Patents

Literature

30326 results about "Vacuum pump" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A vacuum pump is a device that removes gas molecules from a sealed volume in order to leave behind a partial vacuum. The first vacuum pump was invented in 1650 by Otto von Guericke, and was preceded by the suction pump, which dates to antiquity.

Method for sterilizing medical appliance

InactiveCN1634601AAvoid influenceImprove sterilization effectDiagnosticsSurgeryVacuum pressureMicrowave

A medical instrument sterilization method is disclosed, which characterizes in following process: pending medical instrument for sterilization treatment being placed in a closed container, then being vacuum pumped, the vacuum pressure of the container being controlled between 1 Pa to 1500 Pa, air and / or oxygen and / or inert gases are charged to closed container and the vacuum pressure being between 1 Pa to 1500 Pa, microwave is fed, the favorable power of which should make the gas charged into the container to generate ionization, the microwave be cut after the sterilization, then air being charged to release vacuum to finish the whole process.

Owner:吉林省中立实业有限公司

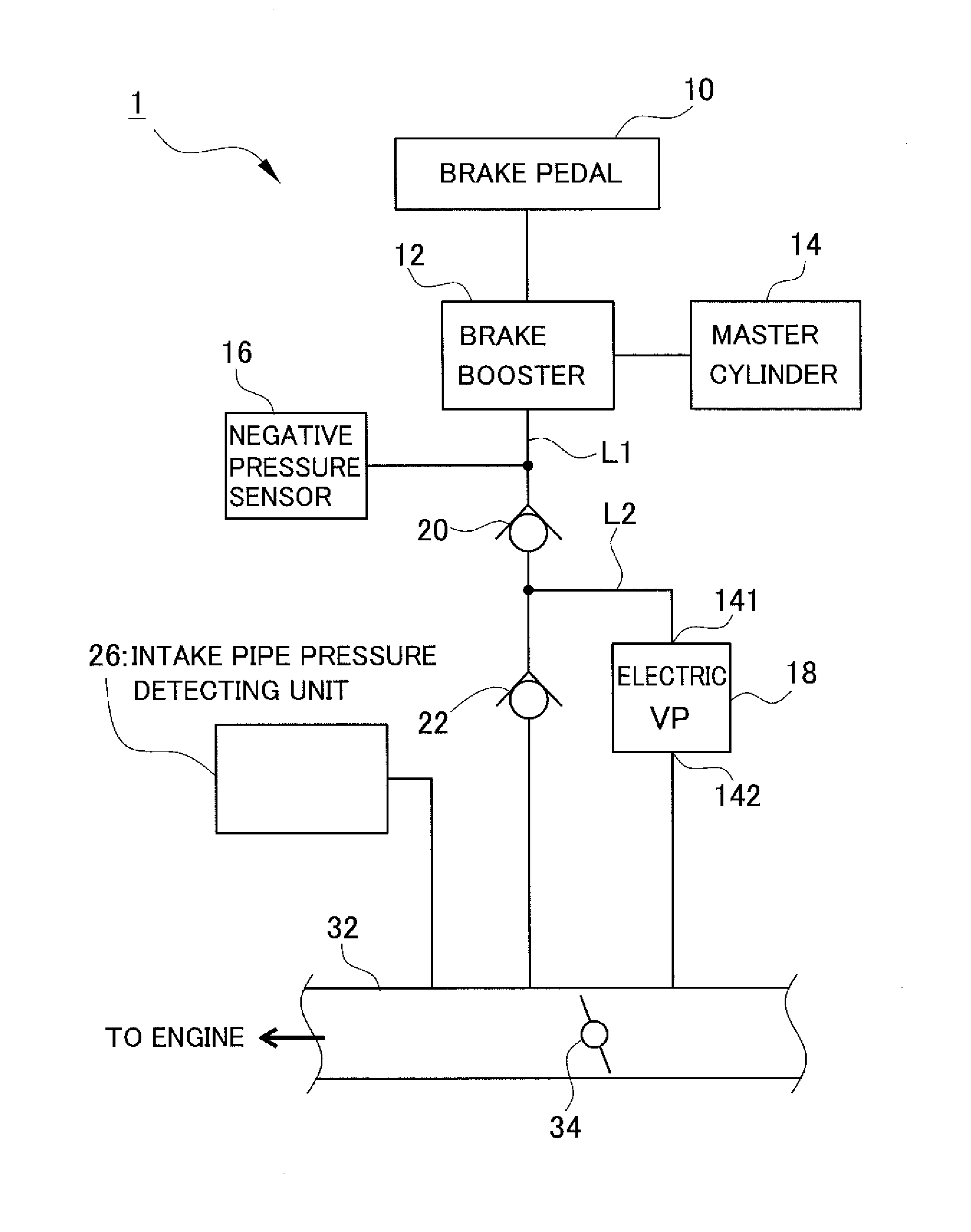

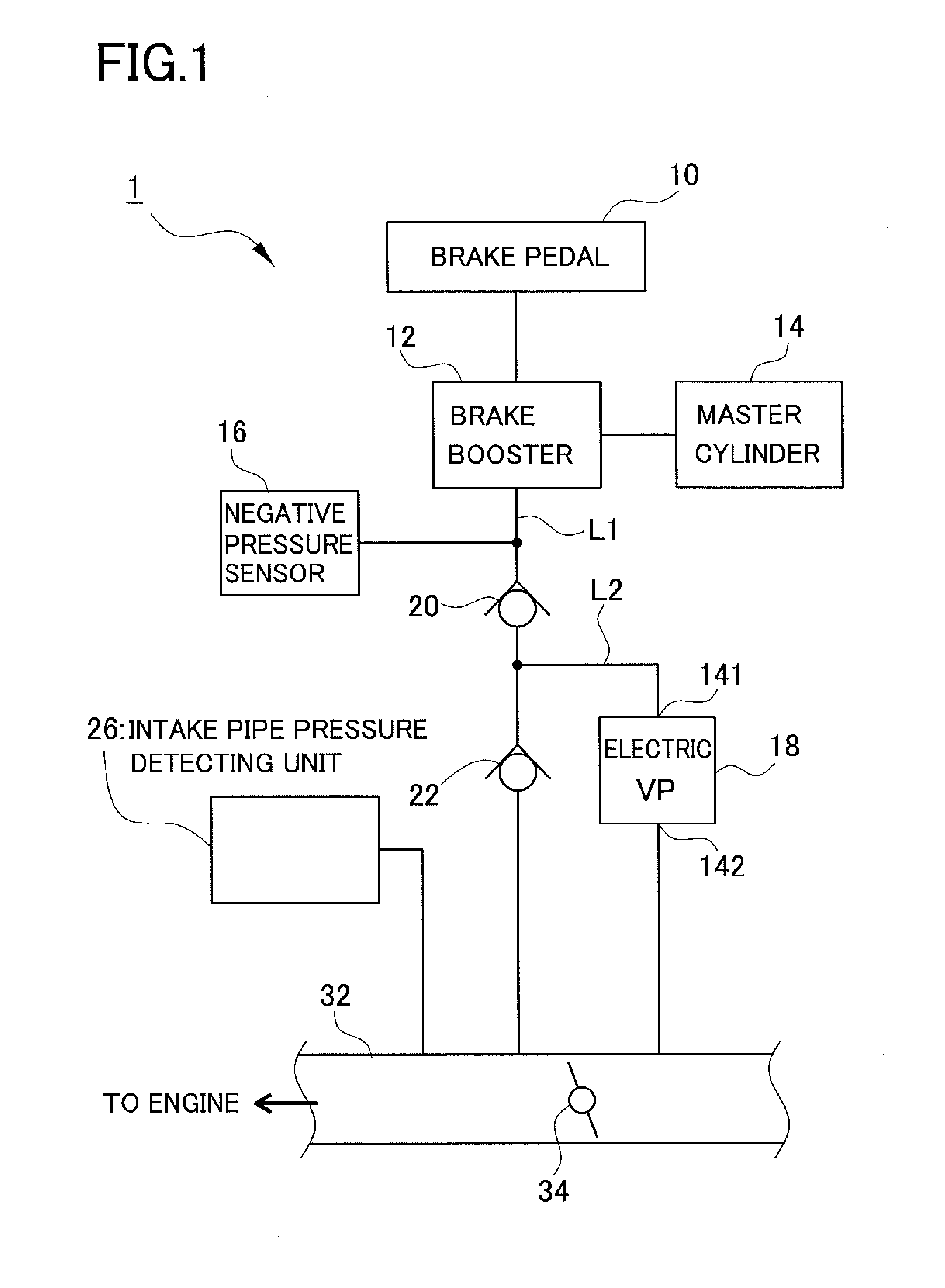

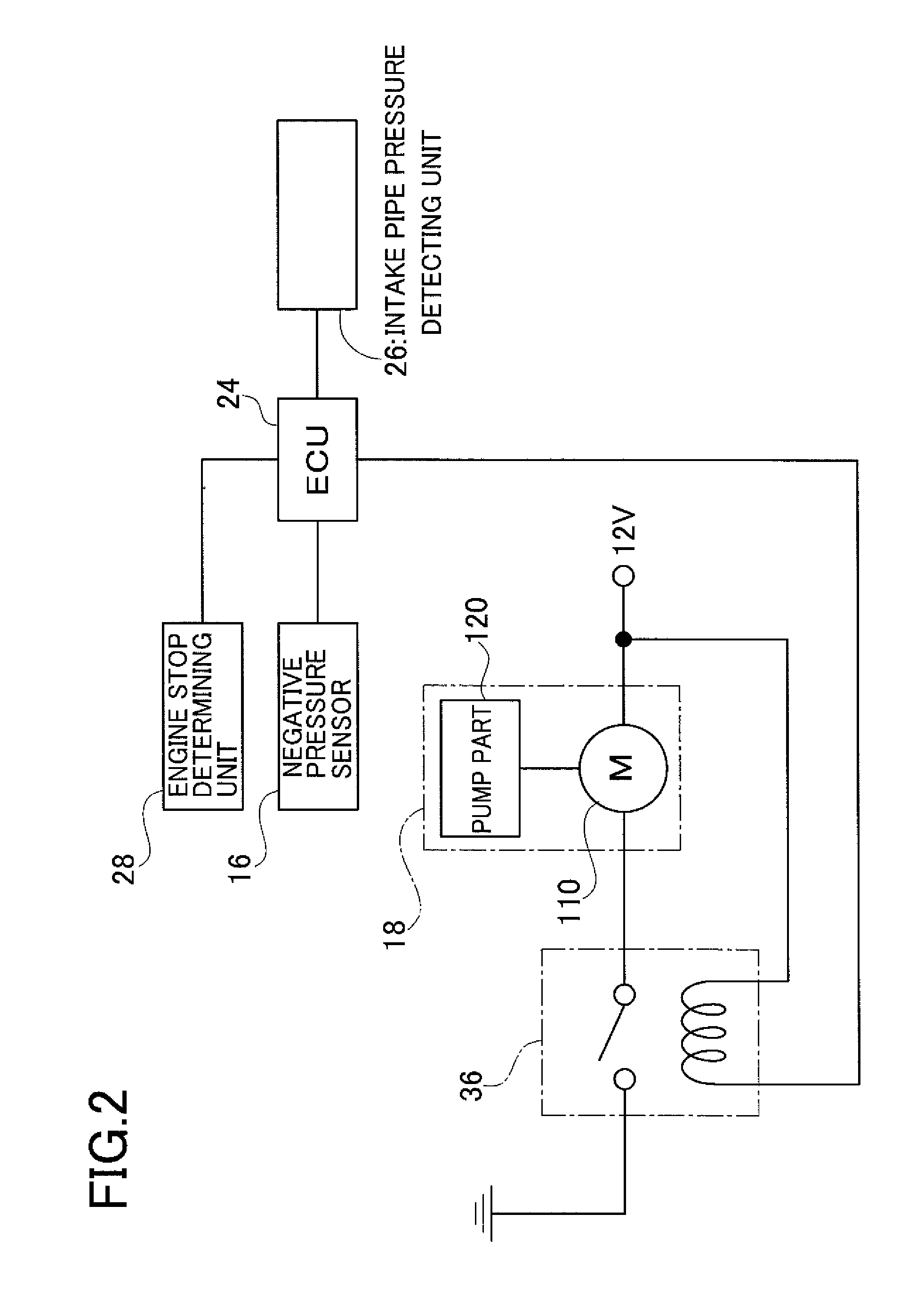

Electric vacuum pump

InactiveUS20140248167A1Small sizeImprove accuracyRotary piston pumpsRotary piston liquid enginesEngineeringVacuum pump

In an electric vacuum pump, a pump housing and a lower-end cover member respectively include positioning retainers respectively formed on outer peripheries of the pump housing and the lower-end cover member. A case includes positioning retainers each protruding inward from an inner peripheral surface of the case. The positioning retainers are in contact with the positioning protrusions, thereby positioning the pump housing and the lower-end cover member with respect to the case. The positioning protrusions are formed with screw holes.

Owner:AISAN IND CO LTD

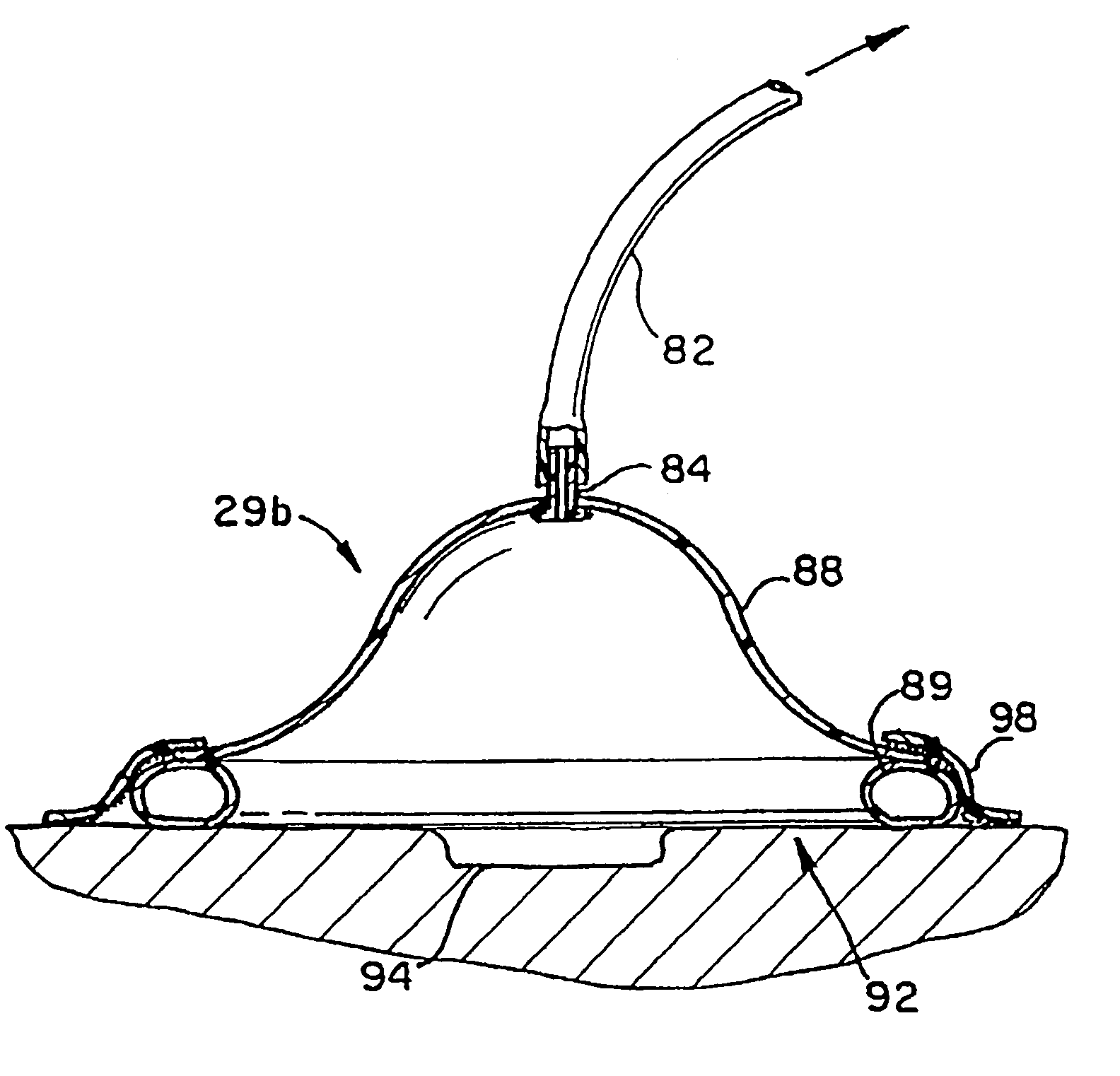

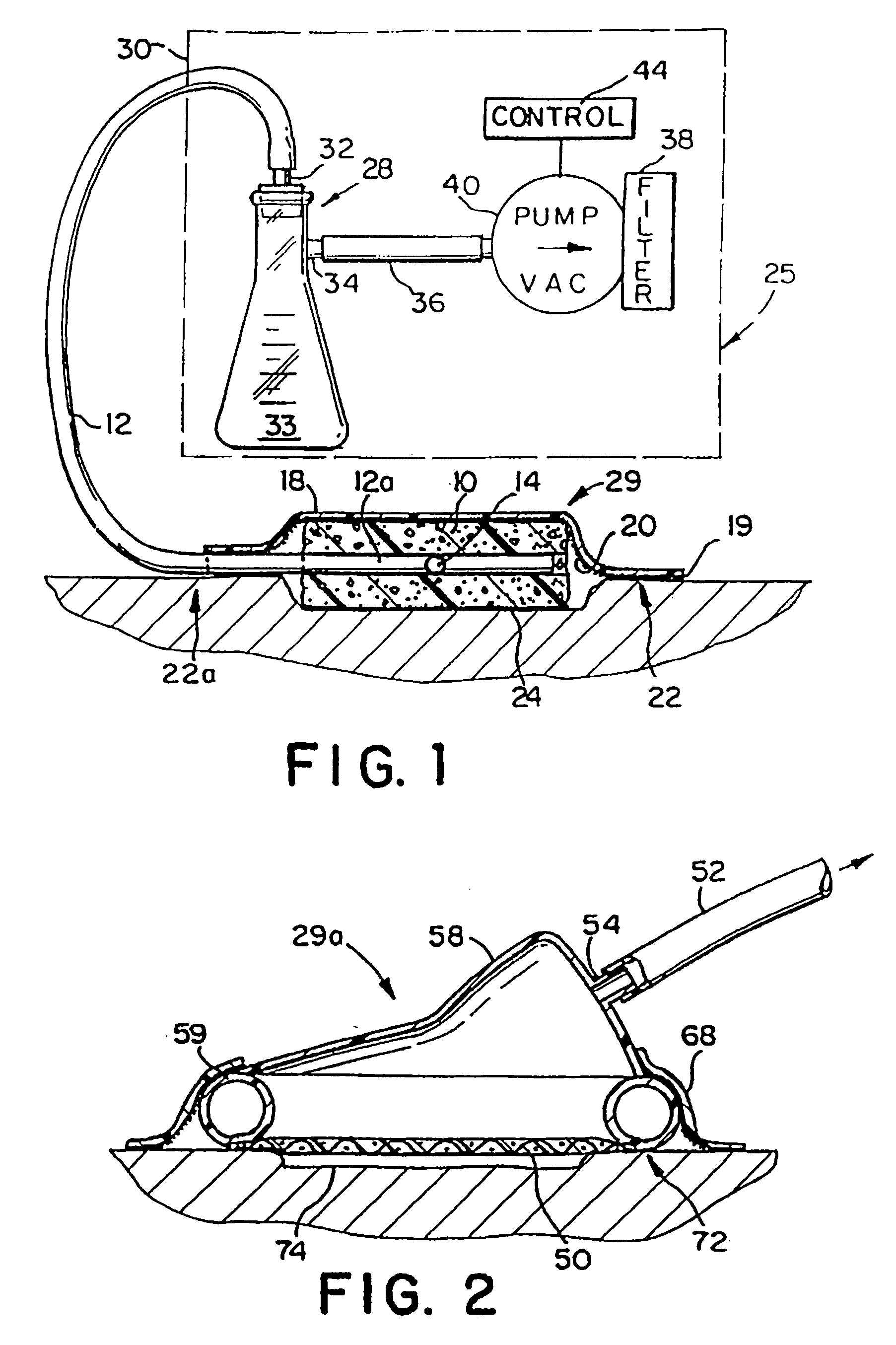

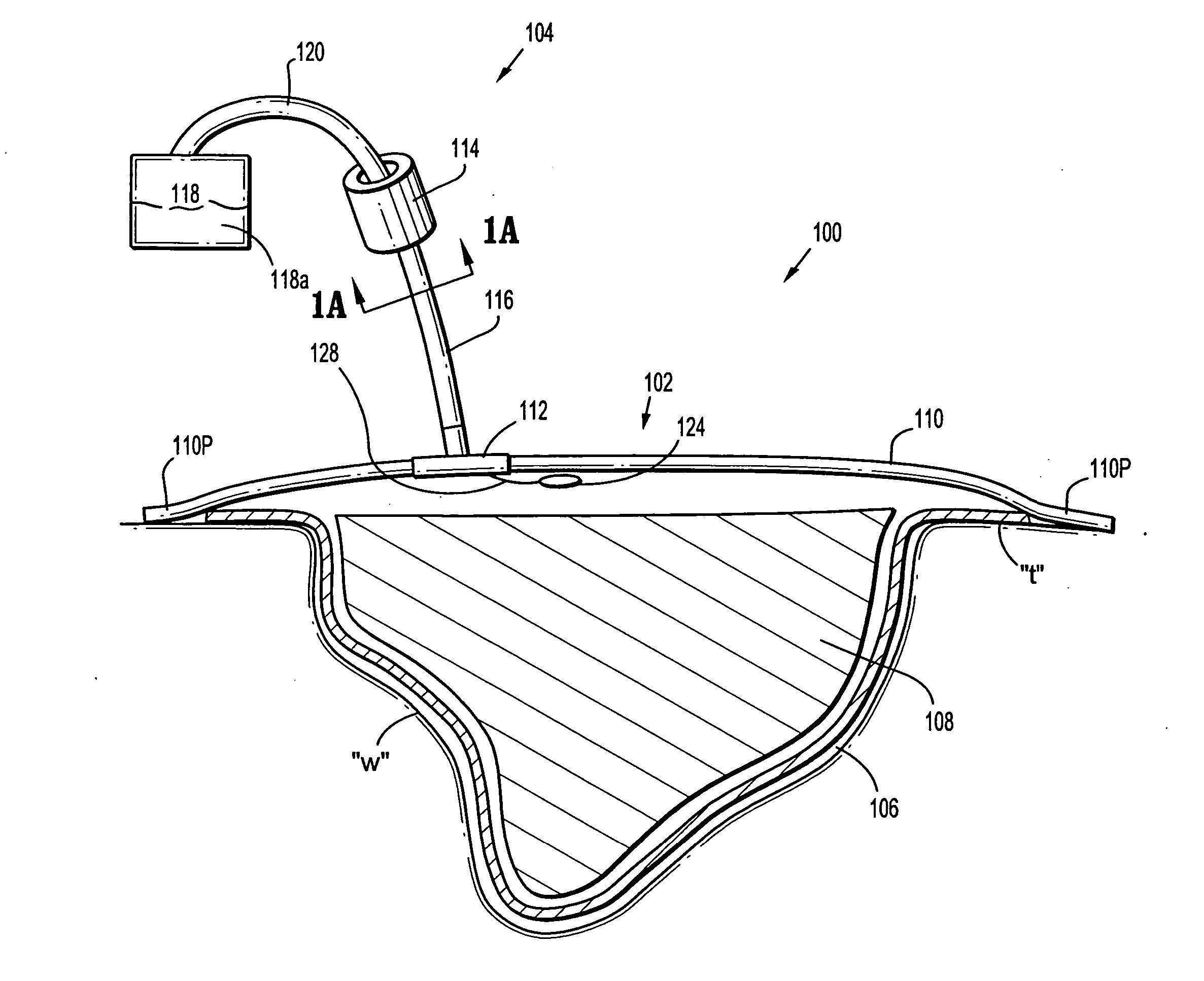

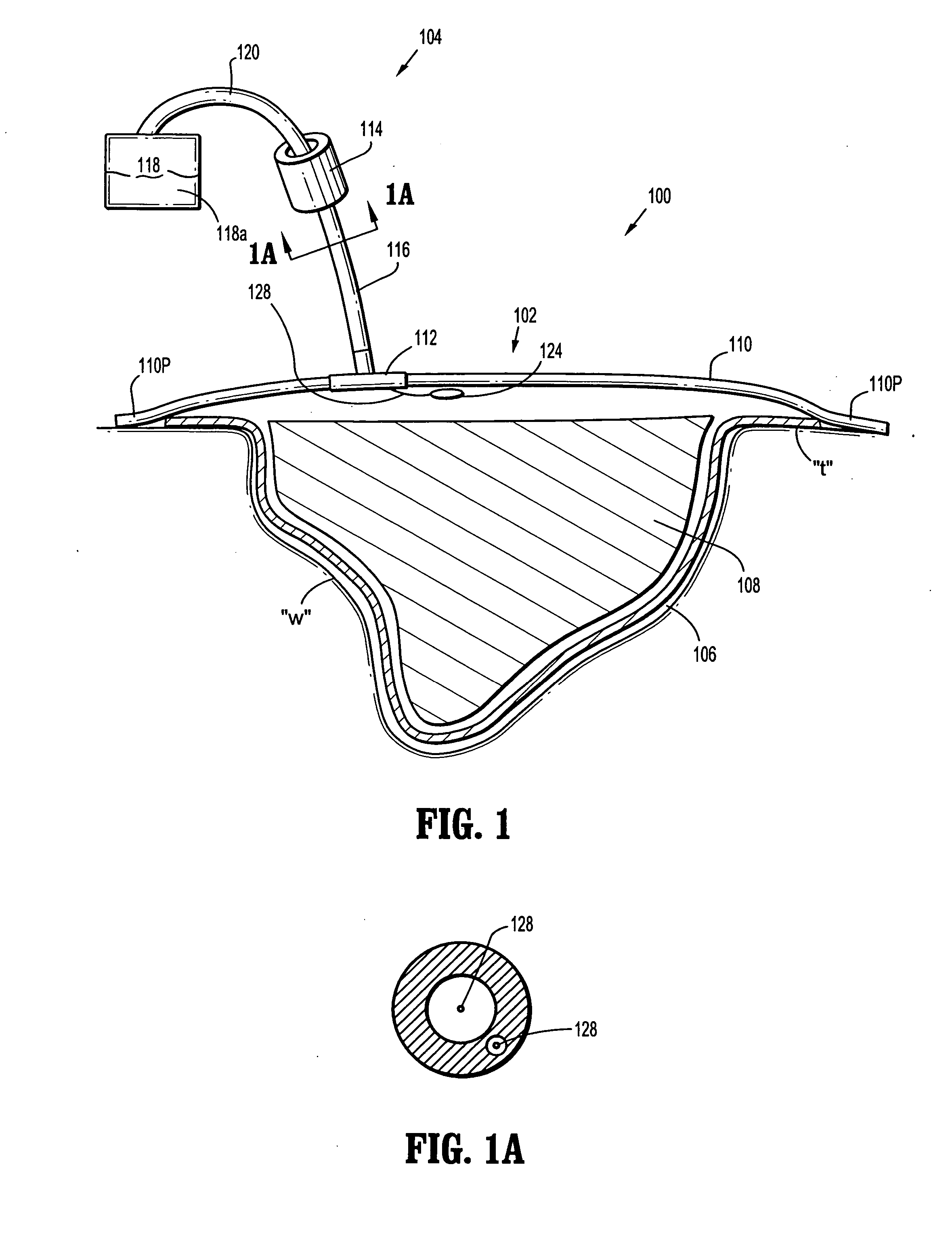

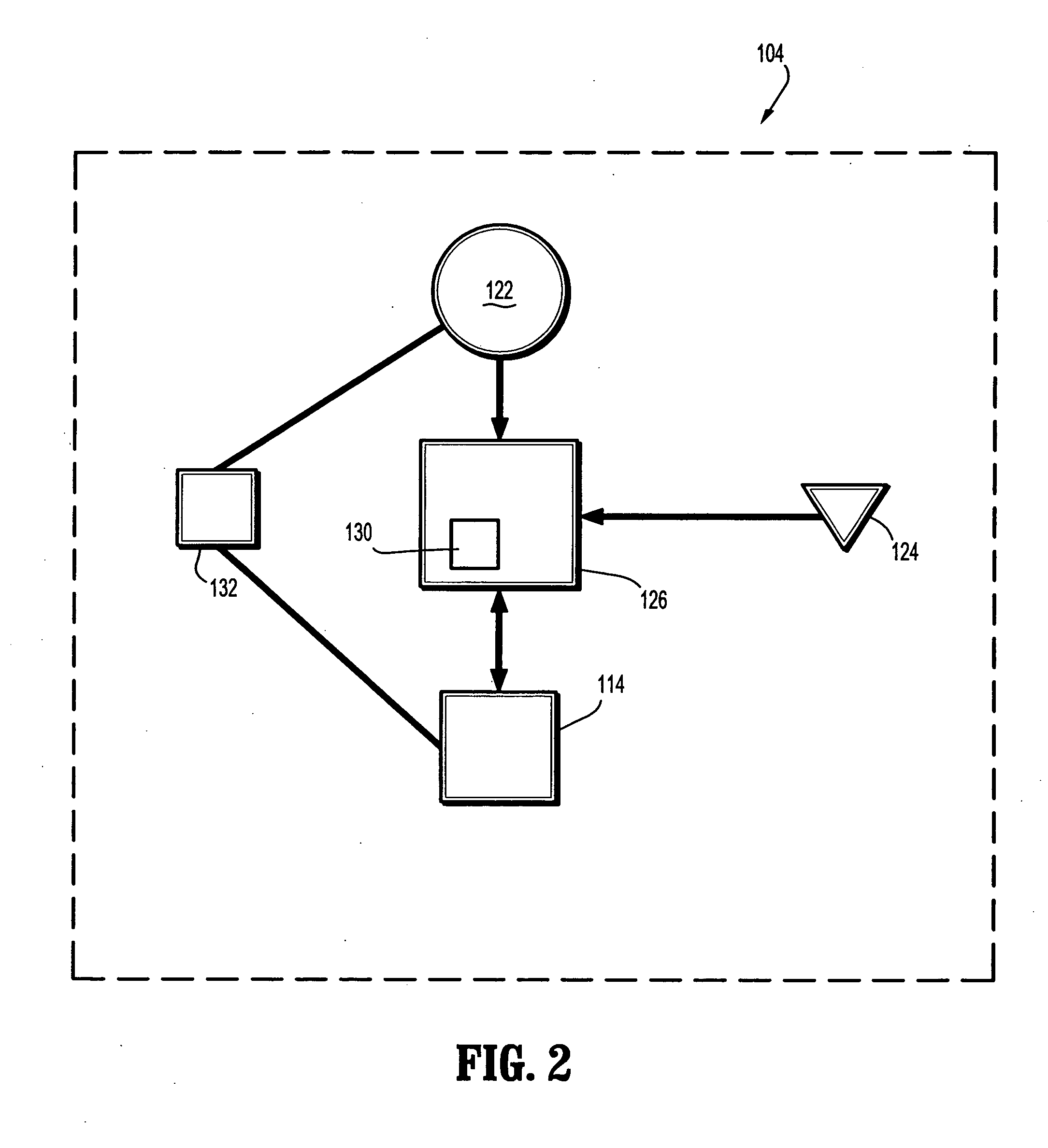

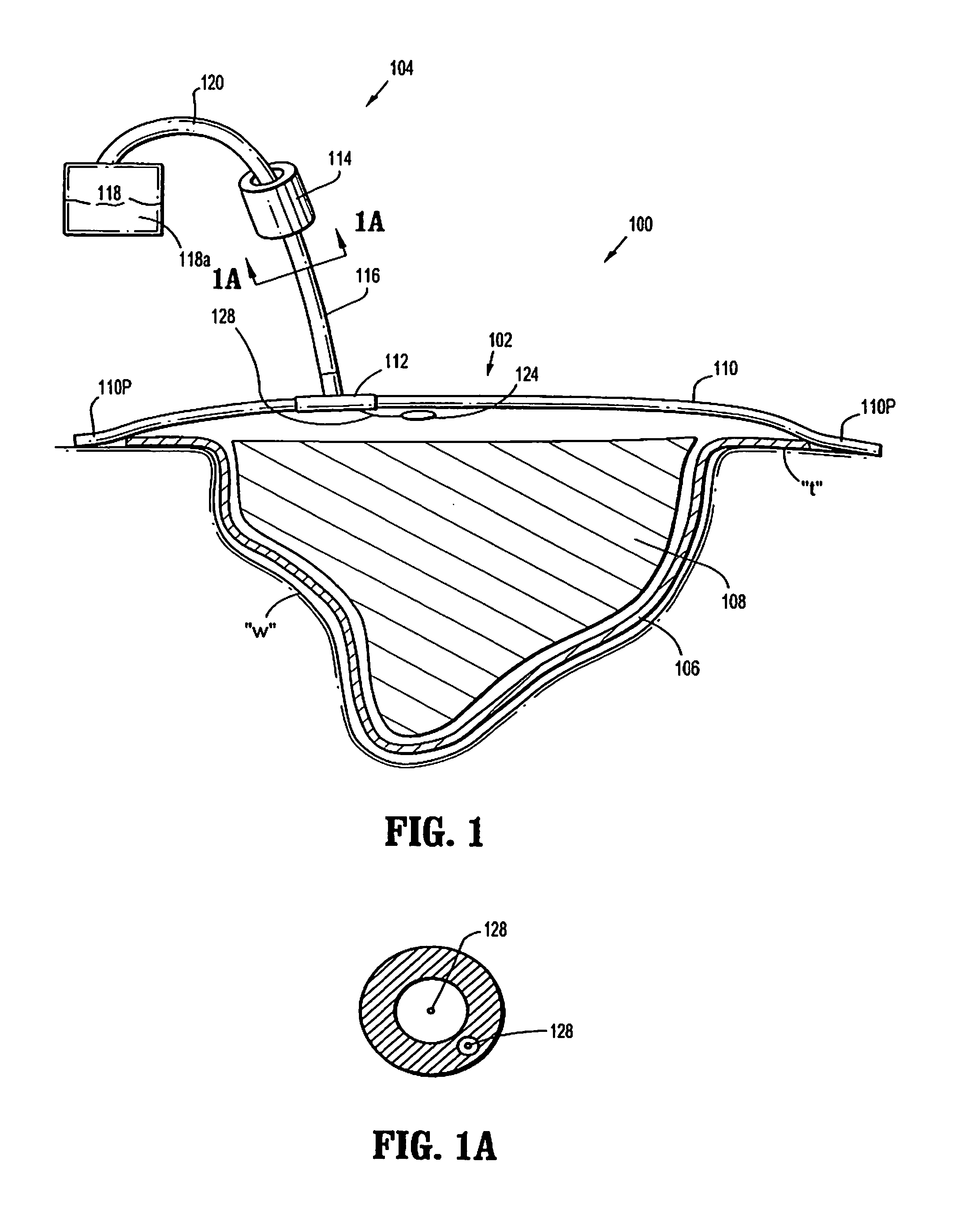

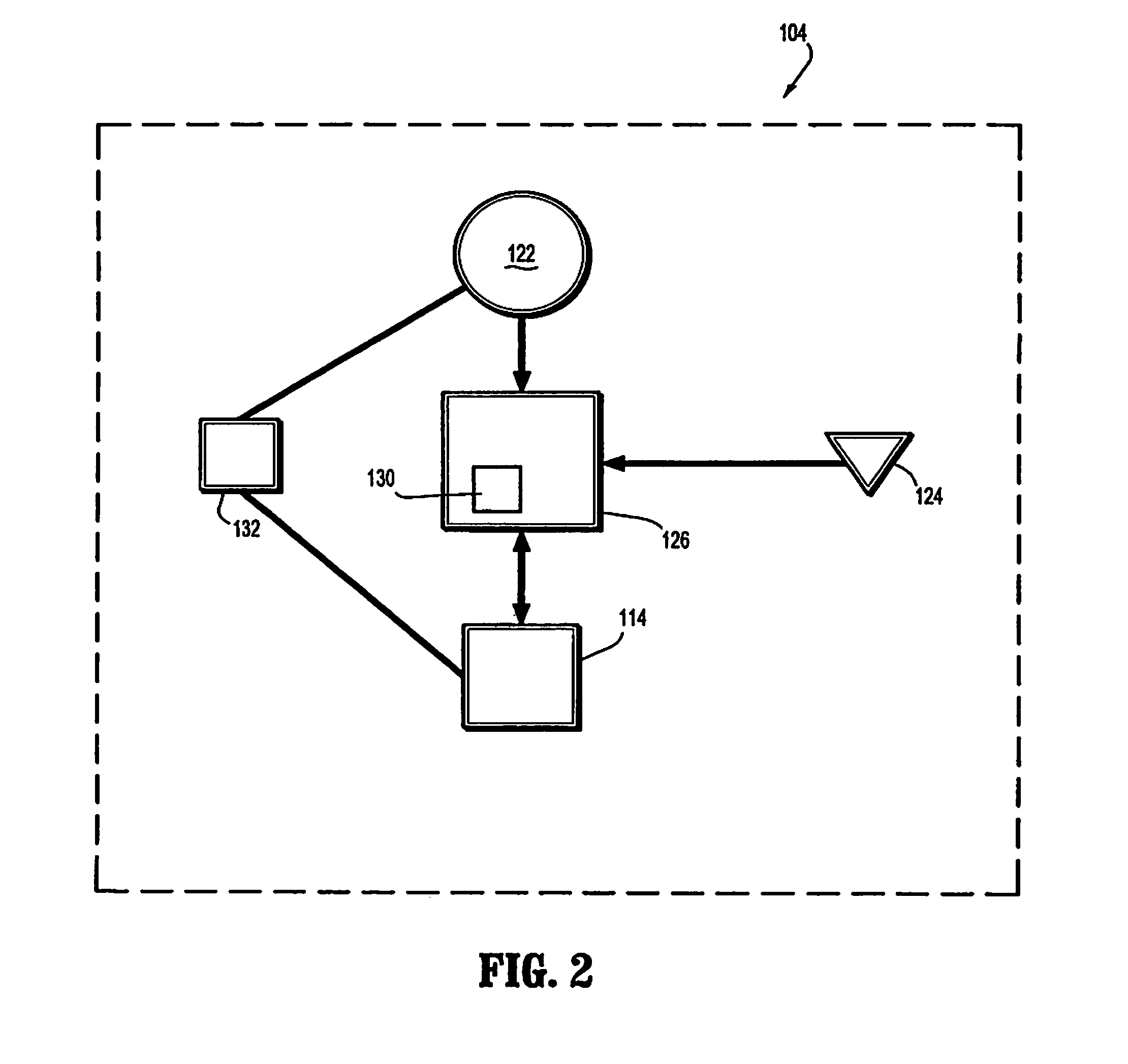

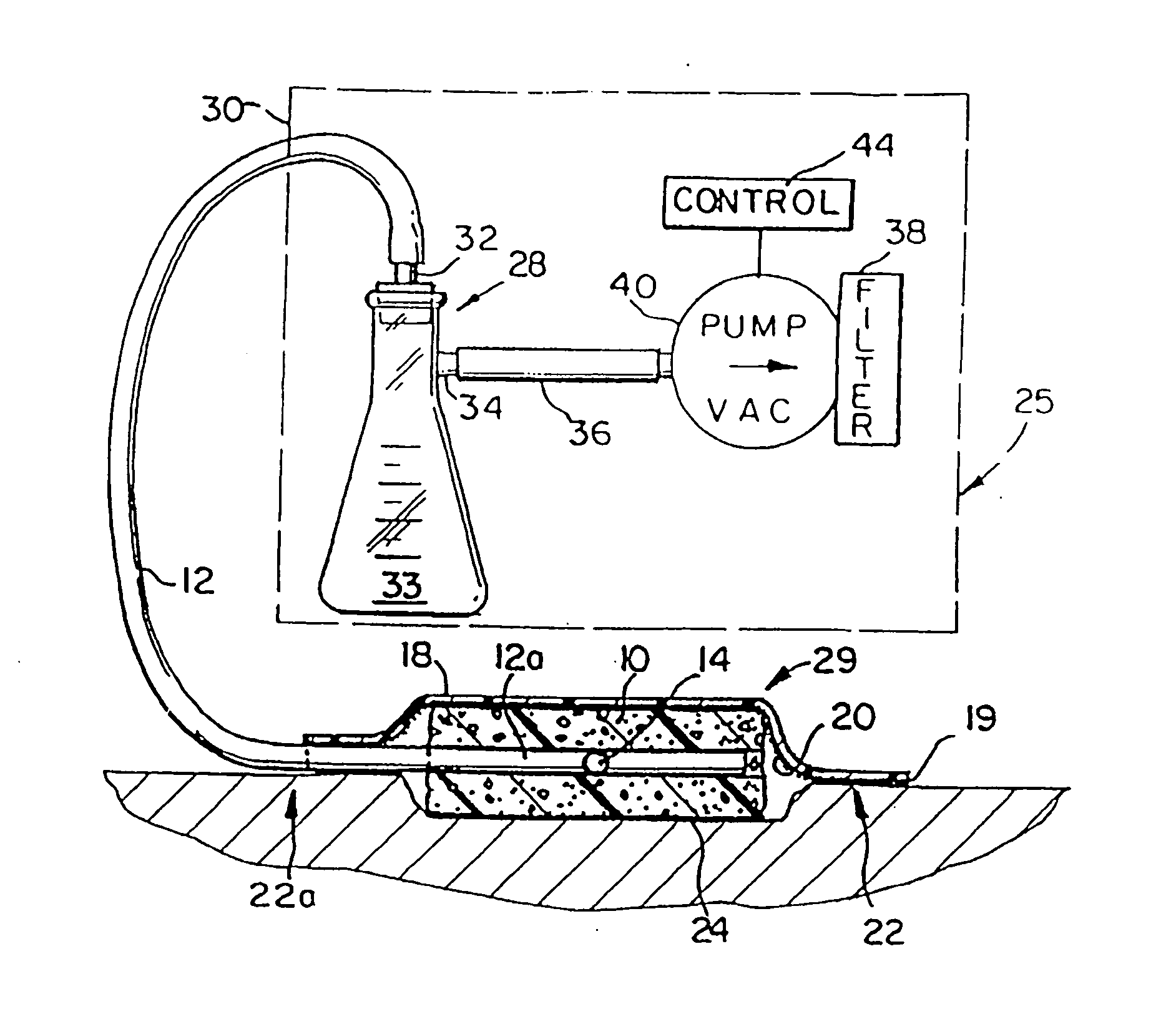

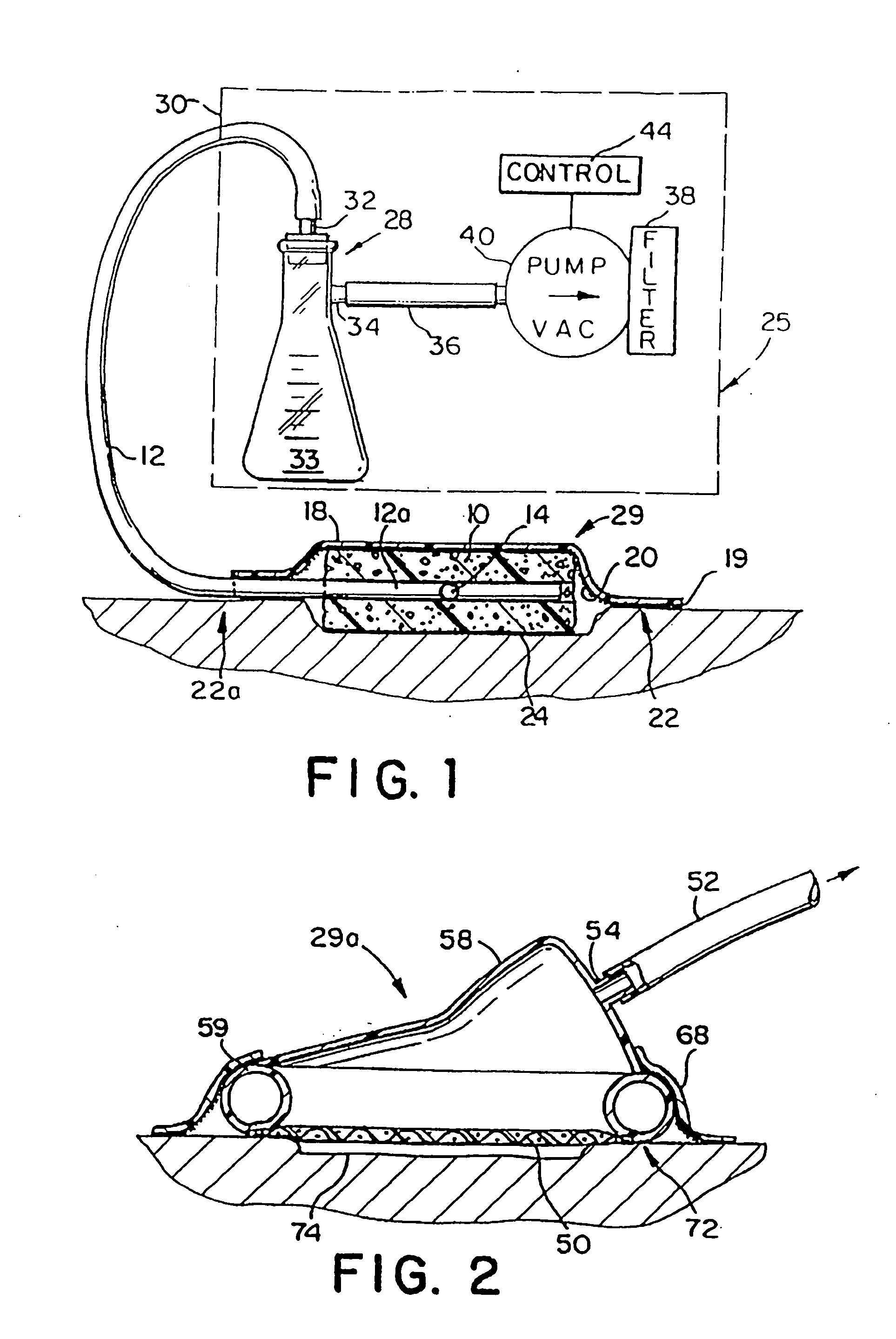

Wound treatment employing reduced pressure

InactiveUS7216651B2Reduce pressureIncreased formationDiagnosticsRespiratory masksWound siteVacuum pump

