Patents

Literature

825 results about "Thermal bridge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

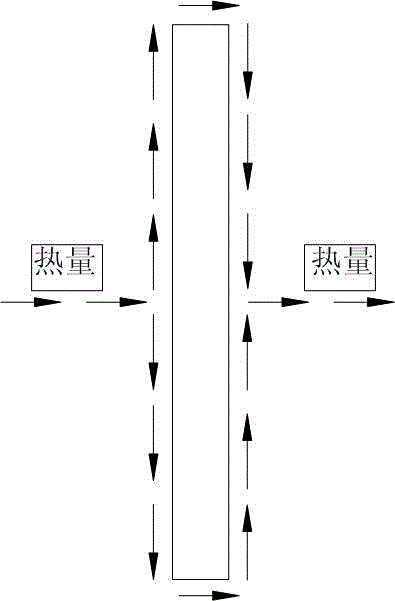

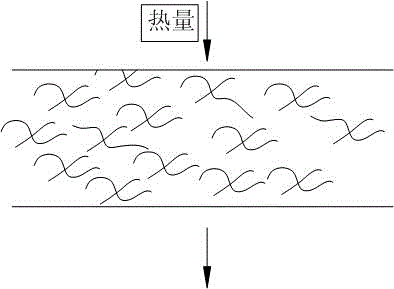

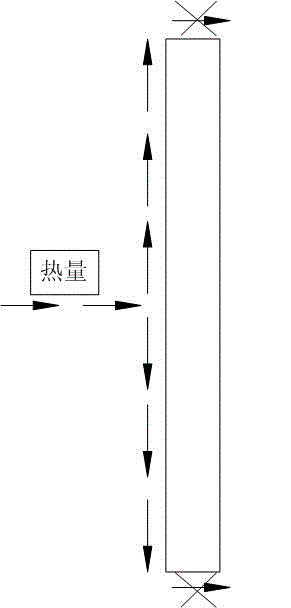

A thermal bridge, also called a cold bridge, heat bridge, or thermal bypass, is an area or component of an object which has higher thermal conductivity than the surrounding materials, creating a path of least resistance for heat transfer. Thermal bridges result in an overall reduction in thermal resistance of the object. The term is frequently discussed in the context of a building's thermal envelope where thermal bridges result in heat transfer into or out of conditioned space.

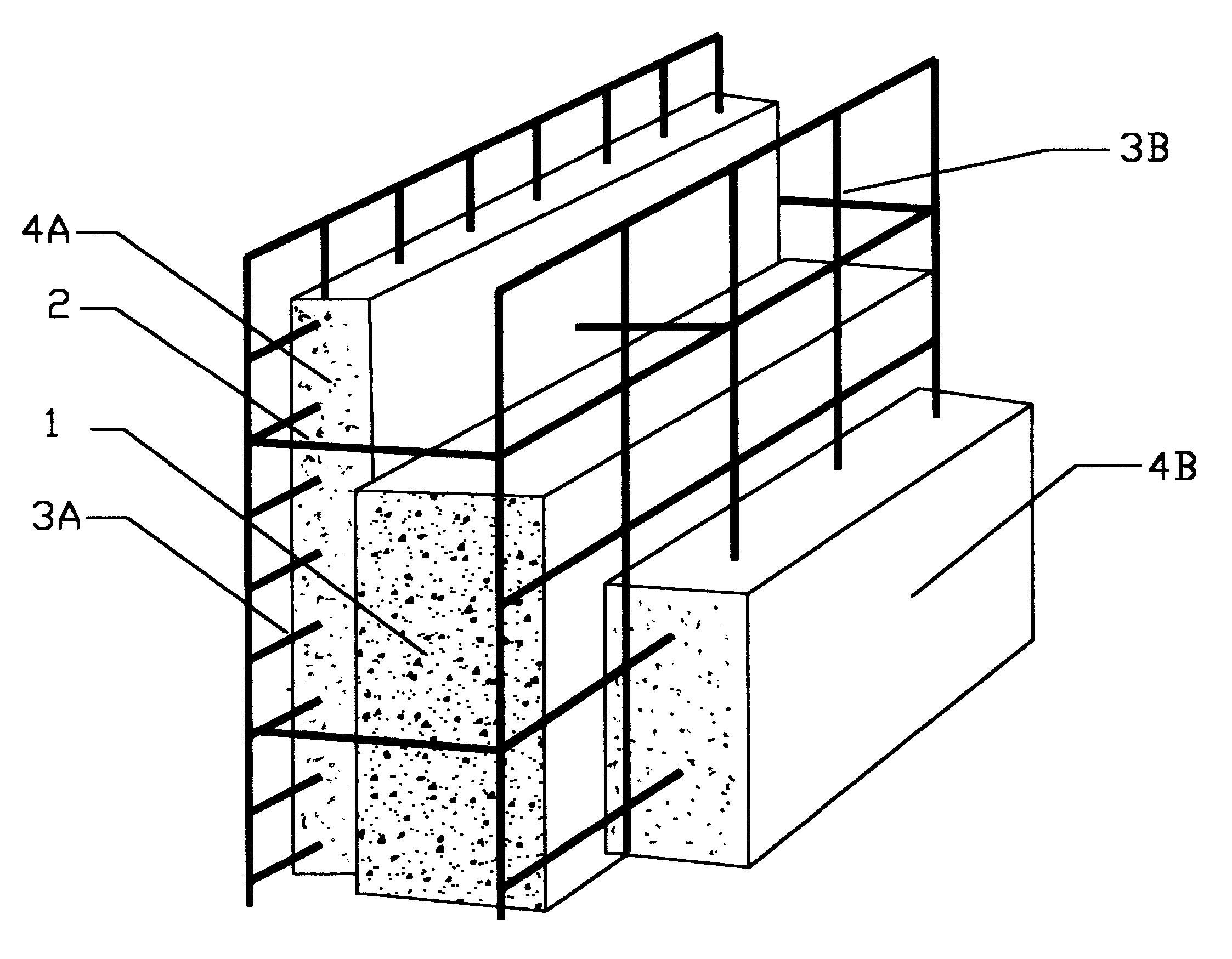

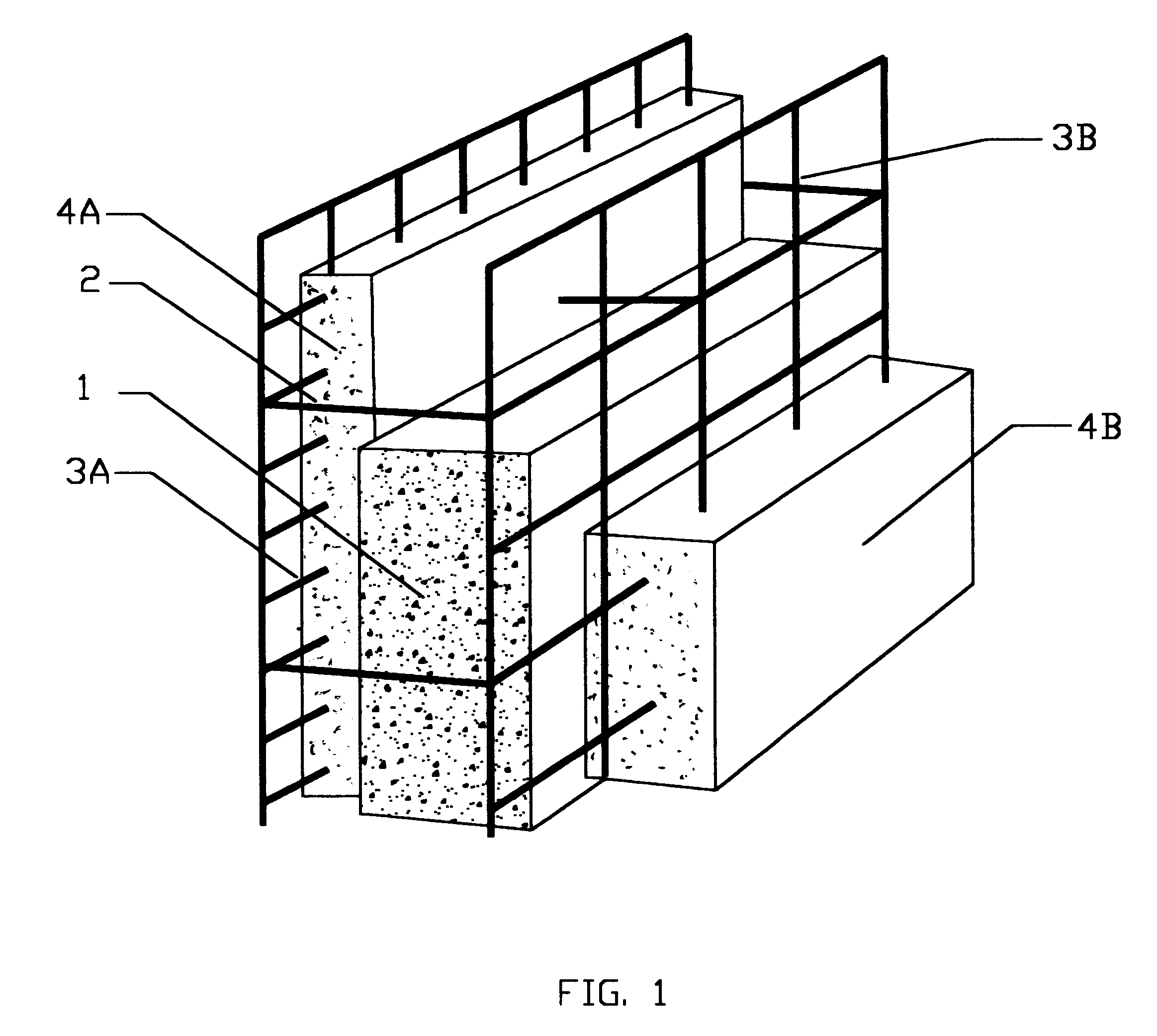

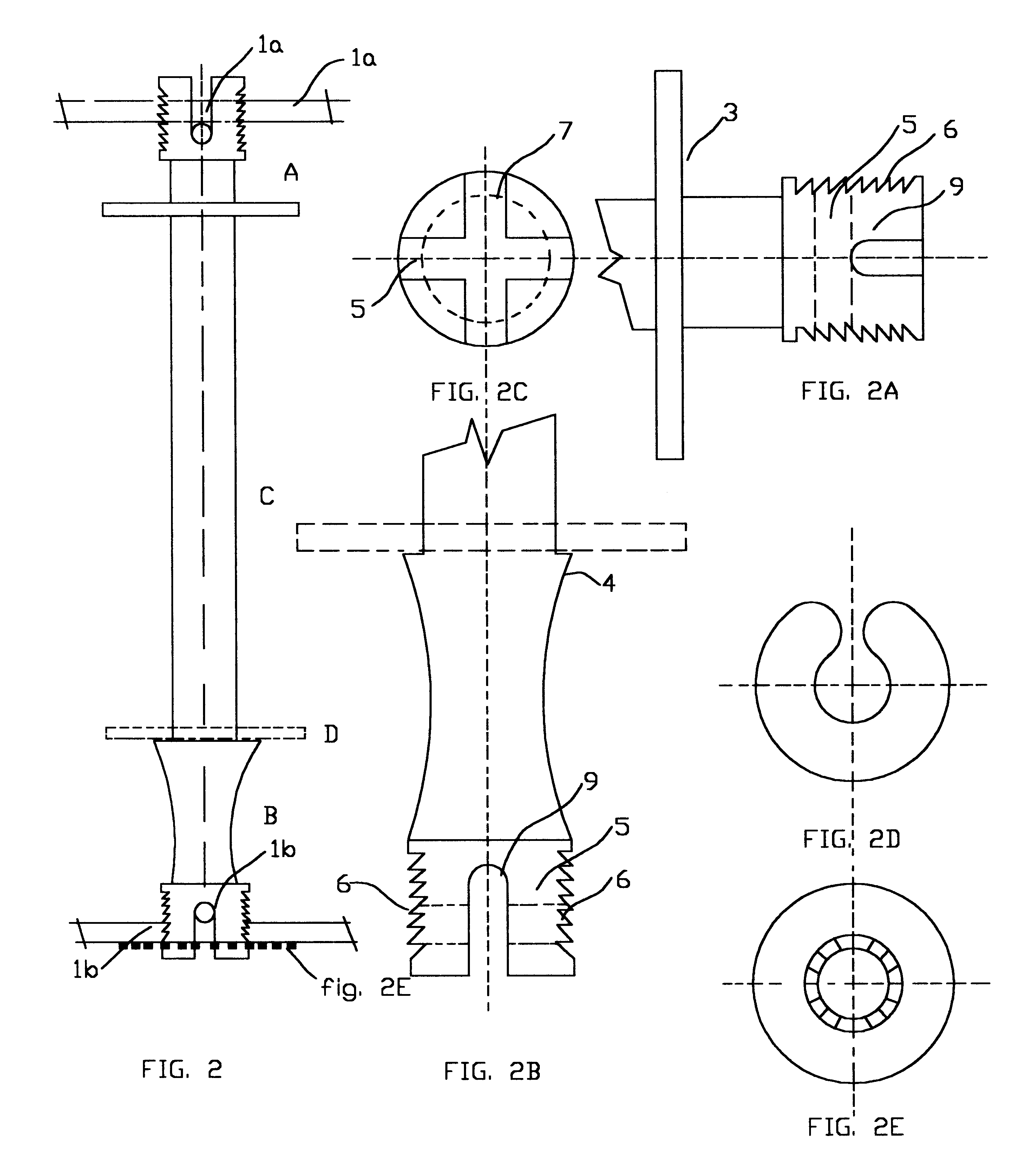

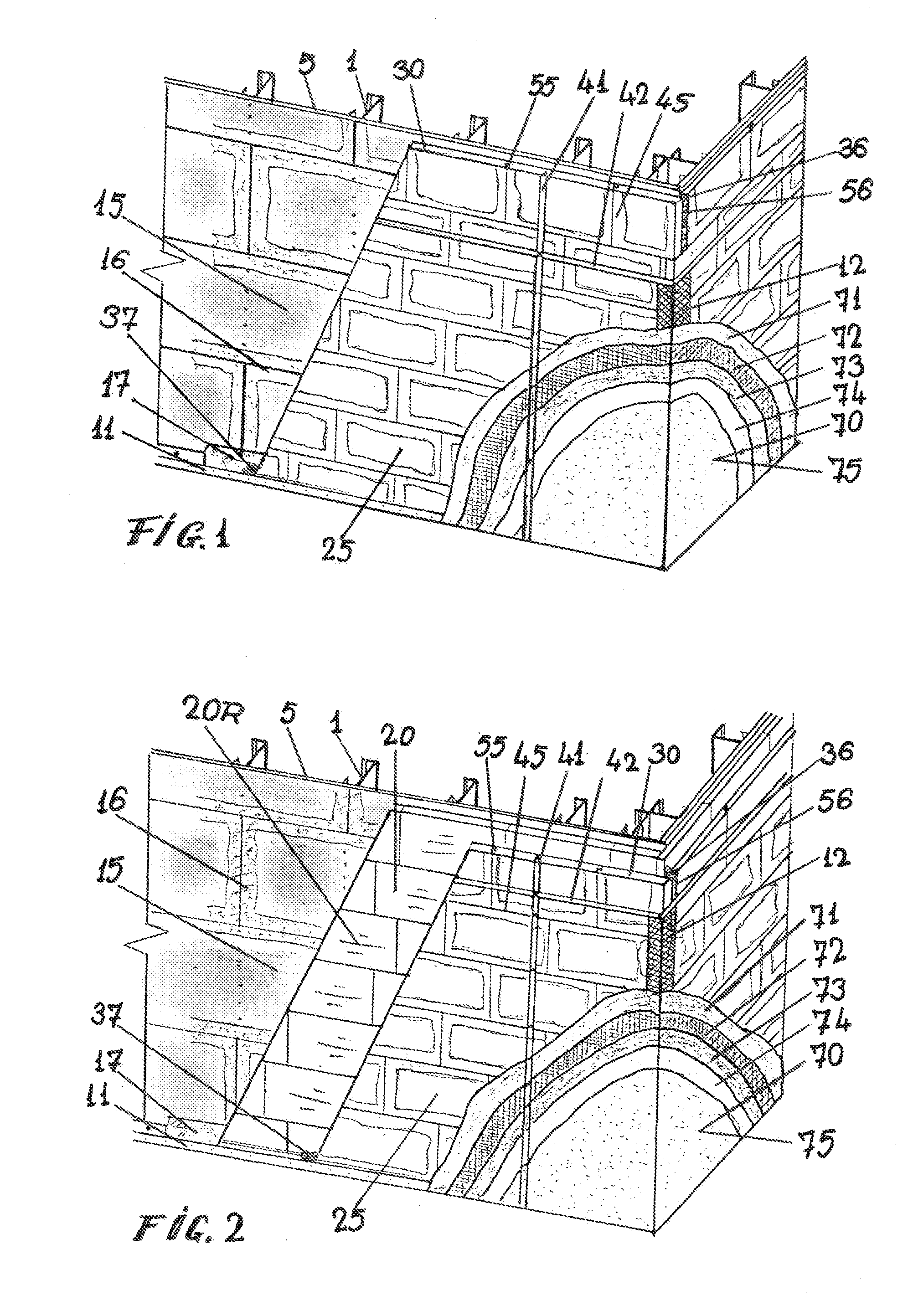

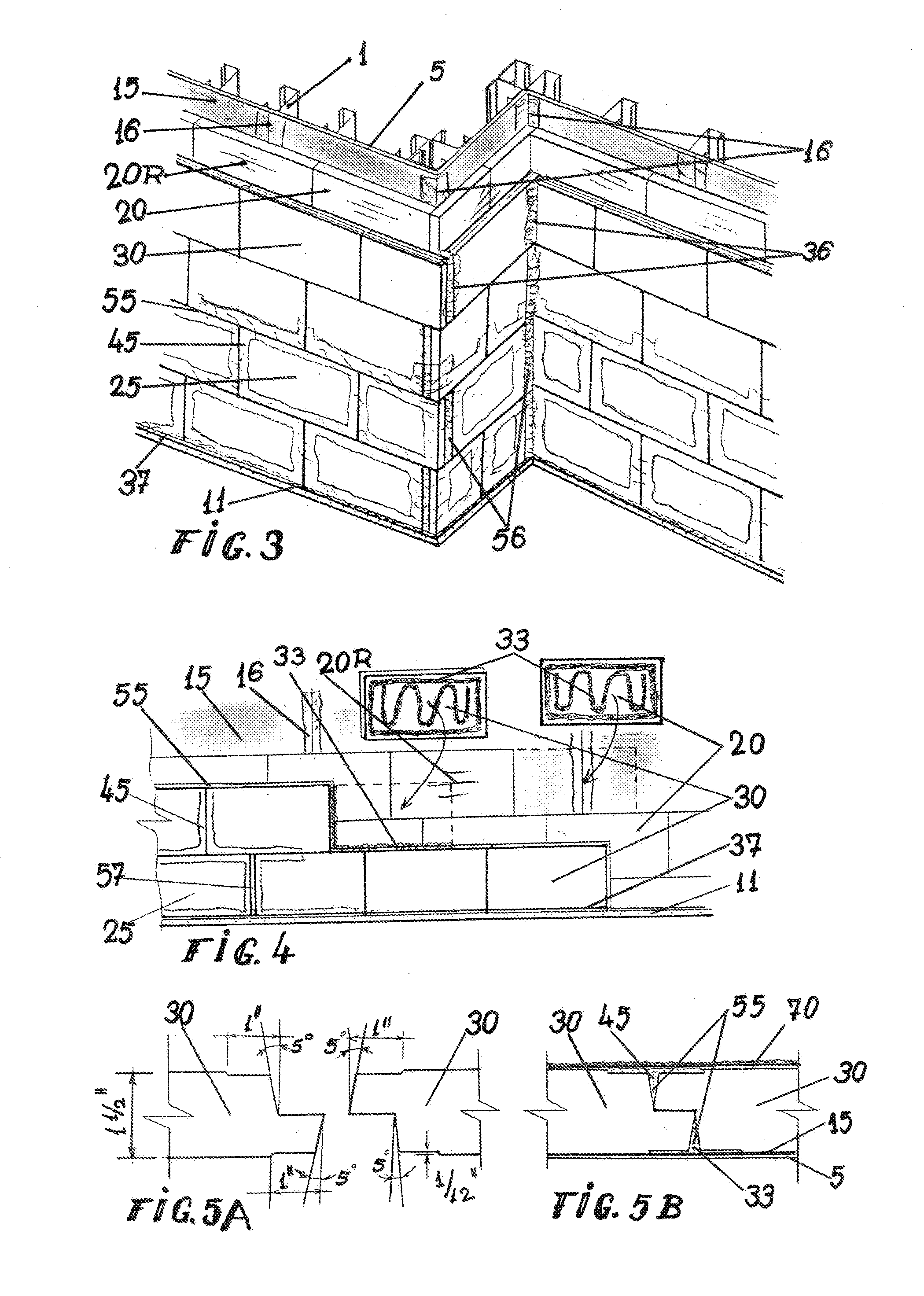

Method for concrete building system using composite panels with highly insulative plastic connector

InactiveUS6202375B1Easy to assembleEasy to transportBuilding roofsConstruction materialFiberShotcrete

The present invention comprises a concrete building system with a method for fabricating composite panels using an improved design plastic connector and assembling them at the construction site to a structure which will be shotcreted on both sides to a concrete building which is highly insulated, is fire and termite proof, hurricane, earthquake and flood resistant and fulfills the requirement for flexible design. The Composite Panels are composed of two concrete layers, enclosing an insulative foam core. The skins are reinforced with wire mesh as structurally required and are connected through the foam core by structural highly insulative plastic connectors using the snap connection on both ends of the connectors so they form a tri-dimentional system and hold the wire mesh in place for the onsite shotcrete application, which includes an application of fiber for shrinkage and cracking. This replaces the welded wire fabric use for secondly reinforcing and let the wire mesh reinforcing only related to the structural strength of the composite panel. The plastic connector guarantees that no thermal bridging occurs like in other systems also the inside layer of the shotcrete panel.

Owner:FCN FOUND FOR THE CONSERVATION OF NATURE

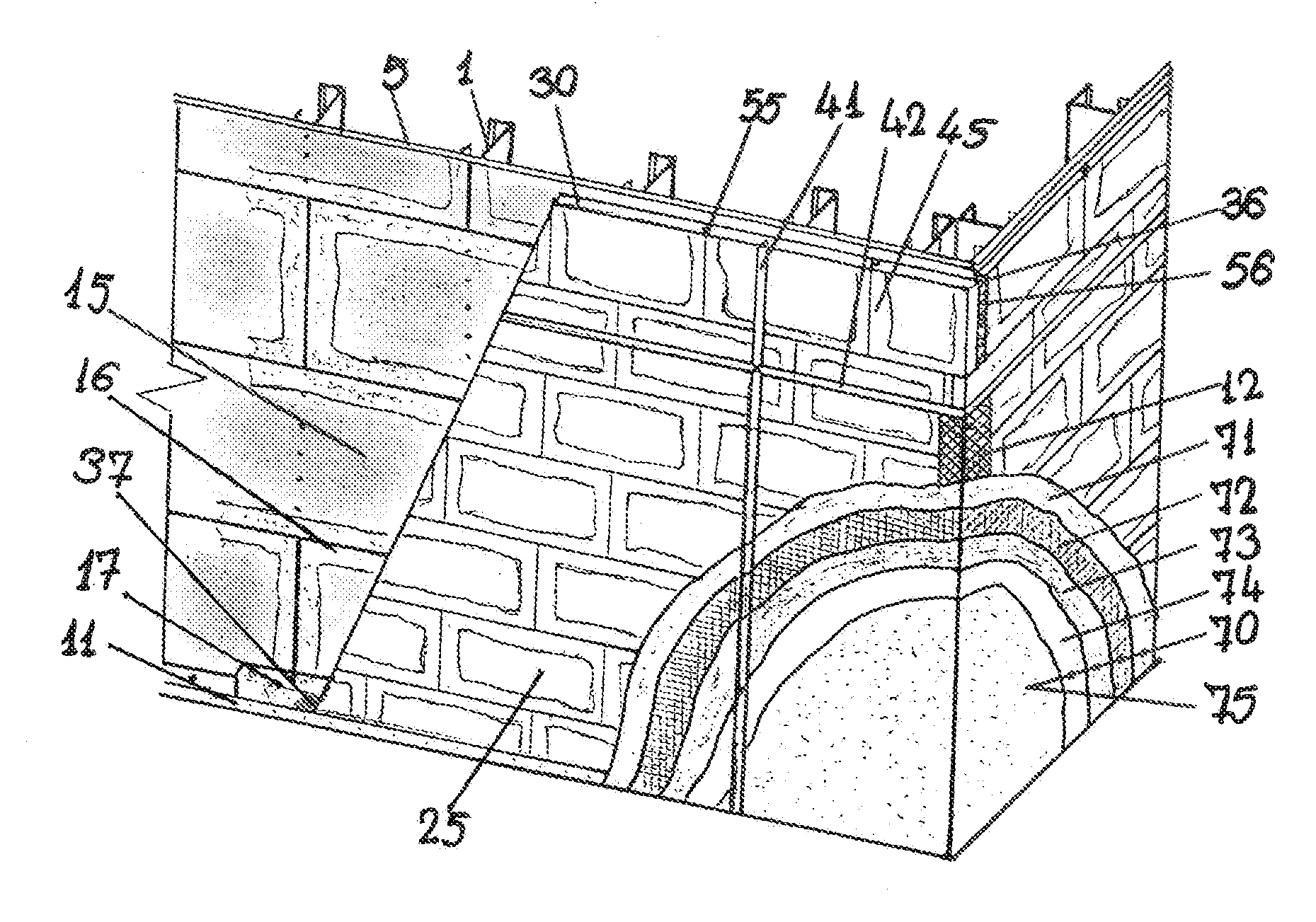

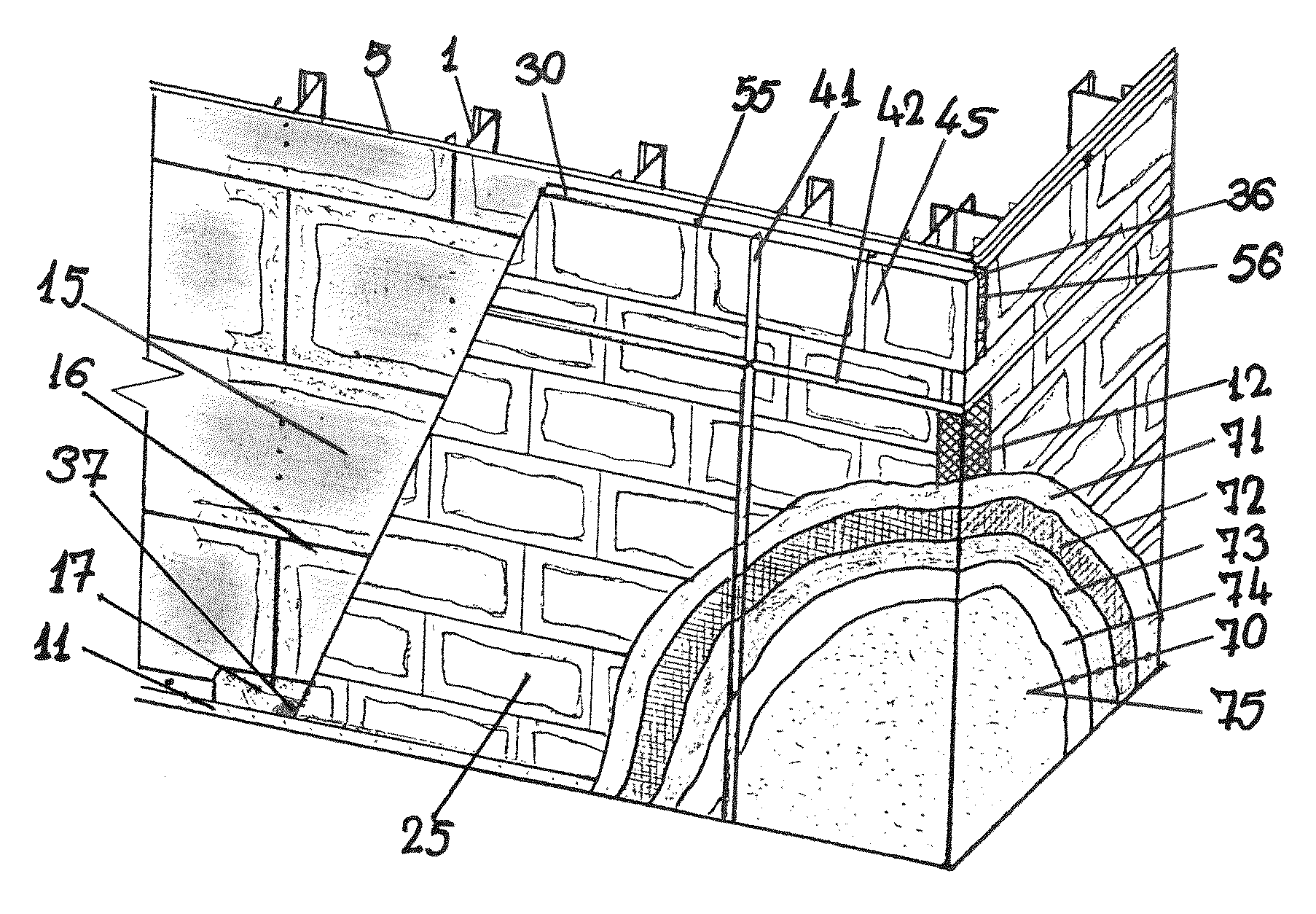

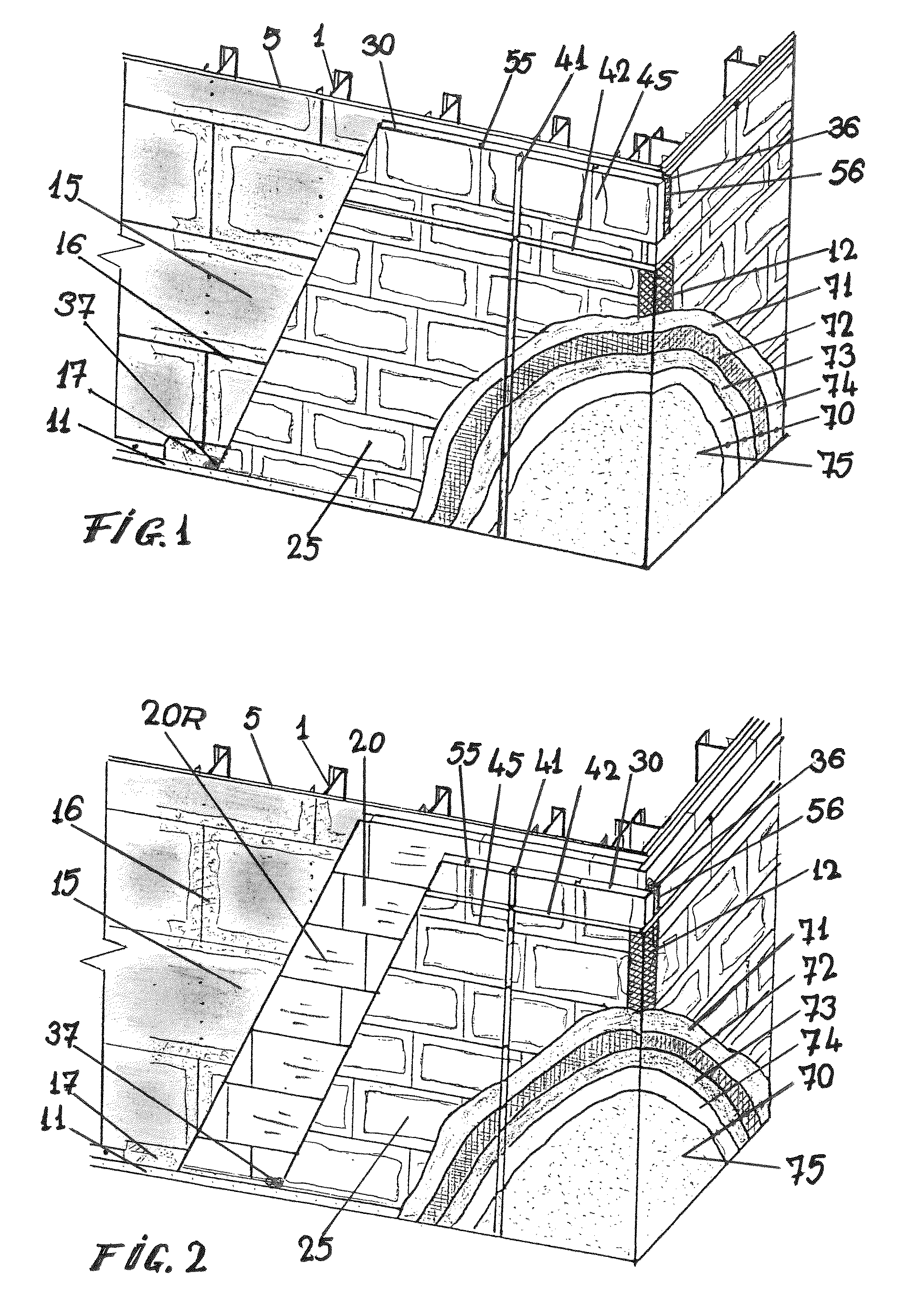

NP-EIFS Non-Permissive Exterior Insulation and Finish Systems concept technology and details

A new concept wall system is provided, wherein the Exterior Insulation and Finish System cladding is created using components with no water absorption, a very low vapor permeability and sealing properties, accommodated with an installation technology which extend the materials properties to the assembly, together with bonding and sealing the intersections and terminations, creating a Non-Permissive to water and vapor diffusion, Exterior Insulation and Finish System (NP-EIFS). The present invention relates to an EIFS cladding having two air and vapor barriers, one applied to the substrate, a continuous liquid membrane with sheathing joints sealed to be moisture barrier for inside vapors, and an exterior weather and vapor barrier which is created using closed cell extruded polystyrene insulation boards, special assembled with joints sealed, to create a non-permissive insulation envelope of the enclosure. Another object of the invention is to provide waterproof and air / vapor-proof details, a new concept of flashing and sealant application around windows / doors and other constructive elements to avoid thermal bridges and air leakage inside thermal envelope and wall assembly. Methods of installation are included.

