Patents

Literature

76 results about "Picosecond pulsed laser" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The picosecond pulsed sources are either laser diode based or LED based devices that can be operated at variable, user-adjustable repetition rates up to 80 MHz. They cover discrete wavelengths from 255 nm to 1990 nm or are tunable in the VIS. Power levels vary between µW and hundreds of mW for the most powerful, fibre amplified versions.

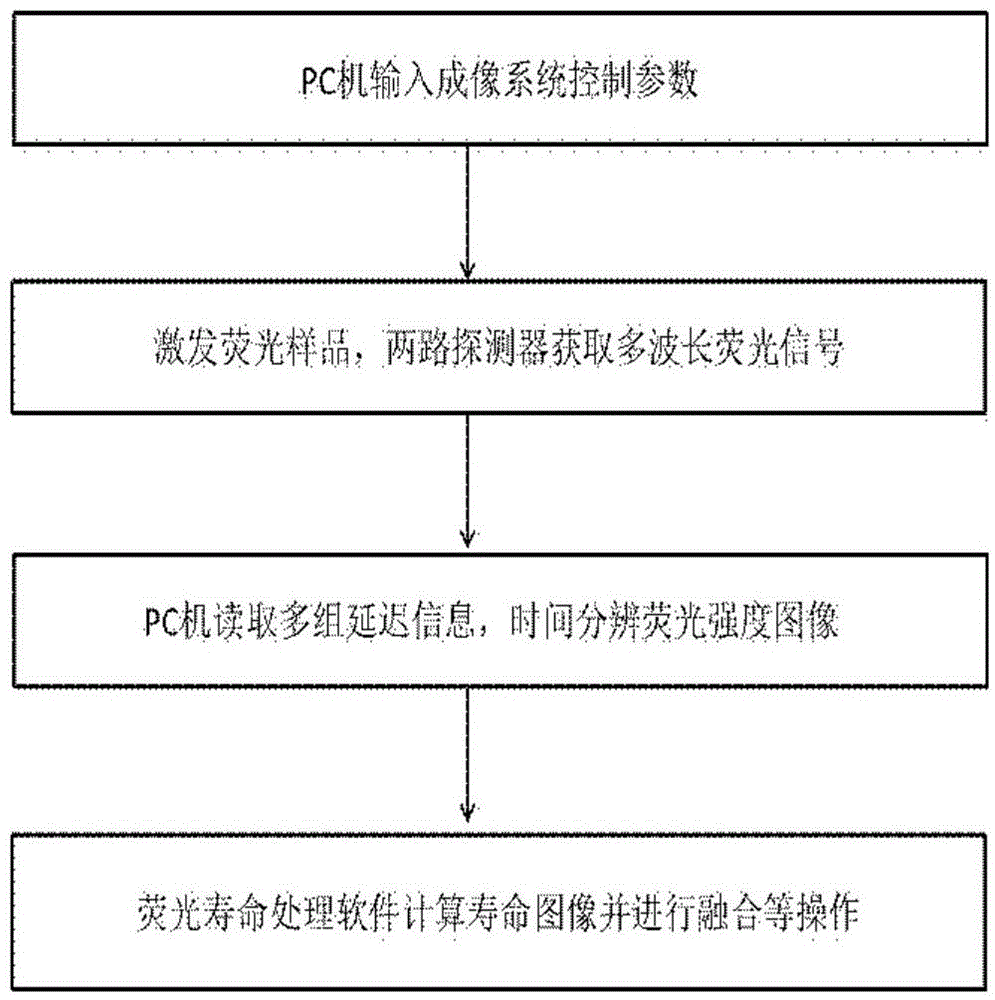

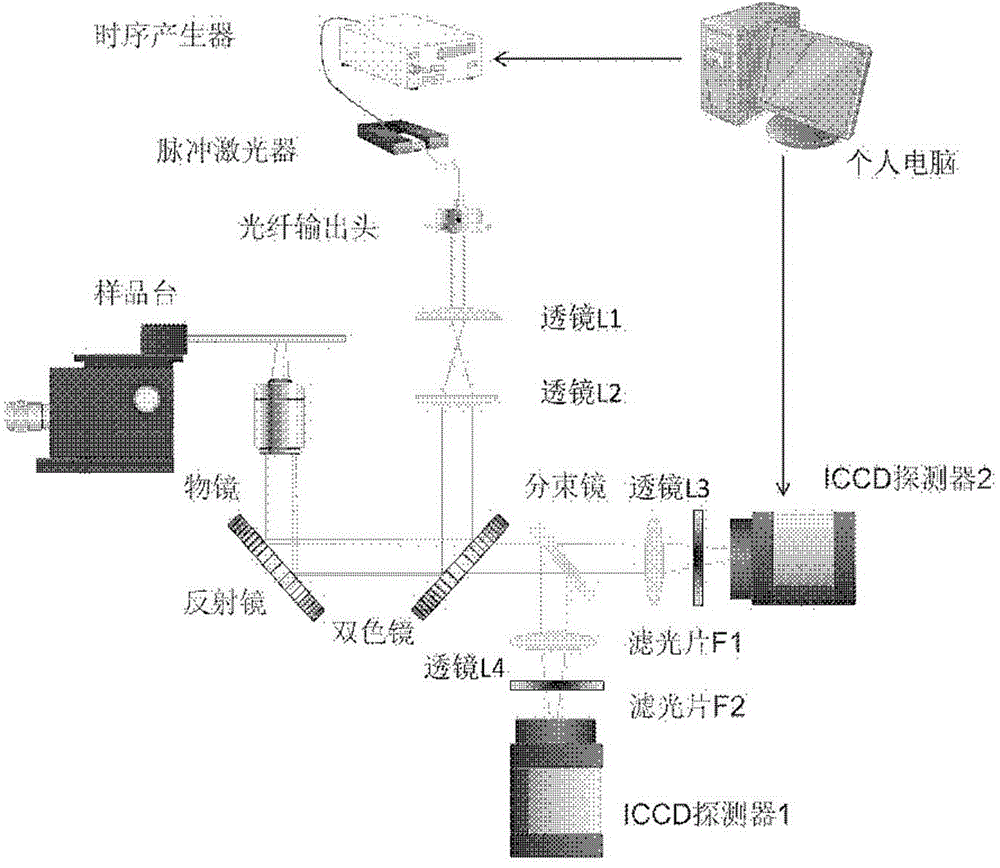

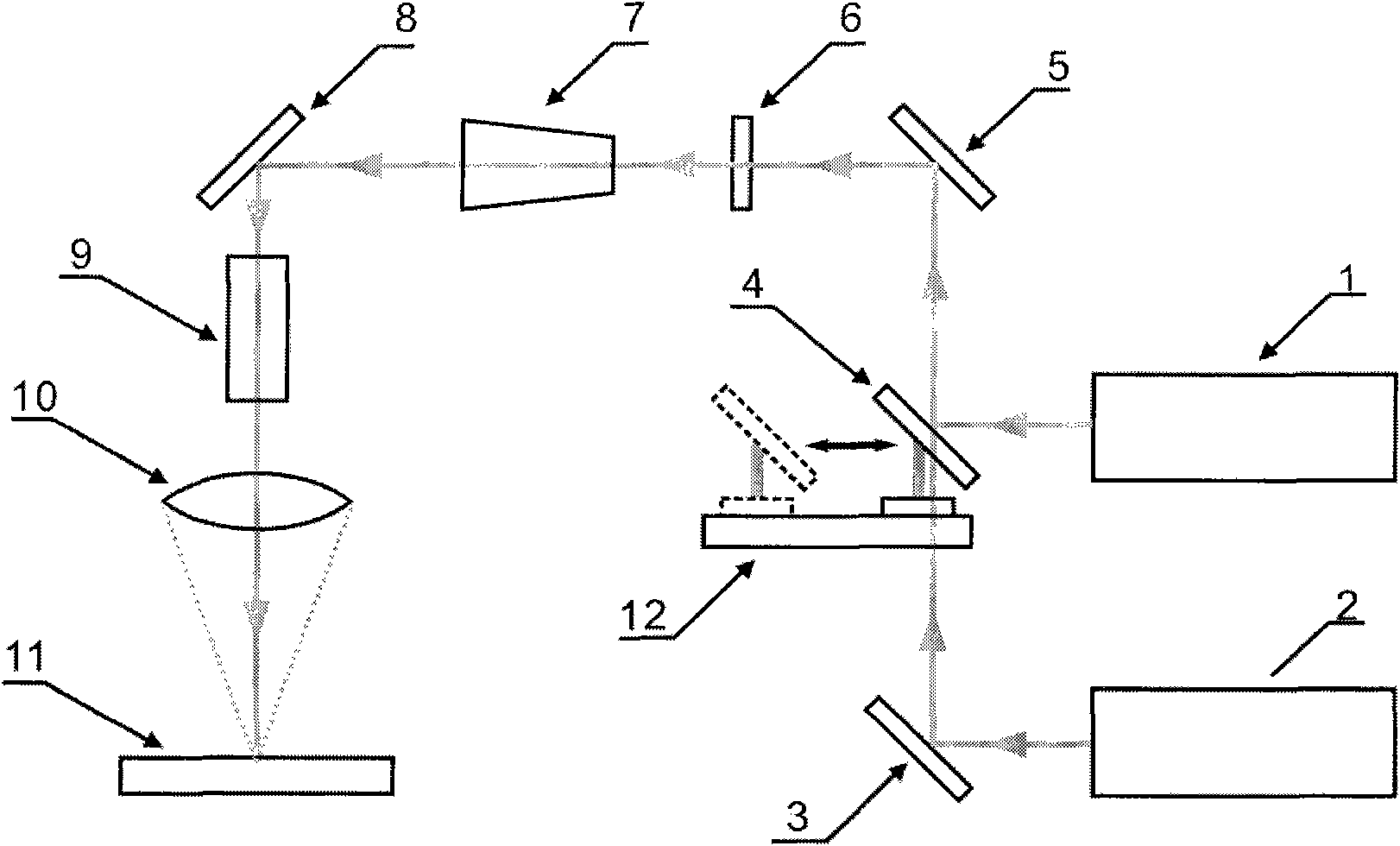

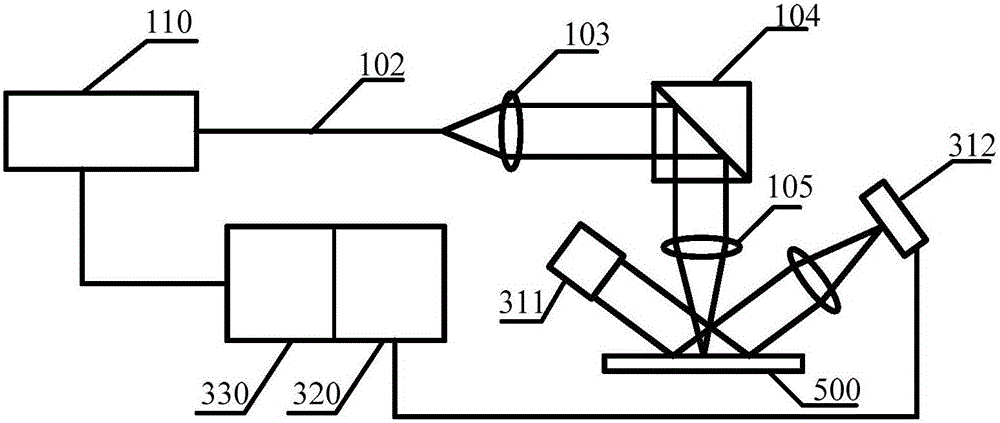

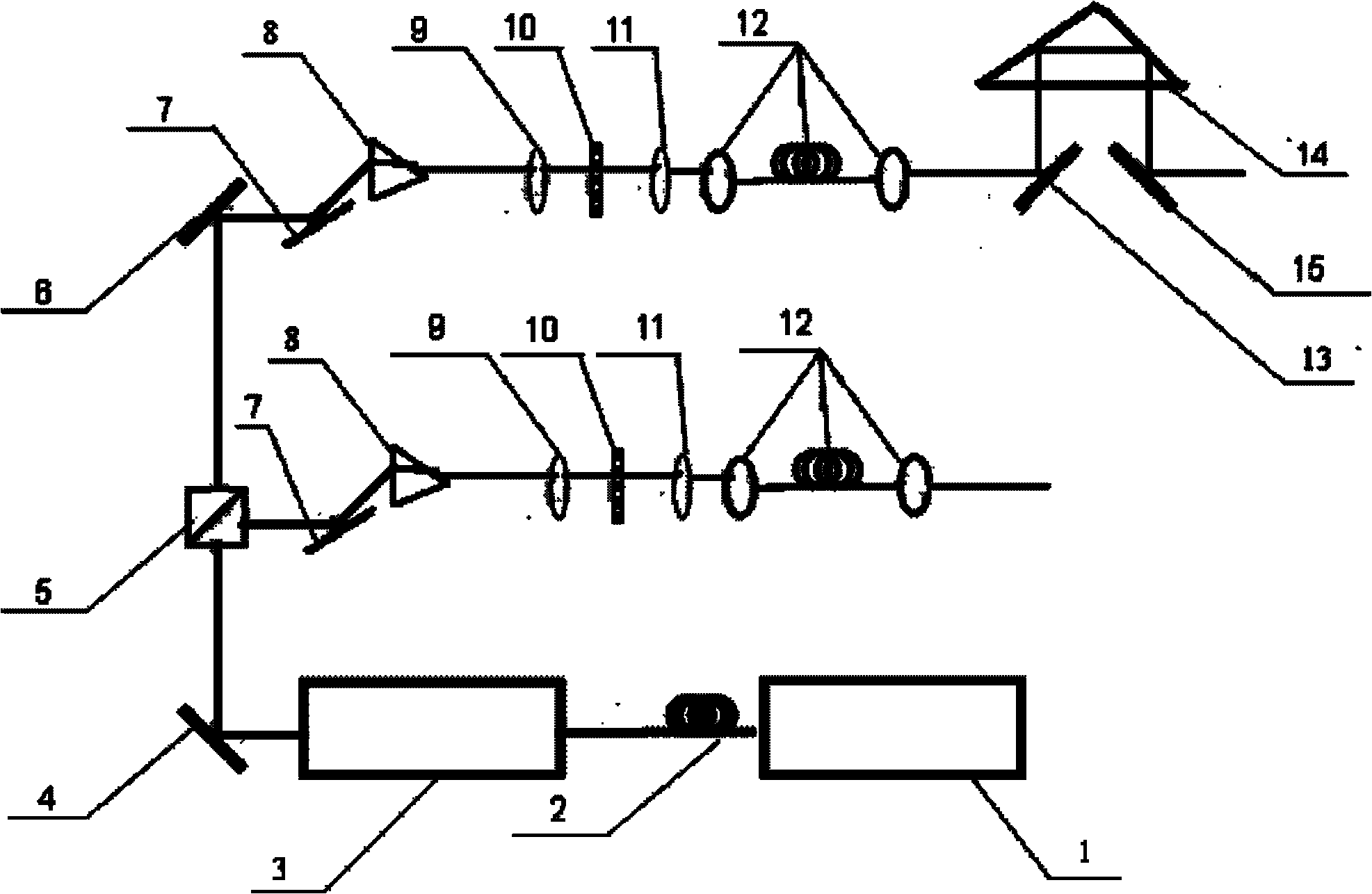

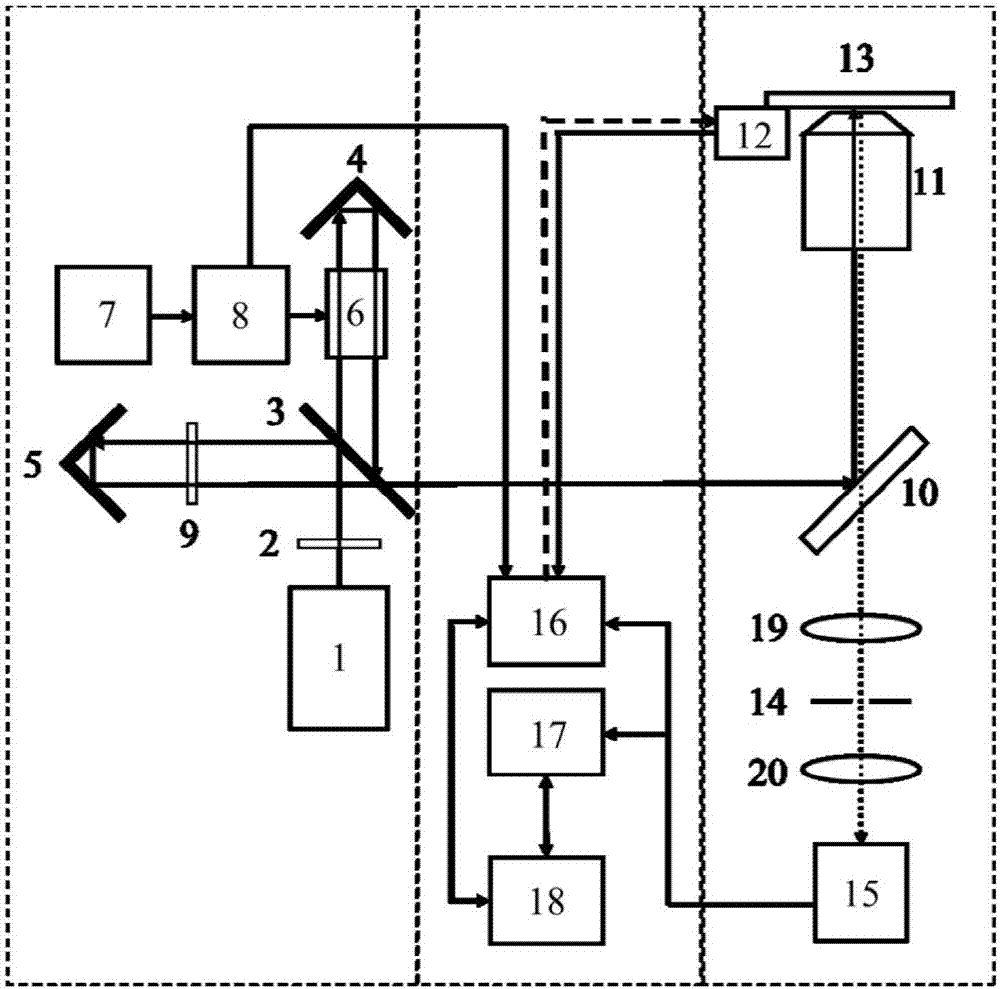

Two channel-based multi-spectrum fluorescent imaging microscopic system and method

ActiveCN104614353AFluorescence Imaging RealizationMicroscopesFluorescence/phosphorescencePicosecond pulsed laserFluorescence microscope

The invention is applicable to the field of optics, biomedicine, life science and the like, and provides a two channel-based multi-spectrum fluorescent imaging microscopic system and method, wherein the two channel-based multi-spectrum fluorescent imaging microscopic system comprises a picosecond pulse laser device, a fluorescent excitation and collection light path, a microscopic objective lens, a light beam lens, a double-ICCD detector, and a control and processing module. The invention further discloses a method for performing multi-spectrum imaging by utilizing the two channel-based multi-spectrum fluorescent imaging microscopic system. According to the two channel-based multi-spectrum fluorescent imaging microscopic system and method, the limitation of the existing fluorescent microscope and a fluorescent life imaging microscopic system only can acquire single wavelength fluorescent signal with one-time detection can be effectively solved, the simultaneous acquisition of the multi-spectrum fluorescent strength and fluorescent light image aiming at the dynamic process of fluorescent intensity-related detection limited in biomedicine and life science can be performed, so that the research and application ranges of biophotonics can be extended.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

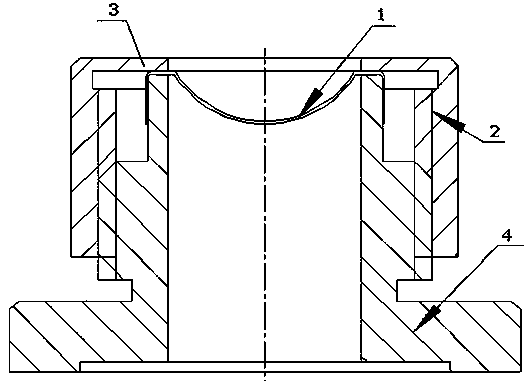

Picosecond pulse laser cutting preparation method for grid-control traveling wave tube grid mesh

ActiveCN103531414AHigh dimensional accuracyImprove consistencyNon-emitting electrodes manufacturePicosecond laserPicosecond pulsed laser

The invention discloses a picosecond pulse laser cutting preparation method for a grid-control traveling wave tube grid mesh. The method comprises the following steps of performing cleaning, hydrogen burning and annealing on a grid mesh material, then pressing the grid mesh material through a die on a punching machine to form a spherical grid mesh blank with high curvature radius precision, performing destressing hydrogen burning on the blank to eliminate stress during processing to guarantee the stability of the curvature radius of a spherical cap of a grid mesh, and finally cutting the grid mesh by adopting picosecond pulse laser of an optimized technology to prepare the grid-control traveling wave tube grid mesh with high size precision and high consistency. According to the preparation method for the grid mesh of a grid-control traveling wave tube, specific technical parameters of picosecond laser cutting are screened through a large number of experiments, the operability is high, the technical design is reasonable, and the application range is large; the prepared grid mesh is high in size precision, high in consistency, high in yield and high in reliability and has an important application value; the shortcoming of an existing electric spark grid mesh processing technology can be effectively overcome.

