Patents

Literature

673 results about "Ternary alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ternary alloys are composed of three different metals such as machinable brass which is a combination of copper, zinc , and lead. In metallurgical engineering , we use phase diagrams to understand the properties of alloys.

Coated lithium electrodes

InactiveUS6955866B2Improve cycle lifeIncrease storageabilityCellsOrganic electrolyte cellsSulfur electrodePolysulfide

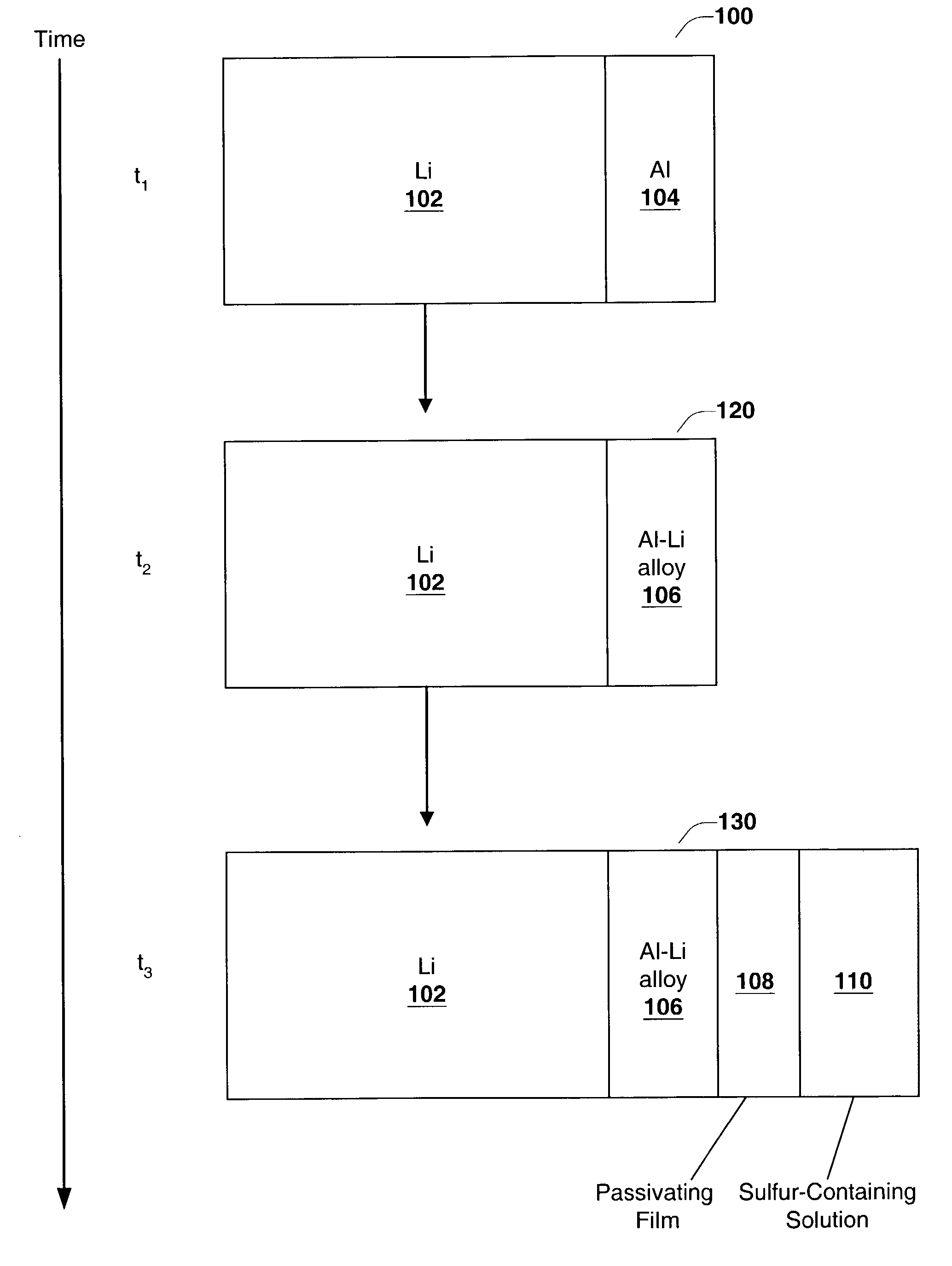

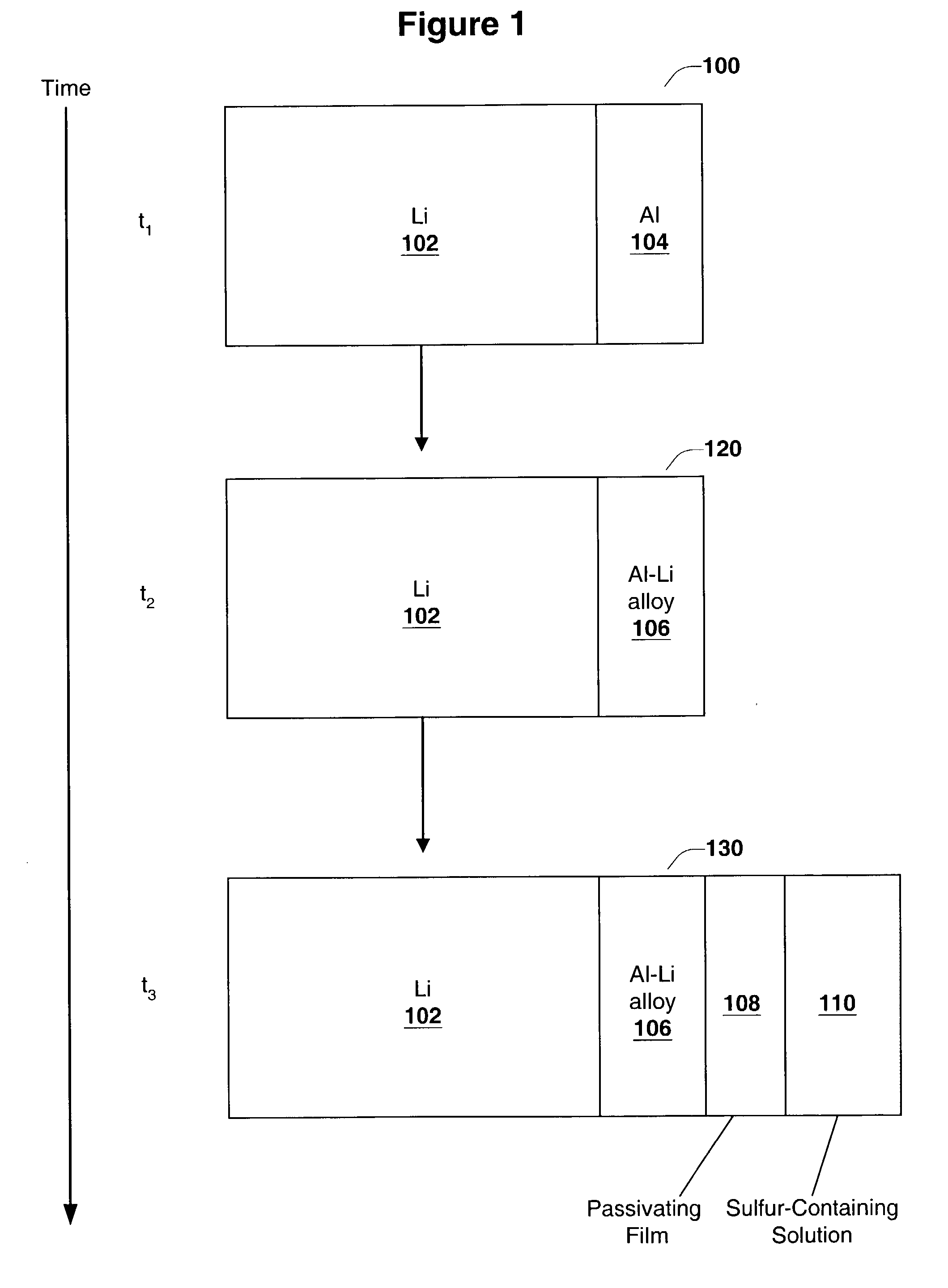

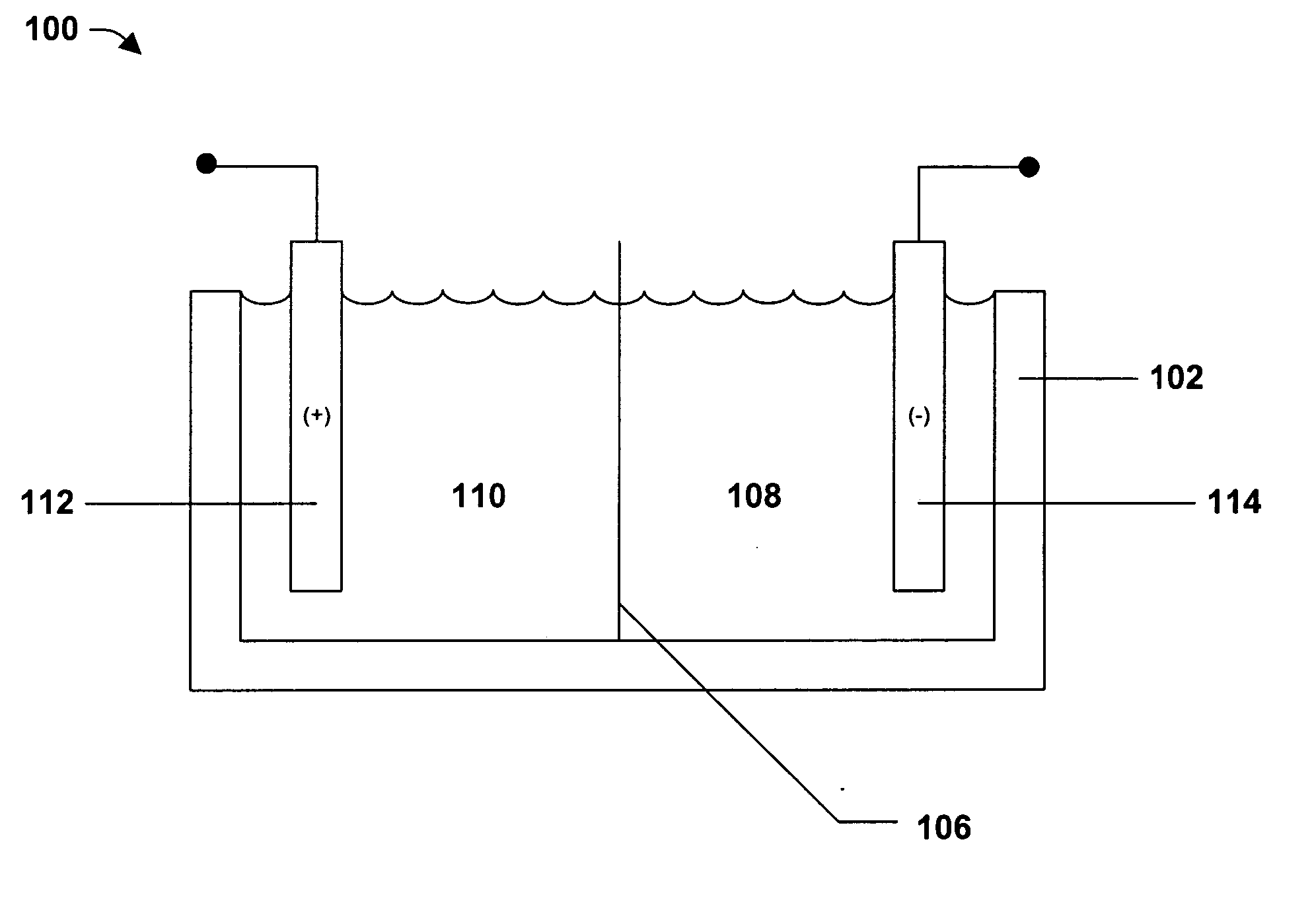

Batteries including a lithium anode stabilized with a metal-lithium alloy and battery cells comprising such anodes are provided. In one embodiment, an electrochemical cell having an anode and a sulfur electrode including at least one of elemental sulfur, lithium sulfide, and a lithium polysulfide is provided. The anode includes a lithium core and a ternary alloy layer over the lithium core where the ternary alloy comprises lithium and two other metals. The ternary alloy layer is effective to increase cycle life and storageability of the electrochemical cell. In a more particular embodiment, the ternary alloy layer is comprised of lithium, copper and tin.

Owner:POLYPLUS BATTERY CO INC

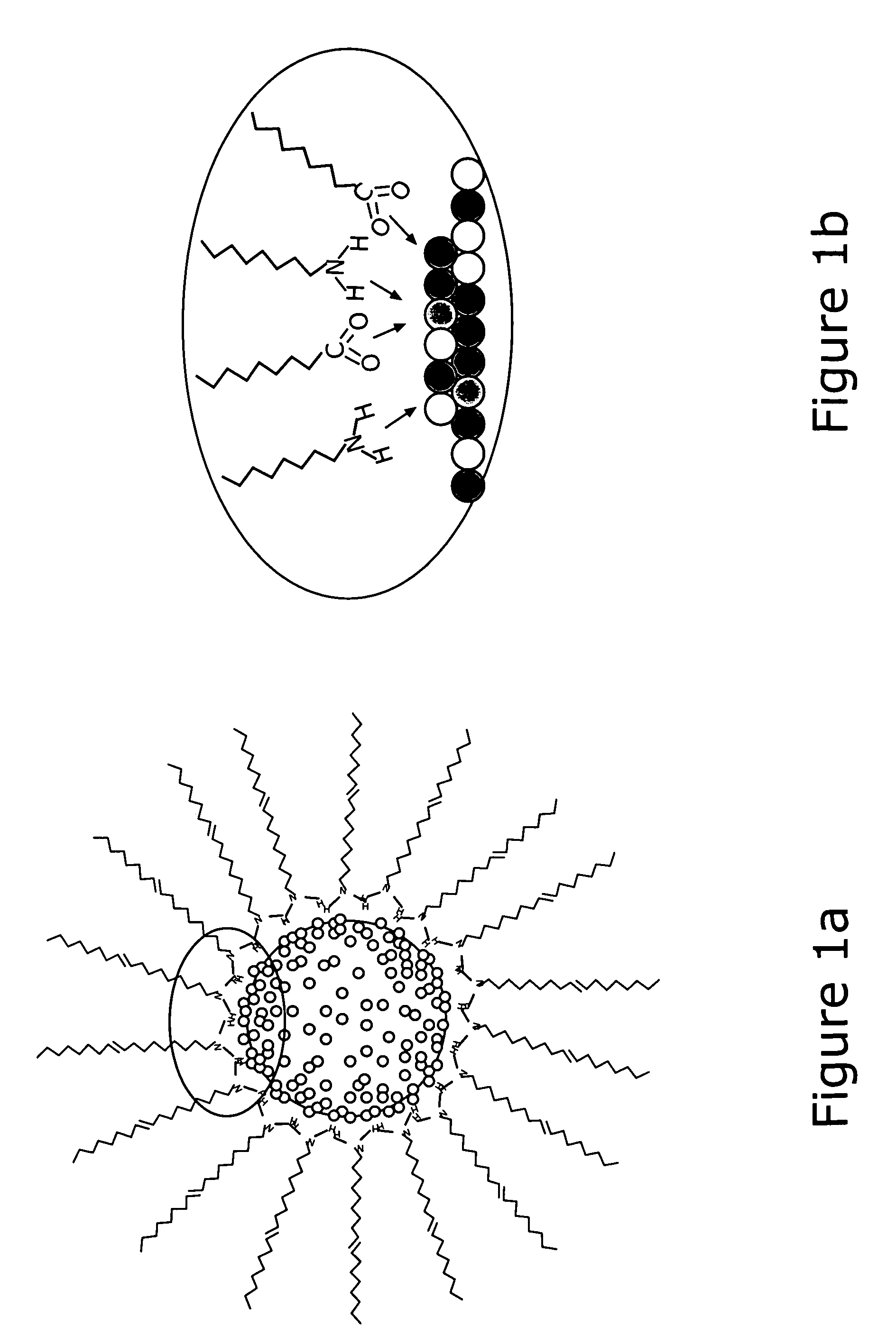

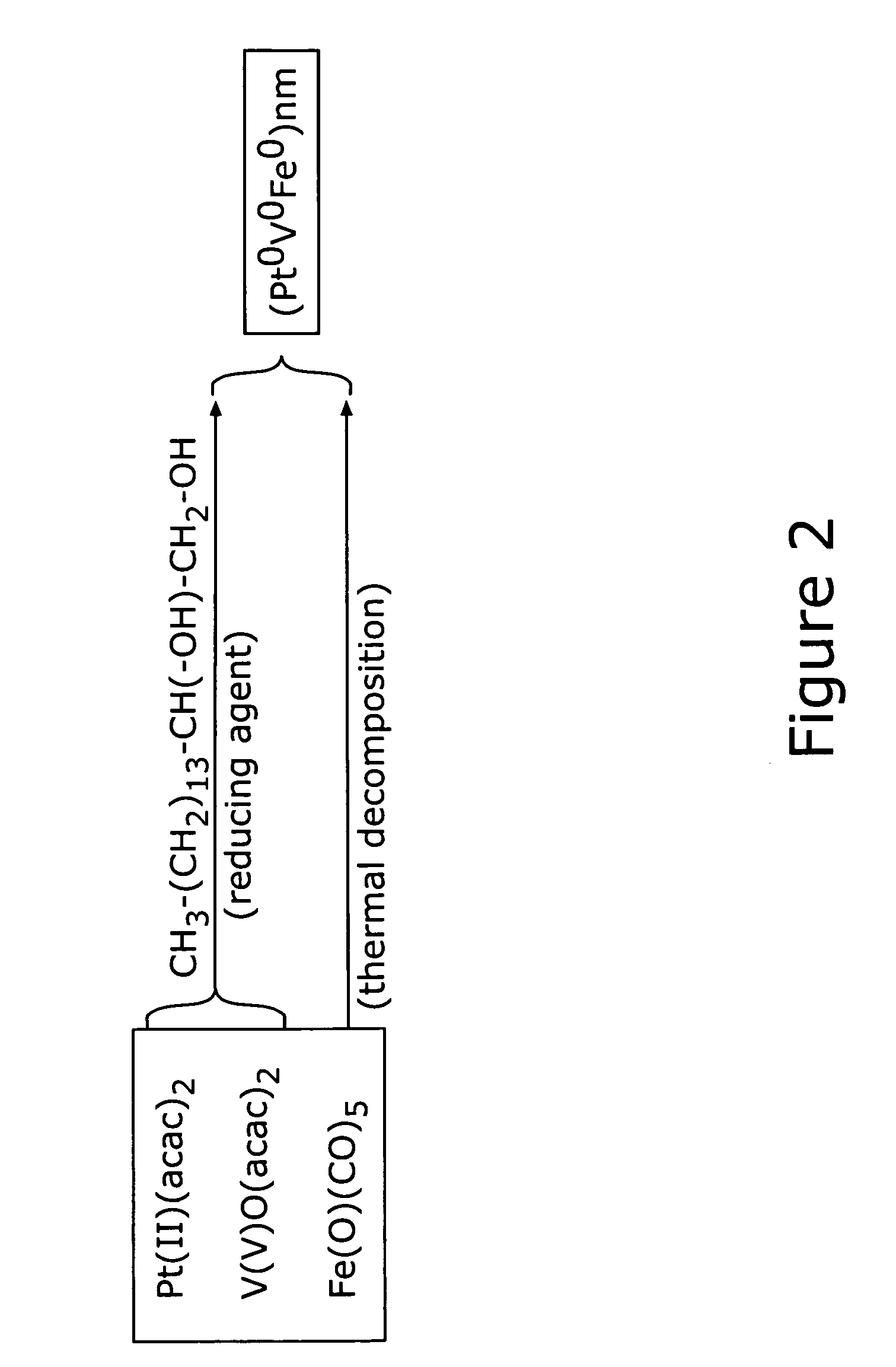

Core-shell synthesis of carbon-supported alloy nanoparticle catalysts

InactiveUS7053021B1Good monodispersityEfficient activationMaterial nanotechnologyTransportation and packagingFuel cellsBiological activation

