Patents

Literature

136 results about "Chemical affinity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In chemical physics and physical chemistry, chemical affinity is the electronic property by which dissimilar chemical species are capable of forming chemical compounds. Chemical affinity can also refer to the tendency of an atom or compound to combine by chemical reaction with atoms or compounds of unlike composition.

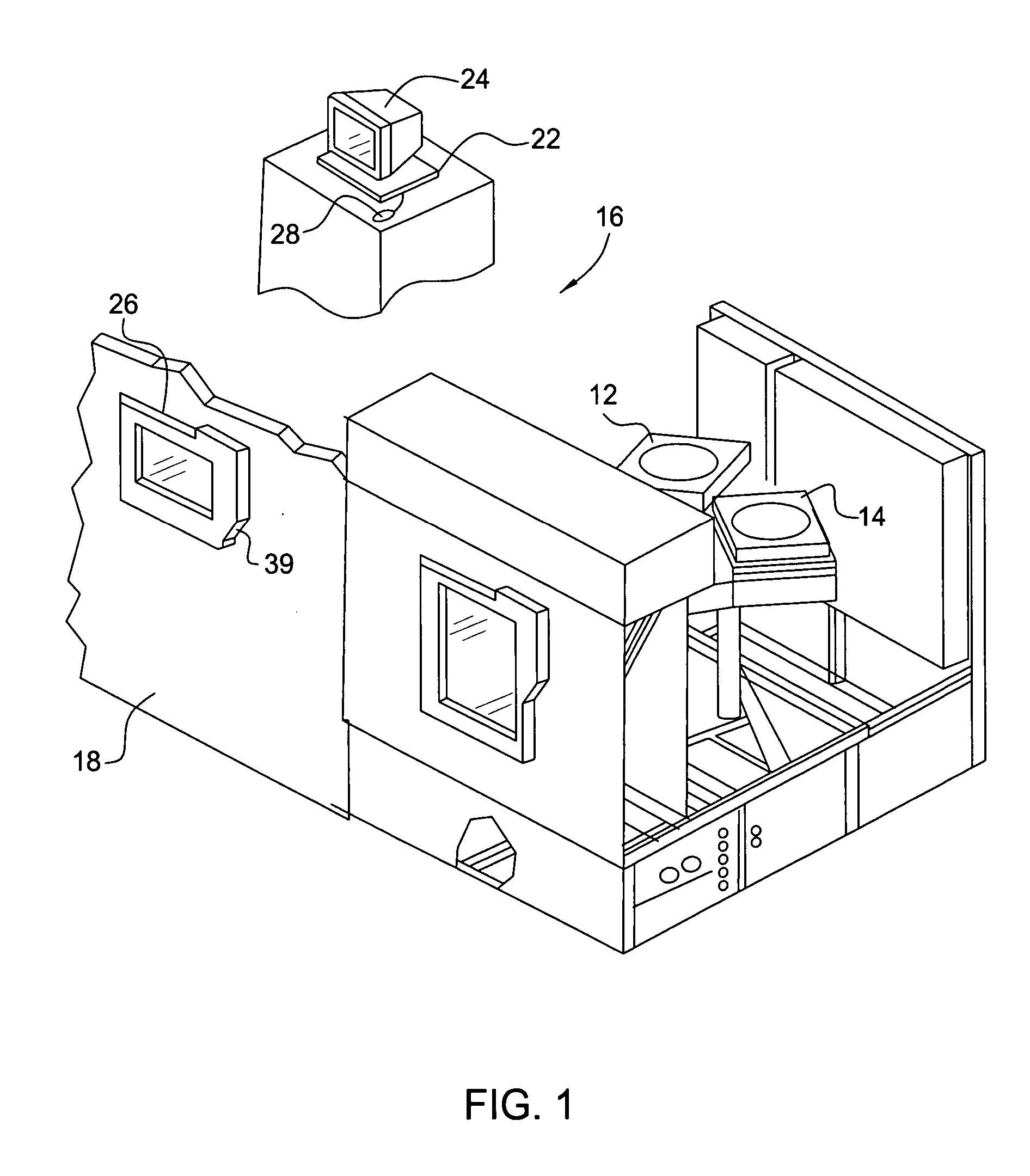

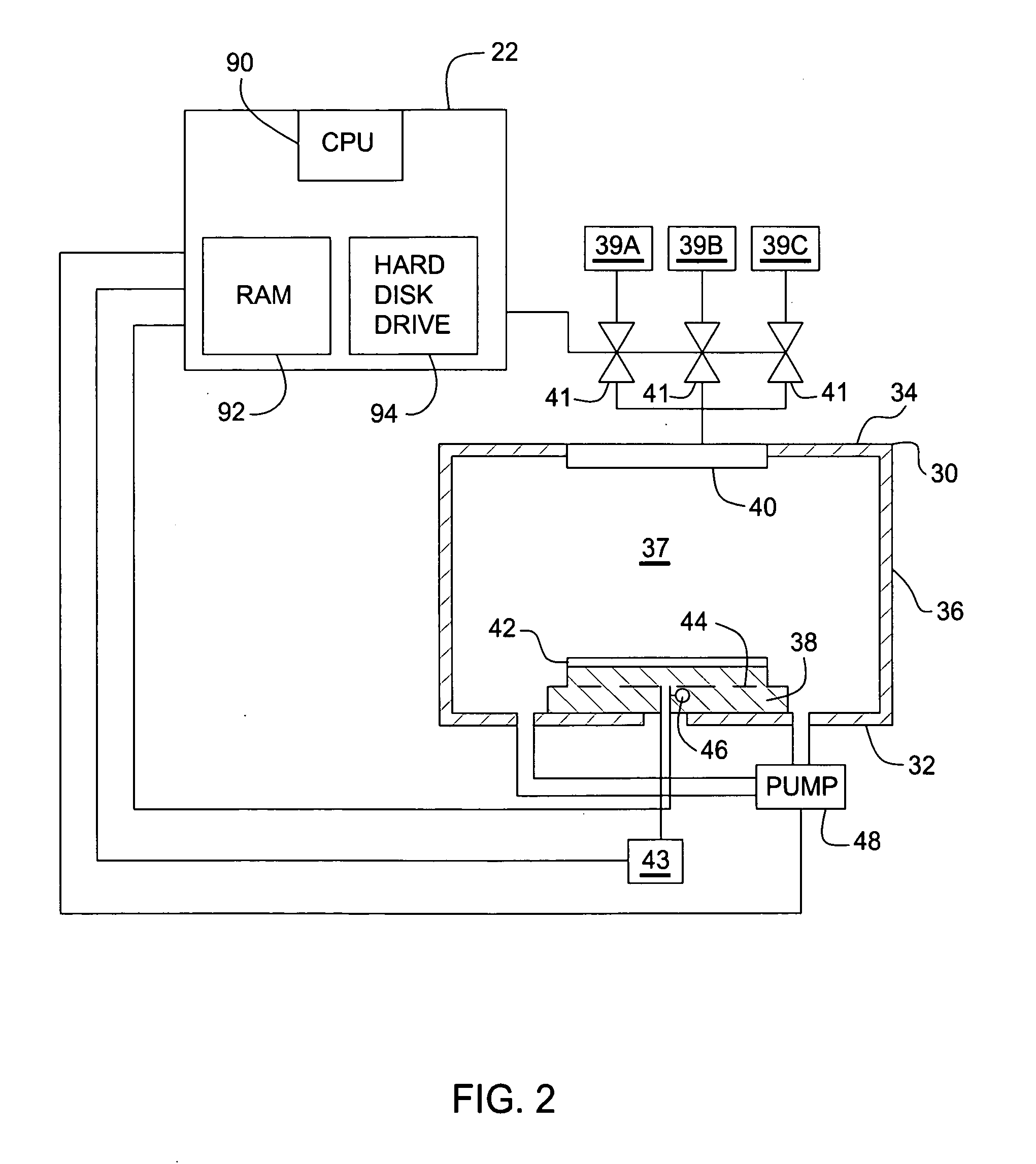

Method and apparatus for depositing tungsten after surface treatment to improve film characteristics

InactiveUS6936538B2Reduce fluorine contentHigh resistivitySolid-state devicesSemiconductor/solid-state device manufacturingChemical speciesNucleation

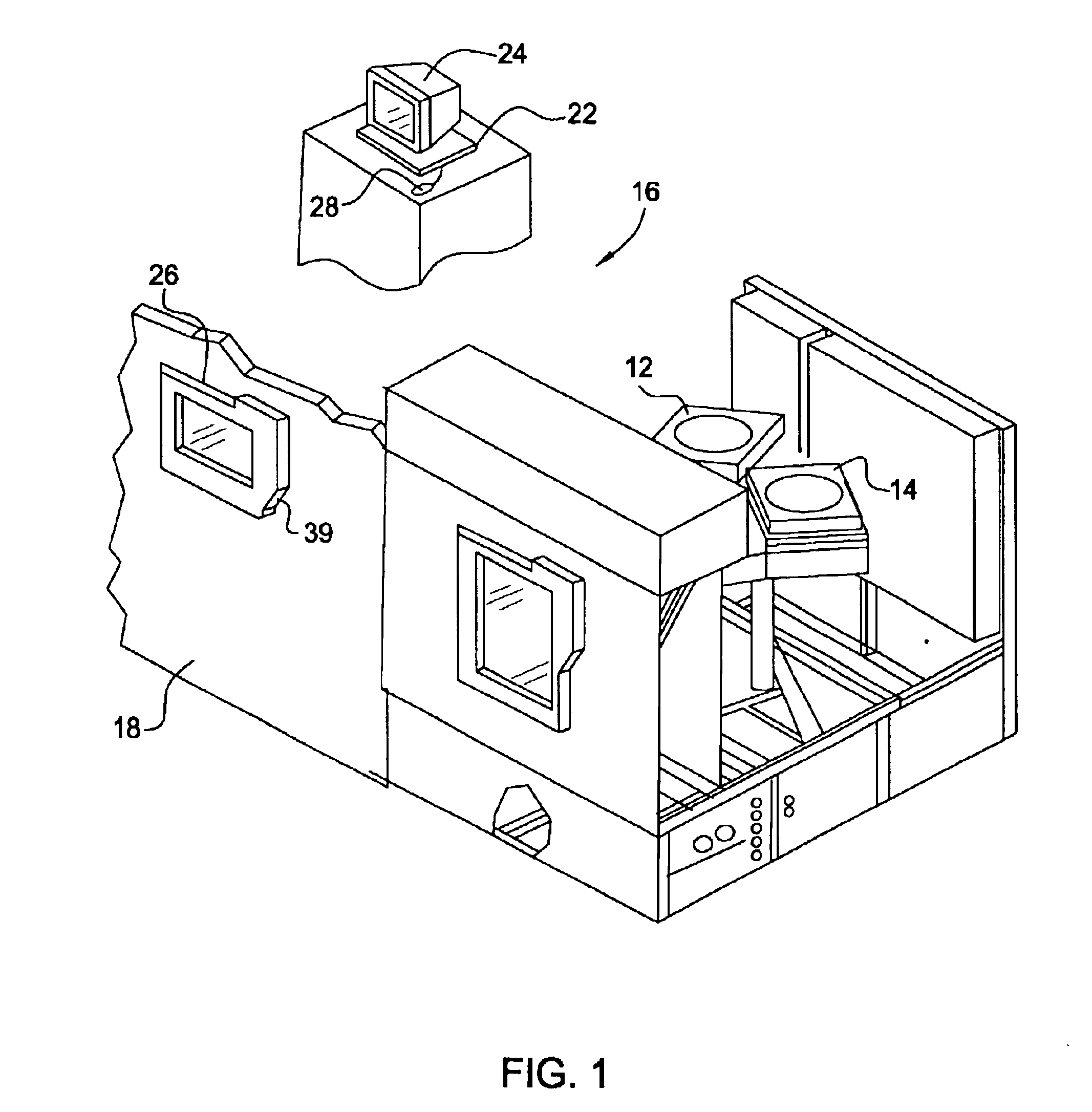

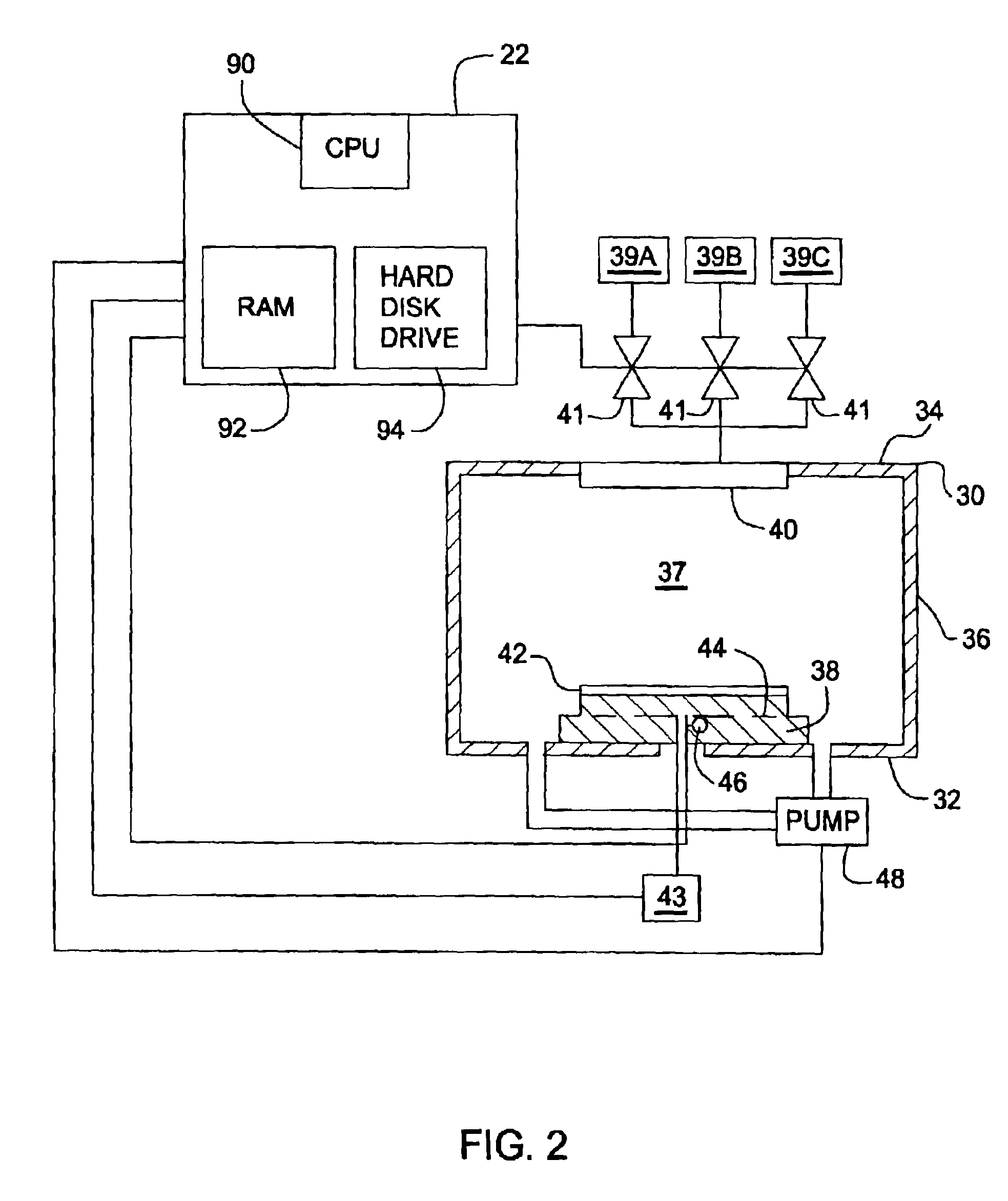

A method and system to form a refractory metal layer over a substrate includes introduction of a reductant, such as PH3 or B2H6, followed by introduction of a tungsten containing compound, such as WF6, to form a tungsten layer. It is believed that the reductant reduces the fluorine content of the tungsten layer while improving the step coverage and resistivity of the tungsten layer. It is believed that the improved characteristics of the tungsten film are attributable to the chemical affinity between the reductants and the tungsten containing compound. The chemical affinity provides better surface mobility of the adsorbed chemical species and better reduction of WF6 at the nucleation stage of the tungsten layer. The method can further include sequentially introducing a reductant, such as PH3 or B2H6, and a tungsten containing compound to deposit a tungsten layer. The formed tungsten layer can be used as a nucleation layer followed by bulk deposition of a tungsten layer utilizing standard CVD techniques. Alternatively, the formed tungsten layer can be used to fill an aperture.

