Patents

Literature

359results about How to "Reduce the chance of cracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

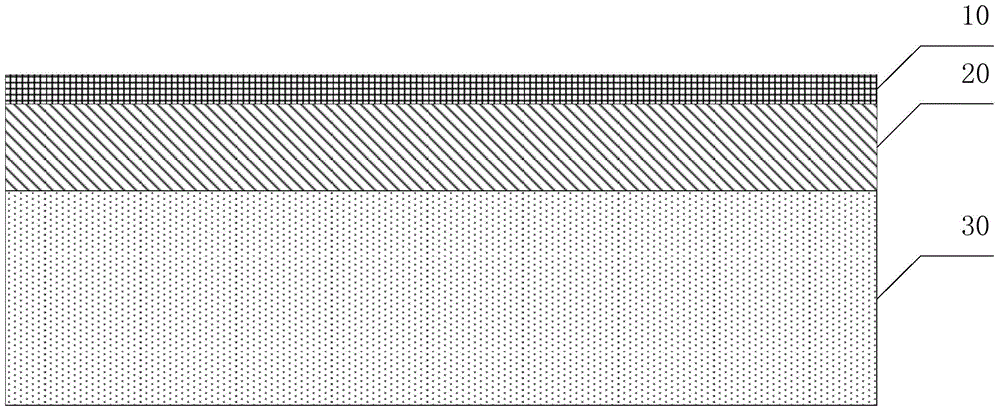

Composite core for power grid transmission line wire and preparation method thereof

The invention provides a composite core for a power grid transmission line wire and a preparation method thereof. The composite core has high strength, high toughness, high glass-transition temperature and surface cleanness. Materials of the composite core comprise a resin material and a strengthening material. The resin material comprises a thermosetting resin, a curing agent, an accelerating agent, a releasing agent, a flexibilizer and nanometer particles. The strengthening material is one kind or a plurality of kinds of carbon fiber, glass fiber, basalt fiber, boron fiber, aramid fiber, silicon carbonate fiber and protein bound iodine (PBI) fiber. The content of composite core fiber Vf=50-80%, tensile strength of the composite core is not lower than 2100MPa, and glass transition temperature of the composite core is not lower than 180 DEG C. The toughness of the composite core is remarkably improved, and breakage and cracking probability caused by brittleness factors in production, transportation and wire hanging construction processes are reduced.

