Integral cast steel dredge bucket

An integral, cast steel technology, applied in the direction of casting mold, casting mold composition, casting molding equipment, etc., can solve problems such as cracking, failure of steel plate connection, deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

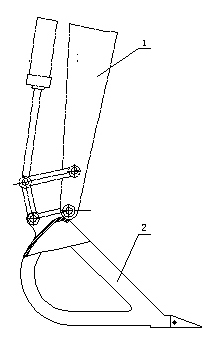

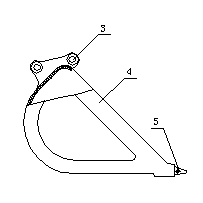

[0020] The integral cast steel bucket of the present invention is composed of bucket ears 3, bucket body 4 and tooth seat 5, which are manufactured as a whole by casting method. When the bucket 2 is in use, the bucket ear 3 is connected to one end of the forearm 1 of the excavator (see figure 1 shown).

[0021] The manufacturing method of described monolithic cast steel bucket is:

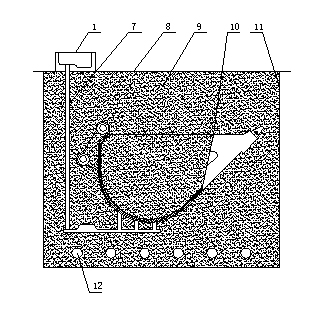

[0022] a. Manufacture the model 10 according to the shape of the bucket, and the model 10 is made of polystyrene material, which is what we usually call the lost foam;

[0023] b. Brush the refractory paint on the surface of the model 10, and form a hard shell after drying;

[0024] c. Put the model 10 and the pouring system 6, 7 into the sand box 11 at the same time, fill in the dry sand 9, vibrate, and cover the plastic film 8 on the top of the sand box 11;

[0025] d. Start the vacuum pump to empty the air in the sand box 11 through the vacuum pipeline 12, so that the dry sand 9 has a certain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com