Patents

Literature

1395 results about "Laser technology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Biomedical device, method for manufacturing the same and use thereof

InactiveUS20120165954A1Reduce usageEasy to processBone implantCeramic shaping apparatusLead zirconate titanatePorosity

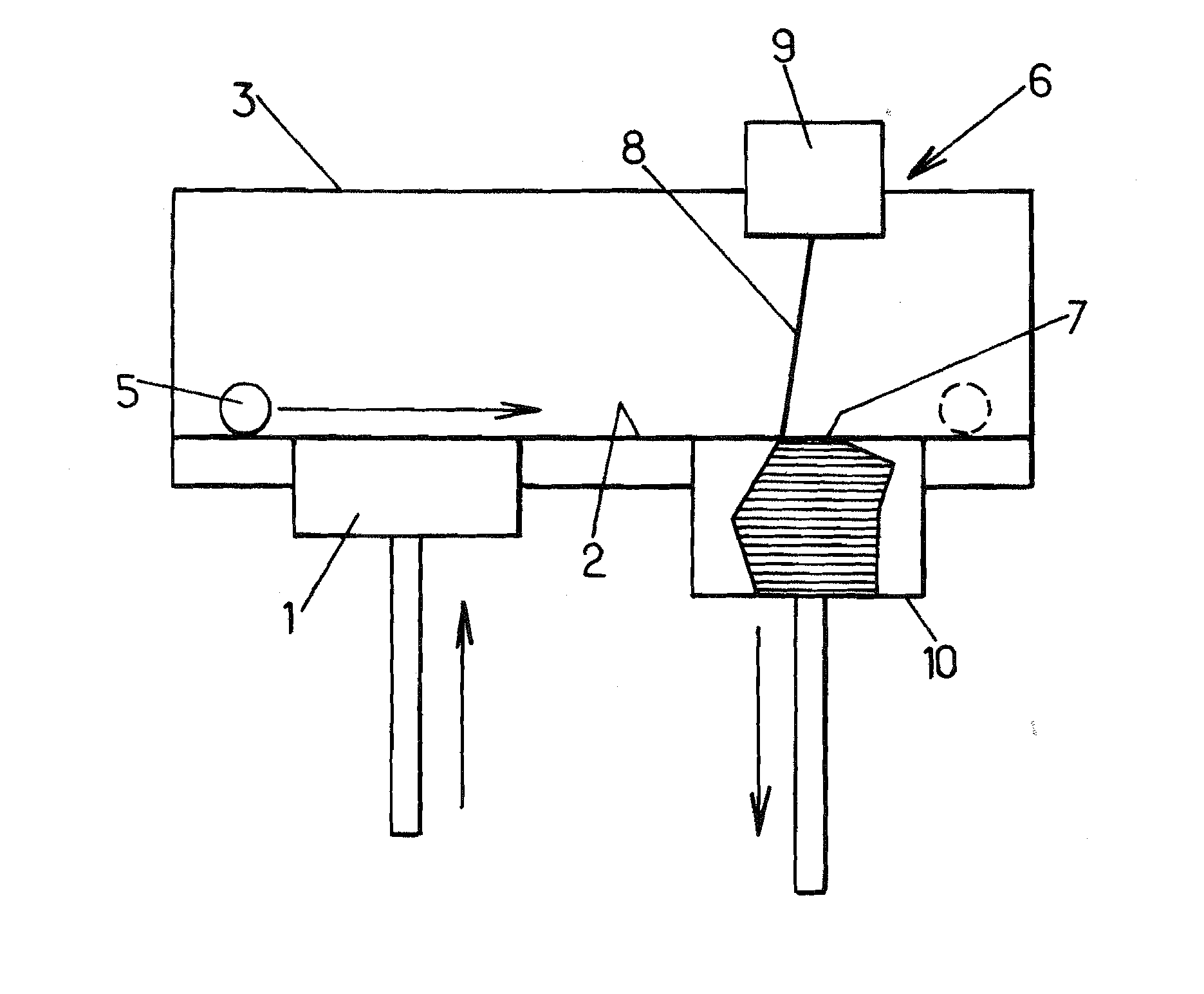

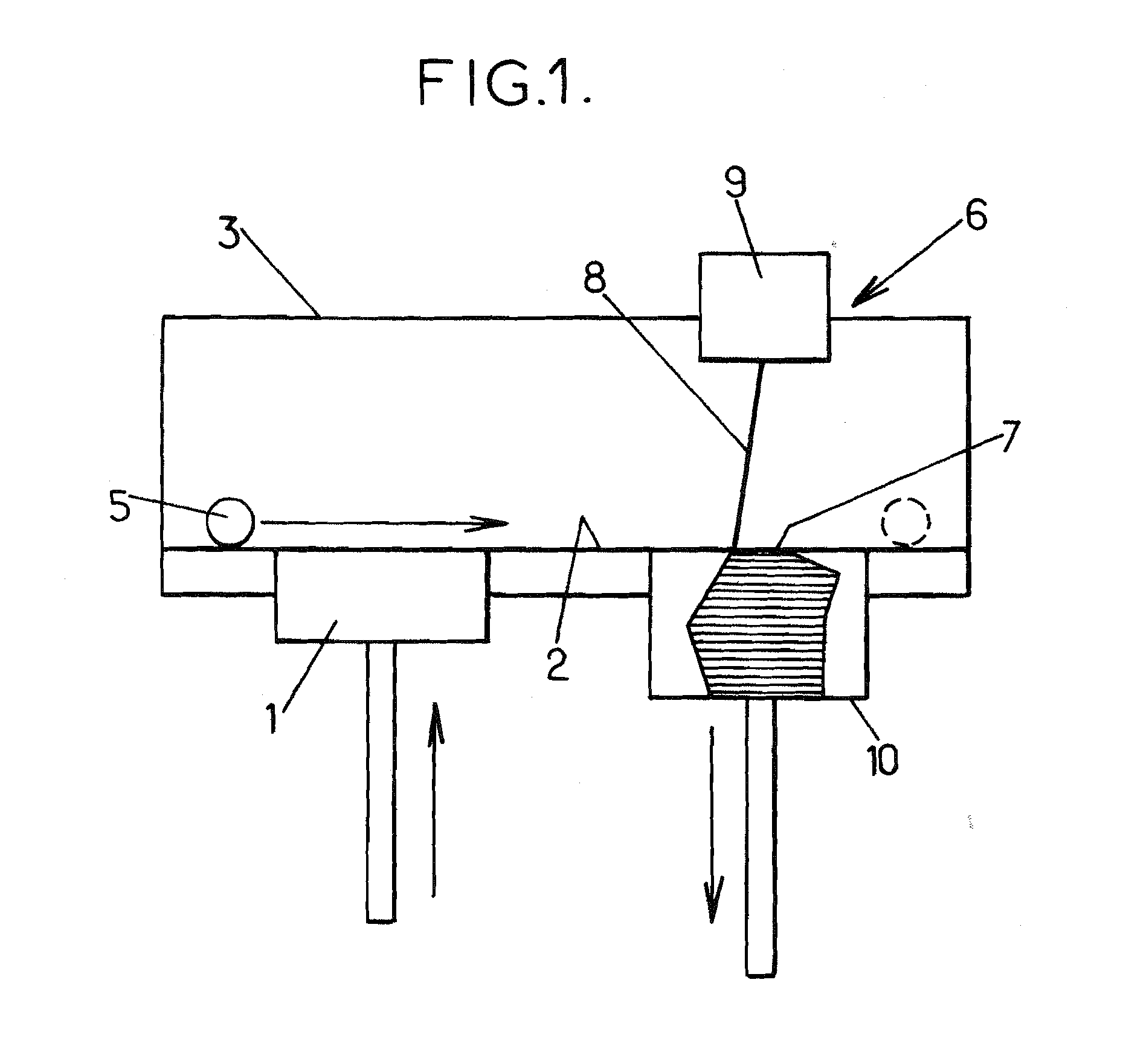

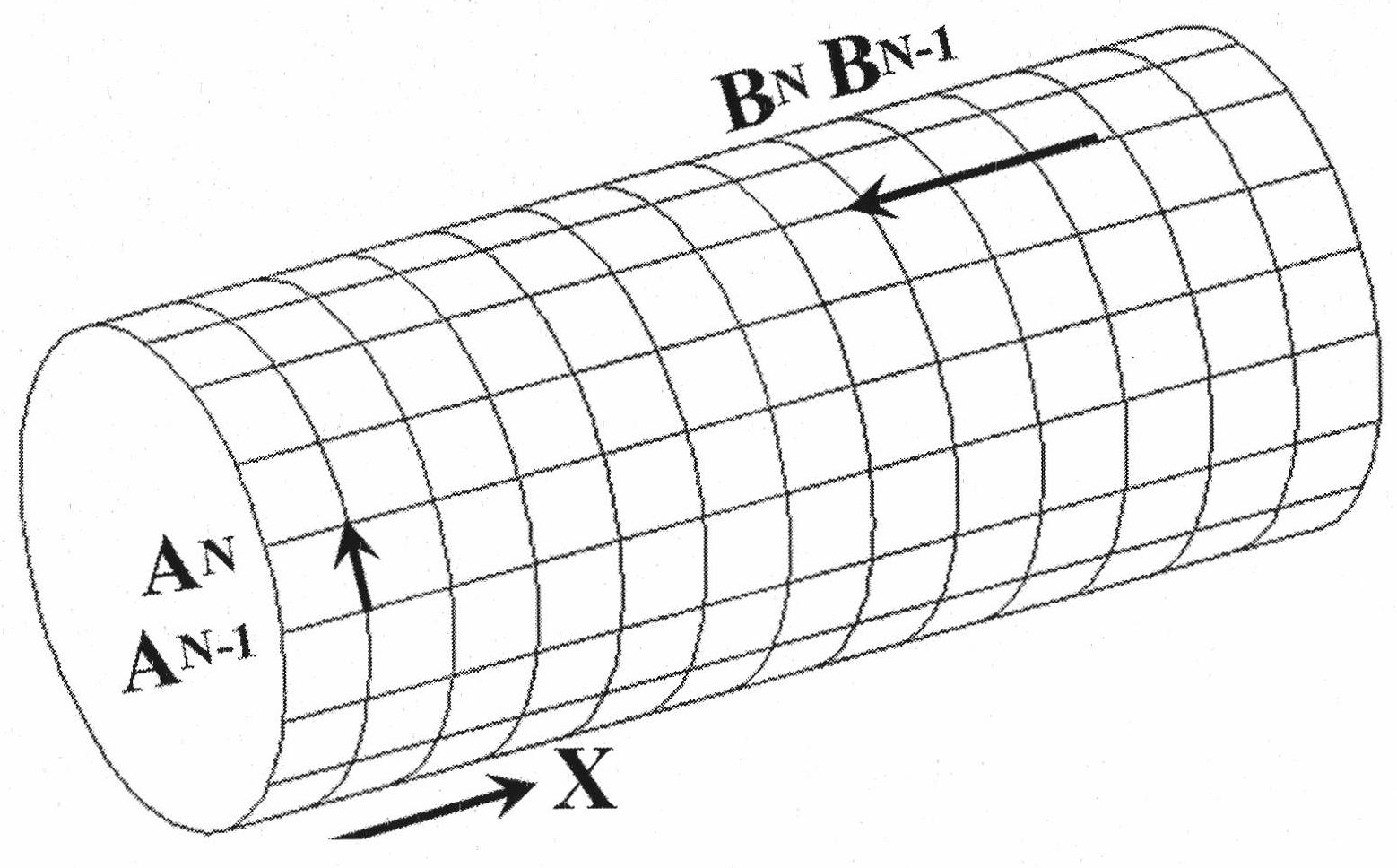

A three-dimensional biomedical device having an osteoinductive first area with a controlled porosity and a second area, which is produced by laser technology from a powder including one of ceramics, metals, metal alloys, bioactive glasses, lead zirconate titanate and biocompatible polymers, or mixtures thereof. The ratio of the porosities from the second area to the first area is equal or less than one, preferably from 0.001 to 0.9. A method for manufacturing the device for fitting in a bone defect, wherein a virtual object is designed with a computer-aid designed software, and the device is manufactured by laser technology including layering a powder onto a plate (7) so that a layer of a predetermined thickness is formed; the laser beam (8) selectively processes the powder to produce a processed layer, and, thus, layer after layer, the layers are joined together until the biomedical device is formed.

Owner:NIMAL DIDIER

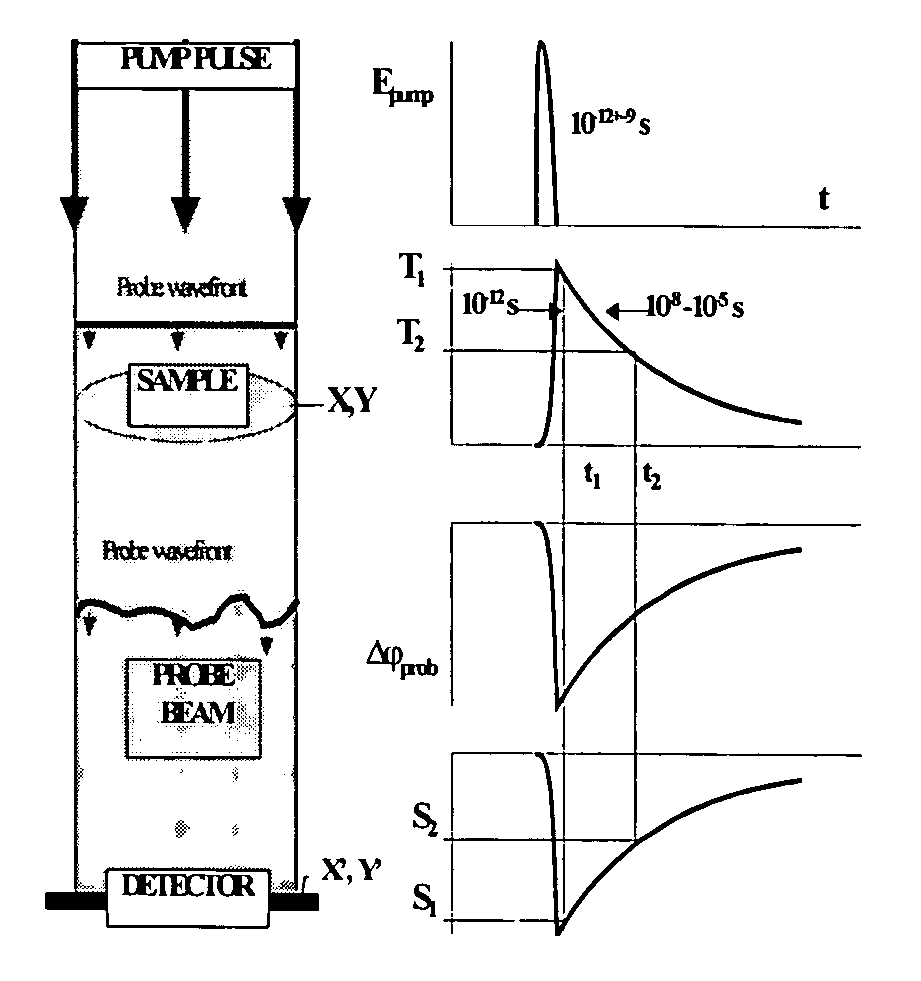

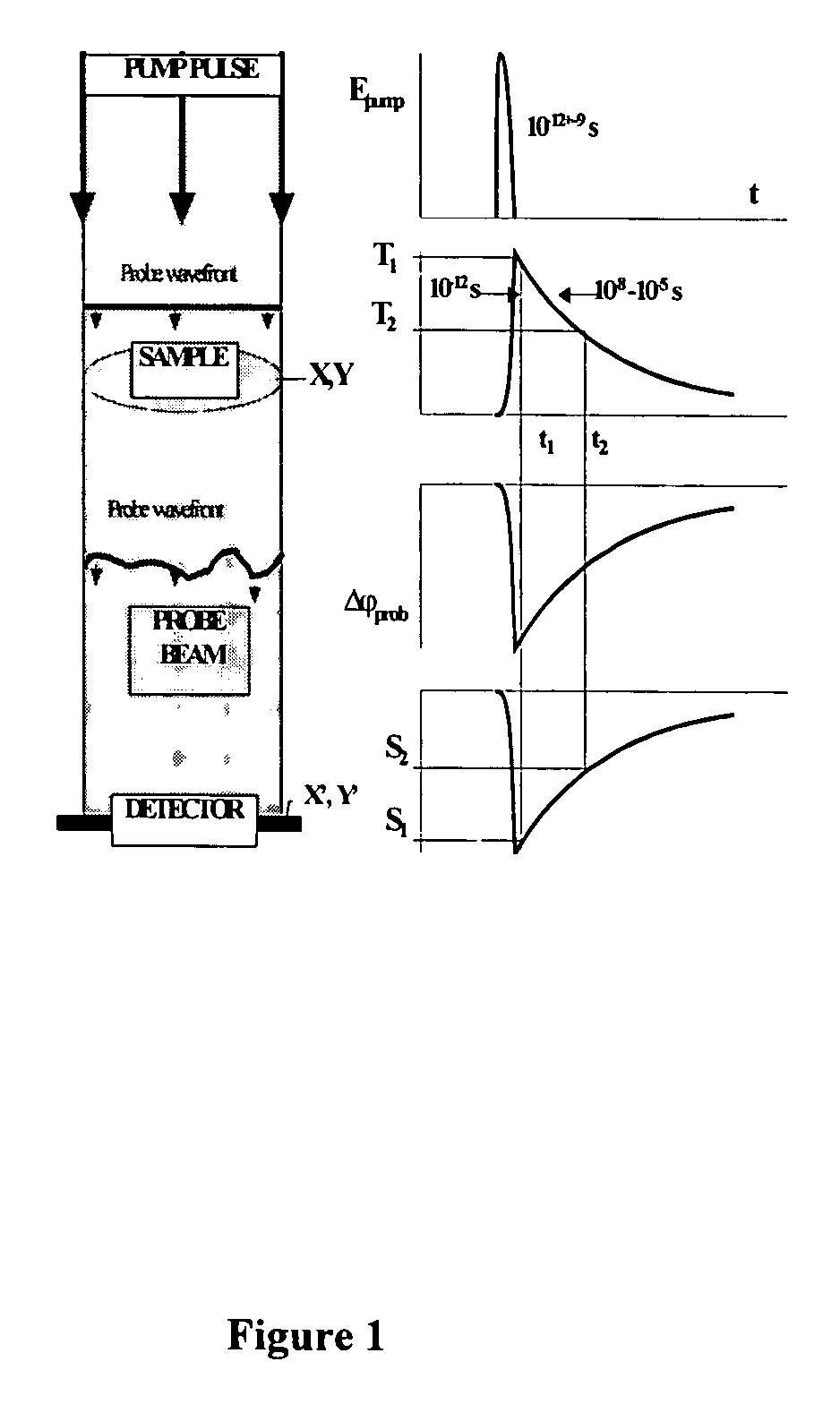

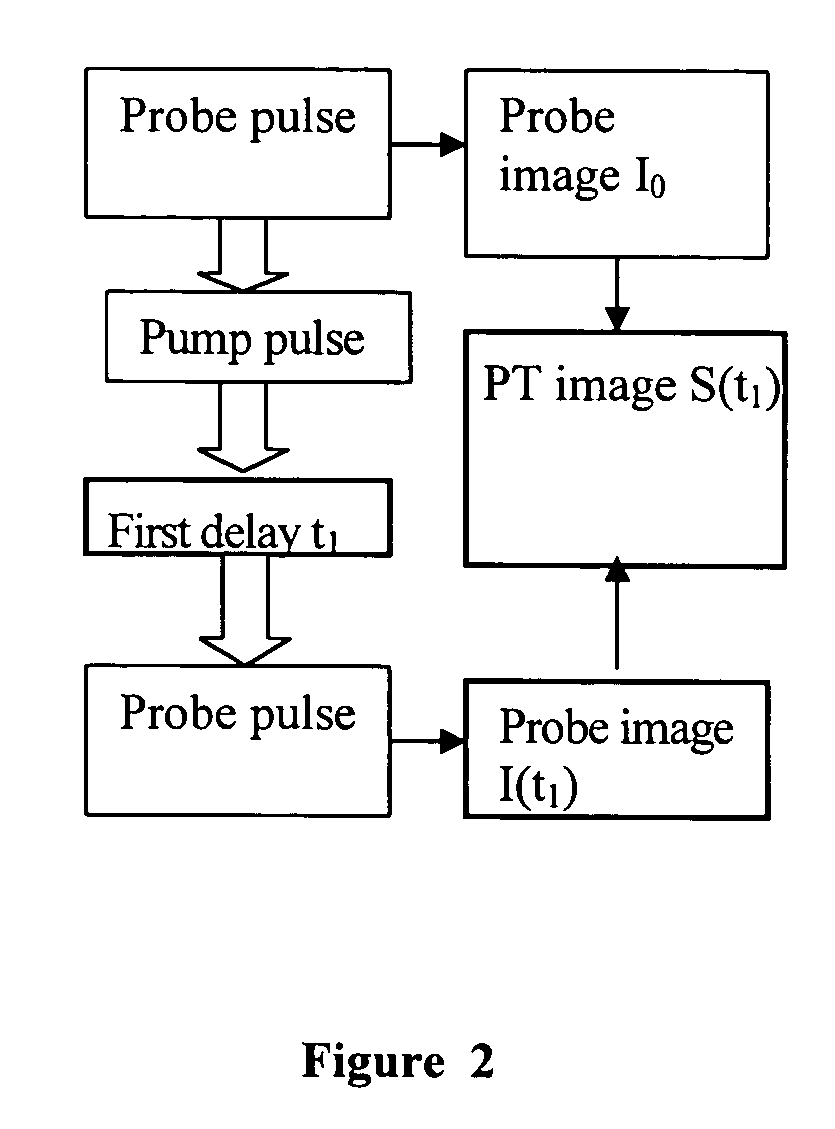

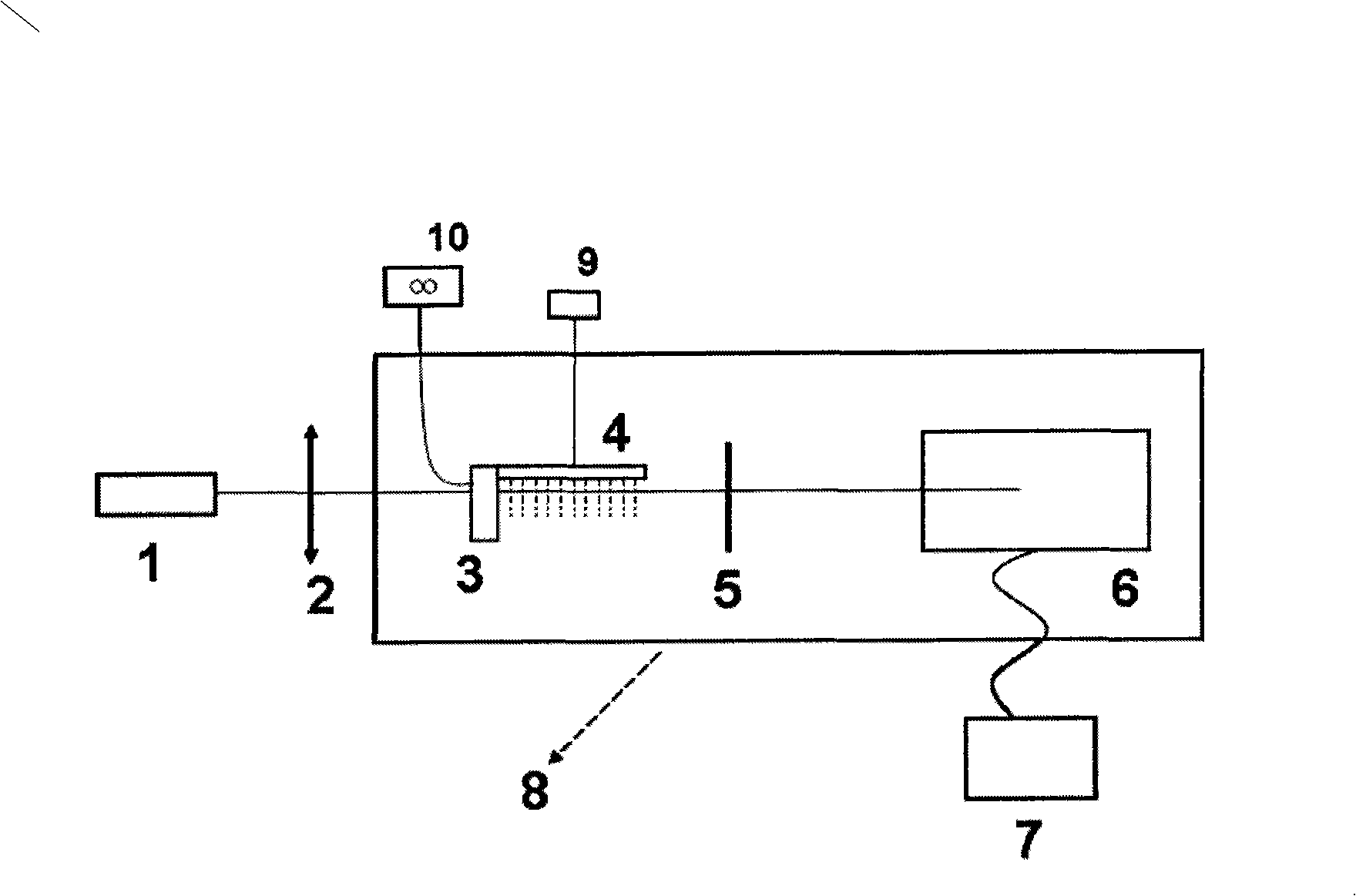

Method and device for photothermal examination of microinhomogeneities

InactiveUS7230708B2Improve resolutionHigh sensitivityMaterial analysis by optical meansRefractive indexLaser beams

The invention relates to optical microscopy, and more particularly to the methods for photothermal examination of absorbing microheterogeneities using laser radiation. The invention can be widely used in laser technique, industry, and biomedicine to examine transparent objects with absorbing submicron fragments, including detection of local impurities and defects in super-pure optical and semiconducting materials and non-destructive diagnostics of biological samples on cellular and subcellular levels.The object of the present invention is to increase sensitivity, spatial resolution and informative worth when examining local absorbing heterogeneities in transparent objects, as well as to detect the size of said heterogeneities even if said size is smaller than the radiation wavelength used.Said object is achieved by the pump beam irradiation of a sample, the duration of said irradiation not being longer than the characteristic time of cooling of the microheterogeneity observed. A relatively vast surface of the sample is irradiated at once, the size of said surface not being larger than the wavelength of the pump laser used. The refraction index thermal variations, induced by the pump beam in the sample and being the result of absorption, are registered by the parameter change of the probe laser beam. A chosen probe beam diameter should not be smaller than the pump beam diameter. The diffraction-limited phase distribution over the probe laser beam cross-section is transformed to an amplitude image using a phase contrast method. The properties of microheterogeneities are estimated by measuring said amplitude image.

Owner:LAPOTKO TATIANA MS

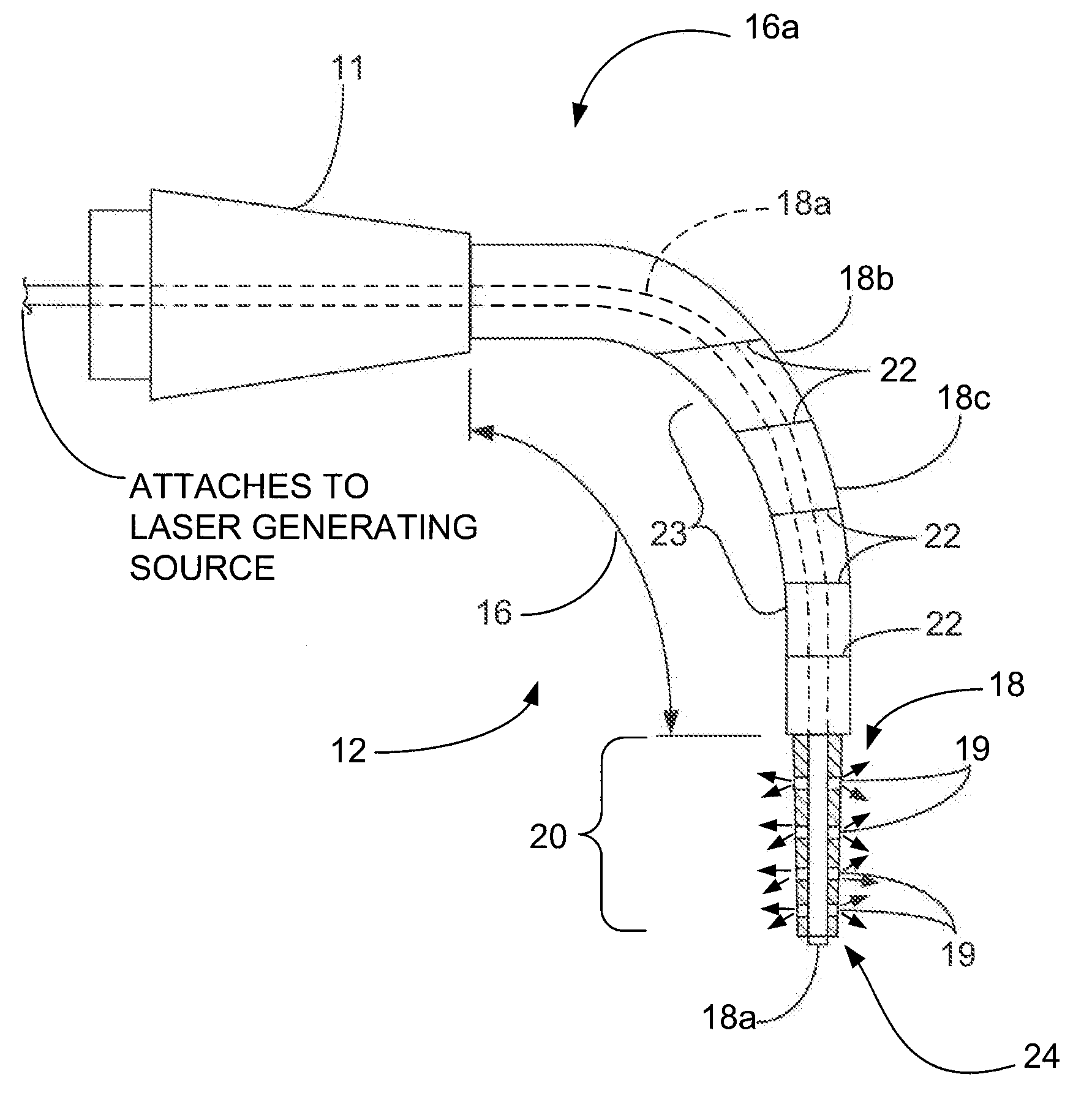

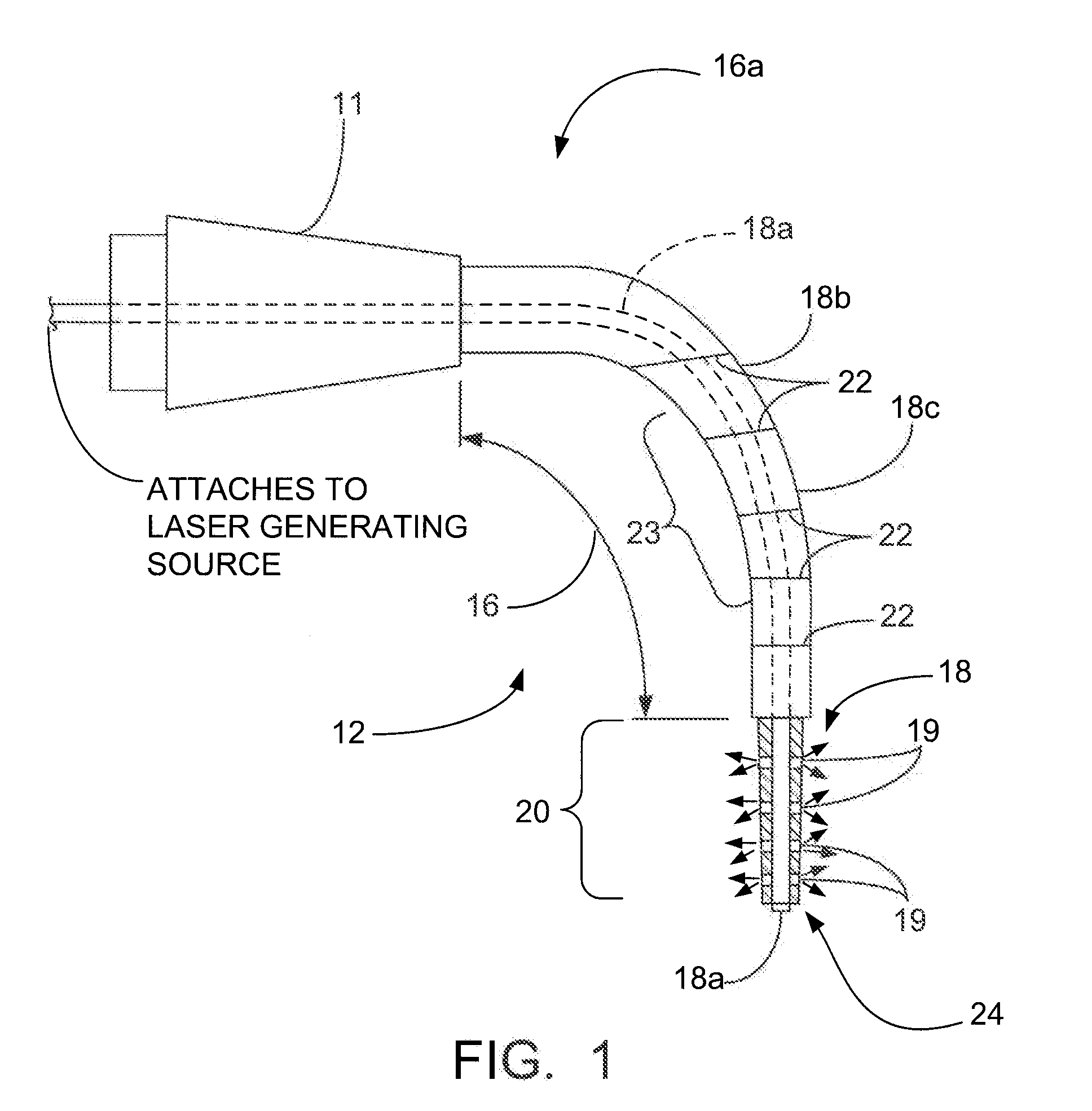

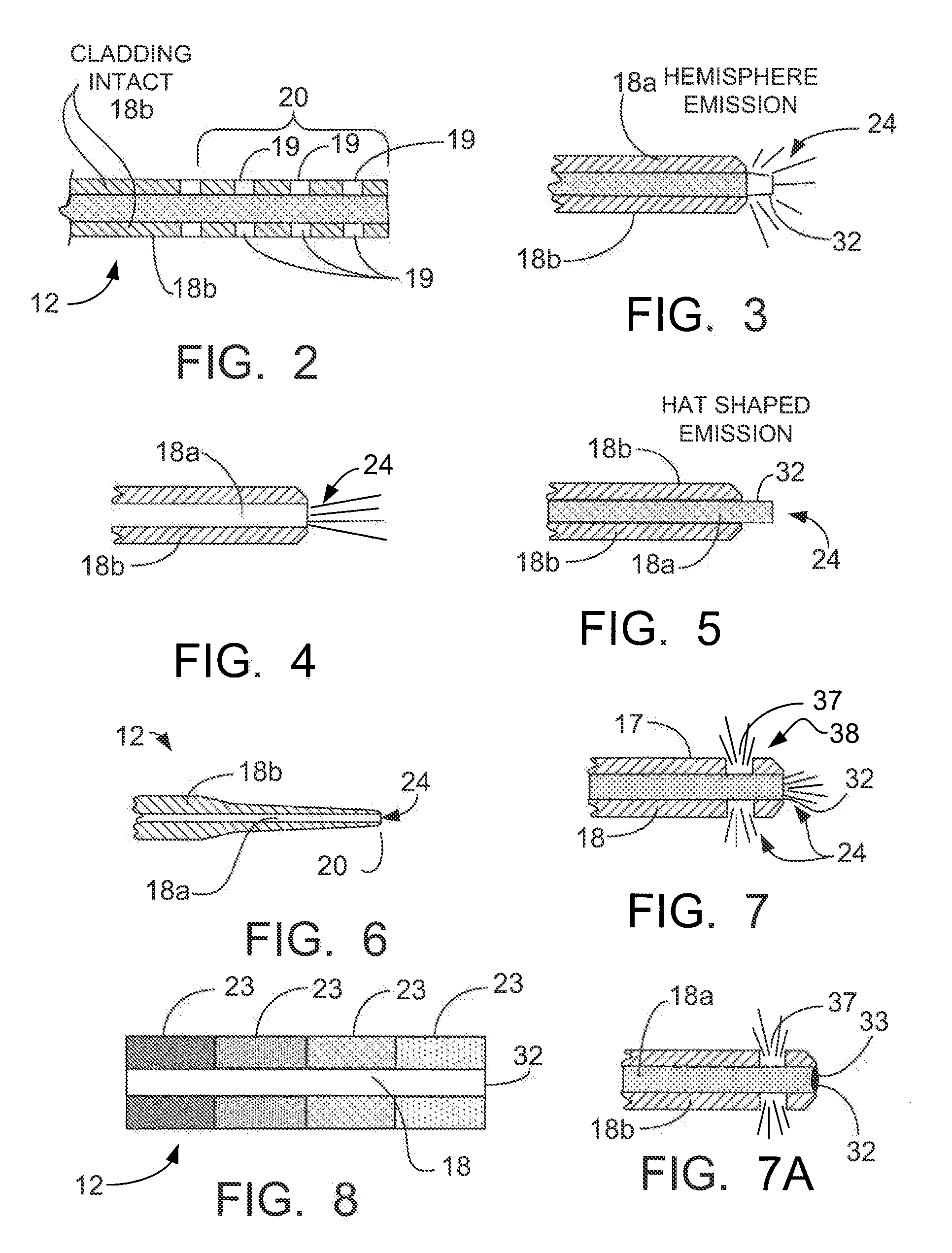

Method and Apparatus for Disinfecting or Sterilizing a Root Canal System Using Lasers Targeting Water

InactiveUS20090130622A1Sufficient deliveryEnhanced light absorptionSurgical instrument detailsDental toolsDiseaseEnergy absorption

Method and apparatus for disinfecting and / or sterilizing a root canal system by targeting the water content of disease and debris in the canals. The laser technique of employs a frequency of the wavelength emissions between about 930 to about 1065 nanometers with an optimum of 980 nm. This range of wavelengths targets the water content of tissue cells and pathogens as well as any residual organic debris in water within the root canal system after its preparation while being poorly absorbed by the surrounding dentin. The selection of the optimum wavelength produces significant effects generating and advancing treatment to the targeted aqueous environments. This is due to the rapid energy absorption by the water and the subsequent creation of gas bubbles, liberation of heat and subsequent propulsion of waves of heat and gas that impact along the canal walls and ramifications resulting in an enhanced bacterial kill and cleaning of the canal walls and ramifications. No dyes or other additives are necessary to enhance the effectiveness of the laser kill of bacteria, etc.

