Patents

Literature

439 results about "Pulse tube refrigerator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

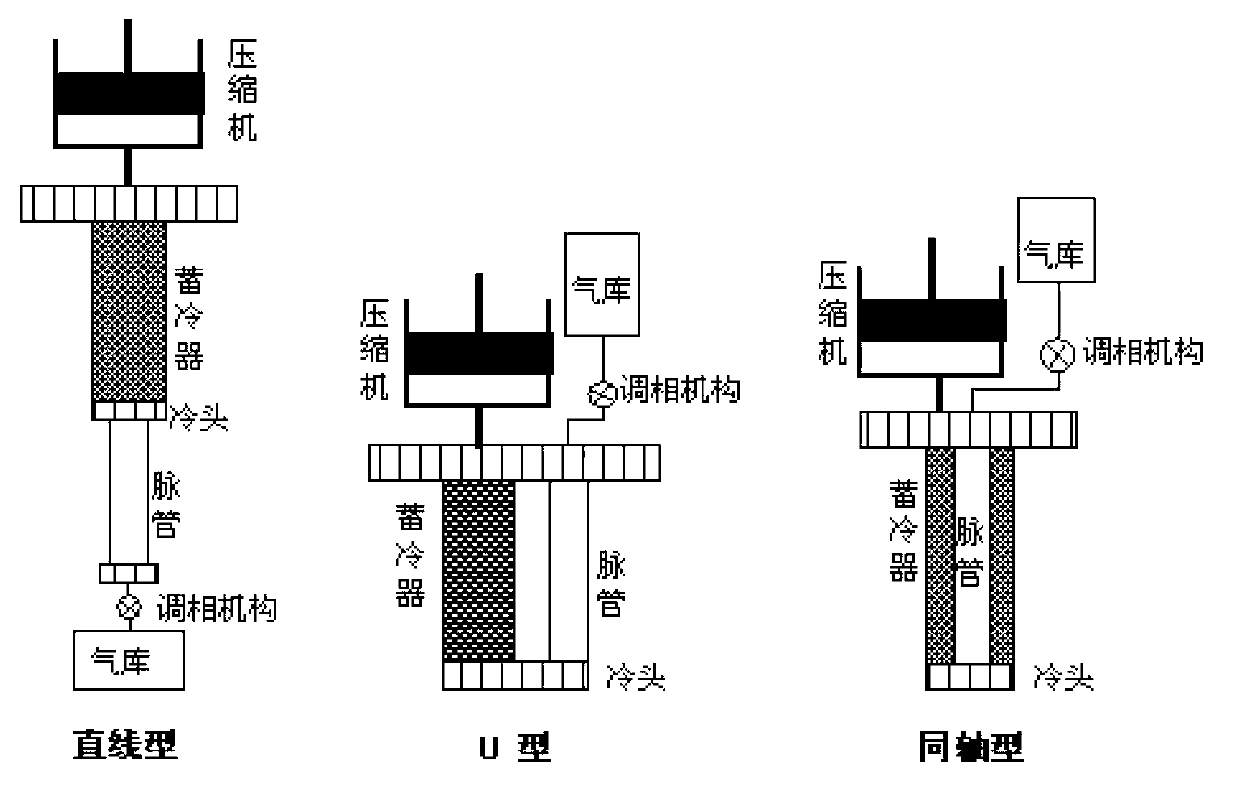

The pulse tube refrigerator (PTR) or pulse tube cryocooler is a developing technology that emerged largely in the early 1980s with a series of other innovations in the broader field of thermoacoustics. In contrast with other cryocoolers (e.g. Stirling cryocooler and GM-refrigerators), this cryocooler can be made without moving parts in the low temperature part of the device, making the cooler suitable for a wide variety of applications.

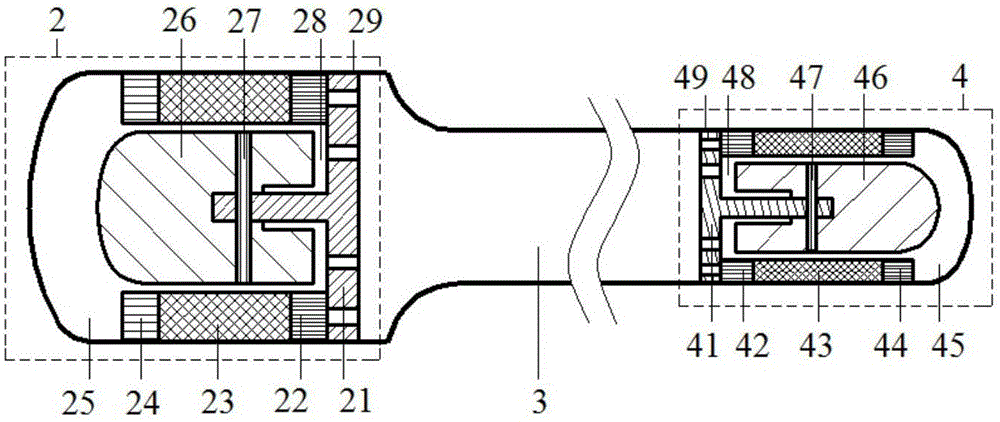

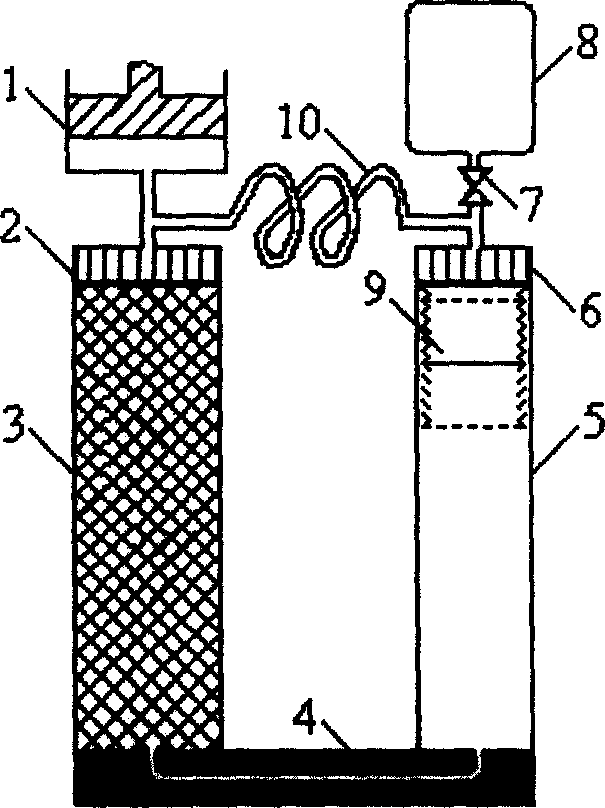

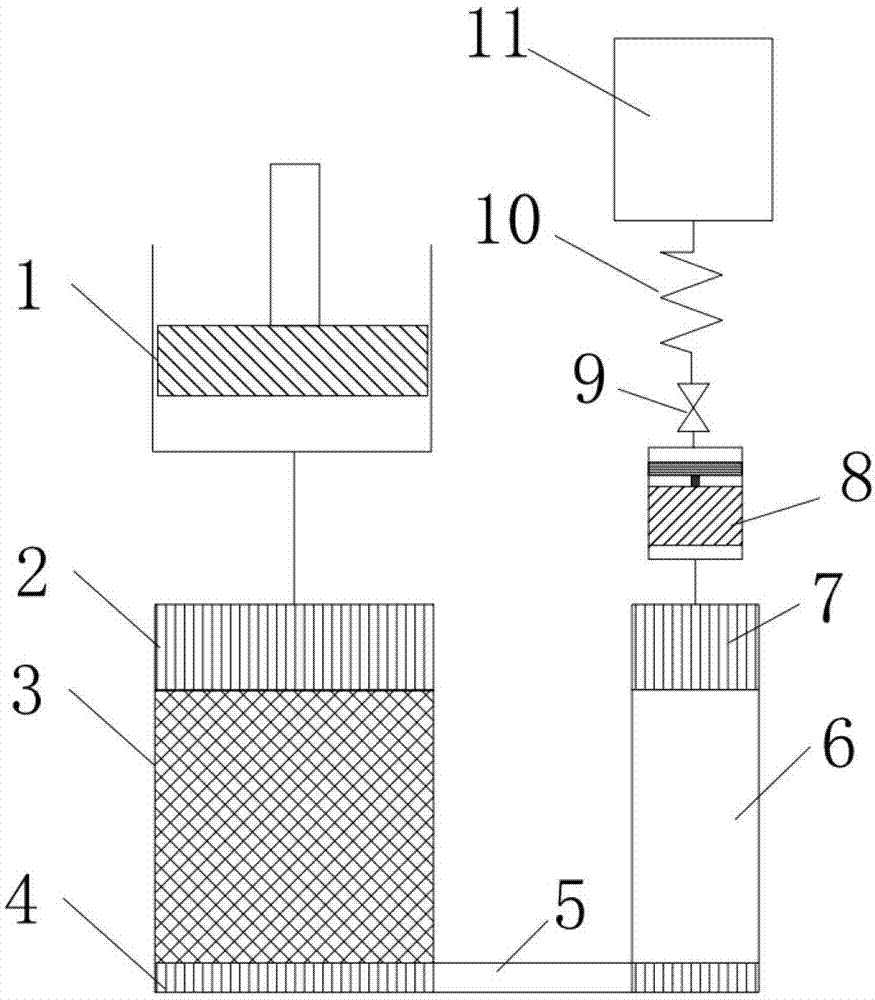

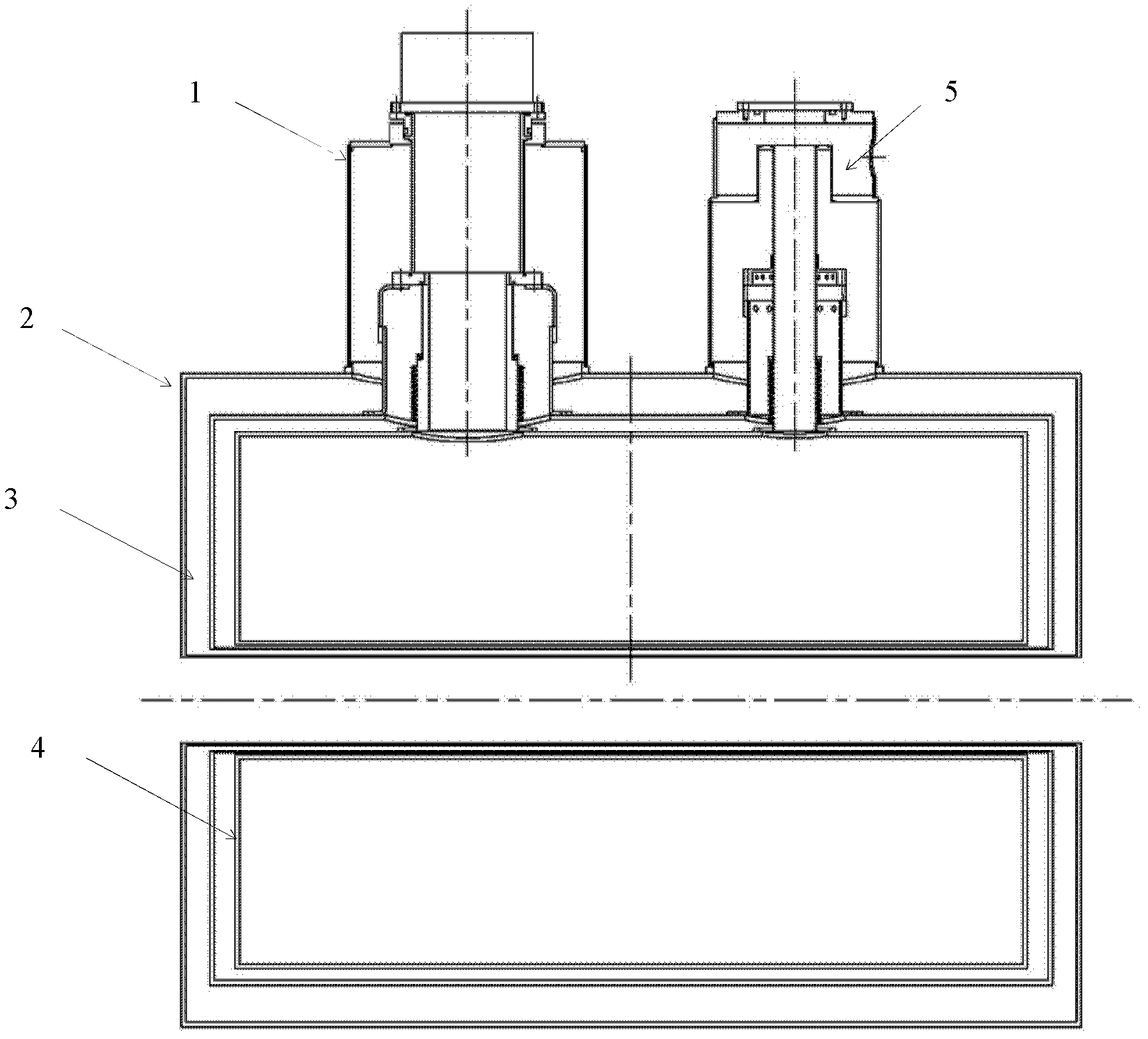

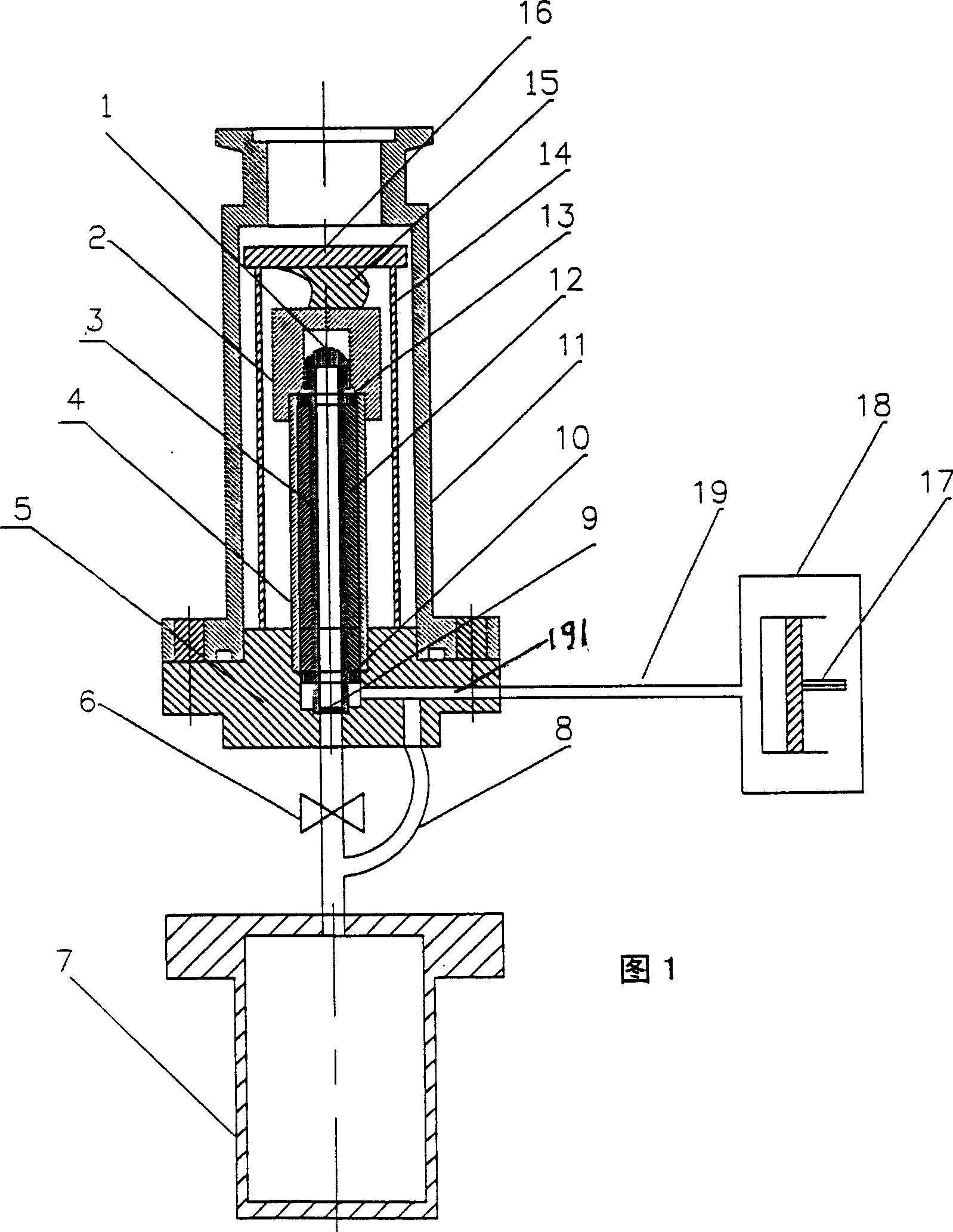

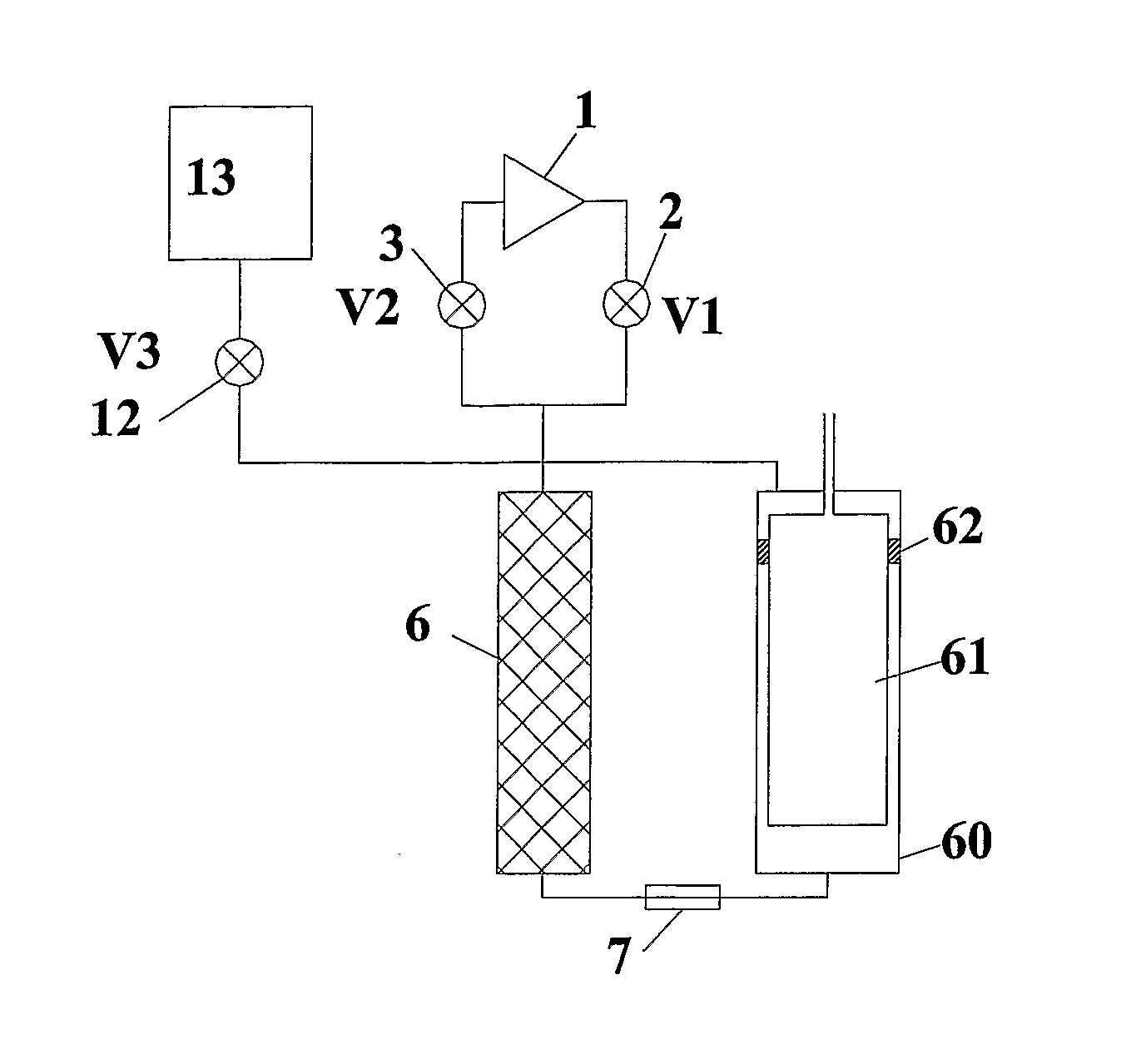

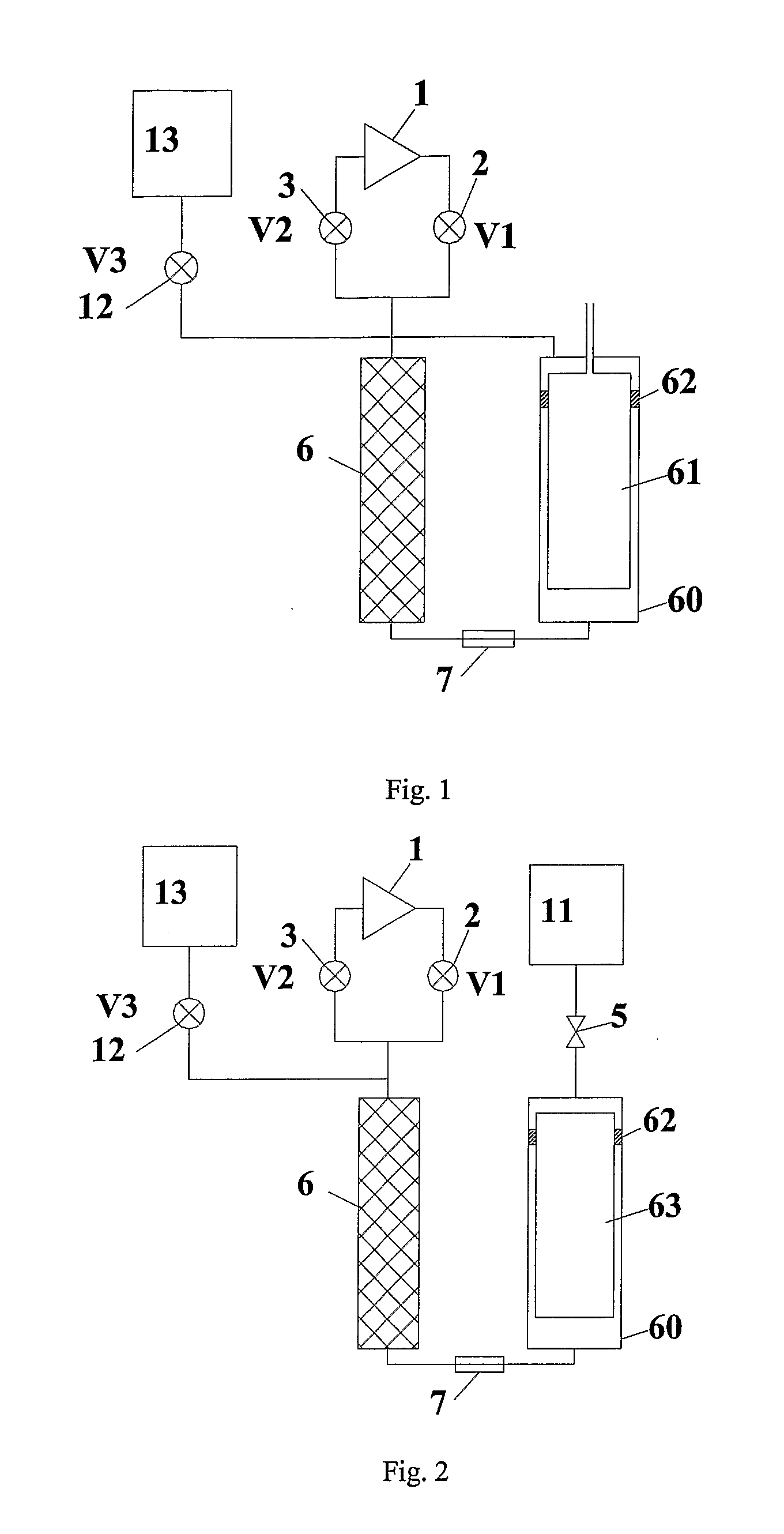

Thermally driven pulse tube refrigerator system

ActiveCN105066500AReduce vibrationReduce processing difficultyCompression machinesPulse tube refrigeratorCore component

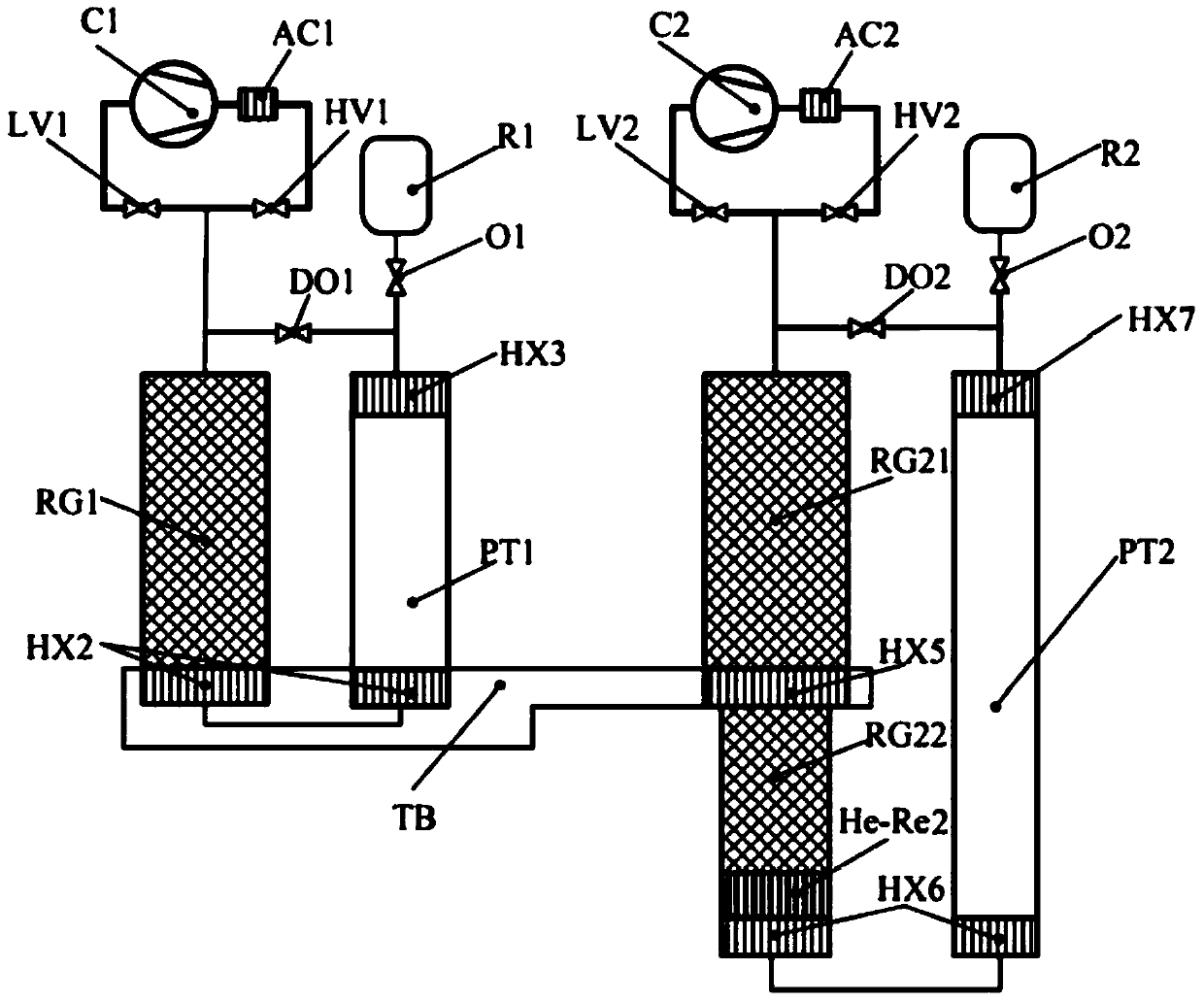

The invention discloses a thermally driven pulse tube refrigerator system which comprises one or two free piston stirling engines, one or two pulse tube refrigerators and one or two acoustic resonance tubes, wherein each acoustic resonance tube is a first-class diameter or variable diameter pipe; each free piston stirling engine and each pulse tube refrigerator are respectively connected to two sides of each acoustic resonance tube; acoustic power generated by the free piston stirling engines is transmitted to the pulse tube refrigerators through the acoustic resonance tubes; the pulse tube refrigerators generate the refrigerating effect; the acoustic resonance tubes not only can play an acoustic power transmission role, but also can play an acoustic field phase modulation role; the acoustic fields in thermo-acoustic and acoustic-cold conversion core components, namely refrigerator regenerators, of the thermally driven pulse tube refrigerator are traveling wave phases; the thermal efficiency is high; meanwhile, no mechanical motion component is arranged in the pulse tube refrigerator; the thermally driven pulse tube refrigerator system has low vibration and high reliability; the refrigerating capacity from hectowatts to kilowatts or even higher can be obtained within a temperature region of 60-150K.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

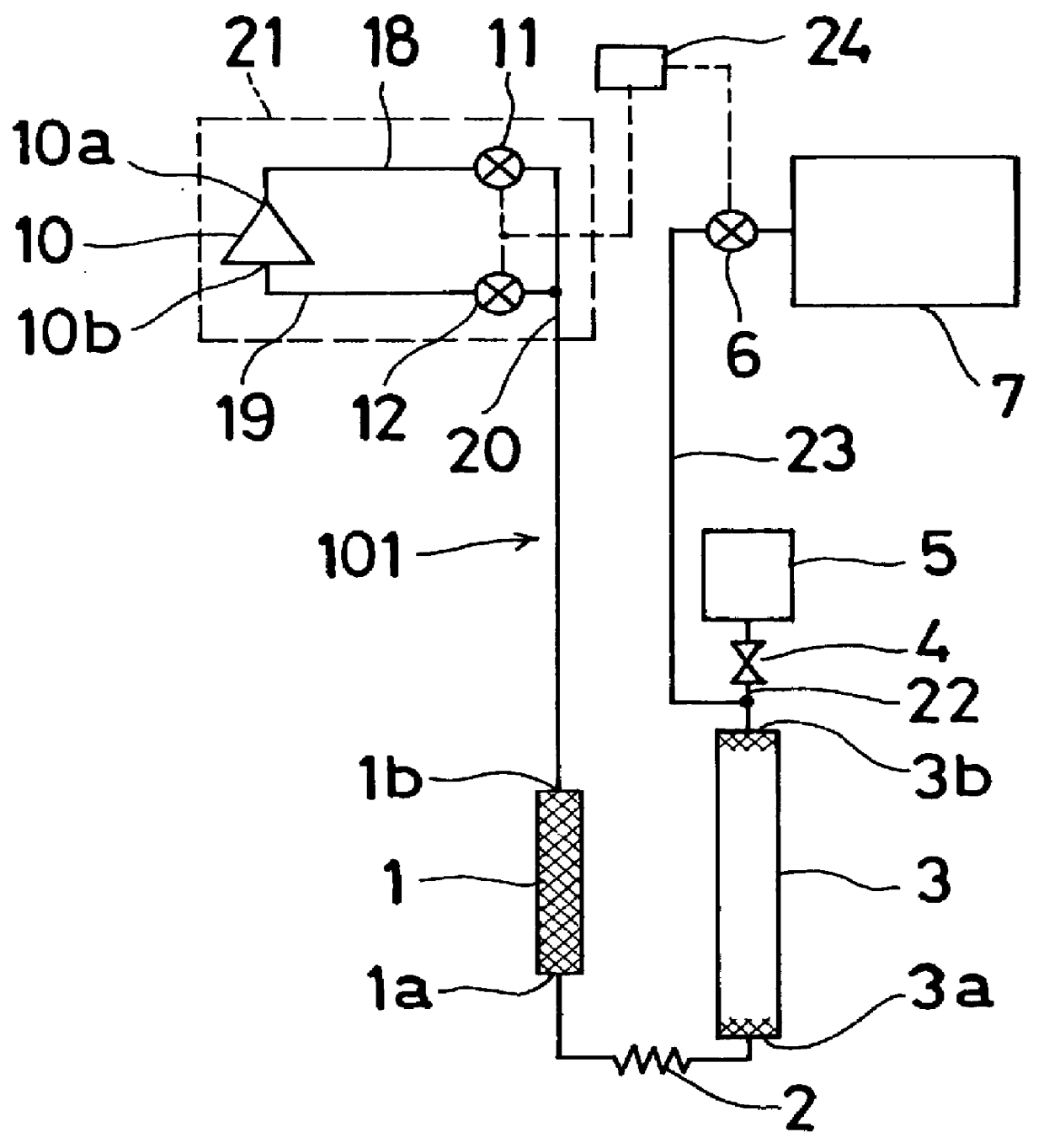

Pulse tube refrigerator

InactiveUS6094921ASuppress relative displacementSuppress fluctuationsCompression machinesGas cycle refrigeration machinesPulse tube refrigeratorEngineering