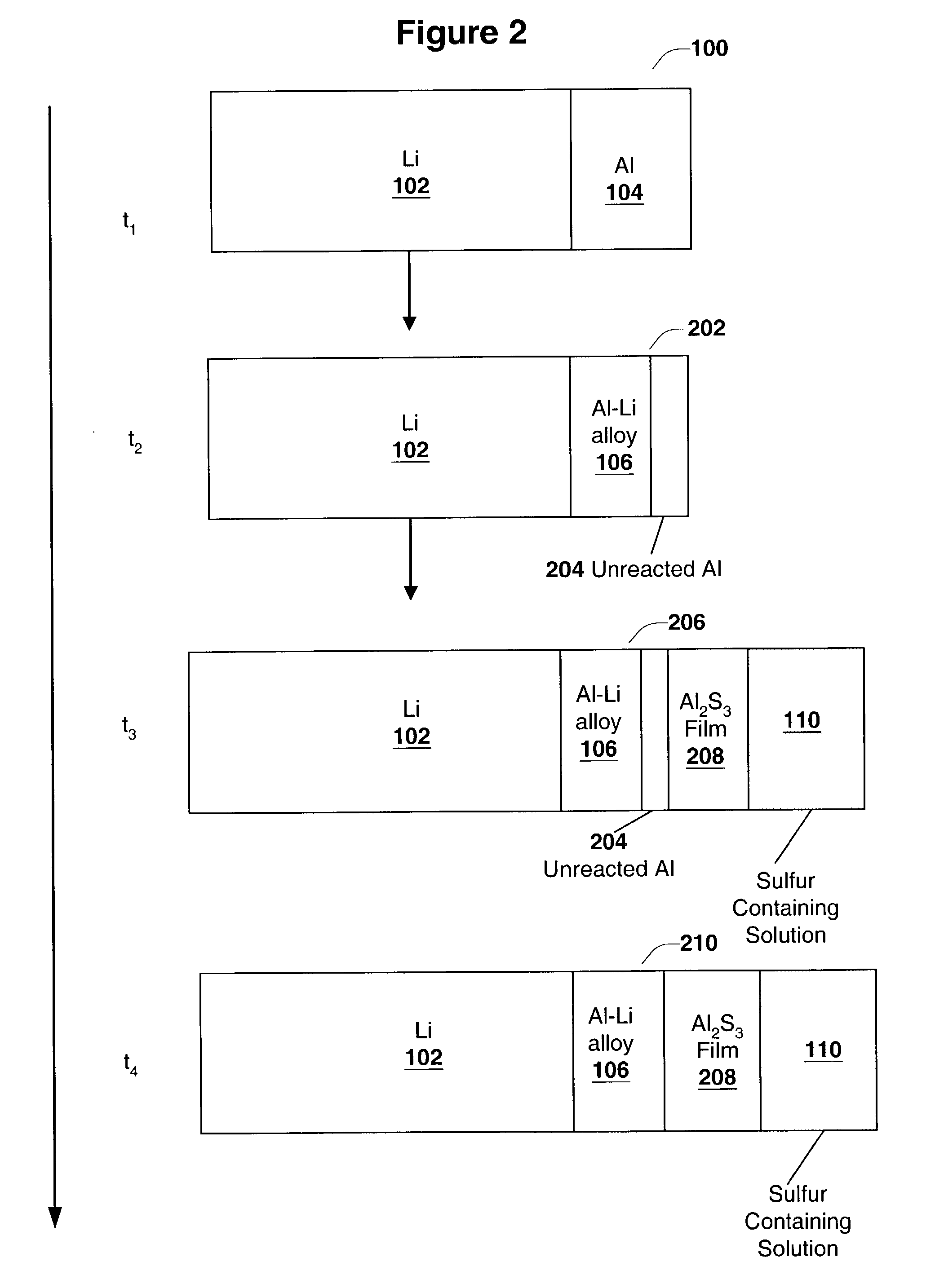

There is provided a method of preparing carbon supported, ternary alloy composition core-shell PtVFe nanoparticles for use as fuel cell electrocatalysts. These catalysts have been found particularly useful for oxygen reduction reactions. The alloy nanoparticles can be assembled on carbon supports which then may undergo subsequent activation and / or calcination treatments. The method, combined with new synthetic feed and processing conditions, provides core-shell PtVFe alloy nanoparticles of 1–3 nm size. The catalyst-produced high monodispersity, controlled composition are highly dispersed, and have a uniform distribution. Finally, the correlation of the preparation and treatment parameters to the ORR catalytic activities of the prepared nanoparticles is described. The catalysts exhibit ORR in the range of 2 to 4 times more than a standard Pt / carbon catalyst.

