Patents

Literature

209 results about "Nanolithography" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nanolithography is a growing field of techniques within nanotechnology dealing with the engineering (etching, writing, printing) of nanometer-scale structures. From Greek, the word can be broken up into three parts: "nano" meaning dwarf, "lith" meaning stone, and "graphy" meaning to write, or "tiny writing onto stone." Today, the word has evolved to cover the design of structures in the range of 10⁻⁹ to 10⁻⁶ meters, or structures in the nanometer range. Essentially, field is a derivative of lithography, only covering significantly smaller structures. All nanolithographic techniques can be separated into two categories: those that etch away molecules leaving behind the desired structure, and those that directly write the desired structure to a surface (similar to the way a 3D printer creates a structure).

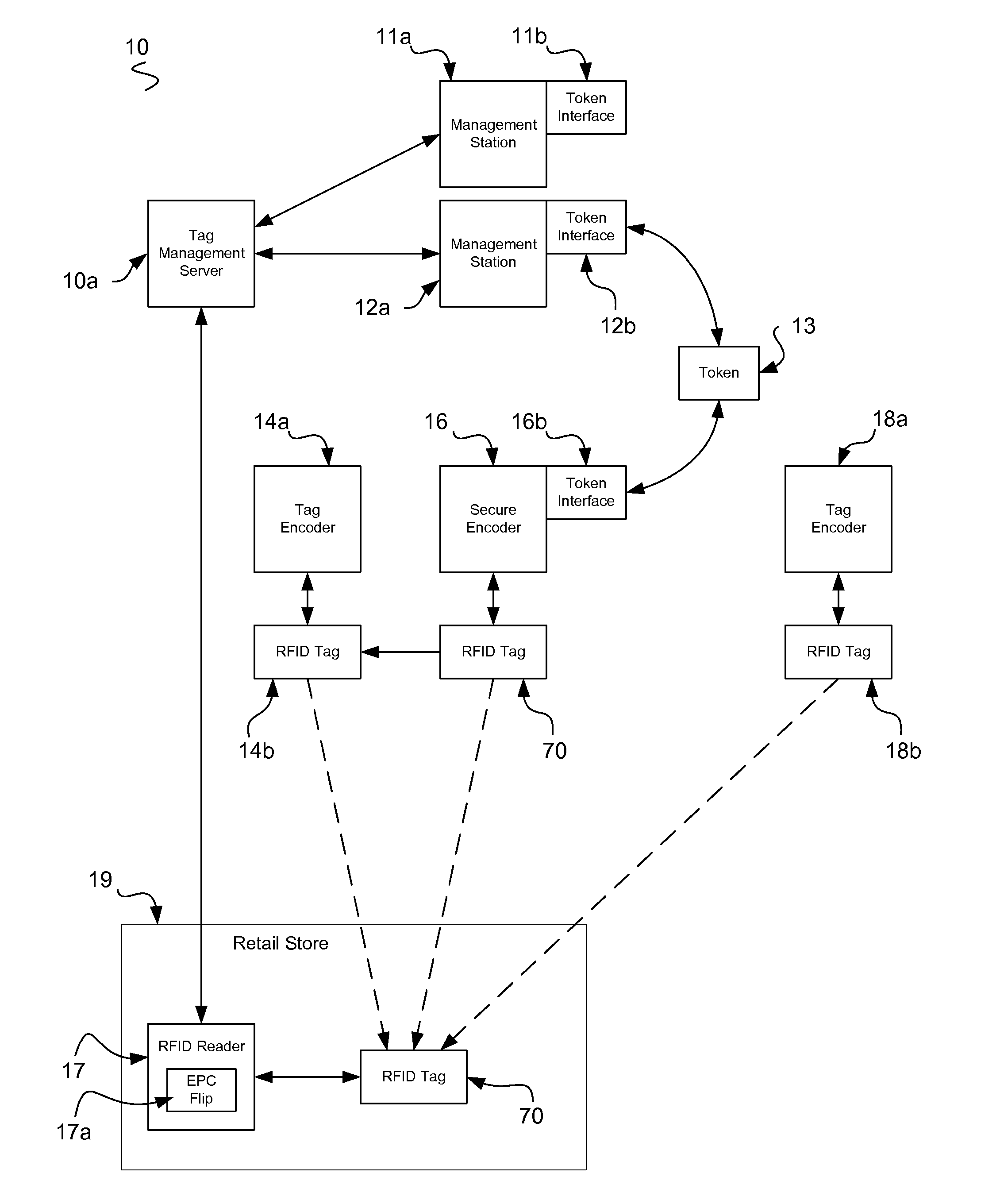

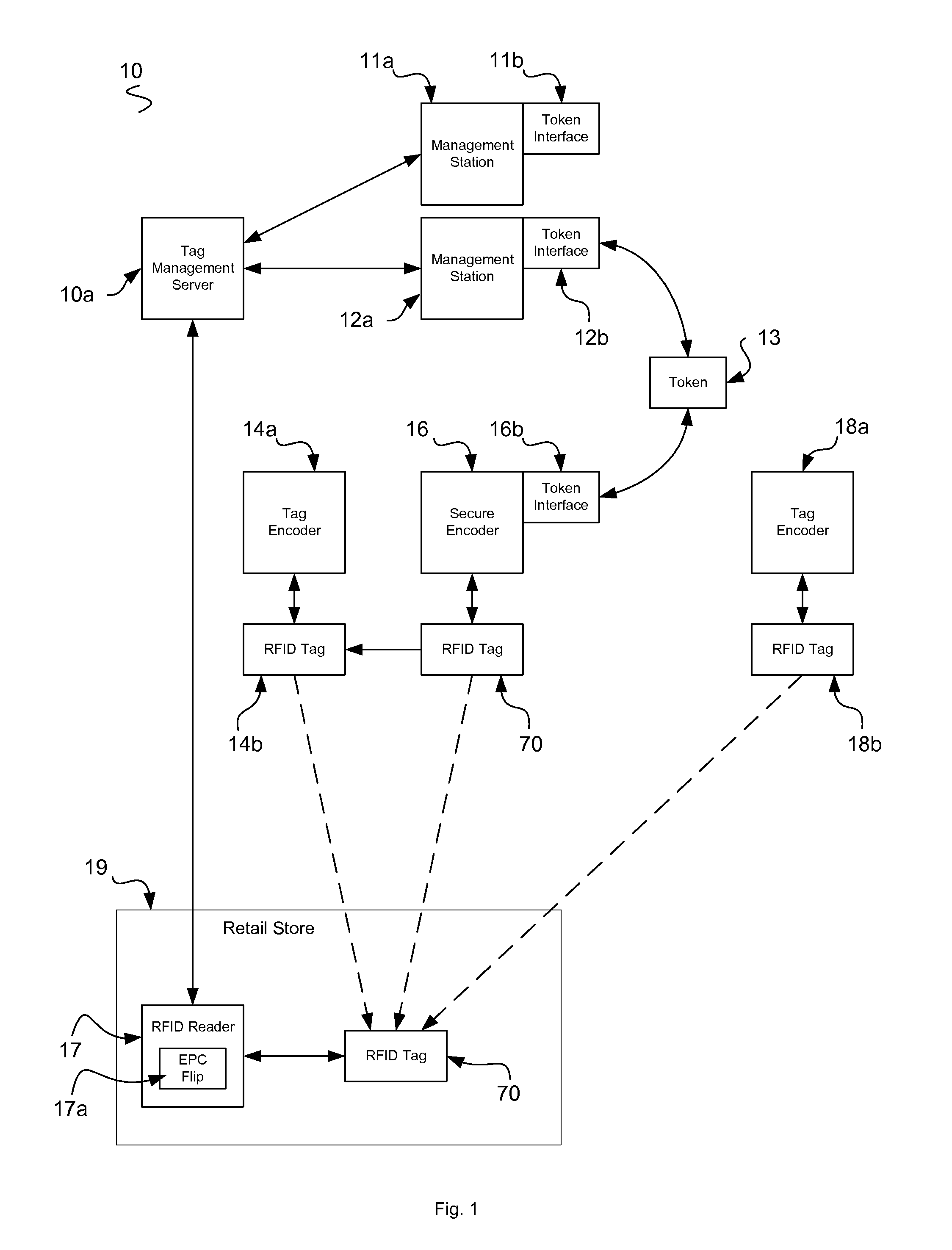

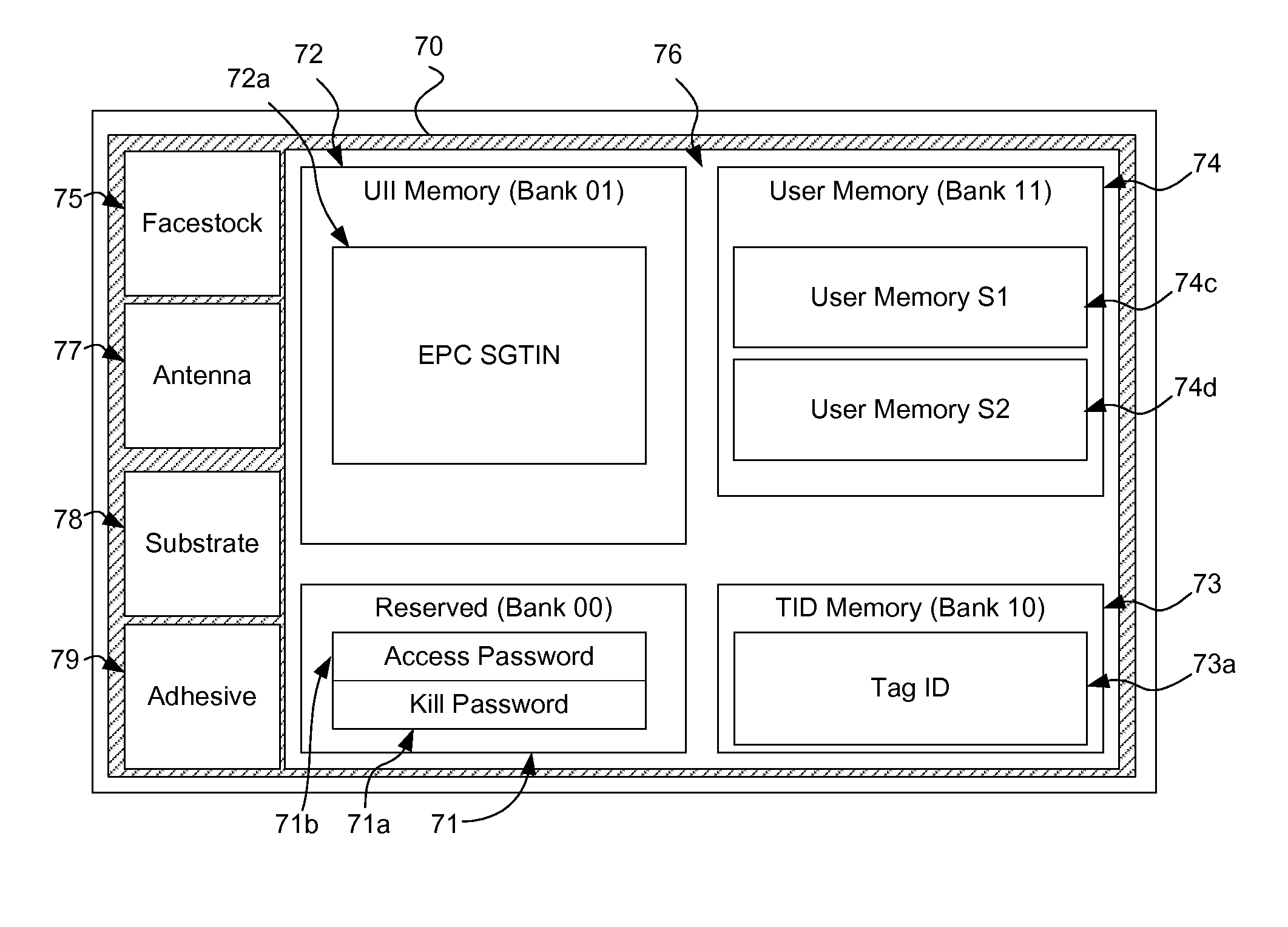

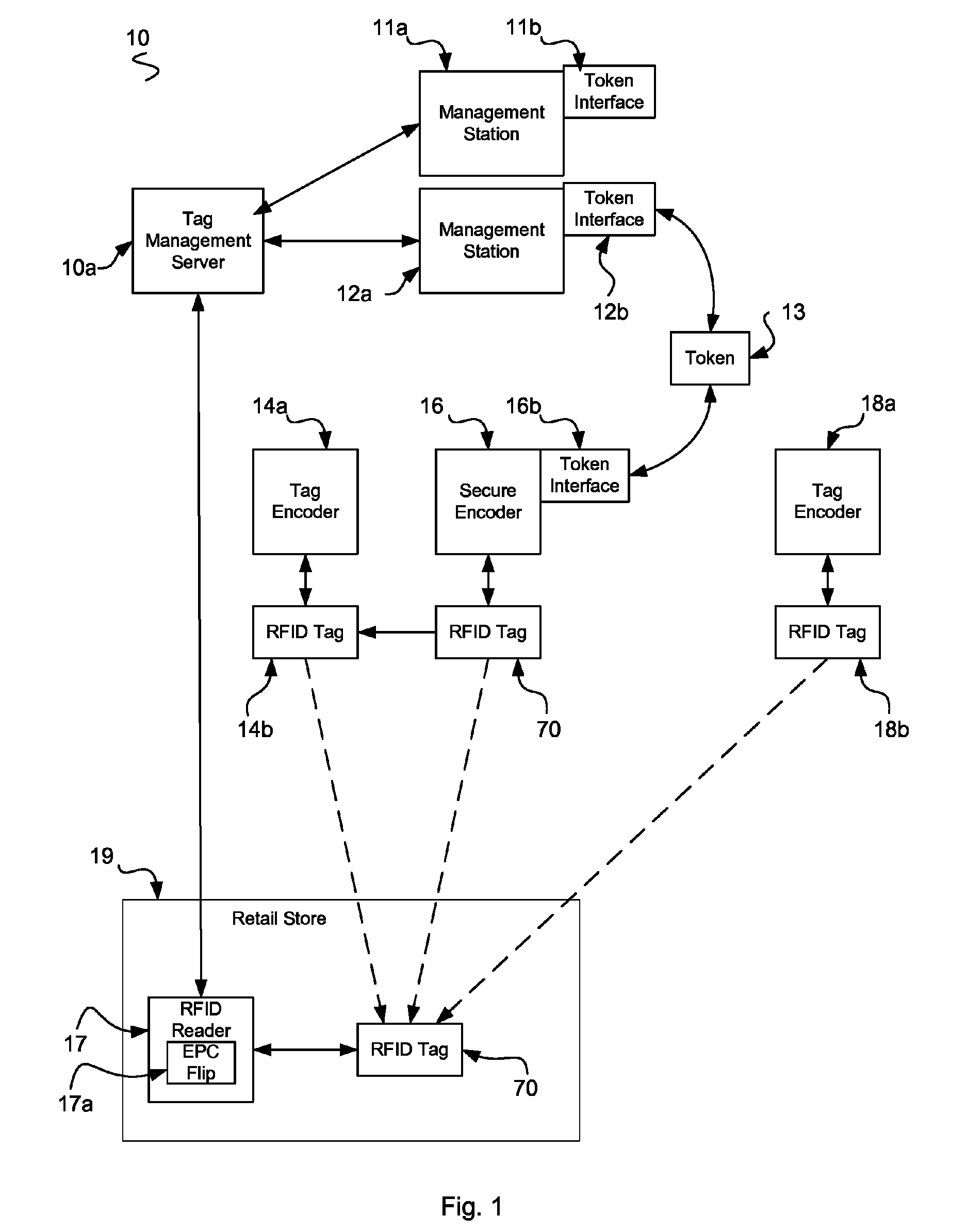

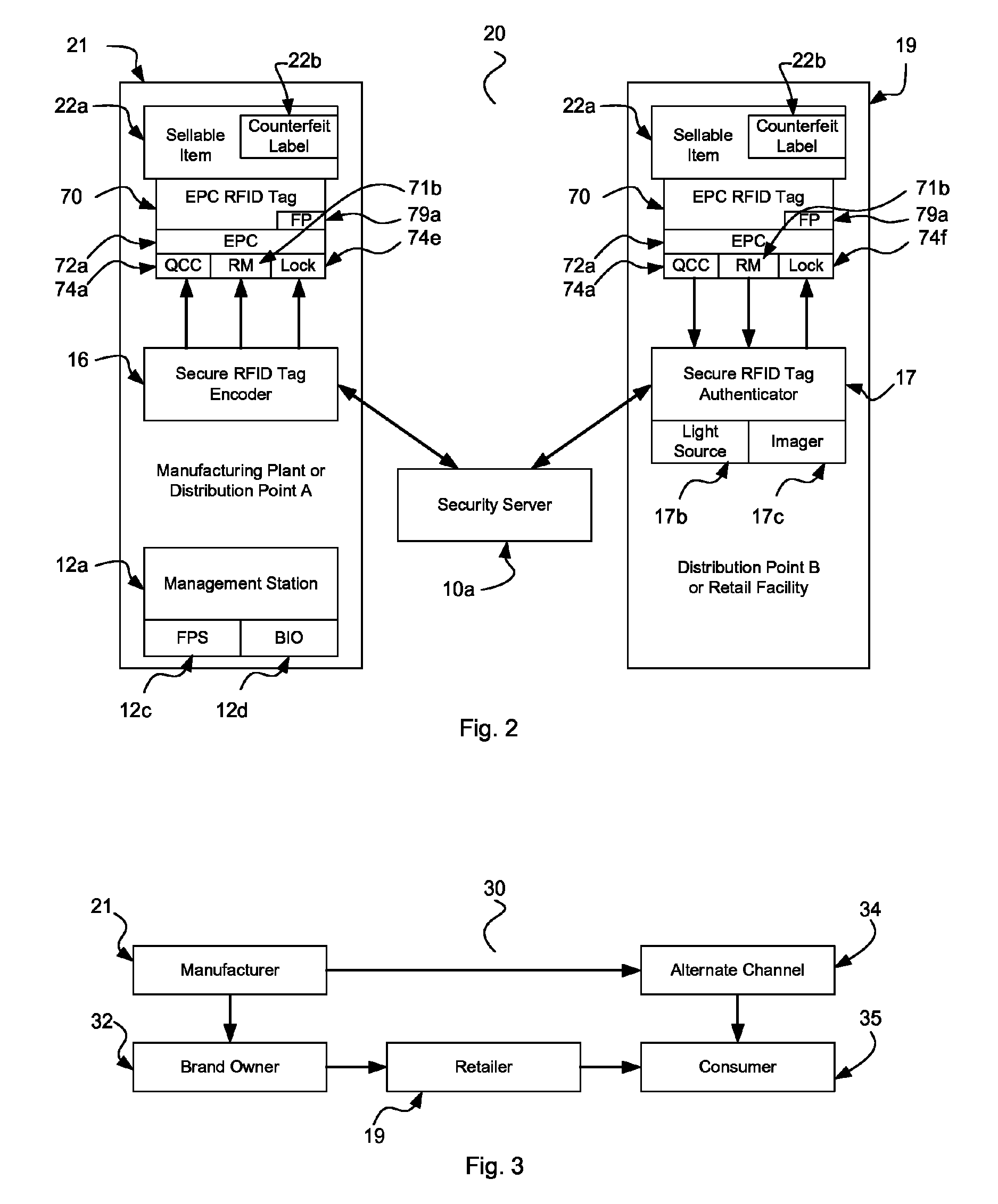

Fully Secure Item-Level Tagging

InactiveUS20100289627A1Efficient and secure and flexibleRobust radio linkDigital data authenticationSubscribers indirect connectionNanolithographyPassword

The present invention provides value to brand owners, retailers, and consumers through the use of radio frequency identification, stenography, nanolithography, fingerprints, novel heuristic threat evaluation, indication, and detection model. Additionally, using cryptography, tag passwords are formulated and identities are reversibly flipped, thus allowing item identities to remain secret to unauthorized observers. This unique combination of heuristics and authentication technologies provides an efficient means of finding and stopping the flow of counterfeit products throughout global supply chains. The present invention includes radio frequency identification (RFID) tags, encoders, servers, identity changers, and authenticity verifiers to make this task a viable and adaptive weapon against the elusive counterfeiters. The present end-to-end RFID system offers unprecedented security for retailers and consumers, while remaining efficient and scalable.

Owner:MCALLISTER CLARKE WILLIAM +1

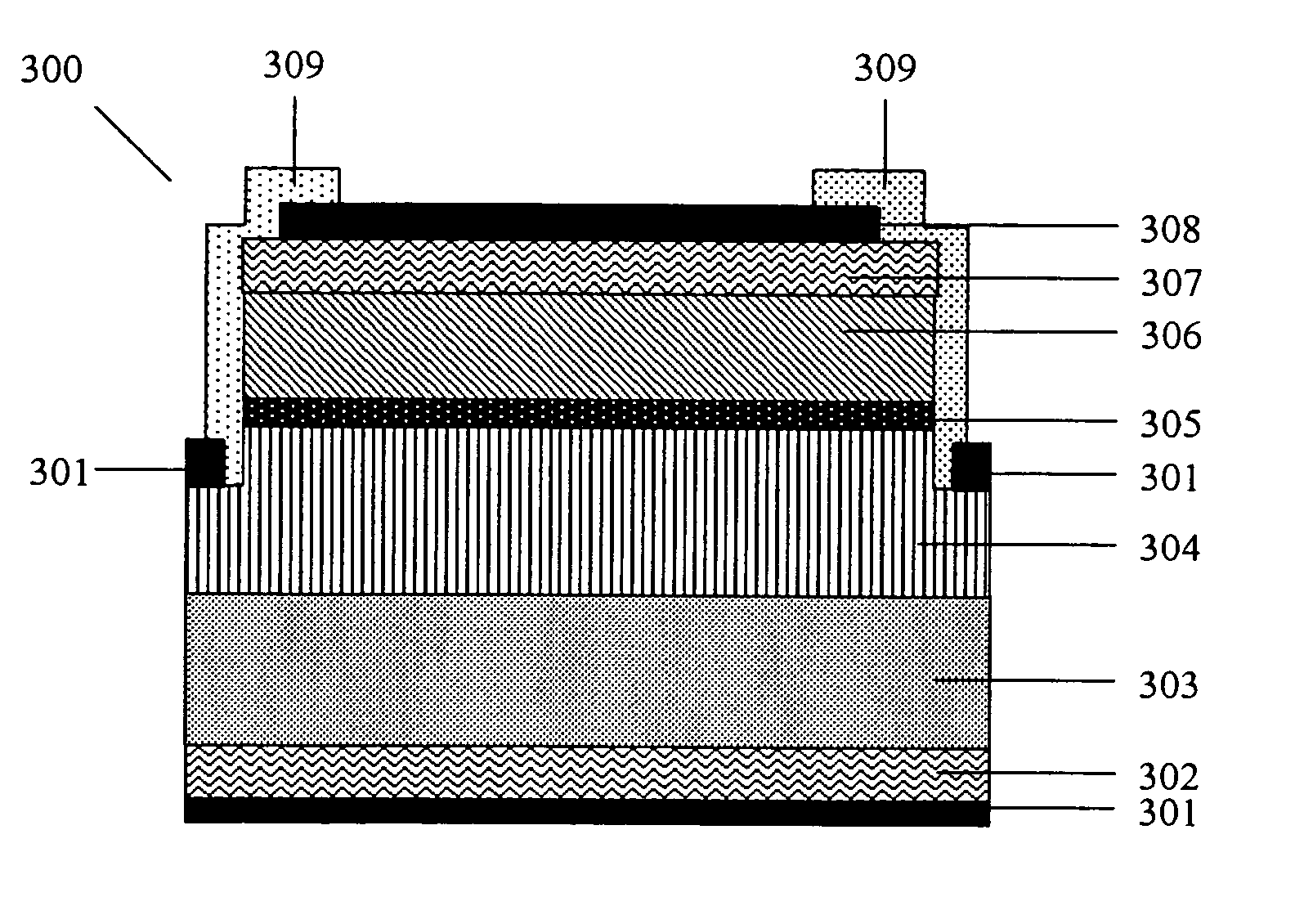

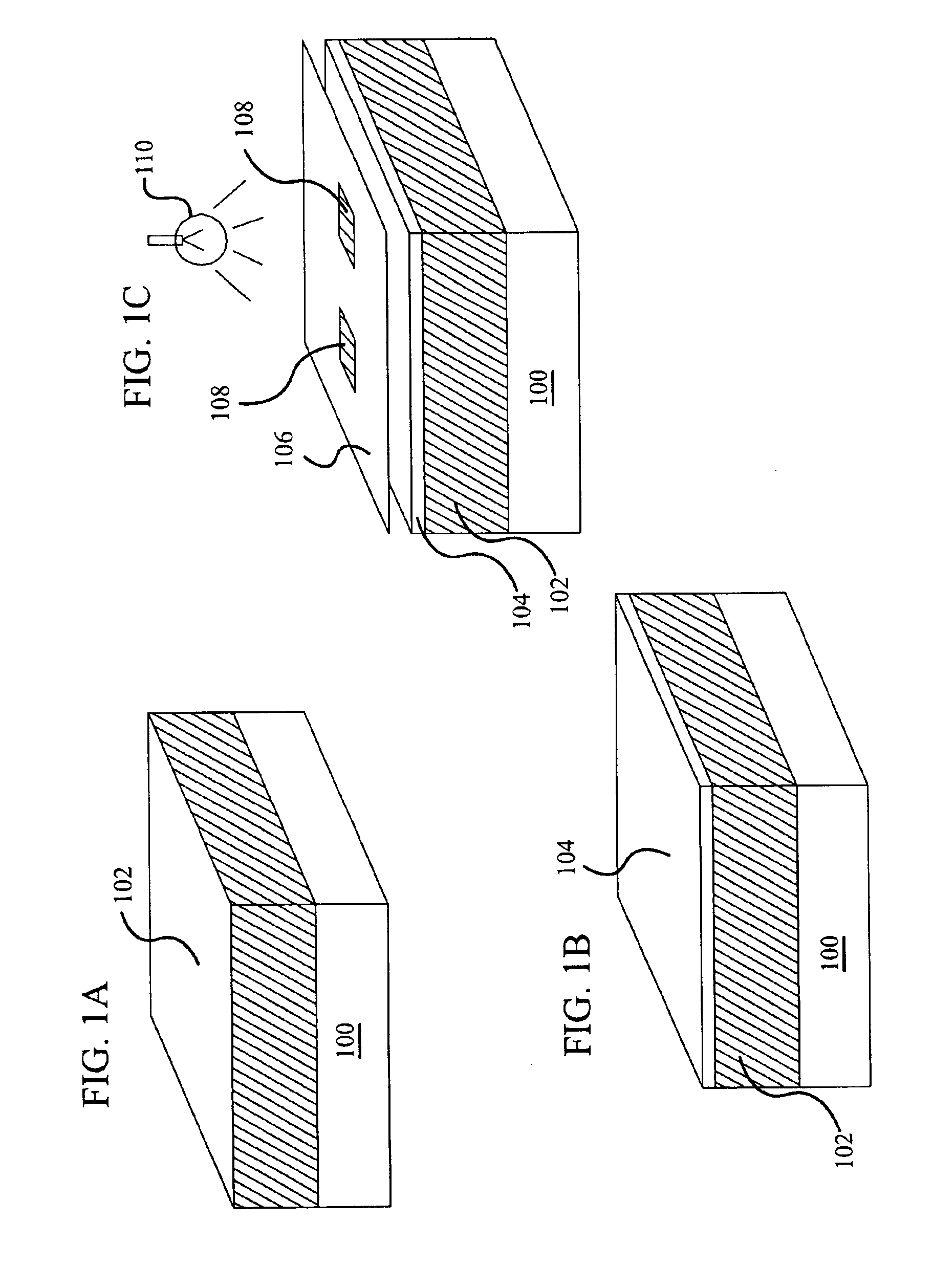

Monolithic light emitting devices based on wide bandgap semiconductor nanostructures and methods for making same

InactiveUS20050082543A1Reduce defectsSmall sizeLaser detailsLaser active region structureNanolithographyPhosphor

The present invention is directed toward a method for fabricating low-defect nanostructures of wide bandgap materials and to optoelectronic devices, such as light emitting sources and lasers, based on them. The invention utilizes nanolithographically-defined templates to form nanostructures of wide bandgap materials that are energetically unfavorable for dislocation formation. In particular, this invention provides a method for the fabrication of phosphor-less monolithic white light emitting diodes and laser diodes that can be used for general illumination and other applications.

Owner:GENERAL ELECTRIC CO

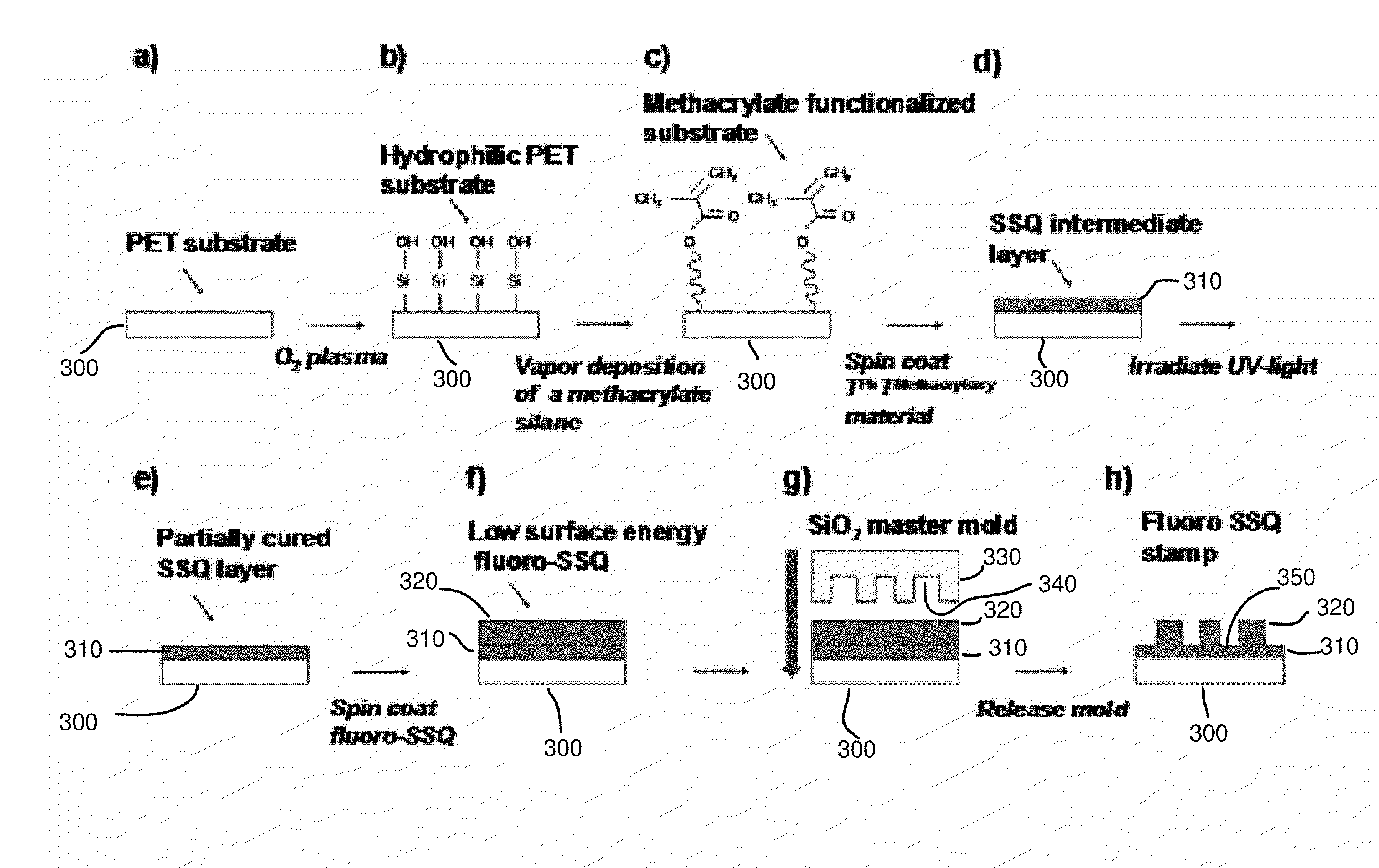

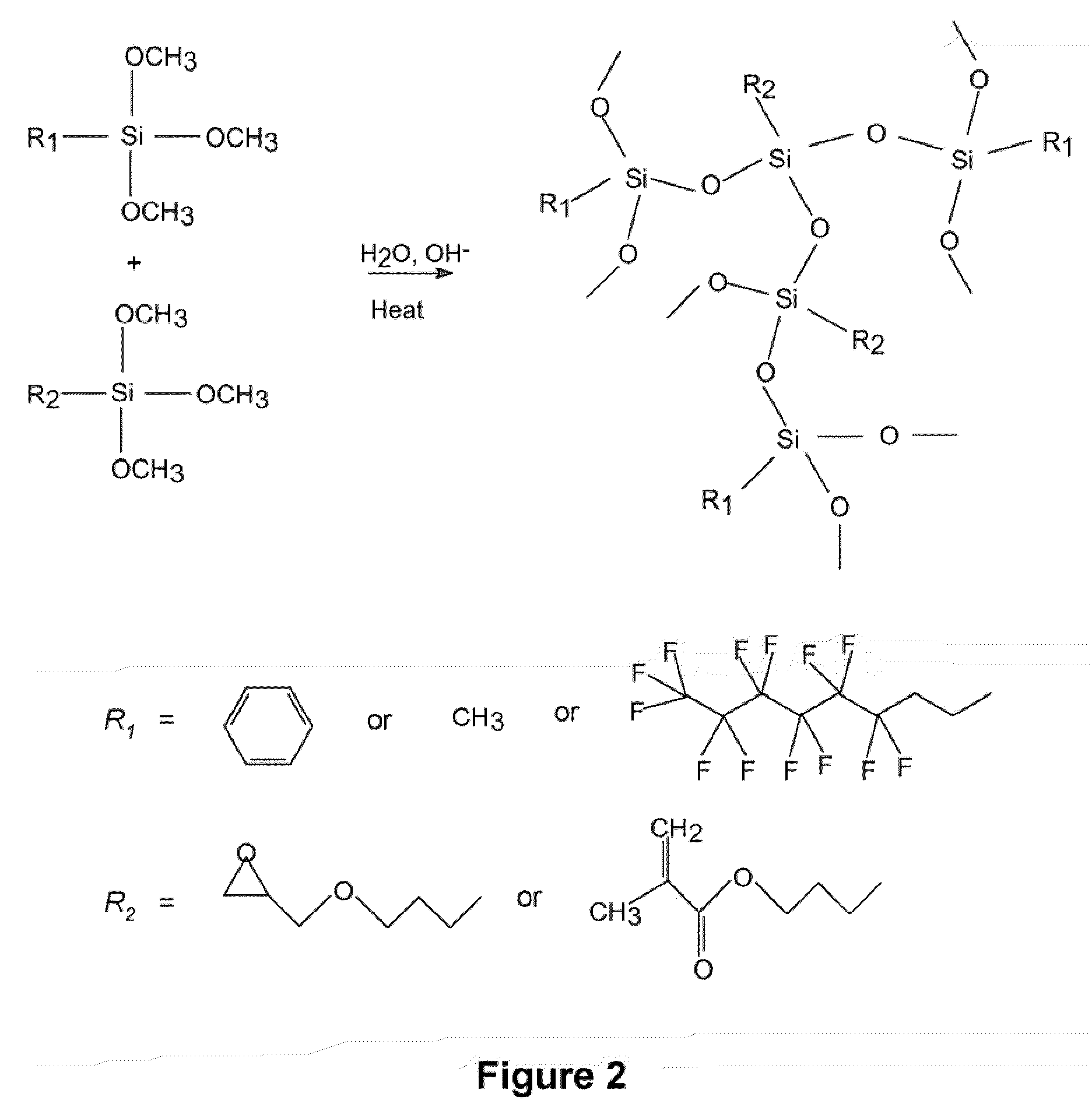

UV Curable Silsesquioxane Resins For Nanoprint Lithography

ActiveUS20090256287A1Simple compositionImprove methodPhotosensitive materialsNanoinformaticsNanolithographyResist

Radiation-curable silsesquioxane resin materials are employed for micro- and nanolithography. The resin materials can include a radiation-curable silsesquioxane resin and a photo-initiator having low viscosity. The low viscosity of the liquid system allows imprinting with low pressure and low temperature; e.g. room temperature. The resist's dry etching resistance is increased and the cured film is more easily separated from the mask. Due to its high modulus after cure, the material allows the fabrication of micro- and nano-features having high aspect ratios while providing a high throughput. Various pattern sizes, for example, ranging from tens of microns to as small as a few nanometers, may be achieved with the UV-curable material system.

