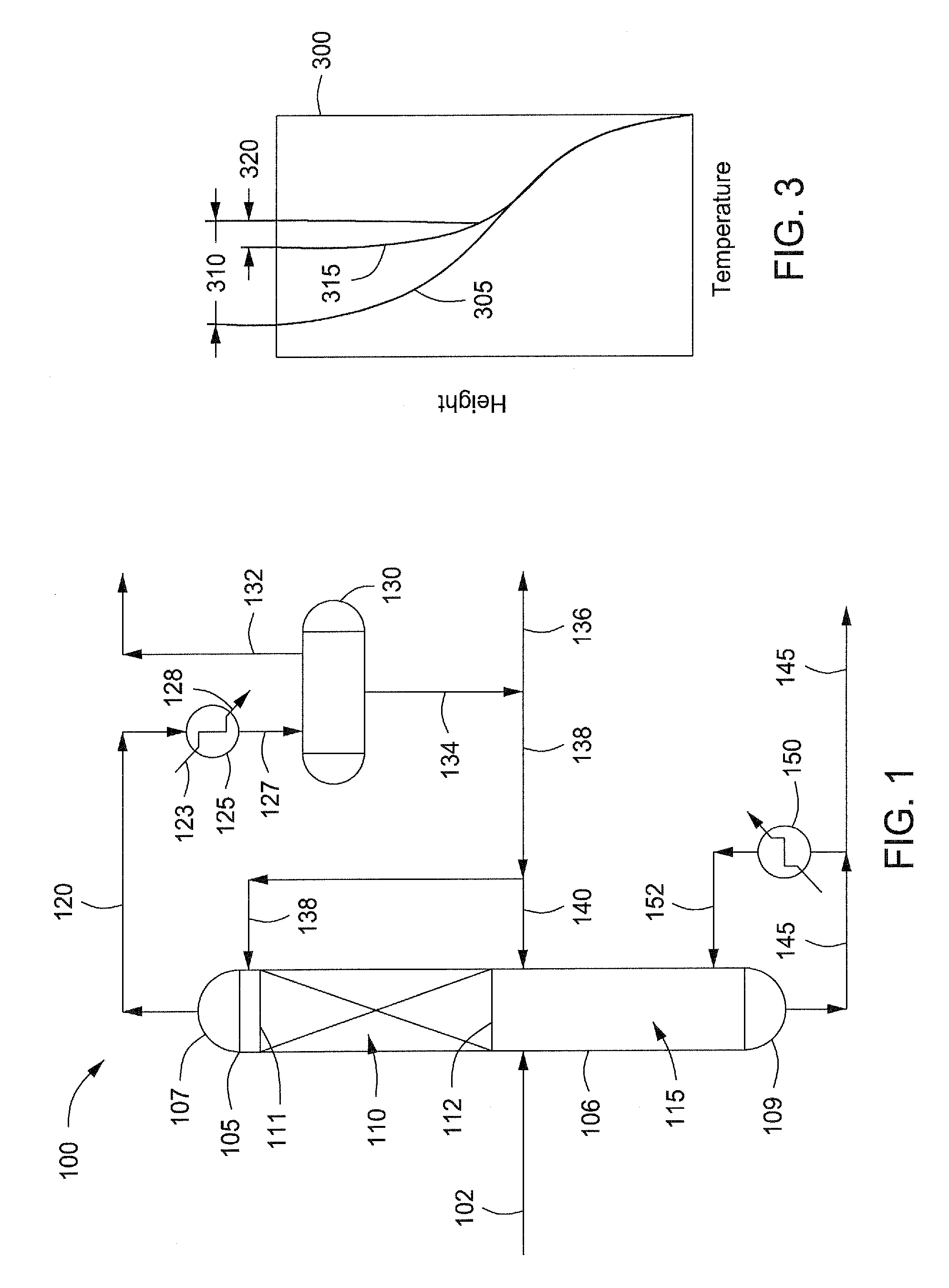

Synthetic process method of methyl acetate and apparatus thereof

InactiveCN101328119ALess investmentOrganic compound preparationCarboxylic acid esters preparationWastewaterReactive distillation

