Patents

Literature

5250results about How to "Easy to weld" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

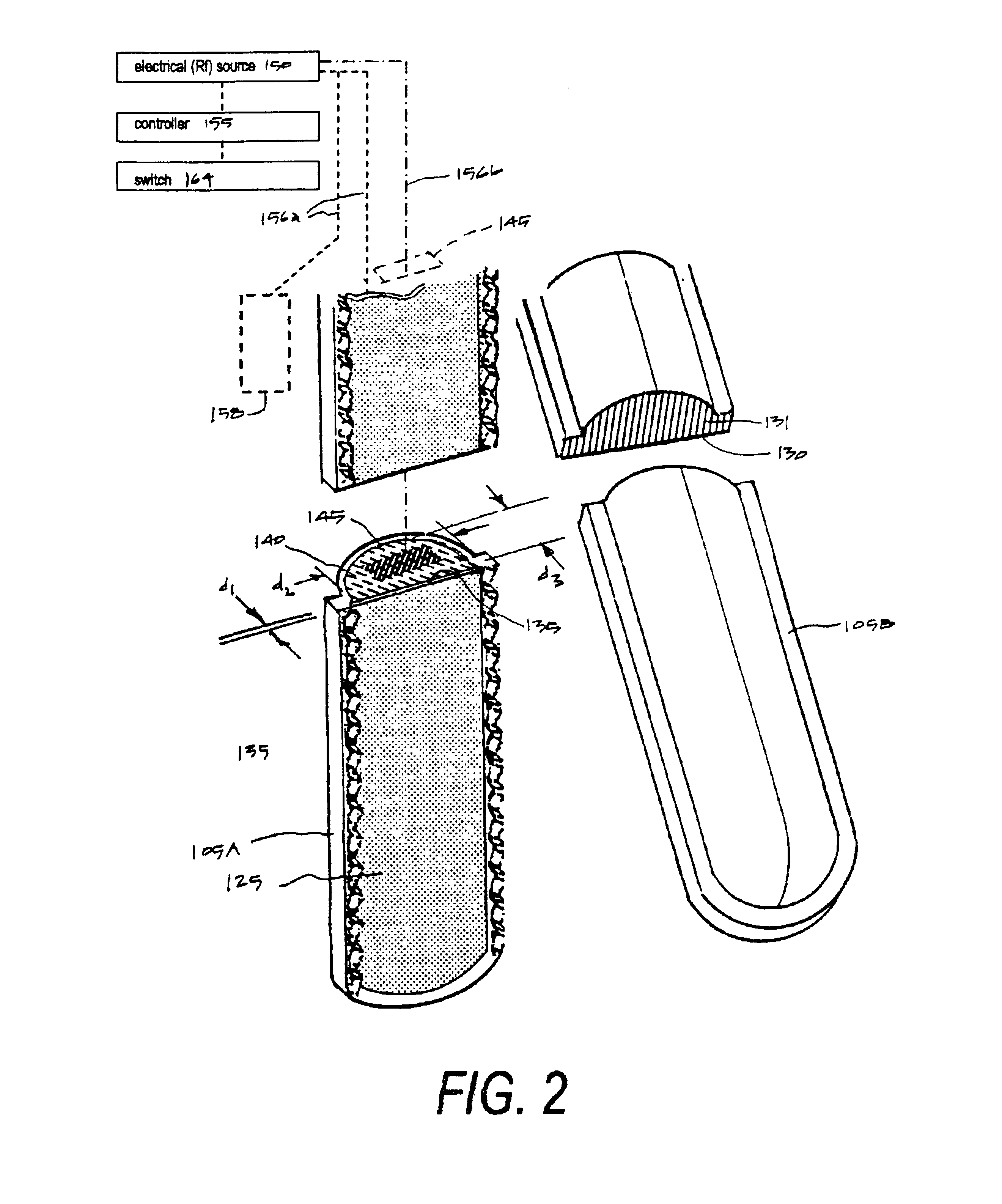

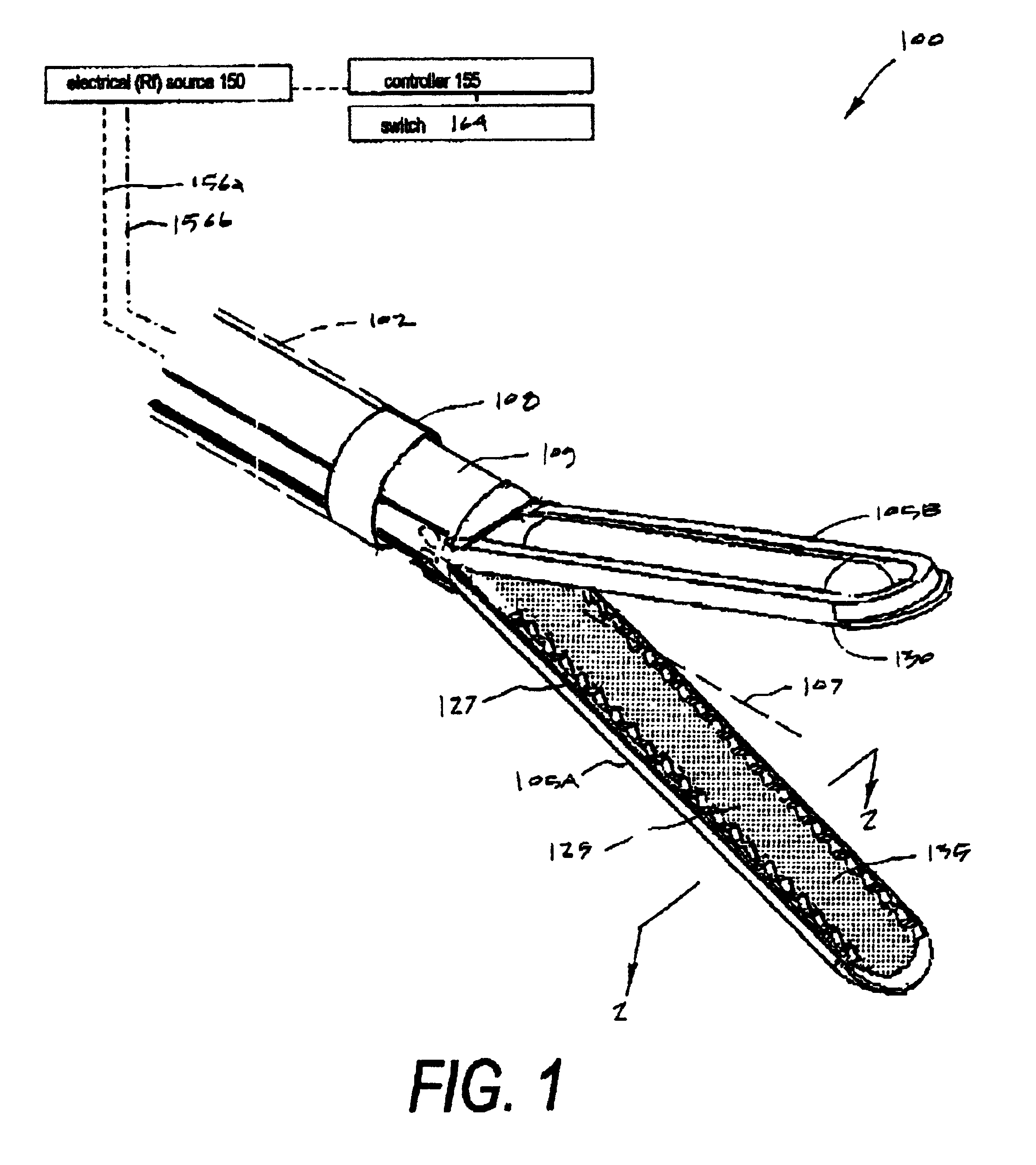

Electrosurgical instrument

InactiveUS6926716B2Prevent any substantial dehydrationEnergy efficiencySurgical instruments for heatingSurgical forcepsElectrical resistance and conductanceVoltage source

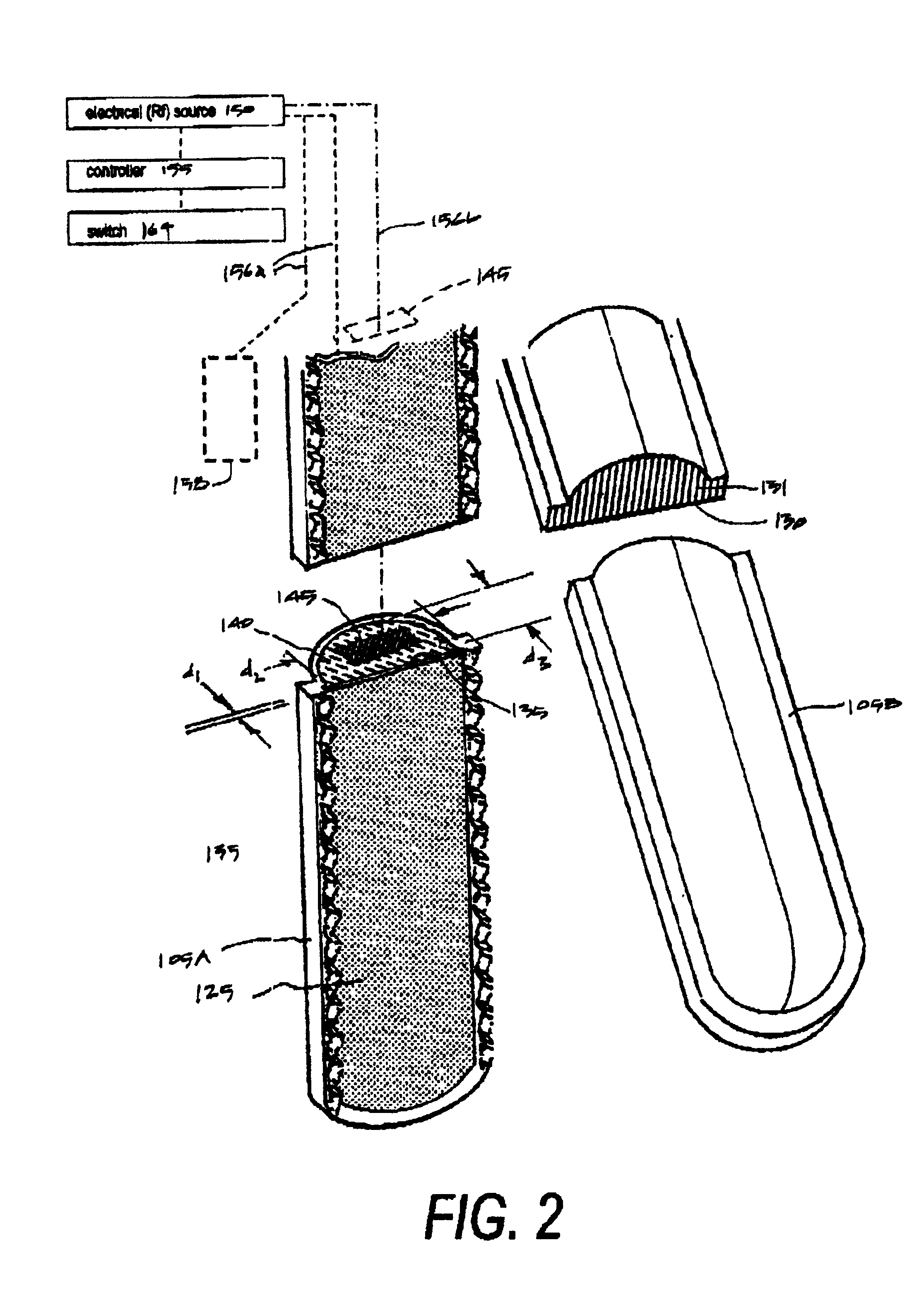

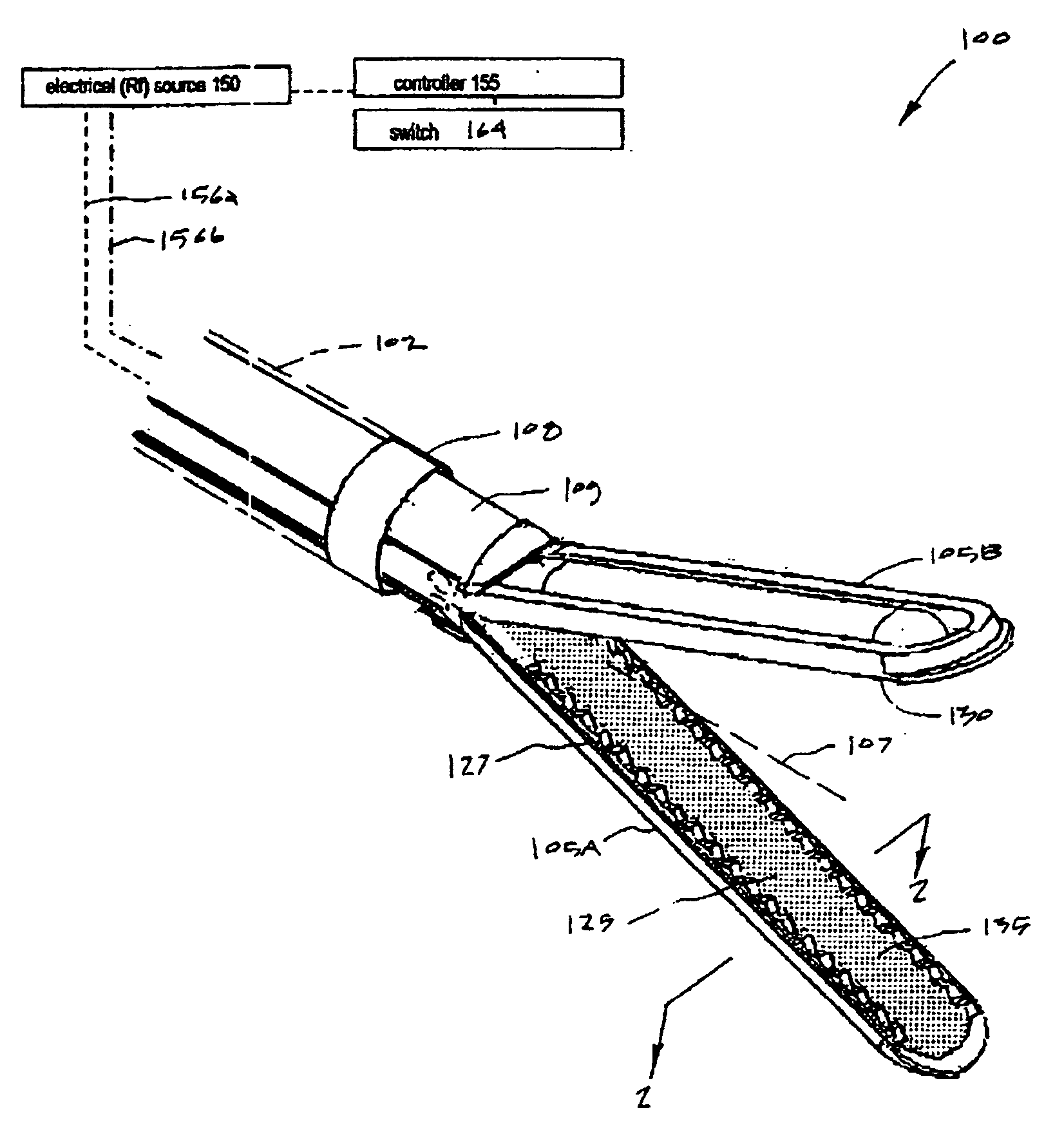

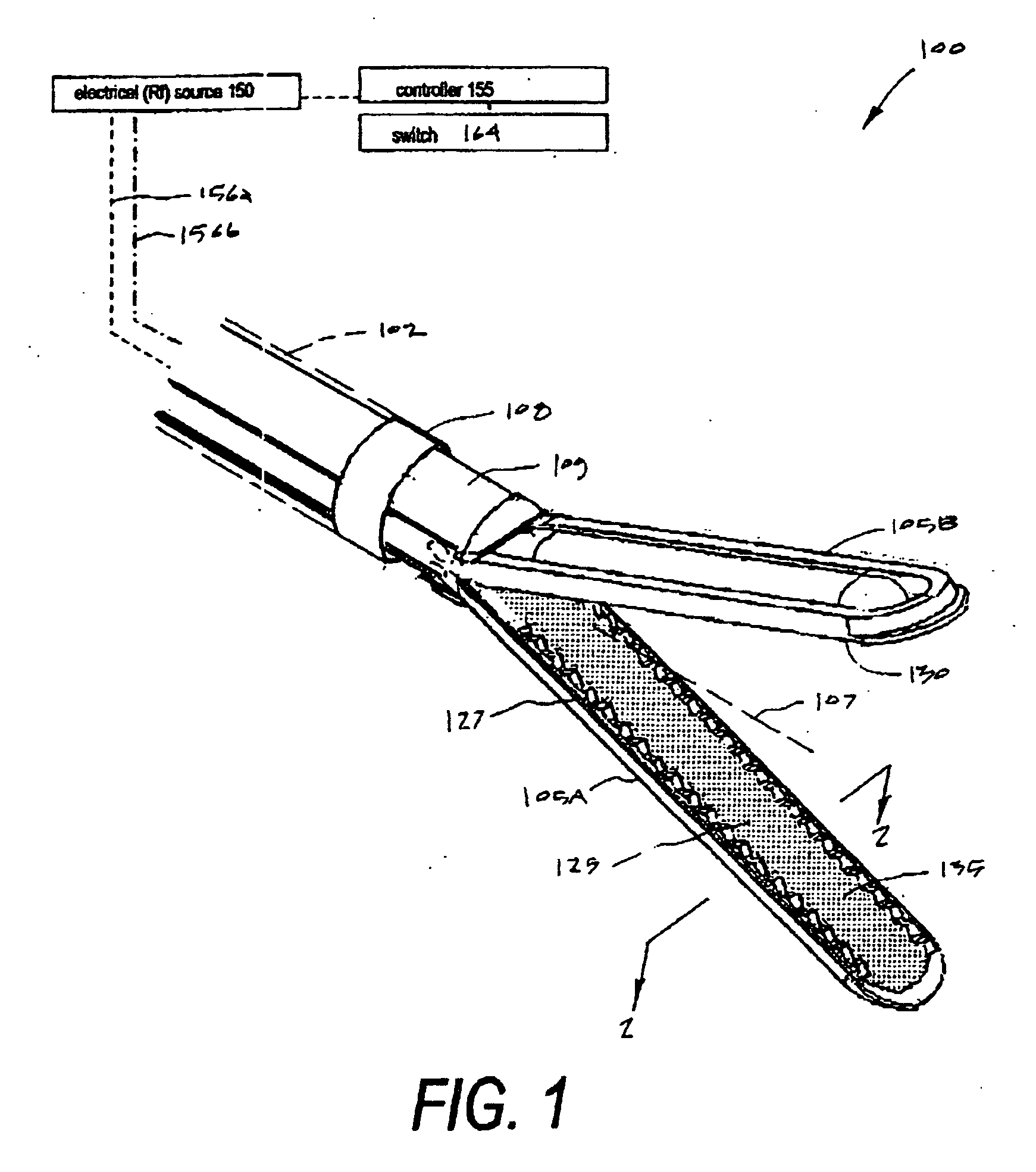

A working end of a surgical instrument that carries first and second jaws for delivering energy to tissue. In a preferred embodiment, at least one jaw of the working end defines a tissue-engagement plane that contacts the targeted tissue. The cross-section of the engagement plane reveals that it defines (i) a first surface conductive portion or a variably resistive matrix of a temperature-sensitive resistive material or a pressure-sensitive resistive material, and (ii) a second surface portion coupled to a fixed resistive material that coupled in series or parallel to a voltage source together with the first portion. In use, the engagement plane will apply active Rf energy to ohmically heat the captured tissue until the point in time that a controller senses an electrical parameter of the tissue such as impedance. Thereafter, the controller switches energy delivery to the second surface portion that is resistively heated to thereby apply energy to tissue by conductive heat transfer.

Owner:ETHICON ENDO SURGERY INC

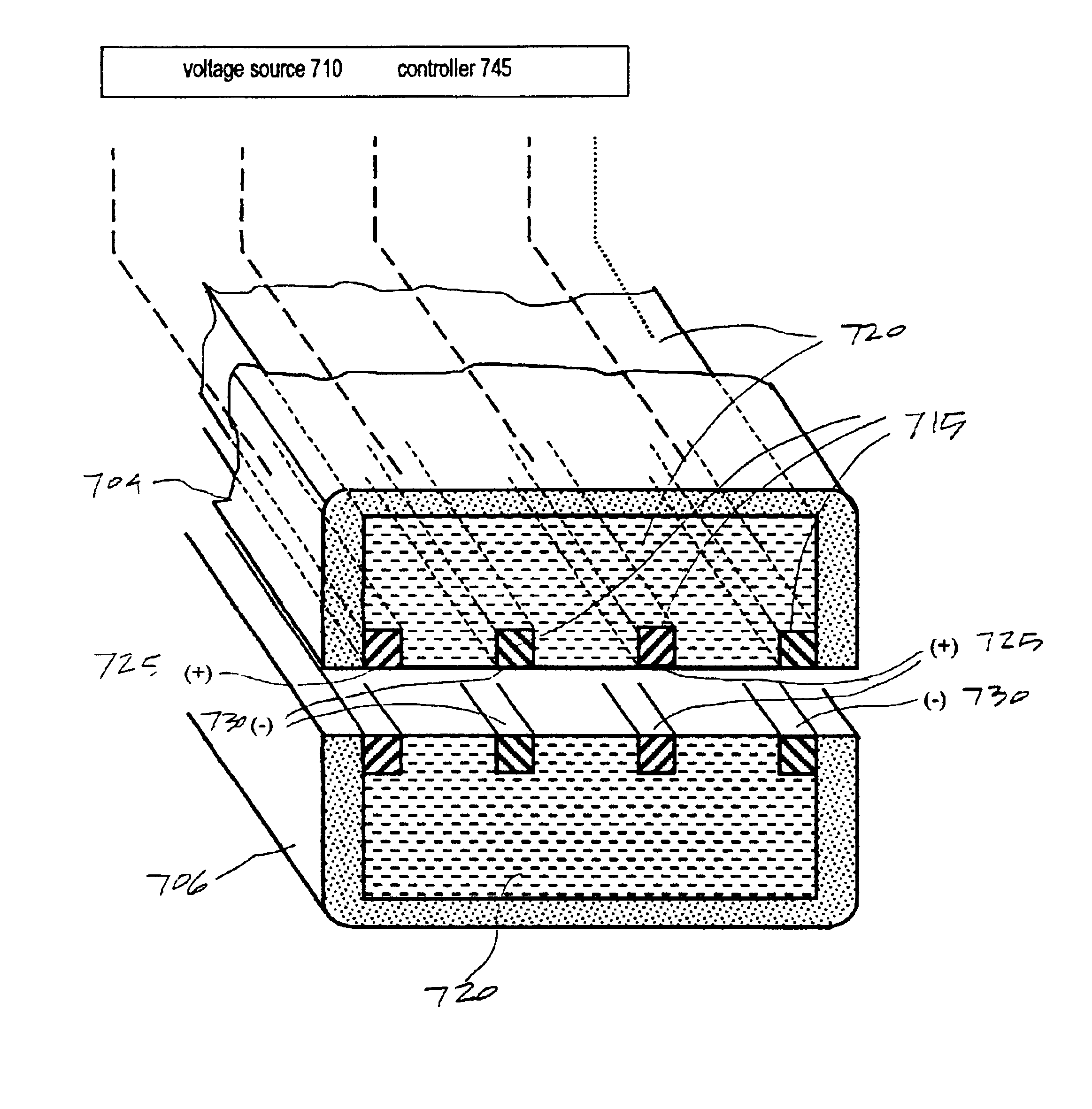

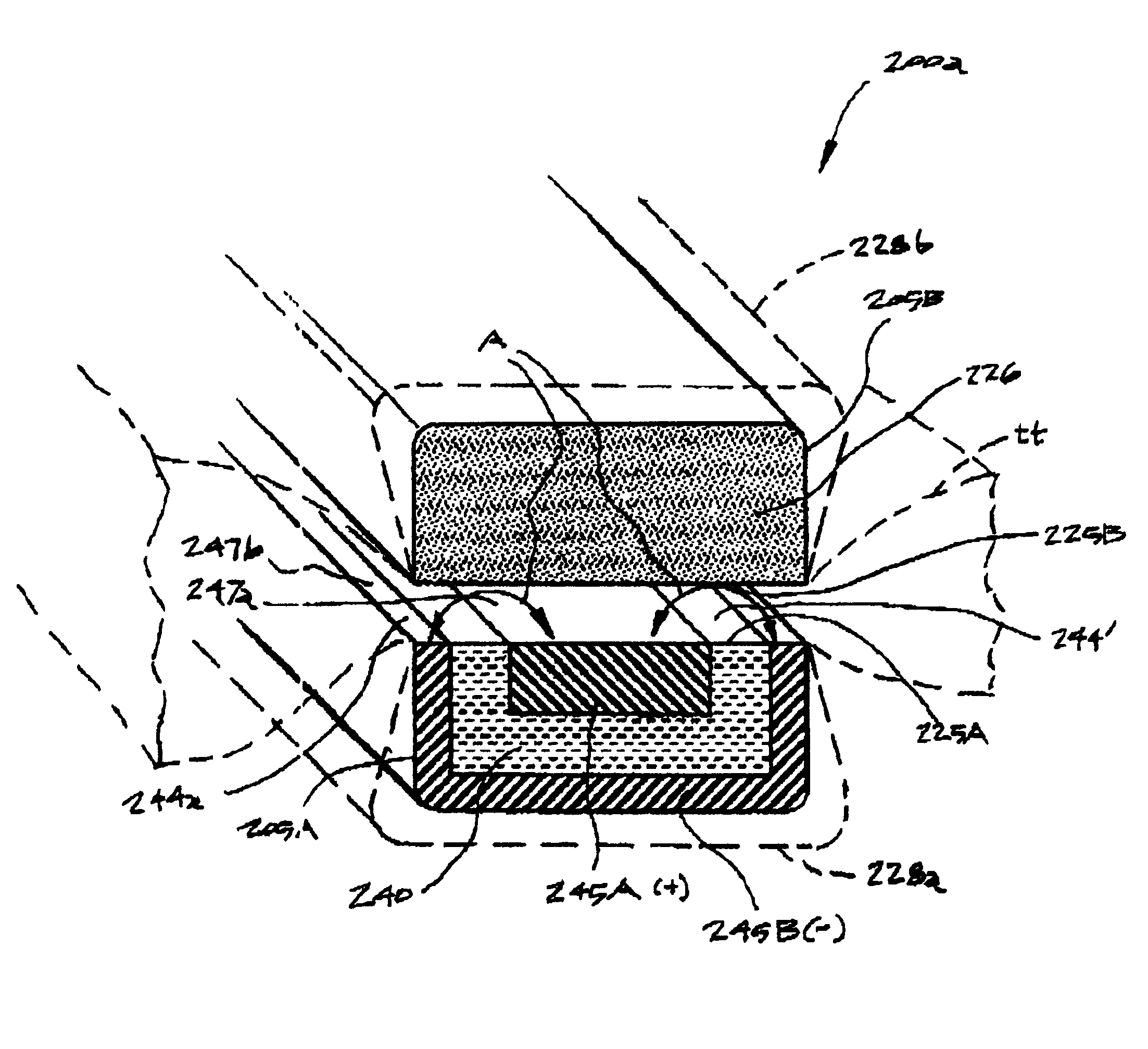

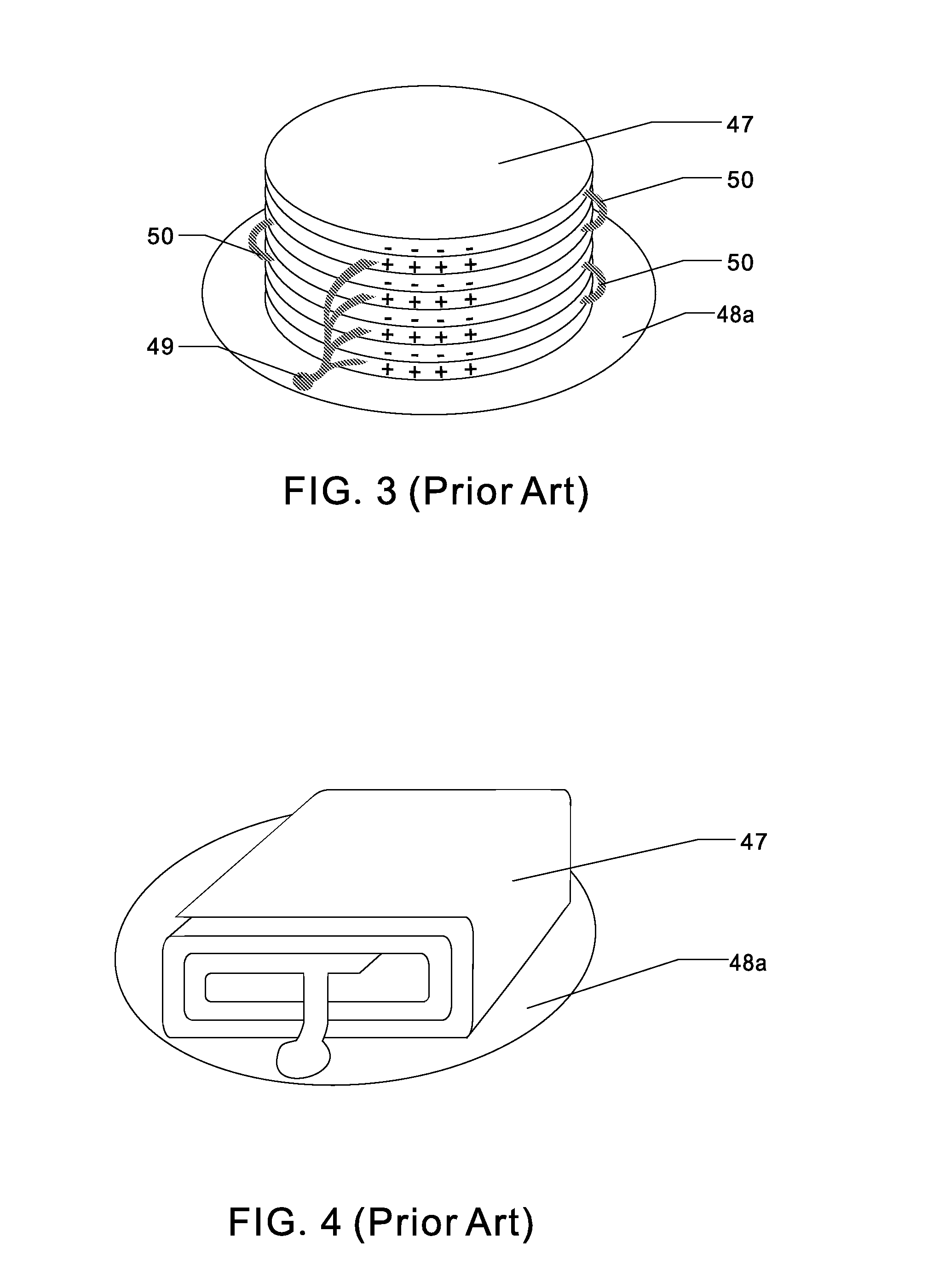

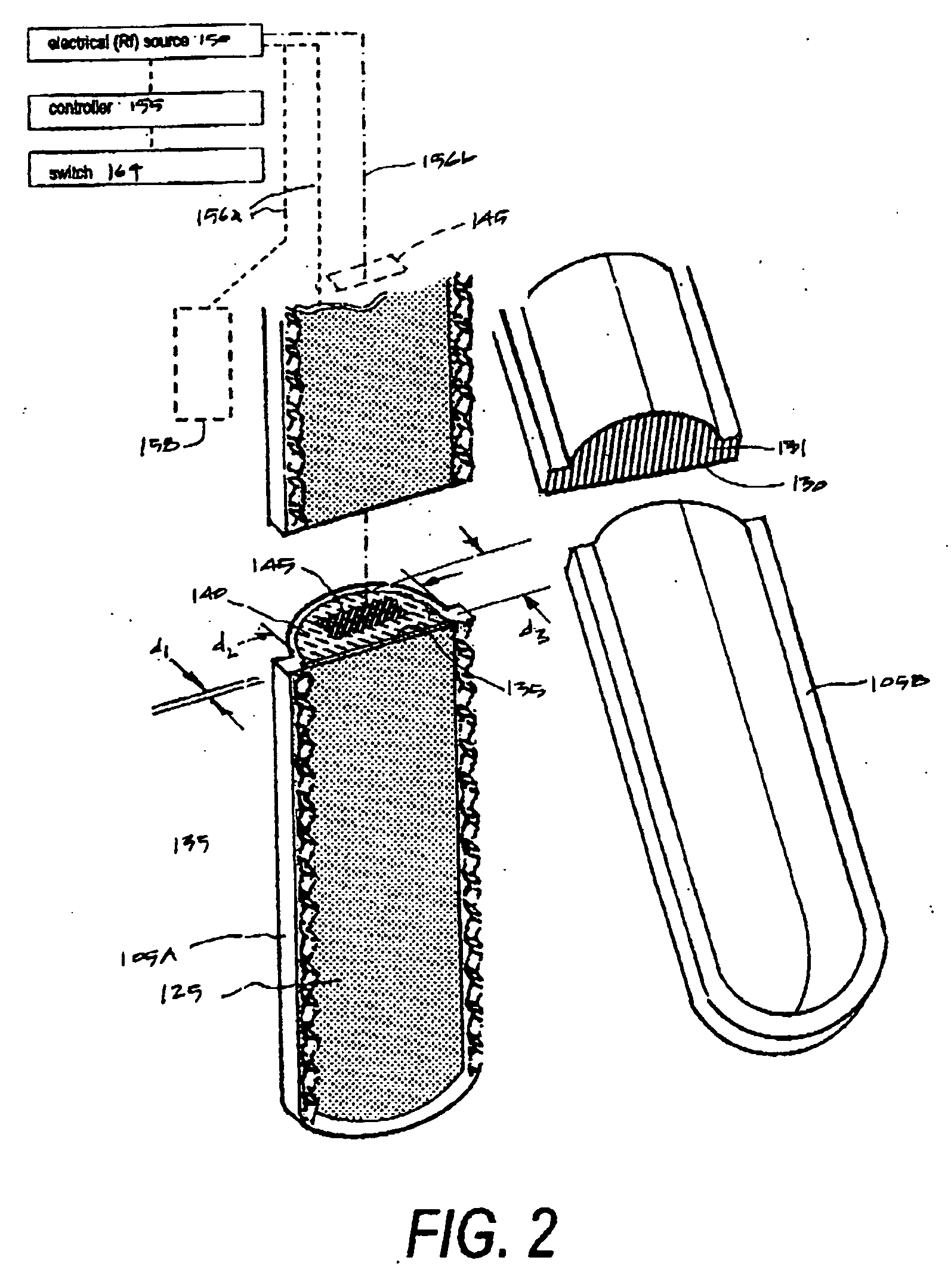

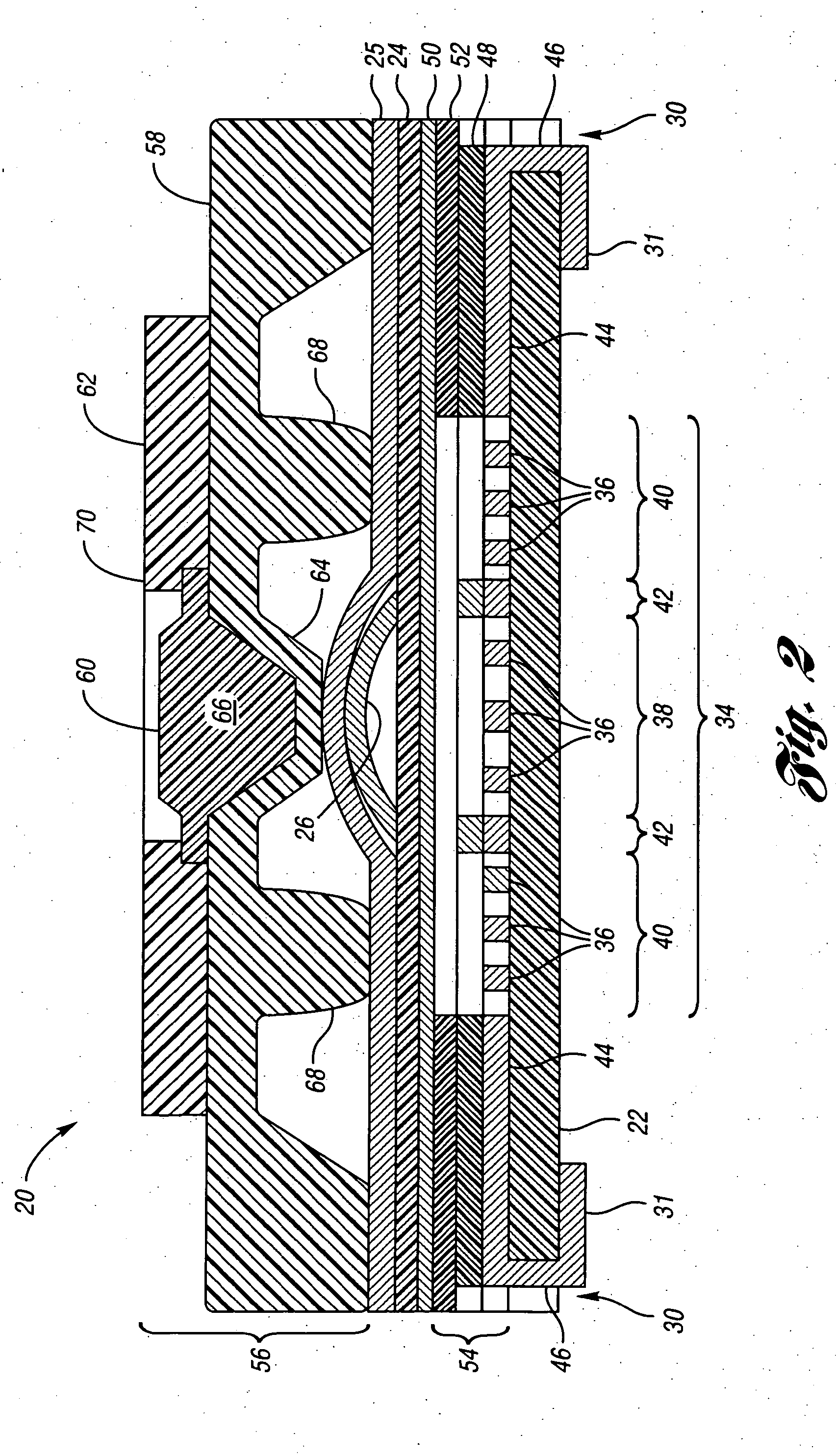

Electrosurgical jaw structure for controlled energy delivery

InactiveUS6929644B2Prevent any substantial dehydrationEnergy efficiencySurgical instruments for heatingCoatingsThermal energyConductive materials

A working end of a surgical instrument that carries first and second jaws for delivering energy to tissue. In a preferred embodiment, at least one jaw of the working end defines a tissue-engagement plane that contacts the targeted tissue. The cross-section of the engagement plane reveals that it defines a surface conductive portion that overlies a variably resistive matrix of a temperature-sensitive resistive material or a pressure-sensitive resistive material. An interior of the jaw carries a conductive material or electrode that is coupled to an Rf source and controller. In an exemplary embodiment, the variably resistive matrix can comprise a positive temperature coefficient (PTC) material, such as a ceramic, that is engineered to exhibit a dramatically increasing resistance (i.e., several orders of magnitude) above a specific temperature of the material. In use, the engagement plane will apply active Rf energy to captured tissue until the point in time that the variably resistive matrix is heated to its selected switching range. Thereafter, current flow from the conductive electrode through the engagement surface will be terminated due to the exponential increase in the resistance of variably resistive matrix to provide instant and automatic reduction of Rf energy application. Further, the variably resistive matrix can effectively function as a resistive electrode to thereafter conduct thermal energy to the engaged tissue volume. Thus, the jaw structure can automatically modulate the application of energy to tissue between active Rf heating and passive conductive heating of captured tissue to maintain a target temperature level.