Owner:RGT UNIV OF MICHIGAN

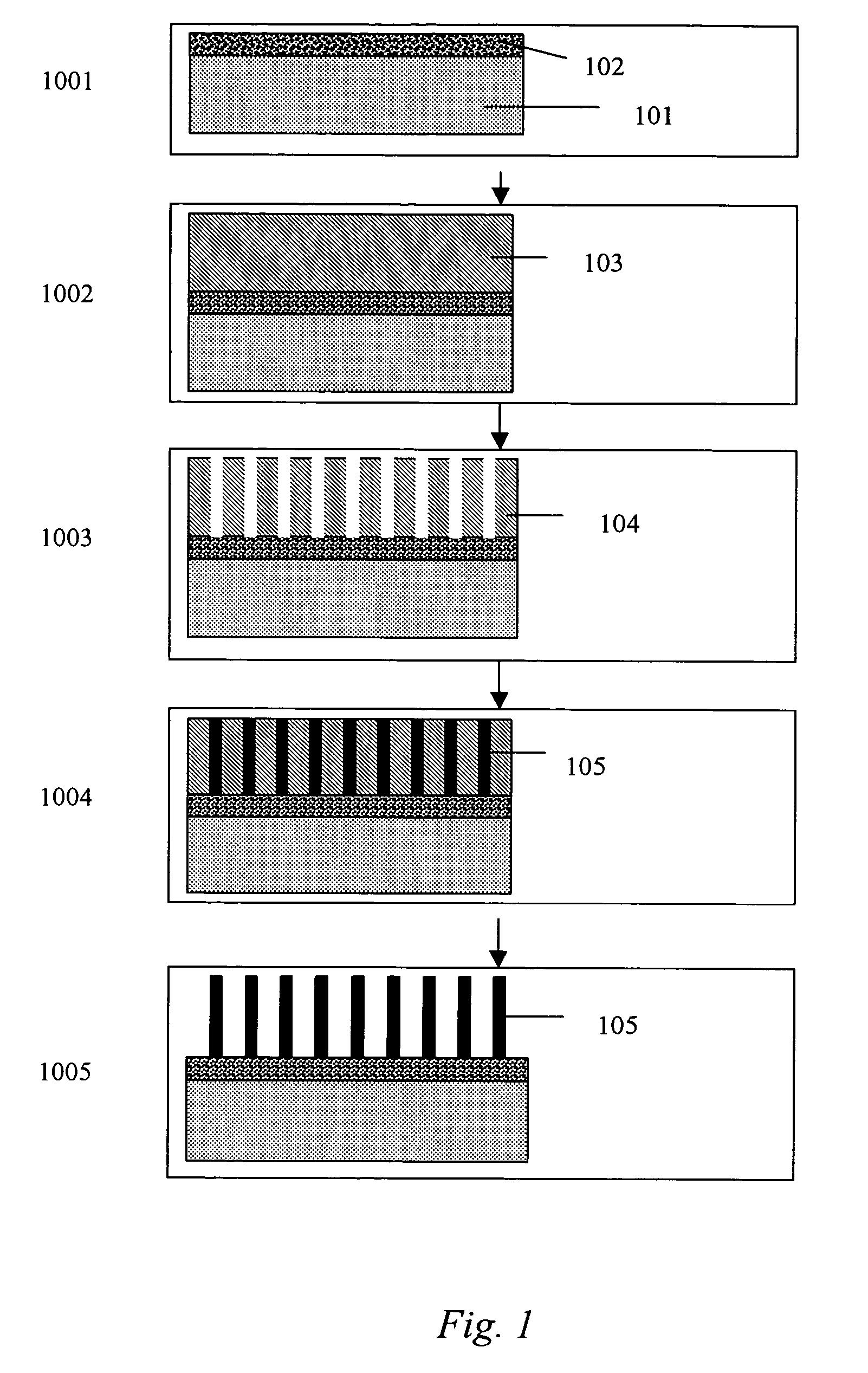

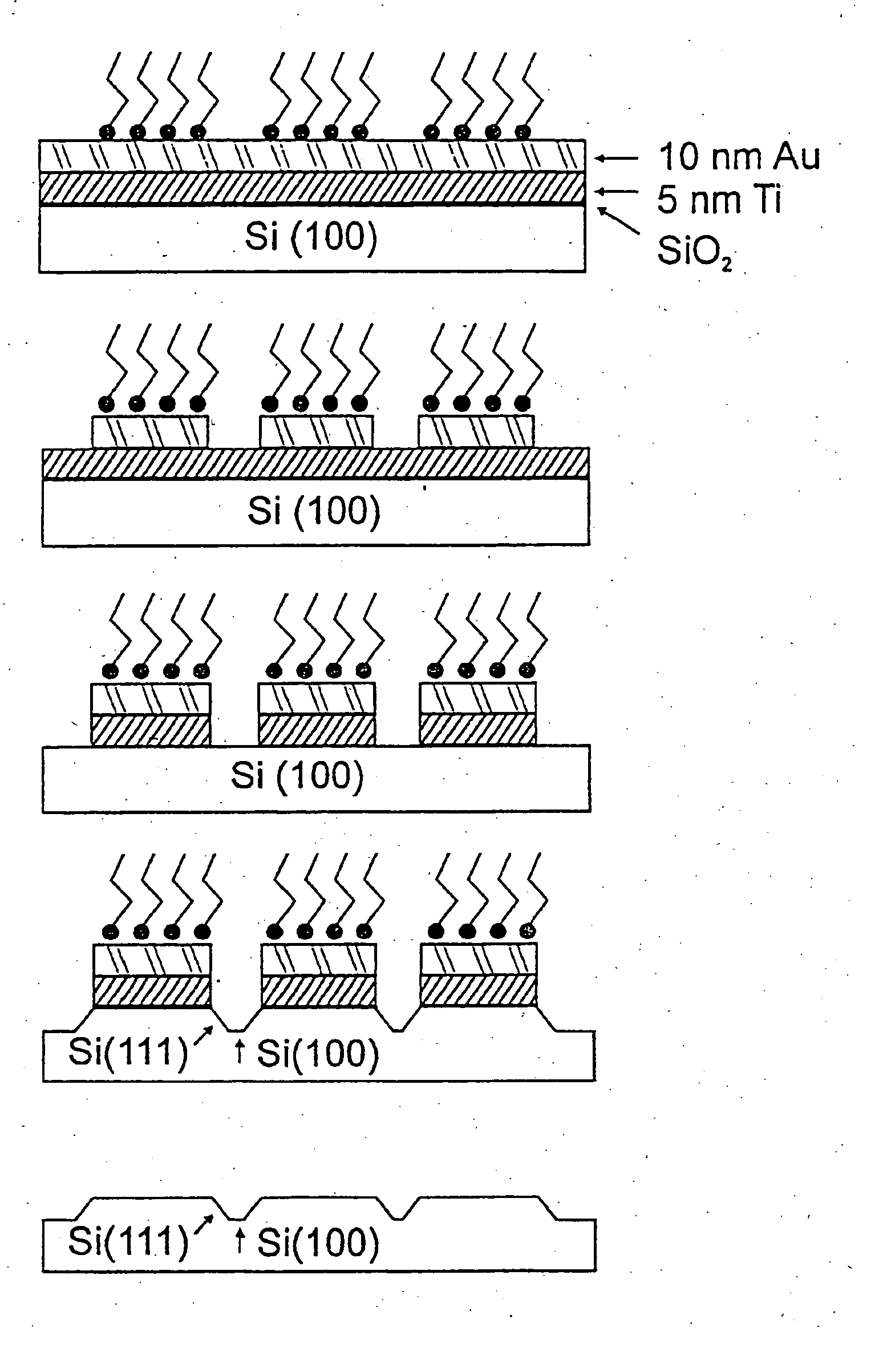

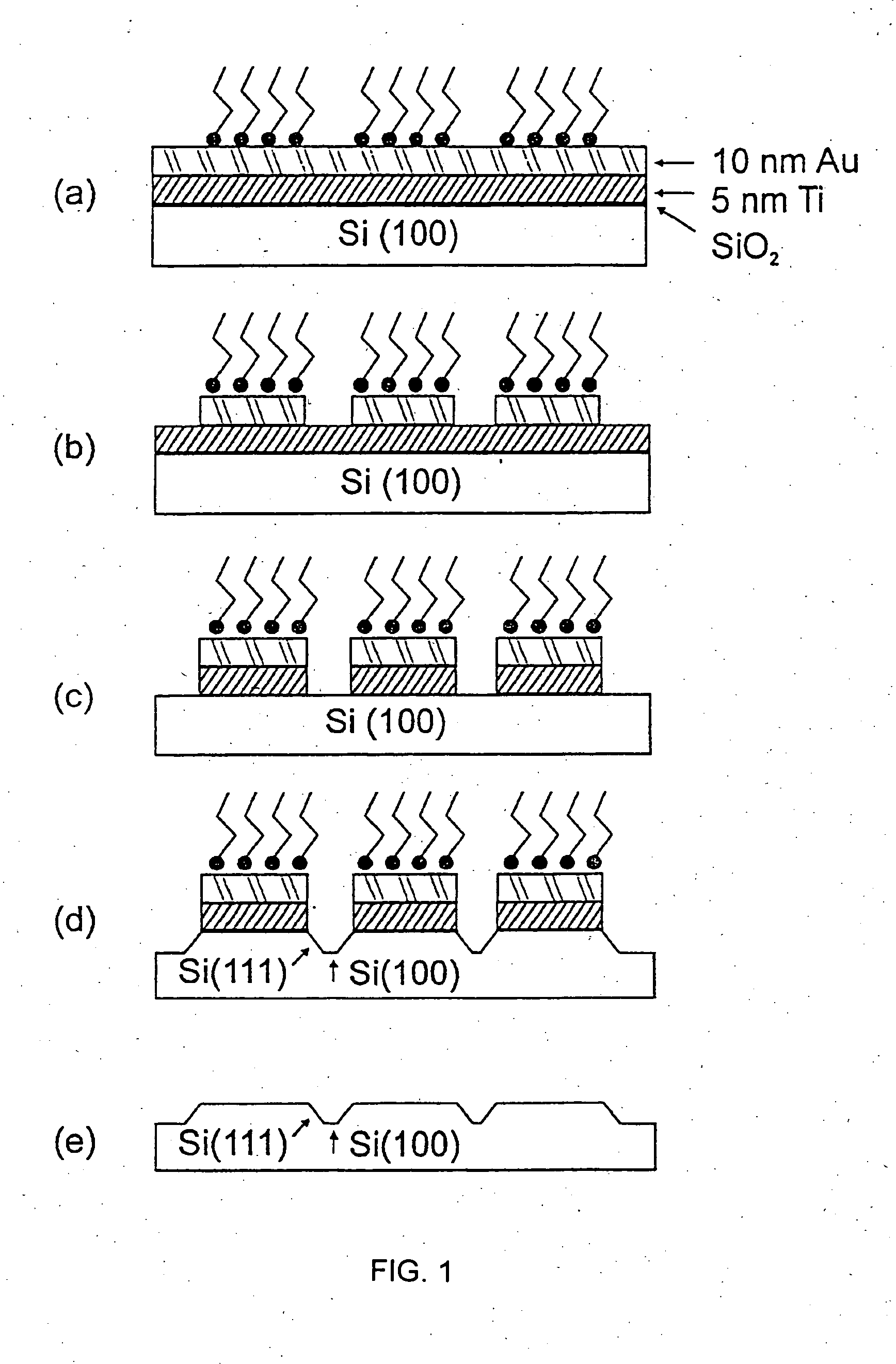

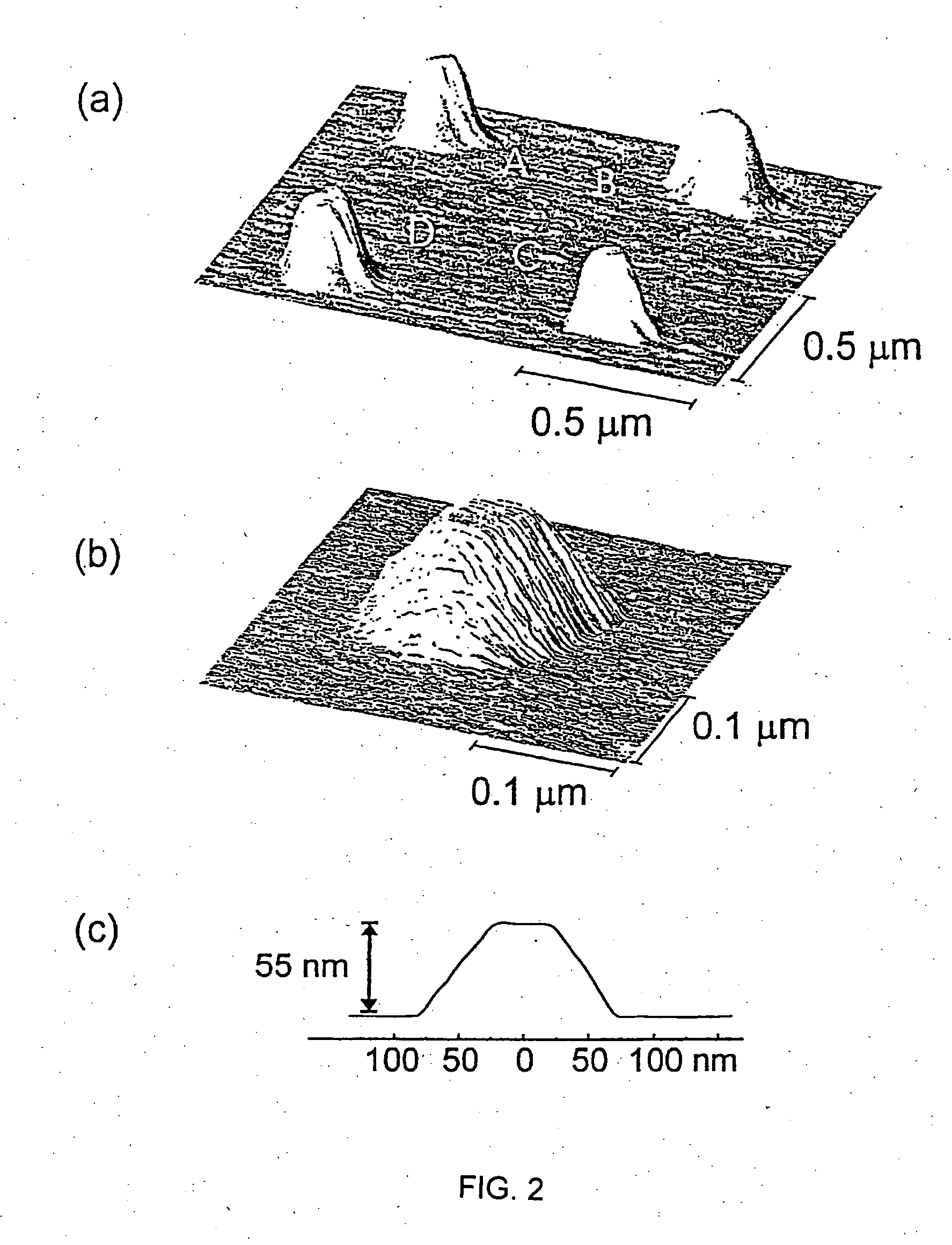

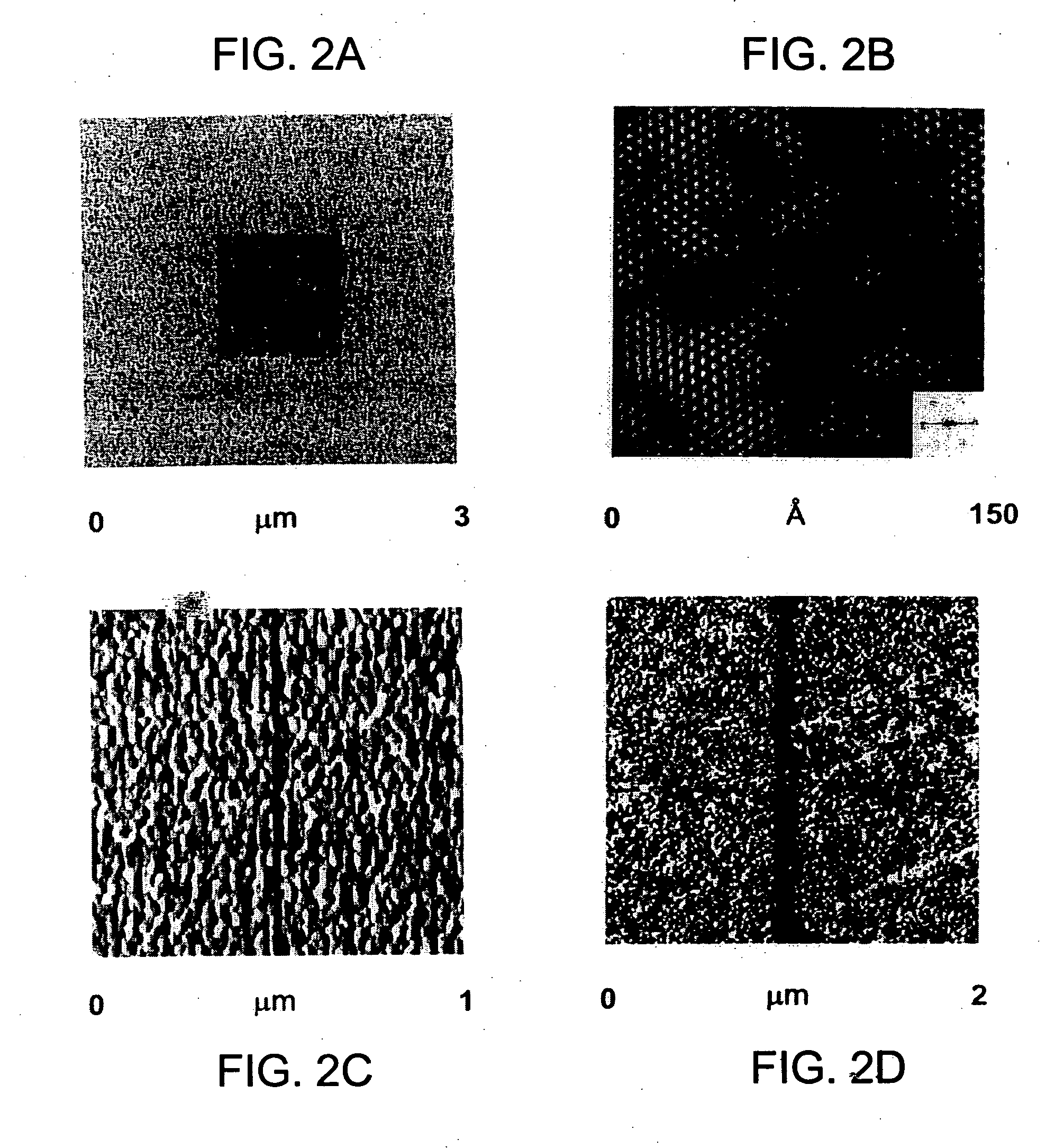

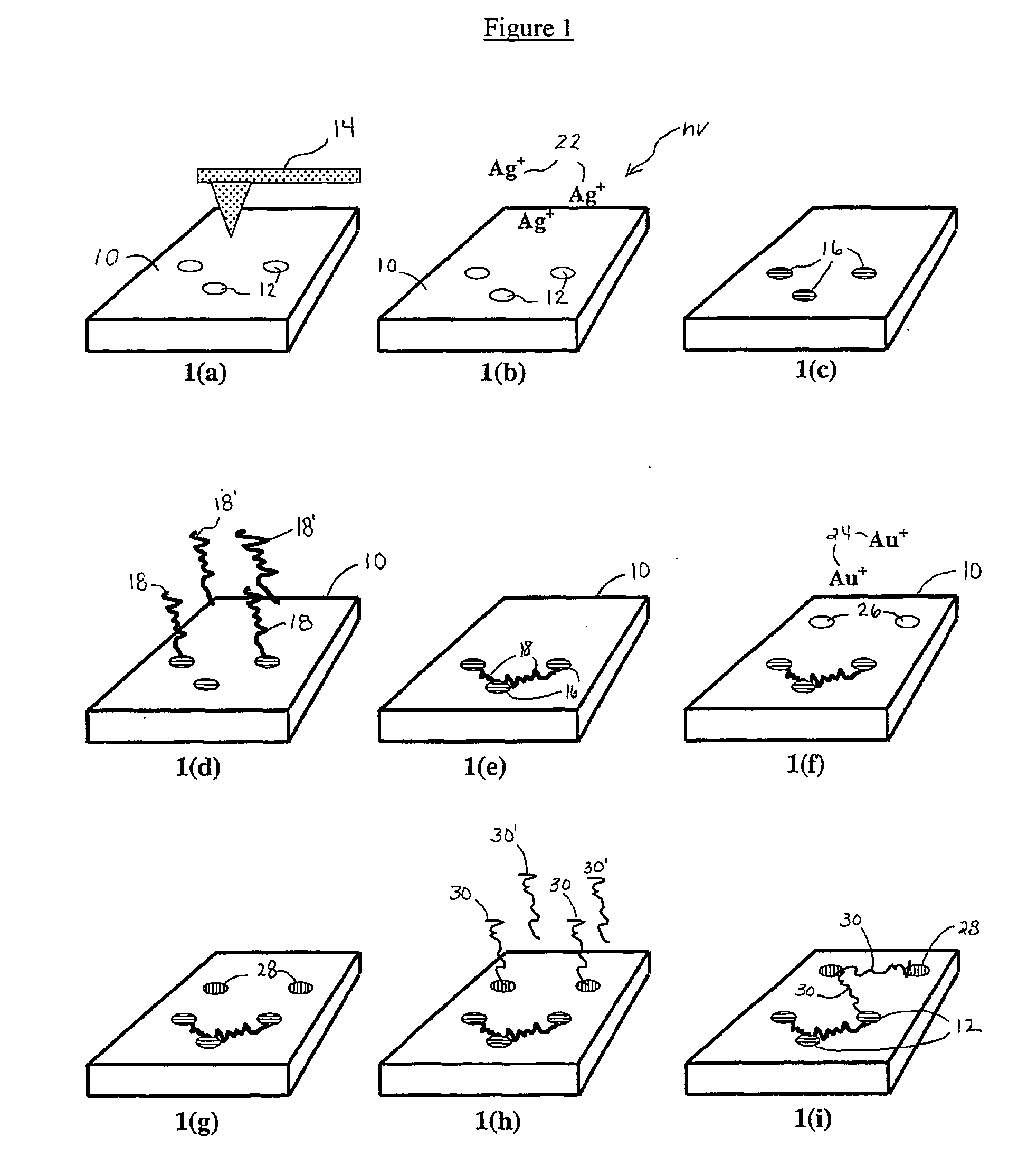

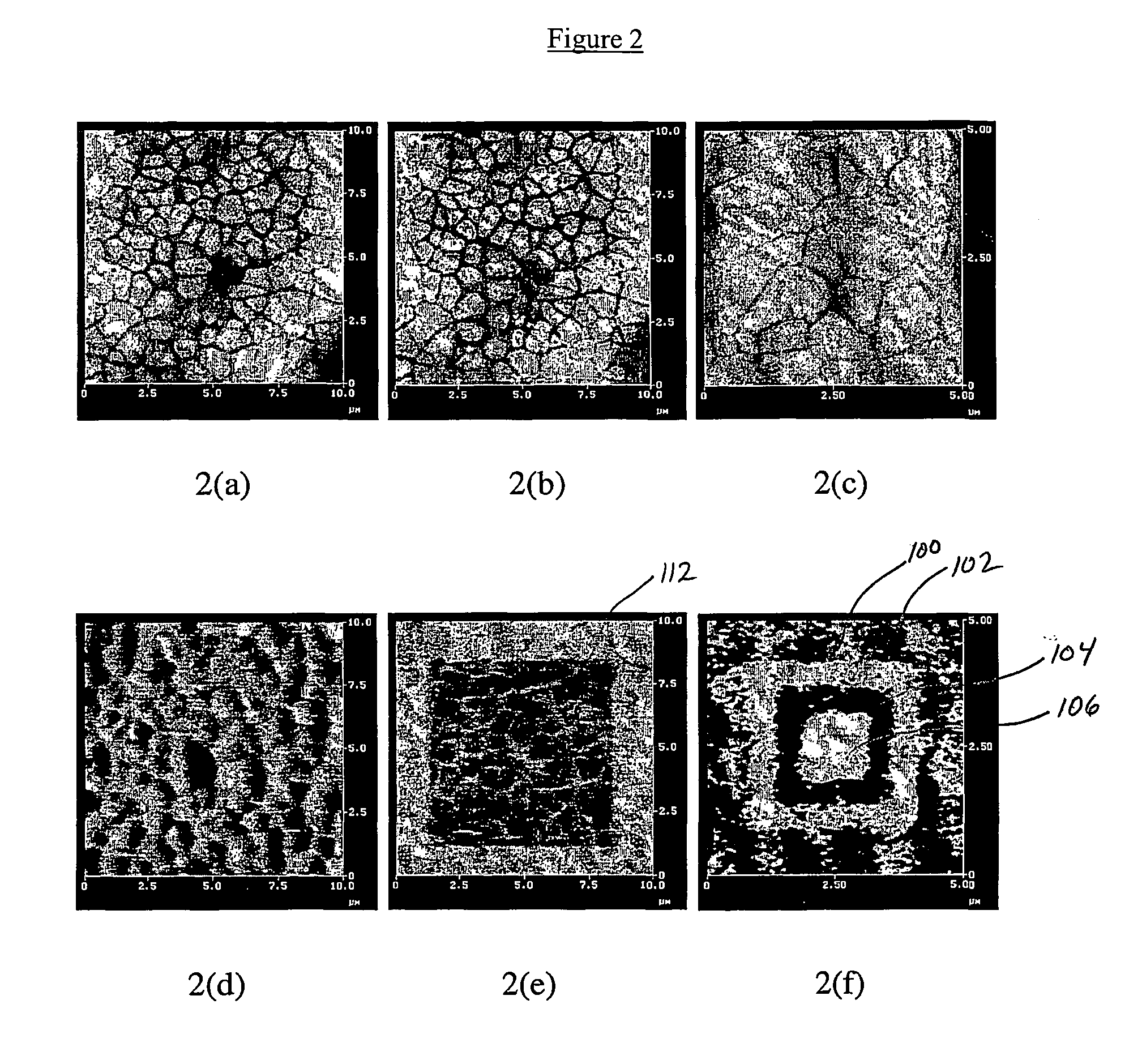

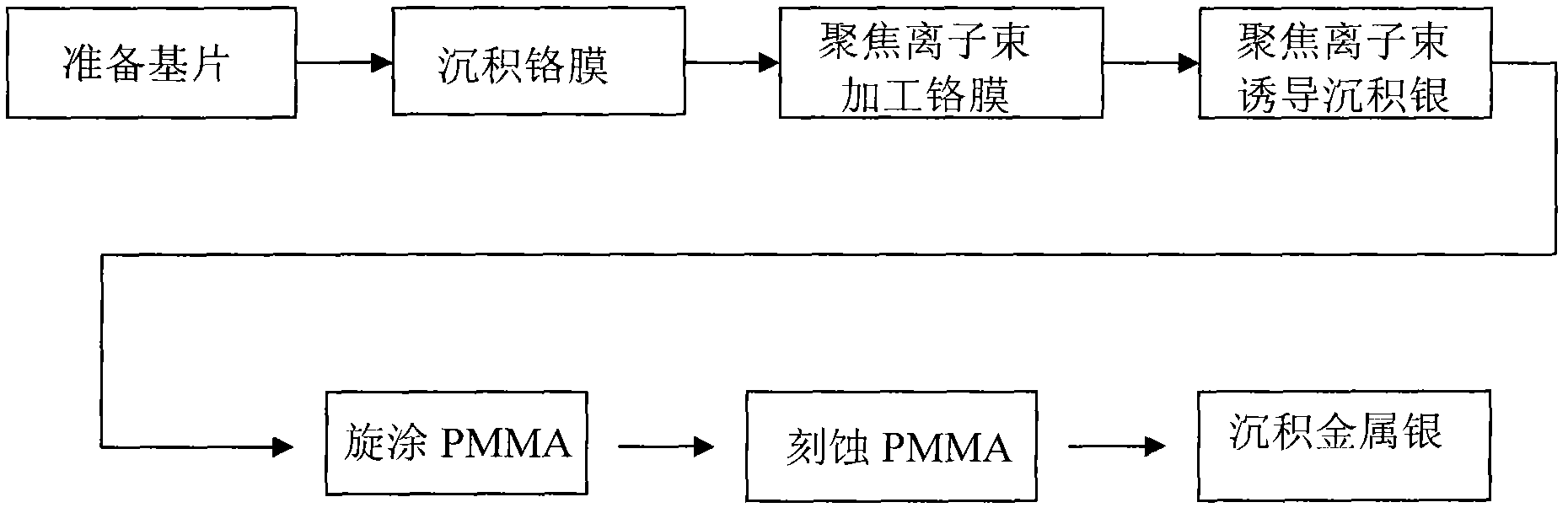

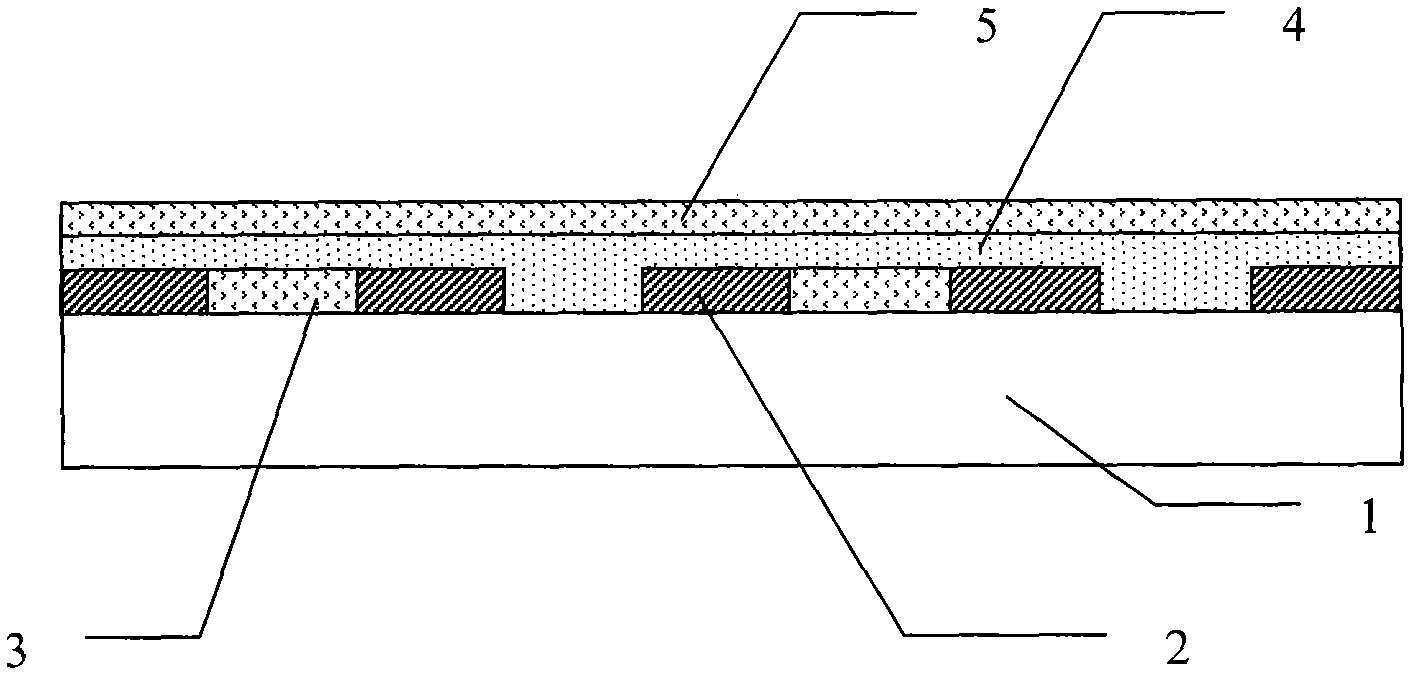

Fabrication of sub-50 nm solid-state nanostructures based on nanolithography

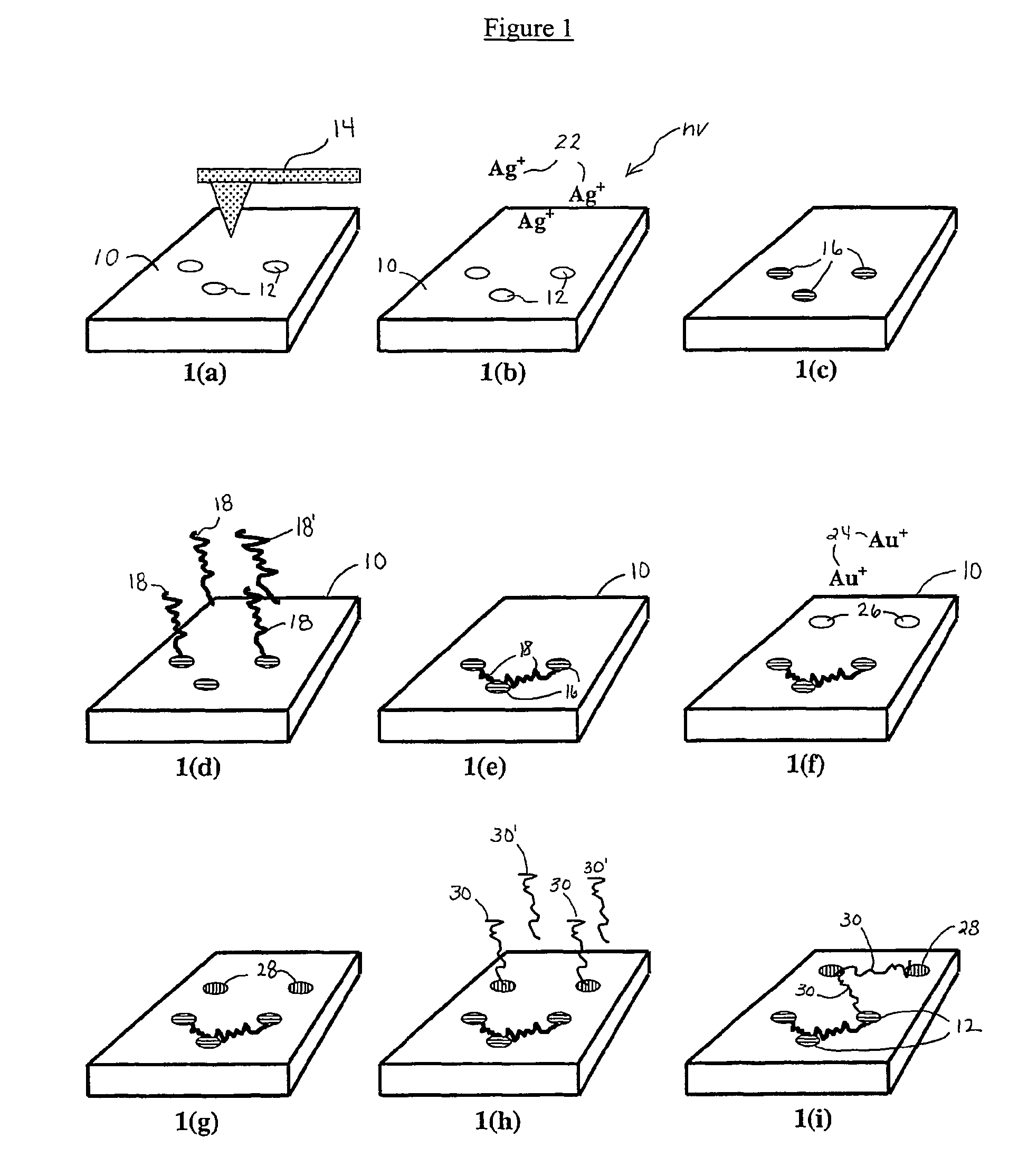

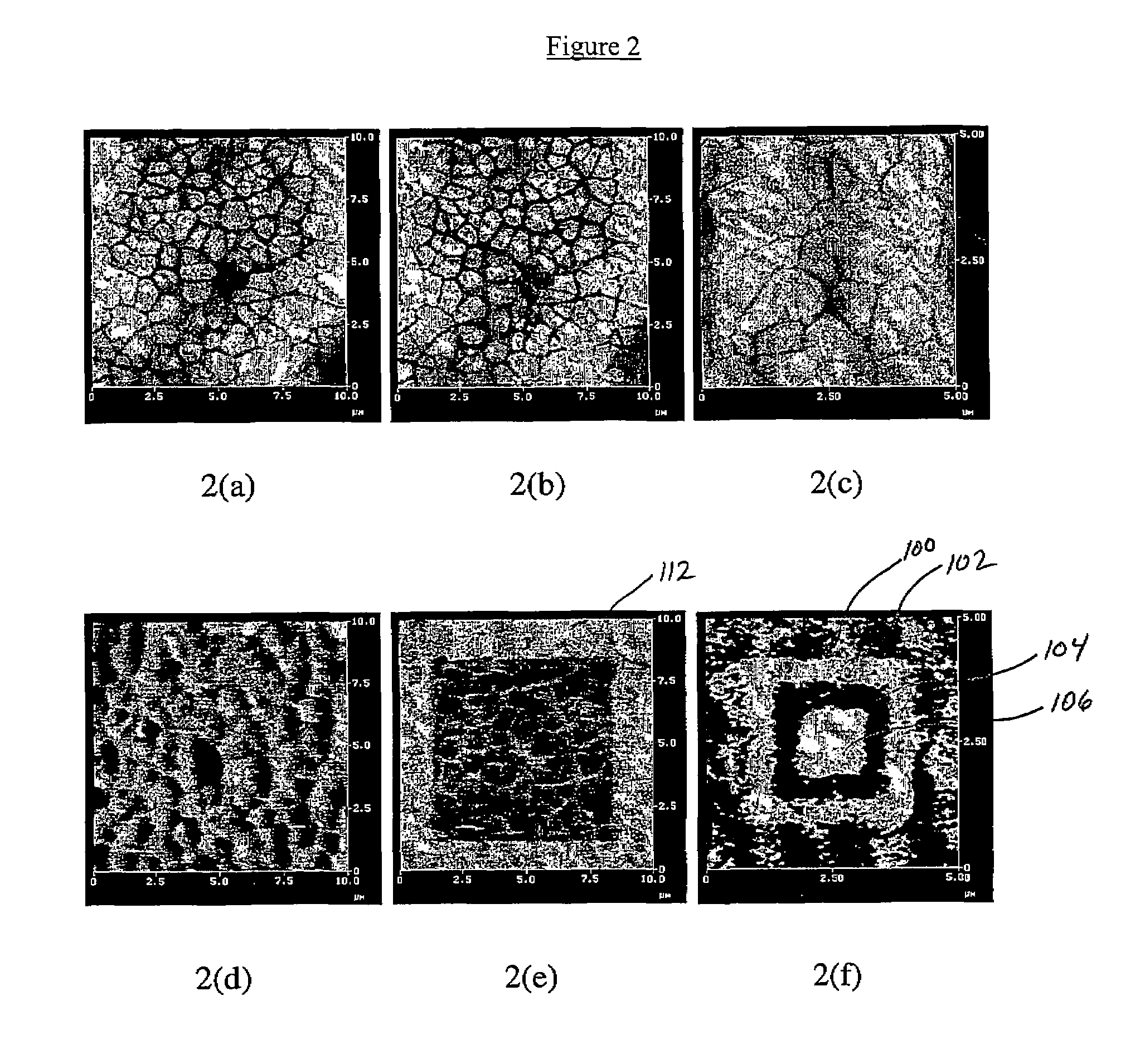

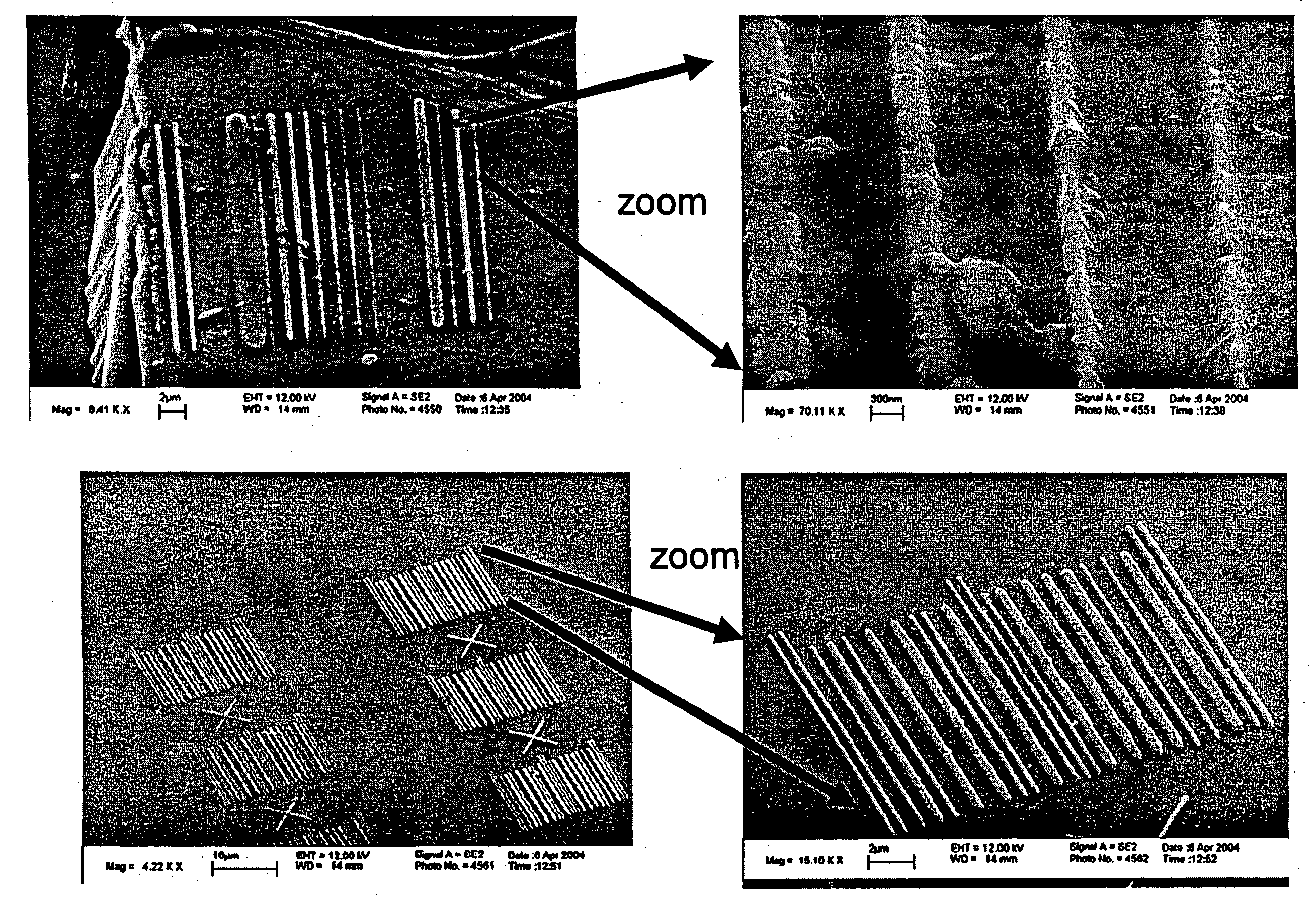

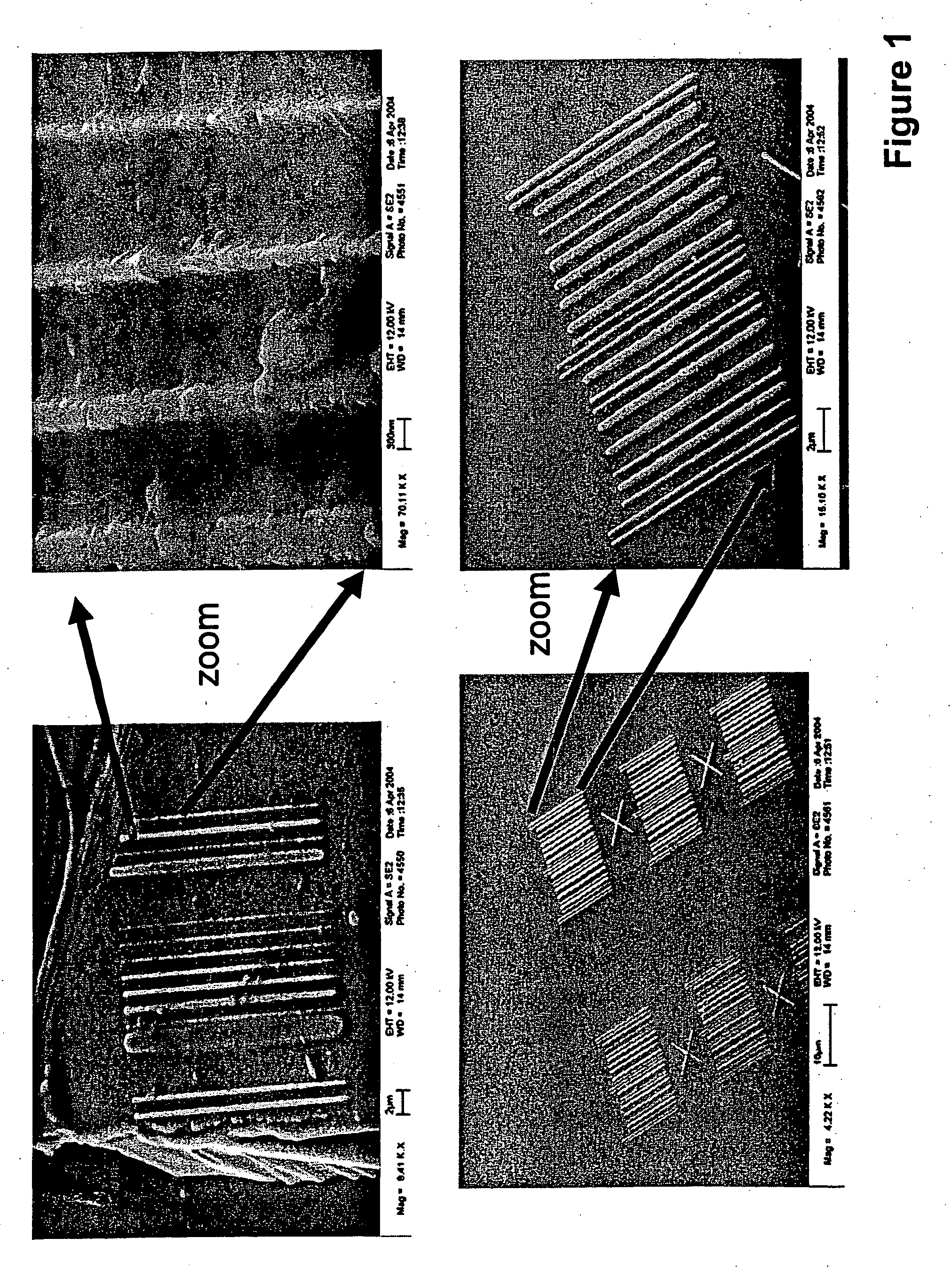

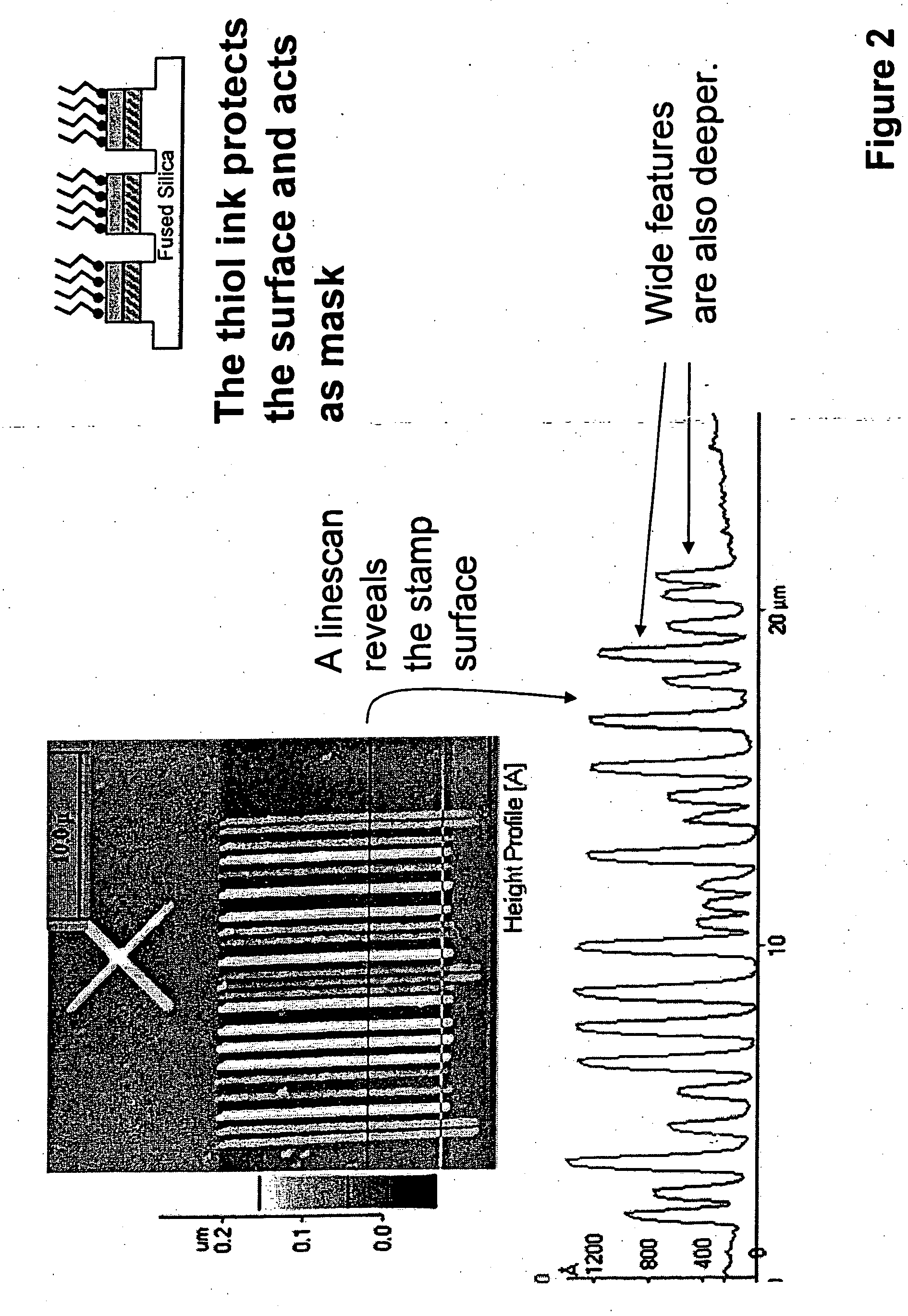

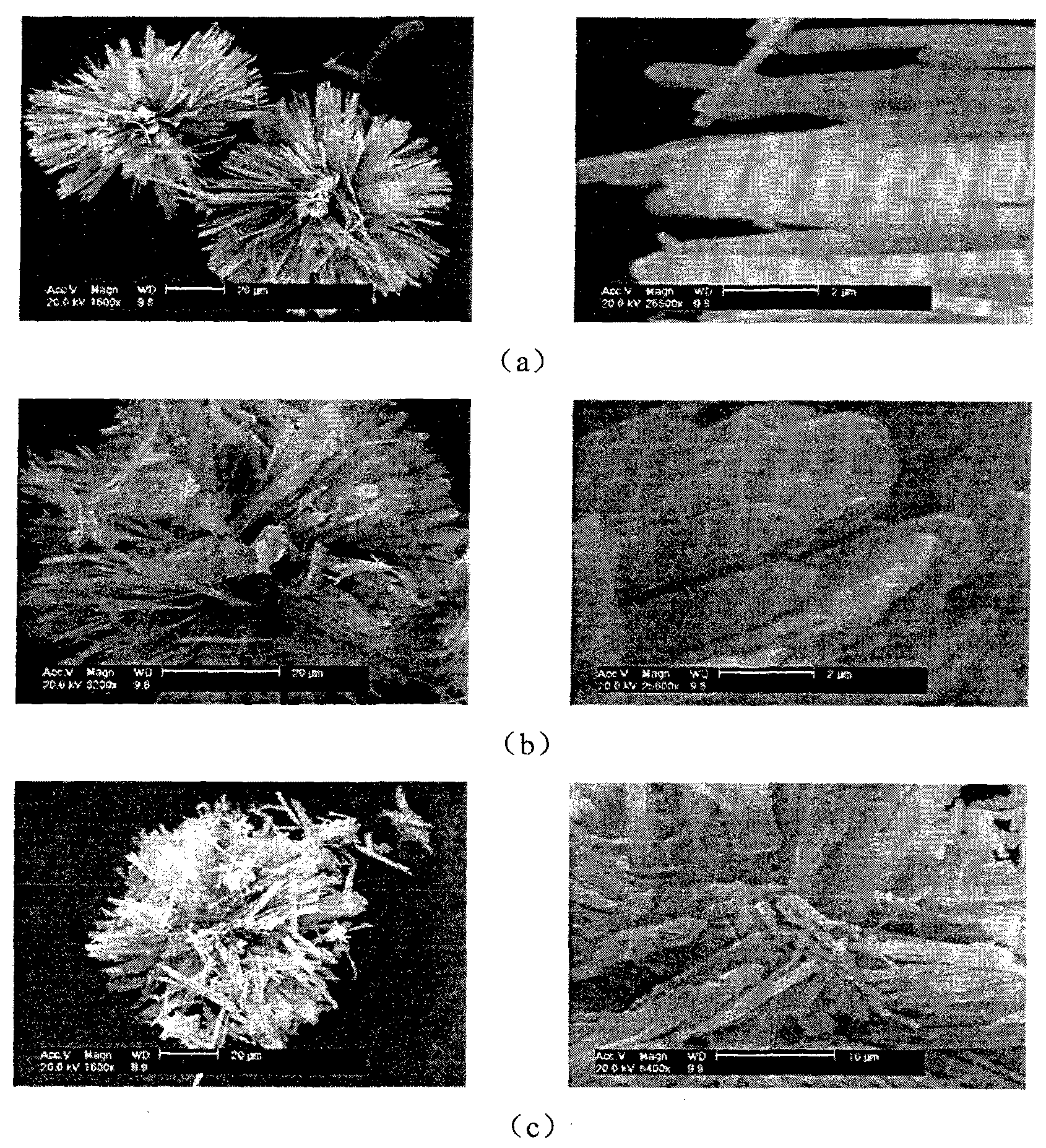

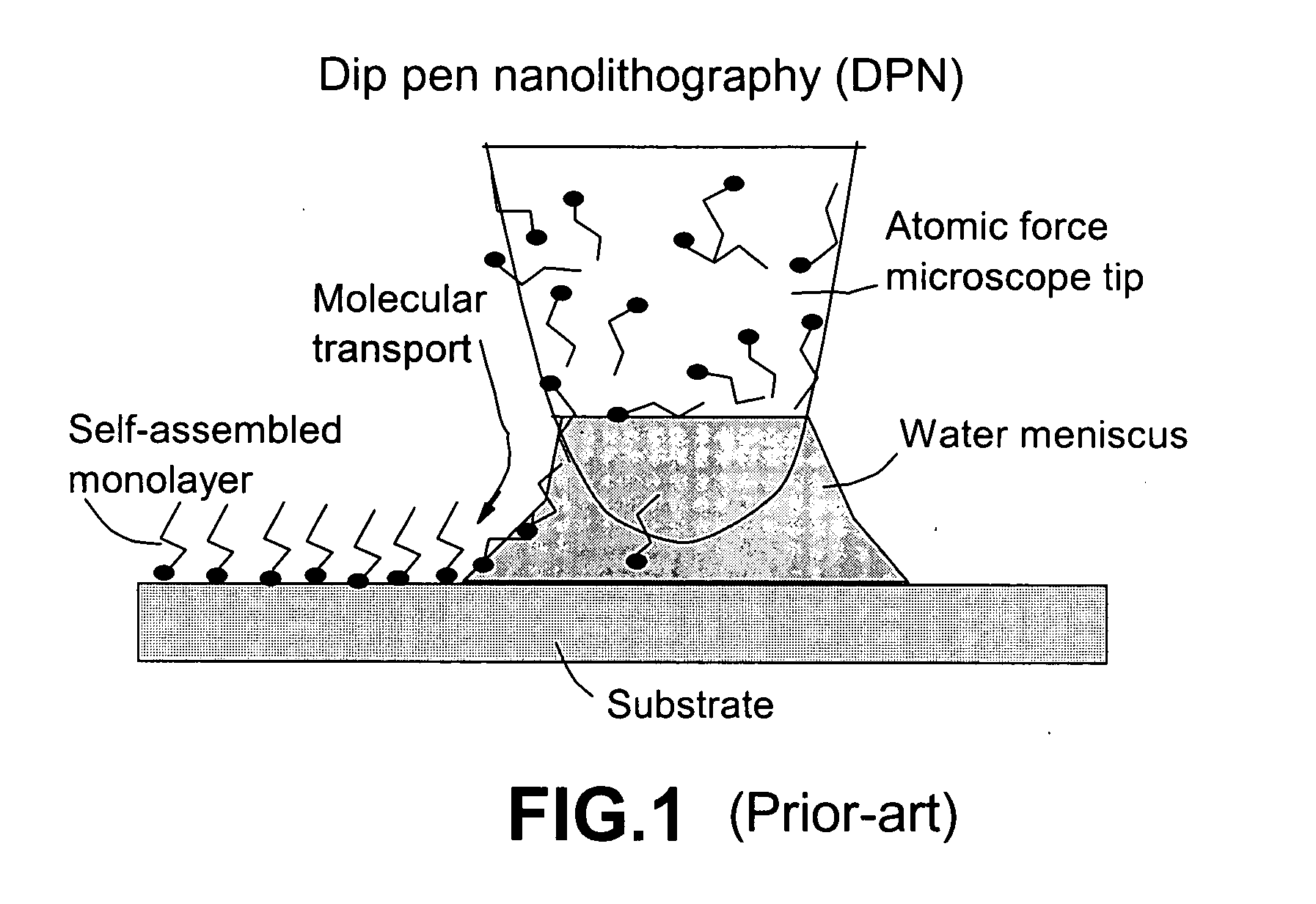

InactiveUS20060014001A1High resolutionMaterial nanotechnologyDecorative surface effectsResistDip-pen nanolithography

Combination of nanolithography and wet chemical etching including the fabrication of nanoarrays of sub-50 nm gold dots and line structures with deliberately designed approximately 12-100 nm gaps. These structures were made by initially using direct write nanolithography to pattern the etch resist, 16-mercaptohexadecanoic acid (MHA), on Au / Ti / SiOx / Si substrates and then wet chemical etching to remove the exposed gold. These are the smallest Au structures prepared by a wet chemical