Owner:CHINA ELECTRIC POWER RES INST +1

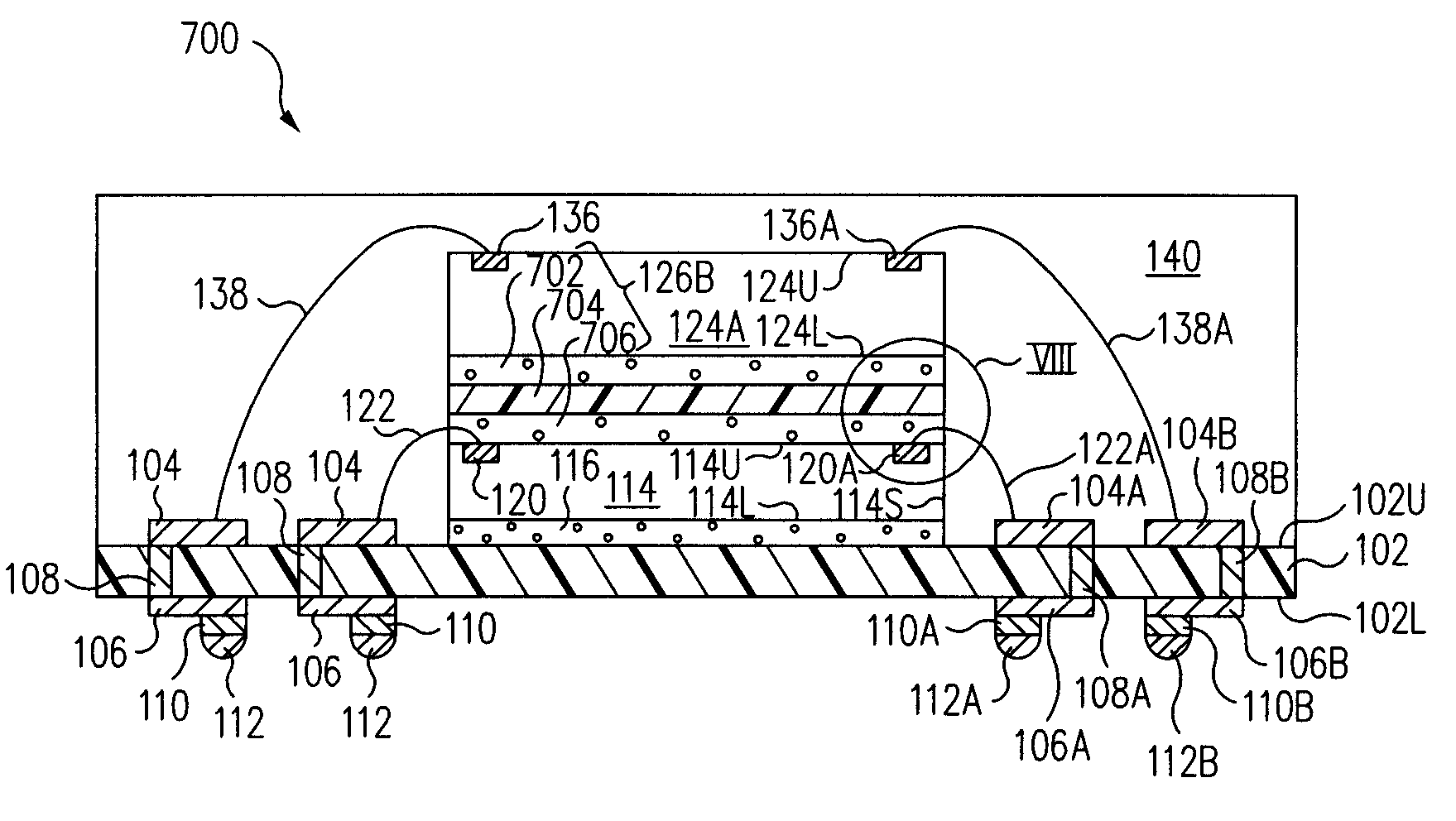

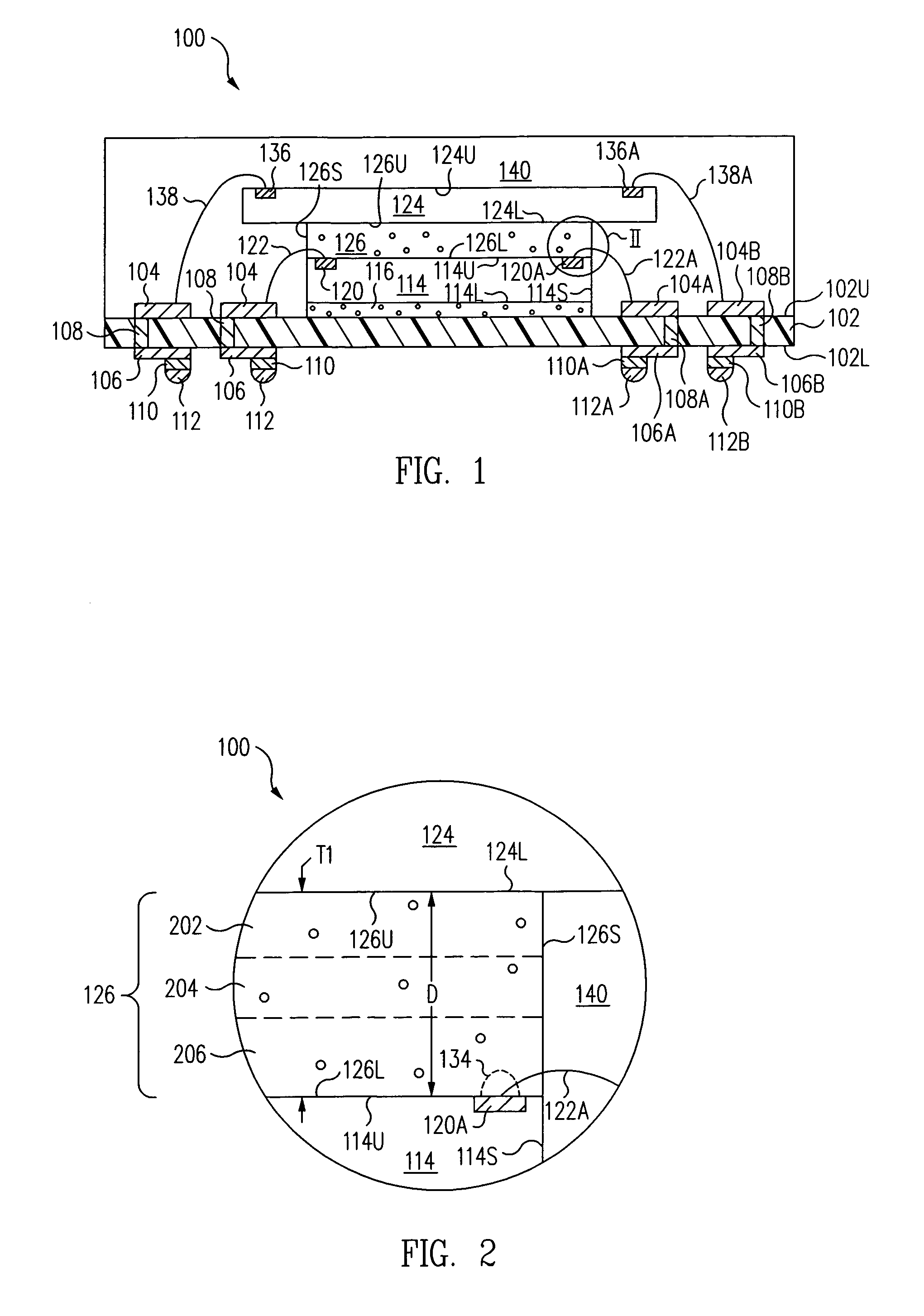

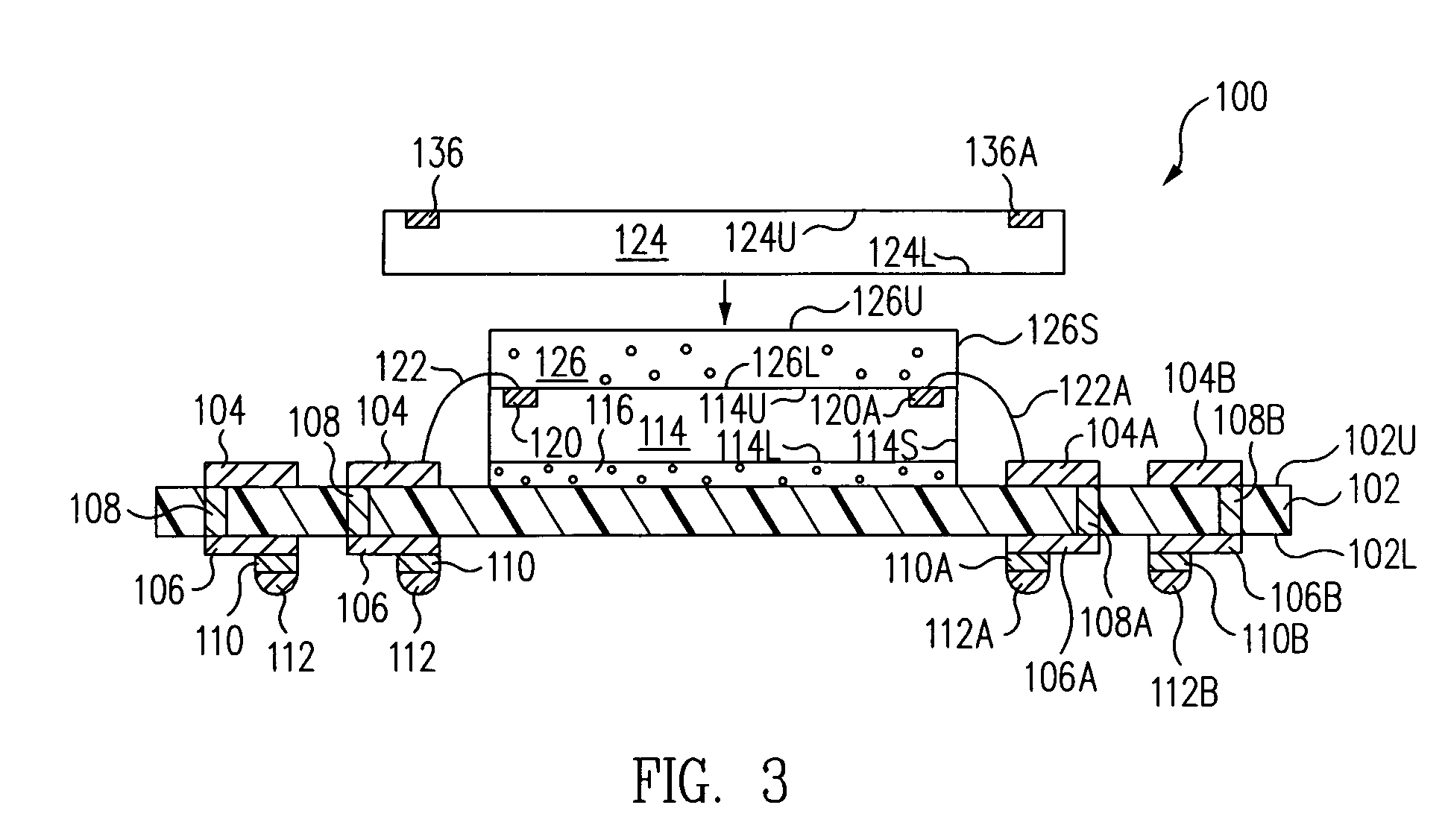

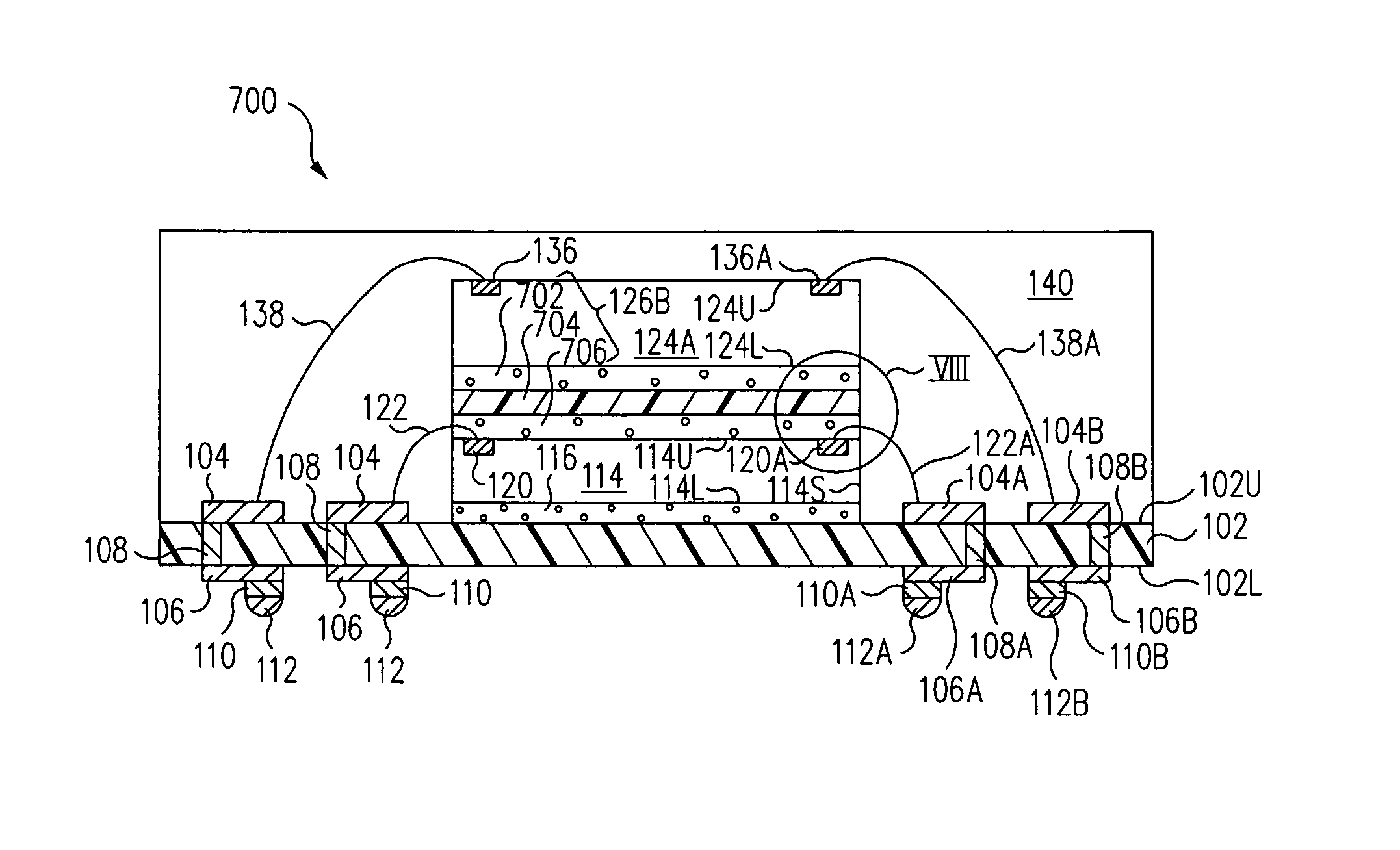

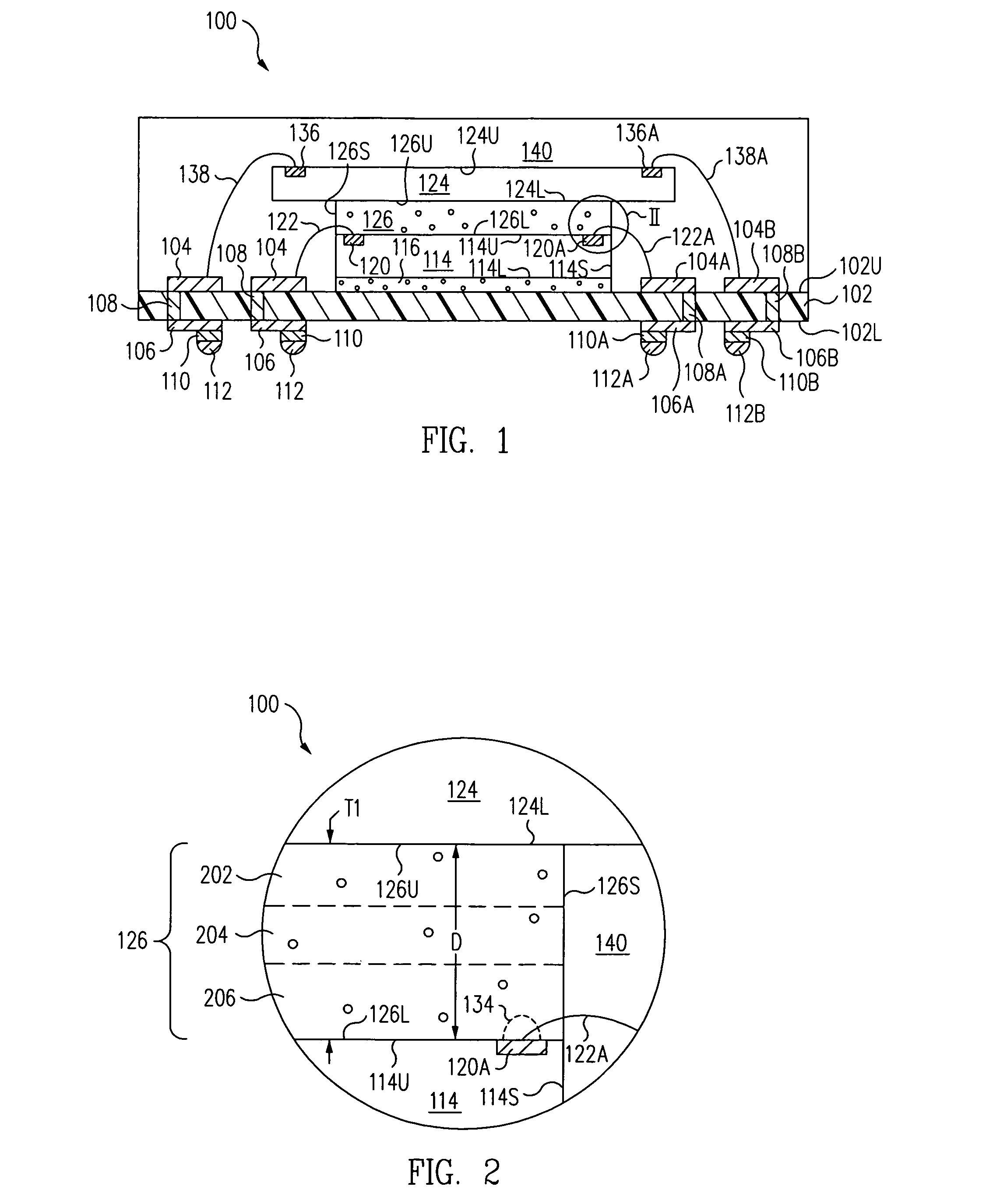

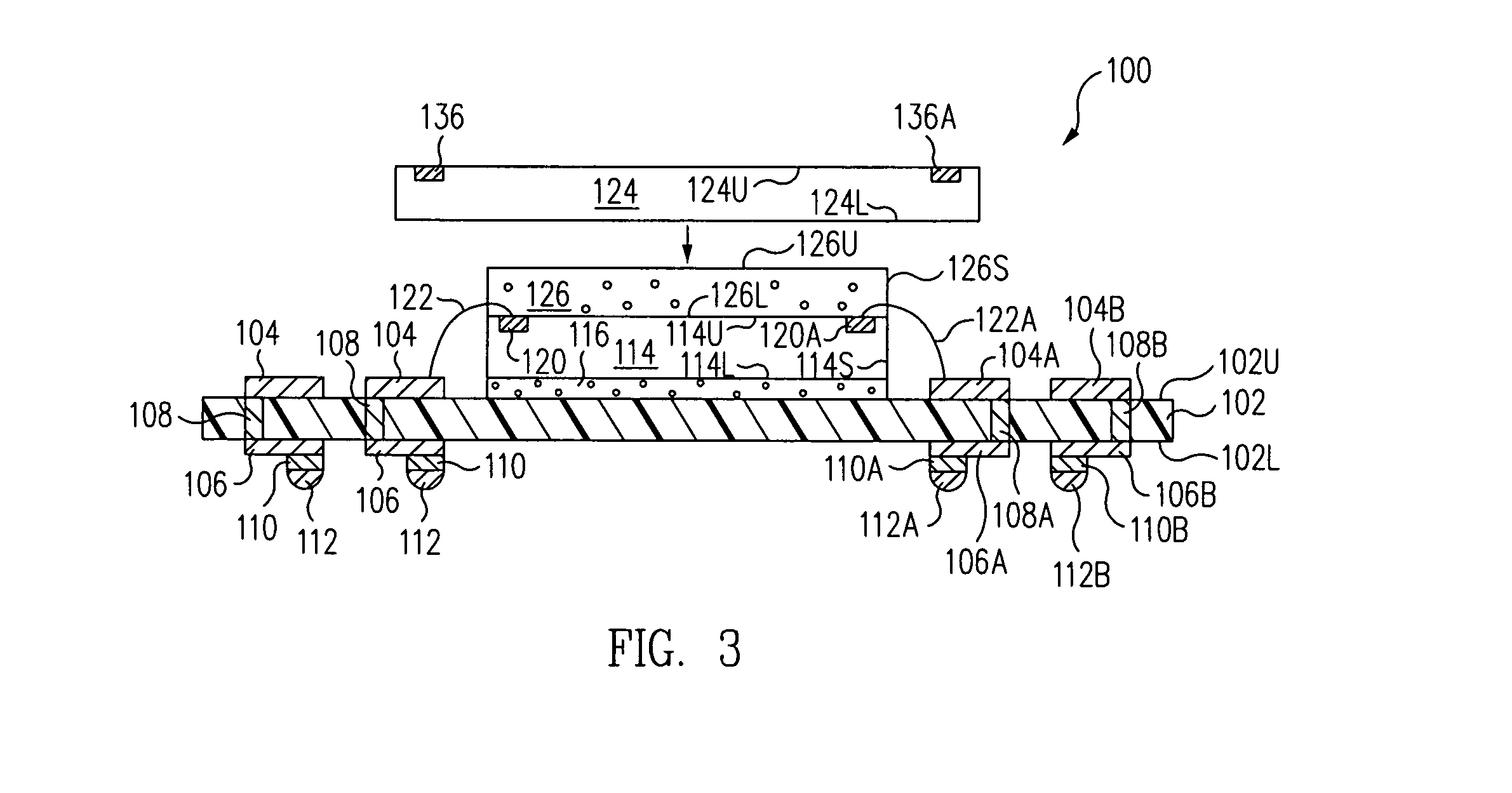

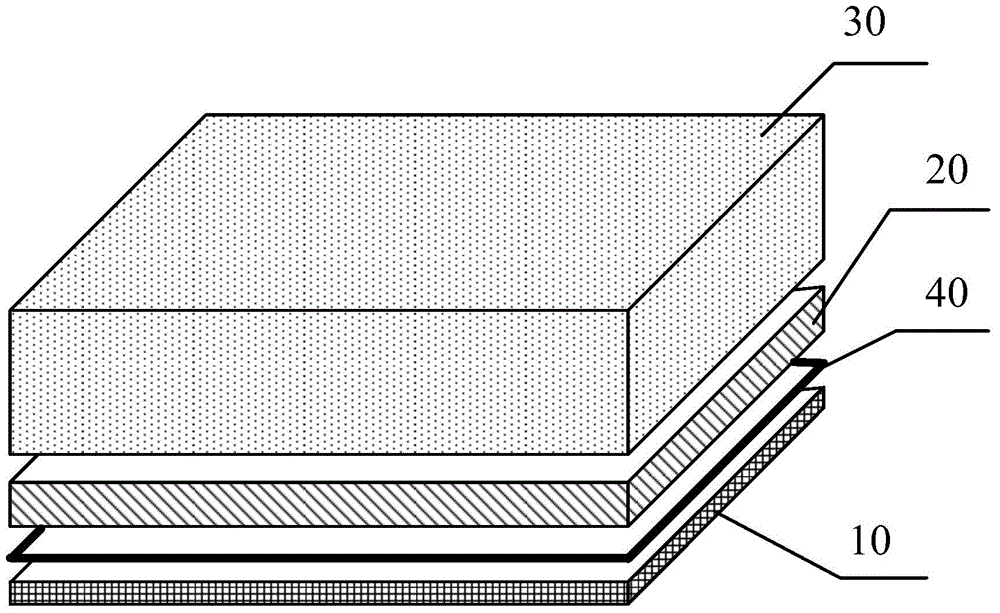

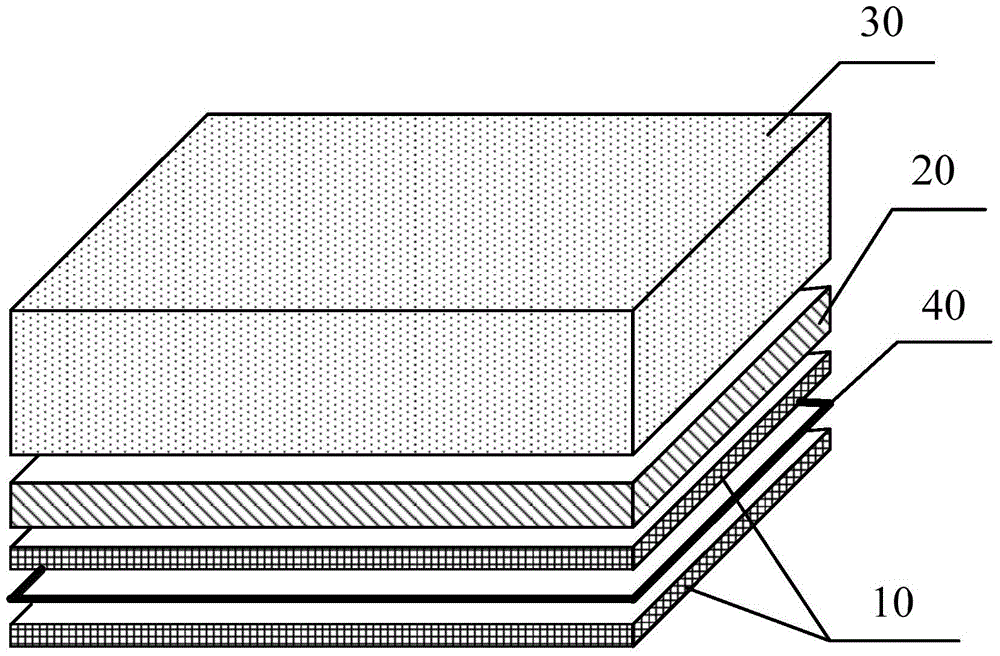

Stacked electronic component package having film-on-wire spacer

ActiveUS7675180B1Decrease stressDecrease chanceSemiconductor/solid-state device detailsSolid-state devicesLead bondingElectronic component

A film-on-wire spacer covers an entire upper surface of a lower electronic component. Accordingly, an upper electronic component is supported above bond pads and lower bond wires of the lower electronic component. This decreases the stress on the upper electronic component, e.g., during wirebonding, and thus decreases the chance of cracking the upper electronic component. Further, the lower bond wires are enclosed in and protected by the film-on-wire spacer. Further, the film-on-wire spacer is thin resulting in a minimum height of the stacked electronic component package.

