Patents

Literature

485 results about "Beam diameter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The beam diameter or beam width of an electromagnetic beam is the diameter along any specified line that is perpendicular to the beam axis and intersects it. Since beams typically do not have sharp edges, the diameter can be defined in many different ways. Five definitions of the beam width are in common use: D4σ, 10/90 or 20/80 knife-edge, 1/e², FWHM, and D86. The beam width can be measured in units of length at a particular plane perpendicular to the beam axis, but it can also refer to the angular width, which is the angle subtended by the beam at the source. The angular width is also called the beam divergence.

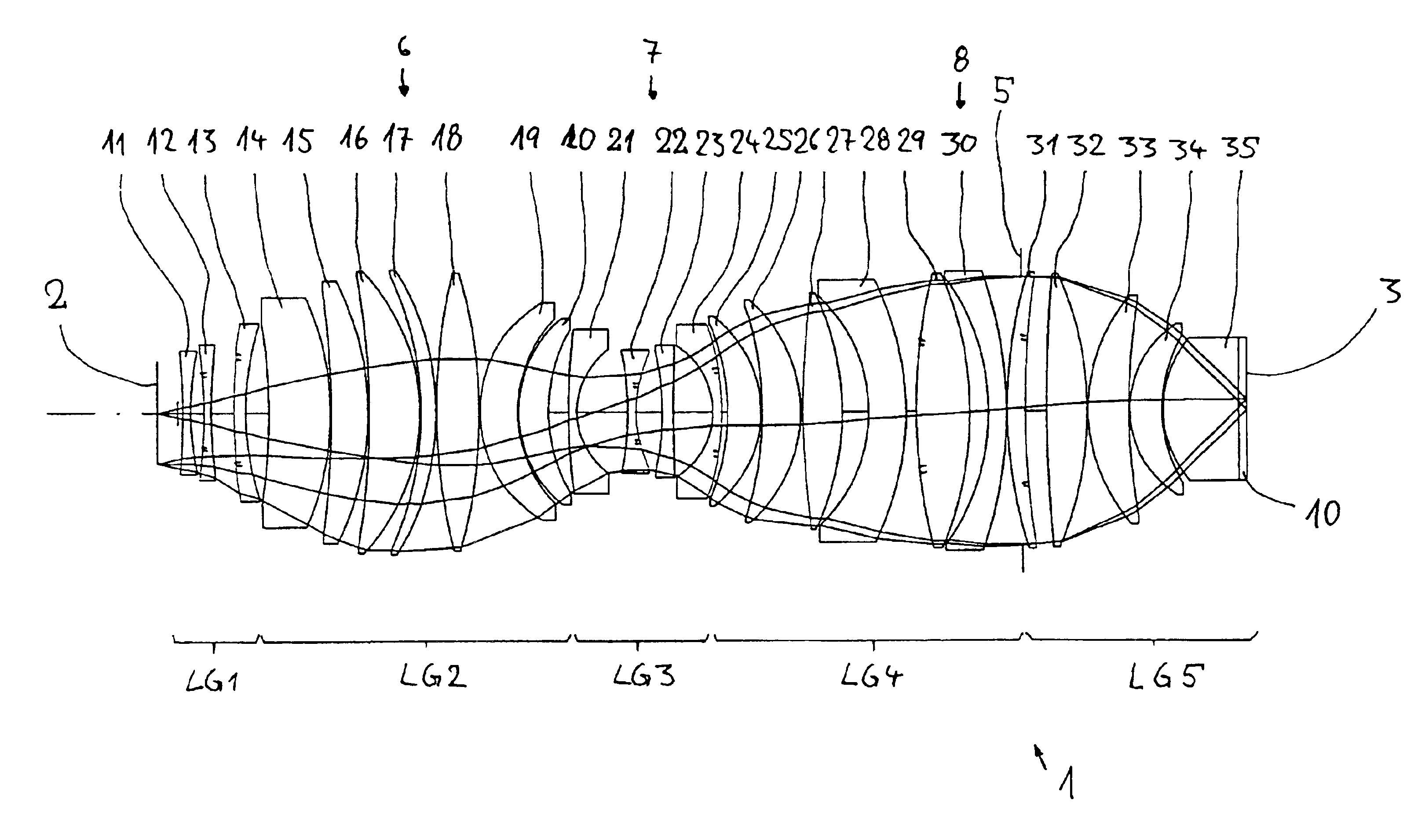

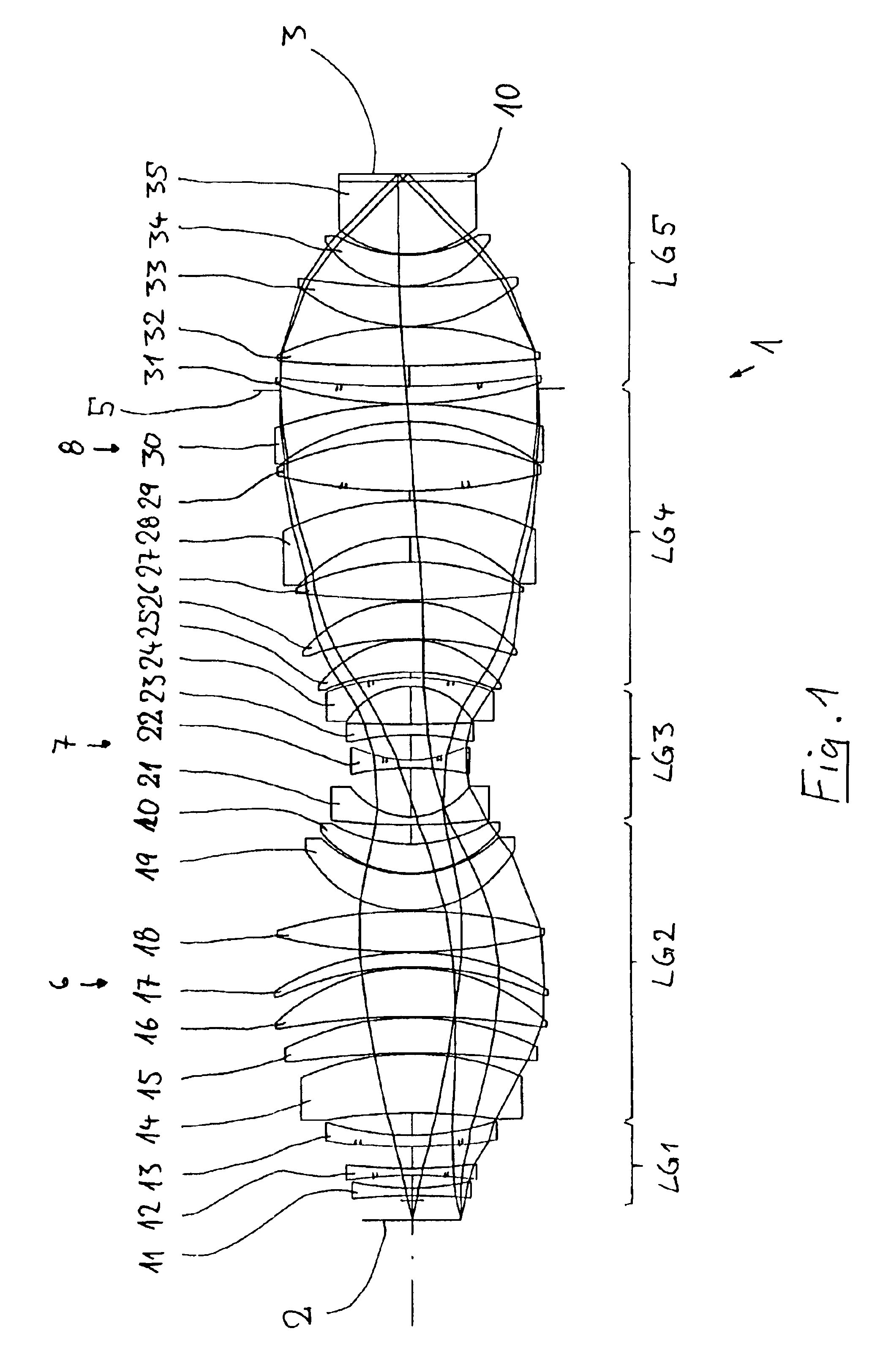

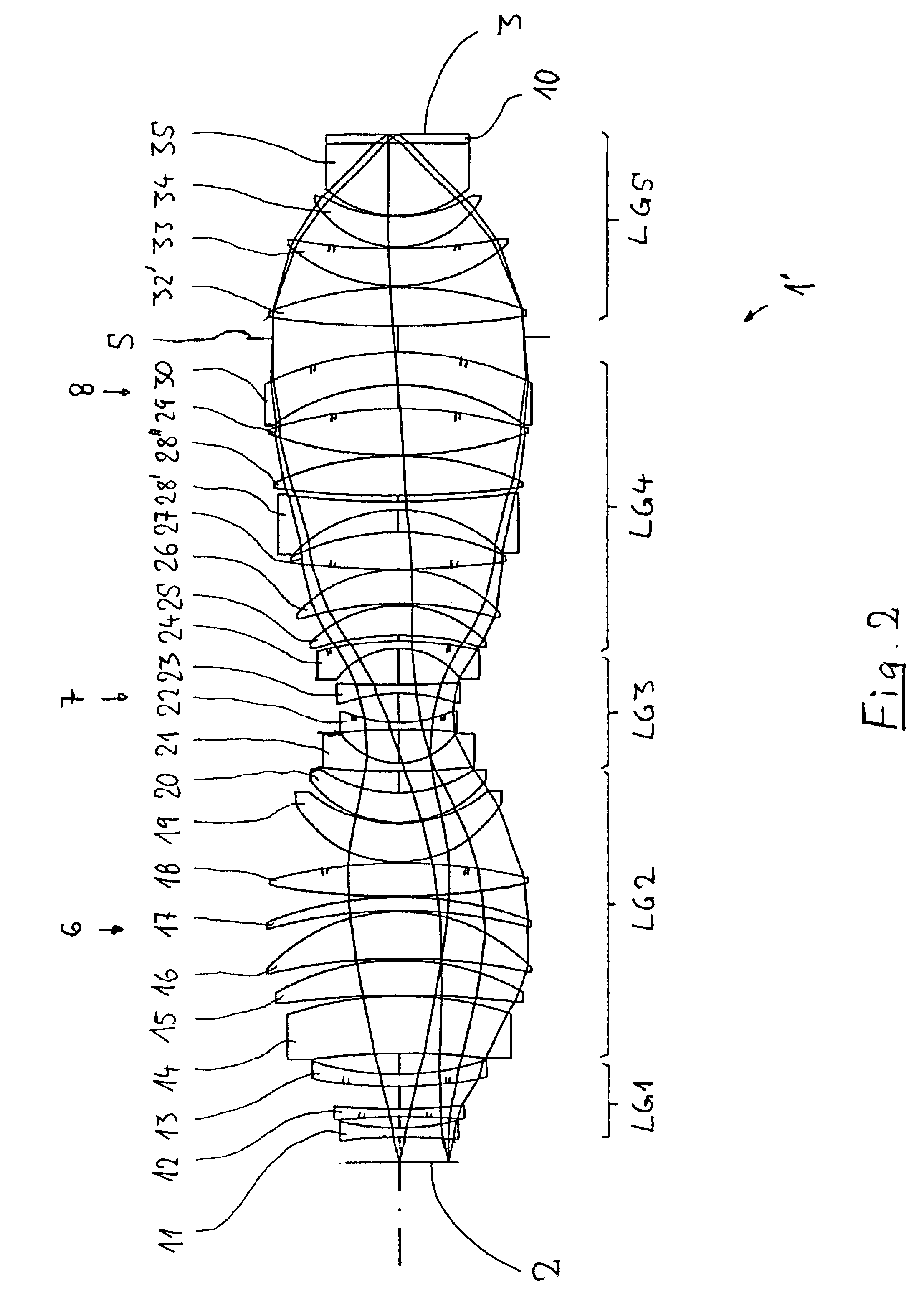

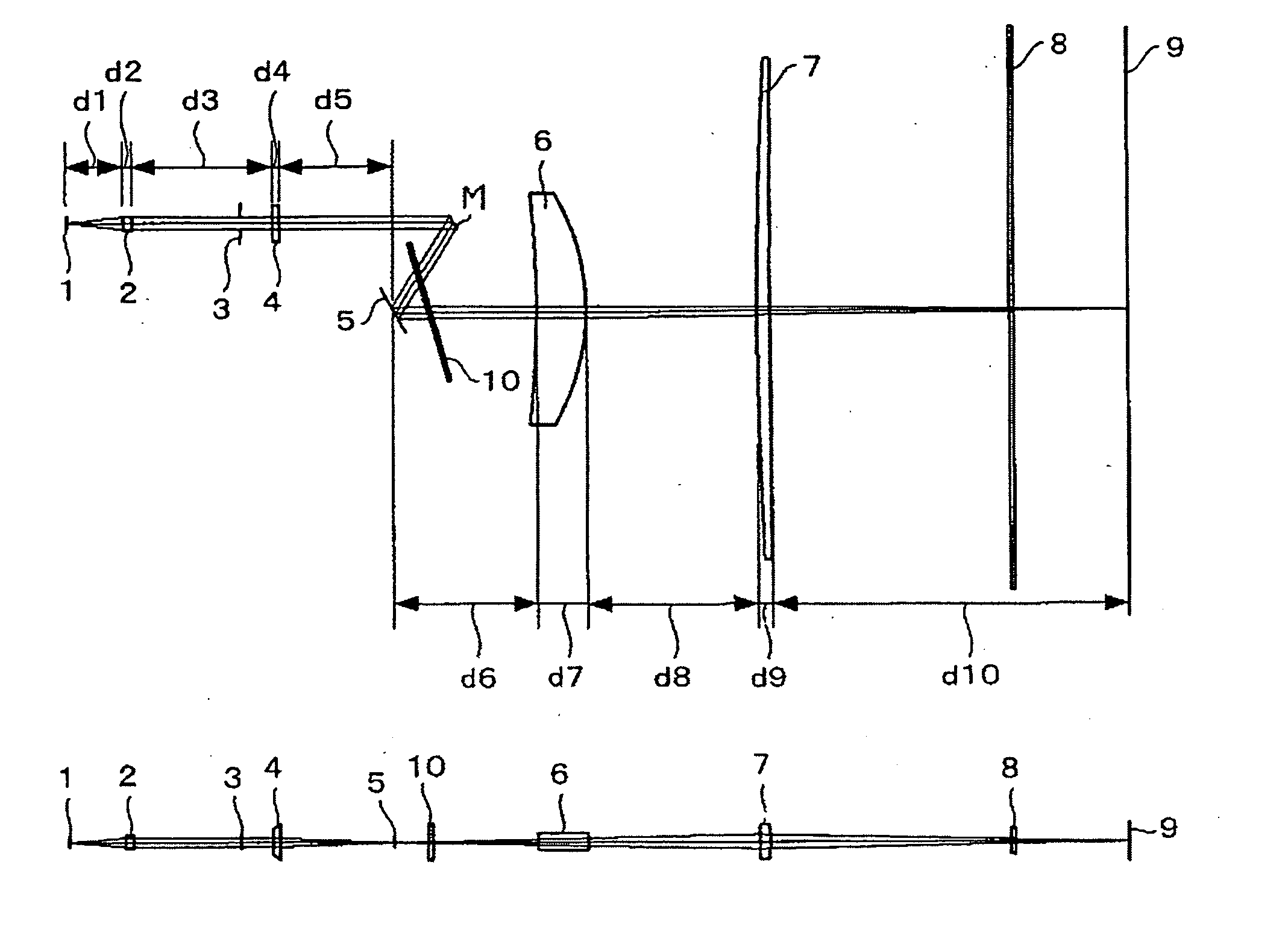

Refractive projection objective for immersion lithography

InactiveUS6891596B2Large numerical apertureGuaranteed true stateSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusLithographic artistBeam diameter

A purely refractive projection objective suitable for immersion micro-lithography is designed as a single-waist system with five lens groups, in the case of which a first lens group with a negative refracting power, a second lens group with a positive refracting power, a third lens group with a negative refracting power, a fourth lens group with a positive refracting power and a fifth lens group with a positive refracting power are provided. The system aperture is in the region of maximum beam diameter between the fourth and the fifth lens group. Embodiments of projection objectives according to the invention achieve a very high numerical aperture of NA>1 in conjunction with a large image field, and are distinguished by a good optical correction state and moderate overall size. Pattern widths substantially below 100 nm can be resolved when immersion fluids are used between the projection objective and substrate in the case of operating wavelengths below 200 nm.

Owner:CARL ZEISS SMT GMBH

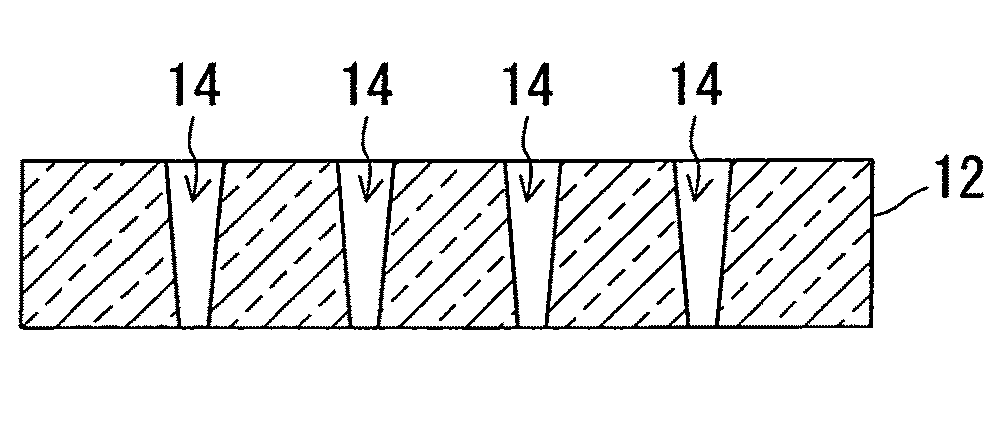

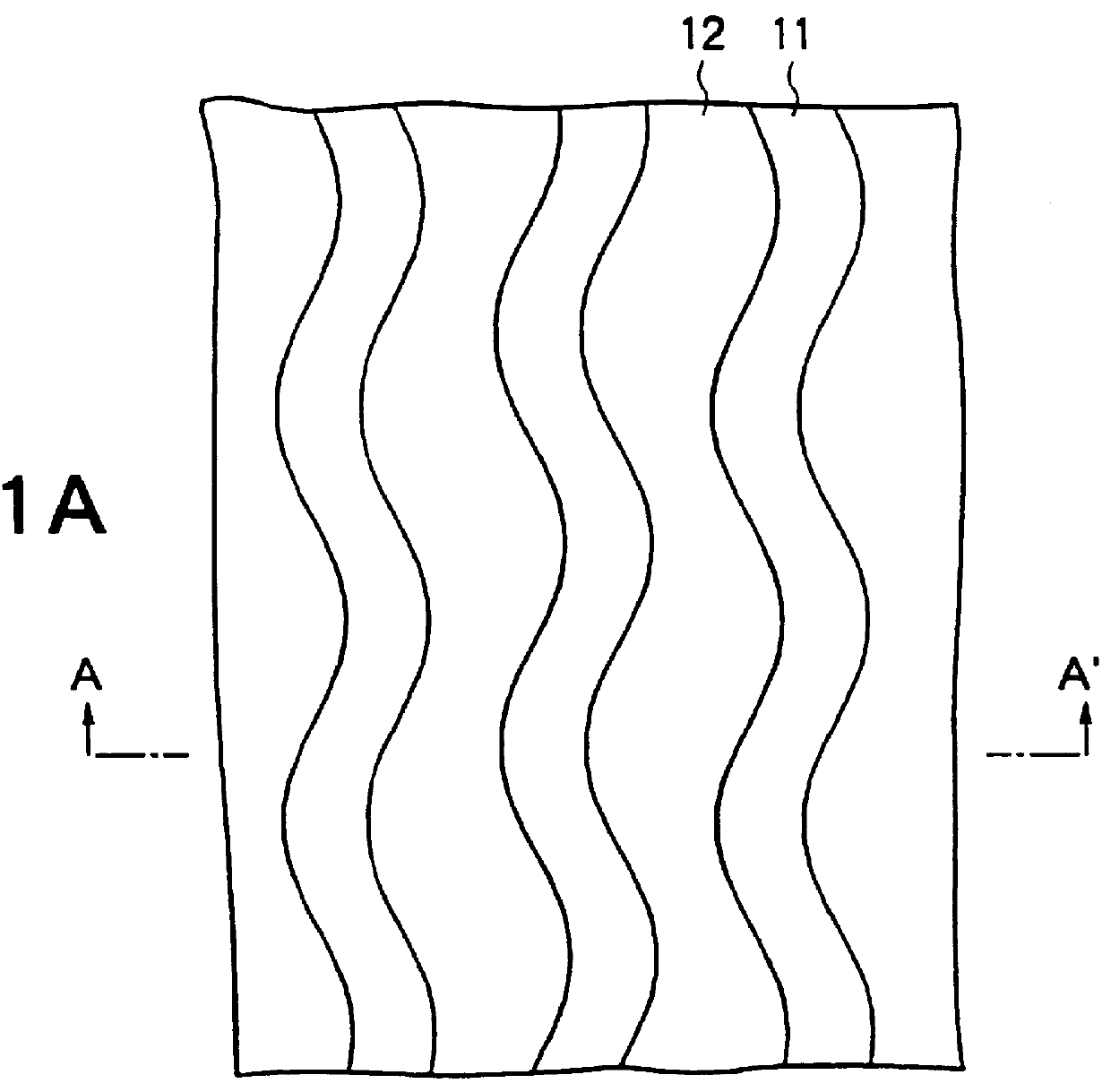

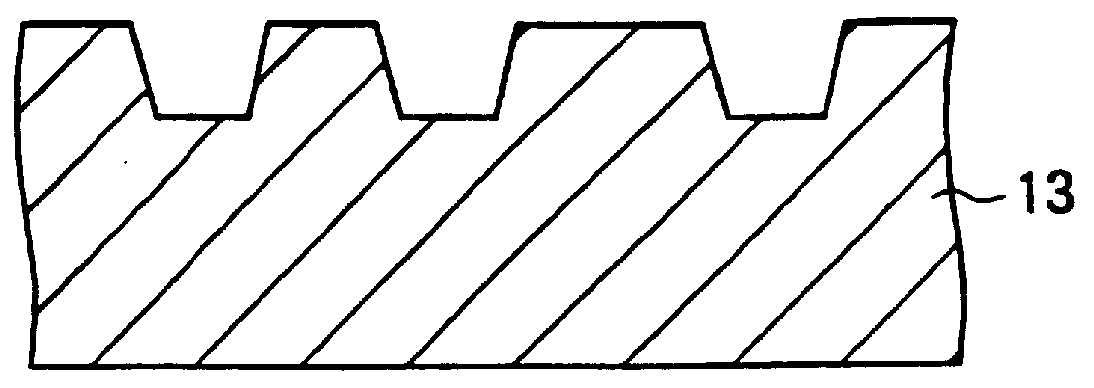

Glass Processing Method Using Laser and Processing Device

InactiveUS20090013724A1Suppress glass deformationProcess economyWelding/soldering/cutting articlesLaser beam welding apparatusBeam diameterLength wave

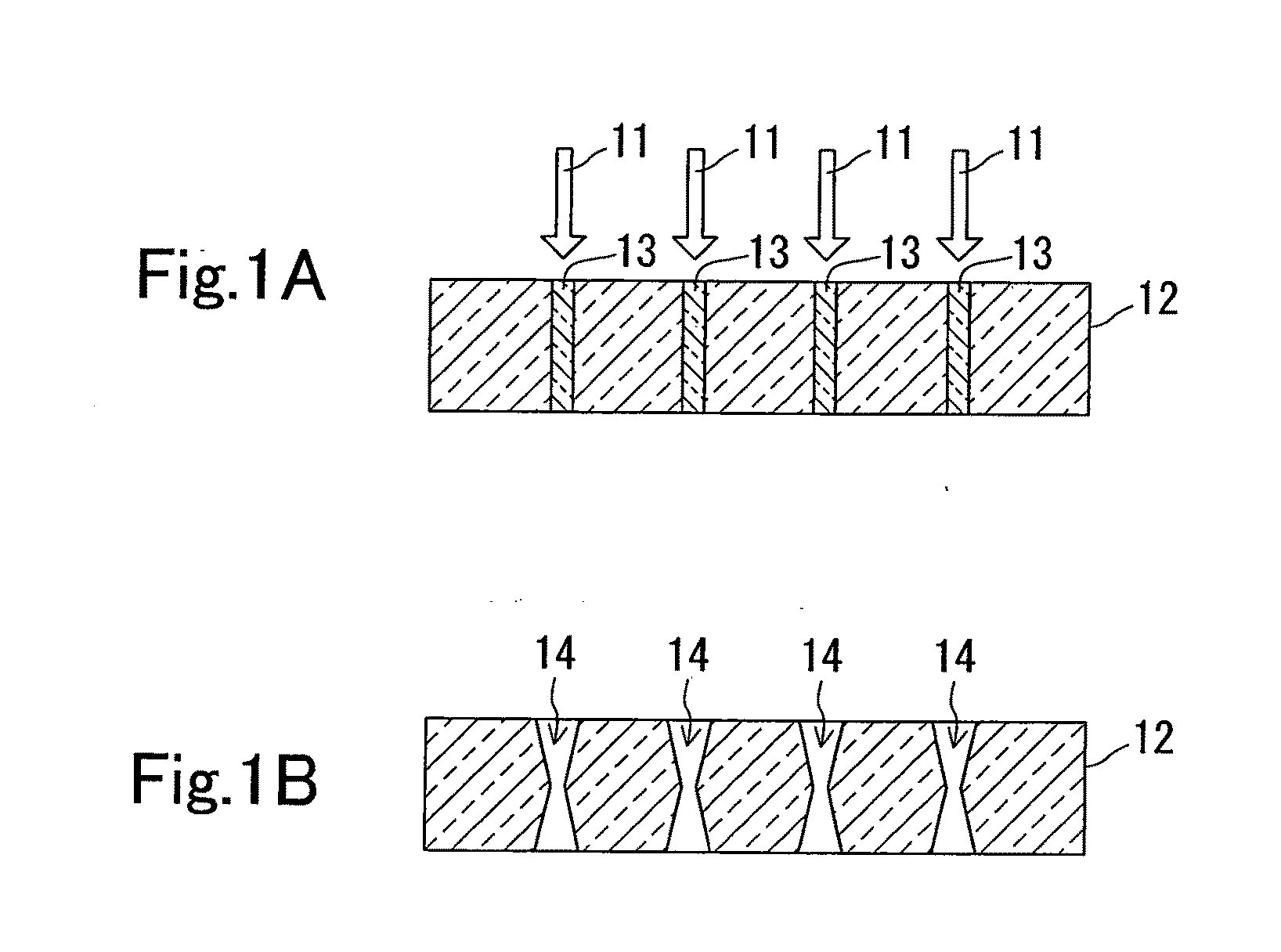

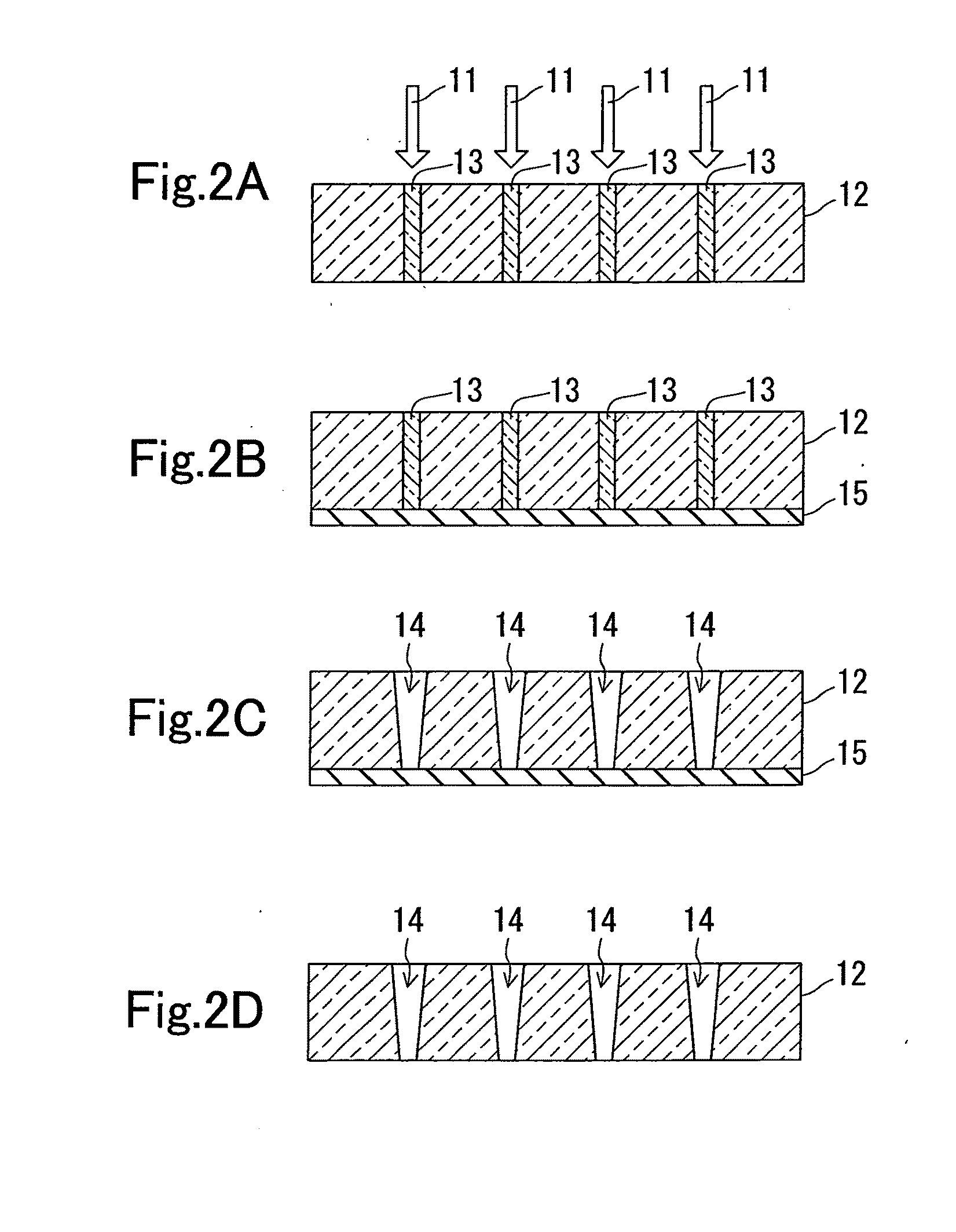

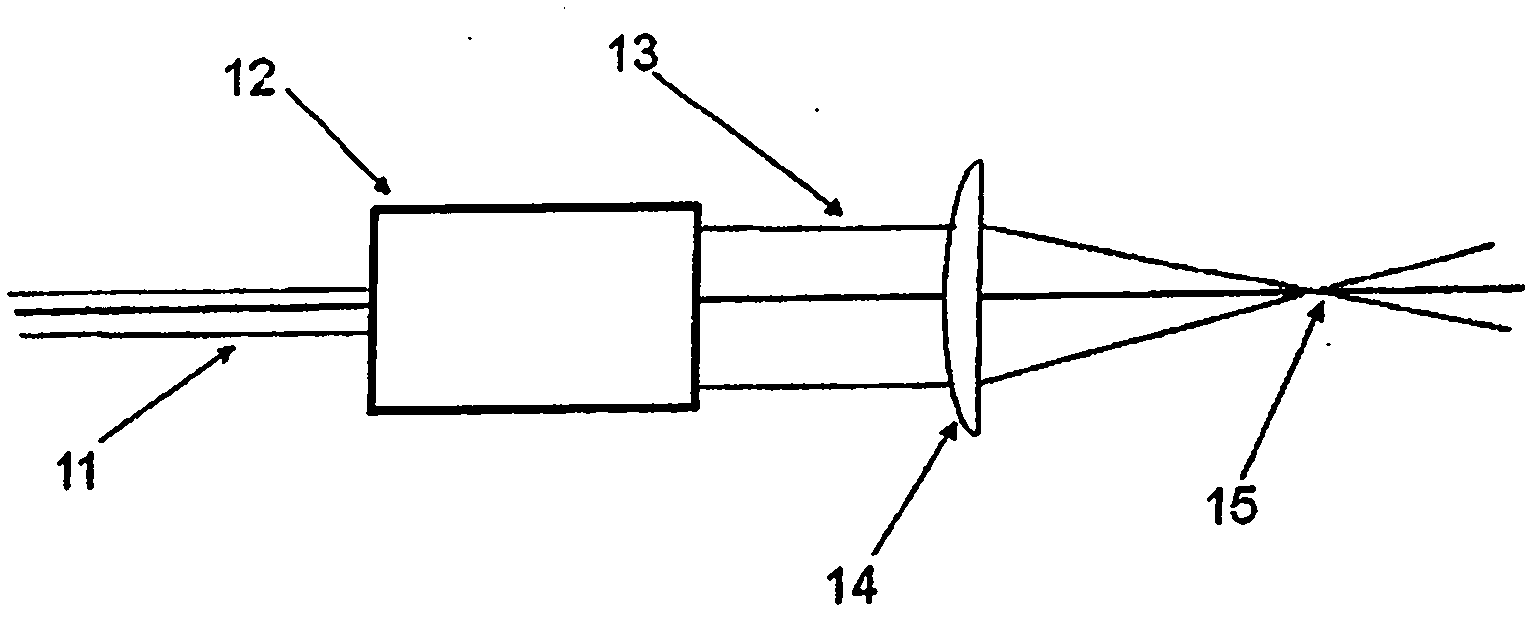

A glass processing method comprising steps (i), (ii) carried out in the order mentioned. In step (i), a laser pulse (11) with a wavelength λ is condensed by a lens and is applied to a glass plate (12) to form an altered portion (13) at the portion, irradiated with a laser pulse (11), of the glass plate (12). In step (ii), the altered portion (13) is etched by using an etchant having an etching rate larger for the altered portion (13) than that for the glass plate (12). The laser beam used includes the following conditions: The pulse width of a laser pulse (11) ranges from ins to 200 ns, with a wavelength λ being up to 535 nm. The absorption coefficient of the glass plate (12) at a wavelength λ is up to 50 cm−1. A value obtained from a lens focal distance L (mm) divided by the beam diameter D (mm) of the laser pulse (11) when entering the lens is at least 7.

Owner:NIPPON SHEET GLASS CO LTD

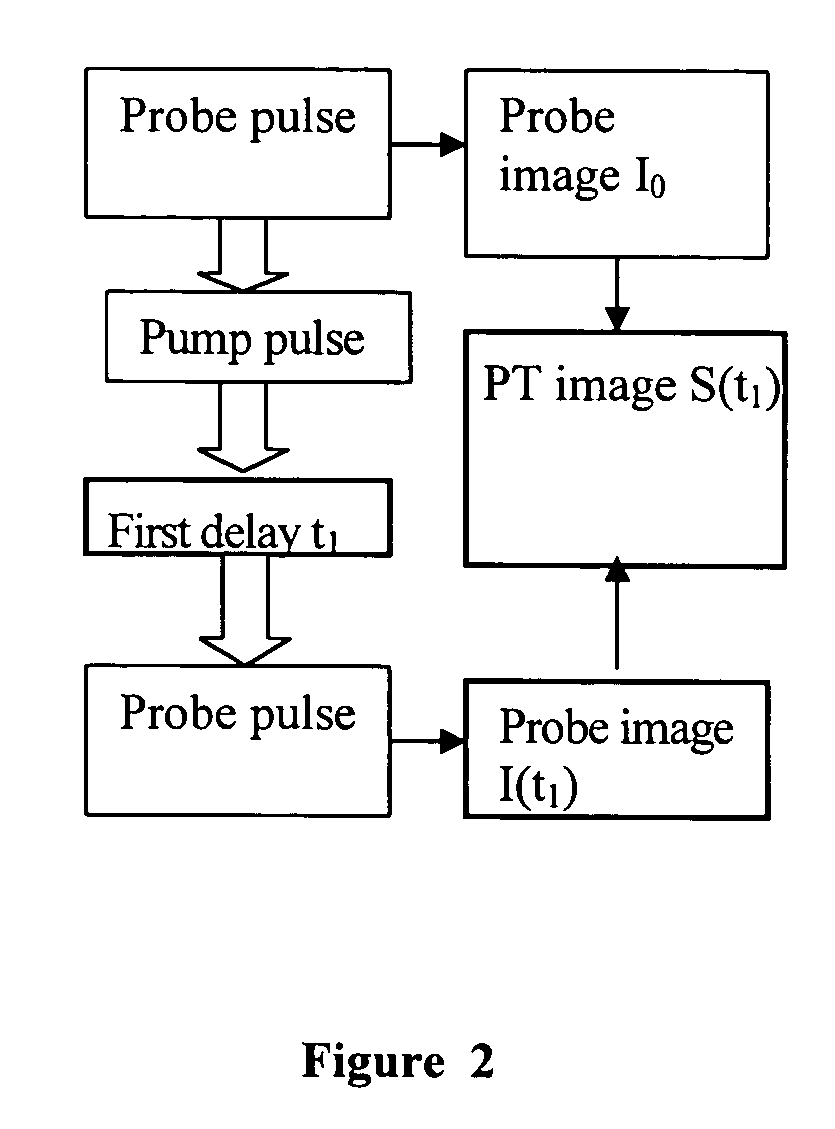

Method and device for photothermal examination of microinhomogeneities

InactiveUS7230708B2Improve resolutionHigh sensitivityMaterial analysis by optical meansRefractive indexLaser beams