Owner:RADOANE MARIUS

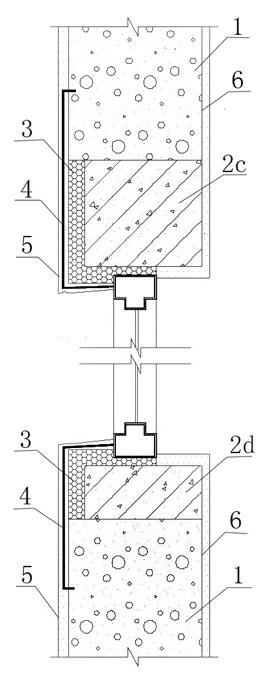

Automatic heat preservation, energy saving and air-entrapping concrete brick wall and manufacturing method thereof

InactiveCN102162282AImprove performanceMeet the requirements of the outer protective structureConstruction materialSolid waste managementInsulation layerThermal bridge

The invention relates to an automatic heat preservation, energy saving and air-entrapping concrete brick wall and a manufacturing method thereof. The invention is characterized that: a heat preservation wall plate is protruded, relative to the outer surfaces of a beam and a stand column or a concrete plate, 20 to 50 millimeters or flatly bricked; beam and column part heat preservation layers are bonded on the outer surfaces of the beam and the stand column or the concrete plate; and alkali-proof grids or steel mesh sheets are paved on the surfaces of the heat preservation layers. During bricking of the wall, the comprehensive performance of the heat preservation wall can be enhanced under the condition of no addition of the heat preservation layers on the whole wall by using energy saving and air-entrapping concrete bricks and heat preservation bricking mortar as well as heat preservation processing measures taken on hot bridge parts such as the beam, the column and the like, so the requirement of a periphery protective structure of a building wall can be met, and heat energy loss due to the hot bridges formed in mortar joints of the wall can be avoided effectively; therefore, the design standard requirement of China on heat preservation and energy saving of a building is met, and the manufacturing cost of the wall and the comprehensive cost of the building are reduced greatly.

Owner:徐振飞

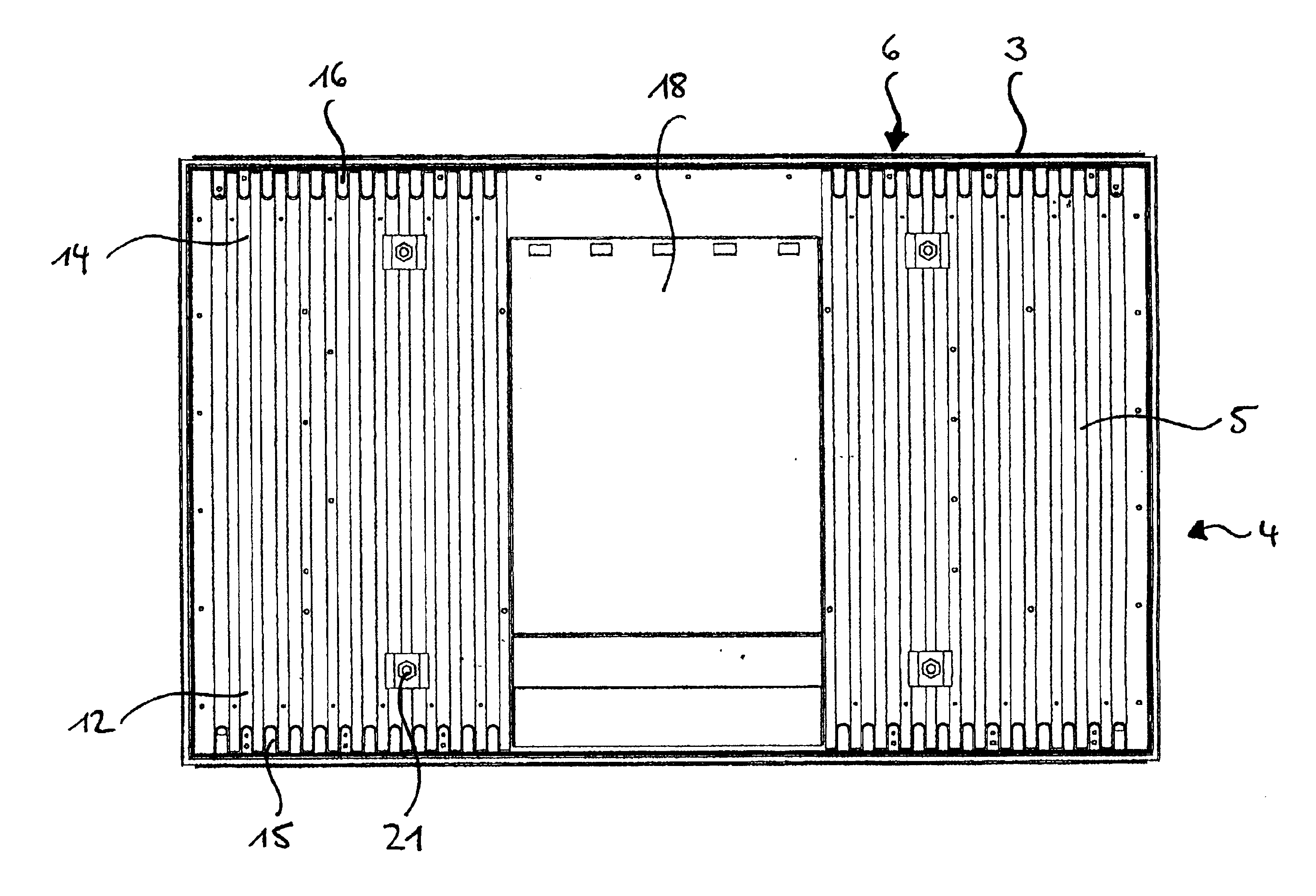

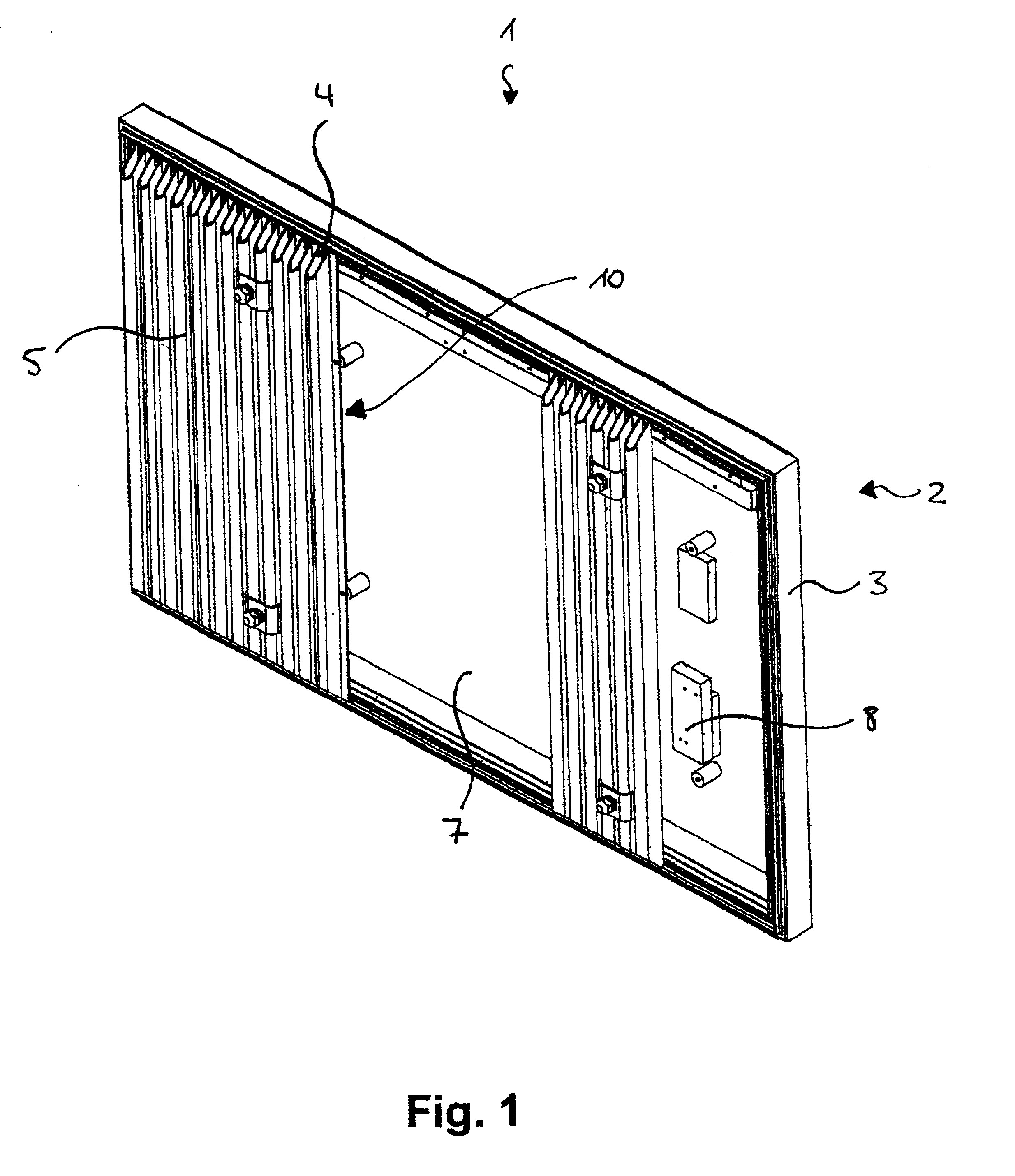

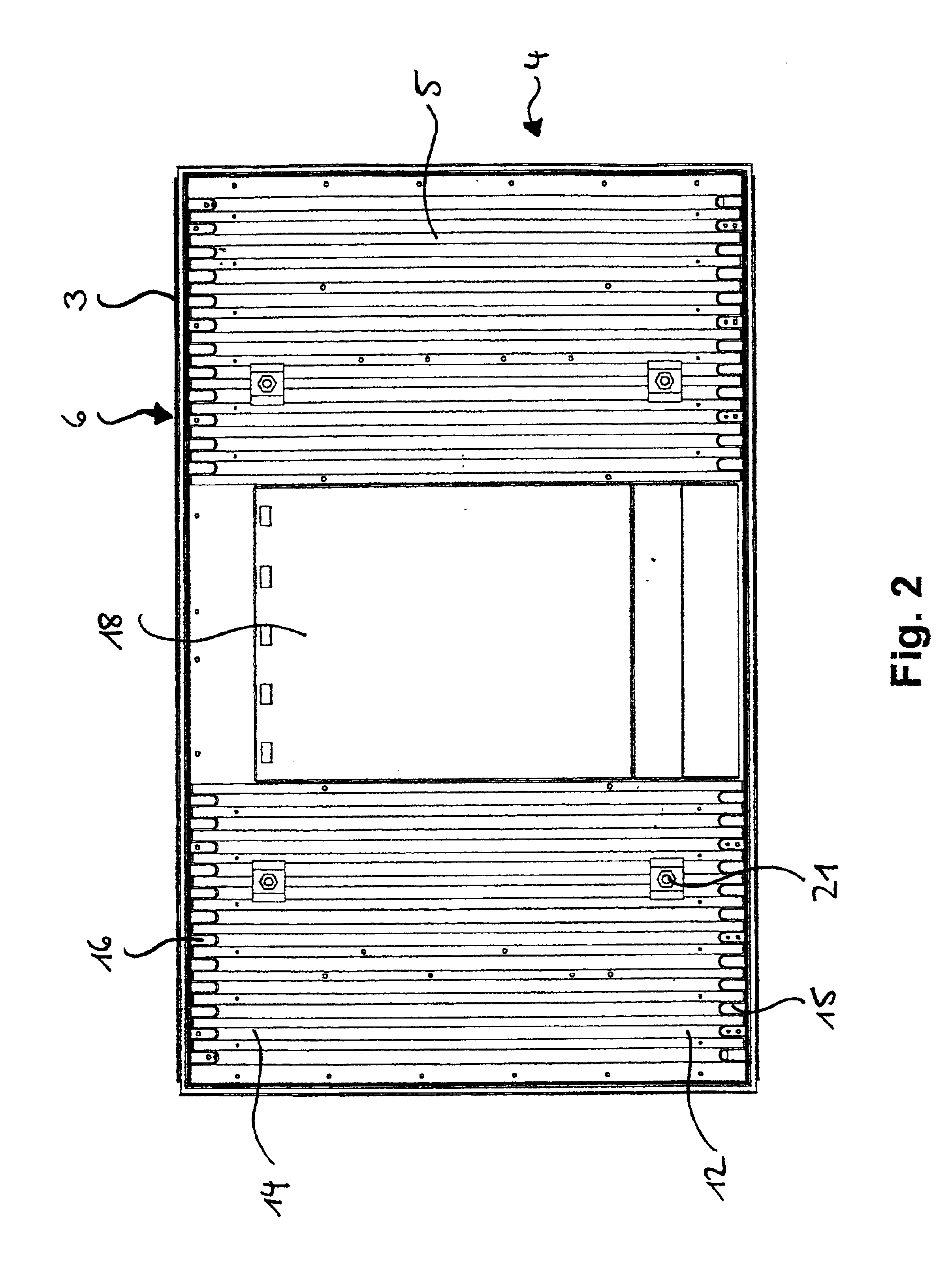

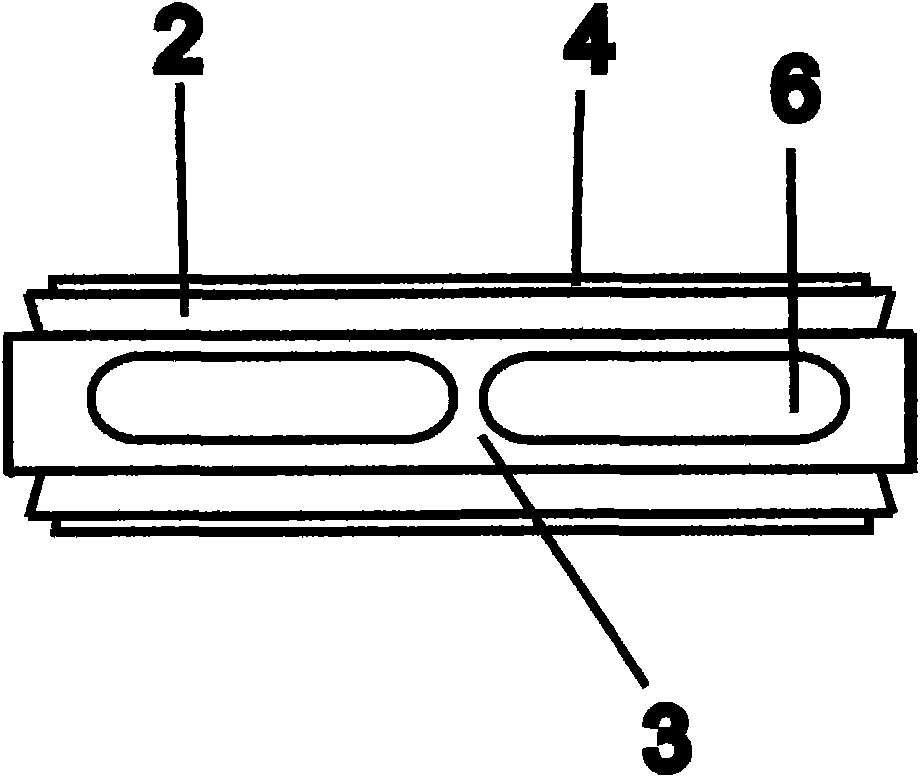

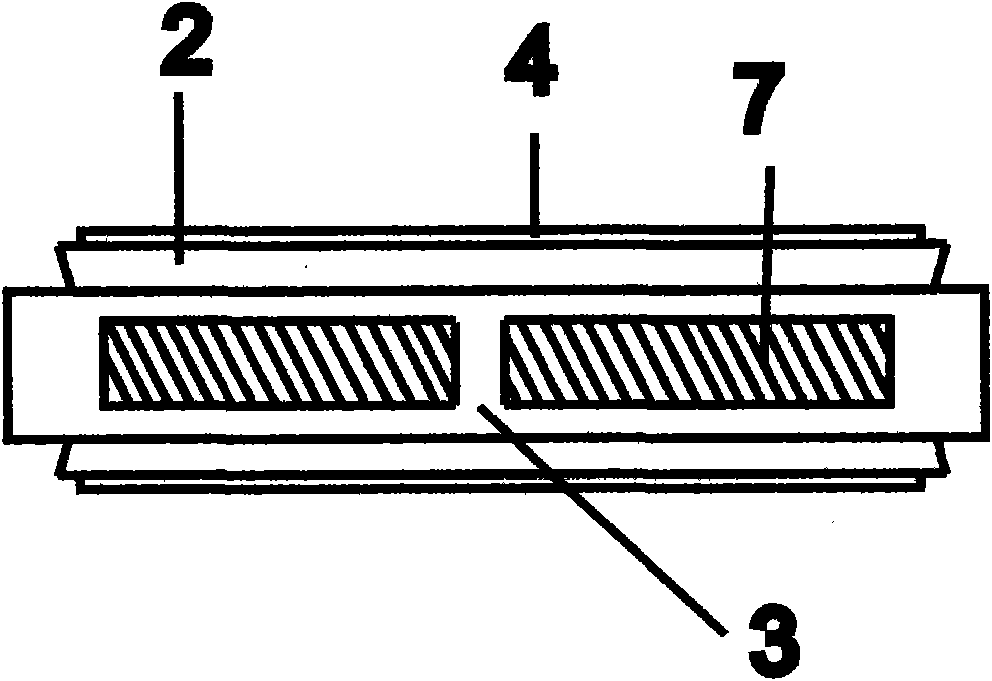

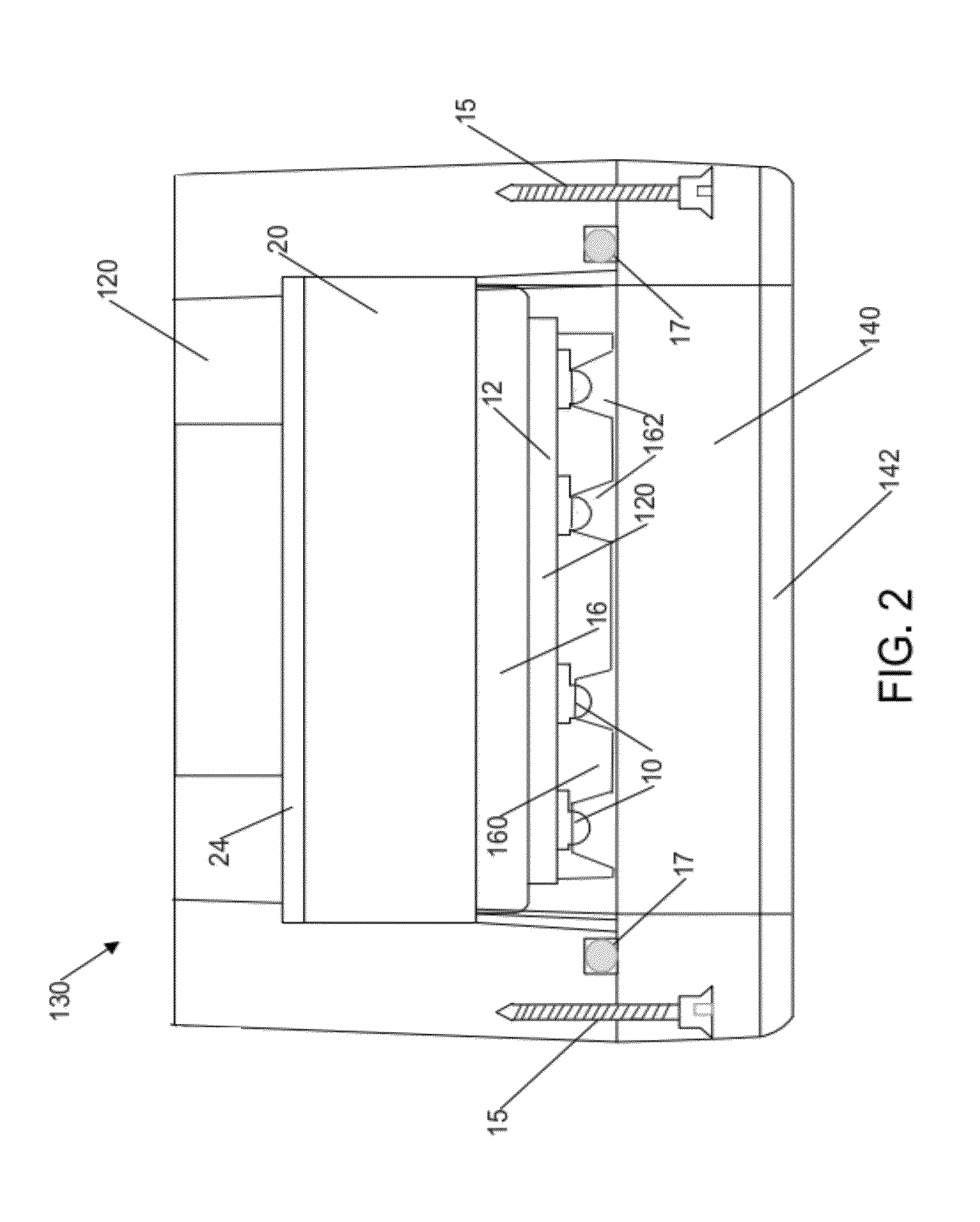

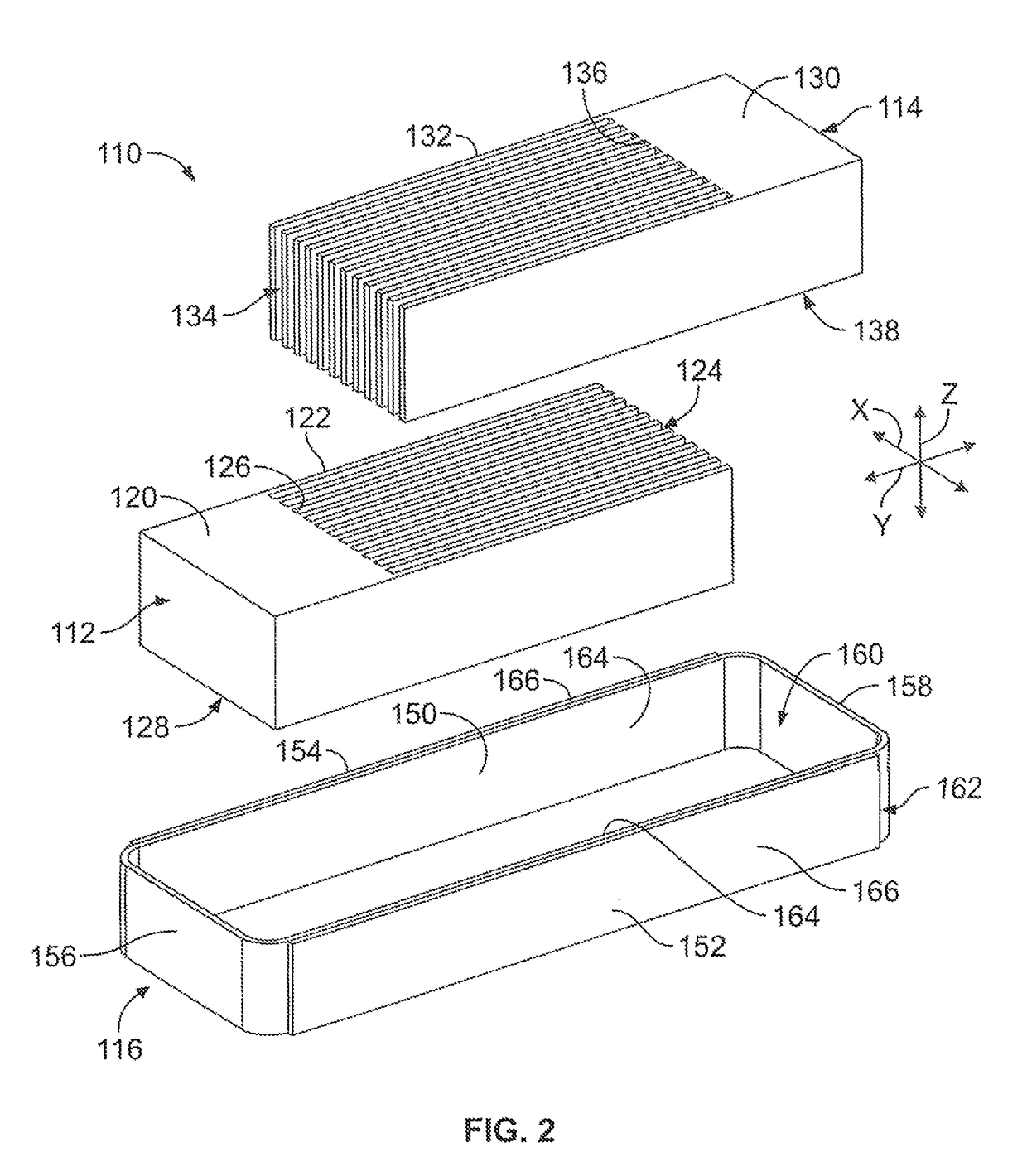

Apparatus for mounting and cooling a flat screen

InactiveUS6714410B2Easy to optimizeReduce weightTelevision system detailsVehicle seatsThermal bridgeEngineering

An apparatus for mounting and cooling a flat screen during operation comprises a housing for accommodating the flat screen and further heat generating electric and electronic units, moreover thermal bridges for conducting the heat generated by at least the flat screen to a heat conductive rear wall of the housing. The rear wall is provided with at least one profile in a manner that a plurality of chimney-like cavities are formed on the rear side of the housing, which comprise in their lower end portion at least one opening for supplying cool air into each cavity, and at least one outlet opening in the upper end portion of each cavity for discharging heated air into the atmosphere.

Owner:INNOWERT

Foamed ceramics energy saving and heat preservation decorative wall brick and manufacture method thereof

InactiveCN101560111ALow thermal conductivityLow densityCeramic materials productionCeramicwareBrickSlurry

The invention discloses a foamed ceramics energy saving and heat preservation decorative wall brick and a manufacture method thereof, including the steps of conducting ball milling on 15-65 percent wt of industrial residues, 10-45 percent wt of plastic clay, 15-60 percent wt of solvent, 10-45 percent wt of pore-forming agent with the fineness being 1-100mum and proper amount of water to form slurry; spray drying or dehydration and clay preparation, and forming powder material or clay segment through staleness; and implementing pressure forming to make billet which is burned under heat preservation at temperature of 1140-1240 DEG C to finally form the foamed ceramics wall brick. The wall brick can be used not only for the heat preservation and decoration of external walls, but also for indoor heat preservation and decoration, and the external wall and the indoor space can realize the organic combination of uniform heat preservation and decoration, which agrees with the development direction of heat preservation material industry of external walls. The wall brick has the advantages of: I. high temperature resistance, acid and alkali-resistance, good chemical stability, no ageing, strong durability, long service life, no generation of heat channel and good adhesive fixity; and II. difficult water seepage and crack, strong anti-corrosion capacity, uneasy deformation and damage, simplification of mounting, laying and sticking procedures, convenience for construction, relief of labor intensity and decrease of material consumption quantity.

Owner:吴汉阳

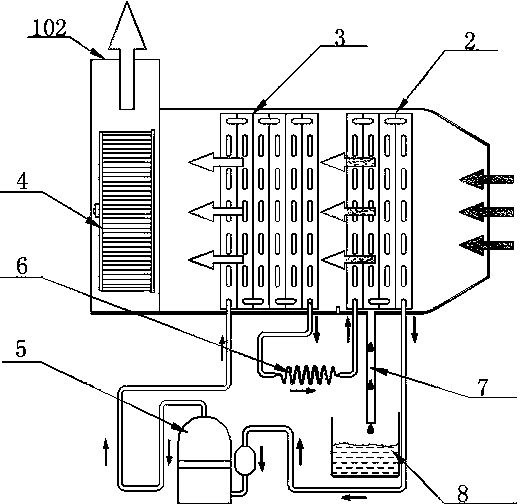

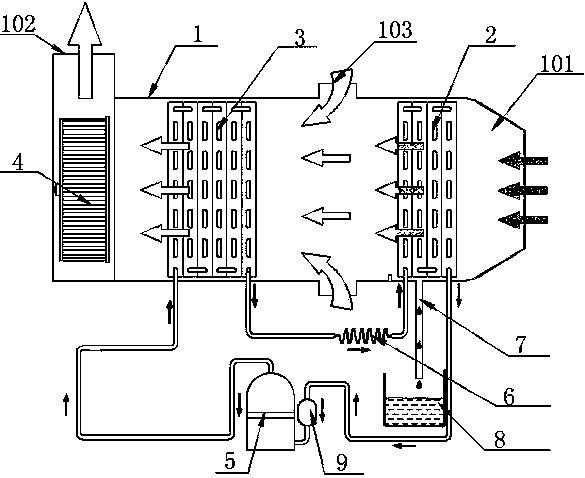

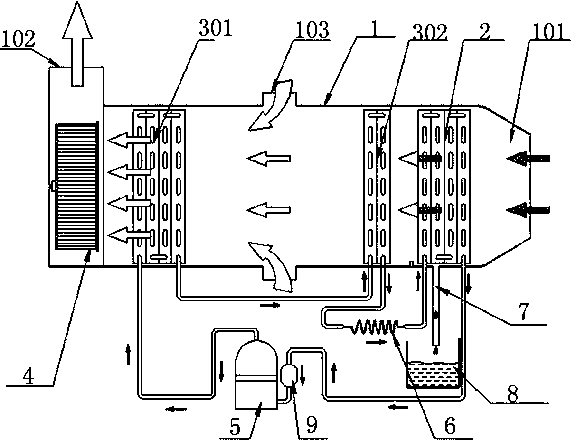

Low-condensing-pressure deep supercooling efficient dehumidifier

ActiveCN104019574AReduce condensing pressureReduce power consumptionCompression machines with several condensersBusiness efficiencyThermal bridge

The invention provides a low-condensing-pressure deep supercooling efficient dehumidifier. The low-condensing-pressure deep supercooling efficient dehumidifier comprises an air flue, a first draught fan and a refrigerating and dehumidifying system. The refrigerating and dehumidifying system comprises an evaporator, a first condenser, a second condenser, a compressor and a throttling device. According to the low-condensing-pressure deep supercooling efficient dehumidifier, a bypass airflow channel is additionally arranged in the air flue between the first condenser and the second condenser, so that the ventilation quantity of the first condenser is increased, and the condensing pressure of refrigerating fluid gas in the condensers is reduced; the first condenser is used for heat release and cooling of a sensible heat portion of the overheated refrigerating fluid gas and heat release, condensation and liquefaction of the refrigerating fluid gas, and the second condenser is used for cooling and supercooling of refrigerating fluid; since a finned thermal bridge between the first condenser and the second condenser is disconnected, the supercooling degree of the refrigerating fluid at the tail end of the second condenser is improved, the vaporization ratio of the refrigerating fluid in the throttling device can be lowered, the evaporation and heat absorption capacity of the refrigerating fluid in the evaporator is improved, and the energy efficiency ratio of the dehumidifier is increased substantially.

Owner:HANGZHOU PREAIR ELECTRICAL APPLIANCE IND

Insulating Wall Panel System

An insulating panel to be used in a panelized insulation system for insulating and finishing walls, including basement walls has a foam core made of inorganic materials. The system incorporates a capillary break, an integrated water drainage system and an electrical wire chase system within an insulating wall panel. Vertical slots are provided for insertion of metal studs for use in attaching the interior finish panel, such as inorganic fiber cement board with a vinyl laminate finish, onto the insulating panels. Embedding metal studs in the panel core reduces the sound transmission though the panel and eliminates thermal bridging between warm and cold surfaces. Steps on the edges and the top / bottom surfaces of the insulating panel allow more panels to join together with shiplap joints.