Owner:AMKOR TECH SINGAPORE HLDG PTE LTD

Glaze material for Jun red glaze and process for preparing Jun porcelain from glaze material

The invention discloses a glaze material for Jun red glaze and a process for preparing Jun porcelain from the glaze material. The glaze material consists of the raw materials of melilite, quartzite, calcite, white feldspar, copper ore, ZnO, SnO, GuO, talc, BaO, zirconium silicate and spodumene. The preparation process comprises the following steps: firstly, smashing roughcast raw materials and conducting moulding to fire a plain roughcast, then immersing the plain roughcast into slurry of the glaze material of the Jun red glaze for glazing, and when the slurry adhered on the surface of the plain roughcast is dried, putting the plain roughcast in a kiln for firing, so as to obtain the Jun red glaze Jun porcelain. According to the glaze material for the Jun red glaze and the process for preparing the Jun porcelain by utilizing the glaze material, spodumene and zirconium silicate are added in the glaze material for the Jun red glaze, so that the fired Jun red glaze Jun porcelain is bright in color, mild and smooth in glaze surface, and uniform in cracking, and breaks through the condition that the general Jun red glaze Jun porcelain is dim in color and nonuniform in cracking; the Jun porcelain is taken as the specialty of China, and represents the advanced level of the manufacture process of China, and the social value of the Jun porcelain is improved.

Owner:JIAXIAN HONGDA PORCELAIN CO LTD

Complex Tang-dynasty jun glaze with blue spots in white and process for preparing jun porcelain by use of complex Tang-dynasty jun glaze

The invention discloses a complex tang-dynasty jun glaze with blue spots in white and a process for preparing jun porcelain by use of the complex Tang-dynasty jun glaze. The process comprises: firstly crushing and molding carcass raw materials, and firing the carcass raw materials into plain carcass; then, immersing the plain carcass into slurry of glaze in white for glazing; applying slurry of the glaze with blue spots in surface points of the plain carcass after the slurry of the glaze in white adhered on the surface of the plain carcass is dried in air; and putting the plain carcass into a kiln for firing after the slurry of the glaze with blue spots is dried, thereby obtaining the complex Tang-dynasty jun glaze with blue spots in white. According to the Tang-dynasty jun glaze with blue spots in white and the process for preparing jun porcelain by use of the complex Tang-dynasty jun glaze disclosed by the invention, milky white glaze is presented in the process of firing by adding zircon into a formula of the glaze in white; and the position of the glaze with blue spots is fixed by use of a secondary glazing mode. A coloring process of overglaze color or underglaze color adopted by general piebald porcelains is broken through; economic value of the jun porcelain is increased through innovation in glazing color and coating; and the jun porcelain, which is a Chinese characteristic, also represents advanced level of the production process in China, thereby increasing the social value of the jun porcelain.

Owner:JIAXIAN SHENQIAN LEGEND CERAMICS CHINAWARE FACTORY

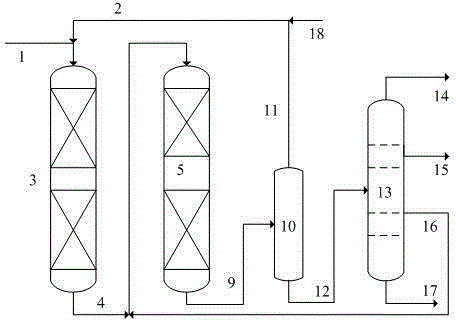

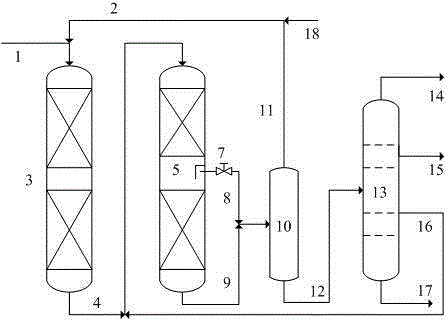

Hydrocracking method

ActiveCN104611040AReduce overhydrogenationReduce hydrogen consumptionTreatment with hydrotreatment processesProcess engineeringNaphtha

The present invention discloses a hydrocracking method. According to the method, heavy distillate oil and hydrogen gas are mixed and then enter a hydrorefining reactor to carry out a hydrorefining reaction; the hydrorefining reaction effluent directly enters a hydrocracking reactor and is subjected to a contact reaction with grading catalyst bed layers in the hydrocracking reactor, wherein at least two cracking catalyst bed layers are arranged inside the hydrocracking reactor, and the hydrogenation activity of the hydrocracking catalyst presents the decrease tendency according to the reaction material flowing direction; and the hydrocracking reaction effluent is subjected to separation and fractionation to obtain the hydrocracking products including heavy naphtha and tail oil. With the method of the present invention, the heavy component hydrocracking effect can be ensured while the excessive hydrogenation and the excessive cracking of the heavy naphtha are reduced, and the chemical hydrogen consumption is reduced, such that the aromatic potential and the selectivity of the heavy naphtha are increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

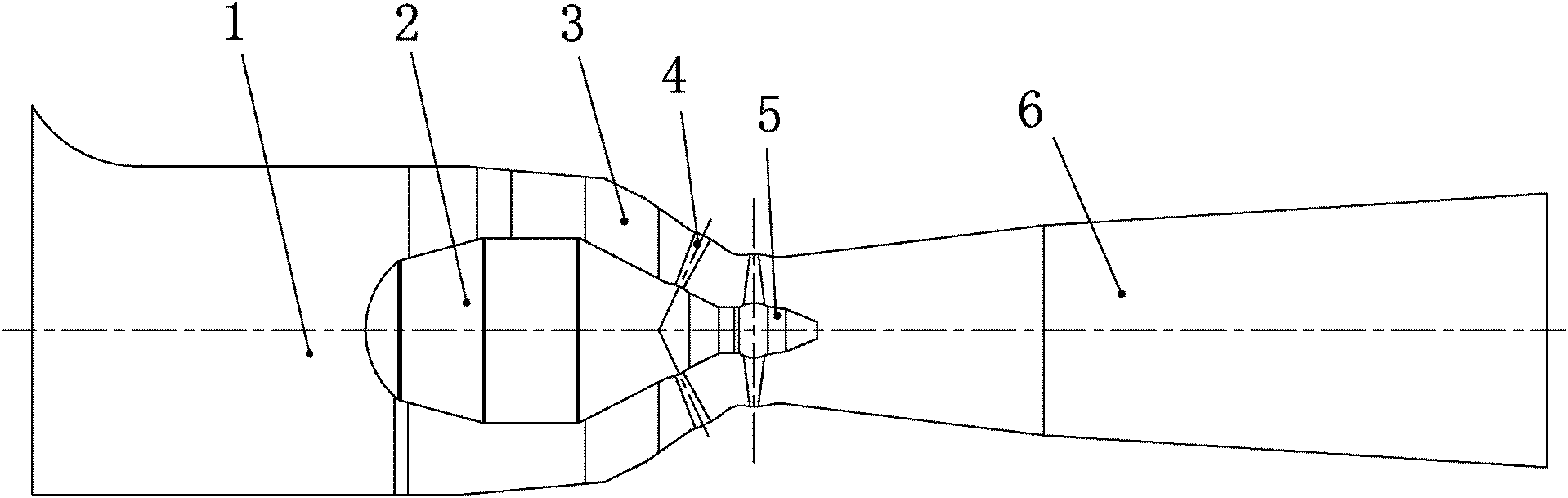

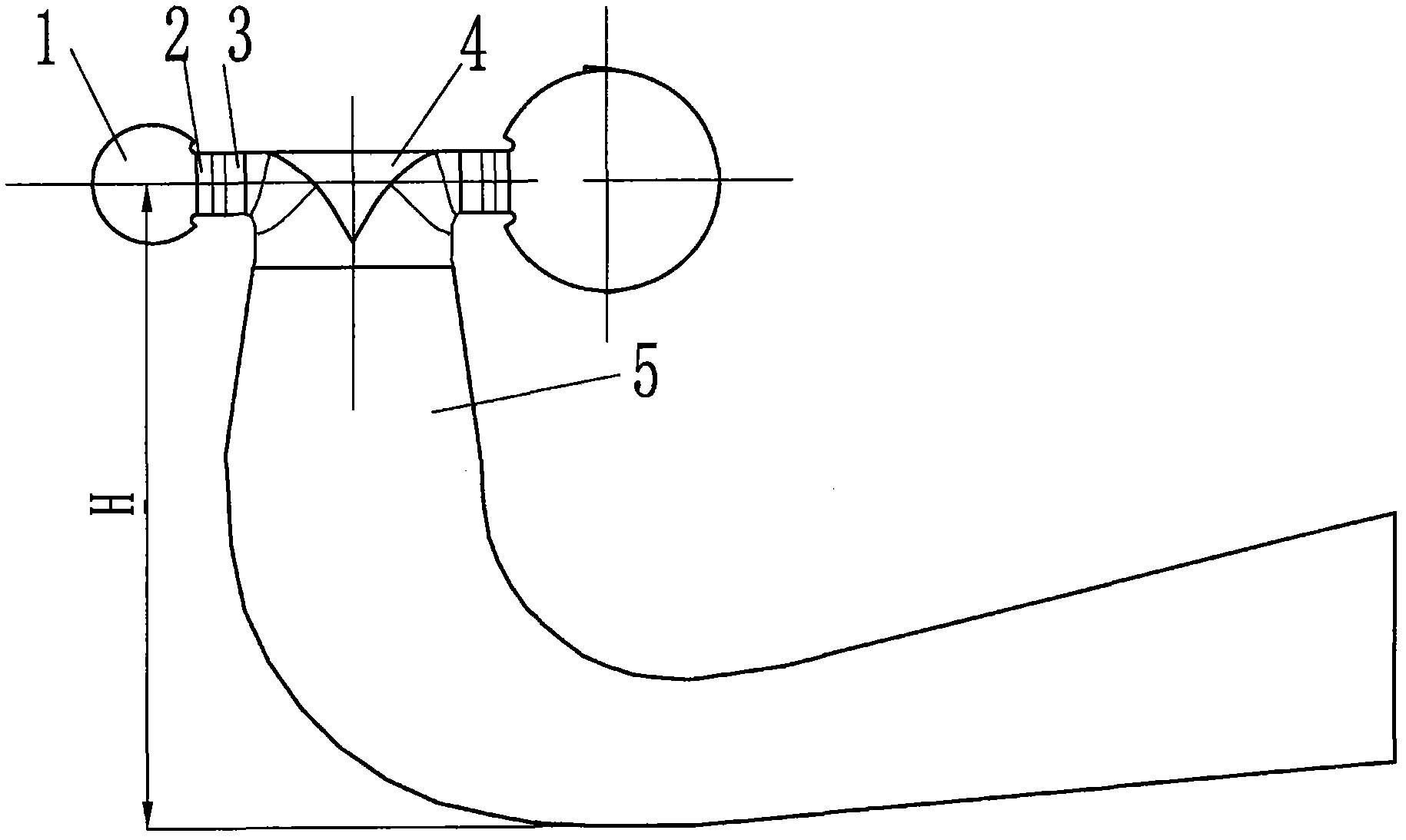

Six-operating-condition bidirectional tide power generation water turbine

InactiveCN102182622AImprove efficiencyReduce vibration and pressure pulsationsReaction enginesEngine componentsFriction lossEngineering

The invention belongs to the technical field of fluid machinery and engineering devices, and in particular relates to a six-operating-condition bidirectional tide bulb through-flow water turbine by adopting the brand new guide vane molded line and revolving wheel blade thickness regularity of distribution. The turbine comprises a water inlet pipe, a bulb head, a tubular seat, a guide vane, a revolving wheel and an exhaust tube; the shape of the guide vane is designed, and a brand new molded line is adopted, thus the flow is more smooth, and the resistance loss in a flow channel is less; the revolving wheel blade is designed, an S-shaped revolving wheel blade is adopted, a new thickness changing discipline is adopted from the inlet to the outlet, and higher efficiency of the operation of the forward and backward bidirectional water turbine is ensured; and compared with the general tide machine set, the turbine provided by the invention has the advantages that the efficiency of the forward and backward bidirectional water turbine is improved, the vibration and pressure pulsation are reduced, the revolving wheel machinery strength is increased, and the dynamic stress of the revolvingwheel blade is reduced, thus the occurrence of cracking probability of the revolving wheel blade is greatly reduced, and the operation stability of the water turbine is improved.

Owner:TSINGHUA UNIV

Cold forging method and metal housing processing method

ActiveCN102688966AReduce the chance of crackingReduced chance of scratchesAnodisationMetal-working apparatusMetallic materialsMetal

The invention provides a cold forging method and a metal housing processing method. The cold forging method comprises steps of performing anodic oxidation treatment to the metal material surface so as to obtain an anode oxide film; enabling the anode oxide film to adsorb a lubricant, forging and pressing the metal material absorbed with the lubricant, and removing the anode oxide film. The damage of a mold in the cold forging process is greatly reduced by the method, and the products prepared by the method are excellent in appearance without scratching.

