Patents

Literature

380 results about "Nanosecond laser" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

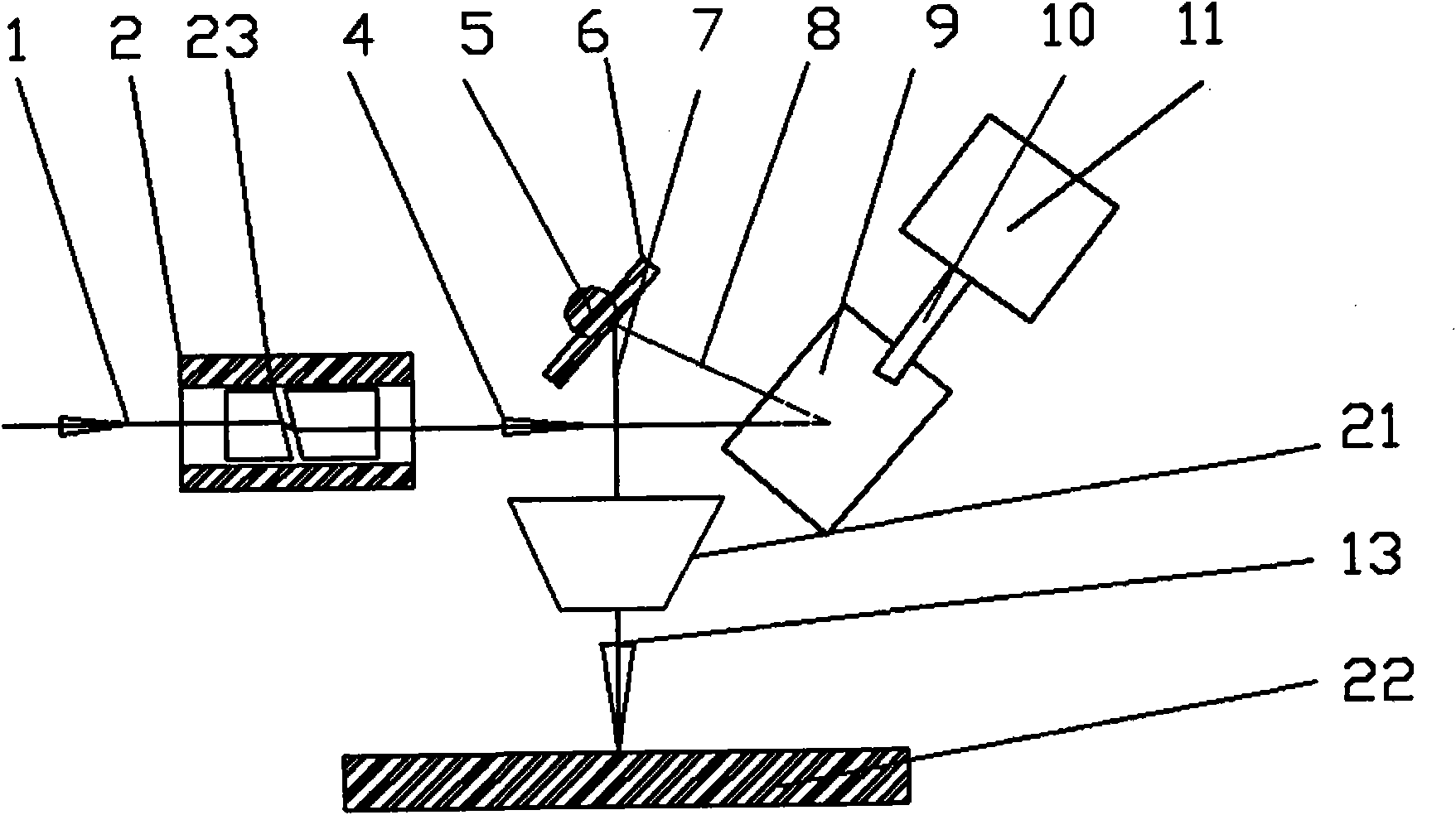

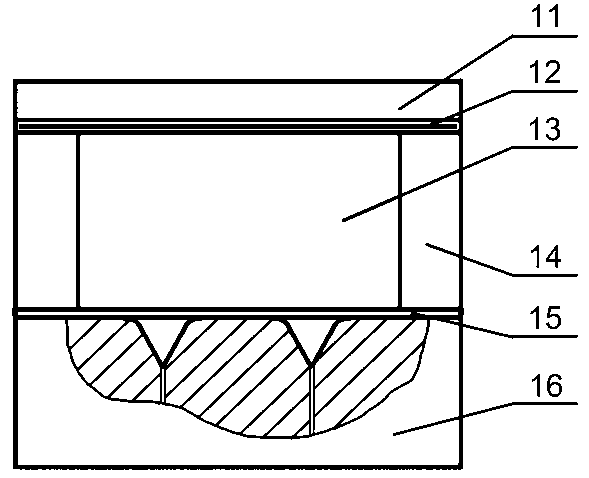

Nano coating preparation method and device based on ultrafast ultrahigh pressure photodynamics effect

InactiveCN101787528AChange compositionChange organizationMetallic material coating processesLaser beamsMechanical property

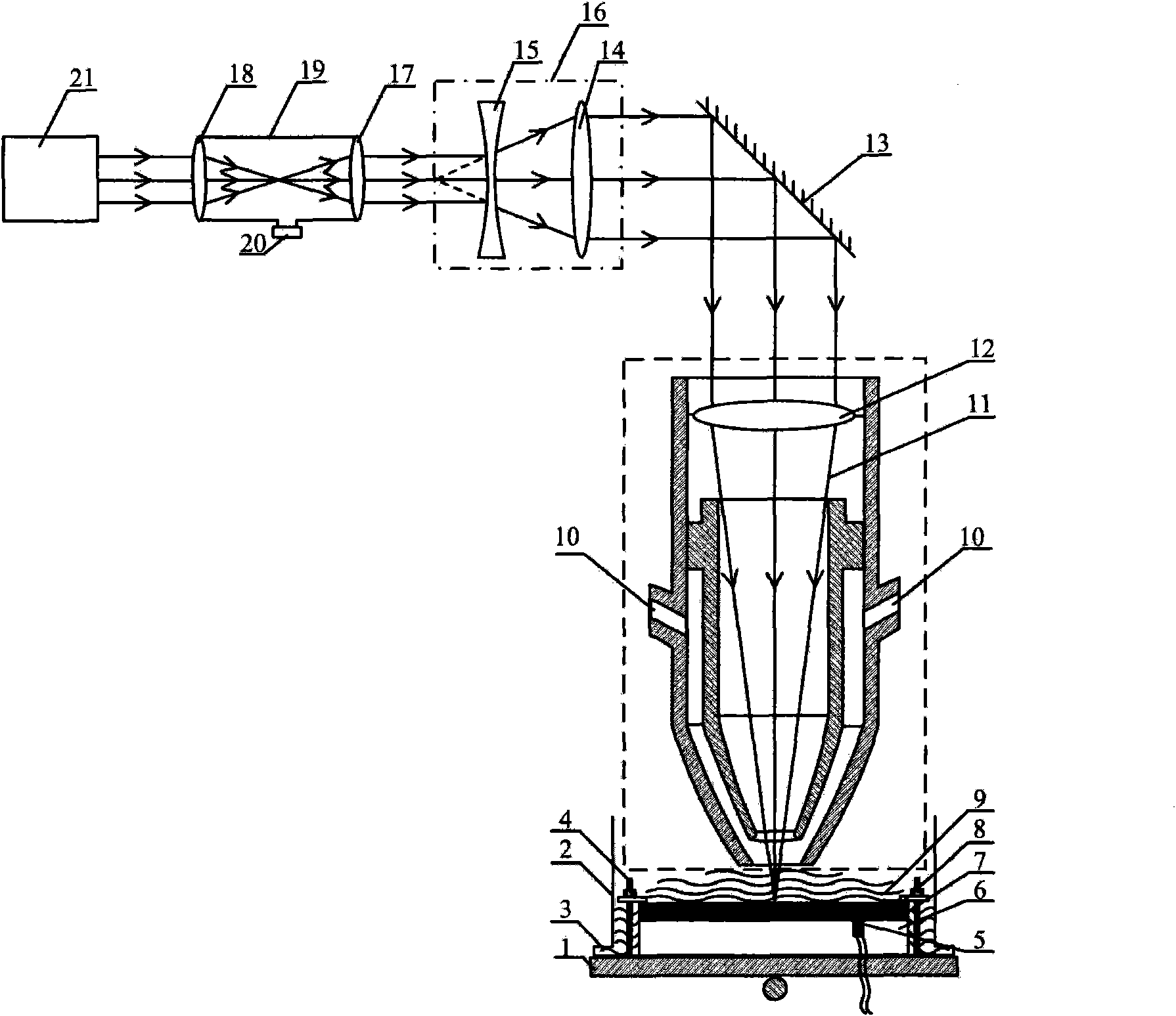

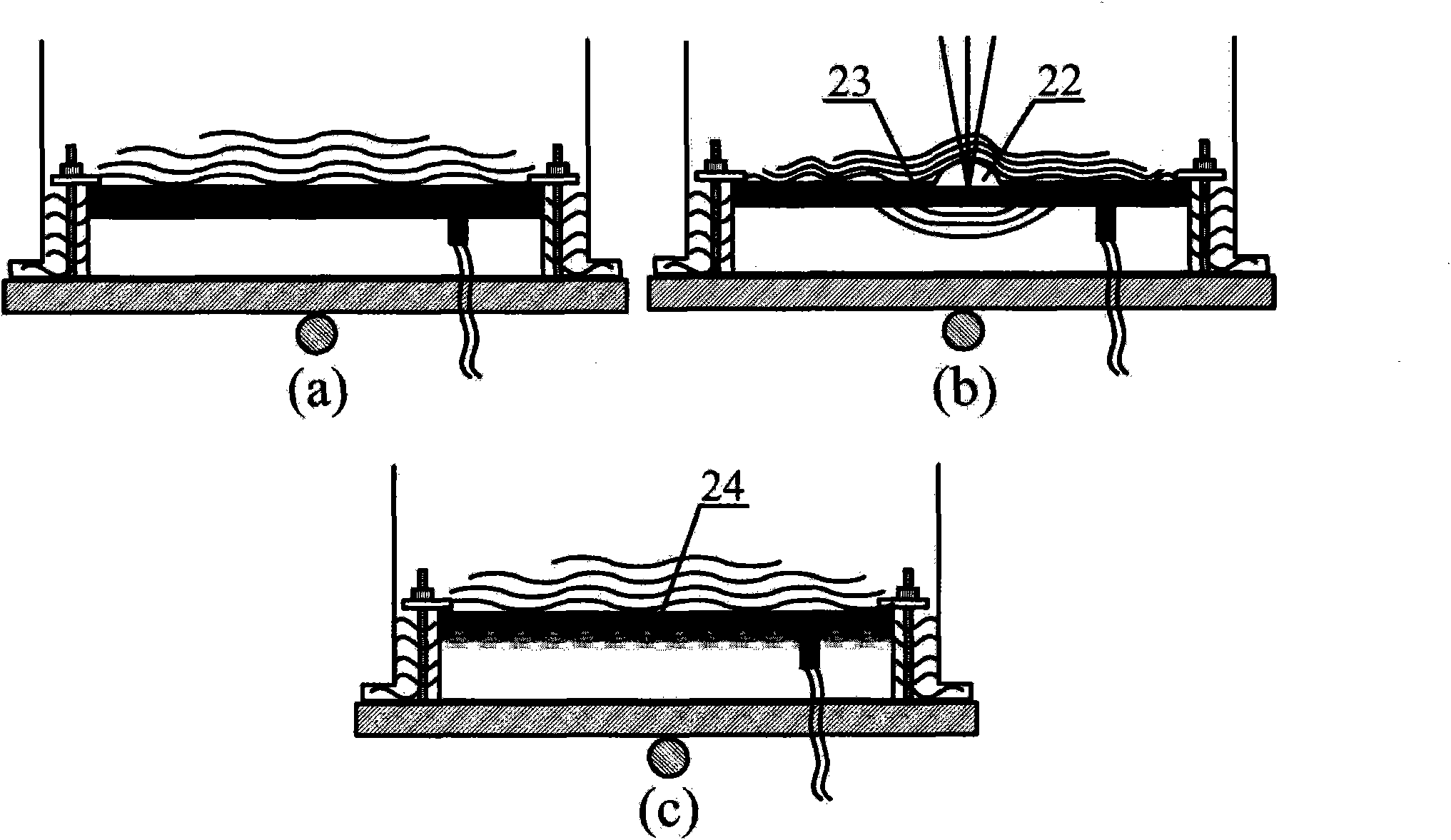

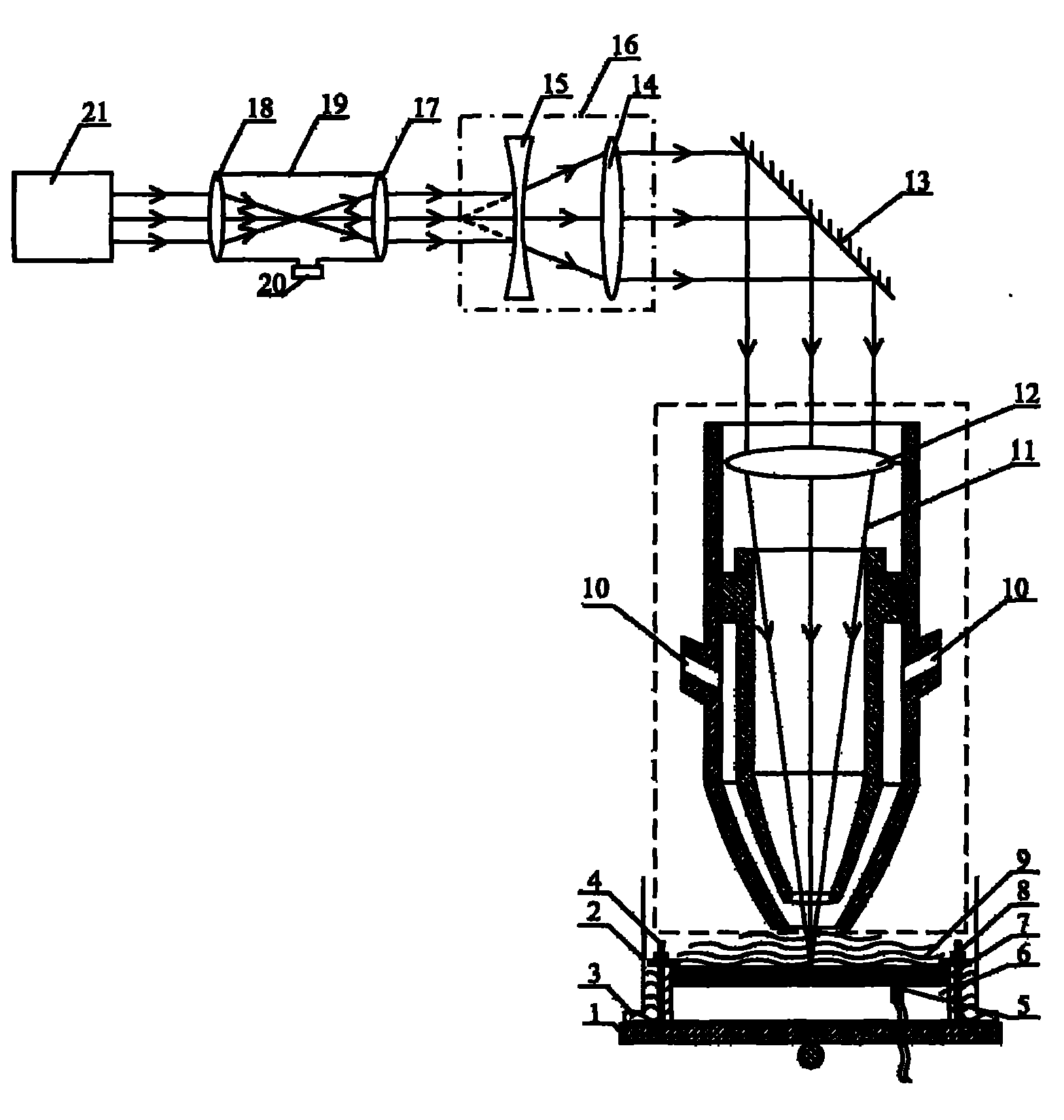

The invention discloses nano coating method and device based on ultrafast ultrahigh pressure photodynamics effect, belonging to the technical field of material surface. The invention is characterized by embedding or cold welding nanometer metal powder, nanometer nonmetal powder or compound nanometer powder which are precoated on the surface of a metal matrix in the surface layer of the metal matrix by means of laser induction mechanics effect, forming a thick nanometer particle strengthening layer or a coating layer which is called as a nano coating on the surface of the metal matrix, wherein the metal matrix is impacted and strengthened by laser. The device comprises a three-dimensional hexad working platform, a water tank, a clamp, a thermocouple, a coaxial synchronous water sender, a laser beam focusing system, a 45-degree fully-reflecting mirror, a laser beam optimizing system and a nanosecond laser. By the invention, the obtained surface nano coating has firm interface joint with the matrix and the mechanical property on the surface of the metal matrix is remarkably improved. The invention has simple technical process and lower cost, and is easy to realize automation and suitable for large-scale batch production.

Owner:JIANGSU UNIV

Edge deletion method for thin-film solar cells

ActiveCN102916081AFast edge cleaningGood edge qualityFinal product manufactureLaser beam welding apparatusNanosecond laserLaser processing

The invention belongs to the field of laser processing, discloses an edge deletion method for thin-film solar cells, and concretely relates to a method for carrying out edge deletion on thin-film solar cells by using ultra-short pulse laser. The method disclosed by the invention is importantly characterized in that high-peak-power ultra-short pulse laser with an extremely high transparent conductive film absorption rate is introduced into an application of carrying out edge deletion on thin-film solar cells. Compared with laser power used by edge deletion implemented by using infrared nanosecond laser, the method can complete high-efficiency and high-quality laser edge deletion by using smaller average laser power; and glass is not easy to be damaged, the compatibility with different kinds of transparent conductive films is extremely strong, and the application cost is reduced.

Owner:张立国

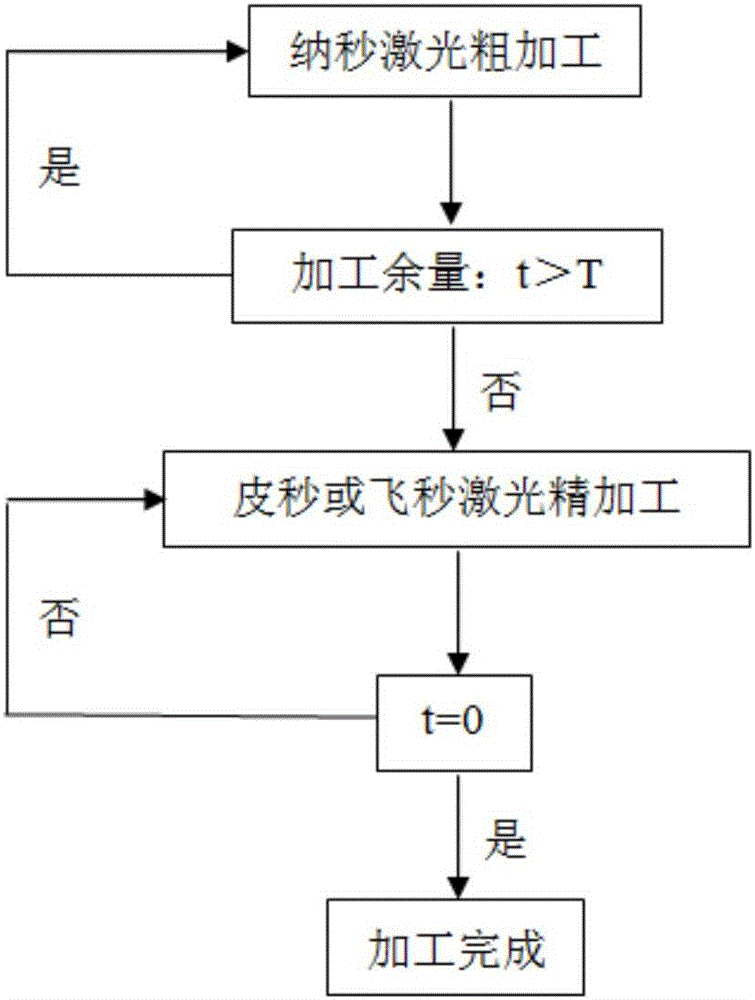

Ceramic drilling method of composite nanosecond-picosecond-femtosecond laser technology

ActiveCN106425125AReduce the temperatureReduce recast layersWelding/soldering/cutting articlesLaser beam welding apparatusNanosecond laserPicosecond laser

The invention discloses a ceramic drilling method of a composite nanosecond-picosecond-femtosecond laser technology. The ceramic drilling mechanism of the composite nanosecond-picosecond-femtosecond laser technology comprises the following steps: S10, providing multi-pulse-width fiber laser devices which comprise a nanosecond laser device, a picosecond laser device and a femtosecond laser device, roughly machining a ceramic workpiece fixed on a working table by using the nanosecond laser device, and meanwhile, spraying auxiliary gas at a position nearby a machining position; S20, carrying out finish machining on the ceramic workpiece which is machined roughly by using the picosecond laser device or the femtosecond laser device, and meanwhile, spraying auxiliary gas at a position nearby the machining position; and S30, presetting allowance for finish machining T, detecting residual allowance for machining t by using a dimension precision measurement instrument, repeating the step S10 when t is greater than T, repeating the step S20 when t is greater than 0 and smaller than or equal to T, and repeating in such a way until t is equal to 0. The auxiliary gas is sprayed at the position nearby the machining position, after rough machining by nanosecond laser, finish machining is implemented by picosecond or femtosecond laser, and therefore, machining precision and machining efficiency of the ceramic workpiece are improved.