Owner:HONDA MOTOR CO LTD +1

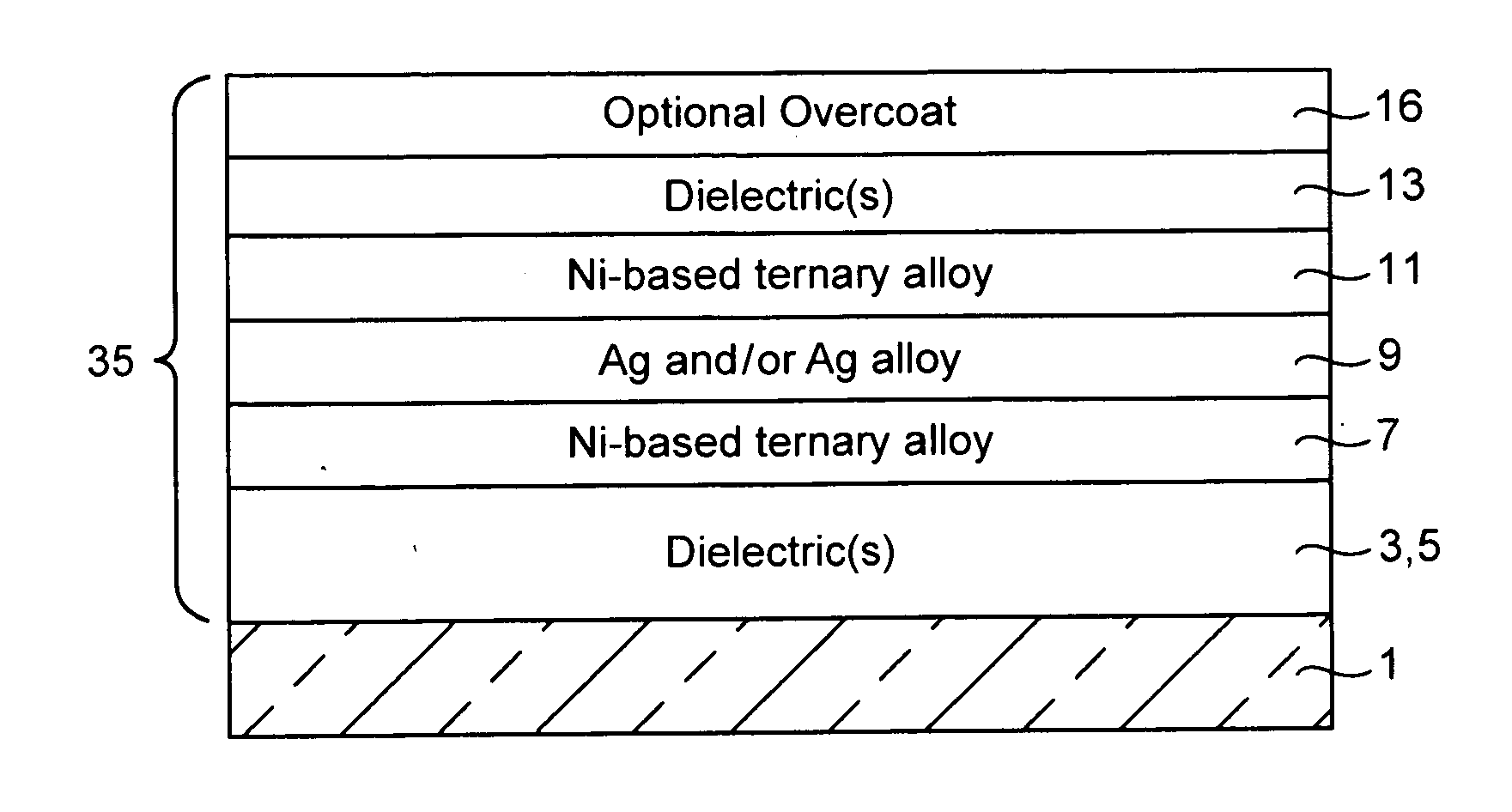

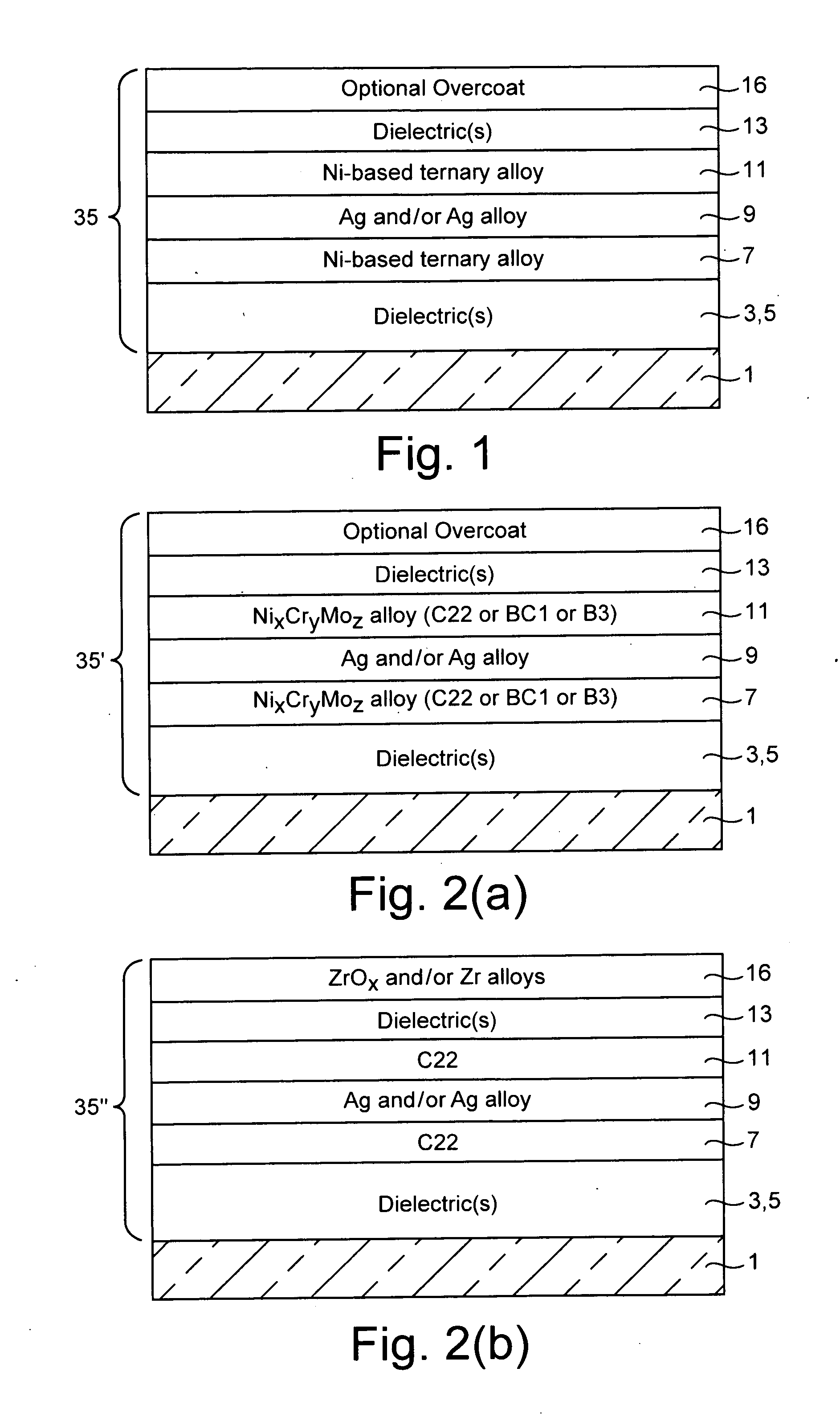

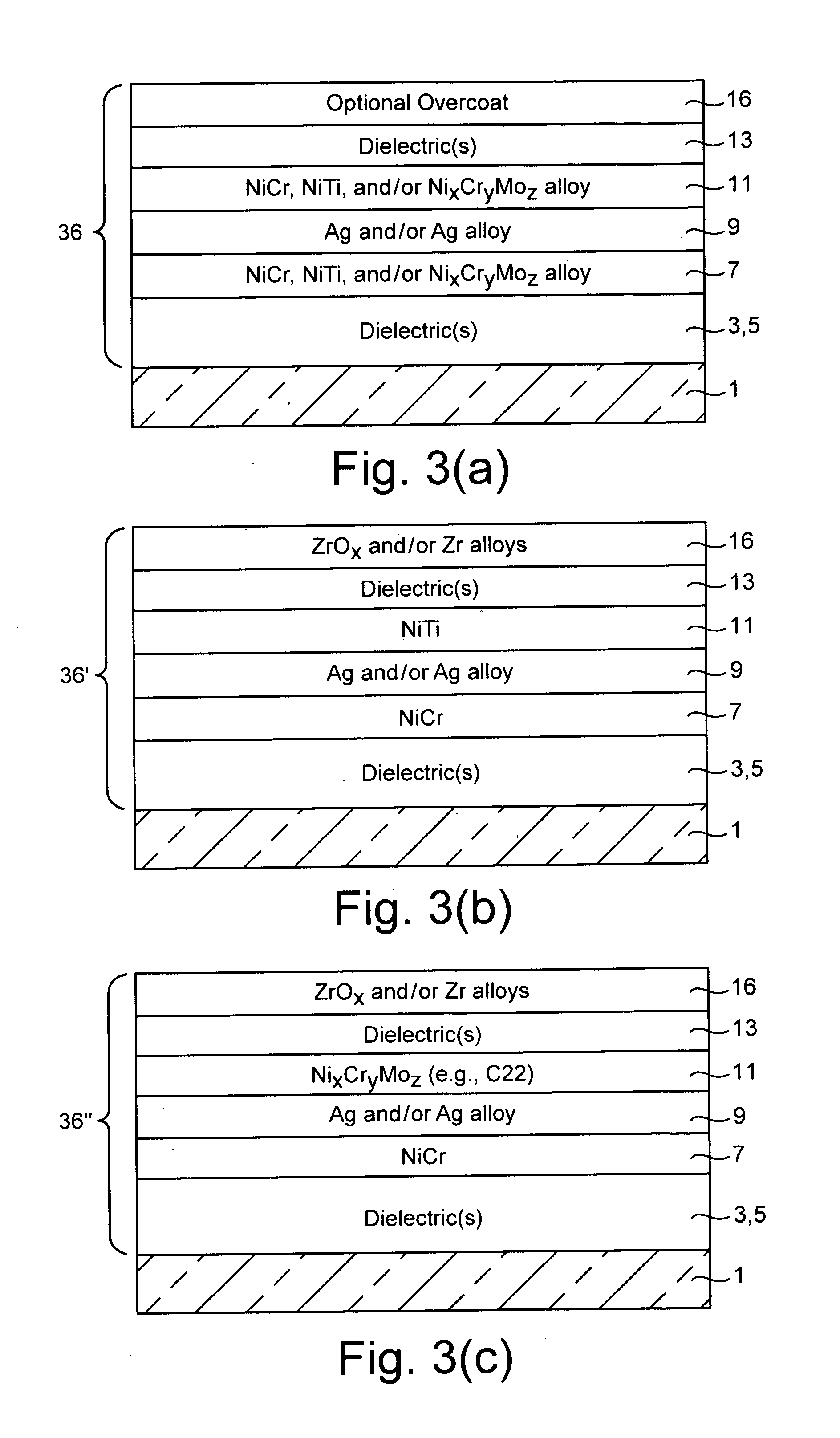

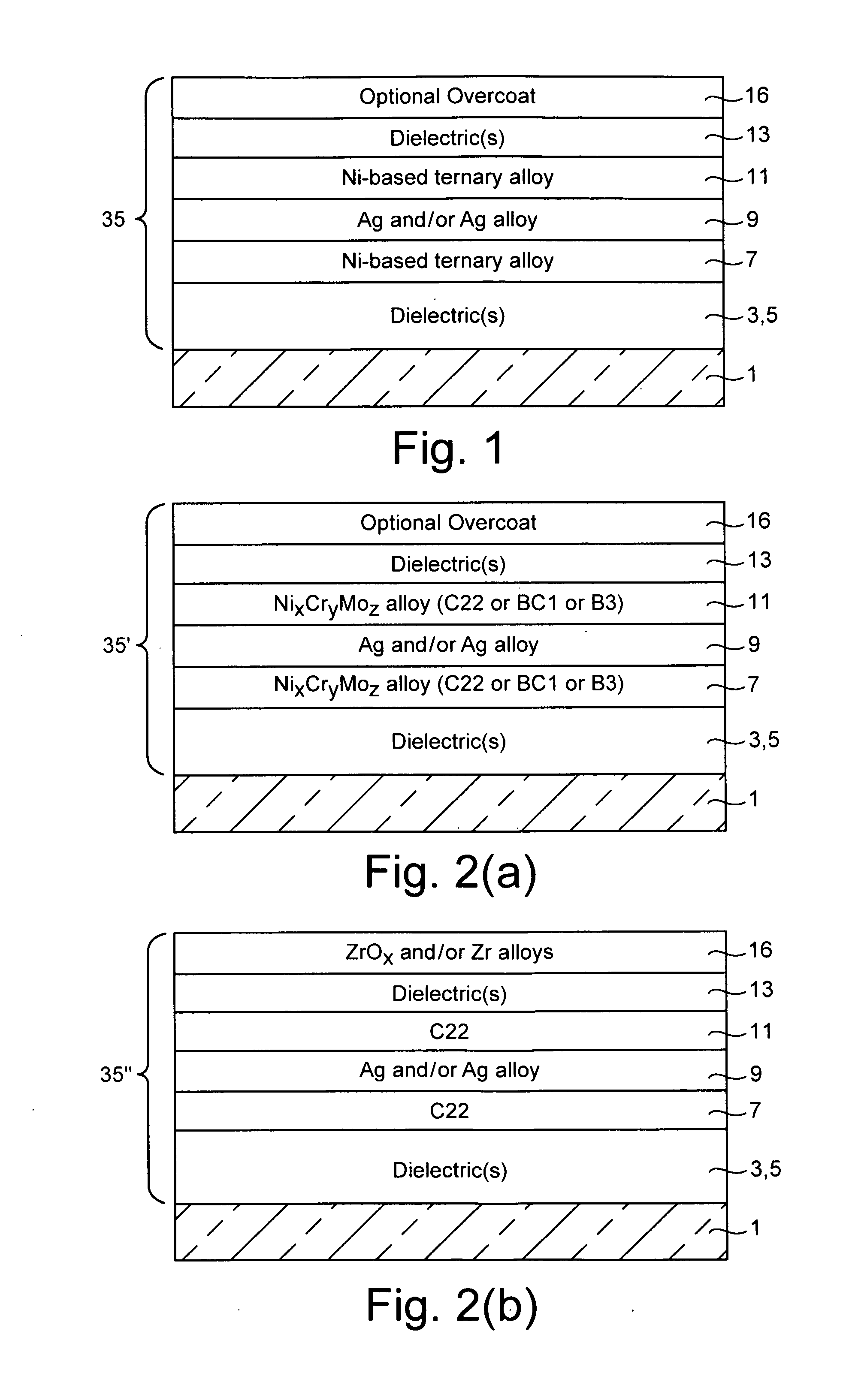

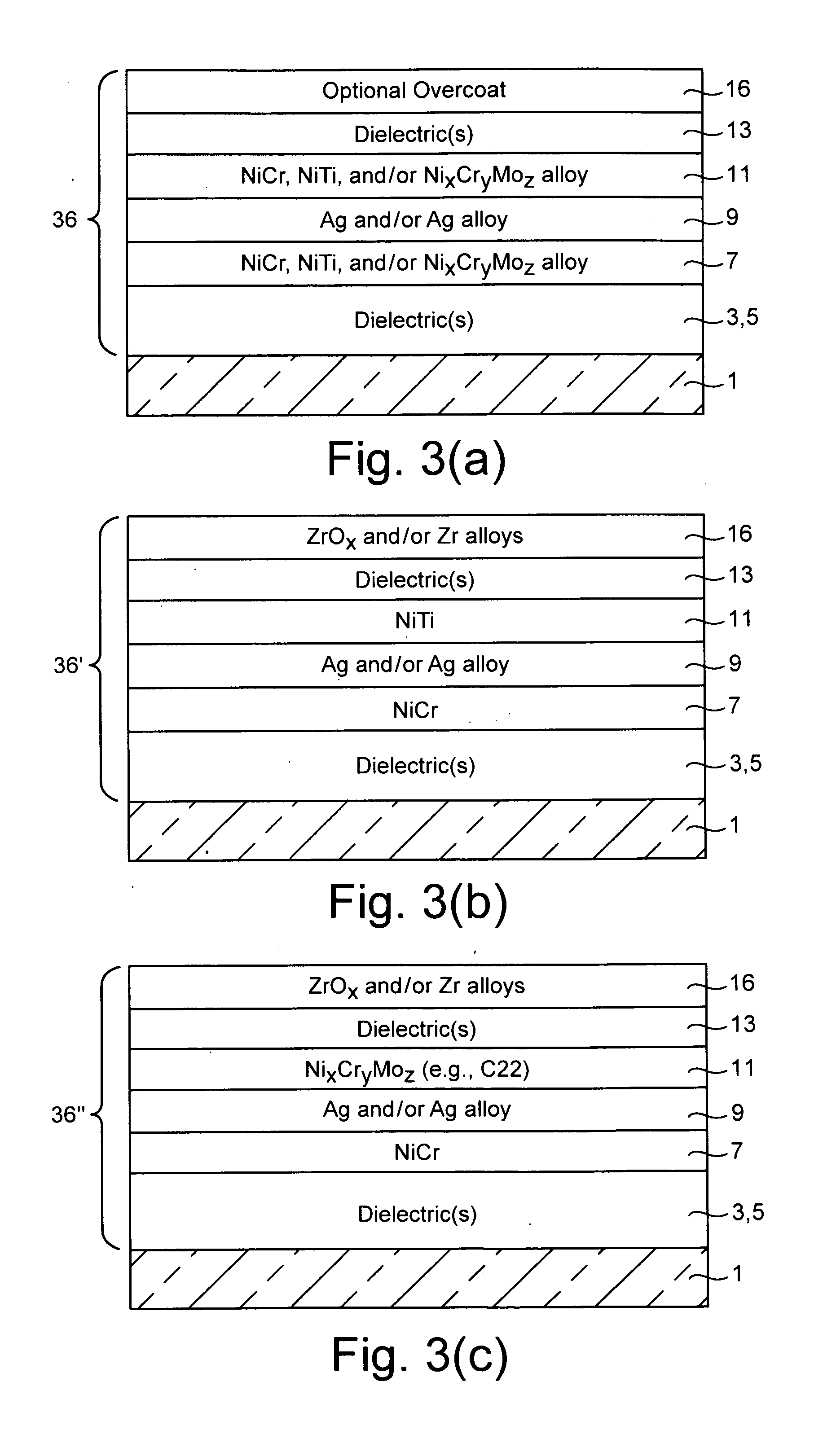

Barrier layers comprising Ni-inclusive ternary alloys, coated articles including barrier layers, and methods of making the same

ActiveUS20120225317A1Reduce sheet resistanceImprove transmittanceVacuum evaporation coatingSputtering coatingMaterials scienceChromium

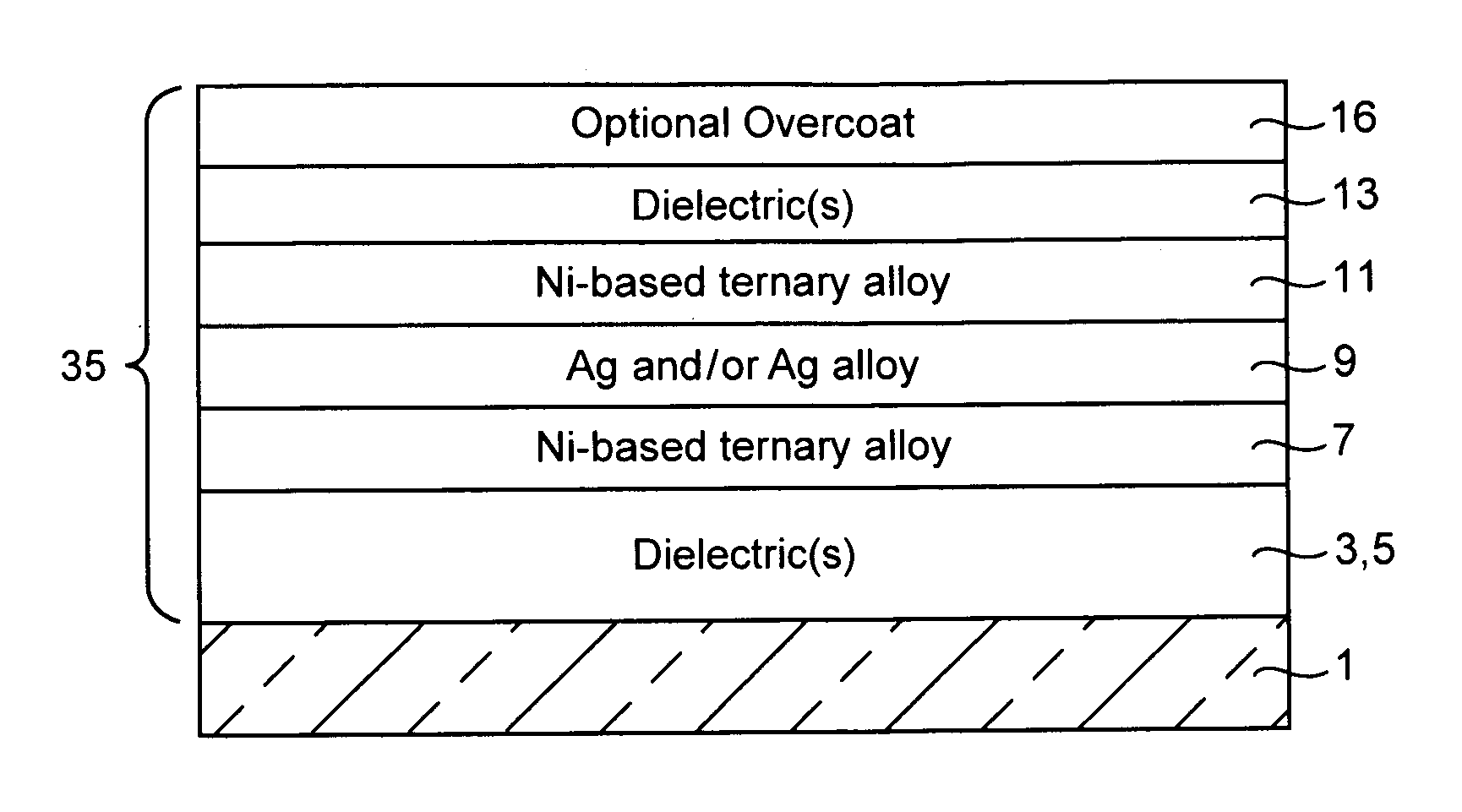

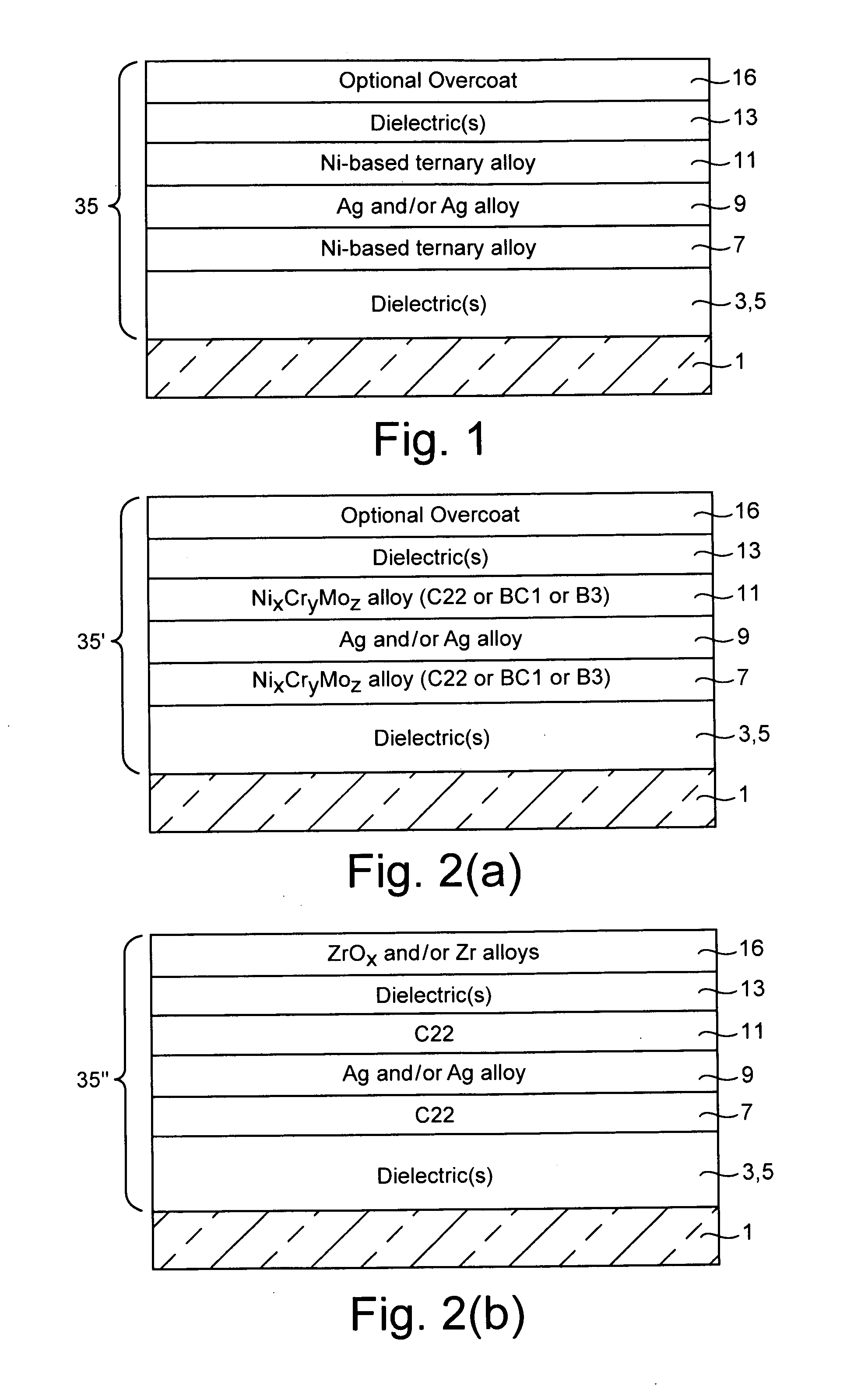

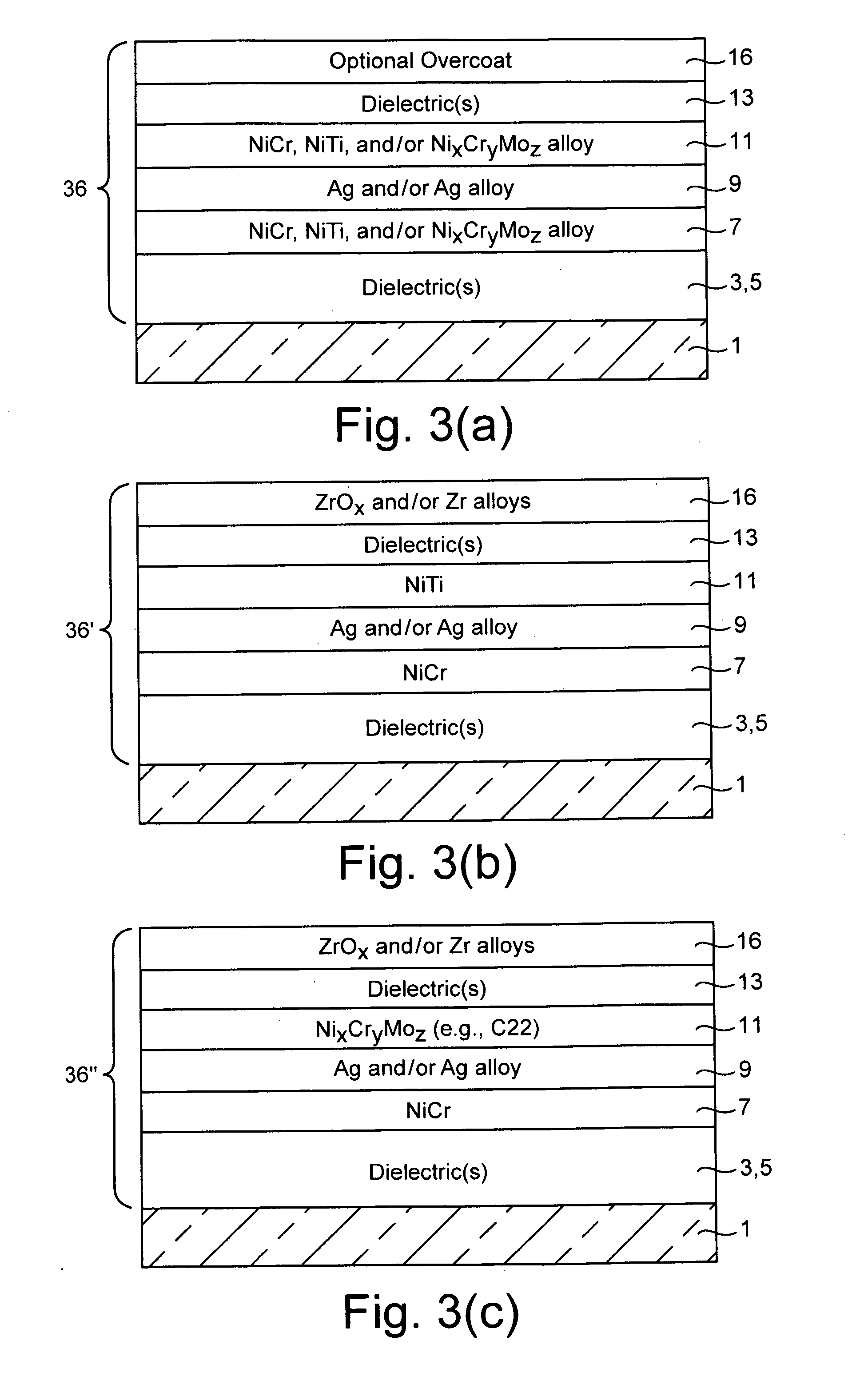

Certain example embodiments relate to Ni-inclusive ternary alloy being provided as a barrier layer for protecting an IR reflecting layer comprising silver or the like. The provision of a barrier layer comprising nickel, chromium, and / or molybdenum and / or oxides thereof may improve corrosion resistance, as well as chemical and mechanical durability. In certain examples, more than one barrier layer may be used on at least one side of the layer comprising silver. In still further examples, a NixCryMoz-based layer may be used as the functional layer, rather than or in addition to as a barrier layer, in a coating.

