Integrated cold head used for co-axial pulse tube refrigerator

A pulse tube refrigerator, an integrated technology, applied in refrigerators, gas cycle refrigerators, refrigeration and liquefaction, etc., can solve the problem that the cooling capacity of the working gas at the cold end cannot be effectively transmitted, and the heat exchanger at the cold end and the working gas The small heat transfer area affects the utilization of the cooling capacity of the pulse tube refrigerator, etc., and achieves the effect of convenient welding, good flow diversion effect, and few solder joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the specific embodiment of the present invention is described in further detail:

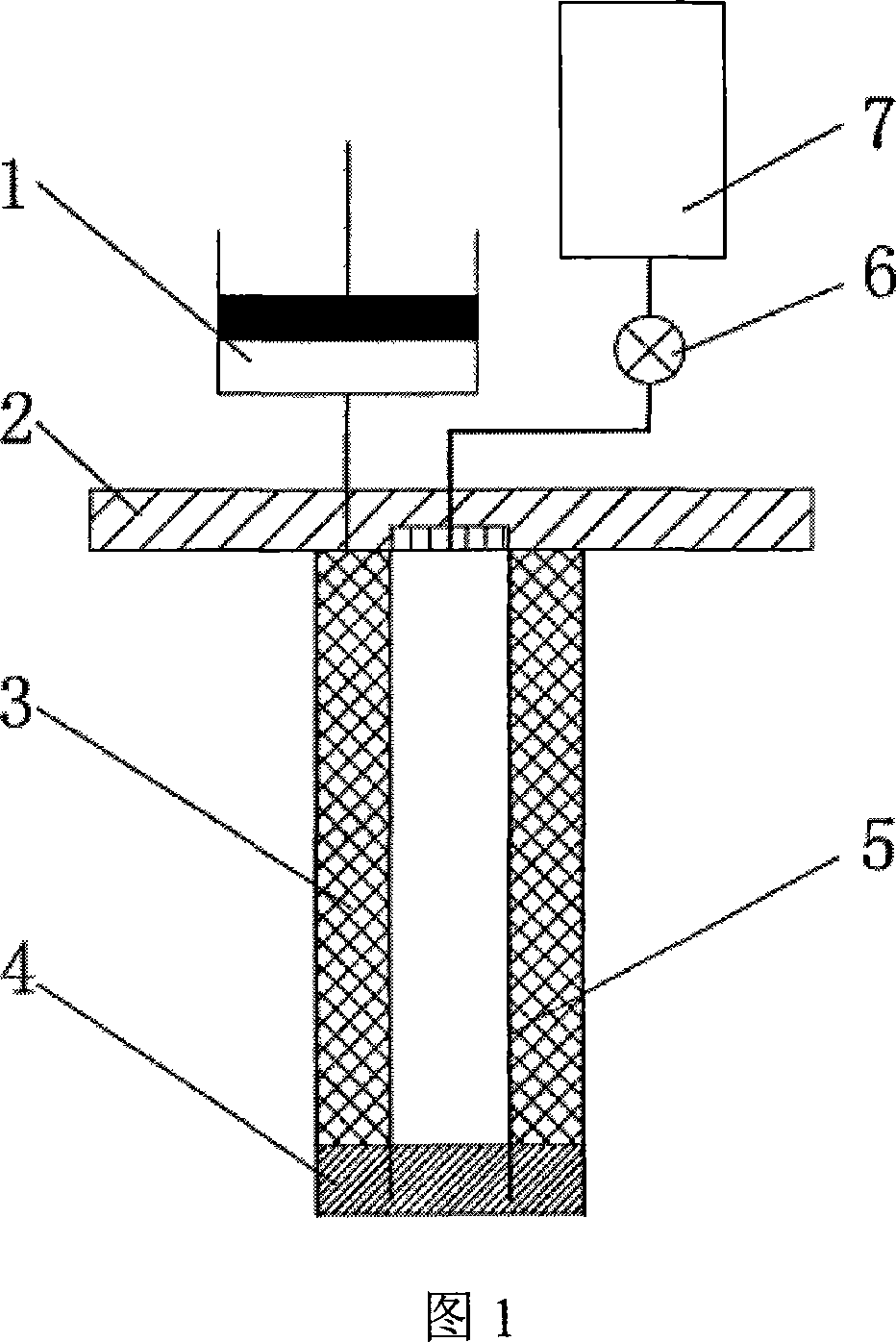

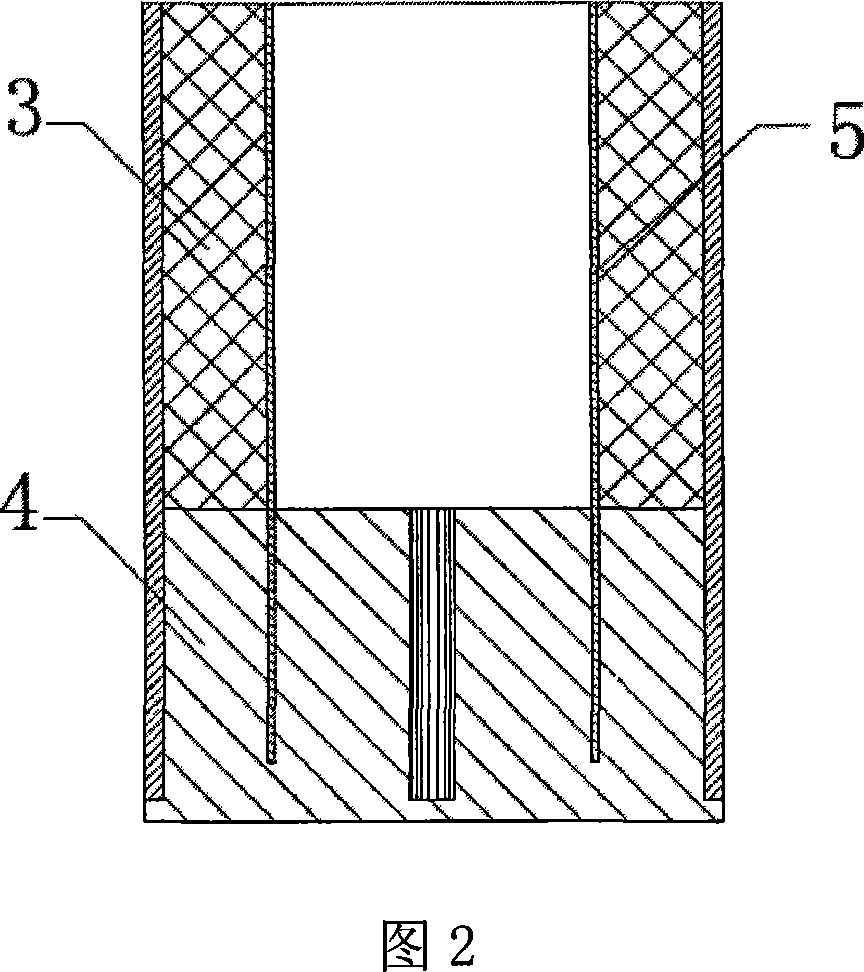