Owner:BOLLINGER JAMES EDWIN +2

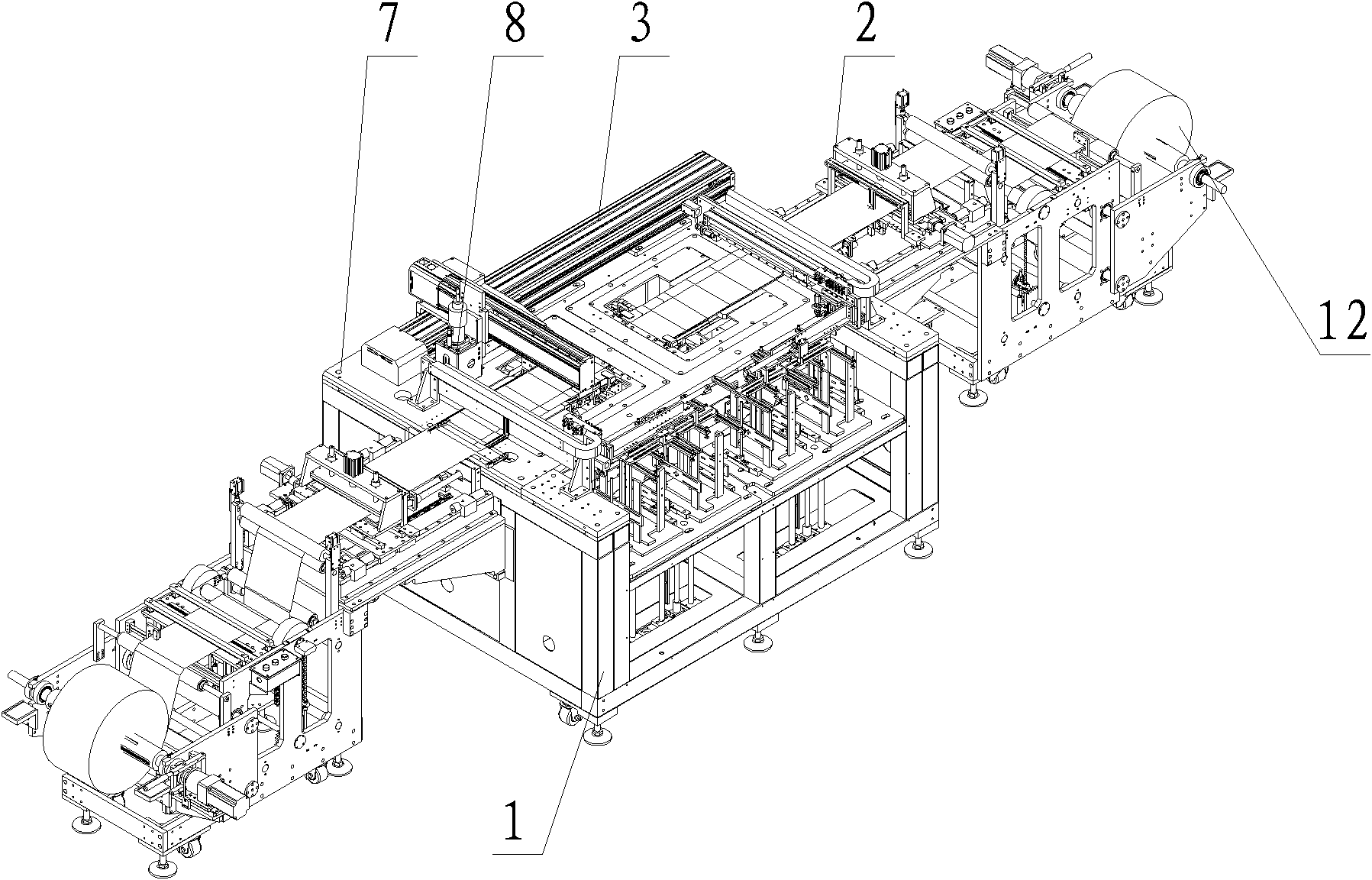

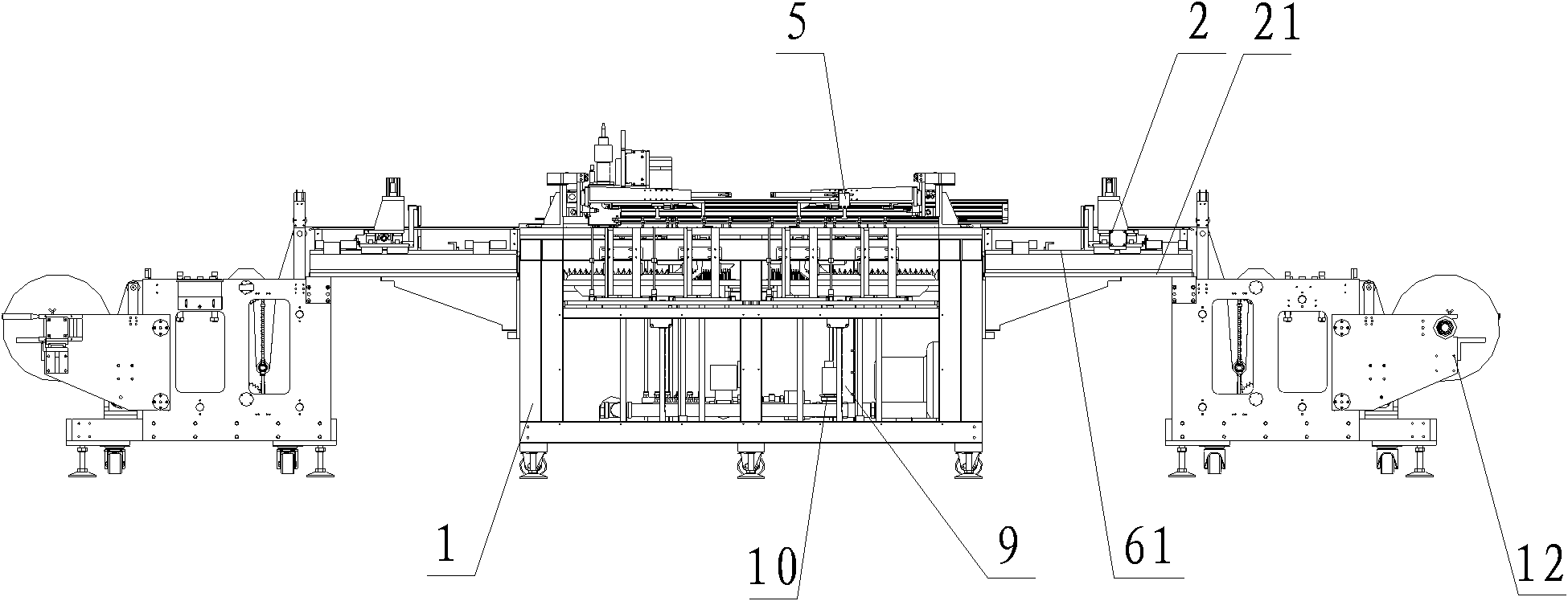

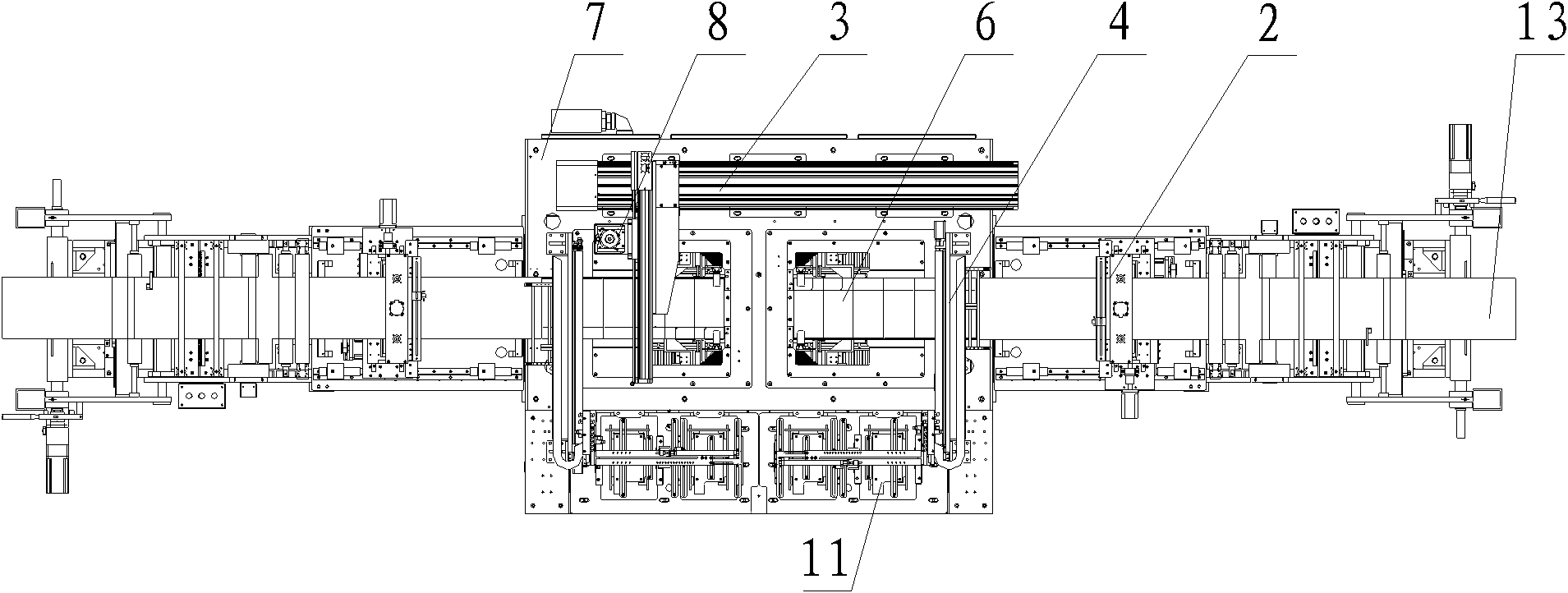

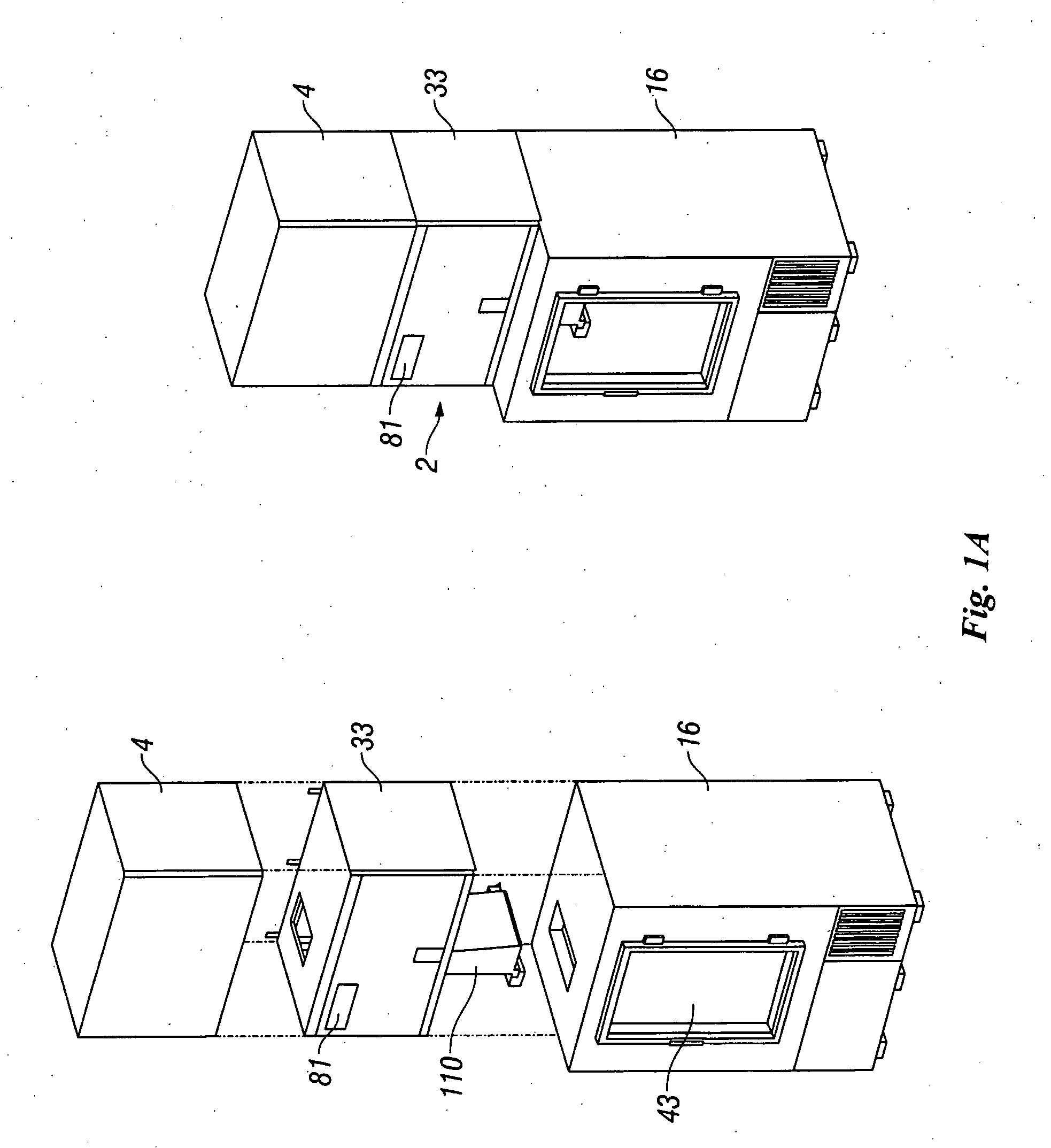

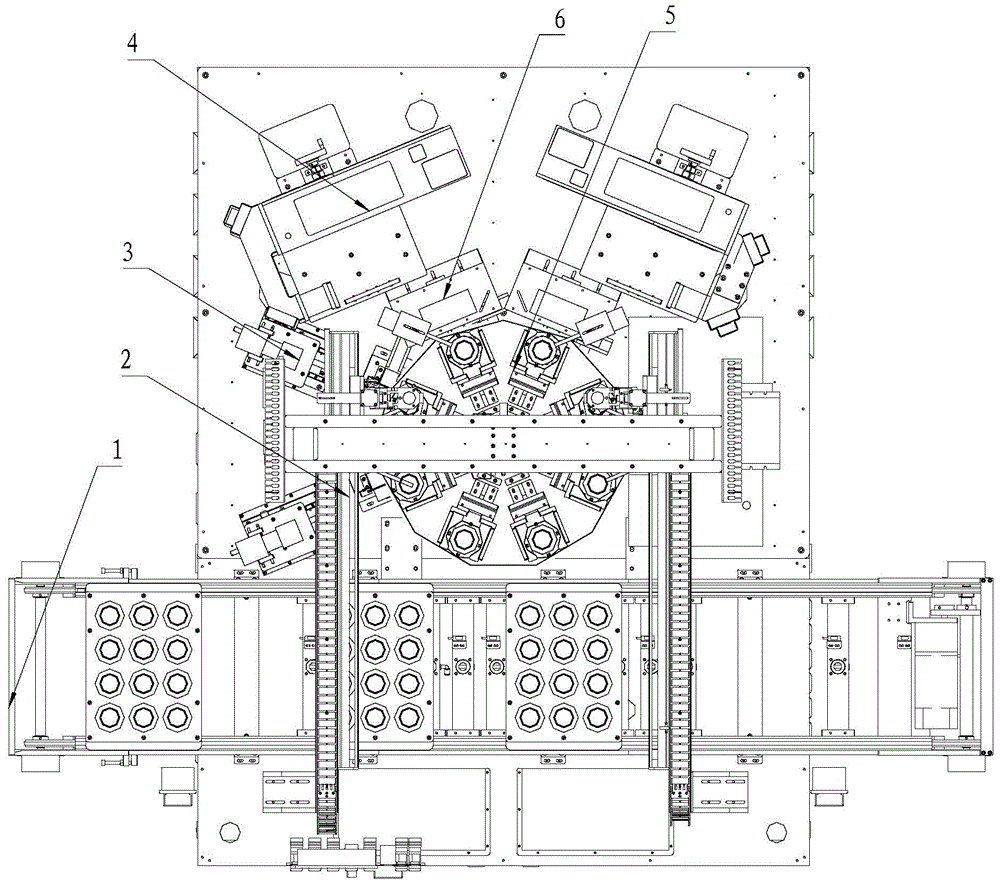

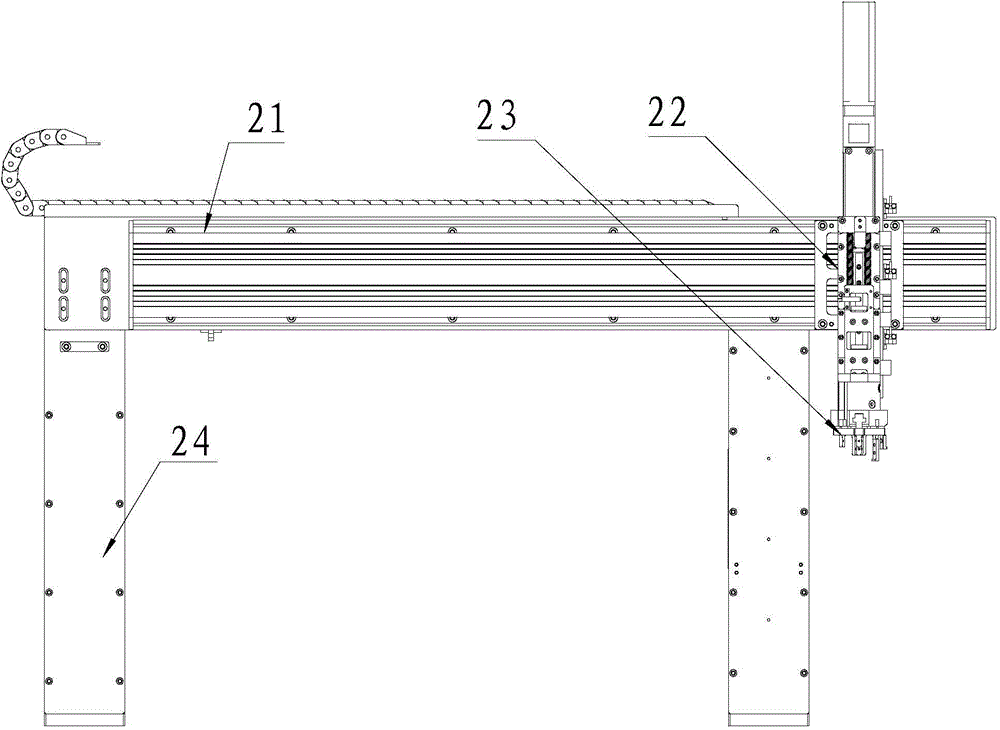

Pole piece laser cutting machine

ActiveCN102642089AOvercome deformationSmall size errorProgramme-controlled manipulatorElectrode manufacturing processesCapacitanceLaser technology

The invention discloses a pole piece laser cutting machine. The machine comprises a base frame part, a laser cutter, a cutting manipulator part, a control system and at least a piece feeding component, wherein the cutting manipulator part is used for driving the laser cutter; each piece feeding component comprises a material clamping manipulator part, a feeding fixed-length part and an emptying part; the cutting manipulator part and the material clamping manipulator part are installed on the base frame part; the feeding fixed-length part is arranged between the material clamping manipulator part and the emptying part; and the control system is connected with the cutting manipulator part, the material clamping manipulator part and the feeding fixed-length part. The machine has the following beneficial effects: the machine realizes the piece preparation processes of the lithium ion batteries or super capacitors by adopting the laser technology, can solve the problem that the pole pieces are easy to deform and have bigger burrs as the traditional cutting processes are adopted in the prior art, simultaneously improves the piece preparation process quality under the control of the control system and increases the yield.