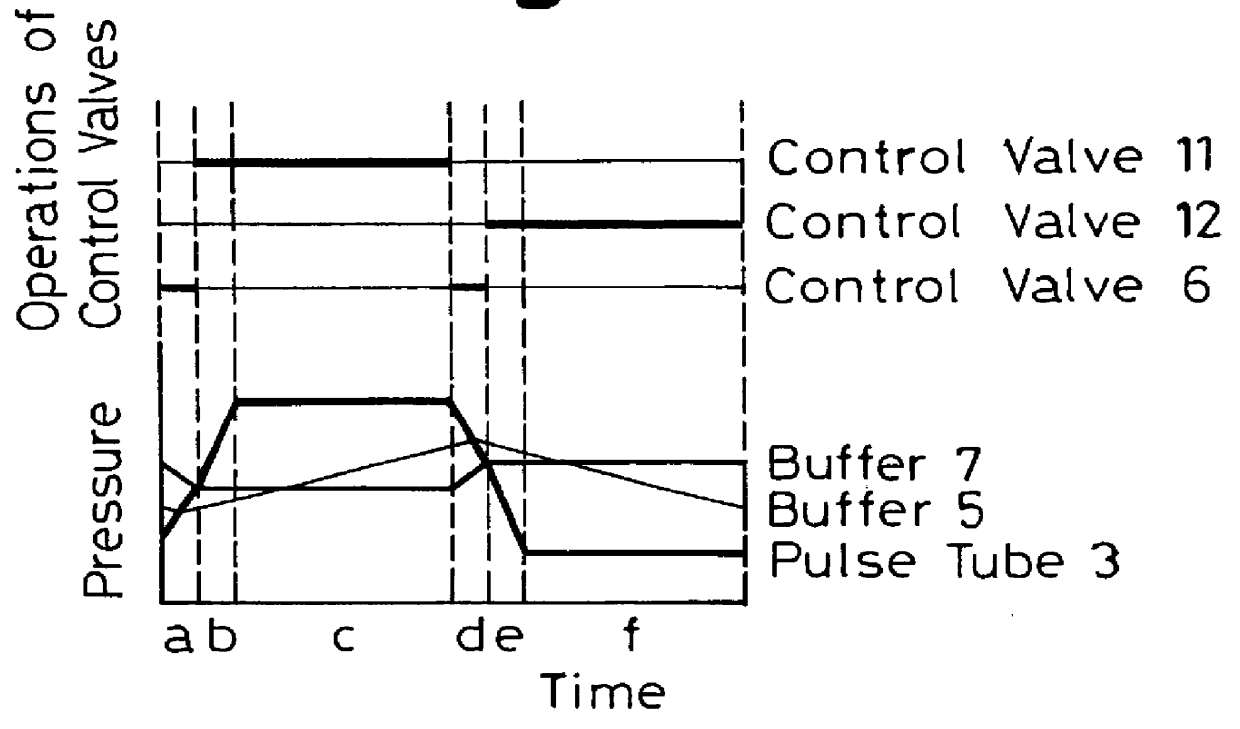

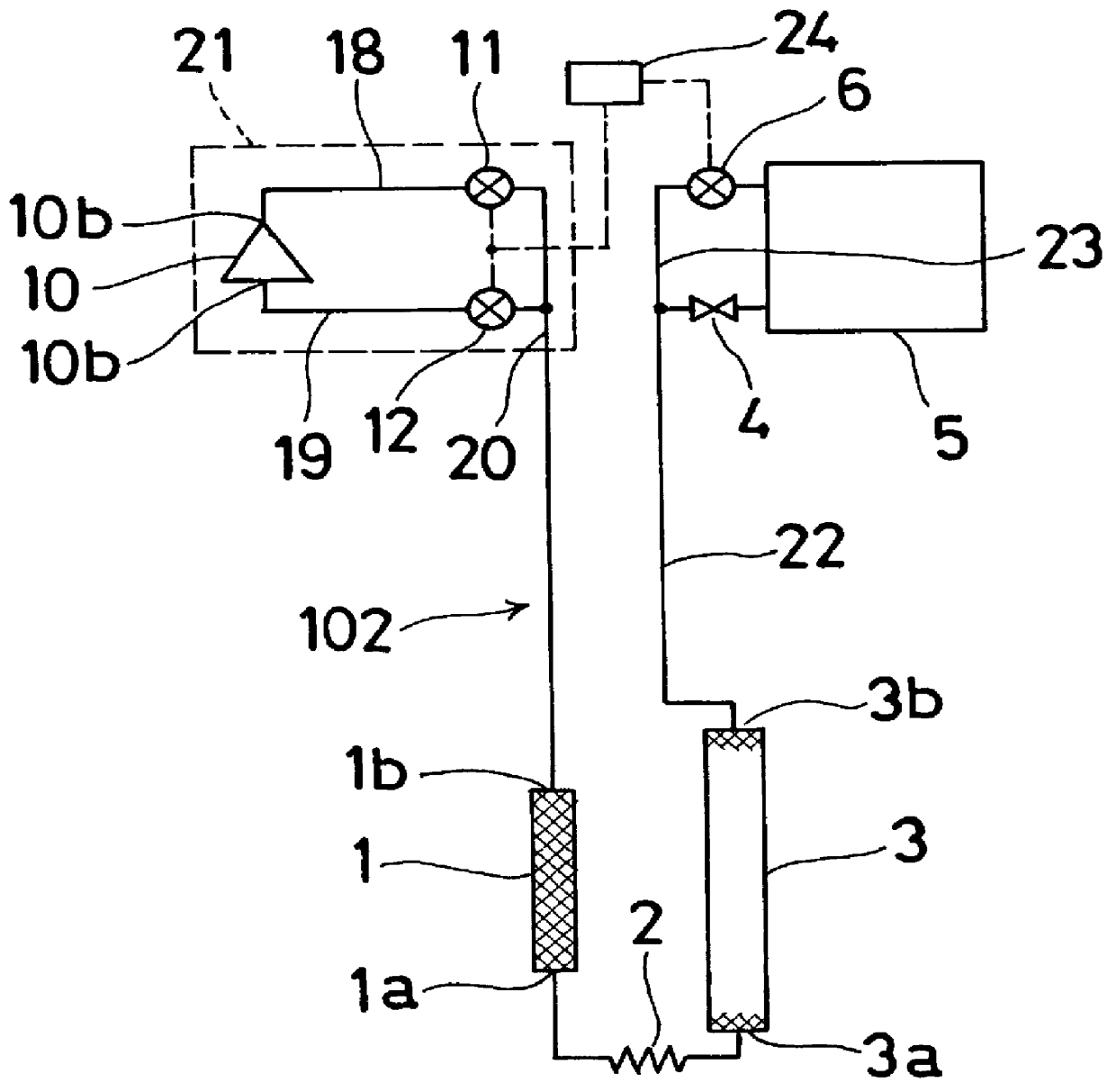

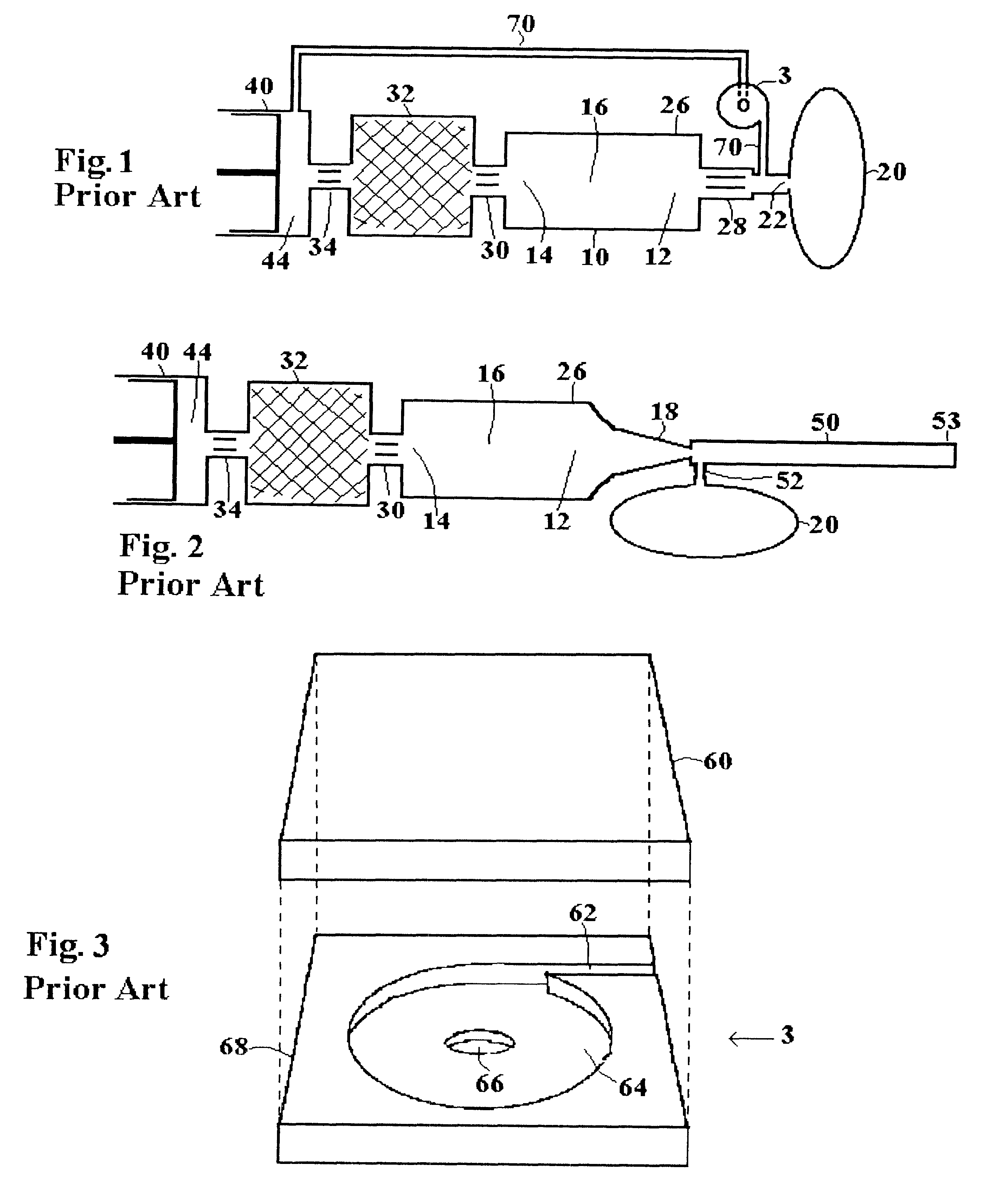

A pulse tube refrigerator includes a regenerator including a cold end and a hot end, a cold head connected to the cold end of the regenerator, a pulse tube having a cold end and a hot end and connected at its cold end to the cold head, a pressure fluctuation source connected to the hot end of the regenerator, a buffer connected to the hot end of the pulse tube through an orifice, and an auxiliary buffer connected to the hot end of the pulse tube through a buffer side control valve. The buffer and the auxiliary buffer may be replaced by a single buffer connected to the hot end of the pulse tube through an orifice and a buffer side control valve which are arranged in parallel.

Owner:AISIN SEIKI KK

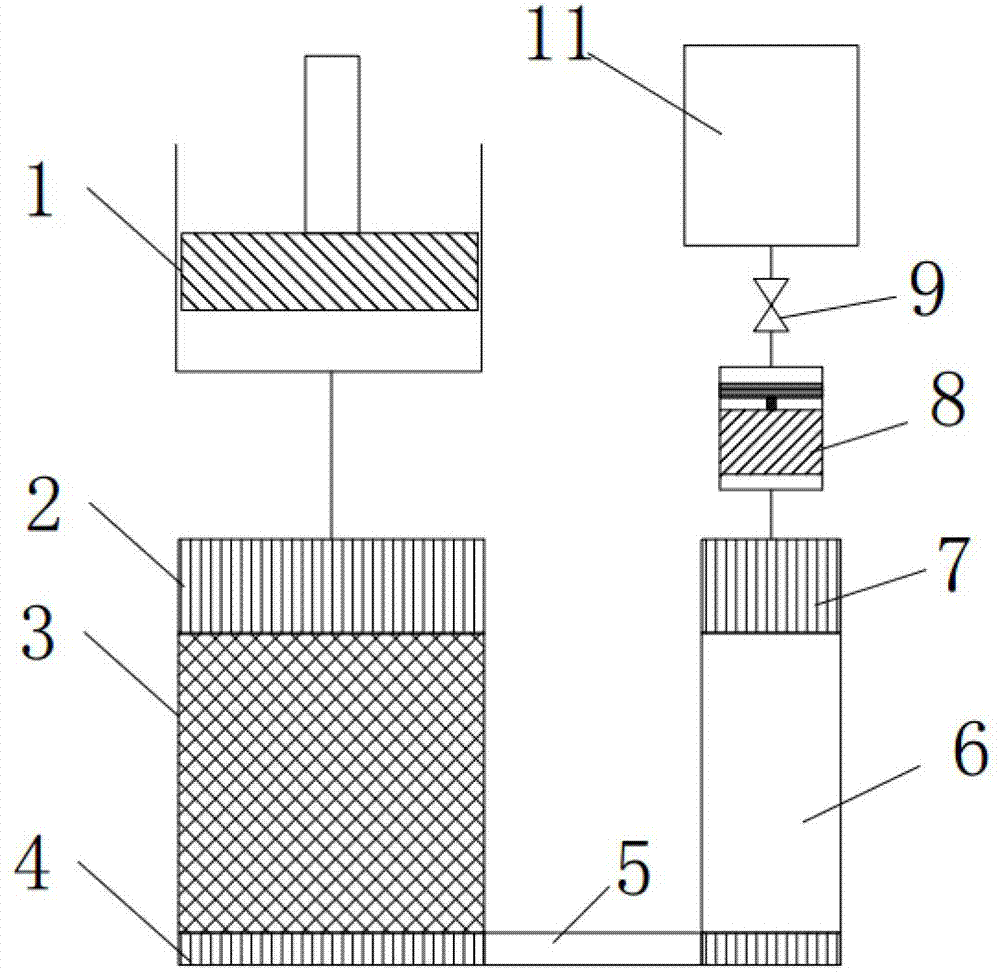

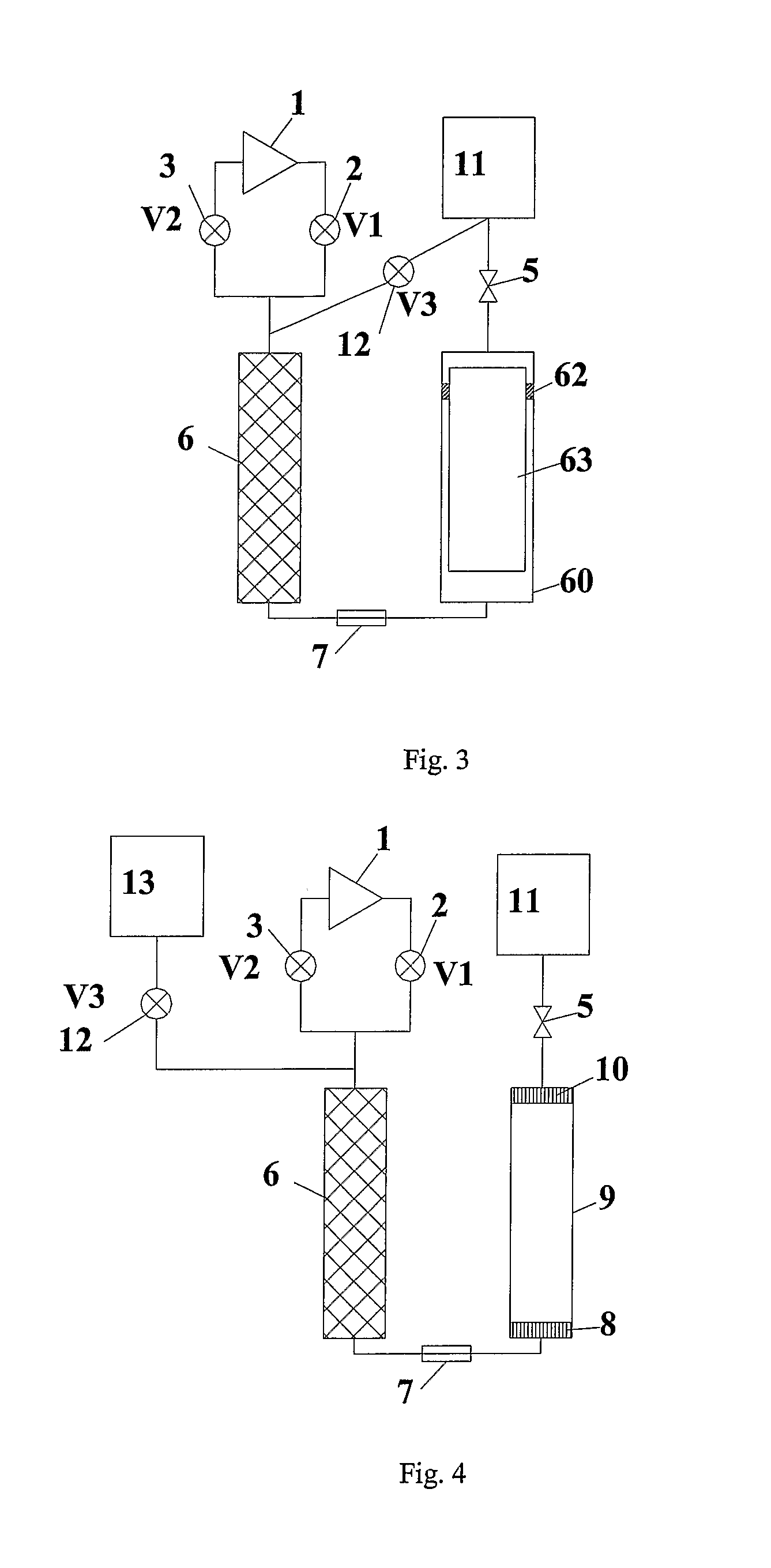

Pulse tube refrigerator with elastic air reservoir

InactiveCN101832675AShorten pre-cooling timeReduce chargeCompression machinesGas cycle refrigeration machinesPulse tube refrigeratorEngineering

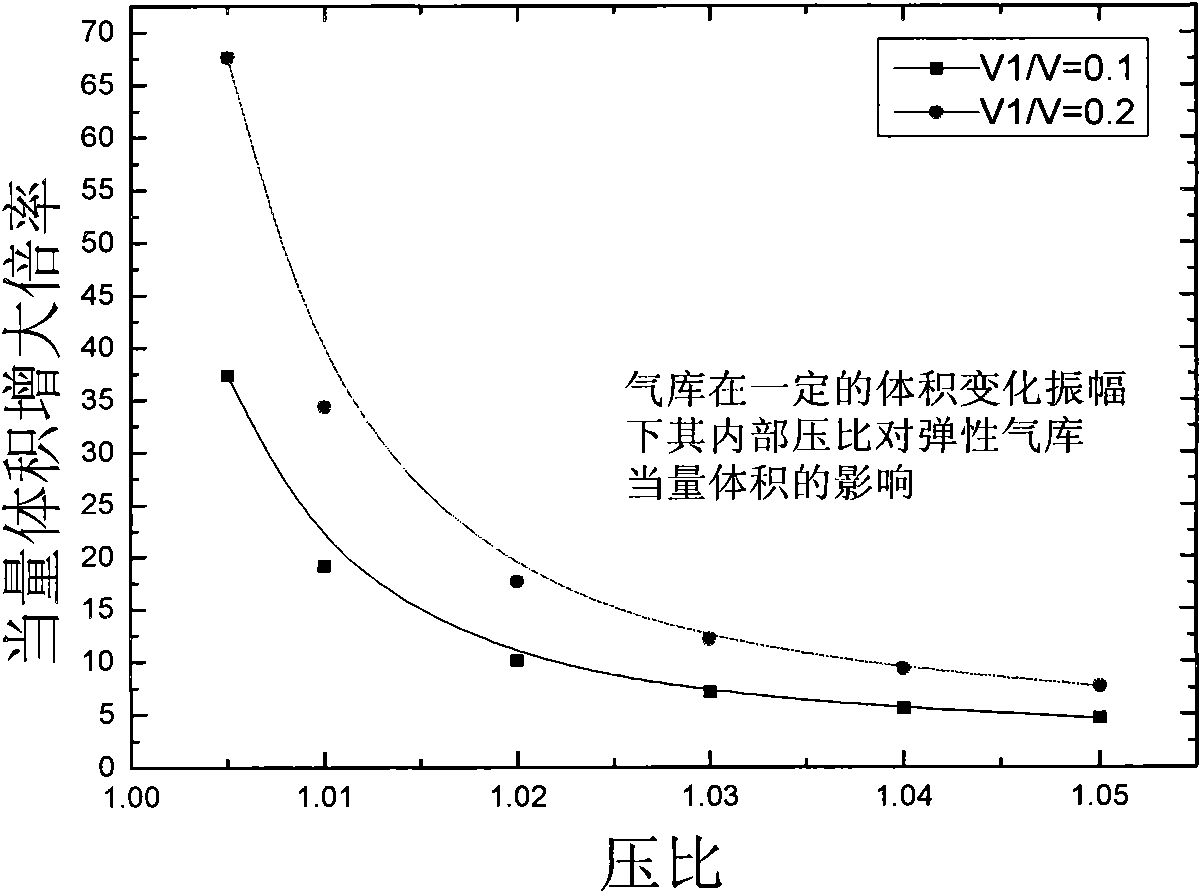

The invention discloses a pulse tube refrigerator with an elastic air reservoir. The pulse tube refrigerator comprises a compressor, a transport tube, a water cooler, a heat regenerator, a cold end connecting pipe, a cold end heat exchanger, a pulse tube, a hot end heat exchanger, an inertance tube and an elastic air reservoir. The compressor is sequentially connected with the transport tube, thewater cooler, the heat regenerator, the cold end connecting pipe, the cold end heat exchanger, the pulse tube, the hot end heat exchanger, the inertance tube and the elastic air reservoir. A pulse tube refrigerator is usually provided with a huge air reservoir to obtain a better performance. The pulse tube refrigerator with the elastic air reservoir can obtain the same phase modulation effect with just a few percent of a common air reservoir in volume after employing the elastic air reservoir, so that the whole system becomes compact, and the charging quantity of working medium is reduced, which is particularly important for rare helium-4 and helium-3. As for the air reservoir in low temperature, the elastic air reservoir can shorten the cooling time and accelerate the cooling speed of a system.

Owner:ZHEJIANG UNIV

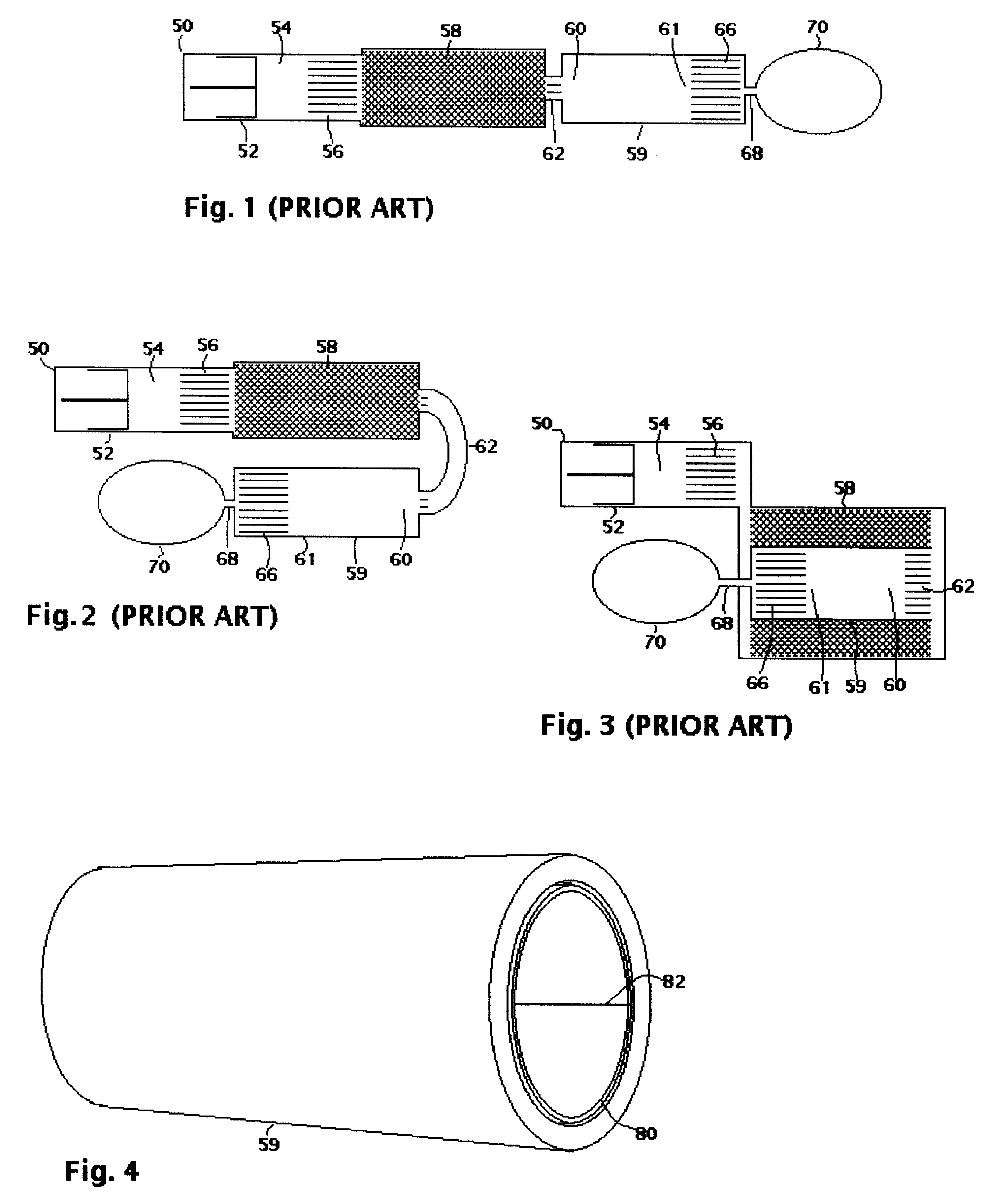

Inertance tube and surge volume for pulse tube refrigerator

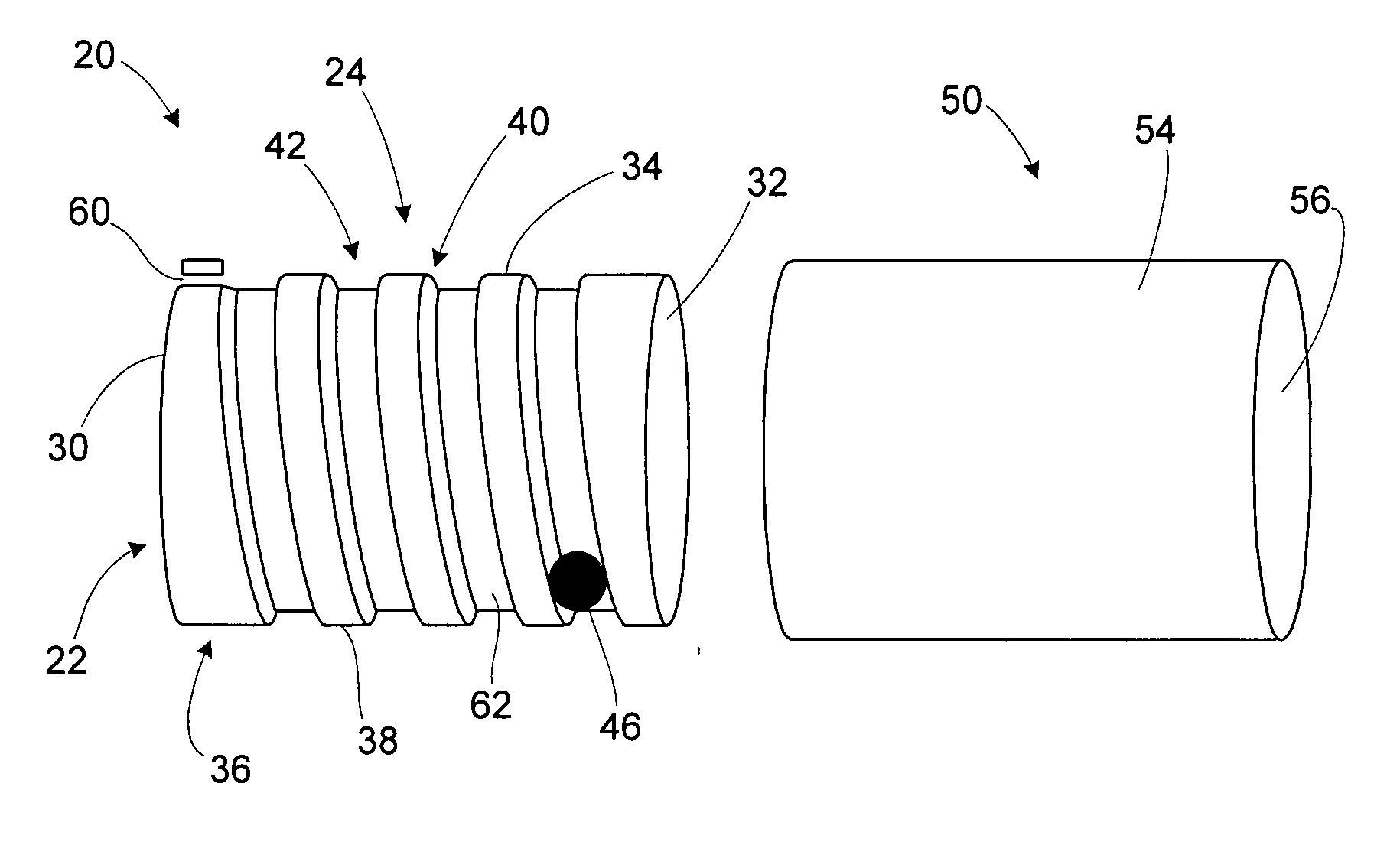

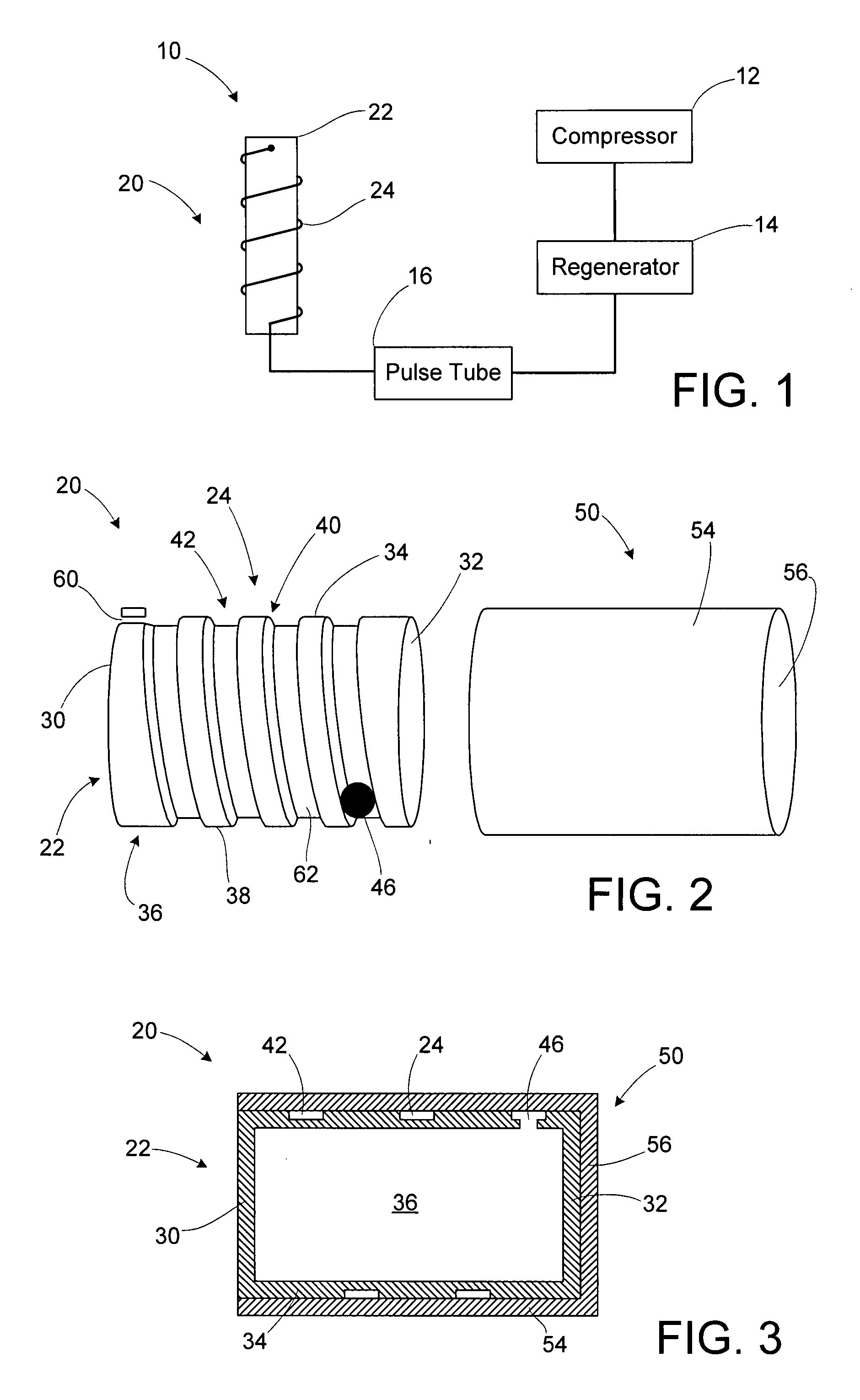

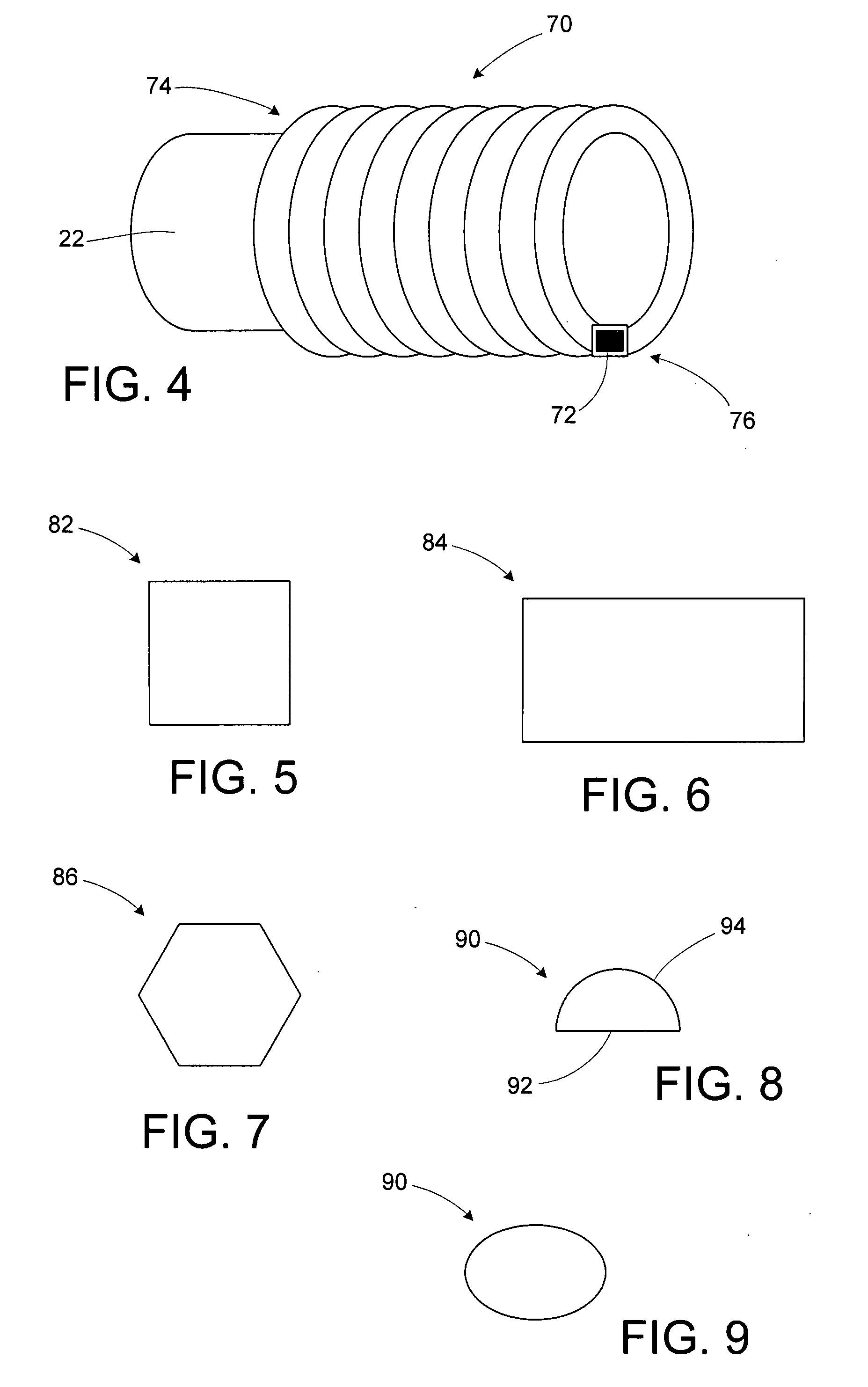

An inertance tube and a surge volume for a pulse tube refrigerator system may be integrally coupled together, such as by the inertance tube being at least in part a channel in a wall of the surge volume. The surge volume may have a helical channel in an outer wall that forms part of the inertance tube. The surge volume tank may be surrounded by a cover that closes off the channel to form the inertance tube as an integral part of the surge volume. The inertance tube may have a non-circular cross section shape, such as a square shape or non-square rectangular shape. The channel may be tapered, perhaps changing aspect ratio. Alternatively, the inertance tube may be a separate tube having a non-circular shape, which may be wrapped around at least part of the surge volume.