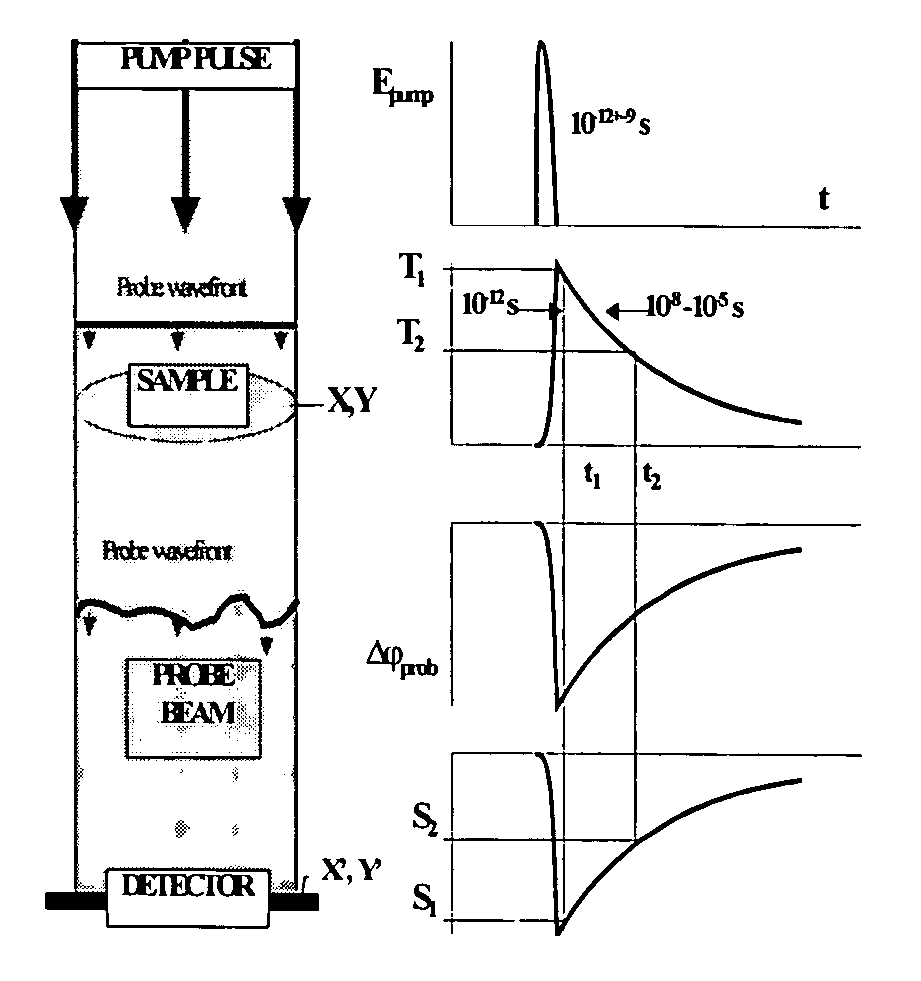

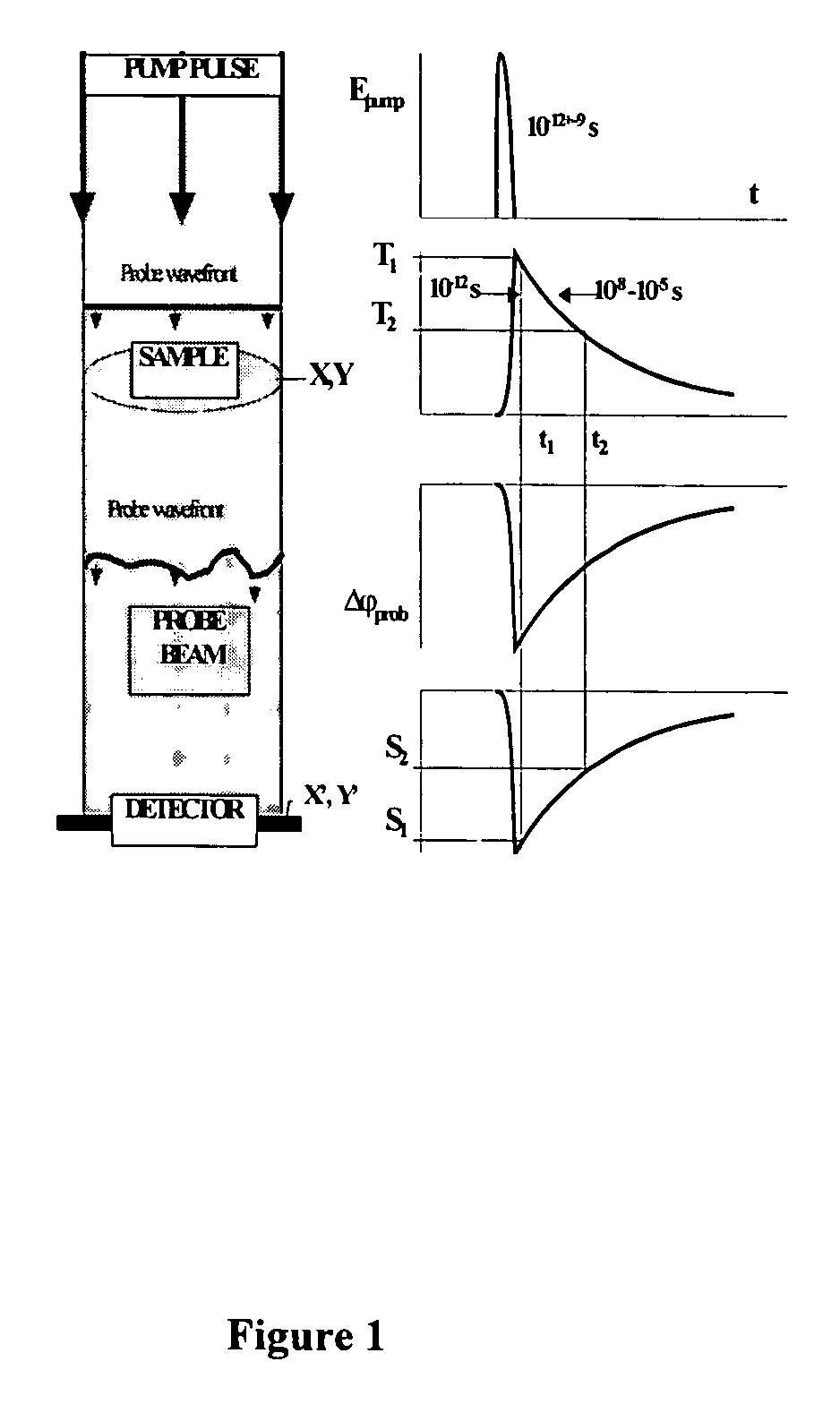

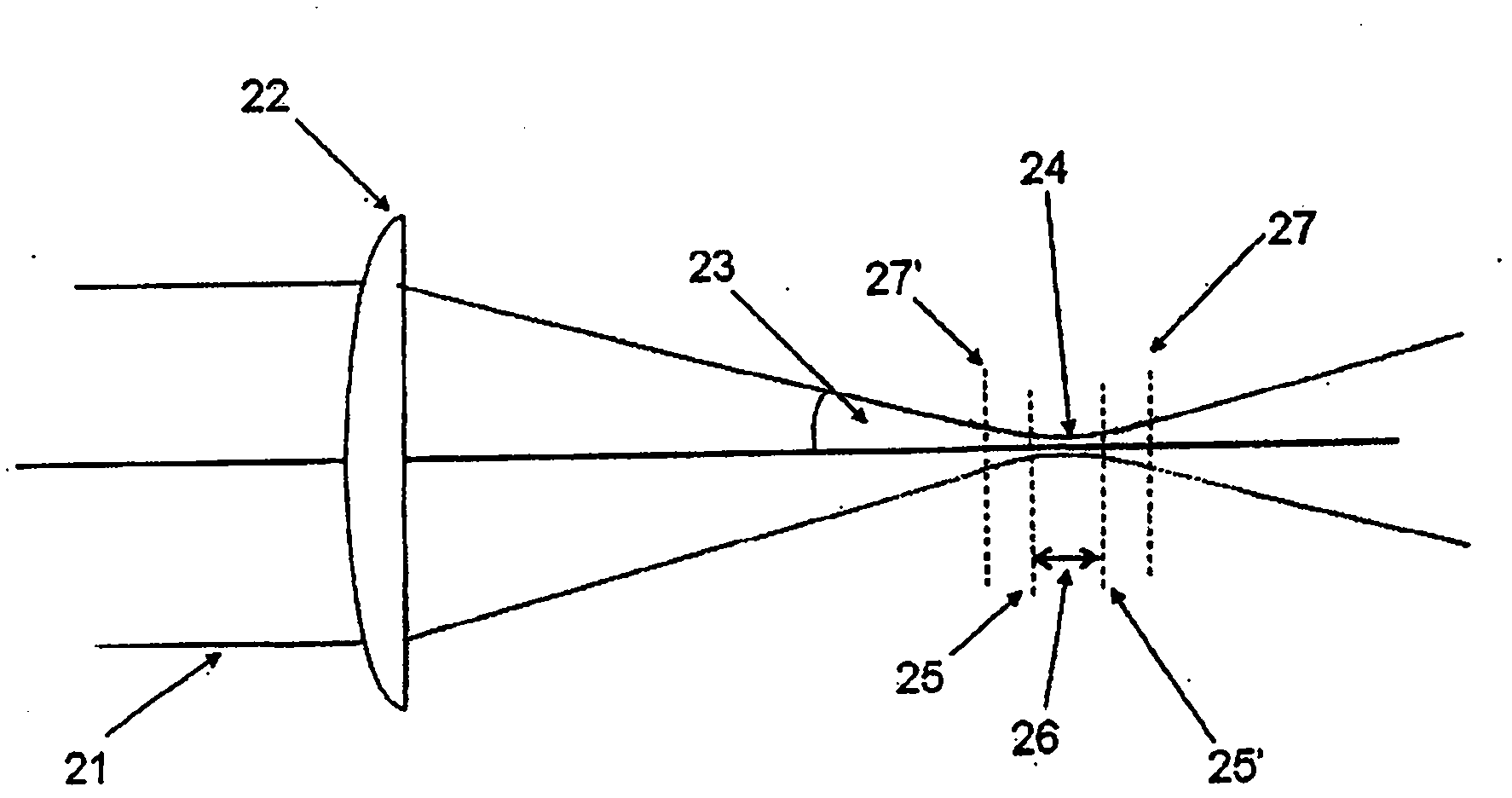

The invention relates to optical microscopy, and more particularly to the methods for photothermal examination of absorbing microheterogeneities using laser radiation. The invention can be widely used in laser technique, industry, and biomedicine to examine transparent objects with absorbing submicron fragments, including detection of local impurities and defects in super-pure optical and semiconducting materials and non-destructive diagnostics of biological samples on cellular and subcellular levels.The object of the present invention is to increase sensitivity, spatial resolution and informative worth when examining local absorbing heterogeneities in transparent objects, as well as to detect the size of said heterogeneities even if said size is smaller than the radiation wavelength used.Said object is achieved by the pump beam irradiation of a sample, the duration of said irradiation not being longer than the characteristic time of cooling of the microheterogeneity observed. A relatively vast surface of the sample is irradiated at once, the size of said surface not being larger than the wavelength of the pump laser used. The refraction index thermal variations, induced by the pump beam in the sample and being the result of absorption, are registered by the parameter change of the probe laser beam. A chosen probe beam diameter should not be smaller than the pump beam diameter. The diffraction-limited phase distribution over the probe laser beam cross-section is transformed to an amplitude image using a phase contrast method. The properties of microheterogeneities are estimated by measuring said amplitude image.

Owner:LAPOTKO TATIANA MS

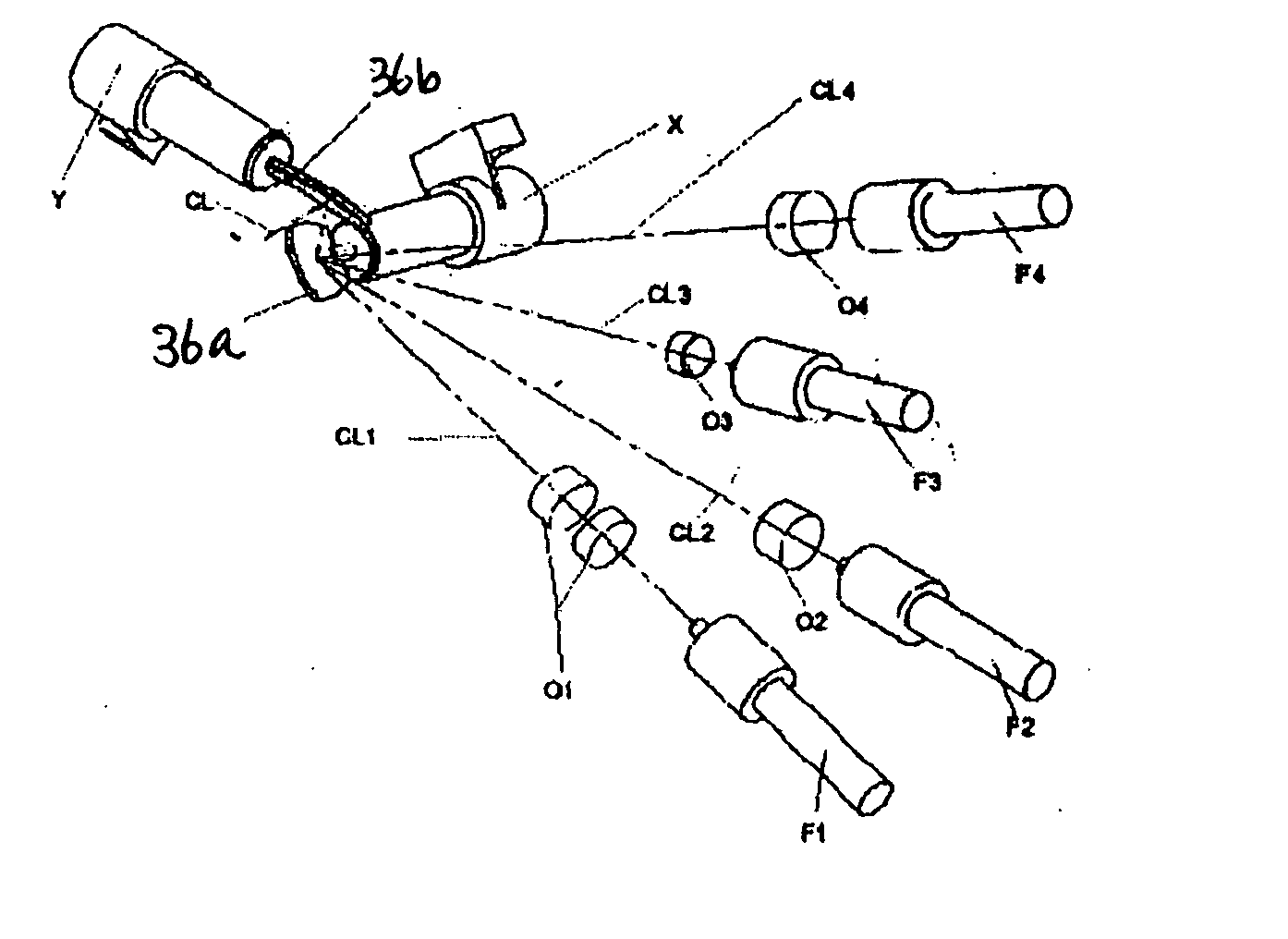

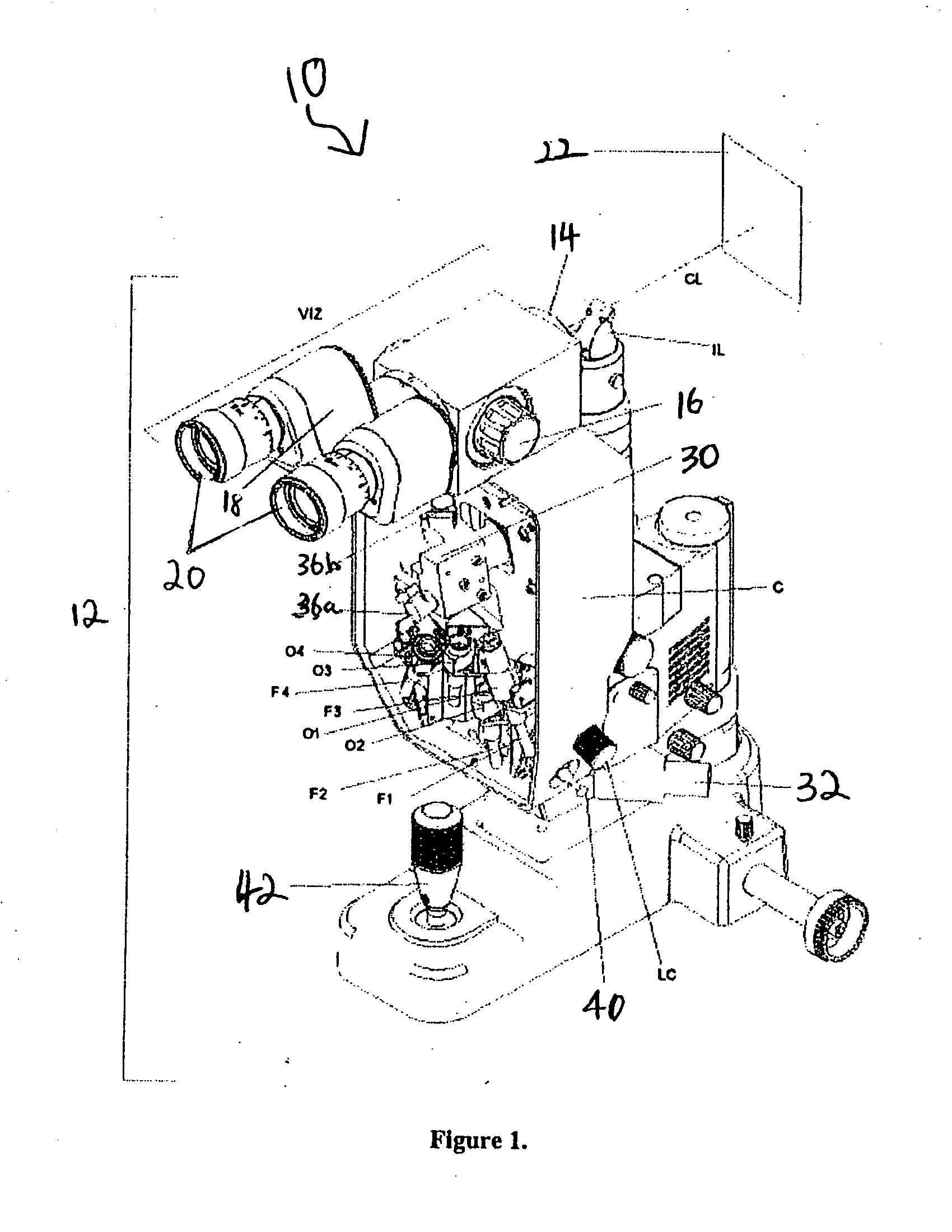

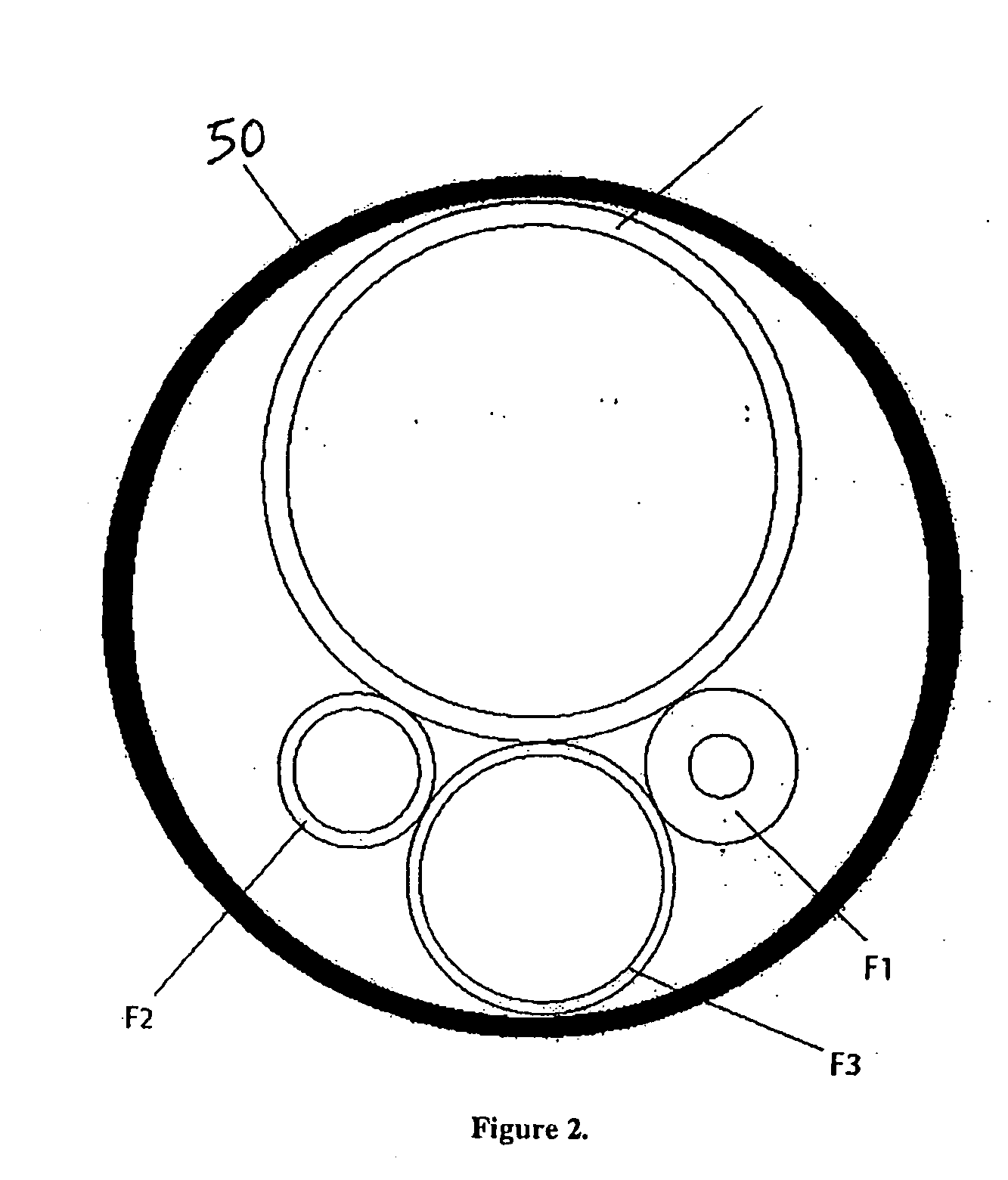

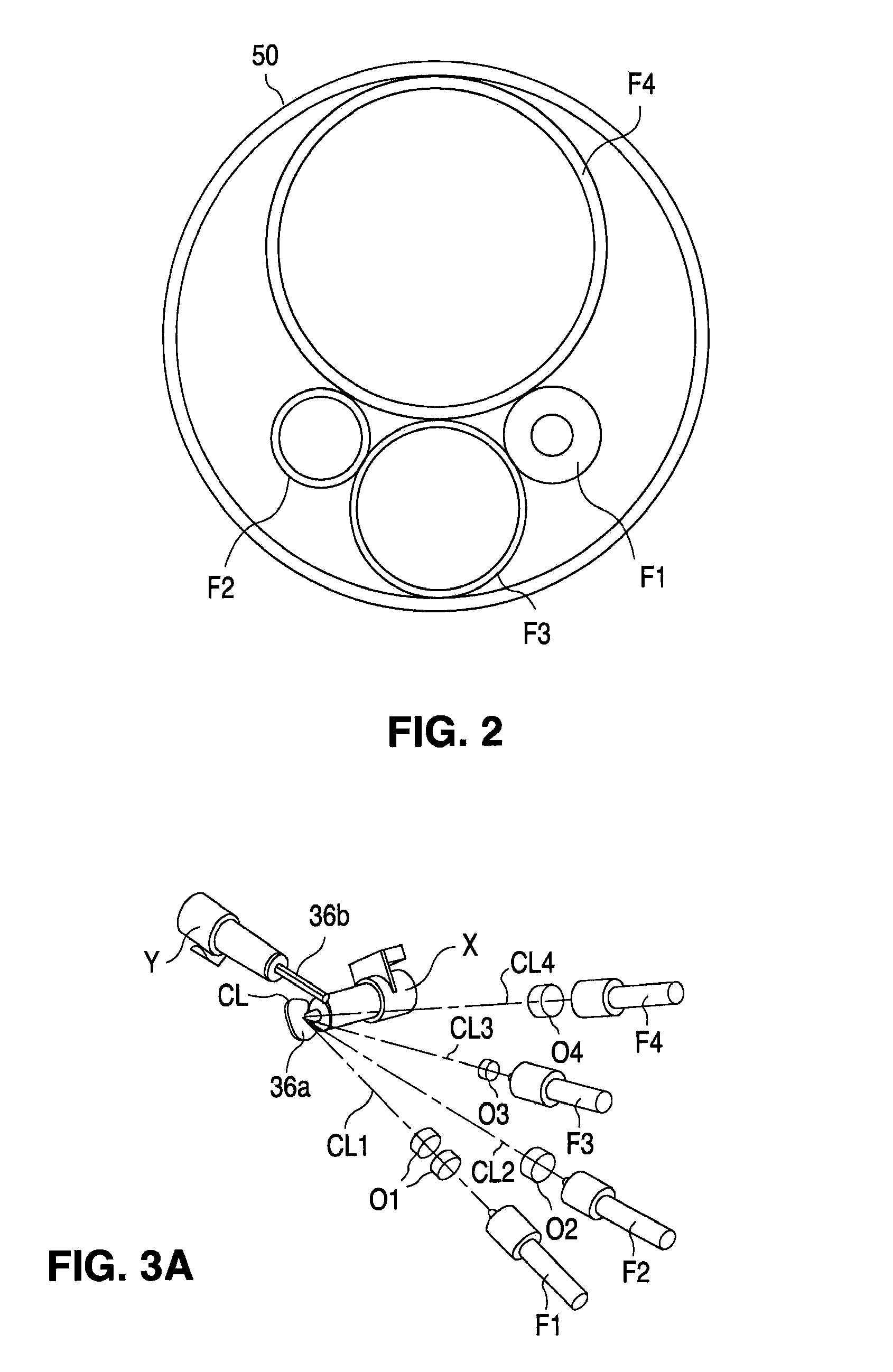

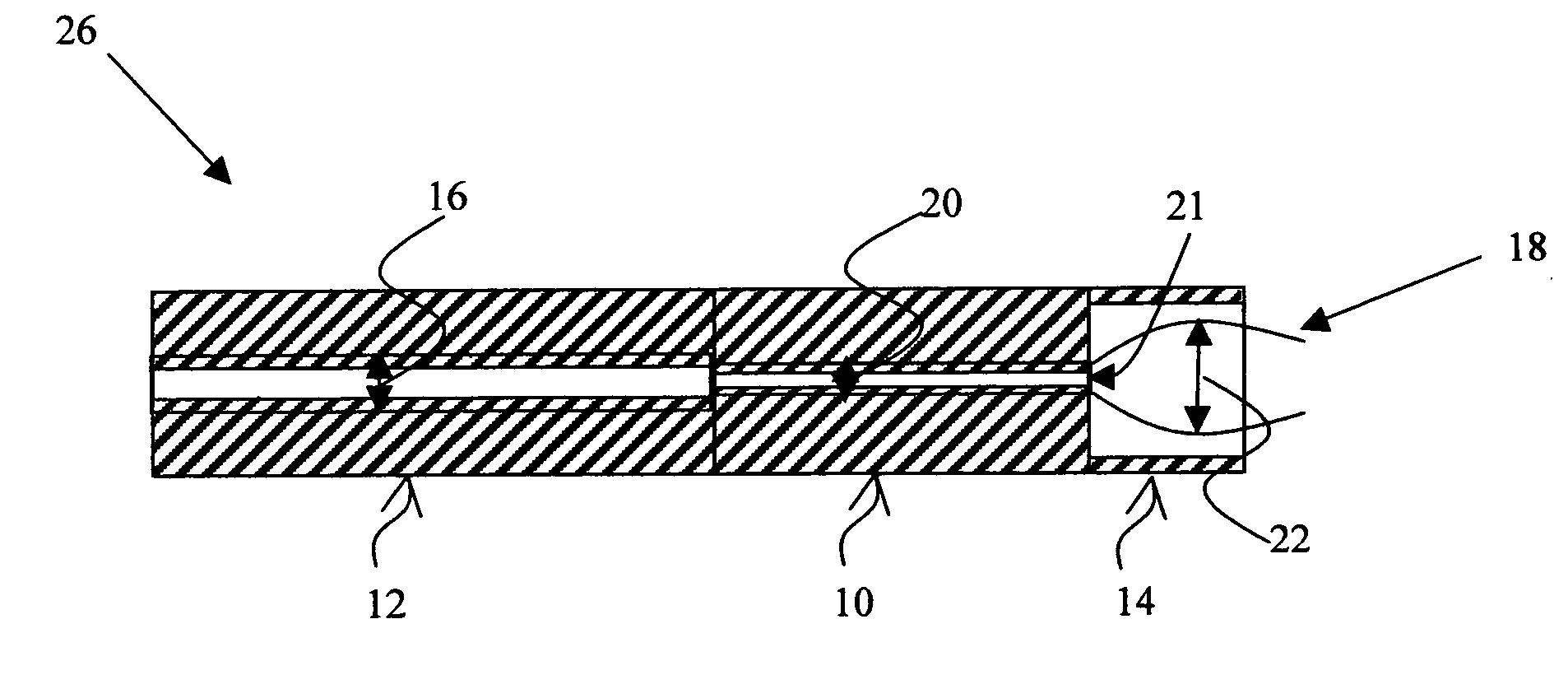

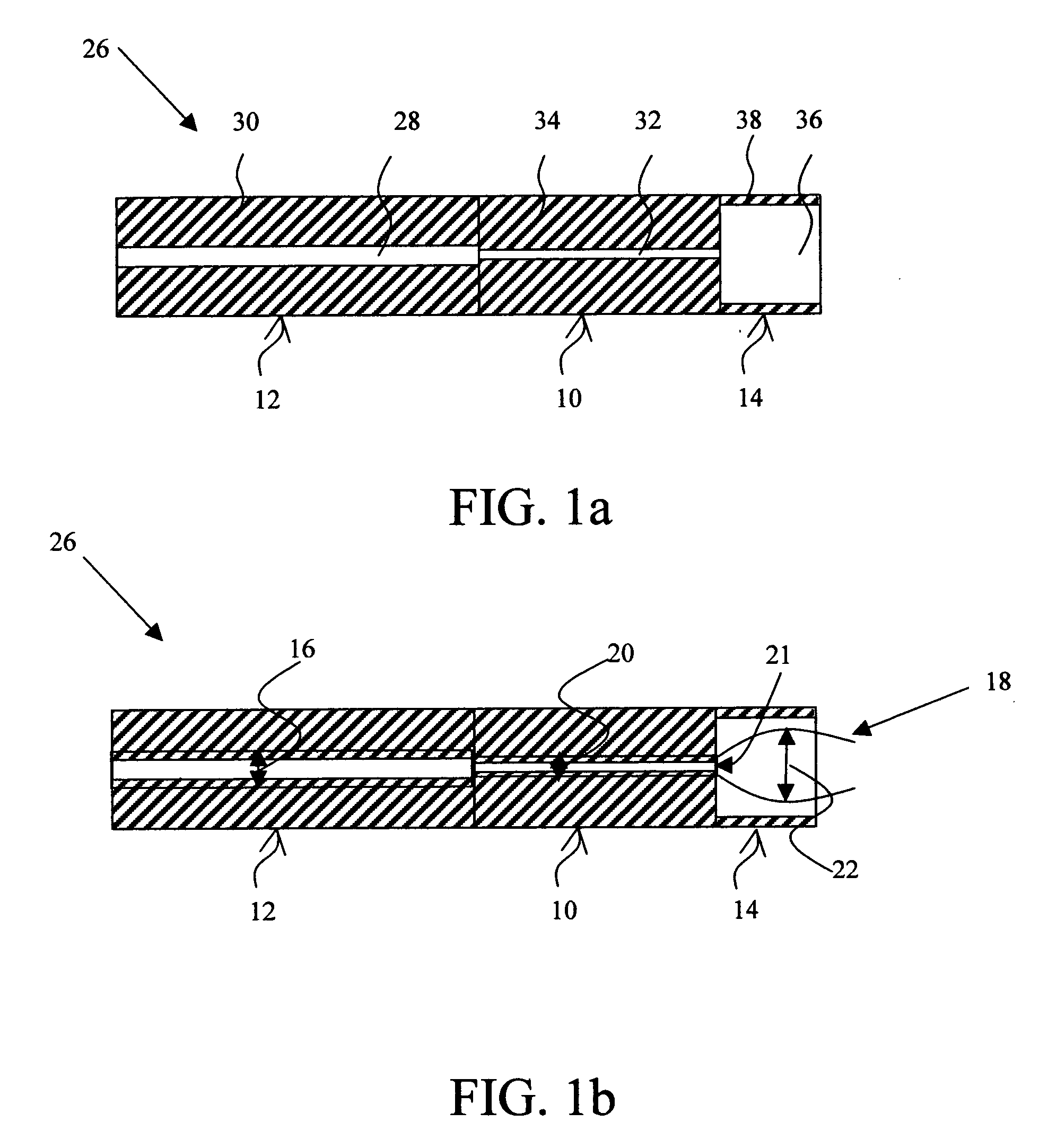

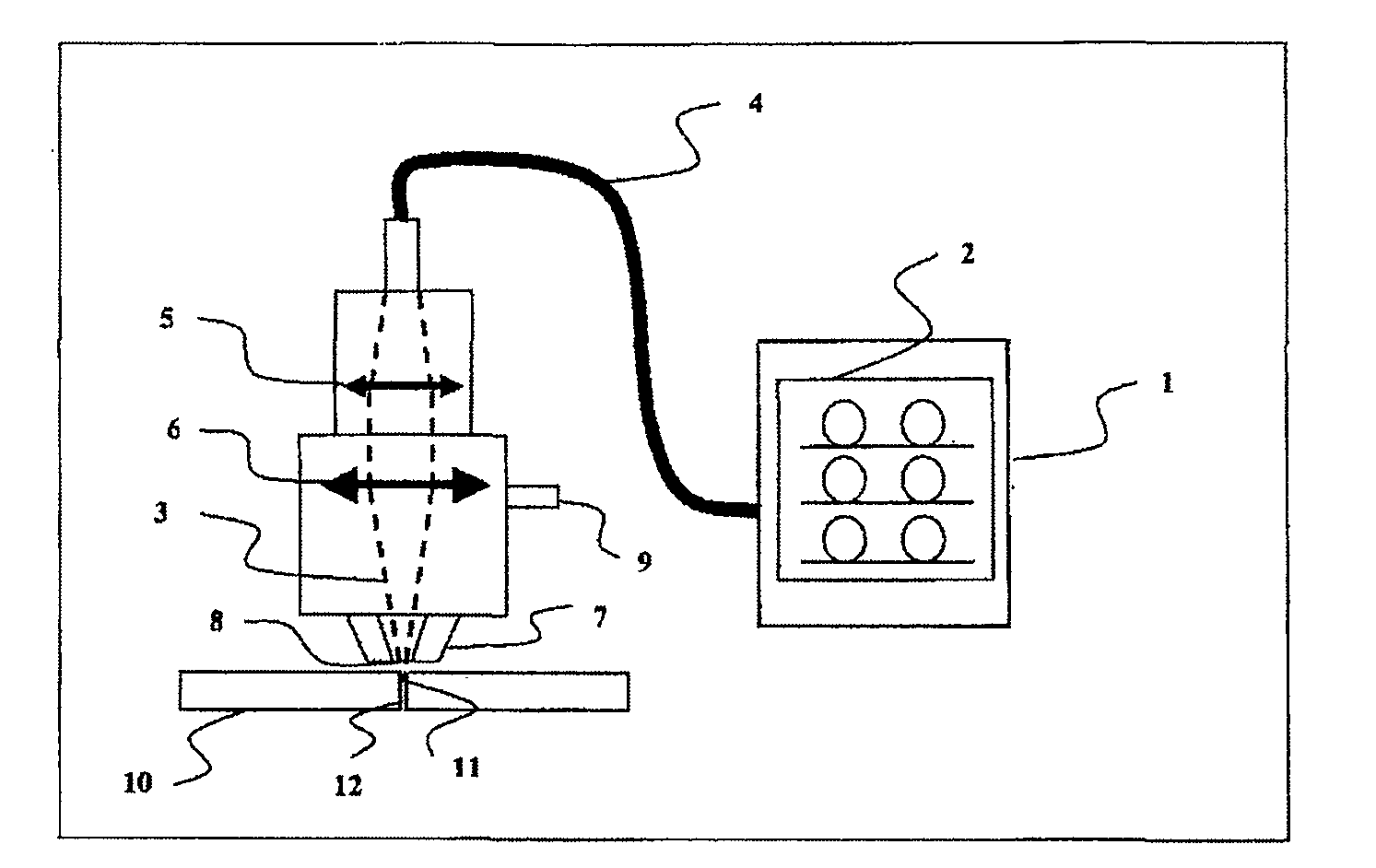

Optical delivery systems and methods of providing adjustable beam diameter, spot size and/or spot shape

ActiveUS20070189664A1Modify characteristicLaser surgeryCoupling light guidesOptical propertyBeam diameter

An optical device and method for varying an optical characteristic of an optical beam can include a plurality of optical fibers each having an input end, an output end, and a core, wherein each of the optical fibers has an effective area and a numerical aperture, and a beam deviating component for moving at least one of the optical fiber input ends and the optical beam relative to each other such that the optical beam selectively enters the input ends one at a time and is transmitted out the output ends one at a time, wherein at least one of the effective areas and the numerical apertures varies among the plurality of optical fibers such that the optical beam transmitted out of the output ends has a varying optical characteristic.

Owner:IRIDEX CORP

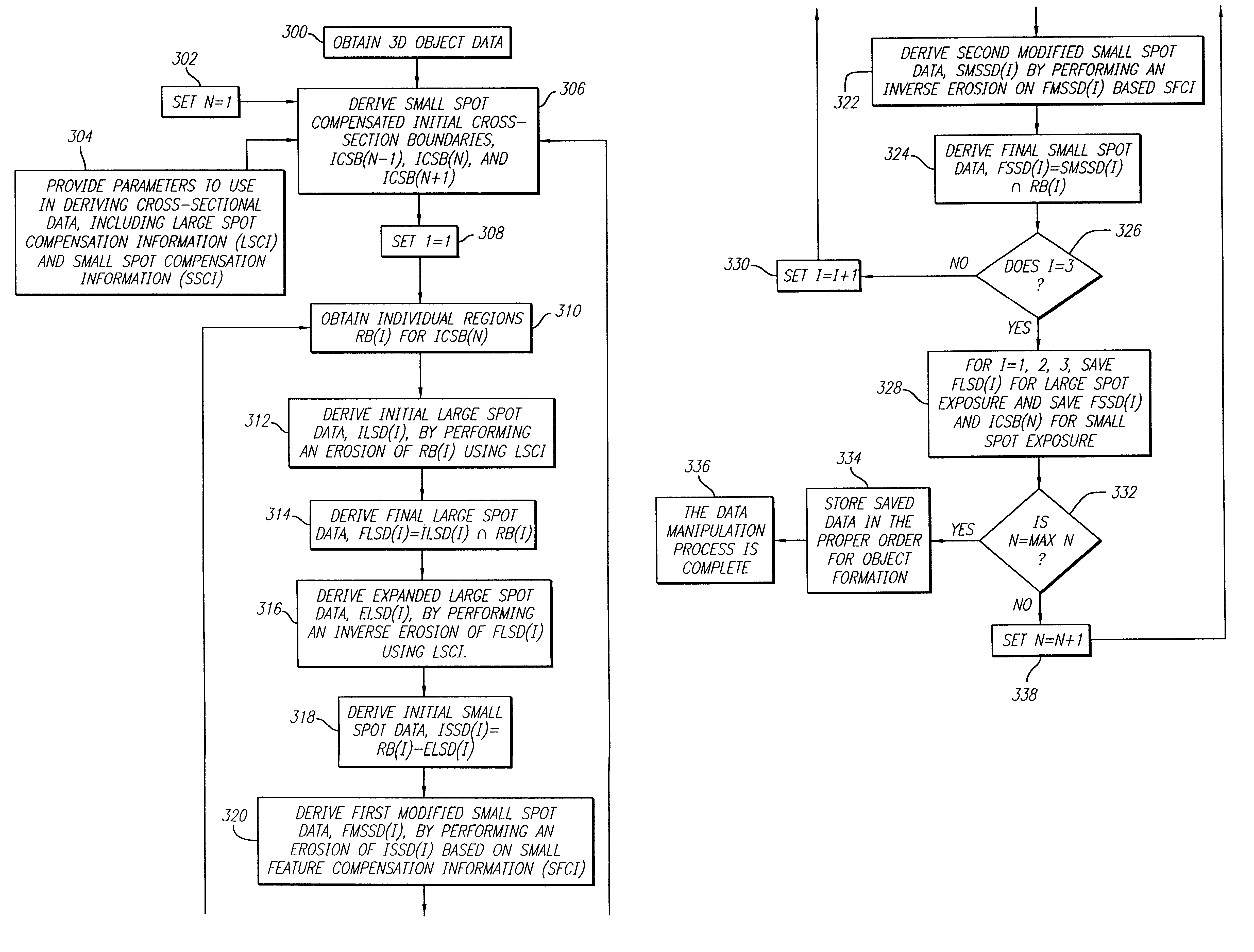

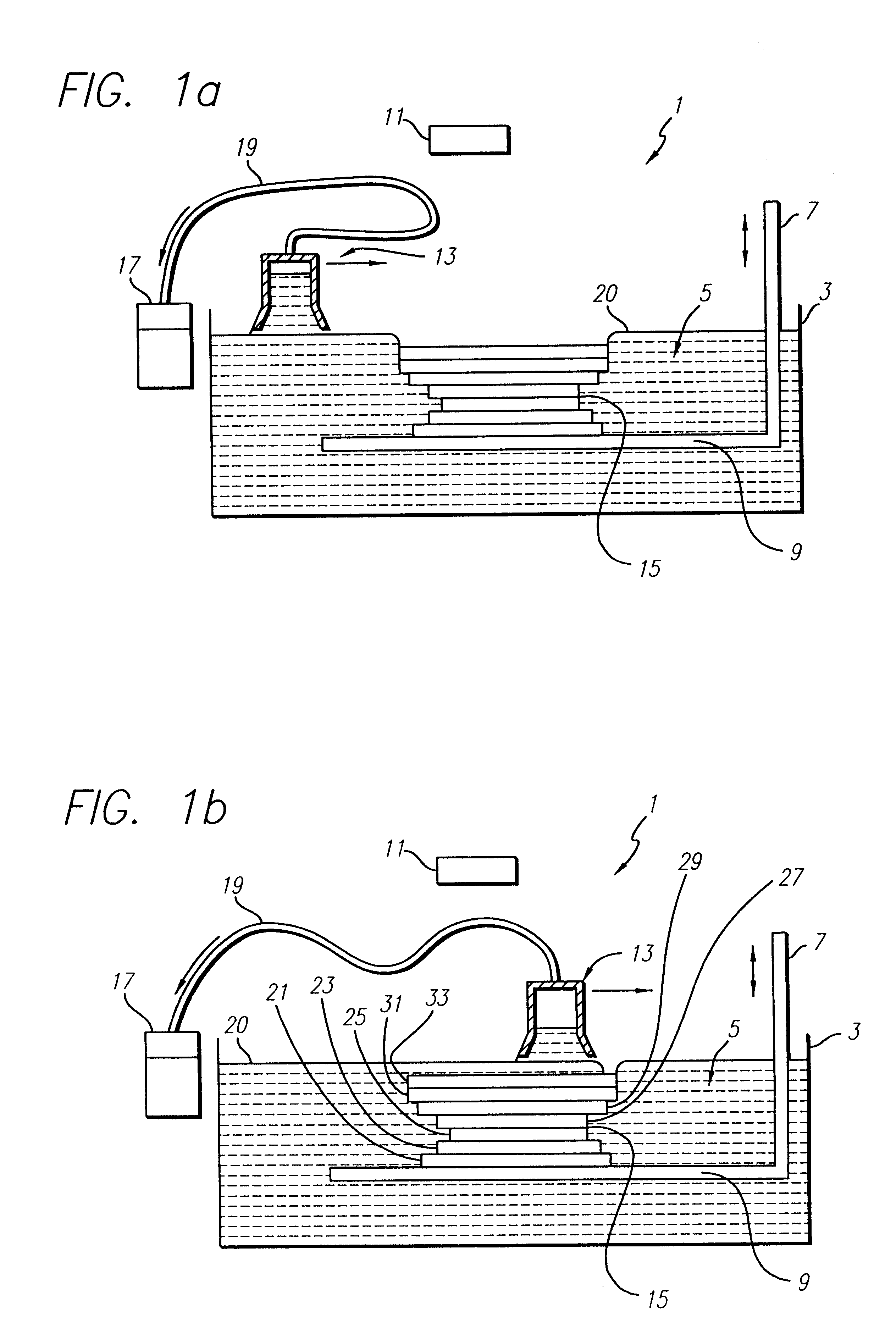

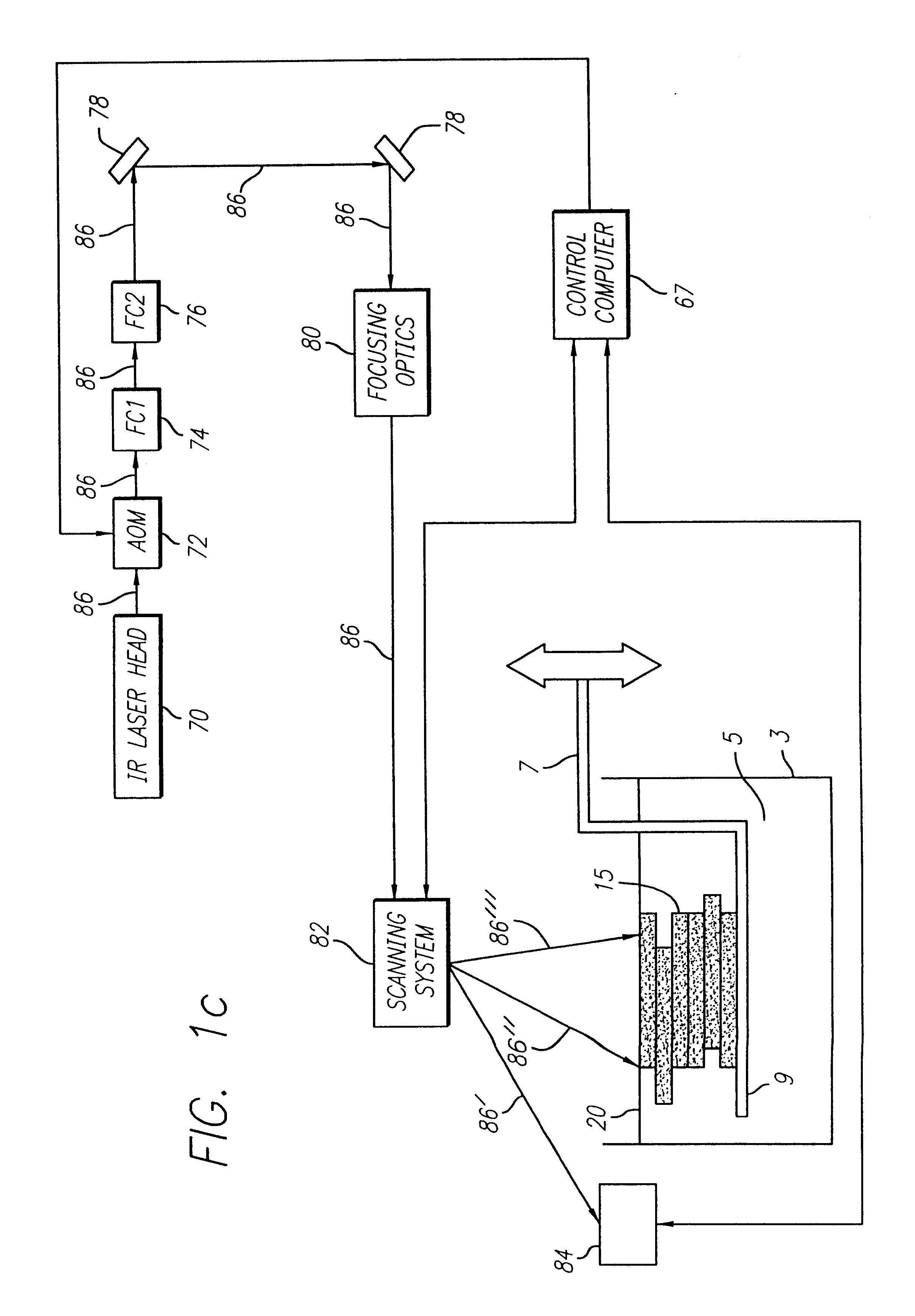

Stereolithographic method and apparatus for production of three dimensional objects using multiple beams of different diameters

InactiveUS6406658B1Reduced object formation timeHigh resolutionAdditive manufacturing apparatusConfectioneryData controlBeam diameter

A rapid prototyping and manufacturing (e.g. stereolithography) method and apparatus for making three-dimensional objects on a layer by layer basis by selectively exposing layers of material to prescribed stimulation, using a beam having a first smaller diameter and a beam having a second larger diameter, to form laminae of the object. The power of the smaller beam is typically lower than the power of the larger beam. Object formation is controlled by data representing portions of the layers to be exposed with the larger beam (large spot portions) and those portions to be exposed with the smaller beam (small spot portions). In a preferred embodiment, portions exposed with the larger beam are formed first, for a given layer. Portions are exposed with the small beam next. Thereafter the entire perimeter of the laminae is traced using the small beam. Data manipulation techniques are used to identify which portions may be formed with the large beam to decrease exposure time and which should be formed with the small beam to maintain accuracy of the lamina being formed. More than two beam diameters may be used.