Owner:ETHICON ENDO SURGERY INC

Radiopaque markers for medical devices

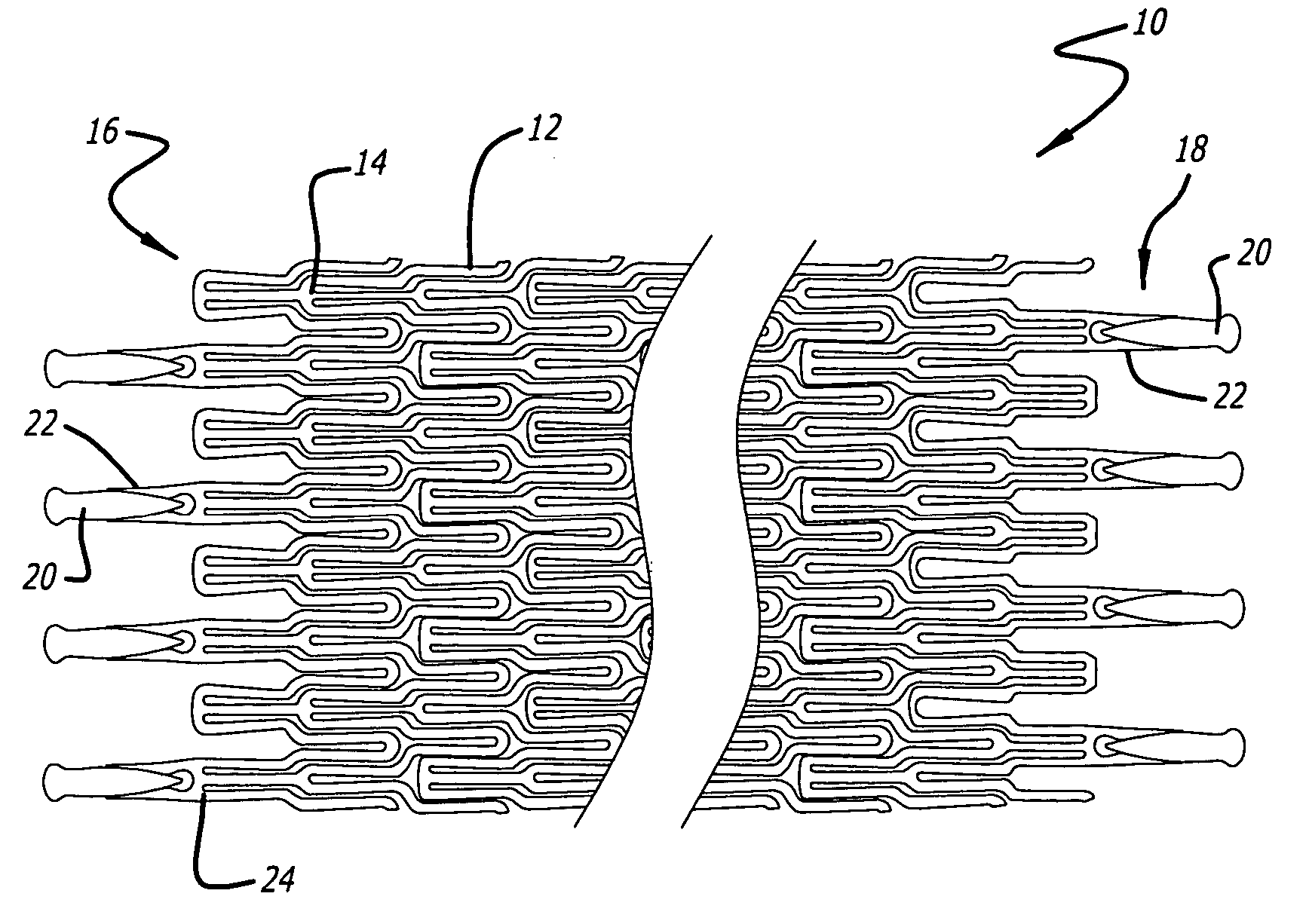

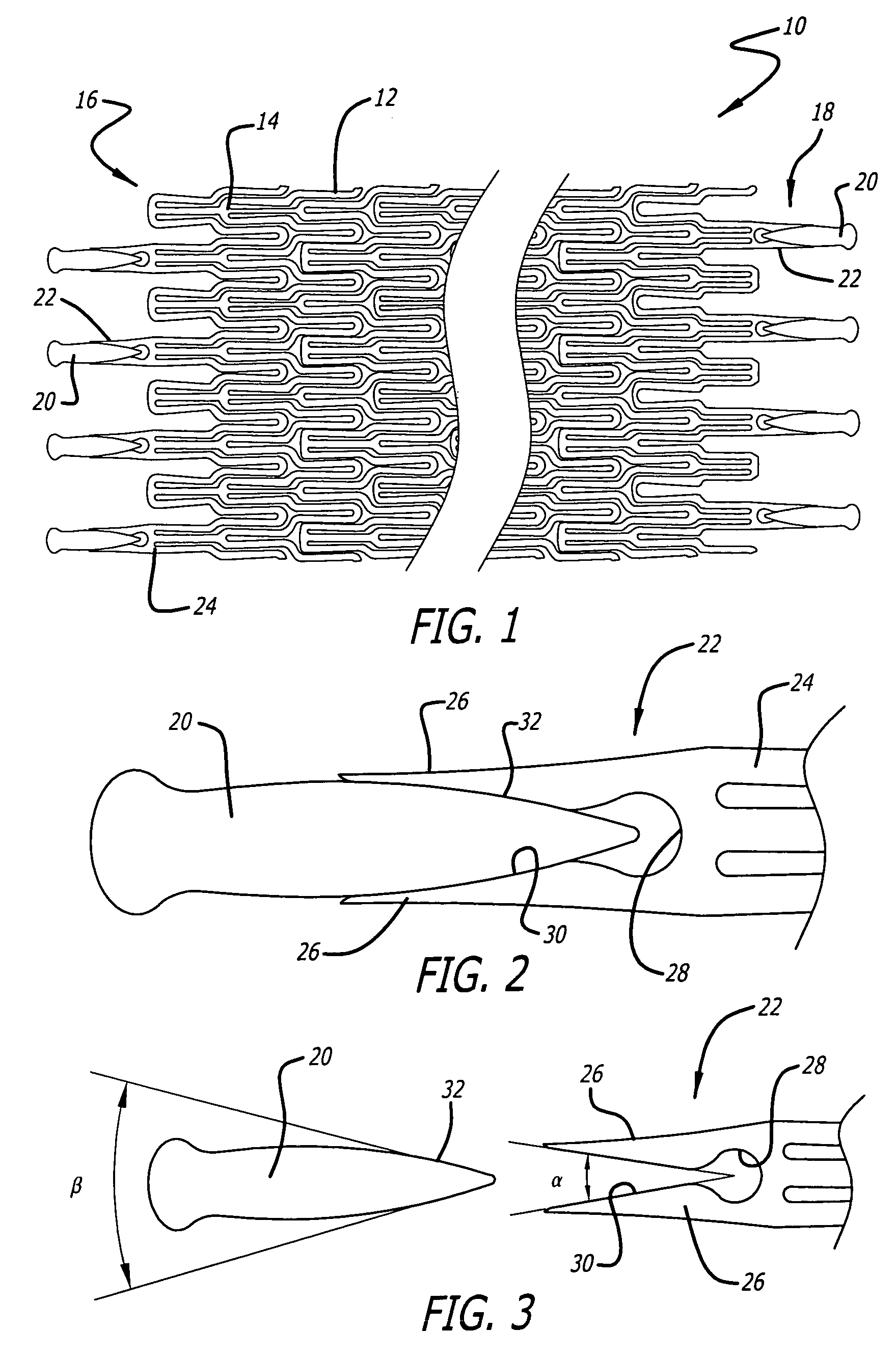

InactiveUS20050060025A1High level of radiopacitySufficient radiopacityStentsBlood vesselsIridiumRhenium

An implantable medical device includes a structural body made from a superelastic material and includes one or more marker holders integrally formed on the structural body. Each marker holder is designed to hold a radiopaque marker which has a level of radiopacity greater than the superelastic material. The radiopaque marker can be made from a nickel-titanium alloy which includes a ternary element. The ternary element can be selected from the group of elements consisting of iridium, platinum, gold, rhenium, tungsten, palladium, rhodium, tantalum, silver, ruthenium, and hafnium. In one form, the marker holder includes a pair of projecting fingers connected together at a notched region to cooperatively create a particular-shaped opening. This opening, in turn, is adapted to receive a similarly shaped portion formed on the radiopaque marker. In one form, the radiopaque marker includes an inner core which is partially, or completely, encased by an outer layer. This inner core can be made from a highly radiopaque material while the outer layer is formed from a material that is easier to weld to the marker.

Owner:ABBOTT VASCULAR SOLUTIONS

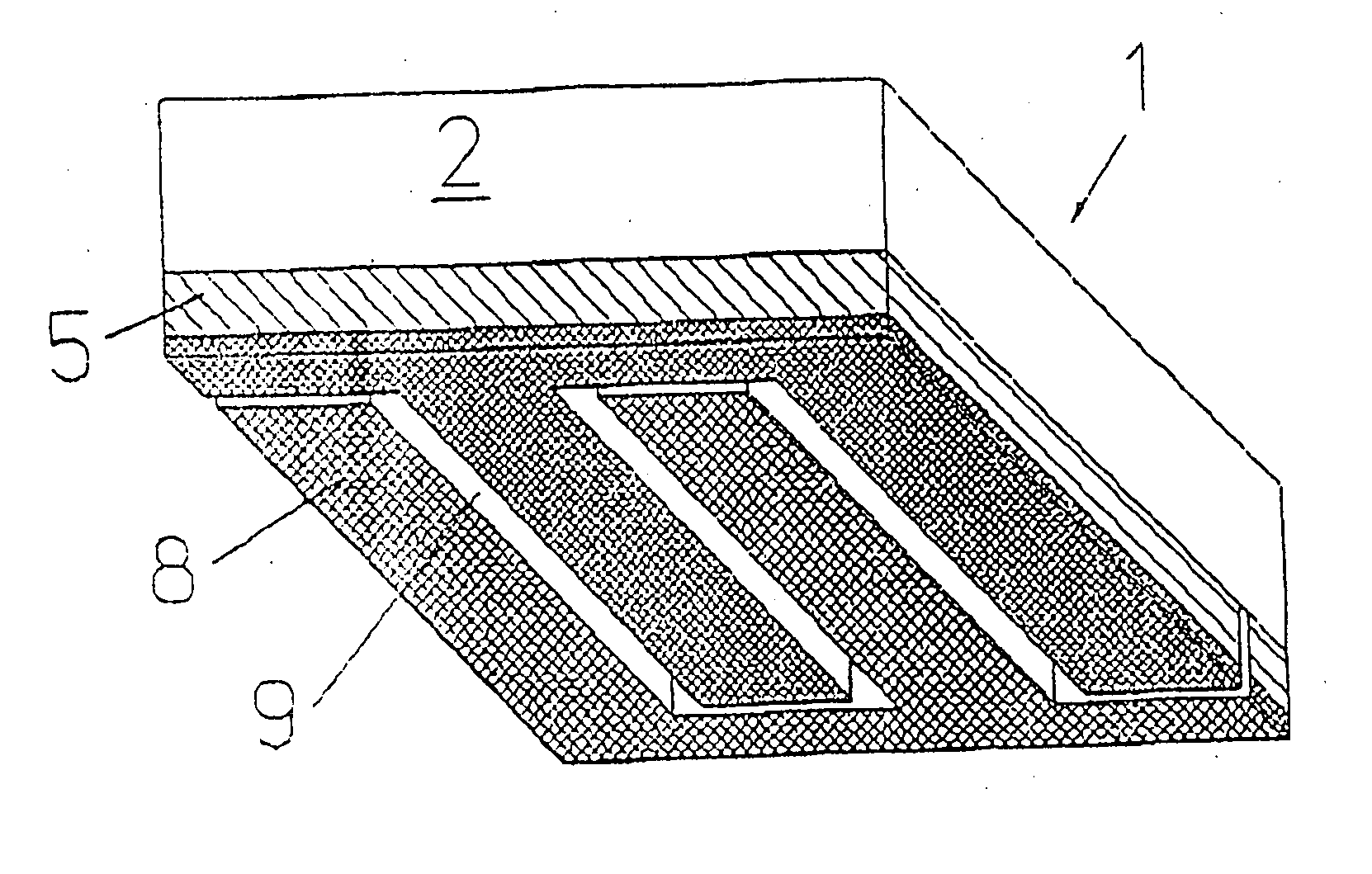

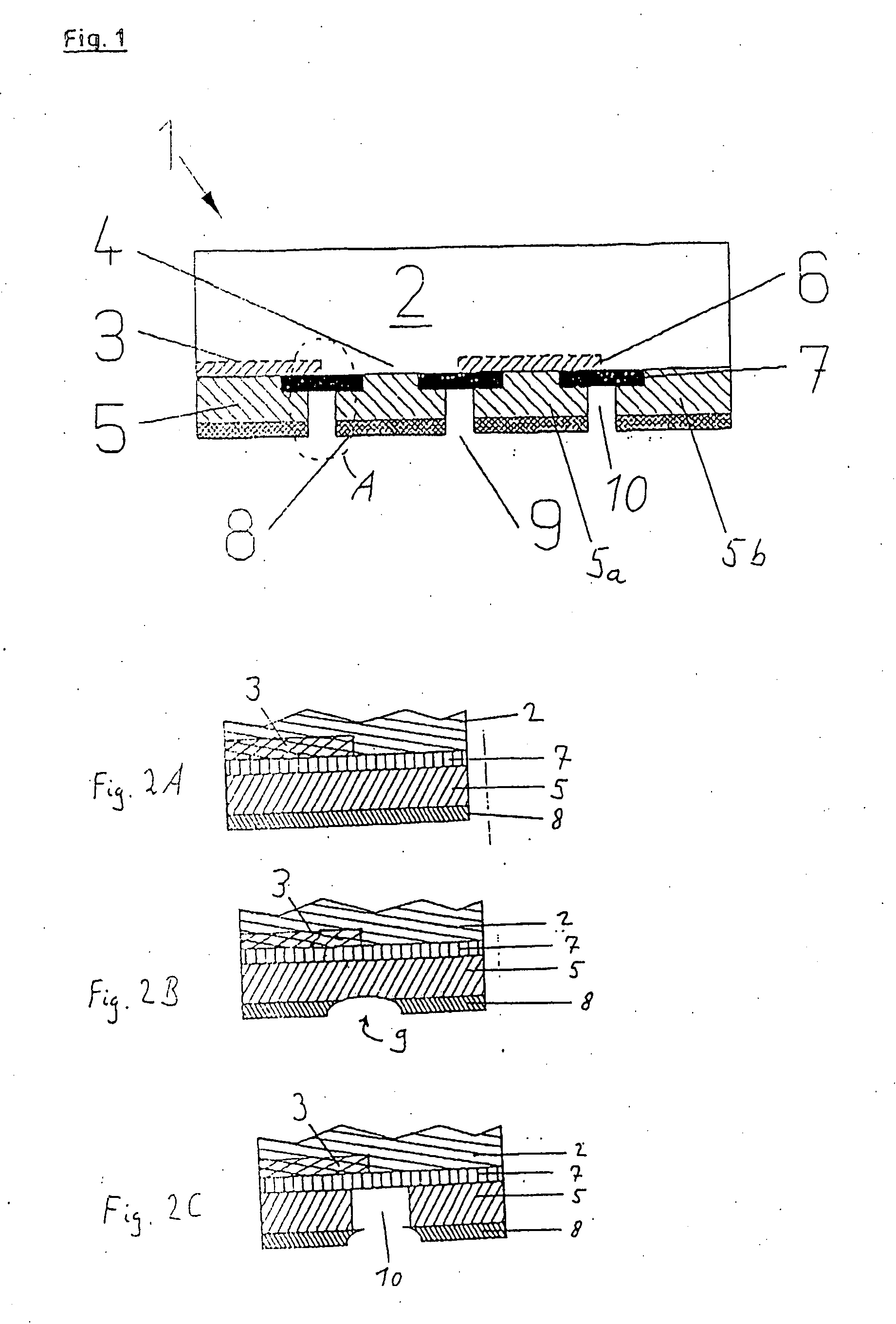

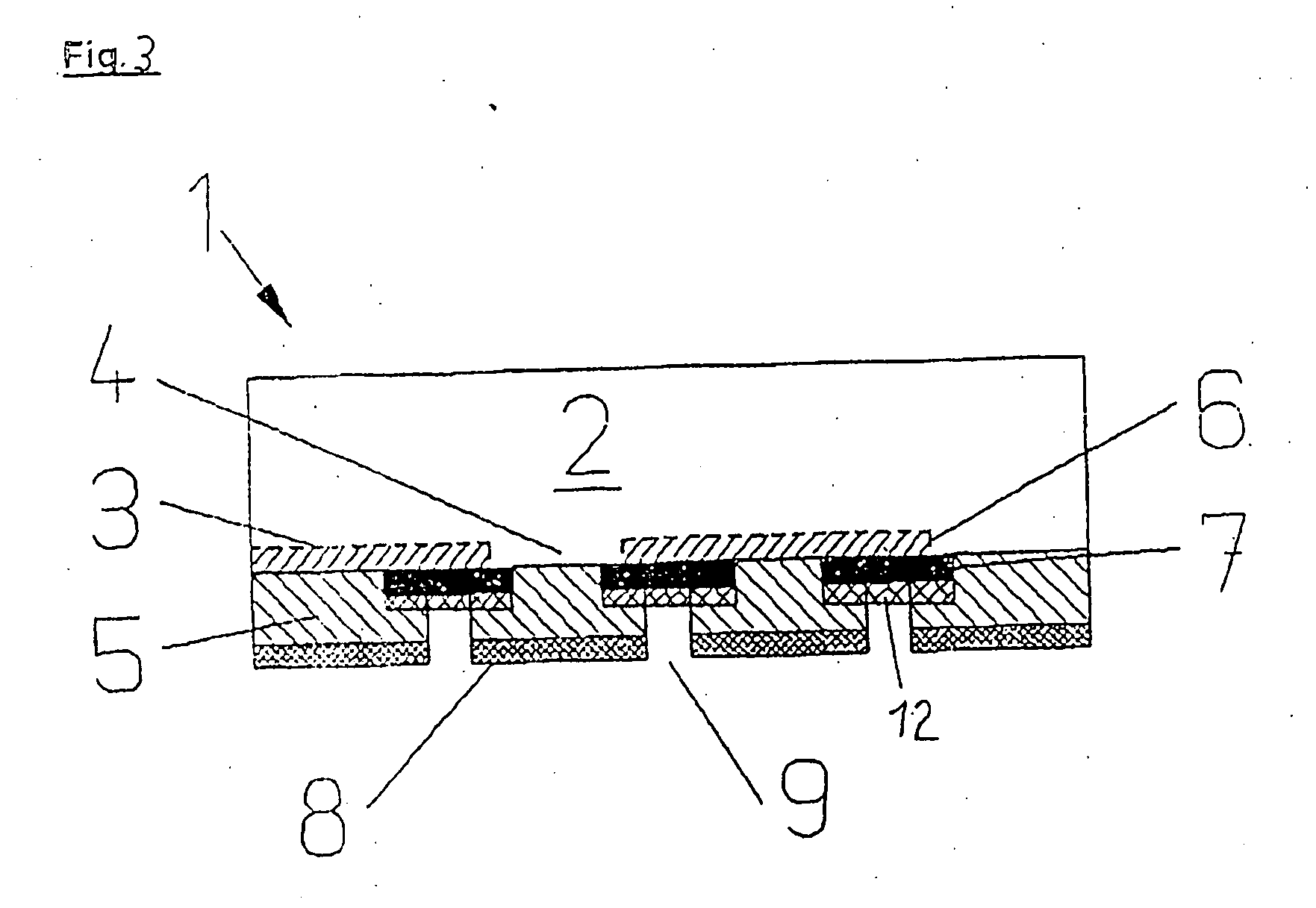

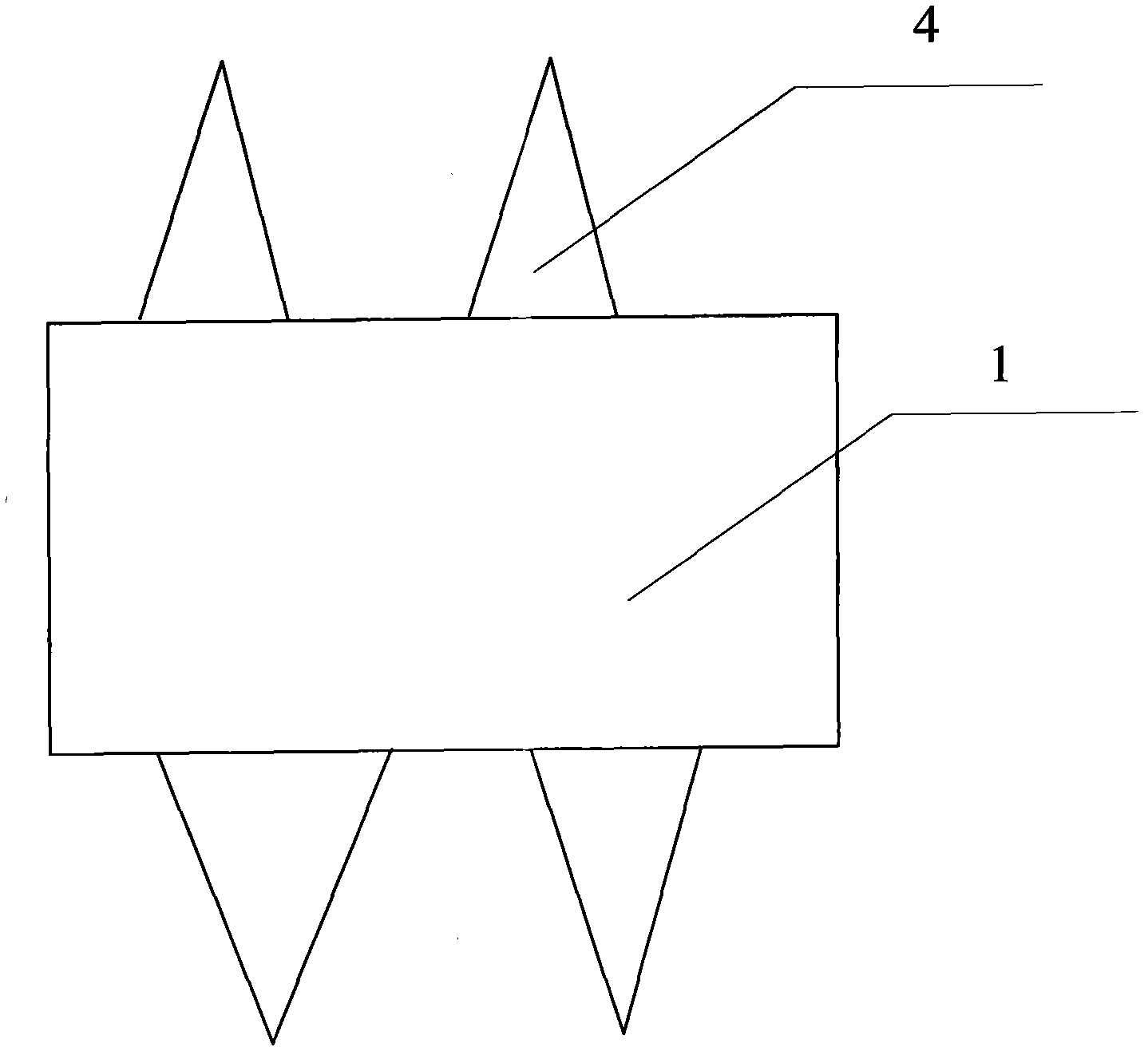

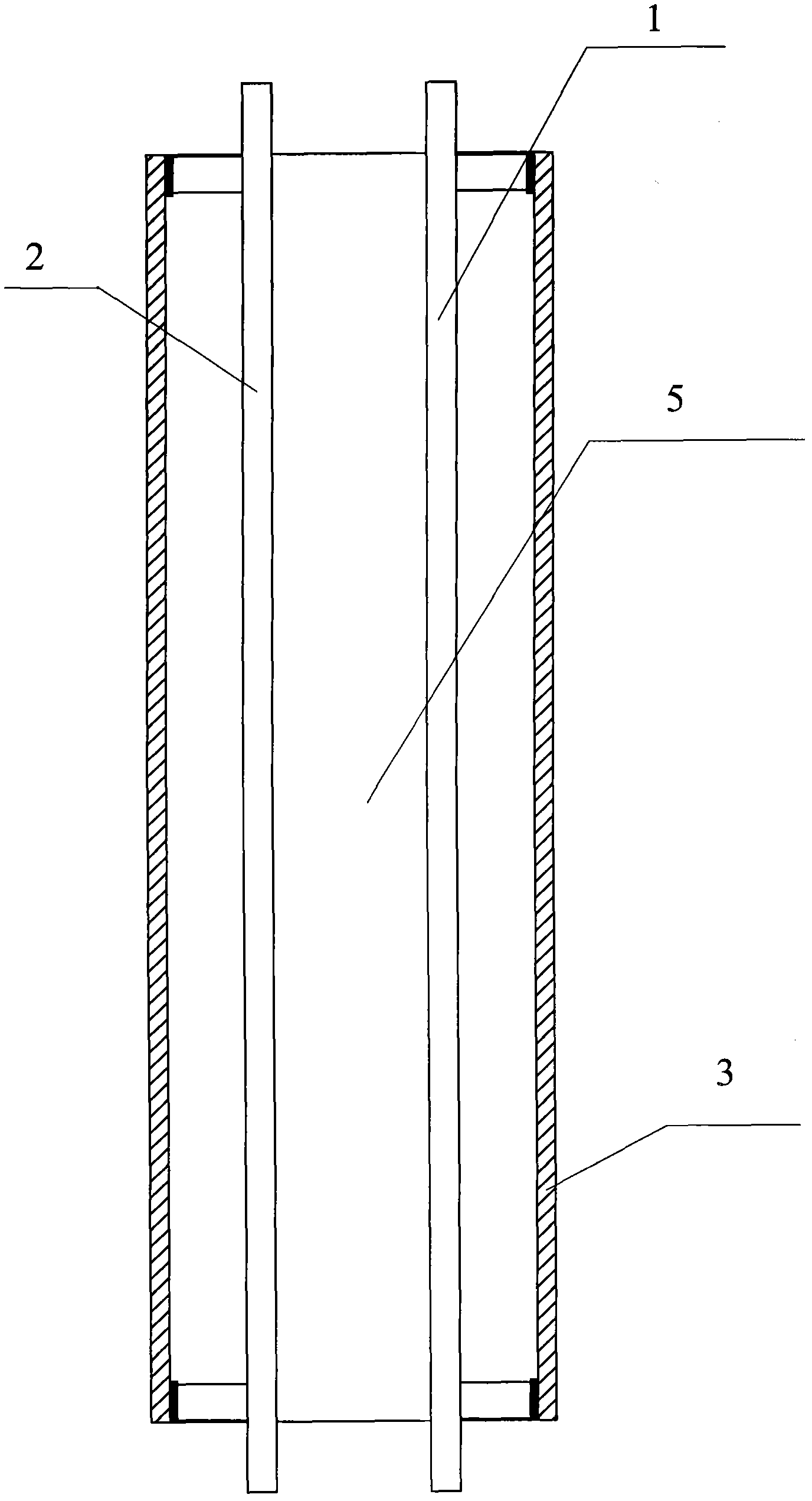

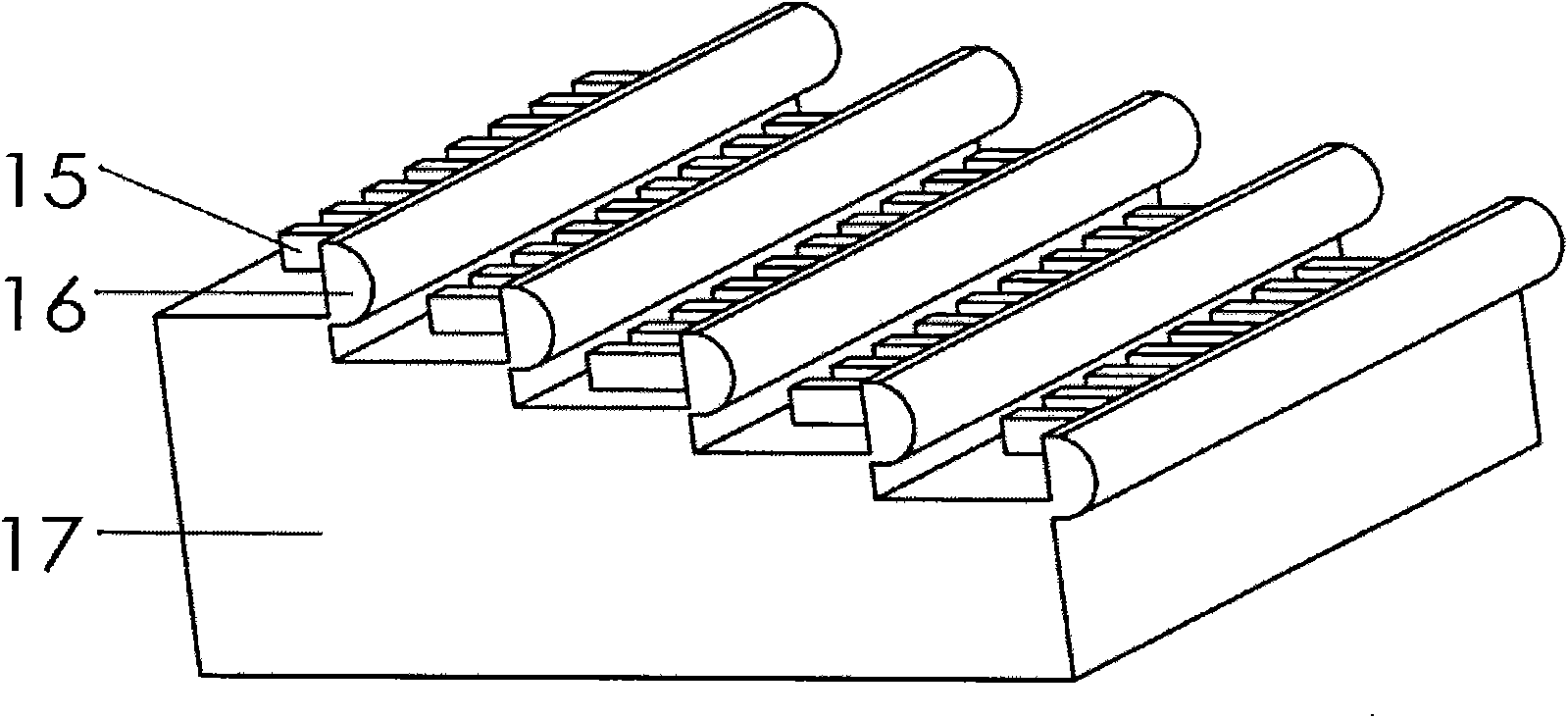

Method for the Contact Separation of Electrically-Conducting Layers on the Back Contacts of Solar Cells and Corresponding Solar Cells

InactiveUS20080035198A1Easy to produceReduce decreaseSemiconductor/solid-state device manufacturingPhotovoltaic energy generationEngineeringConductive materials

A method for fabricating a solar cell (1) comprising a semiconductor substrate (2) is proposed where electrical contacting is made on the back side of the semiconductor substrate. The back side of the semiconductor substrate has locally doped regions (3). The adjacent regions (4) exhibit different doping from the region (3). The two regions (3, 4) are initially coated with electrically conductive material (5) over the entire area. So that the conductive material (5) does not short-circuit the solar cell, the two regions (3, 4) are covered with a thin electrically insulating layer (7) at least at the region boundaries (6). The electrically conductive layer (5) is separated by applying an etch barrier layer (8) over the entire surface which is then removed free from masking and selectively e.g. by laser ablation, locally above the insulating layer (7). The conductive layer is locally removed in the area of the openings (9) of the etch barrier layer (8) by subsequent action of an etching solution.

Owner:INST FUR SOLARENERGIEFORSCHUNG

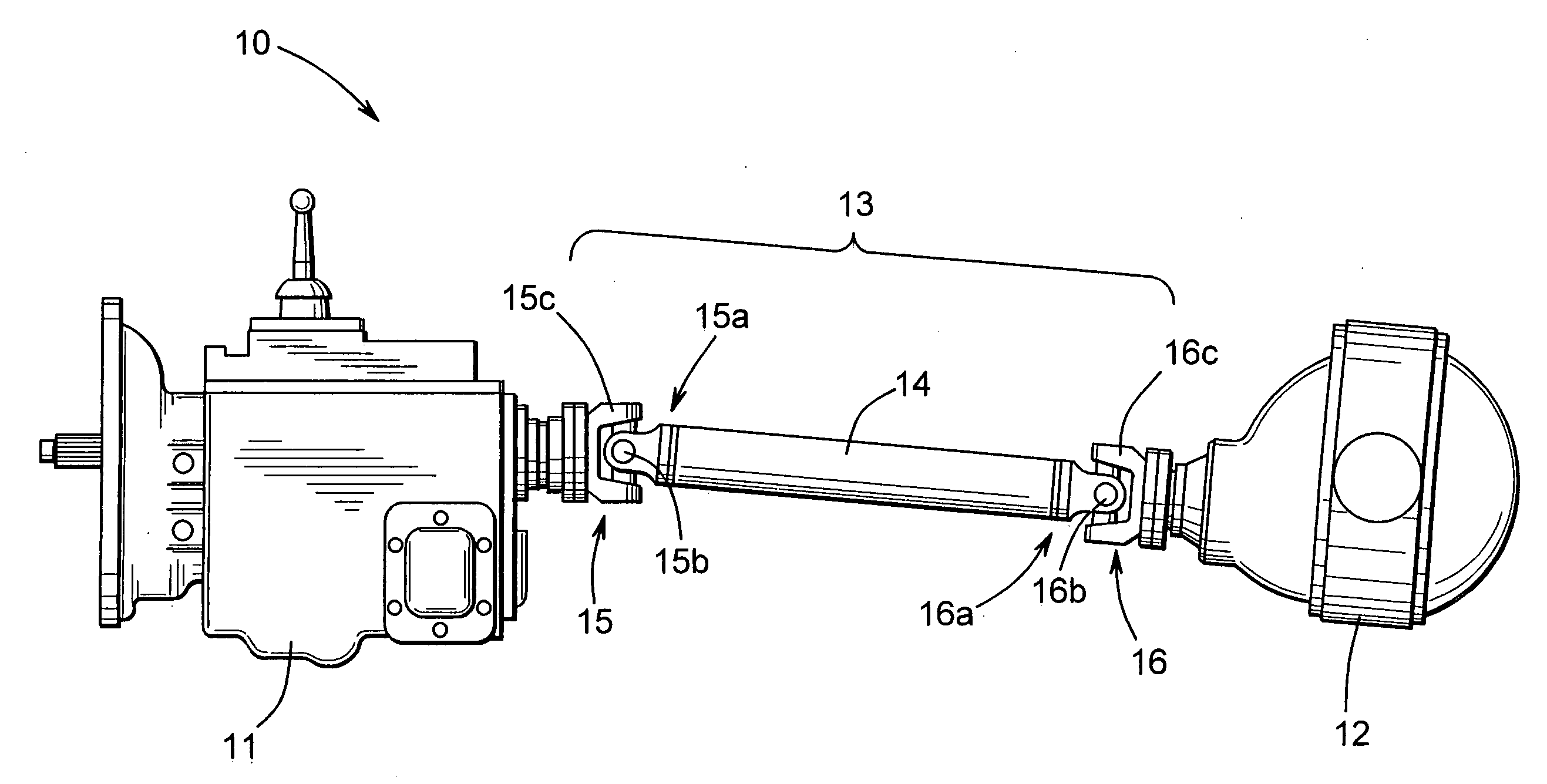

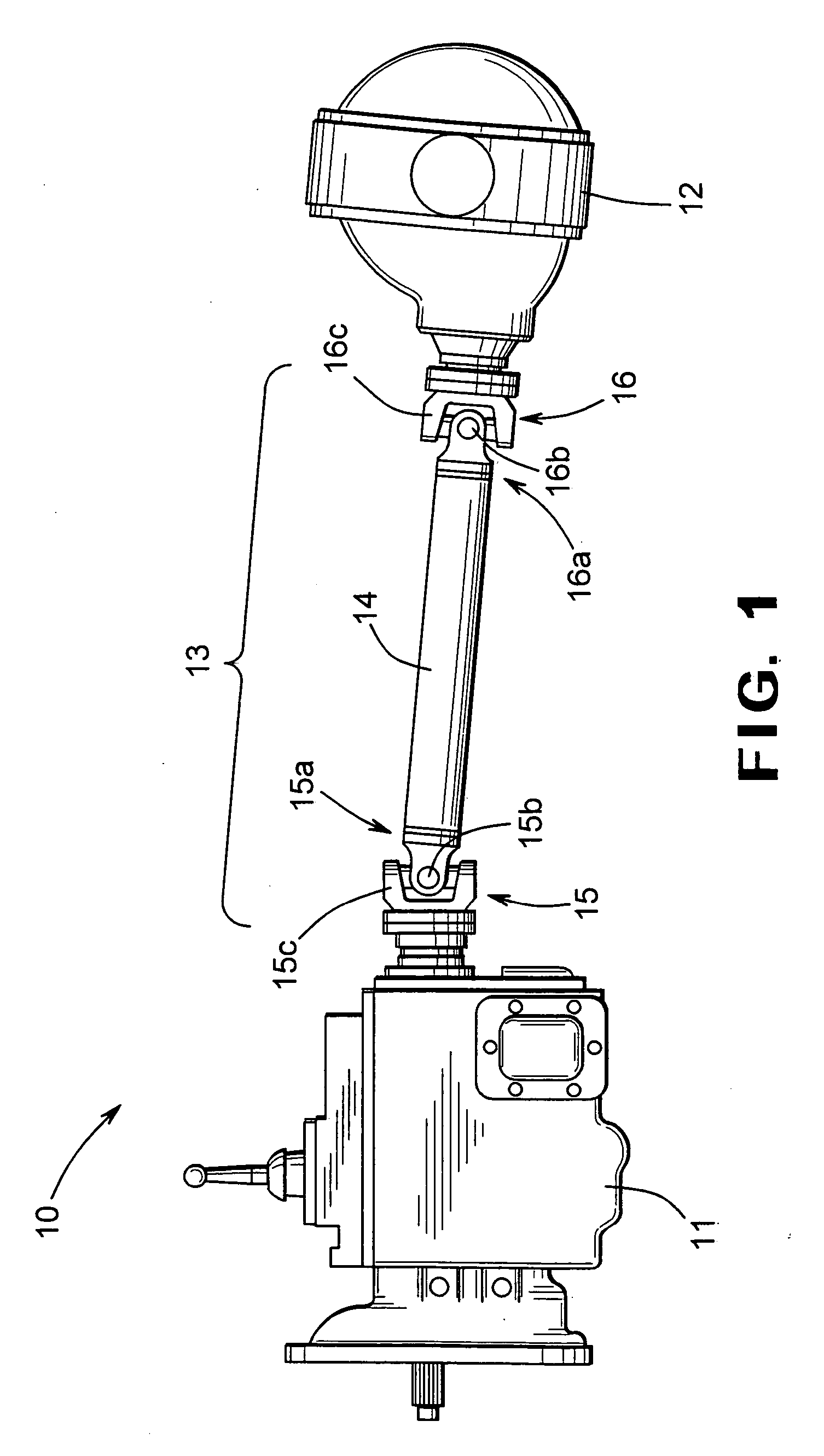

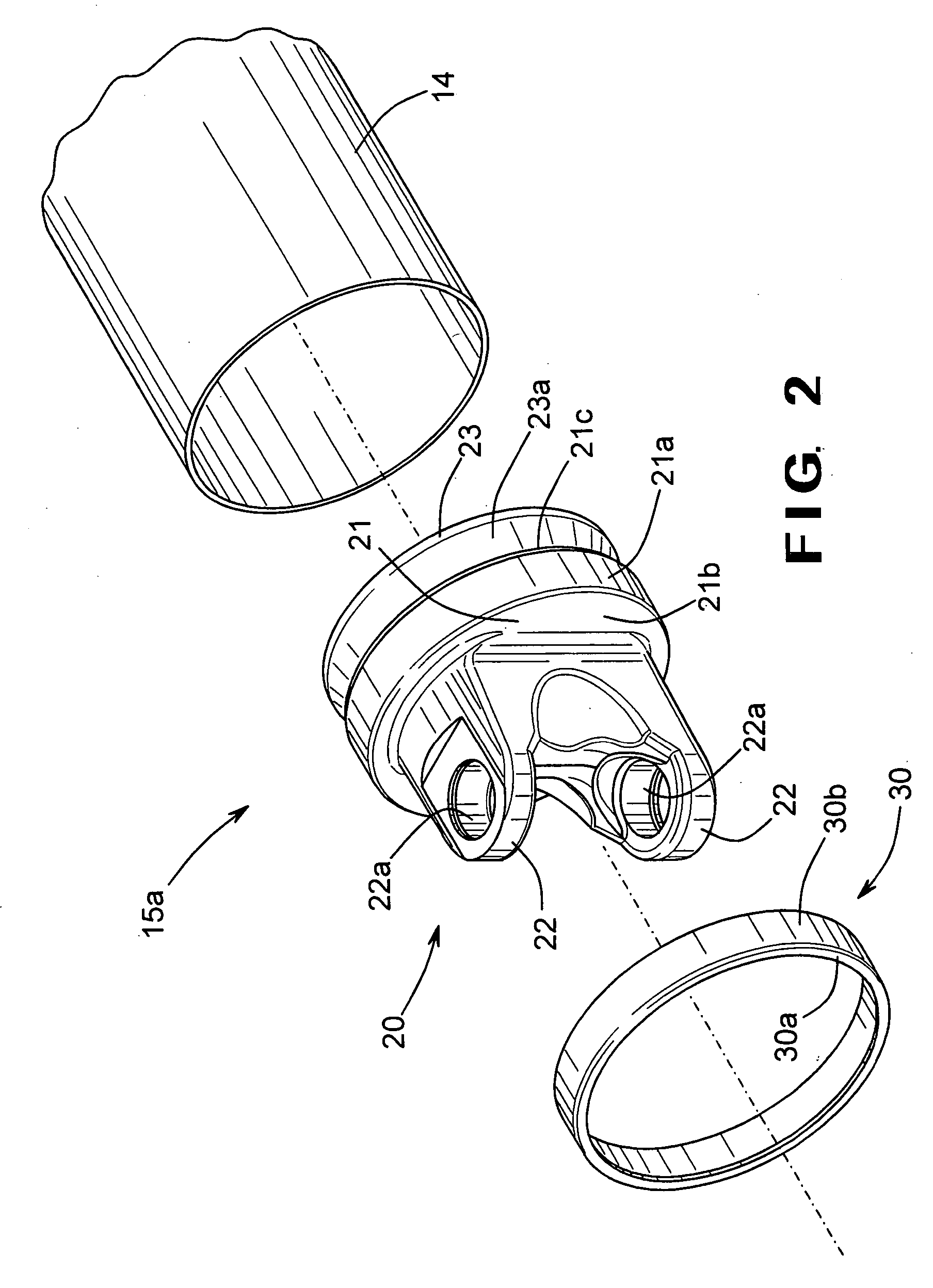

Driveshaft assembly and method of manufacturing same

InactiveUS20070066406A1Protection from damageSimple structureClutchesYielding couplingEngineeringMagnetic pulse welding

A driveshaft assembly includes a yoke including a body portion, a pair of opposed yoke arms that extends generally in a first axial direction from the body portion, and a neck portion that extends generally in a second axial direction from the body portion. A driveshaft tube is secured to the neck portion of the yoke, such as by magnetic pulse welding. A ring is secured to the body portion of the yoke, such as by press fitting, and a balance weight is secured to the ring, such as by welding.