Owner:LEWIS DAVID L

Air insulating structure of vacuum insulation panel and packaging method thereof

InactiveCN101963267AReduce the number of heat-sealed edgesSave on packaging costsThermal insulationPipe protection by thermal insulationVacuum pumpingThermal bridge

The invention provides an air insulating structure of vacuum insulation panel, which is formed by composite material. The composite material does not contain aluminium foil layer; therefore, the heat bridge effect of seal edge during heat seal is avoided. The packaging method of the air insulating structure comprises the following steps of: folding a single piece of composite material to form a bag shaped air insulating structure having a size consistent with that of adiabatic core material according to the specification of the core material and form three seal edges; sealing part of sealing edges with heat, and keeping an opening for placing the adiabatic core material inside; filling the adiabatic core material in the air insulating structure, performing heat seal on the remained opening and keeping a vacuum pumping opening; and placing the air insulating structure, which is filled with the adiabatic core material and has a vacuum pumping opening, in a vacuum room and pumping to produce vacuum, and performing heat seal on the preserved vacuum pumping opening to form a vacuum thermal insulation panel. The air insulating structure has three seal edges, which are fewer than those of the conventional method; therefore, the integral heat bridge effect is reduced, the operation is simple, the appearance planeness of the vacuum insulation panel is improved, and the fold and air leakage of the air insulating structure in convention manufacturing process are avoided.

Owner:SHANGHAI MARITIME UNIVERSITY

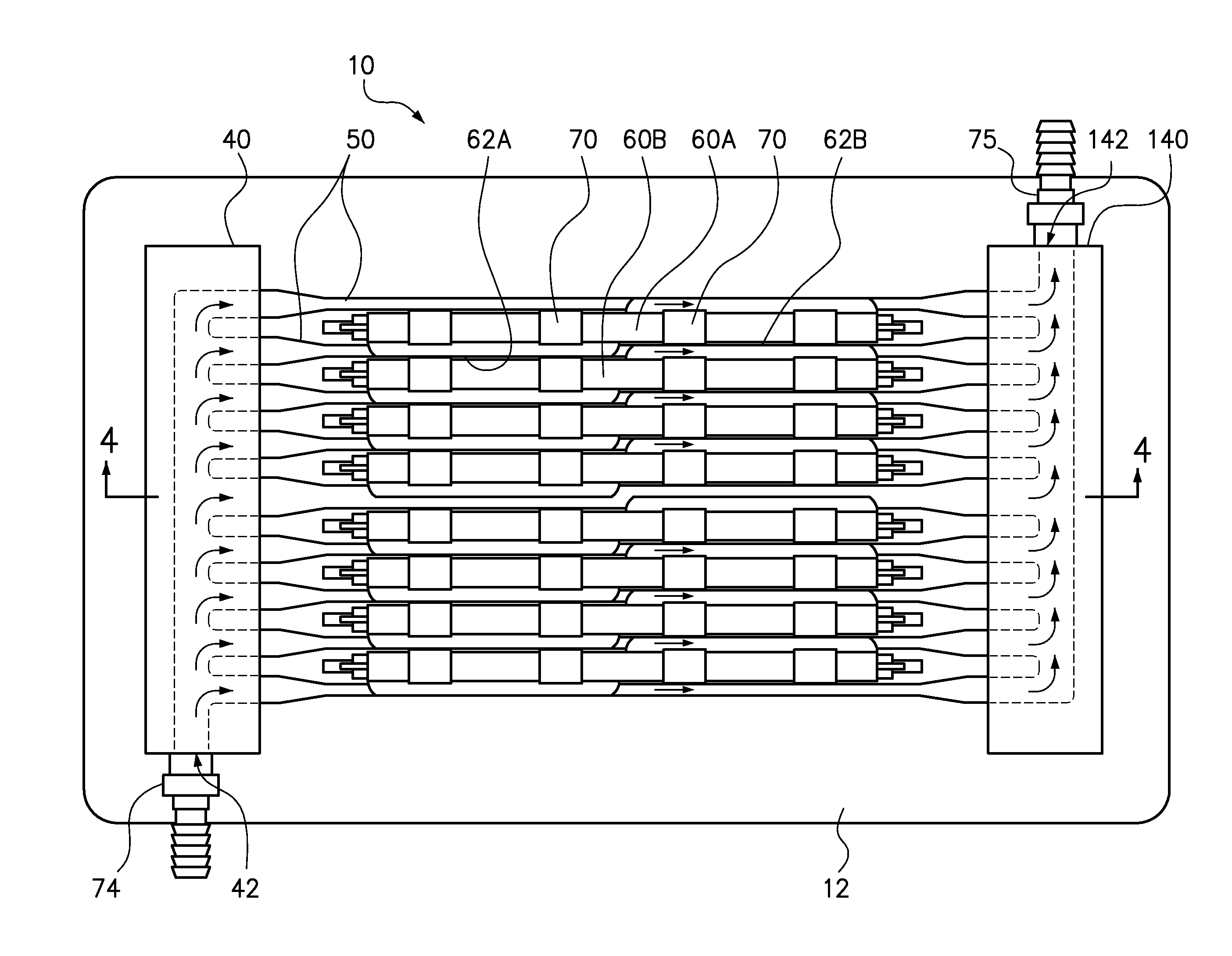

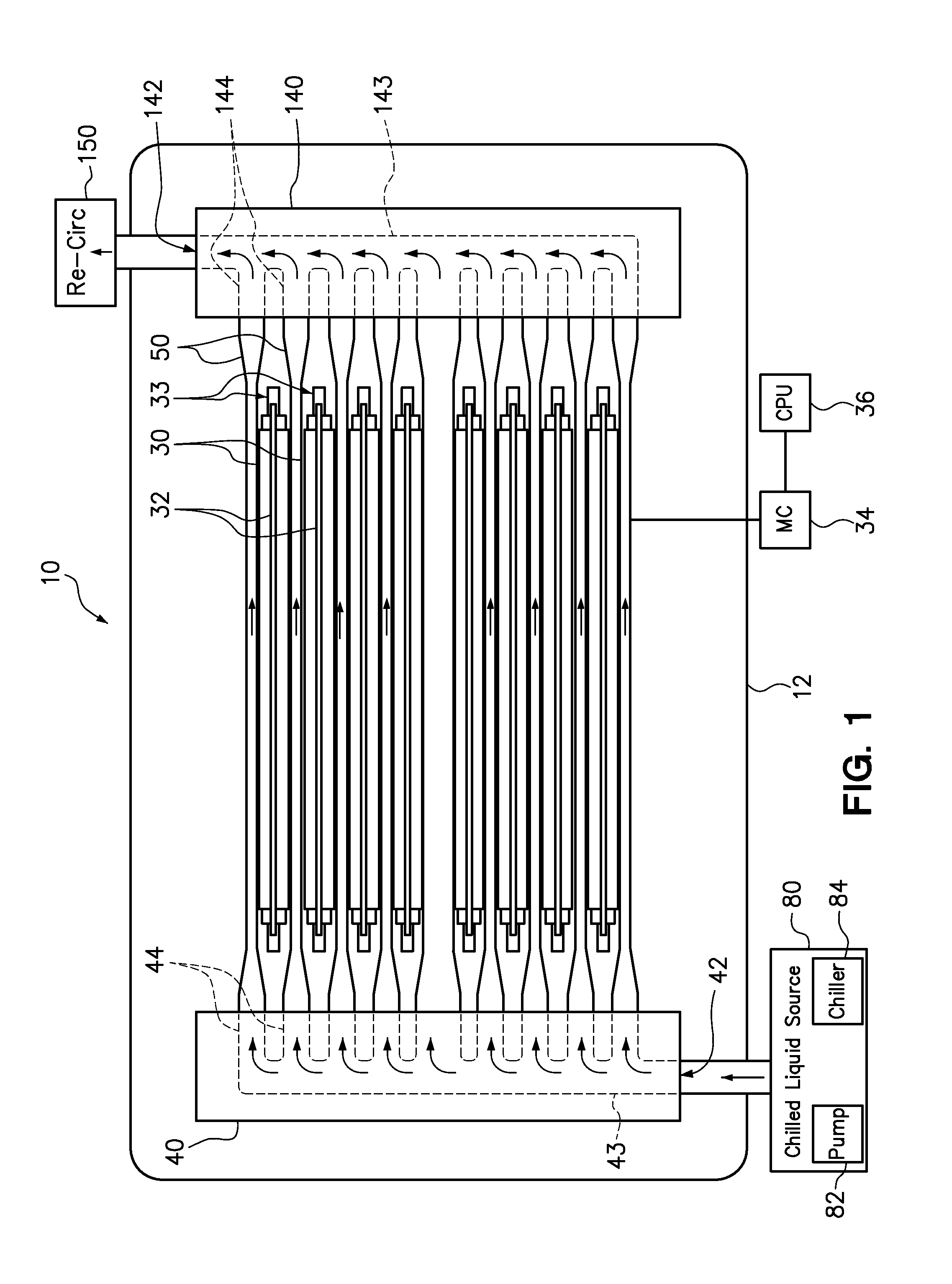

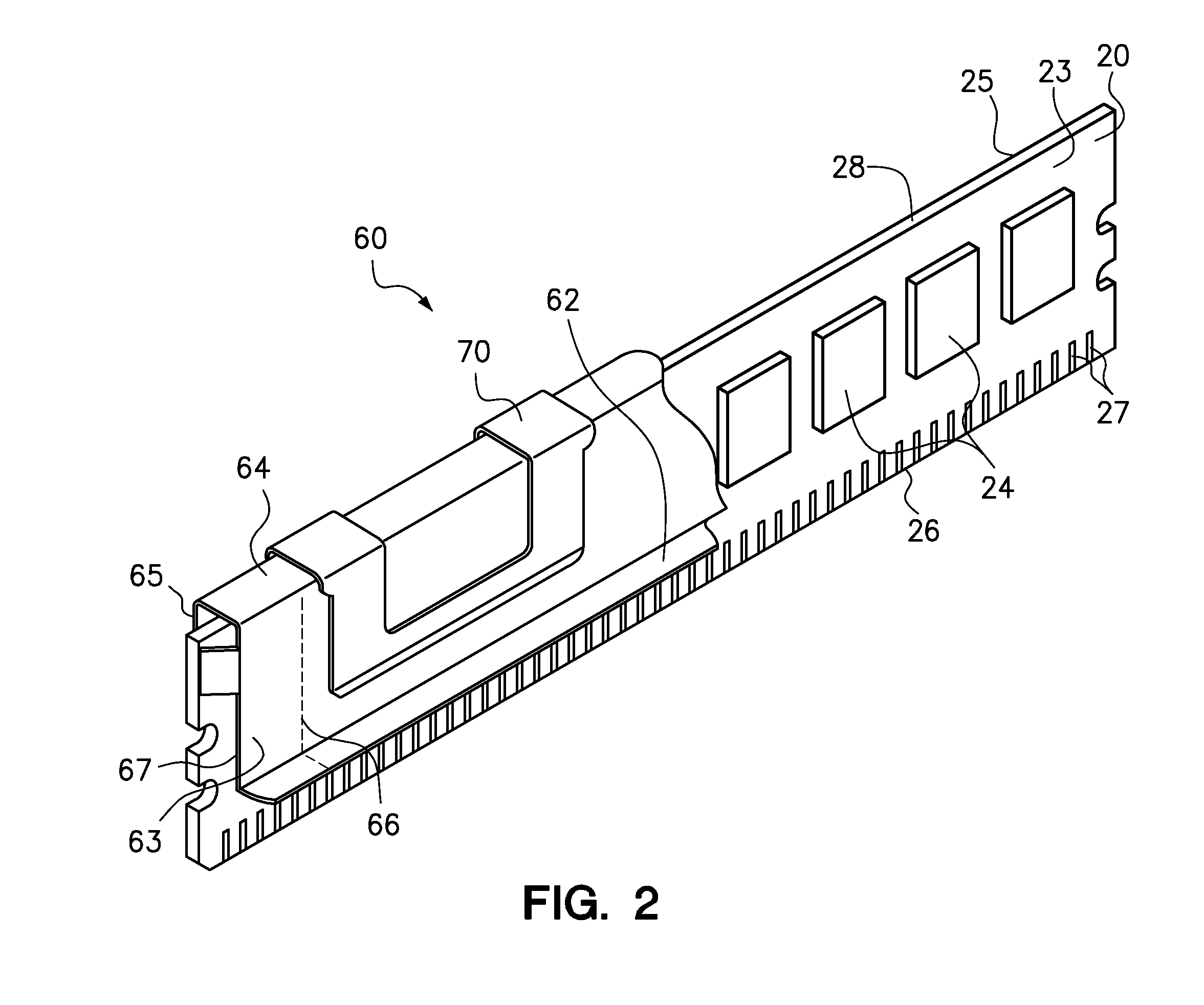

Liquid-cooling memory modules with liquid flow pipes between memory module sockets

ActiveUS8587943B2Digital data processing detailsSemiconductor/solid-state device detailsThermal bridgeComputer module

Owner:LENOVO GLOBAL TECH INT LTD

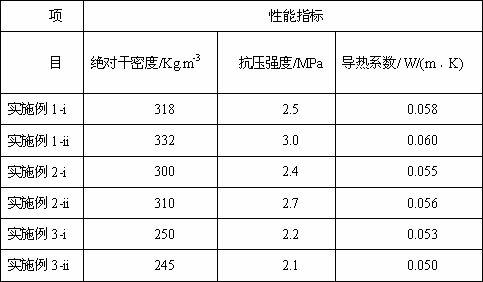

Low-thermal-conductivity aerated concrete and preparation method thereof

ActiveCN102167619ASolve insulation problemsSolve coordination problemsSolid waste managementCeramicwareFoaming agentThermal bridge

The invention discloses low-thermal-conductivity aerated concrete and a preparation method thereof, which belong to the technical field of material science and engineering science and are used for solving the key technical problem of enhancement of extra light aerated concrete. The preparation method comprises the following steps of: stirring a compound foaming agent component and a silicate substrate sizing agent according to a certain weight part ratio; molding; standing; performing autoclave curing; and cutting to obtain a hardened hydrated silicate substrate, wherein the rubber hole ratioof the obtained hardened hydrated silicate substrate is more than 0.95, the porosity is less than 3 percent, the volume ratio of a calcium hydrosilicate crystal to colloid is 1-2.5, self-heat-preserving performance and appropriate intensity of a product are realized, and when the thermal conductivity coefficient is less than 0.06 W / (m.K) and the absolute dry volume density is less than 250 kg / m<3>, the compressive strength of the aerated concrete is still higher than 2Mpa. The low-thermal-conductivity aerated concrete can be applied to self-heat-preserving wall bodies with the energy saving rates of more than 70 percent, fire-proof isolation belts for outer heat-preserving systems of polystyrene plate thin plastered outer walls, treatment of wall body heat bridge positions, shear wall heat-preserving systems and roof heat preserving.