Owner:3D SYST INC

Optical scanning device in image forming apparatus

A first optical system guides a light beam from a light source to an optical deflector, and a second optical system converges the light beam deflected by the optical deflector on a surface to be scanned. The first optical system includes at least one resin lens having a diffractive surface. The second optical system includes at least one resin optical element. A beam diameter depth in a main scanning direction, Wm, that can have a maximum intensity of 1 / e2, satisfies conditions Δm1+Δm2+Δm3−Δd1×(f2 / f1)2<Wm / 40 (1) Δd1>0 and Δm2<0. (2)

Owner:RICOH KK

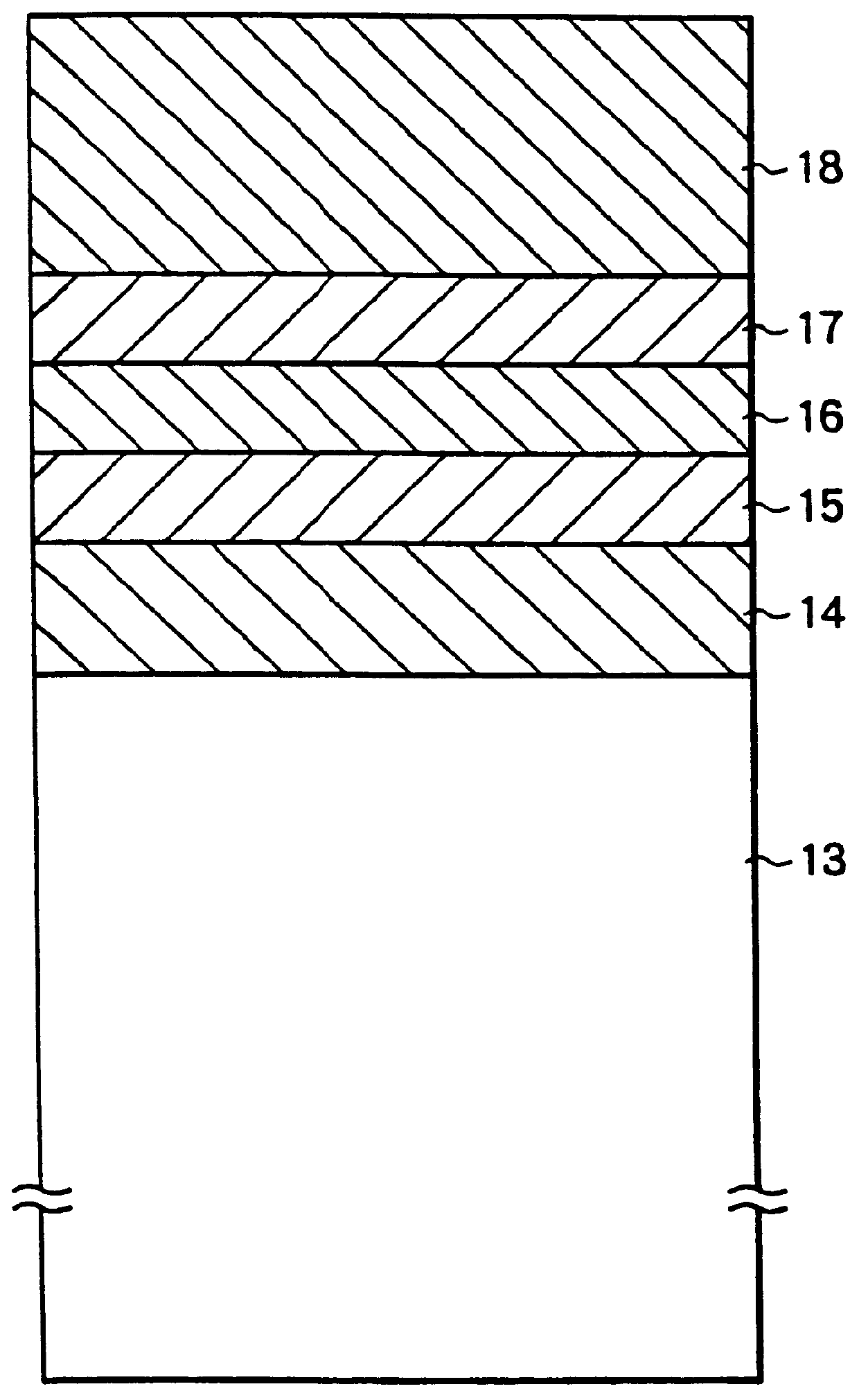

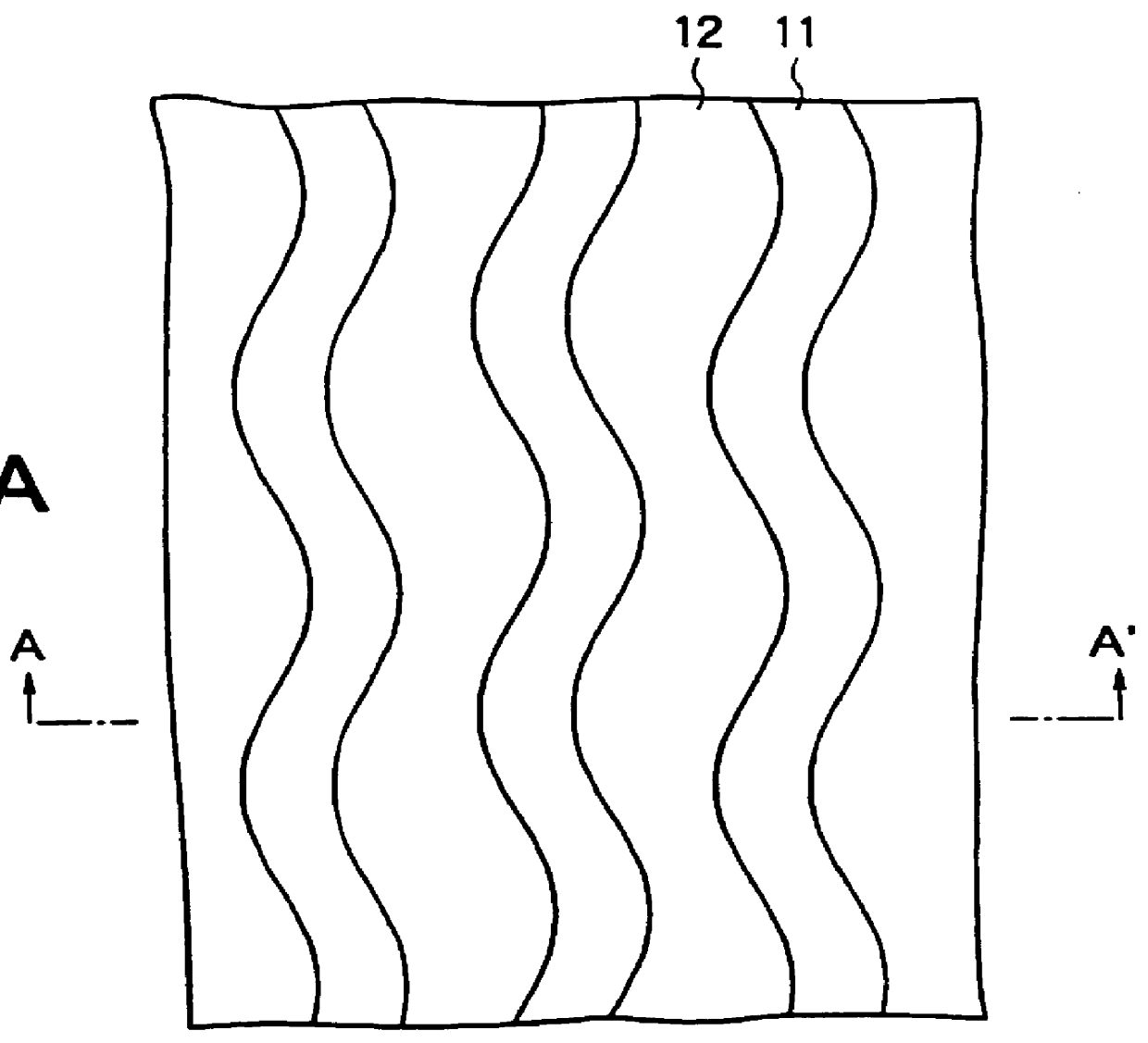

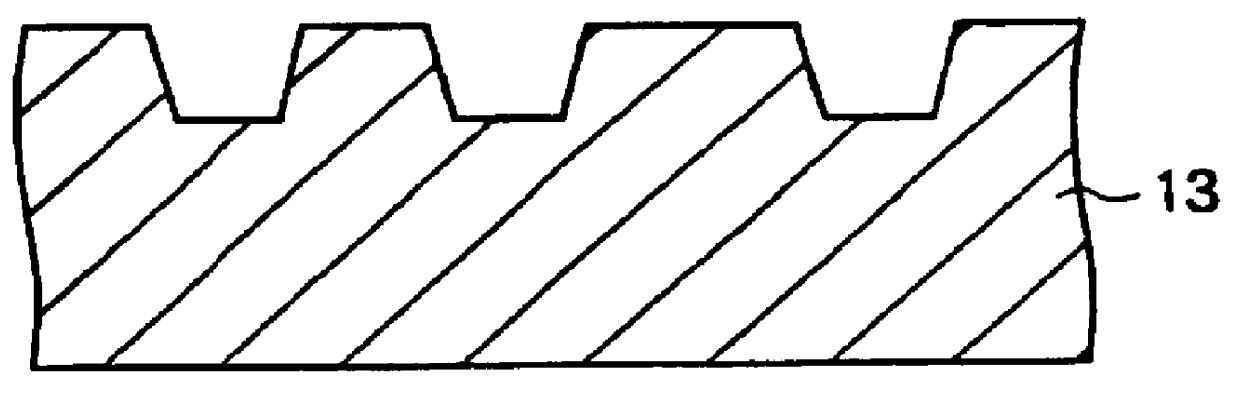

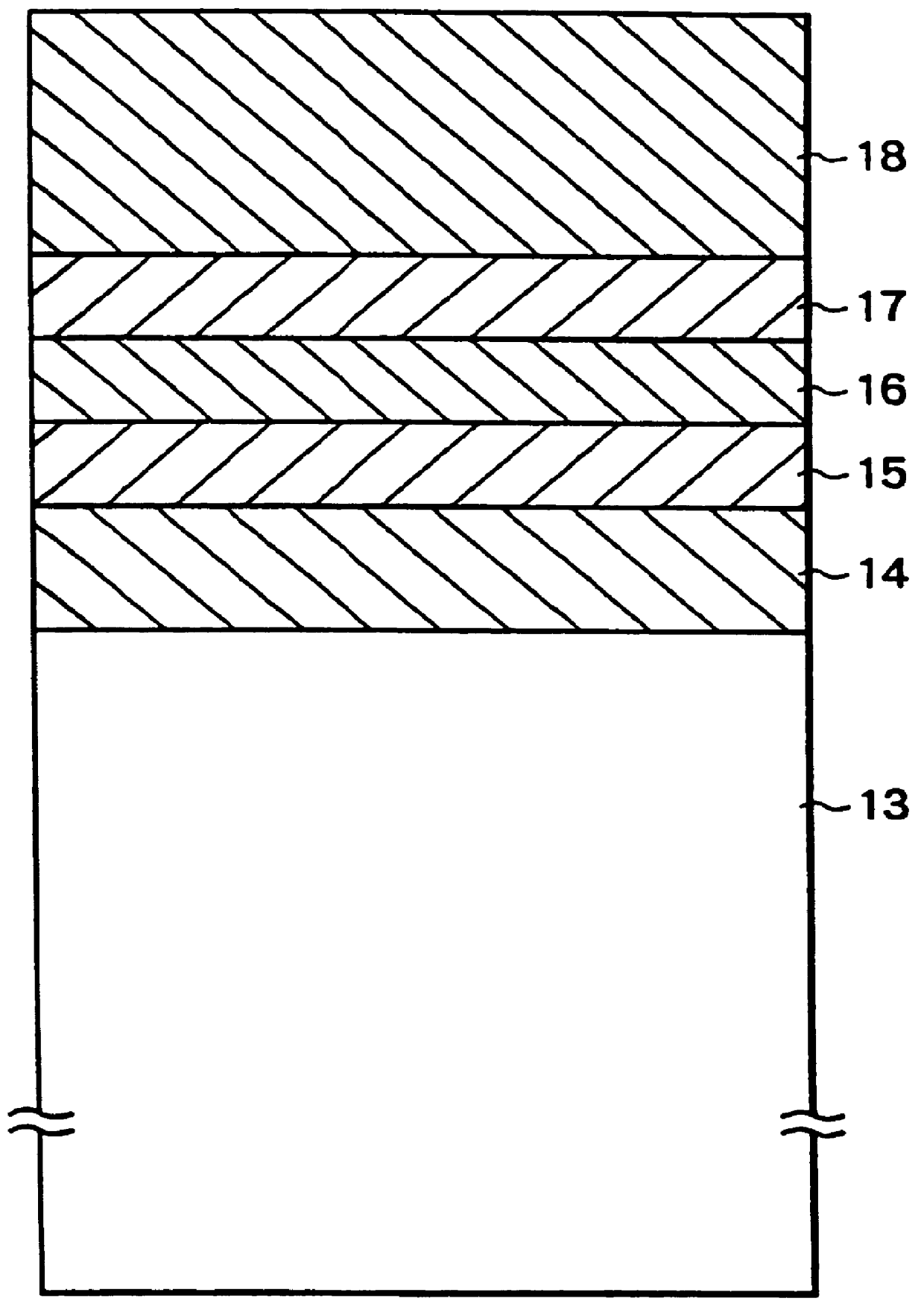

Optical phase-change disc

An optical phase-change disc comprises a substrate having thereon a spiral groove or concentric grooves for guiding a focused light beam, and a layer structure including a recording layer and protective layers sandwiching therebetween the recording layer. The groove has wobble for recording ATIP (absolute time information) or ADIP (address information). The following relationship between the groove width GW, beam diameter R0 and wobble amplitude aw: 0.25< / =GW / R0< / =0.45 or 0.65< / =GW / R0; and 0.03< / =aw / GW< / =0.08 hold for preventing distortion of the groove caused by repeated overwriting operation to improve reliability of the optical disc.

Owner:VERBATIM CORPORATION

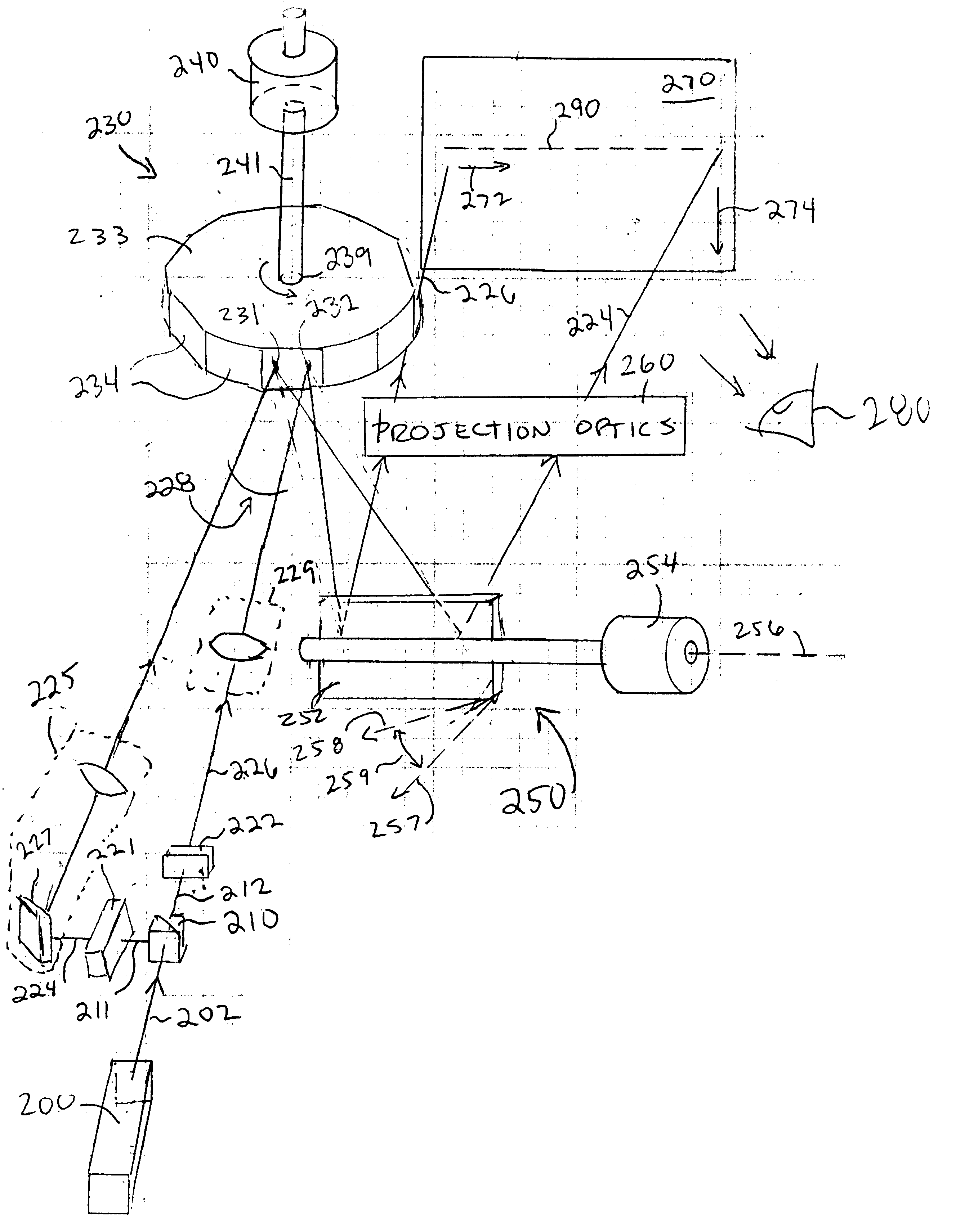

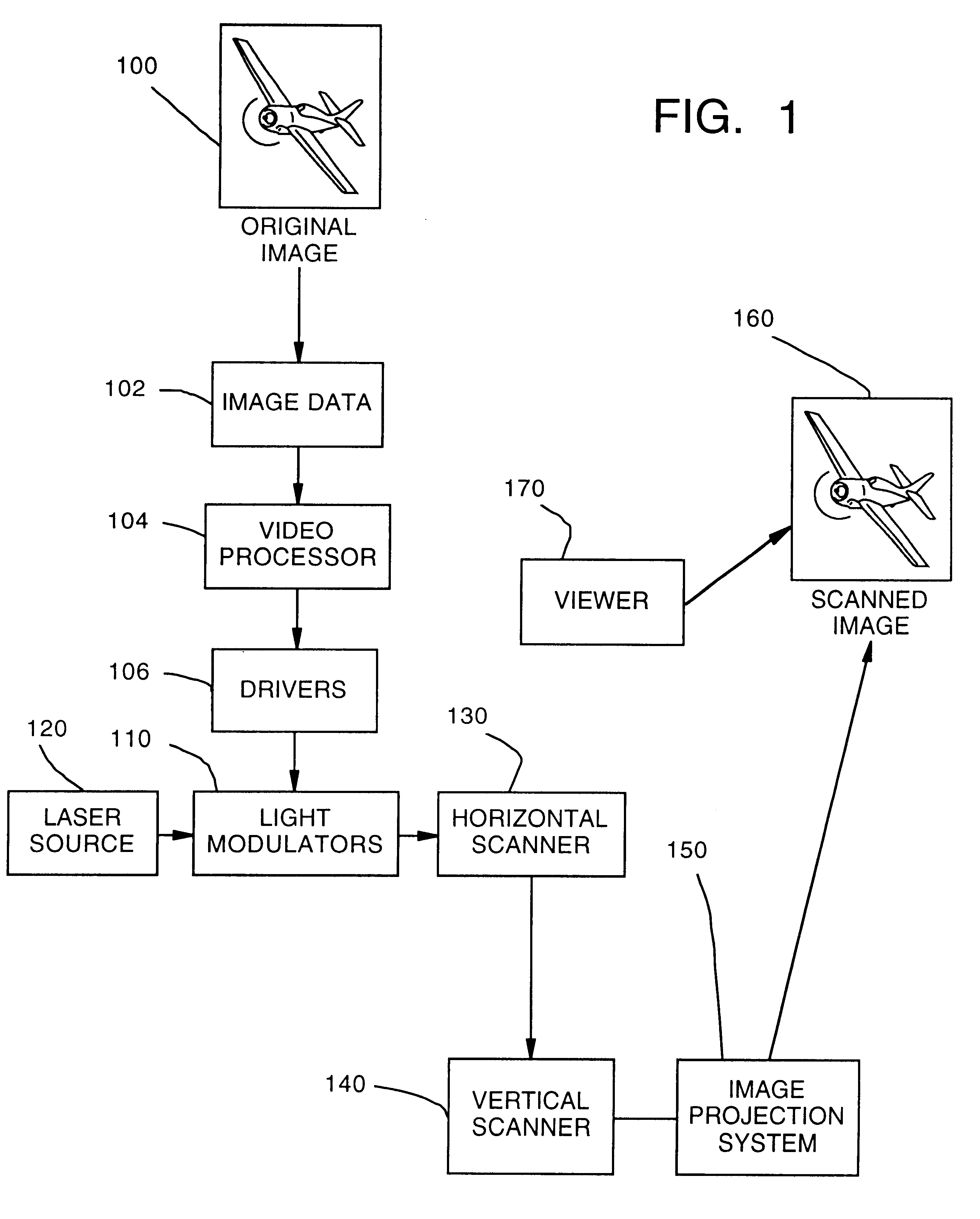

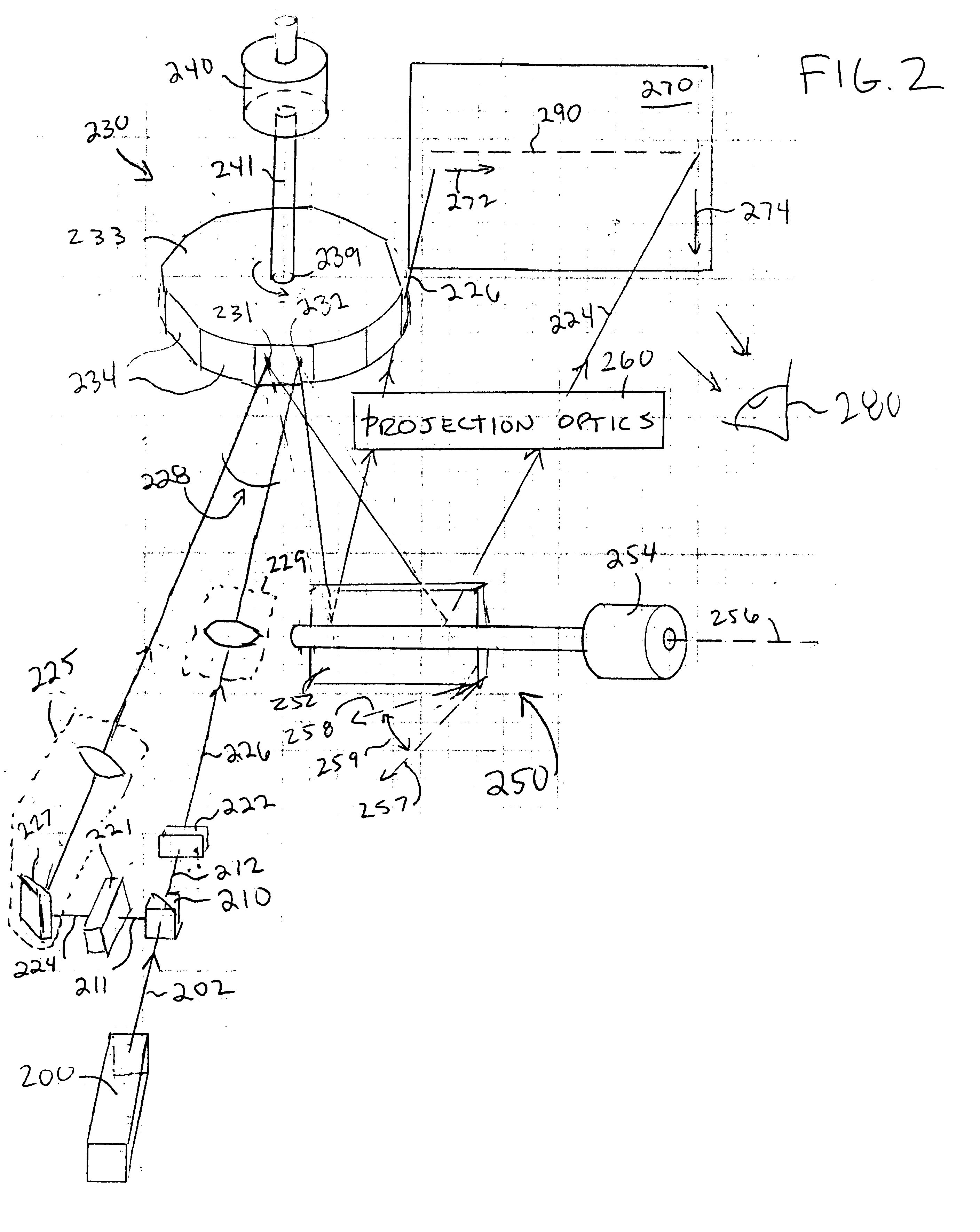

Laser imaging system with progressive multi-beam scan architecture

InactiveUS6351324B1Big cost advantageImprove system efficiencyPicture reproducers using projection devicesPicture signal generatorsColor imageBeam scanning

A progressive scan architecture for displaying a two-dimensional image by alternately scanning two or more laser beams, one after the other with a time delay between adjacent beams. The beams are arranged to become incident upon a polygon scanner in a row with an approximately uniform spatial separation and an approximately equal angle between adjacent beams. The polygon scanner scans horizontally and a galvanometer-driven mirror scans vertically. Adjacent lines are progressively scanned in sequence from top to bottom, which advantageously reduces or eliminates psycho-visual effects and is tolerant of non-linearities in the vertical scanner, allowing use of a low-cost galvo mirror. Typically, the beams in the row are arranged in pairs, and only one beam from each pair will be scanning at any one time. Embodiments are described in which the duty cycle is slightly less than 50% and the laser illumination is switched between two interleaved beam scans thereby allowing a single modulator to be used for both beams which provides significant cost advantages and improves system efficiency. For full-color images, each of the beams described can incorporate separate red, green and blue (RGB) components which are individually modulated by separate red, green, and blue modulators. The system can be scaled up with one or more additional pairs of beams to improve resolution and / or increase pixel count without requiring a high-speed polygon scanner or a highly-linear galvo scanner. Furthermore, the height of each facet in the polygon mirror need be only one beam diameter and its length need only be two beam diameters, which allows the system to approach the minimum pixel size attainable, which is useful to provide high efficiency and high brightness in the image.

Owner:PHOTERA TECH

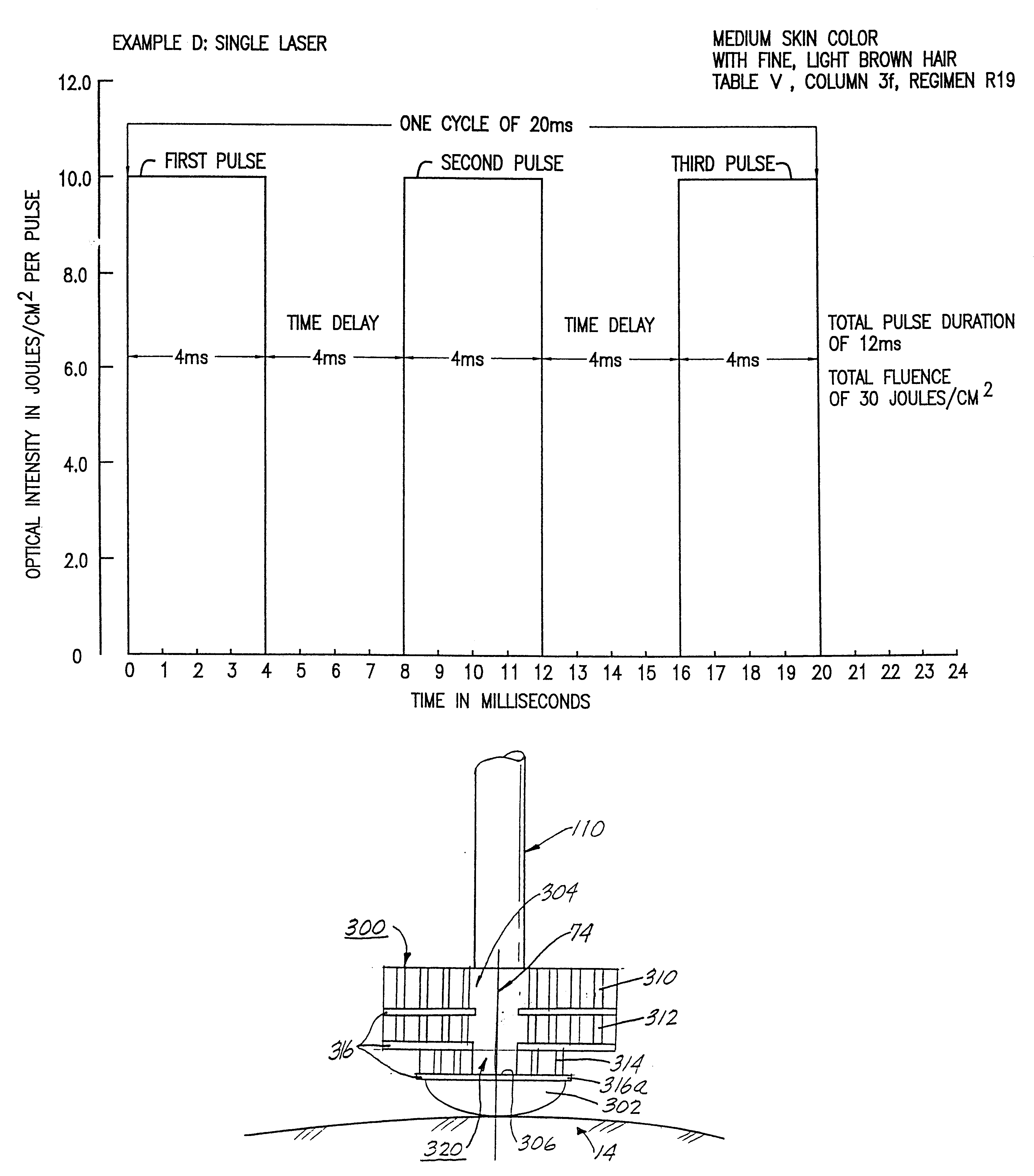

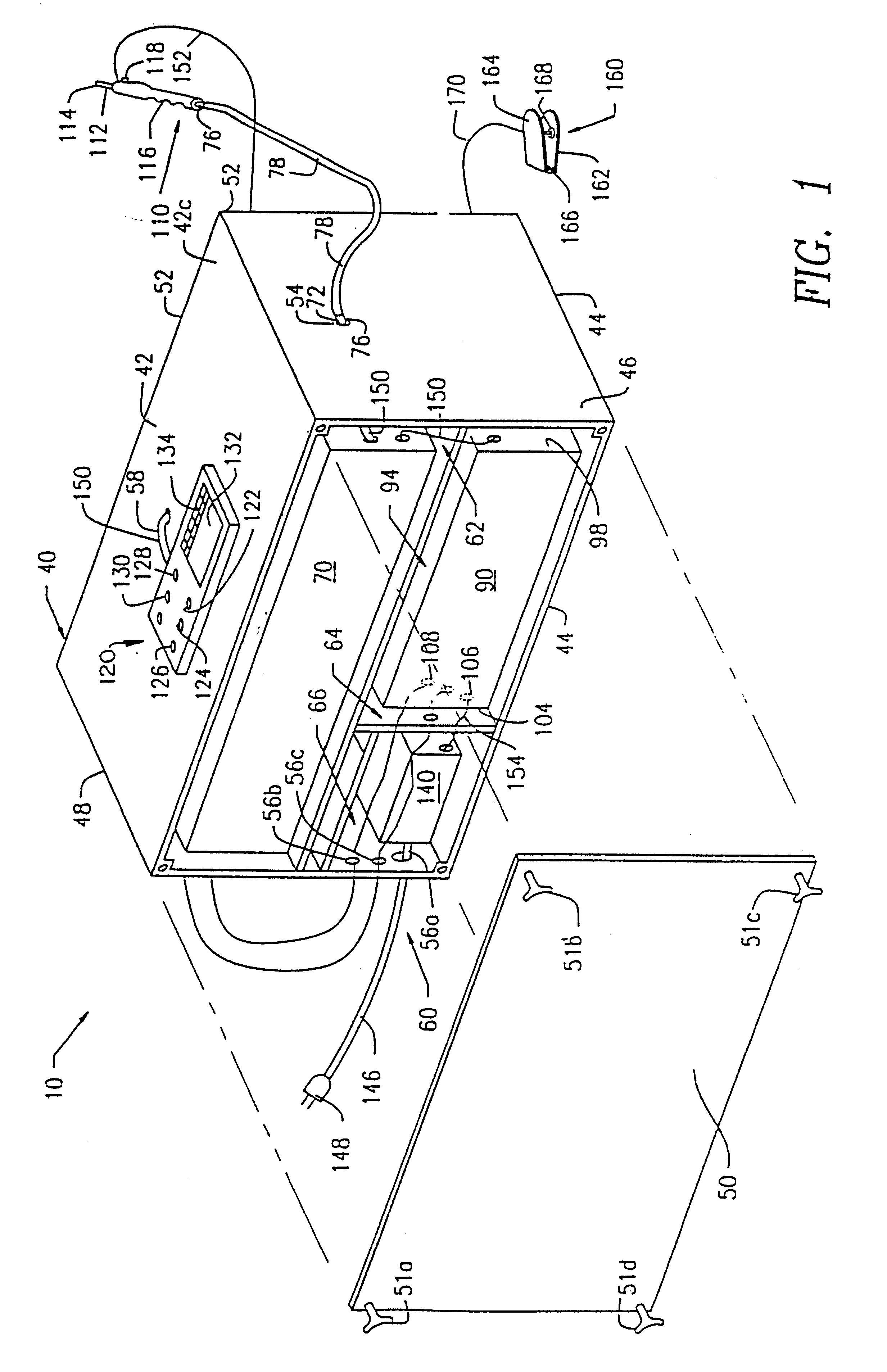

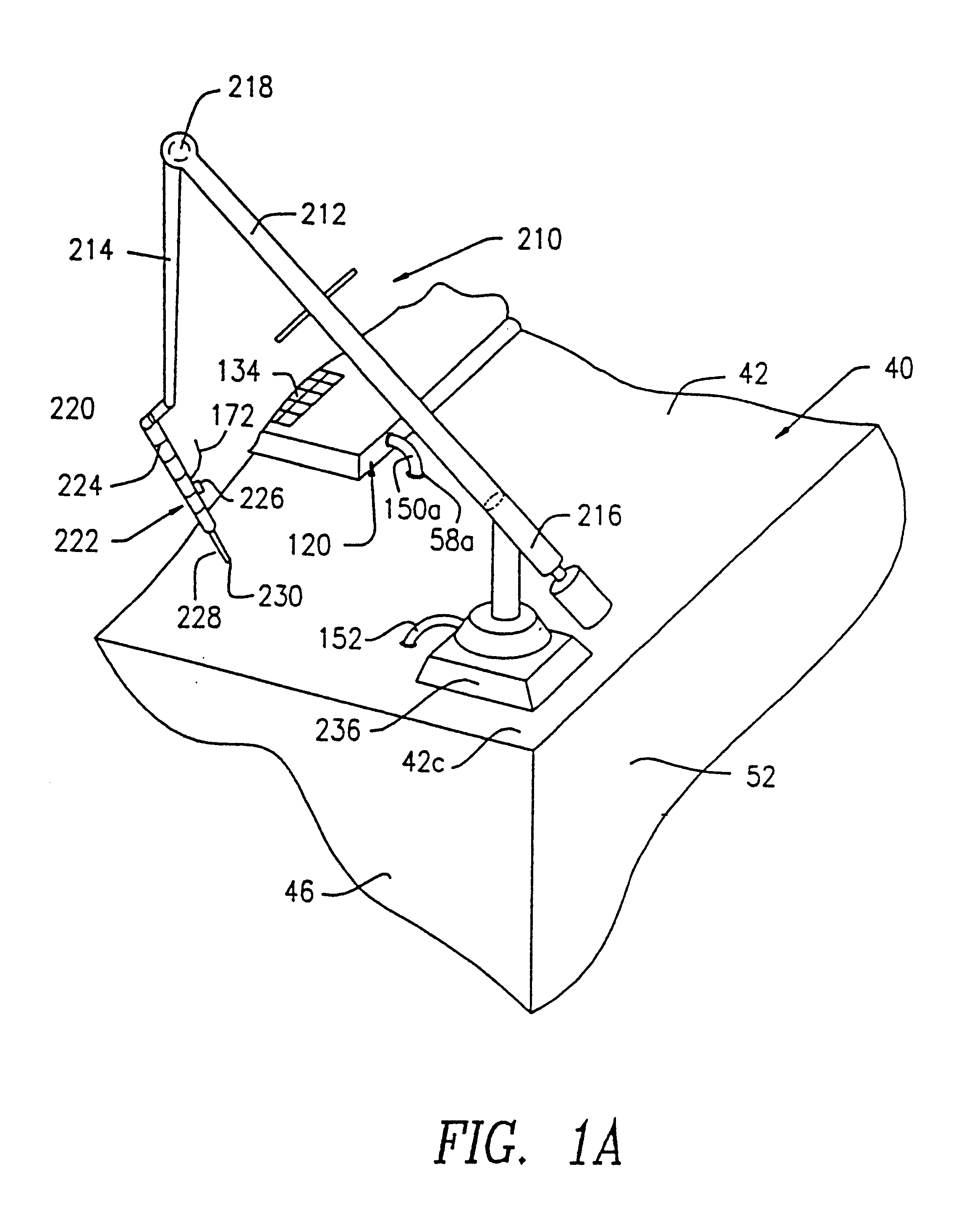

Apparatus and method employing parametrically defined pulse groups for laser hair removal

InactiveUS6595985B1Safely and quickly removing a pluralitySurgical instrument detailsPulse durationBeam diameter

A method is provided of removing hair from the skin of a patient using a laser apparatus capable of producing an emission of laser energy in the form of a group of pulses having defined parameters, being a defined pulse group, and using an optical delivery system, which includes the steps of controlling the laser apparatus in each emission of laser energy to emit a defined pulse group of 2 to 15 pulses of coherent light energy; transmitting the defined pulse group of pulses of coherent light energy through an optical delivery system to the same spot on the skin of the patient; irradiating the same spot on the skin containing the hair to be removed with the defined pulse group of coherent light energy transmitted through the optical delivery system from the laser apparatus; controlling the laser apparatus in each emission of laser energy to emit the defined pulse group through the optical delivery system, the defined pulse group having 2 to 15 pulses at a wavelength in the range of 550 to 1200 nm, each pulse at a power level in the range of 2 to 35 Joules / cm.sup.2 per pulse, each pulse having a pulse duration in the range of 1.2 to 22 milliseconds per pulse, each pulse having a beam diameter on the treatment area in the range of 4 to 50 millimeters, the defined pulse group having a total fluence in the range of 4 to 100 Joules / cm.sup.2, and a repetition rate of the laser apparatus between successive defined pulse groups being 500 to 2000 milliseconds; and cooling the skin during at least one delay between pulses of the defined pulse group, wherein the at least one delay between pulses is longer to accommodate the cooling step, and wherein the step of cooling is performed by spraying cryogen on the patient's skin.

