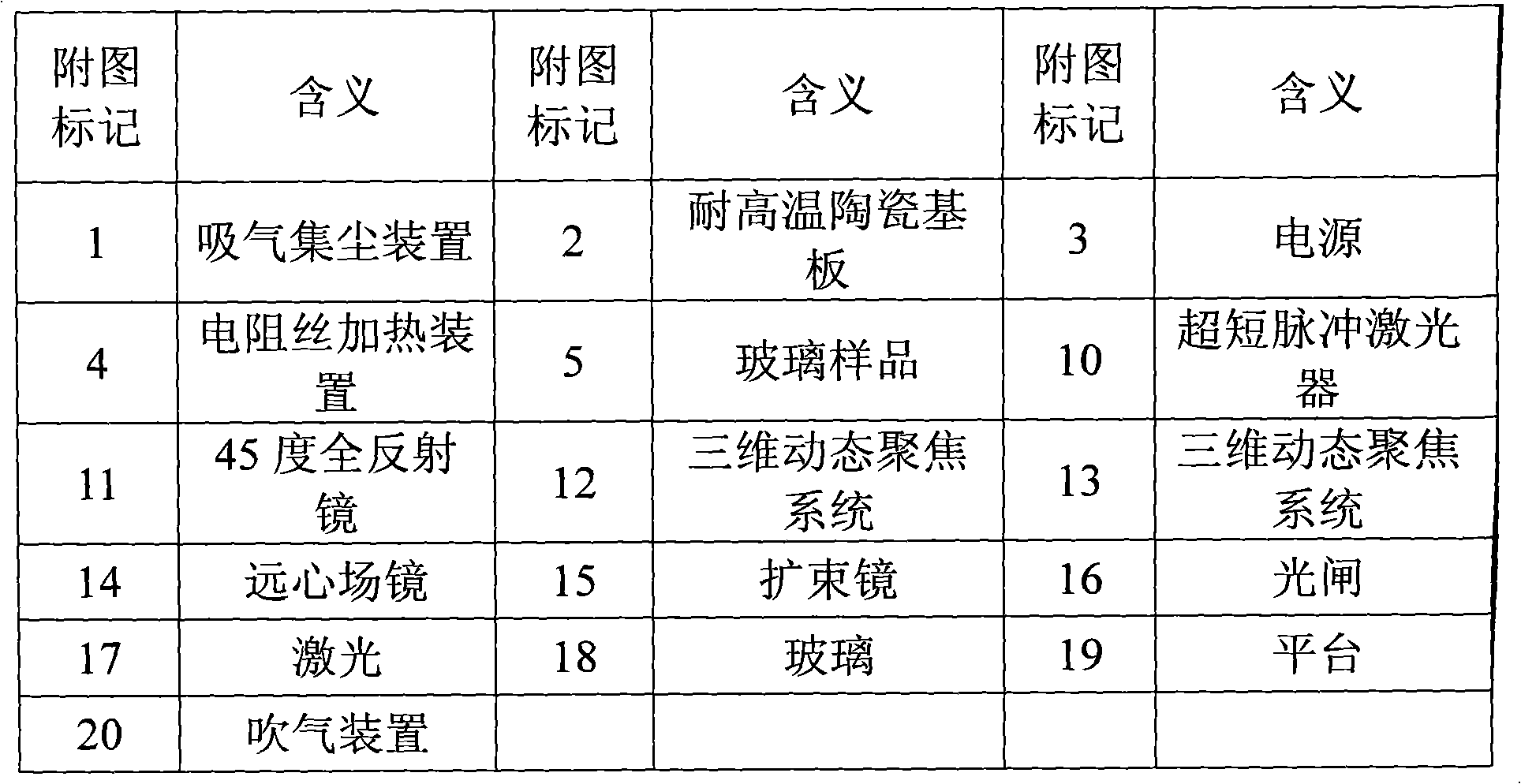

Patents

Literature

1761 results about "Beam expander" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

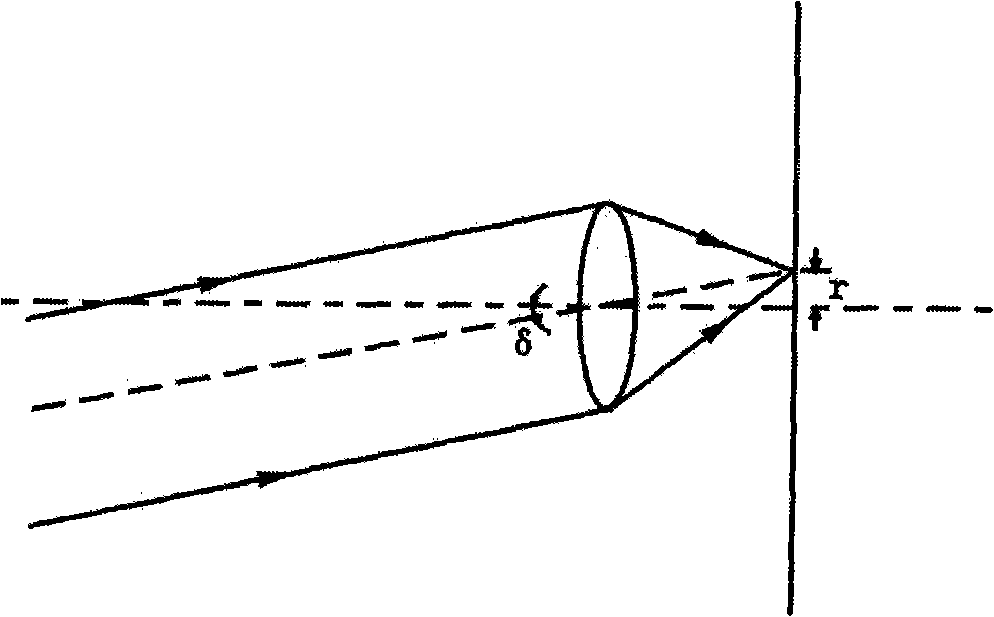

Beam expanders are optical devices that take a collimated beam of light and expand its size (or, used in reverse, reduce its size). In laser physics they are used either as intracavity or extracavity elements. They can be telescopic in nature or prismatic. Generally prismatic beam expanders use several prisms and are known as multiple-prism beam expanders.

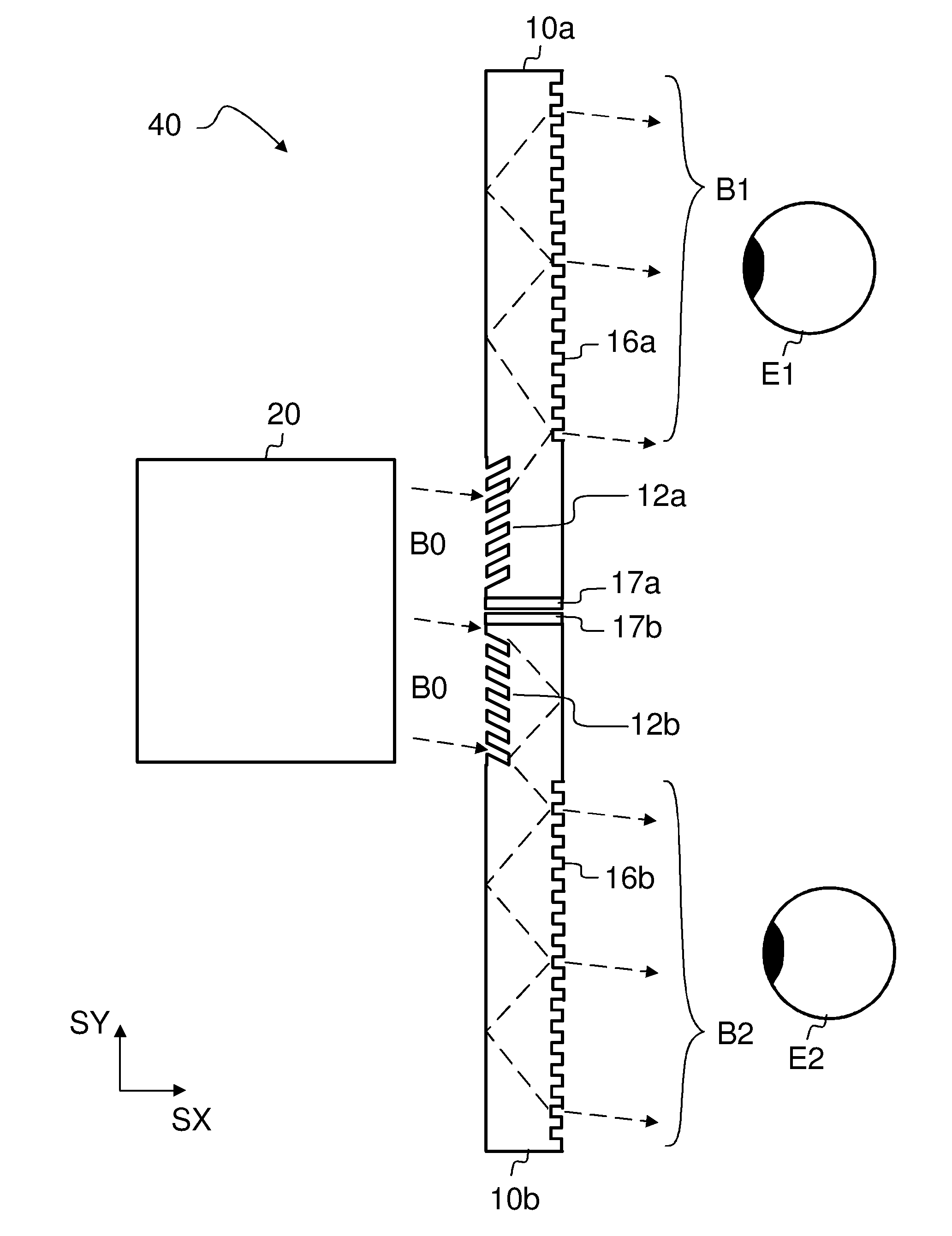

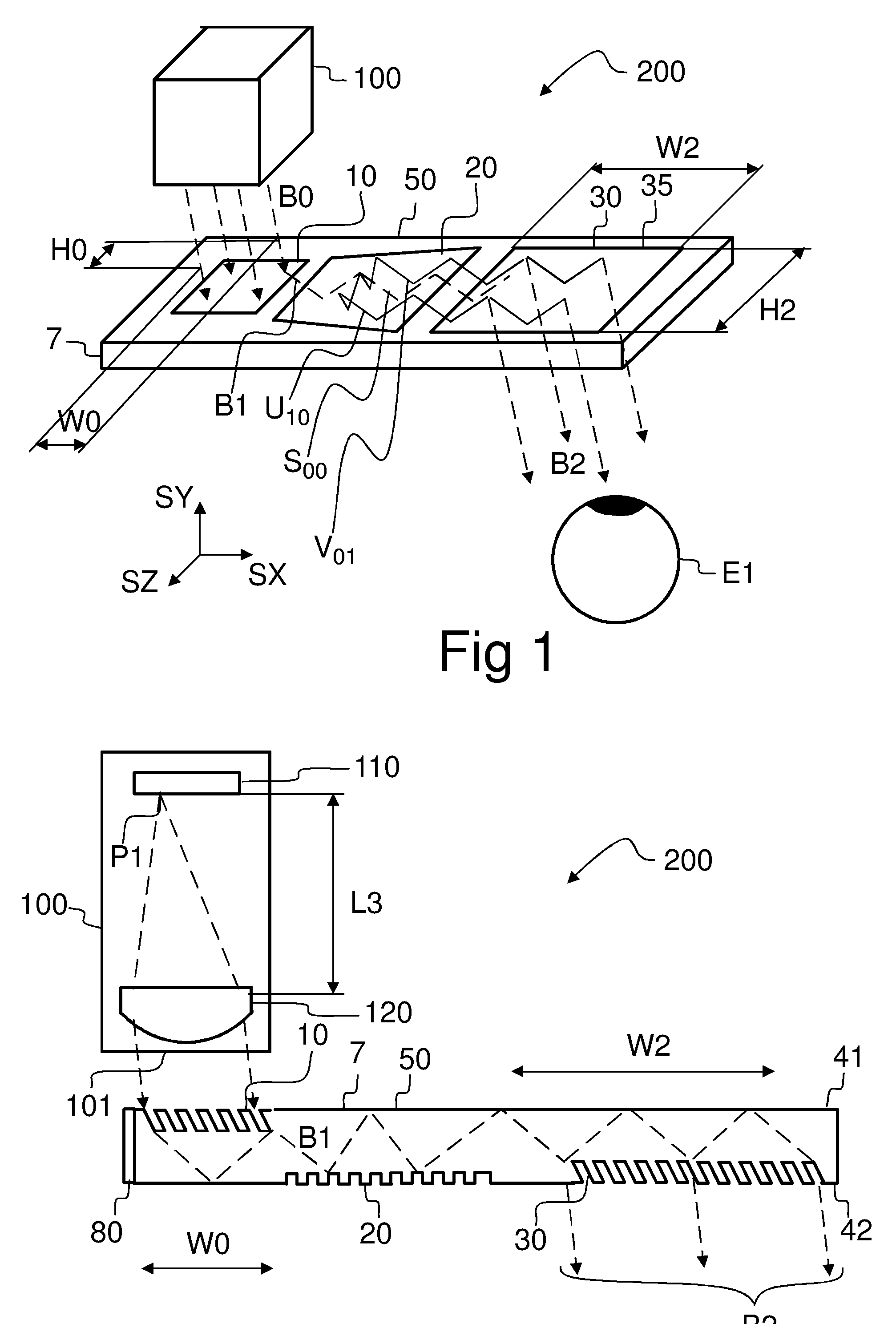

Display Device Having Two Operating Modes

InactiveUS20100277803A1Increasing weight and sizeImprove viewing effectProjectorsDiffraction gratingsBeam expanderGrating

A display device (500) comprises a micro-display (22) and imaging optics (24) to transmit a light beam (BO), and a diffractive beam expander (10) having an output grating (16). The combination of said micro-display (22) and said imaging optics (24) is together adapted to form a virtual image (710) which is observable through the perimeter (15) of said output grating (16) when said diffractive beam expander (10) is positioned to at least partially intercept said light beam (BO). The combination of said micro-display (22) and said imaging optics (24) may also be adapted to project said light beam (BO) onto an external screen (600) in order to display a real image (610). The display device (500) may comprise a movable optical component (10, 380) to switch the device (500) from a virtual display mode to a projecting mode.

Owner:NOKIA CORP

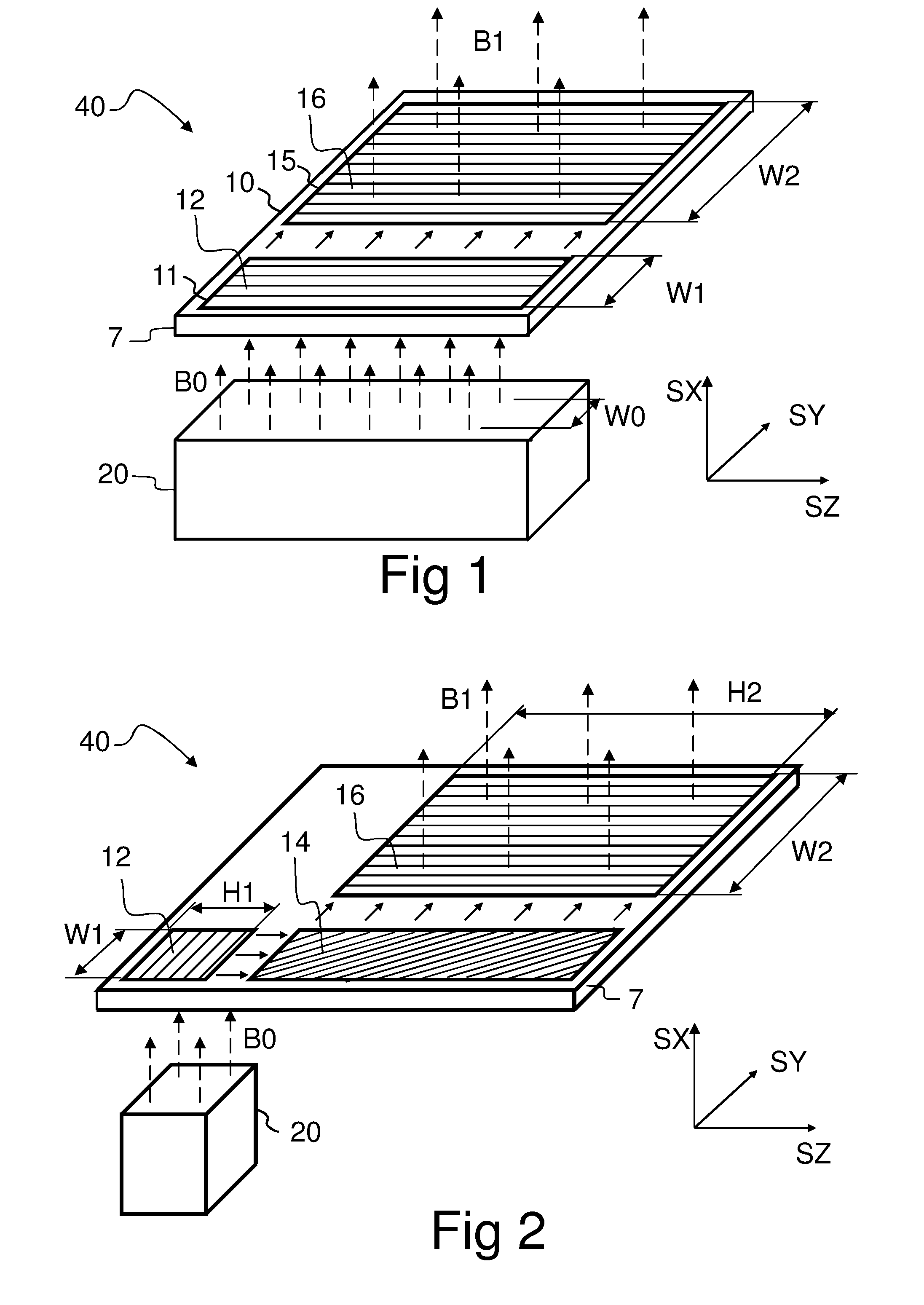

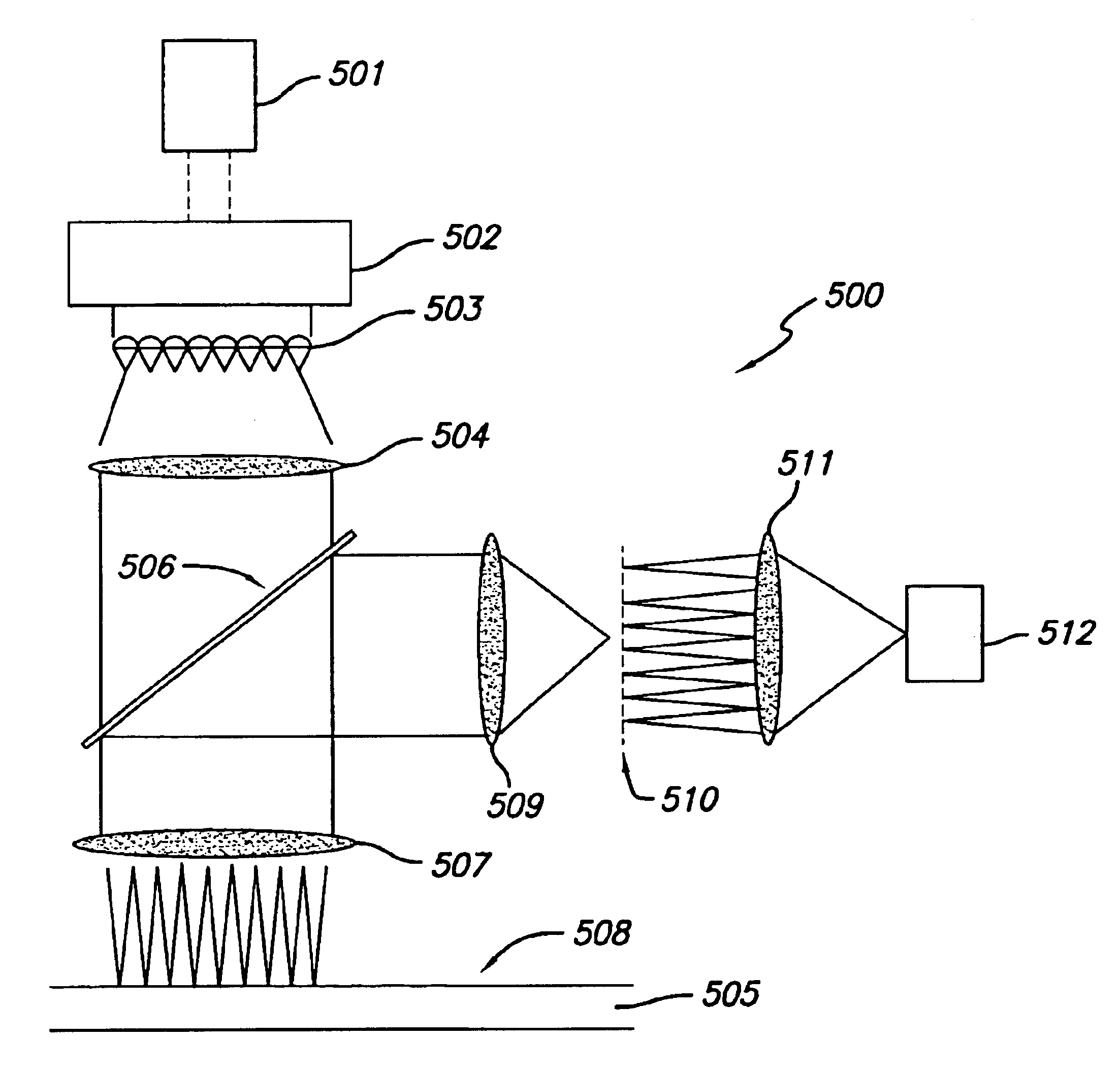

Device for expanding an exit pupil in two dimensions

ActiveUS8160411B2Improve image qualityEfficient couplingDiffraction gratingsCoupling light guidesBeam expanderGrating

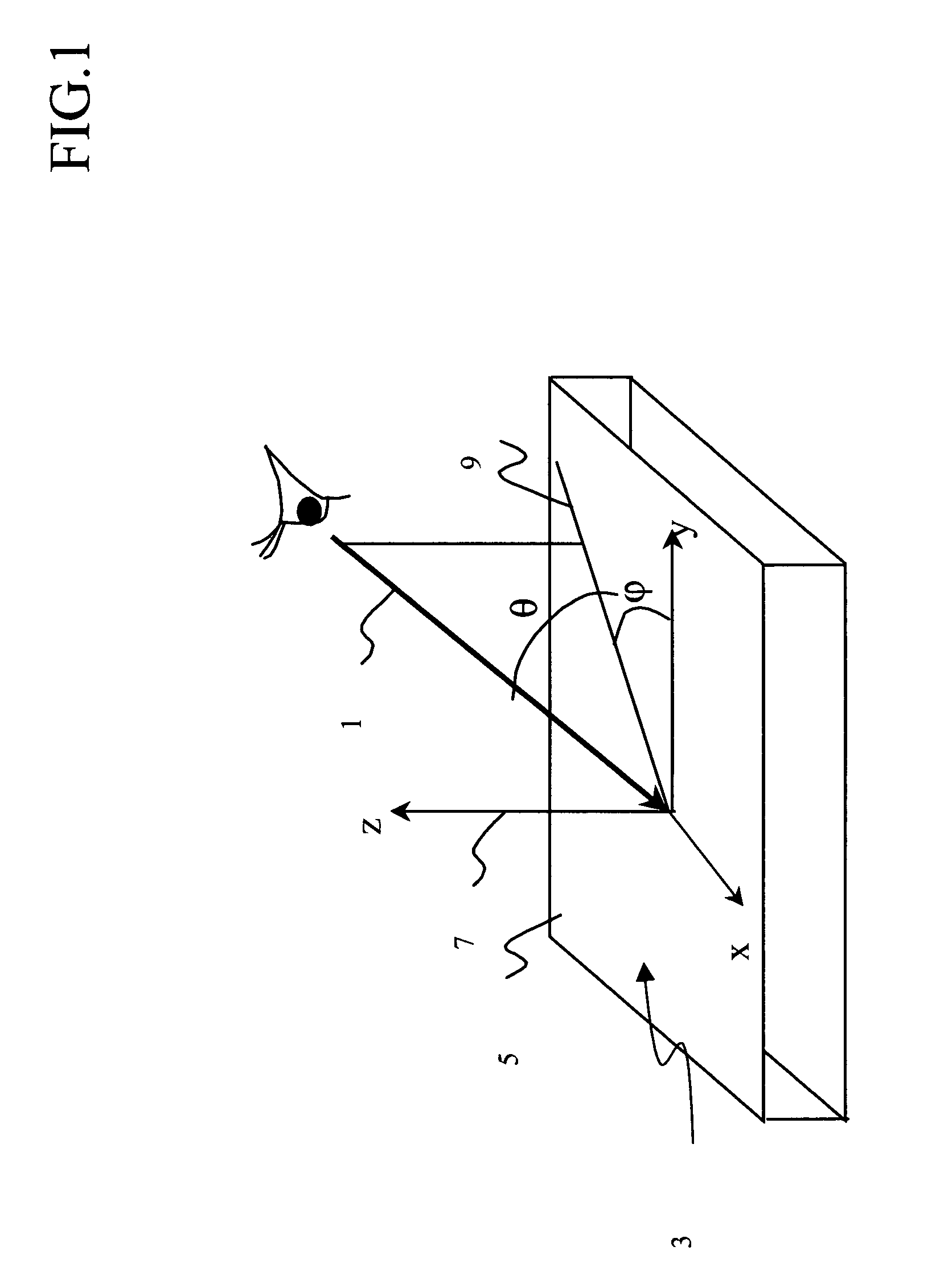

A diffractive beam expander (50) comprises an input grating (10), a crossed grating (20), and an output grating (30) implemented on a planar transparent substrate (7). The crossed grating (20) comprises a plurality of diffractive features (23) arranged along the lines of a first set of parallel lines (25) and along the lines of a second set of parallel lines (26) such that the lines (25) of the first set are parallel to the lines (26) of the second set. The lines of the first set have a first grating period and the lines of the second set have a second grating period. A light beam (B1) coupled into the substrate (7) by the input grating (10) impinges on the crossed grating (20) at a first location (EC1) and further locations (EC2). Interaction at the first location (EC1) provides several sub-beams (S00, S01, S10) which propagate in different directions. Further interactions at second locations (EC2) provide further sub-beams (V01, U10) which propagate in the same direction as the original in-coupled light (B1). Light is subsequently coupled out of the substrate (7) by the output grating (30) to provide a light beam (B2) which is expanded in two directions (SX, SZ) with respect to the beam (B0) impinging on the input grating. A virtual display device (200) may comprise said diffractive beam expander (50).

Owner:MAGIC LEAP INC

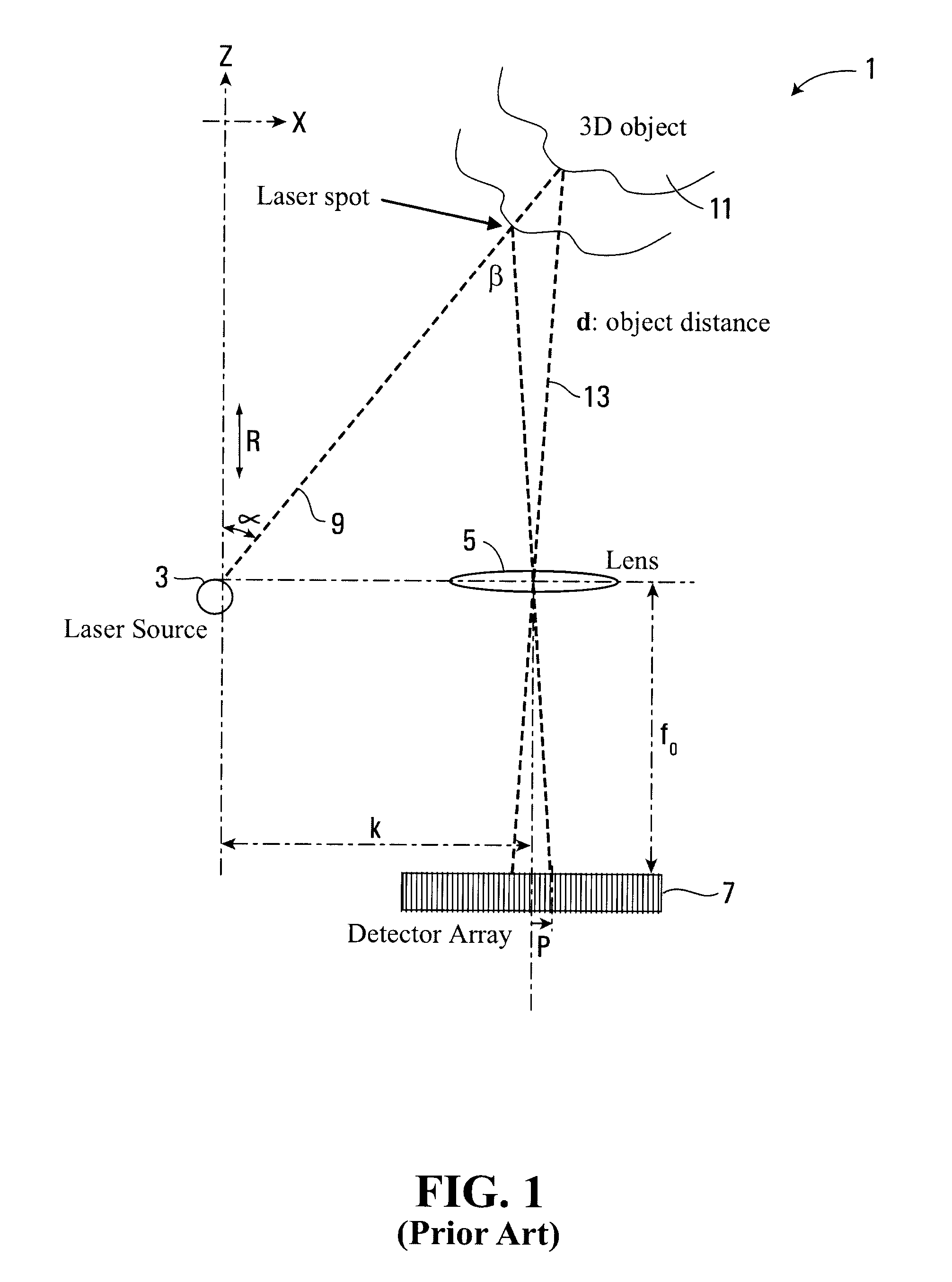

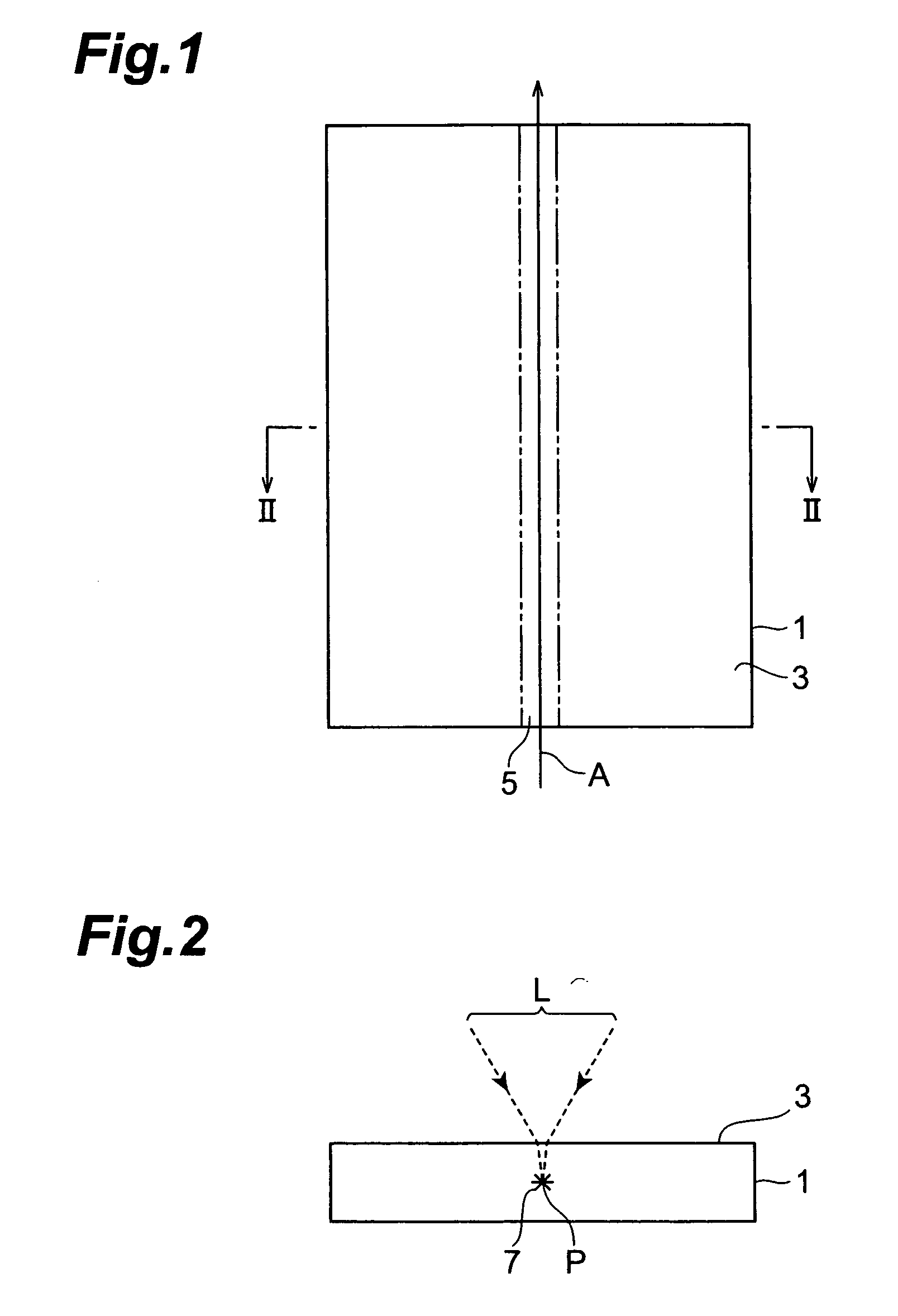

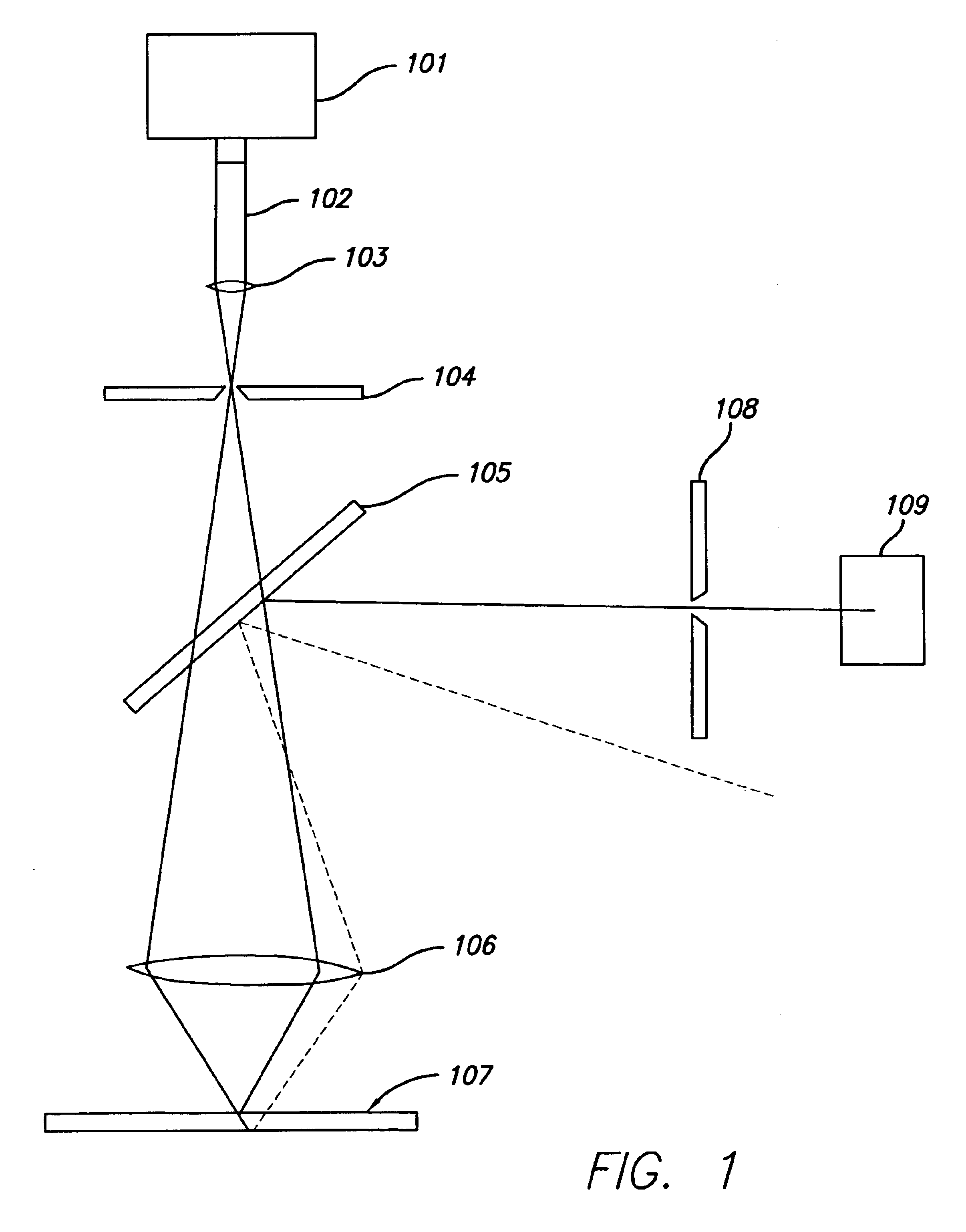

Imaging system and method

InactiveUS20090195790A1Reduce edge effectsReduce errorsUsing optical meansBeam expanderTarget surface

An apparatus for measuring the coordinates of a point on the surface of an object comprises a projection system for projecting a beam of energy onto the surface of the object, a receiving system for receiving reflected beam energy from the target surface, and a detector for detecting the received energy. The projection system comprises a beam expander for expanding the width of the beam, and a focussing device for focussing the projected beam. The position of the reflected beam energy at the detector provides a measure of the range of the point on the target surface using triangulation and the direction of the projected beam provides the x and y coordinates. The focussing device can be controlled to vary the focal length of the projected beam and to control the beam size at the target object to vary the area of the target surface illuminated by the beam and thereby to control the resolution of the measurements.