Owner:NANJING SANLE GROUP

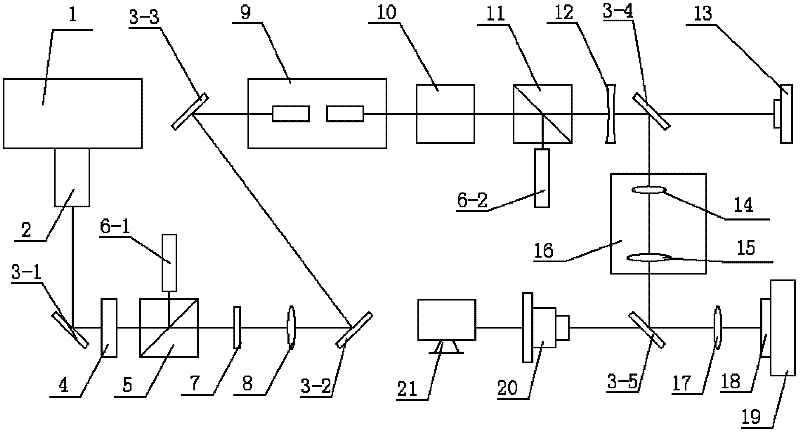

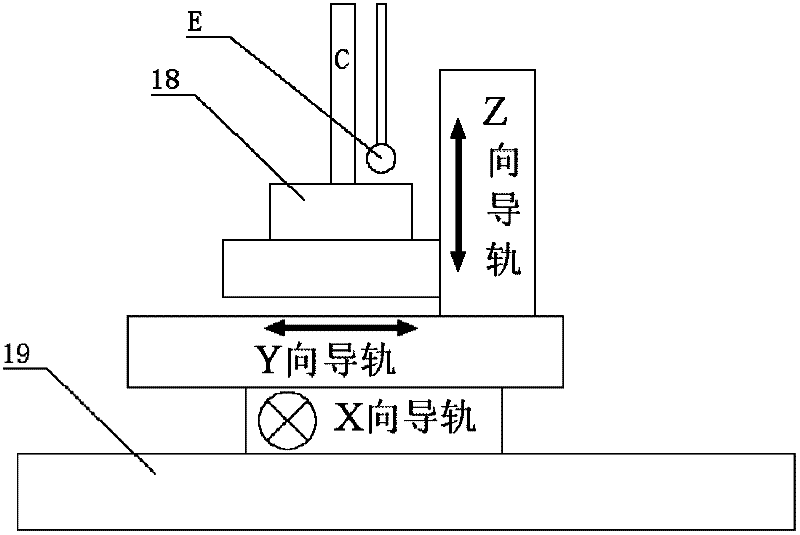

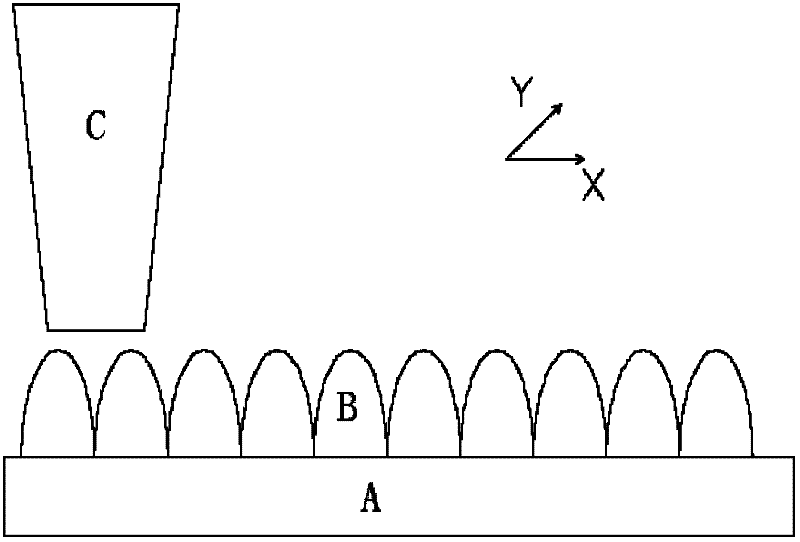

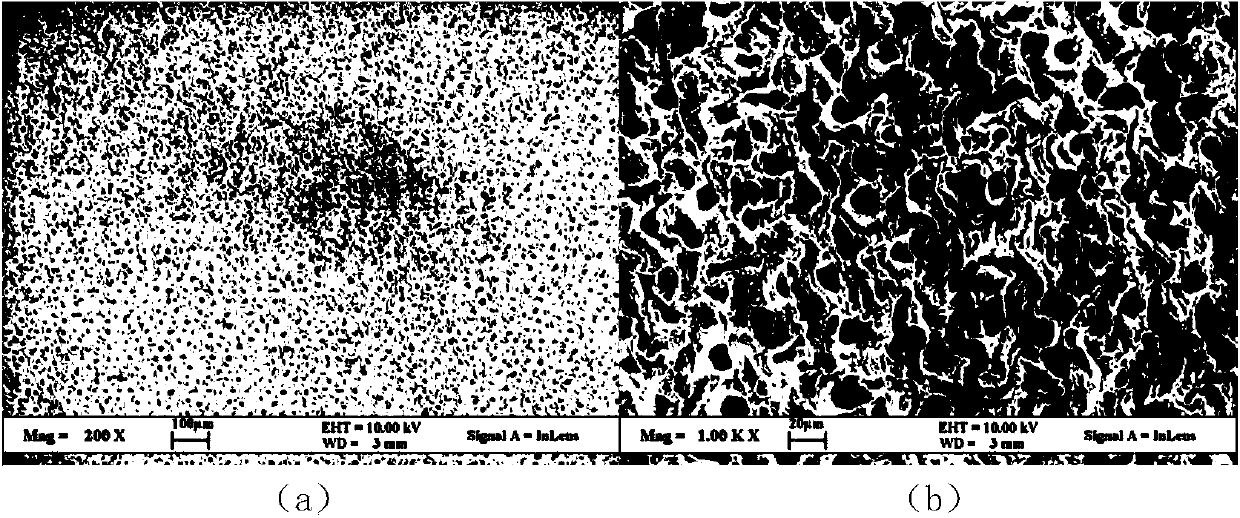

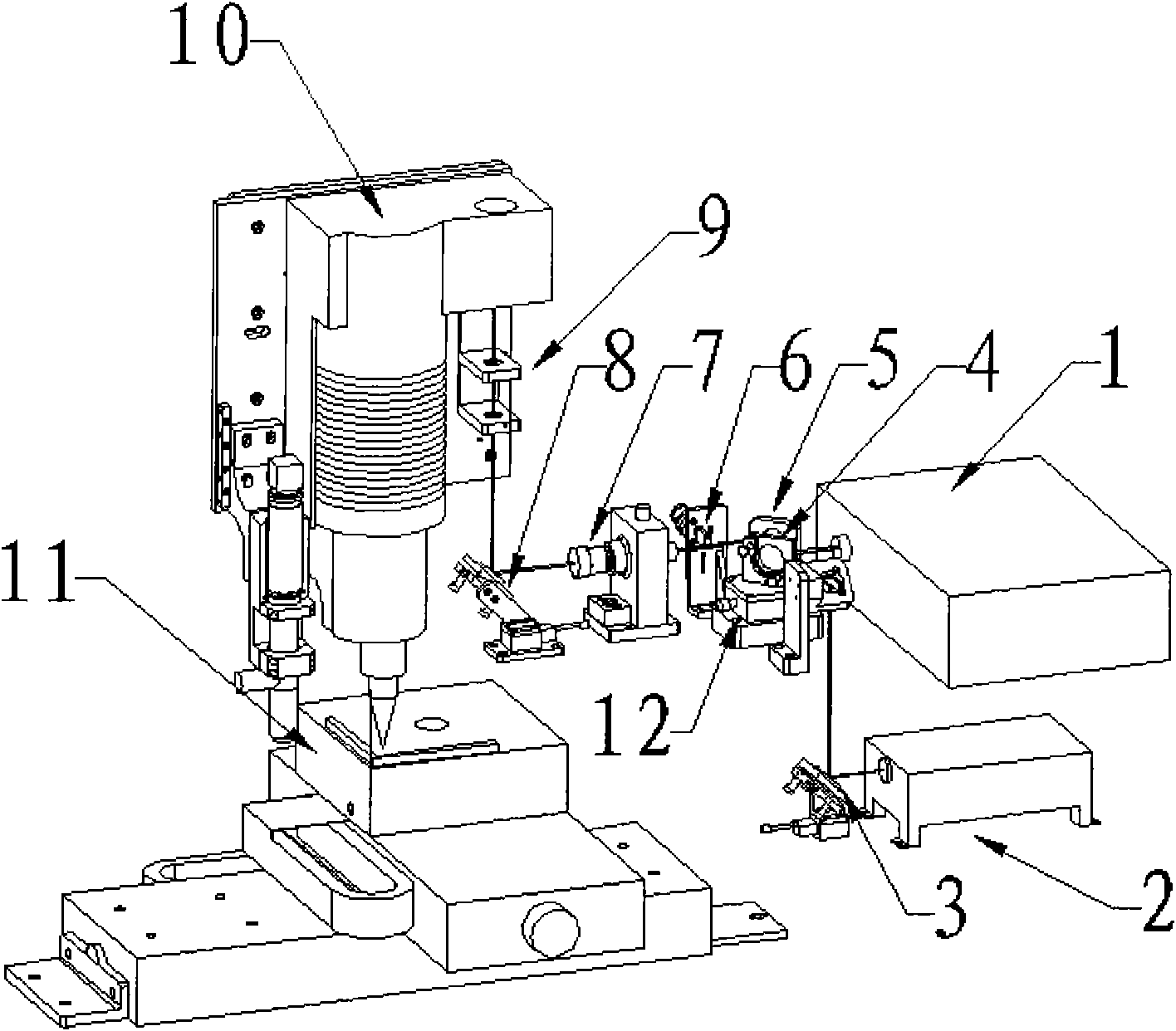

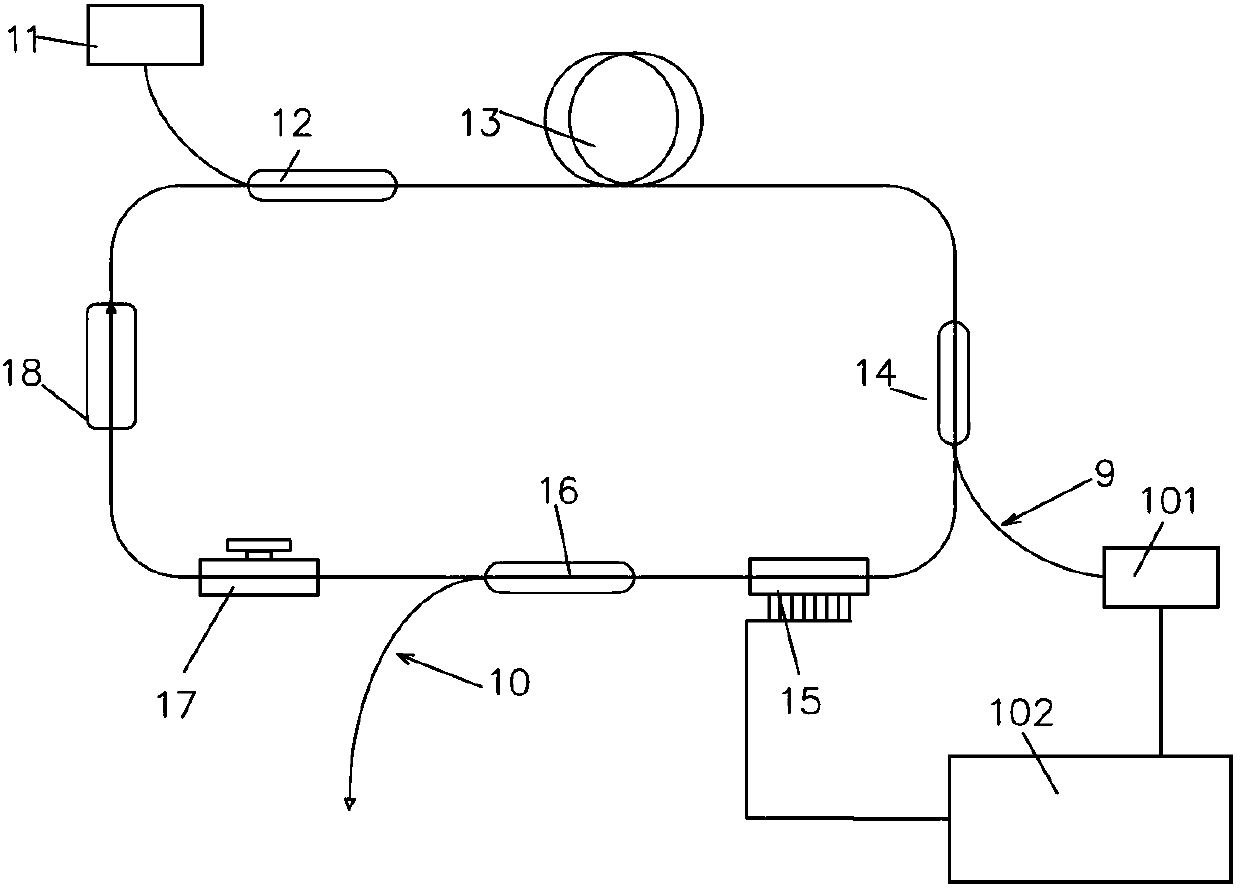

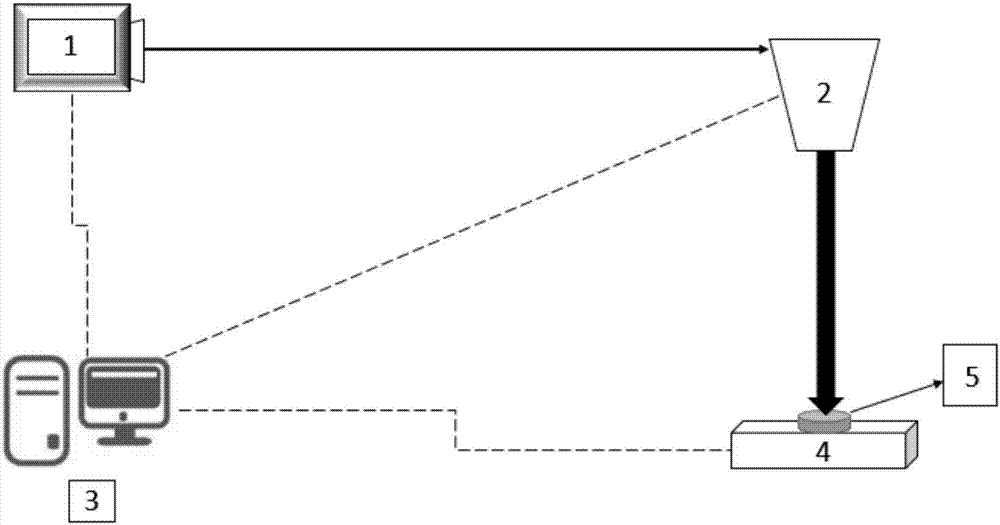

Device and method for ultrafast picosecond pulse laser machining of super-hydrophobicity micro-structure surface

InactiveCN102581478ASolve efficiency problemsReduce investmentLaser beam welding apparatusMicro structurePicosecond pulsed laser

A device and a method for ultrafast picosecond pulse laser machining of a super-hydrophobicity micro-structure surface belong to the field of preparation of functional micro-structure surfaces, and aim to solve the problems of high investment and low output of an existing machining process and existing machining technology for functional elements. The device comprises an ultrafast picosecond pulse laser source, an optical isolator, five reflectors, a rotary liquid crystal polarizing film, a polarization beam splitter, two beam collectors, a half wave plate, a focusing lens, frequency-doubling generator LBO (lithium triborate) crystal, a dichroic mirror, a light control device, a beam profile curvometer, a beam amplifying component Kepler beam expander, a focusing machining lens, a machining platform, a microscopy imaging CCD (charge coupled device) component and a control system. The method includes the stepsof: fixing a steel workpiece onto a surface driven by a Z-directional guide rail of the machining platform; adjusting a light path; detecting the surface of the workpiece by a probe; and driving the workpiece to move by means of movement of an X-directional guide rail and a Y-directional guide rail of the machining platform. The device and the method are used for preparing the super-hydrophobicity micro-structure surface.

Owner:HARBIN INST OF TECH

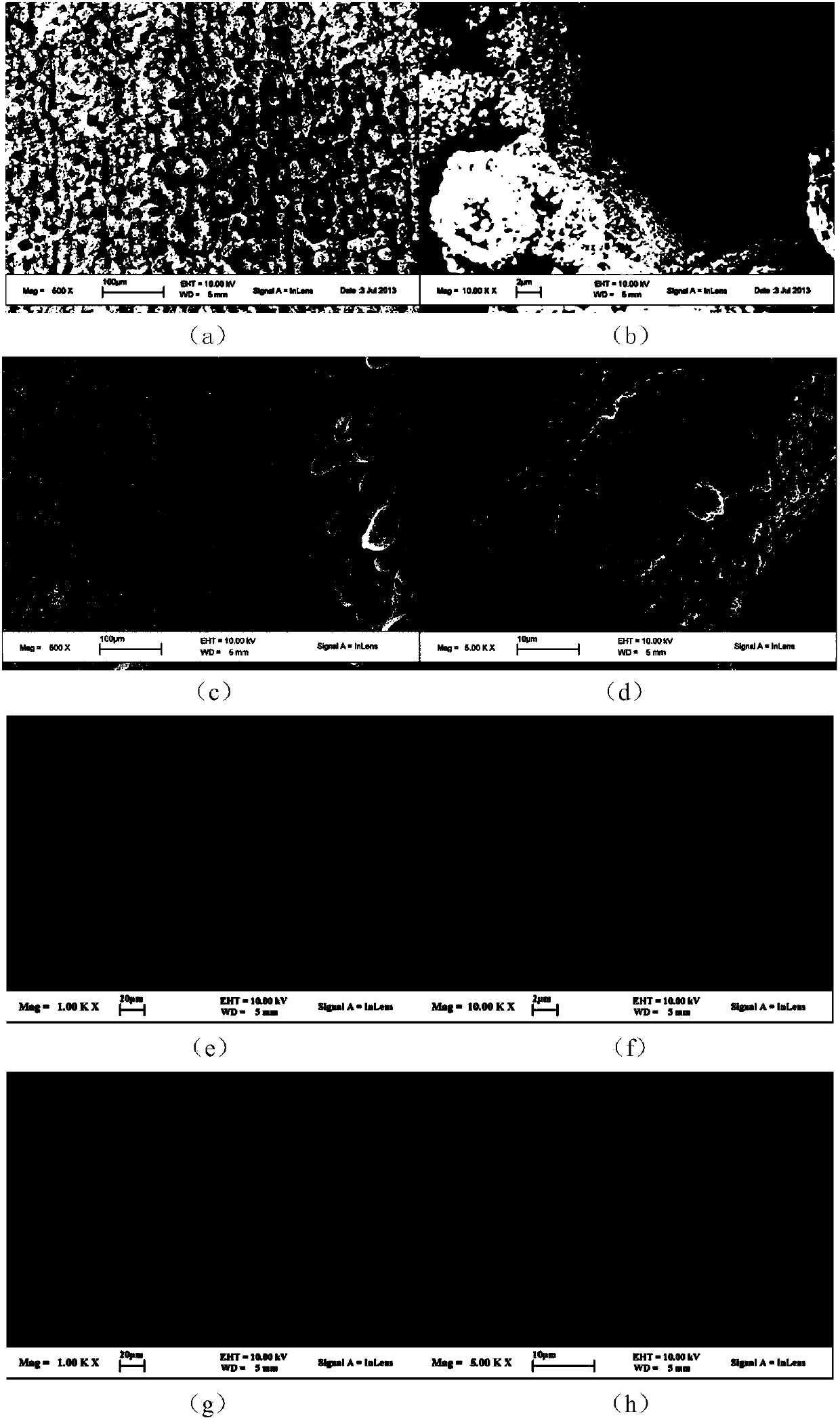

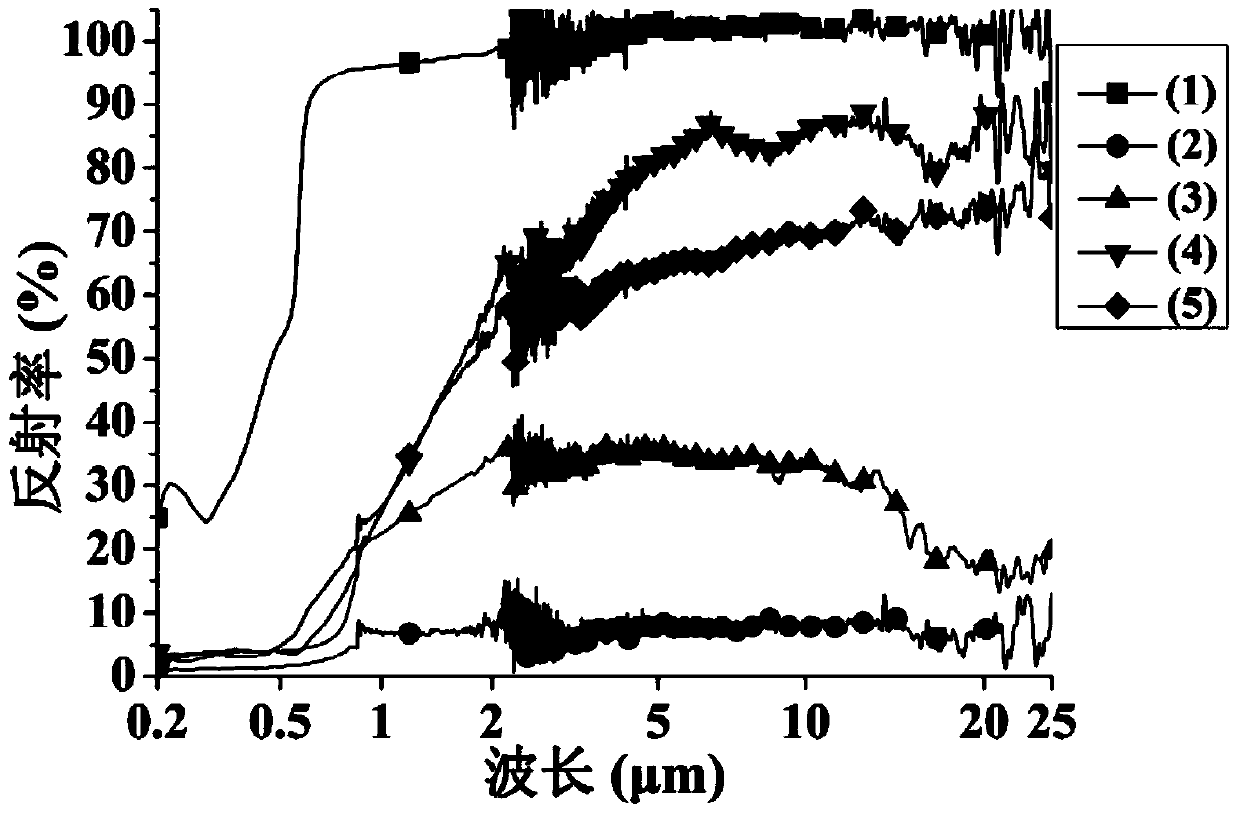

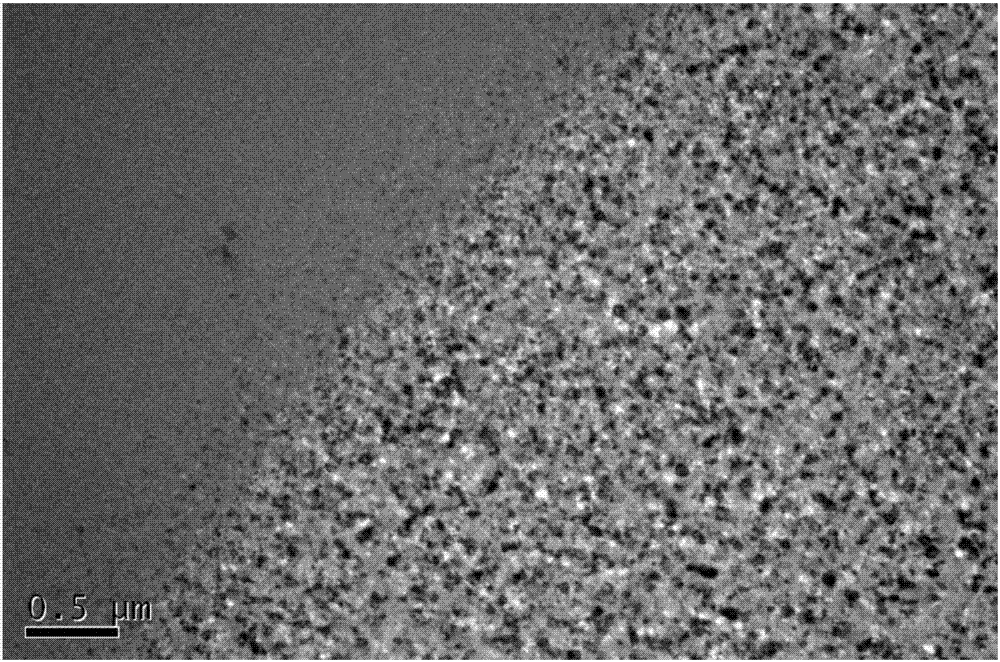

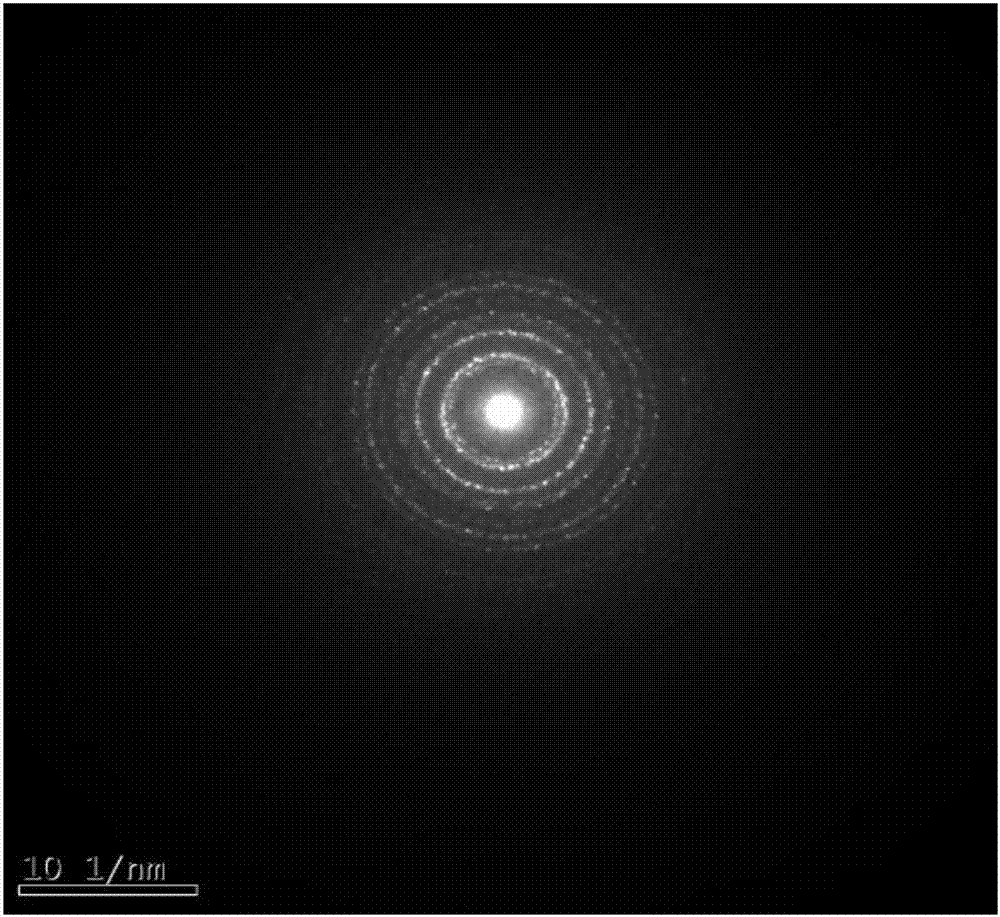

Method of regulating and controlling light absorption property of metal surface by picosecond pulse laser

The invention discloses a method of regulating and controlling light absorption property of a metal surface by picosecond pulse laser. The method comprises the following steps: irradiating the metal surface by picosecond pulse laser; carrying out laser ablation for removal and self-assembly of the metal surface induced by picosecond pulse laser to obtain a micro-nano dual-scale structure on the metal surface thus realizing regulation and control of the light absorption property of the metal surface. The method disclosed by the invention fully exerts a picosecond laser preparation rule or the micron structure in random distribution as well as capacity of forming the self-assembled nanostructure, and is agile and controllable in processing process, low in processing cost and high in efficiency, so that the method is an economical and practical method of regulating and controlling the light absorption property of the metal surface.