Owner:GUARDIAN GLASS LLC

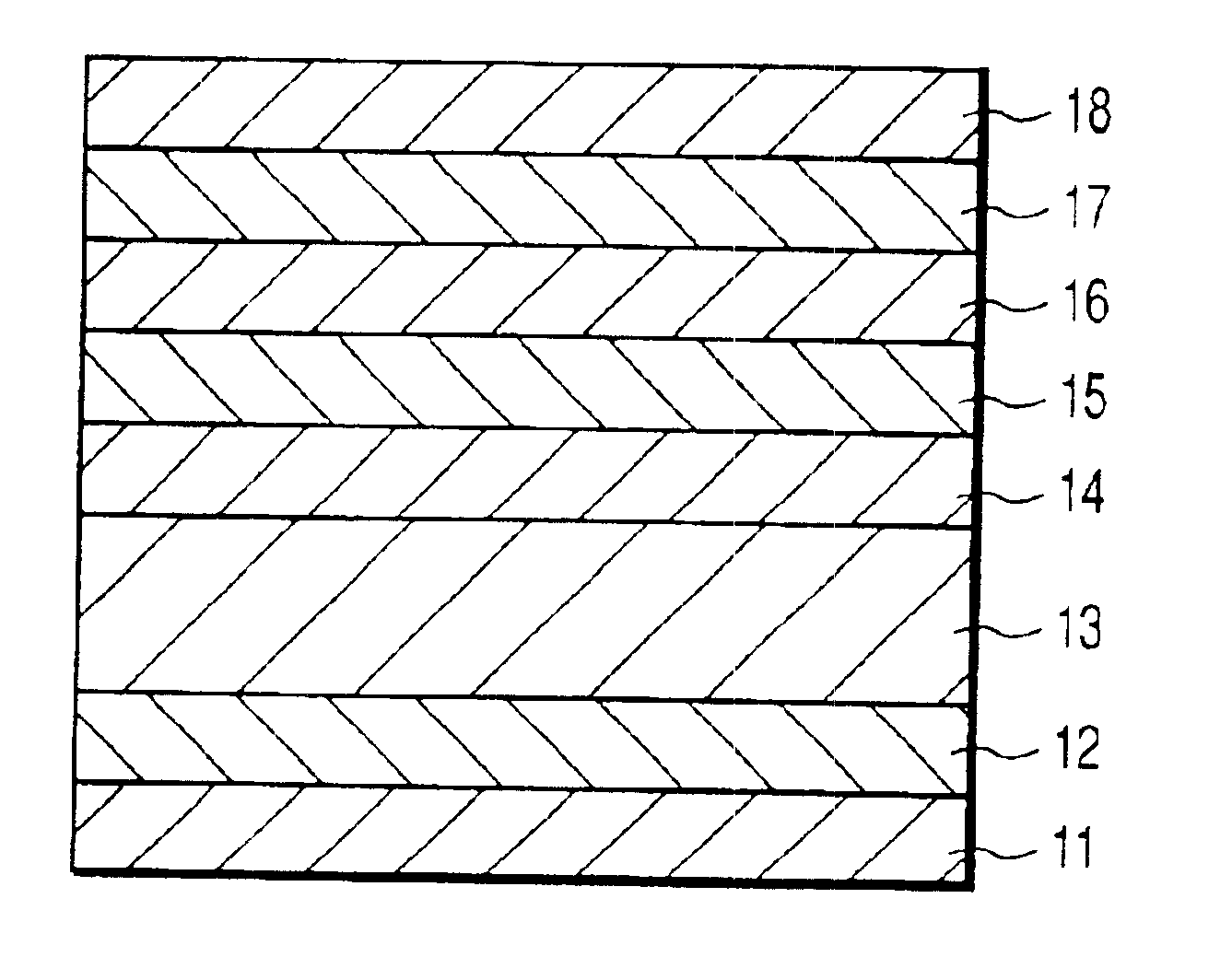

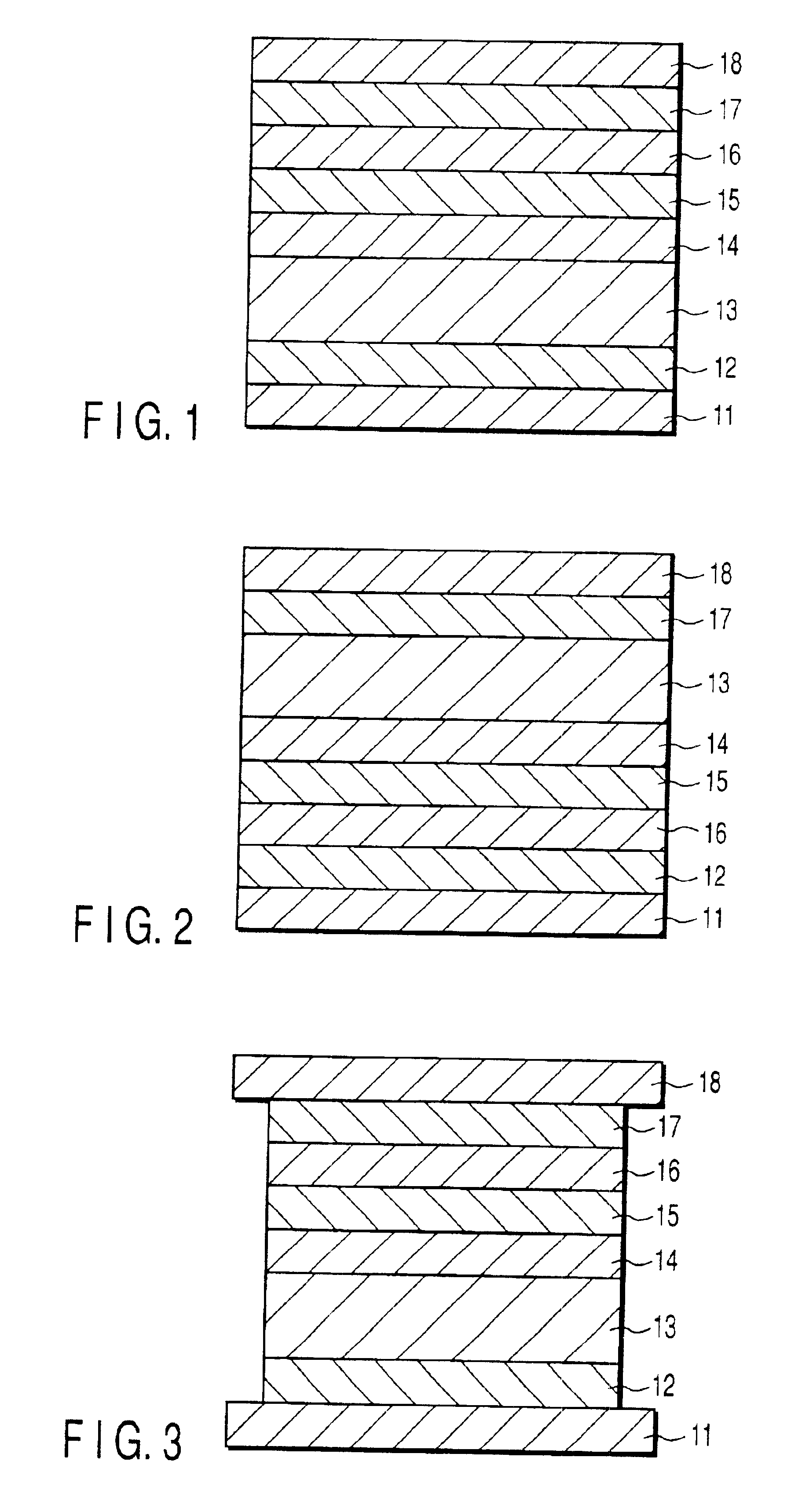

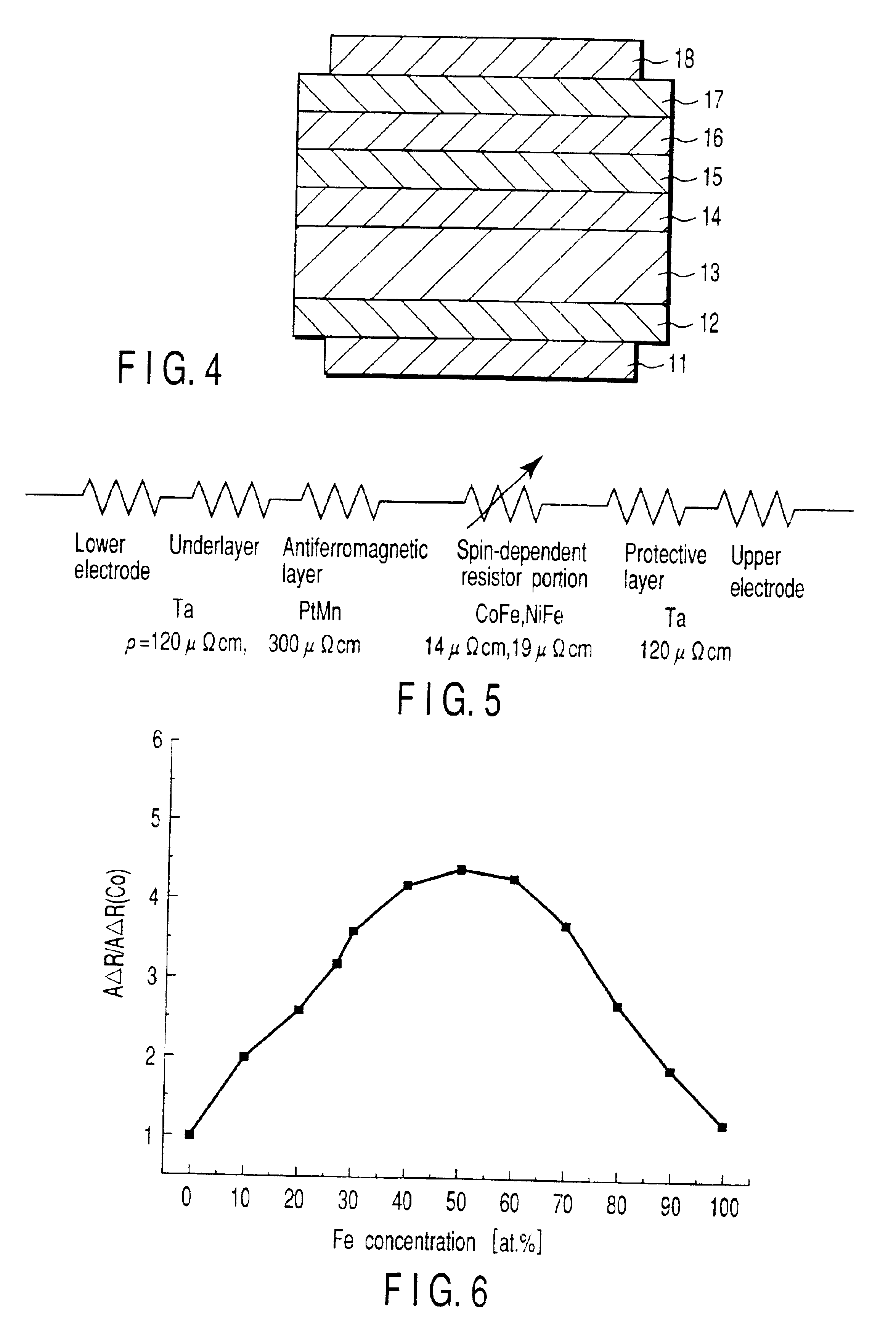

Current-perpendicular-to-plane-type magnetoresistive device, and magnetic head and magnetic recording-reproducing apparatus using the same

A magnetoresistive device includes a magnetization pinned layer, a magnetization free layer, a nonmagnetic intermediate layer formed between the magnetization pinned layer and the magnetization free layer, and electrodes allowing a sense current to flow in a direction substantially perpendicular to the plane of the stack including the magnetization pinned layer, the nonmagnetic intermediate layer and the magnetization free layer. At least one of the magnetization pinned layer and the magnetization free layer is substantially formed of a binary or ternary alloy represented by the formula FeaCobNic (where a+b+c=100 at %, and a≦75 at %, b≦75 at %, and c≦63 at %), or formed of an alloy having a body-centered cubic crystal structure.