Owner:NEPTEC

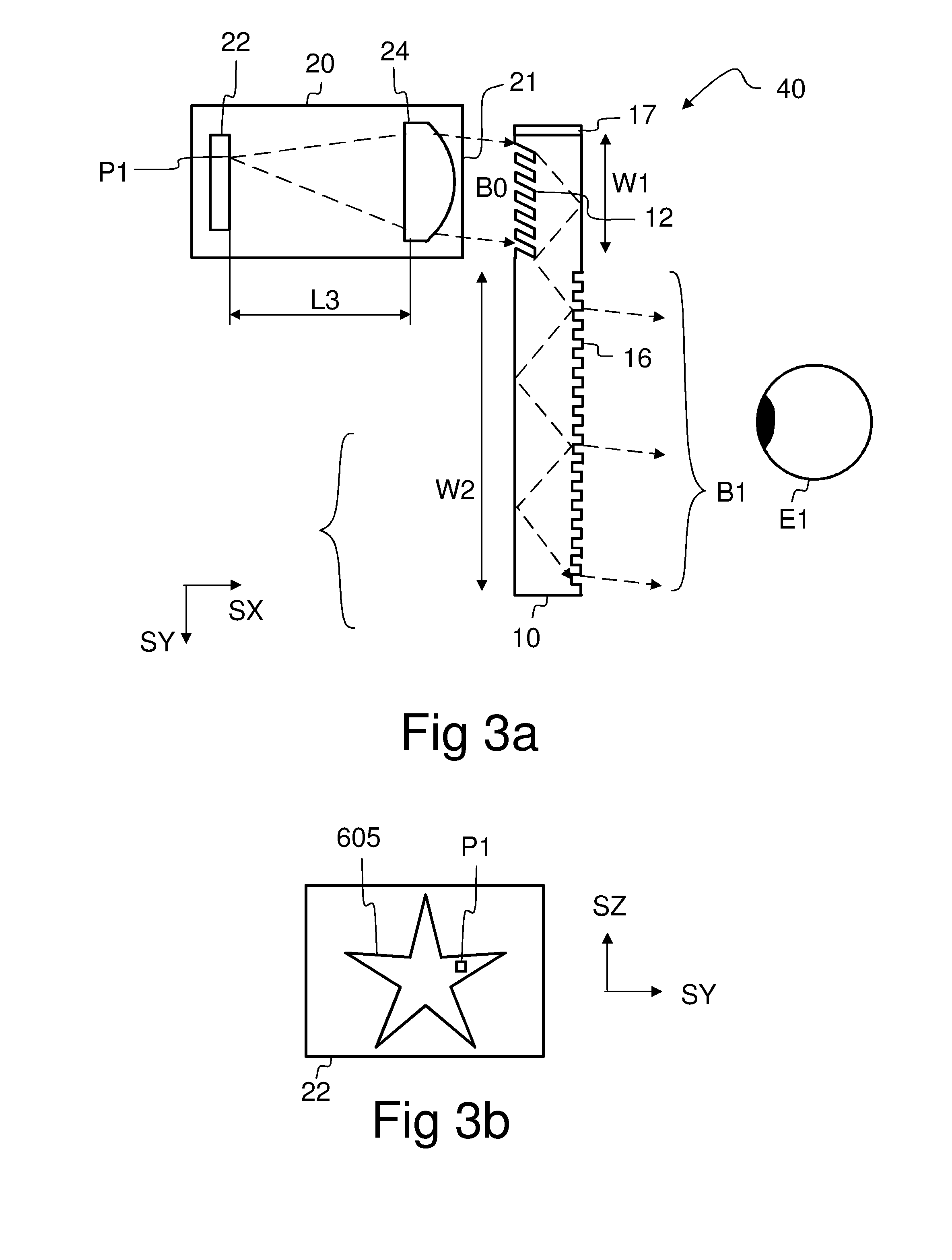

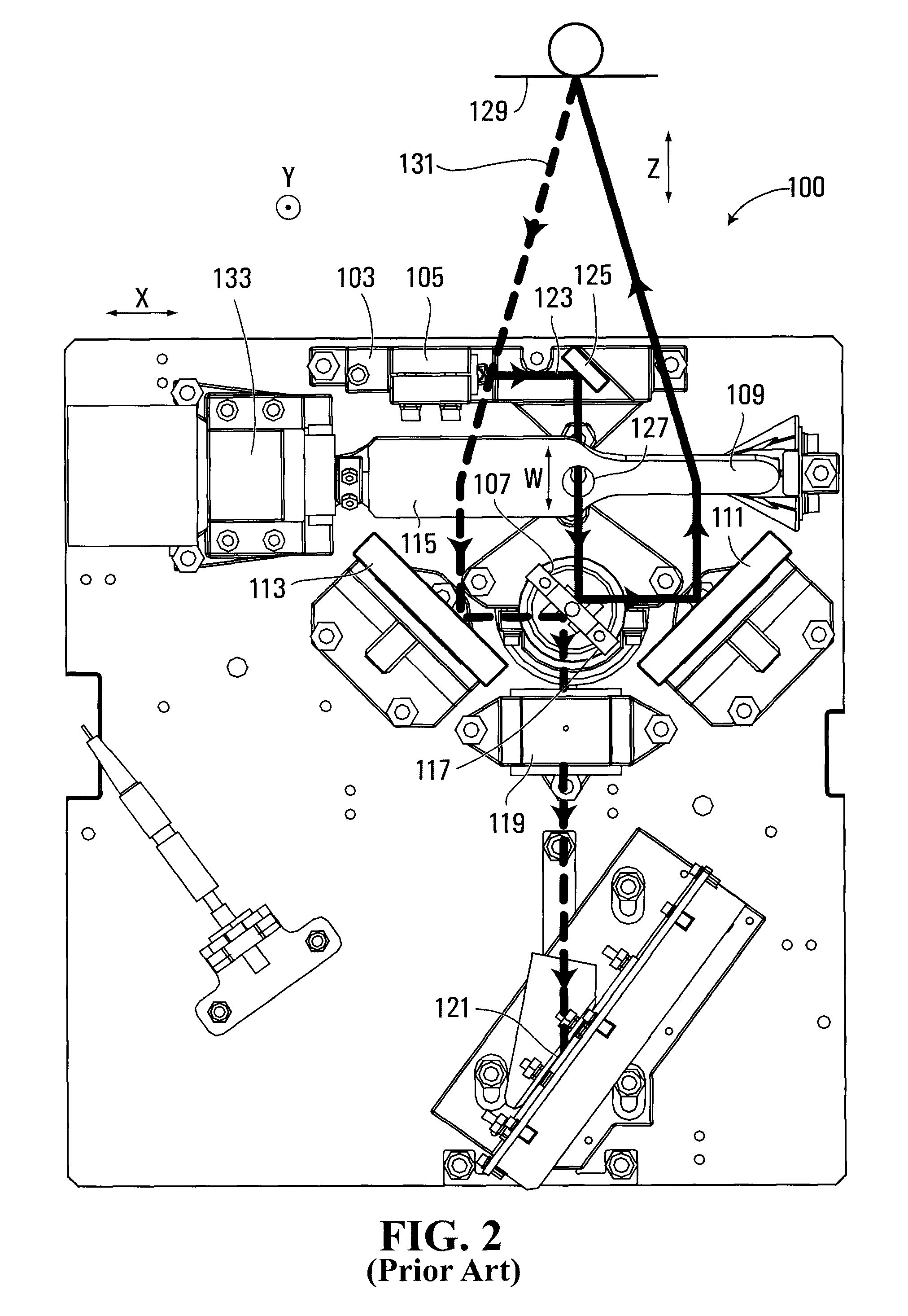

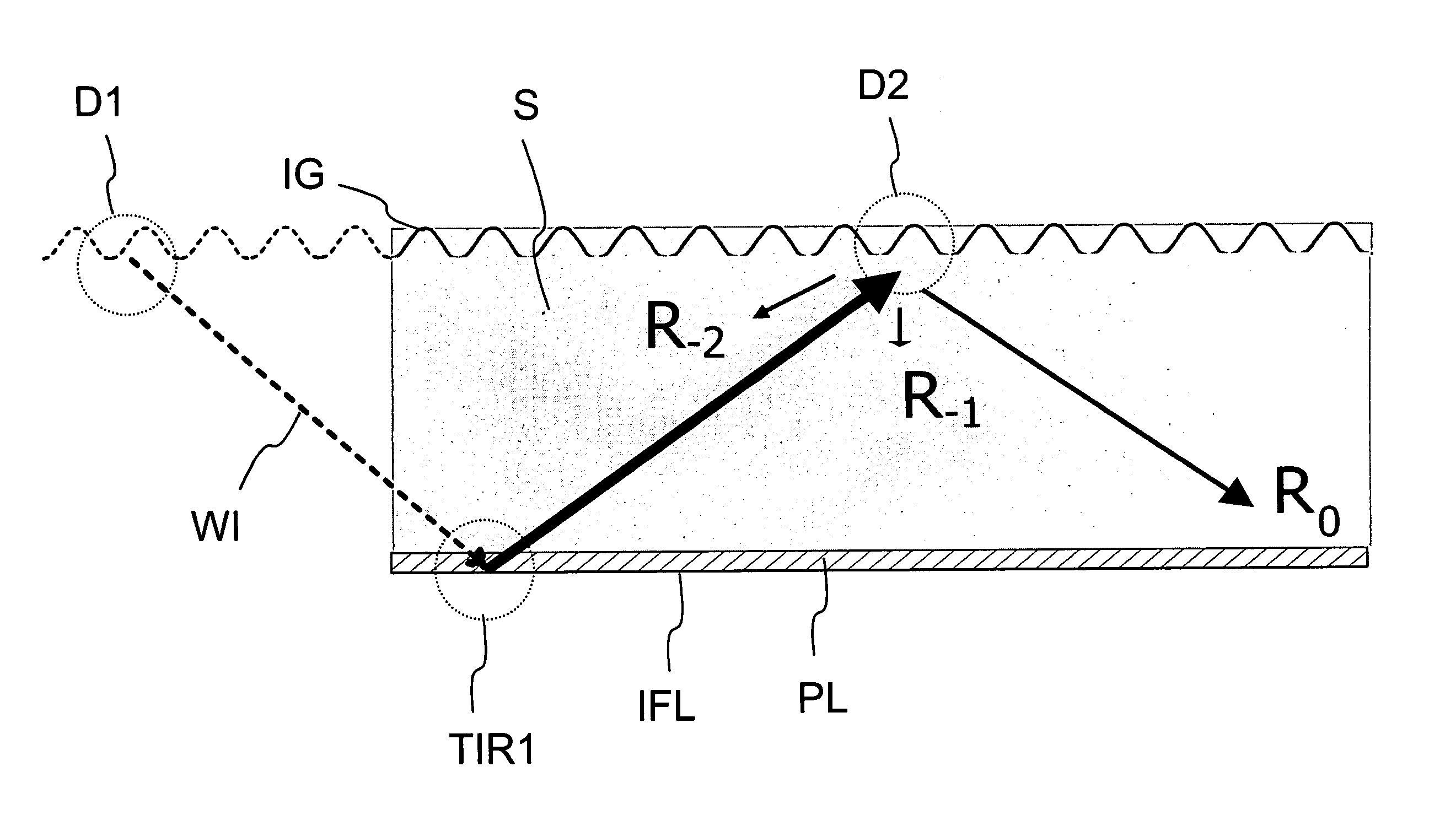

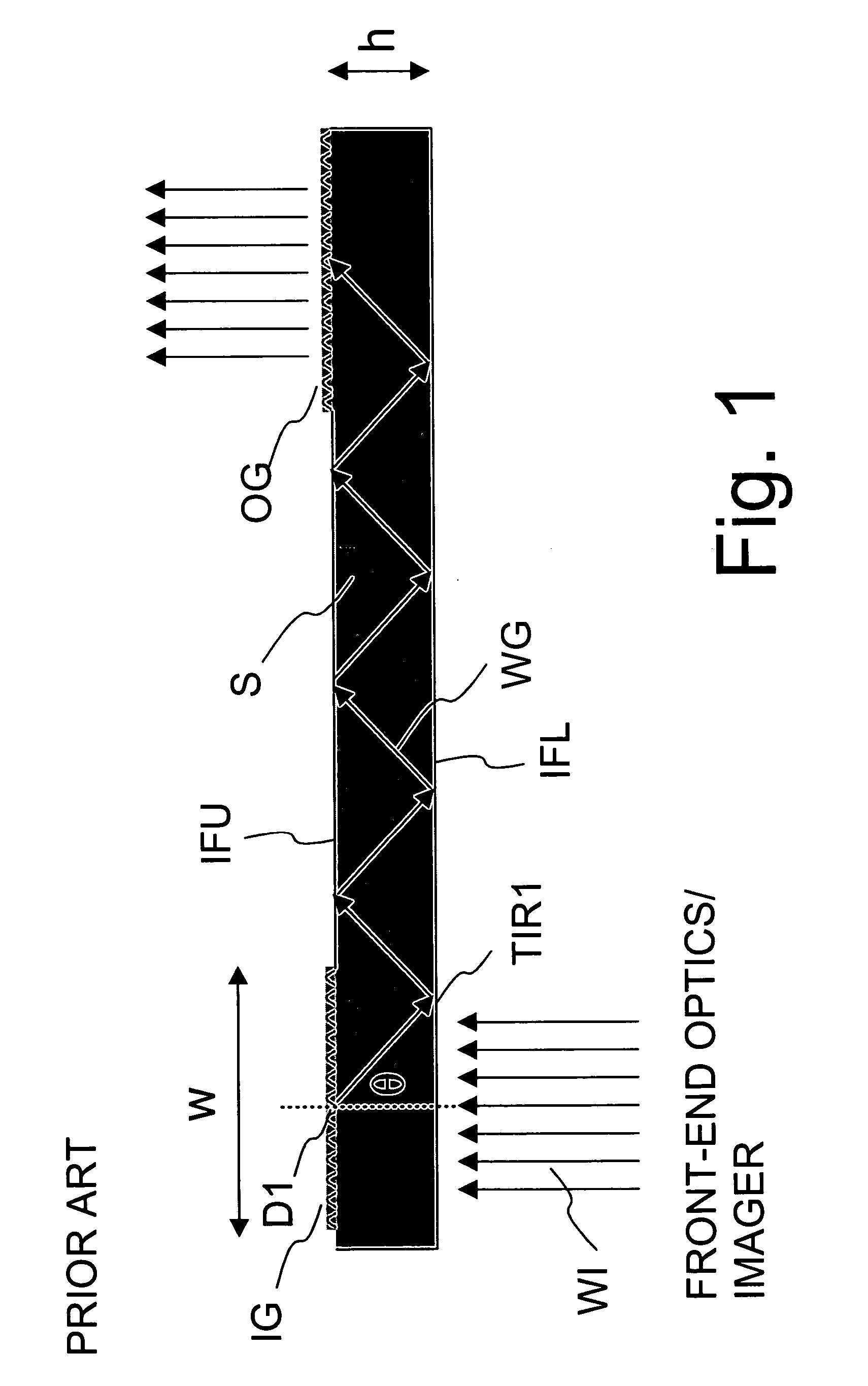

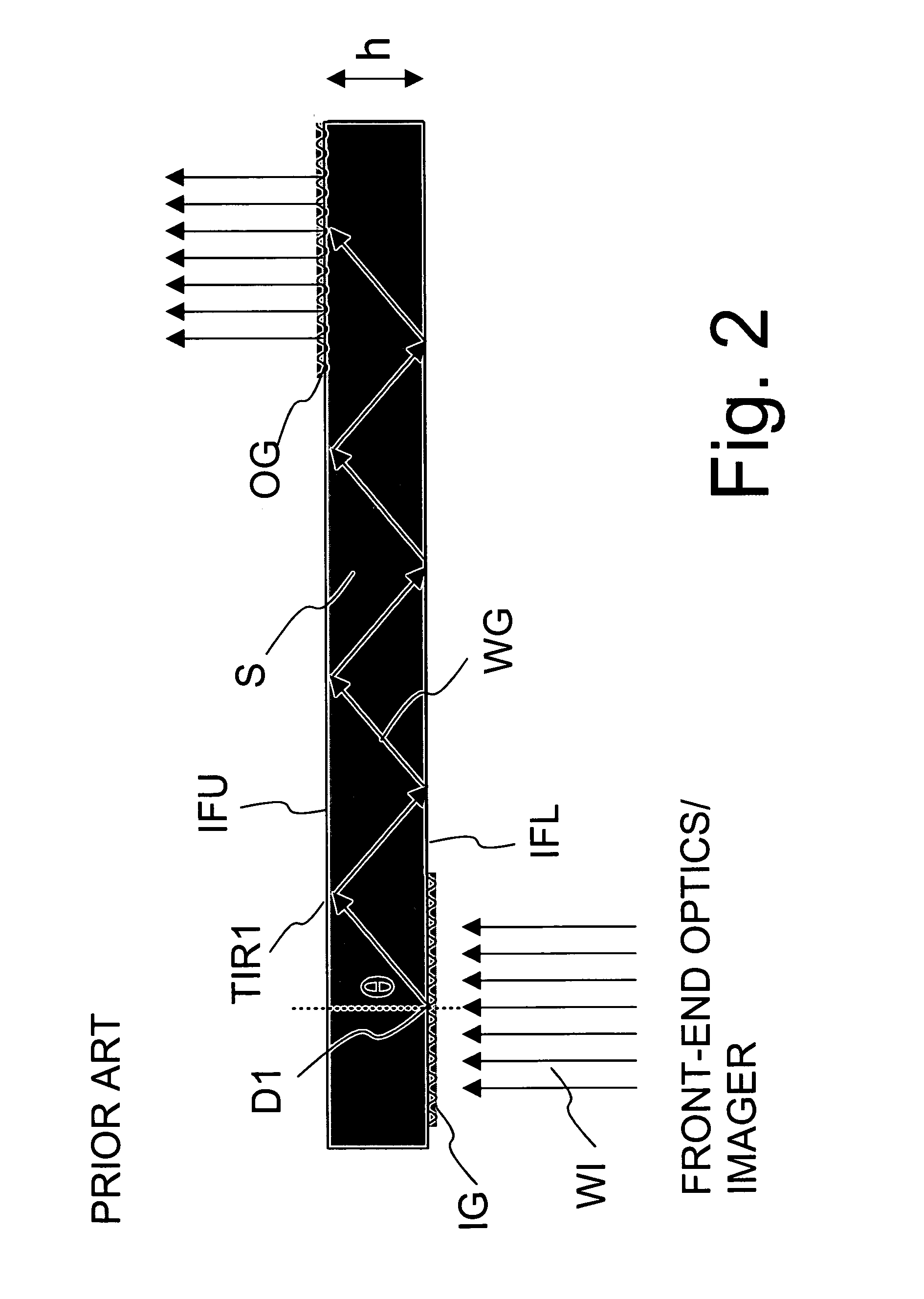

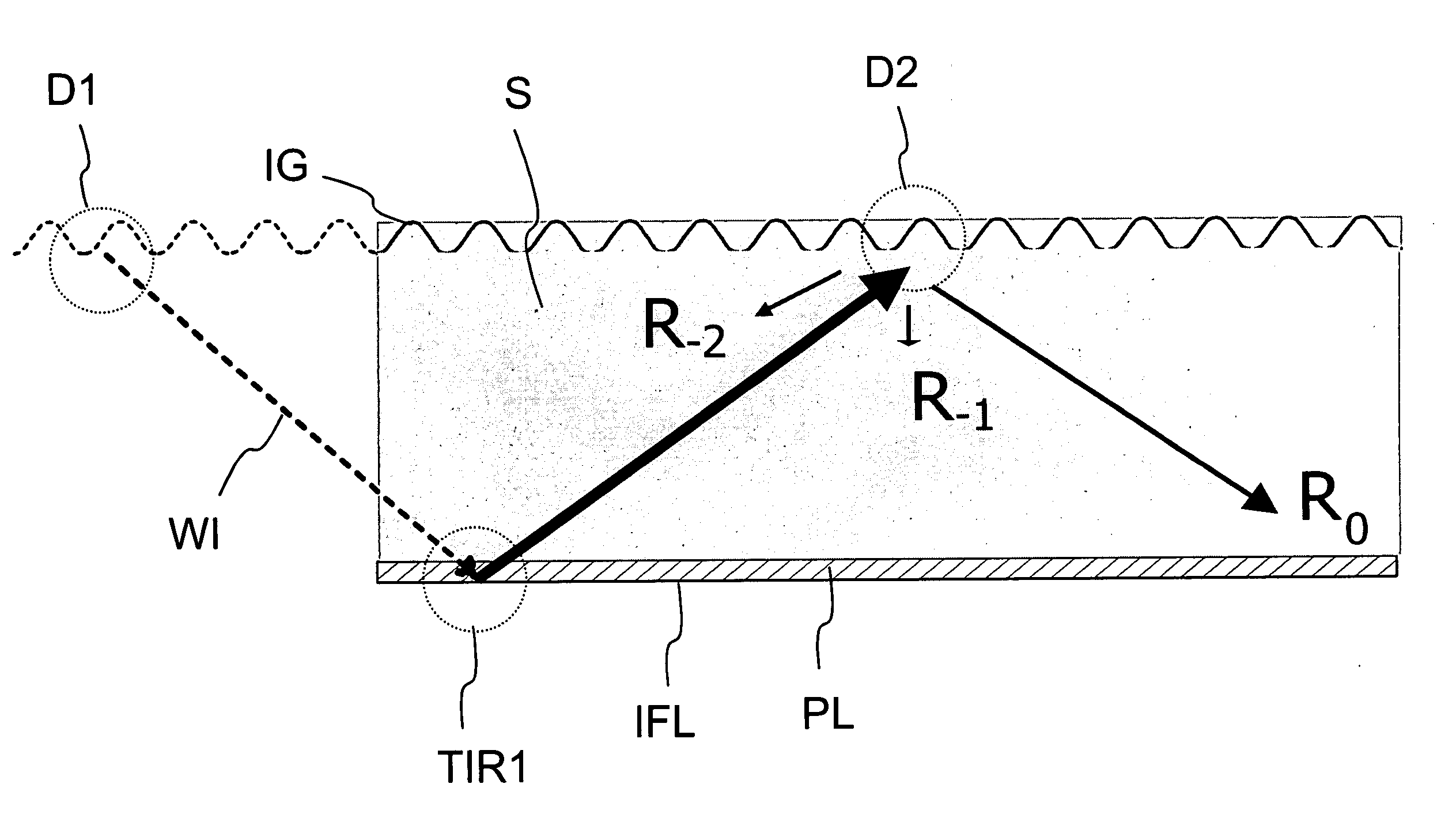

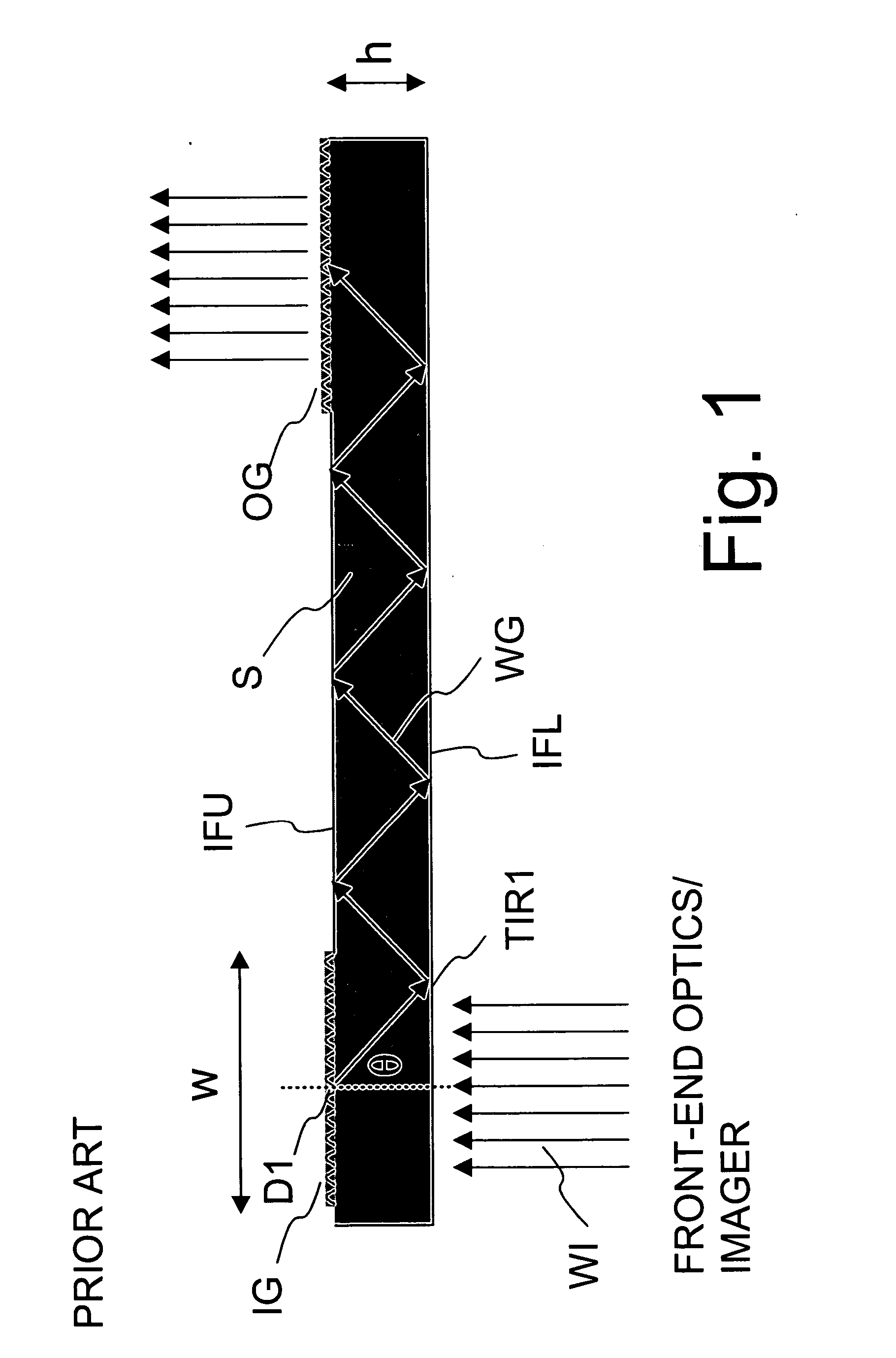

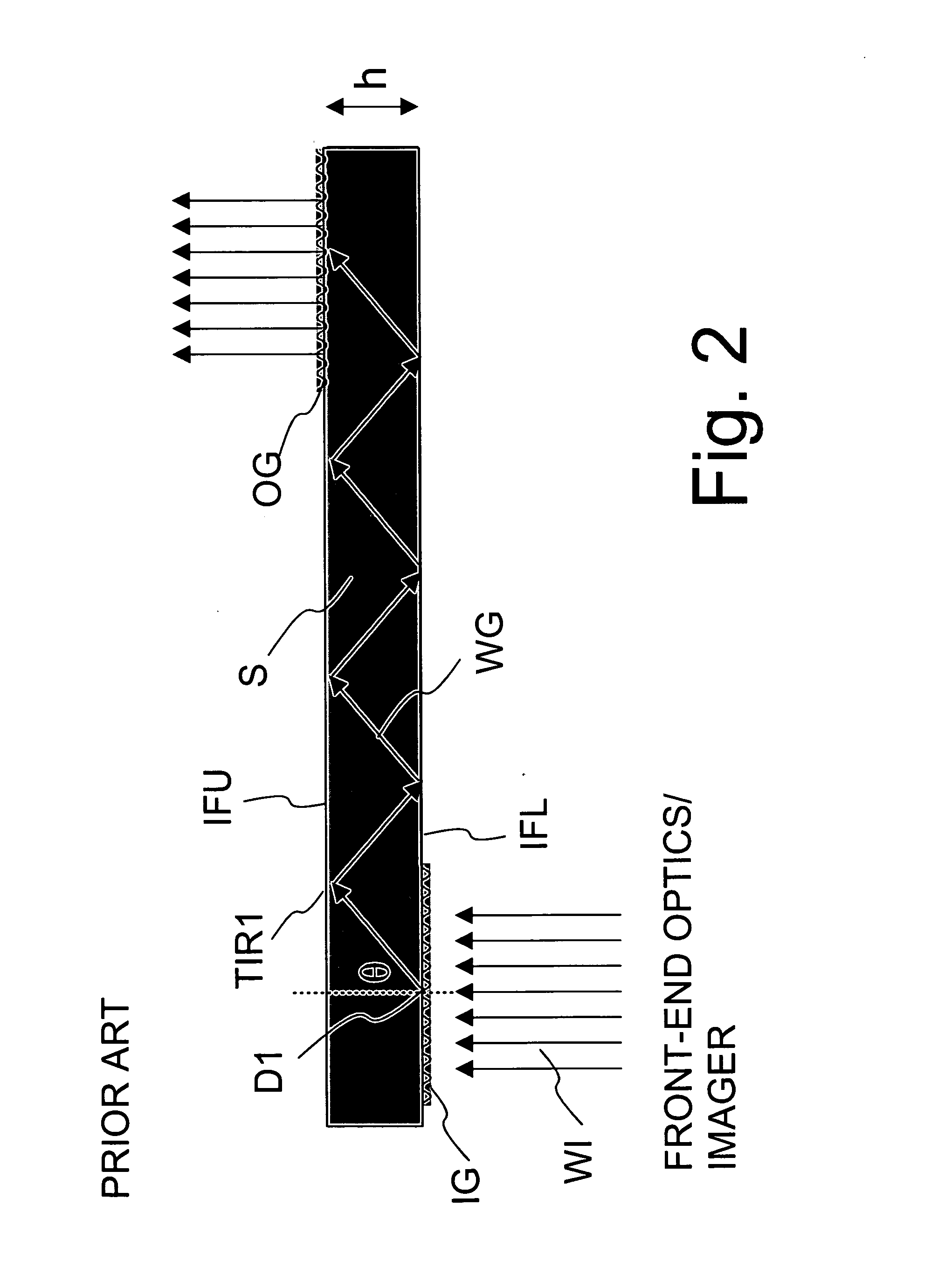

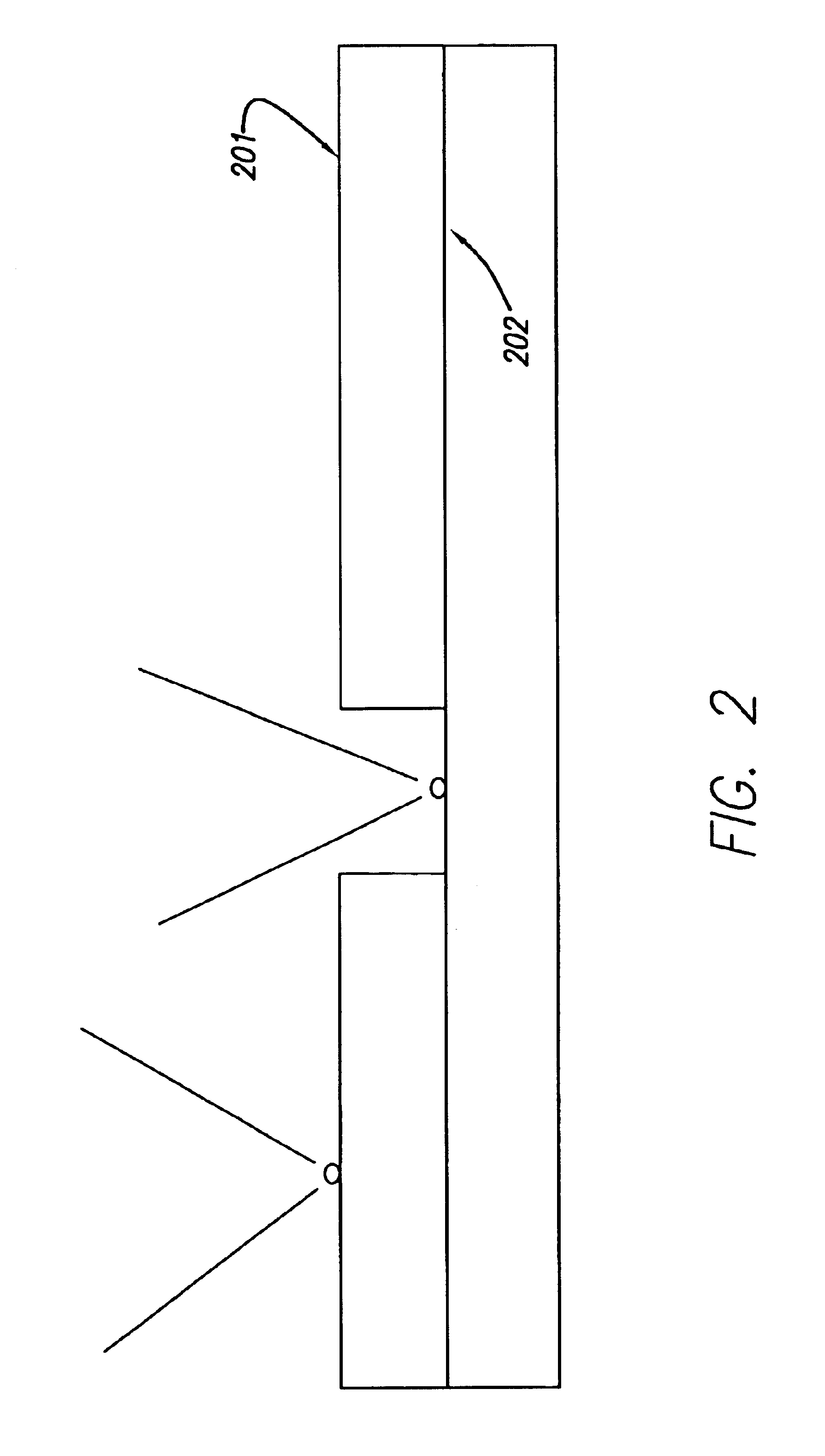

Method and optical system for coupling light into a waveguide

ActiveUS7181108B2Increase width W of in-couplingCoupling light guidesOptical waveguide light guideBeam expanderGrating

A method and optical system for coupling light from an incoming light wave (WI) into a waveguiding substrate (S) arranges the light wave (WI) to interact with a diffractive in-coupling grating element or elements (IG) arranged on or embedded within the substrate (S) and arranged to couple the energy from the light wave (WI) into a waveguided light wave (WG). The polarization state of the light wave (WI) is converted after its first interaction (D1) with the in-coupling grating element / elements (IG) and before a second interaction (D2) with the grating element / elements (IG) takes place. The method minimizes any “reverse” diffractions, which would direct light back towards the front-end optics and therefore to increase the width W of the in-coupling grating / gratings (IG). Preferred embodiments include diffractive beam expanders for virtual displays.