Owner:HOHAI UNIV

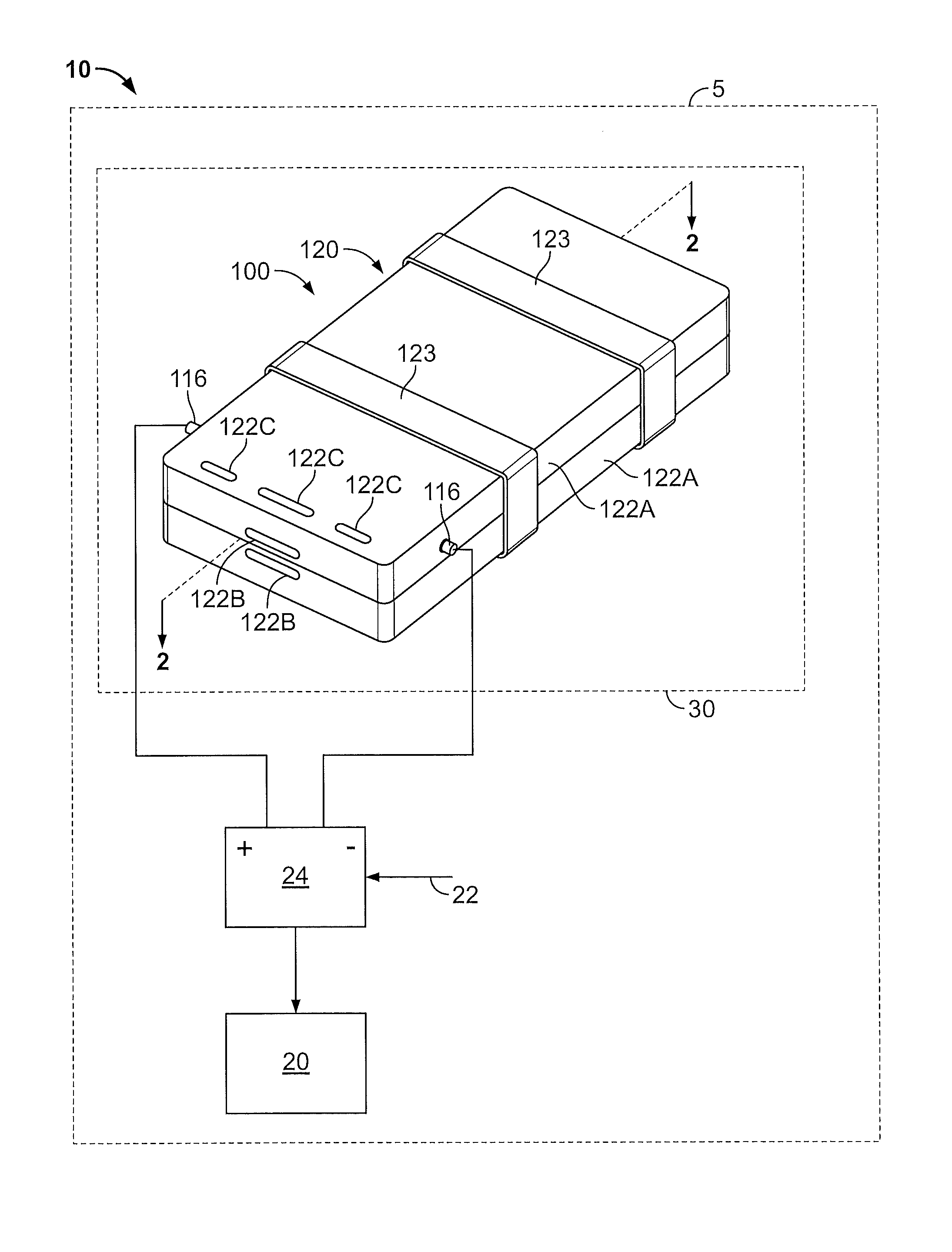

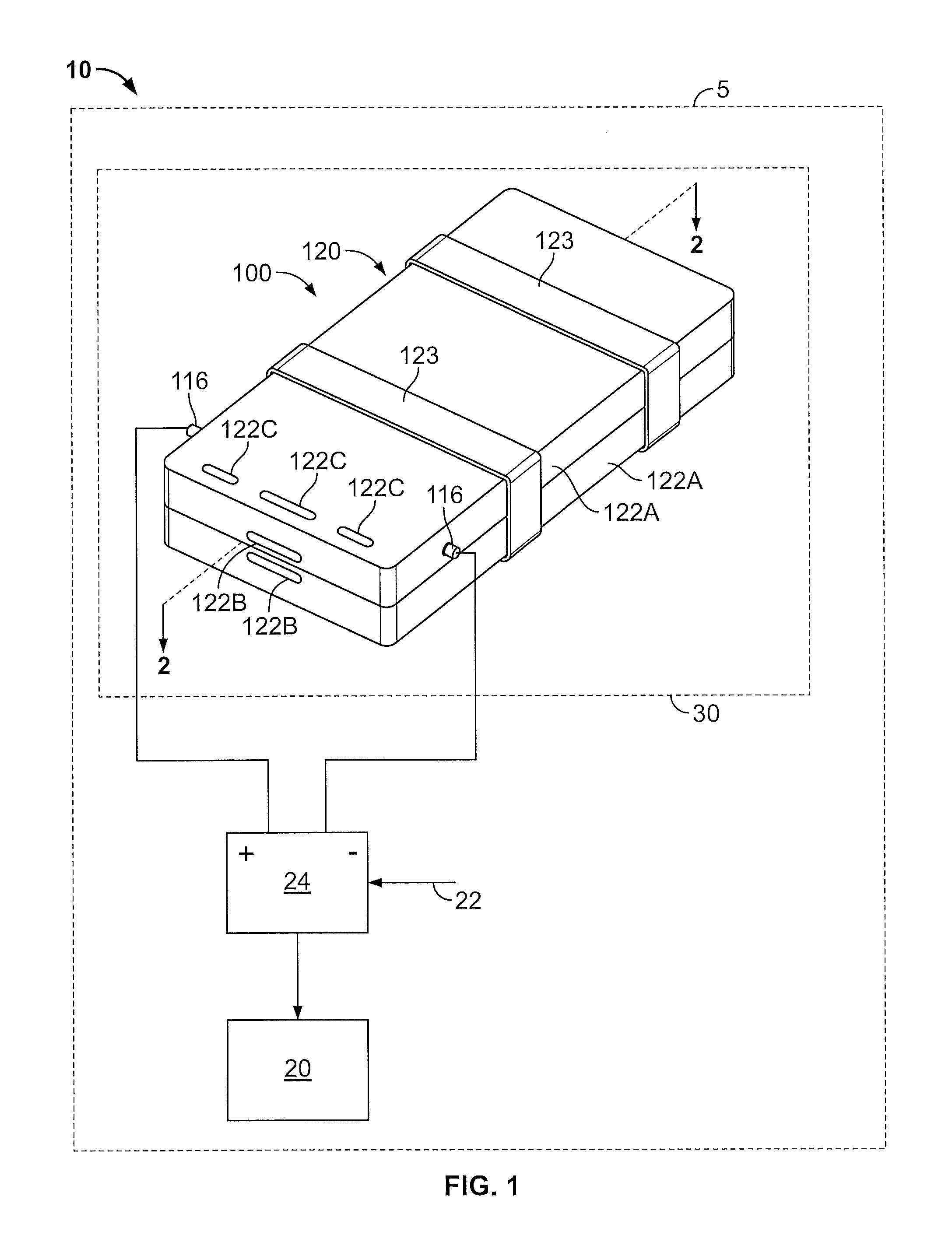

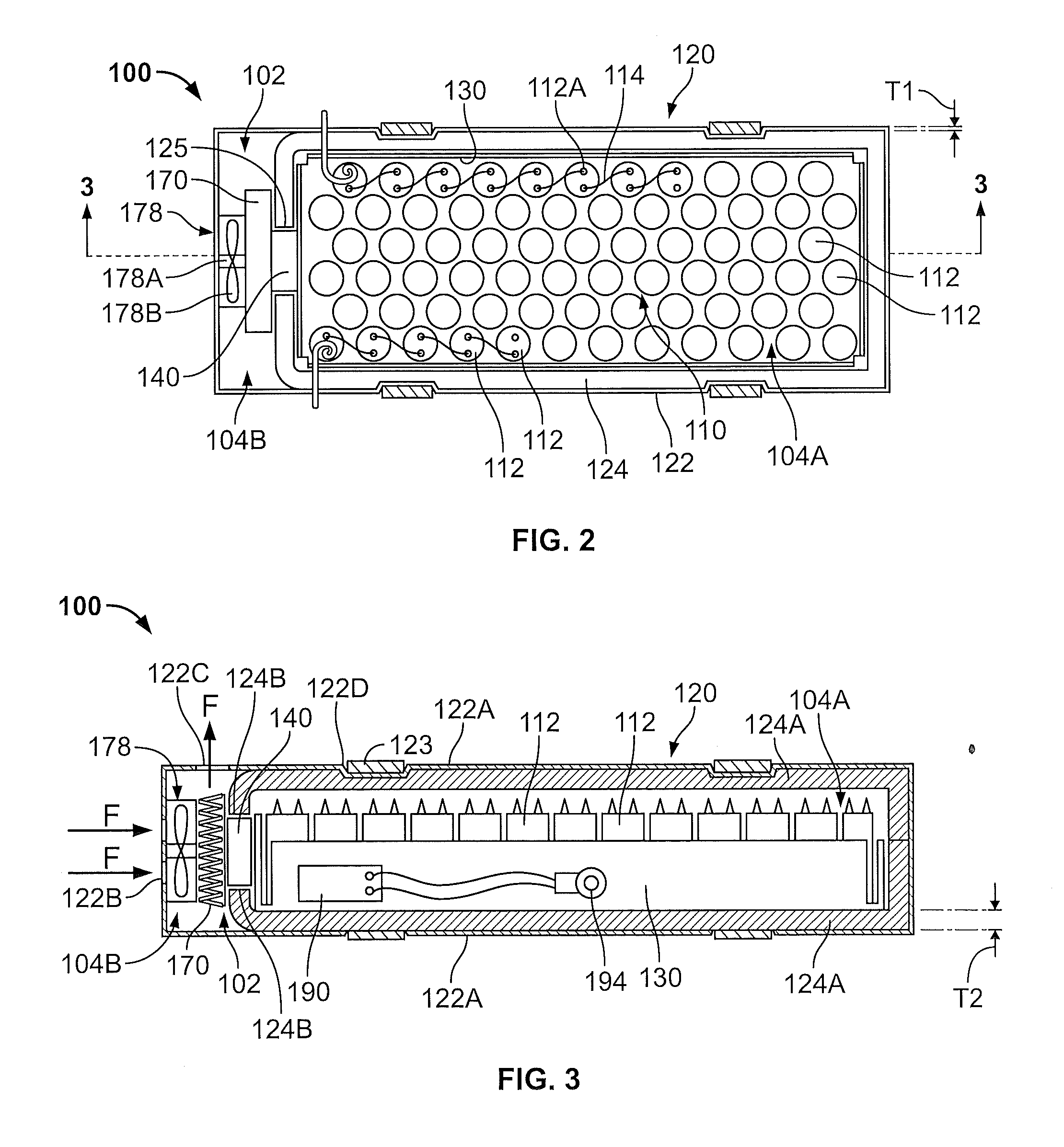

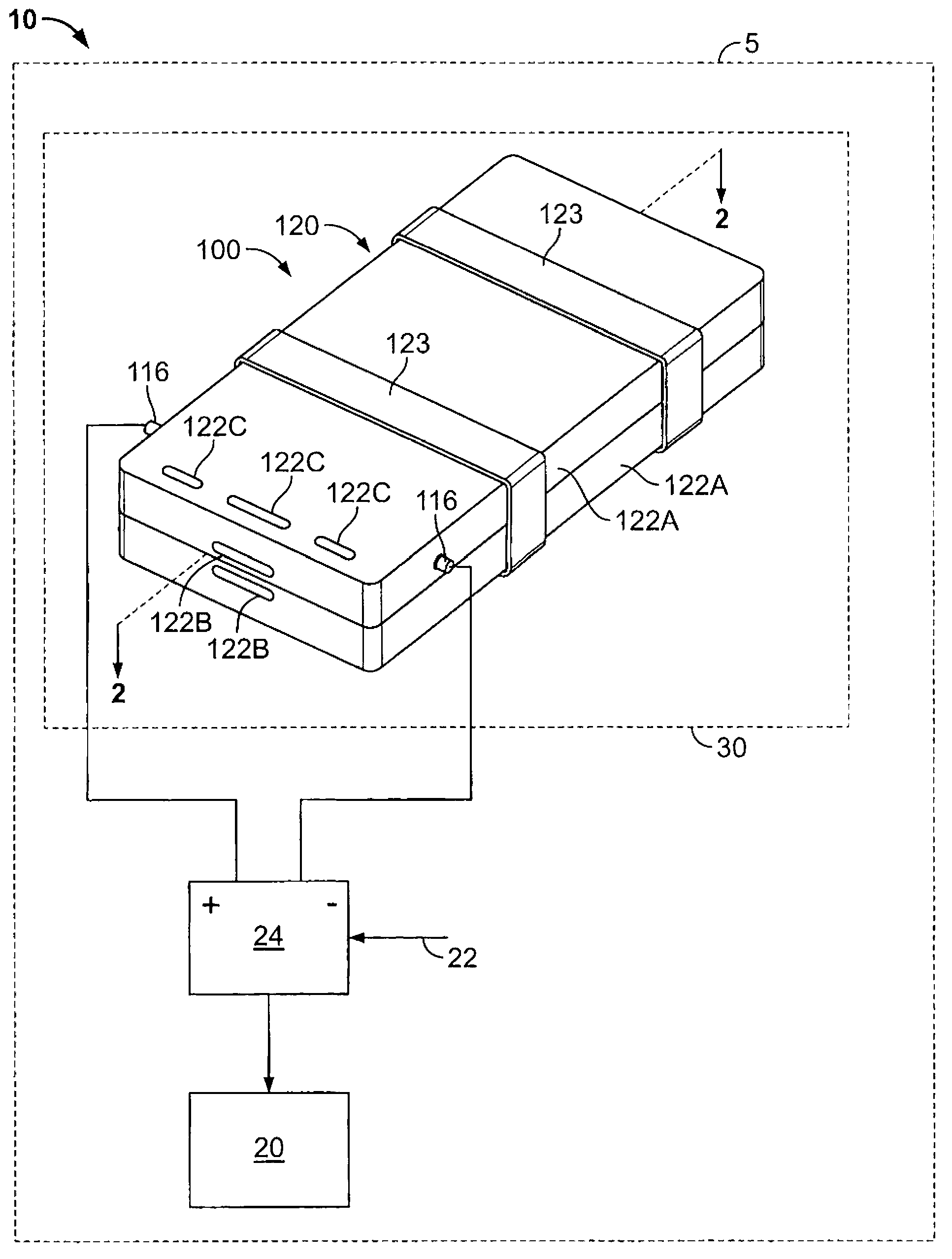

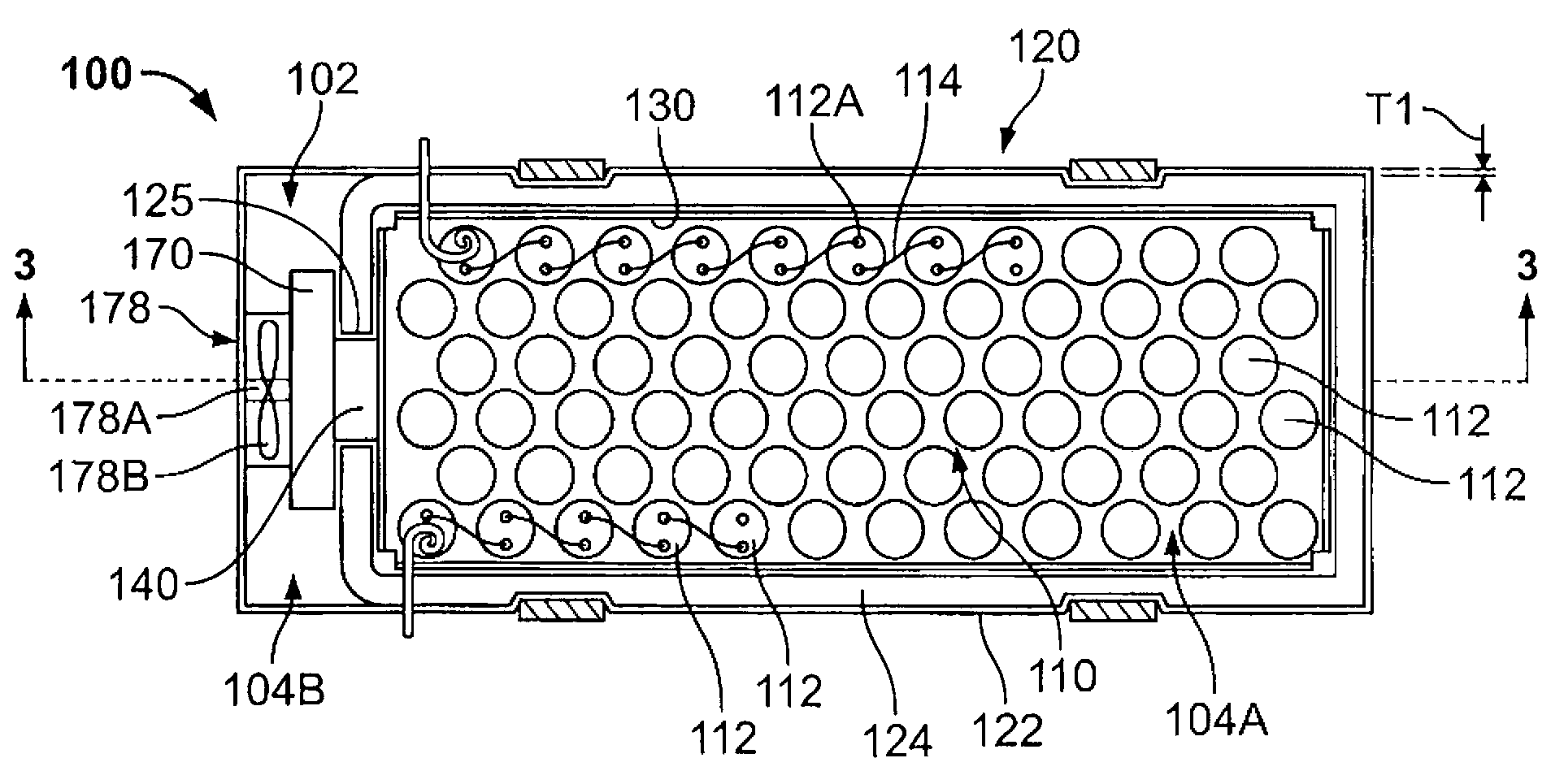

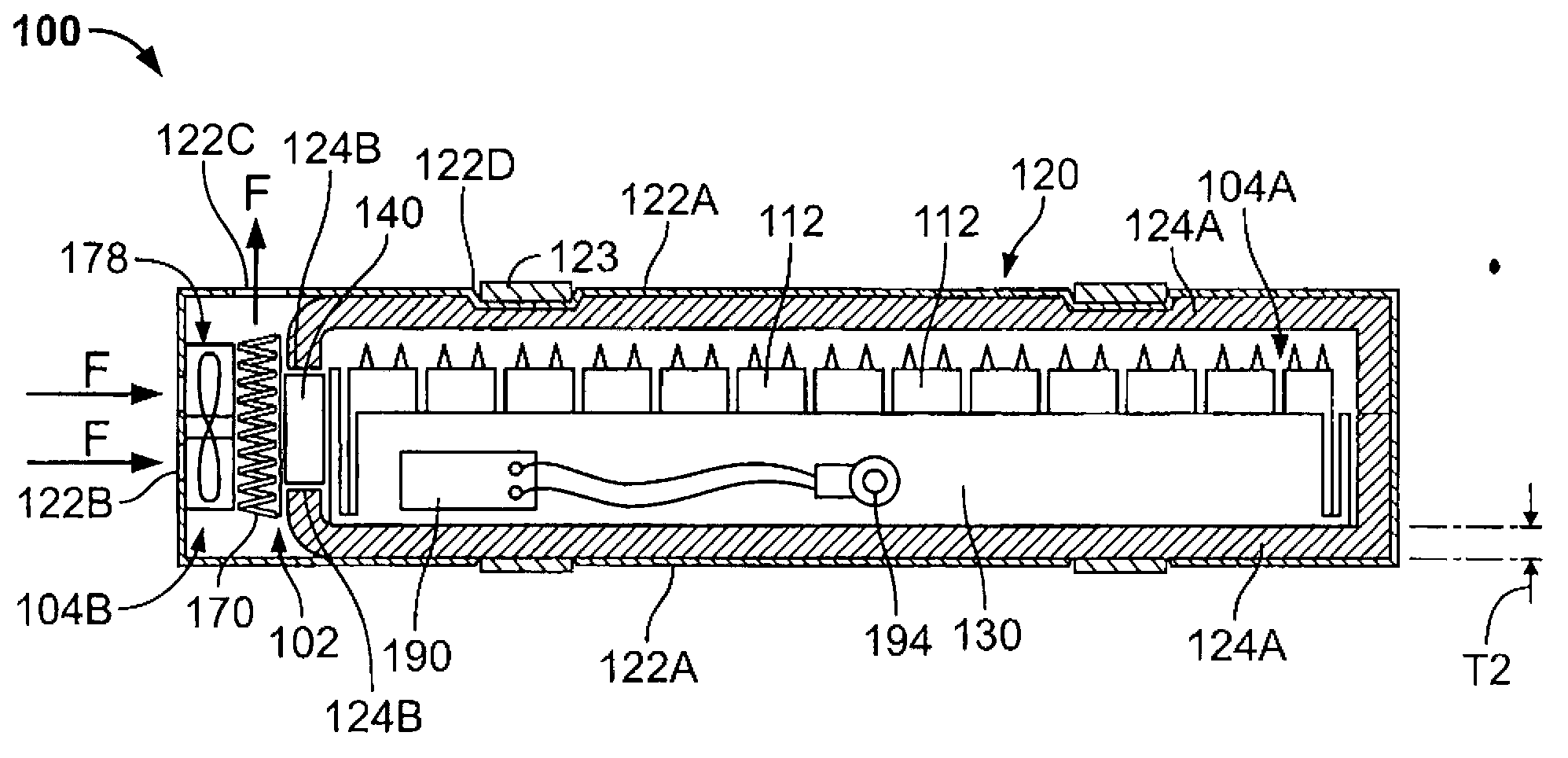

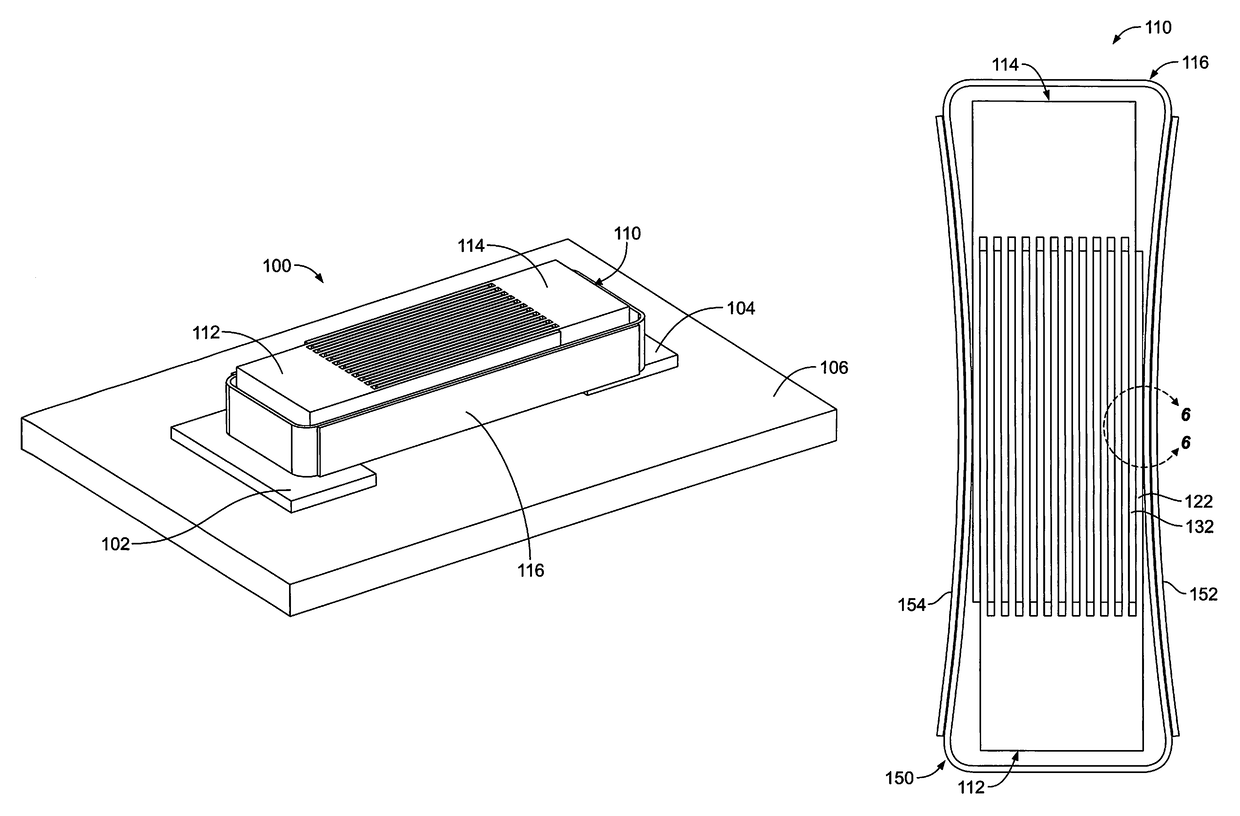

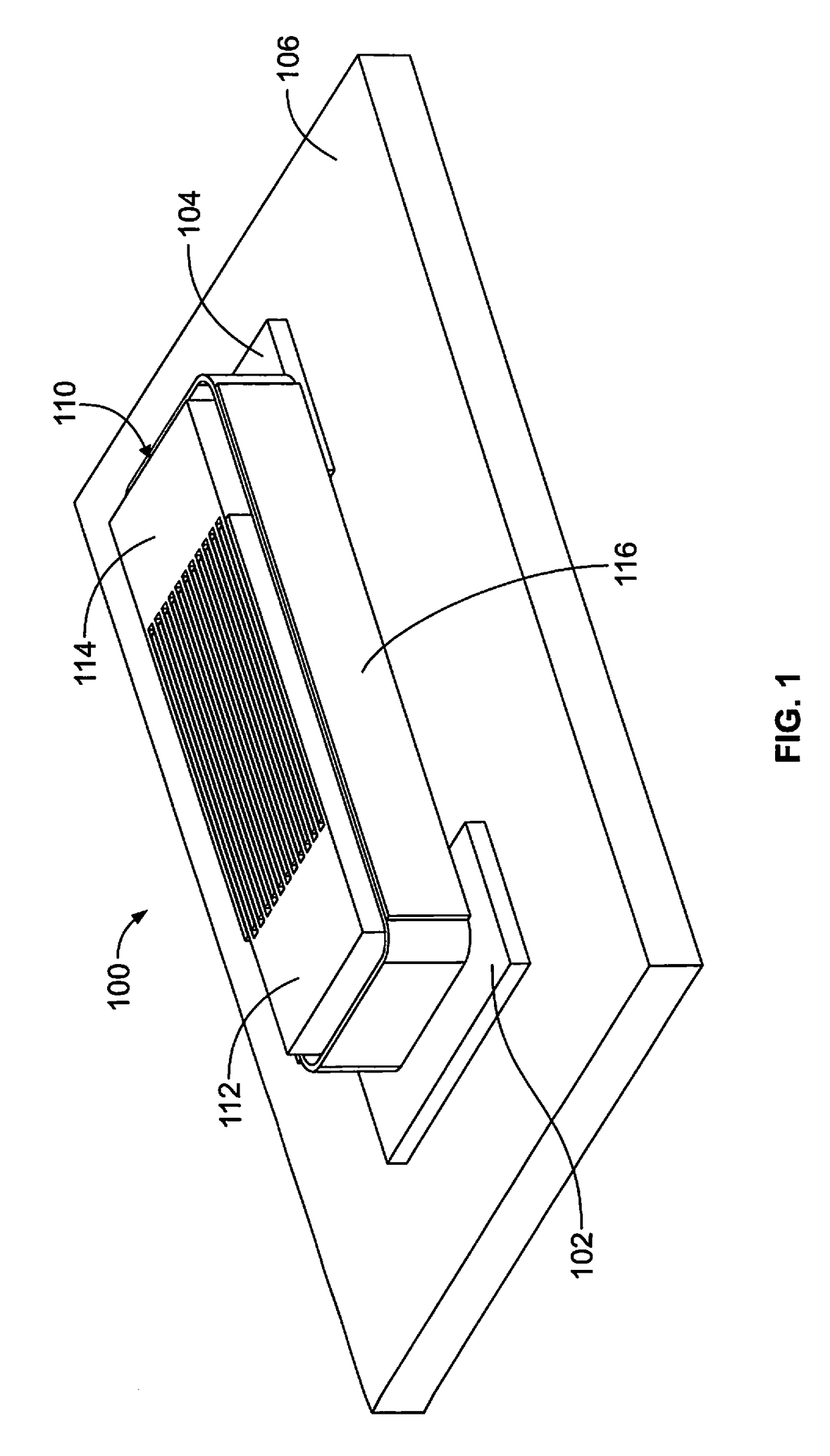

Temperature controlled battery pack assembly and methods for using the same

InactiveUS20110300420A1Thermoelectric device manufacture/treatmentCell temperature controlThermoelectric coolingTemperature control

A temperature controlled battery pack assembly includes a housing defining a battery chamber and including thermal insulation surrounding at least a portion of the battery chamber. At least one battery cell is contained in the battery chamber. The thermal insulation inhibits thermal transfer between the at least one battery cell and the surrounding environment. A thermal bridge conductor is disposed in the battery chamber and engages the at least one battery cell. The battery pack assembly further includes a thermoelectric cooler device having an inner surface and an outer surface. The thermoelectric cooler device is operable to actively transfer heat between the inner and outer surfaces using the Peltier effect. A heat sink device is in contact with or connected to the outer surface to enable thermal conduction between the outer surface and the heat sink device. The battery pack assembly includes a fan operable to force a flow of a heat transfer fluid across the heat sink device and into the environment to enable convective heat transfer between the heat sink device and the environment. The thermal bridge conductor is in contact with or connected to the inner surface to enable thermal conduction between the inner surface and the thermal bridge conductor.

Owner:EATON CORP

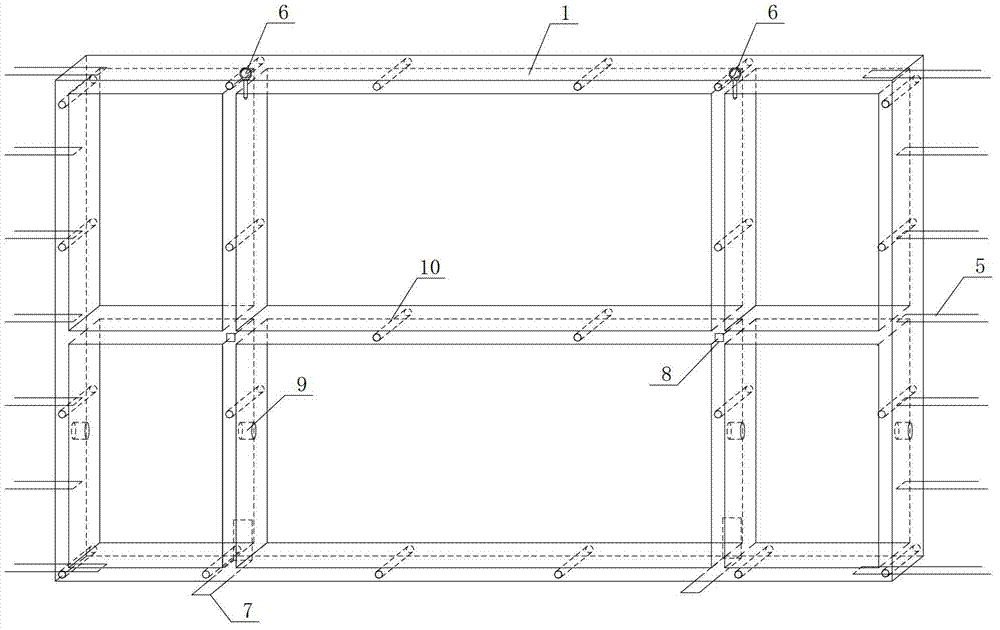

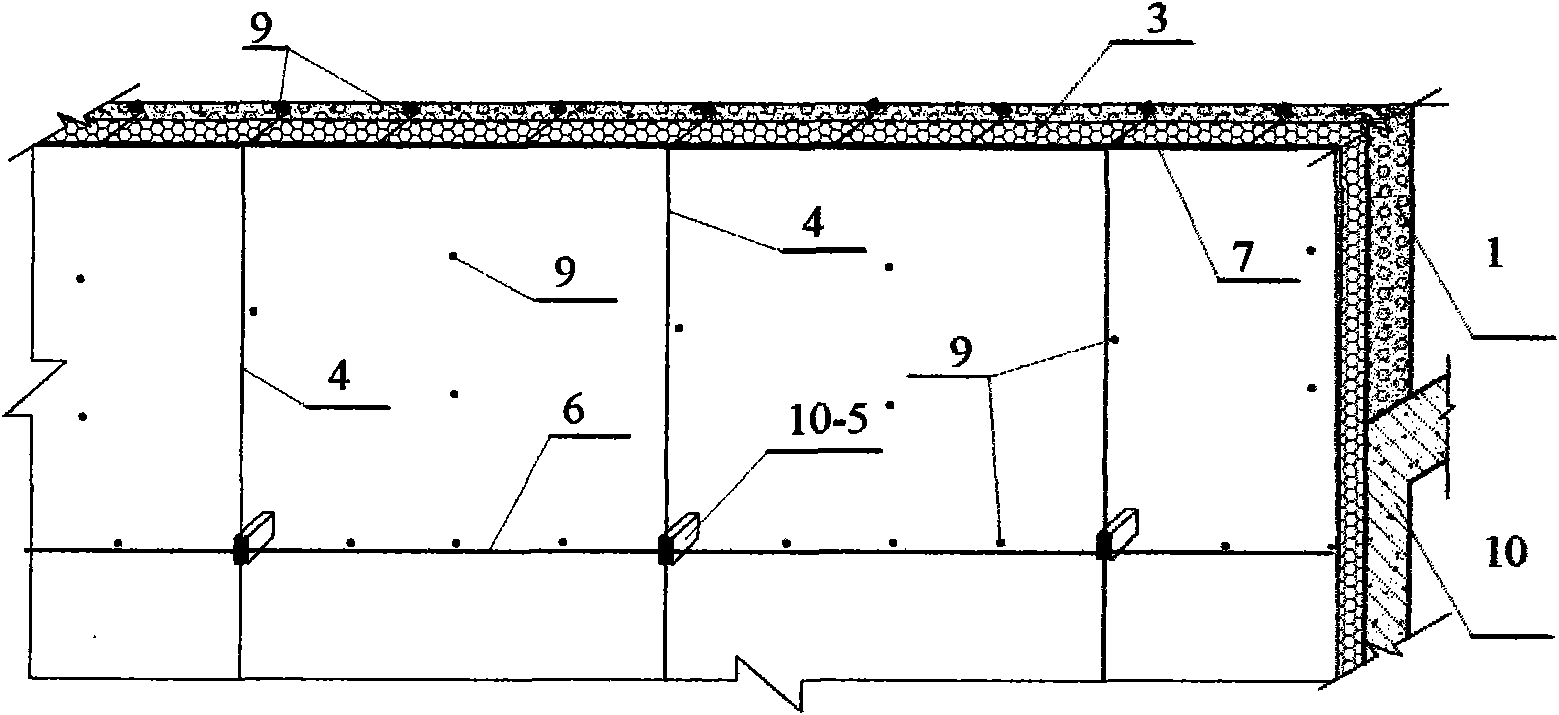

Assemble type multifunctional outer wall body and production and installation method thereof

The invention discloses an assemble type multifunctional outer wall body and a production and installation method thereof. An assemble type outer wall body mainly takes lightweight section as a keel, takes expanded polystyrene (EPS) thermal mortar as a heat preservation interlayer and is mainly applied to steel structure construction at present. The existing assemble type outer wall body has the problems that durability is bad, thermal bridge effect is notable, manufacturing cost is high, adaptability with a reinforced concrete structure is bad and the like. The assemble type multifunctional outer wall body is a frame interlayer composite structure and takes a fine stone reinforced concrete frame as the keel. Cellular concrete is filled in bars of the frame, and a window opening is reserved in the frame. Cement fiber panels are respectively fixedly installed on the inner side and the outer side of the fine stone reinforced concrete frame, and decorating layers are arranged on the cement fiber panels. The assemble type multifunctional outer wall body is suitable for assembling an integrated type structure building or a cast-in-place concrete building, split joint of the assemble type multifunctional outer wall body and a building main body structure is firm, and thus integrity is good. The assemble type multifunctional outer wall body has the integrated functions of protection, heat preservation, decoration, water proofing and the like, all working procedures are settled in one step, an outer scaffold does not need to be arranged in the process of installation, and thus construction speed is fast.

Owner:浙江省建筑科学设计研究院建筑设计所

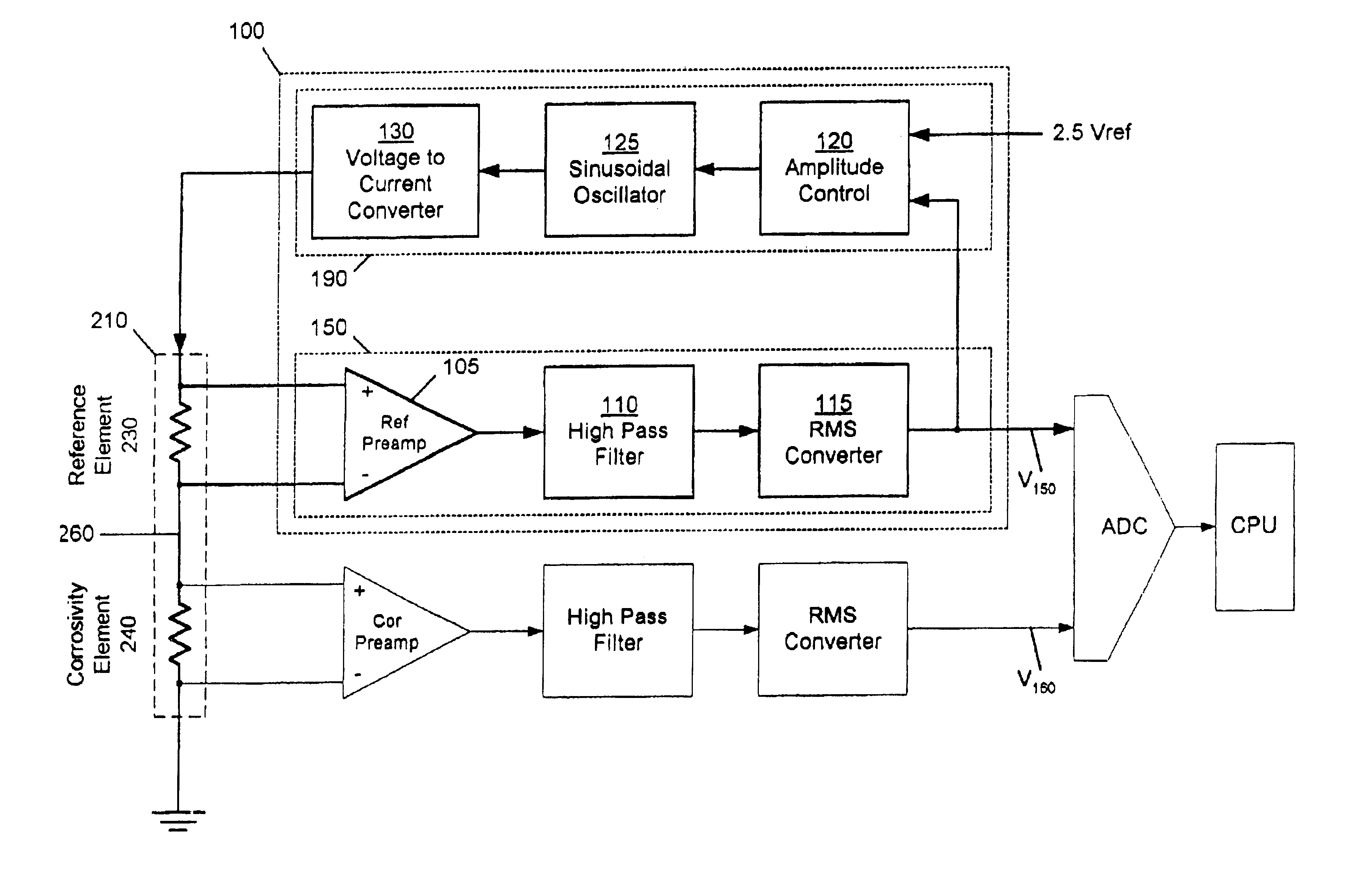

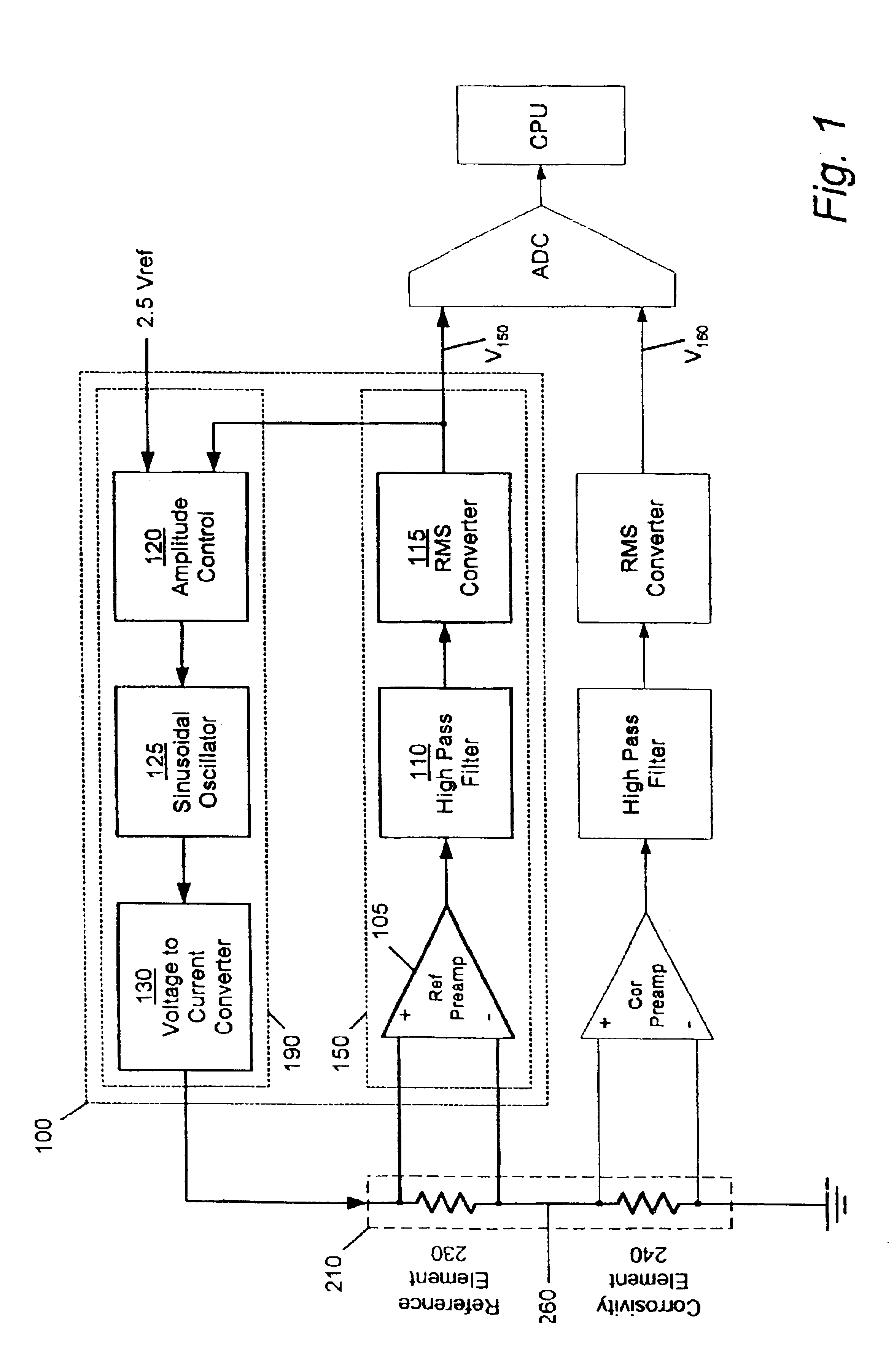

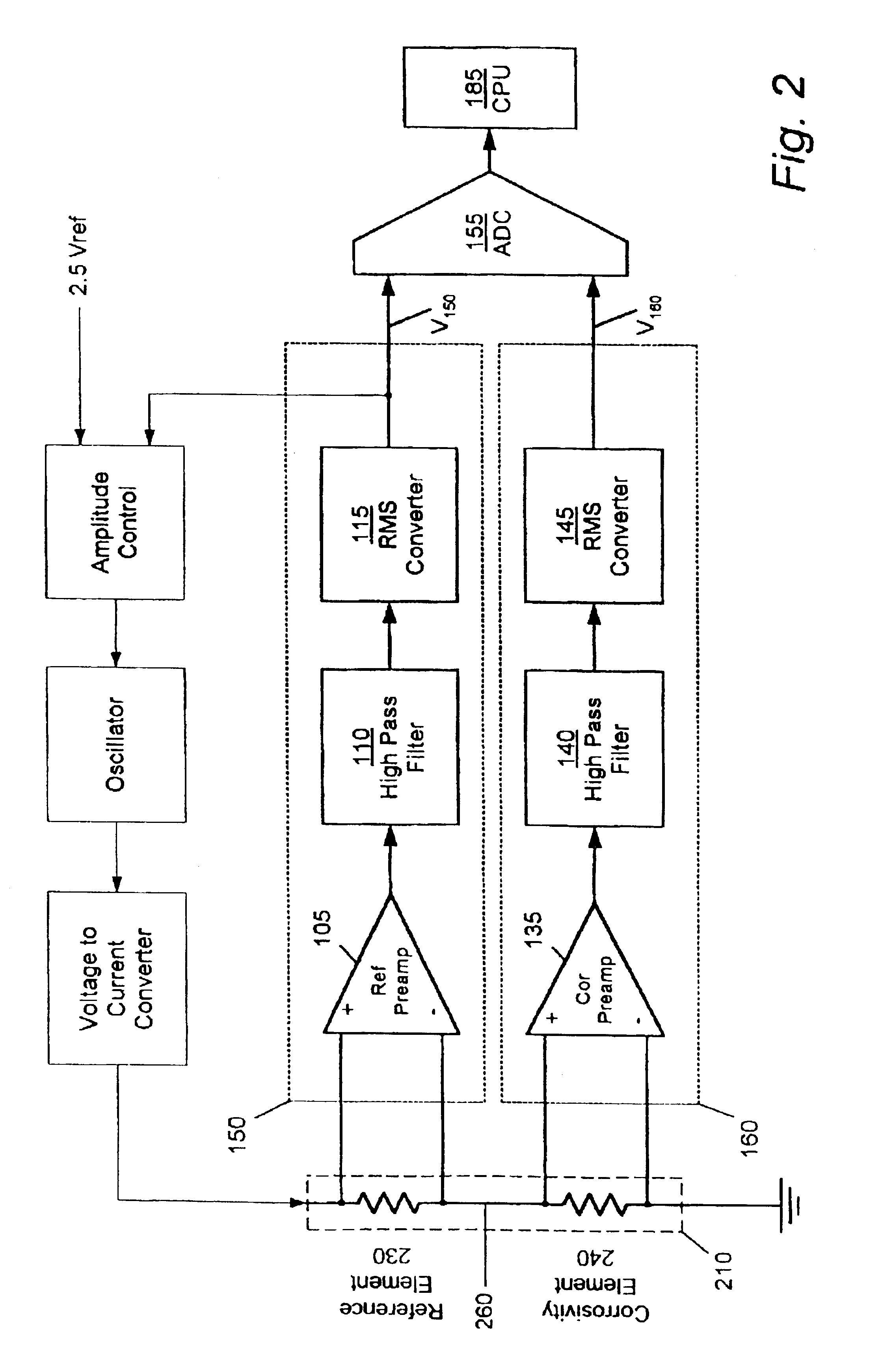

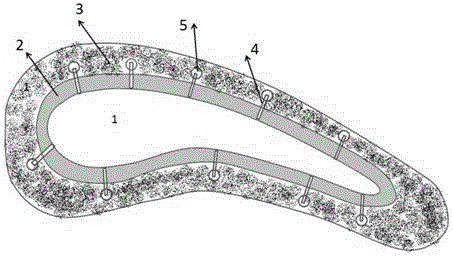

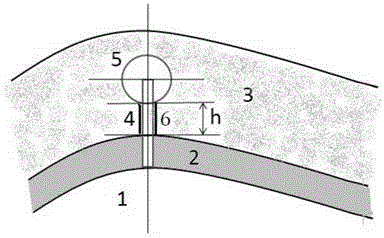

Corrosivity measuring device with temperature compensation

InactiveUS6919729B2Eliminate errorsRapid and stable measurementWeather/light/corrosion resistanceResistance/reactance/impedenceElectrical resistance and conductanceAudio power amplifier

An improved corrosion measurement system for determining the rate of corrosion of a fluid medium. The system is comprised of a highly sensitive excitation and amplification electronic circuitry for registering and displaying the stable and accurate measurement results. A novel current feedback amplifier maintains a constant alternating current voltage across the reference element, by simultaneously controlling the current through the serially connected reference and corroding elements, thereby keeping the corrosivity measurement independent of the probe's ambient temperature. The unique unitized electrical resistance measurement probe is also temperature stabilized using thermally bridged and balanced metallic elements; the first reference element being coated with an impermeable insulating coating, the second, the sacrificial corroding element, being fully exposed to the corrosive fluid medium.

Owner:ROHRBACK COSASCO SYST

Preparation process for preventing surface impure crystal and recrystallization from formation of mono-crystal hollow turbine blade

ActiveCN104550731AInhibition appearsAvoid thermal bridgingPolycrystalline material growthFoundry mouldsThermal bridgePhysical chemistry

The invention provides a preparation process for preventing the formation of surface impure crystals and recrystallization on a mono-crystal hollow turbine blade. According to the preparation process, a spherical wax piece is arranged at an exposed part (tail end) of a positioning platinum wire; a thin wax film is brushed on the other exposed parts; the exposed part is covered with a fireproof material which is the same as a mold shell material in a shell making process; after de-waxing, an end part spherical cavity and a platinum wire face micro-gap are formed; a heat insulation cavity is formed by the cavity and the side micro-gap in a vacuum induction furnace in a mono-crystal preparation process; a heat bridge effect of the exposed platinum wire part is avoided so that an alloy is prevented from partial overcooling and the formation of impure crystal is inhibited; and furthermore, the cavity and the platinum wire side micro-gap provide a releasing space to the deformation of the platinum wire and the partial residual stress is prevented from occurring, and the recrystallization is prevented from occurring in a post heat treatment process of the blade.