Owner:BYD CO LTD

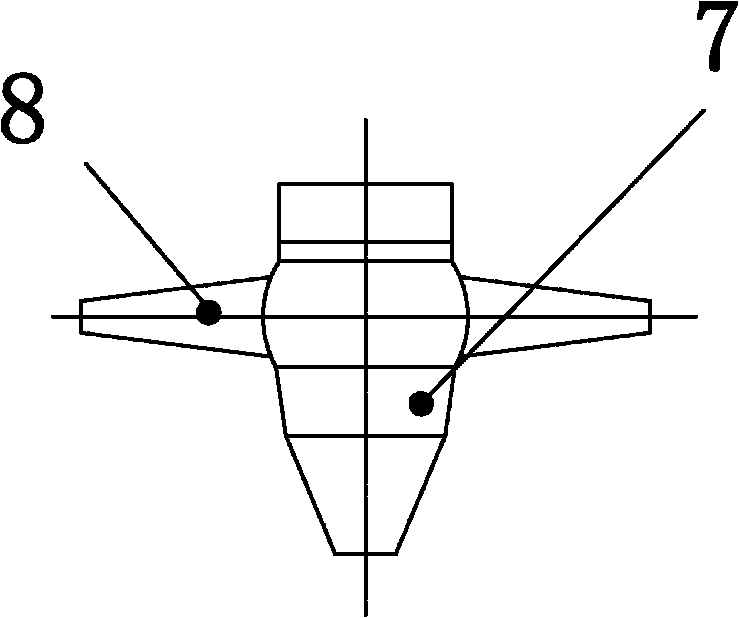

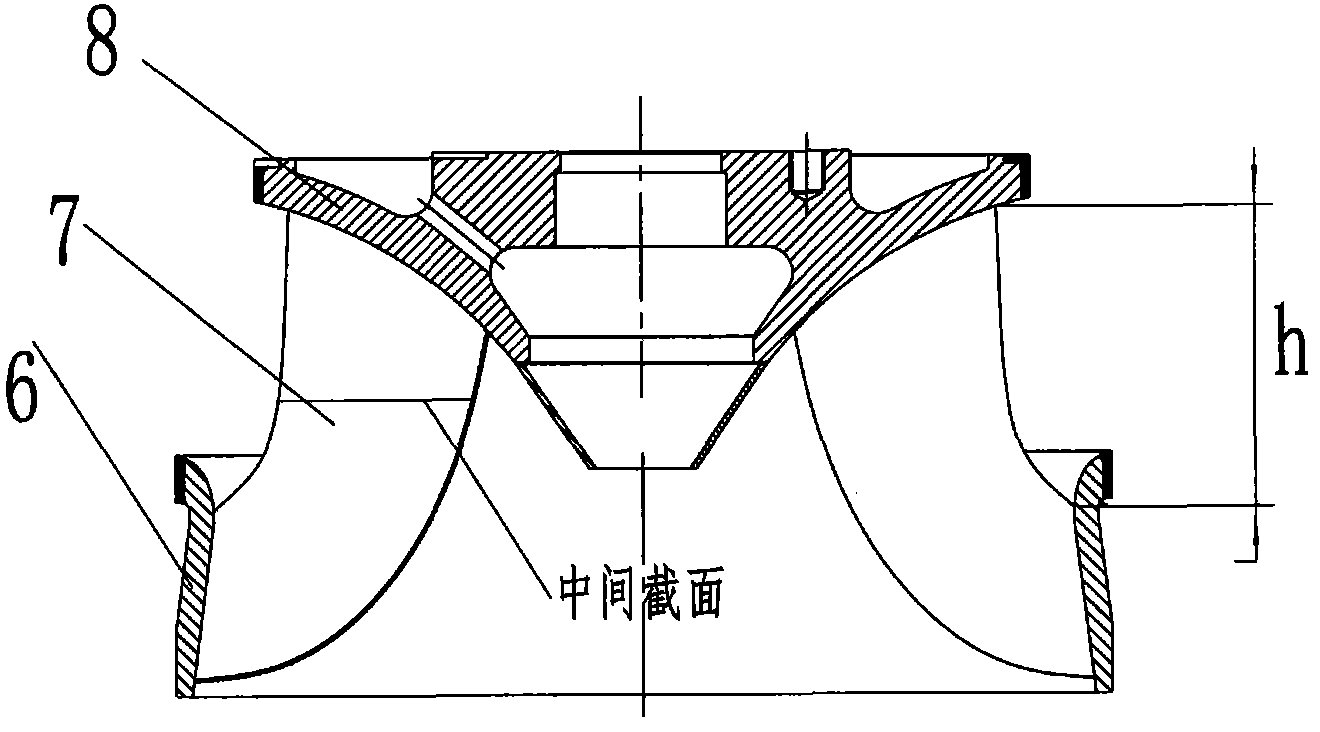

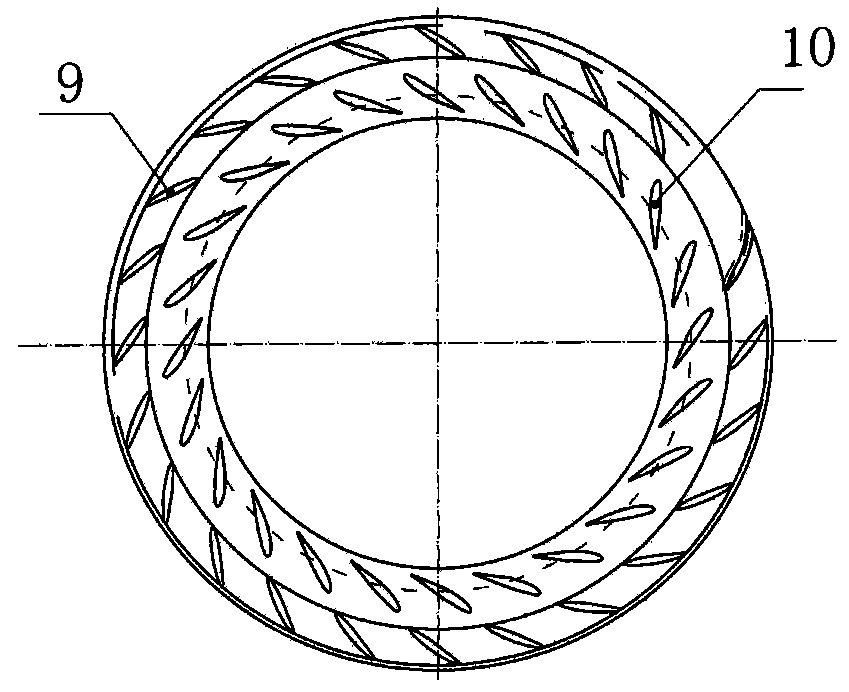

Radial-axial flow turbine employing novel guide blade and runner blade profile

InactiveCN102011672AImprove efficiencyImprove running stabilityHydro energy generationReaction enginesTurbine bladeFriction loss

The invention belongs to the technical field of fluid machinery and engineering equipment, and in particular relates to a radial-axial flow turbine, in particular to a radial-axial flow turbine employing a novel guide blade and runner blade profile. The turbine comprises a volute, a fixed guide blade, a movable guide blade, a runner and an exhaust water pipe; the shape of a nose baffle of the volute and the shape of the movable guide blade are designed, and a brand-new guide blade profile, so the flow is smoother, and the resistance loss in a flow channel is lower; the height difference between an upper crown and a lower ring surface, the length of a straight cone of the exhaust water pipe and a flow angle of outlet liquid of the turbine blade are newly designed; and a novel thickness change rule is adopted for the runner blade from an inlet to an outlet. The novel turbine improves the efficiency, reduces the vibration and pressure fluctuation, improves the mechanical strength of the runner, and reduces dynamic stress of the runner blade. Therefore, the probability for generating cracks on the runner blade is greatly reduced, and the operating stability of the turbine is improved.

Owner:TSINGHUA UNIV +1

White-ground red-spot composite tangjun glaze and process of preparing jun porcelain with same

The invention discloses white-ground red-spot composite tang jun glaze and a process of preparing jun porcelain with the same. The preparing process comprises the steps that a porcelain body material is smashed and molded firstly, plain porcelain body firing is conducted, then a plain porcelain body is dipped in white-ground glaze slurry for glazing, local spot application of red-spot glaze slurry is conducted on the surface of the plain porcelain body after the white-ground glaze slurry attached to the surface of the plain porcelain body is dried in the air, the plain porcelain body is placed in a kiln to be fired after the red-spot glaze slurry is dried in the air, and then the white-ground red-spot composite tang jun glaze jun porcelain is obtained. According to the white-ground red-spot composite tang jun glaze and the process of preparing the jun porcelain with the same, by adding a certain proportion of zirconite to white-ground glaze and adopting secondary glazing, the position of red-spot glaze is fixed, and a glaze layer is cracked evenly and not prone to rupture; the coloring technology of overglaze or underglaze adopted for general piebald porcelain is replaced, the economic value of the jun porcelain is increased through innovation in glazing color and coatings, the jun porcelain represents the advanced manufacturing technology of China, and the social value of the jun porcelain is increased.

Owner:JIAXIAN SHENQIAN LEGEND CERAMICS CHINAWARE FACTORY

Modified formula for enhancing rapidly-dried silica sol

InactiveCN101885036AImprove wet strengthSpeed up evaporationFoundry mouldsFoundry coresFiberEvaporation

The invention relates to a modified formula for enhancing rapidly-dried silica sol. The technical scheme is that: the modified formula consists of the following components in part by weight: 8,500 to 9,800 parts of silica sol, 100 to 1,200 parts of emulsion, 80 to 160 parts of fiber, and 20 to 180 parts of antifoaming agent. The modified formula has the advantages that: by using the interpenetrating and complementary characteristics of the silica sol and the emulsion, coatings coated on the surface of a wax mold are in net distribution, the wet strength of the coatings is improved, and the next-layer sizing agent can be applied to the incompletely dried upper-layer sizing agent; by using the water conduction function of the fiber, the water inside and outside the coatings is balanced, the inner stress is reduced, the mold shell cracking probability is reduced, the evaporation of the water is accelerated, and the drying time is shortened; an ultra-micro gap of the fiber formed by high temperature carbonization can reduce the retained strength of the mold shell, also can improve the air permeability of the mold shell, and comprehensively improves the quality of casting products; and the period of shell making technology is shortened from 5-7 days to 1-2 days.

Owner:武汉市智发科技开发有限公司

Password authentication method

The invention relates to a password authentication method which comprises: a first authentication step that authenticates at least a once entered password and a first set password; and a second authentication step that authenticates a password entered in a next round and a second set password when the first authentication step fails in the password authentication, wherein the second set password has more digits than that of the first set password. The password authentication method of the invention assists in solving problems in the prior art that: if a password is too long, it will be difficult for a user to remember, and if a password is too short, it will be easily cracked.

Owner:李良

White-ground piebald composite tang jun glaze and process of preparing jun porcelain with same

The invention discloses white-ground piebald composite tang jun glaze and a process of preparing jun porcelain with the same. A porcelain body material is smashed and molded firstly, plain porcelain body firing is conducted, then a plain porcelain body is dipped in white-ground glaze slurry for glazing, local spot application of piebald glaze slurry is conducted on the surface of the plain porcelain body after the white-ground glaze slurry attached to the surface of the plain porcelain body is dried in the air, the plain porcelain body is placed in a kiln to be fired after the piebald glaze slurry is dried in the air, and then the white-ground piebald composite tang jun glaze jun porcelain is obtained. According to the white-ground piebald composite tang jun glaze and the process of preparing the jun porcelain with the same, by adding zirconite to the formula of white-ground glaze, opacified white glaze is generated during firing; furthermore, secondary glazing is adopted to fix the position of piebald glaze; the coloring technology of overglaze or underglaze adopted for general piebald porcelain is replaced, and the economic value of the jun porcelain is increased through innovation in glazing color and coatings; furthermore, as a characteristic of China, the jun porcelain represents the advanced manufacturing technology of China, and the social value of the jun porcelain is increased.

Owner:JIAXIAN SHENQIAN LEGEND CERAMICS CHINAWARE FACTORY

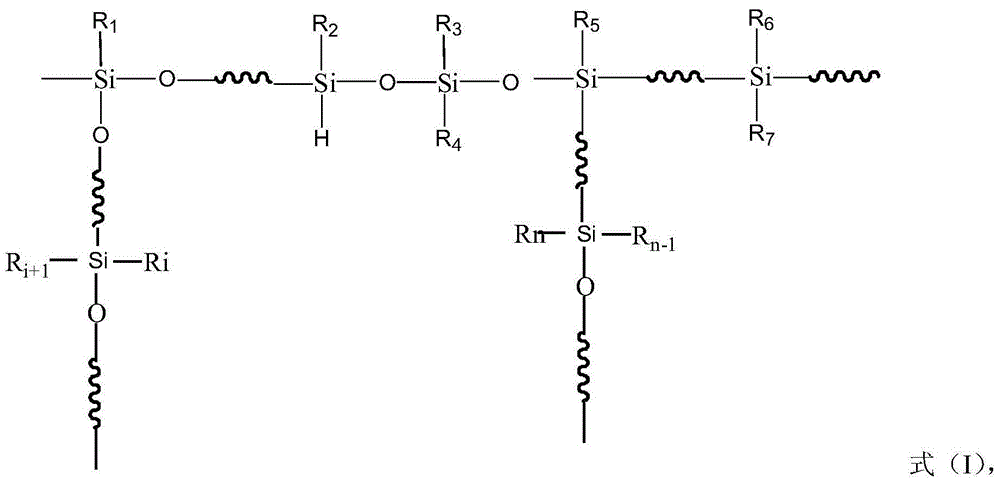

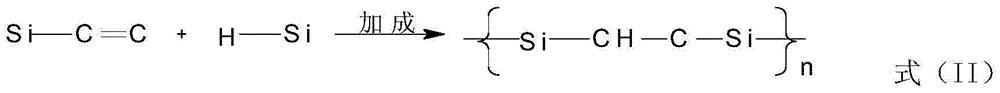

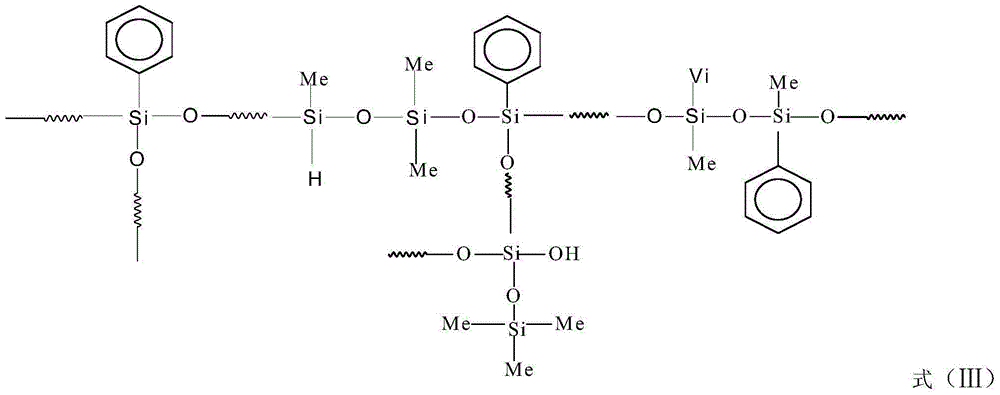

Organic silicon solventless impregnating resin and synthesizing method thereof

The invention discloses organic silicon solventless impregnating resin and a synthesizing method thereof. The method includes the steps of synthesizing organic silicon resin prepolymer, compounding impregnating resin and the like. The organic silicon solventless impregnating resin has low viscosity, uses no organic solvent as medium, and belongs to pollution-free green and environment-friendly insulating materials; after being cured into film, the resin is free of low-molecular-weight polymer prolapse, excellent in electrical performance, free of pollution, good in comprehensive performance, good in application processing property and suitable for vacuum pressure impregnation insulation treatment of motor, transformer or other devices. Meanwhile, the obtained product cured in a die with the diameter of 100 cm has the size about 99.8 cm; generally, the cured product obtained by compounding component A silicon vinyl and component B silicon hydrogen has the size about 98.5 cm, and therefore shrinkage percentage is greatly decreased, the cured product cracking probability is greatly lowered, and the low-shrinkage and low-crack excellent performance is achieved.

Owner:XIANGTAN UNIV

Wood material drying method

InactiveCN106403519AReduce the chance of crackingReduce stressDrying gas arrangementsWood dampingAfter treatmentDrying time

The invention discloses a wood material drying method and belongs to the technical field of wood processing. The wood material drying method specifically comprises the following steps: (1) pre-treating a wood material; (2) pre-drying the wood material; (3) deeply drying the wood material; and (4) performing after treatment after the wood material is dried. The method disclosed by the invention can commendably prevent phenomena of deformation, cracking and flexure of the wood material in a drying process and can also shorten the drying time by 30% to 35%; the cracking probability of the wood material is reduced by more than two times; and the surface of the dried wood material is smoother, so the wood material drying method has quite good promotion and application values.