Owner:TSINGHUA UNIV

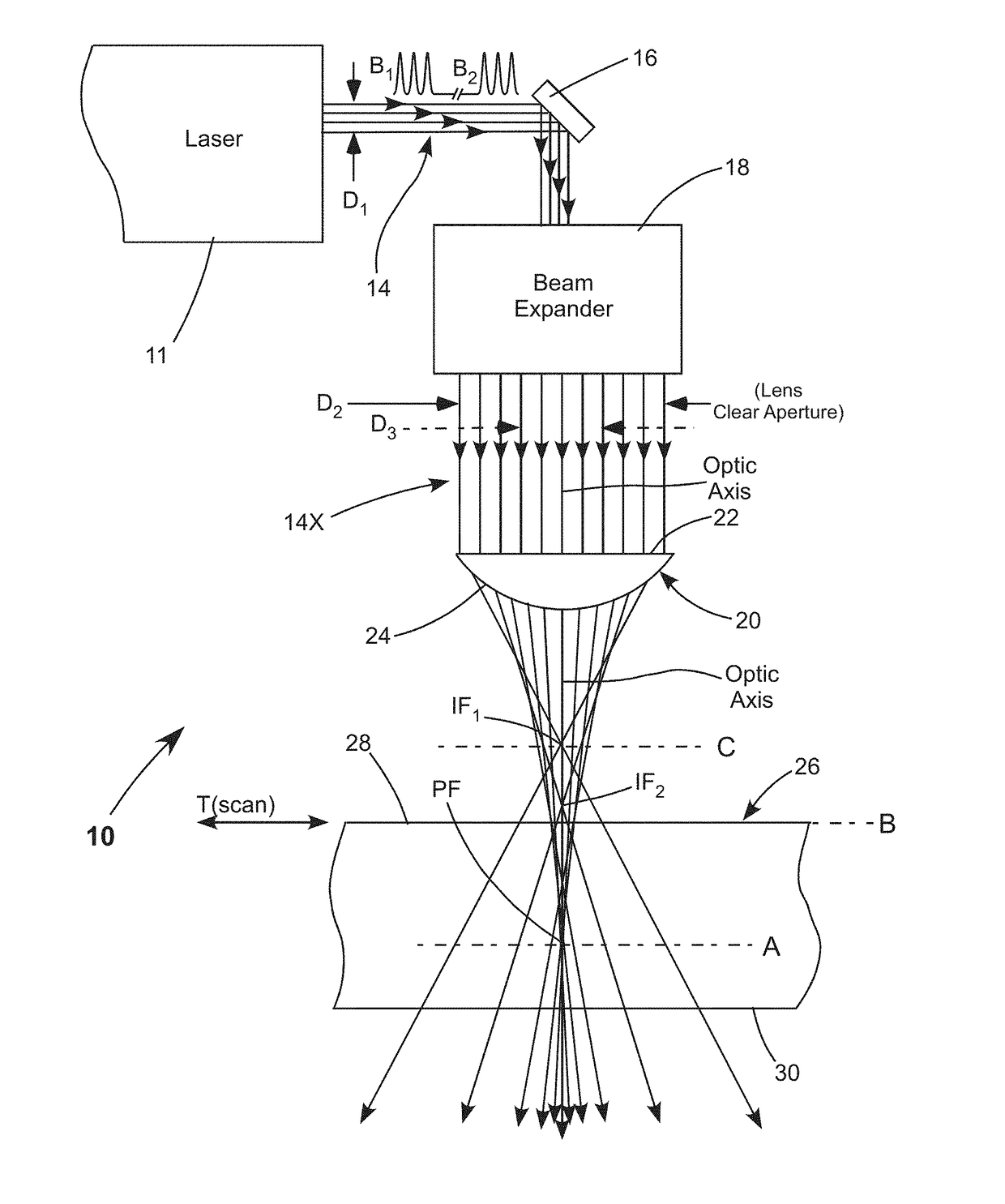

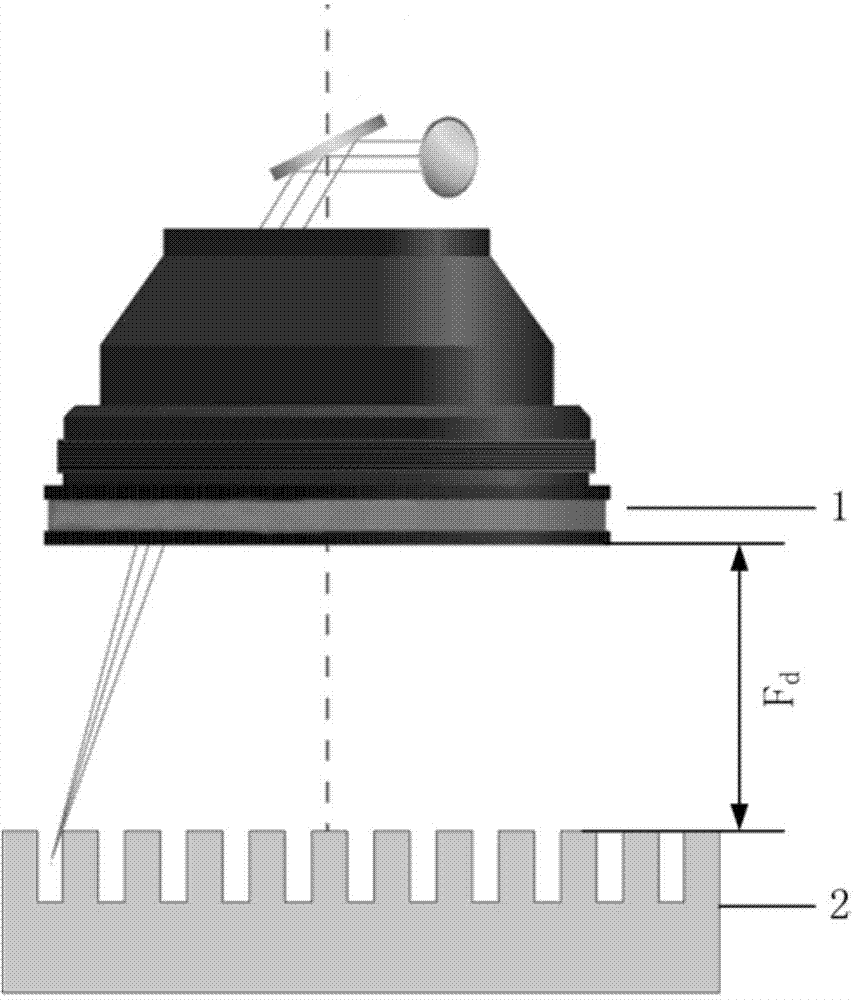

Filamentary cutting of brittle materials using a picosecond pulsed laser

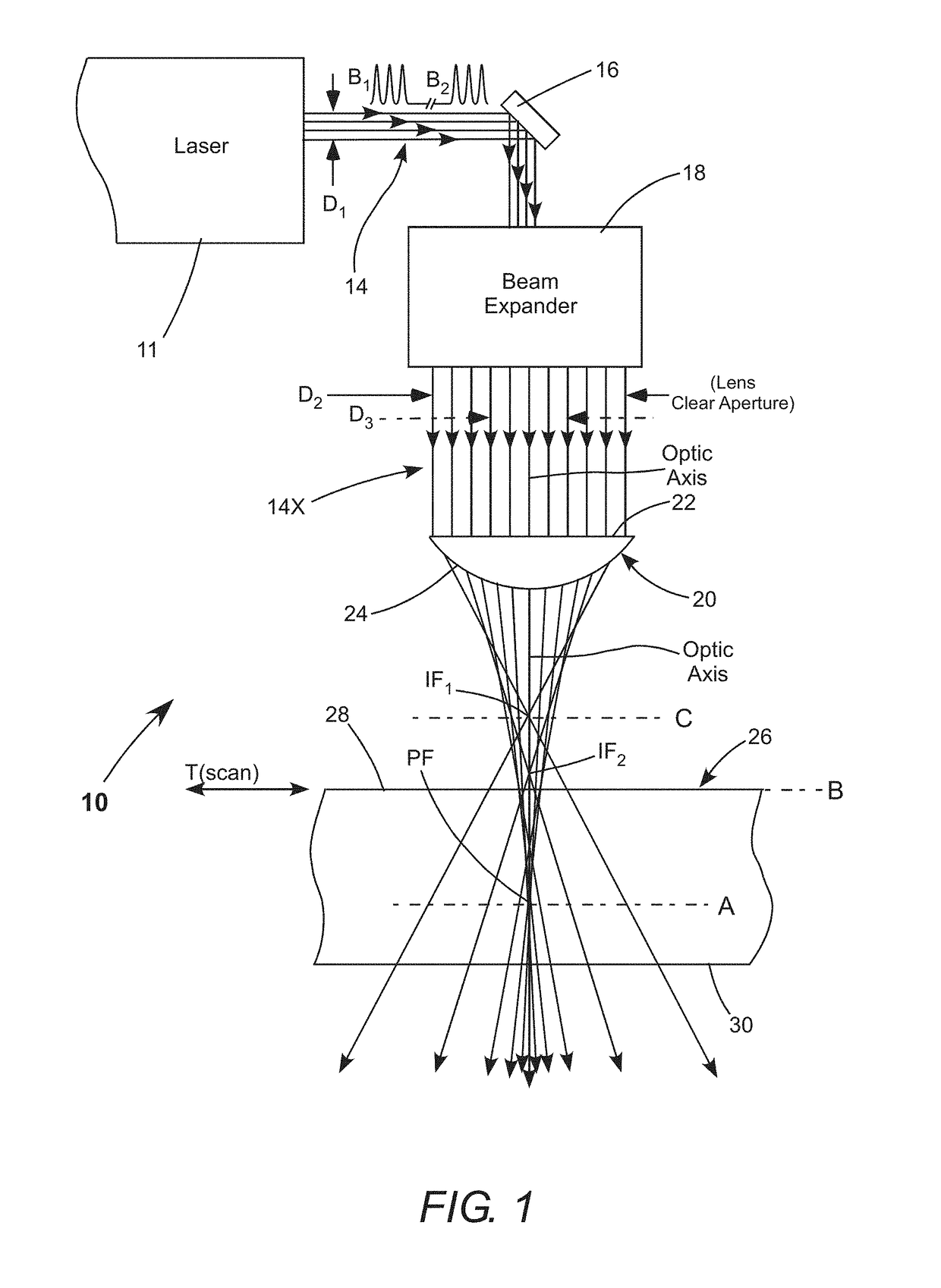

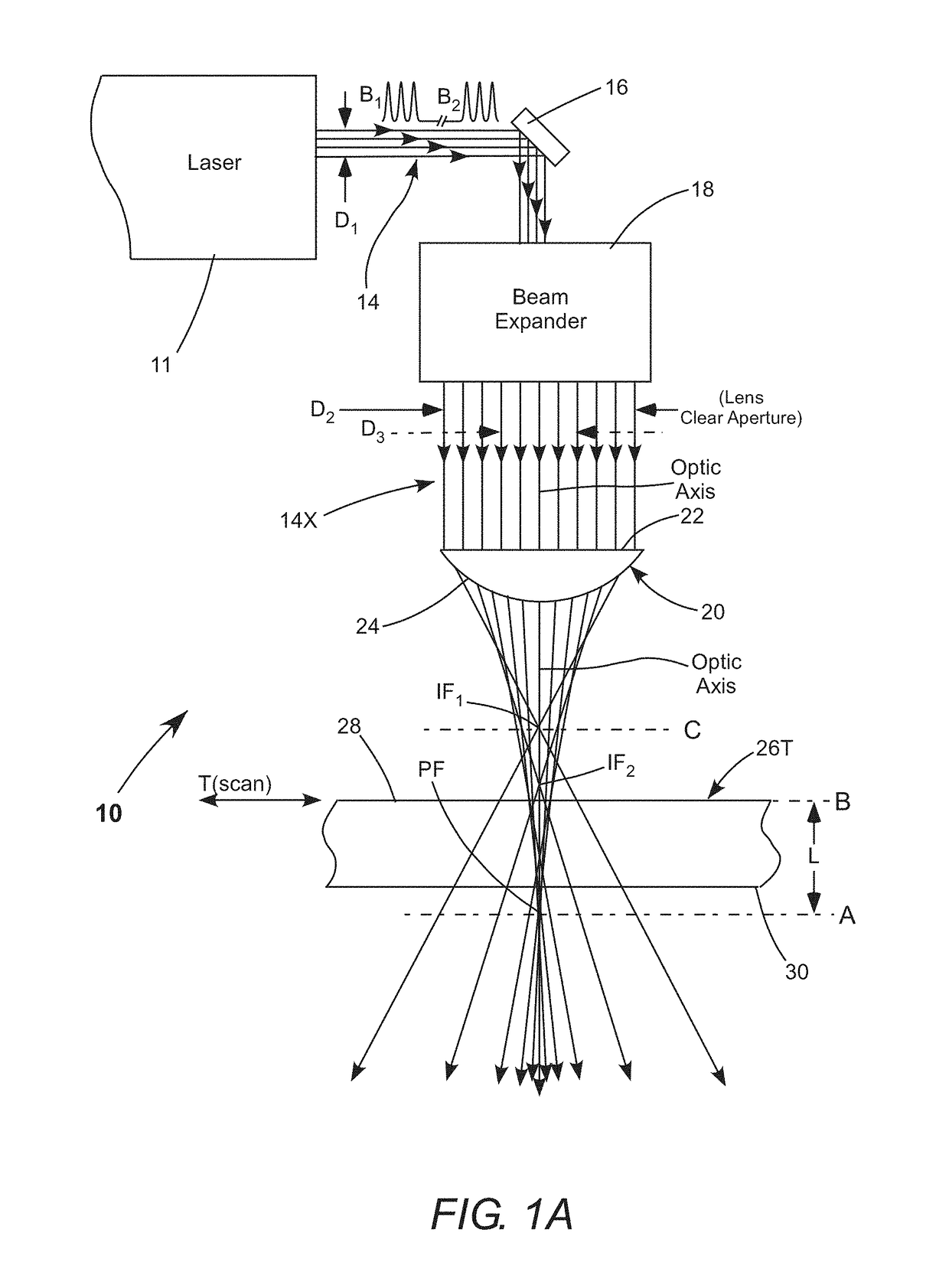

ActiveUS9873628B1Increase the diameterGlass severing apparatusLaser beam welding apparatusPicosecond pulsed laserLight beam

In pulsed-laser apparatus for filamentary cutting a glass-sheet, a laser-beam is focused by a plano-convex focusing lens into the glass-sheet through a first surface of the sheet to a point close to a second surface of the sheet. Pulses from the laser are delivered in repeated bursts. The laser-beam fills the clear-aperture of the lens such that uncorrected spherical aberration in the focusing lens causes radial modulation of the beam between the lens and the focus point. This provides that each burst of pulses generates a filament extending between the first and second surfaces of the sheet.

Owner:COHERENT KAISERSLAUTERN

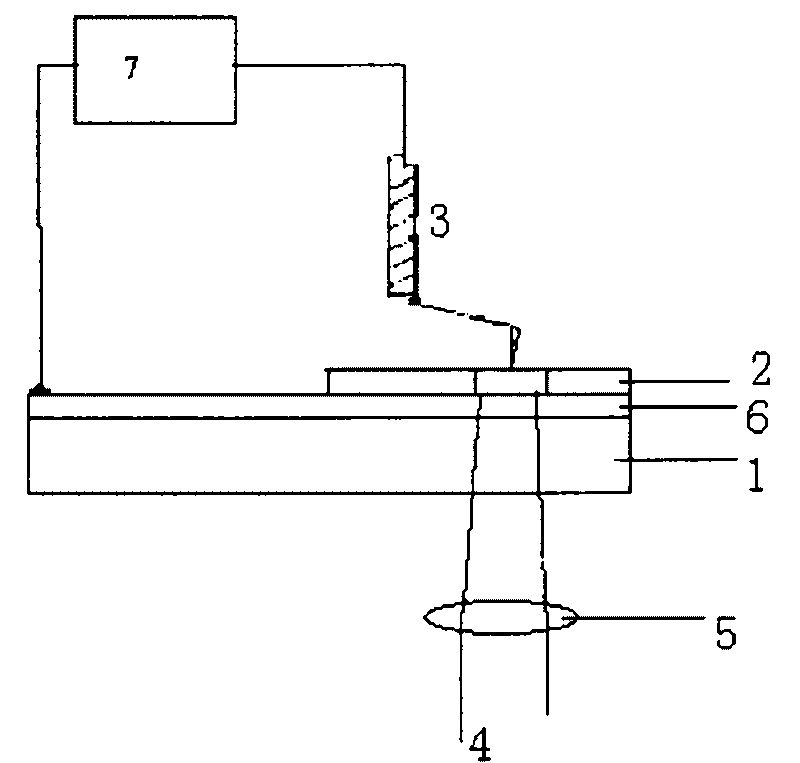

Double light path green light micropore processing device

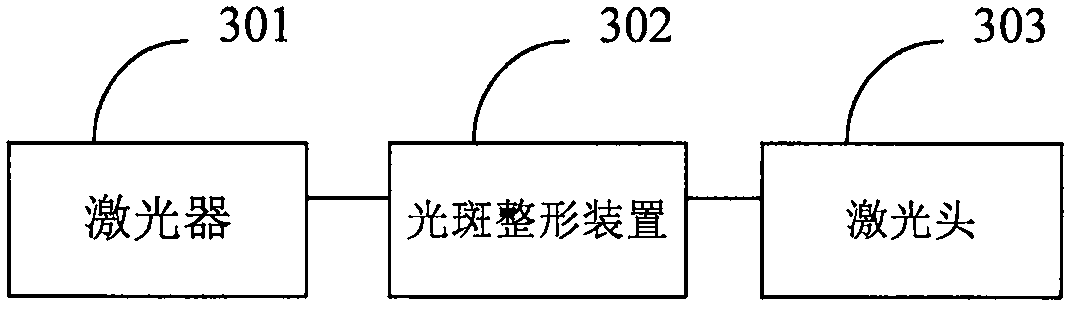

InactiveCN101569962ASimple structureEasy to adjustLaser beam welding apparatusPicosecond pulsed laserOptoelectronics

The invention provides a double light path green light micropore processing device, which comprises a picosecond pulse laser, a nanosecond pulse laser, a light path calibration system and an optical focusing system, wherein the output end of the picosecond pulse laser is provided with a first reflecting mirror; the output end of the nanosecond pulse laser is provided with a second reflecting mirror; the first reflecting mirror and the second reflecting mirror are connected with a third reflecting mirror; the output end of the third reflecting mirror is provided with an optical shutter; the output end of the optical shutter is connected with a beam expanding lens; the output end of the beam expanding lens is connected with a fourth reflecting mirror; and the fourth reflecting mirror is connected with the optical focusing system through the light path calibration system. The two lasers taking the light pulse length as nanoseconds and picoseconds are adopted, the selection of light beams is controlled by a light path selection system, the use of one laser for the processing is allowed, and the two lasers can also be alternately used during the processing. A double light path system maintains the advantage that the laser processes micropores, and can aim at different processing finenesses and cost requirements to flexibly select processing modes.