Owner:DANA AUTOMOTIVE SYST GRP LLC

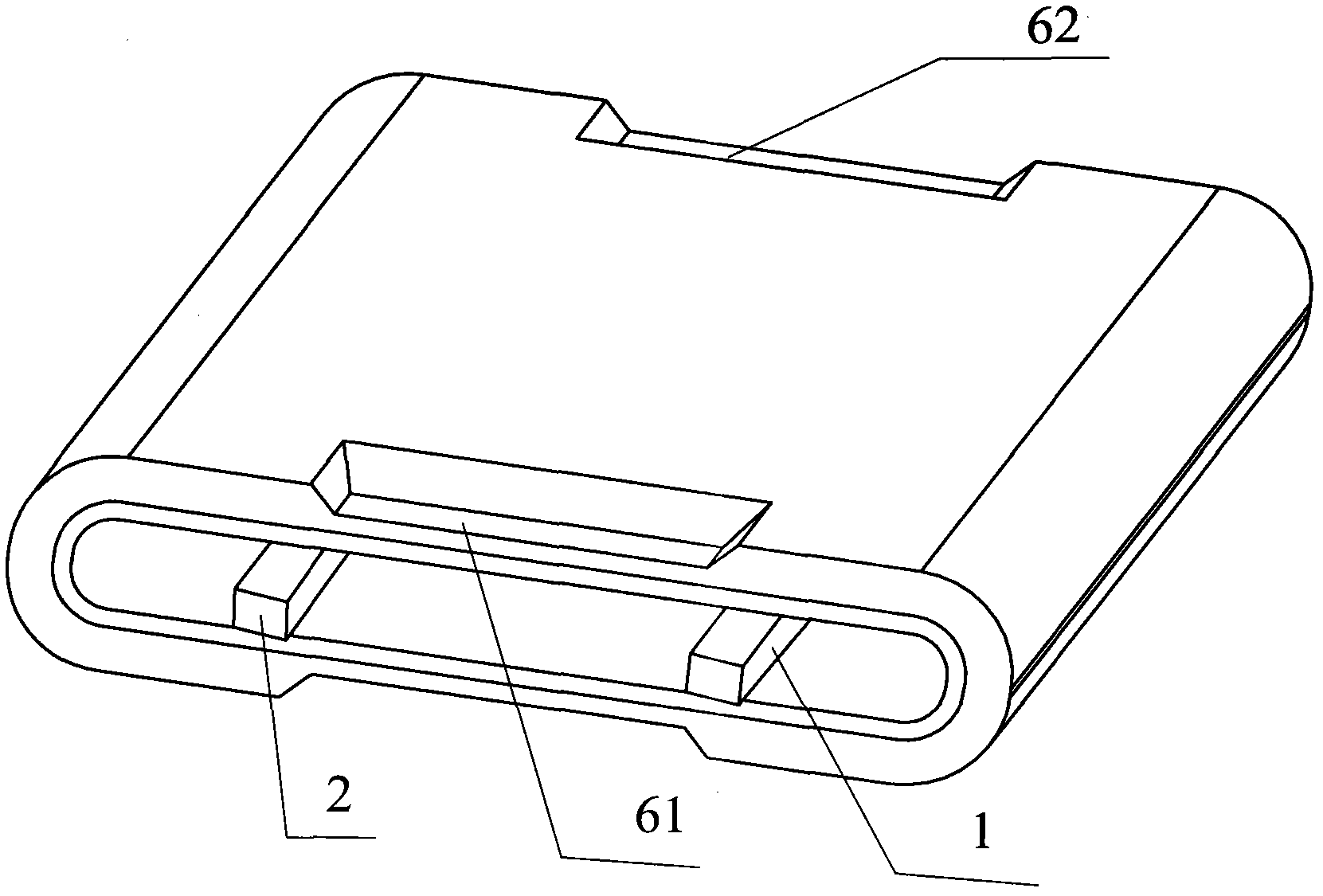

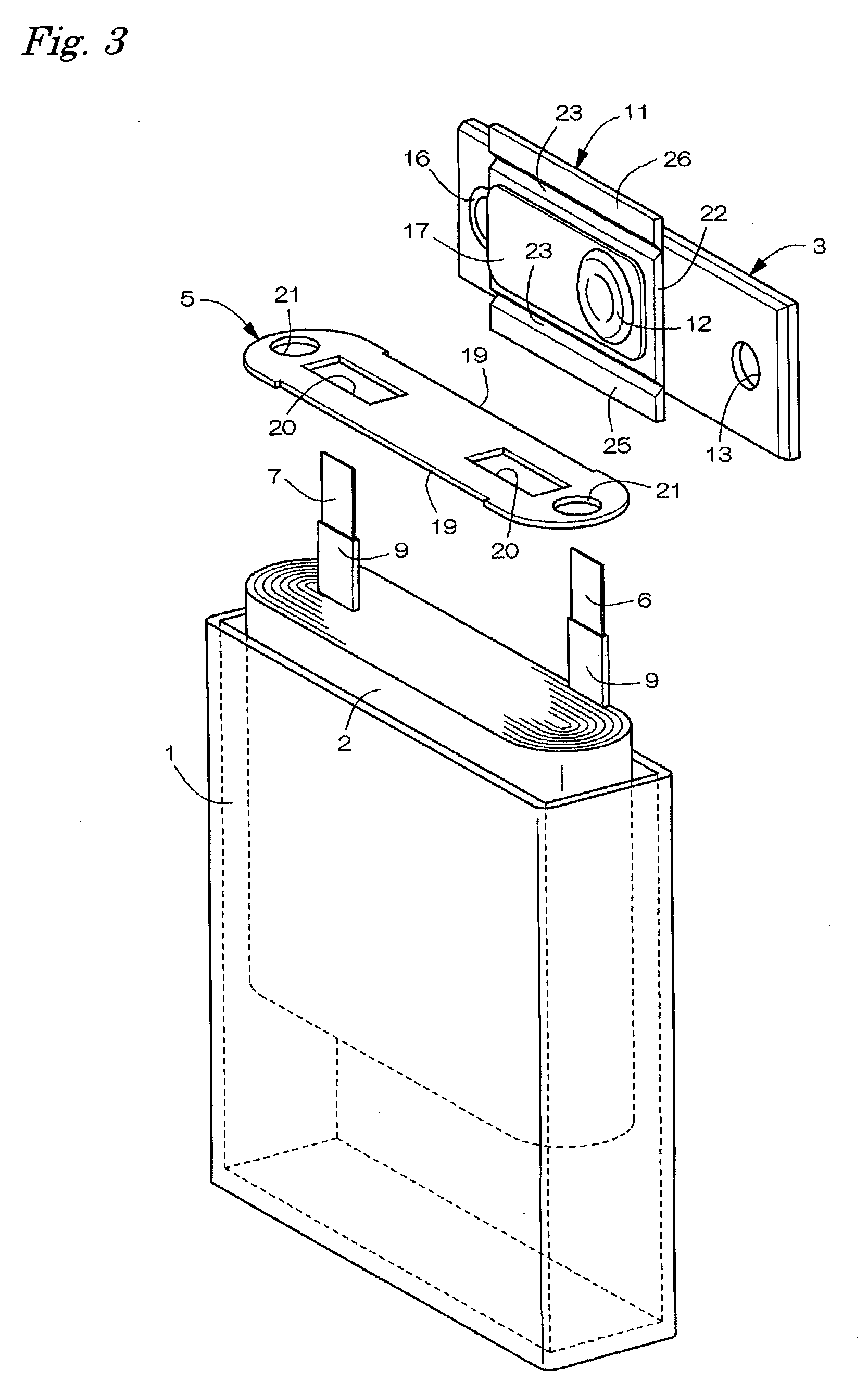

Rechargeable lithium ion button cell battery

ActiveUS20110091753A1Reliable contactEasy to weldCell electrodesFinal product manufactureButton batteryHigh energy

A rechargeable lithium ion button cell battery having a sealed housing comprises an inner casing and an outer casing, both casings have at least one flat area as top or bottom of the battery, and a round or oval side wall vertically formed to the flat area. Said side walls are single wall not folded double walls. An insulation gasket is positioned between said side walls, and the outer casing opening is mechanically crimped to complete the seal of the battery. Inside the sealed housing the anode & cathode electrodes are spiral wound with separator to be a round or oval roll. Said roll axis is vertical to the said flat areas of the casings. The two electrodes are tapered in width and comprise current collectors of metal foils coated with lithium-intercalating active materials, leaving small area of uncoated metal foils as welding tabs for connecting to the casings. The tabs are welded to the casings respectively, or for the tab of the electrode which connecting to outer casing, welded to an aluminum flake first and said flake is pressed on the outer casing by said gasket. Two insulation washers could be applied to inner side of the casings to prevent short circuit. Such battery has high energy density, low impedance, high reliability and long cycle life.

Owner:WANG FANG +1

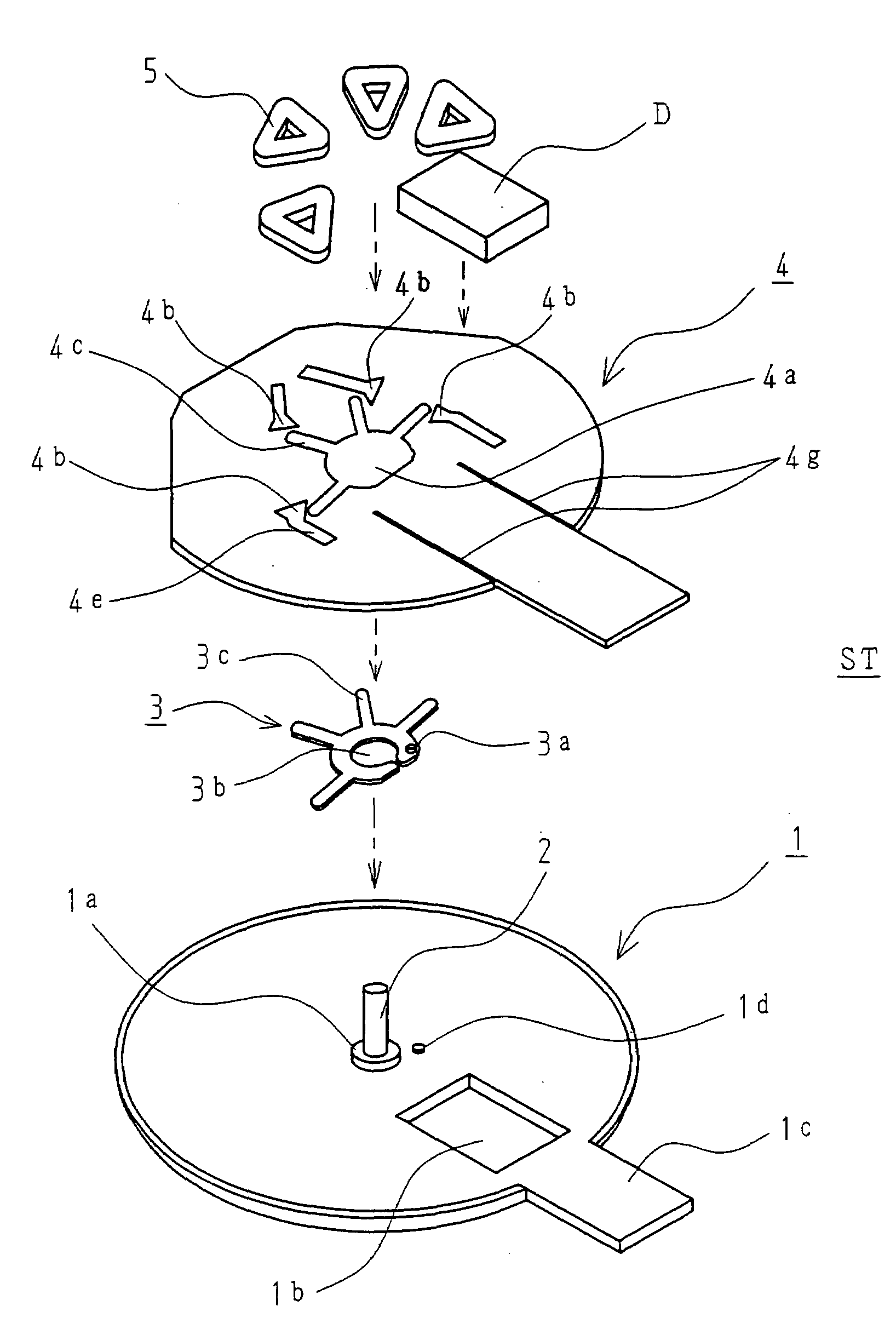

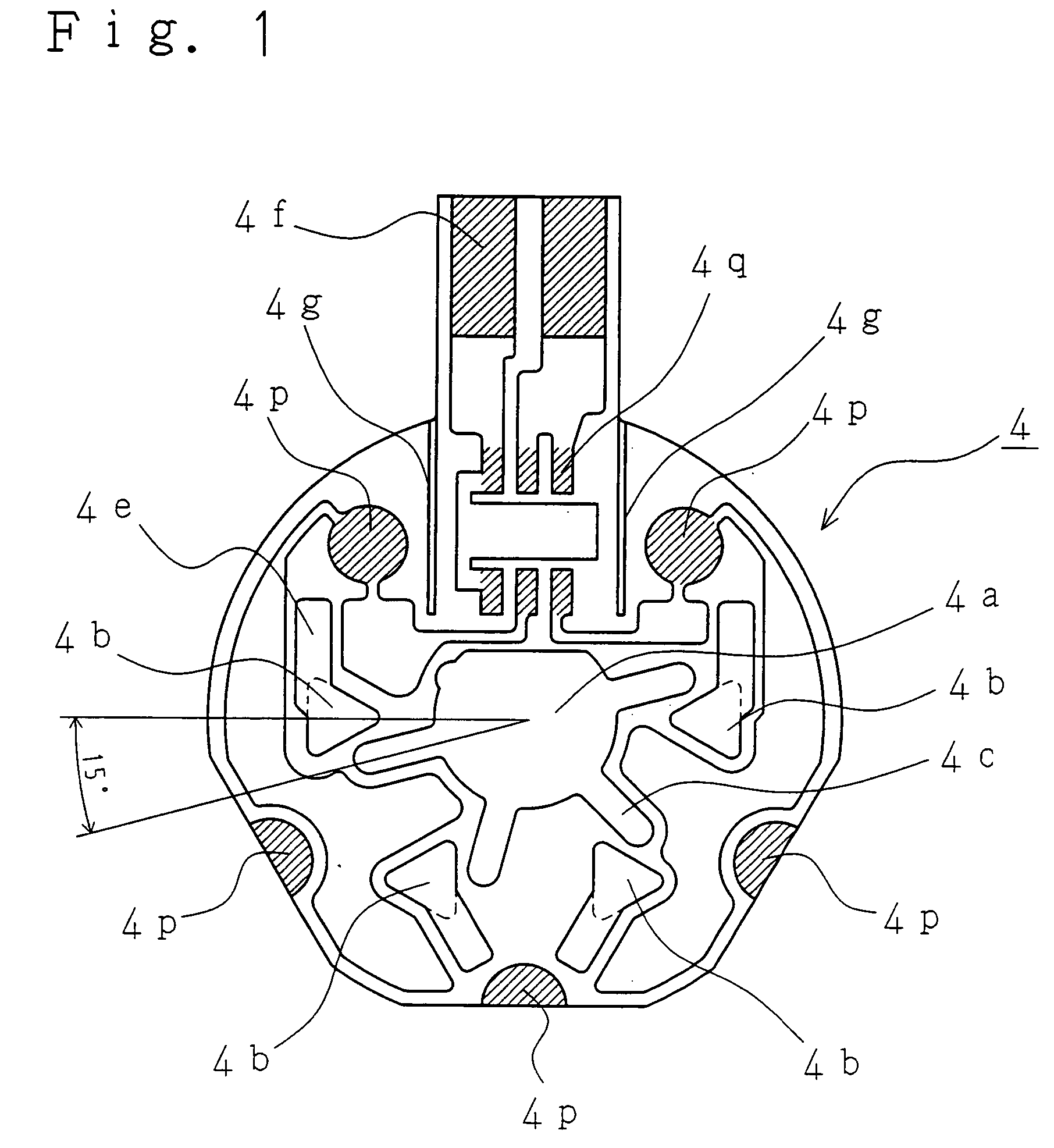

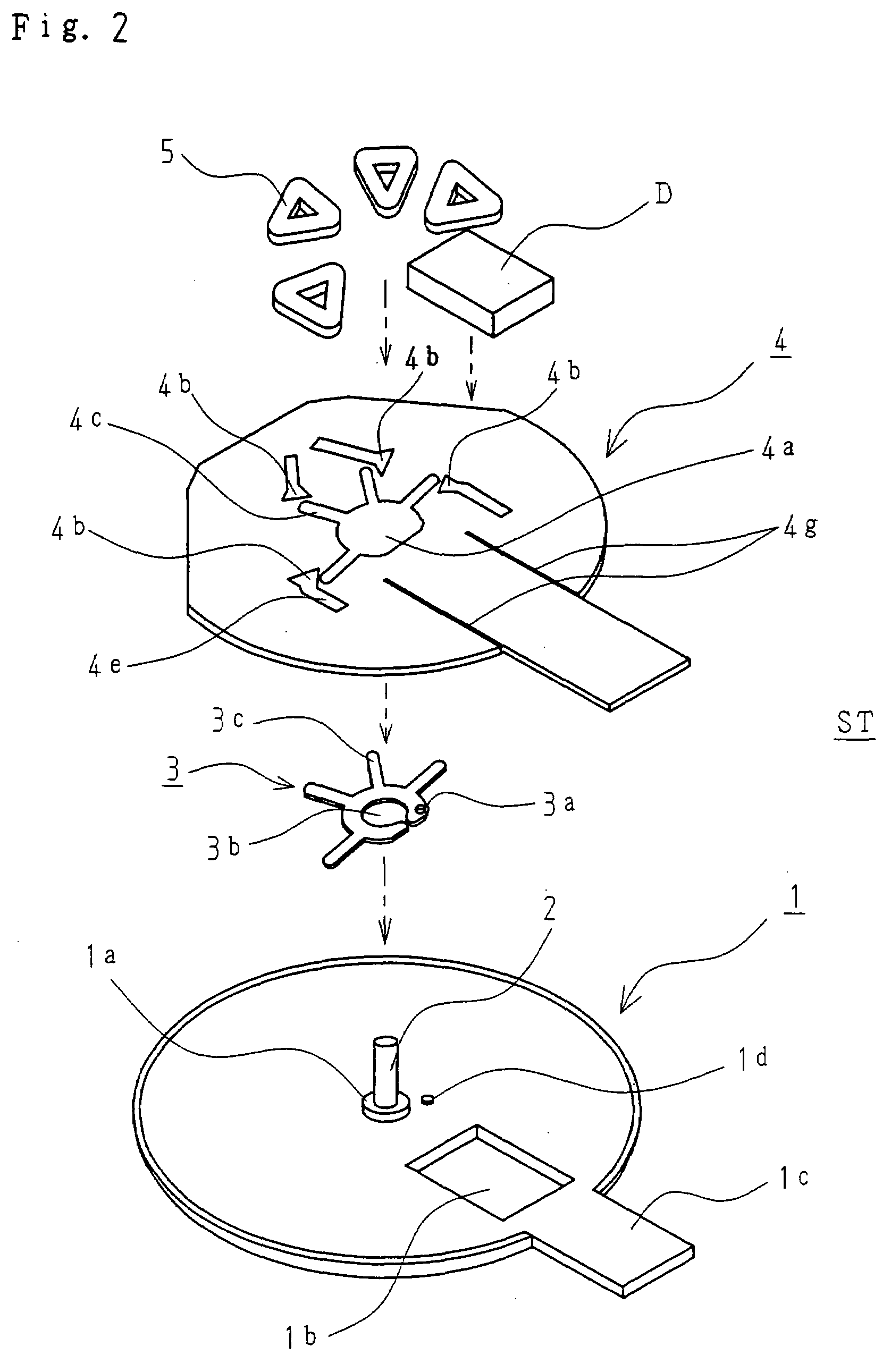

Thin stator, eccentric motor and axial air-gap brushless vibration motor equipped with the same

InactiveUS20080018187A1Sufficient starting torqueInfluence of bracket magnetic force can be suppressedMagnetic circuit stationary partsMechanical energy handlingDetentAir core

A stator includes a bracket having a shaft bearing portion at a center, a stator base including a flexible printed wiring board outwardly attached to the shaft bearing portion, single-phase air-armature coils disposed on the stator base, and a drive circuit member disposed on the stator base so as not to overlap with the single-phase air-core armature coils. The bracket has a through hole at the section corresponding to the bottom of the drive circuit member. The stator base is embedded at least partly in the thickness direction in the through hole and fixed using a resin, and a detent torque generation member is contained in, and is no thicker than, the stator base.

Owner:TOKYO PARTS IND CO LTD

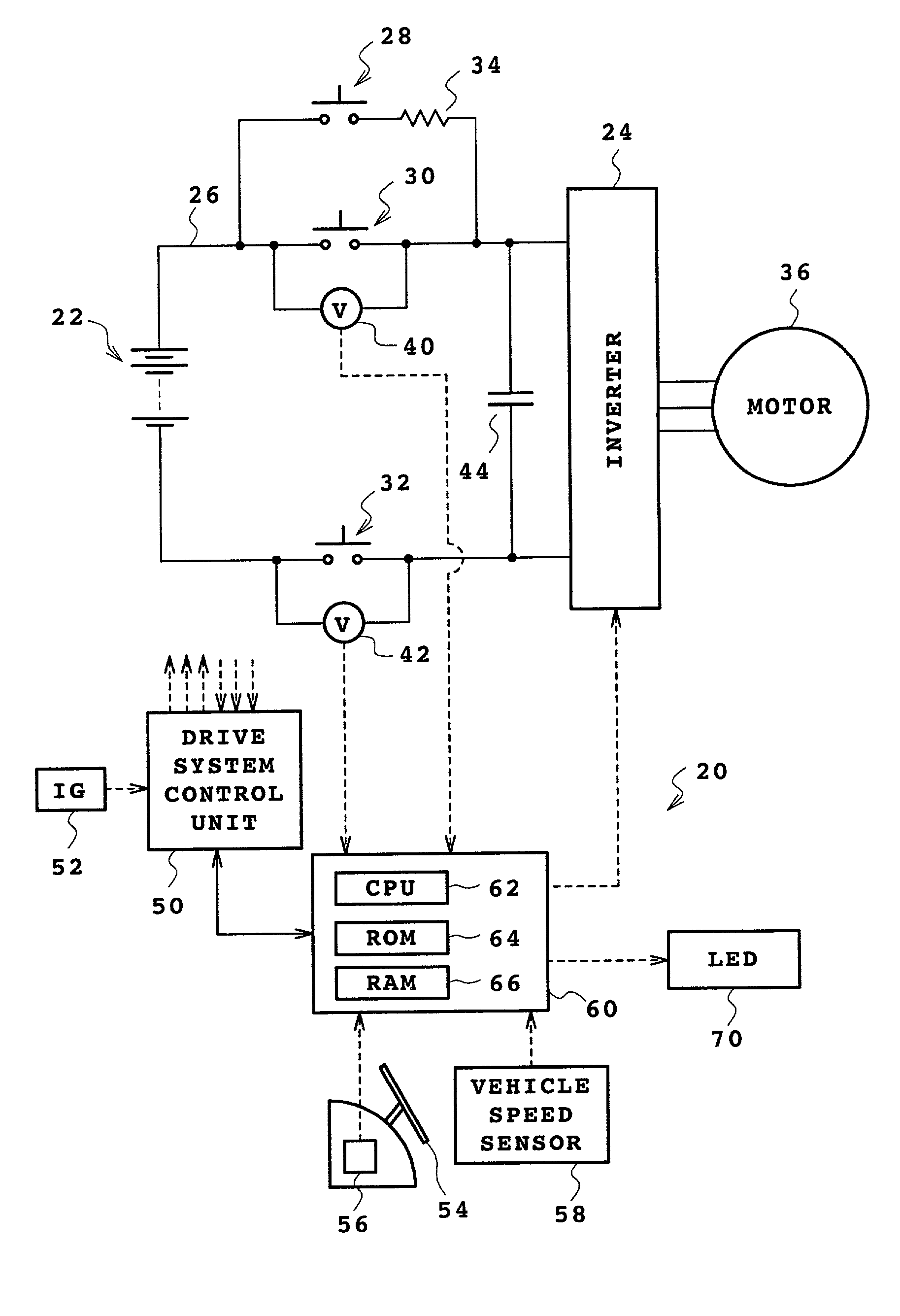

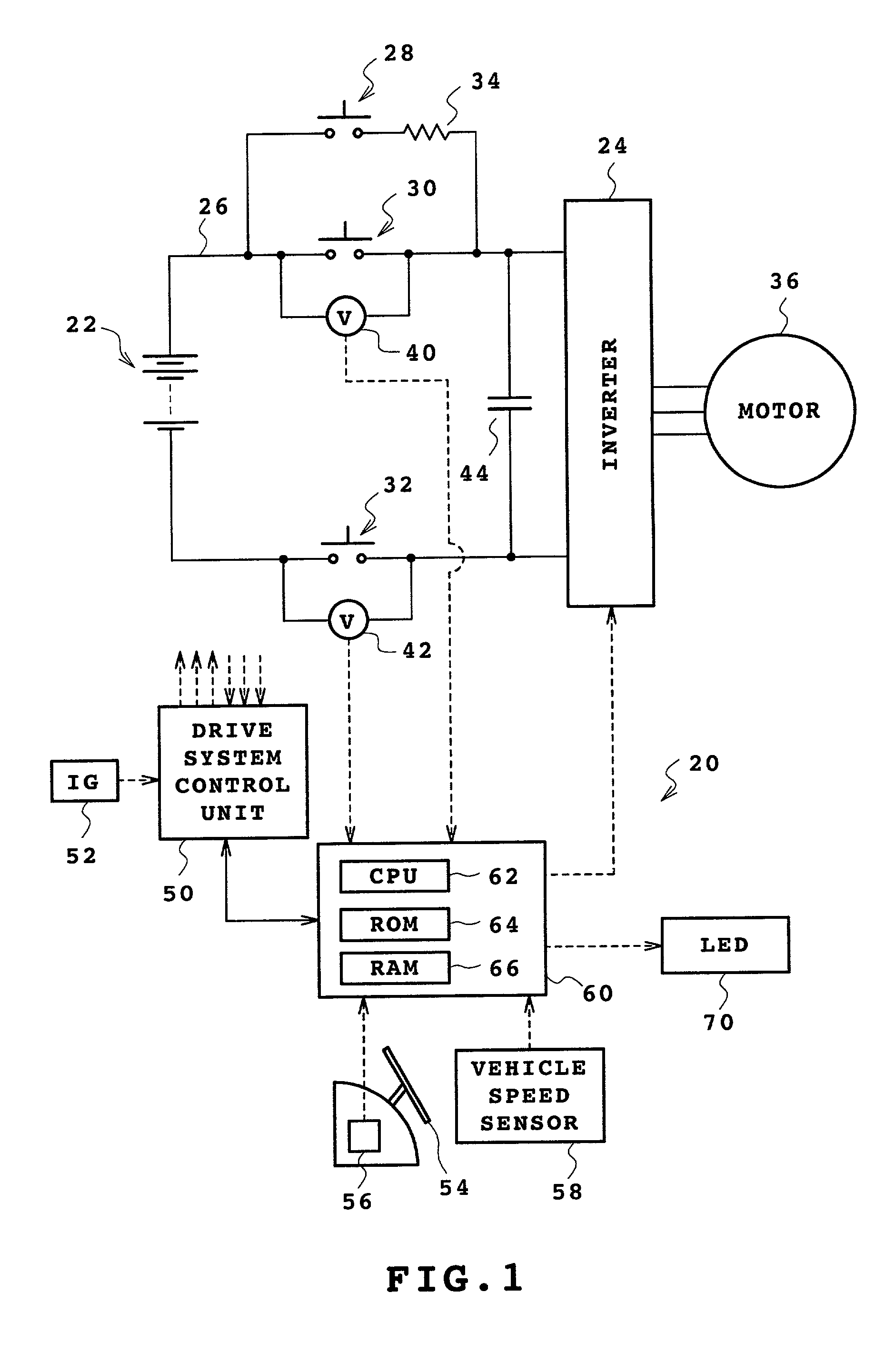

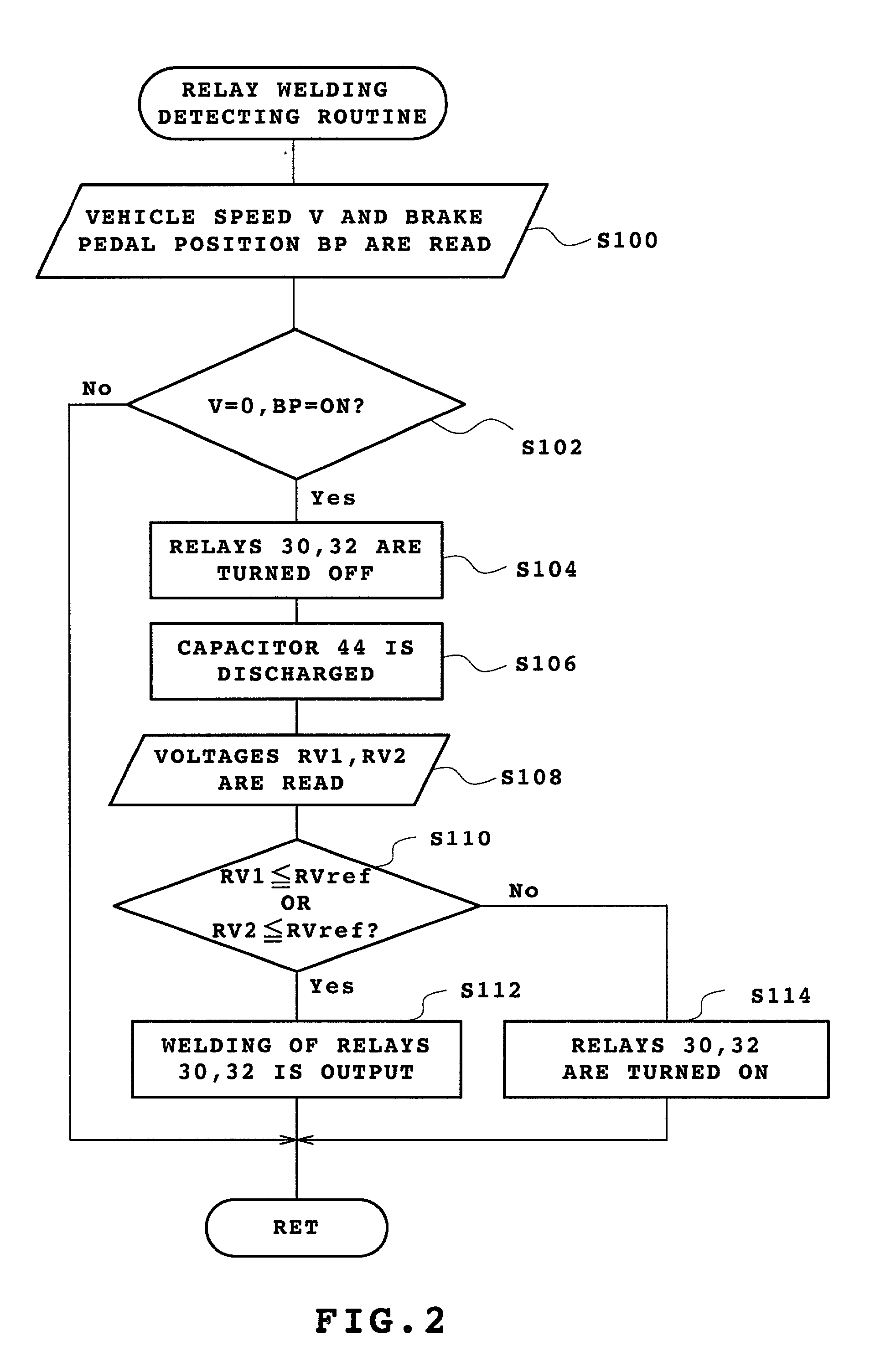

Relay welding detector and detecting method

InactiveUS20020070608A1Frequently performedReduce voltageAC motor controlElectric devicesVoltmeterEngineering

Frequency of judgment of welding of relays is increased to increase likelihood of early detection of welding. It is determined that a battery 22 is not being recharged or discharged when a vehicle speed V of an electric vehicle is approximately 0 and a brake pedal 54 is pressed, and a switching element of an inverter 24 is controlled to be switched to discharge electric charges which are stored in a capacitor 44. After discharging, relays 30, 32 are turned off, and voltages RV1, RV2 between the terminals of the relays 30, 32 are detected by voltmeters 40, 42 to judge whether either of the voltages RV1, RV2 has a threshold value RVref (approximate value 0) or less. When it is so determined, it is judged that the relays 30, 32 are welded, and an LED 70 is illuminated.

Owner:TOYOTA JIDOSHA KK

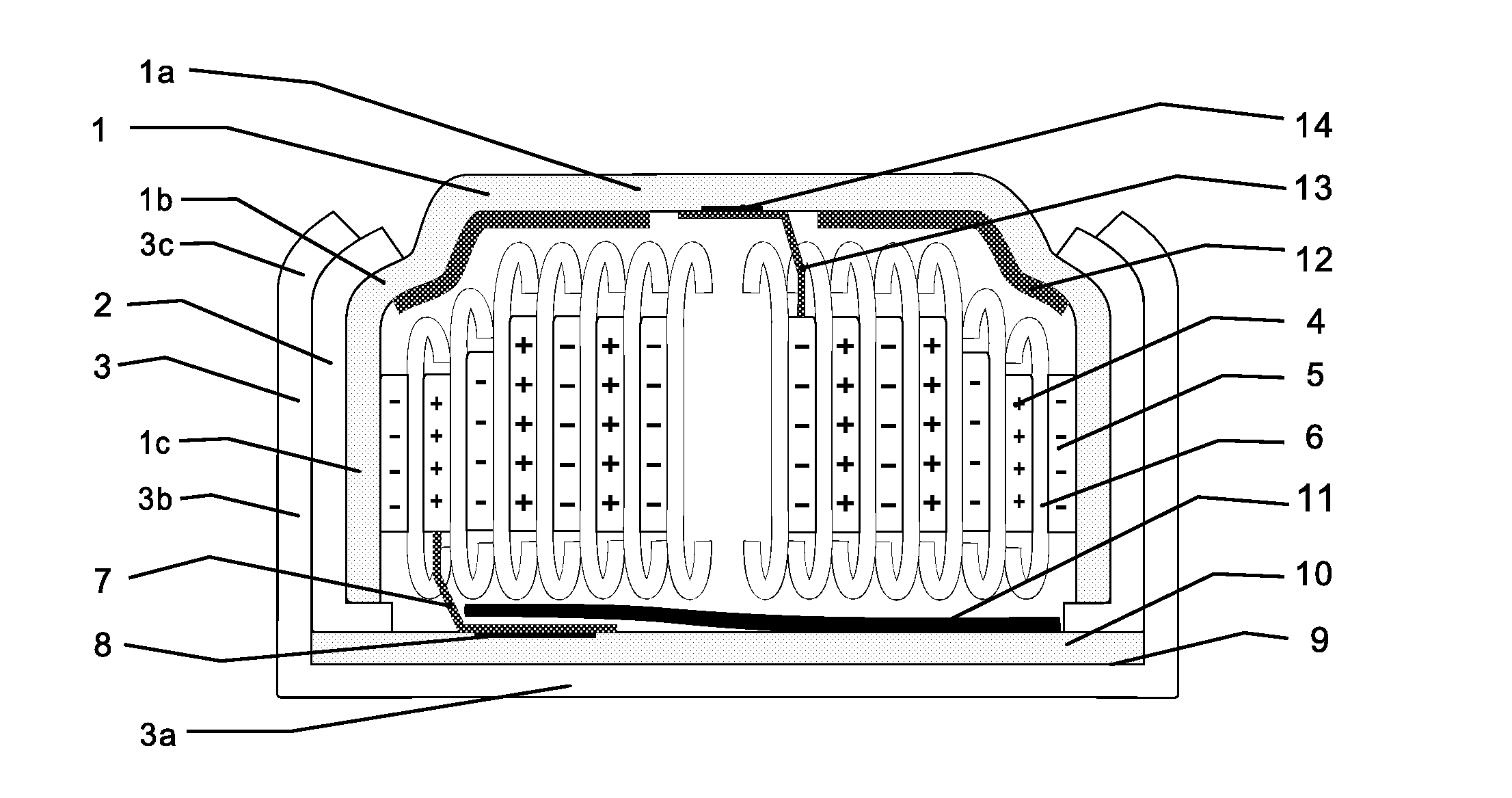

Battery

InactiveCN102569866AStable temperatureConsistent temperatureFinal product manufactureCell temperature controlHeat conductingReaction temperature

The invention provides a battery, comprising a cover plate, a shell, a battery cell and electrolyte. The battery cell and the electrolyte are sealed in the shell of the battery, and the cover plate is hermetically connected with the shell. The battery cell comprises a positive polar plate, a negative polar plate and a diaphragm arranged between the positive polar plate and the negative polar plate. A positive polar lug is arranged on the positive polar plate, and a negative polar lug is arranged on the negative polar plate. The battery cell is further internally provided with a positive polar current and heat conducting member and a negative polar current and heat conducting member, and the positive polar current and heat conducting member and the negative polar current and heat conducting member are mutually insulated. The positive polar current and heat conducting member and the positive polar lug are conducted; the negative polar current and heat conducting member and the negative polar lug are conducted; the positive polar current and heat conducting member and / or the negative polar current and heat conducting member penetrate(s) through the cover plate to leading out current. According to the invention, the internal heat of the battery cell can be reduced rapidly, substances on the polar plates can be prevented from further thermal reaction, and thus, the safety performance of the battery is increased. Meanwhile, the stability of the internal temperature of the battery cell is guaranteed, the cyclic performance and the like of the battery are improved. In addition, the temperature at all parts in the battery cell can be ensured to be consistent so as to eliminate temperature differences and make the reaction temperature of all parts of the polar plates consistent. Meanwhile, the current and heat conducting members can play roles of backbone and support to support the battery cell, and is beneficial to not only assembly but also winding of the battery cell.