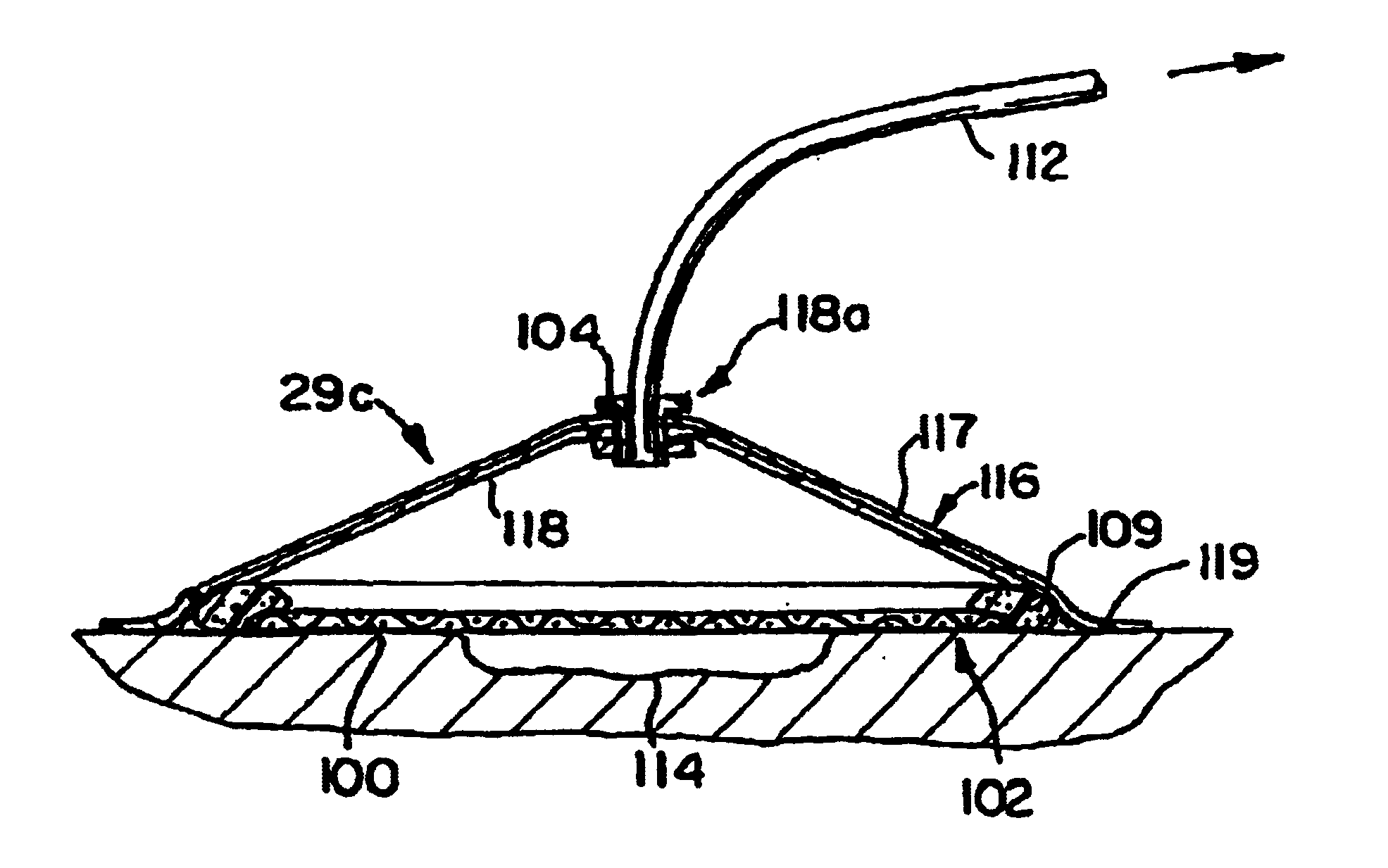

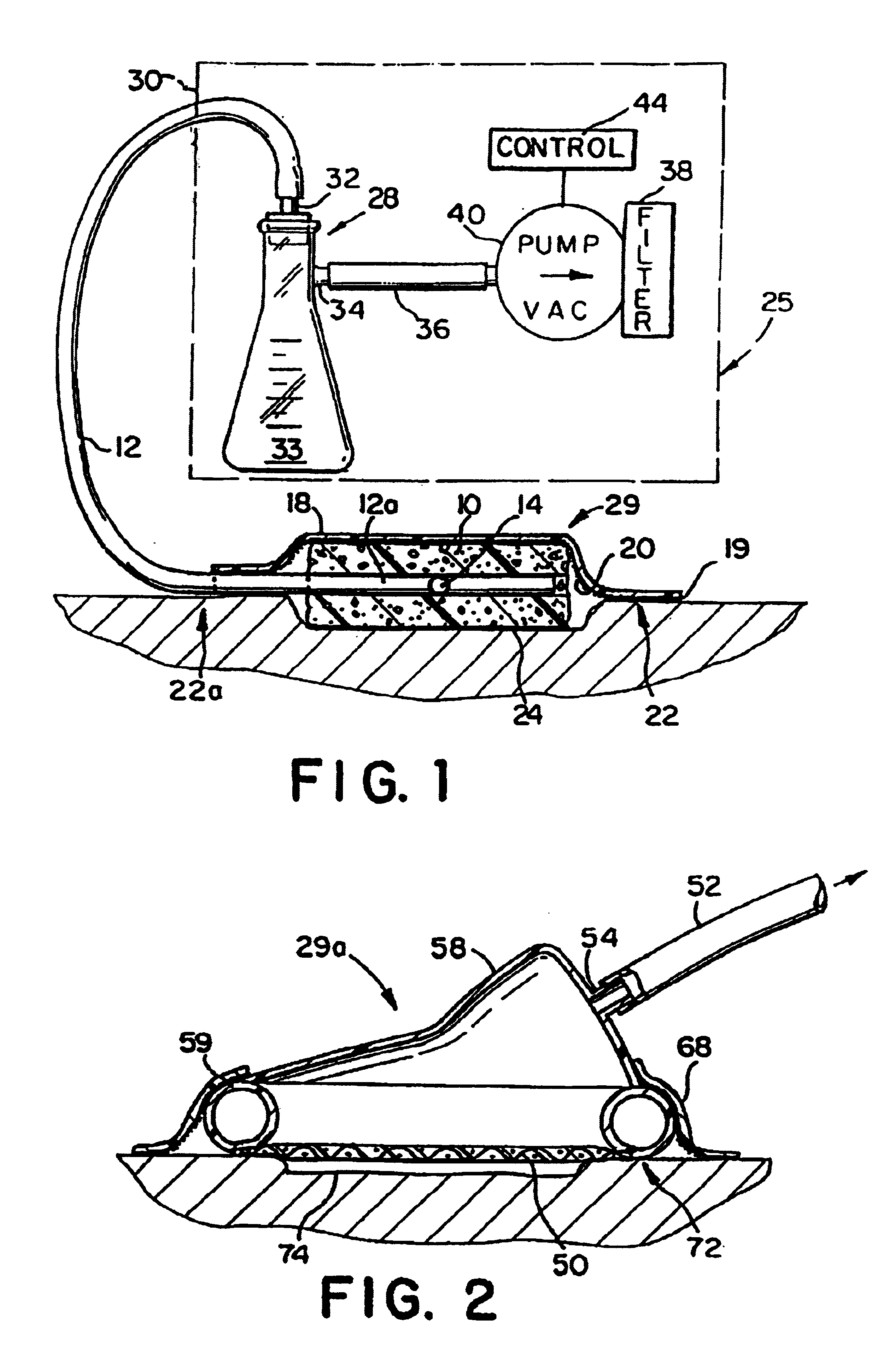

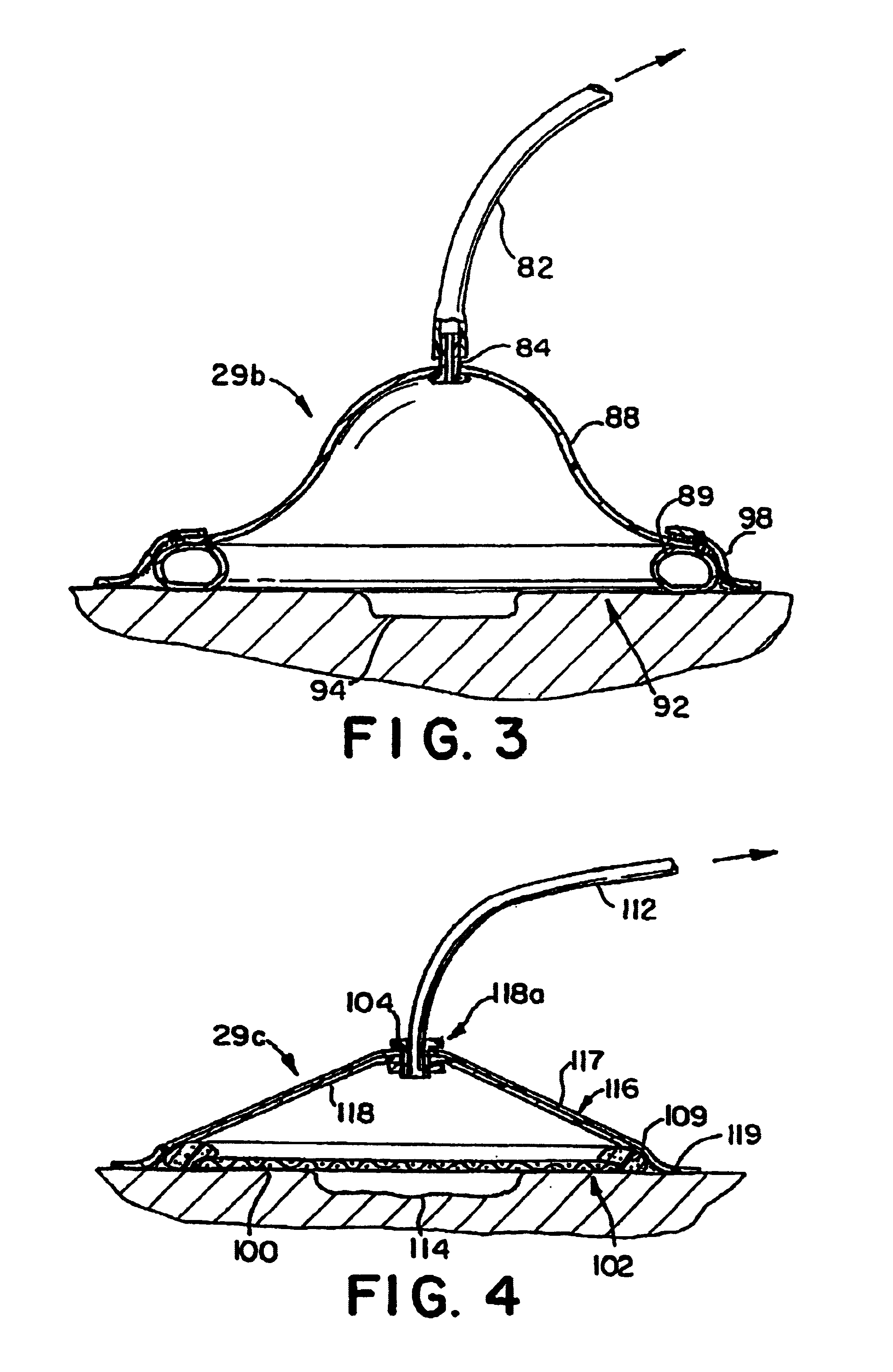

A method of treating tissue damage comprises applying a negative pressure to a wound sufficient in time and magnitude to promote tissue migration and thus facilitate closure of the wound. The method is applicable to wounds, burns, infected wounds, and live tissue attachments. A wound treatment apparatus is provided in which a fluid impermeable wound cover is sealed over a wound site. A screen in the form of an open-cell foam screen or a rigid porous screen is placed beneath the wound cover over the wound. A vacuum pump supplies suction within the wound cover over the treatment site.

Owner:WAKE FOREST UNIV HEALTH SCI INC

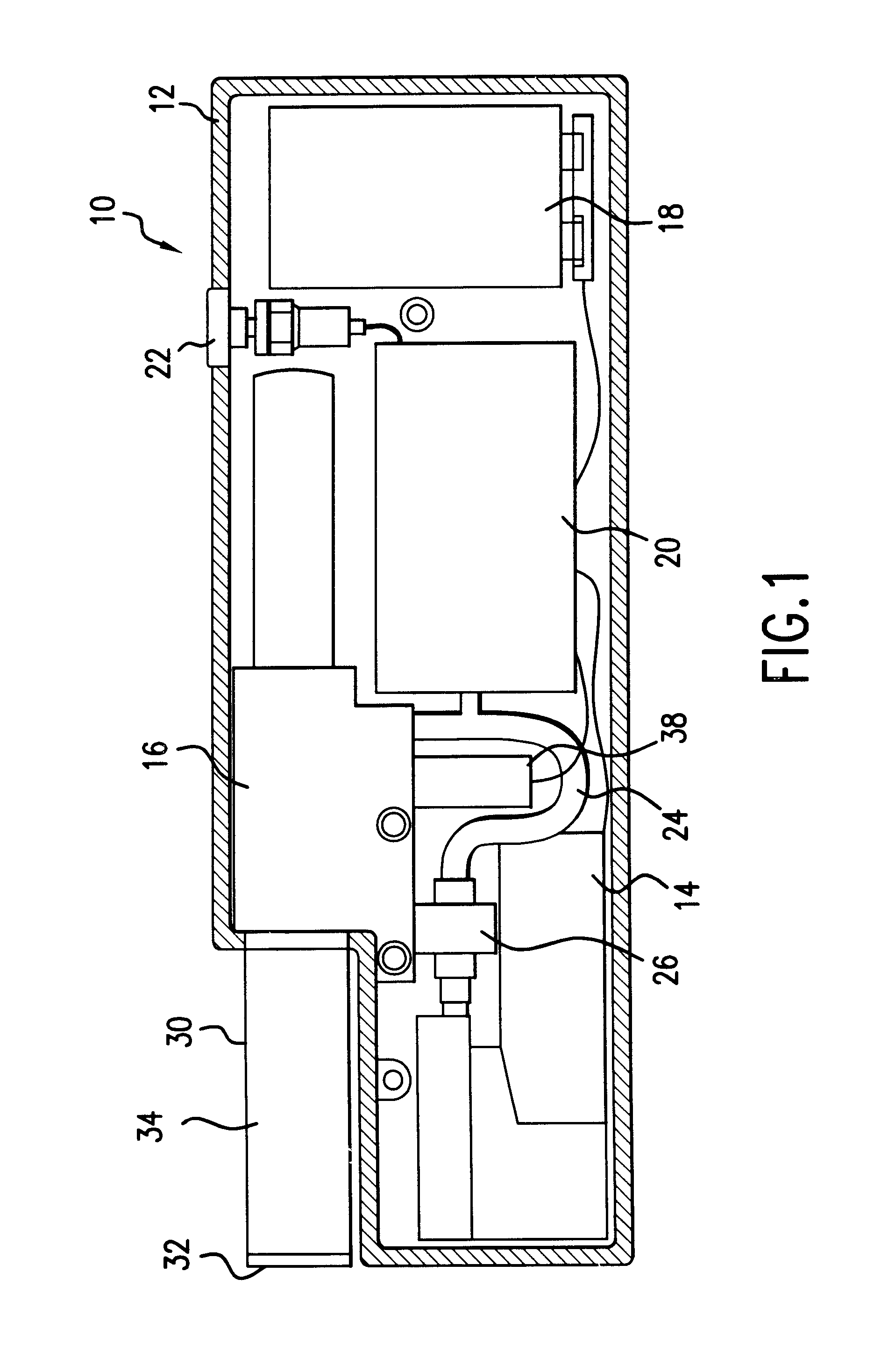

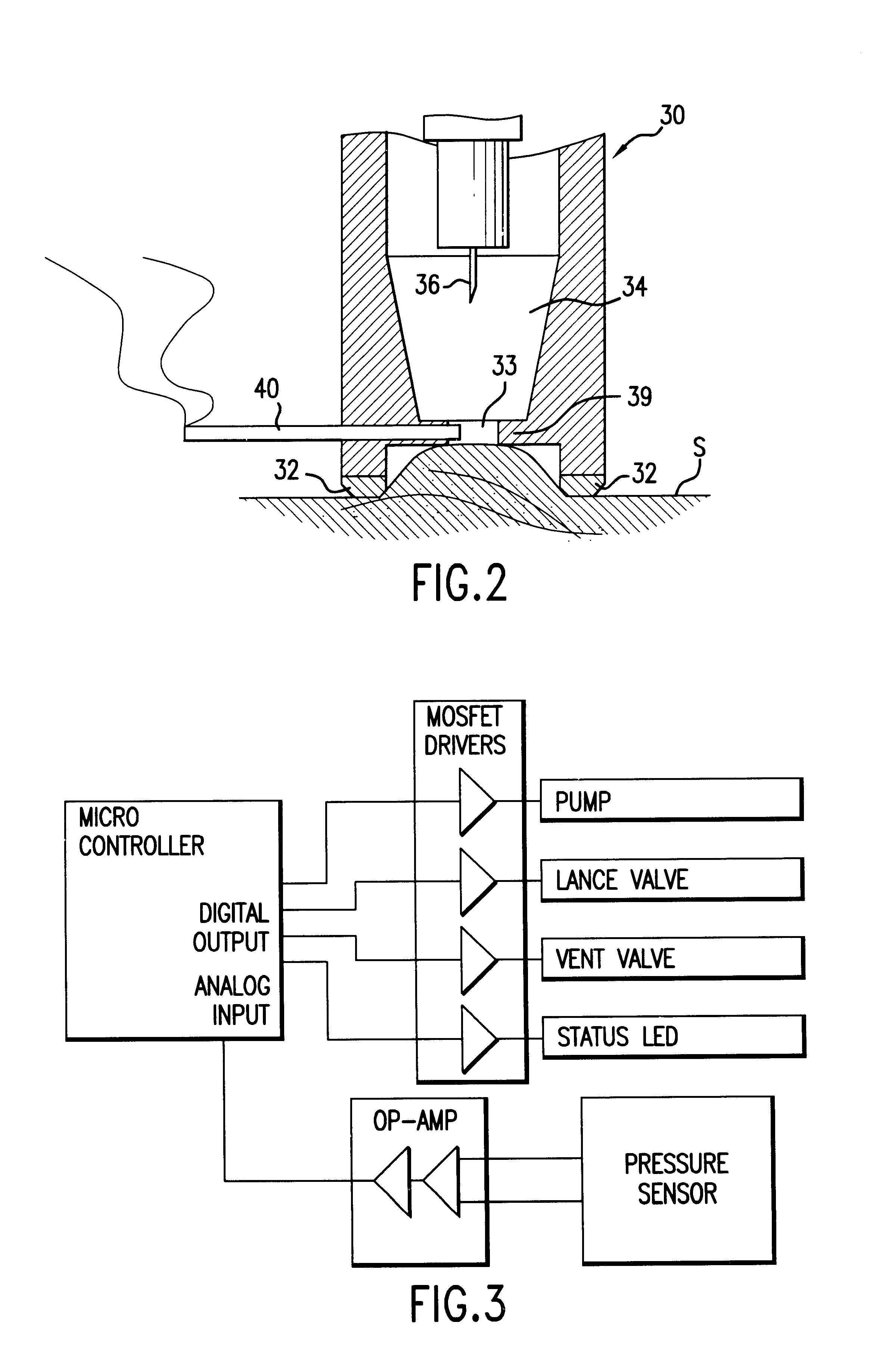

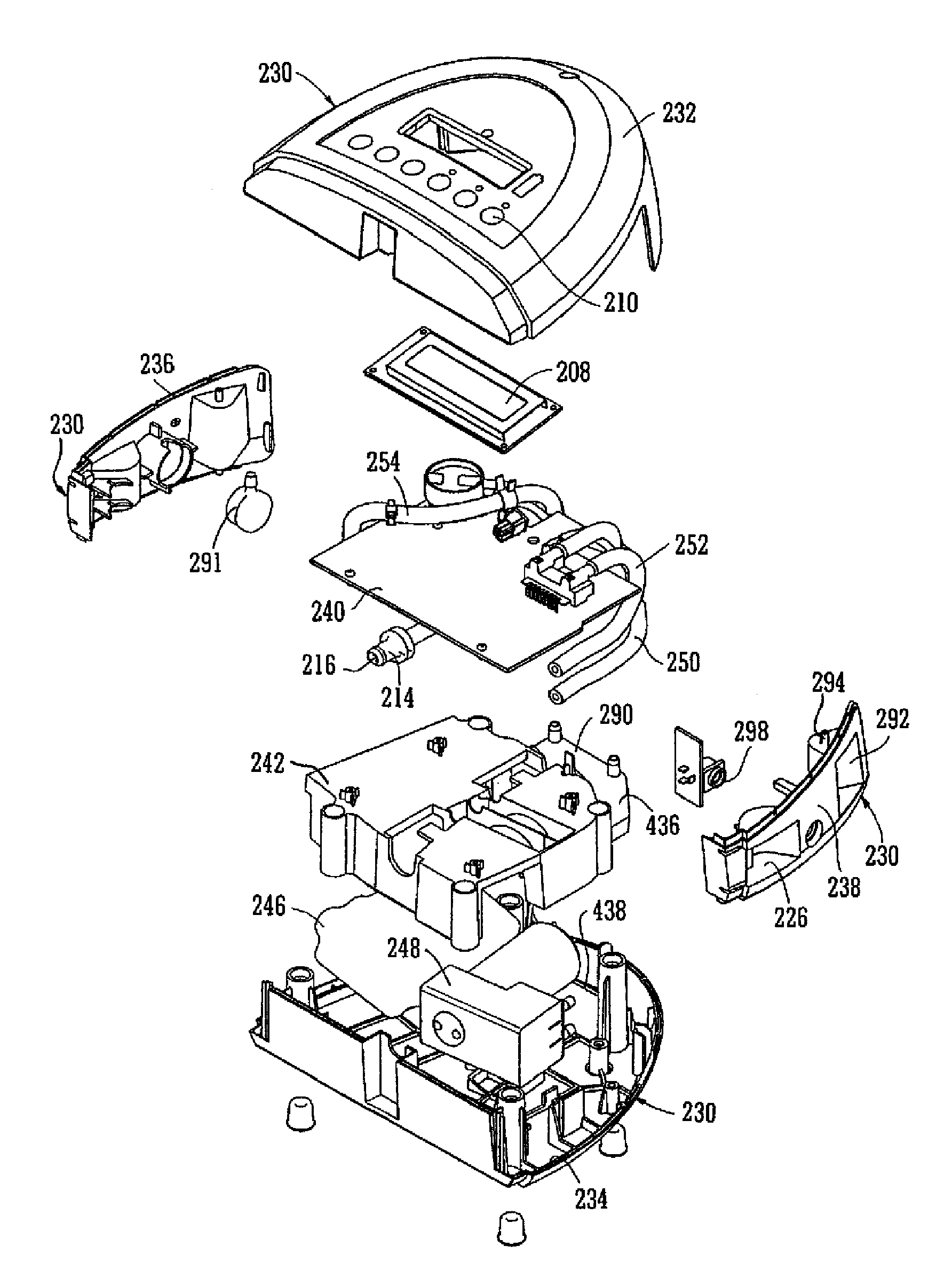

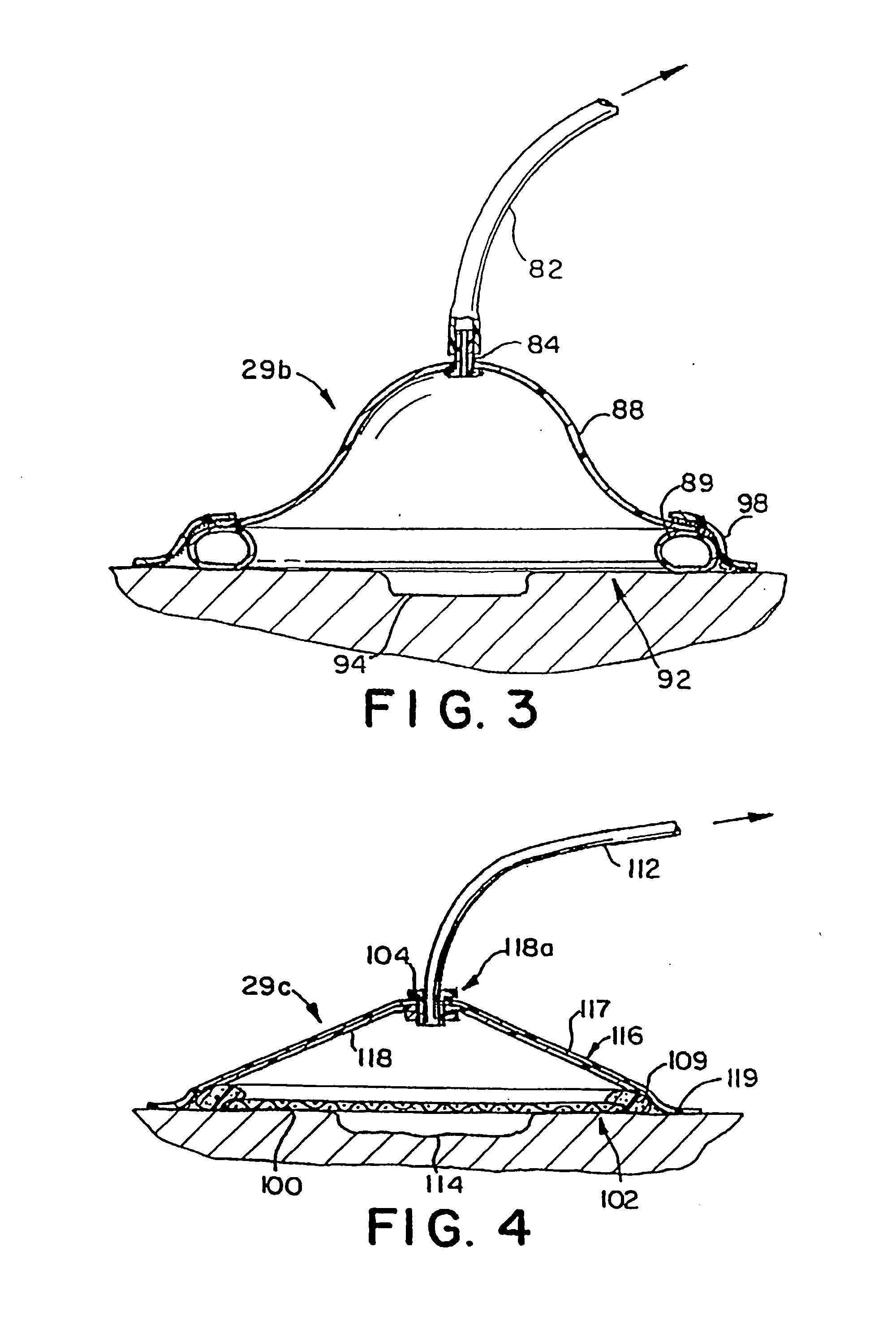

Method and apparatus for obtaining blood for diagnostic tests

Method and apparatus for obtaining a sample of blood from a patient for subsequent diagnostic tests, e.g., glucose monitoring. In one aspect of the invention, the method comprises the steps of:(a) placing a blood collection device over a region on the surface of the skin from which said sample is to be obtained,(b) forming a seal between said blood collection device and said surface of the skin,(c) creating a vacuum sufficient to result in said surface of the skin becoming stretched and engorged with blood,(d) triggering a lancing assembly and causing a lancet to penetrate said skin,(e) retracting said lancet,(f) withdrawing blood toward and onto a fluid collector, and(g) releasing the vacuum.In another aspect of the invention, an apparatus for carrying out the method described previously is provided. The apparatus comprises:(a) a housing having a sealable chamber located therein and a sealable opening in fluid communication with said sealable chamber,(b) a power source,(c) a vacuum pump operably connected to said power source, said vacuum pump in communication with said sealable chamber,(d) a lancing assembly positioned within said housing, said lancing assembly capable of moving a lancet towards said sealable opening, and(e) a fluid collector positioned in said sealable chamber, said fluid collector in fluid communication with said sealable opening.

Owner:ABBOTT LAB INC

Wound treatment employing reduced pressure

A method of treating tissue damage comprises applying a negative pressure to a wound sufficient in time and magnitude to promote tissue migration and thus facilitate closure of the wound. The method is applicable to wounds, burns, infected wounds, and live tissue attachments. A wound treatment apparatus is provided in which a fluid impermeable wound cover is sealed over a wound site. A screen in the form of an open-cell foam screen or a rigid porous screen is placed beneath the wound cover over the wound. A vacuum pump supplies suction within the wound cover over the treatment site.

Owner:WAKE FOREST UNIV HEALTH SCI INC

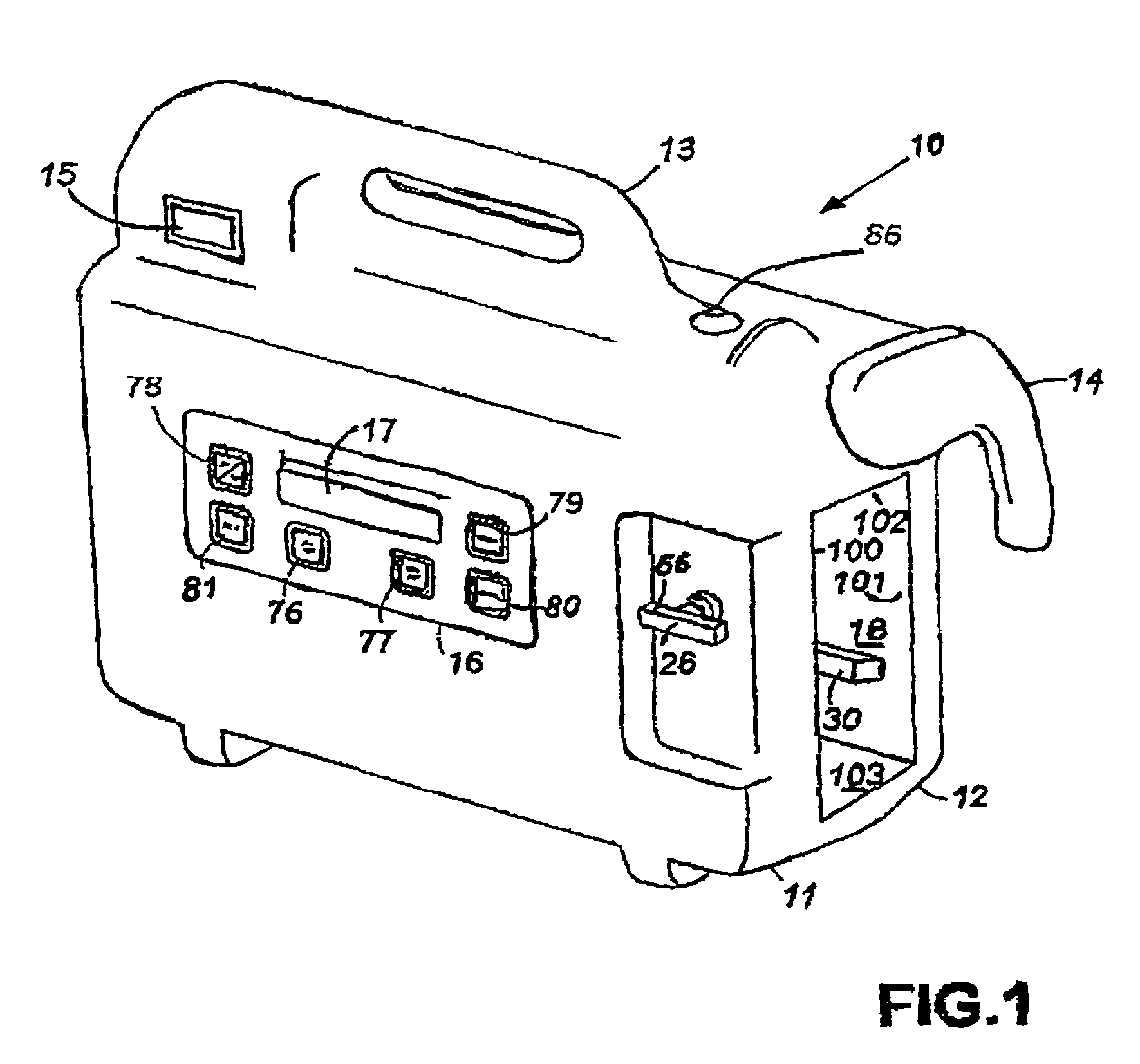

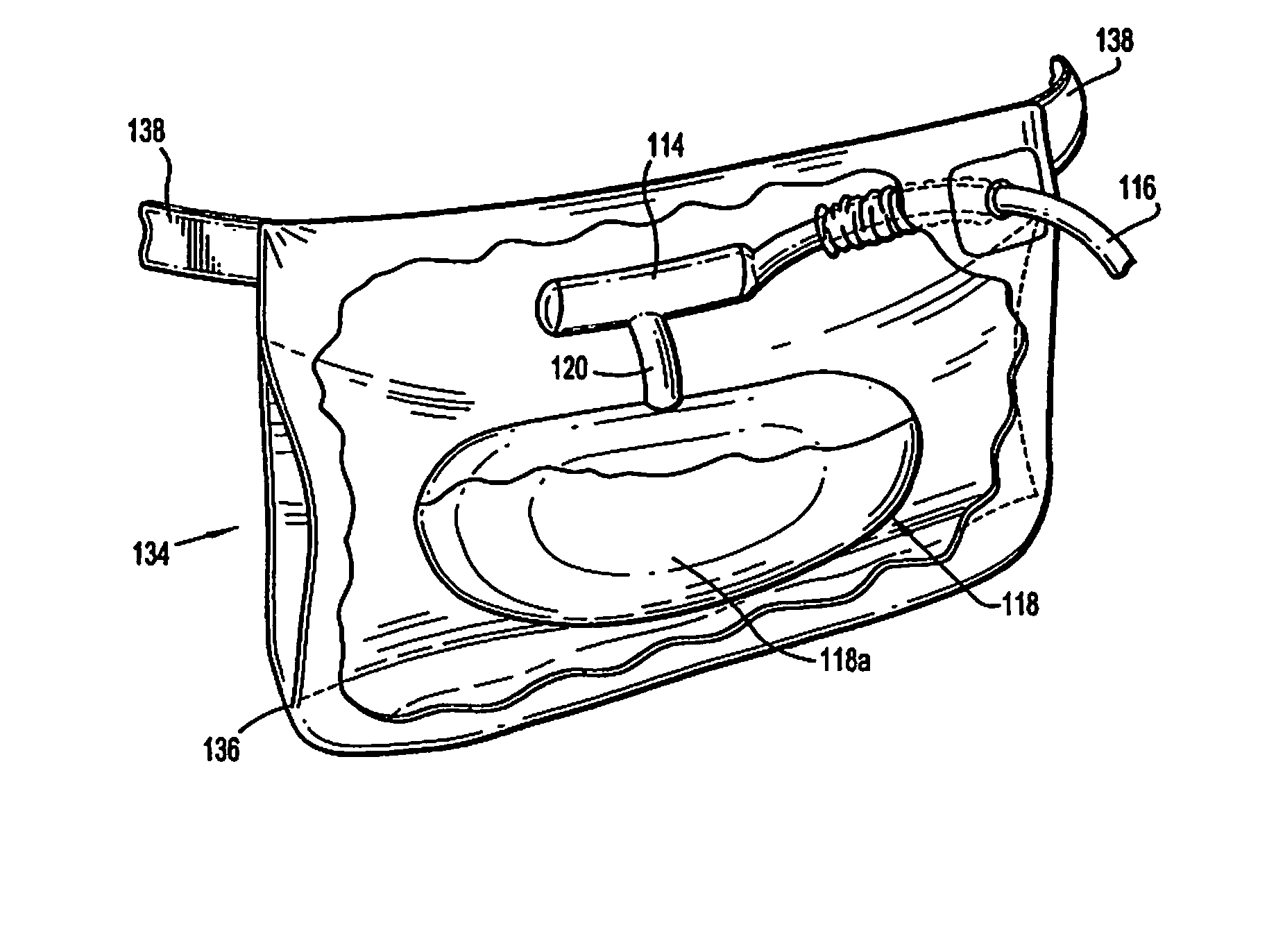

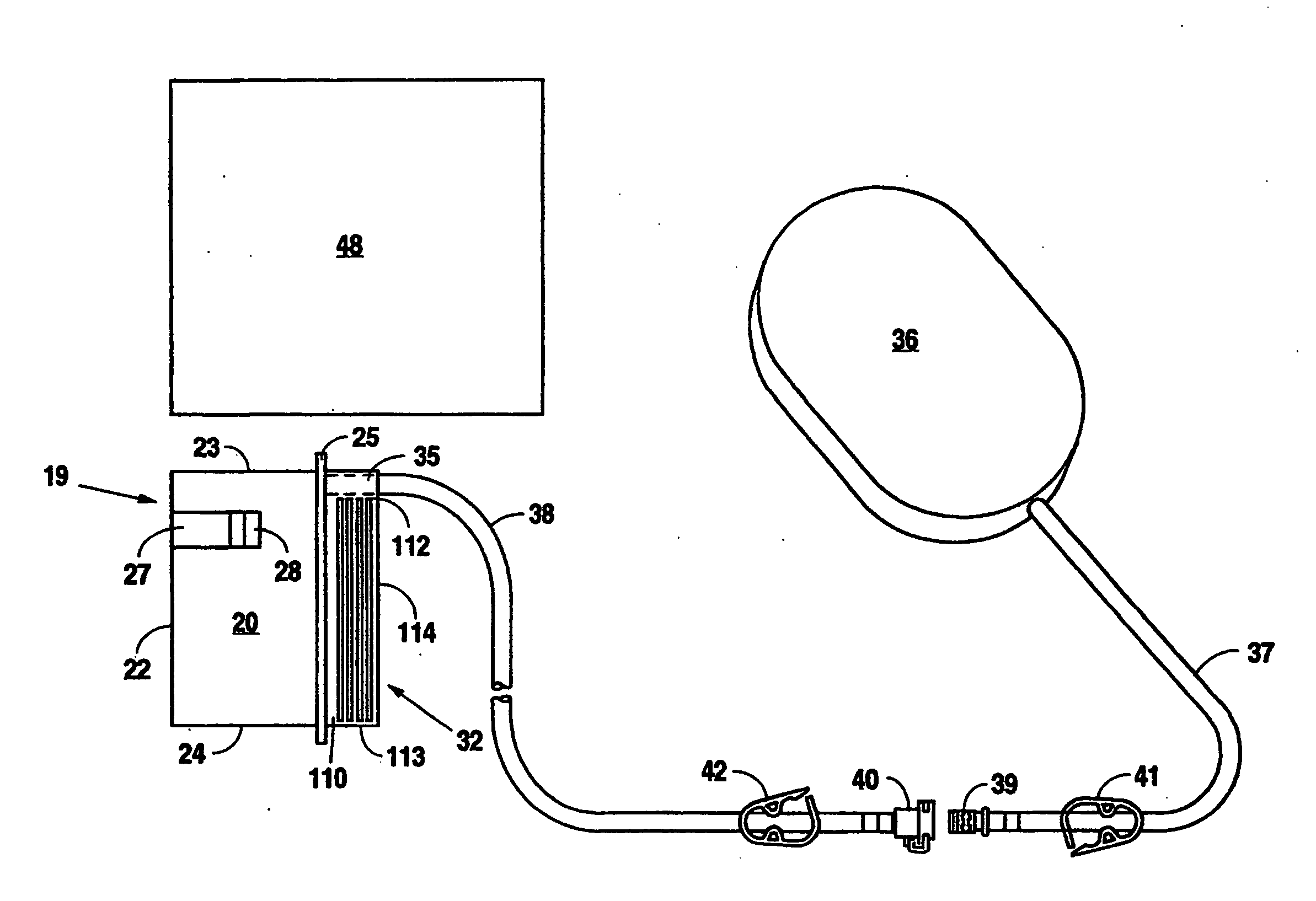

Self contained wound dressing apparatus

InactiveUS20070055209A1Easy to disassemblePromote healingAntibacterial agentsSurgical needlesPeristaltic pumpVacuum pressure

The composite wound dressing apparatus promotes healing of a wound via the use of an external peristaltic vacuum pump. The external peristaltic pump applies a vacuum pressure to the wound to effectively draw wound fluid or exudate away from the wound bed. The external peristaltic pump is tethered to the wound dressing and is portable, preferably, carried by the patient in a support bag, which permits patient mobility. Moreover, the patient does not need to be constrained for any period of time while exudate is being removed from the wound.

