Method for inducing phase-change material film crystallization by using ultrashort pulse pico-second lasers at different wavelengths

A picosecond laser and ultrashort pulse technology, applied to electrical components and other directions, can solve problems such as difficulty in irradiating energy and wasting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

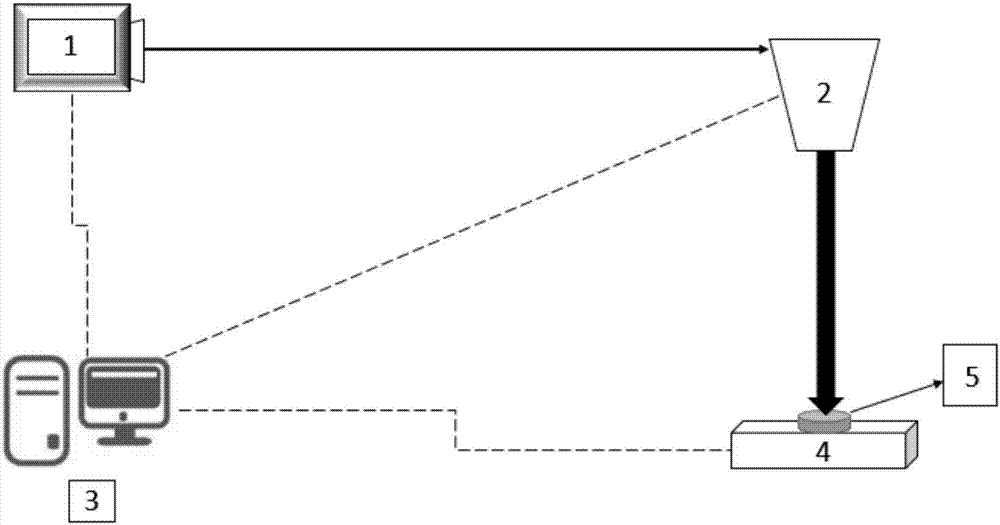

[0025] according to figure 1 Connecting the device, the control center can control the energy of the light source, the replacement of the lens and the movement of the working platform. The pulses emitted by the light source are irradiated on the surface of the material sample after being processed by the lens.