Owner:BYD CO LTD

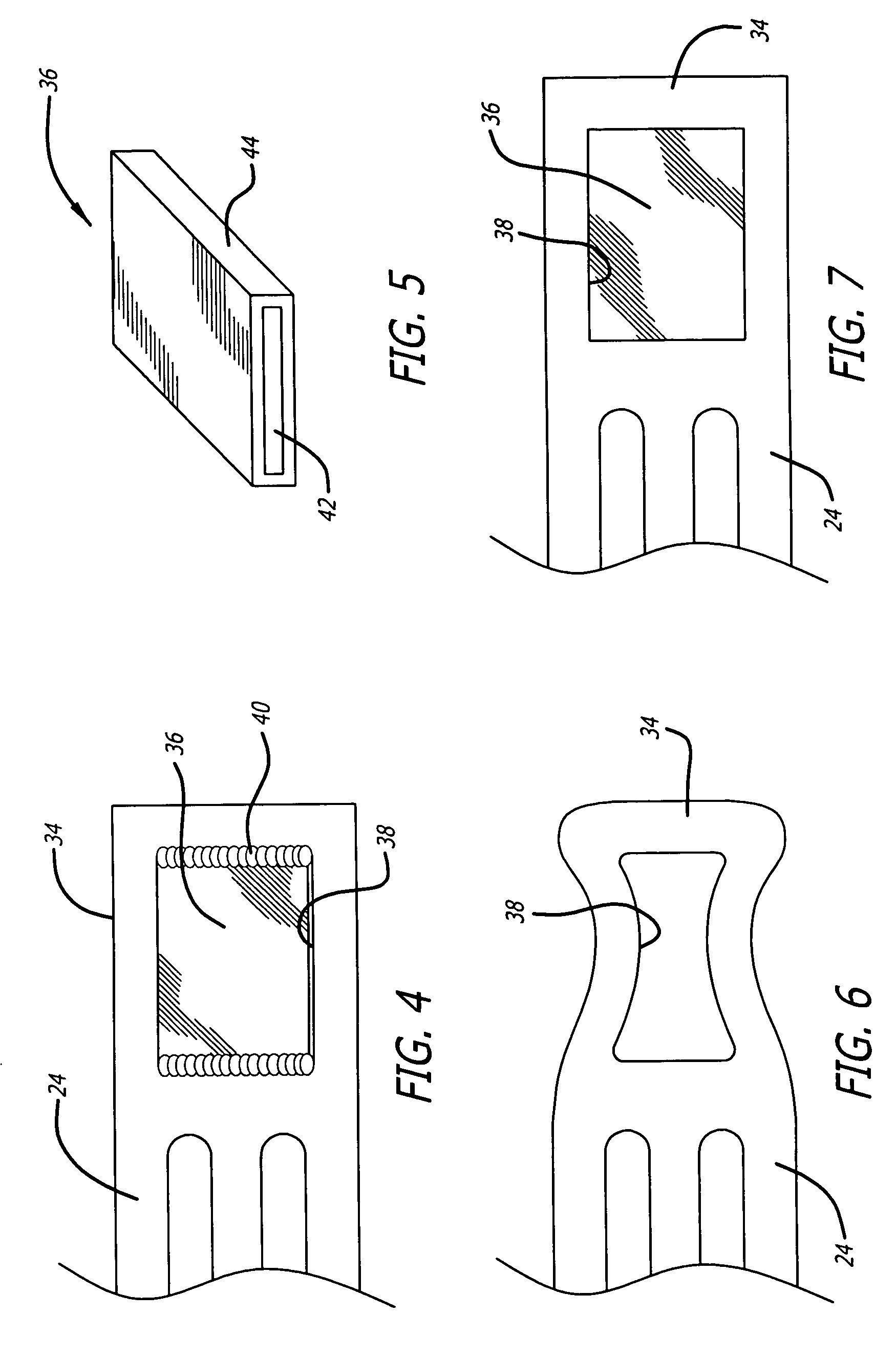

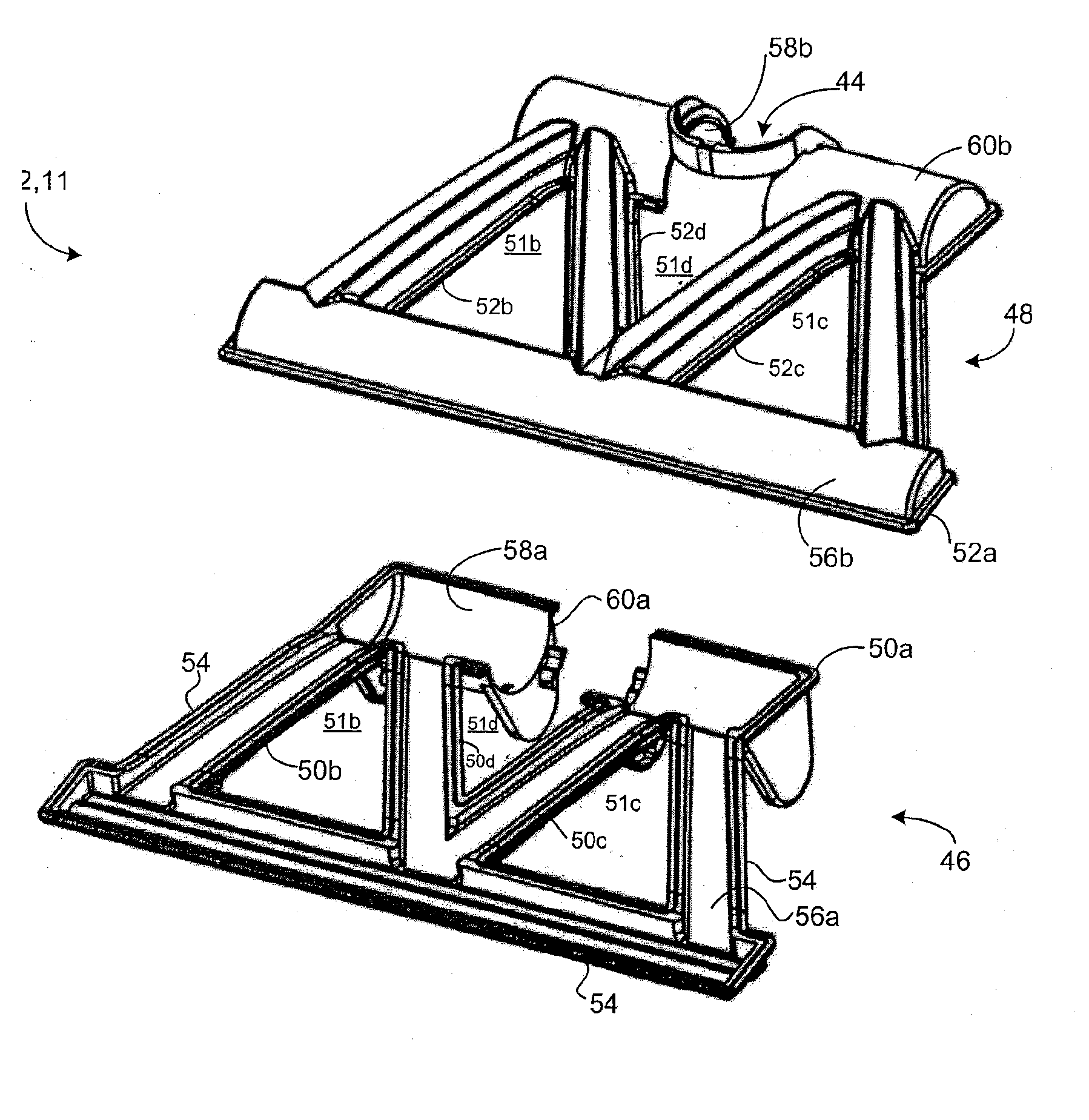

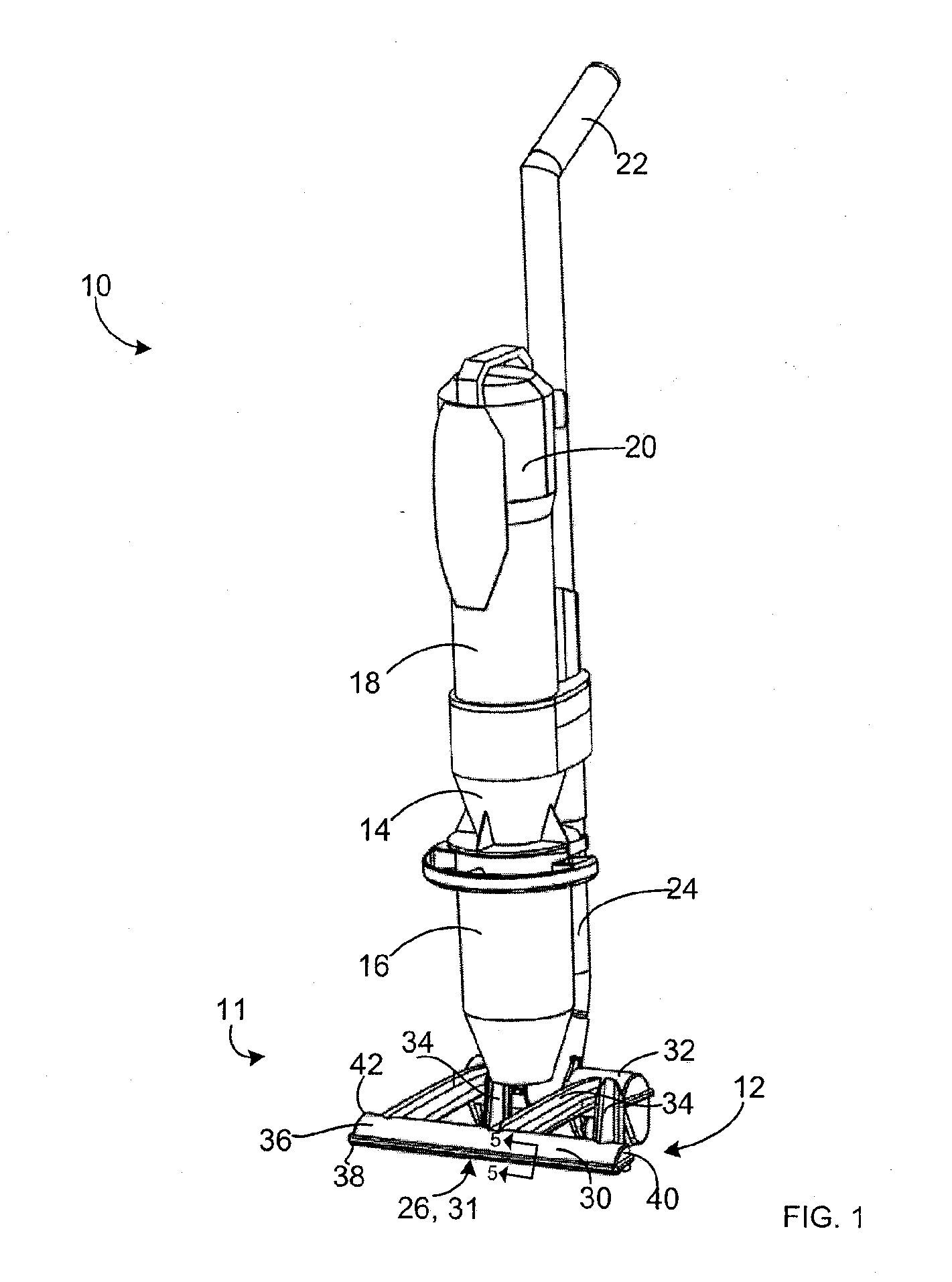

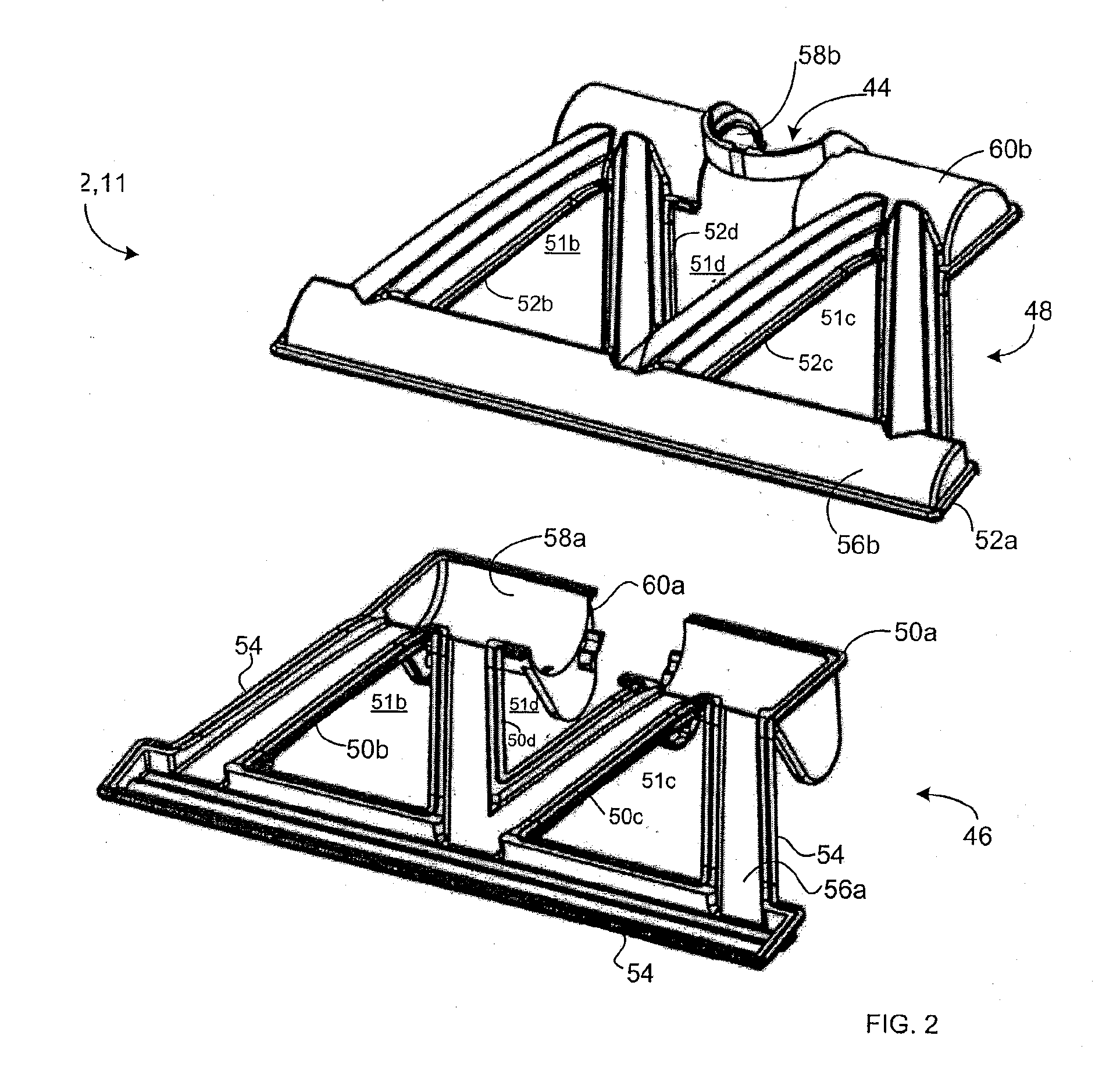

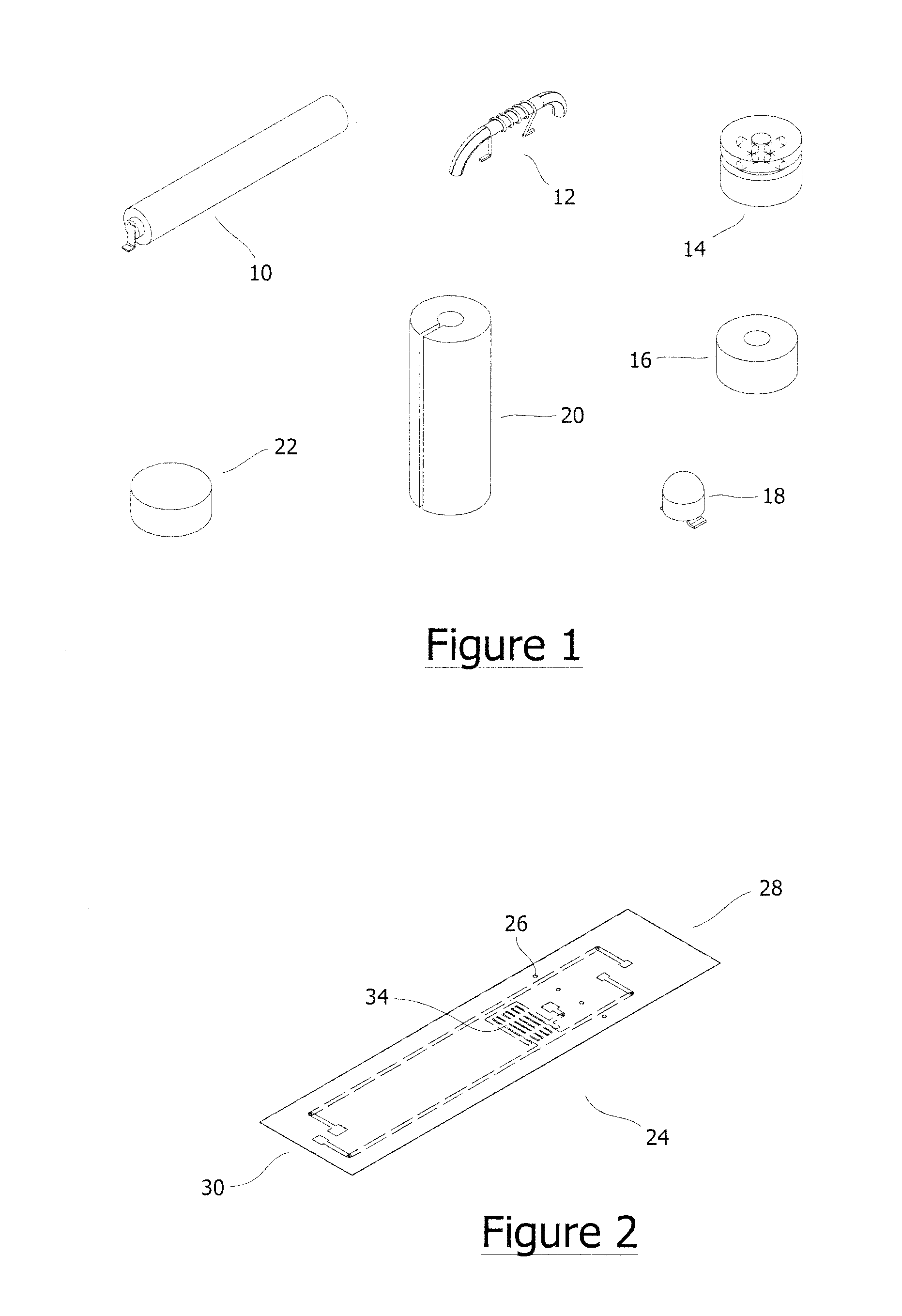

Resistively welded part for an appliance including a surface cleaning apparatus

ActiveUS20100243158A1Easy to weldHigh level of suctionCleaning filter meansLamination ancillary operationsEngineeringSurface cleaning

A part for an appliance, such as a surface cleaning apparatus, a method of making the part, and a method of disassembling the part are disclosed. The part comprises at least first and second plastic members resistively welded together. In some embodiments, the plastic members define a fluid flow cavity, such as a portion of the air flow path through the surface cleaning apparatus.

Owner:OMACHRON INTPROP

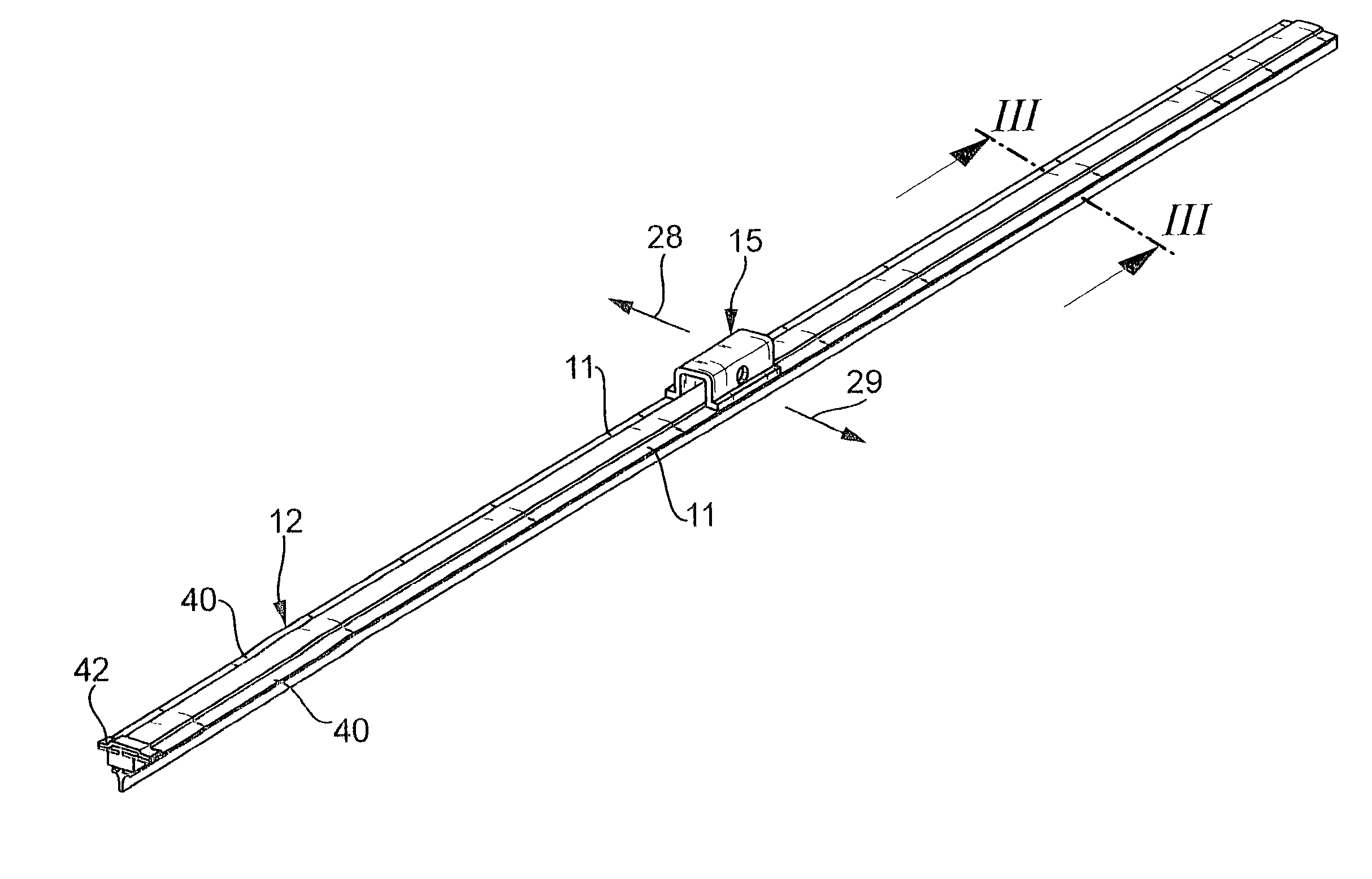

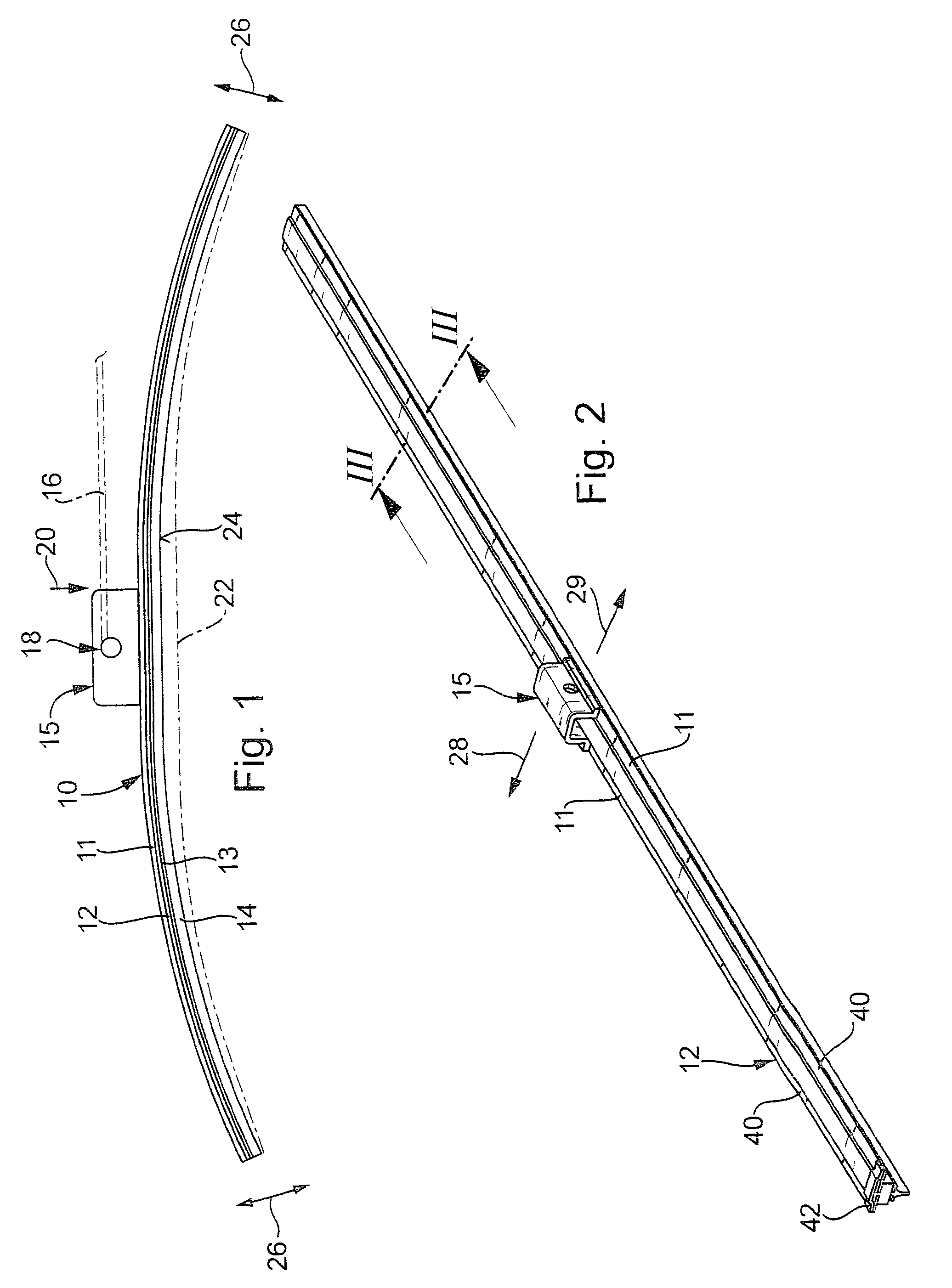

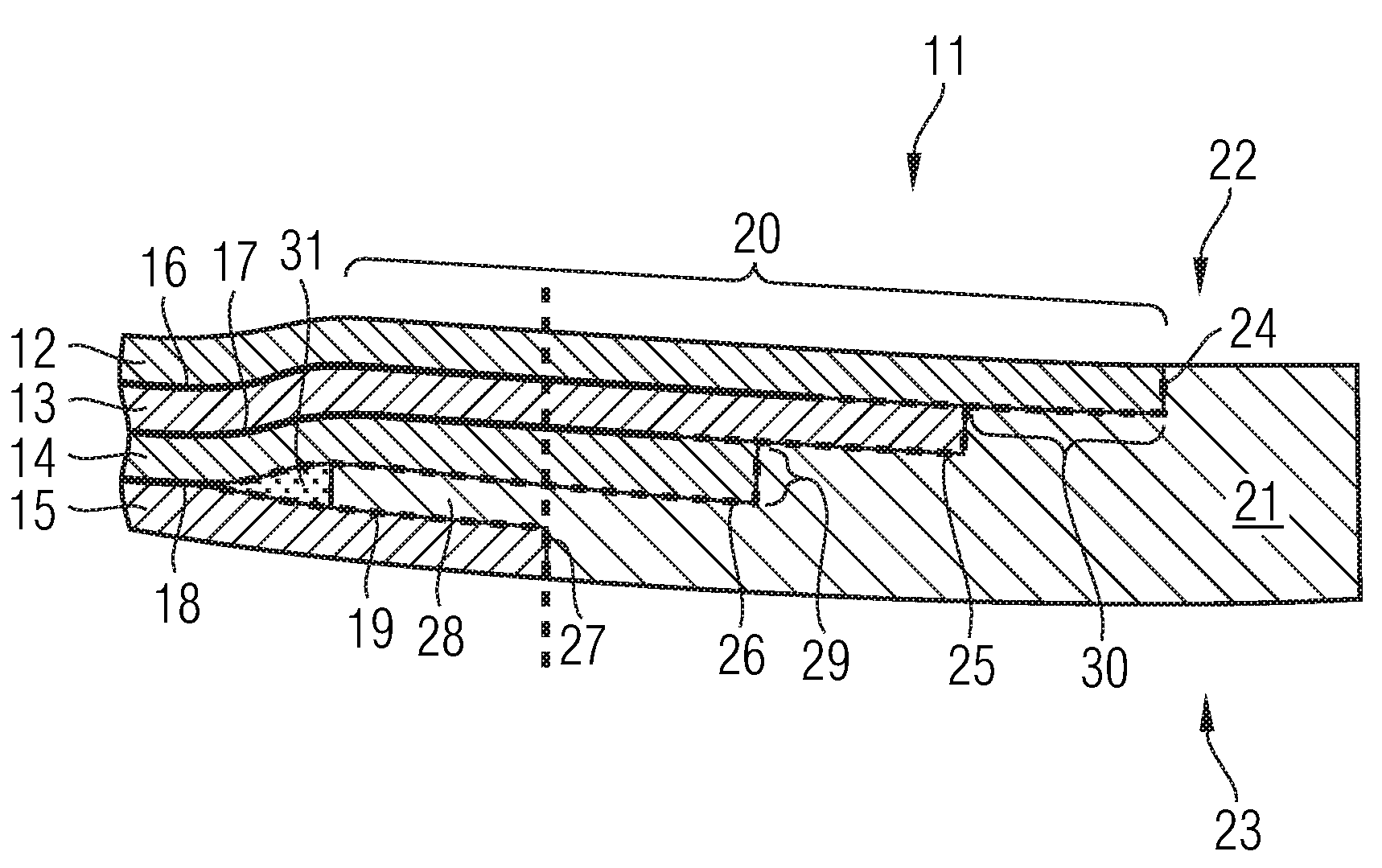

Wiper blade for cleaning glass panes, especially of motor vehicles, and method for the production of said wiper blade

InactiveUS20040025280A1Reduce adverse effectsImprove hardenabilityWindow cleanersVehicle cleaningMobile vehicleSulfur

A wiper blade is proposed for cleaning windows, especially of motor vehicles, is proposed, which is provided with an elongated, rubber-elastic wiper strip that can be placed against the window, which wiper strip is disposed on the lower band face (13), oriented toward the window, of a bandlike-elongated support element (12) made from a spring-elastic steel, on whose other, upper band face (11) facing away from the middle, particularly in the middle portion of the support element, a device (15) for connecting the wiper blade to the free end, urged toward the window, of a driven wiper arm (16) guided on the motor vehicle is welded. It has proved particularly advantageous, in view of the demands made of the support element, if the support element is made from an alloyed quenched and tempered steel, which has the following alloy components: carbon (C), 0.18% to 0.36%; silicon (Si), 0.40% to 0.50 %; manganese (Mn), 1.10 % to 1.80%; phosphorus (P), 0.015% to 0.035%; and sulfur (S), 0.035% to 0.04%.

Owner:ROBERT BOSCH GMBH

Method and apparatus for nucleated forming of semi-solid metallic alloys from molten metals

A method for the forming of semi-solid nucleated metallic alloys that have been sprayed in molten form into a container for intermediate casting. According to the present invention, a molten stream of metallic alloy is disrupted into a plurality of molten metallic alloy droplets, and the droplets are partially solidified as a plurality of degenerative dendritic globules so that approximately 5% to 60% by volume of each average degenerative dendritic globule is solid and the remainder is molten. The partially solidified globules are collected to form a semi-solid mass, and a portion of the semi-solid mass is forced into a die cavity prior to solidification to form a shaped metallic alloy.

Owner:HOT MEAL TECH

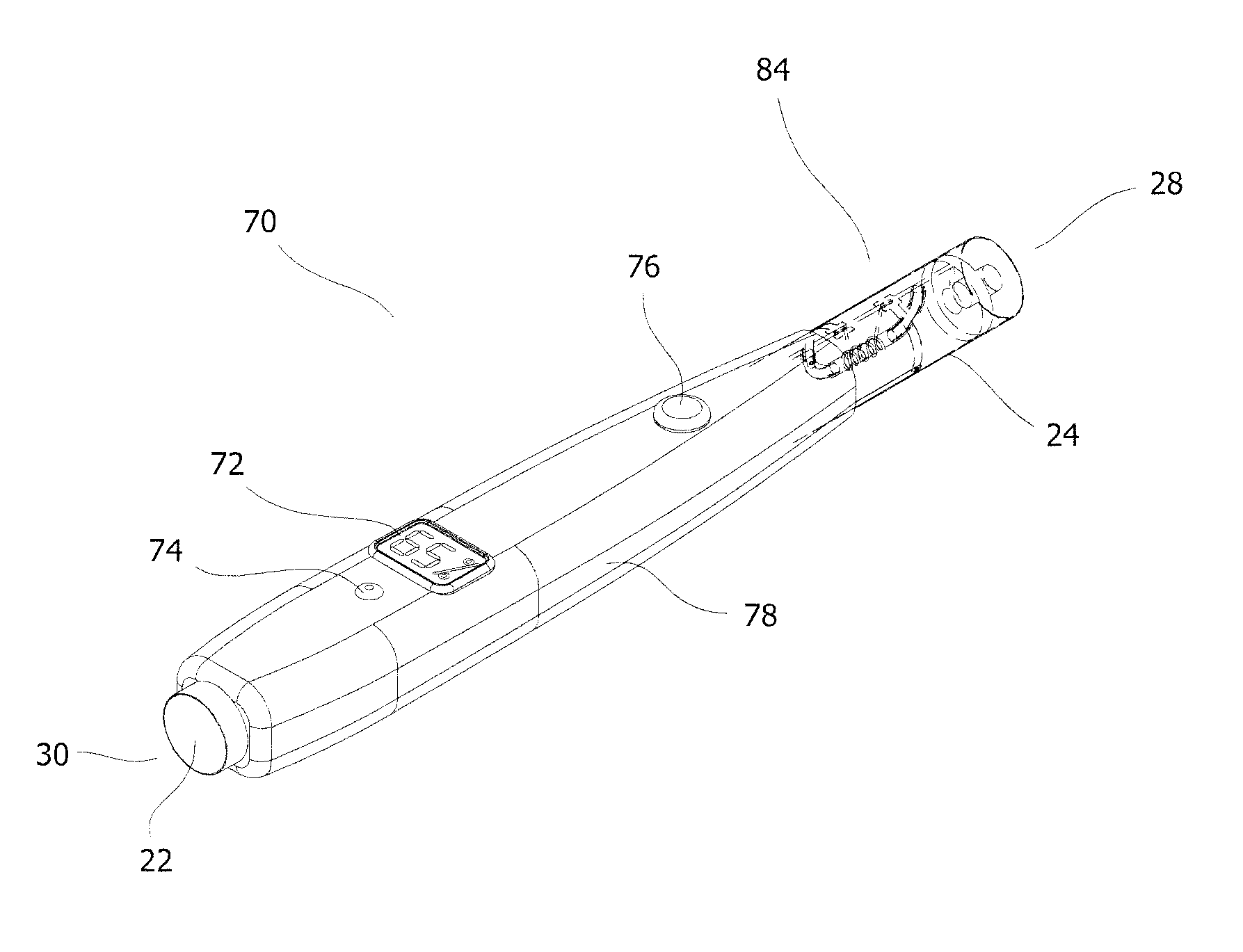

Electronic personal vaporizer

InactiveUS20150078735A1Yield strength is exceededEliminate needMedical devicesIndirect heat exchangersElectronic communicationEngineering

An electronic personal vaporizer is provided, having components including a heating element; a liquid container; a power source to provide power to the heating element; a first bulkhead defining an airway at a first end of the vaporizer;a second bulkhead separating the power source from the heating element and liquid container; and a shell containing the heating element, liquid container and power source. The shell is made of flexible printed circuit and is rolled or folded around the other components to allow for electronic communications to pass along the vaporizer without piercing the bulkheads.