Owner:RAYTHEON CO

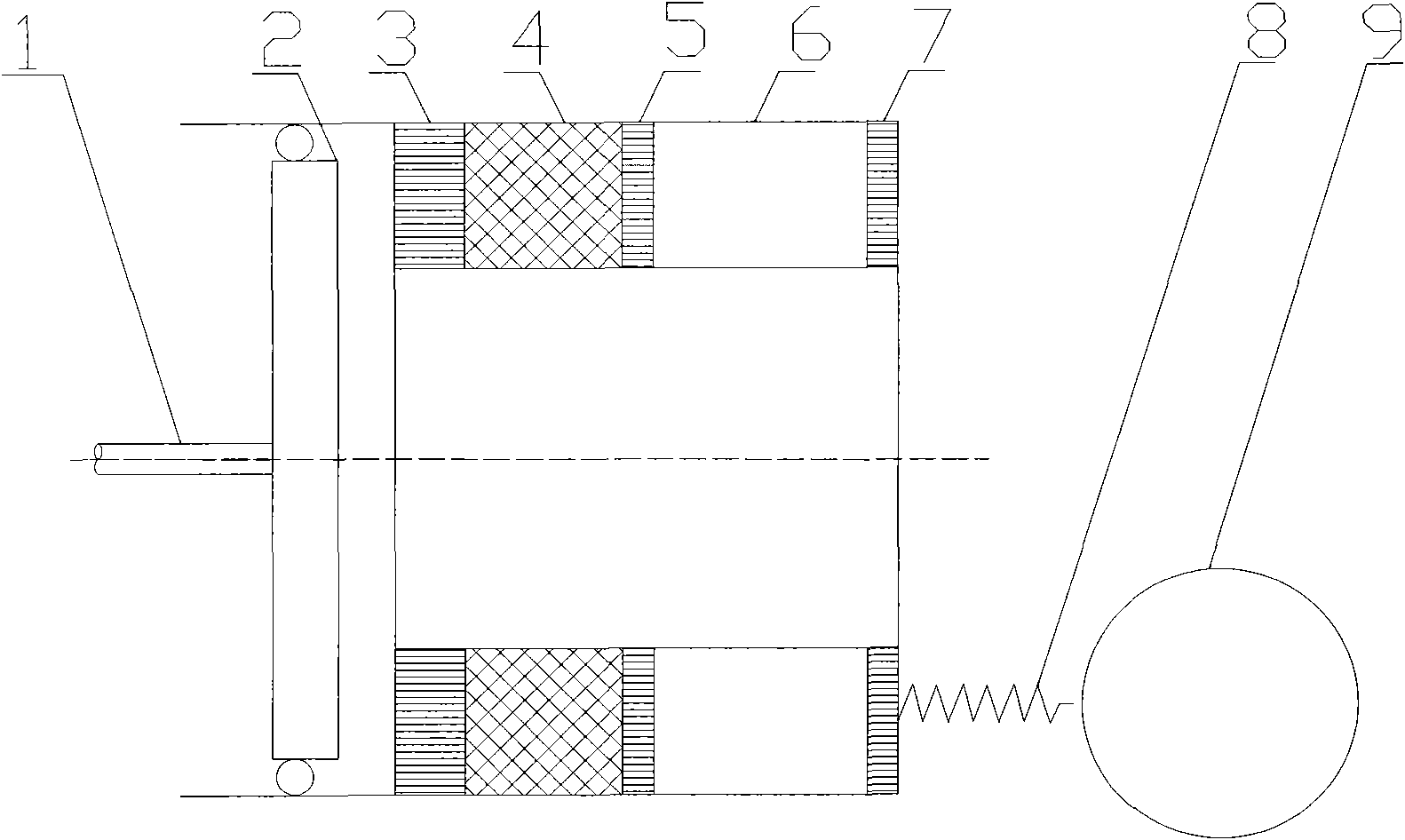

Double inlet arrangement for pulse tube refrigerator with vortex heat exchanger

InactiveUS6442947B1Improve cooling effectEasy to makeCompression machinesGas cycle refrigeration machinesPulse tube refrigeratorMicro heat exchanger

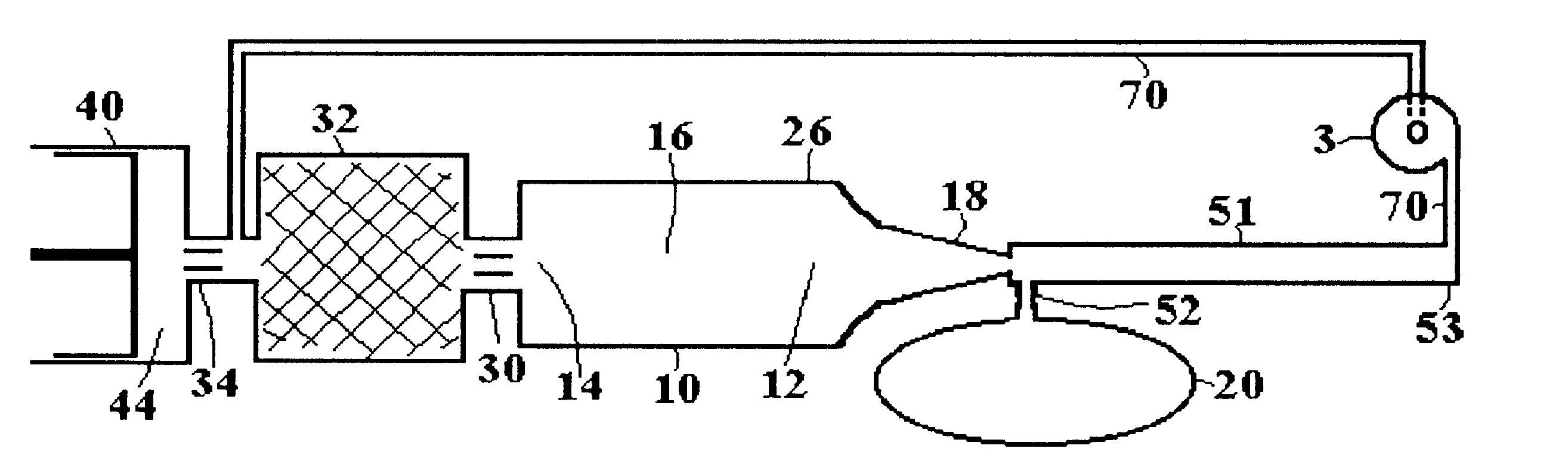

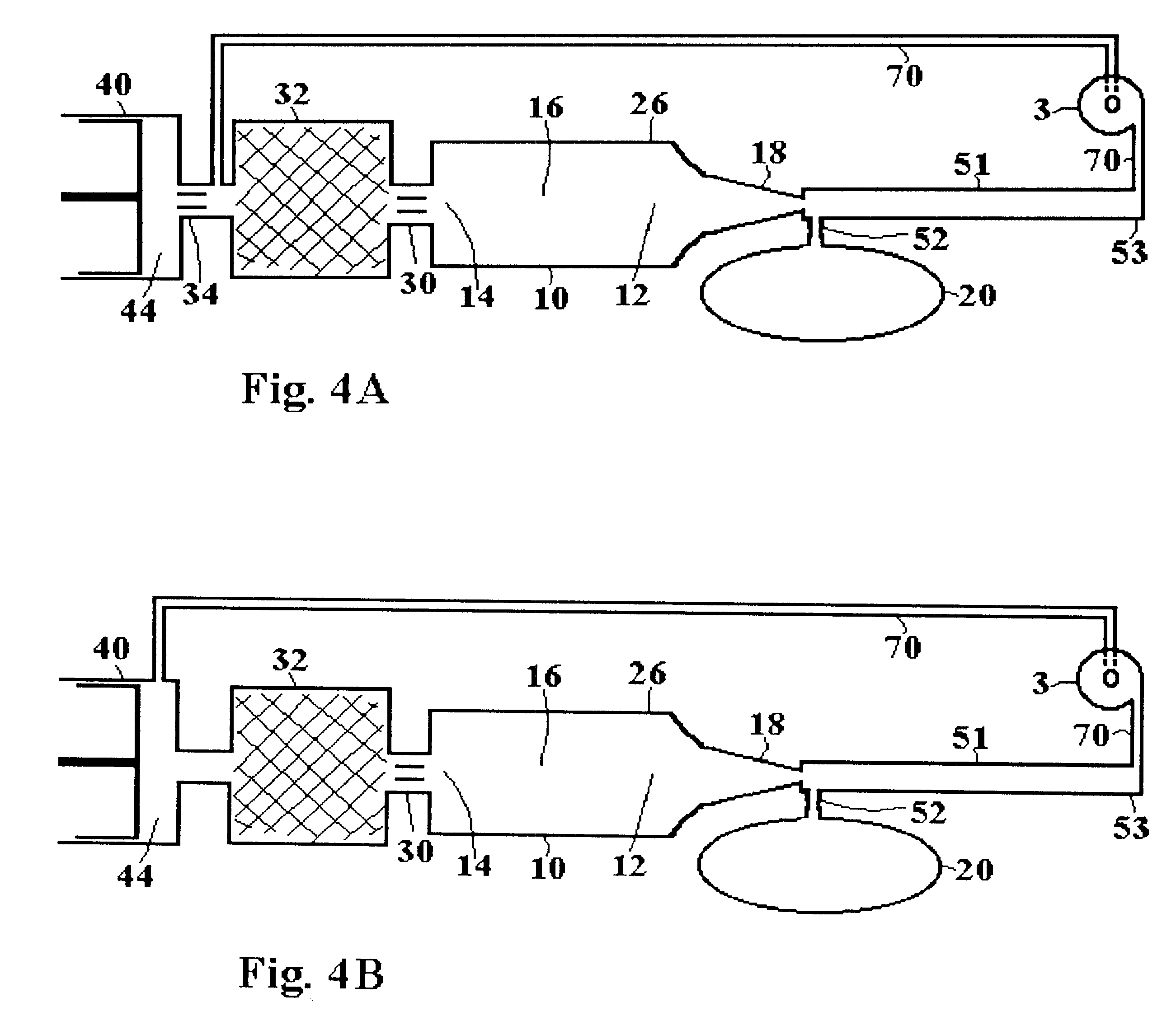

A double inlet passage 70 connects a compressor 40 to remote end 53 of a vortex tube 51 that serves as the heat-rejecting heat exchanger of an orifice pulse tube refrigerator. Double inlet passage 70 includes means 3 for controlling DC flow in that passage. Fluid flows between compressor and reservoir enhance heat-rejecting effectiveness of vortex tube 51.

Owner:MITCHELL MATTHEW P

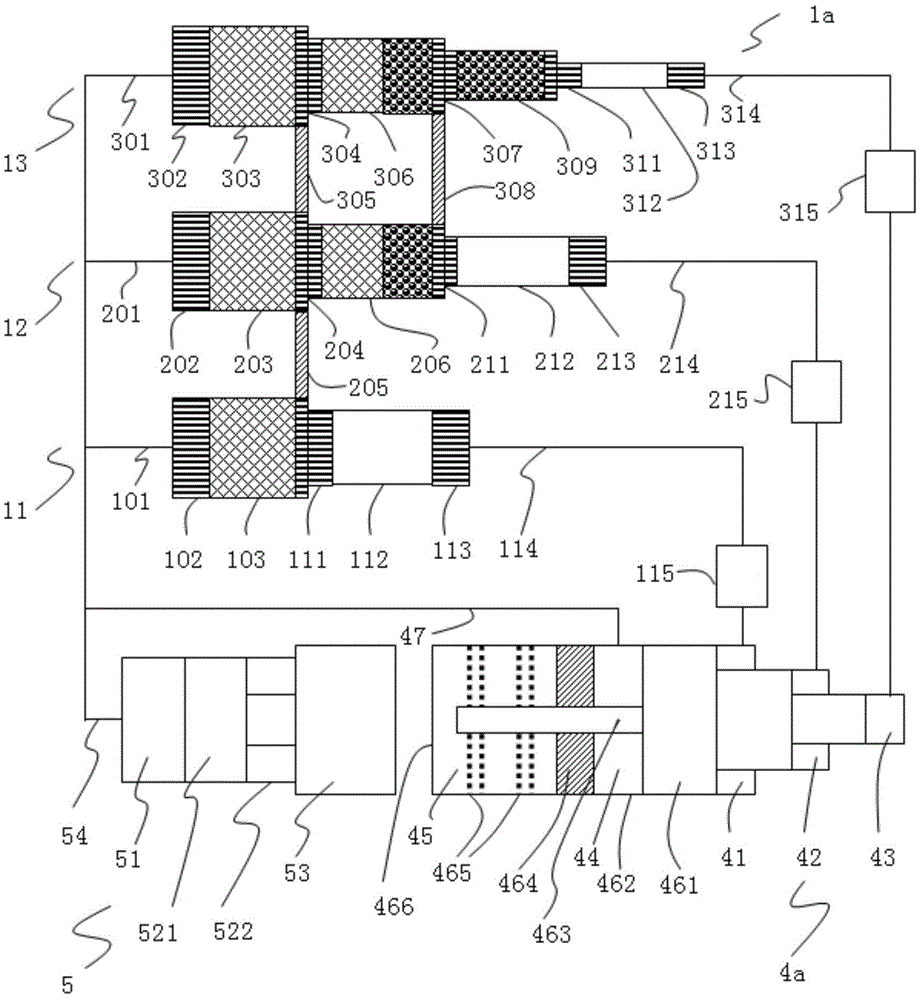

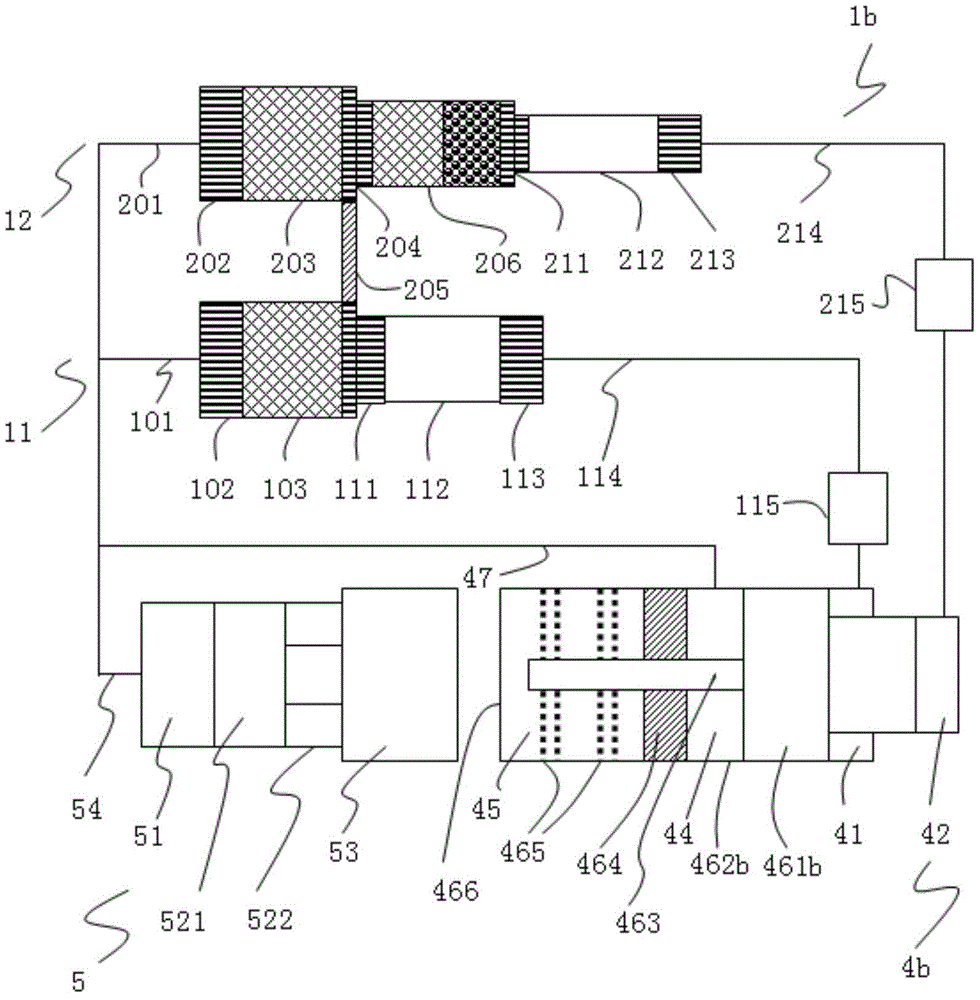

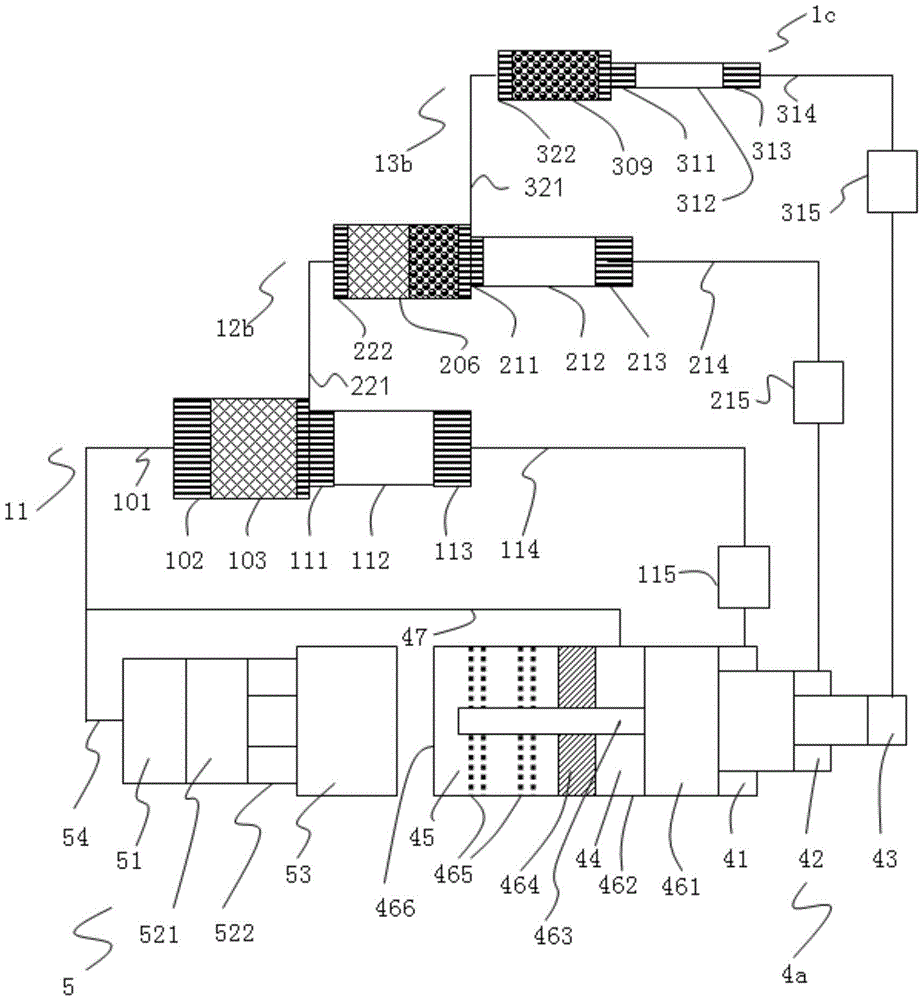

Linear type double-acting refrigeration system

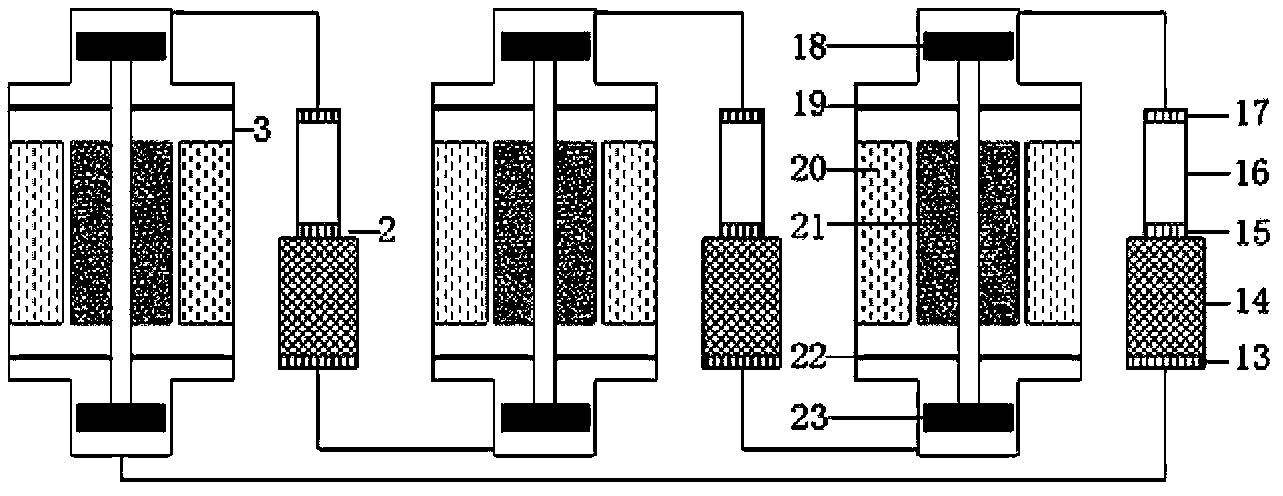

ActiveCN103353184AImprove efficiencySolve Phase ProblemsCompression machinesPulse tube refrigeratorLinear motor

The invention relates to a linear type double-acting refrigeration system. The linear type double-acting refrigeration system consists of N pulse tube refrigerators and N-1 linear type double-acting compressors, which are serially connected between a linear type compressor and a linear type electric generator in sequence and arranged at intervals, wherein the linear type compressor is positioned at the beginning end of the system, and the linear type electric generator is positioned at the tail end of the system; each of the linear type compressor and the linear type electric generator works in a single-piston manner; two pistons of each linear type double-acting compressor work at the same time; N is a positive integer of 2-20. According to the system, inertial tubes and air reservoirs or two-way air inlet equal phase-modulation structures in a traditional pulse tube refrigerator are omitted, so that the structure is compact; required phase can be realized by adjusting the frequency characteristics of linear motors at both ends of each pulse tube refrigerator and motion phases of compression pistons and expansion pistons; the flow-out sound power of the refrigerators is free of dissipation, and is absorbed by the expansion pistons of the linear motors, so that high efficiency and large refrigerating capacity can be obtained; the linear type double-acting refrigeration system has good application prospect in occasions requiring the refrigerators to obtain large refrigerating capacity, high efficiency and long service life.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

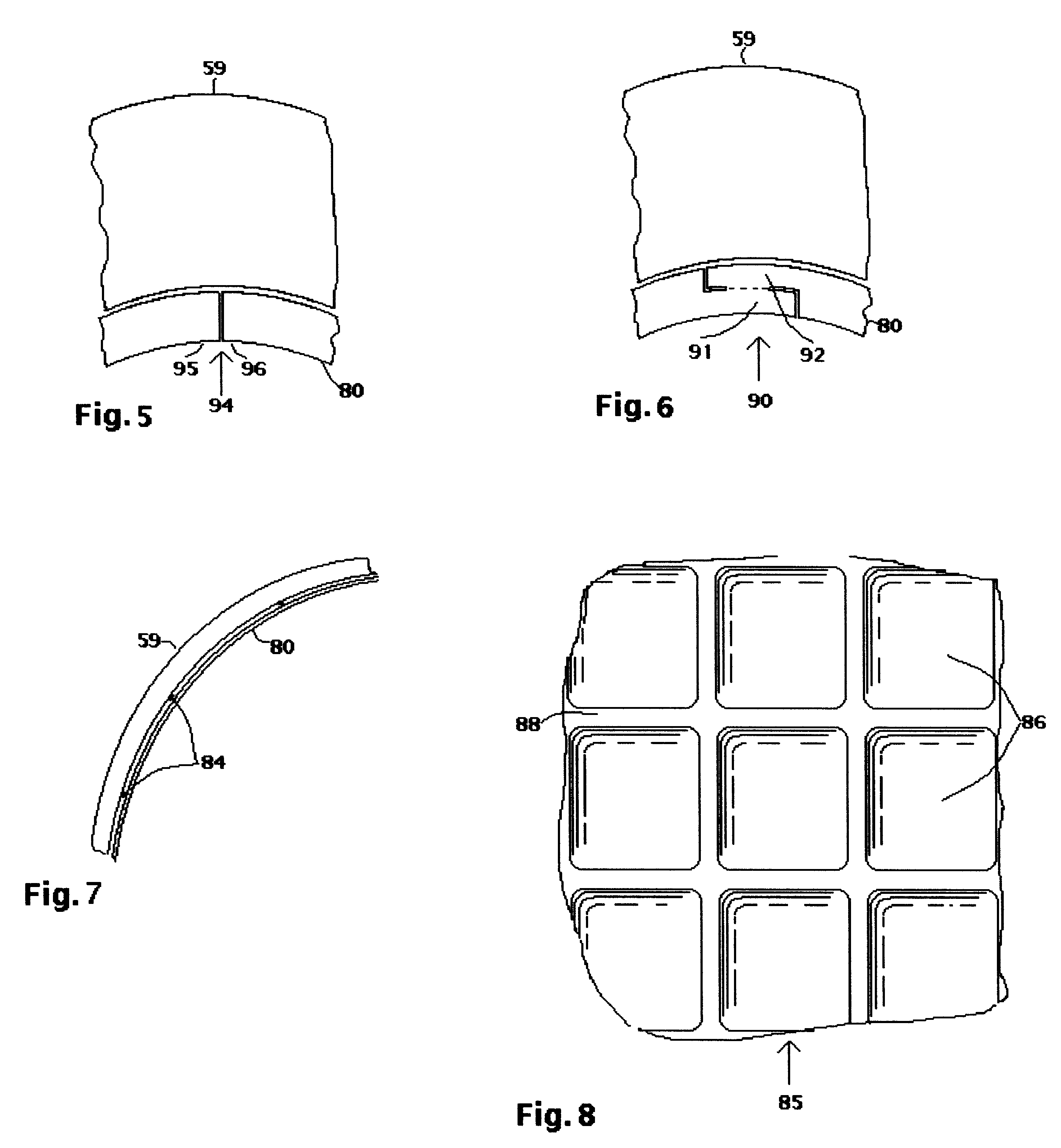

Pulse tube liner

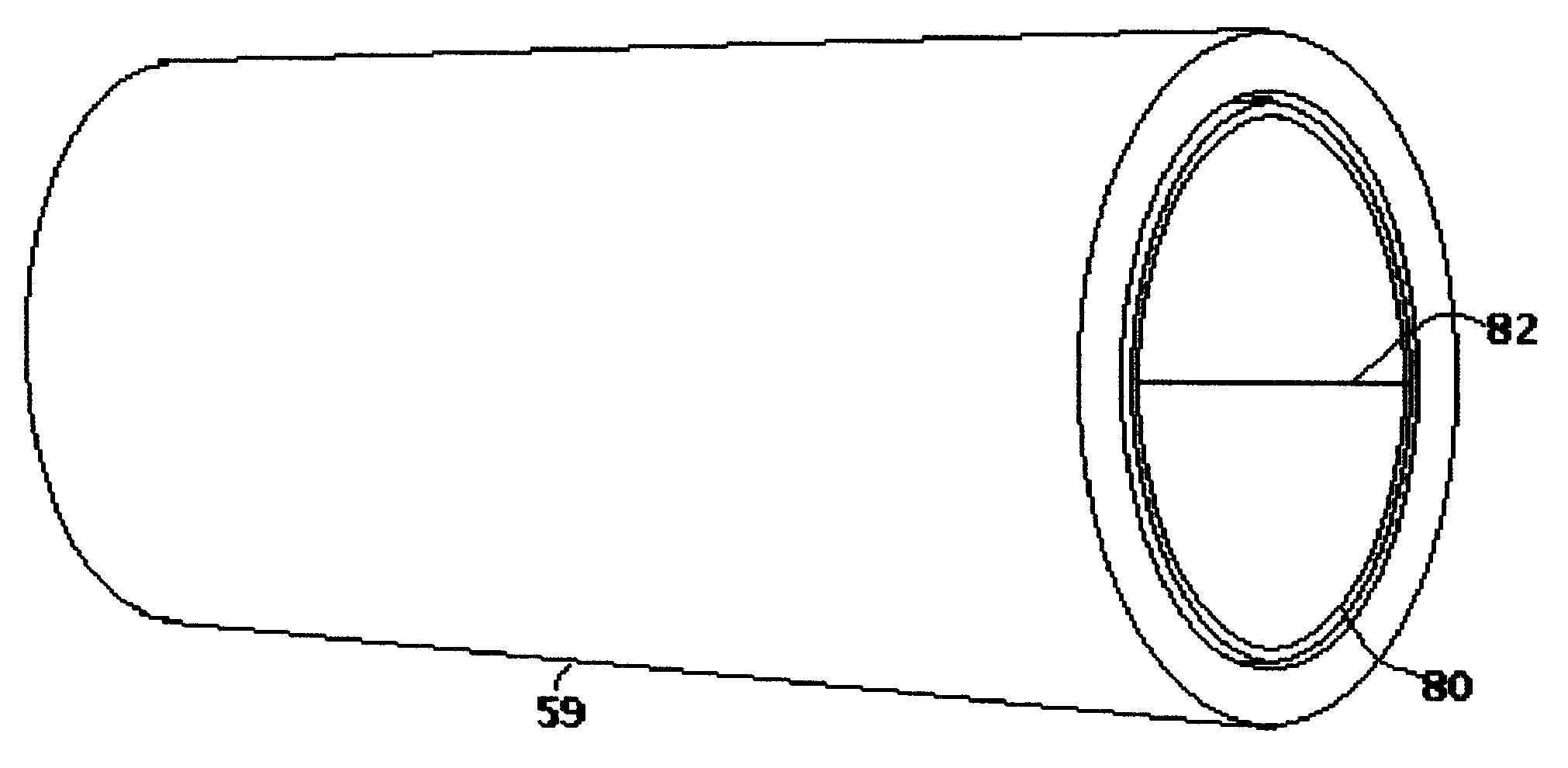

InactiveUS6619046B1Little changeReduce heating capacityCompression machinesGas cycle refrigeration machinesPulse tube refrigeratorEngineering

The pulse tube 59 of a pulse tube refrigerator is equipped with a thin liner 80 of low thermal mass and in poor thermal contact with pulse tube 59. One surface of liner 80 may be furnished with indented recesses 86, making the recessed portions of the liner thinner than the remainder of the material of liner.

Owner:MITCHELL MATTHEW P

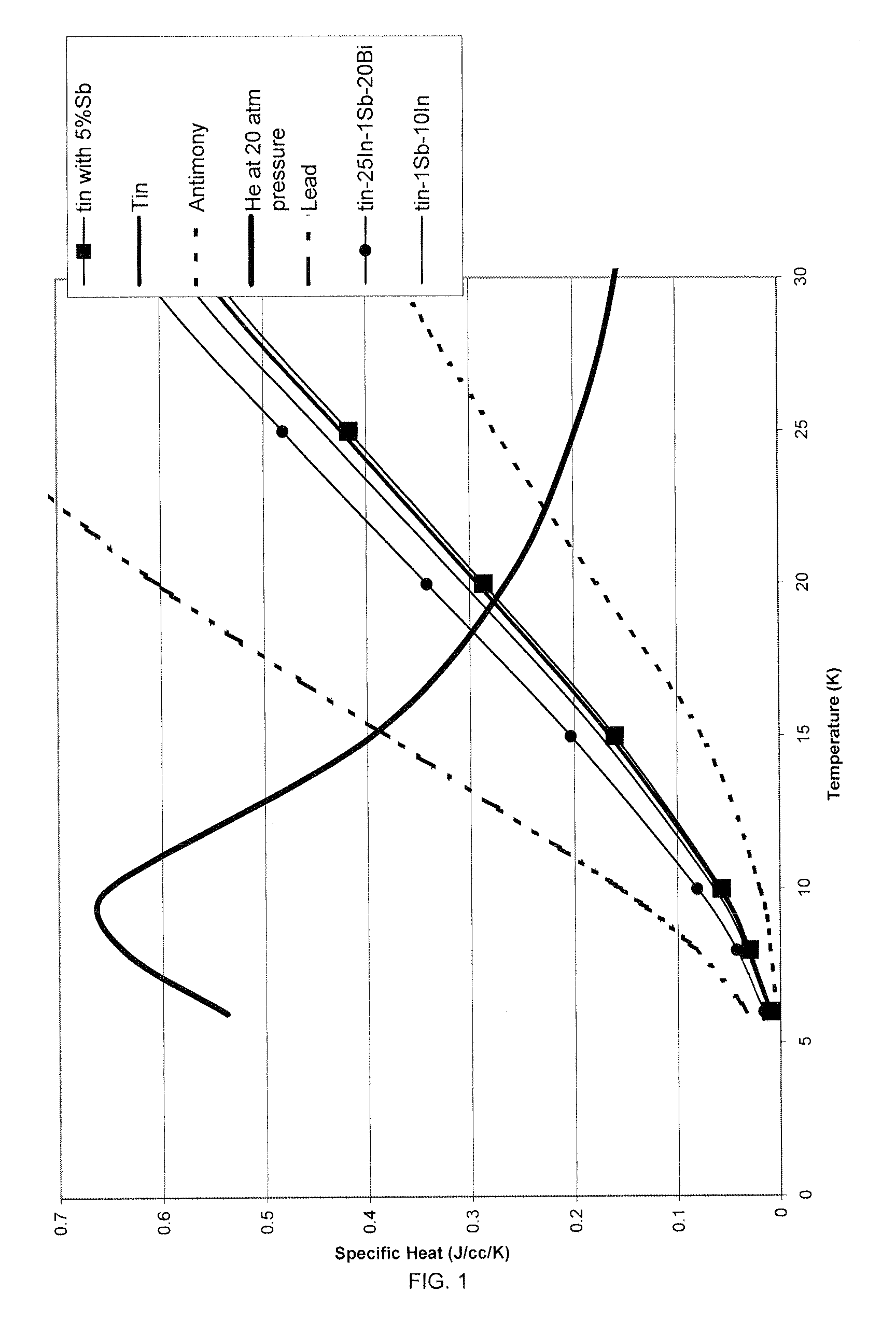

Cryogenic Pump Employing Tin-Antimony Alloys and Methods of Use

ActiveUS20110126553A1High volumetric heat capacityClean vacuum environmentPositive displacement pump componentsCompression machinesPulse tube refrigeratorRefrigerated temperature

A cryogenic refrigerator includes a regenerative heat exchanger material in thermal contact with a working gas including a tin-antimony (Sn—Sb) alloy or a tin-gallium (Sn—Ga) alloy in at least one cooling stage. The re-generative heat exchanger material can include an Sn—Sb-M alloy, with M including at least one element selected from the group consisting of Bi, Ag, Ge, Cu, La, Mg, Mn, Nd, Ni, Pd, Pt, K, Rh, Sm, Se, S, Y, Fe, In, Al, Ce, Dy, Cd, Ti, Au, P, Pr, Yb and Zn. The cryogenic refrigerator can include a Gifford-McMahon refrigerator, a pulse tube refrigerator, or a Stirling refrigerator. A cryopump includes cryopanels adapted to condense or adsorb gases and a cryogenic refrigerator.