Owner:GUANGDONG UNIV OF TECH

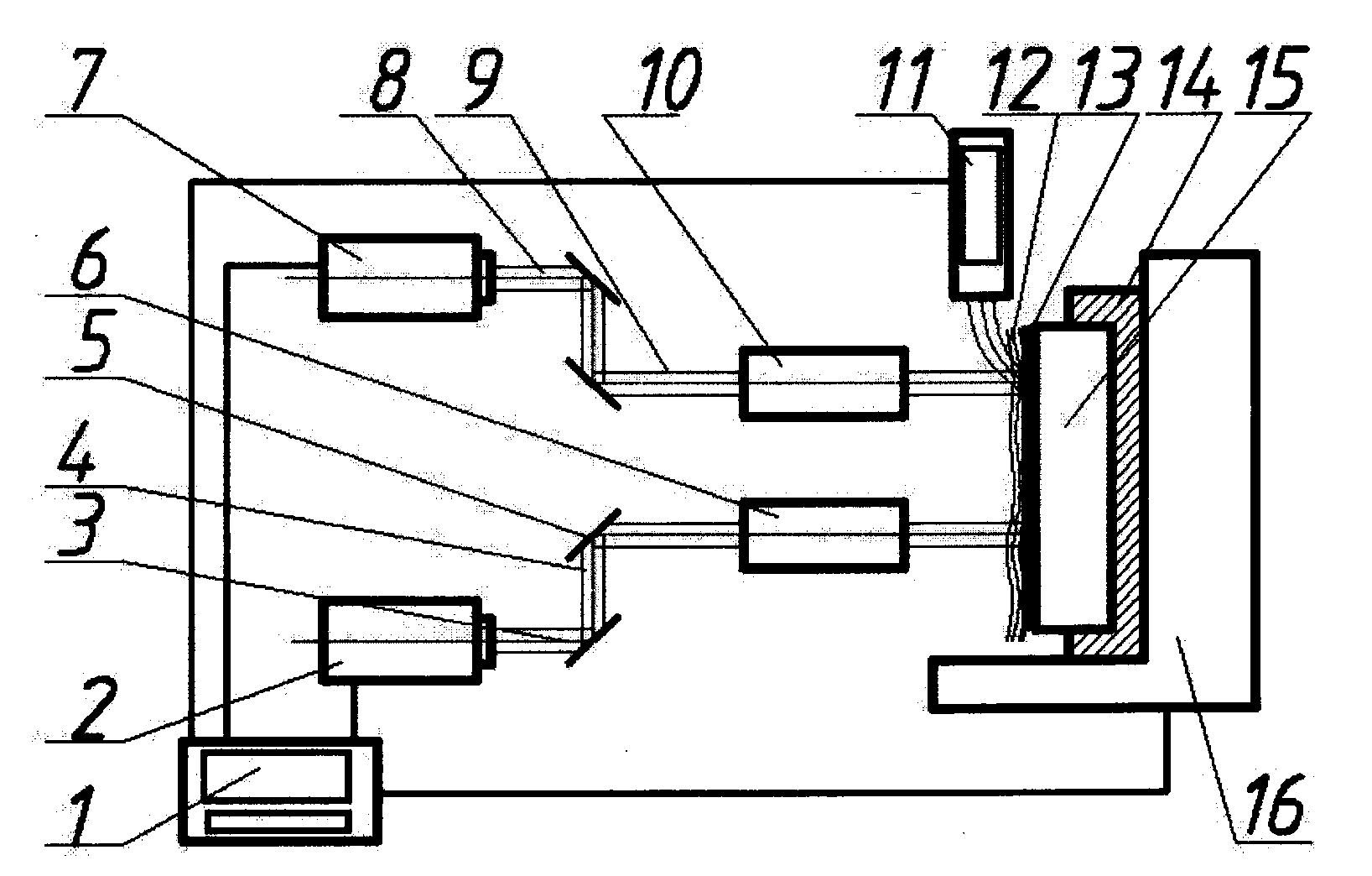

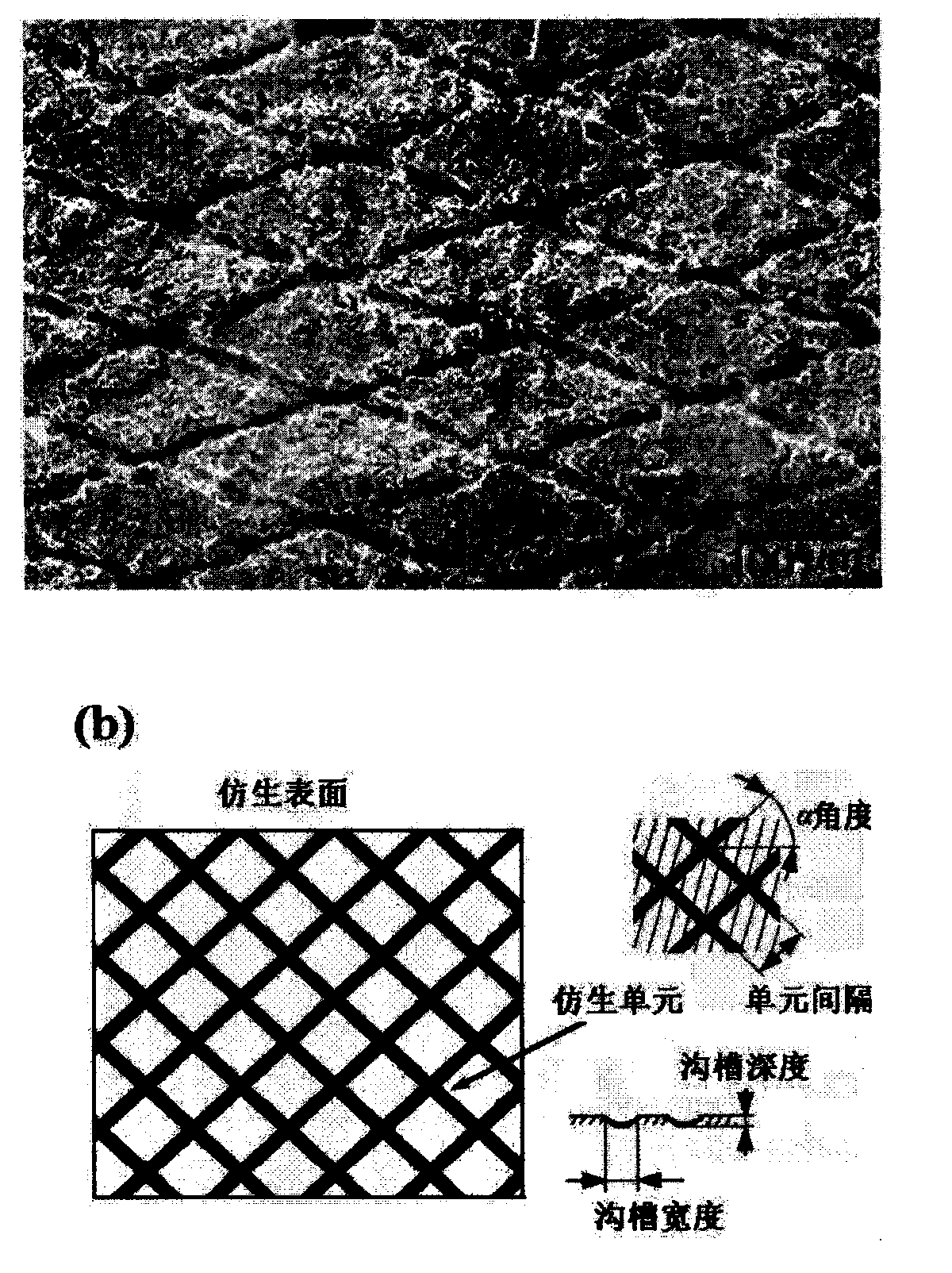

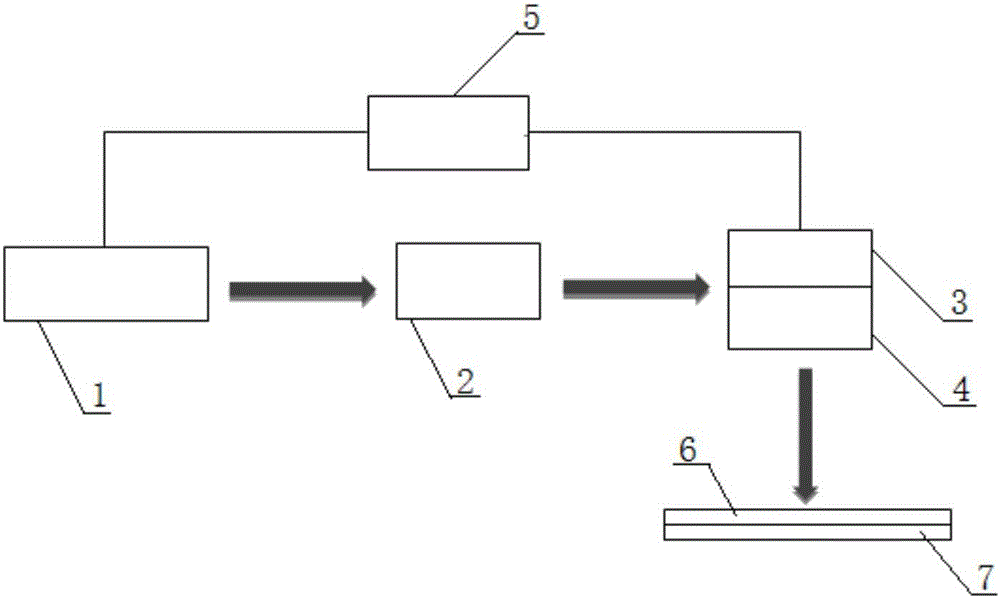

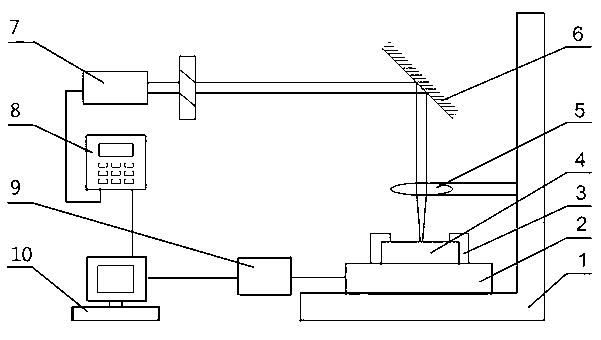

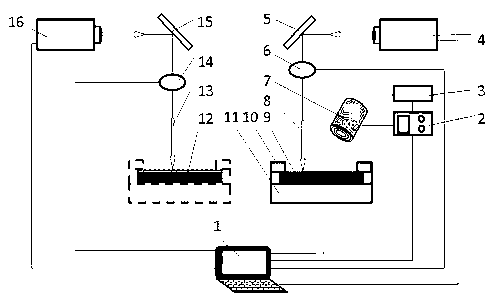

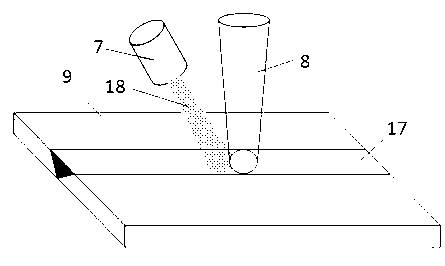

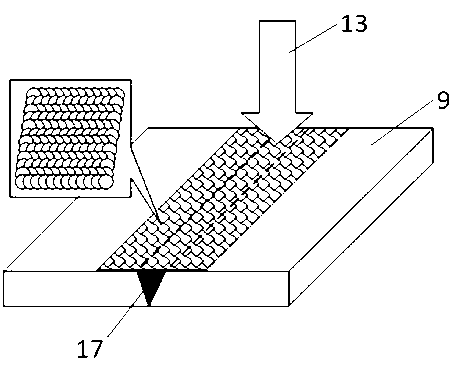

Method and device for compositely preparing surface-layer biomimetic structure by laser

InactiveCN101590569ANo wearNo consumptionLaser beam welding apparatusLight spotVolumetric Mass Density

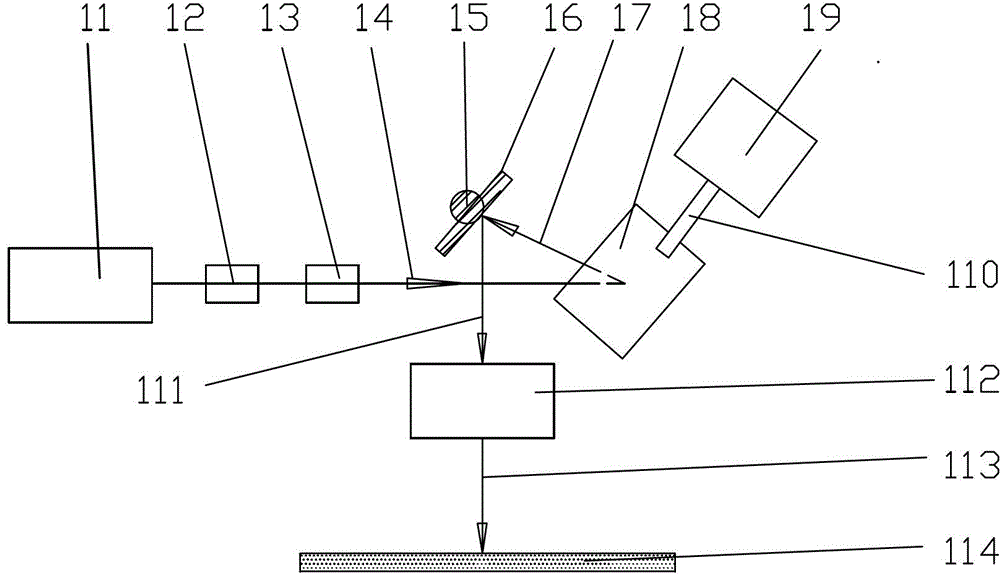

The invention relates to the field of laser processing, in particular to a method and a device for compositely preparing a surface-layer biomimetic structure by mechanical effects based on laser carving and laser shock, which are particularly suitable for processing a biomimetic surface and a friction pair surface. The method is characterized by comprising the following steps: firstly preparing a regular micro geometrical appearance with certain density (space), width, depth, angle and shape on the surface of a workpiece by the laser carving technology; and then forcedly processing the micro geometrical appearance area by laser shock to process a microstructure which has the required shape and management mode and is optimally matched with the requirement of lubricating property on the surface of the workpiece. The device for the implementation method comprises a control device, a nanosecond laser generator, a laser beam I, a light guide tube I, a totally reflecting mirror I, a light spot adjusting device I, a fiber laser, a laser beam II, a light guide tube II, a totally reflecting mirror II, a light spot adjusting device II, an automatic spraying device, a restrain layer, an absorption layer, the workpiece, a workpiece fixture system and a five-axis working platform.

