Fiber coupling module of high-power semiconductor laser

A fiber coupling and semiconductor technology, which is applied in the field of high-power semiconductor laser fiber coupling modules, can solve the problems affecting the heat dissipation of single-tube lasers, difficult to guarantee welding process, and shortened life, and achieve the effects of extended life, convenient debugging, and easy welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

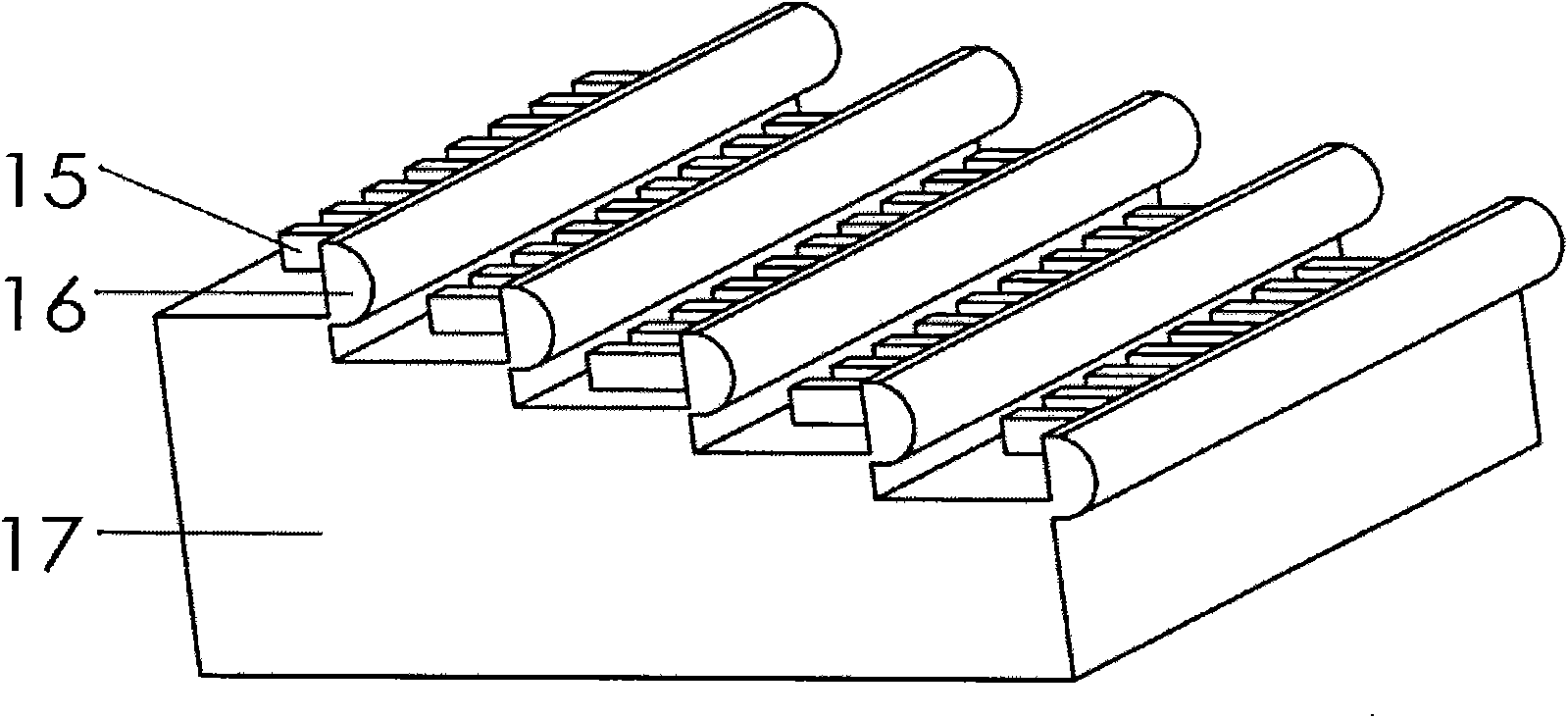

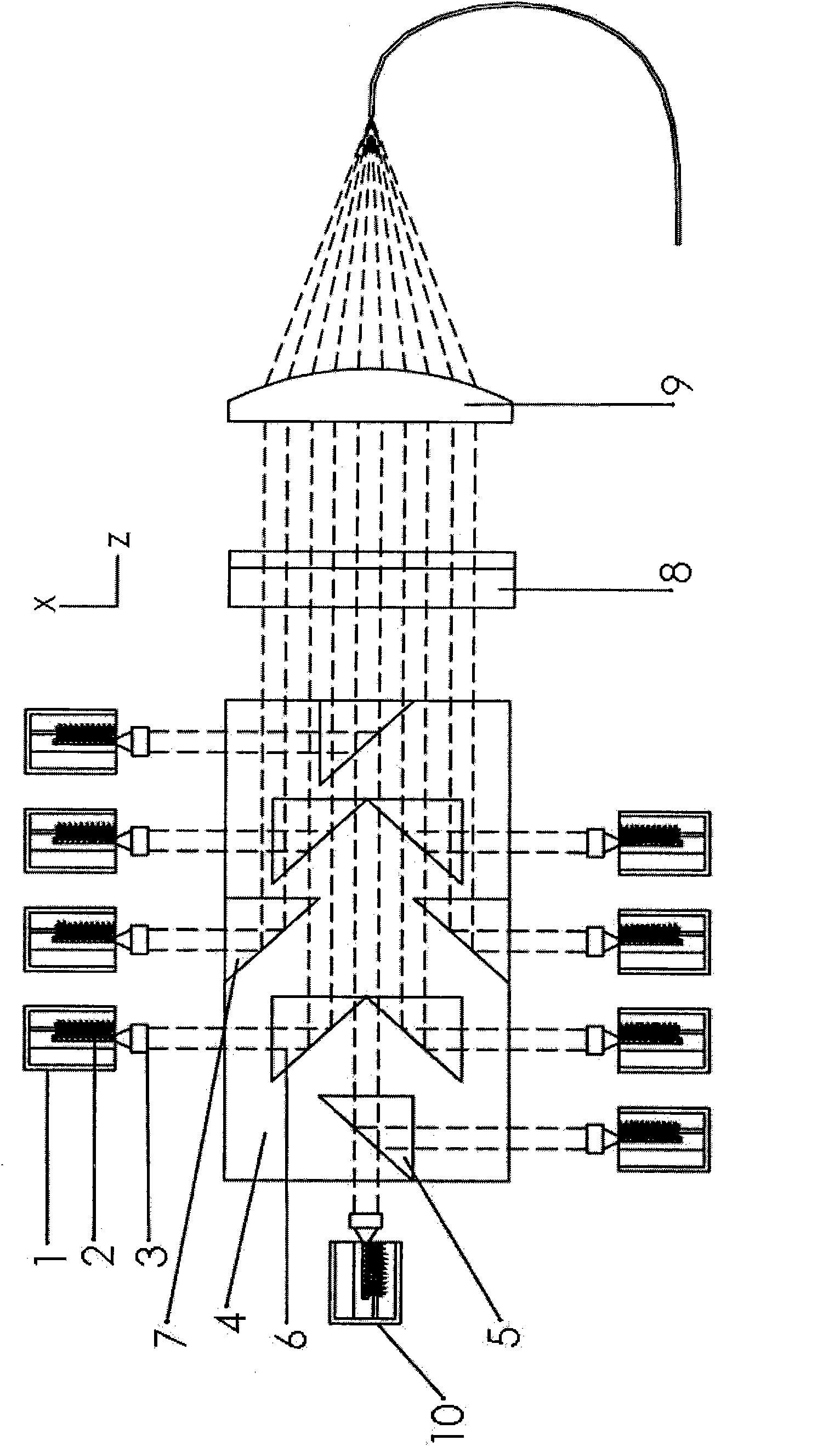

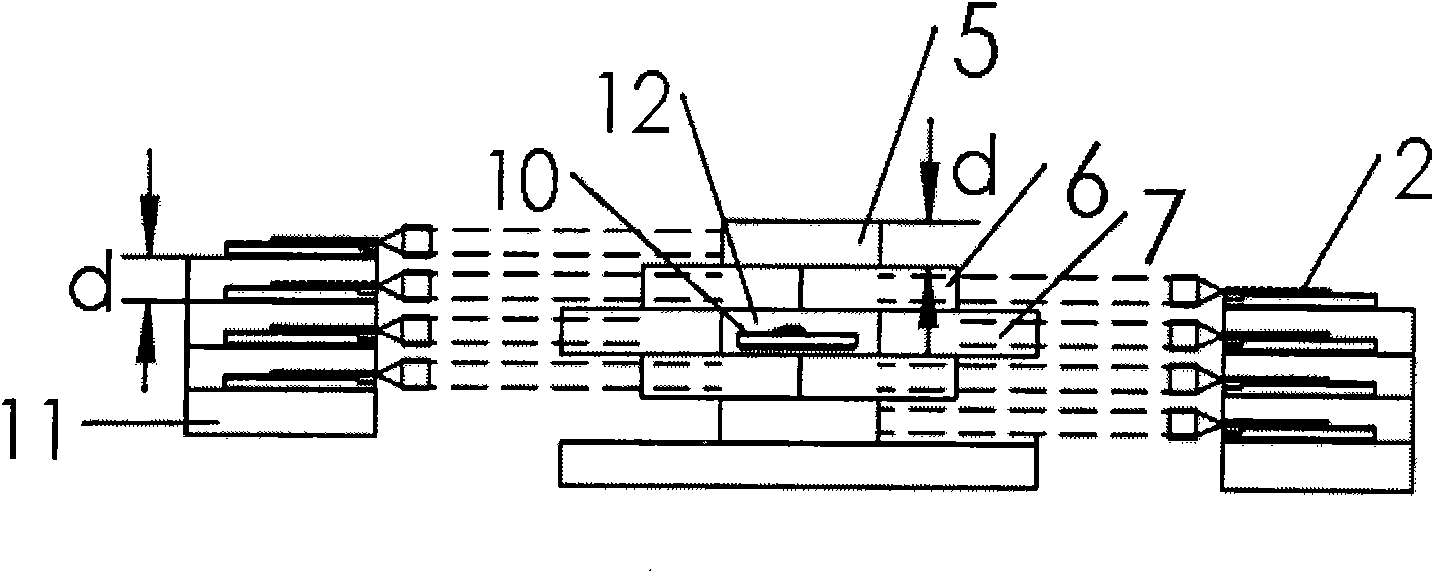

[0014] Such as figure 1 Shown, the high-power semiconductor laser fiber coupling module of the present invention comprises: a plurality of single tube semiconductor lasers 2,10 of the same polarization state of the same wavelength, a plurality of beam collimating lenses 3, a glass plate 4, a plurality of reflective prisms (such as the first Reflective prism 5, second reflective prism 6, third reflective prism 7, etc., these reflective prisms are all the same prisms, but the positions are different), fast axis focusing cylindrical mirror 8 and slow axis focusing cylindrical mirror 9. As far as one group of optical paths is concerned, the single-tube semiconductor laser 2 is welded on the ceramic heat sink 1, and a beam collimating lens 3 is arranged at the output end of the single-tube semiconductor laser 2, and the beam emitted by the single-tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com