[0014] As shown in Fig. 2, the outer diameter of the regenerator 3 in this embodiment is 20 mm, and the outer shell of the regenerator is made of stainless steel; the inner diameter of the vessel 5 is 10 mm, and the wall thickness is 0.3 mm, which is made of titanium alloy.

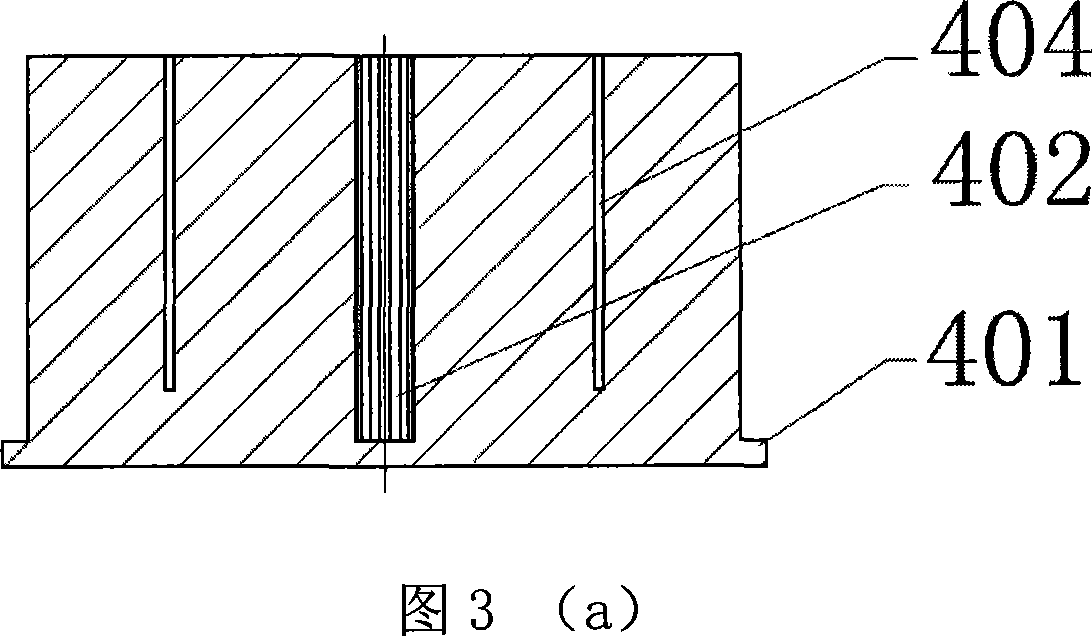

[0015] The integral cold head is a cylinder, and the bottom of the cylinder has a flange 401 for welding with the cold storage shell along the outer periphery. The integral cold head is tightly fitted and inserted into the lower shell of the cold storage. Solder connection. There is a round hole 402 in the center of the cold head 4. The diameter of the round hole 402 is 2.3 mm. There are 18 radial slits 403 evenly distributed around the round hole. The width of the slit is 0.4 mm, and the depth of the slit is 18 mm. The depth of the circular hole is equal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com