Owner:JIANGSU UNIV

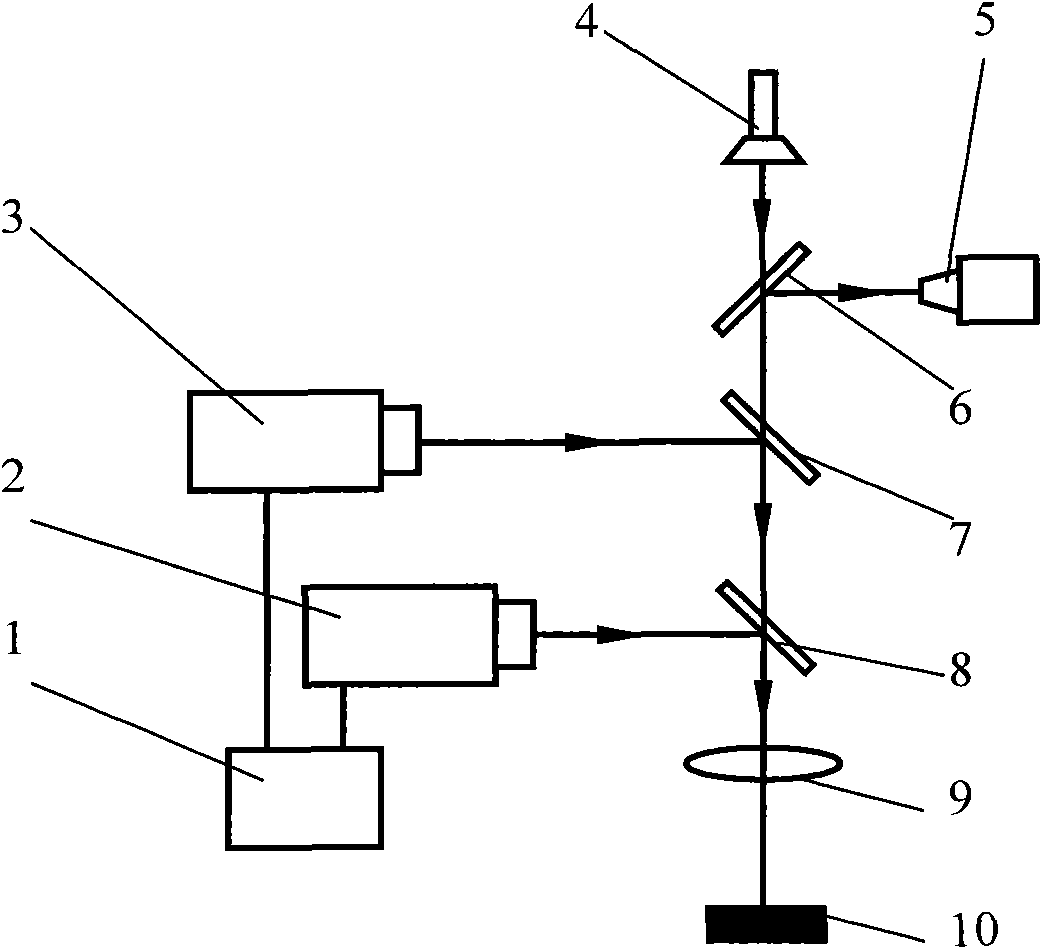

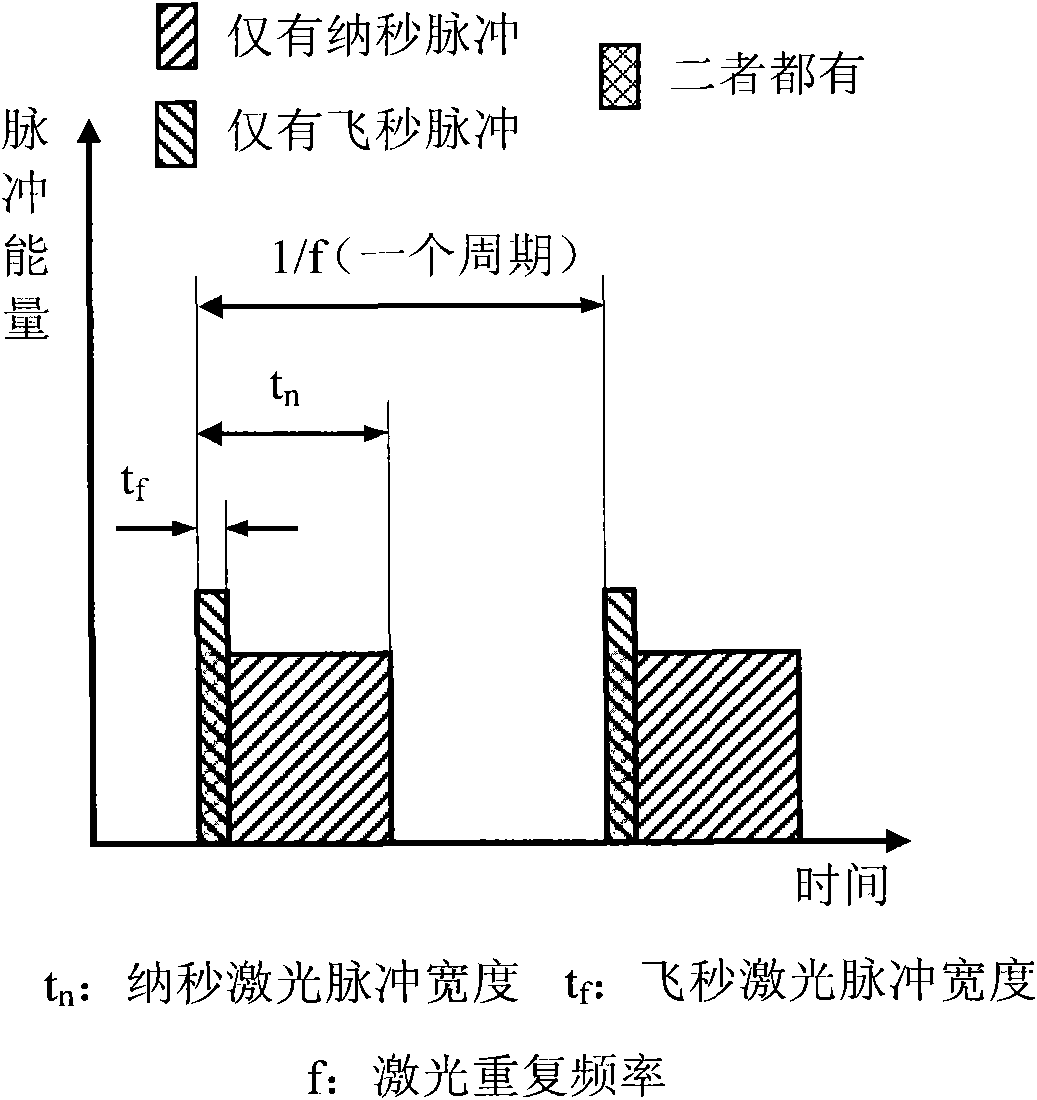

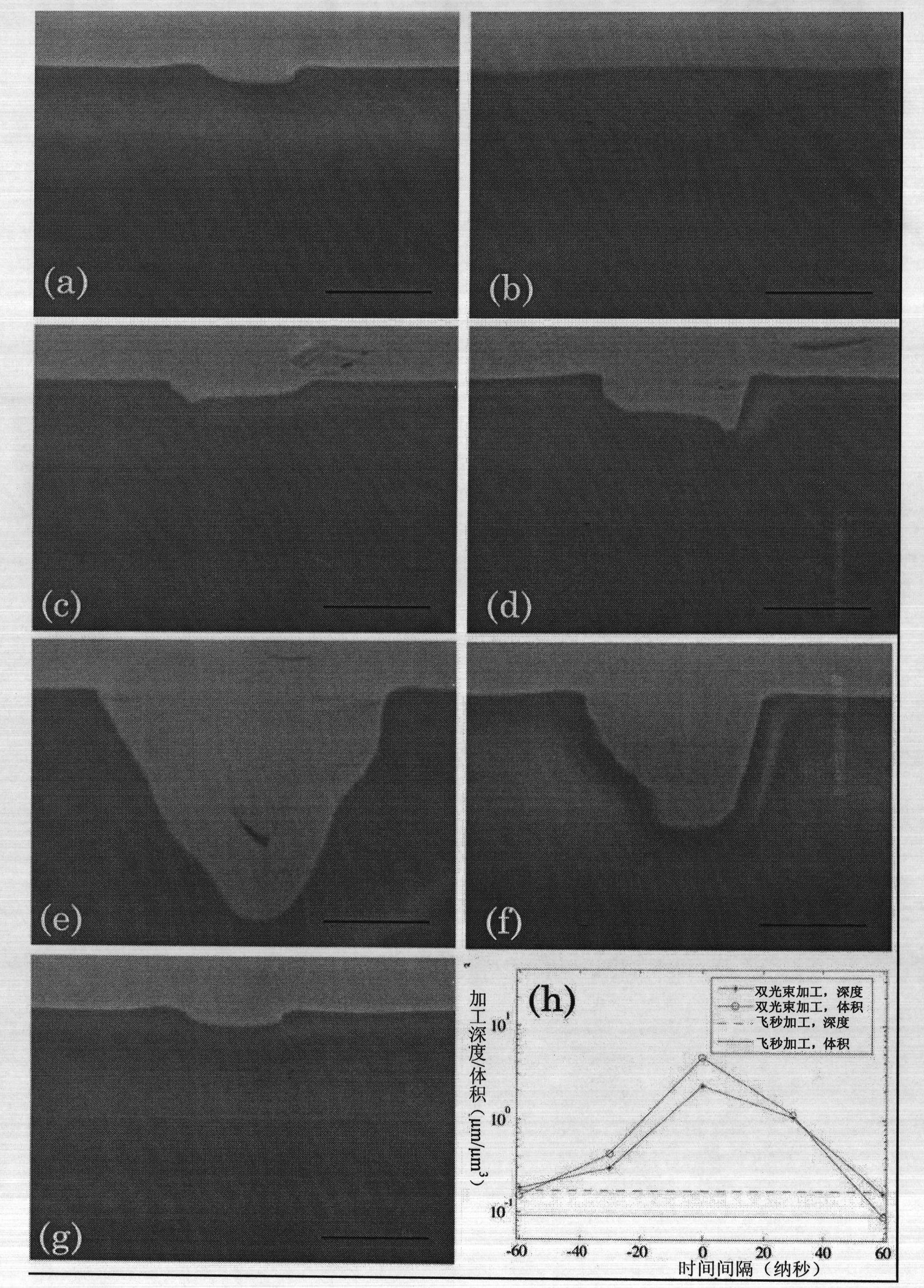

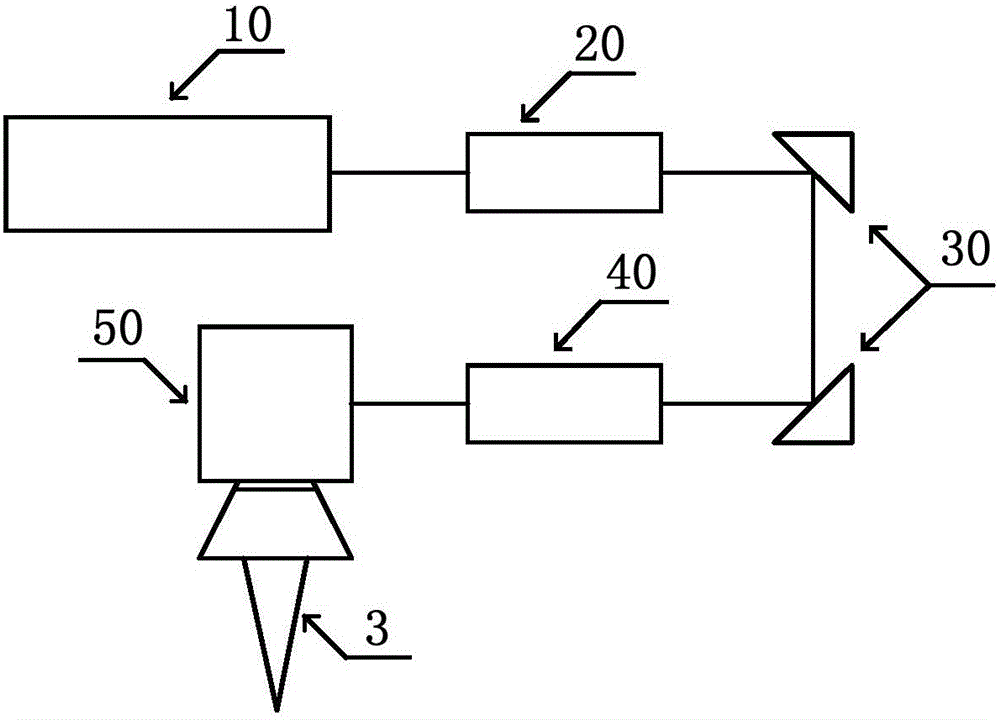

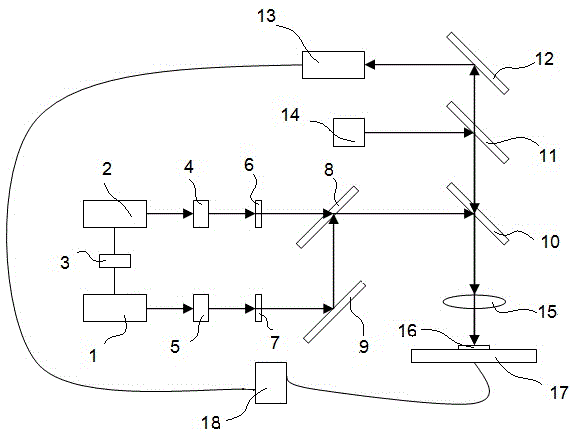

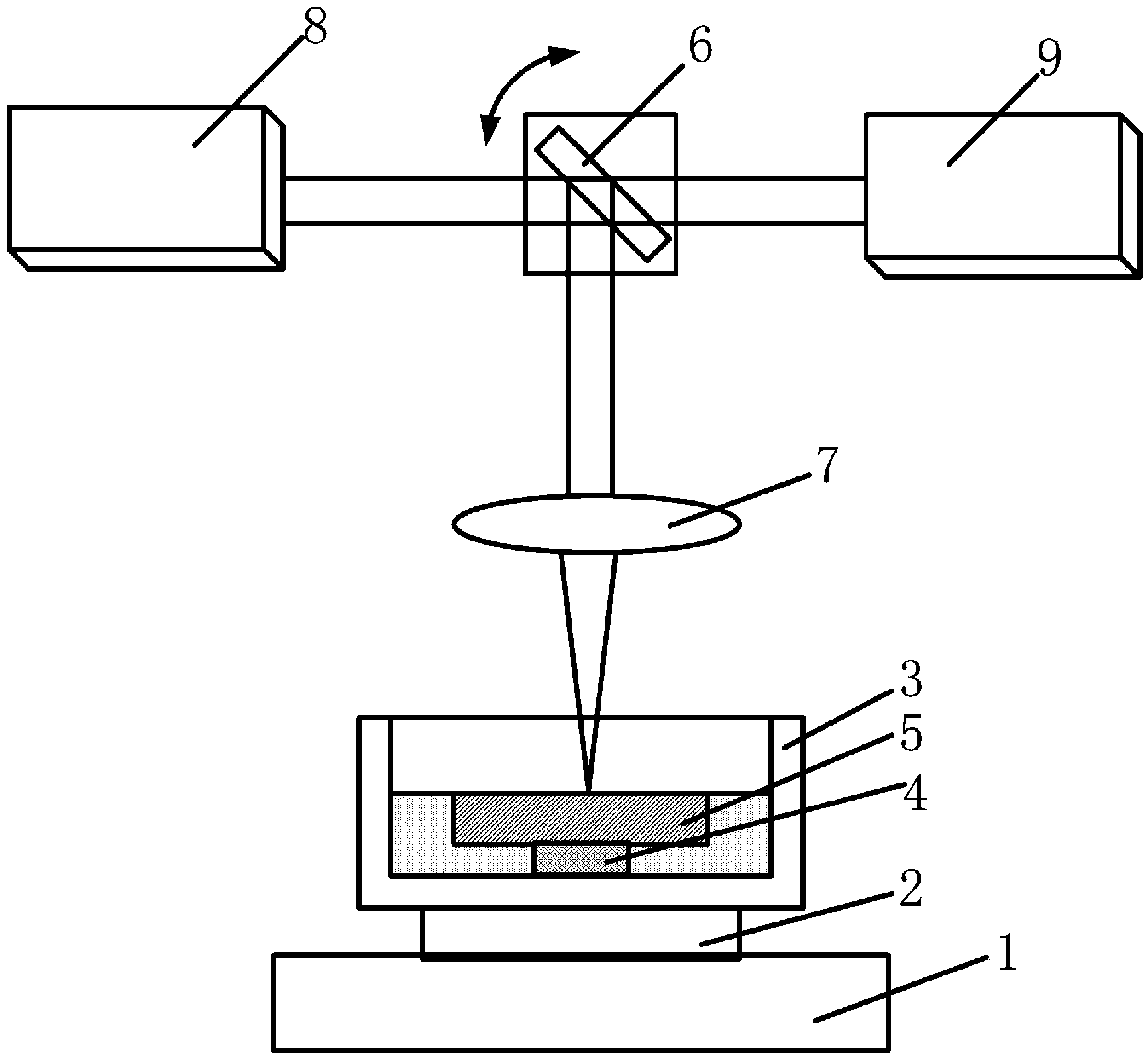

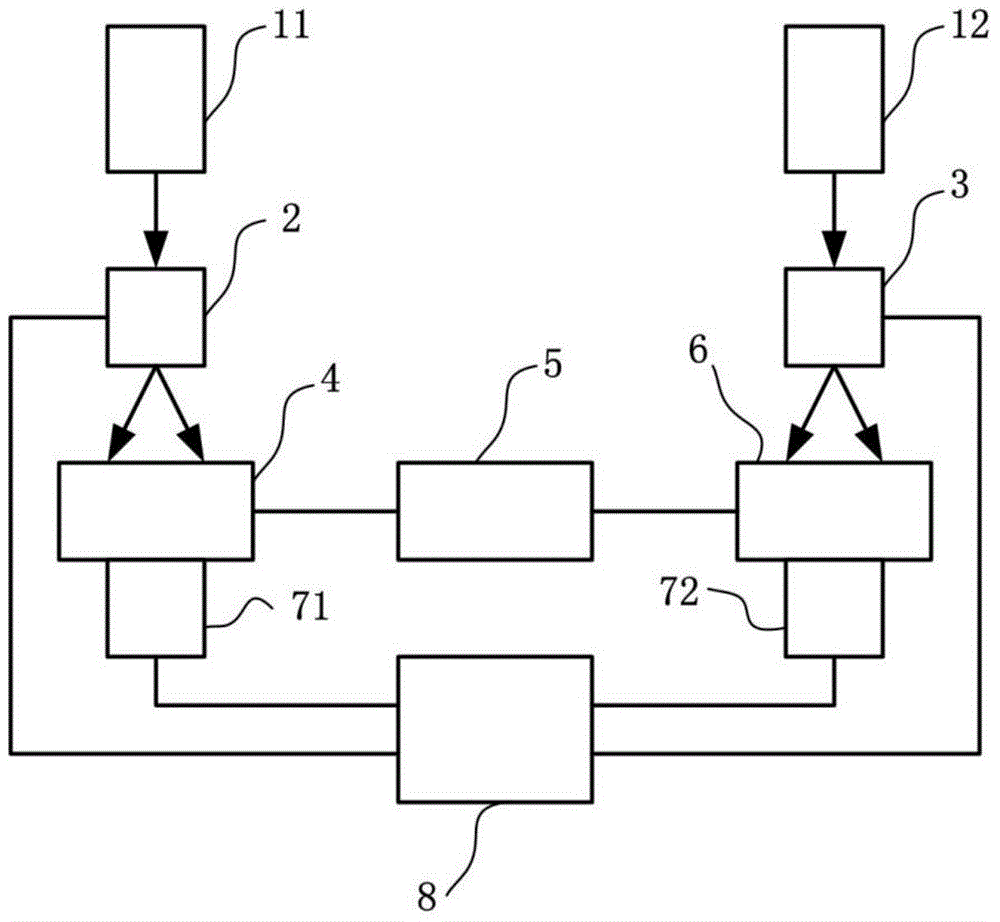

Nano-femtosecond dual-laser composite machining system

InactiveCN102059451AHigh precisionHigh nanosecond laser processing efficiencyLaser beam welding apparatusOptical elementsMicro nanoNuclear fusion

The invention relates to a nano-femtosecond dual-laser composite machining system. The system comprises a femtosecond laser, a nanosecond laser, a synchronous control circuit, an illuminating light source, a semi-transparent semi-reflecting mirror, a first dichroscope, a second dichroscope, a focusing lens and a charge coupled device (CCD) image detector, wherein the synchronous control circuit controls laser pulse output of the femtosecond laser and the nanosecond laser, and accurately adjusts relative time of nanosecond pulse and femtosecond pulse in the aspect of time to synchronize leading edges of the two pulses; the illuminating light source is positioned on one side of the semi-transparent semi-reflecting mirror, and the second dichroscope, the first dichroscope and the focusing lens are coaxially arranged on the other side of the semi-transparent semi-reflecting mirror in turn and are positioned on a straight line together with the illuminating light source; and the CCD image detector is positioned at the tail end of a reflecting light path of the semi-transparent semi-reflecting mirror. Through the system, the advantages of high femtosecond laser machining accuracy and high nanosecond laser machining efficiency are simultaneously integrated, and high-accuracy and high-efficiency micro-nano machining is realized; and the system can be widely applied to the fields such as high-accuracy machining of aviation and aerospace key parts, microstructure machining of a laser fusion ignition target, microstructure machining of a microsensor and the like.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Light beam-rotating galvanometer-scanning focused processing system

InactiveCN101856772ASimple and flexible controlFast acceleration and decelerationLaser beam welding apparatusNanosecond laserLaser processing

The invention, which belongs to the field of laser processing, relates to a light beam-rotating galvanometer-scanning focused processing system. The system is mainly characterized in that: the system combines the light beam-rotating focused laser processing method and the galvanometer-scanning laser processing method into a novel processing method, which can form a wide cut, and thereby sprue can be conveniently spurted out; if the distribution of laser is Gaussian distribution, then laser processing has the laser processing effect of Gaussian intensity distribution, and has a laser processing effect capable of achieving flat-top laser; nanosecond laser is utilized to achieve the processing effect of ultrashort-pulse width laser, however, by comparison, the processing efficiency is greatly increased; the control is simple and flexible, the speed can be quickly increased and decreased, the size is small, and the cost is low.

Owner:张立国

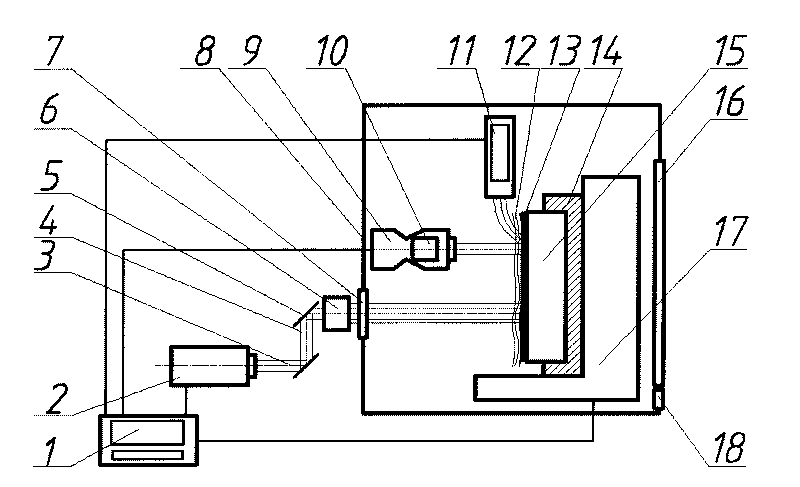

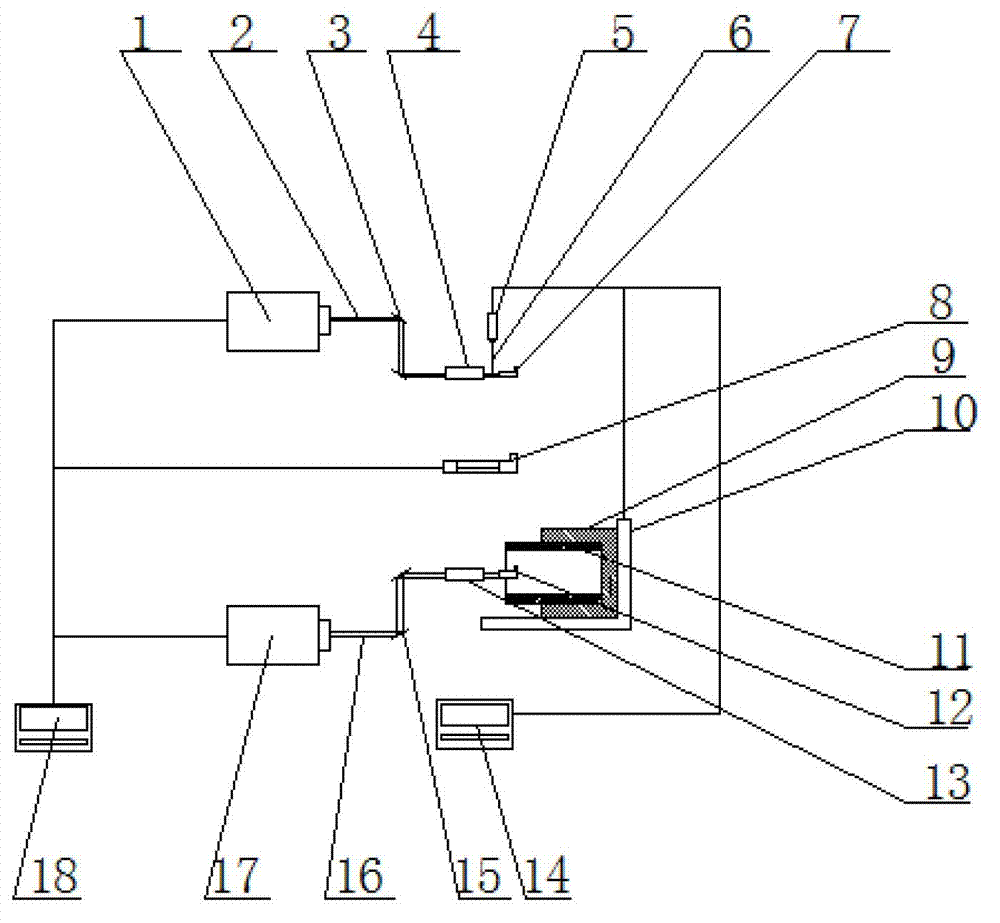

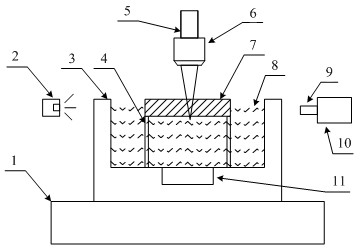

Method and device of laser impact and thermal spraying composite coating preparation

InactiveCN101760719AImprove fatigue lifeParticle refinementMolten spray coatingPorosityThermal spraying

A method and a device of laser impact and thermal spraying composite coating preparation relates to the nontraditional machining field. At first, the invention uses a thermal spraying device to spay powder onto the surface of a metal substrate in order to form a coating. The invention is characterized in that laser is used to impact the metal substrate surface coated with the coating and the coating which has low porosity, high bonding strength and compression stress is formed. The device implementing the method comprises a computer control device, a thermal spraying system I, a laser impact system II, a sealed treatment room, a clamping device, a five-axis workbench and a vacuum pump, which are connected in turn. The thermal spraying system I comprises the thermal spraying device and sprayed powder. The laser impact system II comprises a nanosecond laser generator, laser beam, a light pipe, a 45 degrees totally reflective mirror, a facula adjusting device, a K9 glass window and an automatic spraying system. The invention can form the coating on the surface of the metal, increase the porosity of the coating, improve the bonding strength of the coating and the substrate and change the state of residual stress.

Owner:JIANGSU UNIV

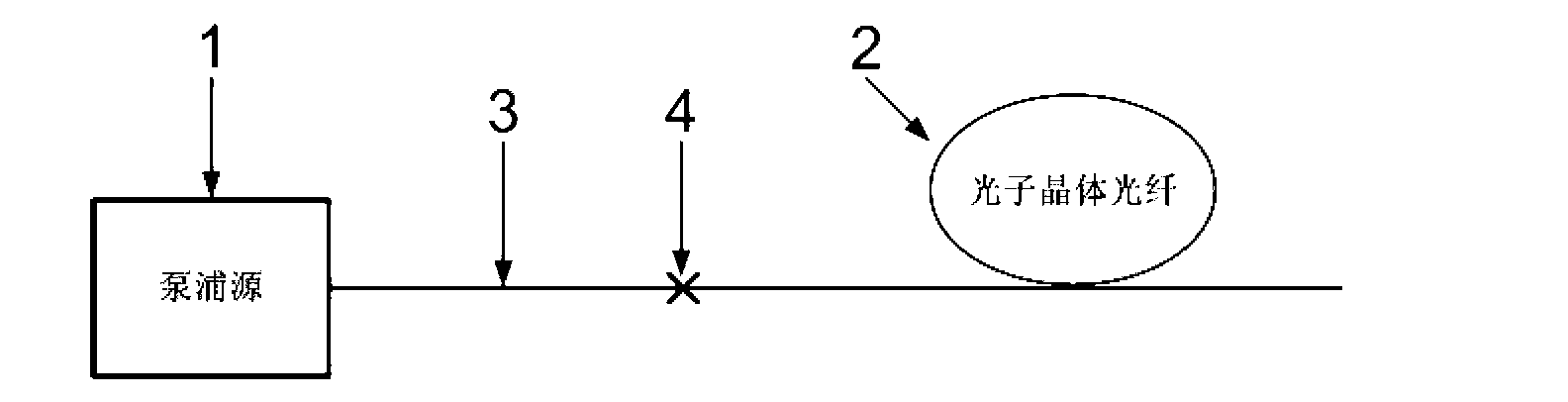

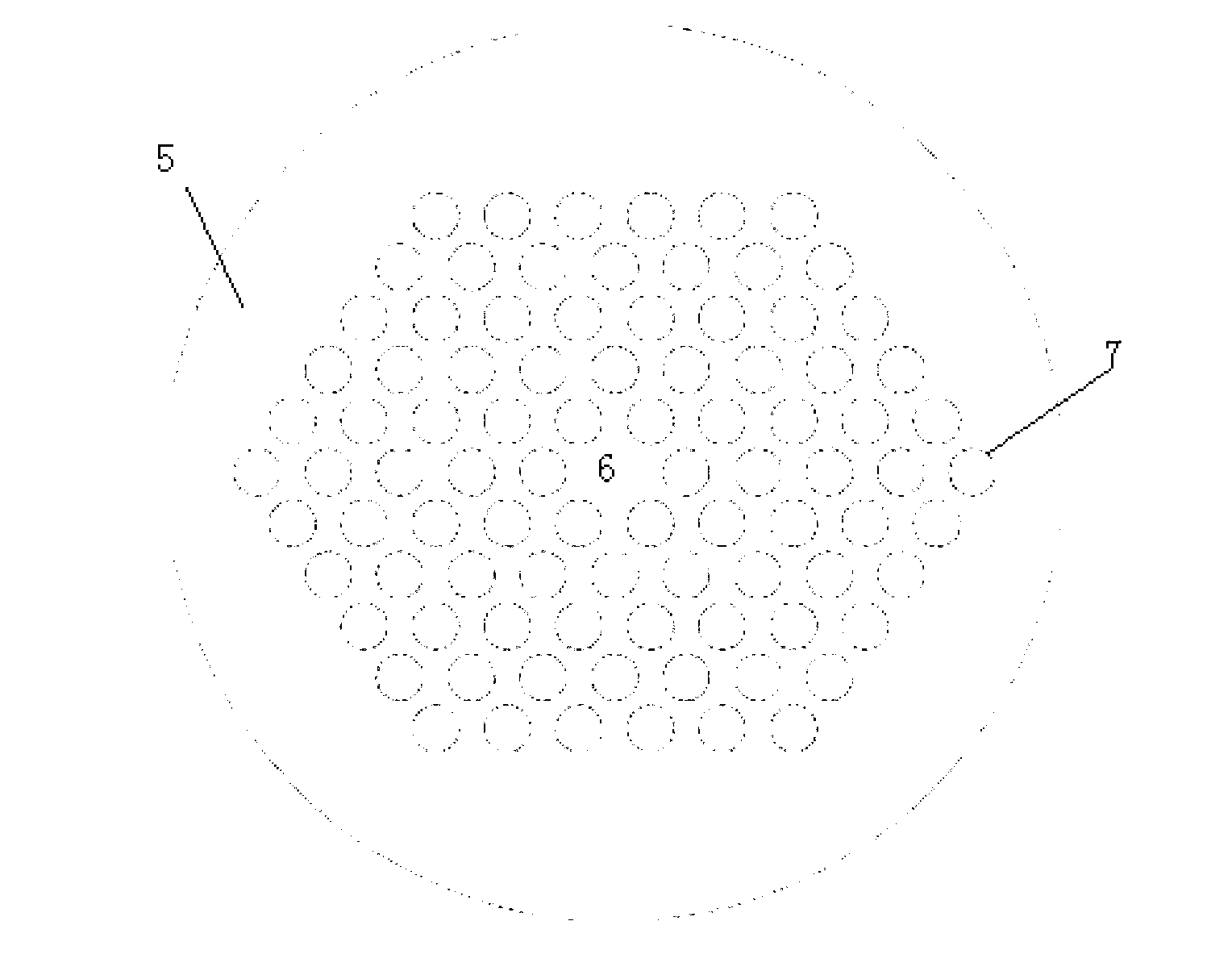

High-power high-efficiency supercontinuum source

InactiveCN103022867AIncrease output powerLow costCladded optical fibreActive medium shape and constructionManufacturing technologyPicosecond

The invention provides a high-power high-efficiency supercontinuum source. By reasonably designing characteristics of photonic crystal fibers, long-pulse pump laser (picosecond, nanosecond laser) acts on a normal dispersion area for the photonic crystal fibers, the central wavelengths of stimulated front stages of Raman-Stokes peaks are positioned in an abnormal dispersion area close to a zero dispersion point of the photonic crystal fibers, and the stimulated Raman-Stokes laser peaks serve as a new pump source for stimulating supercontinuum and meet the requirement of an abnormal dispersion pump mechanism. The supercontinuum source simultaneously has the advantages of a normal dispersion pump mechanism and the abnormal dispersion pump mechanism, and high average output power and continuum output with high optical conversion efficiency and a wider supercontinuum range can be realized. By the aid of mature high-power fiber laser technology, photonic crystal fiber manufacturing technology and photonic crystal fiber post-treatment technology, system cost is reduced, and industrial production and application are facilitated.

Owner:NAT UNIV OF DEFENSE TECH

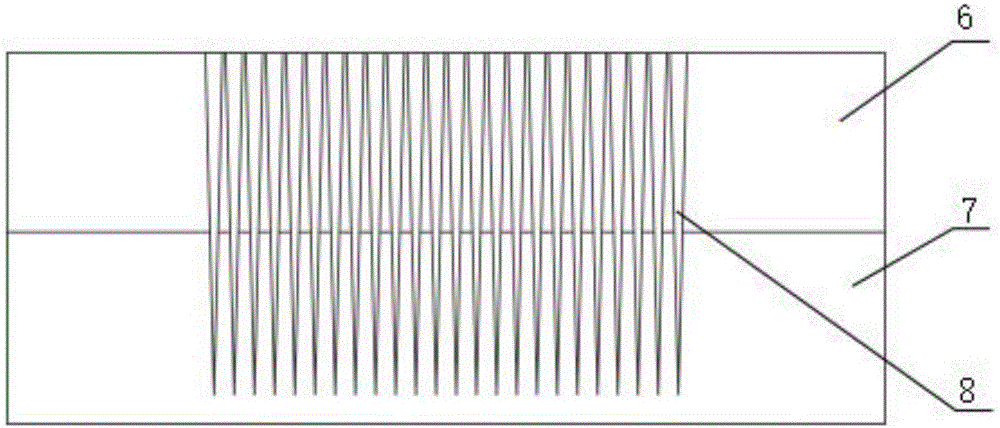

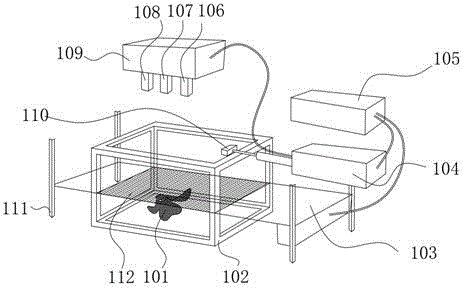

Processing method and device for inner hole of tempered glass

ActiveCN105081564AImprove yield rateHigh speedLaser beam welding apparatusNanosecond laserControl system

The invention discloses a processing method for an inner hole of tempered glass. The processing method comprises the following steps that laser is used for processing the contour of the inner hole in a substrate of the tempered glass firstly, the glass in the hole is separated from the substrate completely at the time, but the glass in the hole does not fall off the substrate; and laser is then used for removing the glass in the inner hole. The invention further discloses a processing device adopting the method. The processing device comprises a workbench, a moving unit, a positioning unit, a laser system and a control system. According to the processing method and device, a processing mode with ultrashort pulse laser and nanosecond laser combined is used, and the processing method and device are applicable to processing of high-intensity tempered glass and inner holes of any shape and size. The processing method and device have the characteristics of being high in speed, good in effect, high in yield, few in consumable, low in cost and the like.