Owner:TACT IP

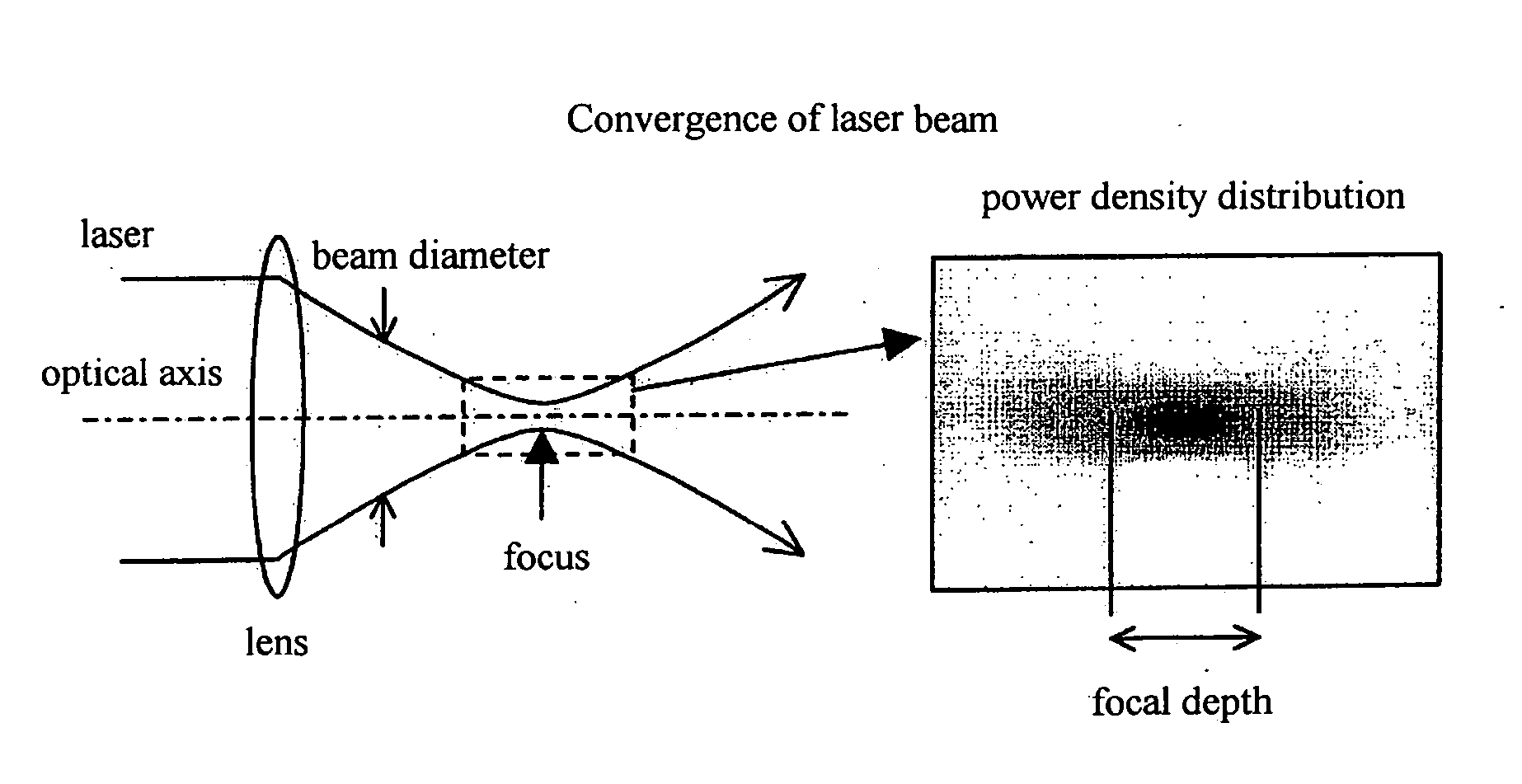

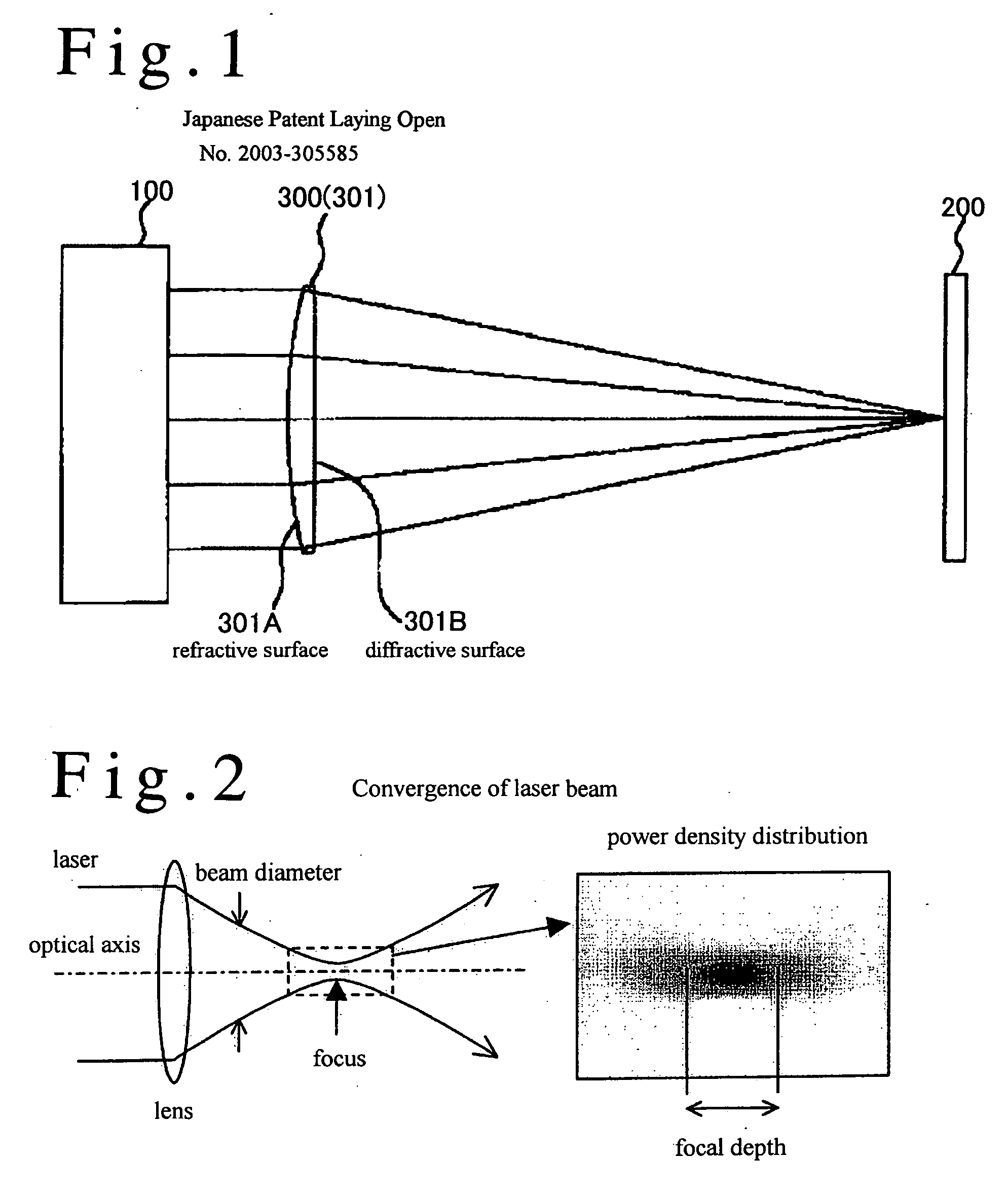

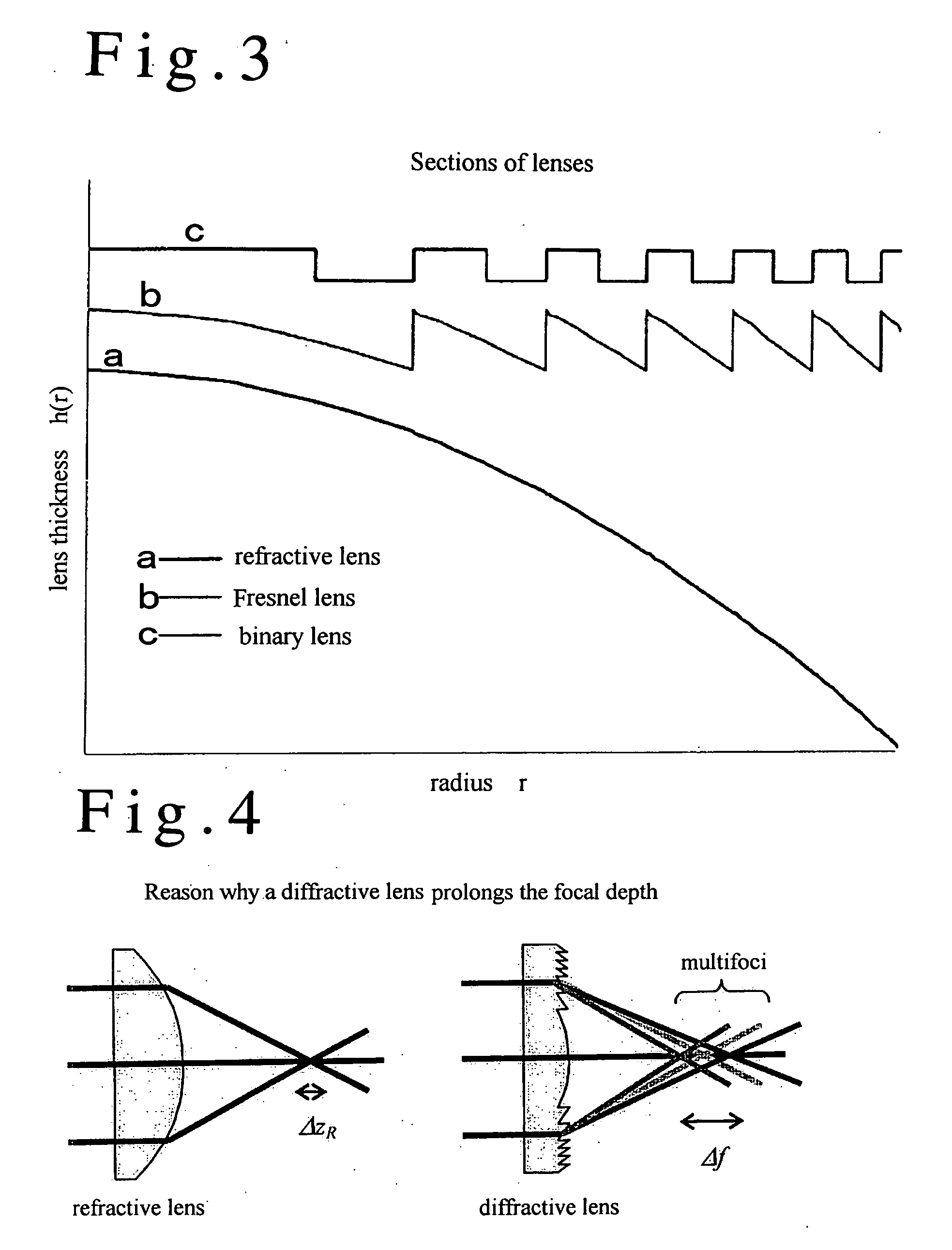

Laser processing method and laser processing apparatus

InactiveUS20060109874A1Lengthens focal depthFocal depth is very shallowLaser detailsDiffraction gratingsLaser processingBeam diameter

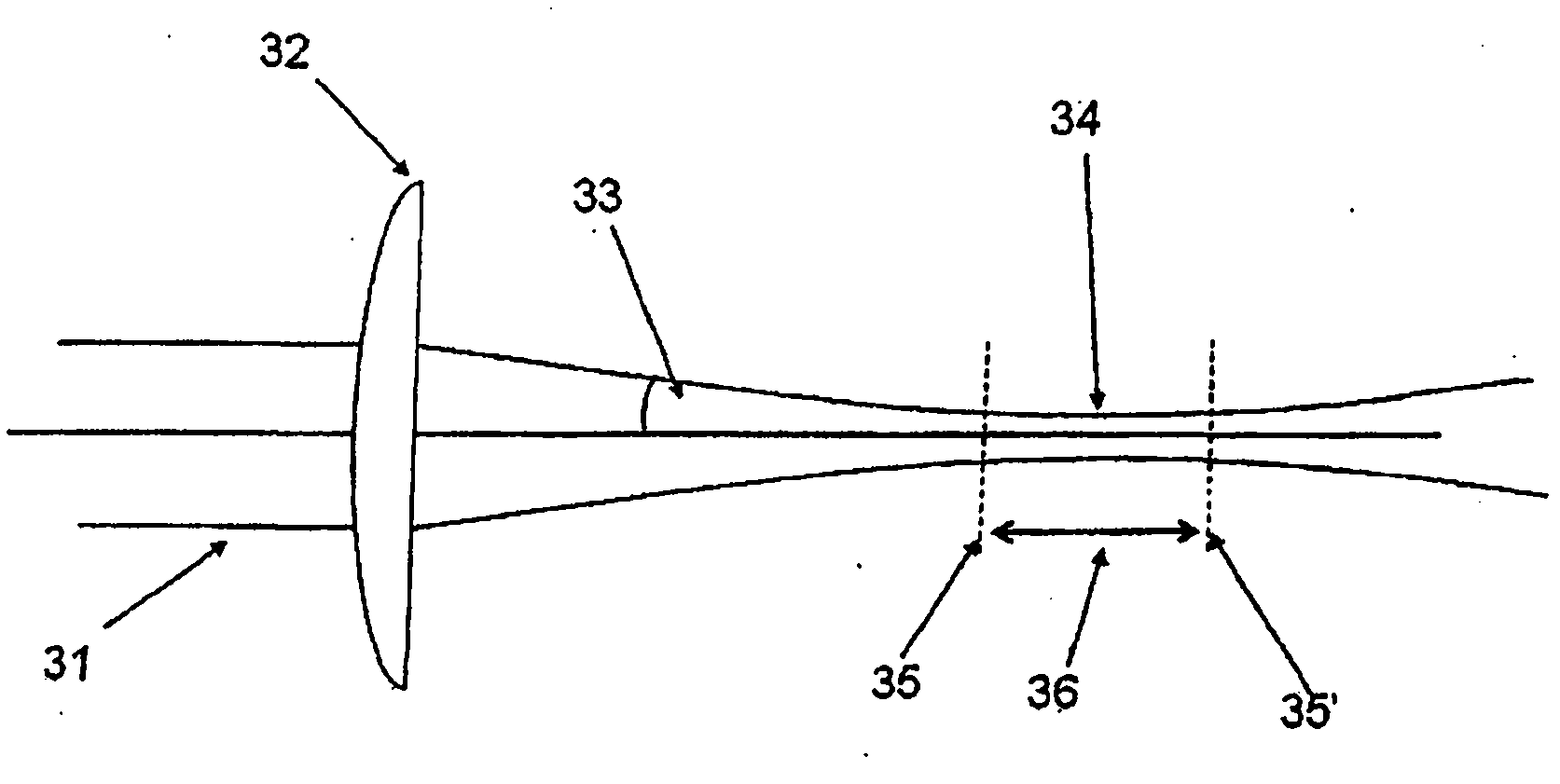

Ultrashort pulse laser processing bores, welds or cuts objects (work pieces) by converging ultrashort laser pulses by a lens on the objects (work pieces) positioned at the focus and heating small spots or narrow lines on the objects (work pieces). Shortage of a focal depth of the lens prevents the ultrashort pulse laser processing from positioning the object (a work piece) and forming a deep, constant-diameter cylindrical hole. Z-parameter is defined to be Z=2fcΔt / Δi2, where Δt is a FWHM pulse width of the ultrashort pulse laser, Δi is a FWHM beam diameter of the ultrashort pulse, f is a focal length of the lens and c is the light velocity in vacuum. Selection of an optical system including a diffraction-type lens which gives the Z-parameter less than 1 (Z<1) prolongs the focal depth. Expansion of the focal depth facilitates the positioning of objects (work pieces) and enables the ultrashort pulse laser apparatus to bore a deep, constant-diameter cylindrical hole.