Owner:APPLIED MATERIALS INC

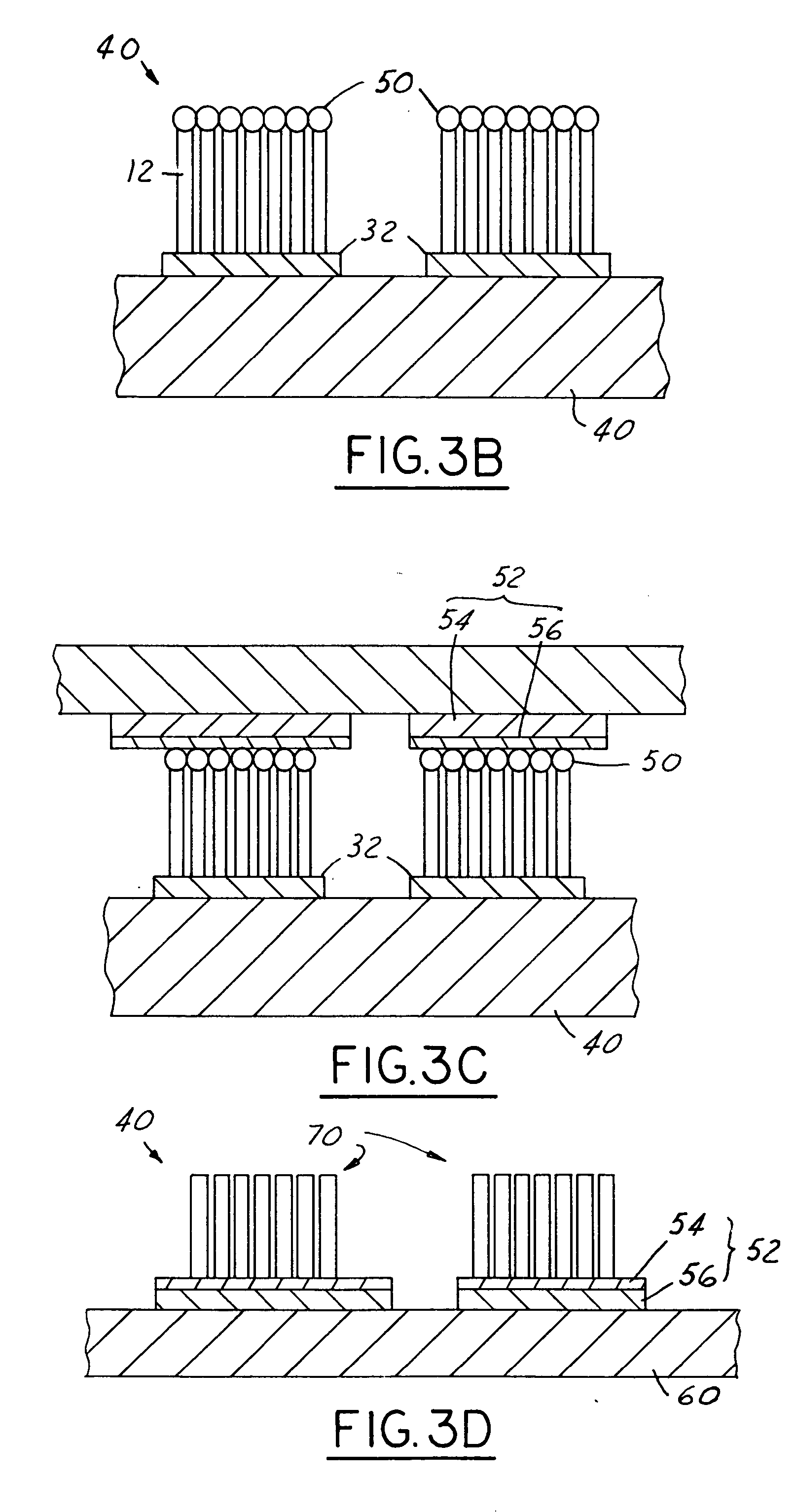

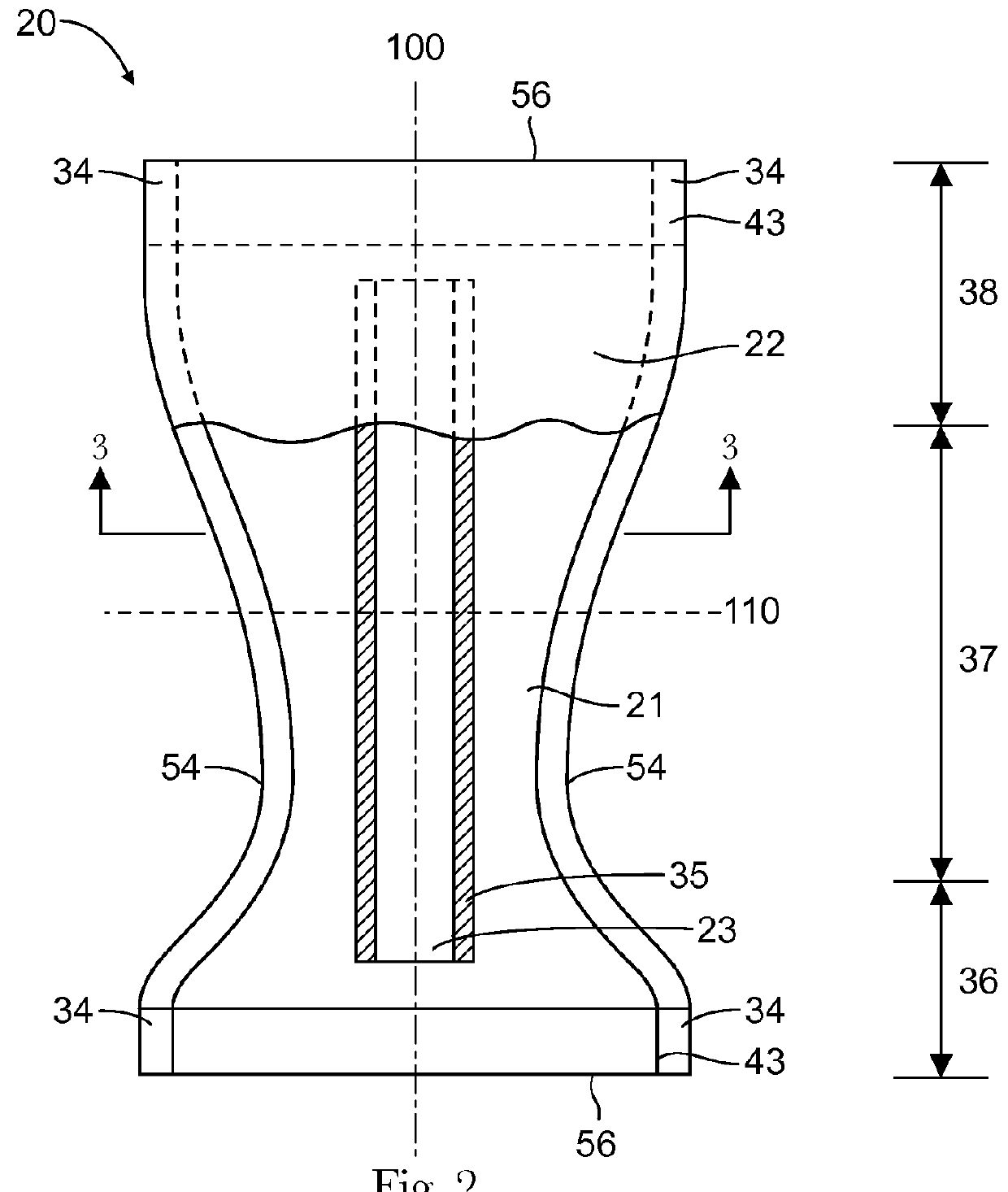

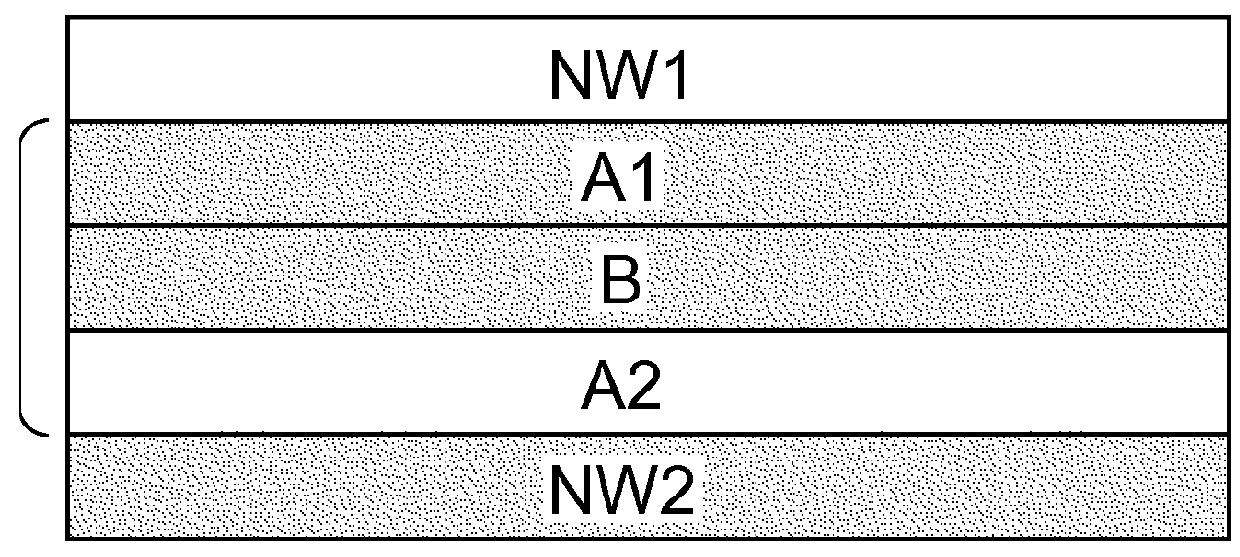

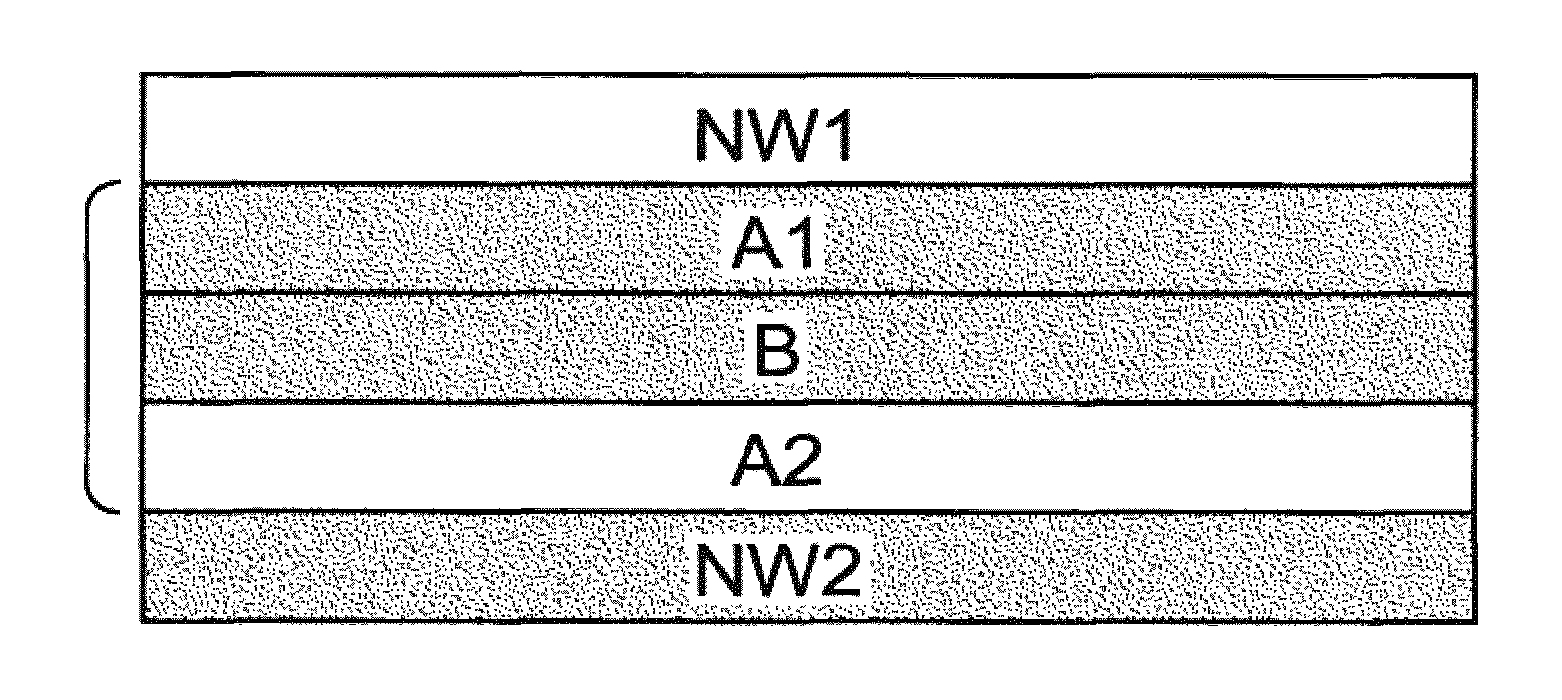

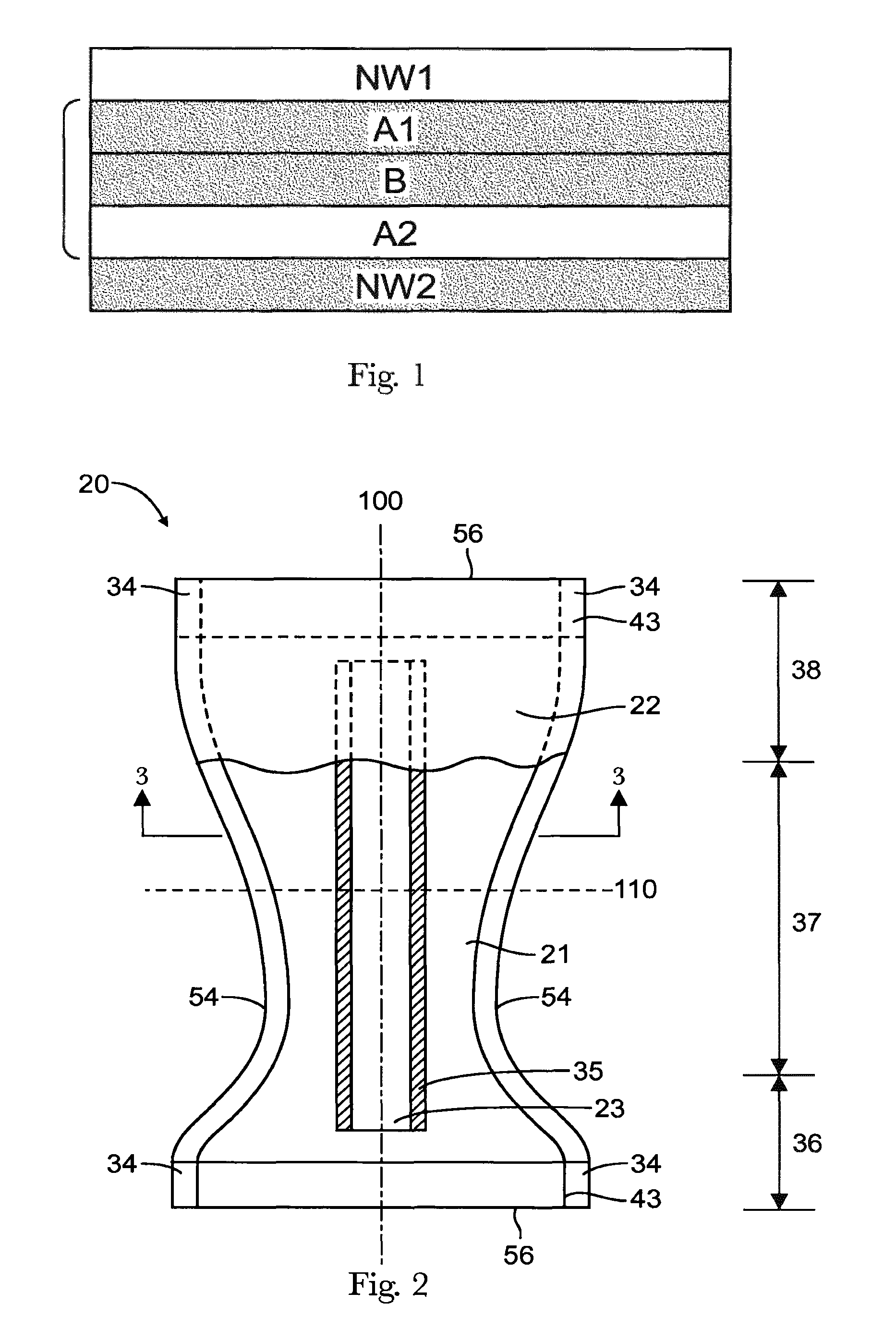

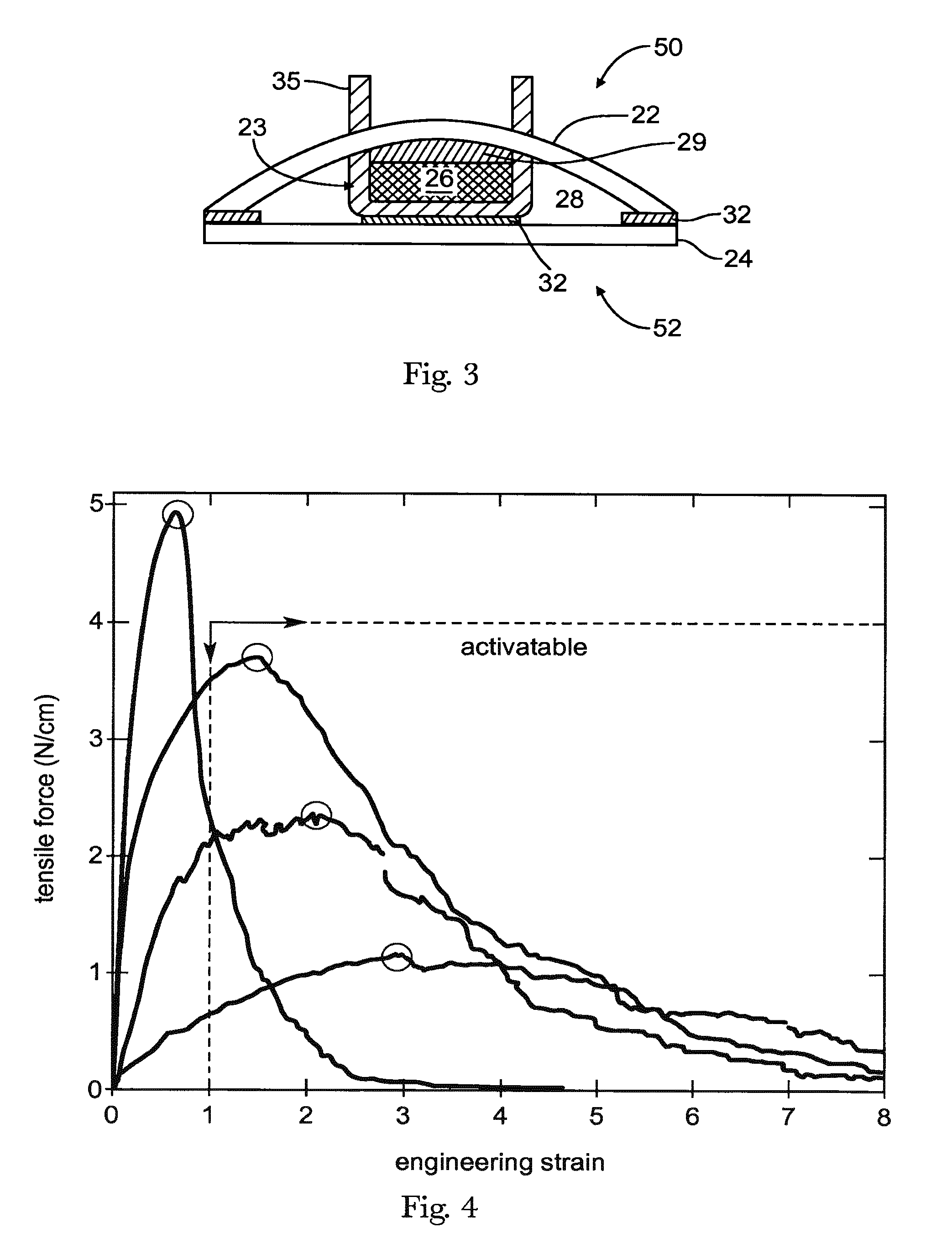

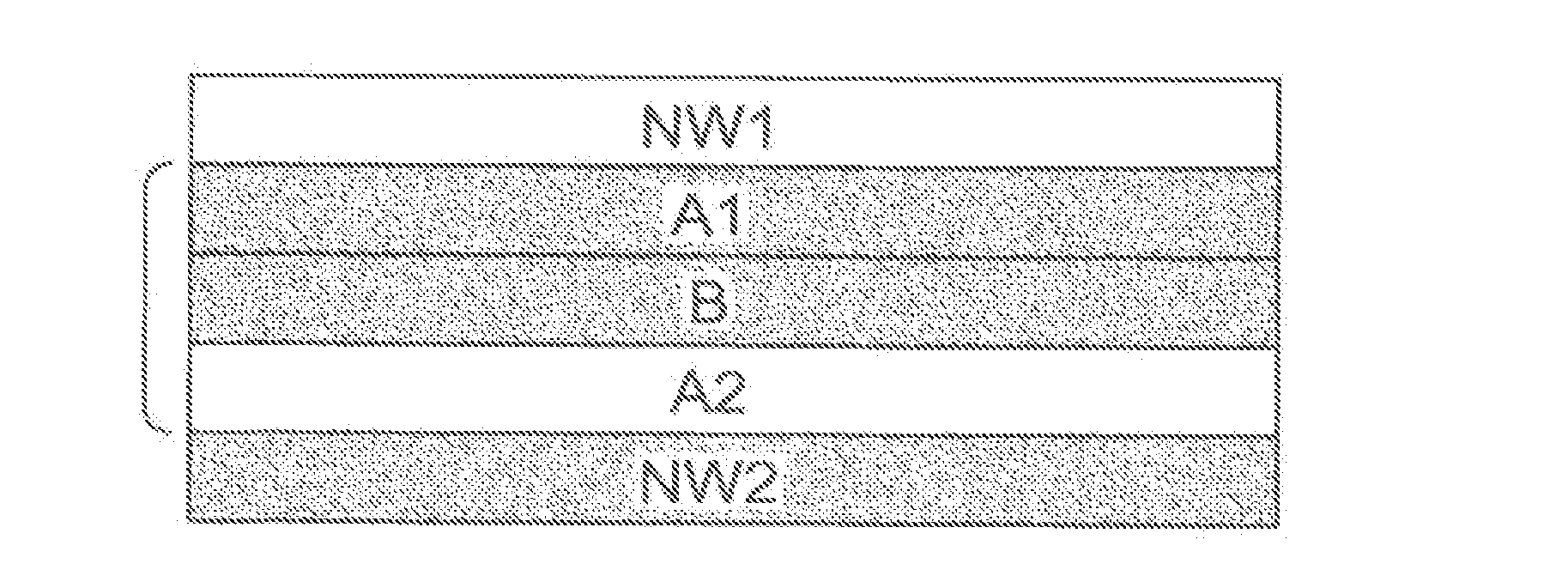

Extrusion Bonded Laminates for Absorbent Articles

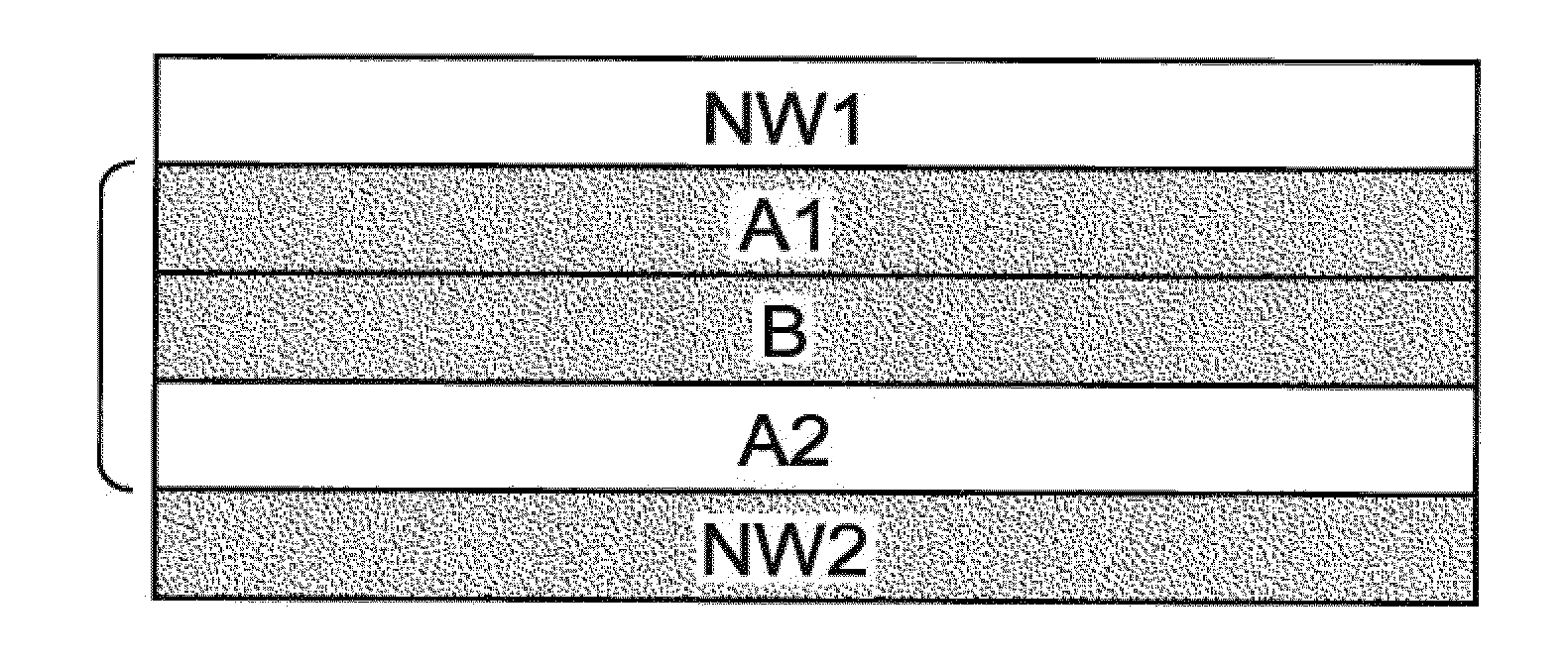

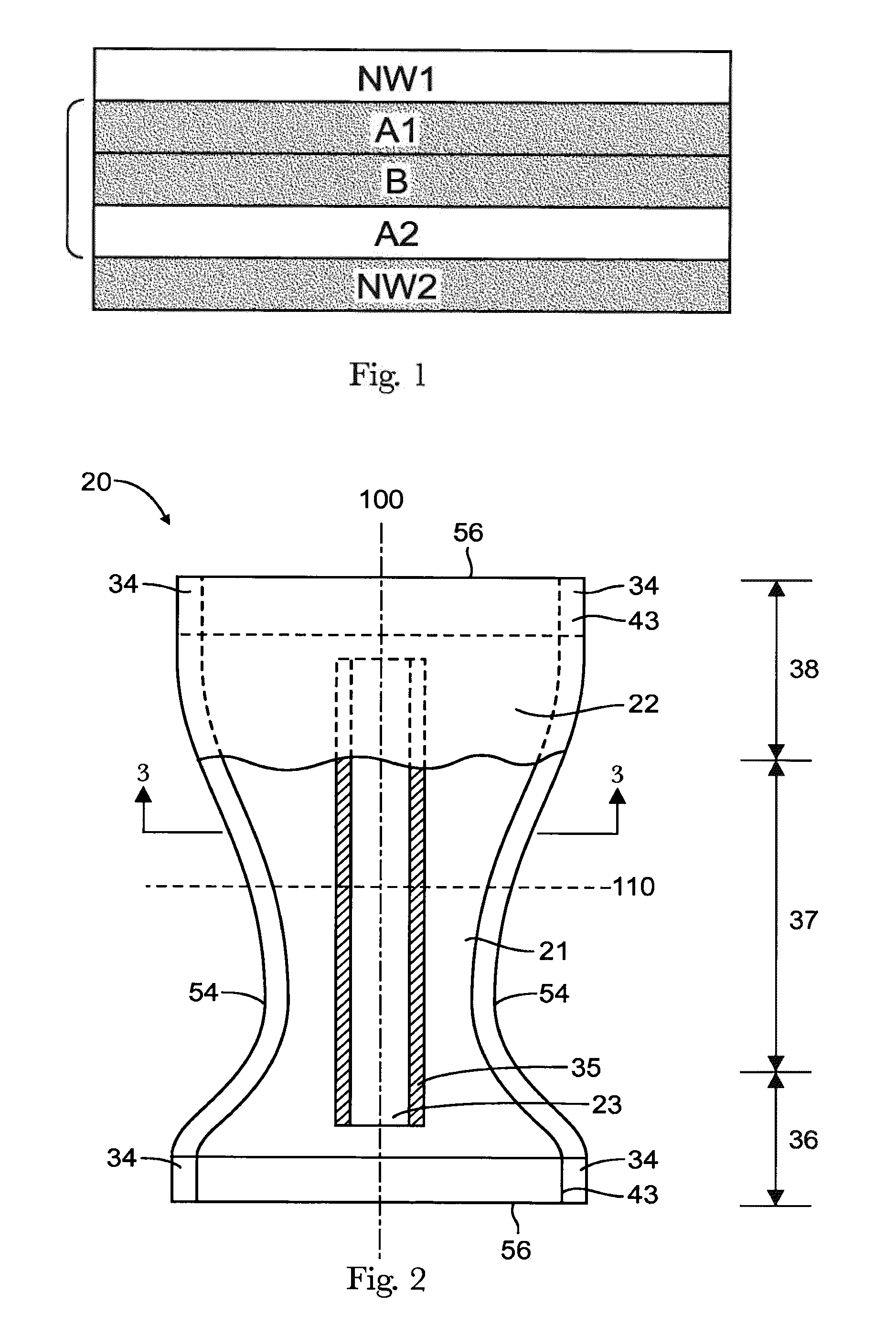

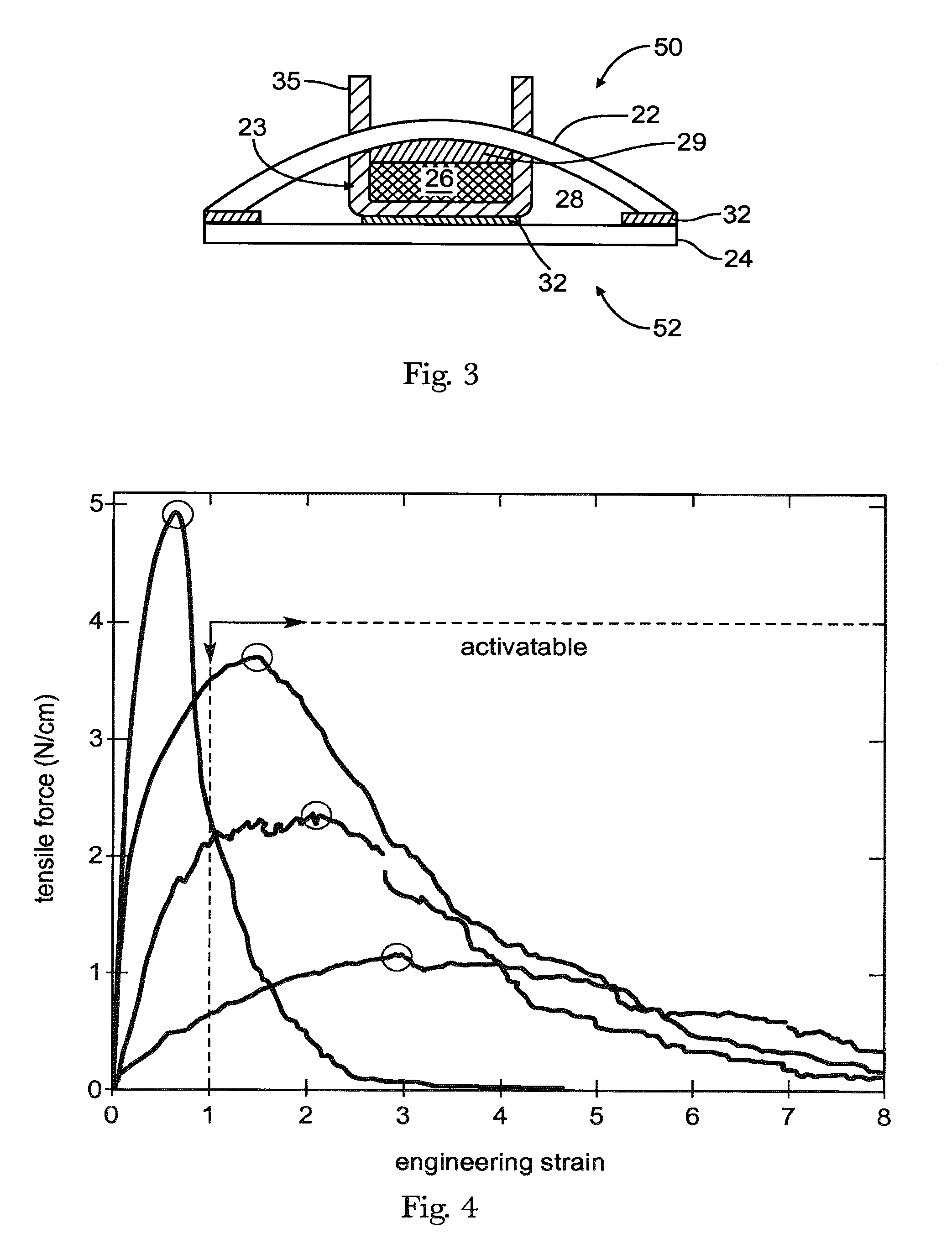

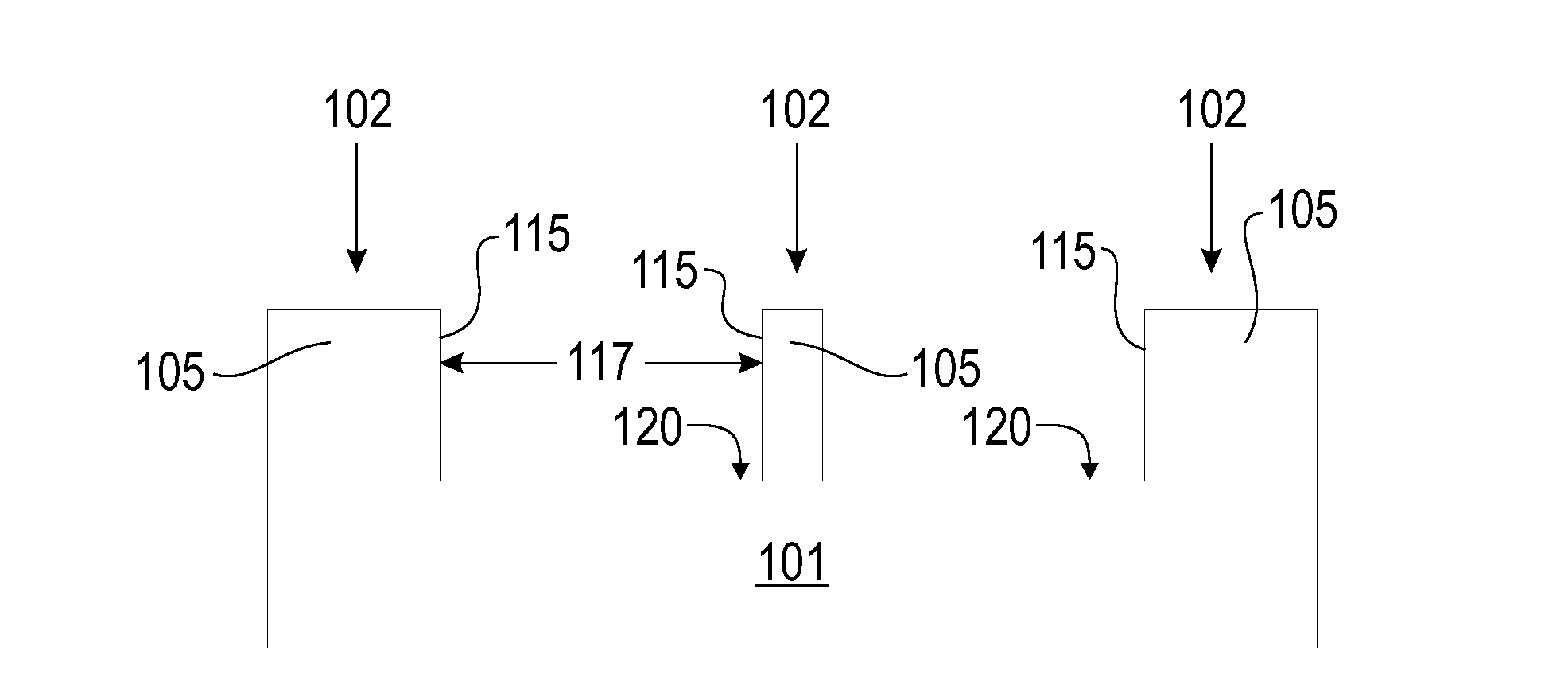

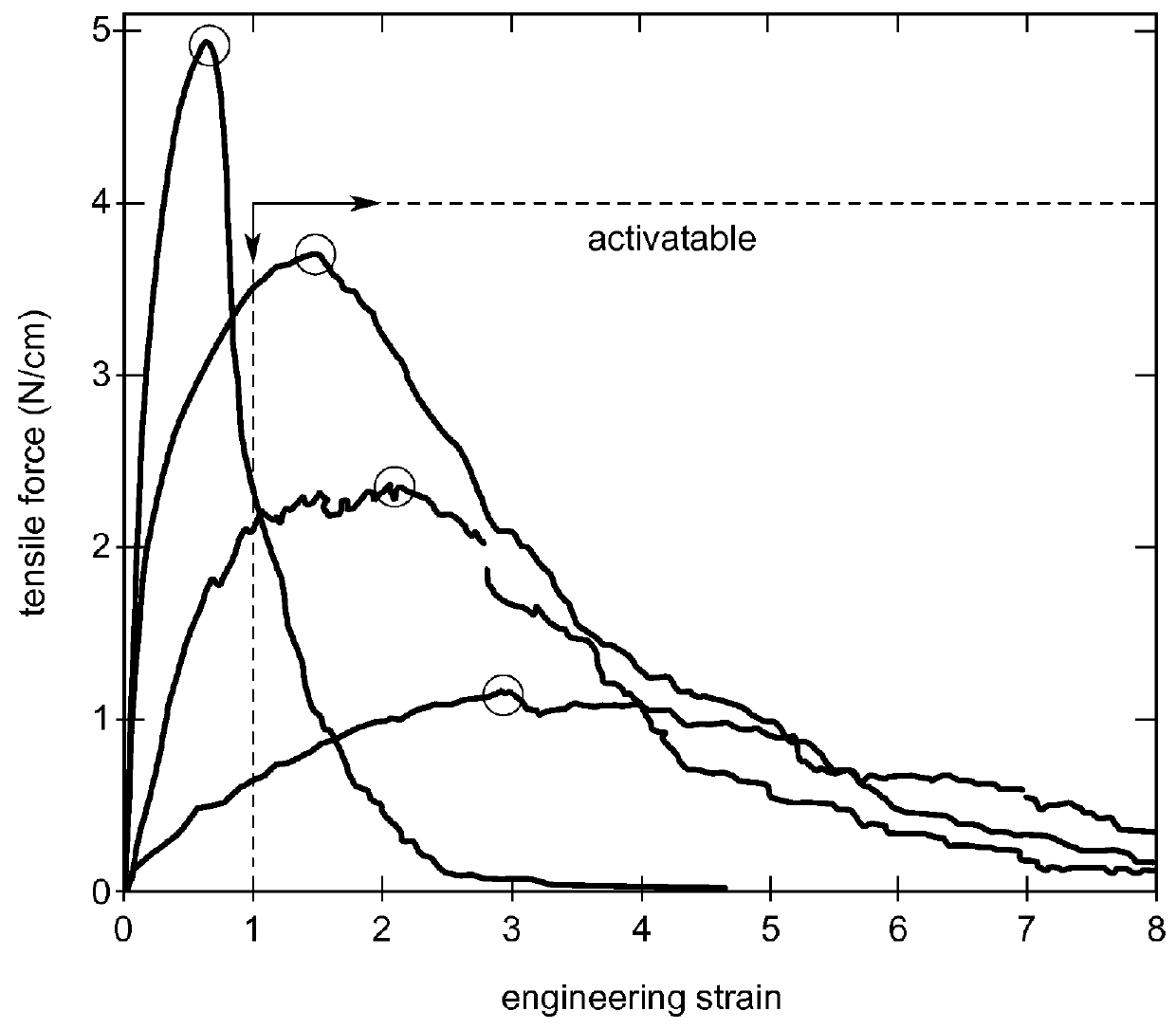

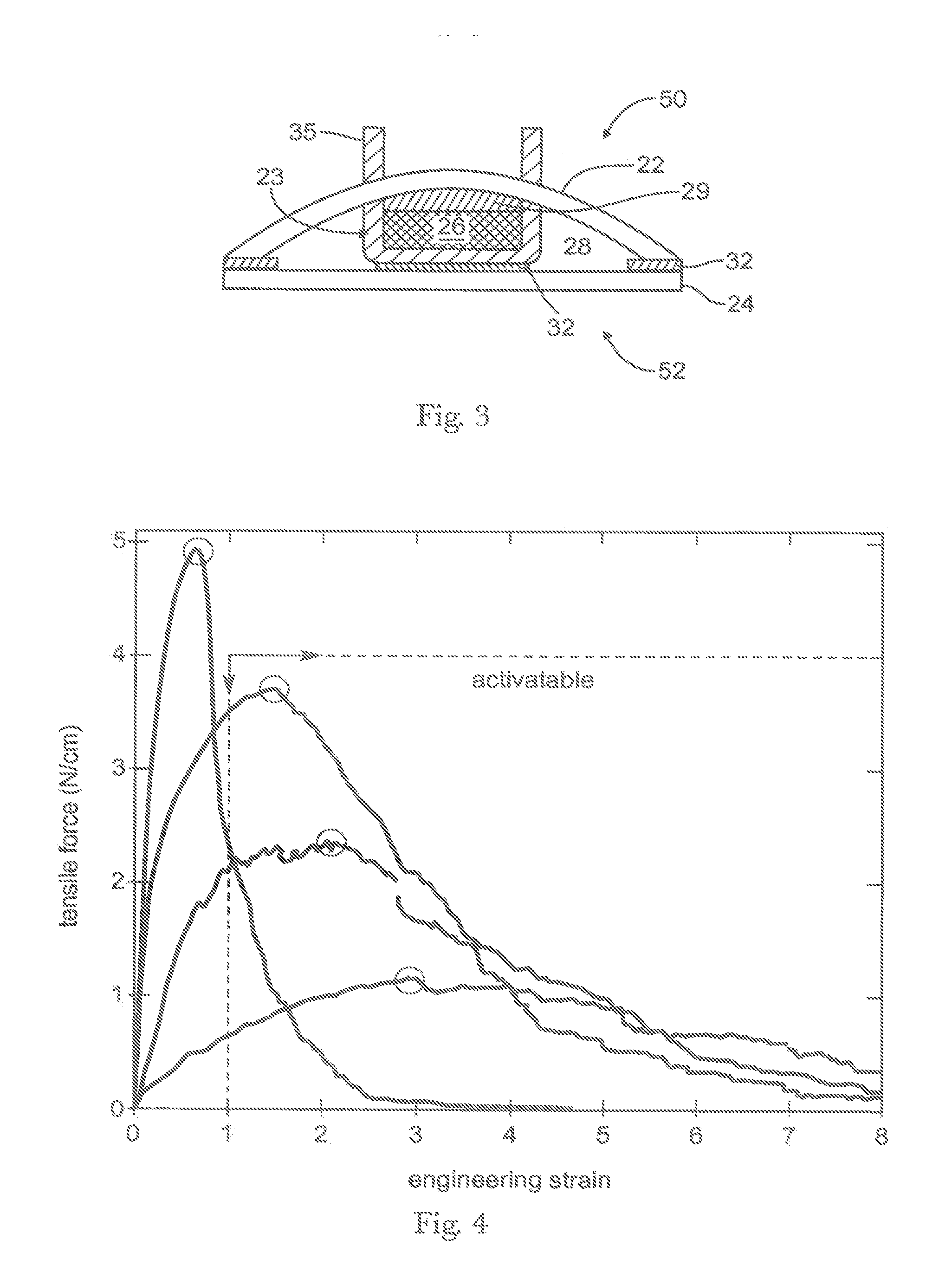

An absorbent article of the present invention may comprise a topsheet, an outer cover, and an absorbent core disposed therebetween. The outer cover may comprise an extrusion bonded laminate. The EBL may comprise a multi-layer coextruded elastomeric film and a nonwoven. The film may comprise a core layer, a first outer layer, and a second outer layer, wherein the core layer is between the first and second outer layers. The nonwoven may comprise fibers and / or filaments. The first outer layer may be non-adhesively joined to the nonwoven via extrusion coating. Further, the outer cover may be elastic to at least about 50% engineering strain. The nonwoven may have high chemical affinity for the first outer layer. The first outer layer may have a low chemical affinity for the core layer. And, the first outer layer may comprise an amount of draw down polymer greater than about 45 wt %.