Owner:MAGIC LEAP INC

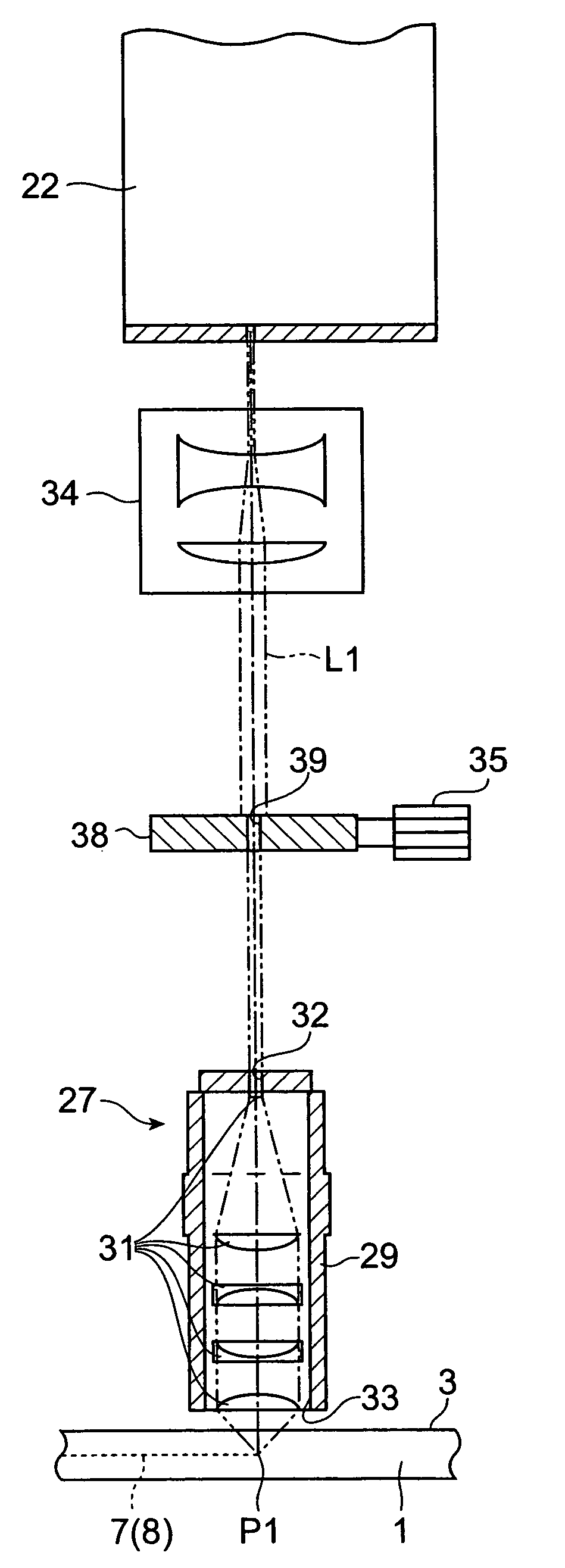

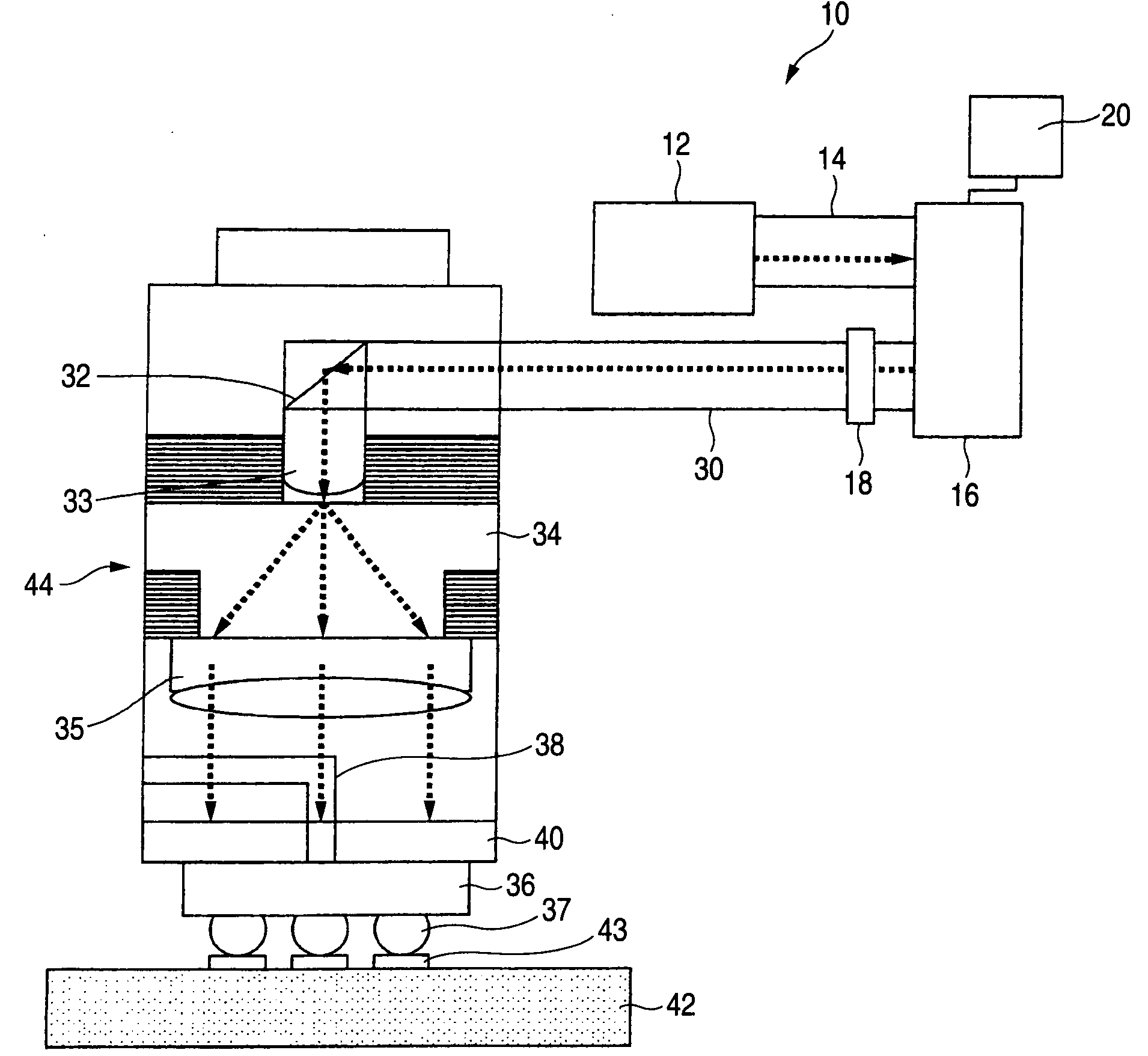

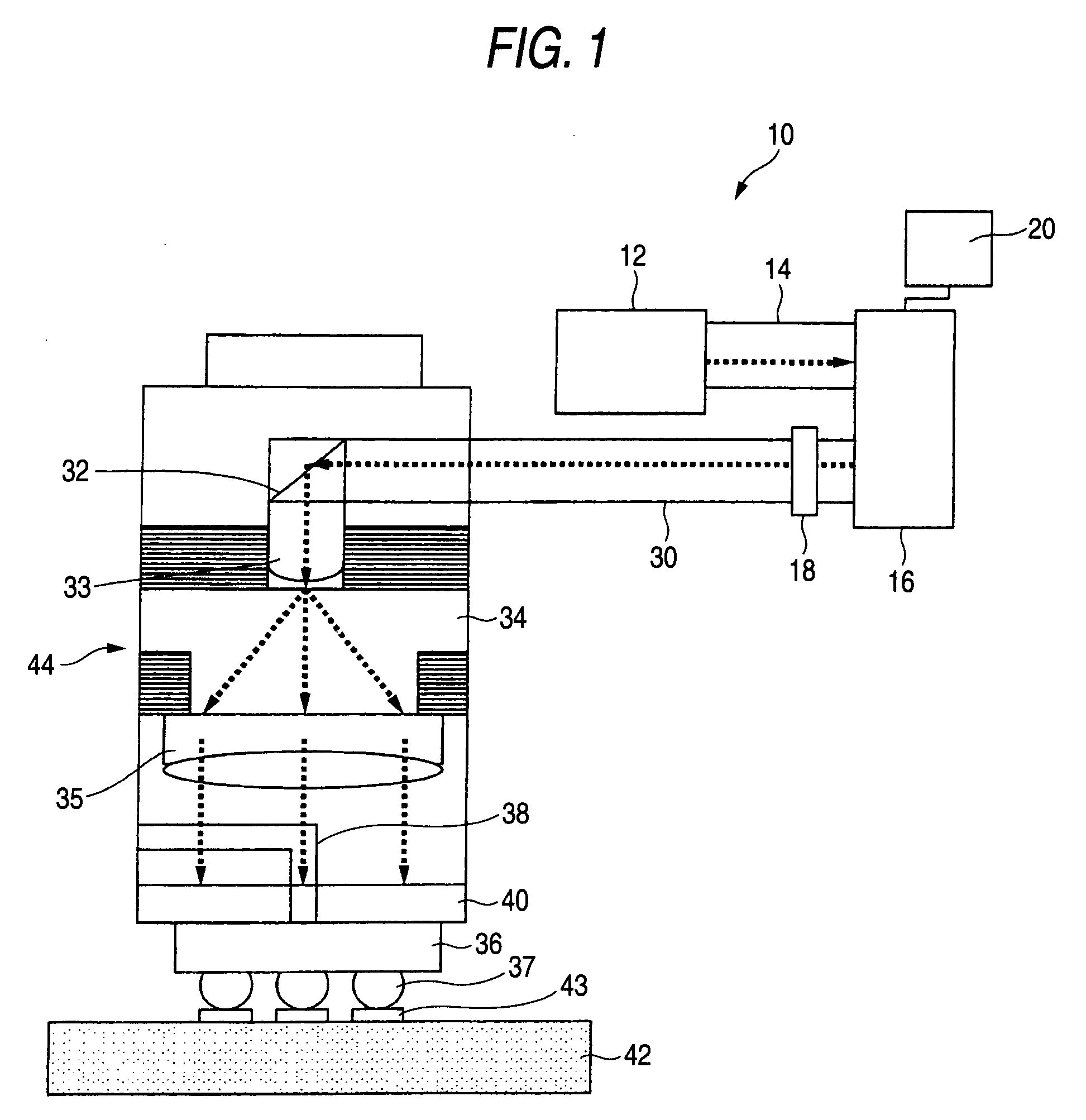

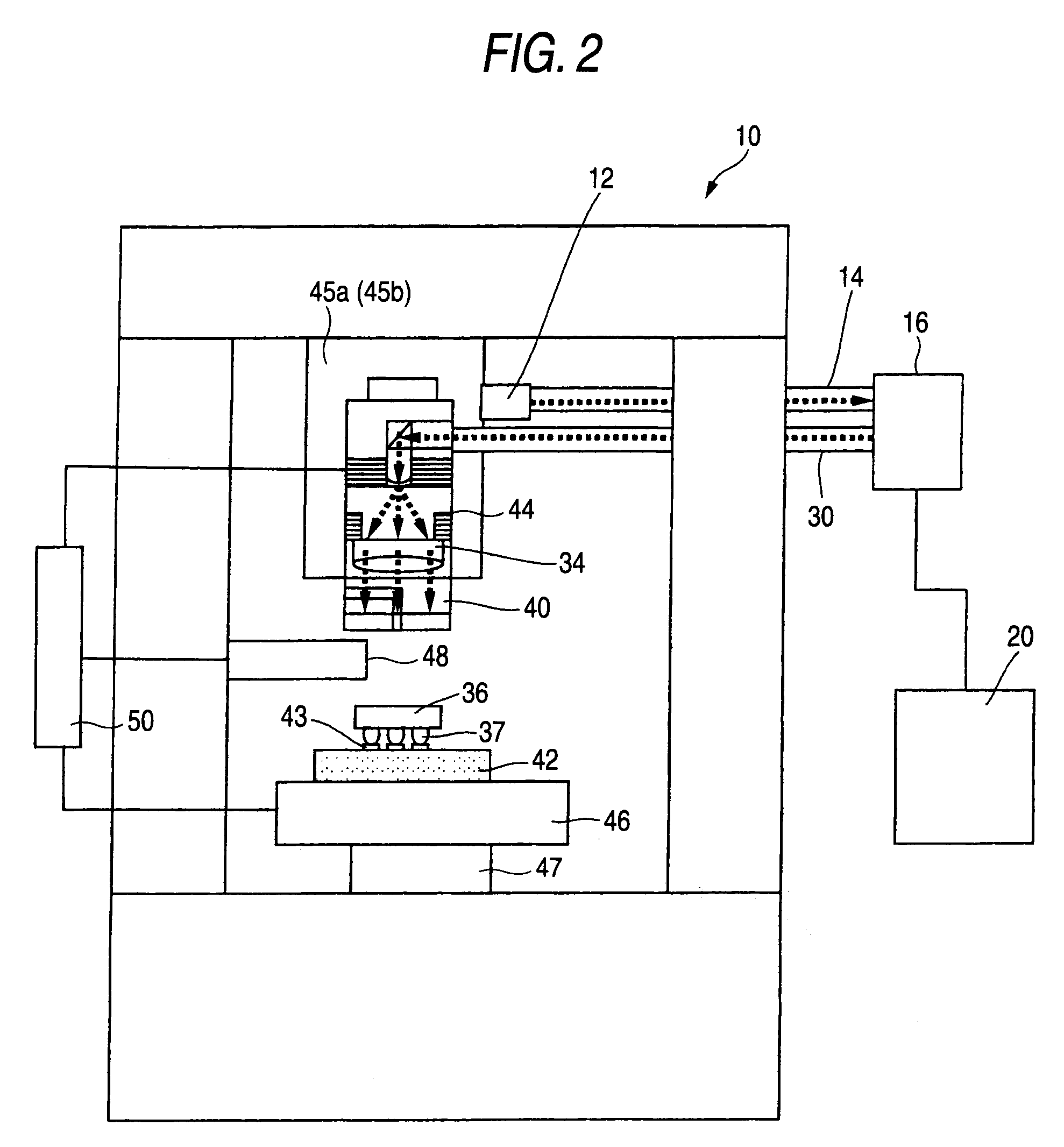

Laser processing device

ActiveUS7489454B2Suppress positional fluctuationReduce lightLaser detailsFine working devicesBeam expanderLaser processing

A laser processing apparatus which can suppress the positional fluctuation in light-converging point of laser light during laser processing is provided. On an optical path of laser light L1 connecting a beam expander 34 and a first light-transmitting hole 32 of a lens holder 29 to each other in a laser processing apparatus 20, a stop member 38 including a second light-transmitting hole 39 having the same diameter as that of the first light-transmitting hole 32 is disposed. Hence, the amount of laser light L1 cut by the surrounding part of the first light-transmitting hole 32 can substantially be eliminated, whereby the lens holder 29 can be prevented from being heated upon irradiation with the laser light L1. Also, even when the stop member 38 is heated by the laser light L1 cut by the surrounding part of the second light-transmitting hole 39, heat is prevented from being transmitted from the stop member 38 to the lens holder 29, since the stop member 38 is separated from the lens holder 29. Therefore, the positional fluctuation in light-converging point P1 of the laser light L1 during laser processing can be suppressed to a low level.

Owner:HAMAMATSU PHOTONICS KK

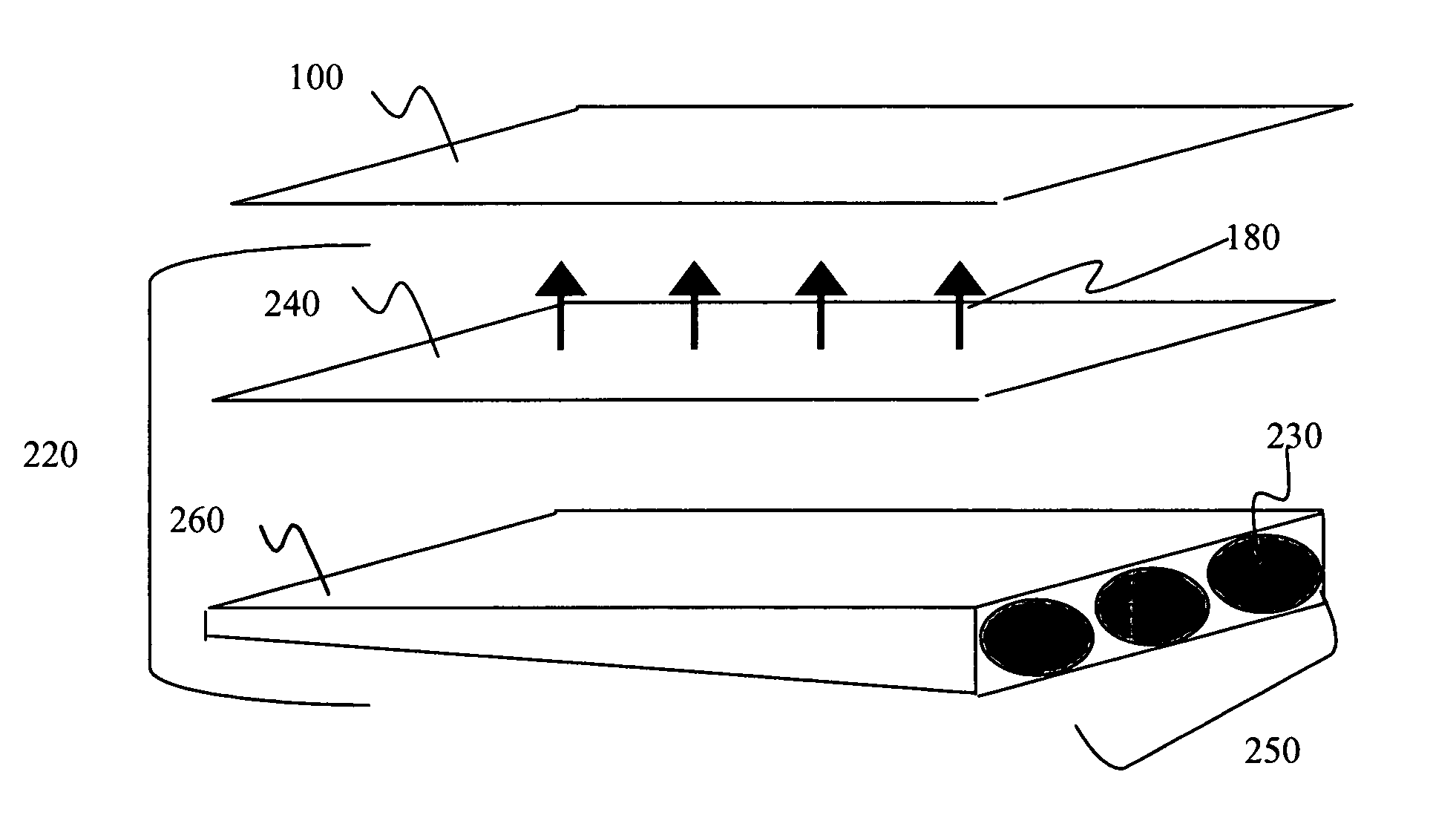

Display device using vertical cavity laser arrays

InactiveUS20050275615A1Reduced divergence angleProcess controlStatic indicating devicesSolid-state devicesDielectricBeam expander

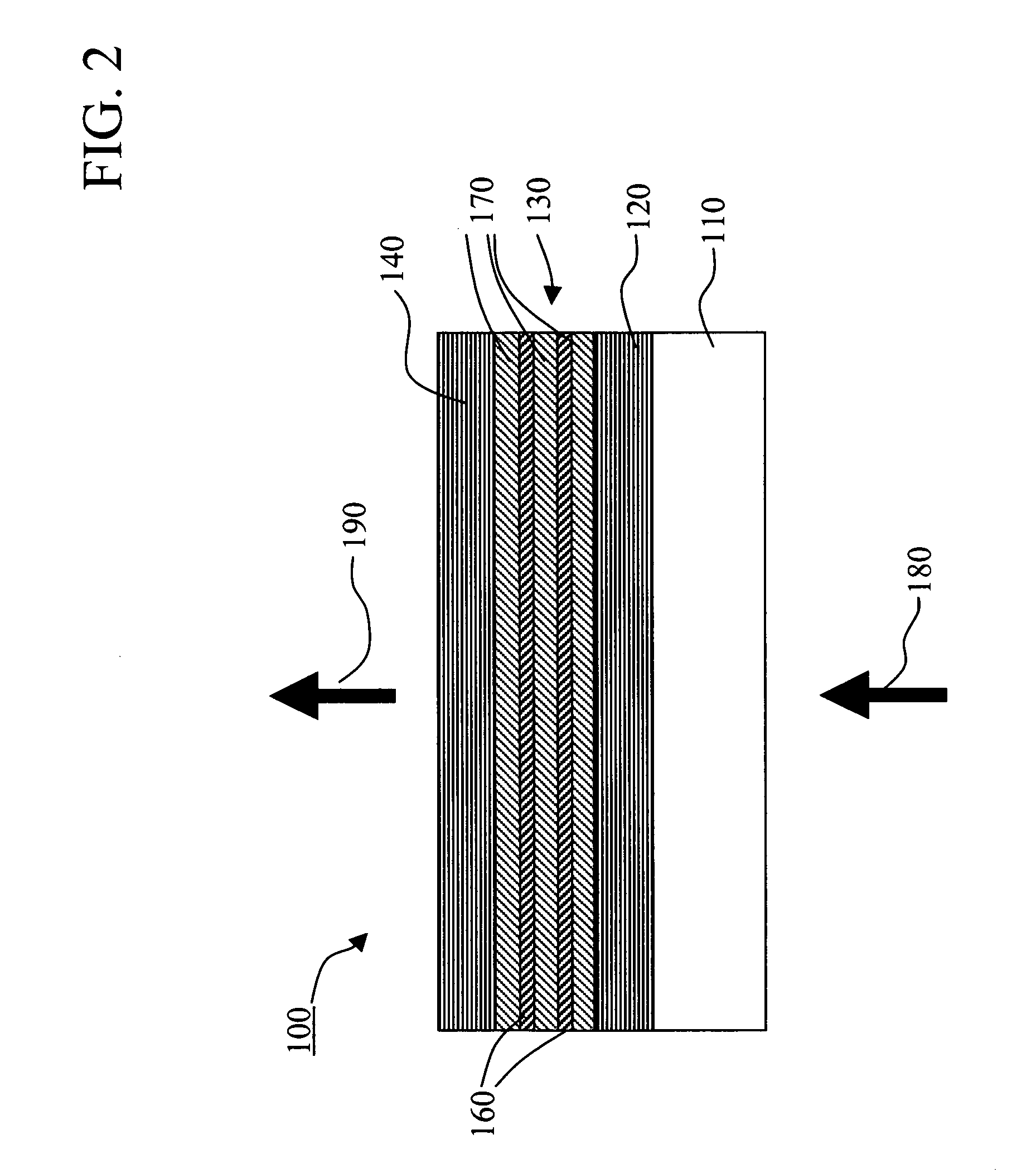

A display apparatus for producing colored pixelated light includes a backlight unit for providing a pump-beam light. The apparatus also includes a microcavity light-producing array responsive to pump-beam light and having pixels wherein each pixel including a transparent substrate, a bottom dielectric stack reflective to light over a predetermined range of wavelengths, an active region responsive to pump-beam light for producing display light, and a top dielectric stack spaced from the bottom dielectric stack and reflective to light over a predetermined range of wavelengths. The apparatus further includes a light shutter for permitting selected display light from the microcavity light-producing array to pass therethrough, a polarizing layer disposed between the microcavity light-producing array and the light shutter, and a beam expander disposed over the light shutter for increasing the angular cone of view of the display light.

Owner:EASTMAN KODAK CO

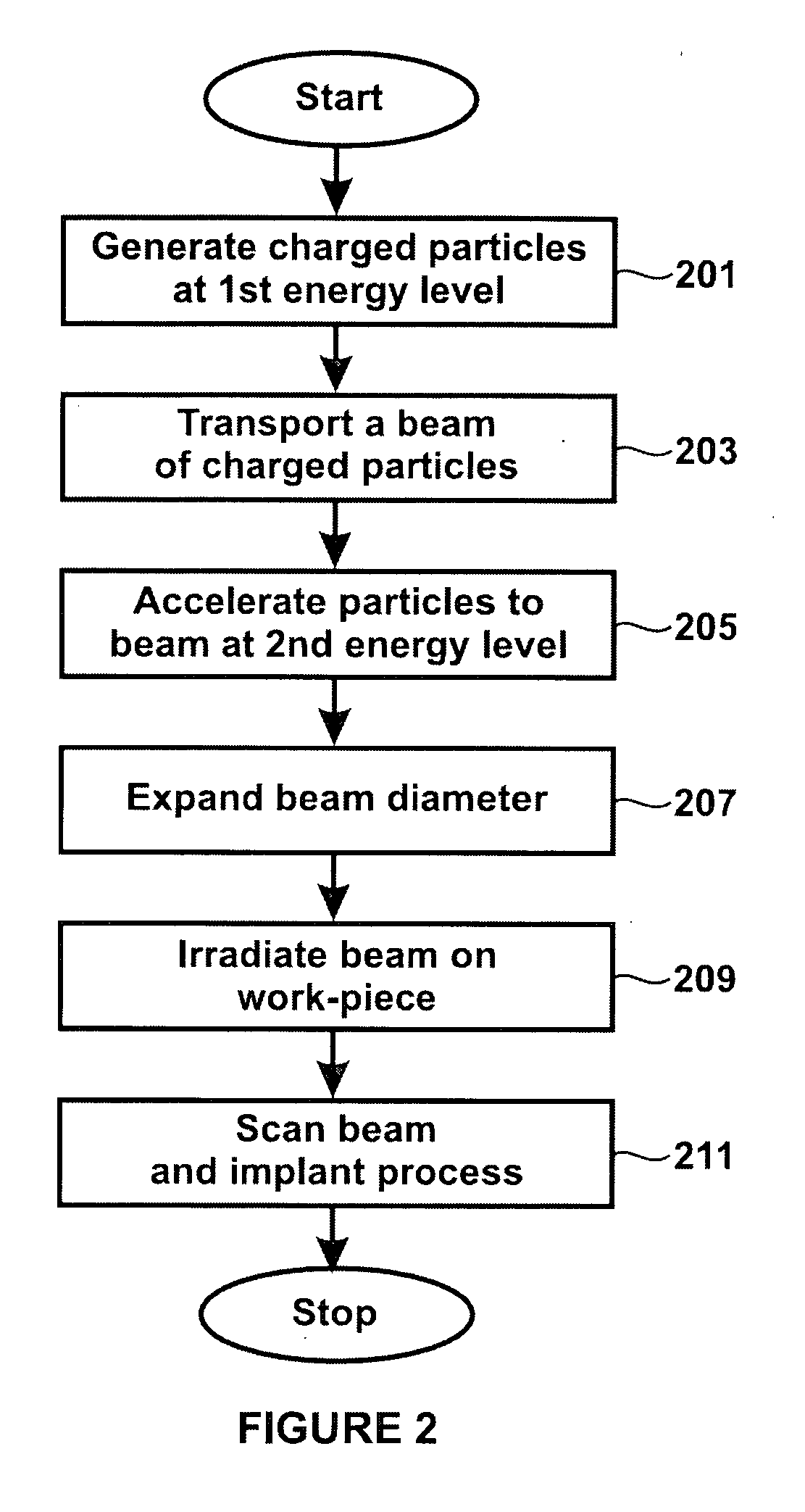

Apparatus and method for introducing particles using a radio frequency quadrupole linear accelerator for semiconductor materials

InactiveUS20080128641A1Cost effectiveQuality improvementElectric discharge tubesSemiconductor/solid-state device manufacturingBeam expanderSemiconductor materials

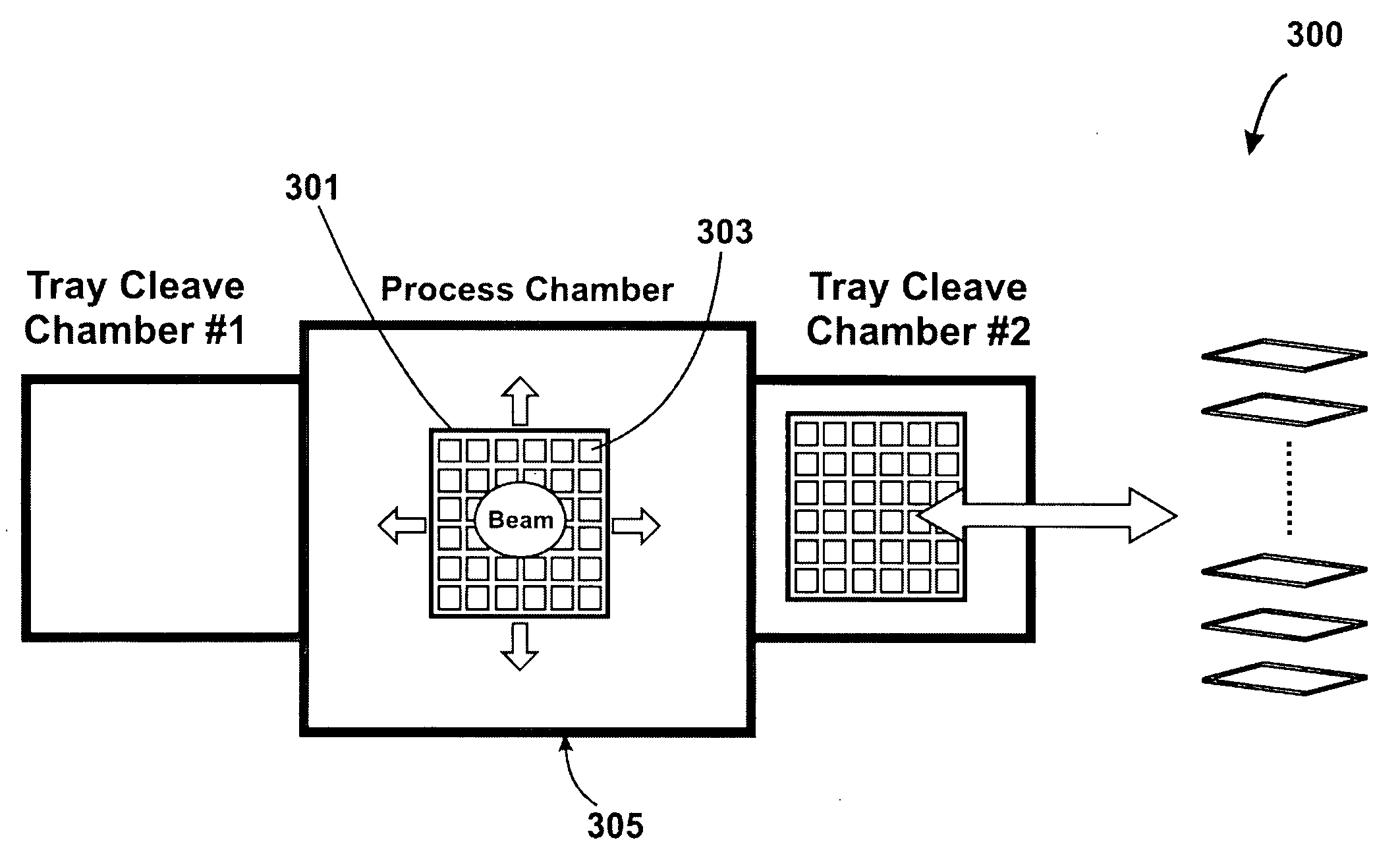

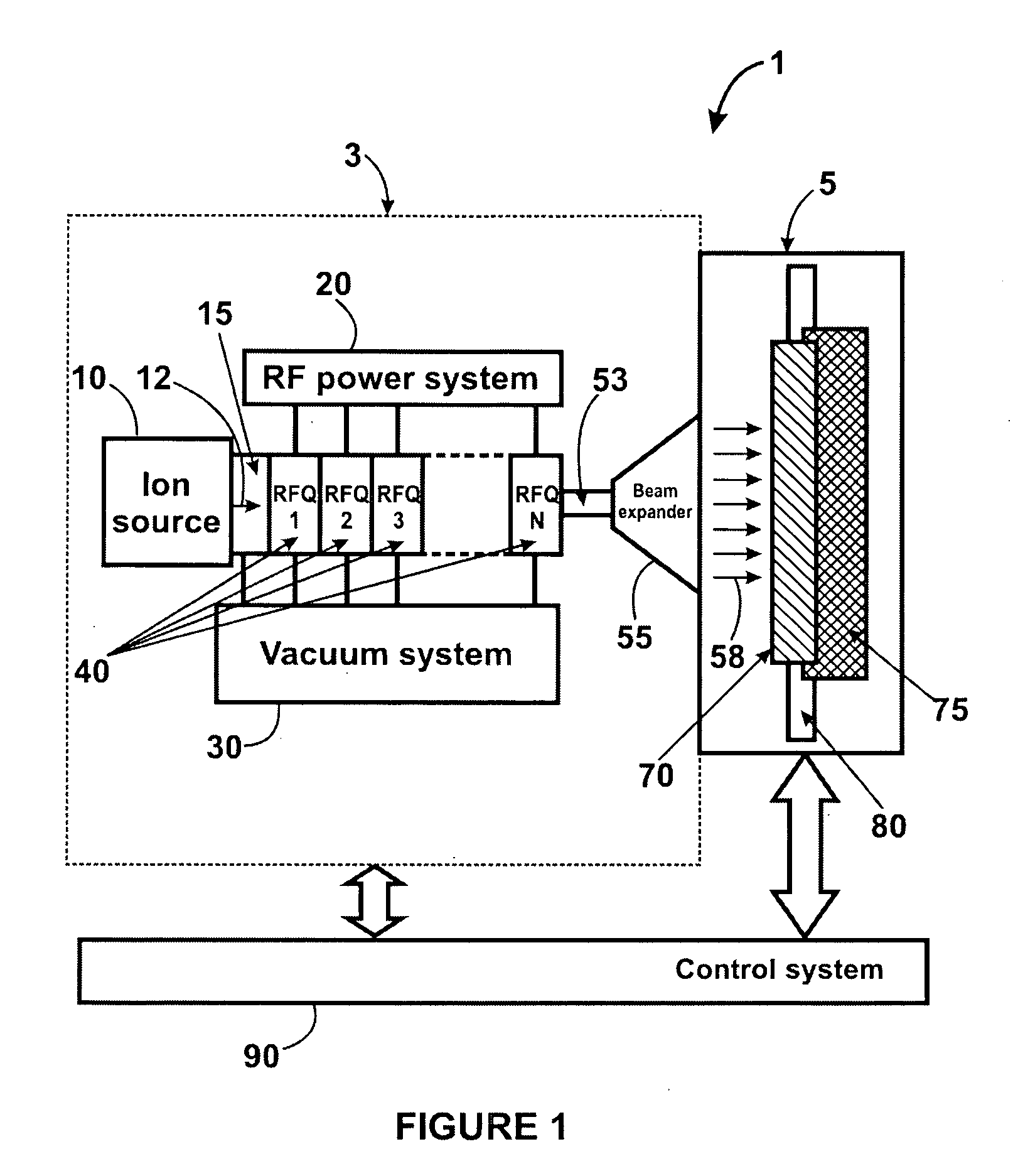

A system for forming one or more detachable semiconductor films capable of being free-standing. The apparatus includes an ion source to generate a plurality of collimated charged particles at a first energy level. The system includes a linear accelerator having a plurality of modular radio frequency quadrupole (RFQ) elements numbered from 1 through N successively coupled to each other, where N is an integer greater than 1. The linear accelerator controls and accelerates the plurality of collimated charged particles at the first energy level into a beam of charge particles having a second energy level. RFQ element numbered 1 is operably coupled to the ion source. The system includes an exit aperture coupled to RFQ element numbered N of the RFQ linear accelerator. In a specific embodiment, the system includes a beam expander coupled to the exit aperture, the beam expander being configured to process the beam of charged particles at the second energy level into an expanded beam of charged particles. The system includes a process chamber coupled to the beam expander and a workpiece provided within the process chamber to be implanted