Owner:TYCO HEALTHCARE GRP LP

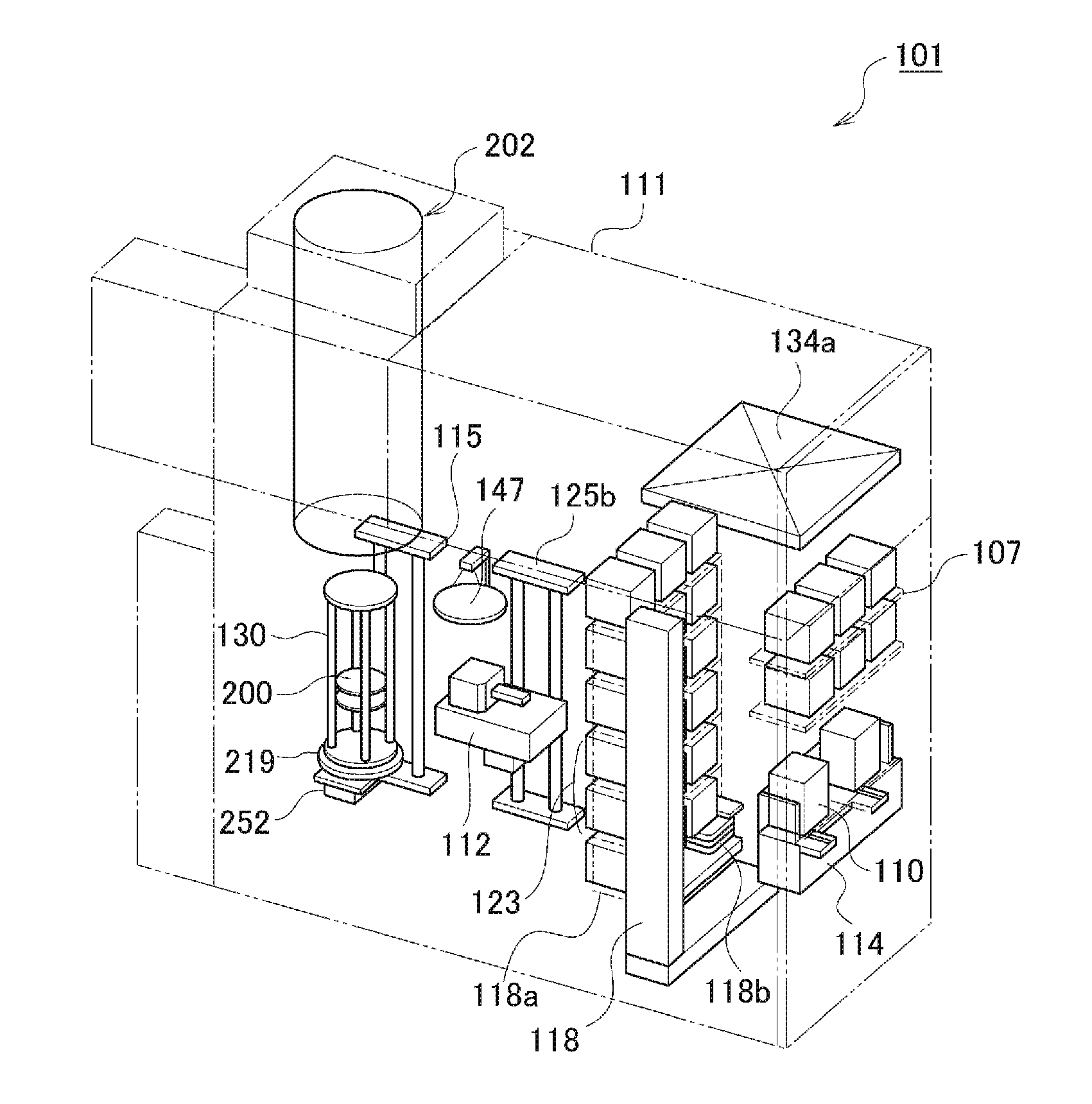

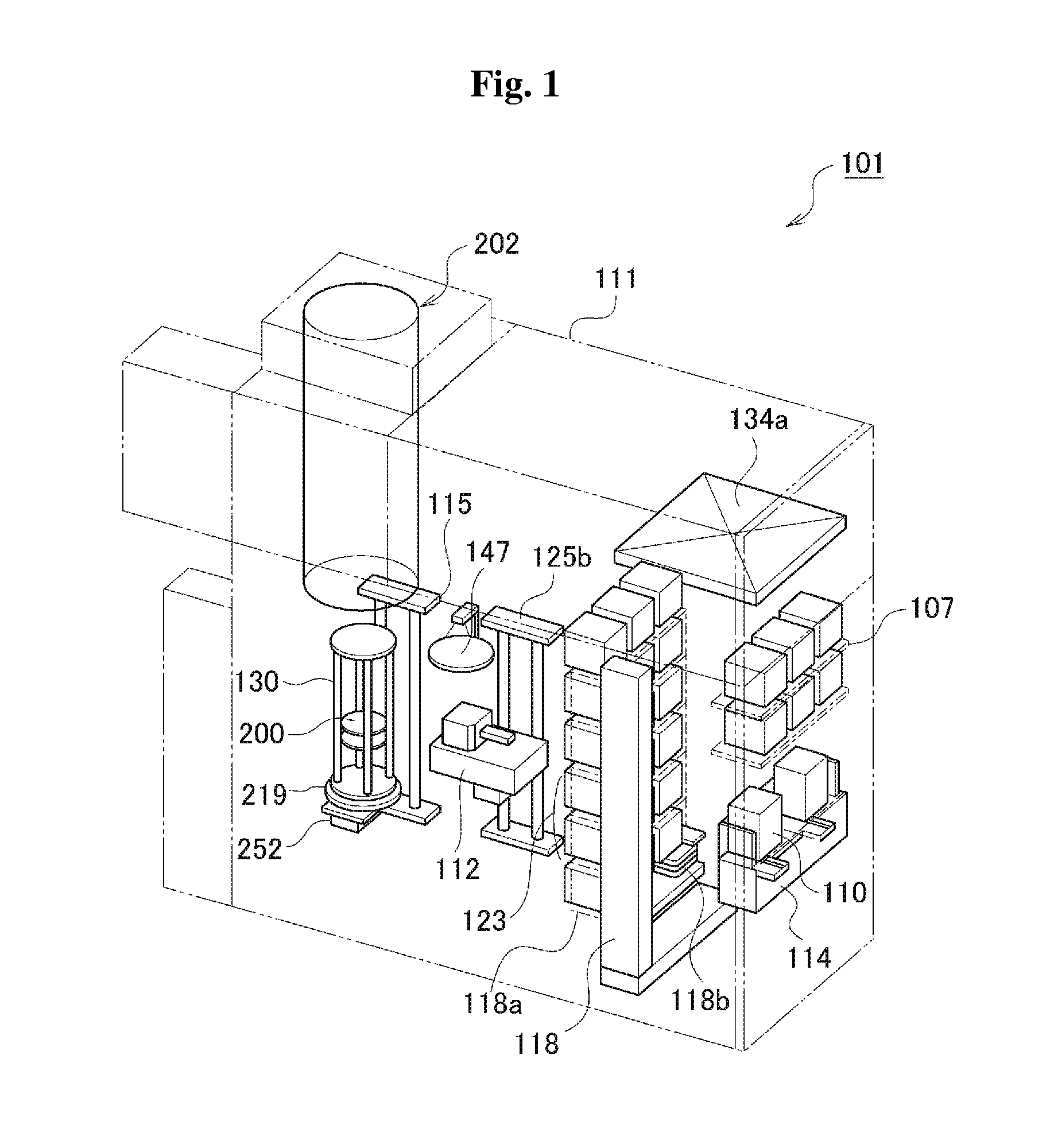

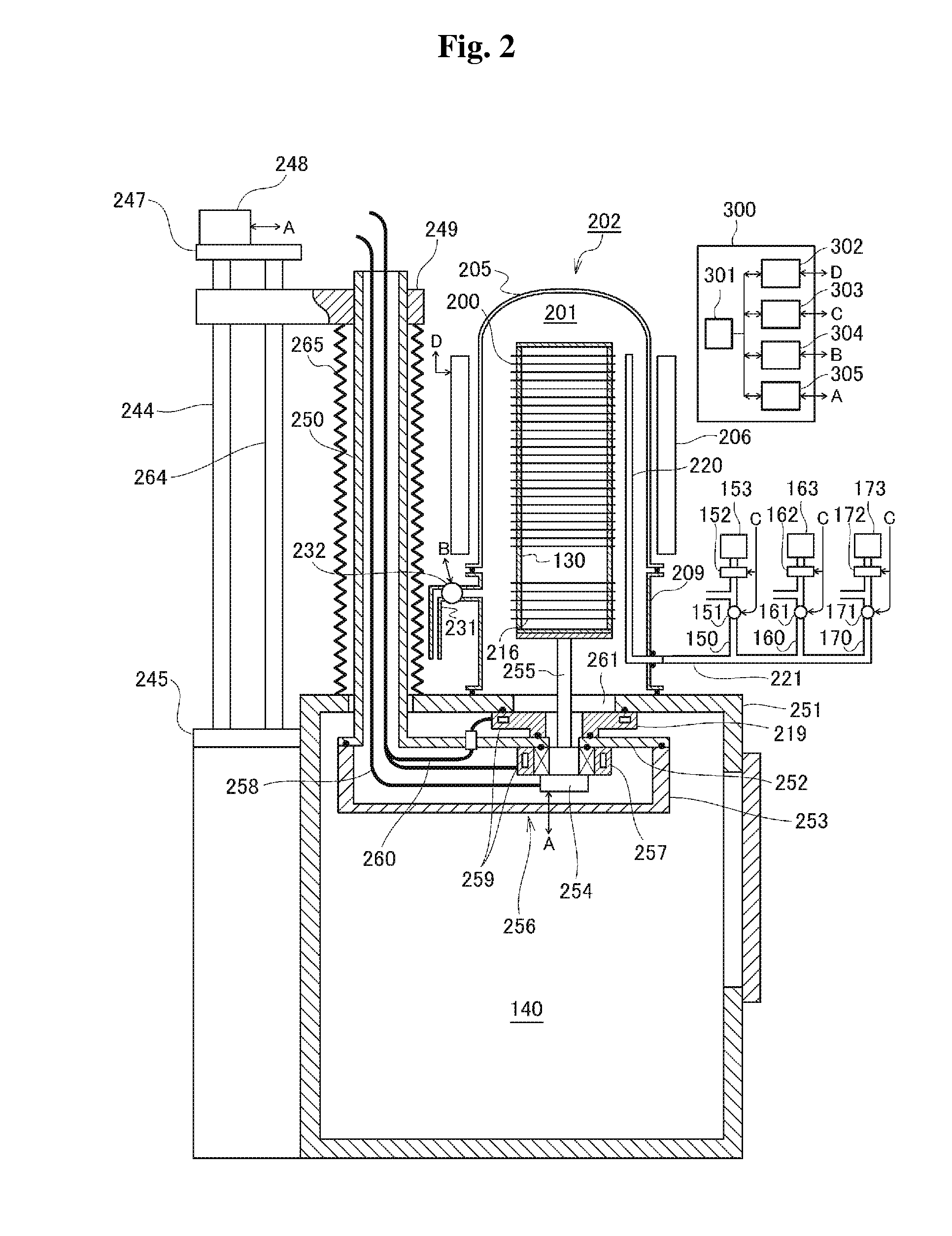

Substrate Processing Apparatus

InactiveUS20100058984A1Inhibited DiffusionPolycrystalline material growthSemiconductor/solid-state device manufacturingProcess engineeringVacuum pump

Process gas discharged from a bypass pipe to a gas exhaust system can be prevented from diffusing back to the inside of a process chamber without having to install a dedicated vacuum pump at the downstream side of the bypass pipe. The substrate processing apparatus includes a process chamber accommodating a substrate, a gas supply system supplying process gas from a process gas source to the process chamber for processing the substrate, a gas exhaust system configured to exhaust the process chamber, two or more vacuum pumps installed in series at the gas exhaust system, and a bypass pipe connected between the gas supply system and the gas exhaust system. The most upstream one of the vacuum pumps is a mechanical booster pump, and the bypass pipe is connected between the mechanical booster pump and the rest vacuum pumps located at a downstream side of the mechanical booster pump.

Owner:KOKUSA ELECTRIC CO LTD

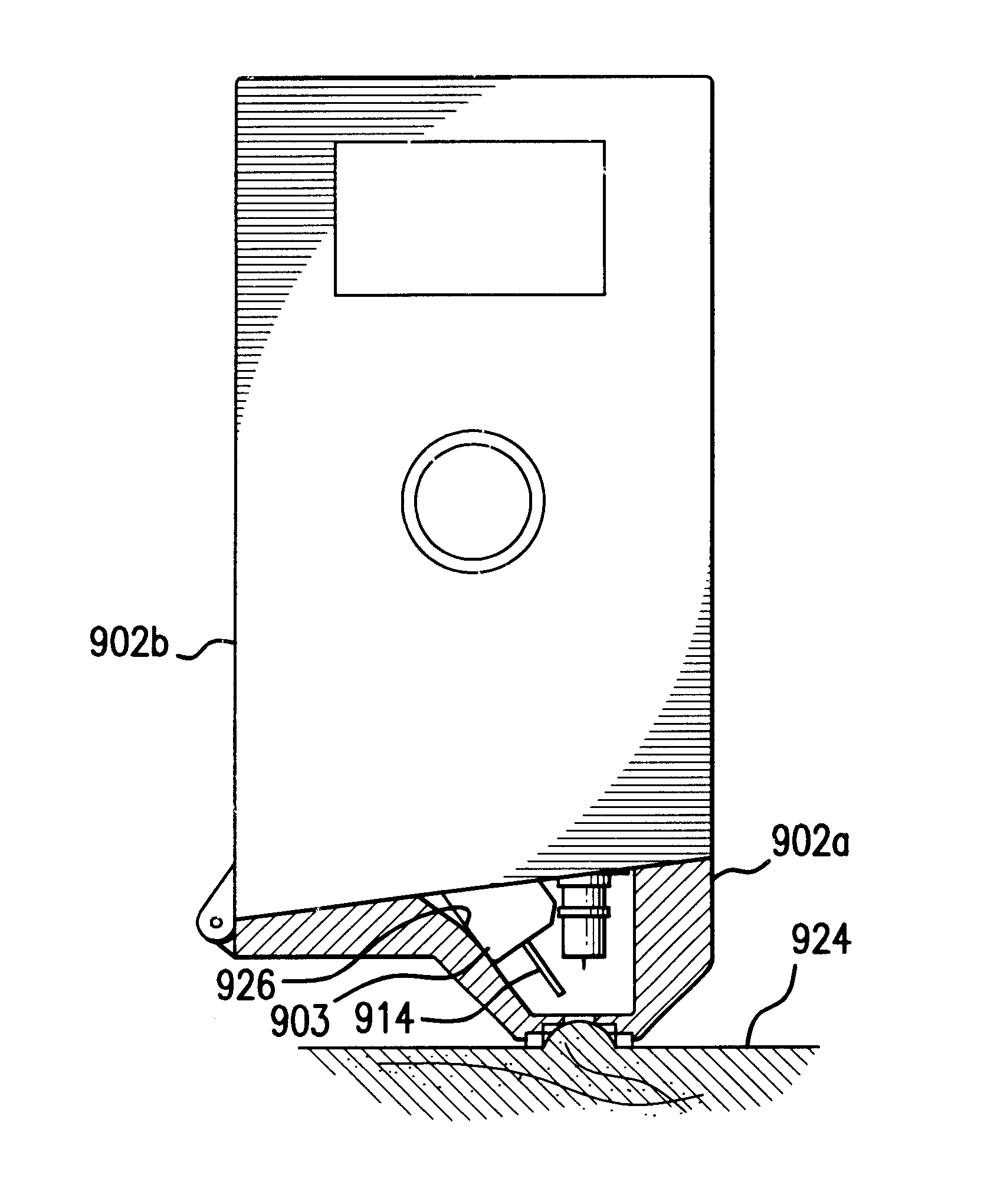

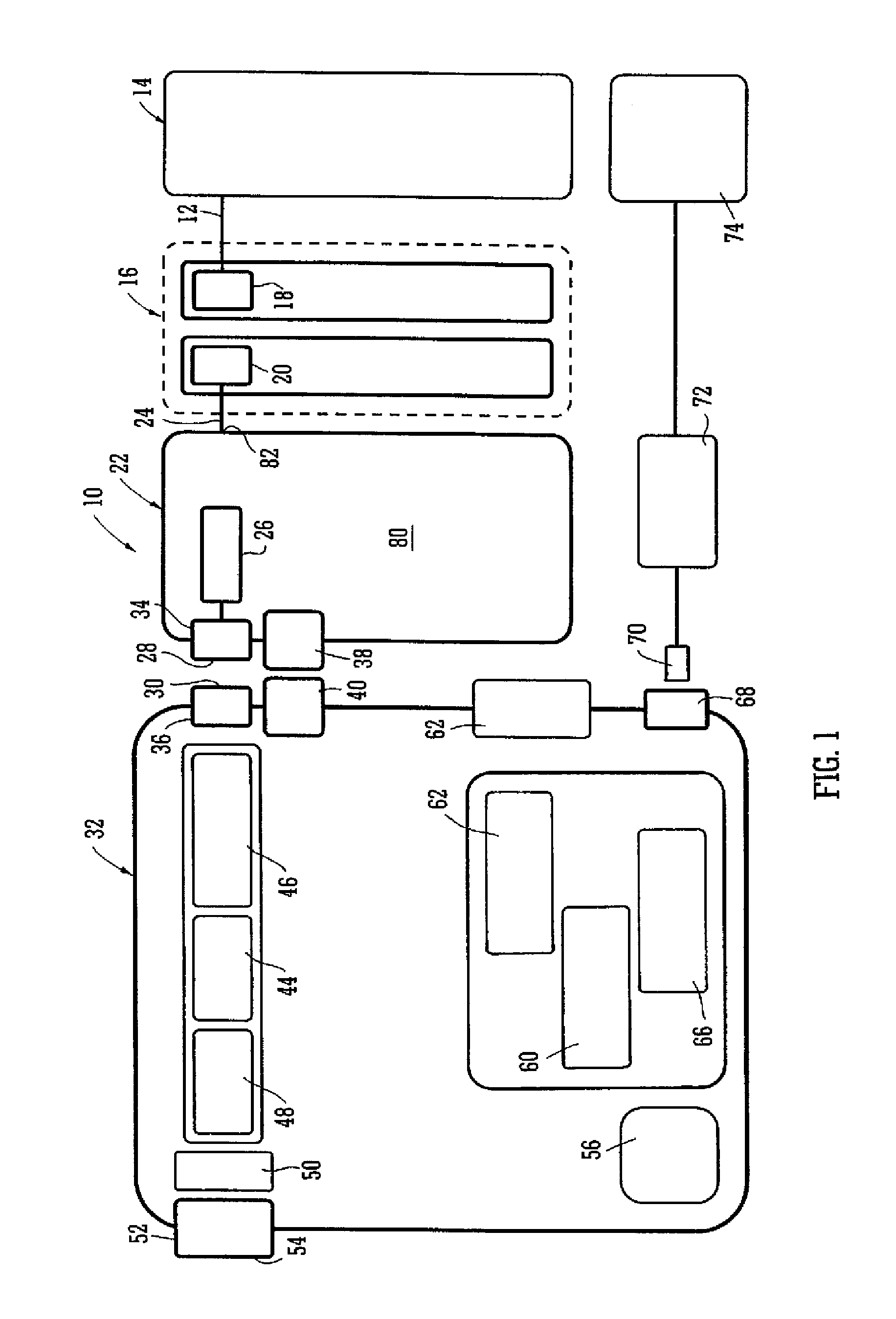

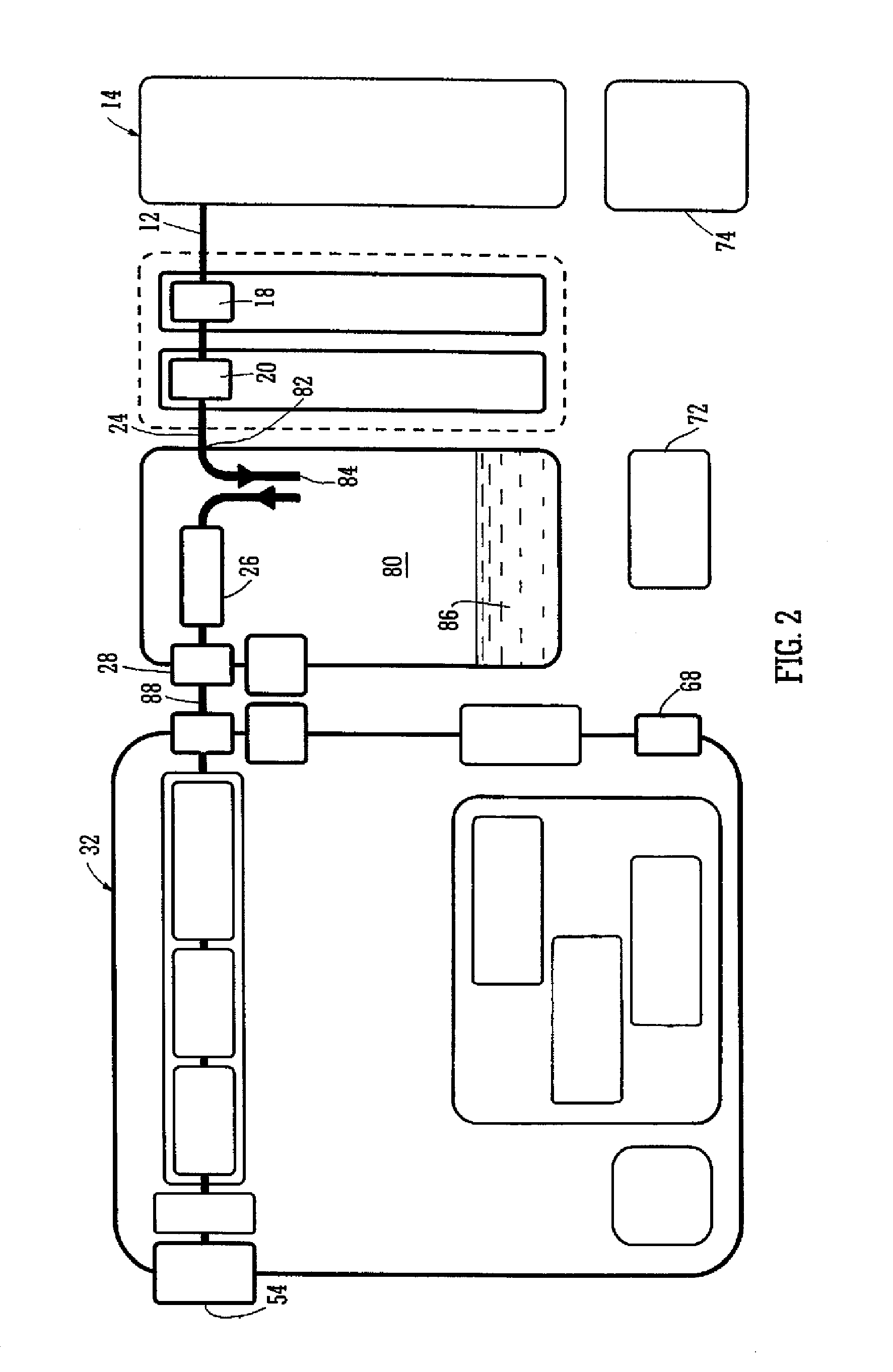

Wound therapy device and related methods

A wound closure apparatus is disclosed which includes a housing that contains a vacuum pump and a chamber for holding a disposable wound fluid collection canister. The canister resides within the chamber and connects at an outlet with the vacuum pump and at an inlet with a pad. The pad is placed over a wound and adhesively secured thereto. When the vacuum pump activates, it evacuates air from the canister resulting in wound fluids flowing from the wound into the canister. After the canister is filled, it is removed from the chamber and replaced with another canister to continue the removal of wound fluids.