Owner:EDWARDS VACUUM LLC

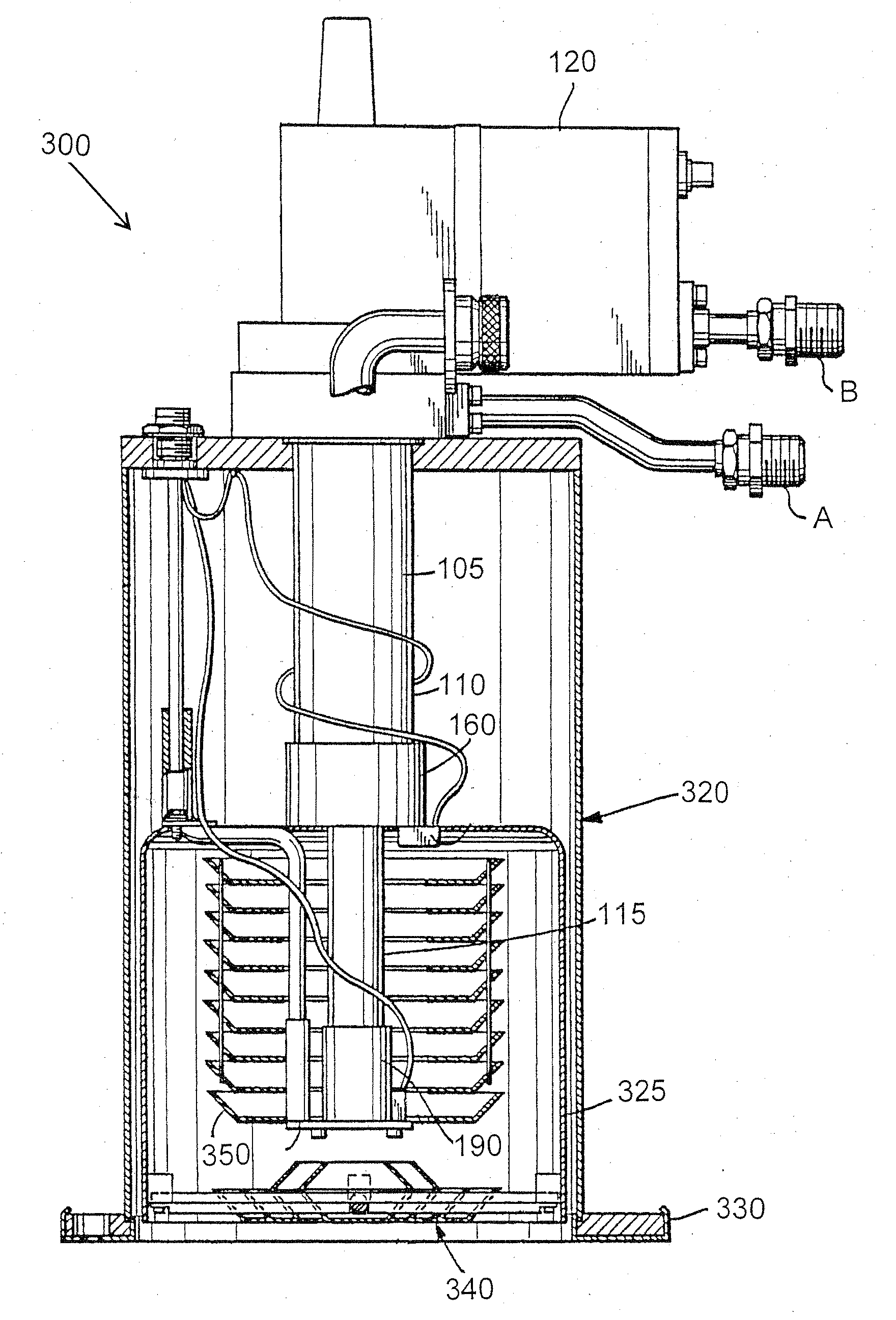

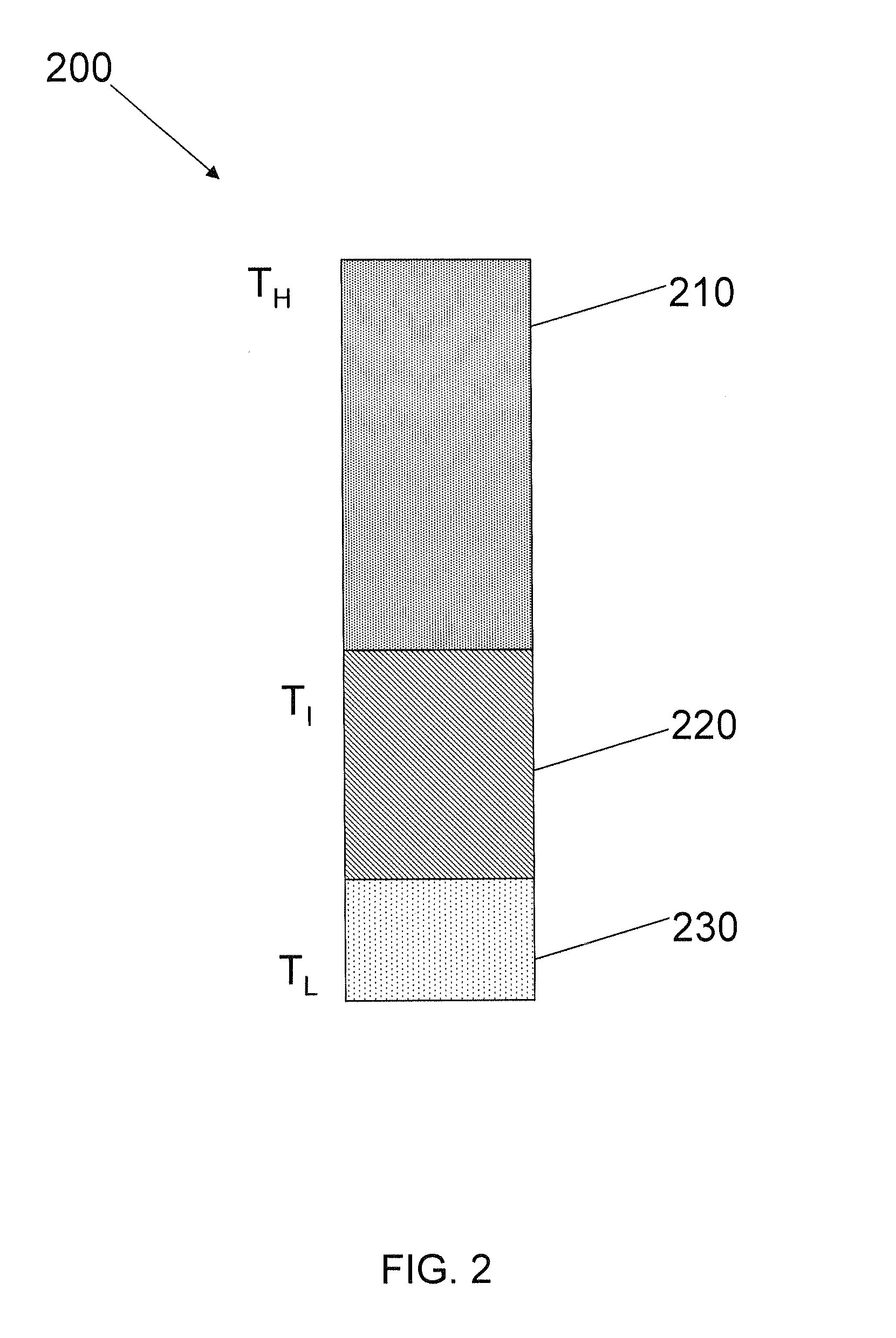

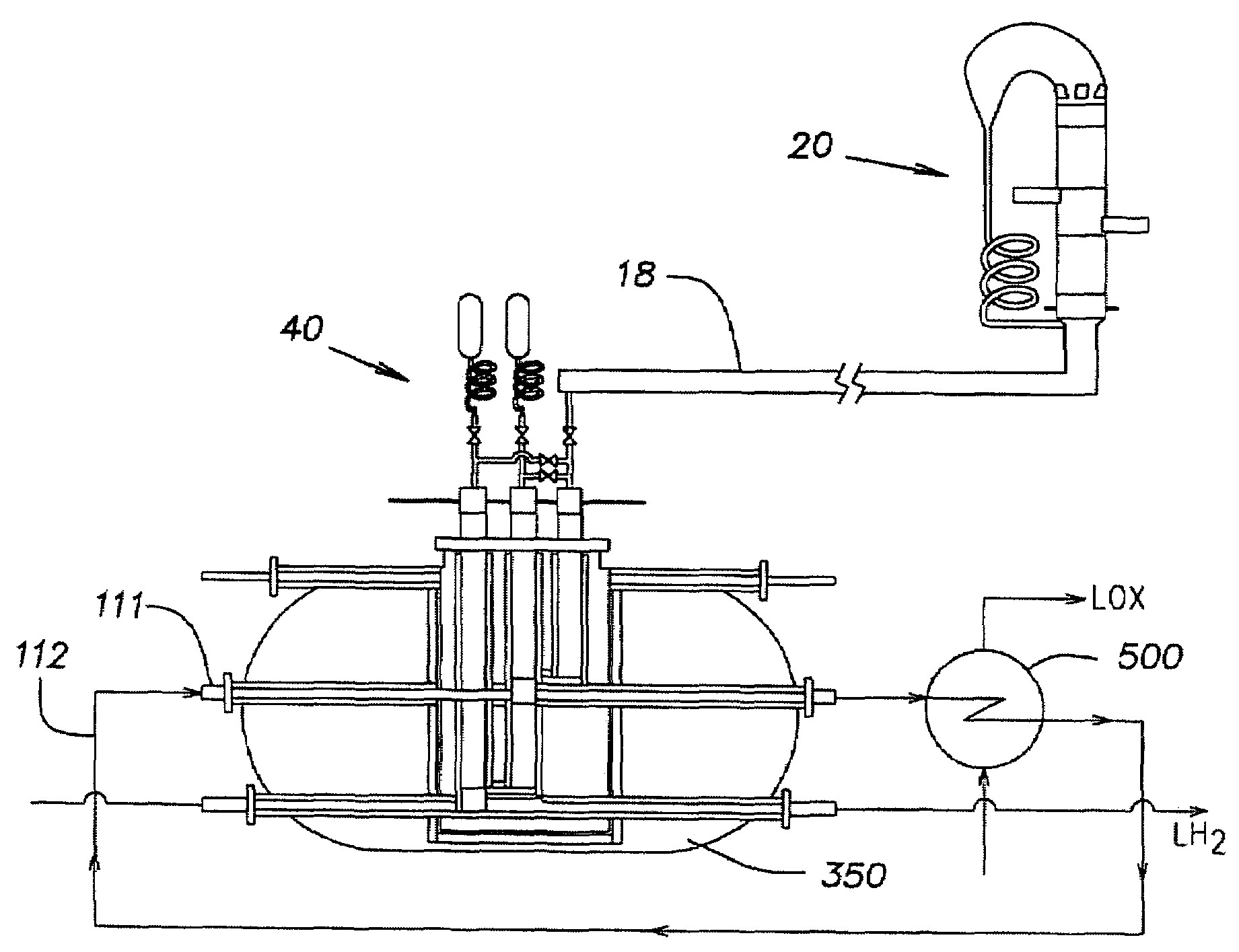

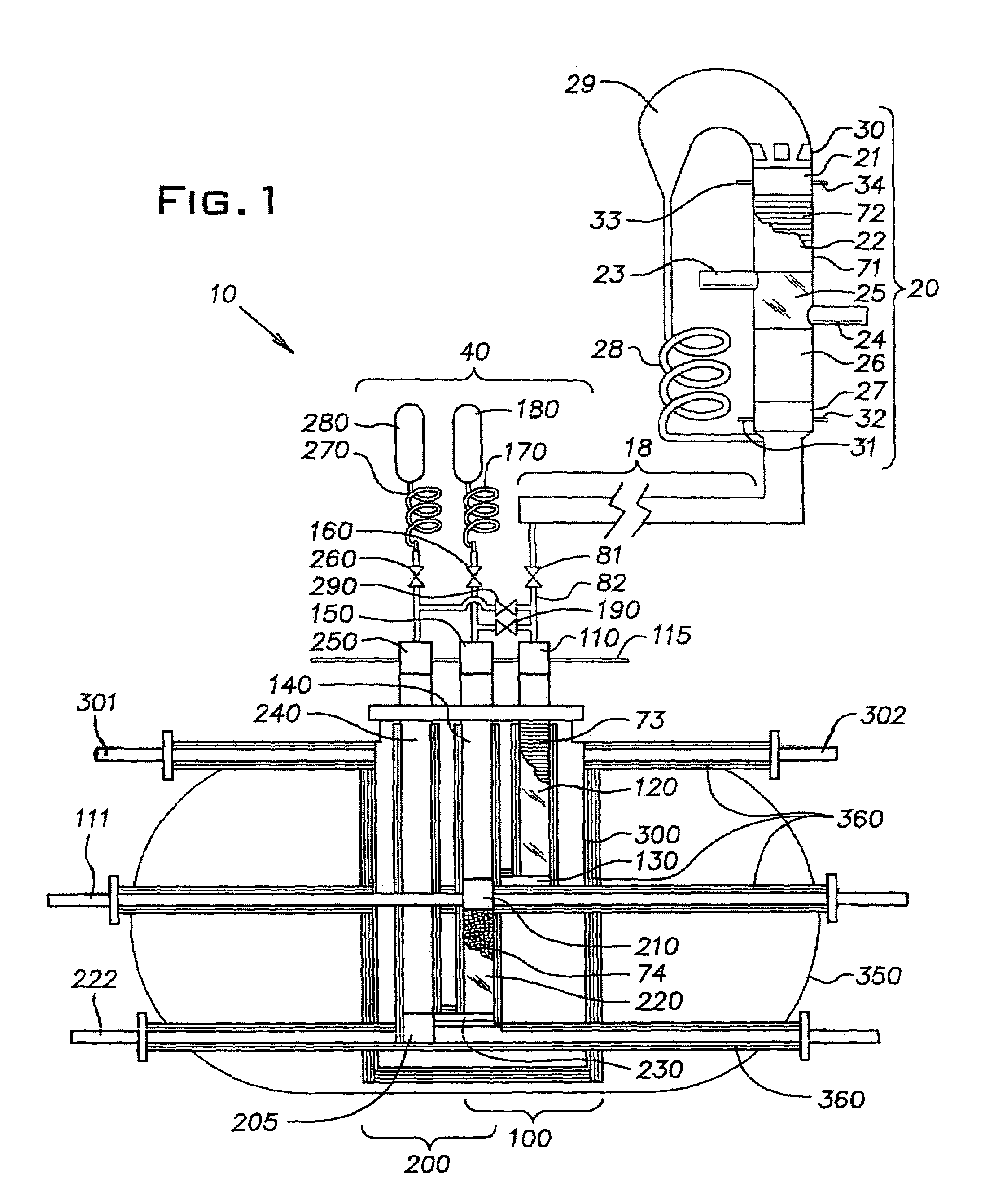

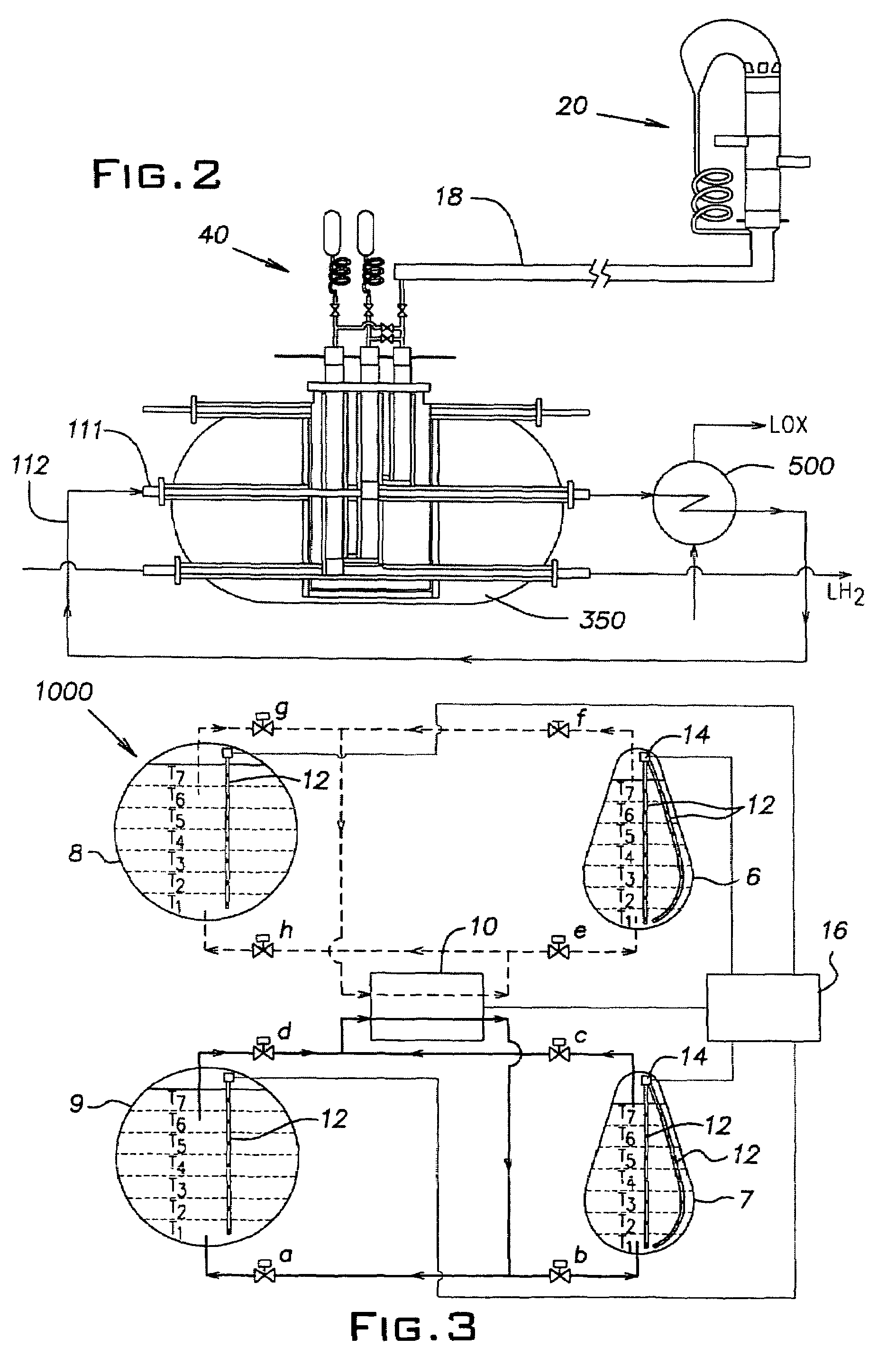

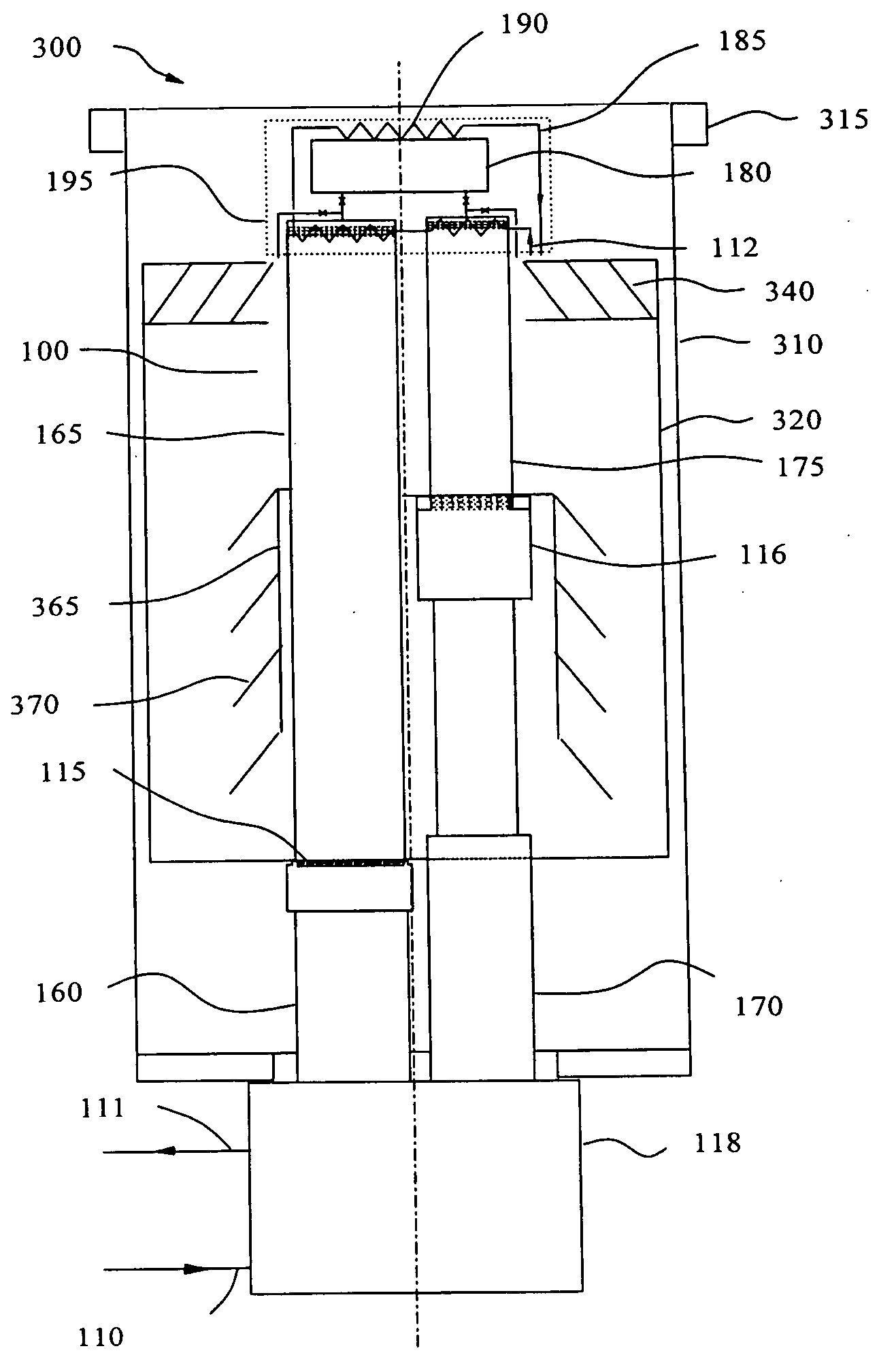

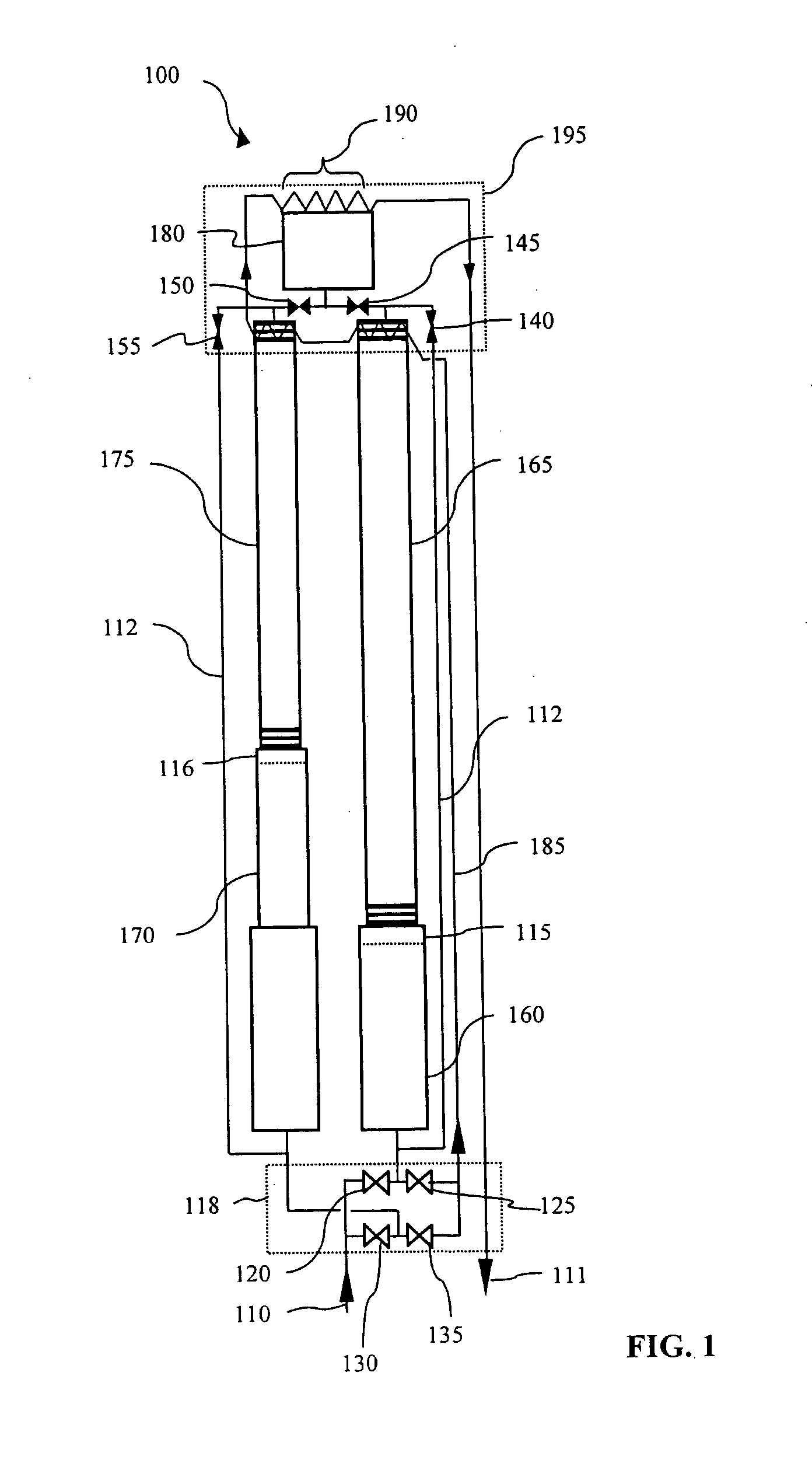

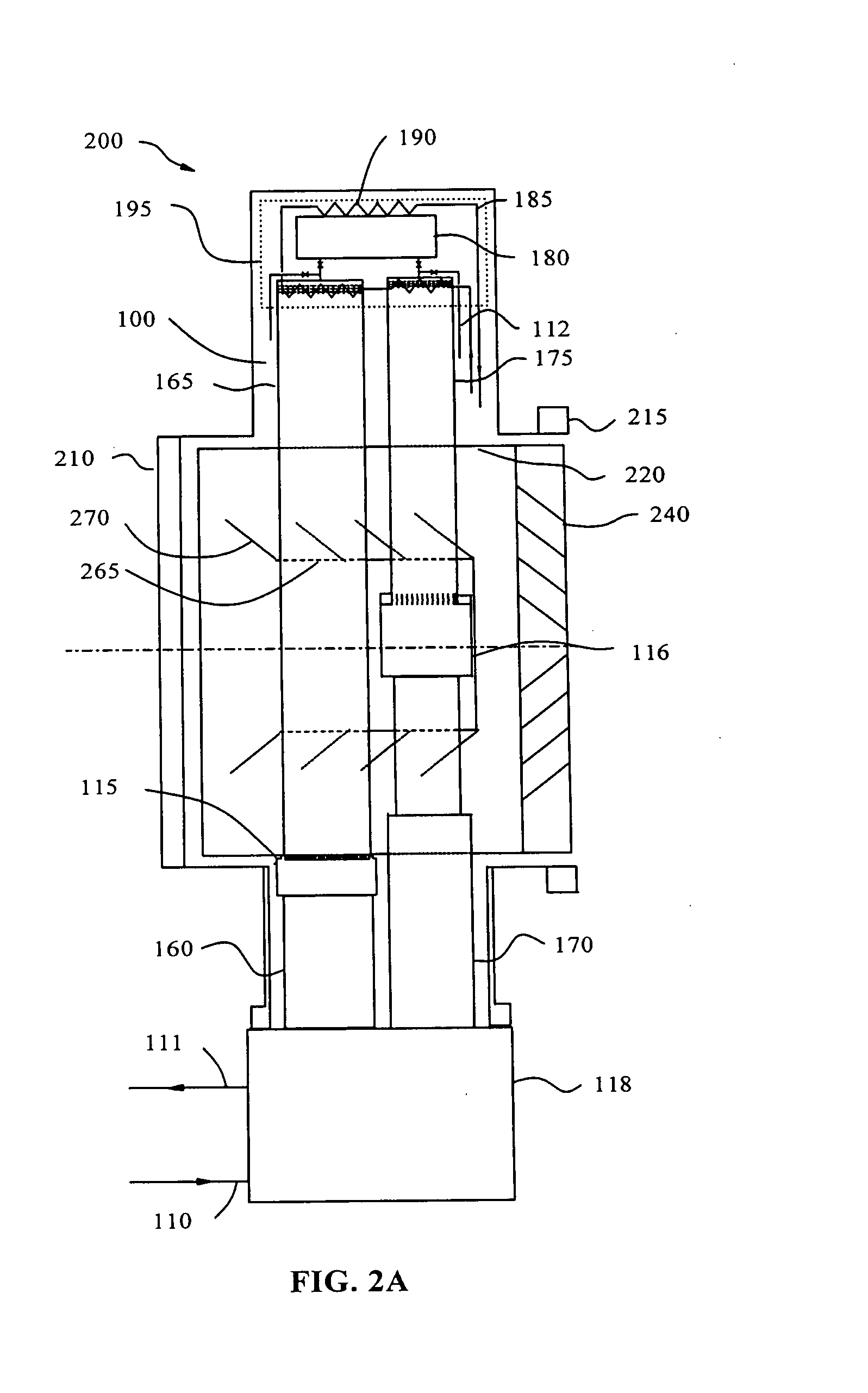

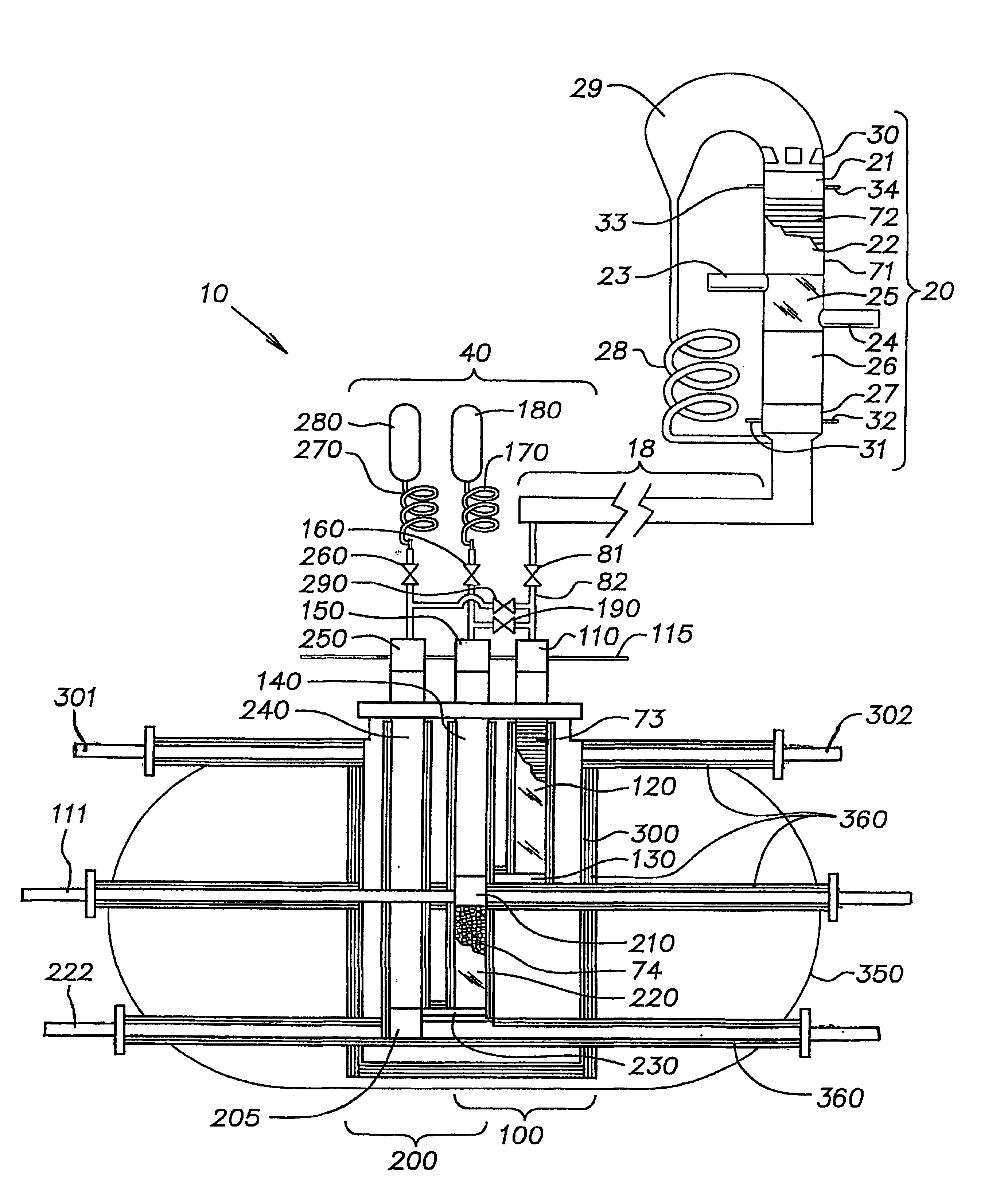

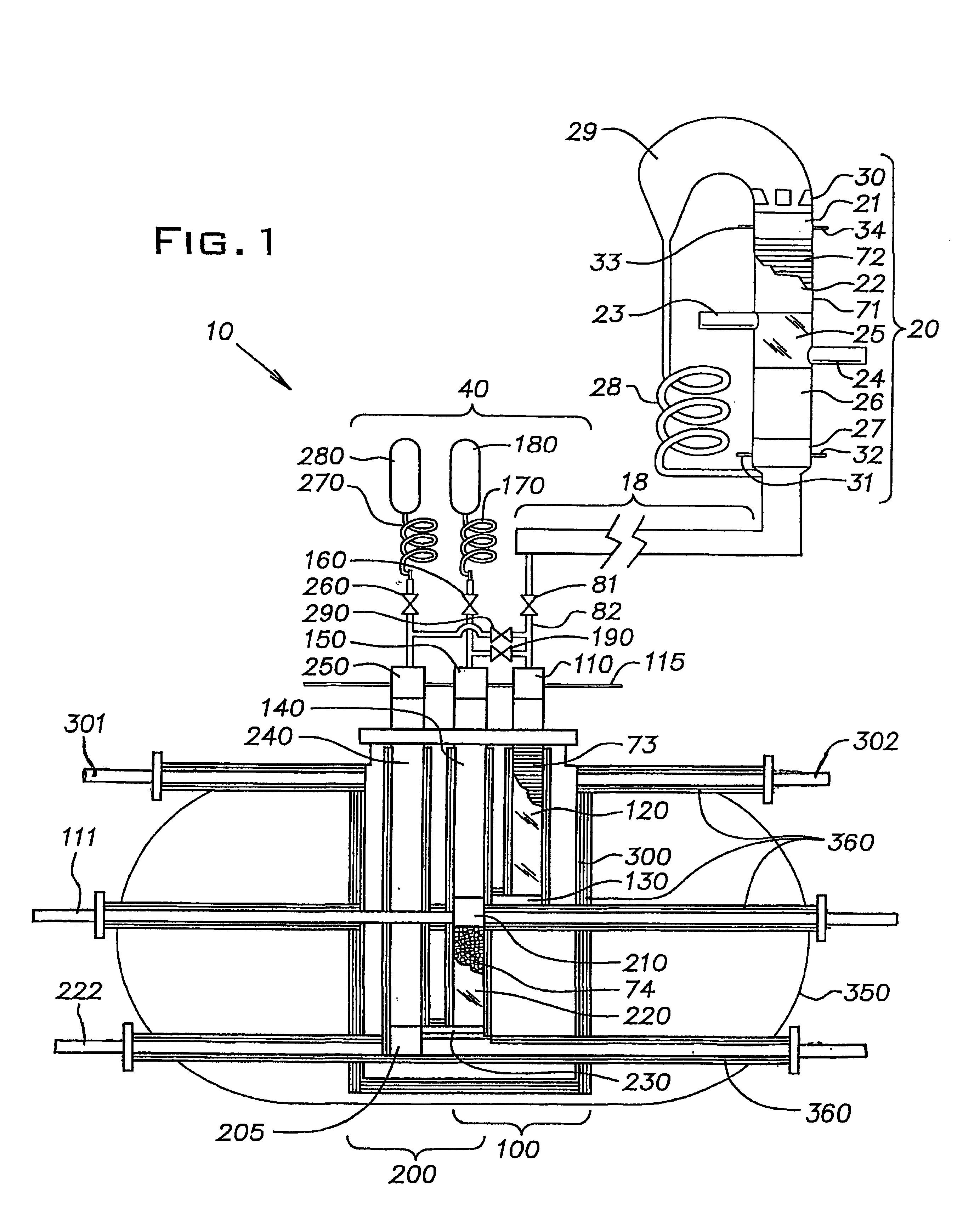

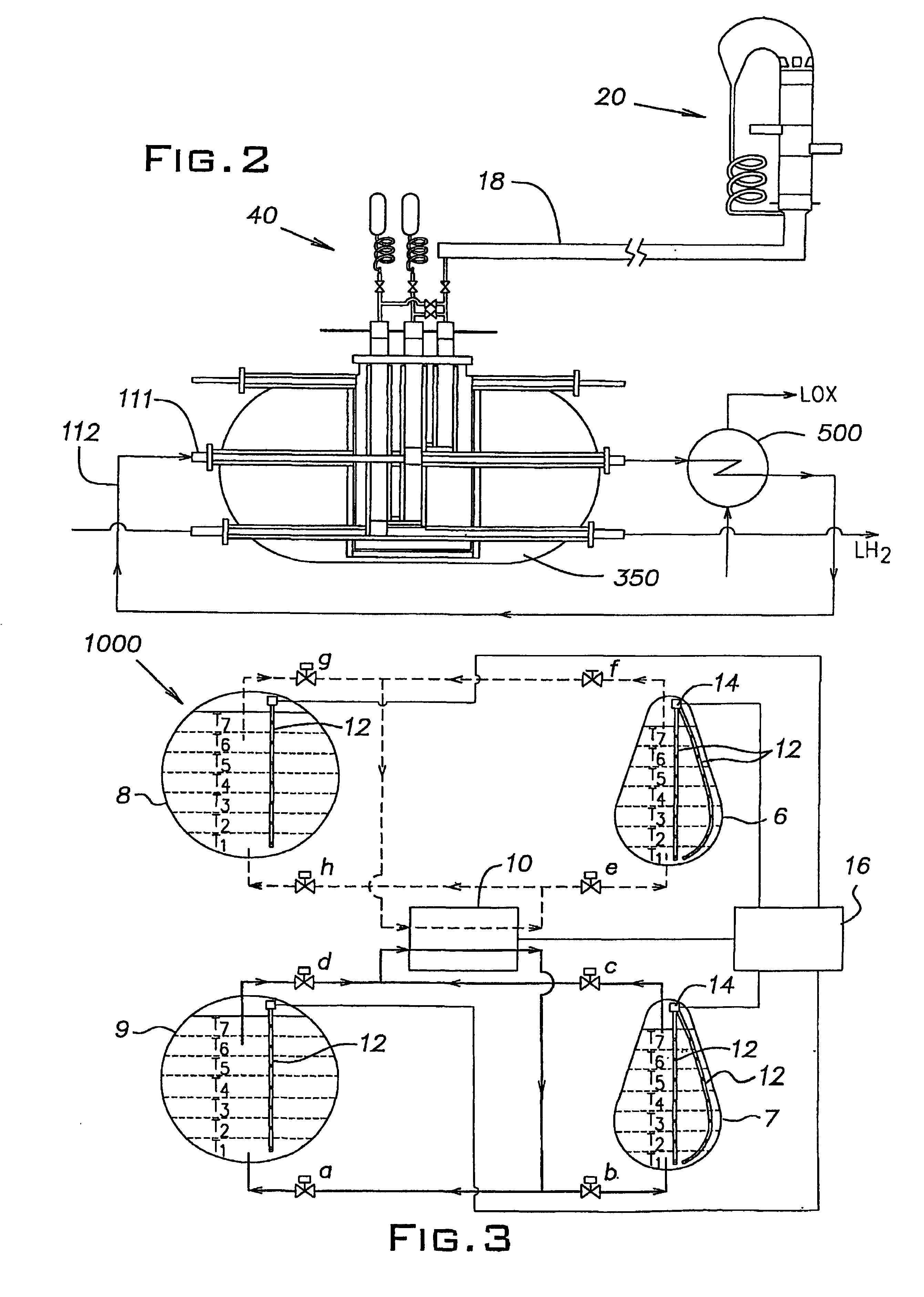

Densifier for simultaneous conditioning of two cryogenic liquids

A densifier is provided which in one embodiment can simultaneously densify two cryogenic liquids at different temperatures. The densifier has an oscillatory power source for generating oscillatory power and a two stage pulse tube refrigerator. The oscillatory power source can be a thermoacoustic heat engine or a mechanical oscillatory power source such as a linear flexure bearing compressor. The first stage densifies a first cryogenic liquid to a first cryogenic temperature, and the second stage densifies a second cryogenic liquid to a second, lower cryogenic temperature. A densified propellant management system also is provided which has a densifier for simultaneously densifying two cryogenic liquids at different temperatures, and a cryogenic temperature probe for measuring the temperature gradient in a cryogenic liquid.