Owner:SUZHOU DELPHI LASER

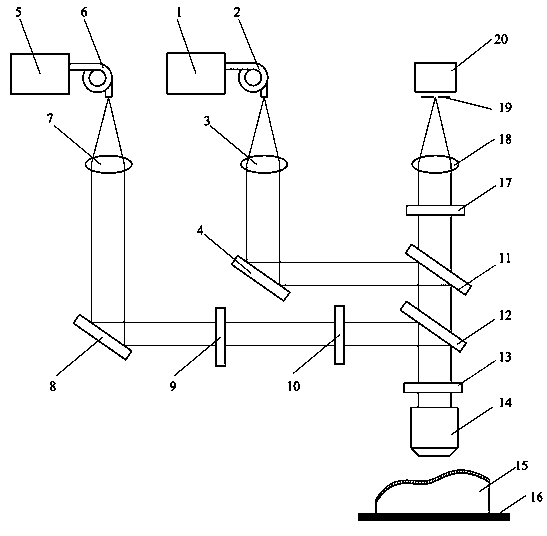

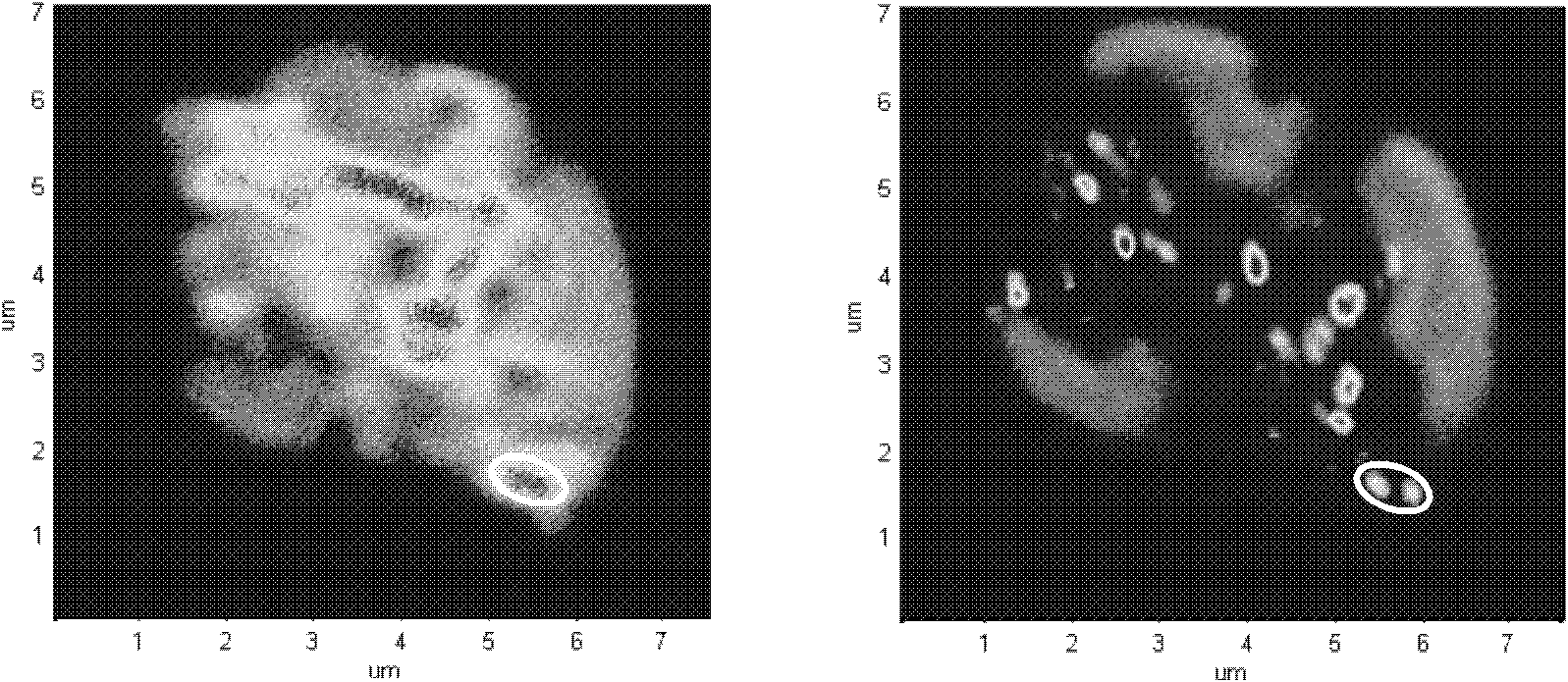

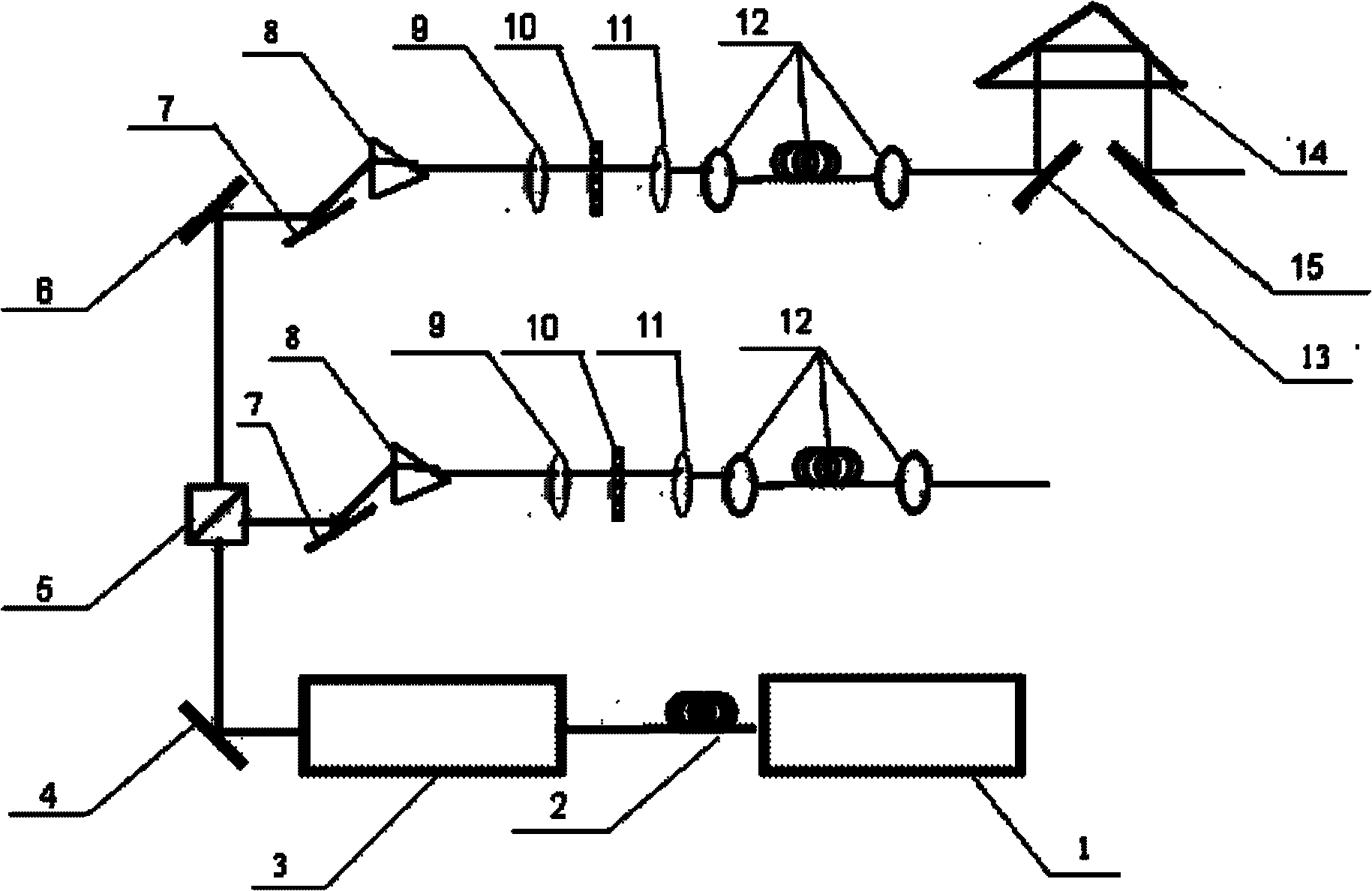

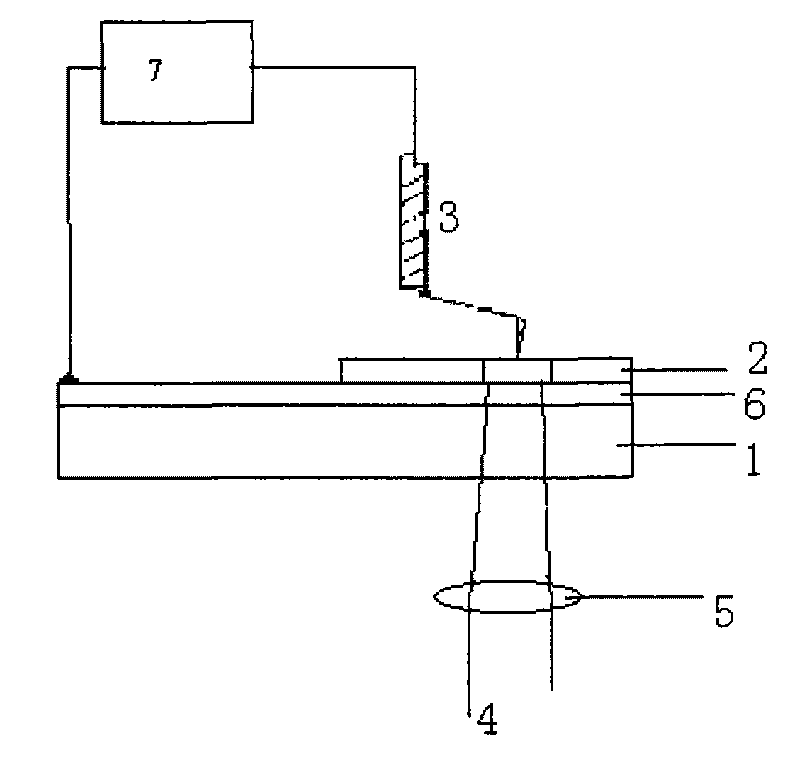

STED (stimulated emission depletion)-based device and method for measuring smooth free-form surface sample

InactiveCN104279982ARealize the collectionAchieving super-resolution imagingUsing optical meansPicosecond pulsed laserMirror reflection

The invention relates to an STED (stimulated emission depletion)-based device and method for measuring a smooth free-form surface sample, belonging to the field of the optical microscopic measurement. The device comprises a first picosecond pulse laser, a first conduction optical fiber, a first collimator objective, a first plane reflecting mirror, a second picosecond pulse laser, a second conduction optical fiber, a second collimator objective, a second plane reflecting mirror, a vortex-shaped phase modulation plate, a half-wave plate, a first dichroscope, a second dichroscope, a quarter-wave plate, a focusing object lens, a coating sample, a three-dimensional micro-displacement carrier table, an optical filter, a collection object lens, a pin hole and a photoelectric detector. The surface of the sample is coated with a fluorescent membrane, so that an industrial sample can be measured by utilizing the STED microscopy; meanwhile, the fluorescent membrane radiates fluorescence in different directions under the illumination of the laser, so that the problem that the signal light is difficult to collect caused by the mirror reflection of the light beam on a smooth free-form surface can be avoided. By adopting the device and method, the surface appearance of the smooth sample with a large angle between a normal and the optical axis direction can be high precisely measured.

Owner:HARBIN INST OF TECH

Method for precisely processing sapphire through double-laser beam sequence scanning

ActiveCN103952767AImprovement of precision etching processing efficiencyEtching processing efficiency is improvedAfter-treatment detailsPicosecond laserPicosecond pulsed laser

The invention provides a method for precisely processing sapphire through double-laser beam sequence scanning. The method comprises the following steps: installing a sapphire workpiece and a laser processing head, outputting a nanosecond pulse laser beam, and carrying out scanning motion according to the to-be-machined track once; then closing the nanosecond pulse laser beam, starting an ultrasonic generator for carrying out chemical corrosion; then outputting a picosecond pulse laser beam for carrying out scanning motion once, and fastly removing a thin-layer material; repeatedly carrying out the steps until the depths of holes or grooves in the surface of the sapphire workpiece meet the processing requirement; and finally, carrying out ultrasonic abrasive polishing to the surface of the sapphire workpiece by adopting an ultrasonic driven abrasive grain polishing solution. The sequence combined processing effects of four precise processing technologies including nanosecond laser thermal treatment, ultrasonic chemical corrosion pretreatment, picoseconds laser precision processing and ultrasonic abrasive grain polishing aftertreatment are combined, the power demand of a needed picoseconds laser device can be effectively reduced under the requirement of equal etching processing efficiency, and the picosecond laser processing time and equipment cost can be shortened and lowered.

Owner:ZHEJIANG JIATAI LASER SCI & TECH CO LTD

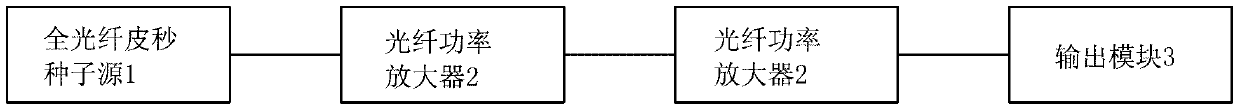

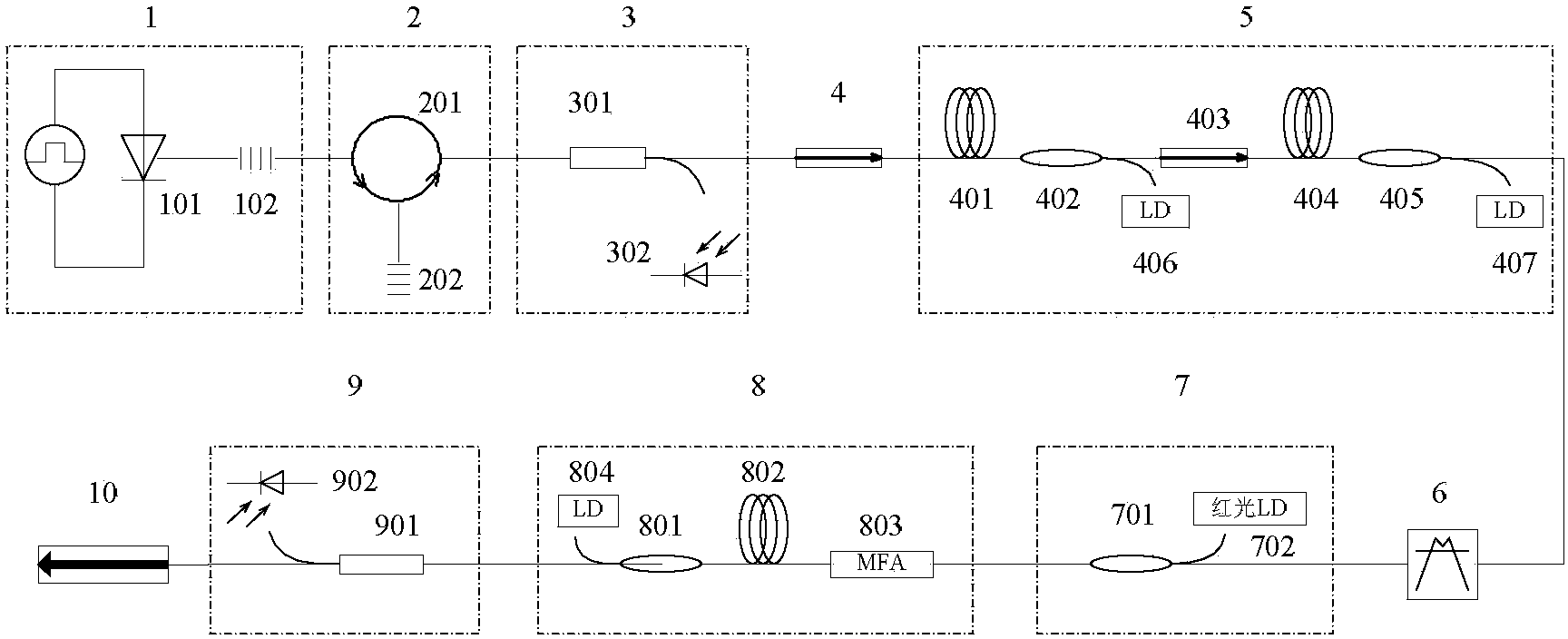

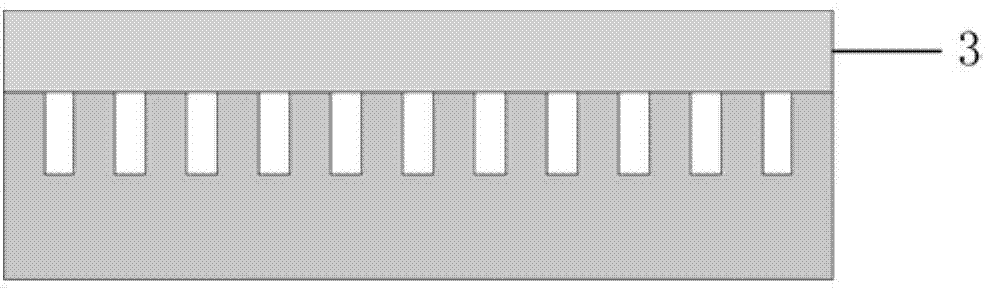

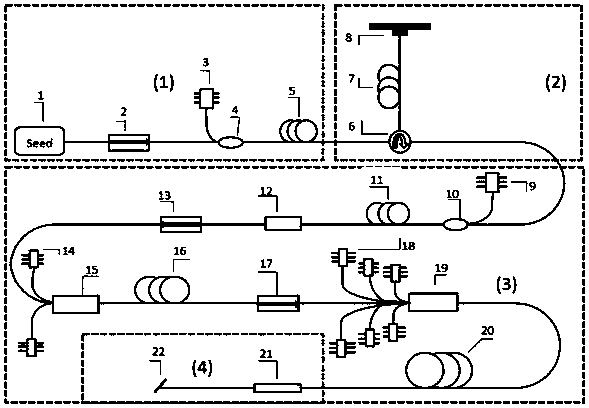

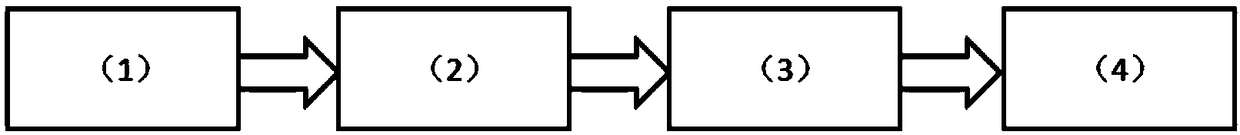

Gain narrowing controlled all-fiber laser amplifier for high-power picosecond pulses

InactiveCN103001118AHas a narrow spectral width output characteristicSimple structureLaser arrangementsActive medium materialPicosecond pulsed laserMultiplexer

The invention discloses a gain narrowing controlled all-fiber laser amplifier for high-power picosecond pulses. The laser amplifier comprises an all-fiber picosecond seed resource. An optical fiber amplifier is connected to an output end of the all-fiber picosecond seed resource, and an output module is connected to an output end of the optical fiber amplifier; the all-fiber picosecond seed resource is a mode-locked laser in an all-fiber ring cavity structure and comprises a pump laser, a wavelength division multiplexer, a gain optical fiber, an output coupler, a first polarization controller, a polarization beam splitter, a second polarization controller and a polarization independent isolator; and a polarization-maintaining output end of the polarization beam splitter serves as an output end of the all-fiber picosecond seed resource, a non polarization-maintaining output end of the polarization beam splitter is connected with an input end of the polarization independent isolator, the second polarization controller is fixed on an optical fiber between the polarization beam splitter and the polarization independent isolator, and an output end of the polarization independent isolator is connected with the other input end of the wavelength division multiplexer, accordingly, an all-fiber ring structure is formed. By means of the gain narrowing controlled all-fiber laser amplifier for high-power picosecond pulses, long-term stable high-power picosecond pulse laser is obtained easily, and the manufacture cost of a high-power optical fiber laser system can be reduced.

Owner:广东华快光子科技有限公司

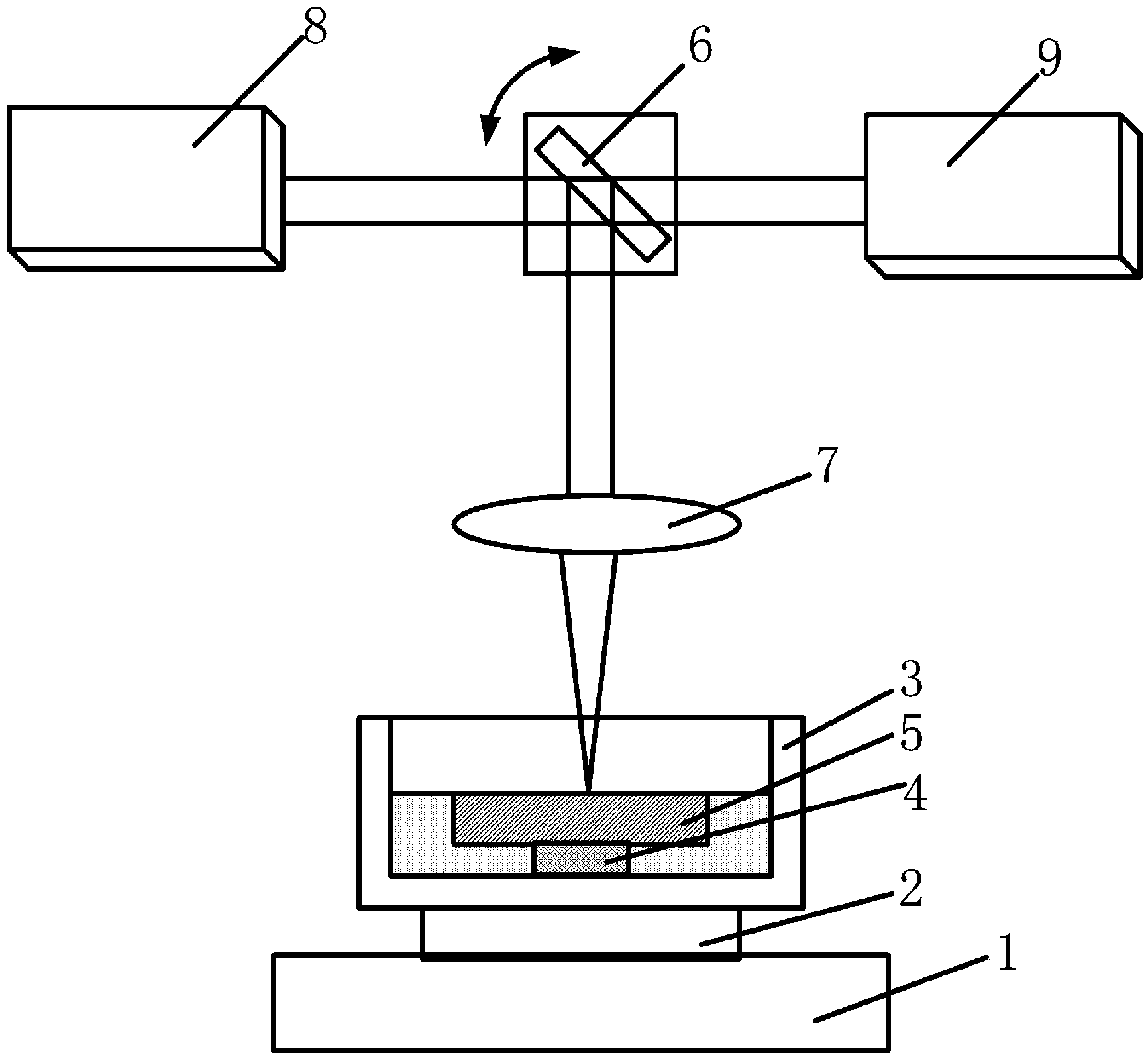

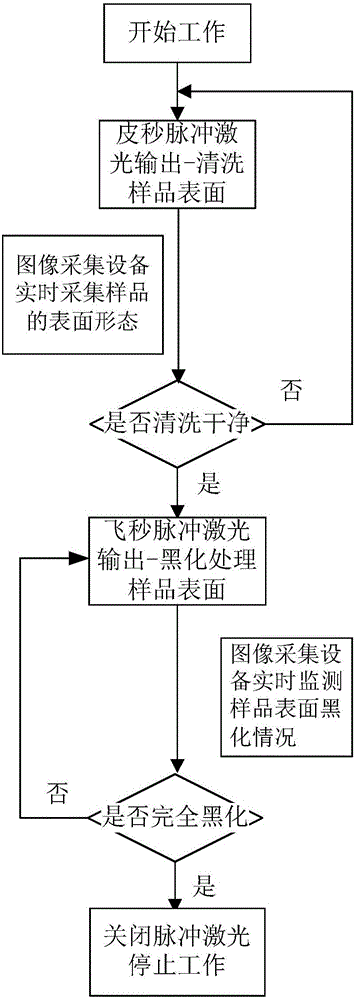

Pretreatment method and system for material surface before laser welding

ActiveCN106624367AImprove welding qualityImprove welding efficiencyLaser beam welding apparatusMicro nanoPretreatment method

The invention relates to a pretreatment method and system for a material surface before laser welding. The method comprises the following steps: firstly cleaning the surface of a sample by picosecond pulse laser, acquiring surface morphology of the sample in real time by image acquisition equipment while the surface of the sample is cleaned by virtue of the picosecond pulse laser, and judging whether the surface of the sample is clean or not according to the surface morphology of the sample, if the surface of the sample is not clean, continuing to clean the surface of the sample by virtue of the picoseconds pulse laser; if the surface of the sample is clean, turning off the picoseconds pulse laser, and carrying out blackening treatment on the surface of the sample by virtue of femtosecond laser; during the blackening treatment, monitoring the blackening condition of the surface of the sample in real time by the image acquisition equipment, when the surface of the sample is completely blackened, turning off the femtosecond laser, thus completing pretreatment on the material surface before welding. The method provided by the invention has the advantages that strong reflection action of the sample on lights can disappear, a micro-nano structure is formed on the surface, absorption efficiency of a material on laser in a laser welding process is greatly improved, and laser welding efficiency and quality are effectively improved.