Owner:深圳市大族半导体装备科技有限公司

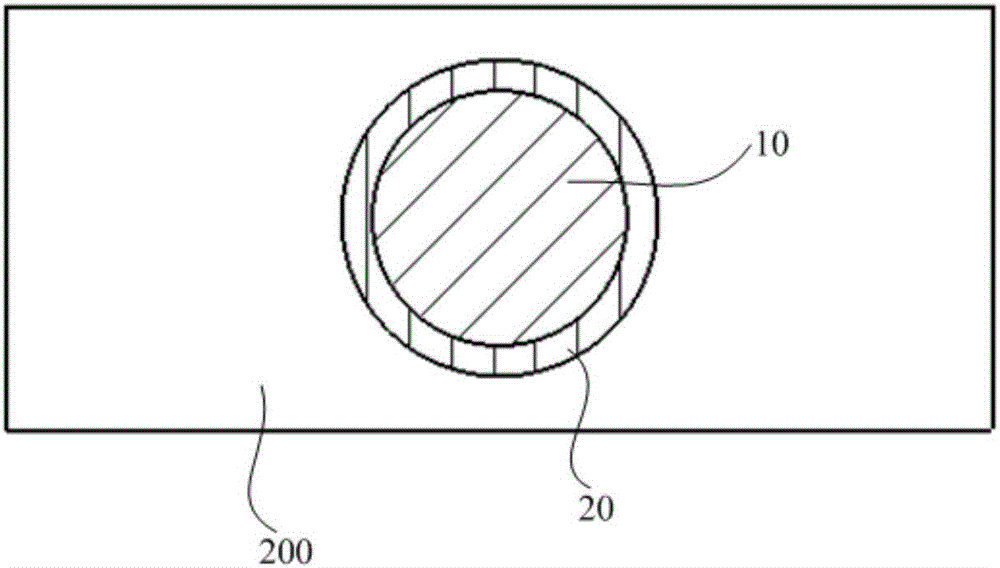

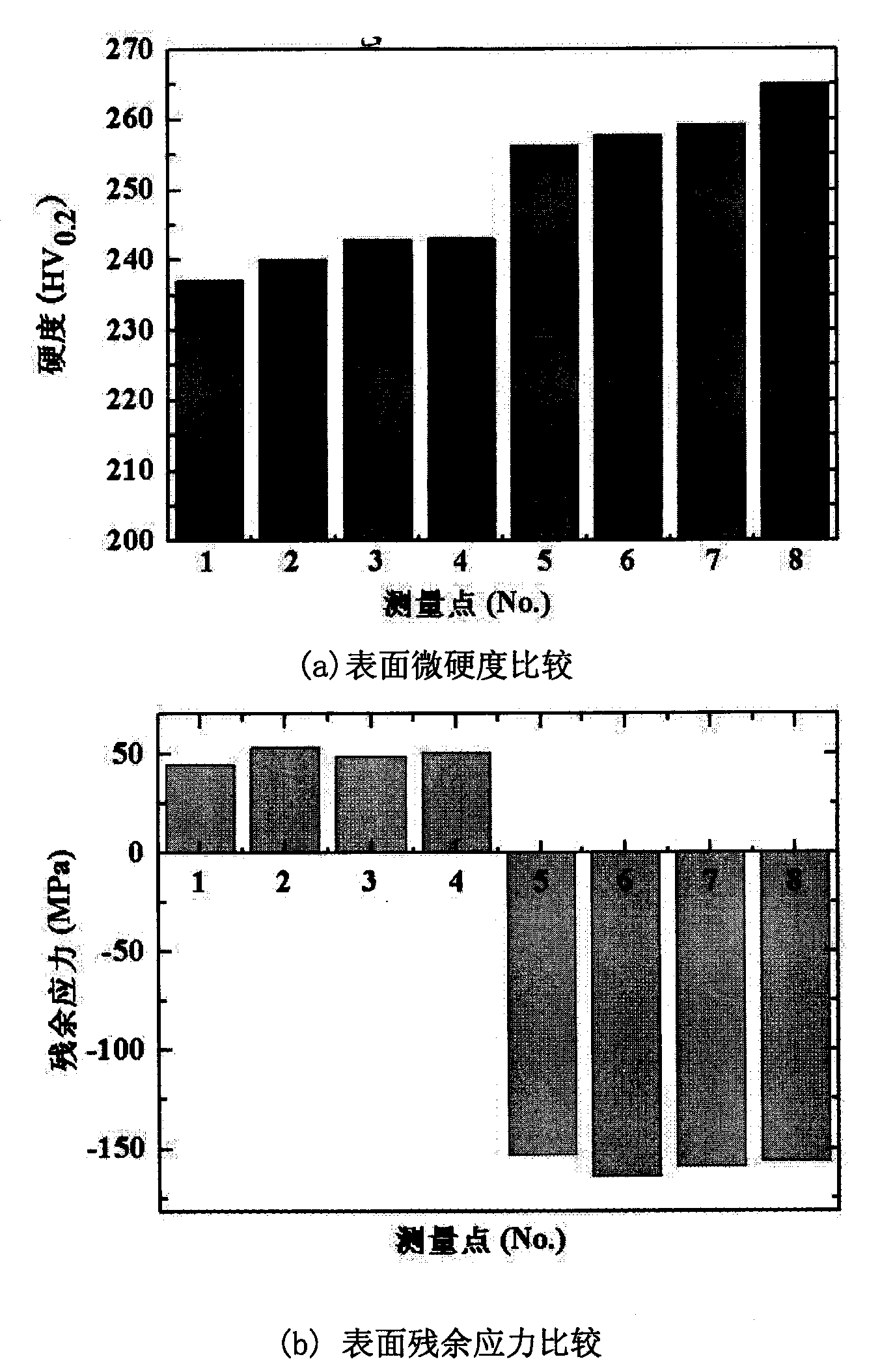

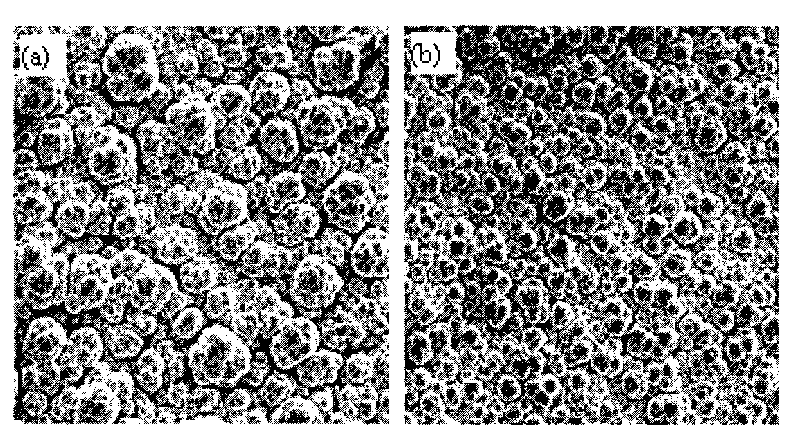

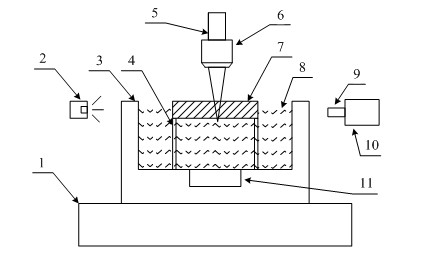

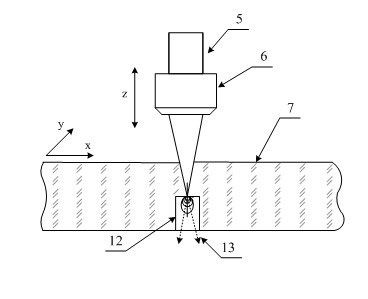

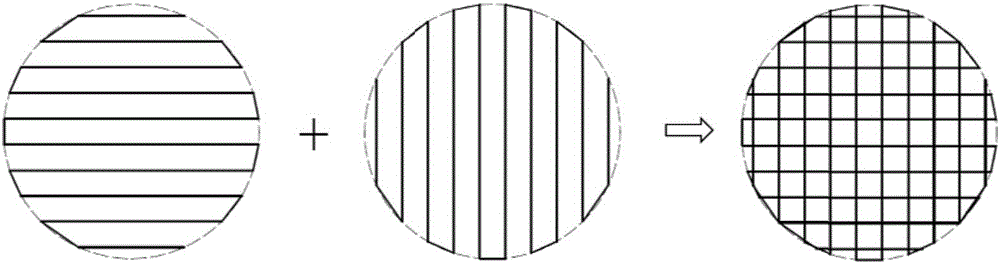

Method and device for forming micro-texture in composite mode on inner surface of cylinder sleeve through laser

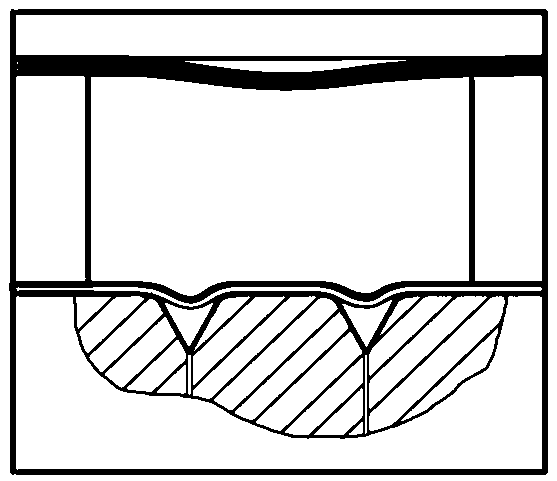

InactiveCN103111752AImprove mechanical propertiesImprove friction performanceLaser beam welding apparatusFriction reductionShock wave

The invention provides a method for forming micro-texture in a composite mode on the inner surface of a cylinder sleeve through laser. The method comprises the following steps: step (1), a femtosecond laser device is used for processing a needed microcosmic shape on the inner surface of the cylinder sleeve; and step (2), a nanosecond laser device is used for strengthening the area of the microcosmic shape processed in the step (1) through laser shock waves. Under the condition of dry friction, micro-concave surface texture can be used as a storage device for storing wear particles to reduce abrasive wear and furrows on the friction surface, and therefore the wear rate is lowered. The laser shock waves can eliminate residual tension after the micro-texture is formed on the inner surface of the cylinder sleeve, and therefore deep residual compressive stress is formed, grain refinement is enabled to be more uniform, the hardness, the abrasive resistance and the anti-fatigue performance of the cylinder sleeve are improved, and the service life of the cylinder sleeve is prolonged. The invention further provides a device for forming the micro-texture in the composite mode on the inner surface of the cylinder sleeve through the laser at the same time.

Owner:WENZHOU UNIVERSITY +1

Method and device for preparing microchannel in glass material

InactiveCN102092931ALow costFast processingGlass severing apparatusNanosecond laser pulseNanosecond laser

The invention discloses a method and device for preparing a microchannel in a glass material. The method comprises the following steps: (1) the glass material to be treated and inscribed is placed in an ultrasonic environment to ensure that the lower surface of the glass is soaked in clean water and the upper surface of the glass is exposed in air; (2) the laser emitted by a nanosecond laser is focused by a focus lens, the focused nanosecond laser pulse is emitted to the upper surface of the glass material to be treated and inscribed vertically, the focus of the nanosecond laser pulse is on the lower surface of the glass material to be treated; and (3) a laser beam is emitted by the nanosecond laser from bottom to top according to a preset scanning path to ensure that a three-dimensional microchannel is inscribed in the glass. The device in the invention contains a three-dimensional platform, an ultrasonic cleaner, a support and a focus mirror. When the device in the invention works, the ultrasonic cleaner is fixed on the three-dimensional platform; and the glass material to be treated is placed in the cavity of the ultrasonic cleaner through the support, and the focus mirror is fixed on the vertical shaft of the three-dimensional platform. By adopting the method in the invention, the defects of the prior art such as low production efficiency, high cost and limited depth-to-width ratio can be overcome.

Owner:HUAZHONG UNIV OF SCI & TECH

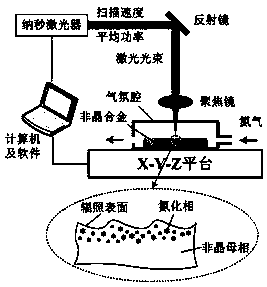

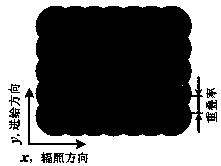

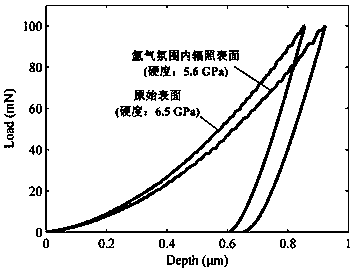

Method for improving zirconium-based or titanium-based amorphous alloy surface hardness through laser irradiation in nitrogen

ActiveCN108546893AHigh hardnessSolve the problem of significant reduction in surface hardnessSolid state diffusion coatingNanosecond laserNitrogen atmosphere

The invention relates to a method for improving zirconium-based or titanium-based amorphous alloy surface hardness through laser irradiation in nitrogen, and belongs to the technical field of amorphous alloy surface modification. Chemical affinity of the zirconium or titanium element and the nitrogen element under the high temperature or other conditions is used, nanosecond laser irradiation is carried out on the zirconium-based or titanium-based amorphous alloy surface in the nitrogen atmosphere, a nitriding phase (zirconium nitride or titanium nitride) is led into an amorphous parent phase of the surface of a zirconium-based or titanium-based amorphous alloy, and the surface hardness of the zirconium-based or titanium-based amorphous alloy is improved. The method effectively solves the problem that when the amorphous alloy surface is treated through an existing laser irradiation method, the surface hardness of the amorphous alloy is obviously reduced. Laser irradiation parameters arechanged, so that regulation and control of the content of the nitriding phase on the amorphous alloy surface are conveniently achieved, and regulation and control of the zirconium-based or titanium-based amorphous alloy surface hardness are achieved. The method is simple in implementation process, high in efficiency and high in practicability, the method can be used for regulating and controllingthe zirconium-based or titanium-based amorphous alloy surface hardness, and function application of the zirconium-based or titanium-based amorphous alloy is strengthened.

Owner:JILIN UNIV

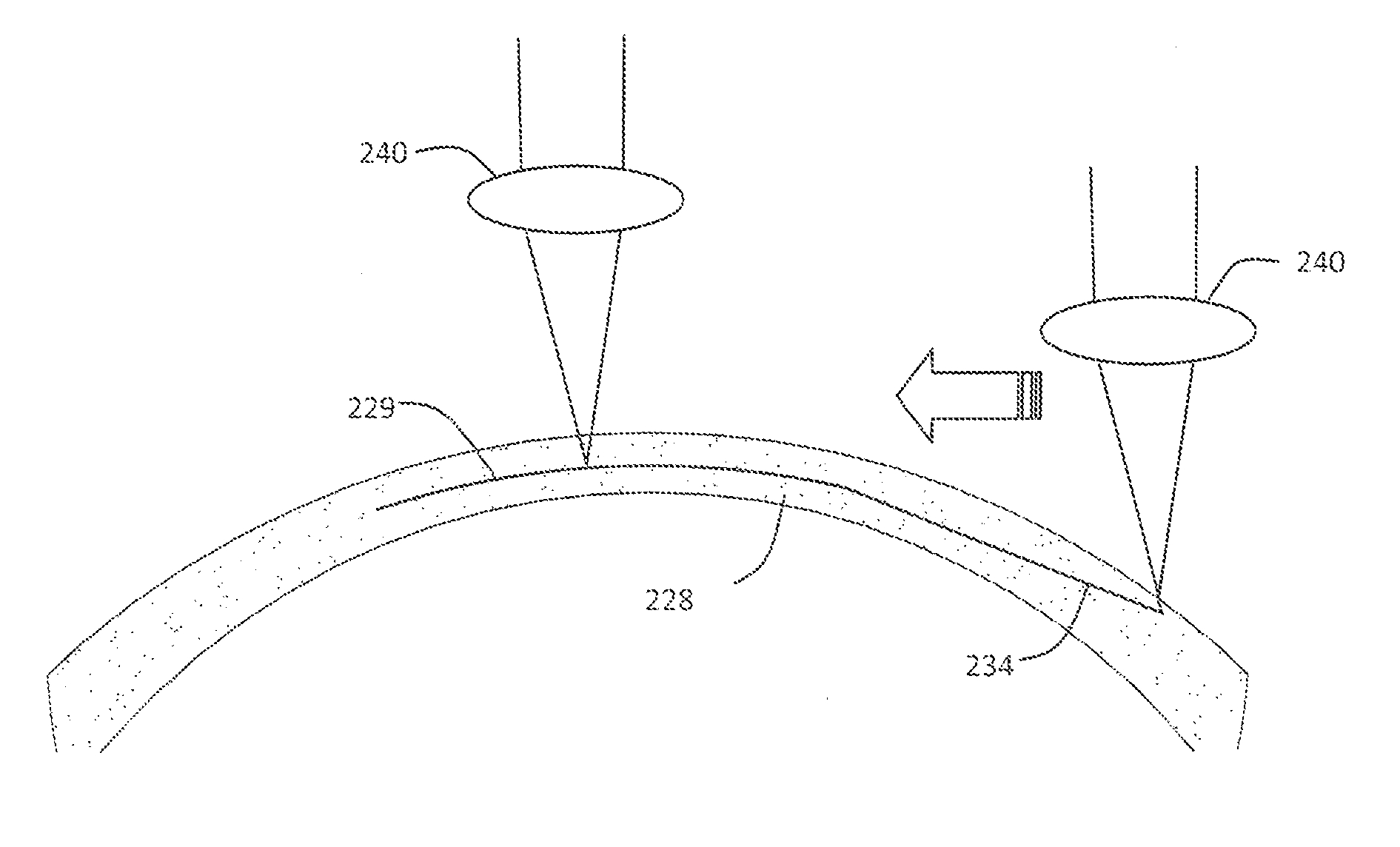

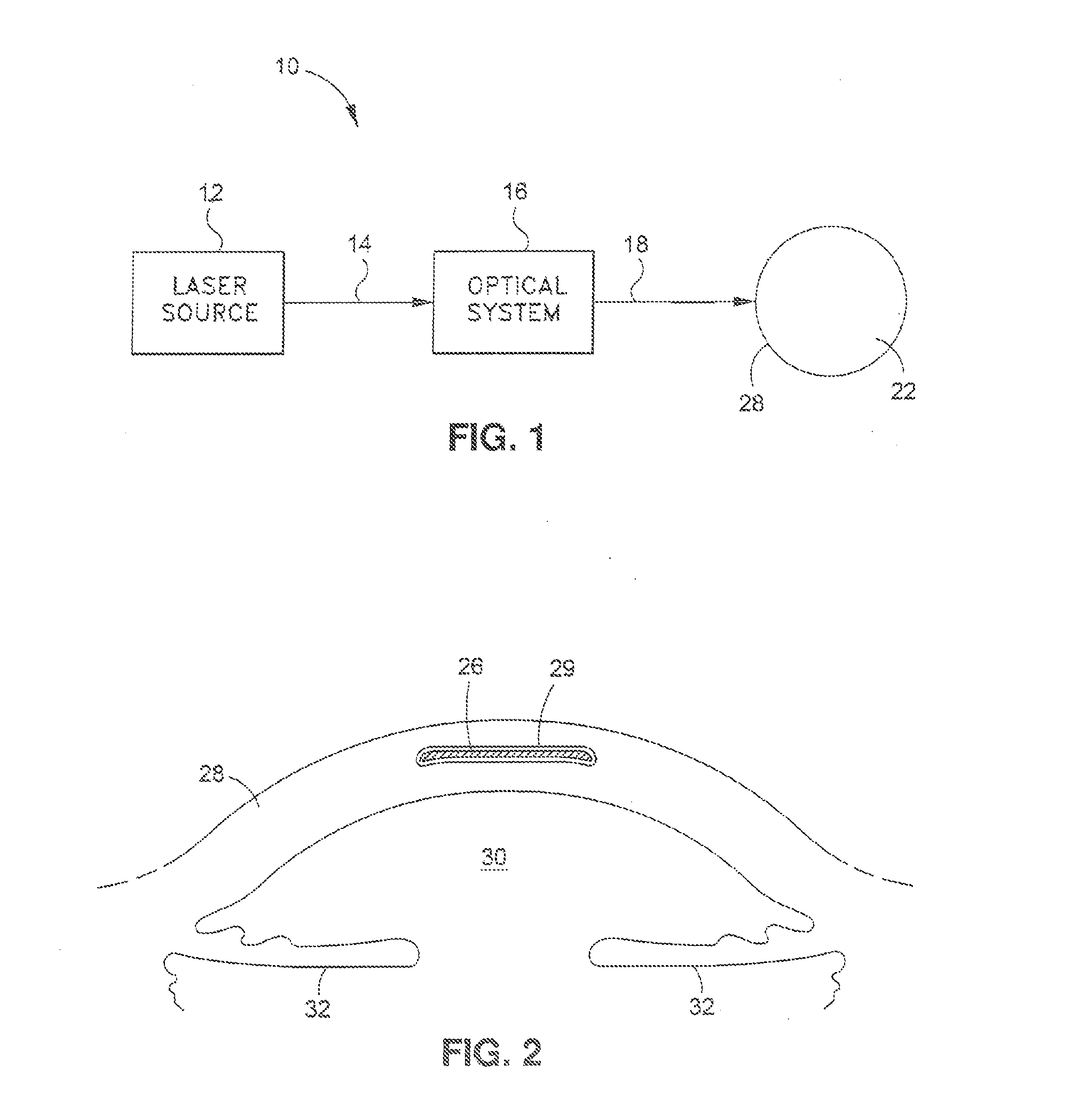

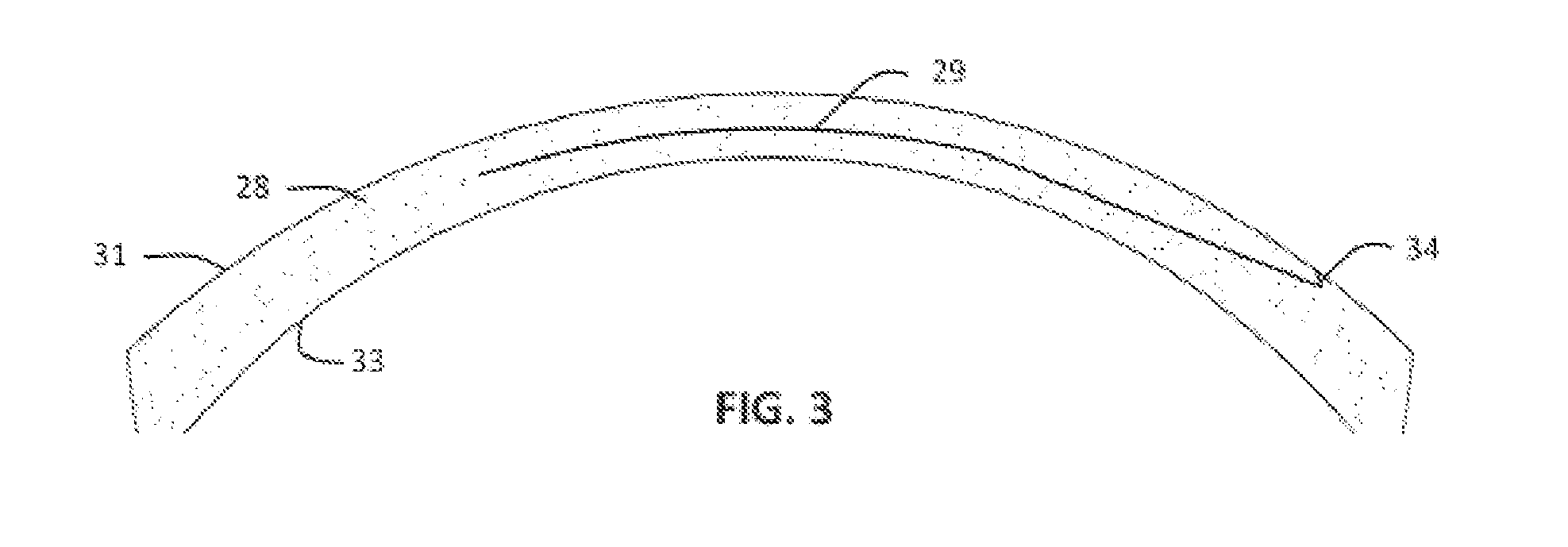

Method for Laser Cutting a Corneal Pocket

ActiveUS20110319876A1Compensation effectEliminate spaceLaser surgeryEye implantsNanosecond laserThulium-YAG laser

A method for using a laser to create a pocket in a patient's cornea is provided. The pocket is created using a femtosecond or a nanosecond laser. The laser ablates tissue within the cornea in a specific shape. The shape of the pocket can be determined by software to custom program a three-dimensional path of the laser. A variety of corneal pocket configurations or computer programmed shapes can be used accommodate various corneal lens shapes and sizes. An intracorneal lens can then be inserted into the pocket, in order to correct the patient's vision.