Owner:SILICON GENERAL CORPORATION

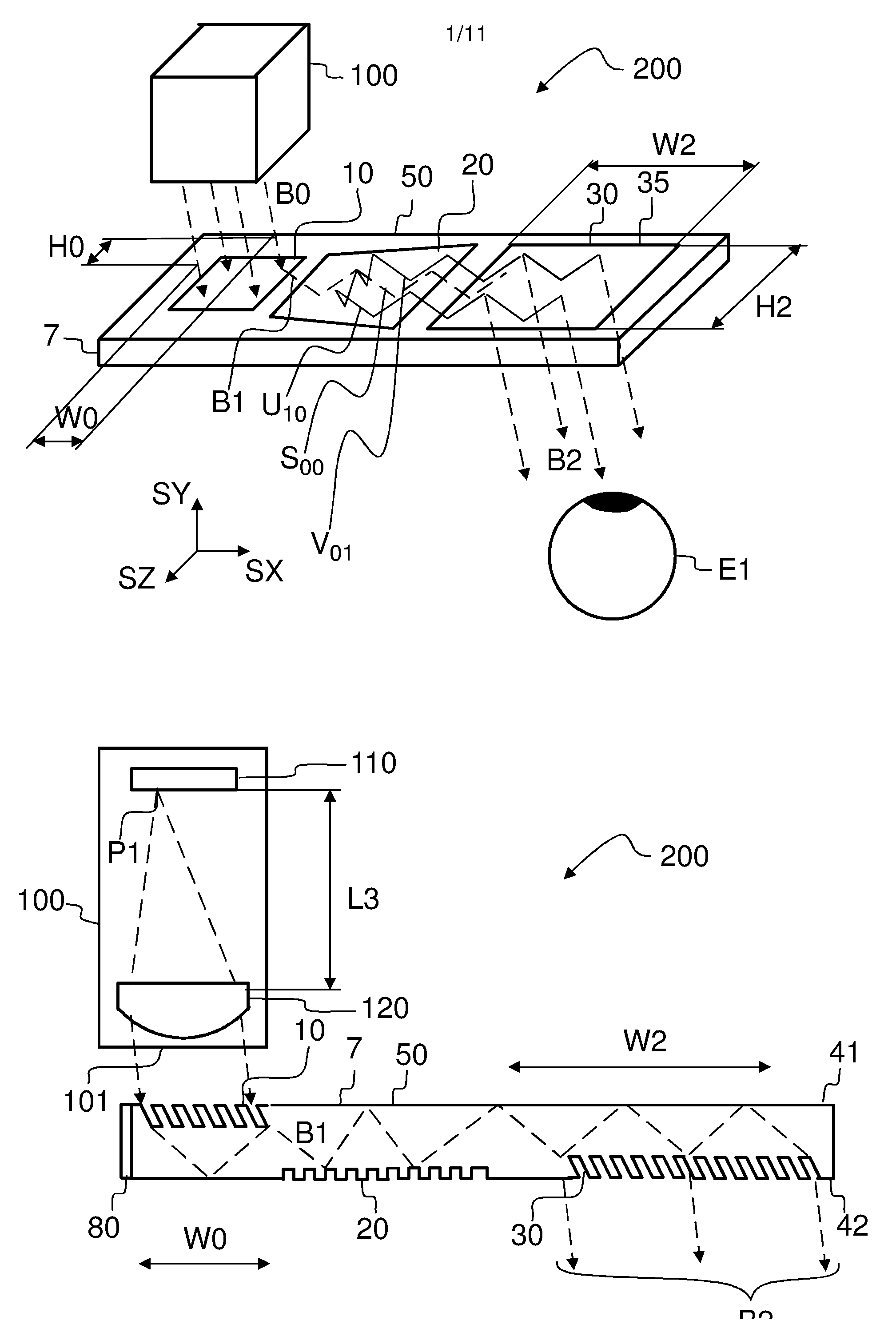

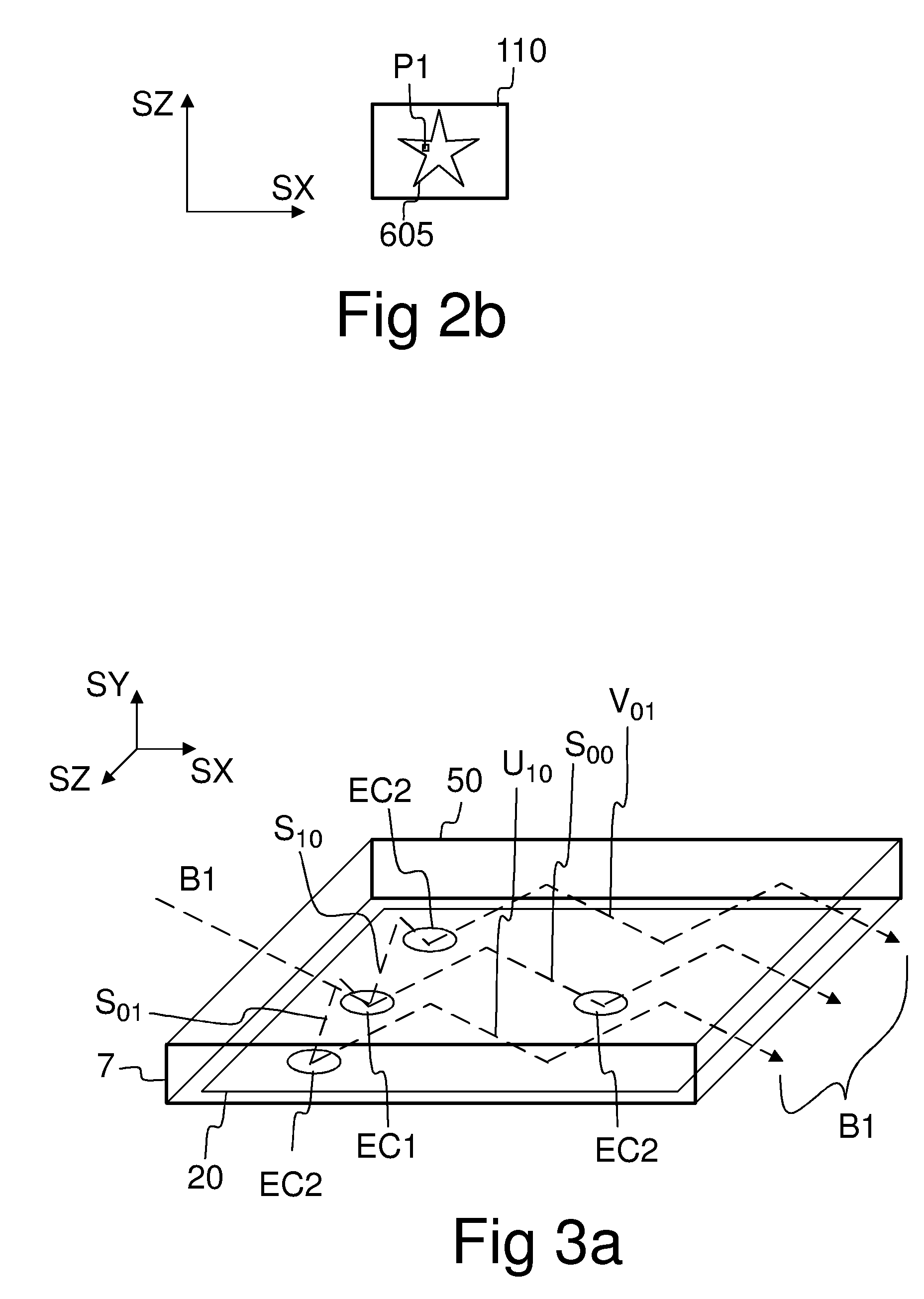

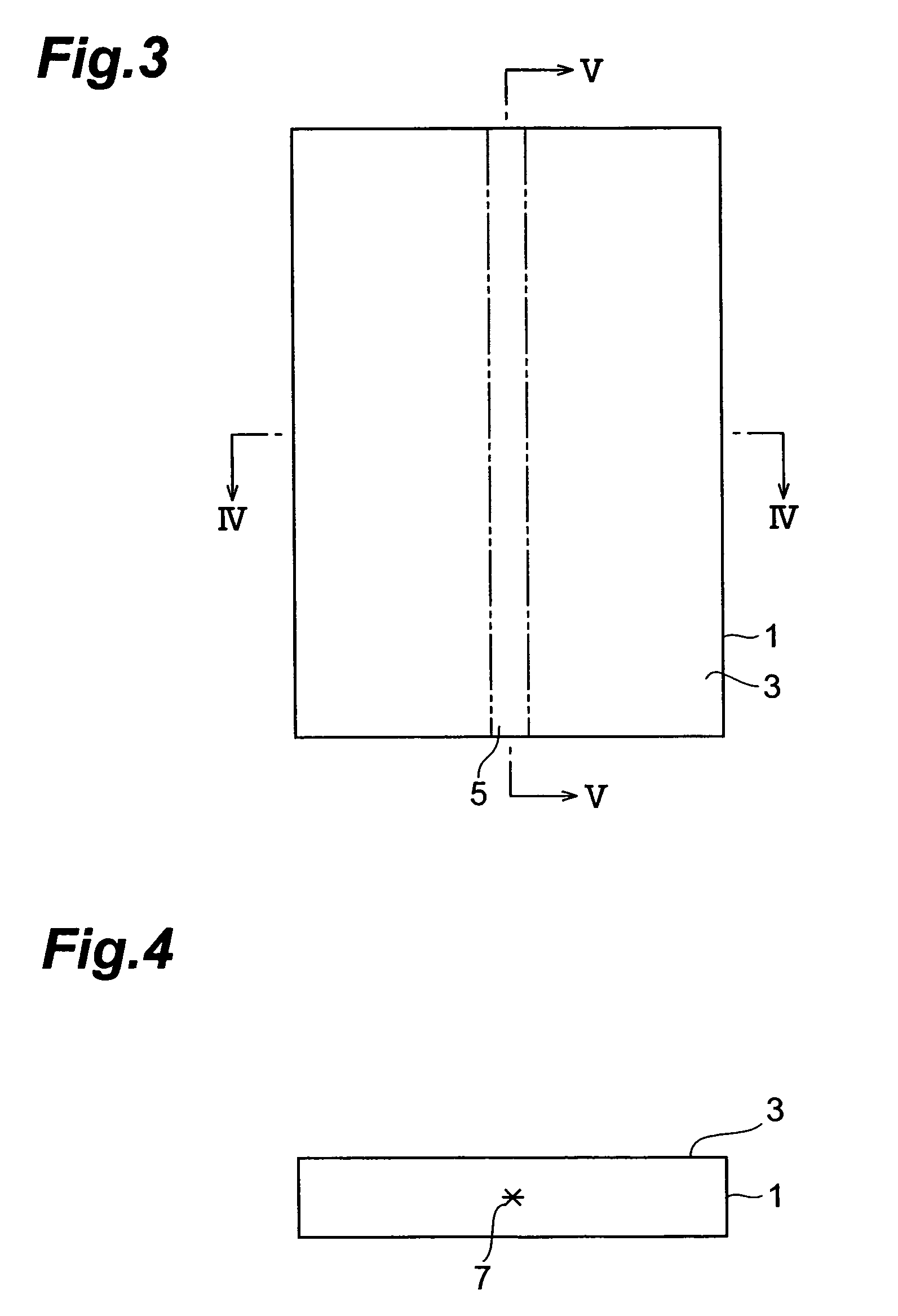

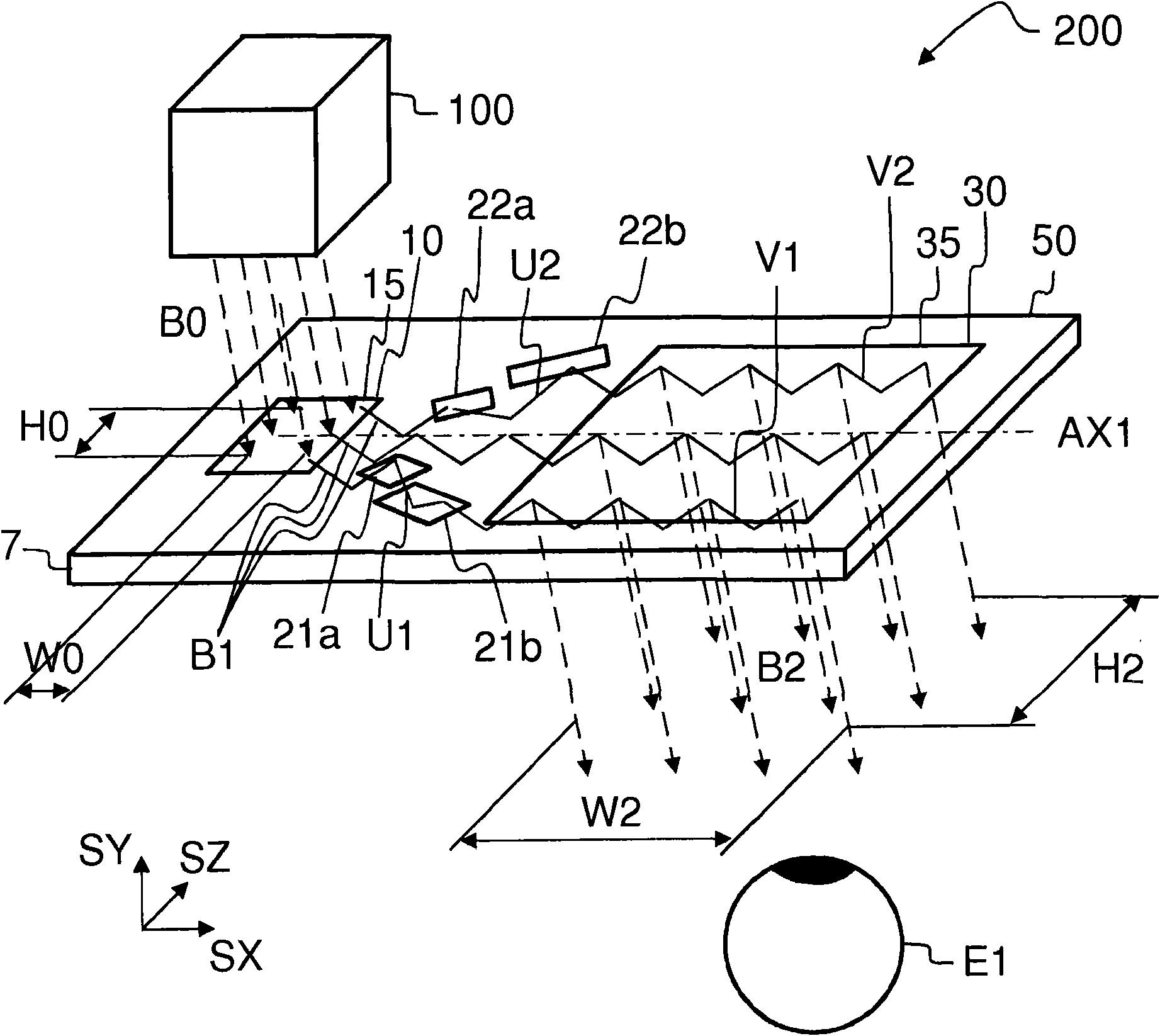

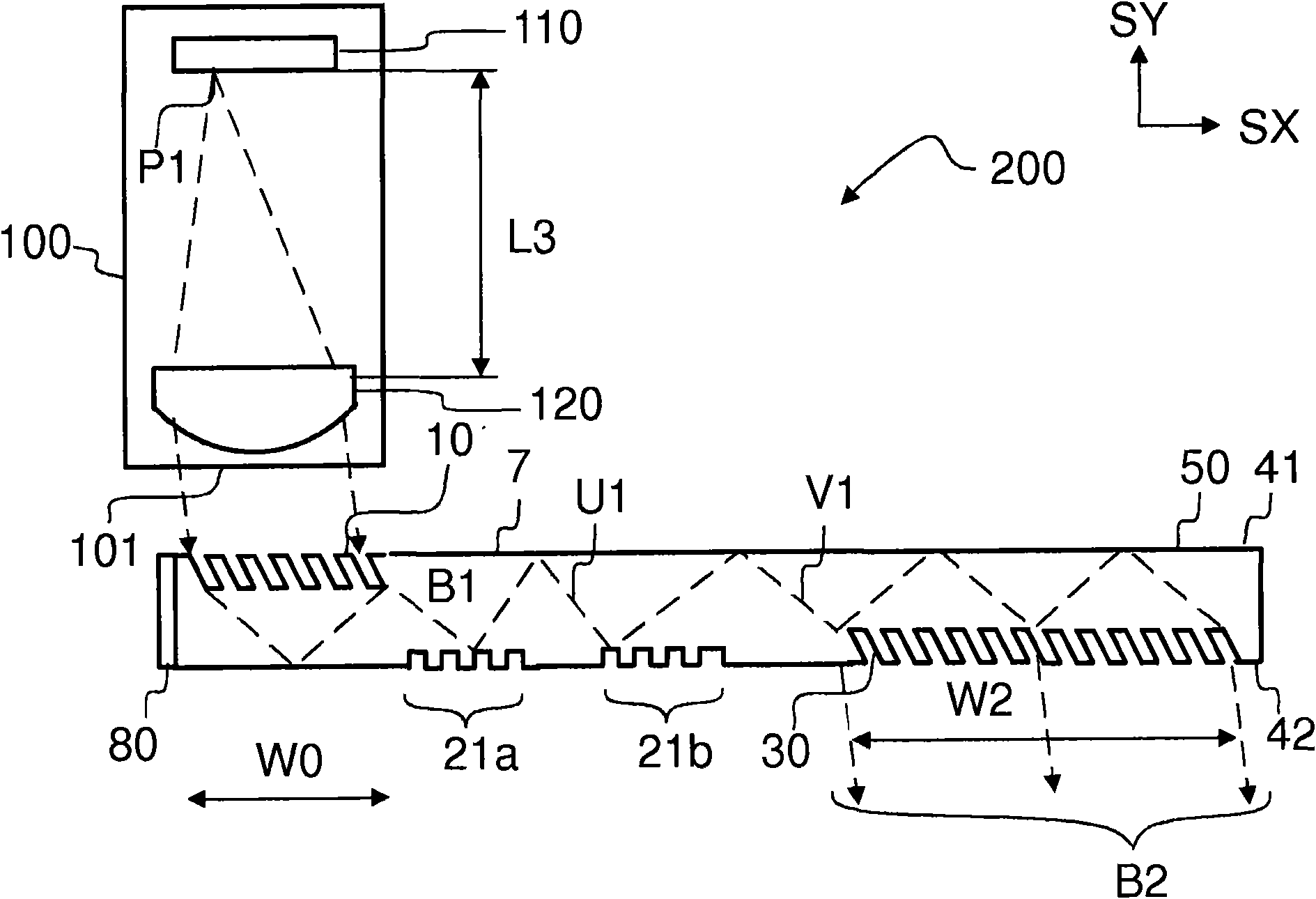

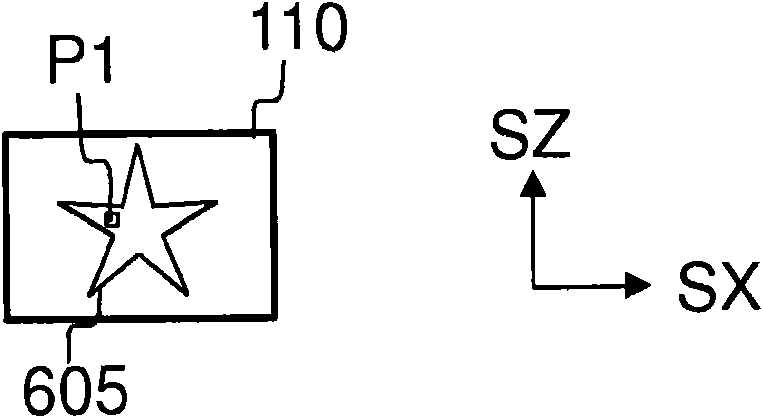

A diffractive beam expander and a virtual display based on a diffractive beam expander

ActiveCN101688977AReduce the number of interactionsImprove parallelismDiffraction gratingsPlanar/plate-like light guidesBeam expanderGrating

A diffractive beam expander (50) comprises a substantially planar waveguiding substrate, an input grating (10) to provide an in-coupled beam (B1) propagating within said substrate, and an output grating (30) to provide an out-coupled beam. The expander (50) comprises also four or more further grating portions to expand the height of the in-coupled beam (B1). A part of the in-coupled light is diffracted by a first deflecting grating portion (21a) to provide a first deflected beam. A part of the in-coupled light is diffracted by a second deflecting grating portion (22a) to provide a second deflected beam. The first deflected beam propagates downwards and the second deflected beam propagates upwards with respect to the in-coupled beam (B1). The first deflected beam impinges on a first direction-restoring grating portion (21b) and the second deflected beam impinges on a second direction-restoring grating portion (22b). The first restoring grating portion (21b) provides a first restored beam (V1) and the second restoring grating portion (22b) provides a second restored beam (V2), which both have the same direction as the in-coupled beam (B1). Out-coupling provides an output beam which is parallel to the input beam, and has a greater vertical dimension than said input beam.

Owner:MAGIC LEAP

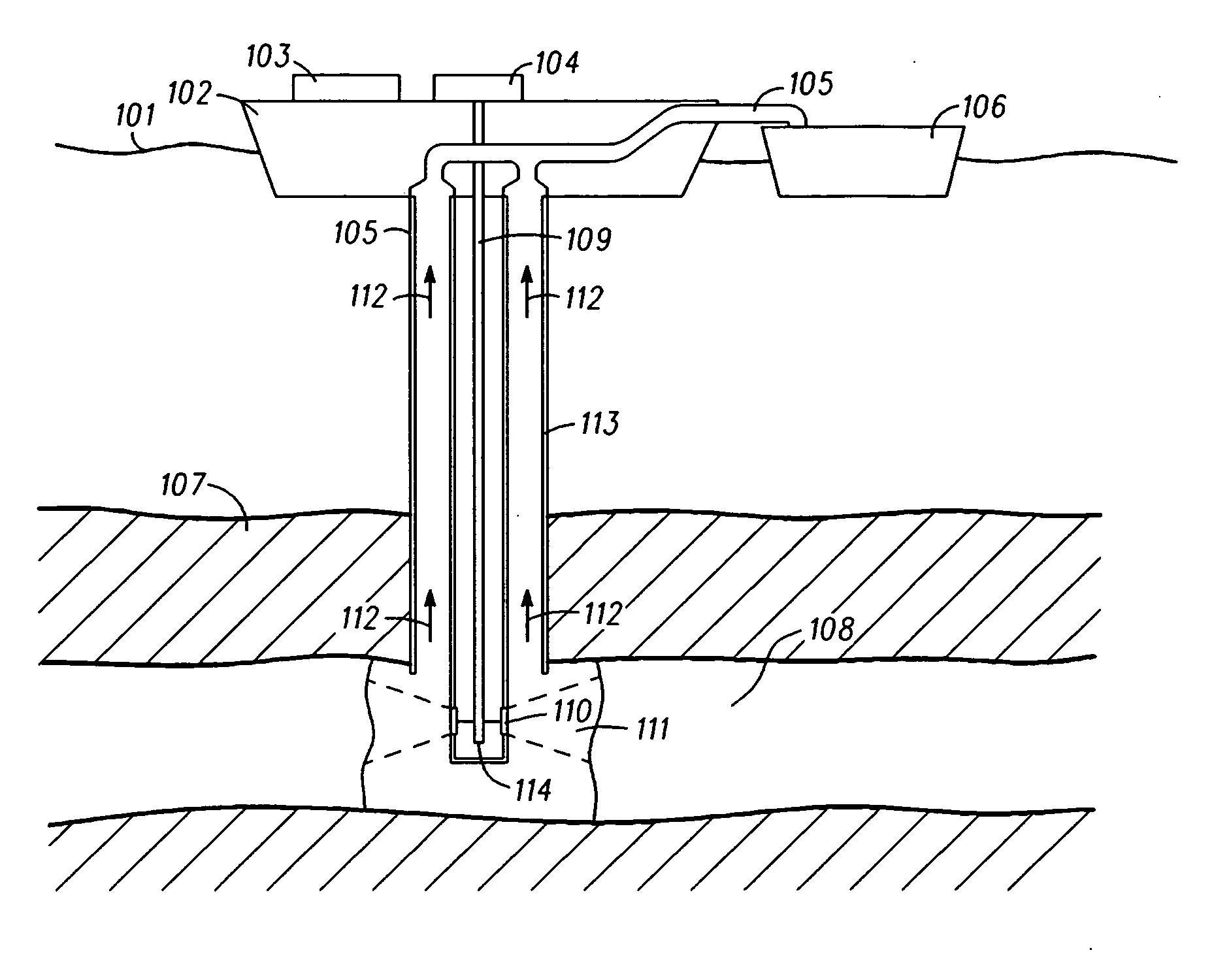

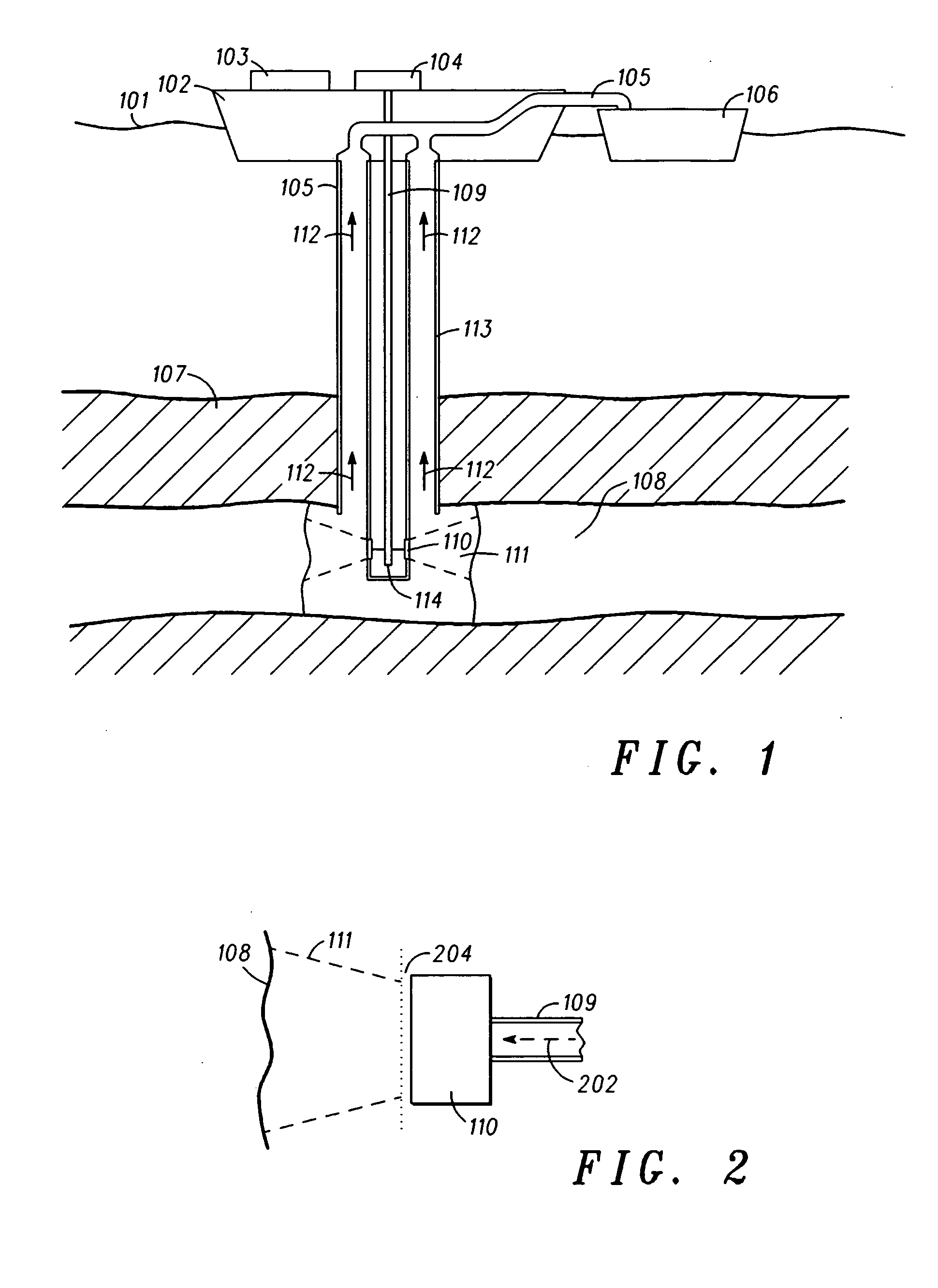

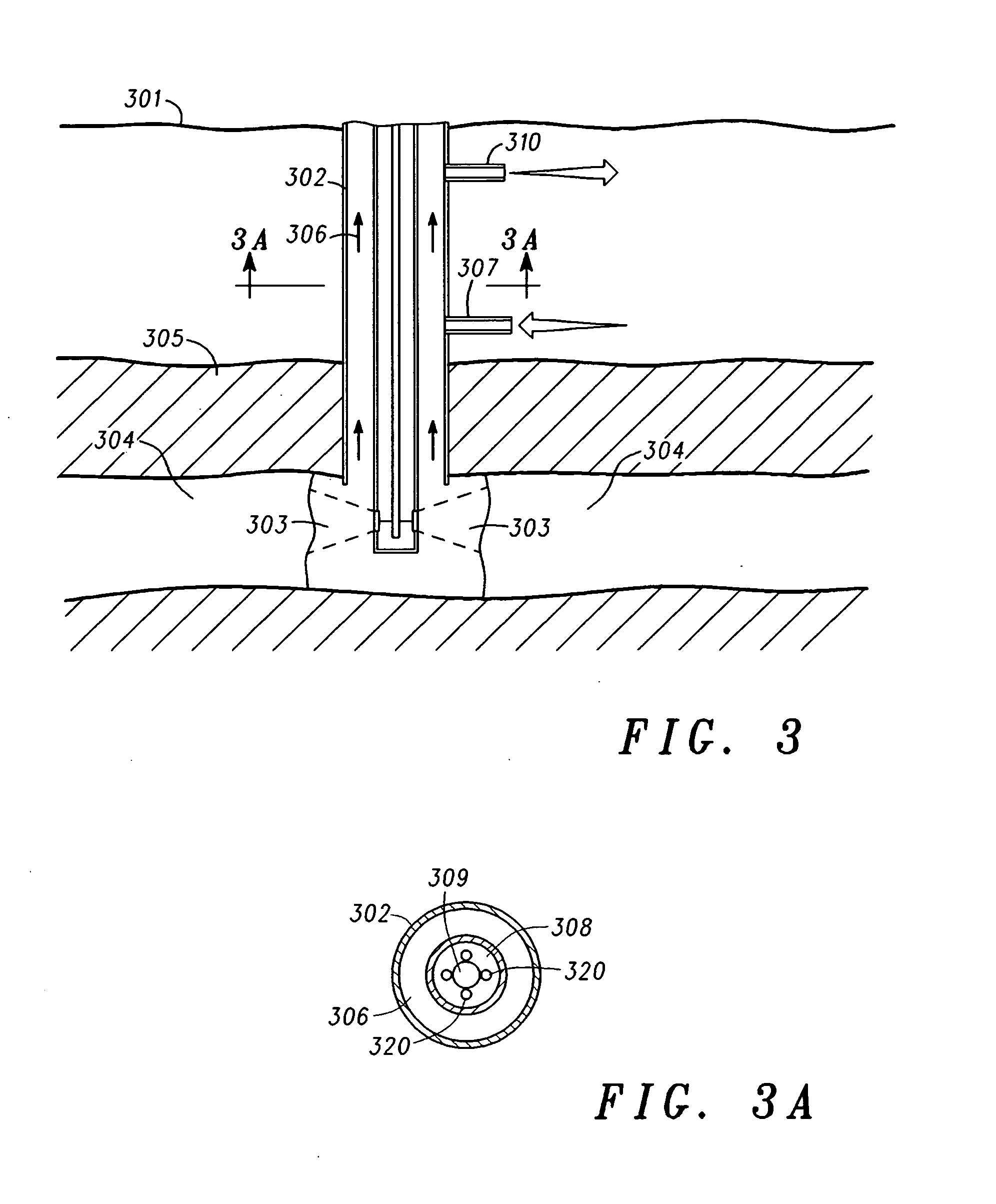

Methane extraction method and apparatus using high-energy diode lasers or diode-pumped solid state lasers

InactiveUS20070267220A1Efficient productionConstructionsDisloding machinesFiberDiode-pumped solid-state laser

A method and apparatus for extracting methane gas from methane hydrate. The method includes heating the methane hydrate with a laser apparatus. The laser apparatus includes a diode laser or a solid state laser that is pumped with a diode laser. The laser is guided to a working end of a tool with a fiber optic bundle. The tool is guided to heat the methane hydrate with the laser, which emanates from a beam expander at the working end of the tool. The tool can be modified for removing obstructions of methane hydrate in pipelines. Also, the tool can be modified for extracting methane from mined methane hydrate, which is in a container. The characteristics of diode lasers or diode-pumped solid state lasers such as efficiency, size, nature of operation, environmental impact and durability, make methane gas extraction from methane hydrate economically feasible.

Owner:NORTHROP GRUMAN CORP

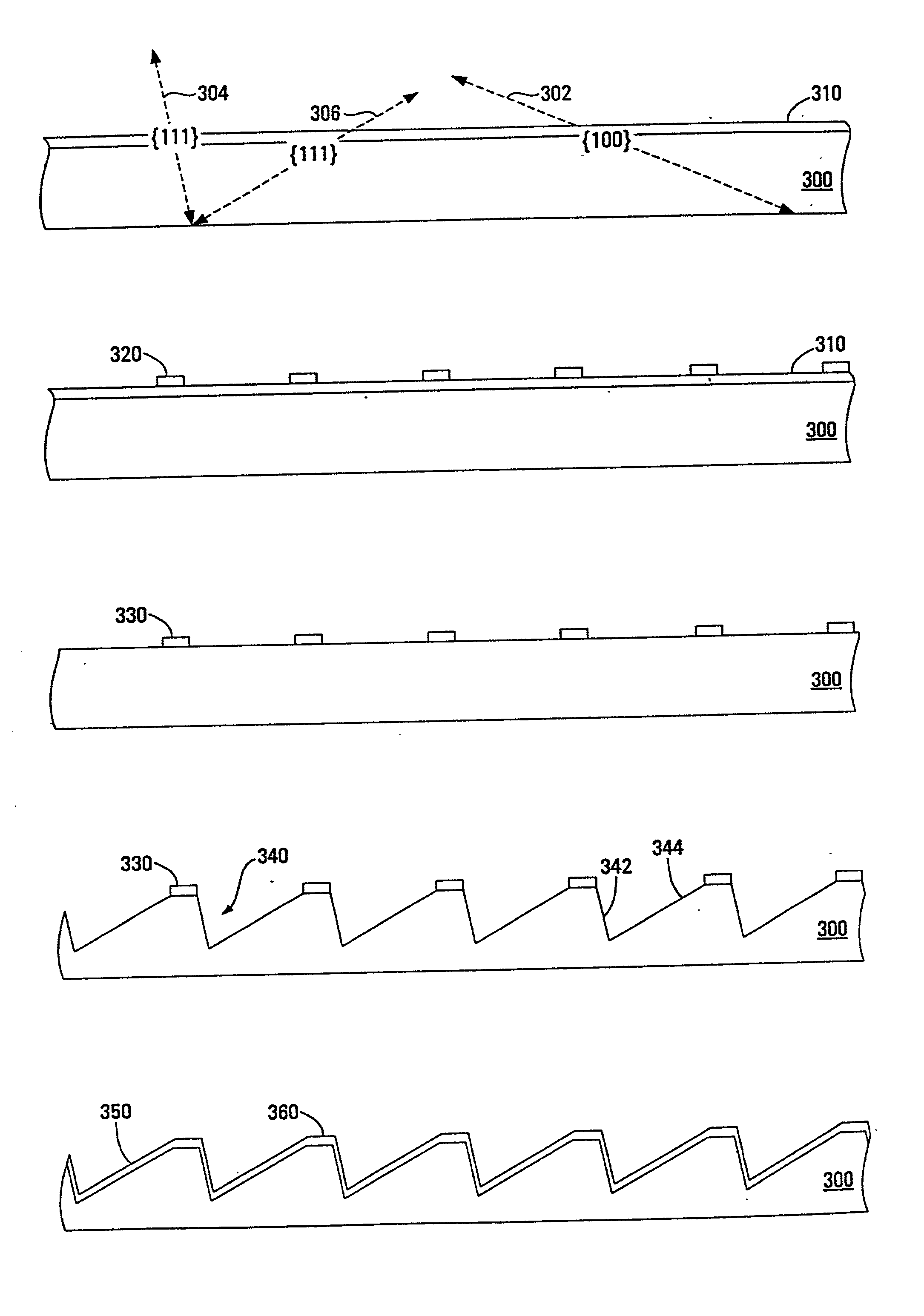

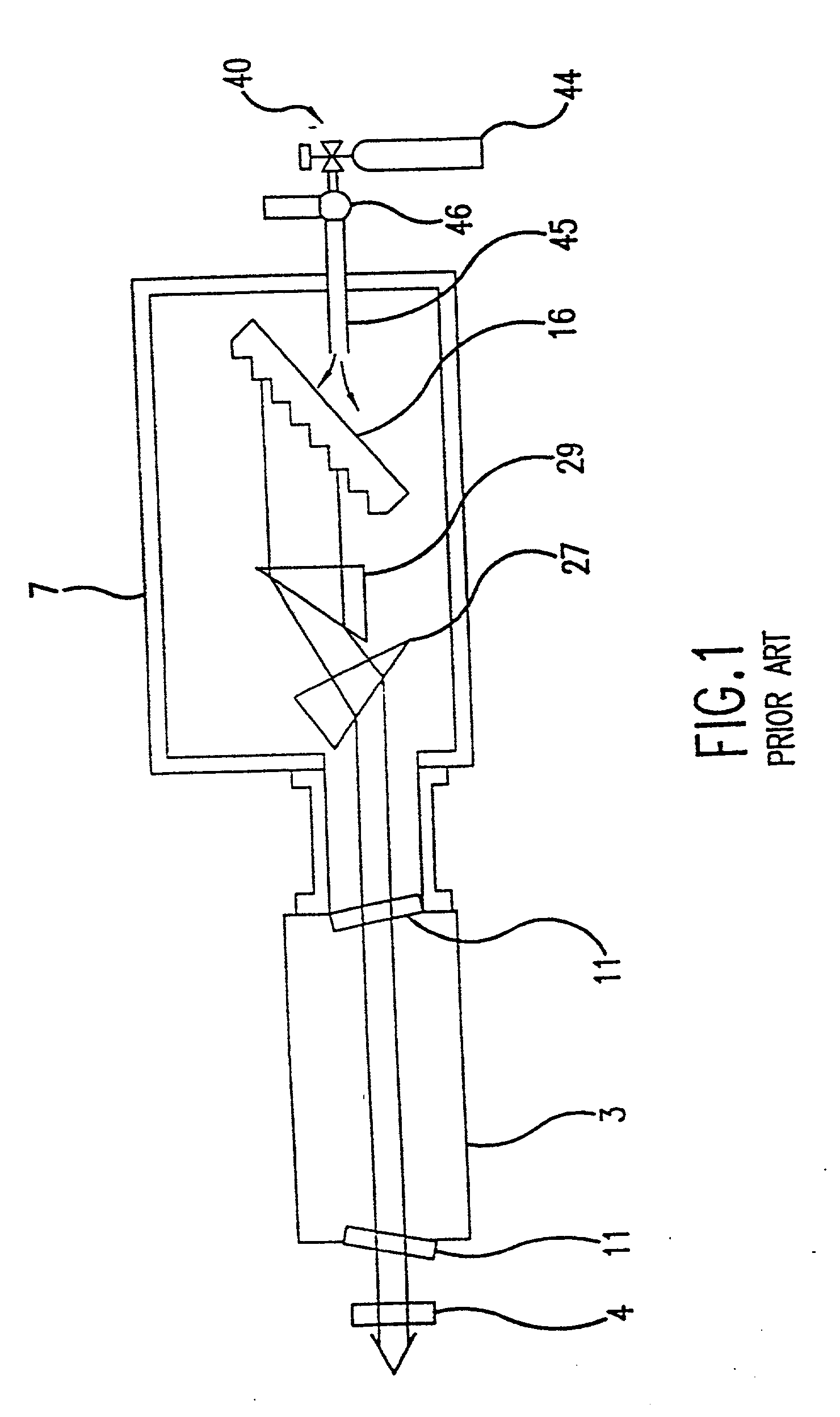

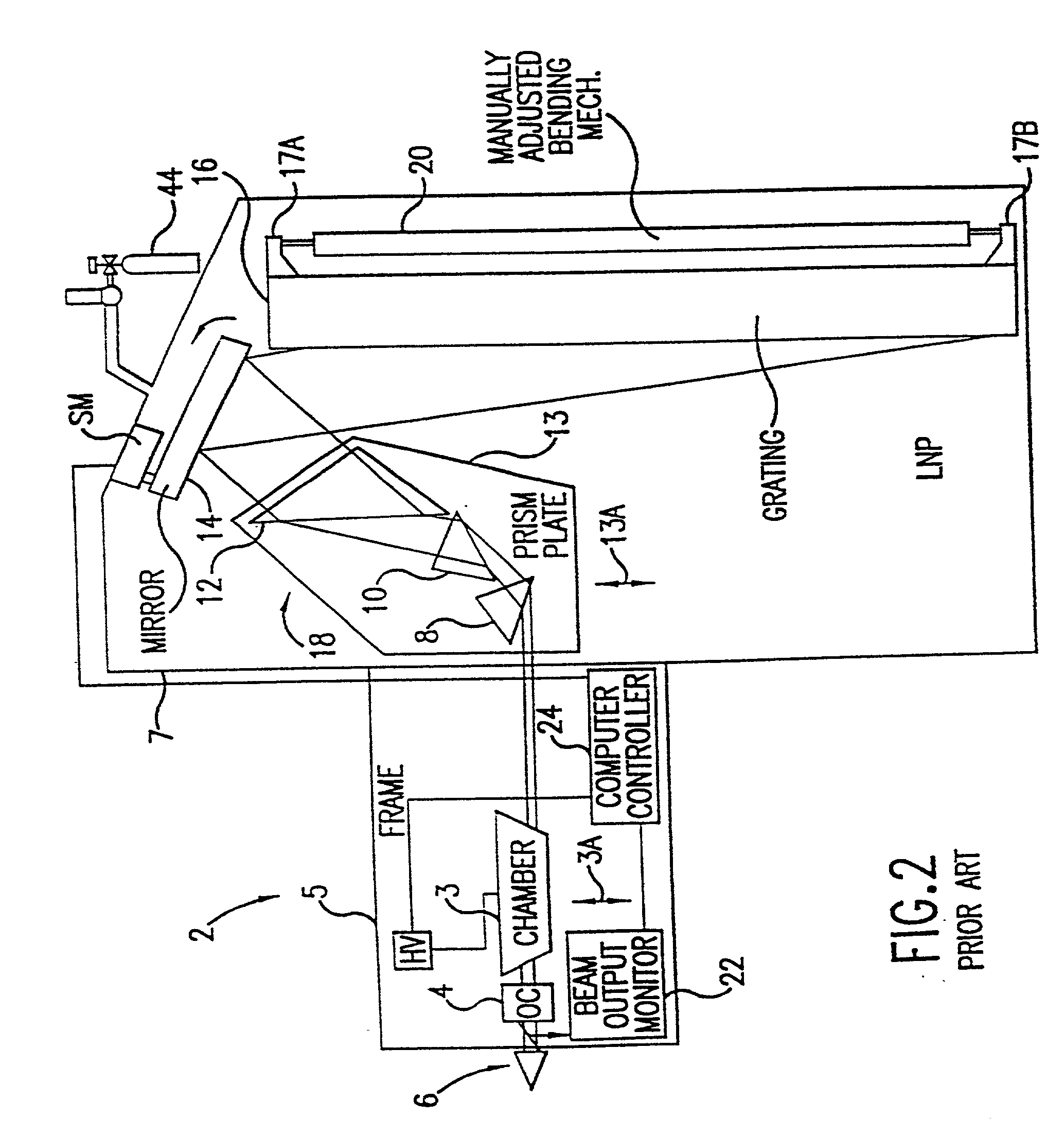

Large diffraction grating for gas discharge laser

InactiveUS20020127497A1Increased beam expansionSmall bandwidthPhotomechanical apparatusDiffraction gratingsBeam expanderLithography process

A grating based line narrowing unit for gas discharge lasers with increased beam expansion to produce smaller bandwidths. The grating has a grating surface larger than 100 cm.sup.2 and is a replica grating produced from a master grating produced with a lithography process on a single crystal substrate. In preferred embodiments, a beam from the chamber of the laser is expanded with four prism beam expanders. The large grating, much larger than gratings historically produced from diamond lined gratings, permit substantial reductions in bandwidth while maintaining laser efficiency. A narrow band of wavelengths in the expanded beam is reflected from a grating in a Littrow configuration back via the bi-directional beam expanders into the laser chamber for amplification.