Owner:SUMITOMO ELECTRIC IND LTD

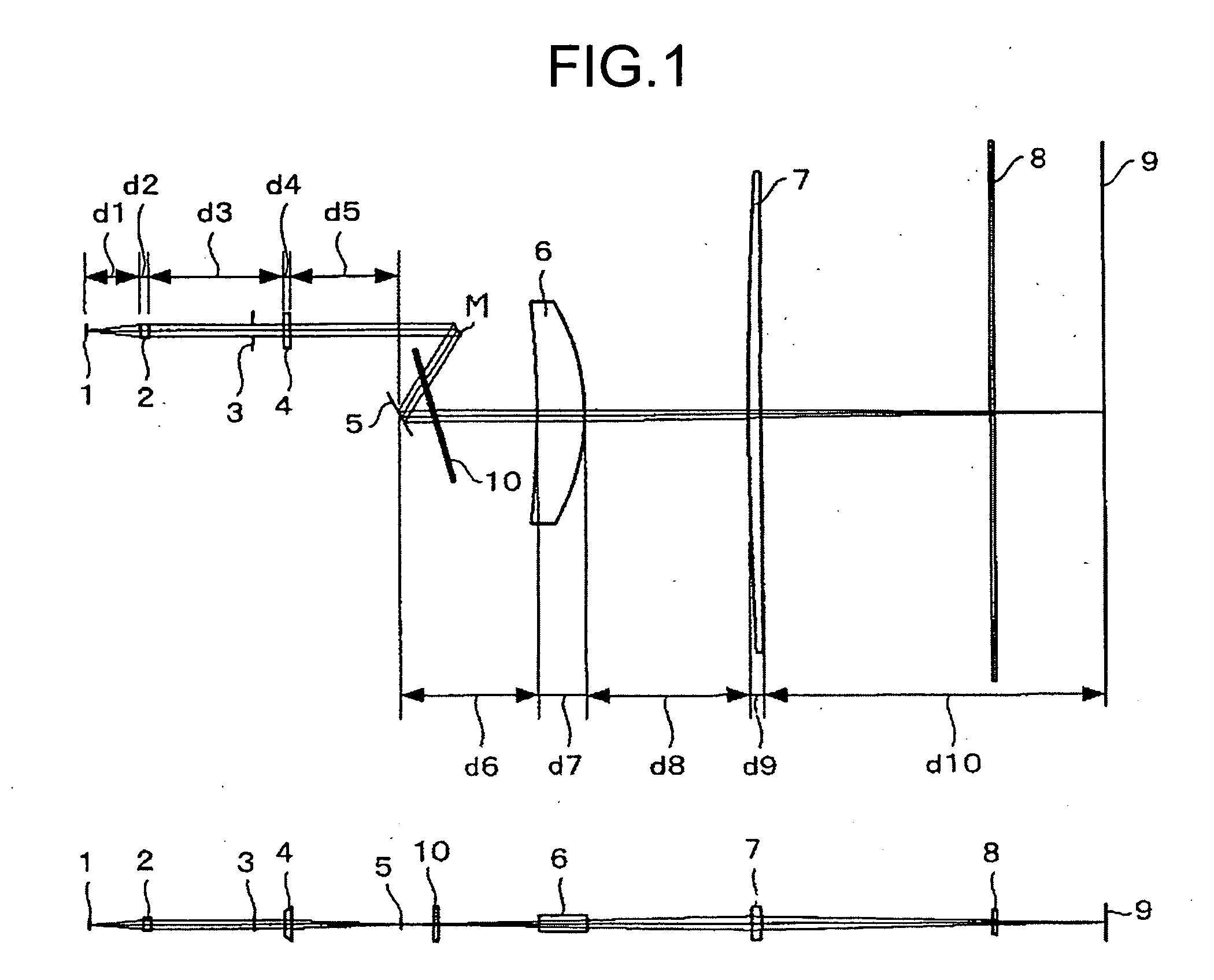

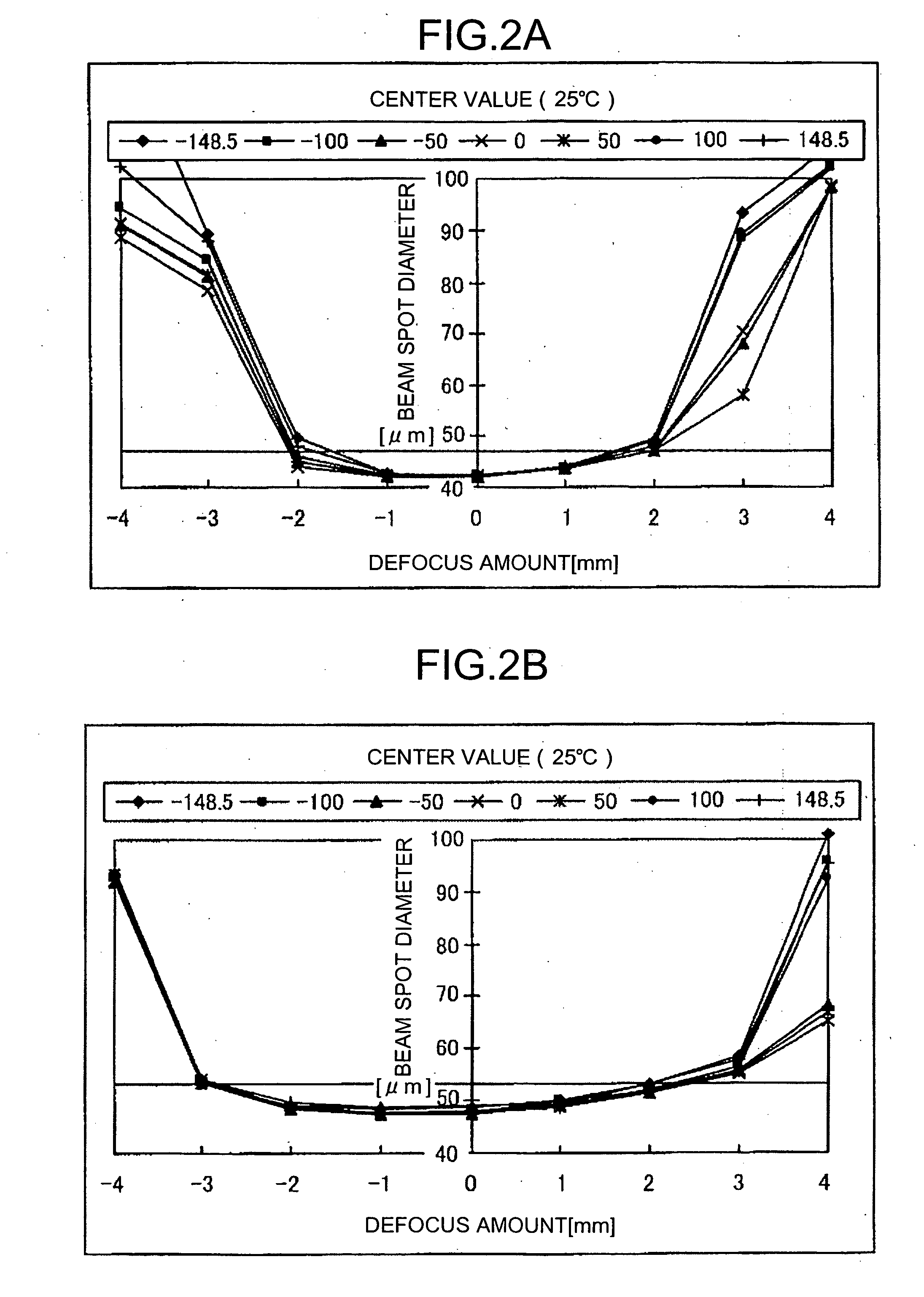

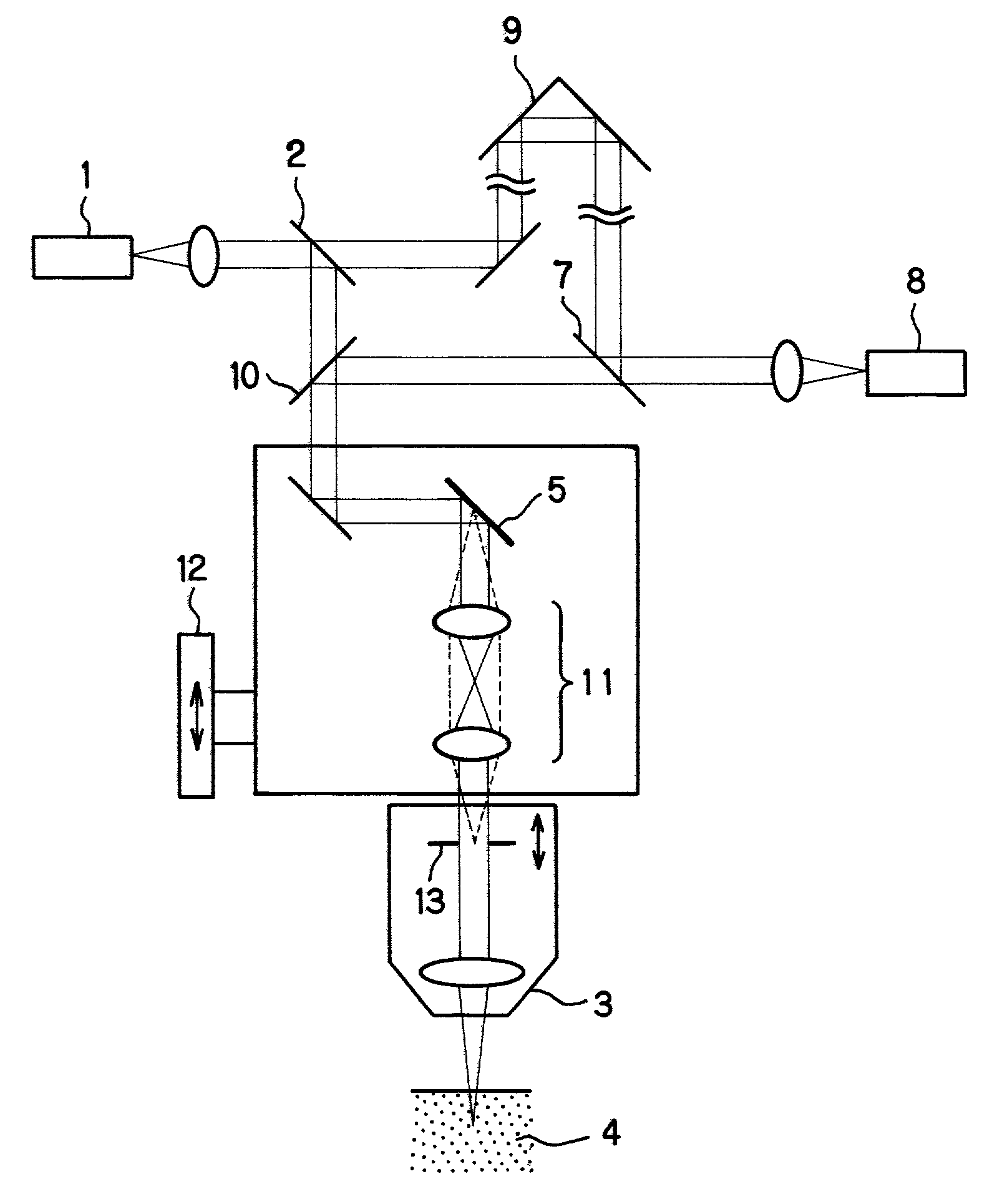

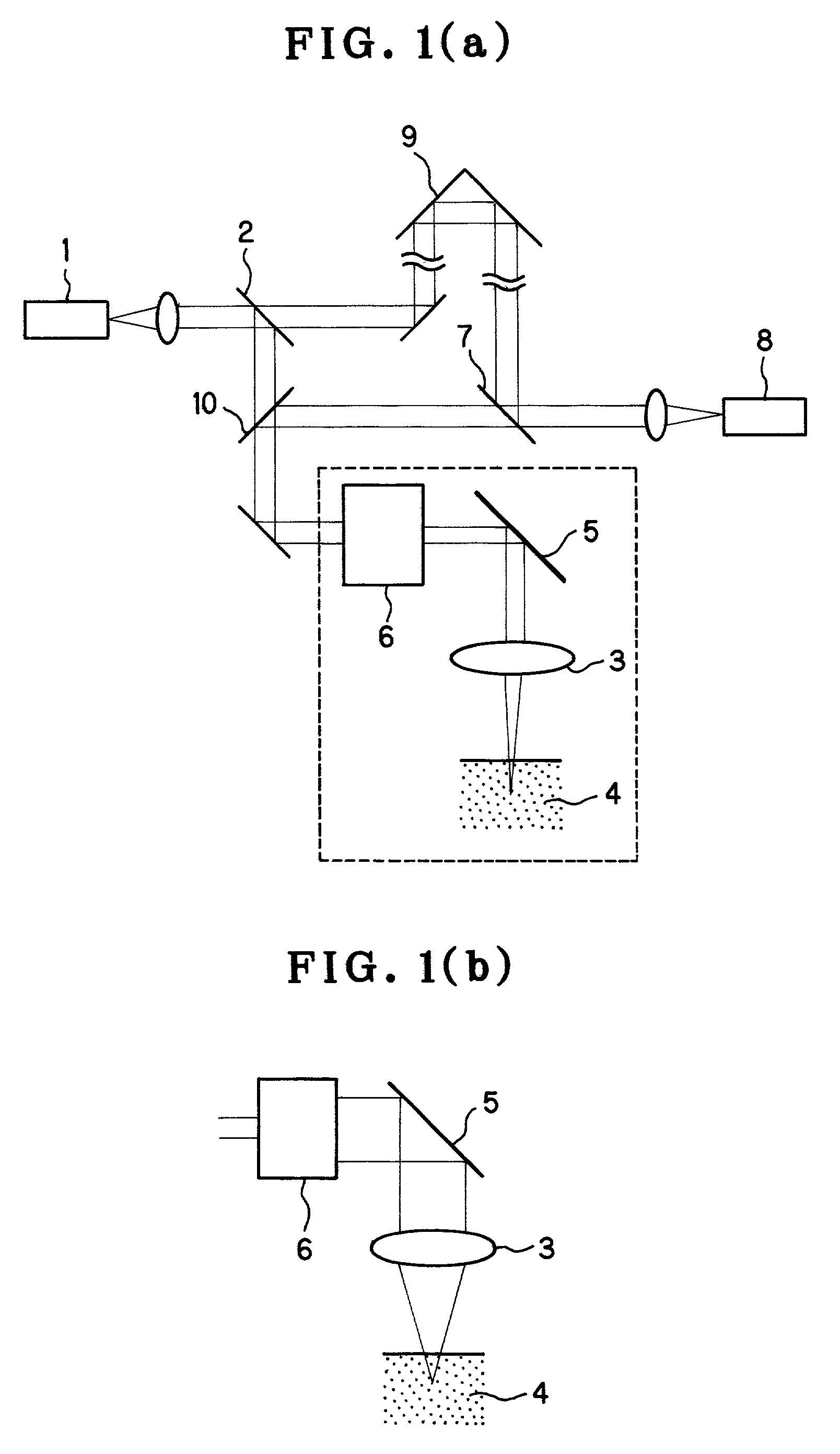

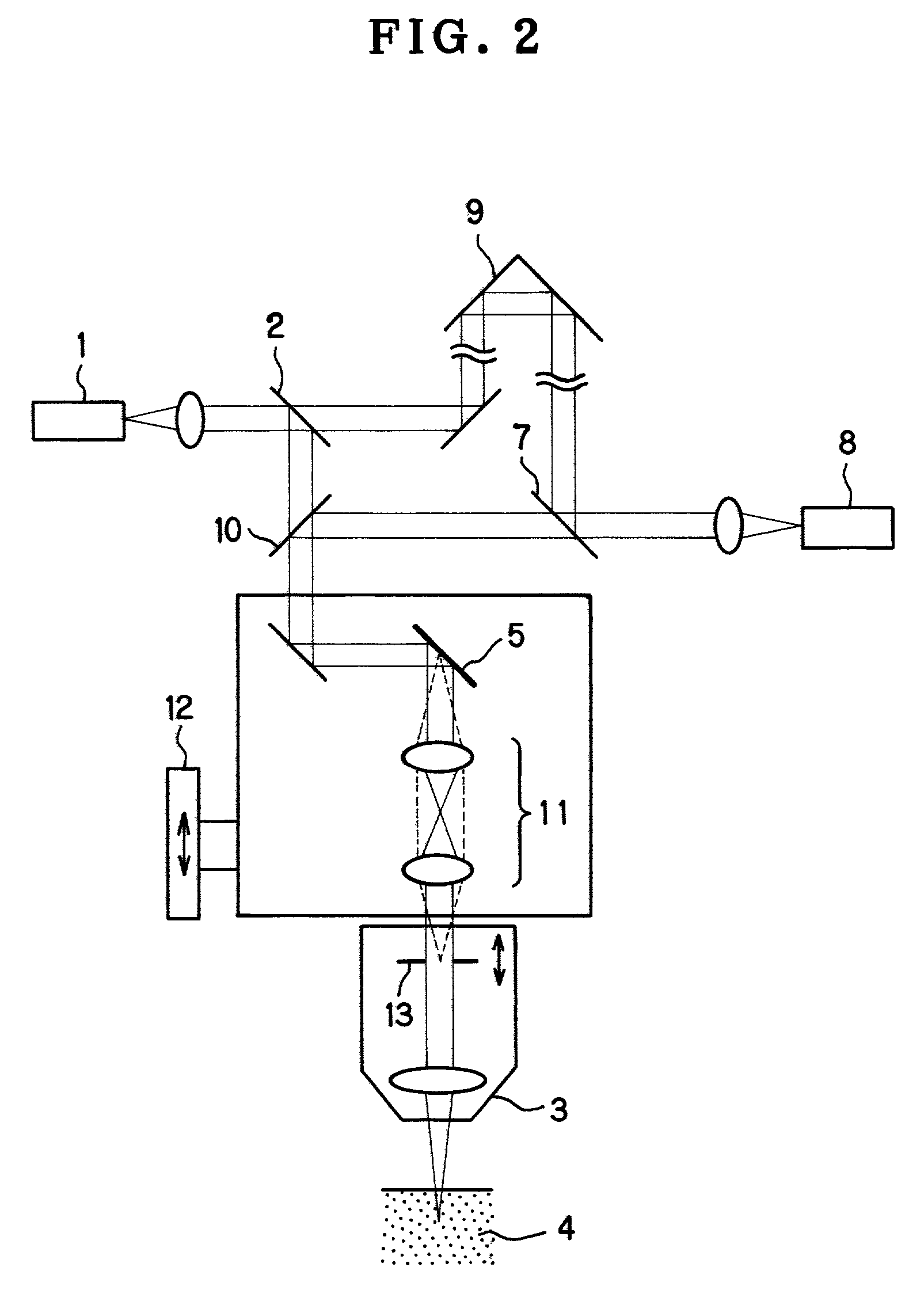

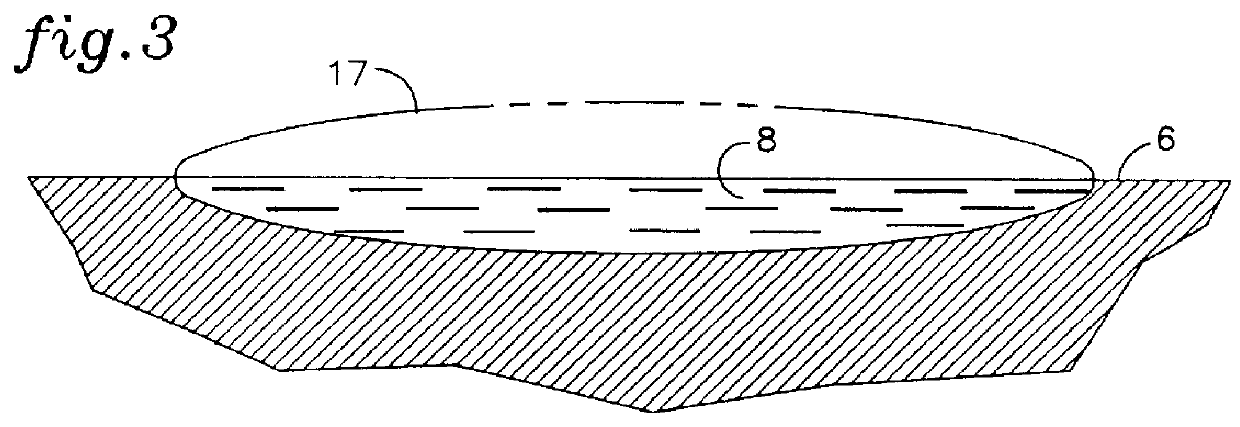

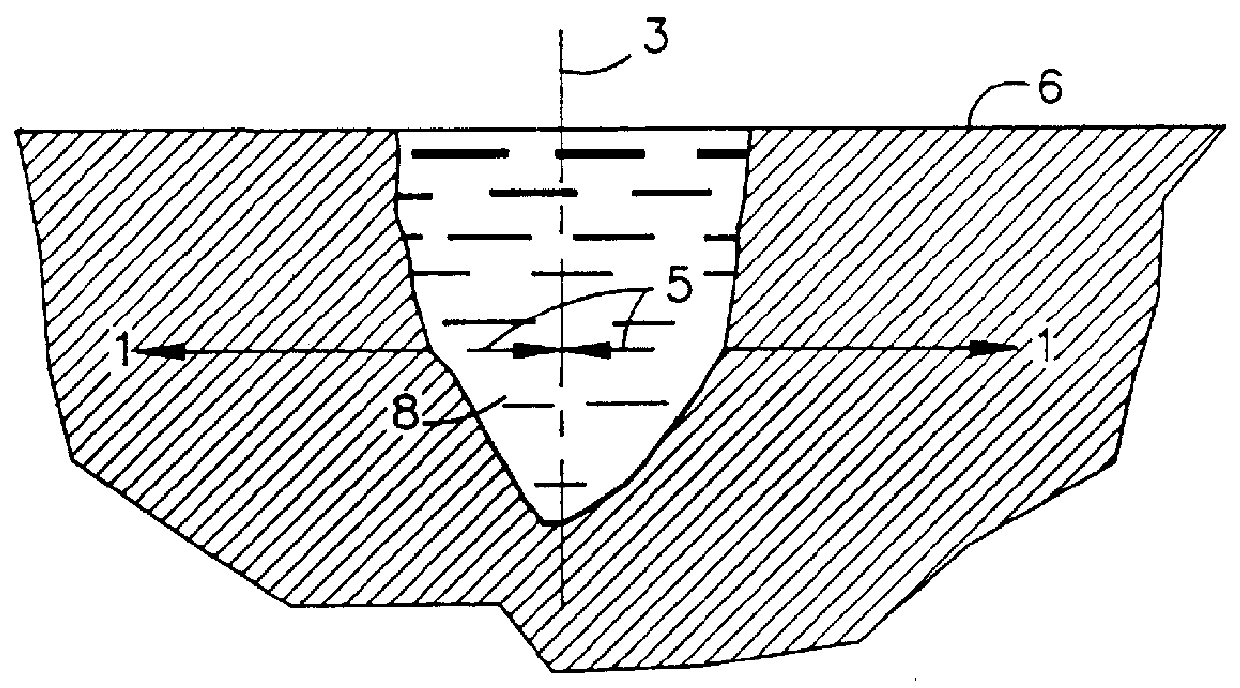

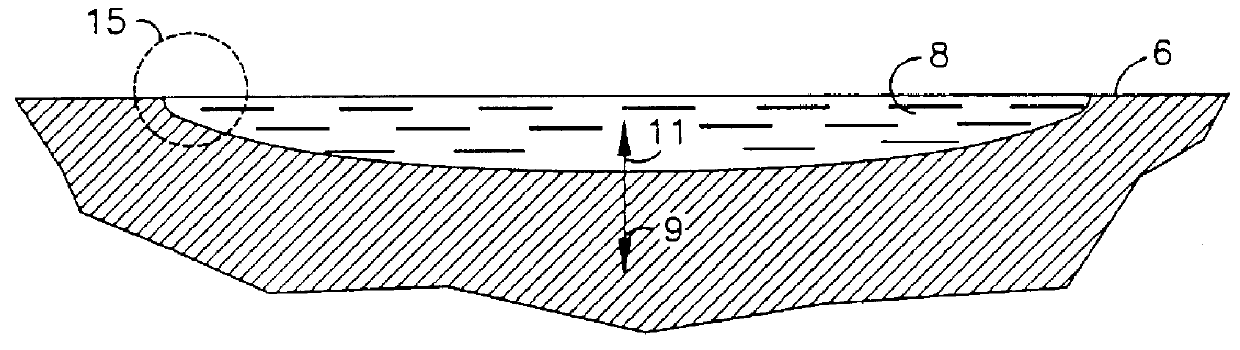

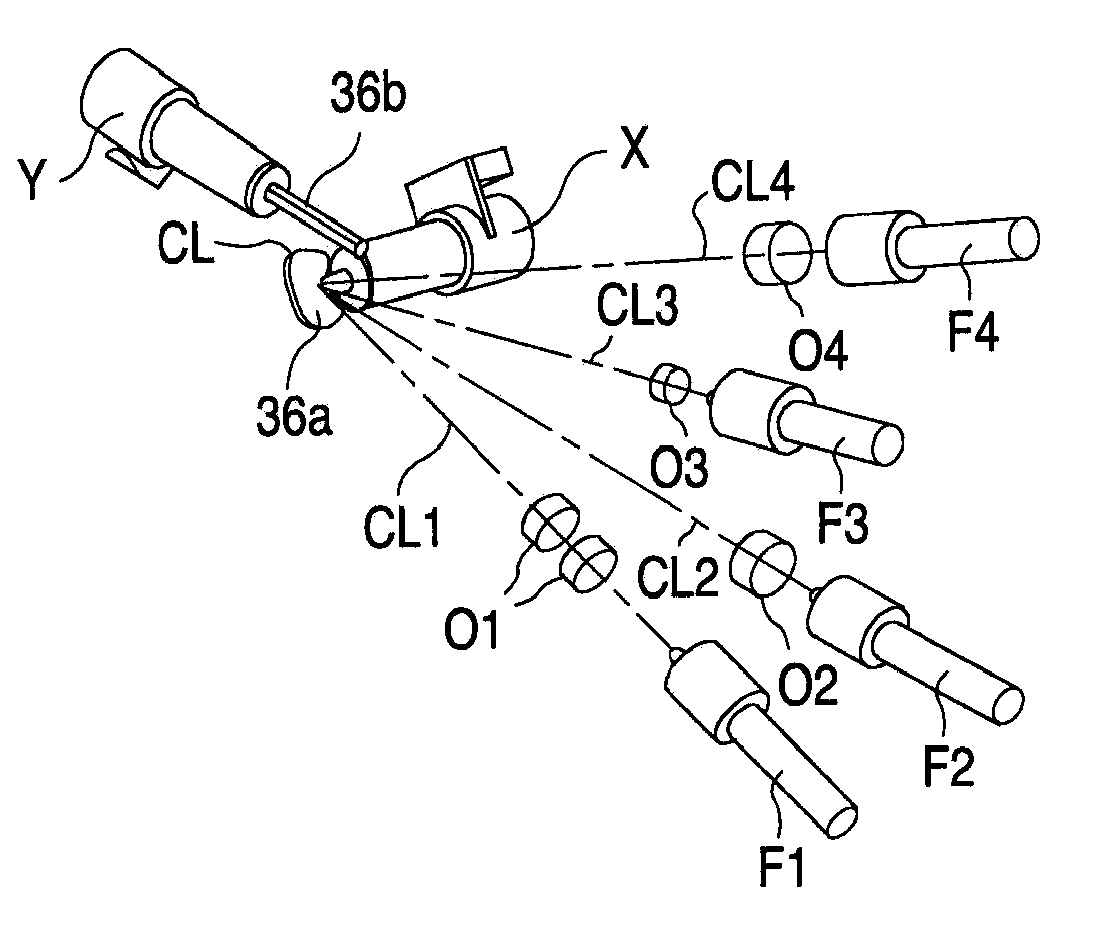

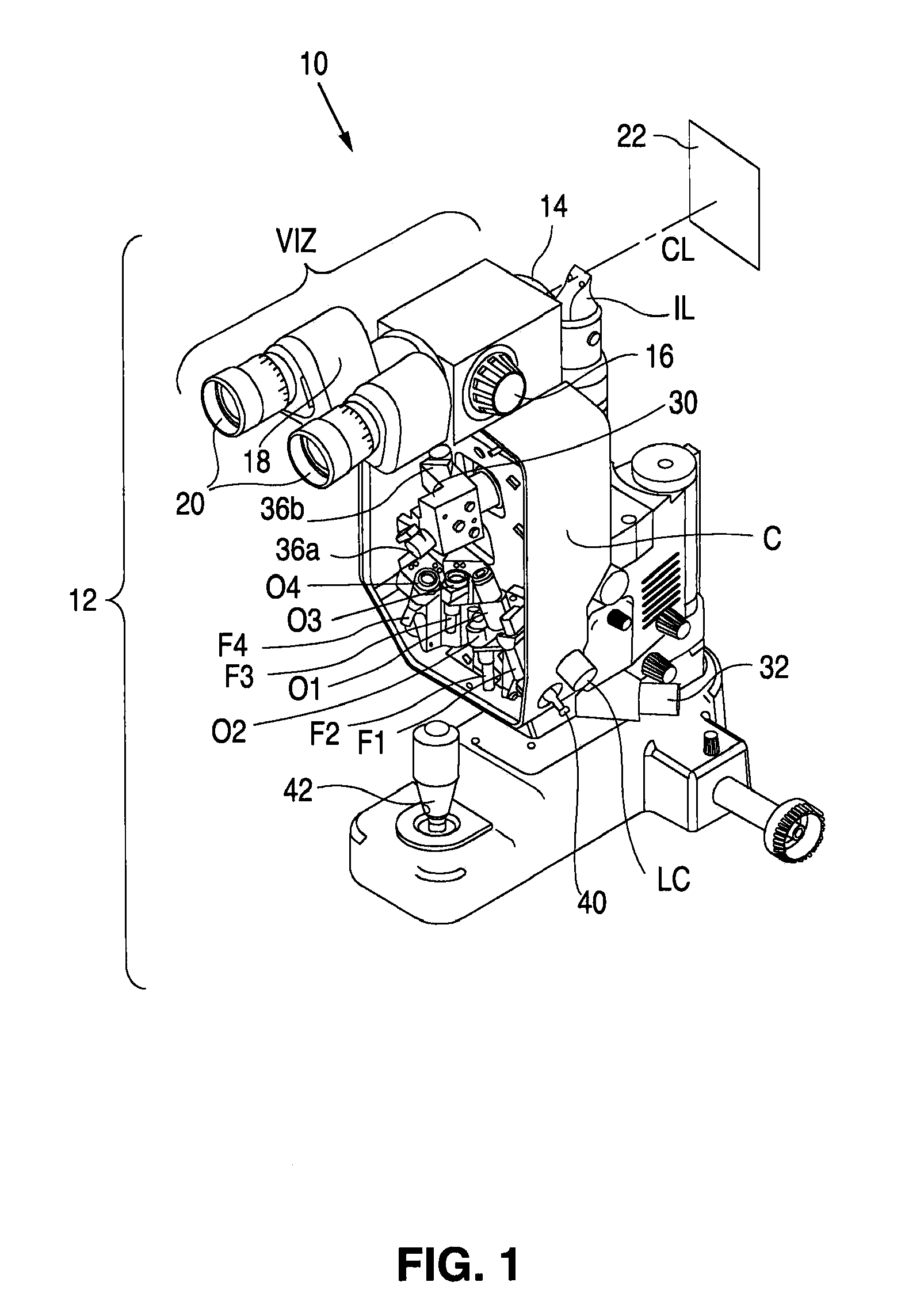

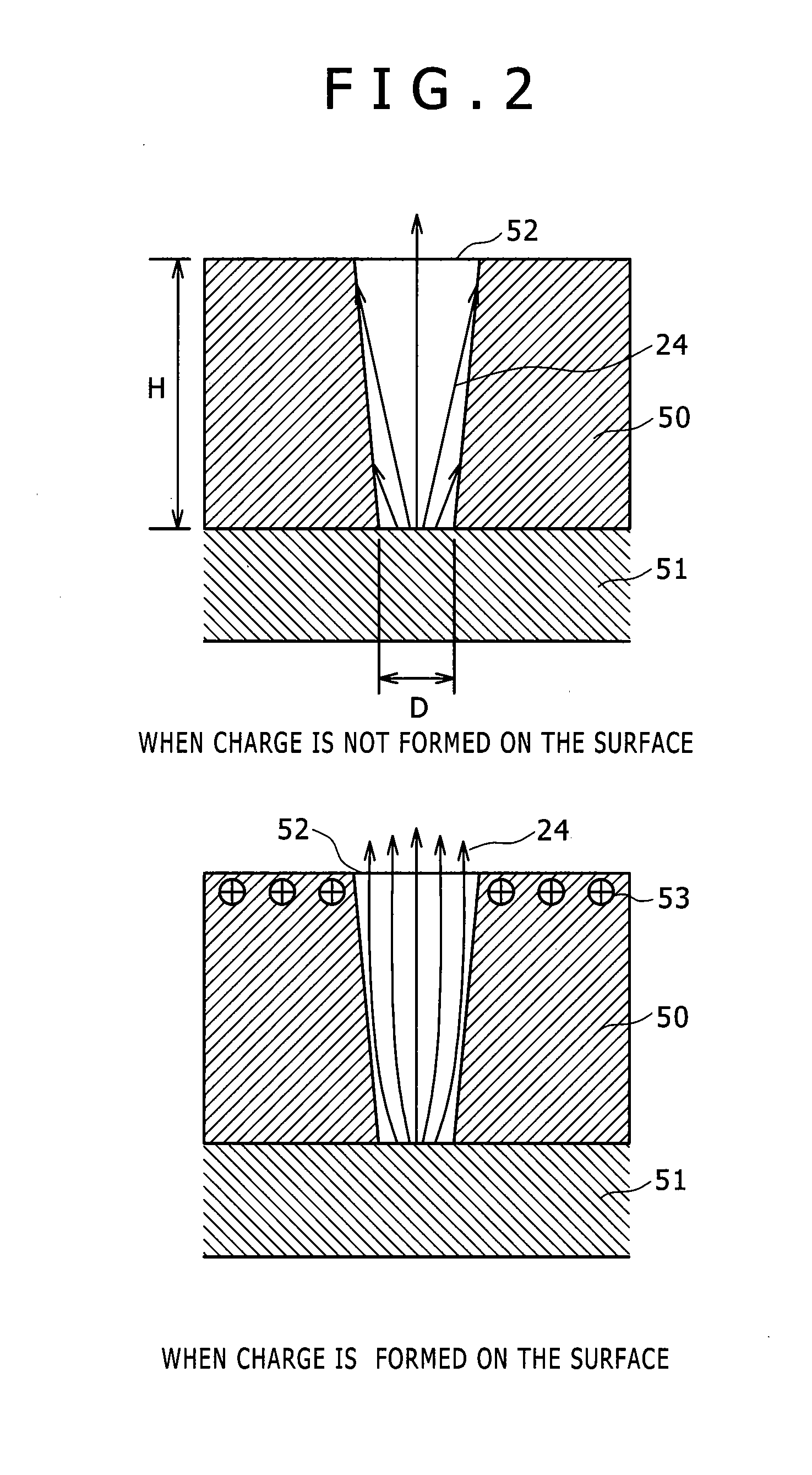

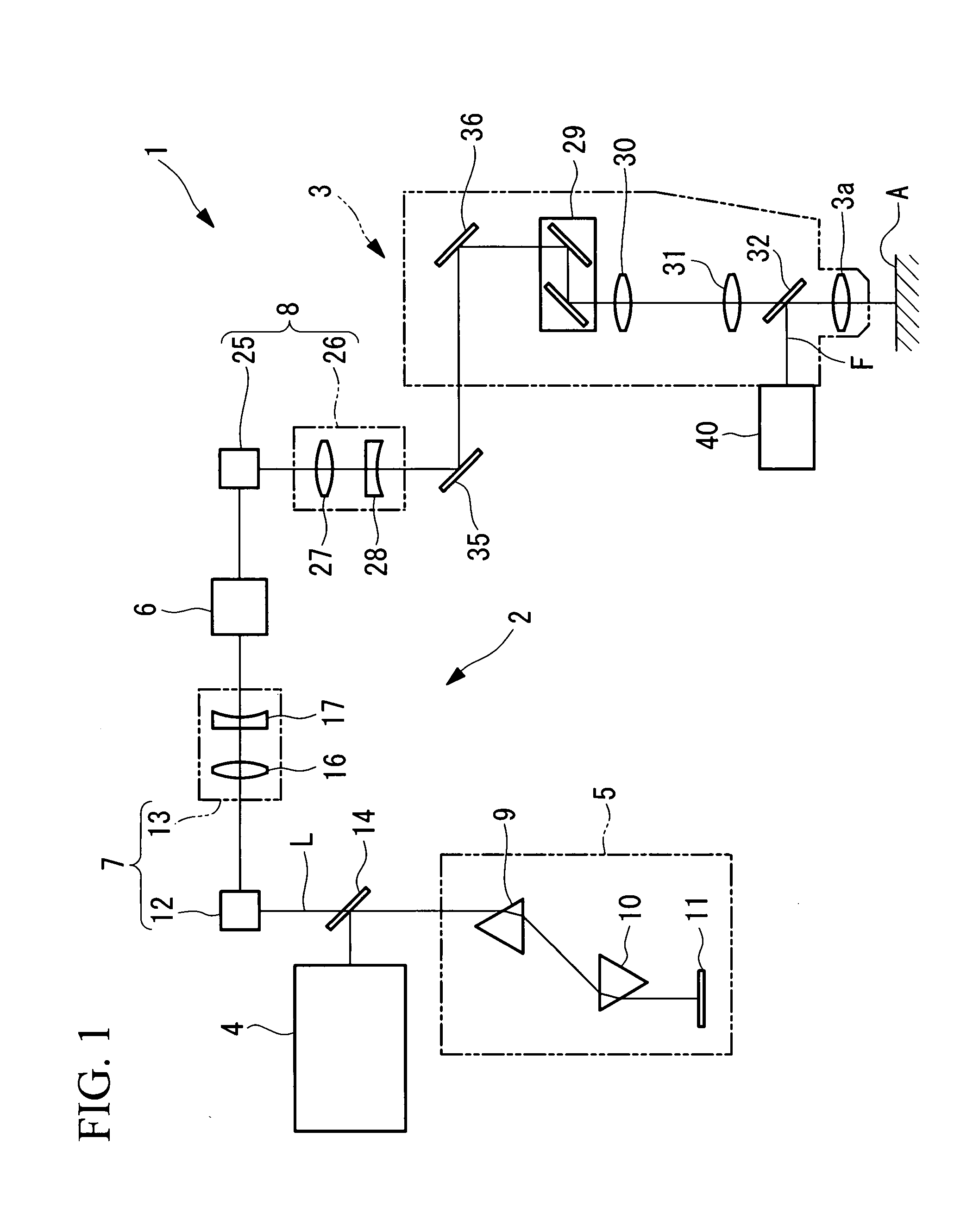

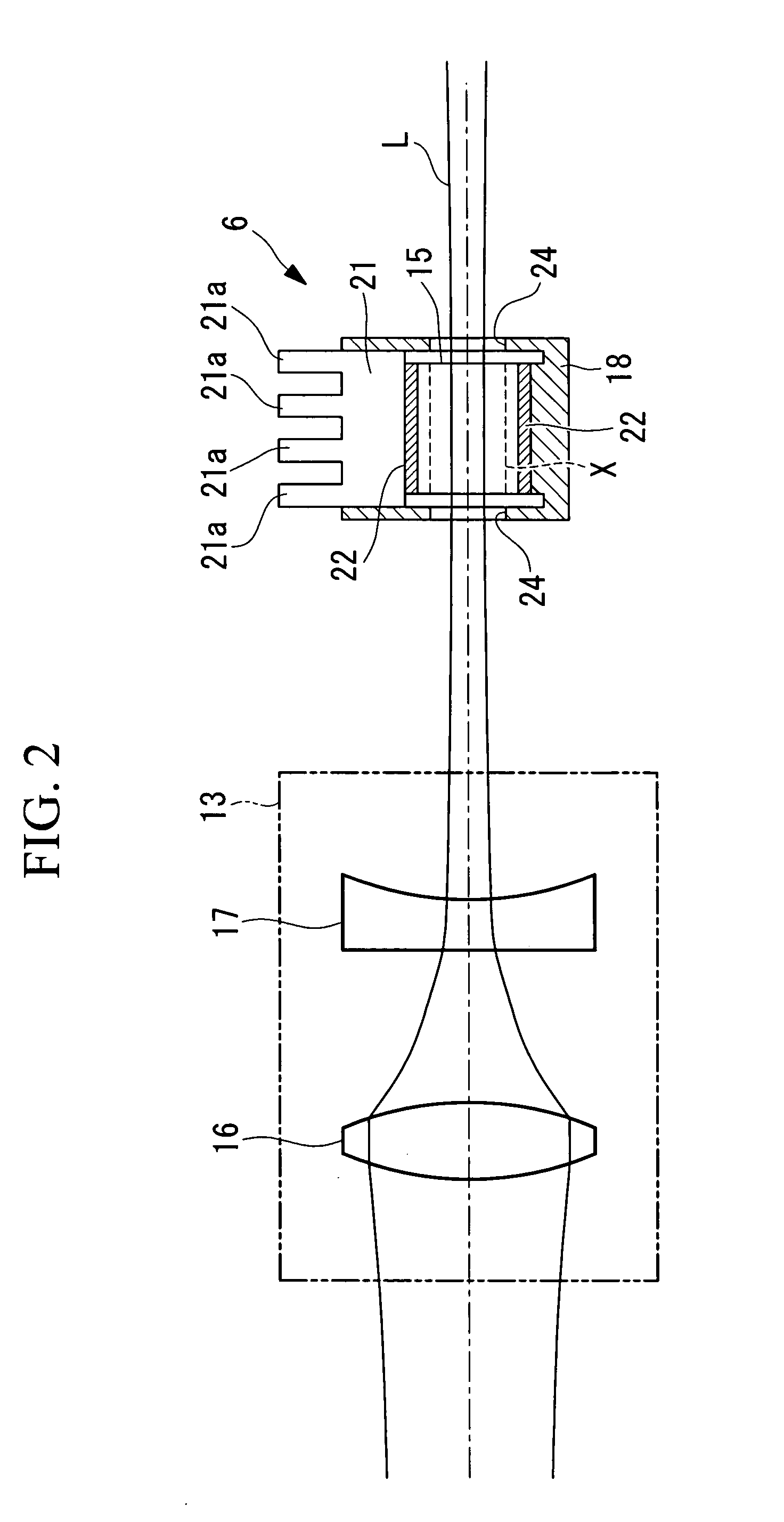

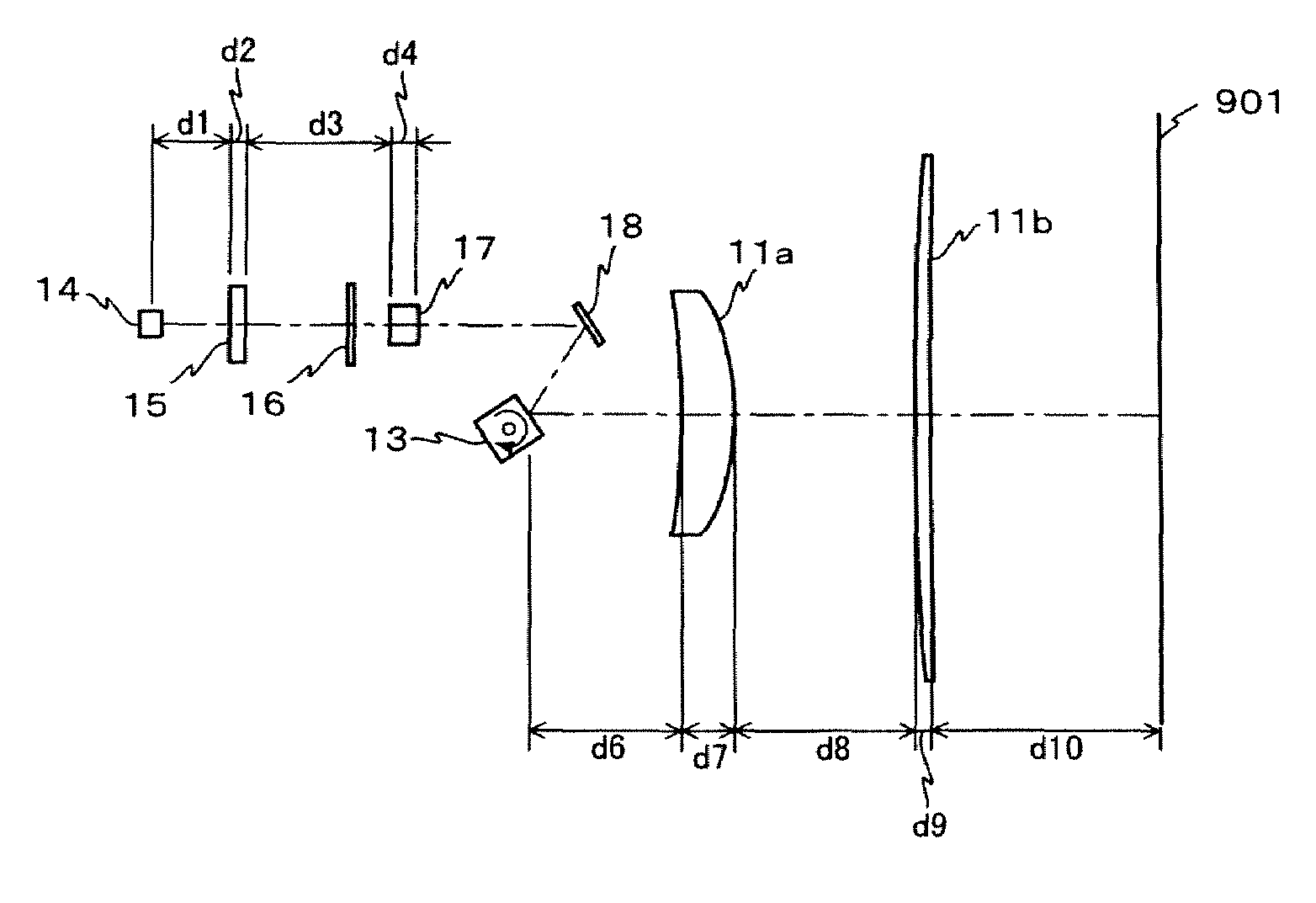

Optical system and optical apparatus capable of switching between optical coherence tomography observation and optical coherence microscopy observation

InactiveUS7236251B2Easy to findHigh resolutionScattering properties measurementsUsing optical meansBeam diameterLight beam

An optical system and optical apparatus prevent degradation of the S / N ratio due to switching between OCT and OCM observation modes and attain a high S / N ratio in both the observation modes. The optical system includes a light source 1 and a light-branching member 2 for branching light from the light source 1 into a reference light path and a signal light path. An objective 3 is placed in the signal light path. A light-scanning system 5 scans light in the signal light path with respect to a sample 4 placed in the signal light path. A beam diameter changing optical system 6 changes the beam diameter of light entering or exiting the light-scanning system 5. A light-combining member 7 combines together the reference light path and the signal light path. A light-detecting element 8 detects light combined by the light-combining member 7.

Owner:OLYMPUS CORP

Crack free metallic articles

InactiveUS6103402AReduce material stressReduce solidificationTurbinesBy zone-melting liquidsCrazingClosed loop

A containerless method of producing a crack free metallic article of near-net shape includes melting a filler material into a metallic substrate or seed under conditions chosen to preclude cracking. In a preferred embodiment of the invention, a laser beam is operated at a relatively low power density and at a relatively large beam diameter at the substrate surface for an extended length of time to produce a molten pool with a low aspect ratio. Near-net shape is achieved by applying the process in a closed-loop, multi-axis material deposition system.

Owner:UNITED TECH CORP

Optical phase-change disc having a grooved substrate, with the groove having specific wobbled and non-wobbled regions

An optical phase-change disc comprises a substrate having thereon a spiral groove or concentric grooves for guiding a focused light beam, and a layer structure including a recording layer and protective layers sandwiching therebetween the recording layer. The groove has wobble for recording ATIP (absolute time information) or ADIP (address information). The following relationship between the groove width GW, beam diameter R0 and wobble amplitude aw: 0.25< / =GW / R0< / =0.45 or 0.65< / =GW / R0; and 0.03< / =aw / GW< / =0.08 hold for preventing distortion of the groove caused by repeated overwriting operation to improve reliability of the optical disc.

Owner:VERBATIM CORPORATION

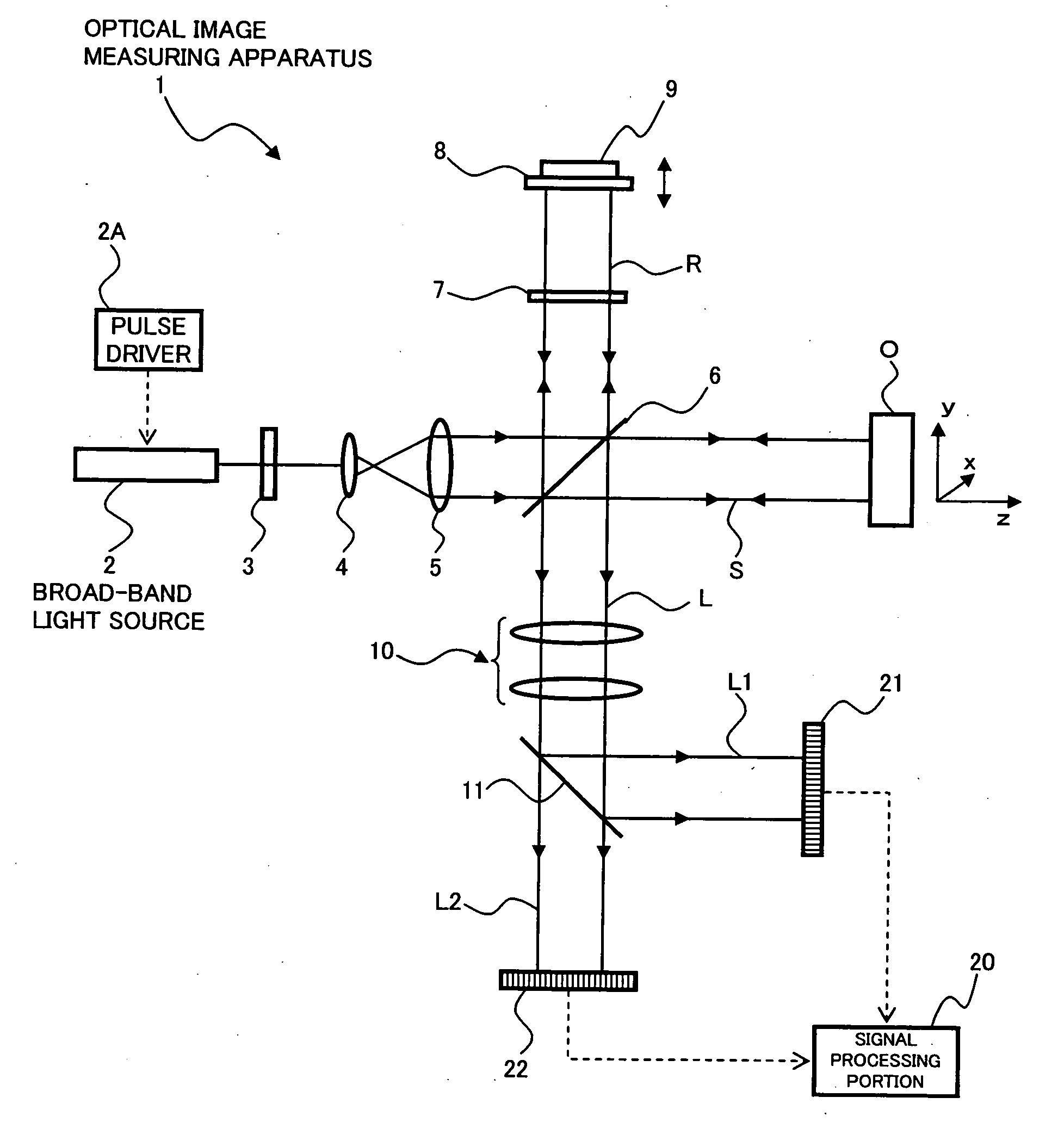

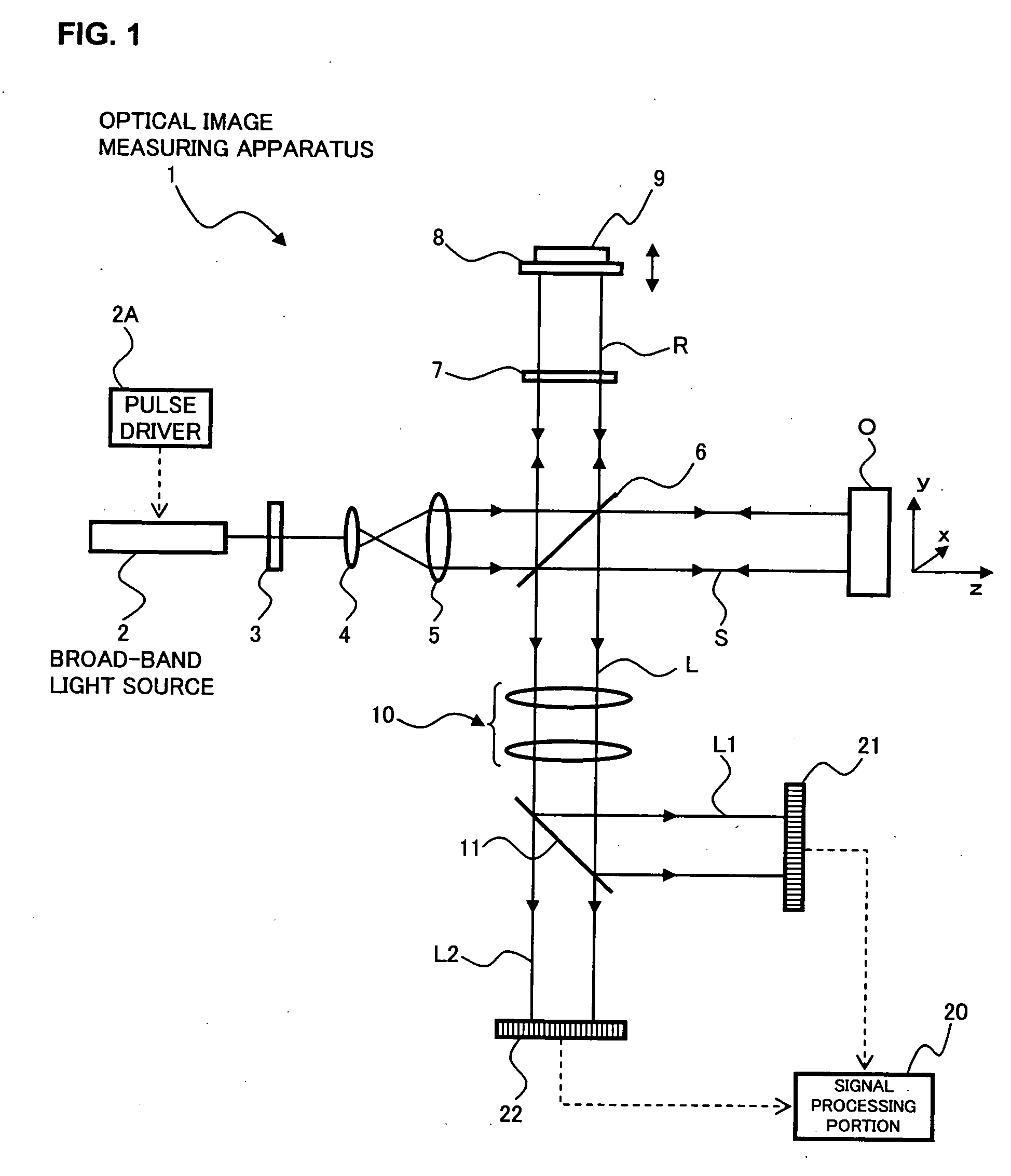

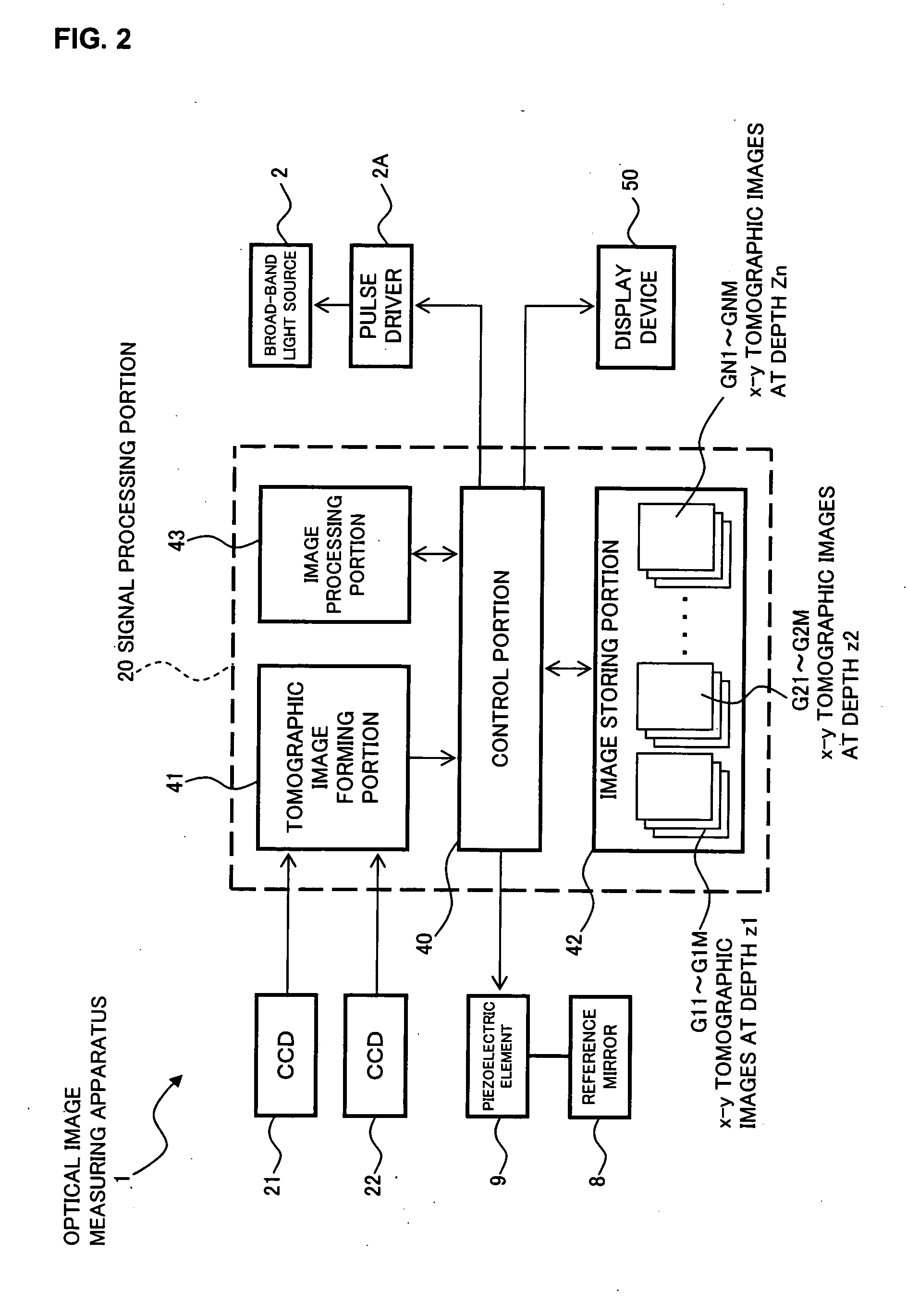

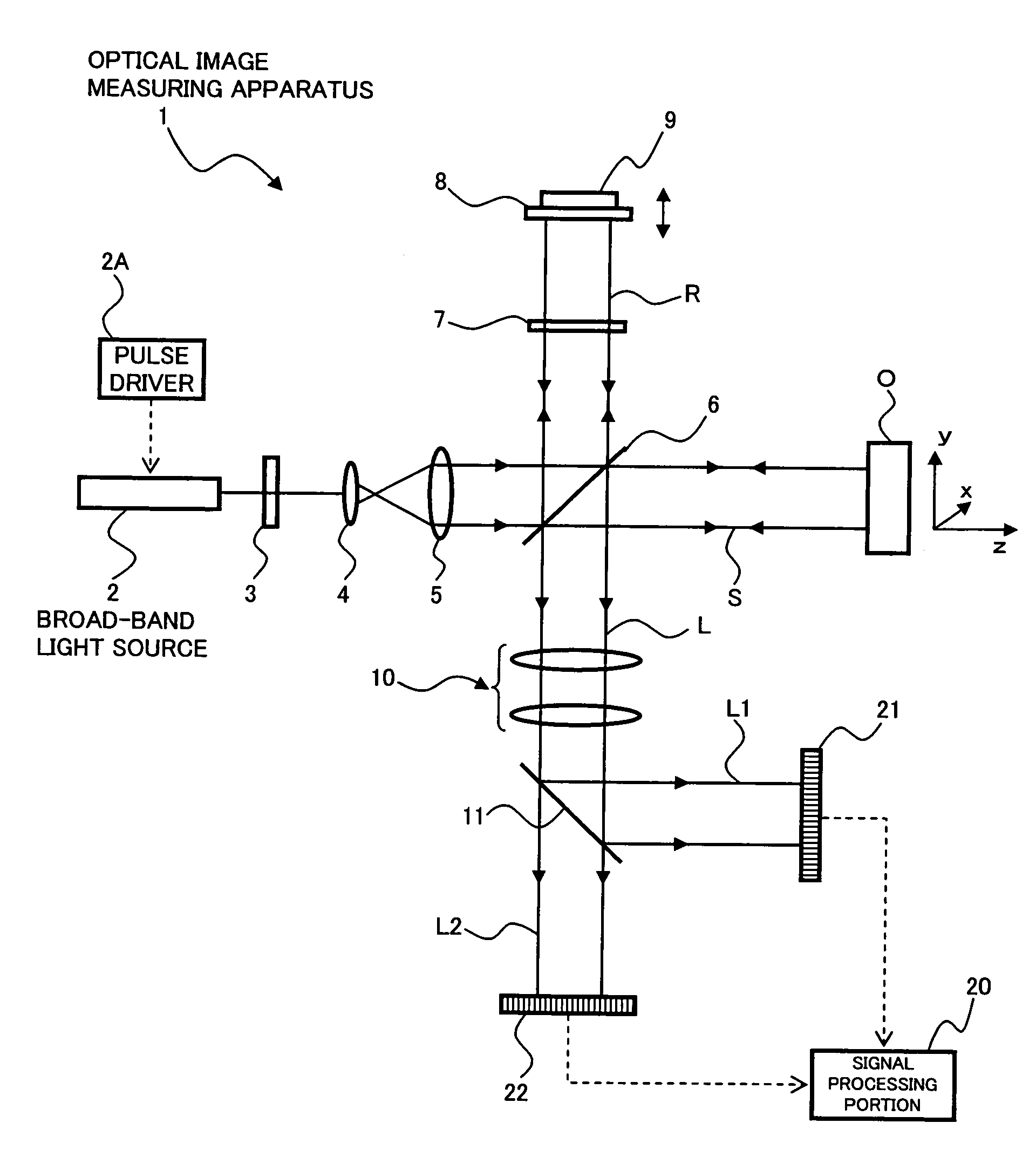

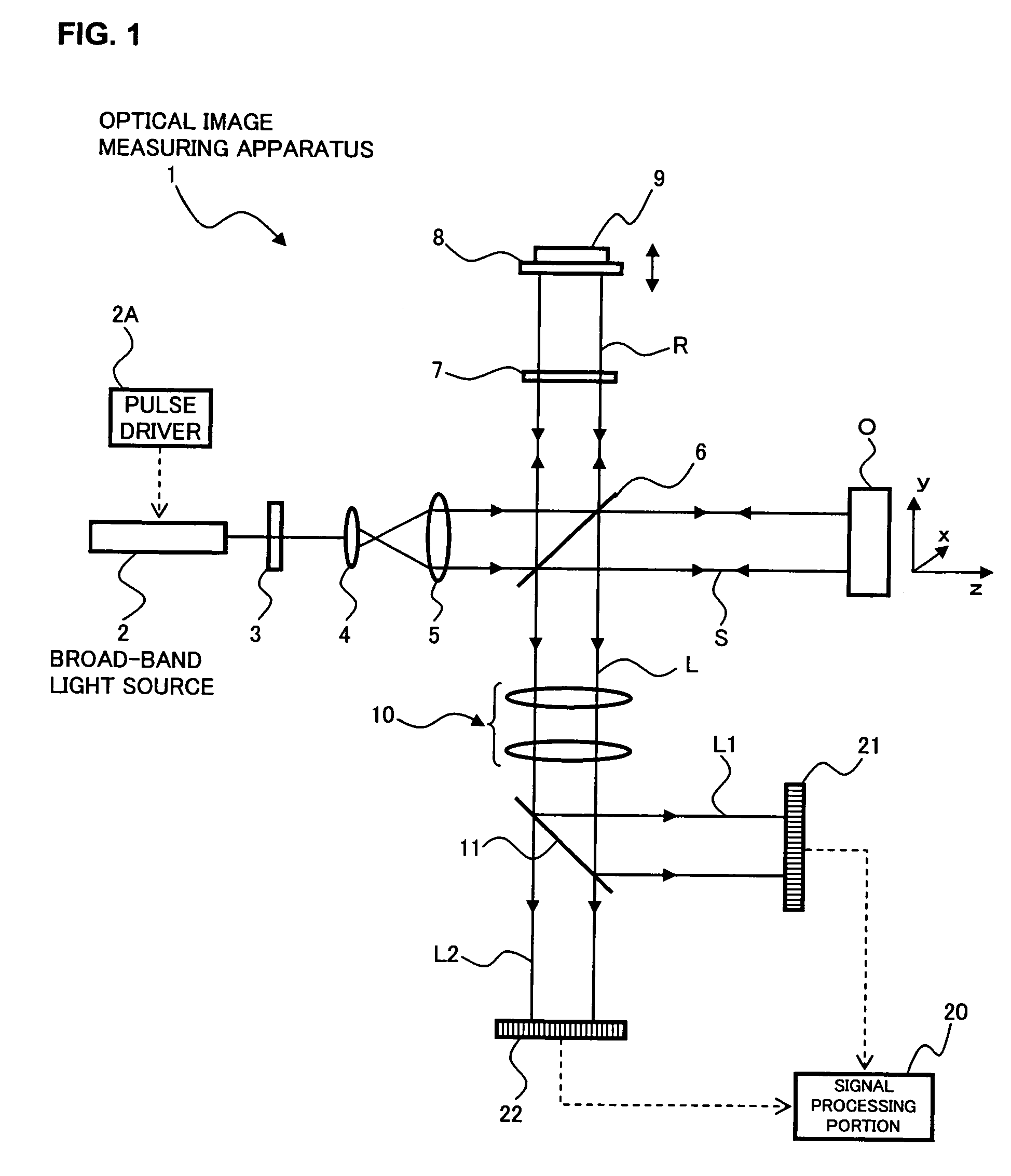

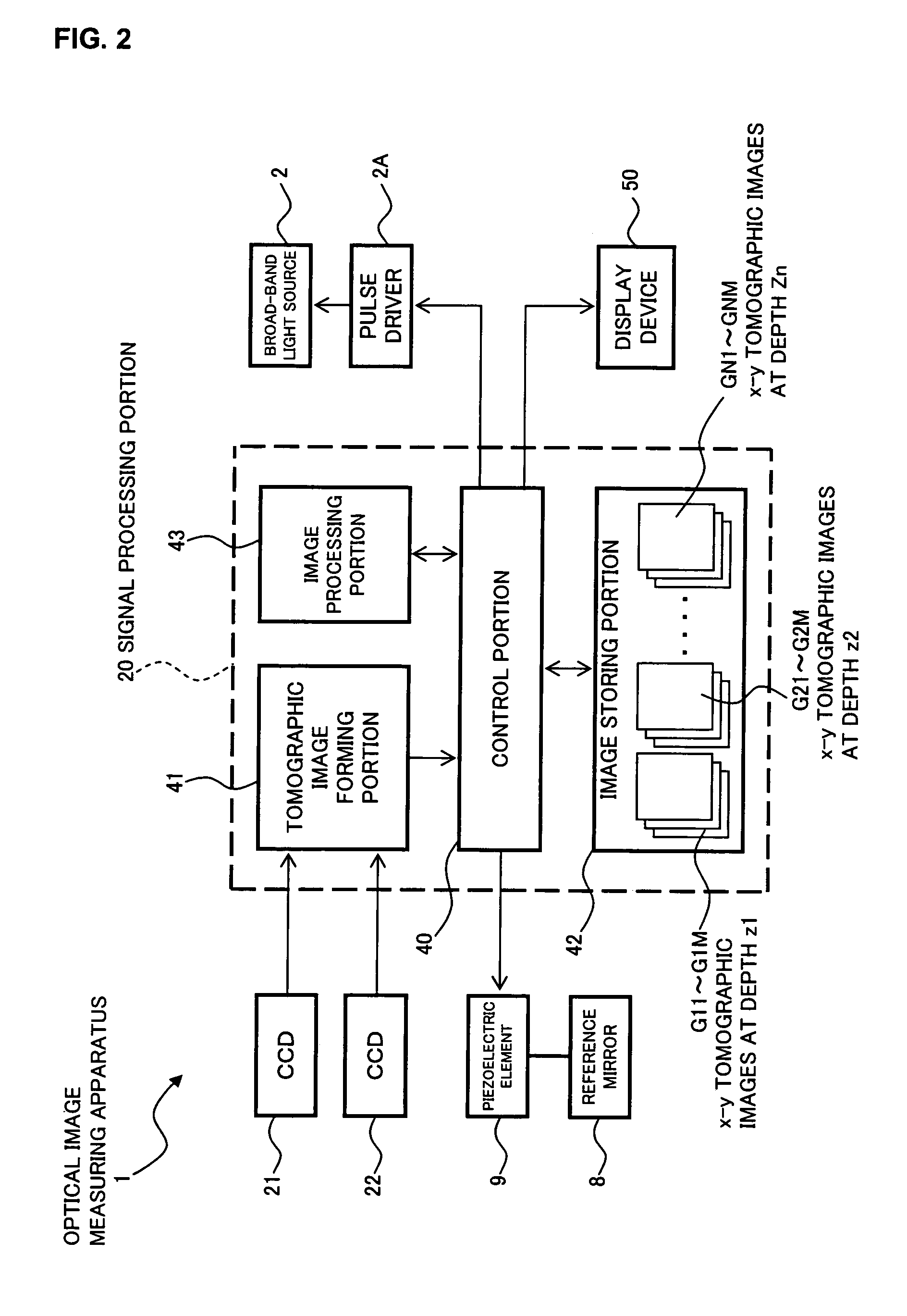

Optical image measuring apparatus and optical image measuring method

InactiveUS20060100528A1Efficient measurementDiagnostics using lightInterferometersSignal lightIntensity modulation

Provided is an optical image measuring apparatus capable of speedily measuring a velocity distribution image of a moving matter. Including a broad-band light source, means for increasing a beam diameter, a polarizing plate converting the light beam to linearly polarized light, and a half mirror, a wavelength plate converting the reference light to circularly polarized light, the half mirror superimposing the signal light whose frequency is partially shifted by the moving matter in the object and the reference light is circularly polarized light to produce superimposed light including interference light, CCDs for receiving different polarized light components of the interference light, and outputting detection signals including interference frequency components corresponding to beat frequencies of the interference light, and a signal processing portion for forming the velocity distribution image based on interference frequency component corresponding to a beat frequency equal to an intensity modulation frequency of the light beam.

