Patents

Literature

7278 results about "Vacuum pumping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

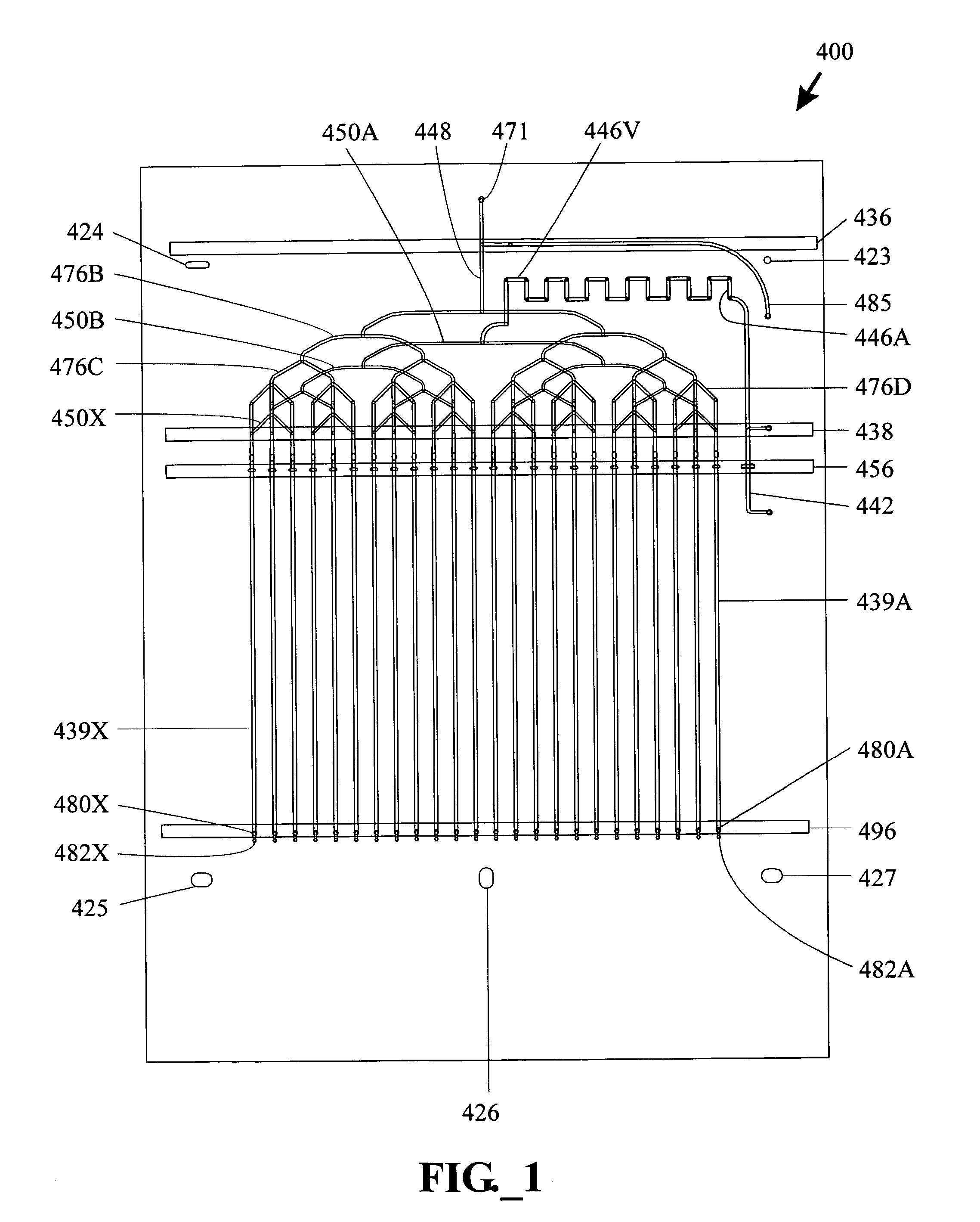

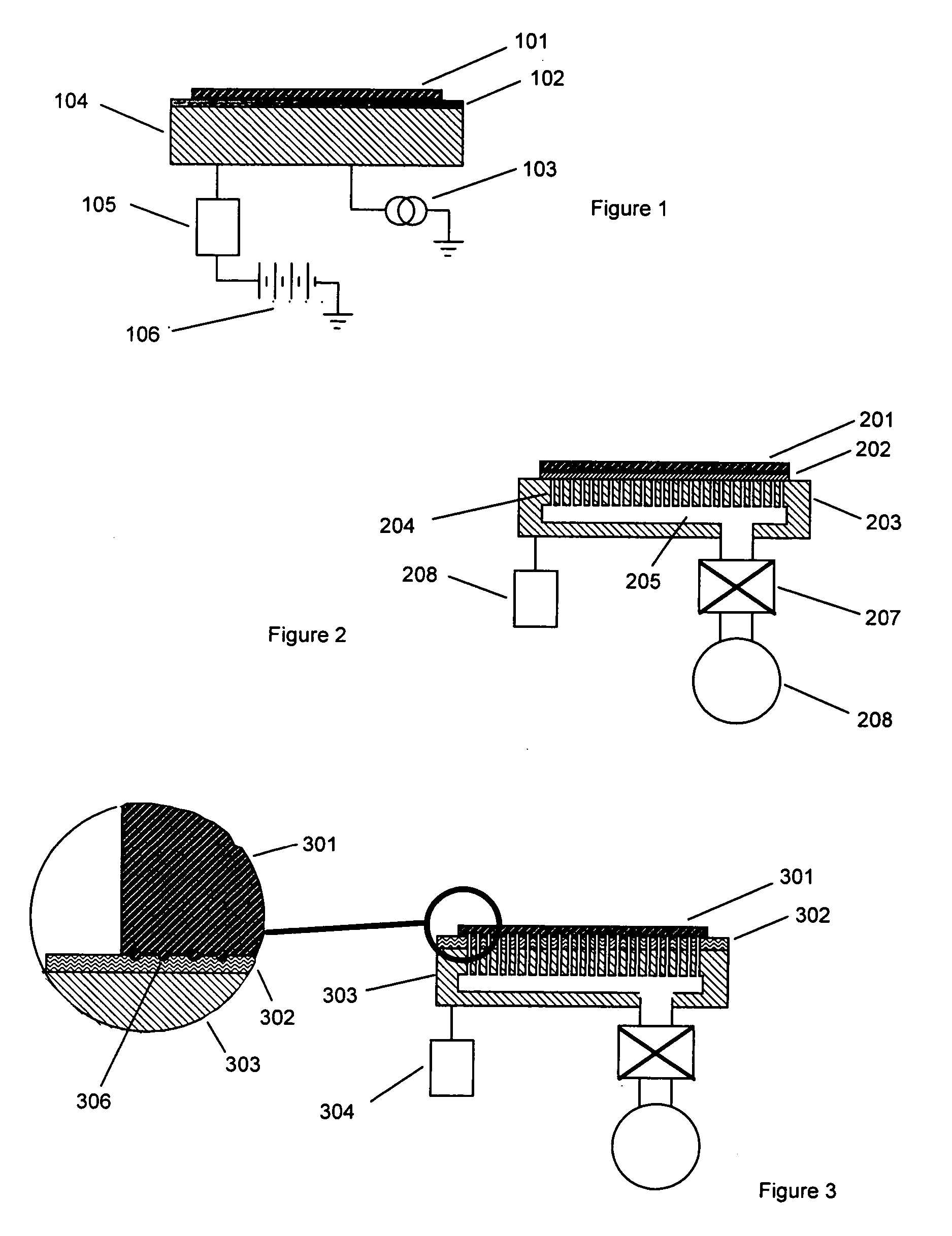

Method and system for performing different deposition processes within a single chamber

ActiveUS20110135842A1Reduce pollutionLiquid surface applicatorsElectric discharge tubesVacuum pumpingGas phase

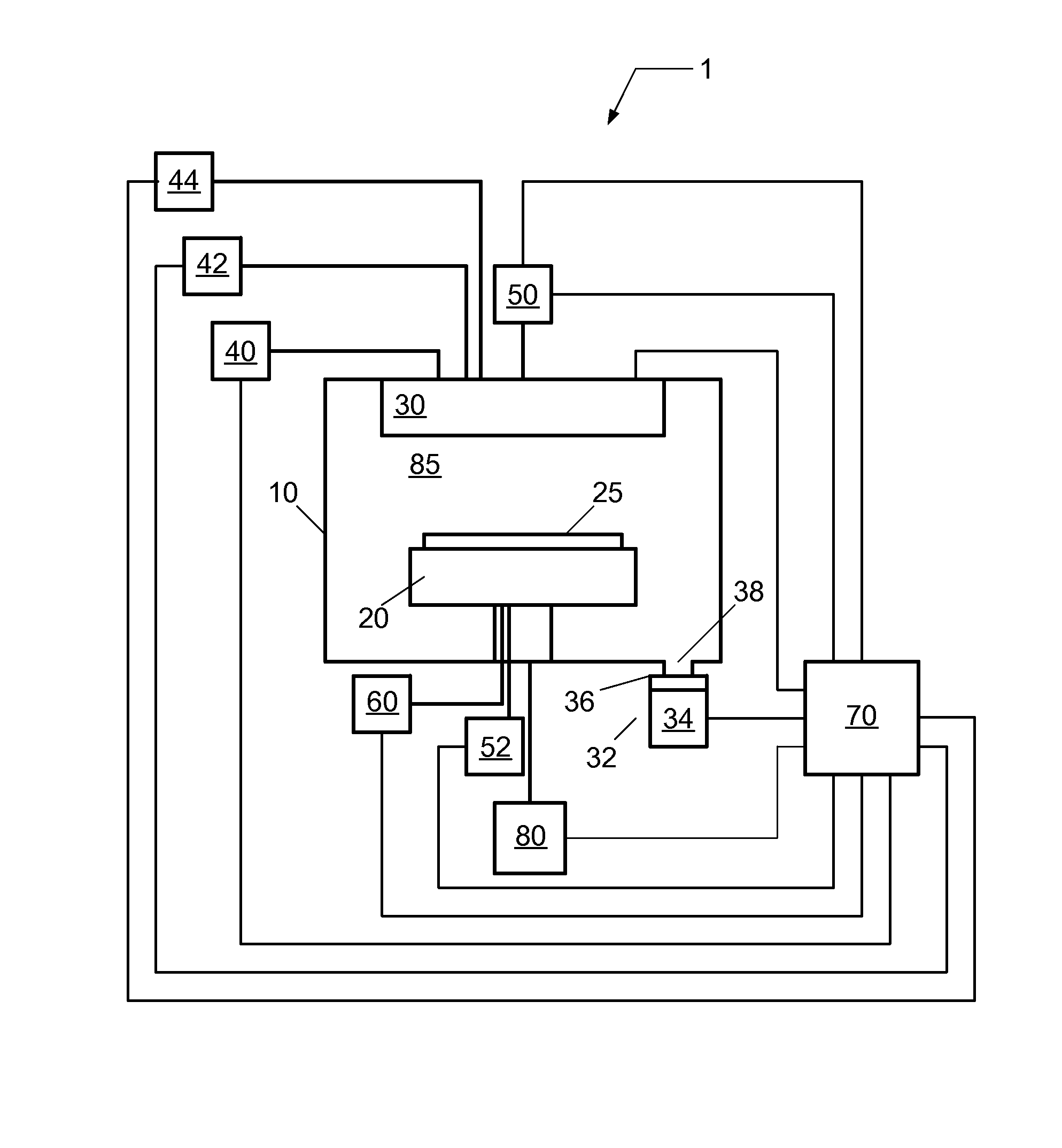

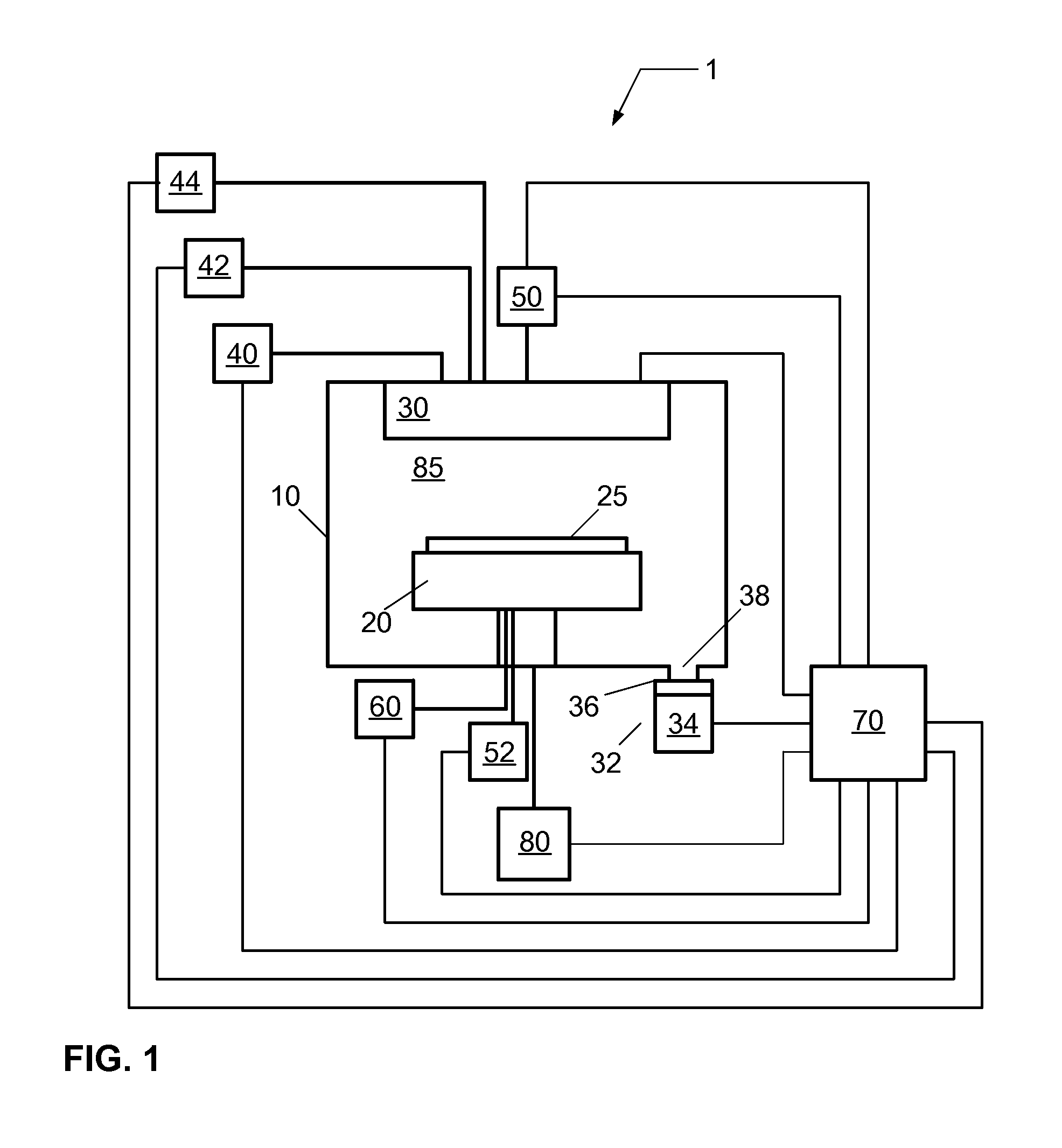

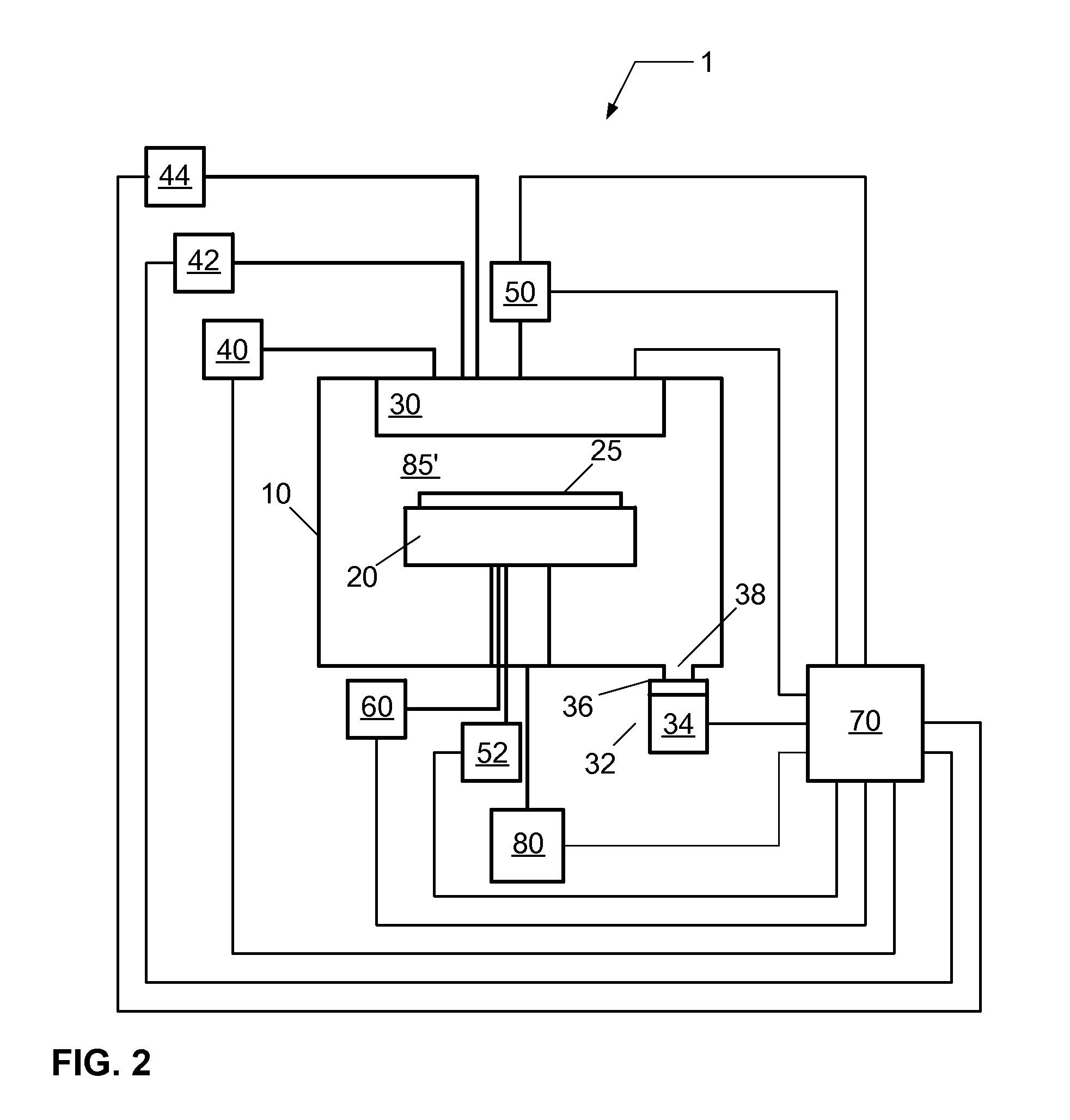

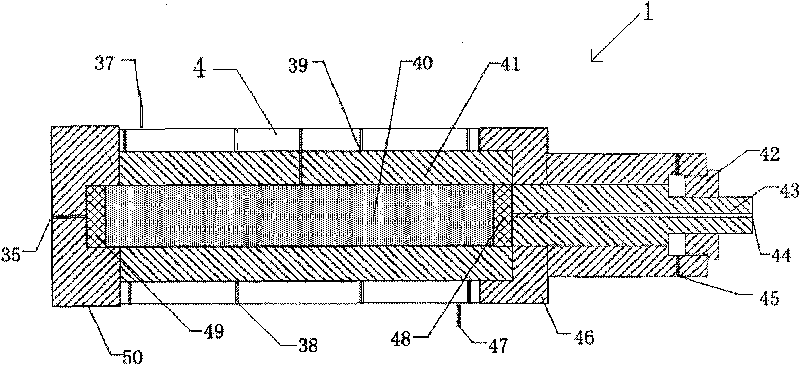

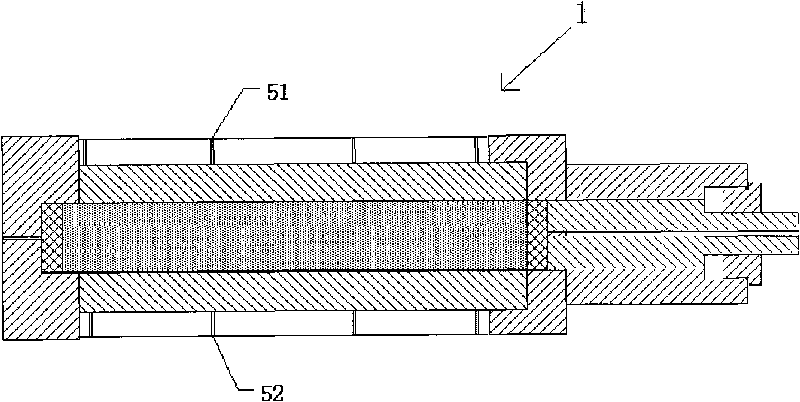

A method and system for plasma-assisted thin film vapor deposition on a substrate is described. The system includes a process chamber including a first process space having a first volume, a substrate stage coupled to the process chamber and configured to support a substrate and expose the substrate to the first process space, a plasma generation system coupled to the process chamber and configured to generate plasma in at least a portion of the first process space, and a vacuum pumping system coupled to the process chamber and configured to evacuate at least a portion of the first process space. The system further includes a process volume adjustment mechanism coupled to the process chamber and configured to create a second process space that includes at least a part of the first process space and that has a second volume less than the first volume, the substrate being exposed to the second process space.