Owner:FUSIONFLEX

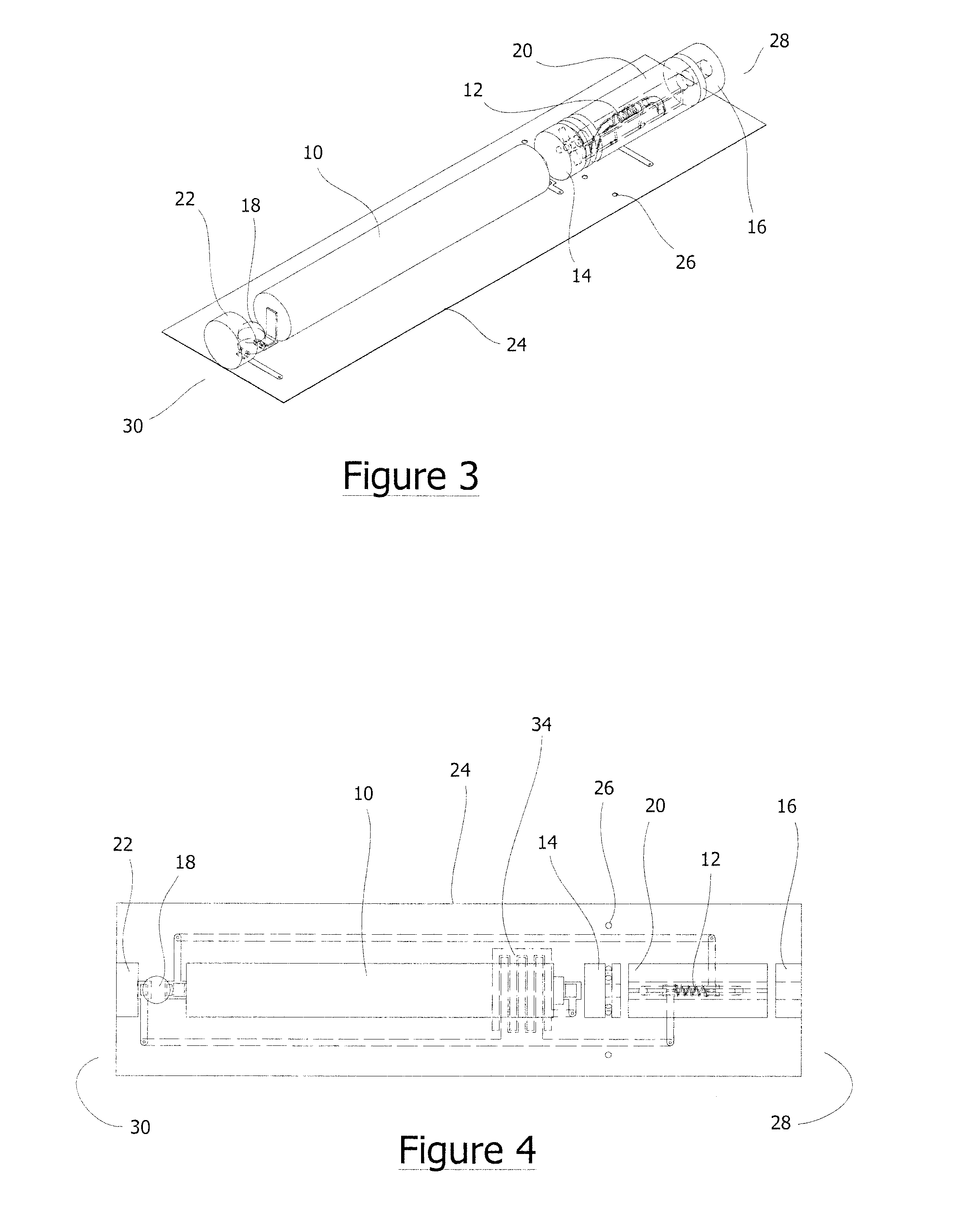

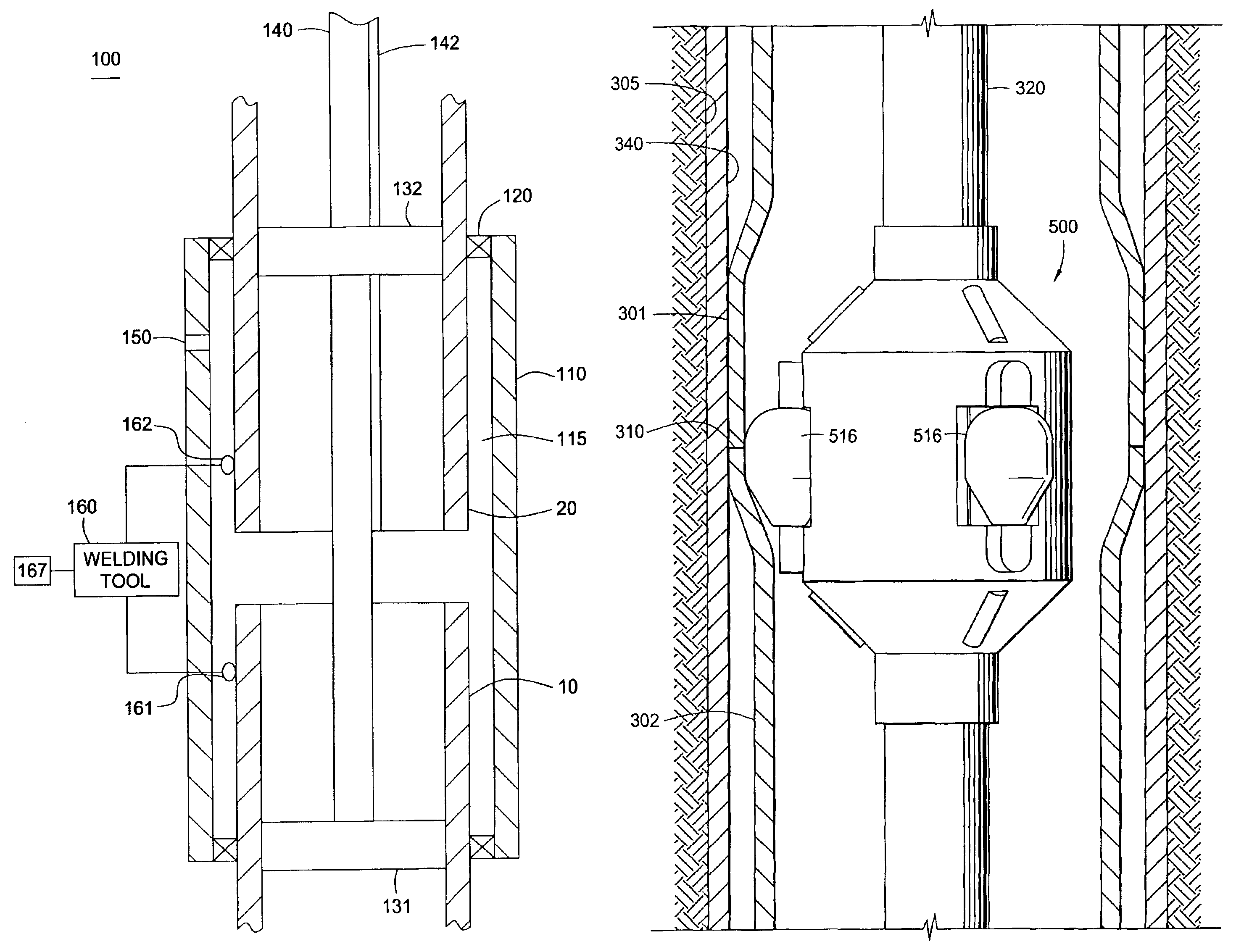

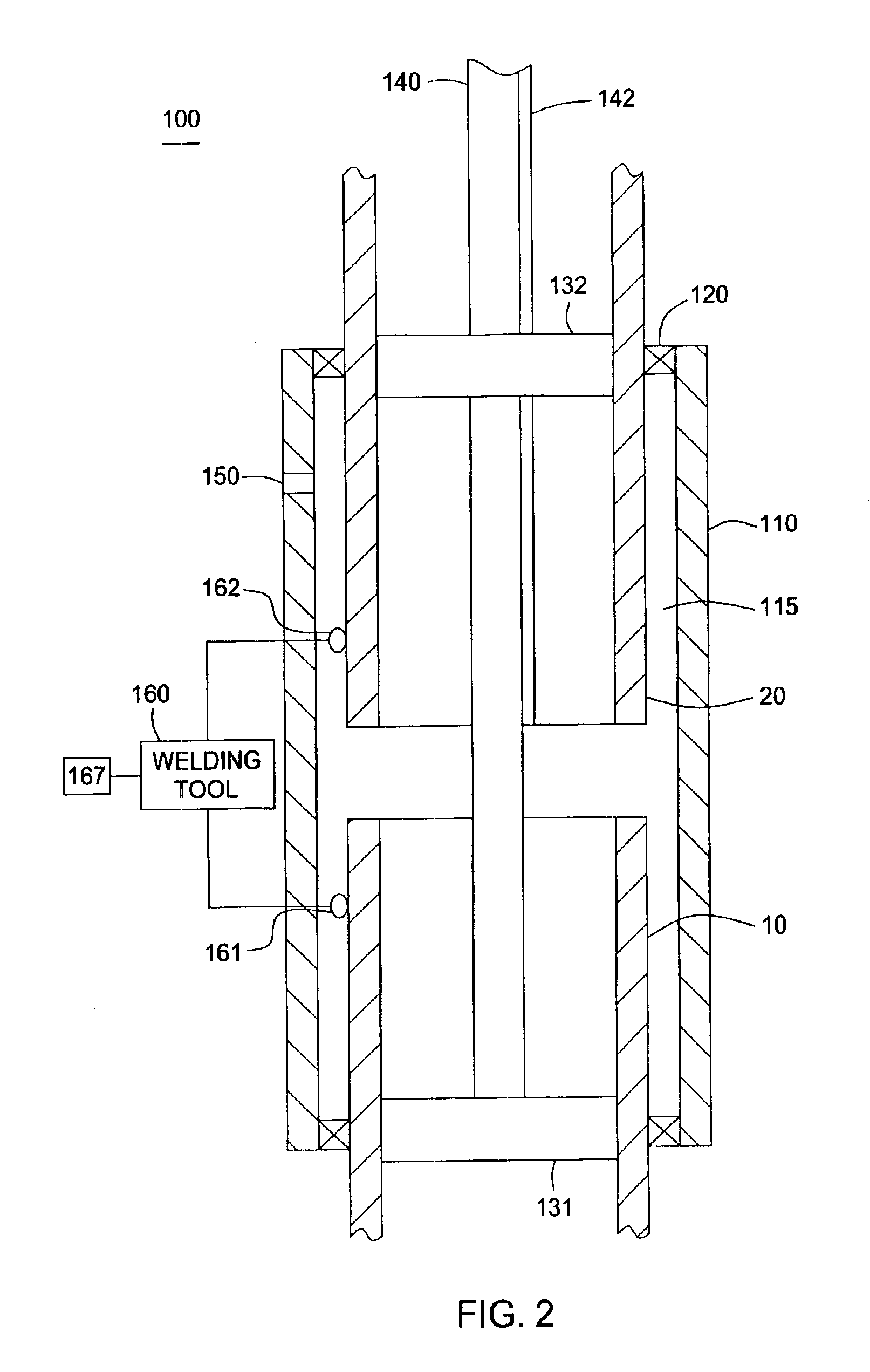

Flash welding process for field joining of tubulars for expandable applications

InactiveUS6935429B2Improve reliabilityAvoid enteringDrilling rodsFluid removalEngineeringFlash welding

The present invention generally relates to methods of connecting two expandable tubulars. In one aspect, the method includes flash welding the ends of the expandable tubulars together. Thereafter, the connected tubulars are lowered into the wellbore for expansion. The flash welding process provides a highly reliable joint for expansion.

Owner:WEATHERFORD TECH HLDG LLC

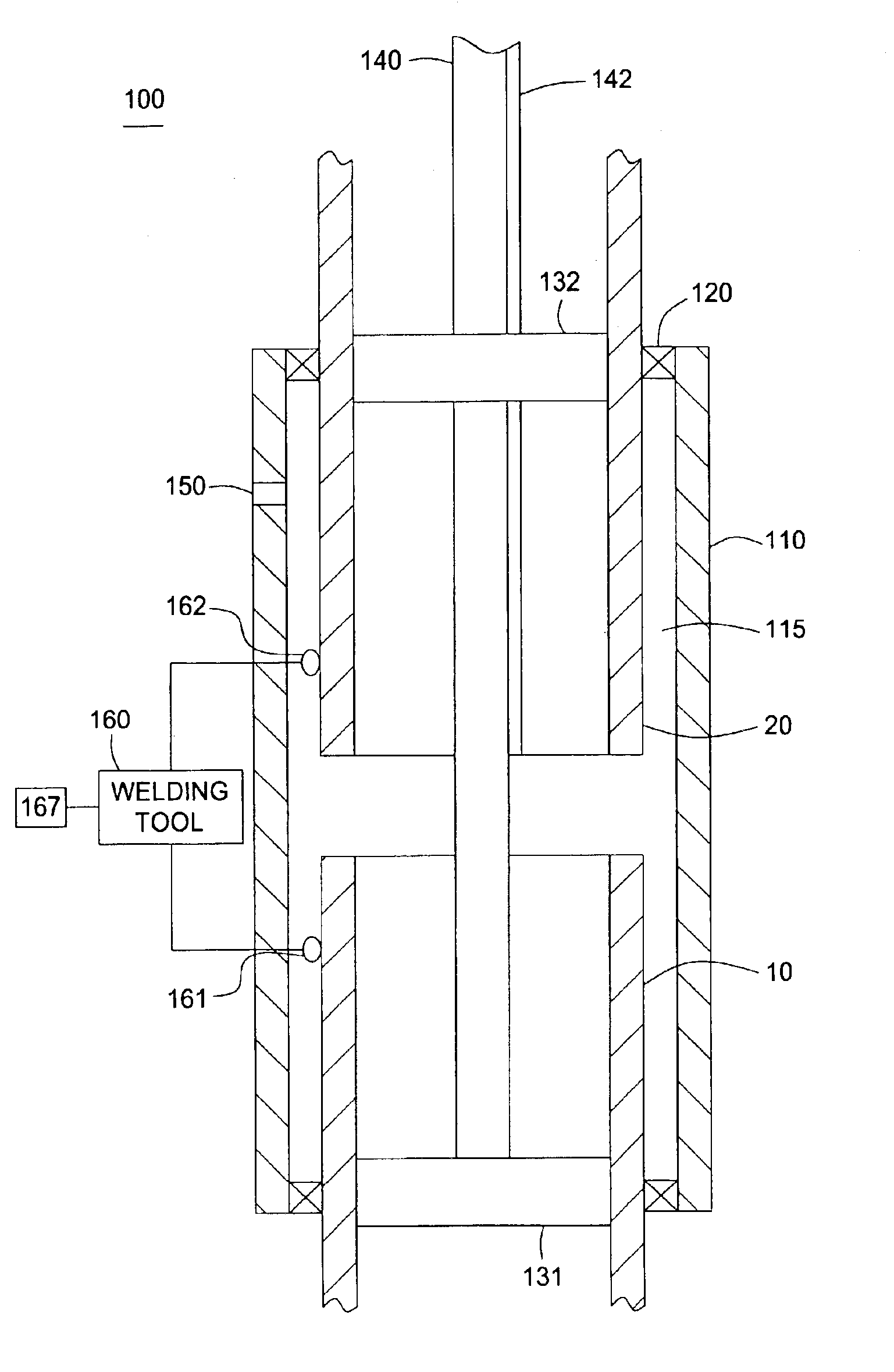

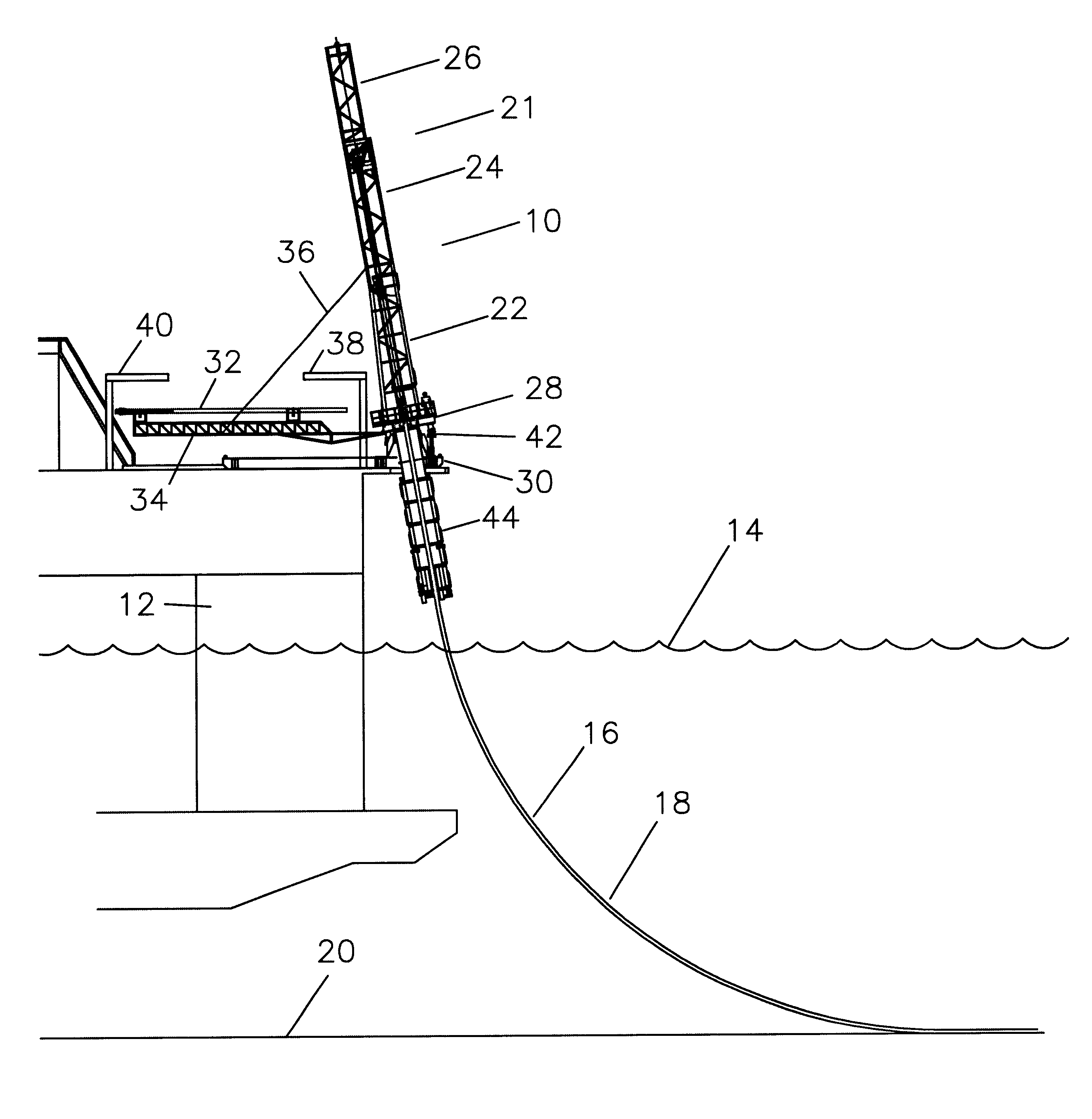

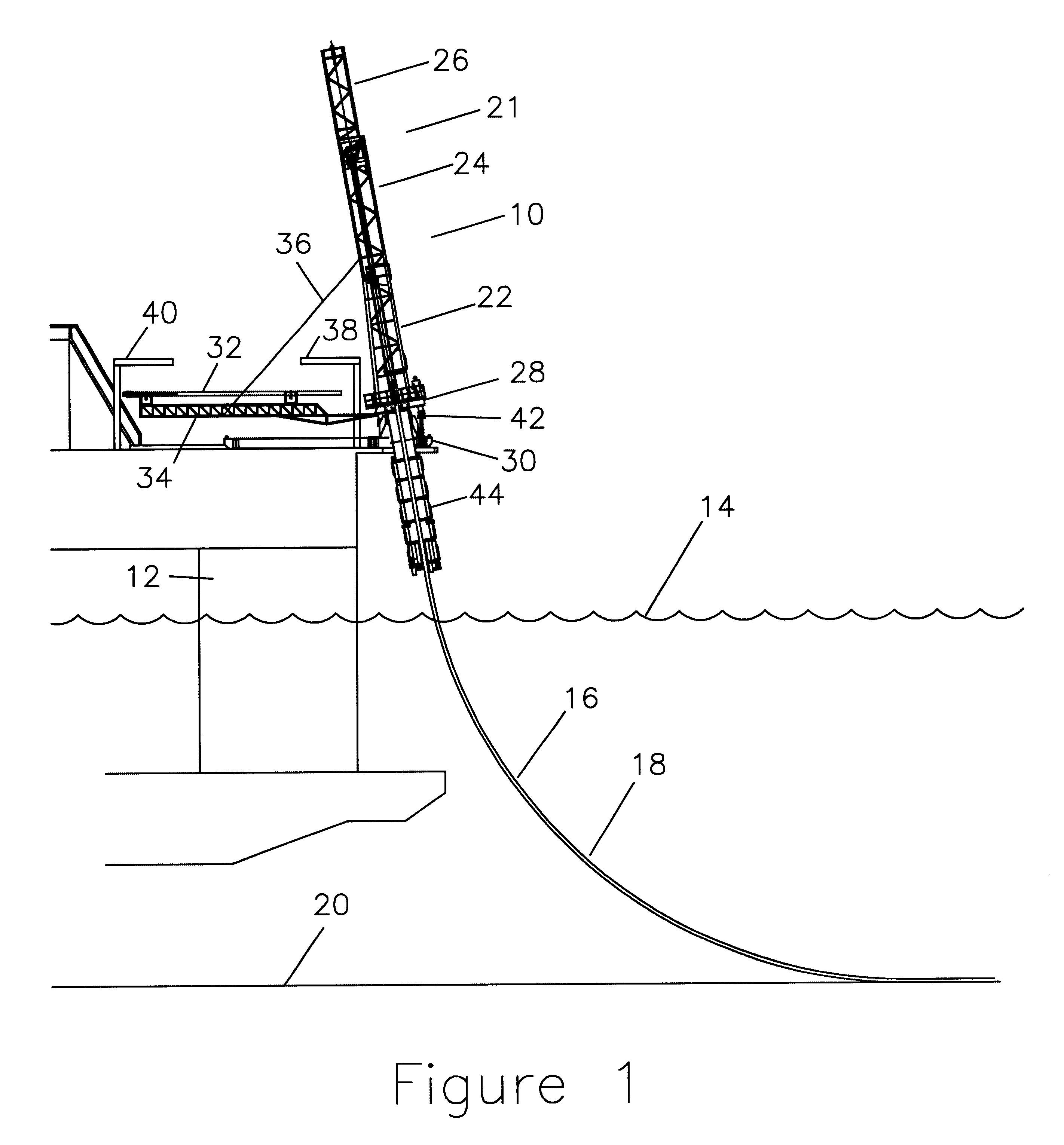

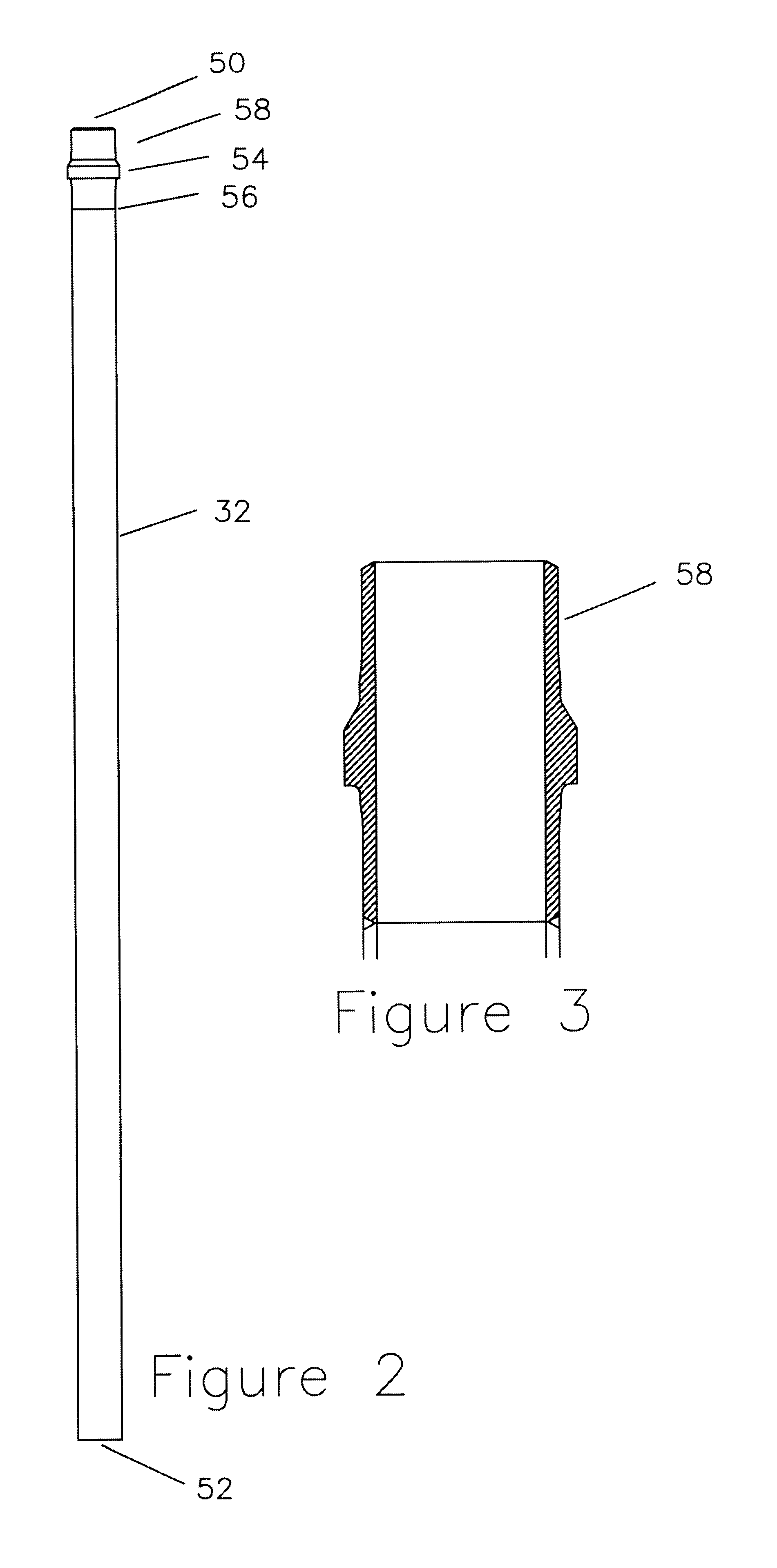

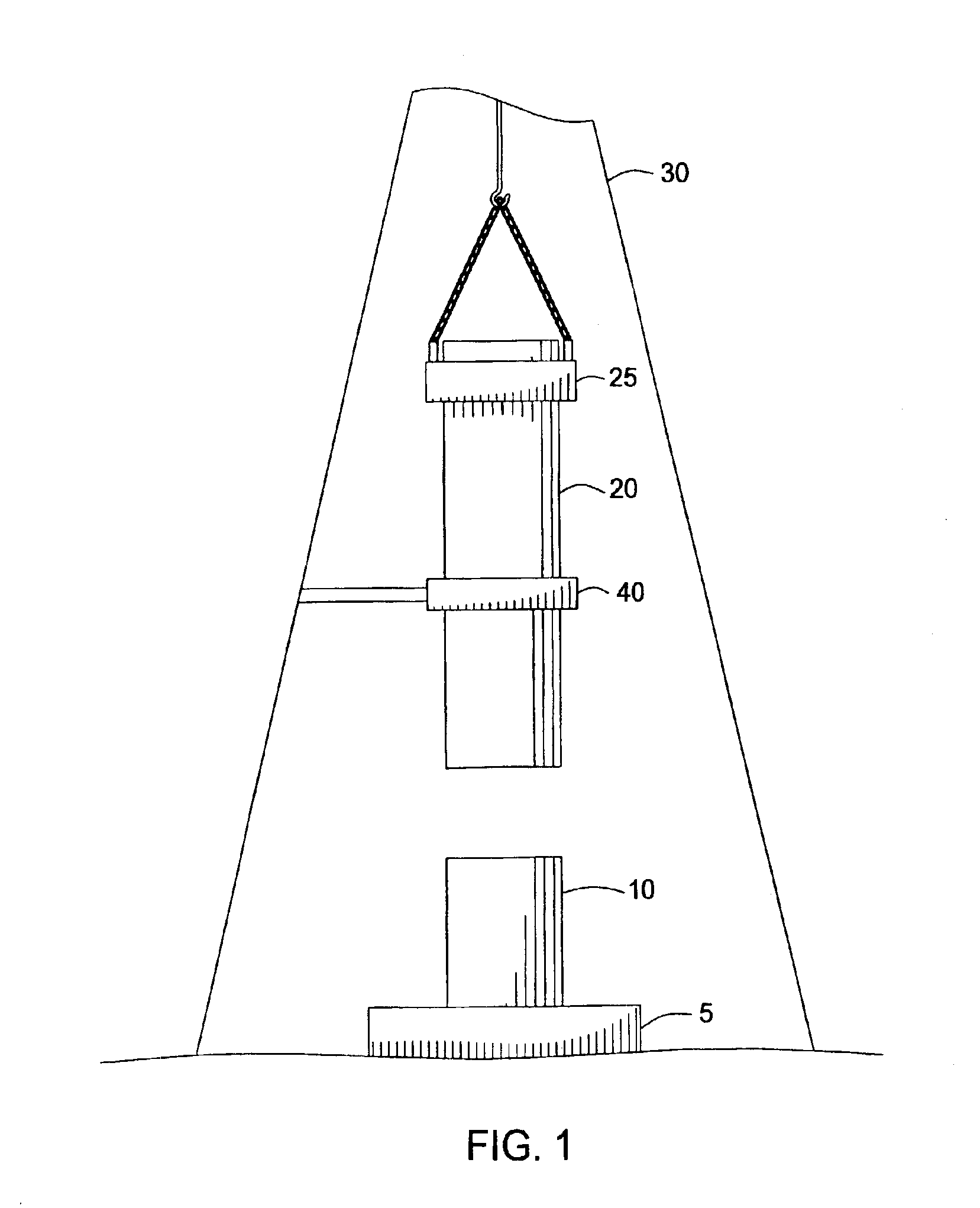

Erector for J-Lay pipe laying system

InactiveUS6910848B1Easy to weldPrecise alignmentPipe laying and repairLifting devicesOcean bottomEngineering

A system for laying a pipeline from a floating vessel onto the ocean floor in relatively deep ocean water which provides an erector for raising new pipe sections to be added to a pipeline which is depending from the system, the pipe sections being raised into accurate alignment with the mast of the system although the mast is free to be gimbaled in any direction within two degrees of angular freedom.

Owner:BAUGH BENTON F

Battery and manufacturing method thereof

InactiveUS20050048365A1Easily manufactured structureHigh power outputFinal product manufactureSmall-sized cells cases/jacketsFlangeElectrode

A battery which realizes high power output, cost reduction and increase in capacity. An enlarged port section is formed in an open end of a battery case. A ring-shaped support rack section is formed inside of the enlarged port section, and a ring-shaped insulating gasket is set on and supported by the support rack section. The battery has a collector of one pole, to which an end portion of an electrode plate of one pole protruding from an electrode plate group is connected. A ring and flange-shaped collar section, which is tiered with a step, is provided in the periphery of the collector, and the flange-shaped collar section is set on the bottom face of the insulating gasket. A port sealing member, in which a filter section and a cap-shaped terminal section are integrated with each other, is connected onto the collector. The enlarged port section is inwardly caulked, to fix the flange-shaped collar section of the collector and the periphery of the port sealing member, which are overlaid with each other, with the insulating gasket interposed therebetween.

Owner:PANASONIC CORP

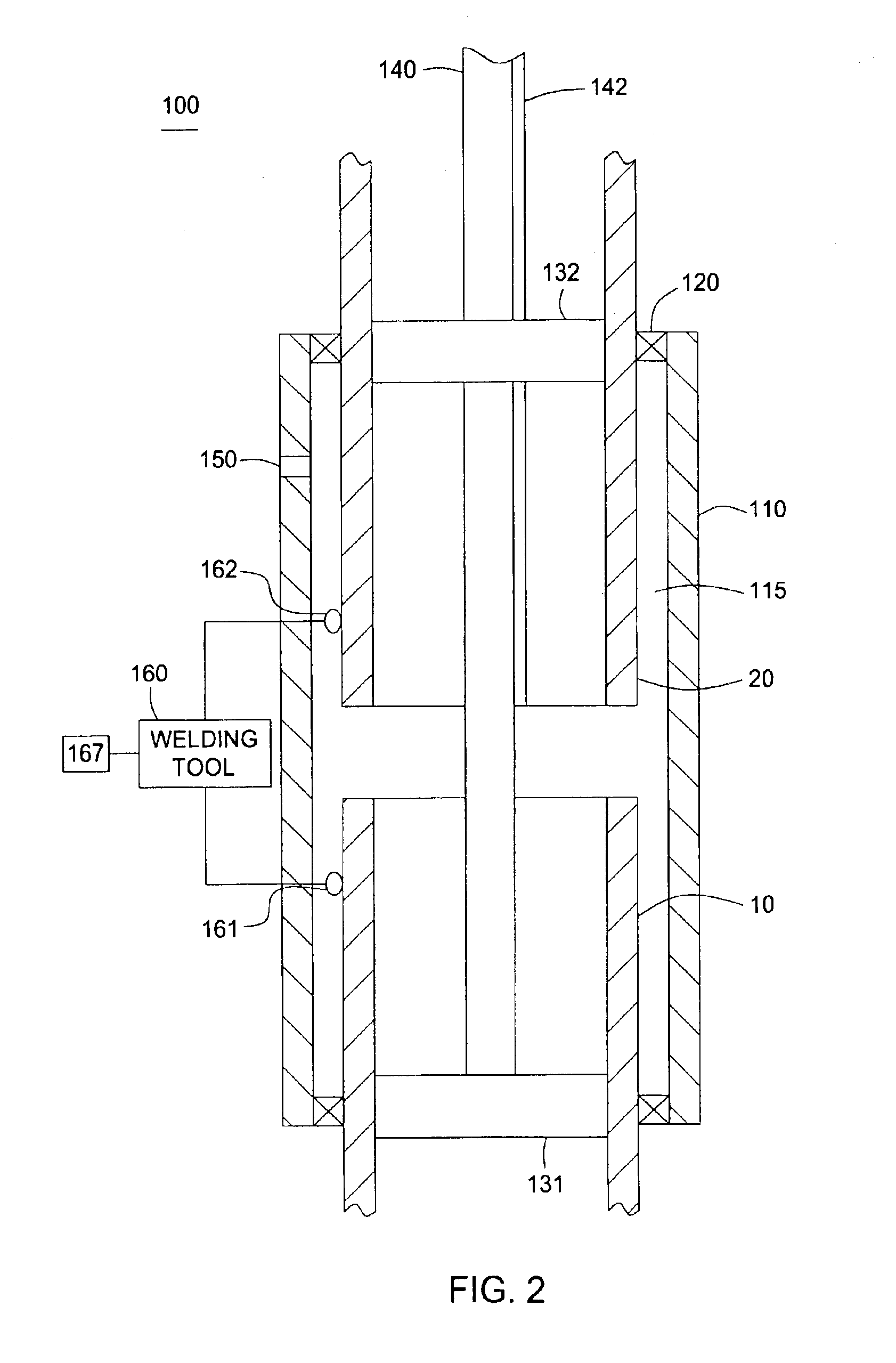

Method and apparatus for expanding a welded connection

InactiveUS6935430B2Improve reliabilityAvoid enteringDrilling rodsFluid removalEngineeringFlash welding

The present invention generally relates to methods of connecting two expandable tubulars. In one aspect, the method includes flash welding the ends of the expandable tubulars together. Thereafter, the connected tubulars are lowered into the wellbore for expansion. The flash welding process provides a highly reliable joint for expansion. In another aspect, the present invention provides a method for expanding a non-uniform tubular. In one embodiment, the non-uniform tubular is formed by connecting two misaligned tubulars.

Owner:WEATHERFORD TECH HLDG LLC

Expandable polylactic acid resin particles, expanded polylactic acid resin beads and molded article obtained from expanded polylactic acid resin beads

Expandable polylactic acid resin particles including (a) a base resin containing a polylactic acid resin having at least 50 mol % of lactic acid monomer component units, (b) a polyolefin wax in an amount of 0.0001 to 1 part by weight per 100 parts by weight of the base resin, and (c) a blowing agent in an amount of 1 to 30% by weight based on the weight of the resin particles. The expandable resin particles can give expanded beads having an average cell diameter of 10 to 500 μm. The expanded beads can give in-mold foam moldings.