Owner:KK TOPCON

Optical delivery systems and methods of providing adjustable beam diameter, spot size and/or spot shape

An optical device and method for varying an optical characteristic of an optical beam can include a plurality of optical fibers each having an input end, an output end, and a core, wherein each of the optical fibers has an effective area and a numerical aperture, and a beam-deviating component for moving at least one of the optical fiber input ends and the optical beam relative to each other such that the optical beam selectively enters the input ends one at a time and is transmitted out the output ends one at a time, wherein at least one of the effective areas and the numerical apertures varies among the plurality of optical fibers such that the optical beam transmitted out of the output ends has a varying optical characteristic.

Owner:IRIDEX CORP

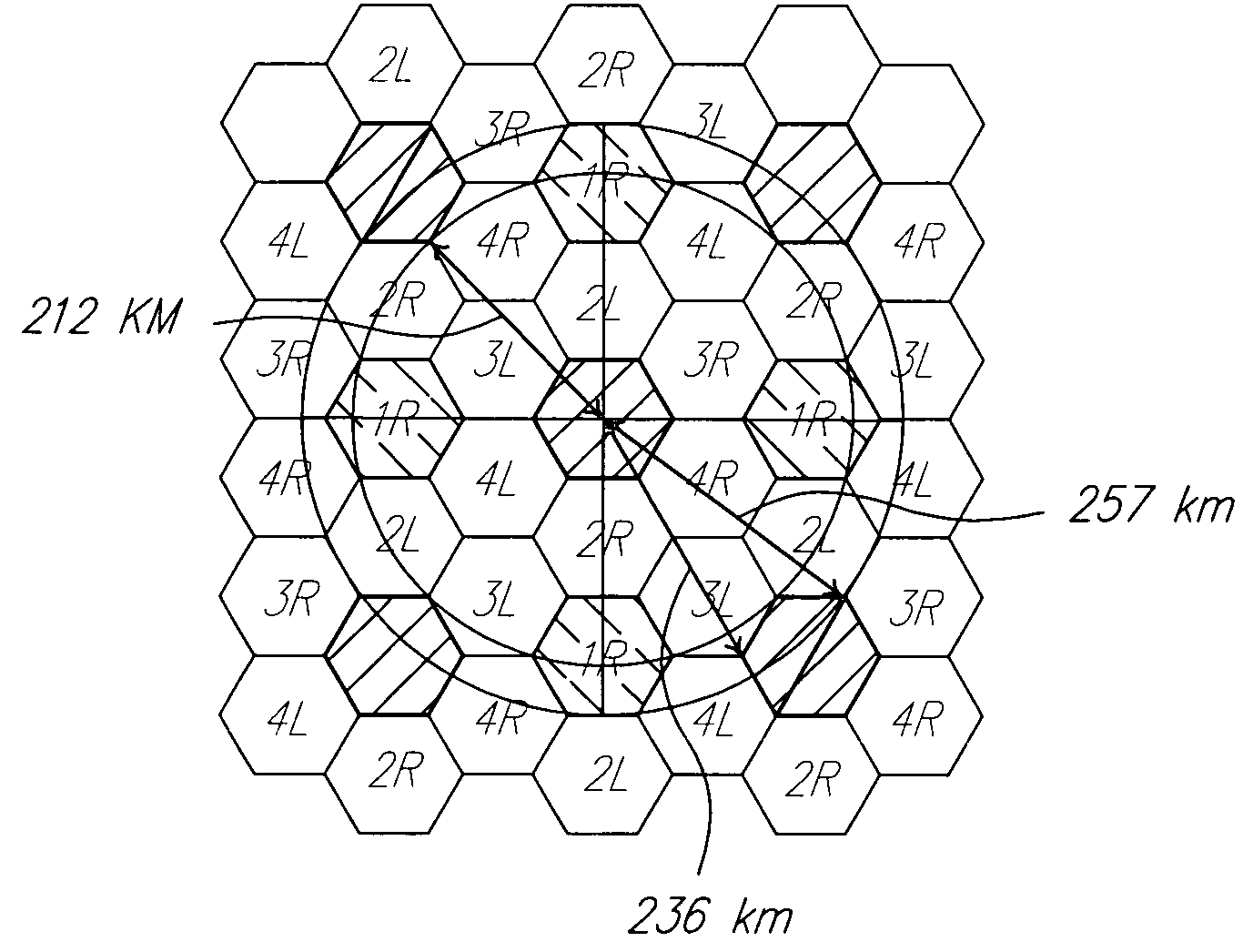

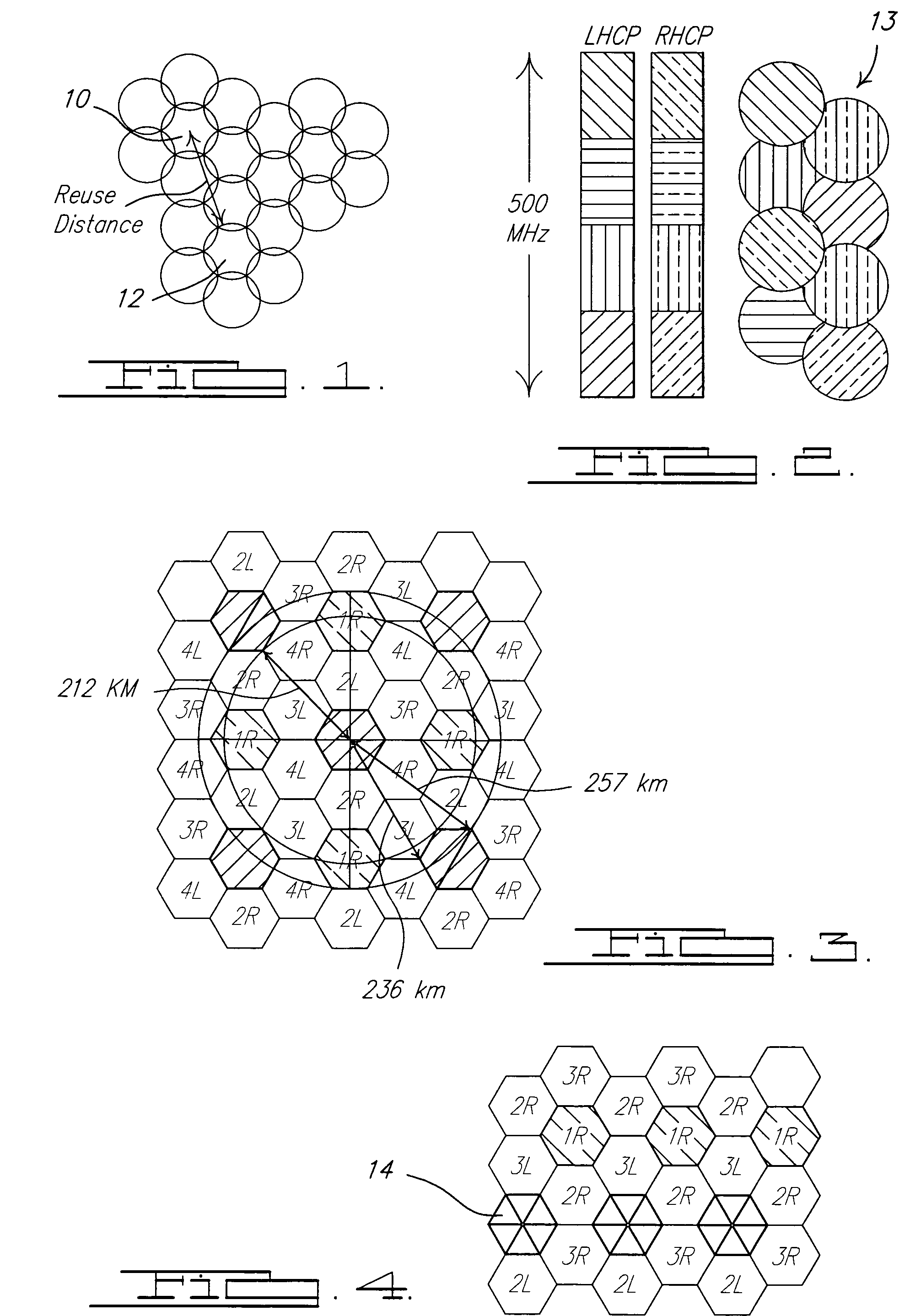

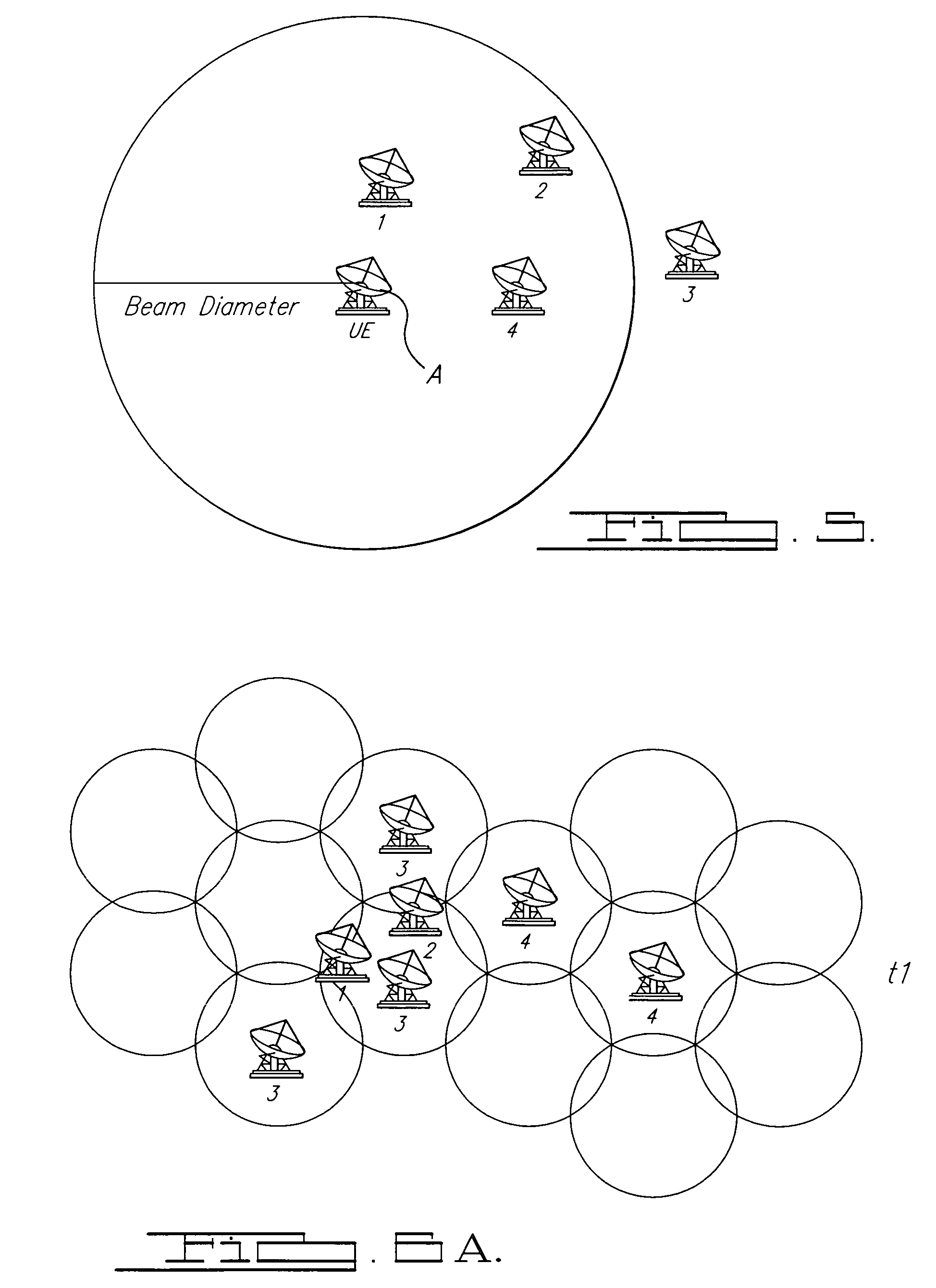

Managing satellite fixed beam uplink using virtual channel assignments

ActiveUS6993288B2Frequency-division multiplex detailsTime-division multiplexTelecommunicationsFrequency reuse

A method of coordinating communications between ground stations and fixed beam satellites is provided, wherein each beam of a satellite antenna is assigned a color to create a color pattern that matches a frequency reuse pattern for the antenna, thereby using the same frequencies in a different beam with the same color. In operation, a ground station requests a virtual channel number from a resource manager, which sends a virtual channel number that is not used by another ground station within a beam diameter of the requesting ground station. The ground station then determines the position of the satellite, the beam and beam color, and further computes the frequency, polarization, and time slot, among other information, to communicate with the satellite. A method is also provided for managing virtual channels that comprises a network manager that groups ground stations and limits the number of virtual channels per group.

Owner:THE BOEING CO

Method and apparatus for controlling the size of a laser beam focal spot

A method and apparatus is described that allows the width of fine line structures ablated or cured by a focussed laser beam on the surface of flat substrates to be dynamically changed while the beam is in motion over the substrate surface while simultaneously maintaining the beam focal point accurately on the surface. A three-component variable optical telescope is used to independently control the beam diameter and collimation by movement of first and second optical components relative to the third optical component. The method allows different focal spot diameters and different ablated or cured line widths to be rapidly selected and ensures that the beam shape in the focal spot remains constant and the depth of focus is always maximized.

Owner:盈天实业(深圳)有限公司

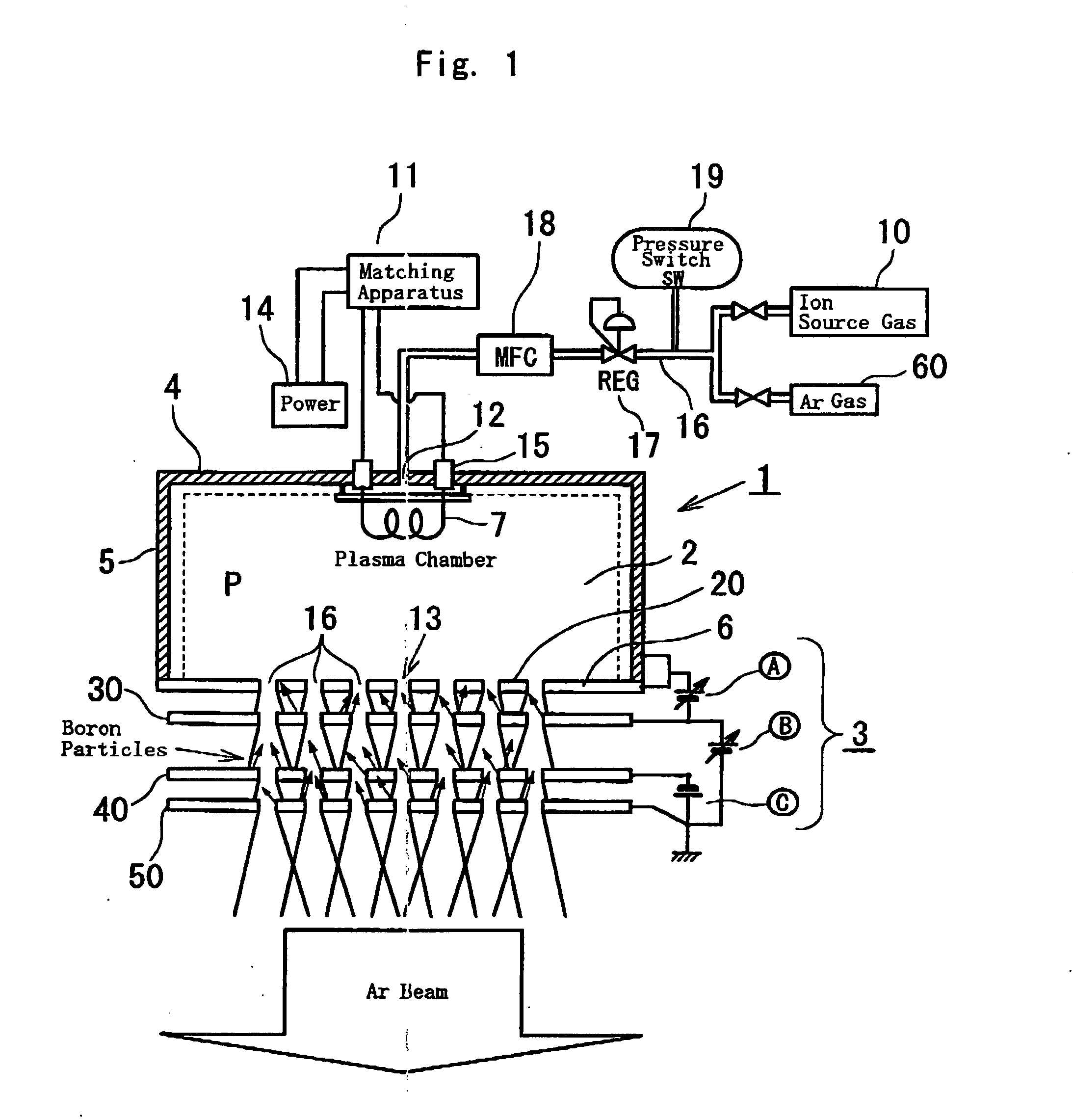

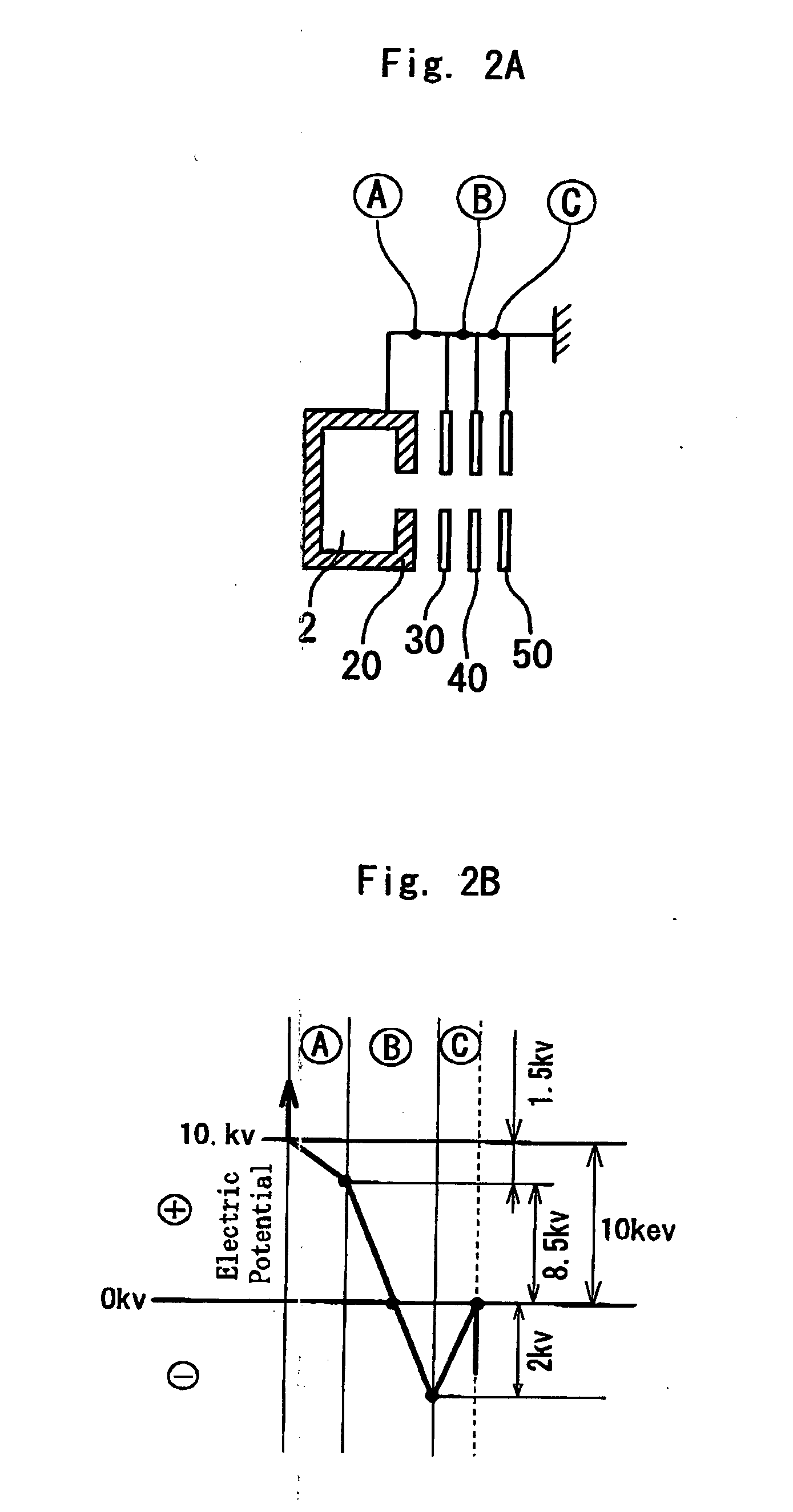

Ion source apparatus and cleaning optimized method thereof

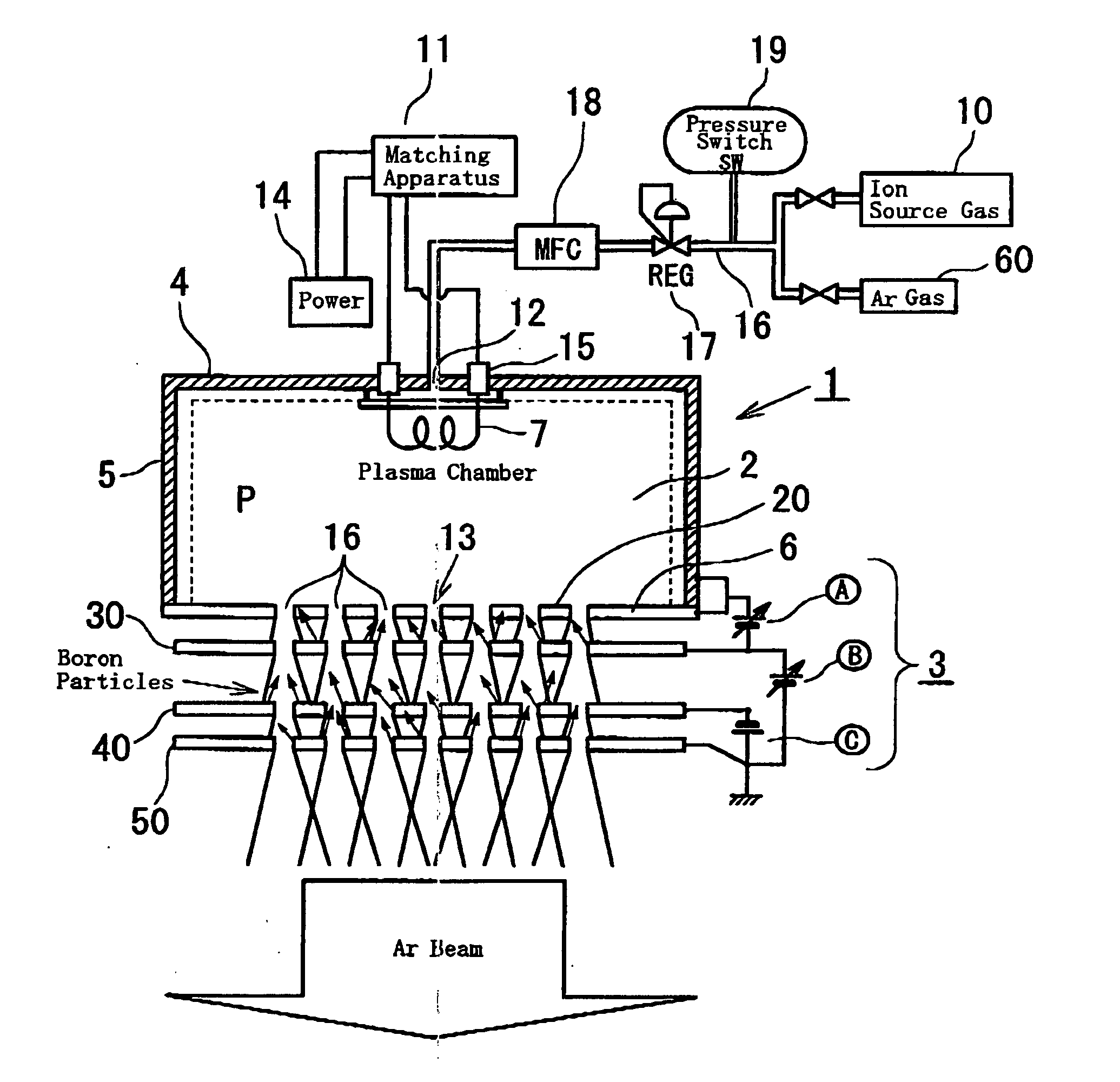

InactiveUS20050016838A1Optimized diameterIncreased durabilityCellsVacuum evaporation coatingNoble gasInsulation layer

An ion source apparatus includes a rare gas supply source supplying rare gas instead of ion source gas to a plasma chamber, means to determine time and timing for cleaning electrodes in consideration of a collecting amount of insulation layers accreting to the electrodes of an extraction electrode system. Based on the above, the ion source apparatus removes the insulation layers by sputtering with ion beam of the rare gas while adjusting extraction or accelerate voltage and supply amount of the rare gas as a setting parameter. Moreover, by adjusting the setting parameter which changes a diameter of ion beam based on the rare gas when the ion beam collides onto each electrode surface of the extraction electrode system, the beam diameter is focused within an effective range in which intension of the sputtering of the insulation layers is maximized thus evenly removing the insulation layers.

Owner:SEN CORP AN SHI & AXCELIS

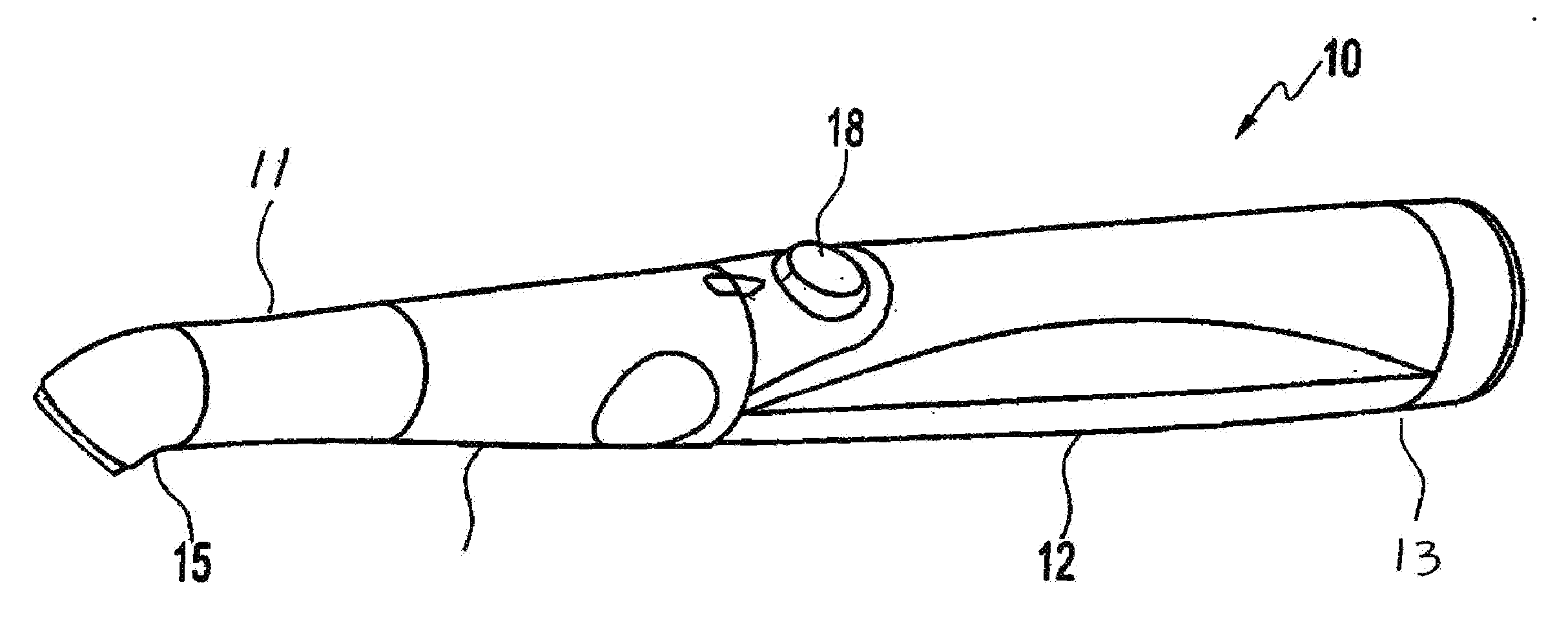

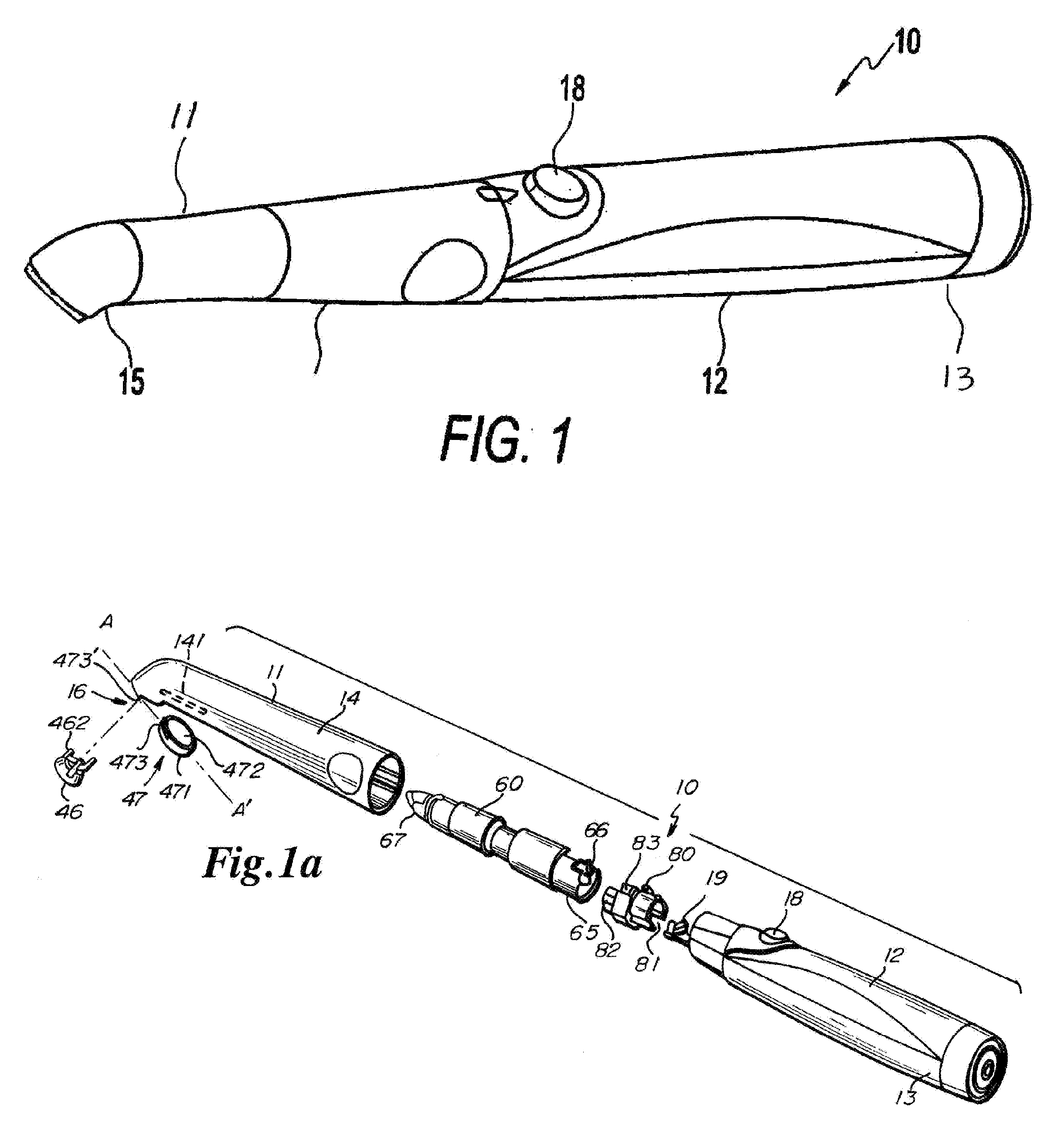

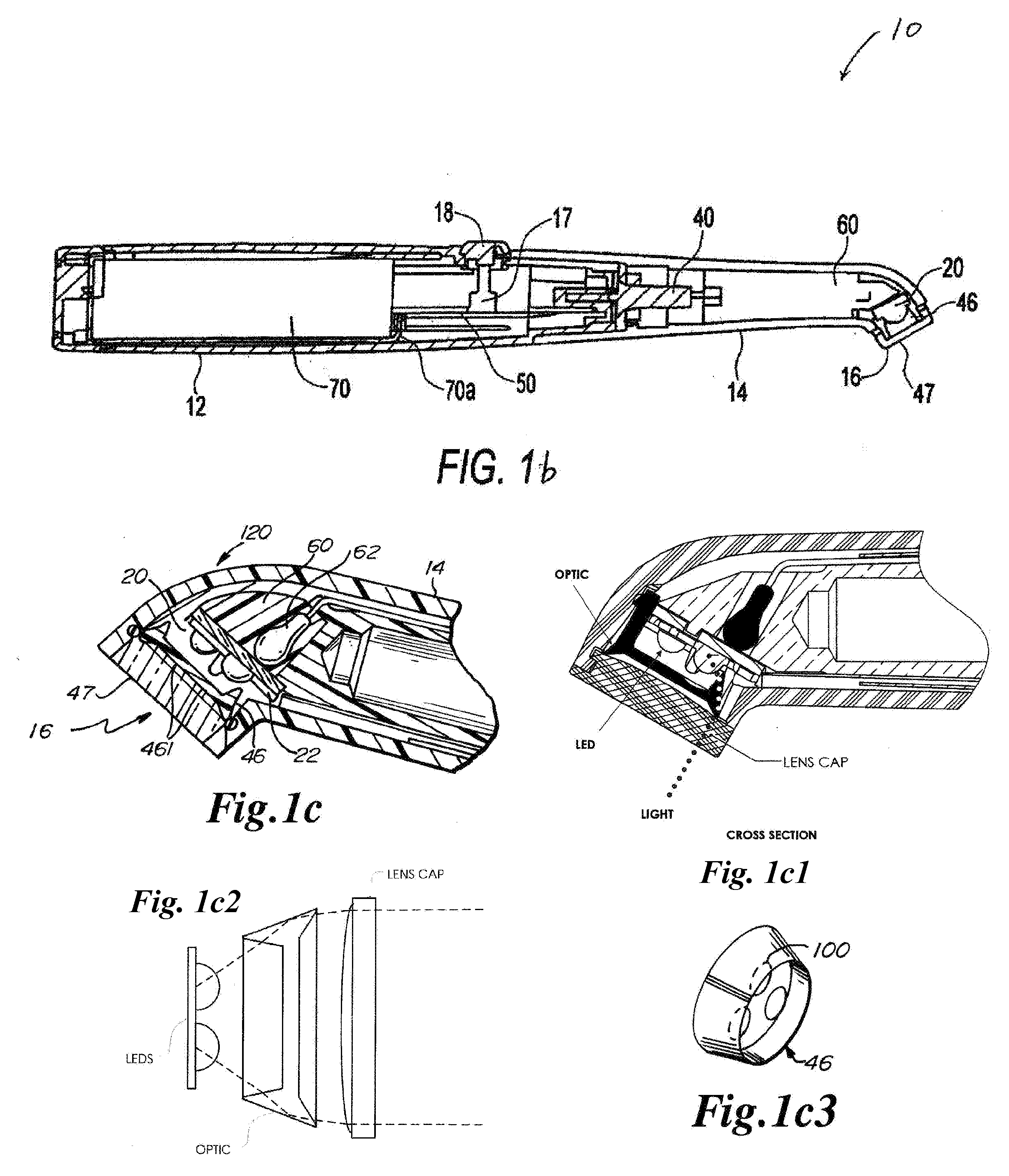

Curing Light

InactiveUS20090208894A1Large effective beam diameterSlow fall offDental toolsLight therapyCamera lensBeam diameter

The present invention relates to curing light devices for use in dentistry. Specifically, this invention relates to curing light devices generating convergent and uniform light with high intensity. The curing light device has a handle portion and a front portion wherein a light module is located in a desirable position in the interior of the front portion. The light module may include a light source comprising at least three LEDs in a compact manner, an optical element adapted to direct and / or focus the LEDs, and a lens cap to protect the LEDs and the optical elements. The lens cap may include a peripheral groove extending more than half of the periphery of the lens cap, which provides a longer engagement portion and thus a more secured attachment when “over-centeredly” engaging with a receiving edge on the light emitting end. A substantially precise alignment is achieved between the LEDs and corresponding lenses on the optical element to minimize heat dissipation and to increase the runtime and intensity of the curing light device. The curing light has an effective beam diameter of at least about 9 mm with output homogeneity of up to about 6 mm away from the emitting end.