Owner:SHENYANG POLYTECHNIC UNIV

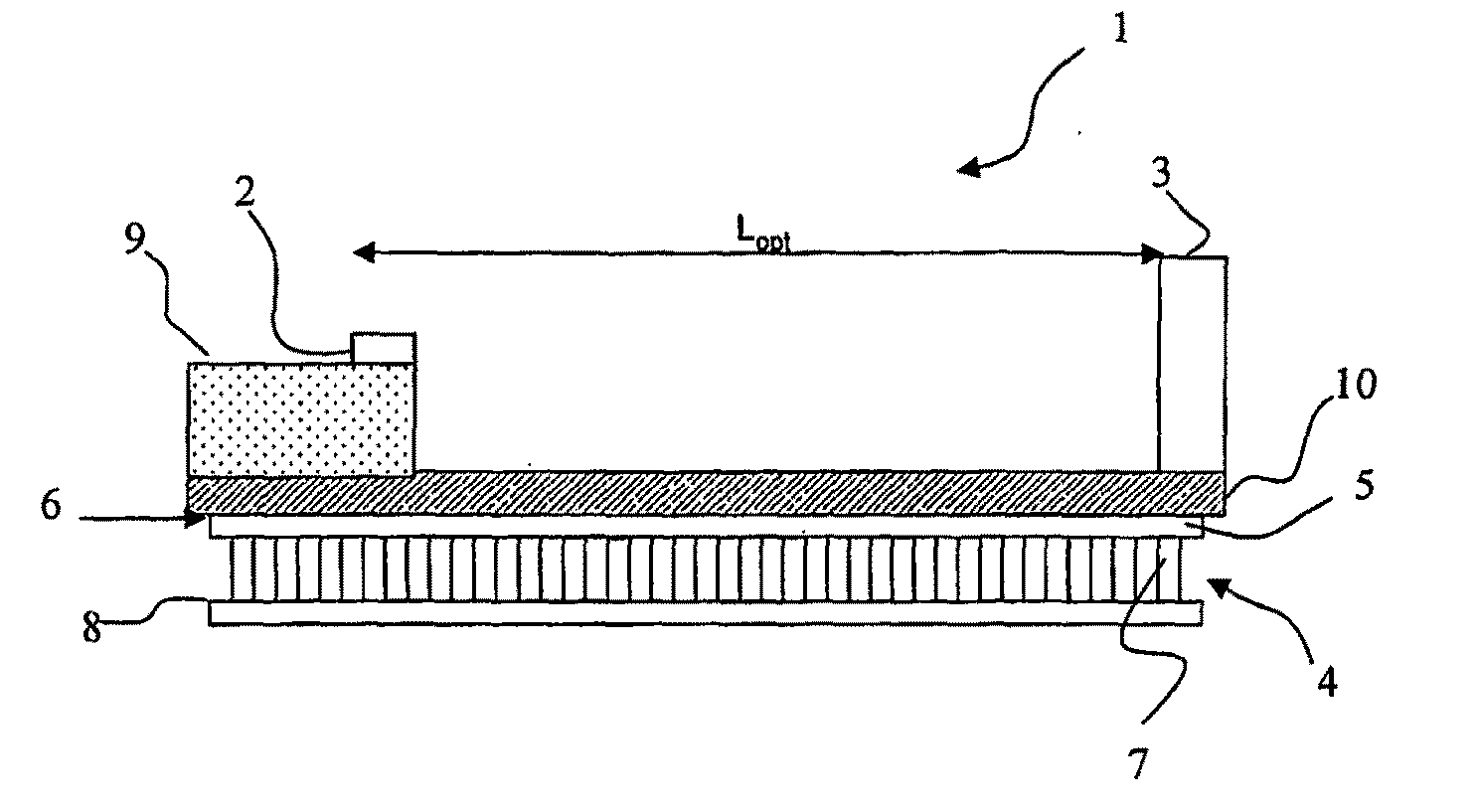

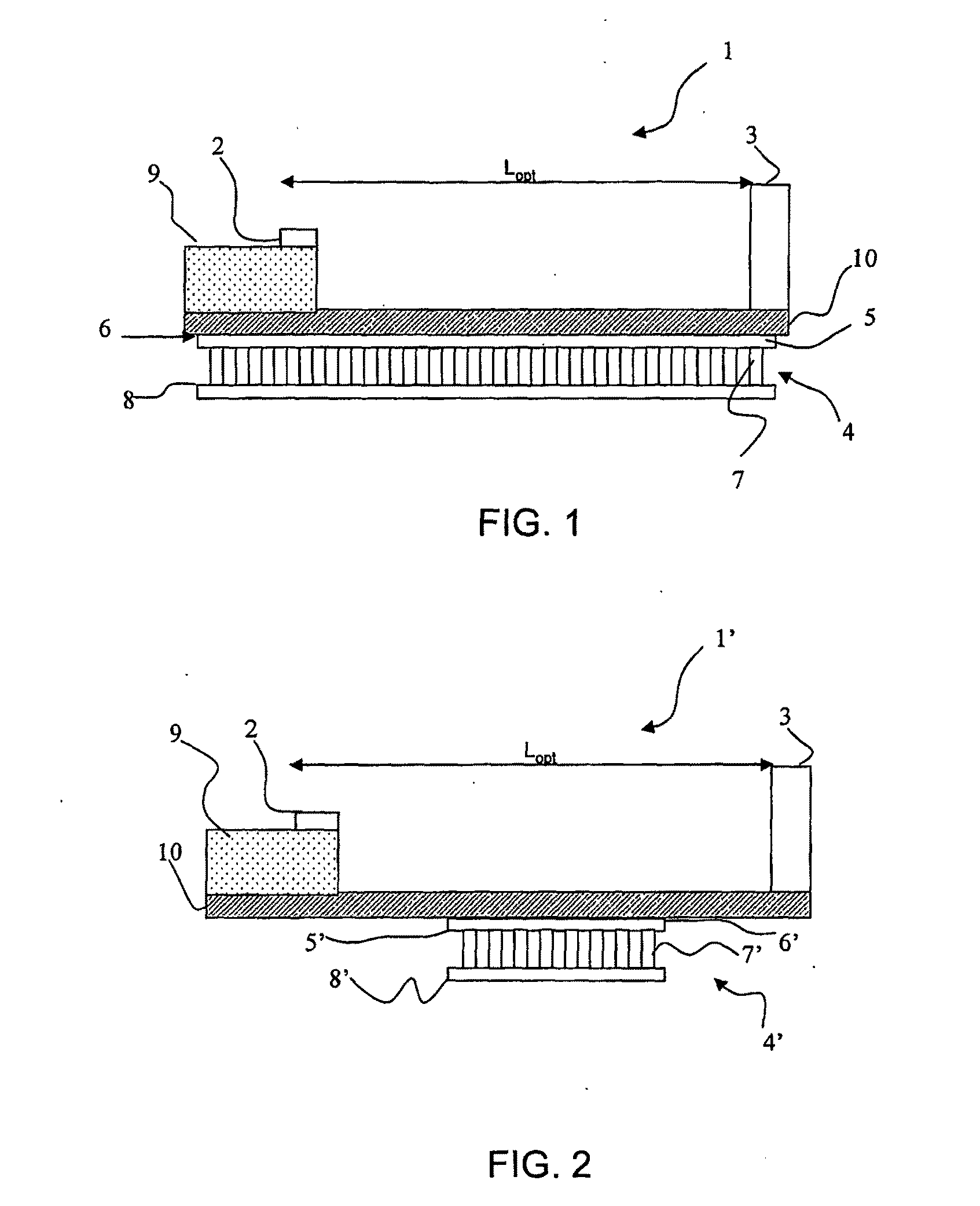

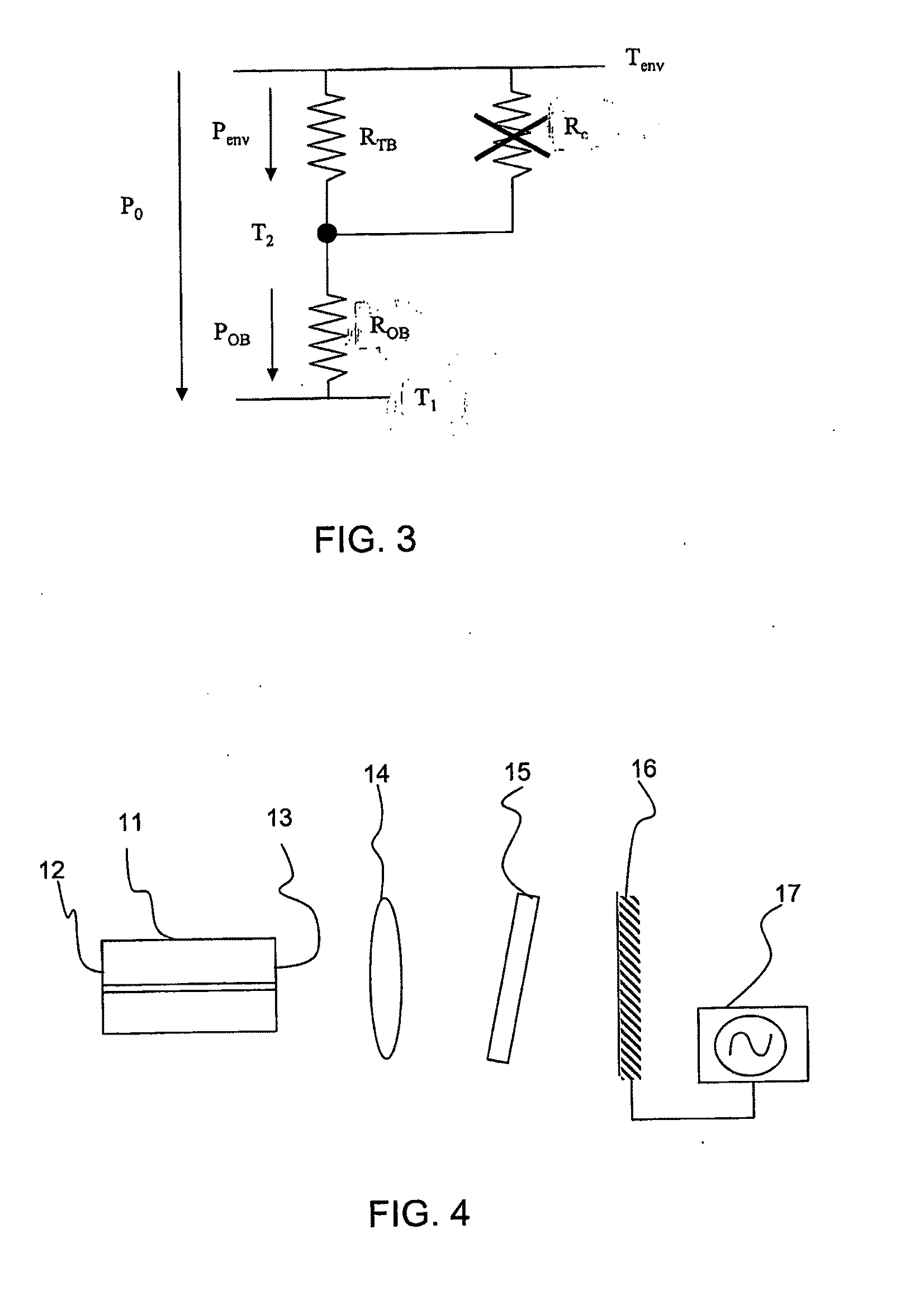

Passive Phase Control in an External Cavity Laser

ActiveUS20100177793A1Small fluctuationHigh densityLaser optical resonator constructionSolid-state devicesThermoelectric coolingExternal cavity laser

An external-cavity laser module includes a package defining an enclosure, the package including a base having a surface internal to the enclosure, a thermoelectric cooler within the enclosure, the thermoelectric cooler including an upper carrier plate and a lower carrier plate, the lower carrier plate being placed on the internal surface of the base and the thermoelectric cooler (TEC) being configured to stabilise the temperature of the upper carrier plate at a substantially constant temperature. The laser module further includes a laser assembly housed within the enclosure, including a gain medium for emitting an optical beam into the external cavity and an end mirror. Variations of the environmental temperature with respect to the thermally stabilised temperature cause mechanical deformations of the TEC upper carrier plate that is in thermal coupling with the laser assembly. The mechanical deformations in turn induce variations in the optical path length of the laser cavity. Thermal bridge of the gain medium to the environmental temperature is achieved by the use of a thermal bridge element for conducting heat either from or to the gain medium.

Owner:GOOGLE LLC

Zipper-type architectural wall plate

The invention relates to a zipper-type architectural wall plate which has the main technical characteristics that the lateral surface of the wall plate is provided with a zipper slot forming a star-shaped rabbet with a big wide exterior and small narrow interior; when installing the wall plates, the rabbets of two plates are closely spliced, and a dedicated slurry is coated to flatten the two zipper slots of the opposite rabbets to the bottom of the plate surface of an anti-cracking slot; and after the slurry is coagulated and dried, a star-shaped cylinder is formed, or the cylinders in othershapes, which have the locking function of the star-shaped cylinder, lock the joint as firm as the zipper. The wall plate fundamentally solves the problems of cracking at the plate-to-plate, plate-to-stake, plate-to-post, plate-to-beam and plate-to-other-wall bonding joints, and cold and thermal bridges at the solid bonding joints, and has the advantages of easy production and convenient construction.

Owner:内蒙古拉锁式新型建材科技有限公司

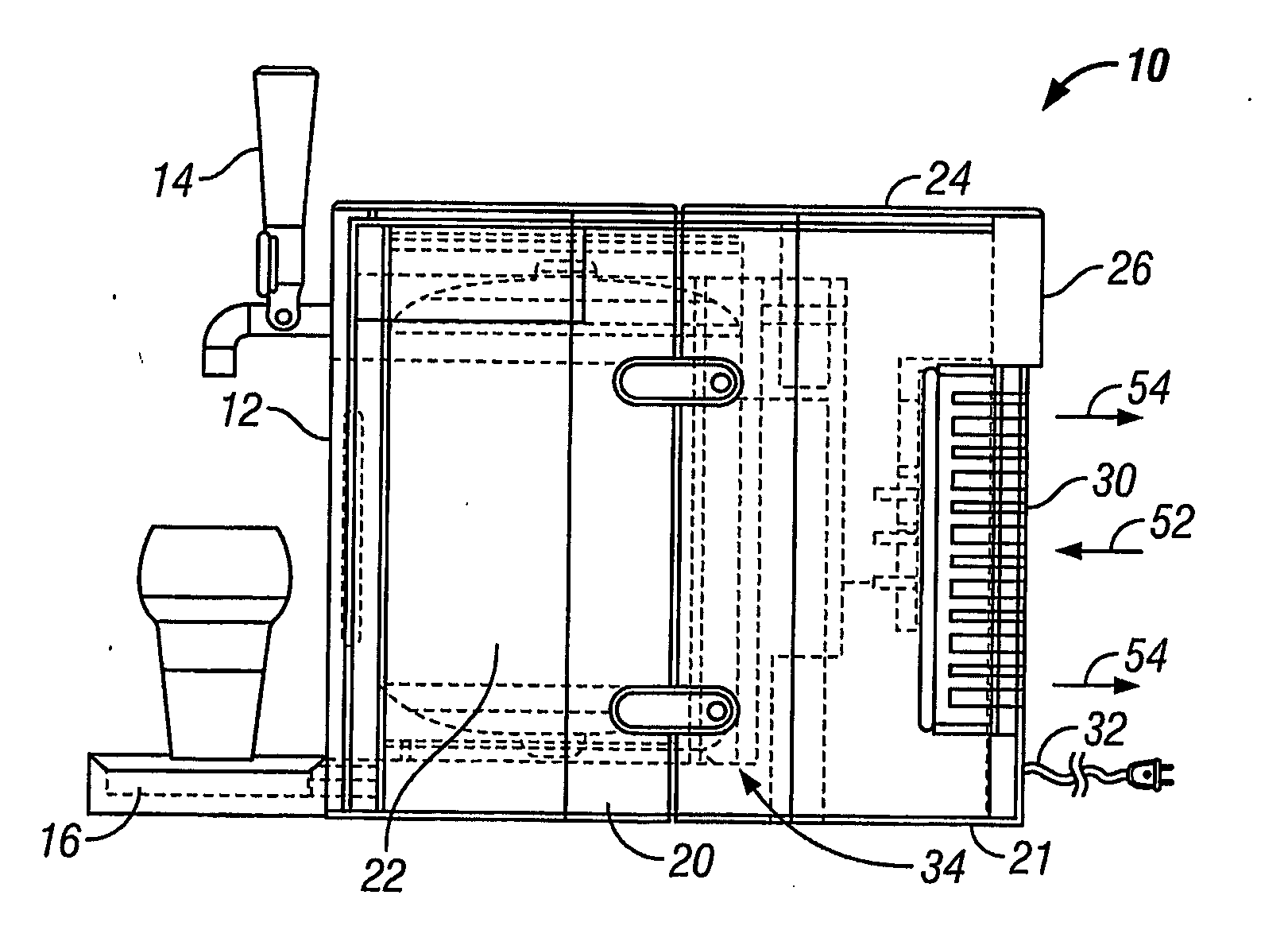

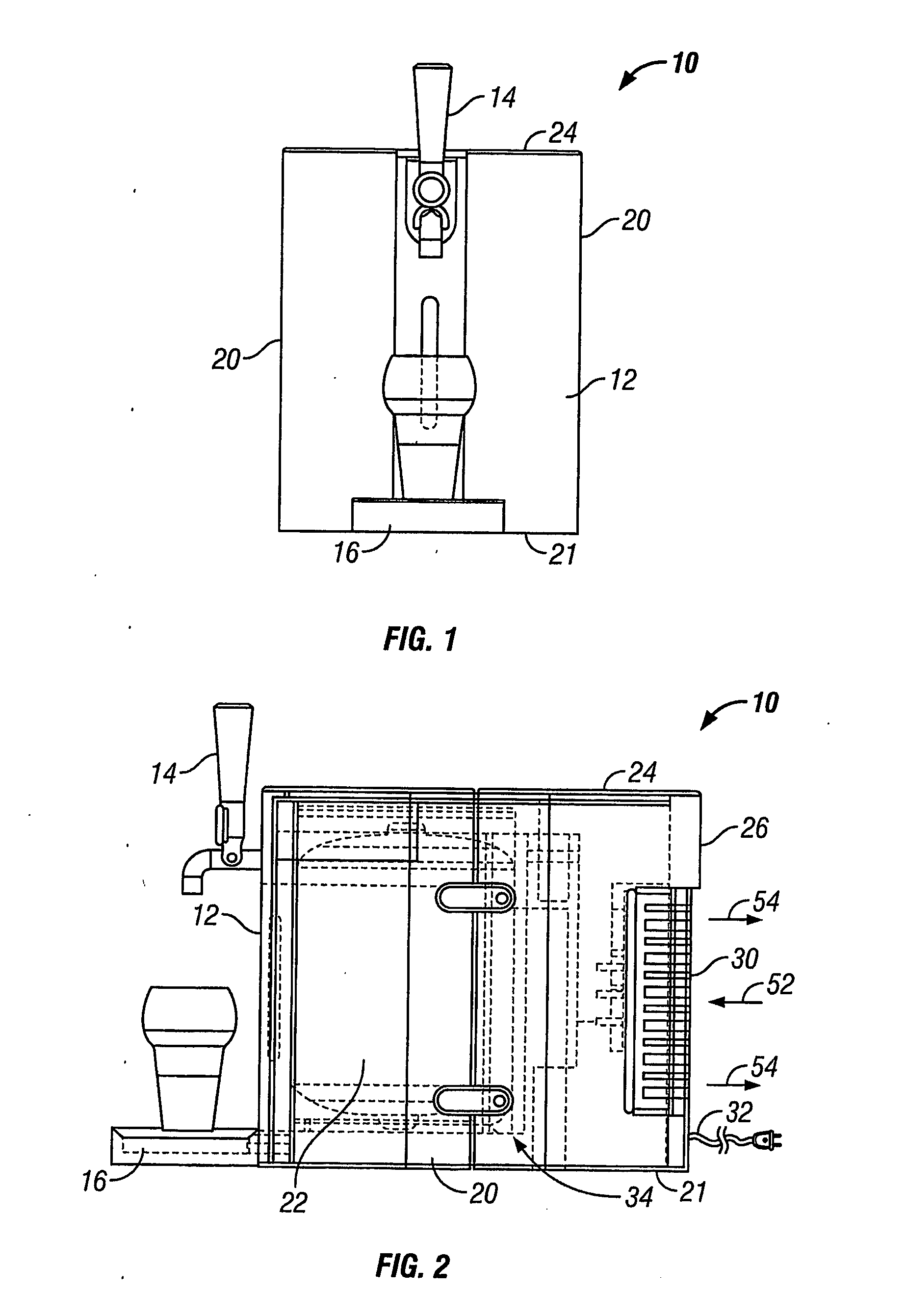

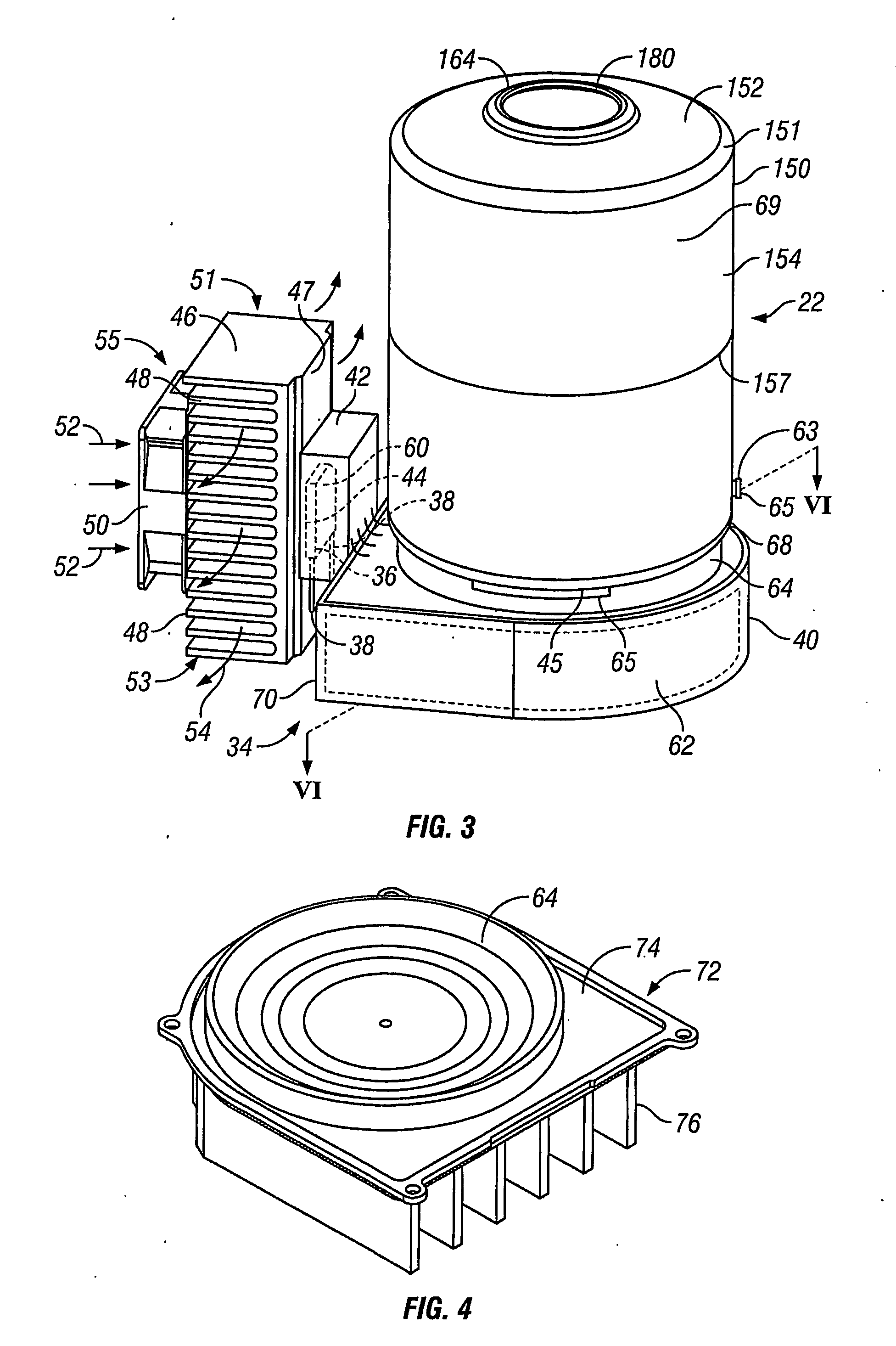

Alcohol beverage dispensing apparatus

InactiveUS20060150637A1Reduce manufacturing costMachines using electric/magnetic effectsLiquid dispensingThermoelectric coolingElectrical resistance and conductance

A cooling system for a home beer dispensing apparatus has a mediated thermal bridge providing a bank of latent cooling capacity. The bridge may have a cavity filled with a cooling solution with at least one series of spaced apart heat exchange fins extending substantially along and interstitially into the cavity from at least one wall of the cavity so as to enhance heat transfer across the cavity. The bridge is arranged in thermal conducting relation through a cooling plate between a keg containing the beer and a Peltier thermoelectric cooling device adapted to cool the cooling solution by extracting heat therefrom to an active heat sink. A fan directs air flow horizontally along the fins of the sink and out the two lateral open sides of the heat sink. This prevents heat from rising in the apparatus and thereby affecting other system component parts. The cooling solution may comprise 5% by volume glycol and freezes at a temperature below that of water providing an improved thermal bank. The cooling plate has an electrical resistance heater mounted therein to maintain the temperature of beer in the keg adjacent a bottom portion thereof above the freezing temperature of the beer. The cooling system is economical in its space requirements and enhances the chilling of the beer to a desired serving temperature. The invention also provides a beer keg for such systems.

Owner:ANHEUSER BUSCH INBEV SA

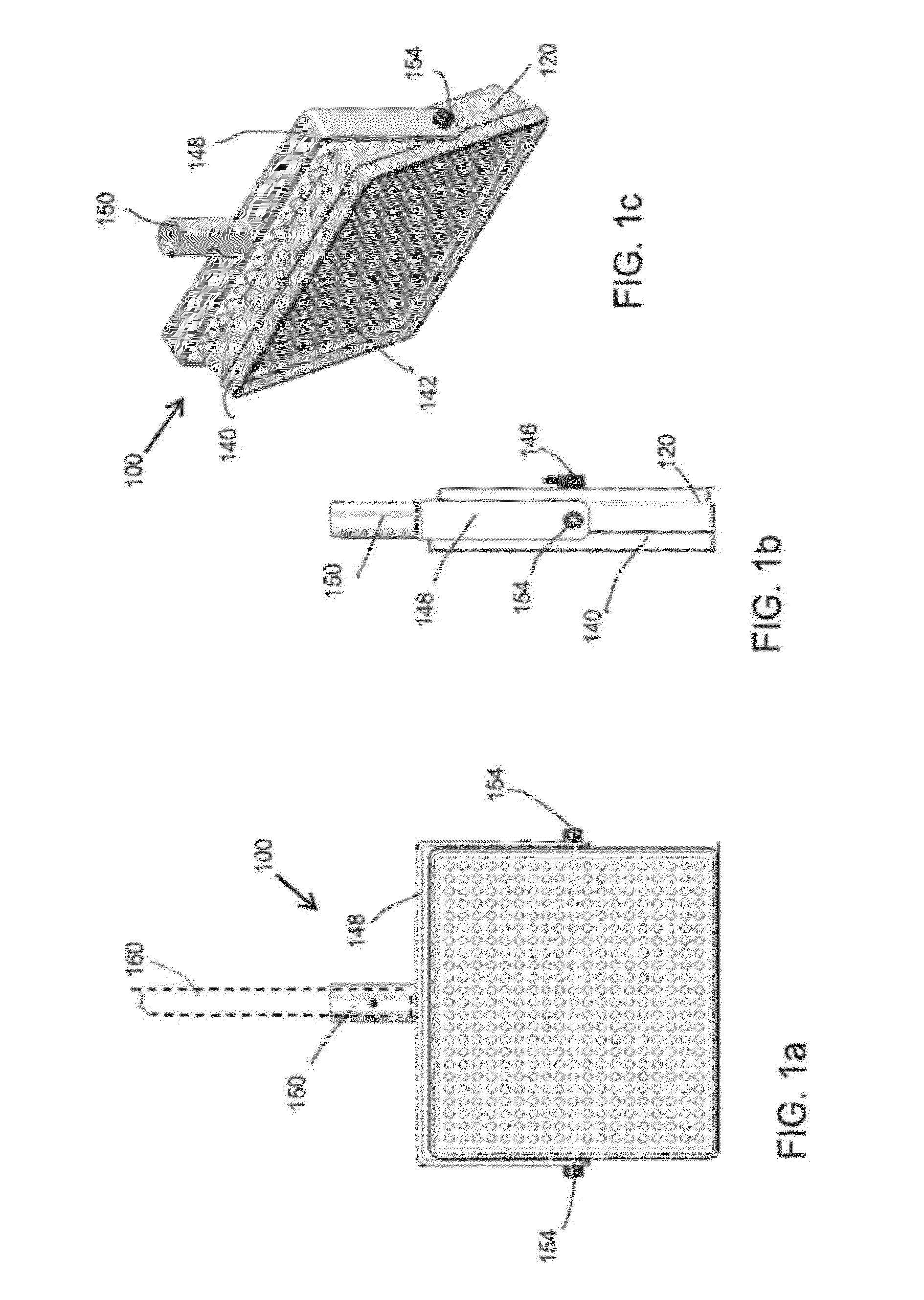

Modular lamp for illuminating a hazardous underwater environment

ActiveUS8292449B2Rapidly inserted into and removedExtended service lifePlanar light sourcesMechanical apparatusLed arrayThermal bridge

A modular light unit for illuminating a hazardous underwater environment includes a housing having a front portion with a light transmissive window and a back shell portion which enclose a layered lighting assembly. The layered lighting assembly includes a PCB with an array of LEDs mounted thereon with the LEDs in thermal communication with a bottom surface of the PCB. A thermal bridge abuts the bottom surface of the PCB on one side and a heat sink on the other. A thermally conductive potting material fills spaces between the heat sink and the back shell portion. An underwater connector provides releasable connection to an electrical cable for providing power to drive the plurality of LEDs. A quick-release mechanical fastener is attached to the housing for releasably attaching the modular light unit to a support structure installed within the hazardous underwater environment.

Owner:REMOTE OCEAN SYST

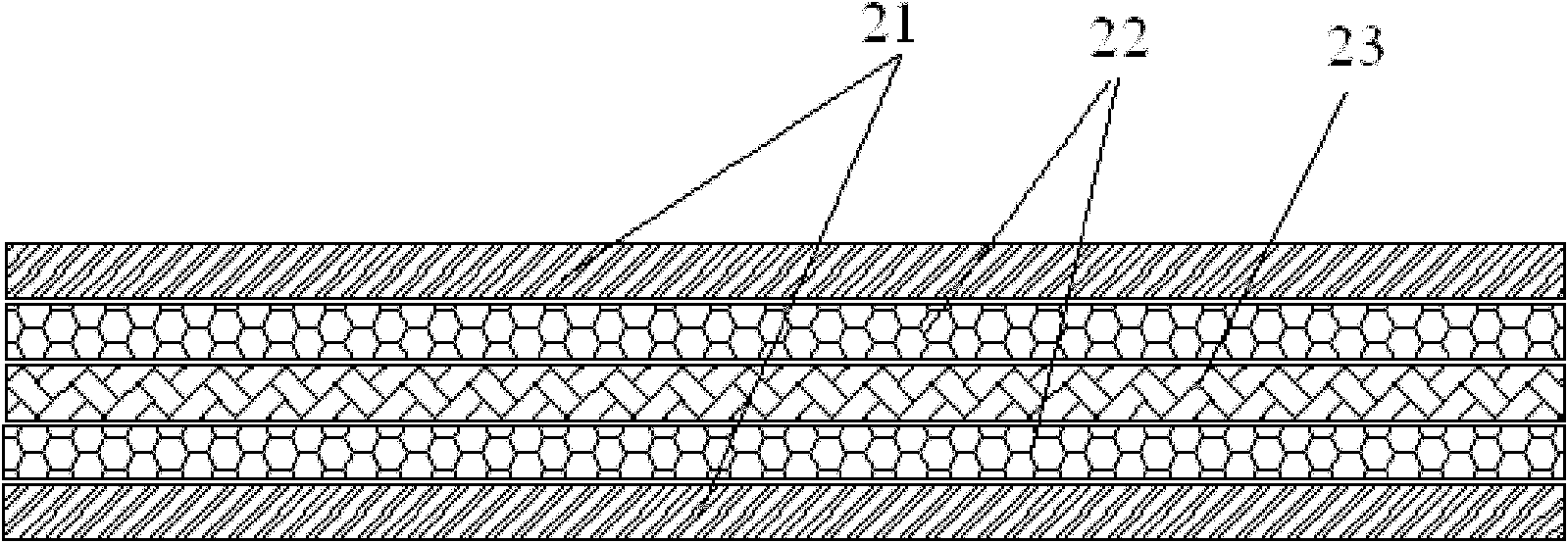

Vacuum thermal insulation board and preparation method thereof

ActiveCN102720923AEvenly distributedAvoid thermal bridgingGlass making apparatusThermal insulationGlass fiberThermal bridge

The invention provides a vacuum thermal insulation board, which can solve the problem of poor thermal insulation effect in the prior art. According to the technical scheme, the vacuum thermal insulation board comprises an outer coating material and a core material; a getter is arranged in the core material; the outer coating material is formed by combining through a single-faced or double-faced coating material without an aluminum foil; the core material is a glass fiber assembly in a uniform lamination structure; and glass fiber is 1-3 microns in diameter. The invention further provides a preparation method of the vacuum thermal insulation board. As the internal vacuum degree of the vacuum thermal insulation board is very high, and heat is blocked by the glass fibers in the core material layer by layer in a transfer process, the speed of heat transfer is greatly reduced, and good thermal insulation effect can be achieved. Meanwhile, an edge thermal bridge effect is eliminated as no aluminum foil is arranged on the coating material, so that the vacuum thermal insulation board has a good thermal insulation effect.