Owner:THE PROCTER & GAMBLE COMPANY

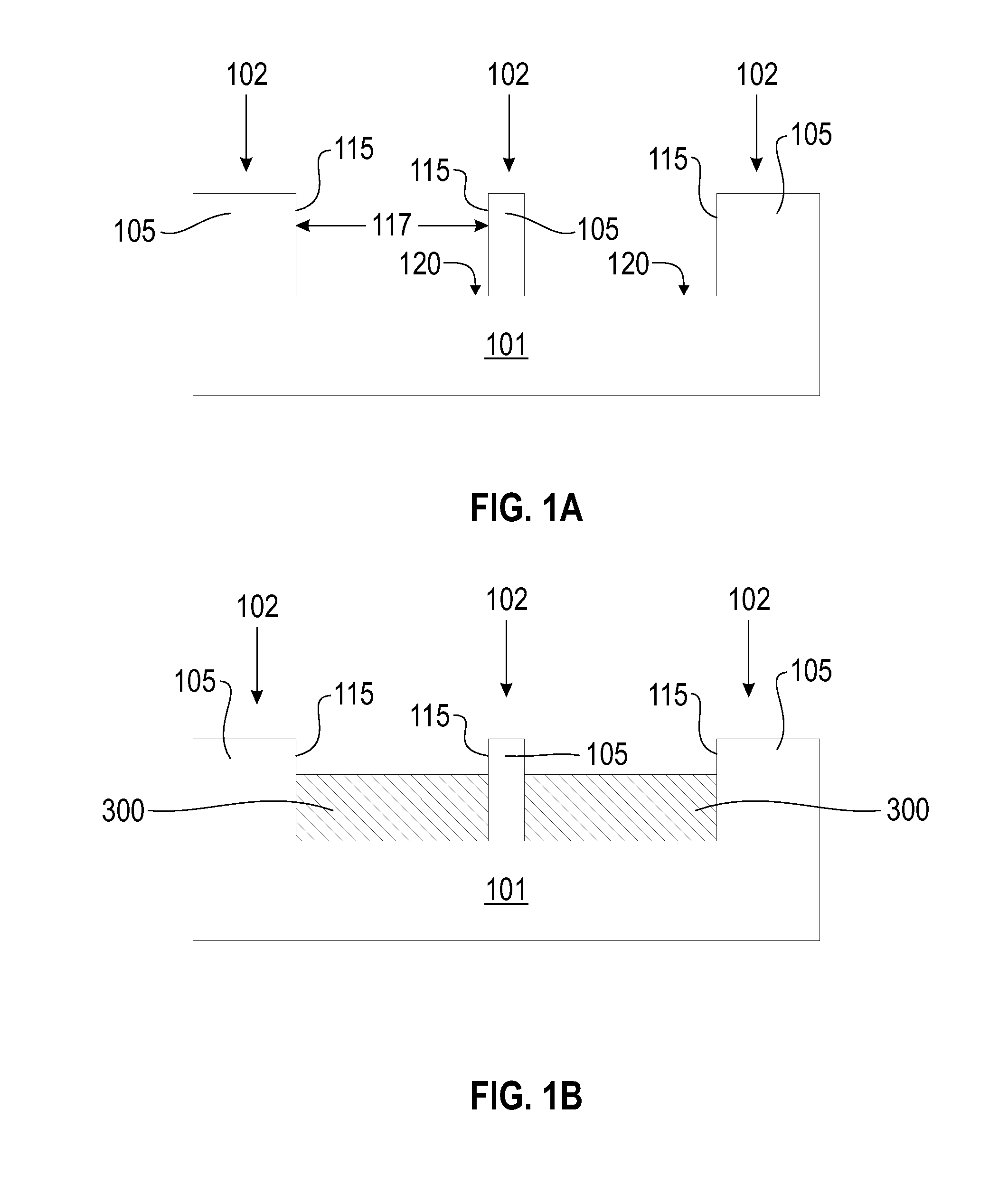

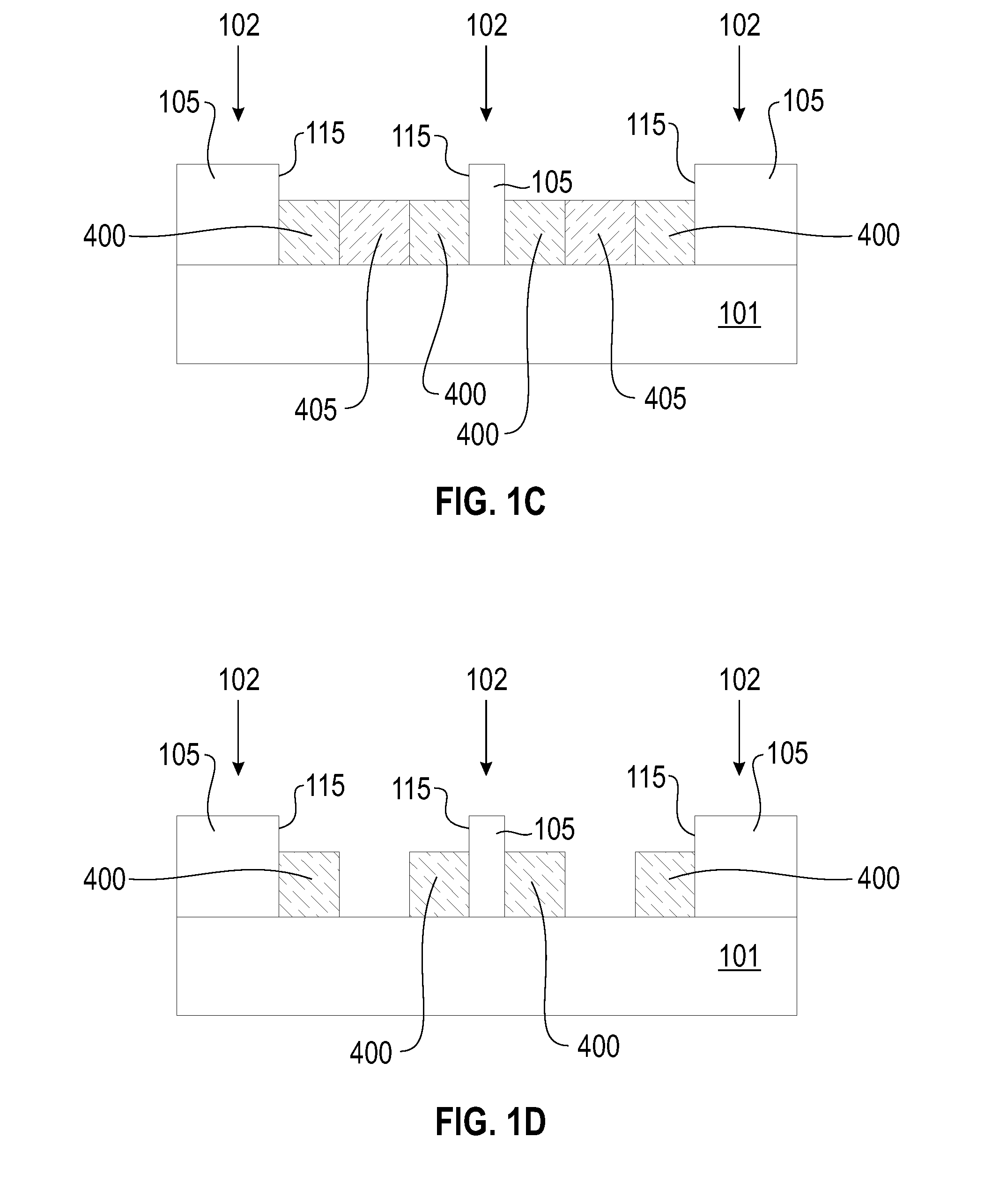

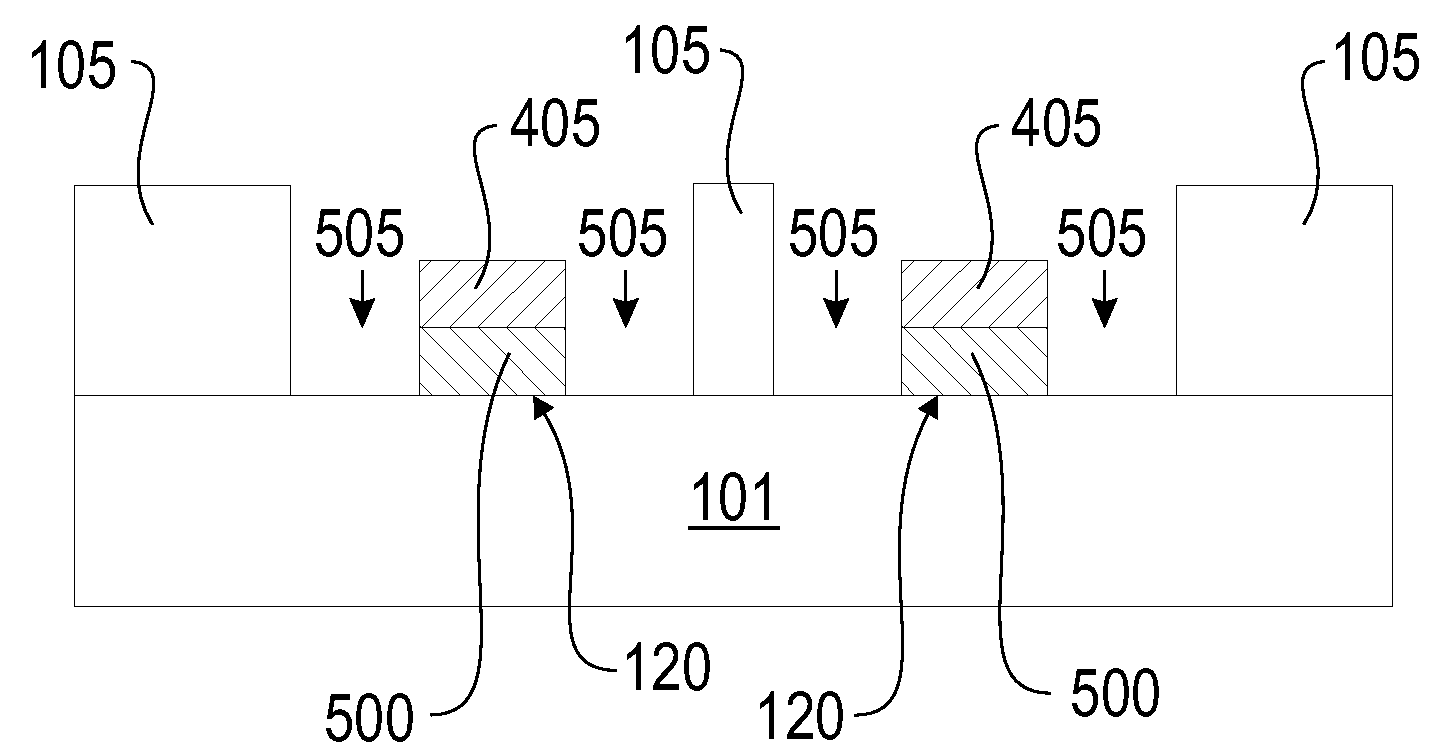

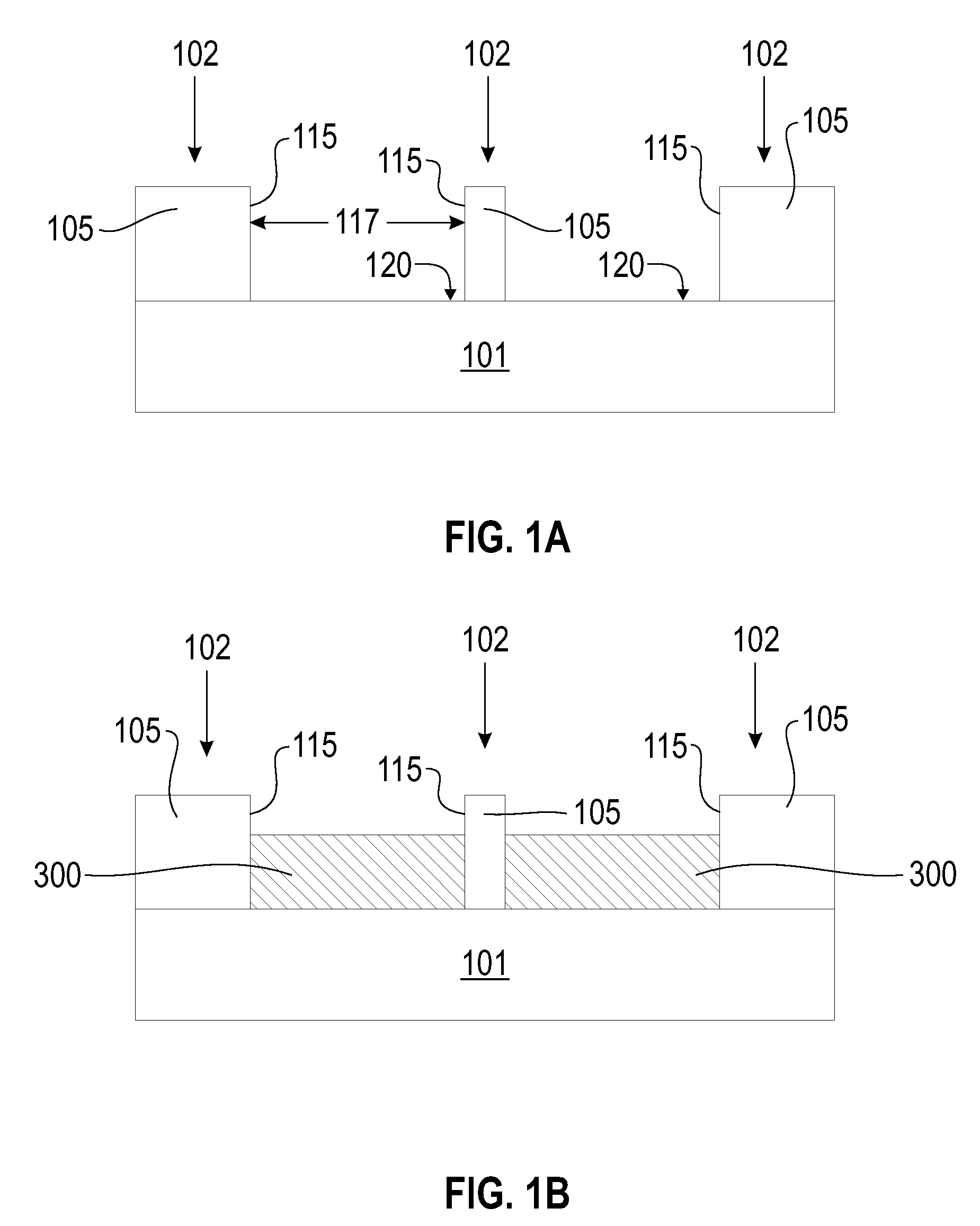

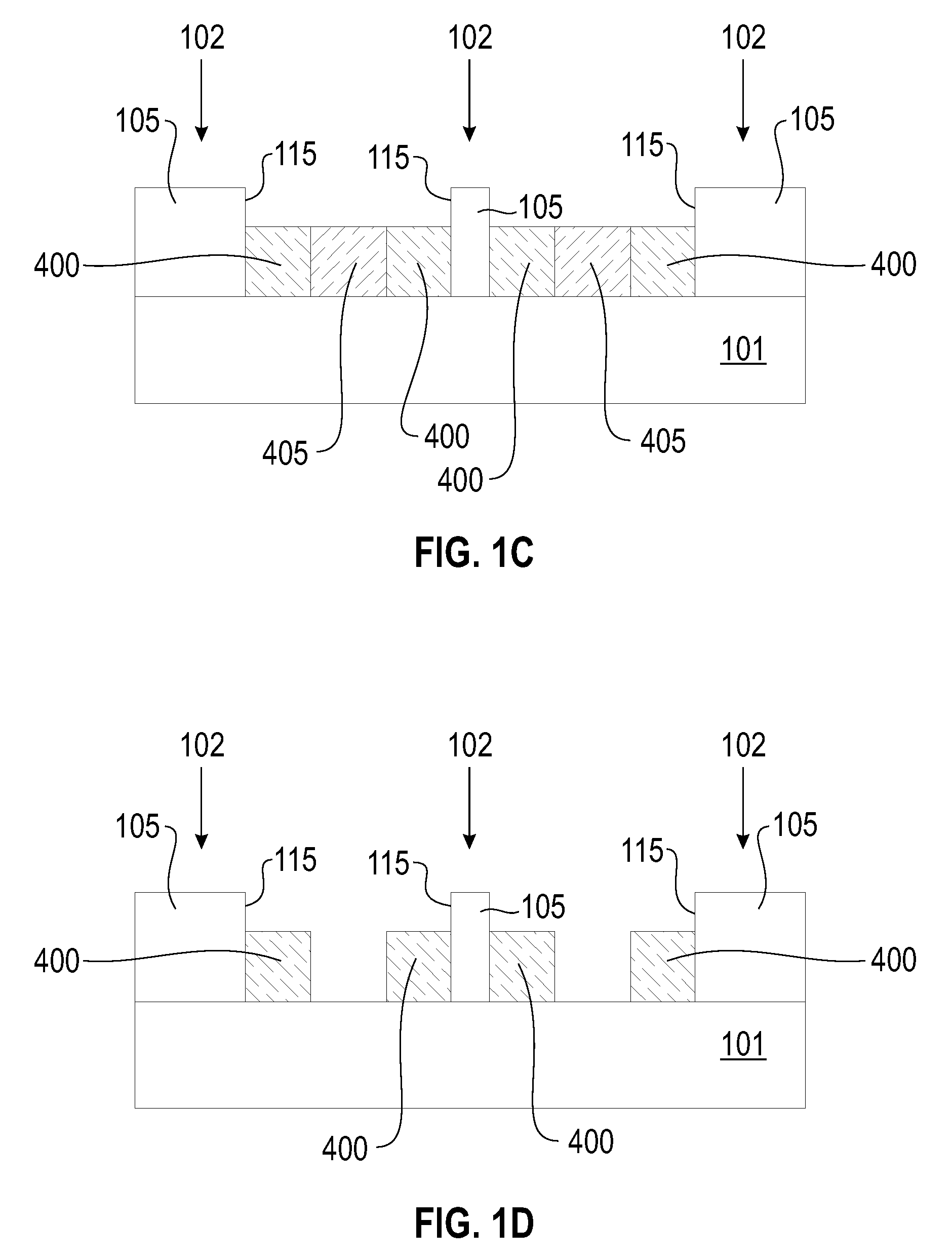

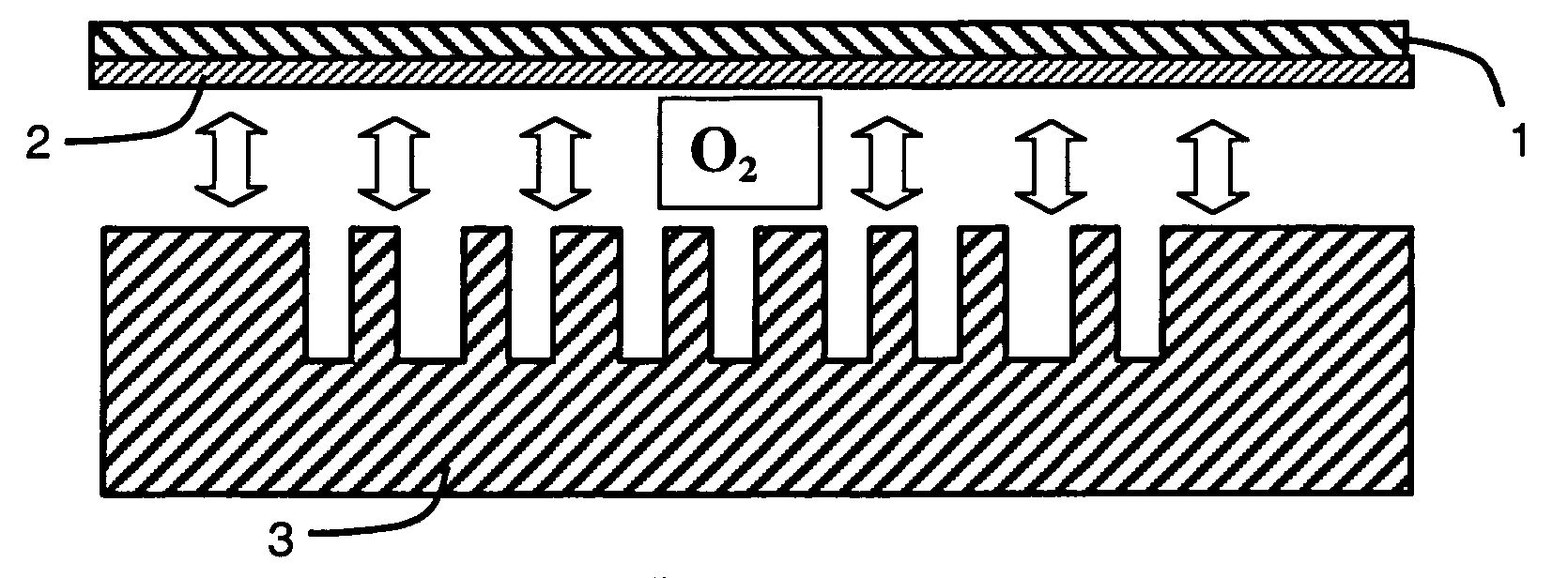

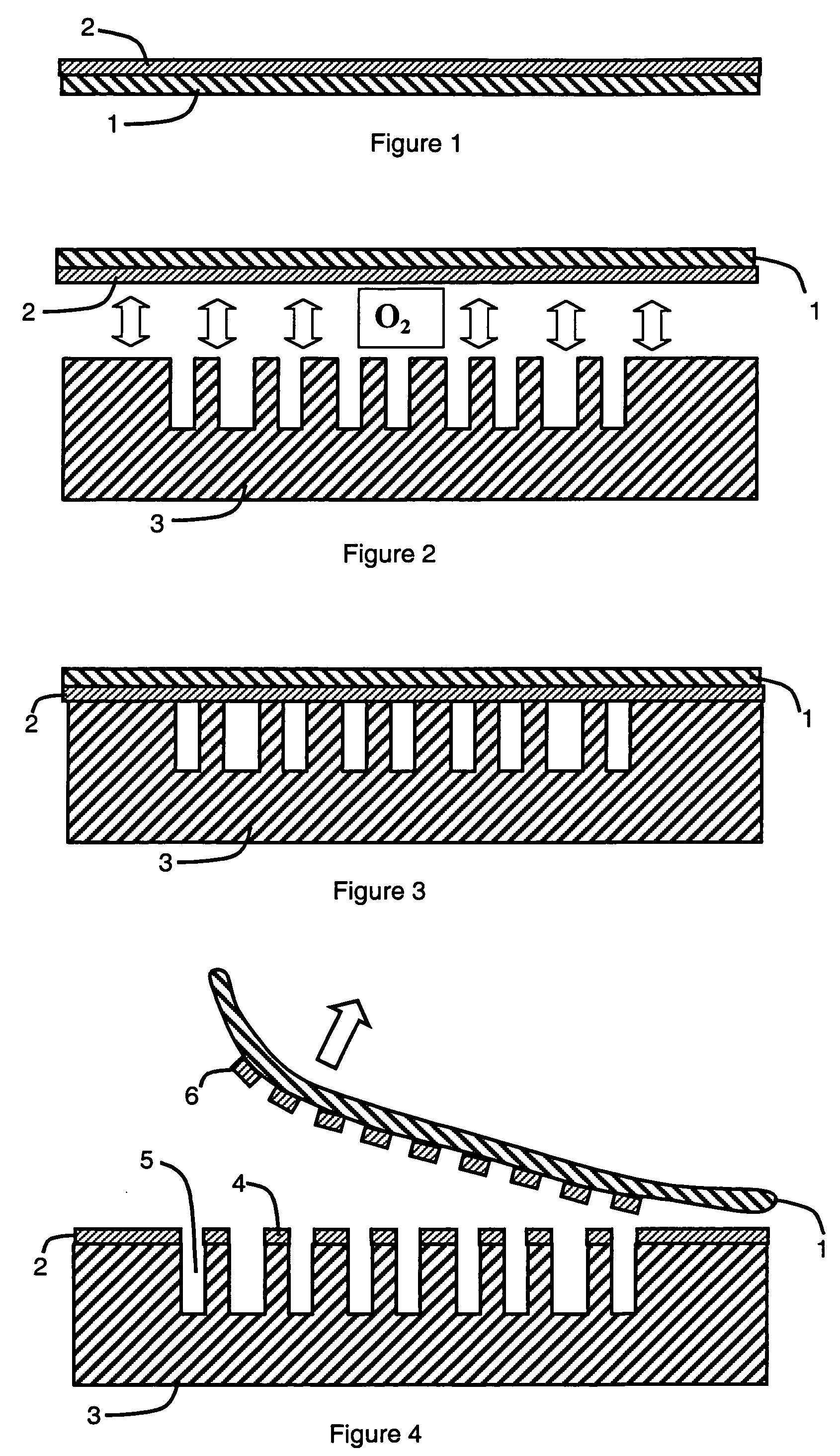

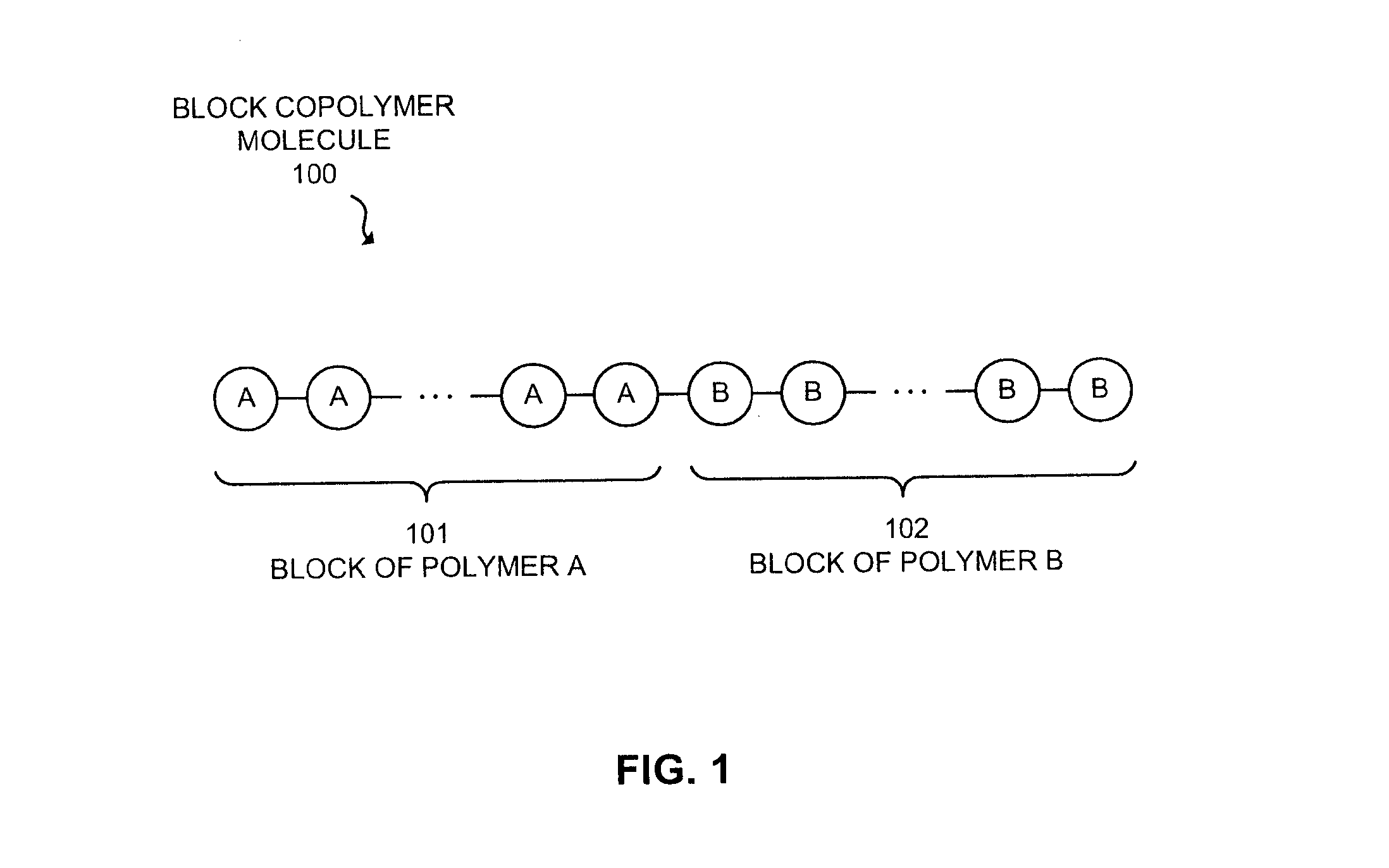

Methods for aligning polymer films and related structures

Methods and a structure. The method includes applying a solution including two or more immiscible polymers to a substructure including features having at least one sidewall and a bottom surface. The immiscible polymers include a first polymer and a second polymer. The at least one sidewall includes a material. A selective chemical affinity of the first polymer for the material is greater than a selective chemical affinity of the second polymer for the material. The first polymer is segregated from the second polymer. The first polymer selectively migrates to the at least one sidewall, resulting in the first polymer being disposed between the at least one sidewall and the second polymer. One or more immiscible polymers is selectively removed. At least one immiscible polymer remains, resulting in forming structures including the substructure and the immiscible polymer remaining. Two additional methods and a structure are also included.

Owner:GLOBALFOUNDRIES US INC

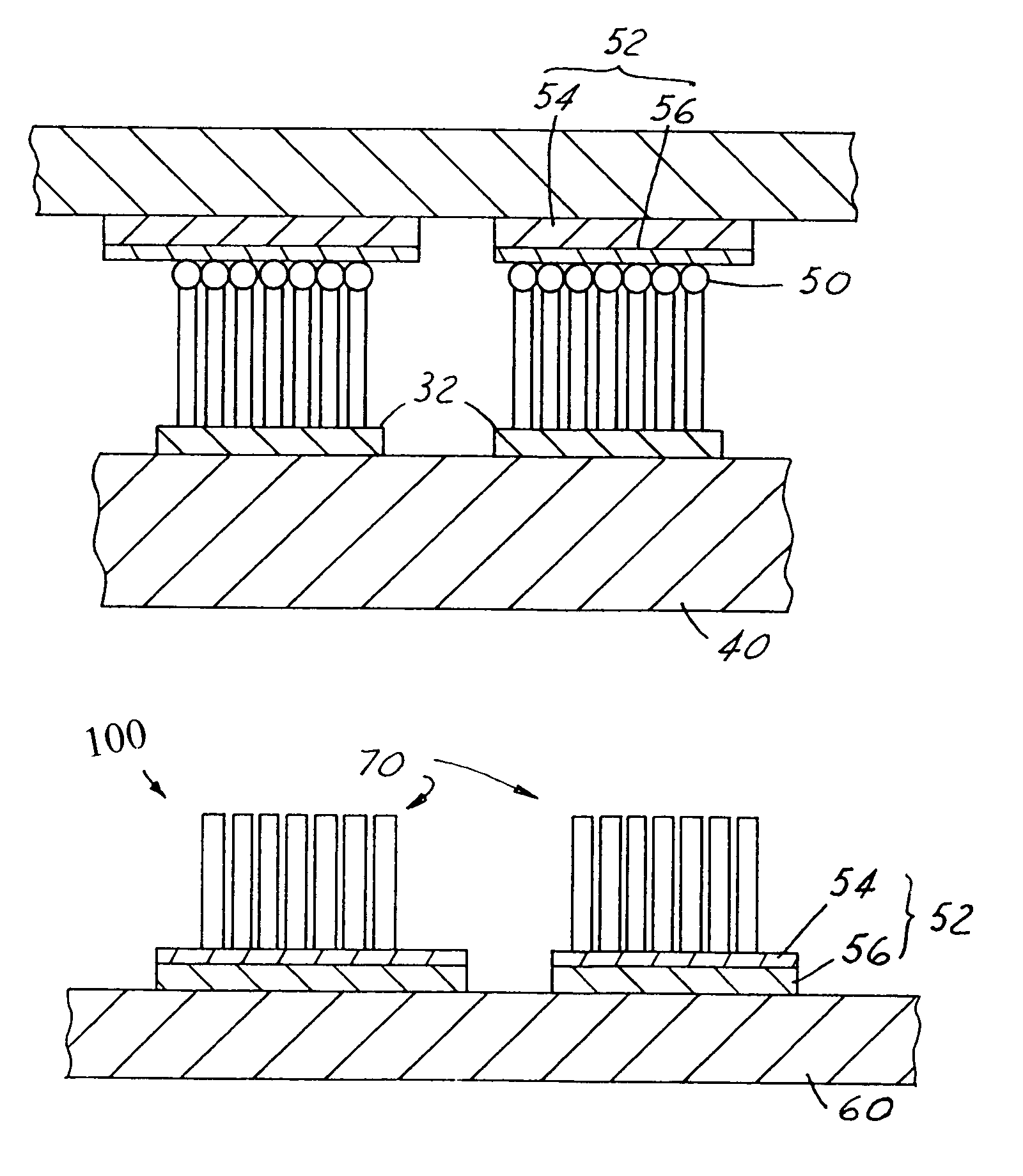

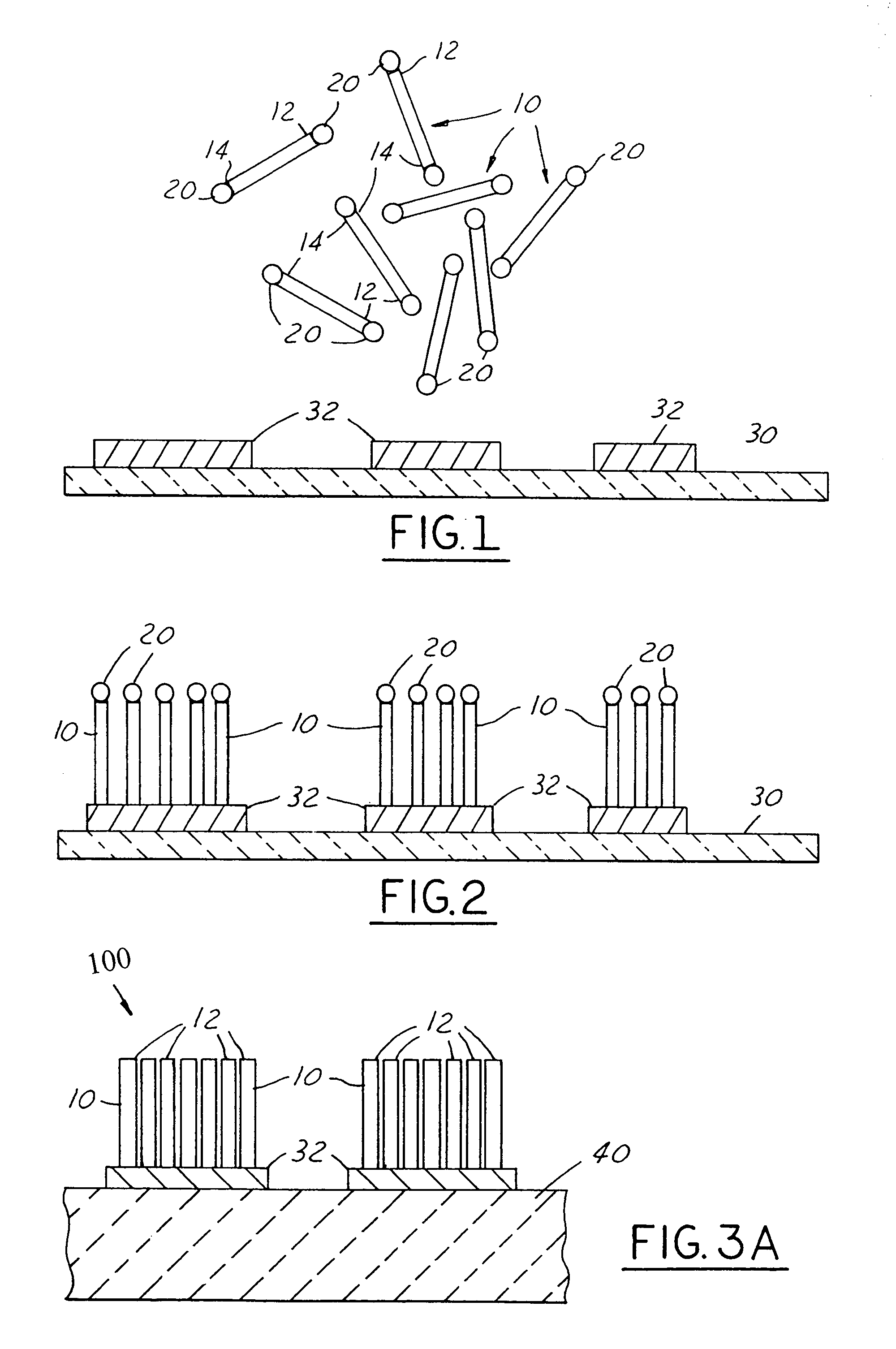

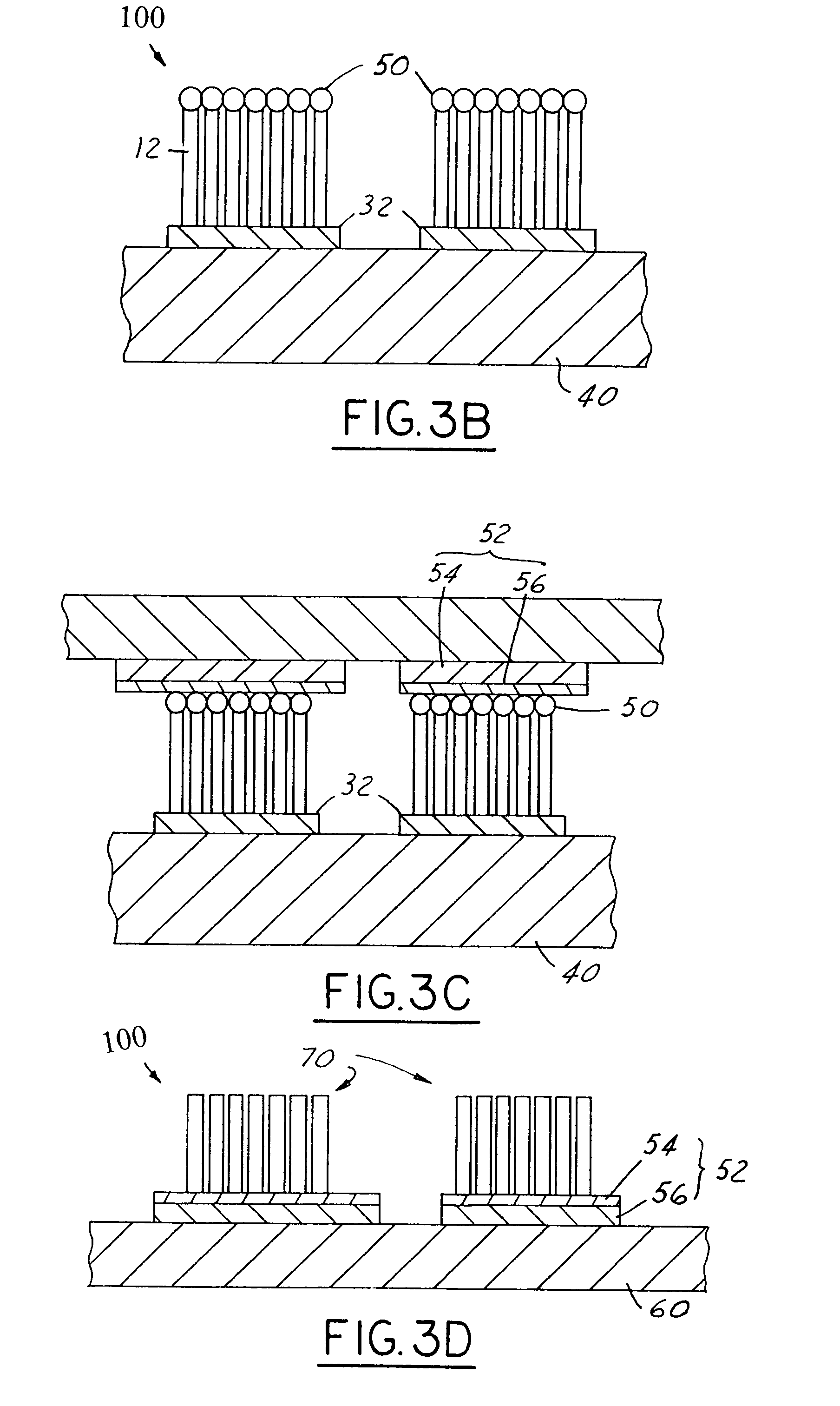

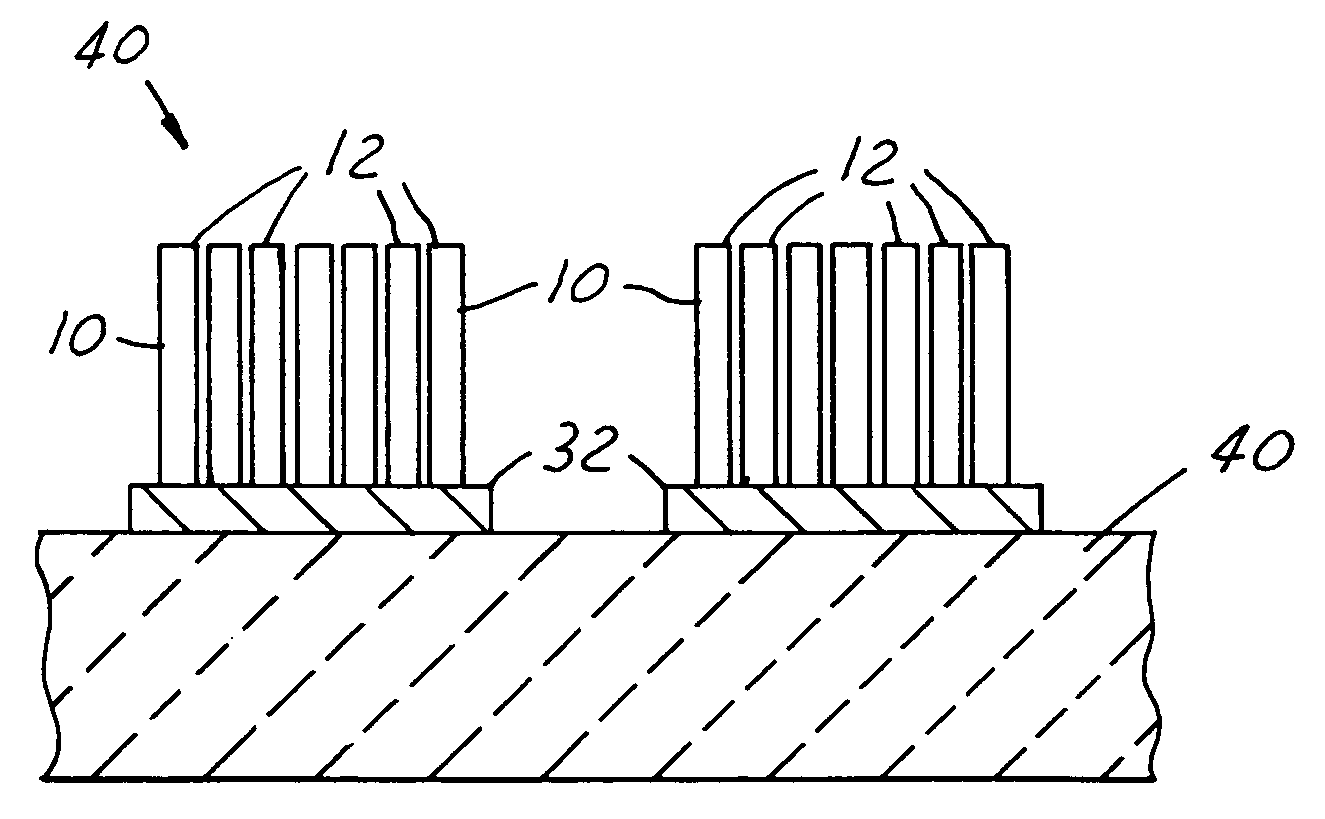

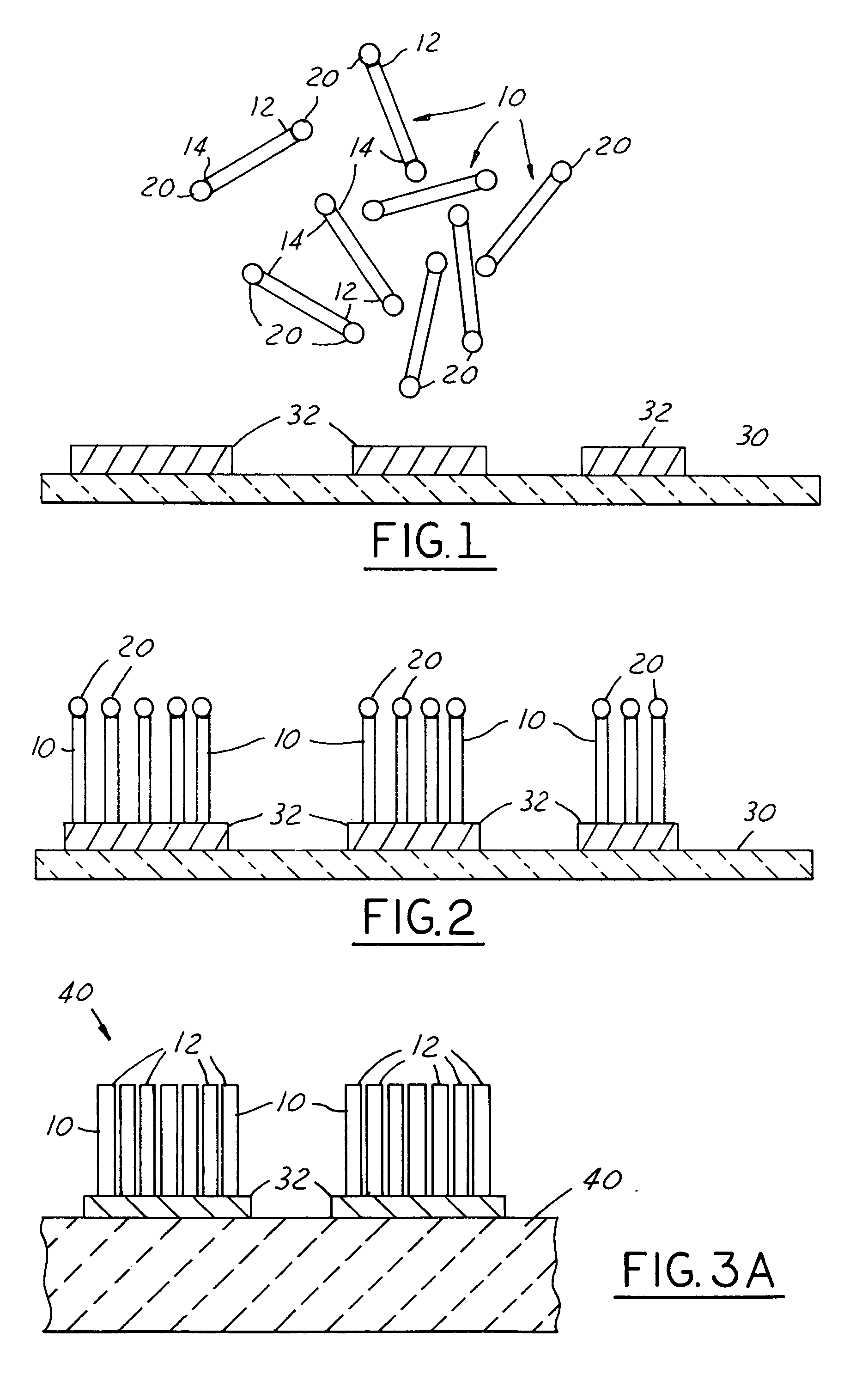

Self-assembled nanometer conductive bumps and method for fabricating

Owner:IND TECH RES INST

Aligning polymer films

InactiveUS20090212016A1Decorative surface effectsSemiconductor/solid-state device manufacturingPolymer thin filmsSubstructure

A Method. The method includes forming a substructure, on a substrate, including a feature having a sidewall of a first material and a bottom surface of a second material. Applying a solution including two immiscible polymers and third material to the substructure. The immiscible polymers include a first and second polymer. A selective chemical affinity of the first polymer for the material is greater than a selective chemical affinity of the second polymer for the material. The first polymer is segregated from the second polymer. The first polymer selectively migrates to the at least one sidewall, resulting in the first polymer being disposed between the at least one sidewall and the second polymer. The first polymer is selectively removed. The second polymer remains, resulting in forming structures including the substructure, the third material, and the second polymer. The substructure has a pattern. The pattern is transferred to the substrate.

Owner:GLOBALFOUNDRIES INC

Self-assembled nanometer conductive bumps and method for fabricating

ActiveUS20050048697A1Semiconductor/solid-state device detailsNanoinformaticsCarbon nanotubeNanometre

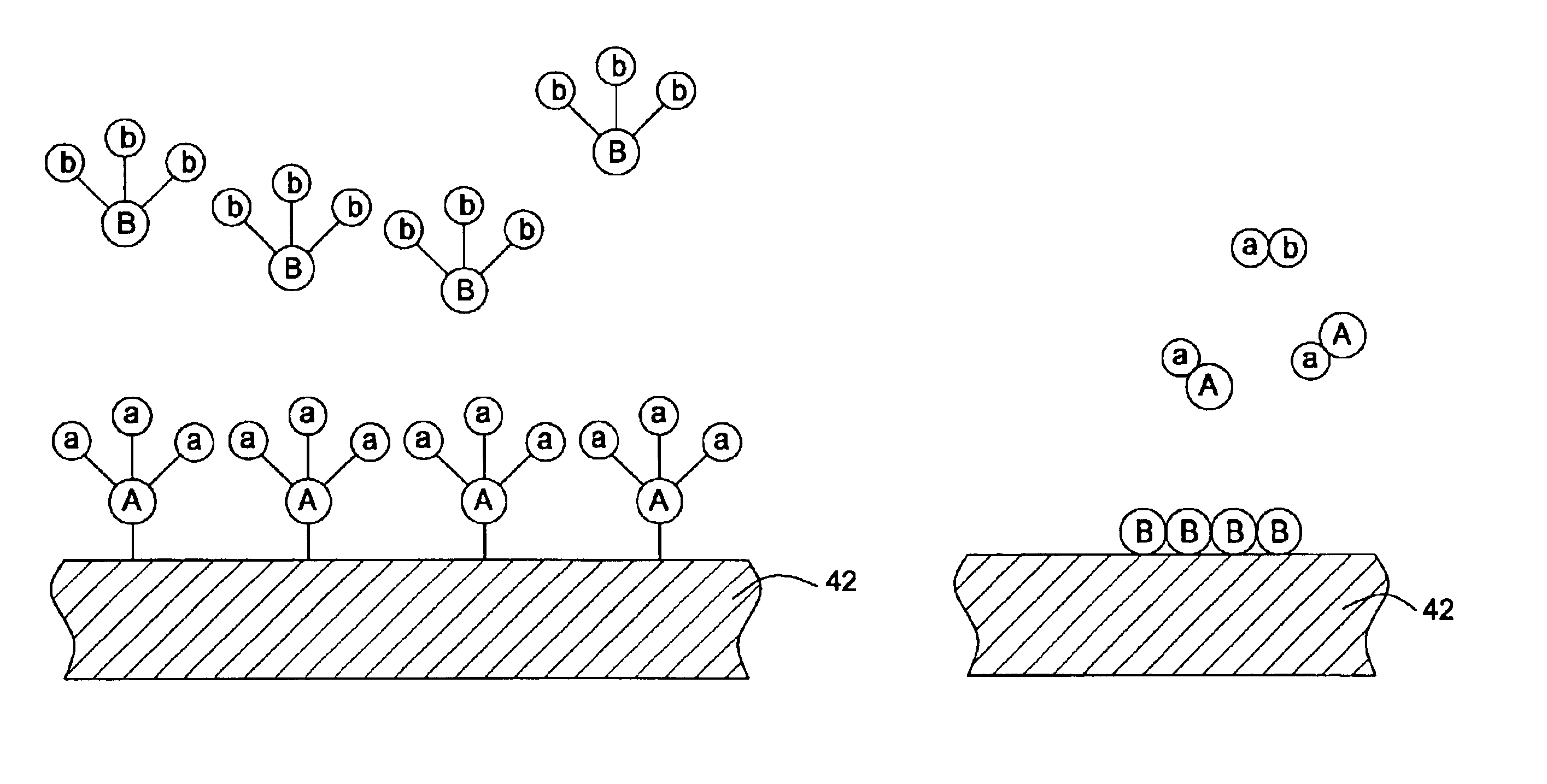

A self-assembled nanometer conductive bump and a method for fabricating the bump. In the method, a multiplicity of carbon nanotubes that are coated at two ends with chemically functional groups is first provided. A substrate that is equipped with at least one bond pad on a surface is then positioned juxtaposed to the carbon nanotubes for forming a bond between the carbon nanotubes and the metal pads facilitated by a chemical affinity existed between the functional groups and the metal pad.