etching strategy. Also, Dip-Pen Nanolithography (DPN) has been used to generate resist layers on Au, Ag, and Pd that when combined with wet chemical etching can lead to nanostructures with deliberately designed shapes and sizes. Monolayers of mercaptohexadecanoic acid (MHA) or octadecanethiol (ODT), patterned by DPN, were explored as etch resists. They work comparably well on Au and Ag, but ODT is the superior material for Pd. MHA seems to attract the FeCl3 etchant and results in nonuniform etching of the underlying Pd substrate. Dots, lines, triangles and circles, ranging in size from sub-100 to several hundred nm have been fabricated on these substrates. These results show how one can use DPN as an alternative to more complex and costly procedures like electron beam lithography to generate nanostructures from inorganic materials.

Owner:NORTHWESTERN UNIV

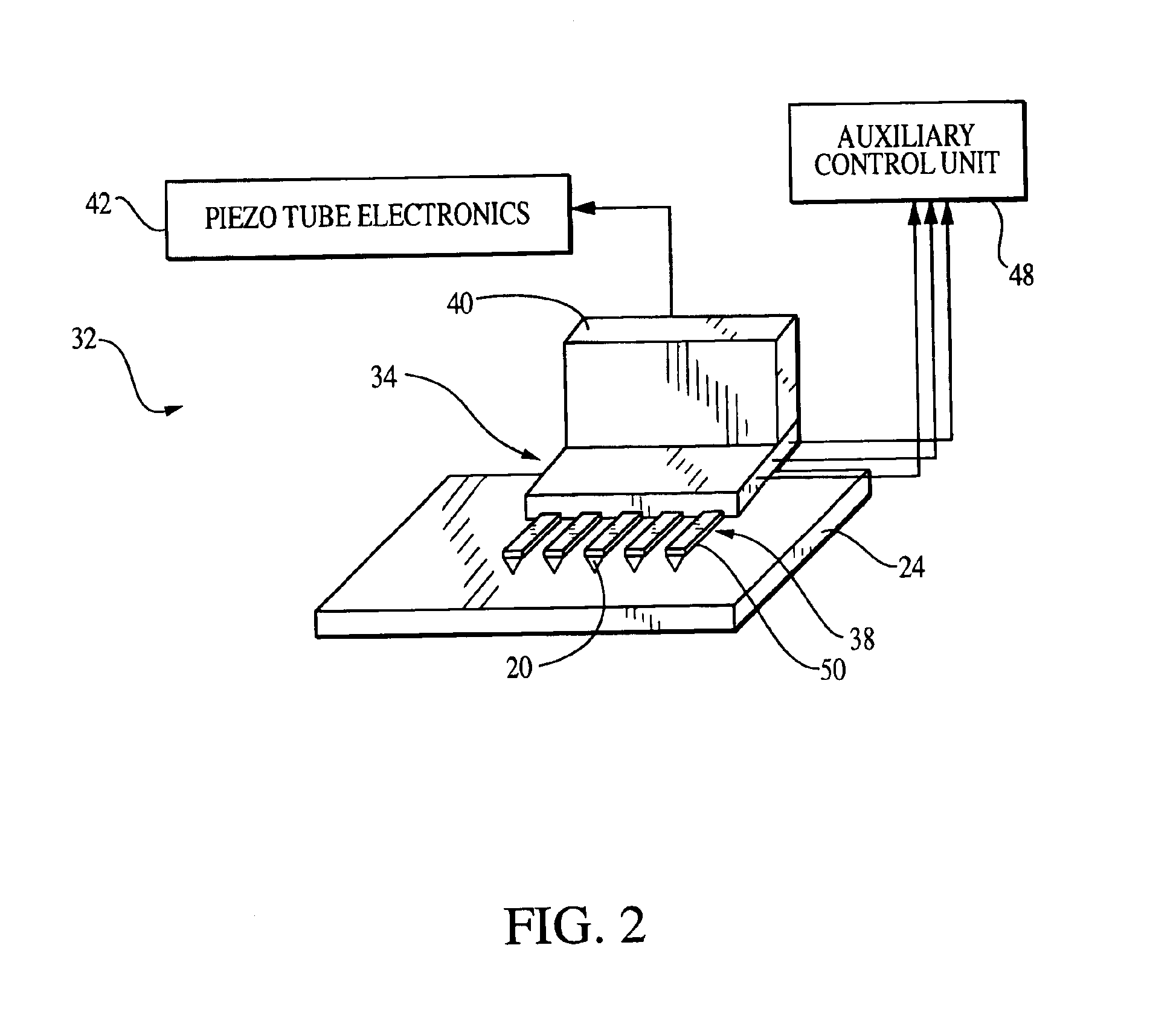

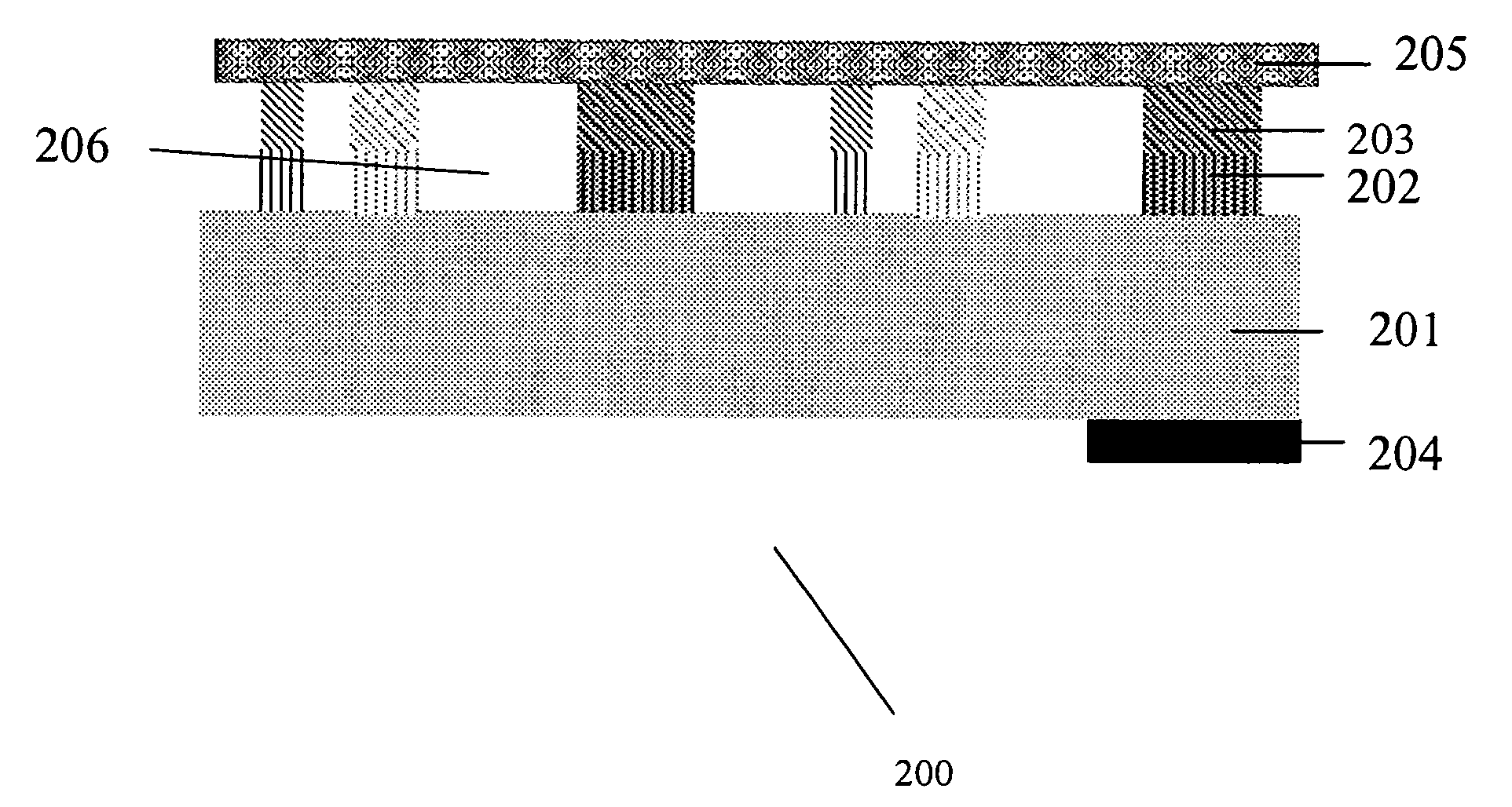

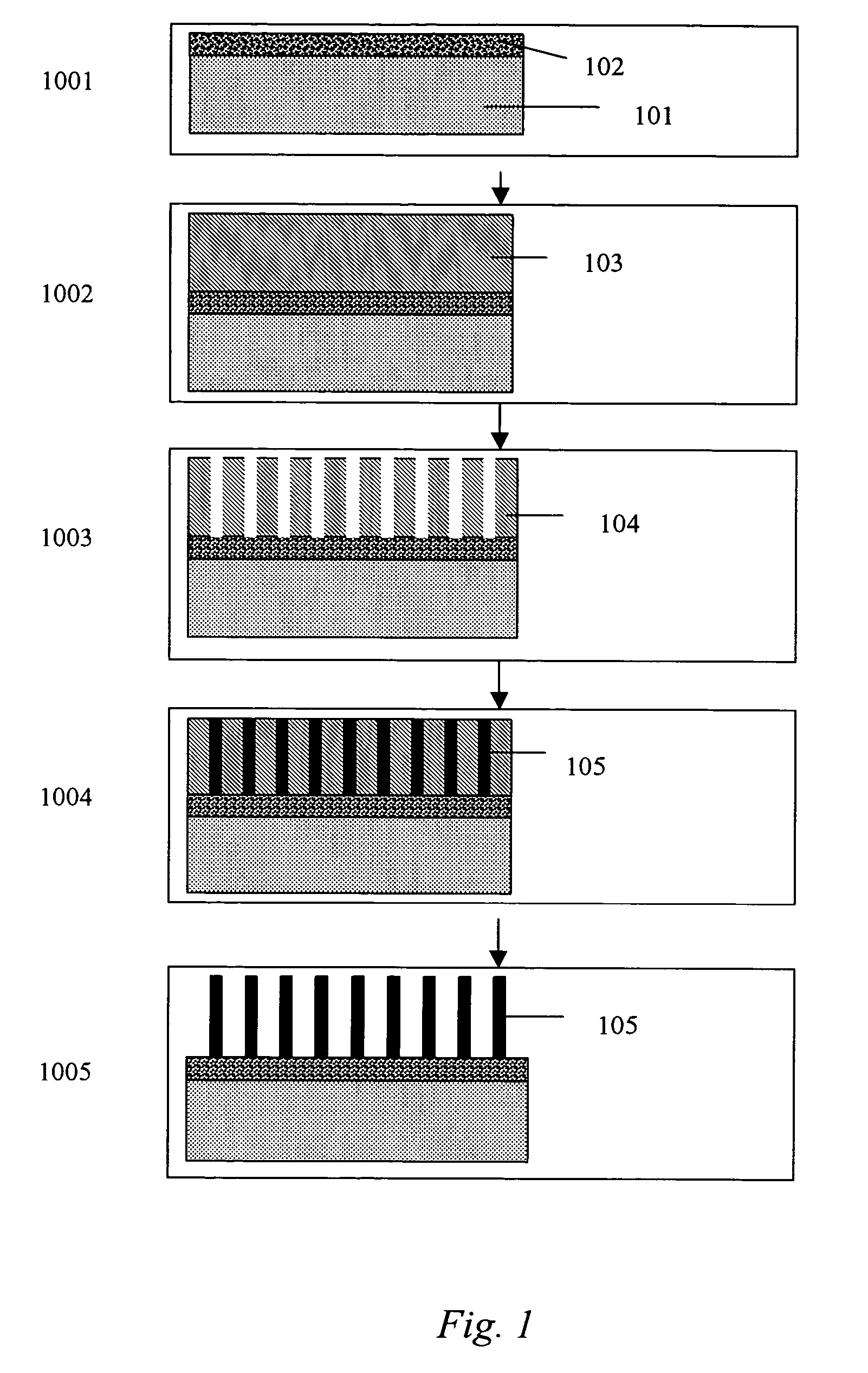

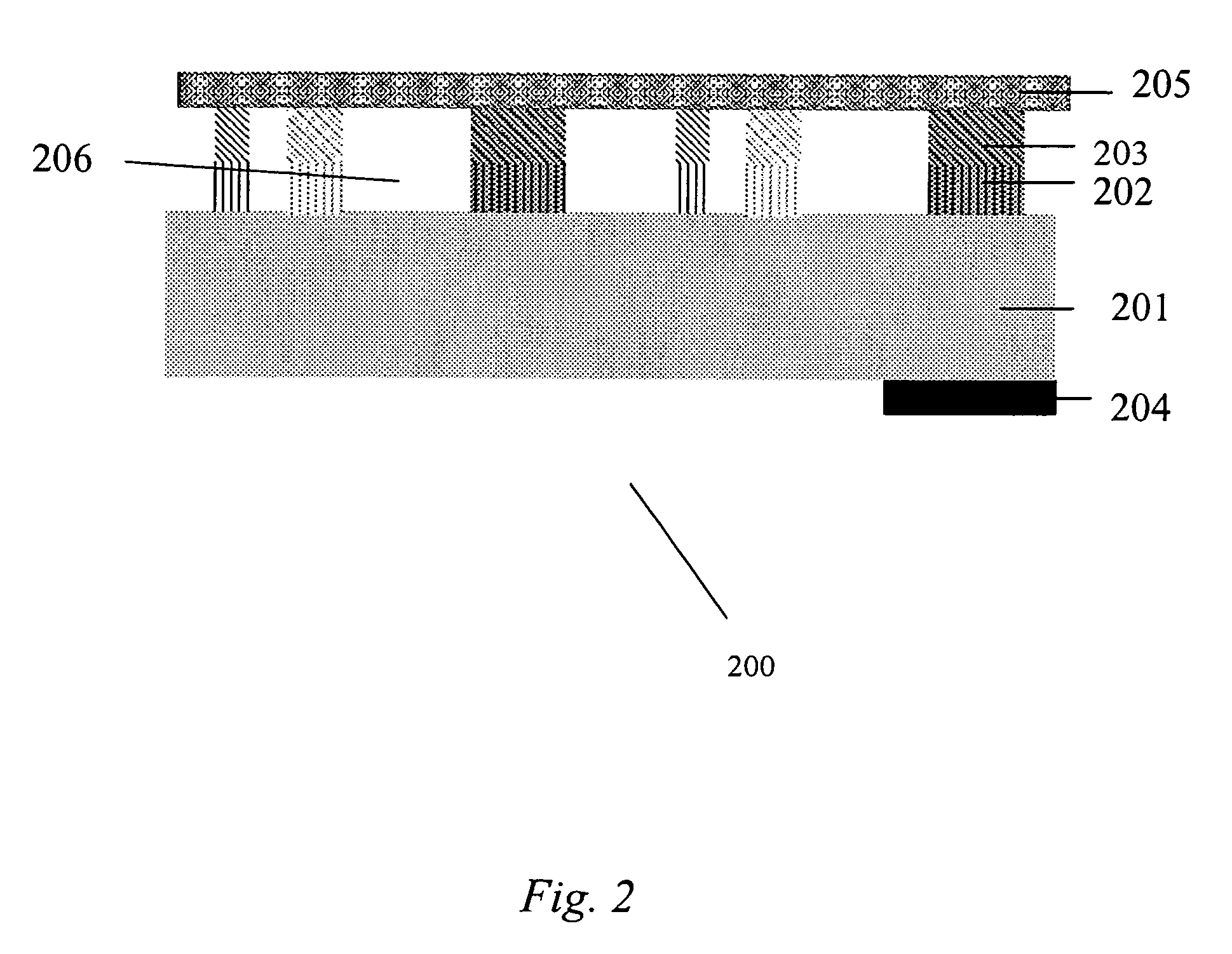

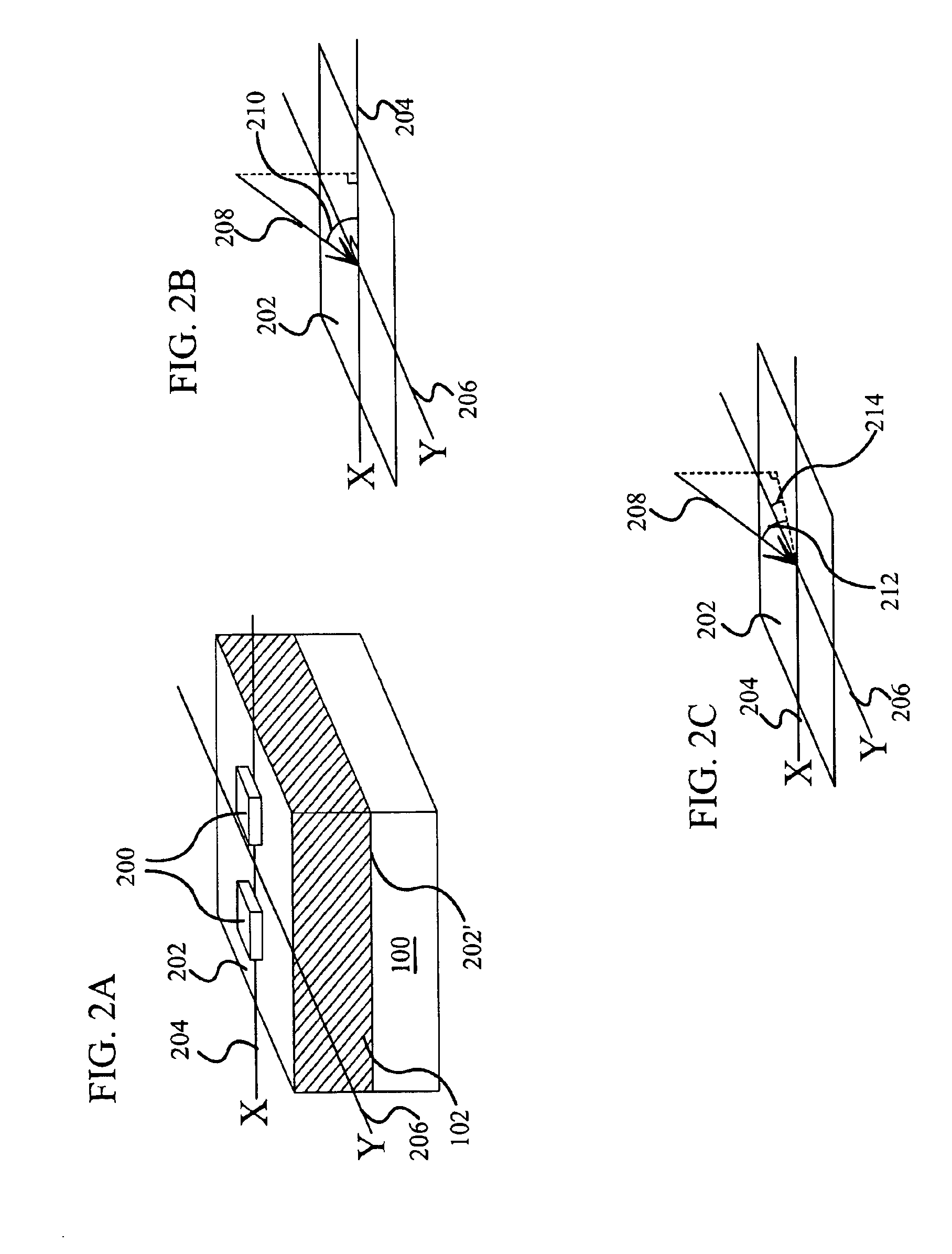

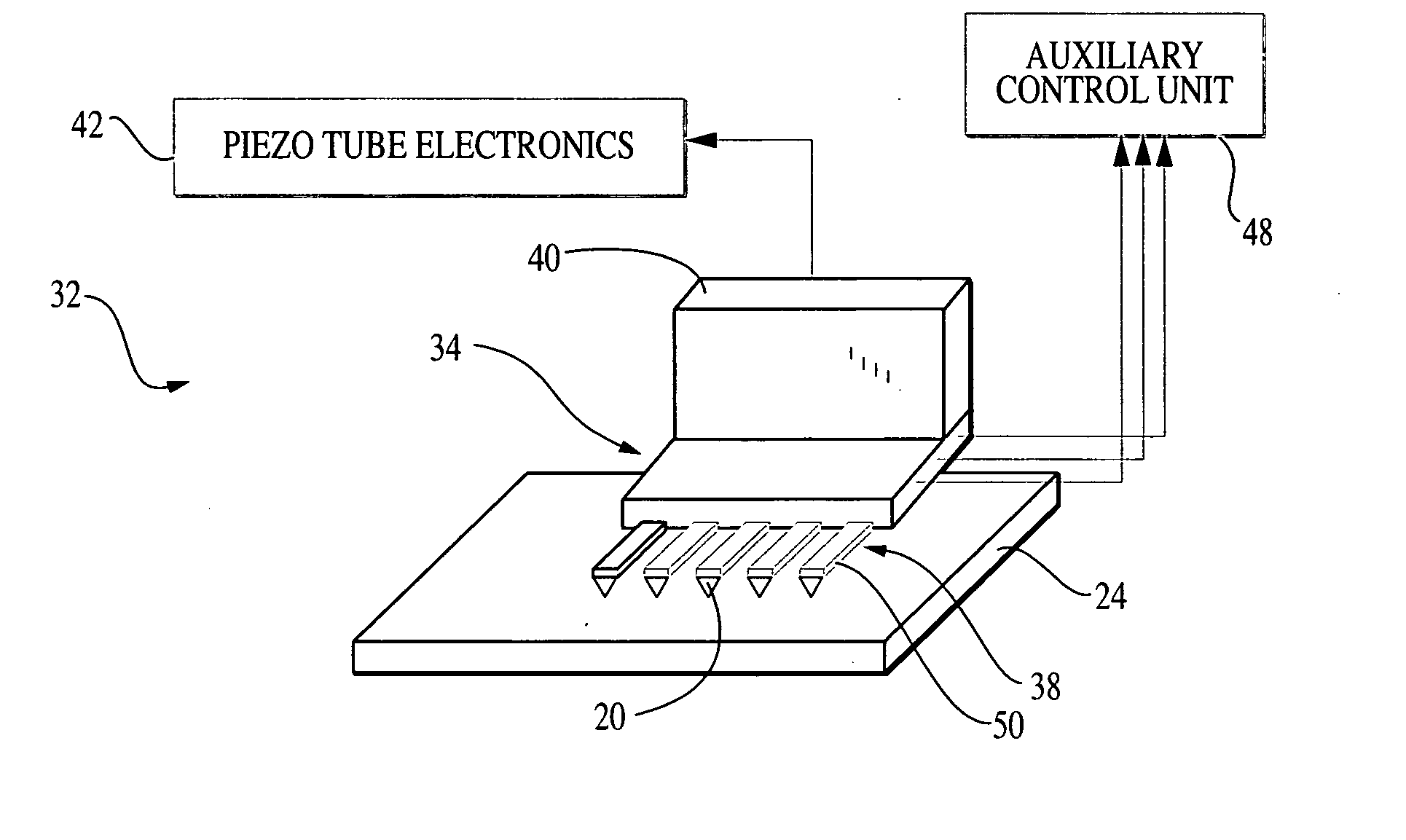

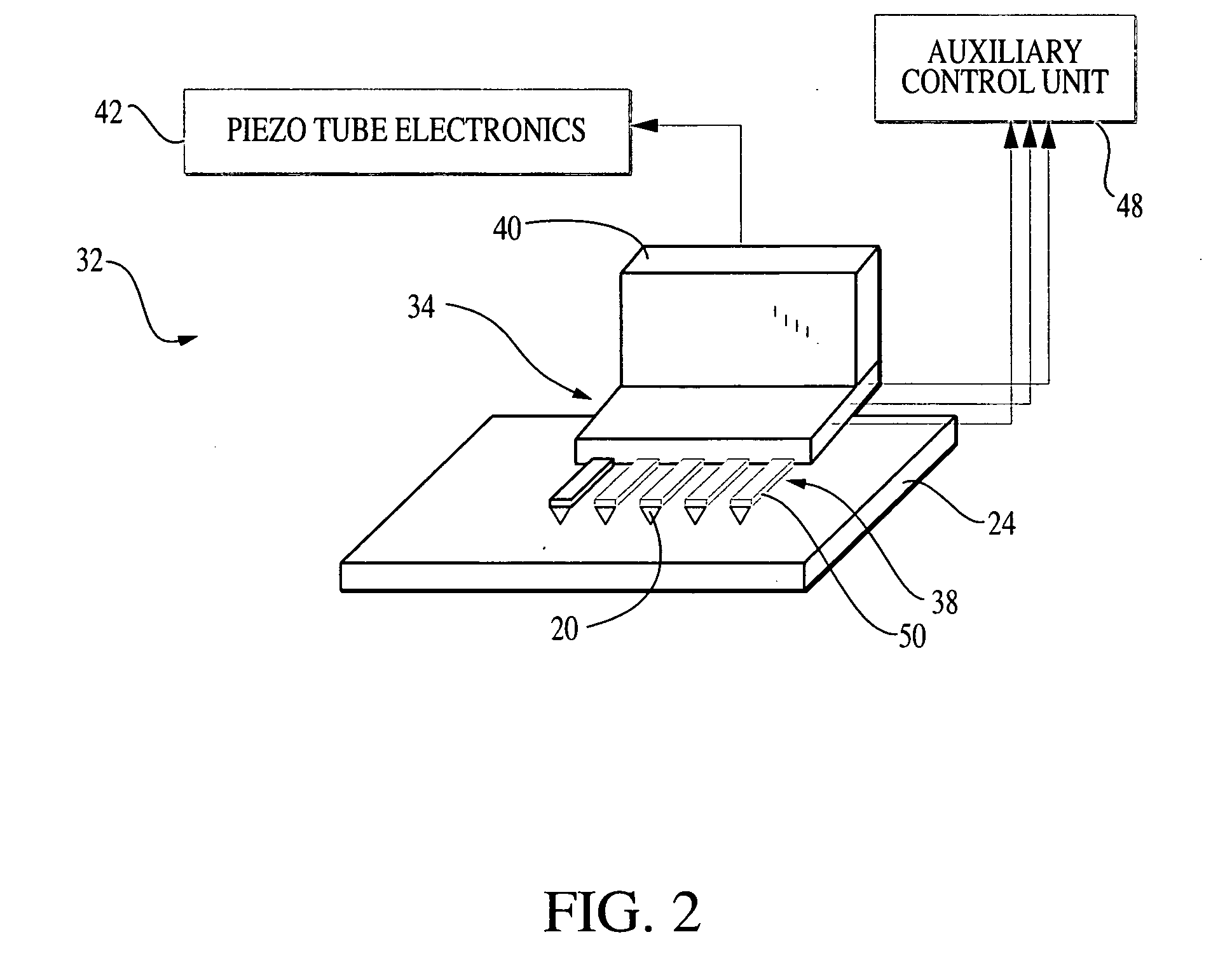

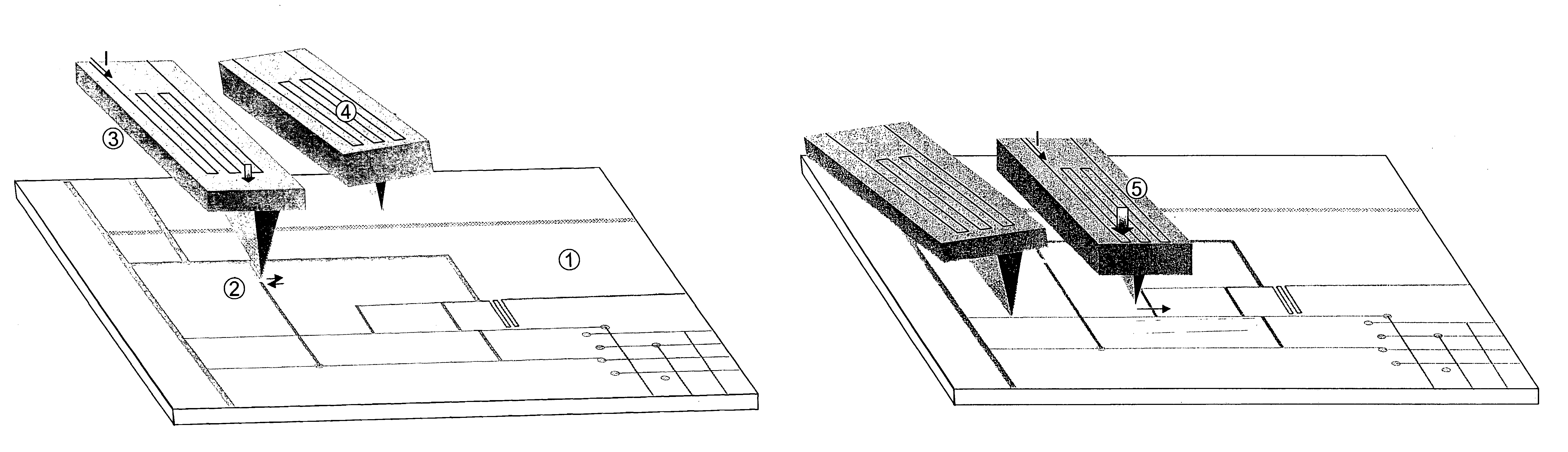

Parallel, individually addressable probes for nanolithography

InactiveUS6867443B2Increase temperatureImprove completenessNanoinformaticsSolid-state devicesNanolithographyImage resolution