Owner:SHENZHEN GEESUN INTELLIGENT TECHNOLOGY CO LTD

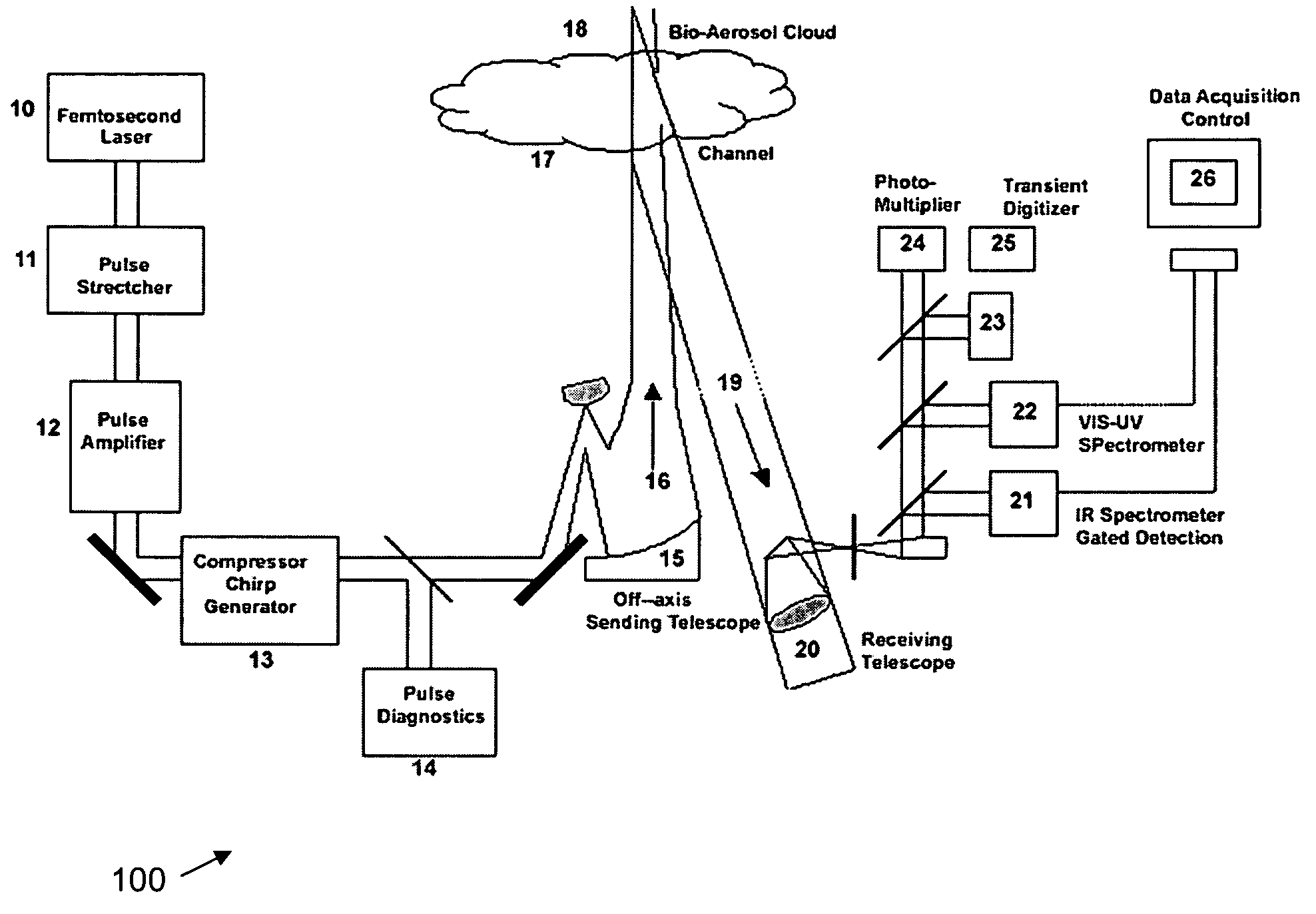

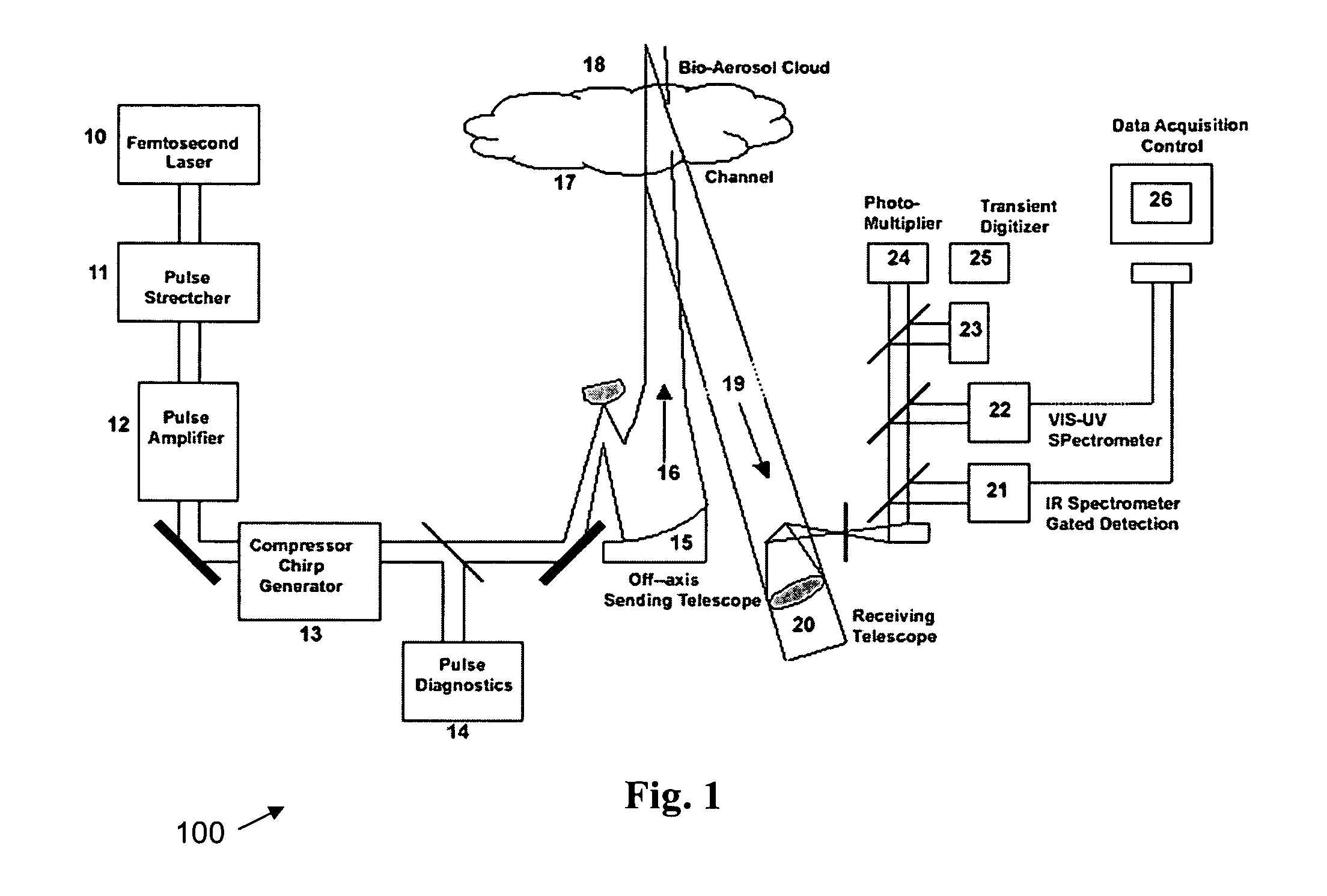

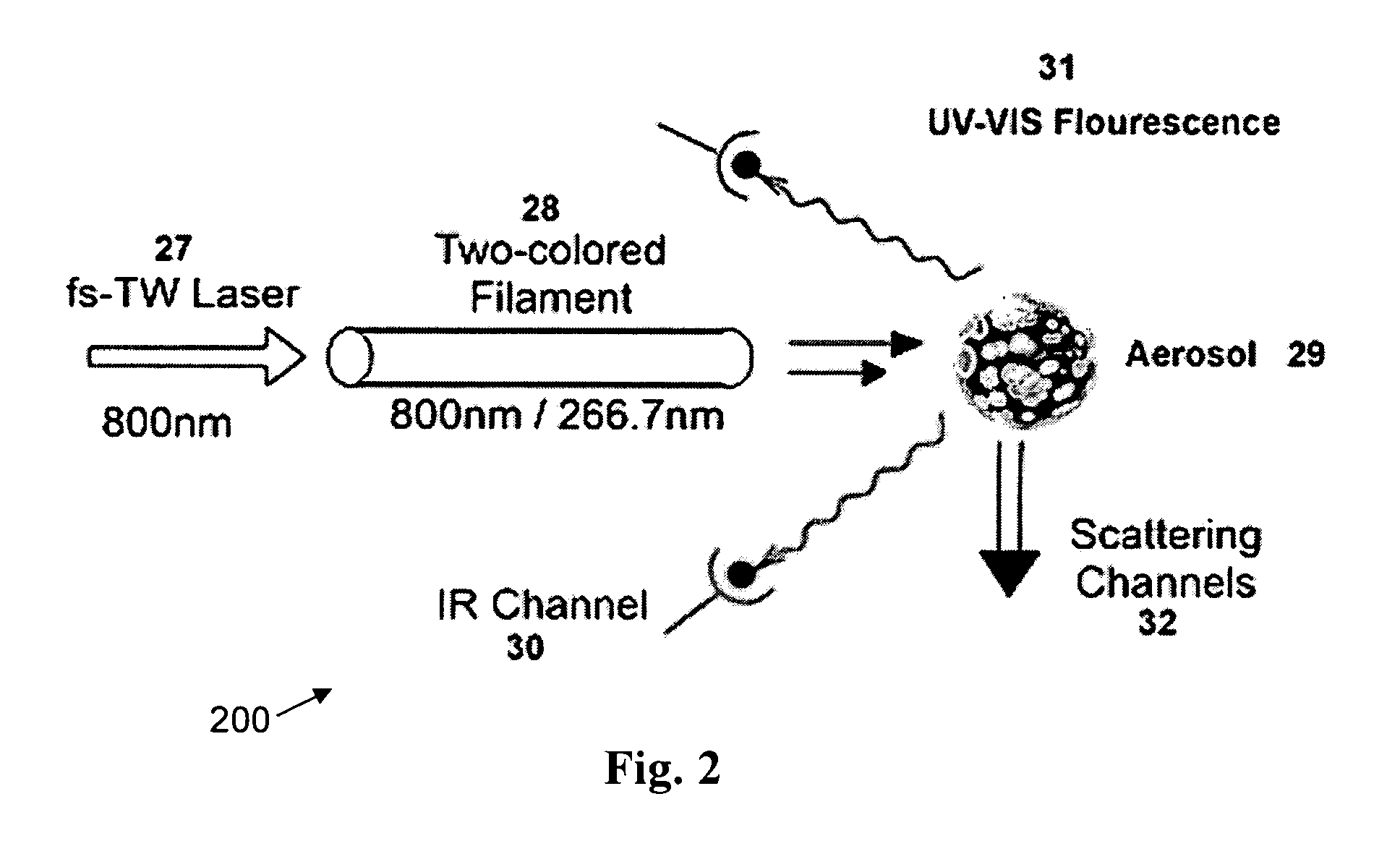

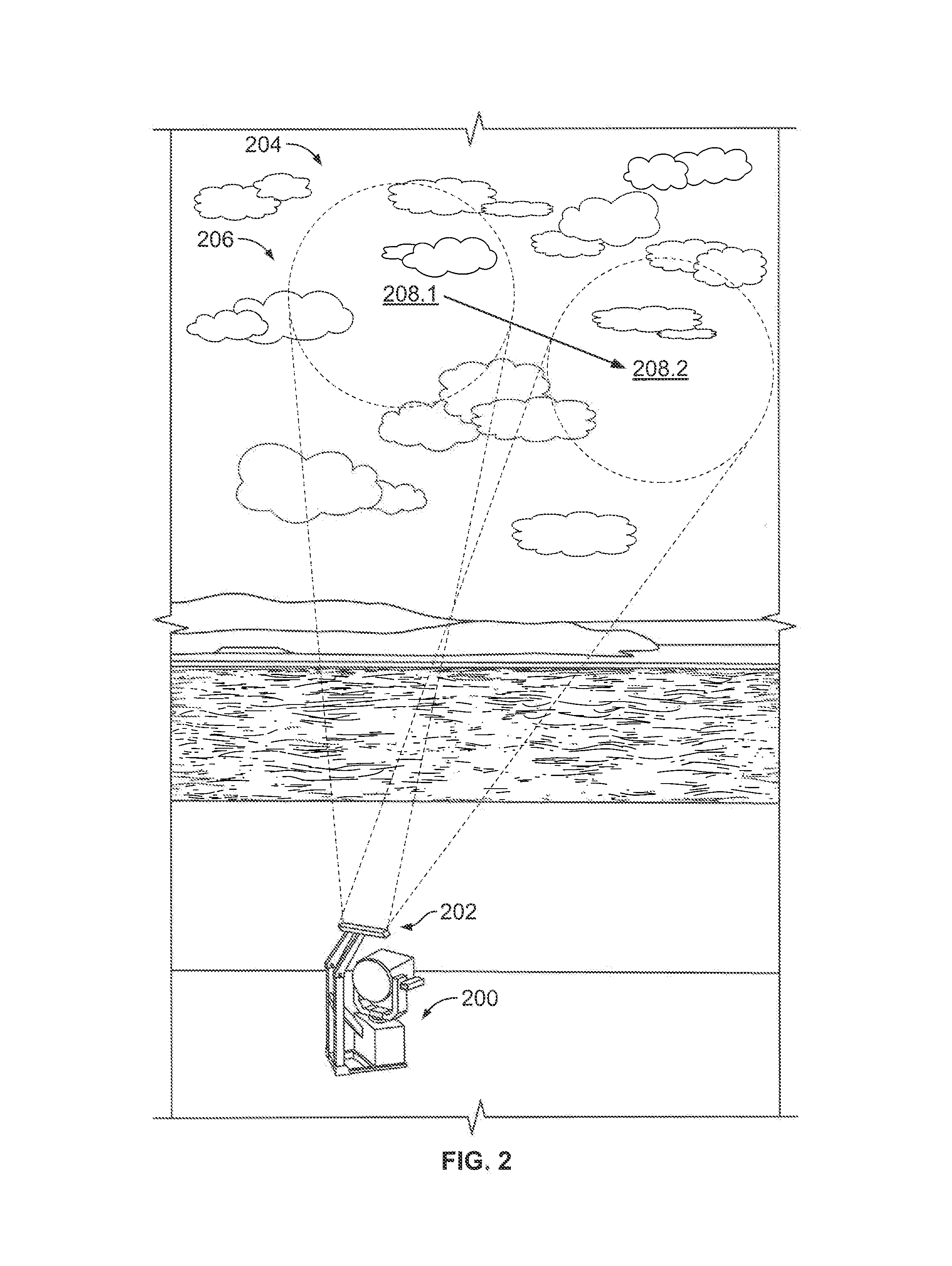

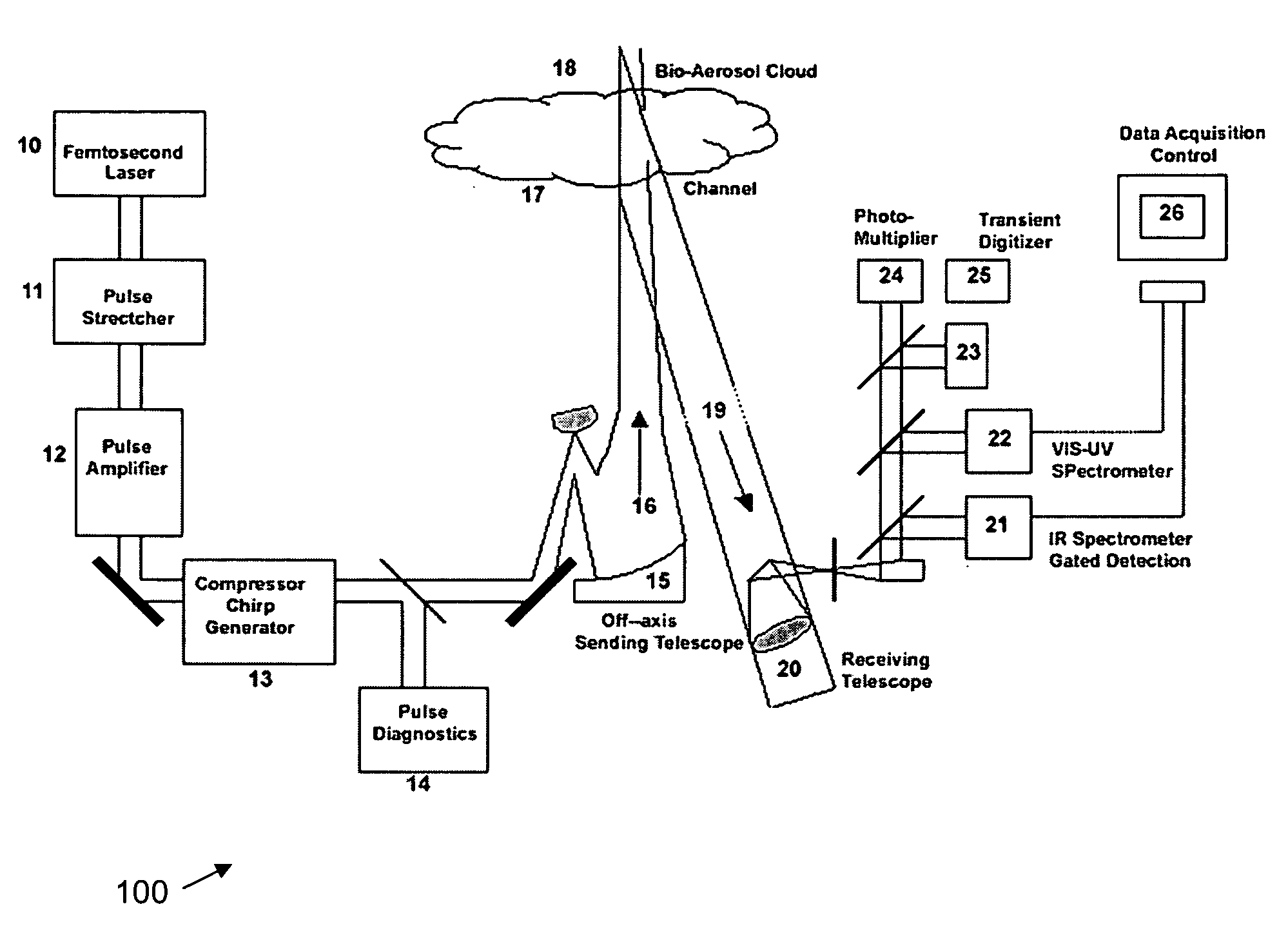

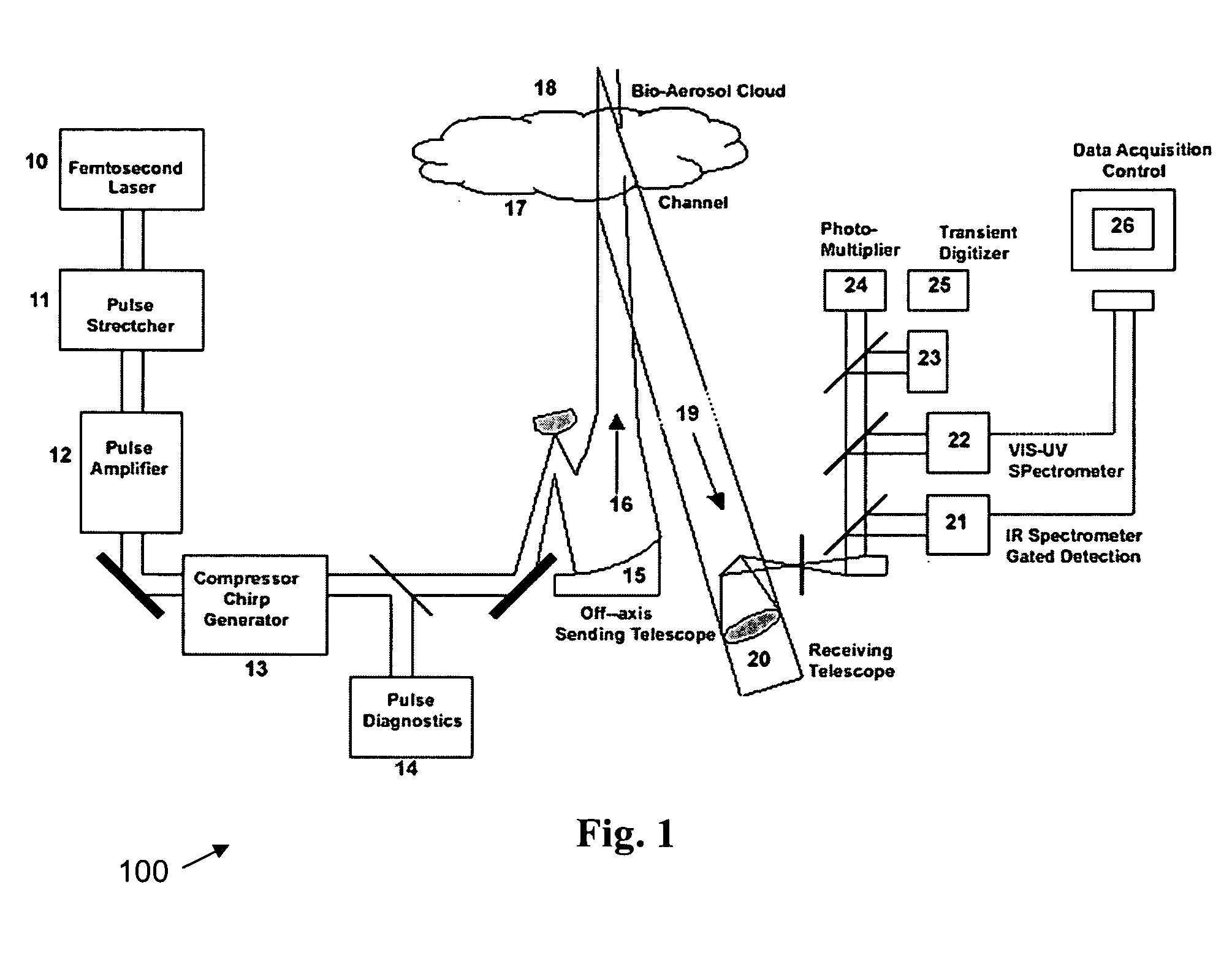

Mobile terawatt femtosecond laser system (MTFLS) for long range spectral sensing and identification of bioaerosols and chemical agents in the atmosphere

InactiveUS7391557B1Reduce probabilitySimultaneous measurementRadiation pyrometryLaser detailsFilamentationUltraviolet

The present invention relates to a system for detection and identification of airborne biological, chemical and / or nuclear threats such as toxins, spores, bacteria, and viruses in real time at distances from a few meters to several kilometers. Compact femtosecond terawatt laser technology is combined with spectroscopic and mathematical methods for spectral sensing of airborne warfare agents such as bio-aerosols. Trigger sensors and standoff devices based on mobile terawatt femtosecond laser systems are provided that may be placed at strategic monitoring locations. Furthermore, the invention relates to the propagation of airborne ultra-short, ultra-intense laser pulses giving rise to plasma channels (filamentation) producing white light supercontinuum ranging from the ultraviolet (UV), visible (VIS), near infra-red (NE) and middle infra-red (MIR). According to this invention, the supercontinuum can be directly produced in a particle cloud and hence is uniquely suitable for multi-spectral long-range atmospheric agent and radioactive isotope detection.

Owner:APPLIED PHOTONICS WORLDWIDE

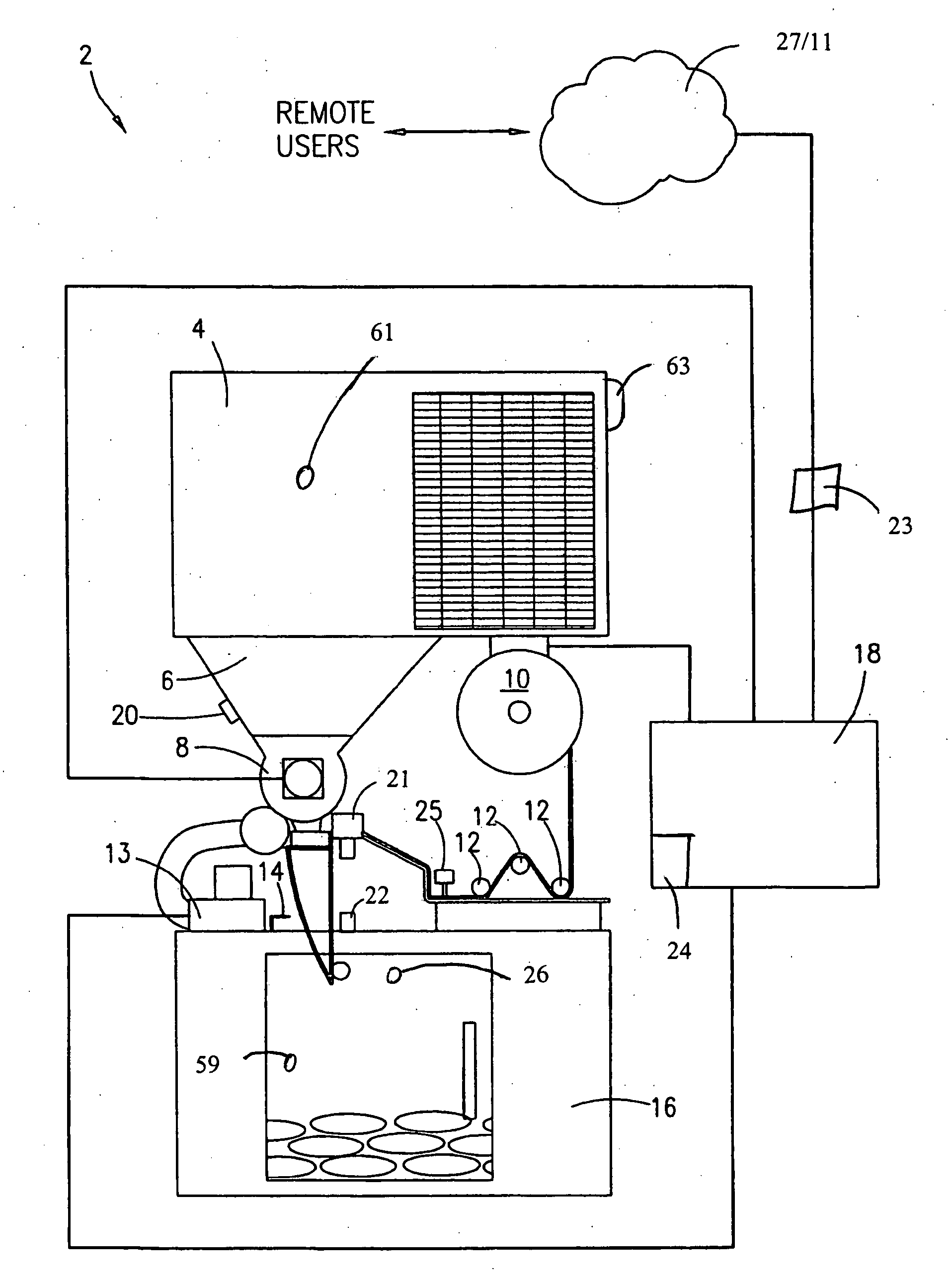

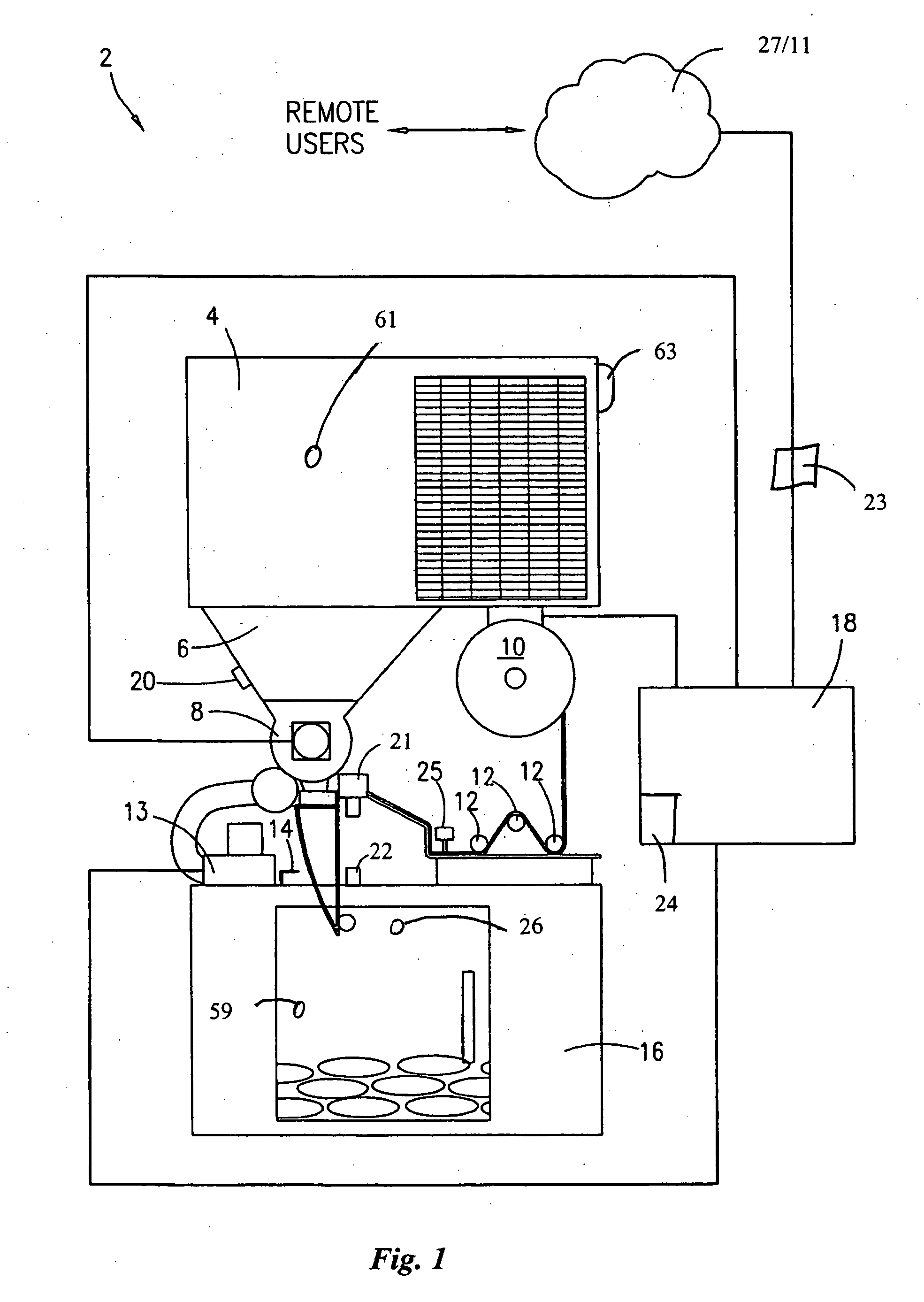

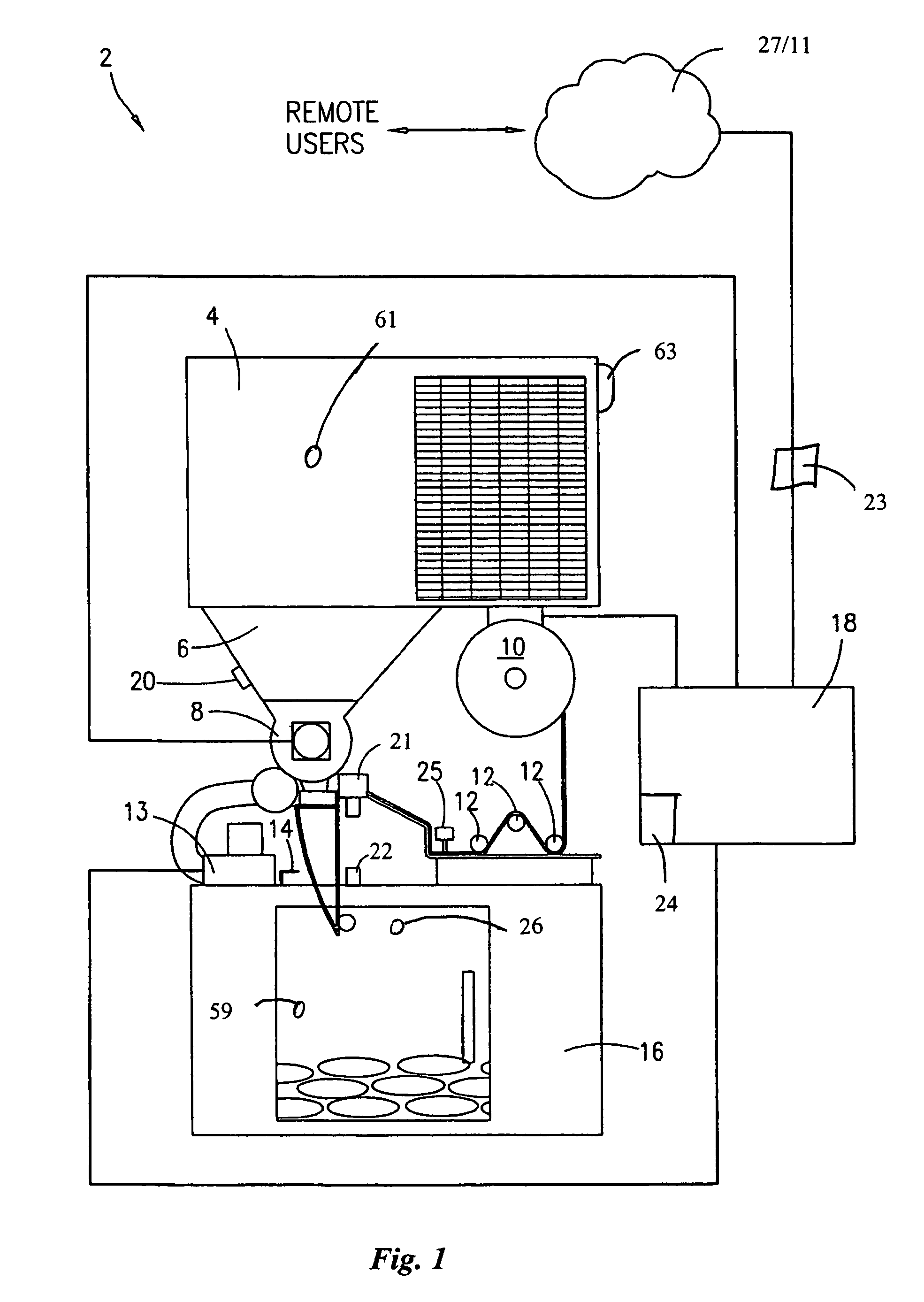

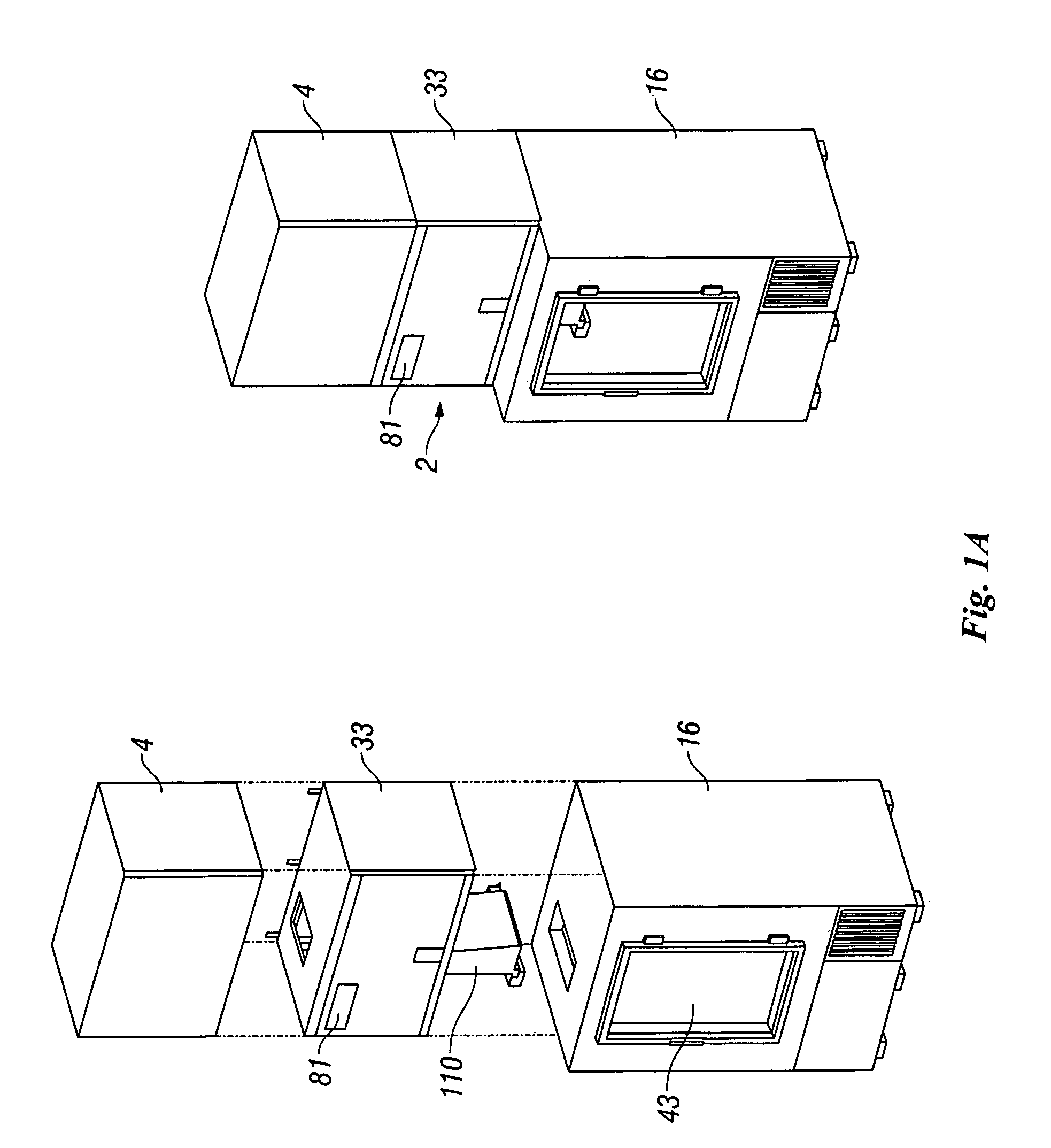

Ice bagging system and method

InactiveUS20080110129A1Lighting and heating apparatusPackage sterilisationLaser technologyEngineering

This apparatus relates to ice-bagging apparatuses with an ice maker and a hopper for receiving ice from the ice maker. The apparatus utilizes rotating drums designed for delivering ice into a bag. The apparatus also possess bagging and drop mechanism which fills and mechanically seals each bag of ice and drops it into a freezer for storage. The apparatus has an electronic operating system that has been greatly simplified using infrared technology and / or laser technology. The operating system is connected with the internet and a central processing center to allow for complete managing and monitoring of the system.

Owner:ICEX HLDG +1

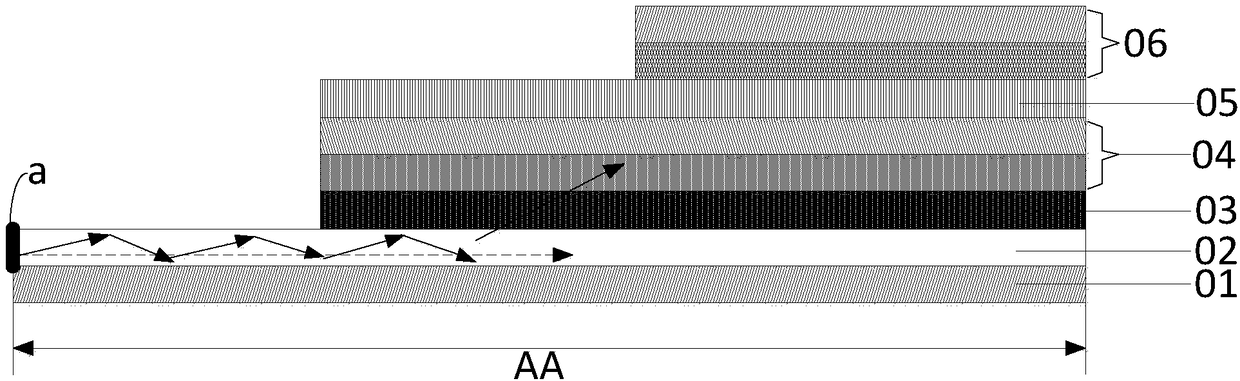

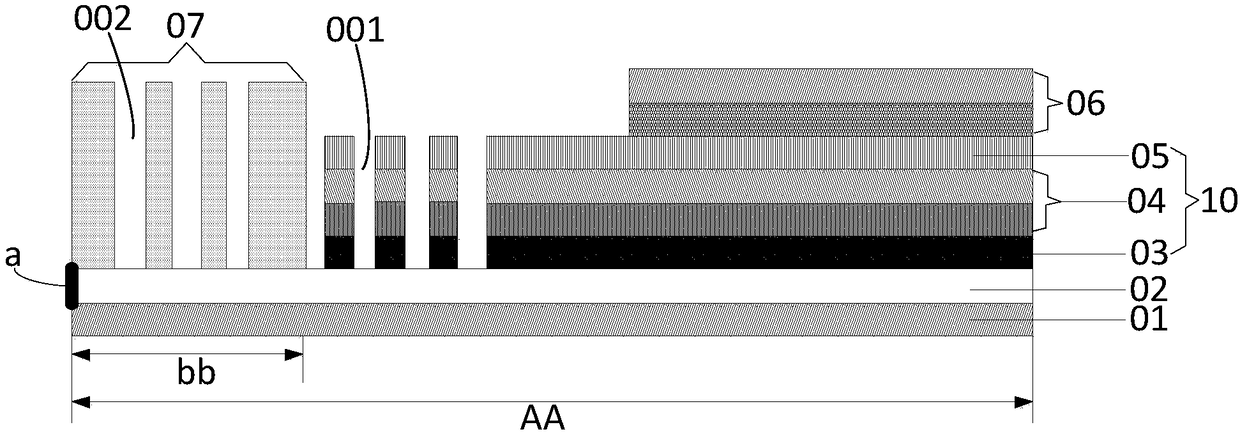

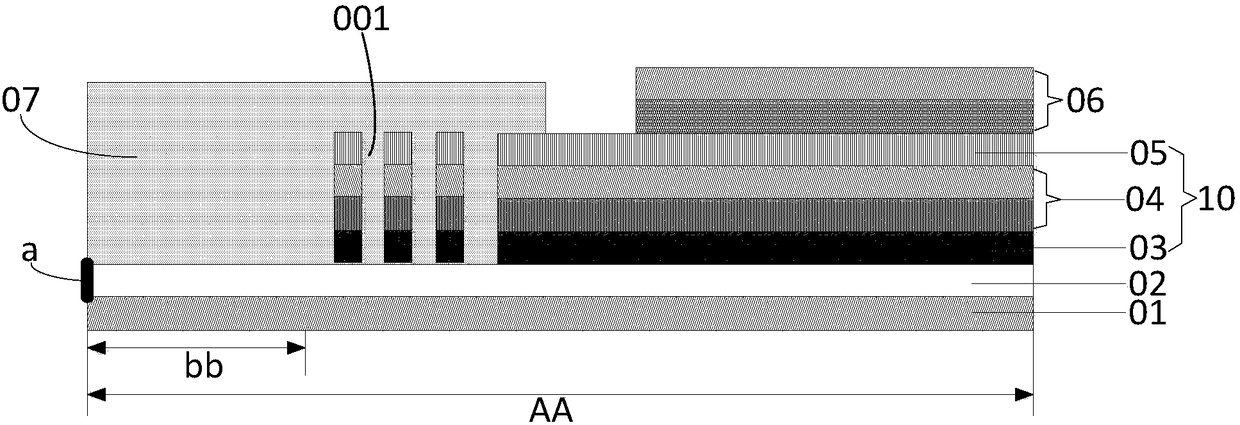

Display panel and manufacturing method thereof

ActiveCN108281570APrevent proliferationSolid-state devicesSemiconductor/solid-state device manufacturingLaser technologyCrack spread

The invention discloses a display panel and a manufacturing method thereof. The display panel comprises a substrate, the substrate comprises a display area and a surrounding area surrounding the display area, and the display panel further comprises at least one layer of protective layer covering the cutting area corresponding to a cutting line of the surrounding area. The display panel has the advantages that the protective layer is arranged at the edge of the surrounding area, the protective layer can absorb laser energy and release impact force when the laser technology is used subsequentlyfor cutting, edge film layers are prevented from being heated and impacted to generate cracks spreading to the display area, and problems that the film layers of the cutting area is prone to cracks due to excessive laser intensity in the existing technology and the cracks conduct inward into the display area to affect the display are solved.