Owner:IND TECH RES INST

Extrusion bonded laminates for absorbent articles

An absorbent article of the present invention may comprise a topsheet, an outer cover, and an absorbent core disposed therebetween. The outer cover may comprise an extrusion bonded laminate. The EBL may comprise a multi-layer coextruded elastomeric film and a nonwoven. The film may comprise a core layer, a first outer layer, and a second outer layer, wherein the core layer is between the first and second outer layers. The nonwoven may comprise fibers and / or filaments. The first outer layer may be non-adhesively joined to the nonwoven via extrusion coating. Further, the outer cover may be elastic to at least about 50% engineering strain. The nonwoven may have high chemical affinity for the first outer layer. The first outer layer may have a low chemical affinity for the core layer; and the multi-layer coextruded elastomeric film may have a basis weight no greater than about 40 gsm.

Owner:PROCTER & GAMBLE CO

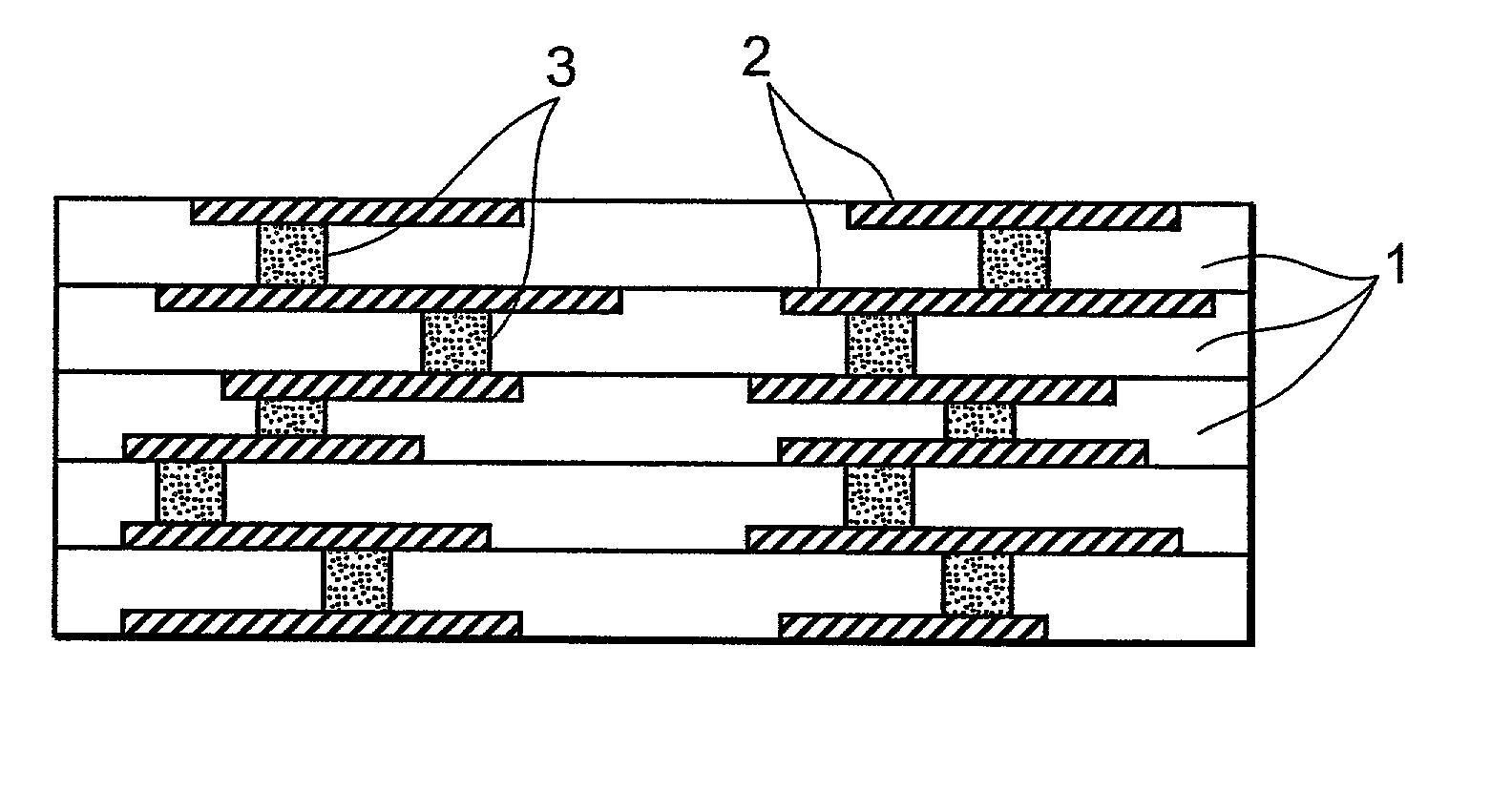

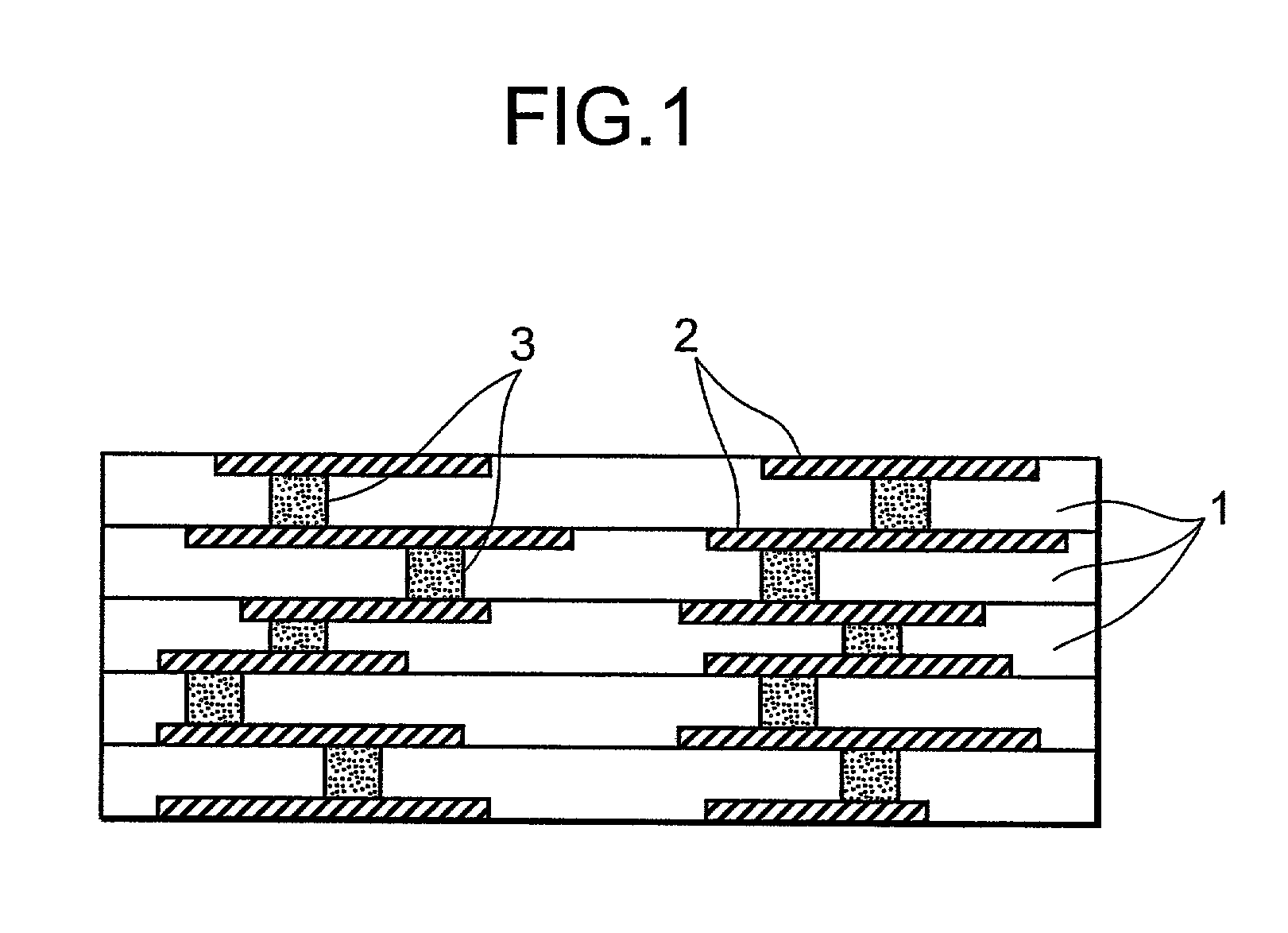

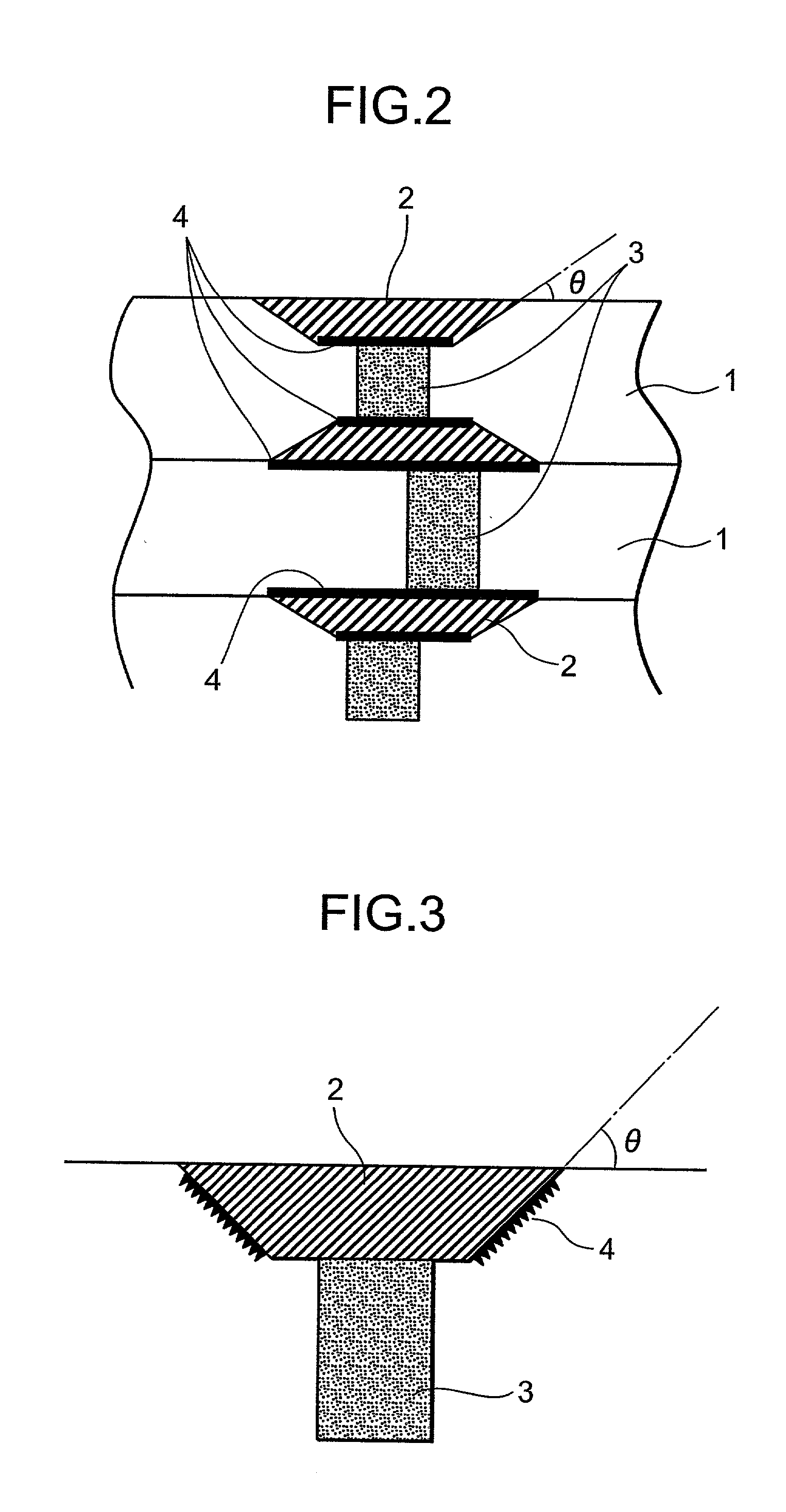

Multi-layer wiring board and method of producing the same

InactiveUS20020162687A1Effectively prevent infiltration of waterEffectively avoiding the deteriorationPrinted circuit assemblingInsulating substrate metal adhesion improvementElectrical conductorHigh humidity

Disclosed is a multi-layer wiring board comprising insulating layers of a thermosetting resin having through-holes formed therein, conductor wiring layers buried in the surfaces of said insulating layers, and via-conductors formed by filling said through-holes with an electrically conducting paste, the via-conductors being electrically connected to said conductor wiring layers, wherein coupling layers comprising a silane coupling agent are formed in the interfaces between said conductor wiring layers and said via-conductors or said insulating layers. The multi-layer wiring board features an increased chemical affinity between the conductor wiring layer and the insulating layer, effectively suppressing the infiltration of water through the interface between the conductor wiring layer and the insulating layer or through the insulating resin, and effectively preventing deterioration in the properties under a high-temperature and high-humidity environment of an extended period of time.

Owner:KYOCERA CORP

Method for reproduction of a compnent with a micro-joint and component produced by said method

InactiveUS20060048885A1Reduce complexityReduce manufacturing costFixed microstructural devicesVolume/mass flow measurementPolymerReproduction

The method for production of a component with a micro-joint comprises a first step of deposition of a layer of polymer designed to constitute an assembly joint on a transfer substrate, a second step of bringing the polymer layer into contact with a micro-structured substrate and a third step of removing the transfer substrate. Due to the difference of the chemical affinity between the polymer layer and the transfer substrate on the one hand and the chemical affinity between the polymer layer and the micro-structured substrate on the other hand, the zones of the polymer layer, which are in contact with the micro-structured substrate during the second step, remain on the micro-structured substrate after the third step. These zones constitute the assembly joint.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

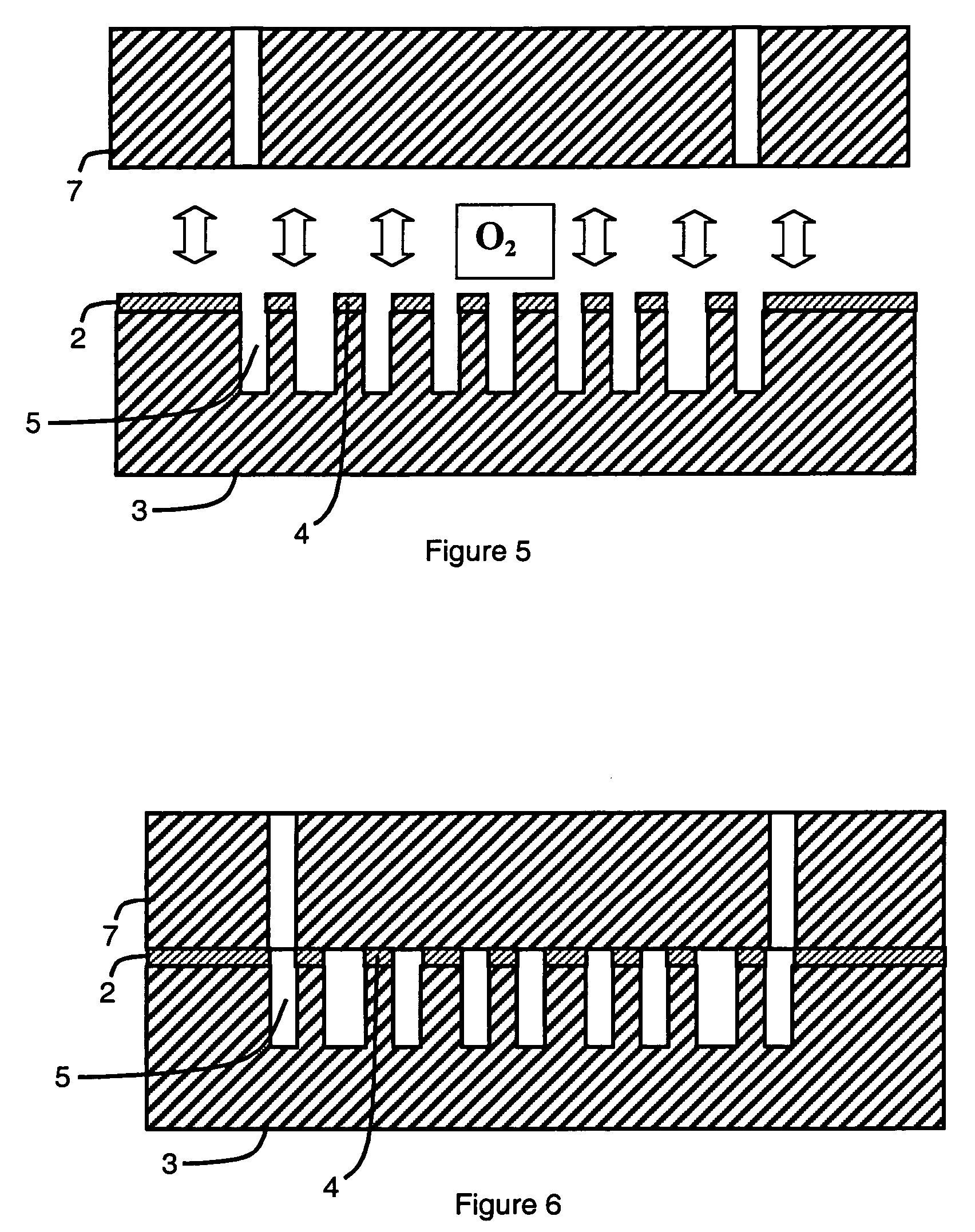

Flame inhibiting and retarding chemical compositions for general use on multiple solid surfaces

Owner:GANG HENRY

Design of new materials whose use produces a chemical bond with a descriptor of said bond

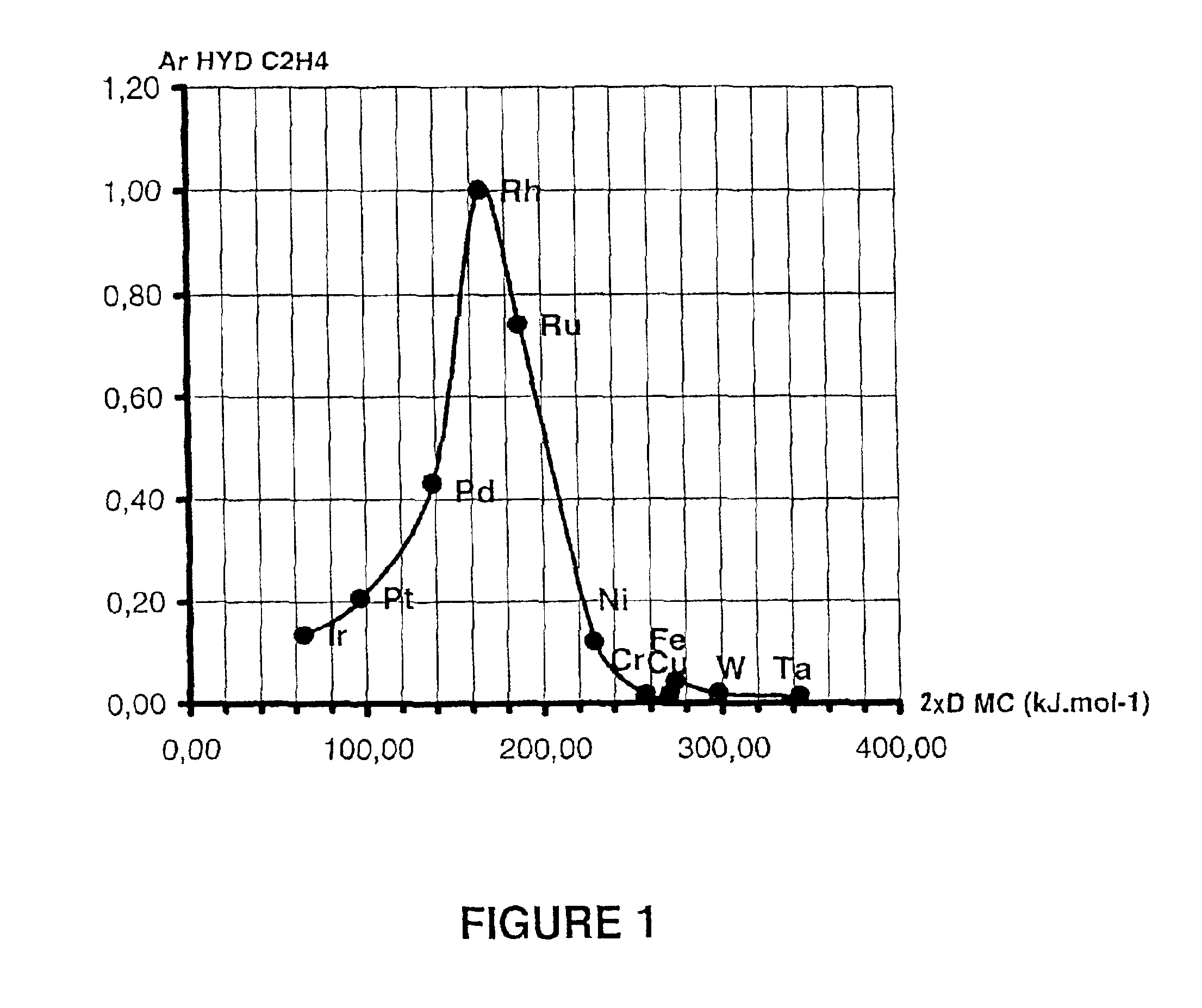

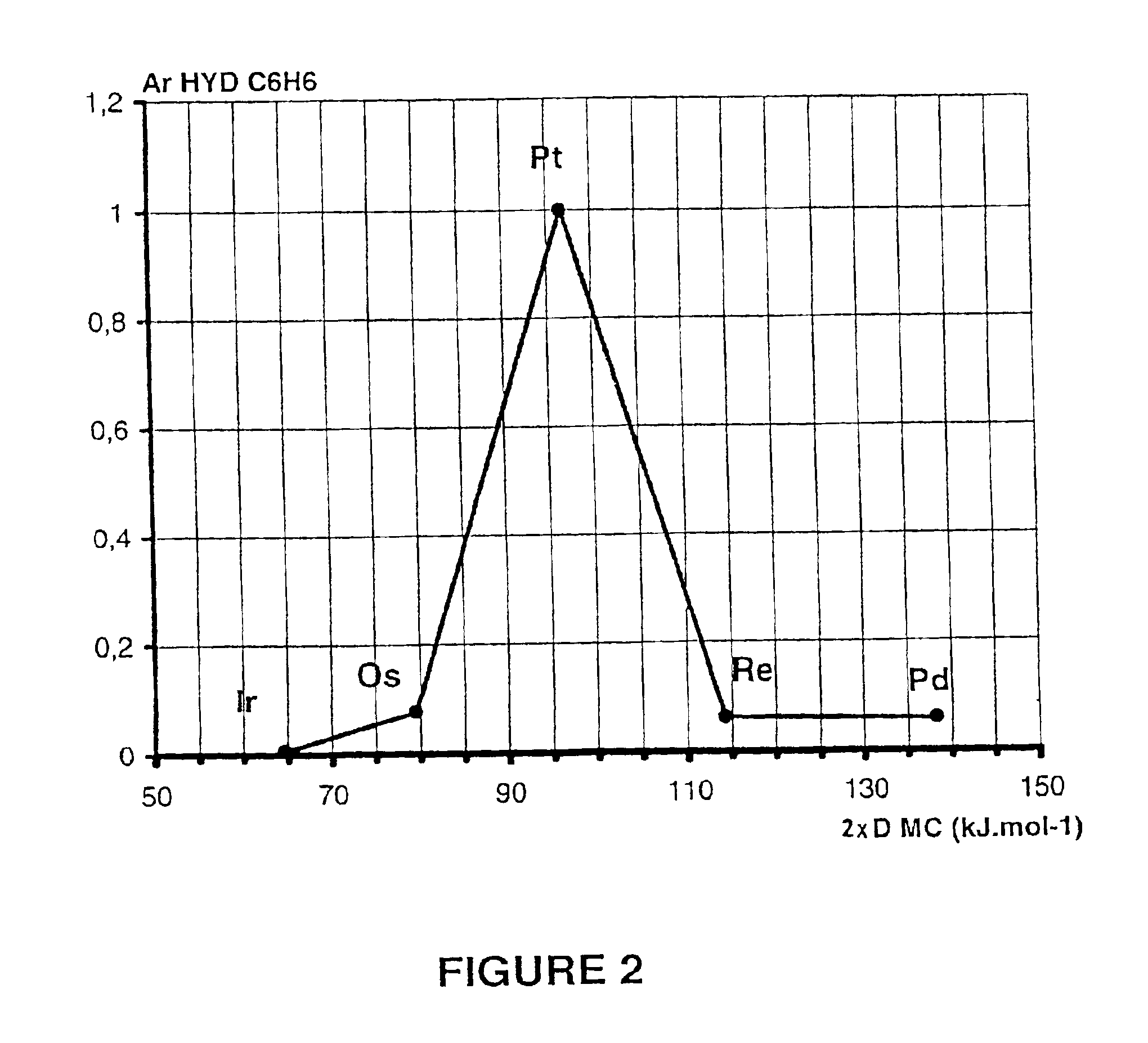

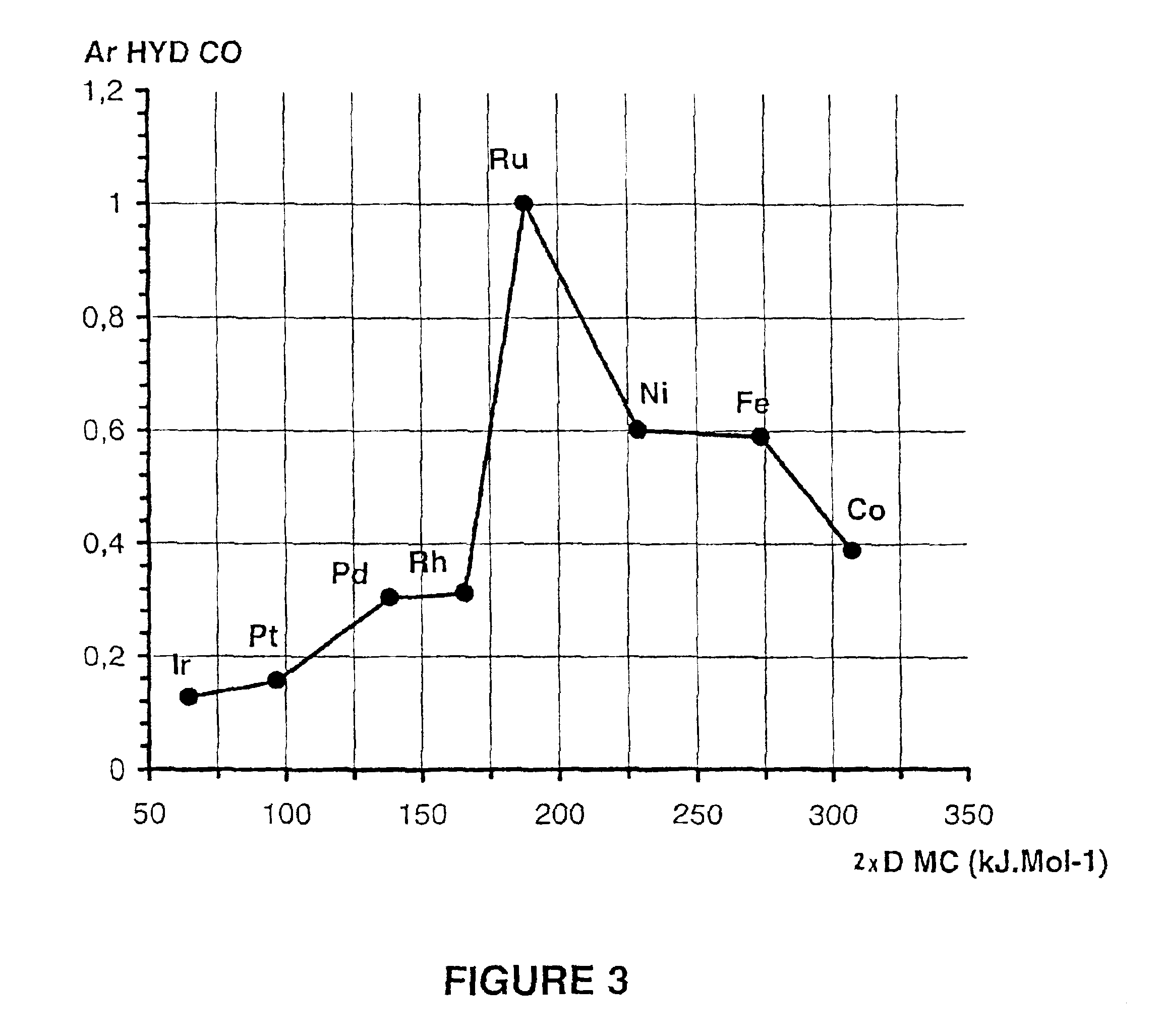

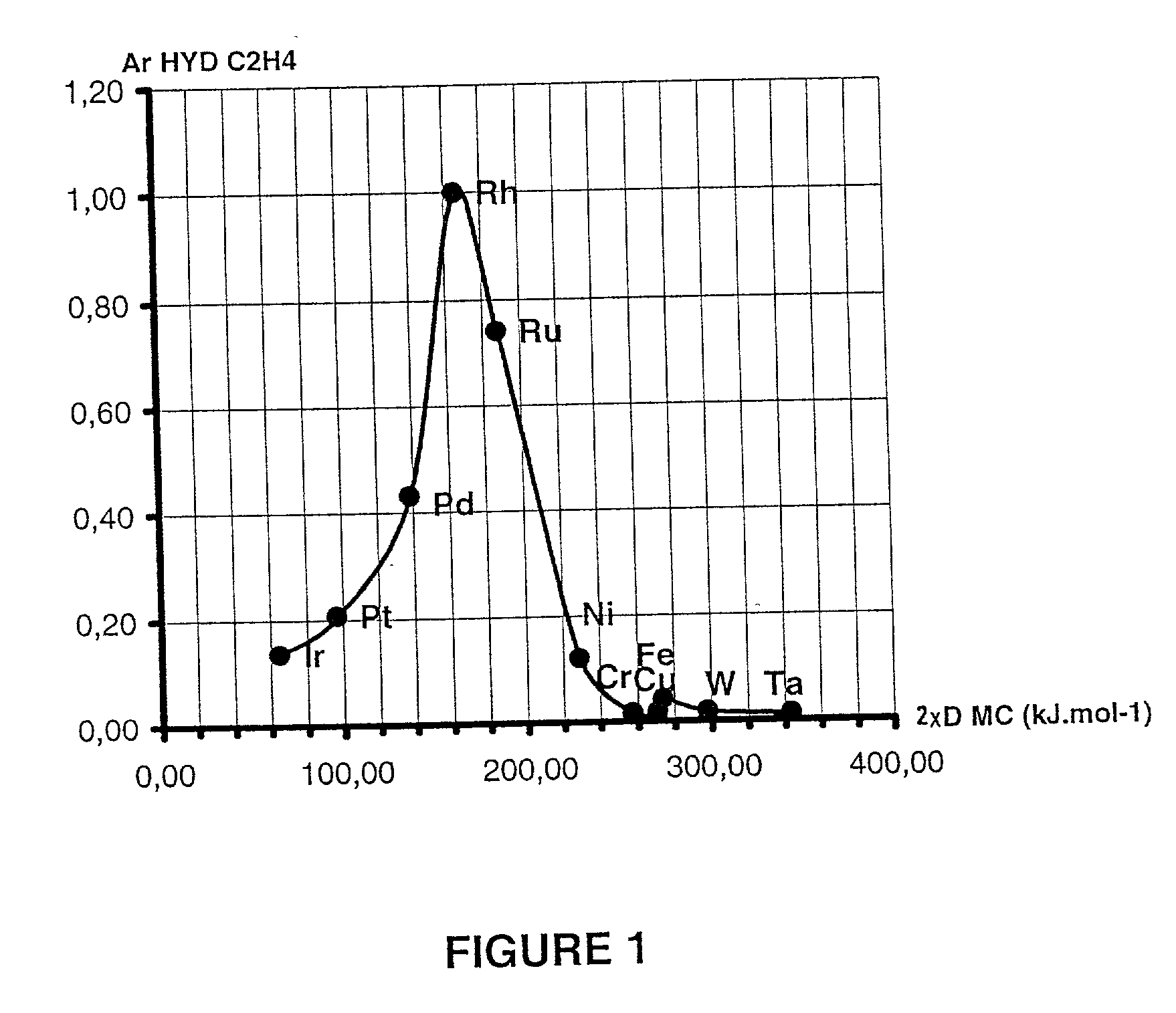

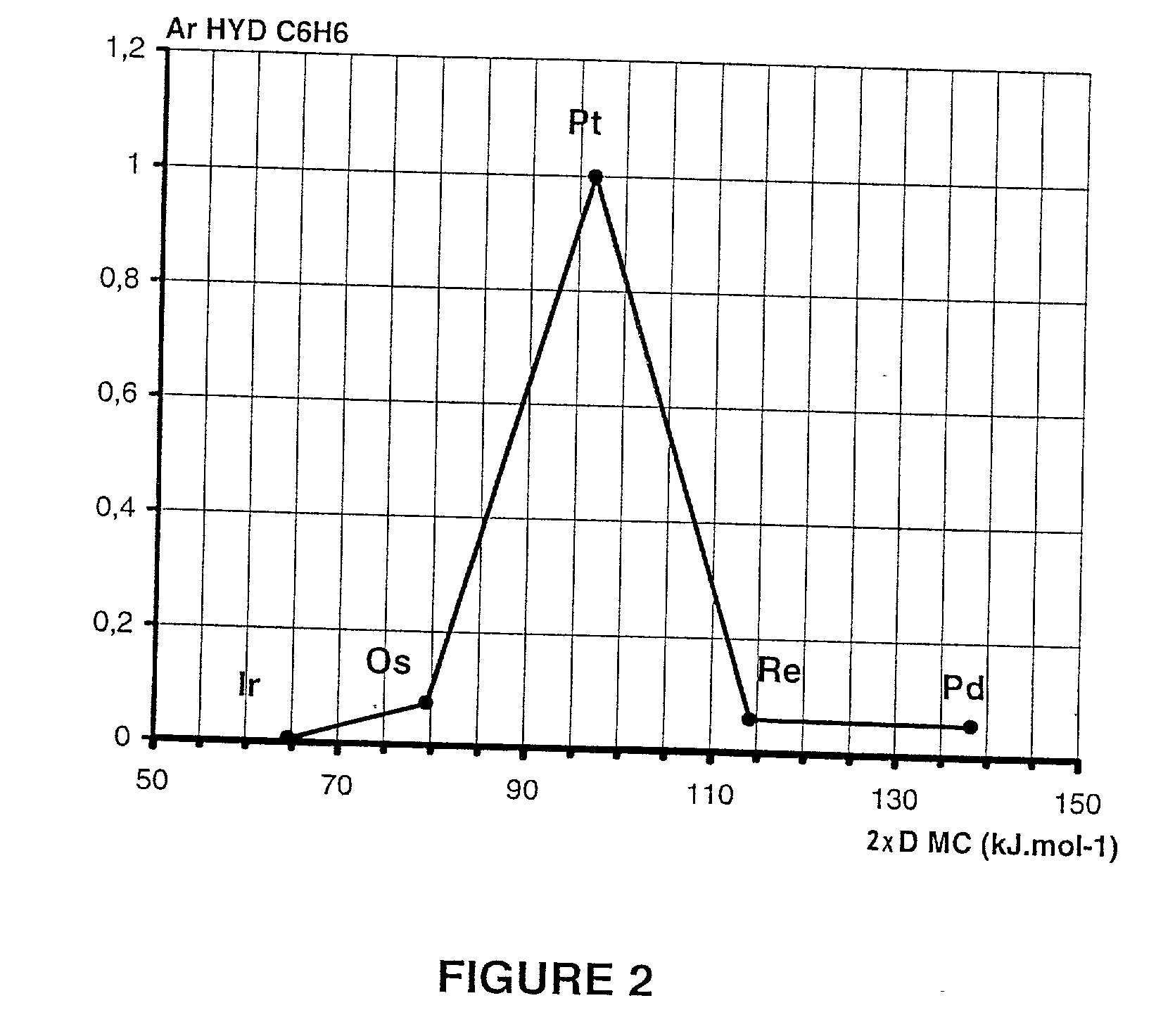

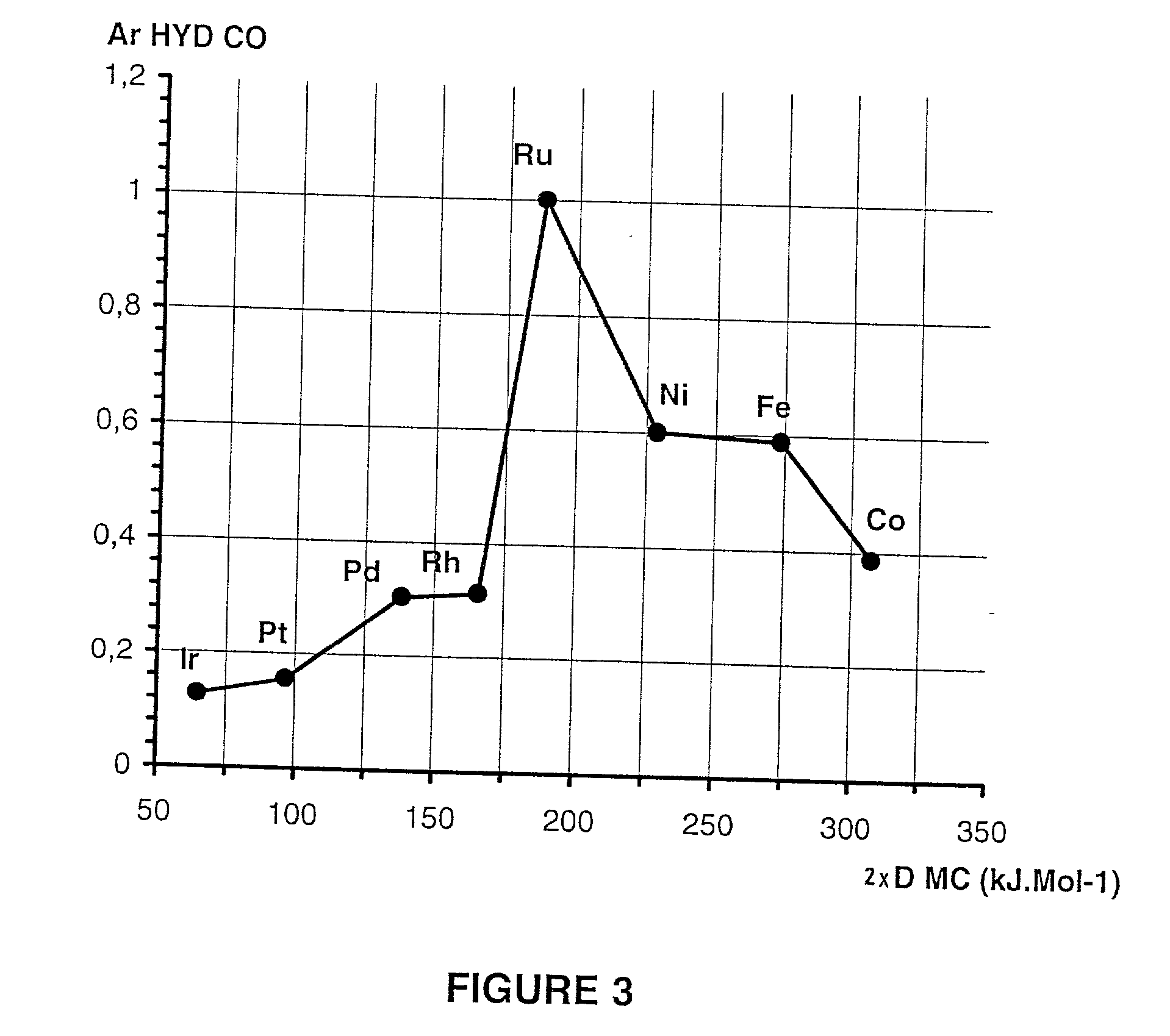

InactiveUS6799089B2Sampled-variable control systemsChemical analysis using catalysisMineral matrixNew materials

For estimating a property of use, for example the activity of a catalyst or the ability to hold a ratio-element in a solid mineral matrix, or a material MAB whose active element is AB, there are used a descriptor DAB of the chemical bond between A and B, which has the dimension of an energy, and index RAB that measures the property of use of said material. The invention also relates to a process for determining the chemical affinity of an element or a set of elements B for a matrix A with a descripor DAB. The process according to the invention advantageously can be used for the design of new materials whose use produces the formation or the modification of at least one chemical bond or makes it necessary to prevent the formation of said bond.