Owner:TOKYO ELECTRON LTD

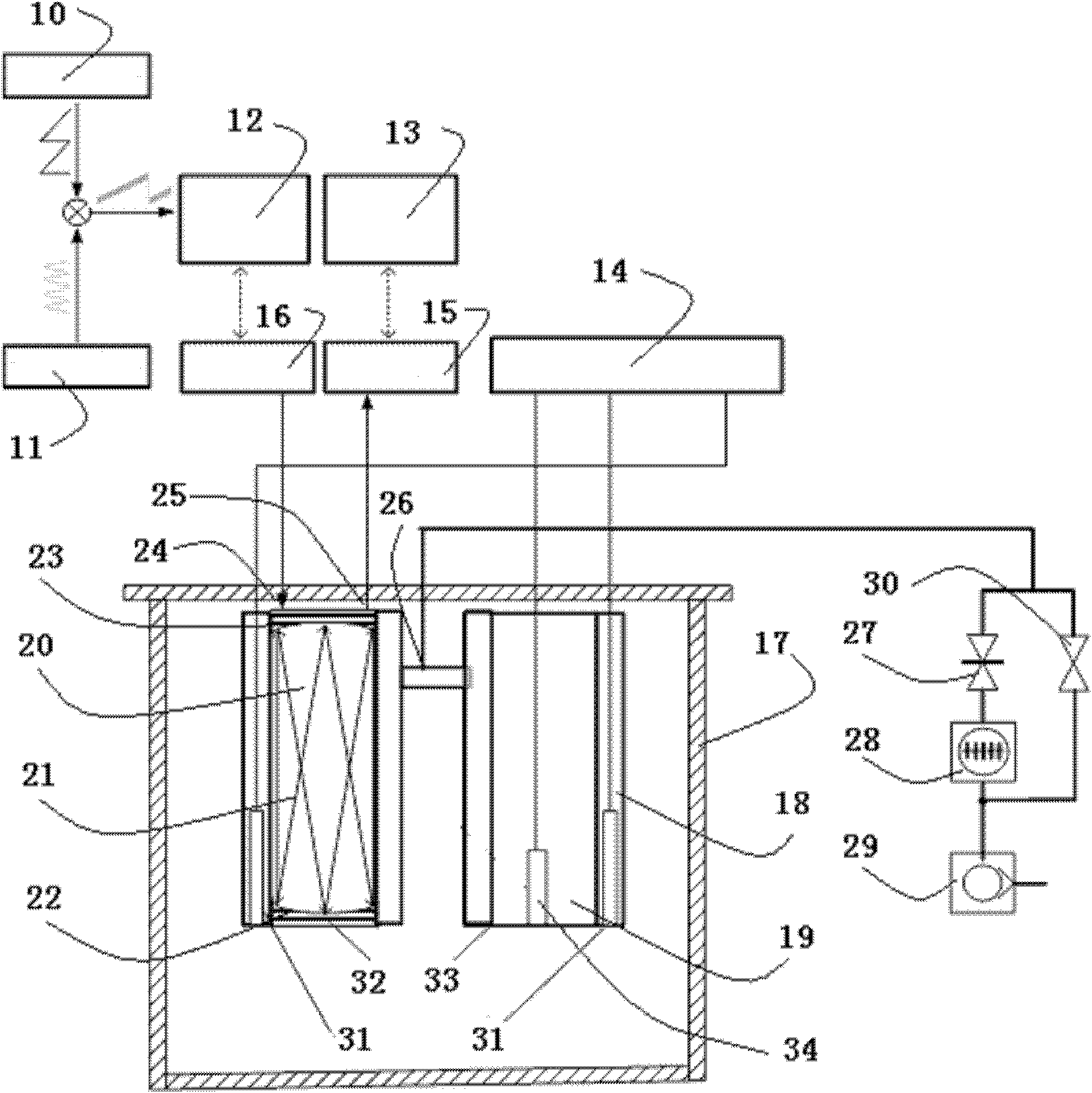

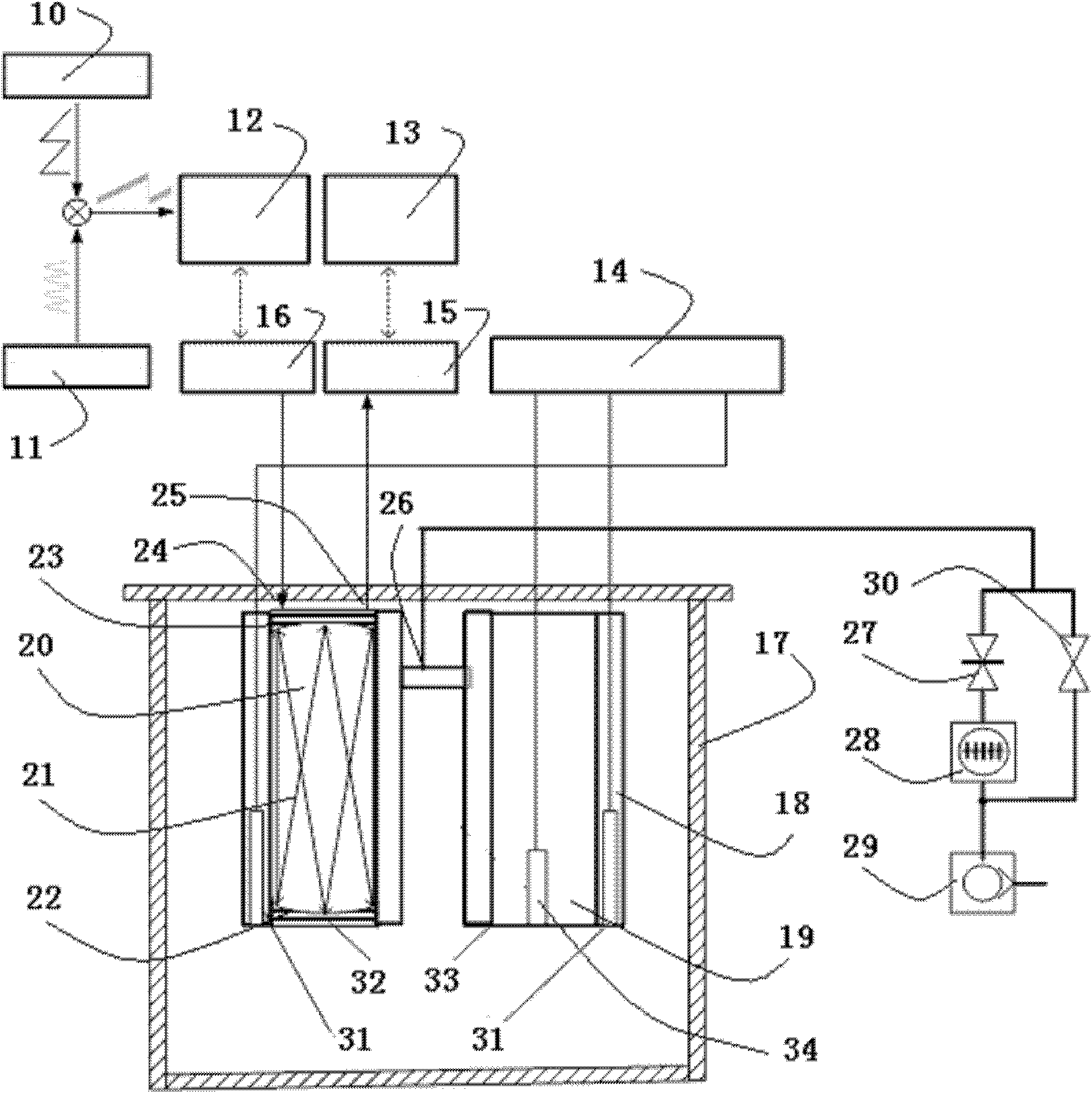

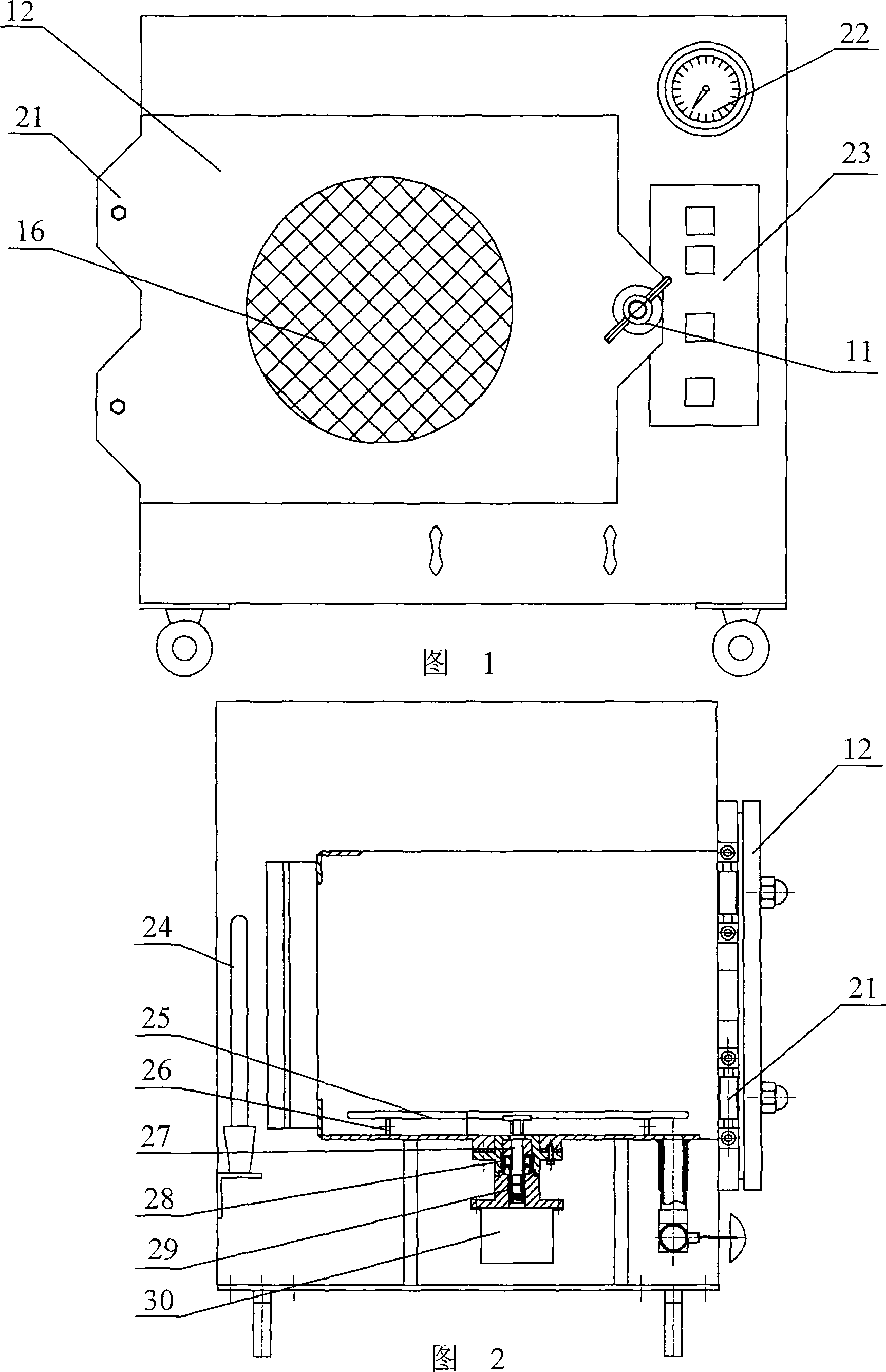

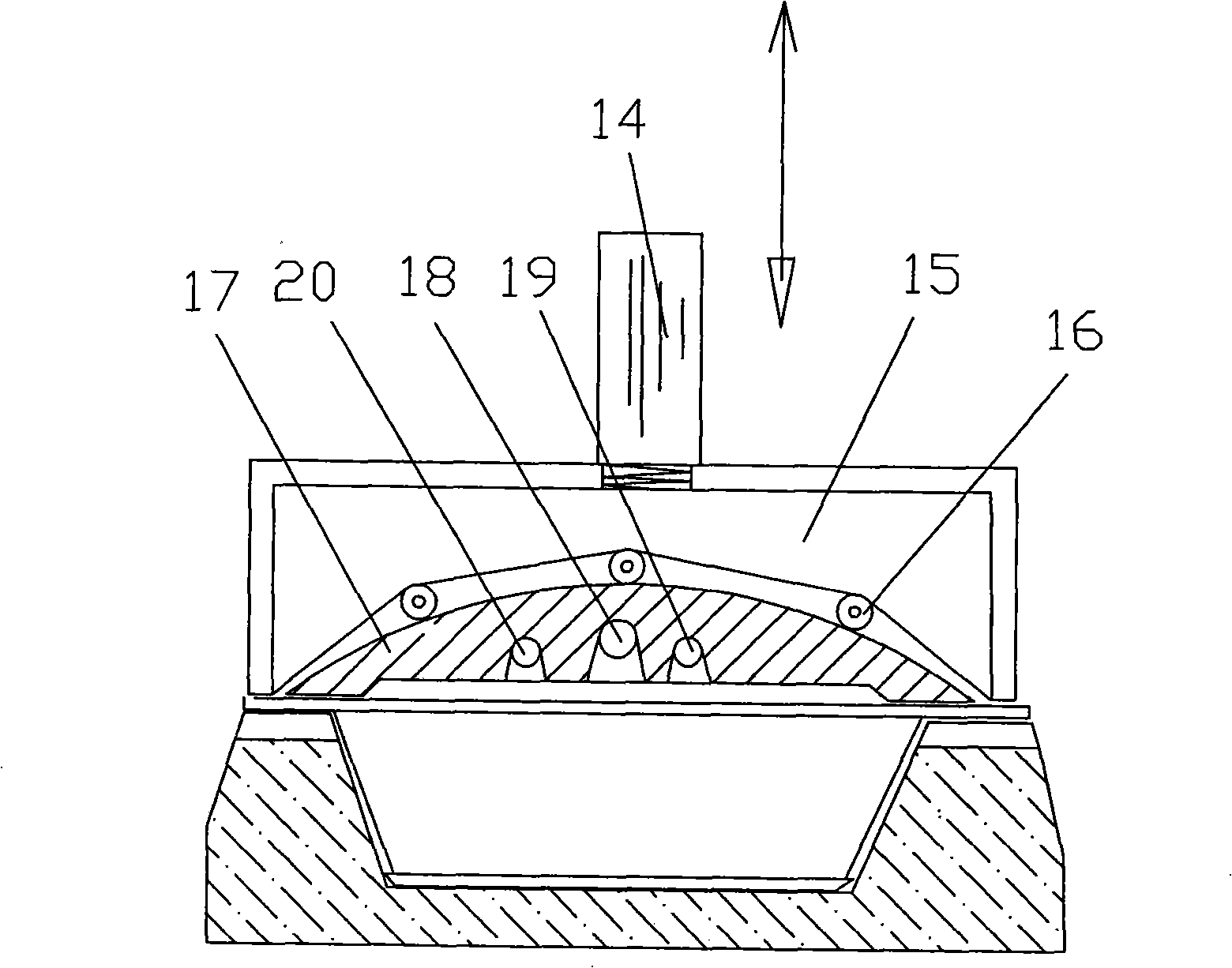

Temperature measurement and calibration platform in space vacuum environment

ActiveCN102539019ASolve the problem of large differences in measurement resultsSolve the traceability problemThermometer testing/calibrationVacuum pumpingSpace environment

The invention relates to a temperature measurement and calibration platform in space vacuum environment. The temperature measurement and calibration platform is favorable for realizing the simultaneous calibration of contact type temperature measurement and non-contact type temperature measurement, so the temperature measurement and calibration platform is served for heat vacuum and heat balance experiments of spacecrafts such as satellites, spaceship and the like. The temperature measurement and calibration platform comprises a constant temperature bath, wherein a double-sub-cavity vacuum cavity, the double-sub-cavity vacuum cavity comprises a first vacuum cavity body and a second vacuum cavity body, the first vacuum cavity body and the second vacuum cavity body are connected with a vacuum pumping device through a three-way valve, standard temperature indicator sensors are respectively arranged on the outer wall of the first vacuum cavity body and on the outer wall of the second vacuum cavity body, the standard temperature indicator sensors are connected with a temperature secondary meter, a laser light path reflecting device is arranged in the vacuum cavity of the first vacuum cavity body for calibrating a non-contact type temperature measuring system based on the tunable diode laser absorption spectrum technology, and the vacuum cavity of the second vacuum cavity body is used for accommodating a temperature sensor for calibrating a contact type temperature measuring system adopting the temperature sensor.

Owner:BEIJING DONGFANG MEASUREMENT & TEST INST

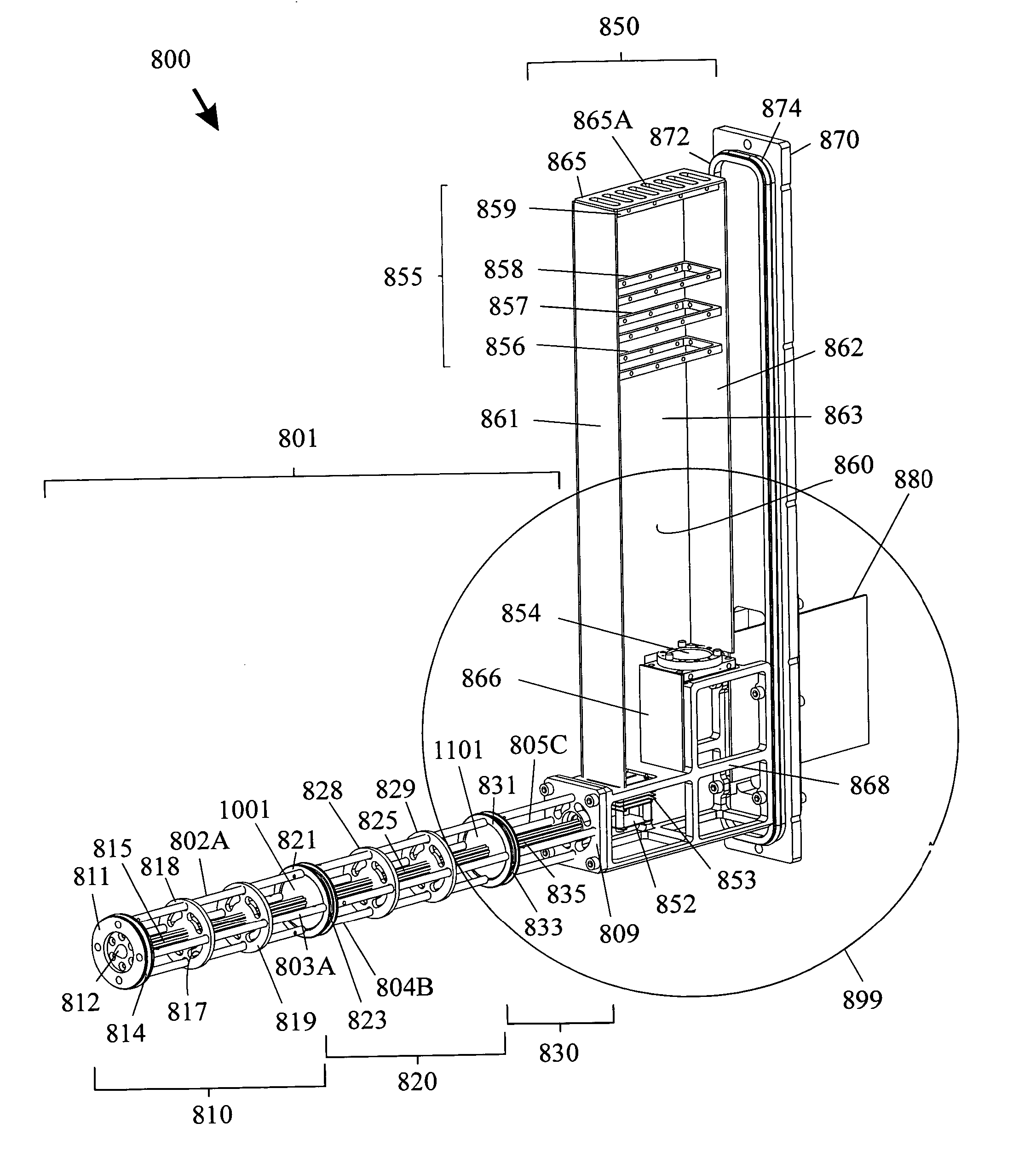

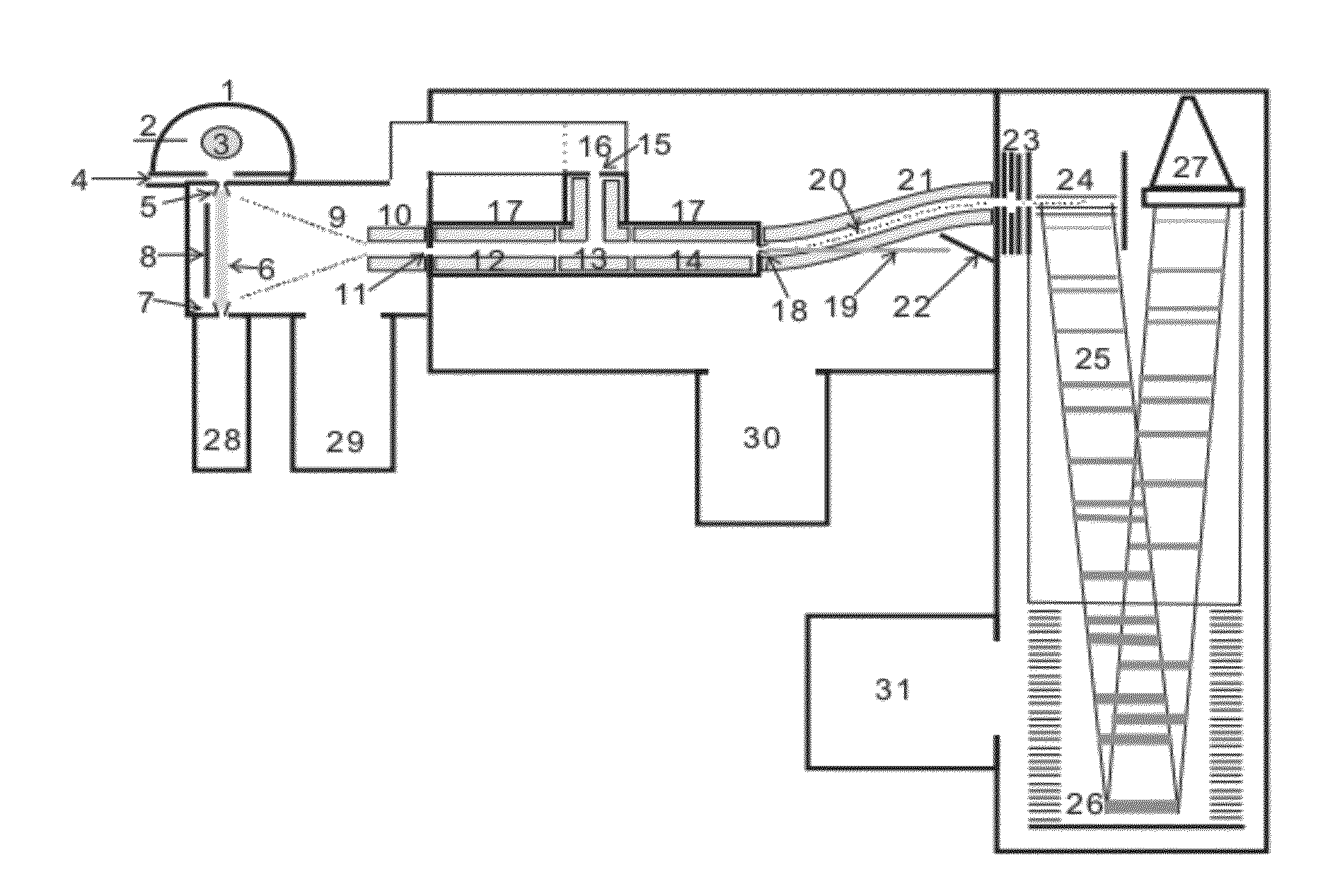

High throughput systems and methods for parallel sample analysis

Systems and methods for analyzing multiple samples in parallel using mass spectrometry preferably coupled with fluid phase separation techniques are provided. A modular mass spectrometer includes a vacuum enclosure, multiple sample inlets, multiple common vacuum pumping elements, and multiple mass analysis modules disposed substantially within the enclosure, with each module preferably including a mass analyzer and a transducer. In one embodiment, the modules mate with the vacuum enclosure to define multiple sequential vacuum regions, with each vacuum region having an associated common vacuum pumping element. At least one multi-pole ion transfer optic element is preferably associated with each module. Fluid phase separation devices may include microfluidic devices utilizing chromatographic, electrophoretic, or other separation methods.