Owner:BOE TECH GRP CO LTD +1

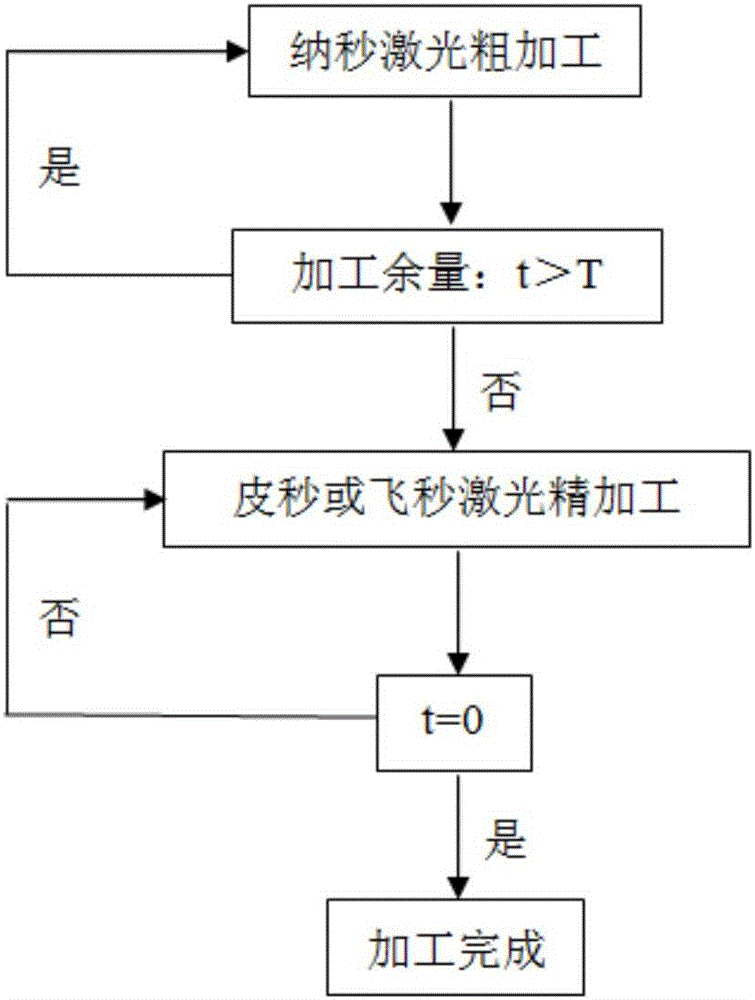

Ceramic drilling method of composite nanosecond-picosecond-femtosecond laser technology

ActiveCN106425125AReduce the temperatureReduce recast layersWelding/soldering/cutting articlesLaser beam welding apparatusNanosecond laserPicosecond laser

The invention discloses a ceramic drilling method of a composite nanosecond-picosecond-femtosecond laser technology. The ceramic drilling mechanism of the composite nanosecond-picosecond-femtosecond laser technology comprises the following steps: S10, providing multi-pulse-width fiber laser devices which comprise a nanosecond laser device, a picosecond laser device and a femtosecond laser device, roughly machining a ceramic workpiece fixed on a working table by using the nanosecond laser device, and meanwhile, spraying auxiliary gas at a position nearby a machining position; S20, carrying out finish machining on the ceramic workpiece which is machined roughly by using the picosecond laser device or the femtosecond laser device, and meanwhile, spraying auxiliary gas at a position nearby the machining position; and S30, presetting allowance for finish machining T, detecting residual allowance for machining t by using a dimension precision measurement instrument, repeating the step S10 when t is greater than T, repeating the step S20 when t is greater than 0 and smaller than or equal to T, and repeating in such a way until t is equal to 0. The auxiliary gas is sprayed at the position nearby the machining position, after rough machining by nanosecond laser, finish machining is implemented by picosecond or femtosecond laser, and therefore, machining precision and machining efficiency of the ceramic workpiece are improved.

Owner:GUANGDONG UNIV OF TECH

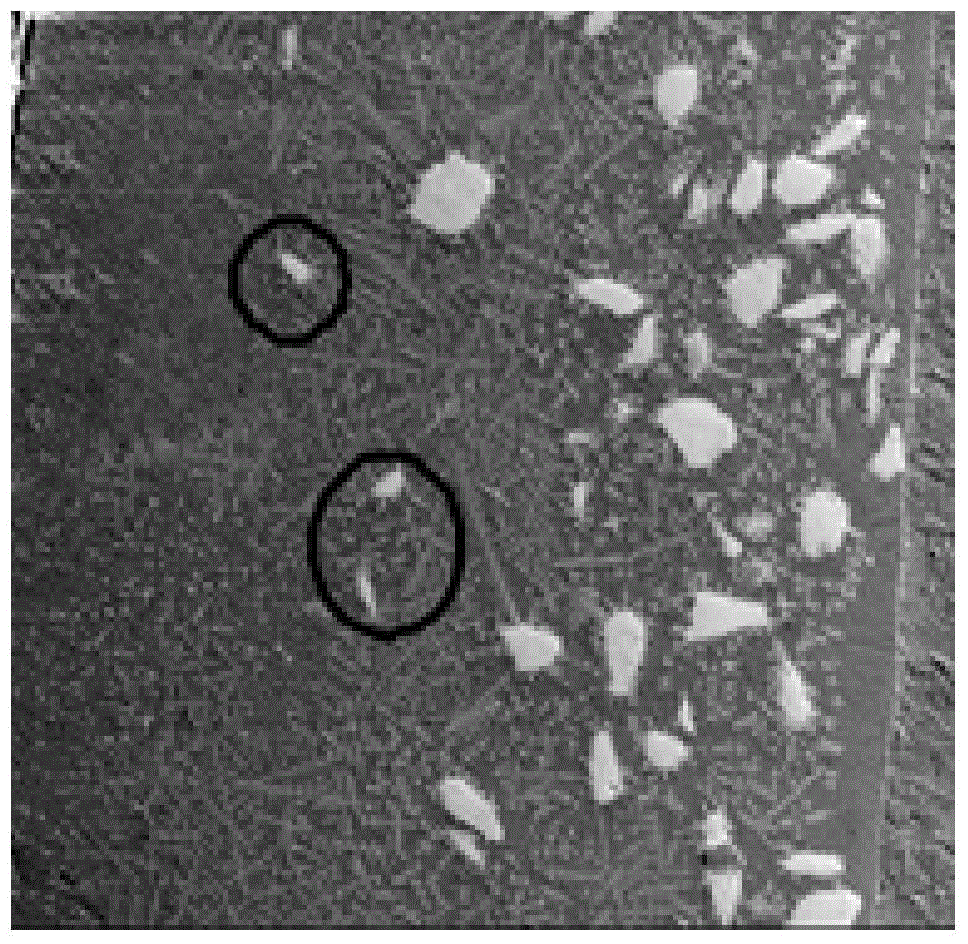

Method for preparing ultra-high hardness cladding layer through synchronous ultrasonic vibration assisting laser technology

InactiveCN104451673AIncreased microhardnessImprove wear resistanceMetallic material coating processesCeramic coatingLiquid metal

The invention provides a method for preparing an ultra-high hardness cladding layer through the synchronous ultrasonic vibration assisting laser technology. According to the specific scheme, the method includes the steps that ultrasonic vibration is synchronously introduced in the Ni-based metal ceramic coating cladding process, mobility of liquid metal can be improved in the mode, tissue distribution is more uniform, in the solidification process, a growing dendrite net can be broken and made to be dispersed to all portions of melt, small crystal nucleuses which are uniformly distributed are formed, segregation of metal ceramic is avoided, and therefore it is guaranteed that the cladding layer is not prone to cracking when ultra-high hardness is acquired; equipment is simple, calibration and installation are facilitated, energy consumption is low, the working environment is good, and acquired coating metal ceramic particles are uniform in distribution, high in hardness and good in abrasion resistance.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

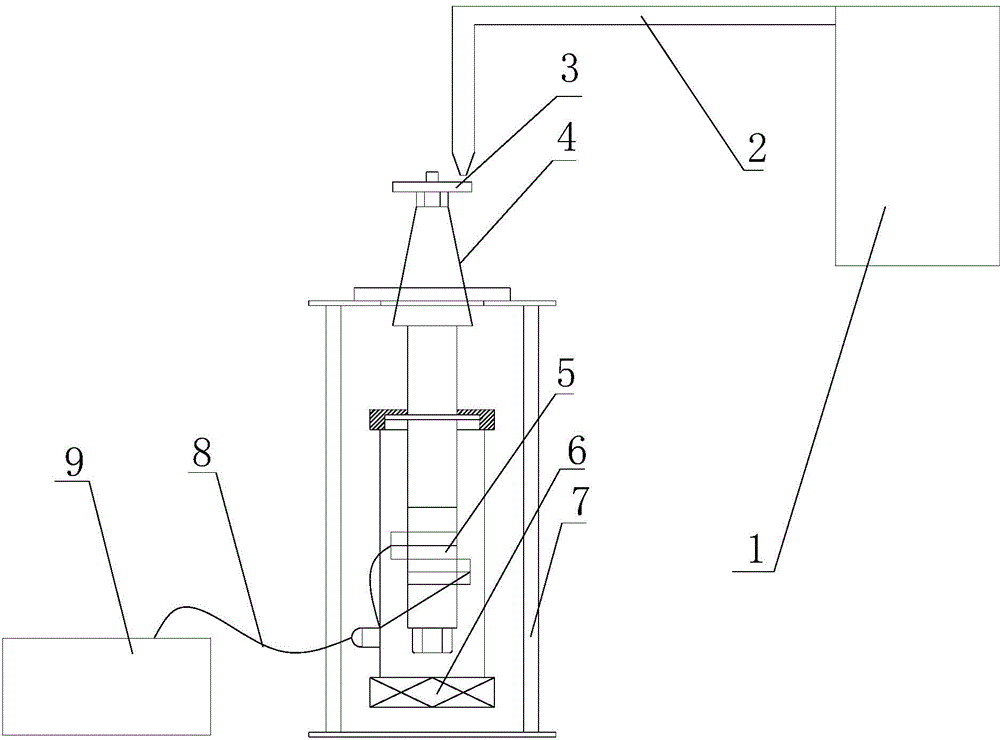

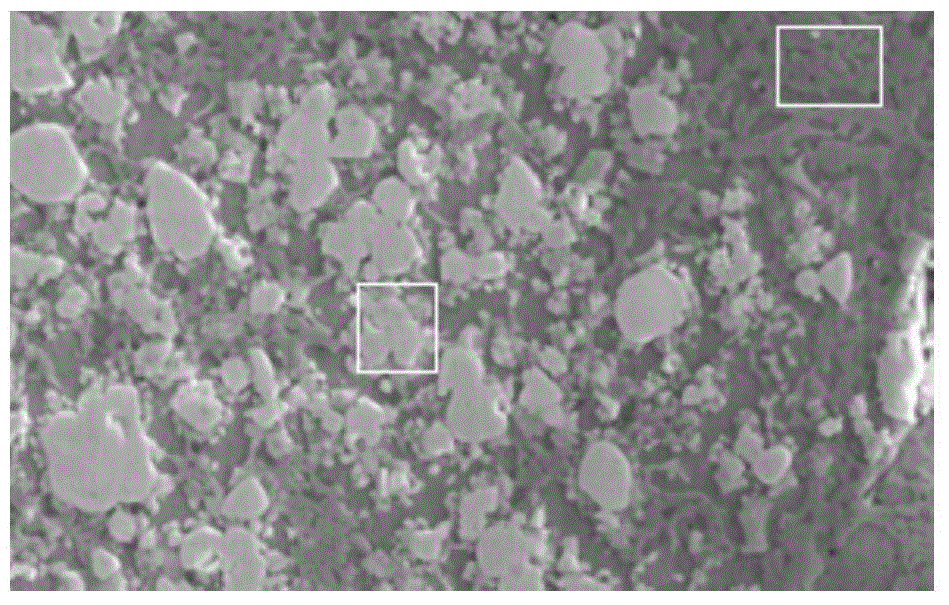

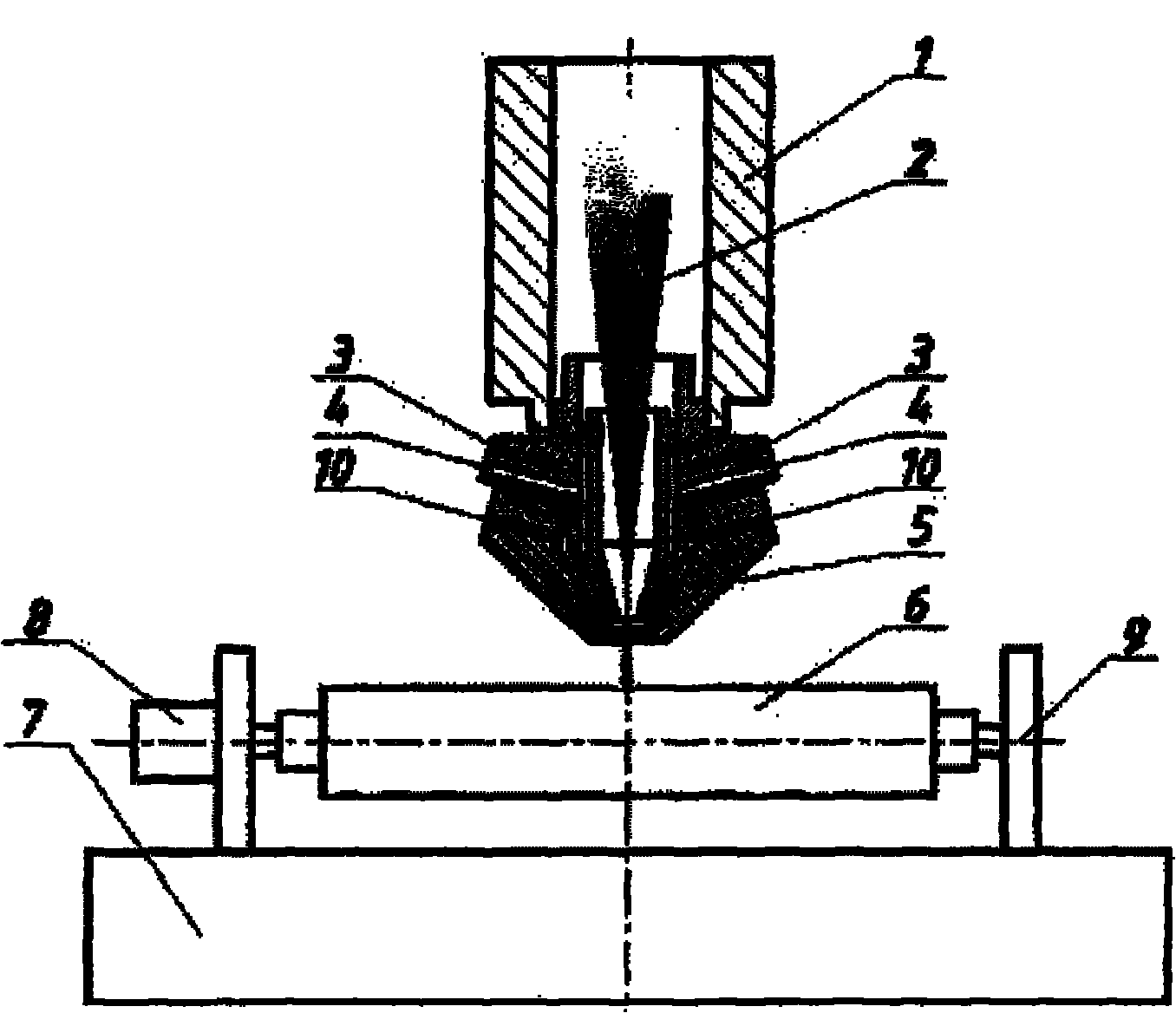

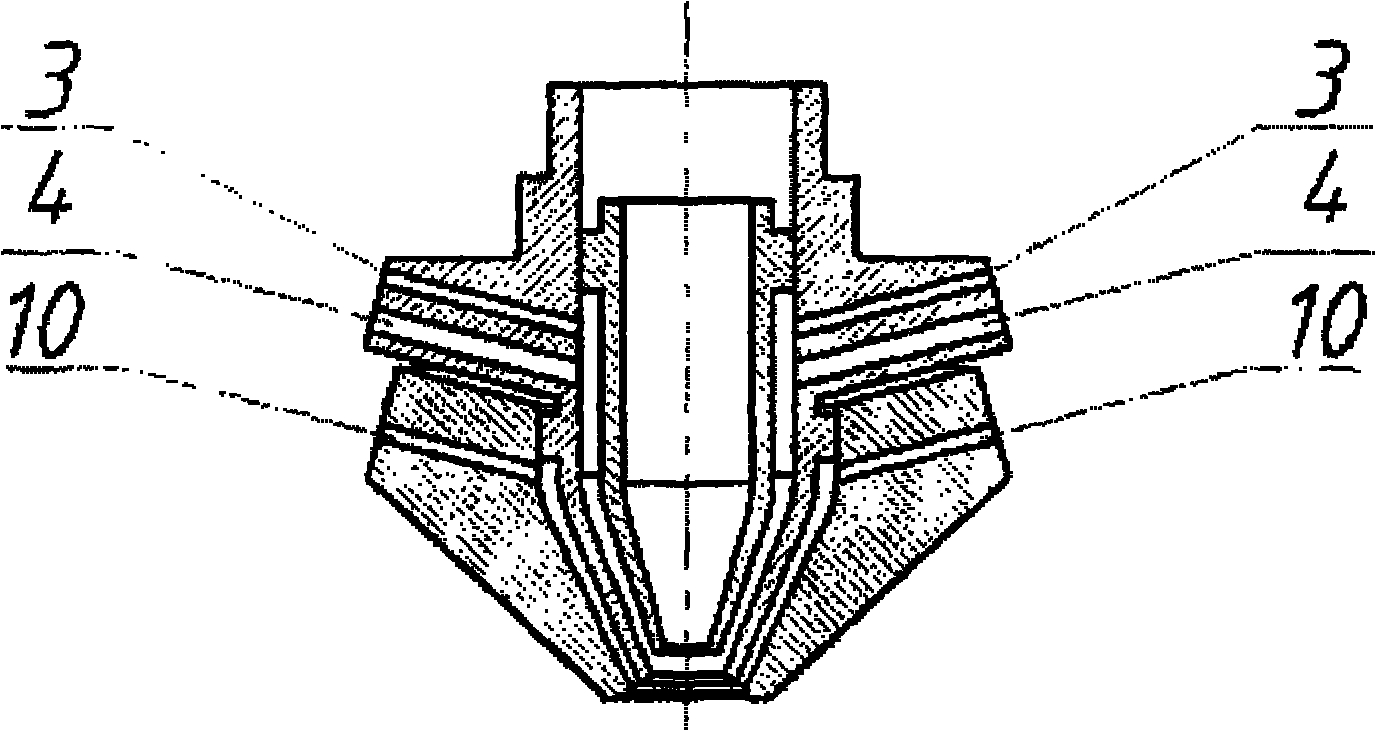

Method and device for preparing working layer of metallurgical hot roll by laser direct deposition

InactiveCN101818342ARealize direct manufacturingReduce flyingMetallic material coating processesLaser technologyAlloy composite

The invention discloses a method and a device for preparing a working layer of a metallurgical hot roll by laser direct deposition, which belong to the field of the application of laser technology. The method is characterized in that high speed steel-like powder and Co-based alloy composite powder are used as the materials for the working layer of the roll. Concretely, the method comprises: filling high speed steel-like powder or mechanically mixed powder which uses Co-based alloy and the like as a substrate material and is added with reinforcing and toughening submicron grains with different amounts into a powder supply system; and performing laser-assisted direct metal deposition on the surface of a roll core, of which the travel is controlled by a worktable, with synchronous powder supply to manufacture the working layer of the roll. A deposition method adopts an alternate deposition mode. The corresponding deposition thickness is determined according to the requirements on the thickness of the working layer. The hard phase content of the powder, in which the Co-based alloy is added as a hard phase, is increased layer by layer so as to form a gradient deposited layer. In the method, the reinforced, toughened and wear-resistance working layer is prepared on the surface of a cheap hot roll core part material by laser-assisted metal direct deposition technology under specific process conditions.

Owner:JIANGSU UNIV

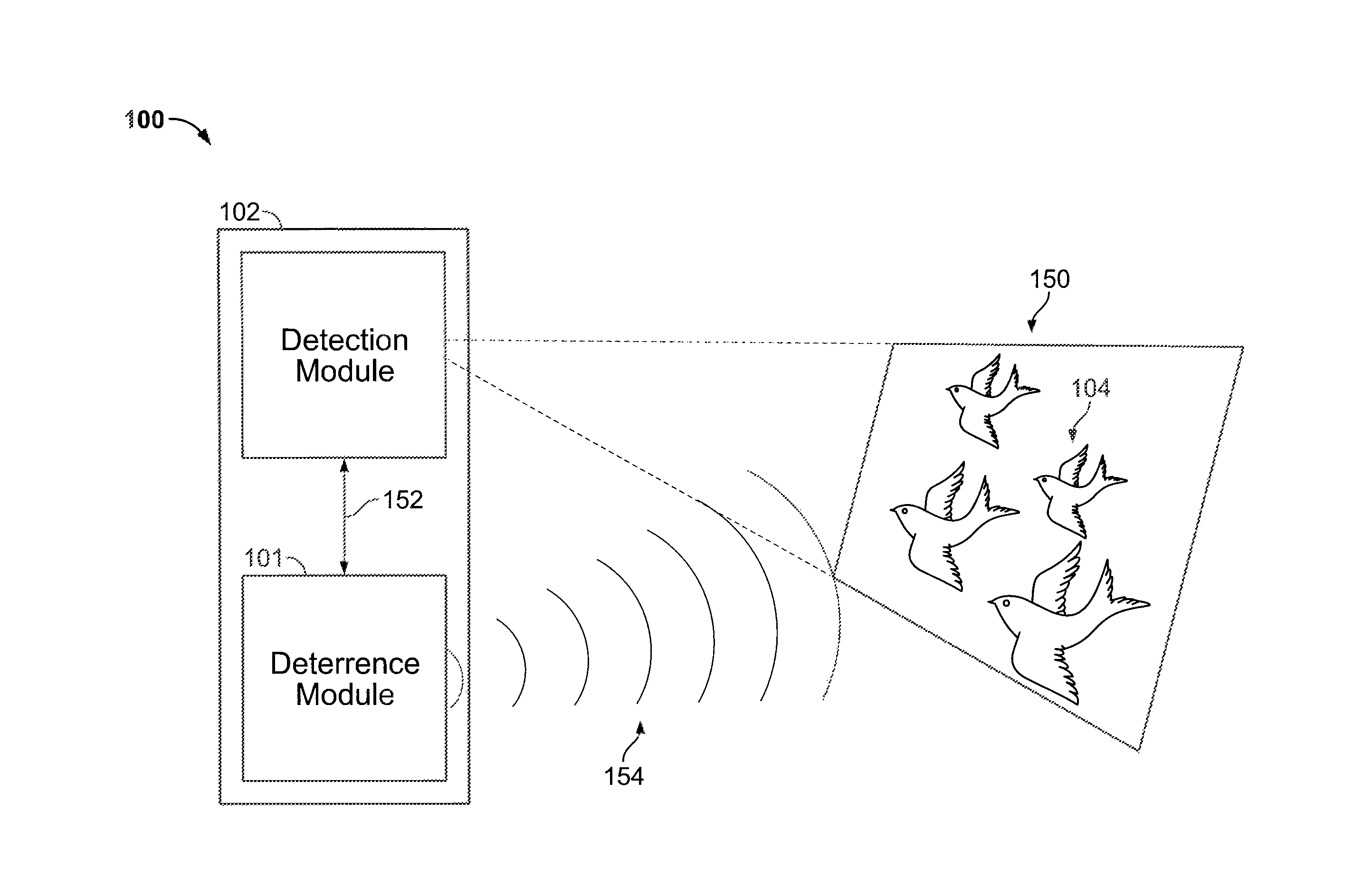

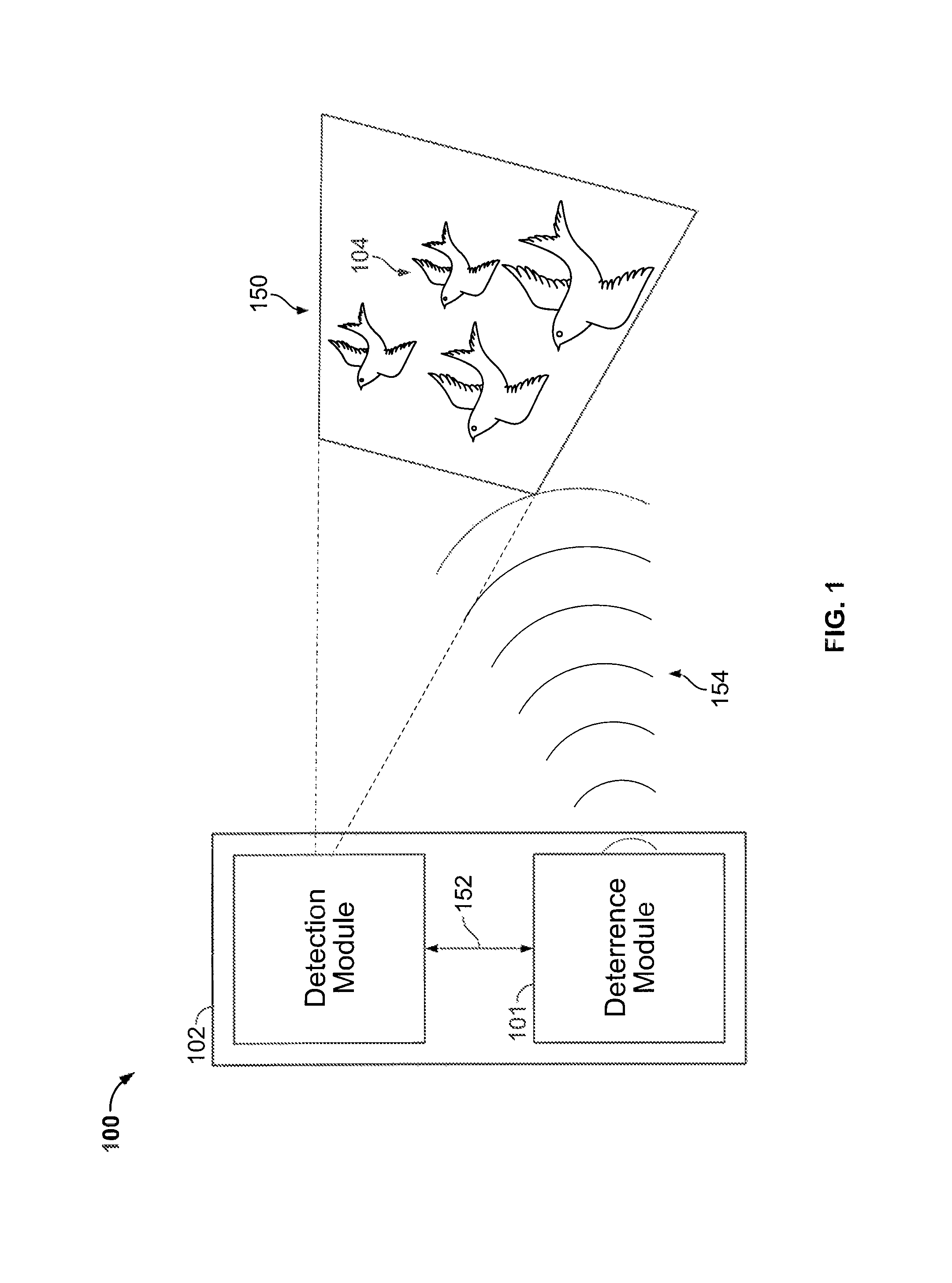

Animal collision avoidance system

Owner:VOLACOM

Mobile terawatt femtosecond laser system (MTFLS) for long range spectral sensing and identification of bioaerosols and chemical agents in the atmosphere

InactiveUS20080180655A1Reduce probabilitySimultaneous measurementLaser detailsRadiation pyrometryFilamentationUltraviolet

The present invention relates to a system for detection and identification of airborne biological, chemical and / or nuclear threats such as toxins, spores, bacteria, and viruses in real time at distances from a few meters to several kilometers. Compact femtosecond terawatt laser technology is combined with spectroscopic and mathematical methods for spectral sensing of airborne warfare agents such as bio-aerosols. Trigger sensors and standoff devices based on mobile terawatt femtosecond laser systems are provided that may be placed at strategic monitoring locations. Furthermore, the invention relates to the propagation of airborne ultra-short, ultra-intense laser pulses giving rise to plasma channels (filamentation) producing white light supercontinuum ranging from the ultraviolet (UV), visible (VIS), near infra-red (NIR) and middle infra-red (MIR). According to this invention, the supercontinuum can be directly produced in a particle cloud and hence is uniquely suitable for multi-spectral long-range atmospheric agent and radioactive isotope detection.

Owner:APPLIED PHOTONICS WORLDWIDE

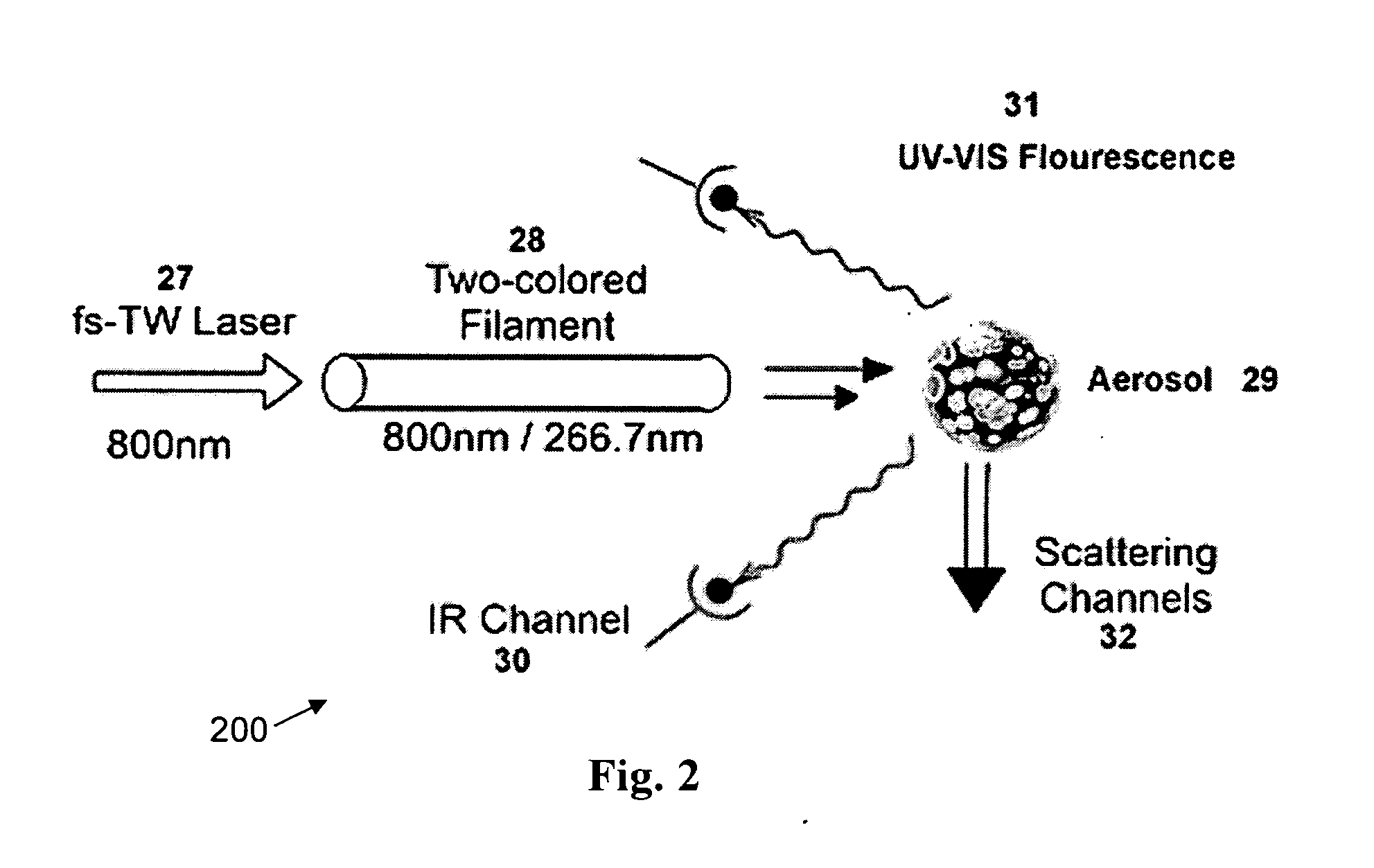

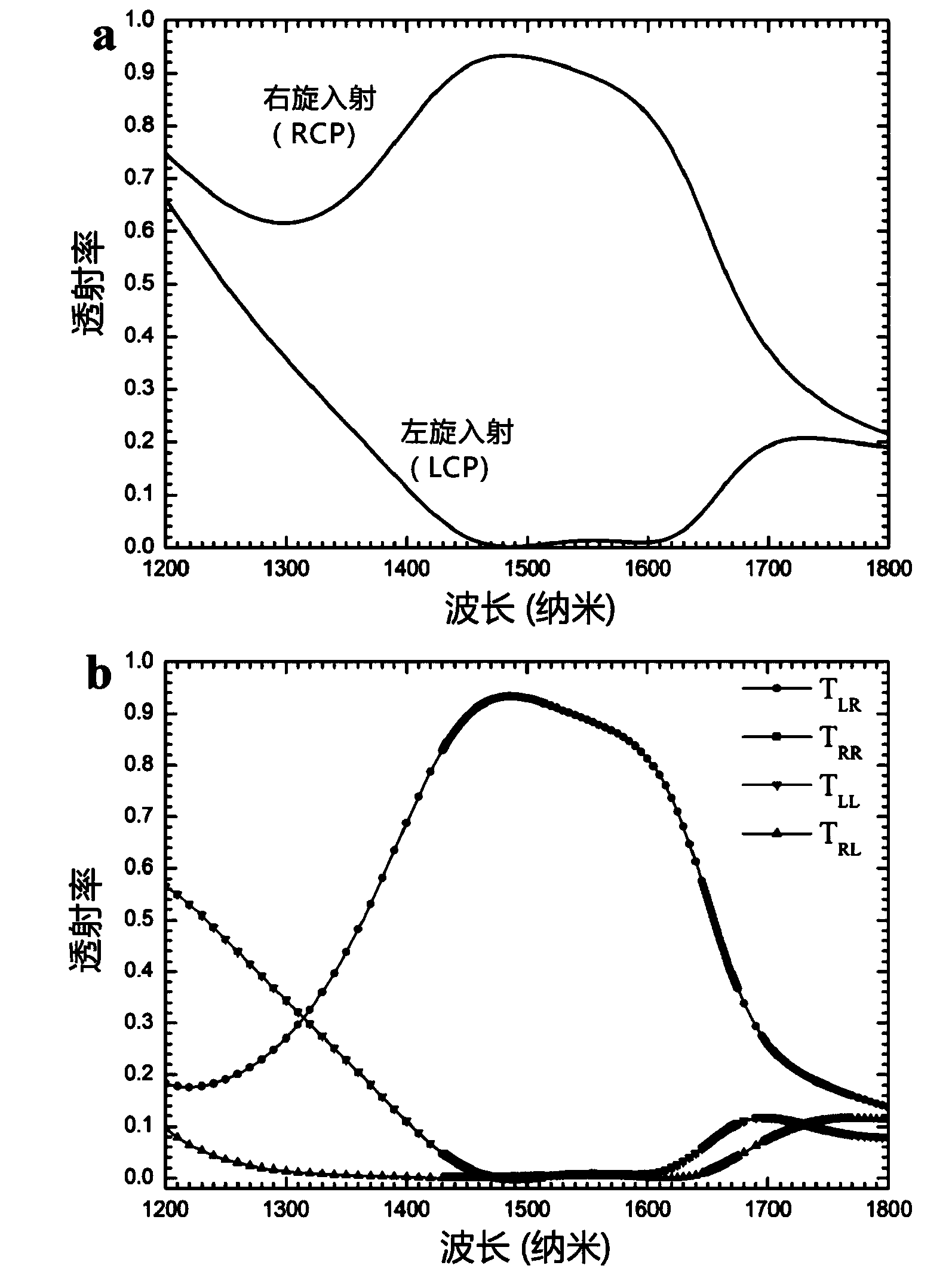

Single-layer planar chirality metal structure circular polarizer

InactiveCN104316988AReduce difficultyReduce processing costsPolarising elementsAntennasPlanar chiralityPolarizer

The invention relates to a single-layer planar chirality metal structure circular polarizer which belongs to electromagnetic wave devices, and belongs to the technical field of electromagnetic waves of optics, terahertz, microwaves and other frequency bands. The circular polarizer is formed by a single-layer metal structure with planar chirality, and the functions of the circular polarizer are achieved on the basis of a one-way mode switching principle. The circular polarizer is easy to machine and integrate, thin, small in size and compact in structure, has high efficiency of screening on left-hand and right-hand circular polarization electromagnetic waves, and is low in device absorption loss and high in transmittance. By changing the design of the size and the structural design of the circular polarizer, the circular polarization function can be achieved at different electromagnetic frequency bands such as optics, terahertz and microwaves. The circular polarizer can achieve low-cost and large-area manufacturing, and has important application in the fields of optical microscopy, three-dimensional display, laser technologies, communication, radar and the like.