Owner:PRESBIBIO +1

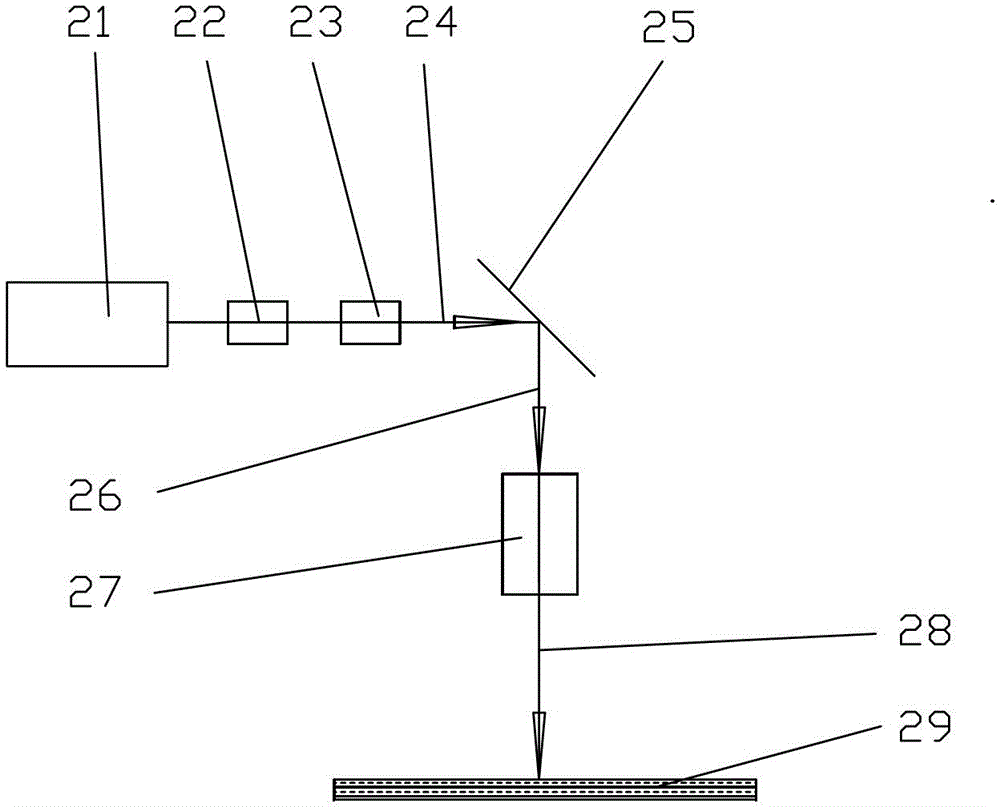

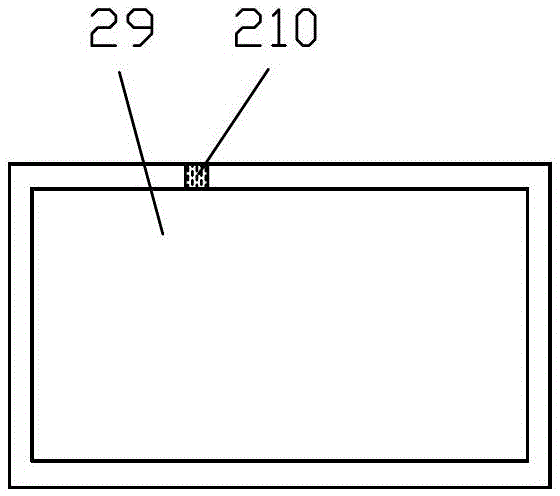

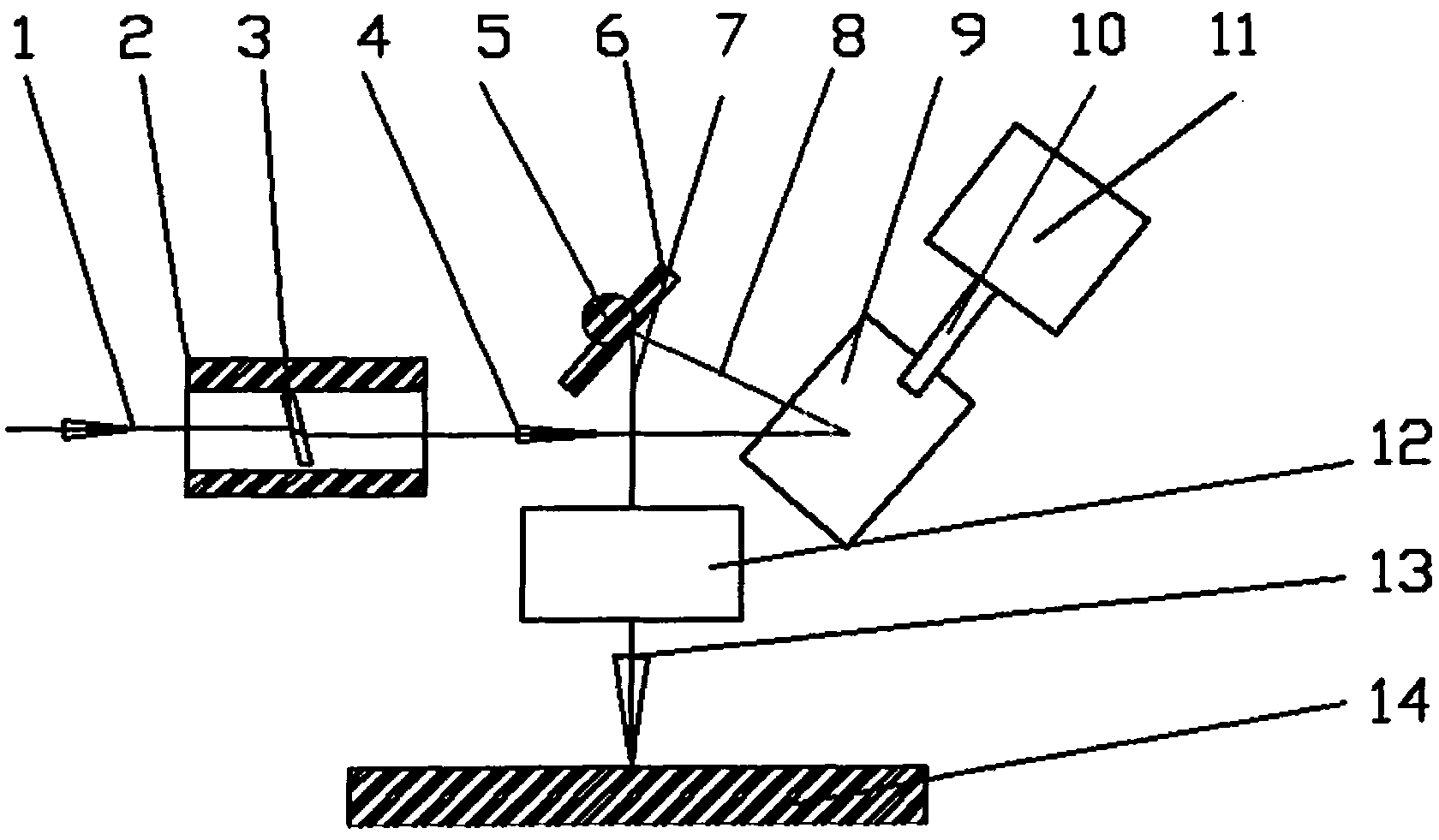

Preparation method and preparation device of high-depth-diameter ratio micropores

ActiveCN104889576AAdd depthNo change in pore sizeWelding/soldering/cutting articlesMetal working apparatusBeam splitterTime delays

The invention relates to a preparation method and a preparation device of high-depth-diameter ratio micropores. The preparation method and the preparation device are used for high-depth-diameter ratio micropores. The preparation method is used for preparing the high-depth-diameter ratio micropores in a dual-pulse combination manner; the laser source comprises two laser combinations different in pulse width; a digital signal time delay generator is used for controlling the two pulse combinations for the time of a sample; the laser pulses of two laser devices are combined and focused on the sample by use of an optical component to perform laser etching on the sample directly; the preparation device comprises a femtosecond laser device, a nanosecond laser device, a digital signal time delay generator, a half-wave plate, an optical polarizer, a beam splitter, a total reflector, a white light source, a charge coupling element, a three-dimensional mobile platform and a computer. The preparation method is capable of directly breaking through the maximum micropore high-depth-diameter ratio limit that can be available by use of single pulse and well solving the technical problem of low depth-diameter ratio in current micropore preparation.

Owner:中国工程物理研究院上海激光等离子体研究所

Nanosecond laser welding method and nanosecond laser welding system for metal sheets

ActiveCN106077953ABite achievedStrong biteWelding/soldering/cutting articlesLaser beam welding apparatusNanosecond laserGalvanometer

The invention discloses a nanosecond laser welding method and a nanosecond laser welding system for metal sheets. The nanosecond laser welding system comprises a nanosecond laser, a beam expanding lens, a galvanometer scanning deflector and a light beam focusing lens which are arranged sequentially through a support frame. Laser beams sent from the nanosecond laser are emitted to a plurality of to-be-welded metal sheets after passing the beam expanding lens, the galvanometer scanning deflector and the light beam focusing lens. The nanosecond laser welding method and the nanosecond laser welding system have the advantages that emission time, strength and the like of the nanosecond laser can be controlled by a controller, deflection angles of the galvanometer scanning deflector can be controlled by the controller, or positions of the to-be-welded metal sheets can be adjusted by a sheet holder, so that a plurality of tiny welding points, which are arranged according to a preset route and formed on the to-be-welded metal sheets by the micro-scale laser beams generated by the system, have larger bite force, and overlarge heat influences on metal are avoided.

Owner:WUHAN HGLASER ENG CO LTD

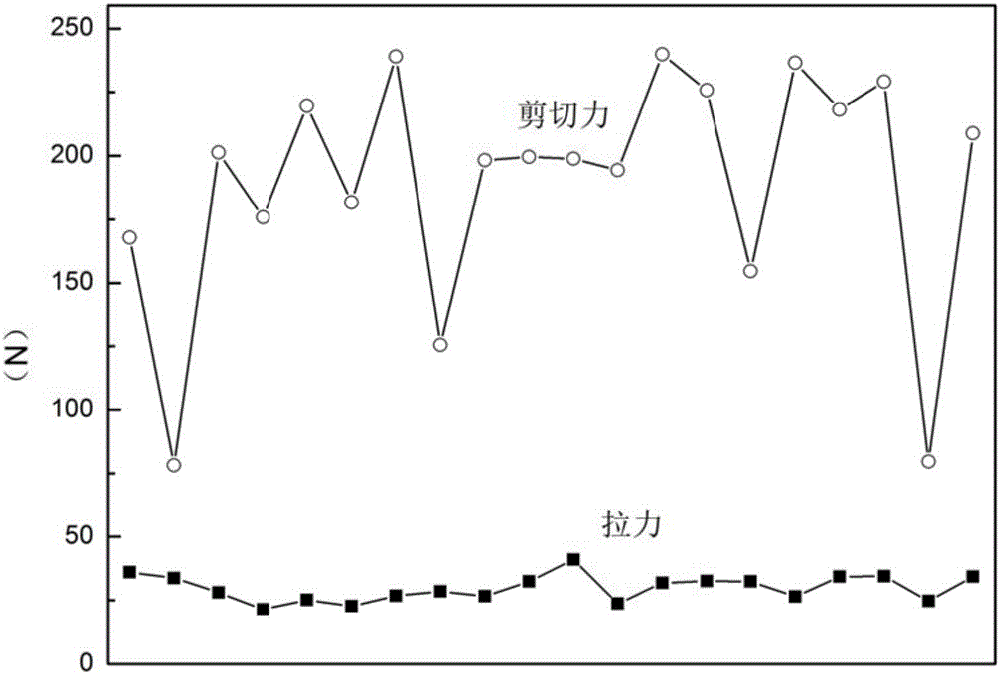

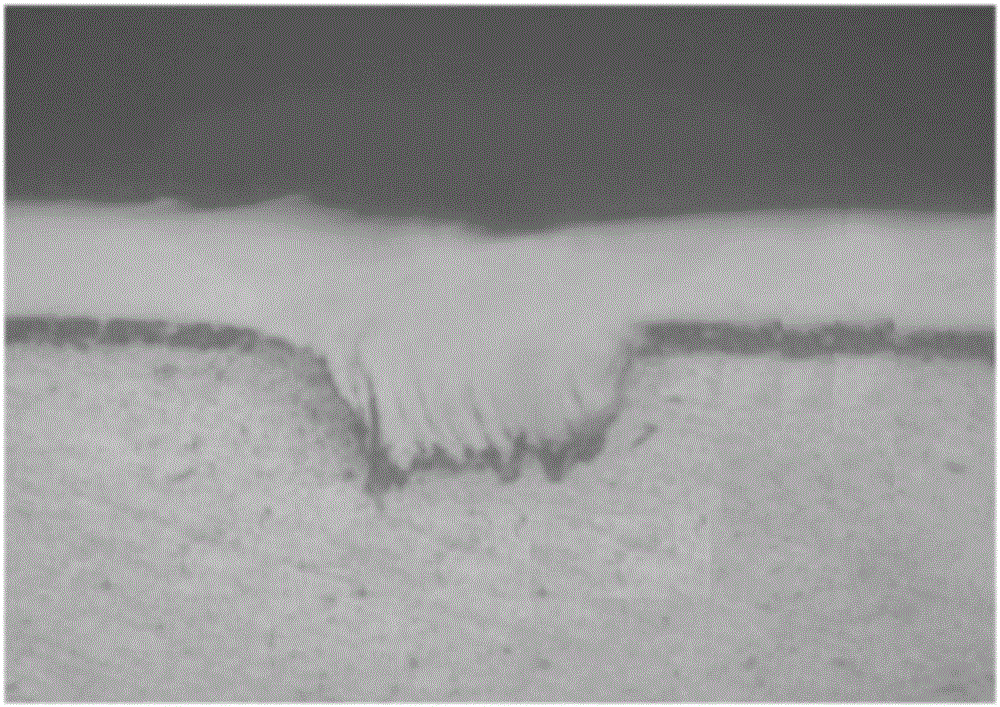

Dissimilar metal micro welding method

ActiveCN106735894AShort pulse widthReduce generationWelding/soldering/cutting articlesLaser beam welding apparatusNanosecond laserGalvanometer

The invention relates to a dissimilar metal micro welding method comprising following steps: A1. an aluminum alloy plate and a stainless steel plate are compressed and fixed by a clamp; A2. a nanosecond laser or a microsecond laser is matched with a high speed scanning galvanometer; the high speed scanning galvanometer controls laser to perform scanning welding on the aluminum alloy plate and the stainless steel plate so that welding spots are formed between the aluminum alloy plate and the stainless steel plate, wherein the welding spots are embedded in the aluminum plate in a tooth like mode. Taking the advantages of extremely short pulse width and low energy of the nanosecond laser or the microsecond laser and by means of high speed scanning mode, the generation of the (Fe, Al) intermetallic compound between the aluminum alloy plate and the stainless steel plate is reduced by accurately controlling heat input so as to avoid micro cracks in welding joints. Besides, the welding spot roots are embedded in the aluminum plate in a tooth like mode; the (Fe, Al) intermetallic compound is distributed along the tooth root with interruptions; the size is reduced; the cracks are reduced compared with traditional welding method; the welding strength is obviously increased.

Owner:HANS LASER TECH IND GRP CO LTD

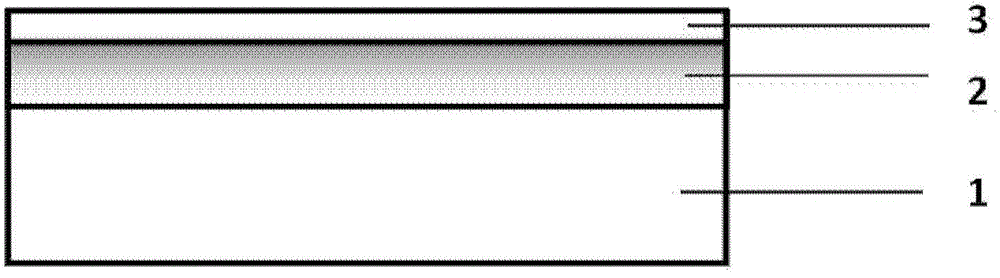

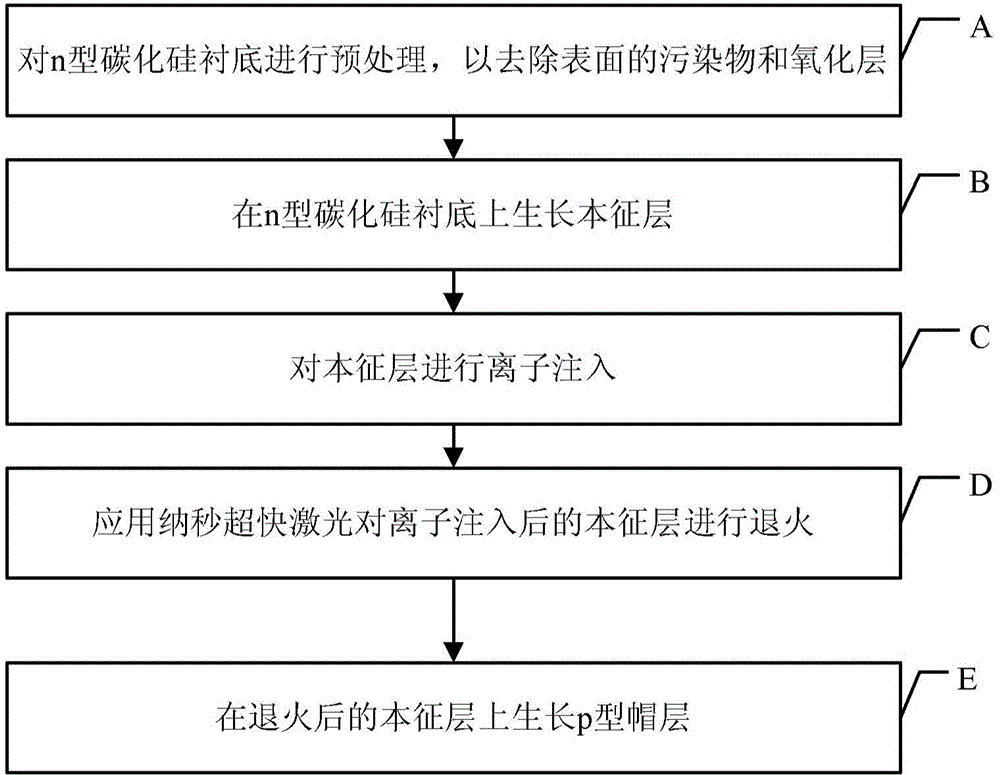

Silicon carbide intermediate zone solar cell and manufacturing method thereof

InactiveCN104409553AImprove conversion efficiencyPromote absorptionFinal product manufacturePhotovoltaic energy generationDeep levelSolar cell

The invention provides a silicon carbide intermediate zone solar cell and a manufacturing method thereof. The silicon carbide intermediate zone solar cell comprises an n-type silicon carbide substrate, an intrinsic layer which is formed on the n-type silicon carbide substrate through deep level impurity ion implantation and nanosecond laser annealing and is taken as an intermediate zone light absorption layer, and a p-type cap layer formed on the intrinsic layer. The silicon carbide intermediate zone solar cell is firstly proposed and can greatly improve light response wavelength and conversion efficiency.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