A microfabricated probe array for nanolithography and process for designing and fabricating the probe array. The probe array consists of individual probes that can be moved independently using thermal bimetallic actuation or electrostatic actuation methods. The probe array can be used to produce traces of diffusively transferred chemicals on the substrate with sub-1 micrometer resolution, and can function as an arrayed scanning probe microscope for subsequent reading and variation of transferred patterns.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

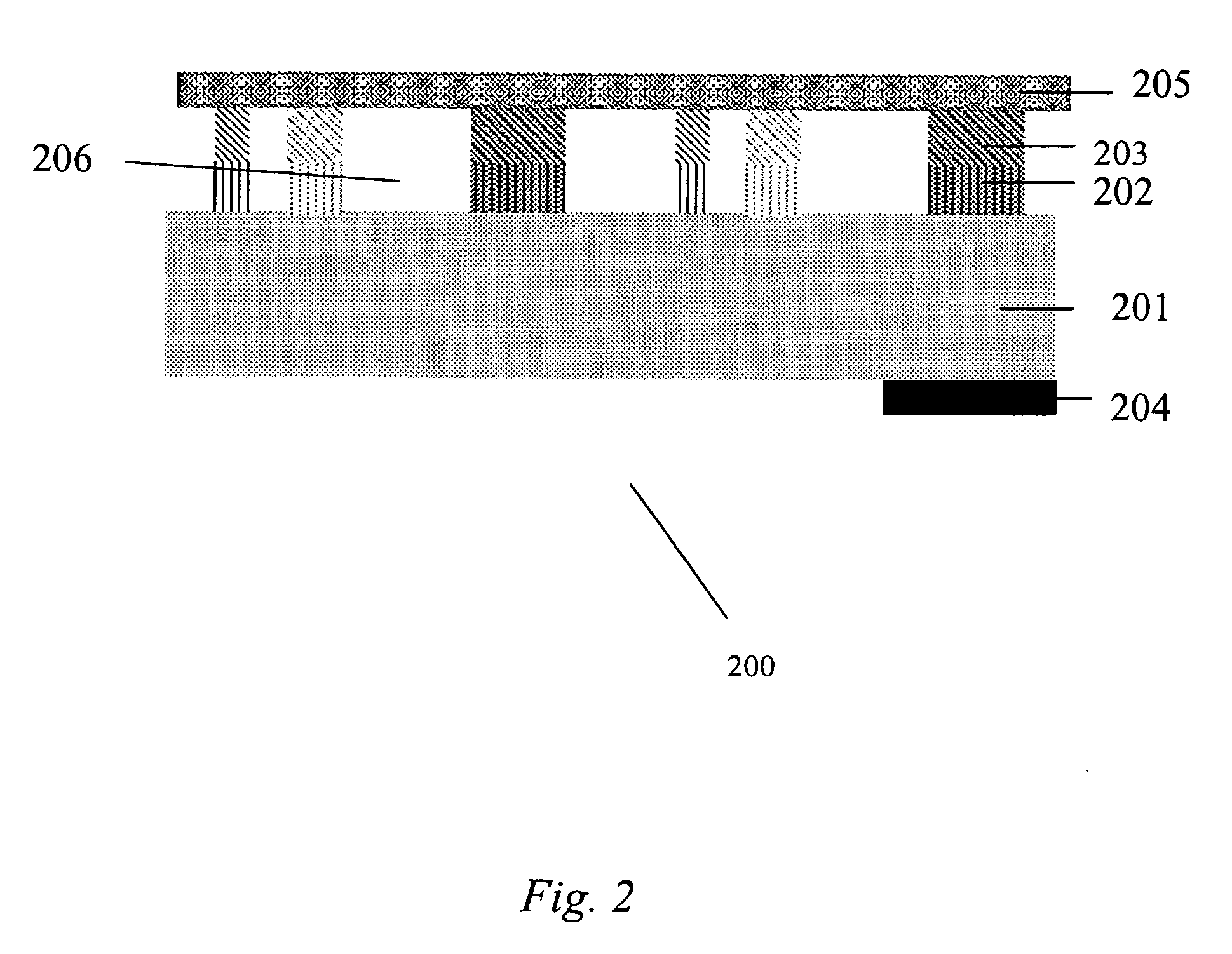

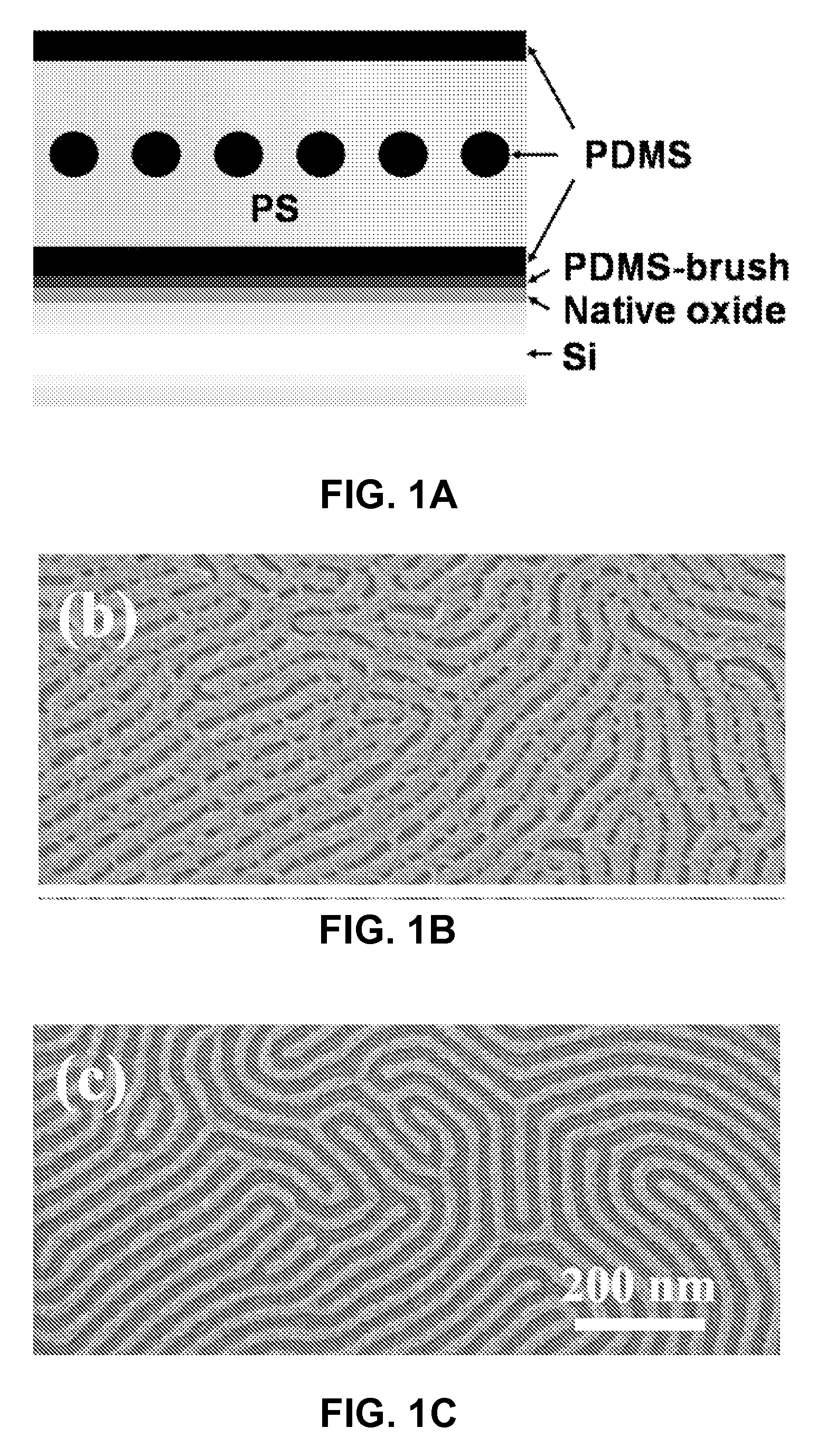

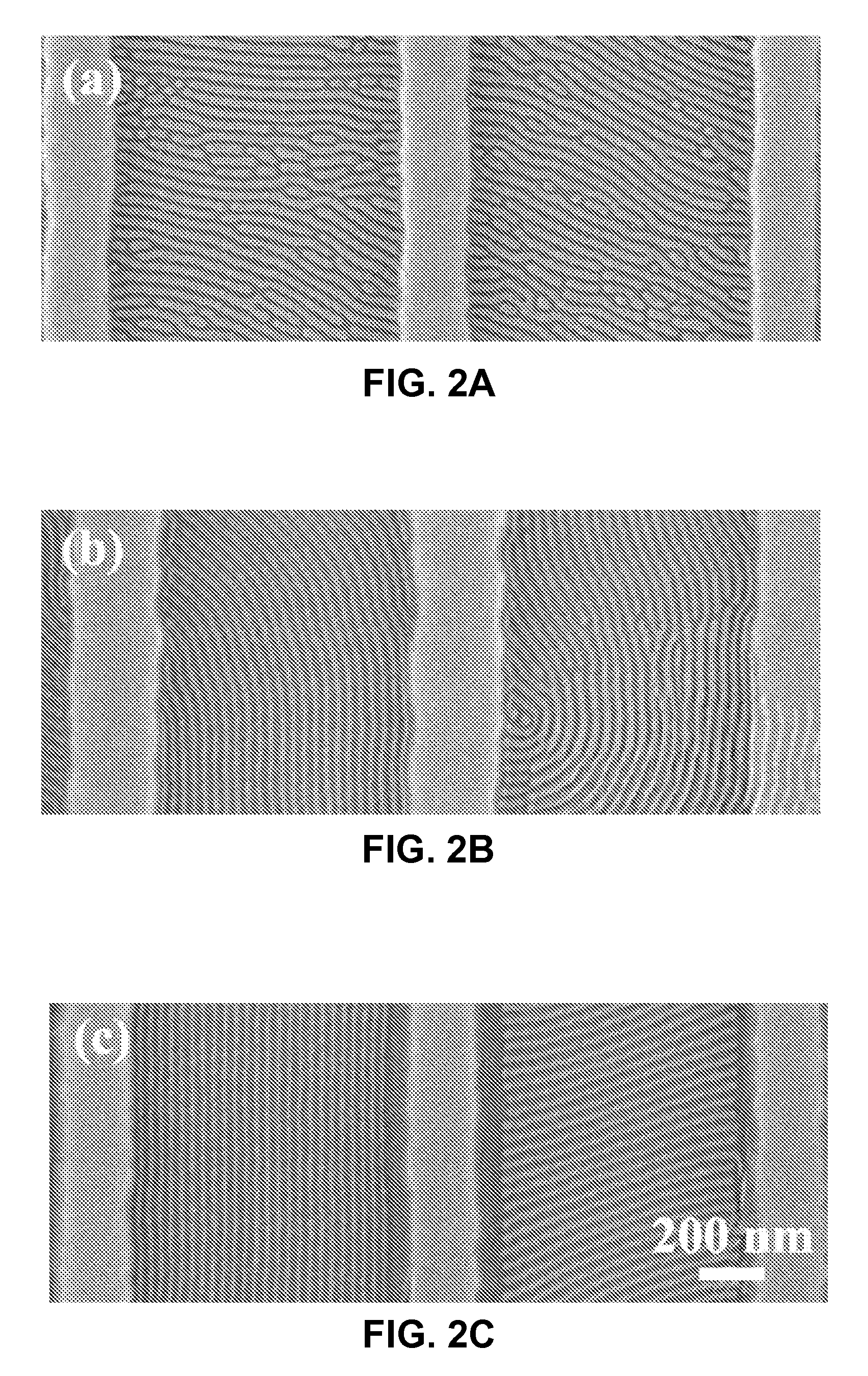

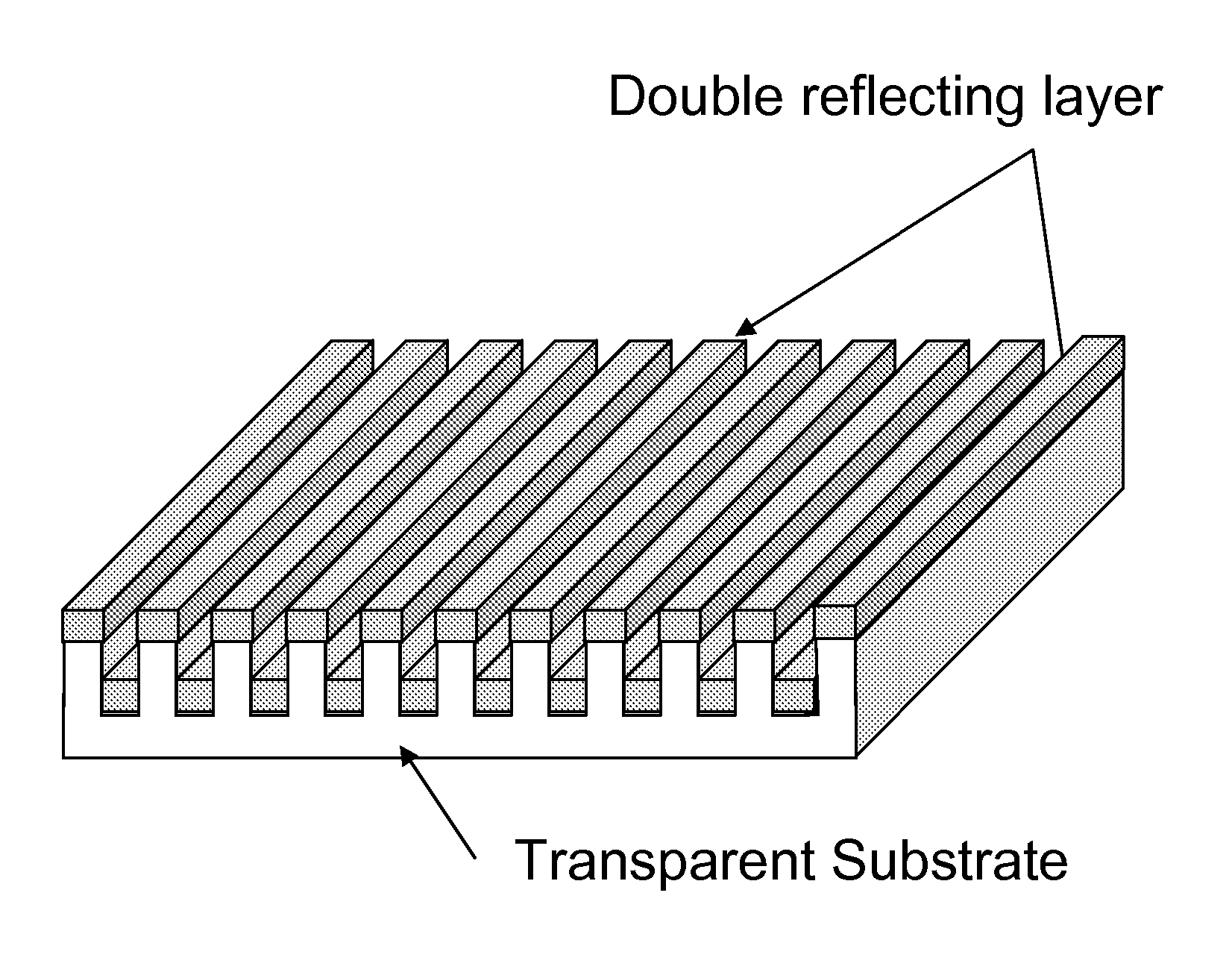

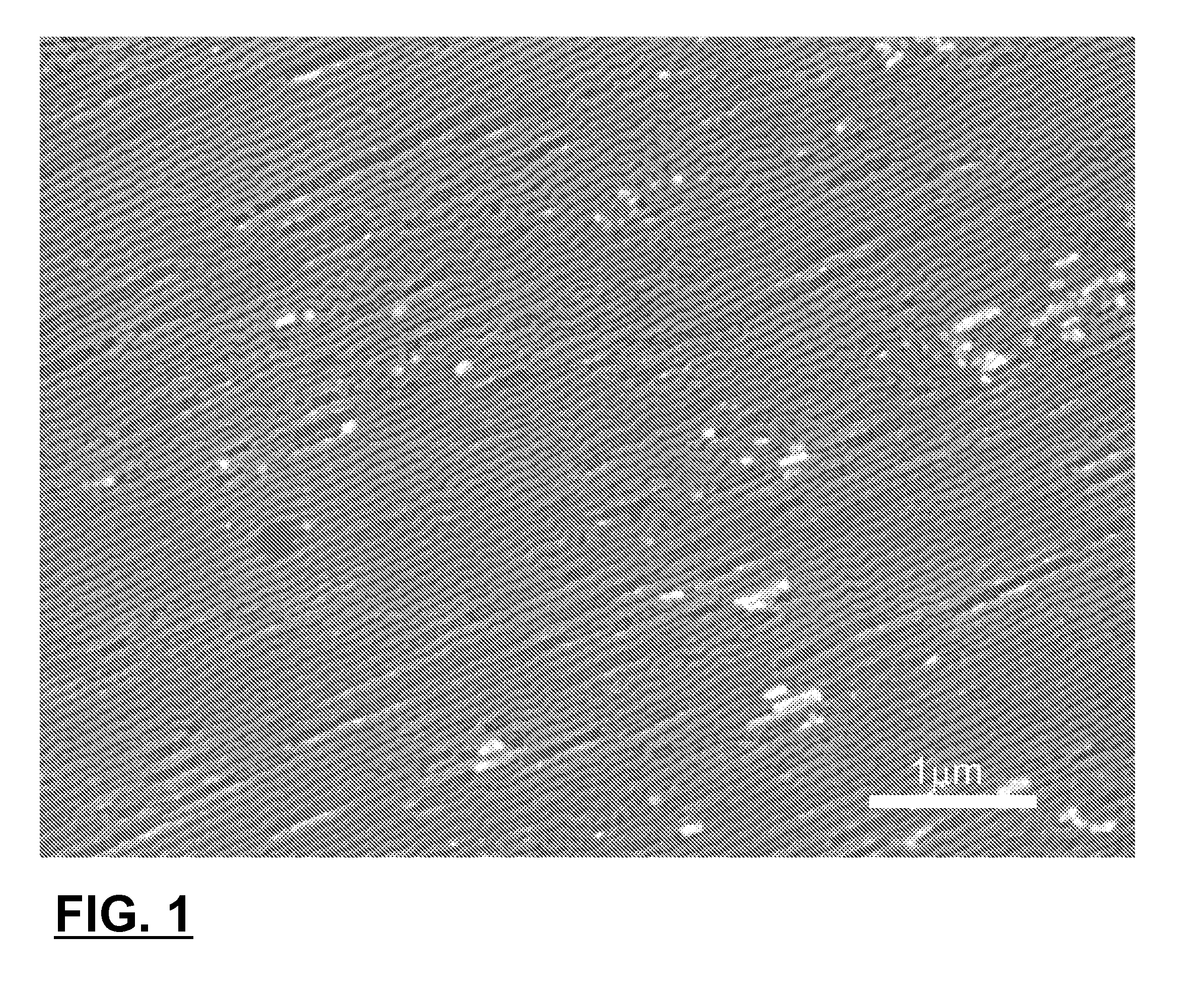

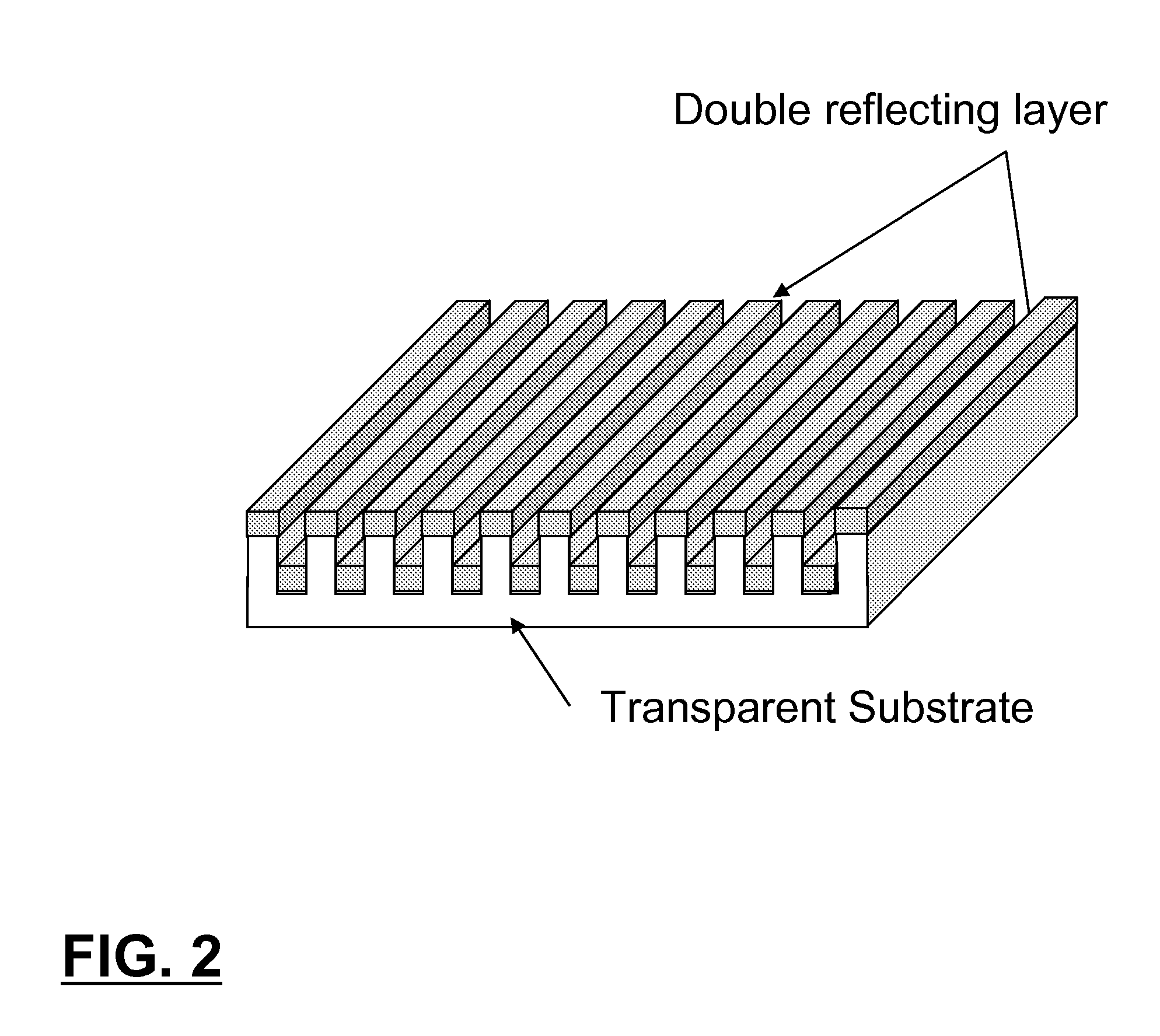

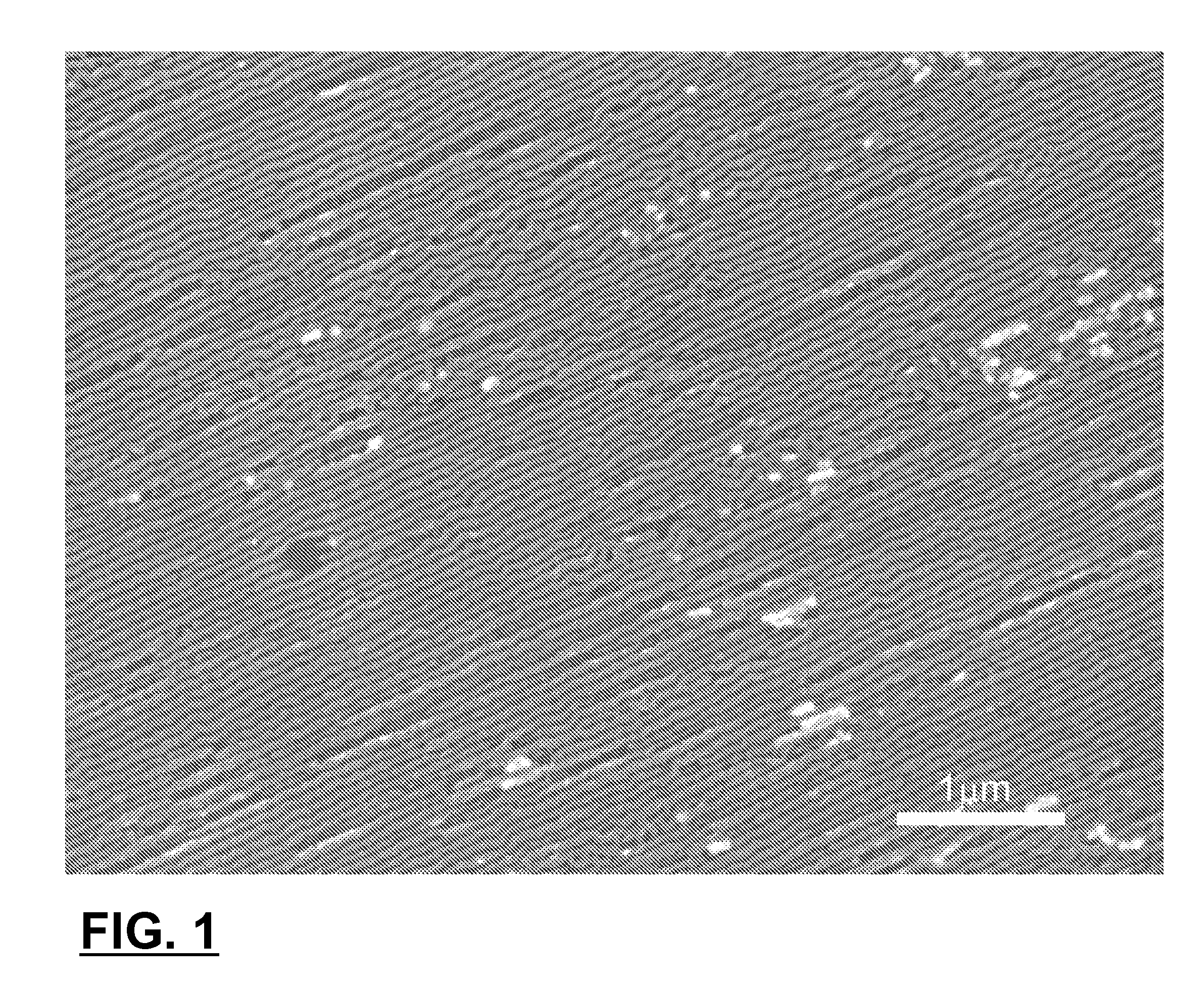

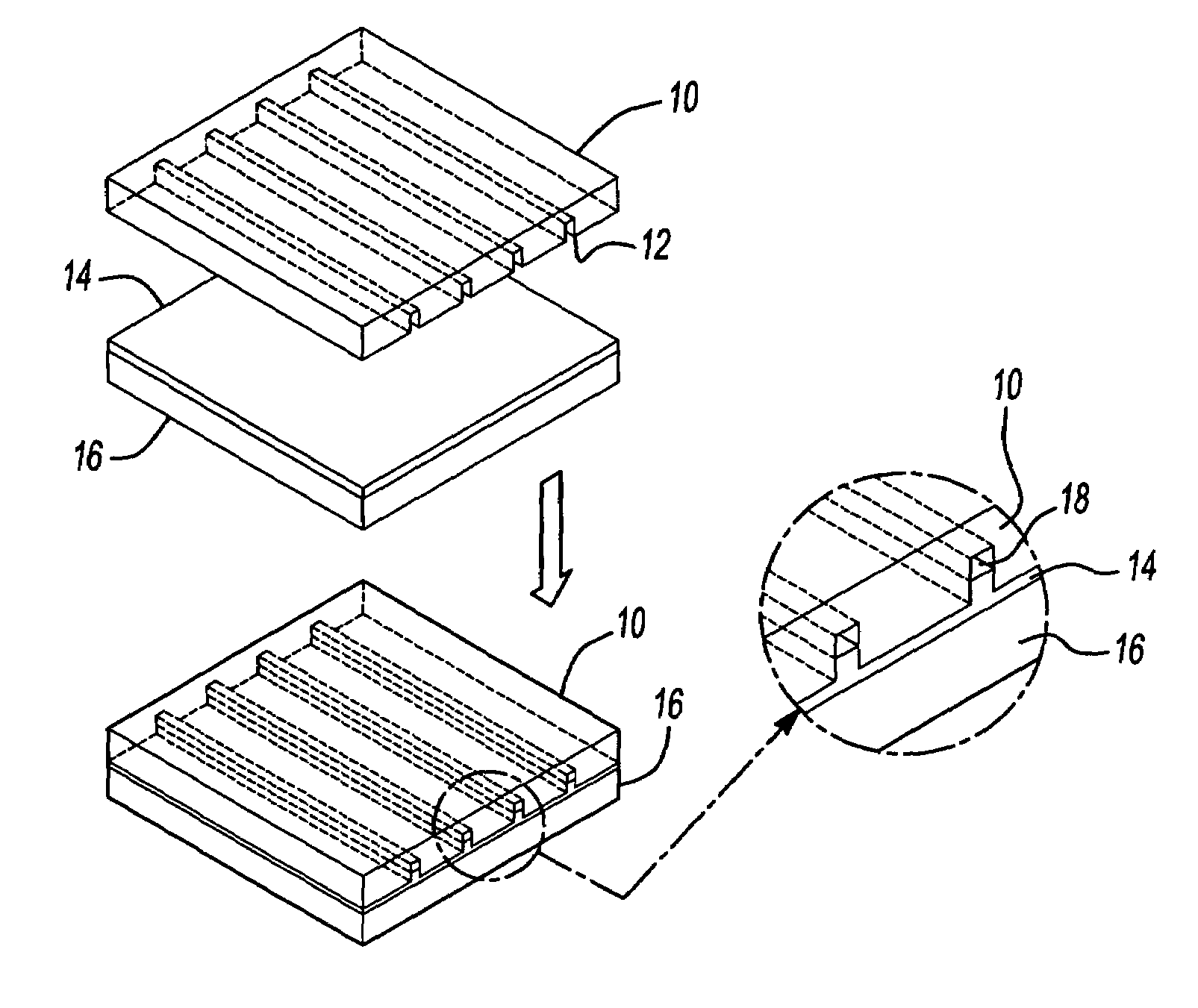

Orientation-controlled self-assembled nanolithography using a block copolymer

InactiveUS20080311402A1Material nanotechnologyRadiation applicationsNanolithographyPatterned substrate

Disclosed is a structure made of a trench patterned substrate having a pre-determined trench period and a pre-determined mesa to trench width ratio, and a block copolymer on top of the trench patterned substrate. The block copolymer has at least an organic block and a silicon-containing block, wherein the block copolymer can have either perpendicular or parallel cylinders. The structure is annealed under a pre-determined vapor pressure for a predetermined annealing time period, wherein the pre-determined trench period, the pre-determined mesa to trench width ratio, the predetermined vapor pressure and the predetermined annealing time period are chosen such that cylinders formed in the block copolymer are either perpendicular or parallel with respect to the trench-patterned substrate. A method is also described to form the above-mentioned structure.

Owner:MASSACHUSETTS INST OF TECH

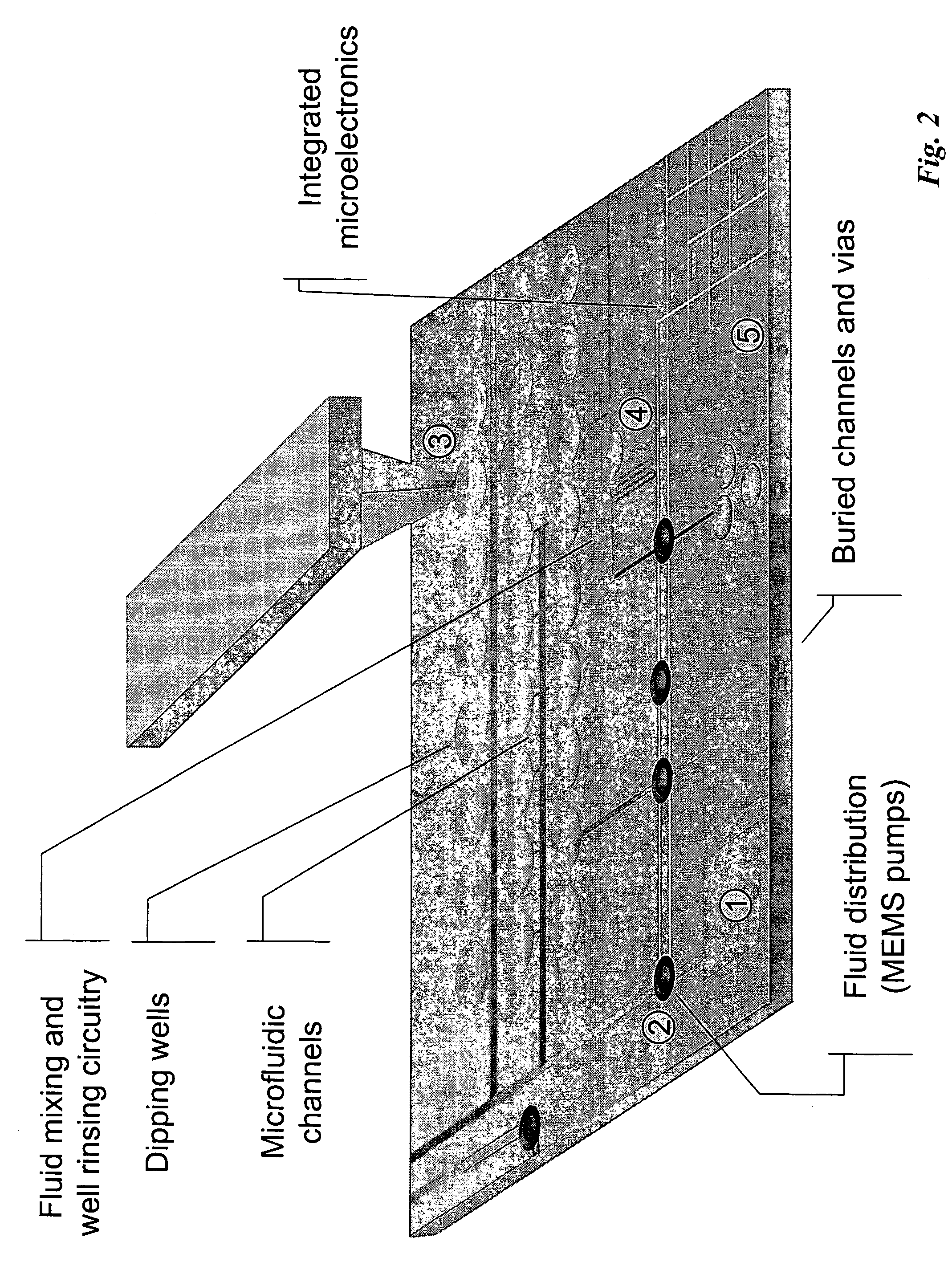

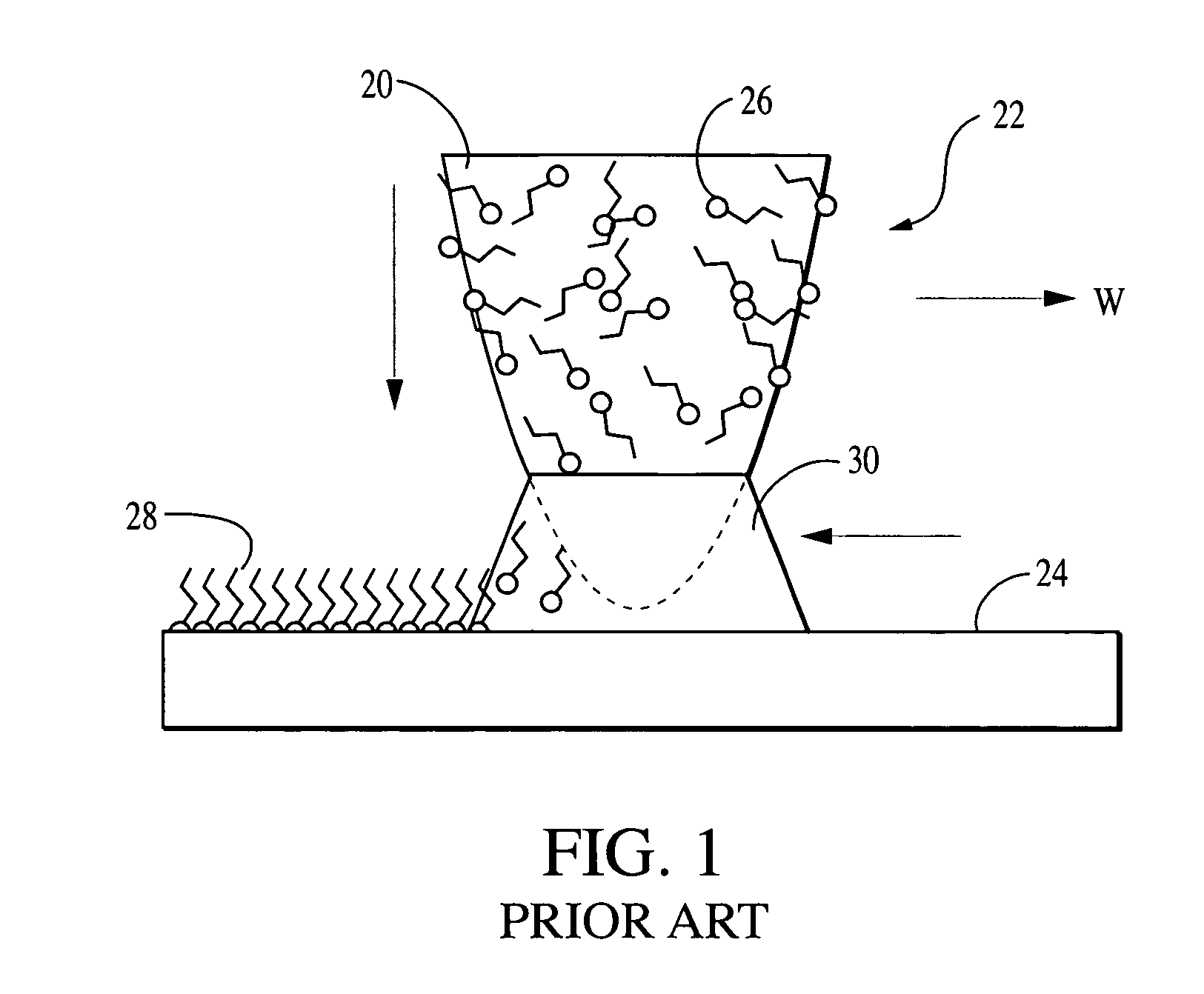

Methods and apparatus for ink delivery to nanolithographic probe systems

InactiveUS7034854B2Improve the level ofEasy to printRecording apparatusMaterial nanotechnologyNanolithographyEngineering

Inkwells adapted for use in direct-write nanolithography and other applications including use of wells, channels, and posts. The wells can possess a geometry which matches the geometry of tips which are dipped into the inkwells. The channels can be open or closed. Hydrophilicity and hydrophobicity can be used to control ink flow. SEM can be used to characterize the inkwells. Ink flow can be monitored with video. Hydrophobic material layers can be used to prevent cross contamination. Microsyringes can be used to fill reservoirs. Satellite reservoirs can be used to prevent bubble formation.