Owner:NAT UNIV OF DEFENSE TECH

Ice bagging system and method

This apparatus relates to ice-bagging apparatuses with an ice maker and a hopper for receiving ice from the ice maker. The apparatus utilizes rotating drums designed for delivering ice into a bag. The apparatus also possess bagging and drop mechanism which fills and mechanically seals each bag of ice and drops it into a freezer for storage. The apparatus has an electronic operating system that has been greatly simplified using infrared technology and / or laser technology. The operating system is connected with the internet and a central processing center to allow for complete managing and monitoring of the system.

Owner:ICEX HLDG +1

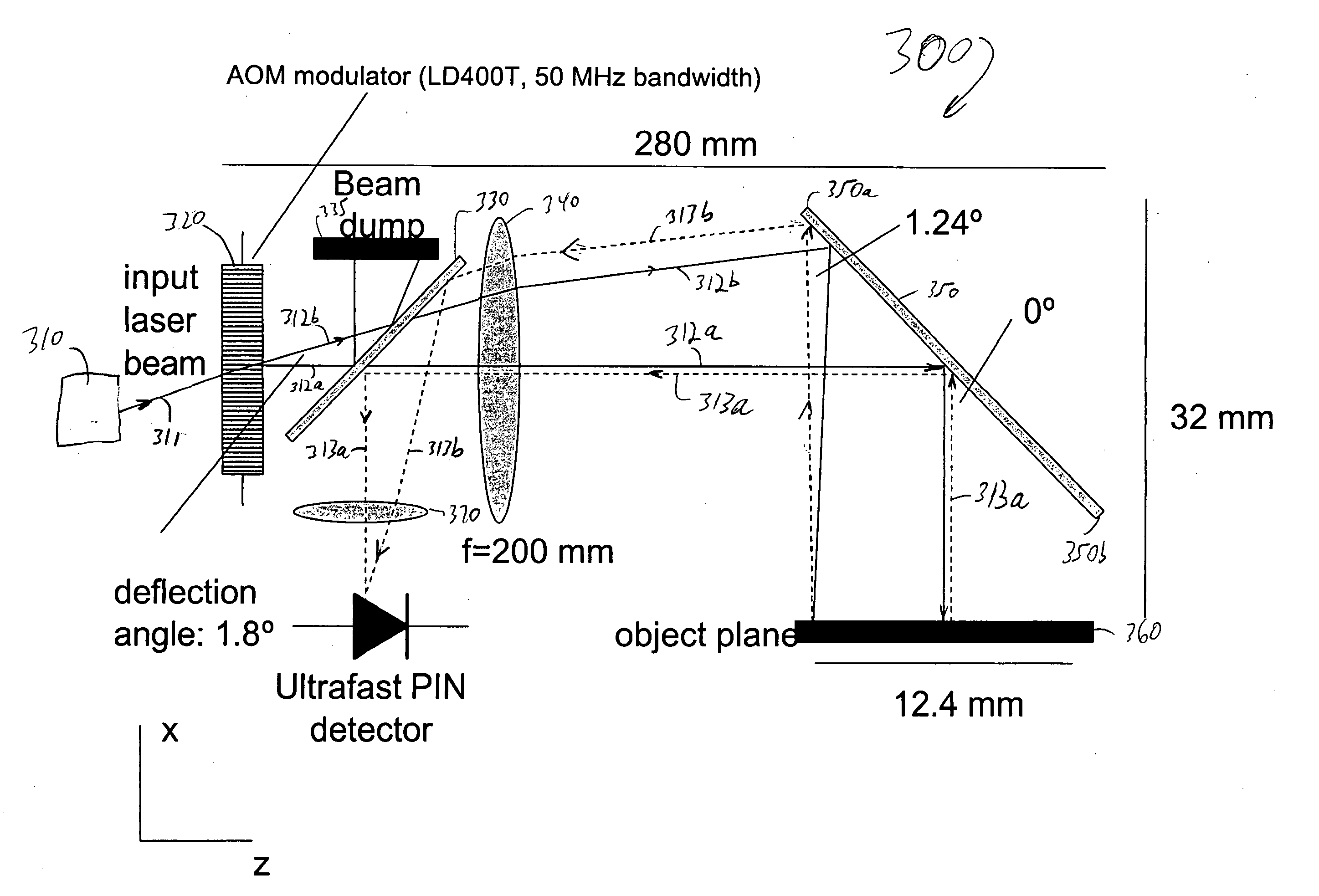

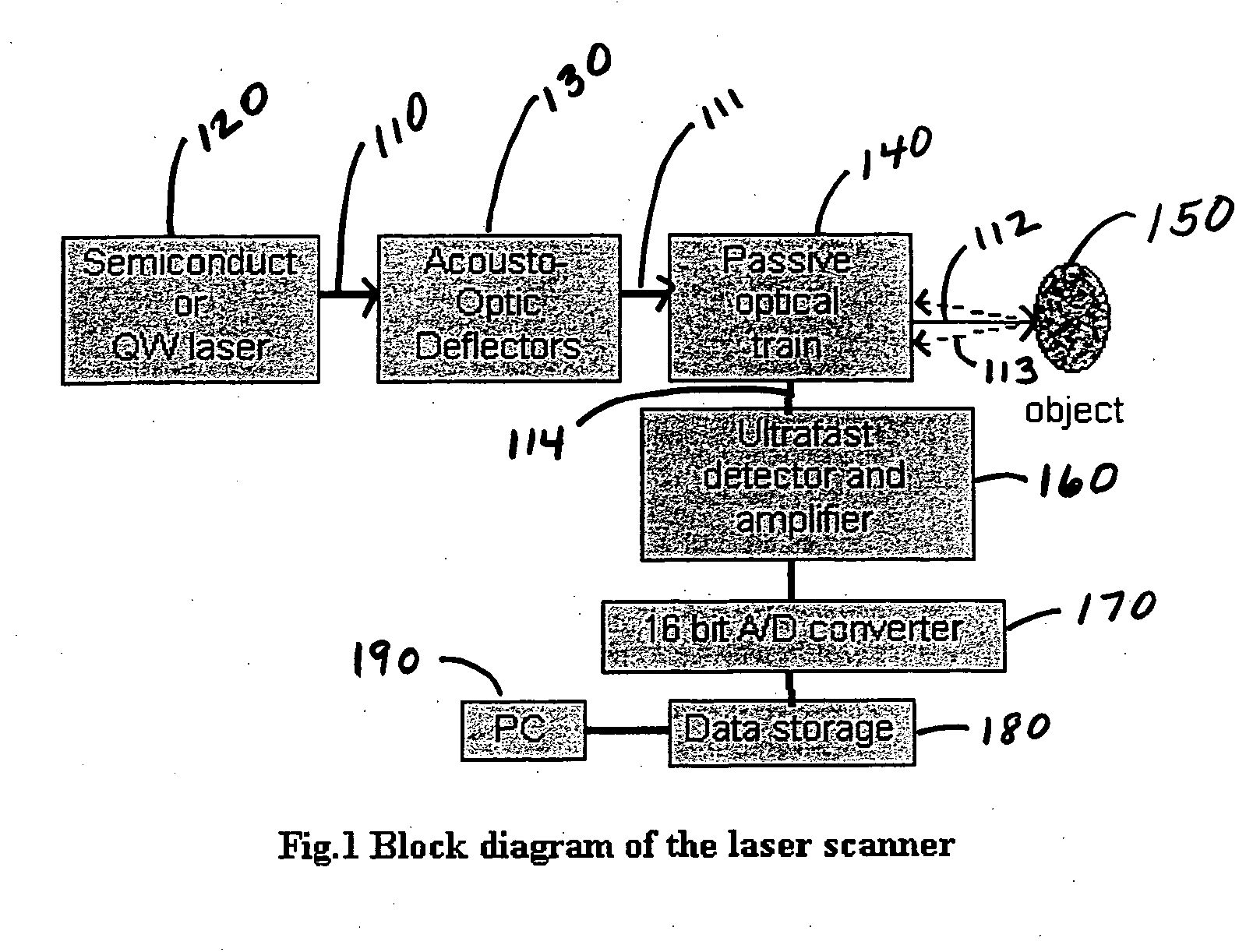

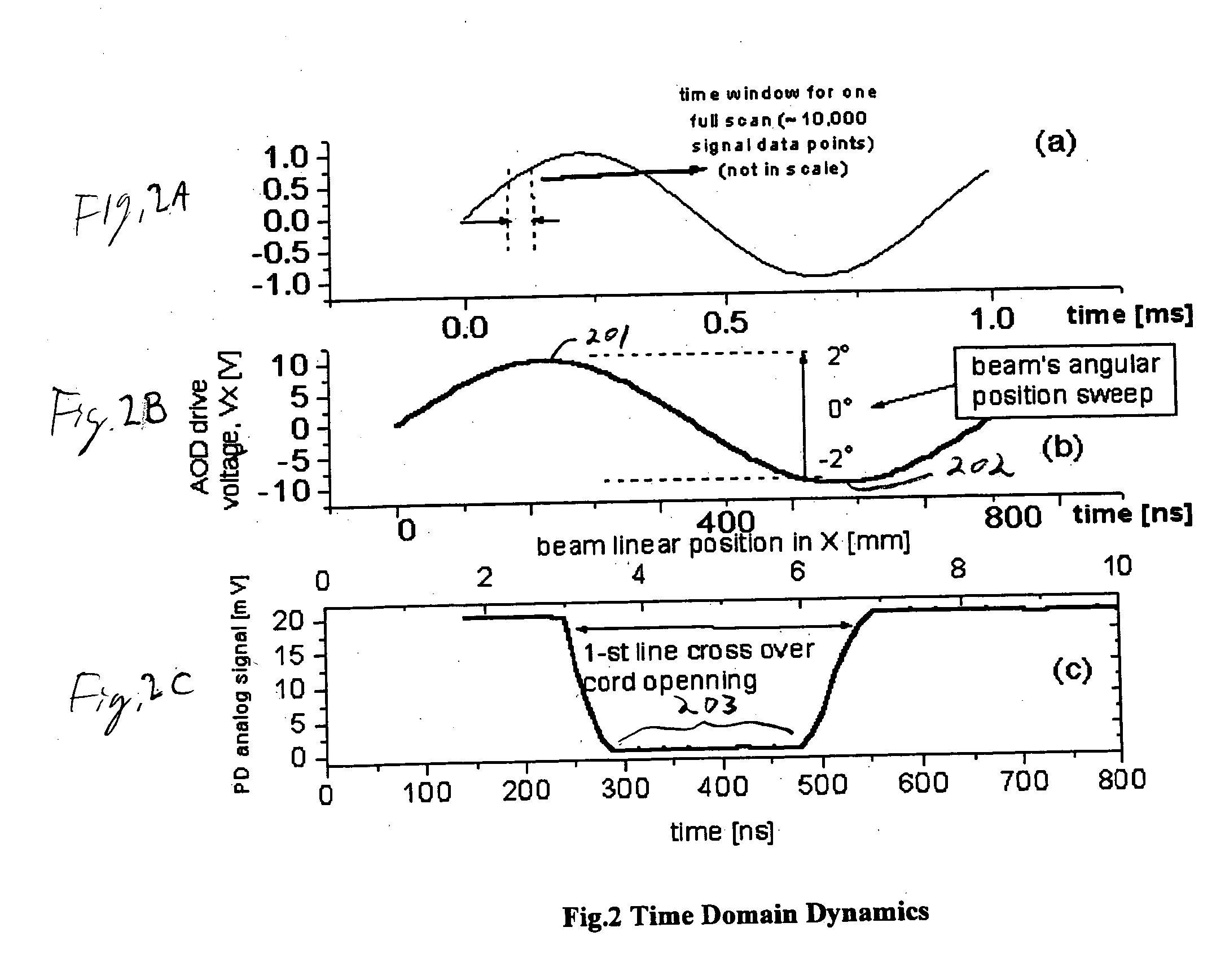

High speed imaging system

InactiveUS20060235693A1Improved current clinical laryngeal imaging instrumentationFast signal processingBronchoscopesLaryngoscopesMillimeterBeam delivery

A system for imaging high speed moving objects, for example, using a scanning beam and beam delivery optics with fast signal processing. It can allow for vocal fold imaging at up to or exceeding approximately 1000 frames per second with grayscale resolution as high as about 100 micrometers or higher and up to about a 12.4 mm square or larger viewing area. The invention can provide imaging of vocal fold vibration that correlates completely with a synchronously-acquired acoustic voice signal. This can enable physicians, voice therapists and research scientists to understand the consequences of abnormal laryngeal dynamics, rather than being limited to simply observing the dynamics. Further, the application of laser technology will allow for accurate measurements of dimension. This can objectify examination findings and treatment outcomes measurement, helping to overcome the serious limitations of current perceptual-based judgments.

Owner:INCRYS

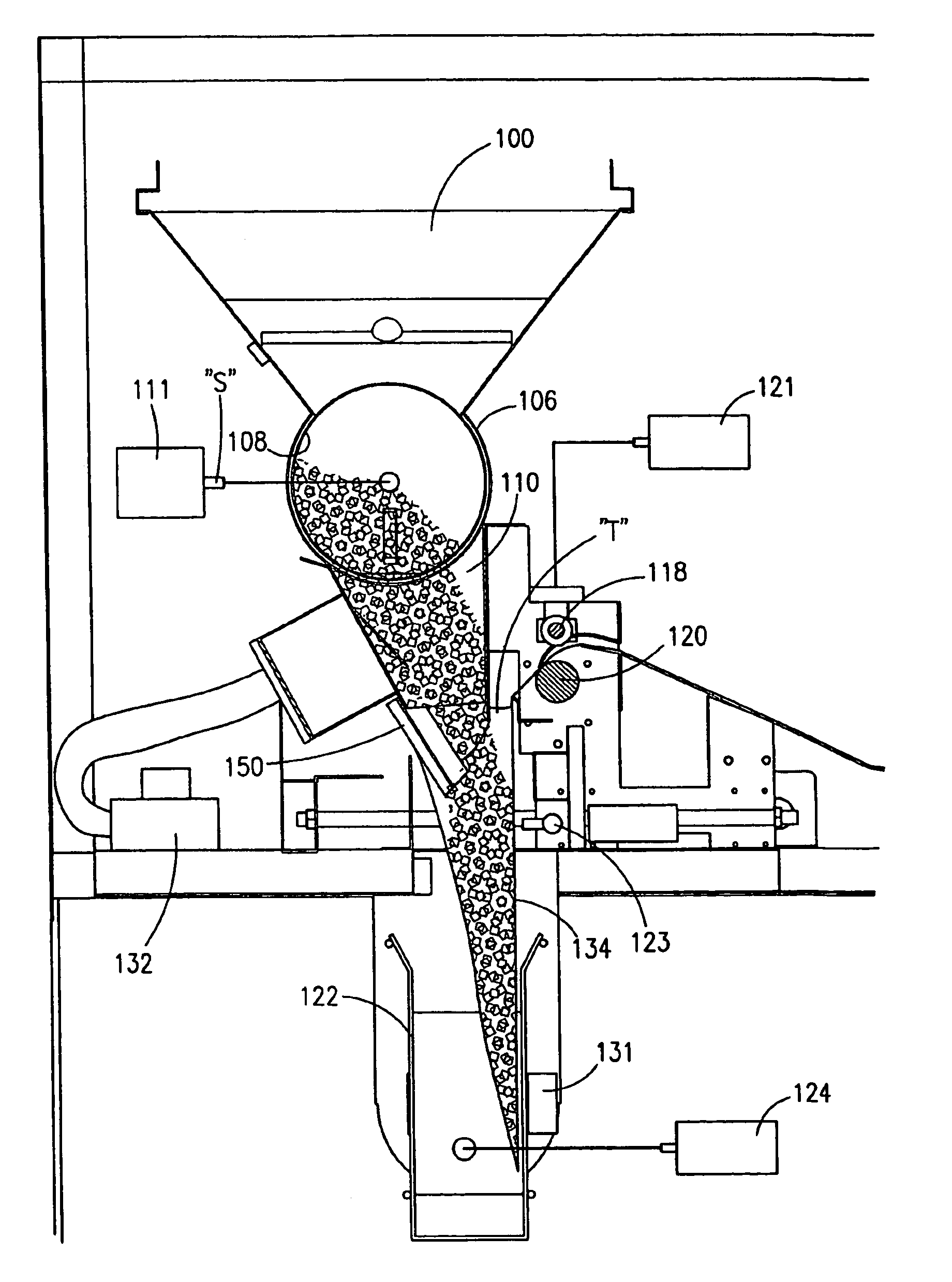

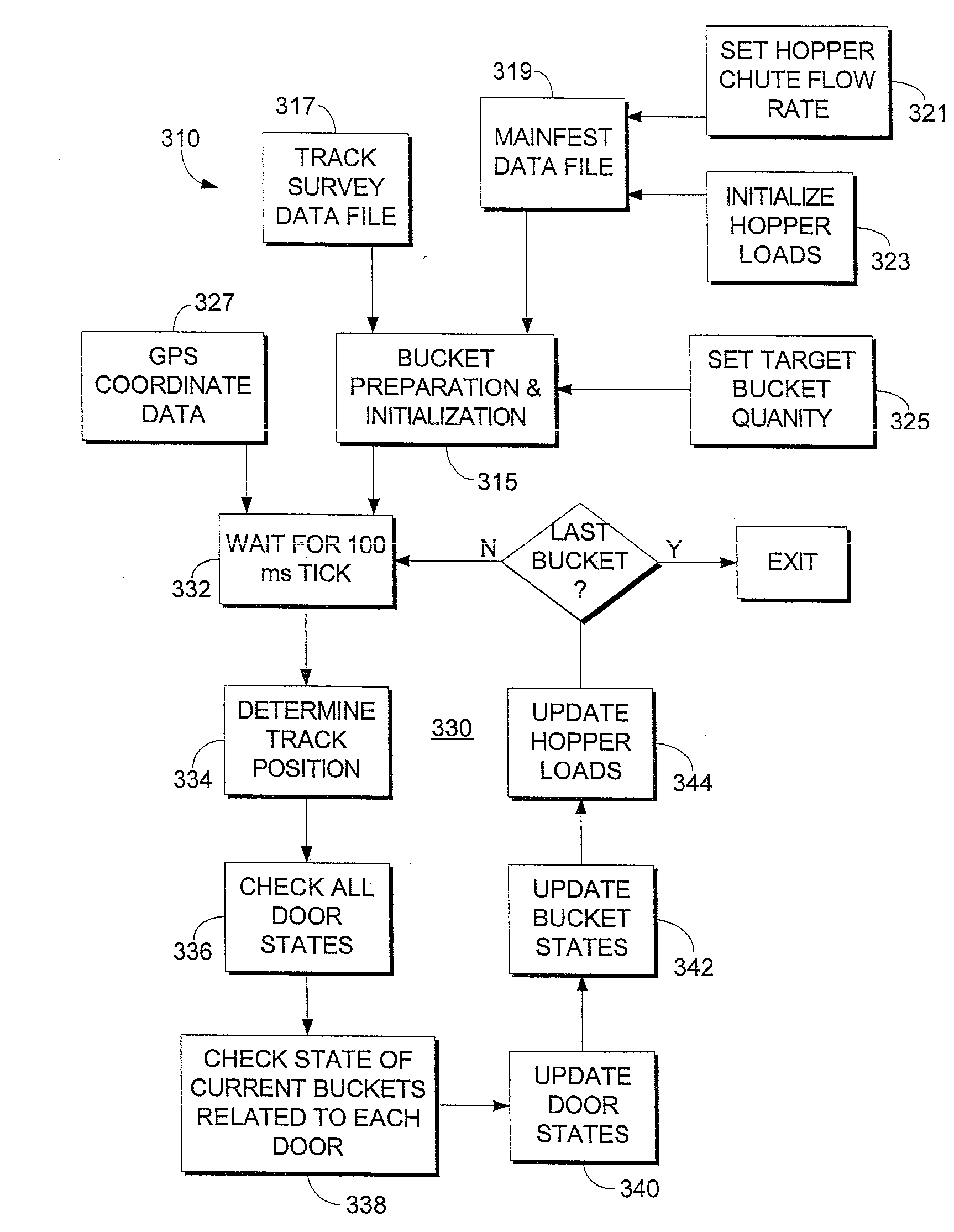

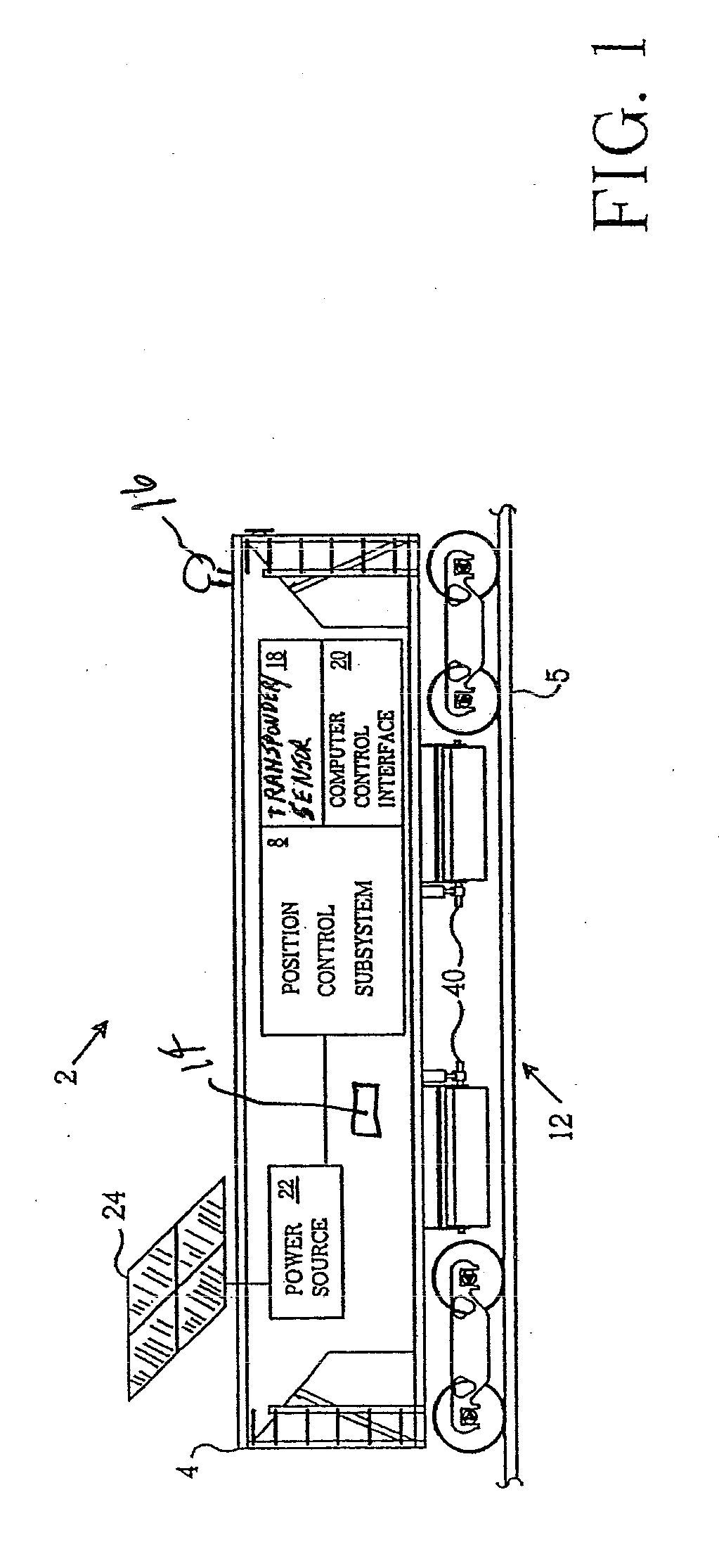

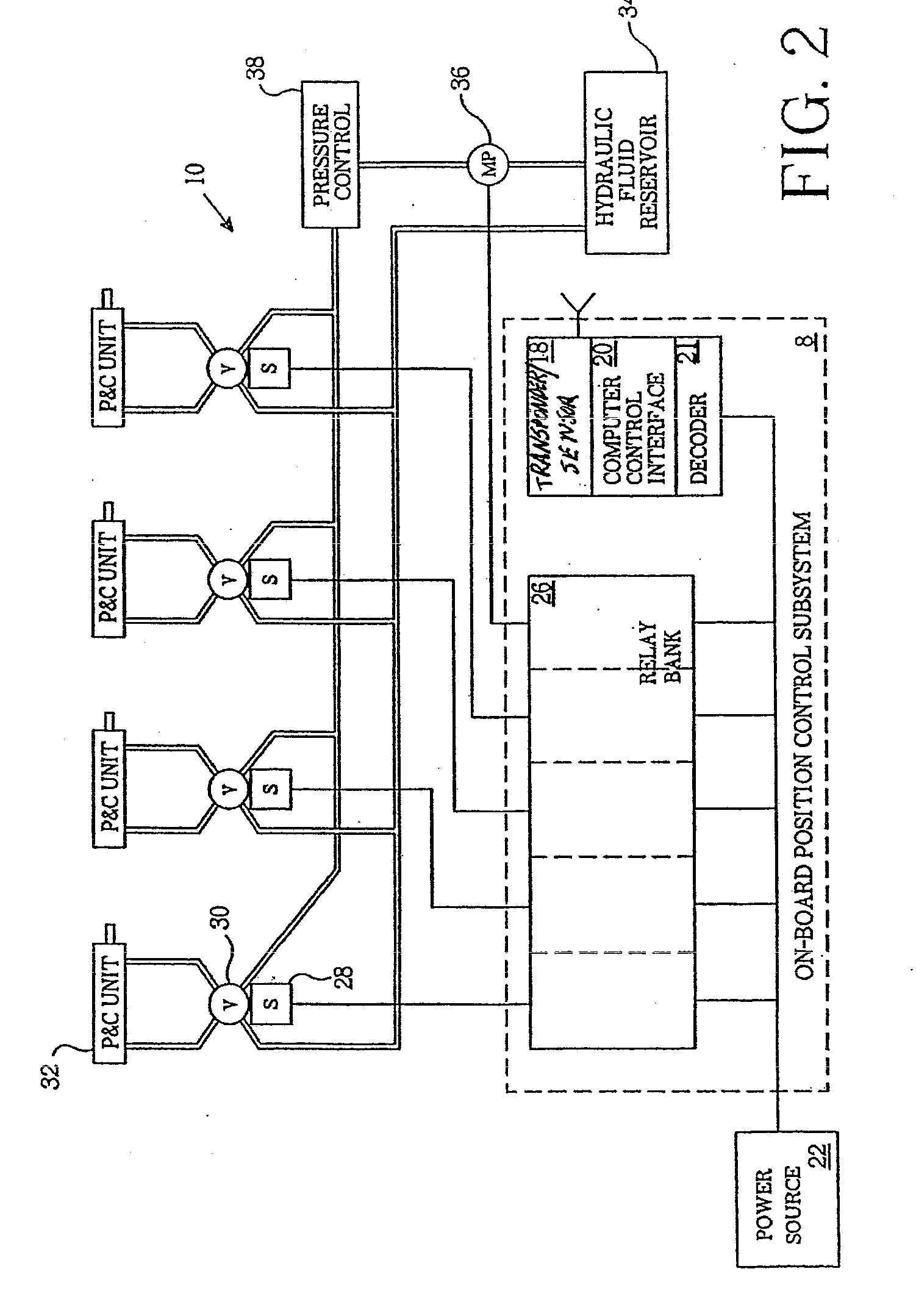

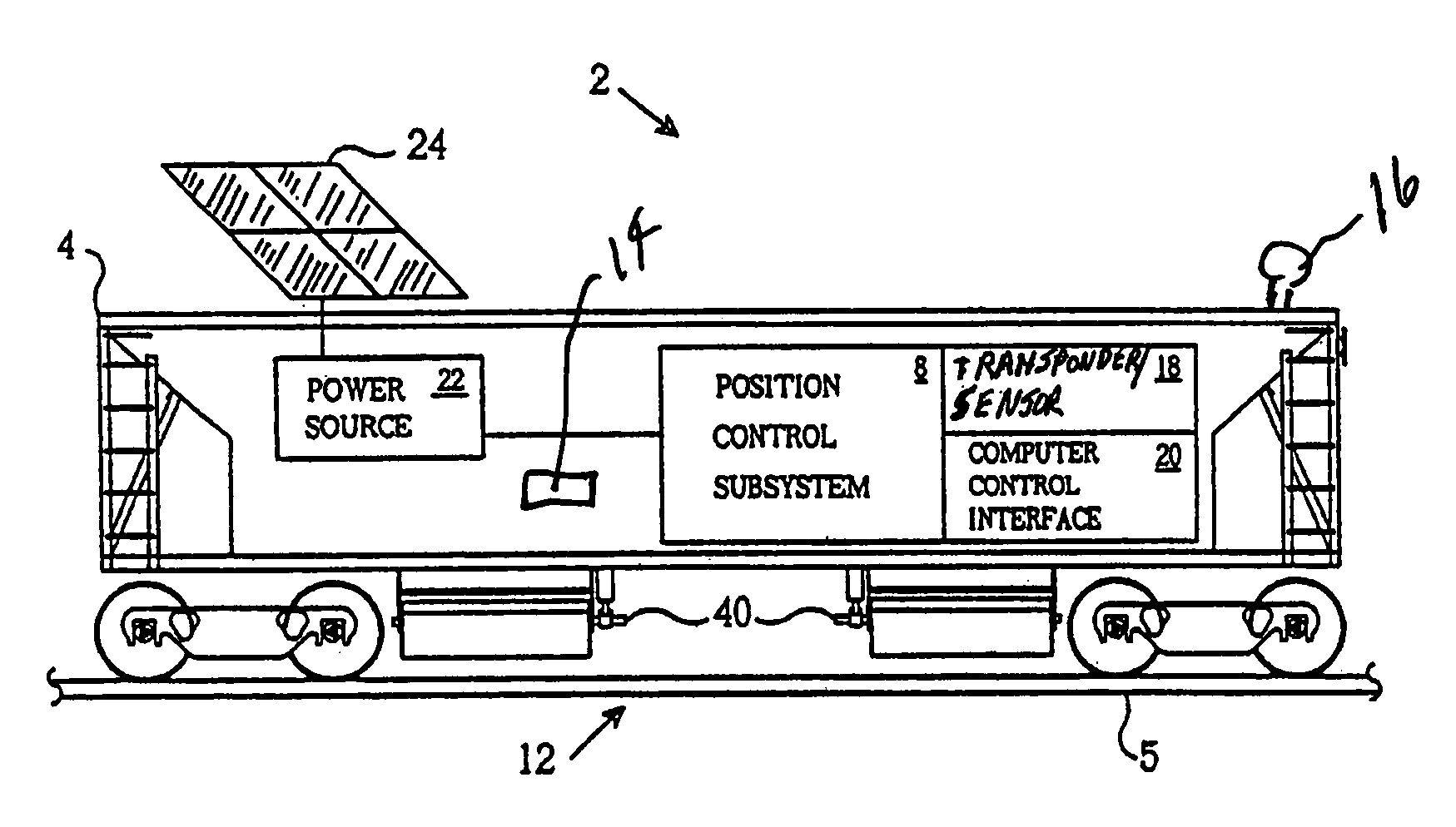

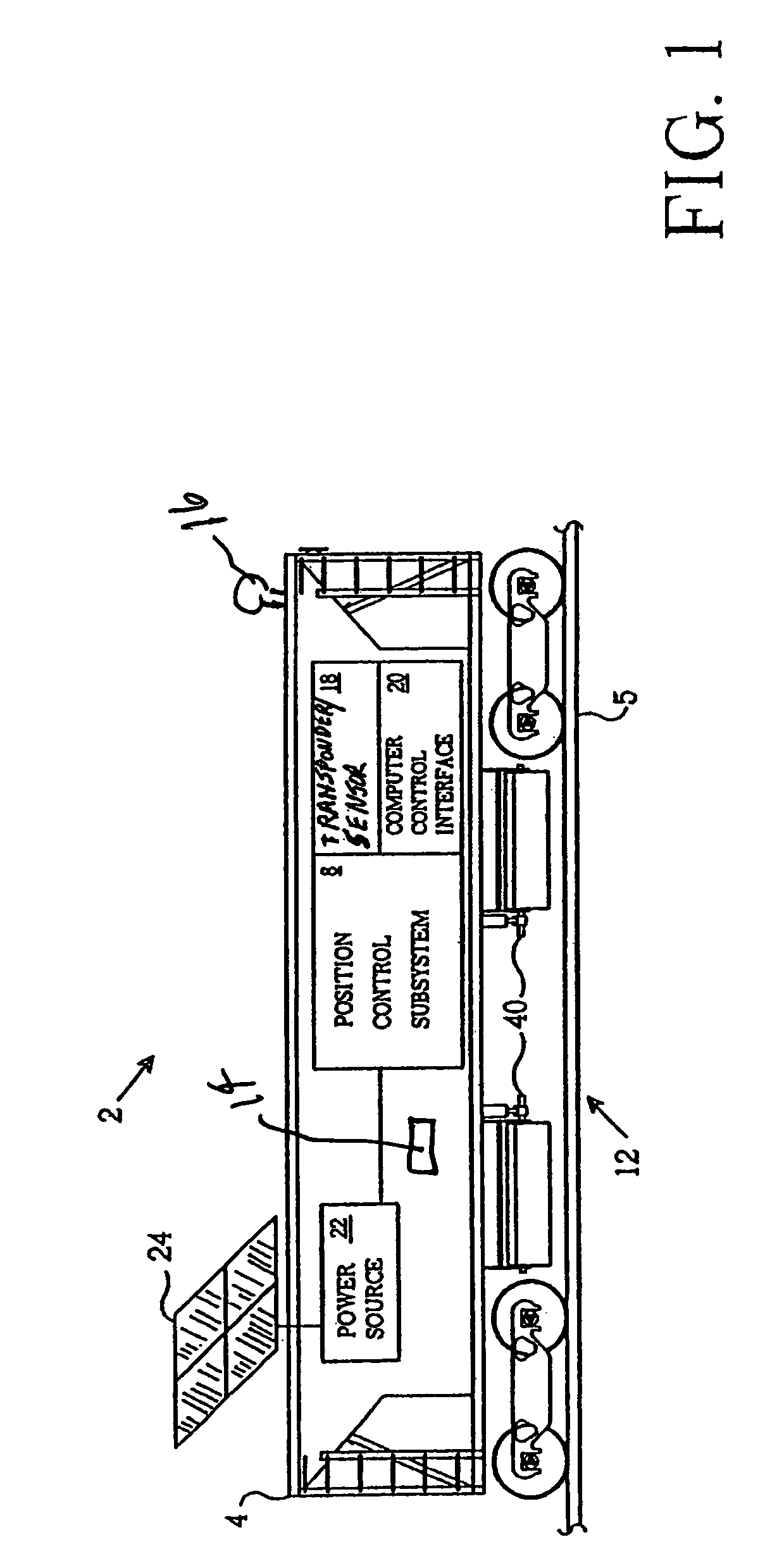

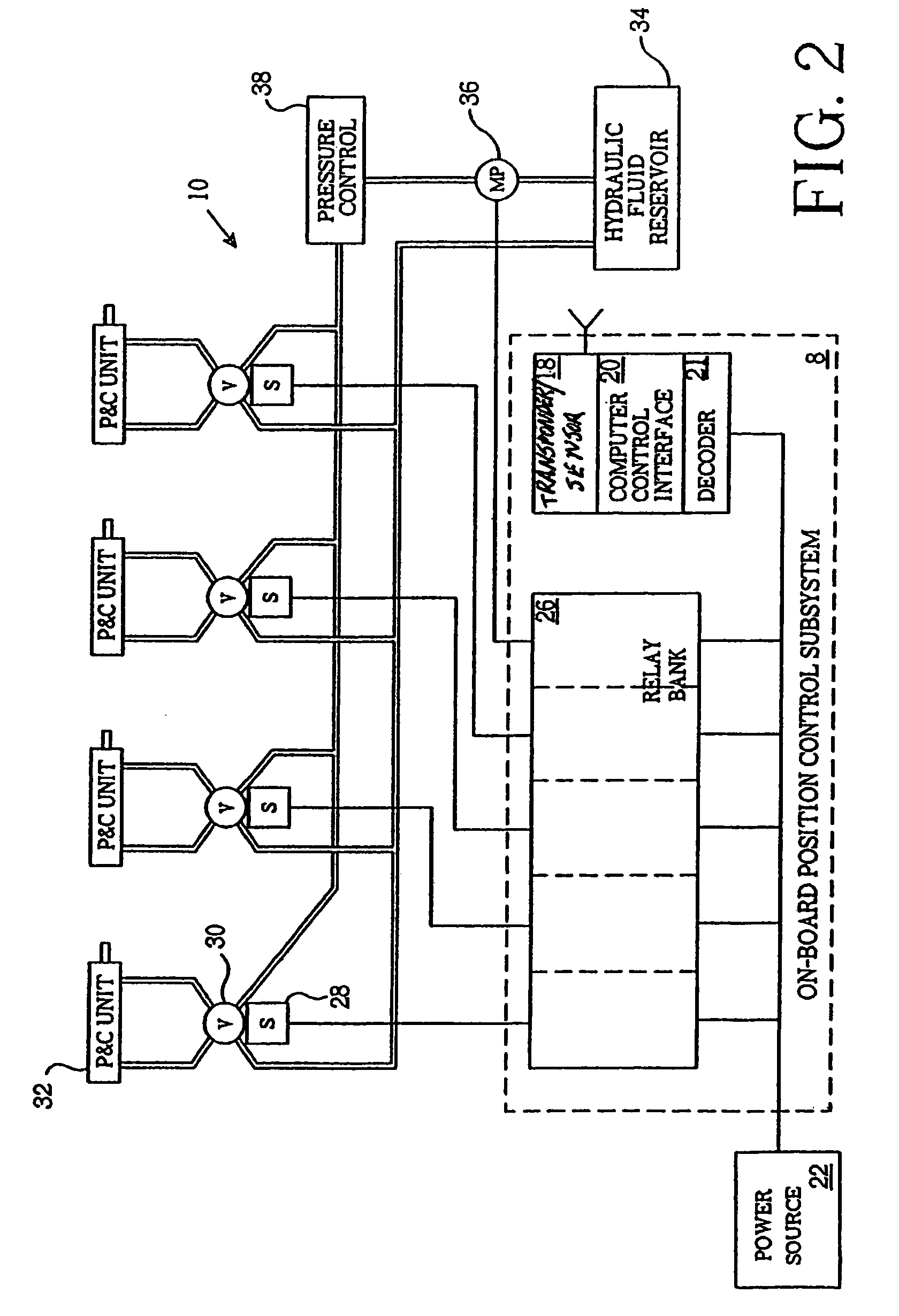

Method and apparatus for applying railway ballast

InactiveUS20070129858A1Control spreadImprove accuracyBallastwayDigital data processing detailsTerrainAviation

A method and apparatus for spreading ballast along railways makes use of an inertial measurement system to determine where to apply ballast from a hopper car. A variety of techniques can be used to determine the location and speed of the ballast spreading train, including manual or automated visual techniques, laser technology, radar technology, radio frequency transponders, magnetic sensor, thermal imaging and aerial photogrammetry. The invention also contemplates “on the fly” surveys and terrain profiling using lasers or radar.