Owner:AGILENT TECH INC

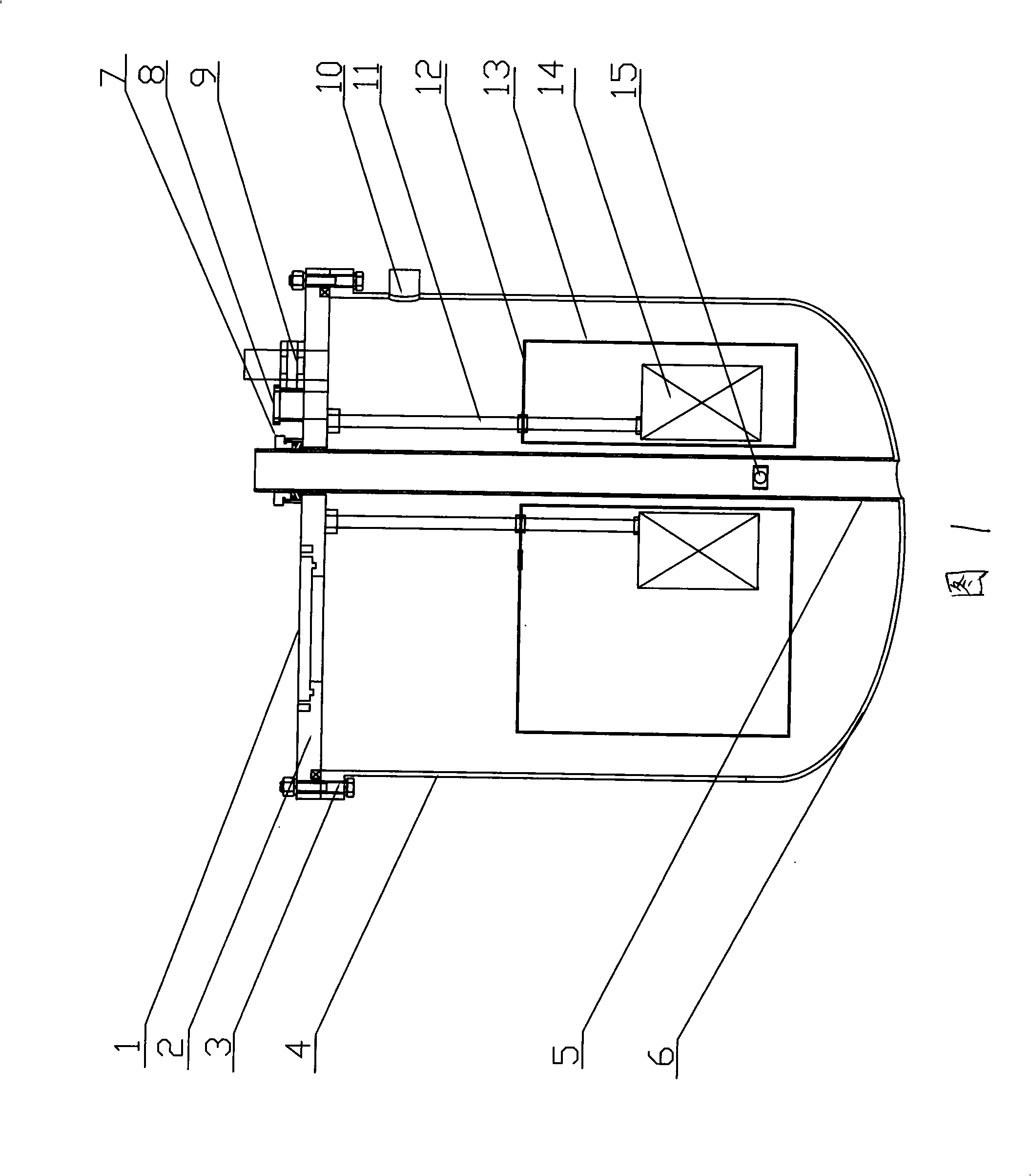

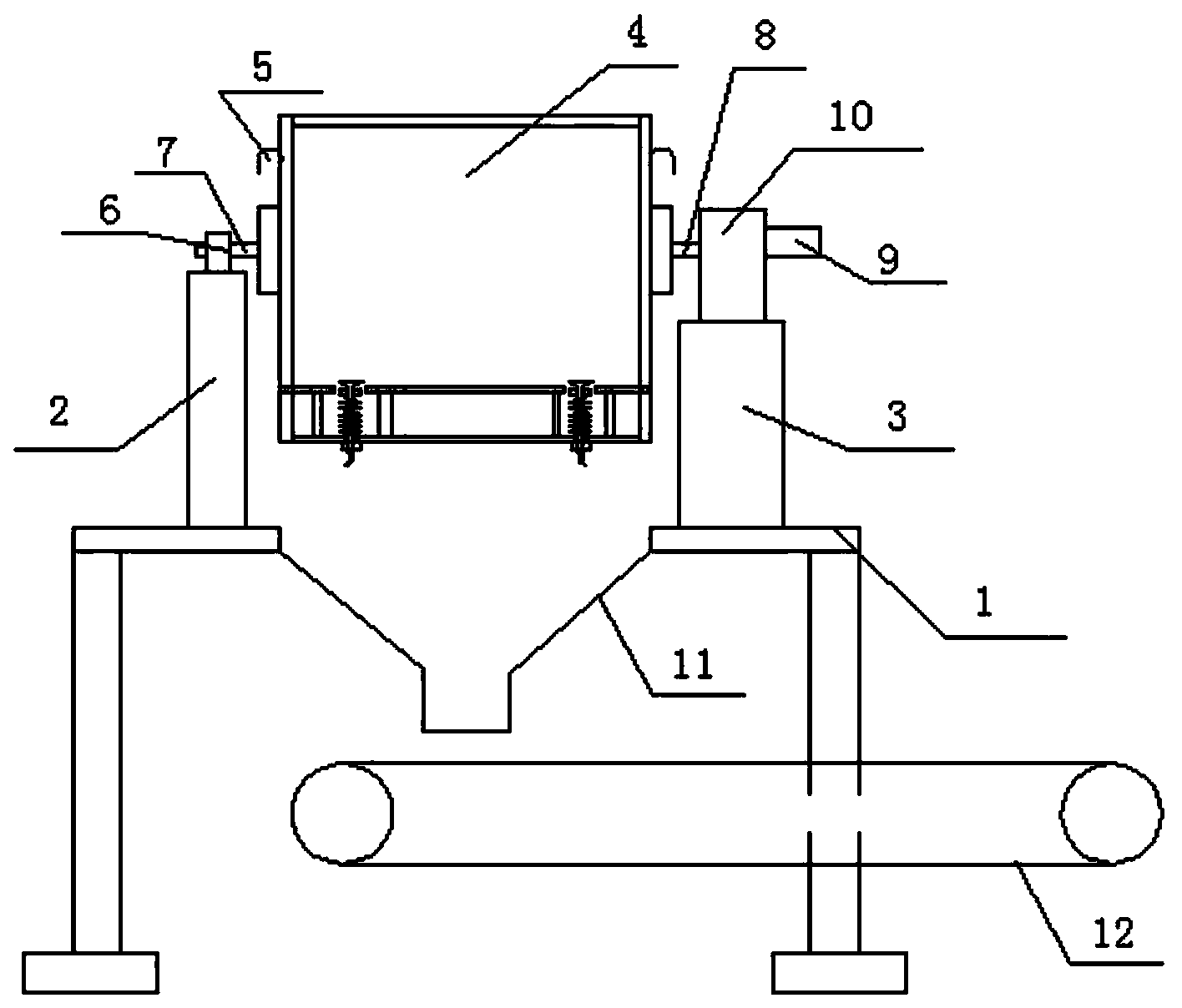

Bidirectional tosh grinding ultra-fine crashing objects and its method

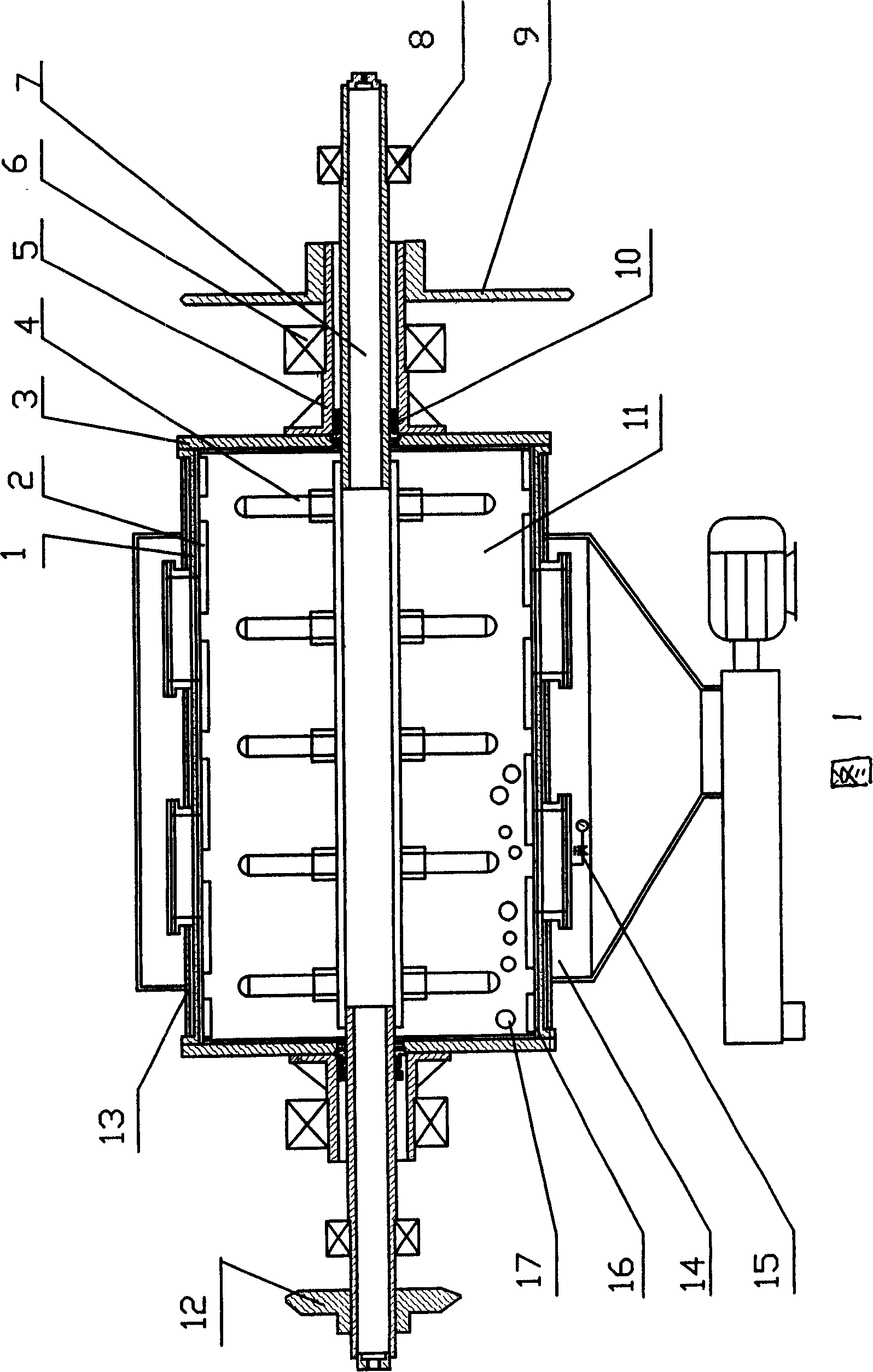

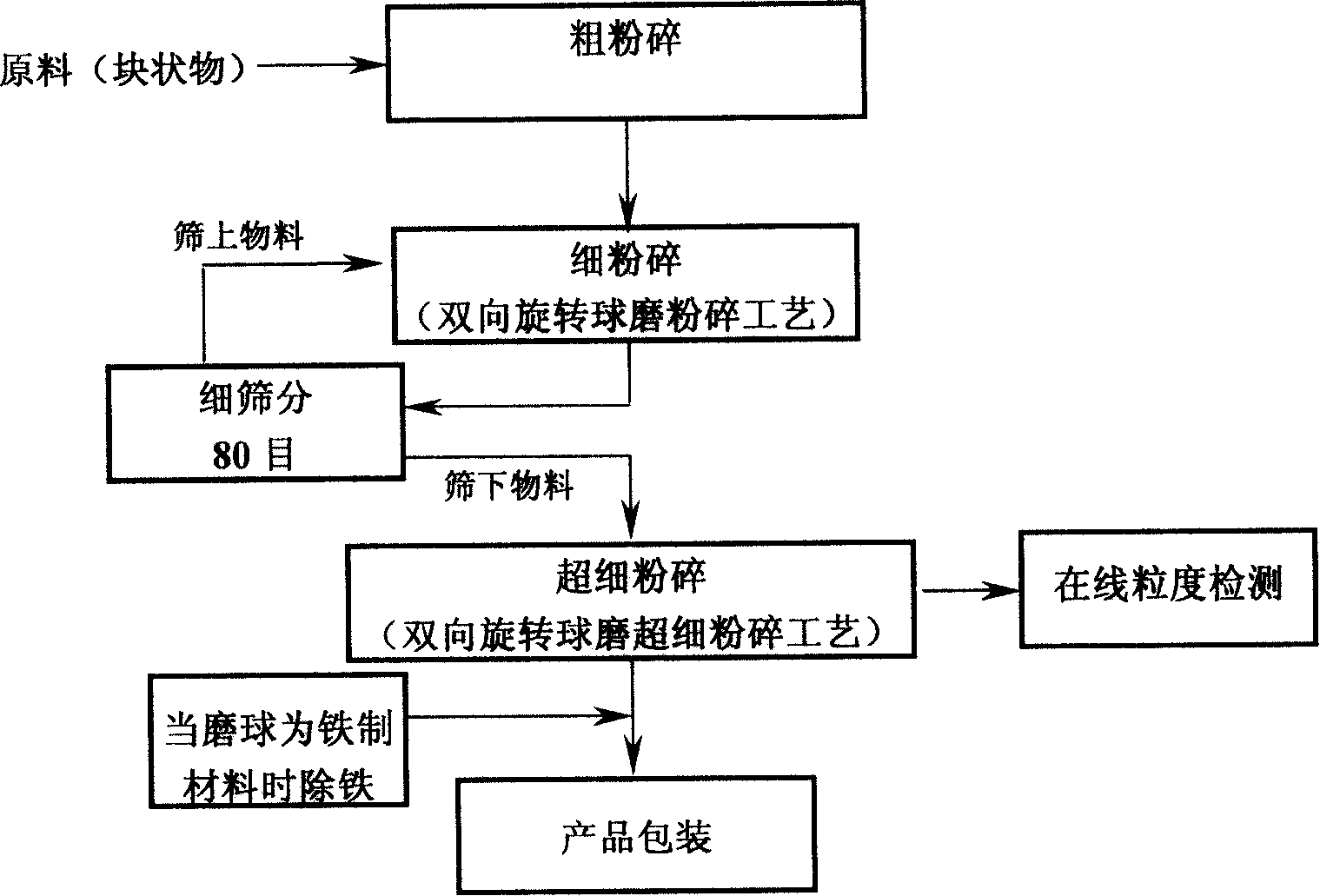

InactiveCN101161347AReduce surface activityReduce the temperatureGrain treatmentsVacuum pumpingMass ratio

The present invention discloses a bidirectional-rotating ball-milling ultra-fine crushing device and the method thereof. The device is arranged with a jacket which is provided with cooling water; a closed material storing warehouse which closes the feeding / discharging material opening is arranged at the lower end of the barrel body; a vacuum pumping valve which is connected with the vacuum pumping device is arranged at random feeding / discharging cover plate on the barrel body; and an inner lining is arranged at the inner surface of the barrel body. The bidirectional-rotating ball-milling ultra-fine crushing method is doing vacuum pumping to the inner side of the barrel body and actuating the transmission device to do ultra-fine crushing when the raw material above 80 mu is added into the barrel body, wherein the rotary speed of the barrel is 40 to 70 rotation / minute and the rotary speed of the inner rotating axle is 20 to 40 rotation / minute; the mass of the grinding ball gradation phi between 5 to 10mm accounts for 35% to 55% of the total grinding ball mass, phi between 10 to 20mm accounts for 25% to 35% of the total grinding ball mass and the phi between 20 to 30mm accounts for 20% to 35% of the total grinding ball mass; and the mass ratio of the material ball is 1:4 to 1:15. The invention has the advantages of short producing time, low energy consumption and reduced producing cost, and the invention overcomes the fine particle problems of easy aggregation to block and fusing-aggregation, etc.

Owner:NANJING UNIV OF SCI & TECH

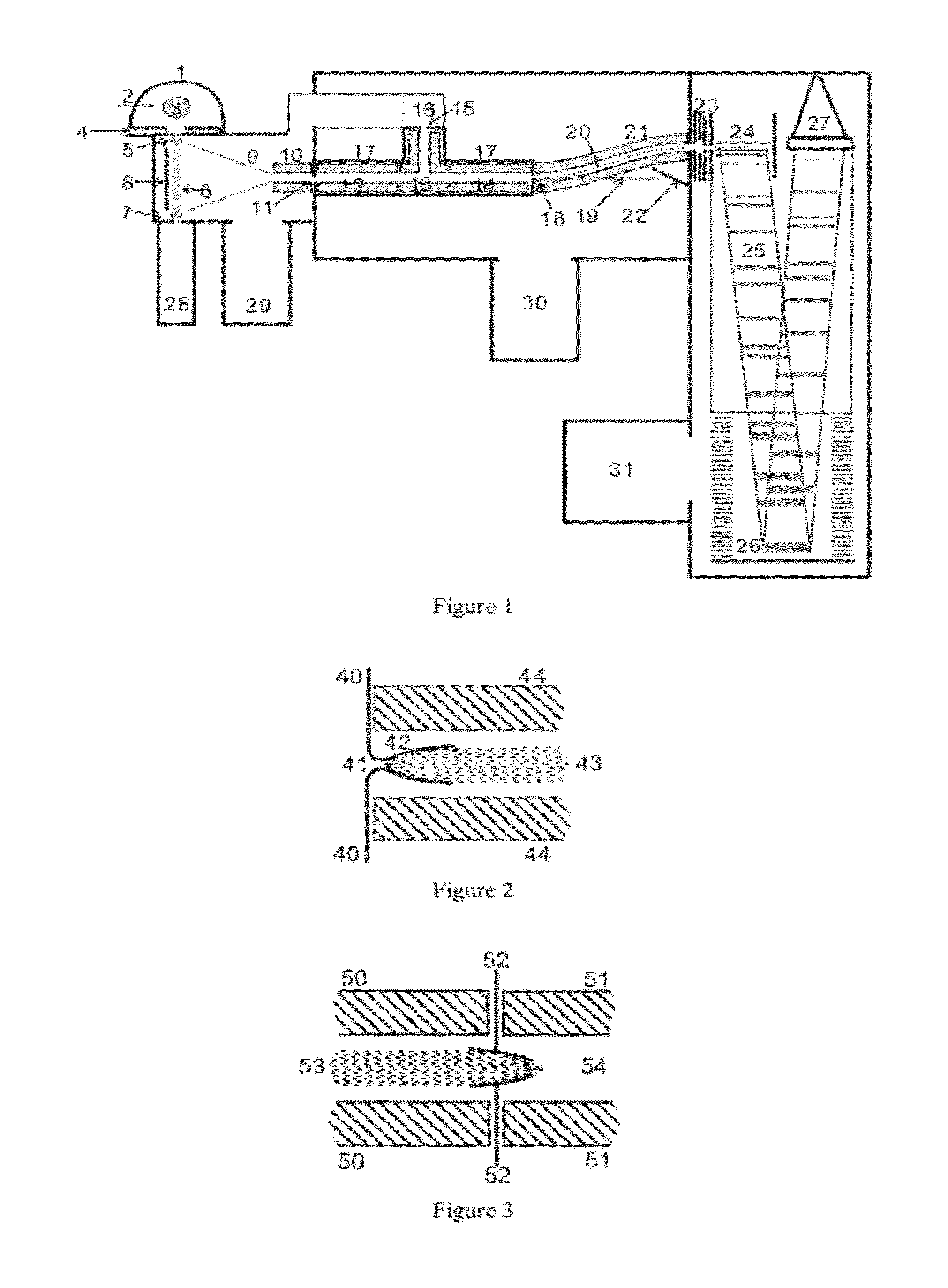

Utilizing gas flows in mass spectrometers

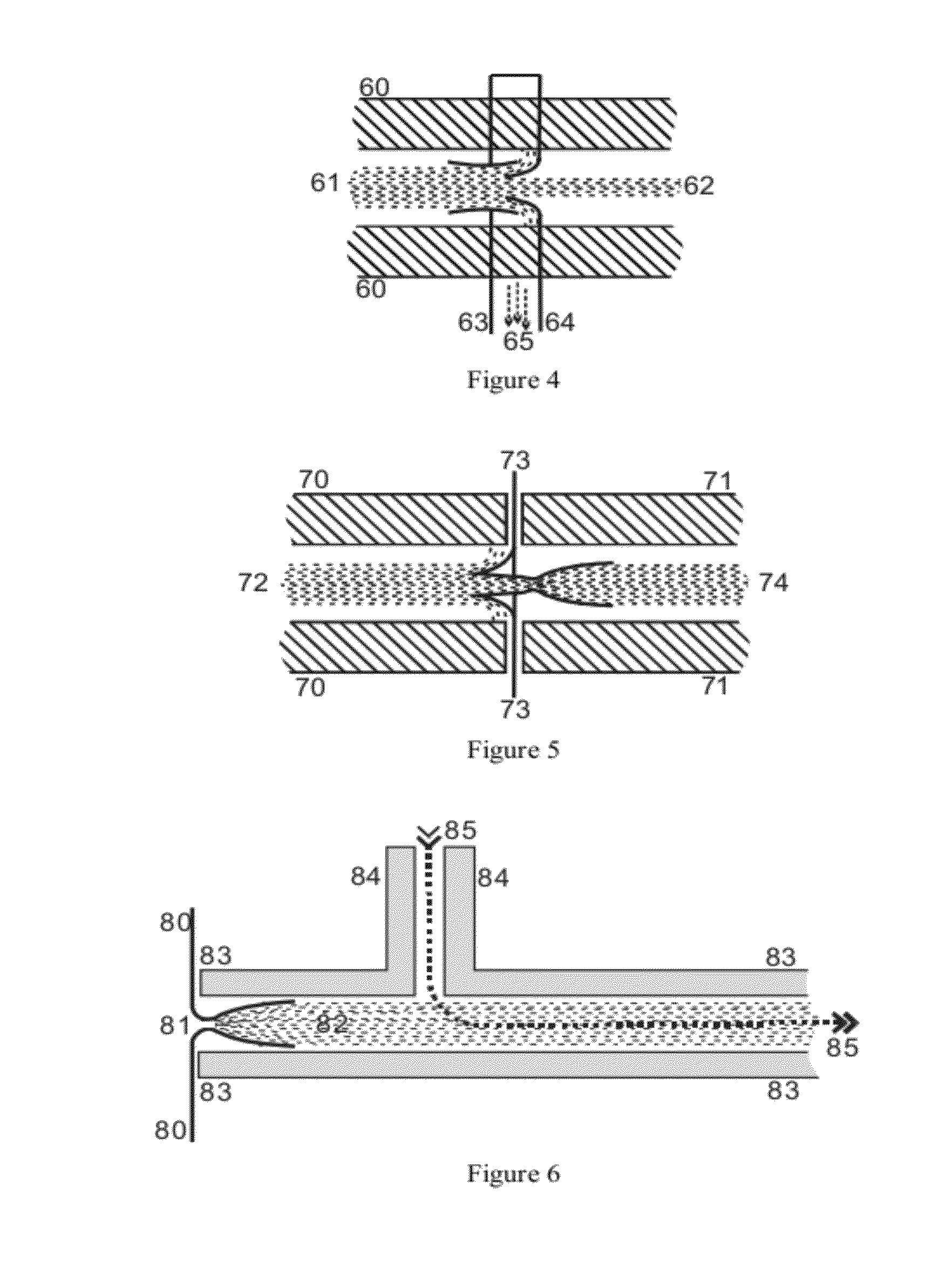

ActiveUS20120228492A1Simple designEasy to operateIsotope separationMass spectrometersVacuum pumpingVacuum pressure

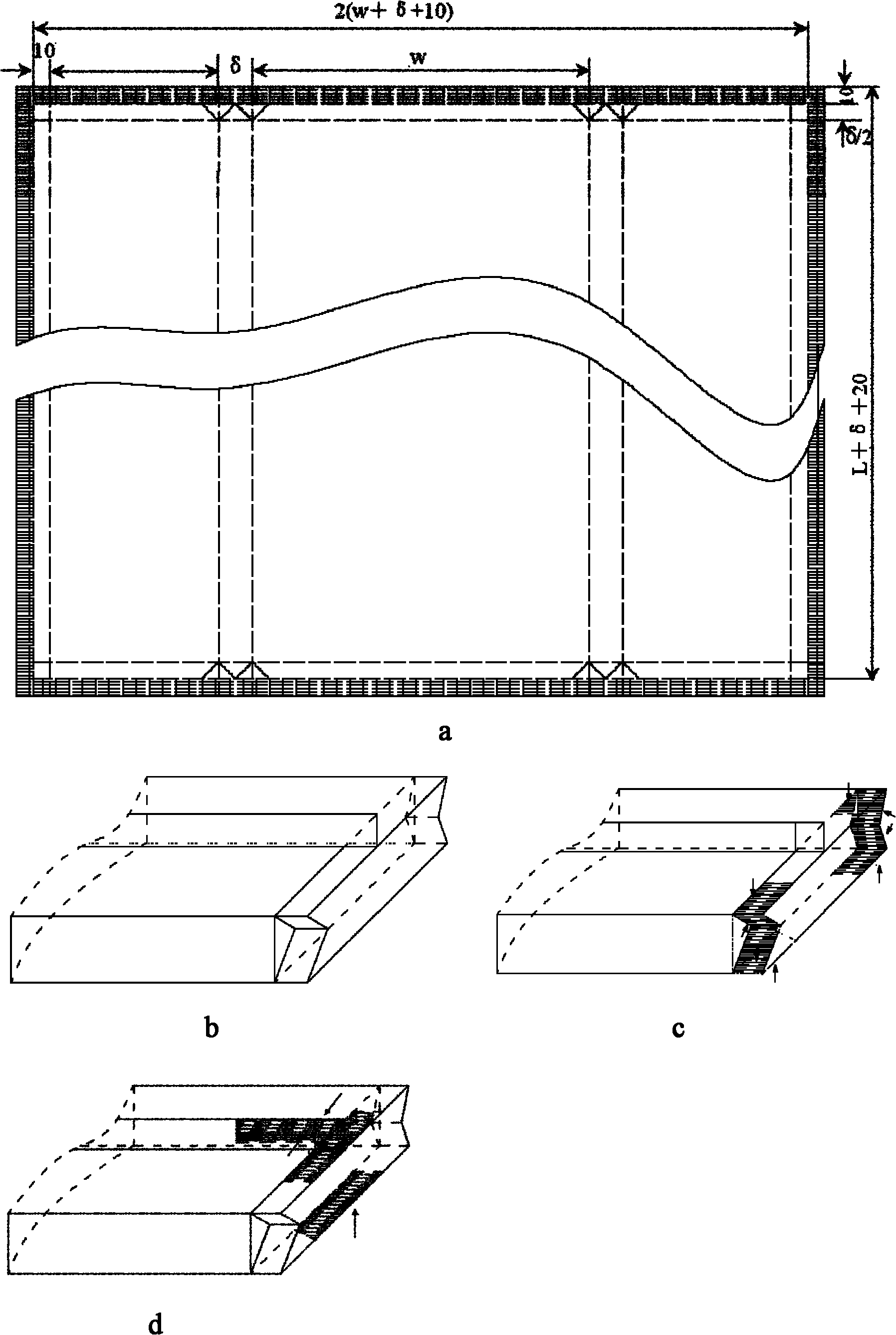

The invention relates to ions guided by gas flows in mass spectrometers, particularly in RF multipole systems, and to RF quadrupole mass filters and their operation with gas flows in tandem mass spectrometers. The invention provides a tandem mass spectrometer in which the RF quadrupole mass filter is operated at vacuum pressures in the medium vacuum pressure regime, utilizing a gas flow to drive the ions are through the mass filter. Vacuum pressures between 0.5 to 10 pascal are maintained in the mass filter. The mass filter may be enclosed by a narrow enclosure to guide the gas flow. The quadrupole mass filter may be followed by an RF multipole system, operated at the same vacuum pressure, serving as fragmentation cell to fragment the selected parent ions. The fragmentation cell may be enclosed by the same enclosure which already encloses the mass filter, so the ions may be driven by the same gas flow at the same vacuum pressure, greatly simplifying the required vacuum pumping system in tandem mass spectrometers. There are many other applications utilizing gas flows including supersonic gas jets in mass spectrometry.

Owner:BRUKER DALTONIK GMBH & CO KG

Micro-wave vacuum equipment

InactiveCN101082464AFast dryingFast concentrationDrying solid materials with heatDrying chambers/containersVacuum pumpingMicrowave

This invention relates to a sort of integral dry and dewatering set of the microwave and vacuum system, it consists of a hothouse of hermetic estate which is used to pose the materiel, the on-off door body which is propitious to gain and put materiel is fitted on the wall of the hothouse, the microwave produced by the microwave generator can cross the wall of the hothouse and it use the microwave to heat the materiel of the hothouse, there has the vacuum connector tub which is extended to the hothouse on the wall of the hothouse, the vacuum connector tub connects with the vacuum-pumping set. Because thin invention makes the microwave heating system connects with the vacuum system in the organic way, the speed of its dryness and condensation is fast, the temperature is low (25 to 45 deg. C), It very fit to the use of the lab, and fit to desiccate and condense the multifarious hydrous, and specially fit to food materiel of the heat sensitivity, and so on, and it is widely used to desiccate and condense the multifarious hydrous in the way of small-scale in the lab, such as the food, the medication, the chemical production.