Owner:DEN MAT HLDG

Optical image measuring apparatus and optical image measuring method for forming a velocity distribution image expressing a moving velocity distribution of the moving matter

InactiveUS7345770B2Efficient measurementDiagnostics using lightInterferometersSignal lightIntensity modulation

Owner:KK TOPCON

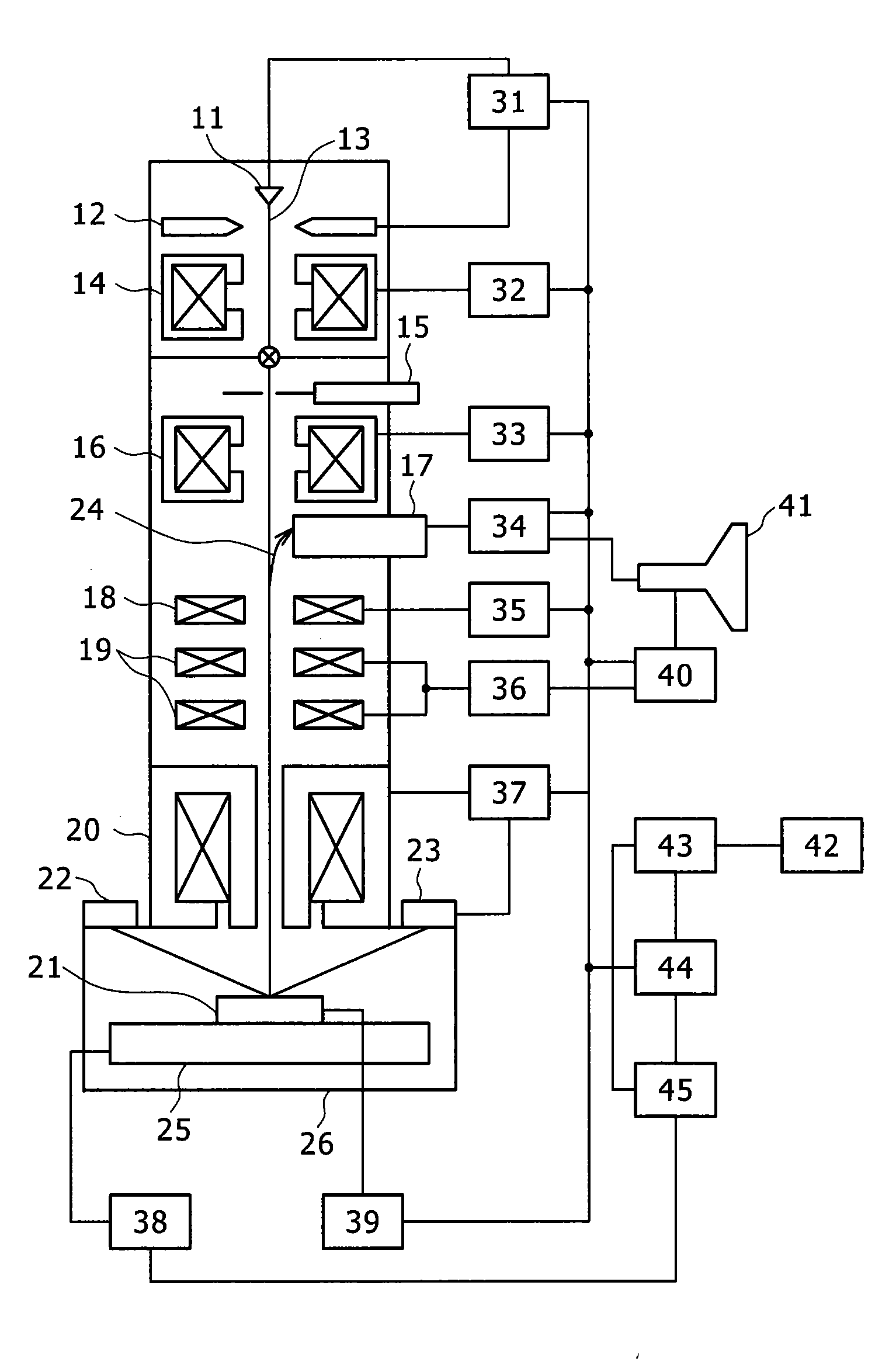

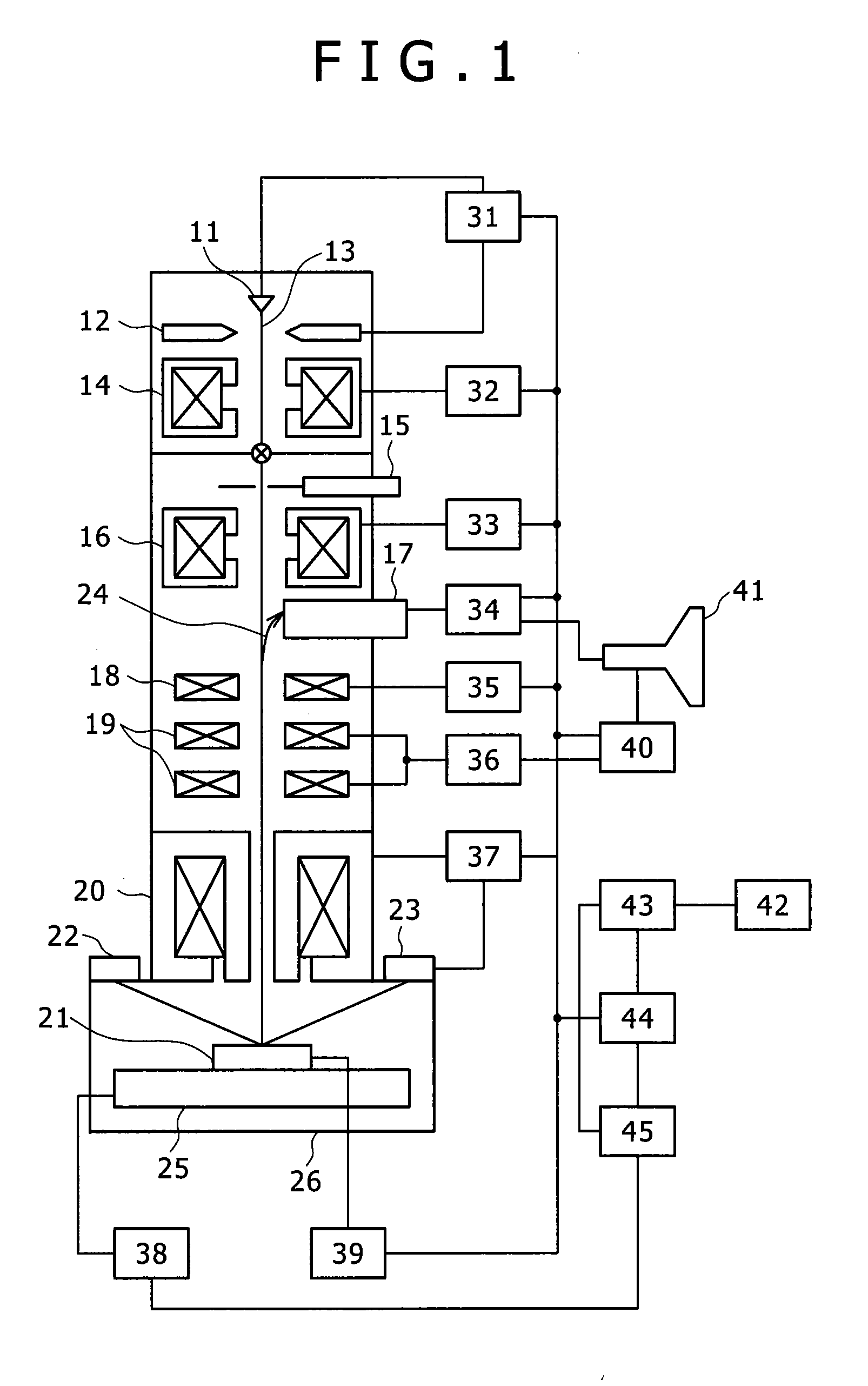

Method for inspecting and measuring sample and scanning electron microscope

ActiveUS20090084954A1Improve spatial resolutionInhibition of variationMaterial analysis using wave/particle radiationElectric discharge tubesScanning tunneling microscopeBeam diameter

As an aspect for realizing accurate observation, inspection, or measurement of the contact hole with large aspect ratio, a method and a device to scan a second electron beam after scanning a first electron beam to a sample to charge the sample are proposed wherein the beam diameter of the first electron beam is made larger than the beam diameter of the second electron beam.

Owner:HITACHI HIGH-TECH CORP

Multiphoton-excitation observation apparatus

The invention provides a multiphoton-excitation observation apparatus comprising a light-source unit for emitting pulsed laser light; an observation apparatus main unit for irradiating a specimen with laser light emitted from the light-source unit and observing fluorescence emitted from the specimen; an incidence adjusting device, disposed between the light-source unit and the observation apparatus main unit, for adjusting the beam diameter of the laser light emitted from the light-source unit; and a control apparatus for controlling the incidence-adjusting unit according to the depth of an observation plane in the specimen.

Owner:EVIDENT CORP

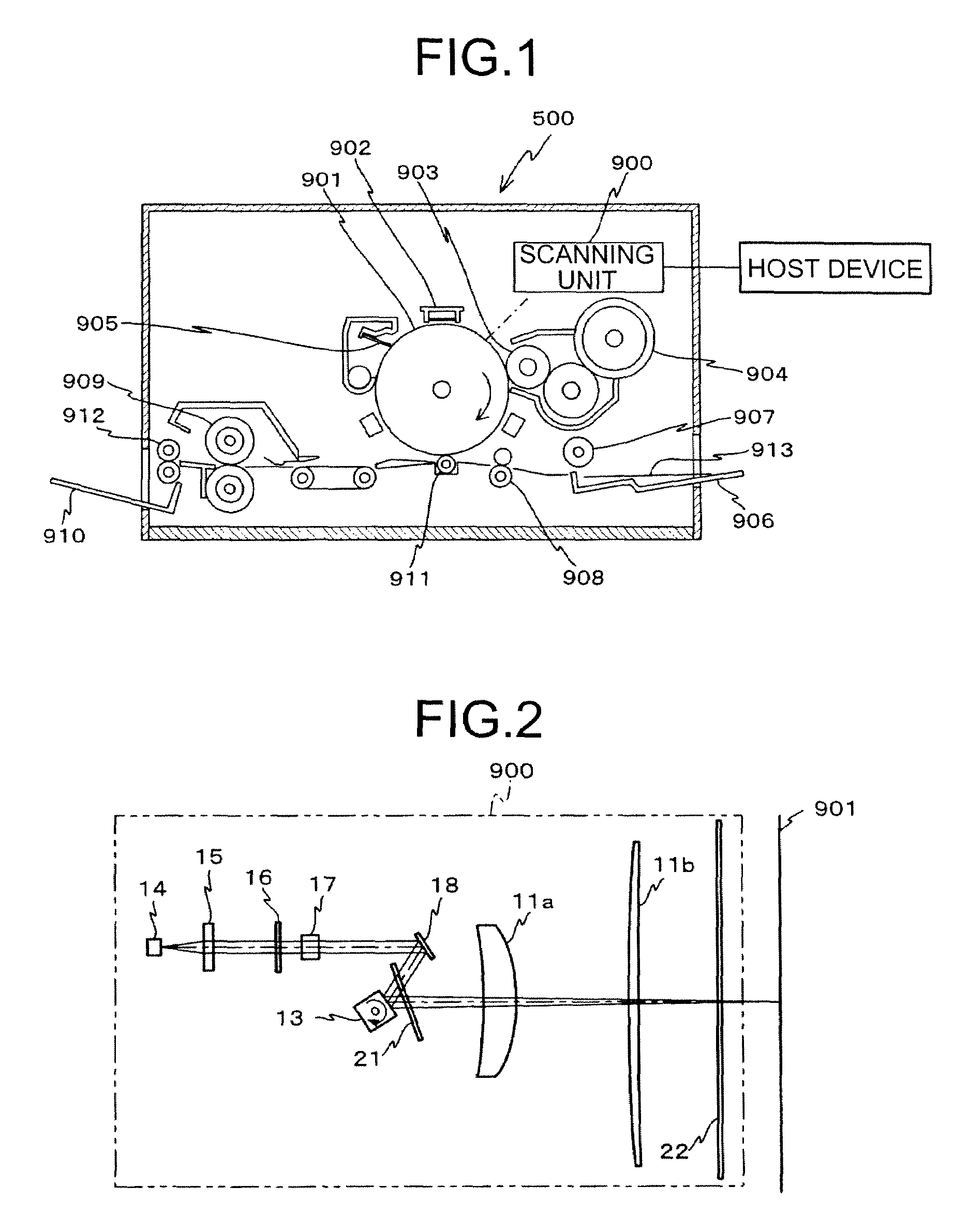

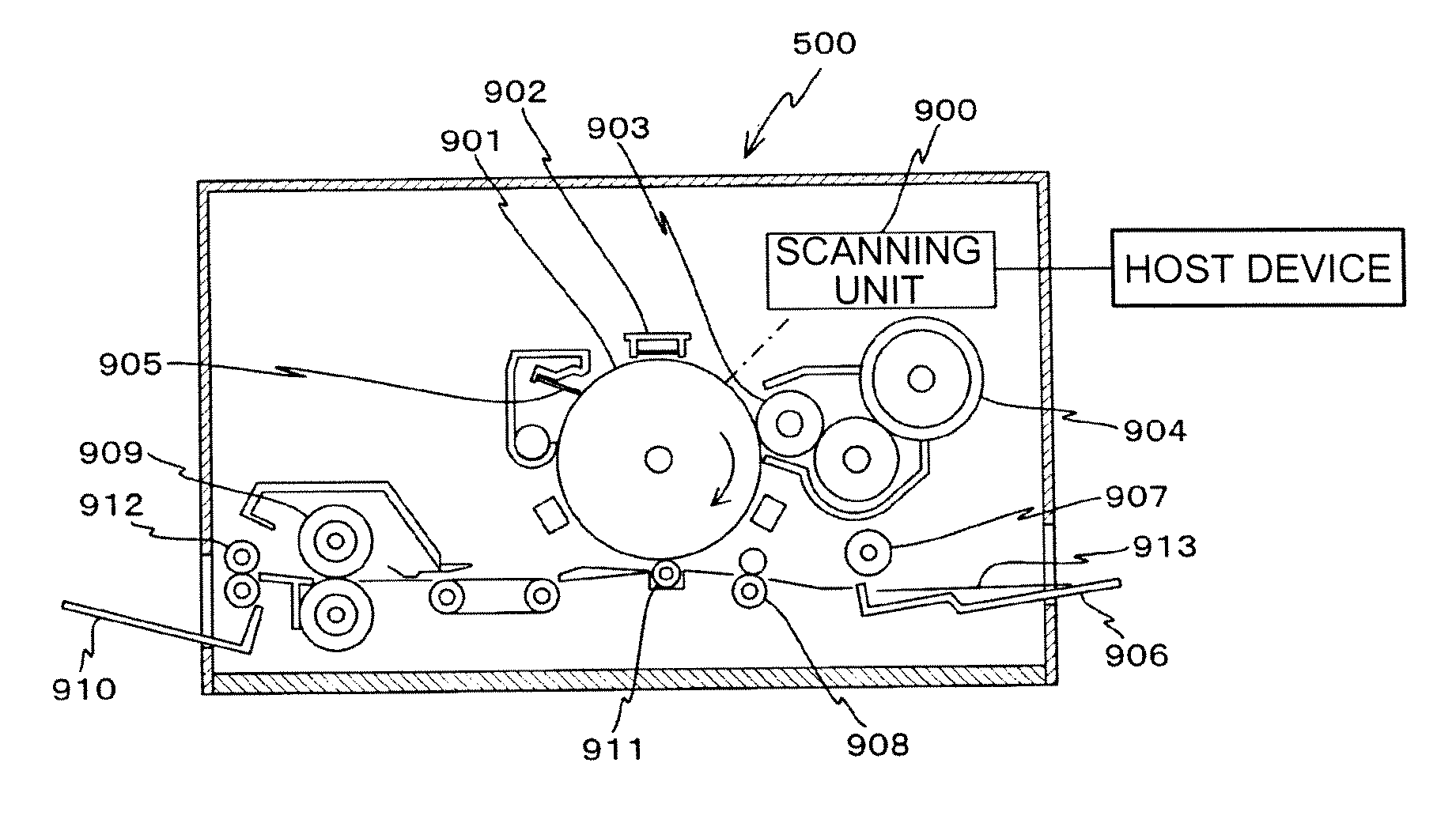

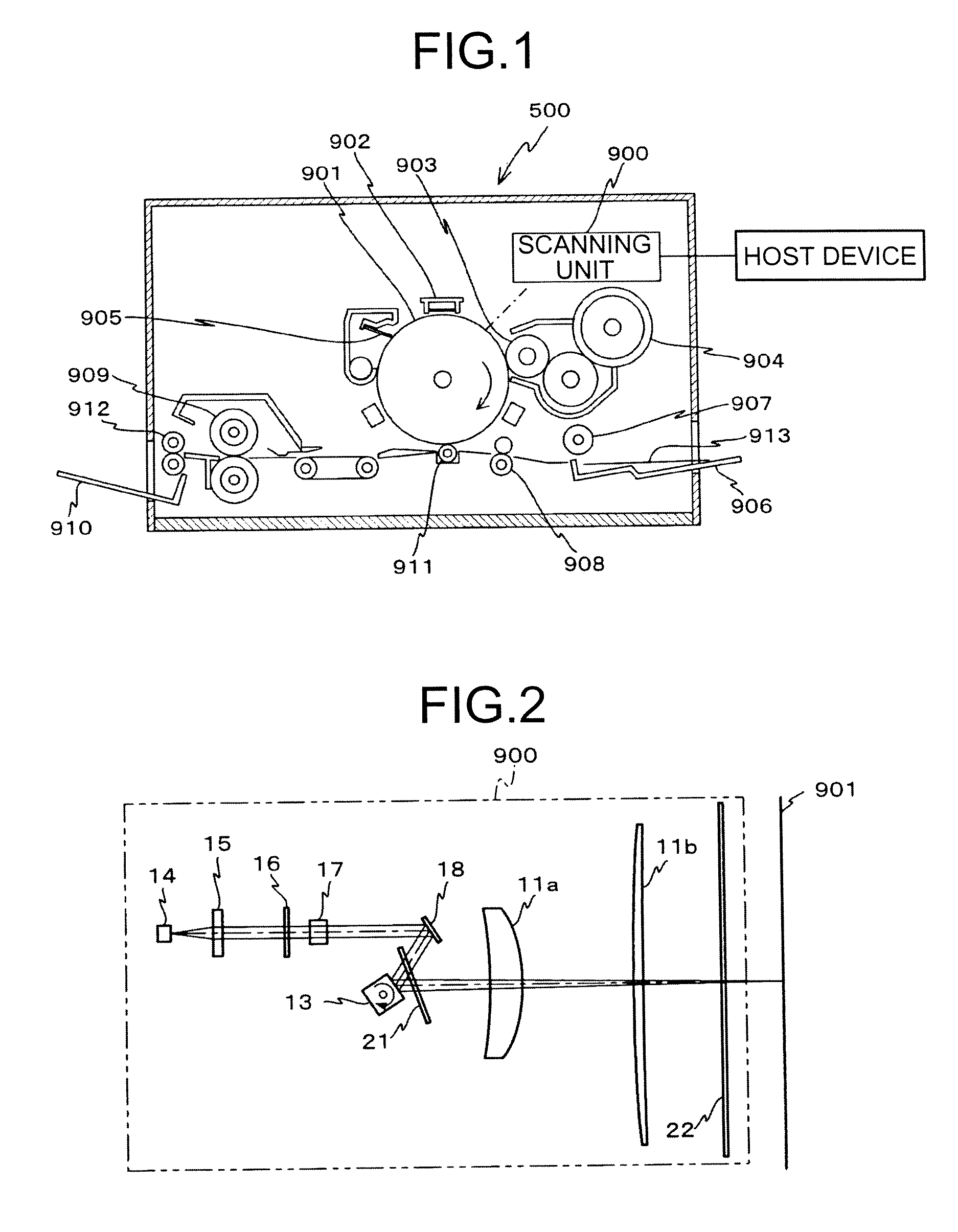

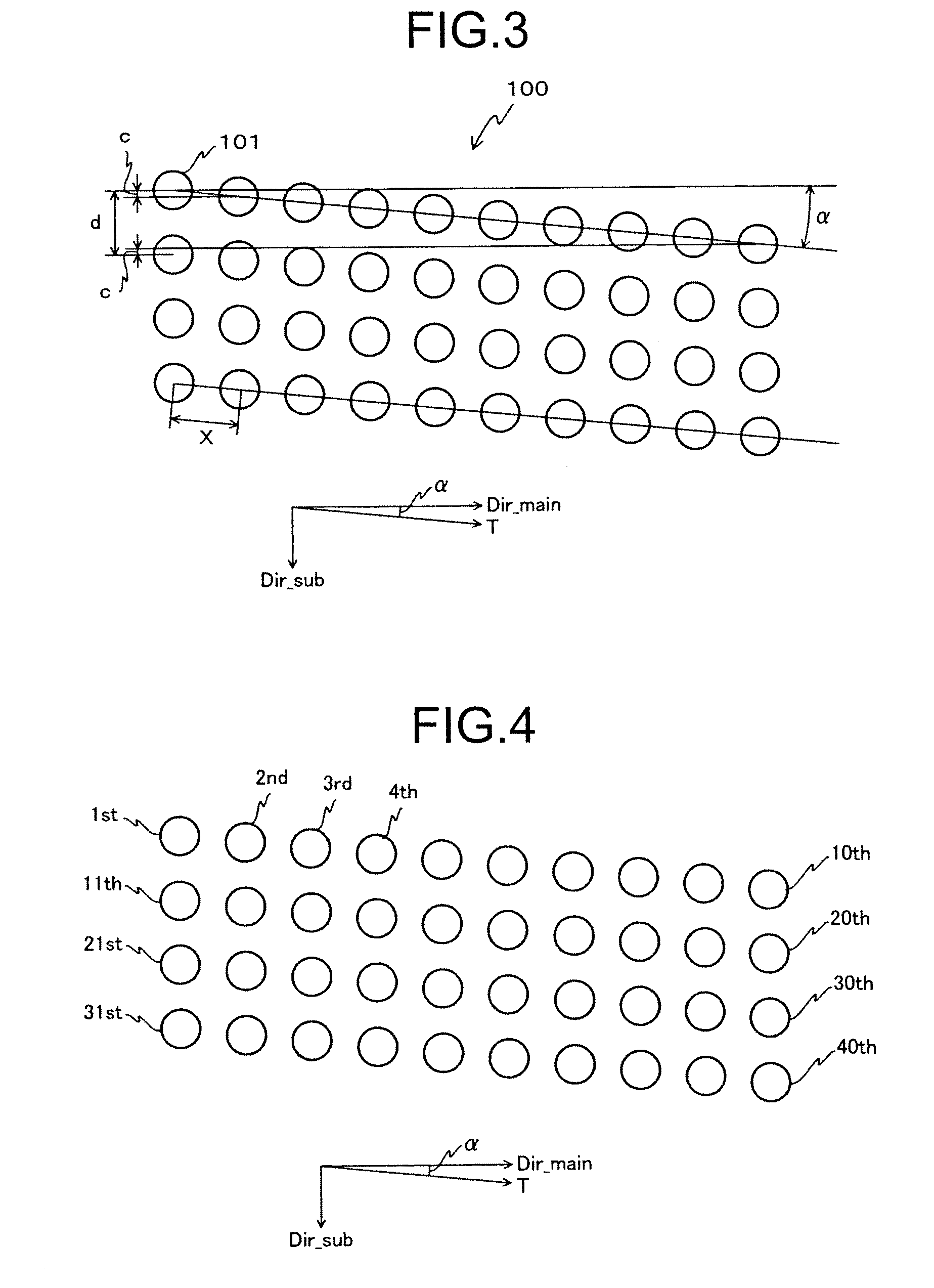

Scanning unit and image forming apparatus

A scanning optical system leads the light fluxes deflected by the polygon mirror to a photosensitive drum. An absolute value of a lateral magnification in a main scanning direction is larger than an absolute value of a lateral magnification in a sub-scanning direction. Moreover, a beam diameter in the sub-scanning direction on a surface of the photosensitive drum is equal to or smaller than a beam diameter in the main scanning direction and larger than a scan line interval.

Owner:RICOH KK

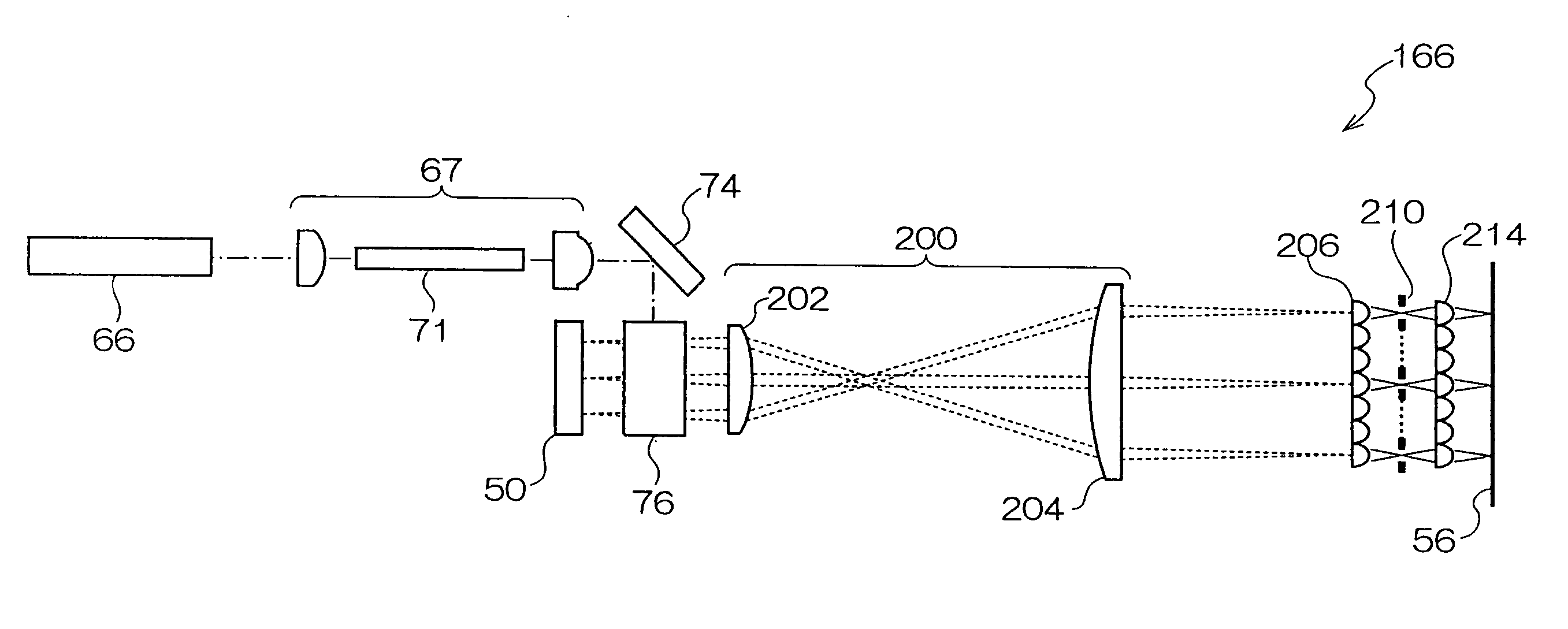

Method and apparatus for detecting defects

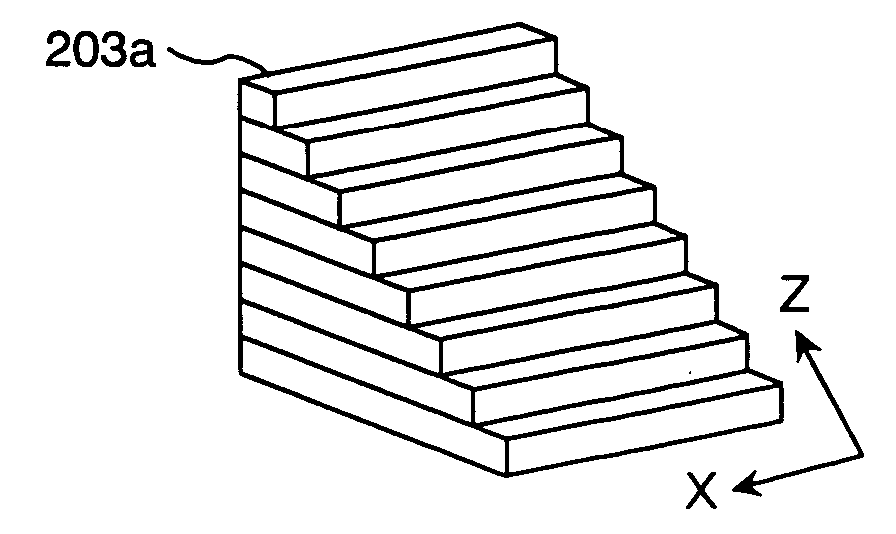

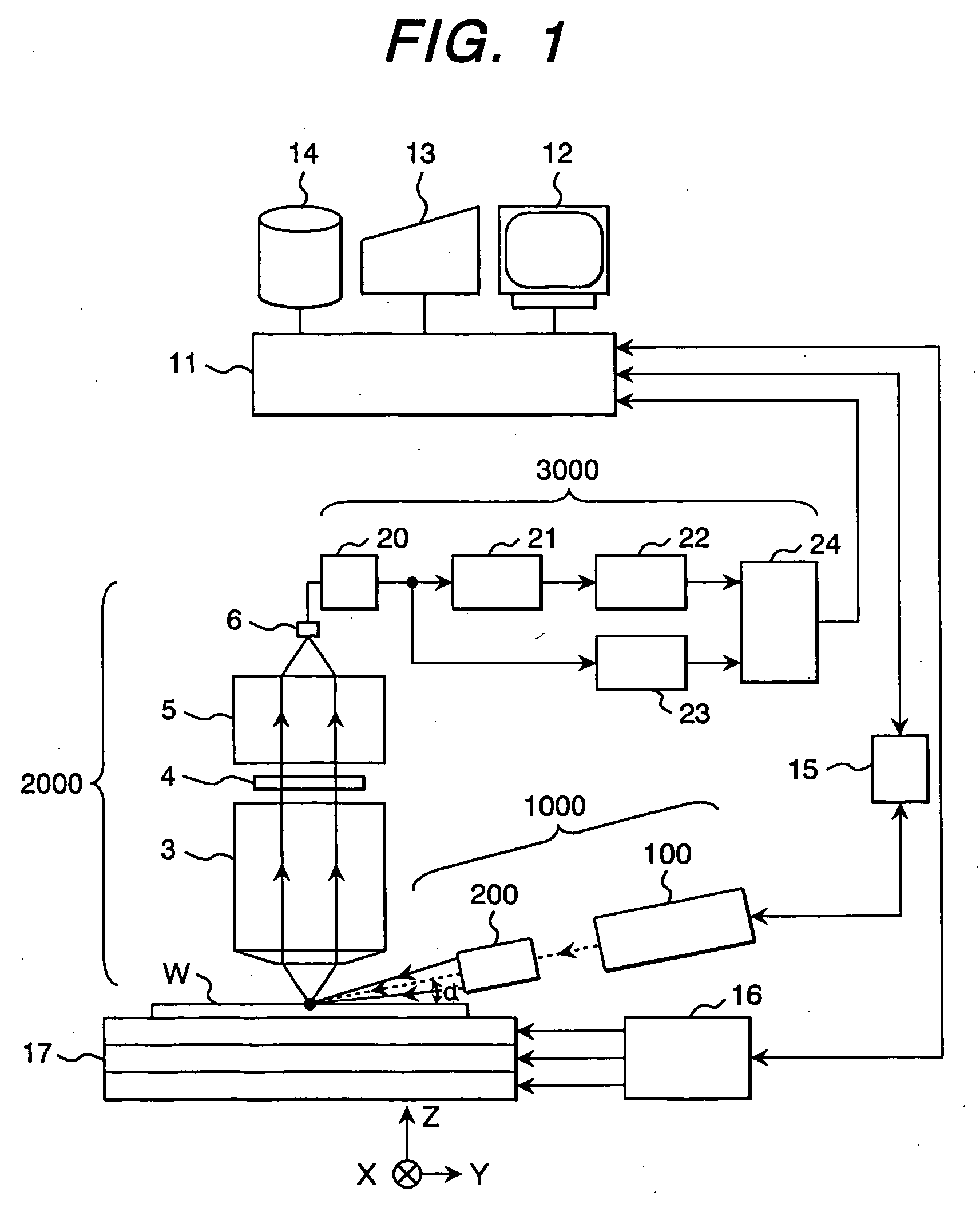

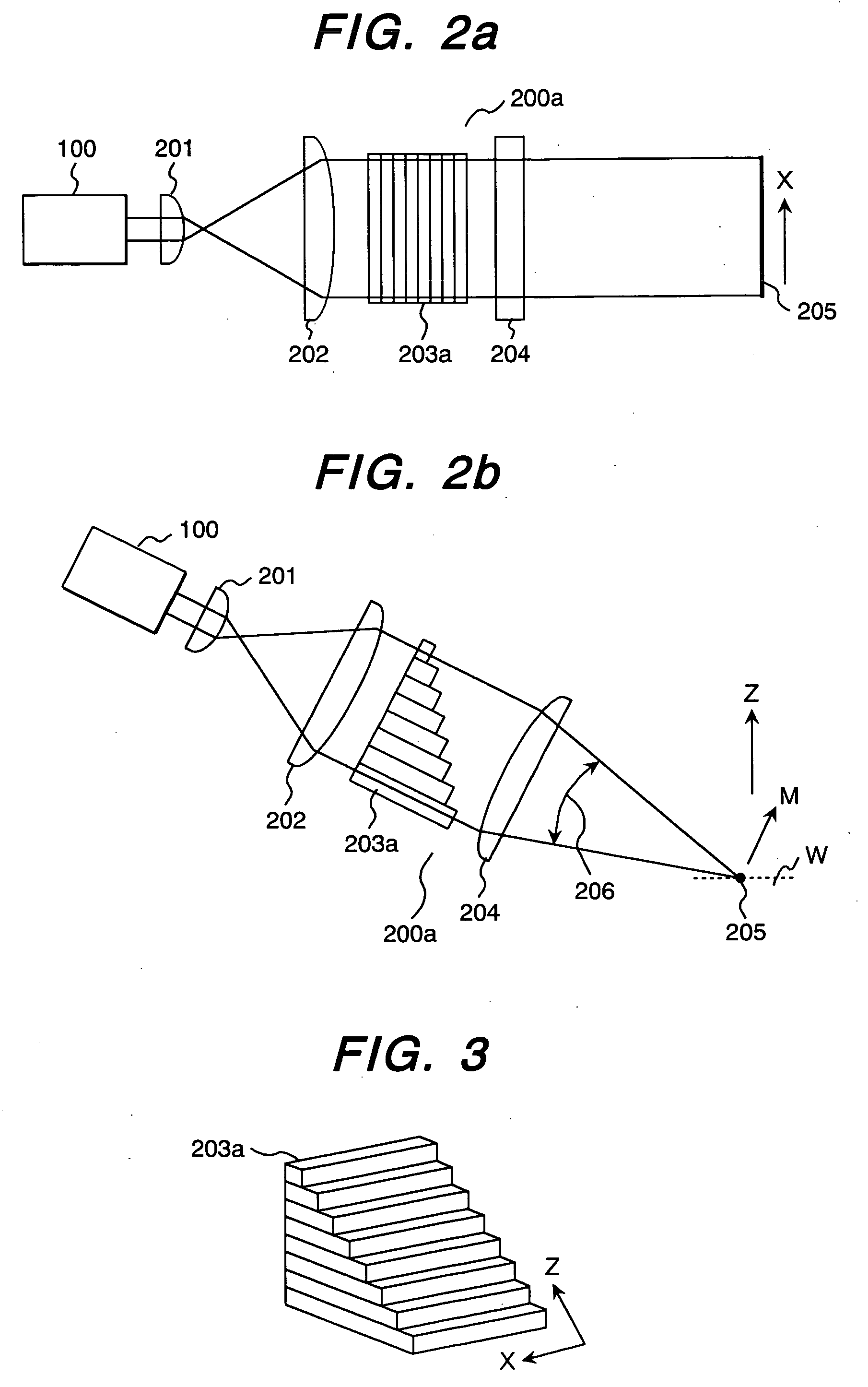

InactiveUS20050264797A1Enhance defect detection sensitivitySimple configurationSemiconductor/solid-state device testing/measurementOptically investigating flaws/contaminationBeam expanderBeam diameter

The present invention relates to a defect detection apparatus and method by which foreign particles and circuit pattern defects can be detected in distinction from the edge roughness of wiring on the substrate. The defect detection apparatus comprises an irradiation optical system includes: a beam expander; an optical member group formed by stacking multiple plate-like optical members each having a different optical path length at least in a beam-converging direction in order to admit the laser beam with the beam diameter extended by the beam expander and emit multiple slit-like beams each spatially reduced in coherence in the beam-converging direction; and beam-converging optical system by which the multiple slit-like beams each emitted from the optical member group is converged into a slit-like beam in the beam-converging direction and the slit-like beam is irradiated from an oblique direction onto the surface of the subject.

Owner:HITACHI HIGH-TECH CORP

Scanning unit and image forming apparatus

A scanning optical system leads the light fluxes deflected by the polygon mirror to a photosensitive drum. An absolute value of a lateral magnification in a main scanning direction is larger than an absolute value of a lateral magnification in a sub-scanning direction. Moreover, a beam diameter in the sub-scanning direction on a surface of the photosensitive drum is equal to or smaller than a beam diameter in the main scanning direction and larger than a scan line interval.

Owner:RICOH KK

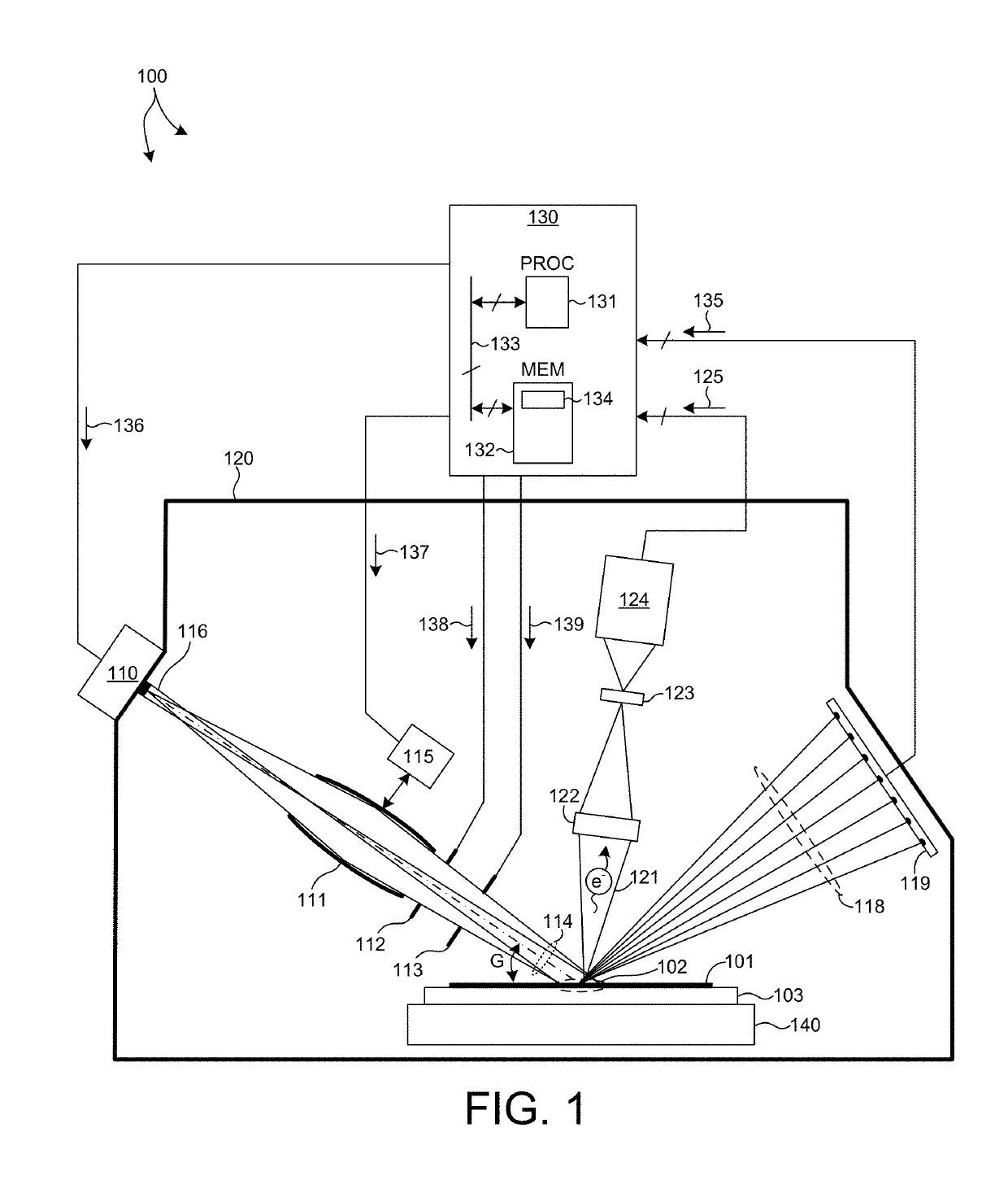

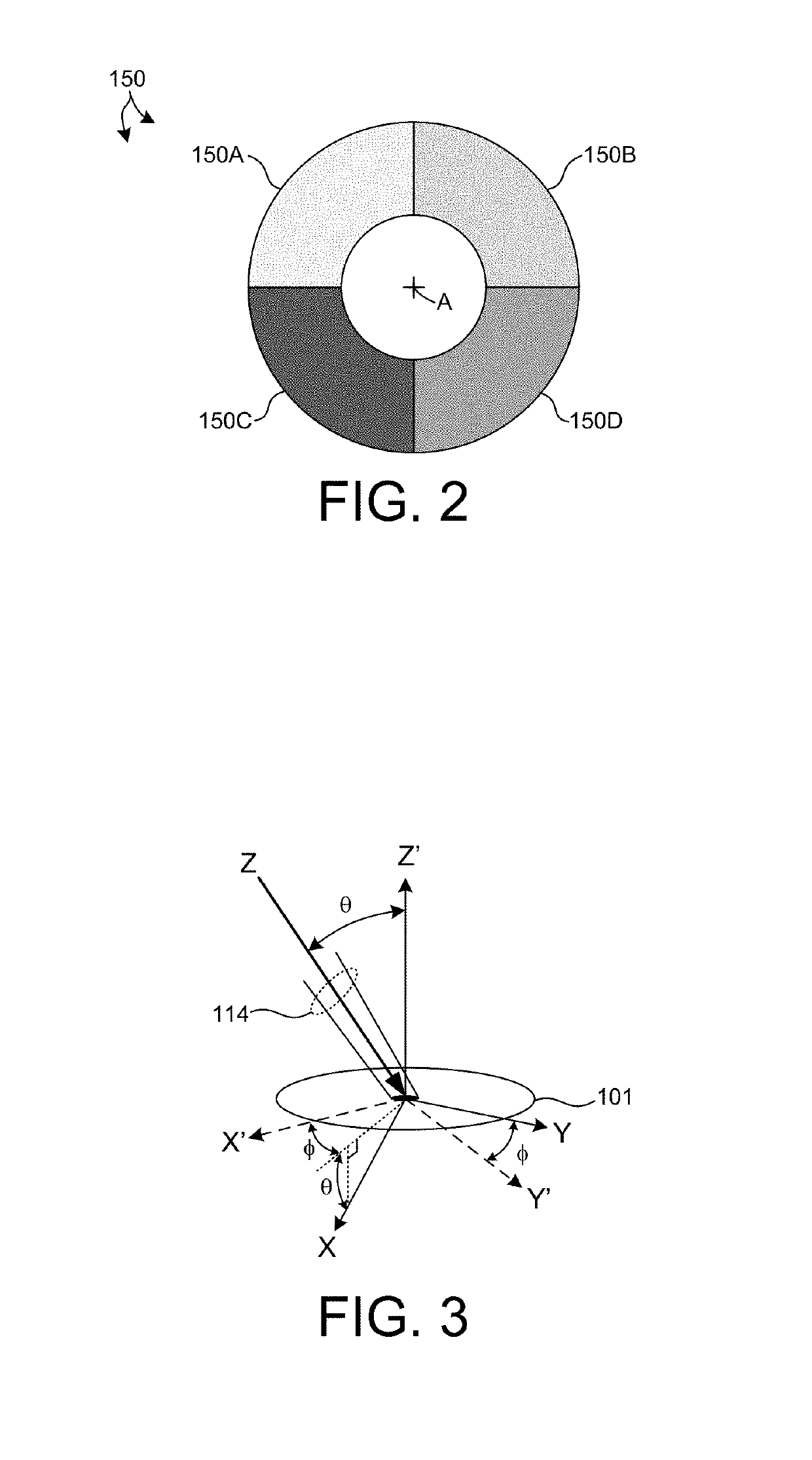

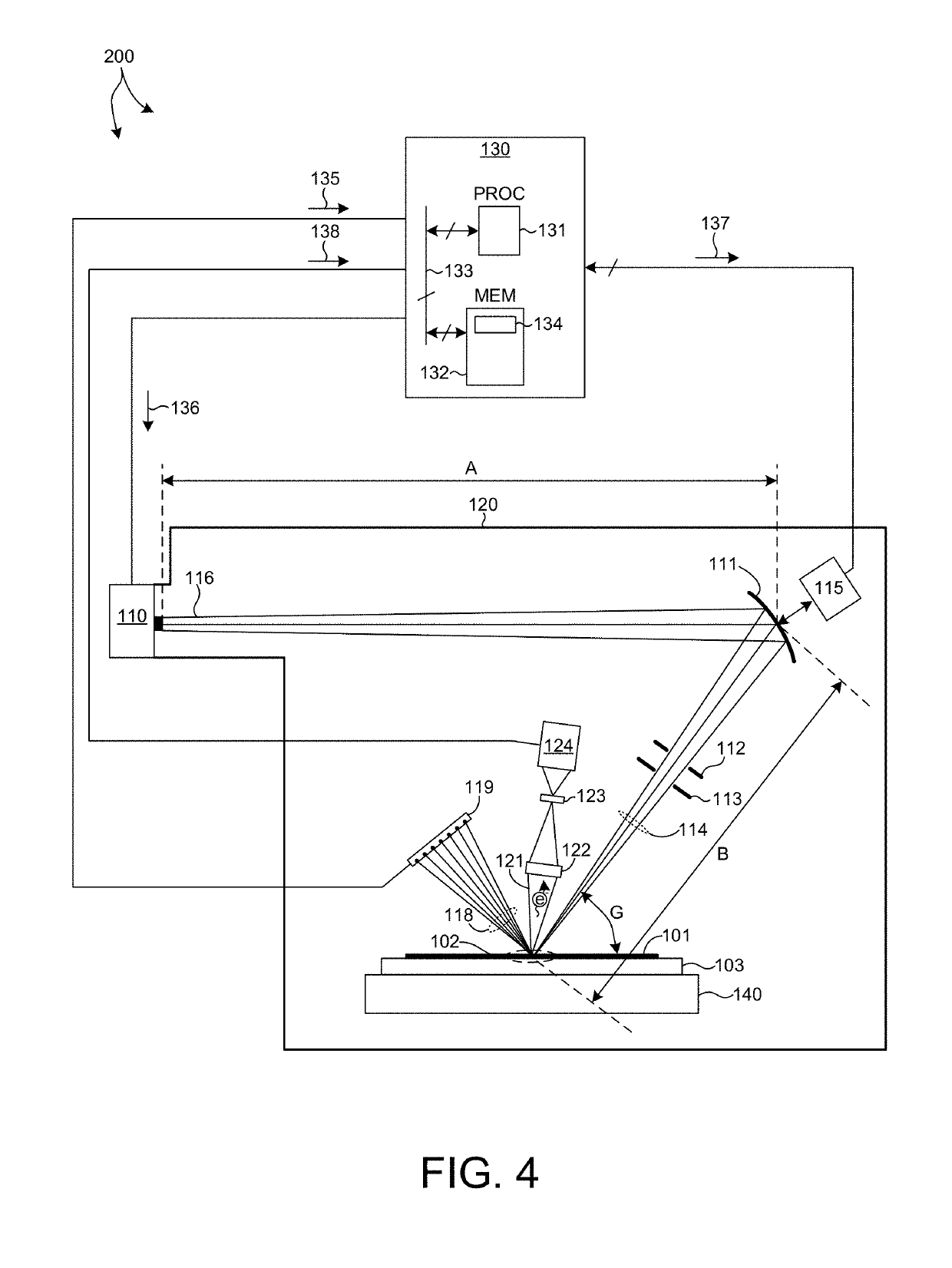

Systems And Methods For Combined X-Ray Reflectometry And Photoelectron Spectroscopy

ActiveUS20190212281A1High measurement accuracyImprove throughputMaterial analysis using wave/particle radiationColor/spectral properties measurementsSemiconductor structureX-ray

Methods and systems for measuring structural and material characteristics of semiconductor structures based on combined x-ray reflectometry (XRR) and x-ray photoelectron spectroscopy (XPS) are presented herein. A combined XRR and XPS system includes an x-ray illumination source and x-ray illumination optics shared by both the XRR and XPS measurement subsystems. This increases throughput and measurement accuracy by simultaneously collecting XRR and XPS measurement data from the same area of the wafer. A combined XRR and XPS system improves measurement accuracy by employing XRR measurement data to improve measurements performed by the XPS subsystem, and vice-versa. In addition, a combined XRR and XPS system enables simultaneous analysis of both XRR and XPS measurement data to more accurately estimate values of one of more parameters of interest. In a further aspect, any of measurement spot size, photon flux, beam shape, beam diameter, and illumination energy are independently controlled.