Owner:KCI LICENSING INC

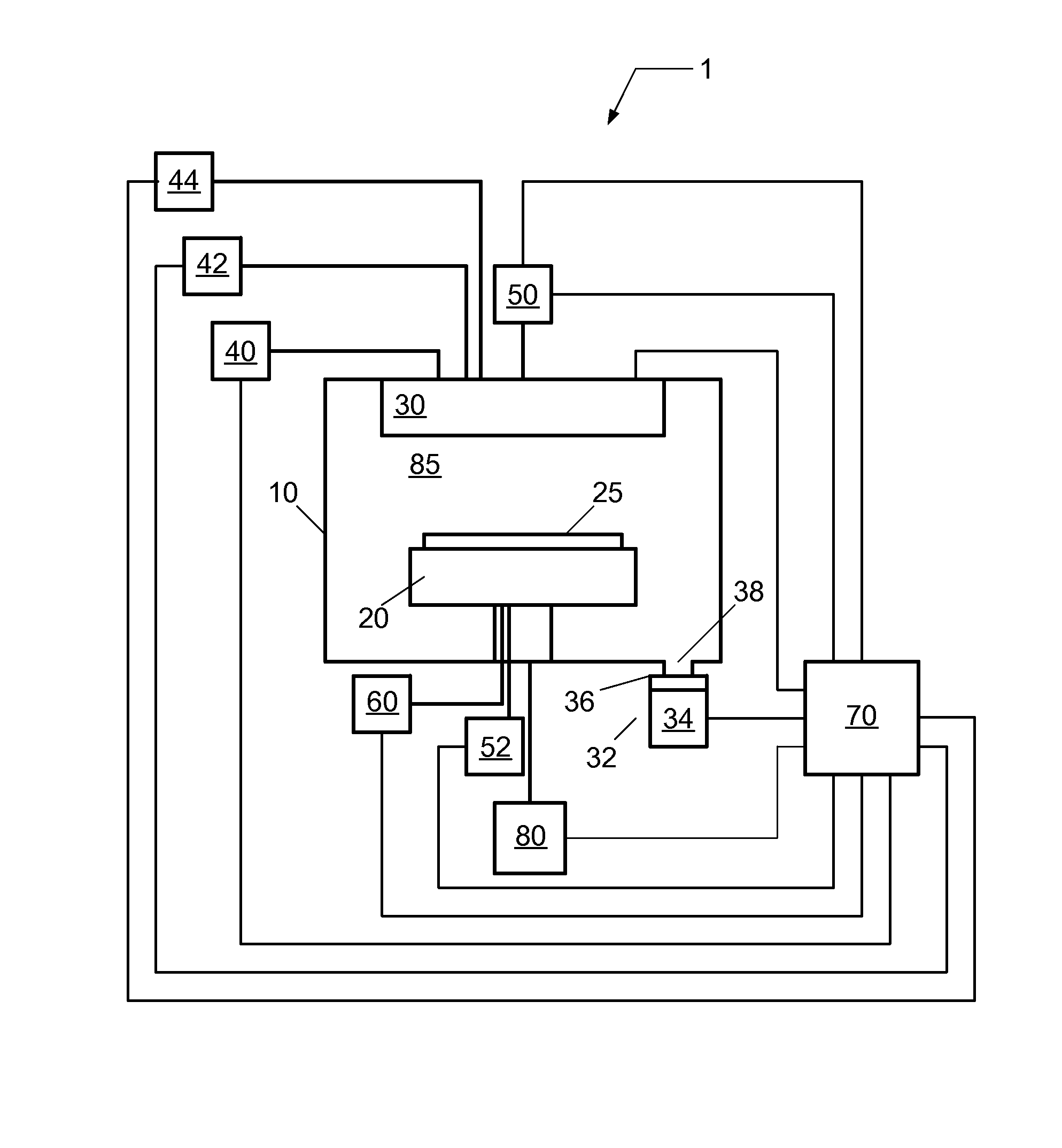

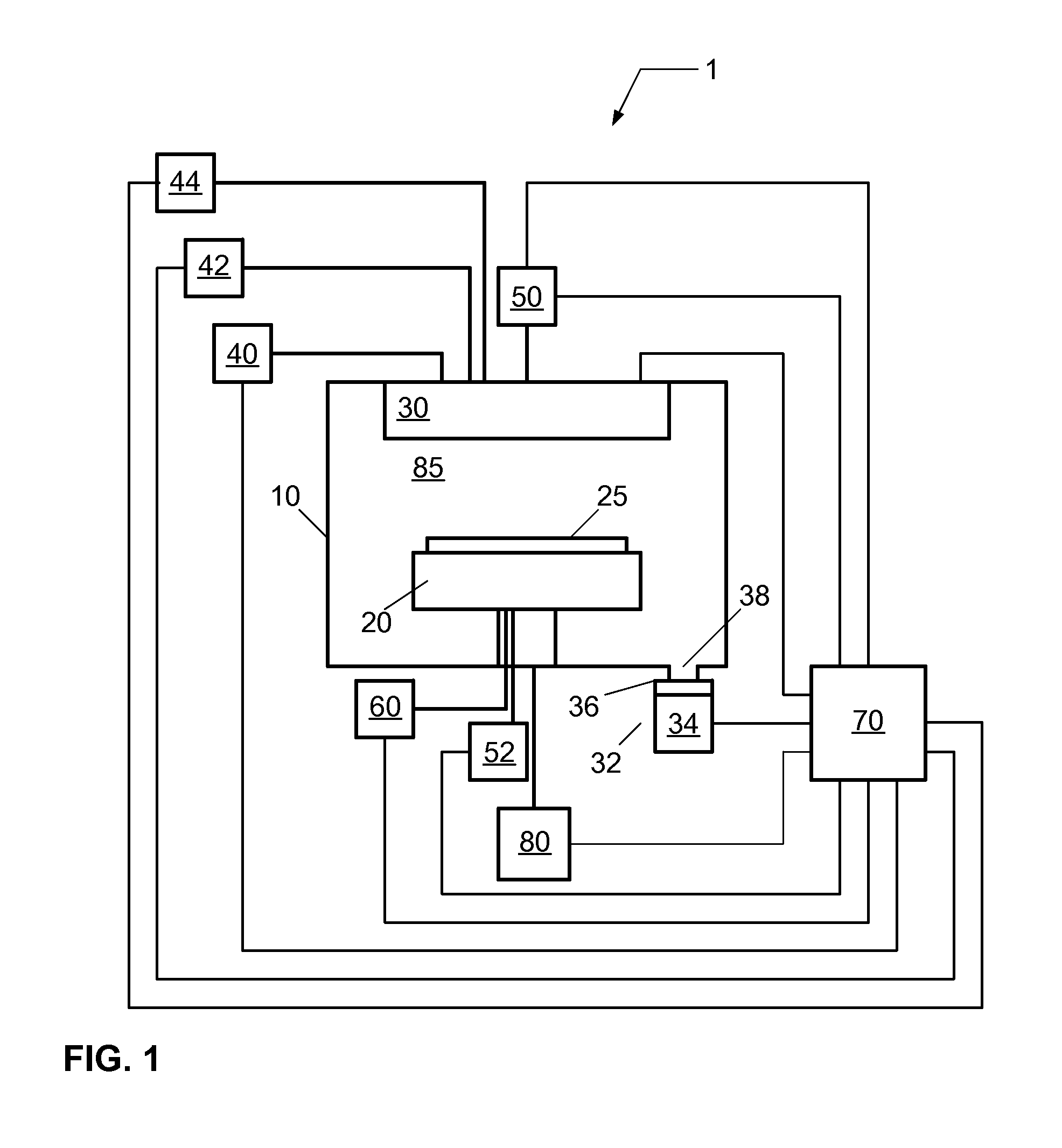

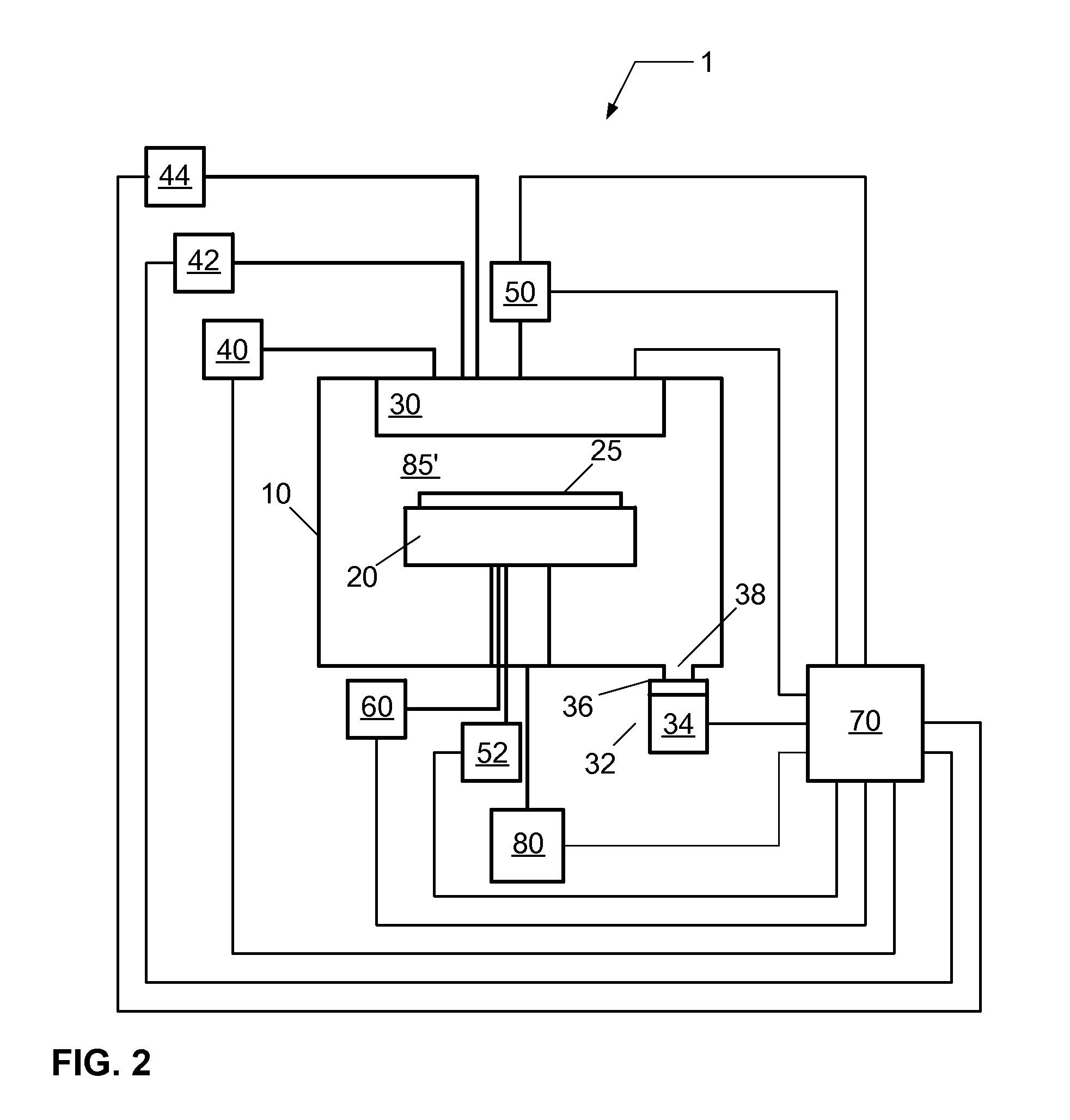

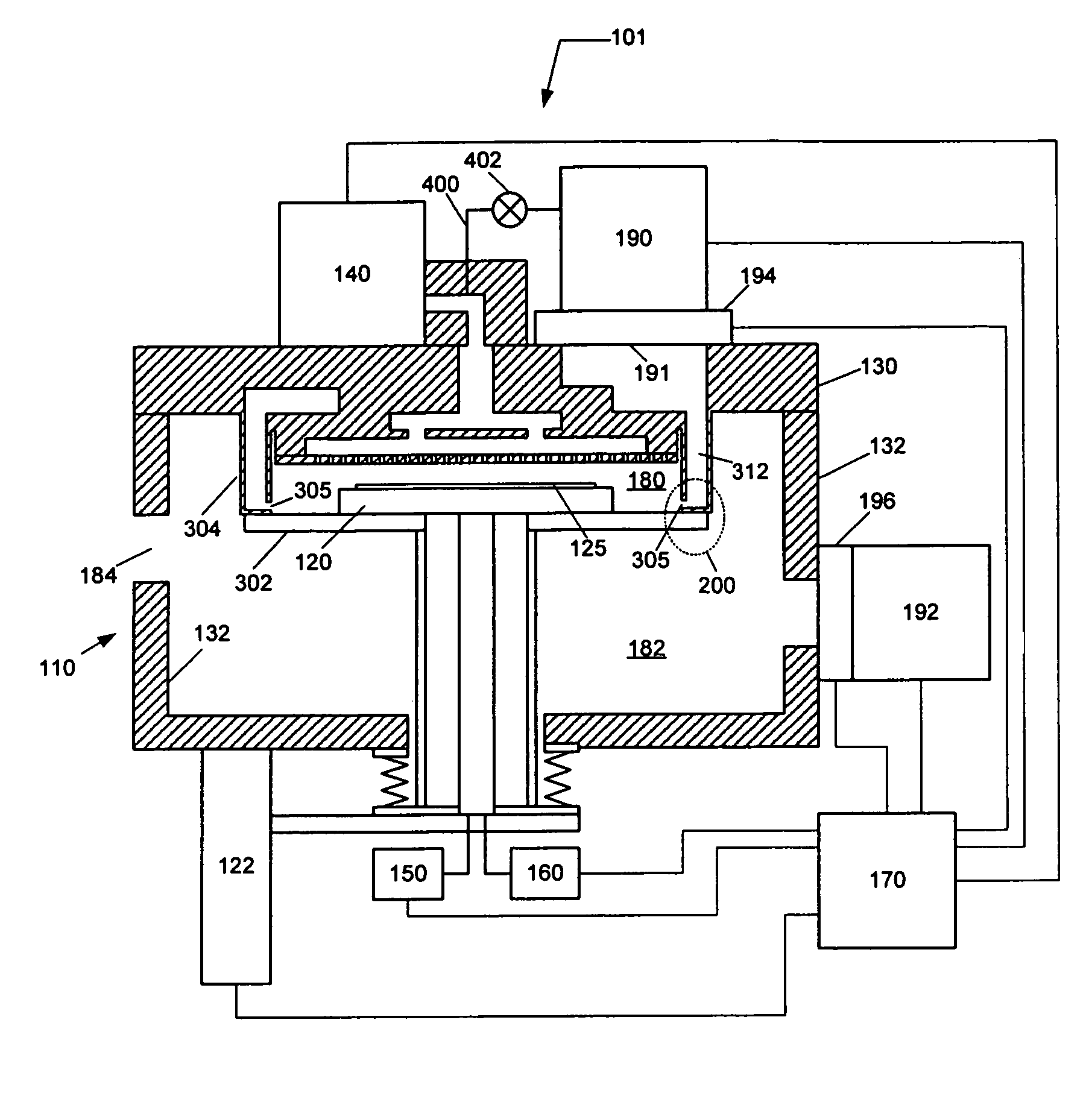

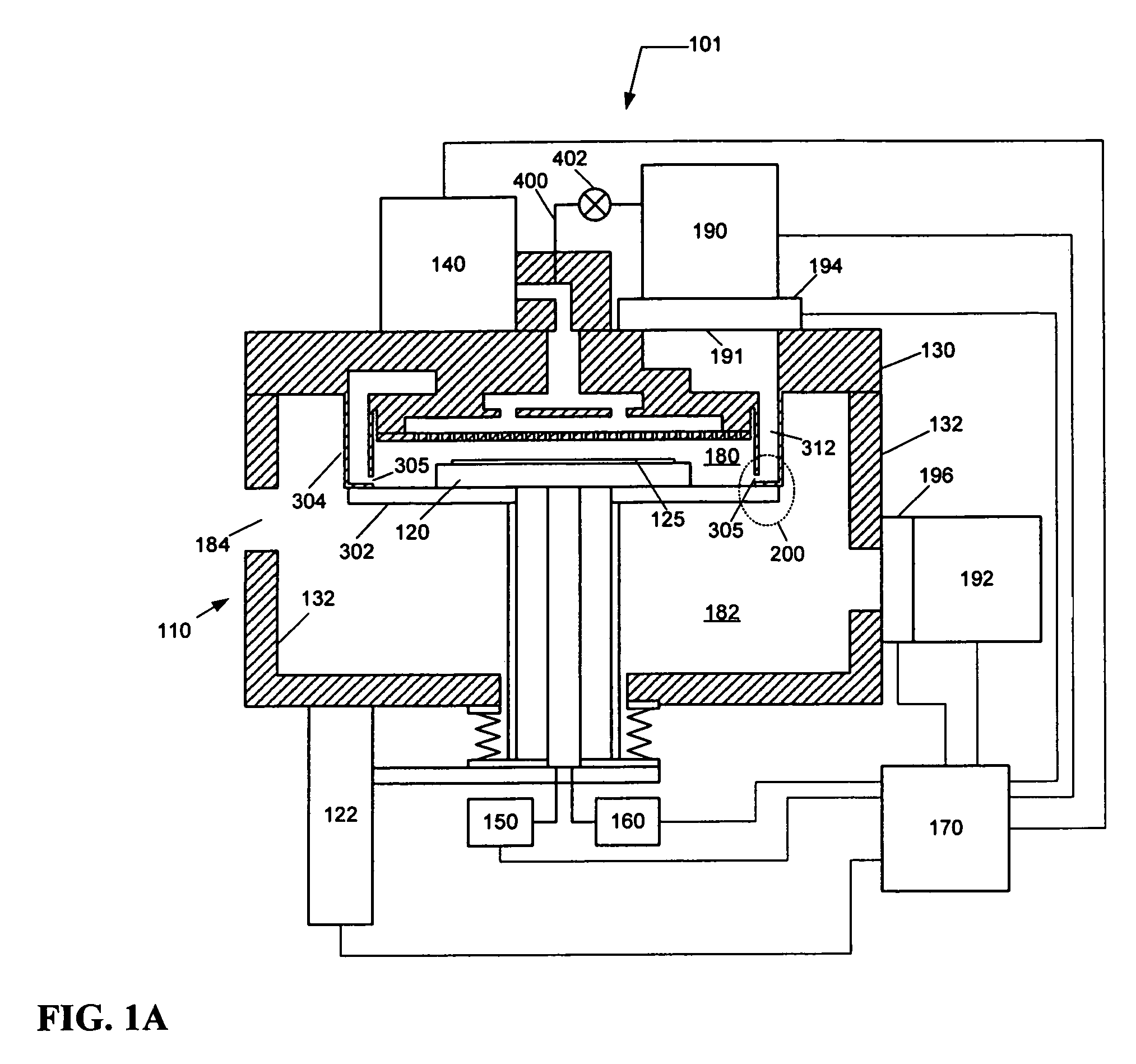

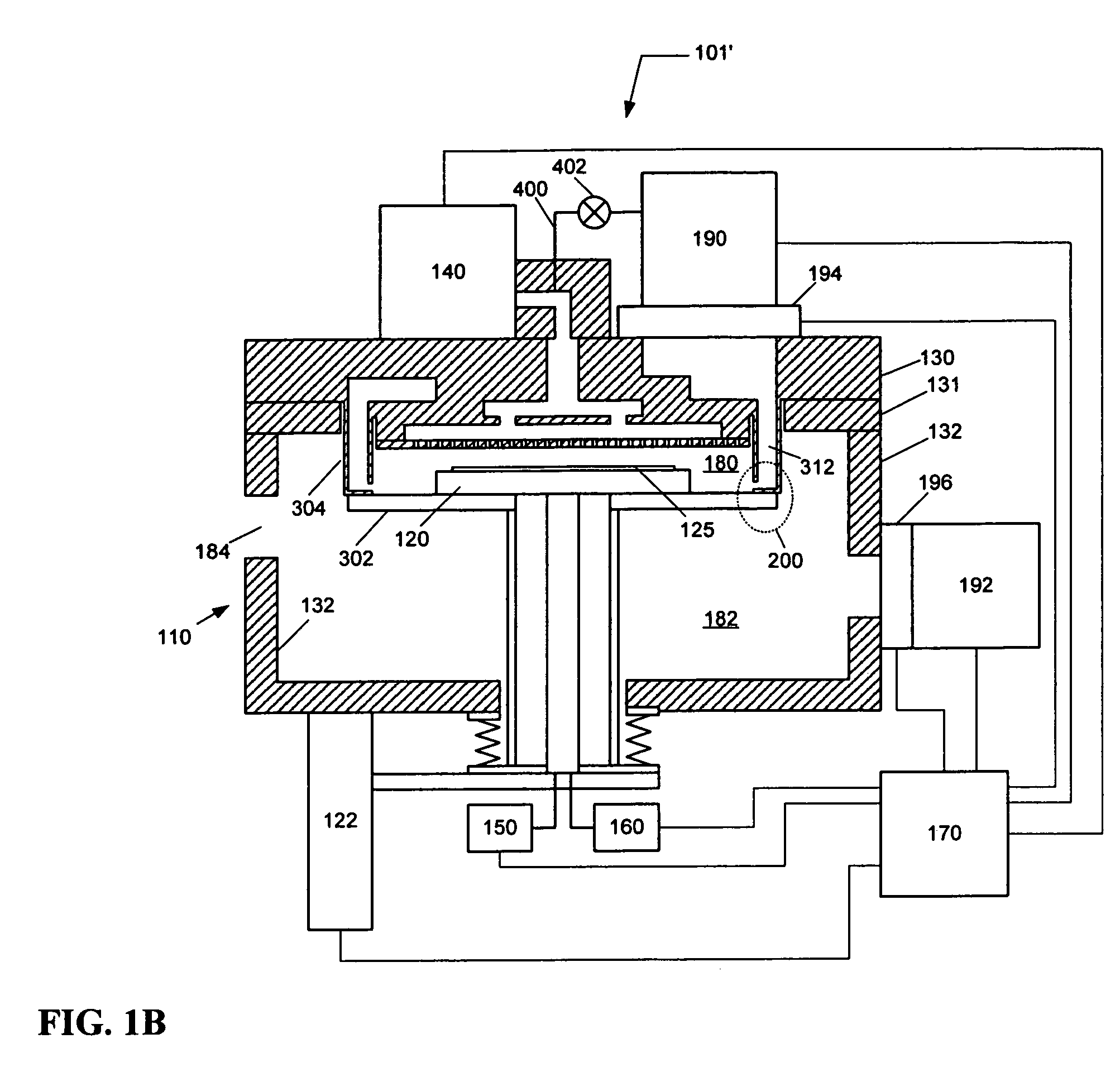

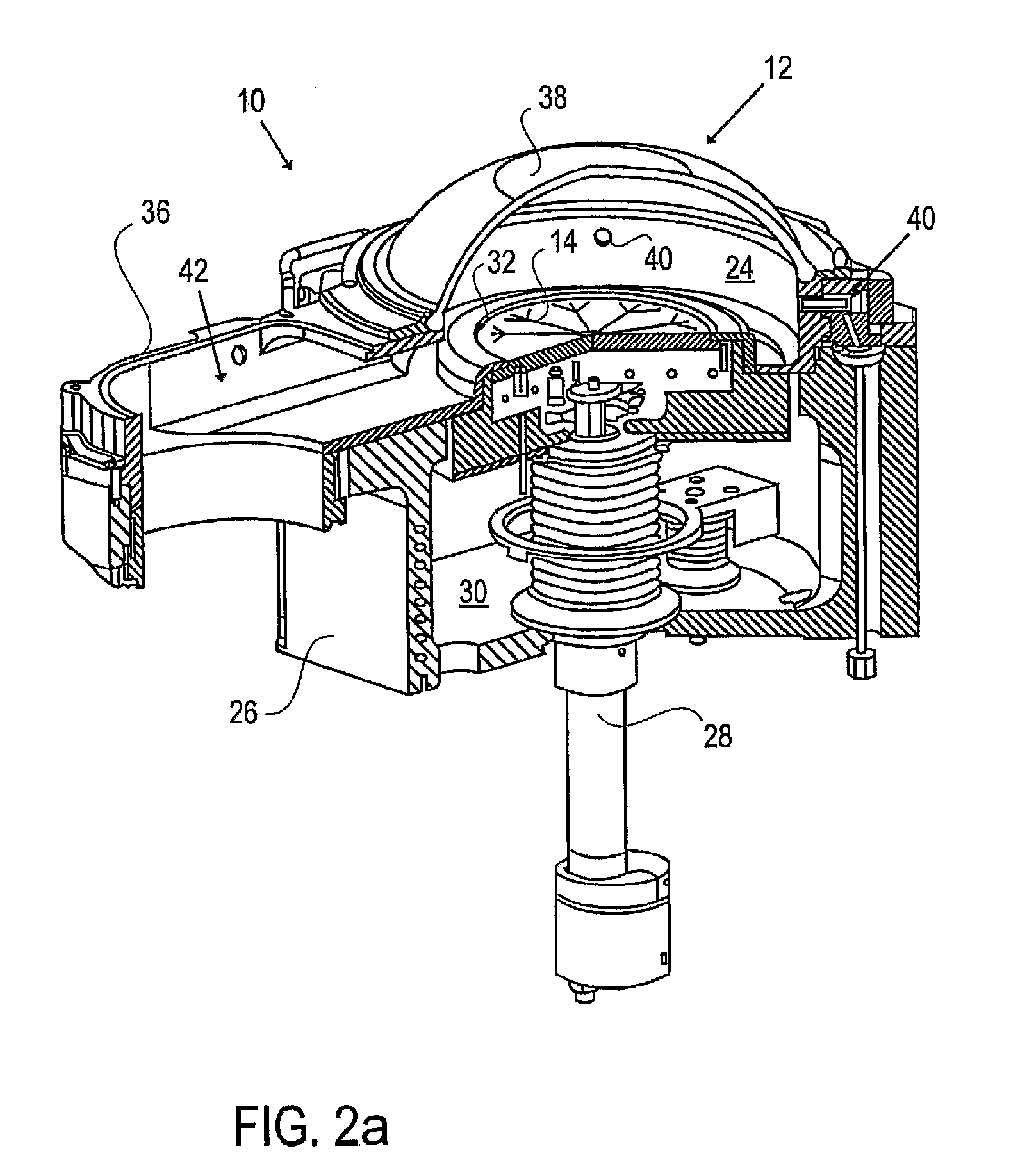

Method and system for performing different deposition processes within a single chamber

ActiveUS20110135842A1Reduce pollutionLiquid surface applicatorsElectric discharge tubesVacuum pumpingGas phase

A method and system for plasma-assisted thin film vapor deposition on a substrate is described. The system includes a process chamber including a first process space having a first volume, a substrate stage coupled to the process chamber and configured to support a substrate and expose the substrate to the first process space, a plasma generation system coupled to the process chamber and configured to generate plasma in at least a portion of the first process space, and a vacuum pumping system coupled to the process chamber and configured to evacuate at least a portion of the first process space. The system further includes a process volume adjustment mechanism coupled to the process chamber and configured to create a second process space that includes at least a part of the first process space and that has a second volume less than the first volume, the substrate being exposed to the second process space.

Owner:TOKYO ELECTRON LTD

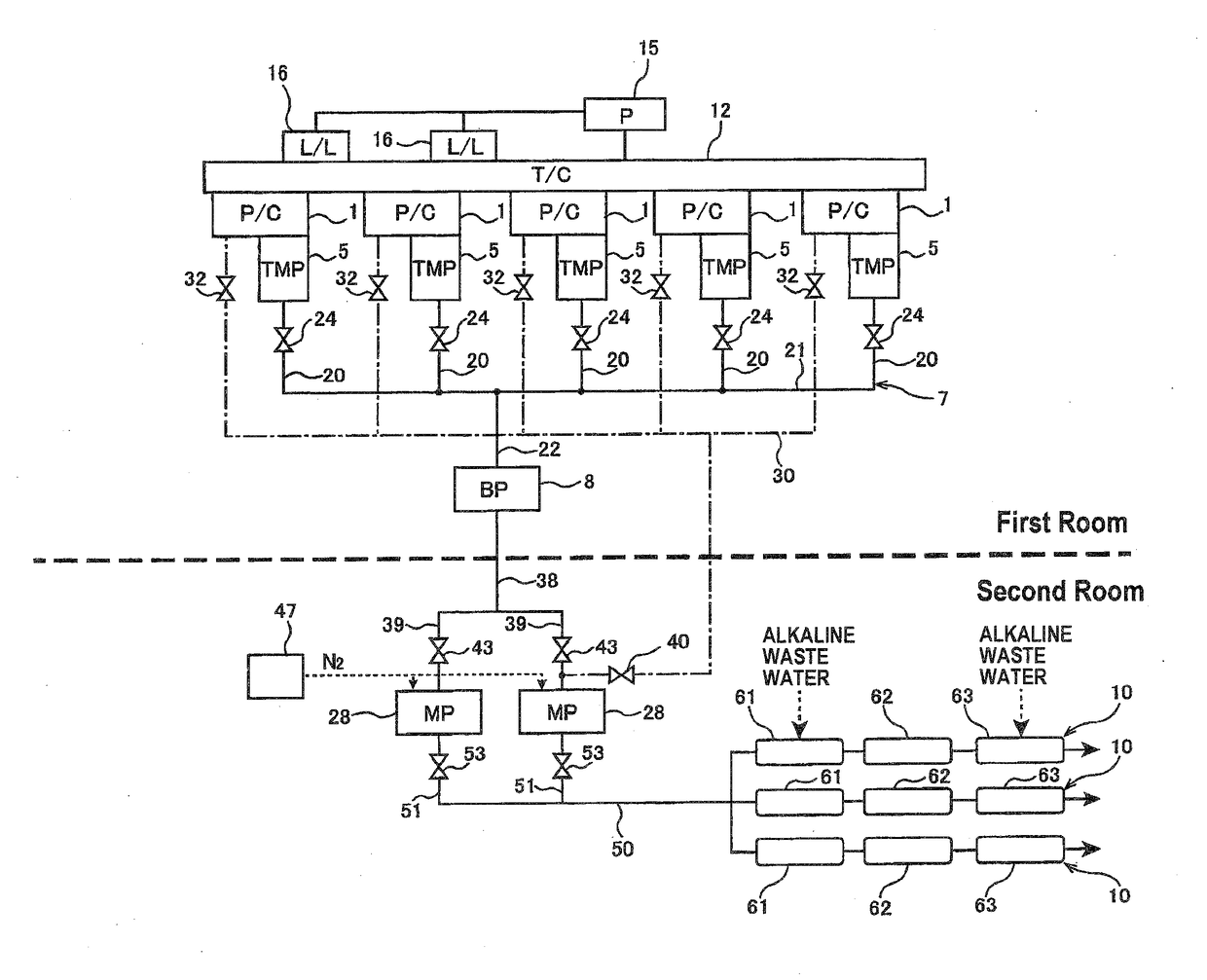

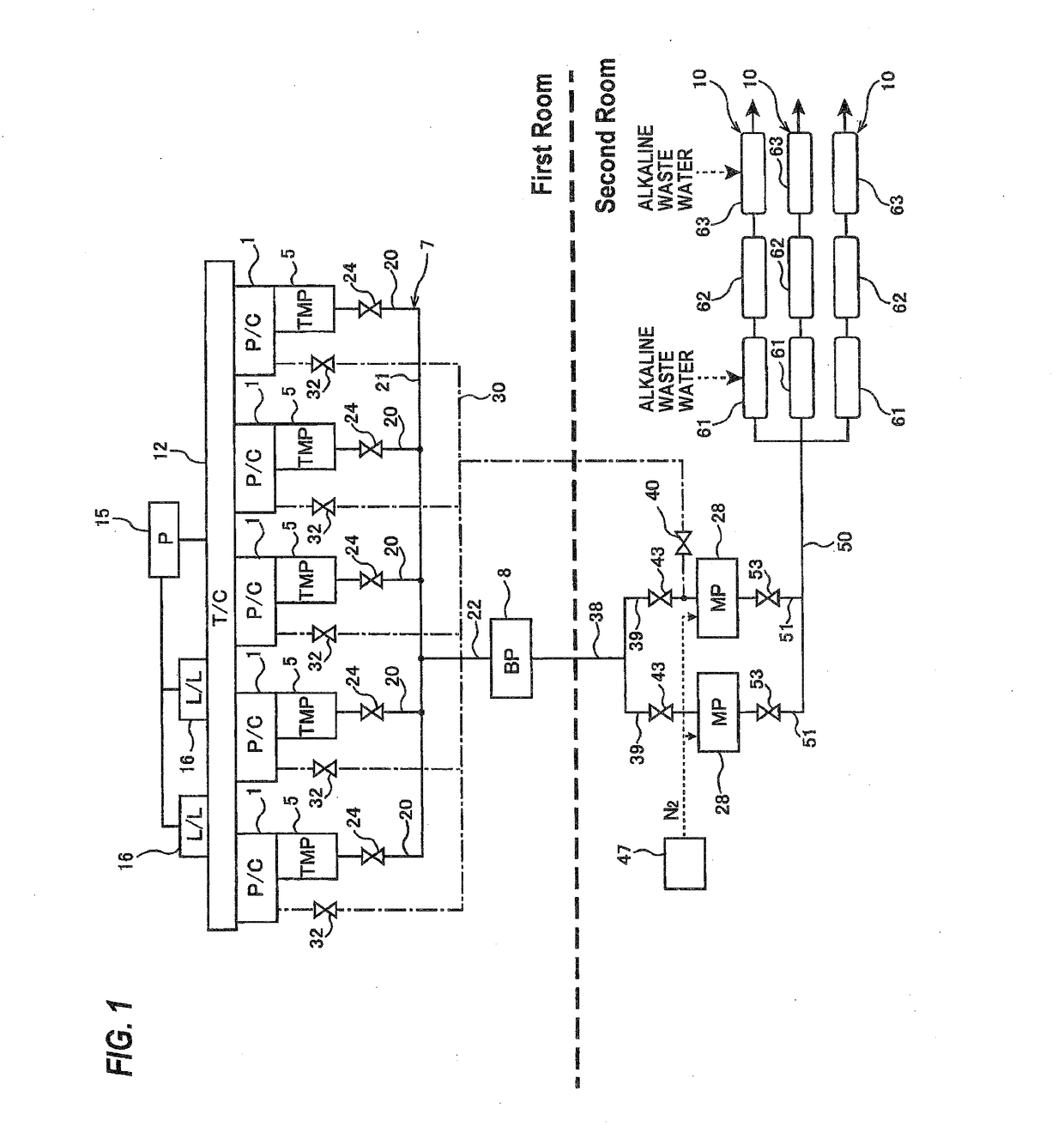

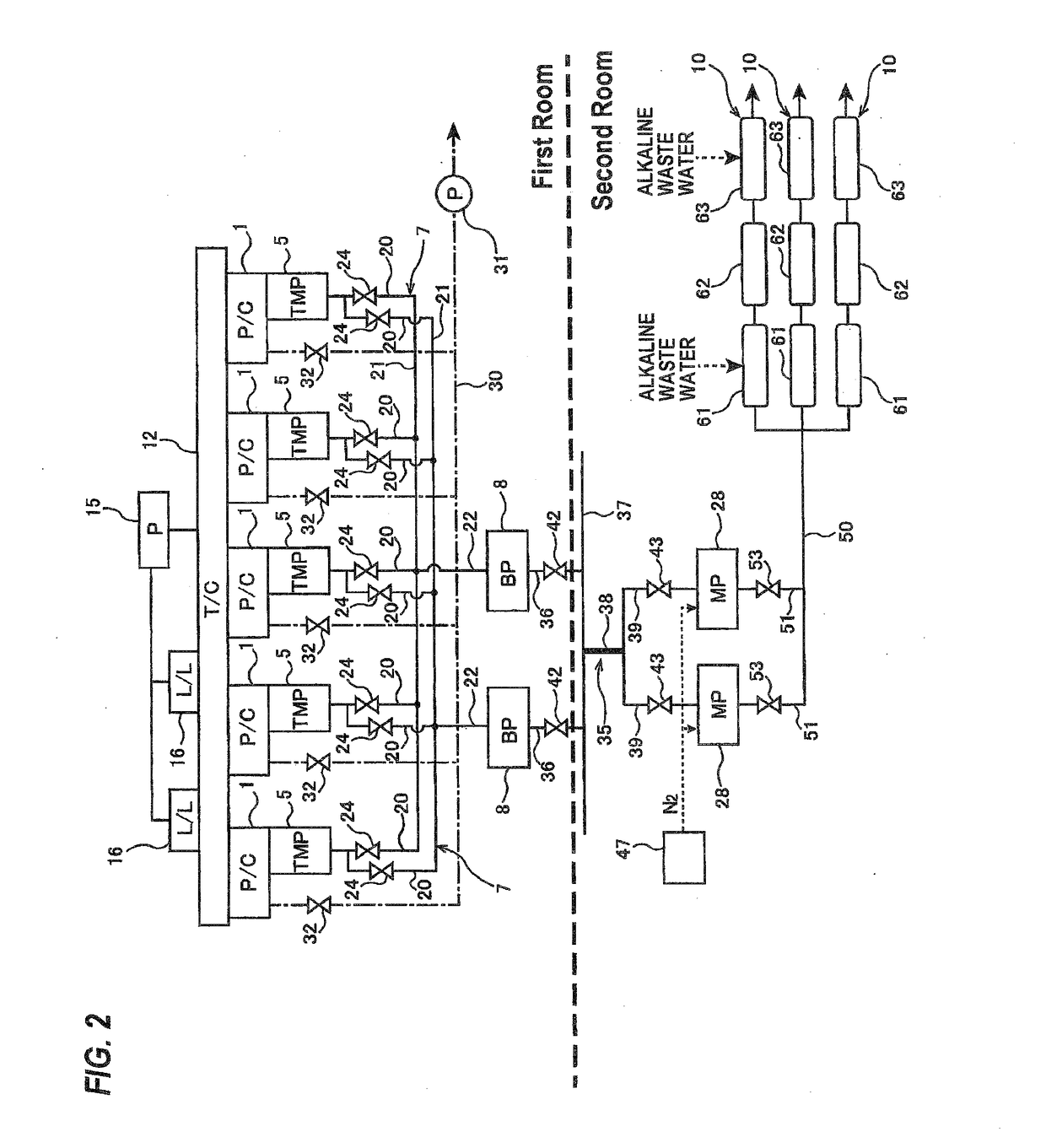

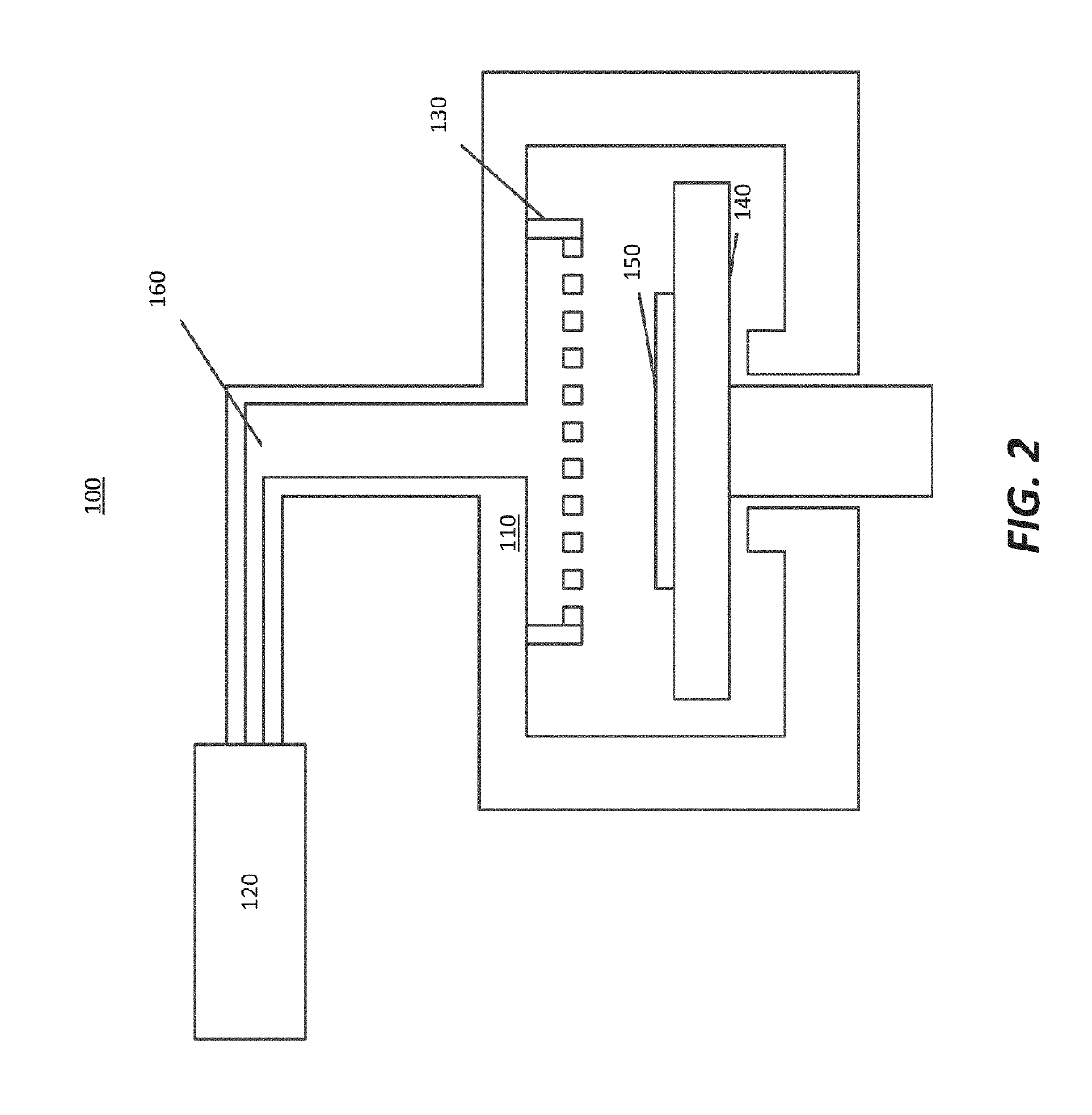

Vacuum evacuation system

ActiveUS20170200622A1Reduce installation costsIncrease pressureElectric discharge tubesFinal product manufactureProcess engineeringVacuum pump

The present invention relates to a vacuum evacuation system used to evacuate a processing gas from one or more process chambers for use in, for example, a semiconductor-device manufacturing apparatus. The vacuum evacuation system is a vacuum apparatus for evacuating a gas from a plurality of process chambers (1). The vacuum evacuation system includes a plurality of first vacuum pumps (5) coupled to the plurality of process chambers (1) respectively, a collecting pipe (7) coupled to the plurality of first vacuum pumps (5), and a second vacuum pump (8) coupled to the collecting pipe (7).

Owner:EBARA CORP

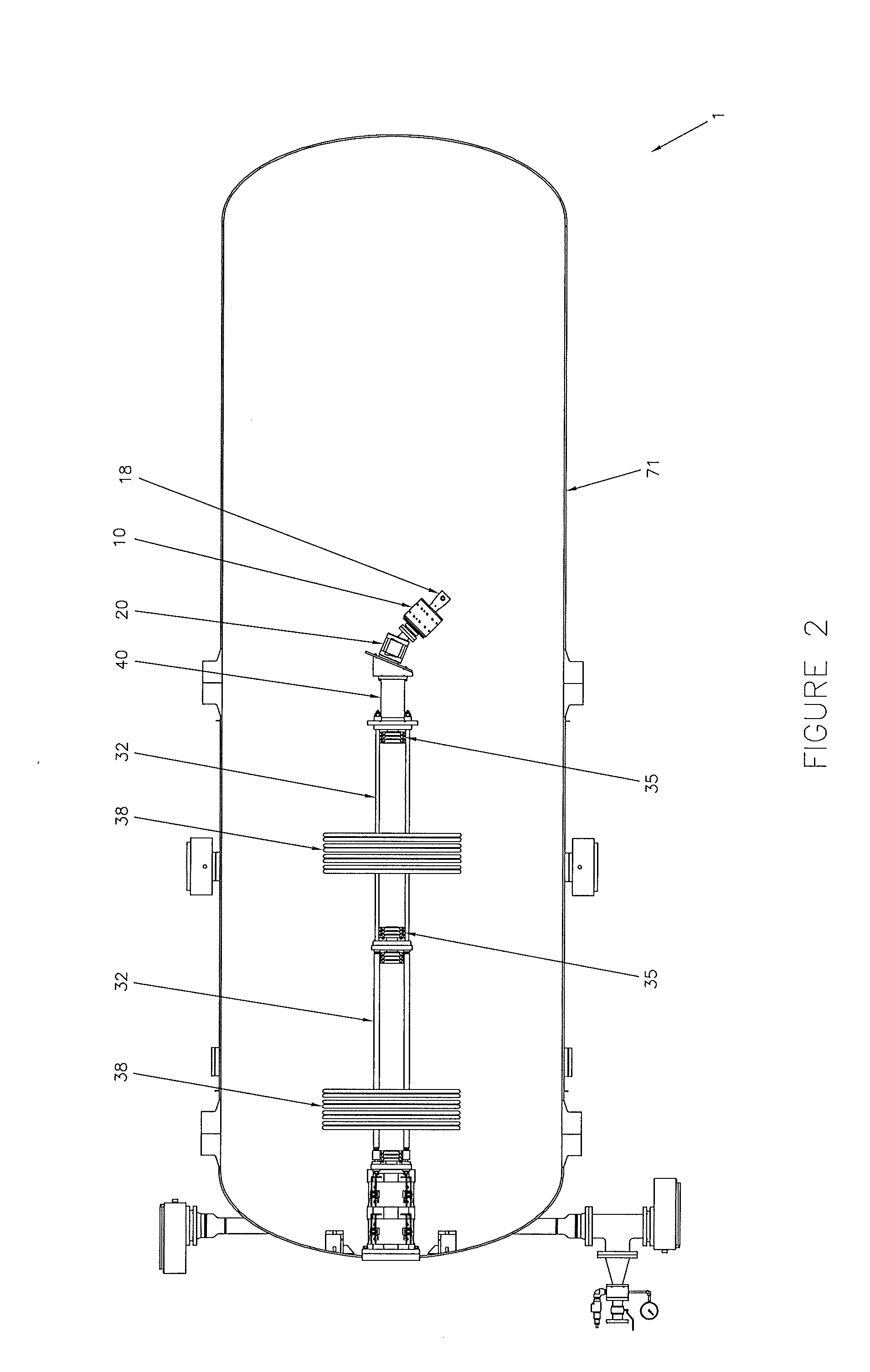

High frequency pressure swing adsorption

InactiveUS6176897B1High purityRecoverable expansion workNitrogen purification/separationGas treatmentSorbentEngineering

Pressure swing adsorption separation of a feed gas mixture, to obtain a purified product gas of the less strongly adsorbed fraction of the feed gas mixture, is performed in a plurality of preferably an even number of adsorbent beds, with each adsorbent bed communicating at its product end directly to a variable volume expansion chamber, and at its feed end by directional valves to a feed compressor and an exhaust vacuum pump. For high frequency operation of the pressure swing adsorption cycle, a high surface area layered support is used for the adsorbent. The compressor and vacuum pump pistons may be integrated with the cycle, reciprocating at twice the cycle frequency. Alternative configurations of the layered adsorbent beds are disclosed.

Owner:AIR PROD & CHEM INC

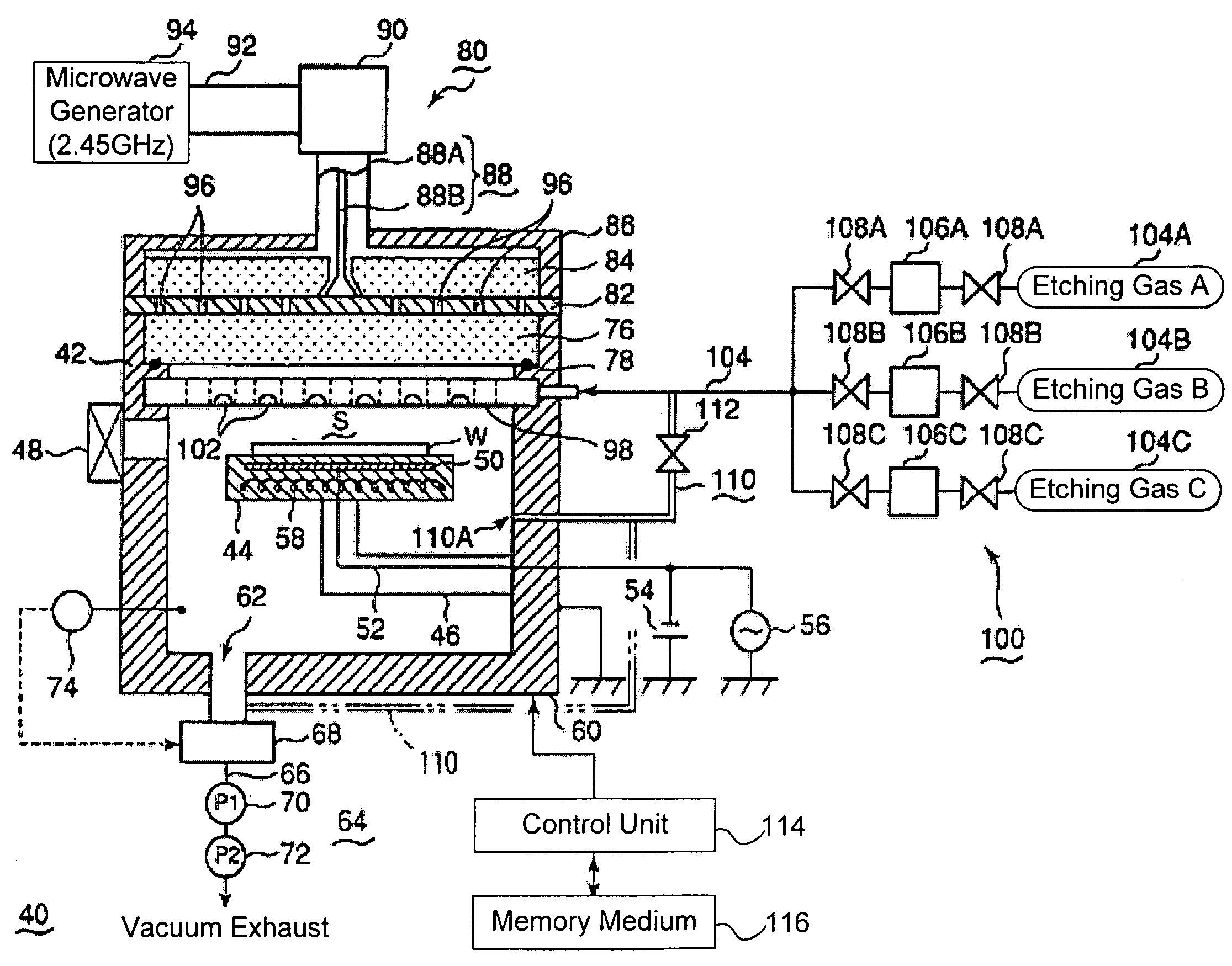

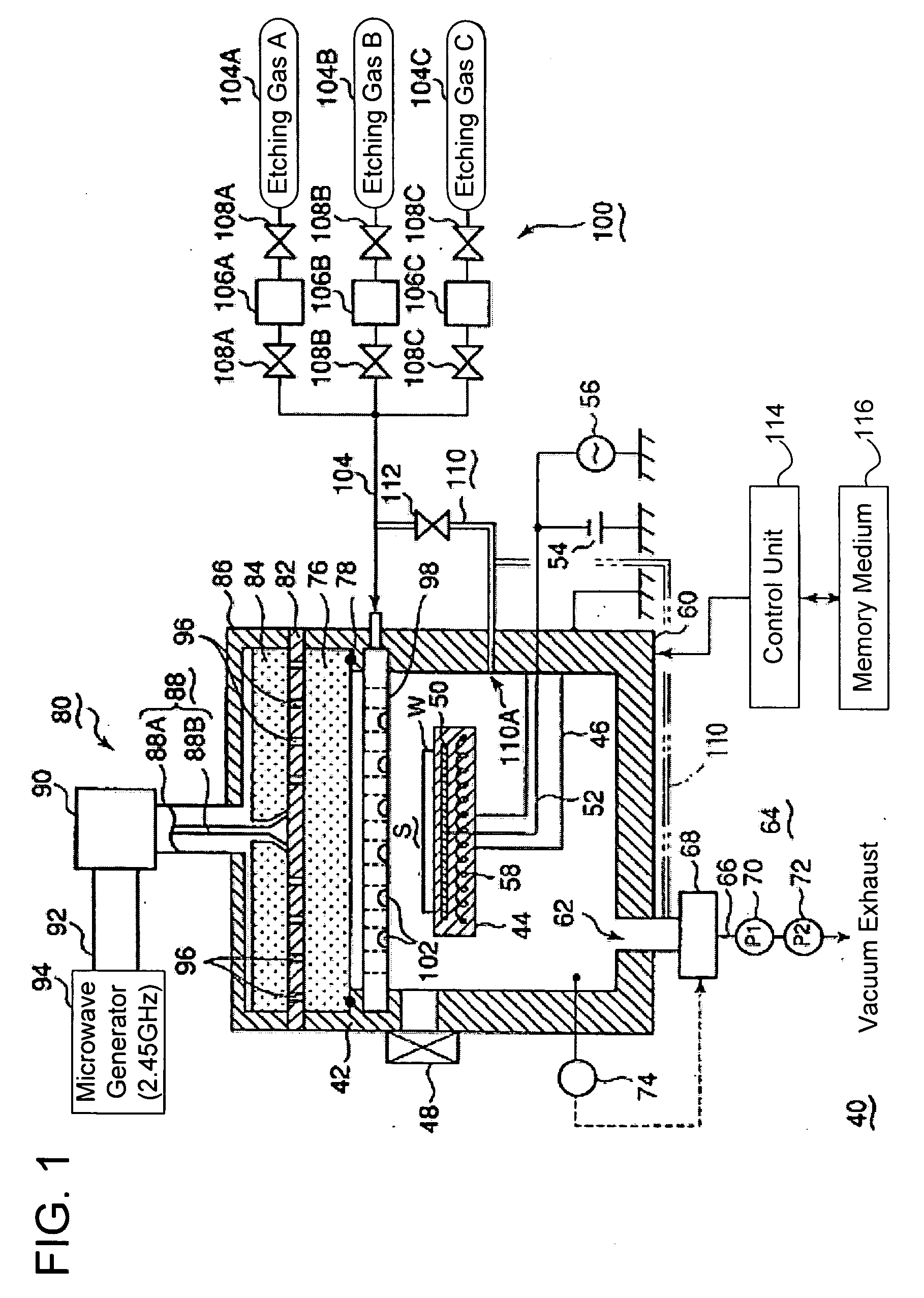

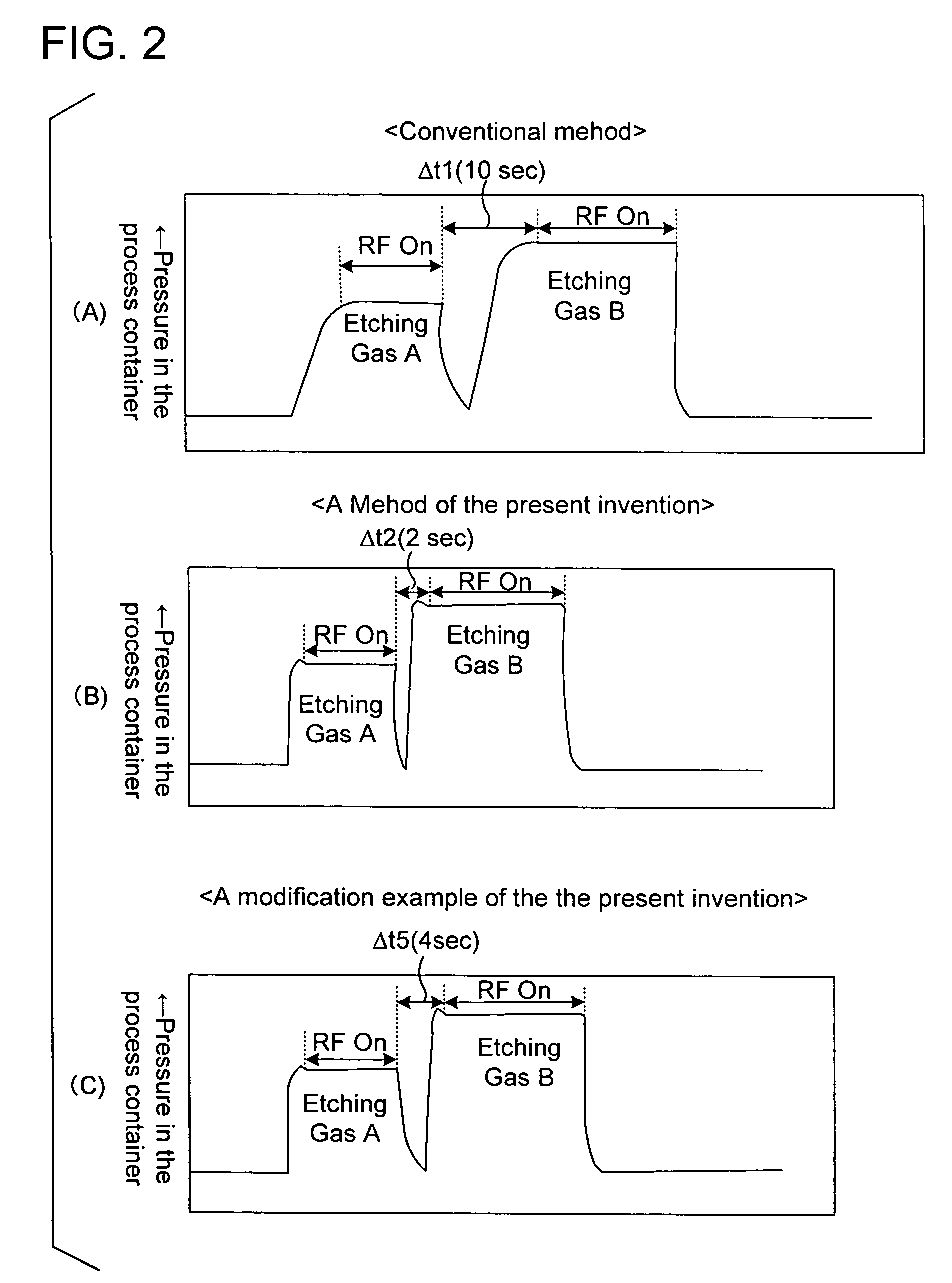

Processing Apparatus and Processing Method

ActiveUS20090053900A1Stable and fastAddressing slow performanceLiquid surface applicatorsElectric discharge tubesProduct gasEngineering

A processing apparatus includes a process container having a placing table for placing a processing object, an exhaust system having vacuum pumps and a pressure control valve for exhausting atmosphere in the process container. A gas injection unit having a gas ejection hole is provided in the process container, as well as a gas supplying unit for supplying a process gas to the gas injection unit. The entire process apparatus is controlled by a controlling unit. The control unit controls the exhaust system and the gas supplying unit. When starting a predetermined process, the process gas at a flow rate greater than a prescribed flow rate is supplied for a short time while exhausting the atmosphere in the process container by the exhaust system, and then the process gas at a prescribed flow rate is supplied.

