Method and device for generating three-dimensional array hollow light spot

A technology of three-dimensional array and generation method, applied in optics, optical components, instruments, etc., can solve the problems of non-adjustable spot position and non-hollow spot intensity distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

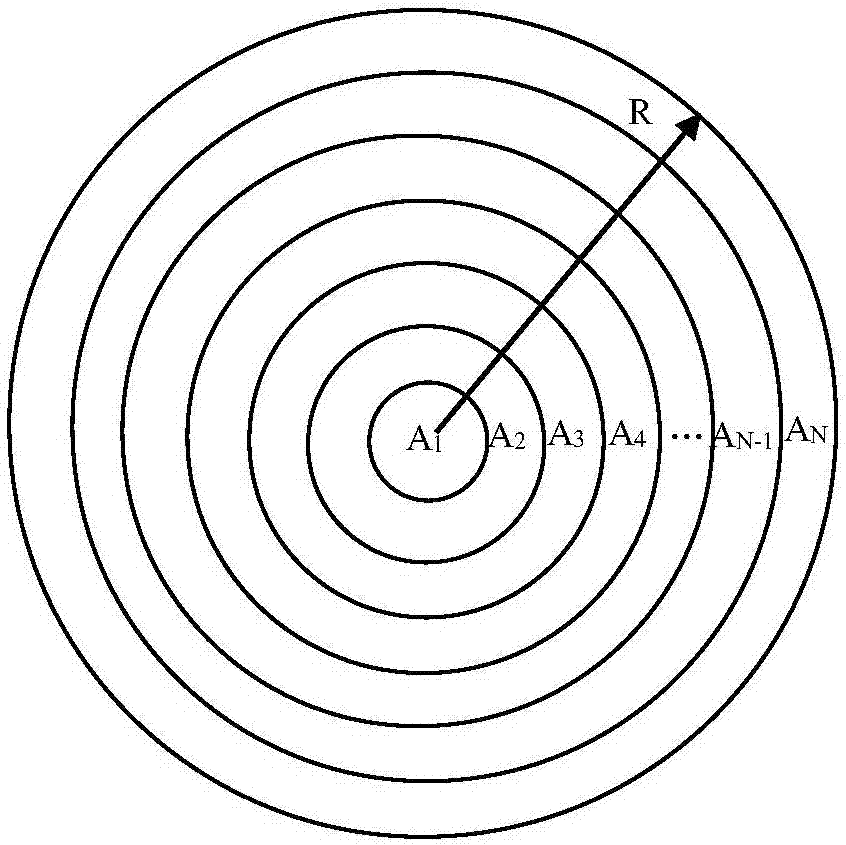

[0103] Select the number of rings N=80, the number of sub-rings M=8, corresponding to M=8, it is a three-dimensional square array, and the position parameter of each light spot is (Δx 1 ,Δy 1 ,Δz 1 )=[2μm, 2μm, 2μm]; (Δx 2 ,Δy 2 ,Δz 2 )=[-2μm, 2μm, 2μm]; (Δx 3 ,Δy 3 ,Δz 3 ) = [-2μm, -2μm, 2μm]; (Δx 4 ,Δy 4 ,Δz 4 )=[2μm,-2μm,2μm]; (Δx 5 ,Δy 5 ,Δz 5 )=[2μm, 2μm, 0μm]; (Δx 6 ,Δy 6 ,Δz 6 )=[-2μm, 2μm, 0μm]; (Δx 7 ,Δy 7 ,Δz 7 )=[-2μm,-2μm,0μm]; (Δx 8 ,Δy 8 ,Δz 8 )=[2 μm, −2 μm, 0 μm].