Owner:CYMER INC

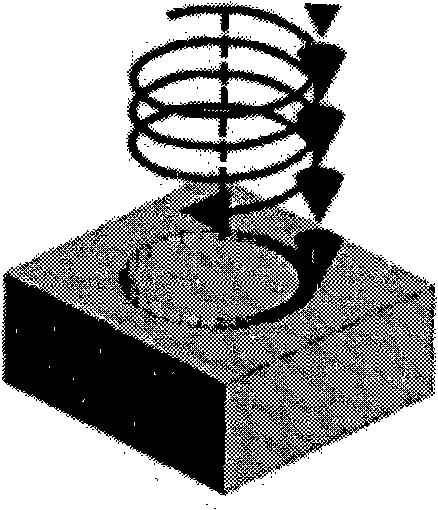

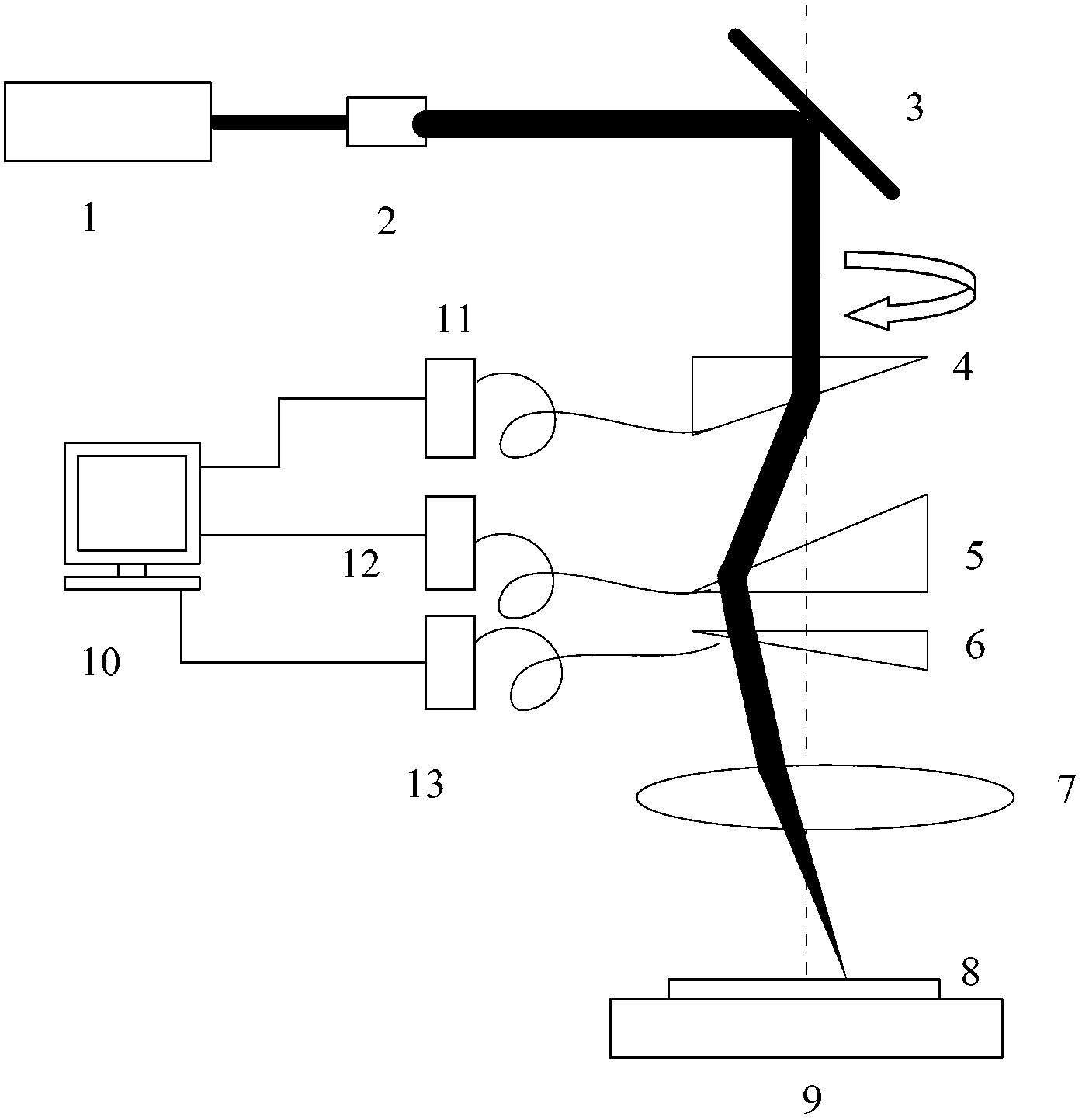

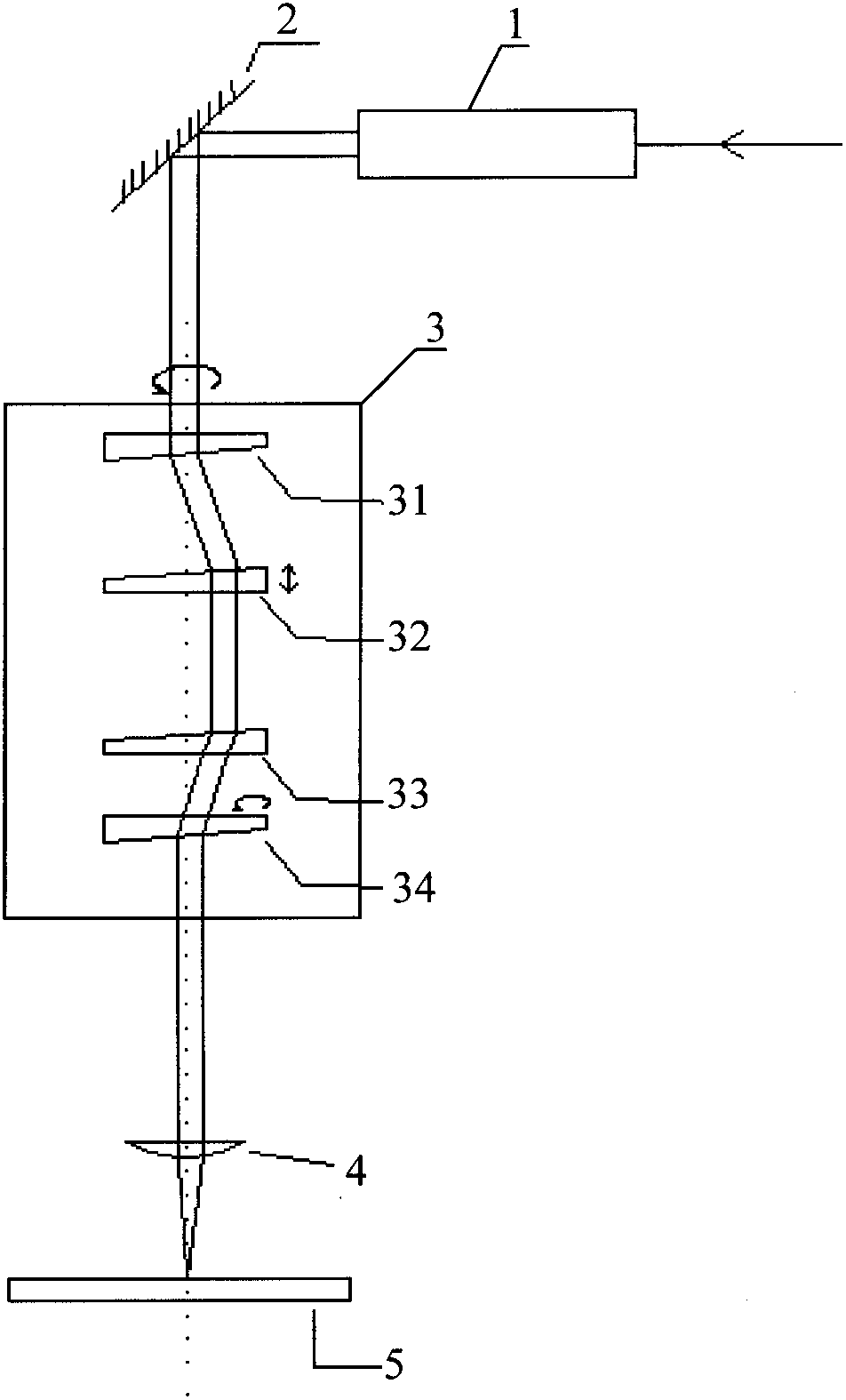

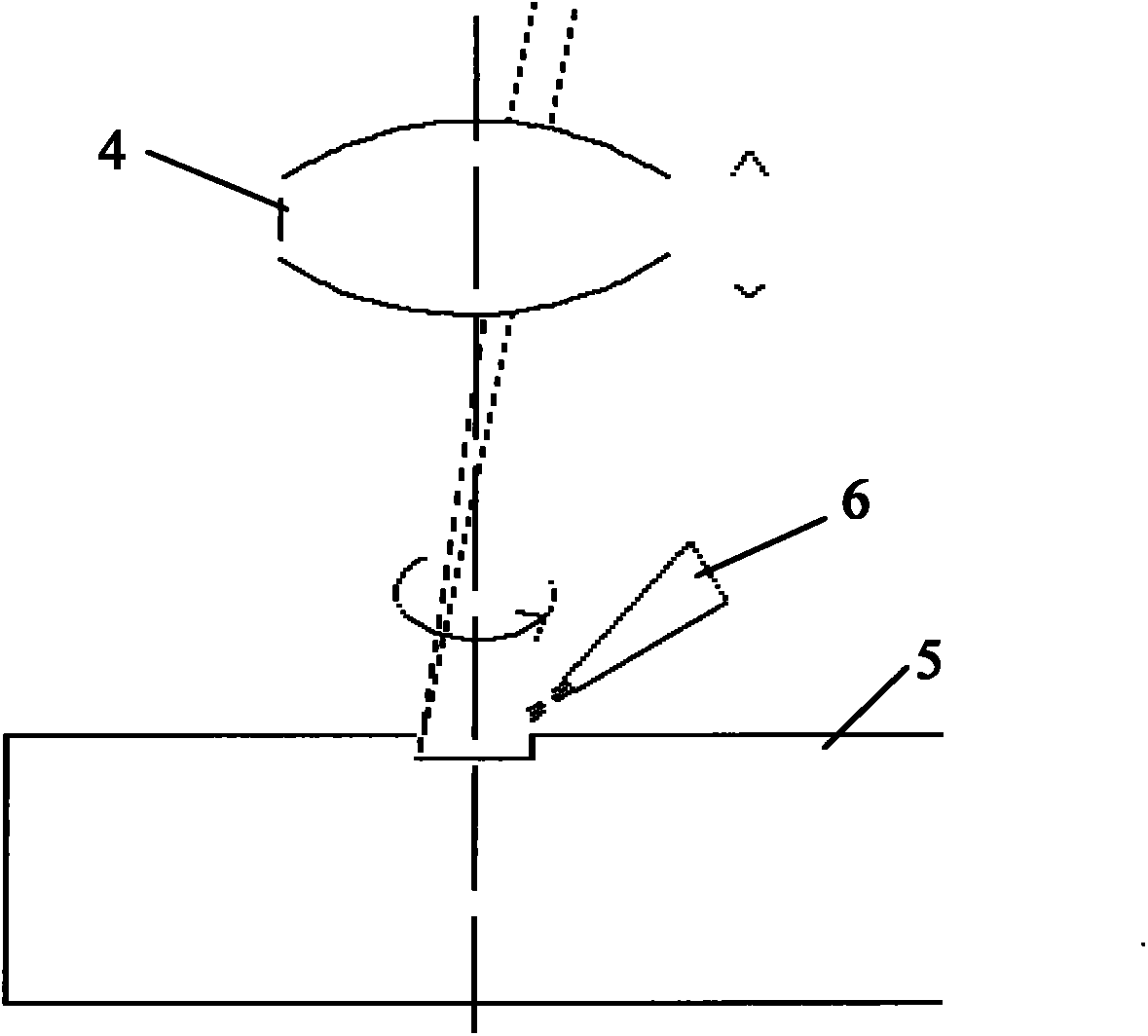

Laser micropore processor of rotating double-optical wedge

InactiveCN101670486ASmall heat affected zoneHigh precisionLaser beam welding apparatusBeam expanderHeat-affected zone

The invention discloses a laser micropore processor of a rotating double-optical wedge, comprising an ultrashort pulse laser output system consisting of a laser, a beam expander and a laser transmission system, a beam deflection system of the double-optical wedge consisting of two optical wedges, a bearing rotary mechanism of the double-optical wedge and a control system, a laser focusing system consisting of a laser focus lamp and a focuser and an adsorption location displacement system of workpieces and a computer system consisting of an installation mechanism of the workpieces and a two-dimensional displacement platform. The invention selects the DPSS laser with high-quality beam and uses the laser focusing system reaching or approaching the diffraction limit to obtain the fine focusesbeams, and then uses double-optical wedge to process the micropore in the situation of high speed revolution, therefore the invention reduces the heat affected zone of the edge of an aperture and improves caliber precision and work efficiency.

Owner:SHANGHAI INST OF LASER TECH

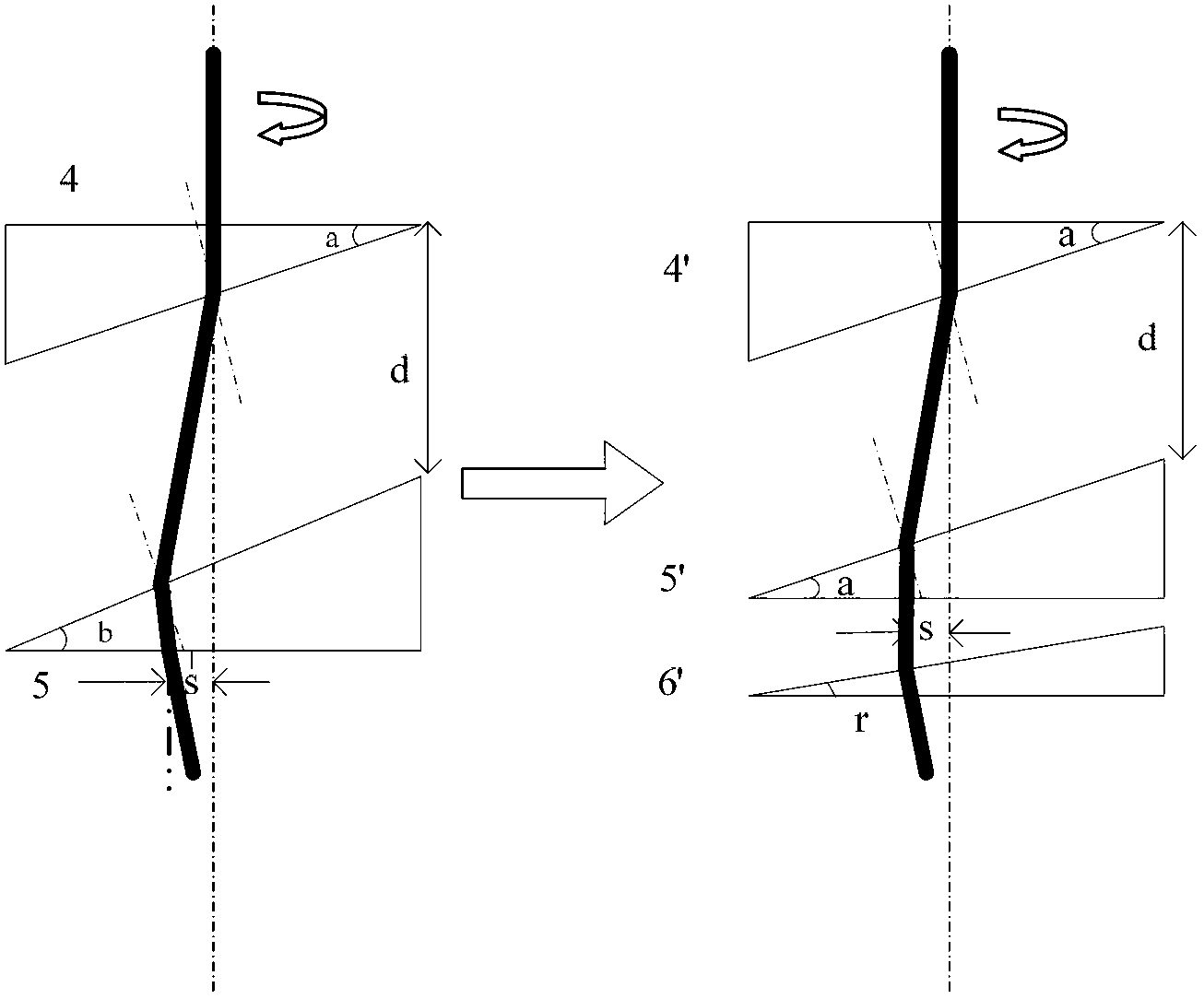

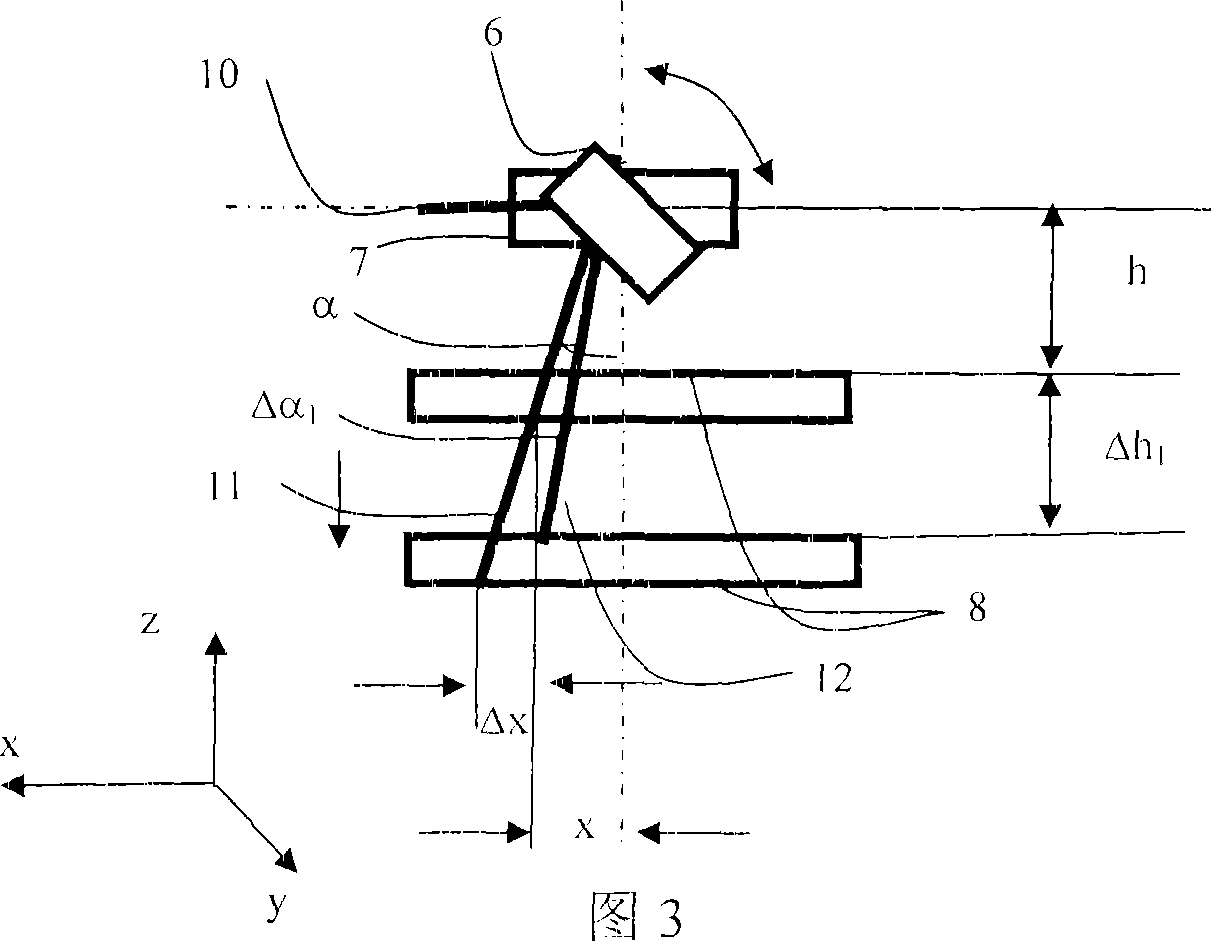

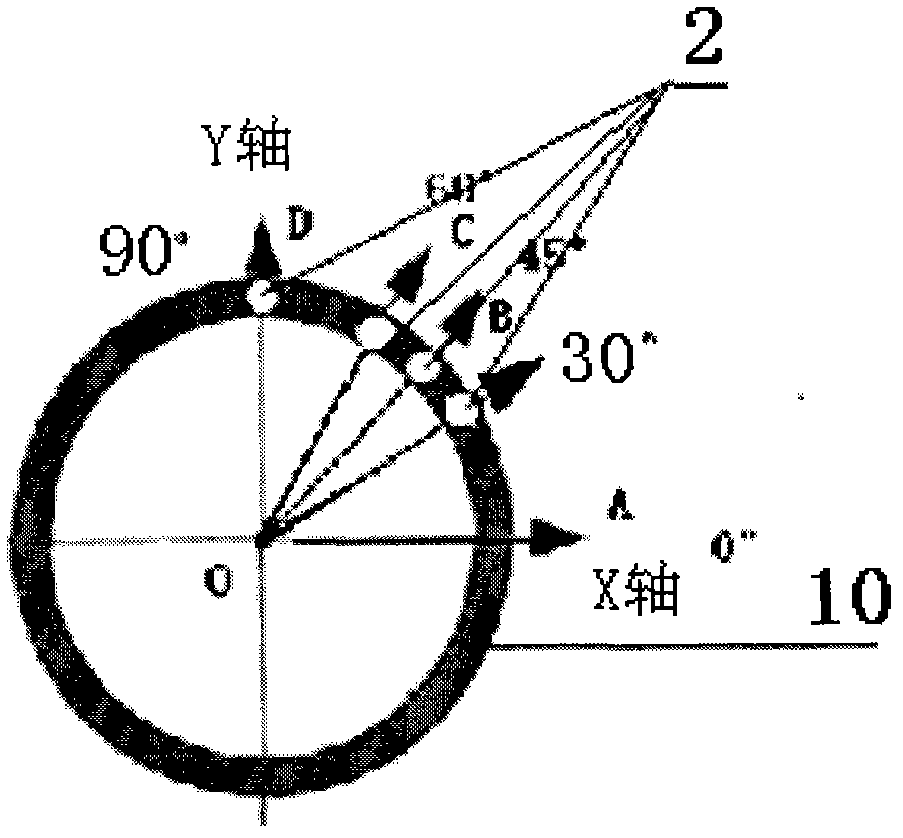

Taper-controllable laser micropore machining light beam scanning device and control method thereof

The invention relates to a taper-controllable laser micropore machining light beam scanning device. The device comprises a laser device and a sample piece to be machined, wherein a beam expander is arranged on the emergent surface of the laser device; a 45-degree reflecting mirror is arranged on the emergent surface of the beam expander; a non-parallel double optical wedge group and a small-angle optical wedge are vertically distributed below the 45-degree reflecting mirror in sequence; a focusing mirror and the sample piece to be machined are vertically distributed below the small-angle optical wedge in sequence; and a laser beam is expanded and collimated by the beam expander, is emitted to the 45-degree reflecting mirror, is reflected by the 45-degree reflecting mirror, is vertically emitted to the non-parallel double optical wedge group below the 45-degree reflecting mirror and is translated and deflected to a certain degree through the non-parallel double optical wedge group, and the deflected beam is refracted to the focusing mirror through the small-angle optical wedge, and is focused on the sample piece to be machined by the focusing mirror. Compared with a galvanometric scanning micropore machining device, the device is high in accuracy; the number of the optical wedges is reduced by one, so that the device is convenient to mount; the number of driving motors and wedge mirrors is reduced by one, so that the device is easy to control; and the loss of laser energy is reduced, and cost is greatly reduced.

Owner:CHINA KEHAN LASER FUJIAN

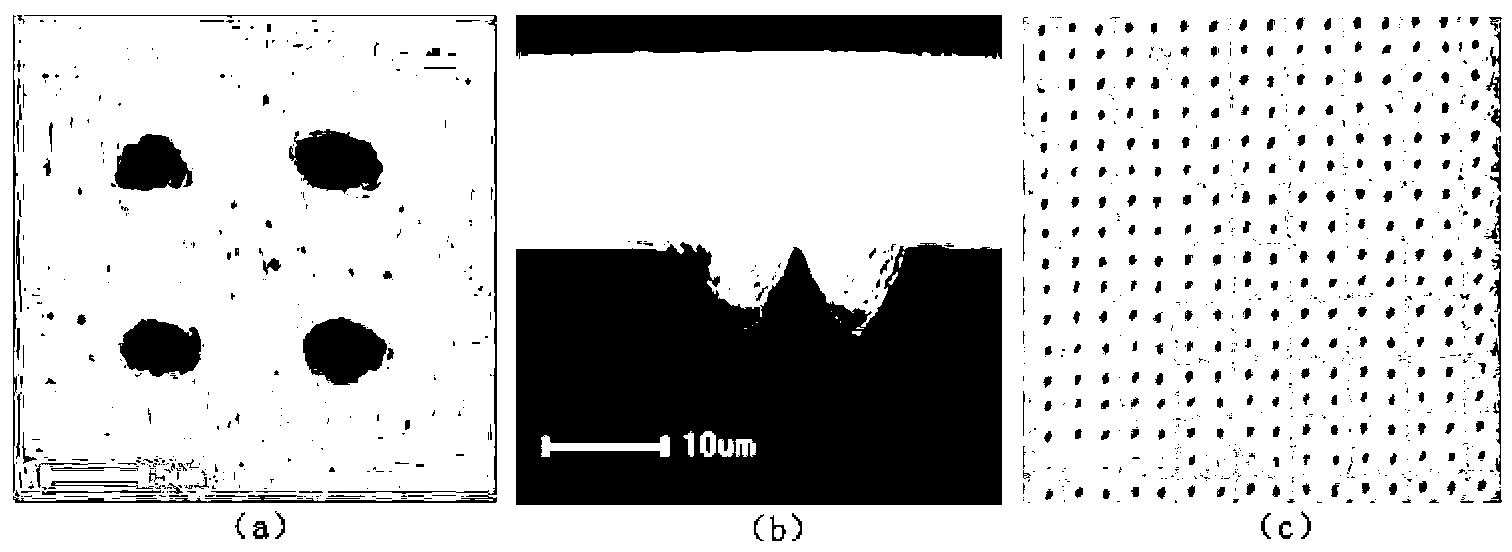

System and method for preparing micro-pore array through femtosecond laser direct writing

InactiveCN103071930AEasy to operateTransformation is easy and feasibleLaser beam welding apparatusFrequency spectrumSpatial light modulator

The invention discloses a system and a method for preparing a micro-pore array through femtosecond laser direct writing. The system comprises a femtosecond vector light field generation system, a spatial filtering component, a computer and a three-dimensional mobile platform, wherein a 1 / 2 wave plate, a Glan-laser polarizer, a beam expander and the femtosecond vector light field generation system are arranged on an output straight light path of a femtosecond laser device in sequence; a 4f system is arranged on a light path behind a reflective pure phase spatial light modulator after a holographic phase plate is loaded; a spatial filter is arranged on a frequency spectrum surface; and positive and negative levels of diffraction light which pass through the spatial filter pass through a 1 / 4 wave plate respectively and are combined into a beam of laser through a Rochi grating. A material is adjusted to a focal position through the spatial filtering component, an electronic diaphragm, a focusing lens and the three-dimensional mobile platform; and the spatial light modulator, the electronic diaphragm and the three-dimensional mobile platform are connected with a computer through data lines. The device has the advantages of simple structure, convenience in operation and capabilities of preparing the micro-pore array with various patterns and improving the machining efficiency.

Owner:NANKAI UNIV

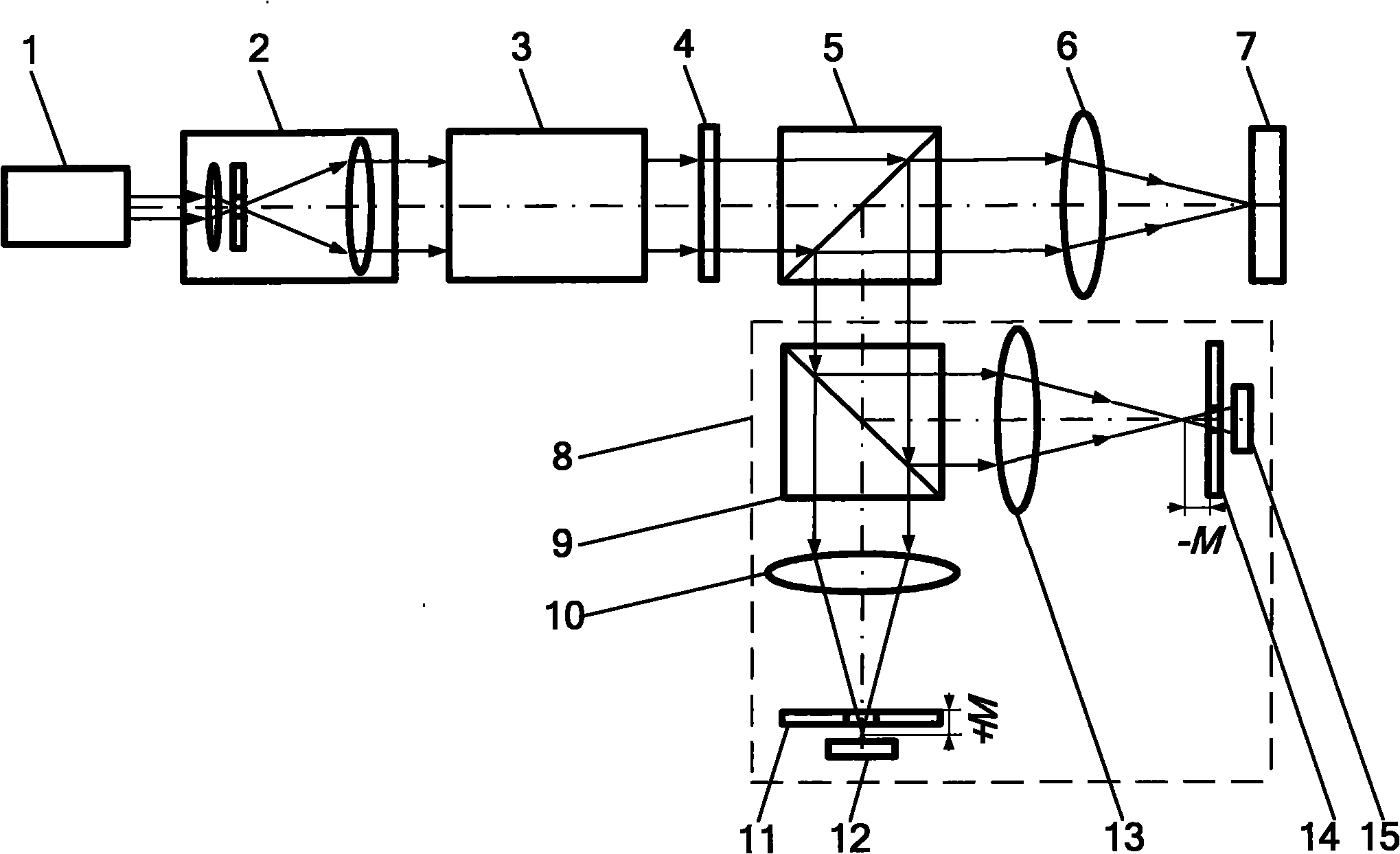

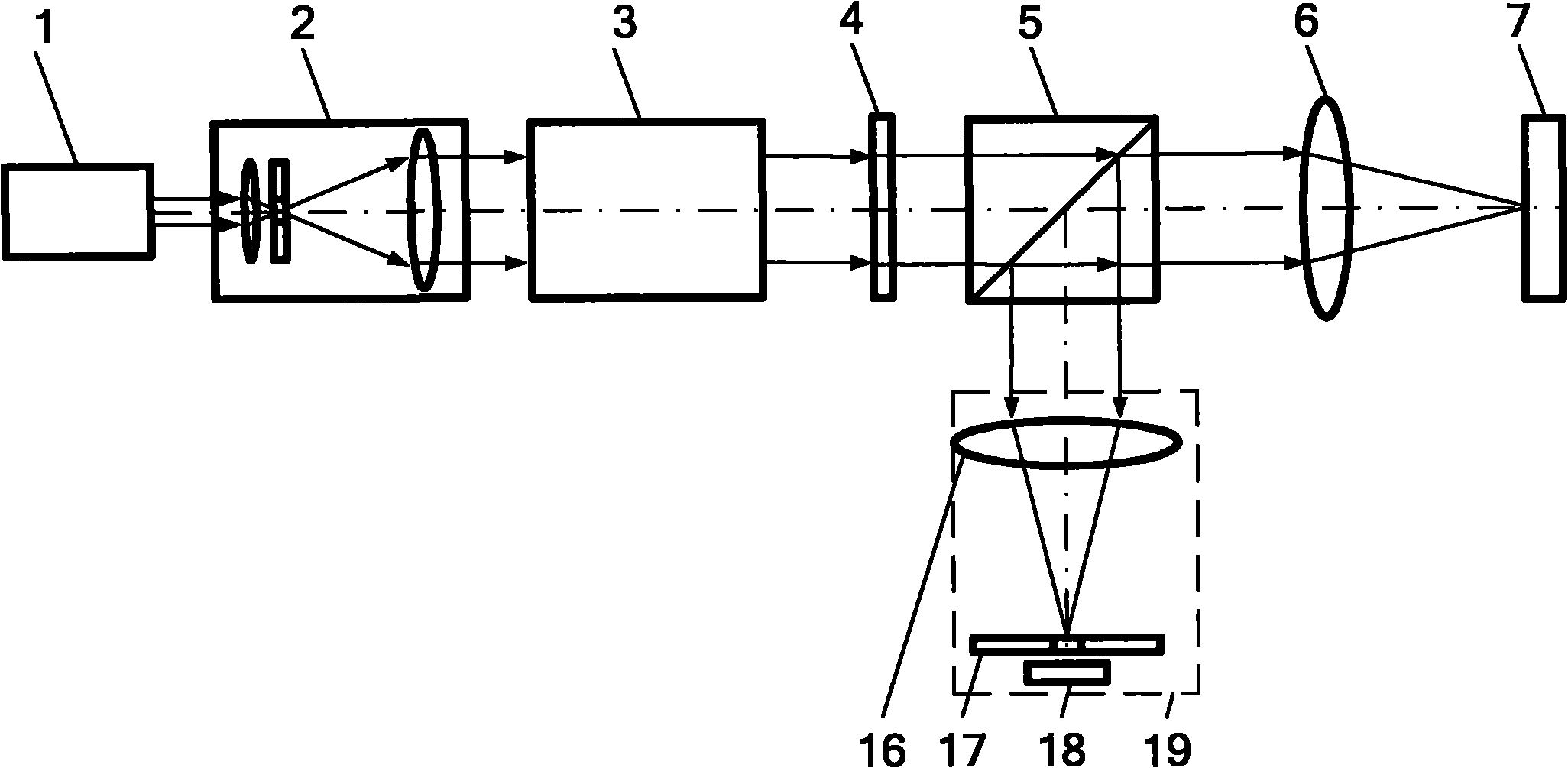

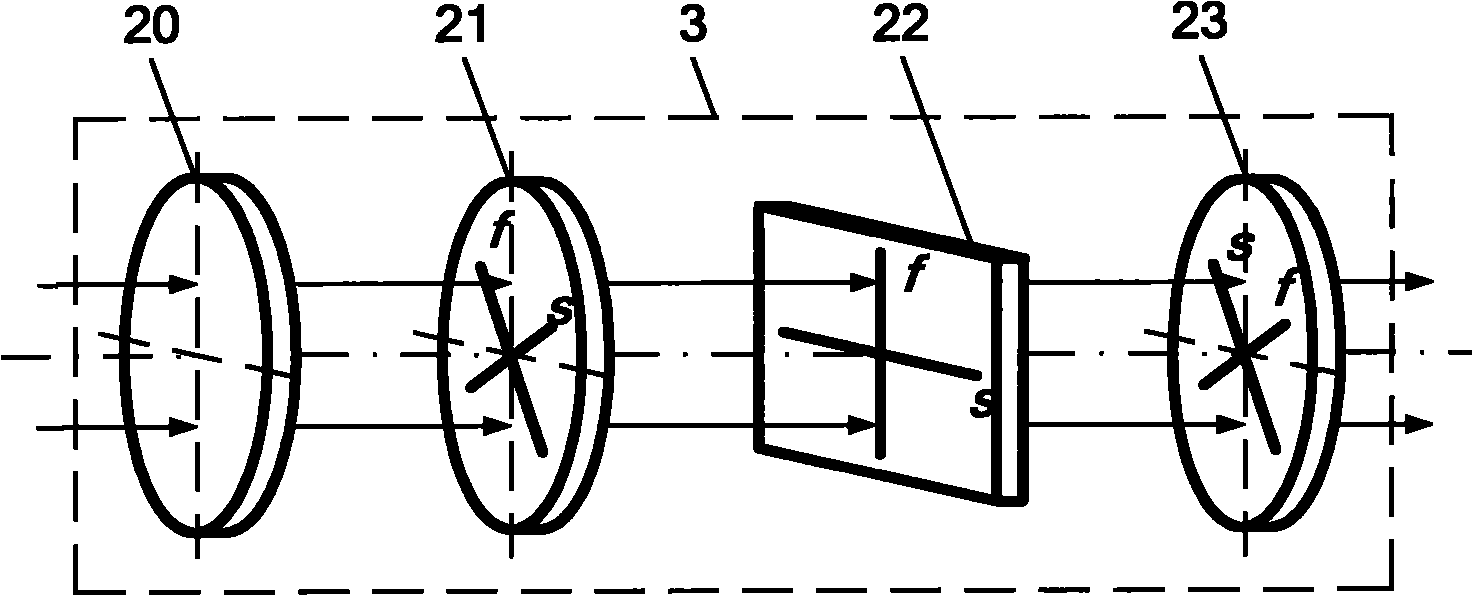

Super-resolution laser polarization differential confocal imaging method and device

ActiveCN101852594AImprove horizontal resolutionImprove linearityUsing optical meansBeam expanderPupil

The invention belongs to the technical field of optical precision measurement, relating to super-resolution laser polarization differential confocal imaging method and device. The method improves the transverse resolution power by combining a radial polarized light and a pupil filtering technology, improves the axial resolution power by using a differential subtraction detection technology of an axial-offset dual-detector system and remarkably improves the spatial resolution power and tomography ability of the system. The device comprises a laser source as well as a beam expander, a polarization state modulation system, a pupil filter and a spectroscope which are sequentially arranged at a transmitting end of the laser source, an objective and a sample which are arranged in the transmitted light direction of the spectroscope in turn, and a differential confocal system in the opposite direction of the reflected light direction of the spectroscope. The invention combines the radial polarized light resolution technology with the pupil filtering technology and improves the transverse resolution power of the system; moreover, the differential work mode of the invention can remarkably improve the axial imaging ability of the system and is applicable to the high-precision detection and metering of nanometer-level geometrical parameters in the nanometer manufacturing field.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