Owner:JIANGNAN UNIV

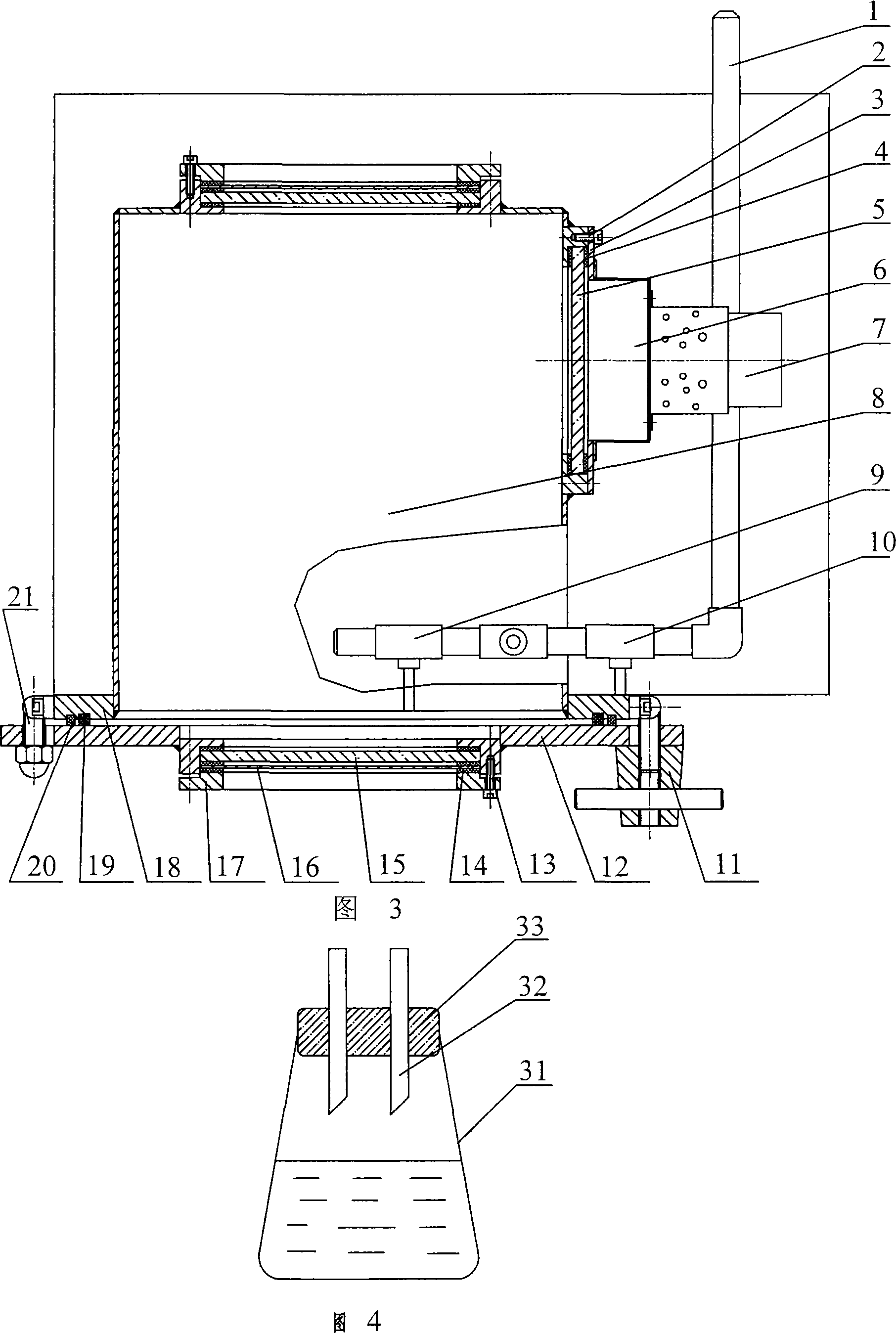

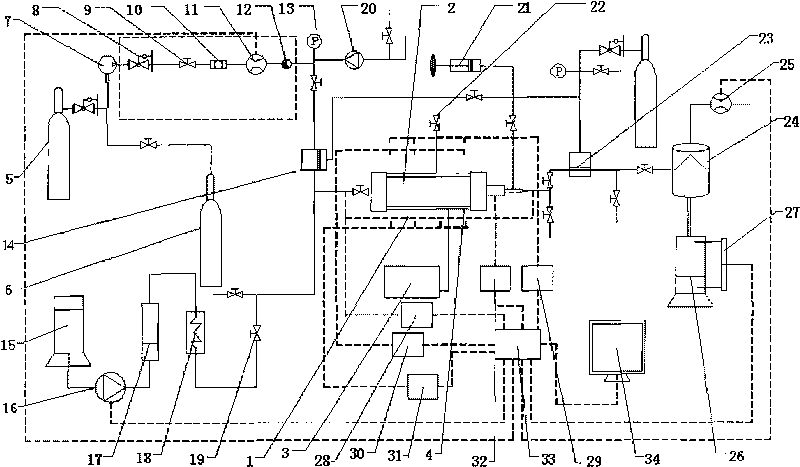

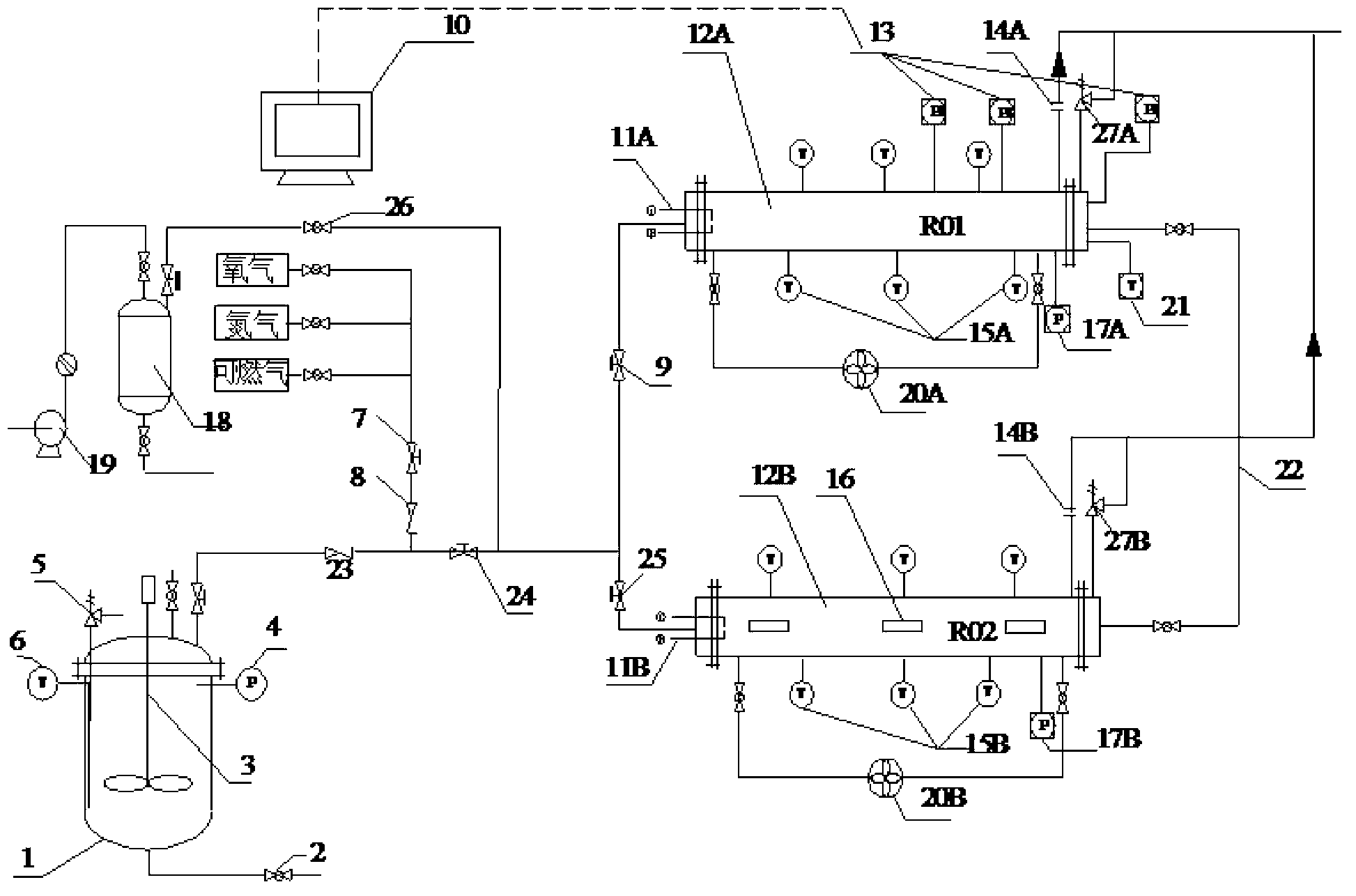

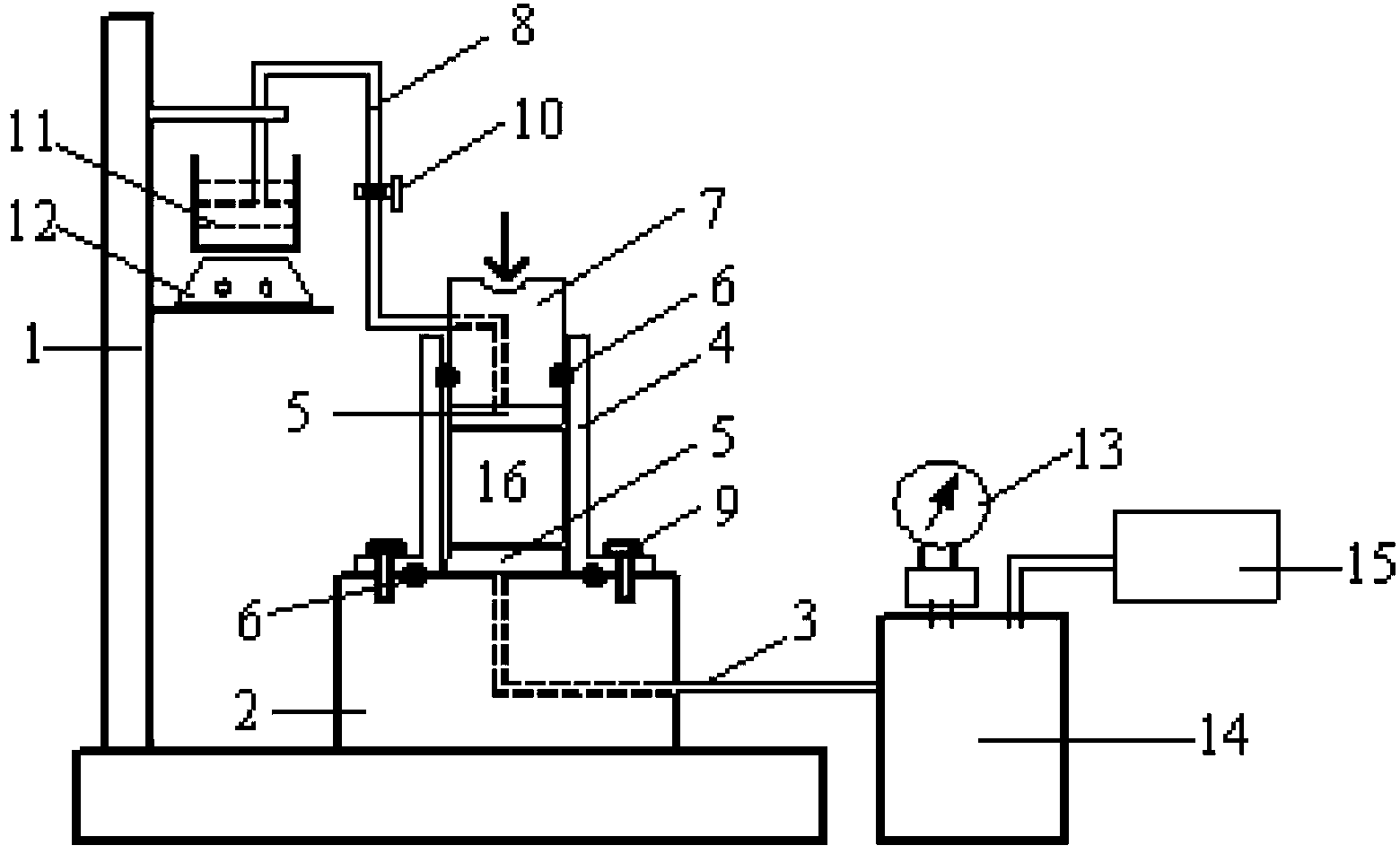

Simulation method and experimental device for carbon dioxide replacement exploitation of gas hydrate

The invention discloses an experimental device and a method for carbon dioxide replacement exploitation of gas hydrate. The experimental device comprises a one-dimensional model, a gas supply unit, a working solution supply unit, an axial compression control unit, a back pressure control unit and an environment control unit. Each unit is respectively provided with a sensor connected to a data processing unit. The one-dimensional model is arranged in the environment control unit. The inside of the one-dimensional model is a sealed simulation cavity. The upper part of the one-dimensional model is provided with a gas and solution inlet, a gas and solution outlet and an axial compression solution inlet. A gas output pipeline of the gas supply unit is communicated with the gas and solution inlet after being connected with a working solution output pipeline of the working solution supply unit. A back pressure acquisition pipeline is communicated with the gas and solution outlet. The axial compression control unit is connected with the axial compression solution inlet. The one-dimensional model is also provided with a vacuum-pumping interface. The invention can really simulate the external environment to carry out simulation exploitation of carbon dioxide replacement of the gas hydrate, and can provide guidance for the carbon dioxide replacement exploitation of the gas hydrate.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

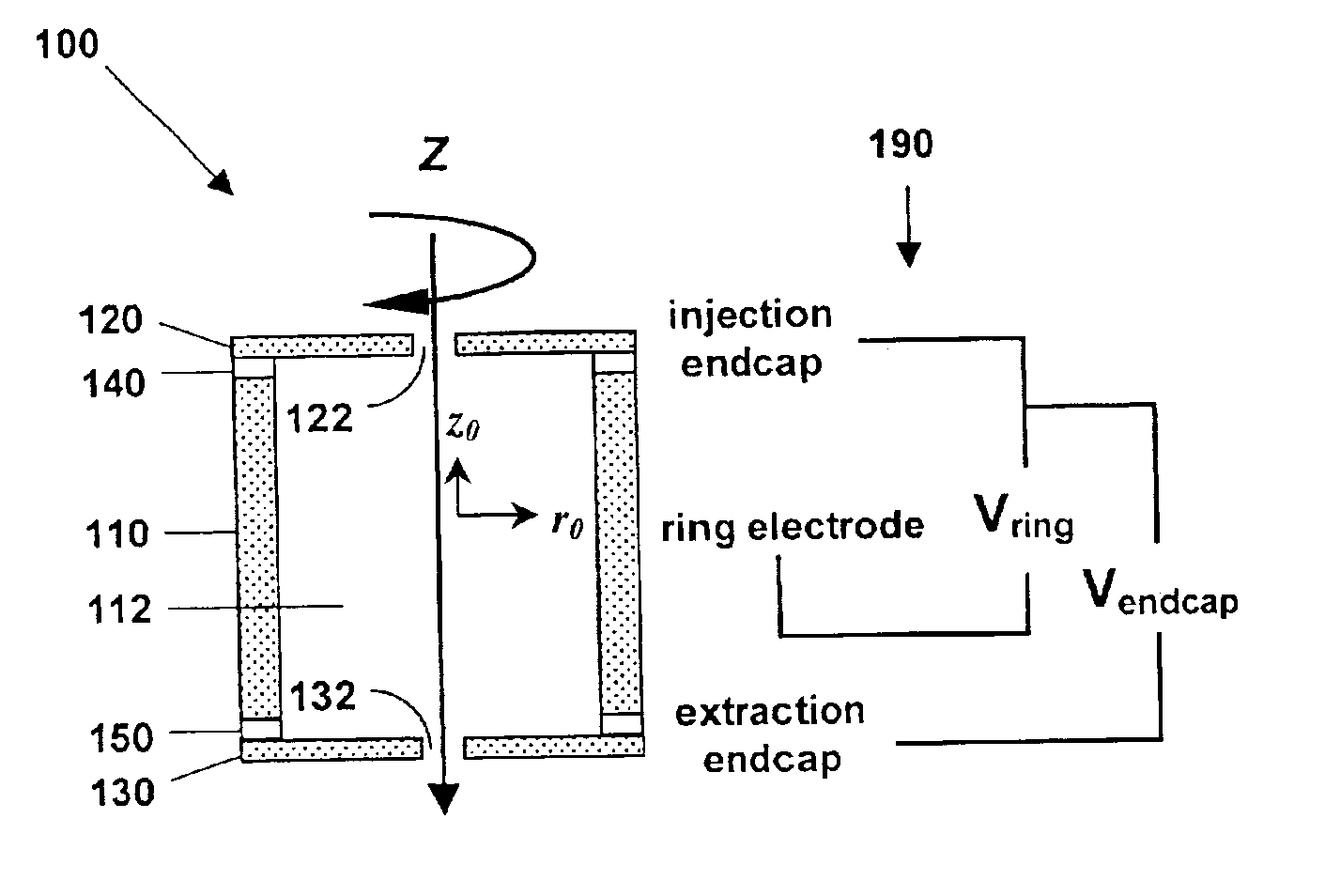

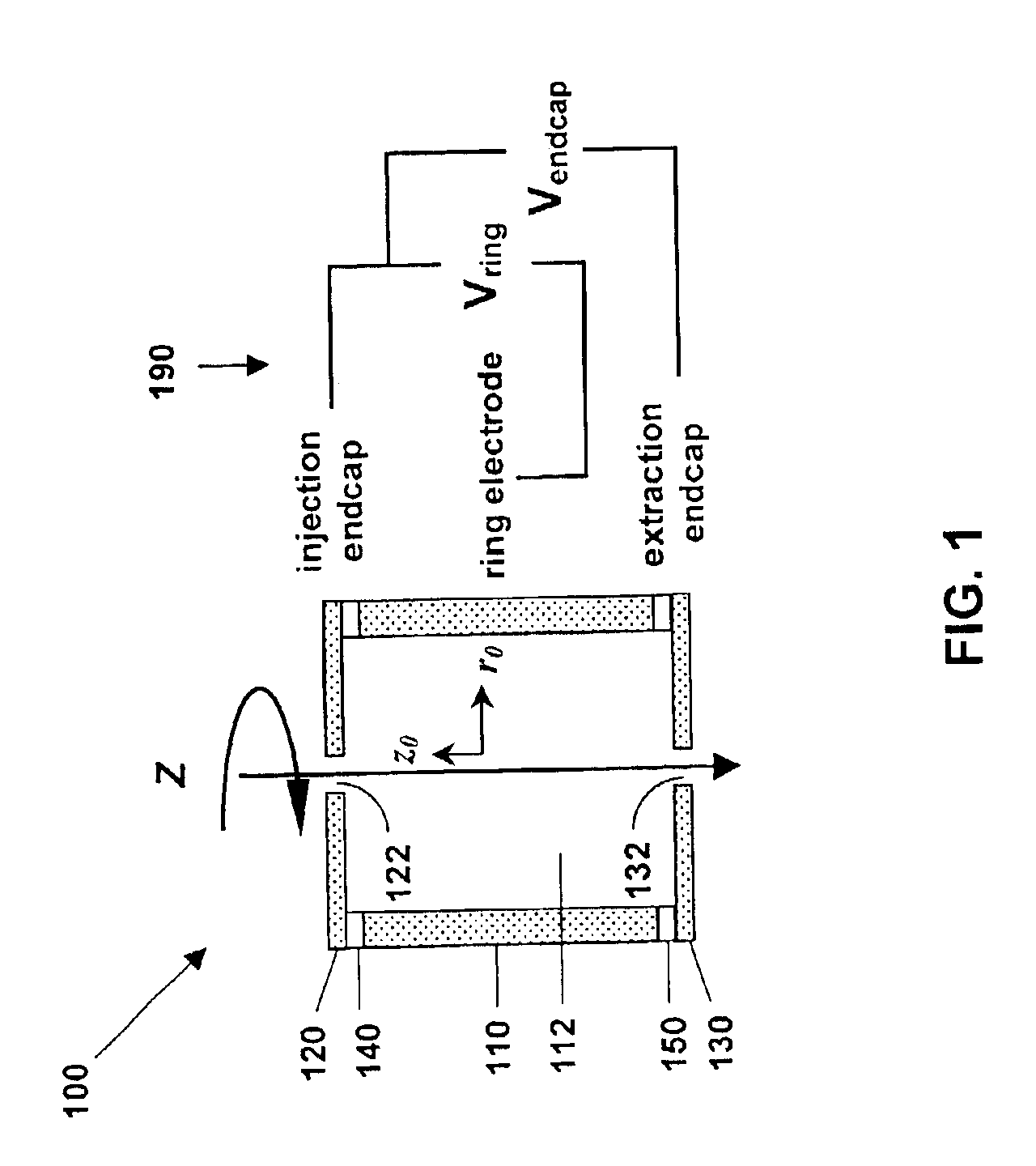

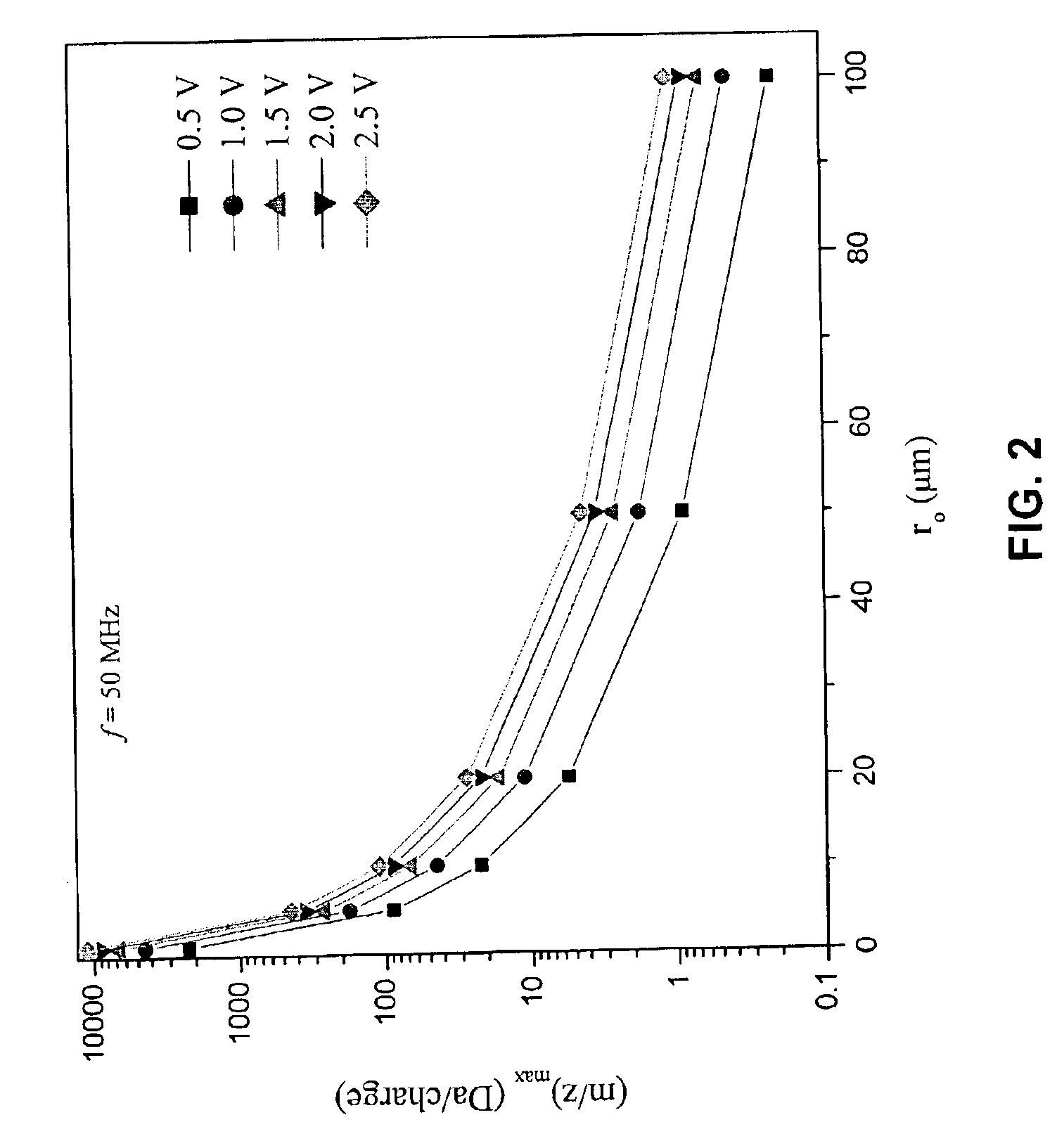

Microfabricated cylindrical ion trap

InactiveUS6870158B1Stability-of-path spectrometersIsotope separationManufacturing cost reductionHigh pressure

A microscale cylindrical ion trap, having an inner radius of order one micron, can be fabricated using surface micromachining techniques and materials known to the integrated circuits manufacturing and microelectromechanical systems industries. Micromachining methods enable batch fabrication, reduced manufacturing costs, dimensional and positional precision, and monolithic integration of massive arrays of ion traps with microscale ion generation and detection devices. Massive arraying enables the microscale cylindrical ion trap to retain the resolution, sensitivity, and mass range advantages necessary for high chemical selectivity. The microscale CIT has a reduced ion mean free path, allowing operation at higher pressures with less expensive and less bulky vacuum pumping system, and with lower battery power than conventional- and miniature-sized ion traps. The reduced electrode voltage enables integration of the microscale cylindrical ion trap with on-chip integrated circuit-based rf operation and detection electronics (i.e., cell phone electronics). Therefore, the full performance advantages of microscale cylindrical ion traps can be realized in truly field portable, handheld microanalysis systems.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

Production method of vacuum insulation wall thermal insulation board by using expanded vitrified microspheres

ActiveCN102296714ALow thermal conductivityImprove insulation effectMixing operation control apparatusClimate change adaptationThermal insulationMetallurgy

The invention discloses a production method for producing a heat insulation board for a vacuum heat insulation wall body by utilizing small expanded and vitrified balls, and the method comprises the following steps: putting the small expanded and vitrified balls, glass fiber, silica fume, bentonite and a getter into a stirring kettle, adding a wetting agent and a bonding agent, and stirring for forming a paste-like material; uniformly spreading the well stirred paste-like material on a micro-wave baking line according to the required thickness for baking, and further cutting into blocks when the water content in the board is below 1%; further placing the board which is cut into the blocks on a vacuum machine assembly line and vacuum pumping till the vacuum degree is below 200Pa; and cutting and packaging the heat insulation board for the vacuum heat insulation wall body. By applying the method provided by the invention for production, the process is simple, the emission of three wastes can be avoided, the produced heat insulation board for the vacuum heat insulation wall body is easy to construct, the fireproof property can be realized, the heat insulation board for the vacuum heat insulation wall body can play great roles in heat preservation and heat insulation, the combustion performance is grade A, the weight is light, the weather-resistant time is long, and the service life can be above 30 years.

Owner:潍坊三强集团有限公司

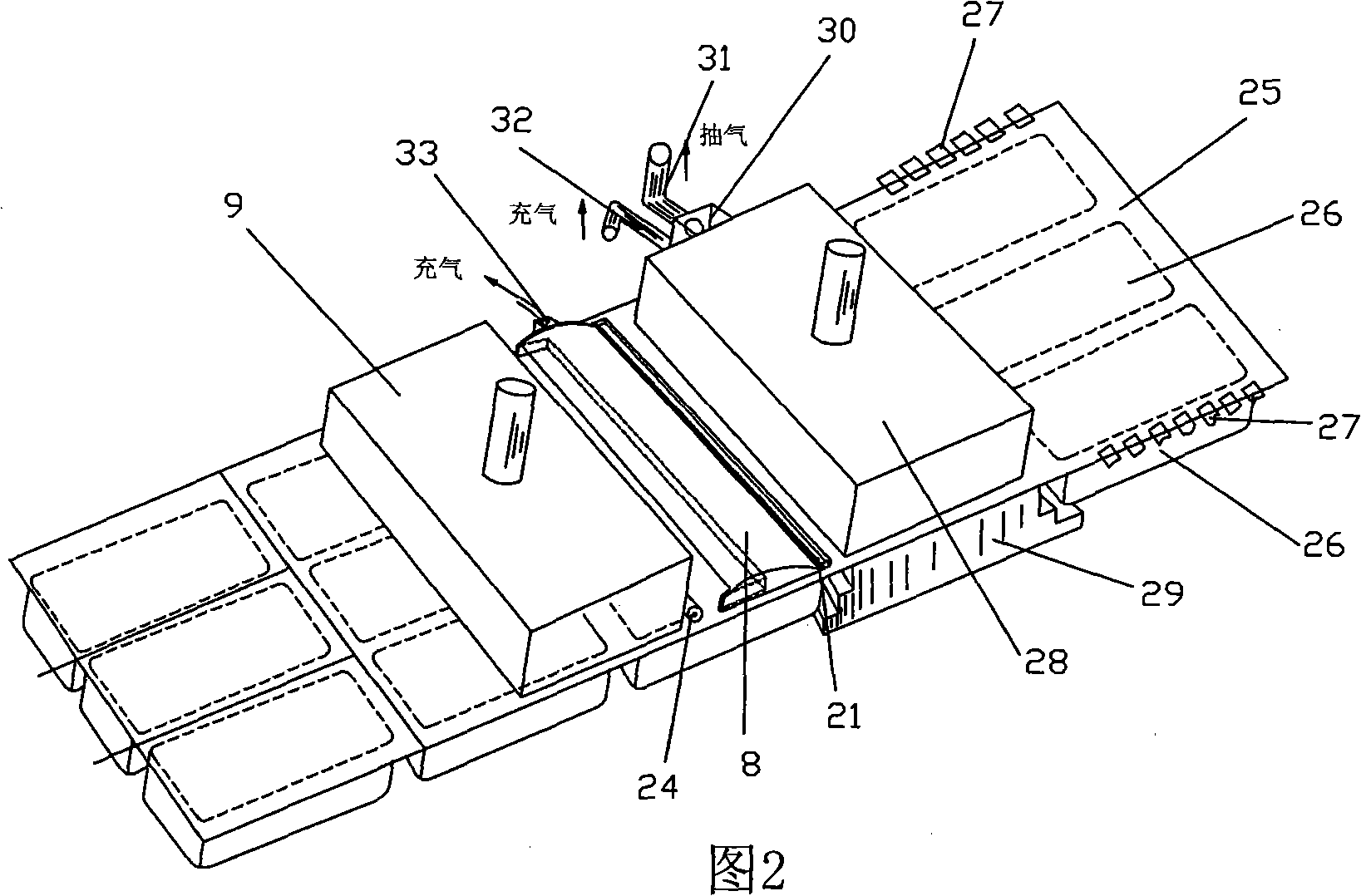

Drying method of lithium-ion battery electric core

ActiveCN102735023AGood water contentReduce labor loadFinal product manufactureDrying solid materials without heatVacuum pumpingElectrical battery

The invention relates to the field of battery manufacturing and particularly relates to a drying method of a lithium-ion battery electric core. The method comprises the following steps that: the electric core to be dried is placed in a closed cavity; constant temperature of the cavity is set; multiple times of vacuum pumping and vacuum relieving are cyclingly carried out; and a cycling air flow is formed in the closed cavity and the electric core is dried. When the lithium-ion battery electric core adopts the drying method provided by the invention, cycling of air pumping and air changing is introduced in the process of vacuum drying, and water content in the lithium-ion battery electric core can be reduced in a relatively short period of time, and operation processes are simplified and work load of an operator is reduced.

Owner:DONGGUAN AMPEREX TECH +1

Entirety quick manufacture method of hot isostatic pressing metal wrapps

InactiveCN101391302ARelief of restrictions that make it difficult to make complex envelopesHot isostatic pressing process goes smoothlyAdditive manufacturing apparatusIncreasing energy efficiencyVacuum pumpingData information

The invention discloses an integral rapid manufacturing method of a hot isostatic pressing metal sheath, comprising the steps: (1) a CAD three-dimensional model of the metal sheath is designed by adopting three-dimensional molding software, and is then processed by slicing software and saved as an STL file, and the data information of the STL file is transmitted to an SLM rapid forming machine; (2) a forming chamber is vacuumized; (3) a metal powder layer is spread on a work platform flatly; (4) a semiconductor pumping YAG laser or a fiber laser is adopted to scan the metal powder positioned at the boundary of the slice layer, and the powder material at the boundary is melted; and (5) the step (3) and the step (4) are repeated until the compact sheath is manufactured. Powder inlet holes can be reserved on the sheath when designing the three-dimensional model of the sheath, so as to facilitate the subsequent processes such as powder filling, compaction by vibration, vacuum pumping and encapsulation. The sheath is compact and has a controllable shape, and can form parts with any complex shapes and structures, and can realize the high utilization rate of material.