Owner:JSP CORP

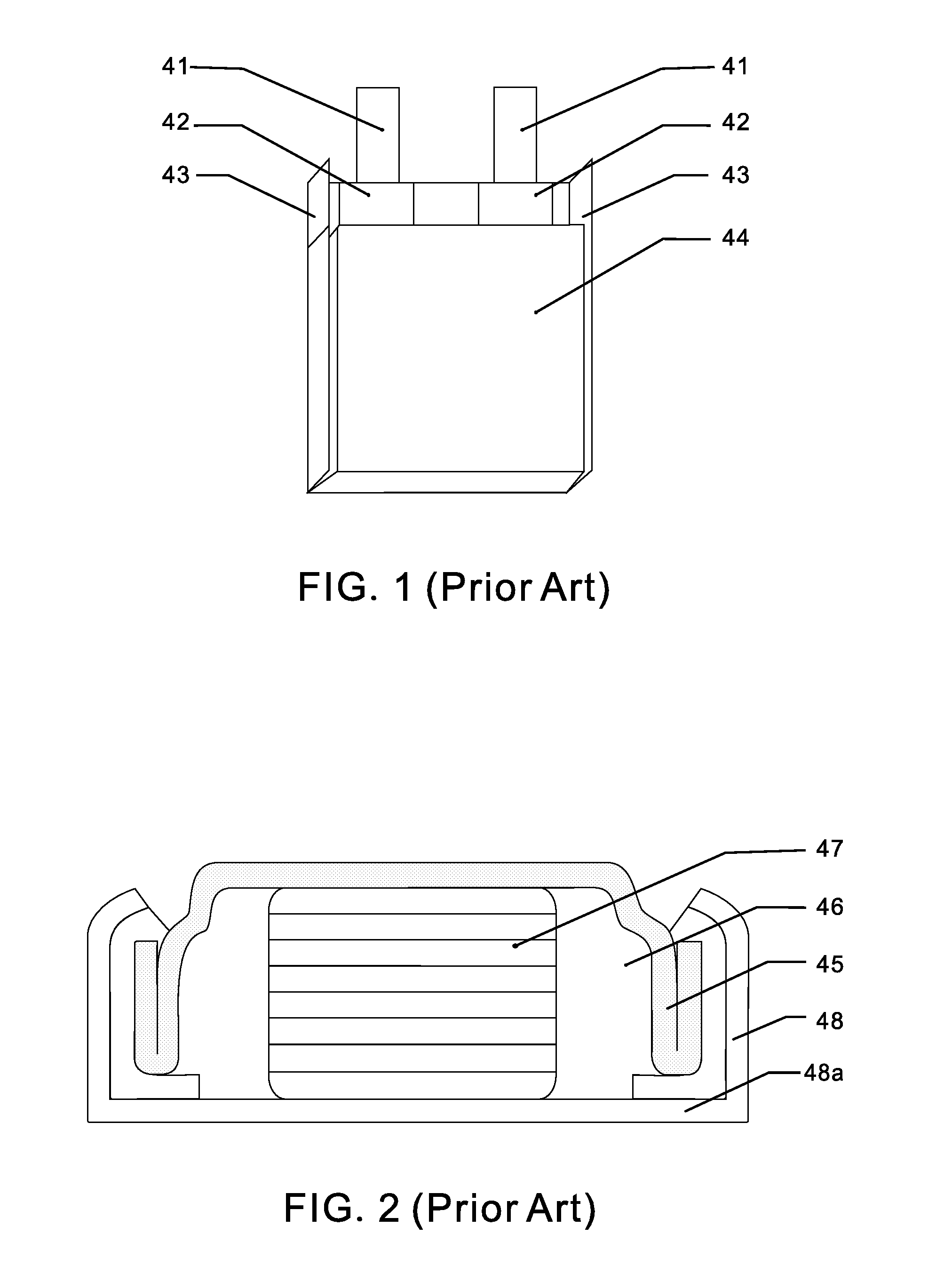

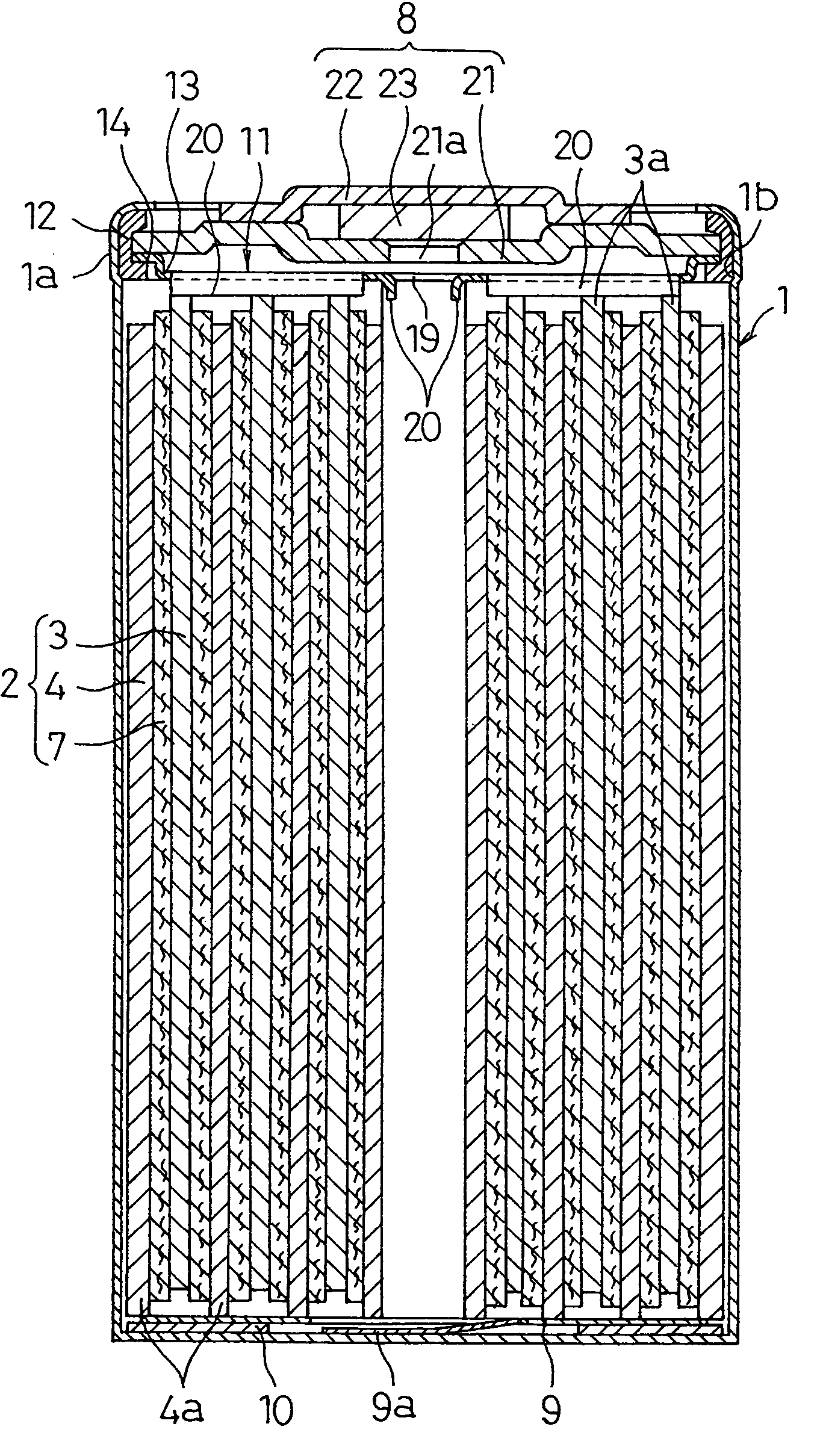

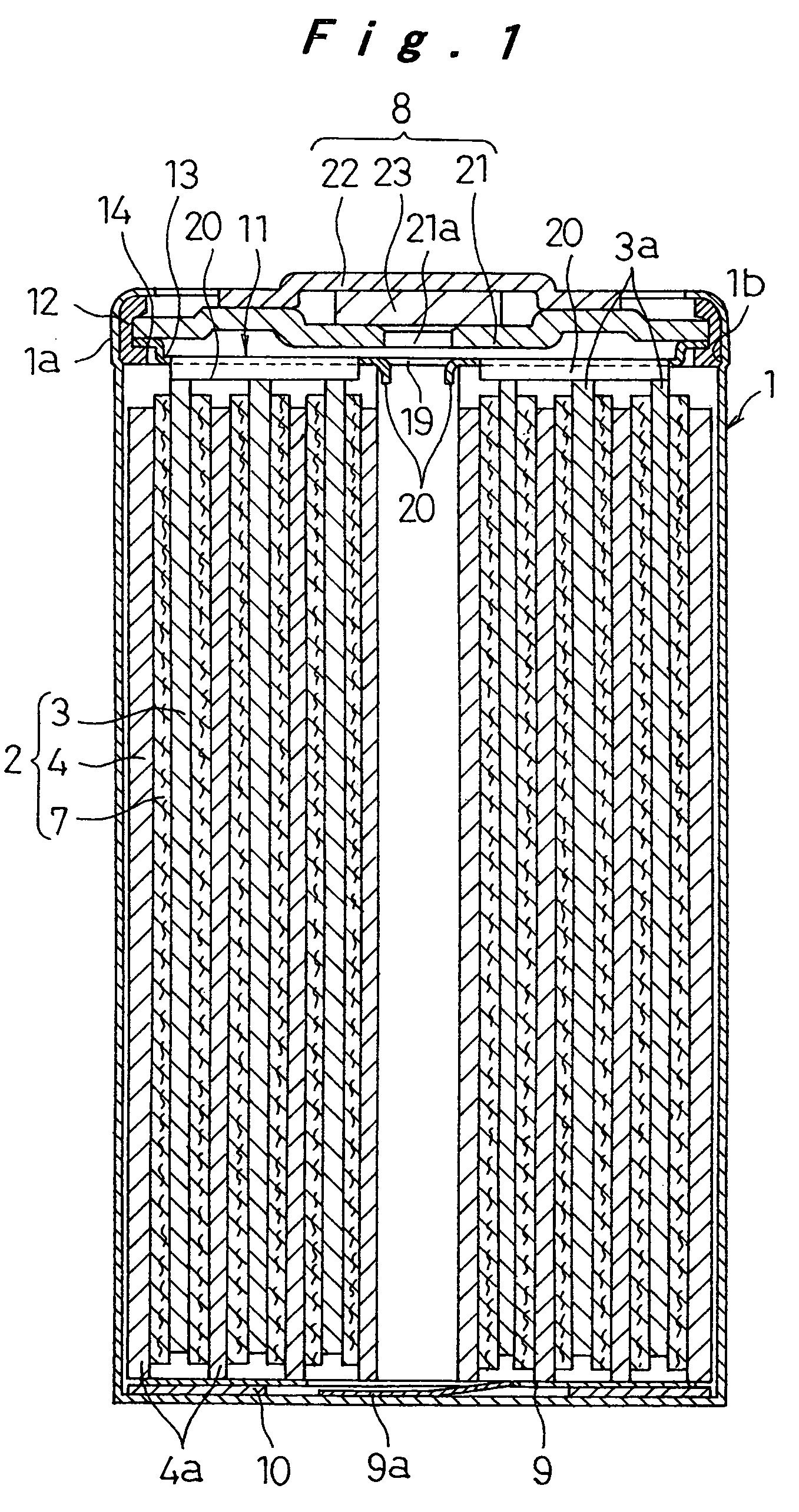

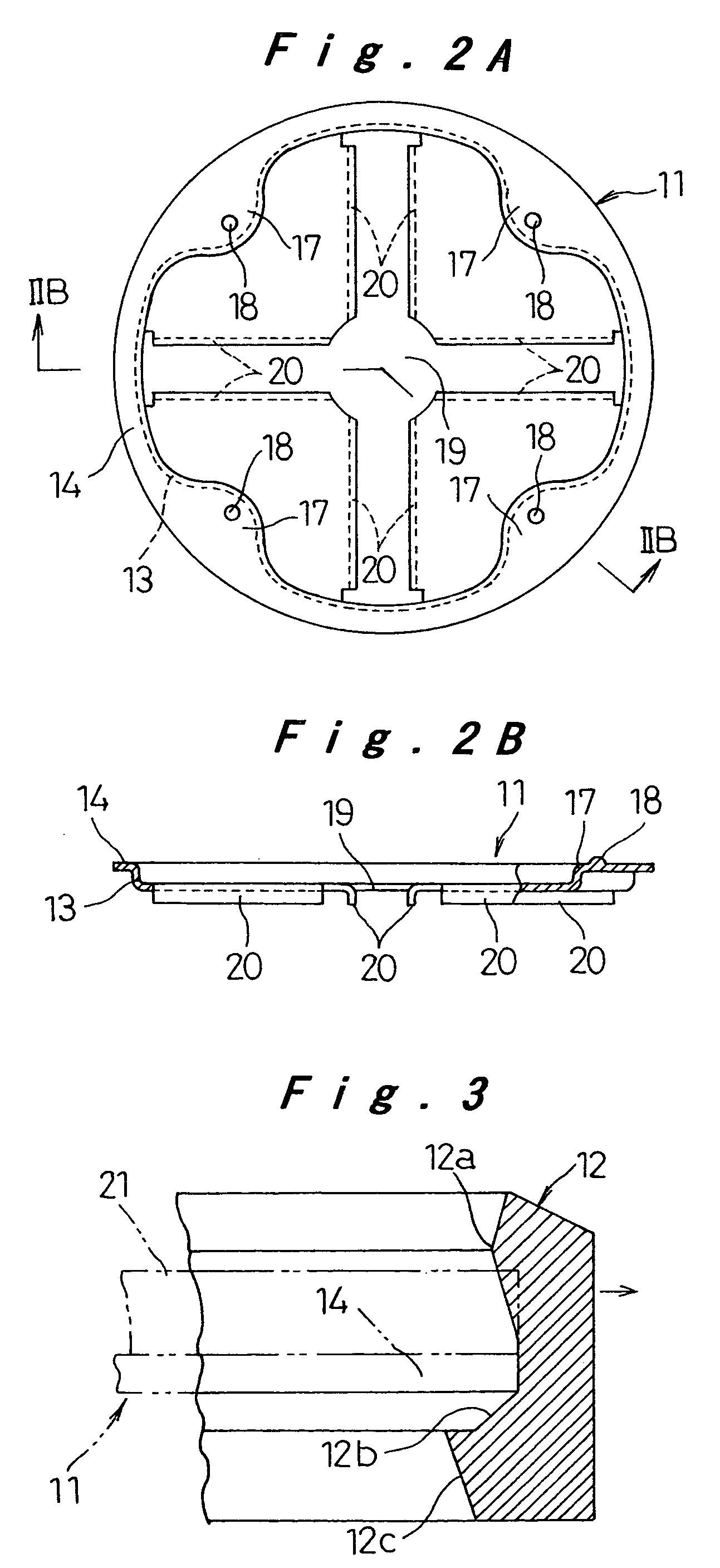

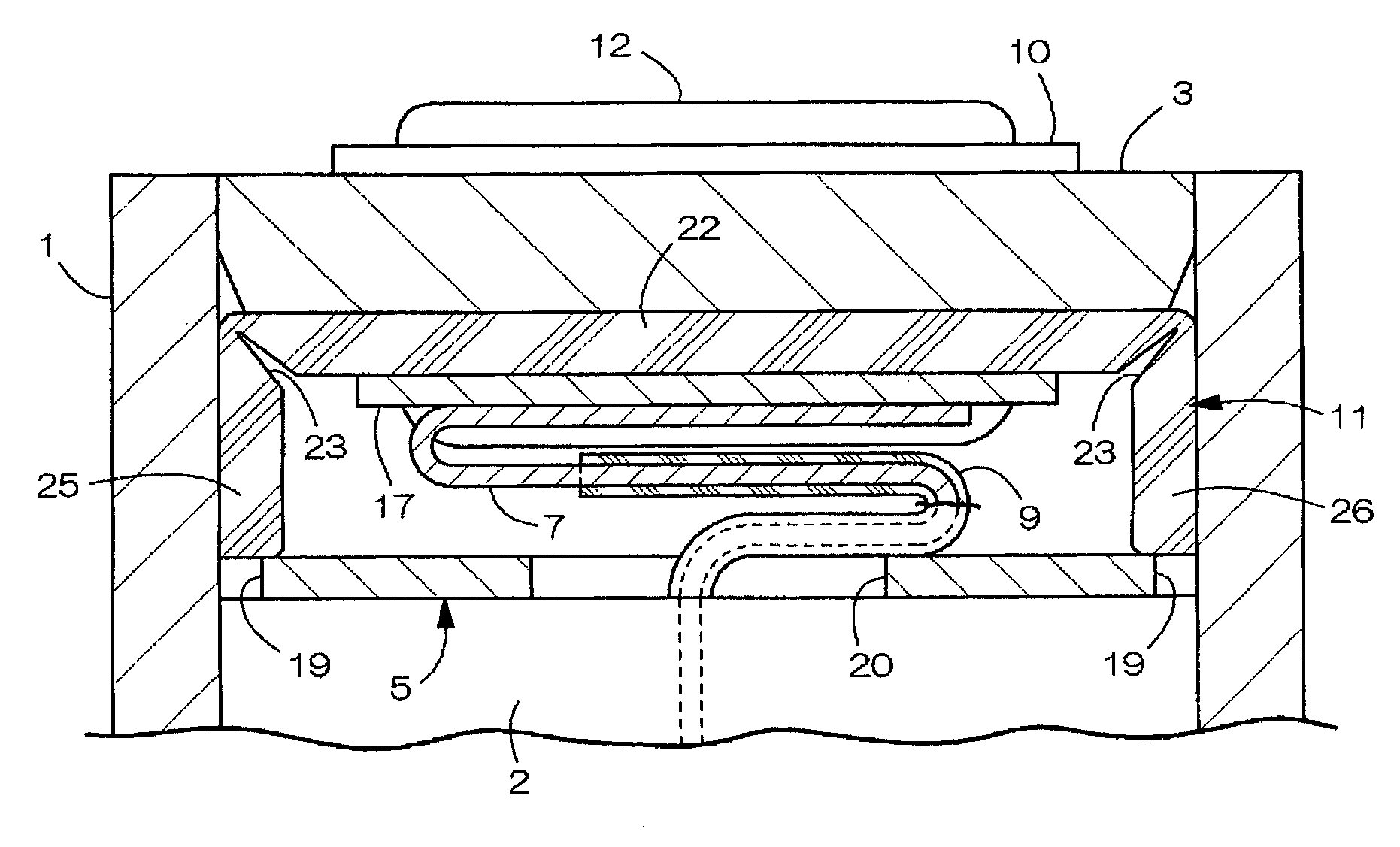

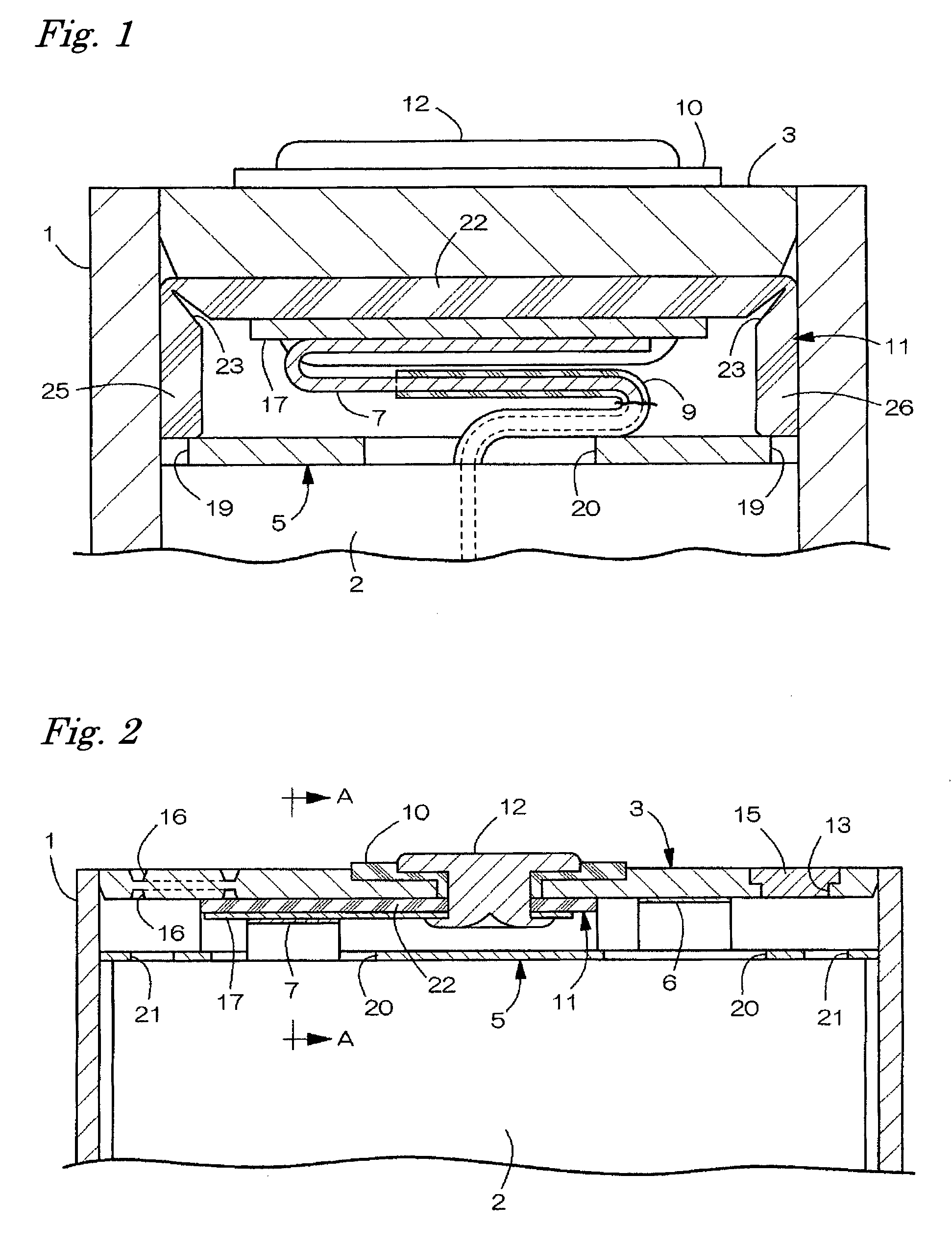

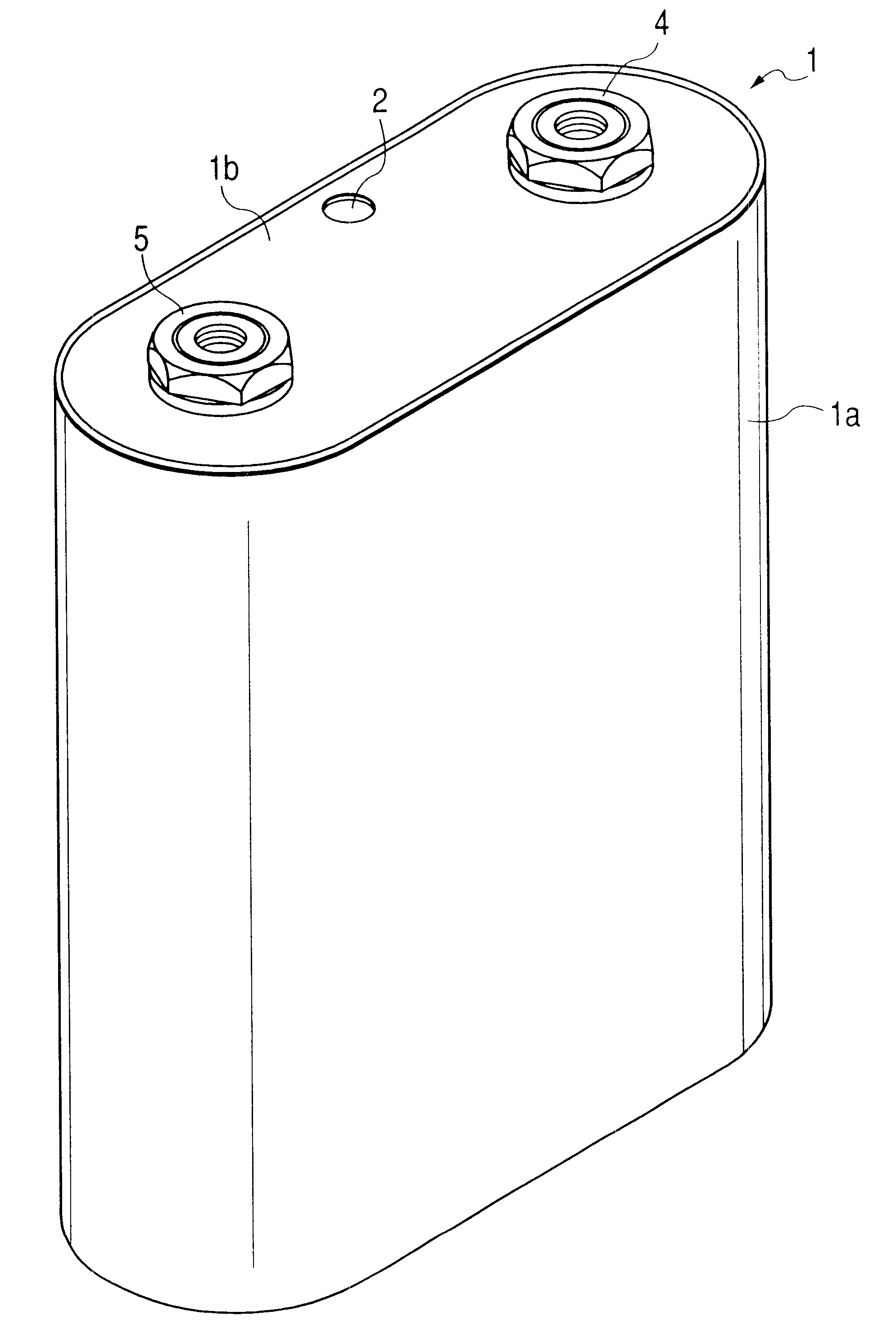

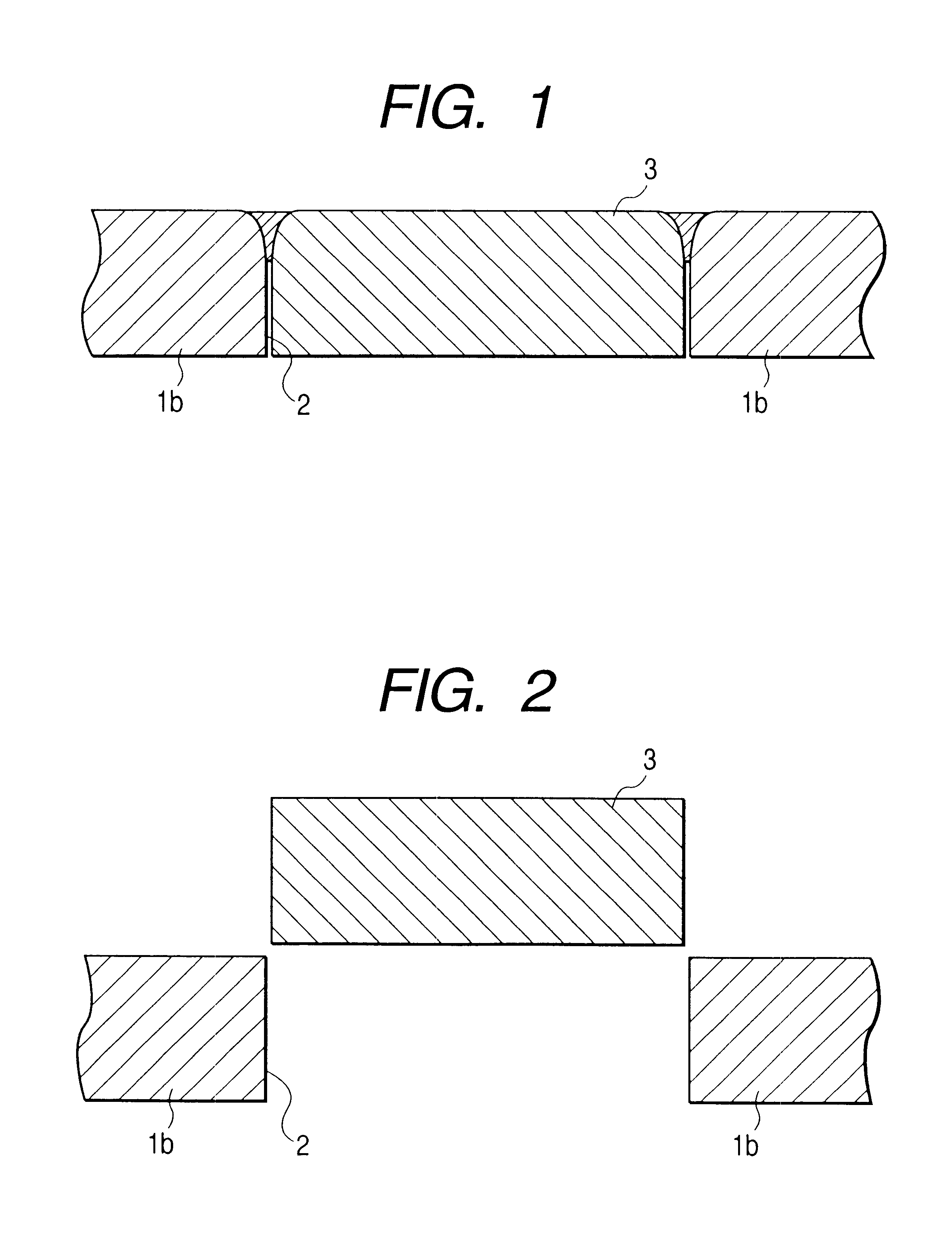

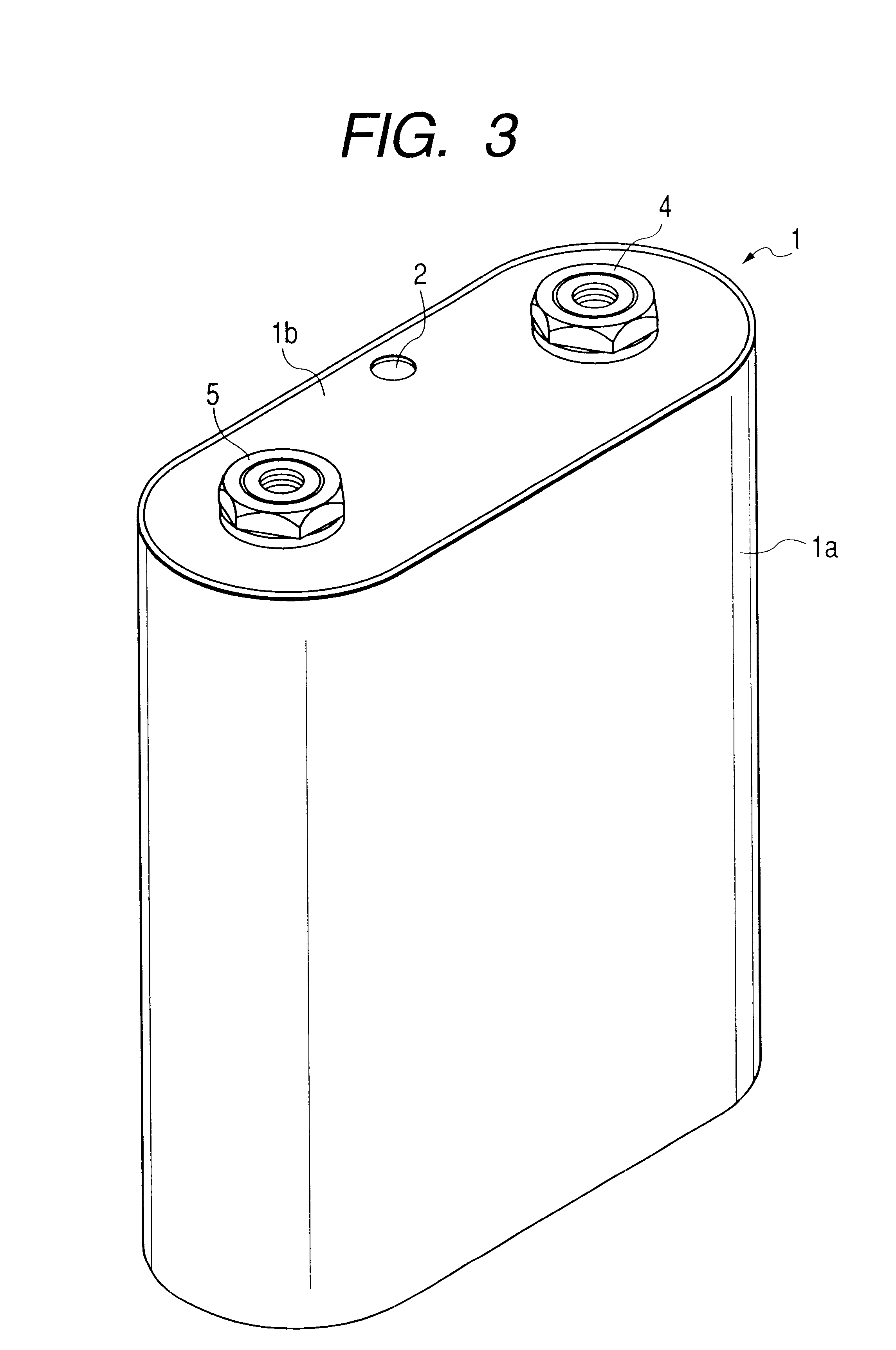

Sealed prismatic battery

InactiveUS20060073382A1Easy to weldImprove workabilityCurrent conducting connectionsWound/folded electrode electrodesLead plateElectrical and Electronics engineering

A lid 3 that closes the upper surface of the opening of a closed-bottom prismatic tubular battery can 1, an electrode body 2 accommodated in the battery can 1, a negative terminal 12 penetratively fastened to the lid 3, an insulating plate 11 placed on the lower surface side of the lid 3, a lead plate 17 placed on the lower surface side of the insulating plate 11, and a negative electrode current collector lead 7 led upwardly of the electrode body 2 are included. The upper end portion of the current collector lead 7 is welded to the lower surface of the lead plate 17 and bent in a position located rather closer to the front wall of the battery can 1. The insulating plate 11 has a lid side insulating portion 22 held between the lid 3 and the lead plate 17 and a front sidewall 25 that extends downwardly from the-front end side of the lid side insulating portion 22. In a free state before the battery is assembled, the lid side insulating portion 22 and the sidewall 25 of the insulating plate 11 extend roughly straightly.

Owner:HITACHI MAXELL ENERGY LTD

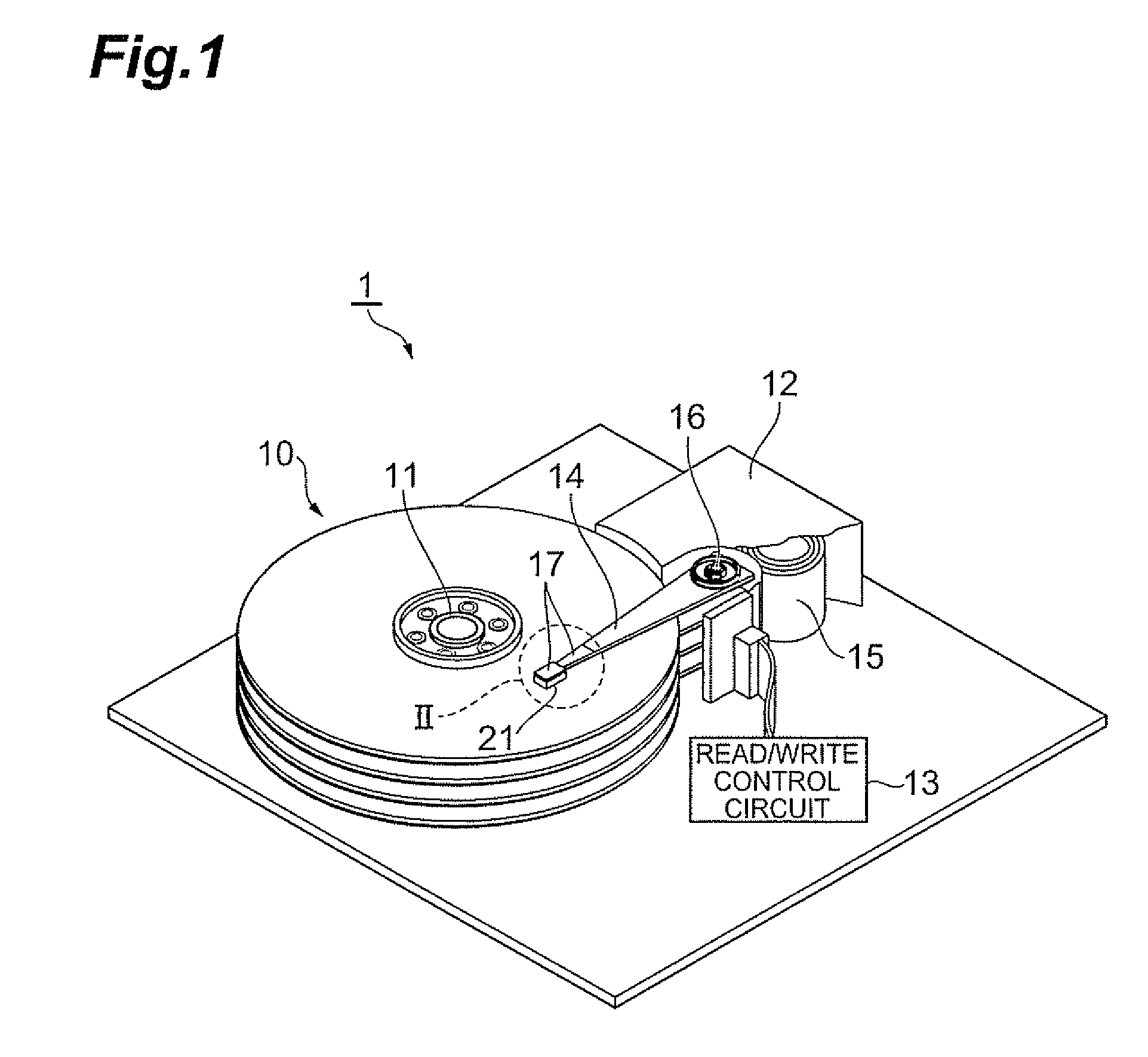

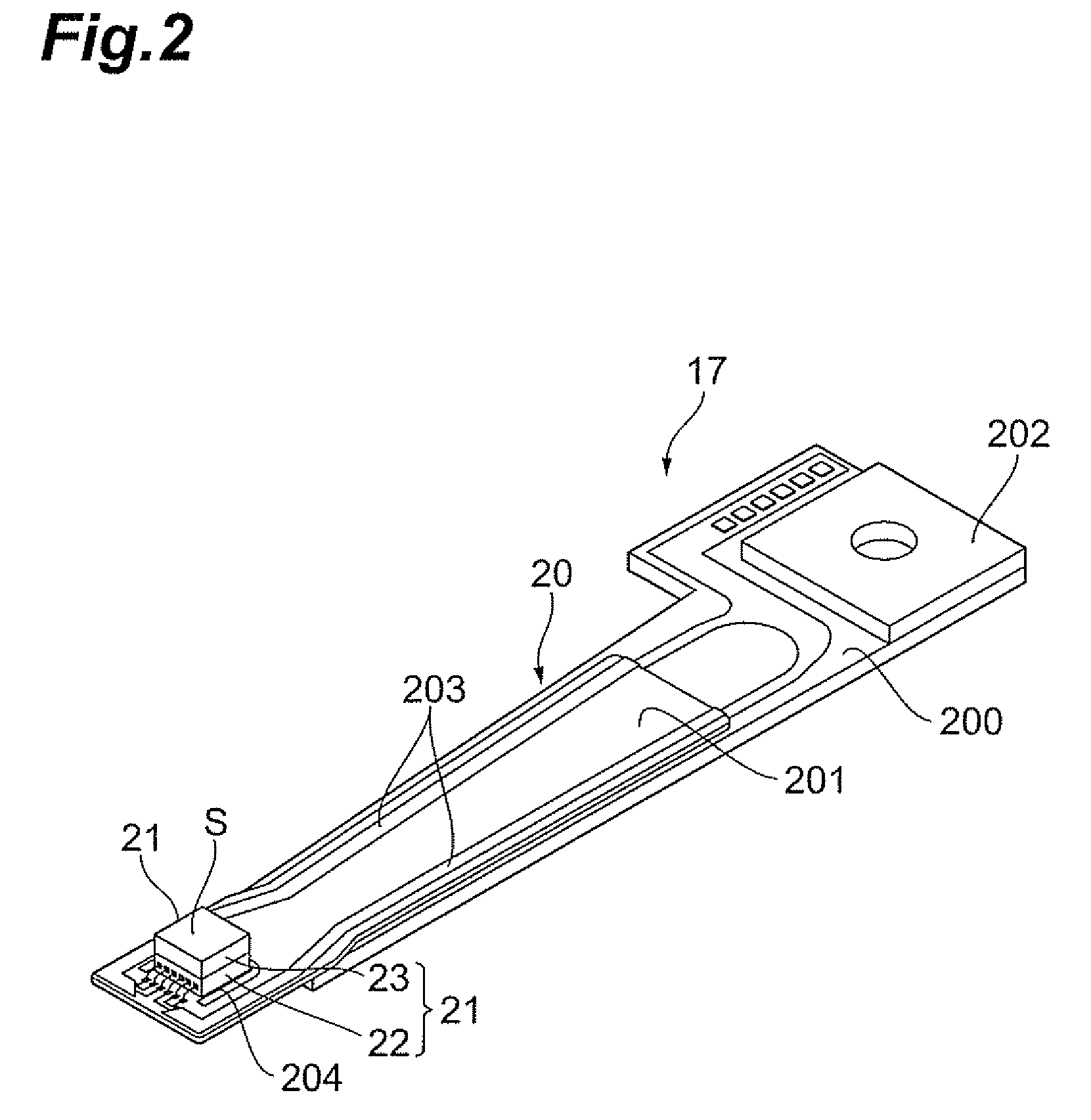

Thermally assisted magnetic head, head gimbal assembly, and hard disk drive

ActiveUS20090052078A1Good yieldReduce failureCombination recordingDisposition/mounting of recording headsHard disc driveMagnetic transducers

A slider has a slider substrate, an electromagnetic transducer, a waveguide for receiving light from a surface on the side opposite from a medium-opposing surface and guiding the light to the medium-opposing surface side, and a device electrode electrically connected to the electromagnetic transducer. A light source unit includes a light source supporting substrate, a light source, and a lead extending from the slider side to the side opposite from the slider and having both end parts exposed at a surface of the light source unit. The device electrode of the slider is exposed at the surface of the slider on the side opposite from the medium-opposing surface without being covered with the light source unit. An end part on the slider side of the lead of the light source unit is soldered to the device electrode of the slider.