Owner:SIERRA LOBO

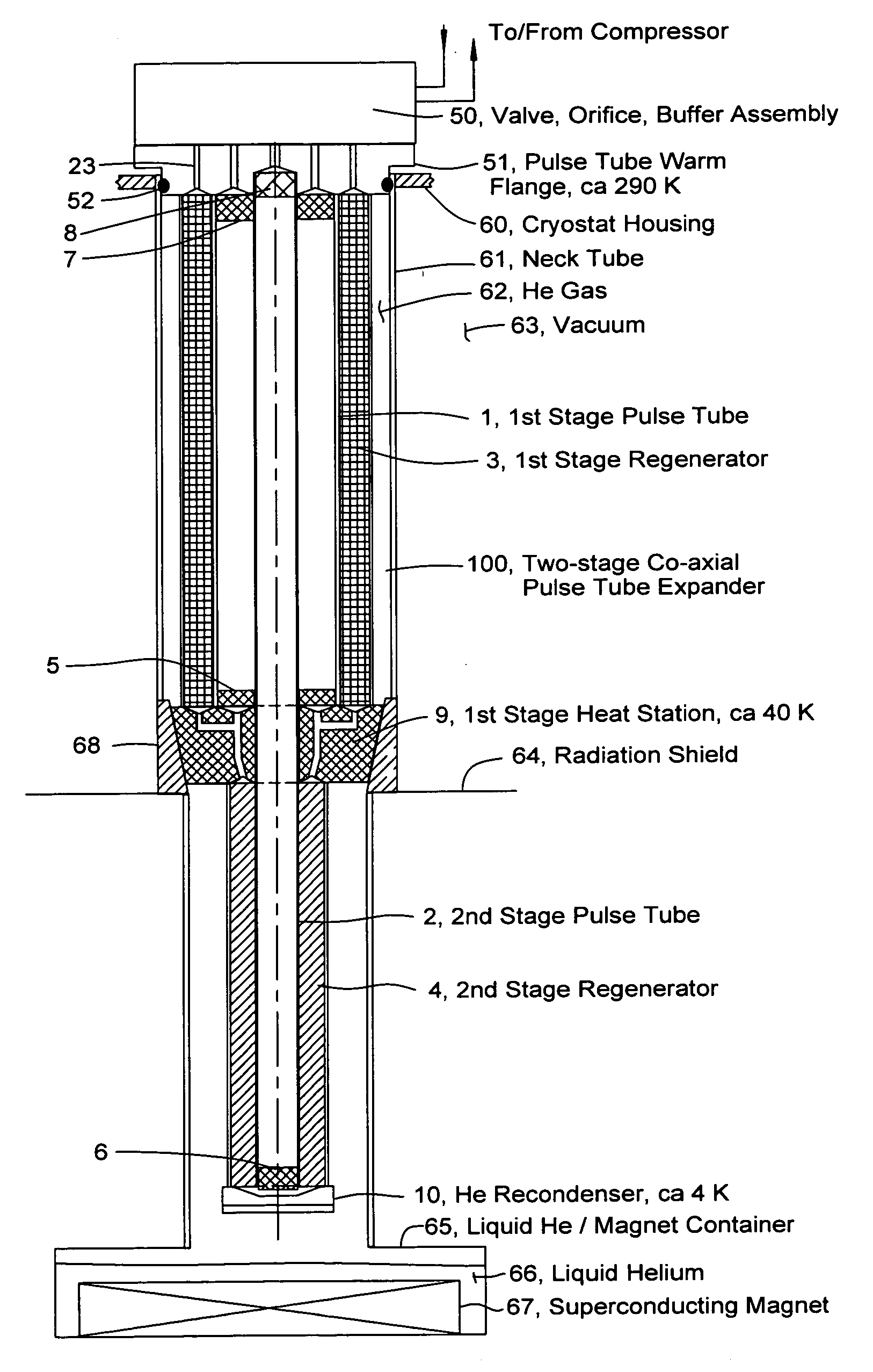

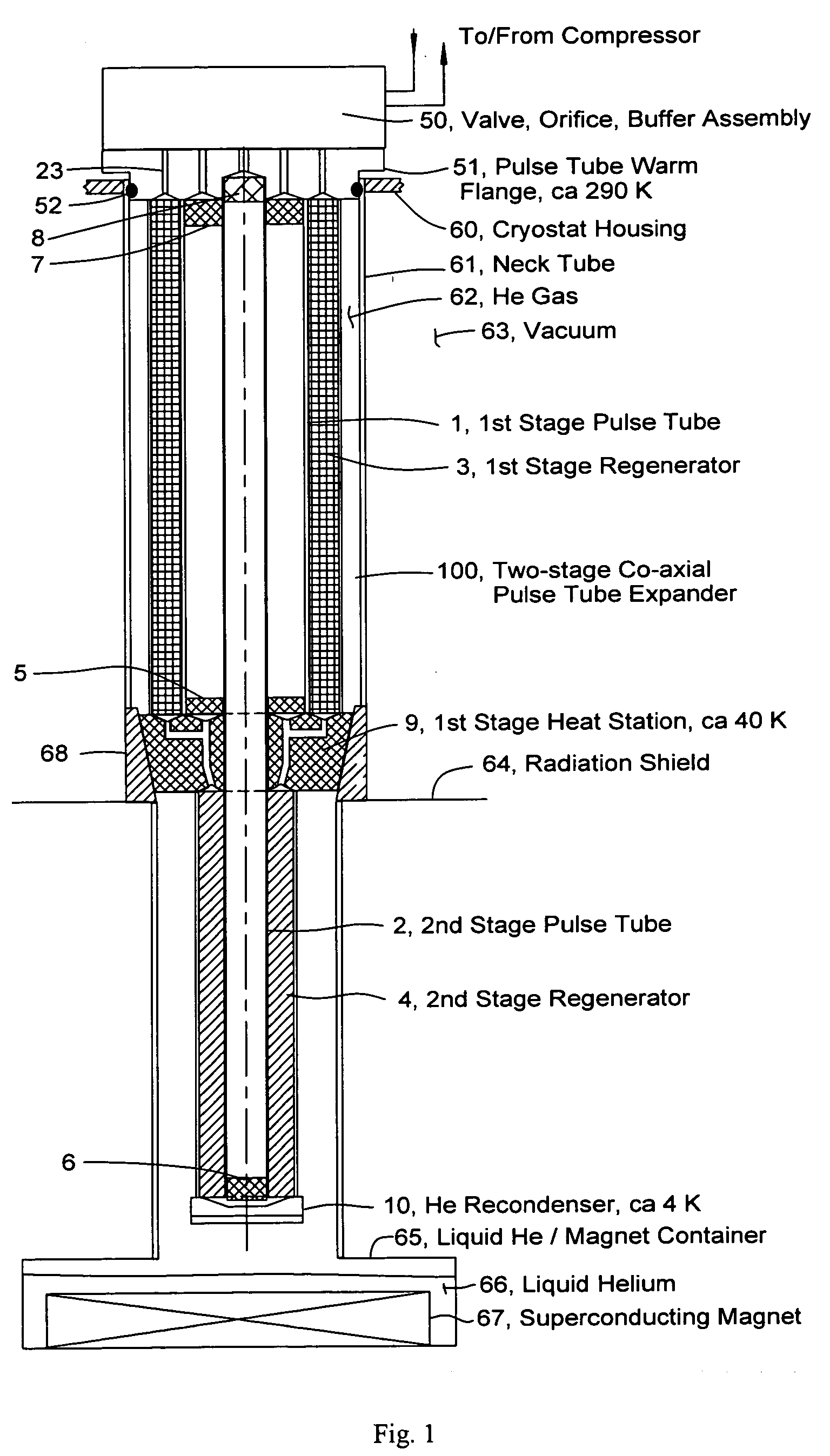

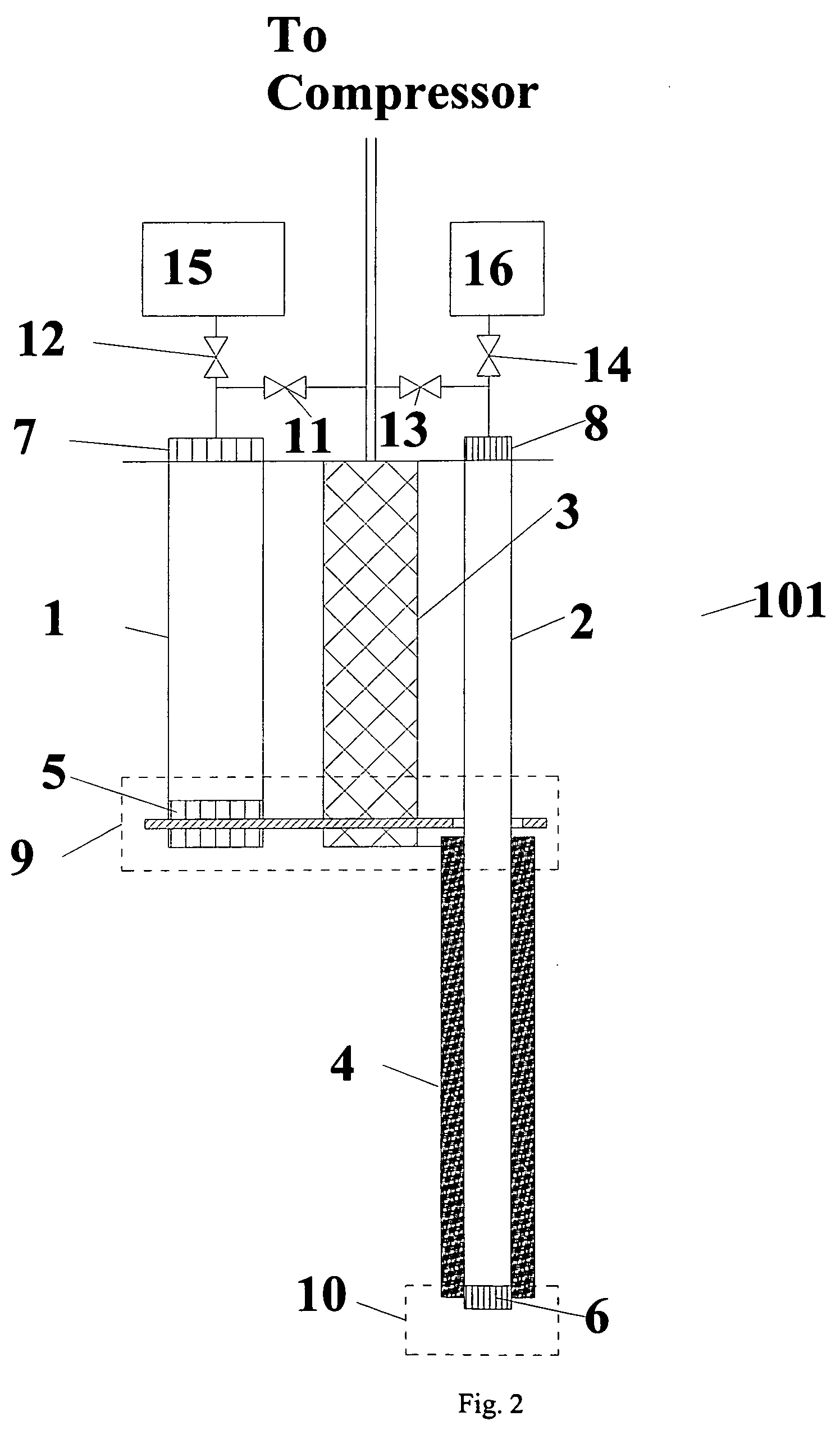

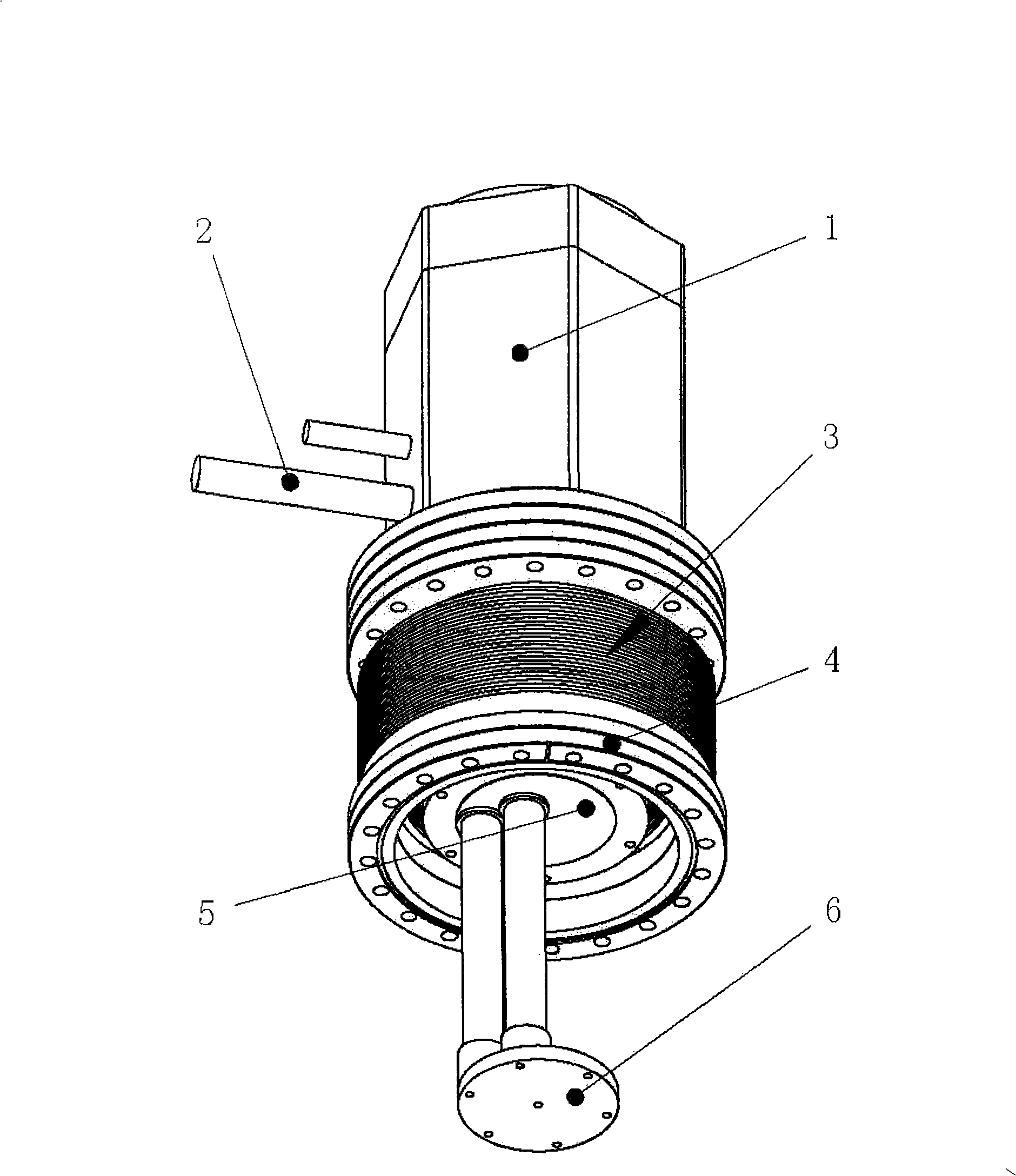

Co-axial multi-stage pulse tube for helium recondensation

InactiveUS20060144054A1Eliminate convection lossHeat loss minimizationCompression machinesRefrigeration devicesThermal bridgePulse tube refrigerator

A two-stage pulse tube refrigerator having a compact design, low vibration and low heat loss is provided where at least the 2nd stage is co-axial but preferably, both stages are co-axial with the second stage pulse tube being central and the first stage pulse tube occupying the annular space between the second stage pulse tube and the first stage regenerator. Convection losses associated with different temperature profiles in the pulse tubes and regenerators are minimized by shifting the thermal patterns in the pulse tubes relative to the regenerators by one or more of spacers in the regenerators, physical differences in length with gas channel connections, adjustment of dc flow, and thermal bridges.

Owner:SUMITOMO HEAVY IND LTD +1

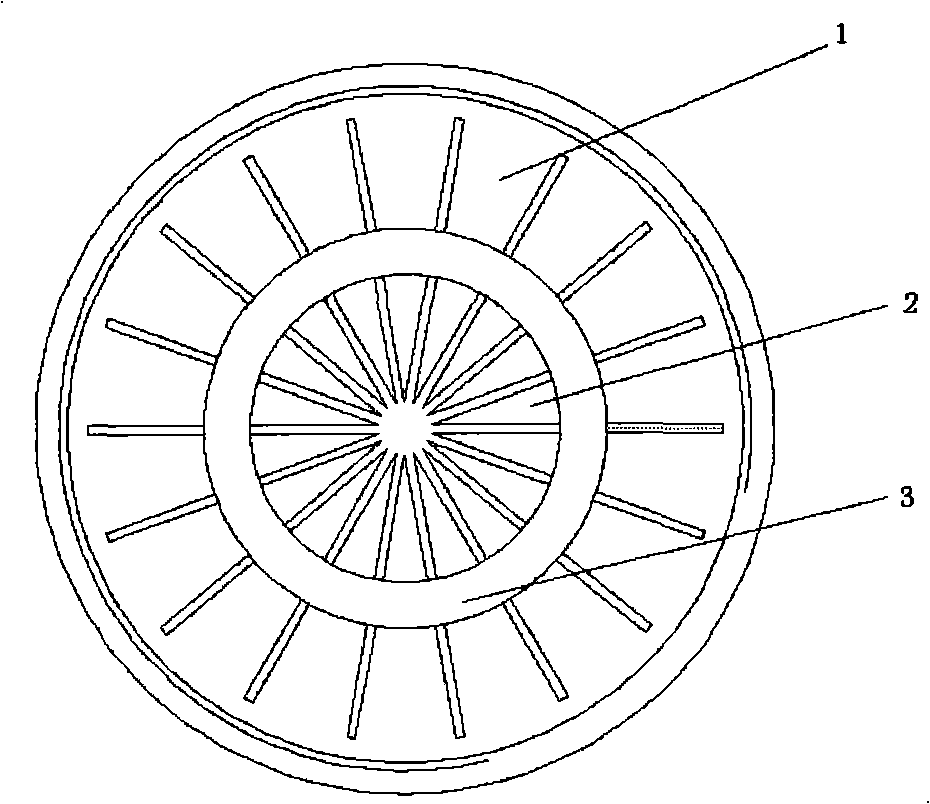

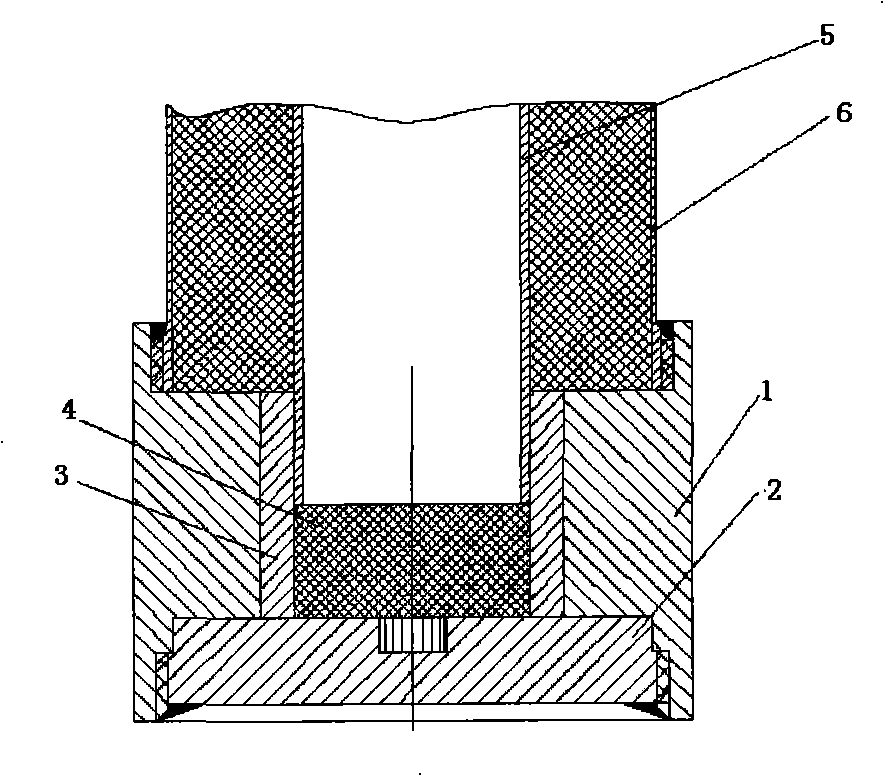

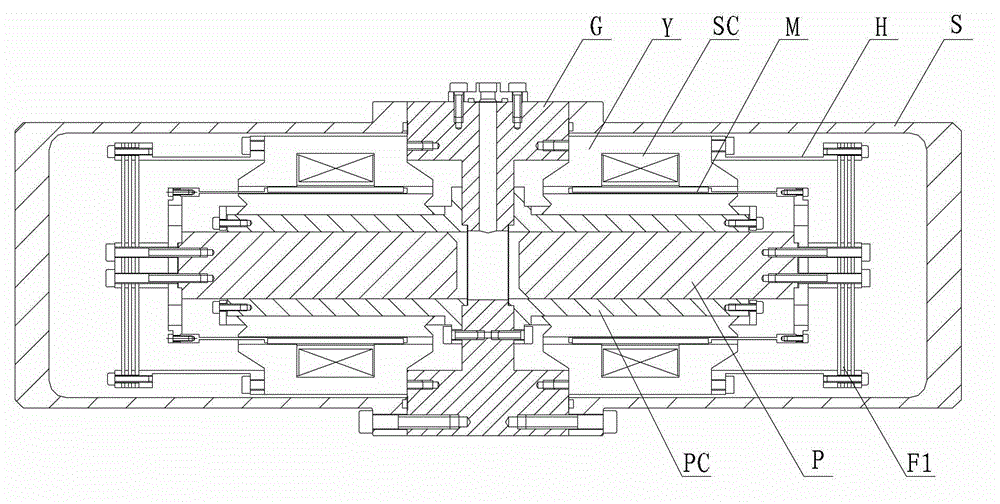

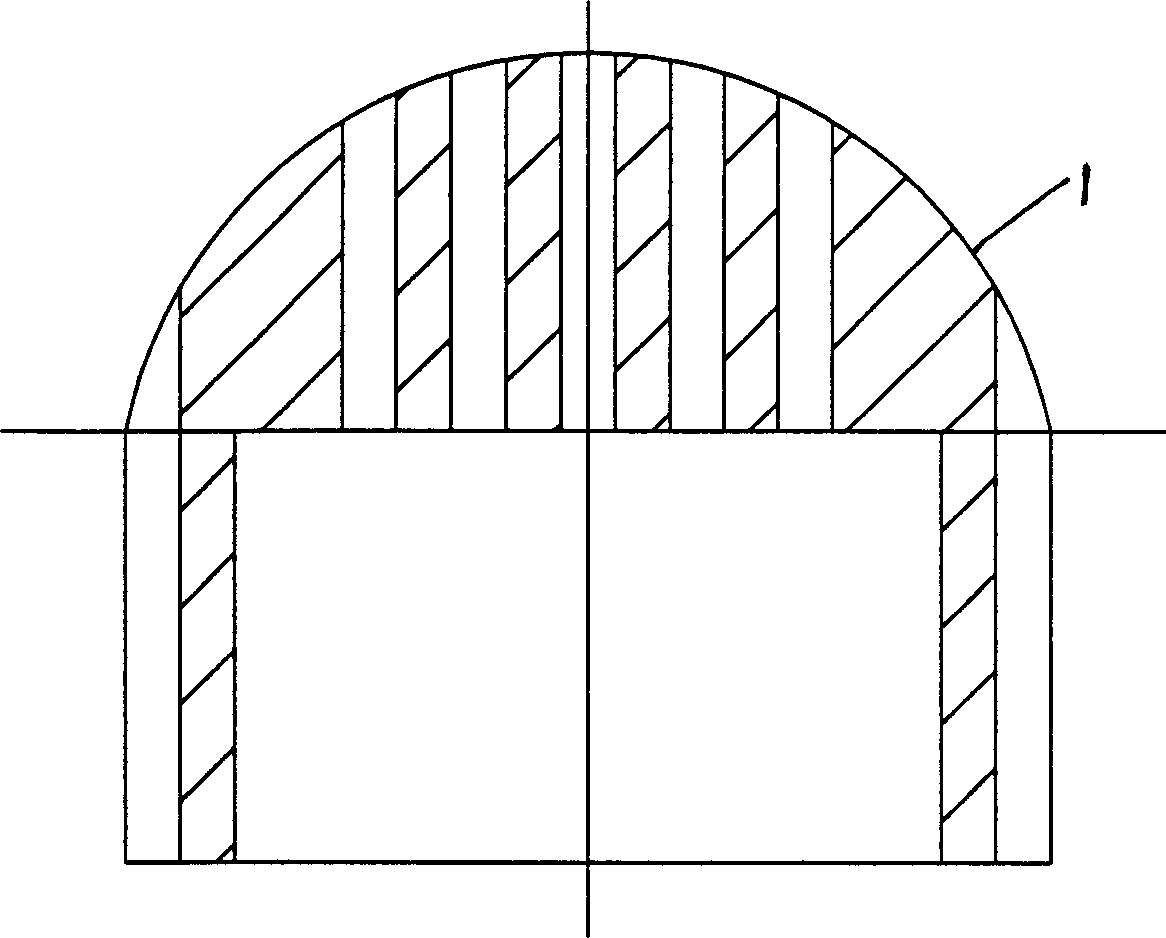

High-power pulse tube refrigerator based on Stirling refrigerator

InactiveCN101561196AImprove reliabilityOvercoming Flow Inhomogeneity ProblemsCompression machinesSuperheatersMature technologyPulse tube refrigerator

The invention discloses a high-power pulse tube refrigerator based on a Stirling refrigerator, which comprises a crank connecting link, a compression piston, an after-stage water cooler, a regenerator, a cold-end heat exchanger and a pulse tube system. A moving part, namely an expansion piston at a cold end of the prior (Phillips) Stirling refrigerator is substituted by the pulse tube system, andthe pulse tube system comprises a pulse tube, a hot-end heat exchanger, an inertance tube and an air reservoir. No moving part exists at a cold end of the high-power pulse tube refrigerator, thereby solving the problems such as machine wear and serious vibration caused by the expansion piston, remarkably improving the reliability of the refrigerator and widening the application range of the refrigerator. The high-power pulse tube refrigerator adopts the annular regenerator with mature technology, reduces the annular flow of gas in the regenerator, effectively solves the problems of nonuniformtemperature and flowing universally existing in the high-power pulse tube refrigerator, and increases the symmetry of radial temperature, thereby reducing the loss of the regenerator in the high-powerpulse tube refrigerator, and improving the efficiency of the refrigerator.