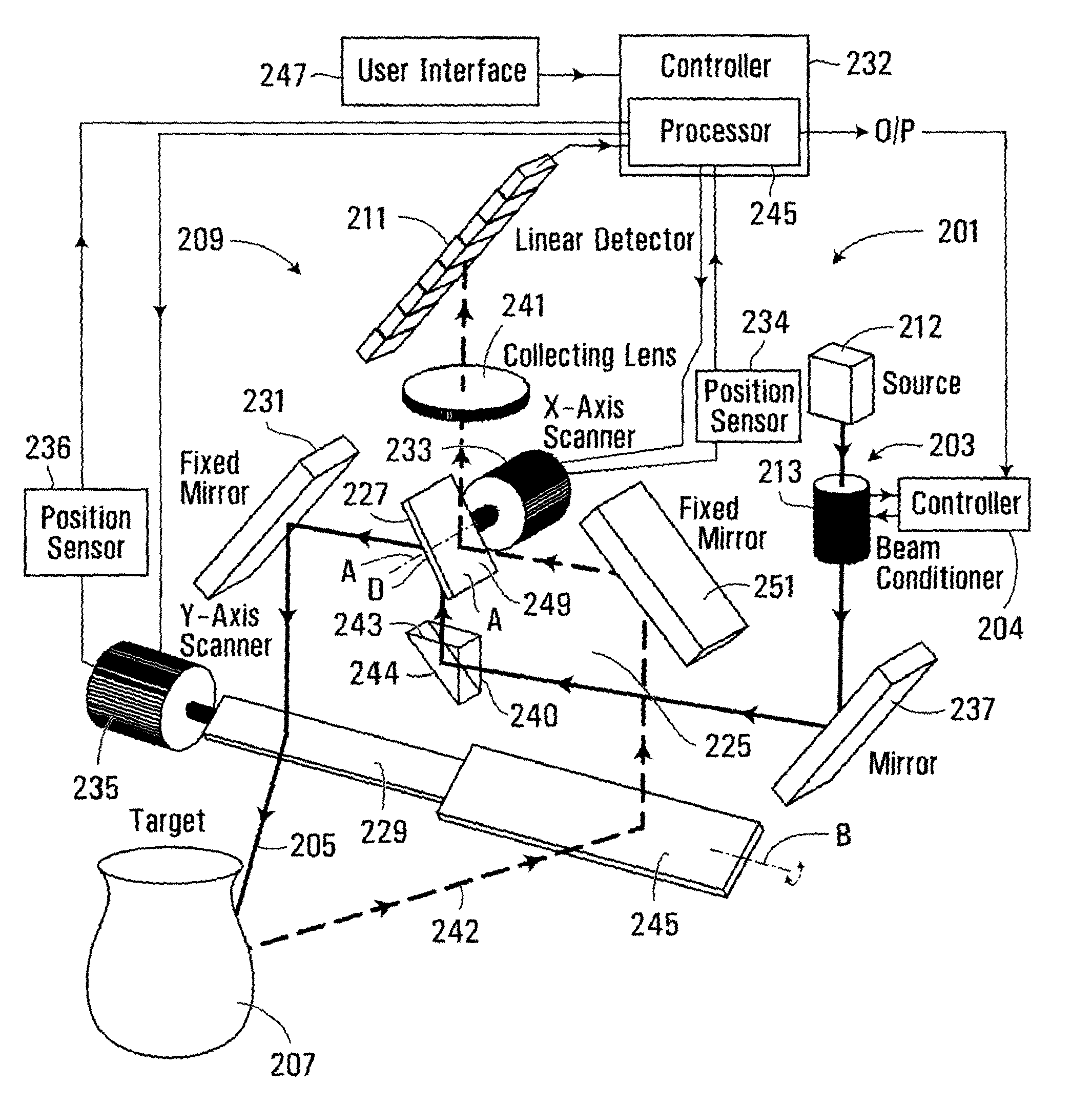

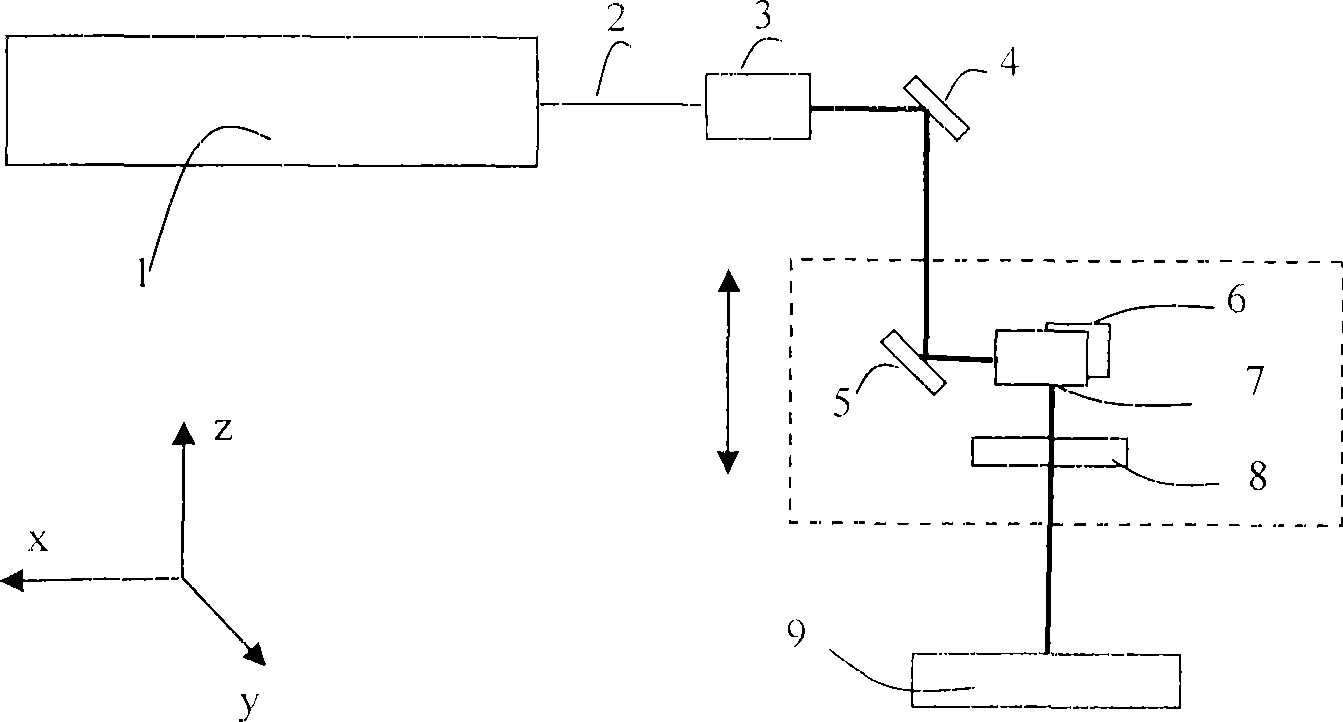

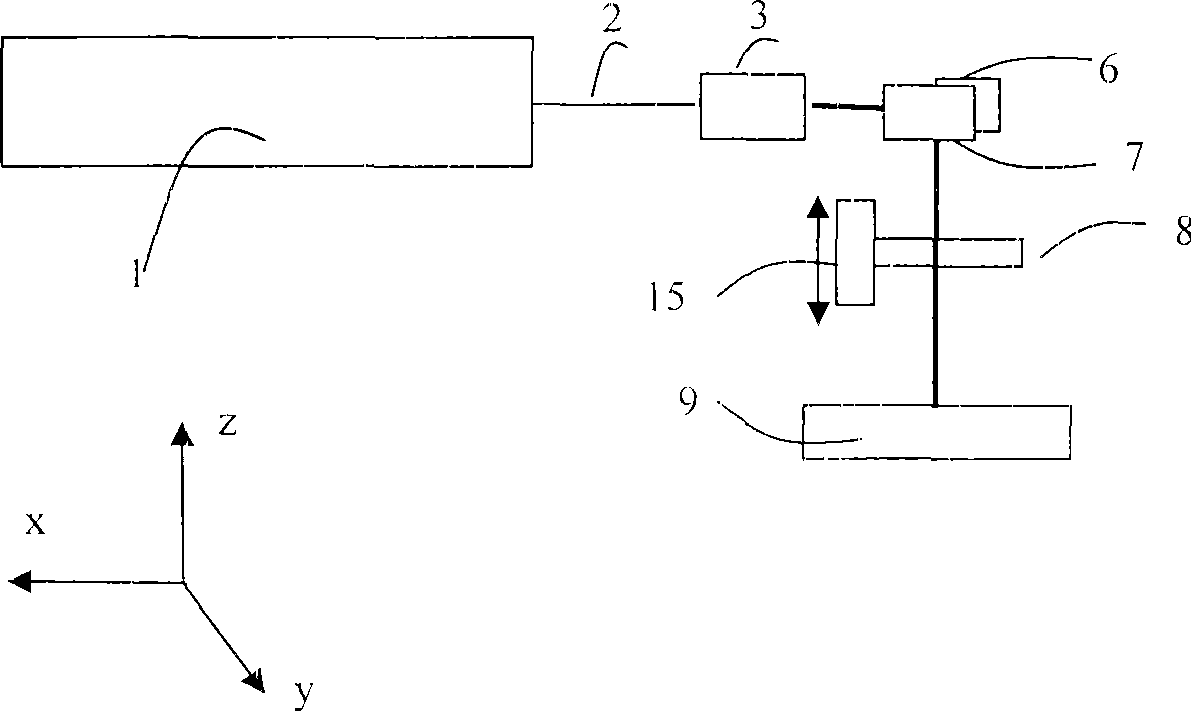

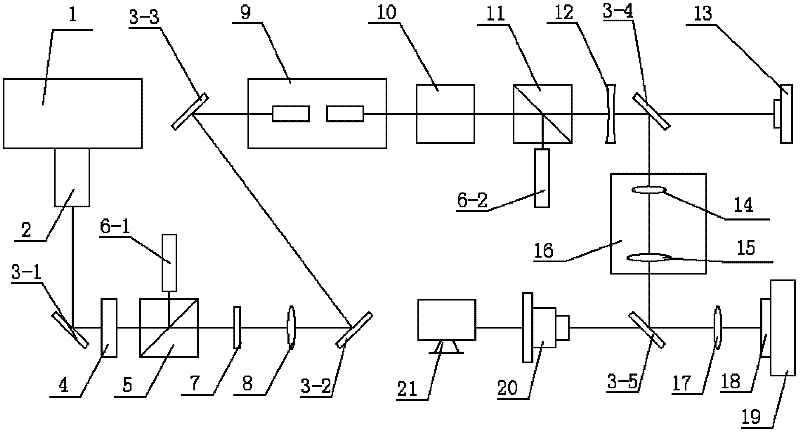

Mirror-vibrating laser three-dimensional scanning system

ActiveCN101419336ARealize the function of three-dimensional processingEasy to debug consistencyLaser beam welding apparatusOptical elementsBeam expanderControl system

The invention discloses a vibration mirror type laser 3D scanning system which comprises a laser, a beam expander, an x-axis scanning vibration mirror, a y-axis scanning vibration mirror, a scanning focusing lens, a z-axis travel mechanism and a control system. The laser emits laser beams, and the laser beams are amplified and collimated by the beam expander and then directly enters the x-axis scanning vibration mirror and the y-axis scanning vibration mirror; the control system controls the z-axis travel mechanism to drive the scanning focusing lens to move up and down in the z-axis direction so as to adjust position of a laser focus point in the z-axis direction. The vibration mirror type laser 3D scanning system realizes 3D stereo processing function by the scanning focusing lens which is fixed on the z-axis travel mechanism and move up and down in the z-axis direction. Two mirrors are removed from the system, which reduce cost of a laser light path, especially for expensive mirrors. Meanwhile, the vibration mirror type laser 3D scanning system is easy for debugging collimation of the whole light path, and improves stability of the whole light path and utilization rate of laser power.

Owner:武汉飞能达激光技术有限公司

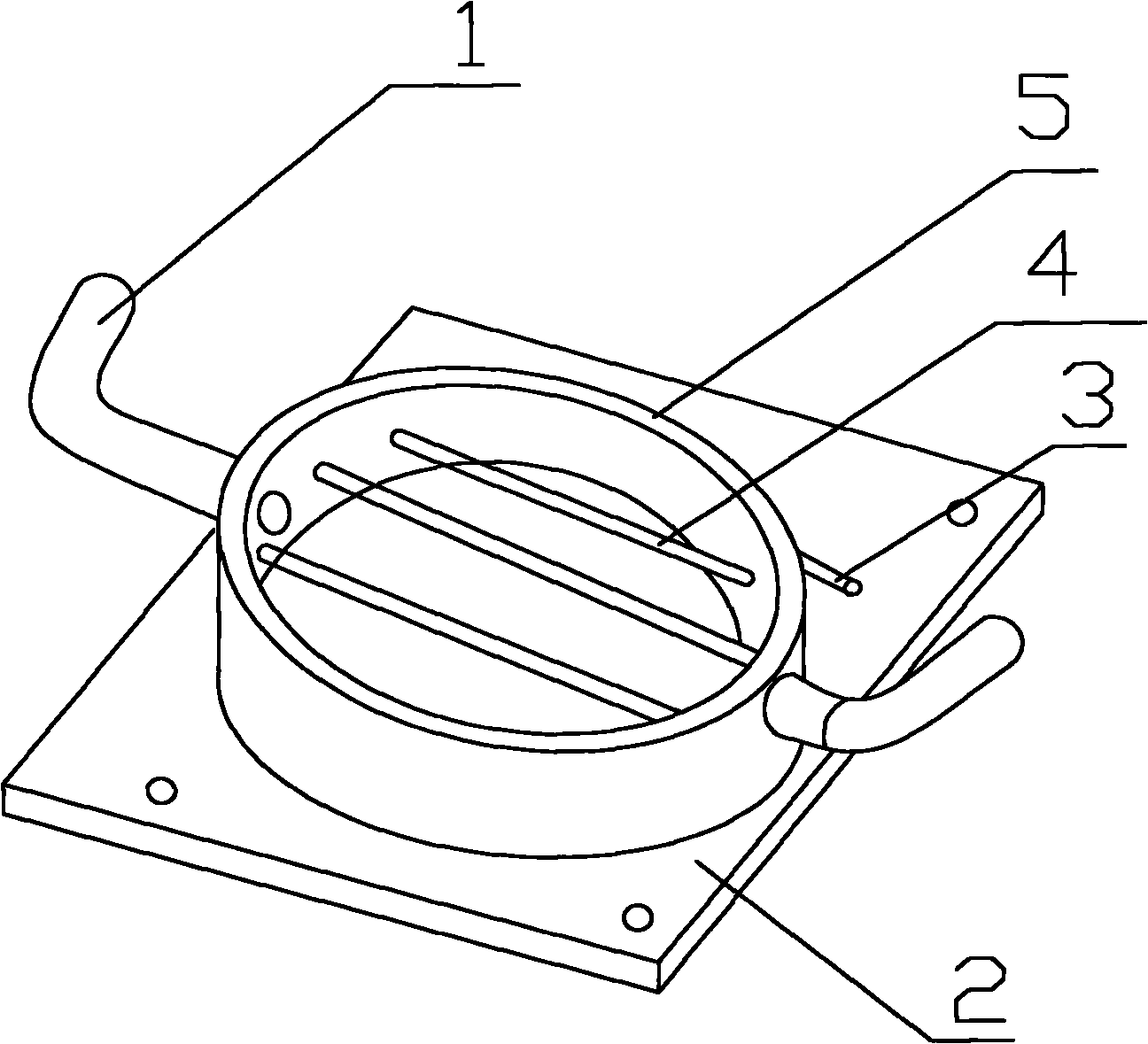

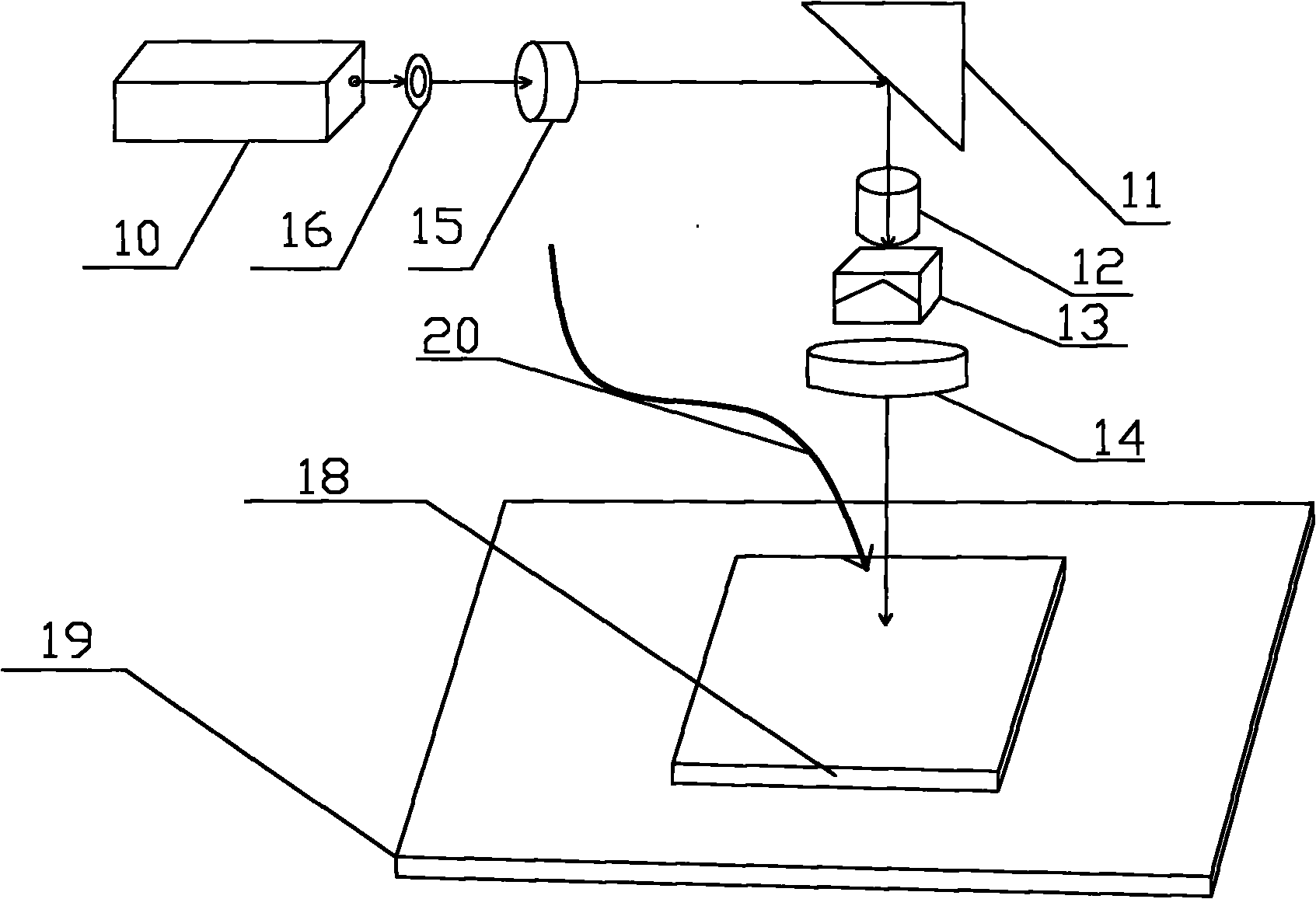

Device and method for abnormally cutting toughened glass by ultra-short pulse laser

InactiveCN102248302AImprove smoothnessImprove cutting efficiencyLaser beam welding apparatusBeam expanderSlag

The invention relates to a device and method for abnormally cutting a toughened glass by ultra-short pulse laser. An output end of an ultra-short pulse laser apparatus is provided with an optical gate, an output end of the optical gate is provided with a beam expander, an output end of the beam expander is provided with a 45-degree holophote, an output end of the 45-degree holophote is provided with a three-dimensional (3D) dynamical focusing system, an output end of the 3D dynamical focusing system is provided with a telecentric field lens which is arranged facing to a platform above which a blowing device is arranged. When the ultra-short pulse laser device is used to cut, a heating device is used for heating the glass; the ultra-short pulse laser is focused in the glass by the 3D dynamical focusing system to abnormally scan the glass along with the laser, and the whole processing procedure is in helical processing; a suction dust-collecting device at the bottom of the platform is used for collecting the scanned glass slag; and the blowing device on the platform is used for blowing the slag and dust particles processed on the surface of the glass. The abnormal graph processing to the toughened glass is a processing form with smooth cutting surface and high cutting efficiency.

Owner:SUZHOU DELPHI LASER

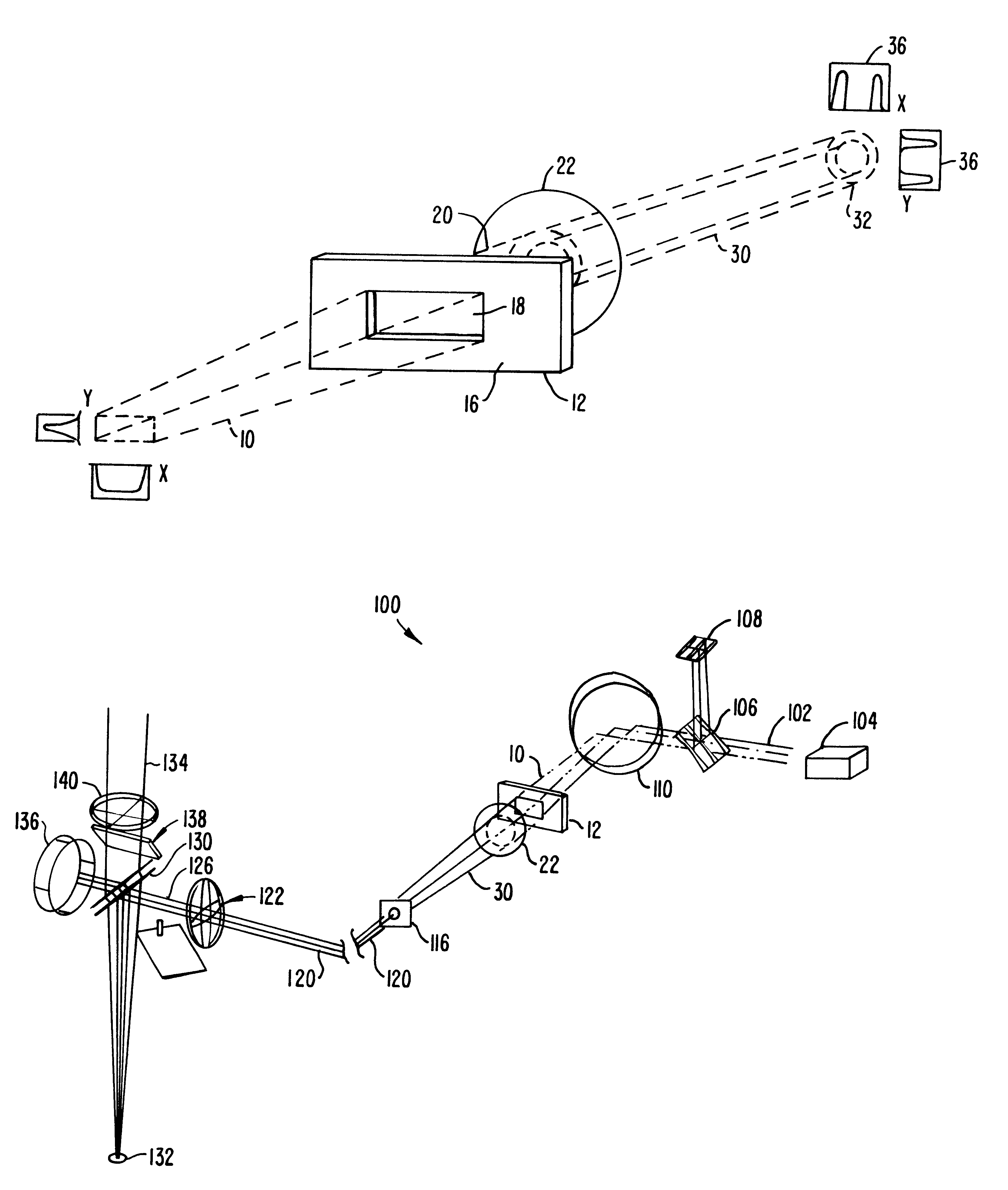

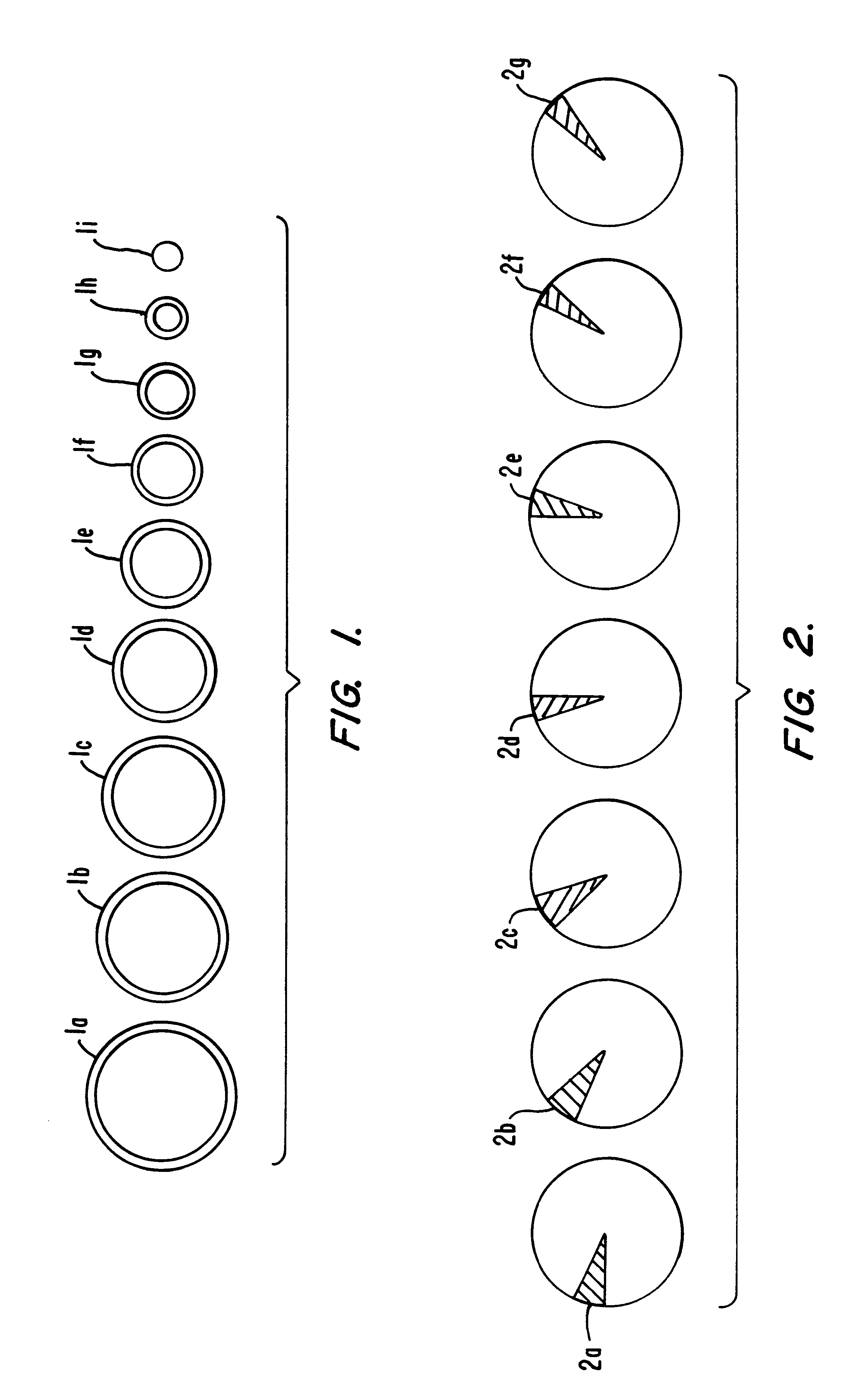

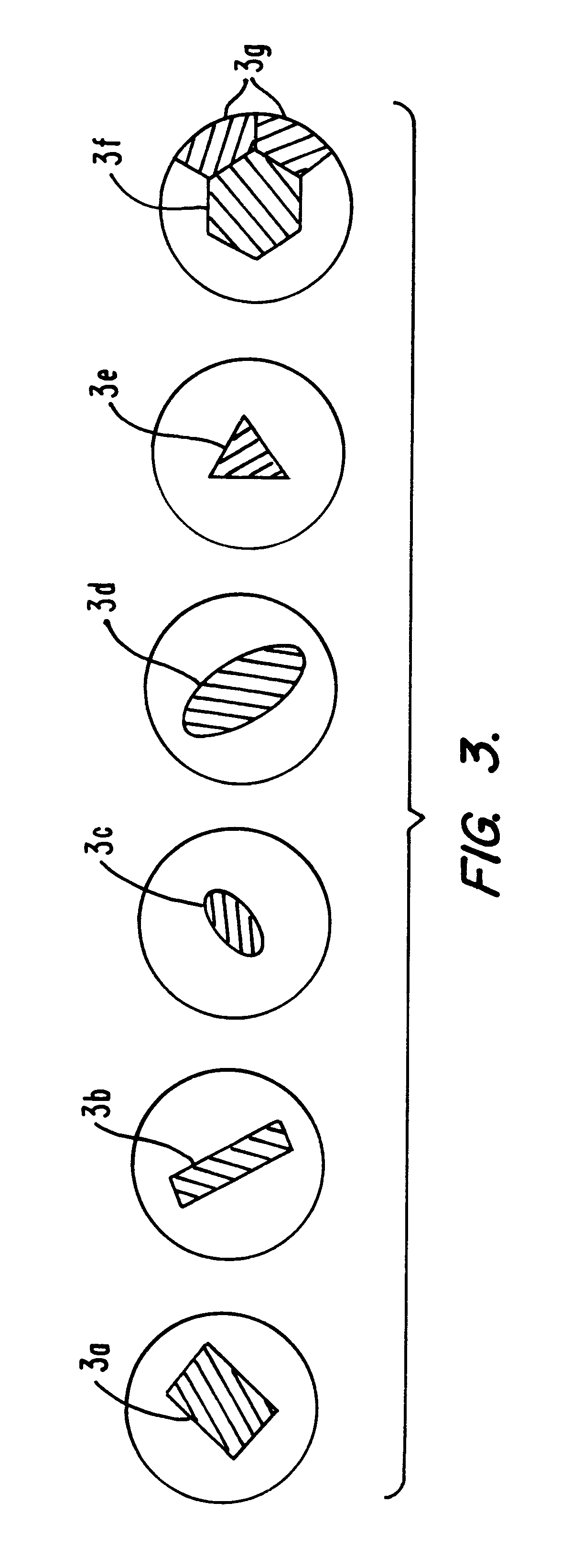

Method for scanning non-overlapping patterns of laser energy with diffractive optics

InactiveUS6193710B1Improve uniformityFacilitates dosage controlLaser surgerySurgical instrument detailsBeam expanderLight beam

A method for laser treatment of the eye using one or more diffractive optical elements for producing unique treatment segments within an ablation zone on the eye. The treatment segments may be annular, pie-shaped, or have other geometries or patterns selected to apply energy in a particular manner, usually in a non-overlapping manner so that energy dosages can be precisely controlled. In a first embodiment of the method, a single diffractive optical element is used and a beam expander expands or converges the beam to achieve the different treatment segments. In a second embodiment, a plurality of diffractive optical elements are used, each of which produces a single treatment segment.

Owner:AMO MFG USA INC

Method and optical system for coupling light into a waveguide

ActiveUS20050002611A1Increase width W of in-couplingCoupling light guidesOptical waveguide light guideBeam expanderGrating

A method and optical system for coupling light from an incoming light wave (WI) into a waveguiding substrate (S) arranges the light wave (WI) to interact with a diffractive in-coupling grating element or elements (IG) arranged on or embedded within the substrate (S) and arranged to couple the energy from the light wave (WI) into a waveguided light wave (WG). The polarization state of the light wave (WI) is converted after its first interaction (D1) with the in-coupling grating element / elements (IG) and before a second interaction (D2) with the grating element / elements (IG) takes place. The method minimizes any “reverse” diffractions, which would direct light back towards the front-end optics and therefore to increase the width W of the in-coupling grating / gratings (IG). Preferred embodiments include diffractive beam expanders for virtual displays.

Owner:MAGIC LEAP

Device and method for calibrating dynamic tracking precision of photoelectric tracking system

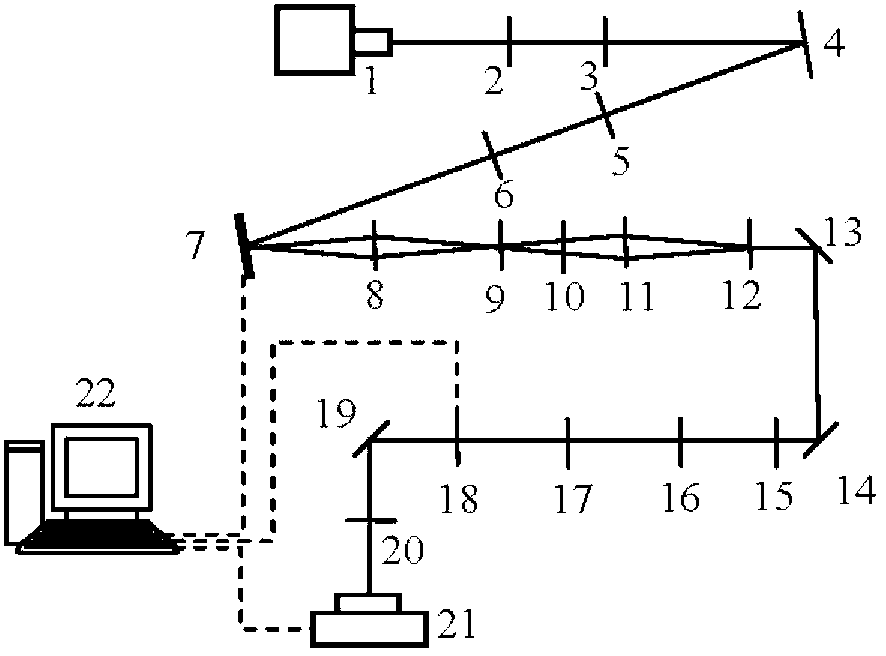

The invention discloses a device and a method for calibrating the dynamic tracking precision of a photoelectric tracking system. The device comprises a beacon light subsystem used for generating beacon light, a high-speed image acquisition system and a processing subsystem, wherein the beacon light subsystem comprises a high-precision laser target simulator, a laser target controller, a first computer and a target plate; the high-speed image acquisition system comprises a high-speed camera; and the processing subsystem comprises a second computer. The beacon light subsystem consisting of a solid laser, a beam expander, a fast tilting mirror and a reflecting mirror is used for generating the beacon light to the target plate and can simulate targets with a plurality of motion modes and movement speeds through faculae, so that the precision of equipment can be tested persuasively. The faculae are acquired by the high-speed image acquisition system and the high test precision can be obtained by using a high-speed digital image processing technology, so that the photoelectric tracking system is quickly and accurately calibrated according to the measurement of the tracking precision.

Owner:NO 27 RES INST CHINA ELECTRONICS TECH GRP

Confocal wafer inspection method and apparatus using fly lens arrangement

InactiveUS6867406B1Severe signal variationThe process is fast and efficientMaterial analysis by optical meansMicroscopesLight energyTransmitter

A semiconductor wafer inspection system and method is provided which uses a multiple element arrangement, such as an offset fly lens array. The preferred embodiment uses a laser to transmit light energy toward a beam expander, which expands the light energy to create an illumination field. An offset fly lens array converts light energy from the illumination field into an offset pattern of illumination spots. A lensing arrangement, including a first lens, a transmitter / reflector, an objective, and a Mag tube imparts light energy onto the specimen and passes the light energy toward a pinhole mask. The pinhole mask is mechanically aligned with the offset fly lens array. Light energy passing through each pinhole in the pinhole mask is directed toward a relay lens, which guides light energy onto a sensor. The offset fly lens array corresponds to the pinhole mask. The offset pattern of the offset fly lens array is chosen such that spots produced can be recombined into a continuous image, and the system utilizes a time delay and integration charge coupled device for rapid sensing along with an autofocus system that measures and cancels topological features of the specimen.

Owner:KLA CORP

Flip-chip mounting apparatus

InactiveUS20090090468A1Reduce displacementReduce generationSoldering apparatusSolid-state devicesBeam expanderSemiconductor chip

A flip-chip mounting apparatus includes a variable-shape mirror 16 for receiving a laser beam emitted from a laser beam oscillating source 12, a sensor 18 for sensing a reflected laser beam from the variable-shape mirror 16, and a controlling portion 20 for controlling the variable-shape mirror 16 by comparing a sensed signal input from the sensor 18 with previously input threshold values such that an intensity distribution of the reflected laser beam corresponds to a distribution of bumps 37 on a semiconductor chip 36, whereby when the reflected laser beam from the variable-shape mirror 16 is irradiated onto the semiconductor chip 36 through a beam expander 34 and a pushing body 40, a beam shape of the reflected laser beam matches with an outer shape of the semiconductor chip 36 and also joined portions are heated concentratedly.

Owner:SHINKO ELECTRIC IND CO LTD

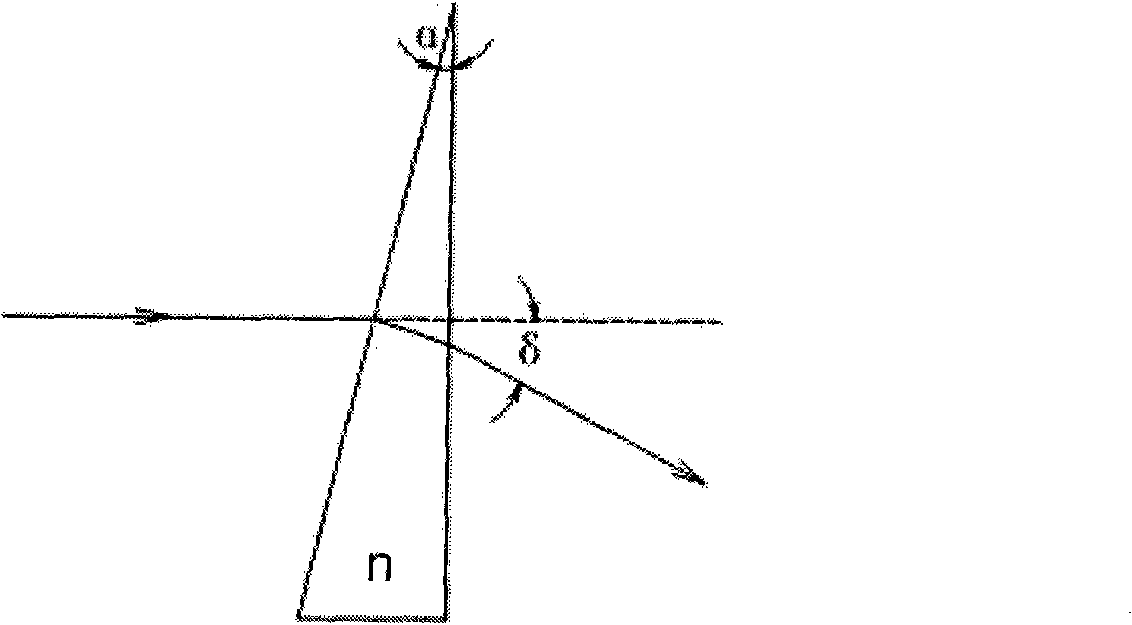

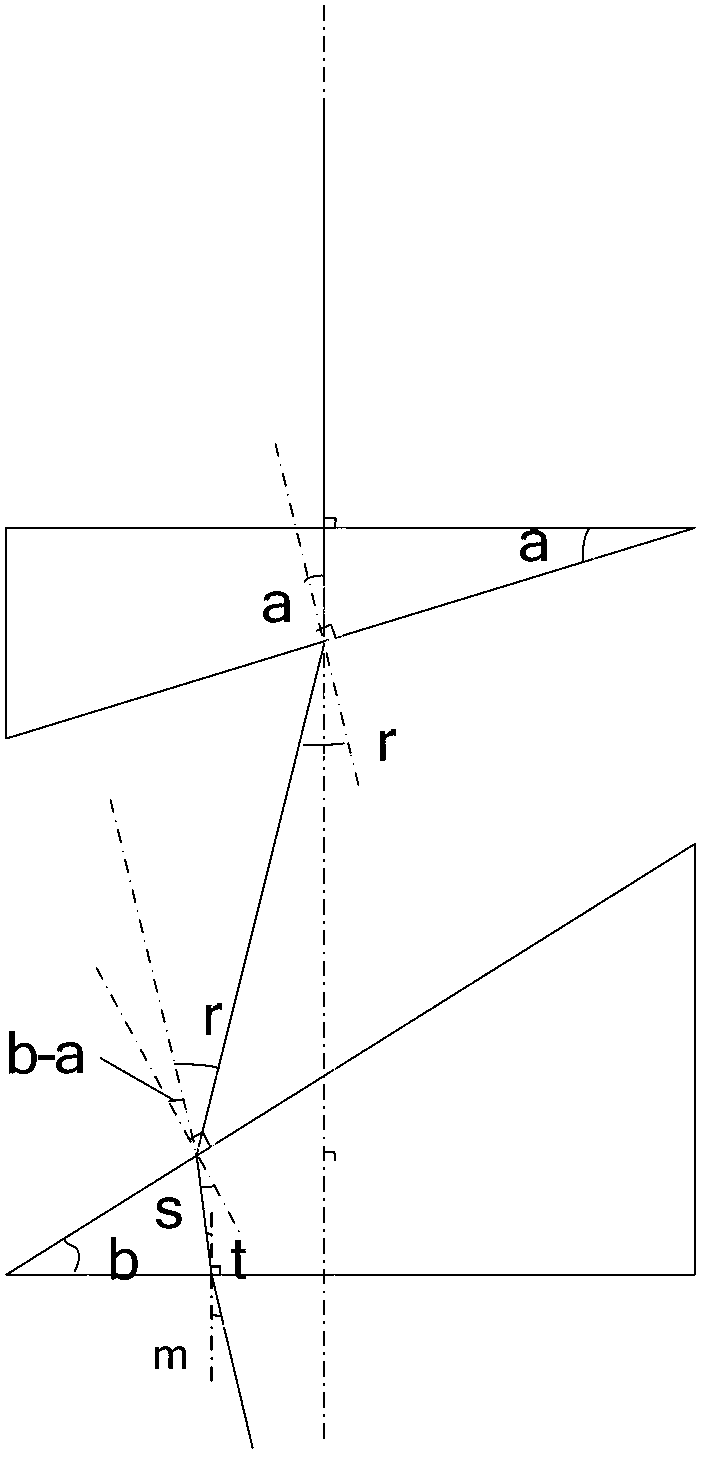

Laser rotary-cut drilling device

InactiveCN102218605AVariable sizeControllable taperLaser beam welding apparatusWedge angleBeam expander

The invention relates to a laser rotary-cut drilling device. The output end of a laser is provided with a beam expander; the output end of the beam expander is provided with a 45-degree total reflection mirror; the output end of the 45-degree total reflection mirror is provided with an optical rotation system; the optical rotation system comprises a first wedge prisma, a second wedge prisma, a third wedge prisma and a fourth wedge prisma; the first wedge prisma and the second wedge prisma have the same wedge angles; the first wedge prisma or the second wedge prisma is connected with a vertical straight-line motion mechanism; the third wedge prisma and the fourth wedge prisma have the same wedge angles; the third wedge prisma or the fourth wedge prisma is connected with a rotation mechanism; the output end of the optical rotation system is provided with a focus lens; and the focus lens is just opposite to a processing platform. The device is used for performing laser rotary-cut drilling on a workpiece, and can process straight holes, variable taper holes and irregular taper holes, so a laser drilling effect of variable sizes, controllable taper and smooth edges is achieved.