Owner:TOKYO ELECTRON LTD

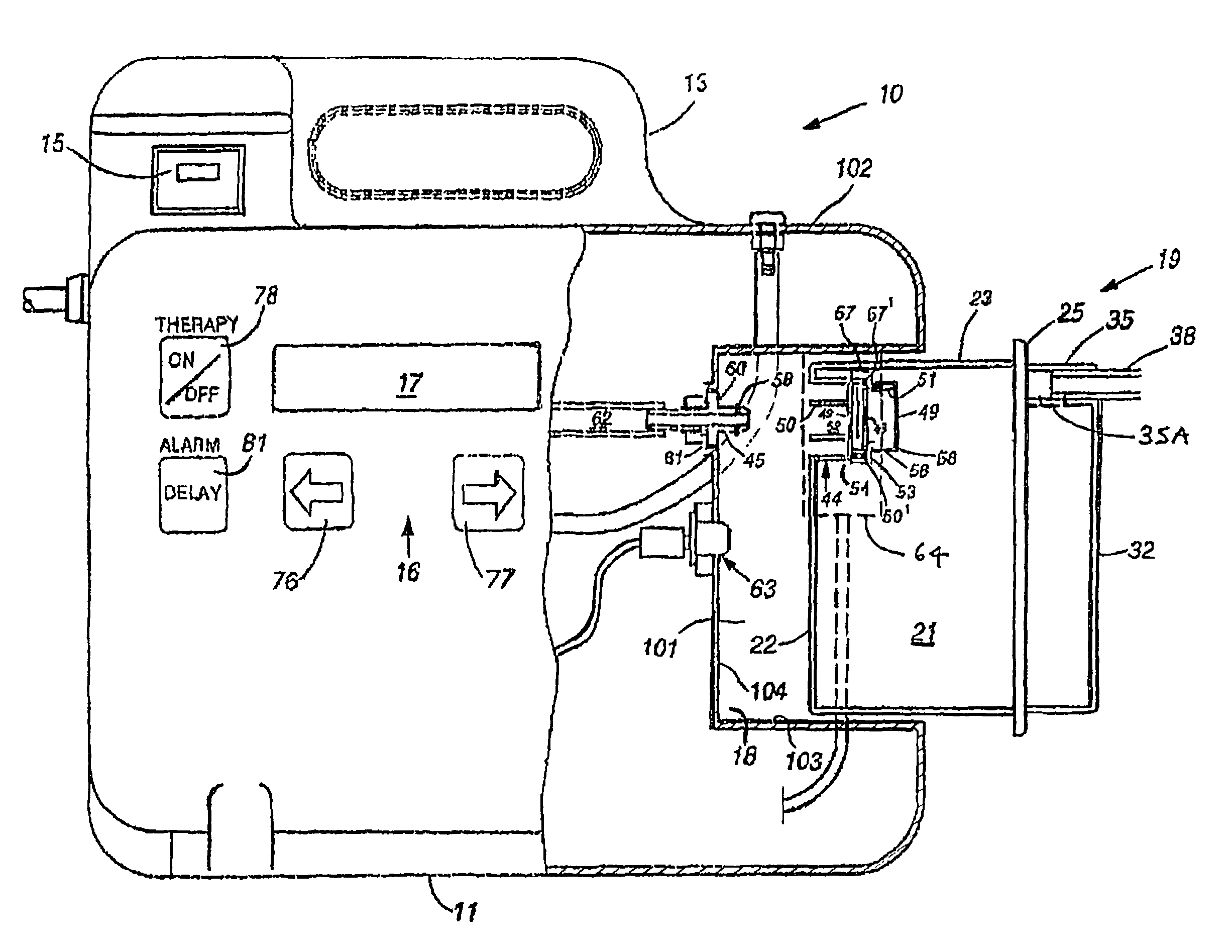

Apparatus and method for applying topical negative pressure

A method and apparatus for alerting a user of topical negative pressure therapy apparatus to a full waste canister condition are described, the apparatus comprising a device having vacuum pump means and a waste canister connected to the device and the waste canister operably connected to a wound dressing by aspiration conduit means for aspirating fluid from the wound, the aspiration conduit means, the waste canister and the device providing a fluid flow path therethrough and the vacuum pump means providing fluid flow through the apparatus, the apparatus further comprising fluid flow restriction means in the fluid flow path of said vacuum pump and fluid pressure sensing means upstream and downstream of said fluid flow restriction means.

Owner:SMITH & NEPHEW INC

Exhaust system for a vacuum processing system

InactiveUS7670432B2Reduce pollutionEasy transitionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingProduct gasProcess engineering

A method, computer readable medium, and system for treating a substrate in a process space of a vacuum processing system is described. A vacuum pump in fluid communication with the vacuum processing system and configured to evacuate the process space, while a process material supply system is pneumatically coupled to the vacuum processing system and configured to supply a process gas to the process space. Additionally, the vacuum pump is pneumatically coupled to the process supply system and configured to, at times, evacuate the process gas supply system.

Owner:TOKYO ELECTRON LTD

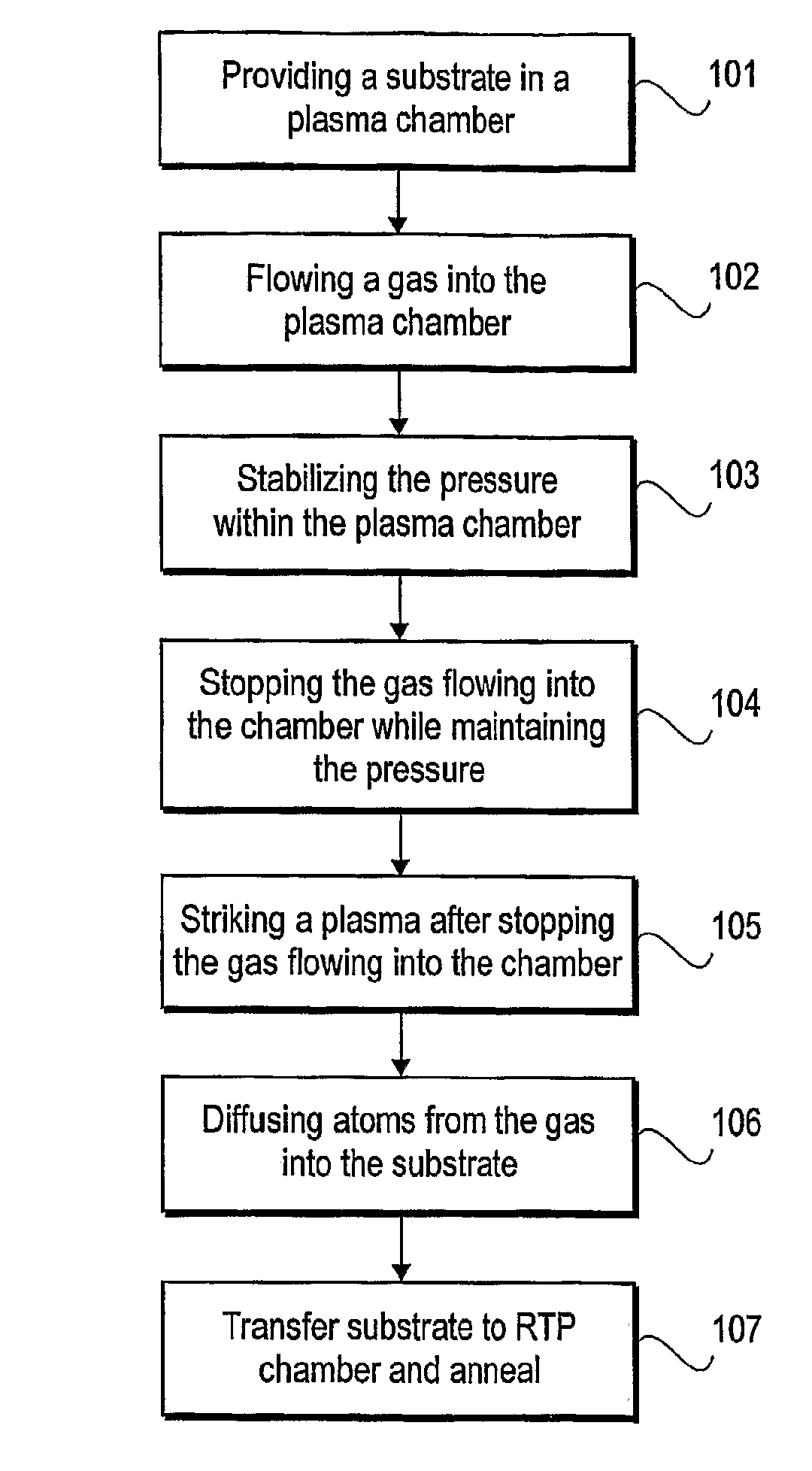

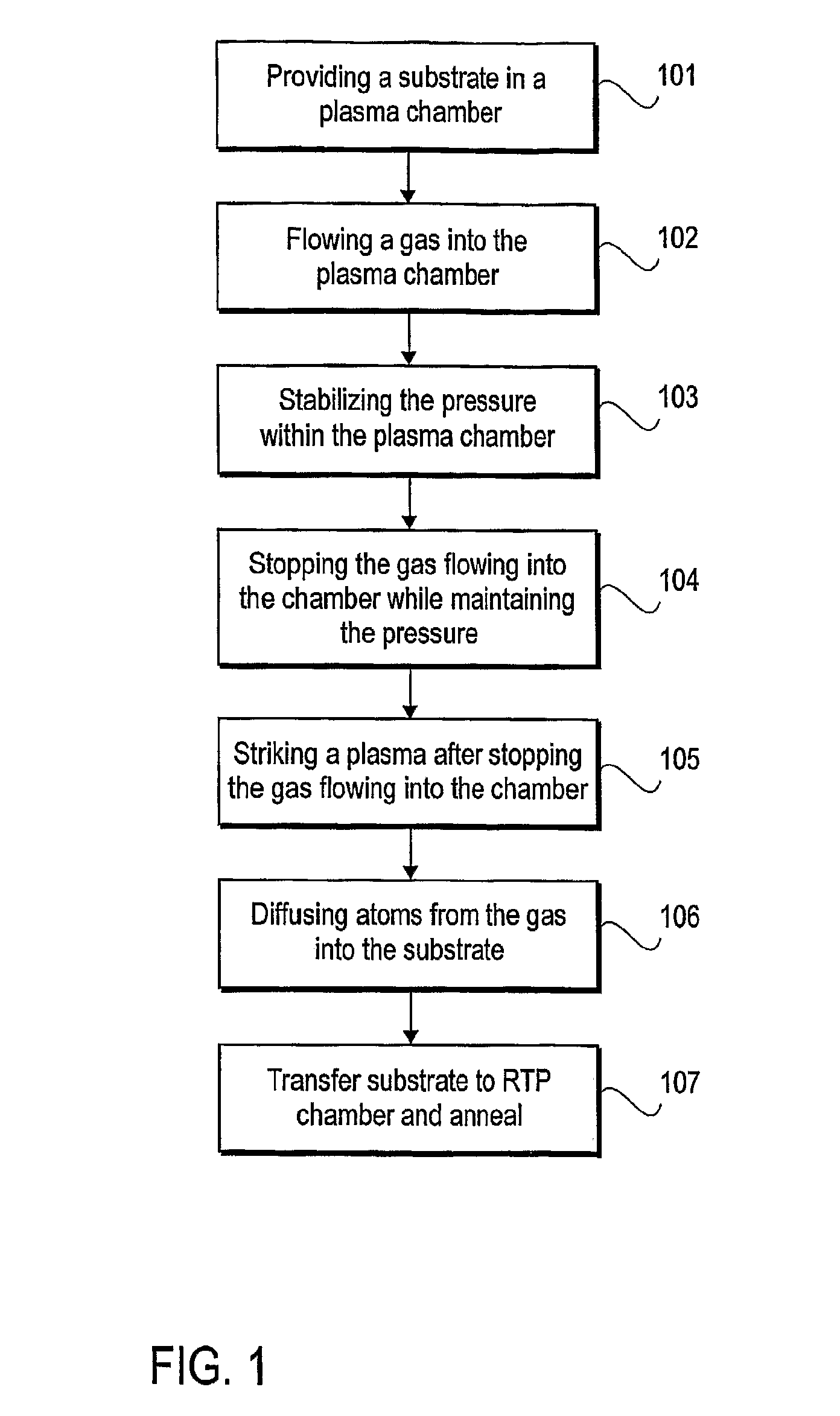

Elimination of flow and pressure gradients in low utilization processes

InactiveUS7955646B2Polycrystalline material growthSemiconductor/solid-state device manufacturingGate dielectricChemical vapor deposition

The amount of atoms diffused into a substrate may be made uniform or the thickness of a thin film may be made uniform in a low species utilization process by stopping the flow of gas into a reaction chamber during the low species utilization process. Stopping the flow of gas into a reaction chamber may entail closing the gate valve (the valve to the vacuum pump), stabilizing the pressure within the reaction chamber, and maintaining the stabilized pressure while stopping the gas flowing into the chamber. Low species utilization processes include the diffusion of nitrogen into silicon dioxide gate dielectric layers by decoupled plasma nitridation (DPN), the deposition of a silicon dioxide film by rapid thermal processing (RTP) or chemical vapor deposition (CVD), and the deposition of silicon epitaxial layers by CVD.

Owner:APPLIED MATERIALS INC

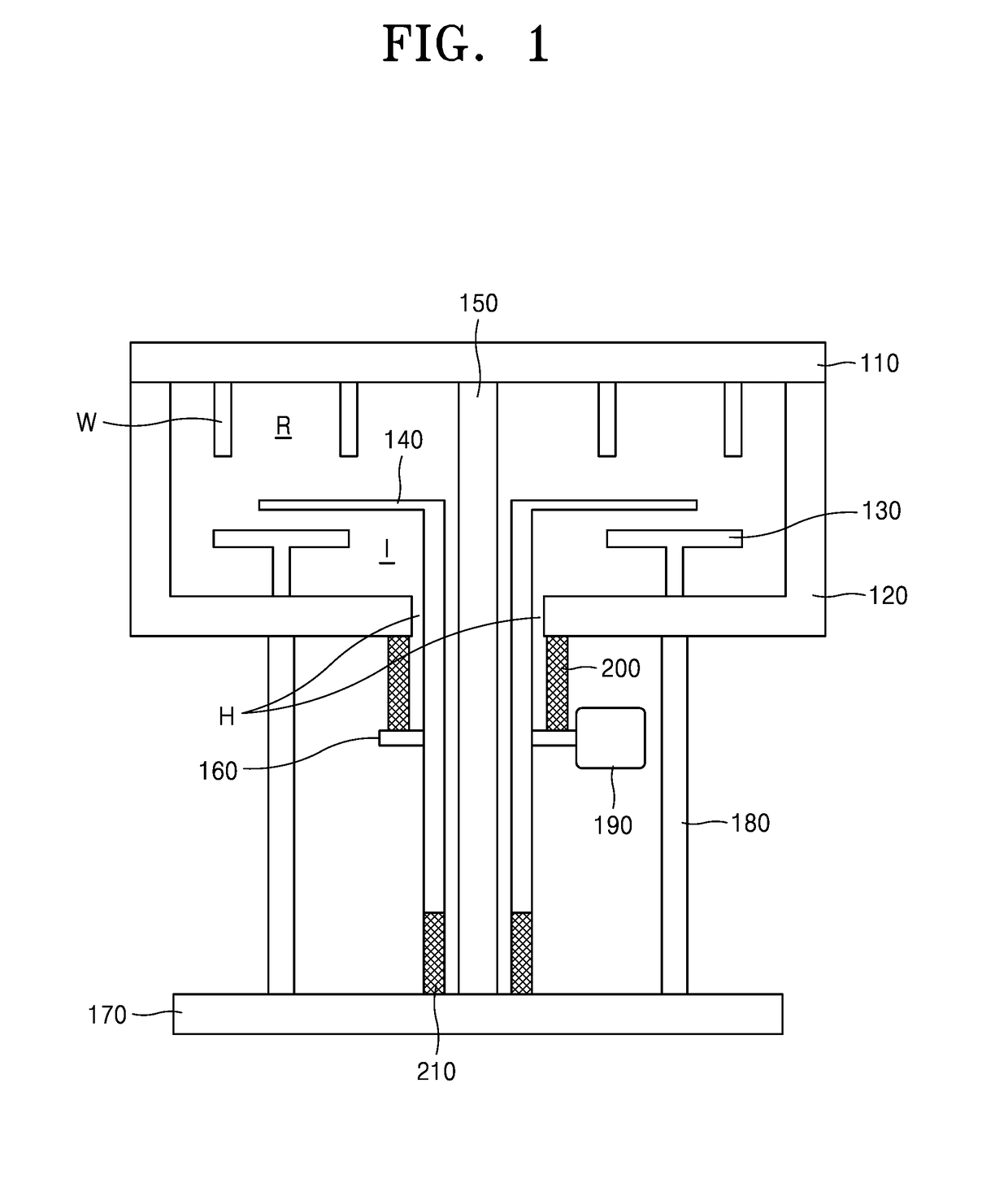

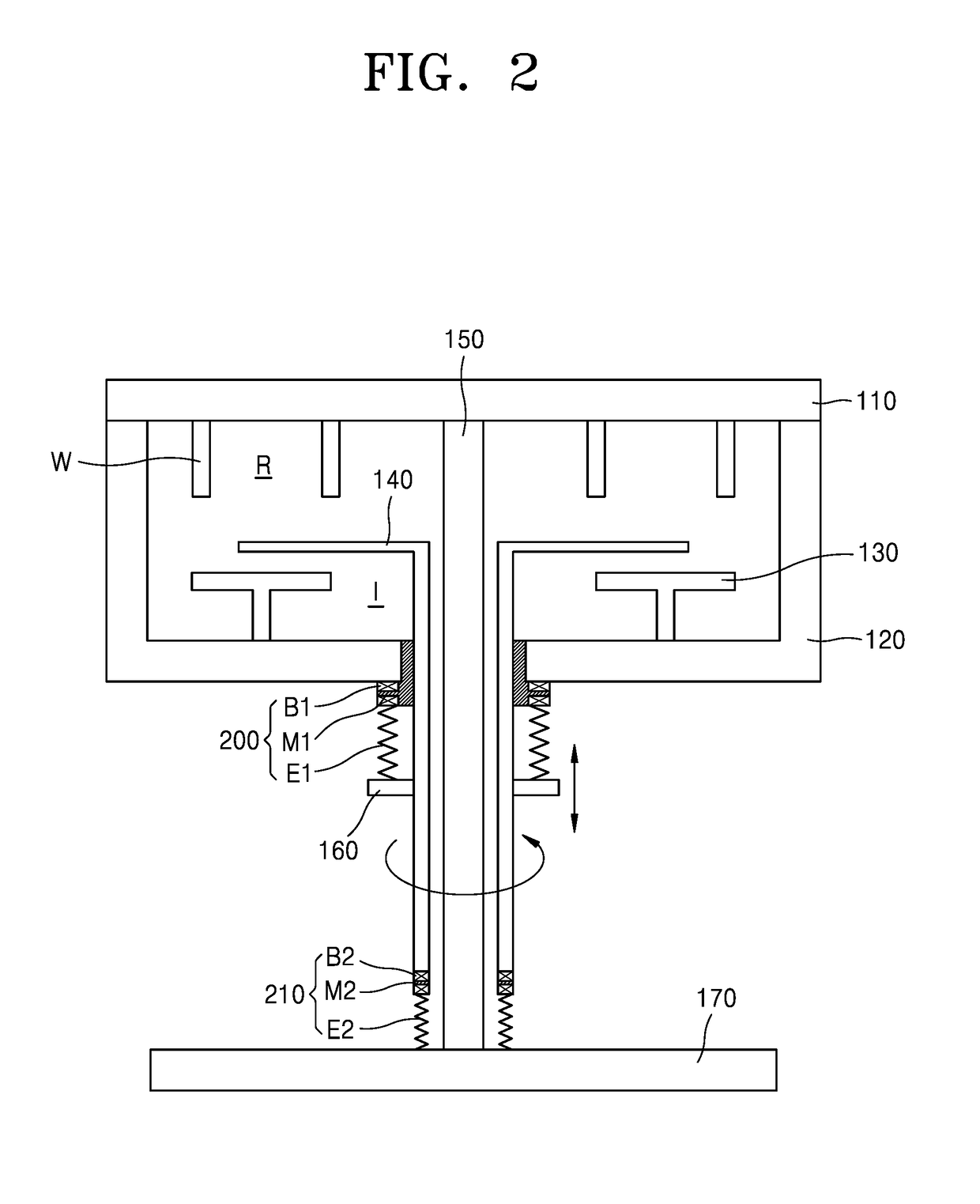

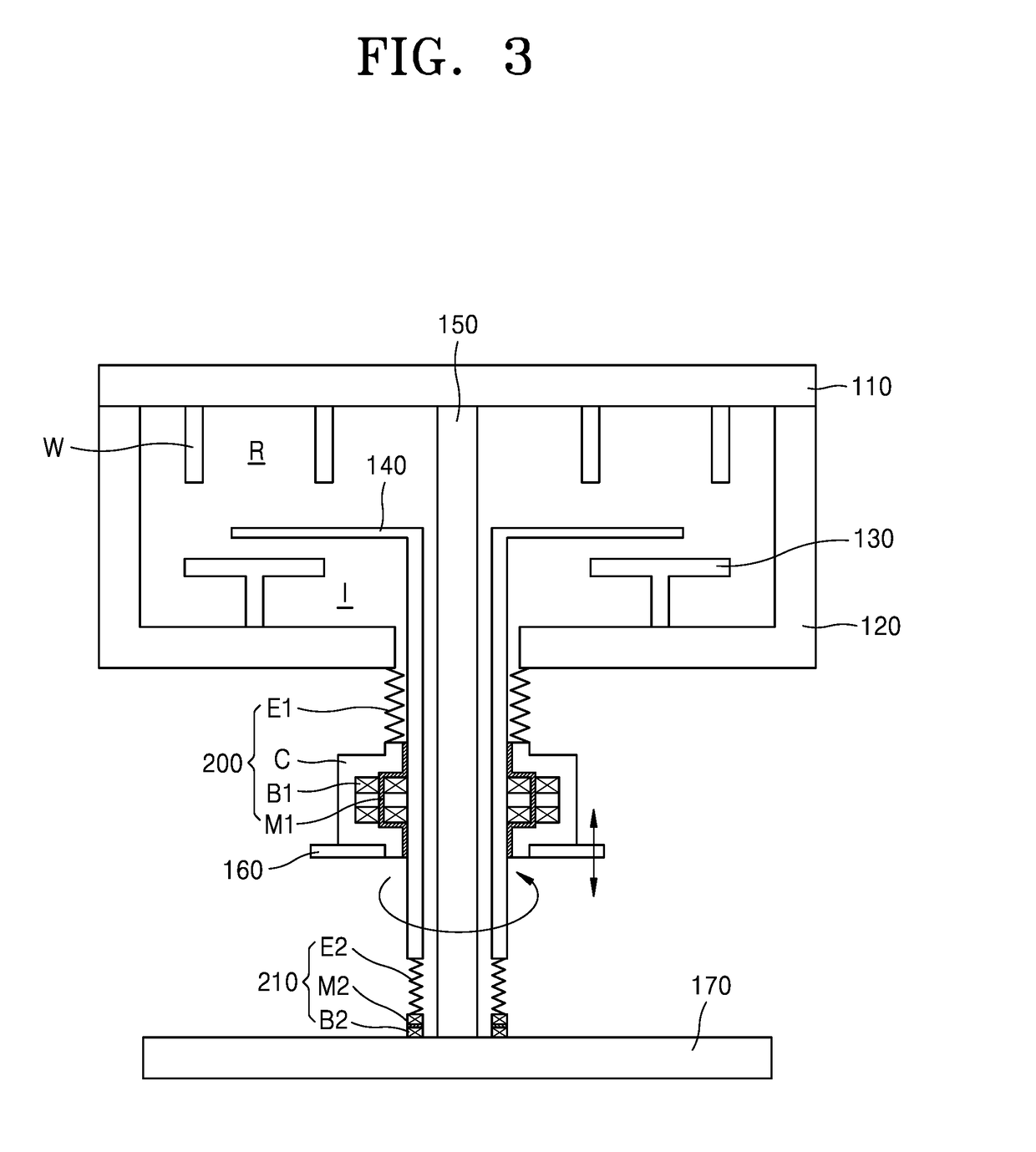

Substrate processing device

Provided is a substrate-processing device capable of preventing a top lid from sagging downward by the own weight of the substrate-processing device and / or a vacuum suction force generated by a vacuum pump and / or thermal shock at high temperature process, in a chamber including a plurality of reactors. Also, provided is a rotating shaft for transferring a substrate between the plurality of reactors.

Owner:ASM IP HLDG BV

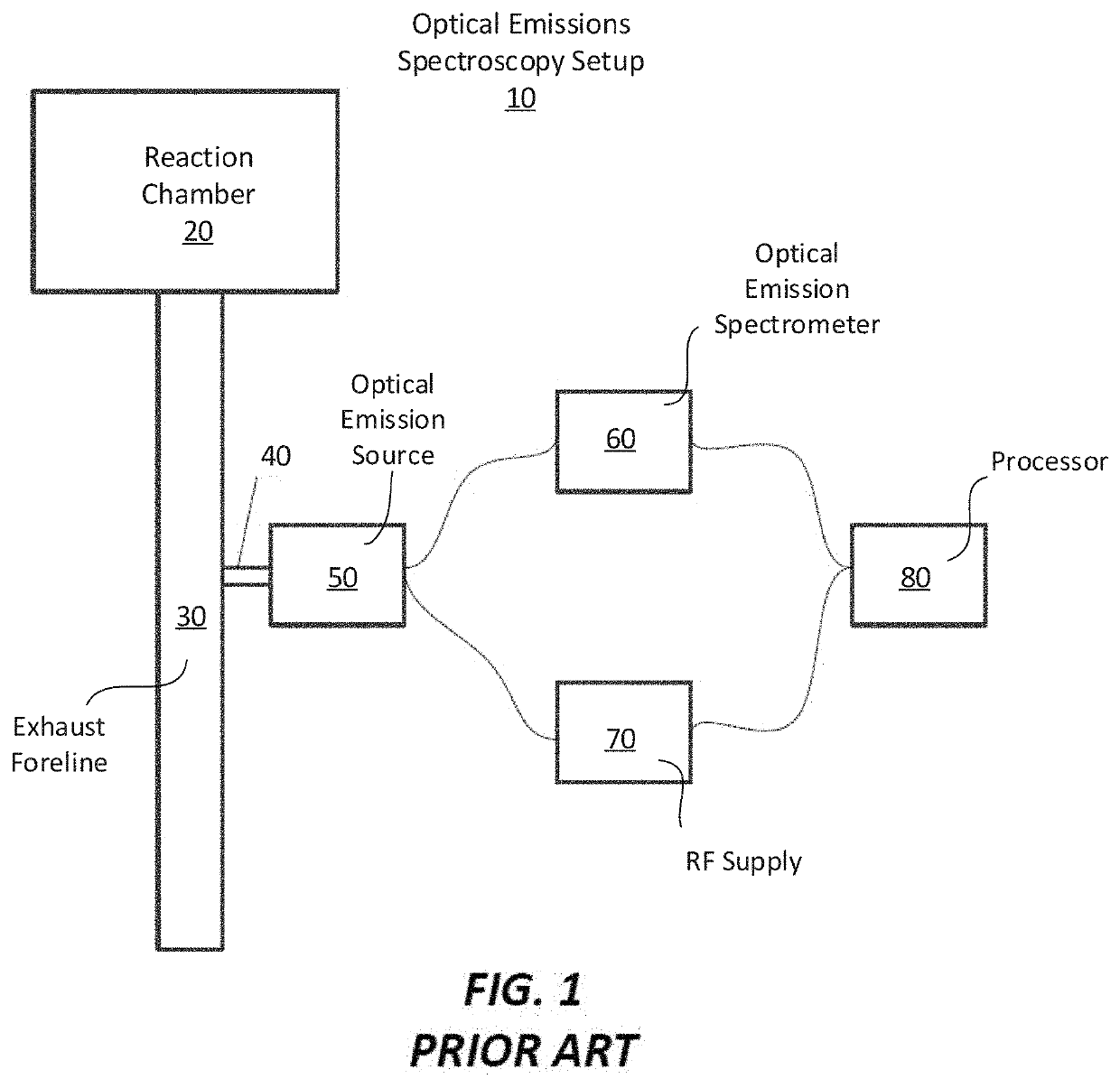

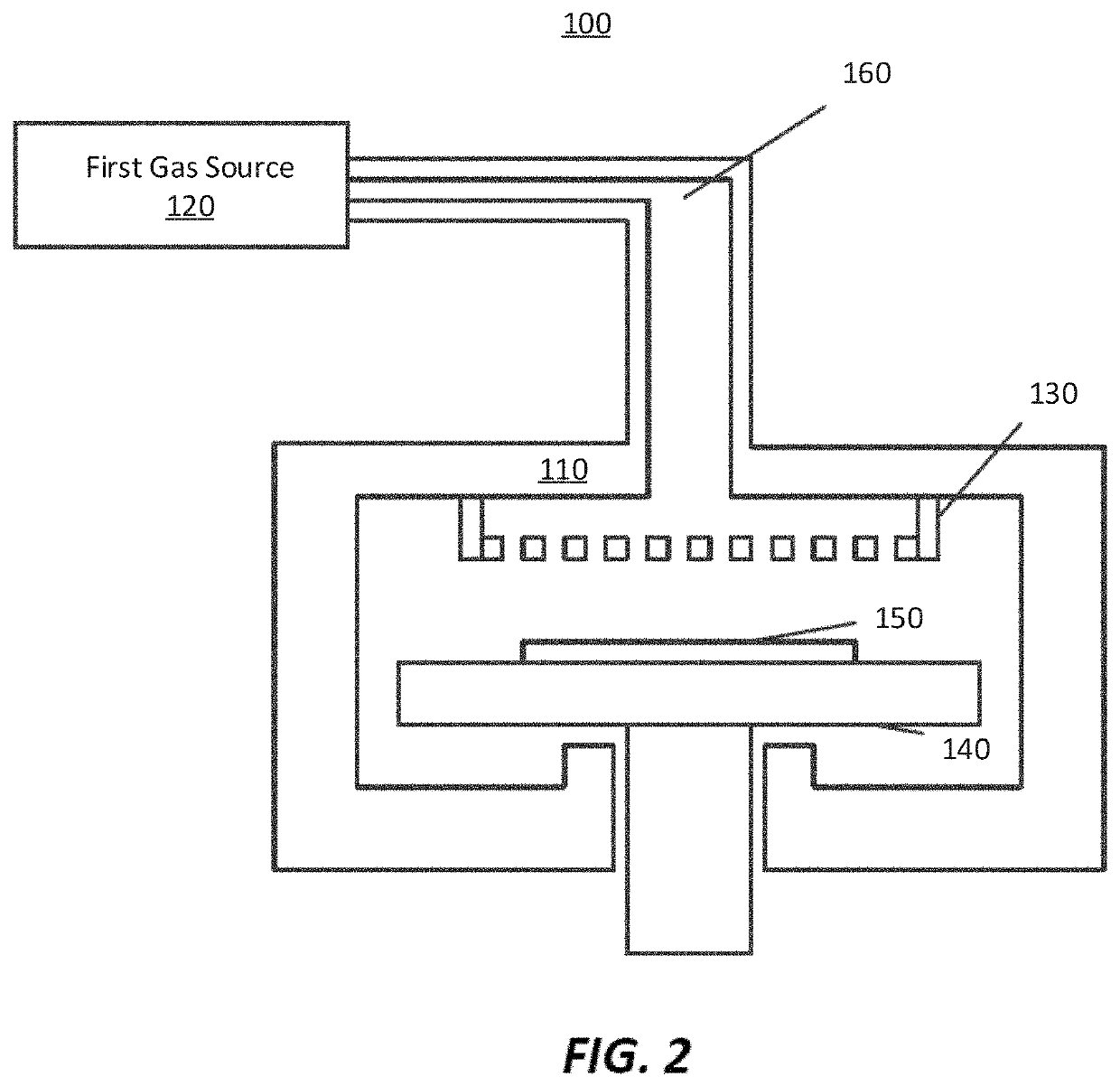

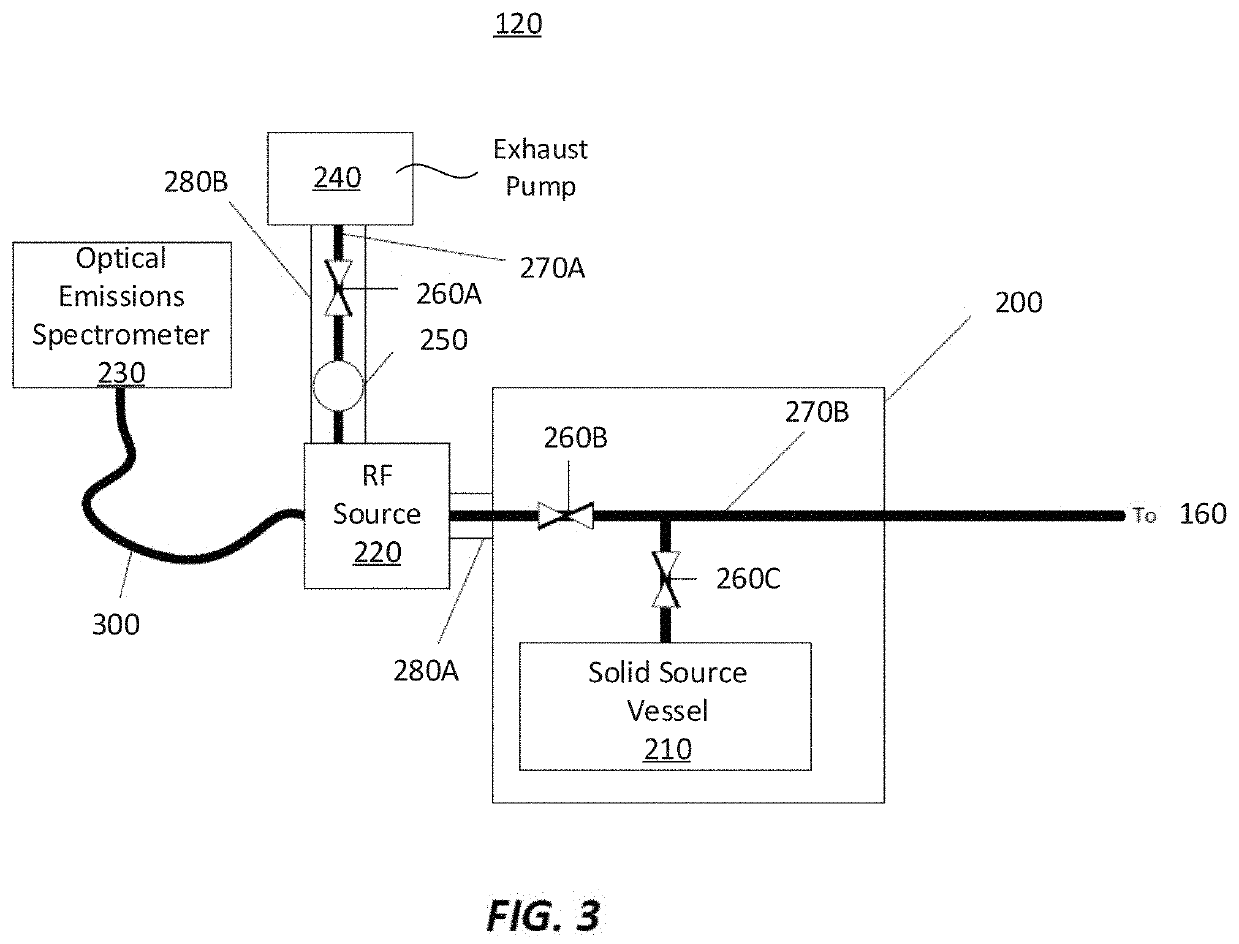

Apparatus for detecting or monitoring for a chemical precursor in a high temperature environment

ActiveUS20190264324A1Emission spectroscopyElectric discharge tubesOptical Emission SpectrometerSmall sample

An apparatus and method are disclosed for monitoring and / or detecting concentrations of a chemical precursor in a reaction chamber. The apparatus and method have an advantage of operating in a high temperature environment. An optical emissions spectrometer (OES) is coupled to a gas source, such as a solid source vessel, in order to monitor or detect an output of the chemical precursor to the reaction chamber. Alternatively, a small sample of precursor can be periodically monitored flowing into the OES and into a vacuum pump, thus bypassing the reaction chamber.

Owner:ASM IP HLDG BV

Apparatus for detecting or monitoring for a chemical precursor in a high temperature environment

ActiveUS20210180189A1Emission spectroscopyElectric discharge tubesOptical Emission SpectrometerOptical spectrometer

An apparatus and method are disclosed for monitoring and / or detecting concentrations of a chemical precursor in a reaction chamber. The apparatus and method have an advantage of operating in a high temperature environment. An optical emissions spectrometer (OES) is coupled to a gas source, such as a solid source vessel, in order to monitor or detect an output of the chemical precursor to the reaction chamber. Alternatively, a small sample of precursor can be periodically monitored flowing into the OES and into a vacuum pump, thus bypassing the reaction chamber.