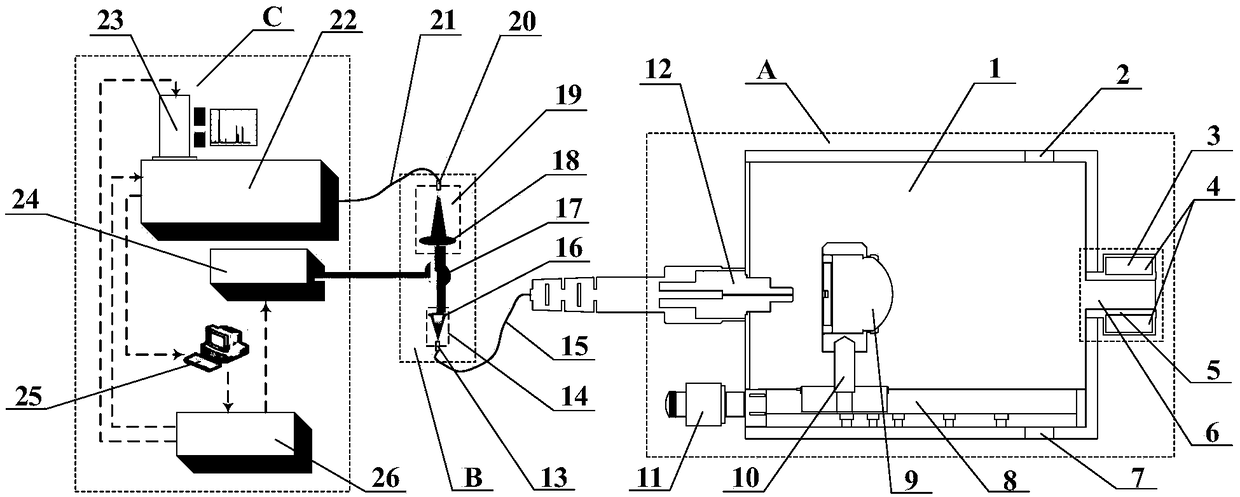

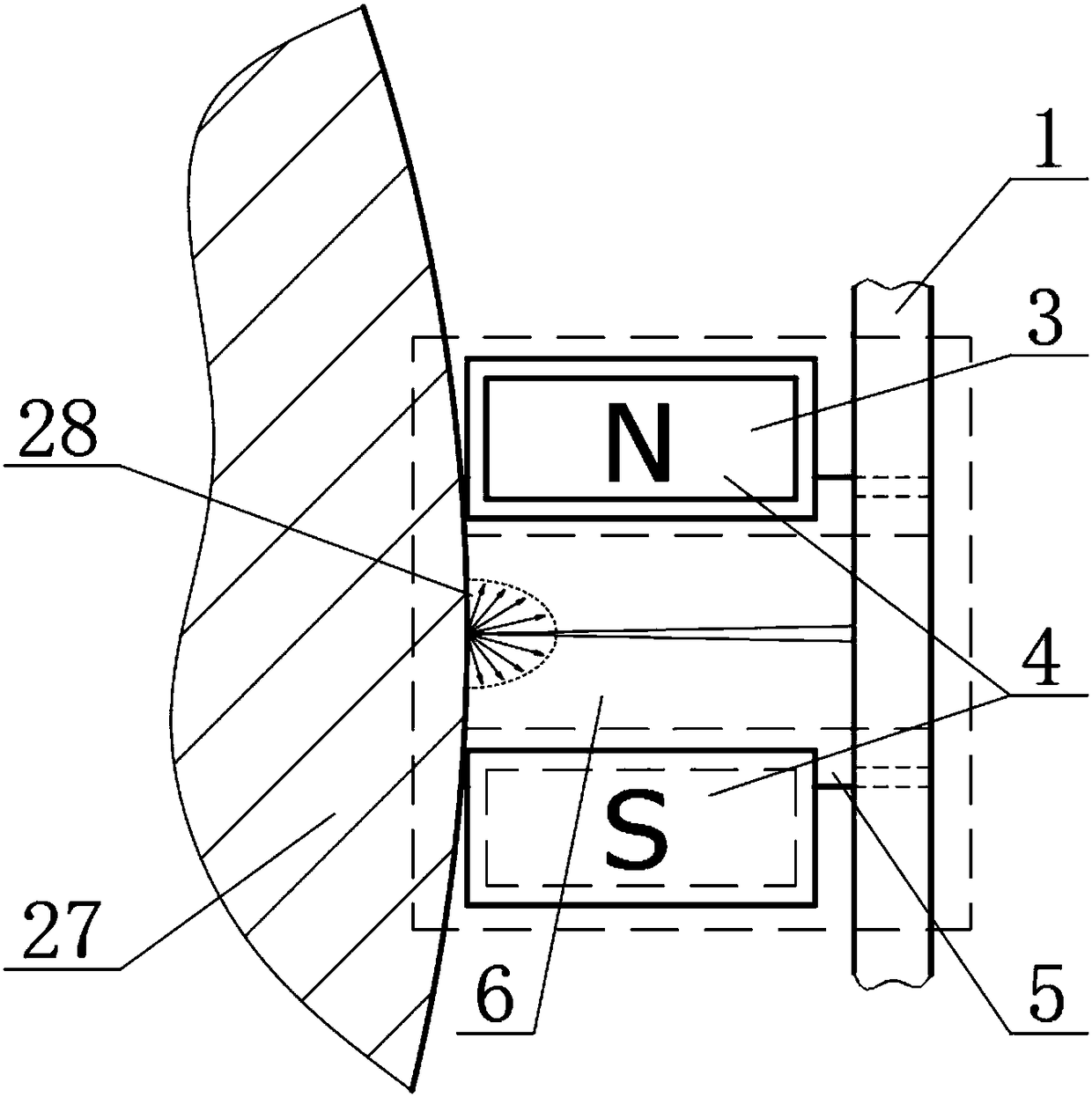

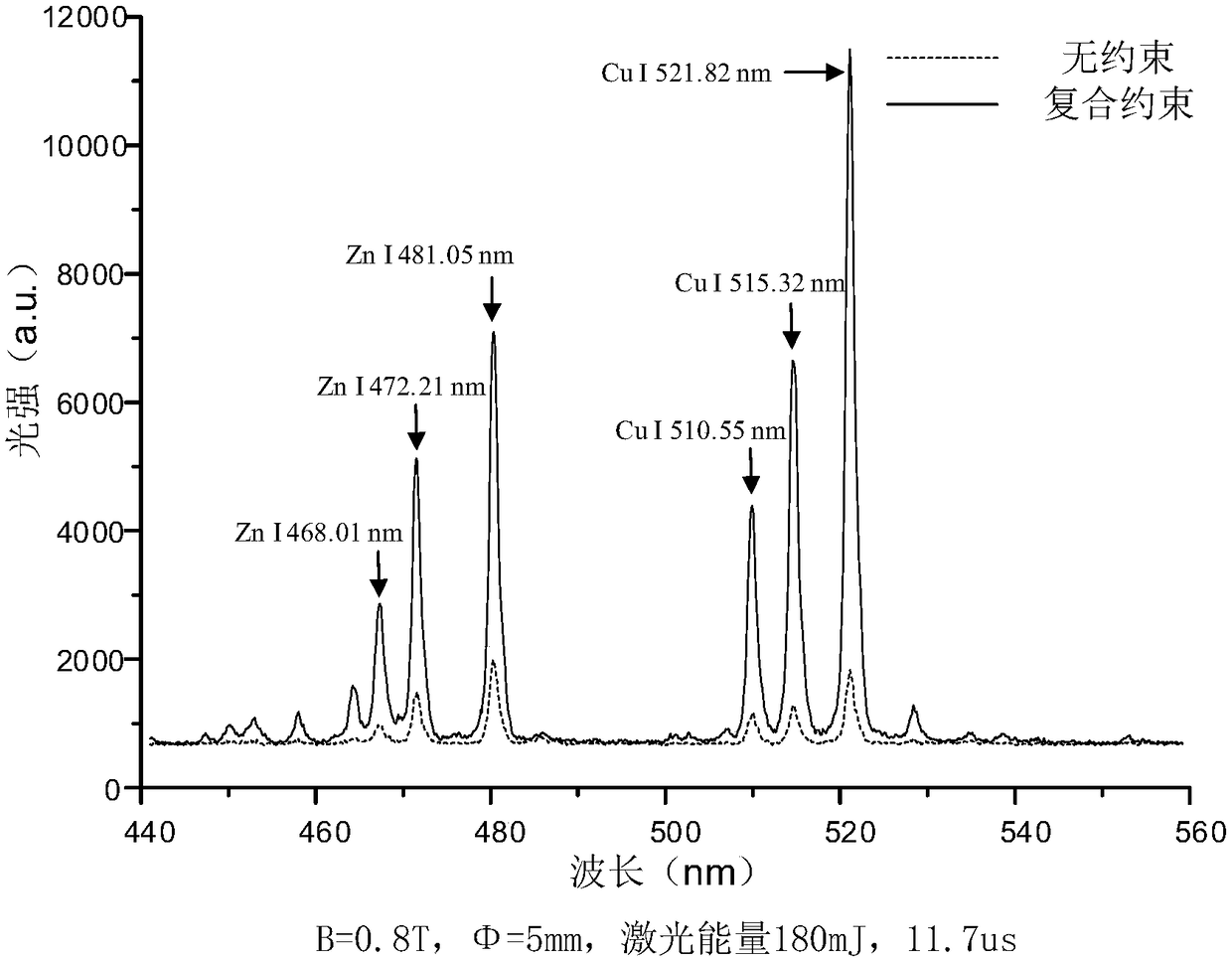

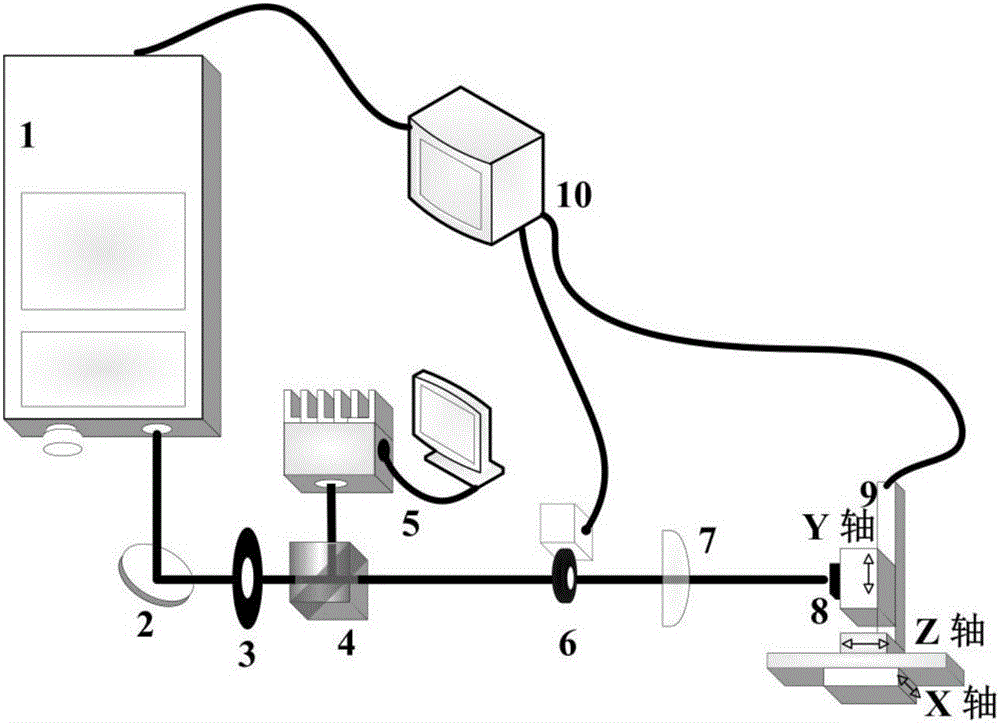

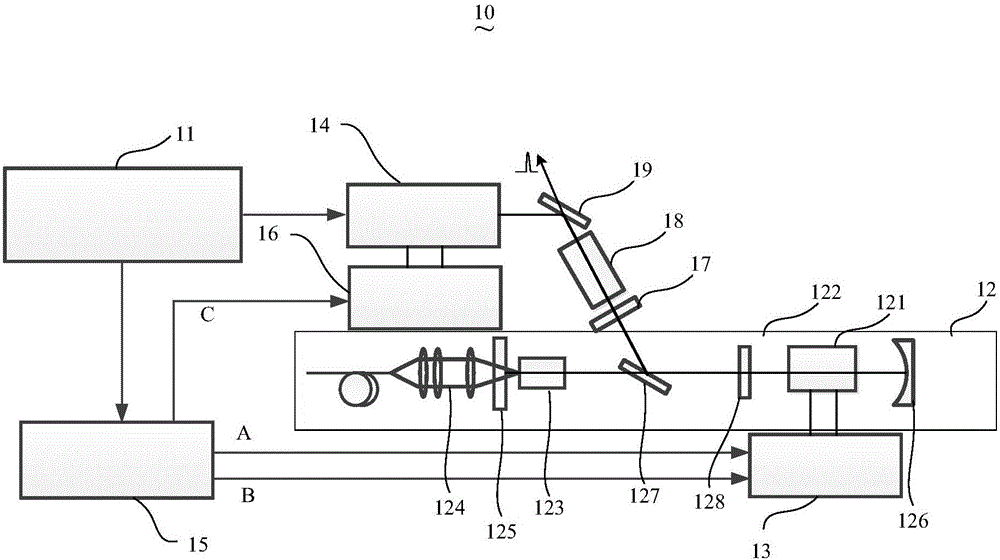

Multi-mode fiber LIBS detector based on composite constraint enhanced spectrum

InactiveCN108362682AHigh sensitivityHigh sensitivity and high spectral signal-to-noise ratioAnalysis by thermal excitationFiberCollection system

The invention discloses a multi-mode fiber LIBS detector based on a composite constraint enhanced spectrum. The multi-mode fiber LIBS detector comprises a LIBS probe, a coupling collection system, anda control detection system, wherein the LIBS probe is composed of a fiber coupling head and a focusing chamber; the coupling collection system comprises a dichroscope, a fiber focusing device, and afiber collector; and the control detection system comprises a nanosecond laser, a spectrometer, a programmable pulse delay generator, an ICCD, and a computer. The multi-mode fiber is taken as a transmission medium, laser is focused to the surface of a to-be-measured sample to break induced plasma according to a convex lens imaging rule, and the element spectrum intensity is increased by a composite constraint enhanced plasma radiation method. The detector can realize simultaneous analysis of a plurality of elements, has the advantages of safe and reliable operation, high sensitivity, high measurement precision, high spectral signal-to-noise ratio, low element detecting limit, fast analysis speed, and high efficiency, realizes remote on-line monitoring, and can effectively satisfy the disadvantages of the traditional fiber LIBS detectors.

Owner:XI AN JIAOTONG UNIV

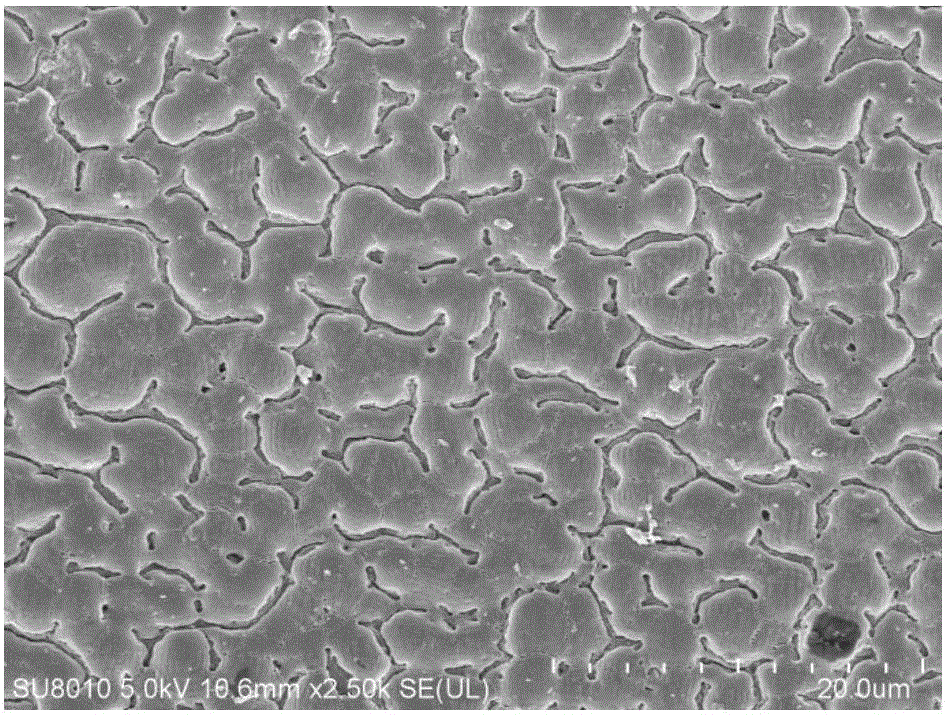

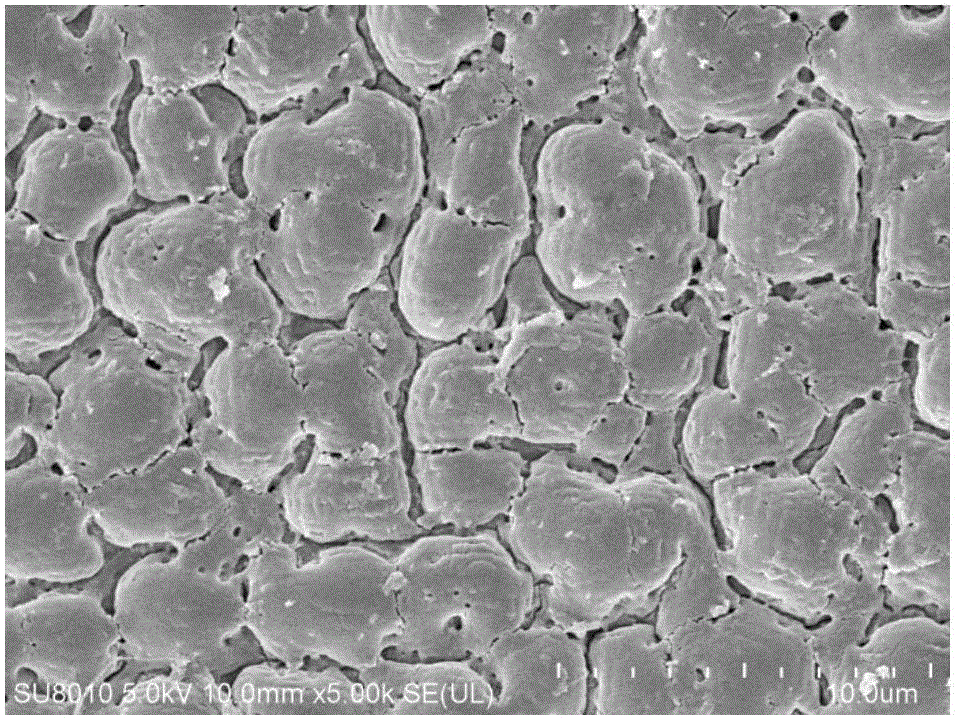

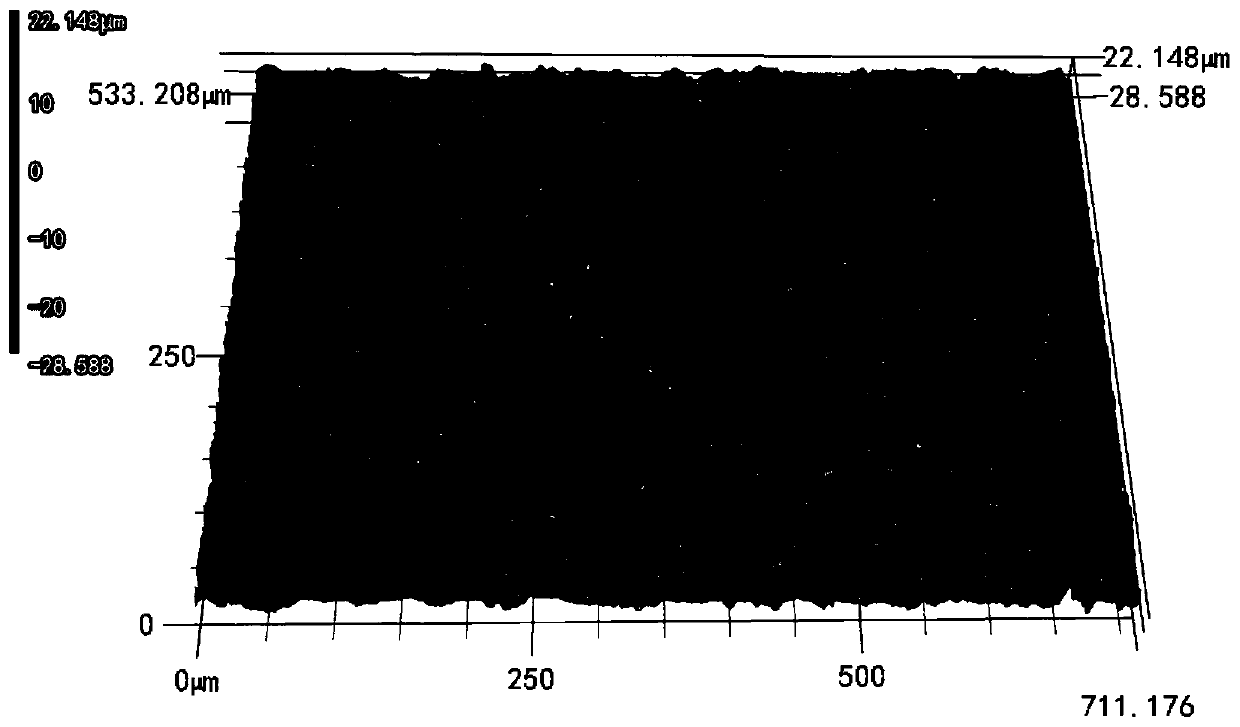

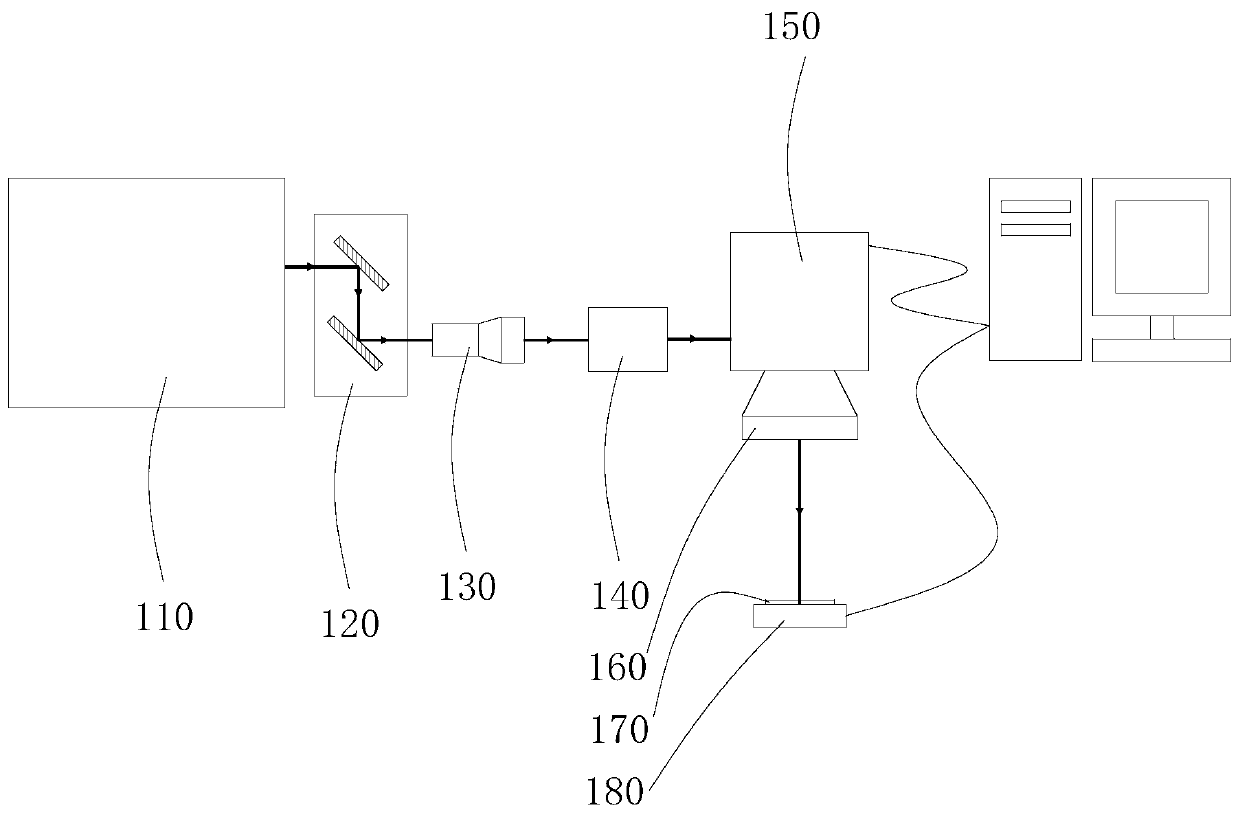

Method for preparing micro-nano composite structure through nanosecond laser induced cracks

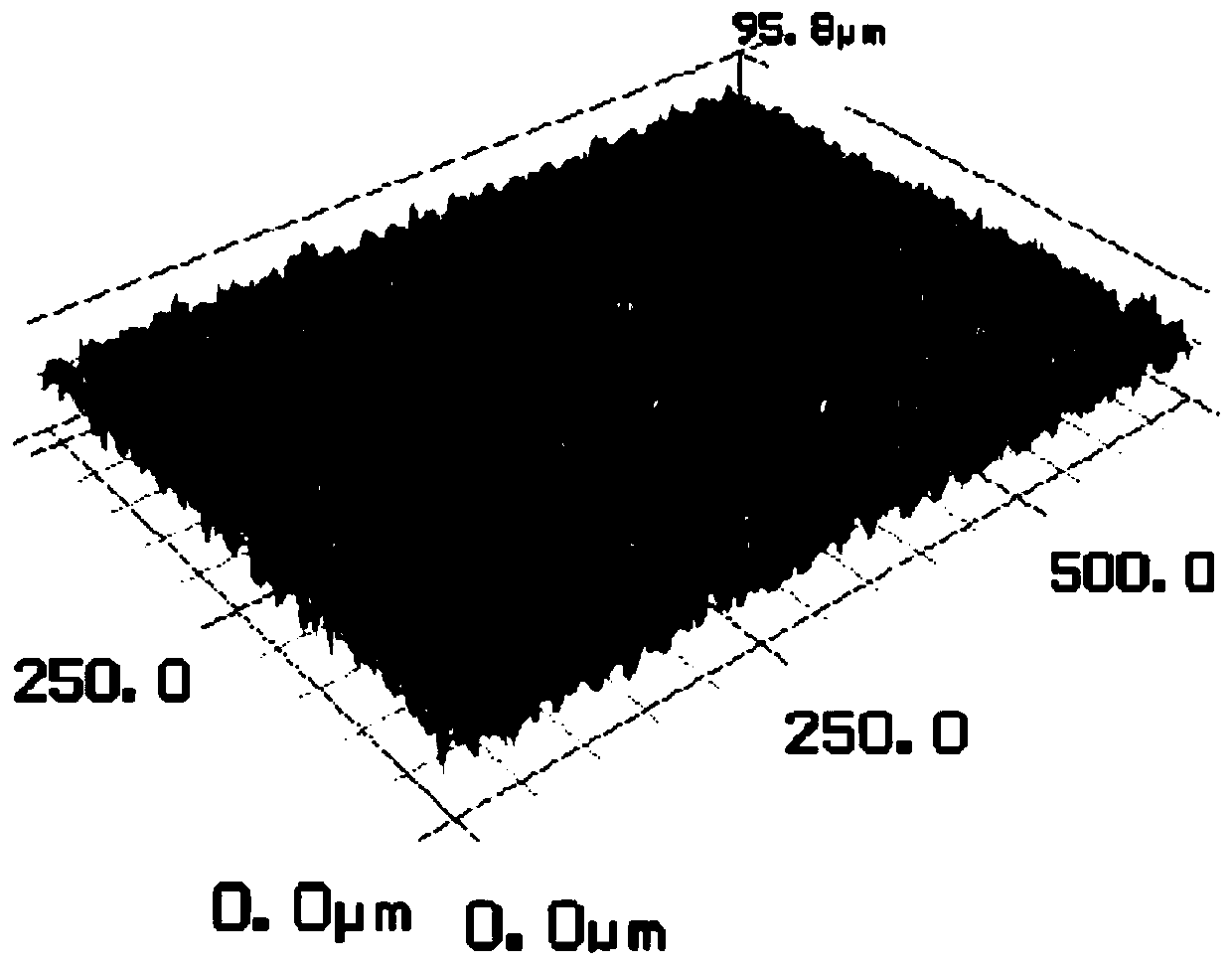

ActiveCN105798454AReduce reflectivityEasy to operateMaterial nanotechnologyLaser beam welding apparatusMicro nanoNanosecond laser

Disclosed is a method for preparing a micro-nano composite structure through nanosecond laser induced cracks. Firstly, commercial pure titanium TA1 is subjected to surface polishing; then a light path is built and comprises a nanosecond laser device; output light of the nanosecond laser device passes through a reflecting mirror to make the light path turn by 90 degrees; reflected light sequentially passes through a small hole diaphragm, a beam splitter prism, a shutter and a focusing lens to vertically irradiate on a processing station of a movable objective table; the nanosecond laser device, the shutter and the movable objective table are connected with a computer; output laser parameters of the nanosecond laser device are adjusted through the computer; and the polished commercial pure titanium is fixed to the processing station of the movable objective table and subjected to nanosecond laser irradiation, the movable objective table is controlled through the computer to move in the horizontal direction, and the surface composite structure with a micron-structure below 5 [mu]m and a nano-structure below 1 [mu]m combined is obtained. According to the method for preparing the micro-nano composite structure through the nanosecond laser induced cracks, characteristics of crack generation under the heating action of a titanium material and microstructural controllable laser propagation are utilized, the operation is simple, and the processing efficiency is high.