Owner:SUZHOU DELPHI LASER +1

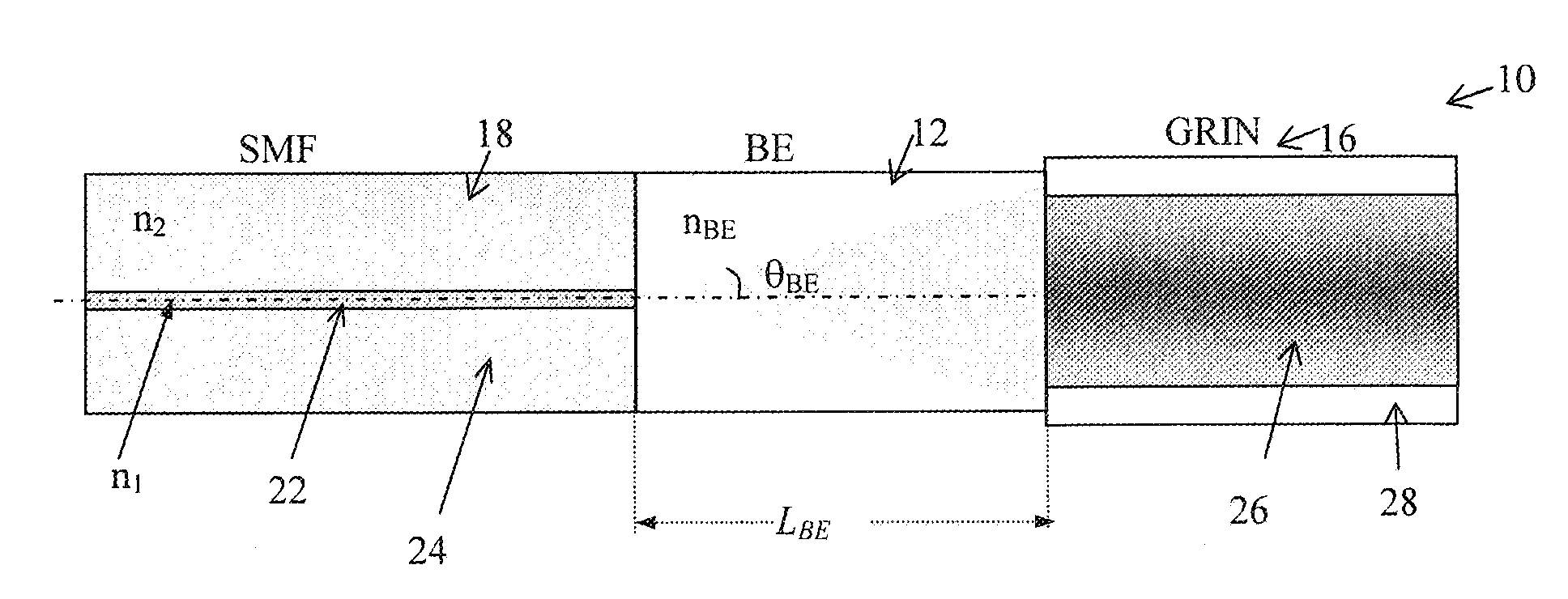

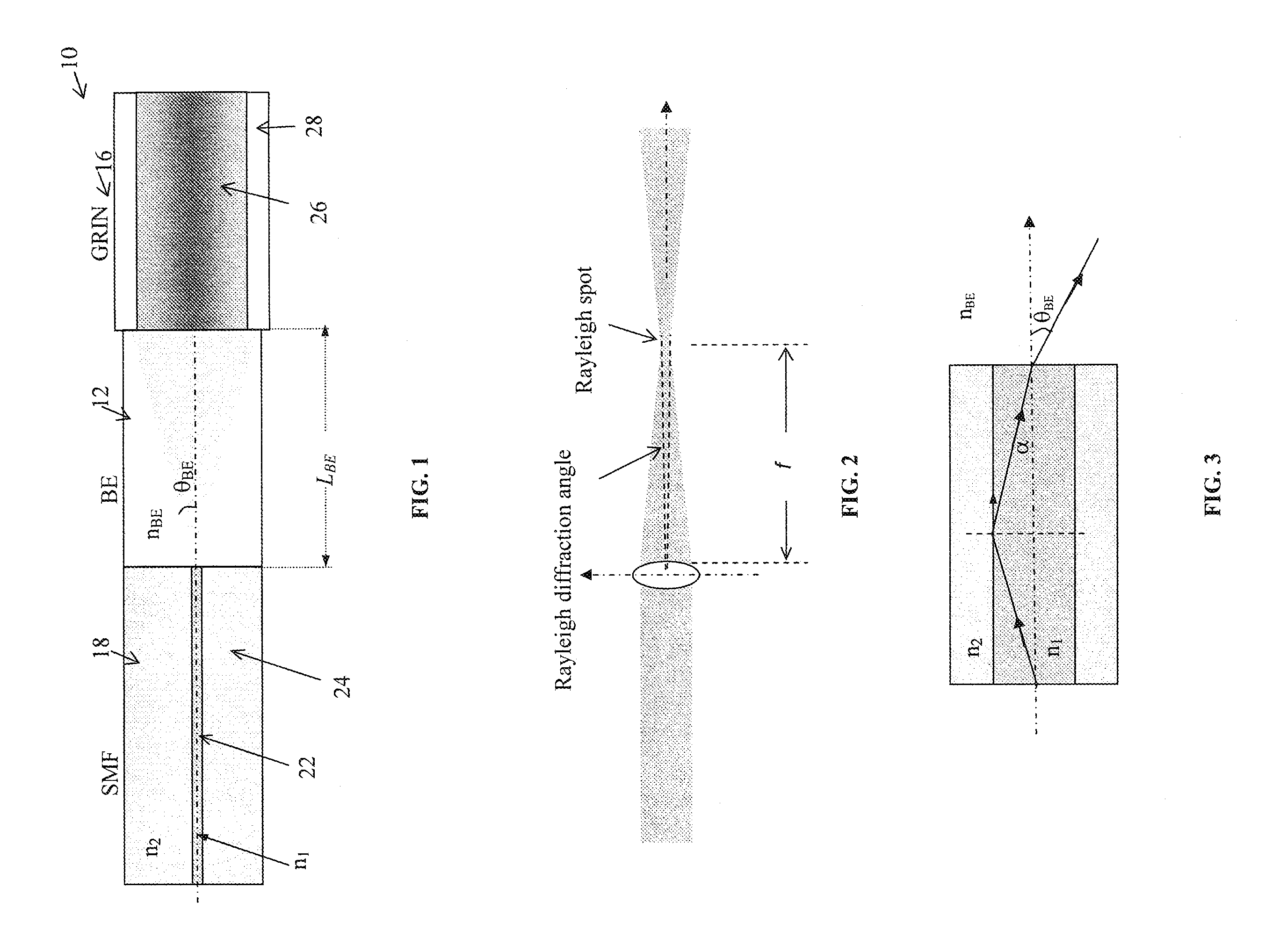

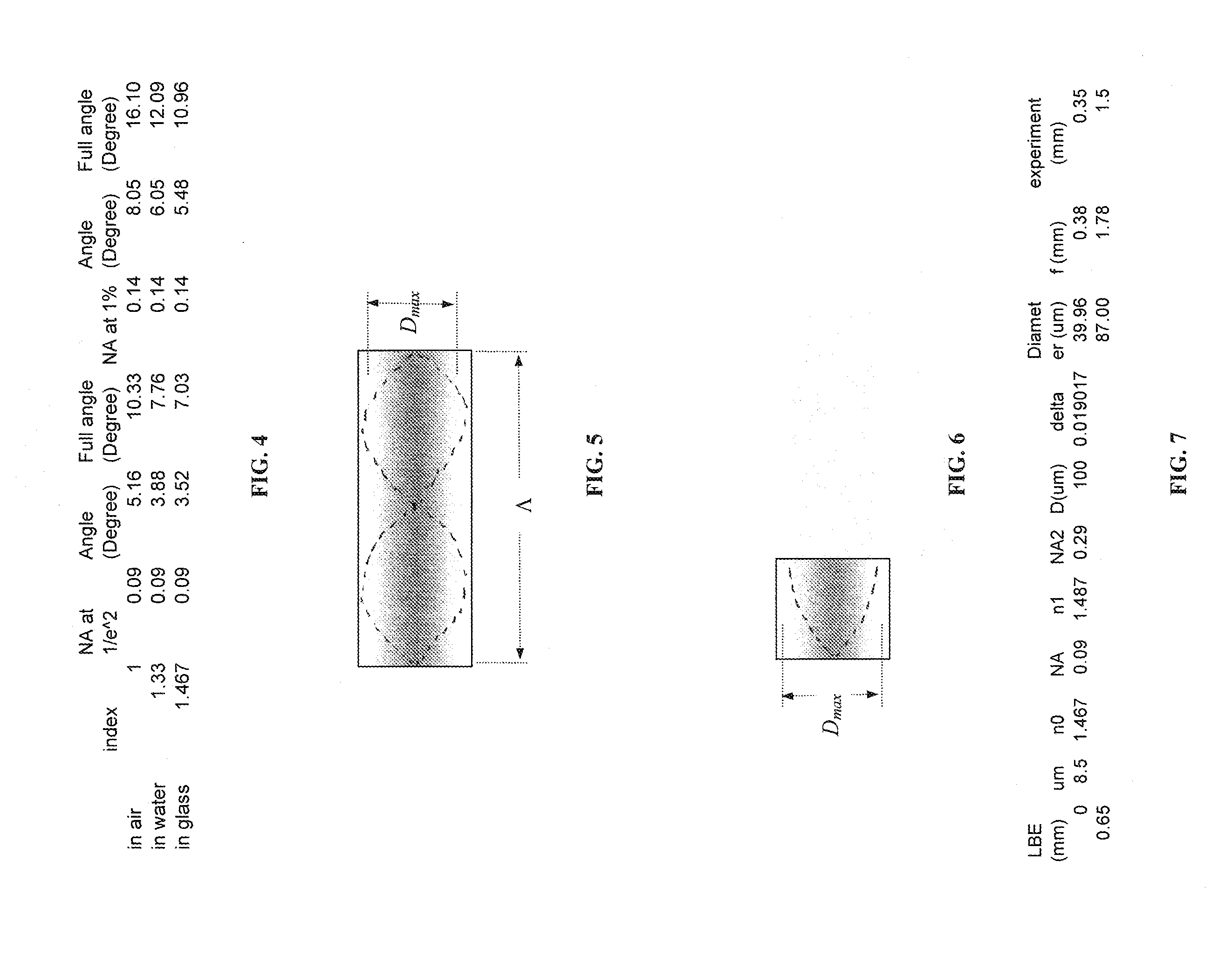

Fiberoptic device with long focal length gradient-index or grin fiber lens

Embodiments of the invention provide a fiberoptic device that uses a gradient-index (GRIN) lens for focusing a light beam emitted by an optical fiber, but achieves a substantially longer focal length than that of a GRIN lens alone by placing a beam expander (e.g., no core fiber or step-index multimode fiber) between the terminal end of the optical fiber and the GRIN lens to simulate free space therebetween. In one embodiment, a fiberoptic device comprises an optical fiber having a fiber core and an end through which a light beam emits from the fiber core; a beam expander having a first end coupled to the end of the optical fiber and having a second end, the beam expander permitting the light beam emitting from the fiber core to pass from the first end to the second end and to expand from the first end to a larger size at the second end; and a gradient-index fiber lens coupled to the second end of the beam expander to receive the light beam from the beam expander and focus the light beam.

Owner:ST JUDE MEDICAL

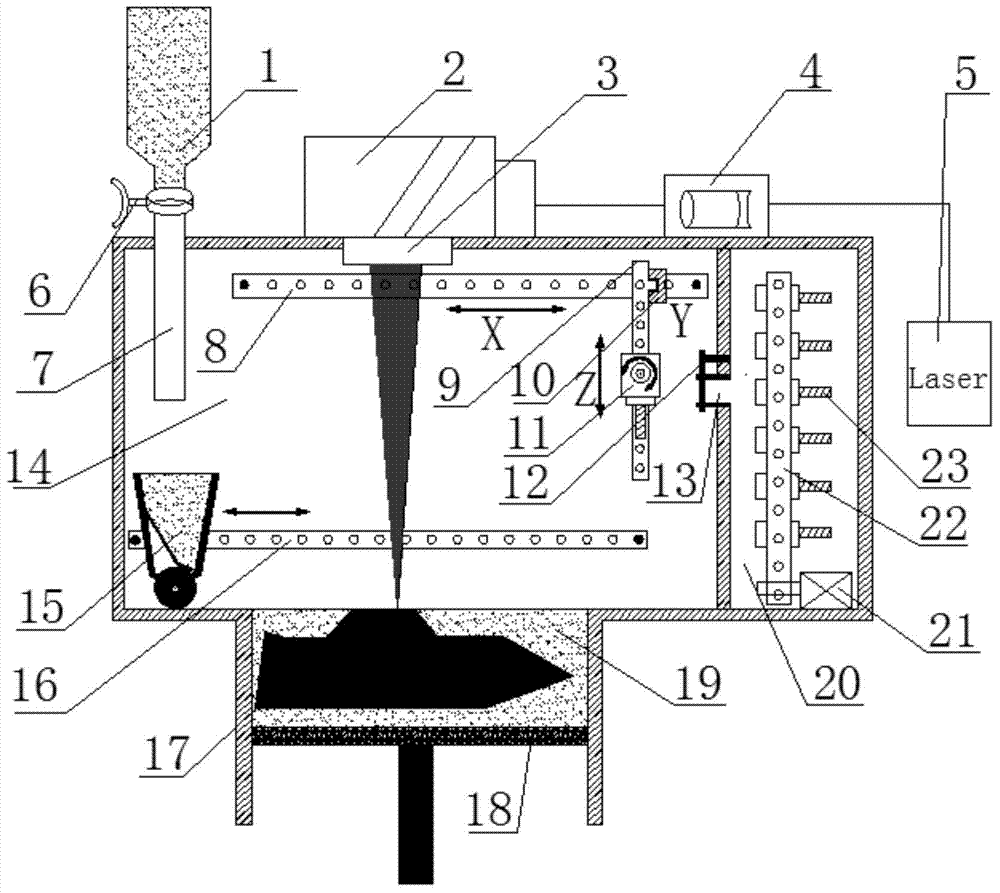

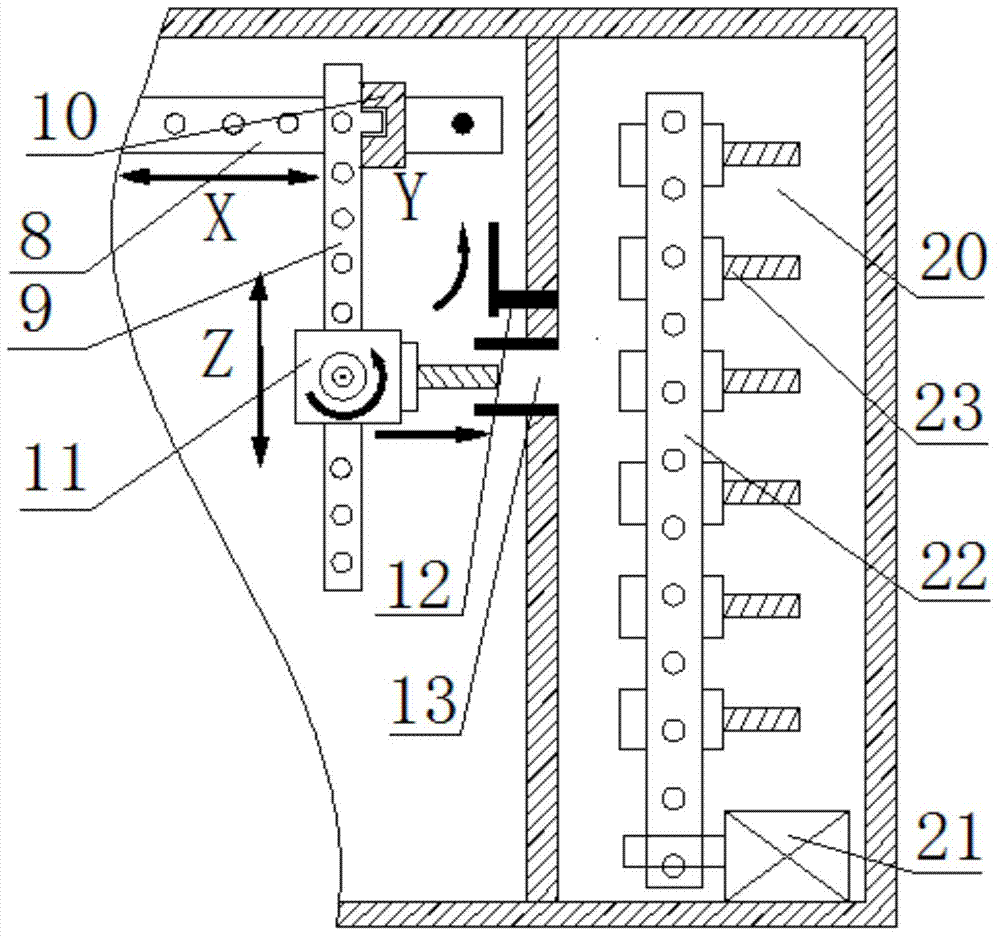

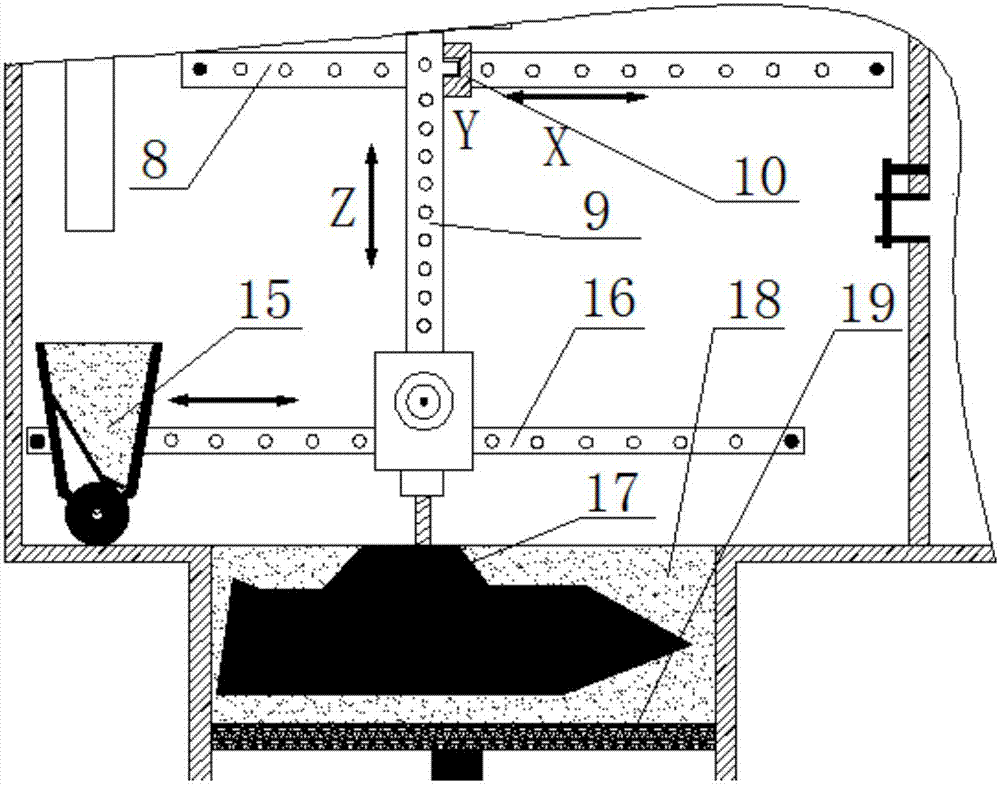

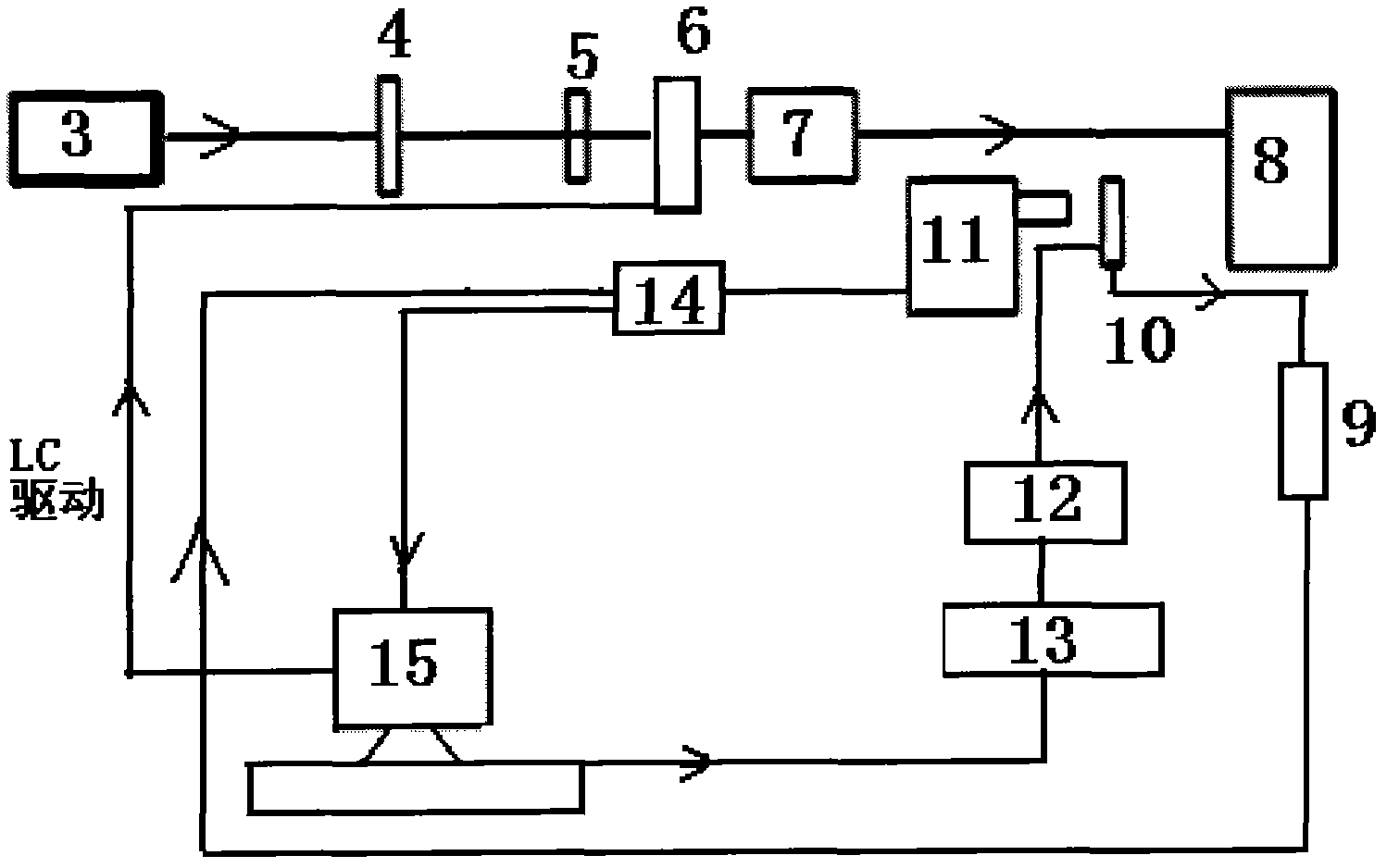

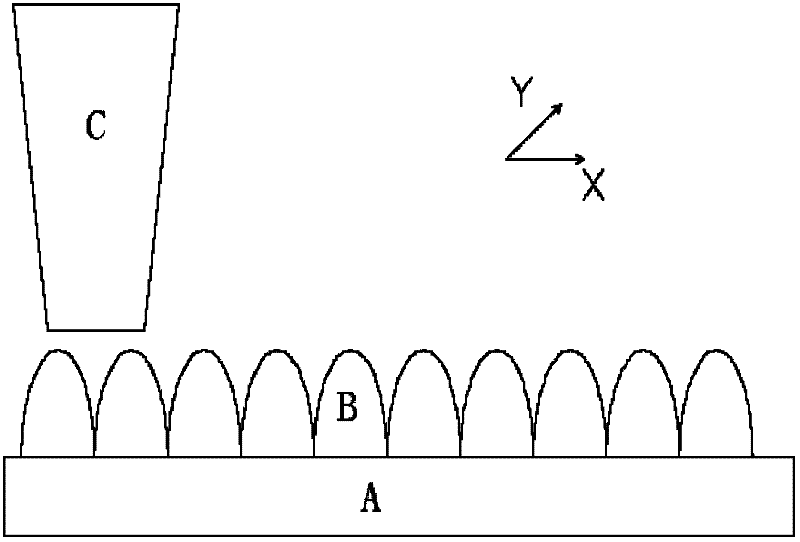

Equipment and method for single-cylinder type selective laser melting and milling composite processing

ActiveCN104493491ASave spaceReduce weightIncreasing energy efficiencyOther manufacturing equipments/toolsBeam expanderSelective laser melting

The invention discloses equipment and a method for single-cylinder type selective laser melting and milling composite processing. The equipment comprises a selective laser melting forming device, a vertical milling machine device and a central control system, wherein the vertical milling machine device is positioned in a forming chamber and comprises a chain type tool magazine, the chain type tool magazine is positioned at the right side of the exterior of the forming chamber, a laser device is positioned at the right side of the forming chamber of the selective laser melting forming device, a collimating beam expander, an optical lens and a scanning vibration lens are arranged at the top part of the forming chamber, and the optical lens is positioned at the upper part of the forming chamber, is embedded in the outer wall of the forming chamber, and is in sealed combination with the outer wall of the forming chamber. The equipment has the advantages that the size accuracy and surface quality of a forming part are improved, so the organic combination of additive manufacturing and high-accuracy milling processing is realized; by closing an automatic tool switching valve and a tool switching opening, the influence on a milling tool caused by metal powder and residual heat during laser processing is avoided, the quality of the milling tool is guaranteed, and the service life is prolonged.

Owner:SOUTH CHINA UNIV OF TECH

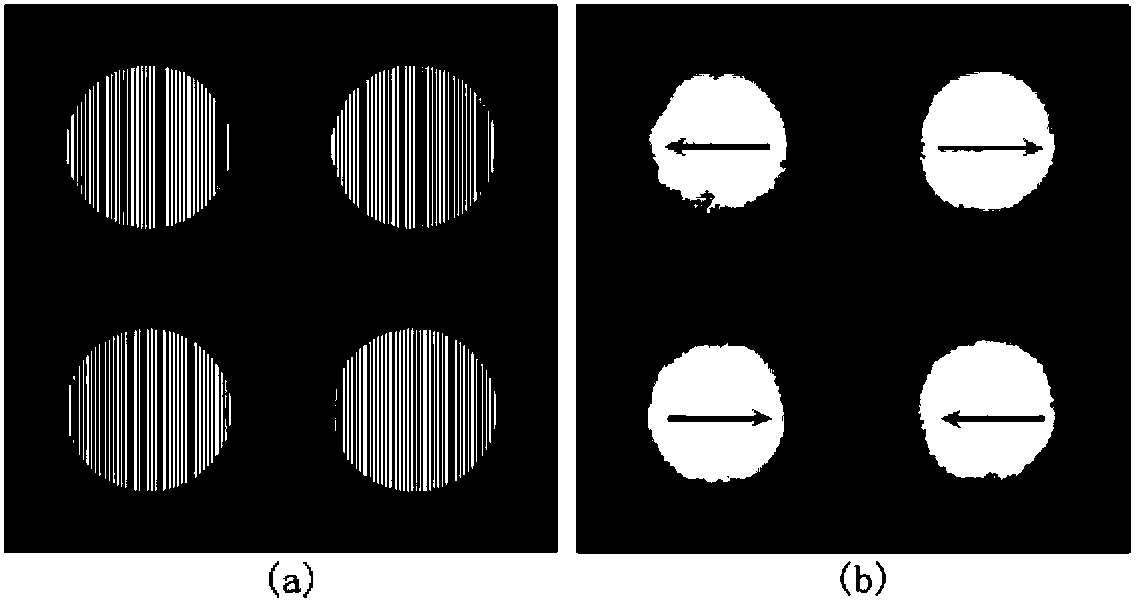

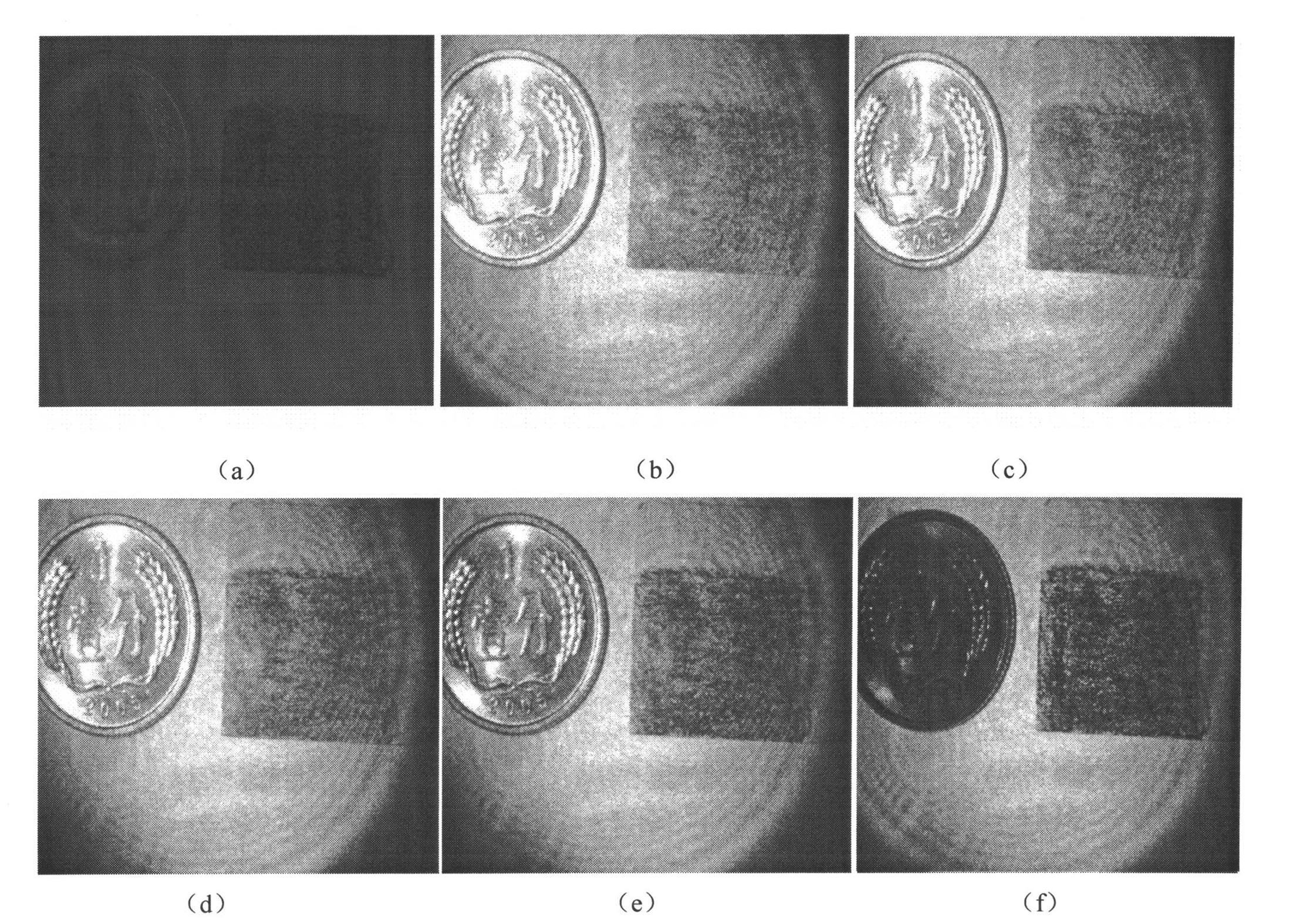

Underwater video camera system based on polarization identification and method thereof

InactiveCN102116997AIncrease contrastImprove clarityTelevision system detailsColor television detailsPolarizerOptical polarization

The invention relates to the technical field of optical instruments, in particular to an underwater video camera system based on polarization identification and a method thereof. The technical scheme is that the underwater video camera system comprises an underwater light source, a polarization modulation part and an image acquisition and processing part, wherein the underwater light source comprises a semiconductor laser, an optical filter, a polarizer, a polarization rotator and a beam expander; the polarization modulation part comprises an analyzer, a stepper motor, a stepper motor controller and an infrared detector; and the image acquisition and processing part comprises a high-frequency CCD (Charge Coupled Device) video camera, an image acquisition system and a computer. The underwater video camera system has the benefits that with the adoption of the underwater camera system and the method, the contrast degree and the definition of target imaging as well as the target detectionand the identification efficiency can be effectively improved; the polarization imaging can utilize the differences of different target back polarizations to eliminate the interference of background light; and as a means for identifying the target from messy background is provided, the method has remarkable advantage as compared with the commoner method for imaging and identifying the target by using light intensity.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