Owner:阜南县环宇柳木工艺制品有限公司

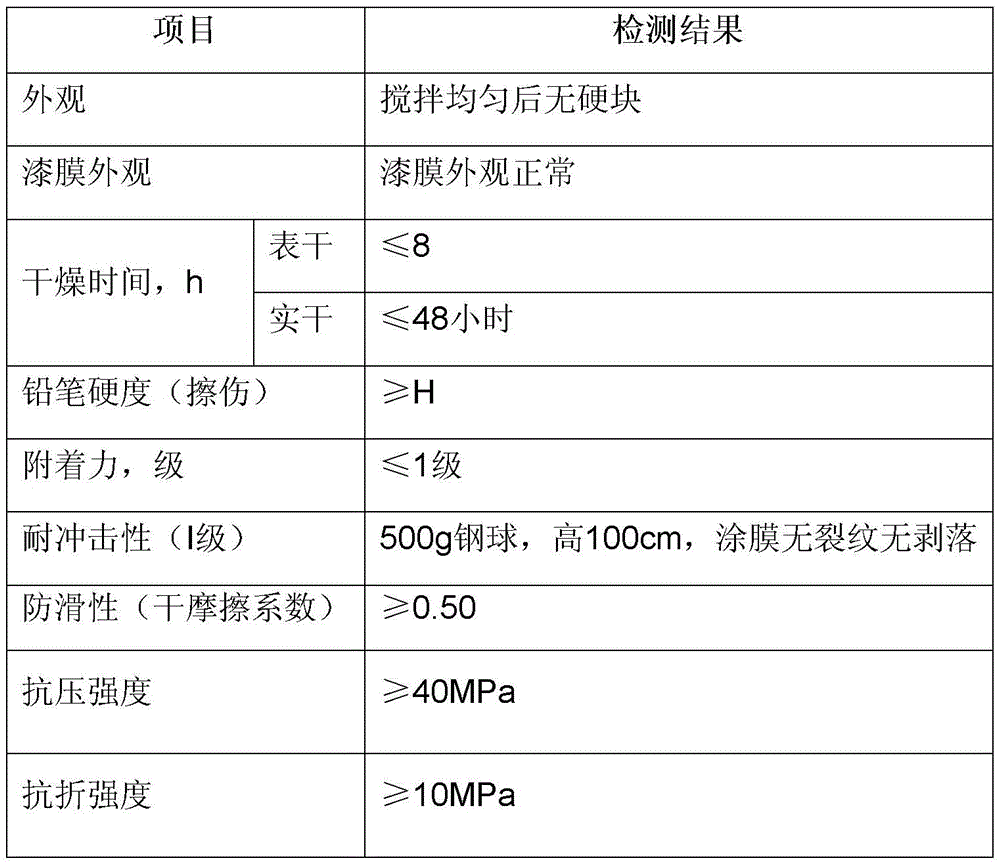

Aqueous epoxy coating for terraces, and preparation method thereof

The invention discloses an aqueous epoxy coating for terraces, and a preparation method thereof. The aqueous epoxy coating for terraces comprises 1.2-1.3 parts of an aqueous epoxy curing agent, 1 part of bisphenol A liquid epoxy resin, and 7-8 parts of a third component, wherein the third component is prepared through mixing 20-30 parts of high grade cement, 15-20 parts of coarse quartz sand, 40-50 parts of fine quartz sand, 0.1-0.2 parts of a water reducer, 0.1-0.3 parts of an antifoaming agent and 0.1-0.3 parts of cellulose. The aqueous epoxy coating for terraces, disclosed in the embodiment of the invention, has good strong acid, strong alkali, wear, pressure, impact, mildew, water, dust and skid resistance, has the advantages of simple preparation method and long service life, avoids obvious connection seams between an original coating layer and a new repairing coating layer as a maintaining and repairing material, and keeps good cracking resistance, flexural strength and compressive strength in the repairing position.

Owner:FIRST NEW MATERIAL TECH DEV

Black background-white spot composite Tang jun glaze, and method used for producing jun porcelain with black background white spot composite Tang jun glaze

The invention discloses a black background-white spot composite Tang jun glaze, and a method used for producing jun porcelain with the black background white spot composite Tang jun glaze. According to the method, a ceramic body raw material is subjected to smashing, moulding, and sintering so as to obtain unglazed porcelain bodies; the unglazed porcelain bodies are immersed into a black background glaze slurry for glazing; after airing of the black background glaze slurry on the surfaces of the unglazed porcelain bodies, the surfaces of the unglazed porcelain bodies are coated with a white spot glaze slurry via spot application; after airing, the obtained unglazed porcelain bodies are delivered into a kiln for sintering so as to obtain the black background-white spot composite Tang jun glaze jun porcelain. According to the black background-white spot composite Tang jun glaze and the method, iron element is added into a black priming glaze at a certain ratio; secondary glazing is adopted; the positions of white sport glaze are immobilized; talc powder and bone meal are added into the black background-white spot composite Tang jun glaze at a certain ratio, so that glaze layer crackles are uniform, and cracking is not easily caused. Overglaze color or underglaze color generally adopted in conventional speckle porcelain production is not adopted in the method, so that economic value of jun porcelain is increased via innovation on glazing color and coating; jun porcelain is a featured product of our country, so that the method is used for reflecting advanced technology of China, and social value of jun porcelain is increased.

Owner:JIAXIAN SHENQIAN LEGEND CERAMICS CHINAWARE FACTORY

Blue background and mottled spot composite Tang jun glaze and technology for preparing jun porcelain through same

The invention provides a blue background and mottled spot composite Tang jun glaze and a technology for preparing jun porcelain through the same. Firstly, casing body raw materials are smashed and molded, and a prime casing is fired; then, the prime casing is soaked into blue background glaze slurry to be subjected to glazed, and after the blue background glaze slurry attached to the surface of the prime casing is dried, mottled spot glaze slurry is applied to local points on the surface of the prime casing; after the mottled spot glaze slurry attached to the surface of the prime casing is dried, the prime casing is placed in a kiln to be fired, and then the blue background and mottled spot composite Tang jun glaze jun porcelain is obtained. According to the blue background and mottled spot composite Tang jun glaze and the technology for preparing the jun porcelain through the same, due to the fact that iron elements, copper elements and cobalt elements are added in the blue background glaze according to specific proportions and a secondary glazing mode is used, glaze layer hacking is uniform and is not prone to bursting. The technology breaks through the overglaze color or underglaze color coloring technology adopted by a common mottled spot porcelain, the economic value of the jun porcelain is creatively increased on the aspects of glaze colors and a coating, the technology represents the advanced level of the manufacturing technology in China, and the social value of the jun porcelain is improved.

Owner:JIAXIAN SHENQIAN LEGEND CERAMICS CHINAWARE FACTORY

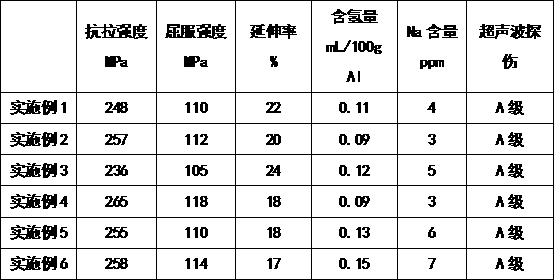

Preparation method of ultra-large-specification high-Mg aluminum alloy round ingot

The invention discloses a preparation method of an ultra-large-specification high-Mg aluminum alloy round ingot. The preparation method comprises the following steps of burdening; smelting; preservingheat; carrying out primary refining, and controlling of argon flow; carrying out online degassing refining, and controlling of the rotating speed of a rotor and the argon flow; casting; and carryingout a soaking treatment. According to the method, a hydrogen content and an alkali metal content of the aluminum alloy can be effectively reduced, the probability of cracking of a cast ingot is reduced, and the production percent of pass is improved.

Owner:广西南南铝加工有限公司

Complex Tang-dynasty jun glaze with blue spots in black and process for preparing jun porcelain by use of complex Tang-dynasty jun glaze

The invention discloses a complex tang-dynasty jun glaze with blue spots in black and a process for preparing jun porcelain by use of the complex Tang-dynasty jun glaze. The process comprises: firstly crushing and molding carcass raw materials, and firing the carcass raw materials into plain carcass; then, immersing the plain carcass into slurry of glaze in black for glazing; applying slurry of the glaze with blue spots in surface points of the plain carcass after the slurry of the glaze in black adhered on the surface of the plain carcass is dried in air; and putting the plain carcass into a kiln for firing after the slurry of the glaze with blue spots is dried, thereby obtaining the complex Tang-dynasty jun glaze with blue spots in black. According to the Tang-dynasty jun glaze with blue spots in black and the process for preparing jun porcelain by use of the complex Tang-dynasty jun glaze disclosed by the invention, an iron element, a copper element and a cobalt element in special proportion are added into glaze in black, are fired at a high temperature to form black glaze which is stable in color generation, uniform in color and luster and full of a jade texture, and the position of the glaze with blue spots is fixed by use of a secondary glazing mode. A coloring process of overglaze color or underglaze color adopted by general piebald porcelains is broken through; economic value of the jun porcelain is increased through innovation in glazing color and coating; and the jun porcelain, which is a Chinese characteristic, also represents advanced level of the production process in China, thereby increasing the social value of the jun porcelain.