Owner:HERZOG CONTRACTING

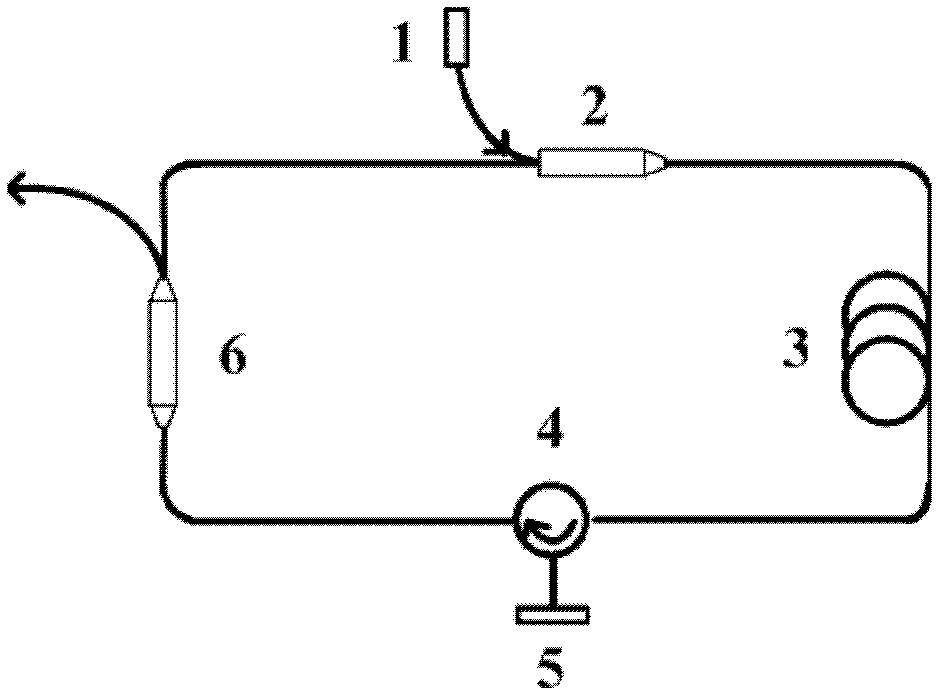

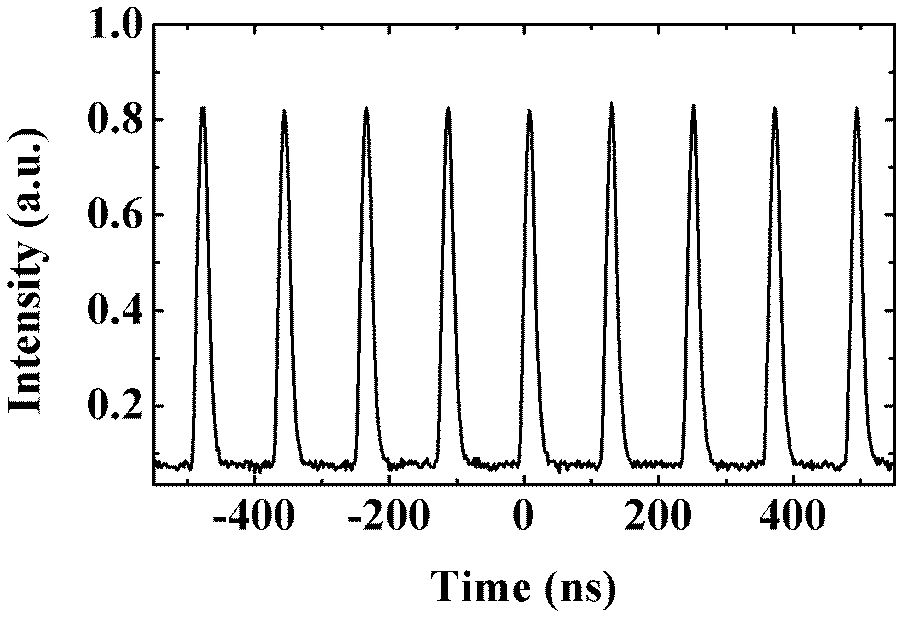

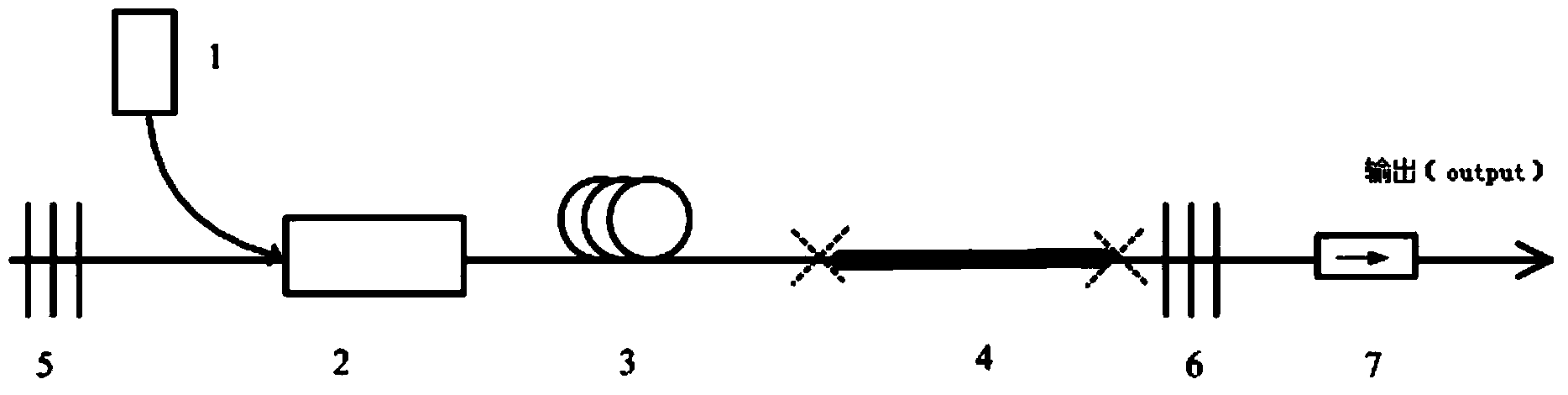

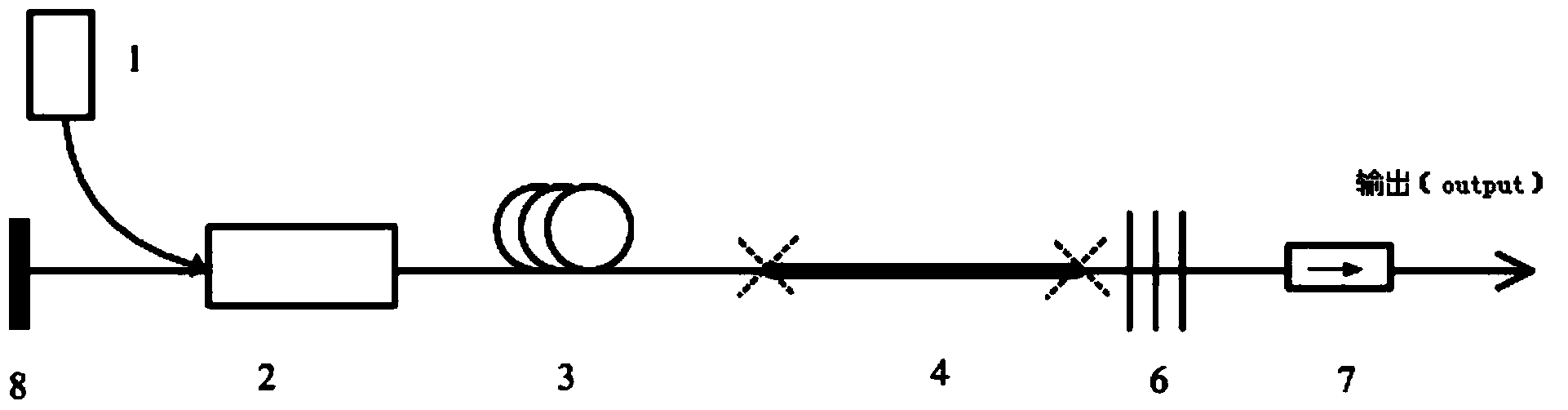

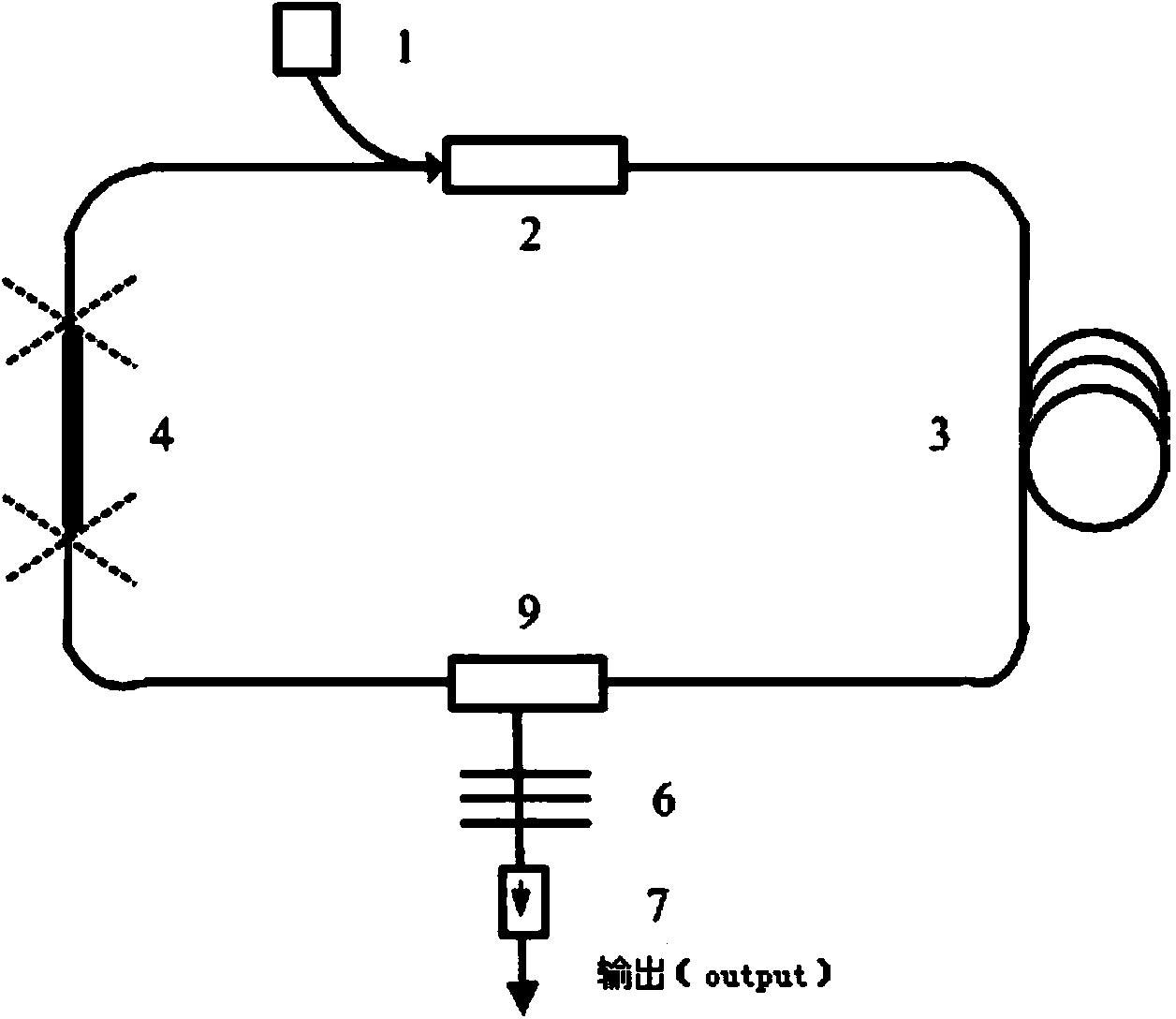

Passive mode-locking ultrashort pulse all-fiber laser with waveband of 2.0 microns

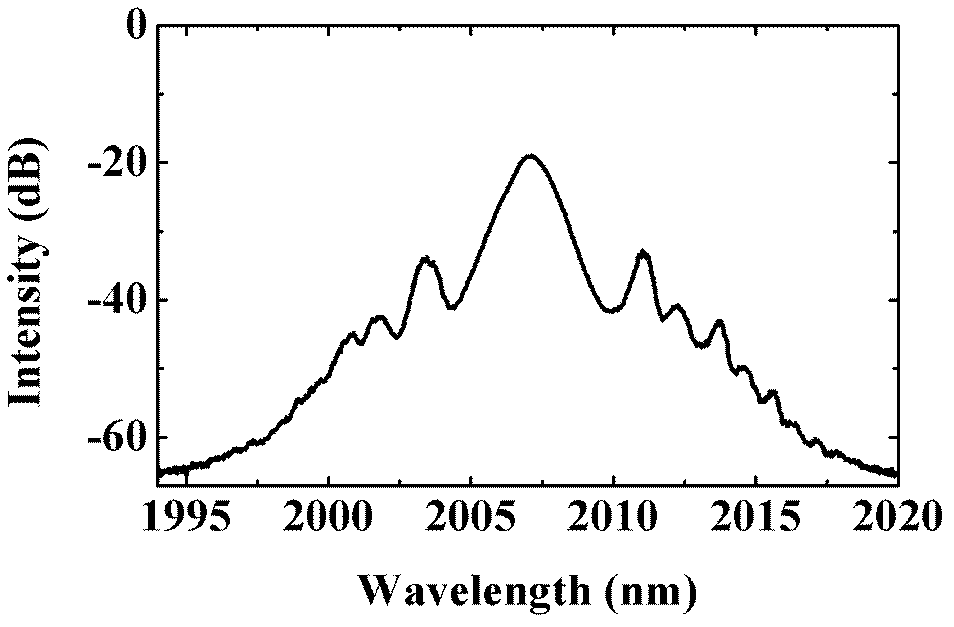

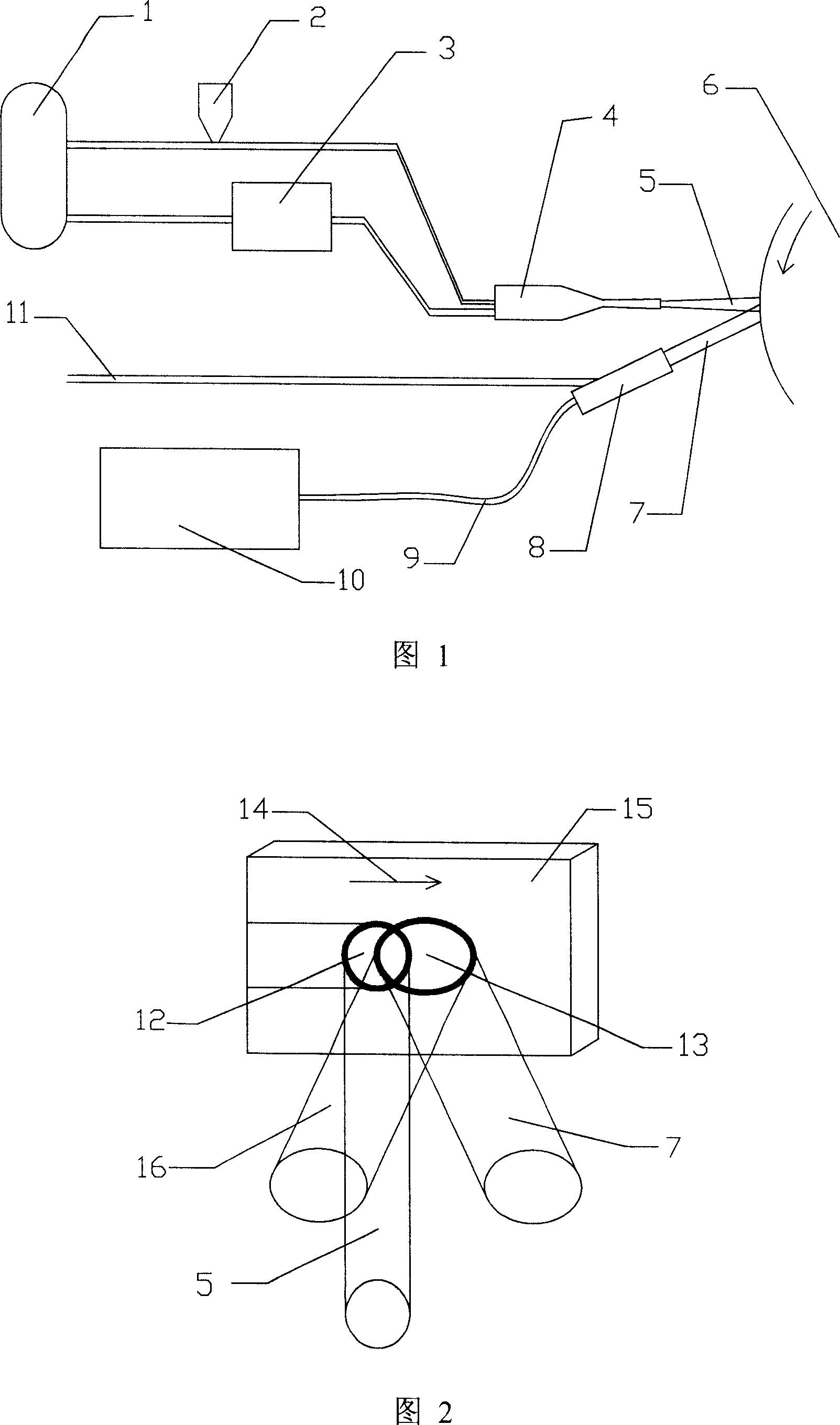

InactiveCN102368584AGood environmental stabilityEasy to realize industrial applicationActive medium materialActive medium shape and constructionGratingNonlinear optics

The invention relates to a passive mode-locking ultrashort pulse all-fiber laser with a waveband of 2.0 microns and belongs to the field of a laser technology and nonlinear optics. The passive mode-locking ultrashort pulse all-fiber laser with the waveband of 2.0 microns mainly comprises a laser pumping source, a pumping combiner, thulium-doped or thulium-holmium-codoped rear earth doped fibers, a circulator, a saturable absorber, a laser beam splitter, an isolator, a fiber bragg grating, a polarization controller and the like. The thulium-doped or thulium-holmium-codoped rear earth doped fibers are used as a gain medium; the saturable absorber is used as a passive mode-locking device; and the output of an ultrashort laser pulse which is in the waveband of 2.0 microns and has high pulse energy is realized. Due to the adoption of the all-fiber structure design, the passive mode-locking ultrashort pulse all-fiber laser with the waveband of 2.0 microns has the advantages of simple structure, high environment stability and the like, and the industrialization application is easy to realize.

Owner:BEIJING UNIV OF TECH

Cold air power spraying and coating method containing laser irradiation

ActiveCN101153393ALow critical speedReduce hardnessHeat inorganic powder coatingOptoelectronicsLaser beams

The invention relates to the cold gas dynamic spray technology and the laser technology, in particular to a cold gas dynamic spray method comprising laser irradiation, wherein, compressed gas which carries with metallic powder impacts against the surface of a plaque at supersonic speed to form a circular spray spot on the surface of the plaque; meanwhile, an elliptic irradiation laser speckle is formed directly ahead of the circular spray spot through laser beam irradiation; moreover, the elliptic irradiation laser speckle and the circular spray spot are partly overlapped. The invention can substantially reduce the particle critical speed during cold gas dynamic spray and increases splicing efficiency and strength to ensure structural stability of spray particles, thereby improving coating performance.

Owner:BAOSHAN IRON & STEEL CO LTD

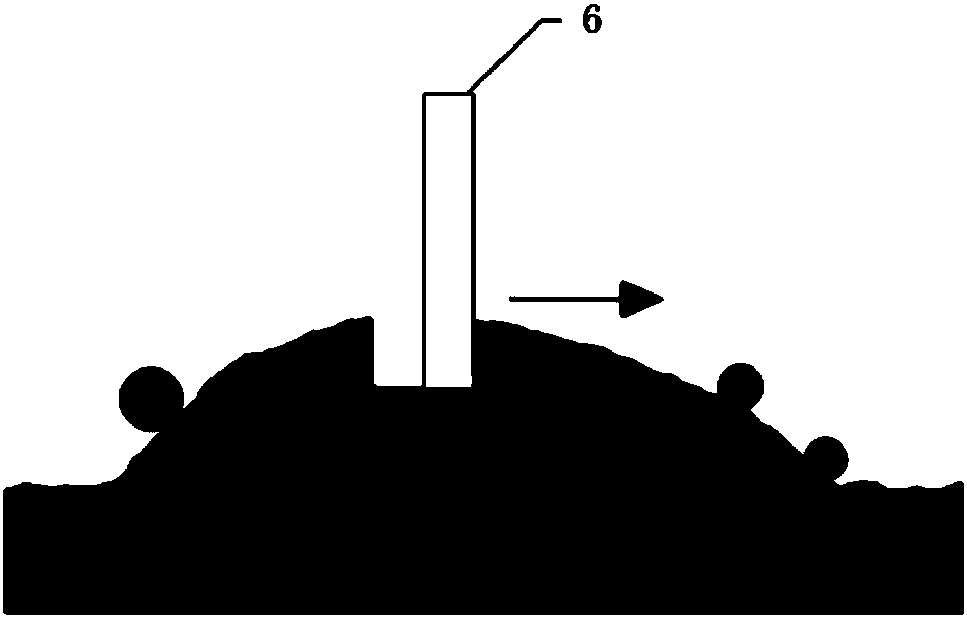

Method for preparing super-hydrophobic bionic metal surface through ultrafast laser technology

ActiveCN108393588AGood drag reduction effectReduce stayLaser beam welding apparatusMicro nanoMicro structure

The invention discloses a method for preparing a super-hydrophobic bionic metal surface through an ultrafast laser technology and relates to the technical field of bionic surface manufacturing. The method comprises the following steps that a metal sample is subjected to mechanical grinding and polishing; the metal sample is subjected to ultrasonic cleaning; ultrafast laser is replaced with a circular polarization glass filter, and then micro-nano structure induction processing is conducted; the metal sample is subjected to anti-dragging micro-structure processing; and the processed metal sample is subjected to ultrasonic cleaning, placed in a fluoroalkyl silane liquid solution for soaking, and taken out to be blown-dried. According to the method, the surface integrating super-hydrophobic and anti-dragging features is successfully prepared by fully utilizing the characteristics of a femtosecond laser micro-nano processing technology, retention of water drops on the metal surface in theflight environment is reduced to the greatest extent, and thus the dampproof and anti-icing effects are maximized.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Method and apparatus for applying railway ballast

ActiveUS7152347B2Control spreadImprove accuracyMachines/dredgers working methodsBallastwayLaser technologyRadar

A method and apparatus for spreading ballast along railways makes use of an inertial measurement system to determine where to apply ballast from a hopper car. A variety of techniques can be used to determine the location and speed of the ballast spreading train, including manual or automated visual techniques, laser technology, radar technology, radio frequency transponders, magnetic sensor, thermal imaging and aerial photogrammetry. The invention also contemplates “on the fly” surveys and terrain profiling using lasers or radar.

Owner:HERZOG CONTRACTING

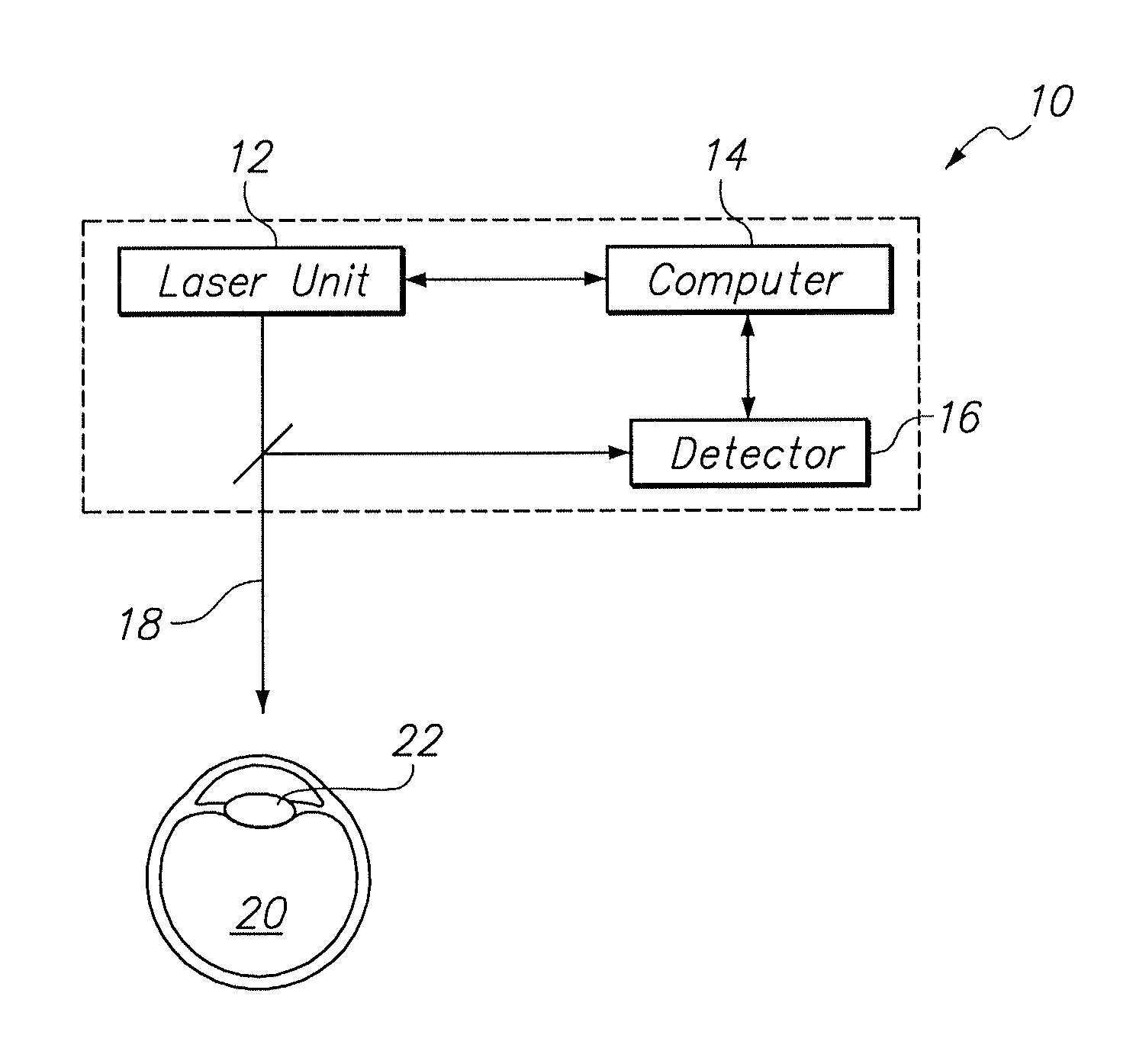

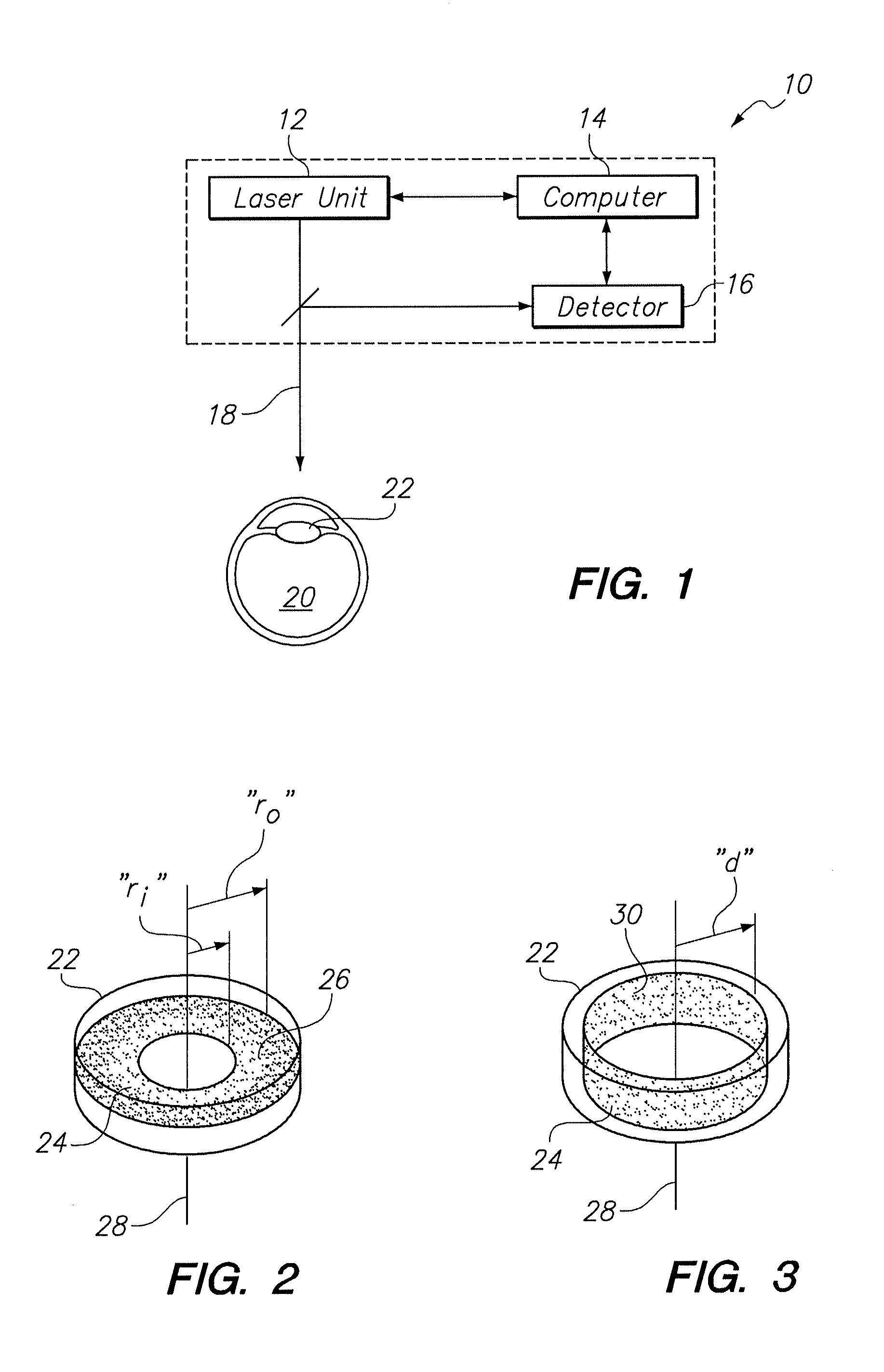

System and method for in situ creation of a small aperture intraocular lens

InactiveUS20130289543A1Increase depth of focusMinimize impactLaser surgerySurgical instrument detailsLaser technologyOptical property

A system and method are provided for altering the optical characteristics of an Intraocular Lens (IOL), in situ, using laser techniques. Specifically, a computer-controlled laser unit either creates microbubbles, or converts inclusions, inside the IOL, to establish a predetermined optical barrier having a predetermined opacity. The resultant optical barrier is oriented in the IOL to control light passing through the IOL, and to thereby minimize or correct adverse optical effects that would otherwise be present.