Owner:INST FR DU PETROLE

Method and apparatus for depositing tungsten after surface treatment to improve film characteristics

InactiveUS20050208763A1Reduce fluorine contentExpand coverageSolid-state devicesSemiconductor/solid-state device manufacturingChemical speciesNucleation

A method and system to form a refractory metal layer over a substrate includes introduction of a reductant, such as PH3 or B2H6, followed by introduction of a tungsten containing compound, such as WF6, to form a tungsten layer. It is believed that the reductant reduces the fluorine content of the tungsten layer while improving the step coverage and resistivity of the tungsten layer. It is believed that the improved characteristics of the tungsten film are attributable to the chemical affinity between the reductants and the tungsten containing compound. The chemical affinity provides better surface mobility of the adsorbed chemical species and better reduction of WF6 at the nucleation stage of the tungsten layer. The method can further include sequentially introducing a reductant, such as PH3 or B2H6, and a tungsten containing compound to deposit a tungsten layer. The formed tungsten layer can be used as a nucleation layer followed by bulk deposition of a tungsten layer utilizing standard CVD techniques. Alternatively, the formed tungsten layer can be used to fill an aperture.

Owner:APPLIED MATERIALS INC

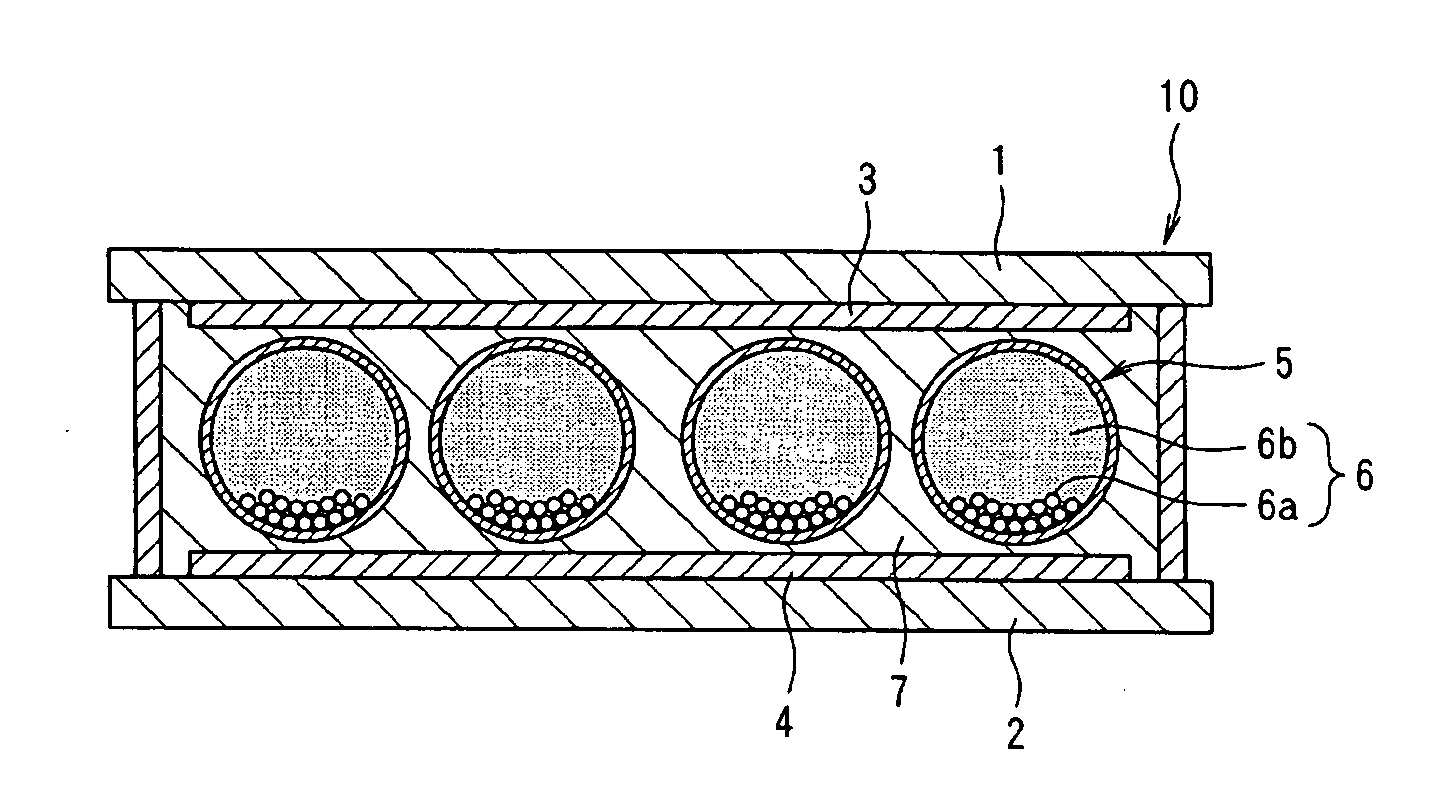

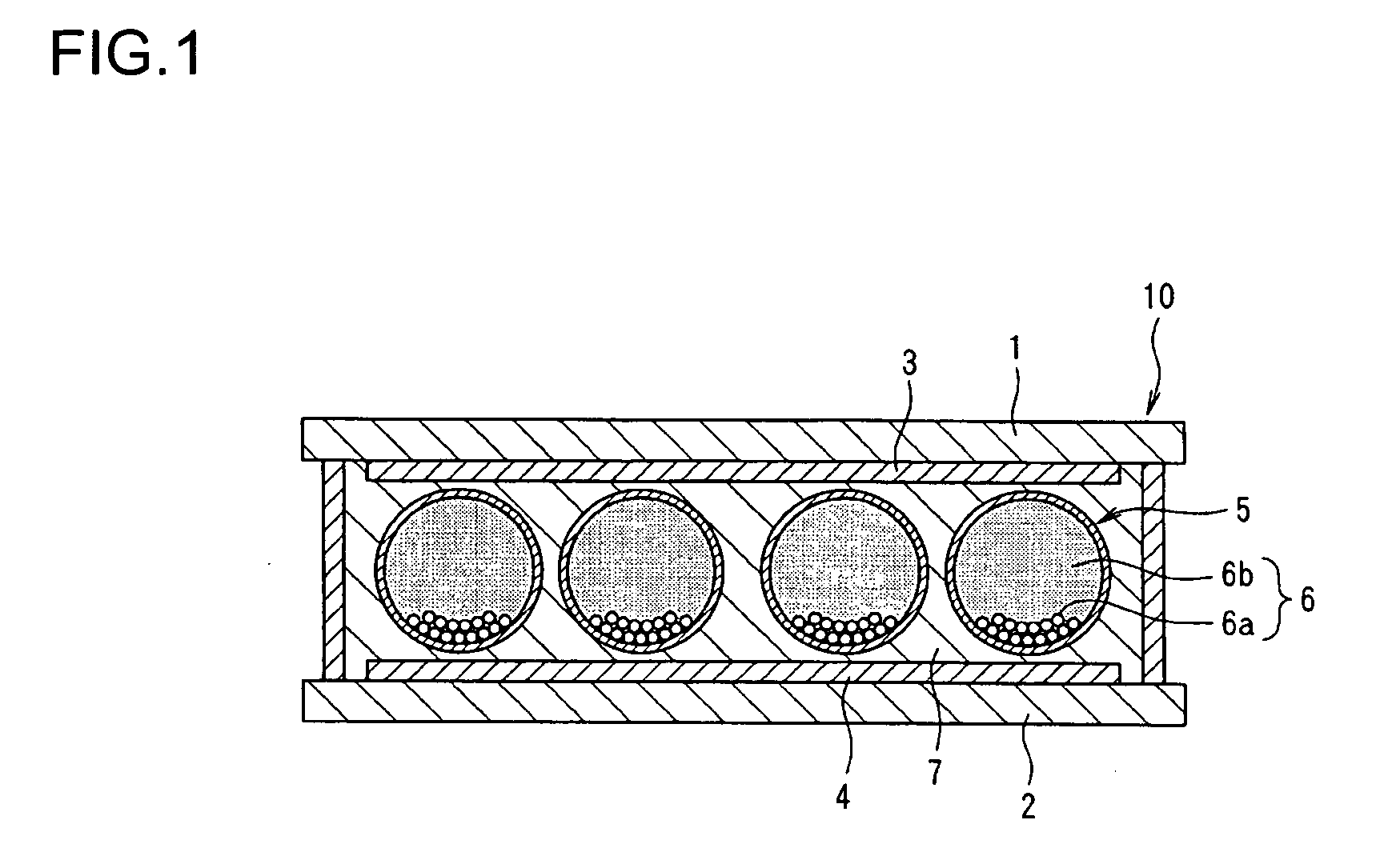

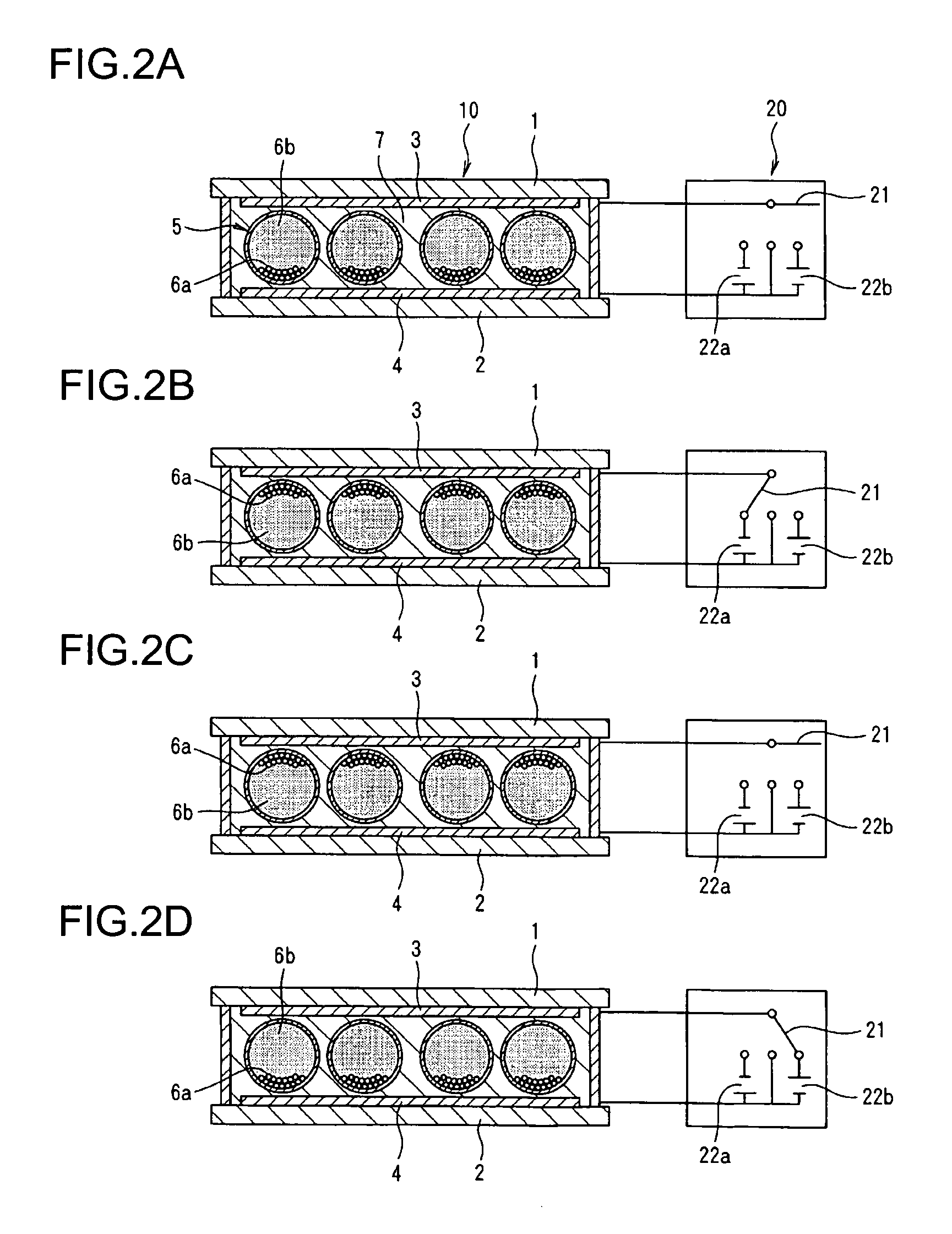

Electrophoretic apparatus and electronic equipment

ActiveUS7292386B2Maintain good propertiesImprove abilitiesStatic indicating devicesMaterial analysis by electric/magnetic meansElectrophoresisElectron

A mixture of a first material having high chemical affinity for the electrophoretic particles 6a and a second material having low chemical affinity therefor is used as a binder for fixing microcapsules 5 between a first electrode 3 and a second electrode 4.

Owner:E INK CORPORATION

Extrusion bonded laminates for absorbent articles

An absorbent article of the present invention may comprise a topsheet, an outer cover, and an absorbent core disposed therebetween. The outer cover may comprise an extrusion bonded laminate. The EBL may comprise a multi-layer coextruded elastomeric film and a nonwoven. The film may comprise a core layer, a first outer layer, and a second outer layer, wherein the core layer is between the first and second outer layers. The nonwoven may comprise fibers and / or filaments. The first outer layer may be non-adhesively joined to the nonwoven via extrusion coating. Further, the outer cover may be elastic to at least about 50% engineering strain. The nonwoven may have high chemical affinity for the first outer layer. The first outer layer may have a low chemical affinity for the core layer. And, the first outer layer may comprise an amount of draw down polymer greater than about 45 wt %.

Owner:PROCTER & GAMBLE CO

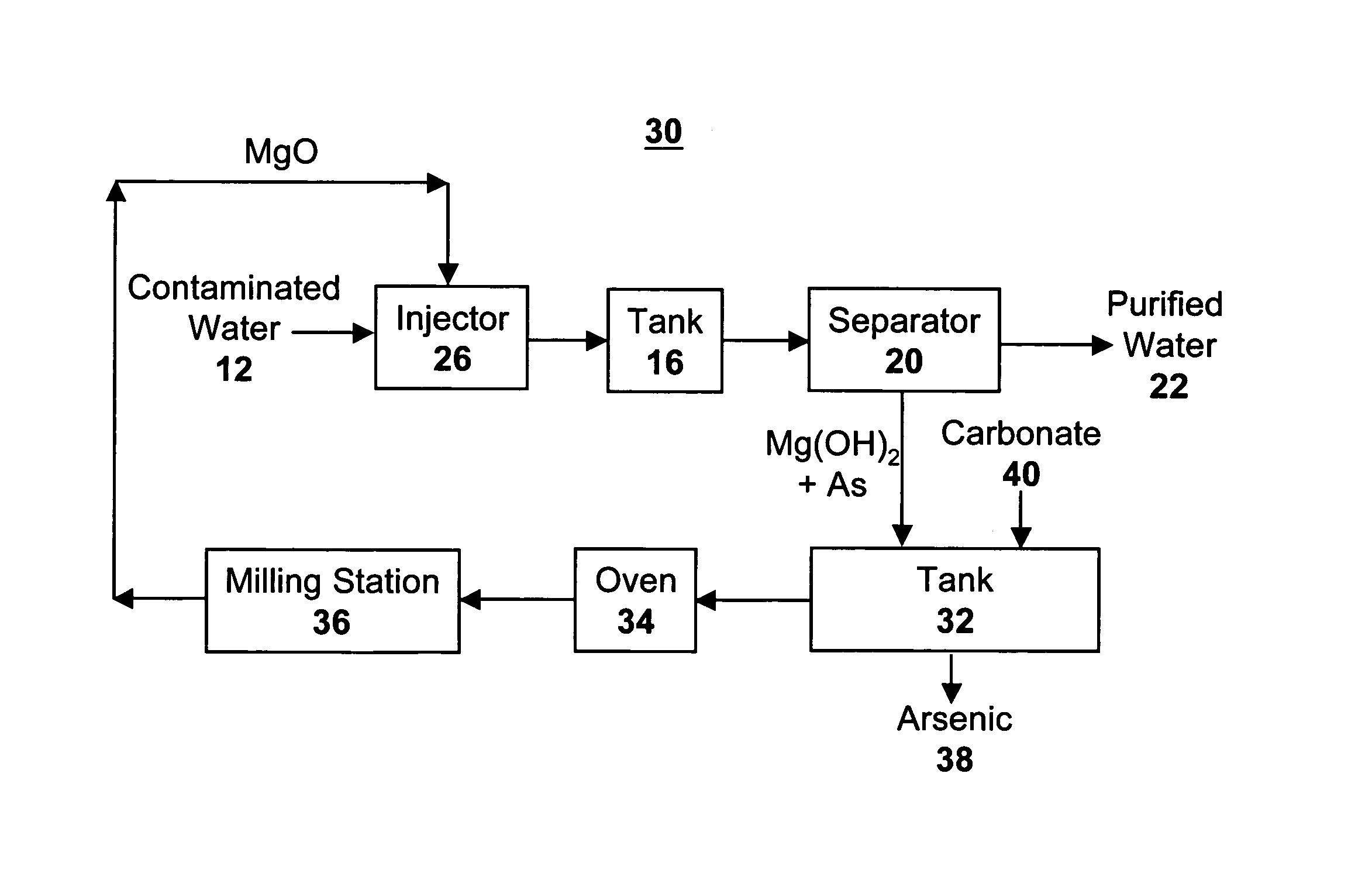

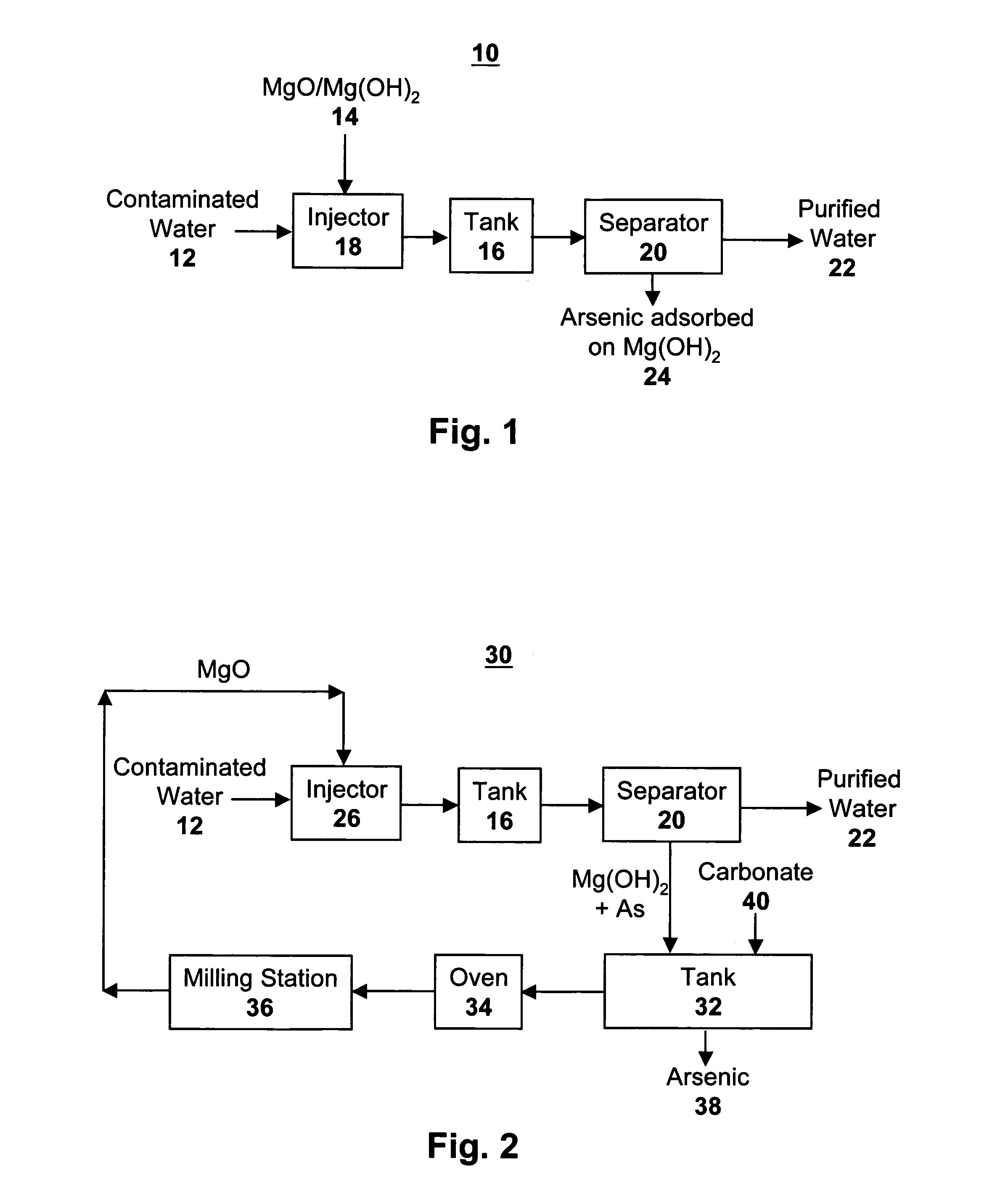

Arsenic removal from water

InactiveUS7247242B1Easy to quantifyEnhance chemical affinityIon-exchanger regenerationWater contaminantsCalcium hydroxideFiltration

Methods for removing arsenic from water by addition of inexpensive and commonly available magnesium oxide, magnesium hydroxide, calcium oxide, or calcium hydroxide to the water. The hydroxide has a strong chemical affinity for arsenic and rapidly adsorbs arsenic, even in the presence of carbonate in the water. Simple and commercially available mechanical methods for removal of magnesium hydroxide particles with adsorbed arsenic from drinking water can be used, including filtration, dissolved air flotation, vortex separation, or centrifugal separation. A method for continuous removal of arsenic from water is provided. Also provided is a method for concentrating arsenic in a water sample to facilitate quantification of arsenic, by means of magnesium or calcium hydroxide adsorption.

Owner:SANDIA NAT LAB

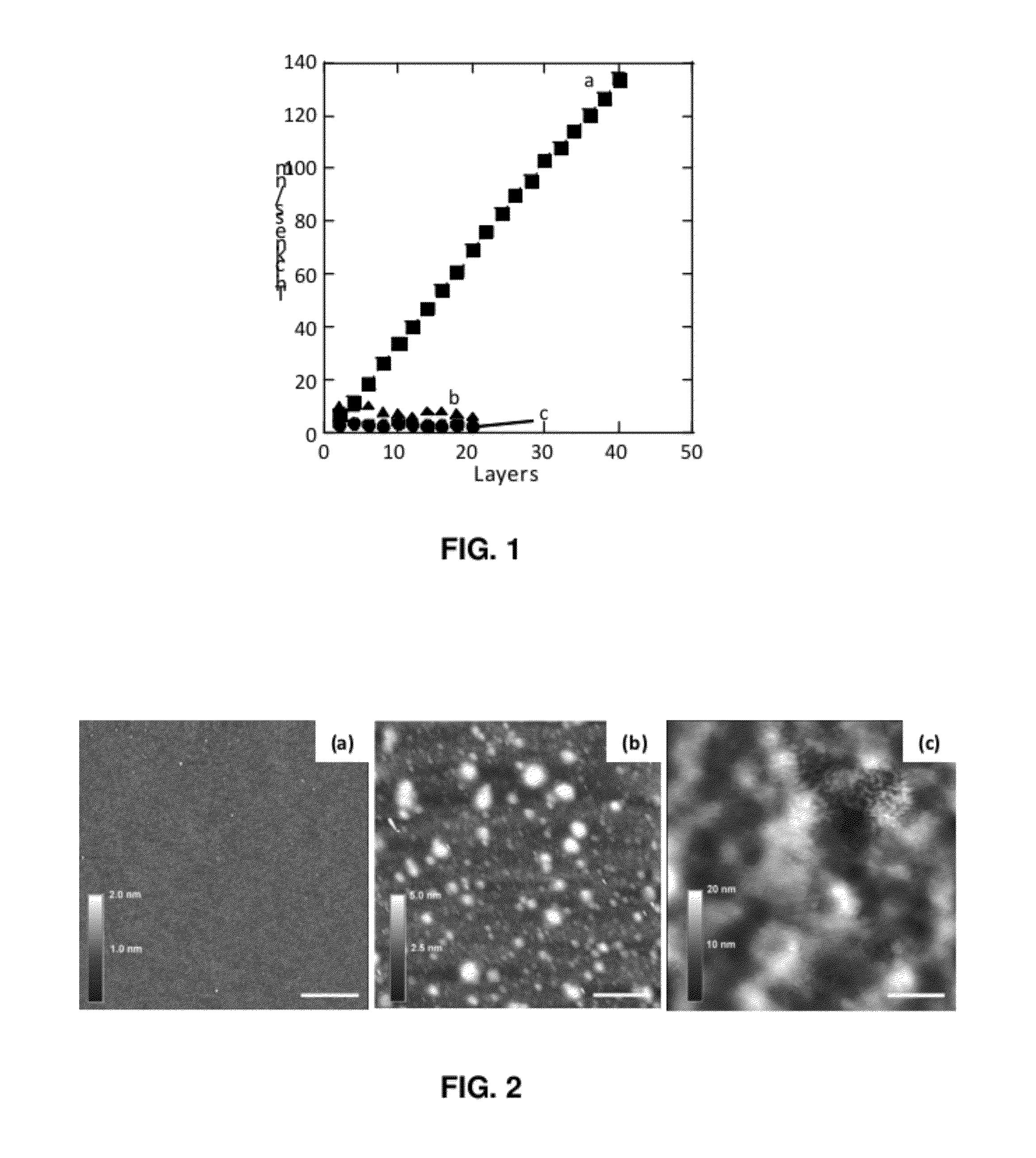

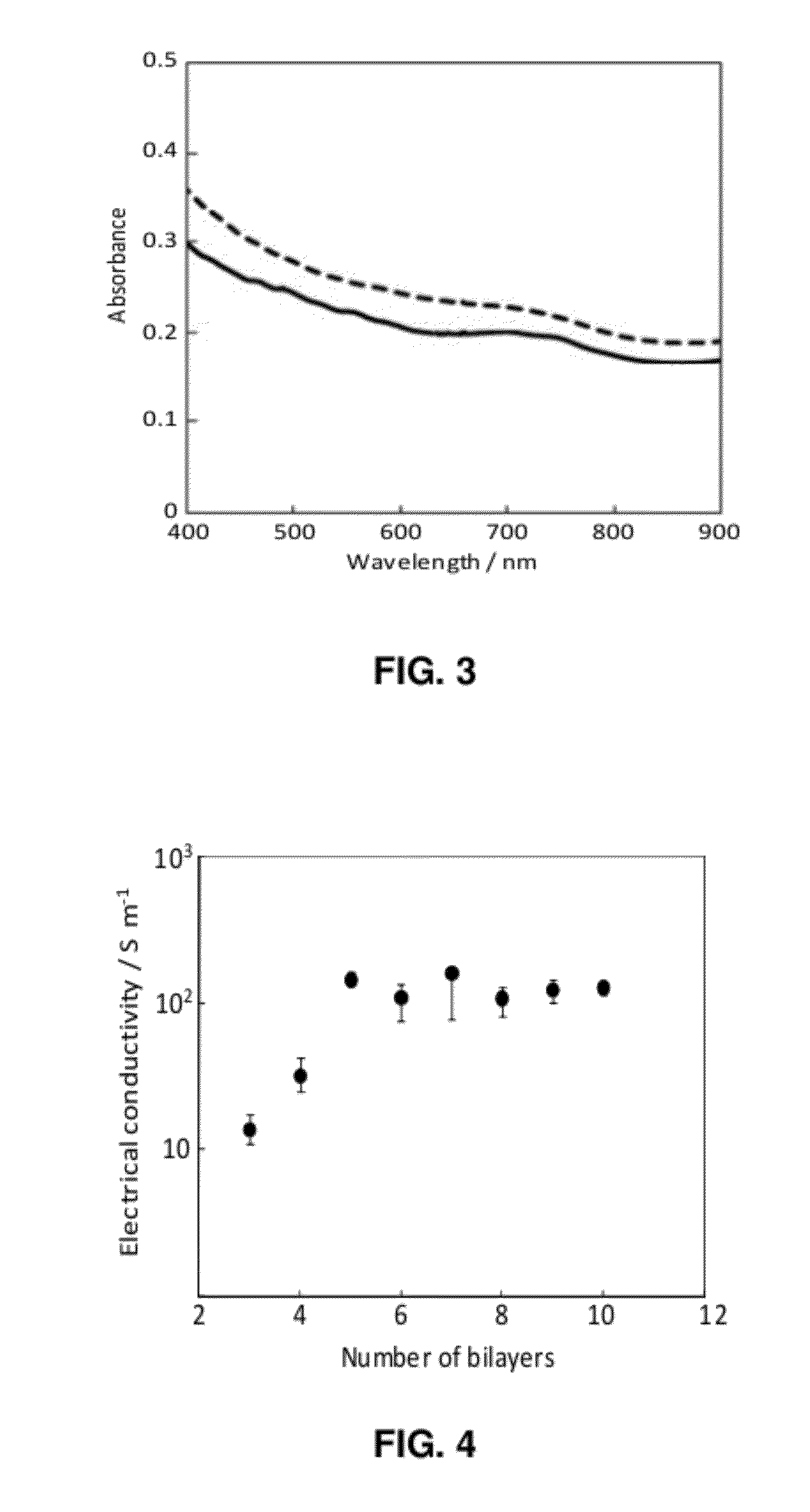

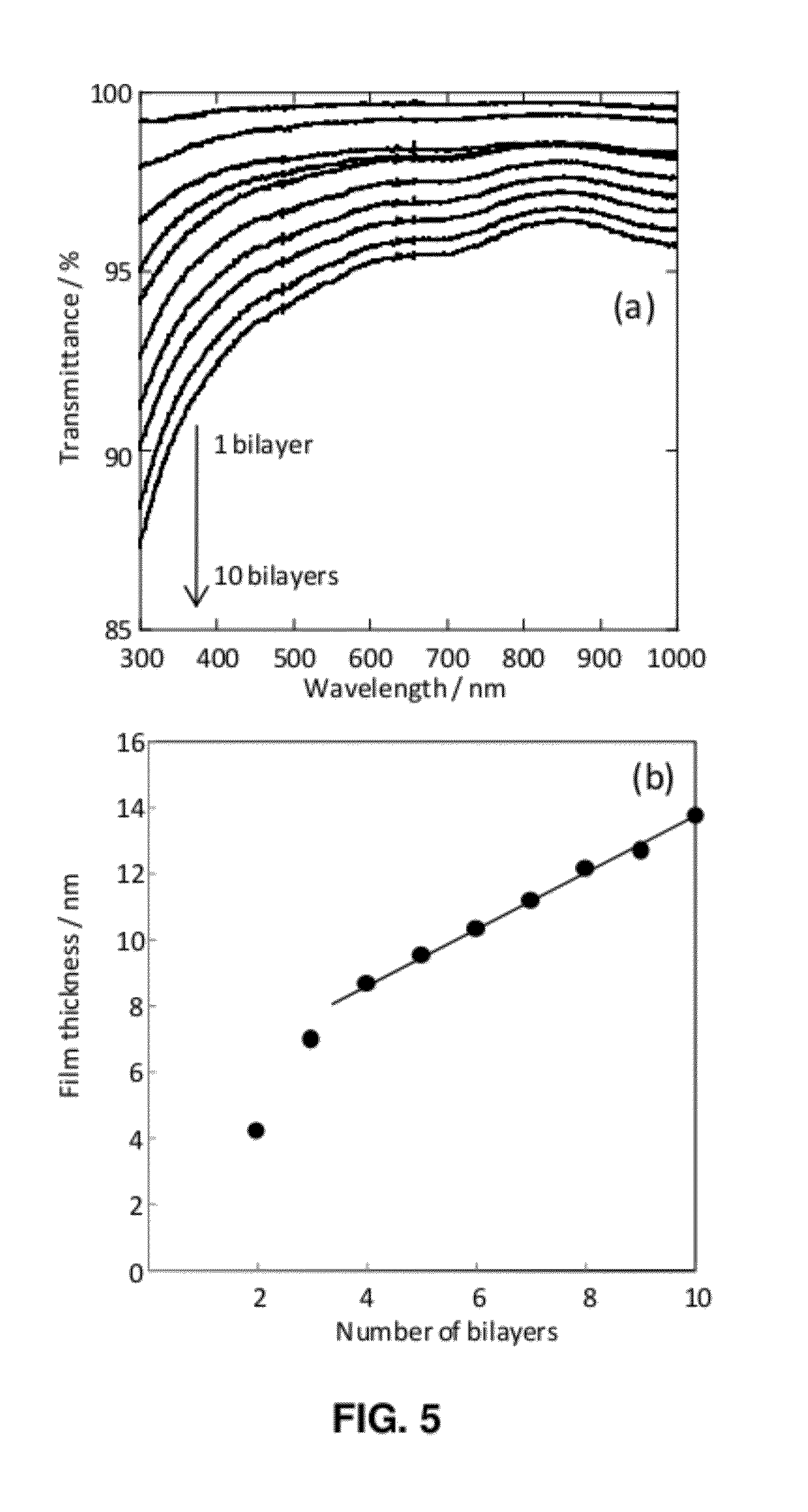

Preparation of layer-by-layer materials and coatings from ionic liquids

ActiveUS20120156389A1High strengthModerate extensibilityMaterial nanotechnologyPretreated surfacesPolyelectrolyteCarbon nanotube

A method for making a layered material can include providing a substrate having a surface with at least one region having a charge and forming layers by sequentially contacting the at least one region with a first solution and a second solution. The first solution comprises a first layering material in an ionic liquid and the second solution comprises a second layering material in a second ionic solution. The first and second layering materials can have a chemical affinity to each other. The first layering material and / or the second layering material can include polyelectrolytes, polymers, carbon nanotubes, or combinations thereof.