Owner:JIAXIAN SHENQIAN LEGEND CERAMICS CHINAWARE FACTORY

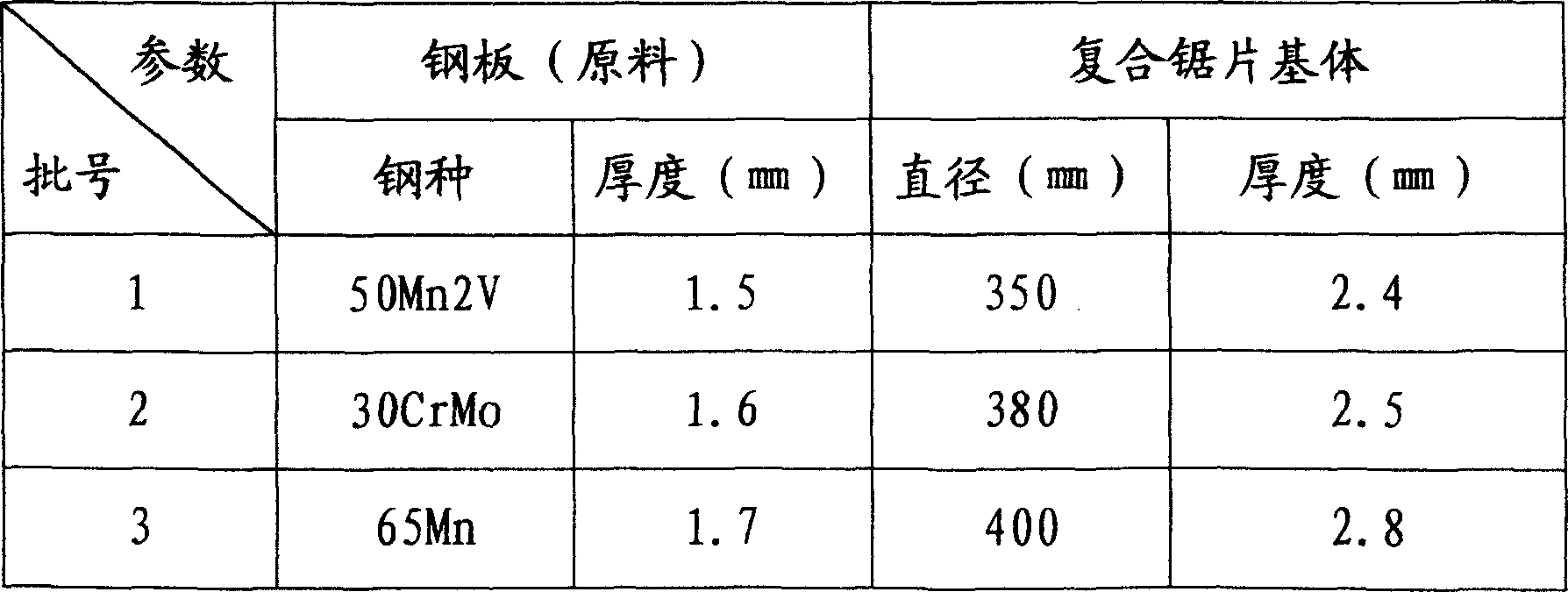

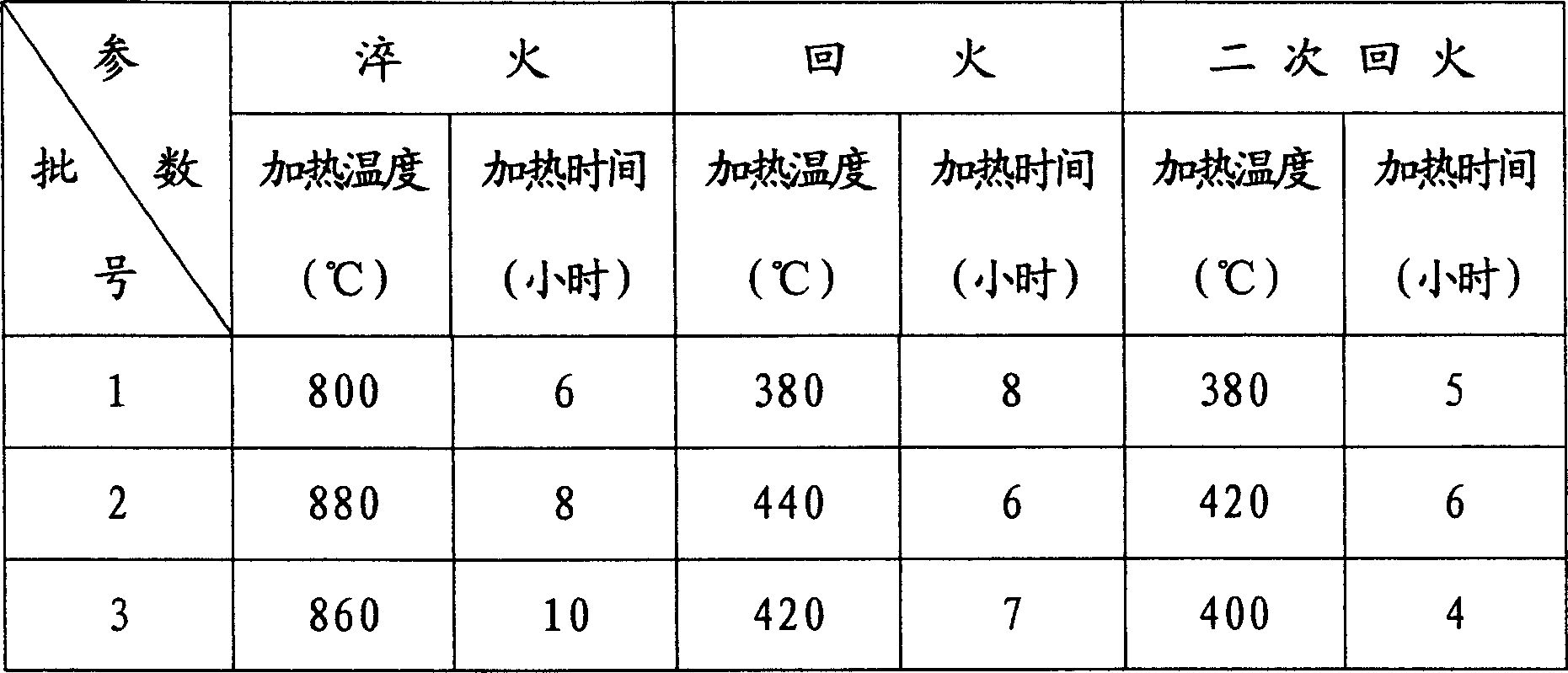

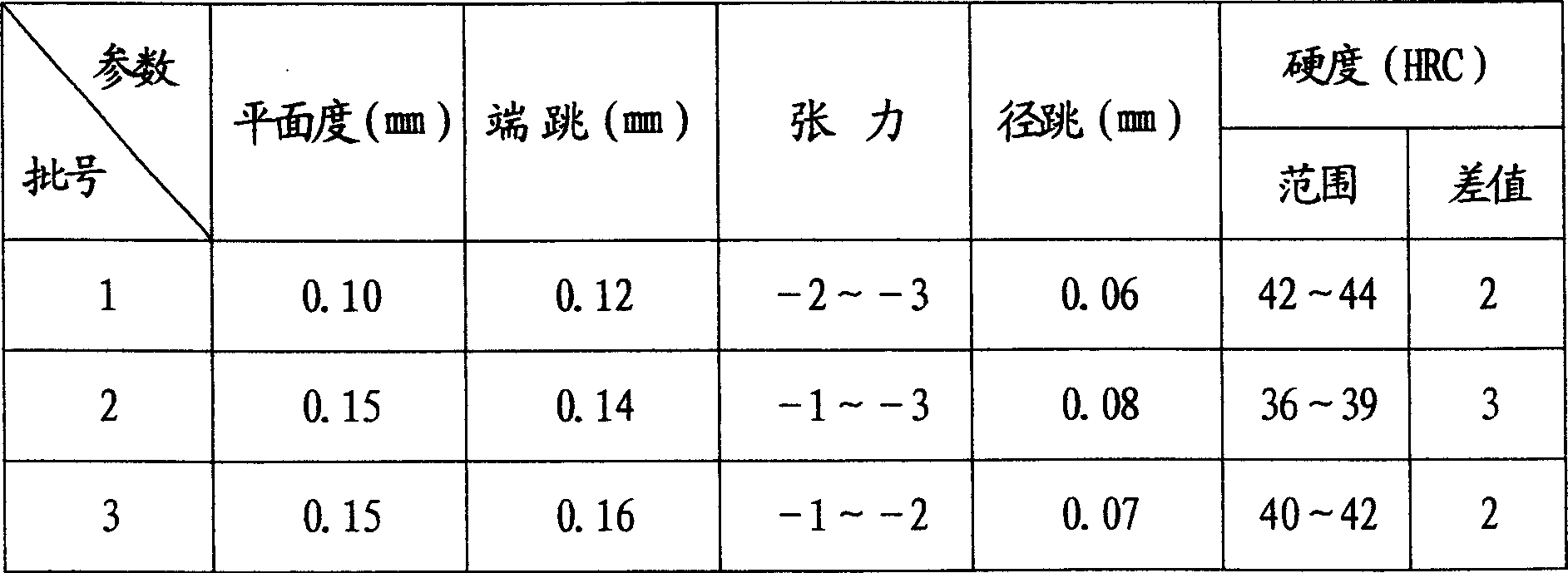

Method for producing composite diamond saw blade substrate

ActiveCN1820883AFlatness controlUniform internal stressMetal sawing tool makingOther manufacturing equipments/toolsComposite substrateHardness

The present invention belongs to the field of cutting tool, and relates to cutting tool for stone material, cement, glass and ceramic product. The production process of composite diamond saw blade substrate includes the technological steps of: preparing two single saw blade substrates, combined dot welding, quenching and tempering, finish machining, secondary tempering and finishing grinding to form the composite diamond saw blade substrate product. The present invention has the advantages of homogeneous hardness, high production efficiency and less crack forming possibility of the composite substrate.

Owner:HEIXUANFENG SAW IND

Stacked electronic component package having film-on-wire spacer

ActiveUS8072083B1Relieve pressureReduce the chance of crackingSemiconductor/solid-state device detailsSolid-state devicesEngineeringElectronic component

A film-on-wire spacer covers an entire upper surface of a lower electronic component. Accordingly, an upper electronic component is supported above bond pads and lower bond wires of the lower electronic component. This decreases the stress on the upper electronic component, e.g., during wirebonding, and thus decreases the chance of cracking the upper electronic component. Further, the lower bond wires are enclosed in and protected by the film-on-wire spacer. Further, the film-on-wire spacer is thin resulting in a minimum height of the stacked electronic component package.

Owner:AMKOR TECH SINGAPORE HLDG PTE LTD

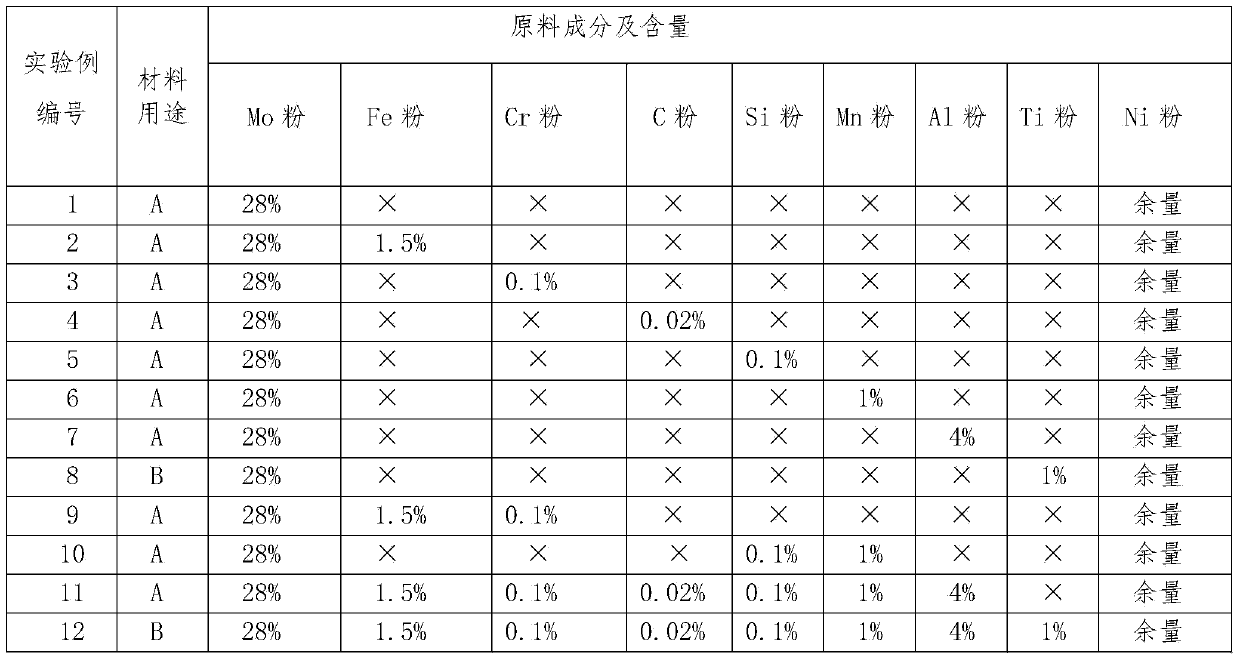

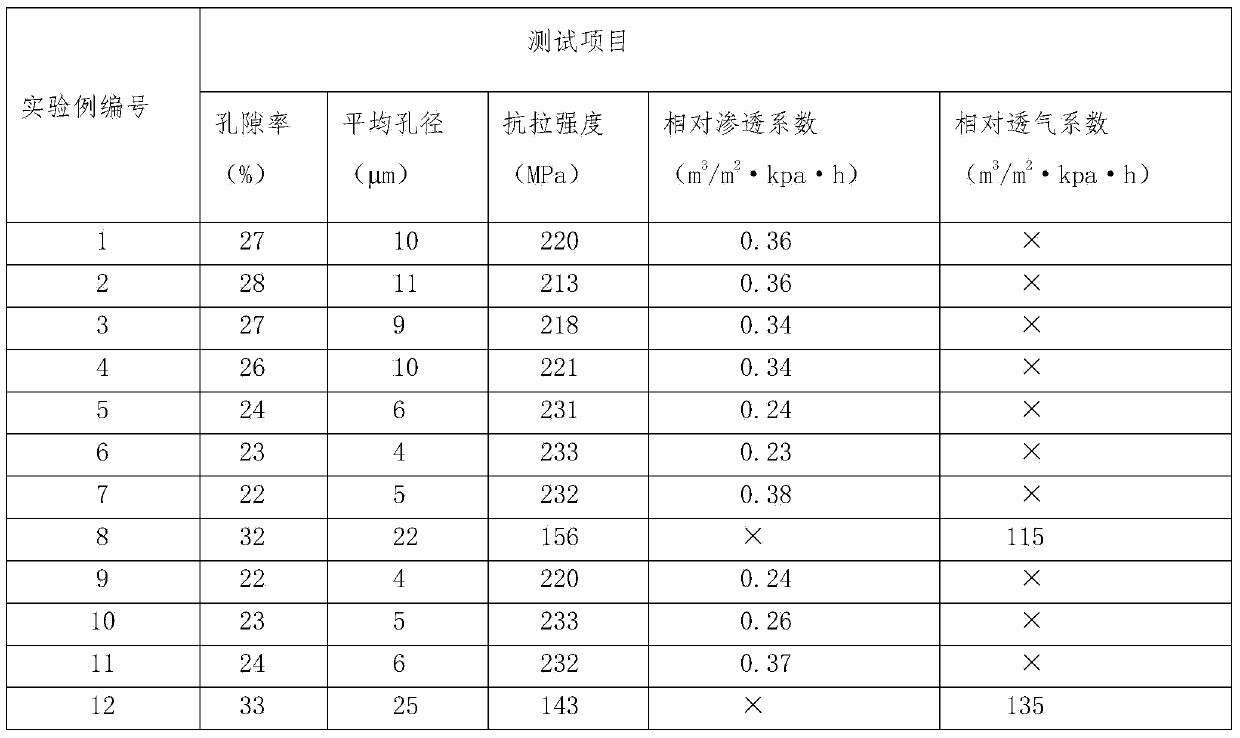

Powder sintered porous filter alloy, preparation method thereof and pre-compression molded body

The invention discloses a powder sintered porous filter alloy, a preparation method of the alloy and a pre-compression molded body for preparing the alloy. The alloy is basically prepared from the ingredients in percentage by mass: 14-17% of Cr, 15-17% of Mo, 0-7% of Fe, 0-4.5% of W, 0-2.5% of Co, 0-0.08% of C, 0-1% of Si, 0-1% of Mn, 0-0.35% of V, 0-0.04% of P, 0-0.03% of S, 0-5% of Al, 0-1.5% of Ti and the balance of Ni; when the alloy is used for filtering liquid, the average pore size is not greater than 20 microns, and the relative coefficient of permeability is not smaller than 0.2m<3> / m<2>.kPa.h; when the alloy is used for filtering gas, the average pore size is not greater than 60 microns, and the relative coefficient of gas permeability is not smaller than 80m<3> / m<2>.kPa.h. The alloy shows superior corrosion resistance in both an oxidizing system and a reducing system; secondly, the alloy is mainly resistant to wet chlorine, various oxidizing chlorides, chloride salt solutions, sulfuric acid and oxidizing salts. The alloy is suitable for being applied to the industrial fields of chemical industry, petrochemical industry, flue gas desulfurization, pulp and paper making, environmental protection and the like.

Owner:CHENGDU INTERMENT TECH

Complex Tang-dynasty jun glaze with white spots in blue and process for preparing jun porcelain by use of complex Tang-dynasty jun glaze

The invention discloses a complex tang-dynasty jun glaze with white spots in blue and a process for preparing jun porcelain by use of the complex Tang-dynasty jun glaze. The process comprises: firstly crushing and molding carcass raw materials, and firing the carcass raw materials into plain carcass; then, immersing the plain carcass into slurry of glaze in blue for glazing; applying slurry of the glaze with white spots in surface points of the plain carcass after the slurry of the glaze in blue adhered on the surface of the plain carcass is dried in air; and putting the plain carcass into a kiln for firing after the slurry of the glaze with white spots is dried, thereby obtaining the complex Tang-dynasty jun glaze with white spots in blue. According to the Tang-dynasty jun glaze with white spots in blue and the process for preparing jun porcelain by use of the complex Tang-dynasty jun glaze disclosed by the invention, an iron element, a copper element and a cobalt element in special proportion are added into a glaze material of glaze in blue, and the position of the glaze with white spots is fixed by use of a secondary glazing mode. A coloring process of overglaze color or underglaze color adopted by general piebald porcelains is broken through; economic value of the jun porcelain is increased through innovation in glazing color and coating; and the jun porcelain, which is a Chinese characteristic, also represents advanced level of the production process in China, thereby increasing the social value of the jun porcelain.

Owner:JIAXIAN SHENQIAN LEGEND CERAMICS CHINAWARE FACTORY

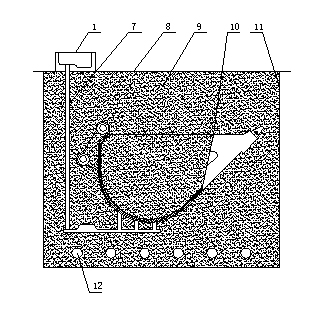

Crack-proof GRC composite prefabricated member and manufacture method thereof

ActiveCN105133778ALow drying shrinkageReduce the chance of crackingConstruction materialCeramic shaping apparatusSurface layerCrack resistance

The invention discloses a crack-proof GRC composite prefabricated member and a manufacture method thereof. The crack-proof GRC composite prefabricated member comprises a GRC surface layer, a GRC structure layer and a concrete layer, which are consolidated as a whole, wherein the GRC surface layer and the concrete layer are respectively disposed at two sides of the GRC structure layer. In the invention, the weight proportion of quartz sand to cement, the weight proportion of quartz sand of 80 mesh to quartz sand of 60 mesh, and the weight of ceramic micropowder in the GRC surface layer are adjusted to thereby effectively reduce the drying shrinkage rate and the crack generation rate of GRC surface layer so that durability and decoration effect of the GRC surface layer and crack-resistance are improved.

Owner:CHINA STATE CONSTR HAILONG TECH CO LTD

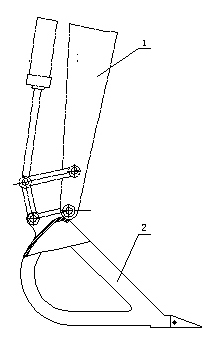

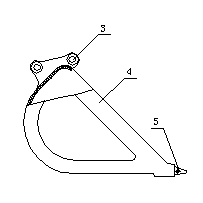

Integral cast steel dredge bucket

InactiveCN101862812AHigh mechanical strengthImprove wear resistanceMechanical machines/dredgersFoundry mouldsWhole bodyWear resistance

The invention relates to an integral cast steel dredge bucket. The dredge bucket consists of a bucket ear, a bucket body and a teeth seat, wherein the bucket ear, the bucket body and the teeth seat are made into a whole body by using a casting method. The dredge bucket is manufactured by using a lost foam shell casting method; the dredge bucket is cast into a whole body by using alloy steel as a raw material; and after the casting process is finished, the base is strengthened by thermal treatment; and thus the mechanical strength and the wearing resistance of the dredge bucket are improved and the probability of deformation and cracking of the bucket wall caused by over-large partial stress is reduced, so that the service life is prolonged.