Owner:BAUSCH & LOMB INC

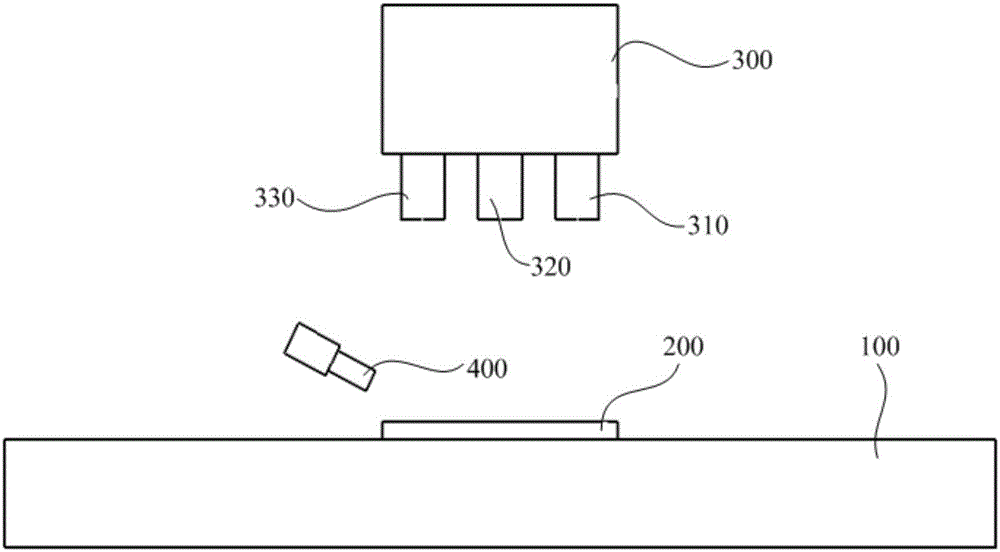

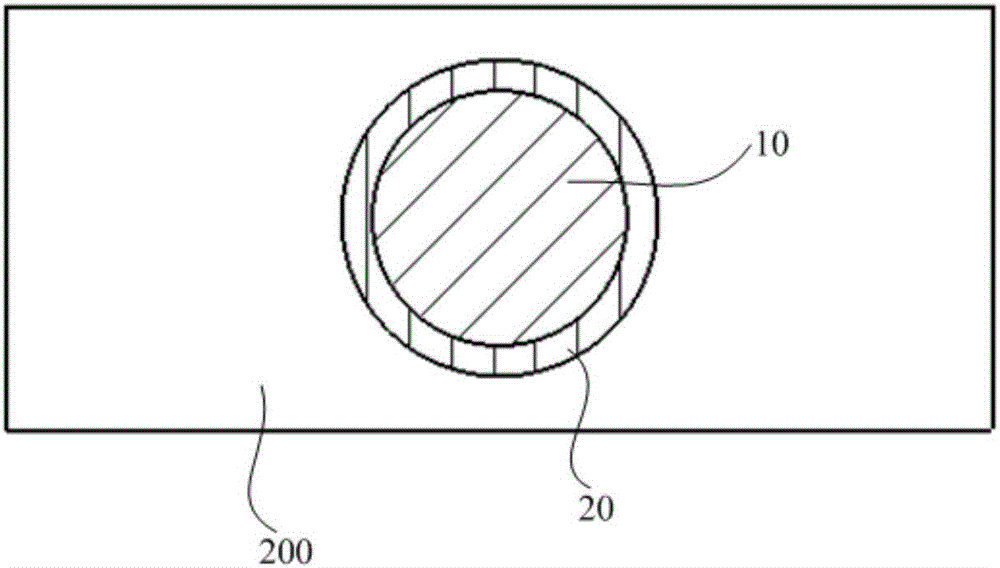

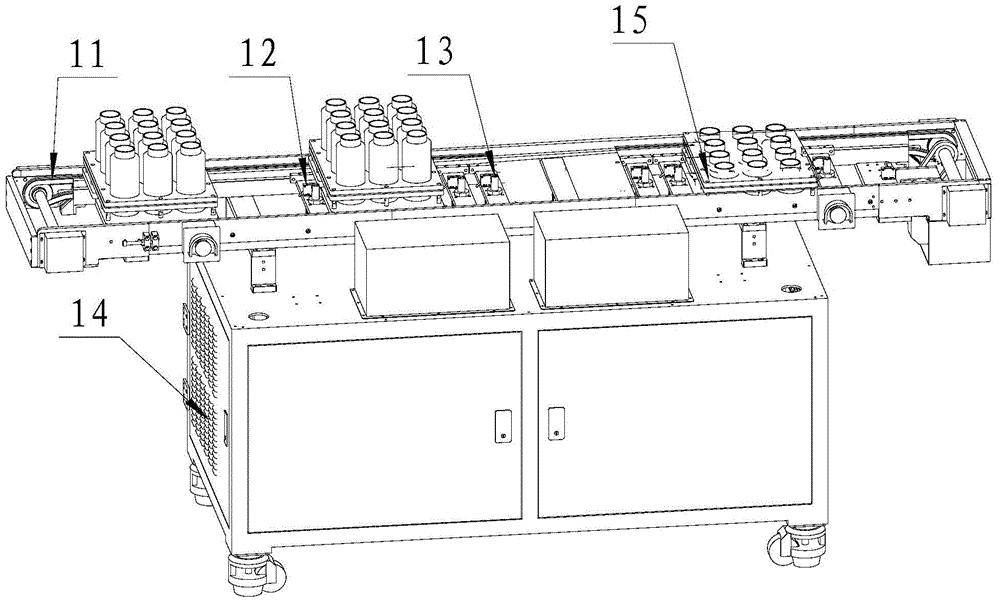

Device and method for using laser technology to mark feeding bottle

The invention relates to the laser processing technology field and discloses a device and a method for using the laser technology to mark the feeding bottle. The device for using the laser technology to mark the feeding bottle comprises an automatic material feeding mechanism, a material receiving-taking mechanism, a laser marking mechanism and a rotary disc mechanism; the automatic material feeding mechanism is provided with a product to be processed and the product to be processed is delivered to a material taking-receiving position of the material taking-receiving mechanism, and the automatic material feeding mechanism is also used for delivering processed products; the taking-receiving material mechanism takes product to be processed and puts the product to be processed on the rotary disc mechanism; the processed product on the rotary disc mechanism is taken away and is put back on the automatic material feeding mechanism; the rotary disc mechanism clamps the product to be processed and drives the product to be processed to rotate to a position corresponding to the position of a laser marking mechanism; and the laser marking mechanism performs laser marking on the product to be processed. The device and method can perform laser calibration on the glass bottle, the structure is simple, the function is reliable and easy to implement, and the automation is realized.

Owner:HANS LASER TECH IND GRP CO LTD

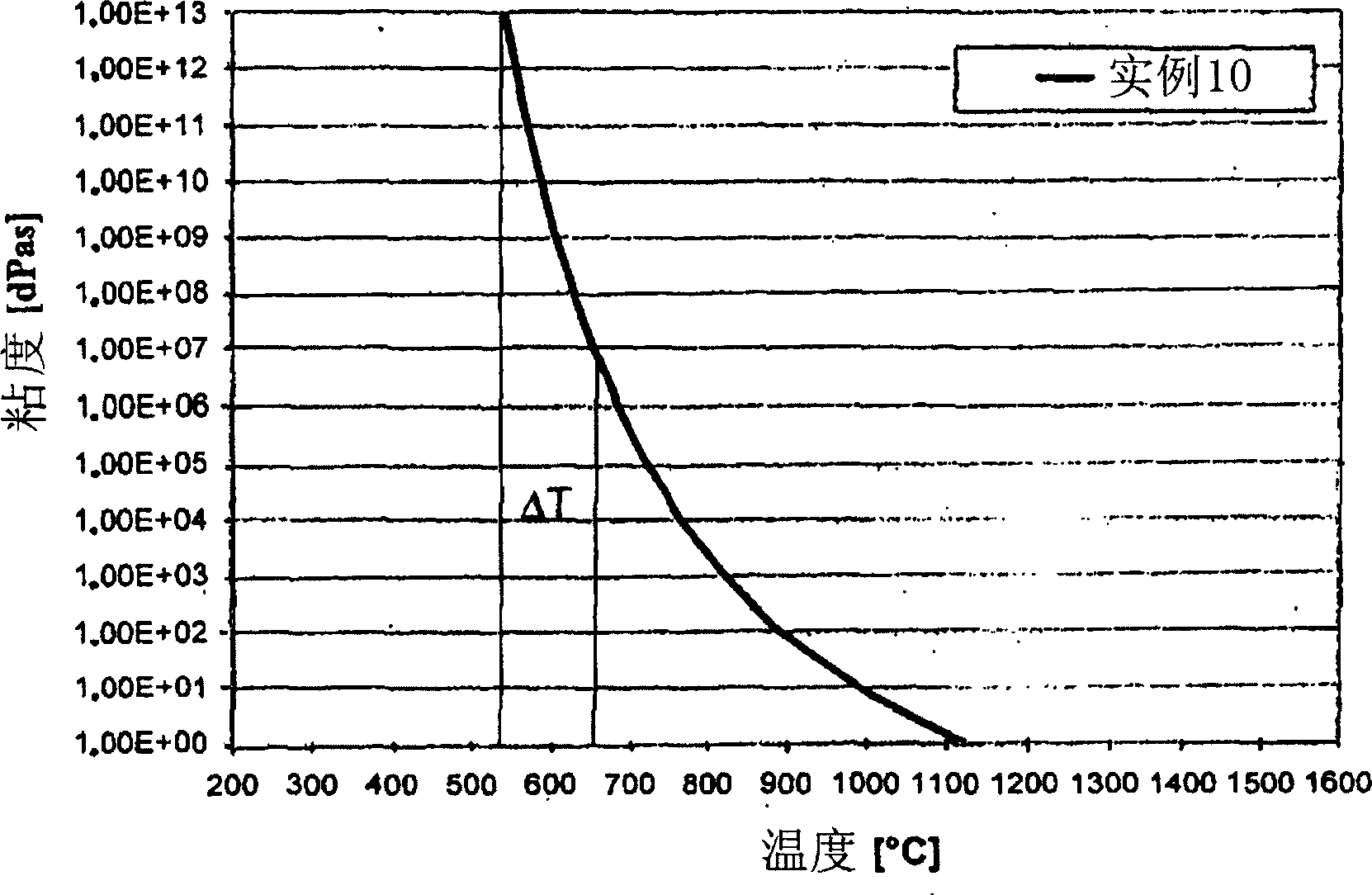

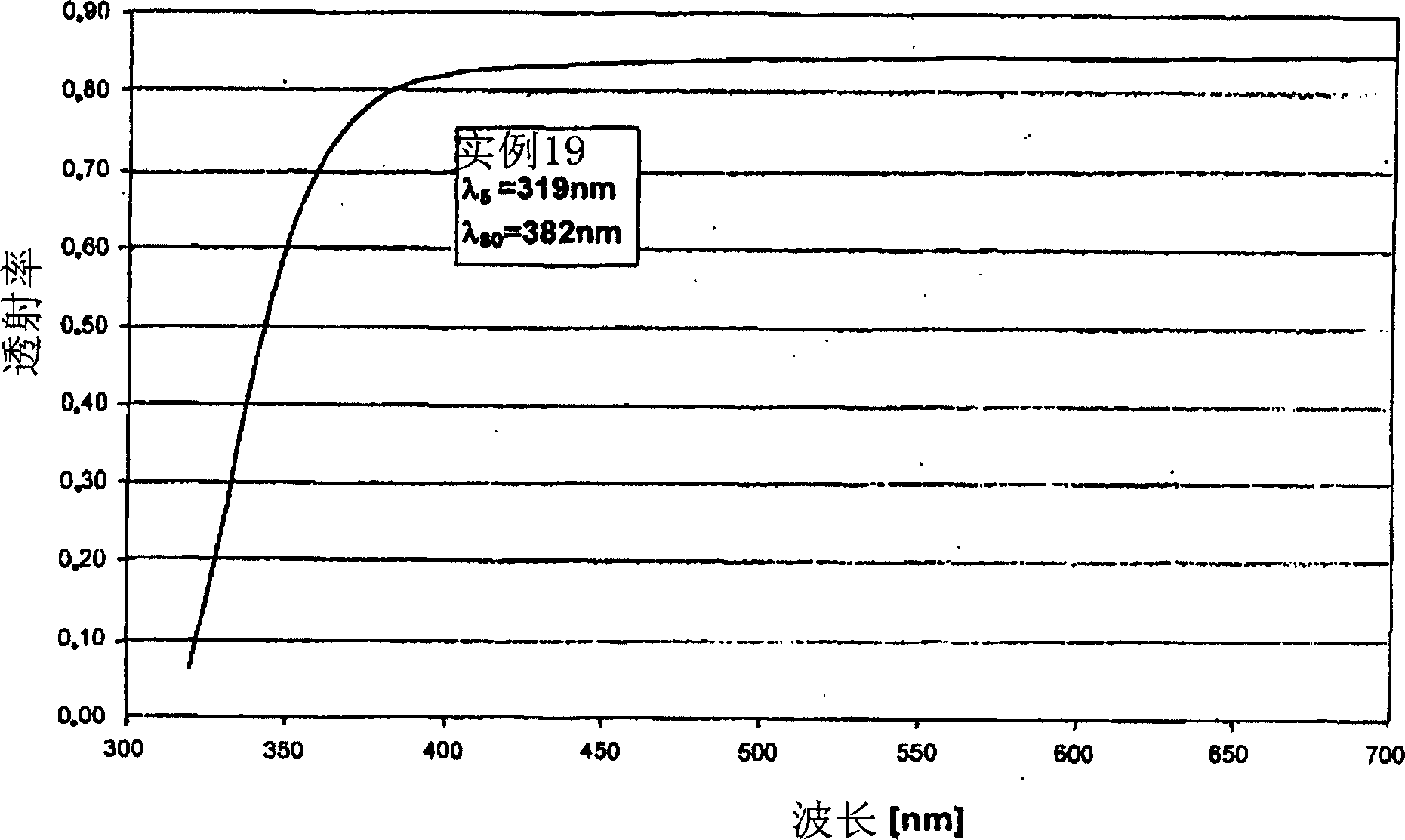

Lead and arsenic free optical lanthanum borate glass

The present invention describes lead and arsenic free and preferably gadolinium and further preferably also fluorine free optical glasses for the application fields mapping, projection, telecommunication, optical communication engineering, mobile drive and / or laser technology with a refractive index of 1.75<=Nd<=1.85, an Abbe number of 34<=Vd<=44 and have a low transformation temperature, namely lower than or equal to 560 DEG C. and preferably lower than or equal to 550 DEG C., as well as good producability and processability and crystallisation stability. The glasses according to the present invention within the following composition range (based on oxide in % by weight) contain the following component B2O3, ZnO, La2O3, Ta2O5.

Owner:SCHOTT AG

Quasi-phase-matching higher harmonic device based on ultrasonic modulation

InactiveCN101515105AExpand the adjustment rangeLarge adjustment rangeNon-linear opticsUltrasonic sensorFemto second laser

The invention relates to a quasi-phase-matching higher harmonic device based on ultrasonic modulation in the laser technical field, which comprises a femto-second laser, a focusing lens, an ultrasonic transducer, a bar type nozzle, a metallic film, an X ray spectrometer, a computer, a vacuum chamber, a decompression gas valve and a control panel. The output light path of the femto-second laser is sequentially provided with the focusing lens, the ultrasonic transducer, inert gases, the metallic film and the X ray spectrometer. Lasers emitted by the femto-second laser is focused below the bar type nozzle by the lens and interact with the inert gases with density periodic variation which is spouted by the nozzle and modulated by an ultrasonic field to radiate higher harmonics which are reflected into the X ray spectrometer after being filtered by the metallic film and then are sent into the computer. The device meets the quasi-phase-matching condition of the higher harmonics by using ultrasonic modulation gas density, is convenient to be operated and simple and easy, can propel the coherent light source of the higher harmonics soft X ray to shorter waver.

Owner:SHANGHAI JIAO TONG UNIV

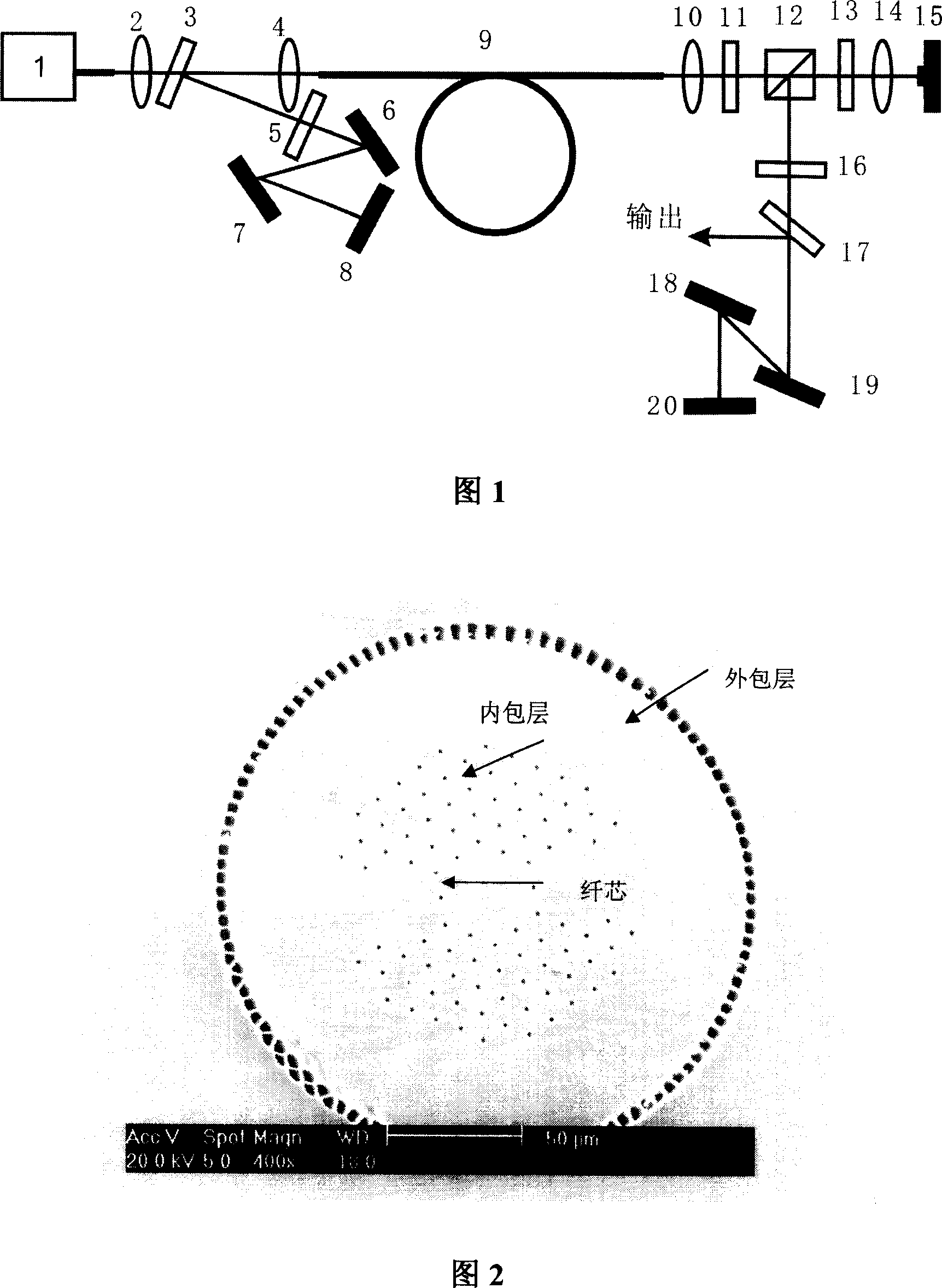

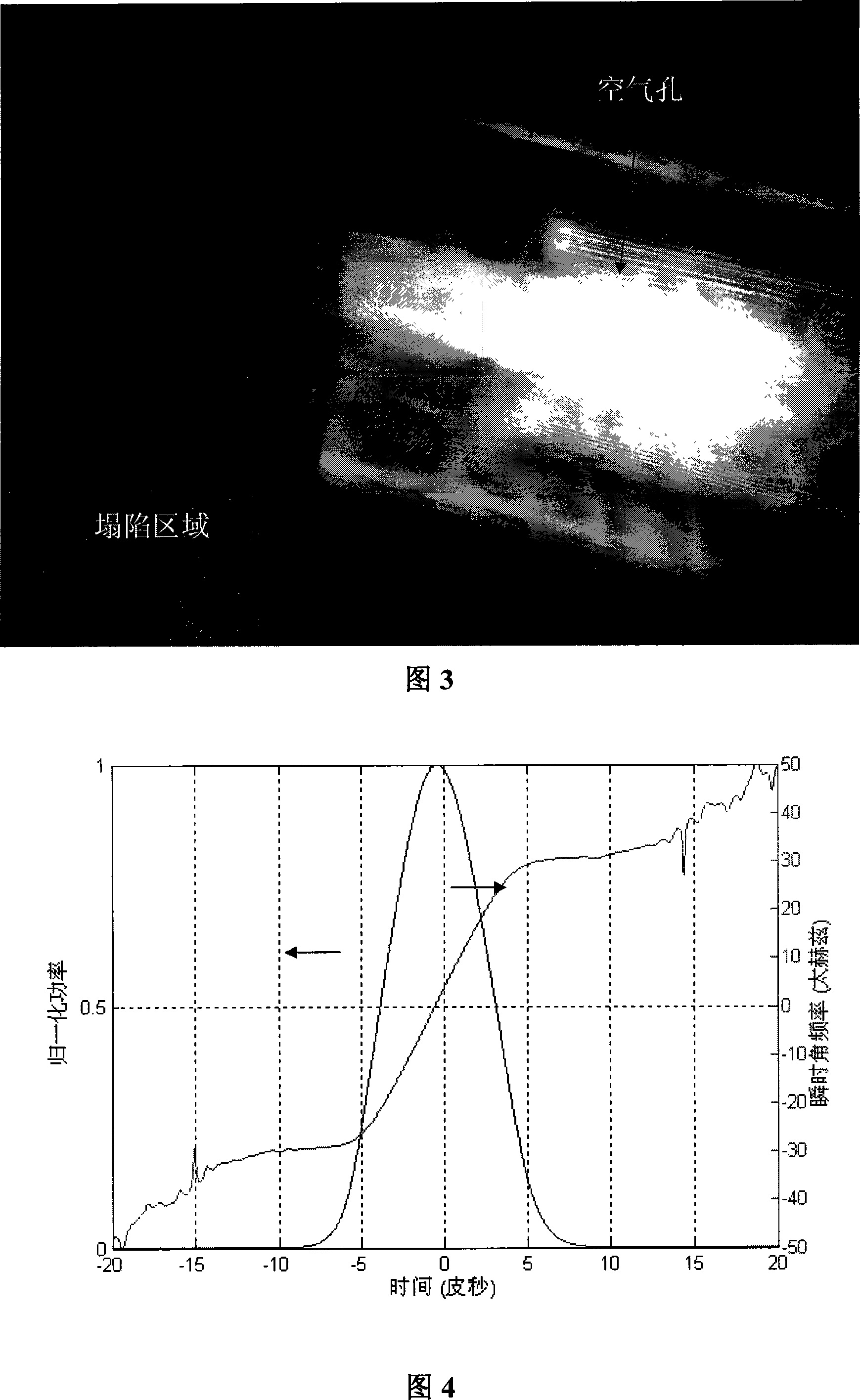

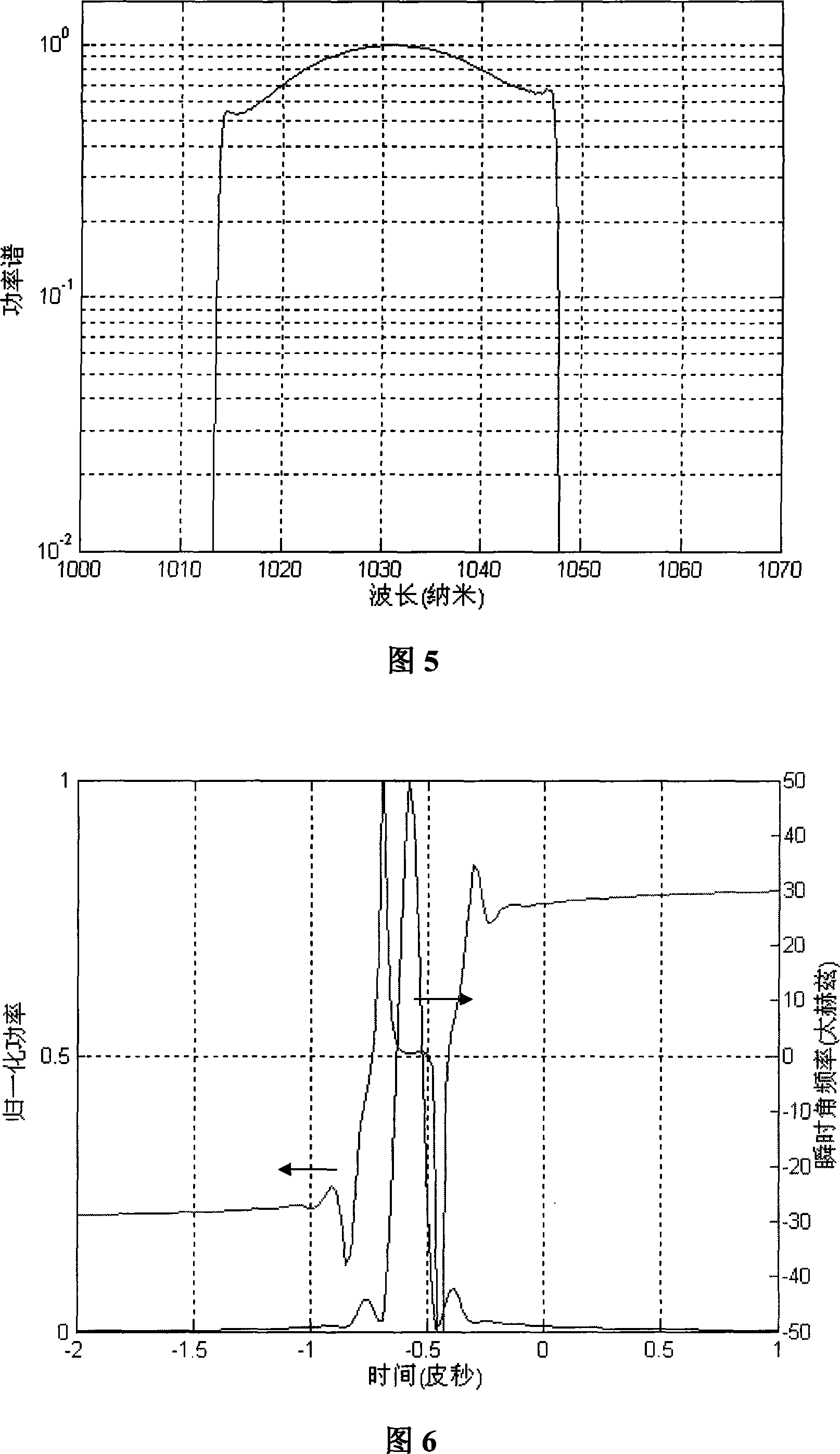

Double cladding large mode field area Yb-doped photon crystal optical fiber femtosecond laser

InactiveCN101101427AGood Polarization Maintaining PropertiesImprove stabilityCladded optical fibreOptical waveguide light guideFrequency spectrumNonlinear optics

The invention discloses a double-coating large-mode-area photon crystal flysecond laser directly obtaining micro joule-level single pulse energy, belonging to the field of laser technique and nonlinear optics, where the laser main body is based on double-coating large-mode-area photon crystal optical fiber of polarization-protection structure and adopts high-power LD laser to directly pump; the laser uses grating pair to compensate dispersion, starts mode locking with the help of semiconductor saturable absorber mirror (SESAM), and controls polarization by wave plate and polarization beam splitter and implements tunable output; laser resonant cavity keeps net positive dispersion inside and runs in self-similar mode locking mode and outside-cavity dispersion compensation is made on the output pulse and the pulse is 100-200fs wide. And the advantages: the laser has good stability, and the output pulse has high energy and high repeating frequency. And the invention can effectively avoid split of pulse running at high energy.