Owner:RGT UNIV OF MICHIGAN

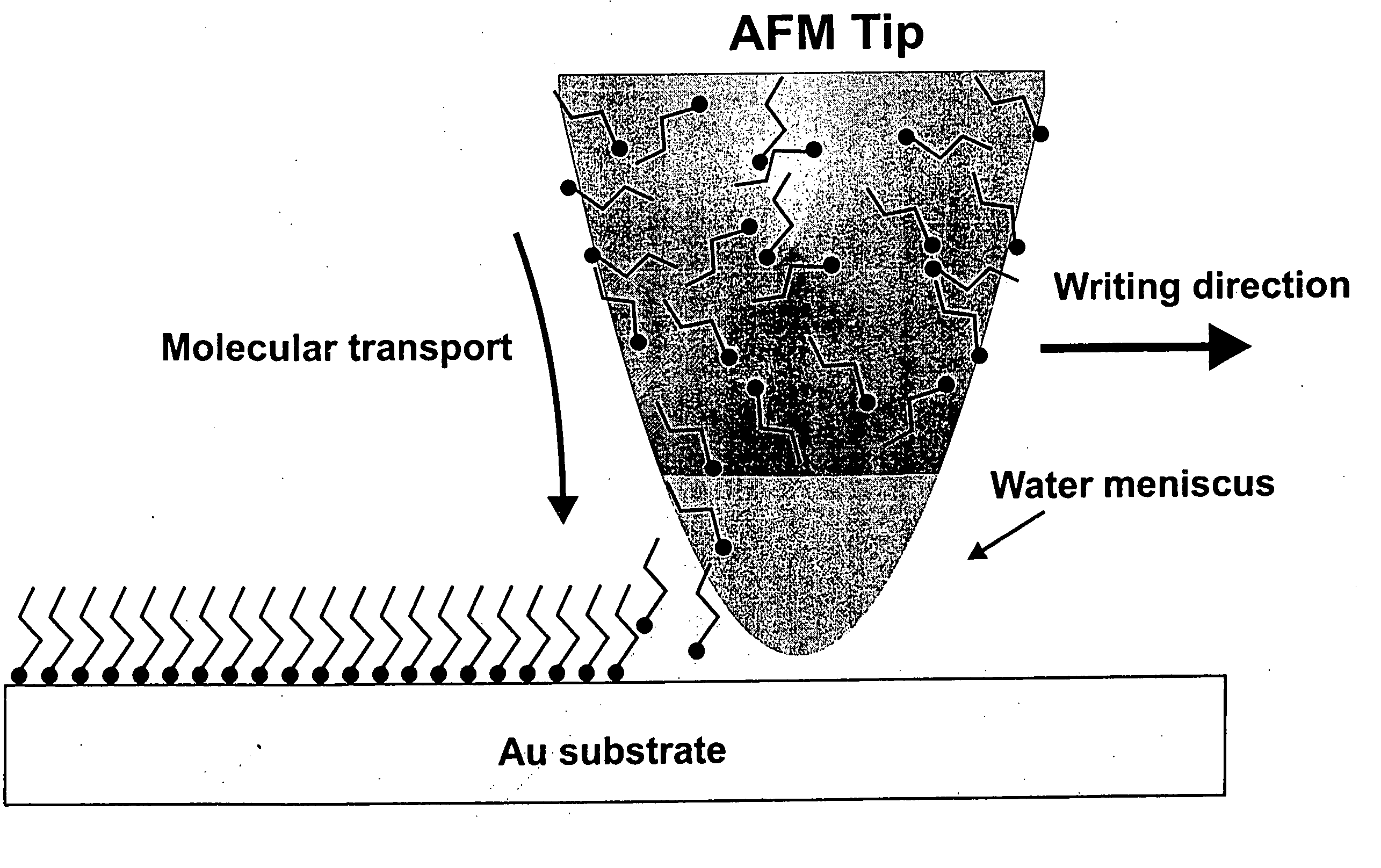

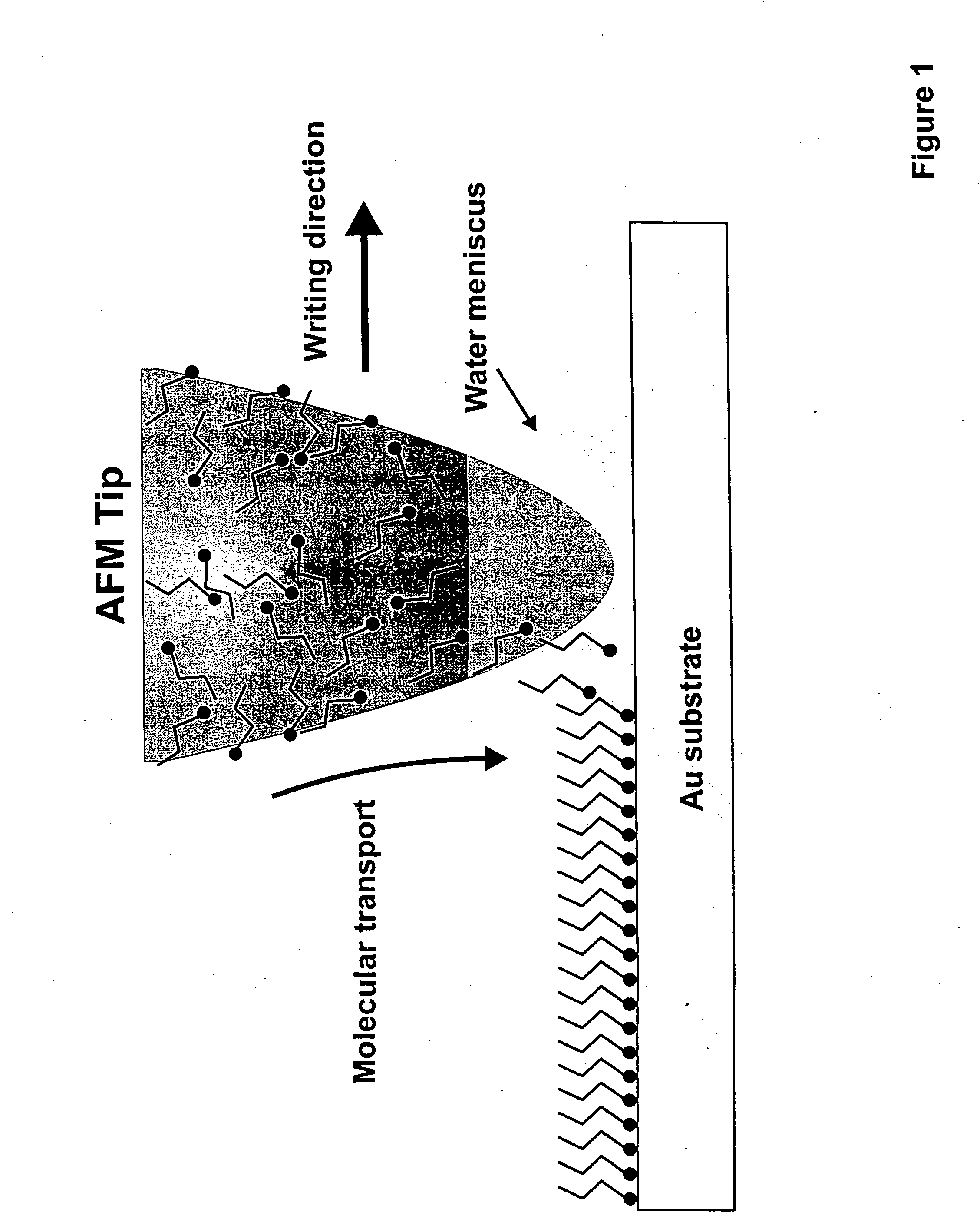

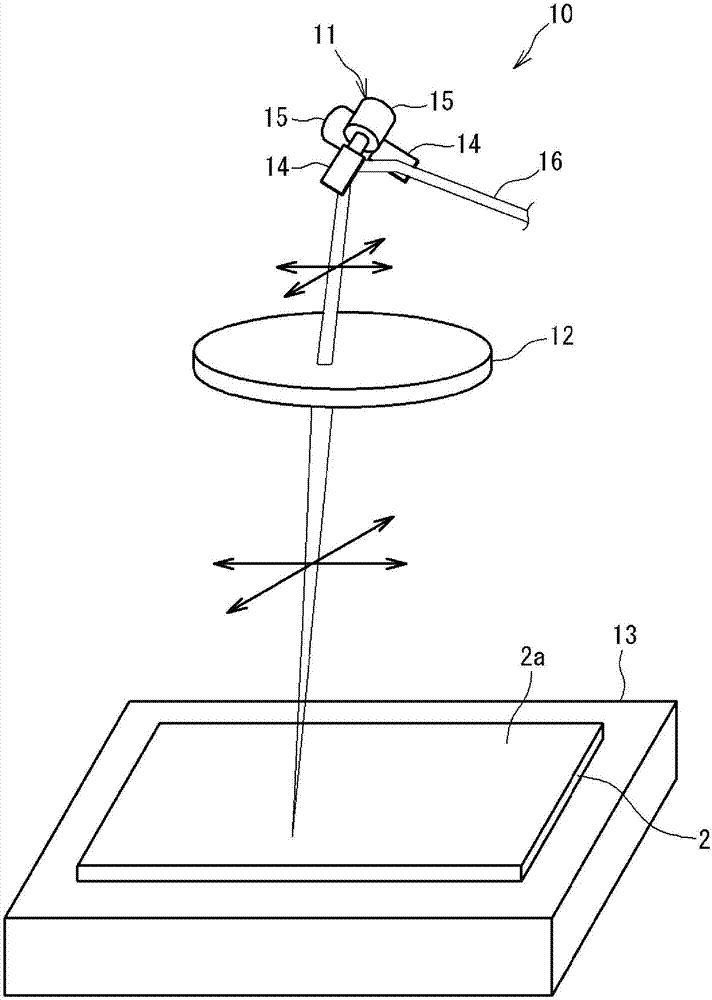

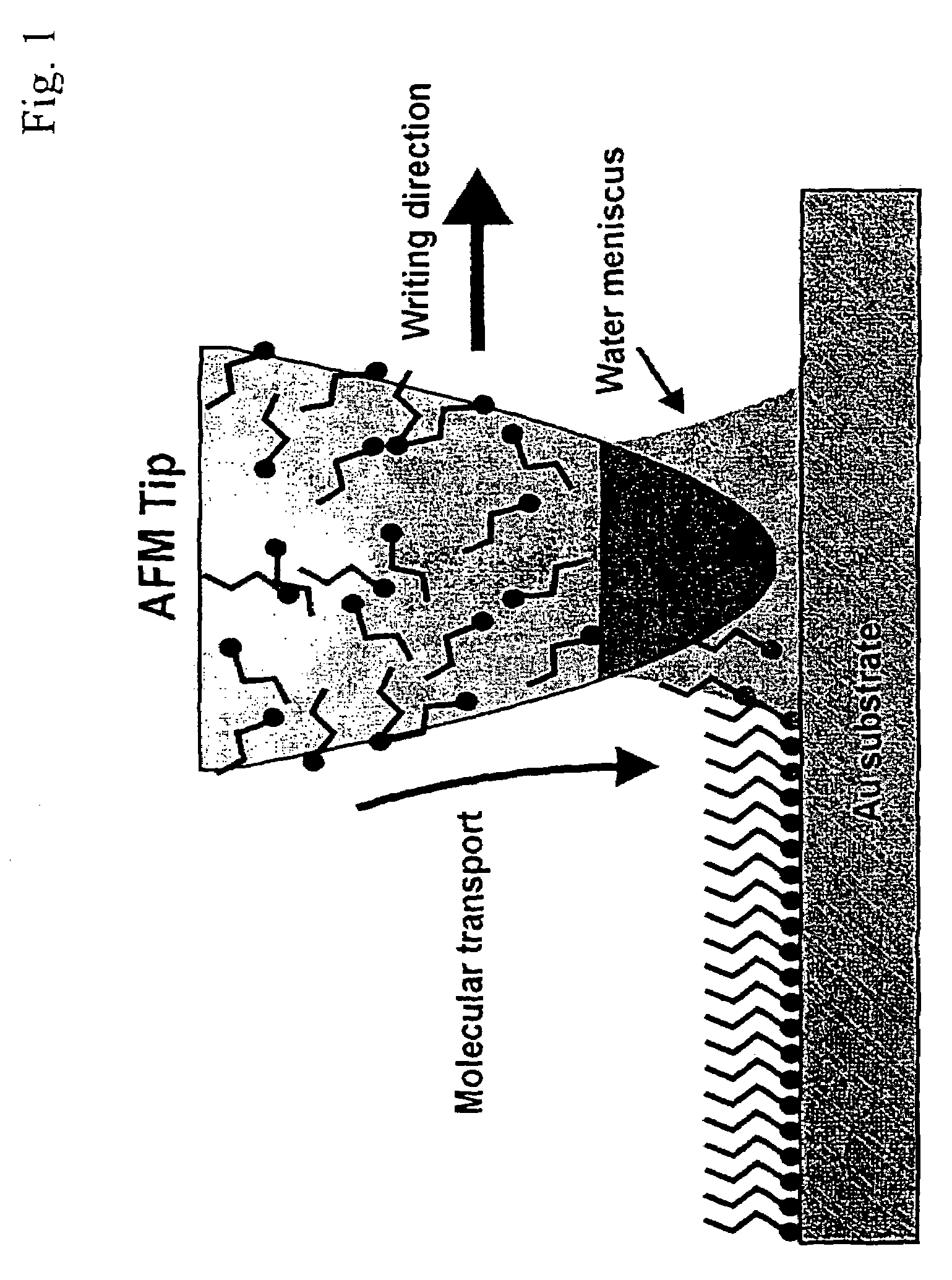

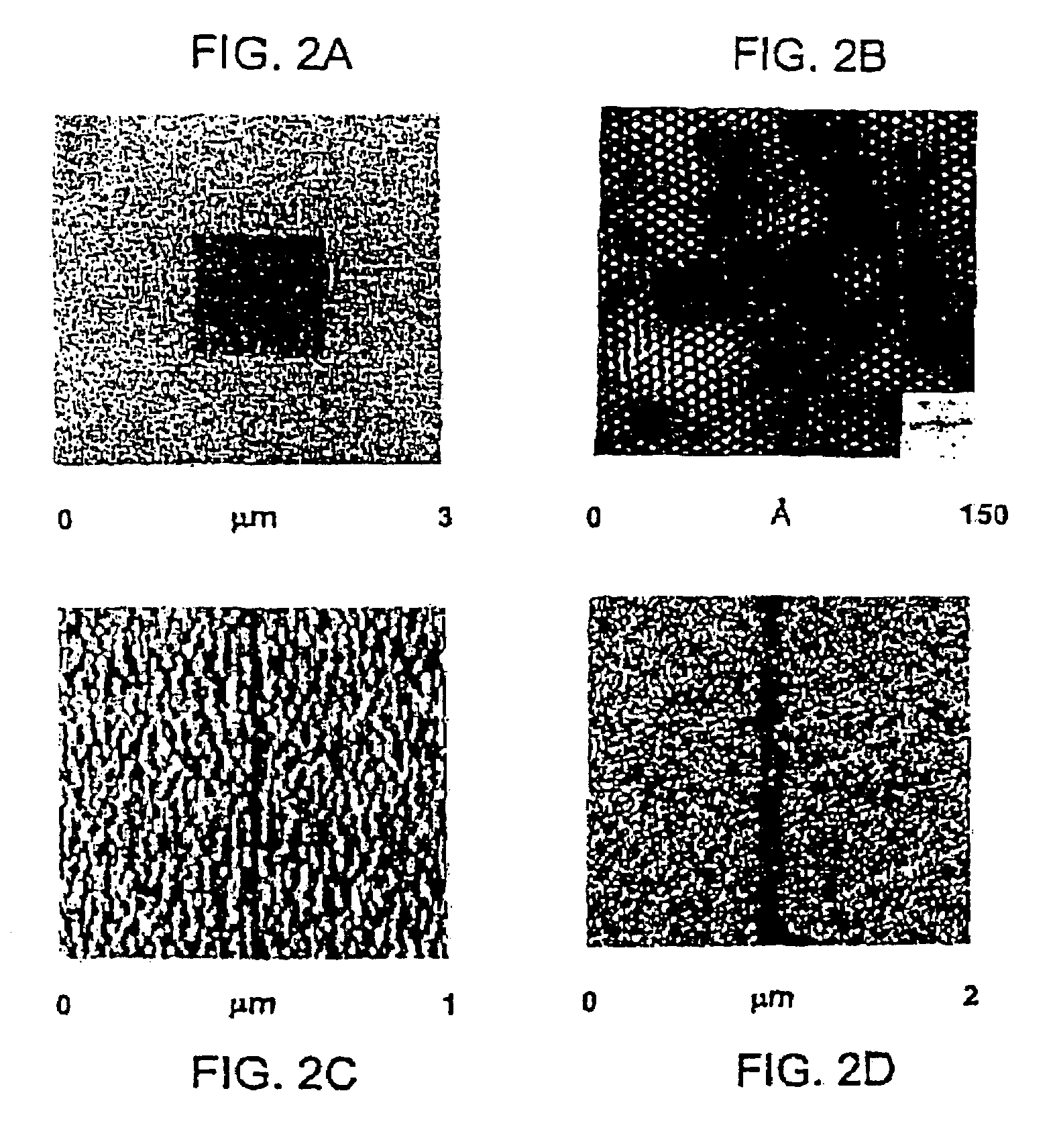

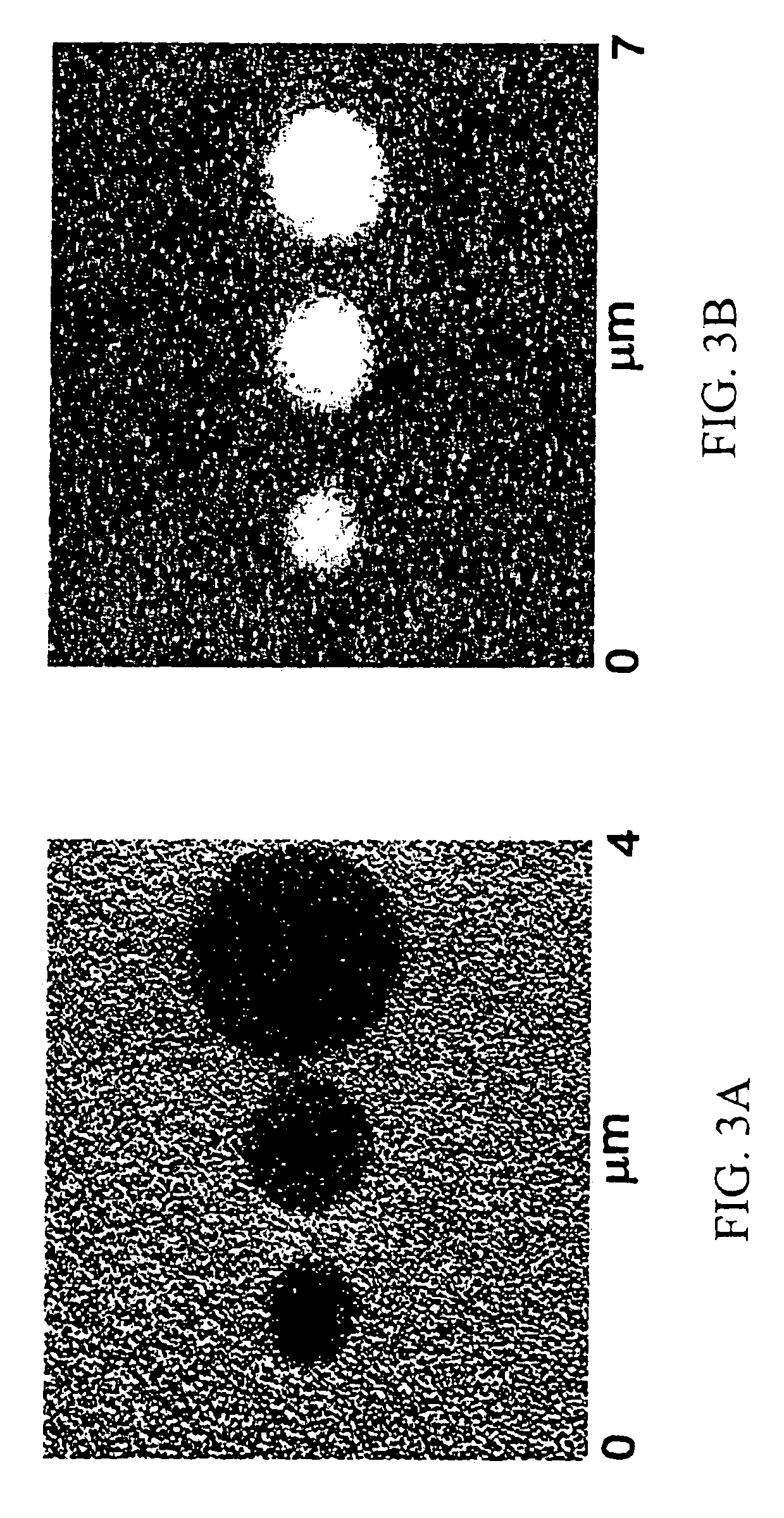

Methods utilizing scanning probe microscope tips and products therefor or produced thereby

The invention provides a lithographic method referred to as “dip pen” nanolithography (DPN). DPN utilizes a scanning probe microscope (SPM) tip (e.g., an atomic force microscope (AFM) tip) as a “pen,” a solid-state substrate (e.g., gold) as “paper,” and molecules with a chemical affinity for the solid-state substratte as “ink.” Capillary transport of molecules from the SPM tip to thee solid substrate is used in DPN to directly write patterns consisting of a relatively small collection of molecules in submicrometer dimensions, making DPN useful in the facrication of a variety of microscale and nanoscale devices. The invention also provices substrates patterened by DPN, including submirocmeter combinatorial arrays, and kits, devices and software for performing DPN. The invention further provides a method of performing AFM imaging in air. The method comprises coating an AFM tip with a hydrophobic compound, the hydrophobic compoind being selected so that AFM imaging perfromed using the coated AFM tipn is improved compared to AFM imaging preformed using an uncoated AFM tip. Finally, the invention provides AFM tips coated with the hydrophobic compounds.

Owner:NORTHWESTERN UNIV

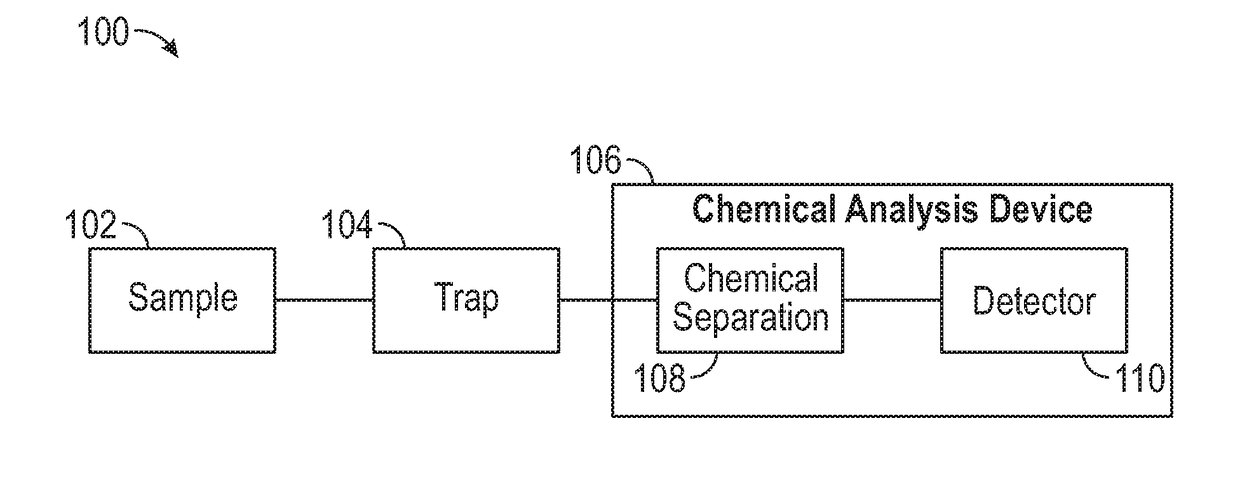

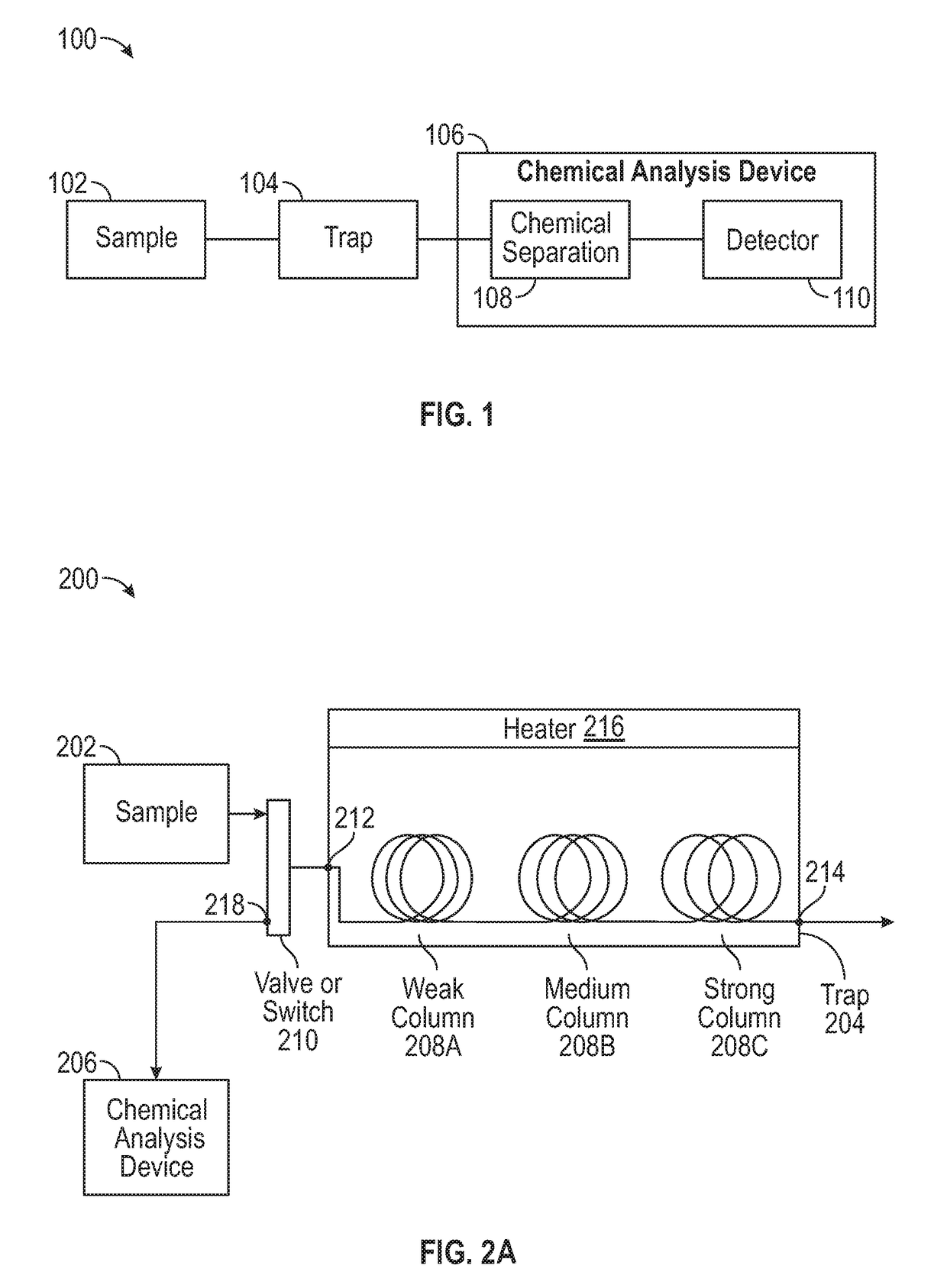

Multi-Capillary Column Pre-Concentration System for Enhanced Sensitivity in Gas Chromatography (GC) and Gas Chromatography-Mass Spectrometry (GCMS)

ActiveUS20170284978A1High strengthHigh affinityComponent separationPreparing sample for investigationGas chromatography–mass spectrometryMass chromatography

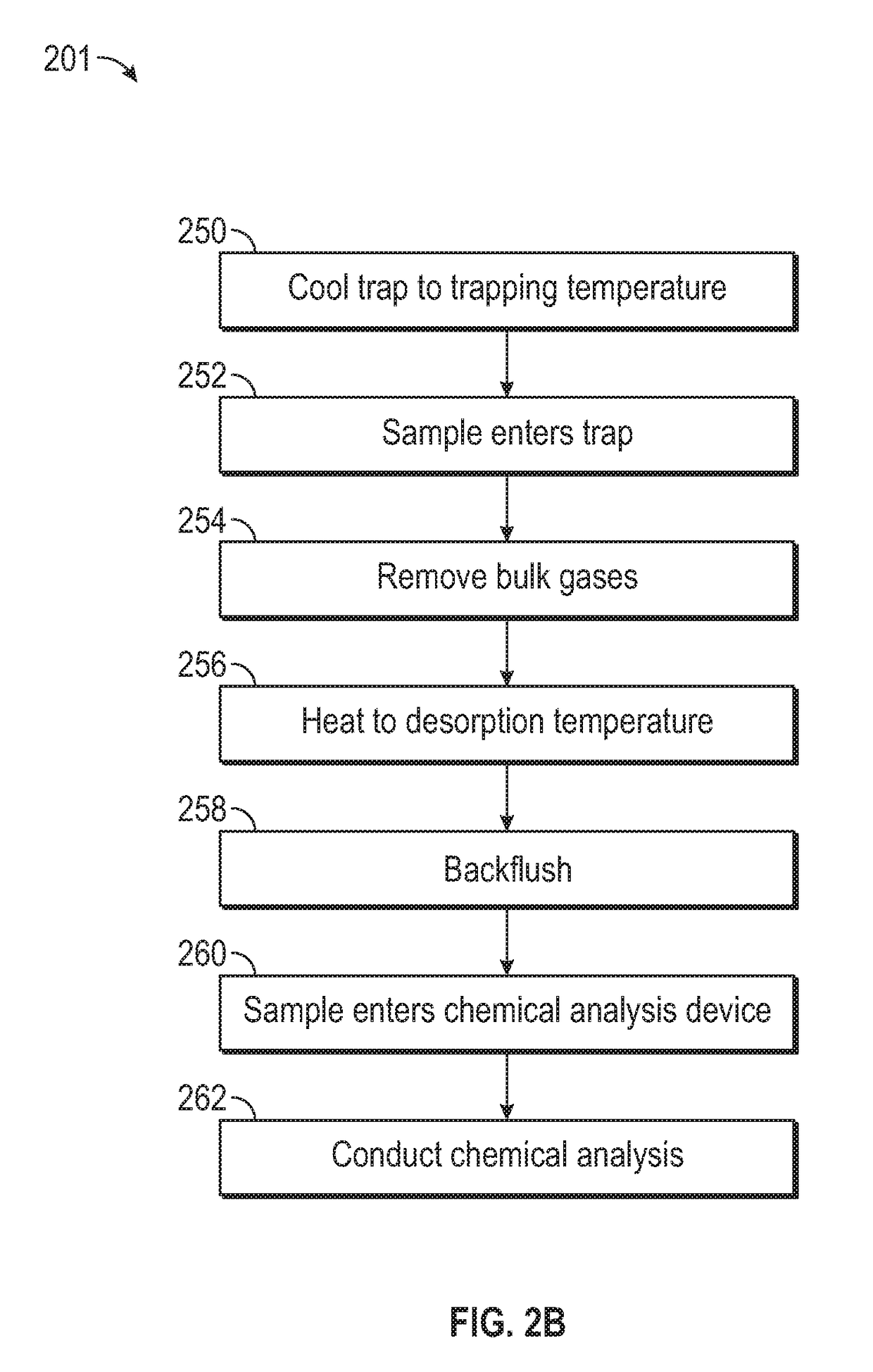

A multi-capillary column pre-concentration trap for use in various chromatography techniques (e.g., gas chromatography (GC) or gas chromatography-mass spectrometry (GCMS)) is disclosed. In some examples, the trap can include a plurality of capillary columns connected in series in order of increasing strength (i.e., increasing chemical affinity for one or more sample compounds). A sample can enter the trap, flowing from a sample vial to a relatively weak column to the relatively strongest column of the trap by way of any additional columns included in the trap, for example. In some examples, the trap can be heated and backflushed so that the sample exits the trap through the head of the relatively weak column. Next, the sample can be injected into a chemical analysis device for performing the chromatography technique (e.g., GC or GCMS) or it can be injected into a secondary multi-capillary column trap for further concentration.