Owner:美戈利浙江轨道交通研究院有限公司

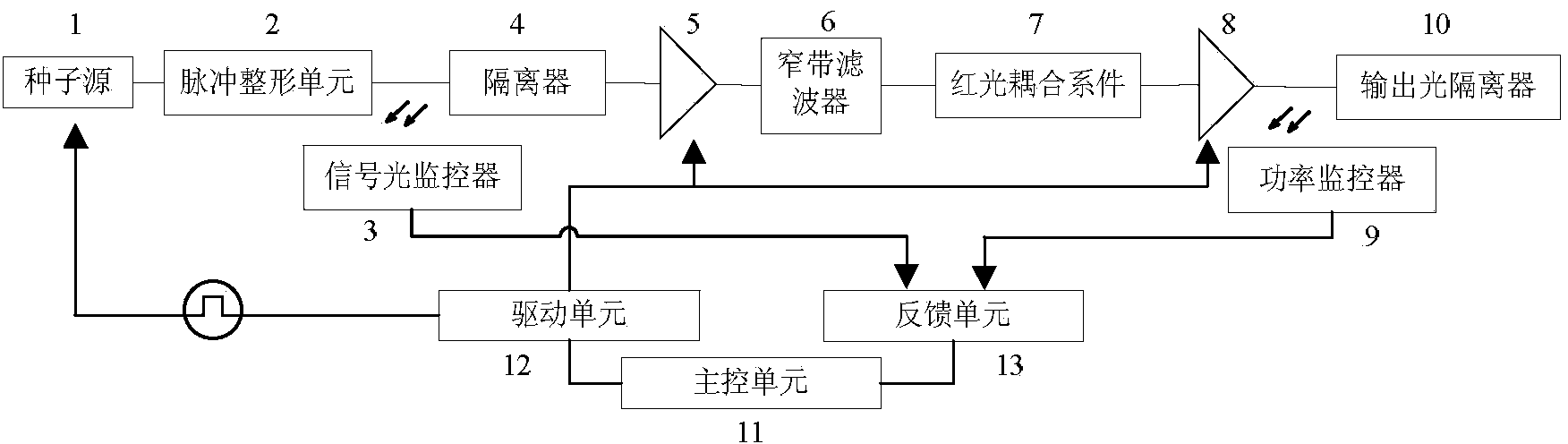

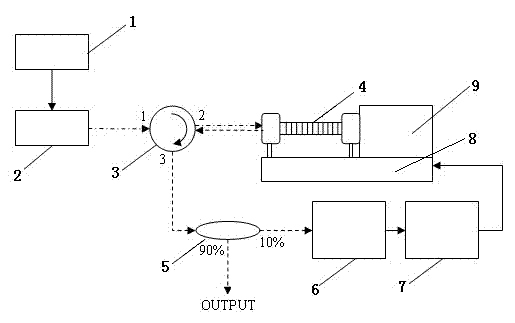

Feedback type high-peak-power picosecond-pulse fiber laser system

InactiveCN104242028AGuaranteed Pulse WidthQuality improvementActive medium shape and constructionHigh peakPicosecond pulsed laser

The invention relates to a feedback type high-peak-power picosecond-pulse fiber laser system. A pulse shaping unit is added to the rear of a seed source to shape pulses, the pulse width of the seed source is compressed, the waveform of the seed source is improved, and the quality of seed light is improved. A fiber isolator and a narrow-band filter are connected to the front of a pre-amplifier stage and the front of a main amplifier stage respectively, harmful ASE is filtered out, and the stability of the system is improved. A red light indicator is added between the pre-amplifier stage and the main amplifier stage, and thus the safety and the flexibility of operation on a laser are improved. Photodiodes are connected to the rear of the seed source and the rear of the main amplifier stage respectively, and real-time protection and dynamic power regulation of the laser are achieved through a master control unit. The feedback type high-peak-power picosecond-pulse fiber laser system is an all-fiber system, and thus the mechanical stability and the adaptability to the environment of the system can be effectively improved. The quality of light beams of the laser is improved through a fiber grating, the narrow-band filter and a pattern adapter, the nonlinear effect in a doped fiber is effectively suppressed, and high-peak-power picosecond-pulse laser output is achieved.

Owner:WUHAN RAYCUS FIBER LASER TECHNOLOGY CO LTD

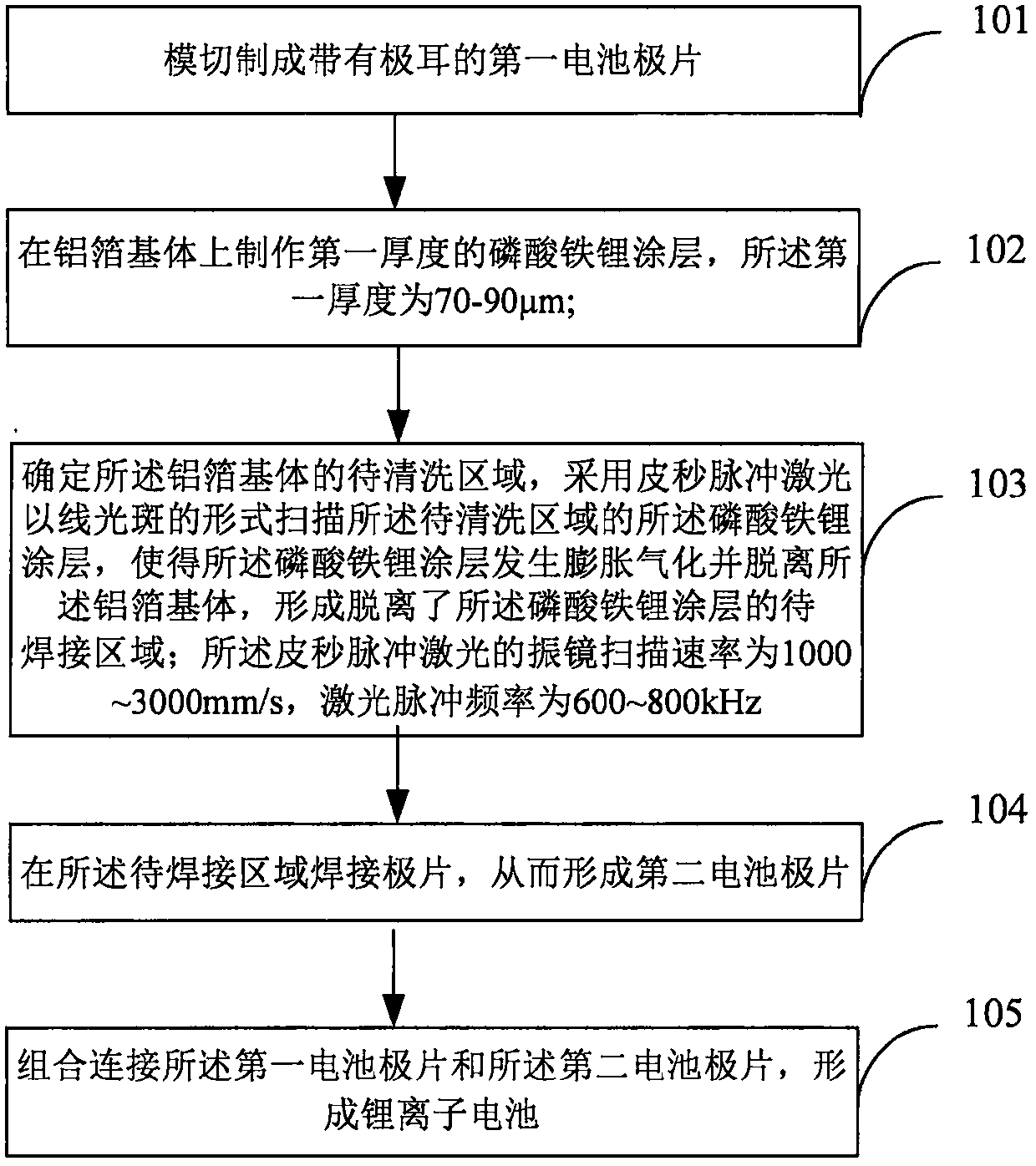

Lithium ion battery, laser manufacturing method thereof and laser washing device

PendingCN107946654AAccurately and neatly obtainedImprove production efficiencyFinal product manufactureElectrode collector coatingManufacturing technologyPicosecond pulsed laser

The invention provides a lithium ion battery, a laser manufacturing method thereof and a laser washing device. Coatings at the specific surface positions of battery pole pieces can be eliminated efficiently, environmentally and stably at high quality, so that the manufacturing technology of the lithium ion battery is simplified, and the manufacturing efficiency is improved. The laser manufacturingmethod comprises the following steps: carrying out die cutting to manufacture a first battery pole piece with a lug; manufacturing a lithium iron phosphate coating with a first thickness on an aluminum foil base body; determining an area to be washed of the aluminum foil base body, and adopting picosecond pulse lasers to scan the lithium iron phosphate coating in the area to be washed in a linearlight spot manner, so that expansion and gasification occur on the lithium iron phosphate coating, the lithium iron phosphate coating is separated from the aluminum foil base body, and an area to bewelded separated from the lithium iron phosphate coating is formed; welding a pole piece in the area to be welded so as to form a second battery pole piece; and combining and connecting the first battery pole piece and the second battery pole piece so as to form the lithium ion battery.

Owner:上海临仕激光科技有限公司

Pretreatment method before thermal spraying of protective coating on surface of polyamide resin matrix composite

InactiveCN108374139AAvoid heat damageAvoid deformationMolten spray coatingSuperimposed coating processAl powderThermal spraying

The invention relates to a pretreatment method before thermal spraying of a protective coating on the surface of a polyamide resin matrix composite. Through the pretreatment technology of combining resin matrix composite surface modeling and metal (or alloy) bottom layer priming, effective deposition of protective facing particles is achieved, and bonding force between the coating and a matrix isgreatly increased, wherein surface modeling adopts the laser etching technology, and a used tool is a nanosecond or picosecond pulse laser; and bottom layer priming adopts the cold spraying technology, and a used material is metal or alloy powder such as the Al powder or the Cu powder. After the pretreatment technology, the bonding strength and the heat-shock-resisting cycling capacity between theprotective coating and the matrix are both greatly improved.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Multi-wavelength micro illumination device

ActiveCN102162907AOvercome the disadvantage of low energy densityOvercome the disadvantages of denaturation or even damageMicroscopesNon-linear opticsFluorescenceLasing wavelength

The invention provides a multi-wavelength micro illumination device. In the device, a laser pulse output by a picosecond pulse laser or a femtosecond pulse laser is incident to a nonlinear photonic crystal fiber to obtain a broadband laser source; the pulsed laser beam output by the broadband laser source is incident to an acoustooptical modulator to obtain a laser pulse beam with a repetition frequency; a beam splitter and a plurality of reflectors are arranged on the optical path of the laser pulse beam; the laser pulse beam is divided into n parallel output beams (n is a natural number equal to or larger than 2); a dispersion prism or a diffraction grating, a lens (a), a spatial light modulator and a lens (b) are sequentially arranged on the optical path of each output beam; and (n-1) output beams respectively pass through a right angle prism after passing through the dispersion prism or the diffraction grating, the lens (a), the spatial light modulator and the lens (b) to obtain n parallel output beams with different delay time. The multi-wavelength micro illumination device provided by the invention can provide laser wavelengths with a wide waveband range from near ultraviolet to mid-infrared and high spectral energy density above 1 nJ / nm, and is suitable for excitation of the most of fluorescence and Raman samples. Additionally, the plurality of laser wavelengths are from the same laser source so as to obviate the problem of synchronous time maladjustment, and the apparatus cost can be reduced greatly by using one pulse laser.

Owner:INNOVATIVE SEMICON SUBSTRATE TECH CO LTD

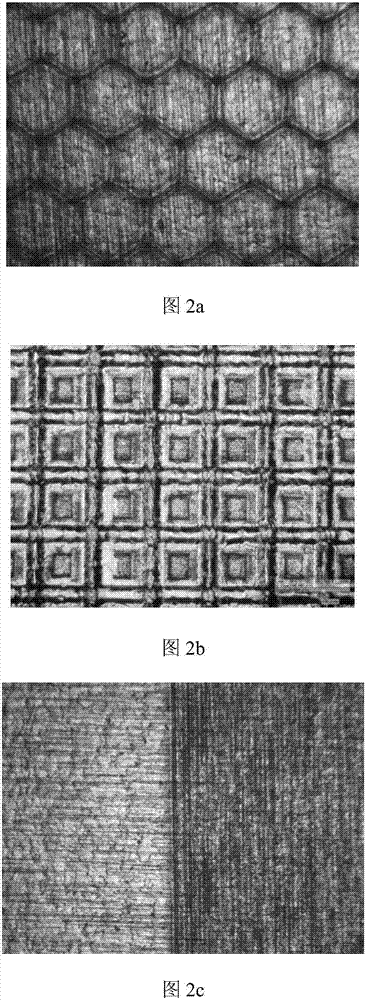

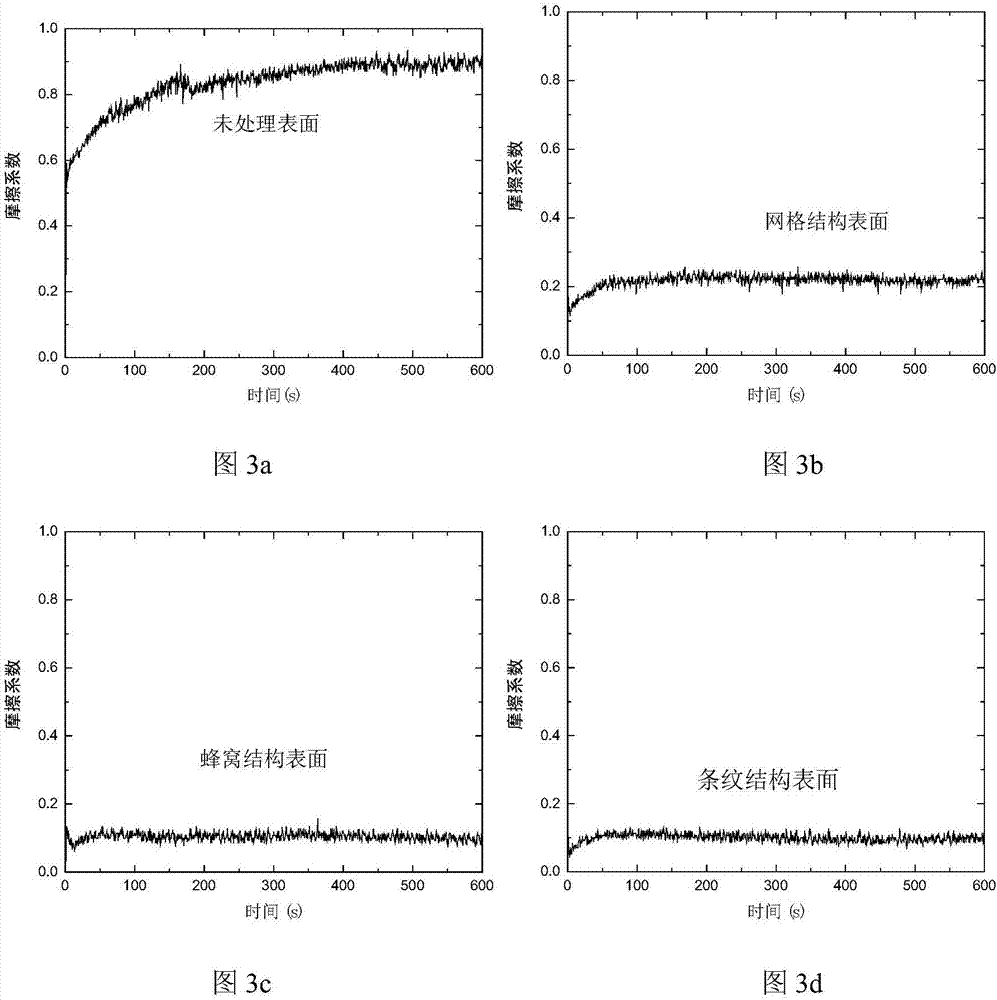

Self-lubricating anti-attrition composite structure surface manufacturing method based on laser texturing

ActiveCN104117773AExtended service lifeAdditivesLaser beam welding apparatusPicosecond pulsed laserWear resistant

The invention provides a self-lubricating anti-attrition composite structure surface manufacturing method based on laser texturing. Firstly, picoseconds pulse laser beams are used for carrying out surface texturing. Secondly, a solidifiable synthetic lubricant is spin-coated. Thirdly, the lubricant is driven through dielectrophoresis force on a gas-liquid interface to fill inside a structure. Finally, deep solidification is realized through quick laser scanning and heating, and a self-lubricating anti-attrition composite function structure surface with the three-dimensional micro-nanometer structure filled with the lubricant is obtained. According to the self-lubricating anti-attrition composite structure surface manufacturing method based on laser texturing, the laser texturing surface structure is filled with the lubricant solid body with controllable depth and controllable position according to intentions of people, so that functions of the surface structure vary at different positions, for instance, the solid lubricant is stored or wear particles are stored; in this way, the self-lubricating anti-attrition composite function structure surface is manufactured, the wear-resistant anti-attrition properties of the surface are improved, and self lubrication of the surface is also realized.

Owner:XI AN JIAOTONG UNIV

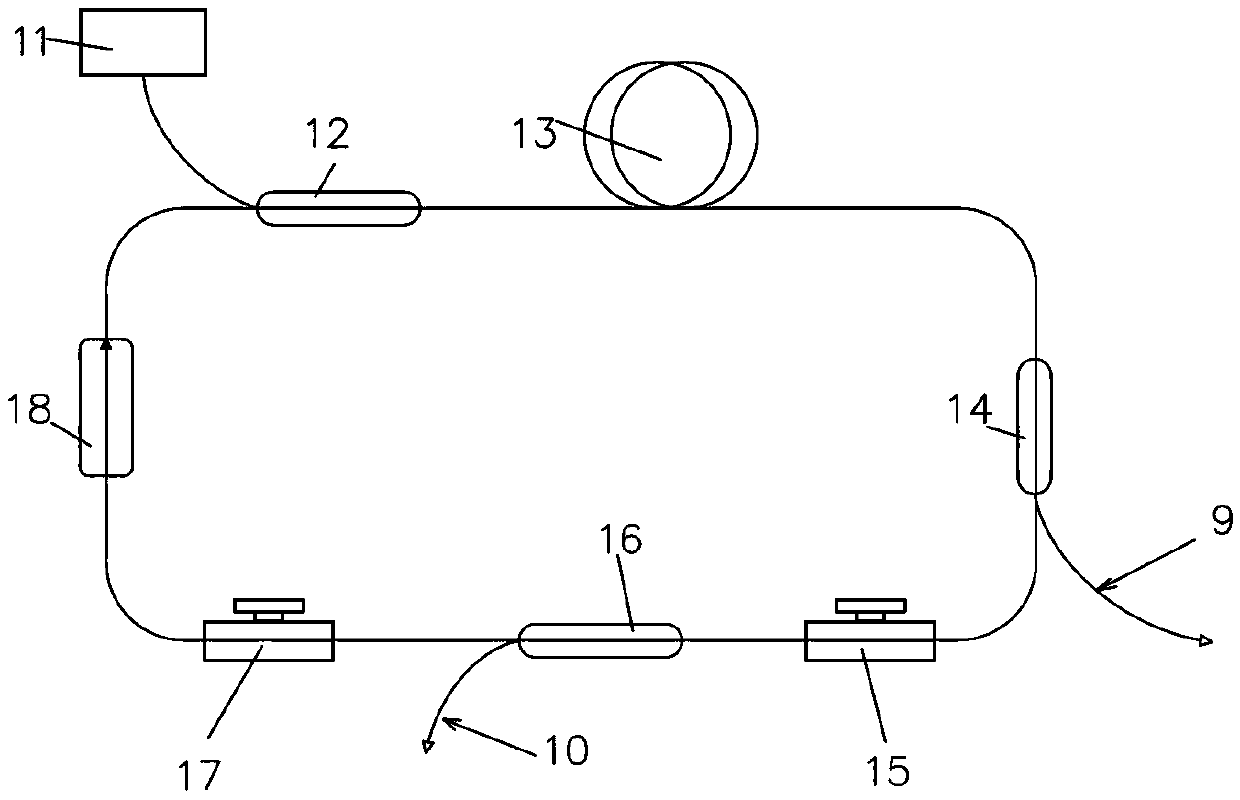

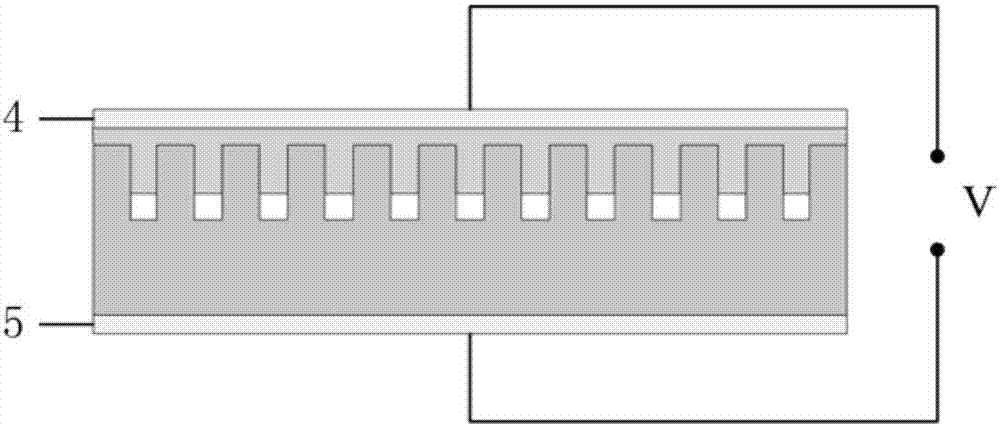

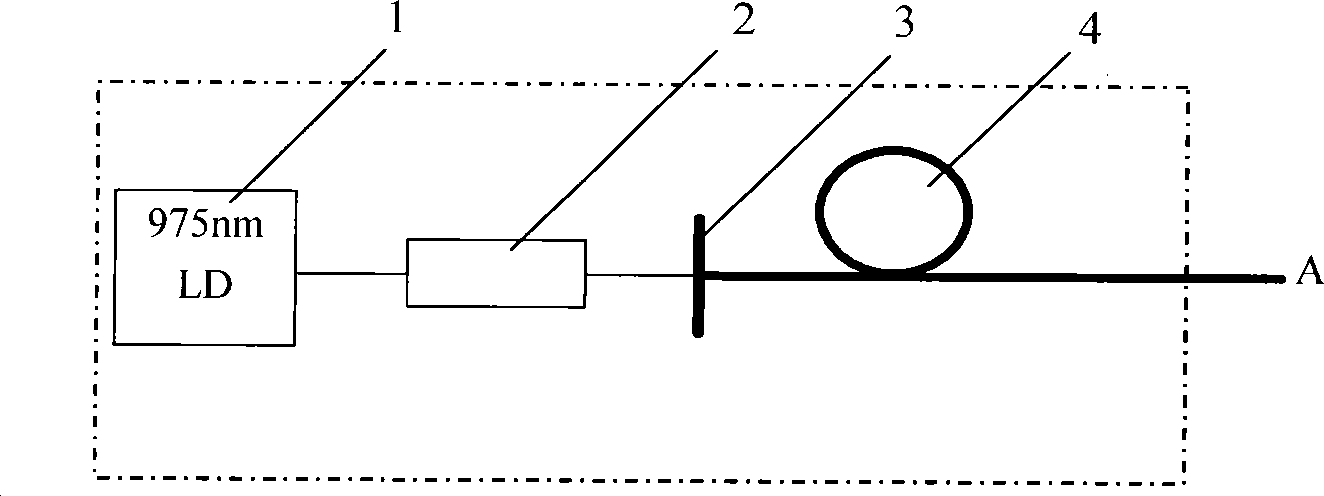

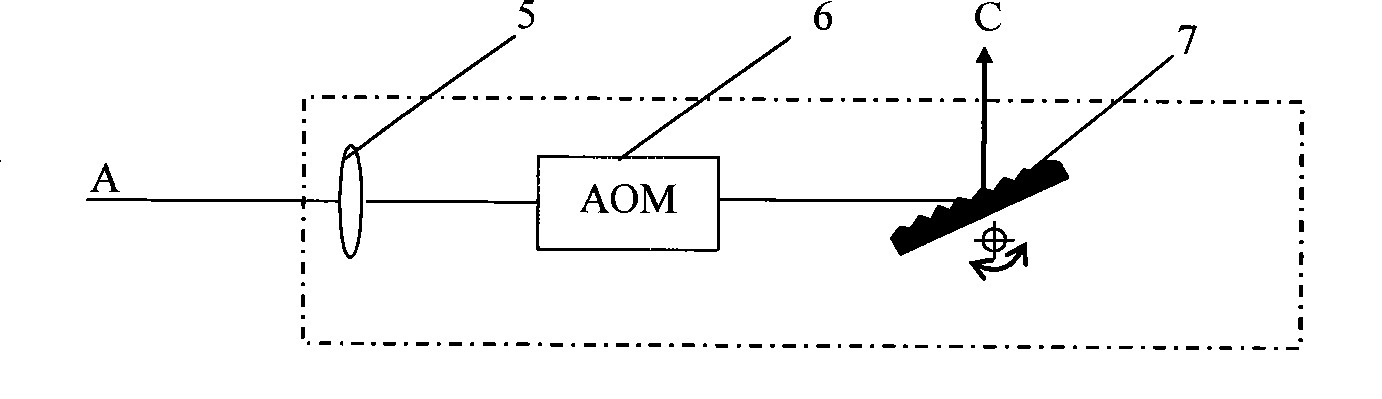

Picopulse optical fiber laser

InactiveCN101414726AHigh outputOptical resonator shape and constructionActive medium shape and constructionPicosecond pulsed laserGrating

The invention discloses a picosecond pulse optical fibre laser which comprises a main cavity resonator and an outer cavity feedback part. A semiconductor laser is adopted as a pumping source; a dichroic mirror and double envelope optical fibre mixing with ytterbium form the main cavity resonator which is coupled to an outer cavity through a collimating lens; a acoustooptic modulator AOM in the outer cavity adopts Raman-Nath diffraction; and a blazed grating outputs zero-level diffraction light generated by a signal light and feeds back any level light in high-level light to the cavity resonator. The invention has simple structure and high cost performance, can realize wide-tune, narrow-line-width and stable picosecond pulse laser output and can be widely applied to the fields of laser processing, laser medical treatment, laser marking, seed light source, etc.