Owner:HAIER GRP CORP +1

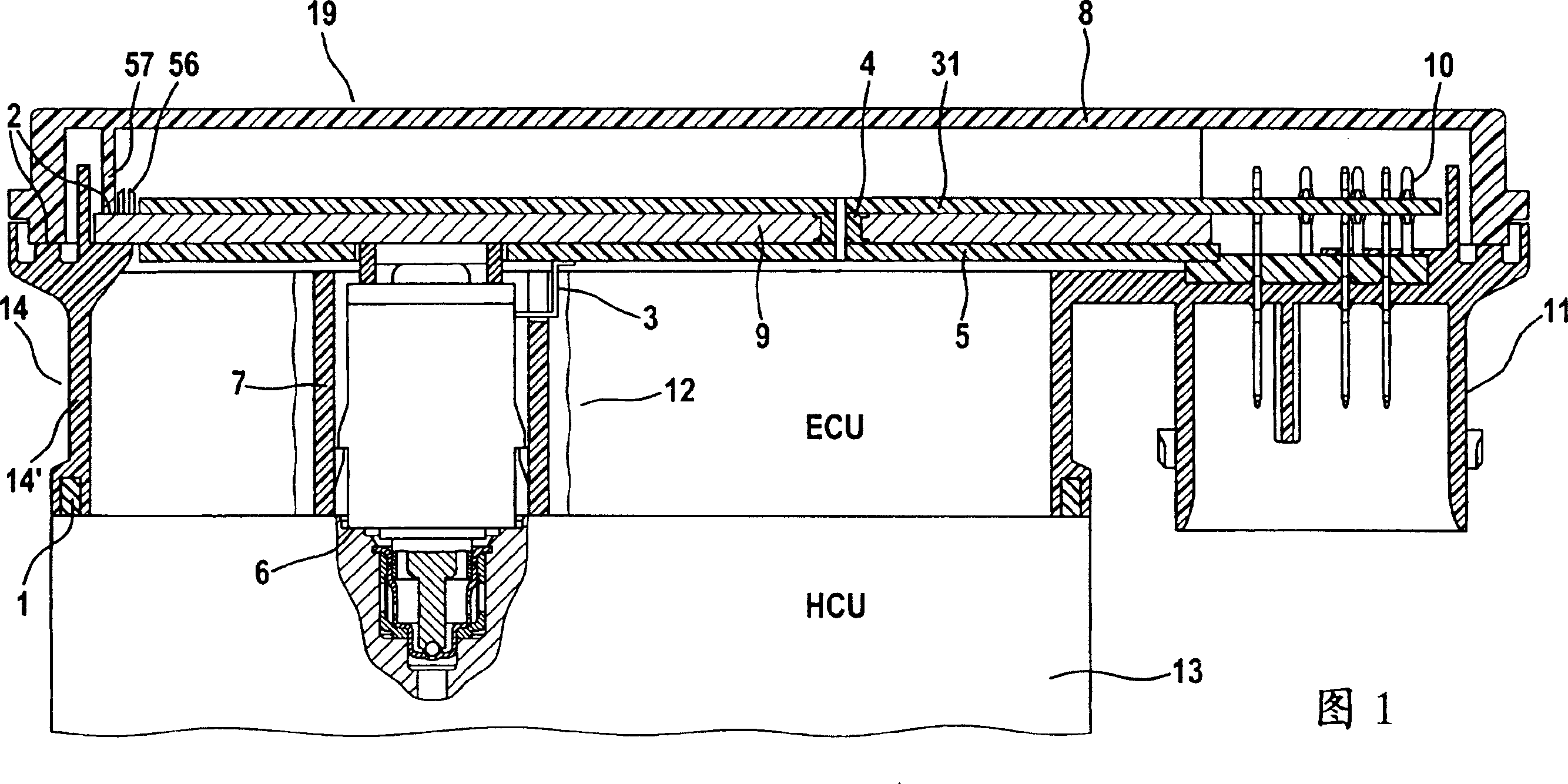

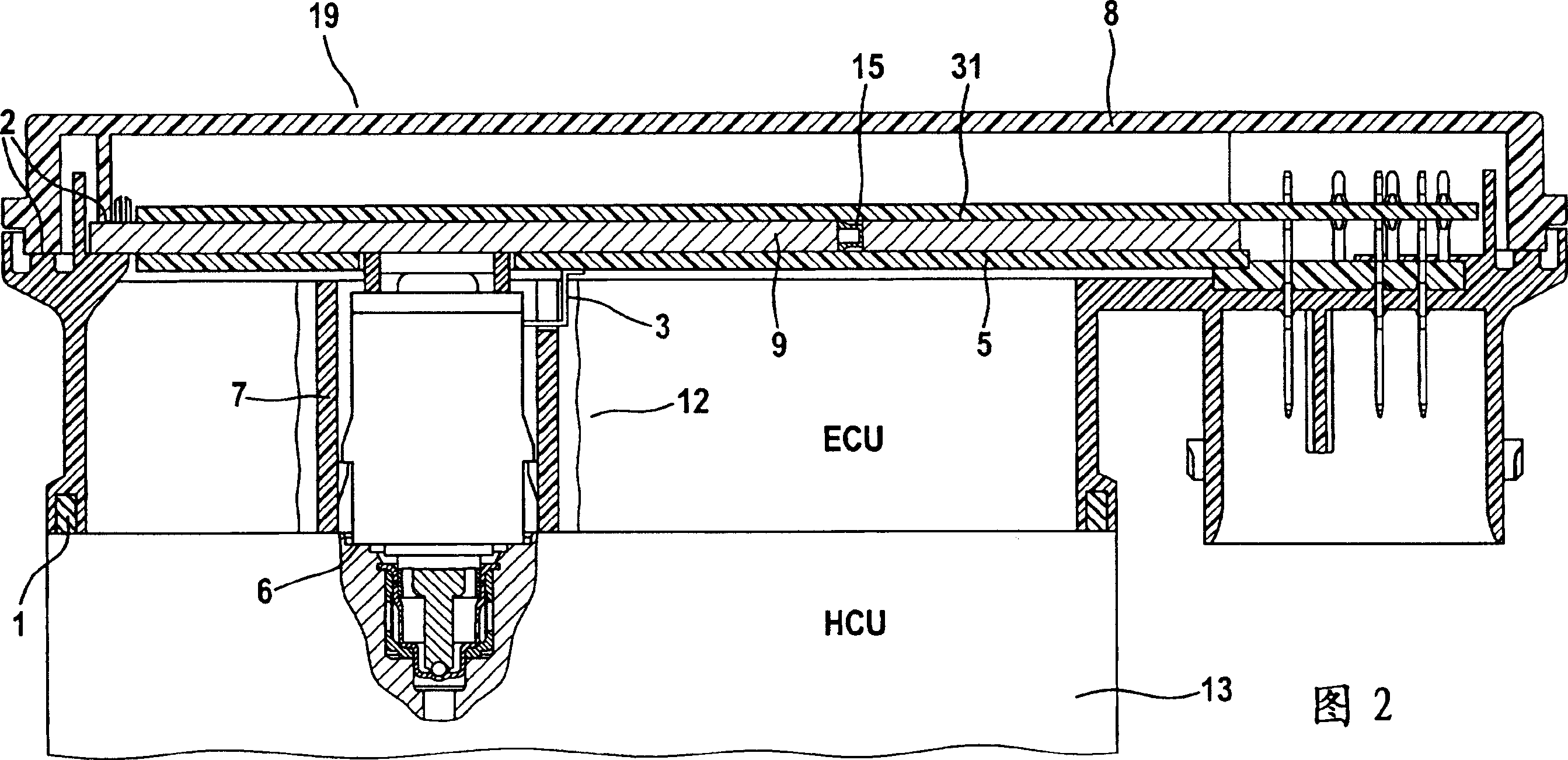

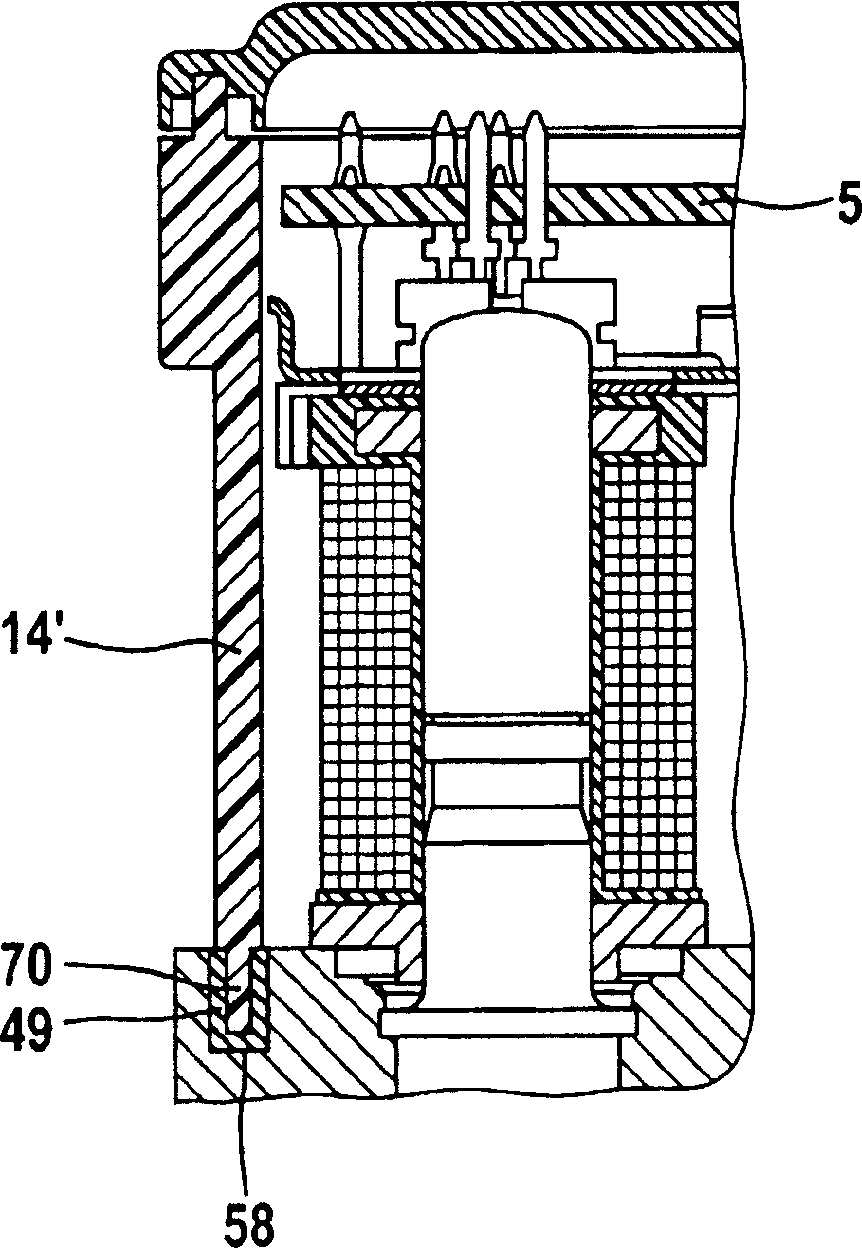

Electronic control unit for motor vehicle braking systems

InactiveCN1898112AMeet electromechanical requirementsMeet electromechanical requirements such as mechanical strengthServomotor componentsCooling/ventilation/heating modificationsElectricityElectronic structure

The invention relates to an electronic control unit (14), in particular in motor vehicle braking systems, which is connected to a hydraulic unit (13) by means of a magnetic connector. Said electronic control unit comprises: an area formed by the housing walls (14'), said area being used to receive several valve coils (12) which are arranged in said area, a housing cover (8, 35), at least one first circuit board (31, 5) which is used to receive electric and / or electronic components and an electric contact part and one first heat conducting plate (9, 32) which is used to guide heat away from the electronic components. The first heat conducting plate is connected in a flat manner to the first circuit board, and at least one heat connecting element (4, 15) which produces a thermal bridge between the first circuit board(s) and the first heat conducting plates, is provided. The invention also relates to a pump drive unit which co-operates with said control unit, whereby a motor base plate (22), for the electronic power components of the motor, is provided. The invention further relates to an electrohydraulic control device, wherein one or several elongate heat conducting elements (172) are arranged, said elements being in contact with the hydraulic block (13) and the cooling element (9) in order to form a thermal bridge. One longitudinal side of the heat conducting elements (172) is connected, in a positive or non-positive fit, to the hydraulic block or to the cooling element (9) and the opposite longitudinal sides thereof (1712) are arranged on the hydraulic block or the cooling element without the detachable non-positive fit connection.

Owner:CONTINENTAL TEVES AG & CO OHG

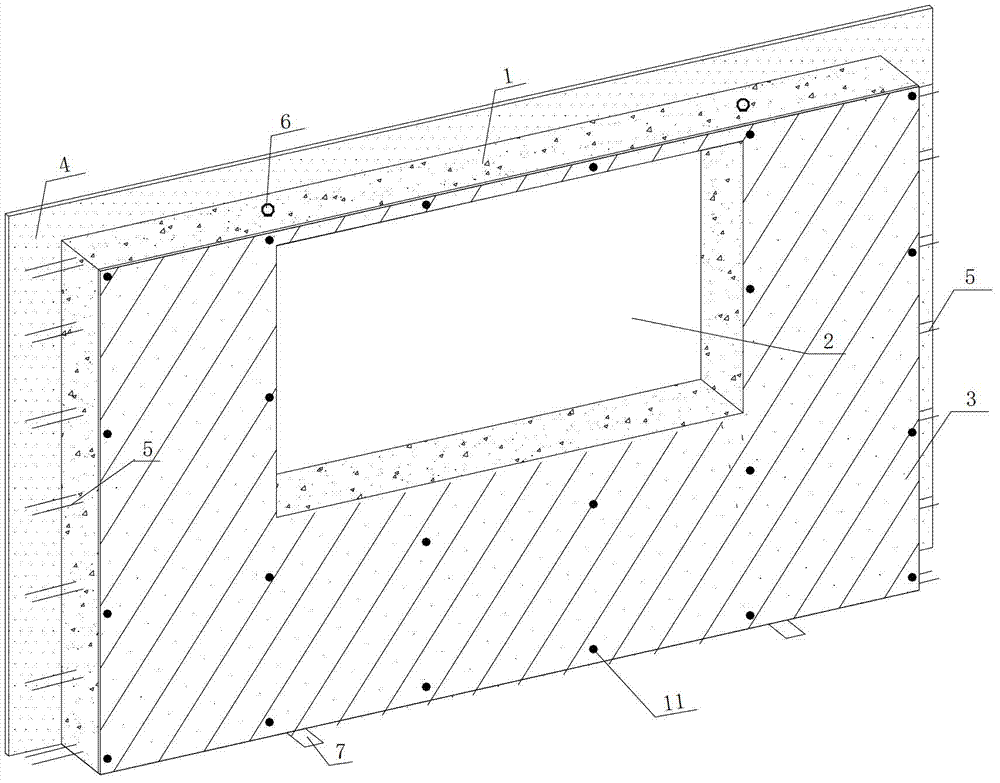

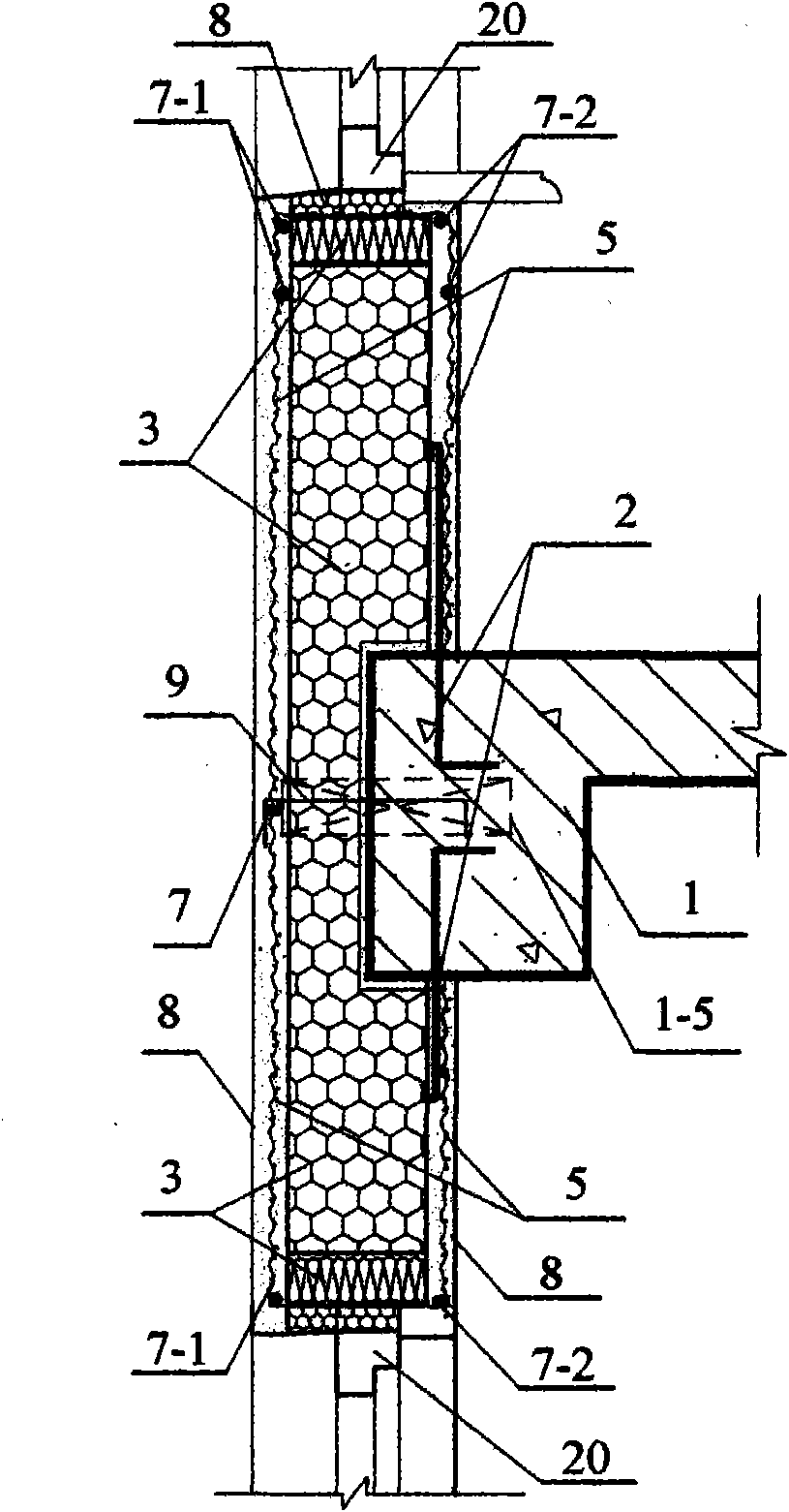

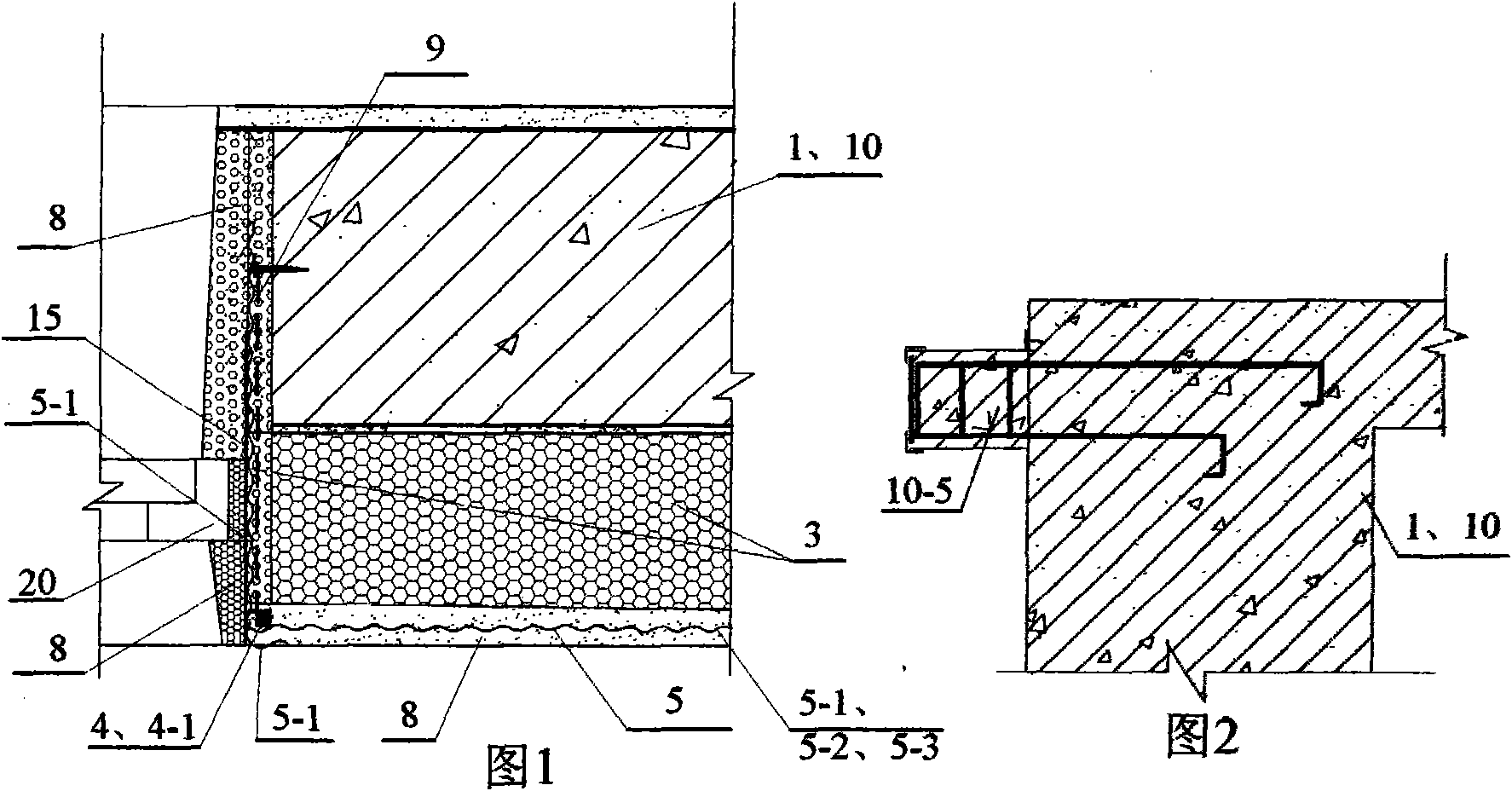

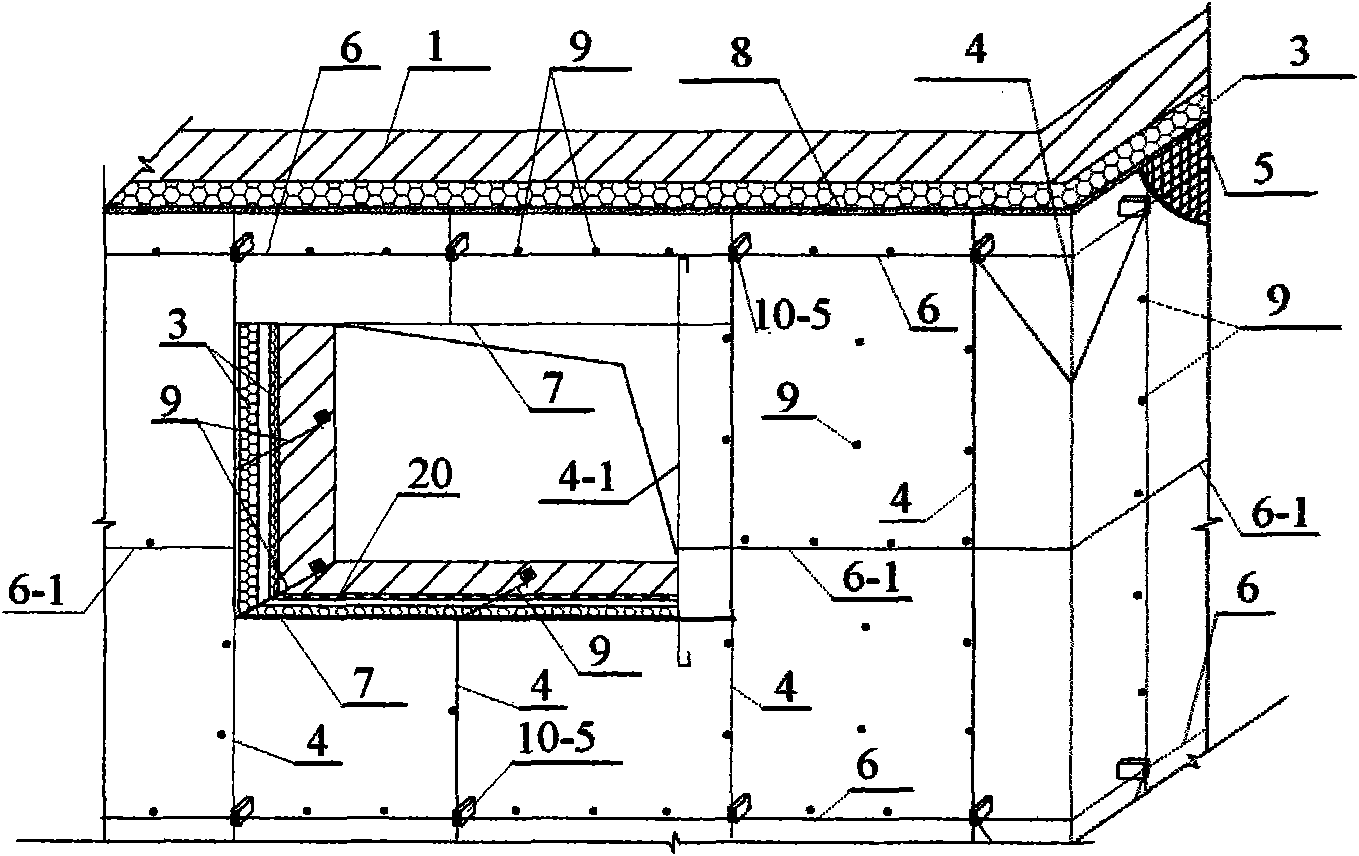

Heat preservation composite wall provided with meshed plaster on two sides

InactiveCN101936046ALower heat transfer coefficientThe energy-saving and thermal insulation effect exceedsWallsClimate change adaptationThermal bridgeSteel bar

The invention provides a heat preservation composite wall provided with meshed plaster on two sides, relates to heat preservation composite walls of buildings, and aims to solve the problem that heat bridges of openings of an energy-saving wall affect the building energy conservation. The heat preservation composite wall comprises a main building structure load-carrying member, short anchoring steel bars, a core layer, a meshed tensile material, outdoor vertical steel bars, indoor vertical steel bars, a supporting cantilever beam piece, outdoor horizontal additional steel bars, indoor horizontal steel bars, doors, windows and protective layers, wherein the short anchoring steel bars and the indoor vertical steel bars are anchored with the main building structure load-carrying member; the outdoor vertical steel bars are fixed with the supporting cantilever beam piece; the outdoor horizontal additional steel bars are fixed with the outdoor vertical steel bars; the outdoor vertical steel bars are fixed with the indoor vertical steel bars; the core layer is fixed between the outside and the inside of a frame; two sides of the core layer are provided with the protective layers; the short anchoring steel bars are overlapped with the meshed tensile material; the doors and the windows are arranged on the core layer; and two sides of the doors and the windows are provided with the protective layers. As the openings of the heat preservation composite wall provided with the meshed plaster on the two sides have a heat insulation broken bridge structure, the energy saving and heat preservation effect of walls is greatly improved.