The invention discloses a process method for synthesizing methyl acetate by utilizing a reactive distillation partition wall tower and a device thereof. The reactive distillation partition wall tower is provided with a partition wall in a vertical direction inside the prior distillation tower, the upper part of the right side of the partition wall is sealed and the whole tower is divided into six areas. Acetic acid is added from the top of an area (2), a catalyst of concentrated sulfuric acid is added from the bottom of the area (2), excessive methanol is added from the middle part of an area (3), the esterification reaction is performed in the area (3) to produce methyl acetate, a methyl acetate product with high purity is produced at the tower top, the excessive methanol is reclaimed on the lateral line, and waste water containing a small amount of sulphuric acid is discharged from a column reactor. The process gives full play to the advantages of the partition wall tower and the reactive distillation, and ensures that the esterification, the product extraction and the reclaiming of the excessive methanol are realized in one towel, thereby greatly reducing the investment on equipment and energy consumption.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

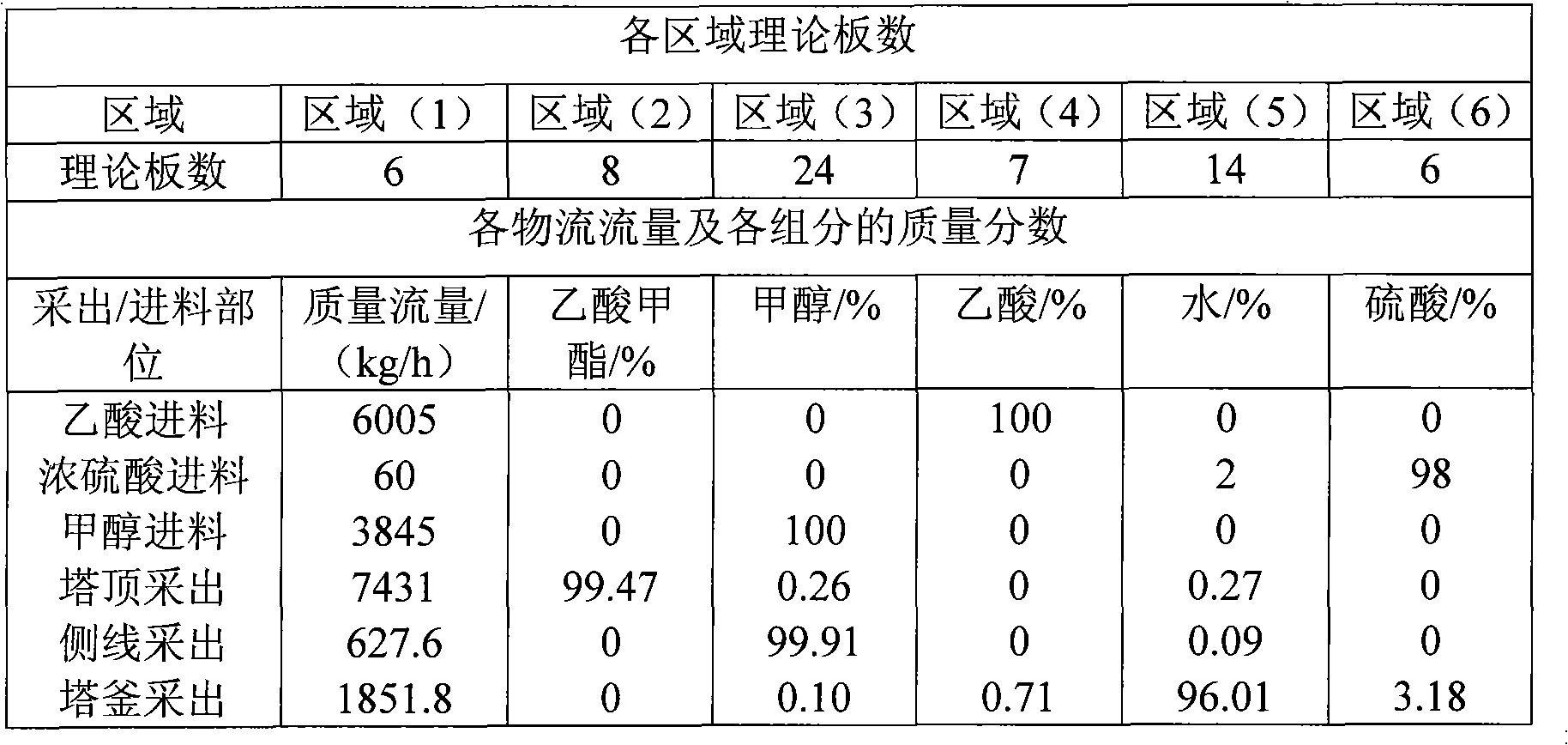

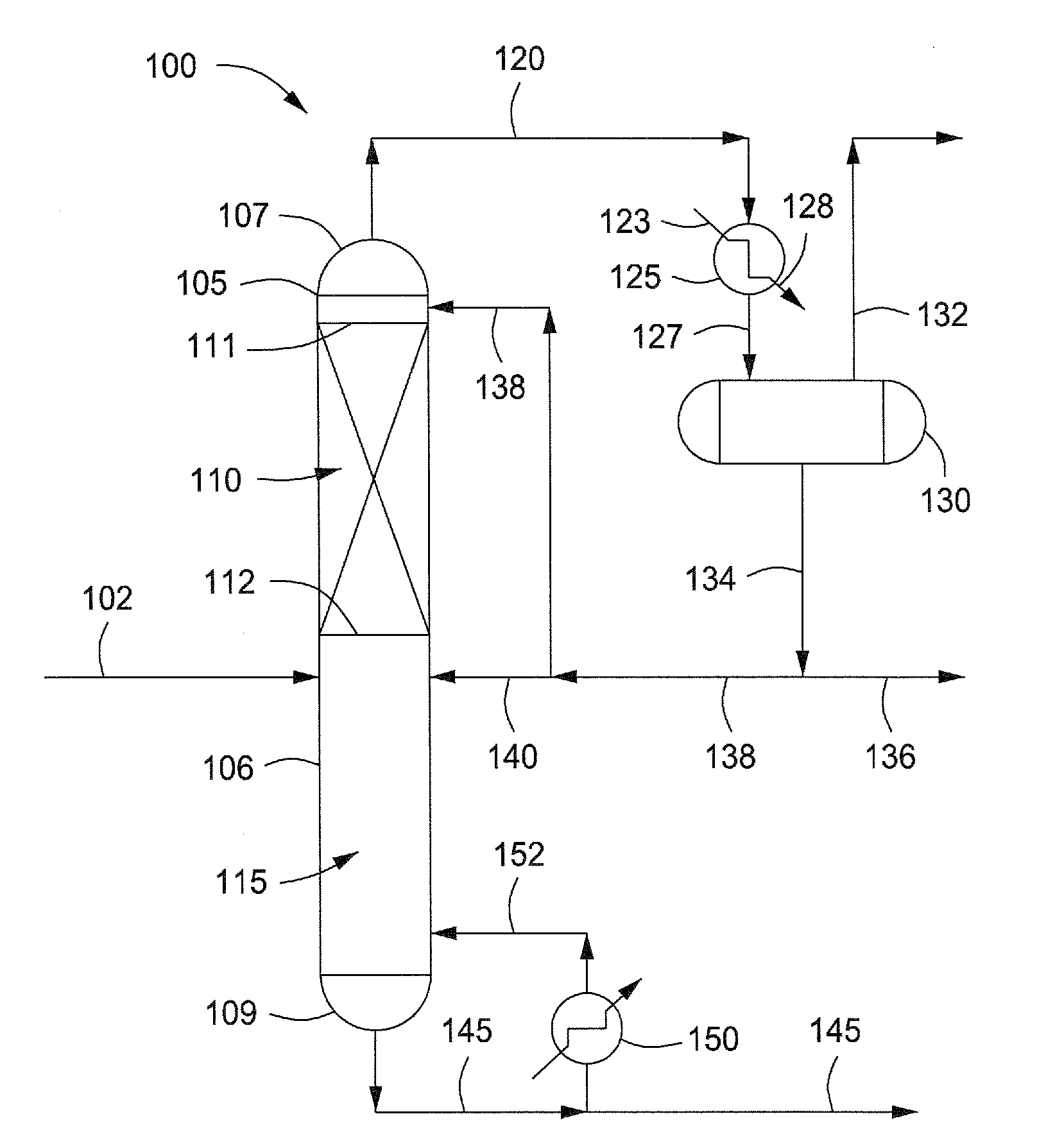

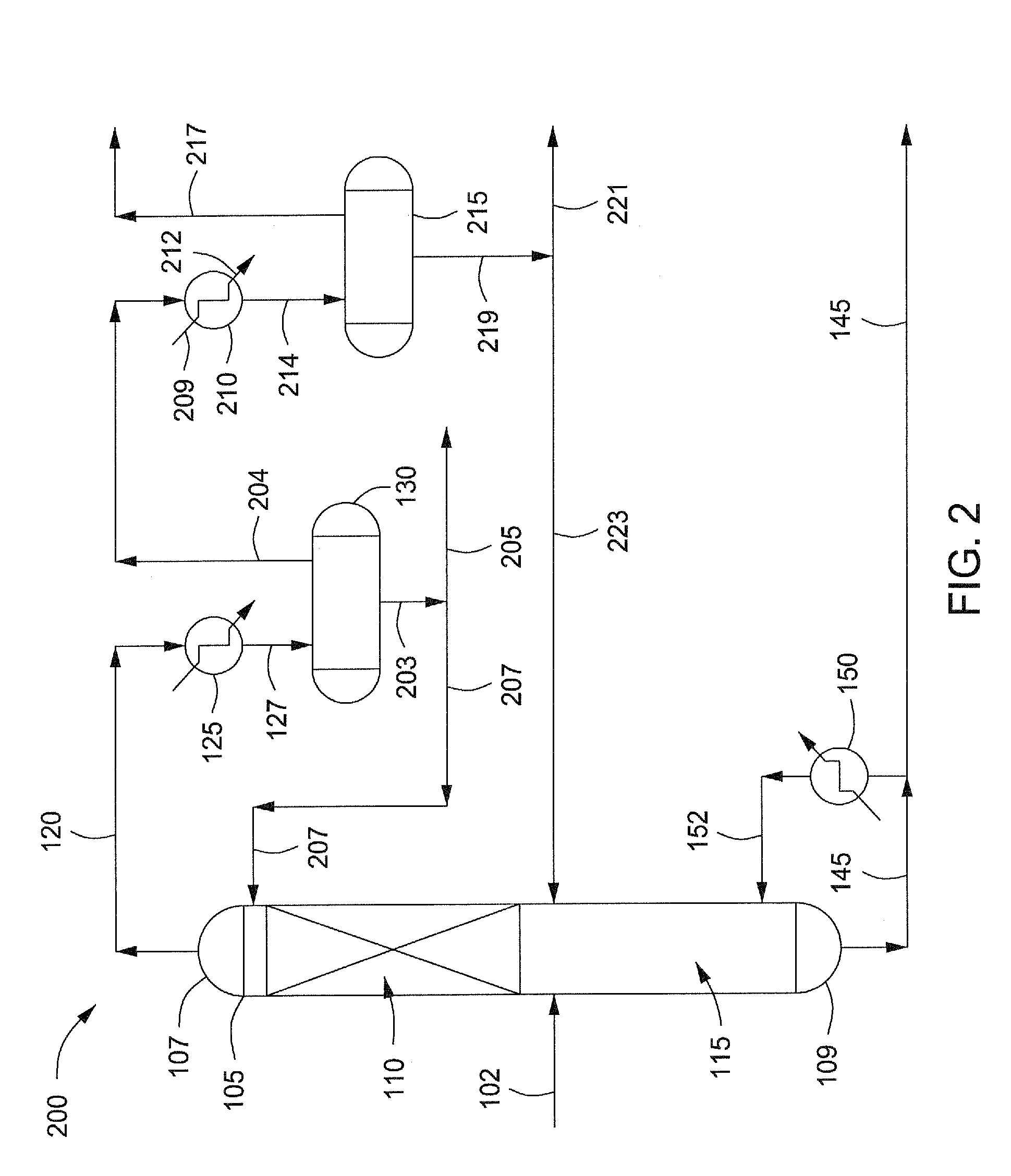

Systems and methods for reactive distillation with recirculation of light components

InactiveUS20100113625A1Organic compound preparationOxygen compounds preparation by reductionGas to liquidsReactive distillation

Systems and methods for producing gas-to-liquids products using reactive distillation are provided. The method for producing gas-to-liquids products can include reacting a feedstock in a column having a distillation zone and a reaction zone to provide a bottoms stream and an overhead stream. A first portion of the overhead stream can be recycled to the column at the top of the reaction zone and second portion of the overhead stream can be recycled to the column at the bottom of the reaction zone.

Owner:STICKNEY MICHAEL J +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com