Owner:BEIHANG UNIV

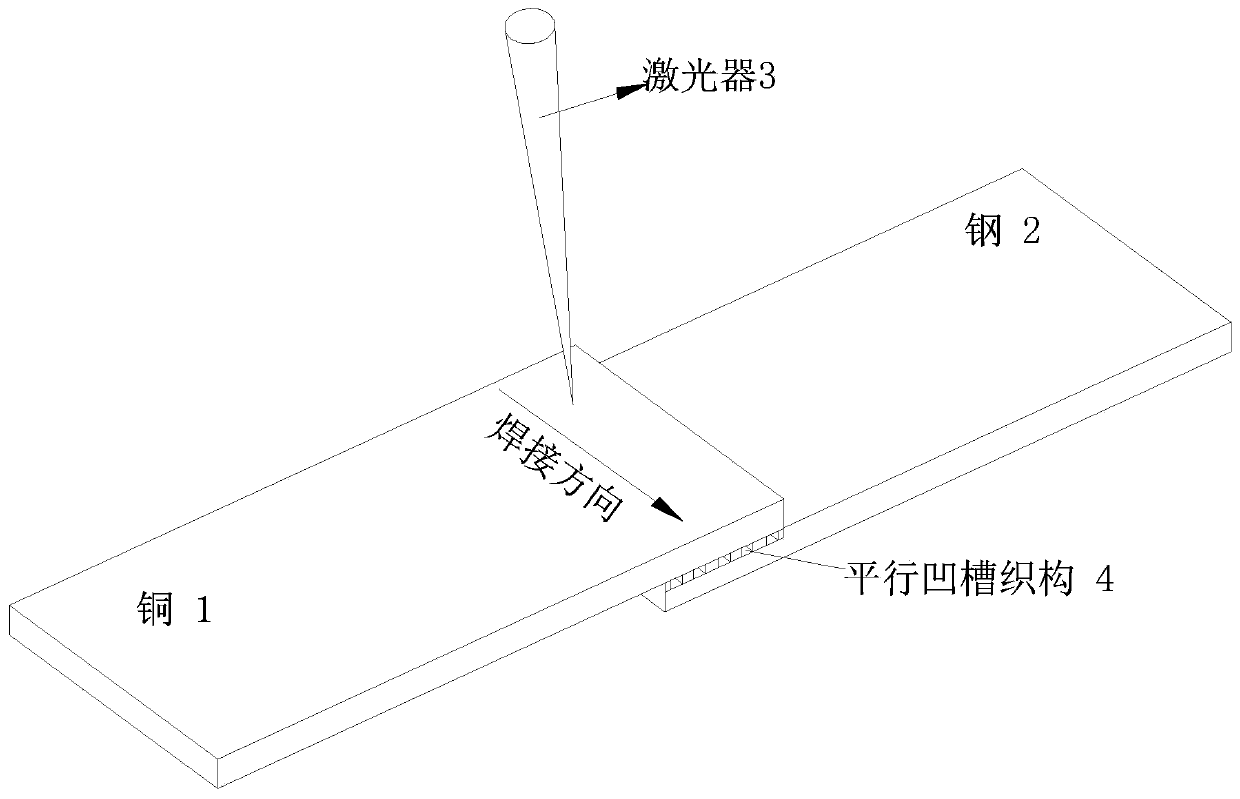

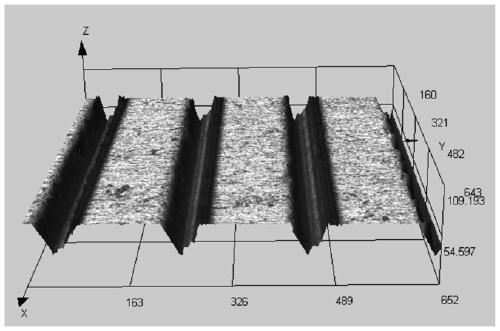

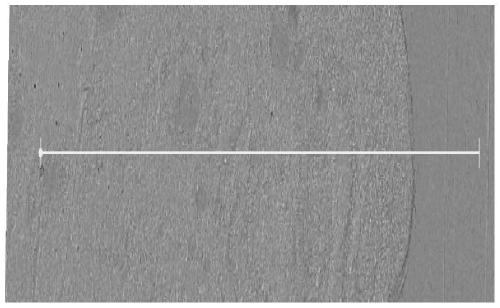

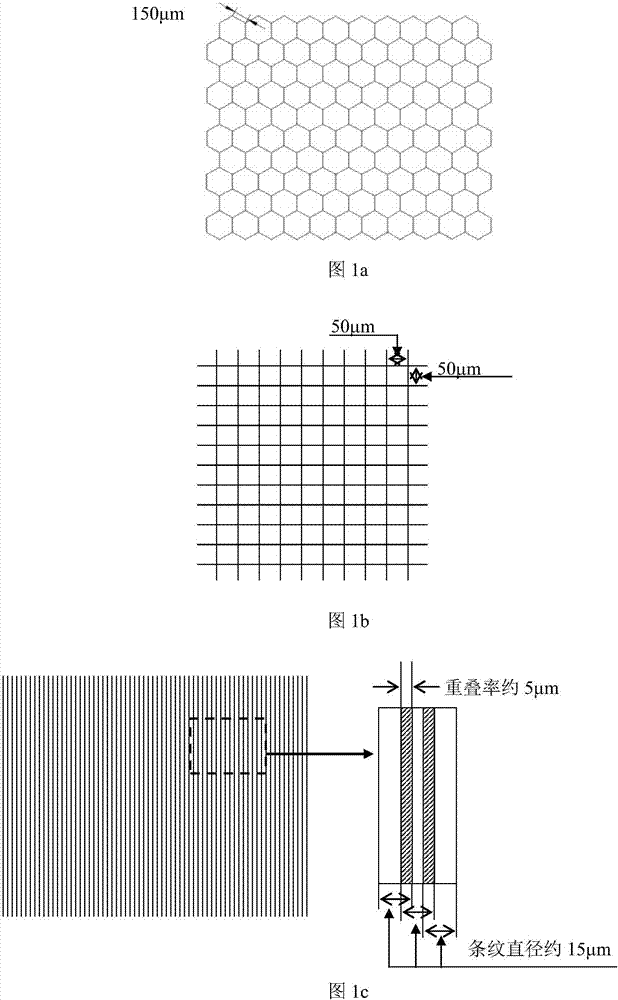

Method for improving strength of laser stitch welding joint of copper and steel dissimilar metal

PendingCN111151875AHigh bonding strengthHigh tensile strengthWelding/soldering/cutting articlesLaser beam welding apparatusPicosecond pulsed laserErbium lasers

The invention relates to a method for improving the strength of a laser stitch welding joint of copper and steel dissimilar metal. The method comprises the steps: firstly, the metal surface at the welding lap-joint position is pretreated; then parallel groove textures are machined and constructed on the metal surface of the welding lap-joint position through a picosecond pulse laser to form shape-controllable, uniform and flat texture surfaces; and finally, laser stitch welding is conducted on the copper and steel dissimilar metal through a pulse green light disc laser to improve the welding strength. A laser texture machining technology and a laser welding technology are combined effectively to improve the bonding strength of the copper and steel dissimilar metal; shape-controllable, uniform and flat parallel microtextures are etched on the metal surface efficiently and quickly, other various microtextures with complex shapes can also be etched, and the machining efficiency is high; welding wires do not need to be additionally used, and thus the production cost is greatly lowered; and through texturing treatment on the welding surface, a metallurgical reaction in a welding pool isimproved, the diffusion effect of Fe on the steel side into the molten pool is enhanced, and the bonding strength of copper and steel metal welding is improved.

Owner:WENZHOU UNIVERSITY

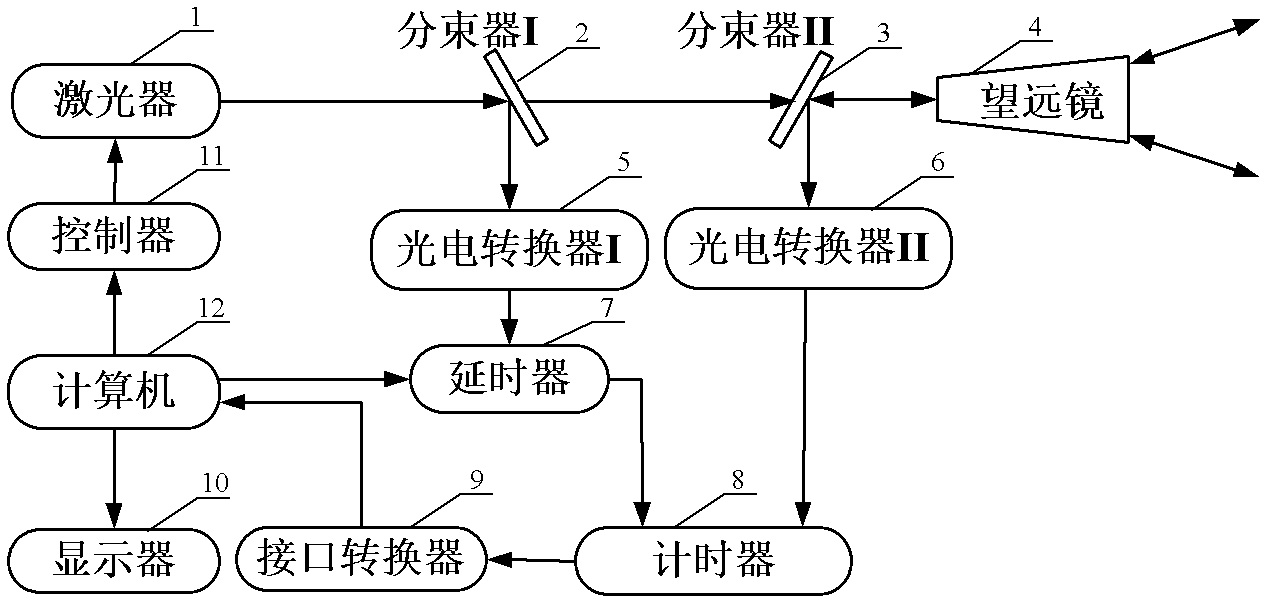

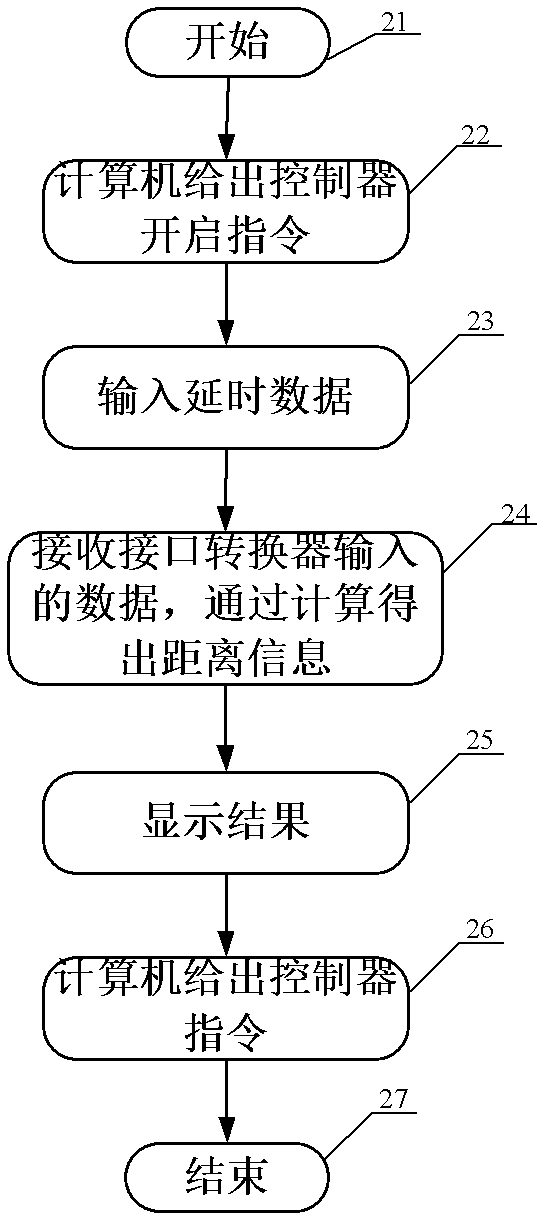

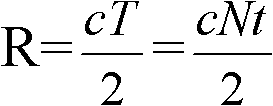

Picosecond-pulse-based high-precision laser distance measuring device

InactiveCN102323591AImprove power densityNarrow pulse widthElectromagnetic wave reradiationPicosecond pulsed laserOptoelectronics

The invention provides a picoseconds-pulse-based high-precision laser distance measuring device. The device combines a picosecond pulse laser technology and a high-speed photoelectric detection technology, and adopts a picosecond pulse laser as a laser emission source and a high-speed PIN photoelectric detector as a receiving unit. A laser light source works in a pulse mode, so the laser transmission power density is high, and consideration is given to the advantages of long measuring distance and high distance measuring precision. The overall device is stable and reliable; the precision for measuring a target away from dozens of kilometers reaches 1 millimeter; and the distance measurement precision is improved by 1,000 times compared with a conventional nanosecond pulse laser distance measuring technology. The device has an ingenious structure design, is simple and practical, and can be used for high-precision measurement of aeronautics and astronautics, marine survey and long distance.

Owner:CHANGCHUN UNIV OF SCI & TECH

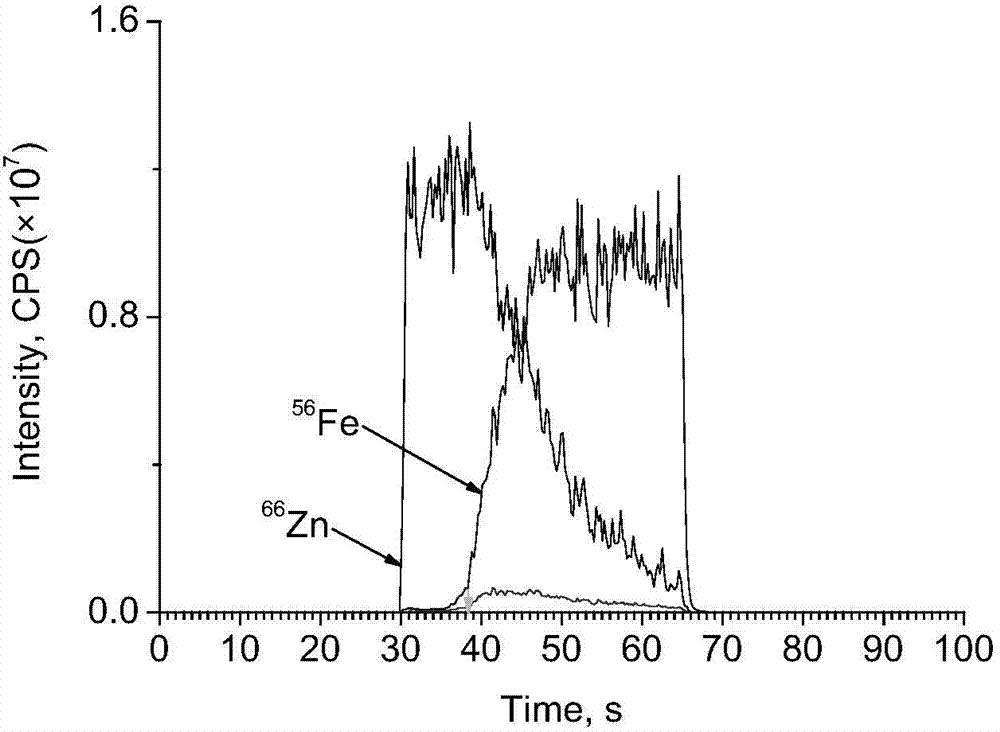

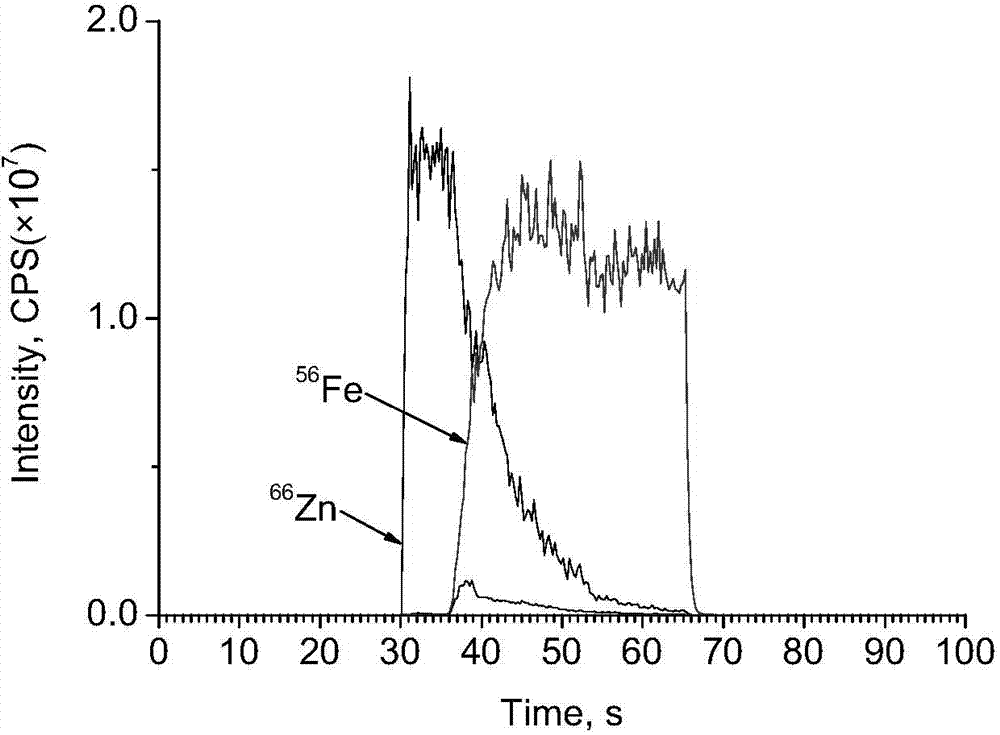

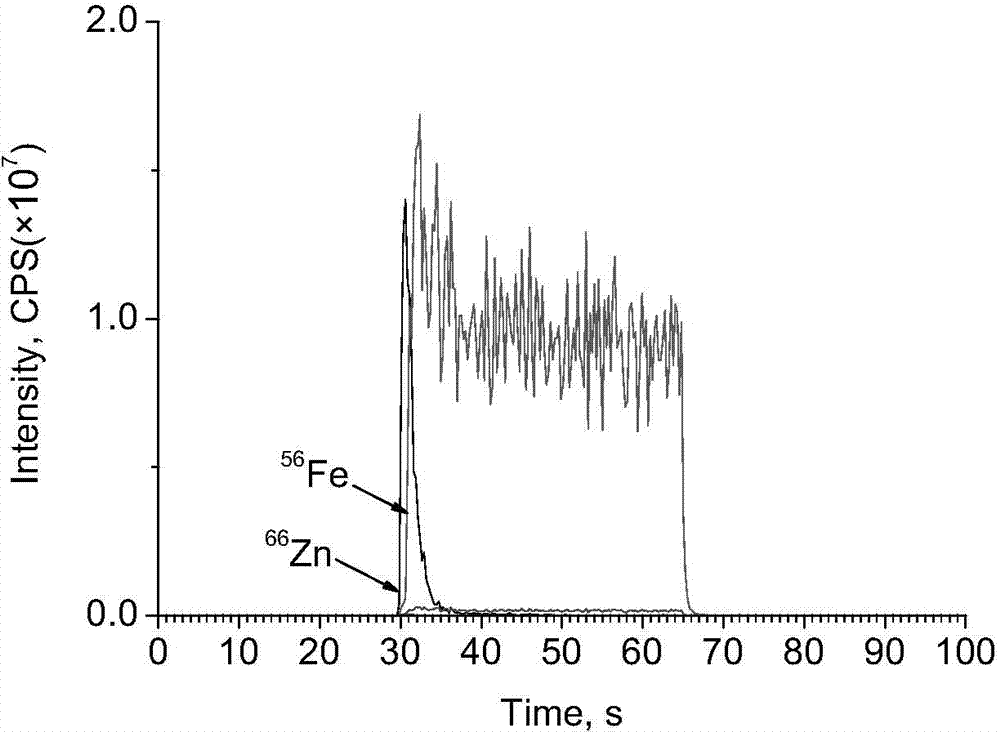

Method for quickly measuring thickness of metal coating

InactiveCN104330069AQuick checkImprove detection accuracyMeasurement devicesElectrical conductorPicosecond pulsed laser

The invention discloses a method for quickly measuring the thickness of a metal coating. The method for quickly measuring the thickness of the metal coating includes that using a picosecond pulse laser to corrode a sample under such special conditions of single-point corrosion, 20 Hz of pulse frequency and 875 micrometers of defocusing distance, obtaining a time-resolved figure capable of intuitively distinguishing coating metal from base metal through an inductively coupled plasma mass spectrometry, confirming the junction point of the coating metal and base metal in the time-resolved figure so as to confirm the corroding time for corroding the coating metal, using the standard piece of the same coating as a standard to calculate the unit pulse corrosion quantity of the metal coating, and calculating according to the unit pulse corrosion quantity and corrosion time to obtain the coating thickness. The method for quickly measuring the thickness of the metal coating realizes the quick and non-destructive detection for the coating thickness, is not limited by the conductivity of the metal coating and does not require sample shape, and moreover, the method for quickly measuring the thickness of the metal coating is capable of precisely distinguishing the boundary of two layers of metal and high in detection precision.