Owner:吴淑环

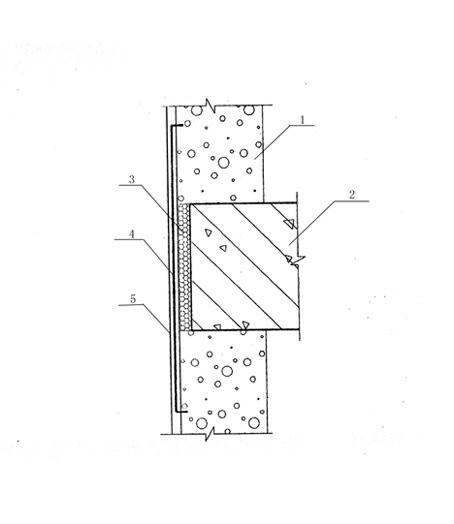

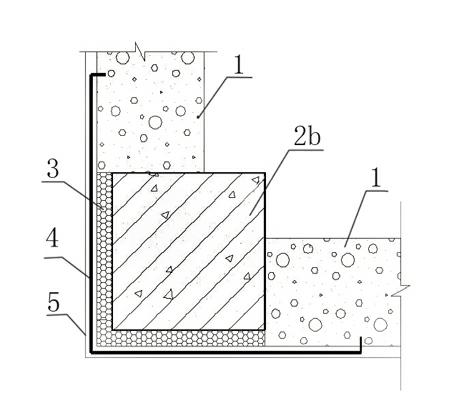

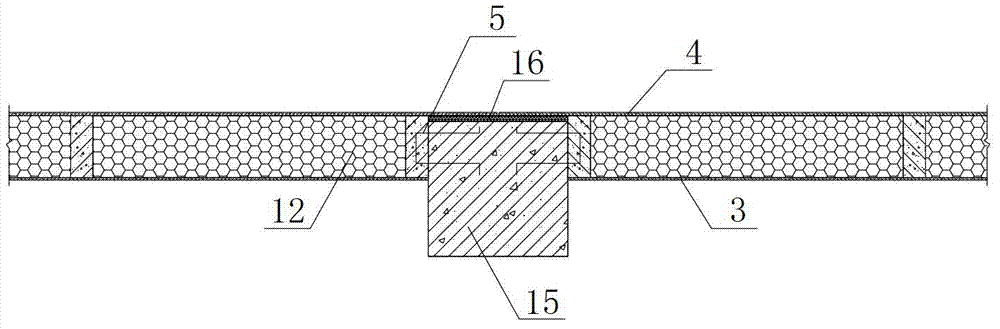

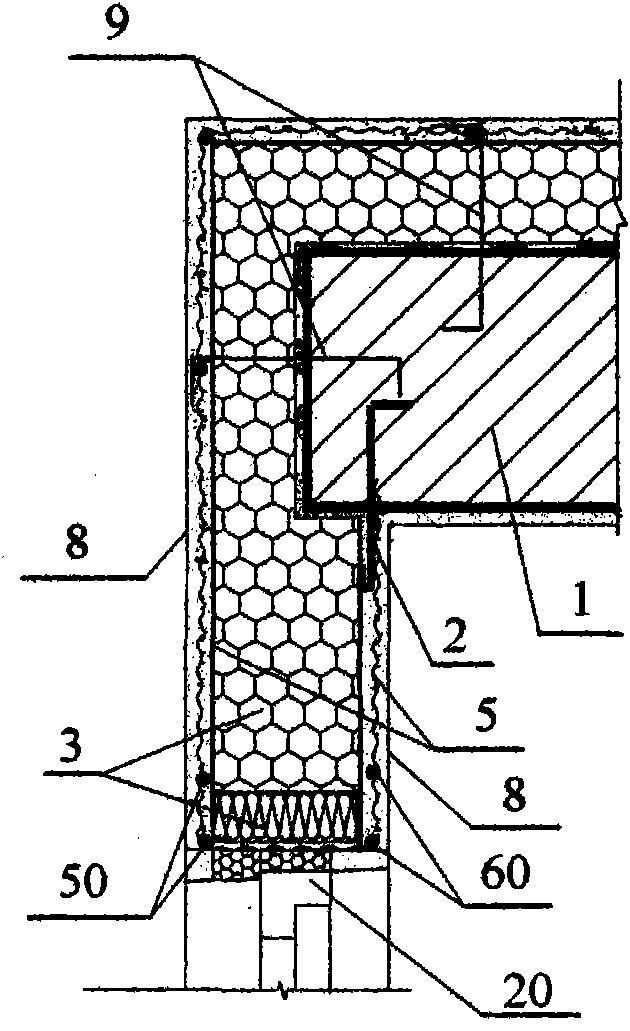

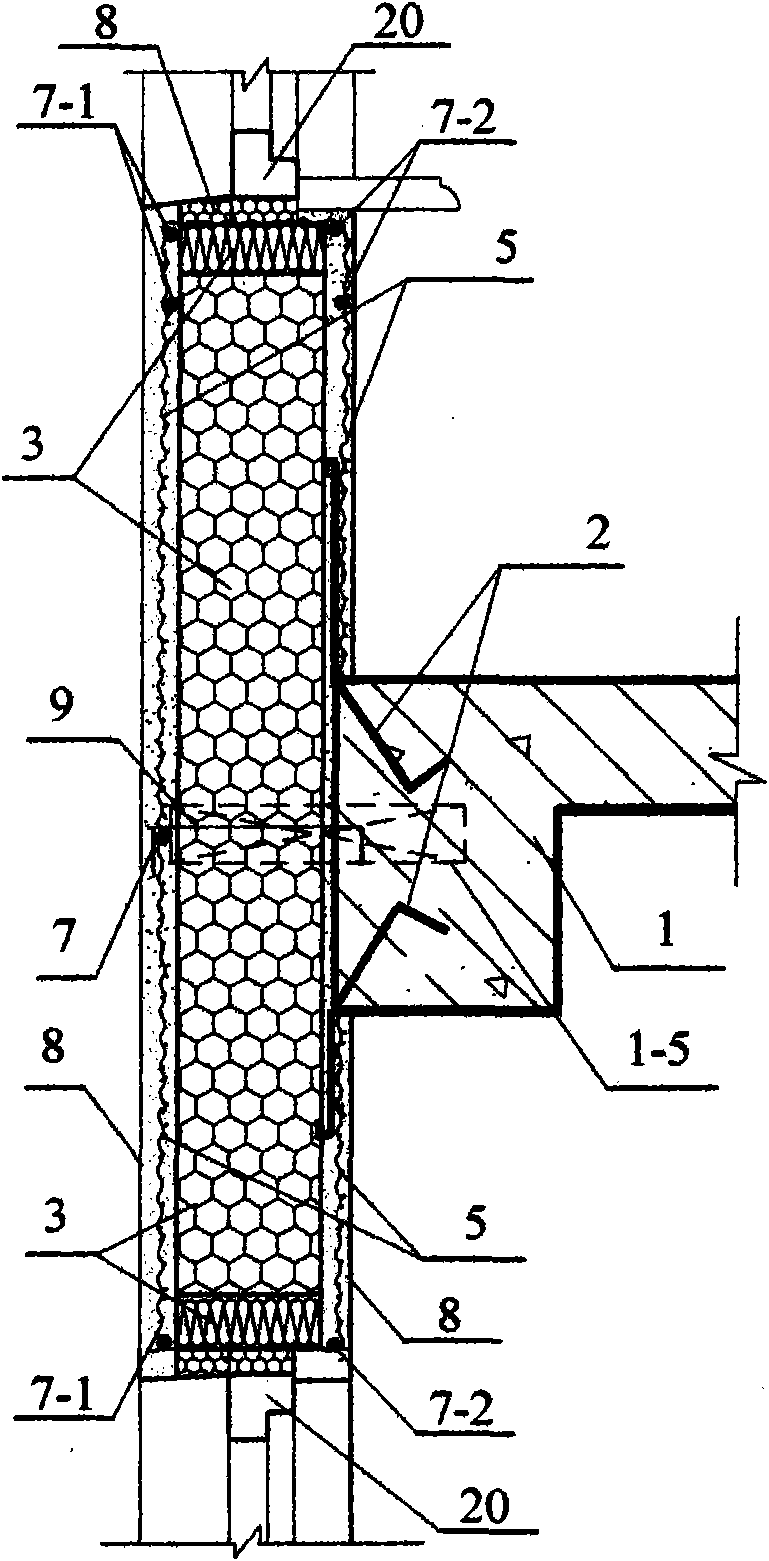

Exterior wall external insulation composite wall body with support

InactiveCN101914961AImprove insulation effectIncreased durabilityCovering/liningsWallsSurface layerThermal bridge

The invention discloses an exterior wall external insulation composite wall body with a support, relates to a building insulation composite wall body and aims to solve the problem of a large number of thermal bridges in the conventional insulation wall. A first structure of the composite wall body is that: a concrete cantilever beam supporting member is fixed in a main body structure of a building; an insulating layer is positioned outside a substrate wall body; a vertical reinforced steel bar is arranged outside the insulating layer and welded with an embedded steel plate of the concrete cantilever beam supporting member; a metal mesh is fixed with the vertical reinforced steel bar; a door and a window are arranged on insulating layers on openings; protective layers are formed outside the insulating layer and on the insulating layers on both sides of the door and the window; and the vertical reinforced steel bar and the metal mesh are positioned in the protective layers. A second structure of the composite wall body is that: the concrete cantilever beam supporting member is fixed in the main body structure of the building; profile steel is welded at the outer end of the concrete cantilever beam supporting member; a decorating large plate protective layer is fixed with the profile steel; and an insulating layer is formed between an external decorating large plate protective layer and a substrate wall body. The composite wall body has the advantages of capacity of reducing the thermal bridges in a large scale, best insulating effect, safe external protective layer and decorating surface layer, high fire resistance, high durability, simple structure and convenient construction.

Owner:吴淑环

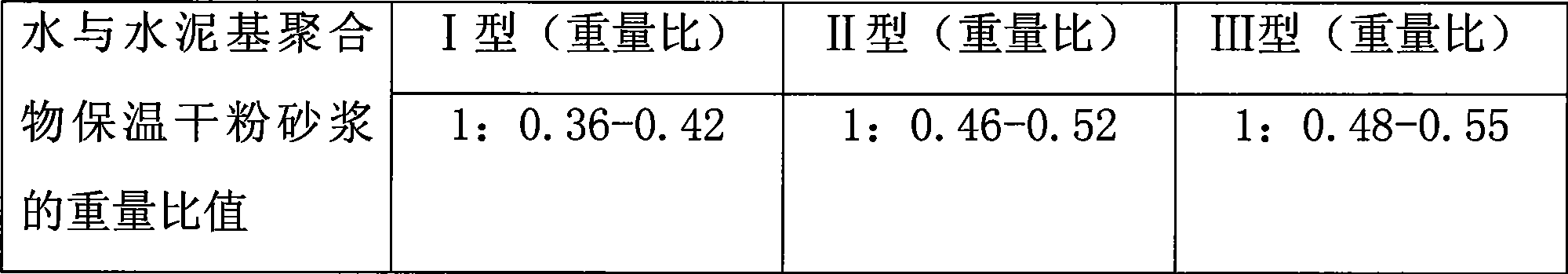

Cement based polymer heat preserving dry powder mortar and using method thereof

InactiveCN101475345AConvenient sourceEasy to manageSolid waste managementPolymer scienceThermal bridge

The invention relates to a cement based polymer heat preservation dry powder mortar in the field of building materials and a method for using the same, and solves the technical problems that the prior construction process has complexity, more procedures, long construction period, poor economical efficiency, and high cost price. In order to solve the technical problems, the invention provides the cement based polymer heat preservation dry powder mortar which comprises the following components in portion by weight: 30 to 40 portions of cement, 40 to 50 portions of light aggregate, 8 to 10 portions of fly ash, and 10 to 20 portions of quartz sand, wherein all the components are combined and stirred evenly according to different weight portions in a limited range, added with water at a use site so as to form the cement based polymer heat preservation mortars of type I, type II and type III; the type III cement based polymer heat preservation mortar is used for building; the type II cement based polymer heat preservation mortar is used for finishing; and the type I cement based polymer heat preservation mortar is used for performing heat bridge treatment.

Owner:CHONGQING DEBANG WATER PROOFING THERMAL INSULATION ENG

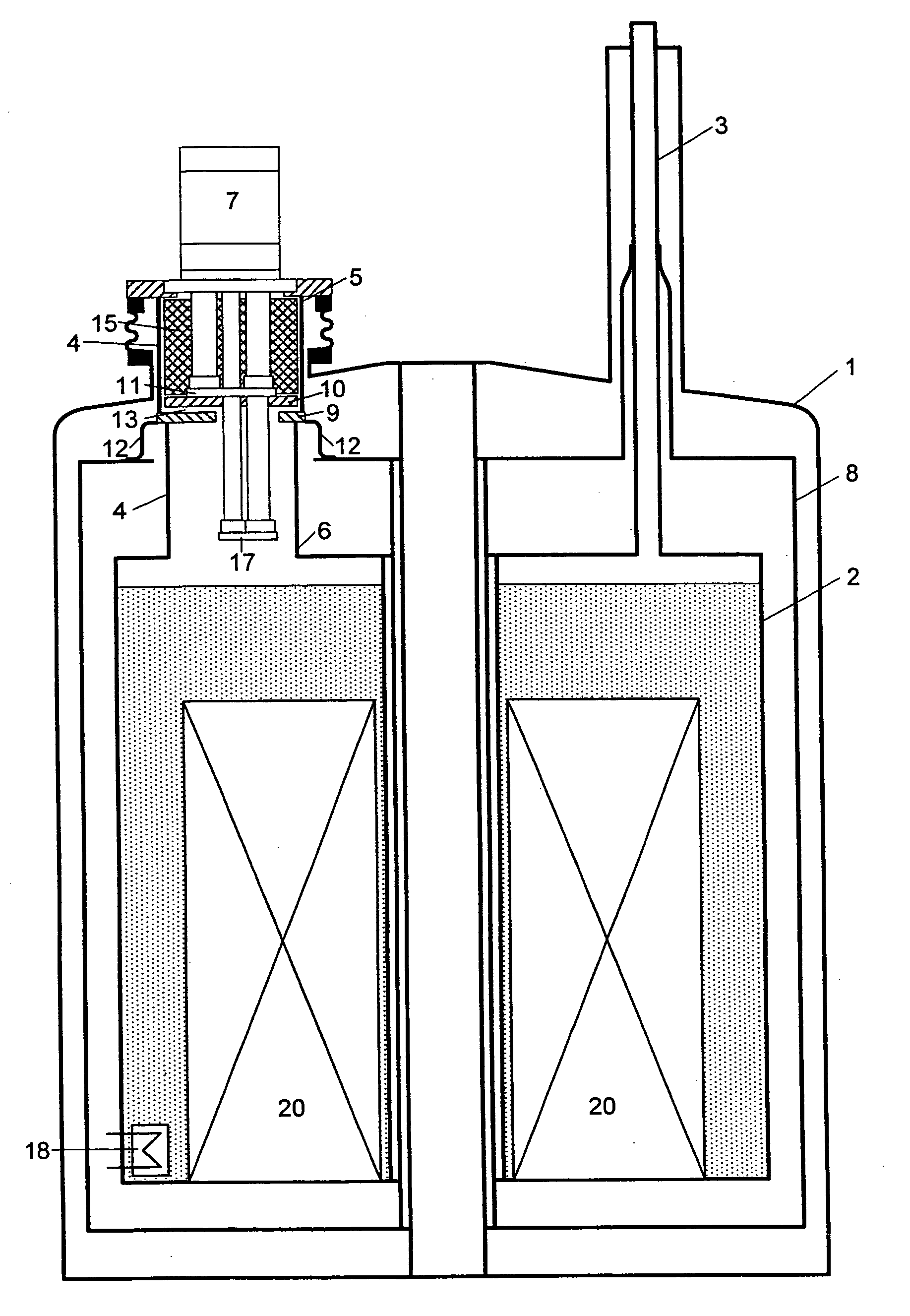

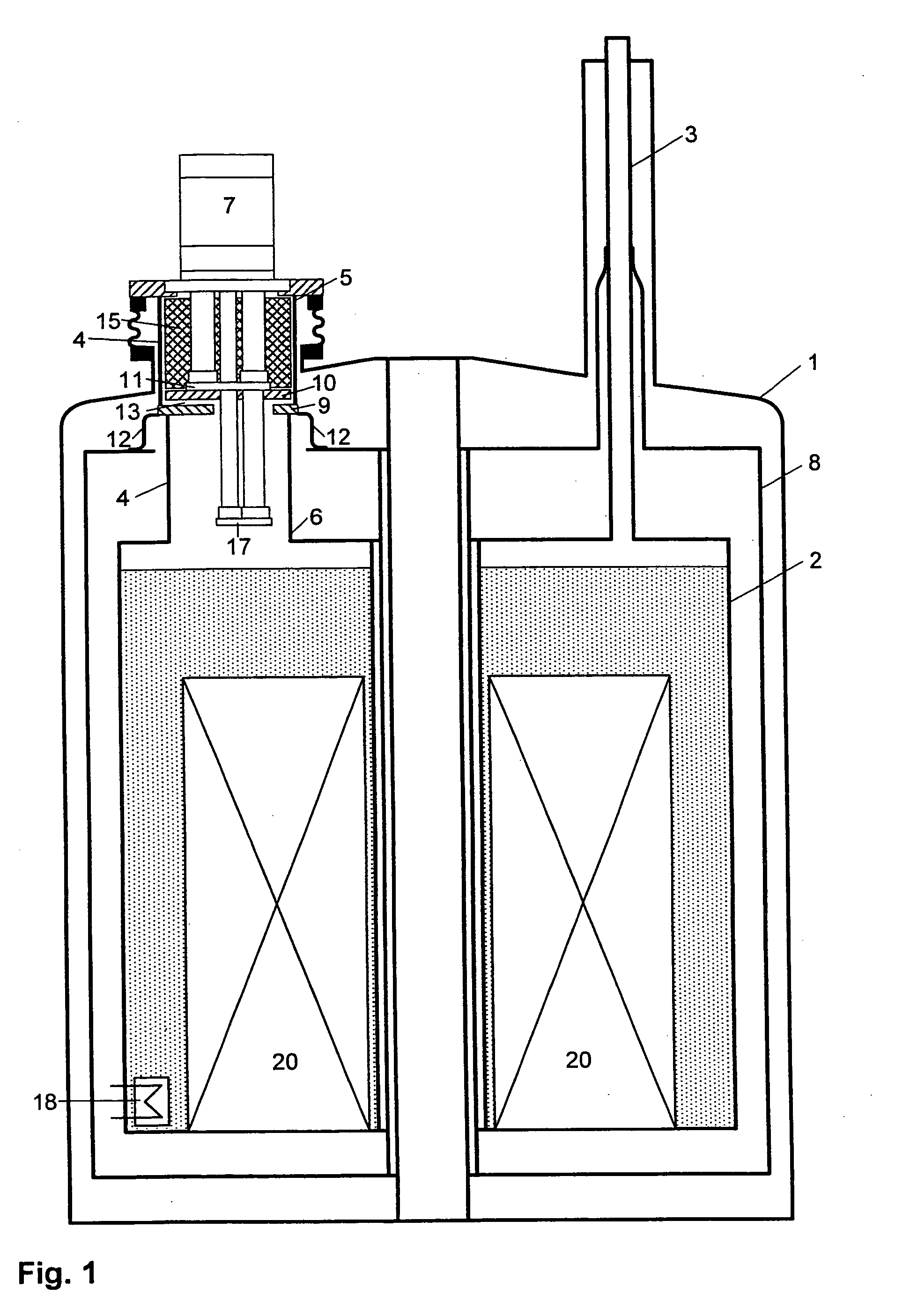

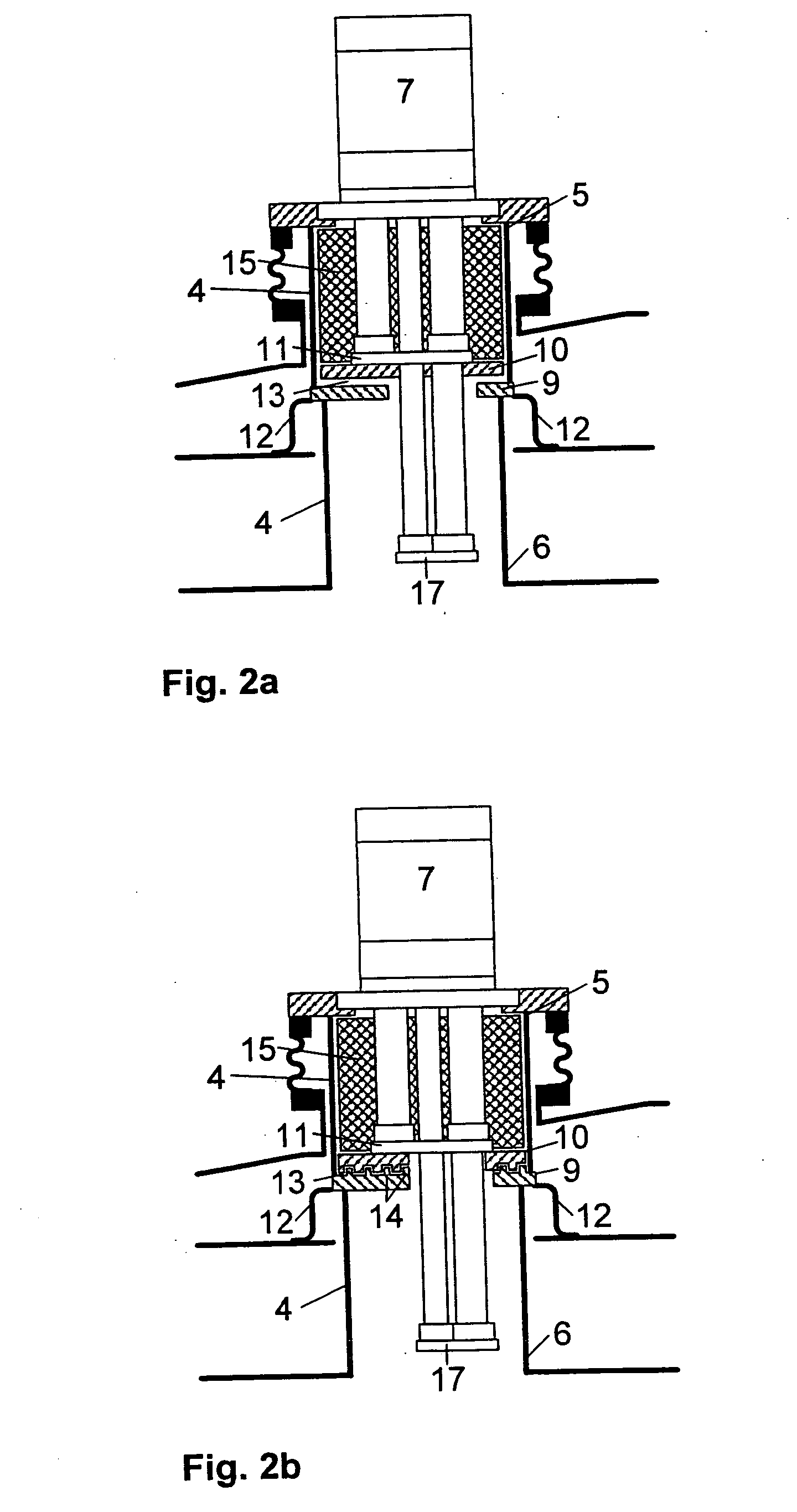

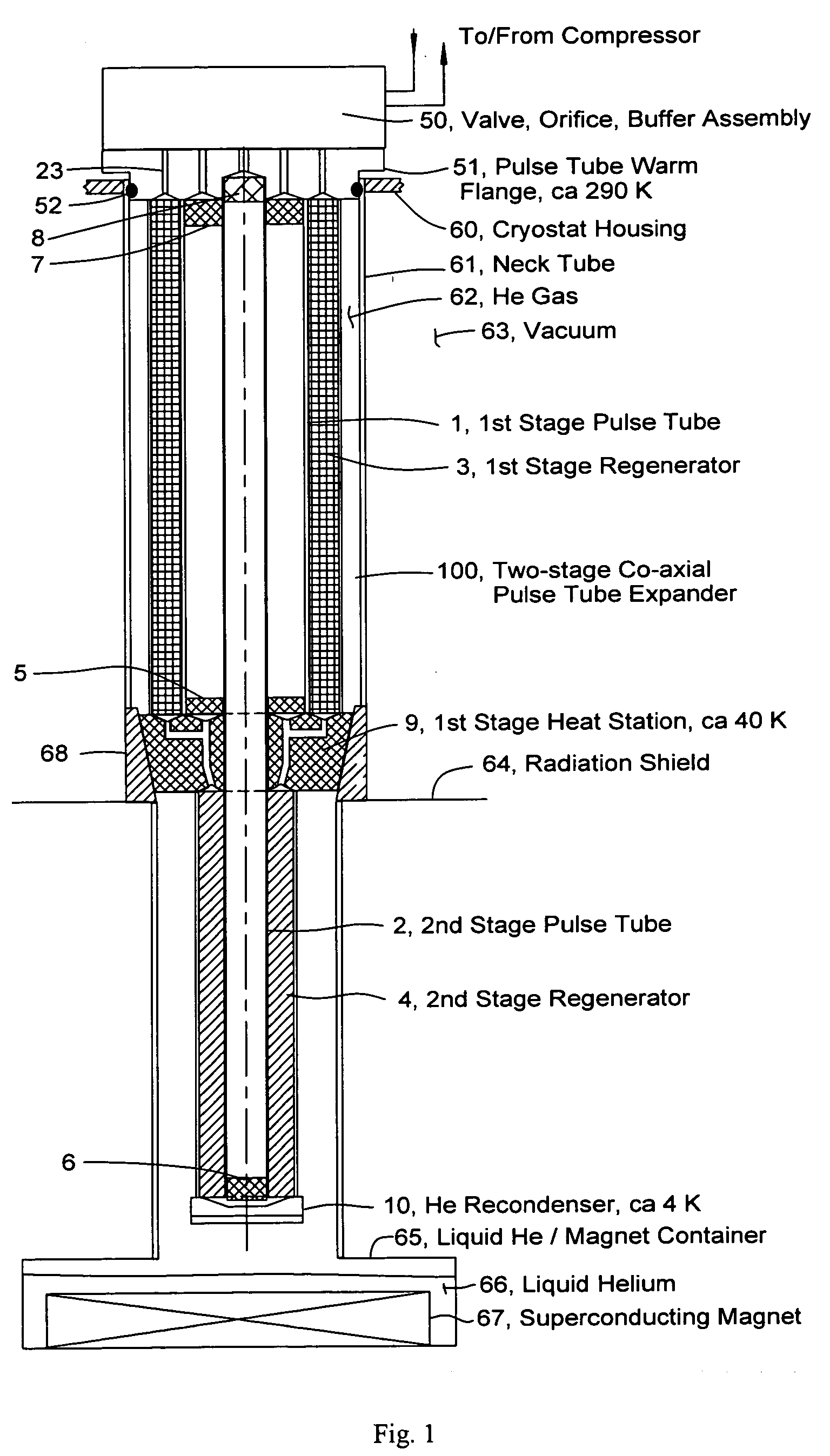

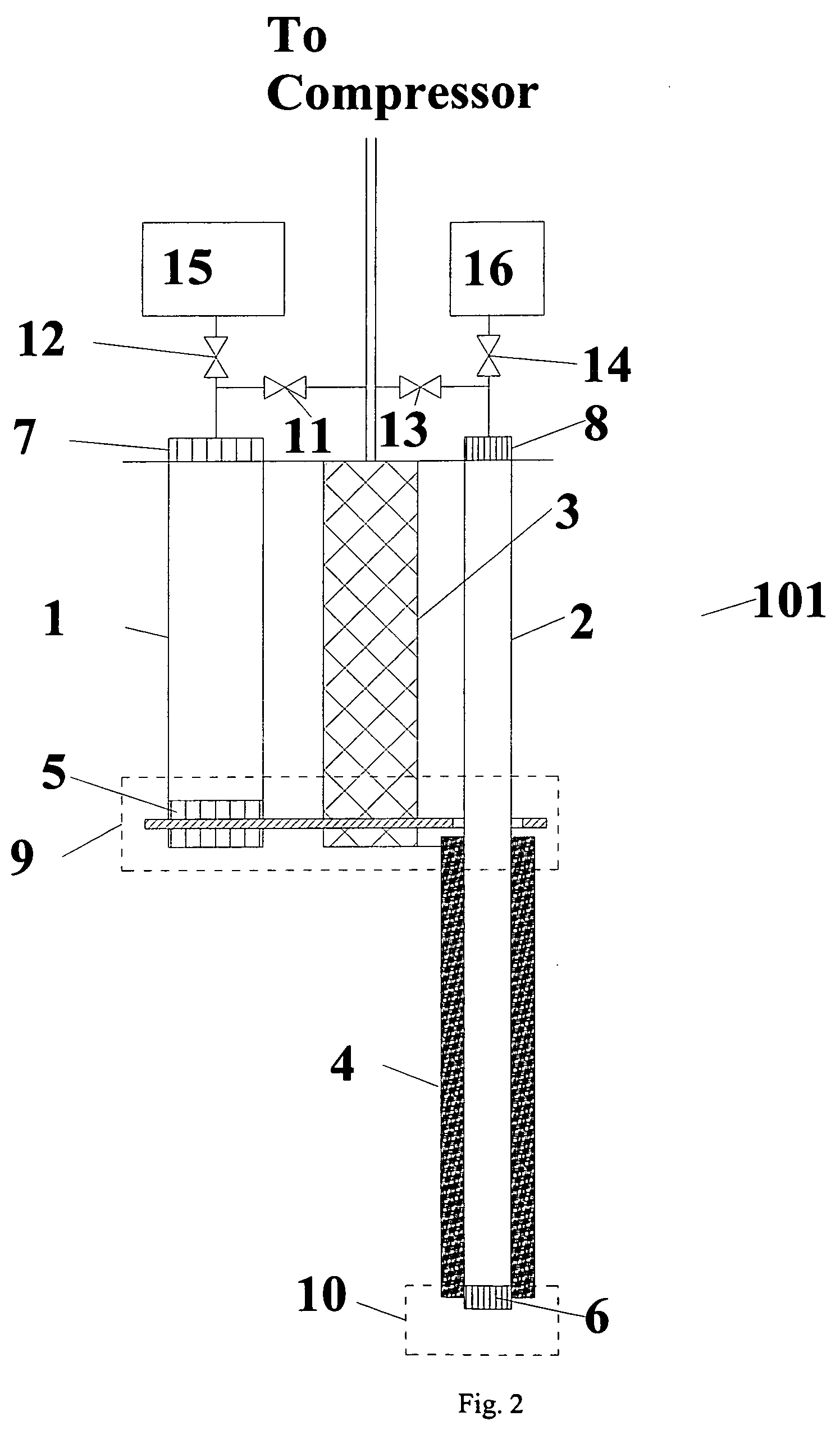

Cryostat configuration with cryocooler and gas gap heat transfer device

InactiveUS20070051115A1Reduce vibrationEffect spectrum qualityCompression machinesRefrigeration devicesHeat conductingThermal bridge

A cryostat configuration for keeping liquid helium comprises an outer jacket (1) surrounding a helium container (2) connected at at least two suspension tubes (3) to the outer jacket (1), and with a neck tube (4) whose upper warm end (5) is connected to the outer jacket (1) and whose lower cold end (6) is connected to the helium container (2) and into which a multi-stage cold head of a cryocooler (7) is installed, wherein the outer jacket (1), the helium container (2), the suspension tubes (3) and the neck tube (4) delimit an evacuated space, and the helium container (2) is surrounded by at least one radiation shield (8) which is connected in a heat-conducting fashion to the suspension tubes (3) and also to a contact surface (9) on the neck tube (4) of the helium container (2). The cryostat configuration is characterized by a gas gap (13) between one or more cold stages of the cold head (7) and one or more contact surfaces (9) in the neck tube (4) which are each connected in a heat-conducting manner to a radiation shield (8) via a fixed, rigid or flexible thermal bridge (12), heat being transferred through the gas gap (13) from the respective radiation shield (8) to the corresponding cold stage of the cold head (7). A cryostat configuration of this type ensures that no vibrations of the cold head (7) stages pass detectably into the cryostat configuration, wherein the quality of the thermal connection between the cold head (7) and the radiation shield(s) (8) is nevertheless sufficient.

Owner:BRUKER BIOSPIN

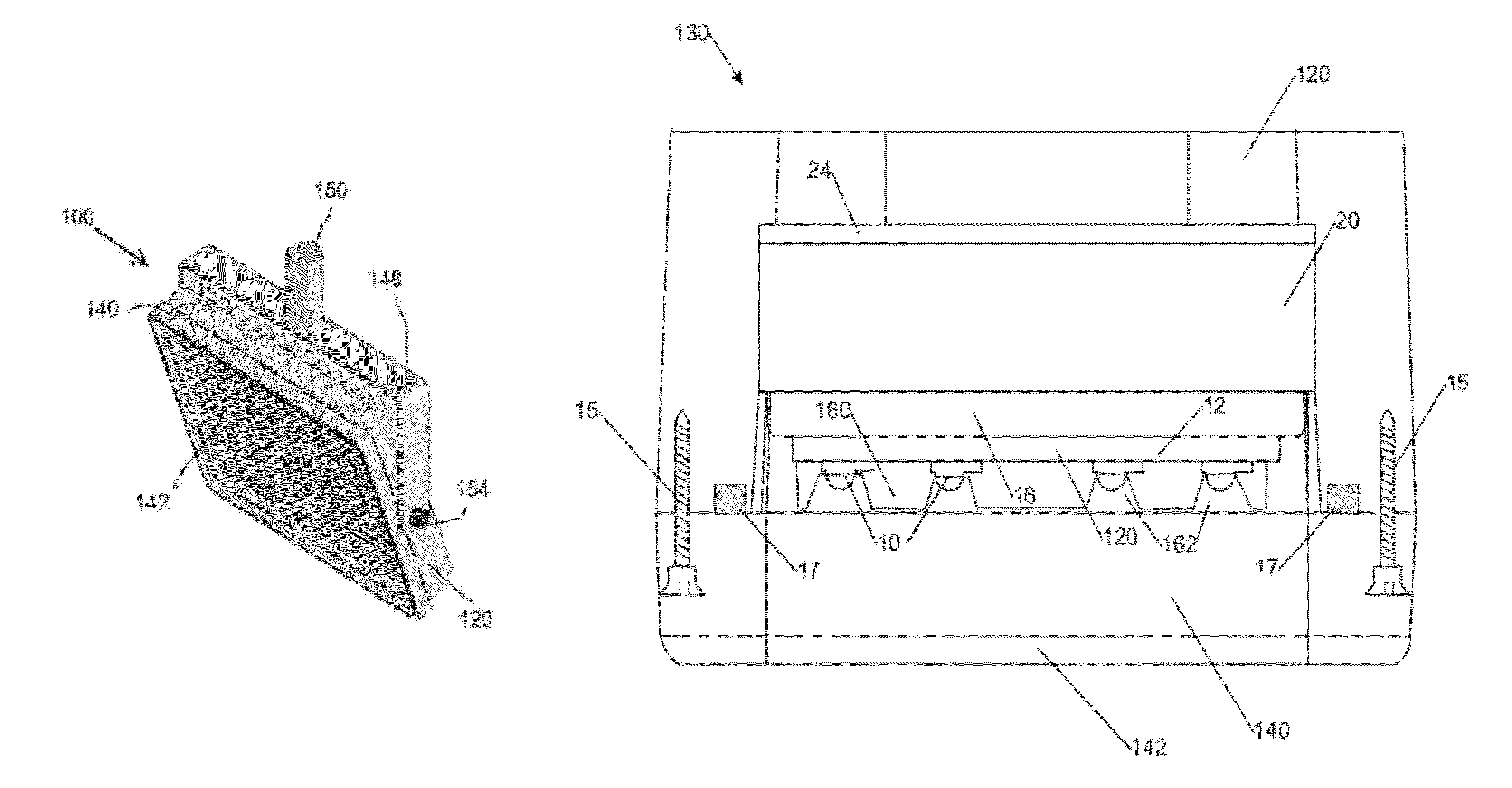

Temperature controlled battery pack assembly and methods for using the same

A temperature controlled battery pack assembly (100) includes a housing (120) containing at least one battery cell, defining a battery chamber (104A) and including thermal insulation (124) surrounding at least a portion of the battery chamber. The thermal insulation inhibits thermal transfer between the at least one battery cell and the surrounding environment. A thermal bridge conductor (130) is disposed in the battery chamber and engages the at least one battery cell. The battery pack assembly further includes a thermoelectric cooler device (160) having an inner surface (162A) and an outer surface (164A), operable to actively transfer heat between the inner and outer surfaces using the Peltier effect. A heat sink device (170) is in contact with or connected to the outer surface. The battery pack assembly includes a fan (178) operable to force a flow of a heat transfer fluid across the heat sink device and into the environment. The thermal bridge conductor is in contact with or connected to the inner surface.

Owner:EATON CORP

NP-EIFS non-permissive exterior insulation and finish systems concept technology and details

A new concept wall system is provided, wherein the Exterior Insulation and Finish System cladding is created using components with no water absorption, a very low vapor permeability and sealing properties, accommodated with an installation technology which extend the materials properties to the assembly, together with bonding and sealing the intersections and terminations, creating a Non-Permissive to water and vapor diffusion, Exterior Insulation and Finish System (NP-EIFS). The present invention relates to an EIFS cladding having two air and vapor barriers, one applied to the substrate, a continuous liquid membrane with sheathing joints sealed to be moisture barrier for inside vapors, and an exterior weather and vapor barrier which is created using closed cell extruded polystyrene insulation boards, special assembled with joints sealed, to create a non-permissive insulation envelope of the enclosure. Another object of the invention is to provide waterproof and air / vapor-proof details, a new concept of flashing and sealant application around windows / doors and other constructive elements to avoid thermal bridges and air leakage inside thermal envelope and wall assembly. Methods of installation are included.