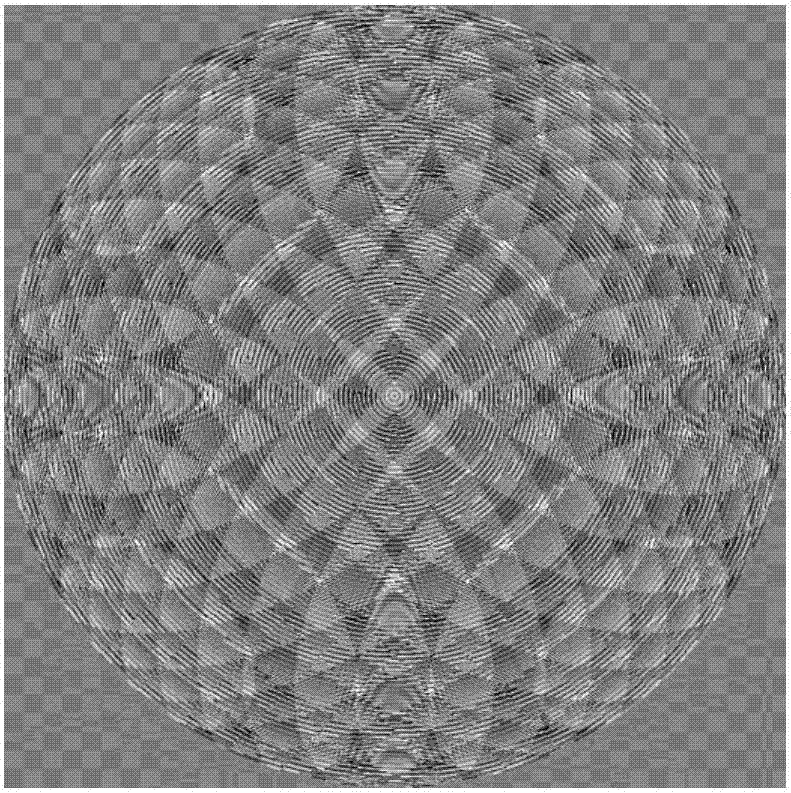

[0104] Figure 4 Shown is a schematic diagram of the device for generating a three-dimensional array of spots. A device for generating a three-dimensional array hollow spot, such as Figure 4 As shown, it includes a laser 1 , a pinhole filter 2 , a collimating lens 3 , a half-wave plate 4 , a spatial light modulator 5 , a light-wave converter 6 , a beam diameter changer 7 and an objective lens 8 . The spatial light modulator 5 is loaded with image 3 Phase shown Figure 10...

Embodiment 2

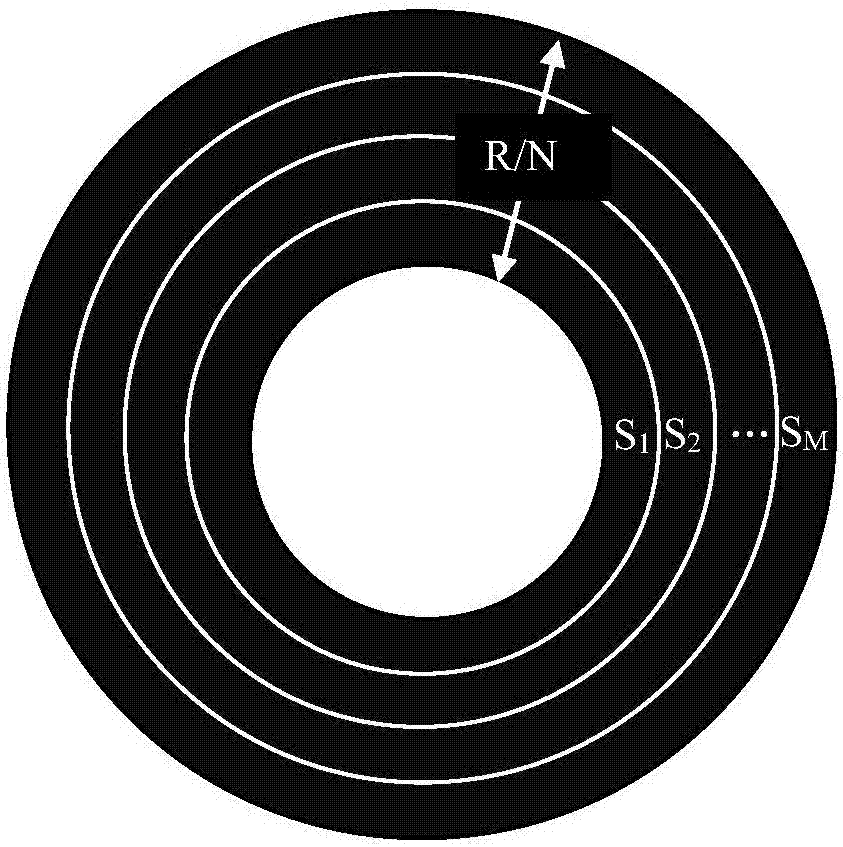

[0111] The phase diagram when M=9 array spots is selected, such as Figure 11 As shown, where the number of rings N=60, corresponding to the position parameters of 9 spots: (Δx 1 ,Δy 1 ,Δz 1 )=[2cos(π / 4)μm, 2sin(π / 4)μm,1μm], (Δx 2 ,Δy 2 ,Δz 2 )=[2cos(π / 2)μm, 2sin(π / 2)μm,1μm], (Δx 3 ,Δy 3 ,Δz 3 )=[2cos(3π / 4)μm, 2sin(3π / 4)μm,1μm], (Δx 4 ,Δy 4 ,Δz 4 )=[2cos(π)μm, 2sin(π)μm,1μm], (Δx 5 ,Δy 5 ,Δz 5 )=[2cos(5π / 4)μm, 2sin(5π / 4)μm,1μm], (Δx 6 ,Δy 6 ,Δz 6 )=[2cos(3π / 2)μm, 2sin(3π / 2)μm,1μm], (Δx 7 ,Δy 7 ,Δz 7 )=[2cos(7π / 4)μm, 2sin(7π / 4)μm,1μm], (Δx 8 ,Δy 8 ,Δz 8 )=[2cos(2π)μm, 2sin(2π)μm,1μm], (Δx 9 ,Δy 9 ,Δz 9 )=[0 μm, 0 μm, −1 μm].

[0112] Figure 12 It shows that when the parameter M=9 is selected and the light-wave converter composed of a helical phase plate and a quarter-wave plate is selected, the light wave is loaded with a phase of topological charge n=1 and the polarization becomes a three-dimensional equation of left-handed circularly polarized light...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com