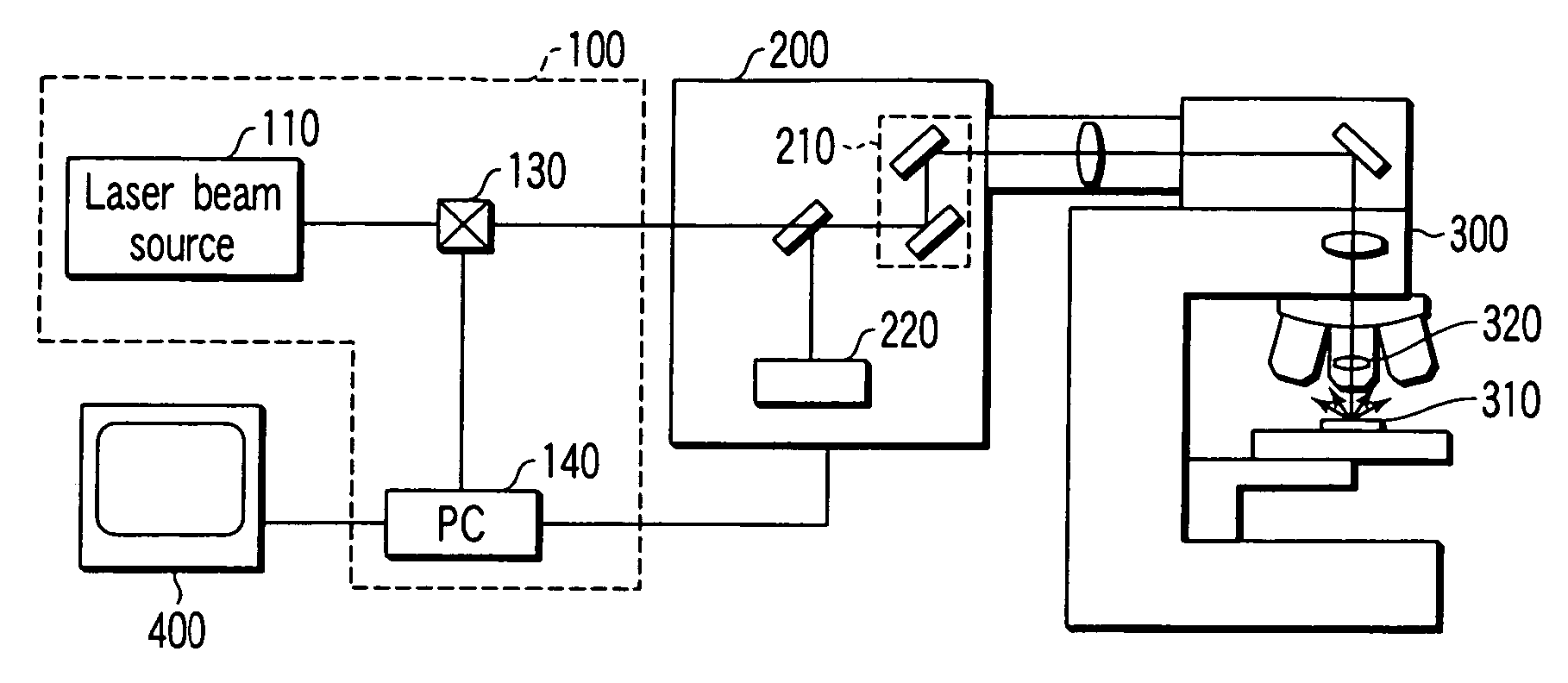

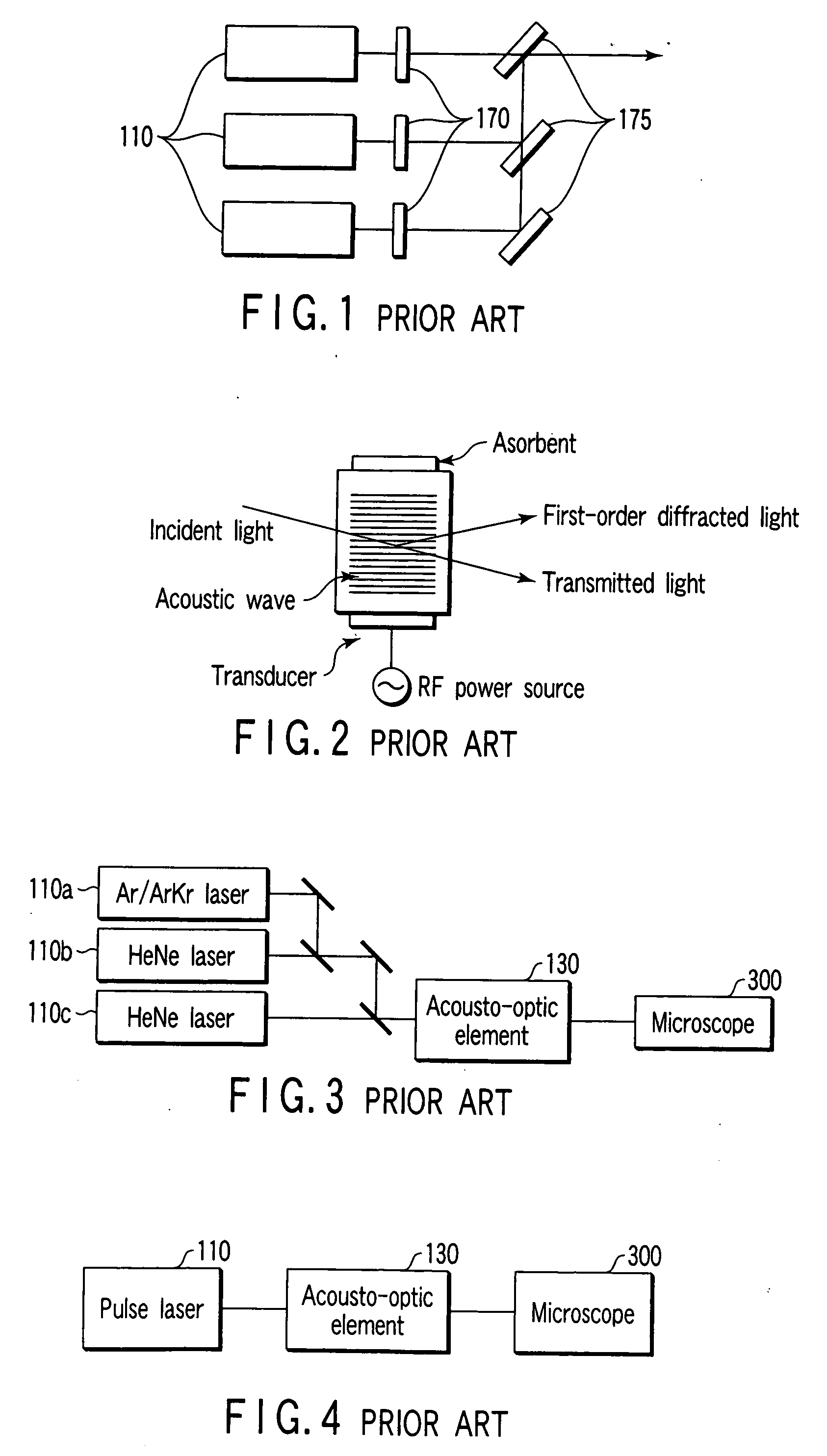

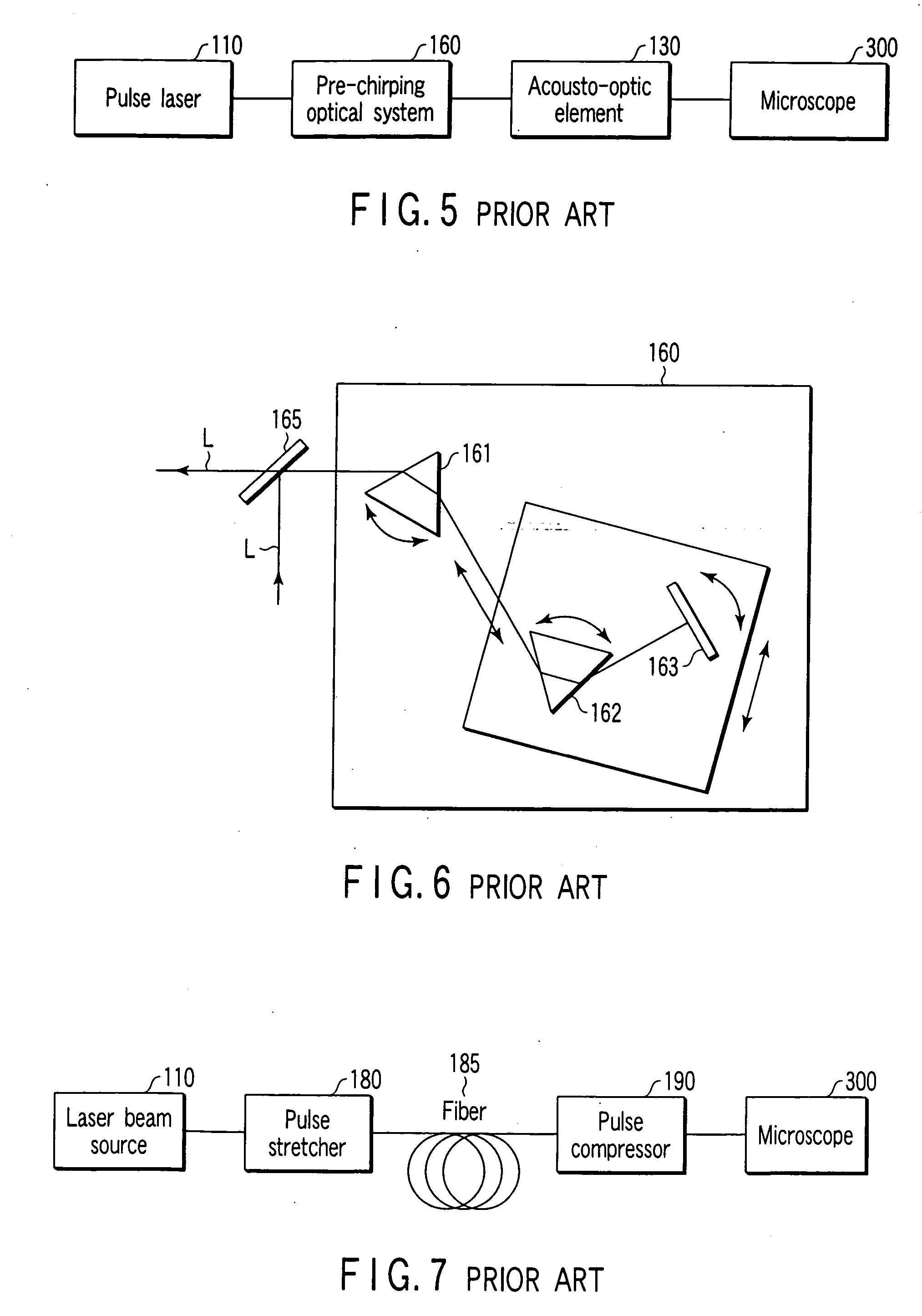

Laser scanning microscope

ActiveUS20050263690A1Beam/ray focussing/reflecting arrangementsPhotometryBeam expanderLaser scanning microscope

A laser scanning microscope includes an acousto-optic element or an electro-optic element in an illumination optical system which introduces a laser beam from a laser beam source of the laser scanning microscope into a microscope. The laser scanning microscope further includes a beam expander disposed between the laser beam source and the acousto-optic element or the electro-optic element.

Owner:EVIDENT CORP

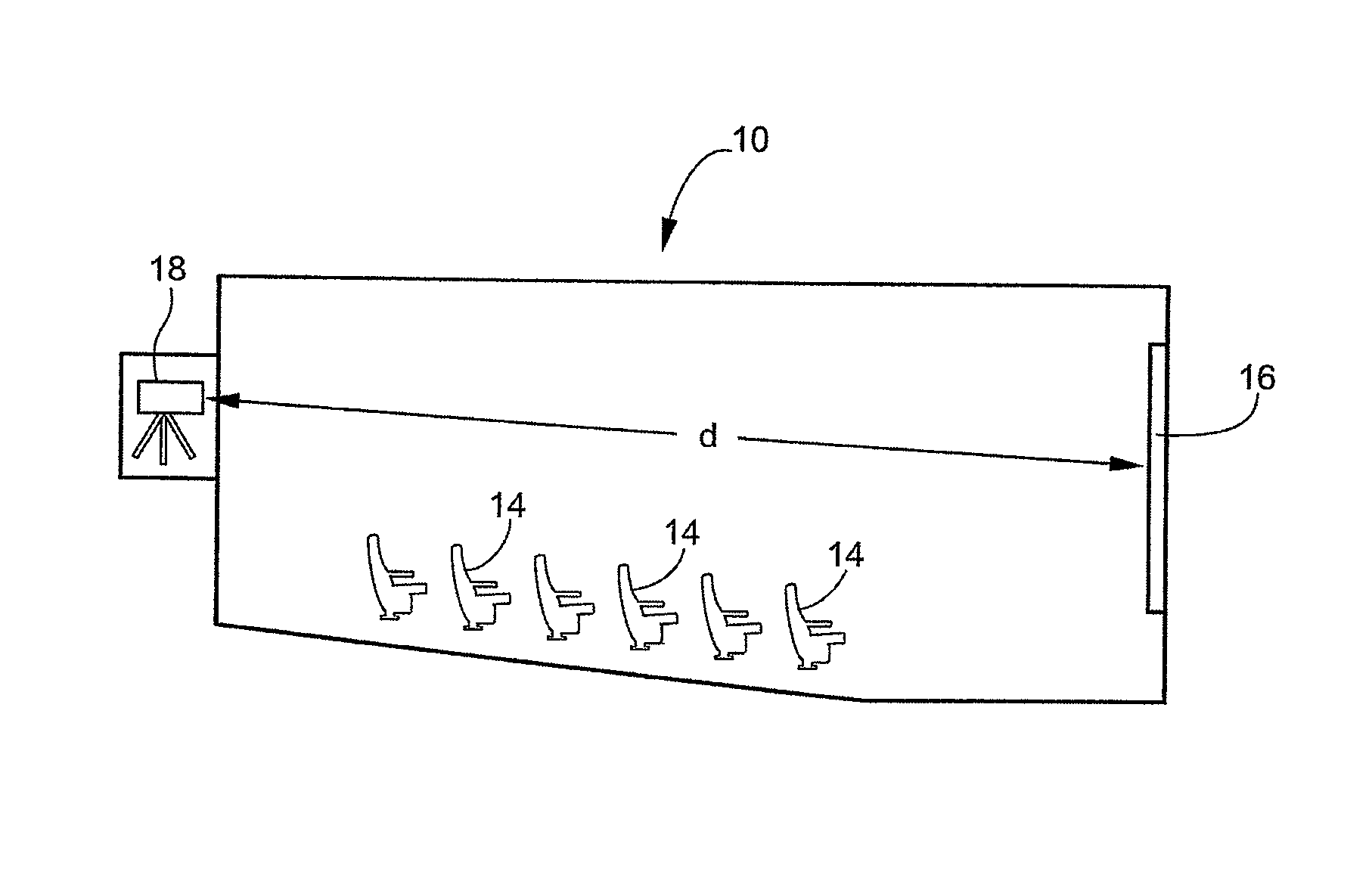

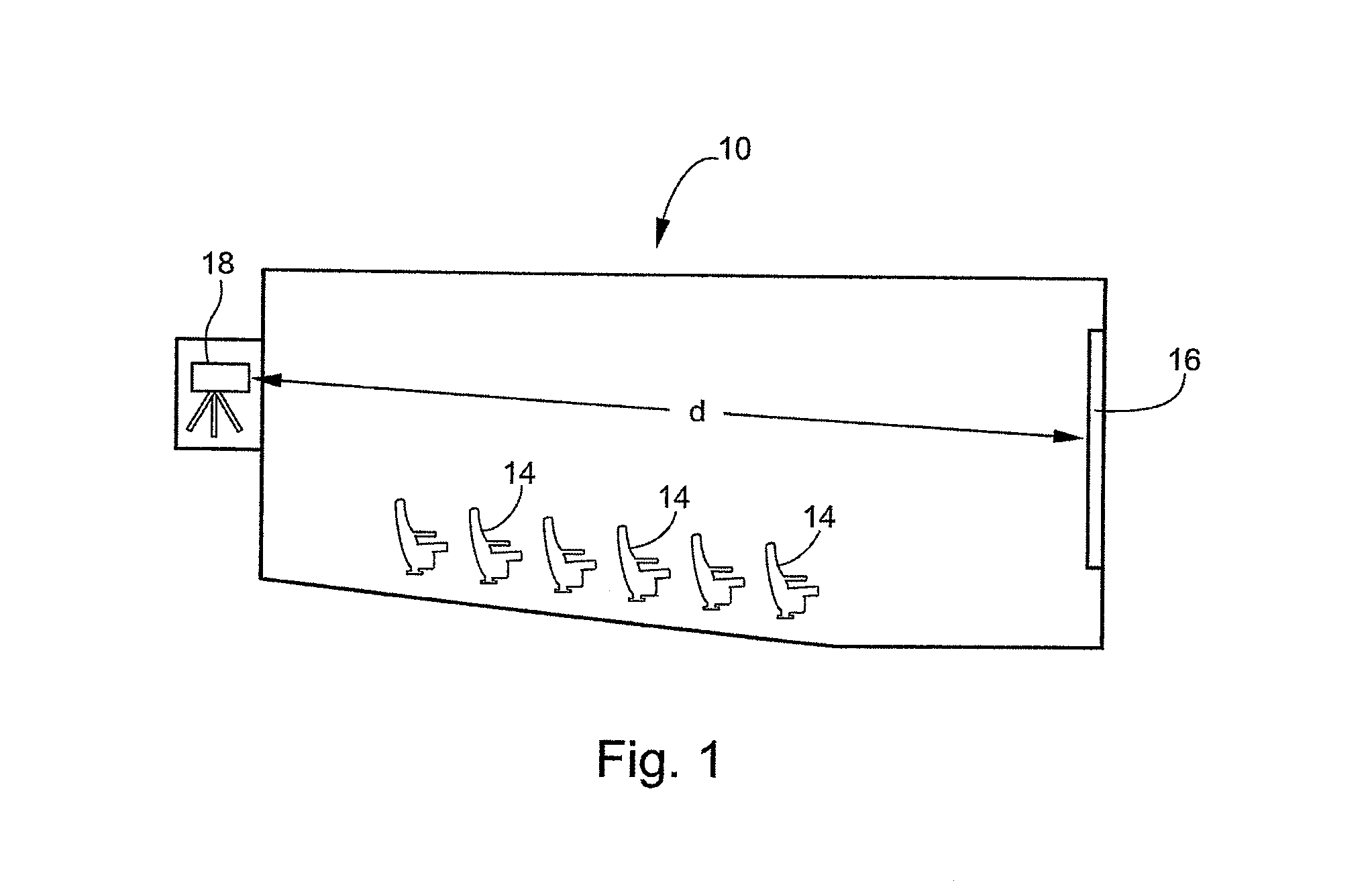

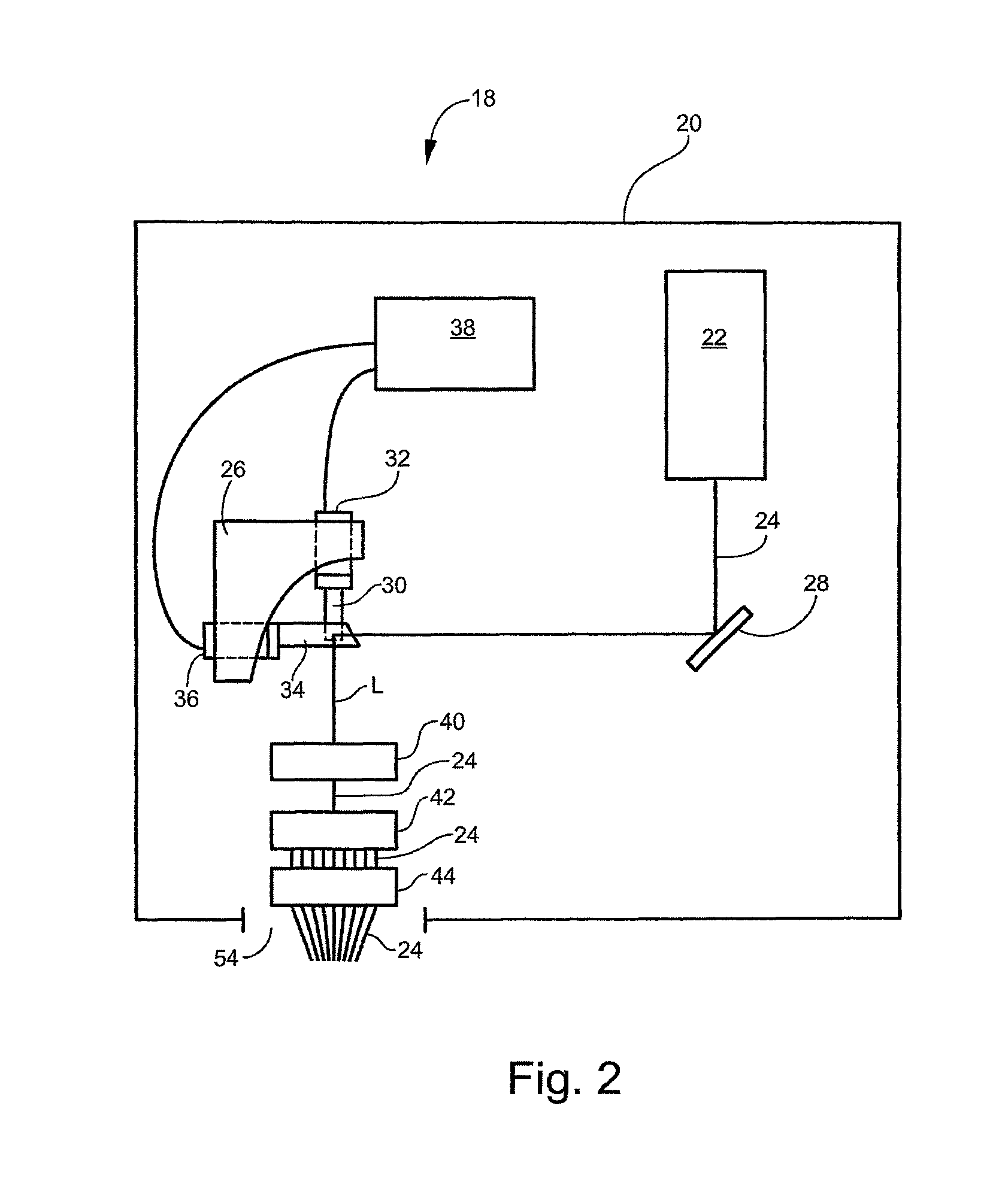

Laser particle projection system

ActiveUS9366861B1Little useReduce energy densityStatic indicating devicesColor television detailsBeam expanderLight beam

An improved particle effect projector is disclosed that reduces the energy density of a laser beam projected through a movie theater or other entertainment venue, comprising an F-theta lens, a beam expander and a beam focuser with a long focal length that approximates the distance between the particle effect projector and the movie screen or other surface onto which the particle effect beam is being projected.

Owner:BLISSLIGHTS LLC

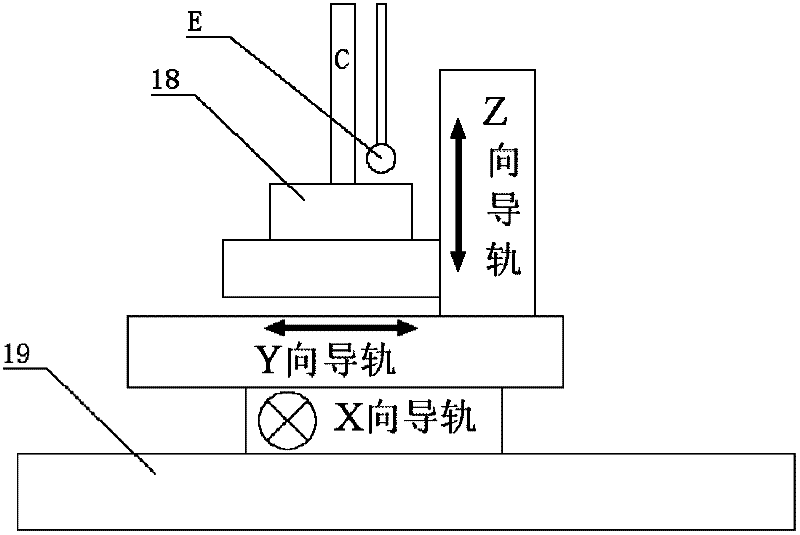

Device and method for ultrafast picosecond pulse laser machining of super-hydrophobicity micro-structure surface

InactiveCN102581478ASolve efficiency problemsReduce investmentLaser beam welding apparatusMicro structurePicosecond pulsed laser

A device and a method for ultrafast picosecond pulse laser machining of a super-hydrophobicity micro-structure surface belong to the field of preparation of functional micro-structure surfaces, and aim to solve the problems of high investment and low output of an existing machining process and existing machining technology for functional elements. The device comprises an ultrafast picosecond pulse laser source, an optical isolator, five reflectors, a rotary liquid crystal polarizing film, a polarization beam splitter, two beam collectors, a half wave plate, a focusing lens, frequency-doubling generator LBO (lithium triborate) crystal, a dichroic mirror, a light control device, a beam profile curvometer, a beam amplifying component Kepler beam expander, a focusing machining lens, a machining platform, a microscopy imaging CCD (charge coupled device) component and a control system. The method includes the stepsof: fixing a steel workpiece onto a surface driven by a Z-directional guide rail of the machining platform; adjusting a light path; detecting the surface of the workpiece by a probe; and driving the workpiece to move by means of movement of an X-directional guide rail and a Y-directional guide rail of the machining platform. The device and the method are used for preparing the super-hydrophobicity micro-structure surface.

Owner:HARBIN INST OF TECH

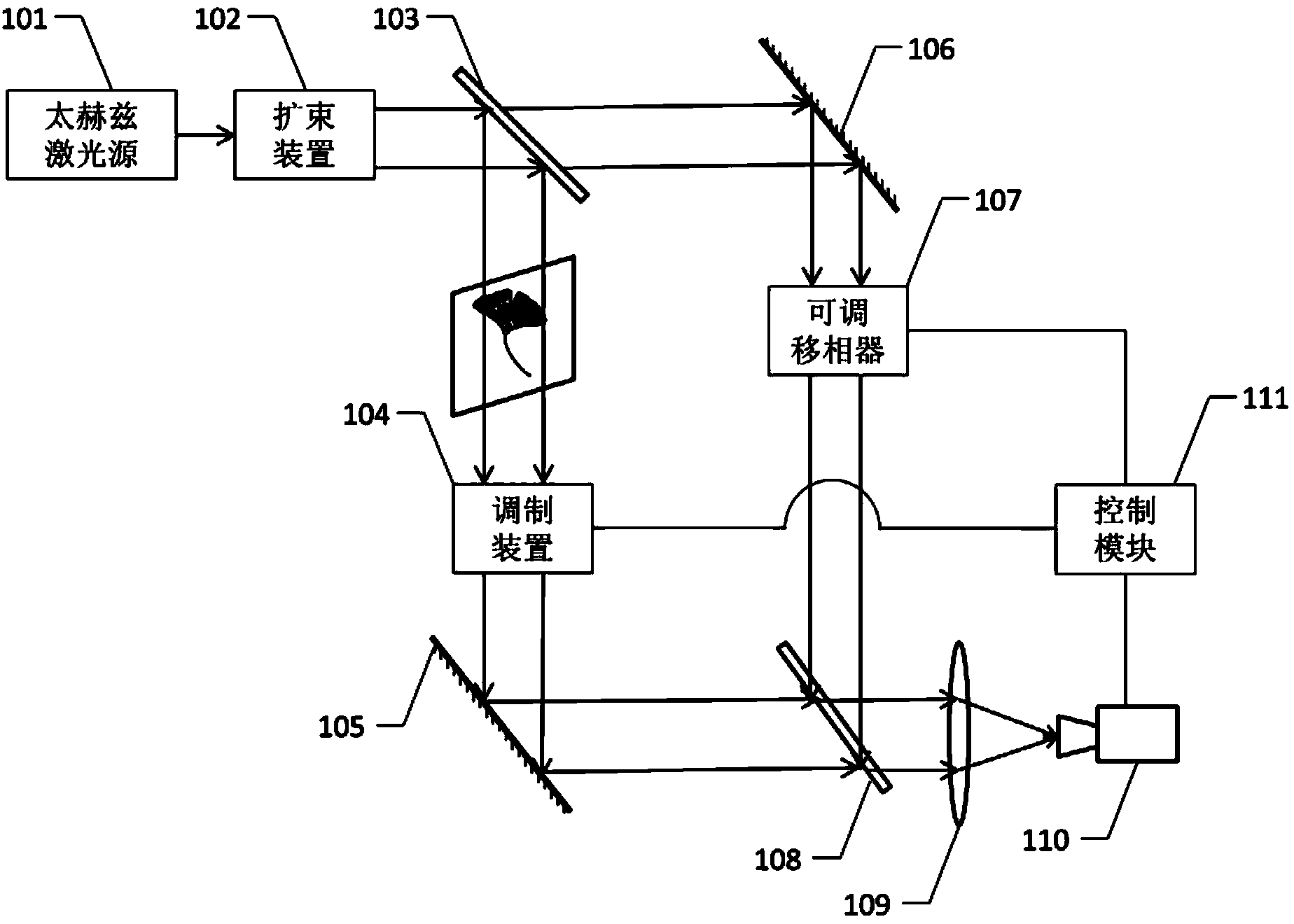

Single-pixel terahertz holographic imaging device and method

ActiveCN103822577ARealize true 3D imagingEasy to refactorMaterial analysis by optical meansUsing optical meansBeam splitterPlane mirror

The invention discloses a single-pixel terahertz holographic imaging device and method. Monochromatic terahertz light emitted by a terahertz laser source is transformed into parallel light with larger beamwidth by a beam expander device, and then divided into object light and reference light through a beam splitter; the object light is encoded by a modulation device in airspace after irradiating an object; the reference light passes through an adjustable phase shifter on the light path after being reflected by a plane mirror; the object light is converged with the reference light on a second beam splitter after being reflected by the plane mirror, enters a single-pixel detector at the focus point of a condenser lens after being converged by the condenser lens; a signal output by the single-pixel detector is fed to a control module to carry out image reconstruction; and terahertz holographic compression sensing imaging of the object is achieved by changing combination of a space code on the modulation device and a phase on the adjustable phase shifter for a plurality of times. The single-pixel terahertz holographic imaging device and method have the advantages that real three-dimensional imaging of the tested object is achieved by combining phase-shifting digital holography with a compression sensing principle, and the single-pixel terahertz holographic imaging device and method are pioneering inventions in the field of terahertz imaging.

Owner:博微太赫兹信息科技有限公司

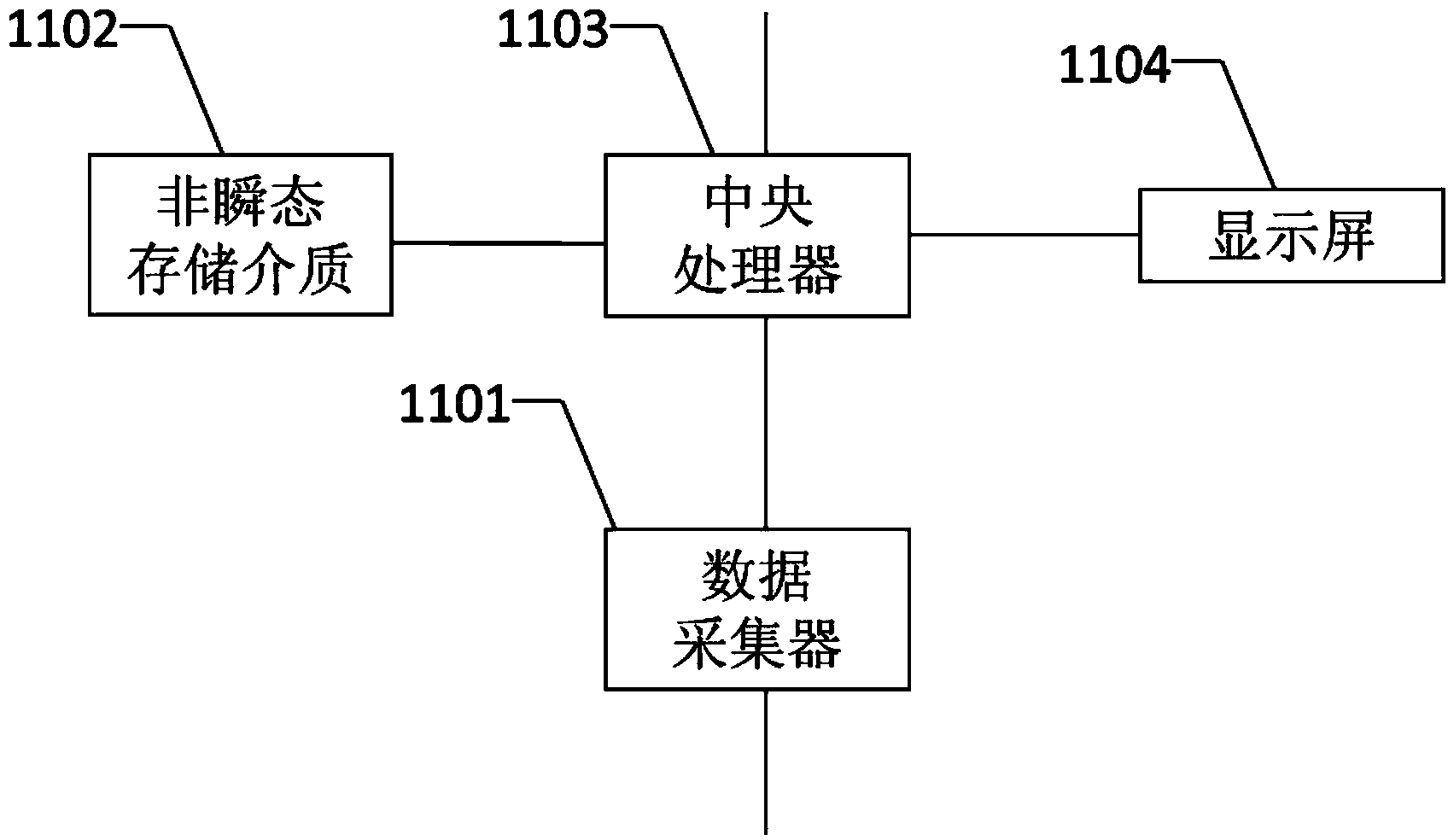

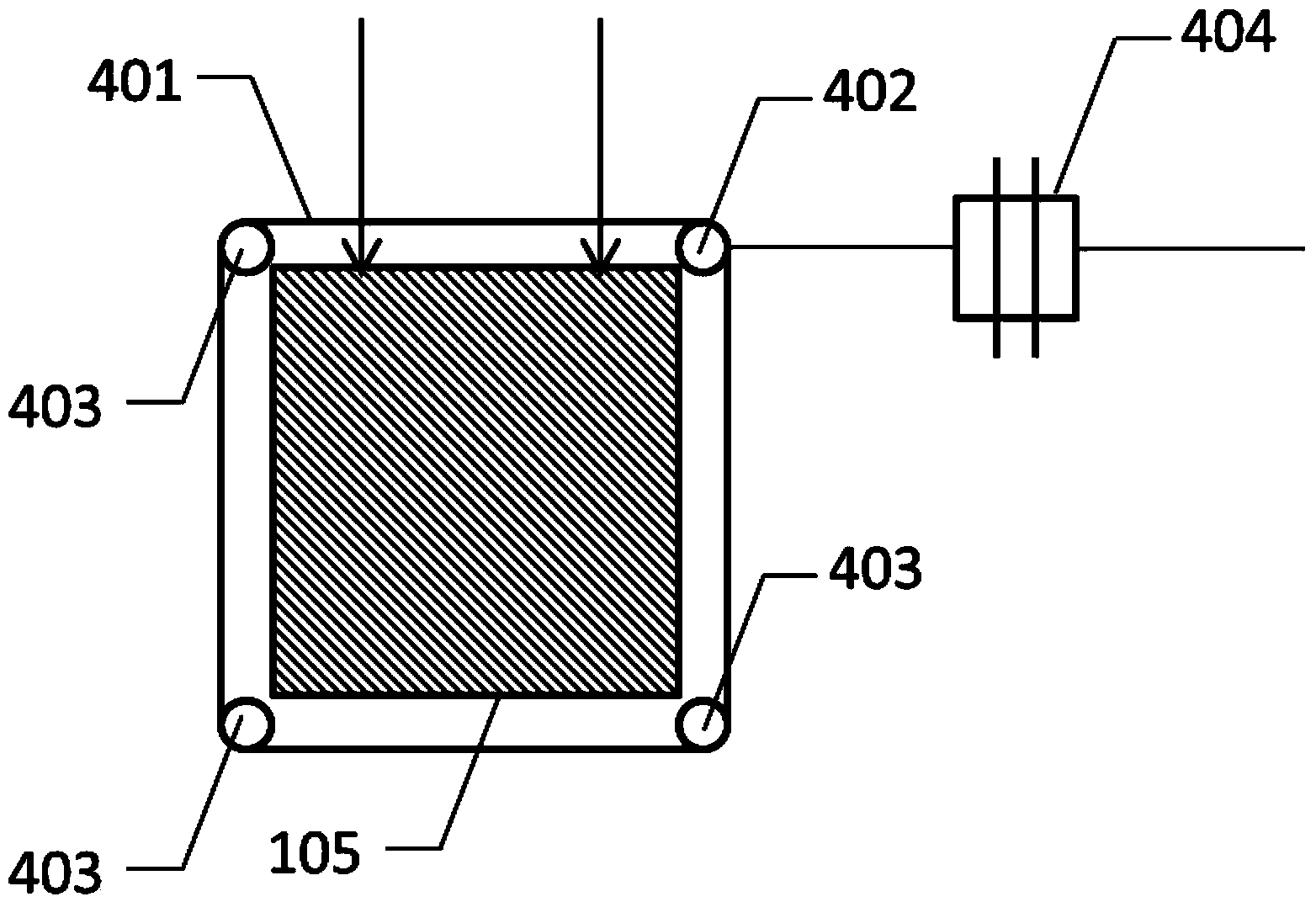

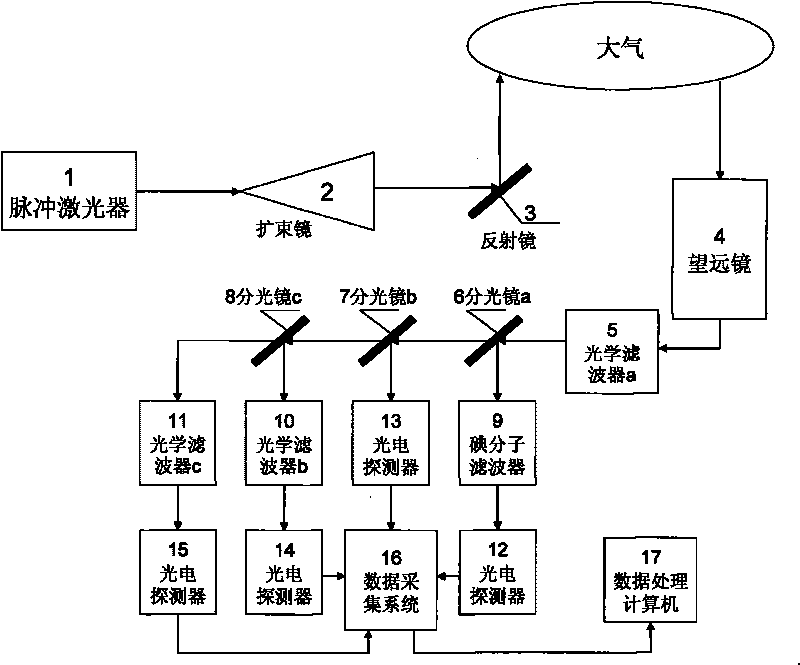

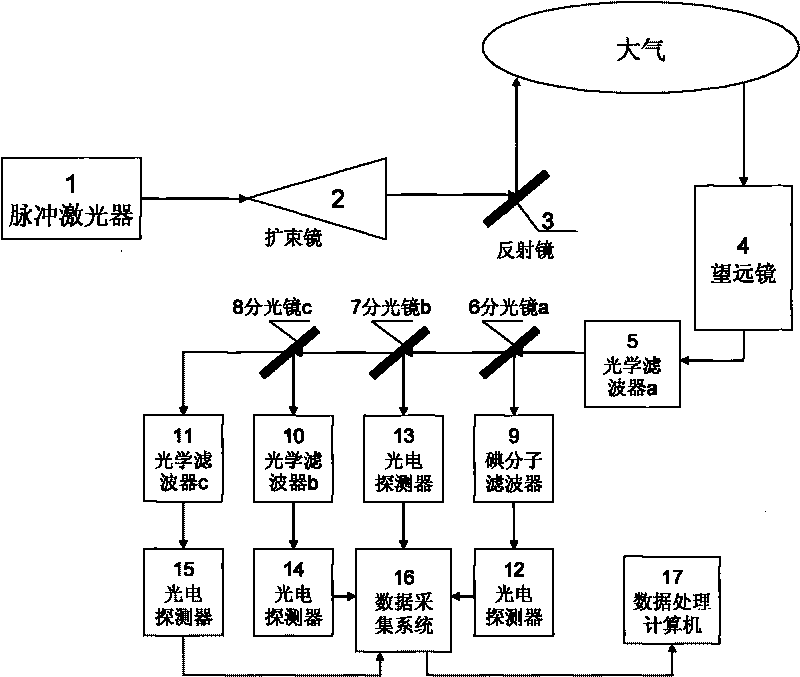

Real-time calibration high spectral resolution lidar device

InactiveCN101710178AImprove measurement efficiencyImprove measurement accuracyElectromagnetic wave reradiationICT adaptationBeam splitterData acquisition

The invention relates to a real-time calibration high spectral resolution lidar device for measuring atmospheric wind field. The invention comprises a transmitting system composed of a pulse laser, a beam expander and a reflector, a receiving system composed of a telescope, optical filters, a molecular iodine filter, beam splitters and photoelectric detectors, a data acquisition system connected with the photoelectric detectors, and a data processing computer. The invention is characterized by also comprising two receiving channels of the rotational Raman, and the two receiving channels of the rotational Raman are connected in parallel by the beam splitters, extracts atmospheric molecule rotational Raman spectrum from the original detecting signal, and connected with the data acquisition system, the data acquisition system is connected with the data processing computer and transmits the acquired information to the data processing computer. The invention is characterized in that gasoloid relative concentration and atmospheric parameters are obtained from primary optical detection, and simultaneously wind speed refutation is carried out, measurement efficiency and measurement accuracy are improved with the wind speed measurement accuracy reaching 1m / s.

Owner:OCEAN UNIV OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com