Owner:NANOINK INC

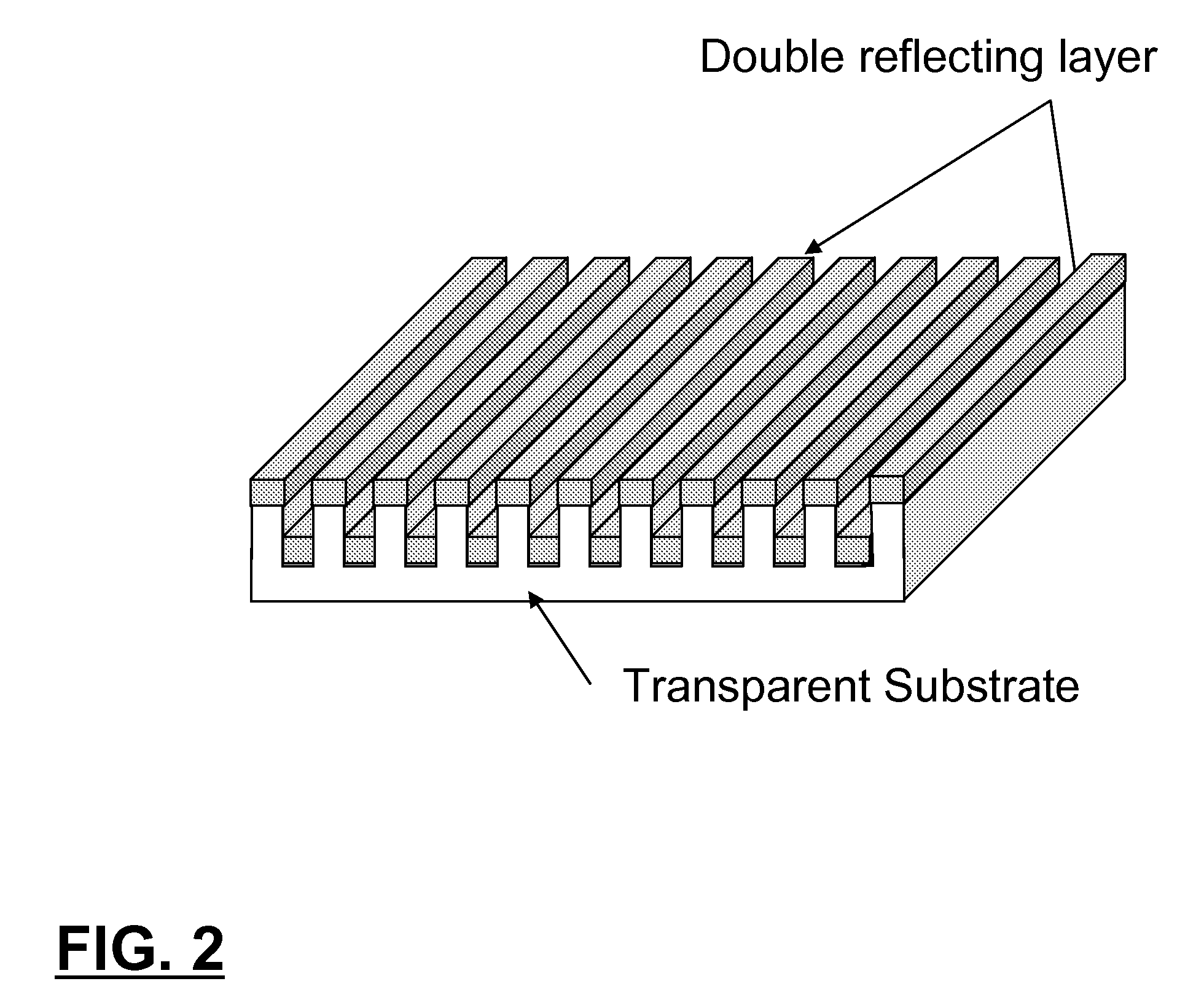

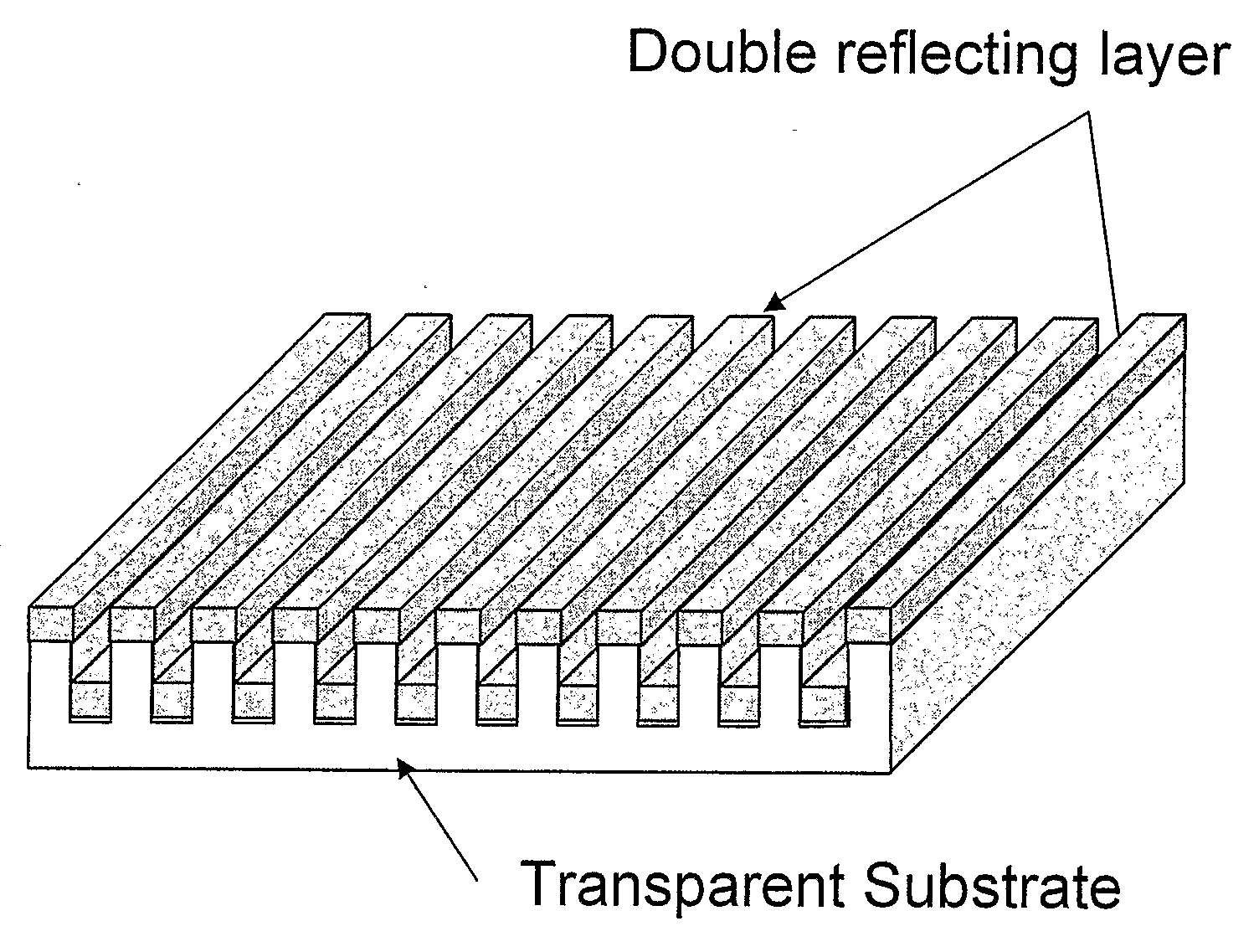

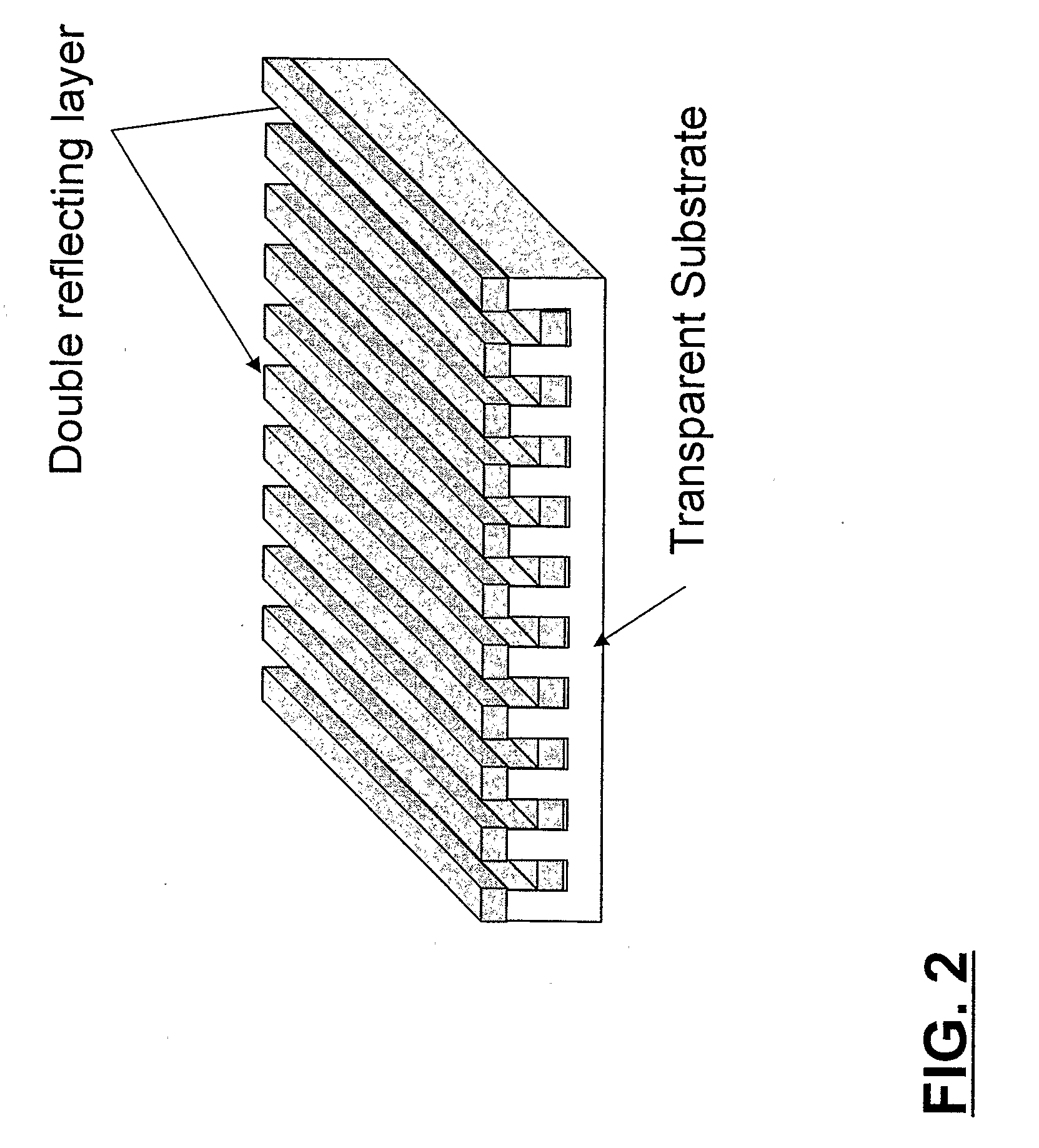

Short-wavelength polarizing elements and the manufacture and use thereof

While gold wire grids have been used to polarize infrared wavelengths for over a hundred years, they are not appropriate for shorter wavelengths due to their large period. With embodiments of the present invention, grids with periods a few tens of nanometers can be fabricated. Among other things, such grids can be used to polarize visible and even ultraviolet light. As a result, such wire grid polarizers have a wide variety of applications and uses, such as, e.g., in the fabrication of semiconductors, nanolithography, and more.

Owner:PRINCETON UNIV +1

Monolithic light emitting devices based on wide bandgap semiconductor nanostructures and methods for making same

InactiveUS7122827B2Reduce defectsSmall sizeLaser detailsLaser active region structureNanolithographyNanostructure

The present invention is directed toward a method for fabricating low-defect nanostructures of wide bandgap materials and to optoelectronic devices, such as light emitting sources and lasers, based on them. The invention utilizes nanolithographically-defined templates to form nanostructures of wide bandgap materials that are energetically unfavorable for dislocation formation. In particular, this invention provides a method for the fabrication of phosphor-less monolithic white light emitting diodes and laser diodes that can be used for general illumination and other applications.

Owner:GENERAL ELECTRIC CO

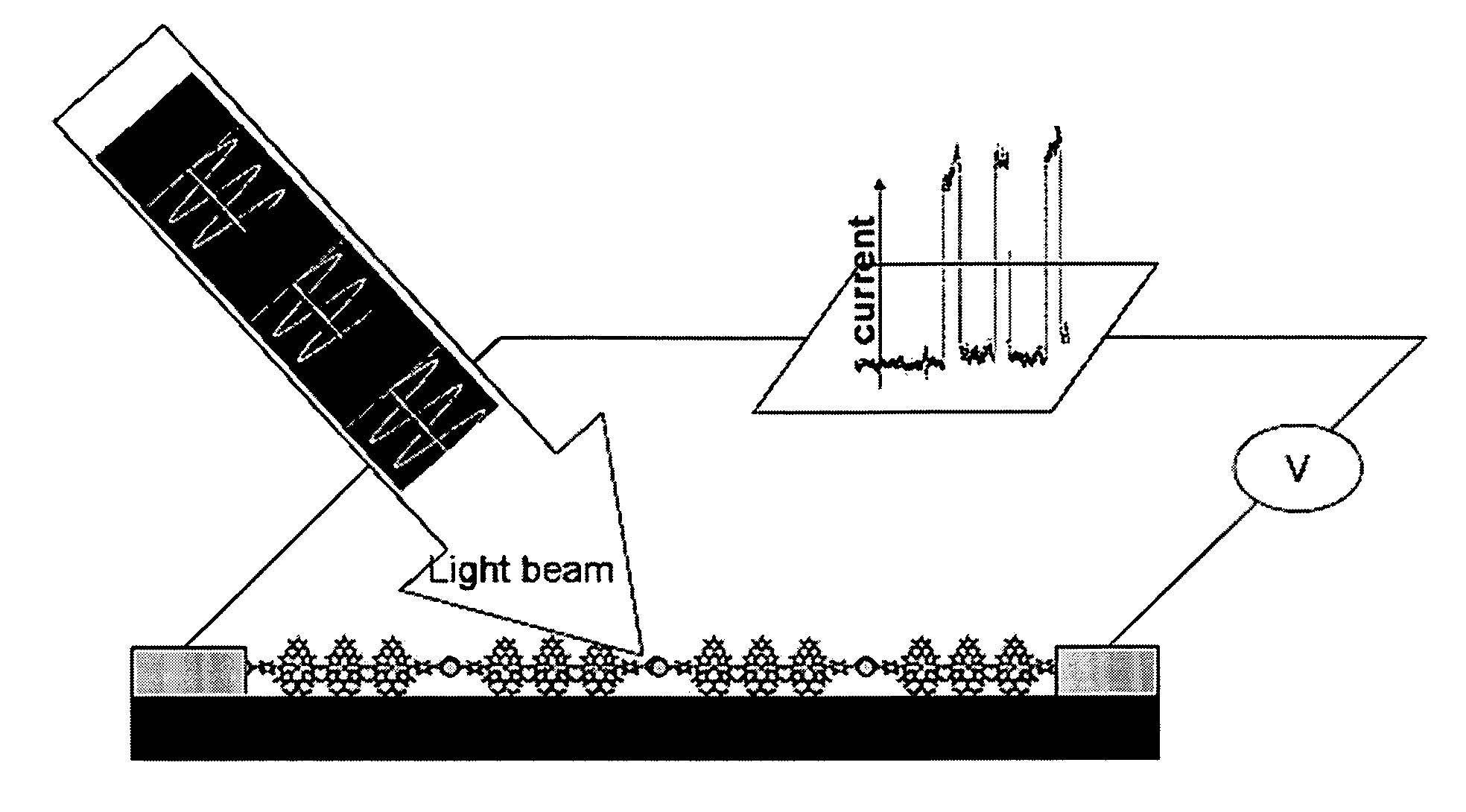

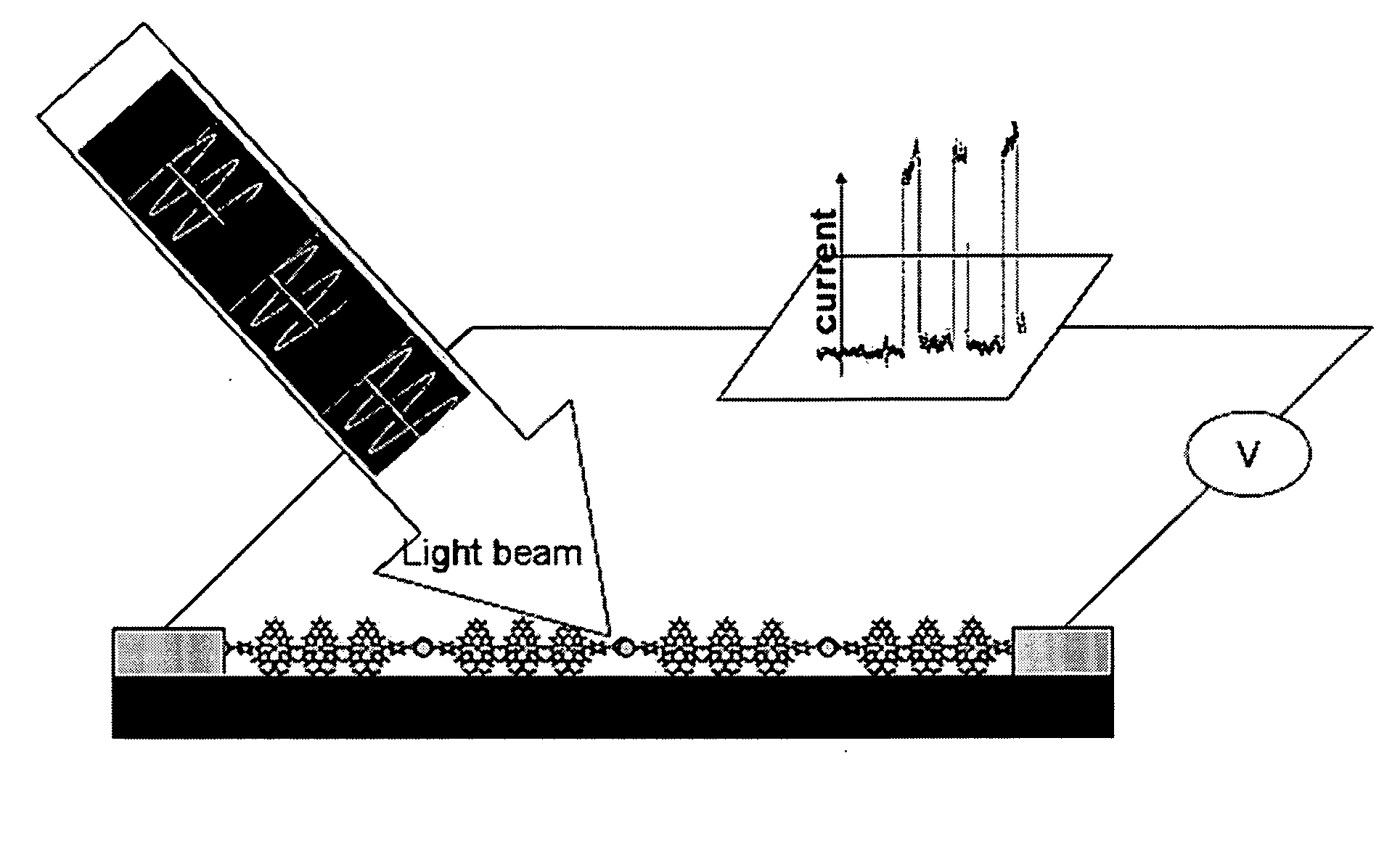

Electronic and optoelectronic devices and methods for preparing same

Disclosed are electronic, plasmonic and opto-electronic components that are prepared using patterned photodeposited nanoparticles on a substrate surface. Also disclosed are ferroelectric nanolithography methods for preparing components, circuits and devices.

Owner:THE TRUSTEES OF THE UNIV OF PENNSYLVANIA

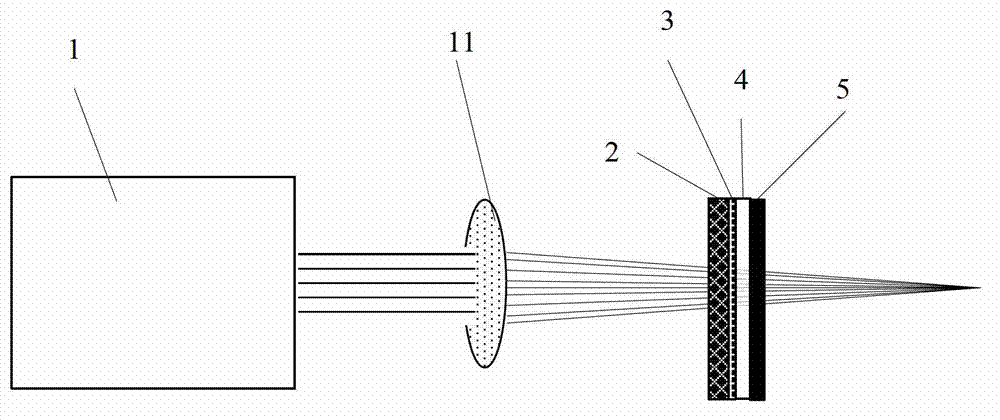

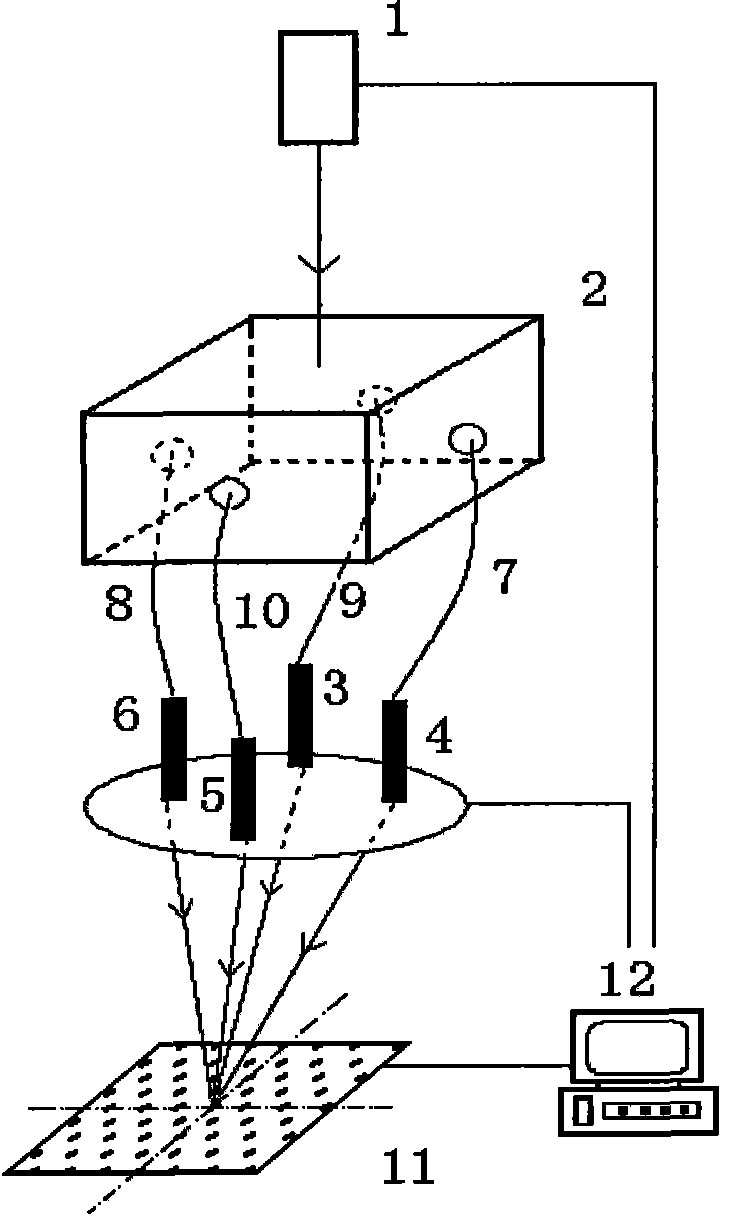

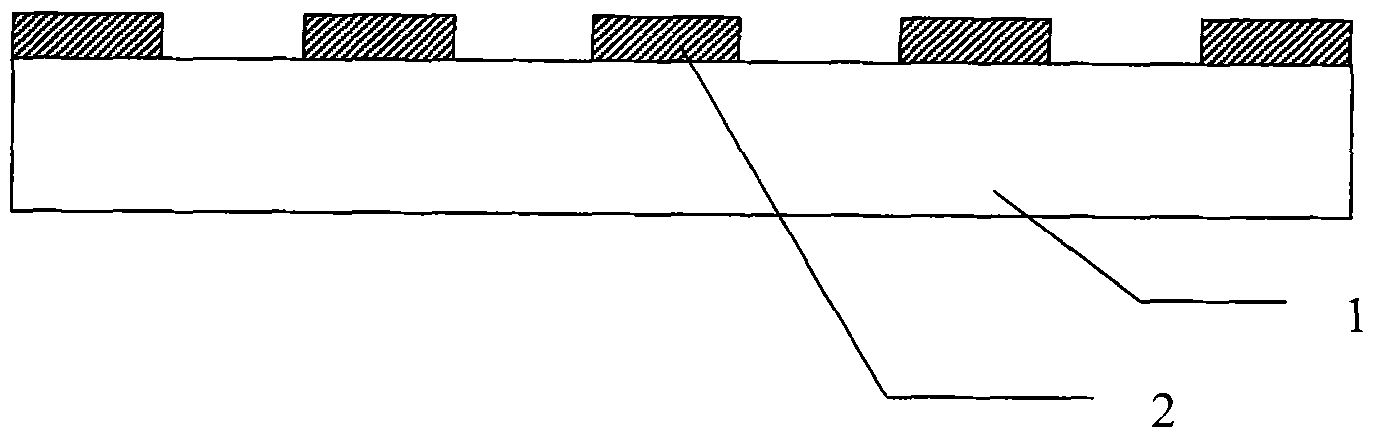

Nanolithography method and nanolithography device

InactiveCN102866580AControl shapeRegulatory distributionPhotomechanical exposure apparatusMicrolithography exposure apparatusNanolithographyTwo-photon absorption

The invention discloses a nanolithography method and a nanolithography device in the technical field of nanolithography. The device comprises a femtosecond laser device, a light transmittance base plate, a photoetching mask plate, photoresist and a substrate. A specific super-diffraction limit graph is formed on the photoetching mask plate through the femtosecond laser device; a plasma excimer excitation structure on the upper surface of the photoetching mask plate is changed, and an exposure wavelength is adjusted by controlling the material of the photoetching mask plate, so that the shape, the distribution and the size of the super-diffraction limit graph can be controlled; moreover, a two-photon absorption phenomenon of the photoresist is introduced; and the line width of an exposure graph of the photoresist is controlled by controlling the power of a femtosecond laser exposure light source.

Owner:TSINGHUA UNIV

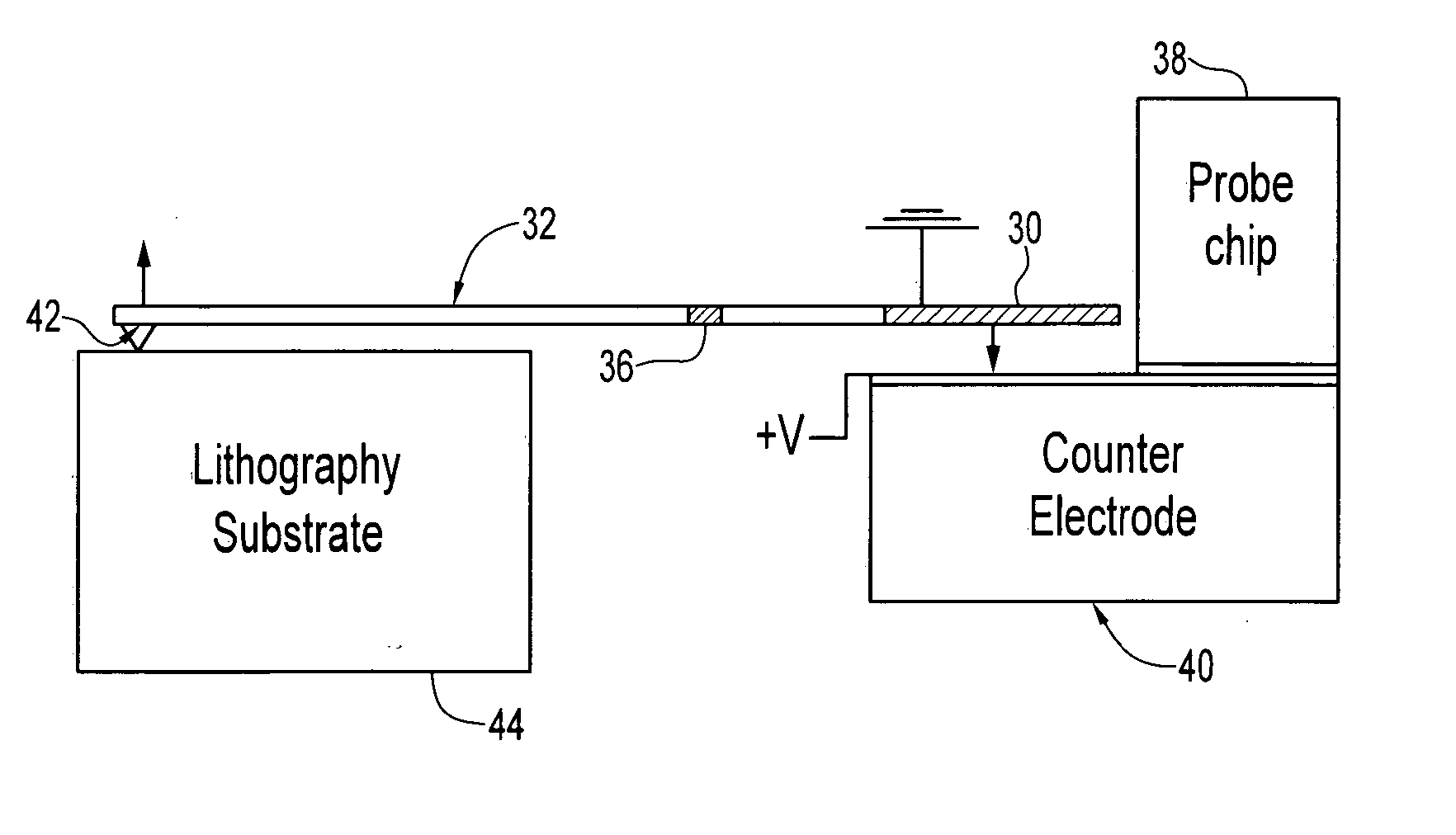

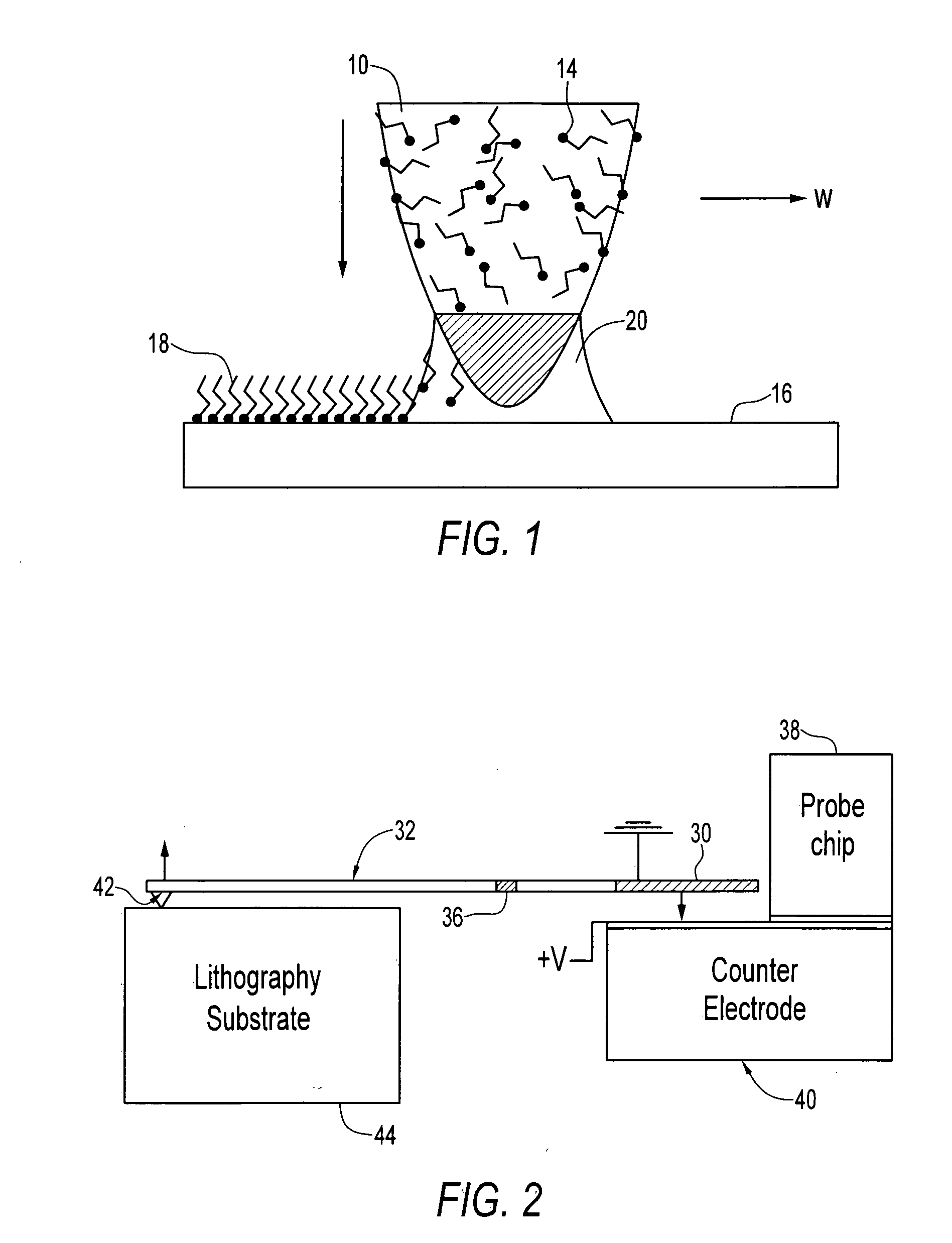

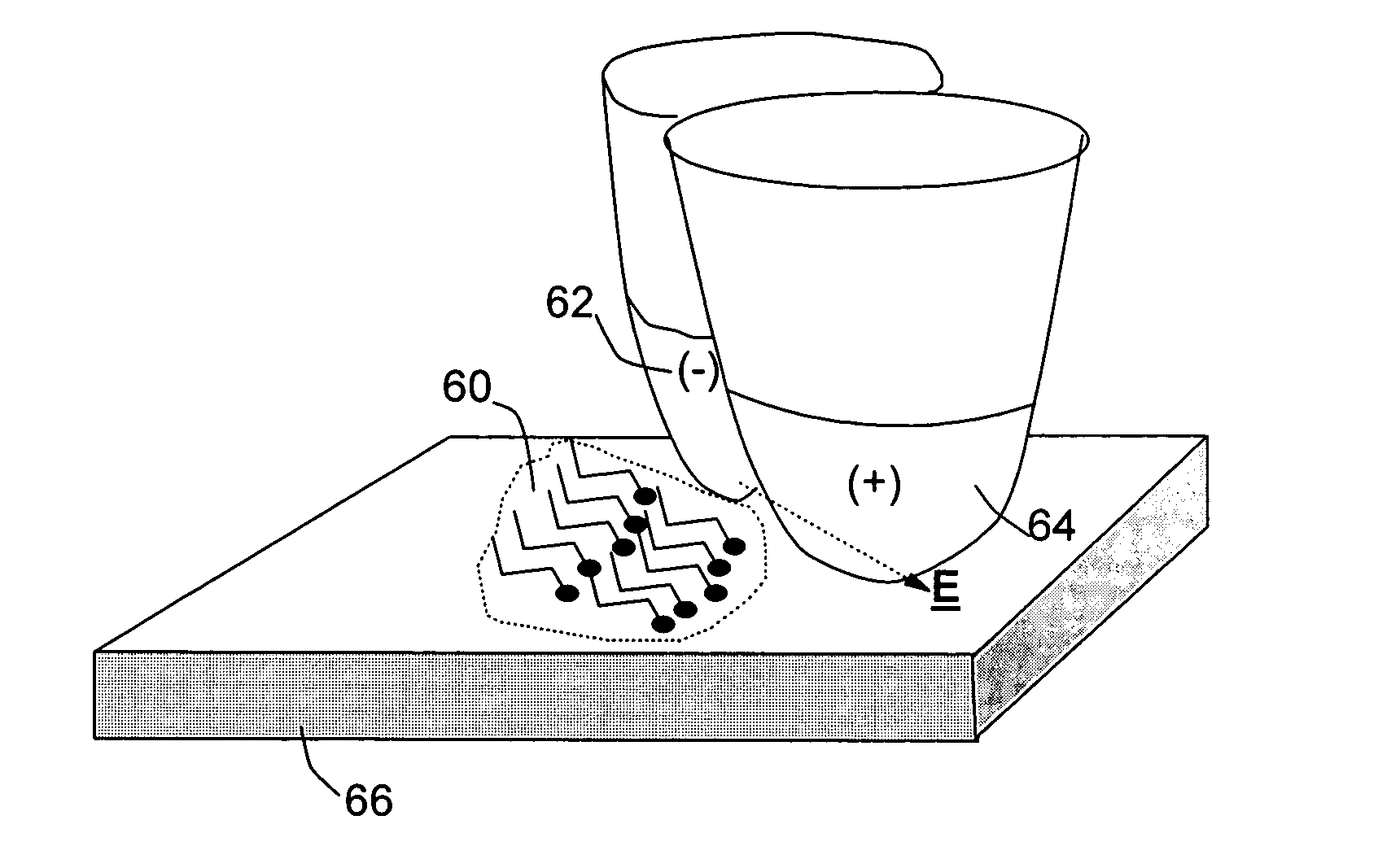

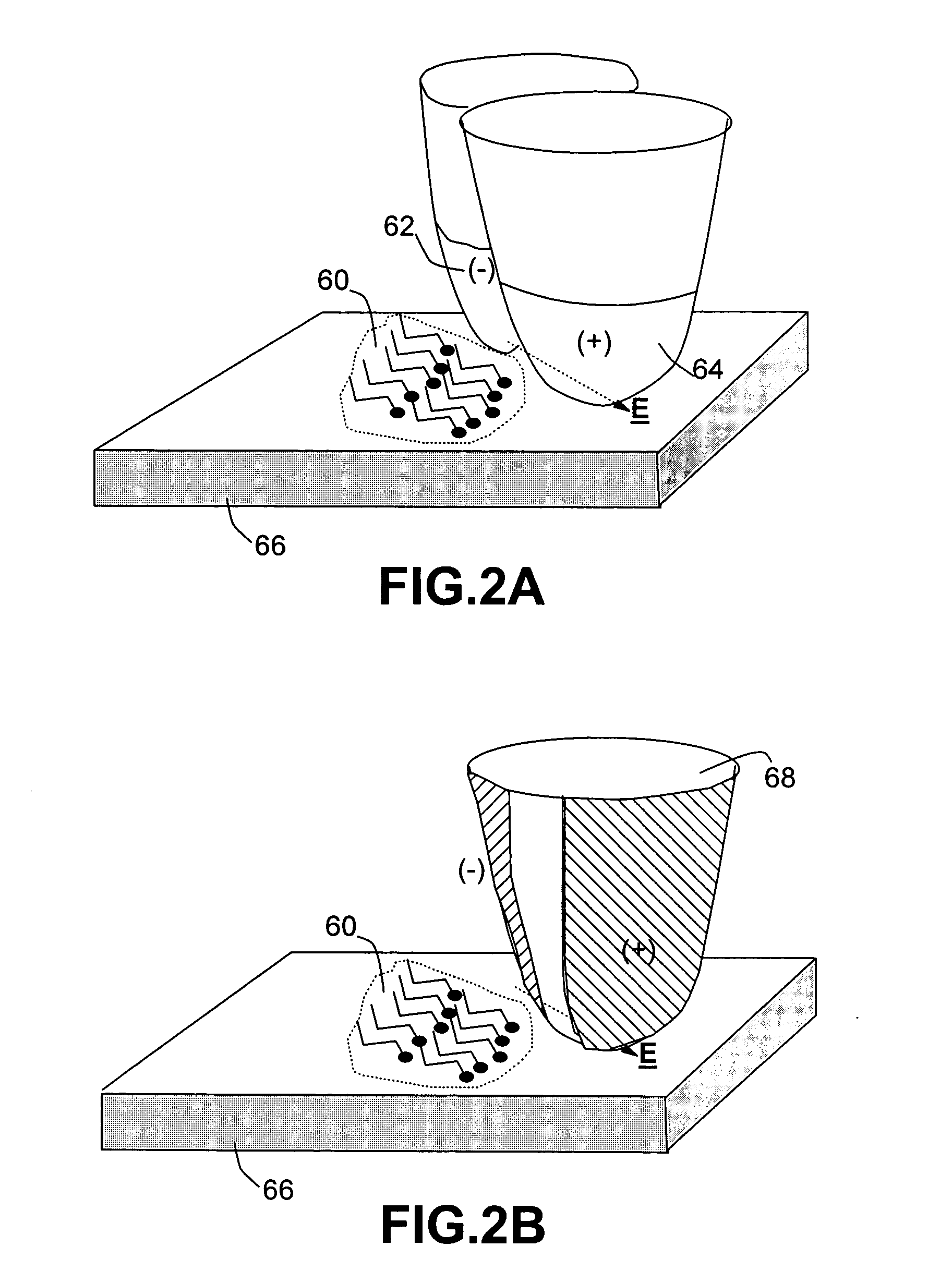

Electrostatic nanolithography probe actuation device and method

Method and apparatus for selectively actuating a cantilevered probe for applying a compound to a substrate in nanolithography. A probe having a probe electrode and a substrate having a counter electrode are provided. Voltage applied to the probe electrode and / or counter electrode provides electrostatic attraction between them, moving a probe tip into sufficient proximity to the substrate to apply the patterning compound. Alternatively, a flexible cantilevered probe anchored to a holder includes a layer of conductive material forming a probe electrode. A counter electrode on the holder faces the probe electrode. The holder and probe are positioned so that a probe tip applies the compound to the substrate. The probe is disposed between the substrate and the counter electrode. An electrostatic attractive force generated between the probe electrode and the counter electrode flexes the probe and lifts the tip away from the substrate to suspend writing.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