Owner:HUAZHONG UNIV OF SCI & TECH

High-temperature high-pressure explosion limit tester, method for determining explosion limit, and application thereof

The invention provides a novel high-temperature high-pressure explosion limit tester comprising a raw material gas supply apparatus, an explosion determination device, a vacuum generating device, and a controlling device. The explosion determination device is mainly composed of a pressure sensor, a temperature sensor, and an igniter. The explosion determination device is used for determining explosion limit, explosion pressure and explosion temperature of the gas or vapor. The vacuum generating device is used in vacuum pumping upon the explosion determination device. The controlling device is used for determining, controlling and collecting experimental data generated during the experiment. Compared with prior arts, the high-temperature high-pressure explosion limit tester provided by the invention has a temperature testing range of room temperature to 400 DEG C, which is higher than 200 DEG C which is a maximal temperature of instruments in existing standards; the tester provided by the invention has a pressure range of normal pressure to 2.2MPa, which is higher than 1.38MPa which is a maximal pressure of instruments in existing standards; and the tester provided by the invention has a test volume of 10L, which is larger than that of an existing tube-type explosion limit tester, such that a wall effect can be better reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

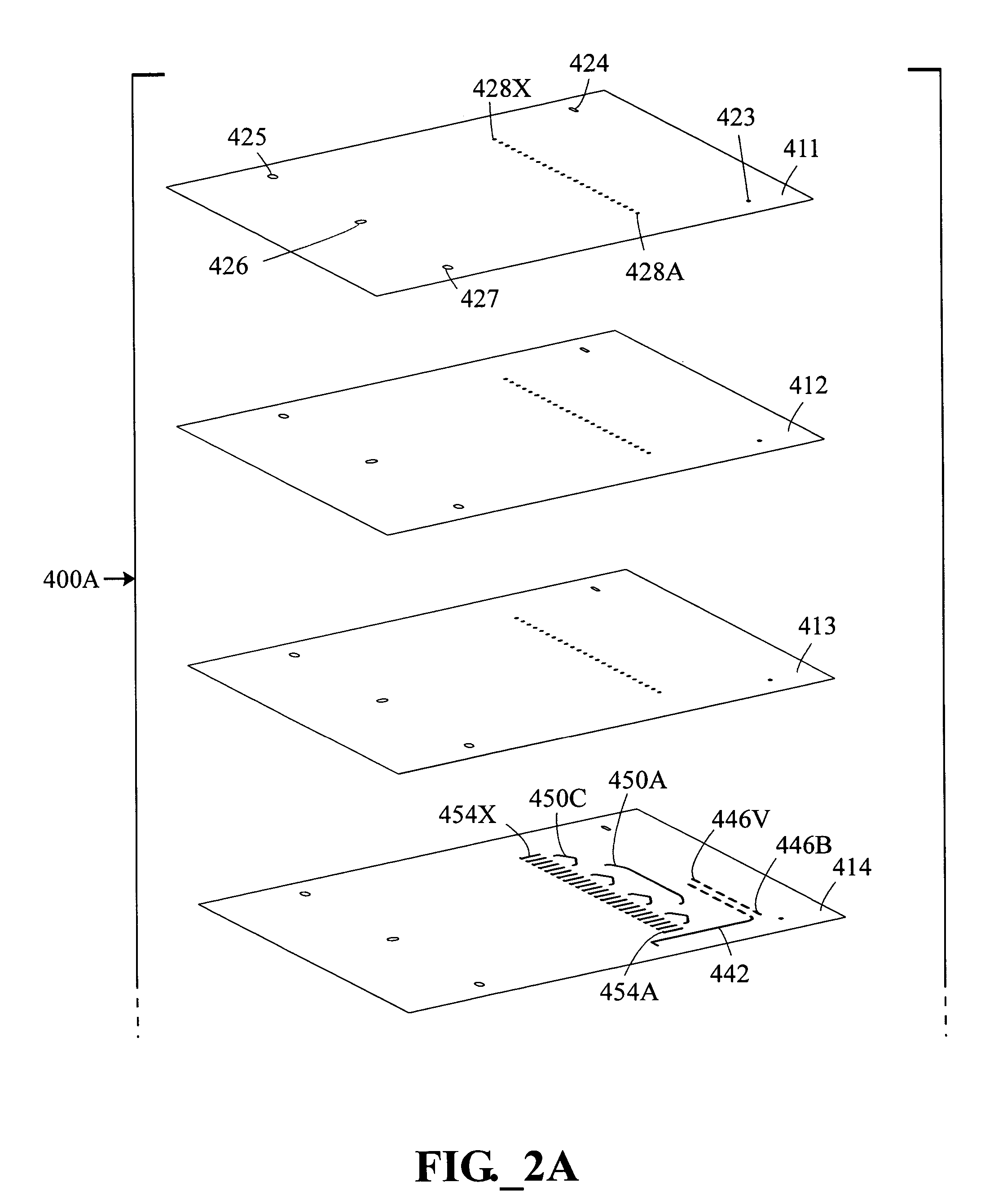

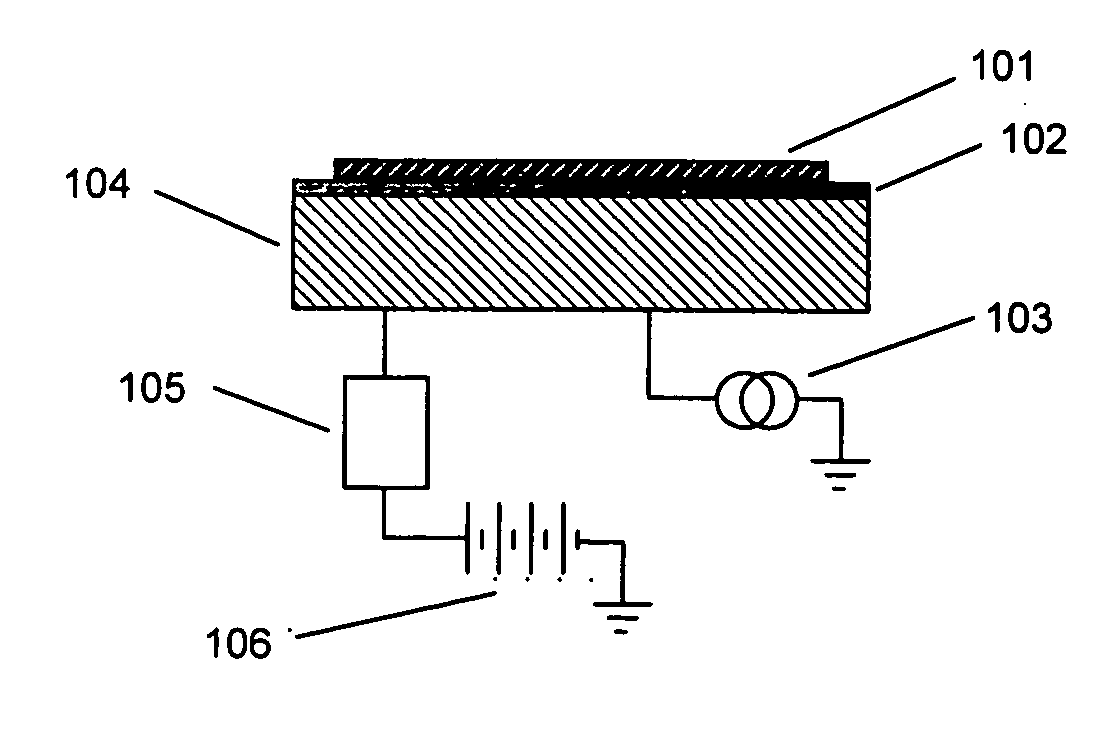

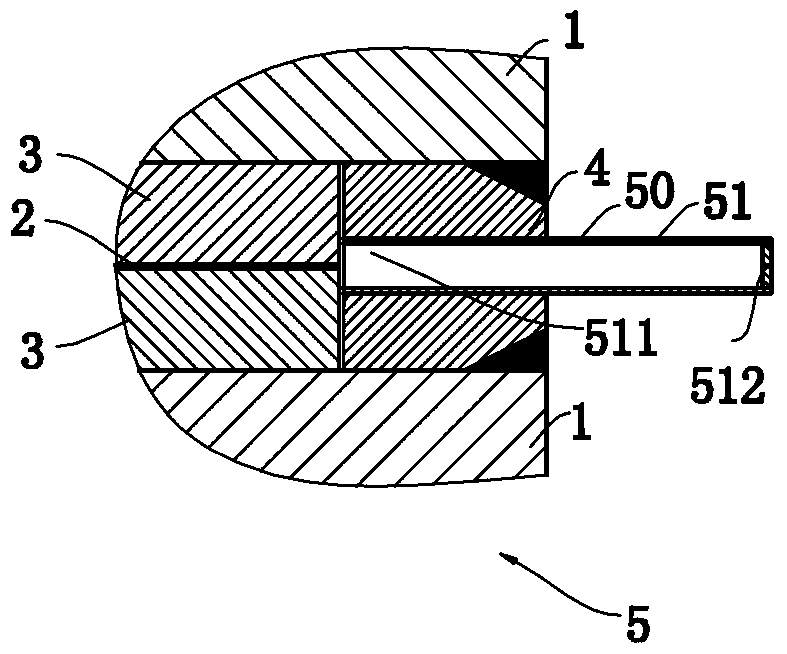

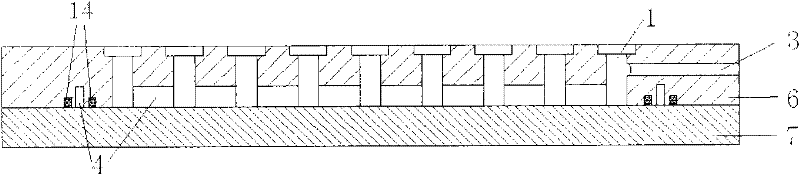

Clamp for holding and efficiently removing heat from workpieces

InactiveUS20050036267A1Effectively safely clampIncrease resistanceSemiconductor/solid-state device manufacturingEmergency protective arrangement detailsEtchingCelsius Degree

The invention described in this disclosure is an apparatus and method for clamping semiconductor wafers or other substrates or workpieces during etching, CVD, or surface modification processes. The purpose of the invention is to achieve improved heat transfer during processing between the wafer / substrate and a temperature controlled pedestal used for supporting it in the process chamber. The typical level of process heat put into the wafer during plasma-based etching or deposition processes will be up to about 10 Watts per centimeter squared while the maximum acceptable temperature differential between wafer / substrate and pedestal is less than about 100 Celsius. In such low gas pressure environments typical for plasma-based processes, the heat removal from the wafer / substrate by gaseous conduction may be inadequate to meet requirements. This invention achieves excellent heat transfer to the pedestal from the wafer / substrate when there is a thin, resilient, electrically insulating layer (tape) bonded to the wafer / substrate or the pedestal. Wafer / substrate clamping for improved process heat removal is achieved by a combination of vacuum clamping of the wafer / substrate beginning prior to evacuation of the processing chamber, along with or followed by electrostatic clamping of the wafer / substrate which continues during processing. The invention also permits the wafer / substrate to be rapidly and safely released from the electrostatic clamping when the chamber is returned to atmospheric pressure by a providing a slight pressure increase, above atmospheric pressure, between wafer and pedestal. The pedestal may have some roughening or narrow grooves on the wafer clamping surface, and some small holes from its surface leading to an evacuated plenum or channel within the pedestal. Alternatively, the pedestal may have a layer of a porous metal extending from its surface down to the evacuated channel or plenum which permits gas to be evacuated. These structures allow vacuum pumping of gas that might otherwise be trapped between the insulating layer and the pedestal. When a wafer / substrate is placed on the pedestal by loading at atmospheric pressure, vacuum pumping through the pedestal is commenced. This causes the workpiece to be pressed to the pedestal clamping surface with approximately atmospheric pressure compressing the soft layer against its clamping surface. This provides sufficient contact of the soft layer with the pedestal to greatly improve heat transfer from the wafer / substrate to the pedestal. A voltage is applied to the pedestal, beginning any time after the wafer is on the pedestal, to further clamp the wafer electrostatically. As the processing chamber is then pumped down to operating pressure for processing the electrostatic clamping voltage maintains sufficient pressure of the wafer / substrate against the pedestal to maintain the heat conductive contact between the soft layer and the pedestal. This permits good heat conduction to be maintained during the low pressure plasma-based etching or CVD processing. Following processing when the wafer / substrate is to be removed it may be rapidly de-clamped from the electrostatic clamping by application of a slight over-atmospheric pressure in the reservoir or pumping channels within the pedestal.

Owner:SAVAS STEPHEN EDWARD +1

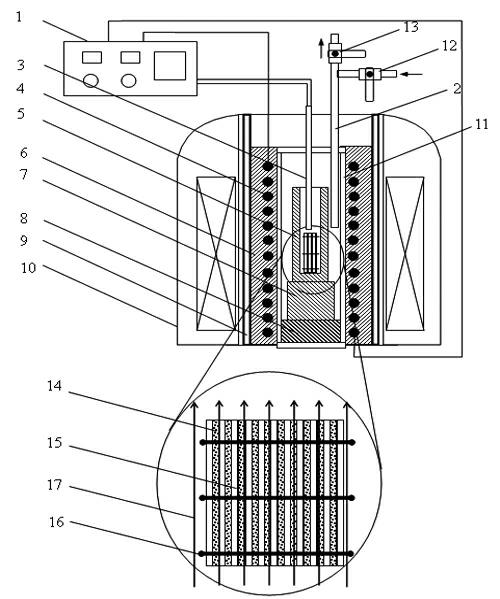

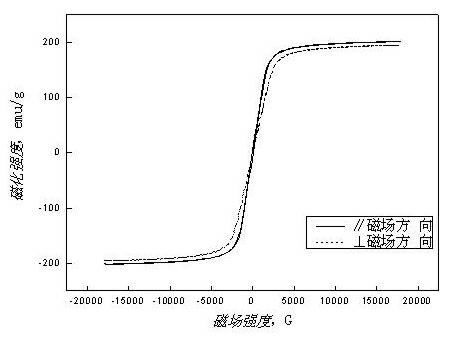

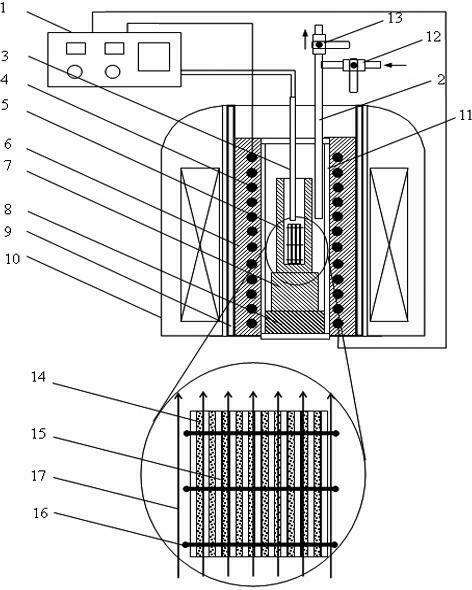

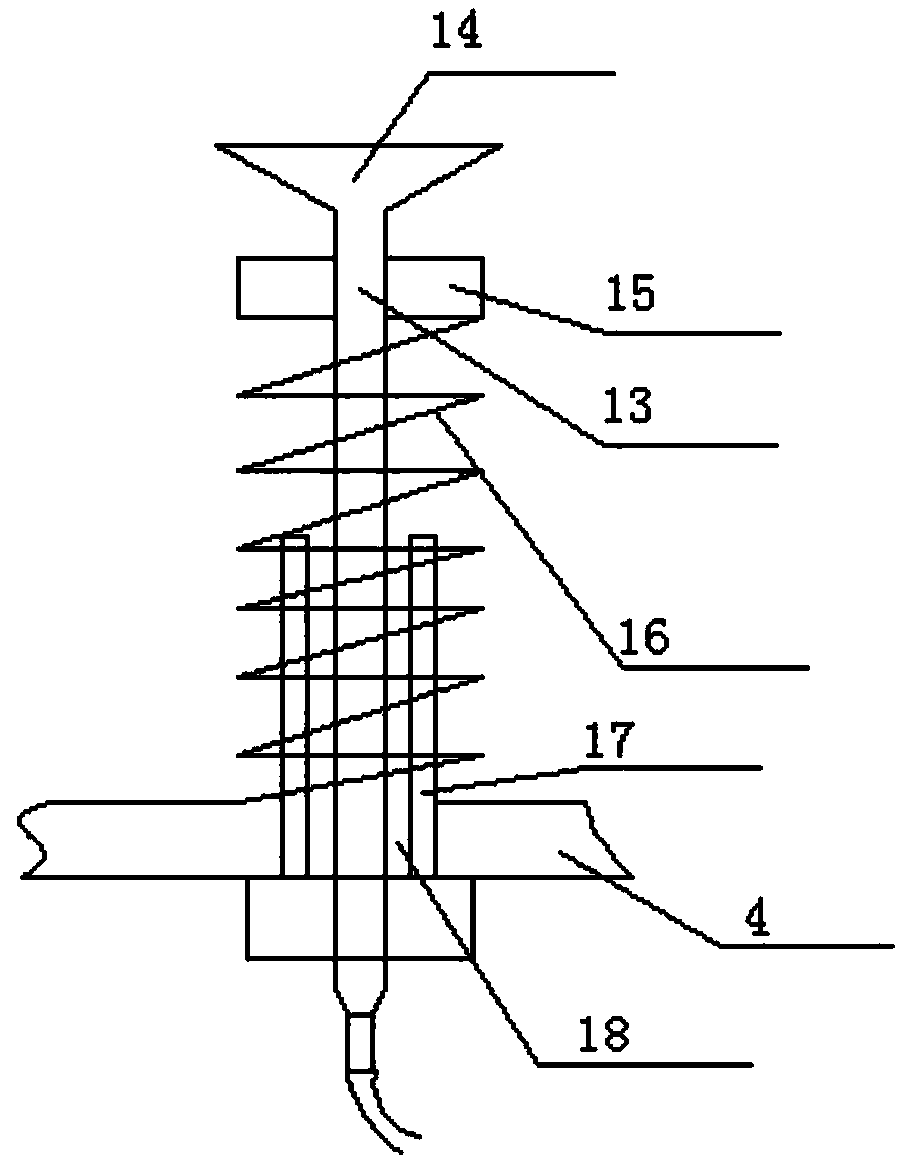

Method and device for preparing high-silicon silicon steel sheet in static magnetic field with powder sintering method

ActiveCN102658367AAccurate control of silicon contentHigh densityInorganic material magnetismInlet valveExhaust pipe

The invention relates to a method and device for preparing a silicon steel sheet in a static magnetic field with a powder sintering method. The specific process of the method consists of the following steps of: mixing Fe-Si powder; rolling into a plate blank; and sintering a Fe-6.5 weight percent Si green compact in a static magnetic field. In the method, 6.5 percent by weight of Si high-silicon steel with high density is obtained by using the influence of the magnetic field on the sintering densification and orientation process of a Fe-6.5 weight percent Si powder green compact, and an easily-magnetized axis is oriented along the magnetic field. An atmosphere / vacuum sintering device in a static magnetic field consists of a temperature control device, an exhaust pipe, a thermocouple, a heating element, a corundum crucible, a refractory fiber, a support block, a heat insulating block, a water-cooled bush, a static magnetic field generating device, a sealed corundum pipe, an inert gas inlet valve, a vacuum pumping valve, a Fe-6.5weight percent Si green compact, a thin corundum plate interlayer and a fixing molybdenum wire. The 6.5 percent Si silicon steel sheet prepared with the method has the advantages of near net molding, superior magnetic property, high orientation degree and the like, and has a remarkable industrial application prospect.

Owner:SHANGHAI UNIV

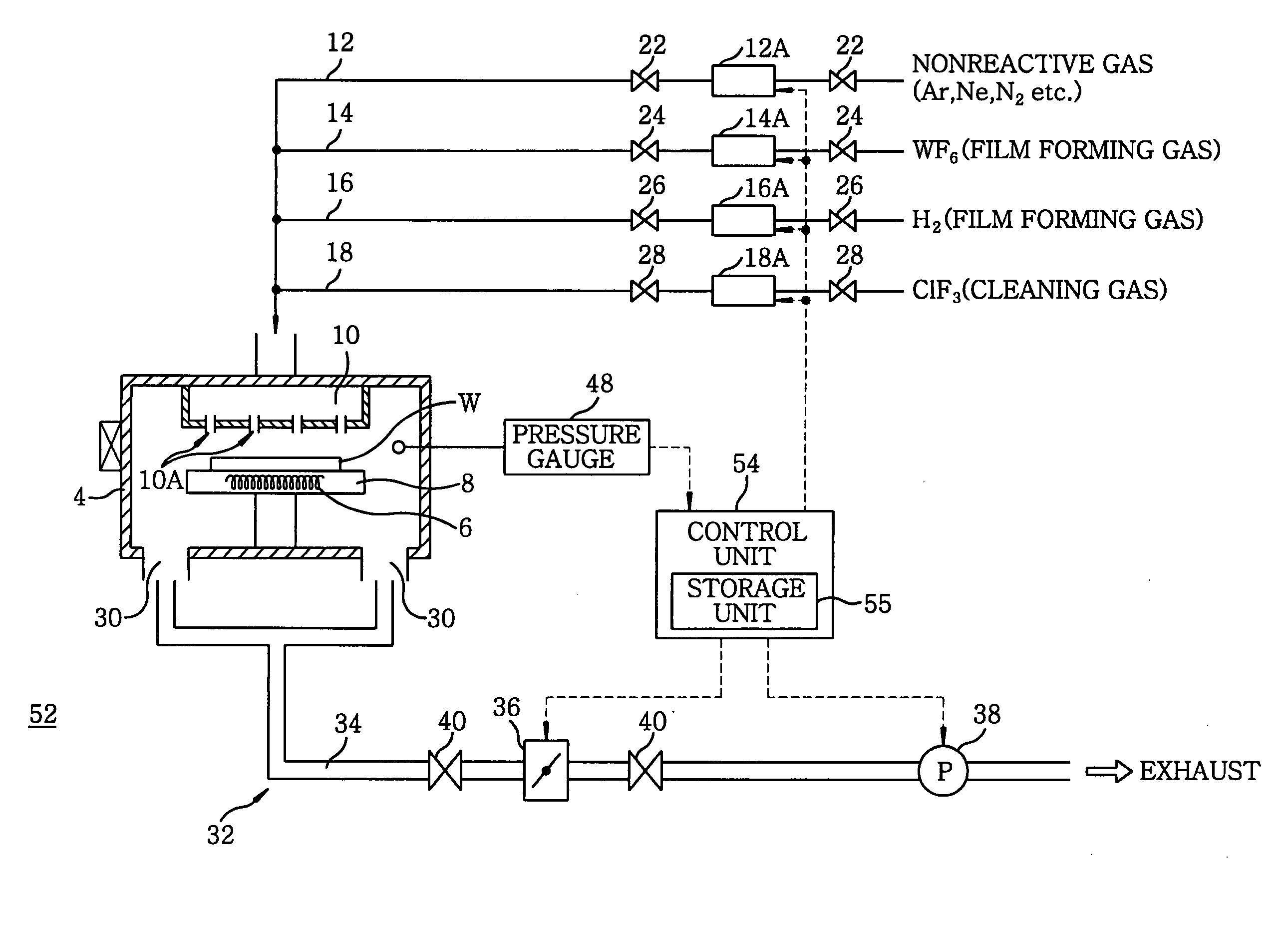

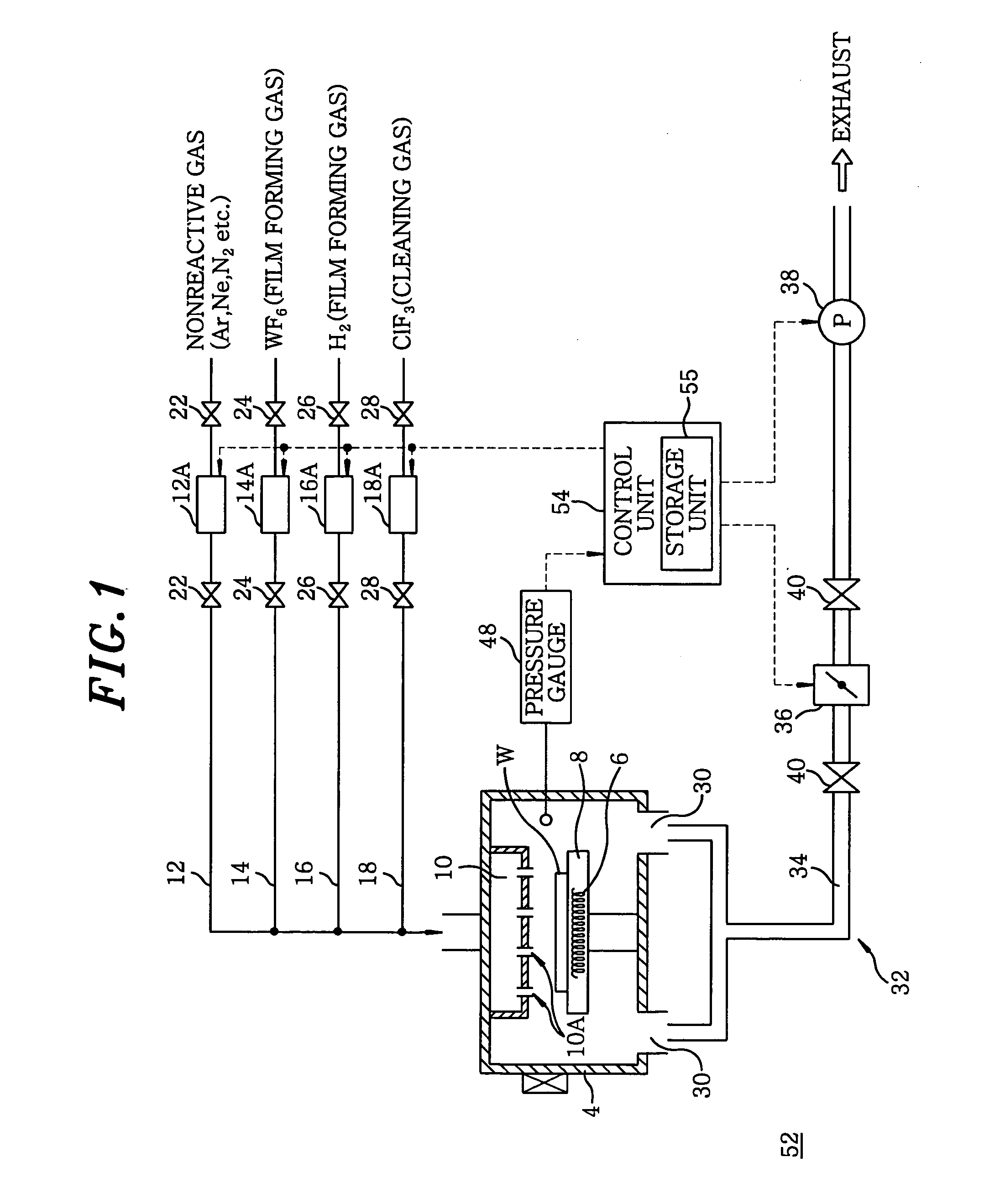

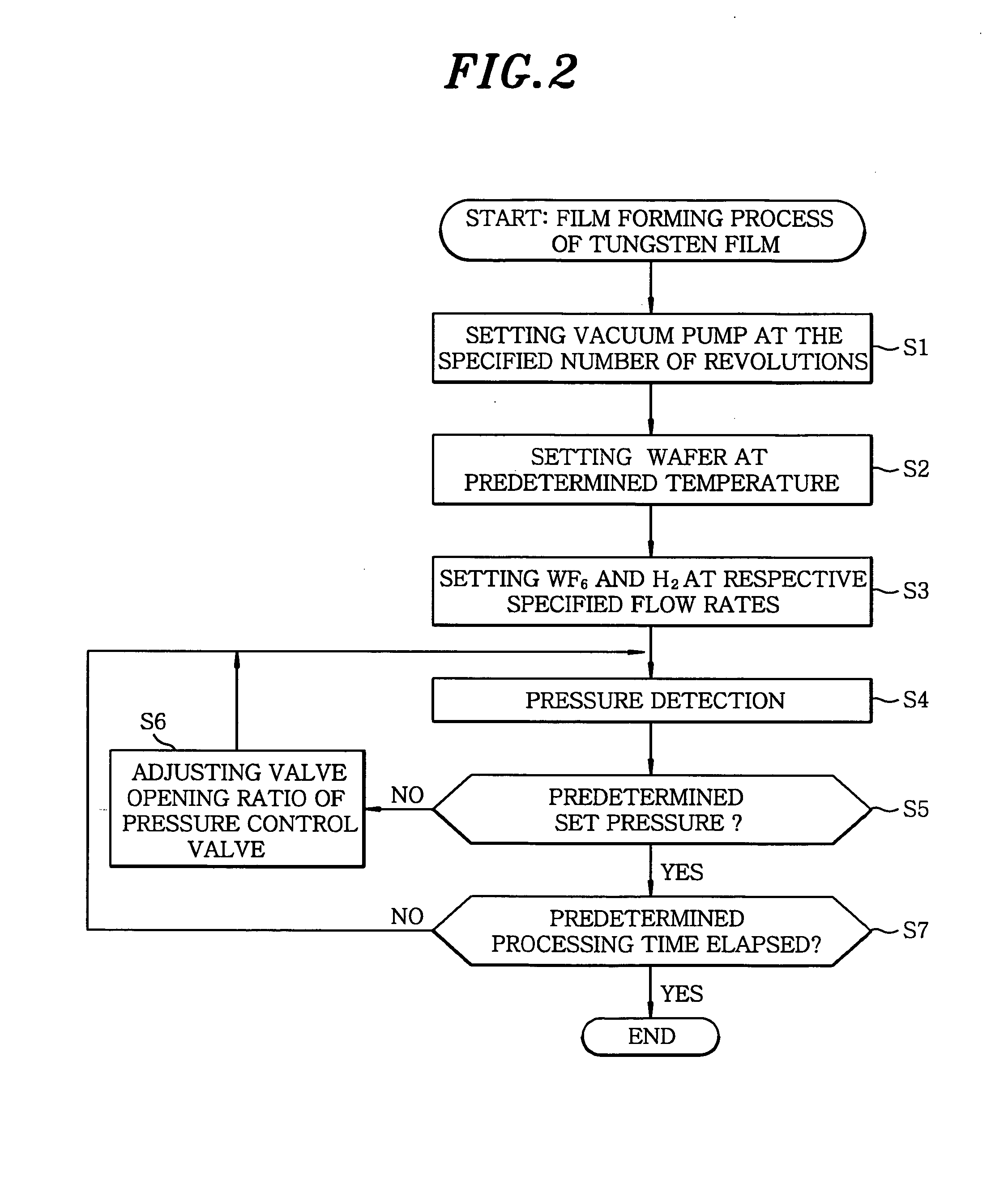

Gas processing apparatus and method and computer storage medium storing program for controlling same

InactiveUS20050189074A1Ensure correct executionWithout usingVacuum gauge using ionisation effectsElectrical testingVacuum pumpingProcess engineering

A processing apparatus includes a processing vessel, a gas introduction unit, a processing gas supply unit, a nonreactive gas supply unit, a vacuum pumping unit, a pressure gauge and a control unit. The control unit controls a valve opening ratio of a pressure control valve based on a detection value of the pressure gauge while making a processing gas flow to a flow rate controller of the processing gas supply unit at a constant flow rate when performing a process in which a partial pressure of the processing gas is important. Meanwhile, when performing a process wherein the partial pressure of the processing gas is relatively unimportant, the control unit fixes the valve opening ratio of the pressure control valve at a predetermined value, and operating a flow rate controller of the nonreactive gas supply unit to control a flow rate based on the detection value.