Owner:RADOANE MARIUS

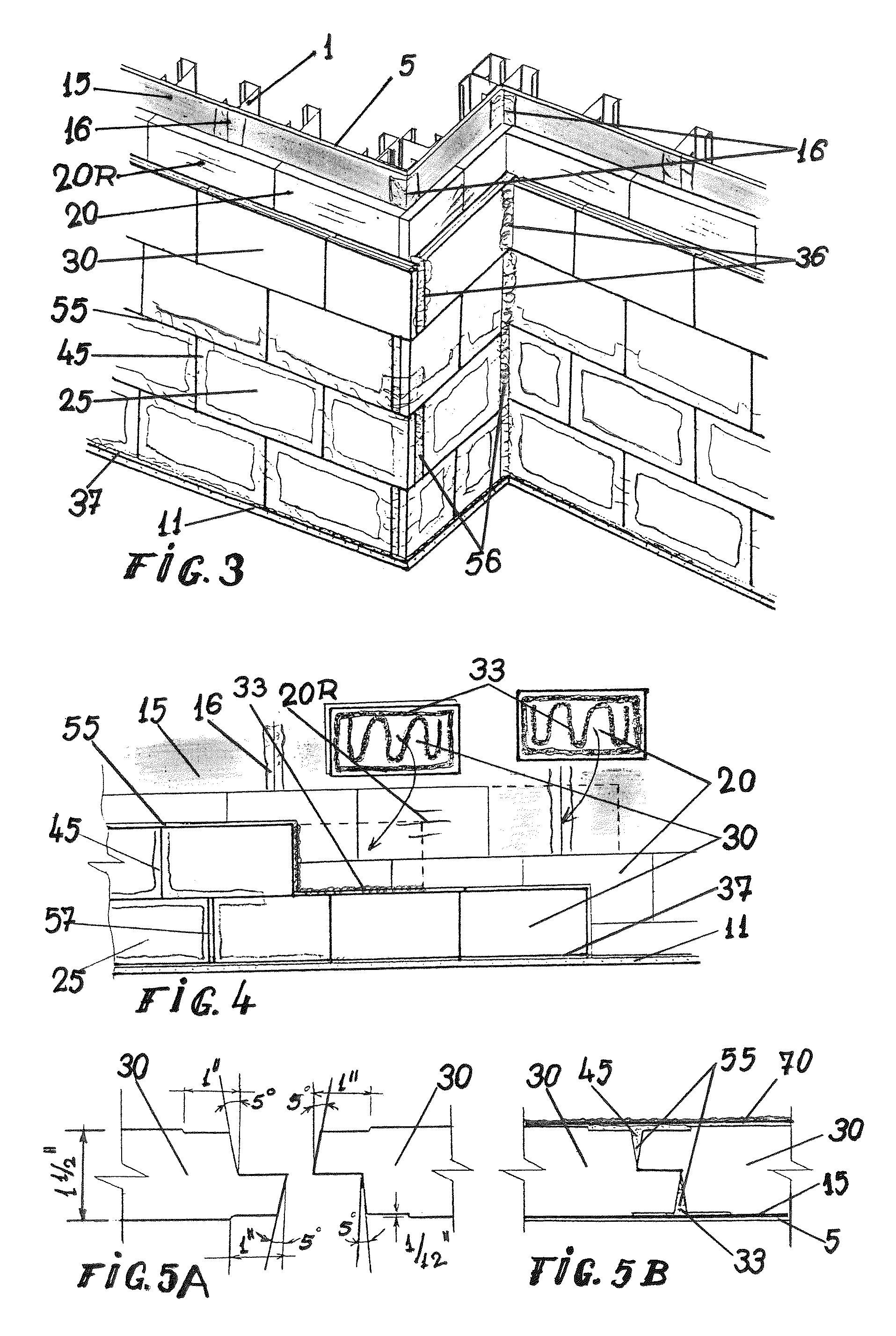

Co-axial multi-stage pulse tube for helium recondensation

InactiveUS20060144054A1Eliminate convection lossHeat loss minimizationCompression machinesRefrigeration devicesThermal bridgePulse tube refrigerator

A two-stage pulse tube refrigerator having a compact design, low vibration and low heat loss is provided where at least the 2nd stage is co-axial but preferably, both stages are co-axial with the second stage pulse tube being central and the first stage pulse tube occupying the annular space between the second stage pulse tube and the first stage regenerator. Convection losses associated with different temperature profiles in the pulse tubes and regenerators are minimized by shifting the thermal patterns in the pulse tubes relative to the regenerators by one or more of spacers in the regenerators, physical differences in length with gas channel connections, adjustment of dc flow, and thermal bridges.

Owner:SUMITOMO HEAVY IND LTD +1

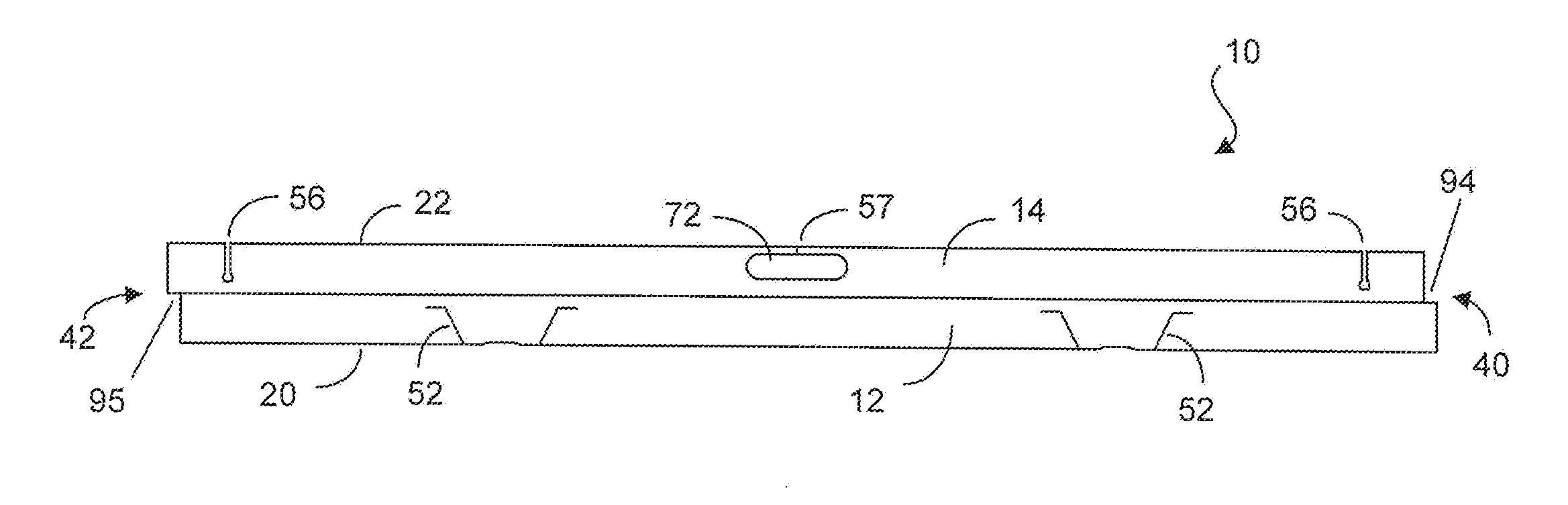

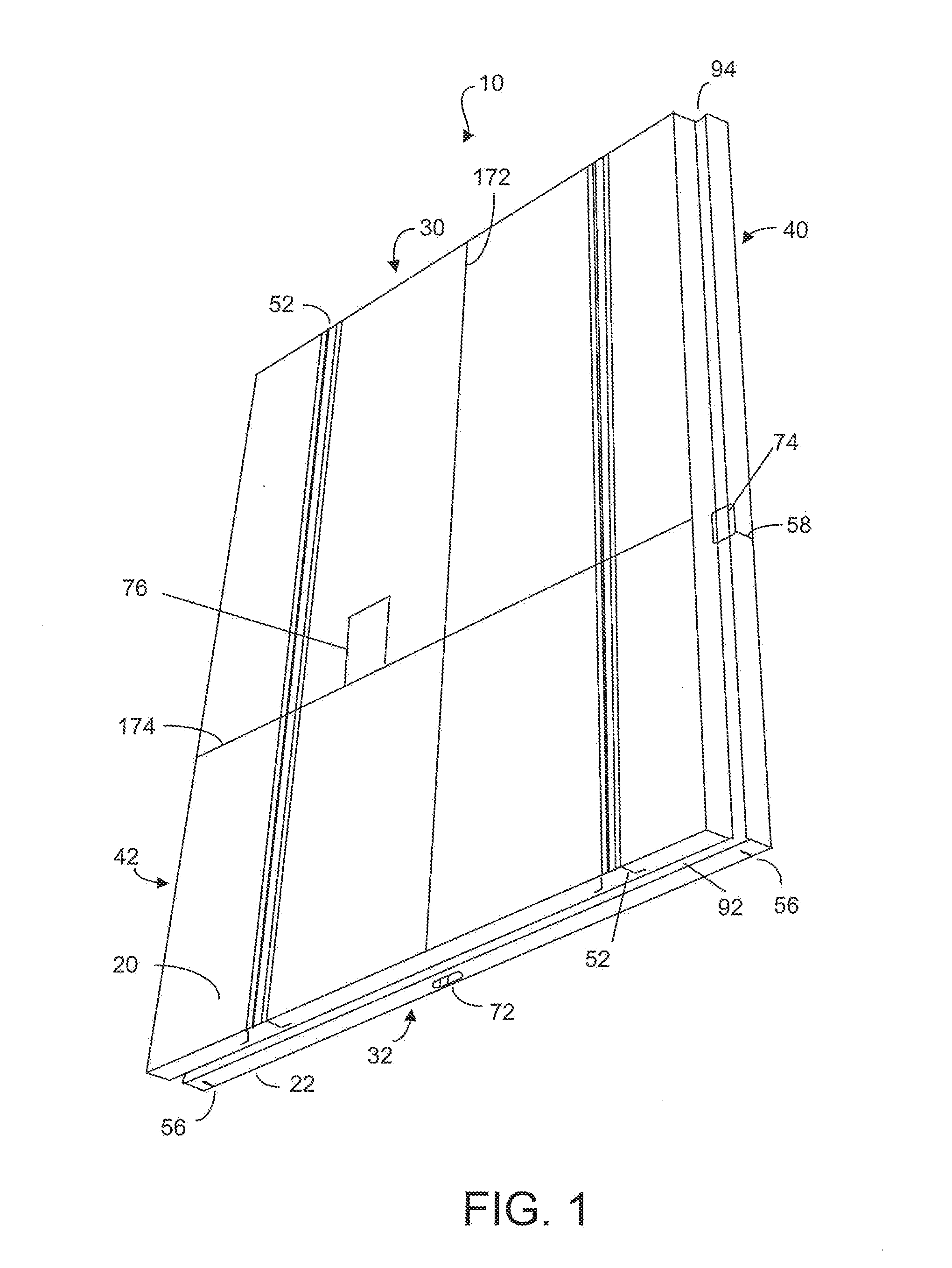

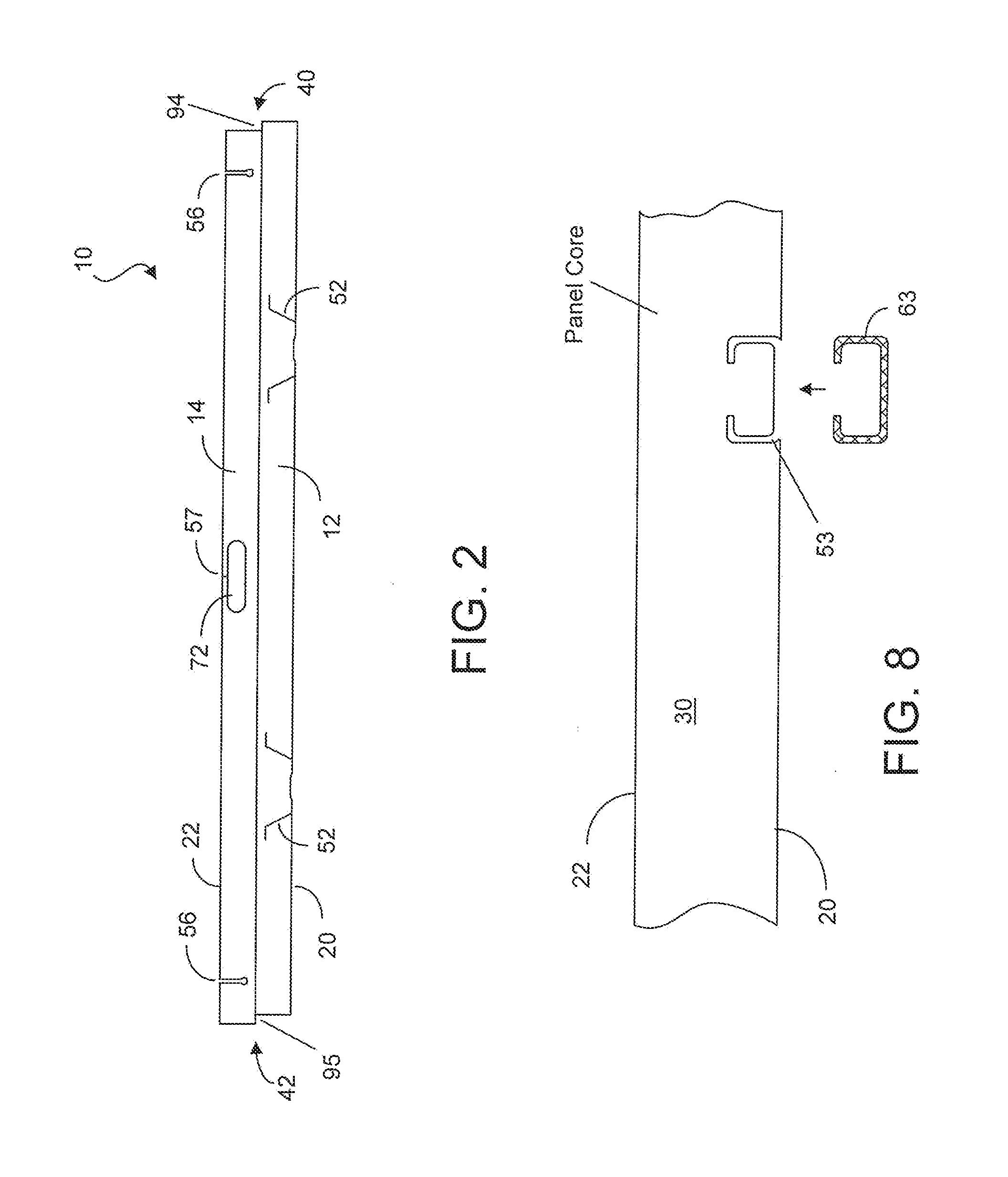

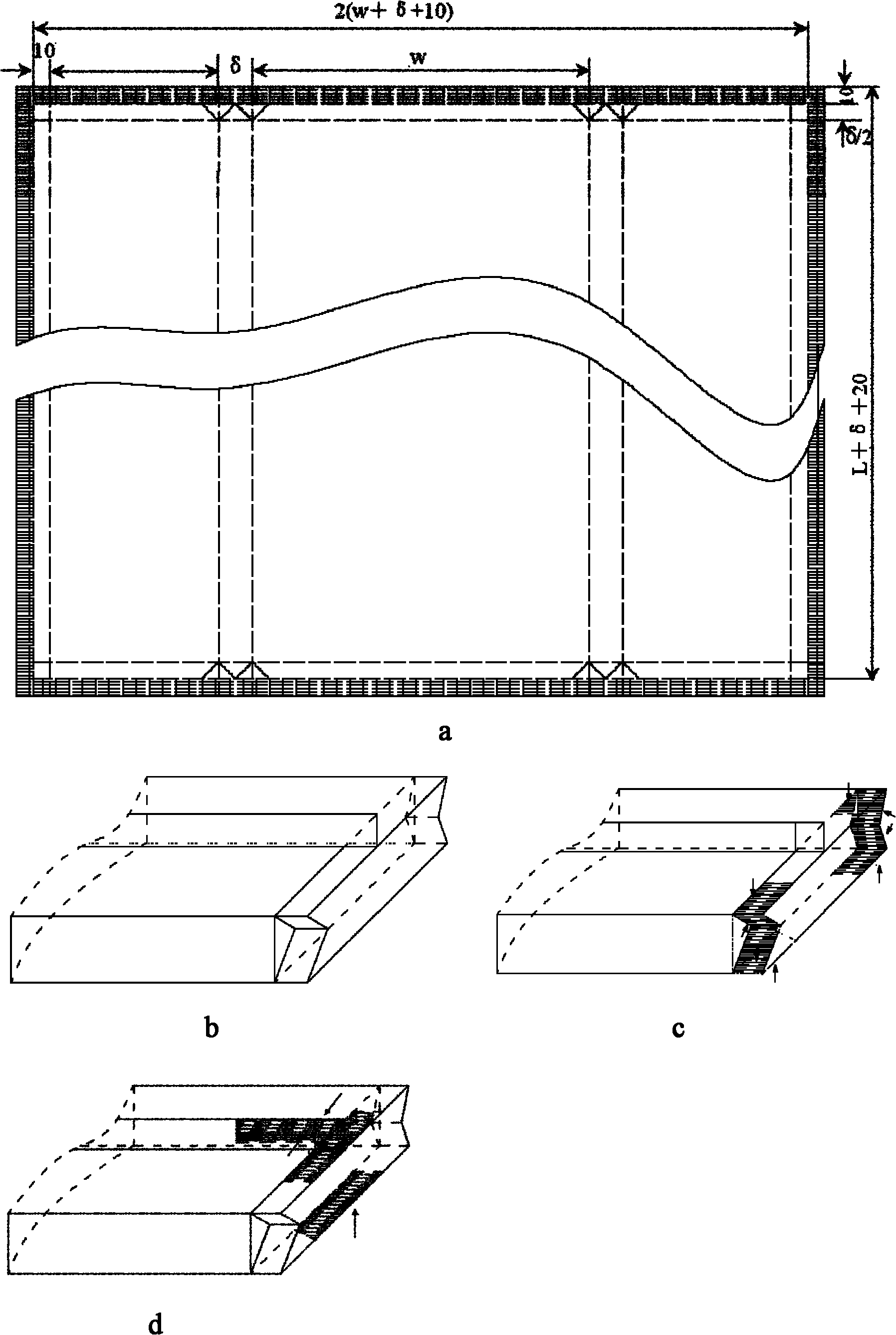

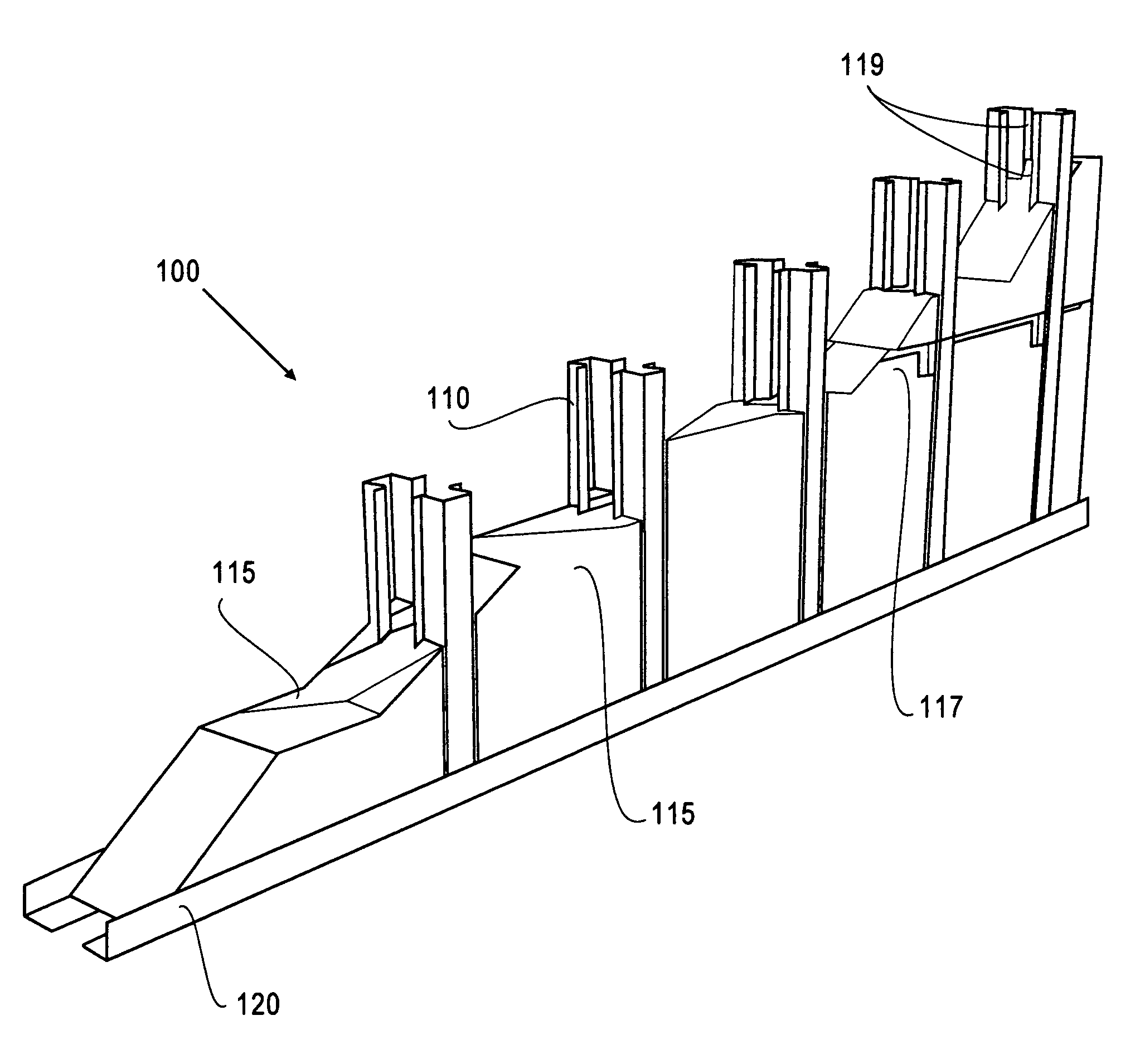

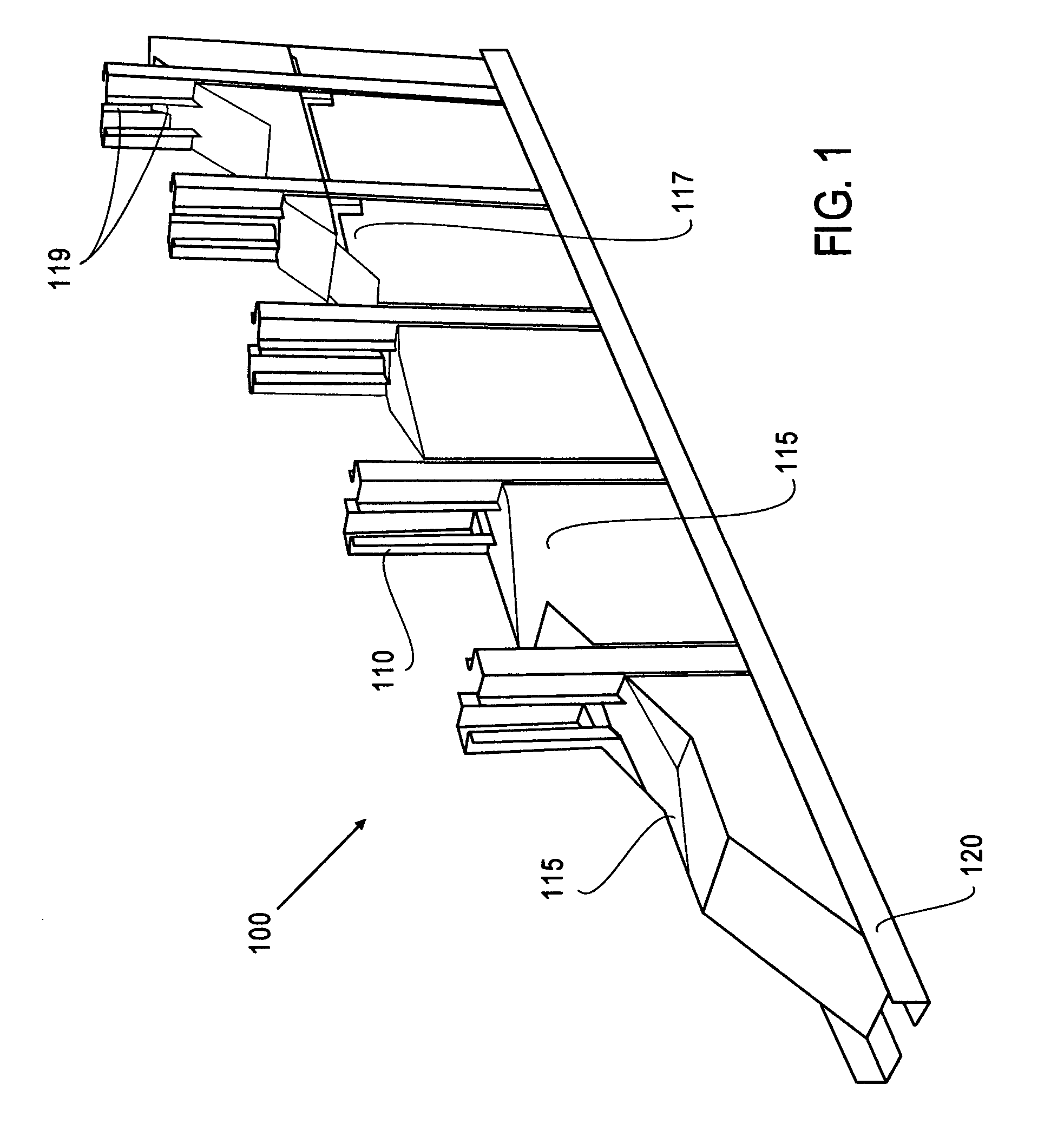

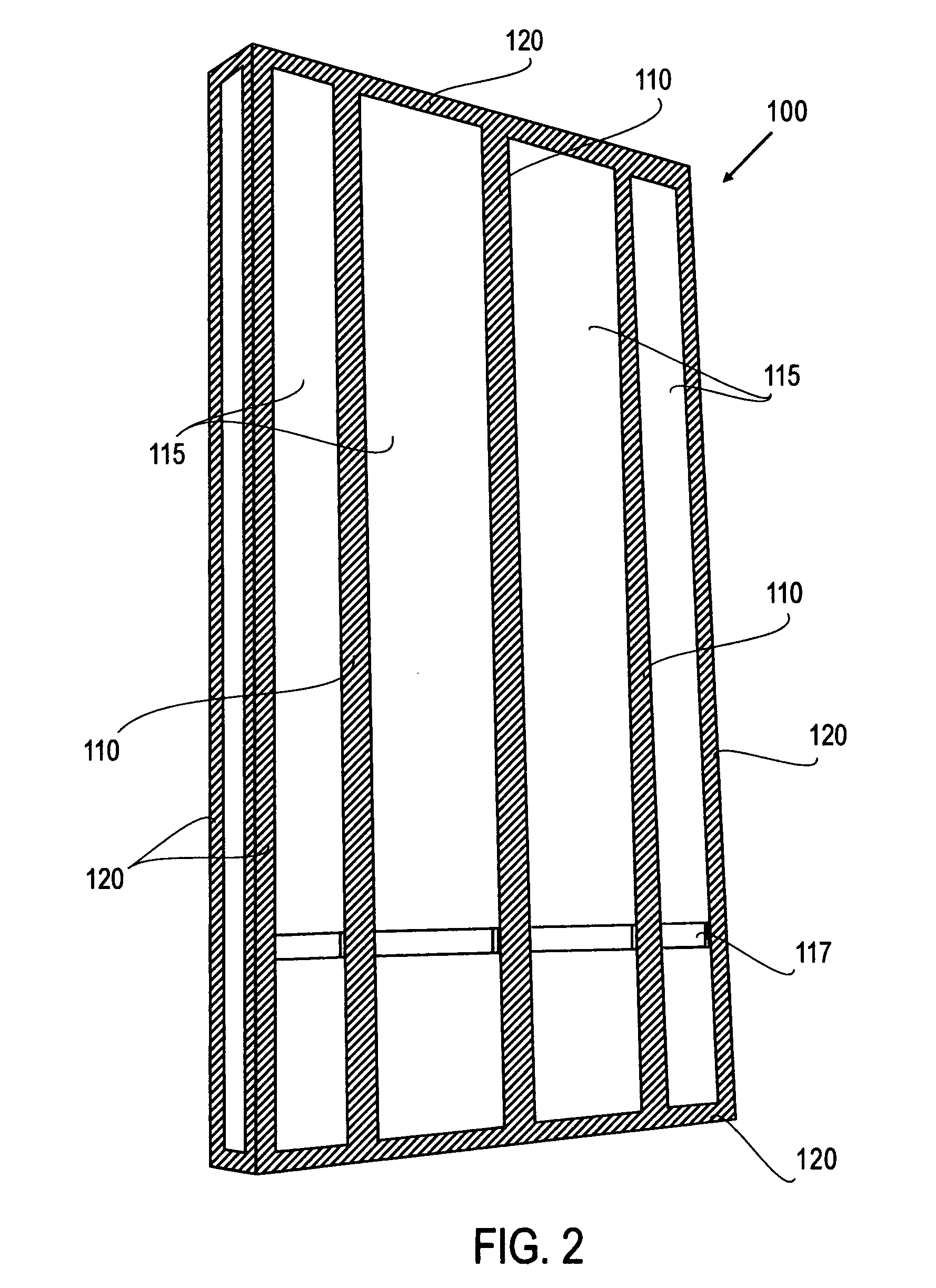

Structural insulated panels with a rigid foam core and without thermal bridging

A structural insulated panel with a rigid foam core without thermal bridging is disclosed. A particular embodiment includes a rigid foam core having first and second faces, a plurality of stud channels being formed on the first and second faces of the rigid foam core, each of the stud channels being formed in the rigid foam core in an L-shape in cross-section, and a plurality of studs being insertable into the plurality of stud channels such that one face of each of the plurality of studs being external to the first and second faces of the rigid foam core and substantially flush with a face of the rigid foam core, each of the plurality of studs being fabricated using no more than four bends to produce a stud with a hat channel shape in cross-section

Owner:FUNFORM LLC

Temperature responsive thermal bridge

ActiveUS9841772B2Temperature control without auxillary powerSemiconductor/solid-state device detailsTemperature responseThermal bridge

Owner:TYCO ELECTRONICS LOGISTICS AG (CH)

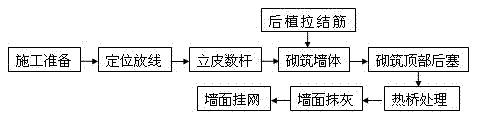

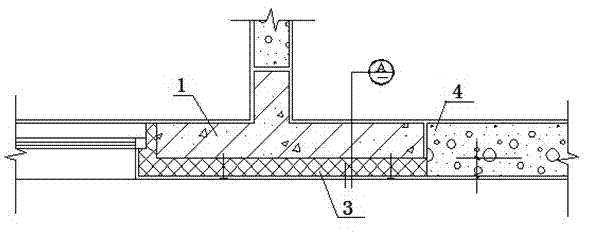

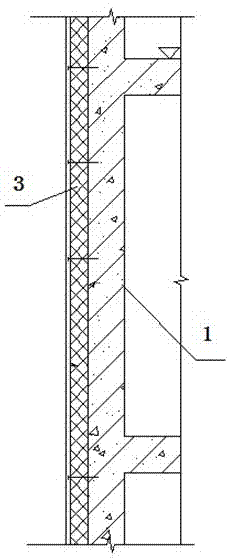

Construction process for self-heat-insulation system of autoclaved aerated concrete block wall

InactiveCN102251670AReduced risk of hollowing and crackingImprove water retentionClimate change adaptationPassive housesReinforced concreteThermal bridge

The invention discloses a construction process for a self-heat-insulation system of an autoclaved aerated concrete block wall. A wall building process is subjected to three necessary technical slot time, namely the time from building and walling of autoclaved aerated concrete blocks to curing lasts for at least 28 days; reserved clearances between the top of the autoclaved aerated concrete block wall and a beam and between the top and a board, namely rear blocking ports can be supplementarily built after at least seven days at interval; and the time from completion of the autoclaved aerated concrete block wall to wall plastering lasts for at least 30 days. By adopting the three necessary technical slot time, the construction surface is fully dried, thus greatly reducing the internal stress of materials due to drying shrinkage deformation and temperature change of the material and preventing crack and leakage of the wall. In addition, an inorganic heat-insulation material or aerated concrete blocks are used for heat insulation at the thermal bridge positions of reinforced concrete walls, posts and beams of outer walls according to thermotechnical calculation, thus eliminating thermal bridges and meeting the energy-saving requirement.

Owner:CHONGQING NO 3 CONSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com