Owner:TDK CORPARATION

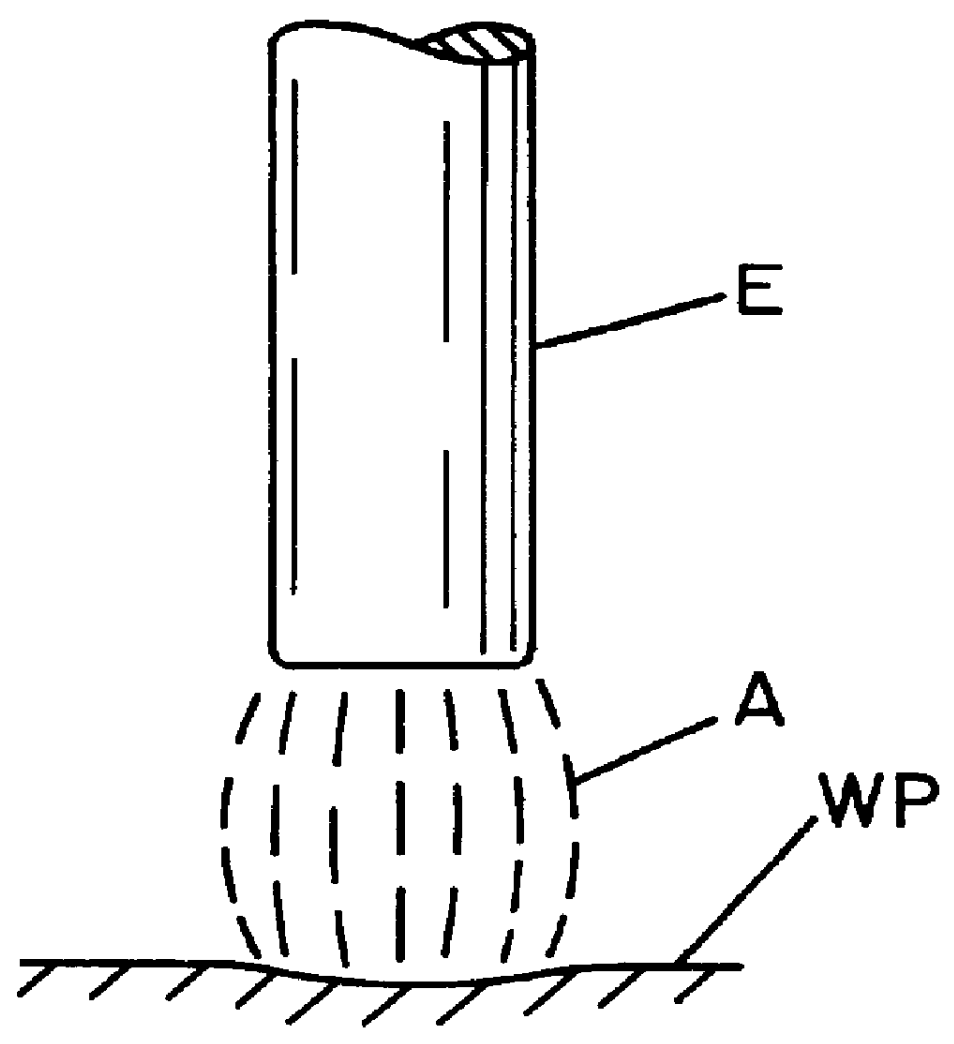

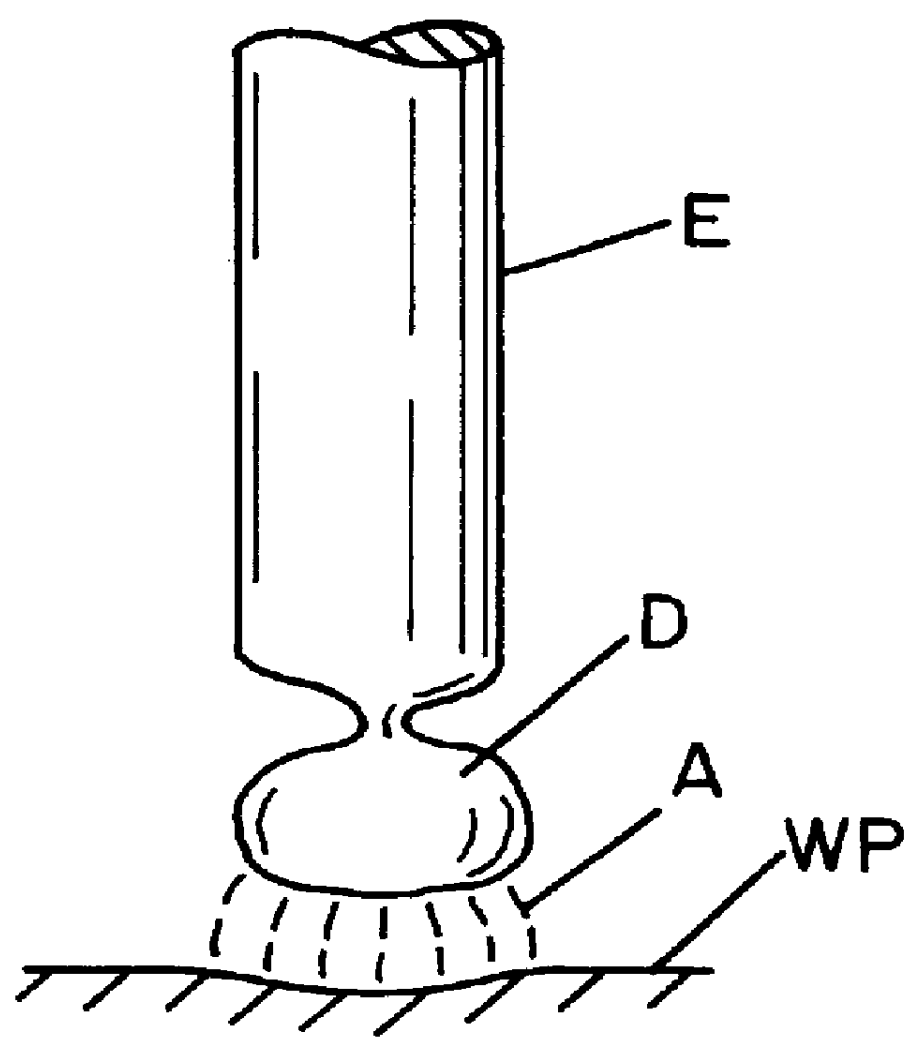

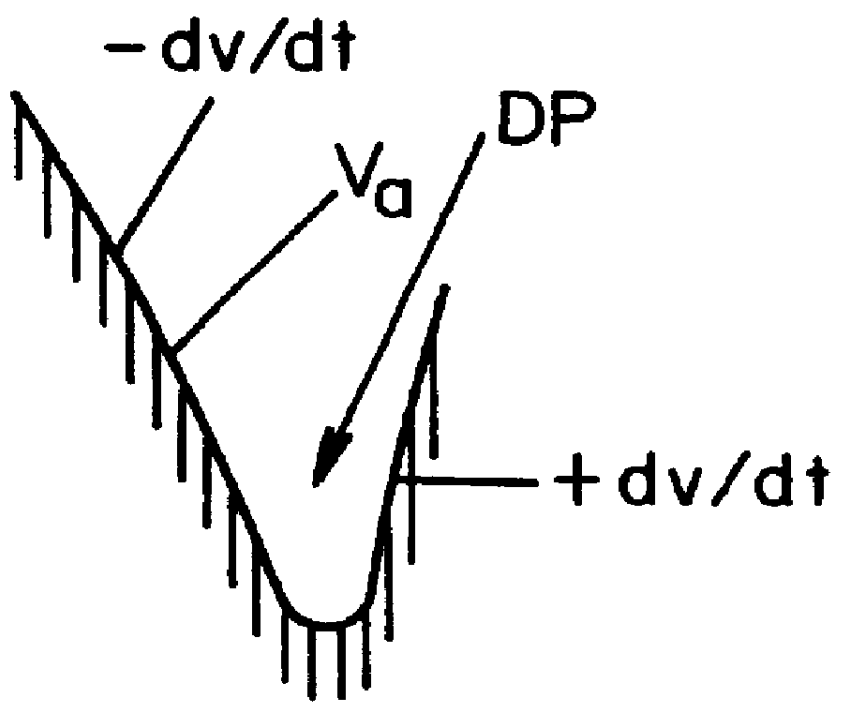

Controller and method for pulse welding

In a power supply for creating a voltage to cause a current pulse between a consumable electrode and a workpiece to melt the end of the electrode into a droplet and propel the droplet toward the workpiece, where the power supply has a plurality of pulse controlling parameters, the improvement comprising: means for determining the real time dv / dt of the voltage during the current pulse; means for creating a detect signal in response to the real time dv / dt shifting from a negative value to a positive value; and means for adjusting at least one of the welding parameters in response to the detect signal.

Owner:LINCOLN GLOBAL INC

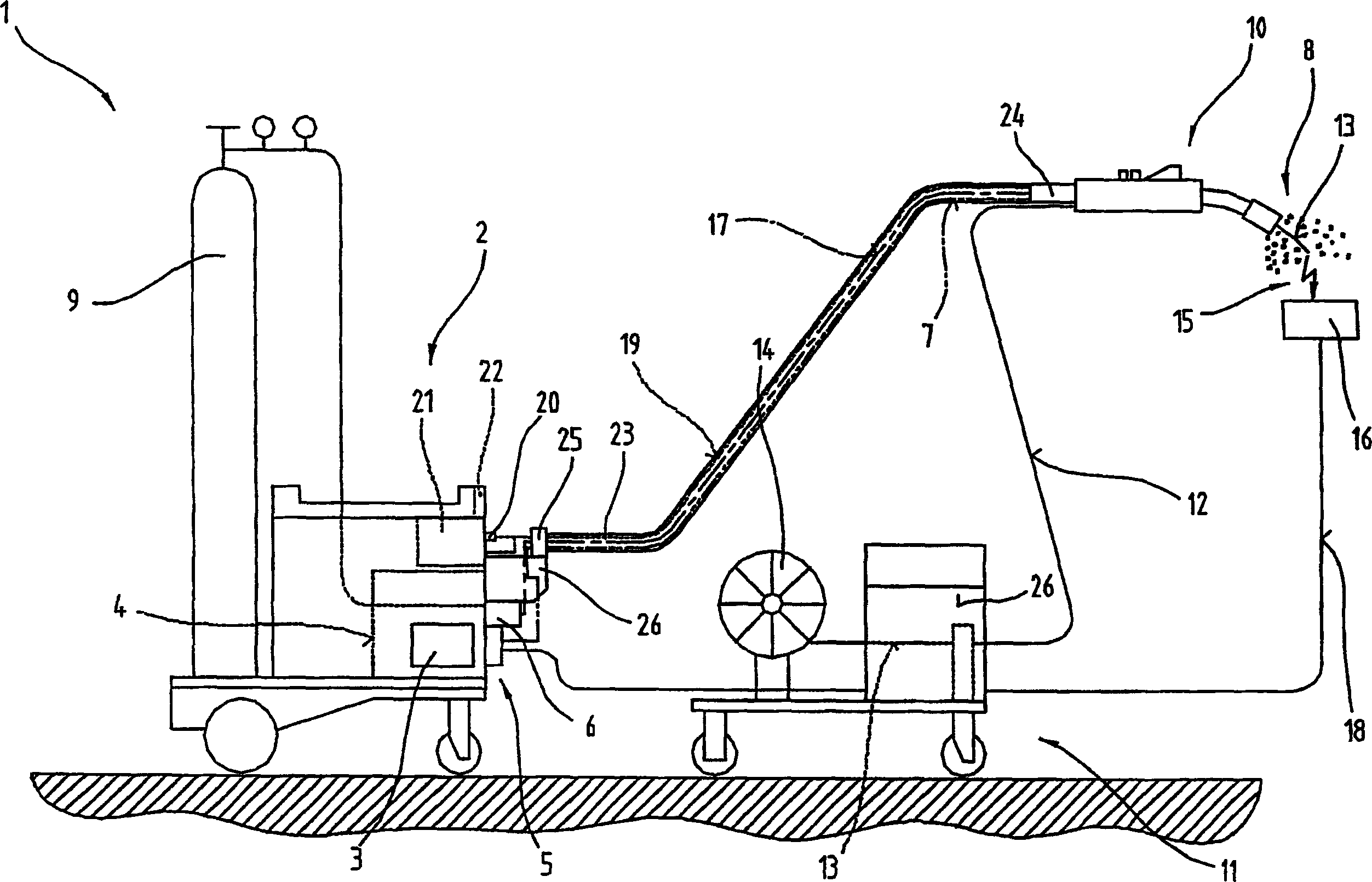

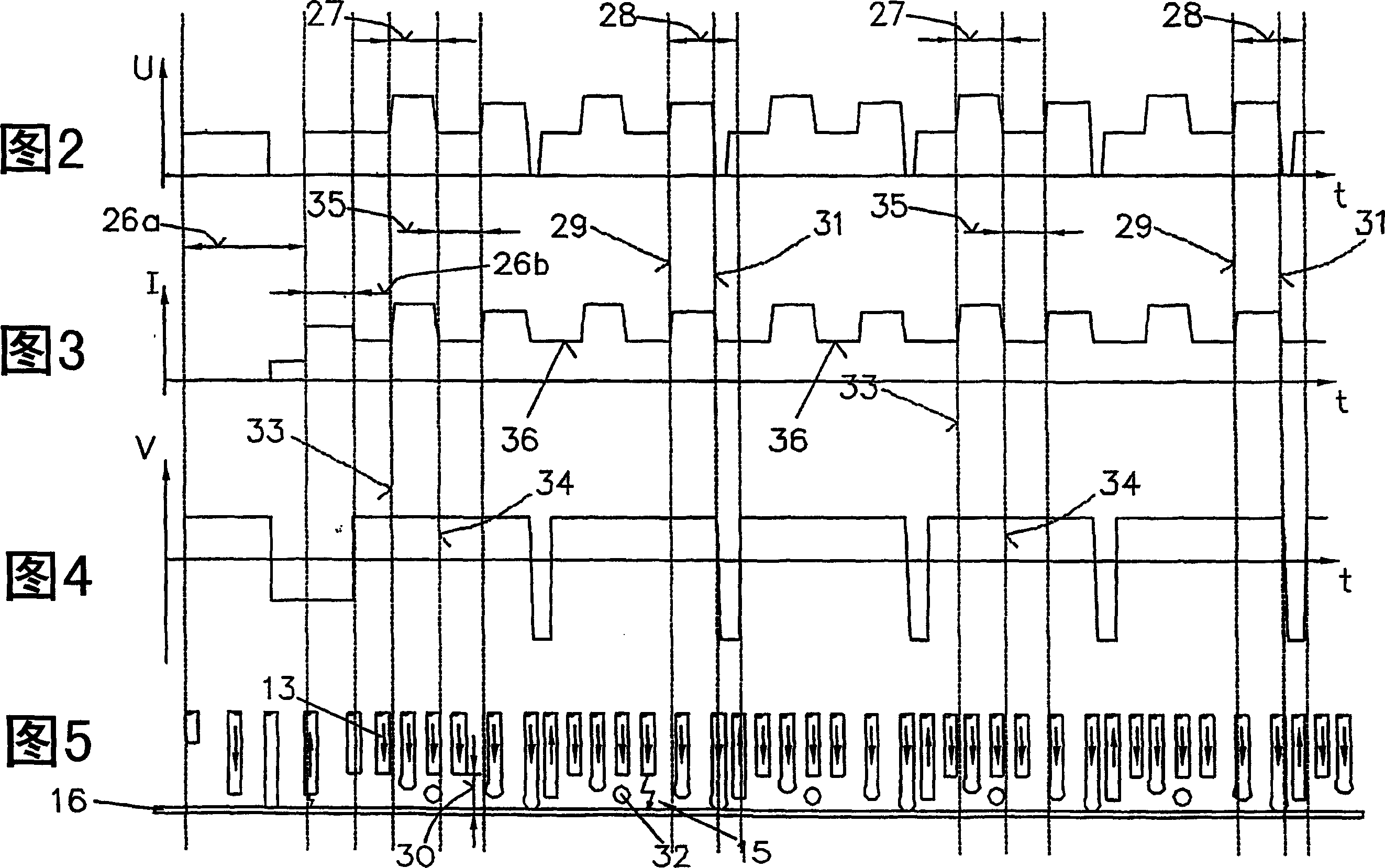

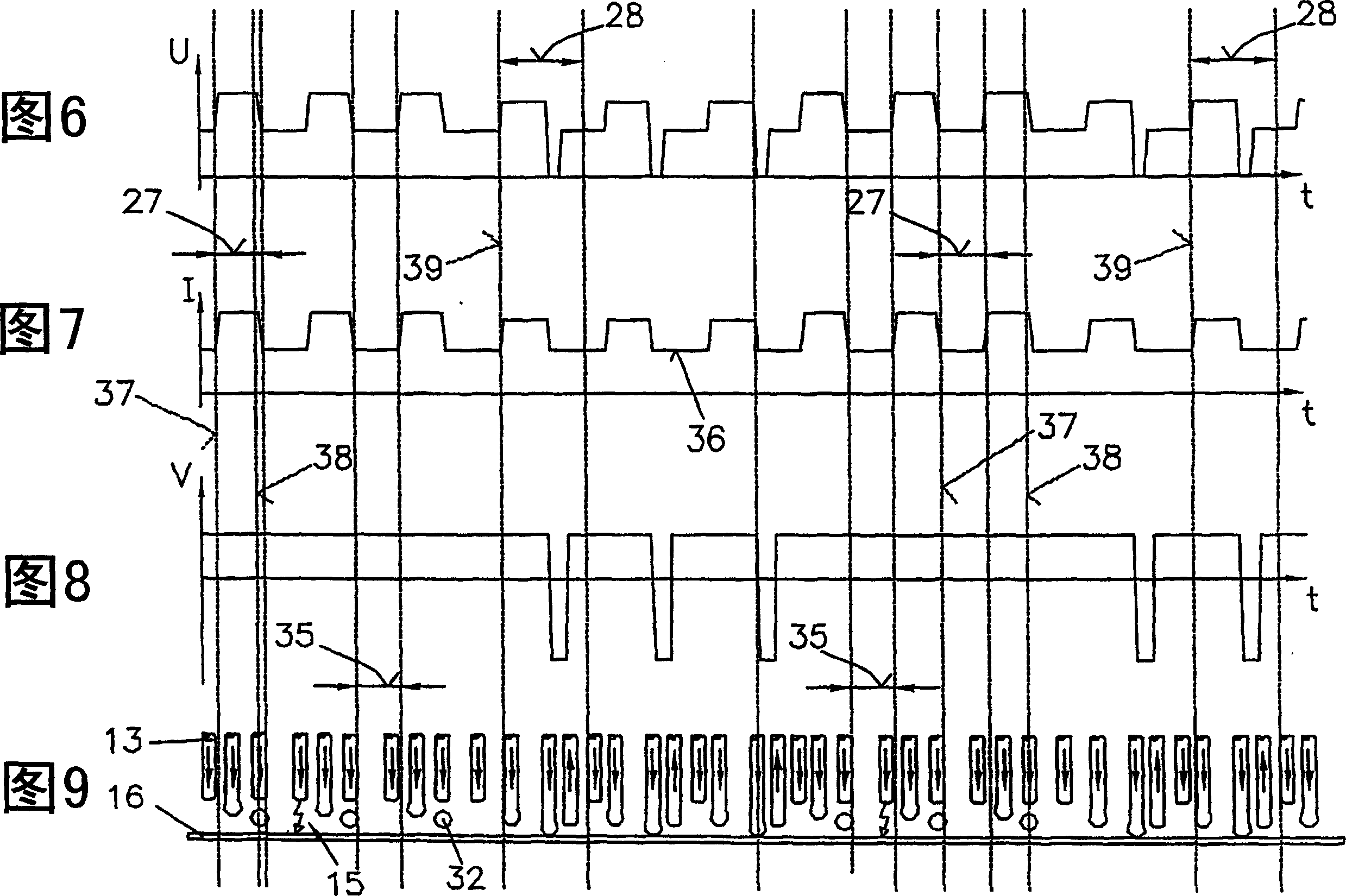

Method for controlling a welding process and welding device for carrying out a welding process

InactiveCN1871093ASimple Heat Balance ControlLow heat inputArc welding apparatusWelding power supplyProcess engineering

The invention relates to a method for controlling and / or adjusting a welding process, using a melting electrode, wherein after ignition of an electric arc, a welding process, which is adjusted on the basis of several different welding parameters, is carried out by means a welding current source (2), said process being controlled or adjusted by a control device (4). The invention also relates to a corresponding welding device used to carry out the process. In order to create said method, wherein the thermal heat economy is adjusted and / or regulated and / or controlled in order to introduce heat into the workpiece (16), at least two different process phases are cyclically combined, said process phases having different inputs of energy via different material transitions and / or arc types, such as a pulse current phase (27) and a cold metal transfer phase (28) in order to influence or control thermal heat economy, particularly the introduction of heat into the workpiece to be processed.

Owner:FRONIUS INTERNATIONAL GMBH

Electrosurgical jaw structure for controlled energy delivery

InactiveUS20050192568A1Prevent any substantial dehydrationEnergy efficiencySurgical instruments for heatingCoatingsElectrical resistance and conductanceConductive materials

A working end of a surgical instrument that carries first and second jaws for delivering energy to tissue. In a preferred embodiment, at least one jaw of the working end defines a tissue-engagement plane that contacts the targeted tissue. The cross-section of the engagement plane reveals that it defines a surface conductive portion that overlies a variably resistive matrix of a temperature-sensitive resistive material or a pressure-sensitive resistive material. An interior of the jaw carries a conductive material or electrode that is coupled to an Rf source and controller. In an exemplary embodiment, the variably resistive matrix can comprise a positive temperature coefficient (PTC) material, such as a ceramic, that is engineered to exhibit a dramatically increasing resistance (i.e., several orders of magnitude) above a specific temperature of the material.

Owner:ETHICON ENDO SURGERY INC

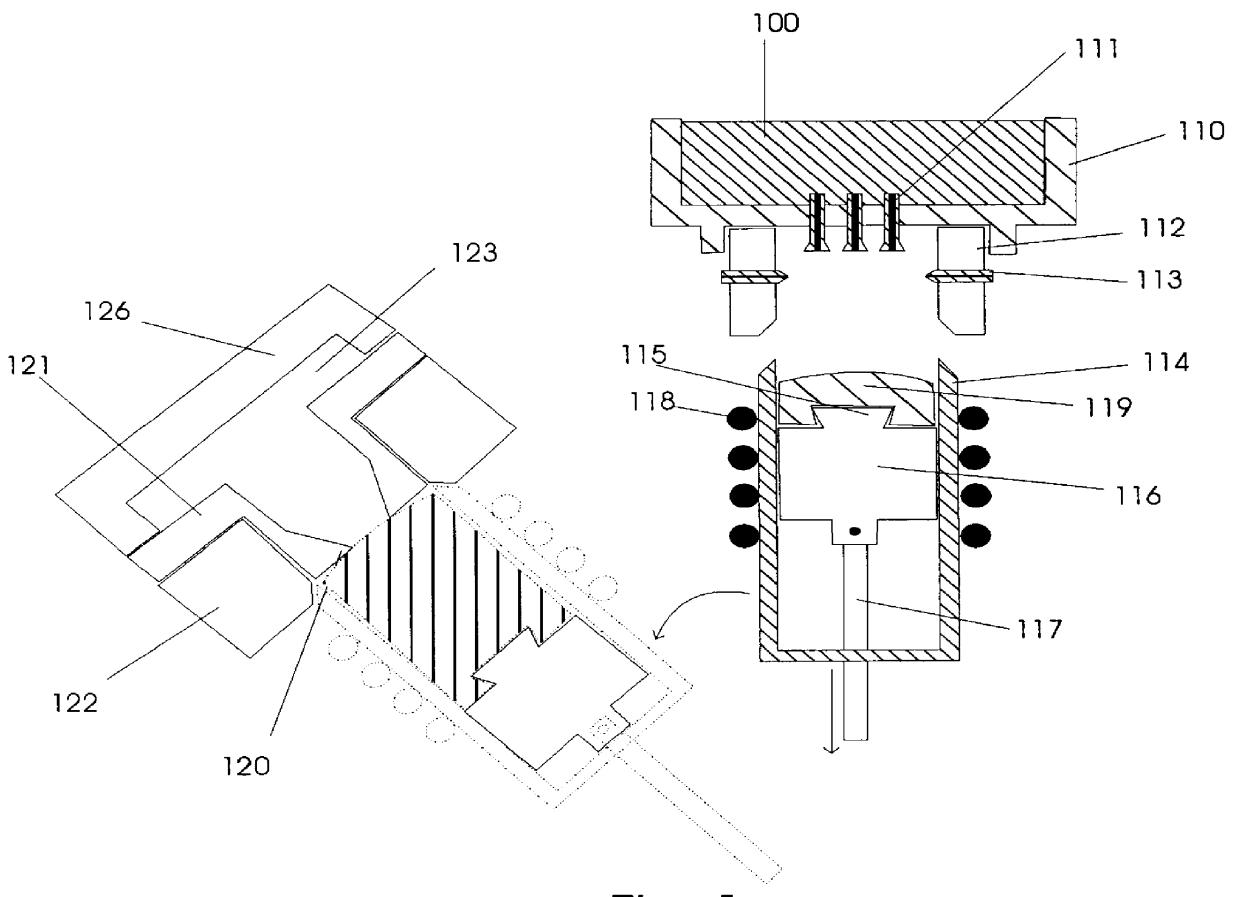

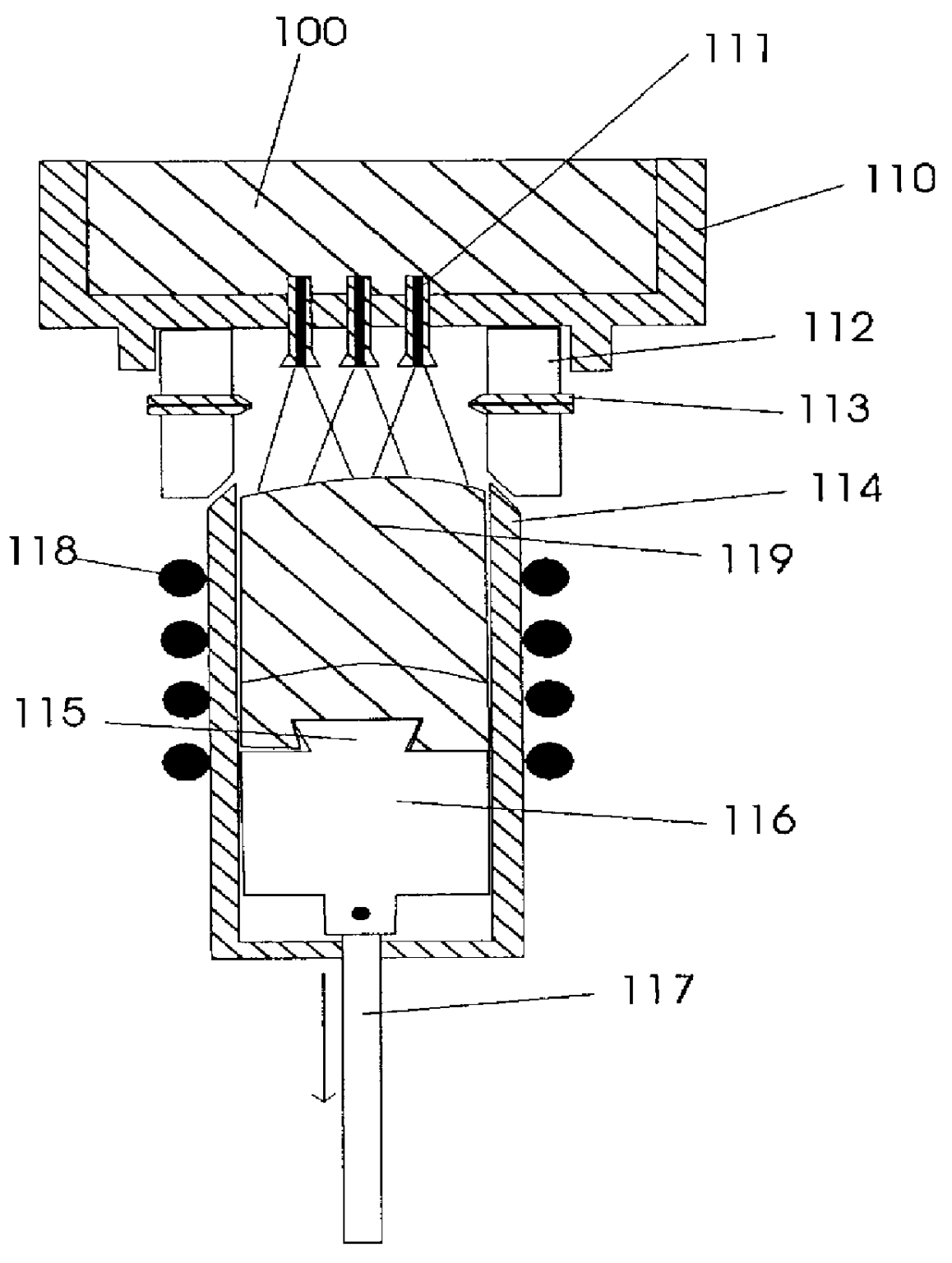

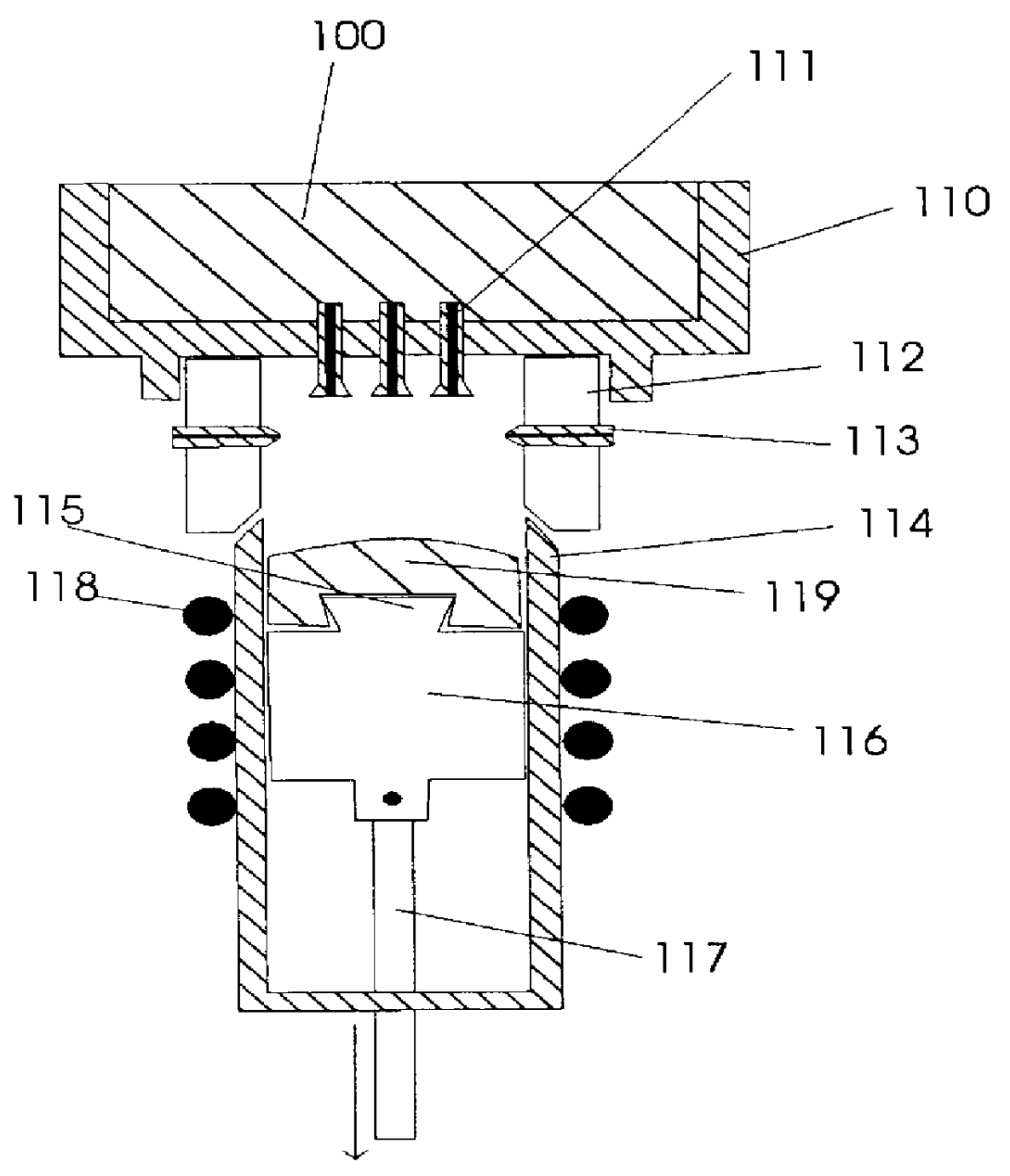

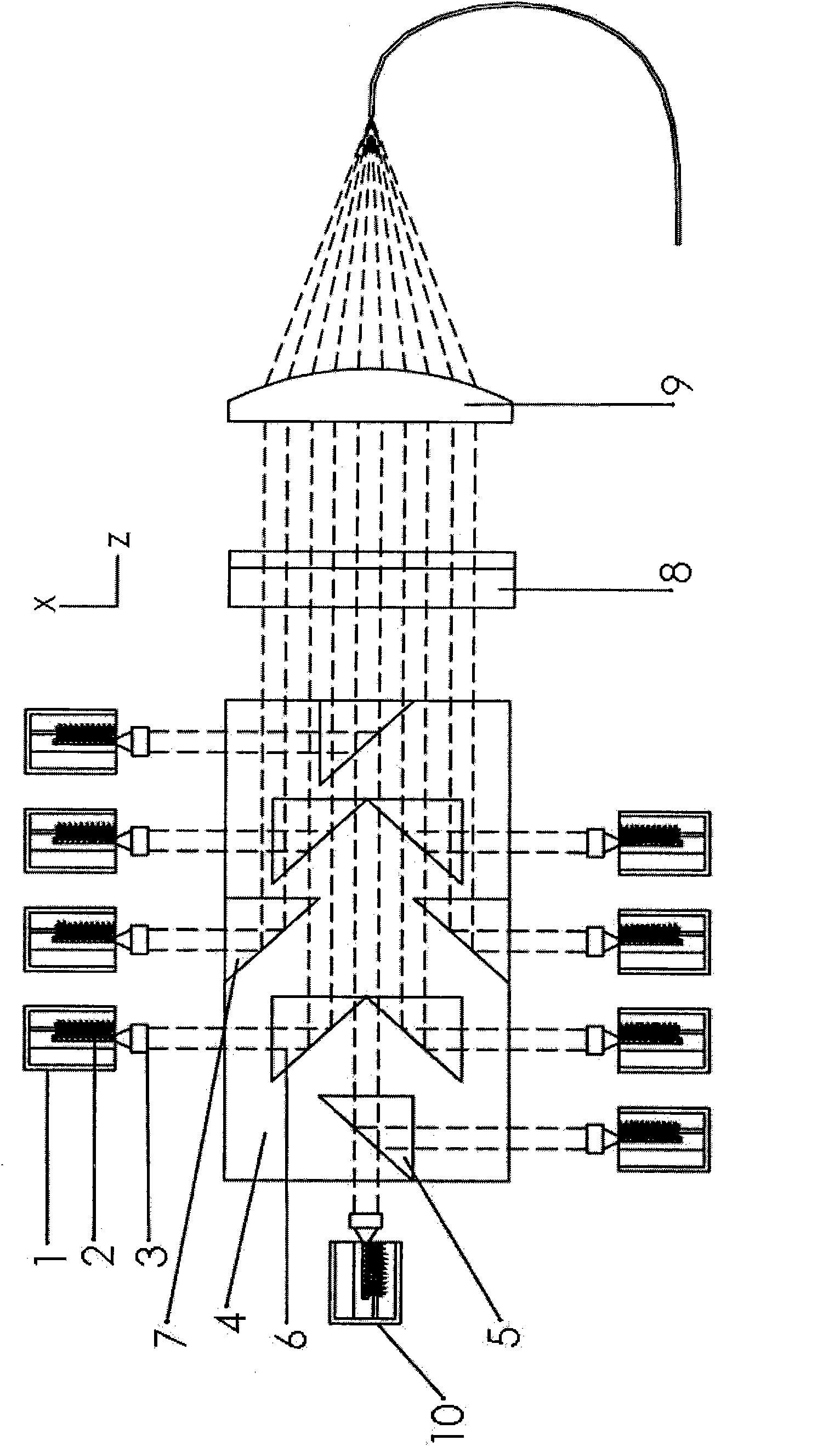

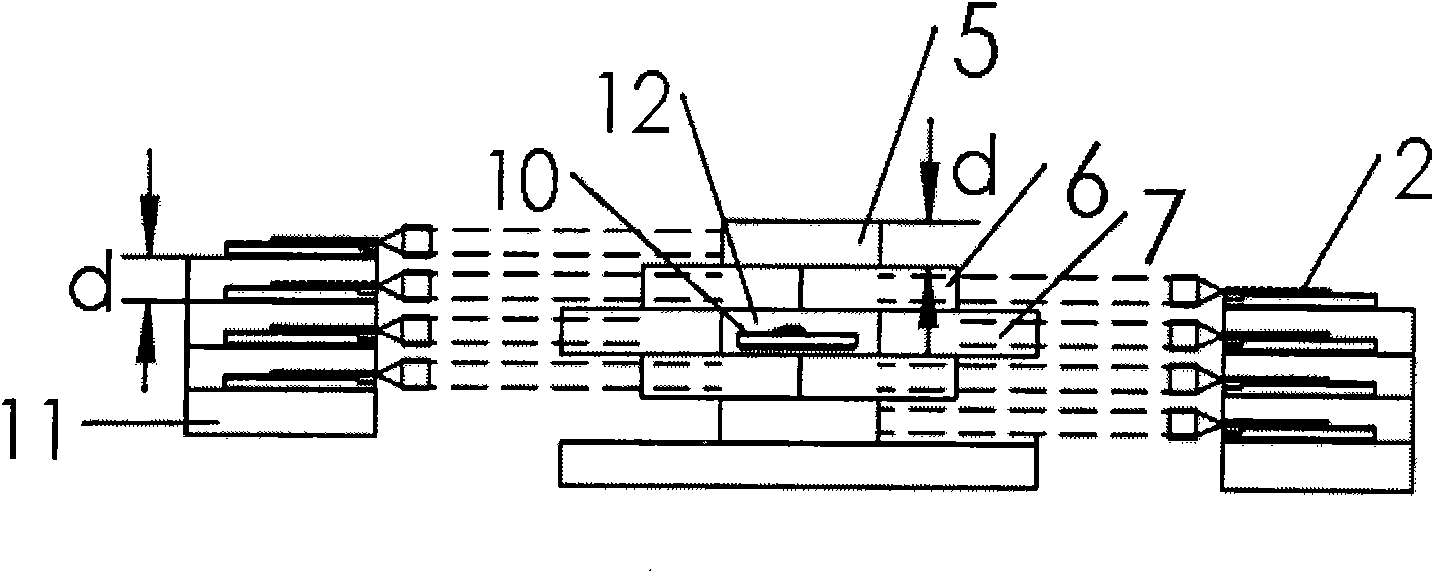

Fiber coupling module of high-power semiconductor laser

InactiveCN101833150ASolve the lack of spaceAdequate cooling spaceCoupling light guidesLight beamPrism

The invention relates to a fiber coupling module of a high-power semiconductor laser, which comprises a plurality of single-tube semiconductor lasers with the same wavelength in the same polarization state, beam collimation lenses, a glass flat plate, reflecting prisms and a focusing device, wherein expect one path of the single-tube semiconductor lasers, the other single-tube semiconductor lasers are all parallel to an axis x and arrayed in a ladder shape; the beam collimation lenses are arranged in front of each single-tube semiconductor laser, and the light emitted by each single-tube laser passes through a beam collimation lens and then passes through a reflecting prism; each reflecting prism keeps consistent with a single-tube laser corresponding to the reflecting prism on the horizontal height; the light emitted by the plurality of single-tube lasers is transmitted to the focusing device through reflecting; and beams emitted by the single-tube lasers arranged in the direction of an axis z is directly transmitted to the focusing device through gaps among the plurality of the reflecting prisms and then combined with other beams to focus together and then enter a fiber. In the invention, the distances of the welding positions of each single-tube laser become longer, and the high-power semiconductor laser fiber coupling module has easy welding, convenient debugging, good heat radiating effect and high coupling efficiency.