Owner:NINGBO ACAD OF SCI & TECH FOR INSPECTION & QUARANTINE

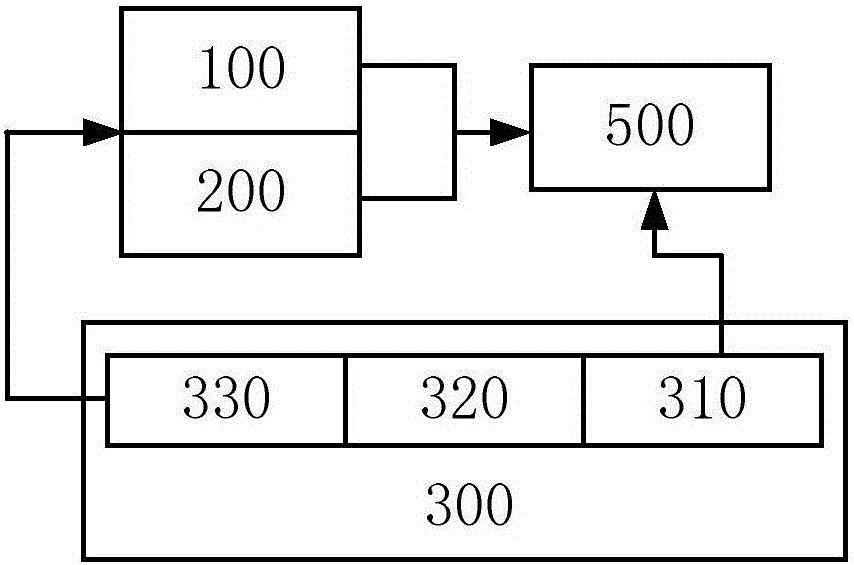

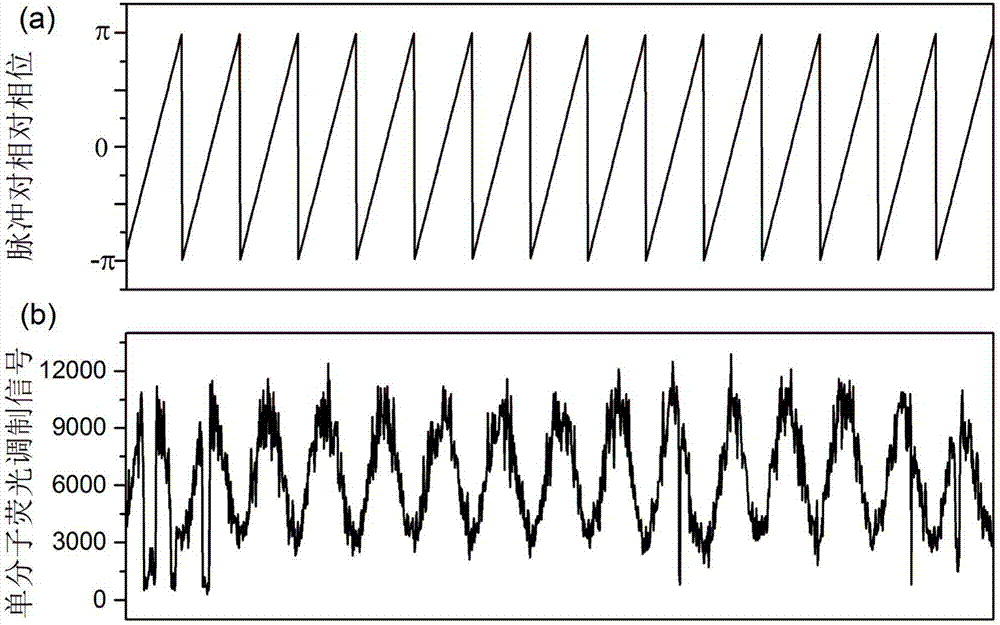

Device and method for increasing contrast ratio of monomolecular optical imaging

ActiveCN107478630AImprove Optical Imaging ContrastSolve the problem of low imaging contrastFluorescence/phosphorescenceBeam splitterPicosecond pulsed laser

The invention relates to a device and a method for increasing contrast ratio of monomolecular optical imaging and belongs to the technical field of optics. The invention mainly aims to solve the technical problem of limited signal to noise ratio of the monomolecular optical imaging caused by monomolecular fluorescence fluctuation and environmental factors at present. According to the technical scheme provided by the invention, the device for increasing contrast ratio of monomolecular optical imaging comprises a laser pulse delaying and phase modulation part, a signal analysis and control part and a monomolecular stimulating and fluorescence detection part, wherein the laser pulse delaying and phase modulation part comprises a subpicosecond pulse laser, a lambda / 2 wave plate, a 50 / 50 beam splitter, a corner cube mirror I, a corner cube mirror II, an electrooptical modulator, a signal generator, a high pressure amplifier and a lambda / 4 wave plate. Compared with the prior art, the device has the advantages of simple operation, high working efficiency, and the like.

Owner:SHANXI UNIV

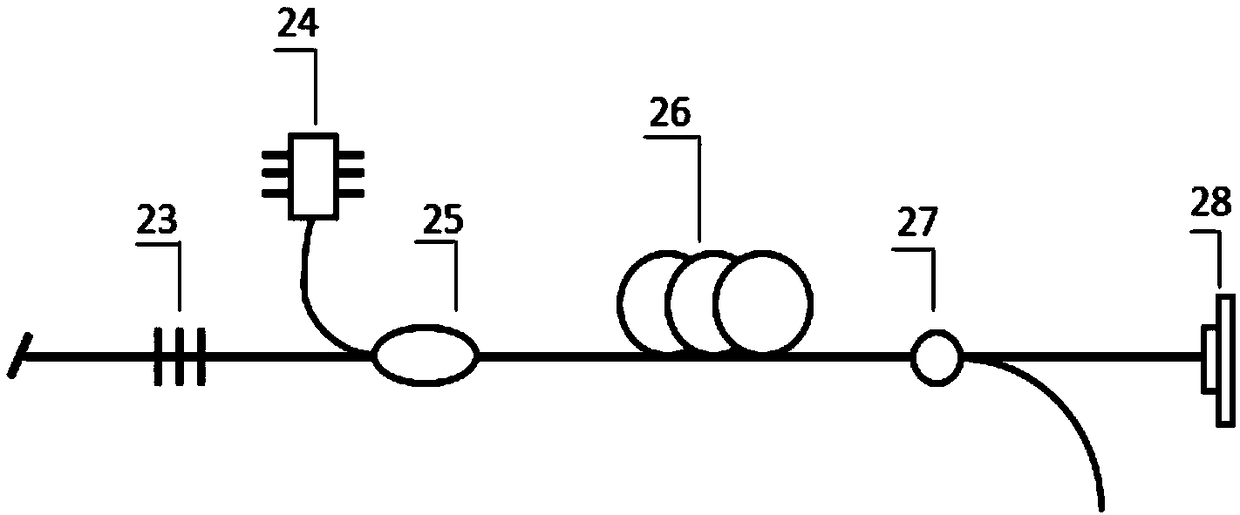

Tens-of-megahertz high-repetition-frequency nanosecond all-optical fiber laser amplifier

InactiveCN109346911AIncrease duty cycleReduce nonlinear effectsCoupling light guidesActive medium shape and constructionPicosecond pulsed laserMode-locking

The invention discloses a tens-of-megahertz high-repetition-frequency nanosecond all-optical fiber laser amplifier. The amplifier comprises a single-mode optical fiber seed source, an optical fiber stretcher, an optical fiber power amplifier and a signal light output system; the single-mode optical fiber seed source is a high-repetition-frequency picosecond pulse laser for realizing passive mode locking based on a semiconductor saturable absorber; the optical fiber stretcher is composed of a chromatic dispersion device and an optical fiber communication device used in cooperation with the chromatic dispersion device, and is used for stretching a front-stage picosecond pulse to an order of a few nanoseconds; and the optical fiber power amplifier is a main oscillation power amplifier which is formed by cascading multistage optical fiber amplifiers. Parameters of a resonant cavity are optimized, and an obtained tens-of-megahertz high-repetition-frequency mode-locking picosecond pulse is injected into the optical fiber stretcher, so that stable nanosecond high-repetition-frequency pulse output is achieved; then the pulse is subjected to multistage amplification by adopting a gain optical fiber; and finally high-repetition-frequency high-power nanosecond pulse output is realized. Moreover, the system realizes an all-optical fiber mode, and is stable in work and high in reliability.

Owner:BEIJING UNIV OF TECH

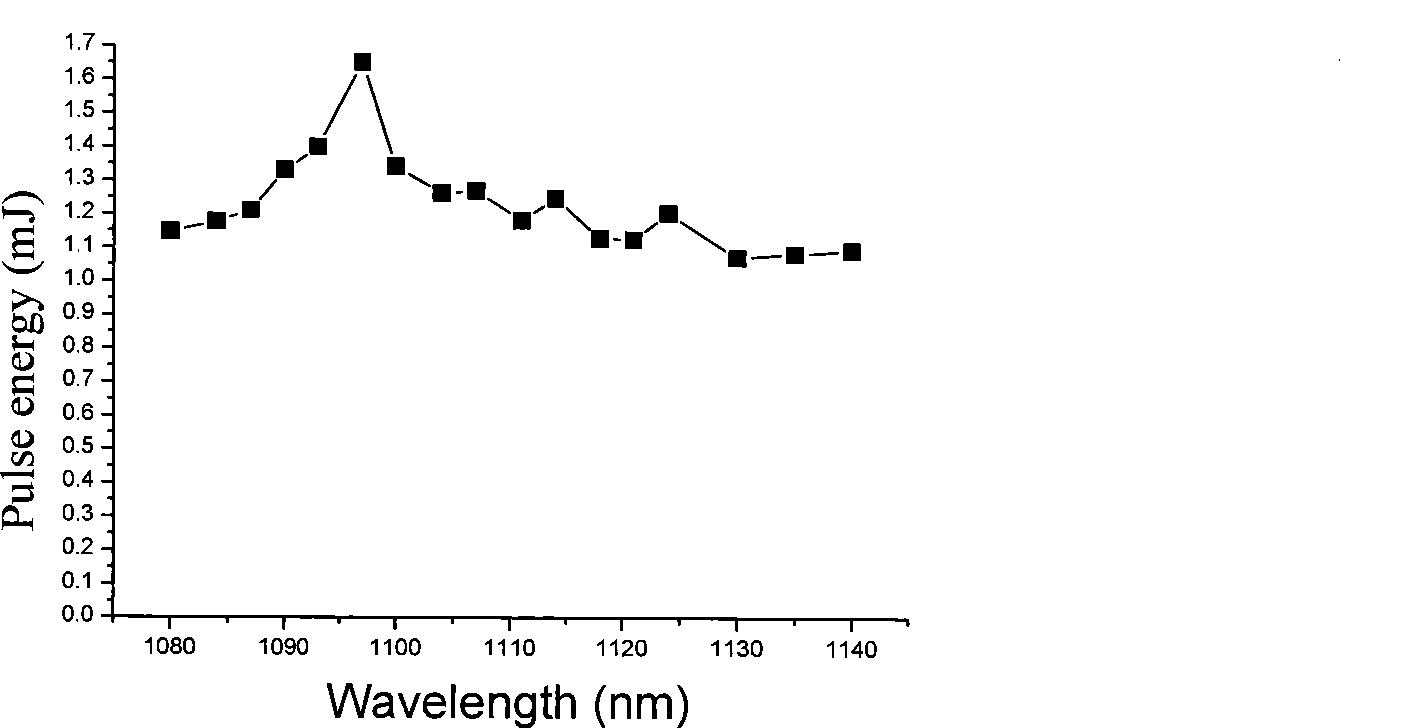

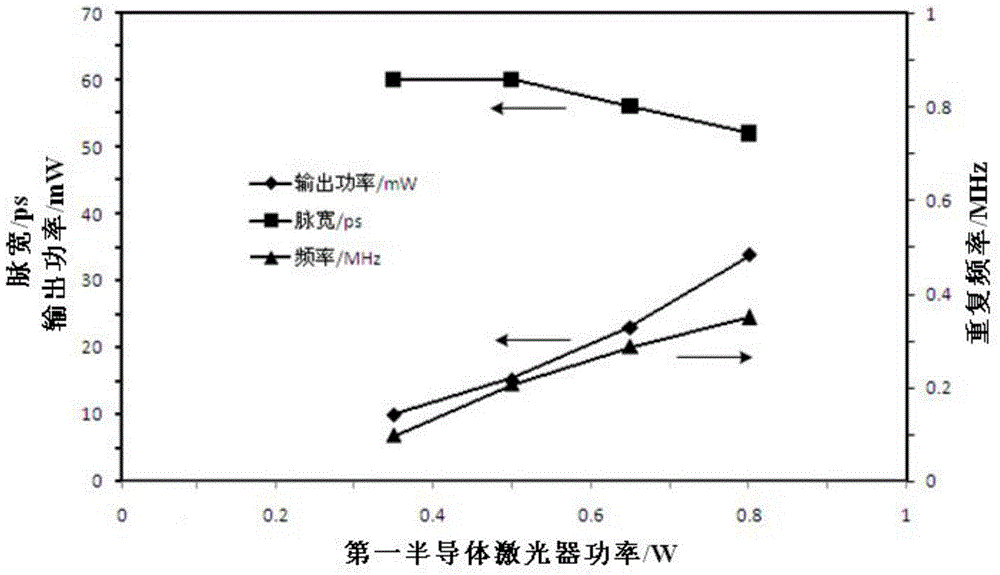

Tunable narrow-line-width picosecond pulse laser device

ActiveCN102957090AWide range of repetition ratesImprove stabilityLaser detailsLaser output parameters controlPicosecond pulsed laserGrating

The invention discloses a tunable narrow-line-width picosecond pulse laser device, comprising a pulse driving circuit, a semiconductor laser device, an annular device, an optical fiber optical grid, a coupling device, a spectrum analysis unit, a main control unit and a micro-spur traction unit, wherein the pulse driving circuit outputs pulse current to drive the semiconductor laser device to generate one-grade relaxation vibration wide spectrum pulse laser; the pulse laser penetrates through the annular device to be reflected by the optical fiber optical grid; then reflected laser output by the annular device enters the coupling device; the reflected laser with the greater energy is output through an output light port of the coupling device; the reflected laser with the smaller energy is output through a feedback light signal port of the coupling device; the reflected laser with the smaller energy is analyzed and processed by the spectrum analysis unit and the main control unit; and the main control unit drives the micro-spur traction unit and the micro-spur traction unit to carry out micro-spur traction on the axial direction of the optical fiber optical grid. The tunable narrow-line-width picosecond pulse laser device has the advantages of simple structure, easiness for operation, good stability, multi-pulse adjustability, high tuning precision and the like.

Owner:HEFEI ZHICHANG PHOTOELECTRIC TECH

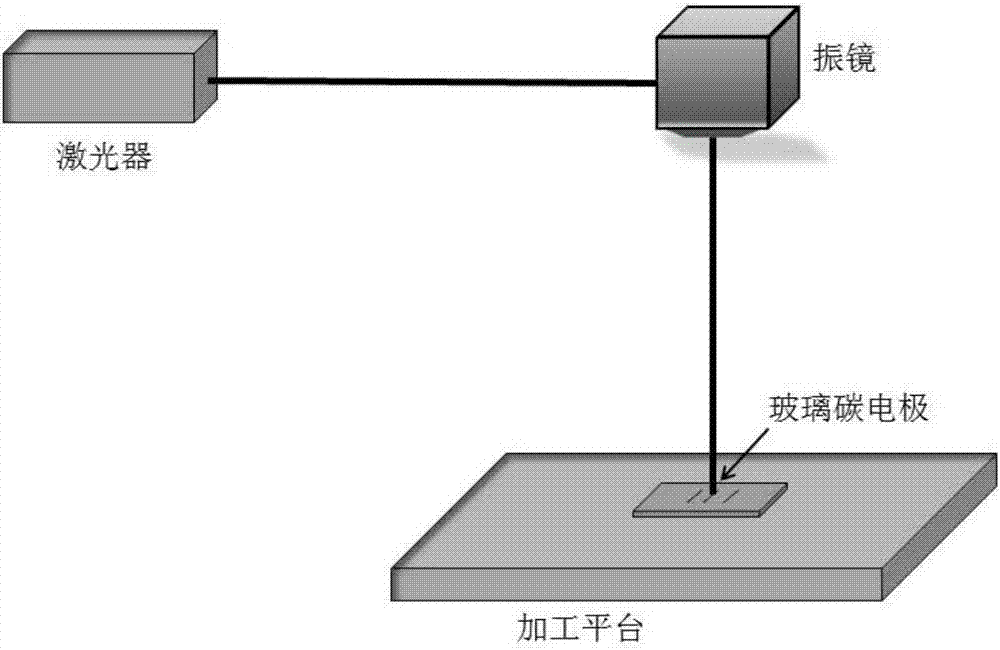

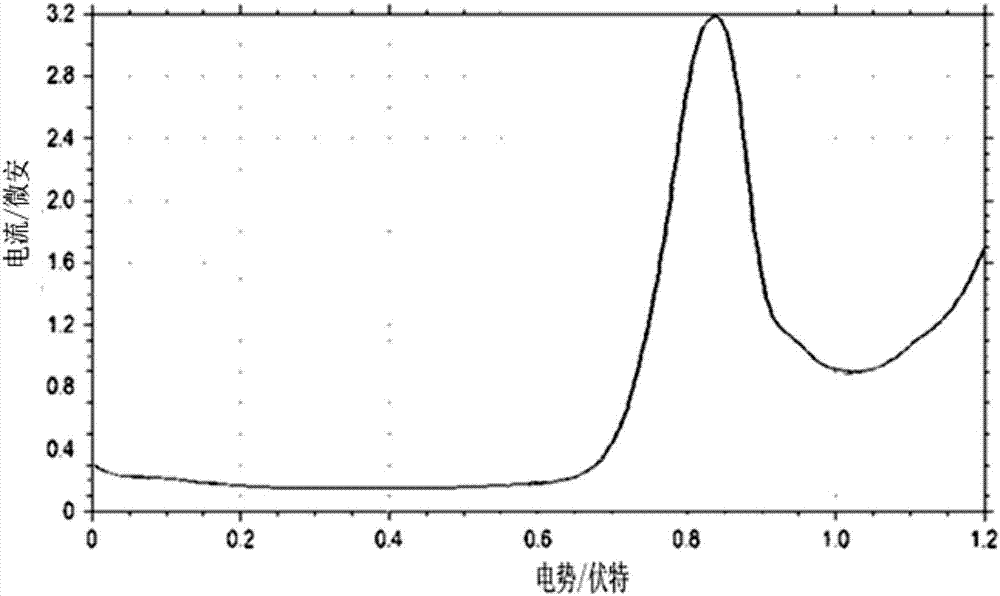

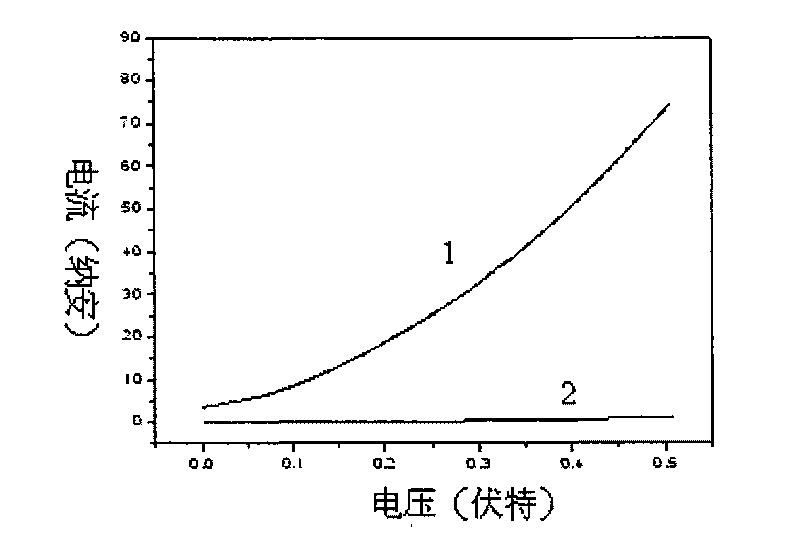

Glassy carbon electrode surface roughing preparation method based on ultra-short pulse laser micromachining

InactiveCN106925895AReduce thermal effectsEasy to processLaser beam welding apparatusMicro nanoPicosecond pulsed laser

The invention relates to a glassy carbon electrode surface roughing preparation method based on ultra-short pulse laser micromachining. The glassy carbon surface is subjected to roughing treatment by using different pulse widths, pulse frequencies, pulse power and machining time. The glassy carbon electrode surface is subjected to roughing through an ultra-short pulse laser, and a micro-nano structure can be generated on the glassy carbon electrode surface, so that electrode catalytic efficiency is greatly strengthened, and the signal-to-noise ratio is greatly increased. A glassy carbon electrode is subjected to roughing treatment by using a picosecond pulse laser, the heat effect is small, machining is fine, the clean and environment-friendly and economic and efficient effects are achieved, and the application prospects of the glassy carbon electrode subjected to roughing treatment are wider in the aspects of electrochemical detection and oxidation-reduction reactions.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