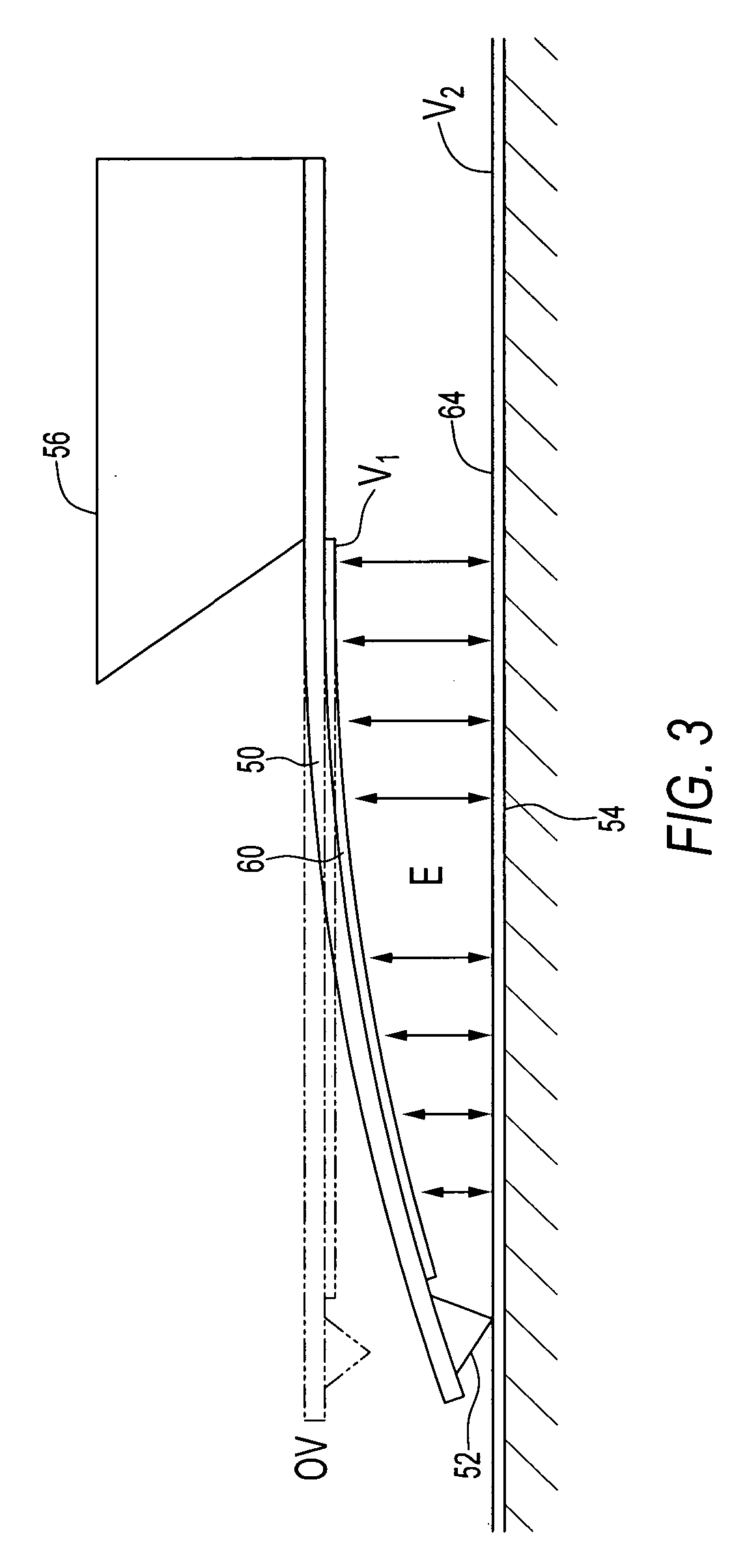

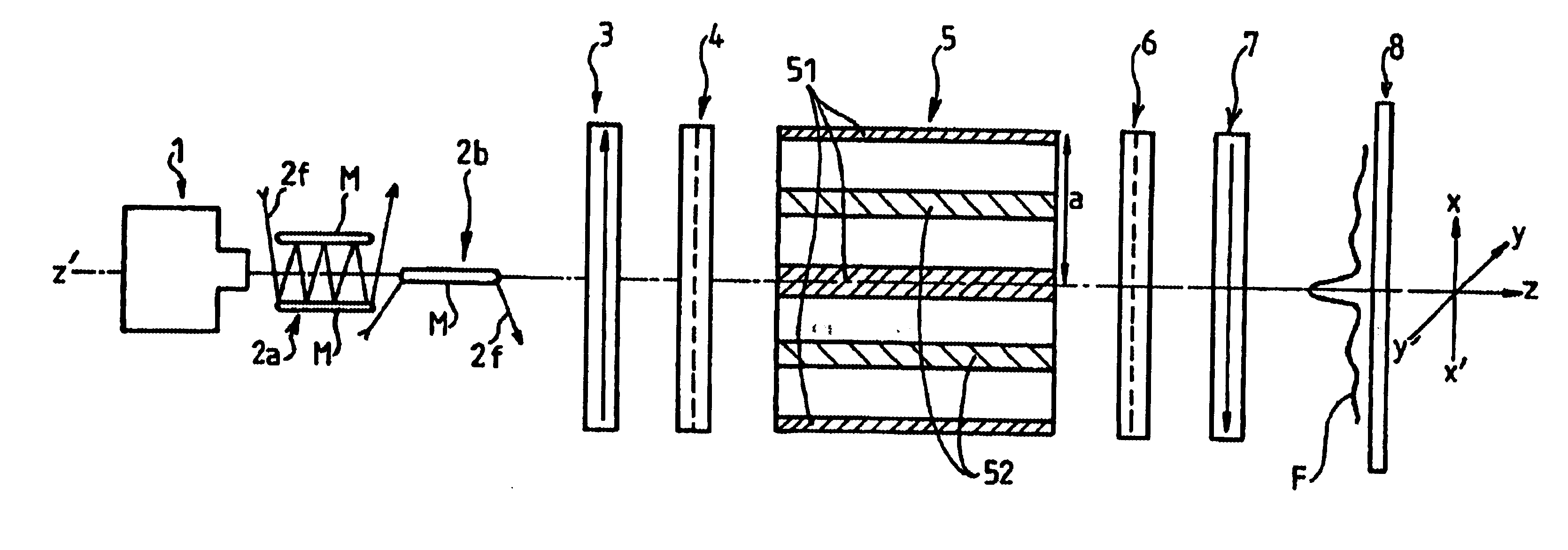

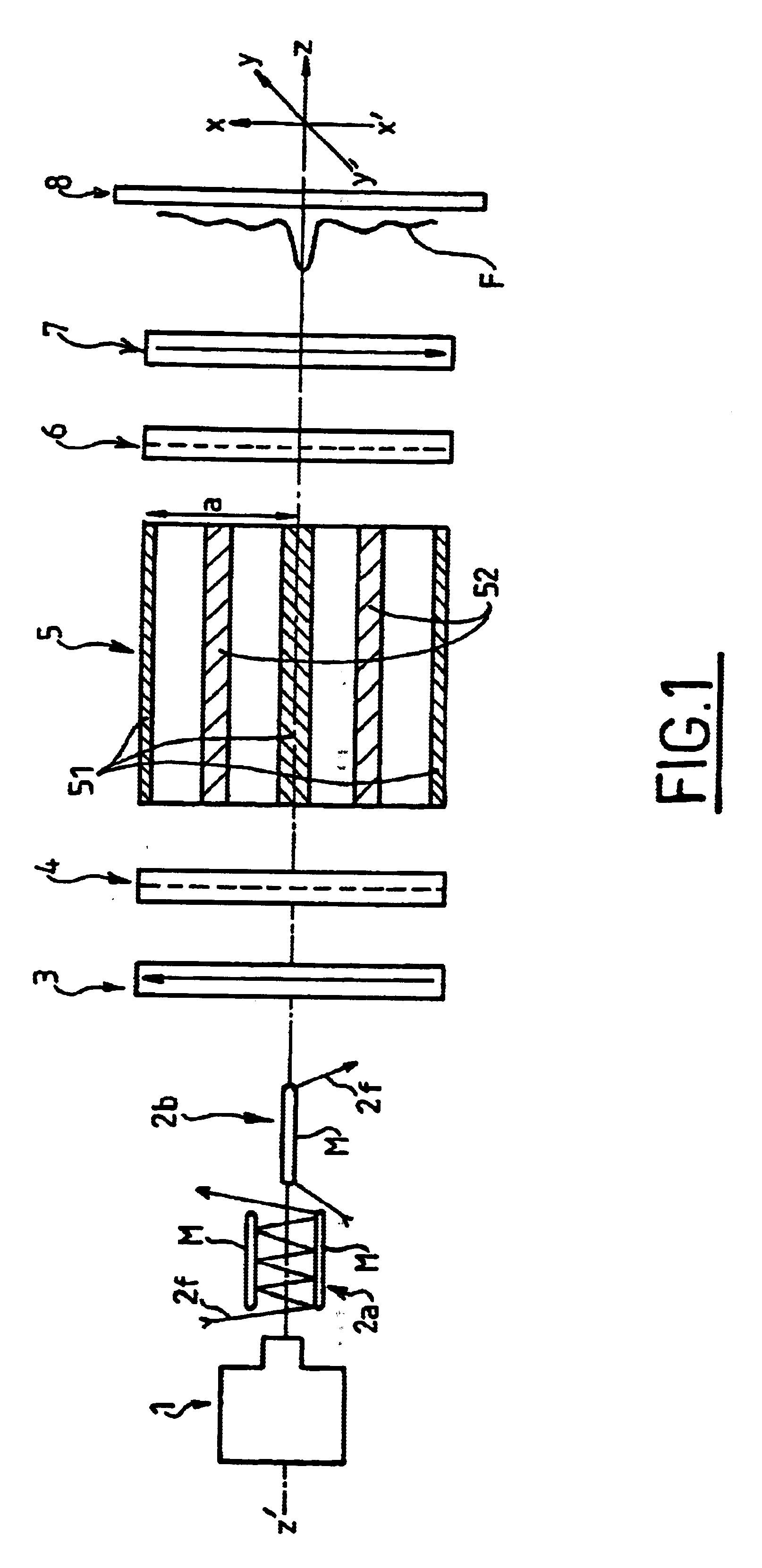

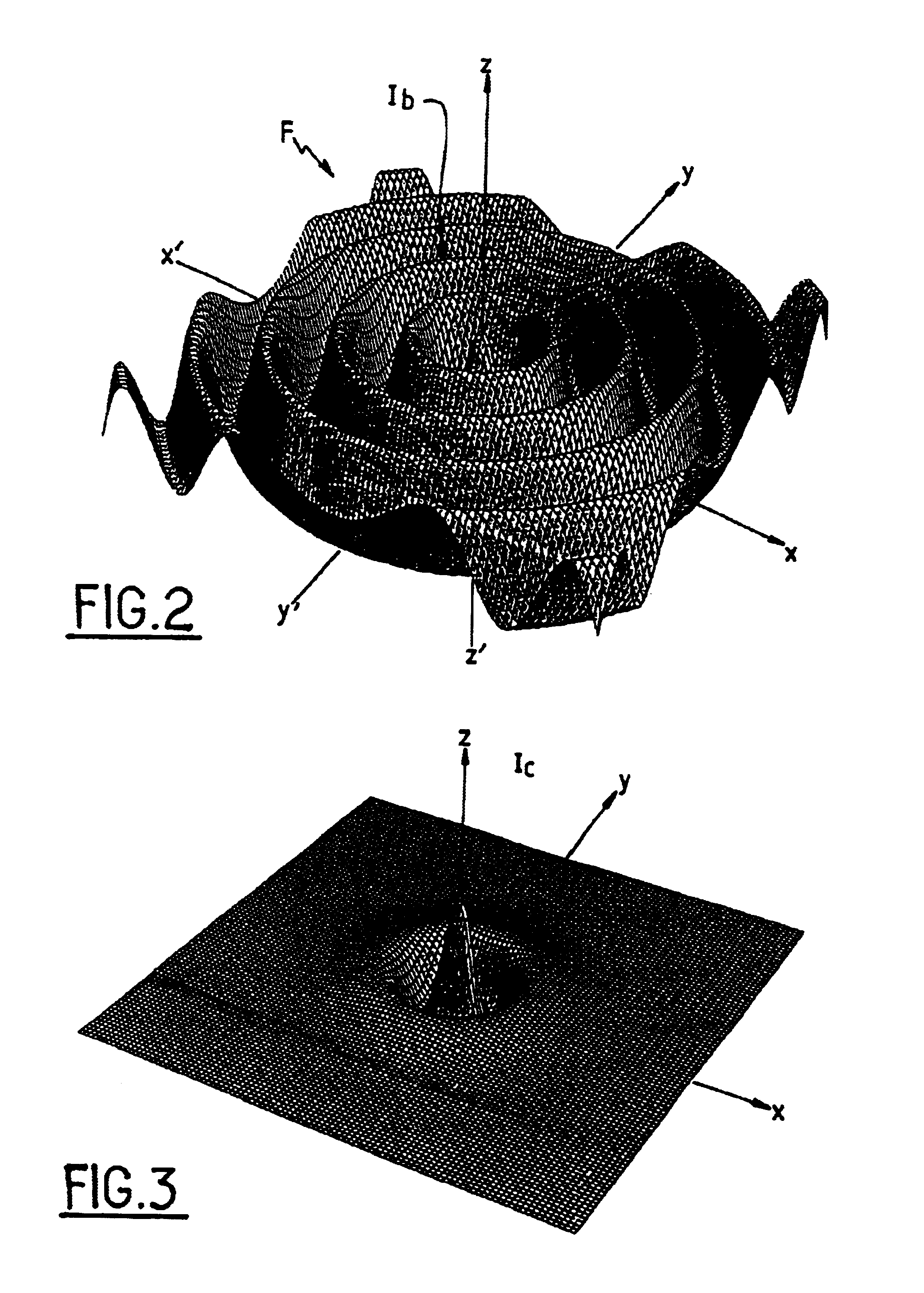

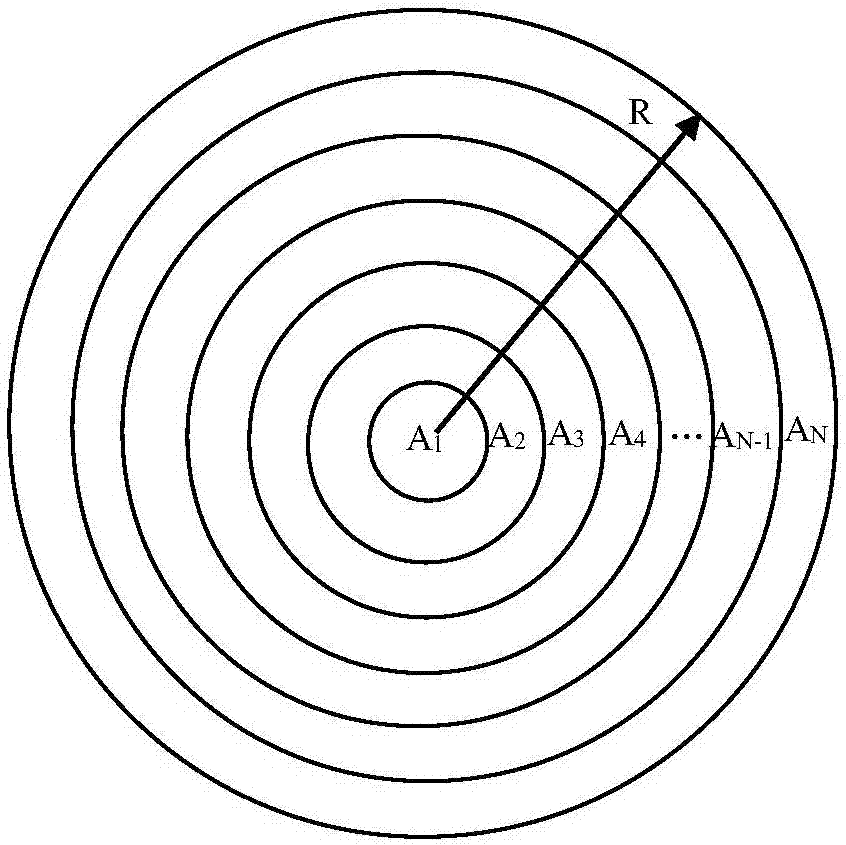

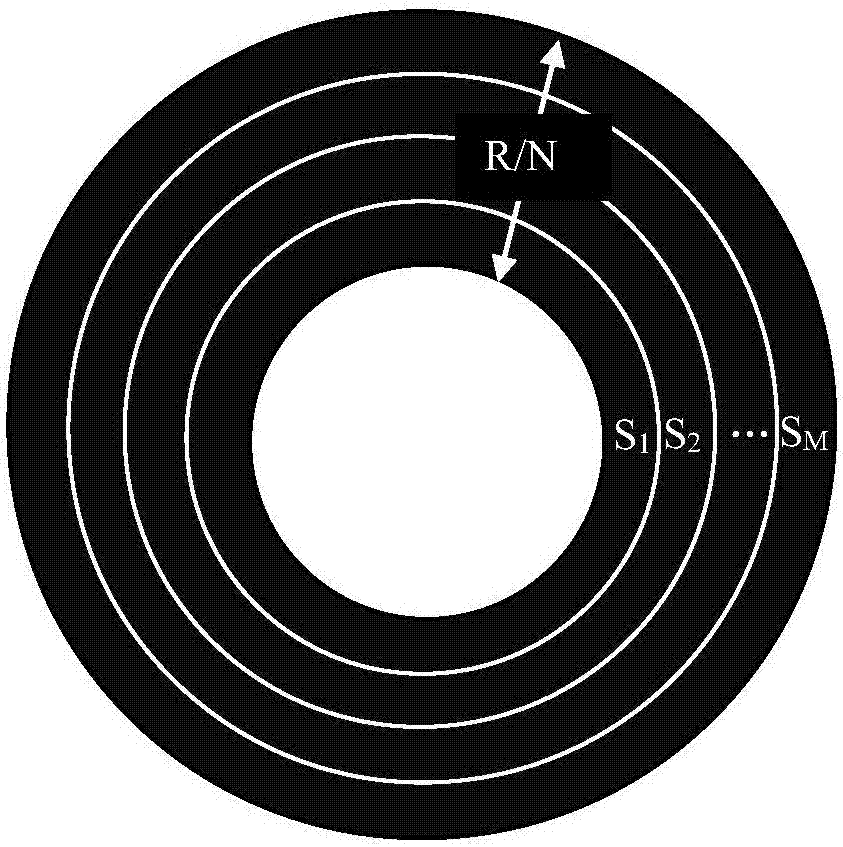

Method and device for atomic interferometry nanolithography

InactiveUS6891623B1Eliminate interference fringesReduce contrastElectric discharge tubesNanoinformaticsNanolithographyUniform field

The invention proposes a novel technique for implementing high performance atomic lithography, and in particular high resolution lithography. The technique makes use of Stern-Gerlach type atomic interferometry enabling disturbances to be implemented in the atomic phase of the beam. Such interaction then directly modulates the intensity of the associated wave in the plane extending transversely to the beam of atoms, and does so in controllable manner. The installation of the invention for nanolithography by atomic interferometry comprises a Stern-Gerlach type interferometer comprising, as its phase object, four-pole magnetic induction having a transverse gradient created by four parallel bars carrying alternating direct currents, bracketed between two separator plates, preceded and followed respectively by a spin polarizer and by an analyzer operating by laser pumping. An additional uniform field is being created by another four additional bars powered in paired manner by adjustable currents in order to create a uniform field of arbitrary intensity and orientation for the interference pattern by adjusting the two current parameters. The source of atoms is a source that continuously discharges metastable helium or argon with approximately Maxwell type speed dispersion of about 30% to 40% in order to obtain a central spot.

Owner:PARIS 13 UNIVERSITY

Short-wavelength polarizing elements and the manufacture and use thereof

While gold wire grids have been used to polarize infrared wavelengths for over a hundred years, they are not appropriate for shorter wavelengths due to their large period. With embodiments of the present invention, grids with periods a few tens of nanometers can be fabricated. Among other things, such grids can be used to polarize visible and even ultraviolet light. As a result, such wire grid polarizers have a wide variety of applications and uses, such as, e.g., in the fabrication of semiconductors, nanolithography, and more.

Owner:PRINCETON UNIV +1

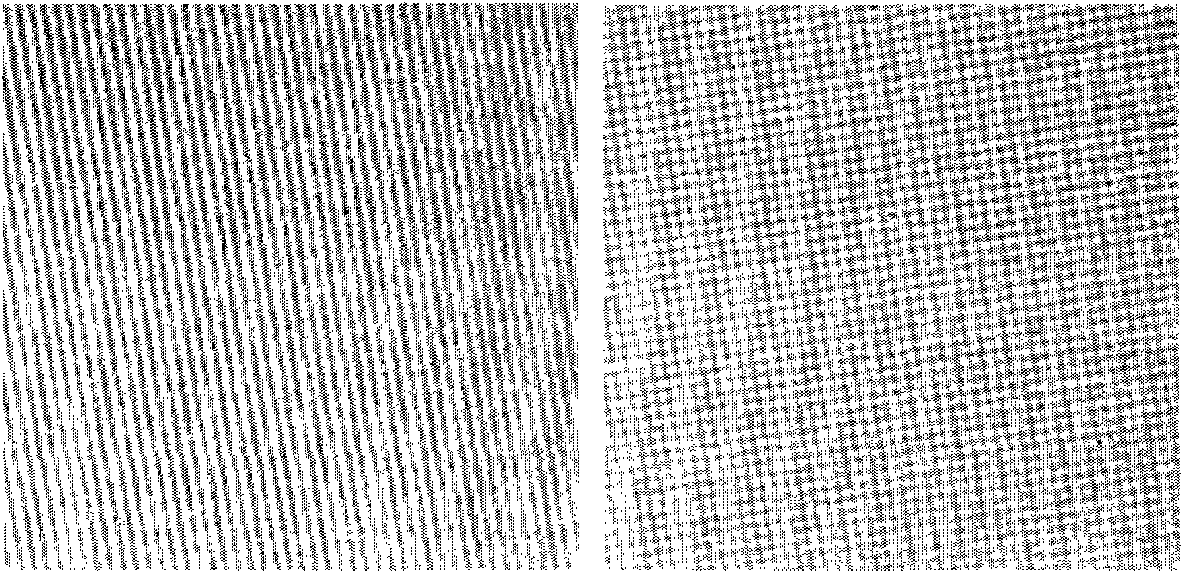

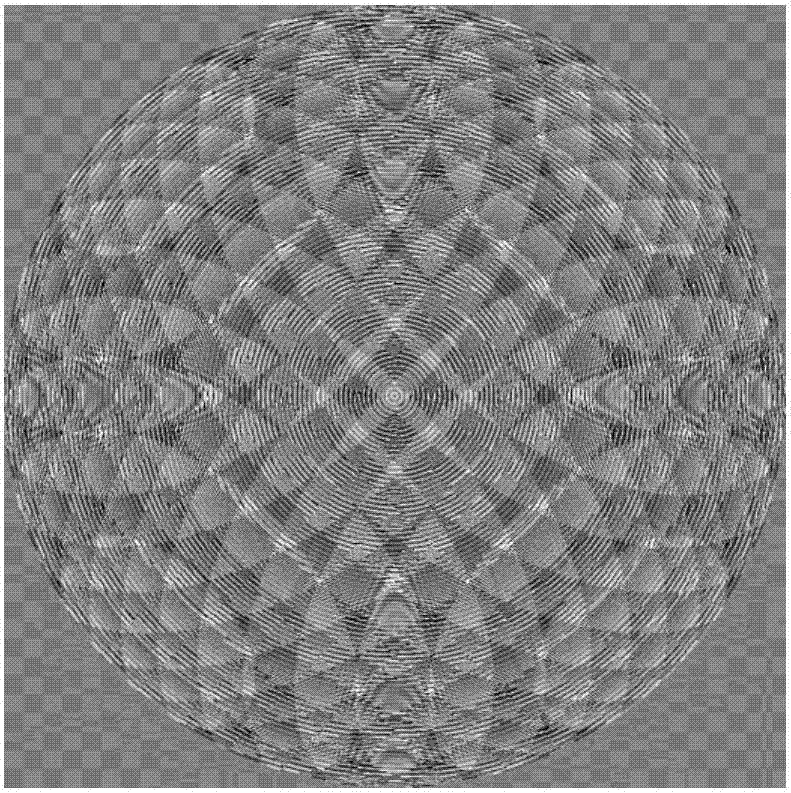

Multi-beam semiconductor laser interference nanoimprinting technology and system

InactiveCN101916042ALow priceReduce volumeLaser detailsPhotomechanical exposure apparatusNanolithographyBeam splitting

The invention discloses multi-beam semiconductor laser interference nanoimprinting technology and system which adopt the following principle that the required two or more bundles of coherent lights can be obtained by using semiconductor pulse laser through beam splitting, the coherent lights are subjected to coupling, beam expansion and reshaping and redistributed on the surface of material by using the light intensity in an interference field to form a periodical interference pattern. When the system is used for imprinting, a photosensing material can be directly subjected to the interference exposure and then etching without masking. By using an optical fiber beam splitting device as a light splitter, the complicity of a light path is greatly reduced, and the system is more stable and reliable; in addition, the selection from two light beams to a plurality of light beams is more flexible and convenient.

Owner:CHANGCHUN UNIV OF SCI & TECH

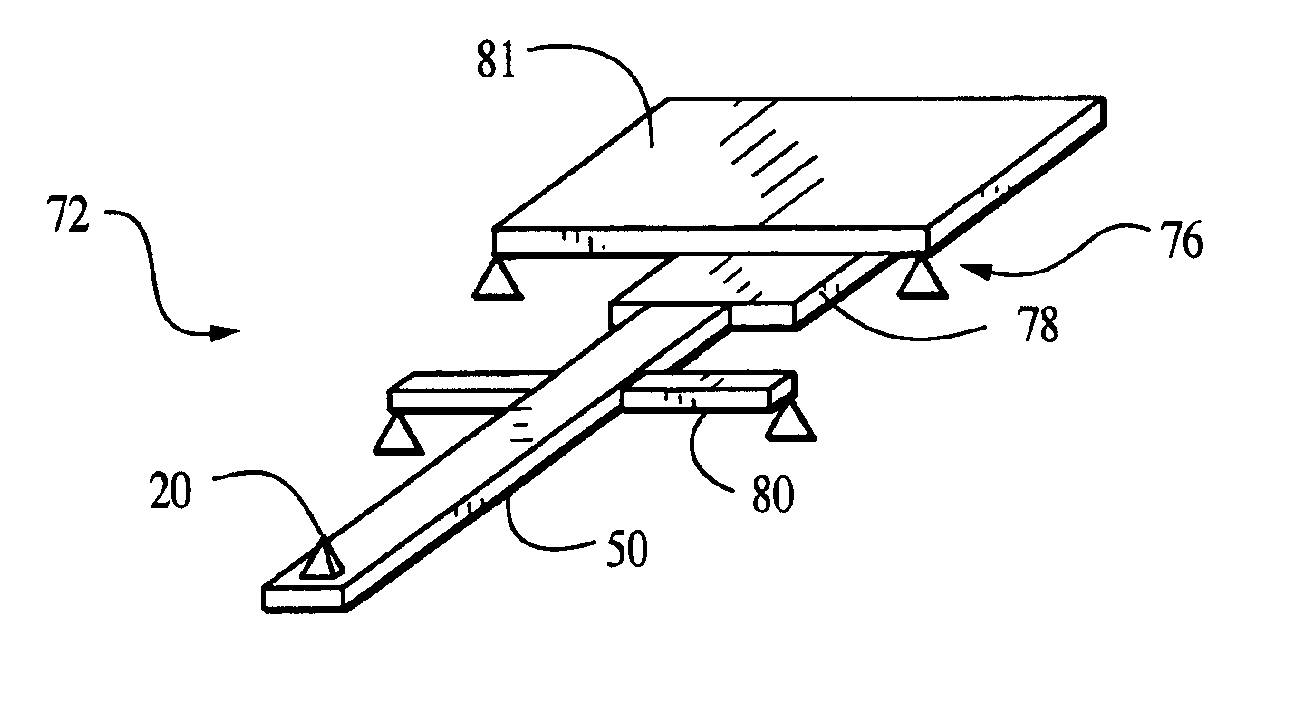

Identification features

InactiveUS20100294844A1Improve throughputSmall separationDrug compositionsRecord carriers used with machinesNanolithographyLithographic artist

Methods for providing pharmaceutical compositions and objects with identification regions and identification features which are difficult to detect. Microlithography, nanolithography, and stamping methods are used. The identification features can be positive protrusions or negative indentations with respect to the surface. The identification regions can comprise bar codes and holograms. DPN printing or other lithographies such as electron beam lithography, optical lithography, or nanoimprint lithography can be used to prepare stamps, which are then used to prepare the identification features. Redundant patterns can be formed. The invention is useful for counterfeit prevention. An apparatus for stamping the identification features is also described.

Owner:ADVANCED NANOSOLUTIONS +1

Method for preparing nano strip V2O5

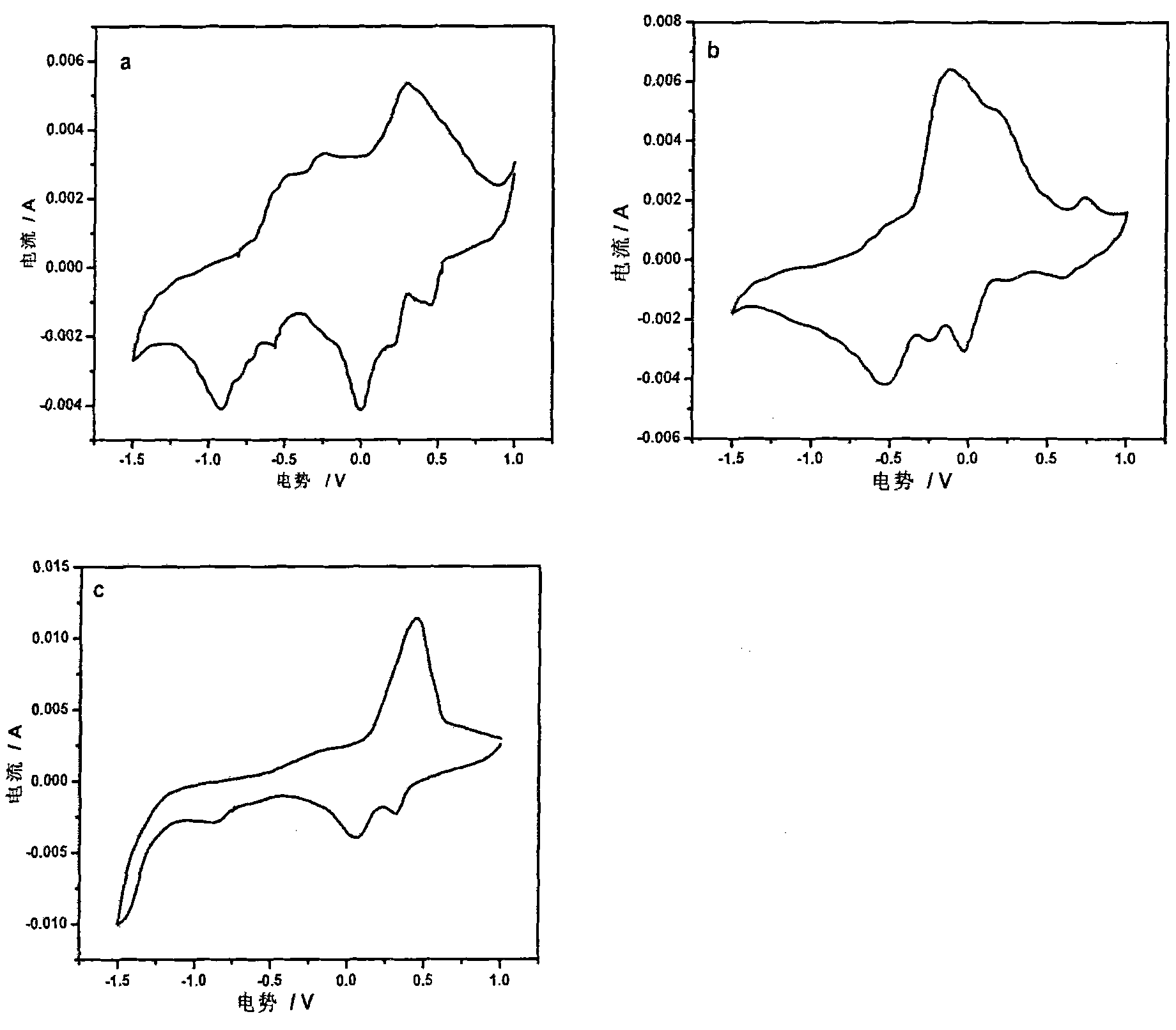

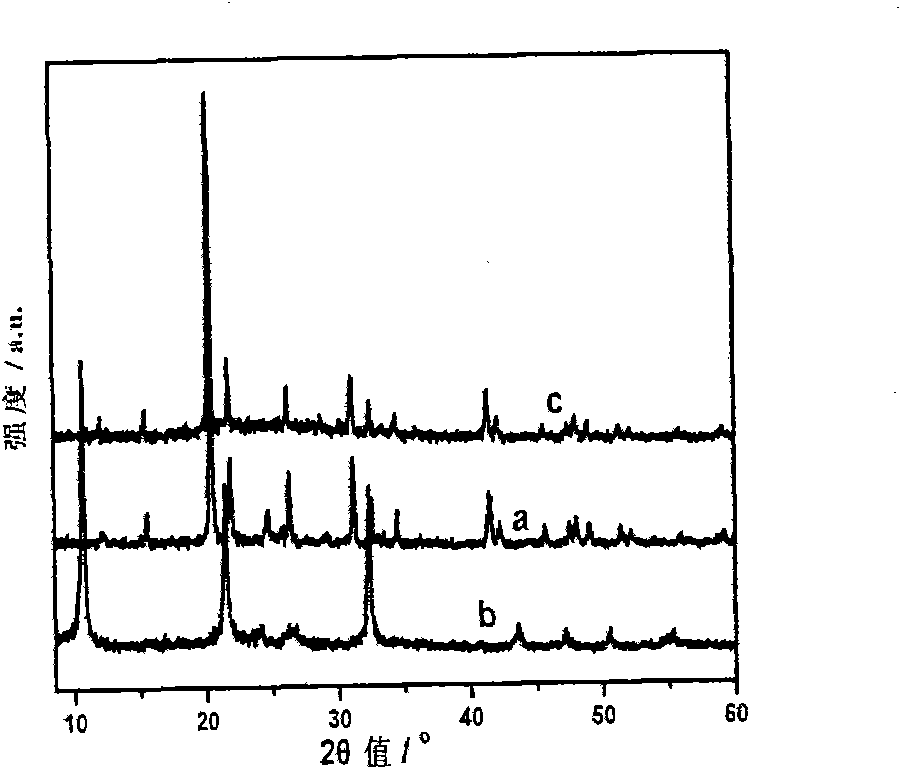

InactiveCN101880058ASimple preparation processShort experiment cycleNanostructure manufactureVanadium oxidesNanolithographyBand shape

The invention discloses a method for synthesizing nano strip V2O5 by a low-temperature hydrothermal process. The method comprises the following steps of: (1) dissolving surfactant into secondary deionized water to obtain 0.001 to 0.01M solution 1; (2) dissolving NH4VO3 into the solution 1, and stirring the solution till dissolution to obtain 14.2 to 428mM solution 2; (3) adding a reducing agent into the solution 2 in a volume ratio of 1: 5-1: 10, stirring the solution, transferring the solution into a lining reaction kettle of polytetrafluoroethylene, performing hydrothermal reaction for 12 to 24 hours at the temperature of between 160 and 180 DEG C, and drying a reaction product to obtain NH4V4O10 sediment; and (4) thermally treating the dried sediment for 1 to 3 hours at the temperature of between 300 and 500 DEG C to obtain the nano strip V2O5. The nano strip V2O5 can be used for preparing a sensor, a spinning electronic device, a nano photo-etching template or a high-capacity electrode material.