Owner:ASM IP HLDG BV

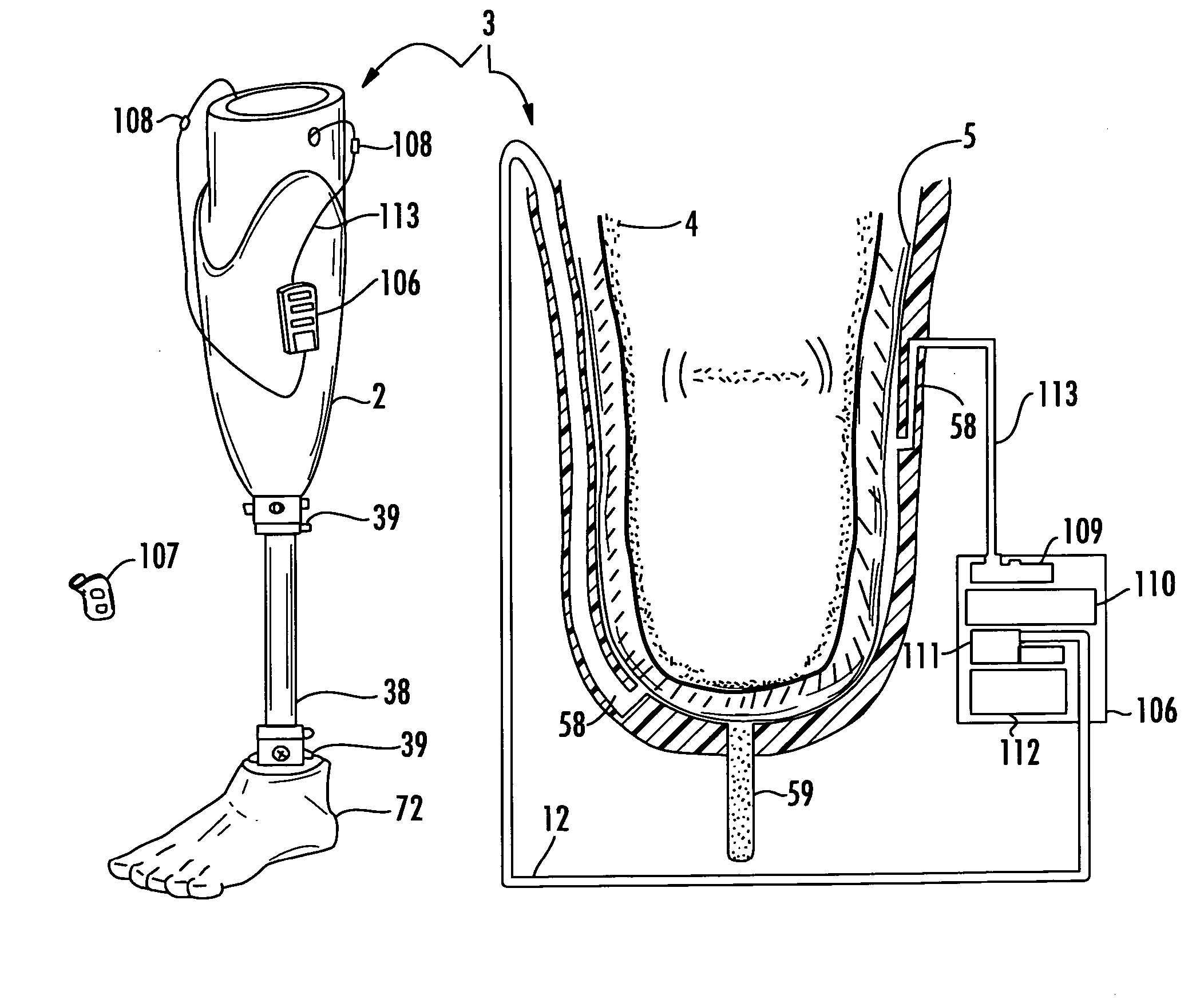

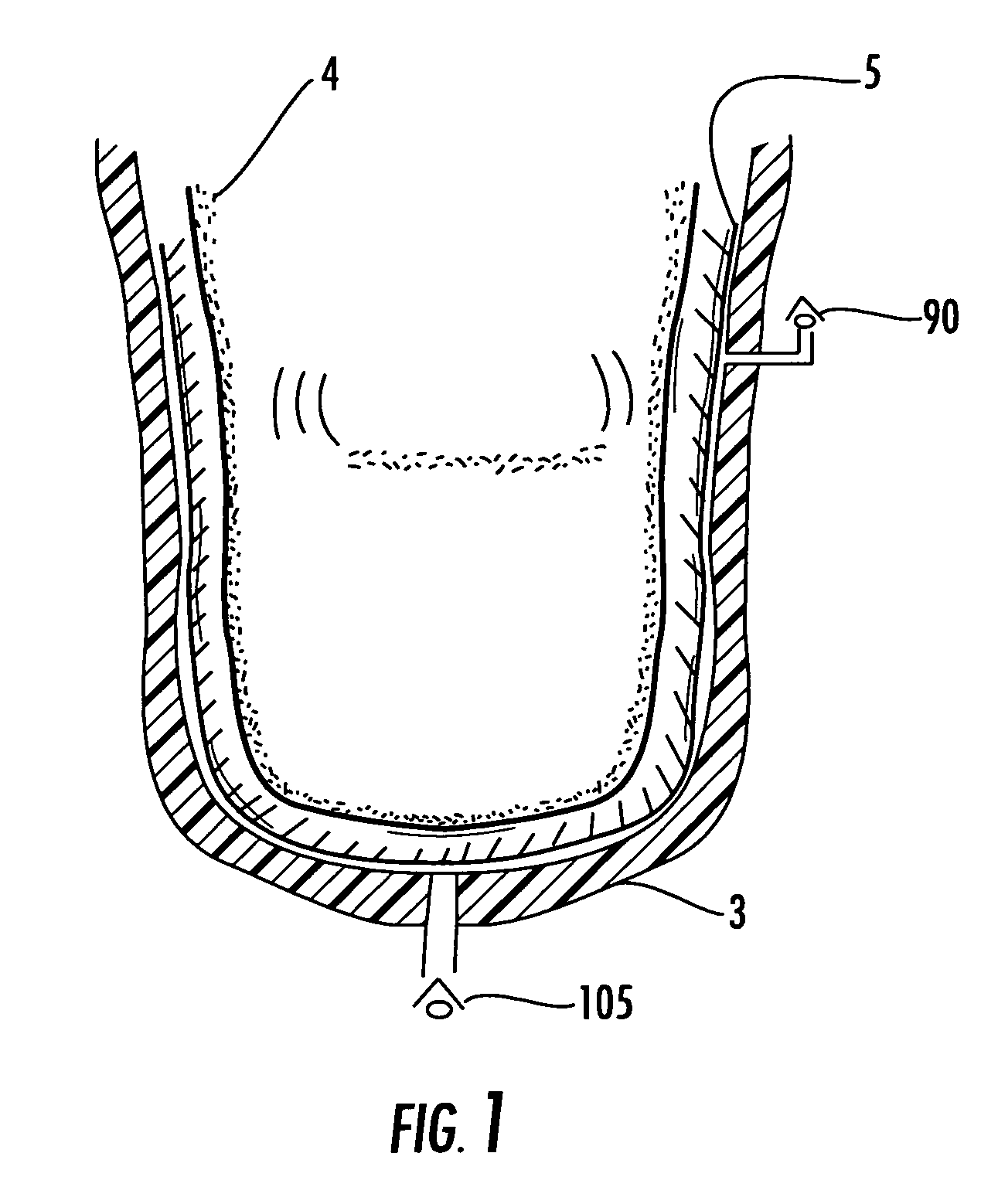

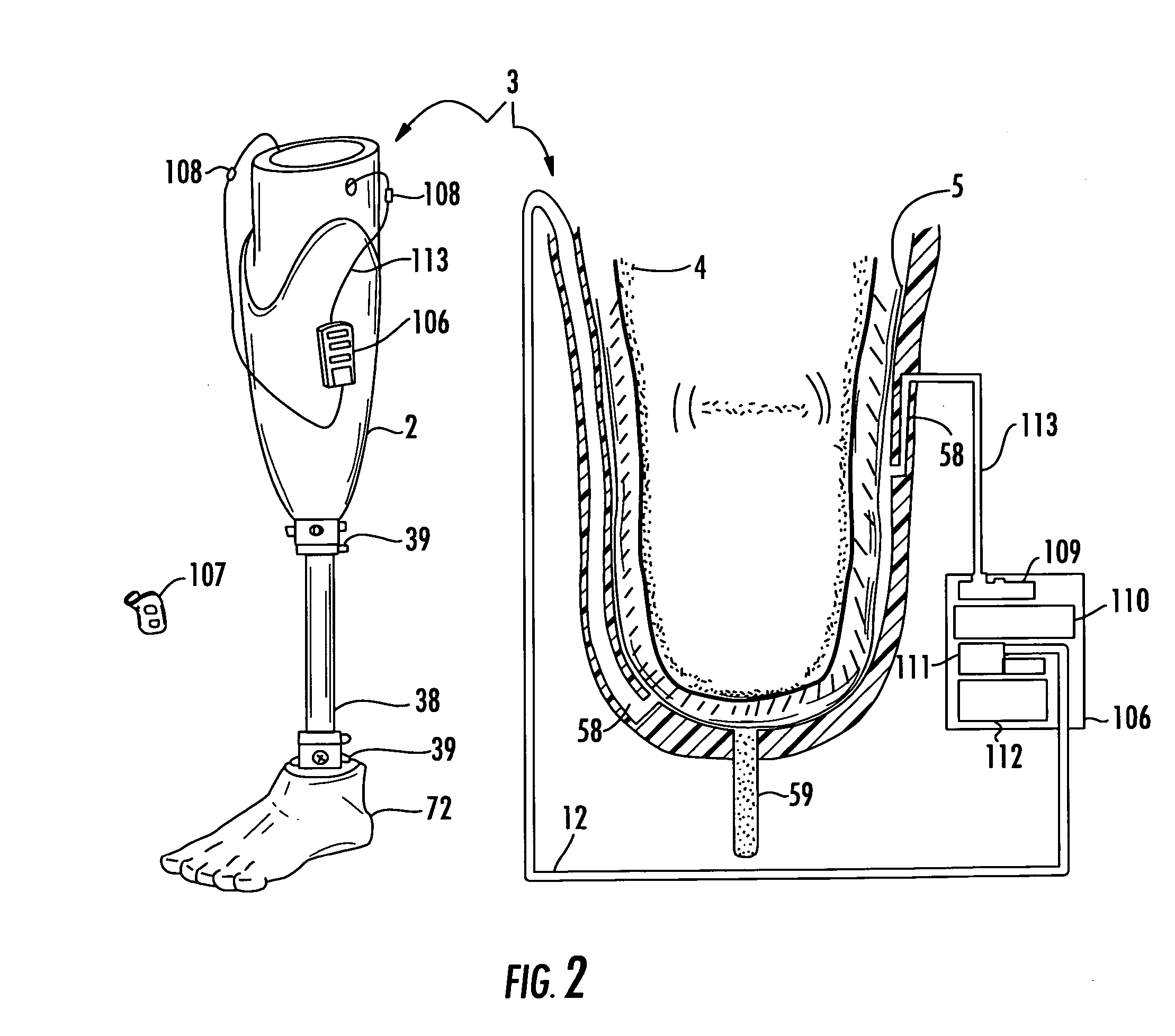

Vacuum assisted heat/perspiration removal system and limb volume management for prosthetic device

InactiveUS20070055383A1Reduce relative motionEasy to hangTherapeutic coolingTherapeutic heatingVacuum assistedPerspiration

The vacuum assisted liner system is for use with a prosthetic device to be attached to a residual limb. The liner system includes a hypobaric prosthetic liner, and a porous wicking material layer to surround at least a portion of the residual limb and define a regulated vacuum environment between the hypobaric prosthetic liner and the residual limb. The hypobaric prosthetic liner has at least one passageway therethrough defining at least one vacuum port, such as an inlet port and outlet port, in fluid communication with the regulated vacuum environment. Internal liner passageways may connect the inlet and outlet ports to the regulated vacuum environment. A vacuum regulation device may include an electric vacuum pump or a motion activated pump connected to the outlet port.

Owner:KING CHARLES

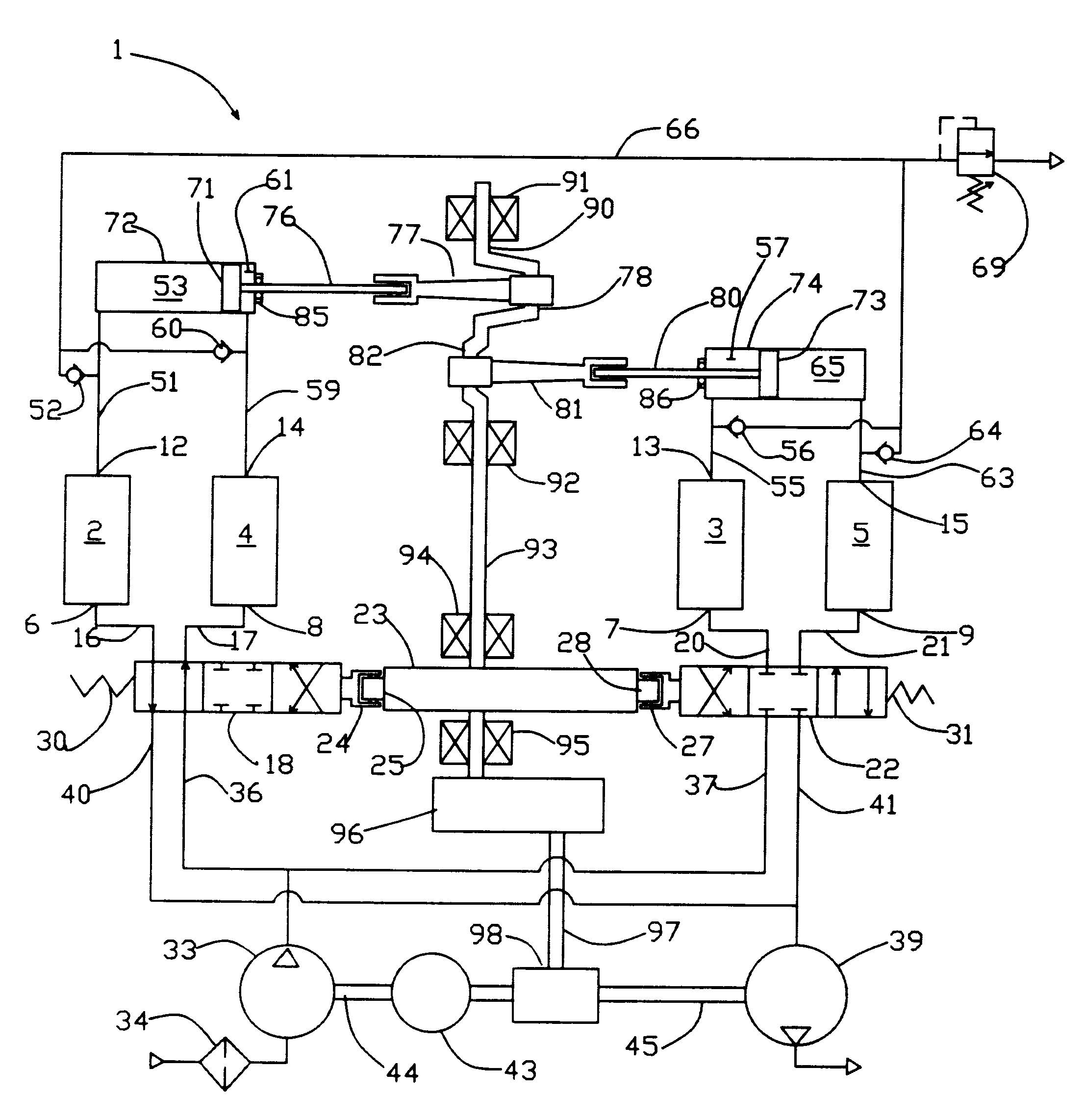

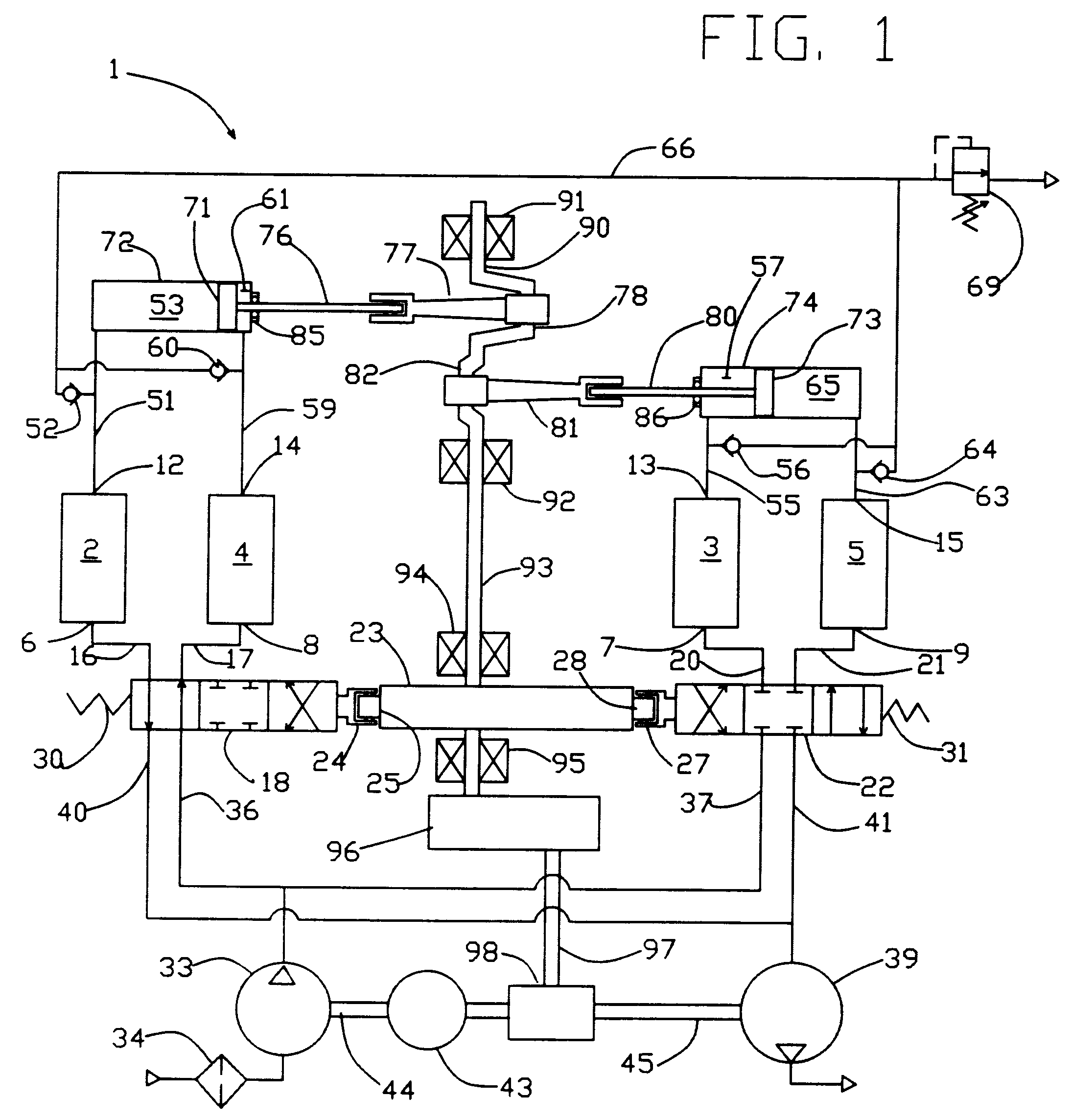

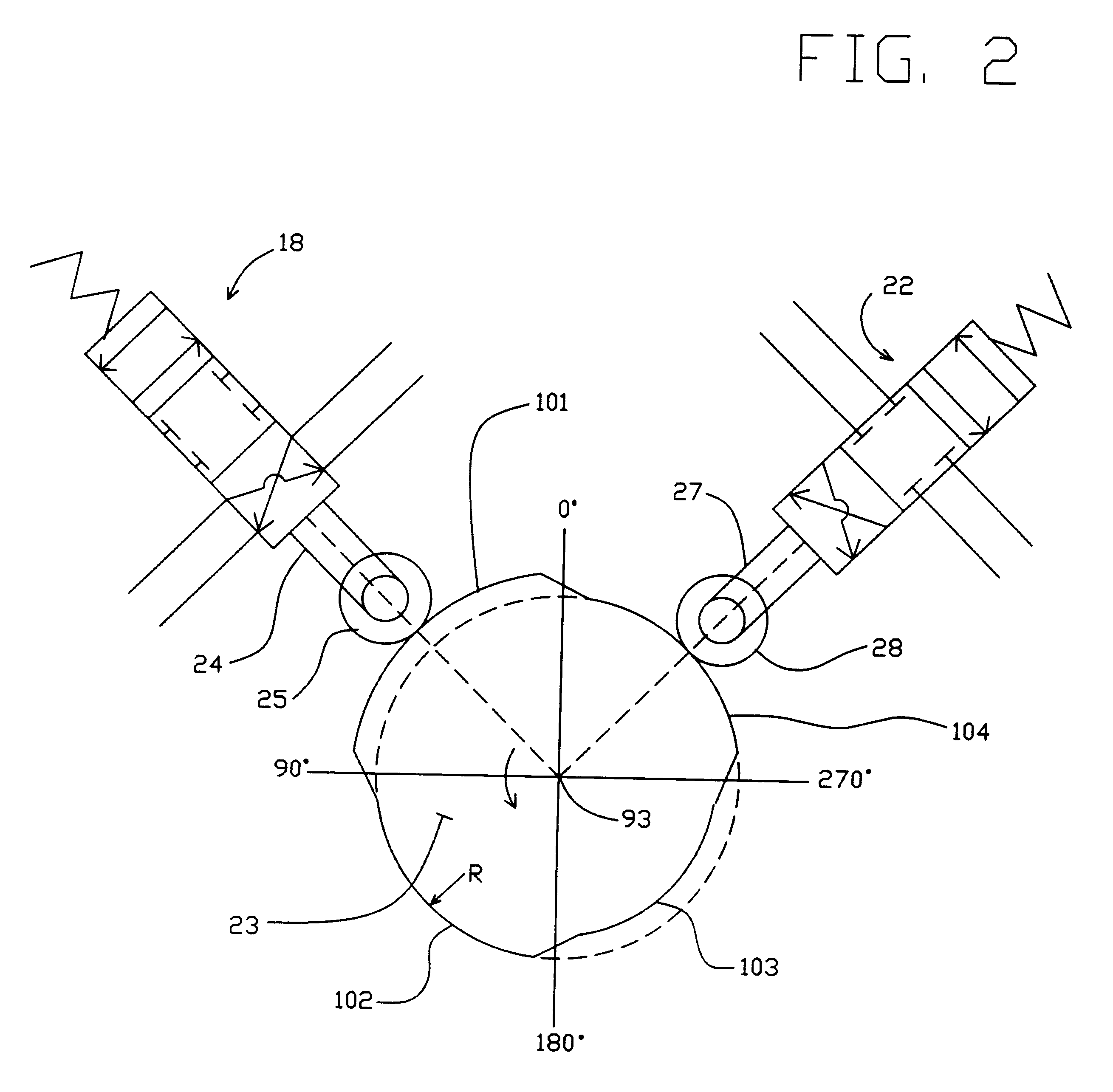

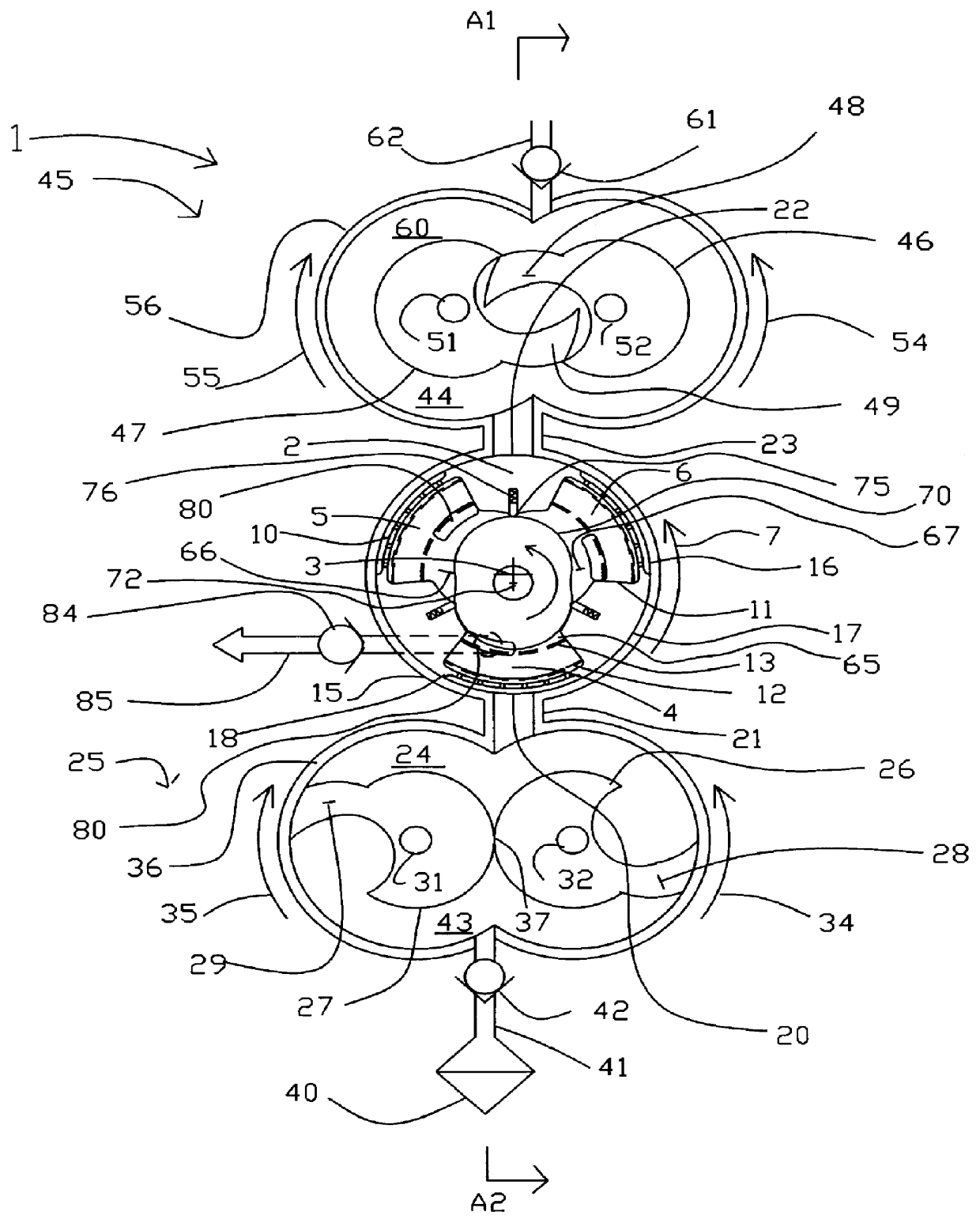

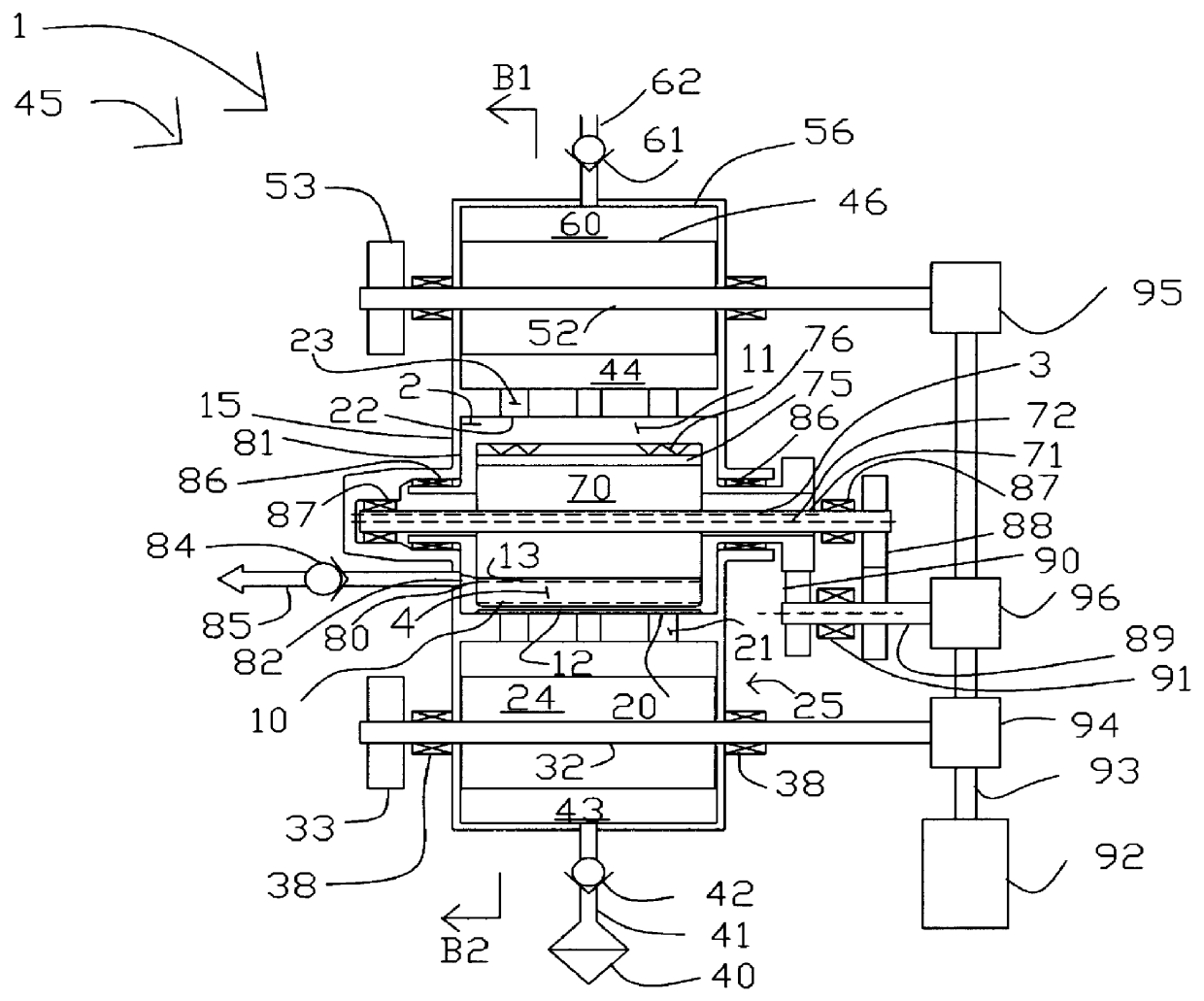

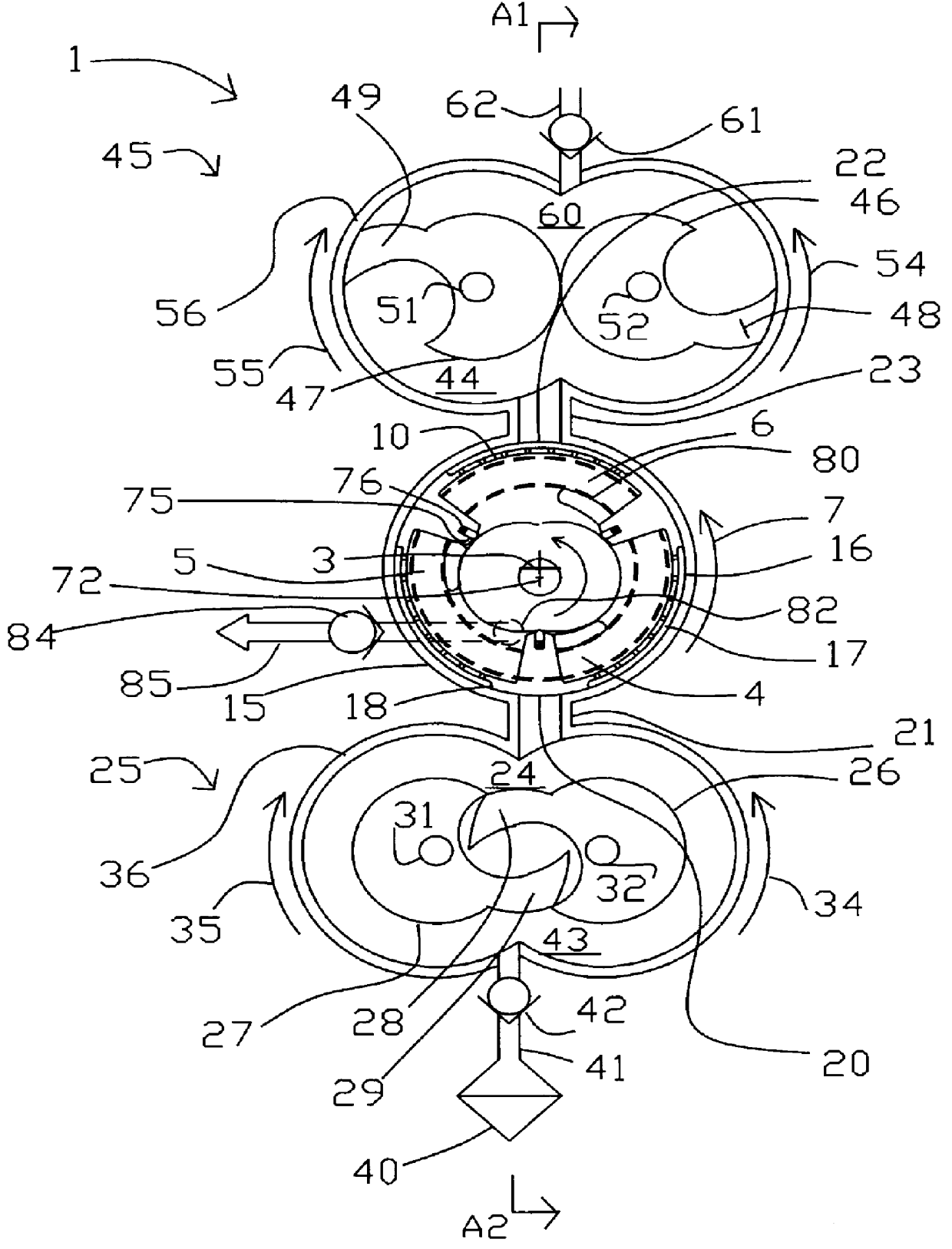

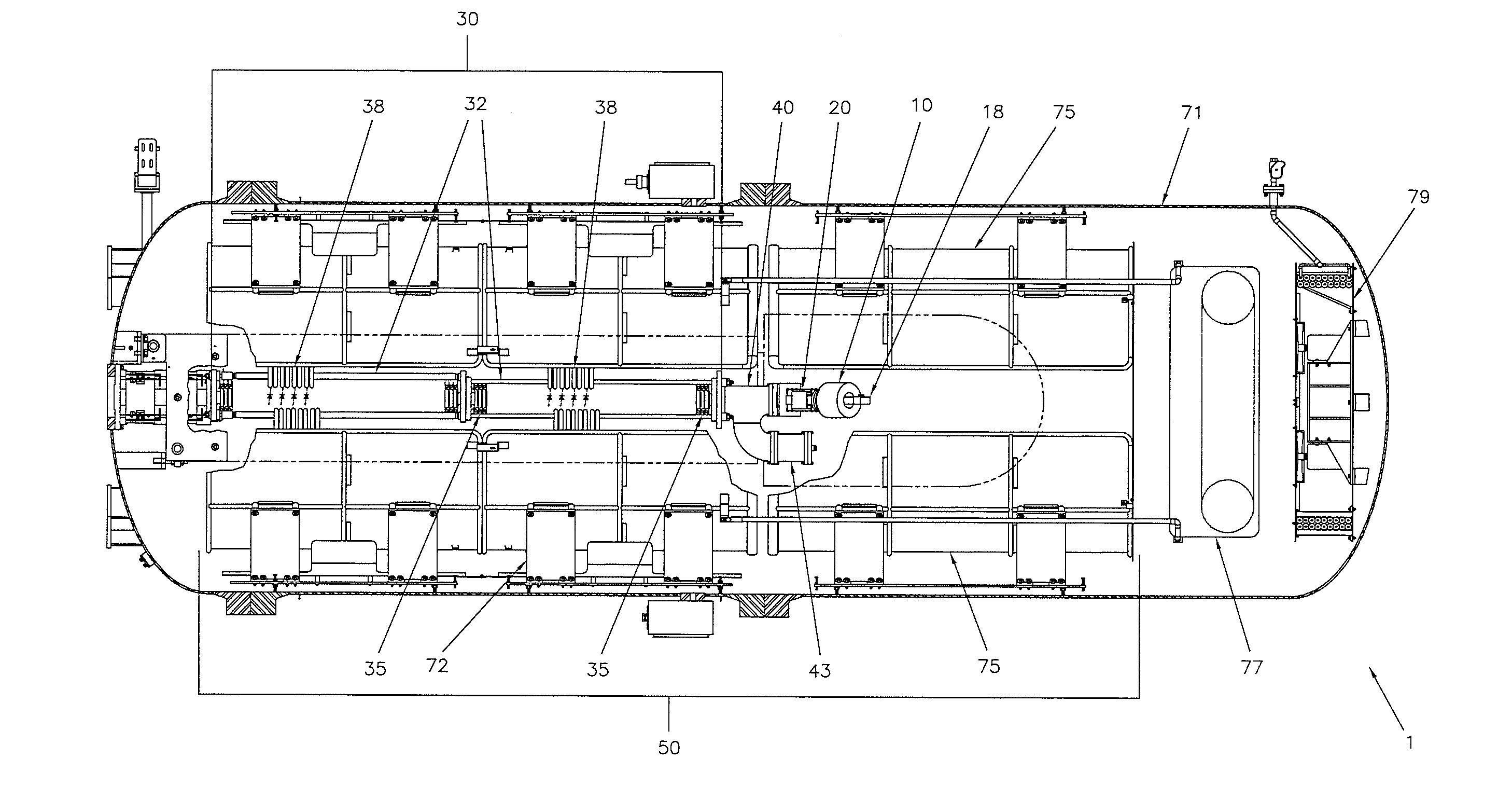

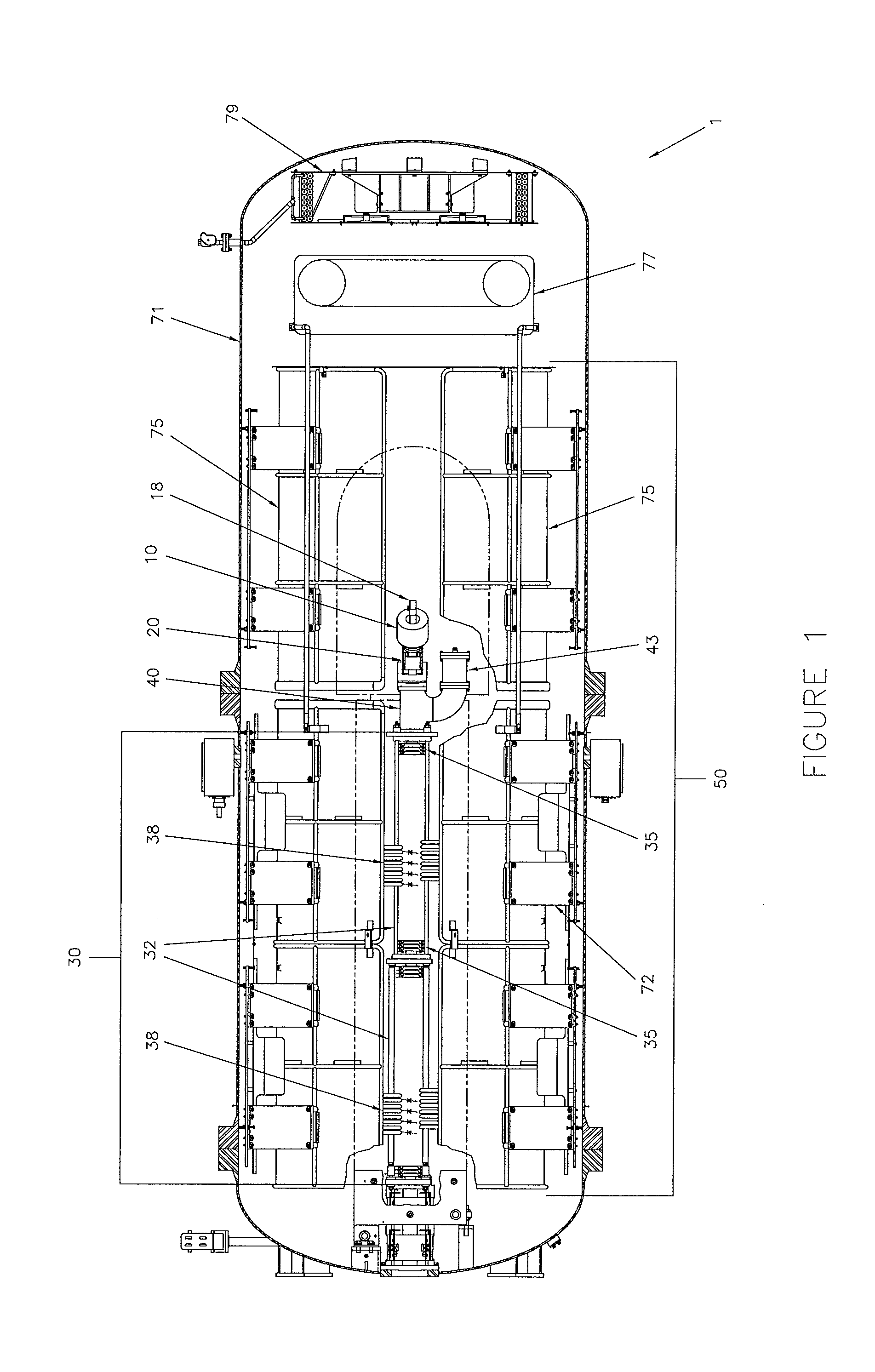

High frequency rotary pressure swing adsorption apparatus

InactiveUS6056804AHigh-frequency operationCompact equipmentGas treatmentIsotope separationProduct gasDistributor

Pressure swing adsorption separation of a feed gas mixture, to obtain a purified product gas of the less strongly adsorbed fraction of the feed gas mixture, is performed with a cooperating set of "N" adsorbers in a rotary assembly, with each adsorber communicating at its product end directly to a rotary cyclic displacement chamber, and at its feed end by rotary distributor valve ports to a rotary piston feed compressor and a rotary piston exhaust vacuum pump. The compressor and vacuum pump are integrated with the cycle, and rotate at "N" times the cycle frequency. Alternative adsorber configurations for high frequency operation are disclosed.