Owner:KLA TENCOR TECH CORP

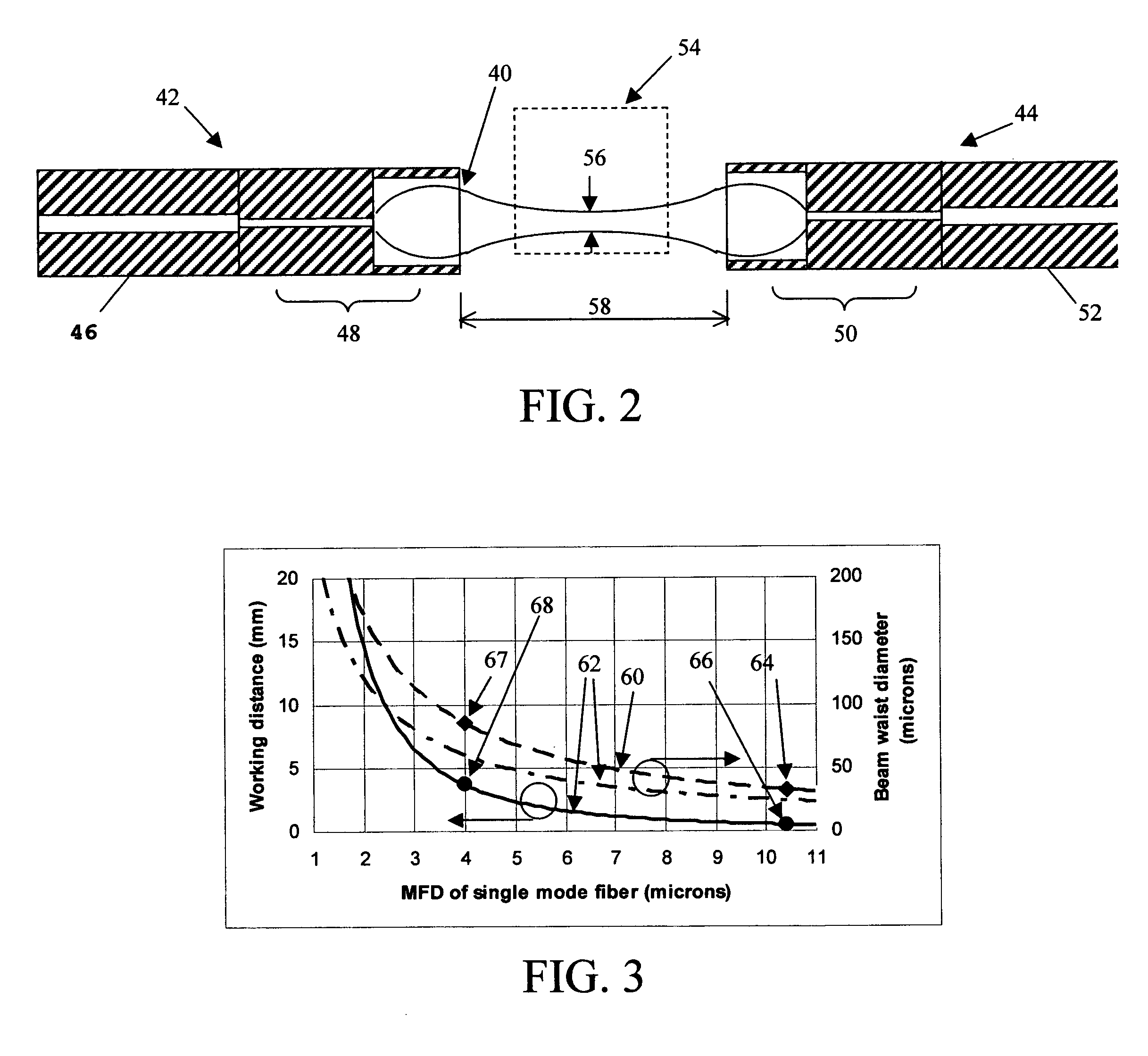

Fiber collimating lenses and method

InactiveUS20050220401A1Large beam diameterLong working distanceOptical fibre with graded refractive index core/claddingCoupling light guidesBeam diameterLight beam

A compact, inexpensive and rugged fiber collimating lens and lens array achieve large beam diameters and provide long working distances. A special single-mode fiber is inserted between a standard single-mode input fiber and a GRIN fiber lens, typically quarter-pitch or slightly longer. The specialty fiber condenses the mode field diameter (MFD) of the beam in the input fiber into its smaller MFD. As a result, the fiber collimating lens provides greater beam expansion due to the larger divergence angle of the specialty fiber, which in turn provides longer working distances.

Owner:BEAMTEK

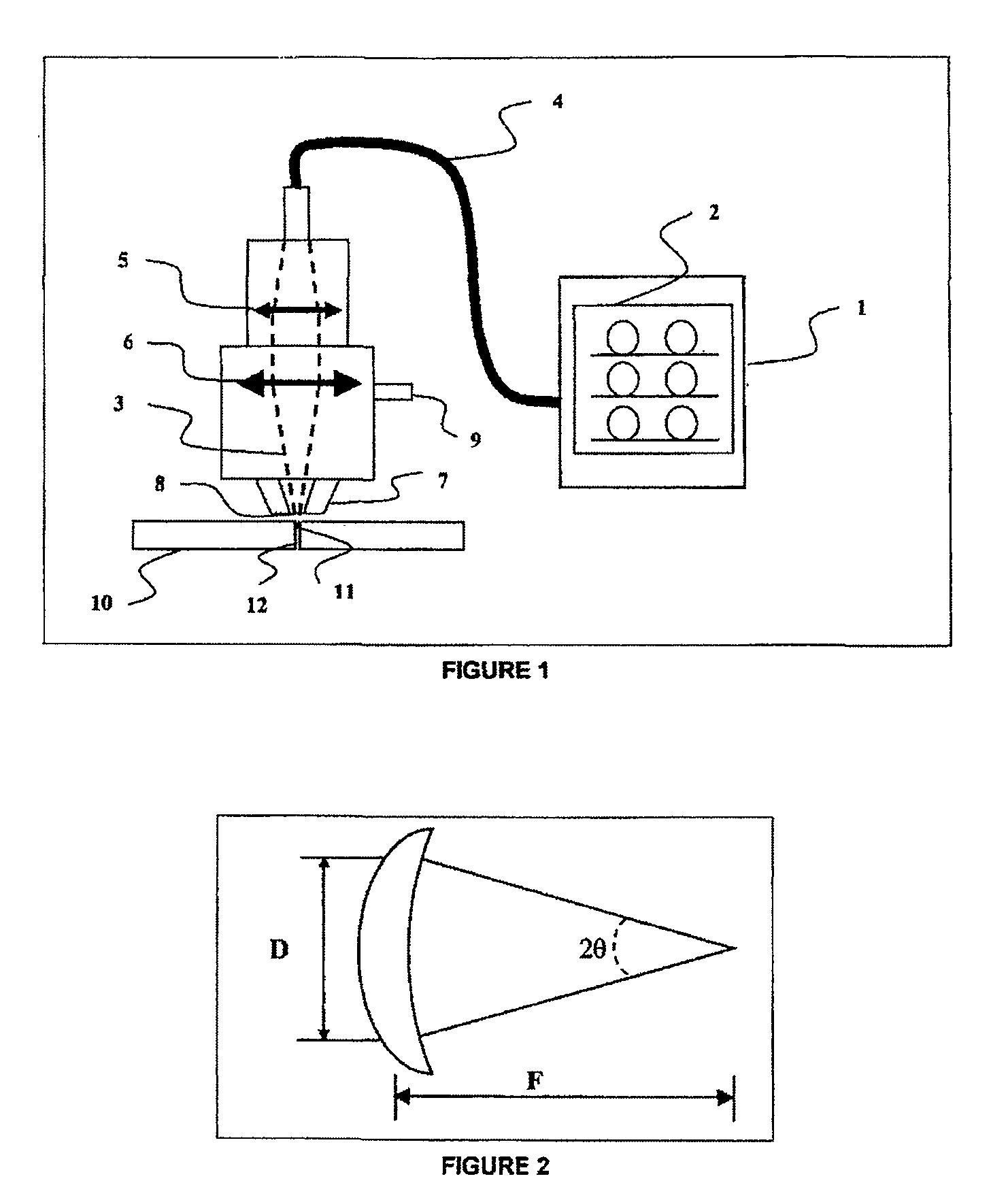

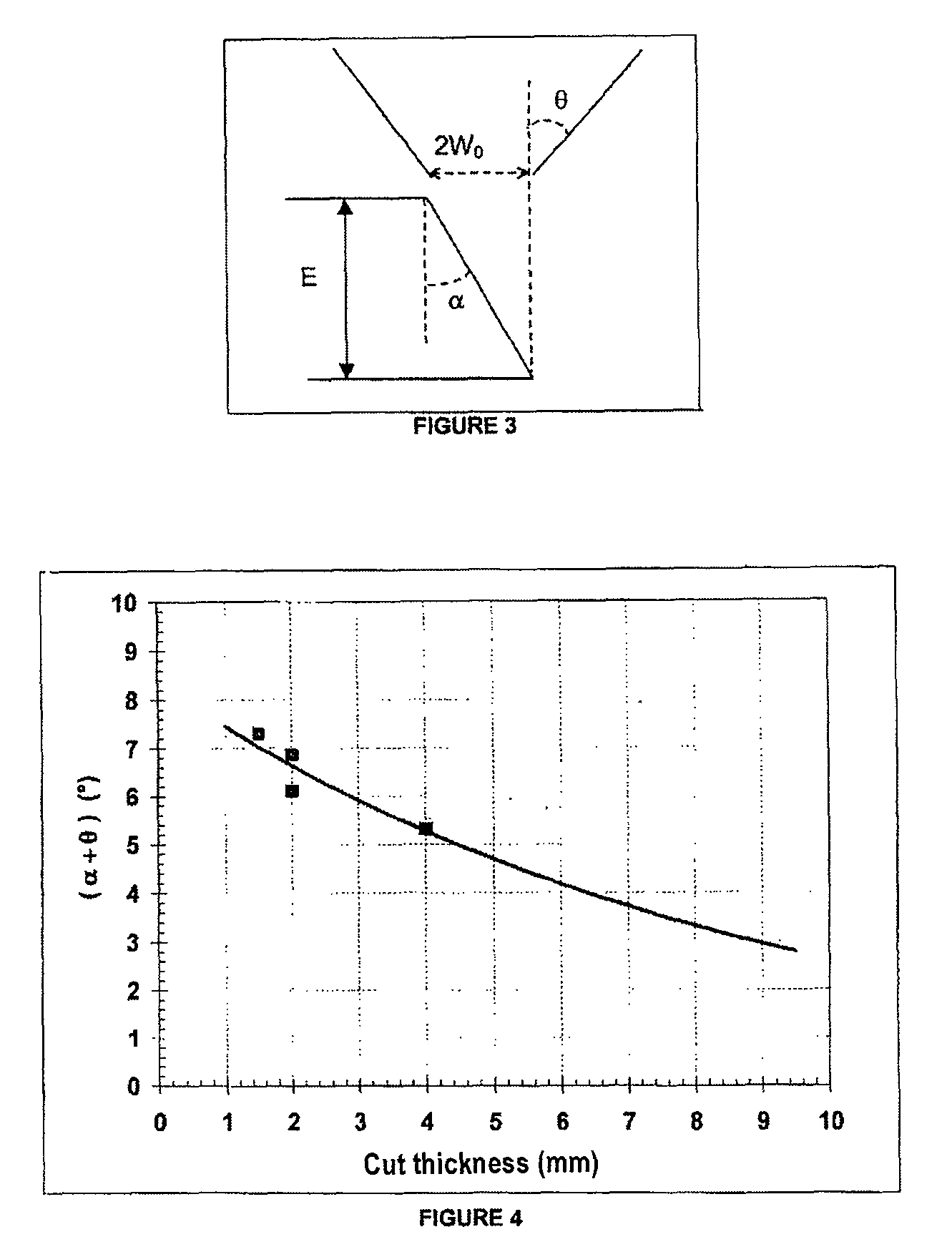

Cutting method using a laser having at least one ytterbium-based fiber, in which at least the power of the laser source, the diameter of the focused beam and the beam quality factor are controlled

InactiveUS8278591B2Active medium shape and constructionLaser beam welding apparatusFiberBeam diameter

The invention relates to method for cutting a part using a laser beam, involving the use of laser beam generation means comprising at least one ytterbium-based fibre having a wavelength of between 1 and 4 μm in order to generate the laser beam. The laser beam is selected to have a power of less than 100 kW, a power density of at least 1 MW / cm2, a focused beam diameter of at least 0.1 mm and a quality factor (BPP) of less than 10 mm·mrad.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

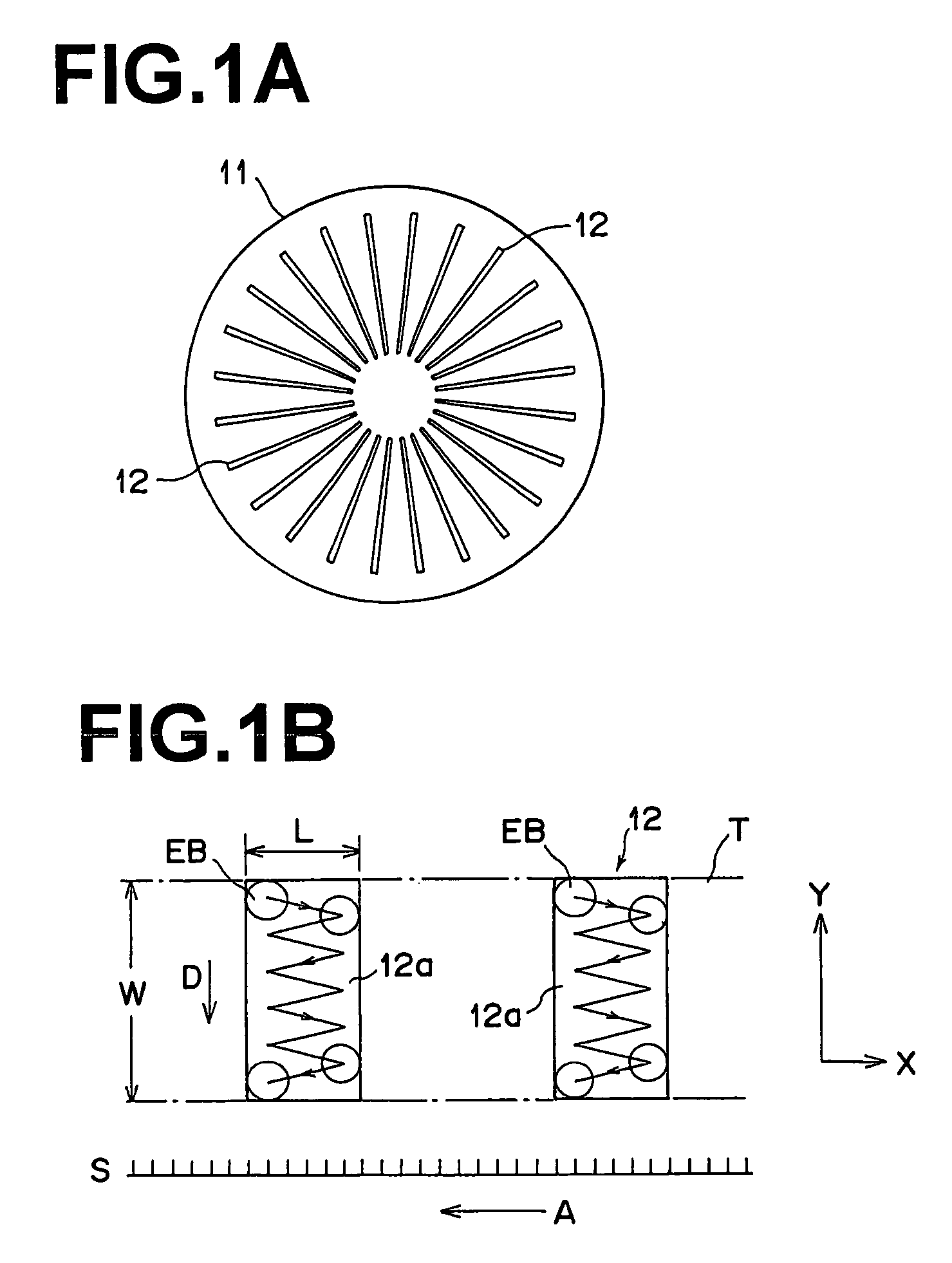

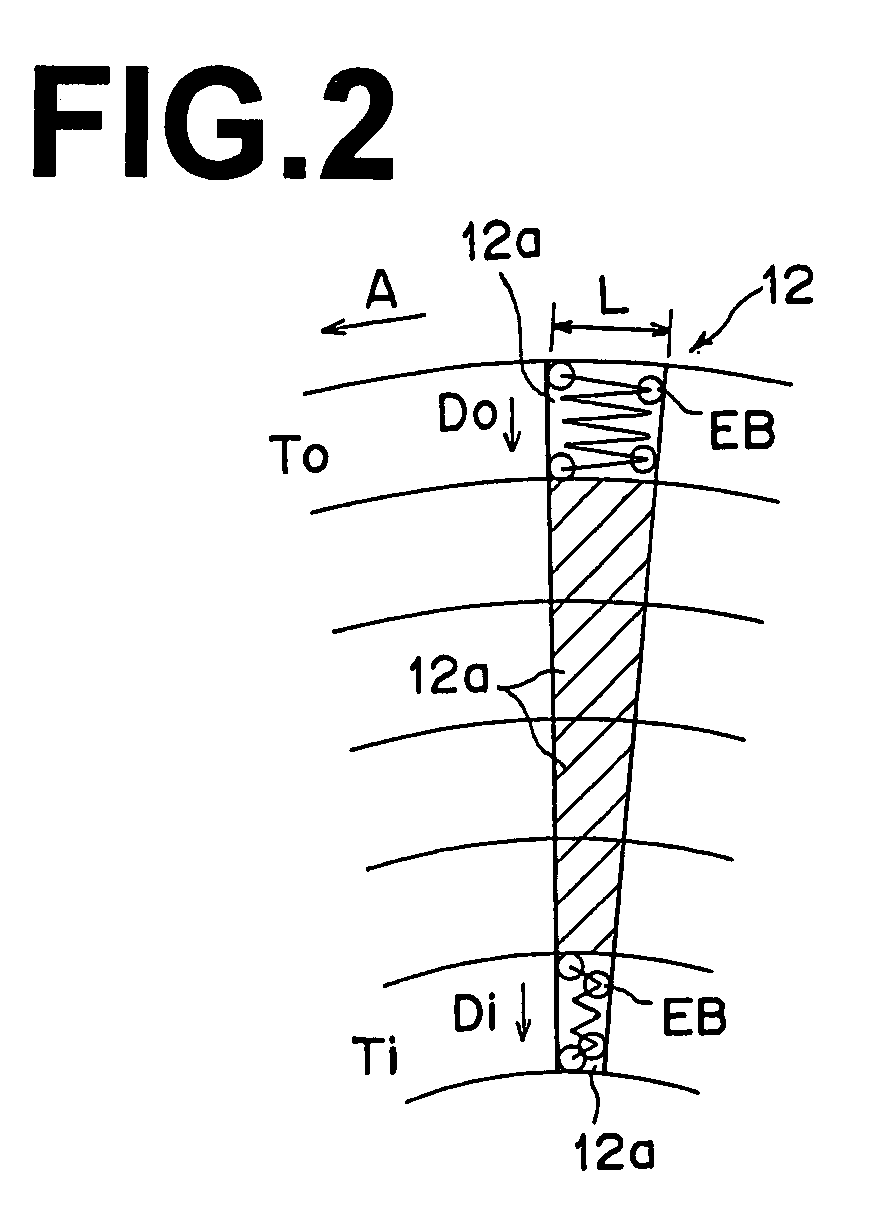

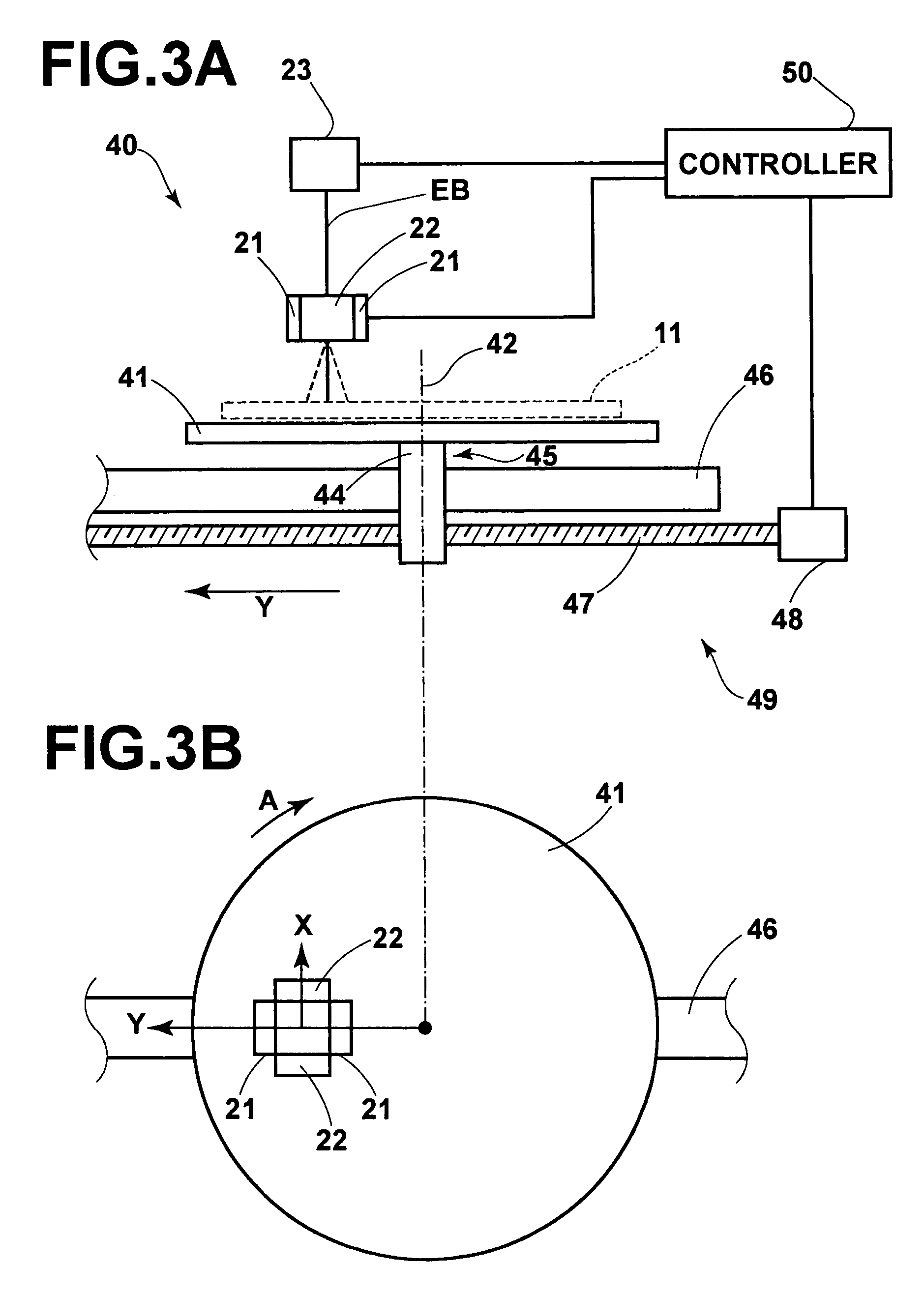

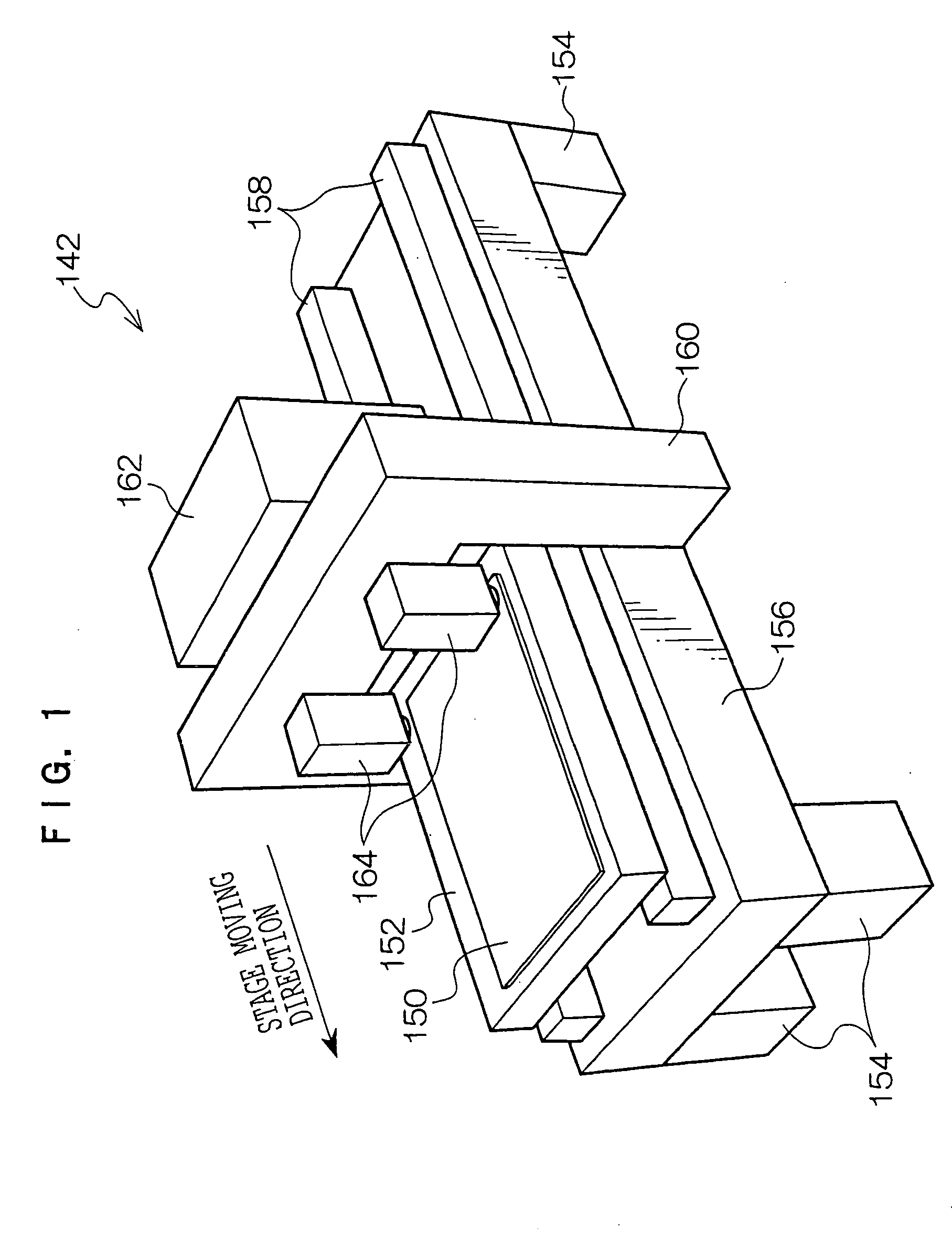

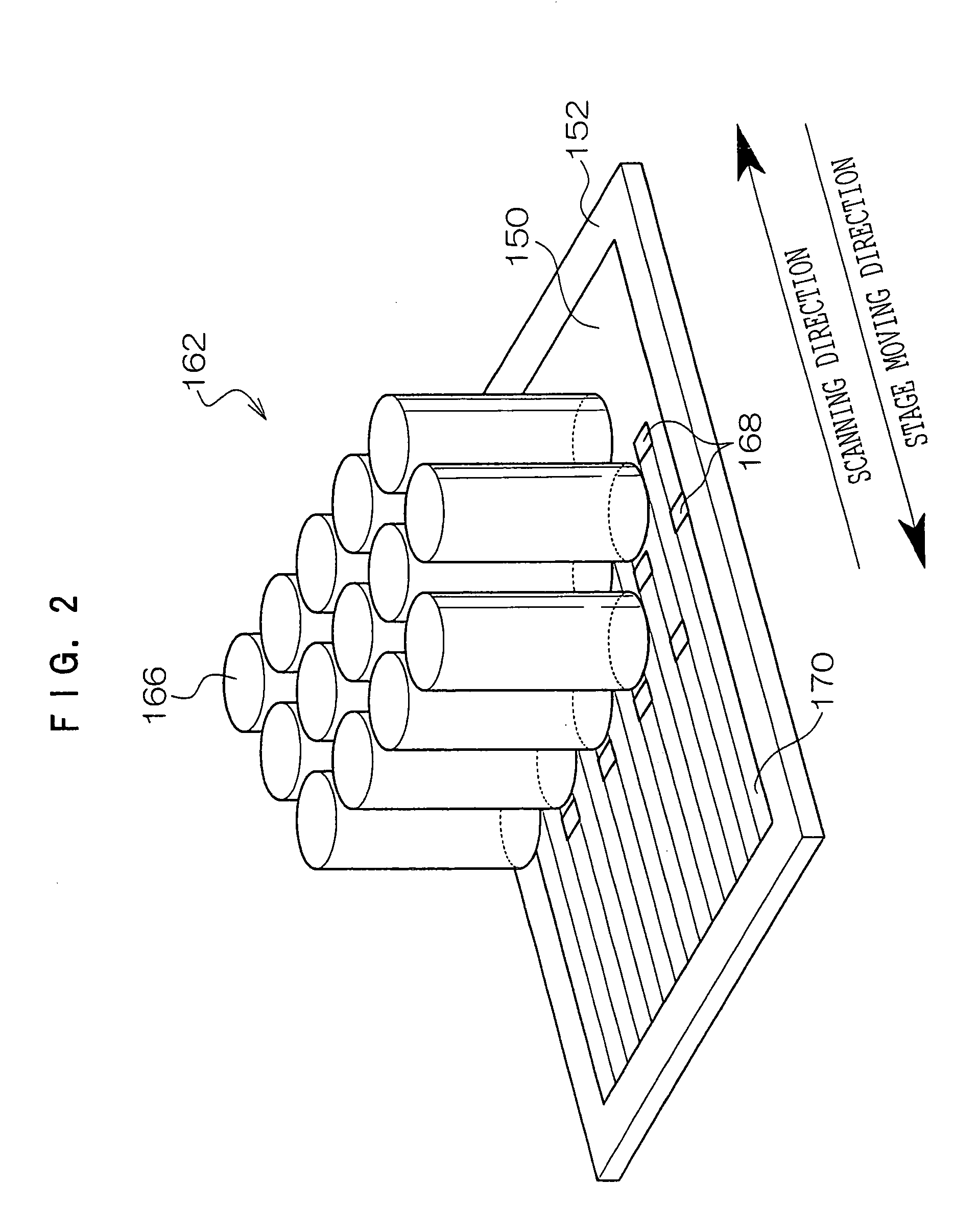

Electron beam lithography method

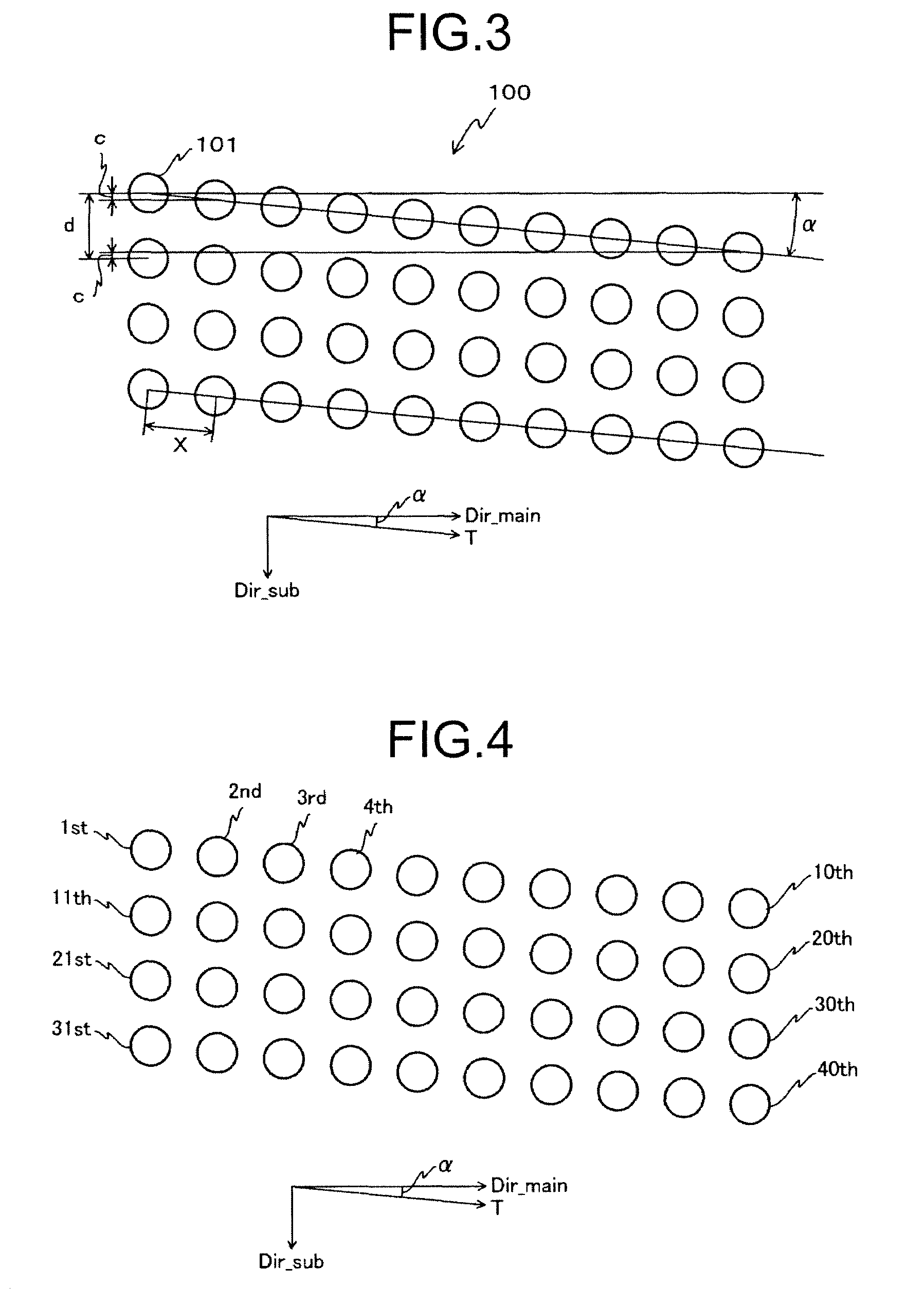

InactiveUS7026098B2High positioning accuracyEasy to shapeOptical re-recordingRadiation applicationsResistBeam diameter

An electron beam lithography method for performing lithography of elements included in a pattern by scanning a disk having resist coated thereon, placed on a rotating stage which is movable in a radial direction of the disk, with an electron beam while rotating the rotating stage. The electron beam has a beam diameter smaller than a minimum width of an element shape. The electron beam is reciprocally oscillated in a circumferential direction X approximately orthogonal to a radial direction Y of the disk and deflected in the radial direction Y, thereby filling in the element shape. Lithography of the elements is sequentially performed by rotating the disk unidirectionally, and thus a desired micropattern is drawn in the entire region of the disk. A lithographic length L of the element in the circumferential direction X may be defined by amplitude of the reciprocal oscillation of the electron beam.

Owner:FUJIFILM HLDG CORP +1

Exposure head

ActiveUS20050024477A1High resolutionReduced beam diameterInking apparatusPhotomechanical exposure apparatusBeam diameterLight beam

In an exposure head of the invention, plural first micro-focusing elements are arranged in a first microlens array so as to correspond to plural micromirrors in a DMD. An aperture array that includes plural apertures arranged so as to respectively correspond to the plural first micro-focusing elements is disposed. The apertures allow only main portions of Fraunhofer diffraction images to be transmitted therethrough. The main portions of the Fraunhofer diffraction images transmitted through the apertures are imaged on an exposure plane by second micro-focusing elements of a second microlens array. According to the exposure head of the invention, cross-talk light and scattered light can be effectively reduced, and beam diameters of beam spots projected on the exposure plane through the apertures can be adjusted to a required size.

Owner:ADTEC ENG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com