Owner:JINAN UNIVERSITY

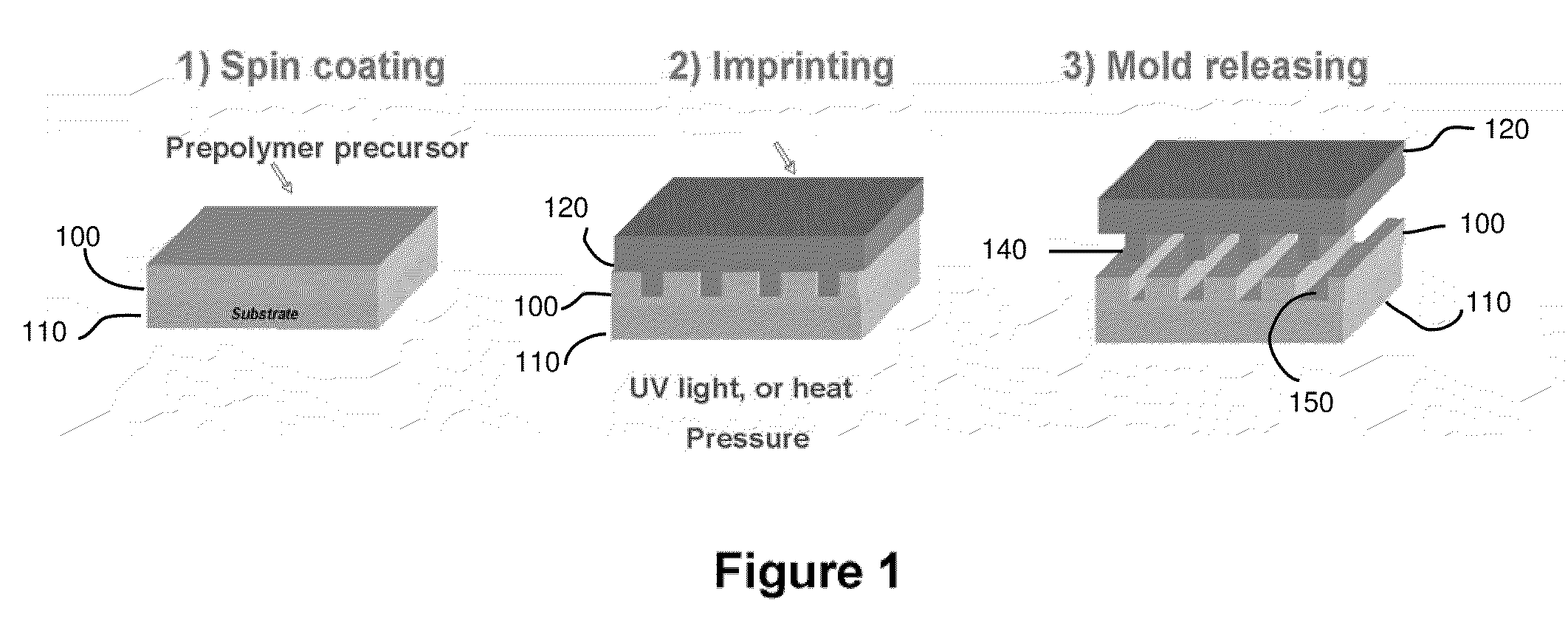

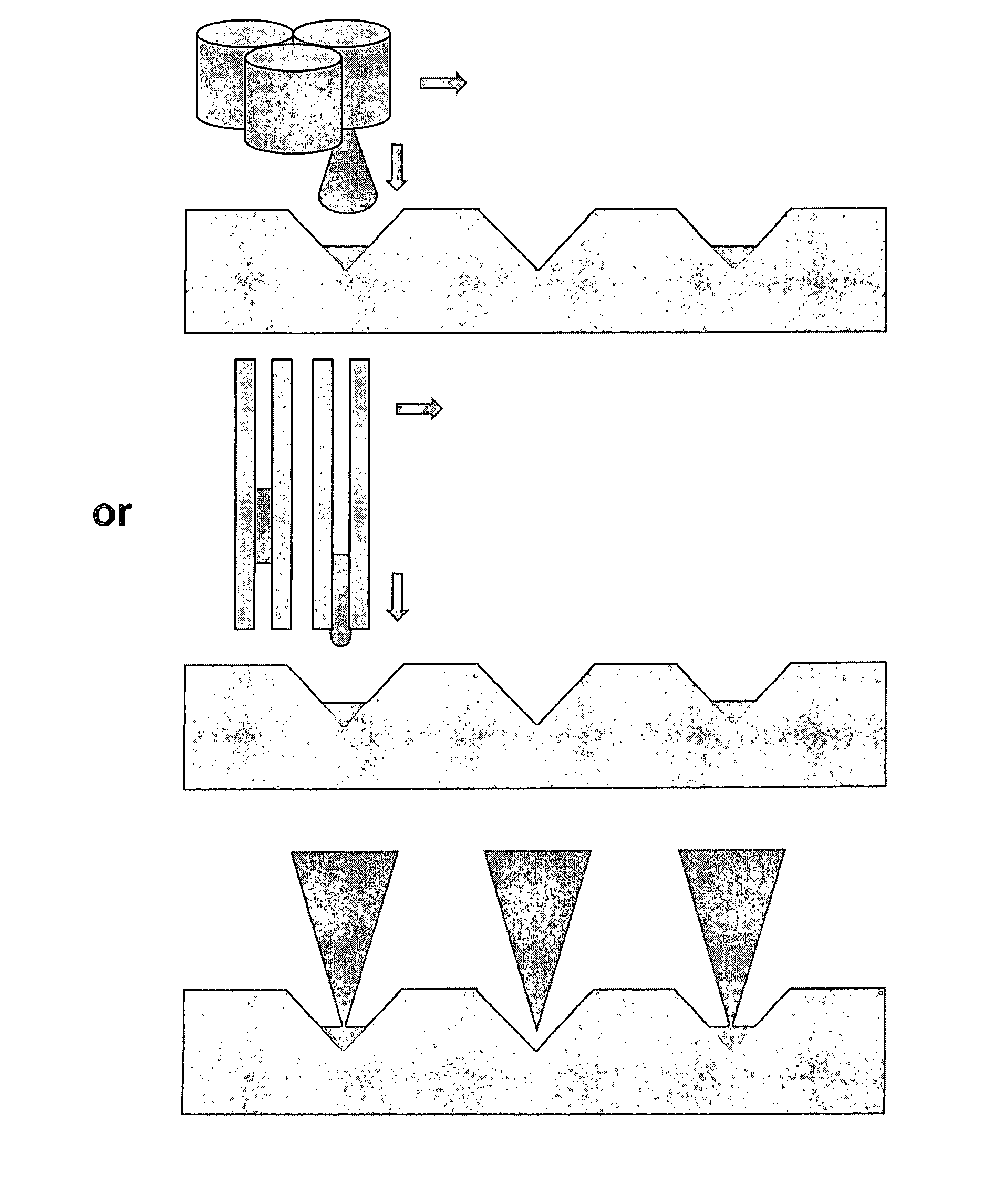

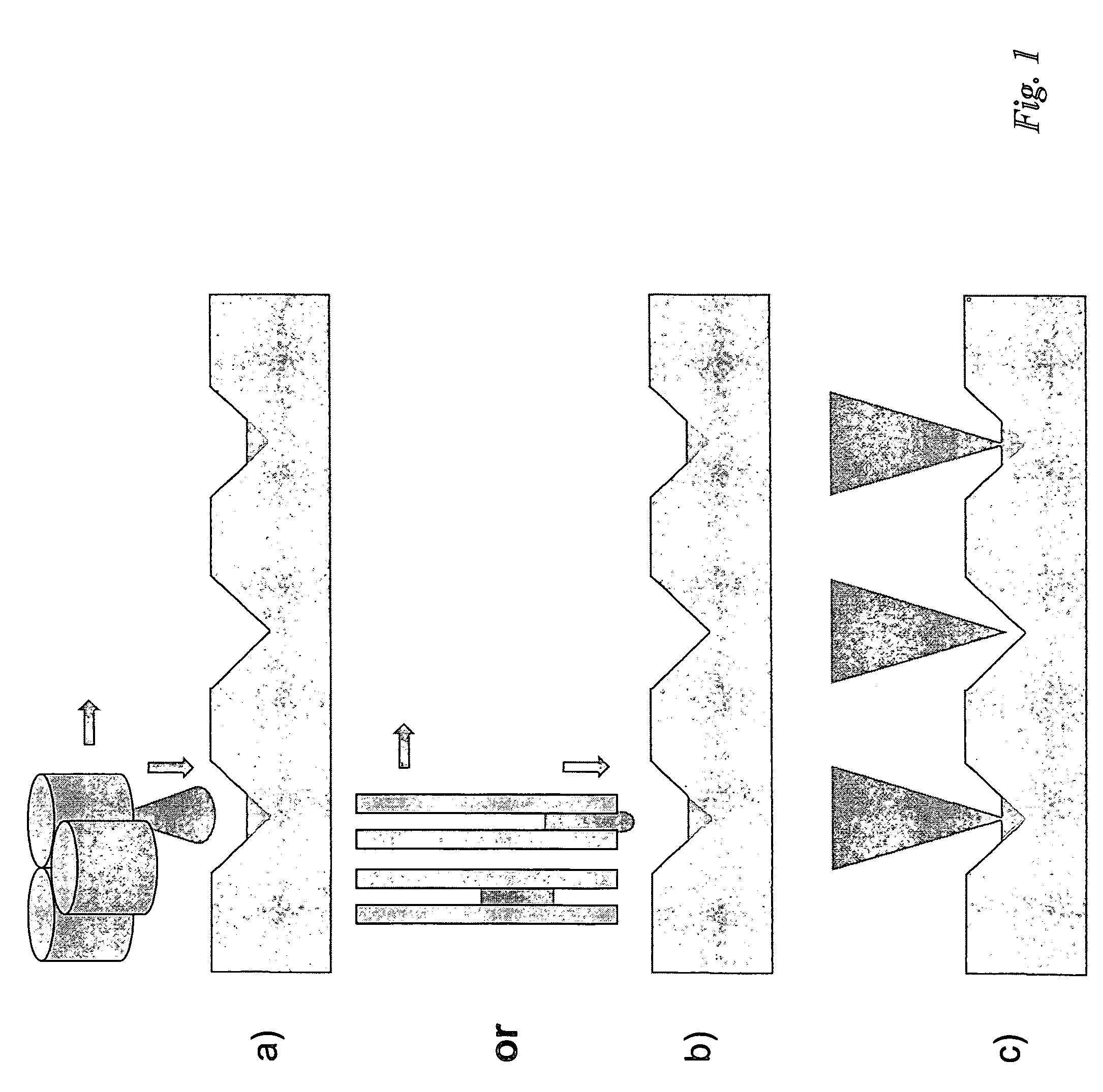

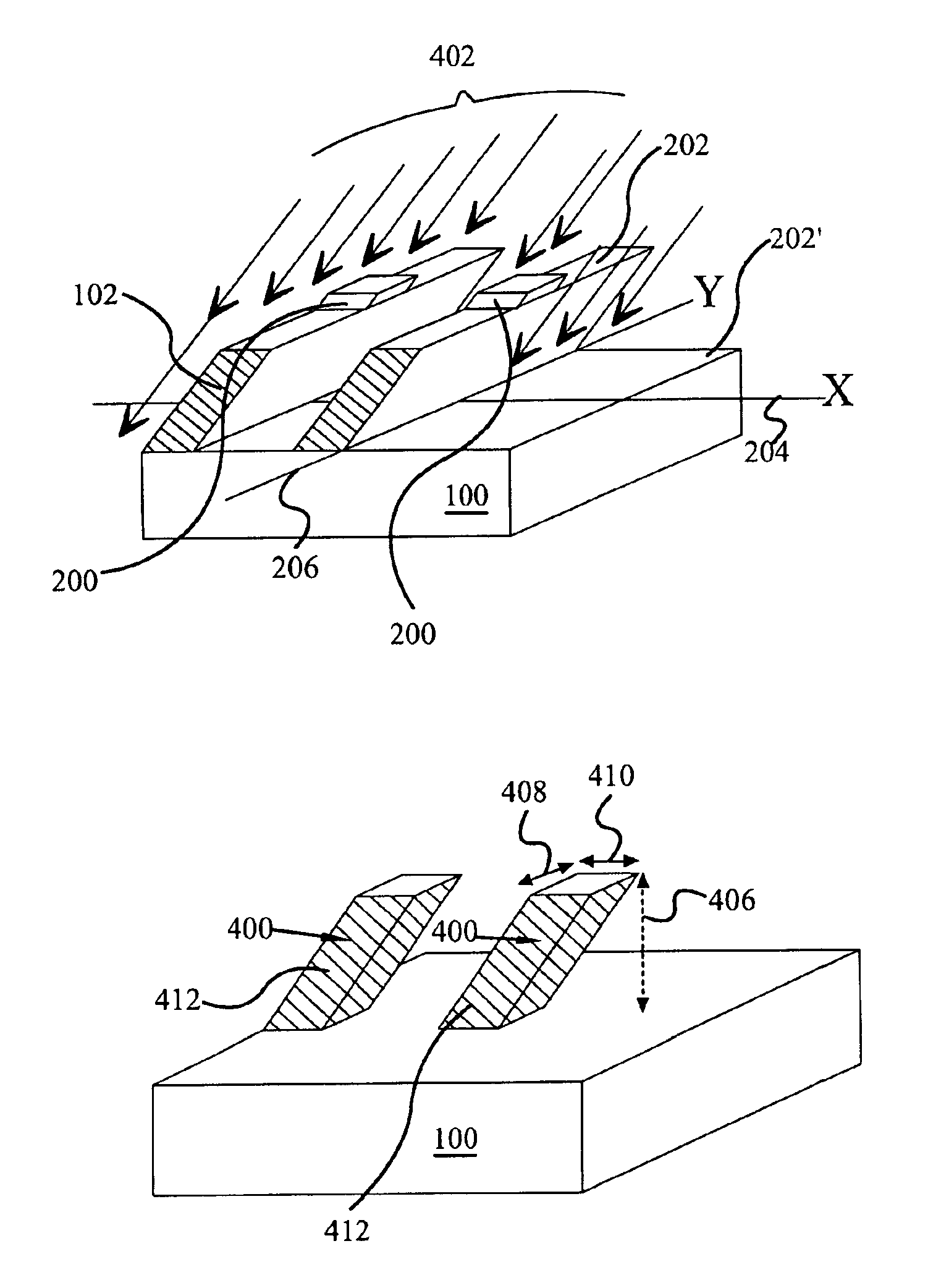

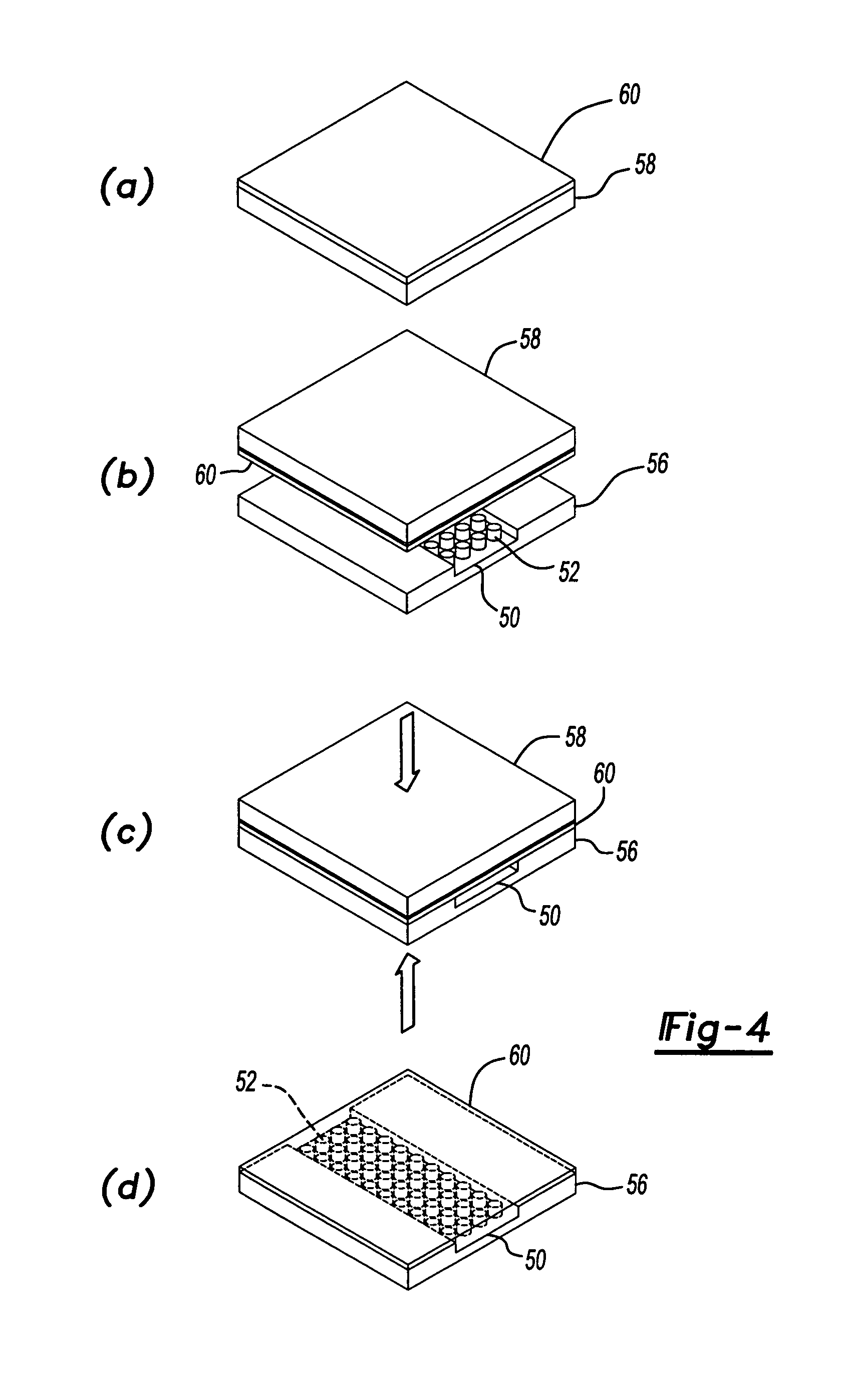

Process for making angled features for nanolithography and nanoimprinting

InactiveUS6897158B2Facilitates insertion and extractionSemiconductor/solid-state device manufacturingNon-linear opticsResistNanolithography

This invention provides a directional ion etching process for making nano-scaled angled features such as may be used, for example, in liquid crystal displays and or nanoimprinting templates. In a particular embodiment a semiconductor wafer substrate is prepared with at least one layer of material. A photoresist is applied, masked, exposed and developed. Anisotropic ion etching at a high angle relative to the wafer is performed to remove portions of the non protected material layer. The remaining photoresist caps shadow at least a portion of the material layer, and as the ion etching is performed at an angle, the protected portions of the material layer also appear at an angle.

Owner:HEWLETT PACKARD DEV CO LP

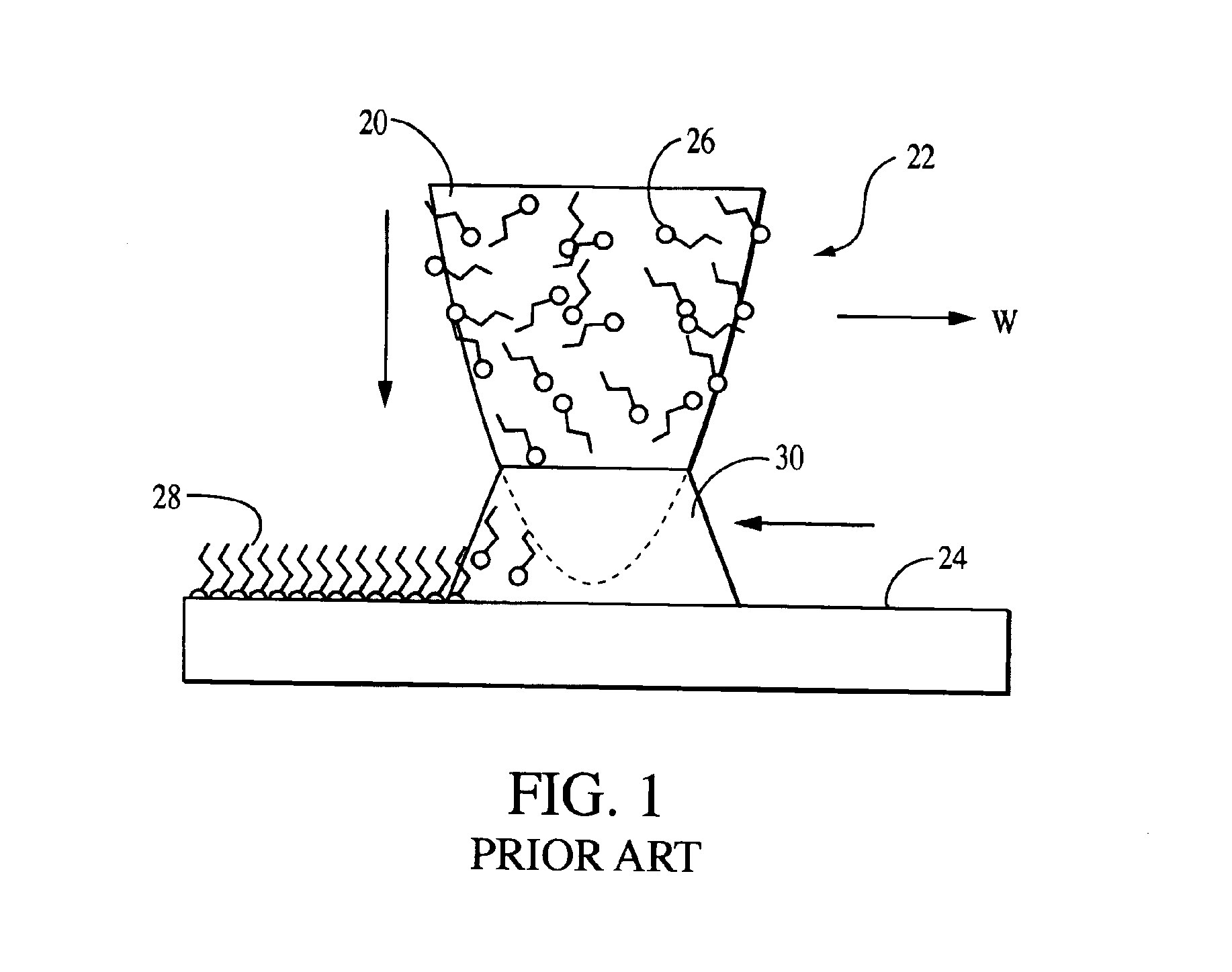

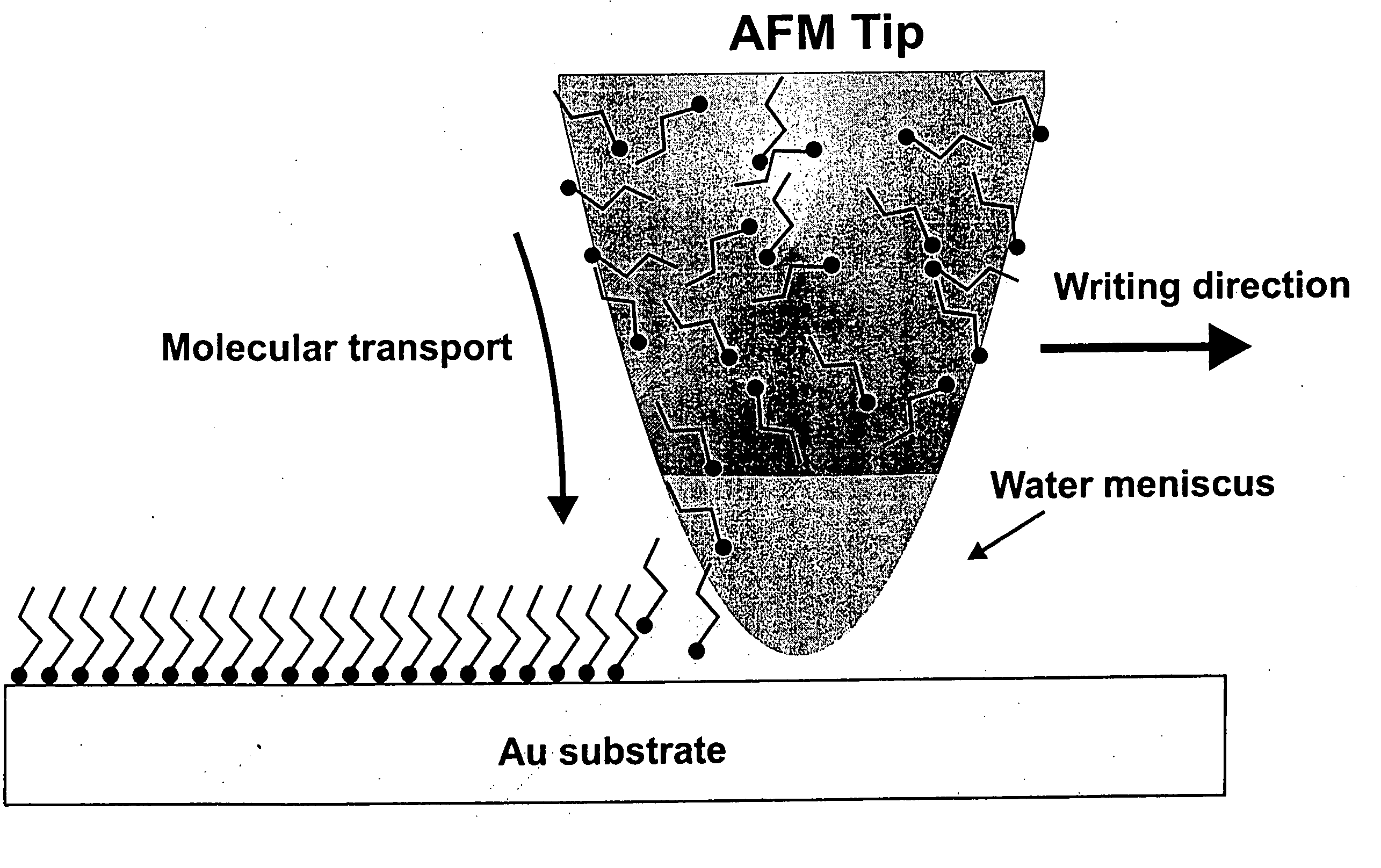

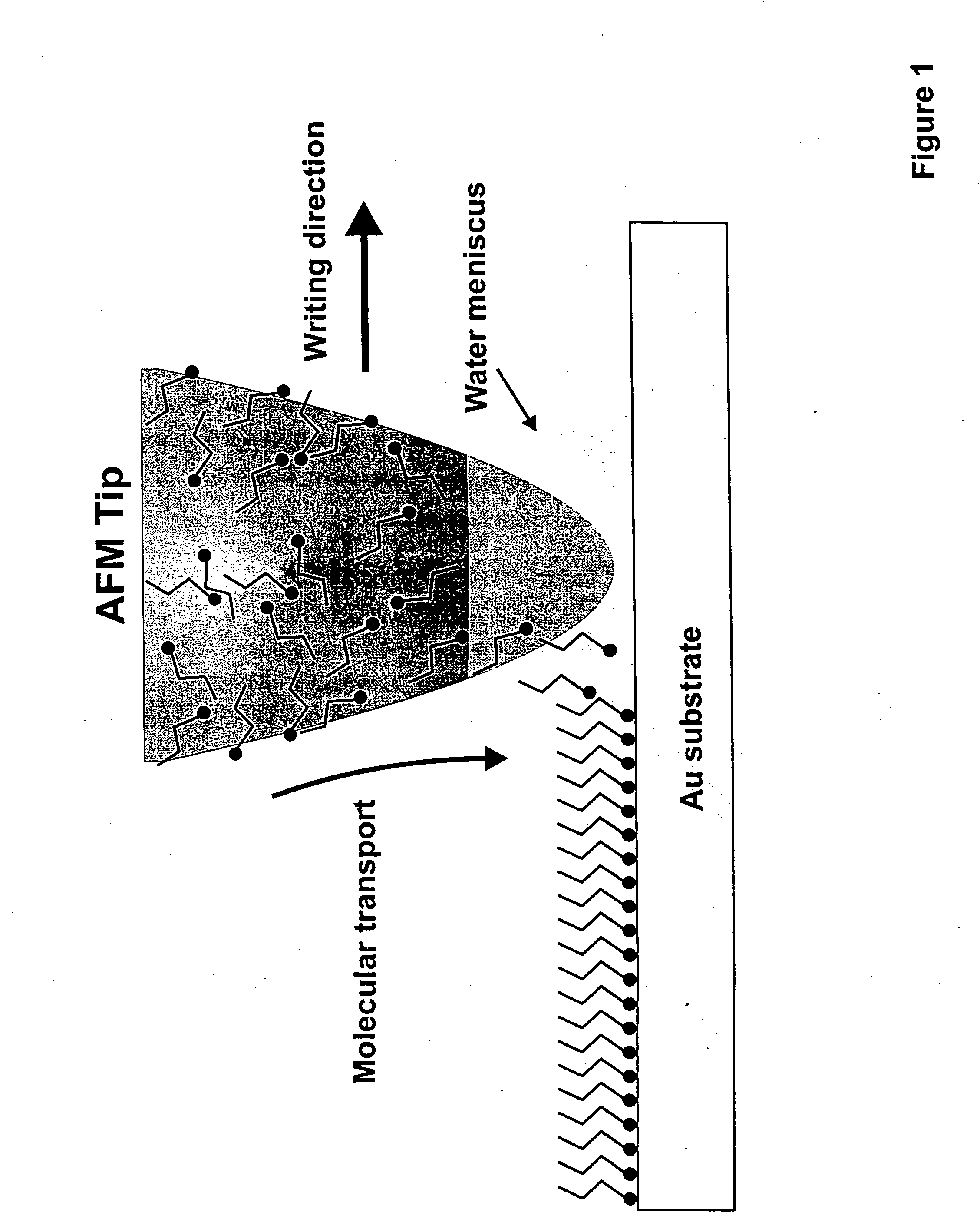

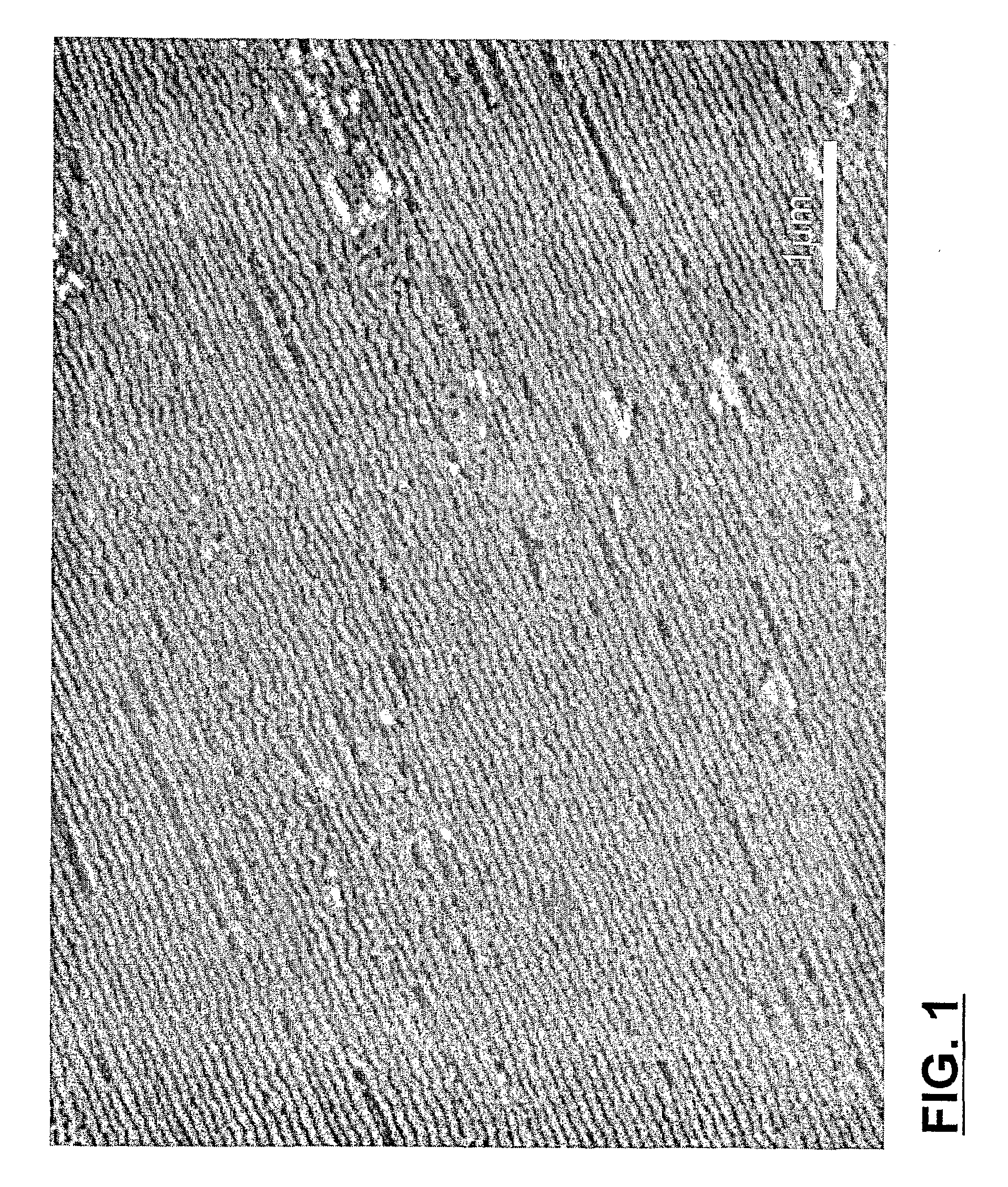

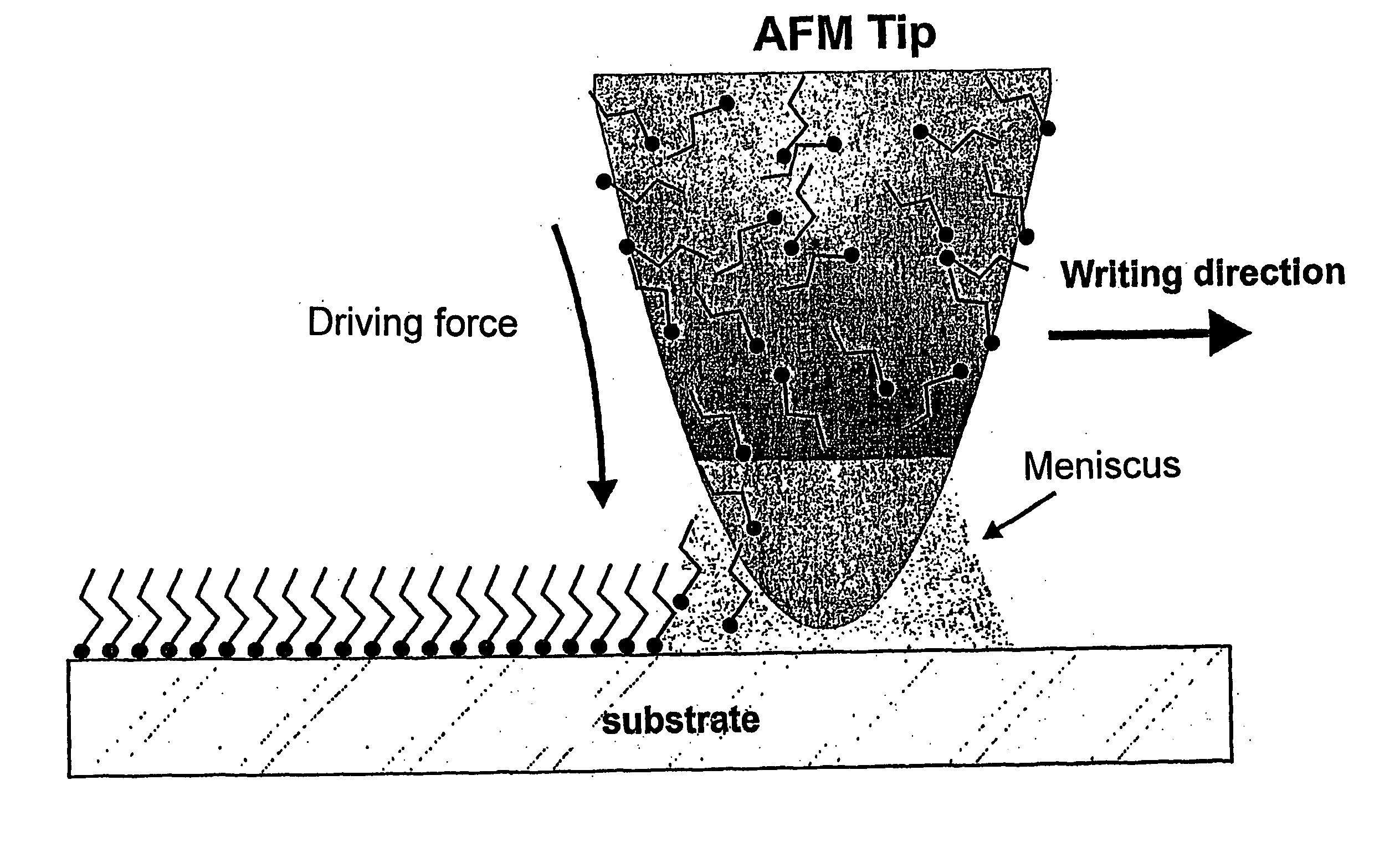

Methods utilizing scanning probe microscope tips and products therefor or produced thereby

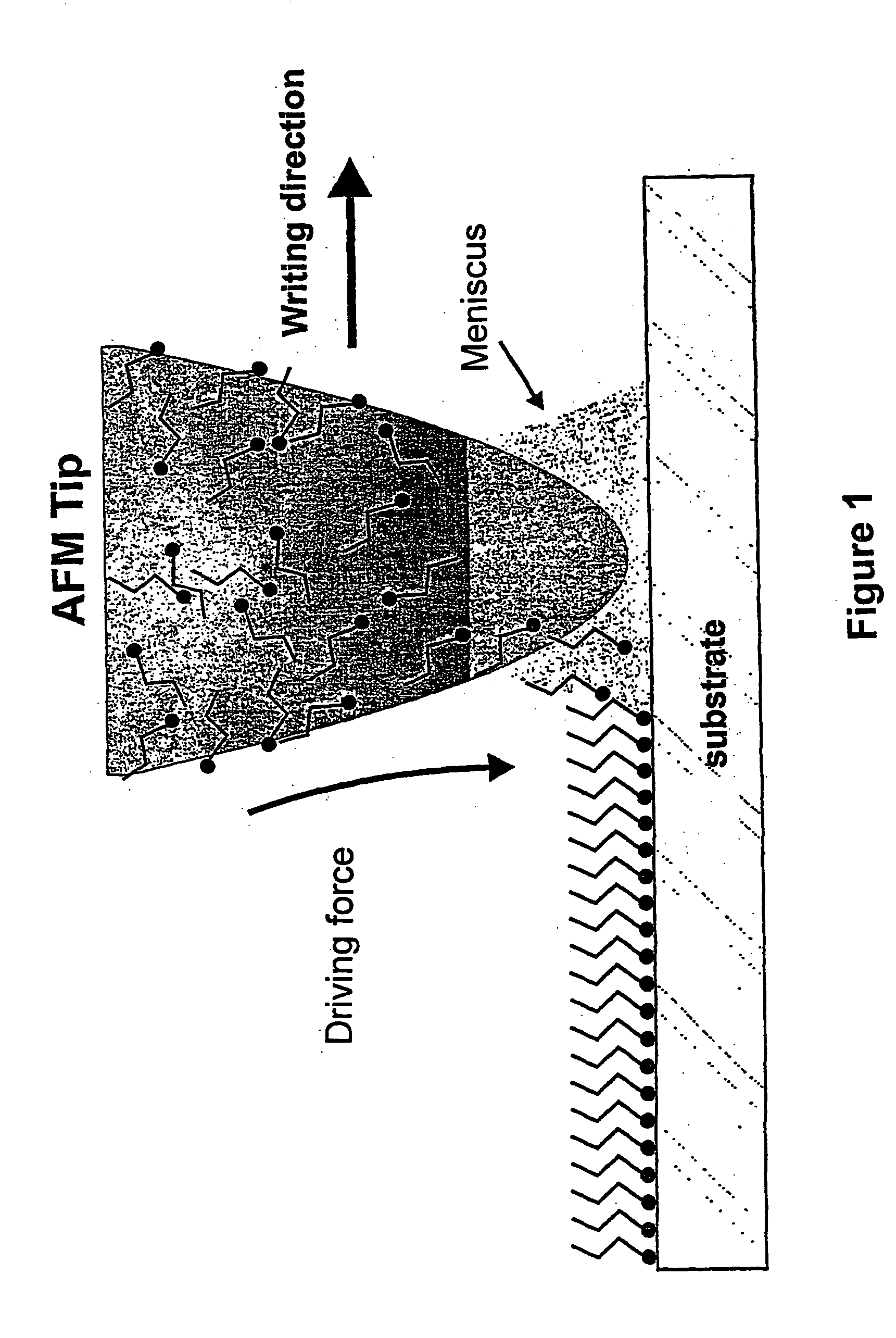

The invention provides a lithographic method referred to as “dip pen” nanolithography (DPN). DPN utilizes a scanning probe microscope (SPM) tip (e.g., an atomic force microscope (AFM) tip) as a “pen,” a solid-state substrate (e.g., gold) as “paper,” and molecules with a chemical affinity for the solid-state substratte as “ink.” Capillary transport of molecules from the SPM tip to thee solid substrate is used in DPN to directly write patterns consisting of a relatively small collection of molecules in submicrometer dimensions, making DPN useful in the facrication of a variety of microscale and nanoscale devices. The invention also provices substrates patterened by DPN, including submirocmeter combinatorial arrays, and kits, devices and software for performing DPN. The invention further provides a method of performing AFM imaging in air. The method comprises coating an AFM tip with a hydrophobic compound, the hydrophobic compoind being selected so that AFM imaging perfromed using the coated AFM tipn is improved compared to AFM imaging preformed using an uncoated AFM tip. Finally, the invention provides AFM tips coated with the hydrophobic compounds.

Owner:NORTHWESTERN UNIV

Fully secure item-level tagging

InactiveUS8917159B2Secure and efficientRobust radio linkKey distribution for secure communicationElectric signal transmission systemsNanolithographyPassword

The present invention provides value to brand owners, retailers, and consumers through the use of radio frequency identification, stenography, nanolithography, fingerprints, novel heuristic threat evaluation, indication, and detection model. Additionally, using cryptography, tag passwords are formulated and identities are reversibly flipped, thus allowing item identities to remain secret to unauthorized observers. This unique combination of heuristics and authentication technologies provides an efficient means of finding and stopping the flow of counterfeit products throughout global supply chains. The present invention includes radio frequency identification (RFID) tags, encoders, servers, identity changers, and authenticity verifiers to make this task a viable and adaptive weapon against the elusive counterfeiters. The present end-to-end RFID system offers unprecedented security for retailers and consumers, while remaining efficient and scalable.