Owner:AIR PROD & CHEM INC +1

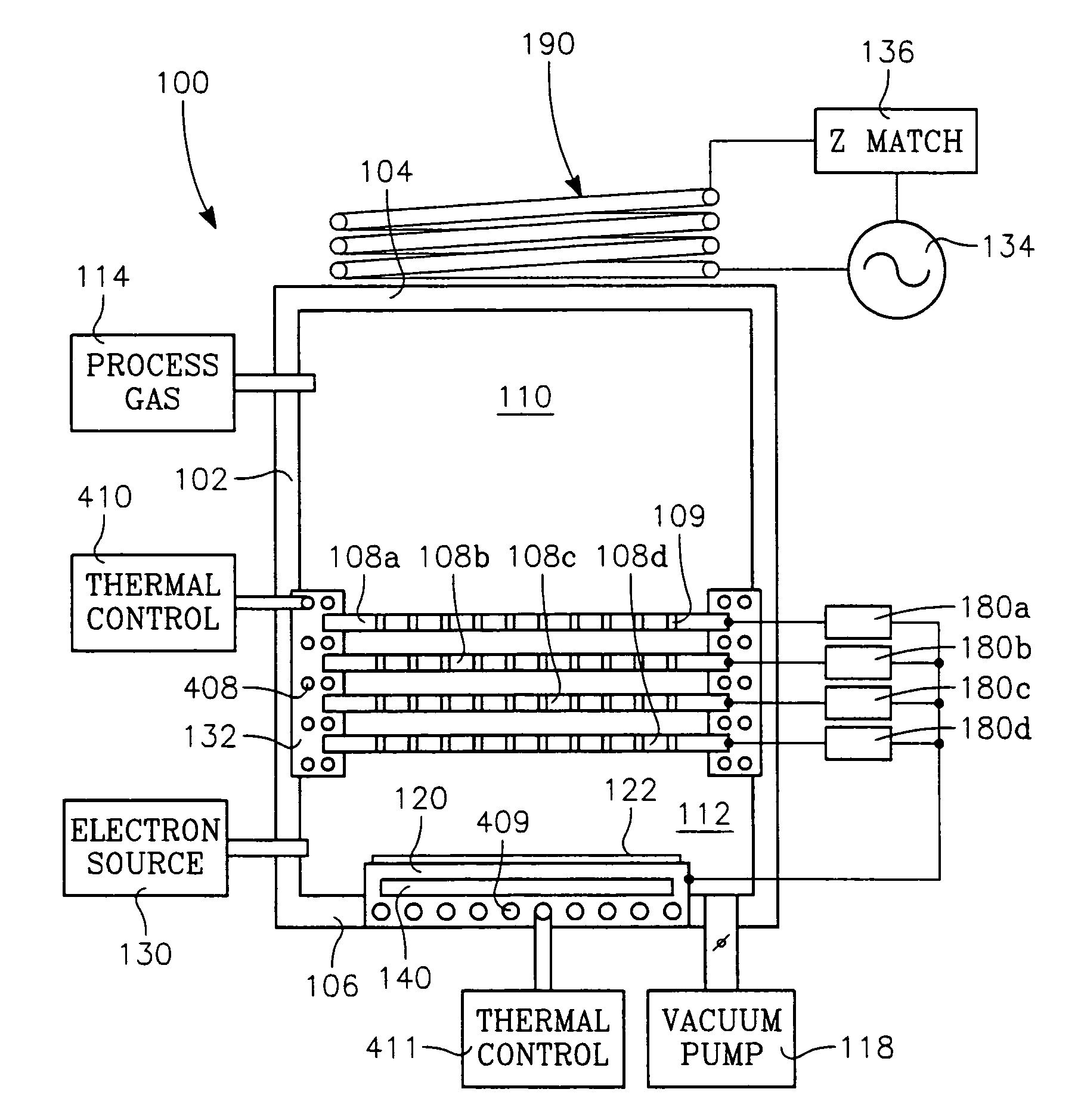

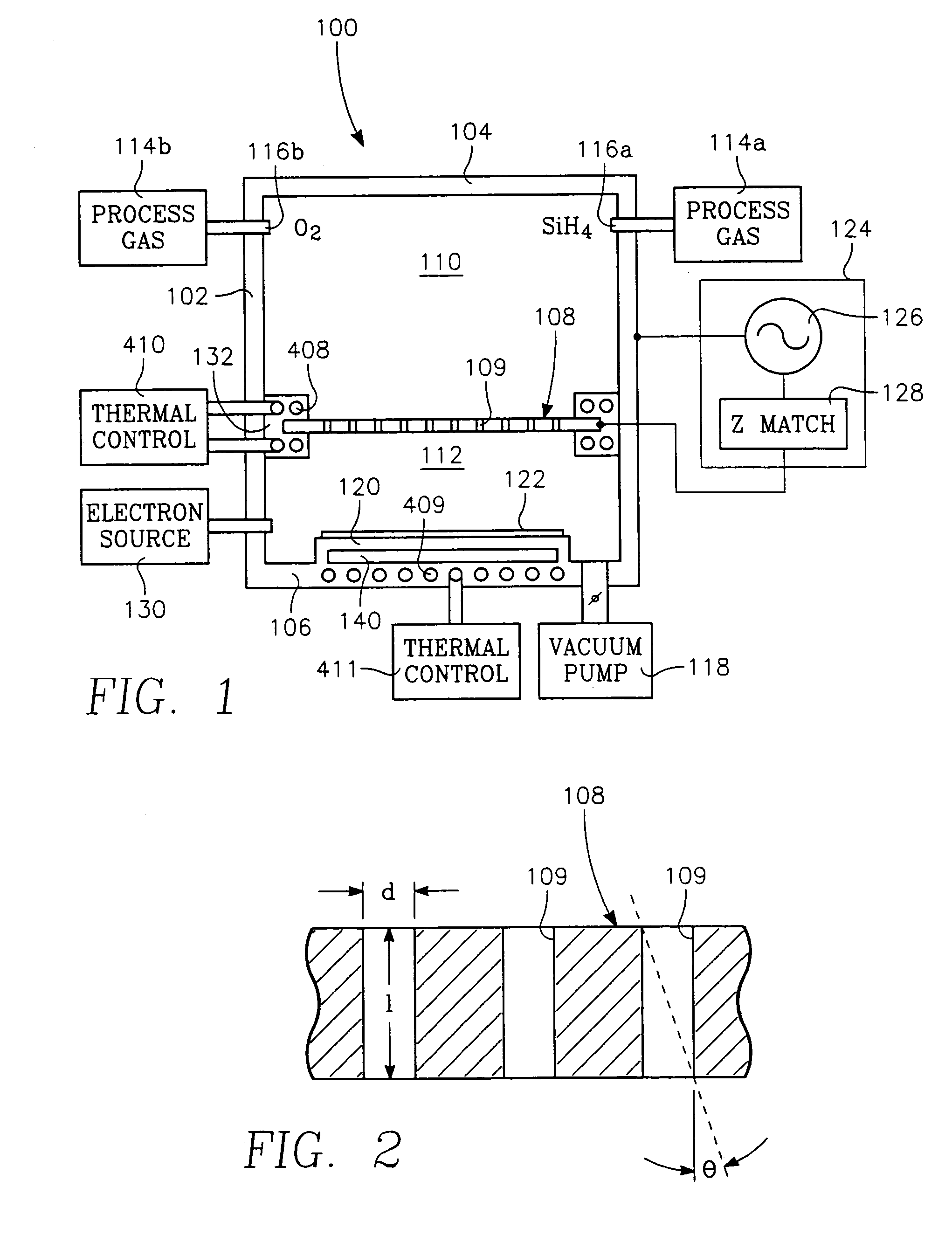

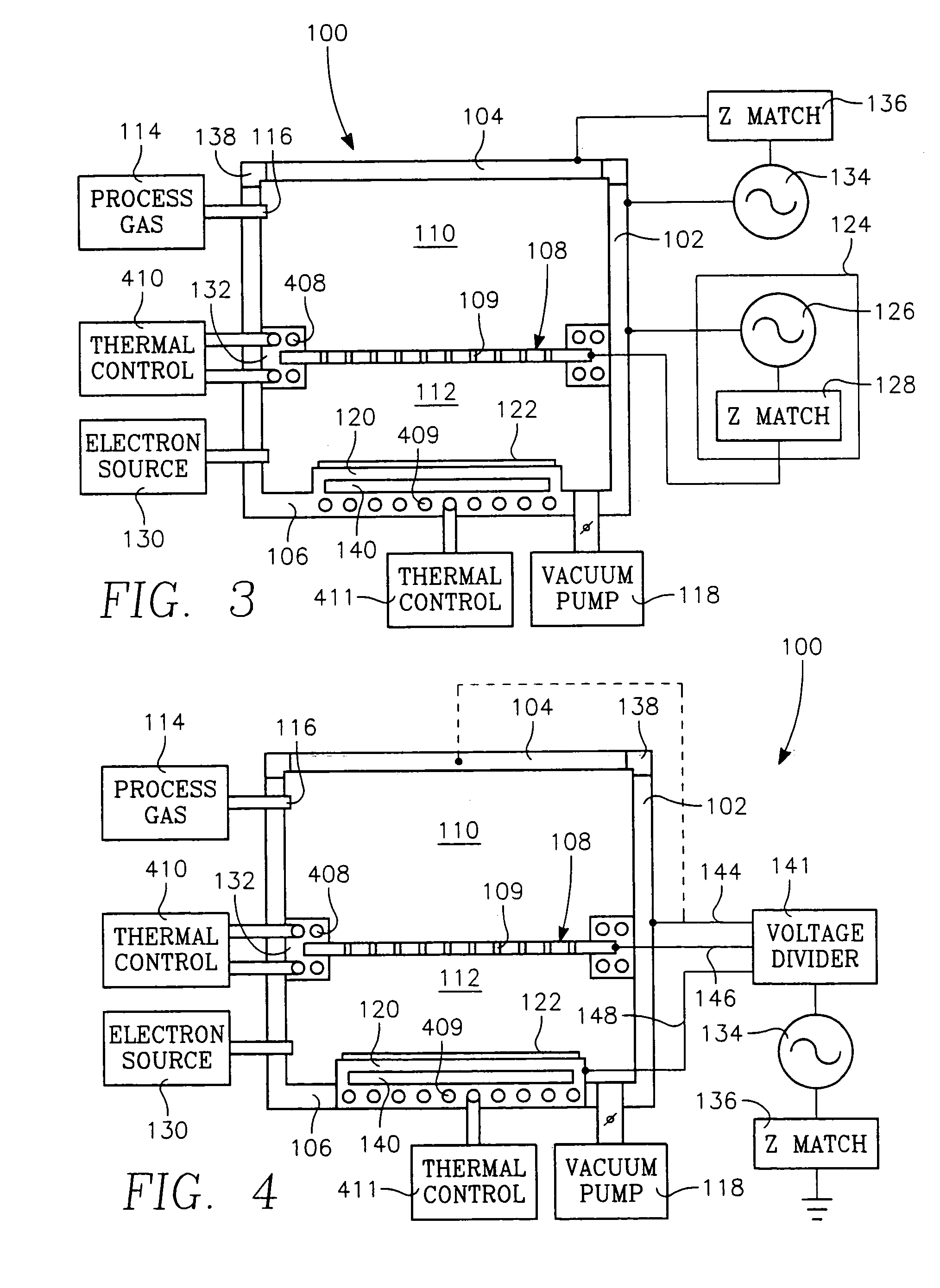

Chemical vapor deposition plasma reactor having plural ion shower grids

ActiveUS7695590B2Electric discharge tubesVacuum evaporation coatingGas phaseChemical vapor deposition

Owner:APPLIED MATERIALS INC

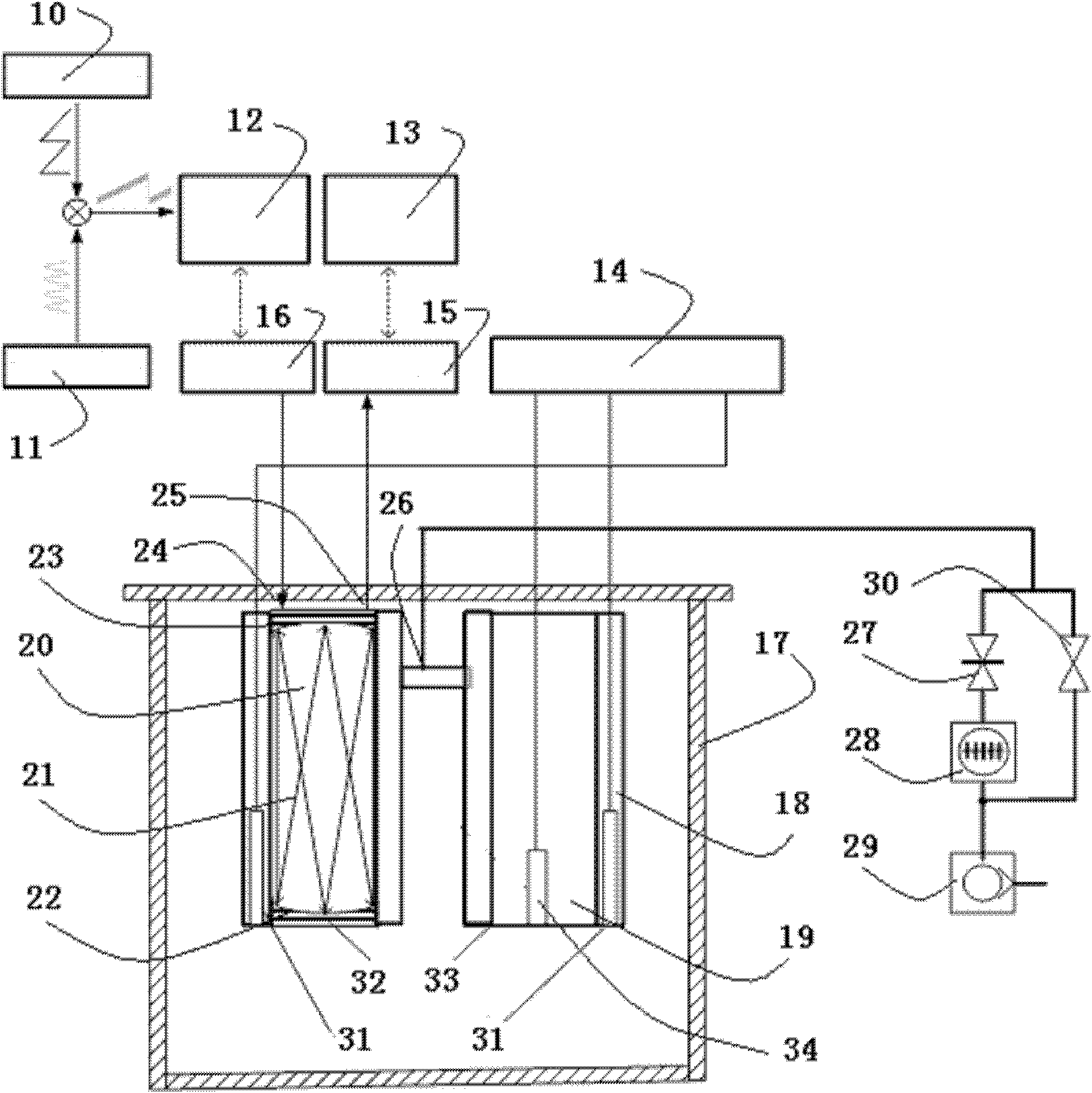

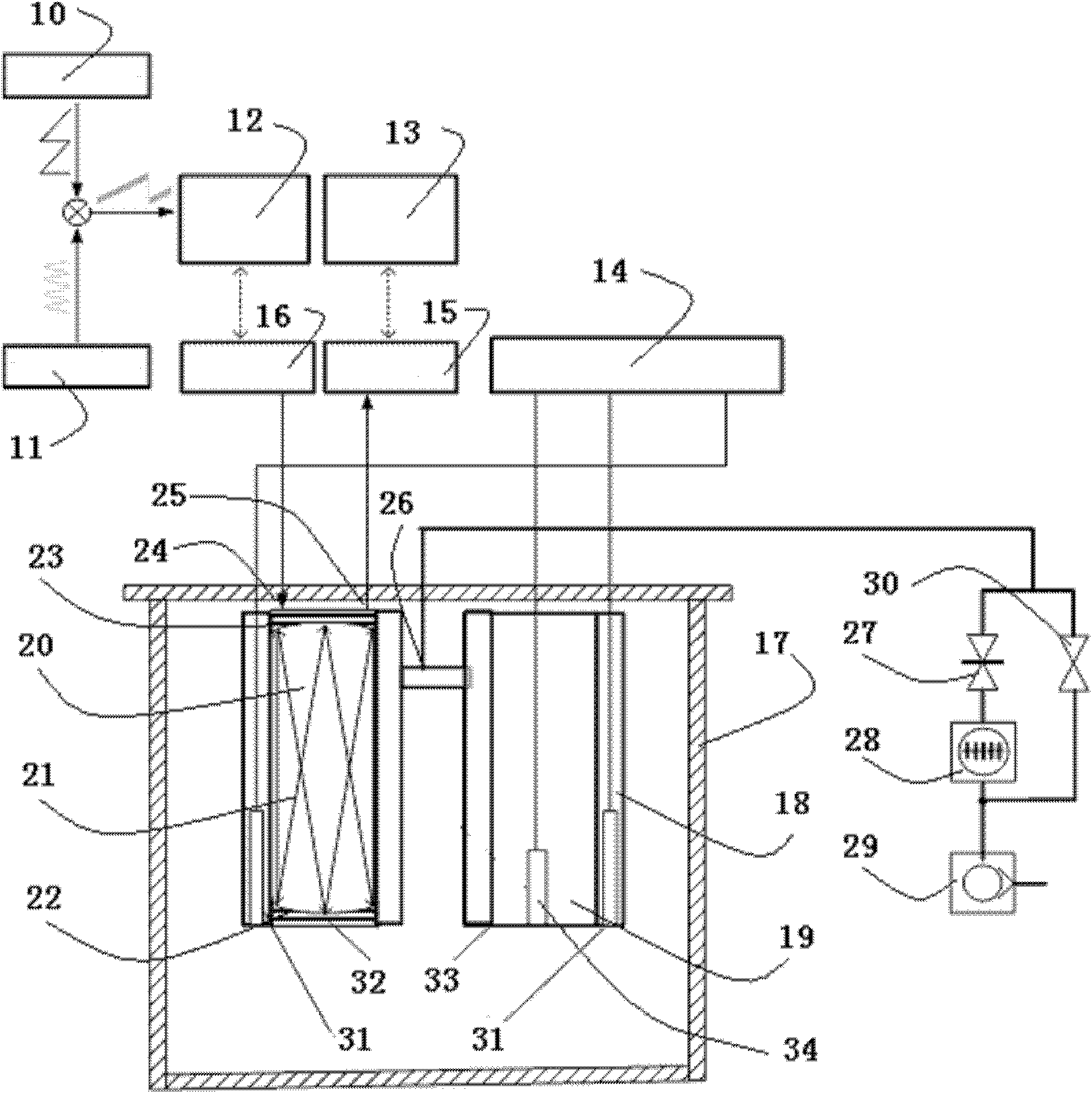

Temperature measurement and calibration platform in space vacuum environment

ActiveCN102539019ASolve the problem of large differences in measurement resultsSolve the traceability problemThermometer testing/calibrationVacuum pumpingSpace environment

The invention relates to a temperature measurement and calibration platform in space vacuum environment. The temperature measurement and calibration platform is favorable for realizing the simultaneous calibration of contact type temperature measurement and non-contact type temperature measurement, so the temperature measurement and calibration platform is served for heat vacuum and heat balance experiments of spacecrafts such as satellites, spaceship and the like. The temperature measurement and calibration platform comprises a constant temperature bath, wherein a double-sub-cavity vacuum cavity, the double-sub-cavity vacuum cavity comprises a first vacuum cavity body and a second vacuum cavity body, the first vacuum cavity body and the second vacuum cavity body are connected with a vacuum pumping device through a three-way valve, standard temperature indicator sensors are respectively arranged on the outer wall of the first vacuum cavity body and on the outer wall of the second vacuum cavity body, the standard temperature indicator sensors are connected with a temperature secondary meter, a laser light path reflecting device is arranged in the vacuum cavity of the first vacuum cavity body for calibrating a non-contact type temperature measuring system based on the tunable diode laser absorption spectrum technology, and the vacuum cavity of the second vacuum cavity body is used for accommodating a temperature sensor for calibrating a contact type temperature measuring system adopting the temperature sensor.

Owner:BEIJING DONGFANG MEASUREMENT & TEST INST

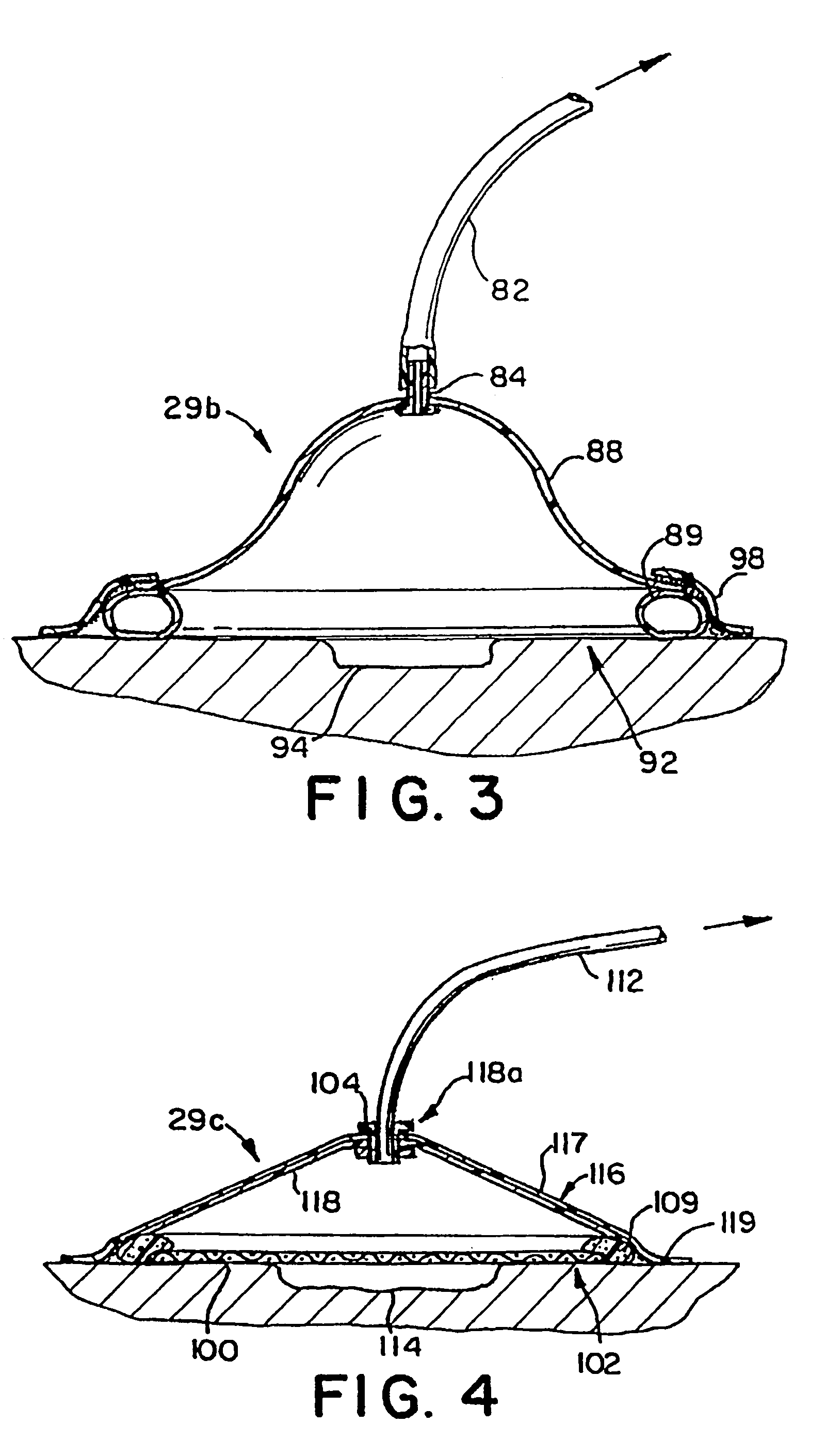

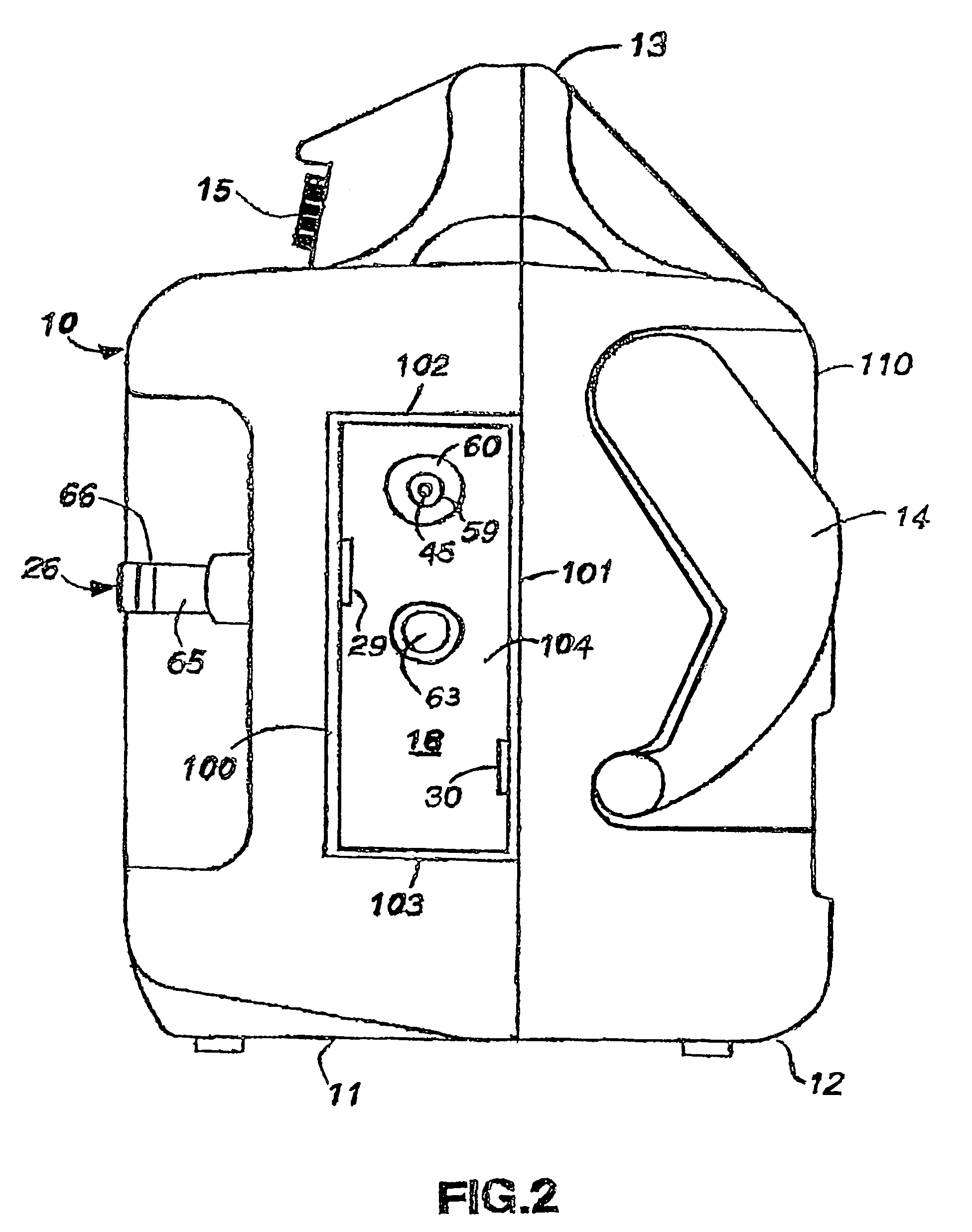

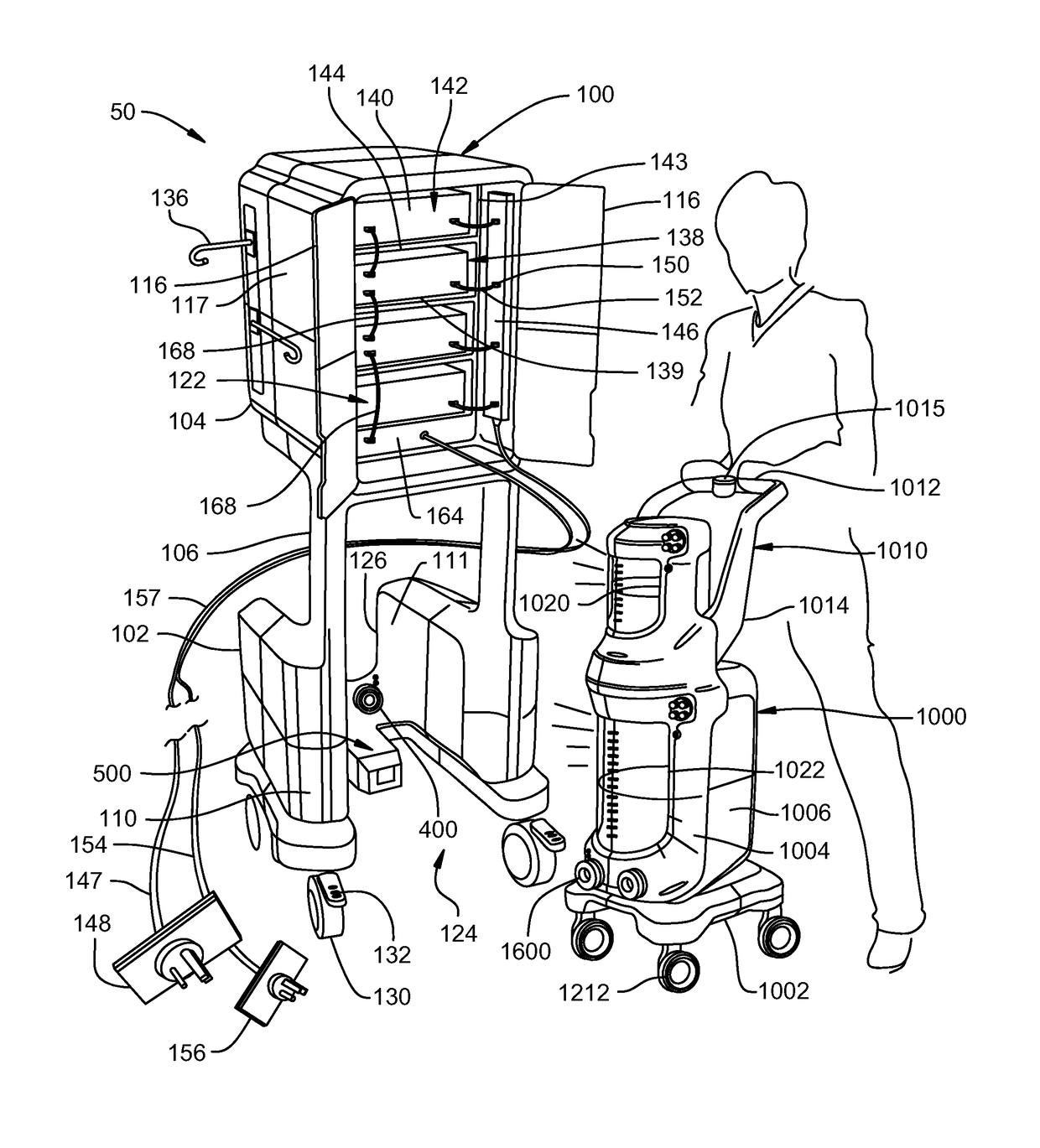

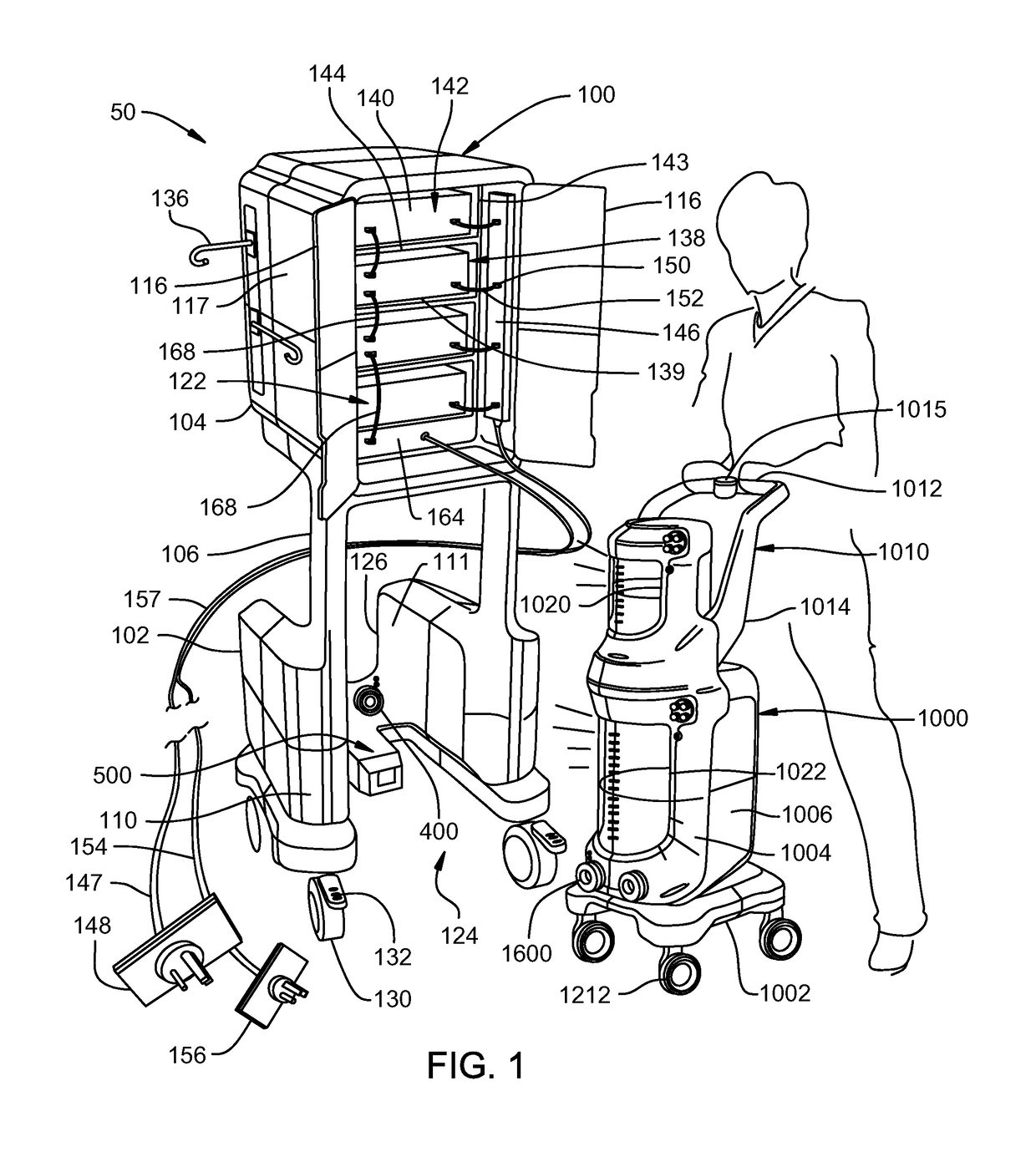

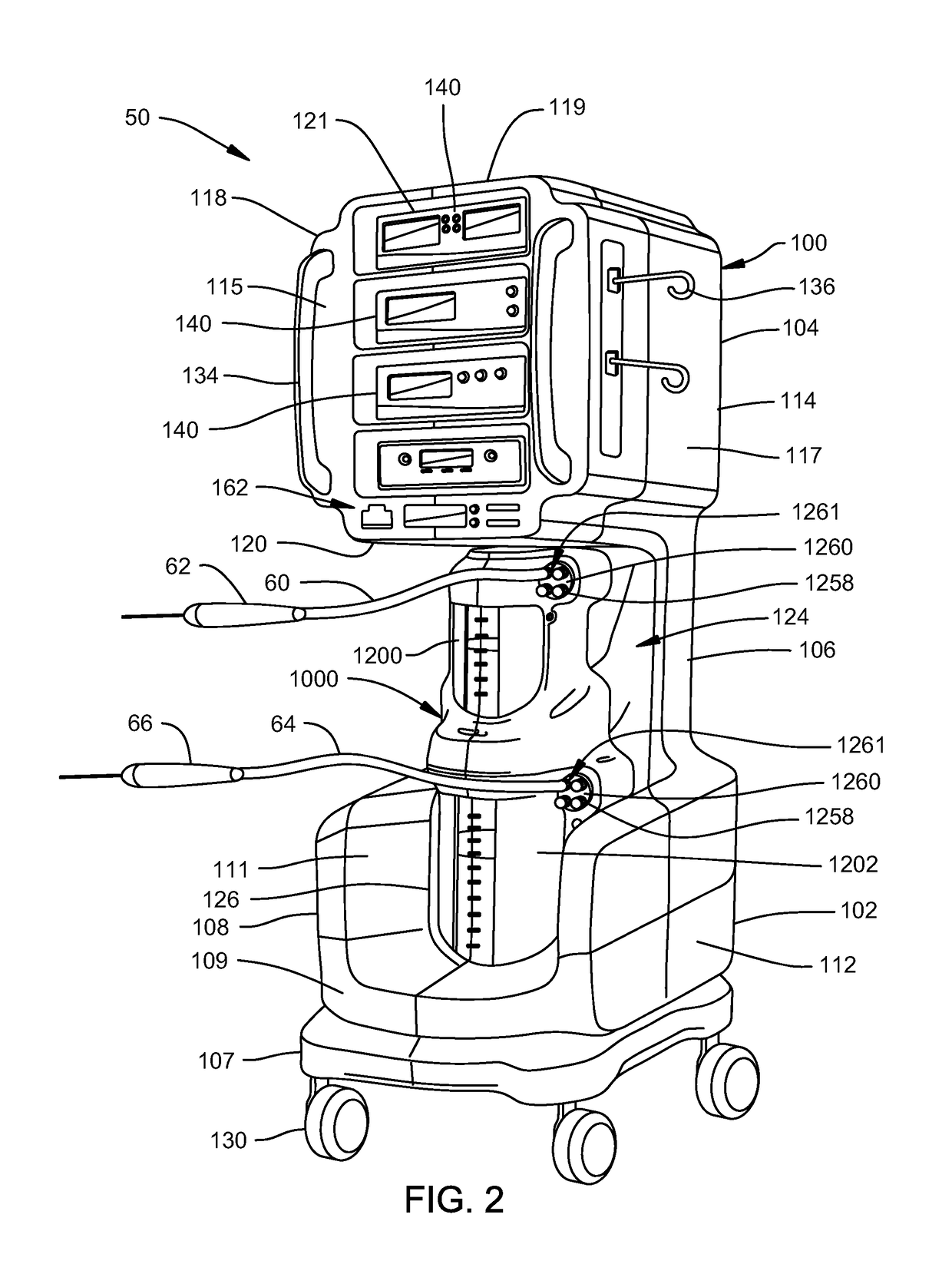

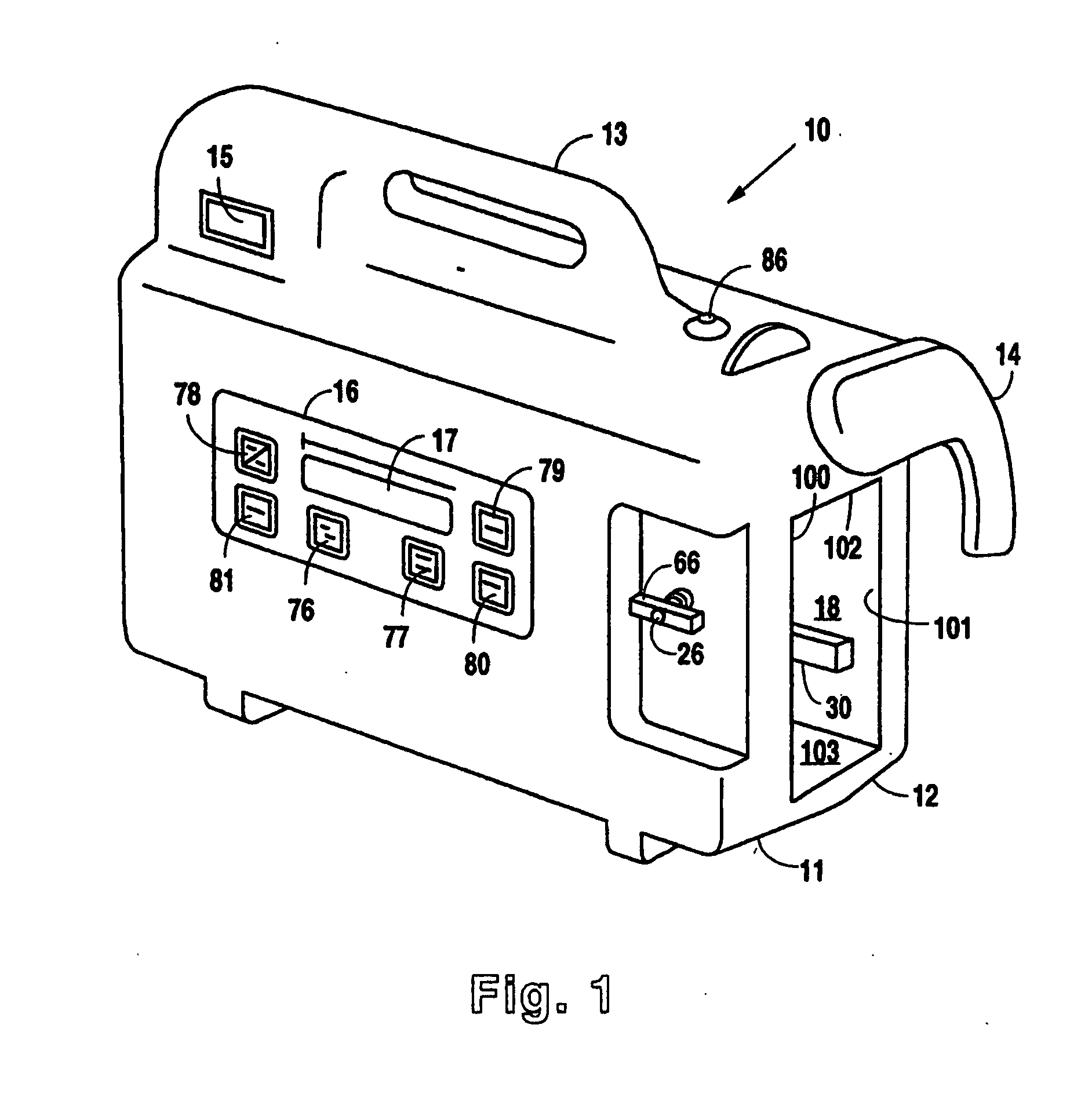

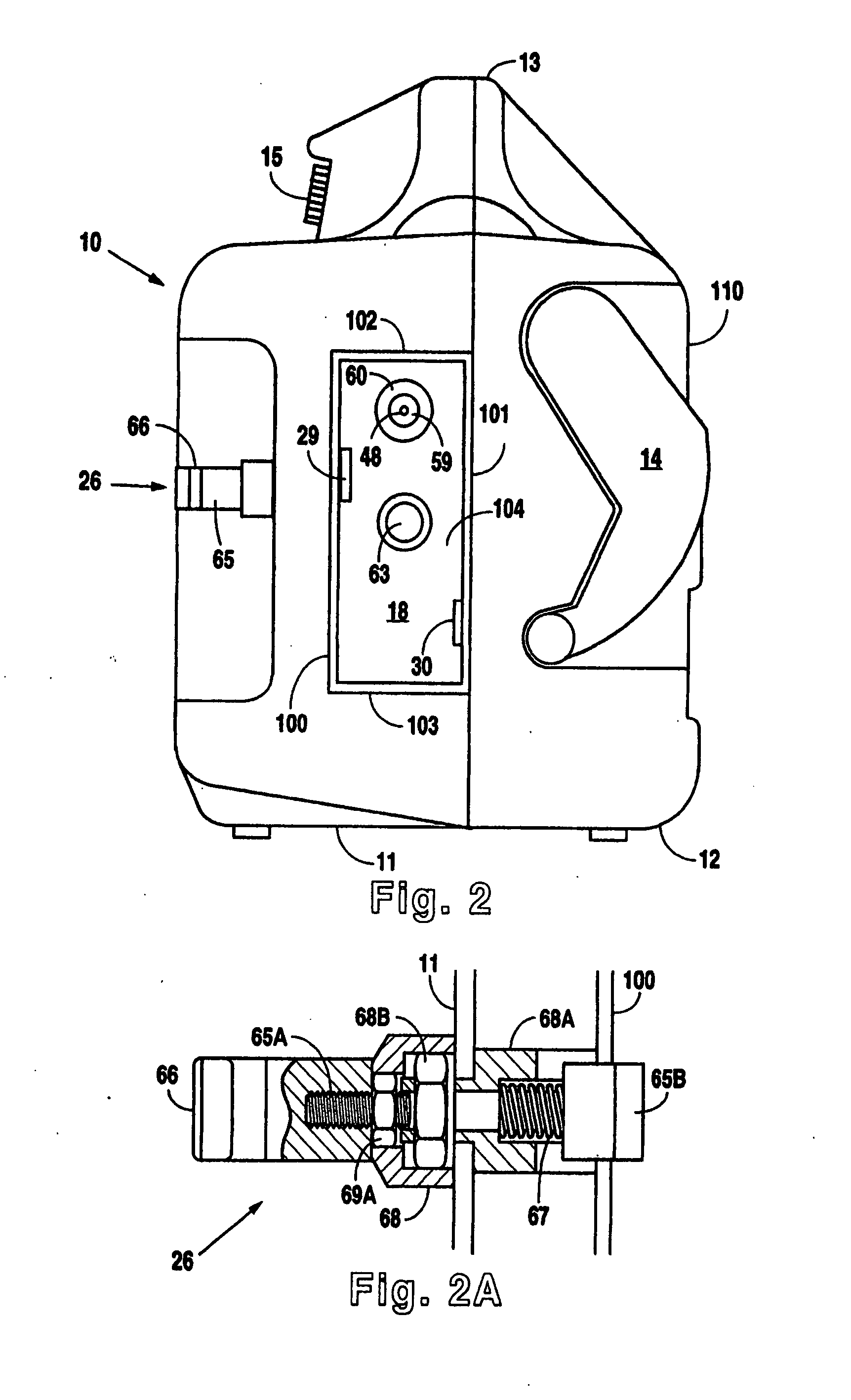

Mobile instrument assembly for use as part of a medical/surgical waste collection system, the assembly including a vacuum source to which a mobile waste collection cart can be releasably attached

ActiveUS10105470B2Reduces weight and sizeReduced footprintSurgical furnitureMedical devicesWaste collectionVacuum pump

A waste collection system for collecting waste during medical / surgical procedures including a mobile container cart with a waste container. A container cart is selectively coupled to a suction cart that includes a vacuum pump. The connection of the carts results in the connection of the vacuum pump to the waste container. The vacuum pump draws a vacuum that results in waste being drawn through a suction line into the waste container. The container cart holds instruments that can be removably attached to the container cart. This facilitates the configuration of the container cart for the specific procedure for which it is necessary to draw a suction.