Owner:XI AN JIAOTONG UNIV

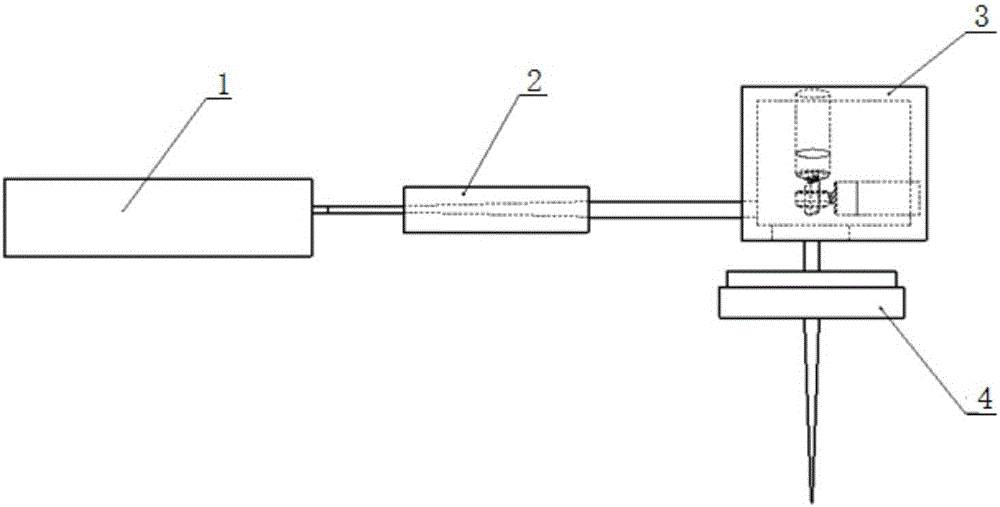

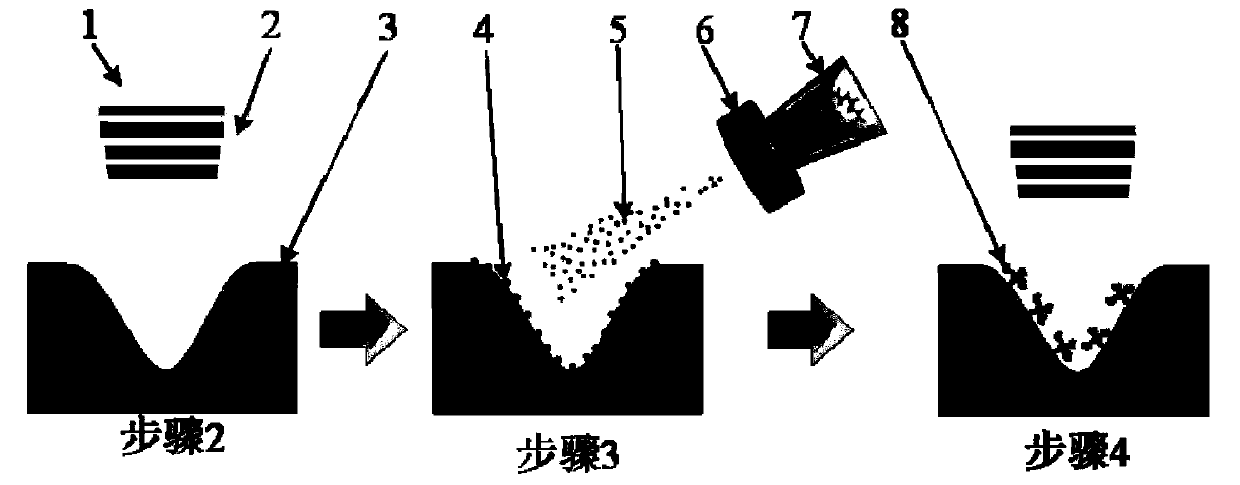

Precise micro-forming device and method thereof based on laser continuous stamping plasticine technology

InactiveCN103252588APrevent springbackEven by forceLaser beam welding apparatusComputer control systemNanosecond laser

The invention discloses a precise micro-forming device and a method thereof based on a laser continuous stamping plasticine technology. The device comprises a laser loading system, a plastic forming system and a computer control system. The laser loading system comprises a nanosecond laser, a reflection mirror and a focusing lens. The plastic forming system comprises a sample system, a clamp body, a three-dimensional moving platform and a base. The computer control system comprises a three-dimensional moving platform controller, a laser controller and a computer. According to the device and the method, plasticine is used for transmitting impact force, in a multi-time impact process, the plasticine and a workpiece are attached together gradually, stress on the workpiece is even, scratching cannot happen, surface quality of the workpiece is improved, and meanwhile according to the characteristic that the plasticine deforms in an plastic mode after being stressed, the workpiece and a micro mould can be attached with each other, rebounding of the workpiece is avoided, and forming precision of the workpiece is guaranteed.

Owner:JIANGSU UNIV

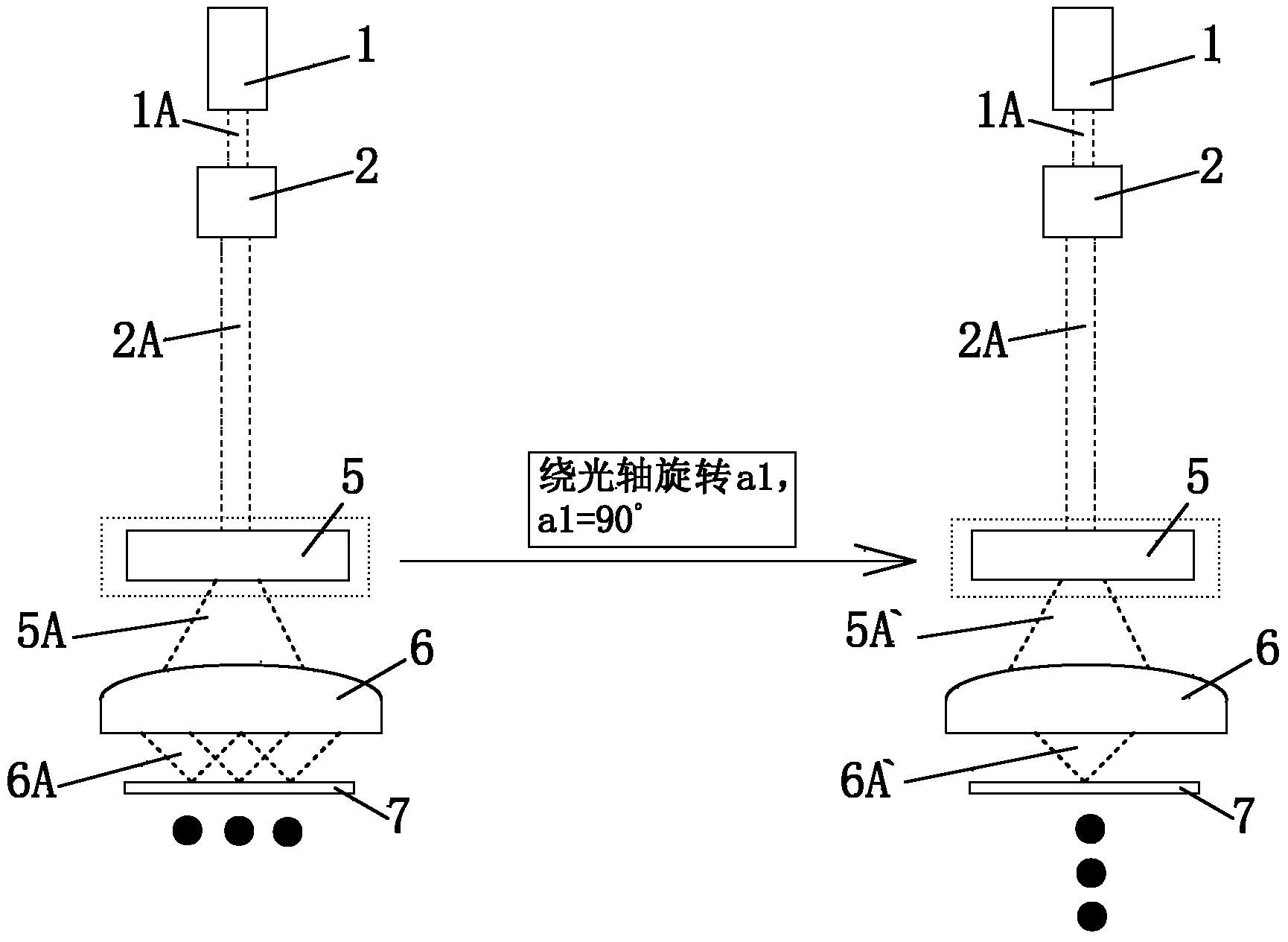

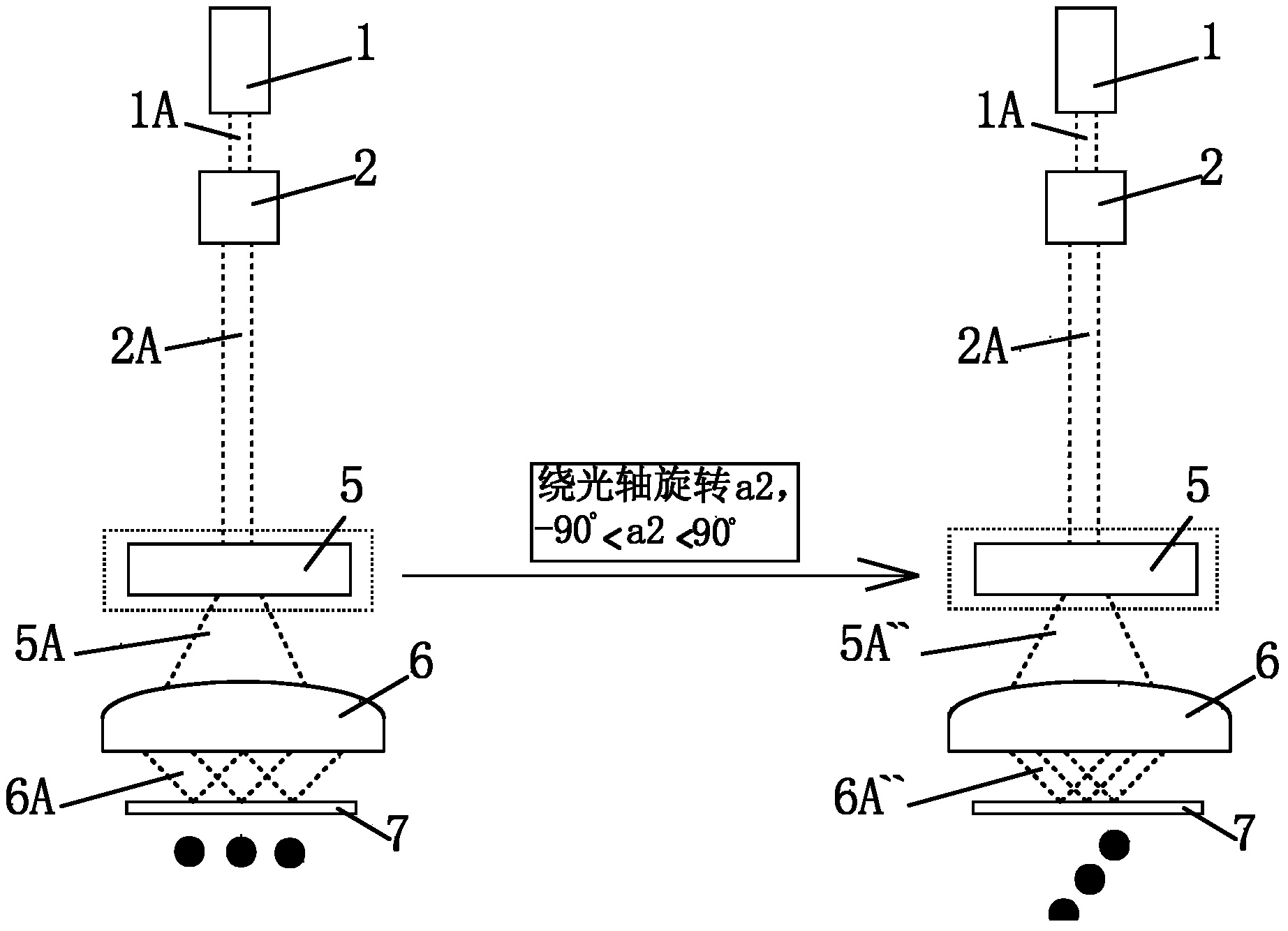

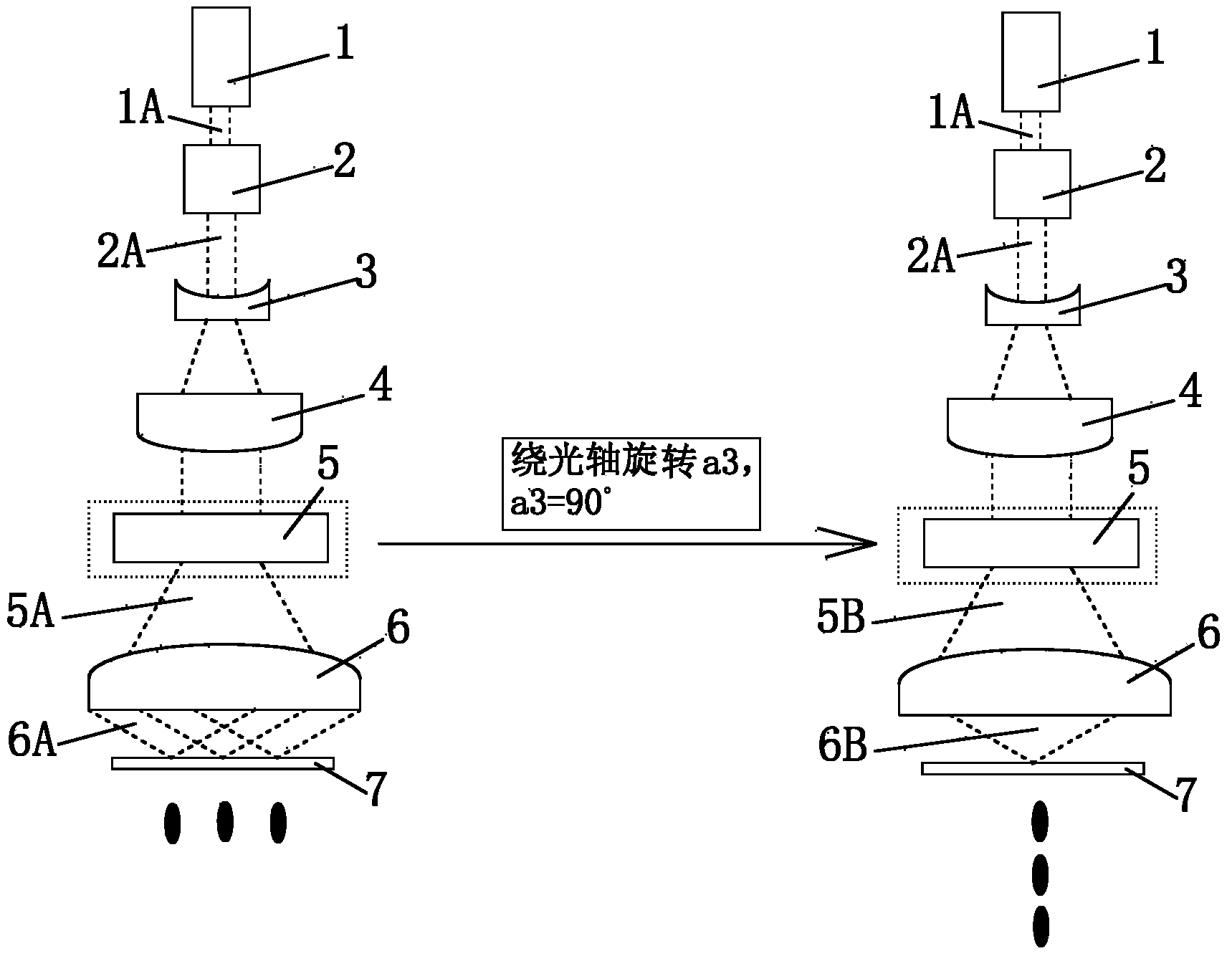

Multi-beam shaping laser processing system

InactiveCN103846547AAchieve shapingImprove laser processing effectLaser beam welding apparatusOptical elementsNanosecond laserLaser processing

The invention discloses a multi-beam shaping laser processing system which comprises a laser, a cylindrical concave lens, a cylindrical convex lens, a one-dimensional diffraction optical element and a focusing lens which are sequentially arranged along the direction of a light path of laser. According to the multi-beam shaping laser processing system disclosed by the invention, a processing effect of common ultraviolet nanosecond laser processing equipment can be improved, and processing efficiency is improved.

Owner:SUZHOU ORCHID OPTOELECTRONICS TECH

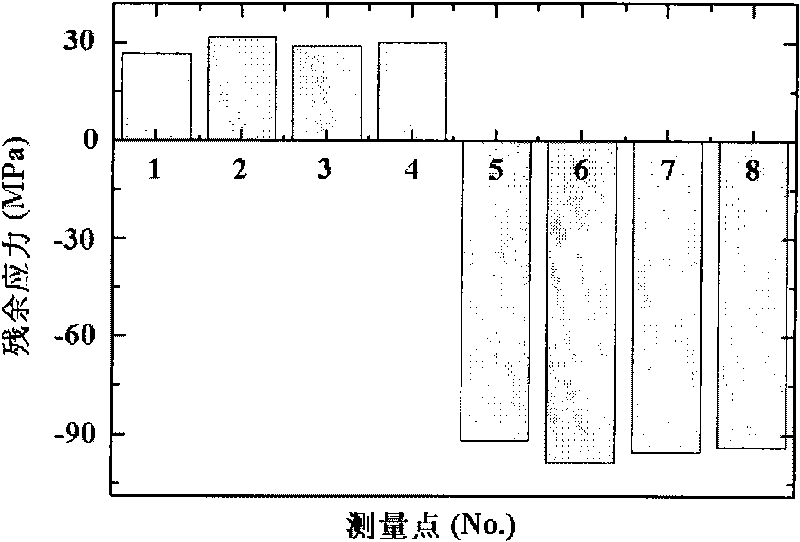

Method and device for improving corrosion resistance of stainless steel weld seams

InactiveCN103320800AReduce corrosion susceptibilityPlay the role of the first layer of protectionMetallic material coating processesNumerical controlSS - Stainless steel

The invention discloses a method and a device for improving the corrosion resistance of stainless steel weld seams. The method comprises the following steps of: firstly, preparing a kind of nanoscale metal corrosion inhibitor particles; then, injecting the nanoscale metal corrosion inhibitor particles into stainless steel weld seams by using a carbon dioxide laser so as to form an anti-corrosion layer; and finally, carrying out shock strengthening treatment on the surfaces of the stainless steel weld seams by using a nanosecond laser, so that a high-amplitude residual compressive stress layer with a certain depth is formed at a stainless steel weld seams area. The device for implementing the method comprises a computer control system, a powder feeder, an argon gas protection device, the carbon dioxide laser, an omni-directional reflector, a transmitting mirror, a powder feeding nozzle, a stainless steel welding part, a clamping device, a three-axis numerical control workbench, a flexible attaching film and the nanosecond laser. According to the invention, the corrosion sensitivity of the stainless steel weld seams in a corrosive environment can be greatly reduced, and the service life of the stainless steel weld seams can be prolonged, therefore, the method and device disclosed by the invention are applicable to the improvement of the corrosion resistance of various stainless steel weld seams, and also can be expanded to the improvement of the corrosion resistance of weld seams of aluminum alloys and titanium alloys and the like.

Owner:JIANGSU UNIV

Method for precisely processing sapphire through double-laser beam sequence scanning

ActiveCN103952767AImprovement of precision etching processing efficiencyEtching processing efficiency is improvedAfter-treatment detailsPicosecond laserPicosecond pulsed laser

The invention provides a method for precisely processing sapphire through double-laser beam sequence scanning. The method comprises the following steps: installing a sapphire workpiece and a laser processing head, outputting a nanosecond pulse laser beam, and carrying out scanning motion according to the to-be-machined track once; then closing the nanosecond pulse laser beam, starting an ultrasonic generator for carrying out chemical corrosion; then outputting a picosecond pulse laser beam for carrying out scanning motion once, and fastly removing a thin-layer material; repeatedly carrying out the steps until the depths of holes or grooves in the surface of the sapphire workpiece meet the processing requirement; and finally, carrying out ultrasonic abrasive polishing to the surface of the sapphire workpiece by adopting an ultrasonic driven abrasive grain polishing solution. The sequence combined processing effects of four precise processing technologies including nanosecond laser thermal treatment, ultrasonic chemical corrosion pretreatment, picoseconds laser precision processing and ultrasonic abrasive grain polishing aftertreatment are combined, the power demand of a needed picoseconds laser device can be effectively reduced under the requirement of equal etching processing efficiency, and the picosecond laser processing time and equipment cost can be shortened and lowered.

Owner:ZHEJIANG JIATAI LASER SCI & TECH CO LTD

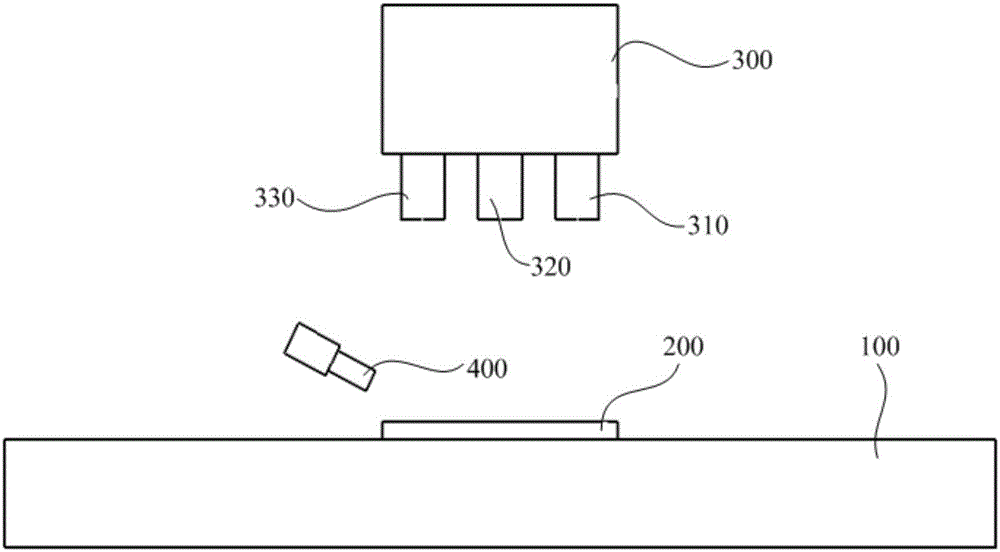

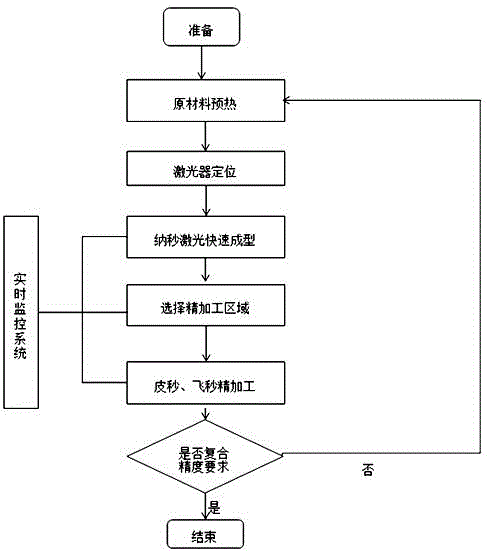

Nanosecond-picosecond-femtosecond laser technology based metal product 3D printing method

ActiveCN104889395APrecise size controlImprove printing efficiencyMacroscopic scaleFemto second laser

The invention discloses a nanosecond-picosecond-femtosecond laser technology based metal product 3D printing method. The nanosecond-picosecond-femtosecond laser technology based metal product 3D printing method adopts an integrated optical fiber laser device to provide nanosecond laser so as to sinter, melt and cure a metal raw material, meanwhile using picoseconds or femtosecond laser to conduct finish machining on a finish machining region. A real-time monitoring system can adopt multiple macroscopic and microcosmic detection means, and specially the detection means selection desponds on accuracies required by products to be manufactured. The nanosecond-picosecond-femtosecond laser technology based metal product 3D printing method can achieve more accurate size control, printing efficiency is improved, and cleaning, polishing and other working procedures required after 3D printing are omitted.