Owner:MCALLISTER CLARKE WILLIAM +1

Parallel, individually addressable probes for nanolithography

InactiveUS20060082379A1Increase temperatureImprove completenessNanoinformaticsSolid-state devicesNanolithographyMicrometer

A microfabricated probe array for nanolithography and process for designing and fabricating the probe array. The probe array consists of individual probes that can be moved independently using thermal bimetallic actuation or electrostatic actuation methods. The probe array can be used to produce traces of diffusively transferred chemicals on the substrate with sub-1 micrometer resolution, and can function as an arrayed scanning probe microscope for subsequent reading and variation of transferred patterns.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

Short-wavelength polarizing elements and the manufacture and use thereof

While gold wire grids have been used to polarize infrared wavelengths for over a hundred years, they are not appropriate for shorter wavelengths due to their large period. With embodiments of the present invention, grids with periods a few tens of nanometers can be fabricated. Among other things, such grids can be used to polarize visible and even ultraviolet light. As a result, such wire grid polarizers have a wide variety of applications and uses, such as, e.g., in the fabrication of semiconductors, nanolithography, and more.

Owner:KK TOSHIBA +1

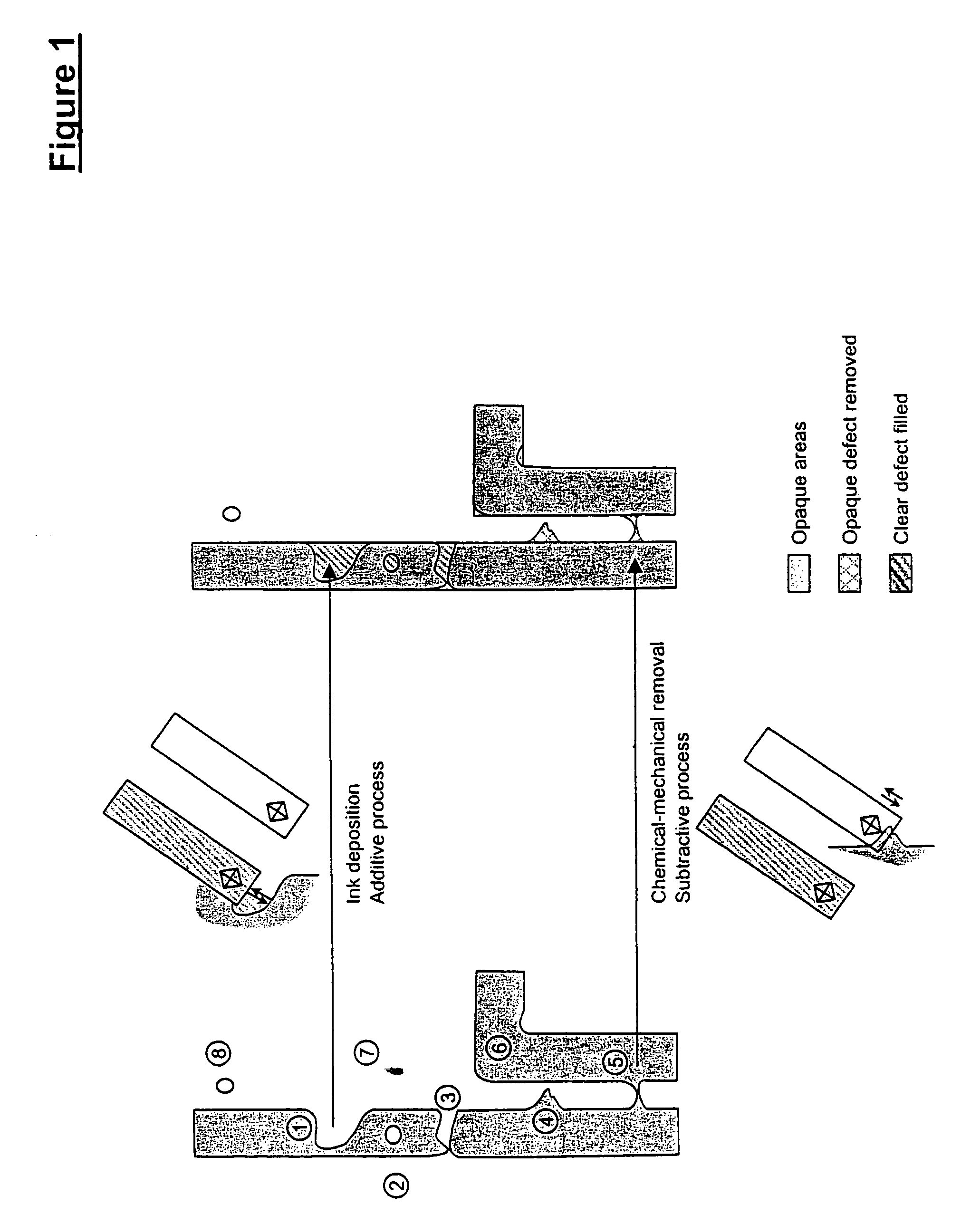

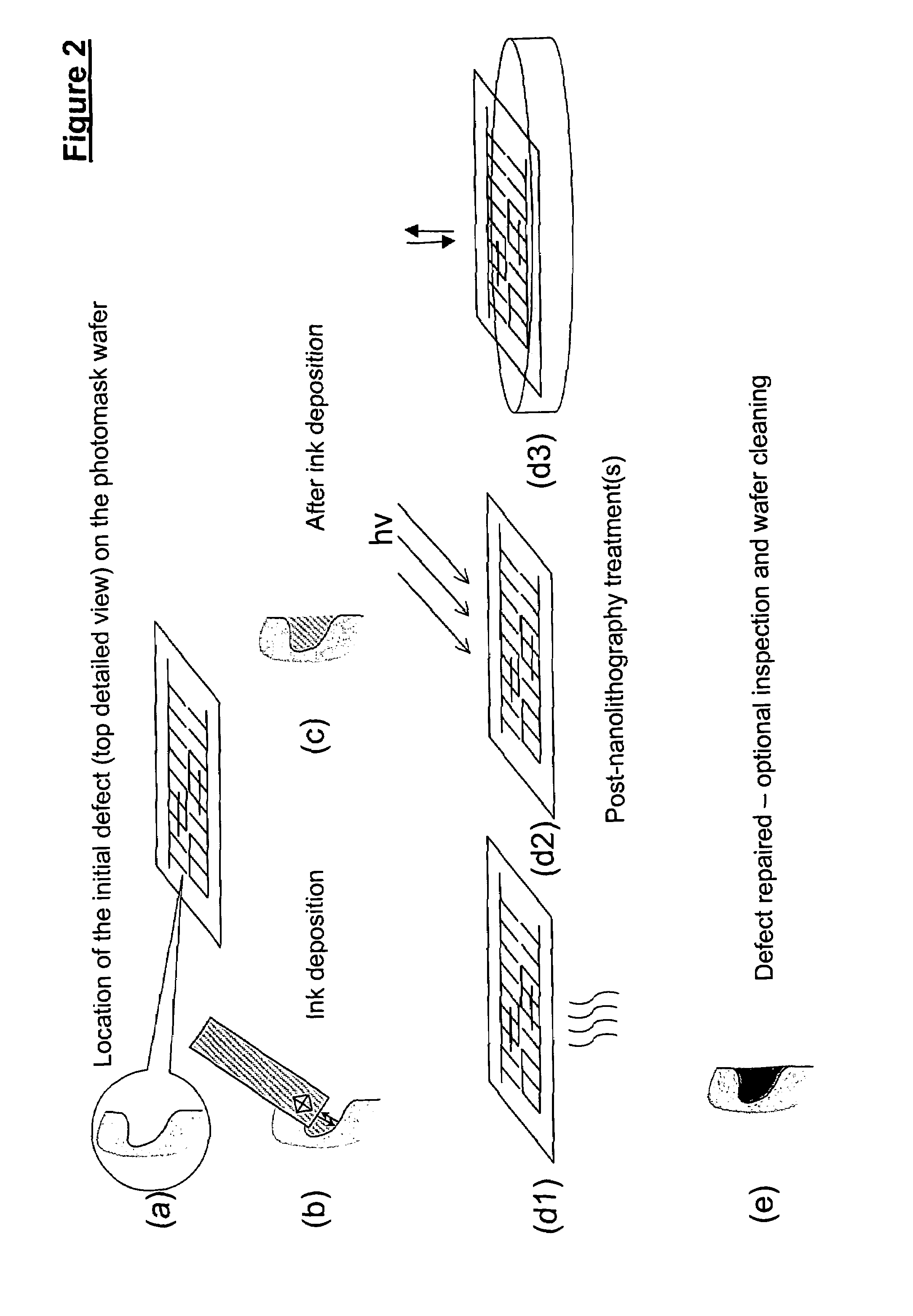

Methods for additive repair of phase shift masks by selectively depositing nanometer-scale engineered structures on defective phase shifters

InactiveUS7691541B2Improve performanceShorten the timeMaterial nanotechnologyNanostructure manufactureNanolithographyOptical transparency

Photomask repair and fabrication with use of direct-write nanolithography, including use of scanning probe microscopic tips (e.g., atomic force microscope tips, etc.) for deposition of ink materials including sol-gel inks. Additive methods can be combined with subtractive methods. Holes can be filled with nanostructures. Heights of the nanostructures filling the holes can be controlled without losing control of the lateral dimensions of the nanostructures. Phase shifters on phase shifting masks (PSMs) are additively repaired with selectively deposited sol-gel material that is converted to solid oxide, which has optical transparency and index of refraction adapted for the phase shifters repaired.

Owner:NANOINK INC

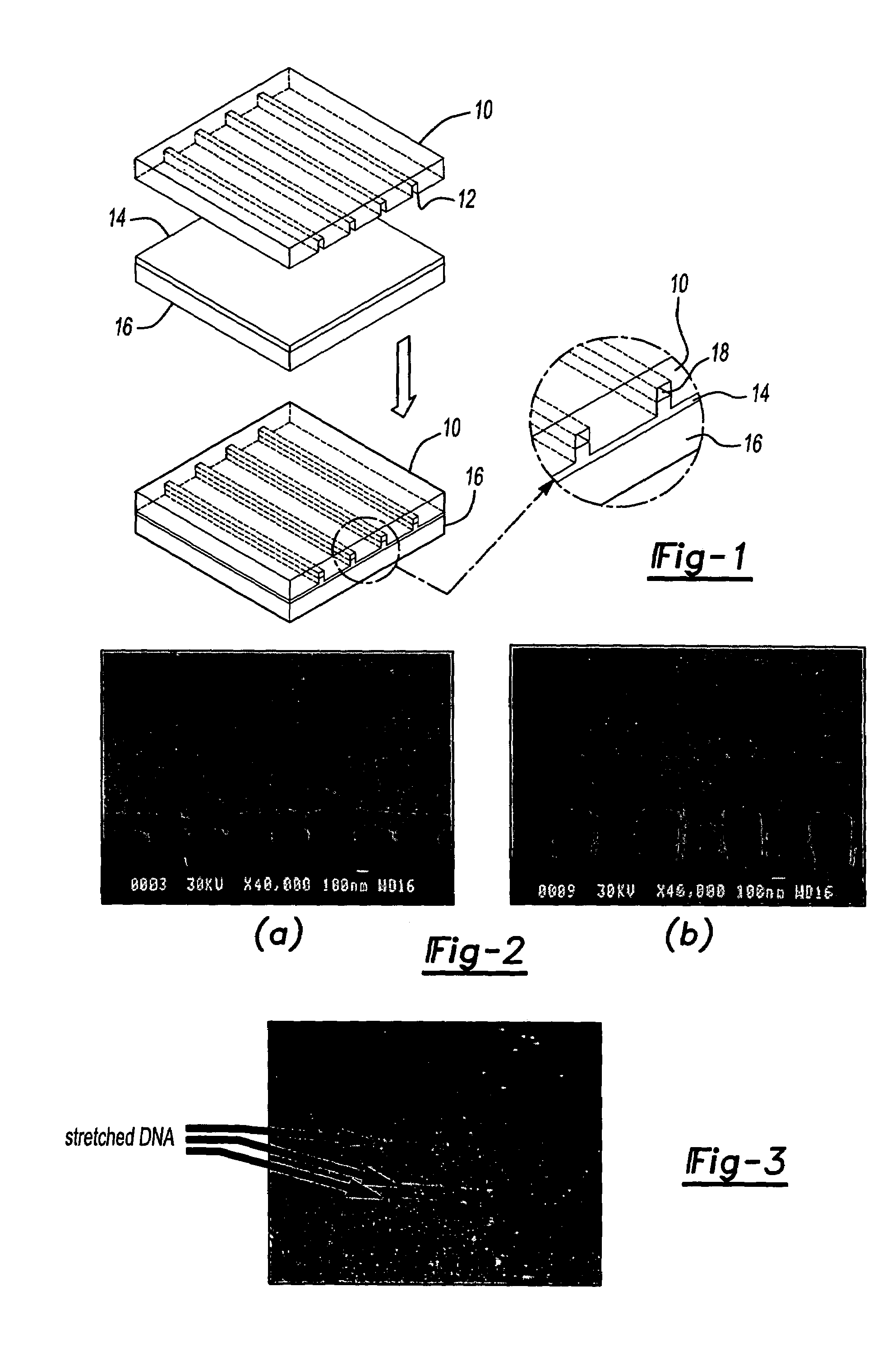

Method of forming nanofluidic channels

InactiveUS7169251B2Easy to manufactureMaterial nanotechnologyFixed microstructural devicesNanolithographyElectrical and Electronics engineering

A method of forming nanofluidic enclosed channels includes providing a first substrate having a layer of a first material disposed thereon. A plurality of nanoscale slots is formed along a second substrate using nanolithography, etching, or other disclosed techniques. The first substrate is then bonded to the second substrate such that the layer of the first material on the first substrate is adjacent the plurality of slots on the second substrate to define a plurality of enclosed nanofluidic channels therethrough.

Owner:RGT UNIV OF MICHIGAN

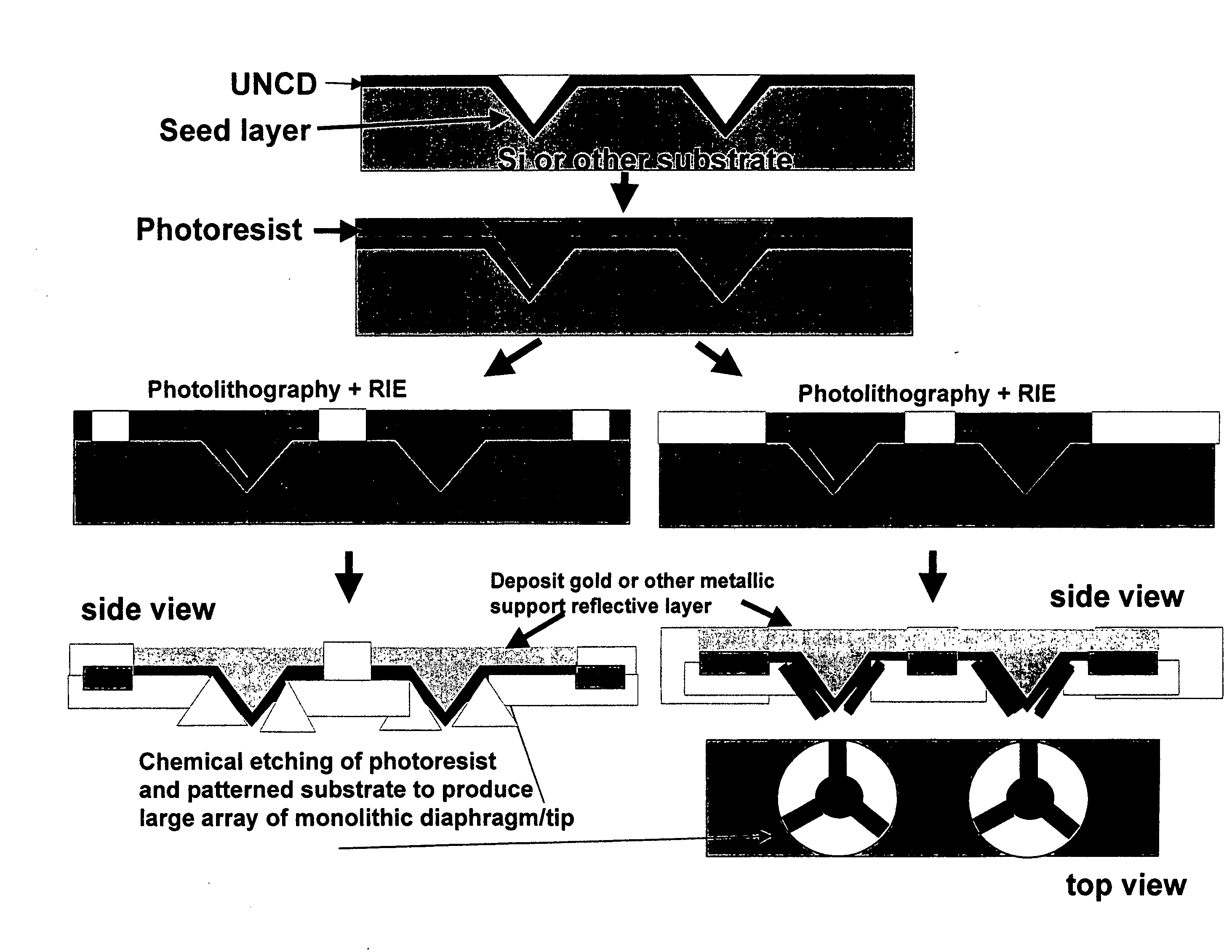

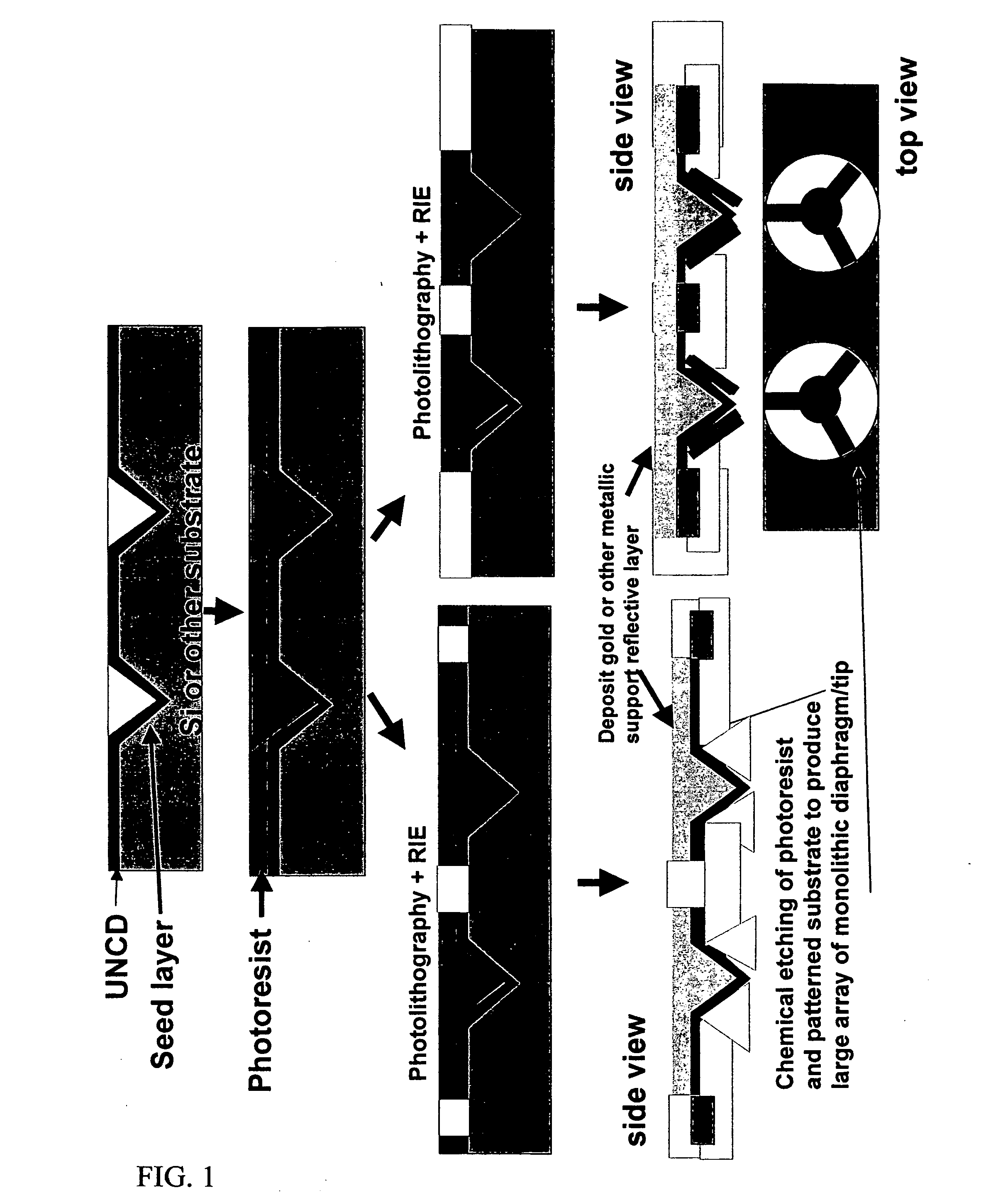

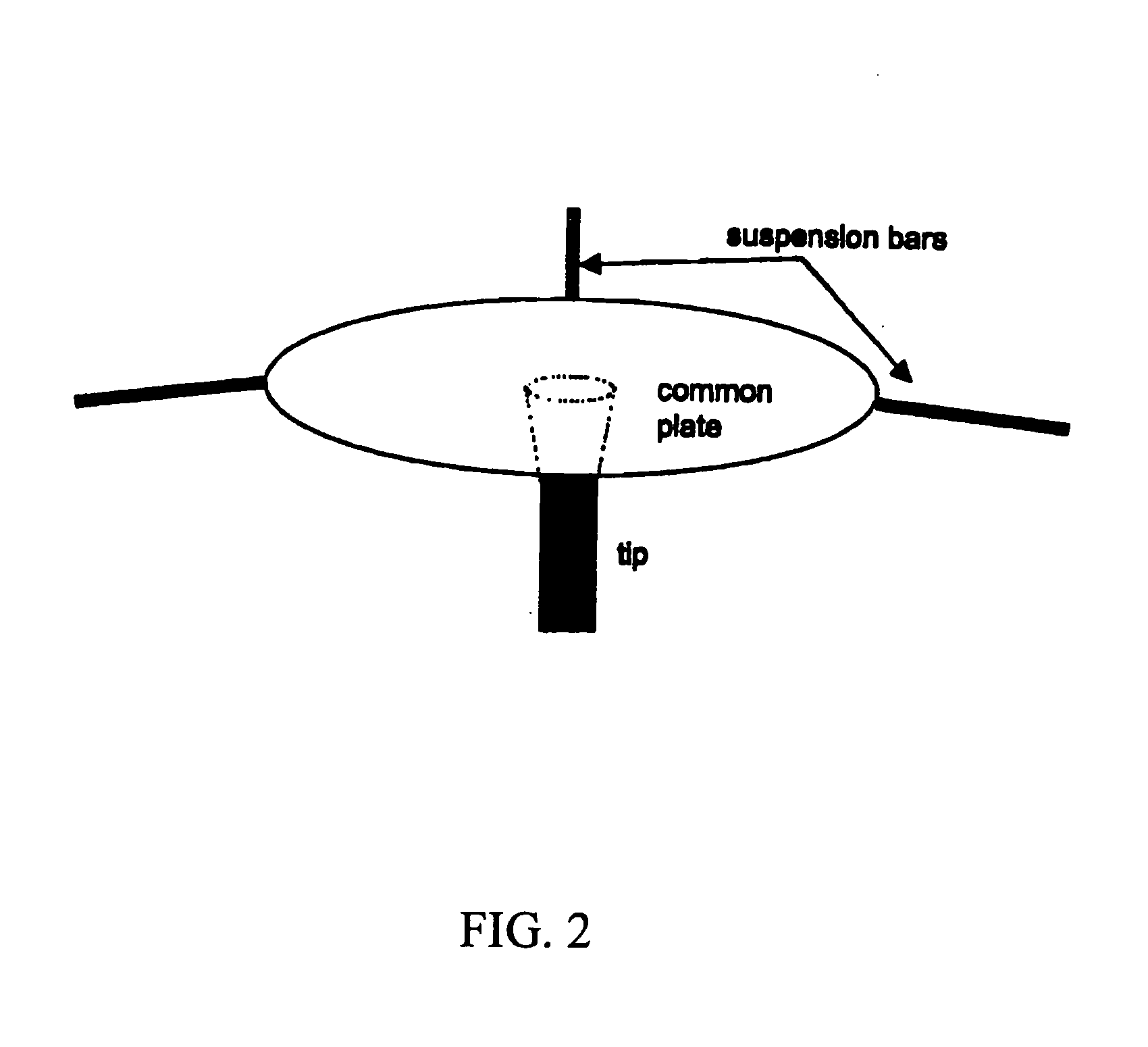

Novel ultrananocrystalline diamond probes for high-resolution low-wear nanolithographic techniques

InactiveUS20070220959A1NanotechnologyMechanical roughness/irregularity measurementsNanodotNanolithography

A monolithically integrated 3-D membrane or diaphragm / tip (called 3-D tip) of substantially all UNCD having a tip with a radius of about less than 50 nm capable of measuring forces in all three dimensions or being used as single tips or in large arrays for imprint of data on memory media, fabrication of nanodots of different materials on different substrates and many other uses such as nanolithography production of nanodots of biomaterials on substrates, etc. A method of molding UNCD is disclosed including providing a substrate with a predetermined pattern and depositing an oxide layer prior to depositing a carbide-forming metallic seed layer, followed by seeding with diamond nano or micropowder in solvent suspension, or mechanically polishing with diamond powder, or any other seeding method, followed by UNCD film growth conforming to the predetermined pattern. Thereafter, one or more steps of masking and / or etching and / or coating and / or selective removal and / or patterning and / or electroforming and / or lapping and / or polishing are used in any combination to form the tip or probe.

Owner:UCHICAGO ARGONNE LLC

Field-assisted micro- and nano-fabrication method

InactiveUS20050112505A1NanoinformaticsSemiconductor/solid-state device manufacturingNanolithographyMolecular electronics

A direct-write micro- or nano-lithography method for depositing a functional material with a preferred orientation onto a target surface. The method includes the steps of (1) forming a precursor fluid to the functional material; (2) operating a sub-micrometer tip to discharge, on contact, the precursor fluid onto the target surface so as to produce a desired pattern of deposited functional material in sub-micrometer dimensions; and (3) during the pattern-producing step, subjecting the deposited material to a highly localized electric or magnetic field for attaining a preferred orientation in at least a portion of the functional material. The method is particularly useful for microfabrication, nanotechnology, and molecular electronics.

Owner:HUANG WEN C +1

Method and device for generating three-dimensional array hollow light spot

InactiveCN106932914APrecise adjustment of spatial positionOptical elementsNanolithographySpatial light modulator

The invention relates to a method and device for generating a three-dimensional array hollow light spot. The device comprises a laser device, a pinhole filter, a collimator lens, a half-wave plate, a spatial light modulator, an optical wave converter, a beam diameter changer and a microobjective. In addition, the method includes: laser emitted by the laser device is converted into a linear polarization type plane wave; wave-front phase modulation is carried out on the linear polarization type plane wave; and then light after wave-front phase modulation is focused by an objective lens to generate an array light spot. The wave-front phases are in three-dimensional spatial position controllable array light spot phase distribution; and the light wave after wave-front phase modulation needs to be processed by modulation of circular polarization with a spiral phase or angular polarization without a spiral phase. The array light spot is formed by a plurality of hollow light spots arranged in three-dimensional space and each light spot can move precisely in the three-dimensional space. The method and device can be applied to array optical tweezers, super-resolution microscopic imaging and super-resolution nanometer lithography fields.

Owner:LUDONG UNIVERSITY

Electronic and optoelectronic devices and methods for preparing same

InactiveUS20050250243A1Improve responseMaterial nanotechnologyNanostructure manufactureNanolithographyNanoparticle

Disclosed are electronic, plasmonic and opto-electronic components that are prepared using patterned photodeposited nanoparticles on a substrate surface. Also disclosed are ferroelectric nanolithography methods for preparing components, circuits and devices.

Owner:THE TRUSTEES OF THE UNIV OF PENNSYLVANIA

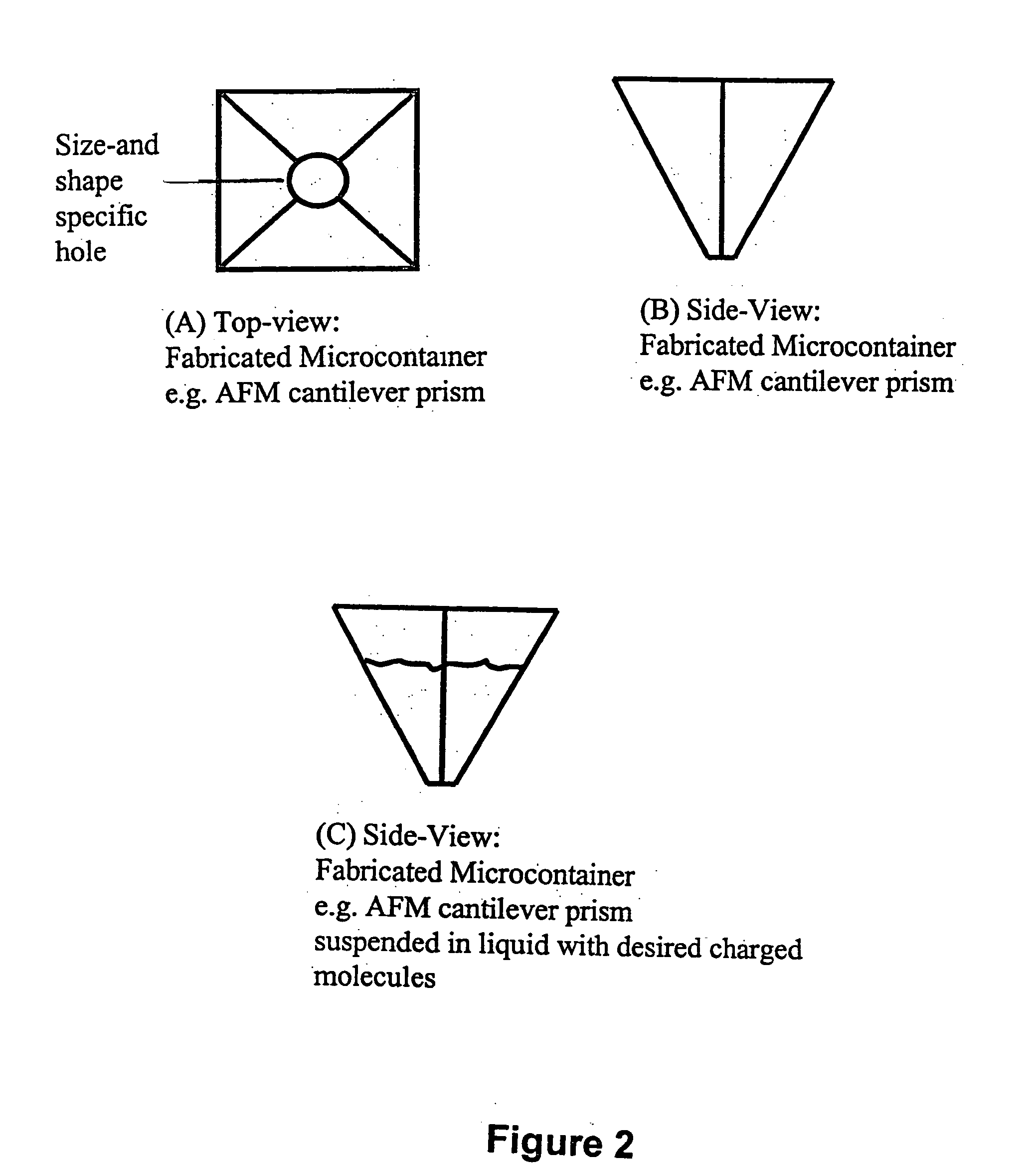

Nanolithography methods and products therefor and produced thereby

InactiveUS20050191434A1Easy to controlMaterial nanotechnologyNanostructure manufactureNanolithographyScanning probe microscopy

In one aspect, a method of nanolithography is provided using a driving force to control the movement of a deposition compound from a scanning probe microscope tip to a substrate. Another aspect of the invention provides a tip for use in nanolithography having an internal cavity and an aperture restricting movement of a deposition compound from the tip to the substrate. The rate and extent of movement of the deposition compound through the aperture is controlled by a driving force.

Owner:NORTHWESTERN UNIV

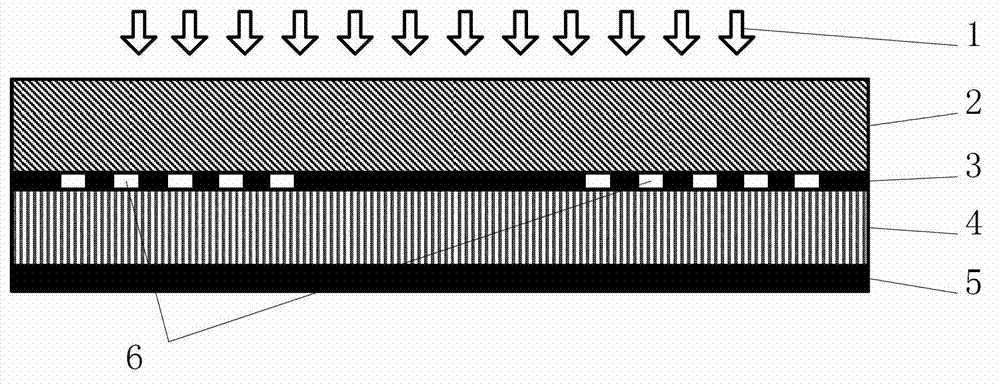

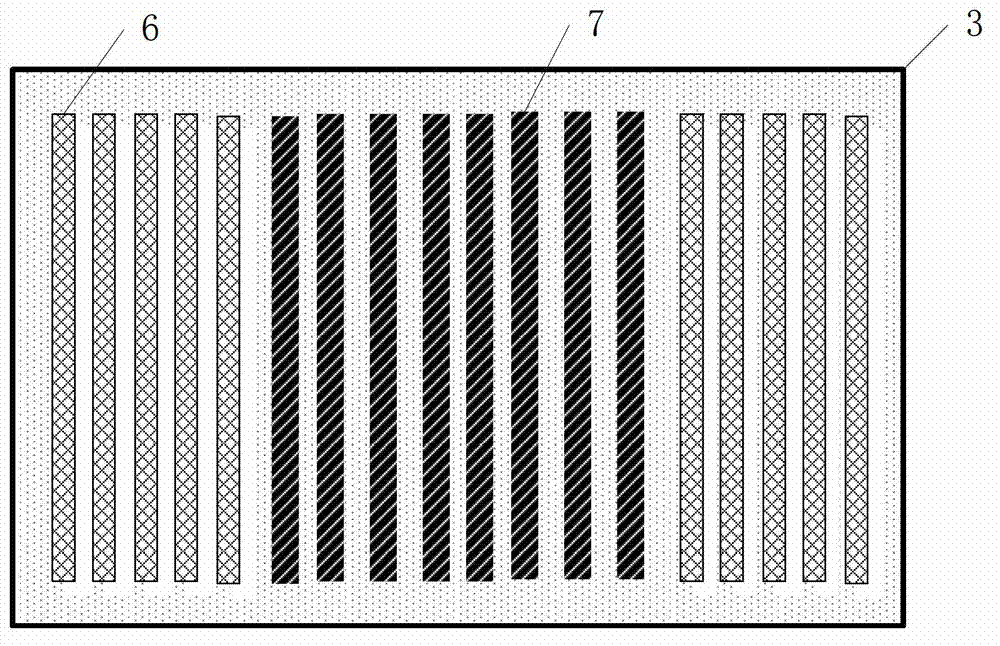

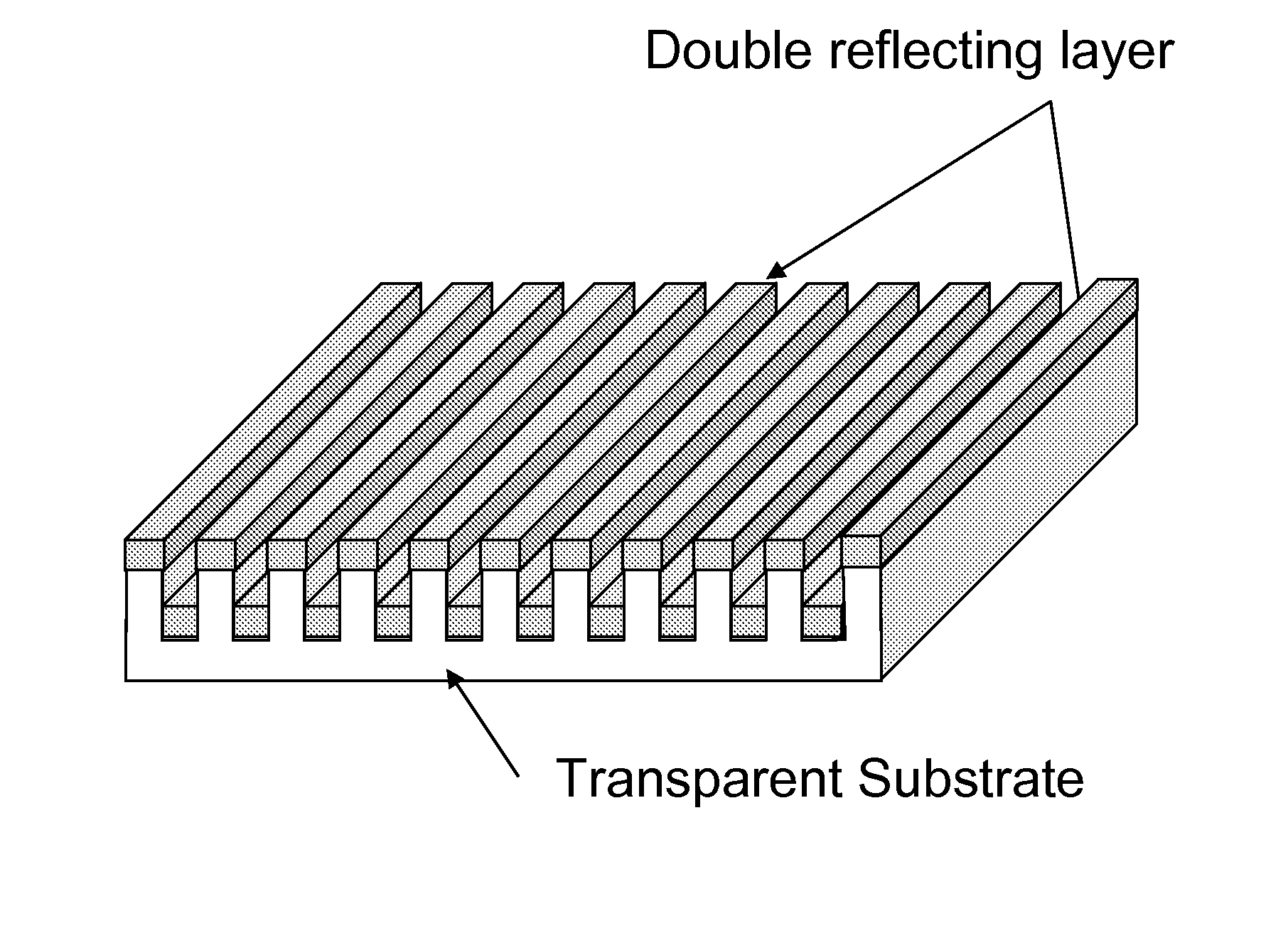

Super-diffraction imaging device for improving resolution based on phase shifting principle and manufacturing method thereof

ActiveCN102096334AImprove modulation efficiencyIncrease profitPhotomechanical exposure apparatusMicrolithography exposure apparatusNanolithographyLithographic artist

The invention discloses a super-diffraction imaging device for improving resolution based on a phase shifting principle and a manufacturing method thereof. Adjacent light transmission areas of the super-diffraction imaging device realize phase delay and phase advance respectively by alternately filling two materials with a positive dielectric coefficient and a negative dielectric coefficient and the phase difference modulation of the material thicknesses is enhanced greatly, so that the device is easier to realize a pi phase difference; therefore, the imaging resolution of the device is further improved. The scheme solves the technical difficult problem that a conventional super-diffraction imaging device is difficult to realize the resolution below the line width of 40 nm and has a broad application prospect in super-diffraction imaging and nano-lithography technologies.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com