Owner:TOKYO ELECTRON LTD

Conduction cooling superconducting magnet dewar convenient for loading and unloading

The invention relates to a conduction-cooled superconducting magnet Dewar with easy loading-unloading, comprising a Dewar cylinder. The conduction-cooled superconducting magnet Dewar is characterized in that the Dewar cylinder is a hollow annular cylinder, the middle of the annular cylinder is provided with a room temperature hole, an annular copper cold shield is arranged in the Dewar cylinder, a refrigerator and a superconducting magnet are arranged in the copper cold shield, a vacuum pumping port is arranged on the Dewar cylinder, a measuring device is arranged on an upper cover of the Dewar cylinder and the Dewar cylinder is in a vacuum state. Compared with the prior Dewar container, the conduction-cooled superconducting magnet Dewar is simpler, has small conduction heat leakage, and has the advantages of easy installation and disassembly; the refrigerator is used for conducting and cooling without a low temperature liquid (such as liquid helium and so on) cooling system; because of simple and safe system, a first-level cold junction of the refrigerator is operated under a temperature of 77K, thereby realizing heat sink of the copper cold shield, an electric lead and a support device; the first-level cold junction of the refrigerator adopts soft connection, thereby reducing temperature increment of the magnet due to vibration of the refrigerator; and the conduction-cooled superconducting magnet Dewar has the advantages of easy operation of manufacture, processing and installation, and is applicable to scale production.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

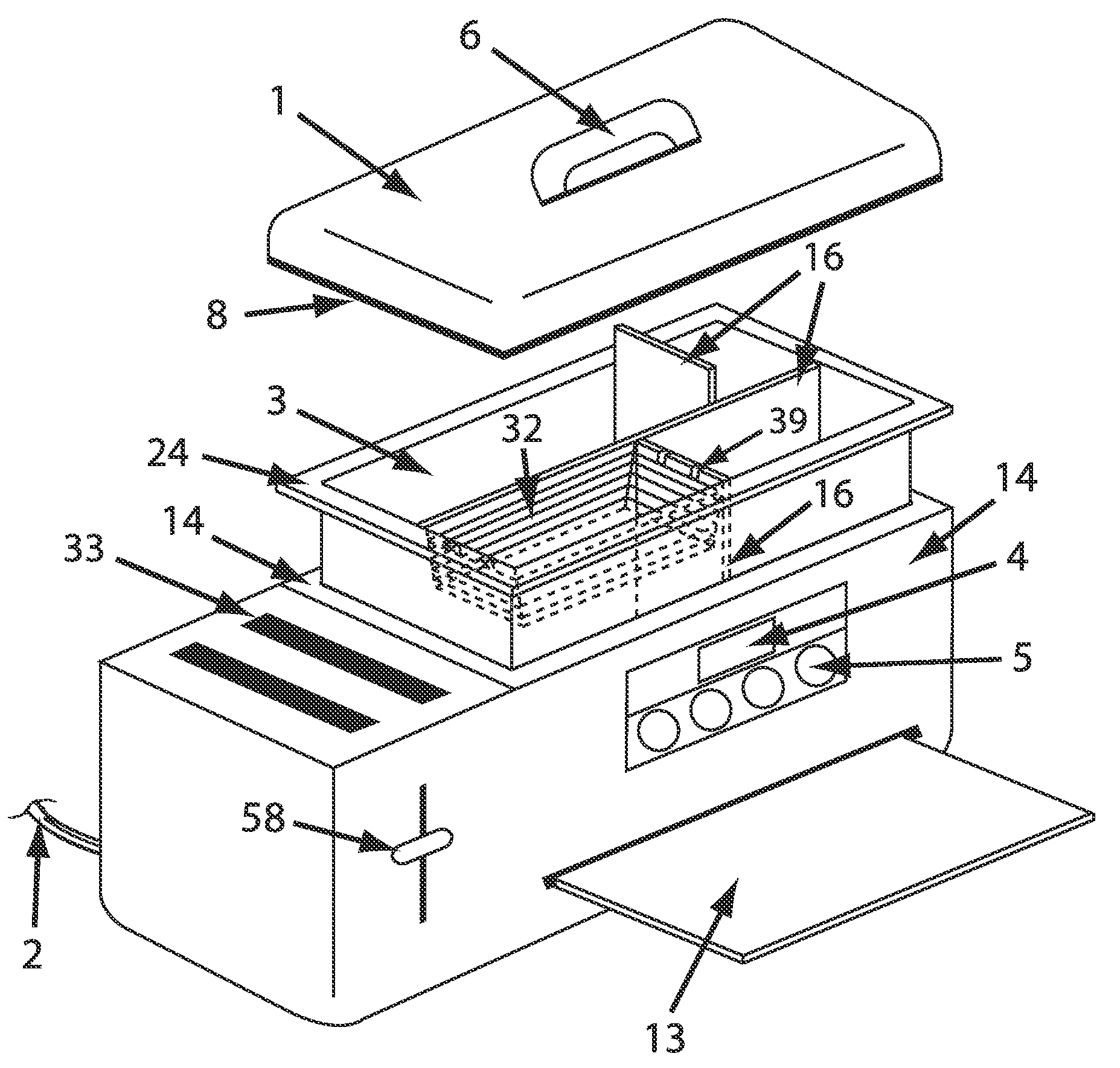

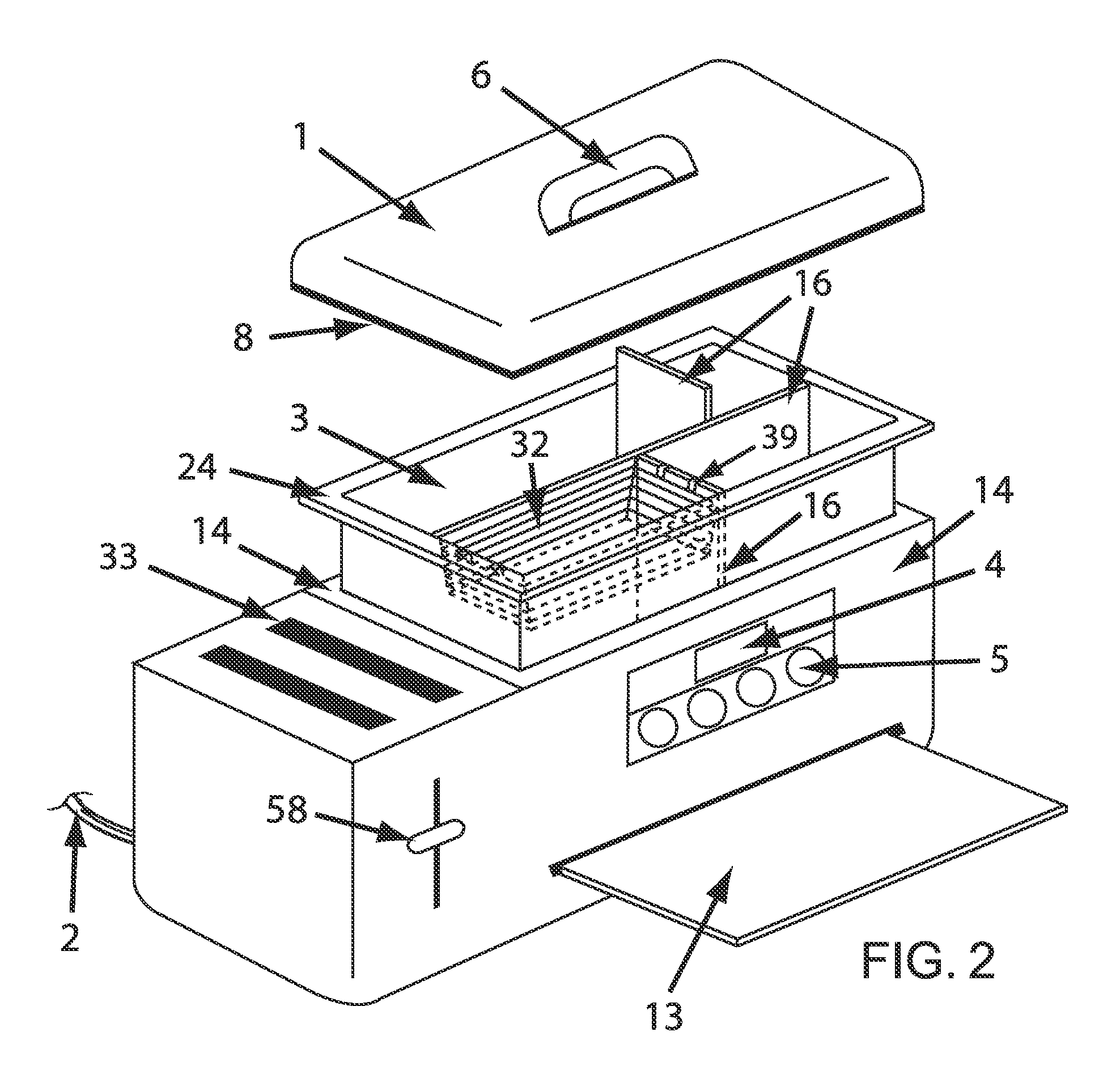

Storage and/or heating system/apparatus for items and food

InactiveUS20090272279A1Improve versatilityEfficient and effective and convenientMilk treatmentCooking vesselsVacuum pumpingEngineering

The invention is a universal or designated storage apparatus, facility, or appliance with increased versatility and sophisticated storage fundamentals and capabilities for the storage of a wide variety of items. It provides support for complimenting and assisting with the use and coordination of the apparatus and the items kept within, while utilizing simple and basic storage means and methods in order to remain efficient, effective, and convenient. Items can then be accessed more frequently without hassle or burden. It may also include vacuum pumping means to remove or expel air from within a sealed storage area in order to form a vacuum or partial vacuum, negative atmospheric pressure, or suction creating means. This provides an air-free environment for items to be kept within, which retains freshness and retards the formation of mold or other contaminants. It may also provide means to allow items kept within to be organized and coordinated in a customizable fashion. It may also provide certain means to allow a user to prepare items for use or consumption. It can be equip with many features which allows it to be used with ease. This apparatus will aid in organization and sanitation.

Owner:KIECK TIMOTHY ADAM

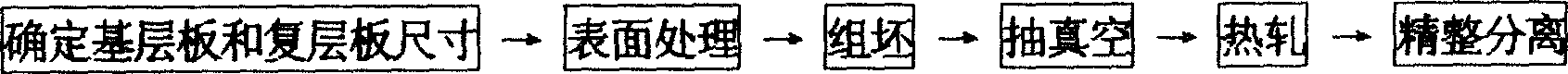

Process for producing brazing hot rolled metal composite plate adopting composite cog

InactiveCN1669687AImprove mechanical propertiesImprove corrosion resistanceSoldering apparatusAuxillary arrangementsVacuum pumpingComposite plate

The invention discloses a method for producing braze metal sandwich by compound compact, which comprises the following steps: ensuring the size of the basal layer and the composite layer, surface processing, making embryo, vacuum-pumping, hot-rolling, finishing and separating. The method can produce metal sandwich by present medium hot-rolling mill, and the sandwich has good mechanical property, non-corrodibility and reprocessing property, the bonding strength of two metal layers is high, and the shearing intensity can reach to 210MPa-350MPa, so the method can be used widely in producing the metal sandwich and roll bending.

Owner:吉欣(英德)热轧不锈复合钢有限公司 +2

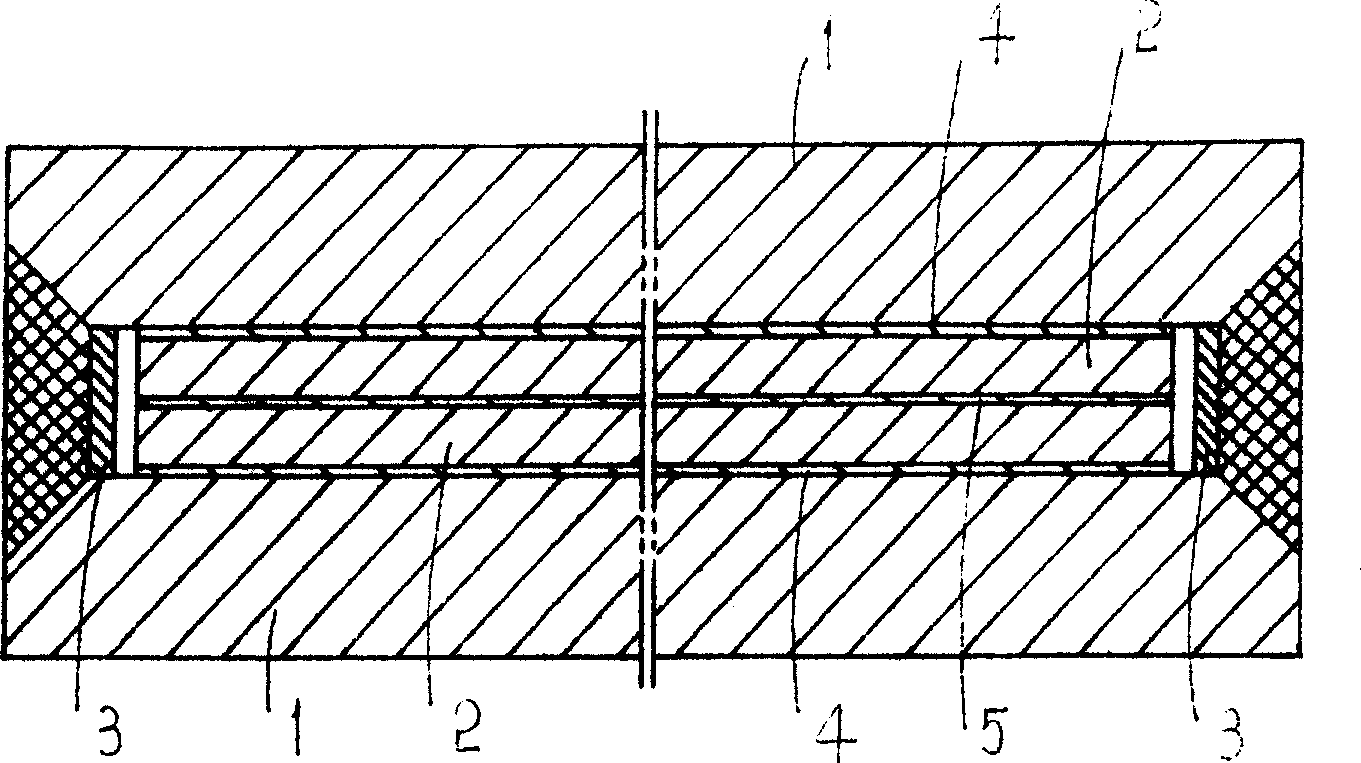

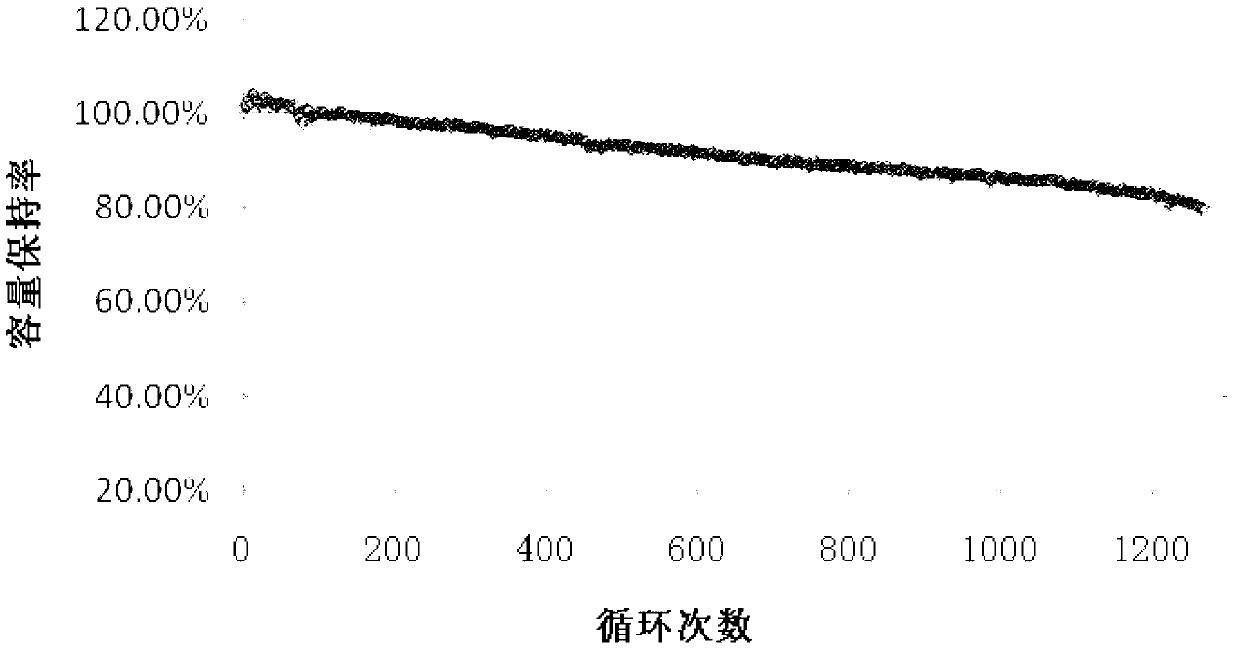

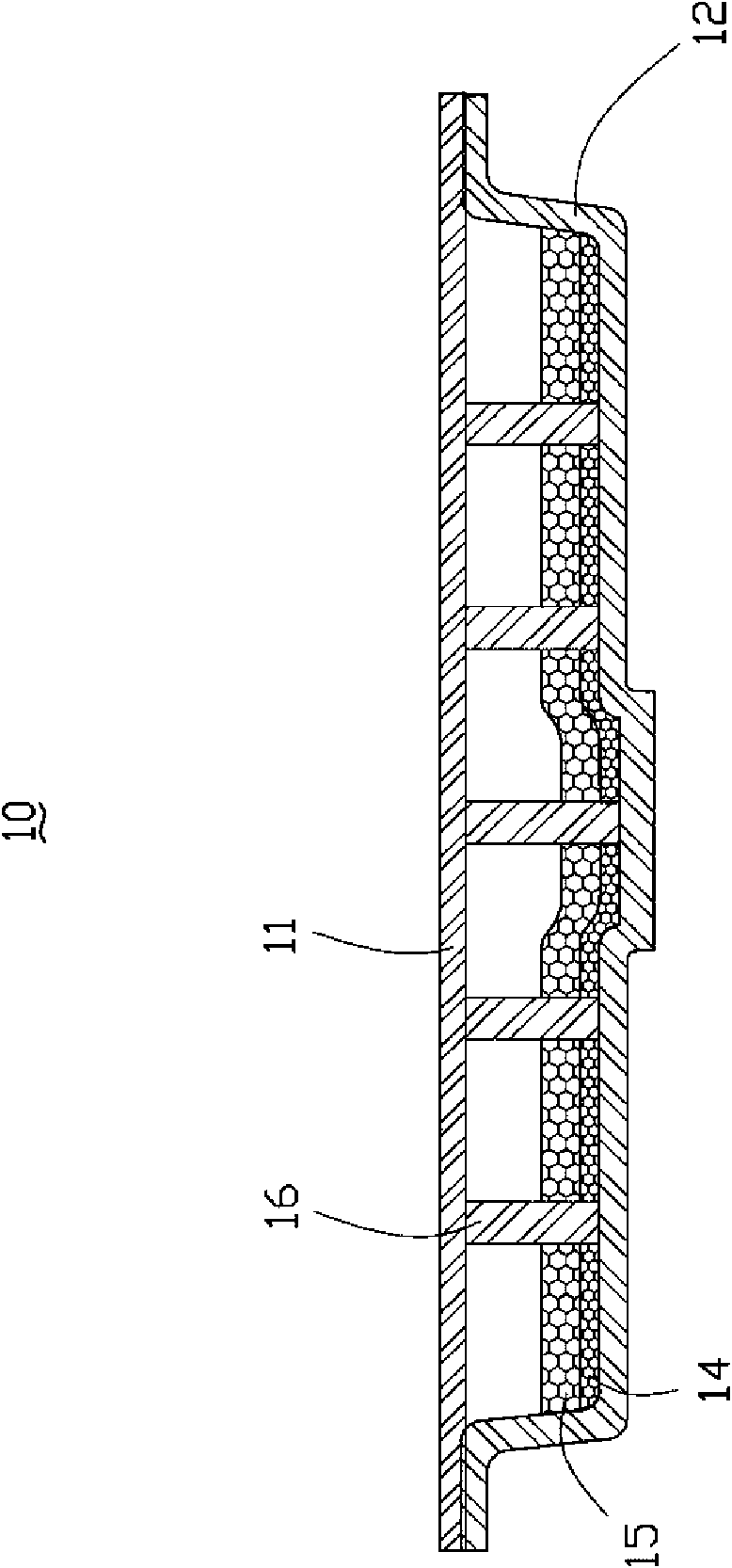

Lithium ion battery cell drying method and lithium ion battery

ActiveCN103344097APrevent agingSave energyDrying using combination processesFinal product manufactureVacuum pumpingEngineering

The invention discloses a lithium ion battery cell drying method and a lithium ion battery. The method includes the following steps that a battery cell is placed in a closed cavity, vacuum pumping is conducted on the cavity, and the vacuum pumping operation lasts for 3-10 minutes after the vacuum degree in the cavity reaches-0.1--0.12 MPa; the battery cell is heated at the temperature ranging from 75-85 DEG C for 2-5 hours; non-oxide gas is inflated in the cavity until the vacuum degree in the cavity reaches-0.01--0.02 MPa; the battery cell is heated at the temperature ranging from 75-85 DEG C for 20-40 minutes; vacuum pumping is conducted on the cavity, and the vacuum pumping operation lasts for 3-10 minutes after the vacuum degree in the cavity reaches-0.1--0.12 MPa. The vacuum pumping operation and gas changing are conducted in a step-by-step mode, so that energy is greatly saved, and drying efficiency is improved.