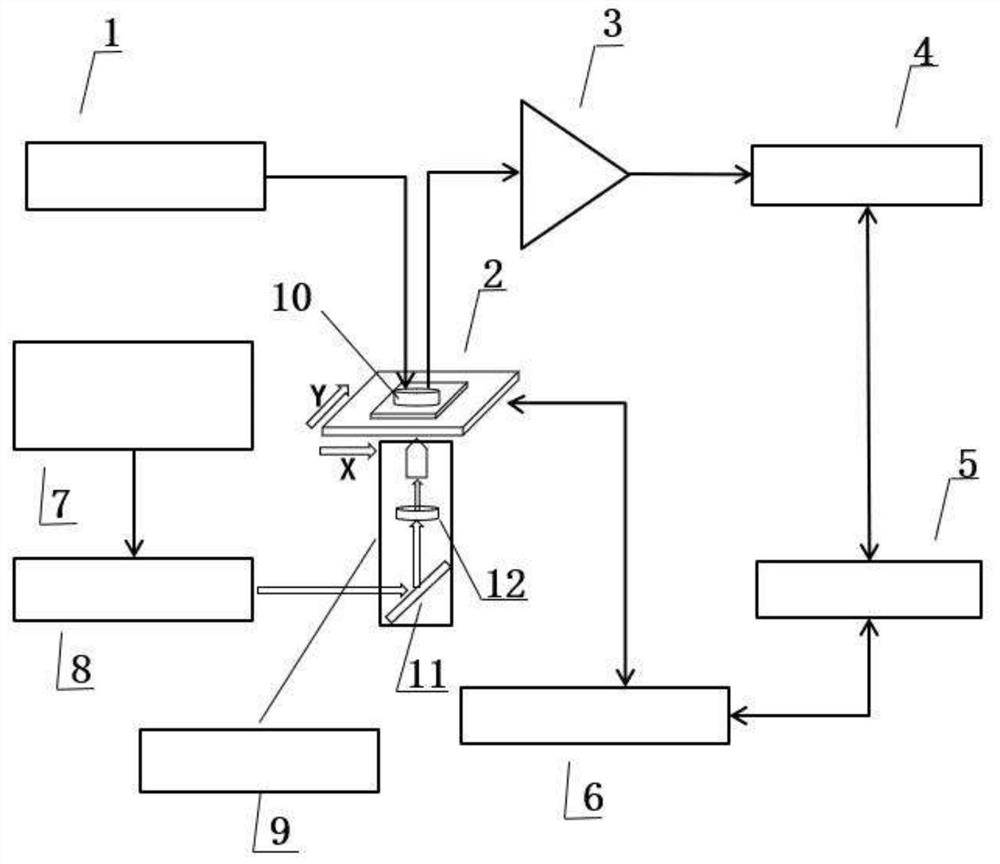

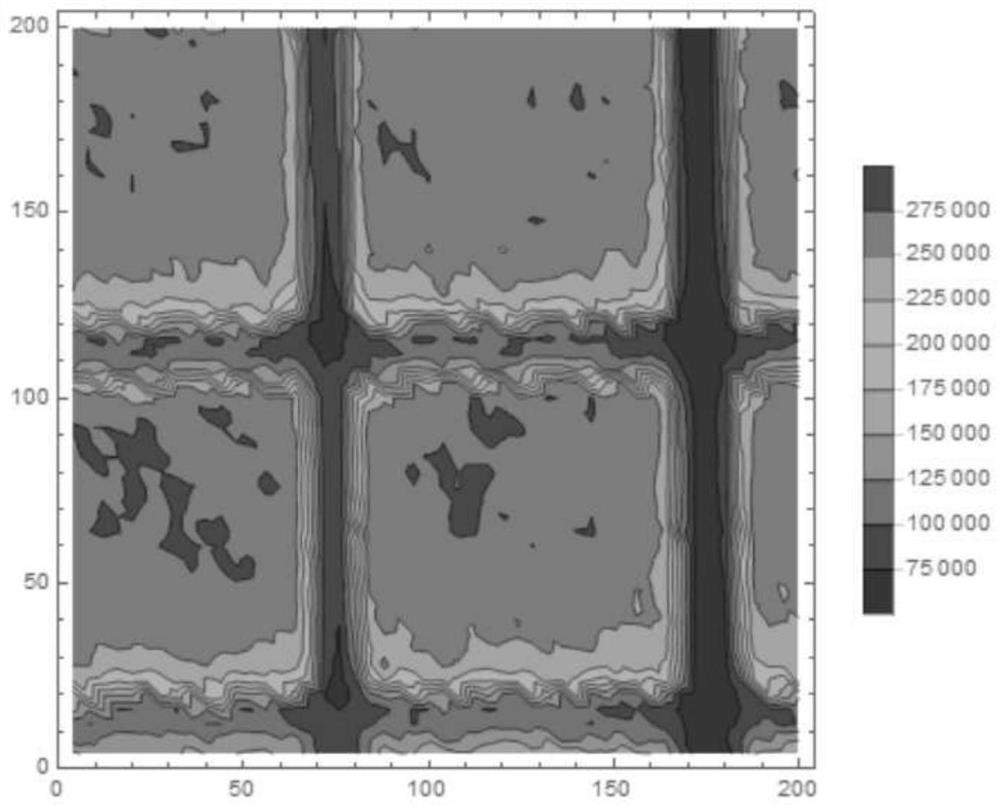

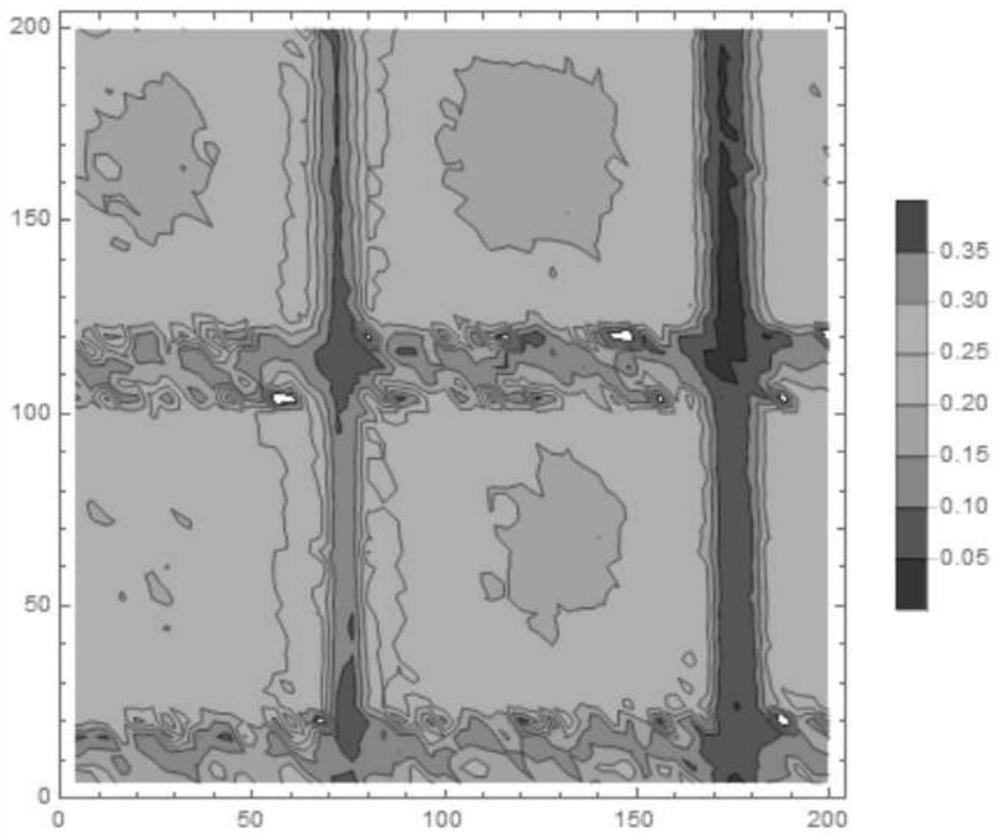

Method for measuring PDE and Pct spatial two-dimensional distribution of silicon photomultiplier

PendingCN112433137AGet spatial distribution informationObtain information of electric field distribution in depletion region indirectlyVacuum tube testingPicosecond laserLow noise

The invention discloses a method for measuring PDE and Pct spatial two-dimensional distribution of a silicon photomultiplier. The method comprises the following steps: placing the silicon photomultiplier in an electromagnetic shielding box, and installing the silicon photomultiplier on a nanometer displacement platform; using a picosecond pulse laser driver to enable a laser head to irradiate picosecond laser beams, and focusing the picosecond laser beams into light spots on the surface of the silicon photomultiplier through a pinhole light-transmitting sheet in the microscope; powering the silicon photomultiplier by a stabilized power supply, amplifying an output avalanche pulse signal by a high-speed low-noise amplifier, and then inputting the amplified signal into a digital oscilloscopeto observe the waveform of the avalanche pulse; and controlling a nano displacement table to move, calculating a group of PDE and Pct at each position through the total pulse counting rate and the background counting rate under different photon equivalent thresholds, and finally drawing a spatial two-dimensional distribution diagram through multiple groups of PDE and Pct data. The relative lightdetection efficiency and optical crosstalk probability spatial two-dimensional distribution information of the silicon photomultiplier can be obtained at room temperature without low-temperature refrigeration.

Owner:XI'AN POLYTECHNIC UNIVERSITY

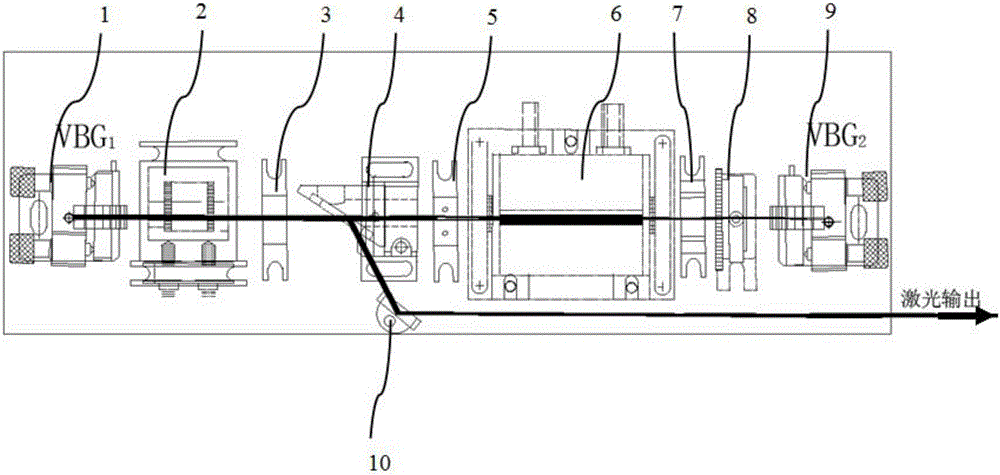

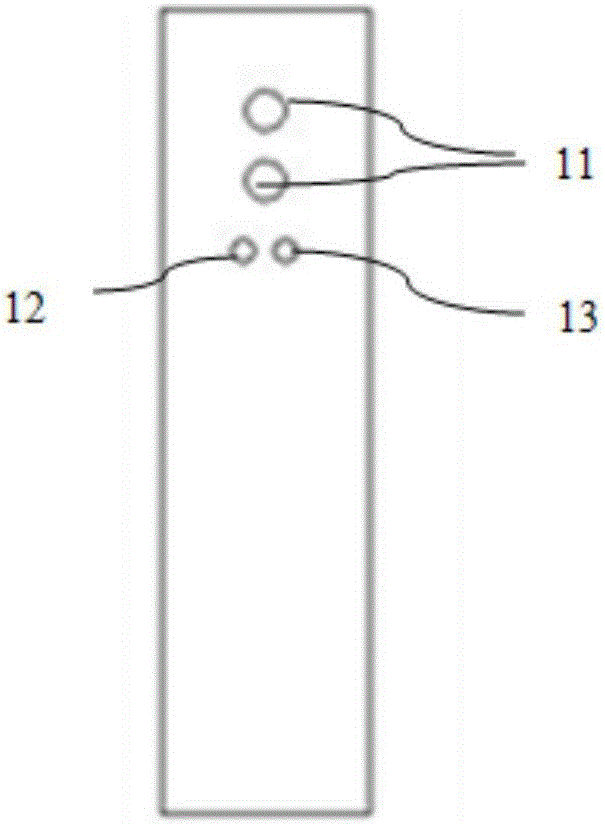

Volume Bragg grating high-energy pisosecond laser

ActiveCN105811231AGuaranteed sizeAvoid damageOptical resonator shape and constructionGratingPicosecond pulsed laser

The invention relates to the technical field of laser, in particular to a volume Bragg grating (VBG) high-energy pisosecond laser. The laser disclosed by the invention comprises a box, wherein two parallel VBG end mirrors are separately arranged at the two ends of the interior of the box to form an optical resonant cavity, an electro-optical switch, a polarizing film, a saturable absorber, a gain pumping module and a concave lens are sequentially arranged in the optical resonant cavity, the gain pumping module is used for strong pumping on a laser crystal to generate oscillation light, the oscillation light is gradually compressed to a short pulse under the effect of the saturable absorber, and meanwhile, the pulse with is further compressed under the effect of the VBG end mirrors. At the maximum pulse energy moment, high voltage is applied to the electro-optical switch, high-energy pisosecond pulse is output through the polarizing film and a full-reflection mirror by a cavity dumping technology to obtain high-energy pisosecond pulse laser, and thus, the problems of large size, device complexity and low stability of the high-energy pisosecond laser at the current stage are solved.

Owner:BEIJING UNIV OF TECH

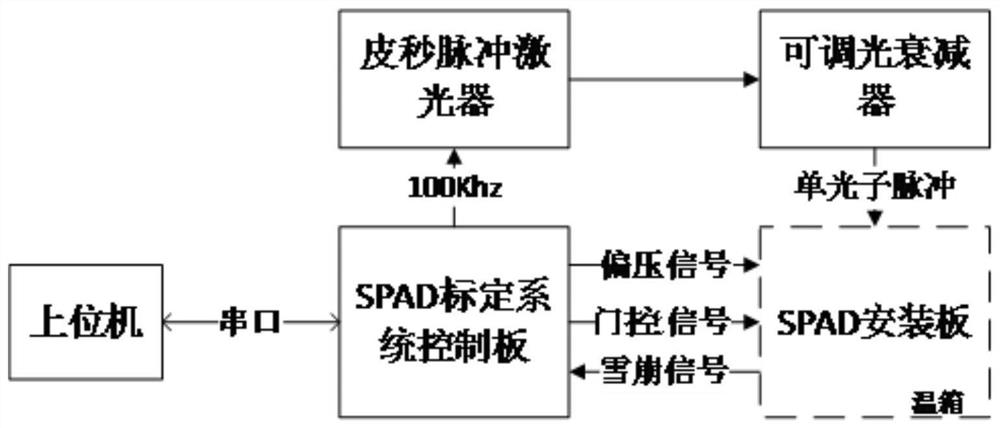

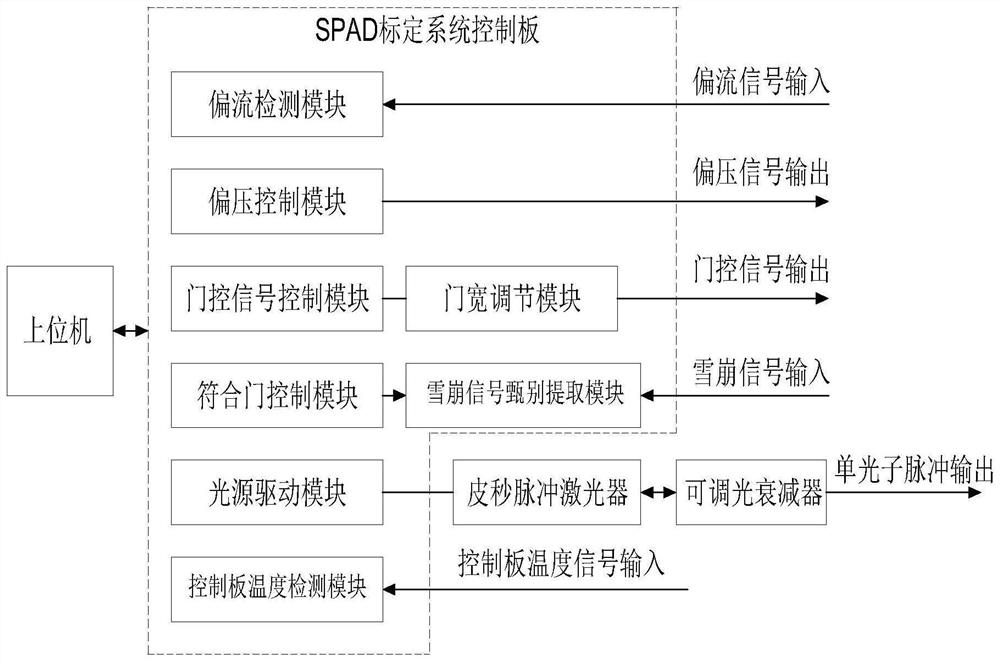

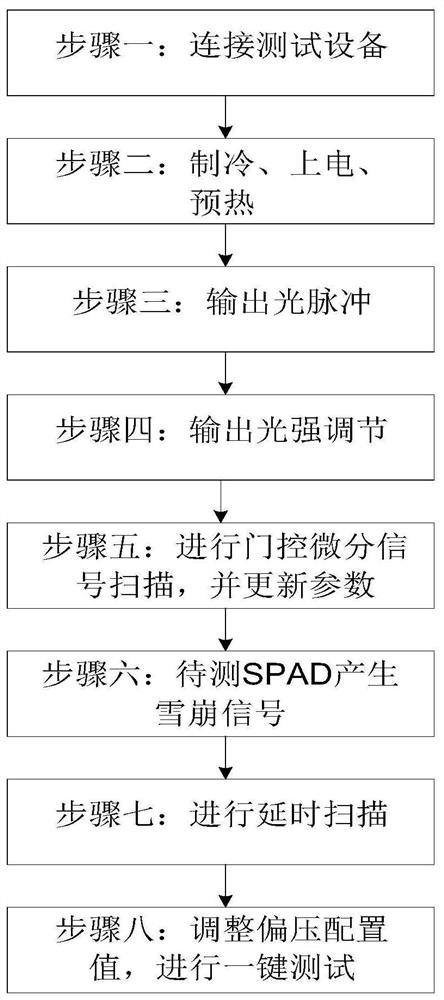

Single-photon avalanche photodiode calibration system and calibration method

PendingCN112098787ALow level of professionalism requiredHigh degree of integrationDiode testingPicosecond pulsed laserEngineering

The invention discloses a single-photon avalanche photodiode calibration system, relates to the field of quantum communication, and solves the problem of how to accurately and automatically test SPADkey parameters. The system comprises an upper computer, an SPAD calibration system control panel, a picosecond pulse laser, a variable optical attenuator, an SPAD mounting plate and a temperature box;the SPAD calibration system control panel is connected with the picosecond pulse laser; the picosecond pulse laser is connected with the variable optical attenuator; the variable optical attenuator is connected to an SPAD to be tested through an optical fiber, and the mounting plate is provided with a gating signal interface, a bias signal interface and an avalanche signal interface. The SPAD tobe tested is mounted on the mounting plate; the mounting plate is mounted in the temperature box; the calibration system control panel is connected with the upper computer; the invention further provides a single-photon avalanche photodiode calibration method. The system has the advantages that multiple performance parameters of the SPAD to be tested can be tested in a short time, and the system is efficient, convenient, easy to operate and easy to learn.

Owner:QUANTUMCTEK

Method for inducing phase-change material film crystallization by using ultrashort pulse pico-second lasers at different wavelengths

InactiveCN107017342AAvoid duplication of experimentsConvenient researchElectrical apparatusSputteringPicosecond pulsed laser

Provided is a method for inducing the phase-change material film crystallization by using ultrashort pulse pico-second lasers at different wavelengths, belonging to the technical field of film crystallization. The device includes a control center and a base light source device that are connected, the light emitted by the base light source is irradiated on a film via a lens. The method includes the following steps of (1) plating a film on the selected substrate by means of magnetron sputtering; (2) using the material obtained in (1), and using a basic lens to irradiate the material with the laser in appropriate energy under the same base light source to make the material undergo phase change, wherein the base light is a pico-second pulse laser at the wavelength of 1064nm; or replacing the lens, under the effect of a frequency multiplication crystal, irradiating the material with the laser in appropriate energy as the wavelength changing into 532nm or 355 nm to make the material undergo phase change.

Owner:BEIJING UNIV OF TECH

Preparation method of metal surface microstructure with abrasion resistance and hydrophobicity

InactiveCN107999976ATypical ultra-short pulse widthTypical Ultra High Peak Power CharacteristicsLaser beam welding apparatusPicosecond laserPicosecond pulsed laser

The invention discloses a preparation method of a metal surface microstructure with abrasion resistance and hydrophobicity. The method comprises the steps that 1, stainless steel to be treated is subjected to ultrasonic cleaning, surface pollutants are removed, drying is carried out, and the clean stainless steel surface is obtained; 2, mapping software is used for doing microstructure two-dimension design drawing, and a graphic file is guided into picosecond laser machining system galvanometer control software; and 3, a picosecond laser machining system is adopted for carrying out laser scanning machining treatment on the stainless steel surface obtained in the step 1 according to the machining graph guided in the step 2, and the stainless steel surface with the specific form microstructure is prepared. Picosecond pulse laser adopted in the method has typical ultra-short pulse width and ultra-high peak power characteristic, the defects of heat effects and the like caused easily by long pulse laser machining can be avoided, compared with femtosecond laser, the machining cost is low, the machining efficiency is high, the surface friction coefficient of the prepared stainless steel microstructure is reduced remarkably, the abrasion resistance is improved, the contact angle to water is increased remarkably, and hydrophobicity is improved.

Owner:SHANGHAI INST OF LASER TECH

Method and element structure for realizing optical recording and electrical reading of information

InactiveCN101714372AImprove recording speedReadout improvementRecording by optical meansElectricityPicosecond pulsed laser

The invention discloses a method and an element structure for realizing the optical recording and electrical reading of information. The method is characterized by laser recording and electrical reading, wherein the laser reading is to complete information recording by forming phase change information points on a phase change thin film by using the action of a picosecond ultrashort laser pulse; and the electrical reading is to realize information reading by using a scanning probe to detect the resistance change in a phase change area. The element structure mainly comprises a transparent substrate, a metal layer serving as a lower electrode and a phase change recording layer serving as a recoding layer. The method combines the characteristics of small pulse width of the ultrashort laser pulse and dramatic resistance change before and after phase change and synchronously realizes quick recording and reading of signal with a high signal to noise ratio.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

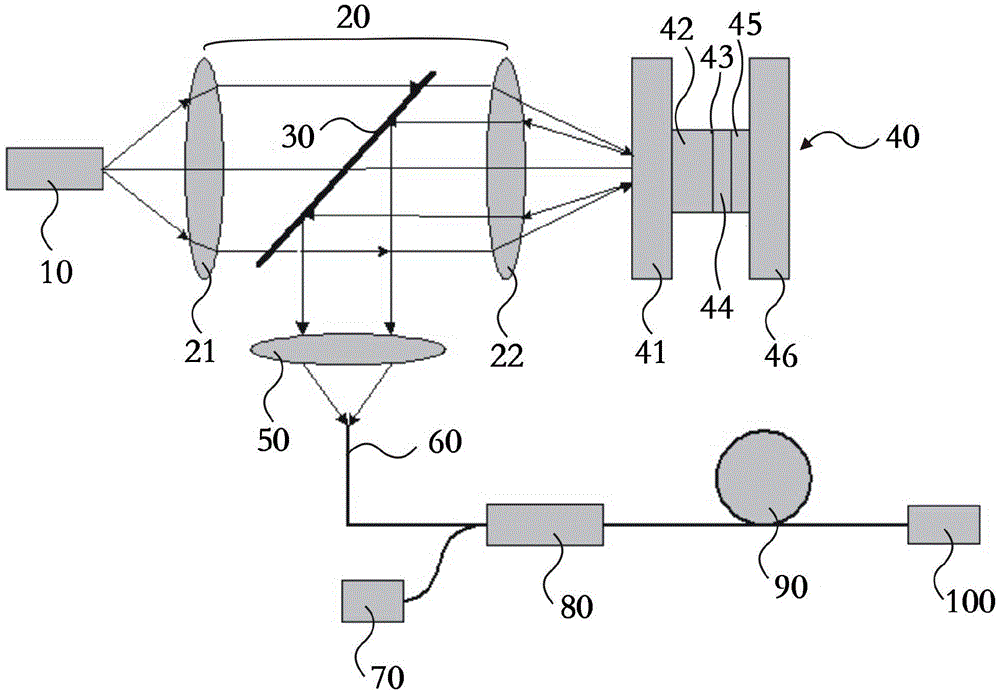

High-power sub-hundred picosecond pulse laser system

InactiveCN104409950ACompact structureIncrease output powerActive medium materialActive medium shape and constructionHigh peakPicosecond pulsed laser

The invention provides a high-power sub-hundred picosecon pulse laser system, comprising a first semiconductor sensor, a laser collimating and focusing lens system, a dichroscope, a composite crystal, an optical fiber coupling lens, an optical fiber, a second semiconductor laser, a beam combiner, a ytterbium-doped active optical fiber and an output isolator; the composite crystal is composed of a non-transparent window, a YVO4-dopted crystal, a Nd3+ and YVO4 crystal, a semiconductor saturable-absorber, a copper heat sink layer and various coating film layers. The micron-sized thin Nd3+ and YVO4 crystal is used as a laser crystal and the output of sub-hundred picosecon pulse seed light is realized by using the passively Q-switched laser of the semiconductor saturable-absorber; in addition, the pulse seed light is amplified by utilizing an optical fiber amplification technology and the output of the sub-hundred picosecon pulse light with high average power and high peak-value power is obtained. The laser system has narrow pulse width, compact structure and high output power and can be widely applied to the fields such as precision processing, biological fluorescence detection and laser ranging.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com