Owner:姚会元

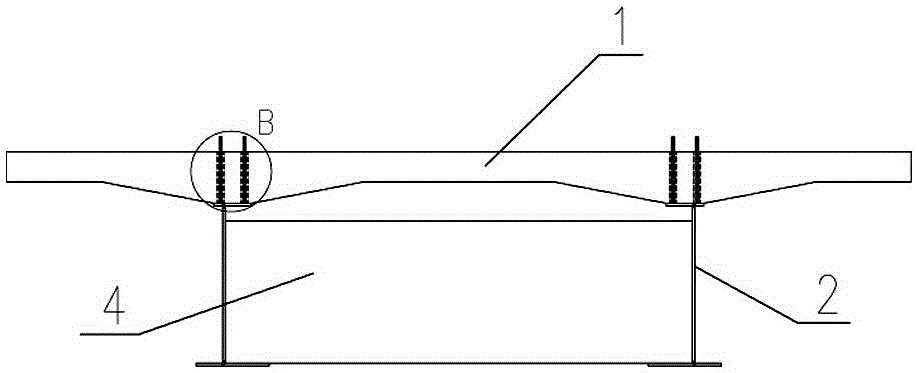

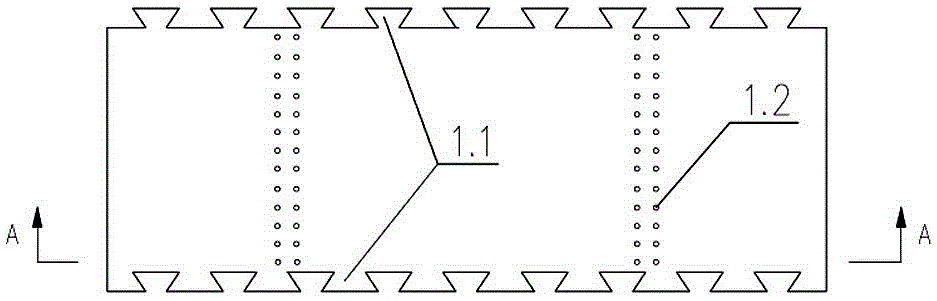

Prefabricated combined corrugated steel web T girder bridge

ActiveCN106677074ASimple structureEasy constructionBridge structural detailsBridge erection/assemblySteel platesRebar

The invention discloses a prefabricated combined corrugated steel web T girder bridge which comprises a reinforced concrete top plate and longitudinal beams arranged under the reinforced concrete top plate, wherein the reinforced concrete top plate is formed in the manner of splicing a plurality of bar-shaped plates in equal width with a girder bridge deck; mutually matched splicing slots are formed on the splicing surfaces of two adjacent bar-shaped plates; inserting holes corresponding to the positions of the longitudinal beams are formed on the bar-shaped plates; the longitudinal beams are arranged as a set of corrugated steel webs which are welded with top edge steel plates and bottom edge steel plates; connecting bolts are welded on the top edge steel plates; the connecting bolts are penetrated through the inserting holes and are integrally fixed with the bar-shaped plates in the manner of concreting; a plurality of horizontal steel separating plates which are arrayed along the longitudinal direction of the bridge are welded between the corrugated steel webs at intervals. A method for combining the prefabricating with the on-site assembling is adopted in a construction process. Thus, the prefabricated combined corrugated steel web T girder bridge provided by the invention has the advantages of simple structure, convenience in construction, low maintenance cost and capability of greatly increasing construction efficiency and service life.

Owner:HENAN PROVINCIAL COMM PLANNING & DESIGN INST CO LTD +1

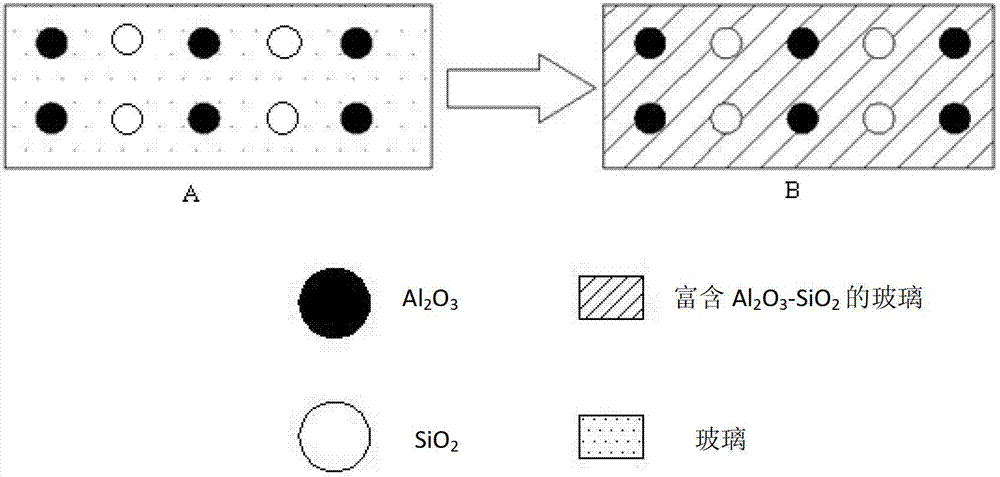

Coating material for platinum material in high-temperature environment and preparation method thereof

The invention provides a coating material for a platinum material in a high-temperature environment and a preparation method thereof. The coating material comprises the following components in percentage by mass: 50-80% of glass powder, 10-30% of aluminum oxide, 5-20% of silicon dioxide and 0-5% of water glass, wherein the silicon dioxide is introduced by means of silica sol or silicon dioxide granules and silica sol. The preparation method of the coating material comprises a sintering method and a water dispersion method. According to the invention, the generation of bubbles in glass caused by hydrogen penetration and the volatilization loss of the platinum material subjected to oxidation corrosion can be prevented, thereby achieving certain practical meanings for improving the yield of a production line and prolonging the life of a glass manufacturing device.

Owner:IRICO DISPLAY DEVICES

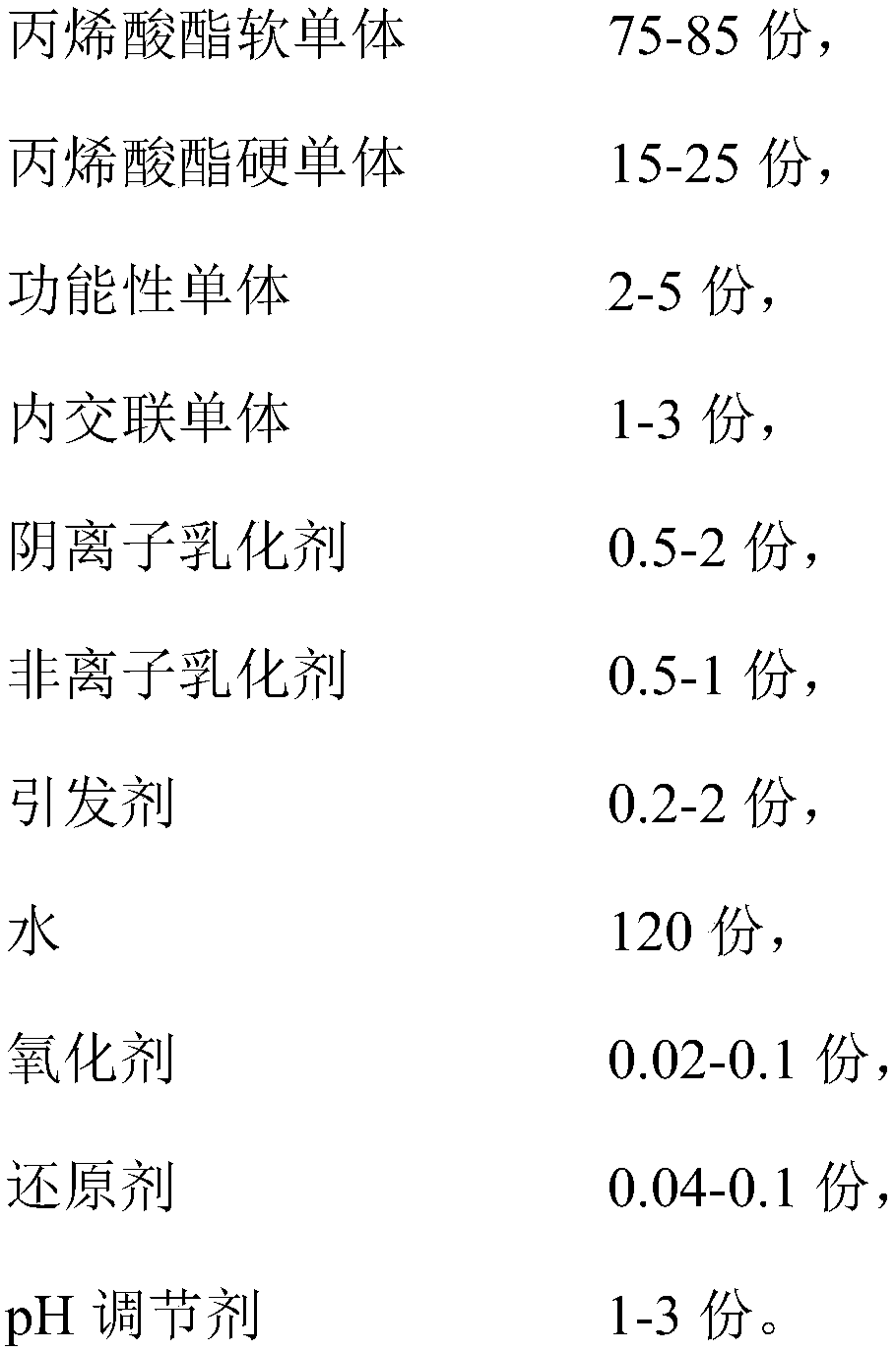

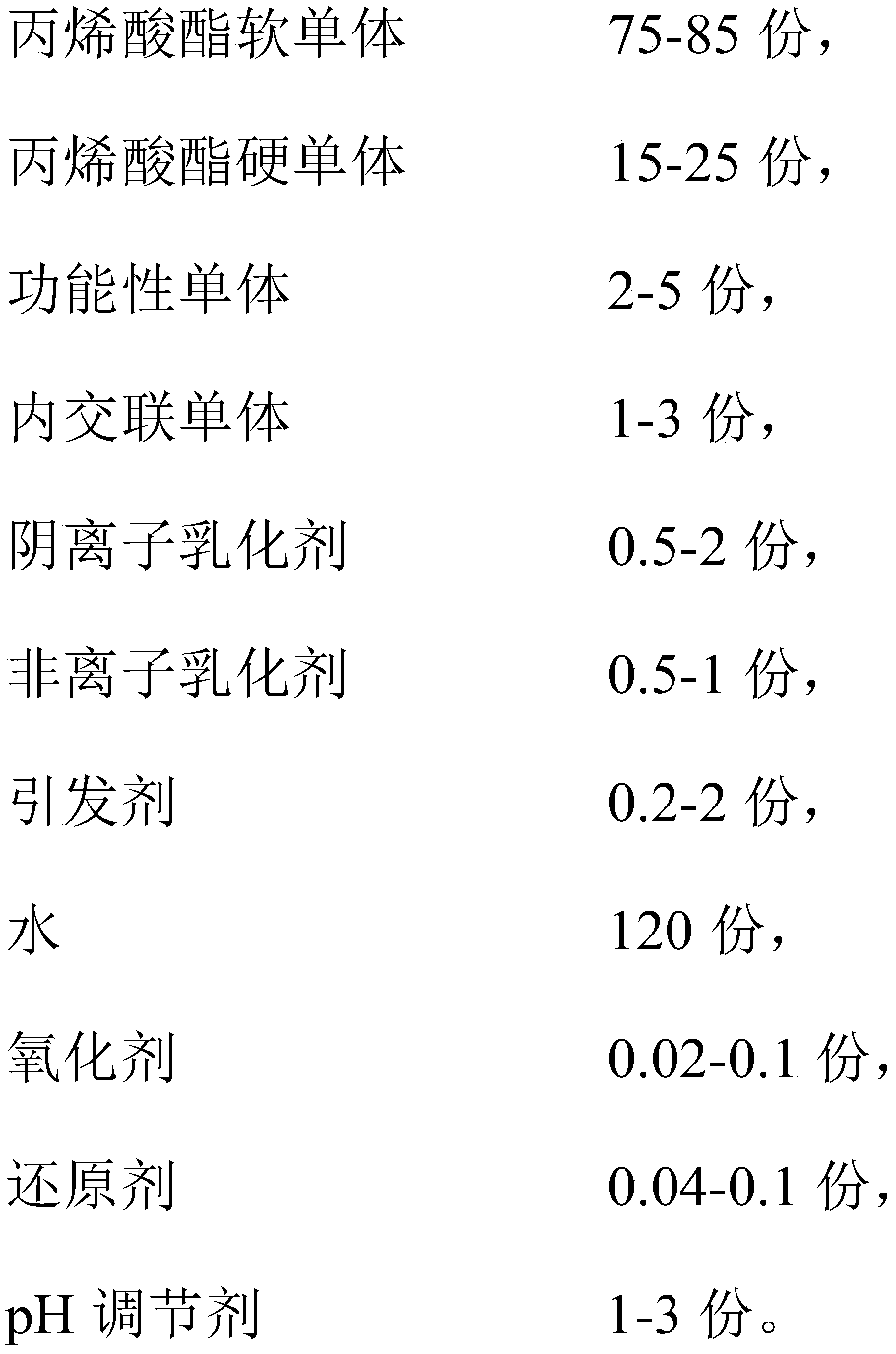

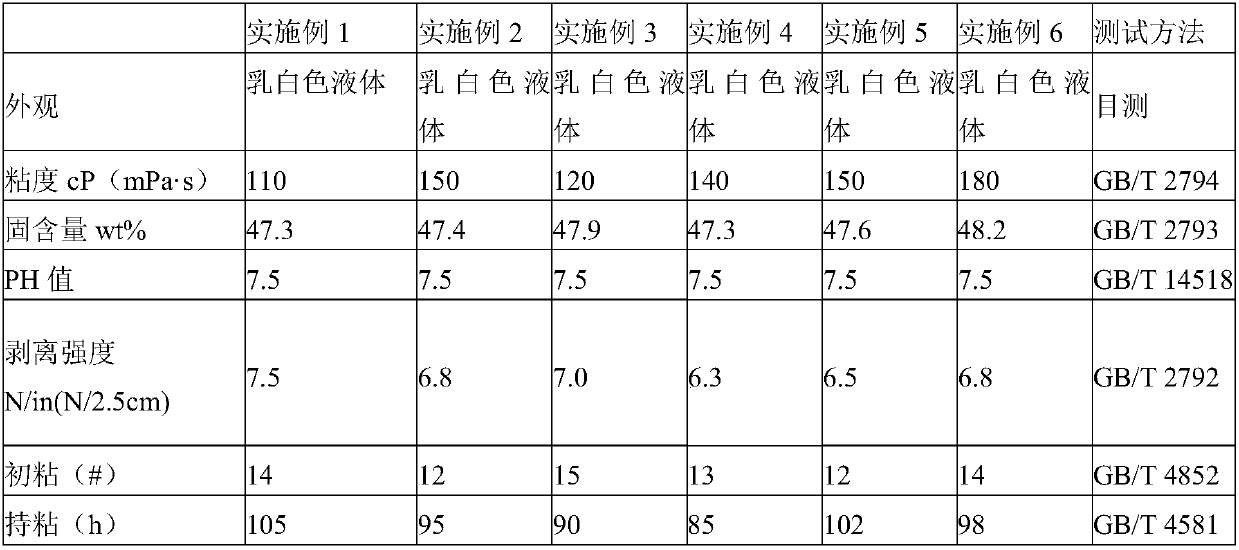

Acrylate pressure sensitive adhesive emulsion of PET substrate for battery packaging, preparation method and application thereof

ActiveCN107603527AHigh fastnessReduce warpingEster polymer adhesivesPressure sensitive film/foil adhesivesFunctional monomerEmulsion

The invention discloses an acrylate pressure sensitive adhesive emulsion of a PET substrate for battery packaging, a preparation method and application thereof. The pressure sensitive adhesive emulsion comprises the following components by weight: 75-85 parts of an acrylate soft monomer, 15-25 parts of an acrylate hard monomer, 2-5 parts of a functional monomer, 1-3 parts of an internal crosslinking monomer, 0.5-2 parts of an anionic emulsifier, 0.5-1 part of a non-ionic emulsifier, 0.1-0.3 part of a buffering agent, 0.02-0.1 part of a defoaming agent, 0.02-0.08 part of a wetting agent, 0.02-2parts of an initiator, 120 parts of water, 0.02-0.1 part of an oxidant, 0.04-0.1 part of a reducing agent, and 1-3 parts of a pH regulator. The pressure sensitive adhesive emulsion provided by the invention has good mechanical properties, can reduce the warping and cracking probability of the PET substrate and ensure the adhesive durability, and is green, low-carbon and environment-friendly.