Owner:ENTECH INSTR INC

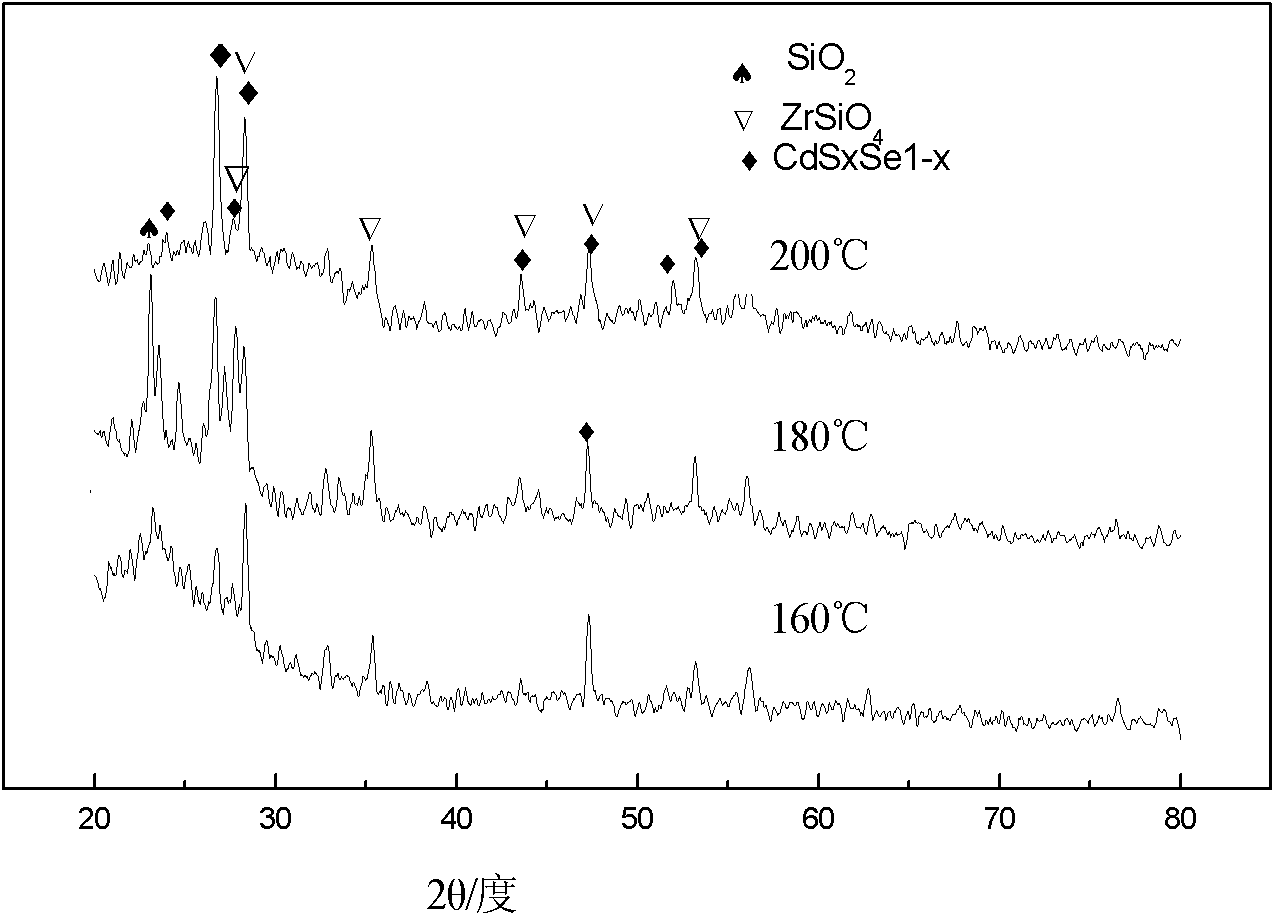

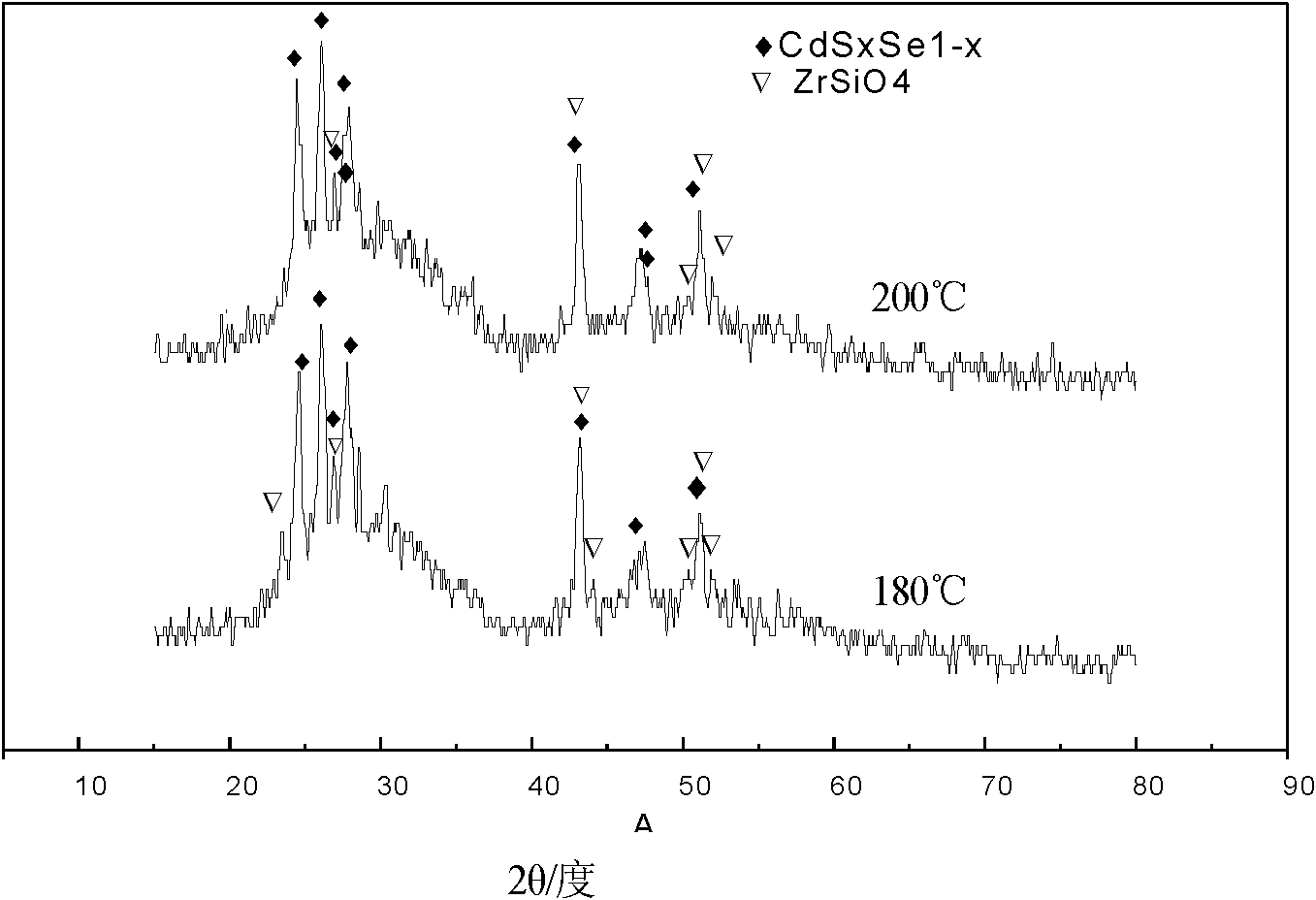

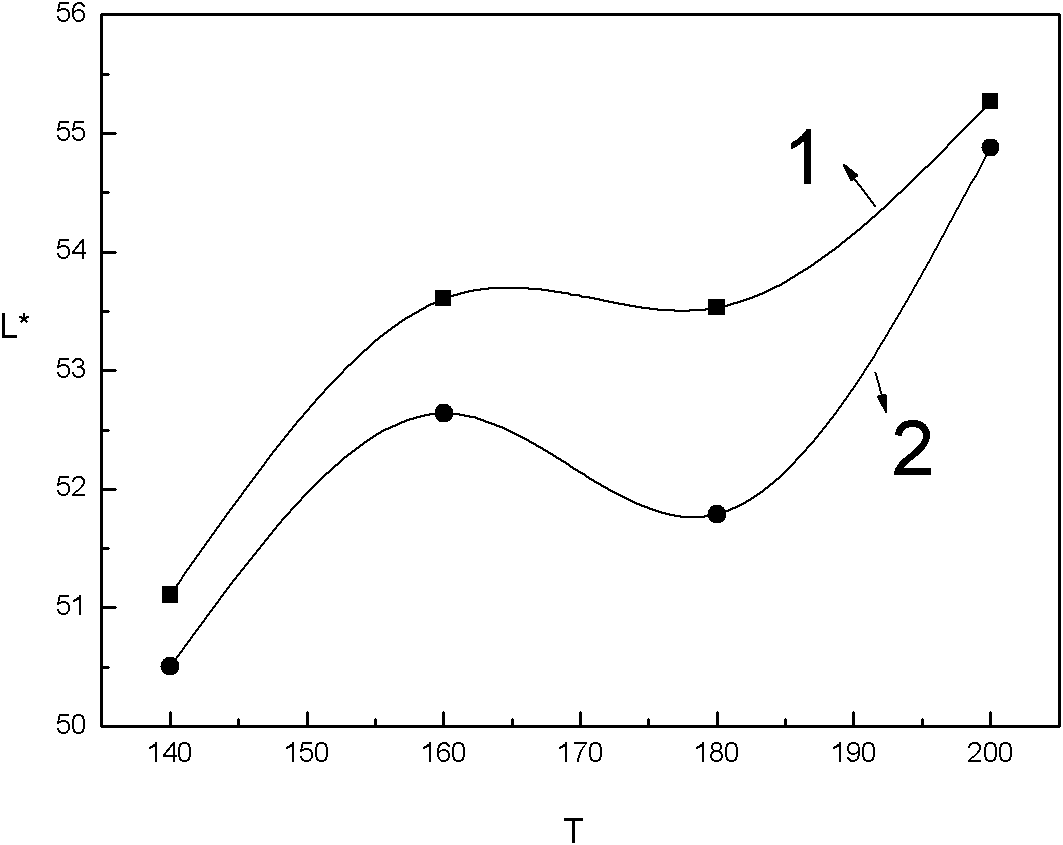

Preparation method for extended red ZrSiO_4-Cd (S_xSe_(1-x)) pigment

InactiveCN101786902ALower crystallization activation energyImproved chemical affinityRare-earth elementChemical reaction

The invention relates to a preparation method for an extended red ZrSiO_4-Cd(S_xSe_(1-x)) pigment.When a presoma is prepared by utilizing a collosol coprecipitation method, a developing body is generated in a solution and rare-earth elements are introduced for being mixed with a colorant, thereby changing the surface activity thereof, improving the chemical affinity of the developing body and a coating, and facilitating the cladding of the presoma to the developing body; microwave hydro-thermal treatment is carried out on the presoma of the ZrSiO_4-Cd(S_xSe_(1-x)) pigment by utilizing a microwave hydro-thermal method to accelerate chemical reactions of the system; ceramic pigment crystals are dissolved out at first, and then the conditions are changed so as to dissolve out inclusion crystals by taking the firstly dissolved crystal as nucluting agent; a transitional face can be generated by materials formed by the rare-earth elements and a mineralizer in the reaction system, ludox and zirconium sol in the forming process of zirconium silicate, the crystallization activation energy of the zirconium silicate can be decreased, the crystallization speed of the zirconium silicate can bequickened, the zirconium silicate can be devitrified in shorter time and the densifying of the zirconium silicate inclusion can be ensured, thereby achieving the purpose of coating the pigment.

Owner:SHAANXI UNIV OF SCI & TECH

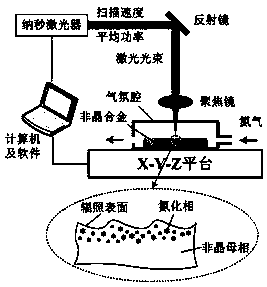

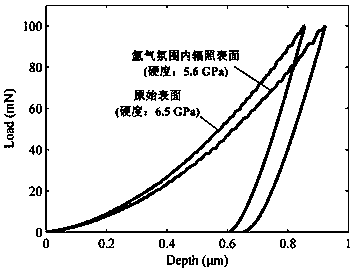

Method for improving zirconium-based or titanium-based amorphous alloy surface hardness through laser irradiation in nitrogen

ActiveCN108546893AHigh hardnessSolve the problem of significant reduction in surface hardnessSolid state diffusion coatingNanosecond laserNitrogen atmosphere

The invention relates to a method for improving zirconium-based or titanium-based amorphous alloy surface hardness through laser irradiation in nitrogen, and belongs to the technical field of amorphous alloy surface modification. Chemical affinity of the zirconium or titanium element and the nitrogen element under the high temperature or other conditions is used, nanosecond laser irradiation is carried out on the zirconium-based or titanium-based amorphous alloy surface in the nitrogen atmosphere, a nitriding phase (zirconium nitride or titanium nitride) is led into an amorphous parent phase of the surface of a zirconium-based or titanium-based amorphous alloy, and the surface hardness of the zirconium-based or titanium-based amorphous alloy is improved. The method effectively solves the problem that when the amorphous alloy surface is treated through an existing laser irradiation method, the surface hardness of the amorphous alloy is obviously reduced. Laser irradiation parameters arechanged, so that regulation and control of the content of the nitriding phase on the amorphous alloy surface are conveniently achieved, and regulation and control of the zirconium-based or titanium-based amorphous alloy surface hardness are achieved. The method is simple in implementation process, high in efficiency and high in practicability, the method can be used for regulating and controllingthe zirconium-based or titanium-based amorphous alloy surface hardness, and function application of the zirconium-based or titanium-based amorphous alloy is strengthened.

Owner:JILIN UNIV

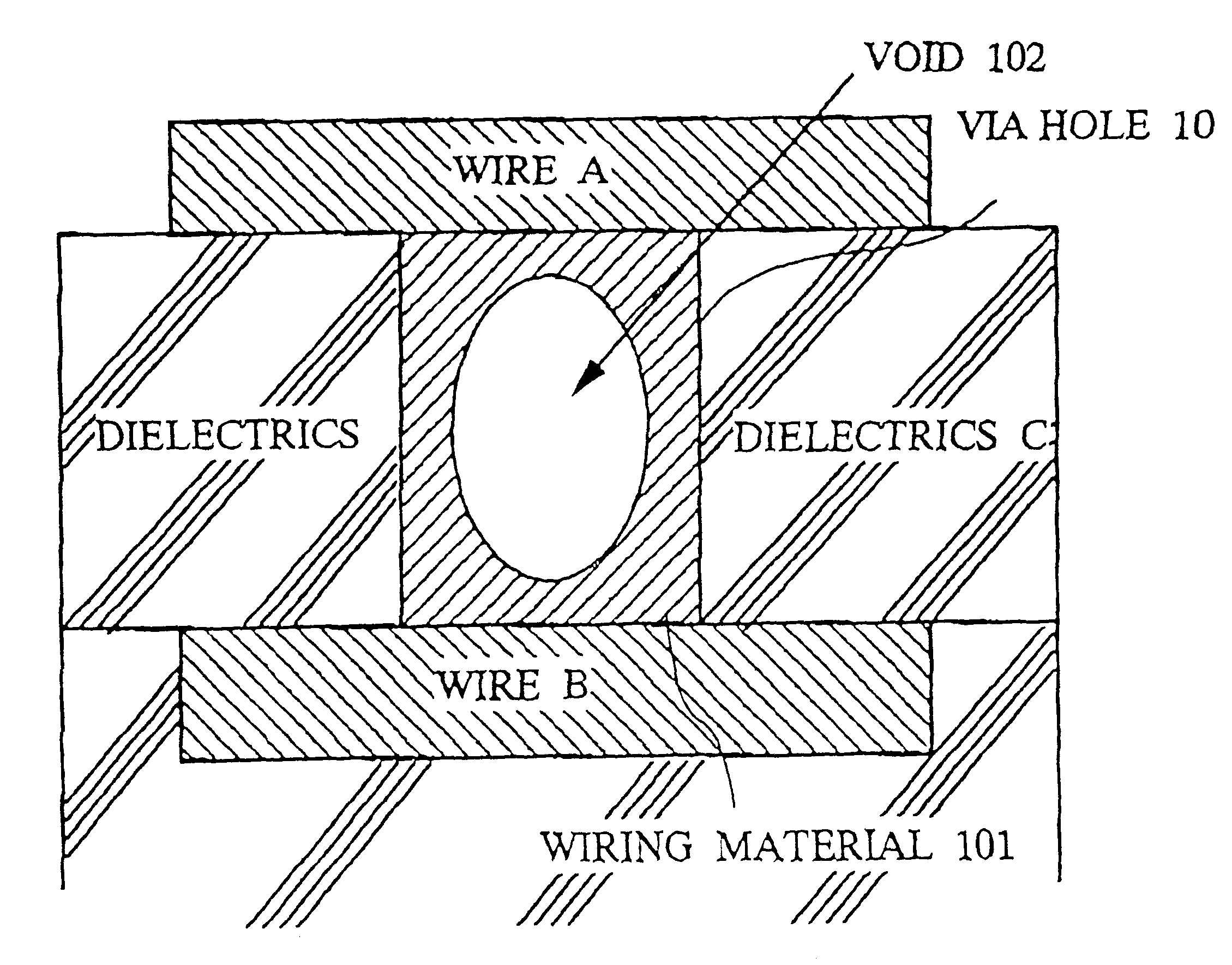

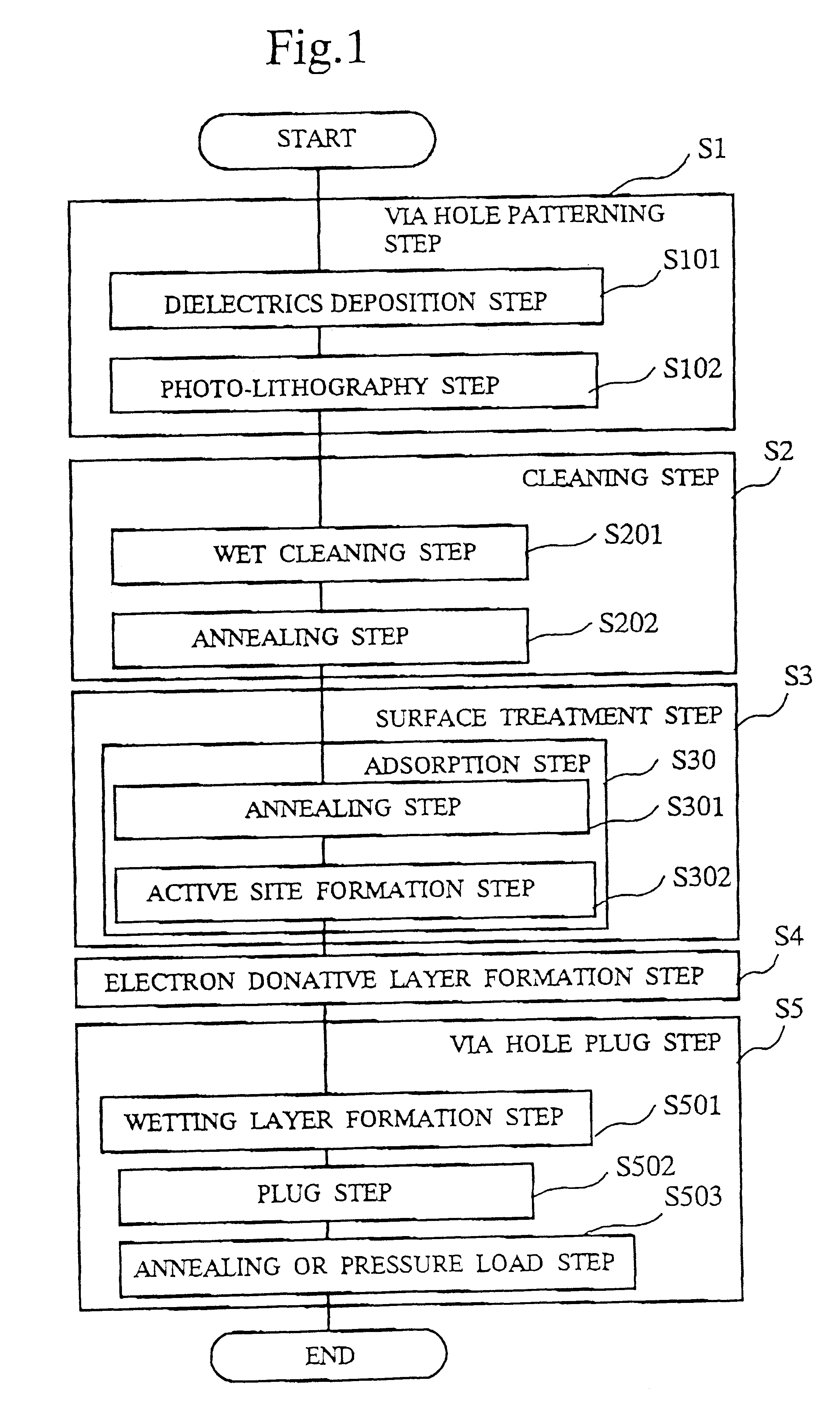

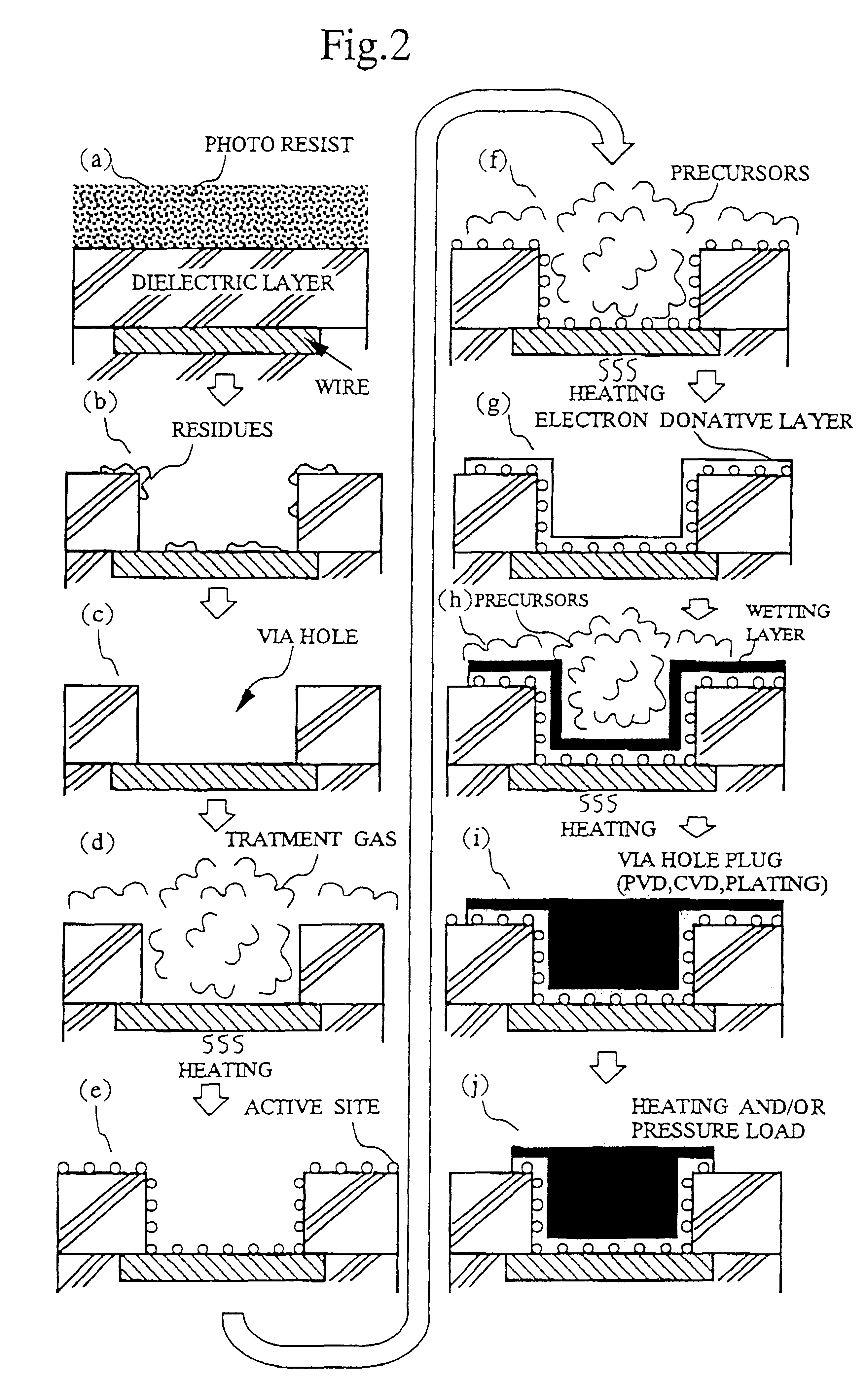

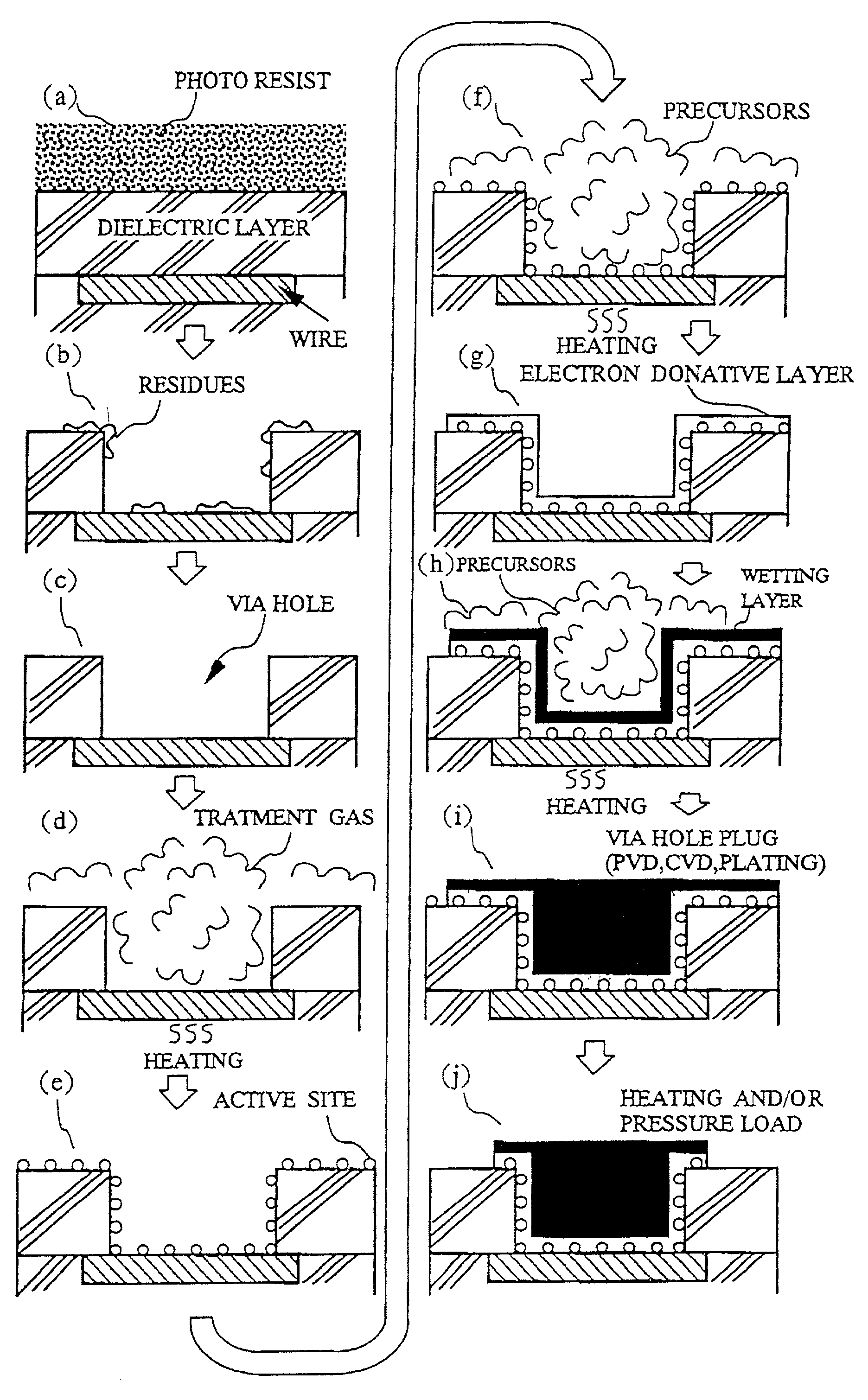

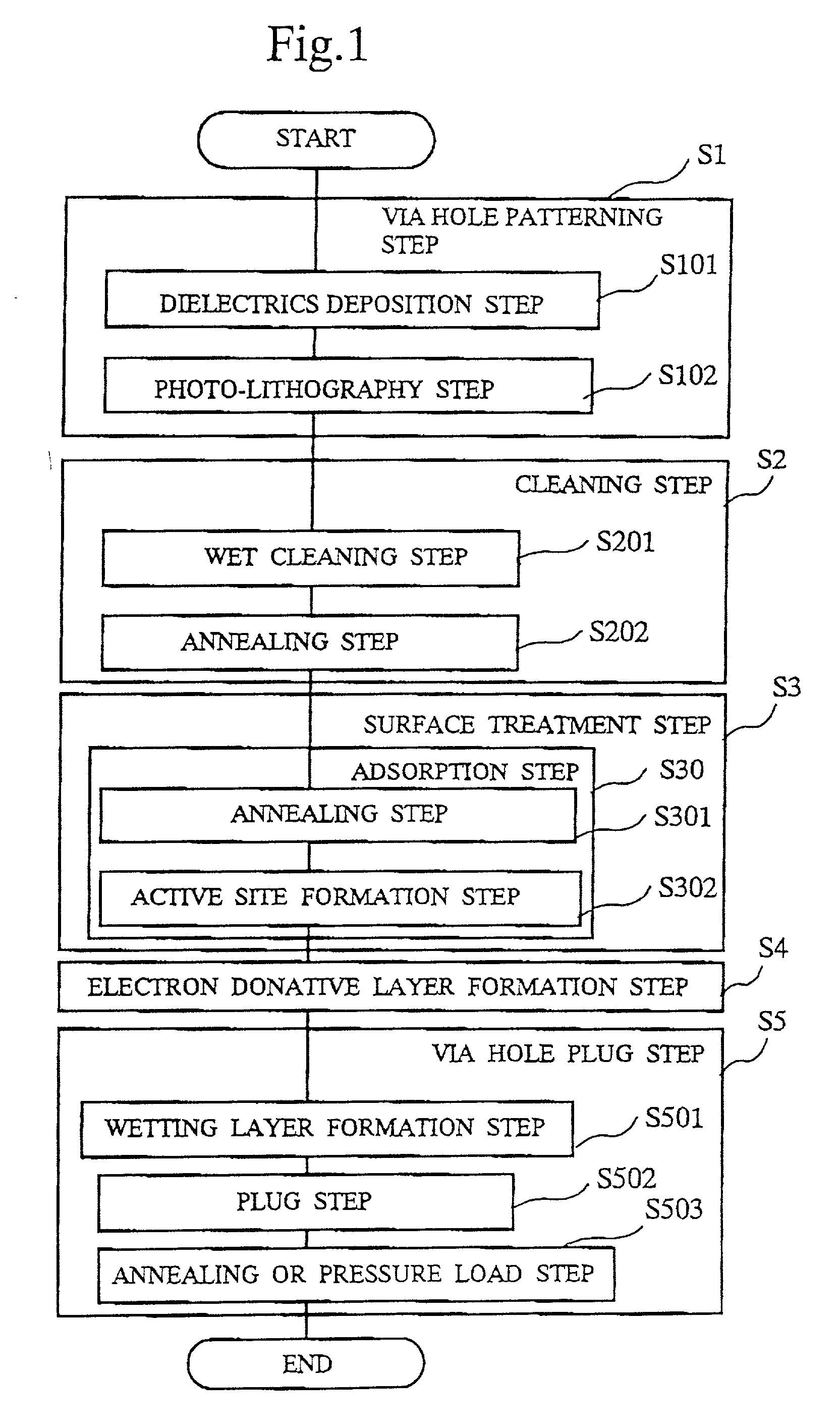

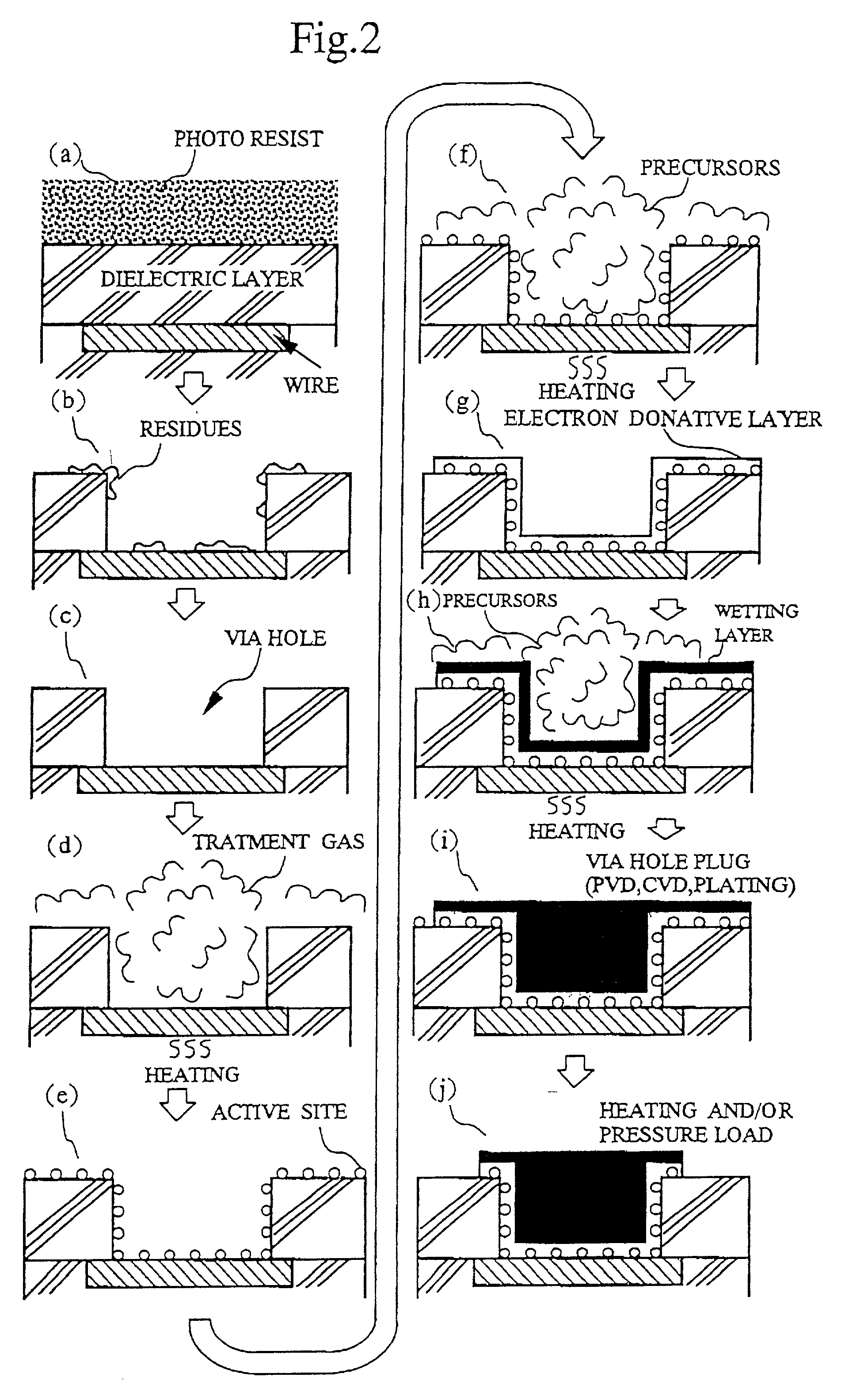

Method and apparatus for wiring, wire, and integrated circuit

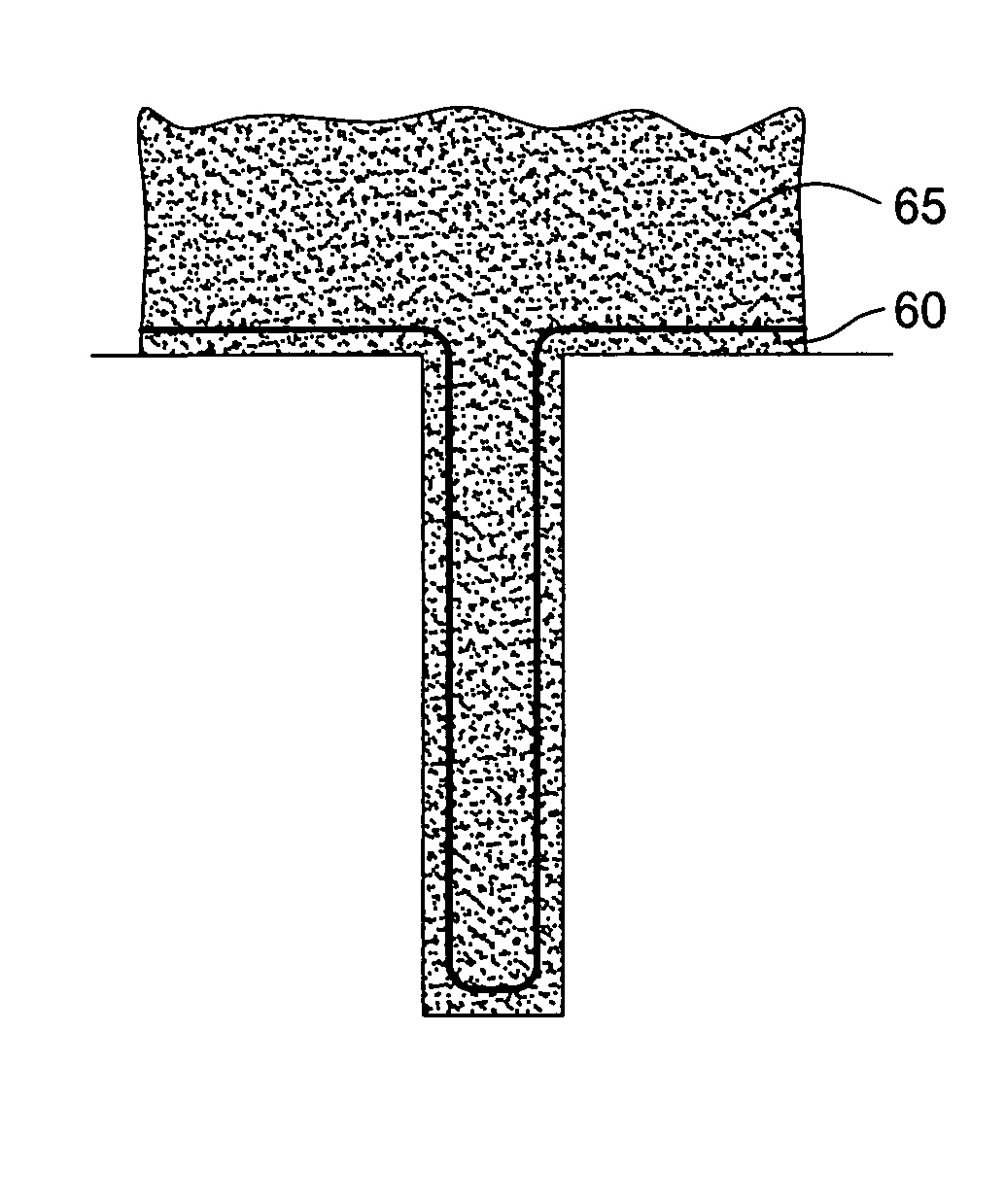

InactiveUS6355545B1Solid-state devicesSemiconductor/solid-state device manufacturingReactive siteConductive materials

The present invention provides a method for wiring, which plugs conductive material sufficiently into a via hole produced in dielectronics (hereinafter, referred to as "a via hole") and prevents generating a void. The via hole is made through a via hole patterning step and a cleaning step. At a surface treatment step, substance having chemical affinity (active site) is adsorbed to the surface of the via hole. Next, an electron donative layer is made by depositing substance having an electron donative characteristic on the active sites acting as cores at an electron donative layer formation step. Then, the wiring material is plugged at a via hole plug step.