Owner:KK TOSHIBA

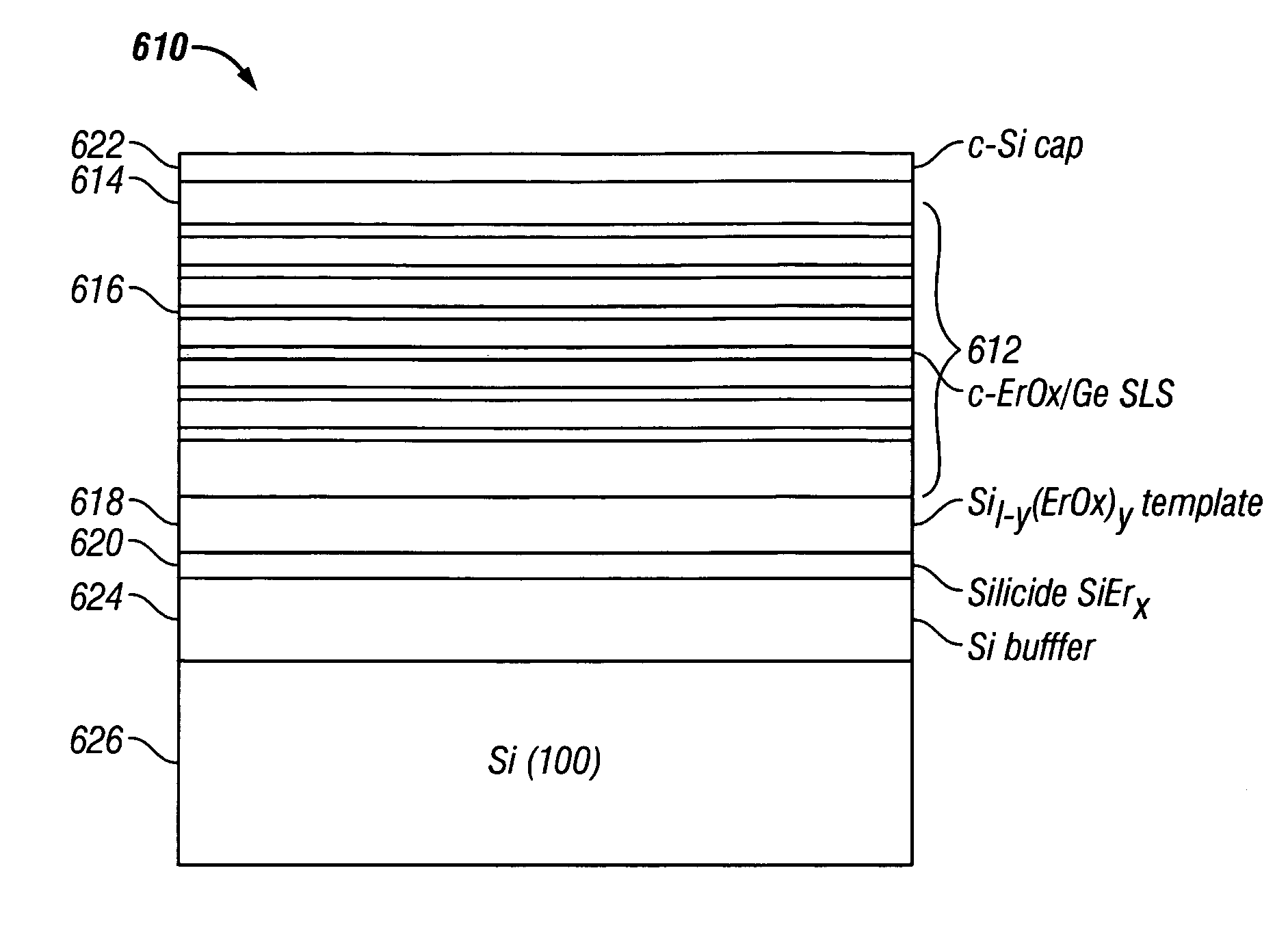

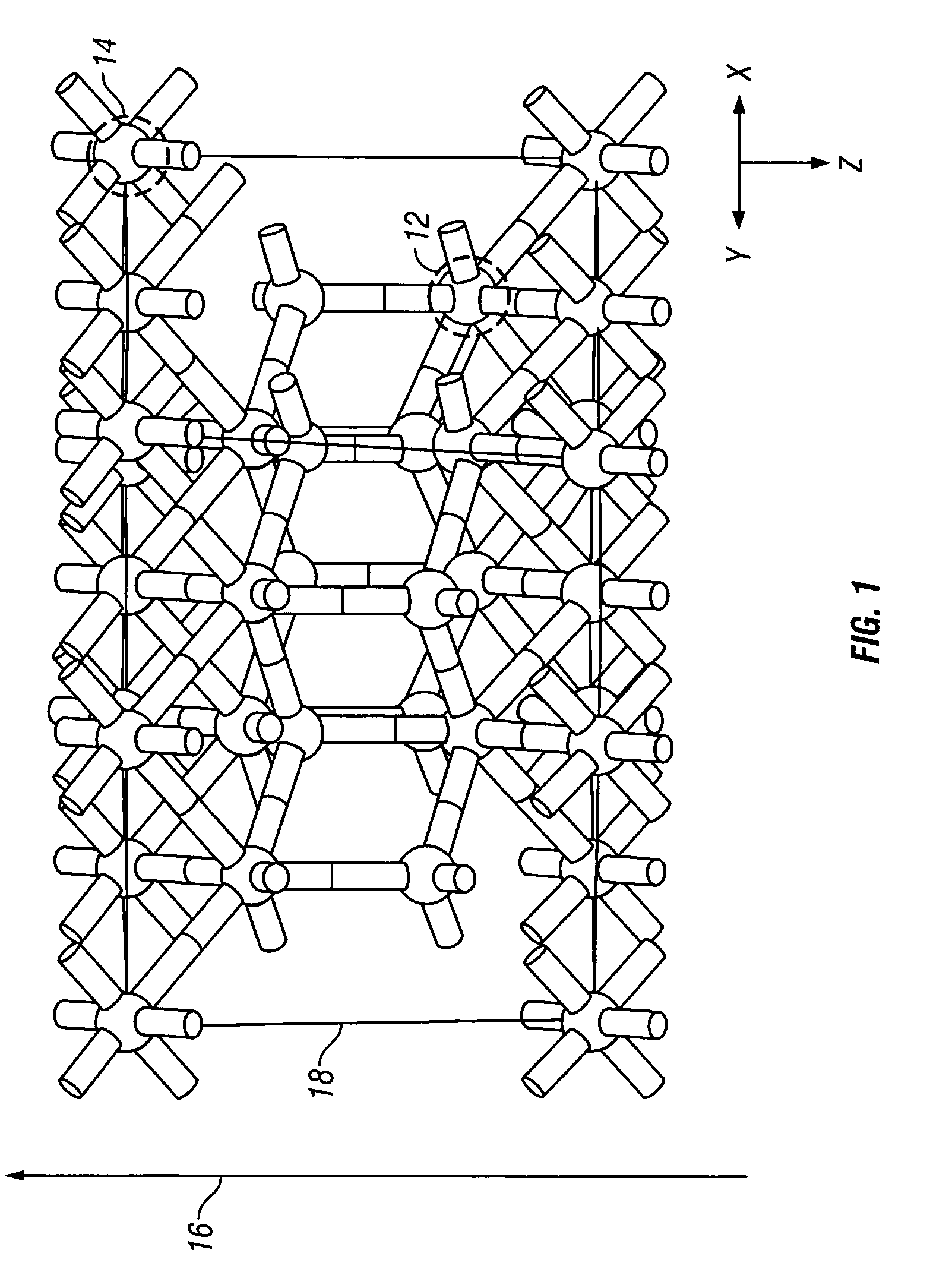

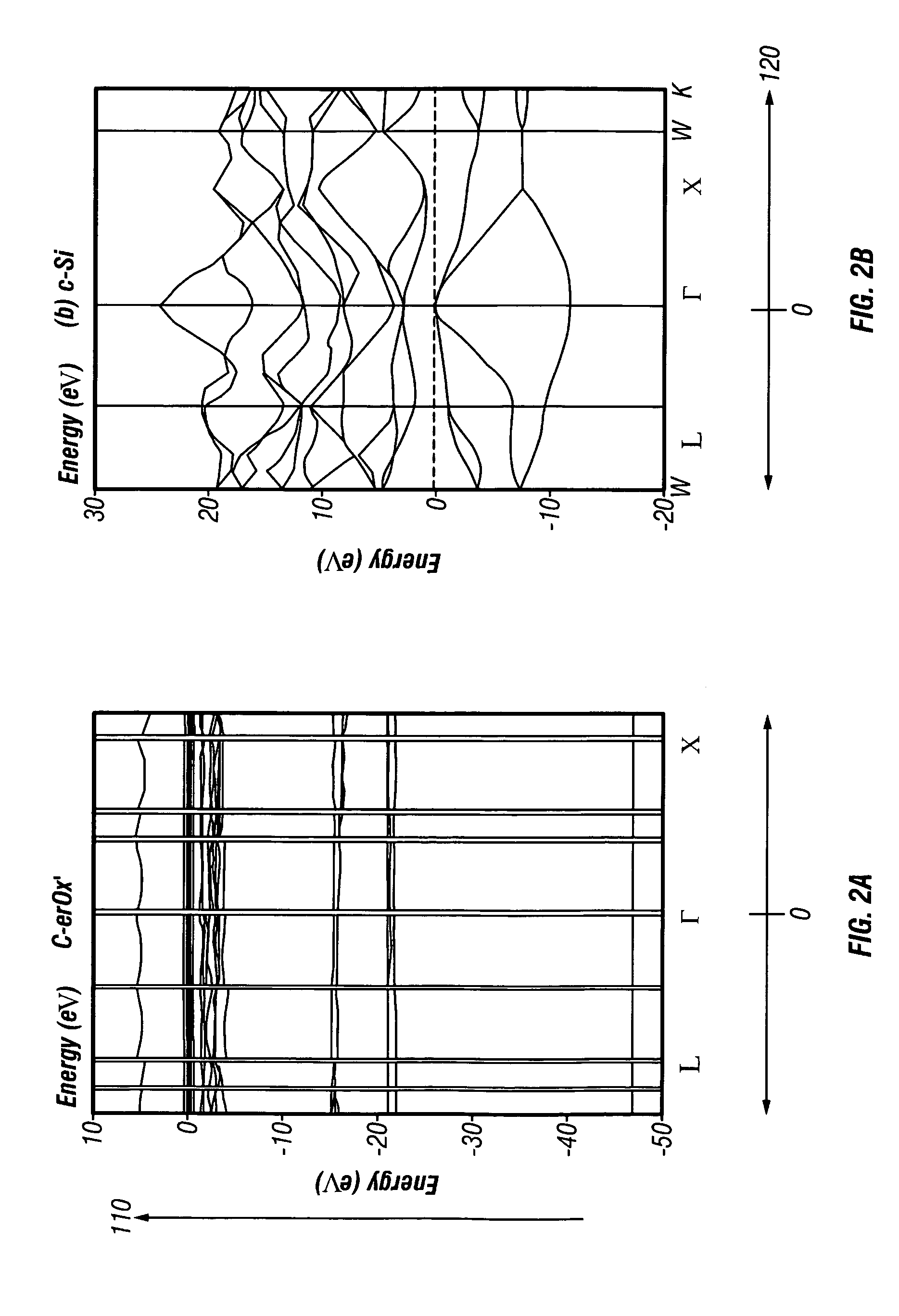

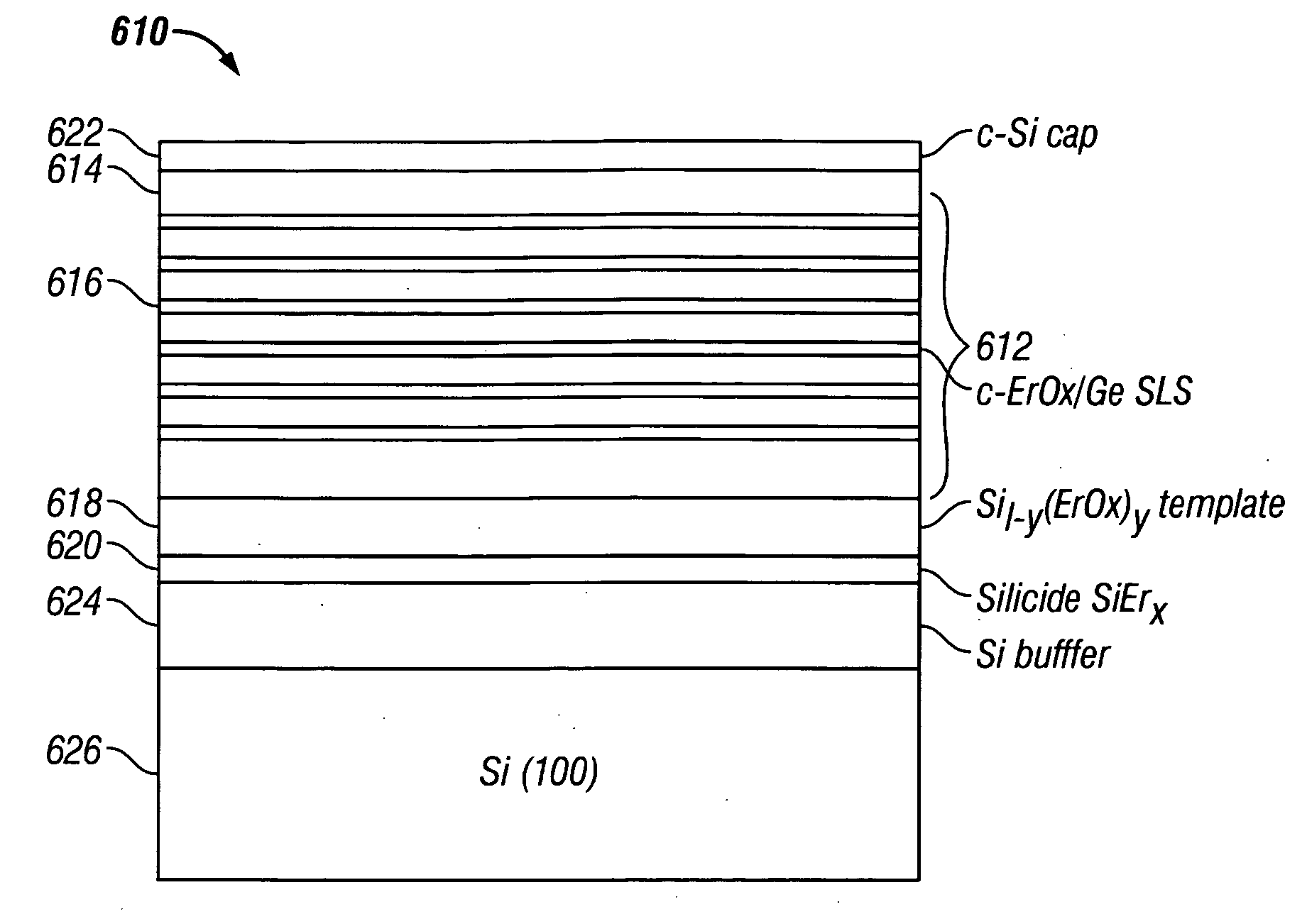

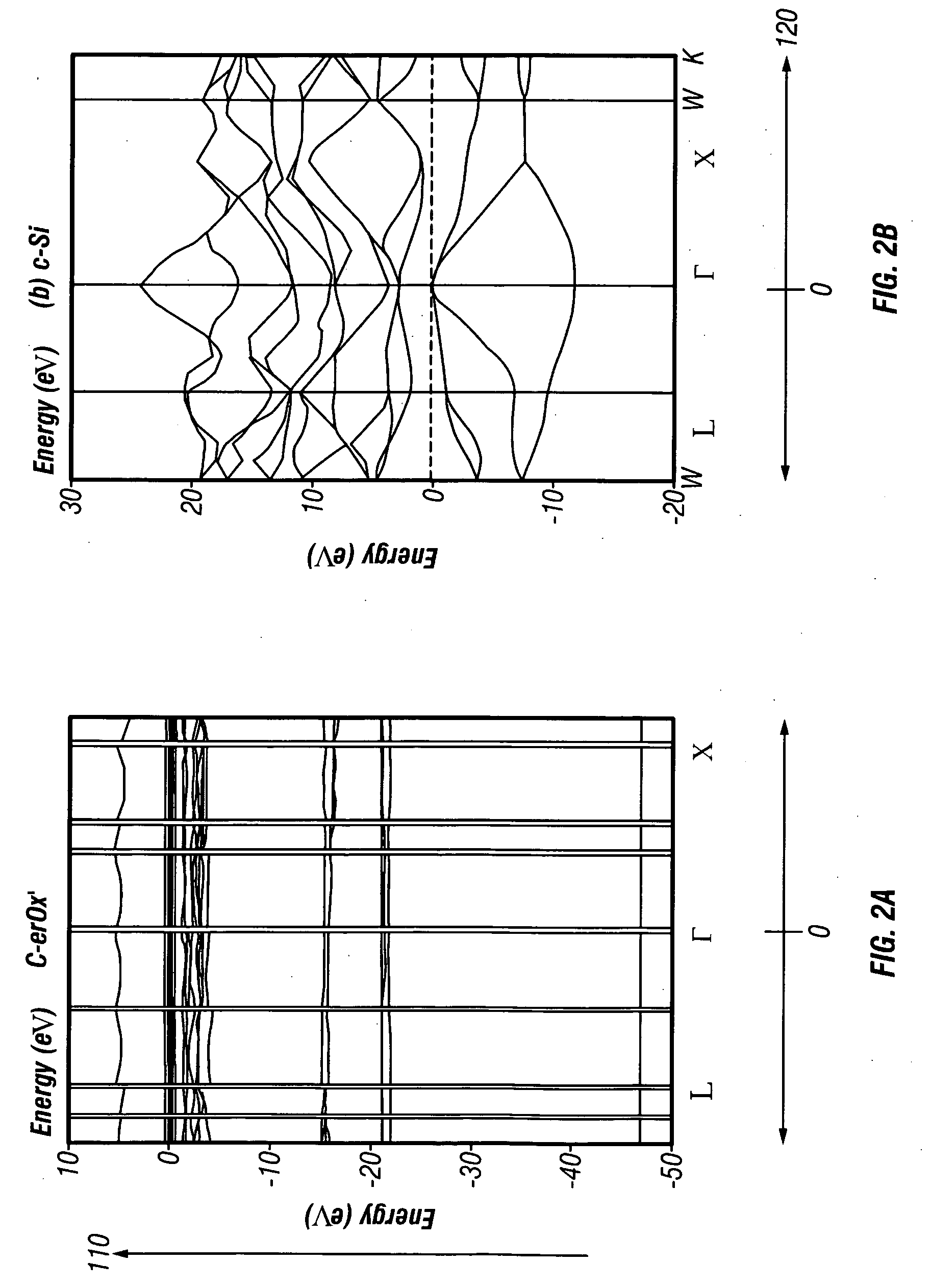

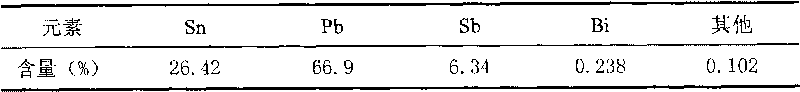

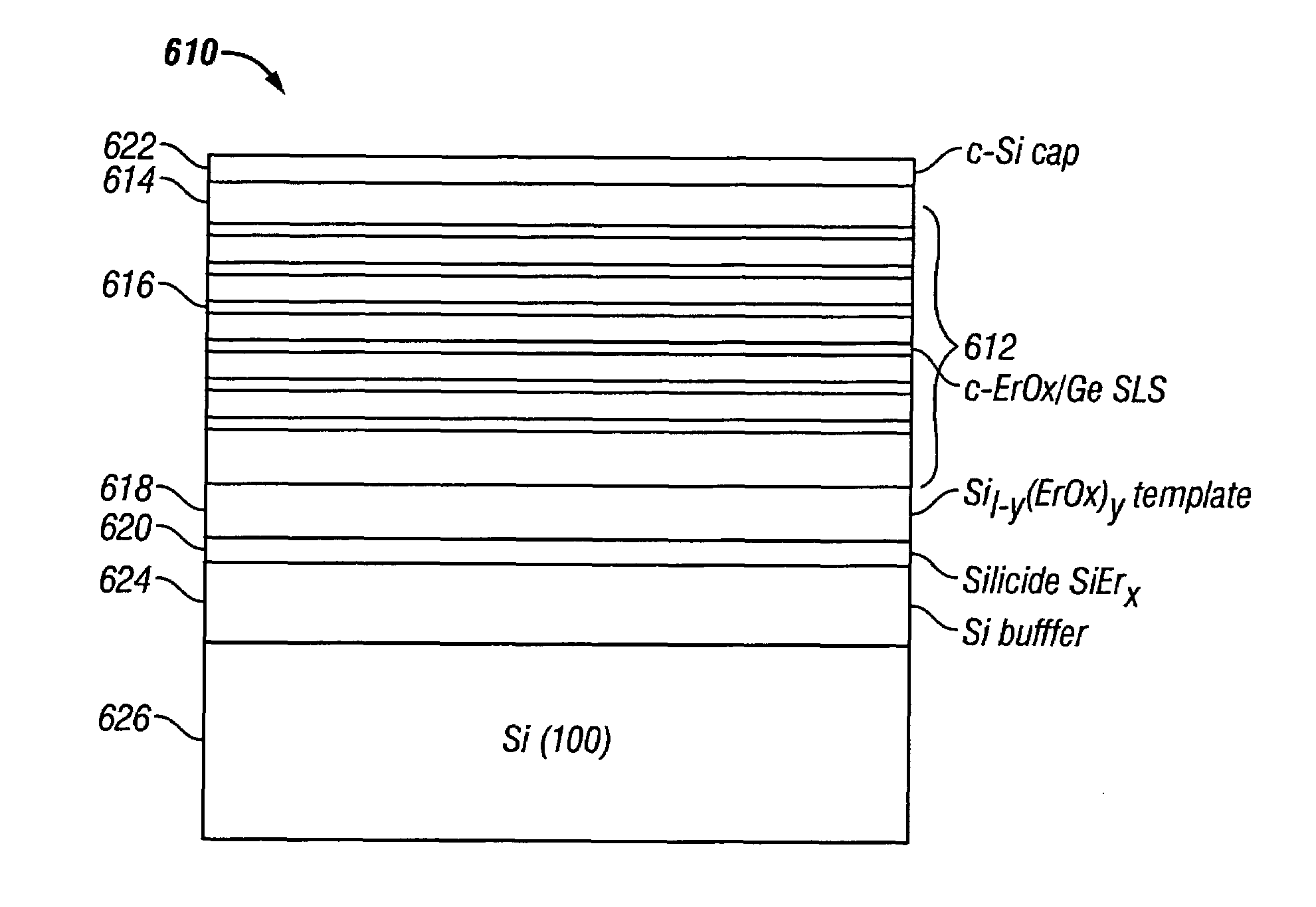

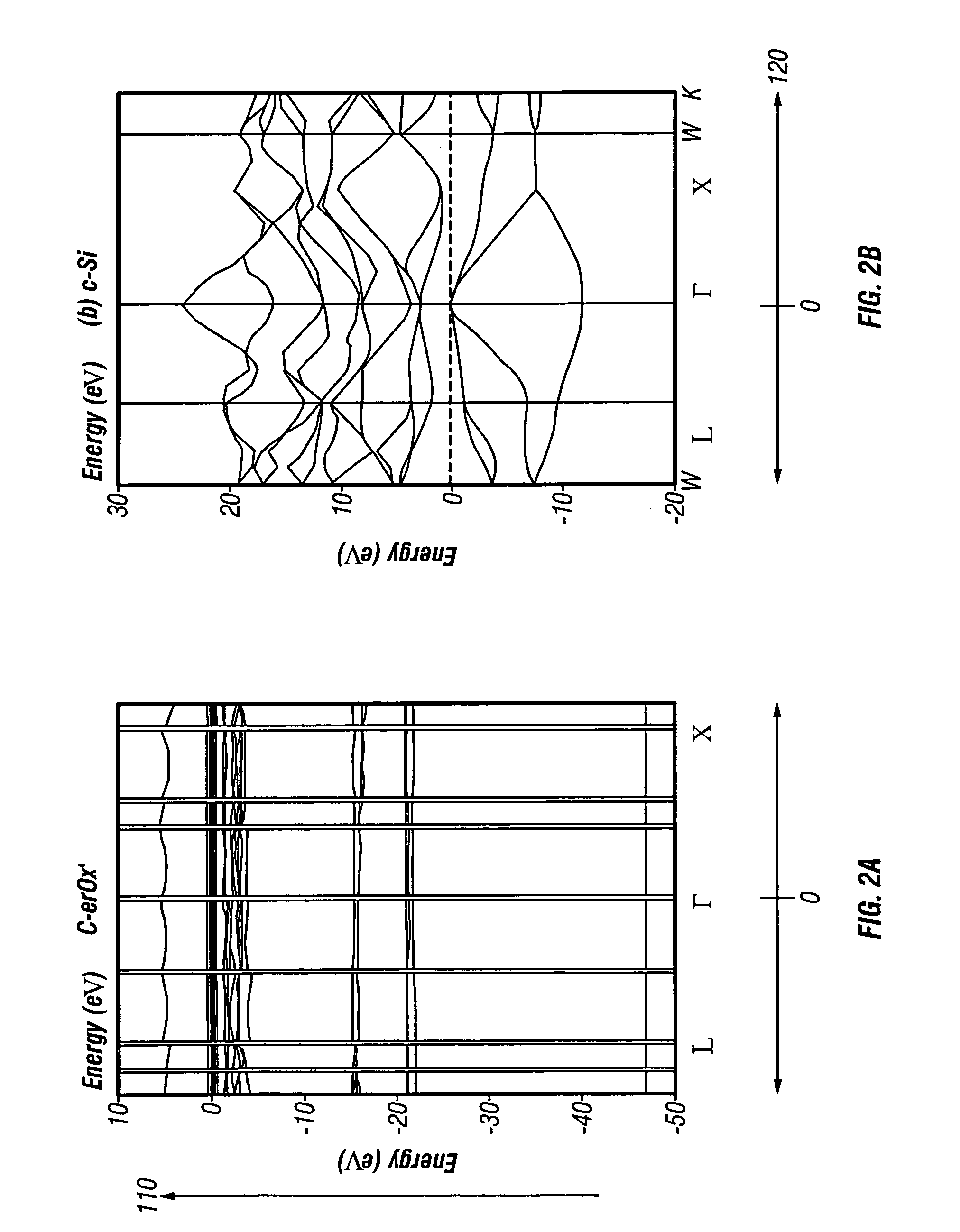

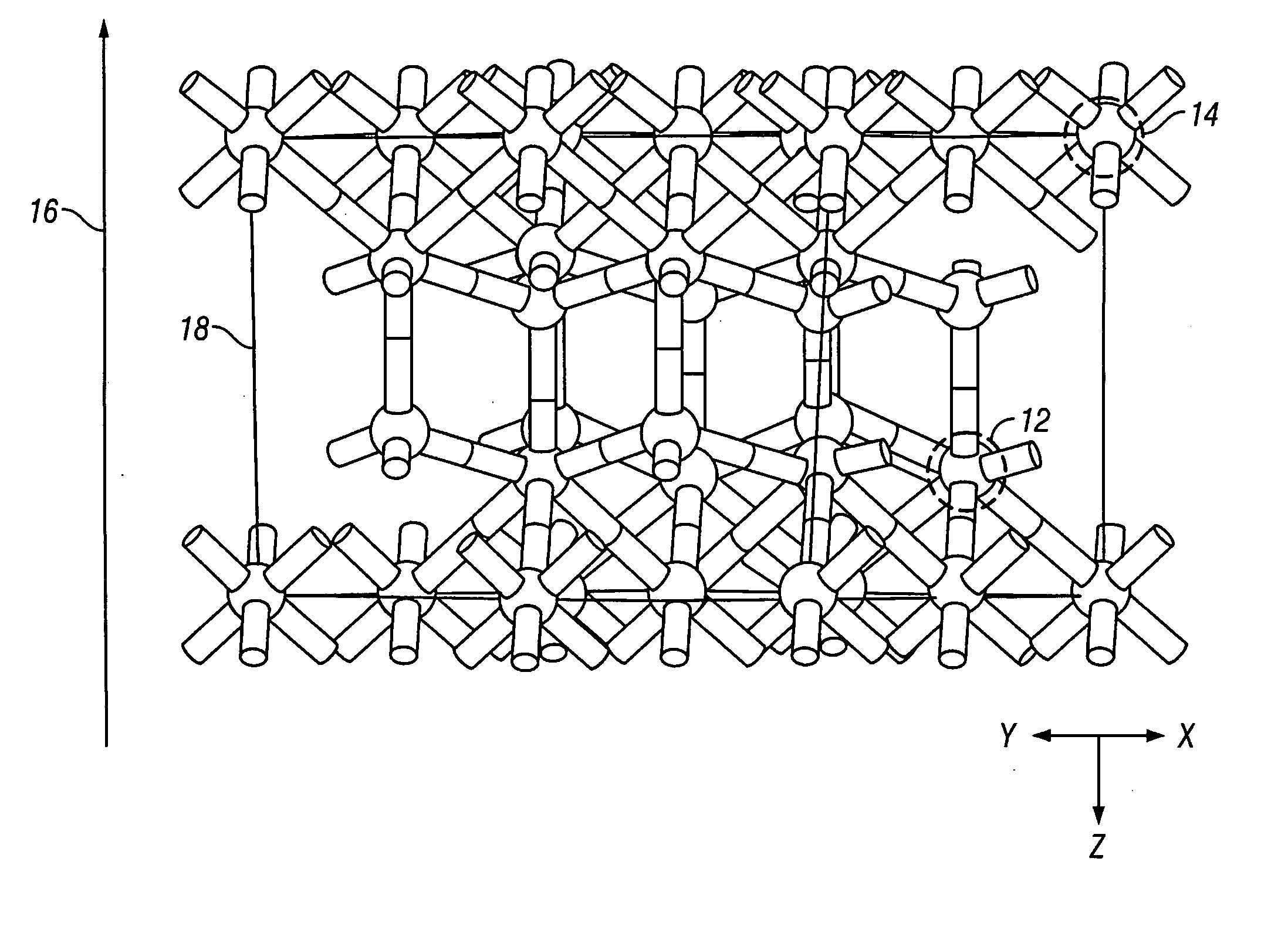

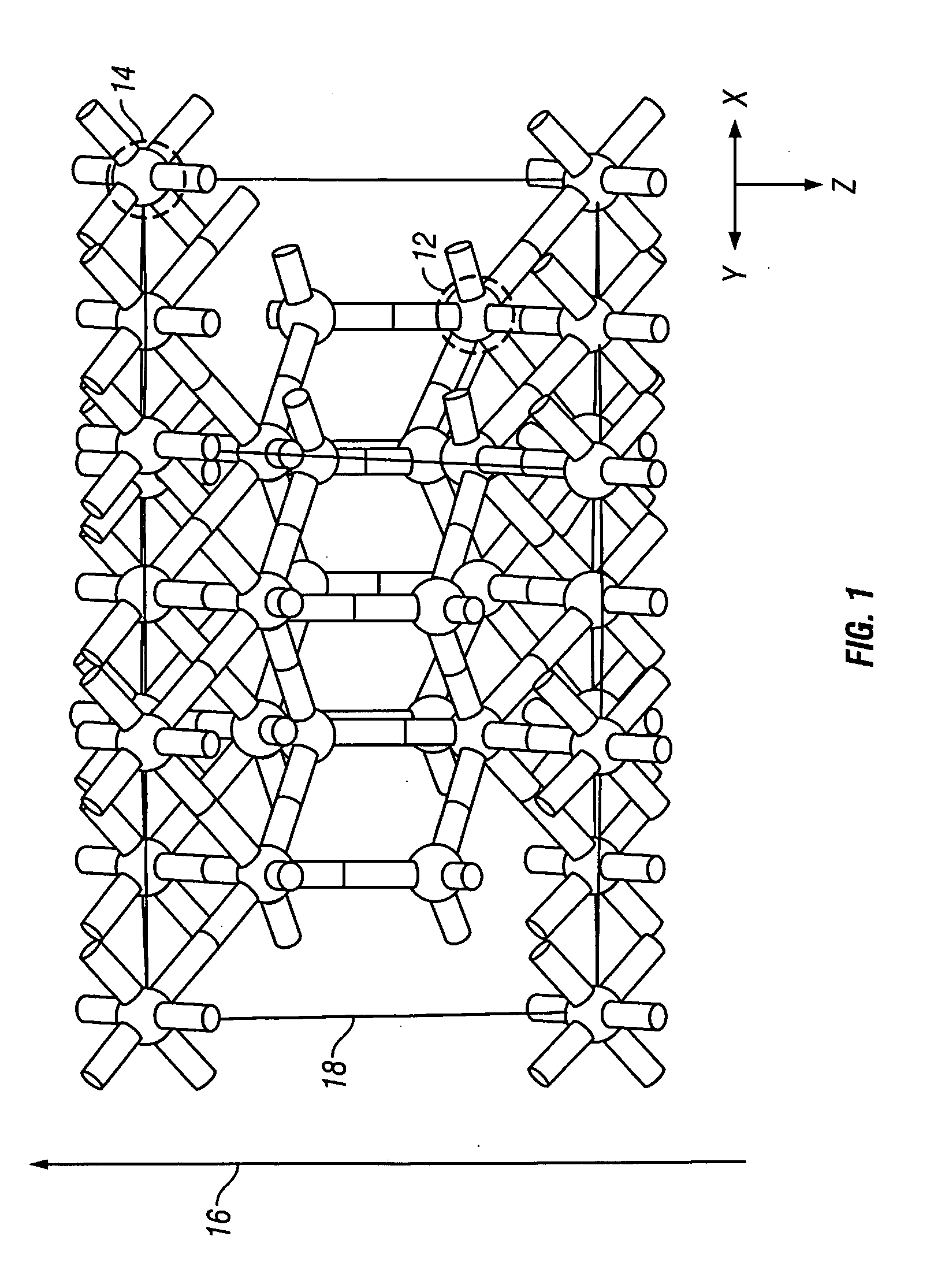

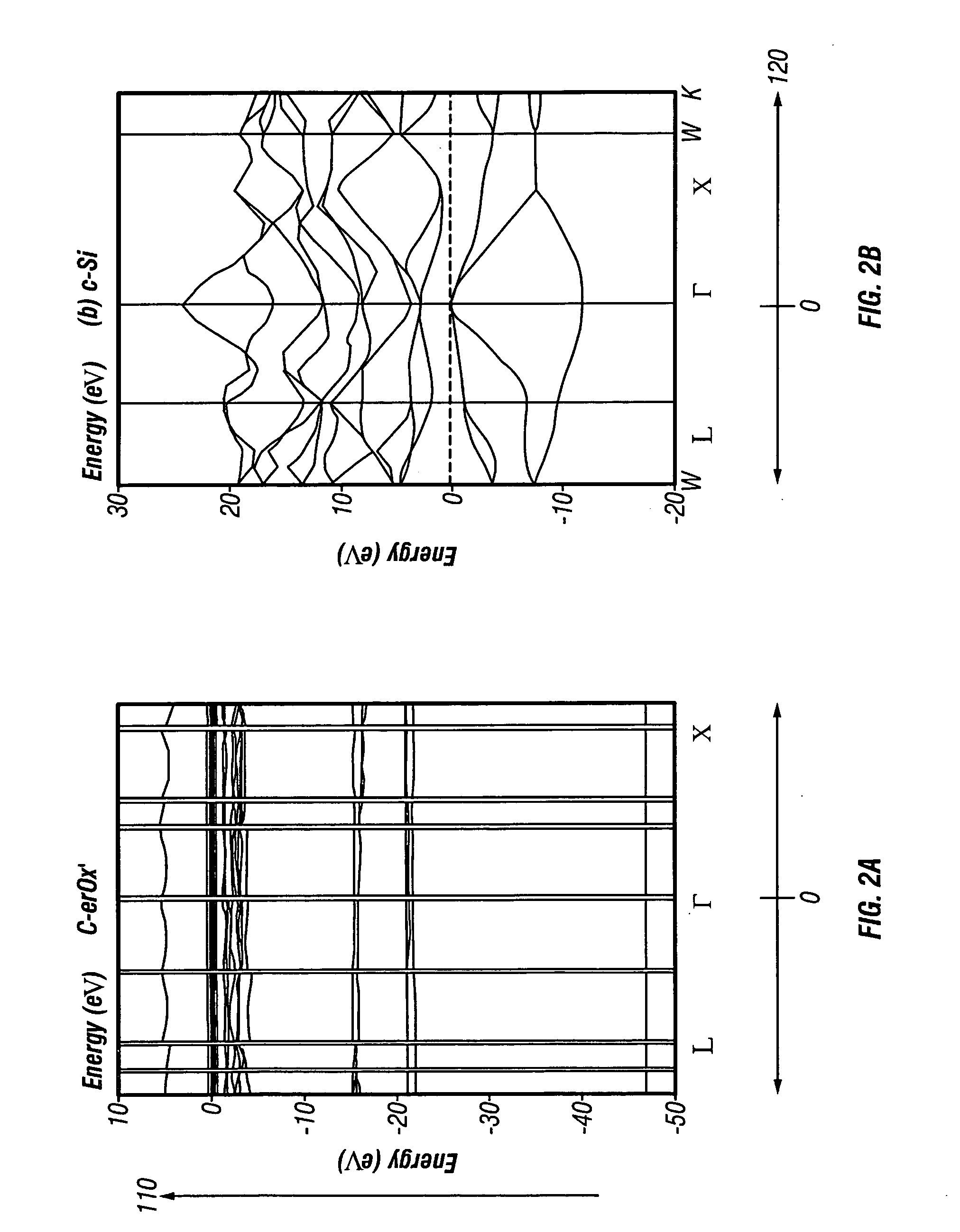

Rare earth-oxides, rare earth-nitrides, rare earth-phosphides and ternary alloys with silicon

Atomic layer epitaxy (ALE) is applied to the fabrication of new forms of rare-earth oxides, rare-earth nitrides and rare-earth phosphides. Further, ternary compounds composed of binary (rare-earth oxides, rare-earth nitrides and rare-earth phosphides) mixed with silicon and or germanium to form compound semiconductors of the formula RE-(O, N, P)-(Si,Ge) are also disclosed, where RE=at least one selection from group of rare-earth metals, O=oxygen, N=nitrogen, P=phosphorus, Si=silicon and Ge=germanium. The presented ALE growth technique and material system can be applied to silicon electronics, opto-electronic, magneto-electronics and magneto-optics devices.

Owner:IQE

Metal alloy fine particles and method for producing thereof

A novel method for preparing fine particles comprising a transition metal and a noble metal which are monodispersed and have almost no particle diameter distribution, and are transferable to a CuAu-I type L10 ordered phase, with safety and at a low cost, wherein a salt or a complex of at least one transition metal selected from Fe and Co and a salt or a