Owner:ZHEJIANG UNIV

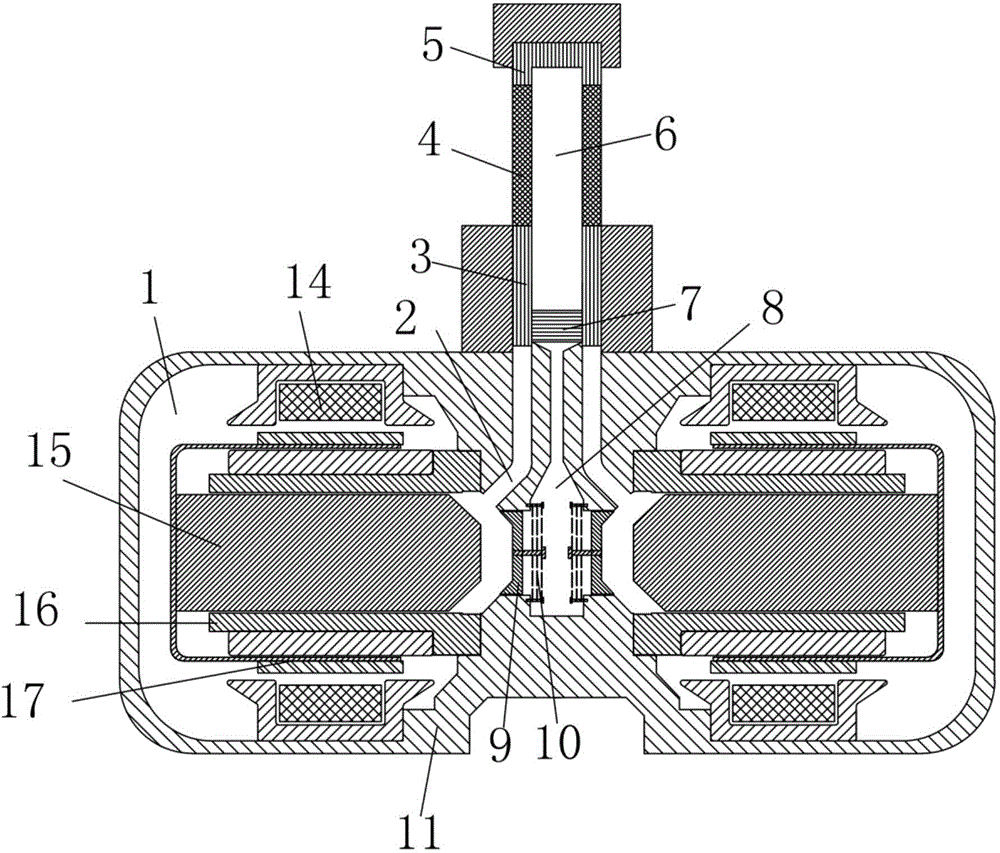

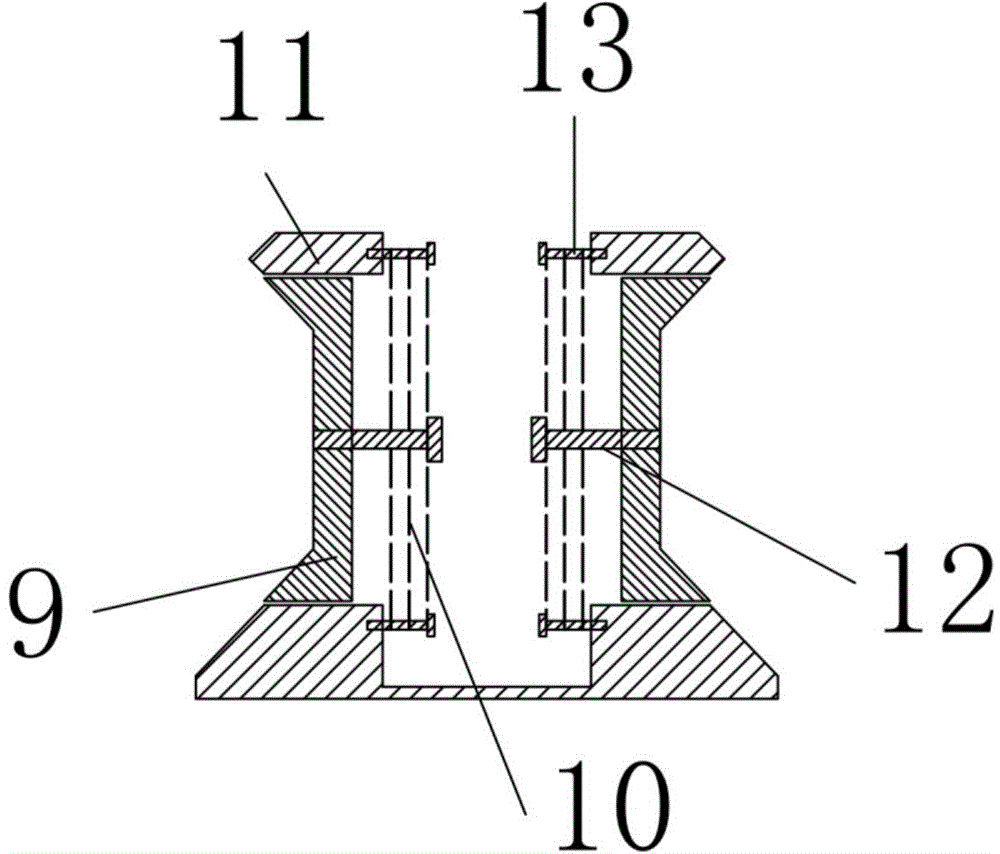

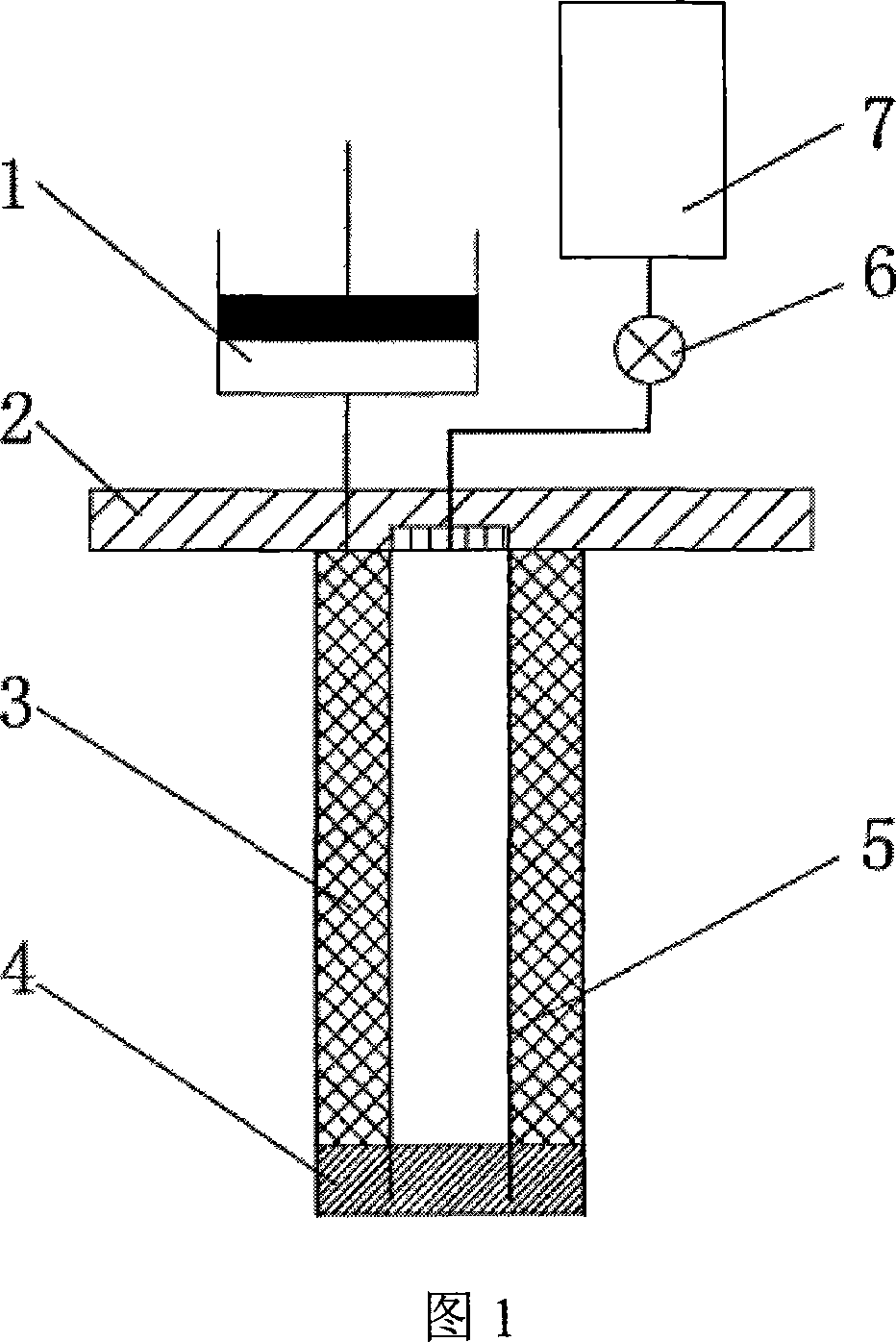

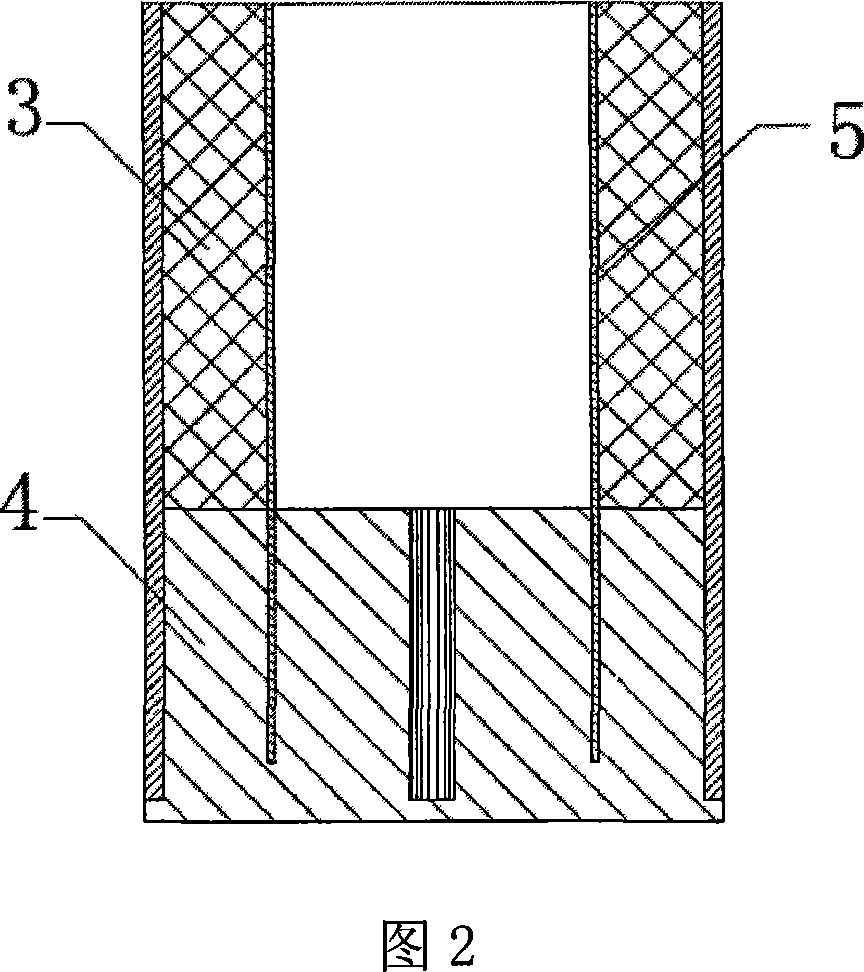

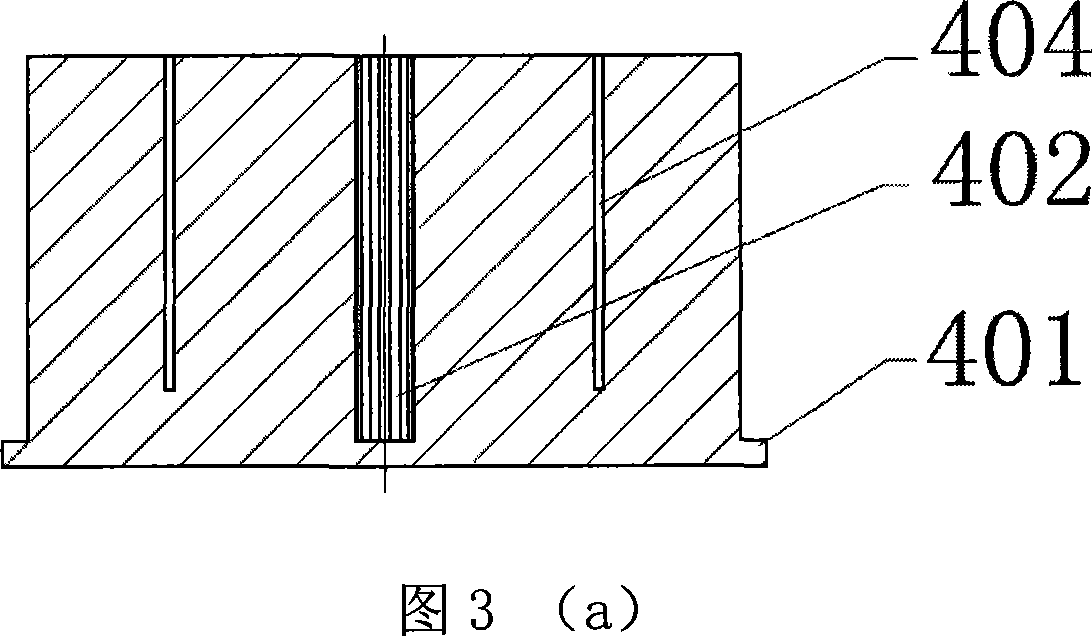

Multistage Stirling type pulse tube refrigerator

ActiveCN104654648AExpansion work can be recoveredCompression machinesGas cycle refrigeration machinesPulse tube refrigeratorCooling capacity

The invention relates to a multistage Stirling type pulse tube refrigerator. The multistage Stirling type pulse tube refrigerator comprises a compressor, n stages of cooling heads and n stages of ladder push piston systems, wherein n is an integer larger than 1, each cooling head comprises a cooler, a heat regenerator, a cooling heat exchanger and pulse tubes, the cooling heat exchanger of the n stage of cooling head serves as the n stage of cooling capacity output end, a compression cavity of the compressor is connected with coolers in the cooling heads, push piston working cavities of the n stages of ladder push piston systems are respectively connected with the pulse tubes, push piston back working cavities of the n stages of ladder push piston systems are communicated with the compression cavity of the compressor, wherein a regulating cavity is connected between the pulse tube of at least one stage of cooling head and the connected ladder push piston working cavity. Compared with the prior art, the multistage Stirling type pulse tube refrigerator enables the gas flow rate and pressure of the cold ends of the pulse tubes to work at the best phase angles through regulating the volume of the cavity, and meanwhile, the multistage Stirling type pulse tube refrigerator gives consideration to the input power distribution of each stage, and moreover, the expansion power can be recycled, and the theoretical efficiency is the same with that of a Carnot engine.

Owner:TONGJI UNIV

Dual-way air-intake vascular refrigeator with corrugated pipe direct-current blocking-up structure

InactiveCN1743761AReduce lossesEliminate negative effectsCompression machinesGas cycle refrigeration machinesPulse tube refrigeratorEngineering

This invention discloses a bi-directional air intake pulse tube refrigerator, which contains compressor, heat exchanger at heat end of heat regenerator, cold heat, pulse tube, pulse tube heat end exchanger, small hole valve, air reservoir, corrugated pipe dc block structure in heat end of pulse tube, and capillary set between air inlet of heat regenerator and heat end of pulse tube. Said invention eliminates the influence of dc to refrigeration temperature and quantity, and operation stability.

Owner:ZHEJIANG UNIV

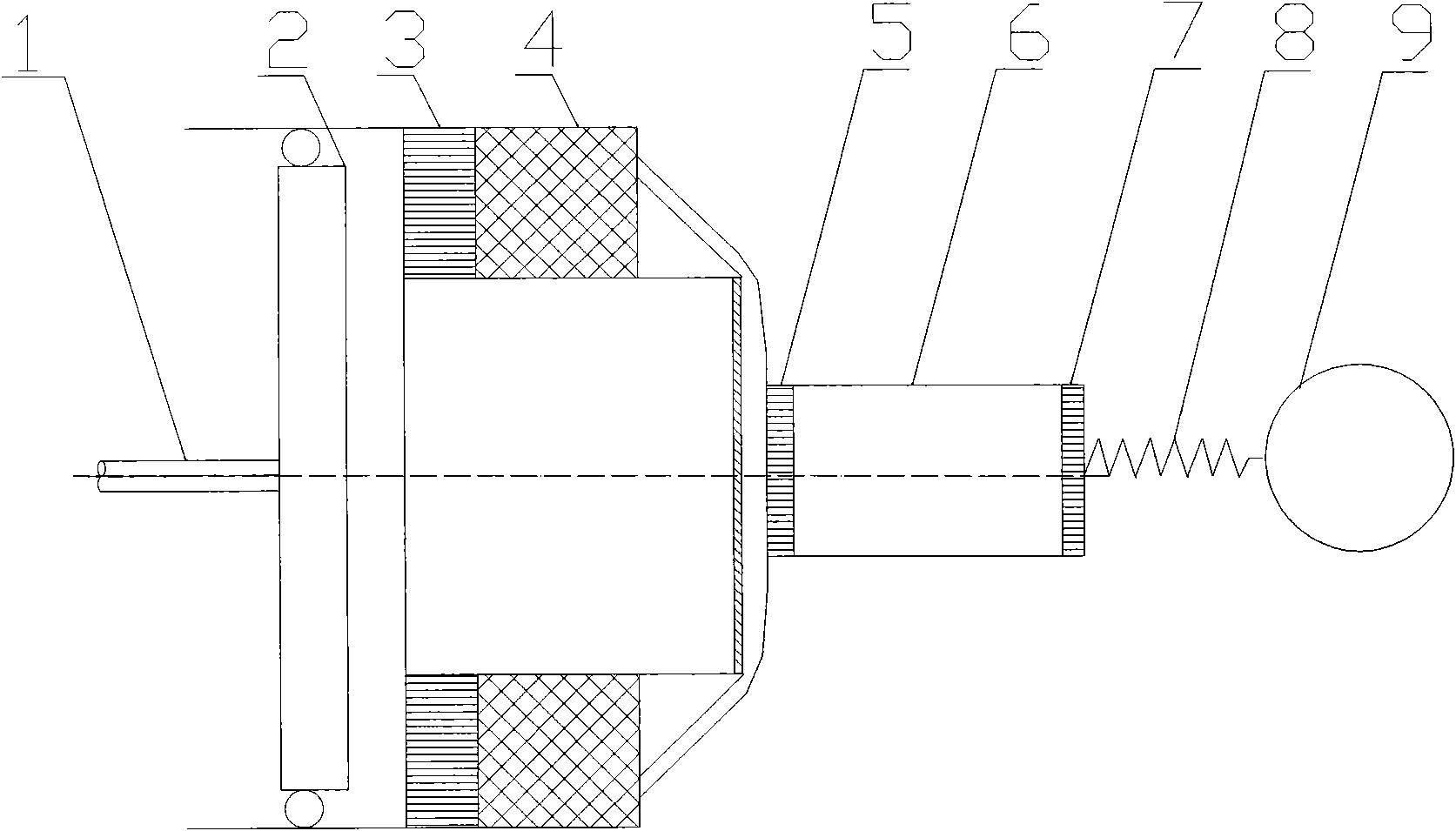

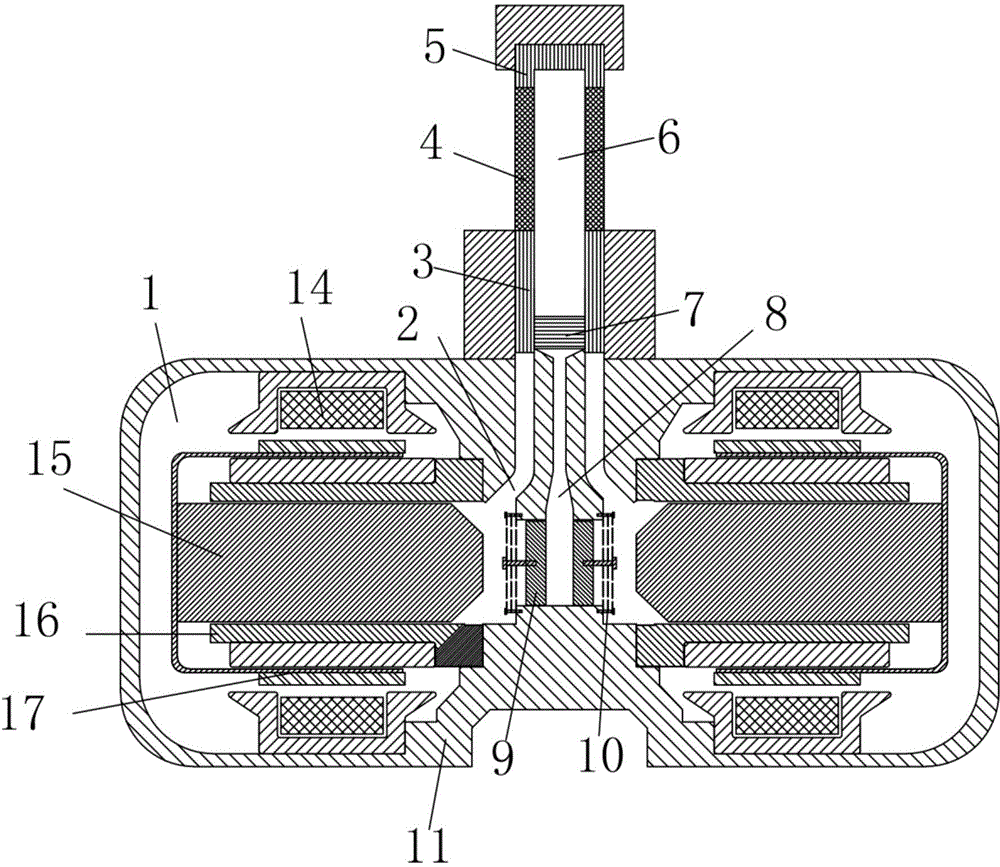

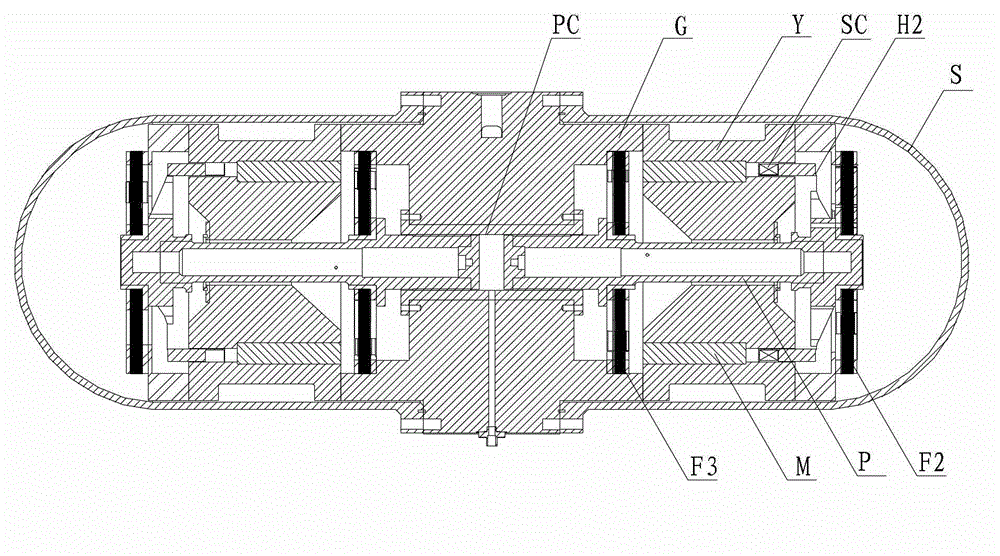

Low-temperature pulse tube refrigerator with mixed structure

ActiveCN104457009AImprove performanceNo vibrationCompression machinesRefrigeration componentsFixed-functionLinear compressor

The invention provides a low-temperature pulse tube refrigerator with a mixed structure. The low-temperature pulse tube refrigerator comprises linear compressor assemblies, wherein the linear compressor assemblies are oppositely arranged, the compressor piston movement is opposite in direction, and the generated vibration is totally offset. Compressor cavities of the compressor assemblies are communicated with each other to form a total compression cavity. A room temperature discharger structure working in a room temperature region is introduced into the total compression cavity. The structure divides the total compression cavity into two parts and is composed of two symmetrical discharger pistons and two symmetrical plate springs. The plate springs are fixedly connected with the discharger pistons and play a supporting and fixing function on the discharger pistons. The two ends of the discharger pistons are free of area difference and high in phase adjustment ability. The discharger structure push the pistons to move through the plate spring rigidity and the pressure difference on the two sides so as to adjust the sound field distribution of a whole machine, impedance boundary adjustment with a pressure fluctuation phase leading the volume flow rate is formed at the hot end of a pulse tube, the acoustic power at the hot end of the pulse tube is recycled, and the performance of the refrigerator is improved, that is, the advantages that the low-temperature side of the pulse tube refrigerator is free of movement components is maintained, and the two ends of the discharger pistons are free of the area difference, the reliability of the whole machine can be improved, and manufacturing difficulty can be lowered.

Owner:LIHAN CRYOGENICS +1

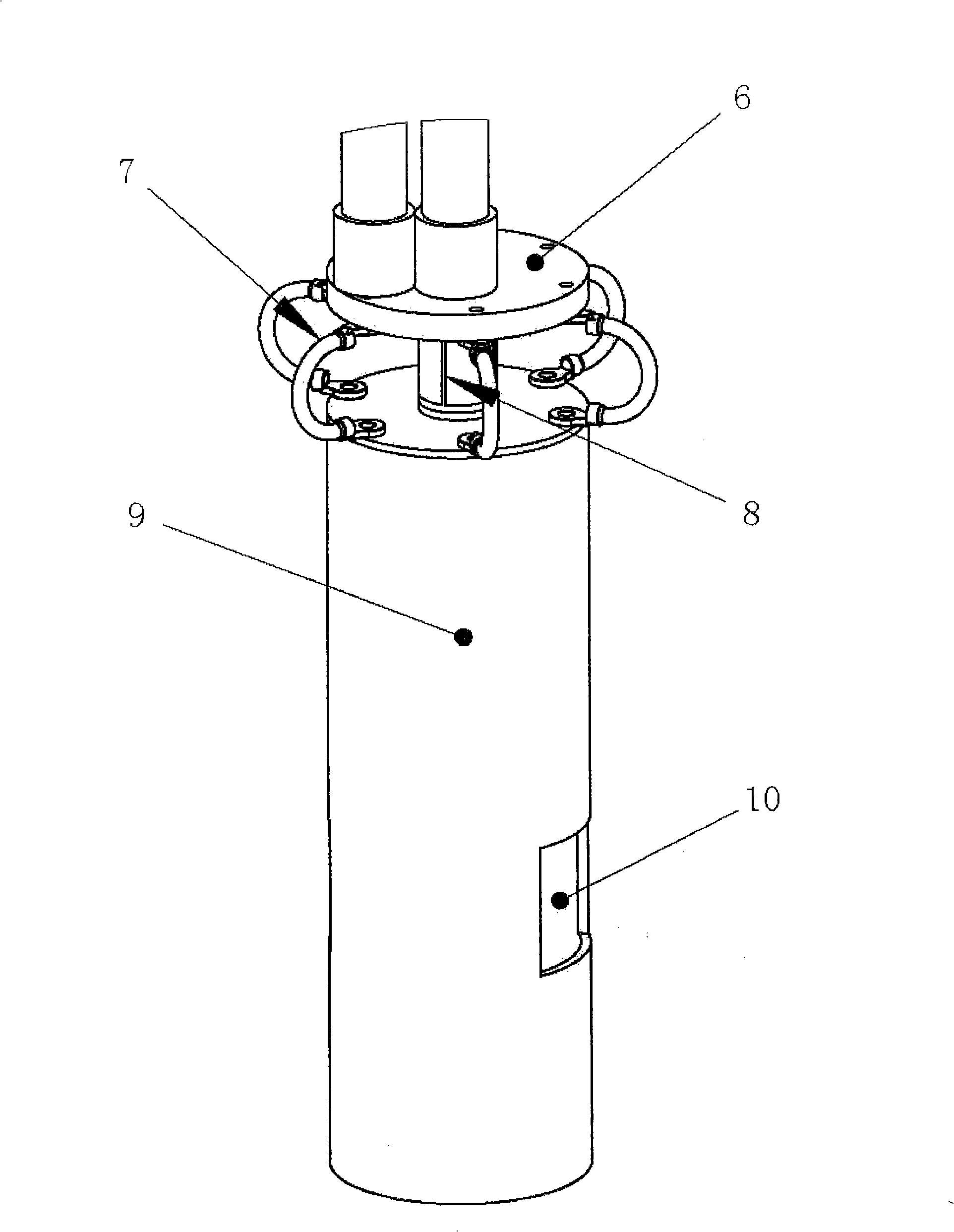

Cryopump with two-stage pulse tube refrigerator

Disclosed is a two-stage pulse tube cryopump cooling system in which the pulse tubes and valves are inline, with the hot ends of the pulse tubes at the top and the valve mechanism is at the bottom and the hot ends and buffer volume are cooled by an inline coolant line from the compressor input to the compressor output and attached in heat exchange relationship with the buffer volume.

Owner:SHI APD CRYOGENICS +1

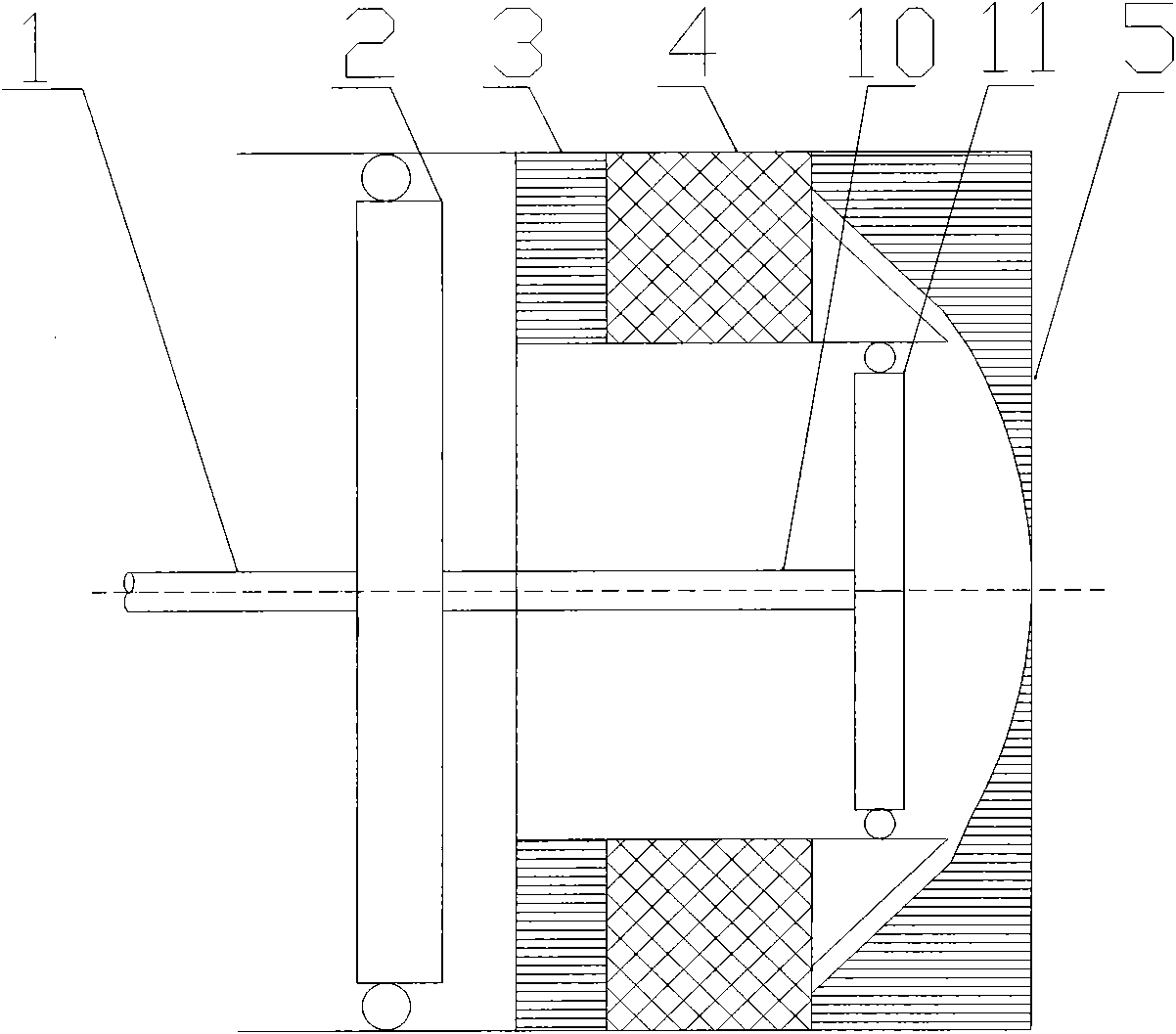

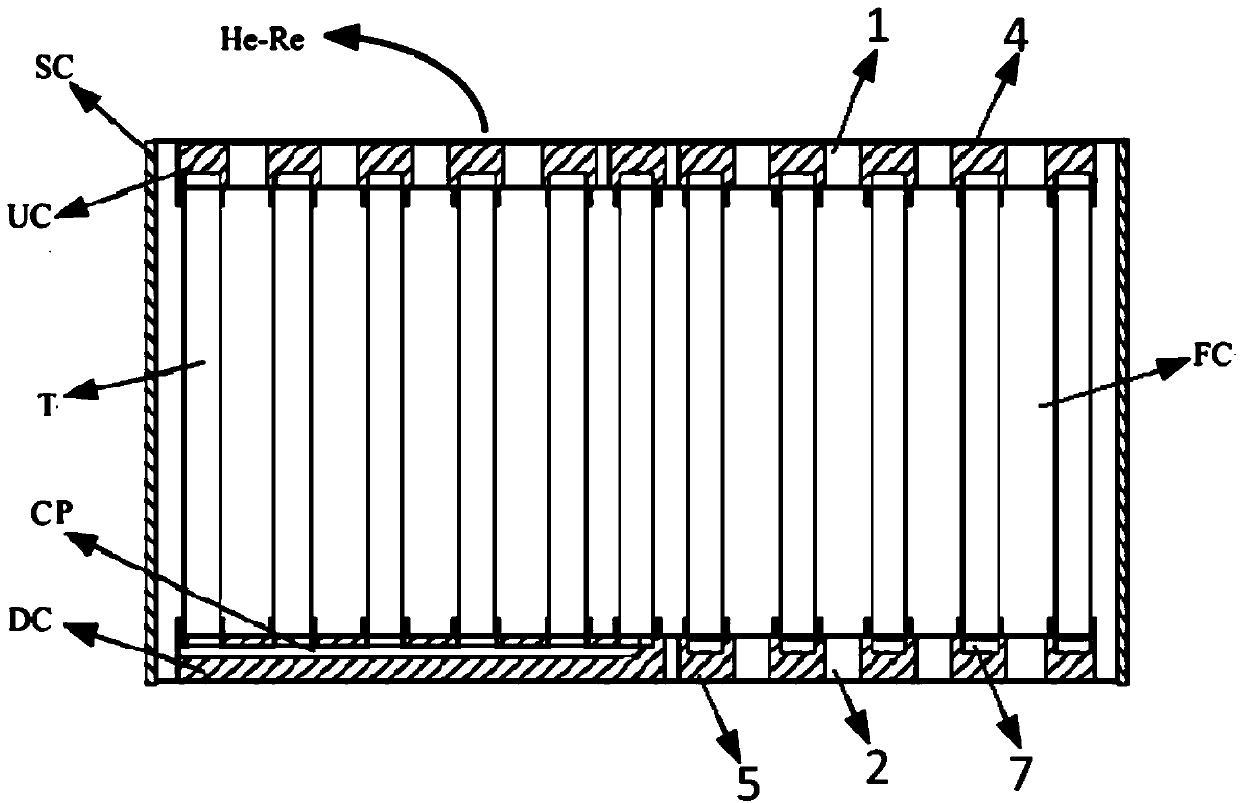

Stirling type pulse tube refrigerator of phasing device with dynamic quality module

ActiveCN103047789AImprove cooling efficiencyEliminates two-way air intakeCompression machinesPulse tube refrigeratorEngineering

The invention discloses a Stirling type pulse tube refrigerator of a phasing device with a dynamic quality module. The phasing device is characterized by being provided with the dynamic quality module. The phasing device with the dynamic quality module comprises the dynamic quality module, a valve and an air reservoir which are sequentially connected to a pulse tube hot-end heat exchanger, or can comprise a valve, an inertia tube, the dynamic quality module and an air reservoir which are sequentially connected to the pulse tube hot-end heat exchanger. The dynamic quality module consists of a dynamic quality piston and a support spring, wherein the dynamic quality piston is mounted in an air cylinder, and the support spring is connected with the dynamic quality piston through a central connecting rod. Depending on inertia of the dynamic quality modules, resistance of the inertia tube or the valve and the like, impedance boundary adjustment with pressure fluctuation phase superior to volume flow rate is formed. Compared with a conventional phasing device, the dynamic quality module can form a high-phase angle by means of inertia thereof, and generate better acoustic impedance relation in a heat regenerator as a core part of the pulse tube refrigerator, and accordingly, performance of the refrigerator is improved.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

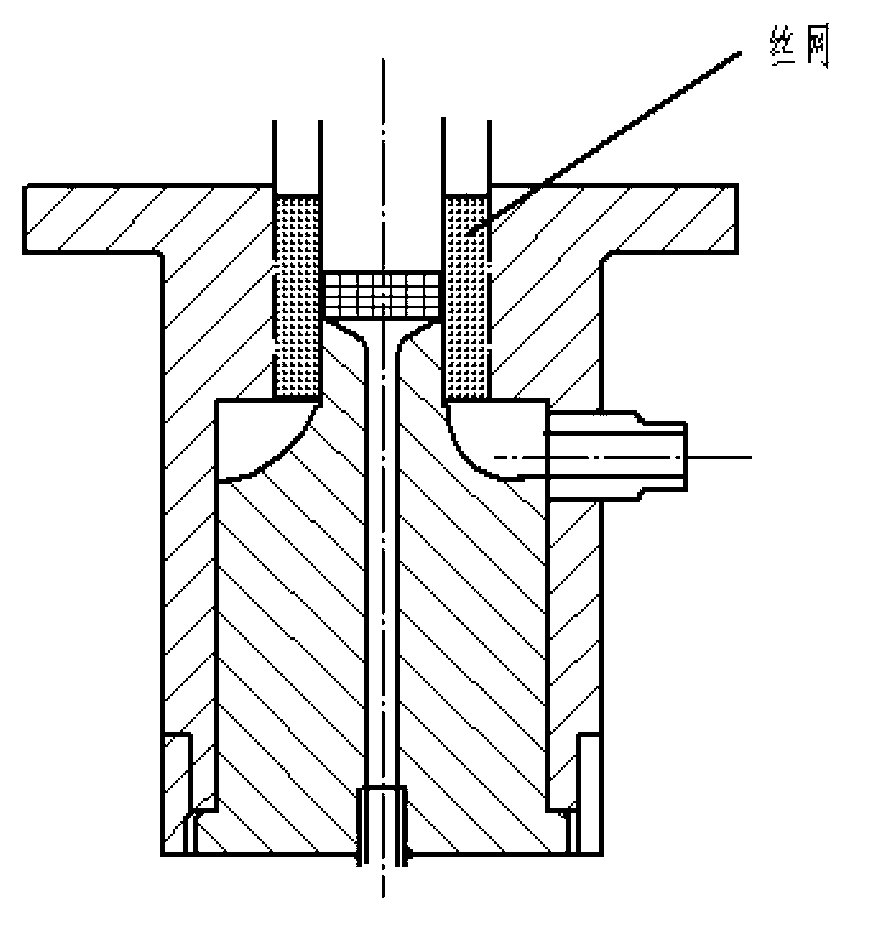

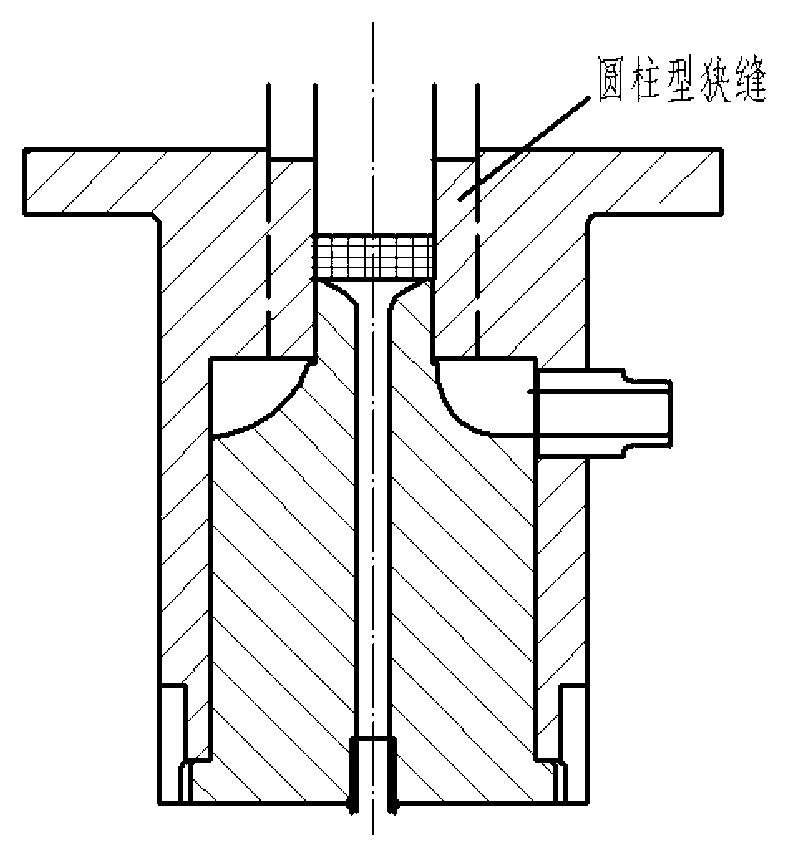

Screw thread welding integral narrow slit type cold junction for coaxial pulse-tube refrigerator

InactiveCN101298948AIncrease the heat exchange areaSmall pressure lossCompression machinesGas cycle refrigeration machinesCopper wirePulse tube refrigerator

The invention discloses a thread weld integral slit type cold head of the coxial vessle refrigerator in the refrigeration technology field, including an upper cold head, a lower cold head, a cold end baffle and a copper wire, wherein the upper cold head and the lower cold head are welded again after the threaded connection, the cold baffle is arranged at the middle of the cold head integer, and the cold baffle is filled with the copper wire, wherein the lower cold head is divided into a base seat and a boss having the uniformly distributed slots in the axial symmetry. The depth of the slot is the same with the height of the boss, and the external thread is arranged at the cirumferential of the base seat; a cylinder is arranged on the upper cold head, a round hole at the center and radial slots in the distributed uniformly arranged at the cirumferential of the round hole. The width of the slot is consistent with the slot of the lower cold head; the internal thread structure of the upper cold head is matched with the external thread of the lower cold head, with the other end in the thread match with the cold accumulator, and is left with the margin for welding after being matched. The invention has large heat exchange area, and the welding structure ensures the leak detection safety of the pressure gas the welding reliability.