Owner:奇瑞新能源汽车股份有限公司

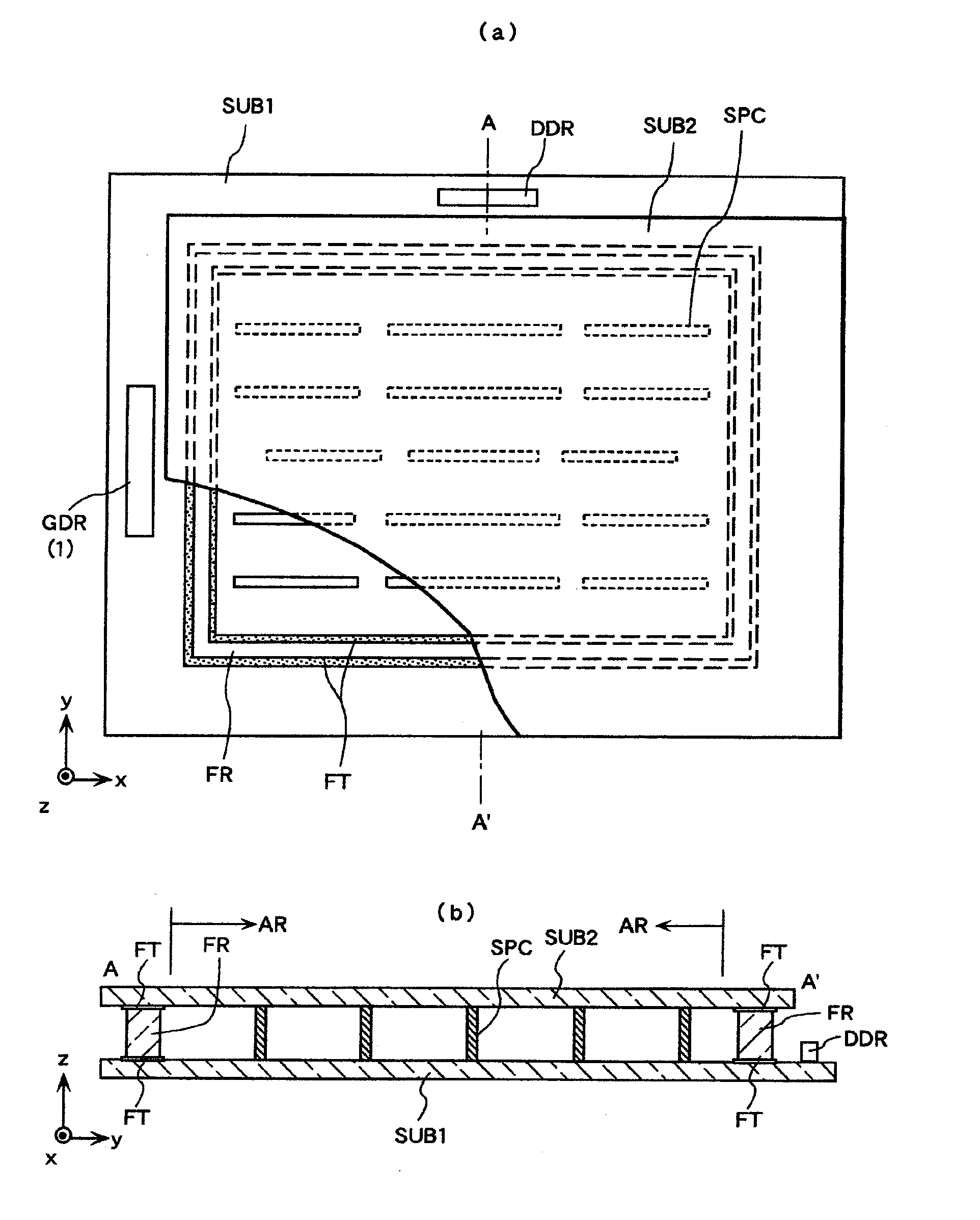

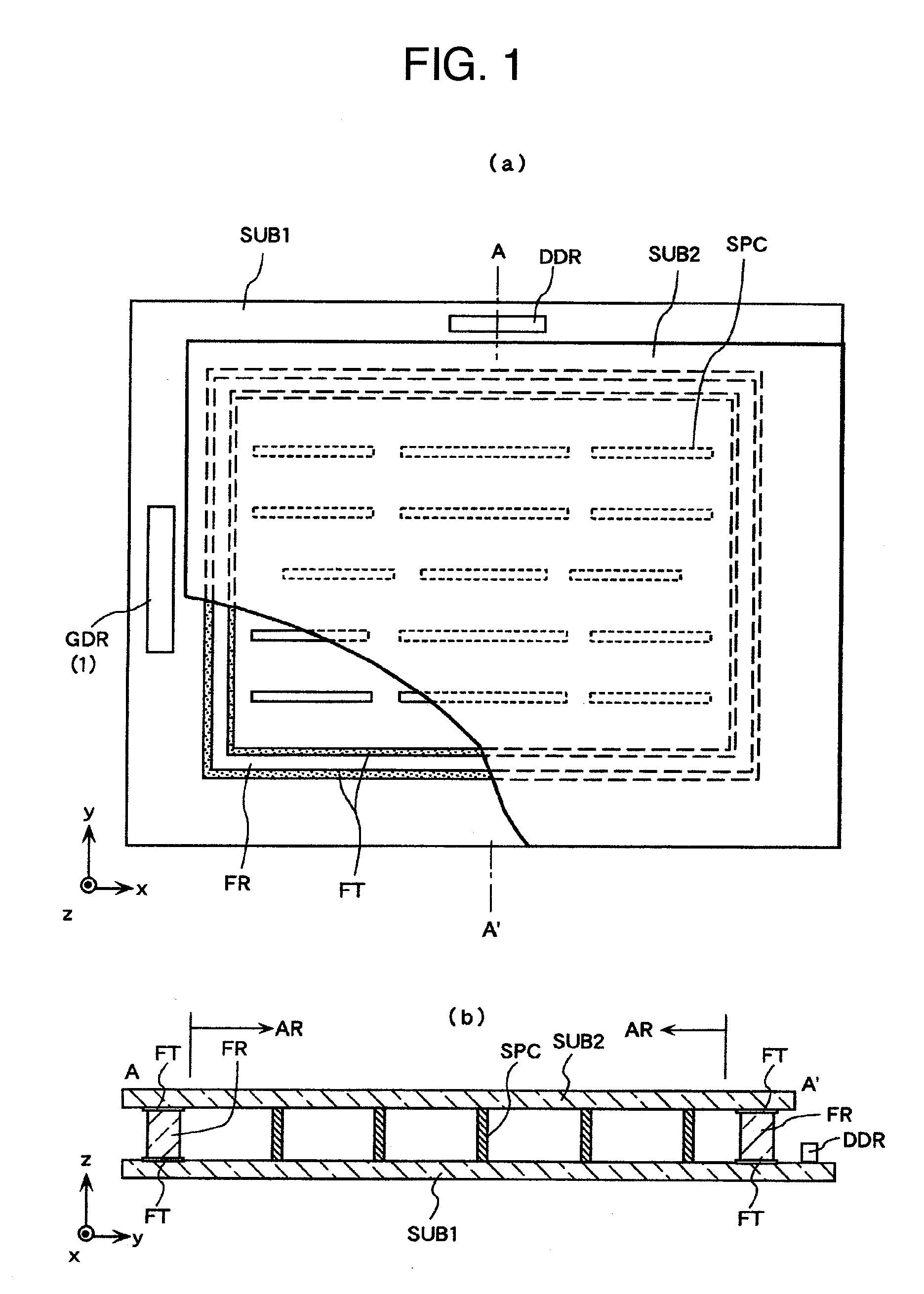

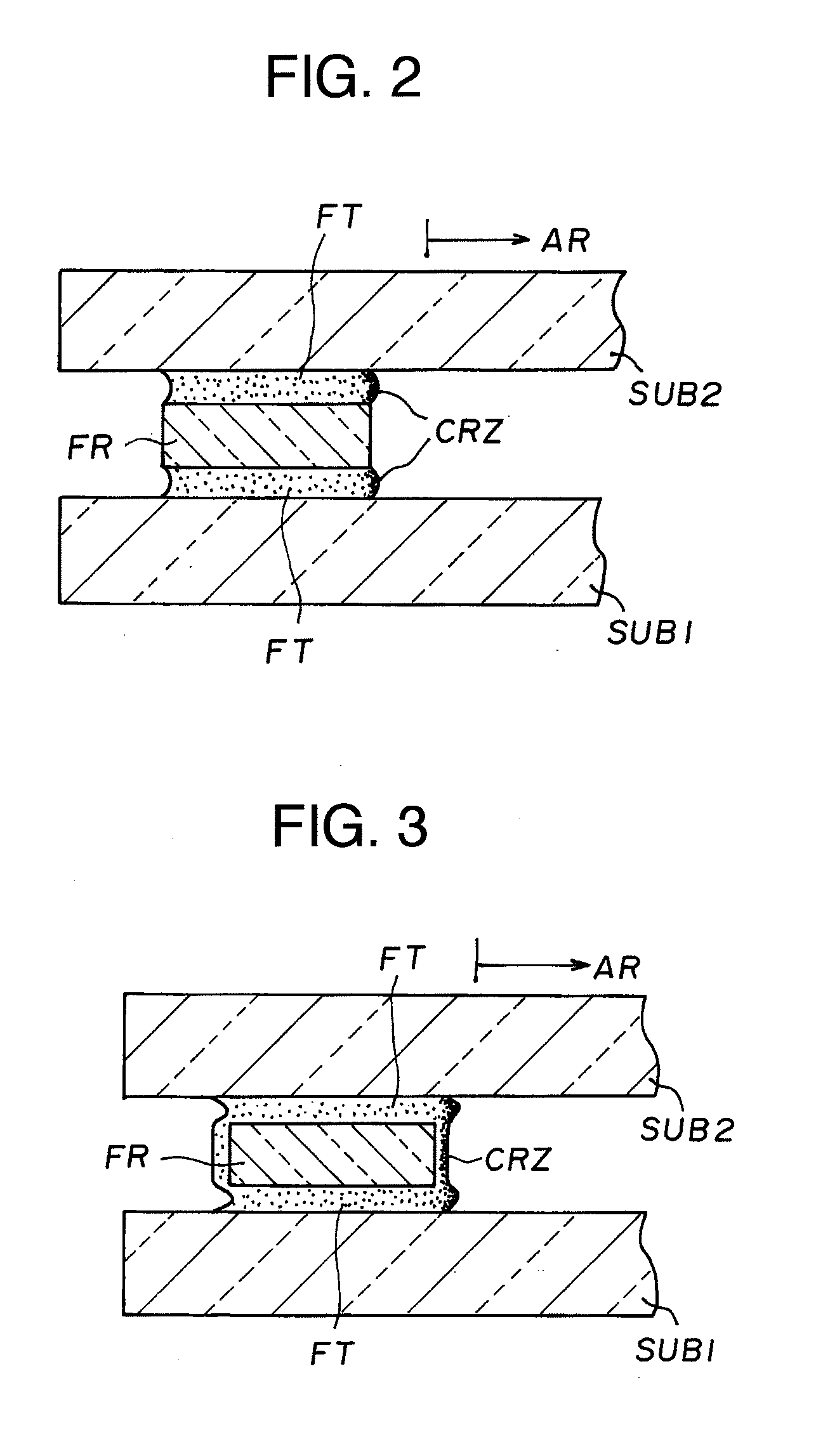

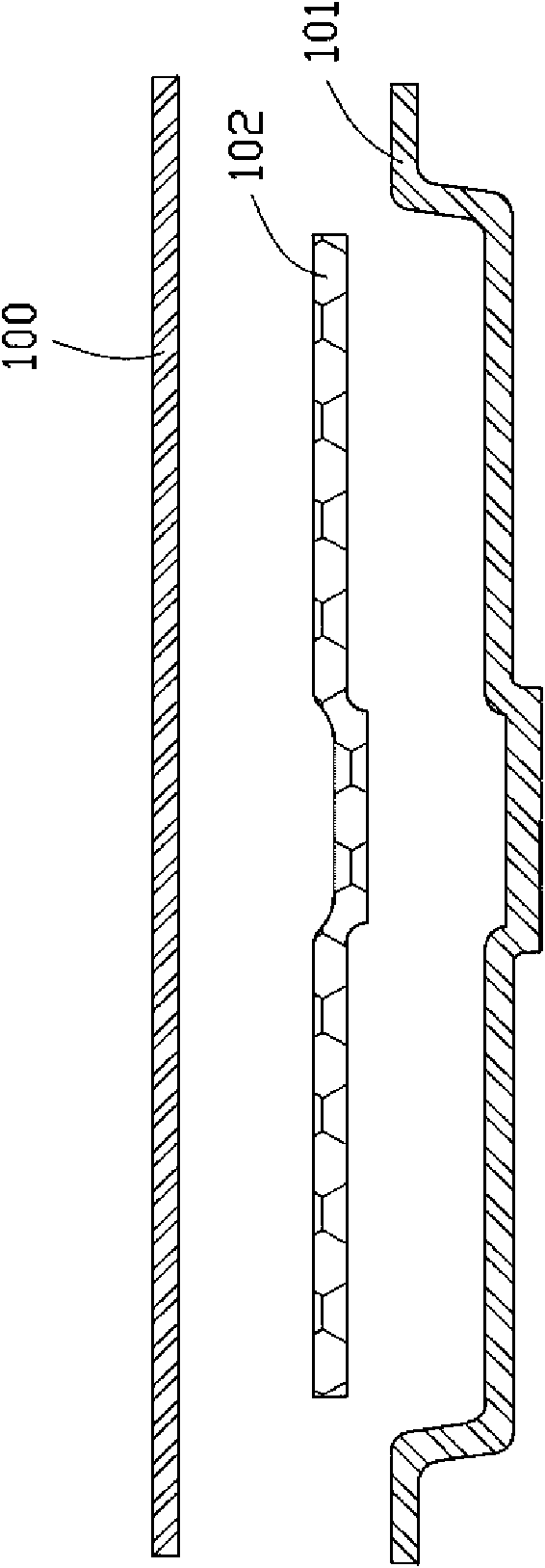

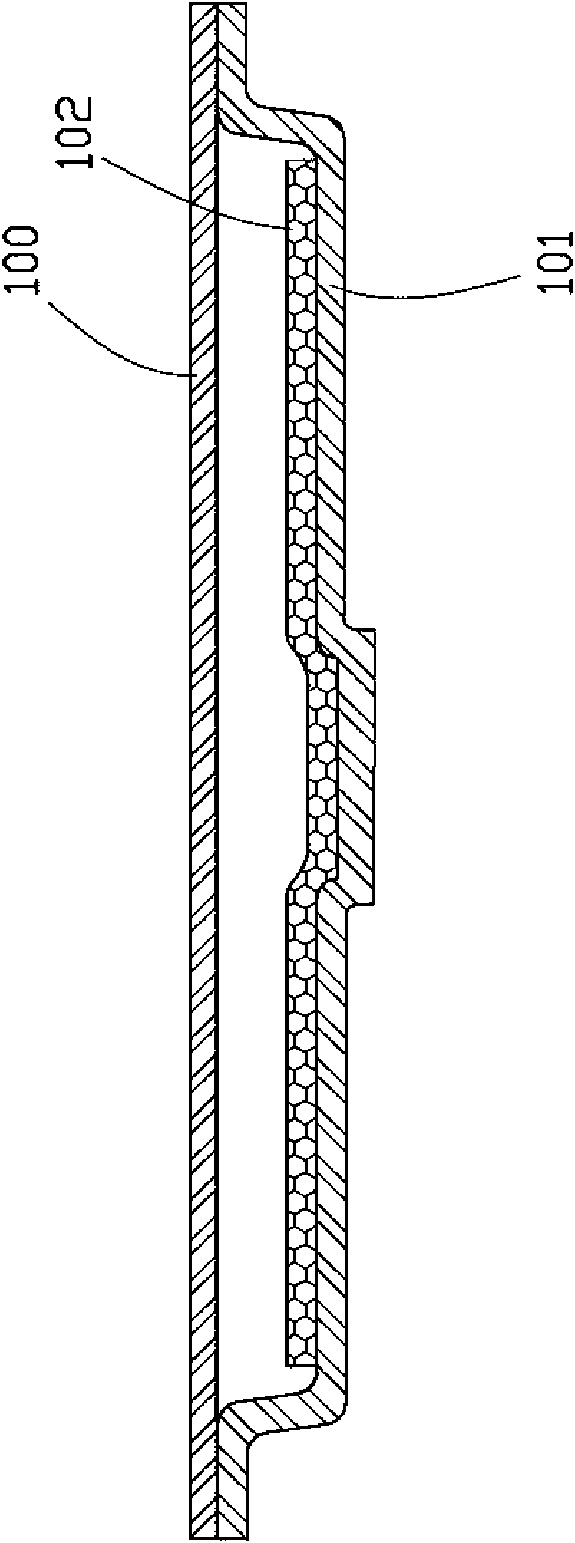

Display Device and Production Method Thereof

InactiveUS20070158021A1Easily crystallizesEasy to useLiquid crystal compositionsCathode ray tubes/electron beam tubesVacuum pumpingDisplay device

An object of the present invention is to provide a highly reliable display device by preventing an adhesive layer from being drawn to the inside at the time of vacuum pumping and by securing a sufficient adhesive strength. A crystalline layer CRZ is formed in the surface of an adhesive layer FT between the respective contact surfaces of a first glass substrate SUB1 and a sealing frame FR, as well as of a second glass substrate SUB2 and the sealing frame FR.

Owner:HITACHI DISPLAYS

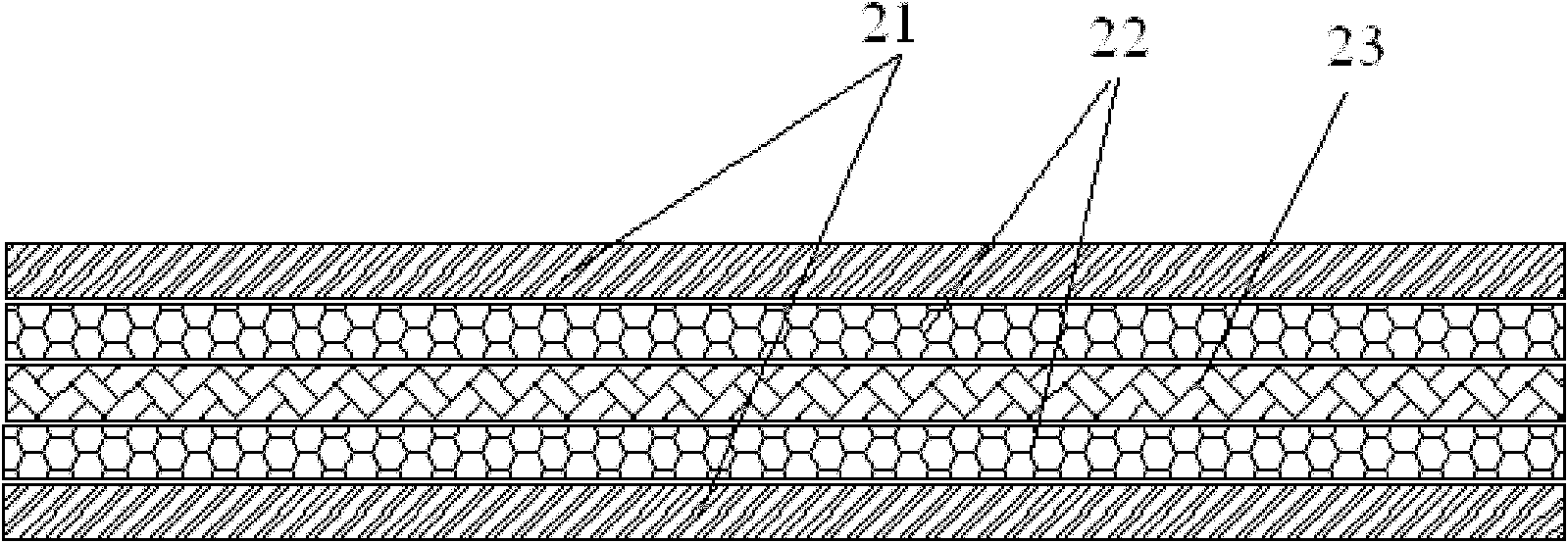

Manufacturing technique and device for composite board

ActiveCN103231216AQuality assuranceAchieve mass productionOther manufacturing equipments/toolsVacuum pumpingComposite slab

The invention discloses a manufacturing technique for a composite board and belongs to the technical field of composite metal strip rolling. The manufacturing technique comprises the following steps implemented successively: joint surface machining, end surface machining, press fit, blank assembly, vacuum pumping and inert gases filling, heating, hot rolling and verifying. By means of the manufacturing technique, the machining accuracy is improved, and volume production of carbon steel-stainless steel composite boards is achieved; simultaneously, air in a combination blank is replaced through vacuum pumping and inert gases filling, oxidization of interfaces of the combination blank is prevented in a subsequent heating process, a little of residual air between the composite interface and two layers of stainless steel interfaces can be squeezed into an air storage bag gradually along with the moving of a roller and the composite blank simultaneously, and the residual air is prevented from expelling a separating agent or oxidizing the composite interfaces, accordingly, the joint of the finished composite slab is improved effectively, and the quality of the composite slab is further improved.

Owner:山东易川新材料科技股份有限公司

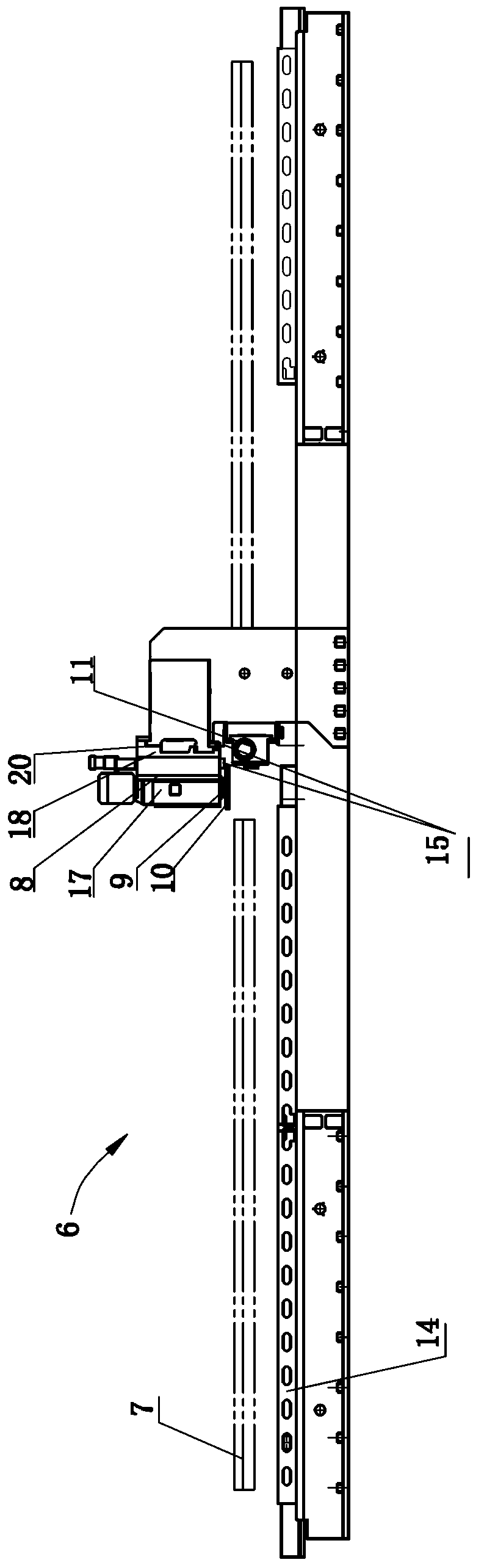

Ton bag feeding device and feeding method

ActiveCN103407797AAchieve accurate meteringRealize deliveryConveyorsBottle emptyingVacuum pumpingEngineering

The invention discloses a ton bag feeding device and a feeding method. The device comprises a support device, a ton bag clamping turnover mechanism, a turnover motive power mechanism, a material collection hopper, a belt weigher and a vacuum absorption device. The method comprises the following steps: putting ton bag packed material into a turnover cage, hanging lifting lugs of the ton bag on ton bag hooks, compressing a vacuum sucker to be clung to the bottom of the ton bag, starting a vacuum pumping device, and absorbing the ton bag by the vacuum sucker; starting a motor, overturning the turnover cage, flowing the material in the ton bag into the material collection hopper, enabling the ton bag to be absorbed due to the absorbing force of the vacuum sucker, and dropping the material gradually until all material in the ton bag is poured out; rotating the turnover cage in an opposite direction, closing the vacuum pumping device, and taking the ton bag down. The device and the method can realize mechanized operation to clean up once; no manual assistance is needed; accurate measuring and delivering of the material are realized; the vacuum sucker adopts an elastic structure; the service life is long; the equipment is simple, and 360 degrees overturning of the ton bag can be realized; the method is suitable for the discharging and the delivering of various ton bag packed material, especially particles and powdery material.

Owner:度测(上海)科技服务中心

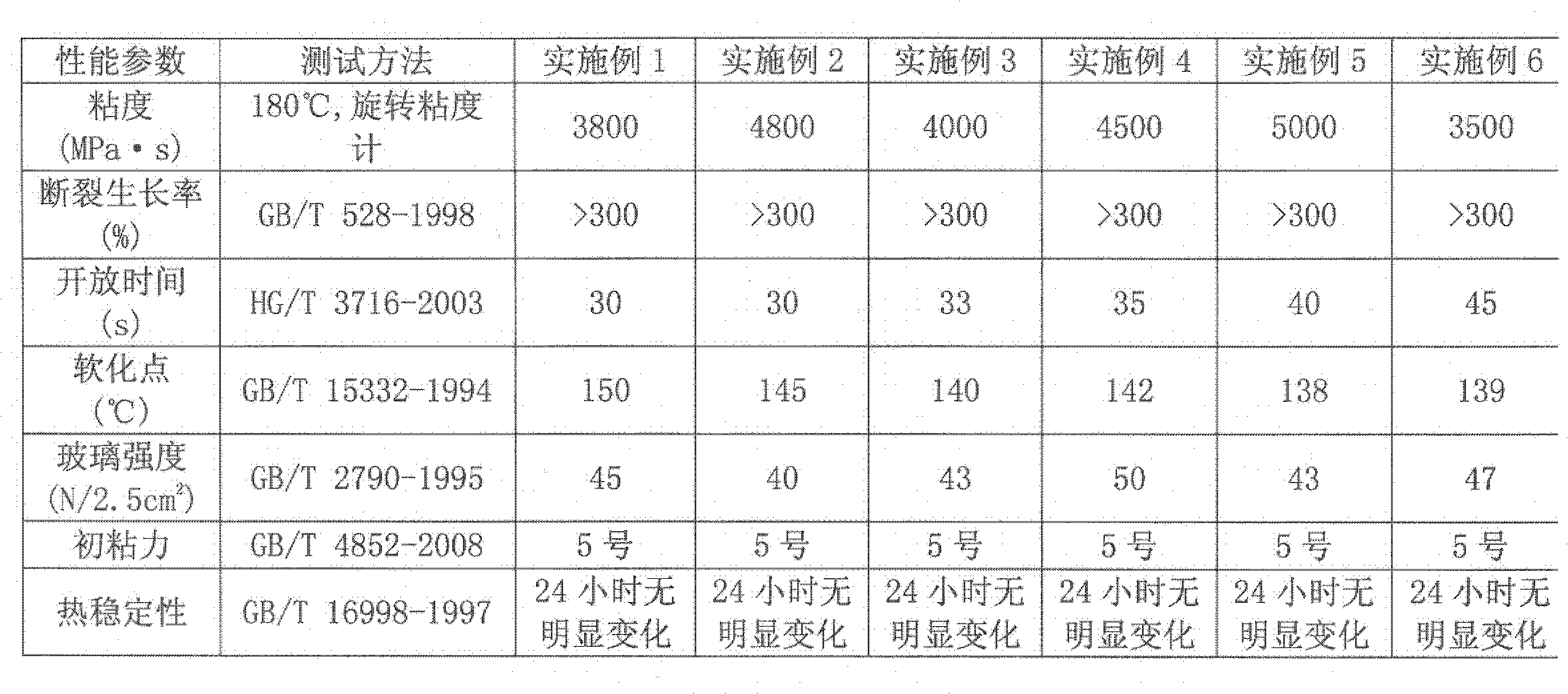

Hot melt adhesive used for automotive interiors, and preparation method of hot melt adhesive

InactiveCN102618211AHarmless to healthHigh bonding strengthWax adhesivesNatural resin adhesivesPolyethylene vinyl acetateParaffin wax

The invention discloses a hot melt adhesive used for automotive interiors, and a preparation method of the hot melt adhesive. The hot melt adhesive used for automotive interiors is characterized by comprising a proportion of paraffin, polyethylene wax, a thermoplastic elastic body SBS, random polyolefin, polyethylene vinyl acetate, C5 petroleum resin, rosin pentaerythritol ester, antioxygen, coupling agent and filler. The preparation method comprising the following steps: heating a stirring kettle to 140 to 160 DEG C, and adding the paraffin and the polyethylene wax; adding the thermoplastic elastic body SBS, vacuum-pumping and keeping warm, adding HMW(high molecular weight) random polyolefin I, HMW random polyolefin II and the antioxygen; adding the coupling agent and the filler; cooling, and adding polyethylene vinyl acetate I and polyethylene vinyl acetate II; cooling and adding the C5 petroleum resin; adding the rosin pentaerythritol ester and keeping warm; and emptying the stirring kettle, pressurizing, discharging and forming. No pollution or poison is produced during the production process of the hot melt adhesive; and the hot melt adhesive has the advantages of high adhesion strength, long opening time, good temperature resistance, strong ageing resistance, good tenacity, strong waterproofness and the like.

Owner:浙江固特新材料科技股份有限公司

Negative pressure osmosis test device

InactiveCN103411869ASolving Penetration Testing ProblemsSimple structurePermeability/surface area analysisWater storageVacuum pumping

The invention discloses a negative pressure osmosis test device which comprises a base, a soil sample ring, a porous permeable stone, a water storage container, an electronic balance, a vacuum pump, a pressure gauge and a sealed container, wherein the soil sample is arranged in the cylindrical soil sample ring, the upper end of a sample is connected with the water storage container, and the bottom end of the sample is connected with the sealed container and the vacuum pump; a pressure difference is formed at two ends of the soil sample through vacuum-pumping, and water seeps in the soil sample under the action of the pressure difference; an osmotic coefficient of the soil sample can be obtained through calculating the amount of water passing though the soil sample in unit time; a load applying piston at the upper end of the sample can apply vertical load so as to solidify the soil; osmosis tests of different solidifying pressures can be performed to simulate the seepage of the practical field soil under different stress environments; the osmosis test can be directly performed on the prepared soil sample. Therefore, the test device has the advantages of simple structure, convenience in use, quick and convenient test, and obviously shortened test time, and is particularly suitable for the osmosis test of low-osmosis soil samples.