Owner:吉林省长光瑞思激光技术有限公司

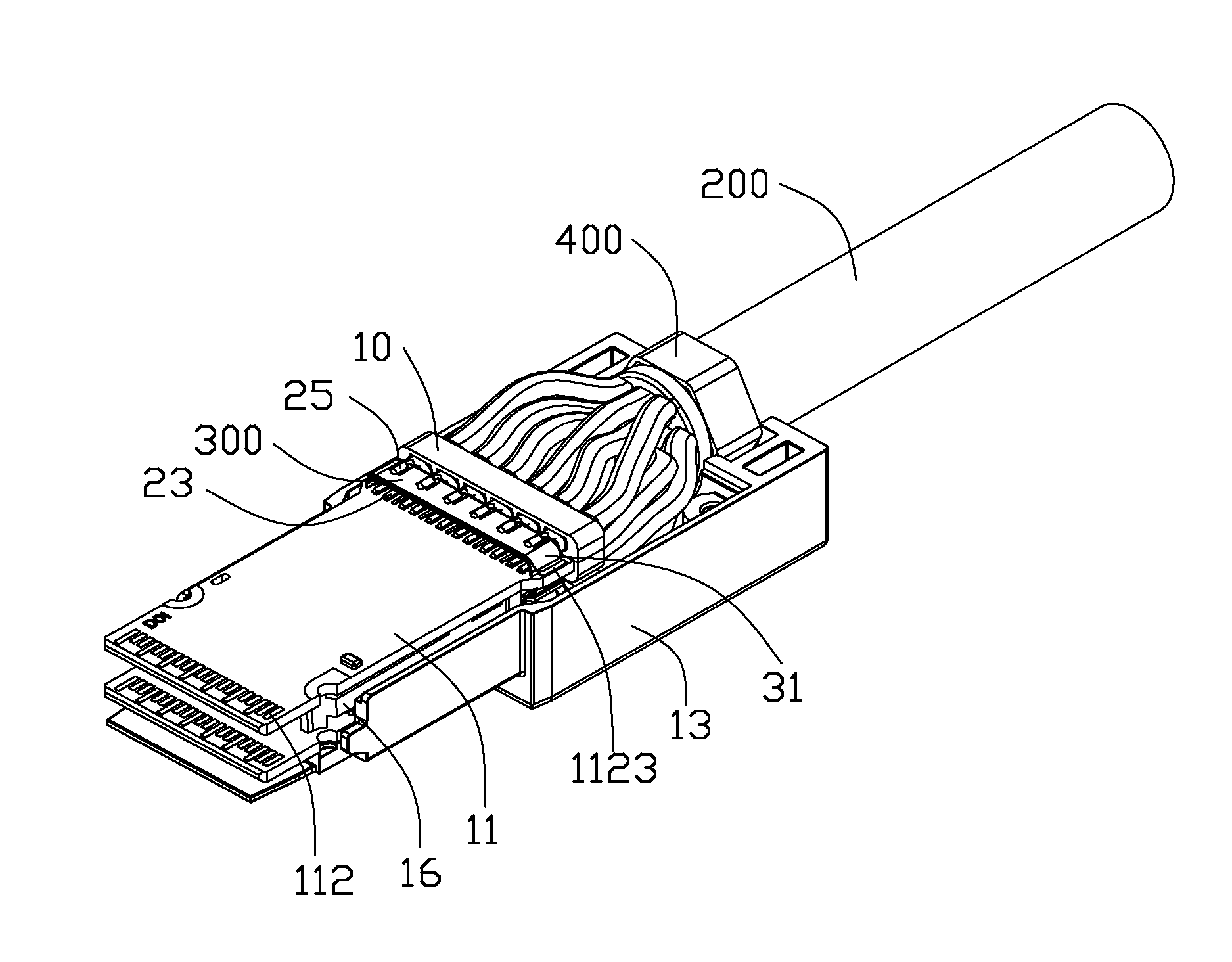

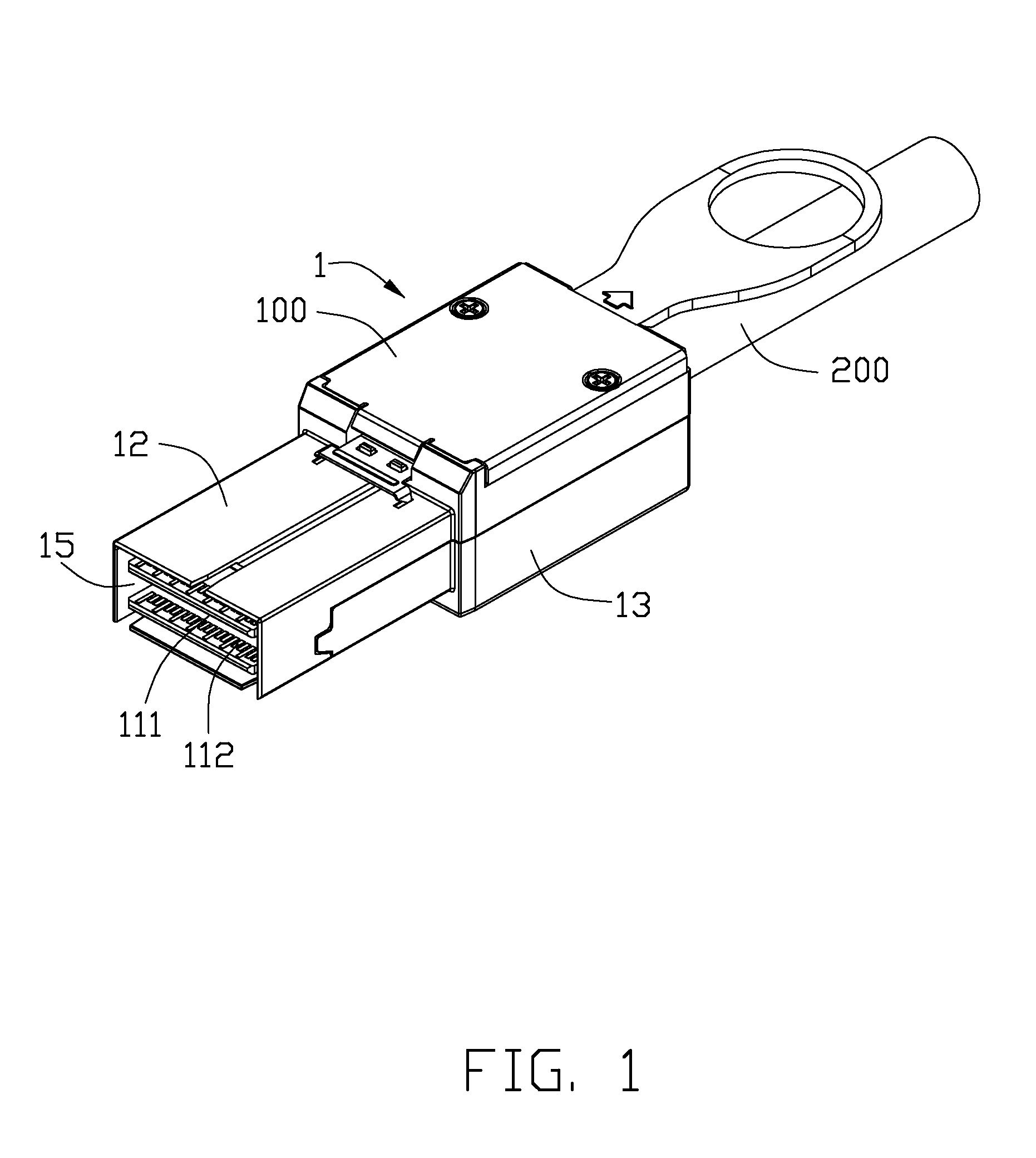

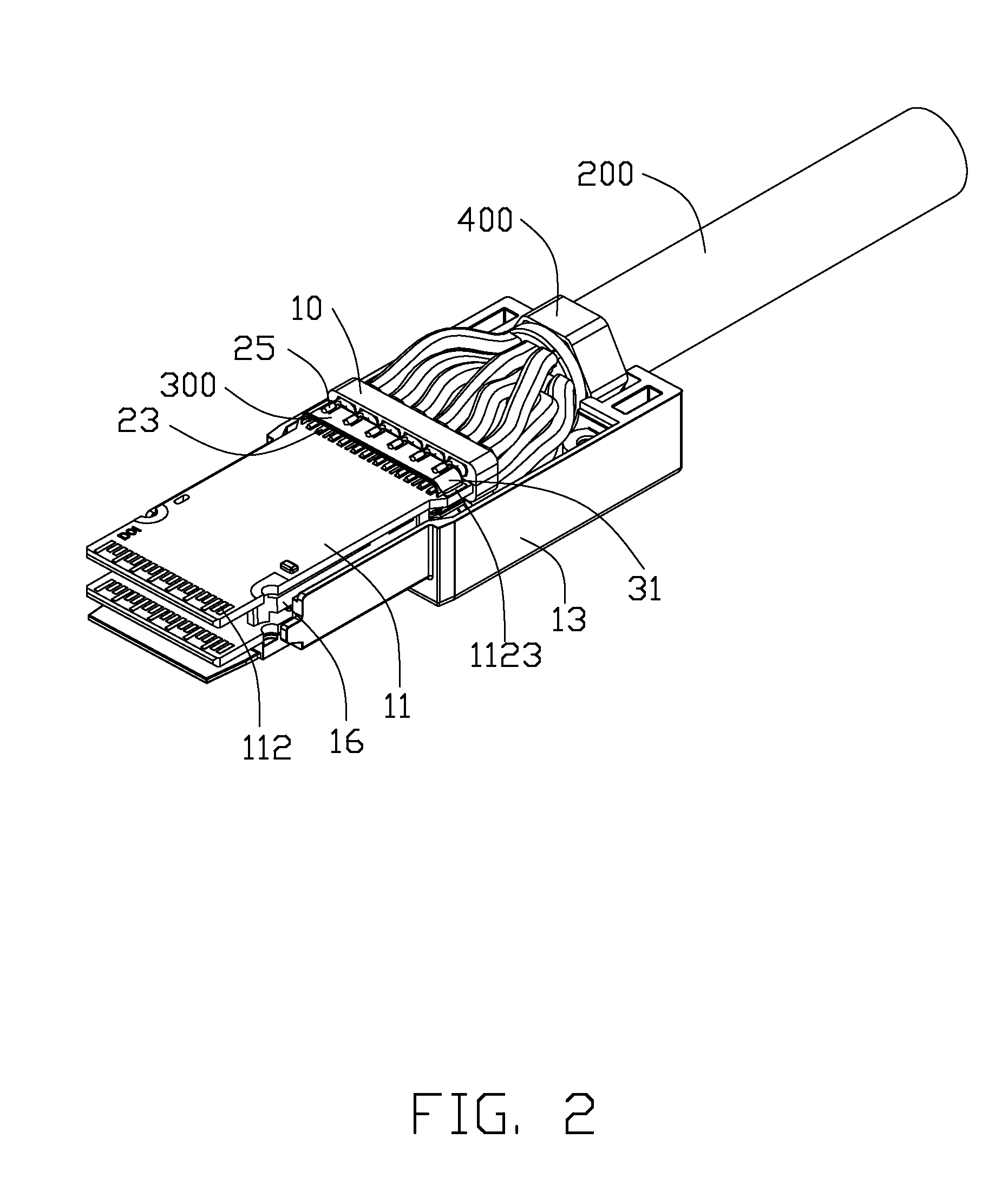

Cable connector assembly having an adapter plate for grounding

InactiveUS20110306244A1Soldering of the second wiresMore roomElectrically conductive connectionsCoupling device detailsElectrical conductor

A cable connector assembly (1) includes a cable (200), a connector (100) including a conductor subassembly (11), and an adapter plate (300). The cable includes a number of wires including a row of first wires (23) and a row of second wires (25). The conductor subassembly (11) has a number of first conductors (1123) and at least one second conductor (1122). The first wires are connected to the first conductors. The adapter plate is disposed between the row of first wires and the row of second wires and includes a conductive layer electrically connecting the second wires to the at least one second conductor.

Owner:HON HAI PRECISION IND CO LTD

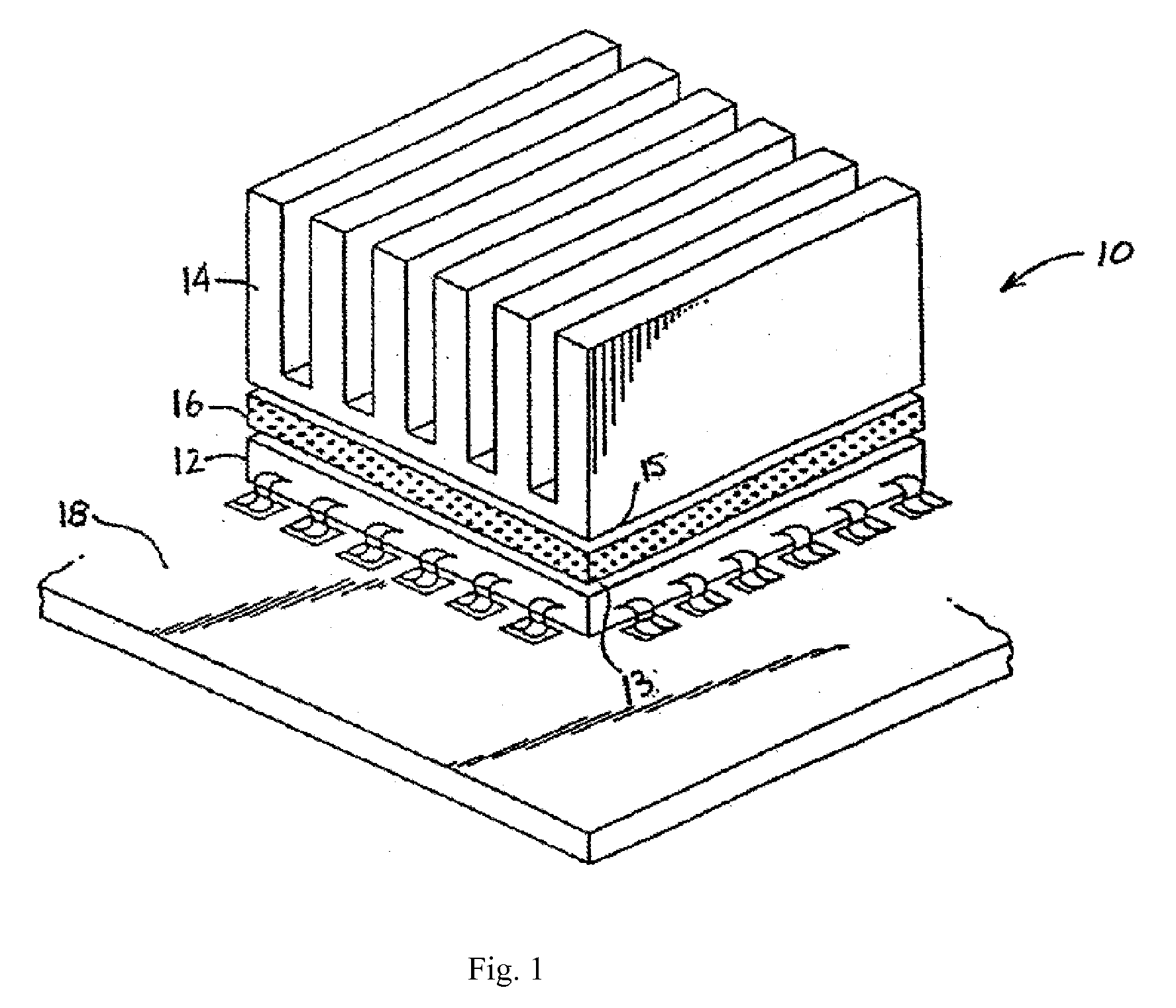

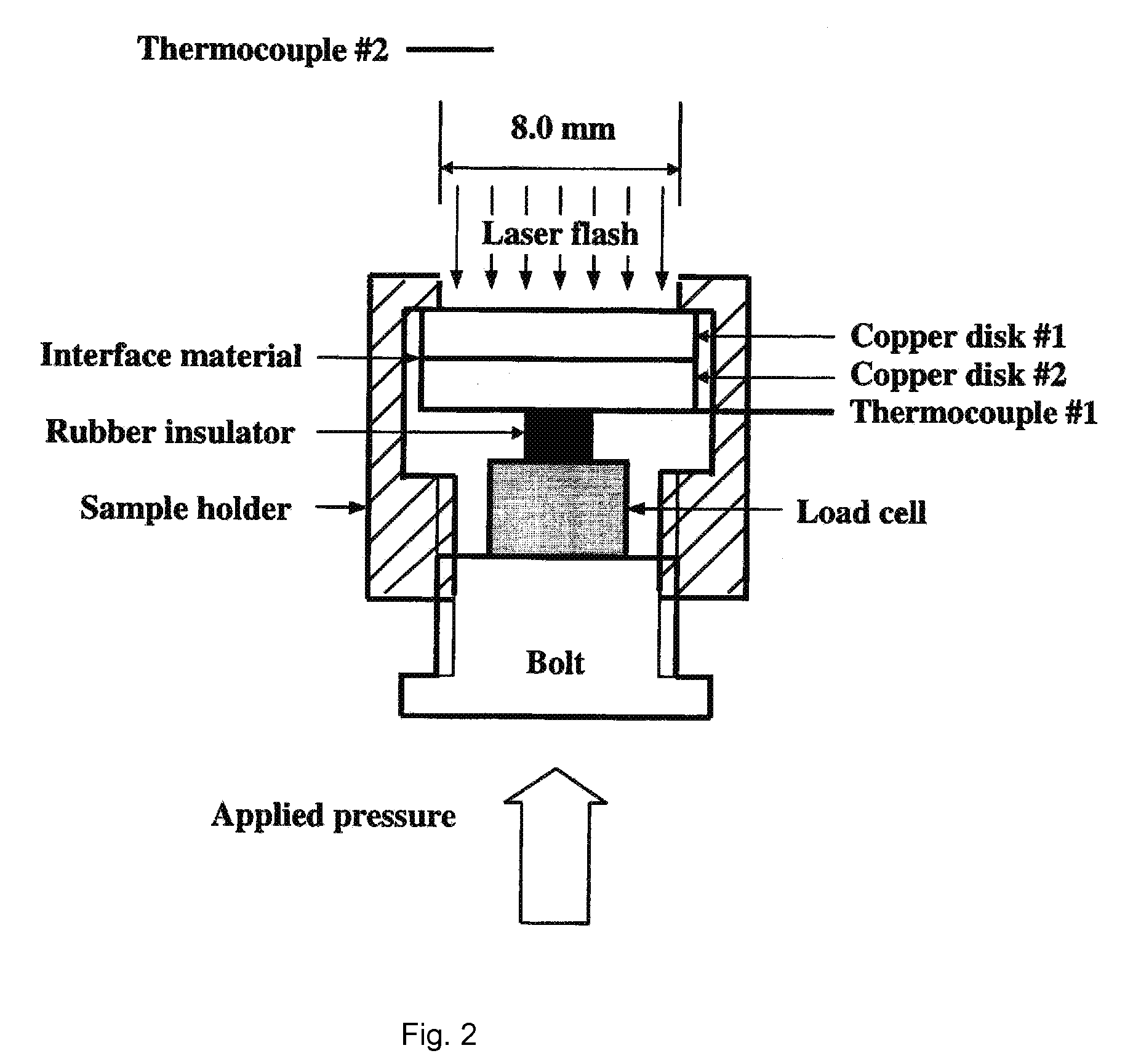

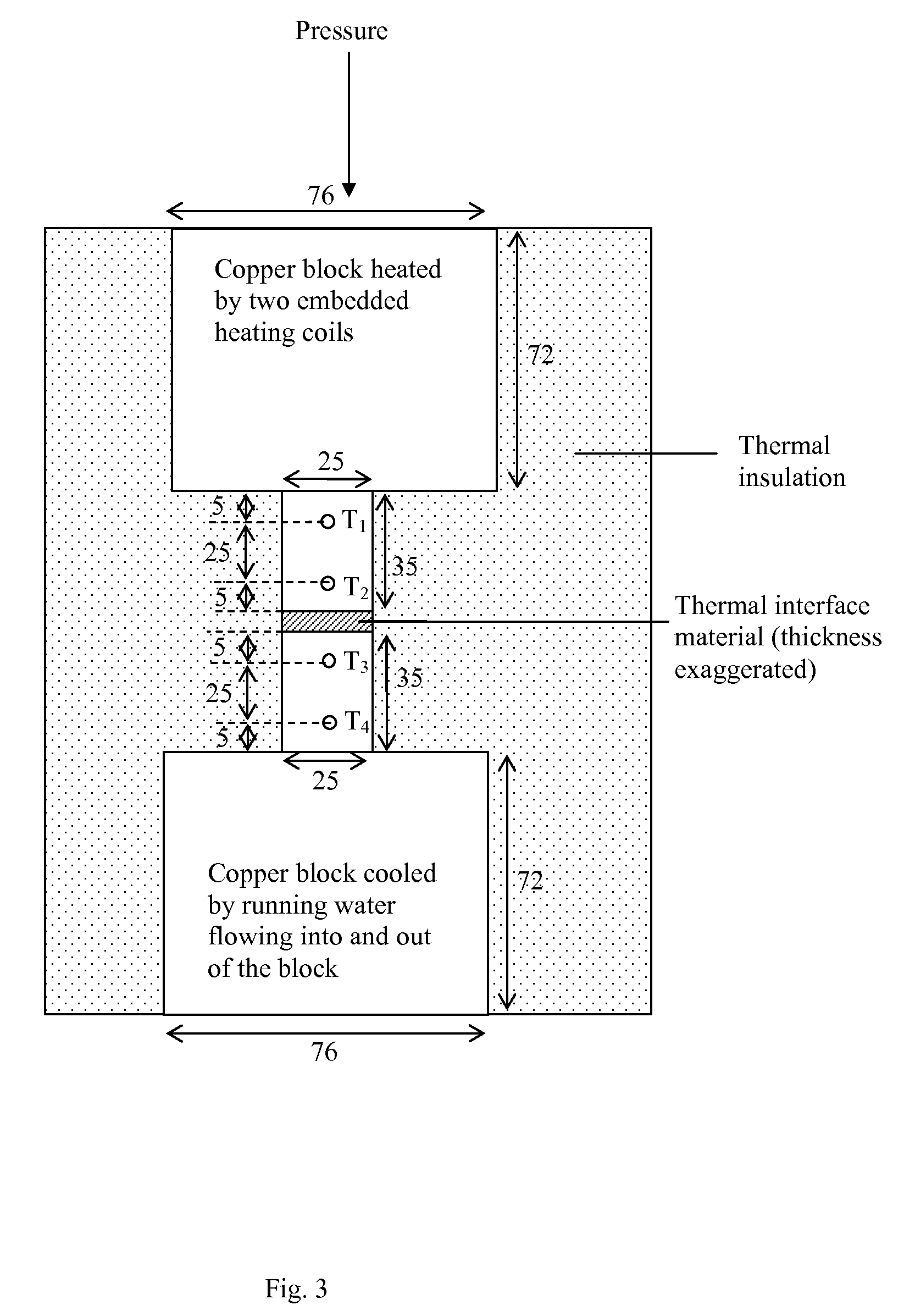

Conformable interface materials for improving thermal contacts

InactiveUS20060246276A1Improve effectivenessImprove thermal conductivitySemiconductor/solid-state device detailsSolid-state devicesConductive pasteThermal contact

A conformable paste comprising porous agglomerates of carbon black dispersed in a paste-forming vehicle is disclosed. The paste is useful as an interface material for improving the thermal contact between two proximate solid surfaces, such as the surfaces of a heat source and a heat sink. Upon compression between the two solid surfaces, the paste forms a material that enhances the thermal contact between said surfaces. This invention also discloses a conformable interface material which, upon compression between two proximate solid surfaces, forms a material that enhances the thermal contact between said surfaces. This interface material comprises (i) a sheet and (ii) a conformable, spreadable and thermally conductive paste on each of the two opposite sides of the sheet, said paste comprising porous agglomerates of carbon black dispersed in a paste-forming vehicle. In addition, a method of providing a thermal contact between two solid surfaces is disclosed. This method comprises disposing between and in contact with said surfaces a material comprising: a conformable, spreadable and thermally conductive paste comprising porous agglomerates of carbon black dispersed in a paste-forming vehicle, and applying a pressure to cause said material to conform to the topography of said surfaces.

Owner:CHUNG DEBORAH D L

Battery having electrolyte injecting plug

InactiveUS6447949B2Easy to weldAirtightness of can not be deterioratedFinal product manufactureCell lids/coversElectrolysisEngineering

An electrolyte injecting metallic plug laser-welded to an outer edge of an electrolyte injecting port on a periphery of a battery case. At least a part of the electrolyte injecting metallic plug is inserted into the electrolyte injecting port.

Owner:GS YUASA INT LTD

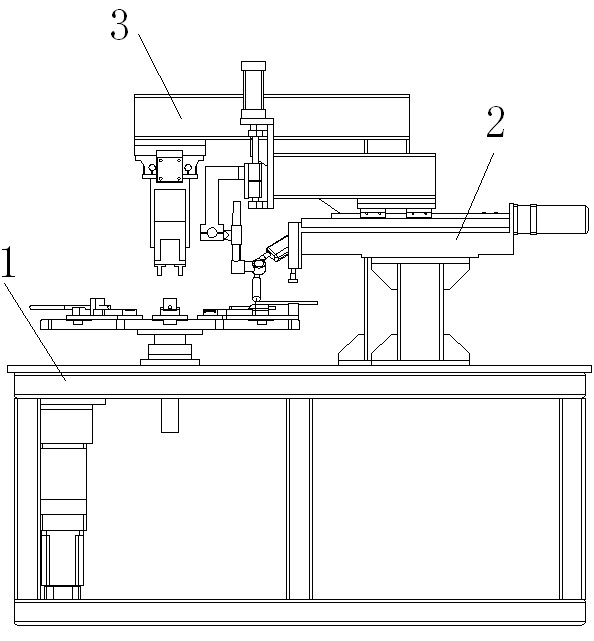

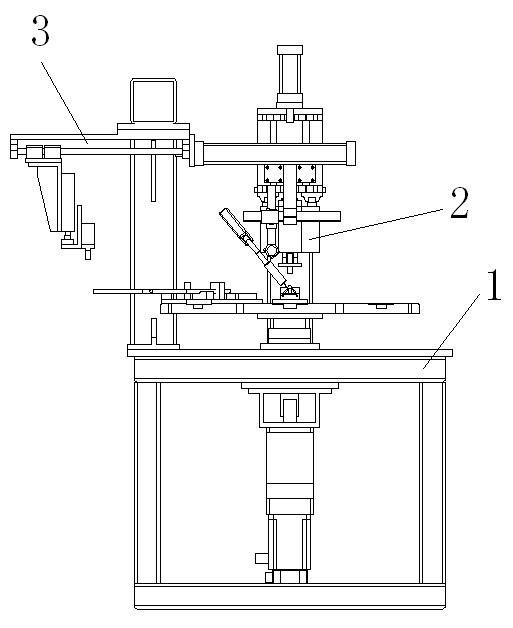

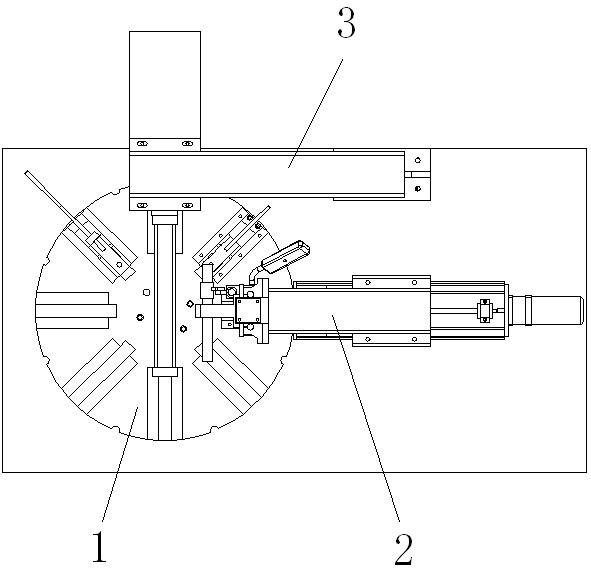

Welding machine

ActiveCN101934447AEasy to moveRealize all-round weldingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringReducer

The invention relates to a welding machine, belonging to welding equipment. At present, no welding machine with simple structure, convenient use and high working efficiency exists. The welding machine is characterized by comprising a rotary table device, a welding gun device and a mechanical arm device, wherein the rotary table device comprises a workbench, a rotary table servo motor, a servo speed reducer, a limiting air cylinder, a rotary table and a plurality of fixtures; the welding gun device comprises a welding gun, a welding gun pushing air cylinder, a translation frame, a slider block, a guide rail, a welding gun servo motor, a screw rod and a main support, the welding gun servo motor is fixed on the main support, the screw rod is installed on the welding gun servo motor, the guide rail is fixed on the main support, the slider block is installed on the guide rail, the translation frame is fixed on the slider block and is matched with the screw rod, the welding gun pushing air cylinder is installed on the translation frame, and the welding gun is installed on the welding gun pushing air cylinder; and the main support and a mechanical arm device are both installed on the workbench. The welding machine has reasonable structural design, convenient use and high welding efficiency, and welded products have high quality.

Owner:QIFENG PRECISION IND SCI TECH

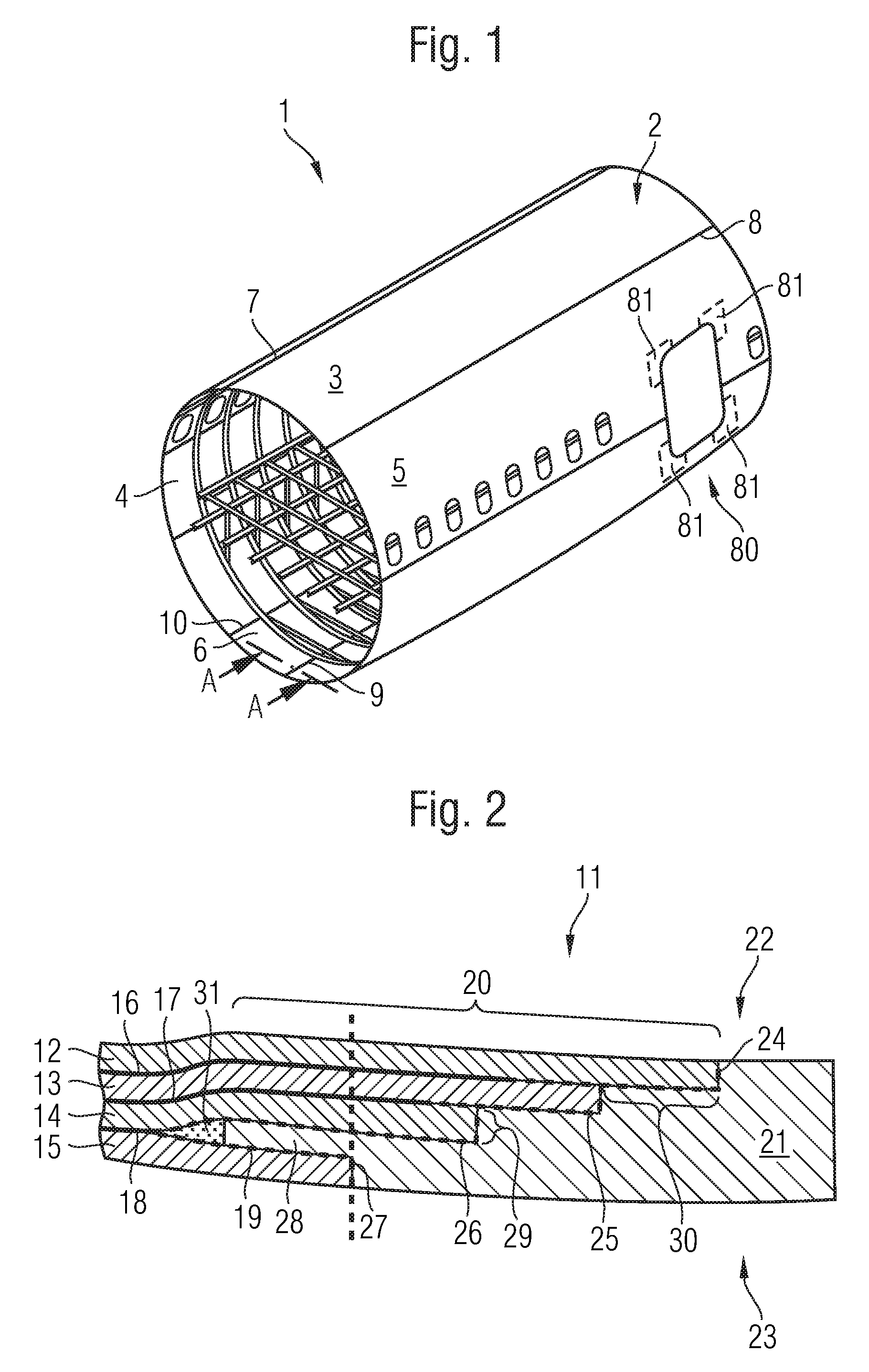

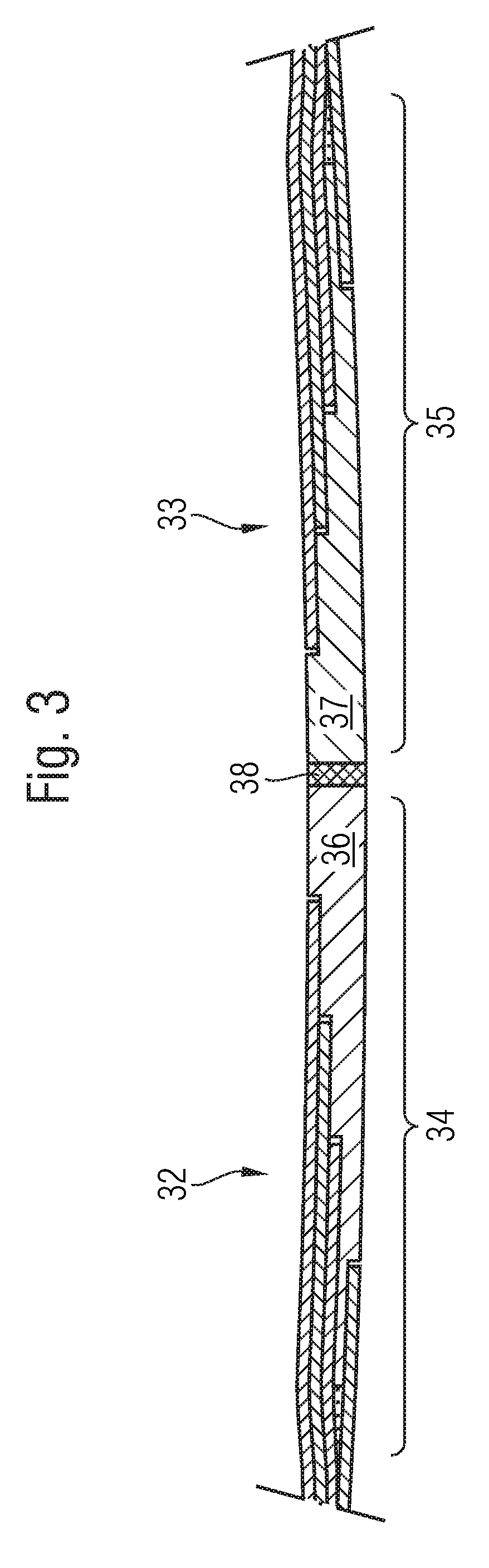

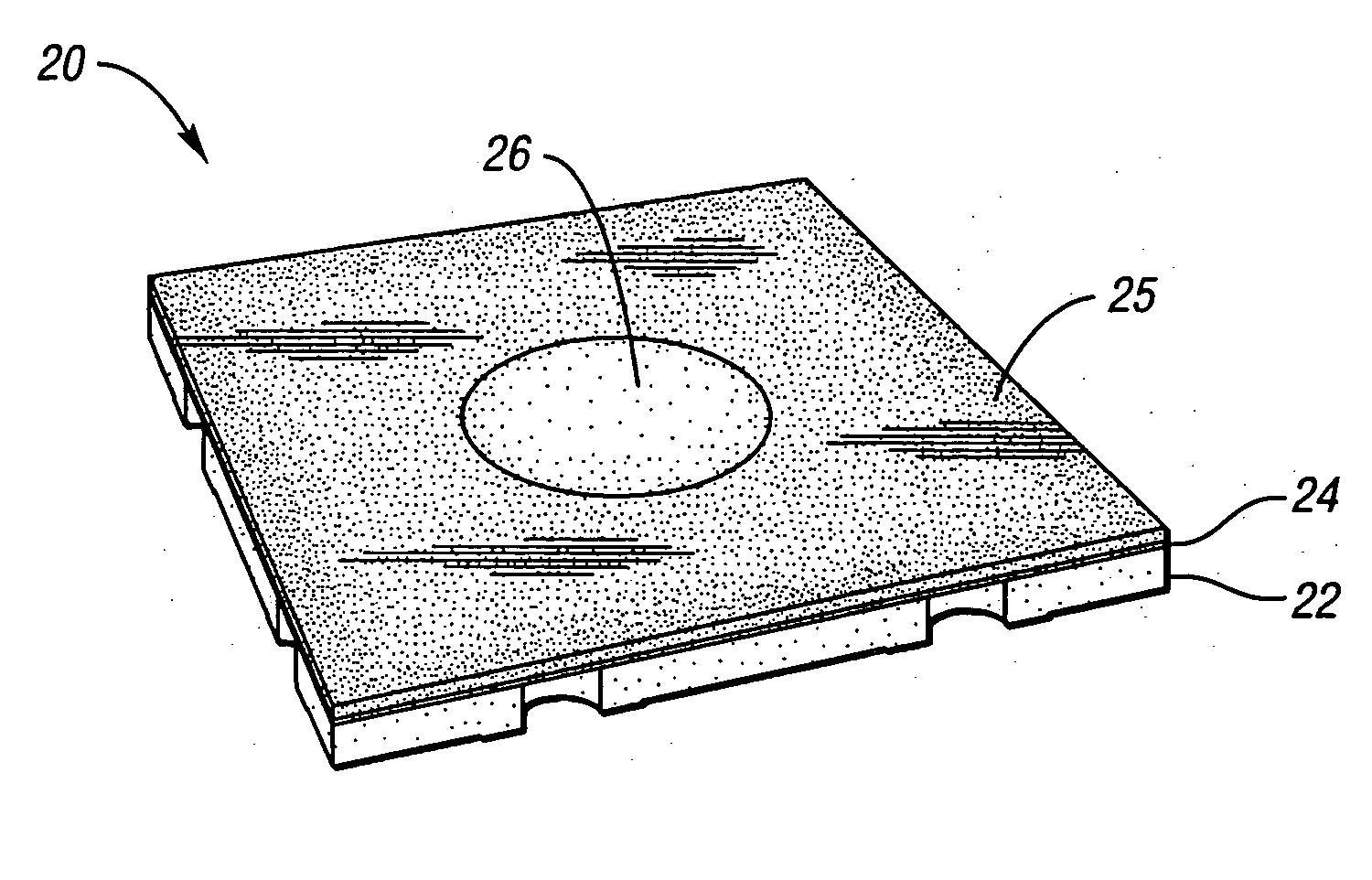

Laminate sheet, in particular for fuselage skin sheets for aircrafts

InactiveUS20080292849A1Improve welding qualityAvoid placingFuselage framesCellulosic plastic layered productsGlass fiberMetallurgy

A laminate sheet, in particular for use as a fuselage skin includes thin aluminium alloy sheets layered on top of one another with each two aluminium alloy sheets being adhesively bonded to one another at least in regions by an adhesive layer which includes at least one unidirectional fibreglass insert impregnated with a curable synthetic resin.

Owner:AIRBUS OPERATIONS GMBH

Force sensing pointing device with click function

ActiveUS20050259069A1Low costReduce complexityPrinted circuit assemblingEmergency actuatorsElectronic systemsEngineering

An input device for an electronic system includes a force sensor having conductive interdigitated traces on a bottom substrate and a flexible substrate spaced apart from the bottom substrate. The flexible substrate has a resistive layer deposited on a bottom side facing the interdigitated traces. A snap dome is positioned over a portion of the force sensor flexible substrate. A flexible keymat membrane is positioned over the force sensor and the snap dome. The keymat membrane bottom surface faces the force sensor flexible substrate. The keymat membrane bottom surface has a protruding region surrounding the snap dome and spaced above the force sensor flexible substrate. A center keycap on the keymat membrane top surface is positioned over the snap dome. A surrounding keycap on the keymat membrane encloses the center keycap and is positioned over the keymat membrane protruding region.

Owner:INTERLINK ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com