Owner:SHANGHAI JIAO TONG UNIV

Integrated cold head used for co-axial pulse tube refrigerator

InactiveCN101067523AImprove uniform distributionImprove the diversion effectCompression machinesGas cycle refrigeration machinesPulse tube refrigeratorEngineering

A kind of integrated cold head is used to the coaxial vas freezer and the cold head is made of the high heat conductivity material and at the bottom along the outside around there is a flanged edge used to weld with the shell of storage cold equipment and in the middle of it opens a round hole and around of the round hole opens radial gap uniformly and the depth of gap is the same with the depth of round hole and there is coaxial opening a ring conduit used to the vas of freezer for inserting. The vas adapts with the inserted ring conduit tightly and the cold head adapts with the shell of storage cold equipment tightly and the flanged edge of cold head welds with the shell of storage cold equipment. So the outside of the ring conduit is the storage cold equipment's cold end gas uniform equipment and the inside of the ring conduit is the vas's cold end gas vane. And the gas in the storage equipment and the vas is conducted by the gap of the bottom of integrated cold head. The maxim merit of it is that: the heat exchange area is large and the affection of guiding flow is well and the points of welding are little and it can deliver the quantity of refrigeration of the vas freezer to the outside face of cold head effectively so it improves performance of the coaxial vas freezer largely.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

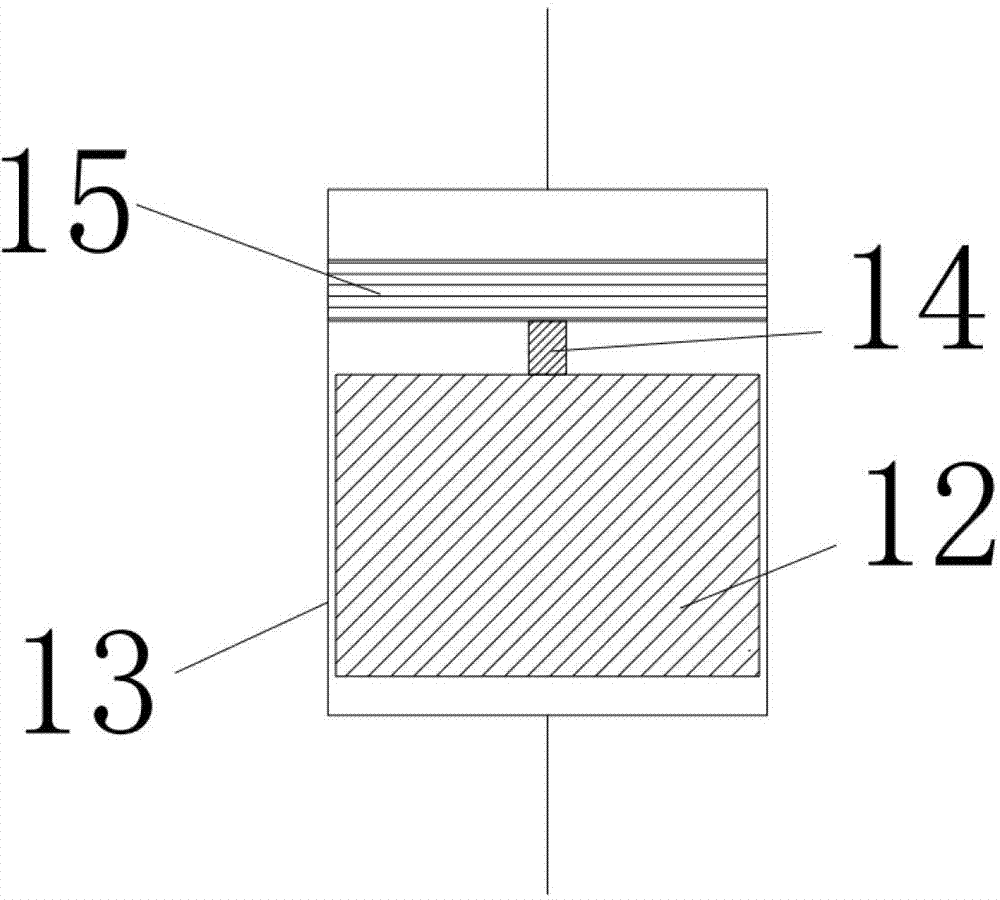

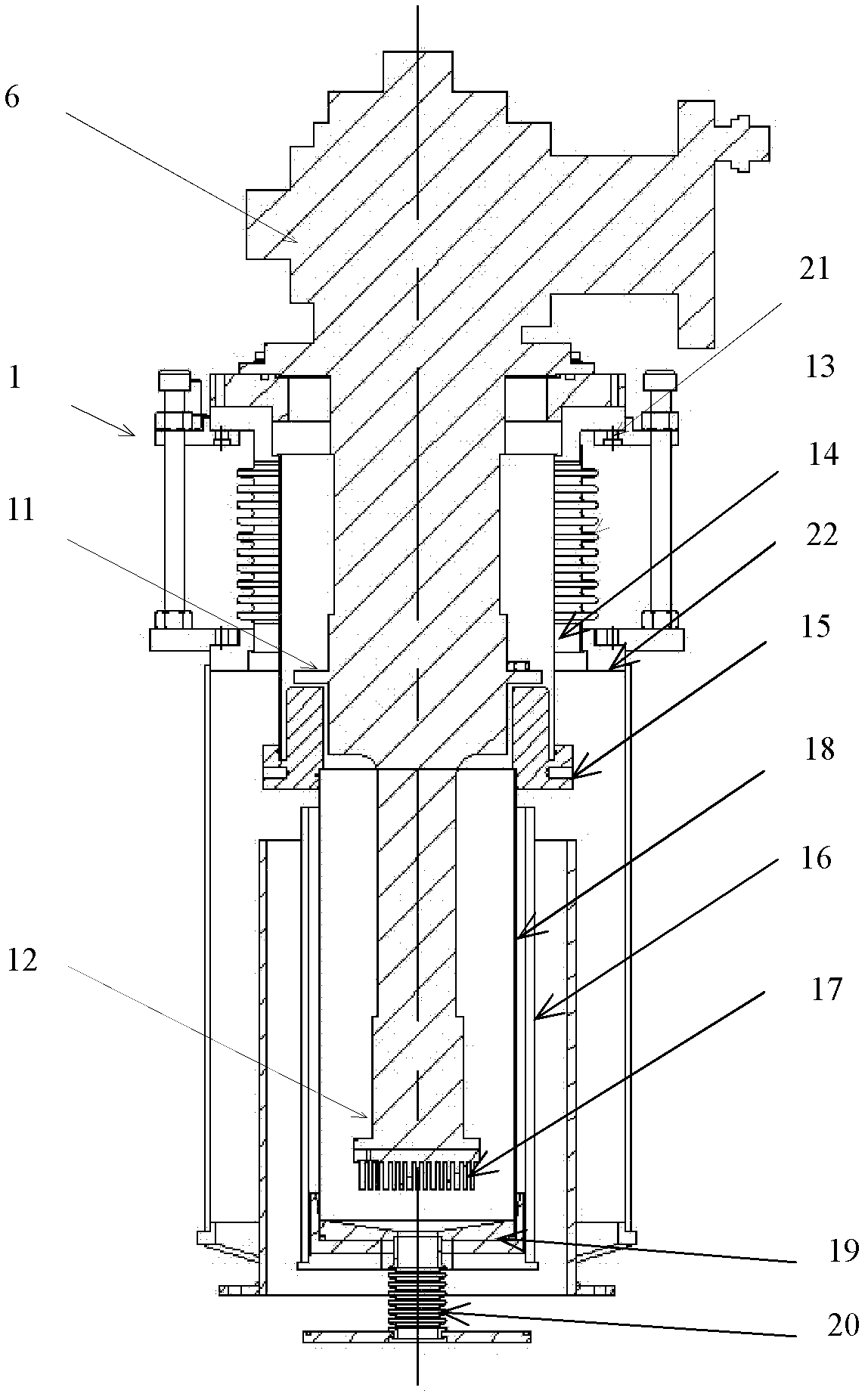

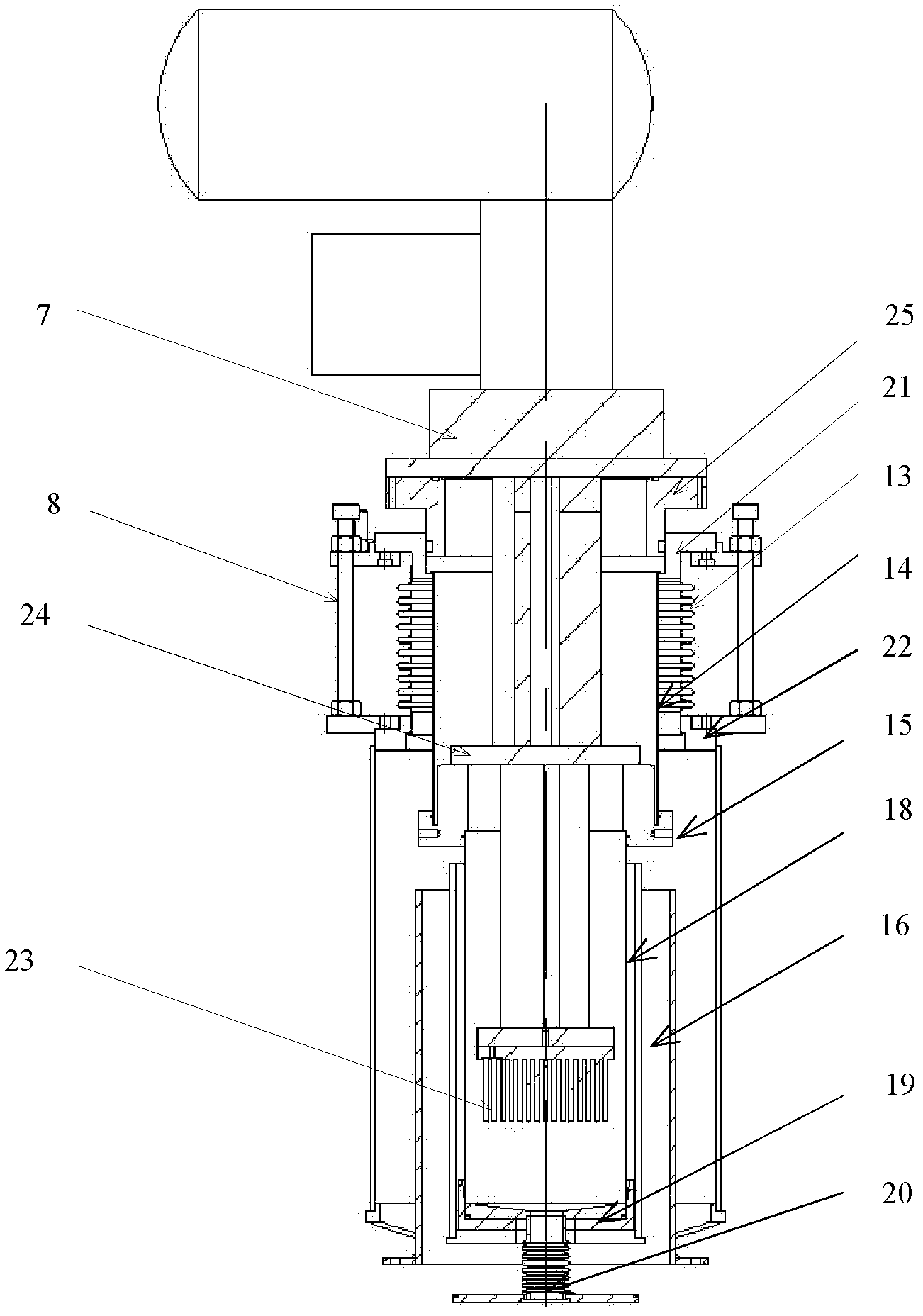

Vibration reduction type cold head container for superconducting magnet

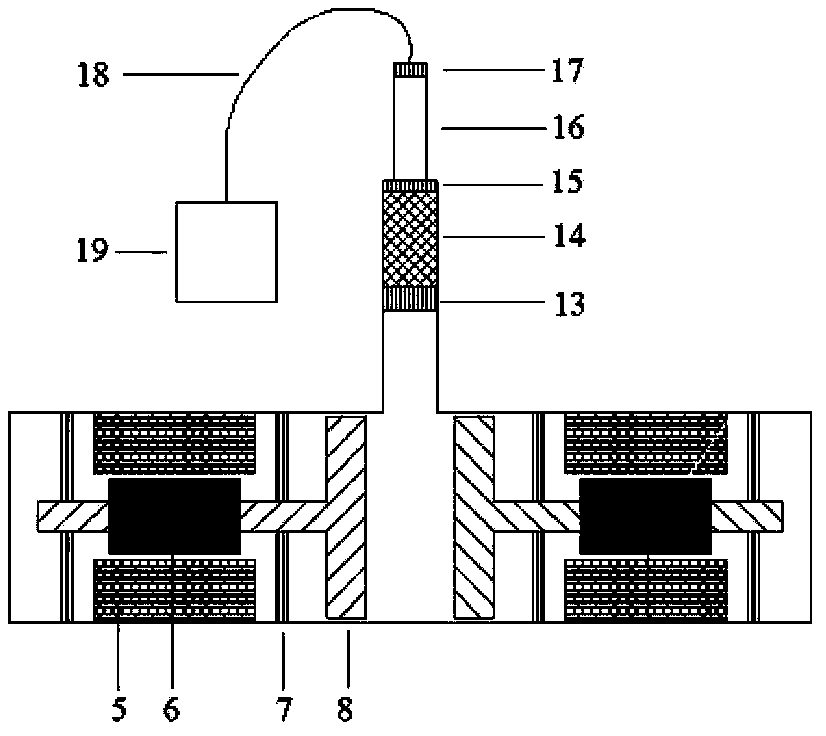

ActiveCN102323557AAvoid vibration transmissionImprove interchangeabilityMeasurements using magnetic resonancePulse tube refrigeratorSuperconducting Coils

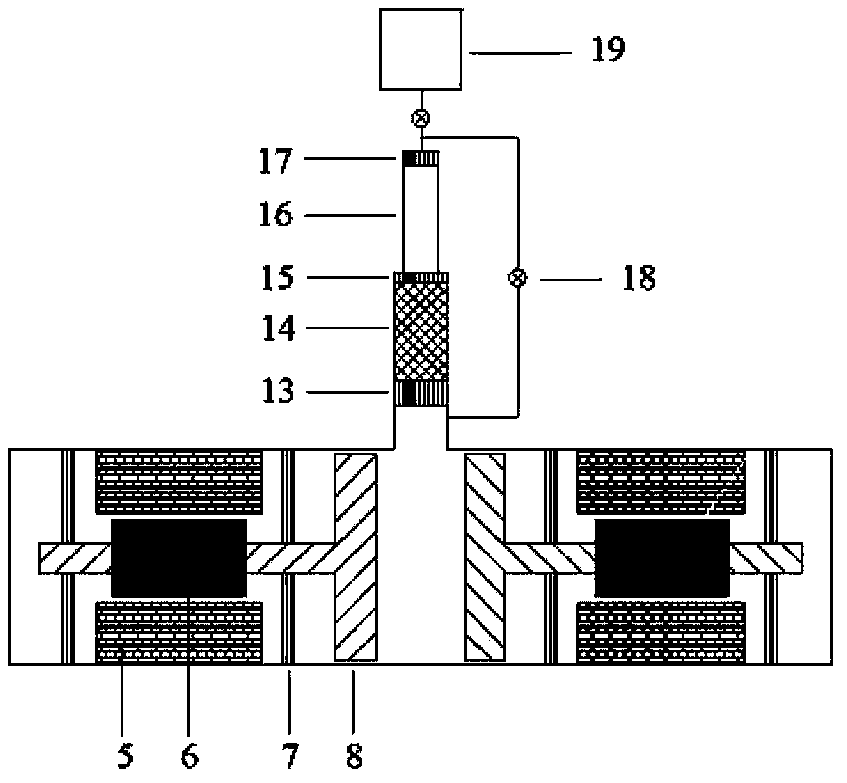

The invention discloses a vibration reduction type cold head container for a superconducting magnet. The container is characterized by comprising a cold head container upper flange (21), a cold head container lower flange (22), a corrugated pipe (13), a primary stainless steel thin-wall pipe (14), a cold head container primary heat-conducting flange (15), a secondary stainless steel thin-wall pipe (18), a magnetic shielding cylinder (16), a bottom connecting corrugated pipe (20) and the like, wherein the vibration reduction corrugated pipe (13) is arranged between the cold head container upper flange (21) and the cold head container lower flange (22); the upper part of the primary stainless steel thin-wall pipe (14) is connected with the cold head container upper flange (21) in an argon arc welding manner, and the lower part of the primary stainless steel thin-wall pipe (14) is connected with the cold head container primary heat-conducting flange (15) in a vacuum brazing manner; the lower part of the cold head container primary heat-conducting flange (15) is connected with the secondary stainless steel thin-wall pipe (18); the bottom of the secondary stainless steel thin-wall pipe (18) is provided with the corrugated pipe (20); the magnetic shielding cylinder (16) is sleeved outside the secondary stainless steel thin-wall pipe (18); and a GM (Gifford-Mcmahon) refrigerator (6) or a pulse tube refrigerator (7) is arranged in the cold head container (1).

Owner:NINGBO JANSEN SUPERCONDUCTING TECH CO LTD

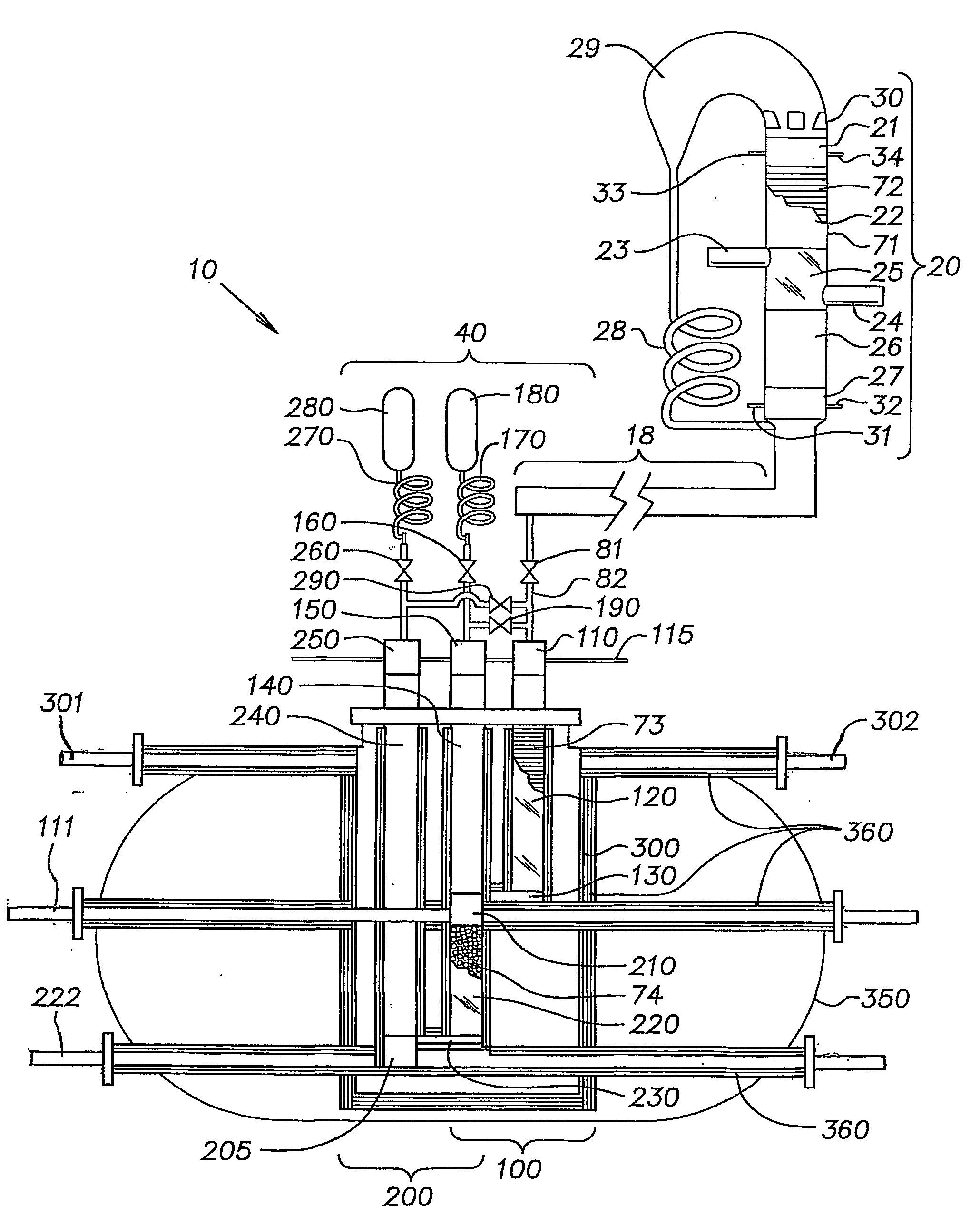

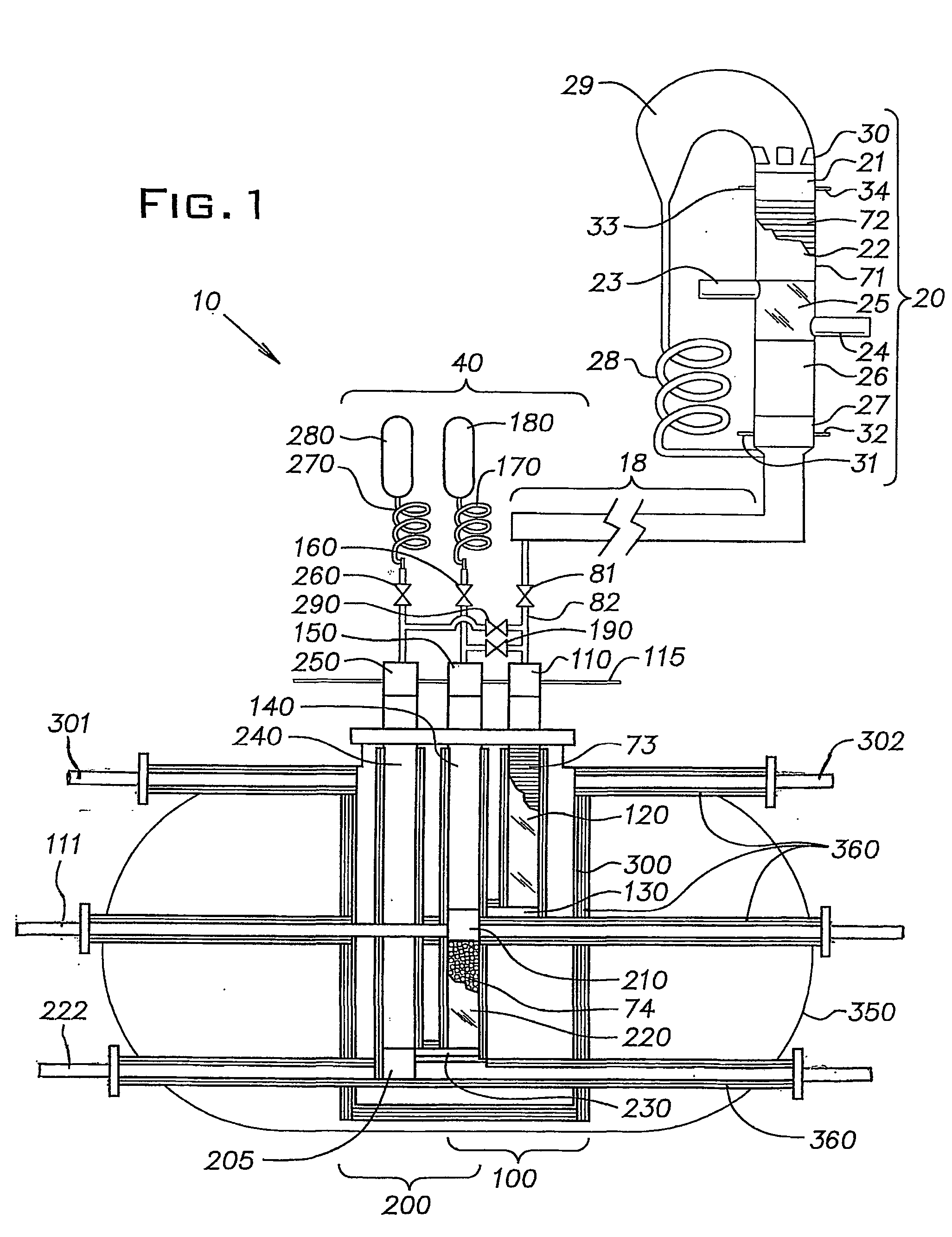

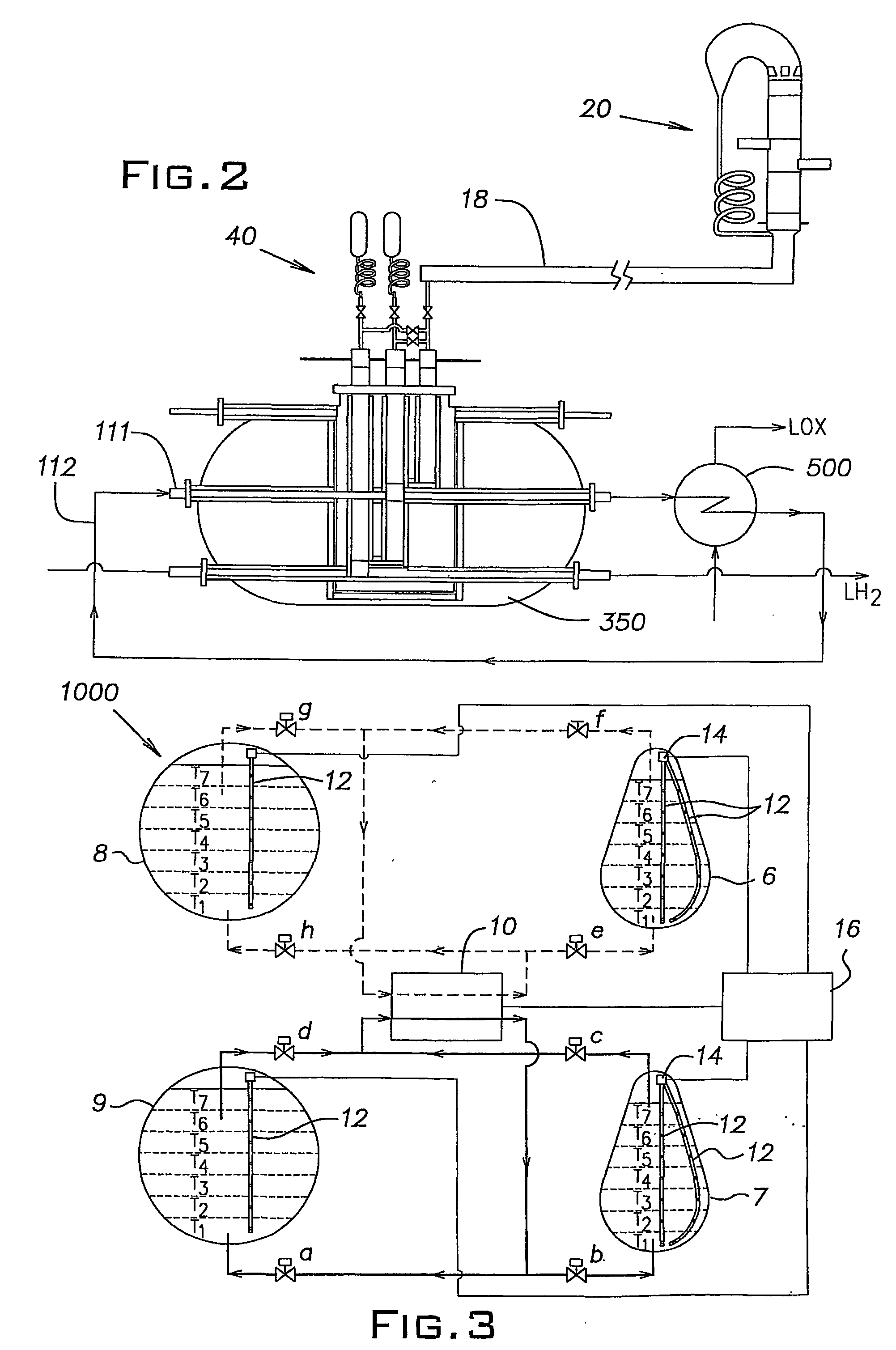

Densifier for simultaneous conditioning of two cryogenic liquids

A densifier (10) for simultaneously densifying two cryogenic liquids at different temperatures is provided. The densifier (10) has a thermoacoustic heat engine (20), a resonance tube (18) and a two stage pulse tube refrigerator (40). The thermoacoustic heat engine (20) generates oscillatory acoustical power required to generate net refrigeration power in the two-stage pulse tube refrigerator (40). The first stage (100) densifies a first cryogenic liquid to a first cryogenic temperature, and the second stage (200) densifies a second cryogenic liquid to a second, lower cryogenic temperature. The thermoacoustic heat engine (20) converts thermal energy to the oscillatory acoustical power required to generate net refrigeration in the first (100) and second (200) stages of the pulse tube refrigerator (40). No mechanical energy input is required, and therefore the invented densifier (10) has no moving parts.

Owner:SIERRA LOBO

Low temperature scanning probe microscope system based on pulsatron refrigeration technology

ActiveCN101294889ALow running costEliminate vibrationSurface/boundary effectInstrumental componentsRetention timeDigital signal processor

The invention relates to a low temperature scanning probe microscope system based on pulse tube refrigeration technology. Aimed at vibration source and characteristics, a multistage active / passive damping device, including a sylphon bellowss, a piezoelectric ceramic tube and a spring are adopted. The sylphon bellowss is used for connecting a main system cavity and a refrigeration head of the pulse tube to realize vibration isolation of the whole system. As for low frequency vibration unique to a pulse tube refrigerator, an active damping device with a piezoelectric ceramic tube and a digital signal processor as the core is adopted. A beryllium copper spring and a damping magnet form a first stage passive damping device to isolate vibration. The system eliminates the vibration from the pulse tube refrigerator and the refrigeration head to the scanning probe, applies to other vibration sensitive occasions that require low temperature, saves a large amount of liquid helium refrigerant, simplifies equipment operation and maintenance, and significantly prolongs the retention time at low temperature.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Densifier for simultaneous conditioning of two cryogenic liquids

A densifier (10) for simultaneously densifying two cryogenic liquids at different temperatures is provided. The densifier (10) has a thermoacoustic heat engine (20), a resonance tube (18) and a two stage pulse tube refrigerator (40). The thermoacoustic heat engine (20) generates oscillatory acoustical power required to generate net refrigeration power in the two-stage pulse tube refrigerator (40). The first stage (100) densifies a first cryogenic liquid to a first cryogenic temperature, and the second stage (200) densifies a second cryogenic liquid to a second, lower cryogenic temperature. The thermoacoustic heat engine (20) converts thermal energy to the oscillatory acoustical power required to generate net refrigeration in the first (100) and second (200) stages of the pulse tube refrigerator (40). No mechanical energy input is required, and therefore the invented densifier (10) has no moving parts.

Owner:SIERRA LOBO

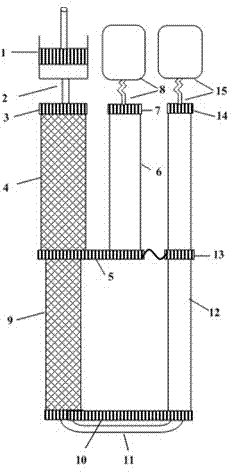

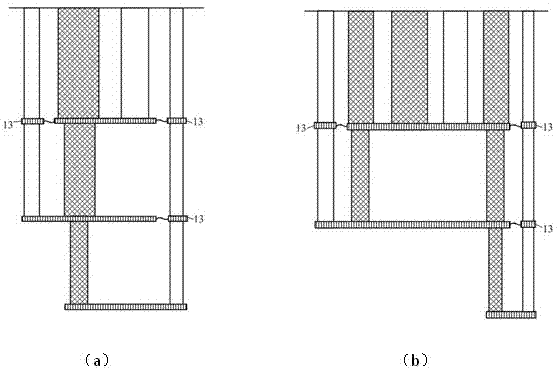

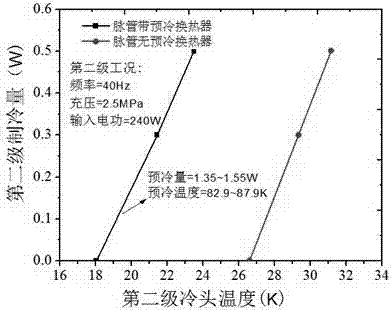

Pulse tube refrigerator with precooling pulse tube

InactiveCN102331105AReduce heat lossImprove performanceCompression machinesPulse tube refrigeratorHeat losses

The invention discloses a pulse tube refrigerator with a precooling pulse tube. A compressor, a hot end connecting tube, a heat regenerator hot end heat exchanger, a first heat regenerator, a first cold end heat exchanger, a first pulse tube, a first pulse tube hot end heat exchanger and a first phase modulating device are connected in sequence; a second heat regenerator, a second cold end heat exchanger, a cold end connecting tube, a second pulse tube, a pulse tube precooling heat exchanger, a second pulse tube hot end heat exchanger and a second phase modulating device are connected in sequence; and the pulse tube precooling heat exchanger is connected with the first cold end heat exchanger. In the invention, the pulse tube is provided with the precooling heat exchanger, so that the temperature gradient of the near cold end of the pulse tube is reduced, and heat loss of the pulse tube is reduced; and meanwhile, the precooling heat exchanger can assist the pulse tube to carry away the heat of gas in the tube, so that the refrigerating performance of a cold head is enhanced. For a multi-stage pulse tube refrigerator, the precooling amount of a next stage pulse tube is supplied by a previous stage cold head or heat regenerator, so that the performance of the cold head in a low-temperature region can be enhanced greatly only by using a cold quantity precooling pulse tube with a smaller high-temperature region. The pulse tube refrigerator is easy to operate and implement.

Owner:ZHEJIANG UNIV

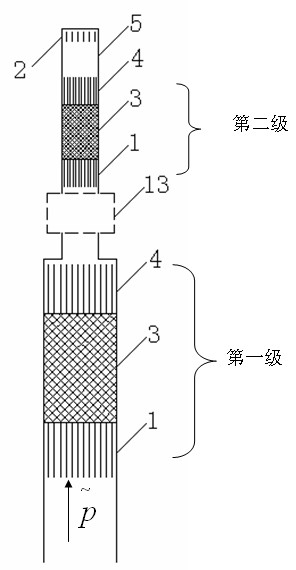

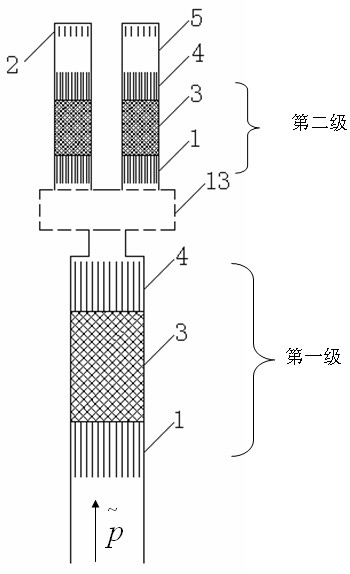

Multi-stage pulse tube refrigerator adopting relay linear compressor

ActiveCN102980321AOptimize layoutEasy to installCompression machinesFluid circulation arrangementLinear compressorPulse tube refrigerator

The invention discloses a multi-stage pulse tube refrigerator adopting a relay linear compressor. The multi-stage pulse tube refrigerator comprises a compressor, a regenerator hot end heat exchanger, a high-temperature section regenerator, high-temperature section regenerator cold end heat exchangers, a first-stage pulse tube, a first-stage pulse tube hot end heat exchanger and first-stage phase-modulating parts, which are sequentially connected, the multi-stage pulse tube refrigerator also comprises a low-temperature section regenerator, low-temperature section regenerator cold end heat exchangers, a second-stage pulse tube, a second-stage pulse tube hot end heat exchanger and second-stage phase-modulating parts, which are sequentially connected, the cold end of the high-temperature section regenerator is also connected with the hot end of the low-temperature section regenerator through a pipeline, and the pipeline is provided with the relay linear compressor which is used for compressing the air passing through the pipeline. The pressure ratio of the cold end of the high-temperature section regenerator of the multi-stage pulse tube refrigerator adopting the relay linear compressor is further increased, consequently, a high pressure ratio is obtained at the cold end of the multi-stage pulse tube refrigerator, and the efficiency of the multi-stage pulse tube refrigerator is ultimately increased; and meanwhile, the multi-stage pulse tube refrigerator has the advantages of compact structure, long service life, high reliability and the like.