Owner:湖南珞佳智能科技有限公司

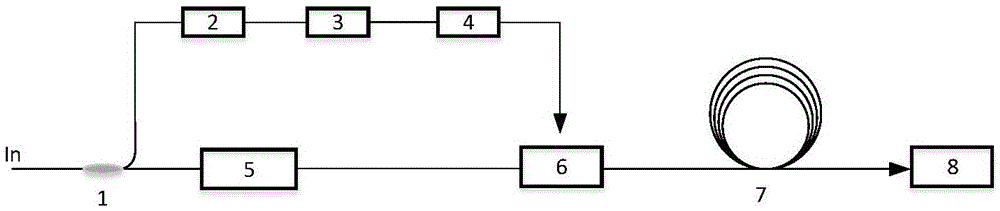

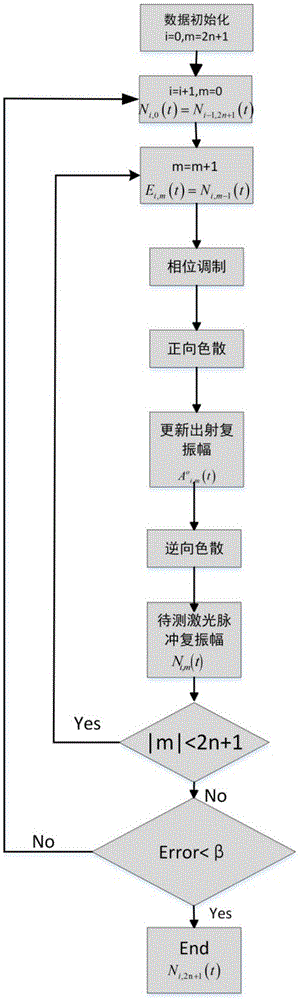

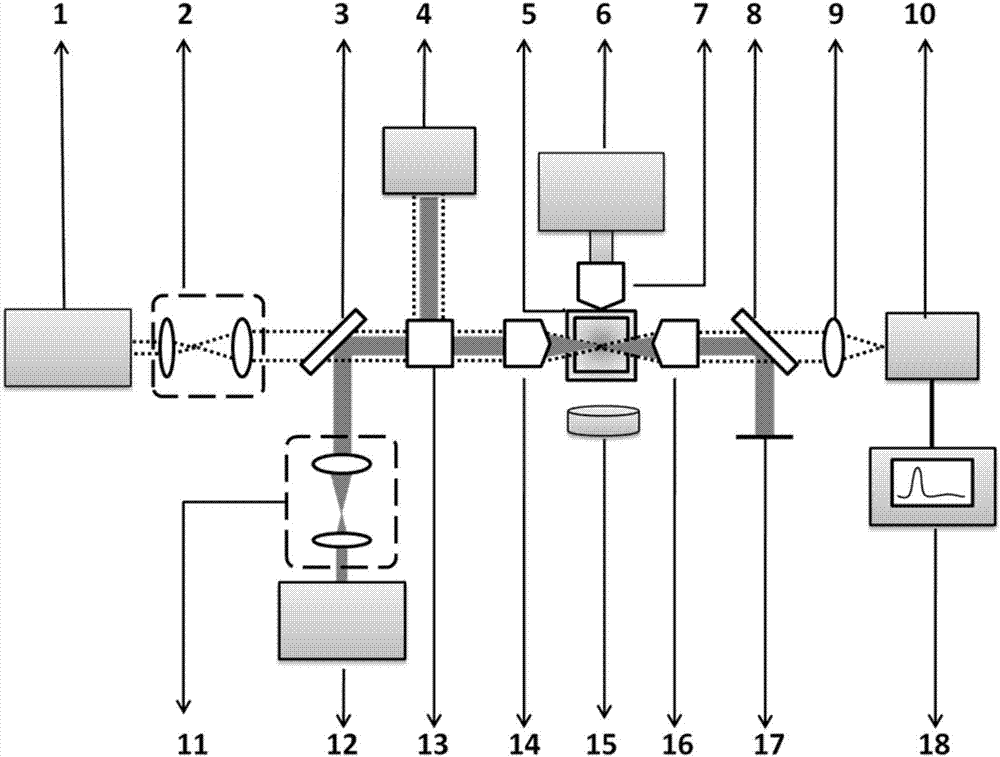

Time domain phase recovery all-fiber laser pulse weak phase measuring device and method

The invention provides a time domain phase recovery all-fiber laser pulse weak phase measuring device and method. The device comprises a fiber splitter arranged long the laser pulse input direction. The fiber splitter divides laser pulses to be measured into a high beam of light and a weak beam of light. An adjustable optical fiber delayer, a high speed optical fiber phase modulator, a dispersion optical fiber and an oscilloscope are successively arranged long the direction of the high light beam. A high speed PIN photoelectric tube, an arbitrary waveform generator and an electric signal amplifier are successively arranged long the direction of the weak light beam. An output end of the electric signal amplifier is connected with a modulation input end of the high speed optical fiber phase modulator. According to the invention, the all-fiber structure is utilized to carry out phase modulation and dispersion transmission on the laser pulses, the structure is compact, simple and flexible, and the measuring method is different from other laser pulse phase measuring modes; in addition, by adopting the measuring device and method, the weak phase picoseconds or nanosecond laser pulses can be measured, and the measuring device and method are applicable to the conditions of a high repetition frequency and a low repetition frequency.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

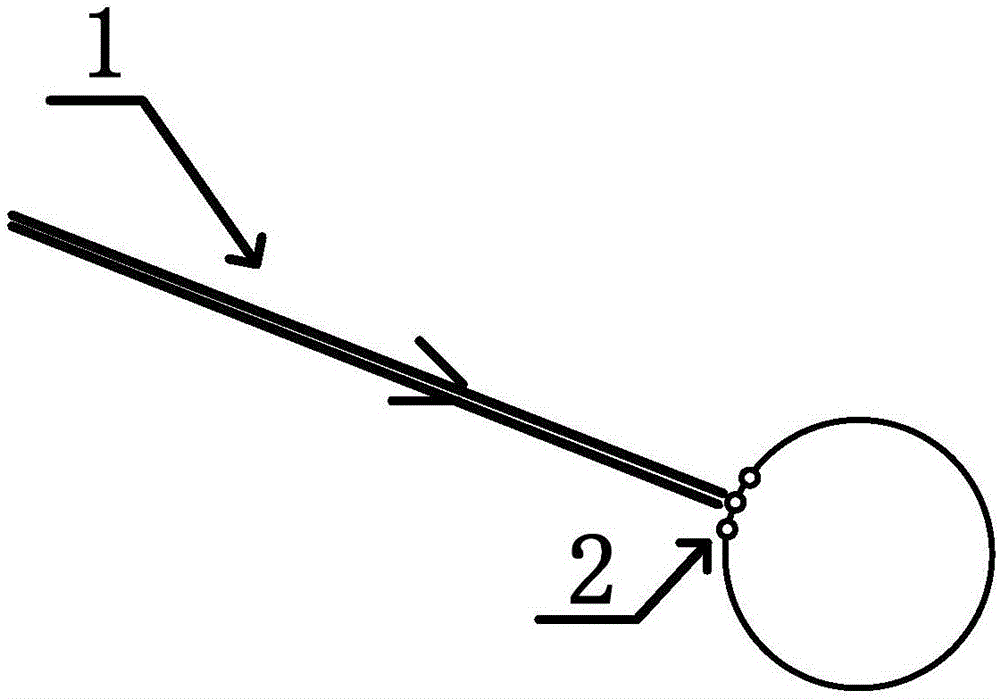

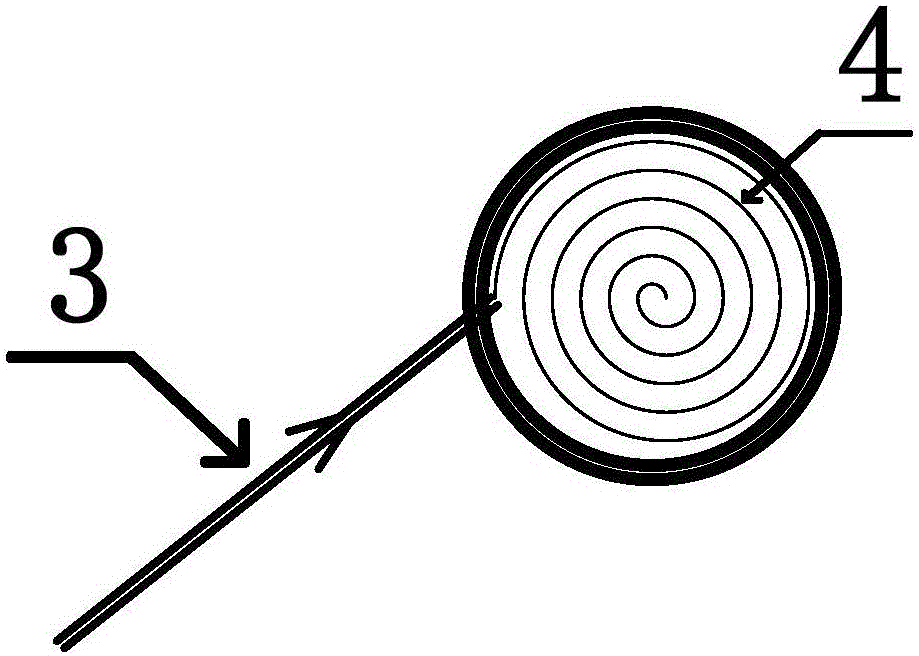

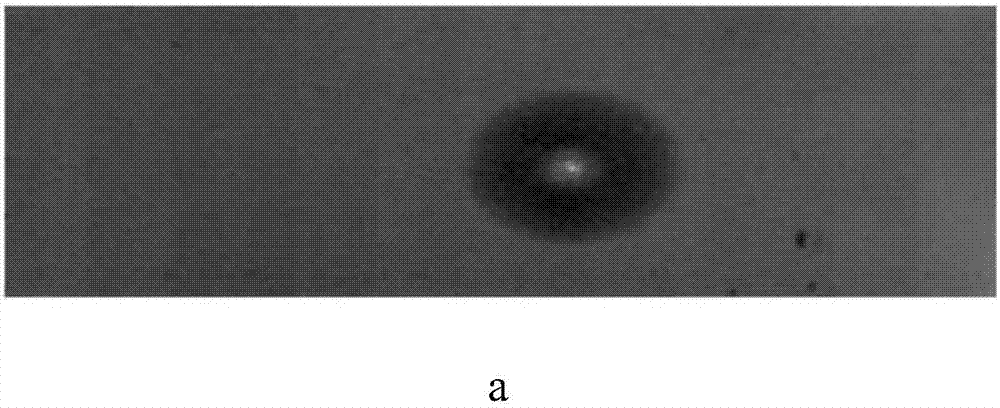

Research system for liquid light induced breakdown and cavitation effect

ActiveCN107300540AImprove treatment efficiencyReduce surgical side effectsScattering properties measurementsMode of actionLaser light

The invention provides a research system for liquid light induced breakdown and a cavitation effect. Laser lights emitted by a pumping source module and a detection source module are subjected to beam combination through a dichroscope A; a 50% spectroscope, a 40x objective lens, a sample cell, a dichroscope, a focusing lens and a photoelectric detector are arranged in sequence in a direction of the principal optical axis of the dichroscope A; a laser energy power meter is arranged in a vertical direction of the 50% spectroscope; objective lenses are clung to three walls of the sample cell, wherein a 10x objective lens is connected with a high-speed camera, and a vertical LED light source is arranged on another wall of the sample cell; the photoelectric detector is connected with a oscilloscope. The research system provided by the invention can realize nanosecond laser induced liquid light induced breakdown, image information of cavitation bubbles formed during breakdown is monitored in real time, and information of laser energy is recorded at the same time; the research system provides a direct theoretical direction and a practical support for selecting a laser dosage and a mode of action and estimating an action effect during laser medical treatment.

Owner:XI AN JIAOTONG UNIV

High-molecular material 3D printing device applying nanosecond lasers to accurately control temperatures

ActiveCN103978685AEvenly distributed temperature gradientReduce defectsNanosecond laserBeam expander

The invention discloses a high-molecular material 3D printing device applying nanosecond lasers to accurately control temperatures. The device includes two laser devices, a beam expander, a light beam scanning controller, a preheating chamber, a powder feeding device, a working platform, two temperature sensors and a control module. Through use of the device and in a laser sintering type printing technological process, energy emitted by the laser devices in unit time can be accurately controlled through controlling increase or decrease of the repetition frequency of pulses outputted by a pulse laser, so that a high-molecular material powder is allowed to maintain in a sufficient accuracy range in preheating and sintering processes, the temperature gradient of the interior of the material is uniformly distributed, defects of the interior of a molded workpiece are greatly reduced, moreover, the workpiece molding quality is better, and higher machining accuracy is maintained.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

Nanosecond laser ablation and chemical thermal decomposition compound preparation method for stainless steel surface super-hydrophobic micro-nano structures

ActiveCN110653493ARealize short process flow manufacturingShort manufacturing cycleMaterial nanotechnologyPretreated surfacesNano structuringSS - Stainless steel

The invention relates to a nanosecond laser ablation and chemical thermal decomposition compound preparation method for stainless steel surface super-hydrophobic micro-nano structures, belongs to thetechnical field of material surface modification, and solves the defects of long preparation period and complex process flow of stainless steel super-hydrophobic surfaces; and fluorine-contained chemical reagents are not used for modification, so that prepared super-hydrophobic micro-nano structures are excellent in quality and stability. The method comprises the following steps: (1) stainless steel samples are ultrasonically cleaned in anhydrous ethanol and aired at a room temperature; (2) the primary infrared nanosecond laser ablation is performed on the samples to obtain micro-nano structures; (3) an ultrasonic atomizer is used for uniformly coating the surfaces of workpieces with stearic acid ethanol solution microdroplets; (4) the secondary infrared nanosecond laser ablation is performed on the samples; and (5) the samples are separately and ultrasonically cleaned by acetone, anhydrous ethanol and de-ionized water by 10 minutes to remove undecomposed stearic acid attached to the surfaces and slag generated by the laser ablation so as to obtain stainless steel super-hydrophobic surfaces with stable super-hydrophobic properties.

Owner:SHANDONG UNIV

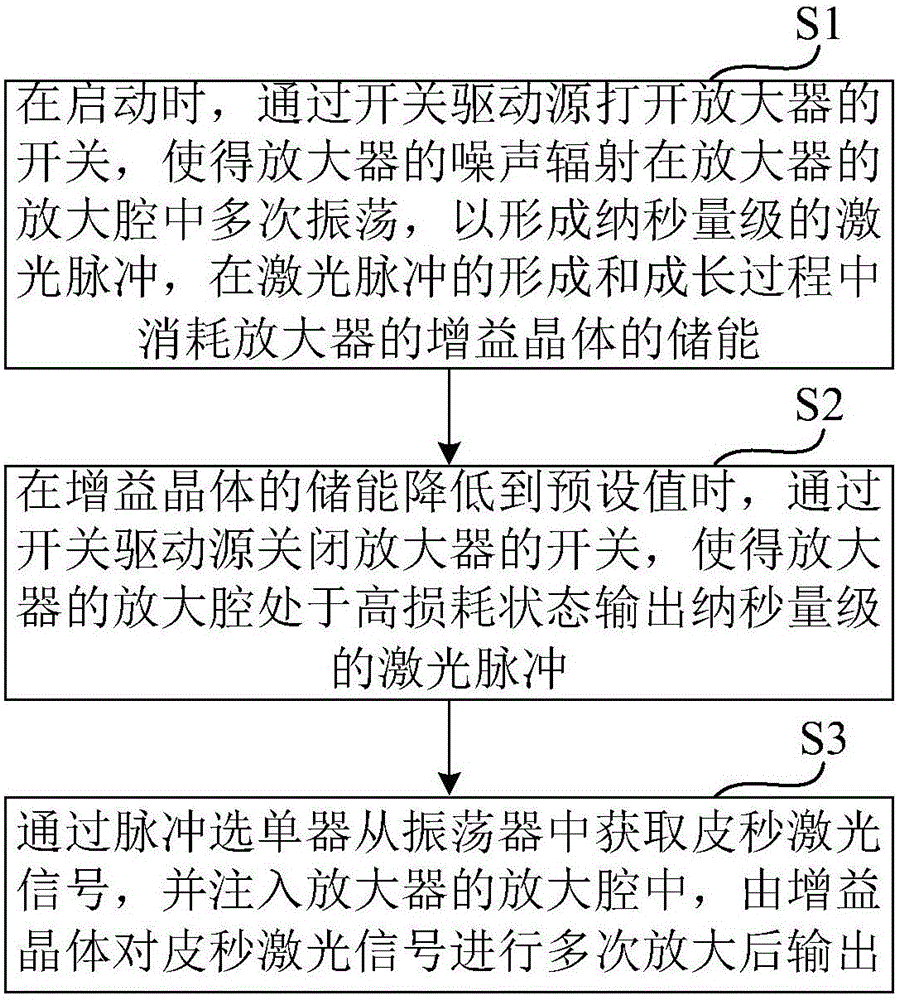

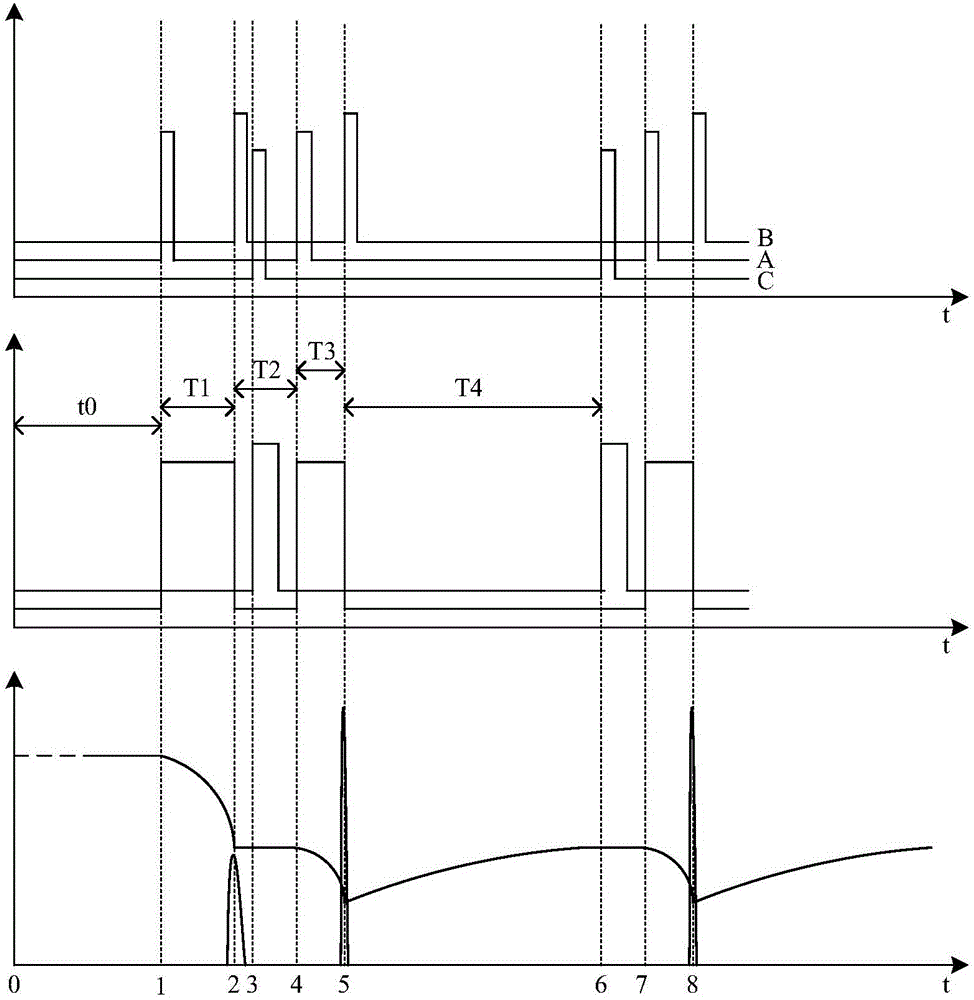

Picosecond laser device and method for inhibiting first pulse in picosecond laser device

InactiveCN105762633AExtended service lifeSuppress energyLaser detailsNanosecond laser pulsePicosecond laser

The invention discloses a picosecond laser device and a method for inhibiting a first pulse in the picosecond laser device. The method comprises the steps that a switch of an amplifier is turned on through a switch driving source during start to oscillate noise radiation of the amplifier in an amplification cavity of the amplifier for multiple times so as to form nanosecond laser pulses, and stored energy of a gain transistor of the amplifier is consumed in the forming and growing process of the laser pulses. When the stored energy of the gain transistor is reduced to a preset value, the switch of an amplifier is turned off through the switch driving source to make the amplification cavity of the amplifier output nanosecond-order laser pulses be in a high-loss state. A picosecond laser signal is obtained from an oscillator through a pulse menu device and is injected into the amplification cavity of the amplifier, and the gain transistor conducts multi-time amplification on the picosecond laser signal and outputs the signal. In the mode, by the adoption of the picosecond laser device and the method, first pulse energy of picosecond laser signals can be inhibited, the service life of optical components and devices can be prolonged, and a laser processing effect can be improved.

Owner:ACAD OF OPTO ELECTRONICS CHINESE ACAD OF SCI

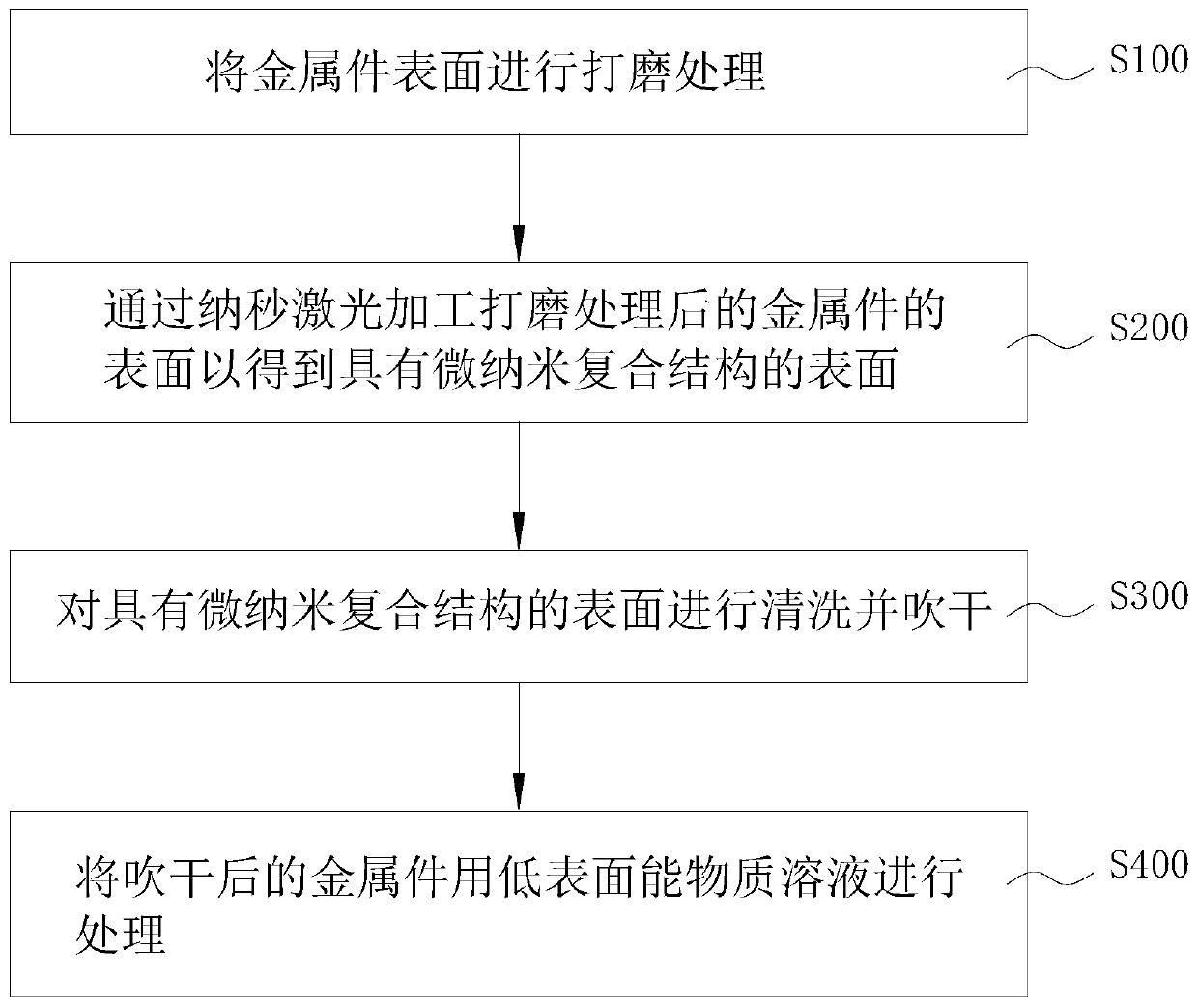

Method for metal surface treatment by nanosecond laser

InactiveCN109954965ALow costExcellent superhydrophobic propertiesLaser beam welding apparatusNanosecond laserMicro nano

The invention relates to a method for metal surface treatment by nanosecond laser. The method comprises the following steps of grinding the surface of a metal piece, polishing the surface of the treated metal piece by the nanosecond laser to obtain a surface with a micro-nano composite structure, cleaning and blow-drying the surface with the micro-nano composite structure, and treating the blow-dried metal piece with a low surface energy substance solution. The surface of the workpiece is treated by a nanosecond laser device with lower cost and is modified by substances with low surface energy, so that the surface of the workpiece has good superhydrophobic performance; and the method is low in equipment cost and simple in preparation process, is not strict in environmental requirement, andis suitable for industrial production.

Owner:HANS LASER TECH IND GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com