Owner:FUJITSU SEMICON LTD

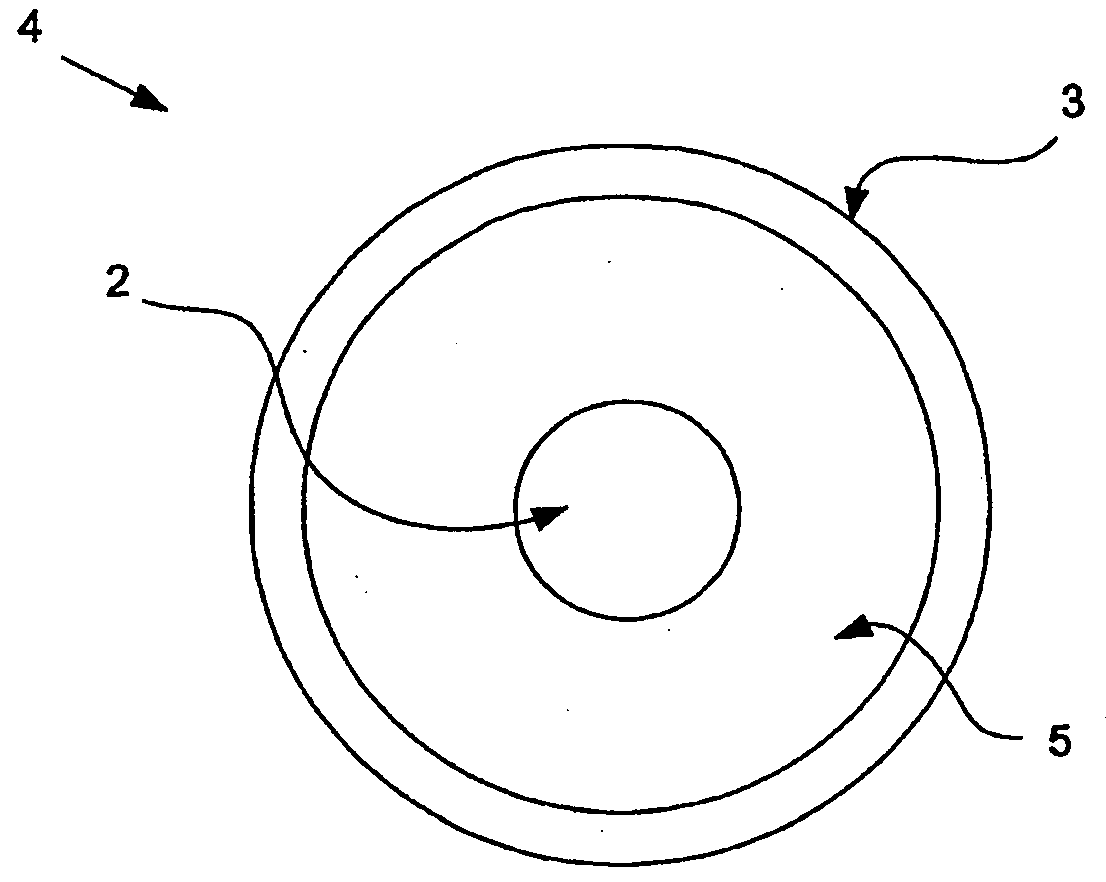

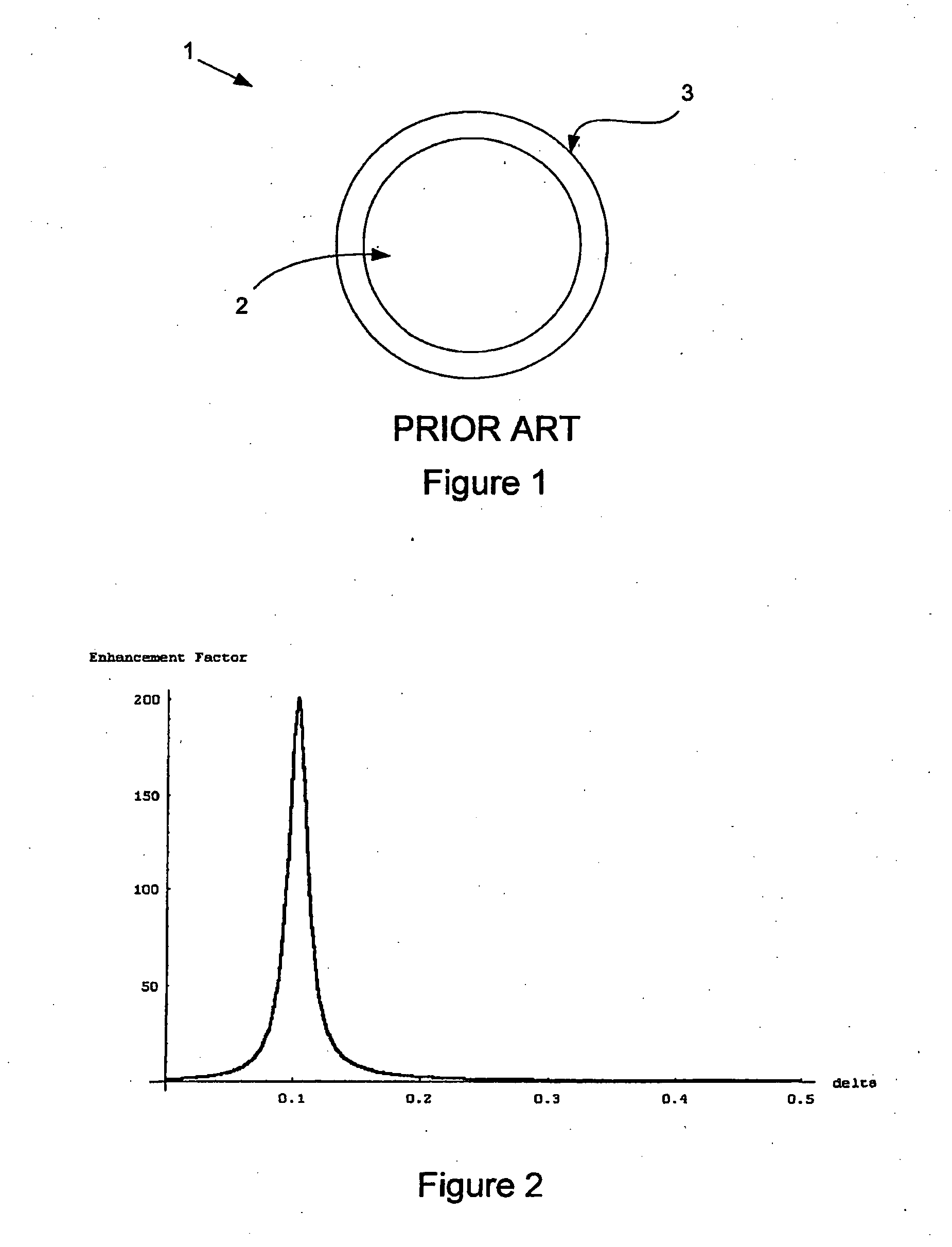

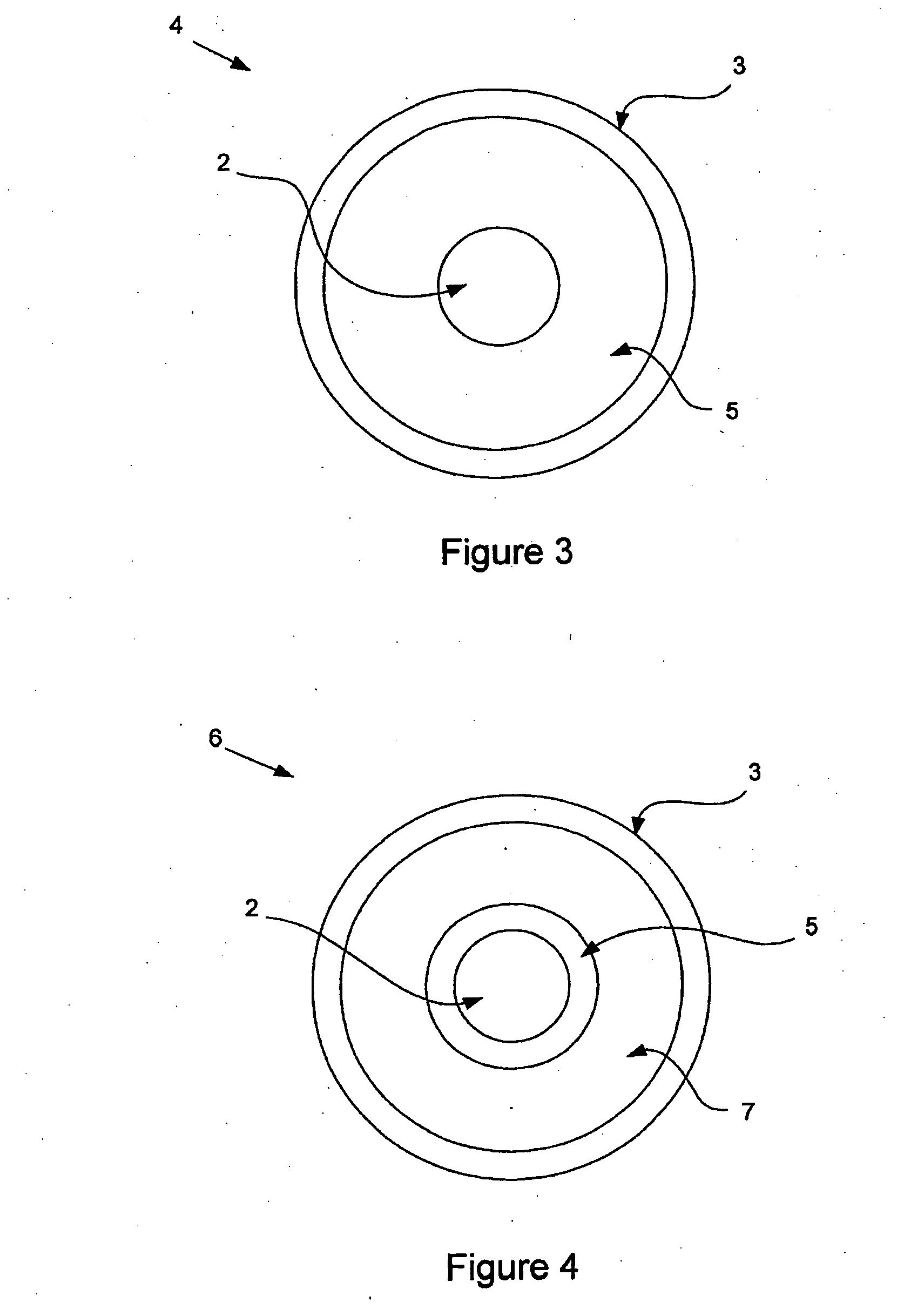

Composite Quantum Dot Structures

InactiveUS20080230764A1Reliable depositionMaterial nanotechnologyLaser detailsOptical propertyCharge carrier

A composite quantum dot structure (4) comprises a charge carrier confinement region, such as a quantum dot (2), a barrier (5) and an electrically conductive layer (3). This structure allows the dimensions of the conductive layer (3) to be substantially independent of the size of the region (2), so that the dimensions of the region (2) can thus be selected in order to achieve desired optical properties, while the electrically conductive layer (3) can be of sufficient thickness to ensure that it can be reliably deposited. The structure may also include a cladding layer (7) (FIG. 4) to compensate for any lack of chemical affinity between the barrier (5) and conductive layer (3). An ensemble of such structures be provided in which the quantum dots (1) have various radii but the dimensions of the conductive layers (3) and the overall dimensions of the structures are substantially uniform, e.g. for use in an amplifier configured to amplify light of various wavelengths.

Owner:TRACKDALE LTD

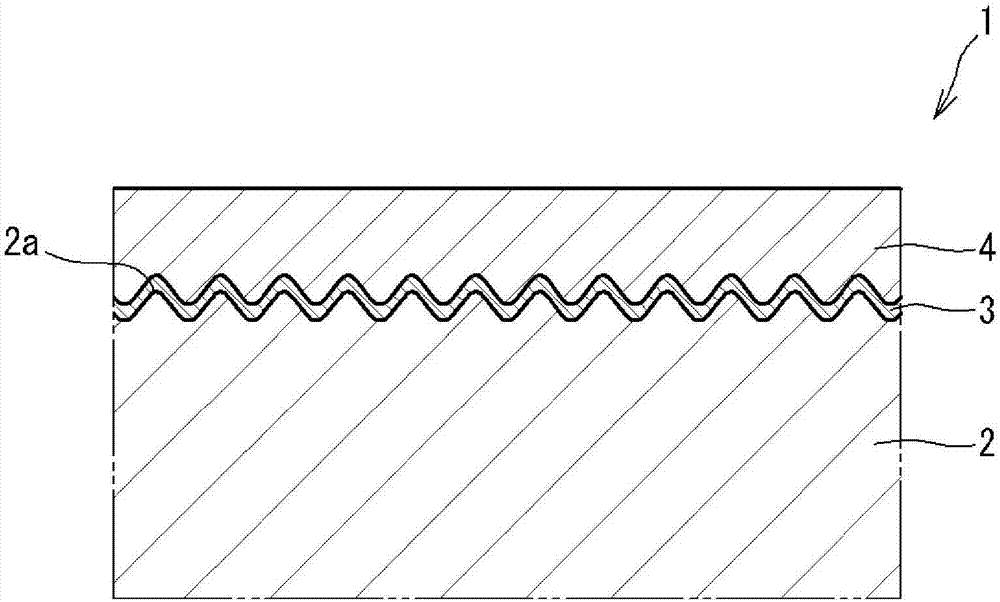

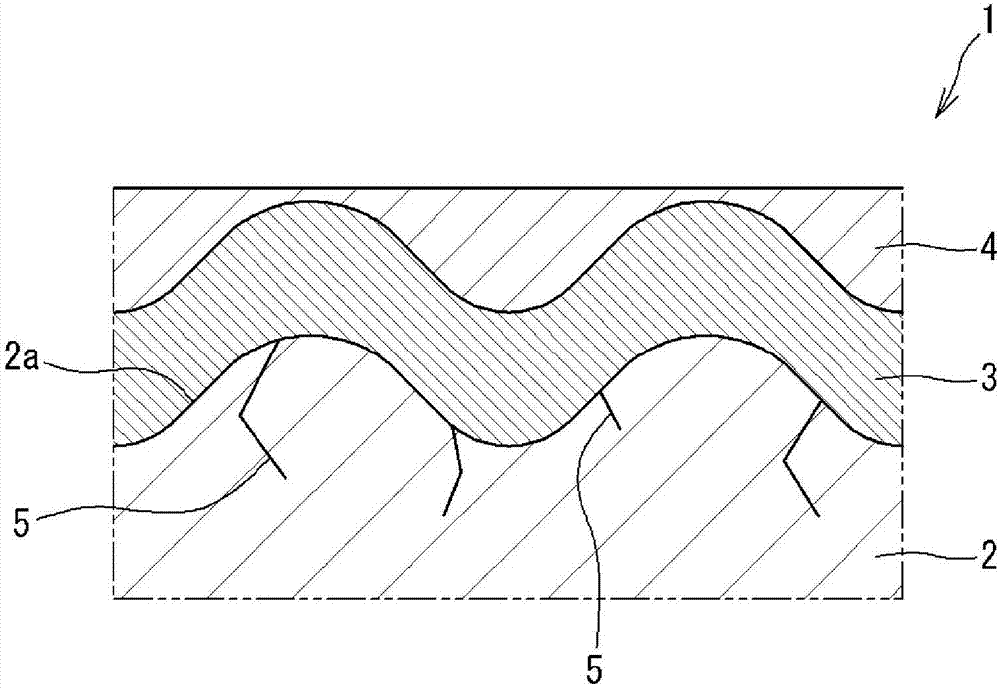

Method for roughening substrate, method for surface-treating substrate, method for producing spray-coated member, and spray-coated member

ActiveCN107532272AExcellent adhesionIncreased durabilityMolten spray coatingSolid state diffusion coatingAtmospheric airSpray coating

A ceramic substrate (2) is irradiated in atmospheric air by a laser having a power density of 1.0 * 107-109 W / cm2, in which the duration of action on an irradiation position is set to 1.0 * 10-7-10-5,the surface of the ceramic substrate (2) is roughened, and an oxide film 3 is formed on the roughened surface (2a). This yields high adhesiveness to a spray coating, formed on the ceramic substrate (2), due to the action of chemical affinity in addition to the physical adhesive force of the roughened surface (2a), without causing any great reduction in substrate strength.

Owner:TOCALO CO LTD

Method and apparatus for wiring, wire, and integrated circuit

InactiveUS20020022365A1Solid-state devicesSemiconductor/solid-state device manufacturingReactive siteEngineering

The present invention provides a method for wiring, which plugs conductive material sufficiently into a via hole produced in dielectronics (hereinafter, referred to as "a via hole") and prevents generating a void. The via hole is made through a via hole patterning step and a cleaning step. At a surface treatment step, substance having chemical affinity (active site) is adsorbed to the surface of the via hole. Next, an electron donative layer is made by depositing substance having an electron donative characteristic on the active sites acting as cores at an electron donative layer formation step. Then, the wiring material is plugged at a via hole plug step.

Owner:FUJITSU SEMICON LTD

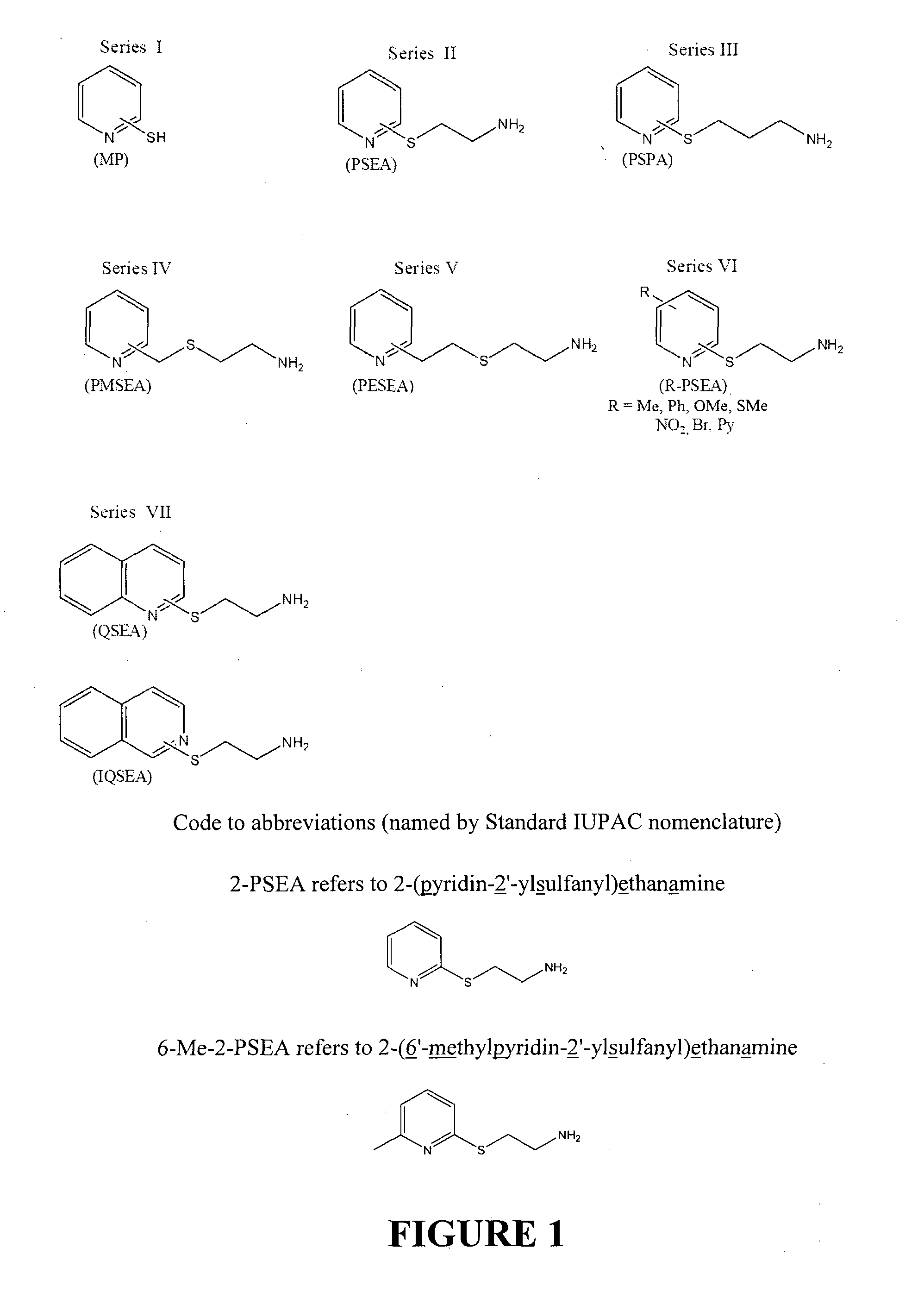

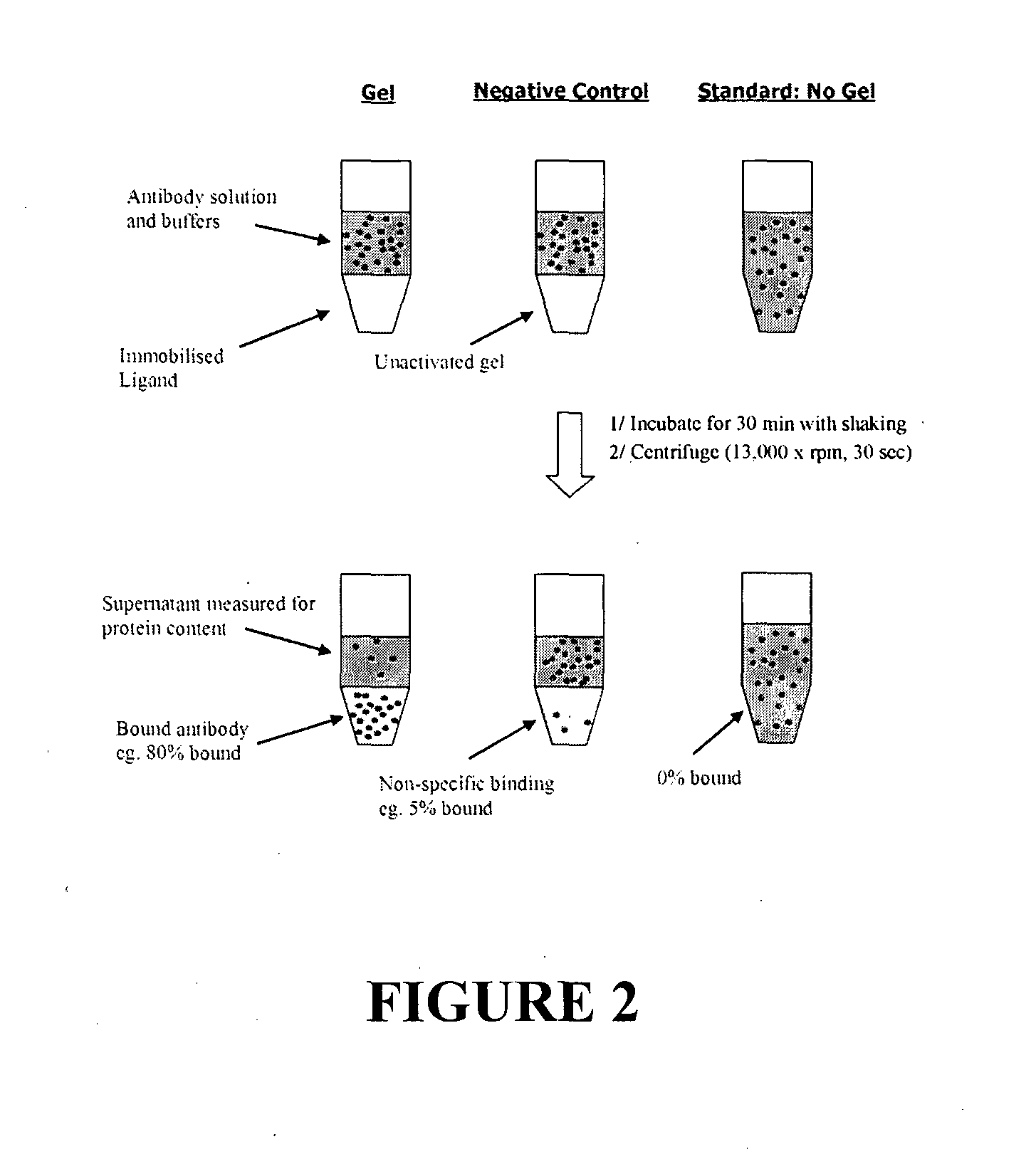

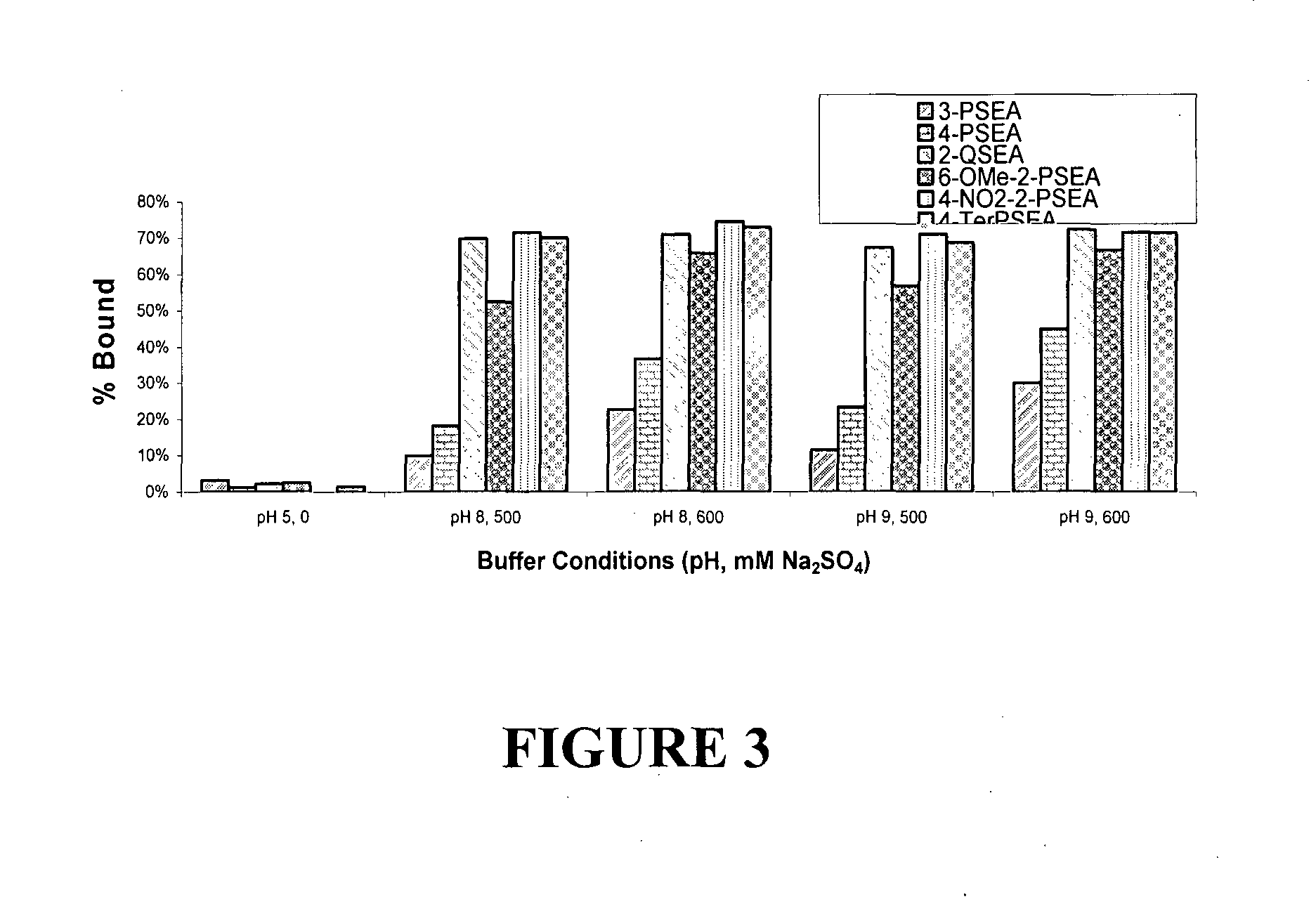

Affinity ligands and methods for protein purification

InactiveUS20120259094A1Sugar derivativesSolid sorbent liquid separationProtein purificationAntibody Affinity Chromatography

The present invention relates generally to affinity ligands and chemical affinity ligand-matrix conjugates for use as chromatographic adsorbents and methods which utilise the adsorbents in the purification of proteins by affinity chromatography. The affinity ligand-matrix conjugates of the present invention comprise ligands of general formula (I): wherein m represents an integer from 0-2, n represents an integer from 0-6, p represents an integer from 0-4, R1 represents H or C1-3 alkyl, R2 is an optional substituent, and X is the position at which the ligand is immobilized, optionally via a linker.

Owner:MONASH UNIV

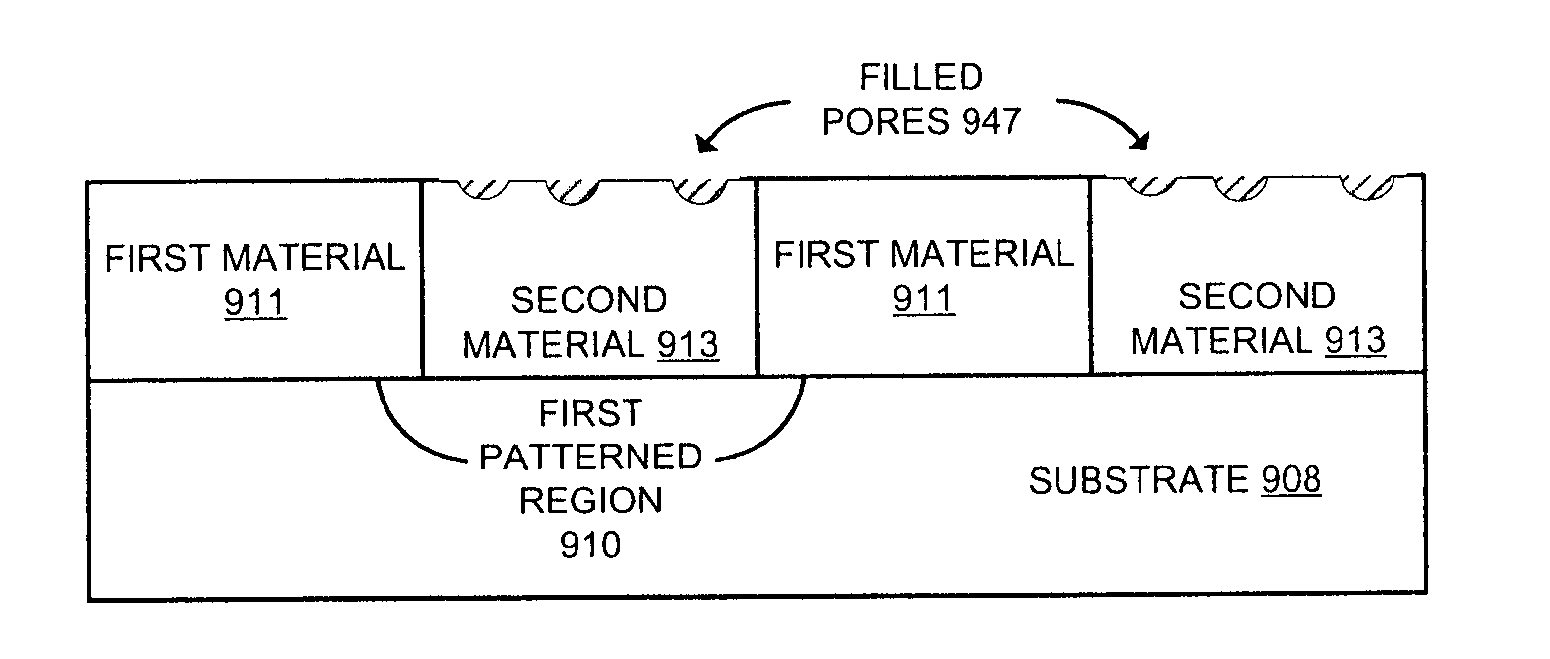

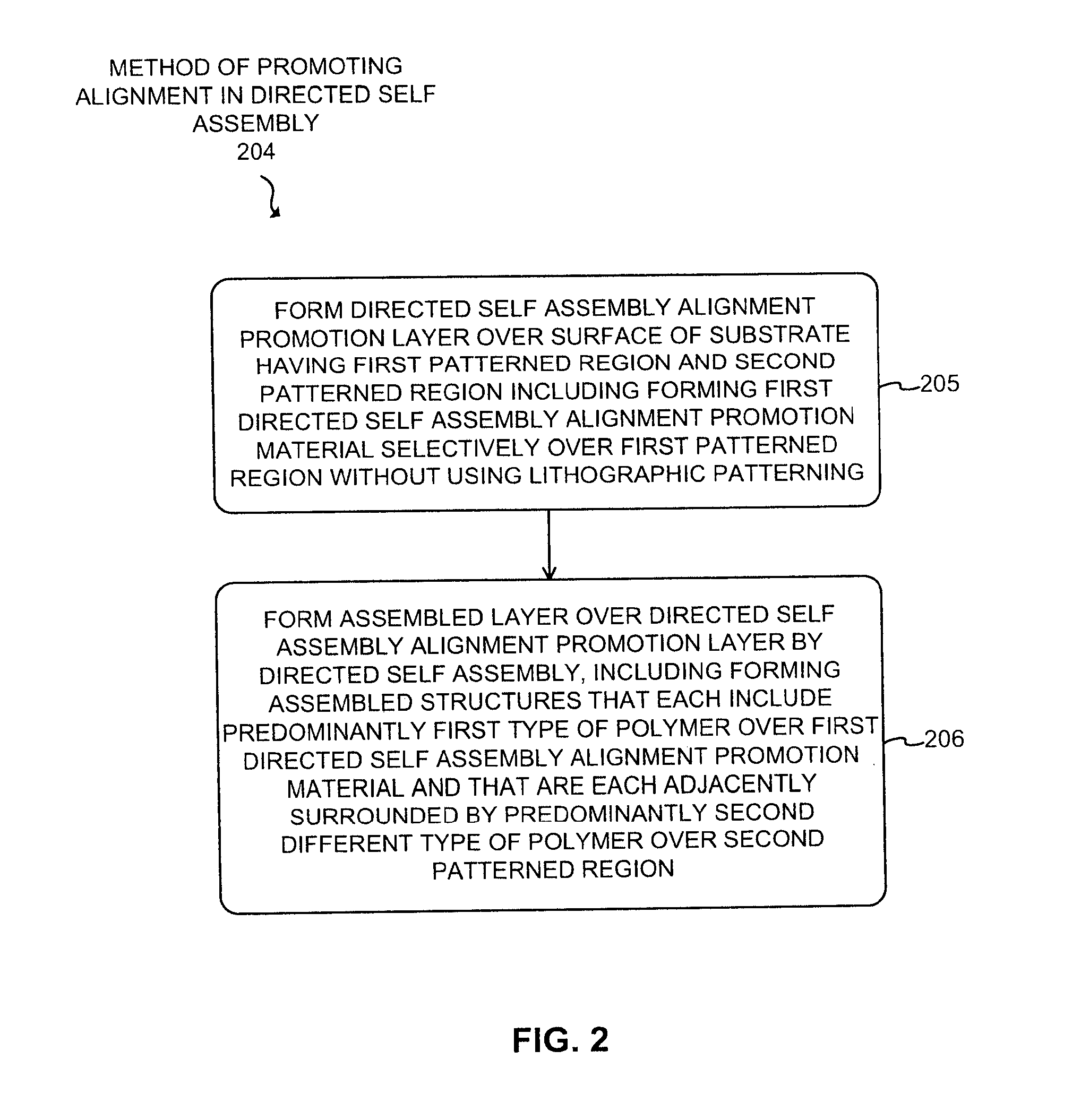

Non-lithographically patterned directed self assembly alignment promotion layers

ActiveUS20160172237A1Semiconductor/solid-state device detailsSolid-state devicesBiomedical engineeringDirected self assembly

A method of an aspect includes forming a directed self assembly alignment promotion layer over a surface of a substrate having a first patterned region and a second patterned region. A first directed self assembly alignment promotion material is formed selectively over the first patterned region without using lithographic patterning. The method also includes forming an assembled layer over the directed self assembly alignment promotion layer by directed self assembly. A plurality of assembled structures are formed that each include predominantly a first type of polymer over the first directed self assembly alignment promotion material. The assembled structures are each adjacently surrounded by predominantly a second different type of polymer over the second patterned region. The first directed self assembly alignment promotion material has a greater chemical affinity for the first type of polymer than for the second different type of polymer.

Owner:INTEL CORP

Design of new materials whose use produces a chemical bond with a descriptor of said bond

InactiveUS20020019684A1Sampled-variable control systemsChemical analysis using catalysisMineral matrixNew materials

The invention relates to a process for estimating a property of use, for example the activity of a catalyst or the ability to hold a radio-element in a solid mineral matrix, or a material MAB whose active element is AB. This process comprises the use of a descriptor DAB of the chemical bond between A and B, which has the dimension of an energy, and an index RAB that measures the property of use of said material. The invention also relates to a process for determining the chemical affinity of an element or a set of elements B for a matrix A with a descriptor DAB. The processes according to the invention advantageously can be used for the design of new materials whose use produces the formation or the modification of at least one chemical bond or makes it necessary to prevent the formation of said bond.

Owner:INST FR DU PETROLE

Aluminum alloy sodium-free refining agent and application thereof

The invention provides an aluminum alloy sodium-free refining agent and belongs to the technical field of casting of aluminum alloys. The sodium-free refining agent comprises the following raw materials in parts by weight: 30-35 parts of K2CO3, 10-12 parts of potassium fluoroaluminate, 5-10 parts of CaF2, 12-18 parts of LiCl, 3-5 parts of calcium oxide, 30-35 parts of BalF3, 5-10 parts of K2SiF6, 10-15 parts of C6Cl6, 5-10 parts of TiO2 and 3-8 parts of CaCl. The aluminum alloy sodium-free refining agent is free of impurity sodium; meanwhile, rare-earth metals are added into the sodium-free refining agent; the rare-earth metals have high chemical affinity with impurity elements such as H2 and S and the like; the rare-earth metals and various impurity elements form compounds; the influence of harmful impurities can be eliminated; the rare-earth metals have the functions of modifying and refining the aluminum alloy structure; the dendrite spacing of the aluminum alloy is effectively reduced; the as-cast grains are refined; the mechanical performance of the alloy is improved; meanwhile, the smelting temperature of the aluminum alloy is maintained at 710-730 DEG C in the process of using the aluminum alloy sodium-free refining agent, so that the effect of removing impurity elements such as H2 and S and the like is more significant.

Owner:贵州航天风华精密设备有限公司

Methods utilizing scanning probe microscope tips and products therefor or produced thereby

InactiveUS7569252B2Enhance the imageMaterial nanotechnologyNanostructure manufactureNanolithographyConfocal

The invention provides a lithographic method referred to as “dip pen” nanolithography (DPN). DPN utilizes a scanning probe microscope (SPM) tip (e.g., an atomic force microscope (AFM) tip) as a “pen,” a solid-state substrate (e.g., gold) as “paper,” and molecules with a chemical affinity for the solid-state substrate as “ink.” Capillary transport of molecules from the SPM tip to the solid substrate is used in DPN to directly write patterns consisting of a relatively small collection of molecules in submicrometer dimensions, making DPN useful in the fabrication of a variety of microscale and nanoscale devices. The invention also provides substrates patterned by DPN and kits for performing DPN.The invention further provides a method of performing AFM imaging in air. The method comprises coating an AFM tip with a hydrophobic compound, the hydrophobic compound being selected so that AFM imaging performed using the coated AFM tip is improved compared to AFM imaging performed using an uncoated AFM tip. Finally, the invention provides AFM tips coated with the hydrophobic compounds.

Owner:NORTHWESTERN UNIV

Extrusion Bonded Laminates For Absorbent Articles

An absorbent article of the present invention may comprise a topsheet, an outer cover, and an absorbent core disposed therebetween. The outer cover may comprise an extrusion bonded laminate. The EBL may comprise a multi-layer coextruded elastomeric film and a nonwoven. The film may comprise a core layer, a first outer layer, and a second outer layer, wherein the core layer is between the first and second outer layers. The nonwoven may comprise fibers and / or filaments. The first outer layer may be non-adhesively joined to the nonwoven via extrusion coating. Further, the outer cover may be elastic to at least about 50% engineering strain. The nonwoven may have high chemical affinity for the first outer layer. The first outer layer may have a low chemical affinity for the core layer; and the multi-layer coextruded elastomeric film may have a basis weight no greater than about 40 gsm.

Owner:PROCTER & GAMBLE CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com