complex of at least one transition metal selected from Pt and Pd (exclusive of the combination of Co—Pd) is dissolved in an organic solvent miscible with water or an alcohol in the presence of an organic protecting agent, and the resultant solution is heated under reflux in the presence of an alcohol in an inert atmosphere, to thereby prepare a binary alloy comprising a transition metal and a noble metal, or a salt or a complex of at least one element selected from the group consisting of Cu, Bi, Sb, Sn, Pb and Ag is further dissolved in the above solvent and the resultant solution is heated under reflux in the presence of an alcohol in an inert atmosphere, to thereby prepare a ternary alloy comprising a transition metal, a noble metal and an additional element.

Owner:HITACHT MAXELL LTD

Functional layers comprising Ni-inclusive ternary alloys and methods of making the same

InactiveUS20120225316A1Improve corrosion resistanceIncreased durabilityLamination ancillary operationsSynthetic resin layered productsMetallic NickelCorrosion

Certain example embodiments relate to Ni-inclusive ternary alloy being provided as a barrier layer for protecting an IR reflecting layer comprising silver or the like. The provision of a barrier layer comprising nickel, chromium, and / or molybdenum and / or oxides thereof may improve corrosion resistance, as well as chemical and mechanical durability. In certain examples, more than one barrier layer may be used on at least one side of the layer comprising silver. In still further examples, a NixCryMoz-based layer may be used as the functional layer, rather than or in addition to as a barrier layer, in a coating.