Owner:STRYKER CORP

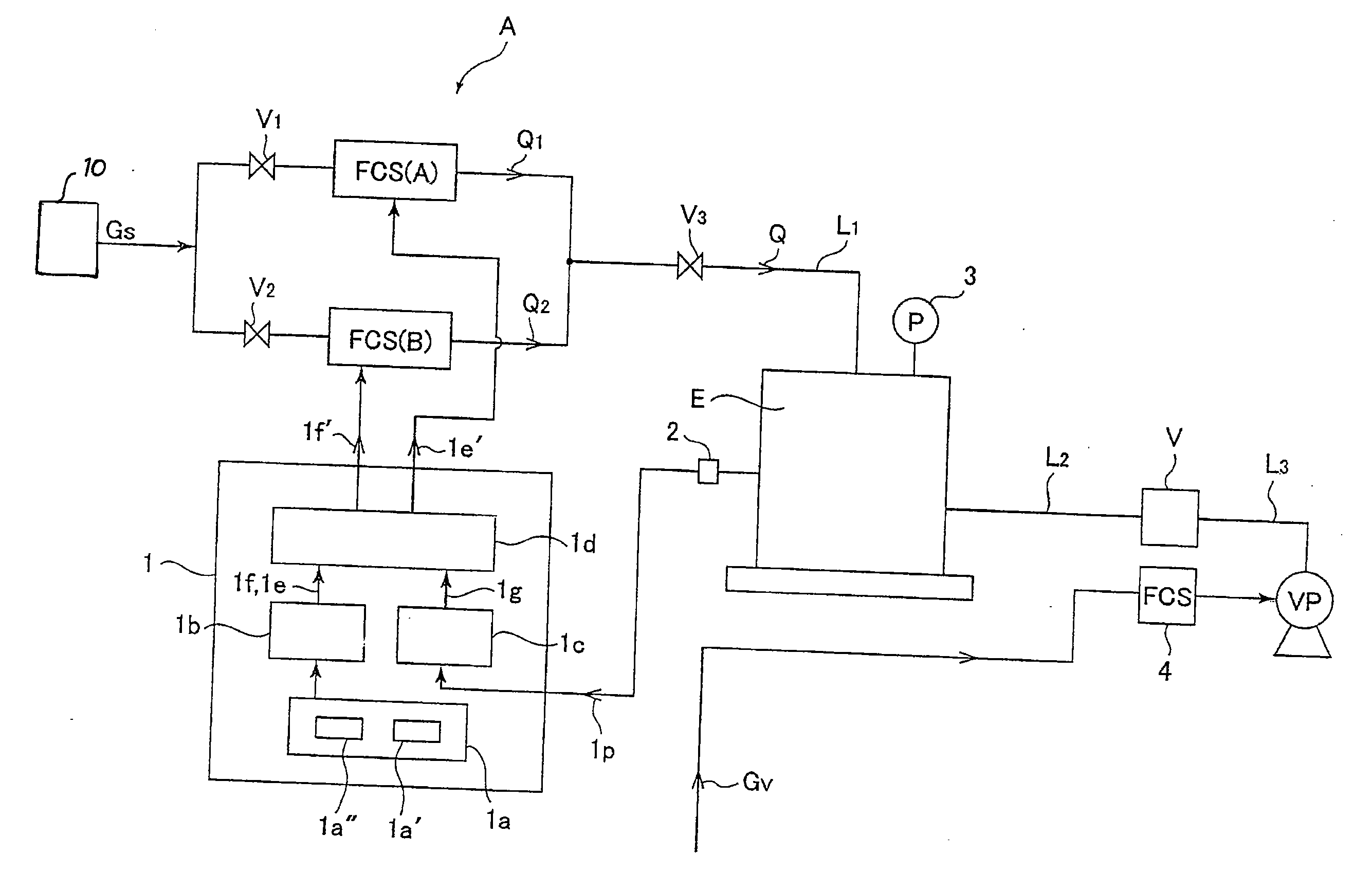

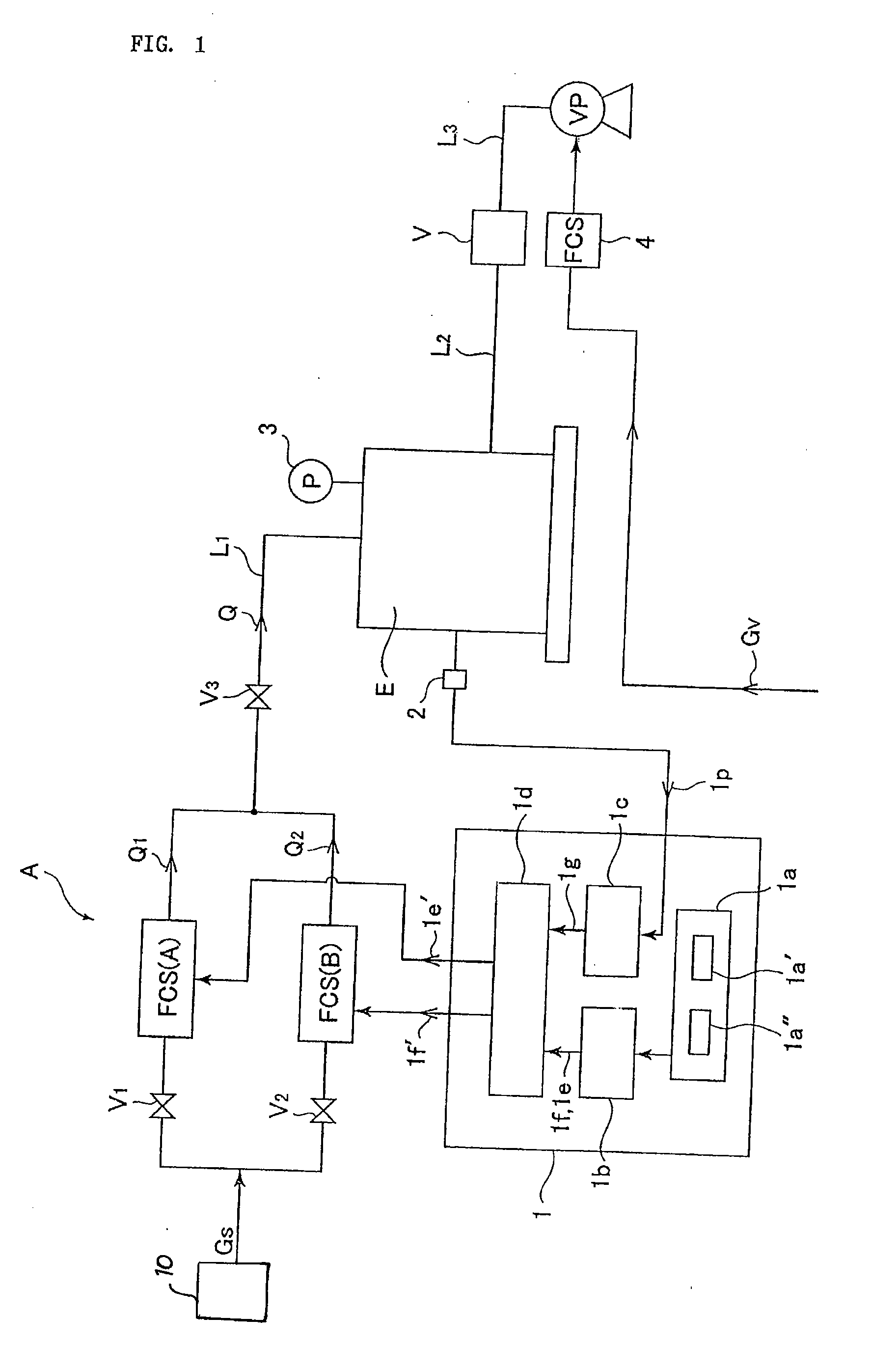

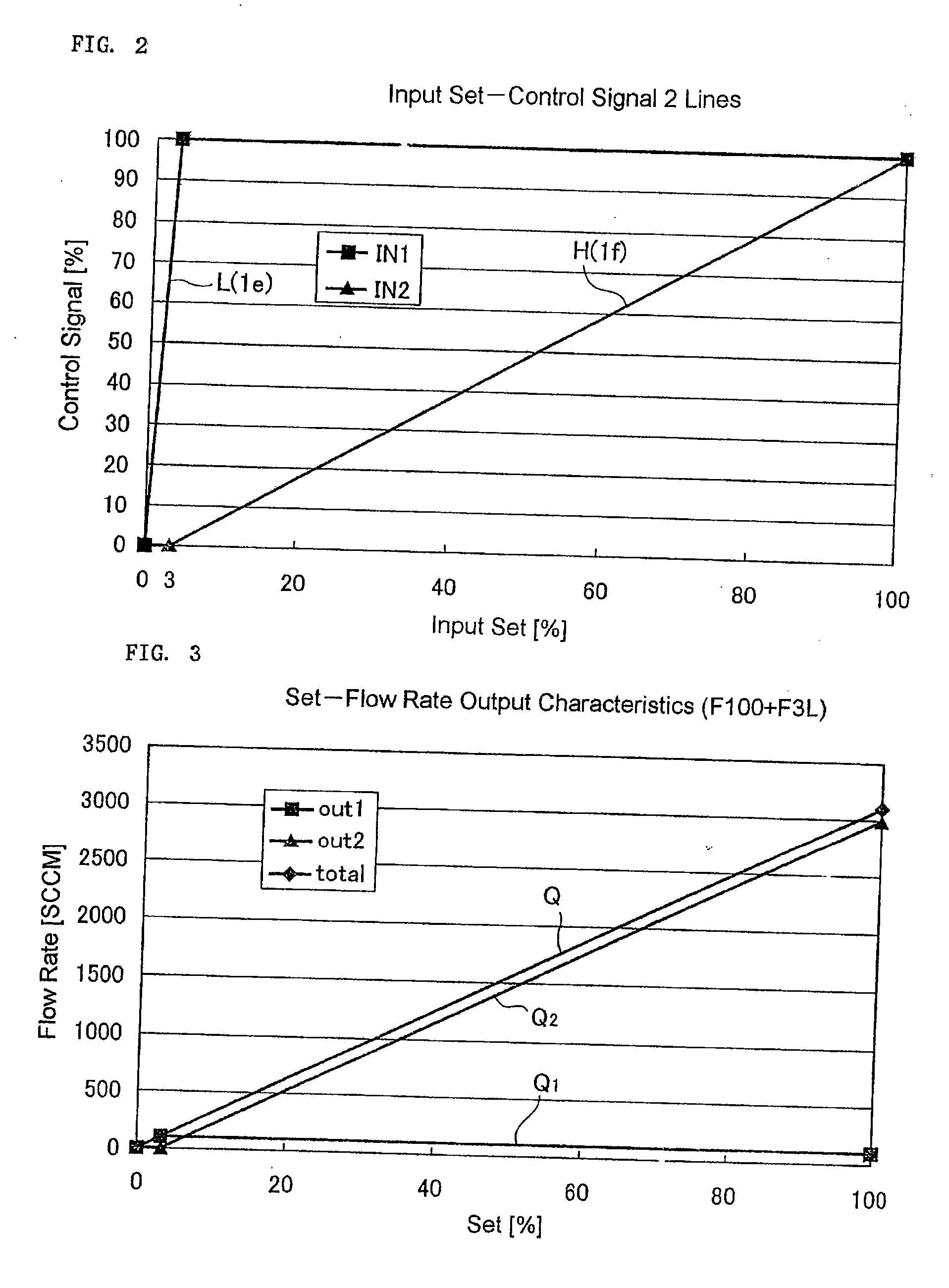

Internal pressure controller of chamber and internal pressure subject -to- control type chamber

InactiveUS20060207595A1Precise flow controlContinuous controlBreathing protectionOperating means/releasing devices for valvesInternal pressureControl signal

A gas supply facility includes a plurality of pressure type flow controllers connected in parallel, and a first controller to control operation of the plurality of pressure type flow controllers so as to supply a desired gas exhausted by a vacuum pump to a chamber while controlling its flow rate, one of the pressure type flow controllers operates as a second controller to control the gas flow rate range up to 10% of the maximum flow rate supplied to the chamber, while the remaining pressure type flow controllers are made to be ones that control the rest of the gas flow rate range. Furthermore, pressure inside the chamber is controlled by installing a pressure detector in the chamber, inputting the value detected by the detector to the controller, and by adjusting a control signal to the pressure type flow controllers.

Owner:FUJIKIN INC +1

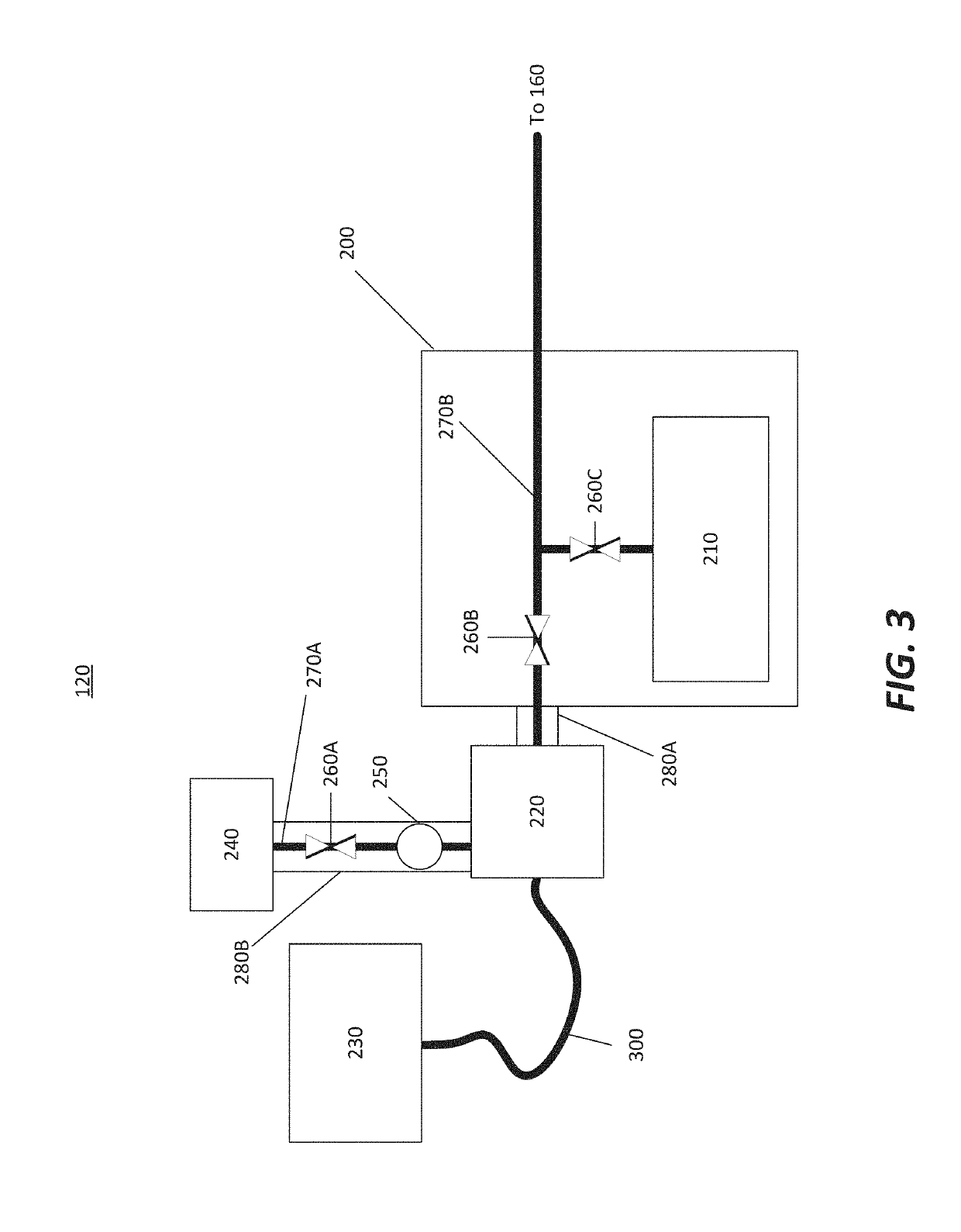

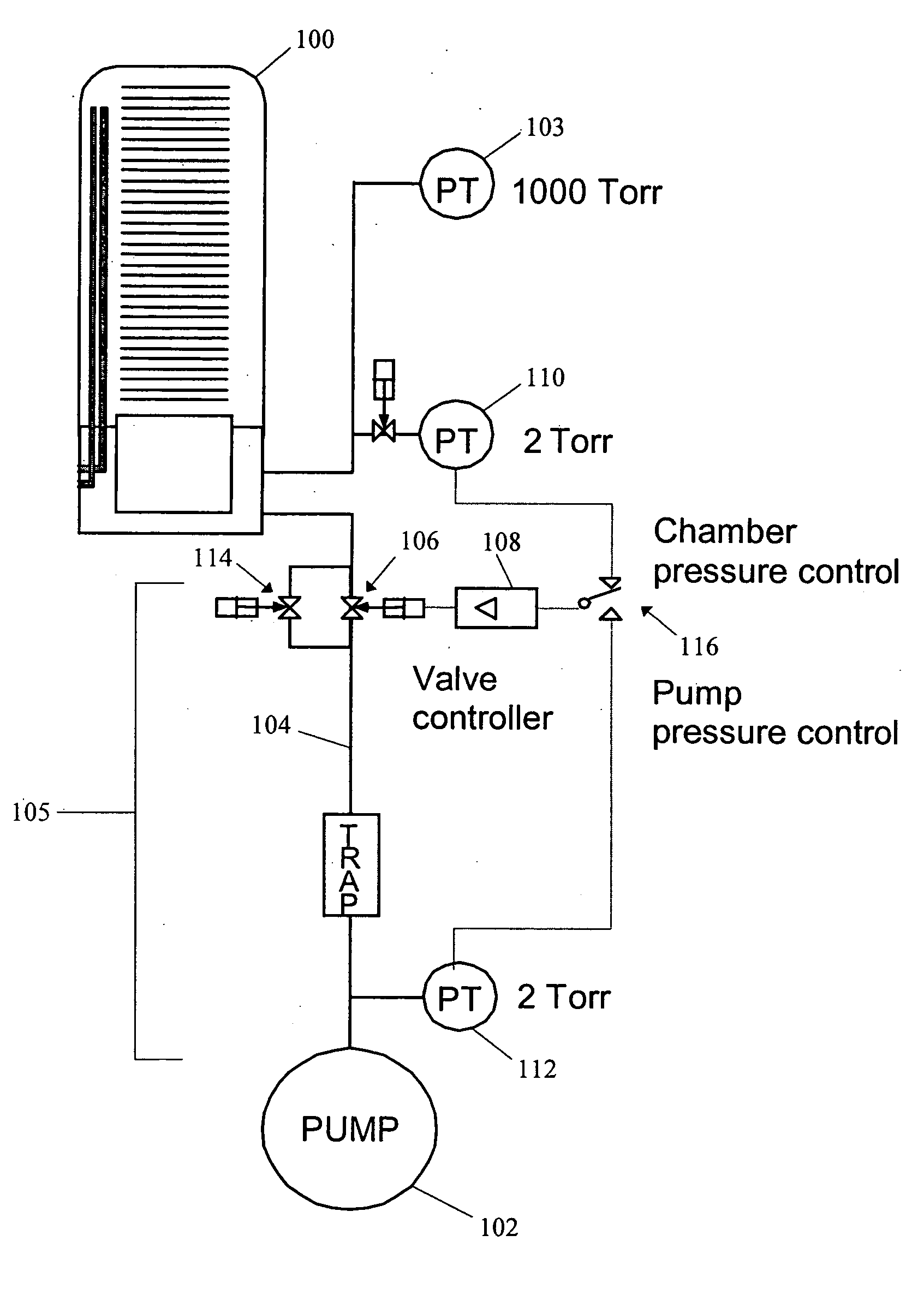

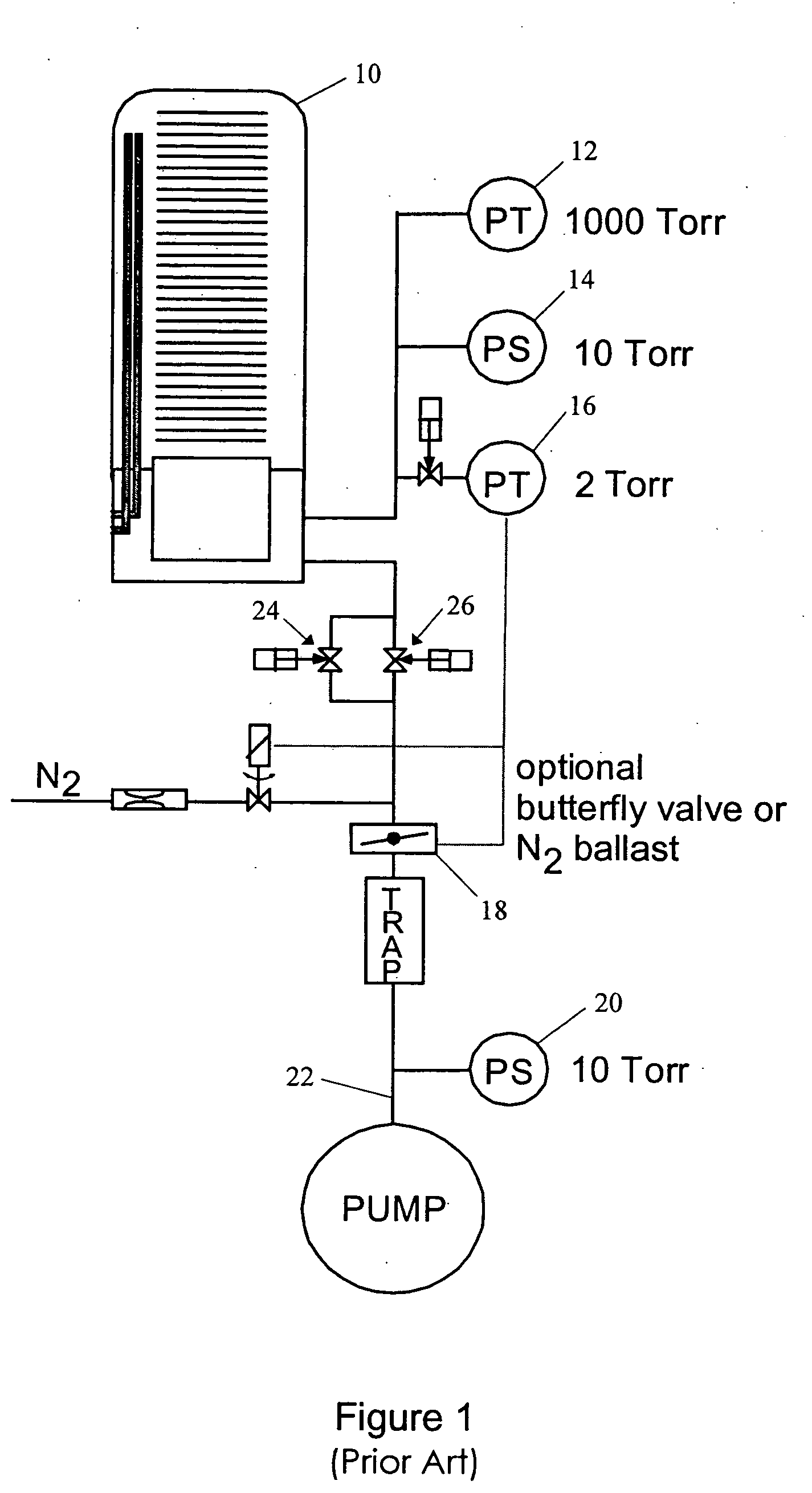

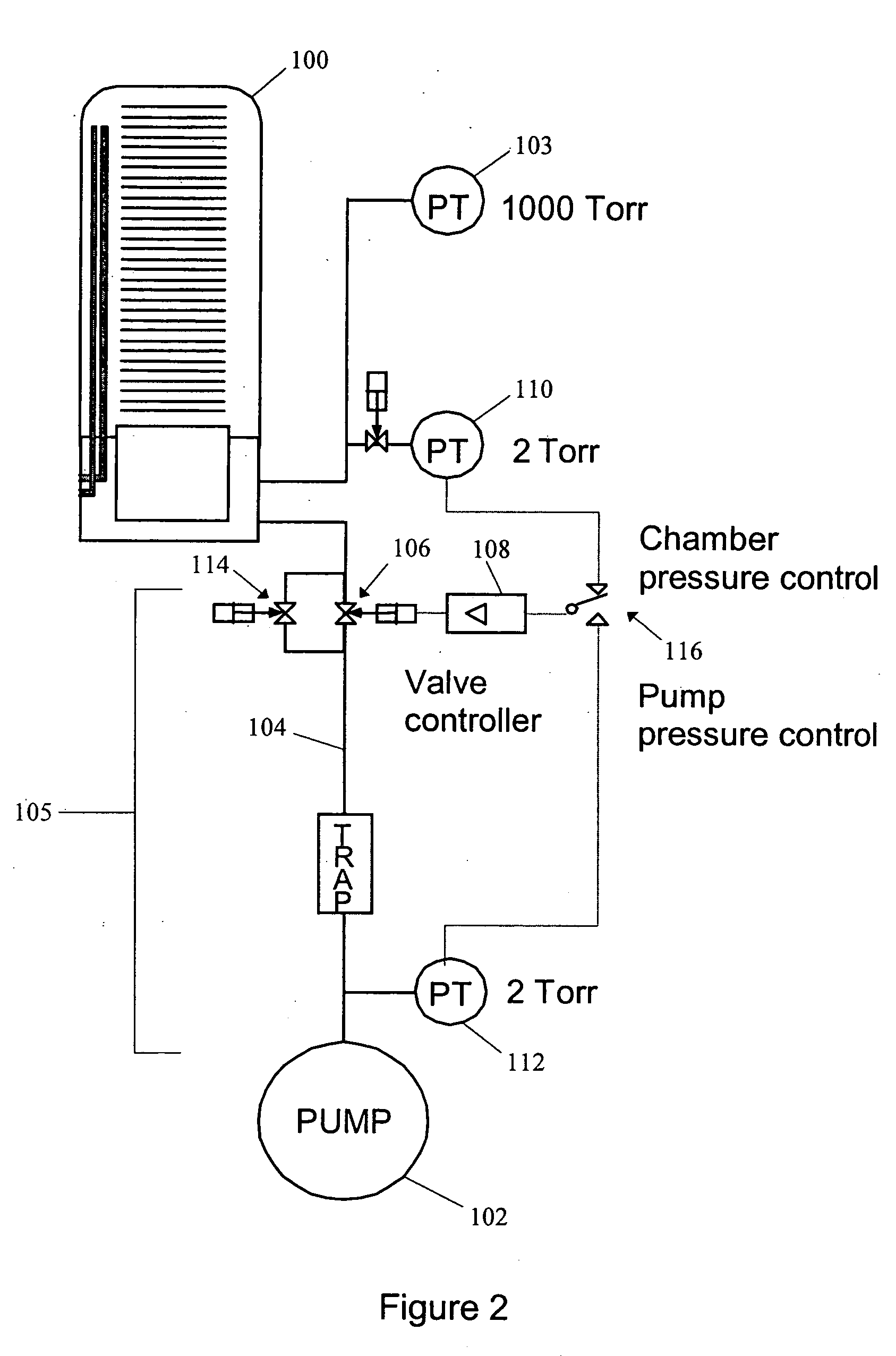

Pressure control system

ActiveUS20050279454A1Semiconductor/solid-state device manufacturingFluid pressure control using electric meansControl systemVacuum pump

A pressure control system allows gas to be evacuated out of a semiconductor process chamber at a substantially constant rate of mass flow. A gas line connects the process chamber to a vacuum pump. A controllable valve having a variable sized opening is positioned between the process chamber and the vacuum pump. A pressure sensor is in turn positioned between the valve and the vacuum pump, proximate the inlet to the vacuum pump. The size of the variable sized opening is regulated based upon the pressure in the gas line measured by the pressure sensor. The size of the valve opening is varied to maintain the pressure measured by the pressure sensor at a constant value. As a result, because the quantity of gas flowing through the gas line is proportional to the gas pressure, a substantially constant mass flow of gas out of the chamber and into the pump can be achieved.

Owner:ASM INTERNATIONAL

Self contained wound dressing apparatus

The composite wound dressing apparatus promotes healing of a wound via the use of a vacuum pump. The vacuum pump applies a vacuum pressure to the wound to effectively draw wound fluid or exudate away from the wound bed. The vacuum pump is tethered to the wound dressing and is portable, preferably, carried by the patient in a support bag, which permits patient mobility. Moreover, the patient does not need to be constrained for any period of time while exudate is being removed from the wound.

Owner:SMITH & NEPHEW INC

Reduced pressure treatment system having a dual porosity pad

A wound closure apparatus having a porous pad adapted to be fluidly connected to a vacuum pump. The pad is placed over or within a tissue site, and the vacuum pump may be activated to draw air and exudates from the tissue site. The pad contains multiple pore sizes to prevent granulation tissue from migrating into the pad as reduced pressure treatment is applied. The pad has an outer surface adjacent the wound with pore sizes of a diameter of approximately 100 microns or less to prevent tissue from growing into the pad and is treated for biocompatibility.

Owner:KCI LICENSING INC

Wound treatment employing reduced pressure

InactiveUS20060213527A1Easy to attachReduce pressureRespiratory masksDiagnosticsWound siteVacuum pump

A method of treating tissue damage comprises applying a negative pressure to a wound sufficient in time and magnitude to promote tissue migration and thus facilitate closure of the wound. The method is applicable to wounds, burns, infected wounds, and live tissue attachments. A wound treatment apparatus is provided in which a fluid impermeable wound cover is sealed over a wound site. A screen in the form of an open-cell foam screen or a rigid porous screen is placed beneath the wound cover over the wound. A vacuum pump supplies suction within the wound cover over the treatment site.

Owner:ARGENTA LOUIS C +1

High-current DC proton accelerator

InactiveUS20100033115A1Reduce harmful effectsLimit divergence of beamTransit-time tubesDirect voltage acceleratorsHigh energyNeutron capture

A dc accelerator system able to accelerate high currents of proton beams at high energies is provided. The accelerator system includes a dc high-voltage, high-current power supply, an evacuated ion accelerating tube, a proton ion source, a dipole analyzing magnet and a vacuum pump located in the high-voltage terminal. The high-current, high-energy dc proton beam can be directed to a number of targets depending on the applications such as boron neutron capture therapy BNCT applications, NRA applications, and silicon cleaving.

Owner:ION BEAM APPL

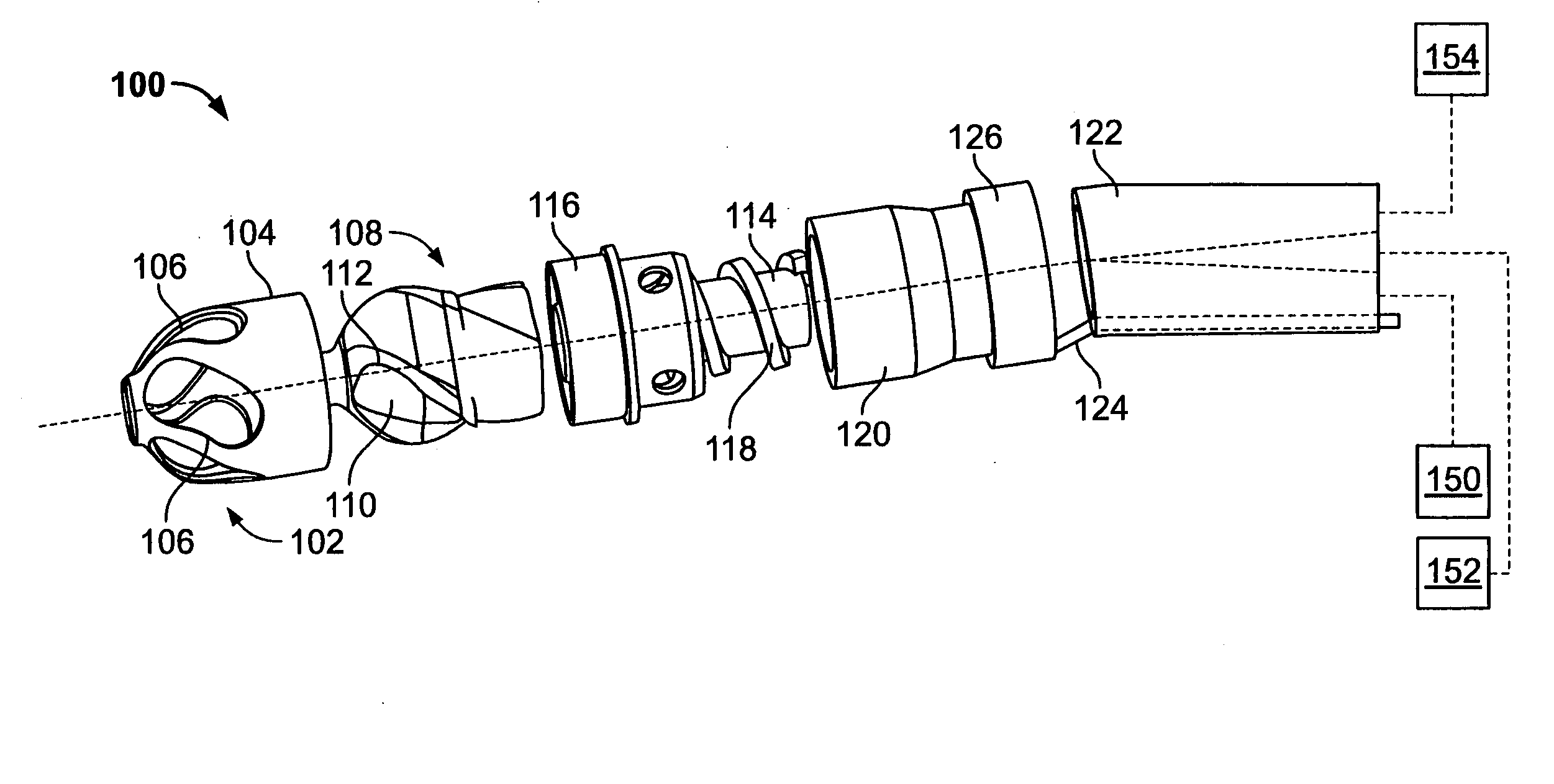

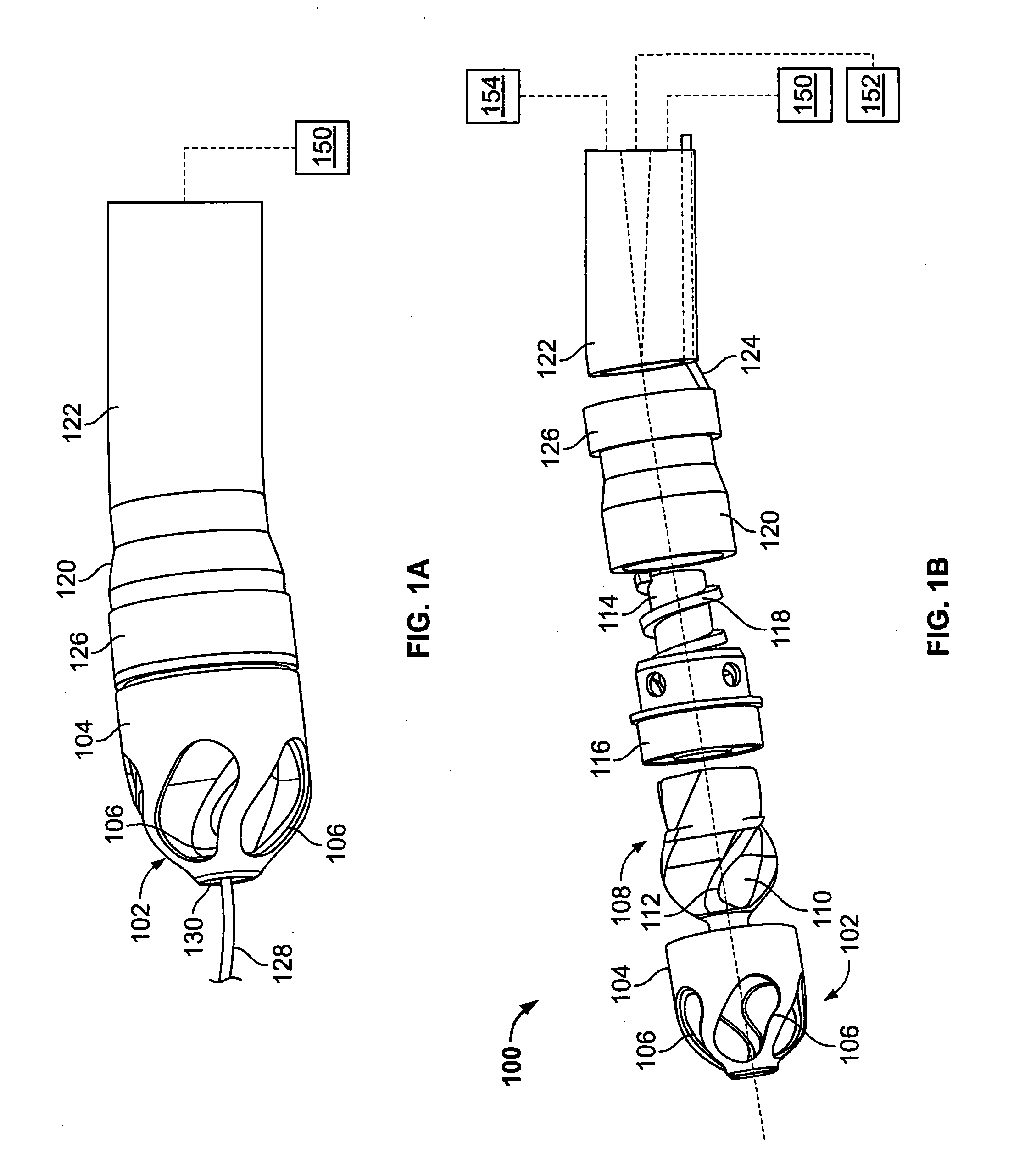

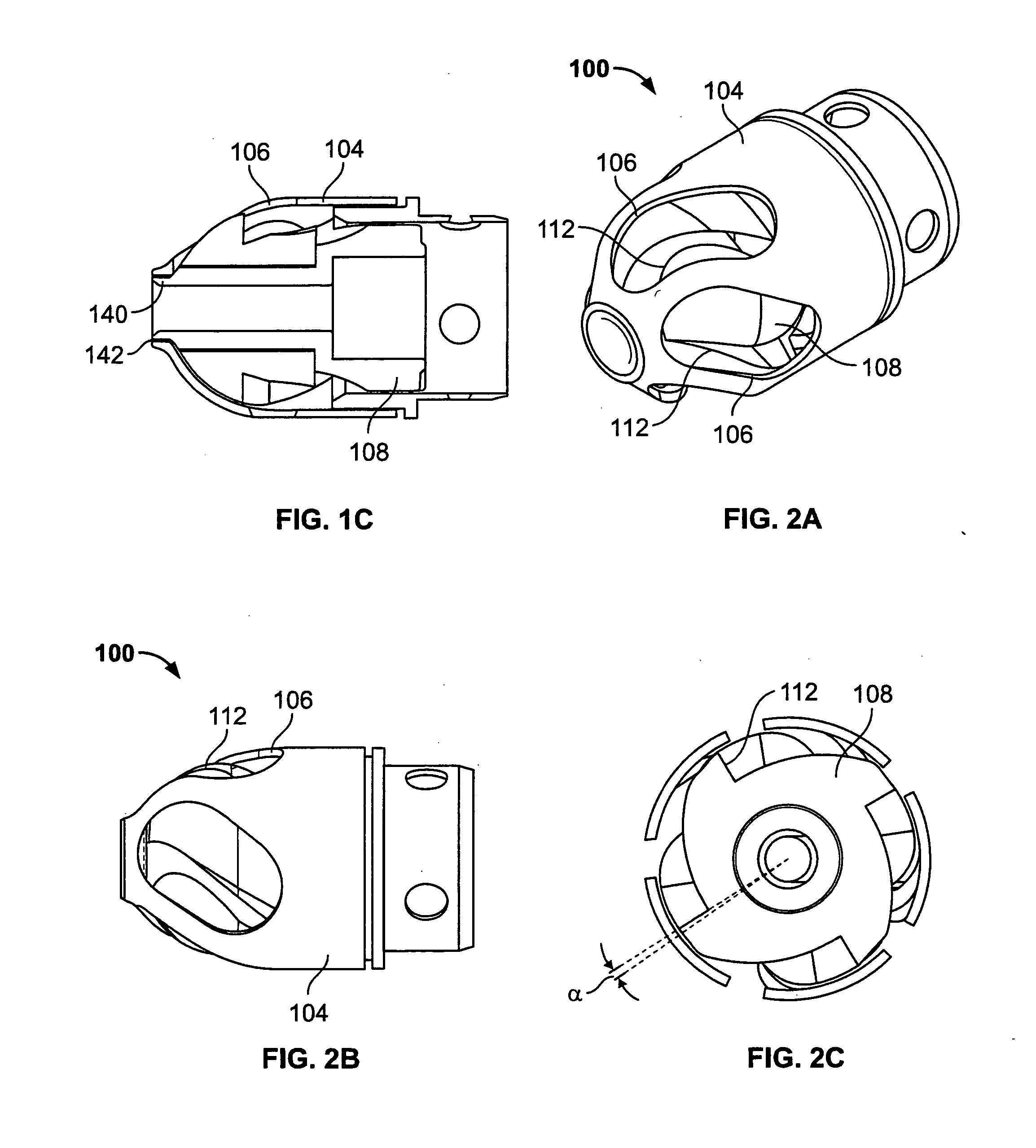

Devices, systems, and methods for cutting and removing occlusive material from a body lumen

A vascular device is provided having a catheter body and a rotatable cutter assembly located at the distal end of the catheter body. The cutter assembly has at least one helical cutting surface within a housing that is coupled by a torque shaft to a drive mechanism. A conveyor mechanism helically wound about the torque shaft conveys occlusive material conveyed into the housing by the helical cutting blade further proximally along the catheter body for discharge without supplement of a vacuum pump. The catheter body is manipulated to insert the distal end of the catheter body within a body lumen and advance the distal end of the catheter body toward the occlusive material. The drive mechanism is operated to rotate the helical cutting surface to cut and convey the occlusive material from the body lumen proximally into the housing and to convey the occlusive material conveyed into the housing by the helical cutting surface further proximally along the catheter body by the conveyor mechanism for discharge without supplement of a vacuum pump. The distal end of the catheter body is deflected and rotated to sweep the cutter assembly in an arc about the center axis of the catheter body to cut occlusive material in a region larger than the outside diameter of the cutter assembly.

Owner:ATHEROMED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com