Owner:ZHEJIANG UNIV

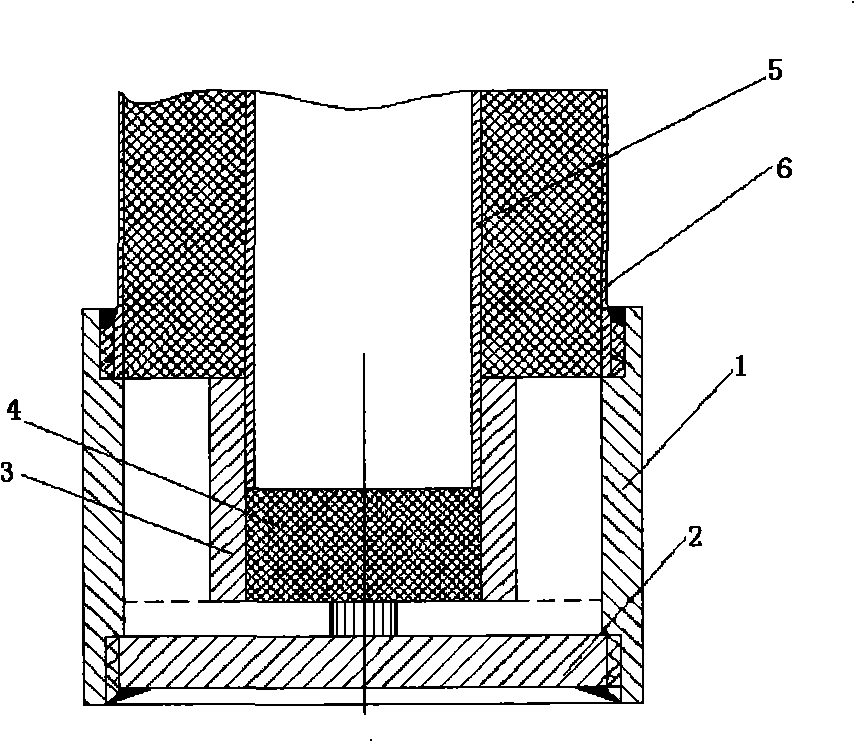

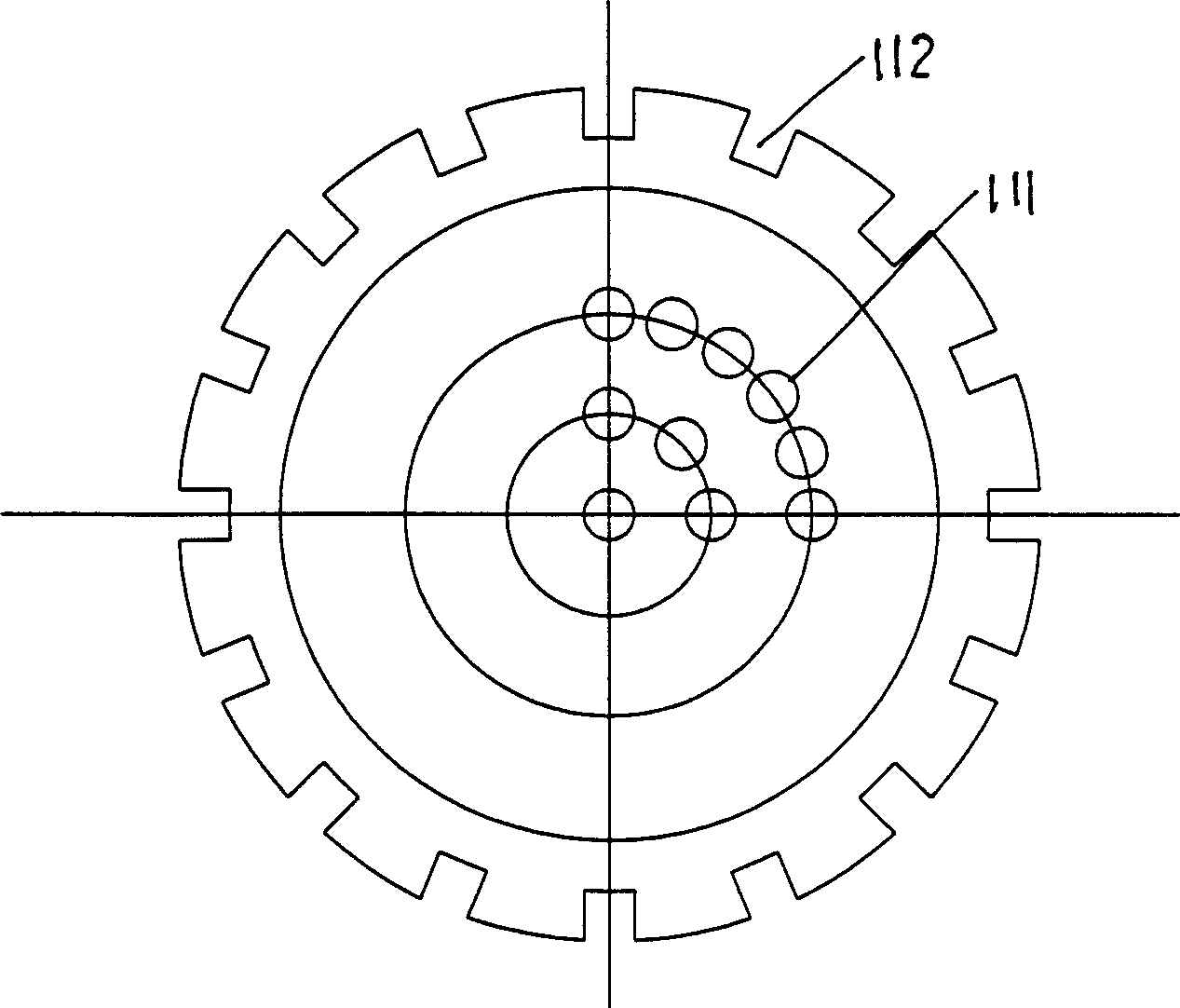

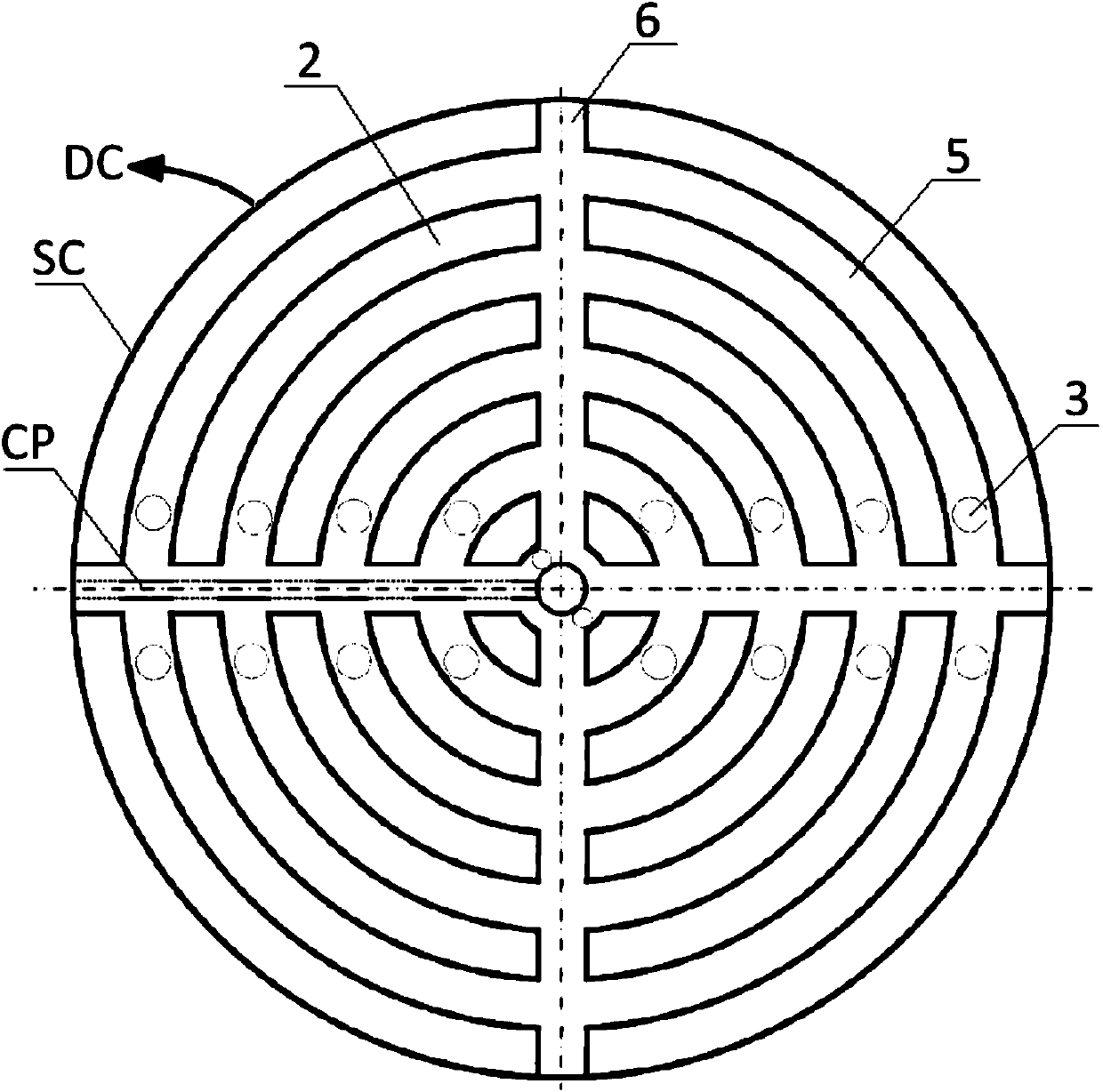

Conical slit-type hot end heat exchanger of coaxial pulse tube refrigerator and manufacturing method

ActiveCN102735088AImprove thermodynamic performanceImprove machine performanceCompression machinesSoldering apparatusPulse tube refrigeratorEngineering

The invention discloses a conical slit-type hot end heat exchanger of a coaxial pulse tube refrigerator and a manufacturing method. The heat exchanger structurally consists of a hot end flange, a conical slit and a hot end plug, wherein the conical slit is inserted into the hot end flange in a tight fit way, the radius of a circle of contact on the top of a cone frustum is equal to the radius of a cold accumulator and the radius of the bottom of the cone frustum is equal to the radius of the hot end plug. The hot end plug and the hot end flange not only can be connected through bolts to form a detachable split-type hot end heat exchanger, but also can be hermetically welded to form an integrated hot end radiator. The conical slit-type hot end heat exchanger has the advantages that the structure is simple, compact and high-efficiency, the hot end radiating capacity of the refrigerator can be exerted to the utmost extent and the hot end pressure ratio of the pulse tube refrigerator is increased at the same time. The structure can intensively realize the major functions of a high-efficiency hot end heat exchanger, a hot end gas flow guide device of the pulse tube refrigerator and a hot end gas even distributor of the cold accumulator, and can improve the performance of the entire pulse tube refrigerator to a great extent.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

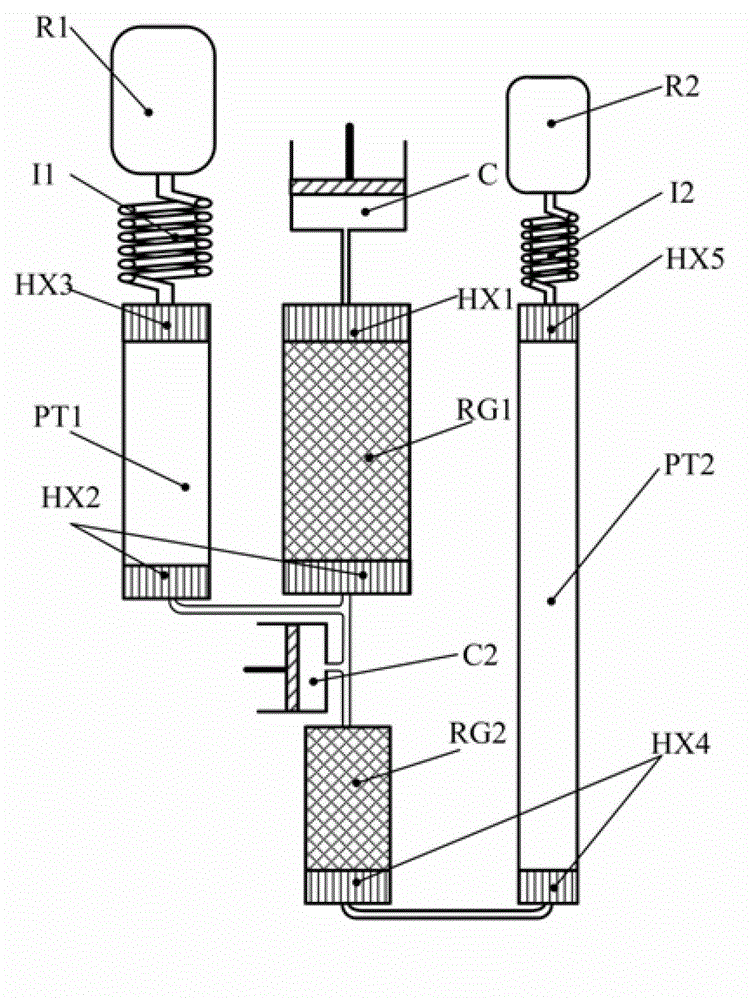

Stirling pulse tube refrigerator connected with displacer

InactiveCN102506513AReduce lossGuaranteed uptimeCompression machinesRefrigeration componentsRoom temperaturePulse tube refrigerator

The invention discloses a Stirling pulse tube refrigerator connected with a displacer. A cold end of a first-stage pulse tube refrigerator is connected with one end of the displacer; the other end of the displacer is connected with a room temperature end of a second-stage pulse tube refrigerator; one or more second-stage pulse tube refrigerators are connected in parallel, or one or more second-stage pulse tube refrigerators are connected in series; the displacer comprises a free single-piston type displacer, a single-piston supporting type displacer and a double-piston supporting type displacer; the free single-piston type displacer is provided with a piston only; a piston of the single-piston supporting type displacer is arranged on one side of an elastic part, and a connecting rod is arranged on the piston and is connected with the elastic part; and pistons of the double-piston supporting type displacer are arranged on two sides of the elastic part, and a connecting rod is arranged between the two pistons and is connected with the elastic part. Compared with the conventional multi-stage pulse tube refrigerator, the Stirling pulse tube refrigerator is connected with the displacer, so that the system is more compact, phase modulation is flexible and accurate, the loss of acoustical power transmitted among stages is reduced, more acoustical power is transmitted to the next stage, large cold quantity is obtained, and the whole system operates more efficiently.

Owner:ZHEJIANG UNIV +1

Nonmagnetic low-vibration coaxial impulse pipe refrigerating machine

InactiveCN1467461AReduce vibration effectsEliminate severe distractionsCompression machinesRefrigeration devicesMagnetic susceptibilityMetallic materials

The invention relates to a non-magnetic low vibration coaxial pulse tube refrigerating machine wherein the pulse tube and the cold accumulation device are in coaxial arrangement, between which cold accumulation stuffing is filled, an arched flow diverter is arranged on an extending section and the end portion, closely spaced vertical through-holes are arranged on the arched portion, vertical grooves are arranged evenly circular ring external wall, the cover type cold end heat exchanger covers the groove and packs by bonding, the horizontal split cold platform supported by the support rod and fixed on the hot end flange vertically are arranged on the cold end heat exchanger, the cold platform and cold end heat exchanger are connected by flexible heat guide band, the coupling channel under the throttle holes are connected to phase modulation capillary.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Reduced Input Power Cryogenic Refrigerator

InactiveUS20080092588A1Reduce pressure drop lossReduce gas volumeSolidificationLiquefactionReflux valveNuclear engineering

Owner:SUMITOMO HEAVY IND LTD +1

Deep hypothermic heat regenerator adopting helium as heat regeneration medium and pulse tube refrigerator thereof

ActiveCN104197591AGuaranteed heat exchange effectImprove performanceCompression machinesSuperheatersThermodynamicsPulse tube refrigerator

The invention discloses a deep hypothermic heat regenerator adopting helium as a heat regeneration medium. The heat regenerator comprises a tube shell and heat regeneration padding arranged in the tube shell. The heat regeneration padding is of a sealed heat exchange structure filled with the helium. The invention further discloses a pulse tube refrigerator adopting the deep hypothermic heat regenerator. According to the pulse tube refrigerator, the characteristic that the helium is high in volumetric specific heat capacity at low temperature is utilized, and the helium is closed in a certain space and used as the heat regeneration medium to exchange heat with helium used as a refrigerating working medium; the helium with the suitable pressure can be selected and charged into the enclosed space according to the work pressure of the pulse tube refrigerator so that the volumetric specific heat capacity of the helium serving as the heat regeneration medium in the deep hypothermic area can be higher than that of the helium serving as the refrigerating working medium, efficient heat regeneration can be achieved, and finally the performance of the pulse tube refrigerator in the liquid helium temperature area can be improved; meanwhile, compared with a magnetic heat regeneration material, the deep hypothermic heat regenerator adopting the helium as the heat regeneration medium has the advantages of being low in price, easy to obtain, free from influence of a magnetic field and the like.

Owner:ZHEJIANG UNIV

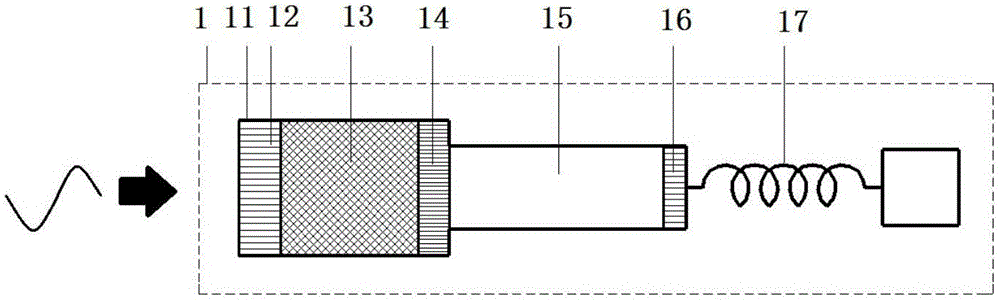

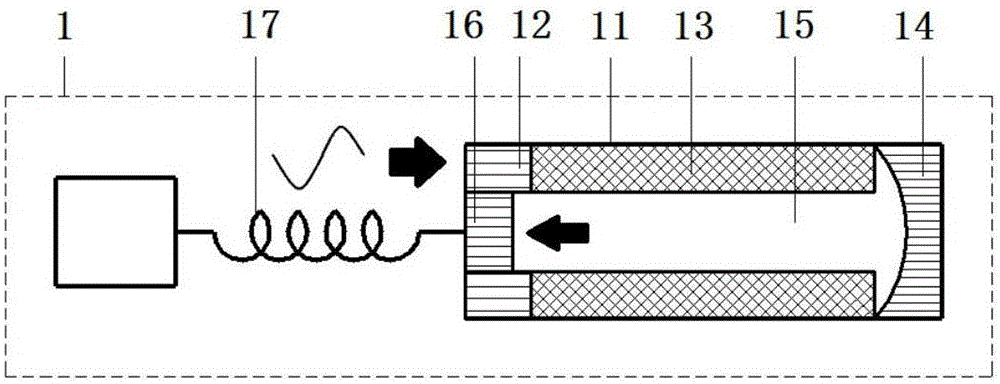

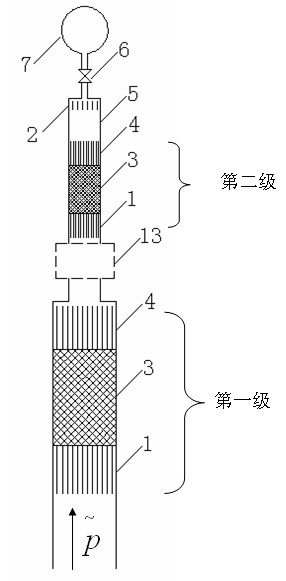

Pulse tube refrigerator

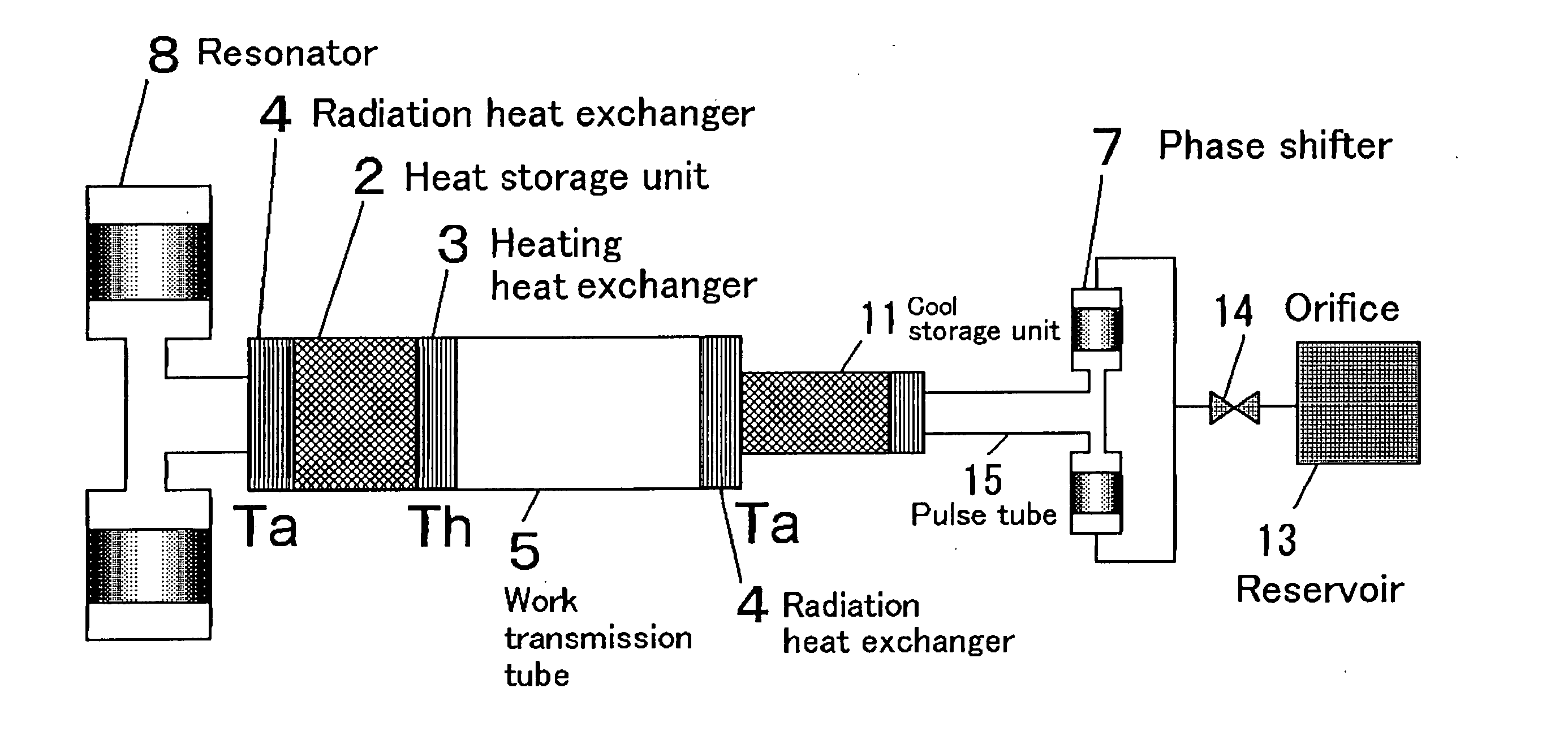

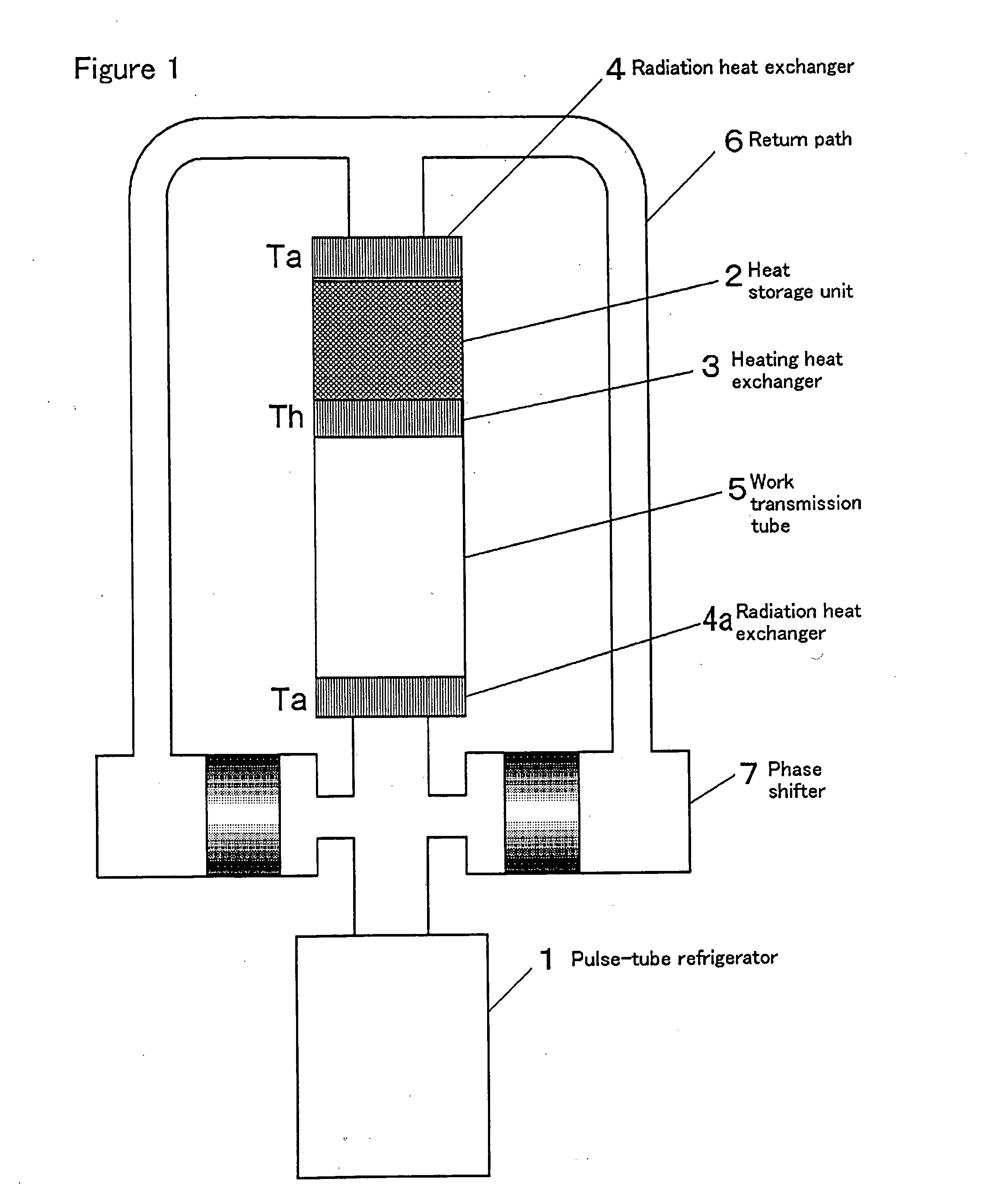

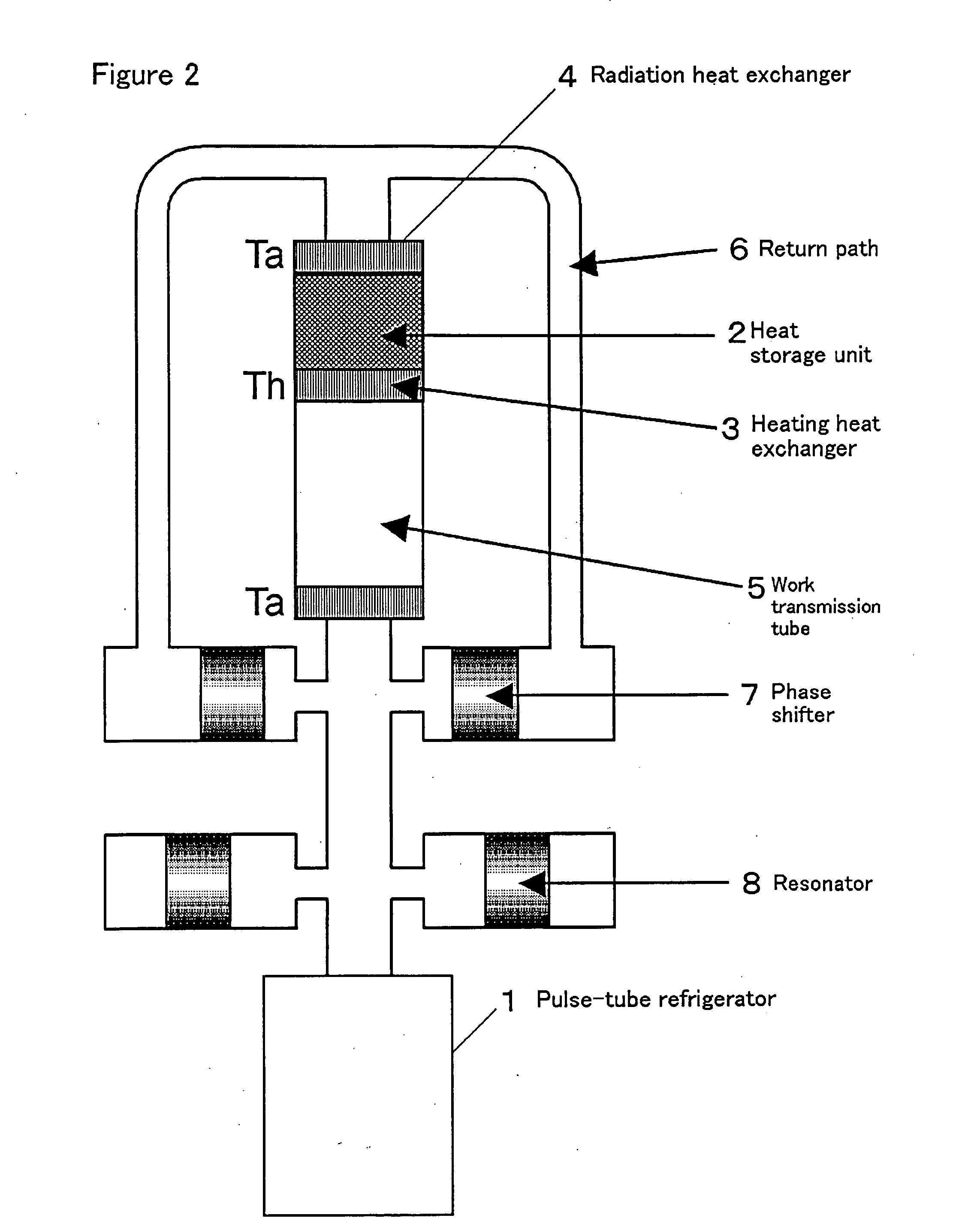

InactiveUS20060277925A1Free noiseFree vibrationCompression machinesGas cycle refrigeration machinesCool storagePulse tube refrigerator

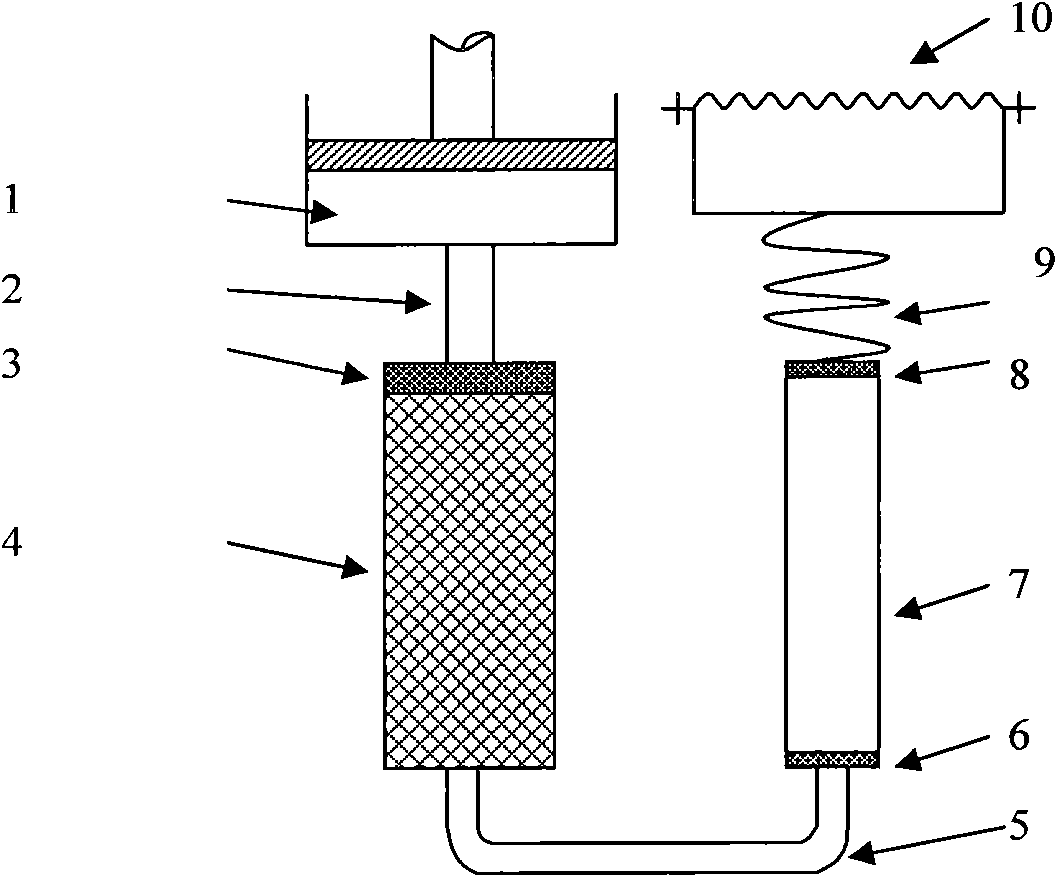

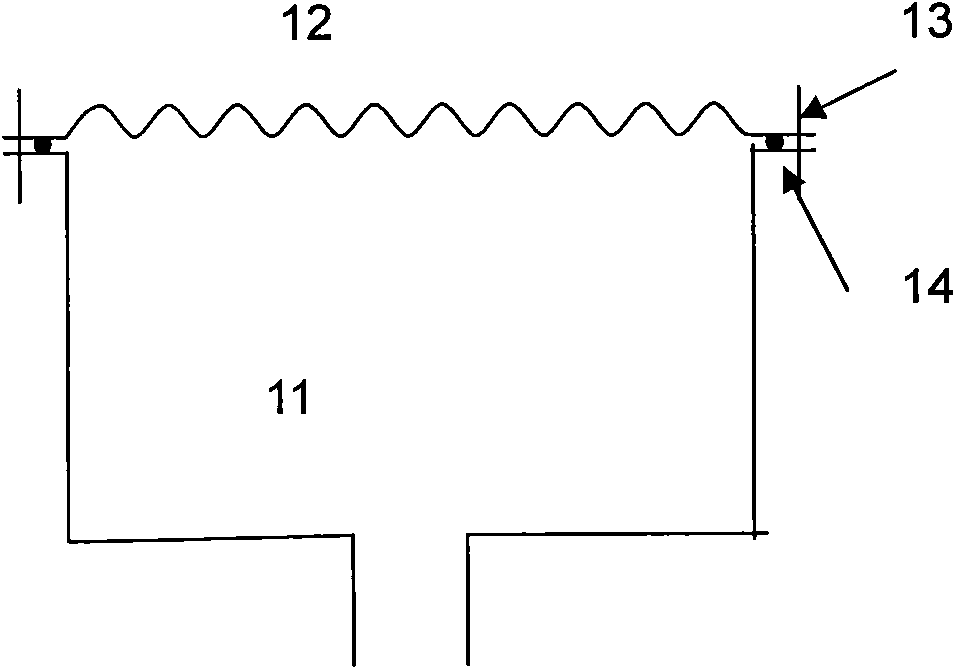

A pulse tube refrigerator that is small in size and free from vibration and electric noise. A pulse tube refrigerator (1) has a pulse tube, a cool storage unit connected to the low-temperature side of the pulse tube, a vibration generator connected to the high-temperature side of the cool storage unit, and a reservoir with an orifice, connected to the high-temperature side of the pulse tube. The vibration generator is a thermally driven pressure wave generator having thermal drive tubes (heat exchangers (4-4a) for heat radiation), a phase shifter (7), and a return path (6). Sufficiently heating a heat exchanger (3) for heating causes self-exciting vibration to be generated in a work transmission tube (5), and work is returned to the thermal drive tubes through the phase shifter (7) and the return path (6) arranged on the work output side of the work transmission tube (5). The work is amplified by the thermal drive tubes, and is then outputted from the work transmission tube (5) and fed to the pulse tube refrigerator (1). A vibration generator for a pulse tube refrigerator that is small in size and free from vibration and noise can be realized.

Owner:JAPAN AEROSPACE EXPLORATION AGENCY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com