Owner:GUARDIAN GLASS LLC

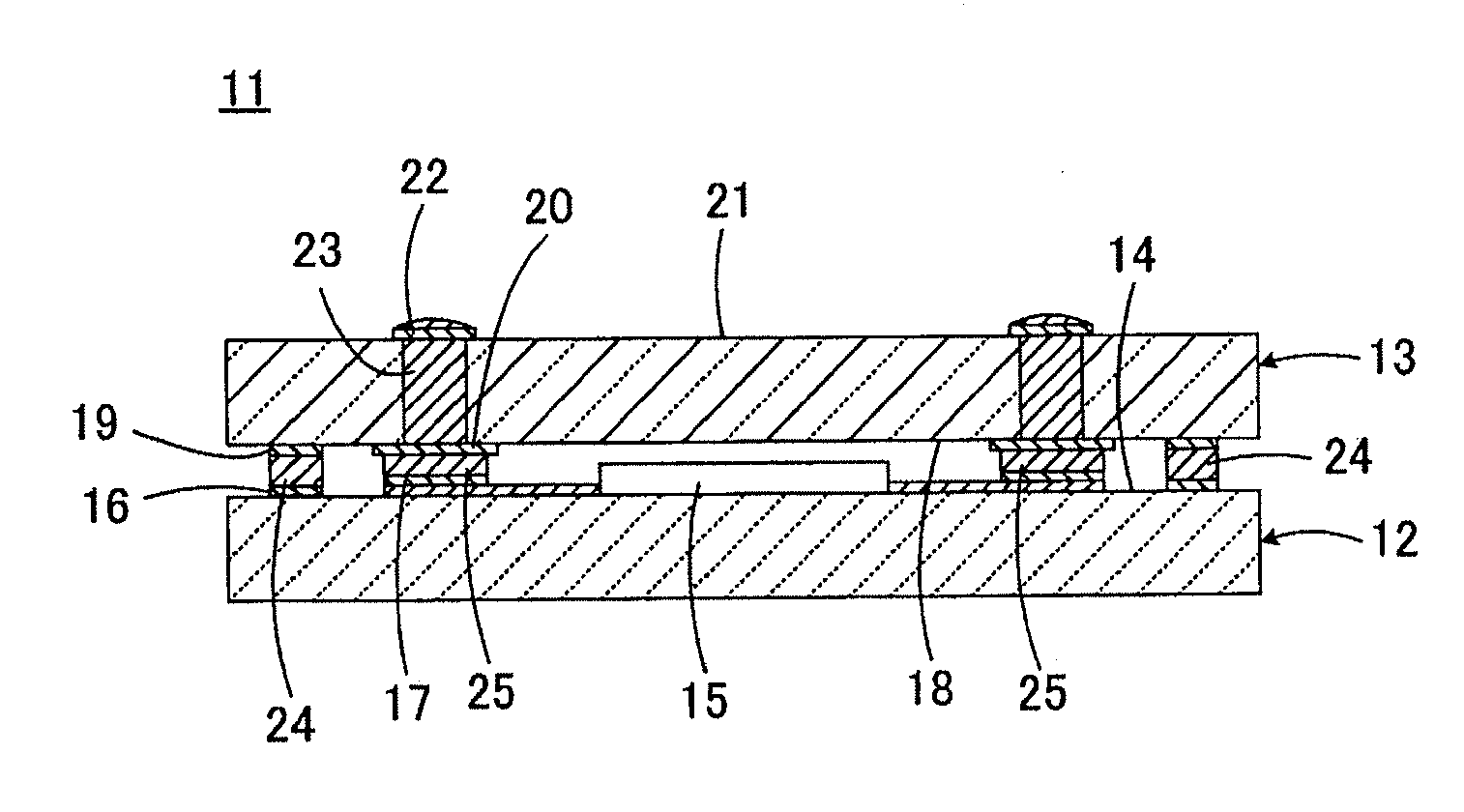

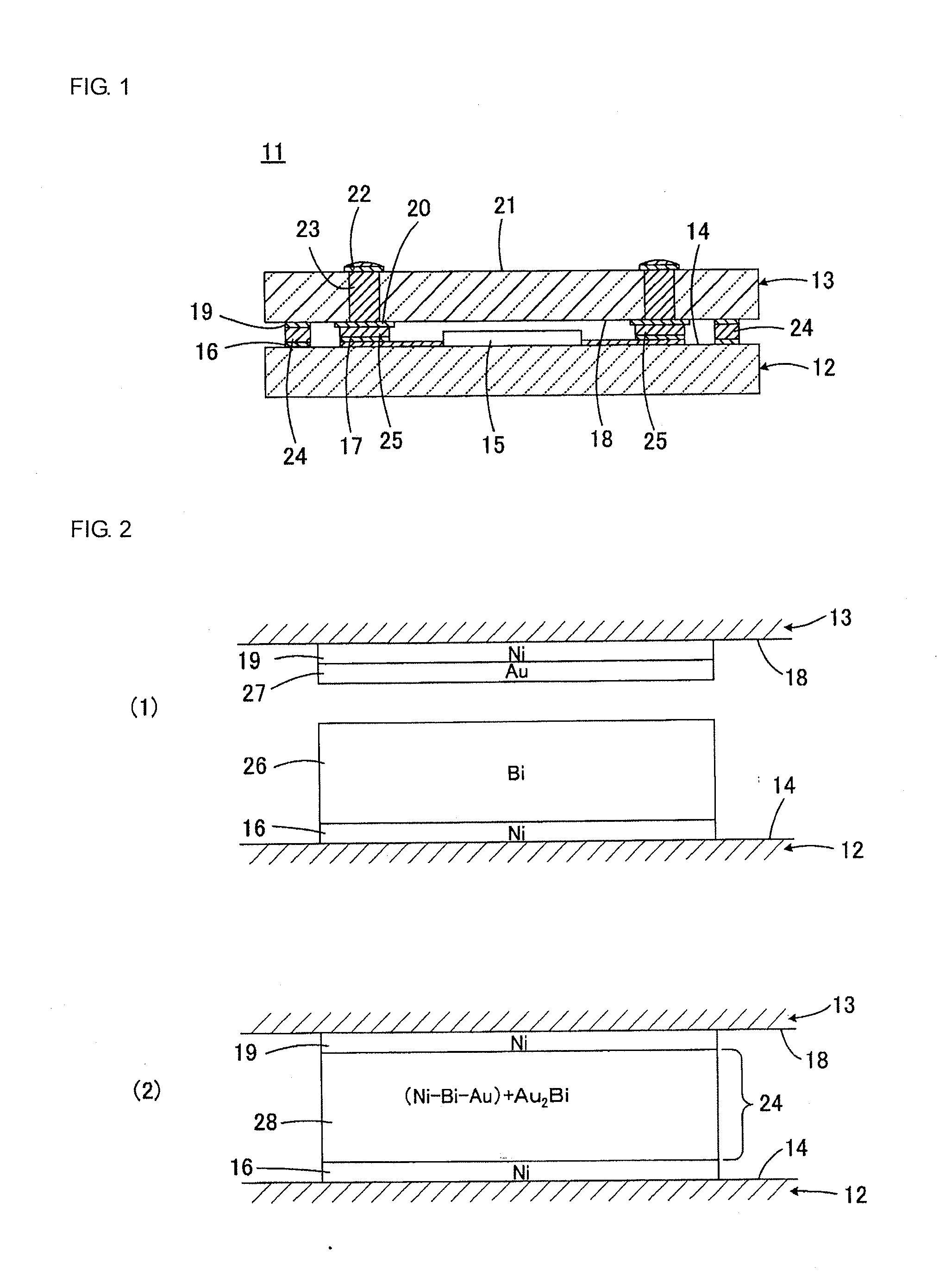

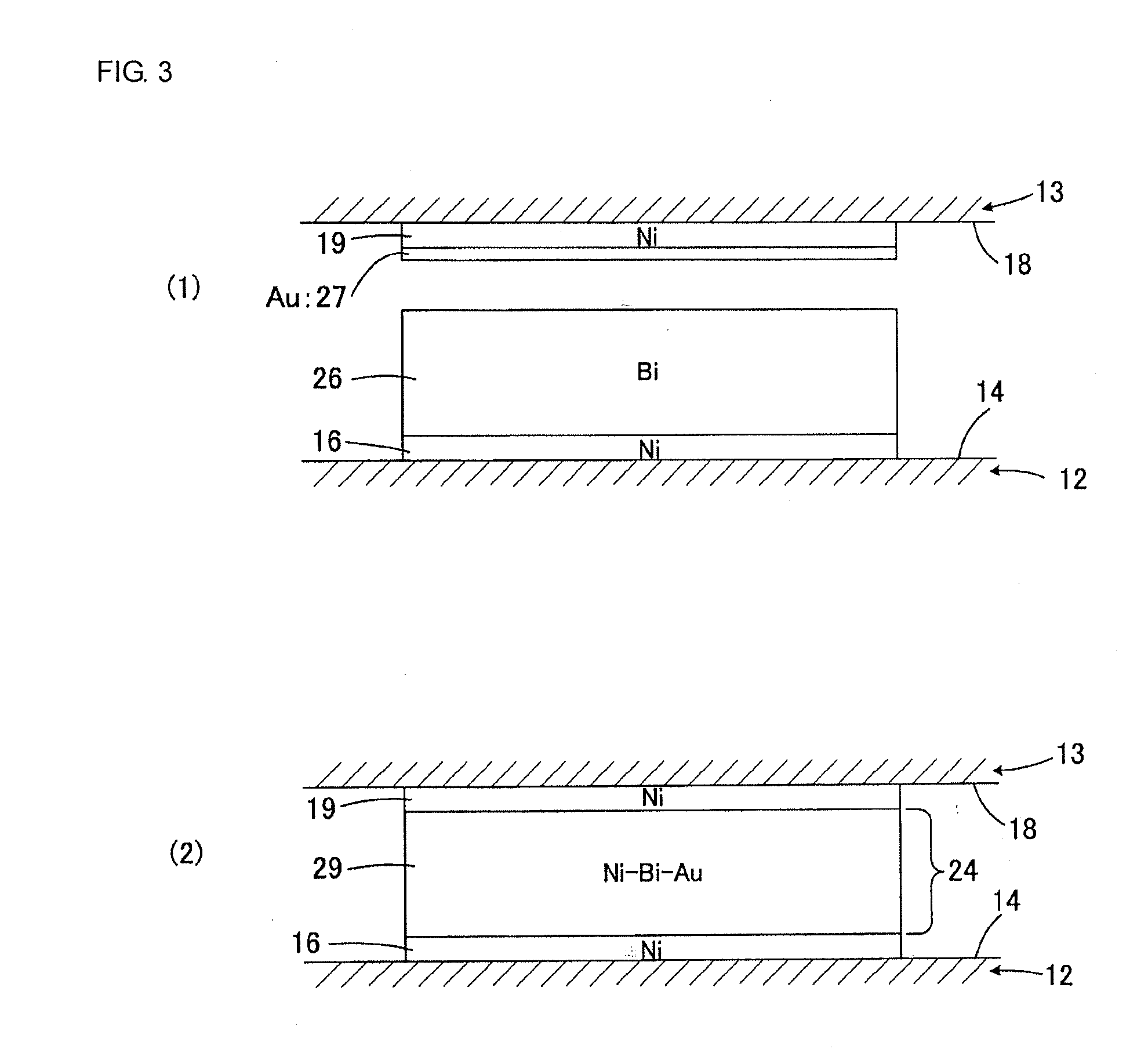

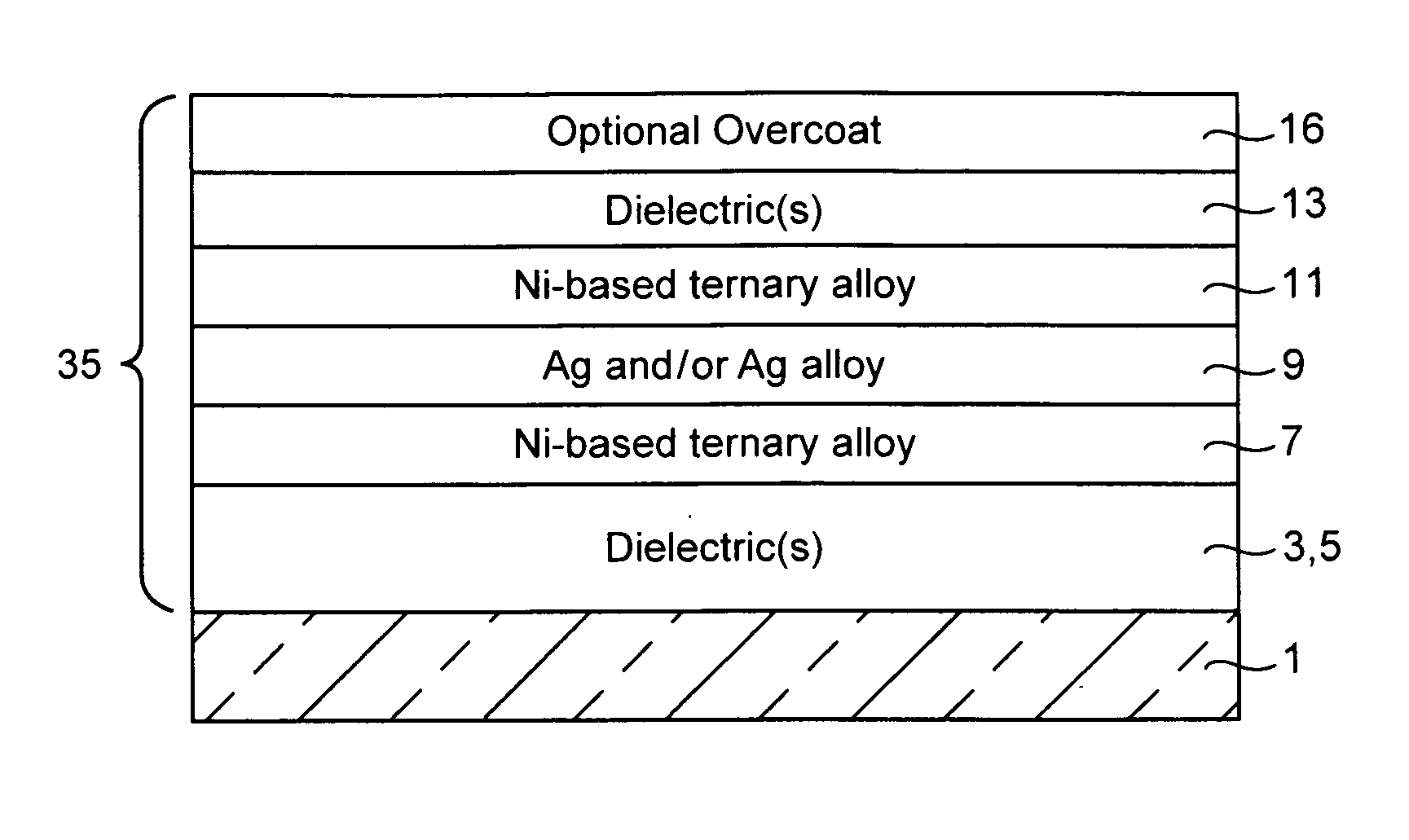

Electronic Component Device and Method for Manufacturing the Same

ActiveUS20110132655A1High speedShort timeImpedence networksSemiconductor/solid-state device detailsEngineeringElectronic component

An electronic component device having a first sealing frame formed on a main substrate and a second sealing frame formed on a cover substrate, both of which are composed of a Ni film. A bonding section bonds the first sealing frame to the second sealing frame. For example, a Bi layer is formed on the first sealing frame and an Au layer is formed on the second sealing frame, and then the first sealing frame and the second sealing frame are heated at a temperature of 300° C. for 10 seconds while applying pressure in the direction in which the first sealing frame and the second sealing frame are close contact with each other to form the bonding section. The bonding section is constituted by a mixed layer predominantly composed of a mixed alloy of a Ni—Bi—Au ternary alloy and Au2Bi.

Owner:MURATA MFG CO LTD

Barrier layers comprising NI-inclusive alloys and/or other metallic alloys, double barrier layers, coated articles including double barrier layers, and methods of making the same

InactiveUS20120225304A1Reduce sheet resistanceImprove transmittanceLight protection screensGlass/slag layered productsDouble barrierMetallic Nickel

Certain example embodiments relate to Ni-inclusive ternary alloy being provided as a barrier layer for protecting an IR reflecting layer comprising silver or the like. The provision of a barrier layer comprising nickel, chromium, and / or molybdenum and / or oxides thereof may improve corrosion resistance, as well as chemical and mechanical durability. In certain examples, more than one barrier layer may be used on at least one side of the layer comprising silver. In still further examples, a NixCryMoz-based layer may be used as the functional layer, rather than or in addition to as a barrier layer, in a coating.

Owner:GUARDIAN GLASS LLC

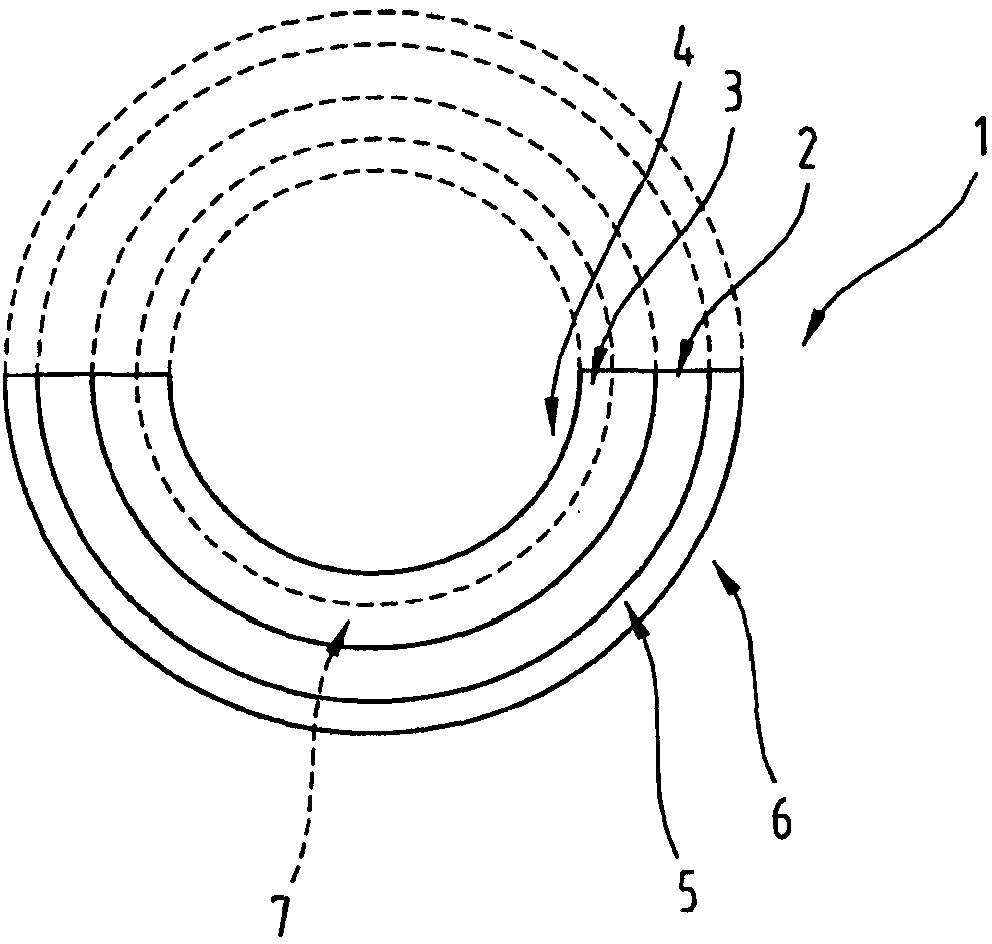

Multi-layer plain bearing having an anti-fretting layer

The invention relates to a multi-layer plain bearing (1) that has a front side (4) that can face the element to be supported and a rear side (6) opposite the front side, comprising a supporting layer (2), a sliding layer (3) arranged on the front side (4), and an anti-fretting layer (5) arranged on the rear side (6), wherein the anti-fretting layer (5) is made of a copper-based alloy having copper mixed-crystal grains. The copper-based alloy of the anti-fretting layer (5) is formed by a binary alloy having an alloying element from the group comprising aluminum, zinc, indium, silicon, germanium, and antimony or by an at least ternary alloy having one alloying element from the group comprising aluminum, zinc, indium, silicon, germanium, tin, and antimony and at least one further element from said group and / or the further group comprising nickel, cobalt, iron, manganese, bismuth, lead, silver, and phosphorus, possibly with unavoidable impurities originating from production, wherein the total fraction of said alloying elements is at least 1 wt % and at most 30 wt %.