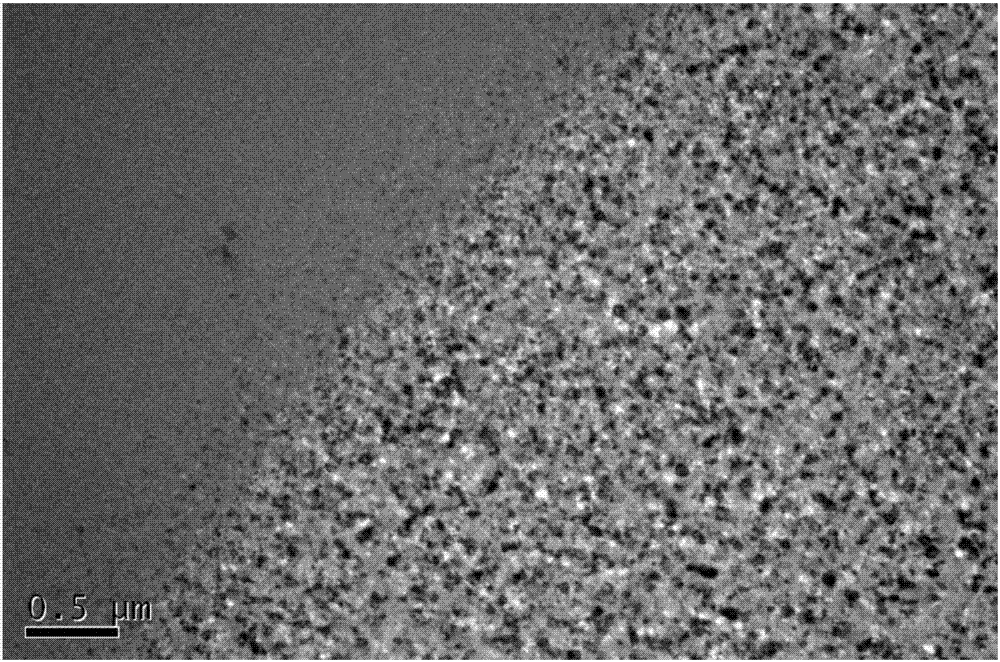

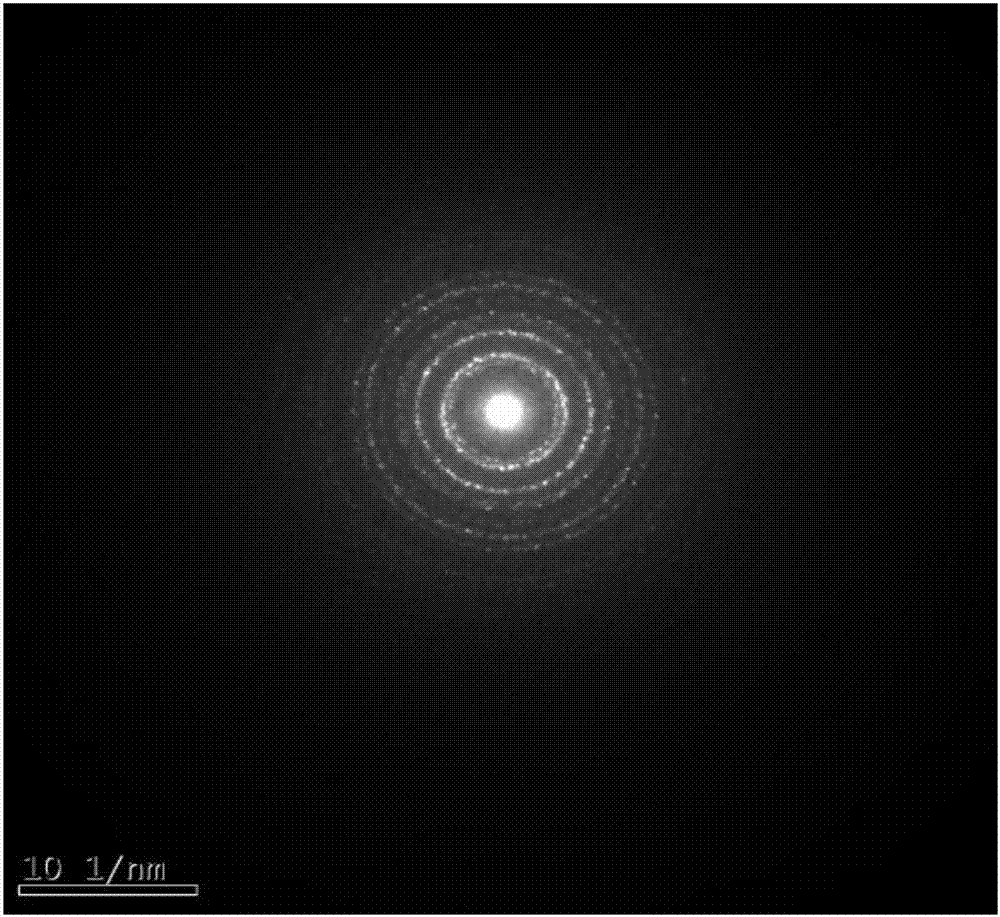

[0026] (1) Coating a layer of amorphous Ge with a thickness of 60 nm on the surface of the carbon support film by magnetron sputtering 2 Sb 2 Te 5 Film, take three samples numbered 1 to 3 respectively.

[0027] (2) Fix the sample 1 on the working platform, select the basic lens, the wavelength is 1064nm, the spot interval is 100nm, and the radiation energy is 22mj / cm 2 ;Remove the sample.

[0028] (3) Put sample 2 on the working platform, replace the frequency doubling lens, the wavelength is 532nm, and the radiation energy is 29mj / cm 2 .

[0029] (4) Put the sample 3 on the working platform, replace the frequency doubling lens, the wavelength is 355nm, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com