Owner:HEFEI UNIV OF TECH

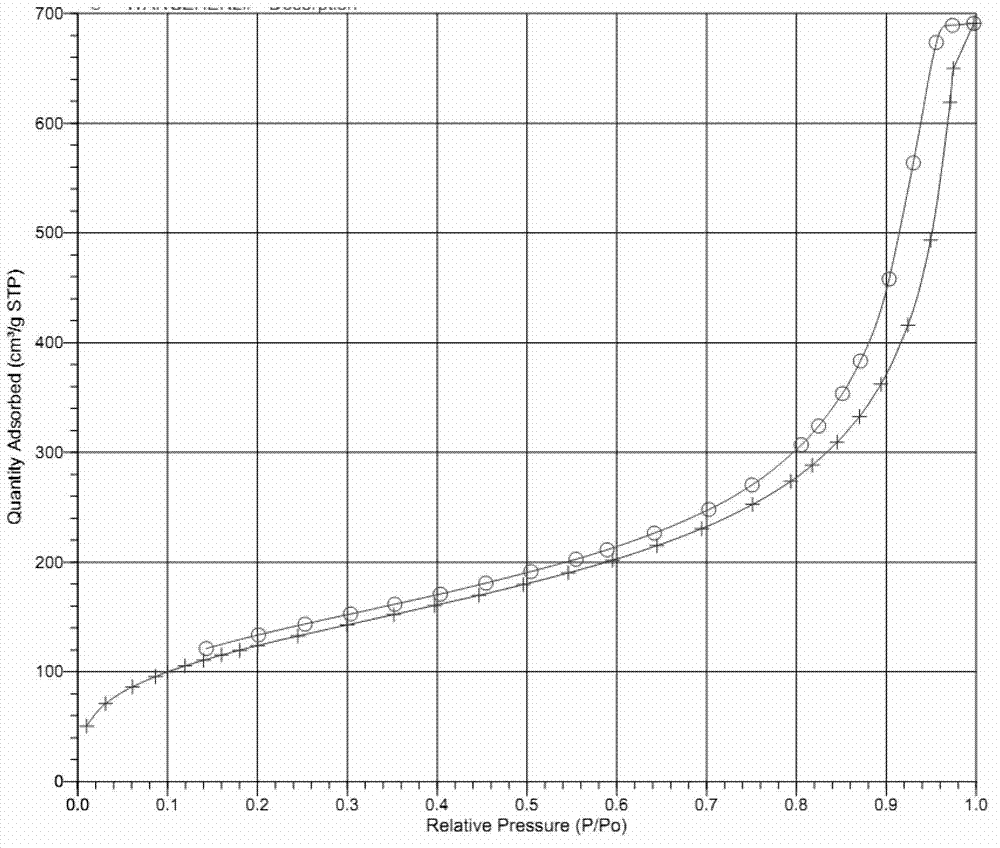

Aerogel preparation method

The invention discloses an aerogel preparation method. The aerogel preparation method comprises the following steps of immersing gel into a solvent, putting the gel solution into a vacuum tank, and carrying out vacuum-pumping so that the solvent is evaporated in vacuum and after the solvent is completely evaporated, aerogel is obtained. The aerogel preparation method is a fast drying method. In vacuum-pumping, the solvent in the gel is fast volatilized so that a large amount of heat is taken away and a system temperature is reduced; reactivity of active groups in a gelskeleton is reduced; and irreversible collapse possibility is reduced. The gelskeleton has strong rigidity at a low temperature so that a gel structure is kept well. The aerogel obtained by the aerogel preparation method has low density, large porosity and a high specific surface area, and has standard features of aerogel prepared by a supercritical method.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Air insulating structure of vacuum insulation panel and packaging method thereof

InactiveCN101963267AReduce the number of heat-sealed edgesSave on packaging costsThermal insulationPipe protection by thermal insulationVacuum pumpingThermal bridge

The invention provides an air insulating structure of vacuum insulation panel, which is formed by composite material. The composite material does not contain aluminium foil layer; therefore, the heat bridge effect of seal edge during heat seal is avoided. The packaging method of the air insulating structure comprises the following steps of: folding a single piece of composite material to form a bag shaped air insulating structure having a size consistent with that of adiabatic core material according to the specification of the core material and form three seal edges; sealing part of sealing edges with heat, and keeping an opening for placing the adiabatic core material inside; filling the adiabatic core material in the air insulating structure, performing heat seal on the remained opening and keeping a vacuum pumping opening; and placing the air insulating structure, which is filled with the adiabatic core material and has a vacuum pumping opening, in a vacuum room and pumping to produce vacuum, and performing heat seal on the preserved vacuum pumping opening to form a vacuum thermal insulation panel. The air insulating structure has three seal edges, which are fewer than those of the conventional method; therefore, the integral heat bridge effect is reduced, the operation is simple, the appearance planeness of the vacuum insulation panel is improved, and the fold and air leakage of the air insulating structure in convention manufacturing process are avoided.

Owner:SHANGHAI MARITIME UNIVERSITY

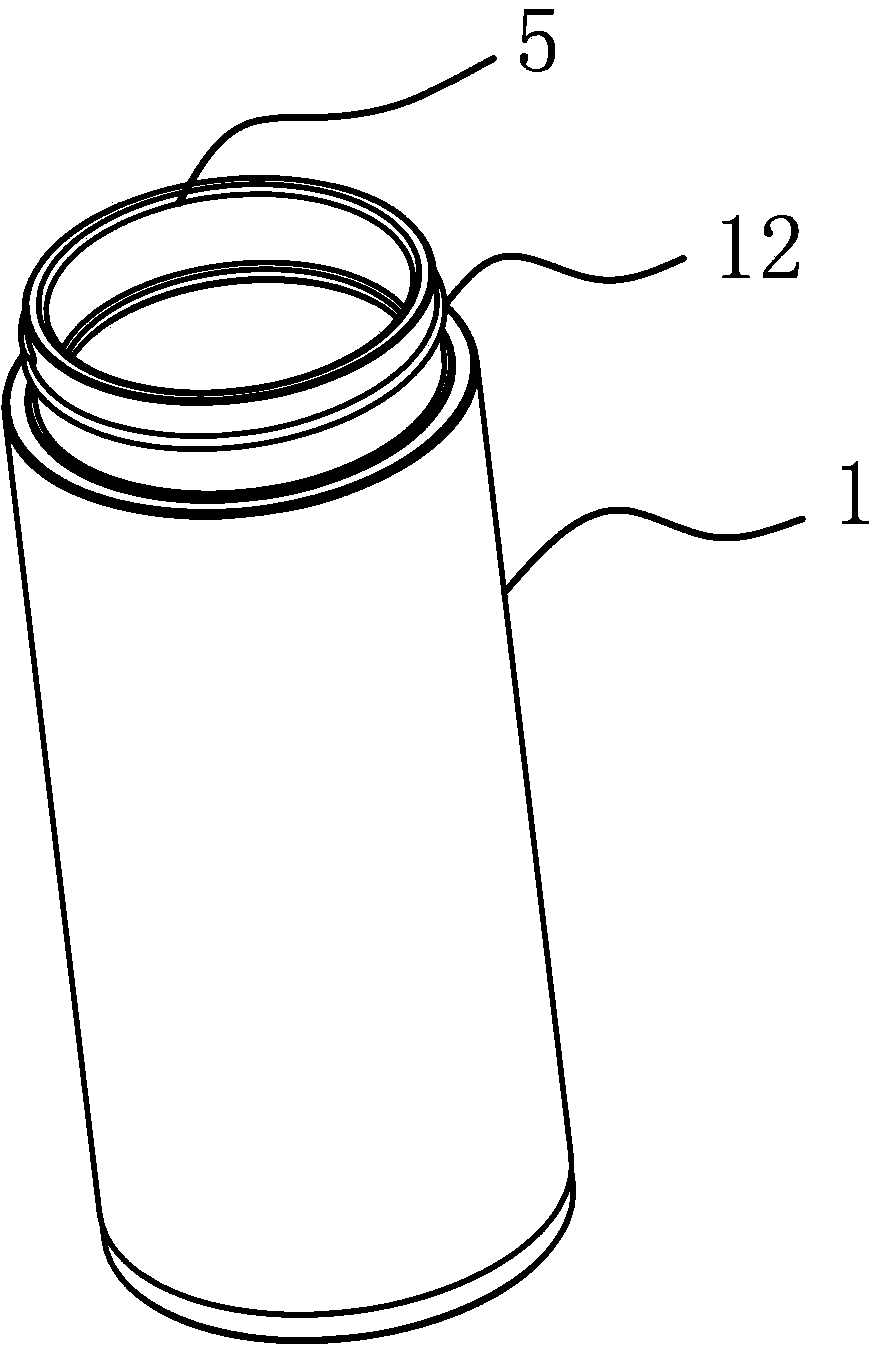

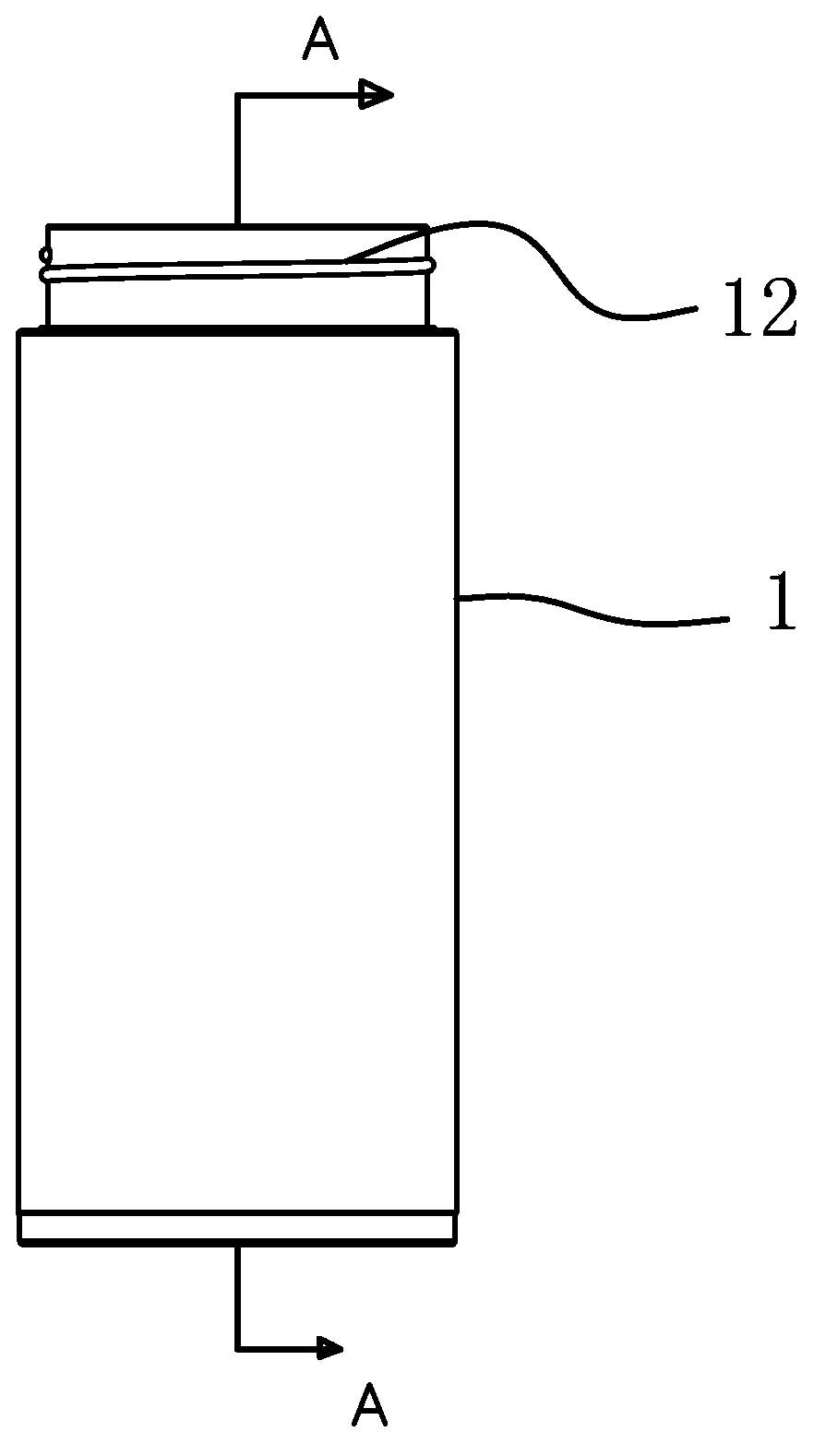

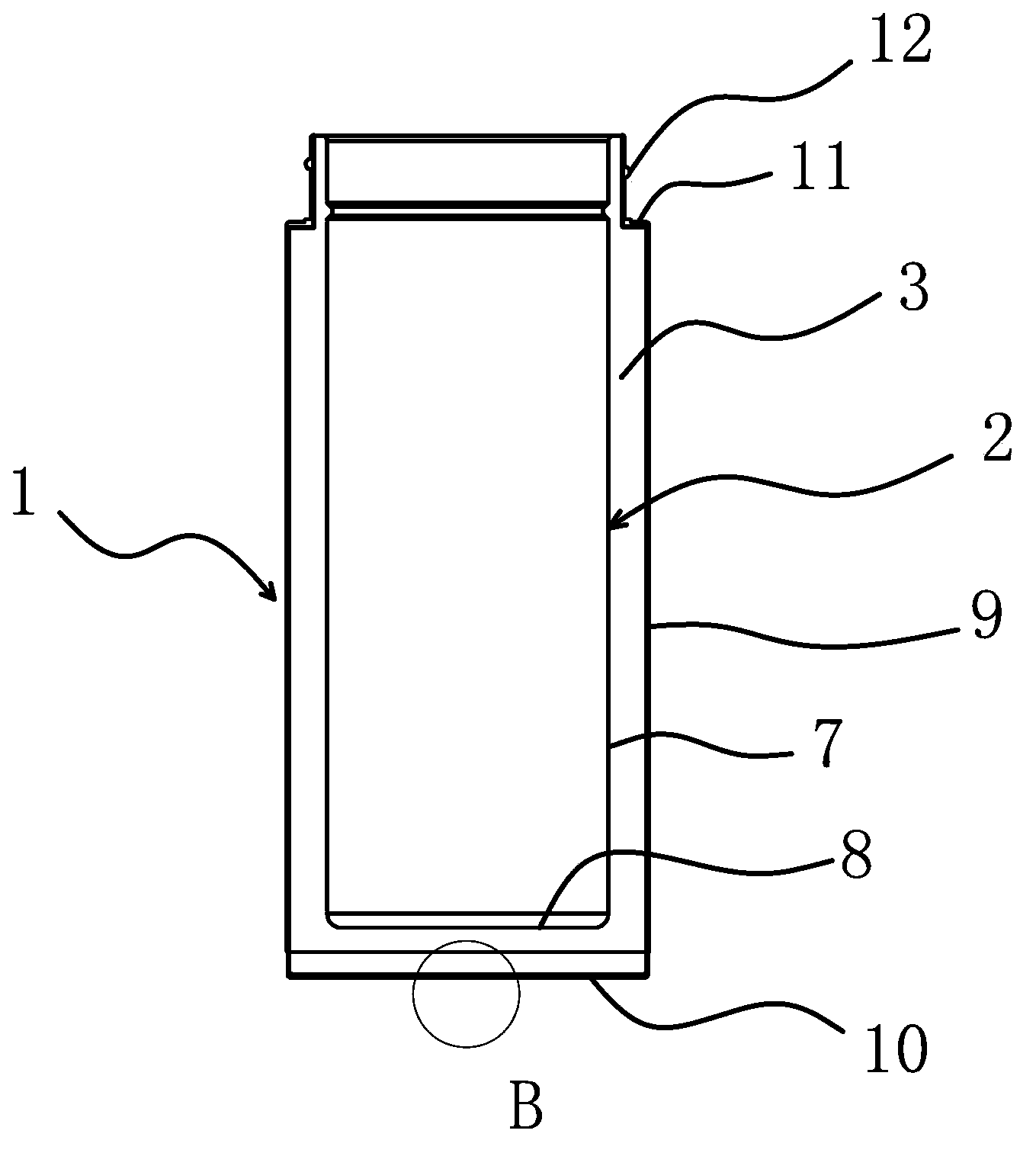

Titanium metal vacuum cup and manufacturing method thereof

ActiveCN103405104AThermal insulationImprove corrosion resistanceDrinking vesselsVacuum pumpingTitanium metal

The invention provides a titanium metal vacuum cup and a manufacturing method thereof, belongs to the technical field of daily necessities, and solves the technical problems that a conventional vacuum cup is lower in corrosion resistance and attractiveness and the like. The vacuum cup comprises an outer cup body and an inner cup body, wherein the inner cup body is sleeved with the outer cup body; the orientation of cup rims of the inner cup body and the outer cup body is identical; the inner cup body and the outer cup body are sealed and fixed annularly at the cup rims; a vacuum interlayer is arranged between the inner cup body and the outer cup body; and both the outer cup body and the inner cup body are made of titanium metal pieces. The manufacturing method of the vacuum cup comprises the procedures as follows: a, blank preparation; b, expansion molding; c, cup bottom sheet installation; d, tailless vacuum pumping; and e, finished product blanking. The titanium metal vacuum cup has the advantages of good corrosion resistance, high attractiveness and the like.

Owner:亚钛军创(金华)控股有限公司

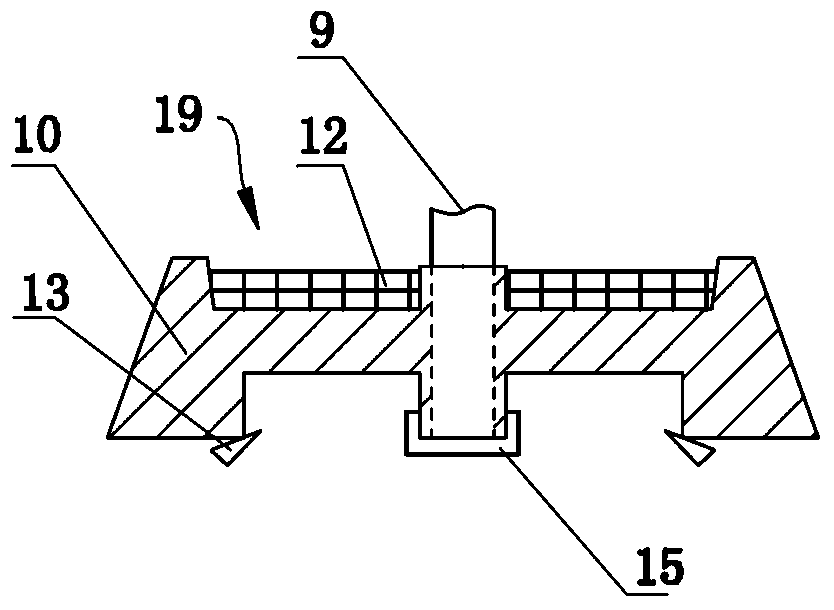

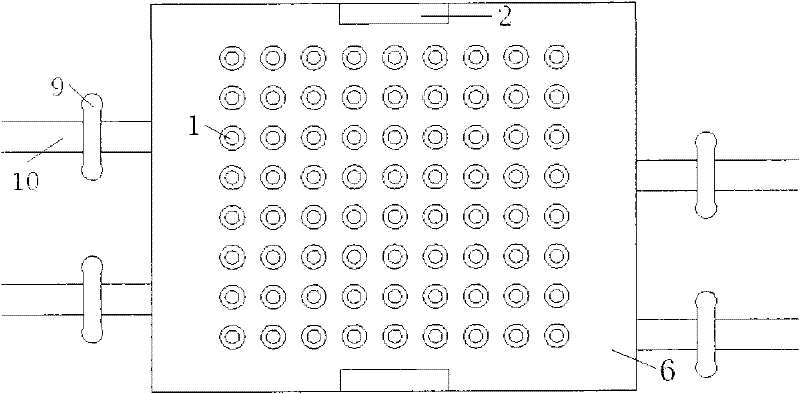

Vacuum adsorption equipment used for fixing thin-wall plane workpiece

InactiveCN102476300ASolve the deformationPlay a fastening rolePositioning apparatusMetal-working holdersVacuum pumpingPulp and paper industry

The invention discloses vacuum adsorption equipment used for fixing a thin-wall plane workpiece, comprising a vacuum adsorption plate and a sealing cover plate. N suction holes penetrating through the vacuum adsorption plate are arranged on the upper surface of the vacuum adsorption plate, m vacuum grooves which are not communicated are arranged on the lower surface of the vacuum adsorption plate, and each vacuum groove is communicated with a plurality of suction holes and is also communicated with an air suction pipe of a vacuum-pumping system. Periphery of each vacuum groove is provided with surrounding vacuum grooves and annular sealing grooves which are not communicated, each vacuum groove is internally filled with a sealing material, and m vacuum adsorption regions which are not communicated are formed on the upper surface of the vacuum adsorption plate by the vacuum grooves and the sealing cover plate. By combining plugs of the suction holes, the problem that workpiece adsorption failure is caused by the fact that one suction hole is suddenly sealed in a working process of a vacuum adsorption device, the vacuum adsorption problem that a workpiece body is provided with a through hole and the problem of cutting operation inside a workpiece in the vacuum adsorption fixed mode can be solved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

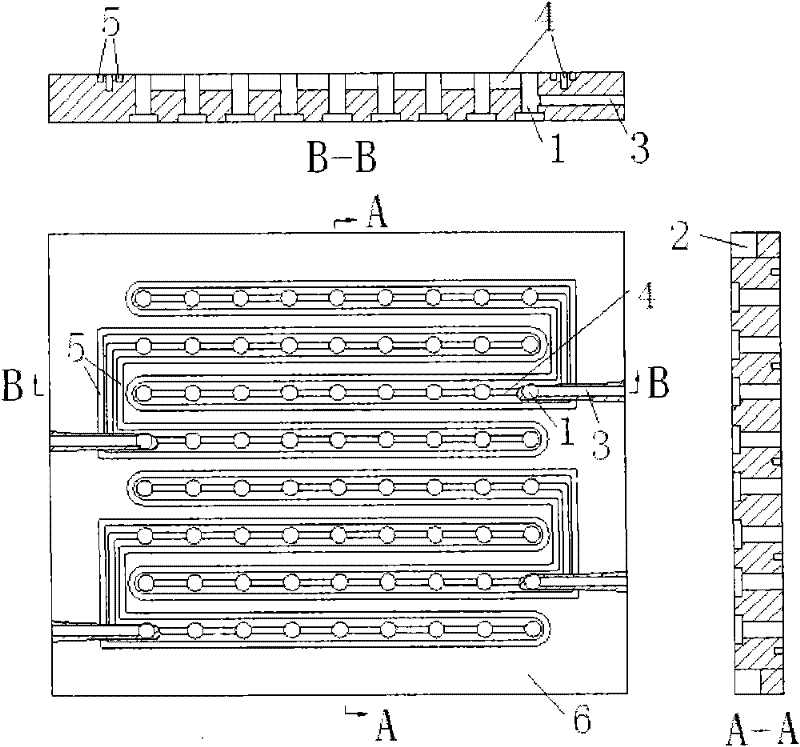

Method for manufacturing flat-plate heat tube

InactiveCN101639331AAppropriate intensityAppearance and shapeIndirect heat exchangersVacuum pumpingWorking fluid

The invention relates to a method for manufacturing a flat-plate heat tube. The method comprises the following steps: (1) providing an upper cover plate and a lower cover plate; (2) providing a plurality of first metal powders, and after being sintered, the first metal powders form a plurality of supporting columns; (3) arranging one end of each of the supporting columns on the upper surface of the lower cover plate, and correspondingly, the height of each supporting column is equivalent to the distance between the corresponding positions of the upper cover plate and the lower cover plate; (4)providing a plurality of second and third metal powders, filling the bottom of the lower cover plate with the metal powders, arranging the metal powders in the way of surrounding the supporting columns, and sintering the lower cover plate at a high temperature so as to enable the second metal powders to form a first capillary structure attached to the upper surface of the lower cover plate and toenable the third metal powders to form a second capillary structure attached to the upper surface of the first capillary structure; (5) welding the supporting columns and the lower cover plate on thelower surface of the upper cover plate so as to form a rough blank; and(6) processing the rough blank by vacuum-pumping, working fluid injection, degasification, sealing and surface heat treatment, thereby obtaining the final product of the flat-plate heat tube.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

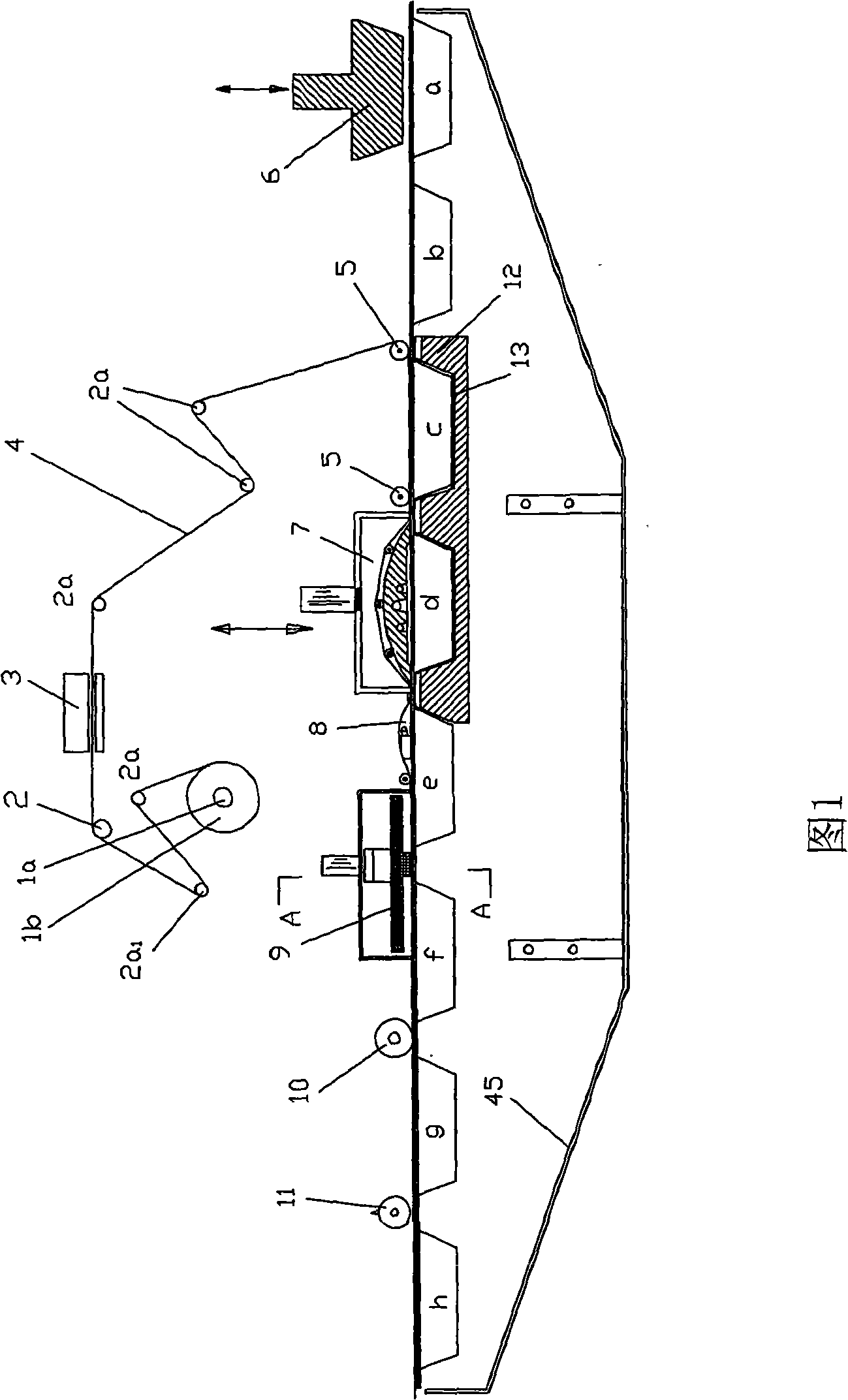

Full-automatic continuous box type gas-control packing device

InactiveCN101357694AImprove applicabilityImprove general performanceWrapping material feeding apparatusPackaging by pressurising/gasifyingVacuum pumpingProduct gas

The invention relates to a completely automatic continuous box-typed air conditioning packaging machine, which is characterized in that operations of vacuum pumping, inflating and box packaging are respectively completed on two continuous working positions; an air replacing device comprises a sealing chamber which is connected with a cylinder shaft; a sealing chamber is internally provided with the air replacing device which respectively carries out the air pumping and inflating of the air replacing chamber by an external pumping pipeline and an inflating pipeline; the external inflating pipeline is arranged on an air conditioning auxiliary device which carries out the conditioning of the air in the box by the external inflating pipeline; a thermal sealing film guiding device and the air conditioning auxiliary device are connected on a frame; the thermal sealing device is fixedly connected with the frame by a connecting screw; a first film cutting device and a second film cutting device are respectively arranged on the frame. The completely automatic continuous box-typed air conditioning packaging machine has high air replacing rate and air mixing precision and quick packaging speed, meets the requirements of changed volume of the packaging products and various styles of exterior of the packaging boxes, and has the advantages of integrating the sealing and slicing into a whole, etc.

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com