Owner:WUXI HAITE NEW MATERIAL RES INST +1

Anti-seepage acid-resisting concrete and preparation method thereof

The invention provides anti-seepage acid-resisting concrete and a preparation method thereof. The anti-seepage acid-resisting concrete is prepared from the following components in parts by weight: 380 to 470 parts of cement, 530 to 630 parts of quartz sand, 800 to 900 parts of basalt, 175 to 190 parts of water, 30 to 40 parts of coal gangue micro powder, 70 to 80 parts of coal ash, 60 to 70 parts of silica fume, 280 to 330 parts of water glass, 200 to 250 parts of synthetic cement, 35 to 45 parts of sodium fluosilicate, 5 to 9 parts of hollow glass fiber and 8.1 to 12.2 parts of additive; the preparation method of the anti-seepage acid-resisting concrete adopts a manner of adding materials in batches, and the stirring time is reasonably adjusted; the anti-seepage acid-resisting concrete provided by the invention is reasonable in component matching structure, the preparation method is simple and effective, and the problems of seepage resistance and acid resistance of concrete are effectively solved.

Owner:邢台建工商品混凝土有限公司

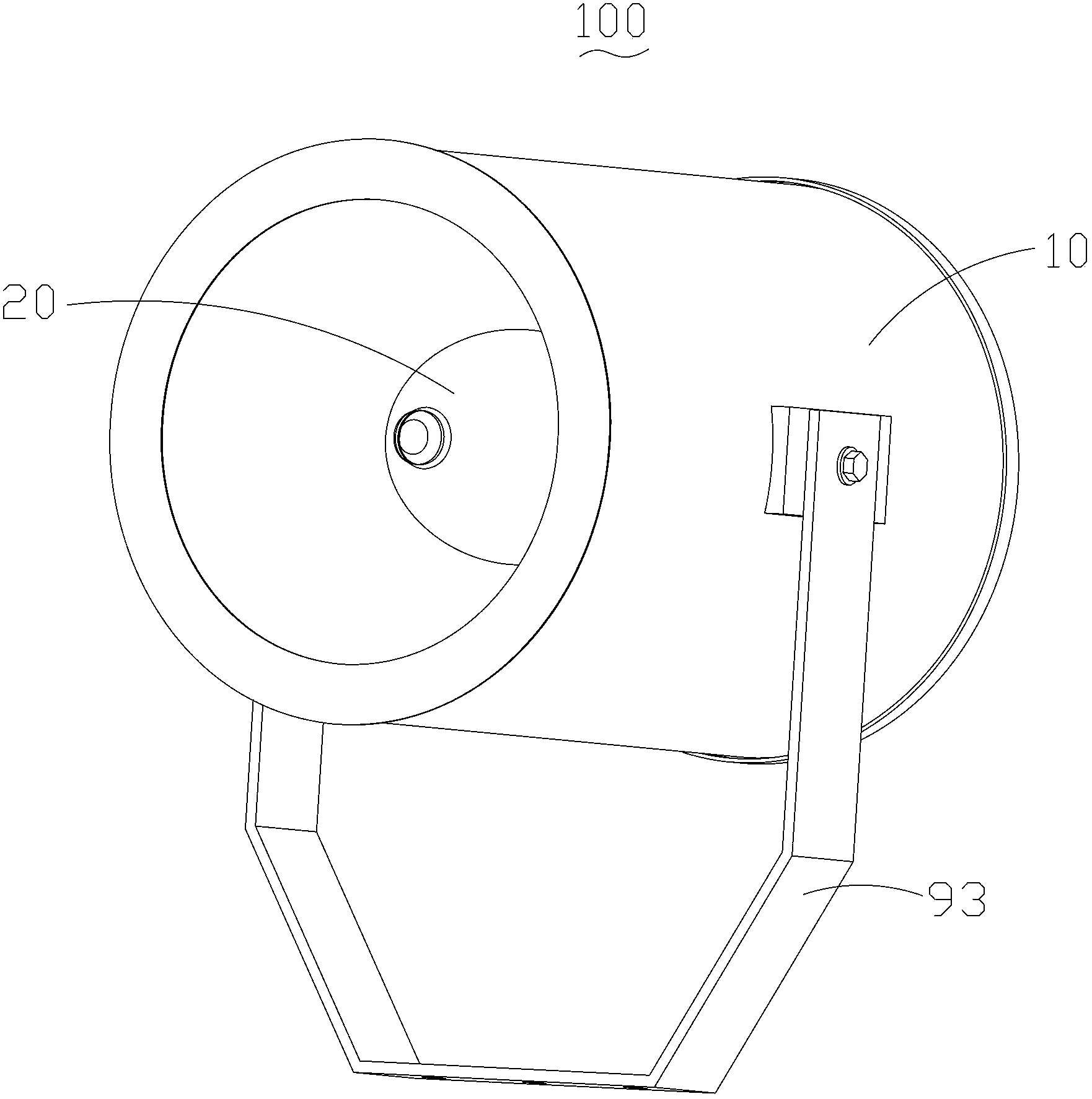

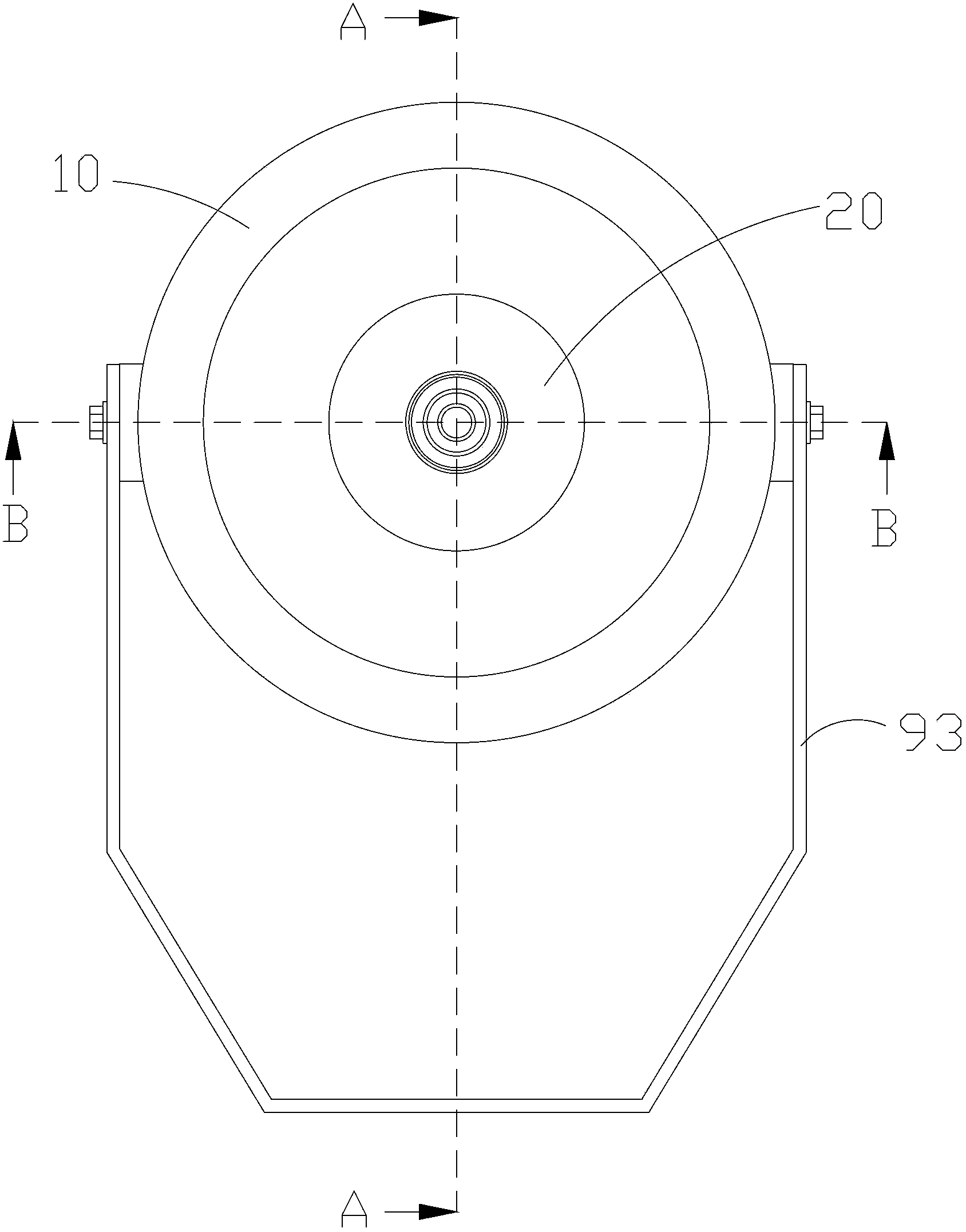

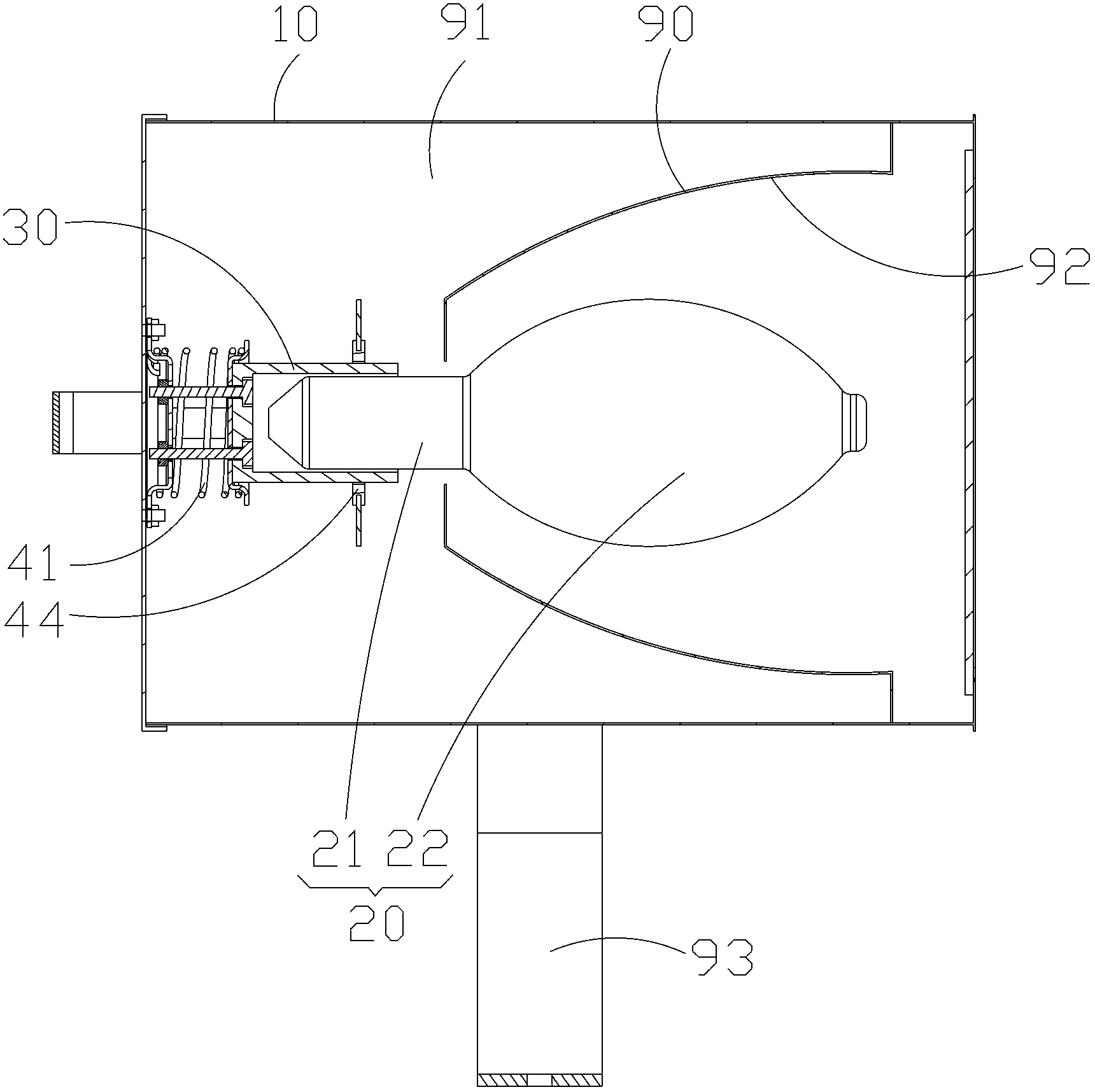

Damping lamp and damping lamp base

ActiveCN103453480AReduce destructive effectsExtend your lifeLighting support devicesProtective devices for lightingLamp shellEngineering

The invention provides a damping lamp base comprising a base body and a damping device connected to the base body. The damping device comprises a damping element disposed between the bottom of the base body and a lamp shell, a limit plate for sleeving the outside of the base body, a support, and an elastic hoop, wherein the support which supports the limit plate is used for fixing the limit plate on the lamp shell, and the elastic hoop for sleeving the outside of the base body is located between the limit plate and the outer surface of the base body. The invention further provides a damping lamp comprising the lamp shell, the damping lamp base installed inside the lamp shell, and a light source installed inside a base body of the damping lamp base. The damping element and the elastic hoop allow the base body and the light source to suffer less destructive influence of external vibration; the base body and the light source are protected; external vibration is reduced to the range acceptable to the base body and the light source; luminous effect of the lamp is improved, and the service lives of the base body and the light source are prolonged.

Owner:OCEANKING DONGGUAN LIGHTING TECH +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com