Owner:TIANJIN UNIV

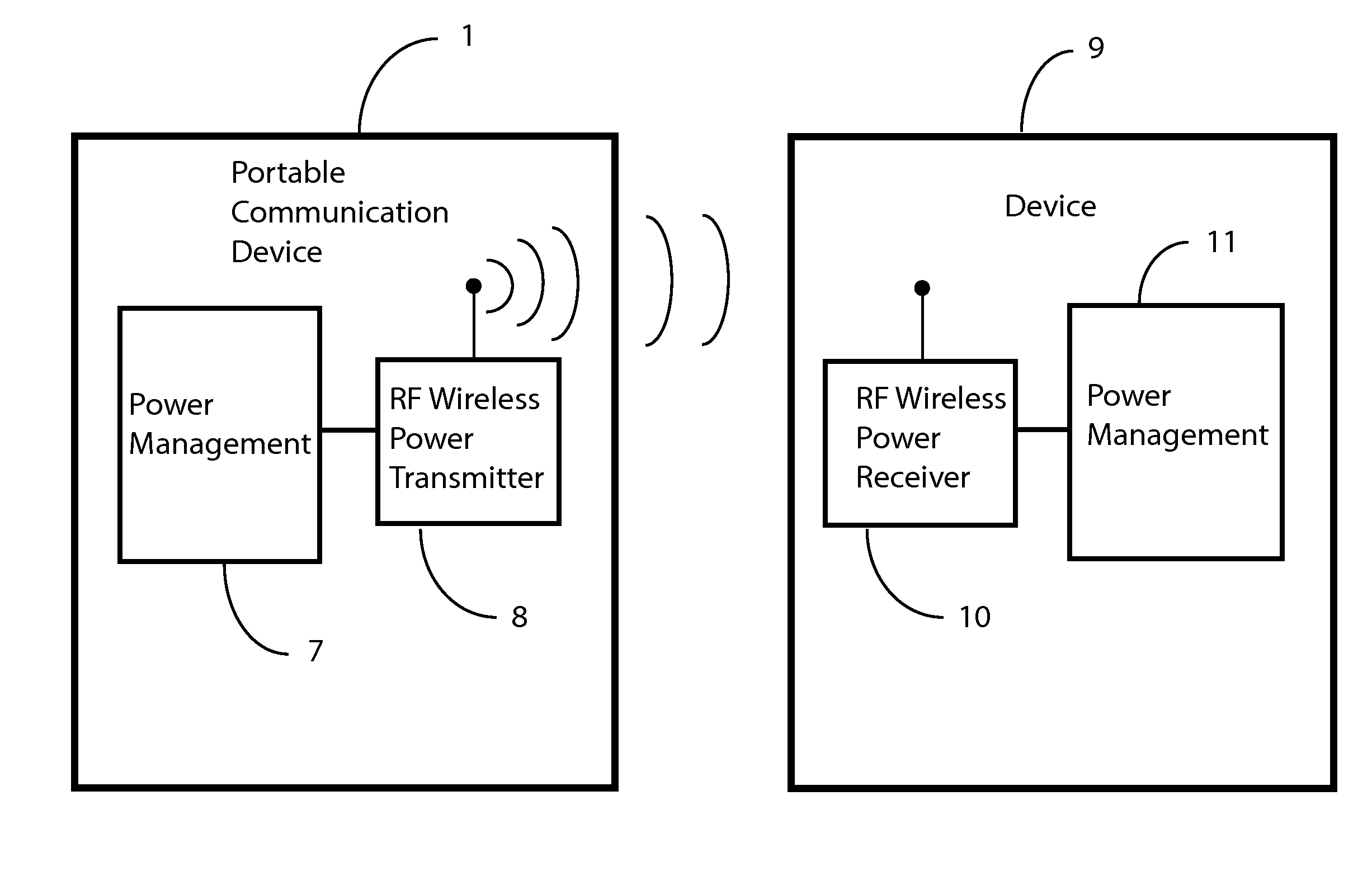

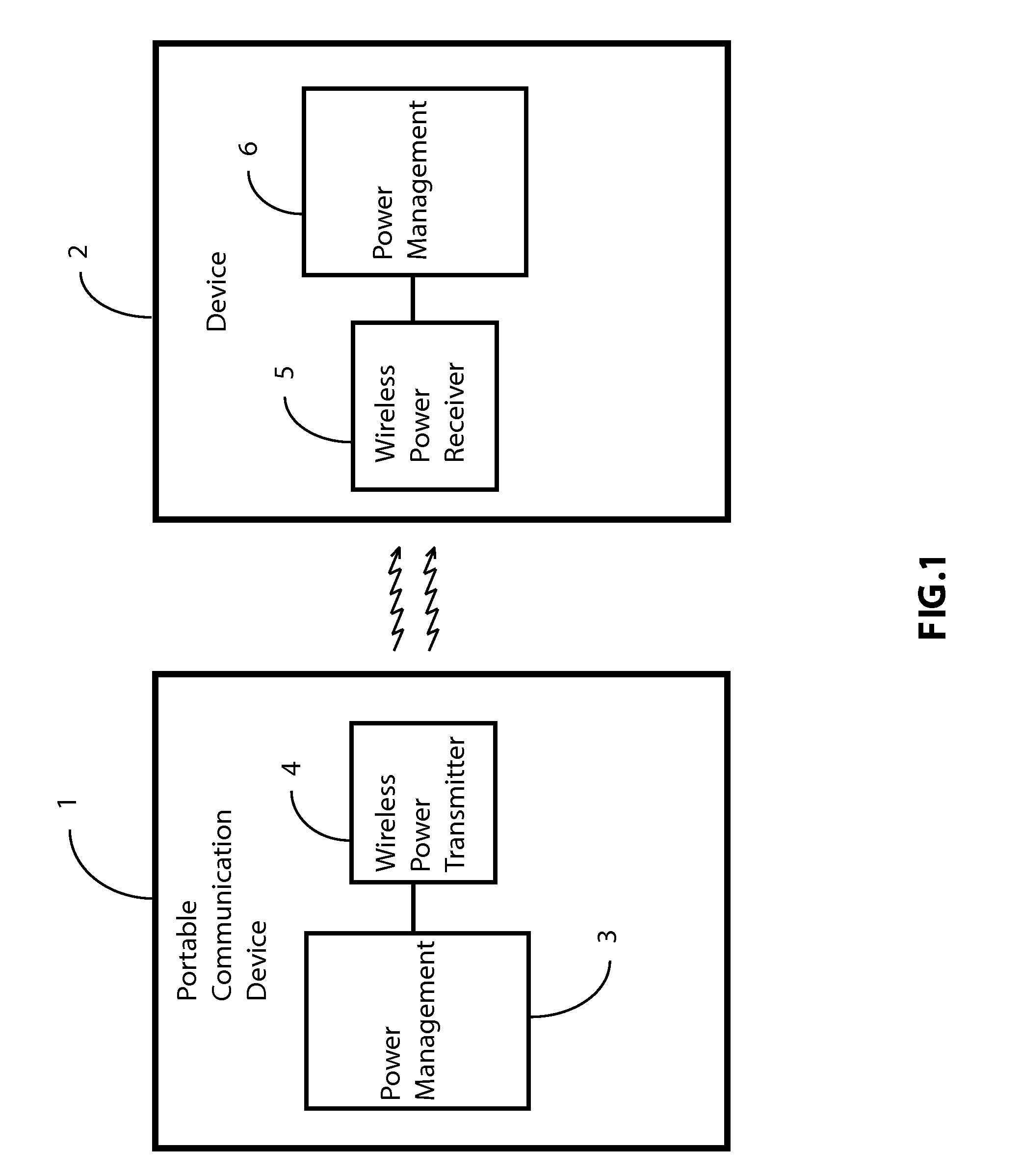

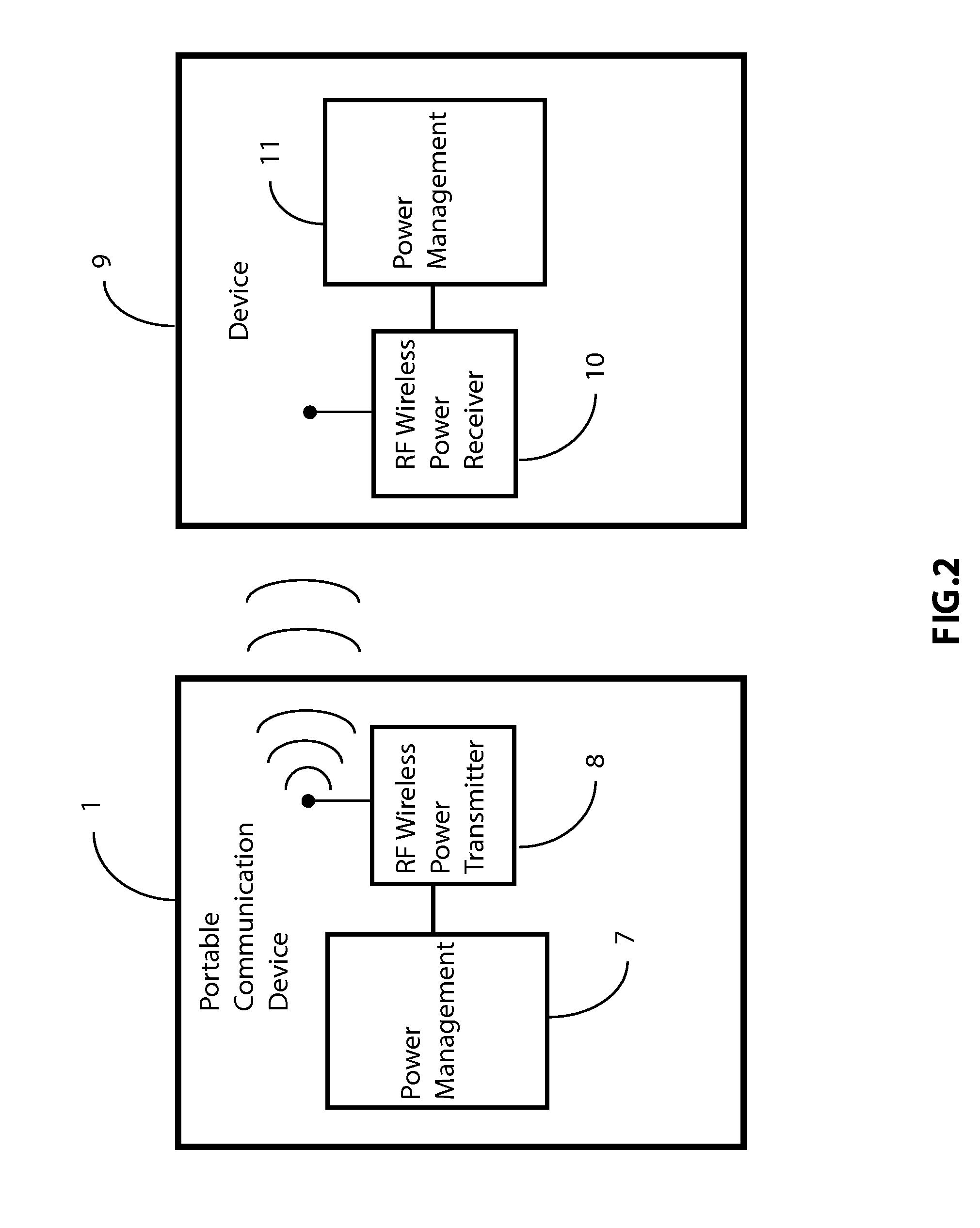

Wireless Power Transmission in Portable Communication Devices

InactiveUS20150102680A1Easily rectifiedEasy to processElectromagnetic wave systemTransformersElectric power transmissionTransmitted power

The present invention describes means to intentionally transmit power wirelessly from a portable communication device like a mobile phone, smart-phone, tablet or telephone watch using radio frequency, ultrasound, microwave or laser technologies to power up or charge devices external to the portable communication device. In particular the wireless power transmitter is physically placed inside the portable communication device or coupled to it, in order to have a means to transfer power without wires or cables to other devices. The present invention may be utilized in applications like sensors, implanted devices for medical use, speakers, mouse, keyboard, electrical glasses for 3D viewing, small displays, gadgets in the car, electronic toys and so on.

Owner:NIRVANALOG INC

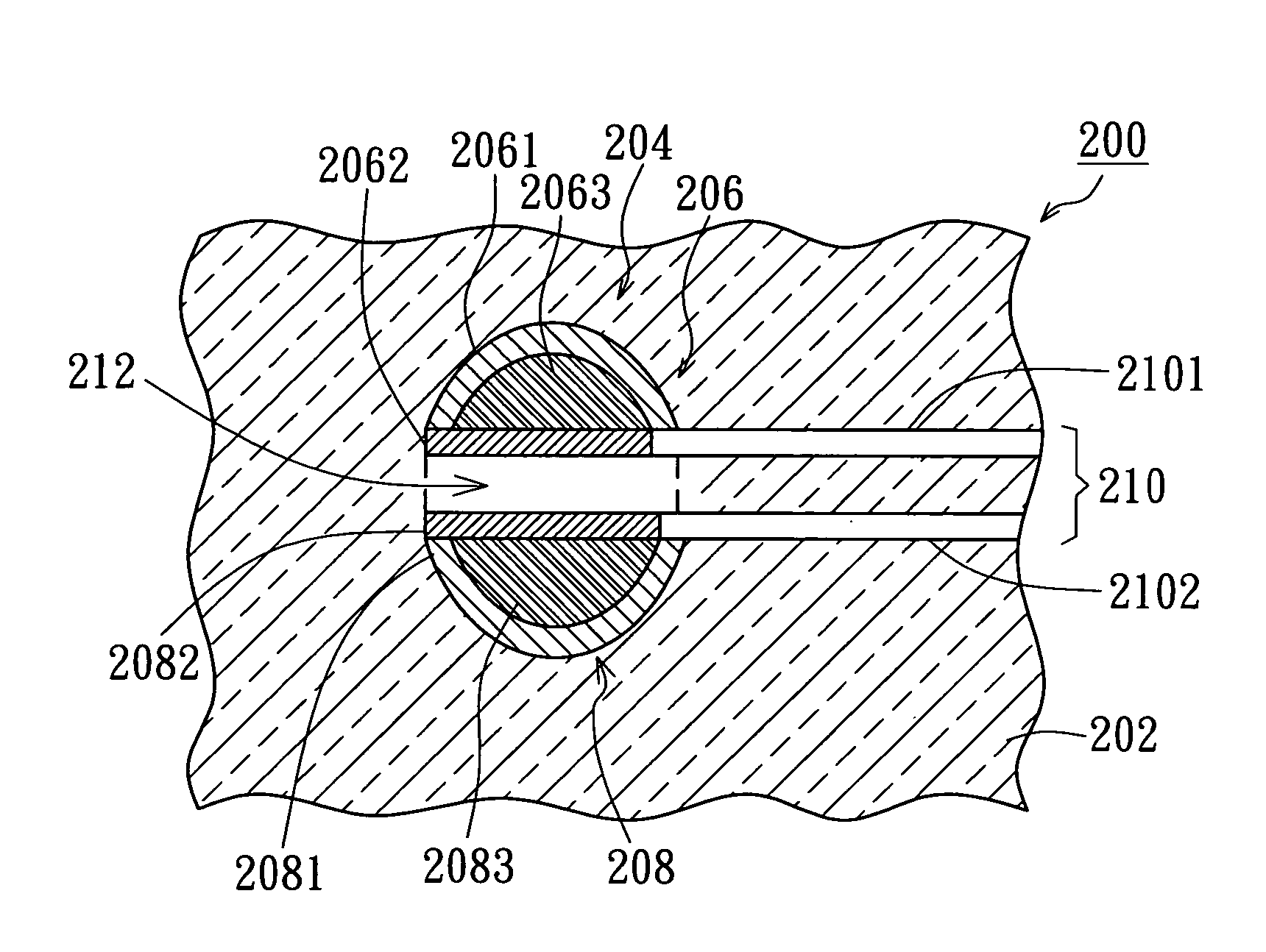

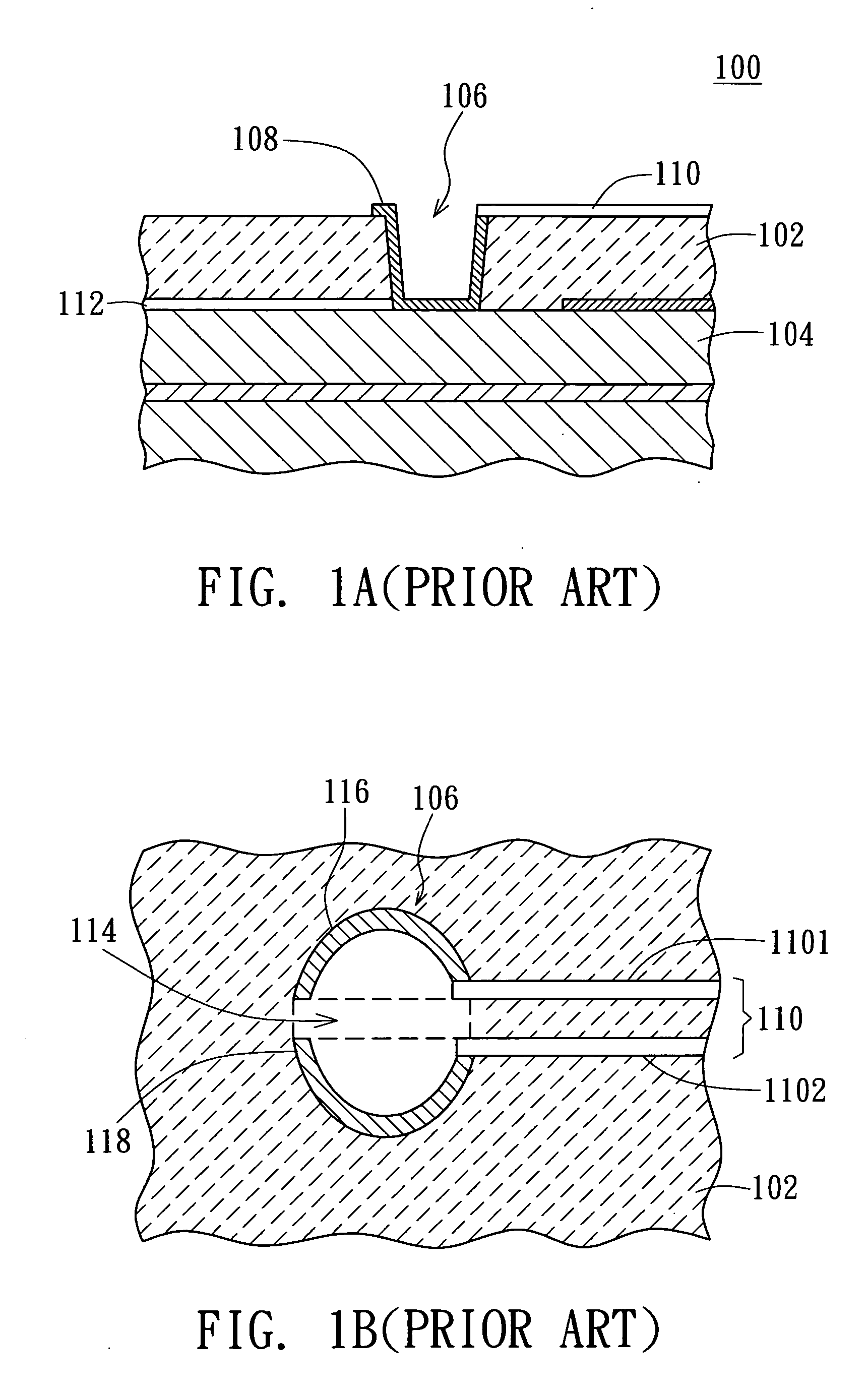

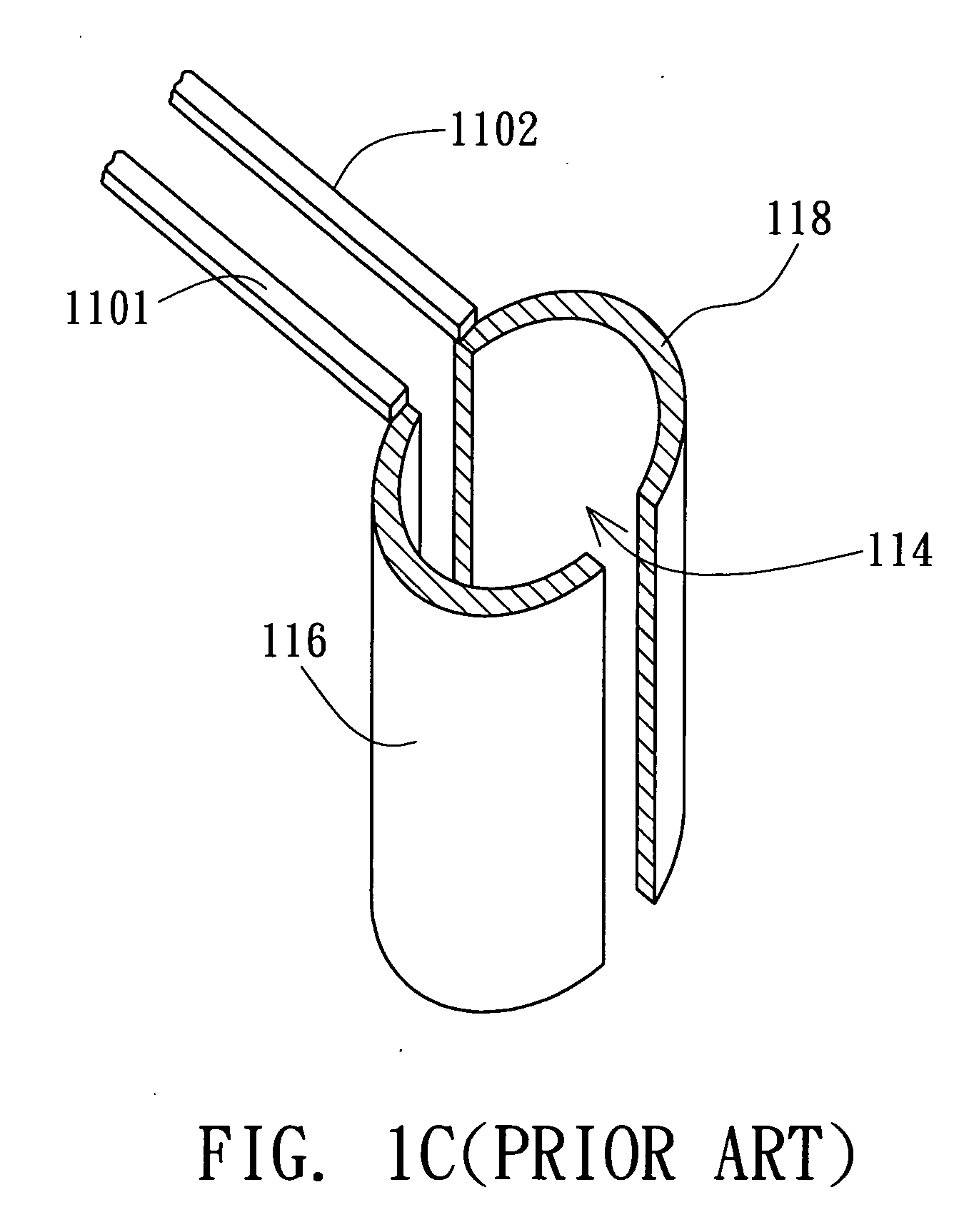

Substrate with micro-via structures by laser technique

ActiveUS20050133251A1Reduce noise disturbanceReduce reflectionPrinted circuit aspectsHigh frequency circuit adaptationsLaser technologyLaser cutting

A substrate to which a laser technique is applied includes a signal layer, a micro via structure, and a differential signal pair. The micro via structure is divided into a first conductive column and a second conductive column after a laser-cutting step. The first conductive column includes a first flat conductive layer, and the second conductive column includes a second flat conductive layer. A first trace of the differential signal pair is parallel to and electrically connected to the first flat conductive layer. A second trace of the differential signal pair is parallel to and electrically connected to the second flat conductive layer. The distance between the first trace and the second trace is the same as the distance between the first flat conductive layer and the second flat conductive layer. The reflection of high-speed signals and the noise interferences can be reduced.

Owner:ADVANCED SEMICON ENG INC

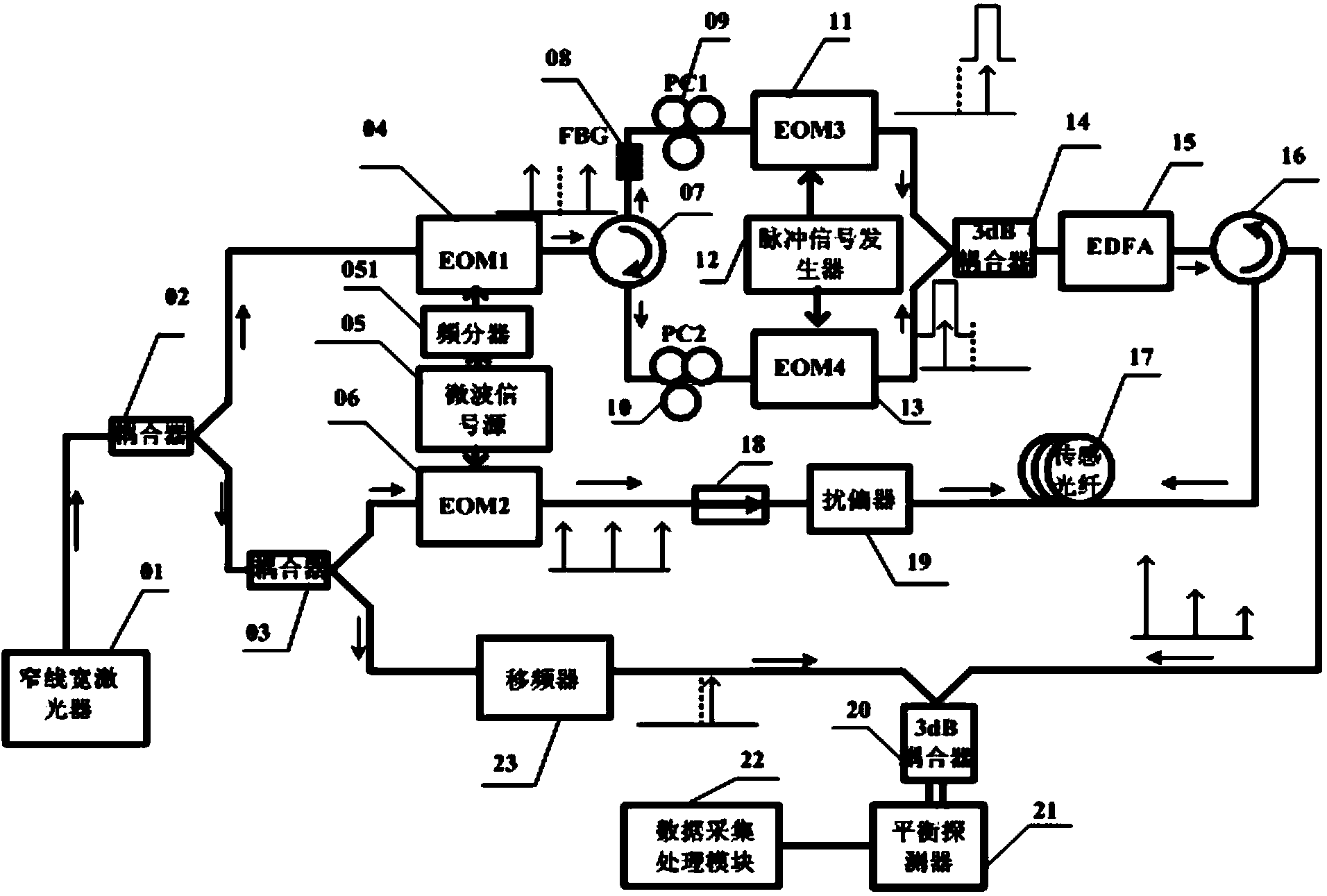

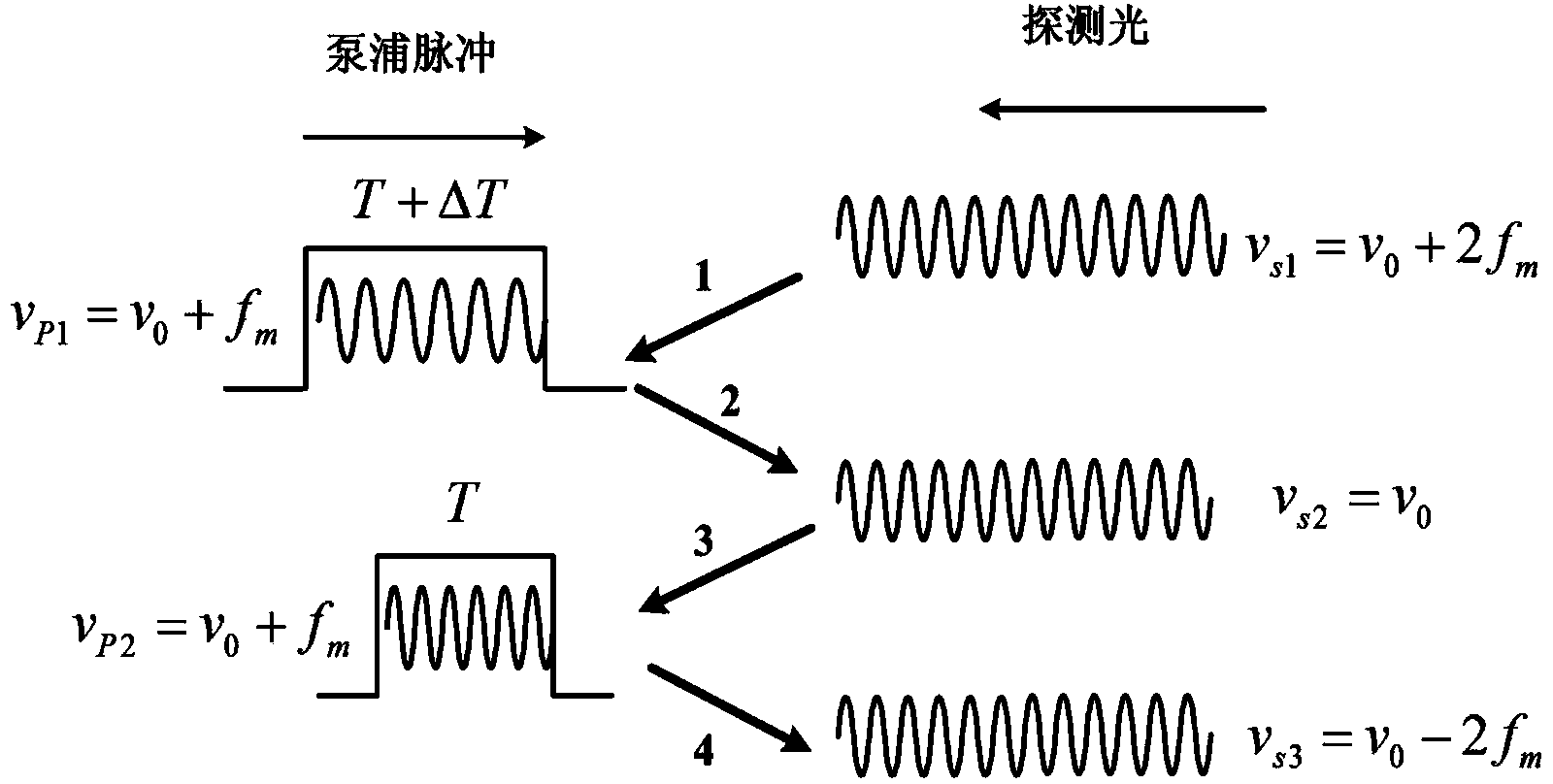

Brillouin optical fiber sensing system and method

InactiveCN103913185AImprove spatial resolutionHigh measurement accuracyConverting sensor output opticallyLaser technologySignal-to-noise ratio (imaging)

The invention discloses a Brillouin optical fiber sensing system and method. A light difference parameter amplifying technology, a three-frequency probe laser technology and a coherent detection technology are adopted at the same time. By means of the light difference parameter amplifying technology, the spatial resolution of the Brillouin optical fiber sensing system can be improved to a sub-meter grade, the coherent detection technology can improve the signal to noise ratio and measurement precision of the system and increase the sensing distance, and the three-frequency probe laser technology compensates power loss of two beams of pump pulse light, can greatly reduce the non-local effect brought by power mismatch of the two beams of the pump pulse light and loss in long-distance sensing, and further improves measurement precision, so that it is guaranteed that the Brillouin optical fiber sensing system has a relatively long sensing distance, and the sub-meter spatial resolution and high measurement precision can be achieved.

Owner:GUANGXI NORMAL UNIV

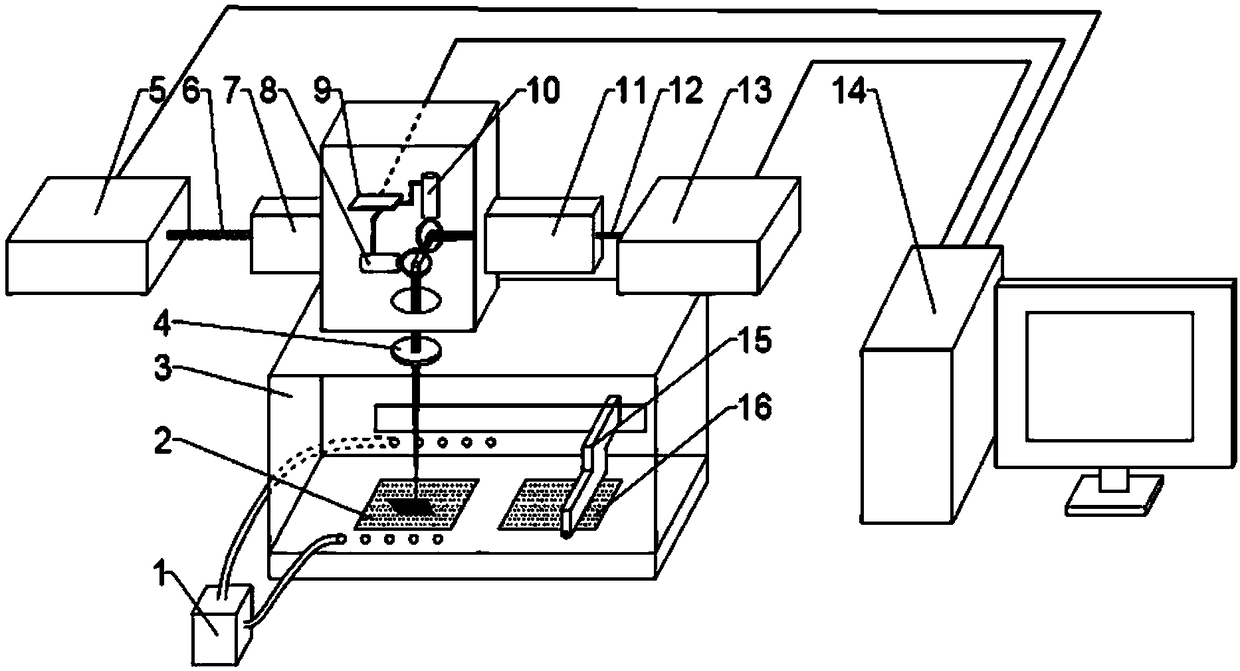

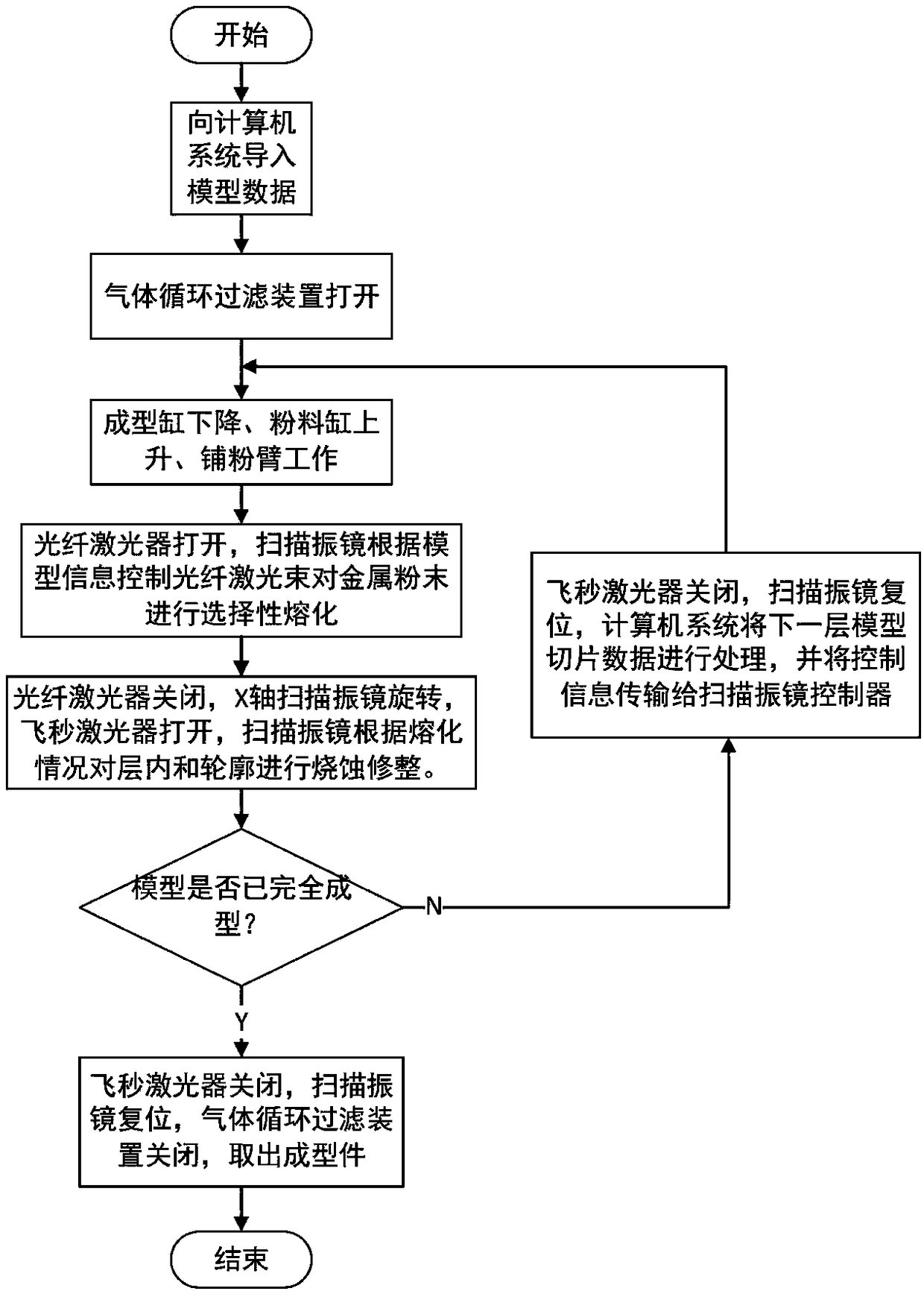

Device and method for improving surface quality of selective laser melting (SLM) forming piece through integrated double-type laser light

PendingCN108311697AImprove yieldImprove performanceAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingSelective laser sintering

The invention discloses a device and a method for improving the surface quality of a selective laser melting (SLM) forming piece through an integrated double-type laser light. The device comprises anoptical fiber laser, an optical fiber laser beam expanding collimator, a femtosecond laser, a femtosecond laser beam expanding collimator, a scanning galvanometer, a lens and the like. During an SLM layered manufacturing process, a femtosecond laser technology is used for ablating and reconditioning spheroidization, bulges, powder adhesion and other defects probably occurred in each forming layerand a profile, so that the surface quality of each SLM forming layer is improved without producing an extra heat influence, the roughness of an upper surface and side surfaces of an SLM forming pieceare improved during an accumulation process, performance indexes such as the compactness and the size precision of the parts are improved, and the rejection rate of SLM processing is reduced.

Owner:SOUTH CHINA UNIV OF TECH

All-fiber pulsed laser

ActiveCN103414093AReduce manufacturing costReduce processing difficultyActive medium shape and constructionFiberNonlinear optics

The invention discloses an all-fiber pulsed laser, and belongs to the field of laser technology and nonlinear optics. The all-fiber pulsed laser includes a pump source (1), an optical combiner (2), a first gain fiber (3), a second gain fiber (4), a first reflective fiber Bragg grating (5), a second reflective fiber Bragg grating (6), an optical isolator (7), a full reflection mirror (8) and a circulator (9), and adopts a structure of linear cavity or annular cavity. By use of the rare earth-doped gain fibers as a laser modulator, with no additional external modulation source and an all-fiber structure, ultrashort pulse laser output of high stability, high power, high energy and high efficiency is achieved. Compared with a semiconductor saturable absorption mirror (SESAM) and graphene (Graphene) modulation Q, mode-locking technology, the all-fiber pulsed laser employs gain fiber for direct pulse modulation, has the advantages of simple design, compact structure and high stability, and is easier to industrialize.

Owner:BWT BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com