Owner:MIBA SINTER AUSTRIA

Rare earth-oxides, rare earth -nitrides, rare earth -phosphides and ternary alloys with silicon

Atomic layer epitaxy (ALE) is applied to the fabrication of new forms of rare-earth oxides, rare-earth nitrides and rare-earth phosphides. Further, ternary compounds composed of binary (rare-earth oxides, rare-earth nitrides and rare-earth phosphides) mixed with silicon and or germanium to form compound semiconductors of the formula RE-(O, N, P)-(Si,Ge) are also disclosed, where RE=at least one selection from group of rare-earth metals, O=oxygen, N=nitrogen, P=phosphorus, Si=silicon and Ge=germanium. The presented ALE growth technique and material system can be applied to silicon electronics, opto-electronic, magneto-electronics and magneto-optics devices.

Owner:IQE

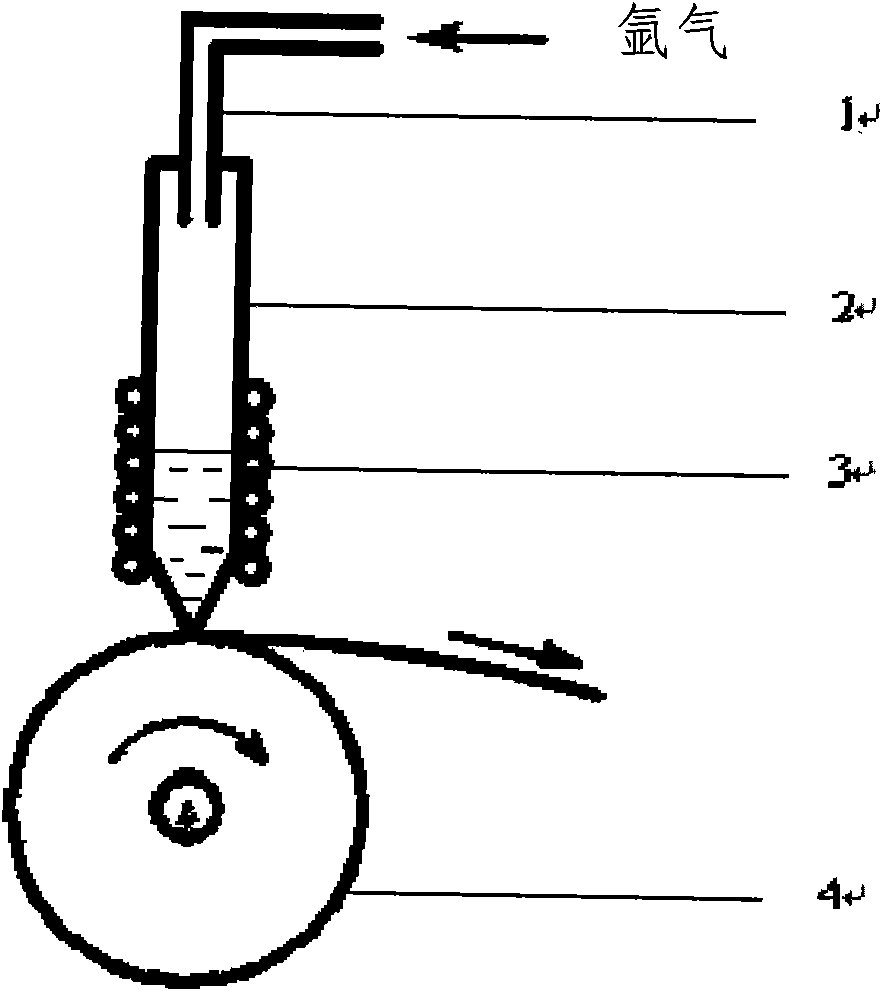

Ultrafine-grain medical magnesium alloy and preparation method thereof

The invention provides an ultrafine-grain medical magnesium alloy which is one of Mg-Zn, Mg-Ca, Mg-Mn or Mg-rare earth binary alloys, or one of ternary alloys or complex alloys formed by the same. The medical magnesium alloy contains at least one of the following metal components in percentage by mass: 0.5-10% of Zn, 0.5-10% of Ca, 0.5-10% of Mn or 0.1-10% of rare earth and the balance of magnesium; the purities of the components in the medical magnesium alloy are all above 99.9%. The invention also provides a preparation method of the superfine-grain medical magnesium alloy. By using the preparation method provided by the invention, mechanical property and corrosion resistance of the magnesium alloy can be greatly improved by combining quick solidification with vacuum hot compression. Compared with a traditional cast magnesium alloy, the ultrafine-grain medical magnesium alloy provided by the invention has the advantages that the room temperature is increased by above 40% compared with the tensile strength, the elongation rate is increased by above 5%, the corrosion speed is reduced to 0.15-0.25 mm / year, the grain size is thinned to be less than 10 microns; and the ultrafine-grain medical magnesium alloy has excellent biocompatibility.

Owner:LEPU MEDICAL TECH (BEIJING) CO LTD

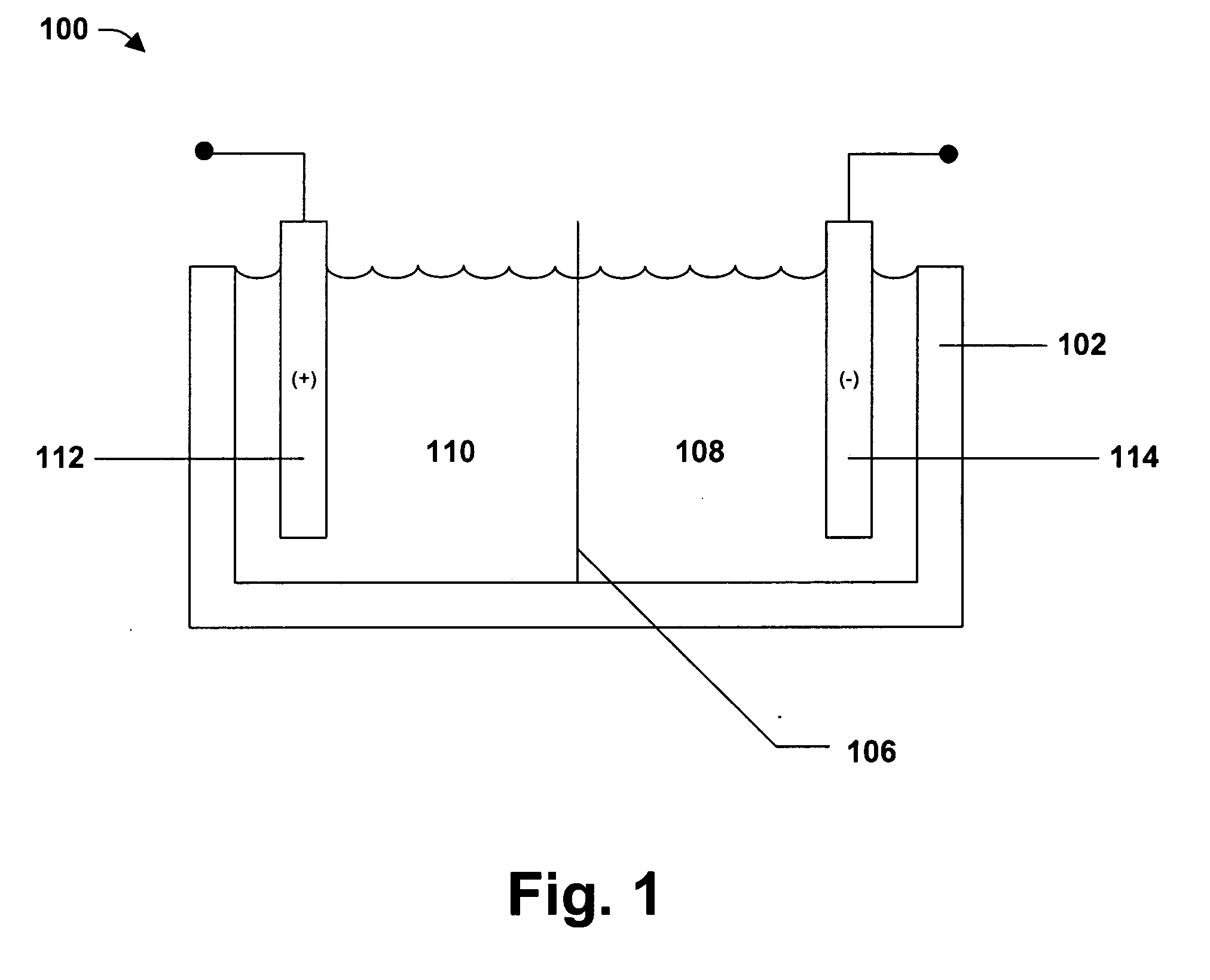

Anticorrosive wearable electrodeposit clad layer of Ni-W-P ternary alloy and manufacturing technique and electroplate liquid thereof

The invention relates to an anticorrosive wearable electrodeposit clad layer of Ni-W-P ternary alloy and manufacturing technique and electroplates liquid thereof, which takes the nickel sulfate, sodium tungstate, phosphate as the main material, electrically depositing the Ni-WP amorphous mixture of amorphous or nanocrystalline alloy coating. The characteristics of the electroplate technique are following: corrosive solution is very small, the entire production of the use of cleaner production, less emissions, in line with the requirements of sustainable production. W of the coating for the content of 1-45wt%, P content of 0.1-5wt%, nickel is the residue. The plating layer is bright and dense; the hardness is 400-1100Hv, which is resistant to acid, alkali, salt and hydrogen sulfide corrosion, wear resistance is better than or equivalent to chrome plating, can not only replace decorative chromium or hard chromium is widely used, and can be used for oil field exploration equipment to deal with wear-resistant anti-corrosion.

Owner:湖南纳菲尔新材料科技股份有限公司

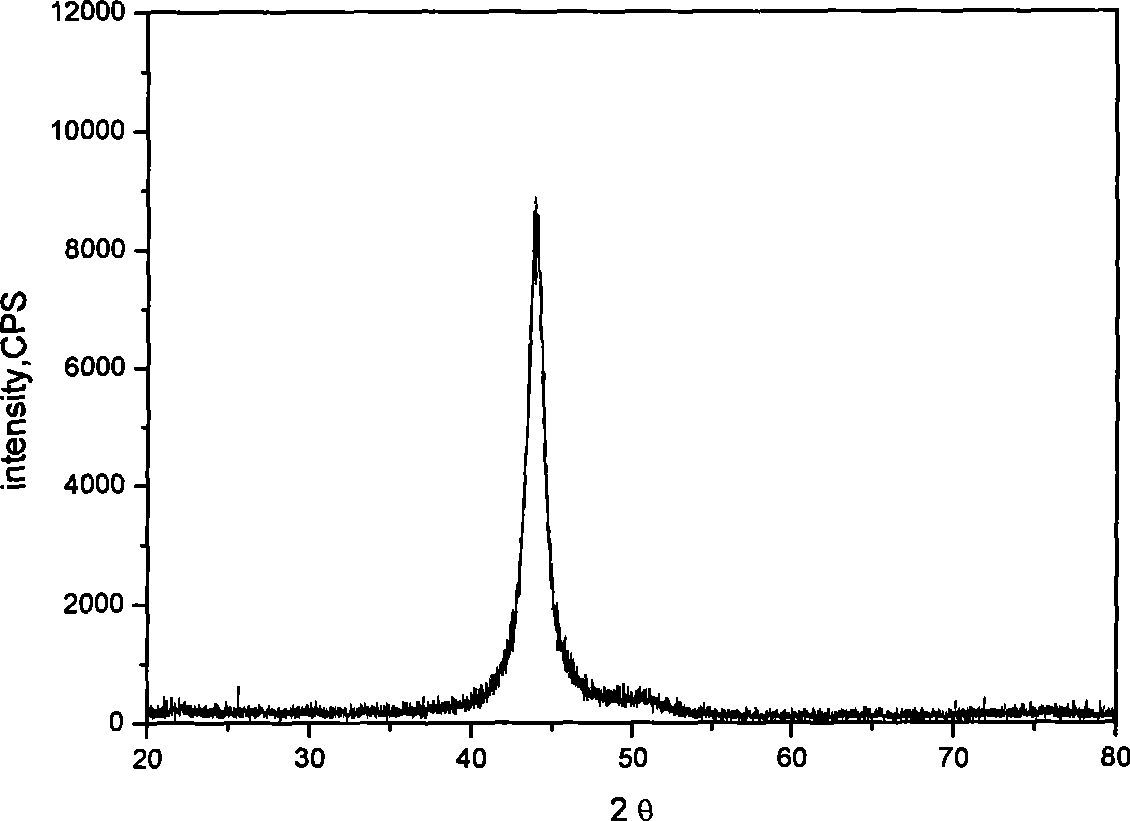

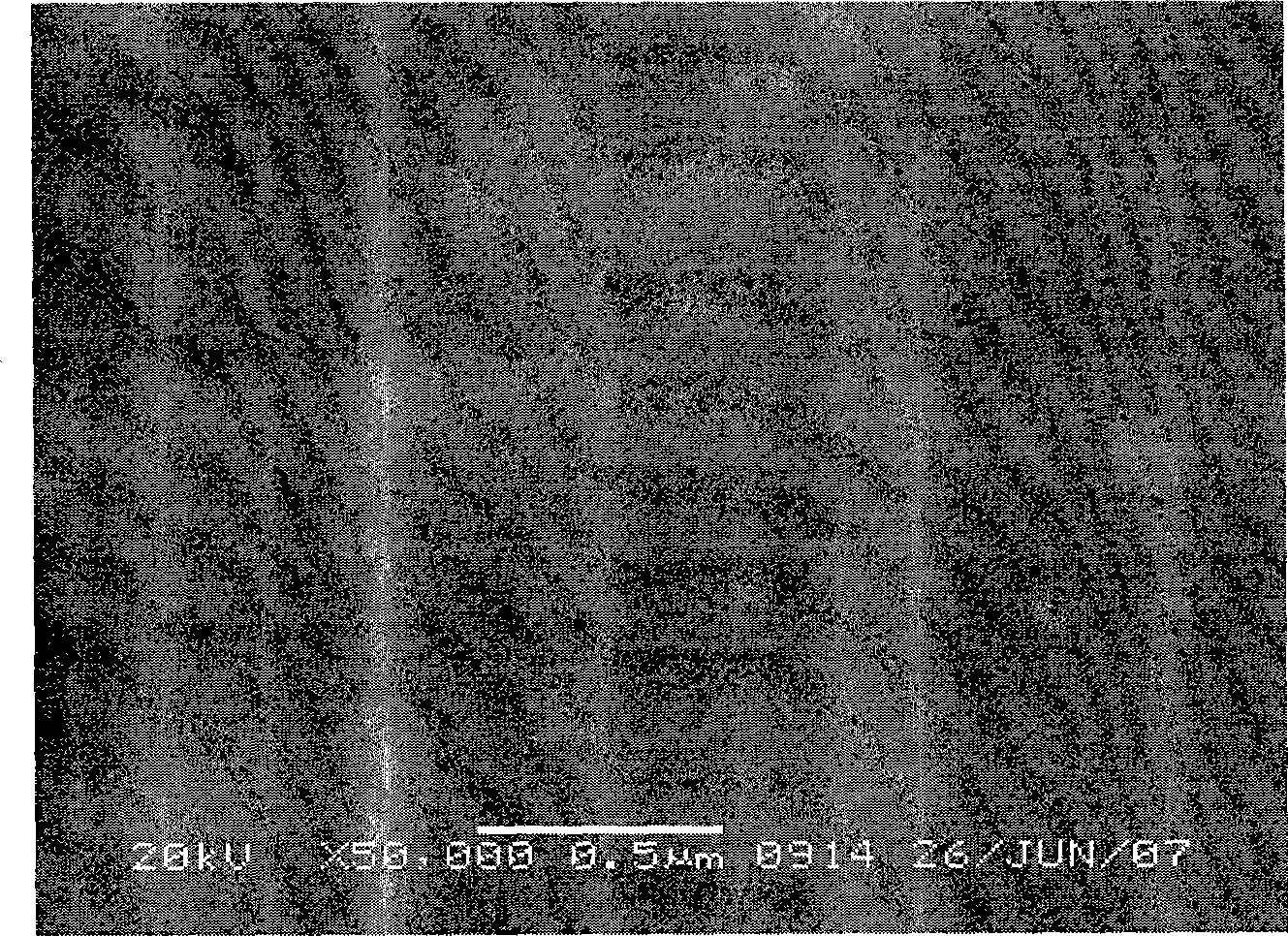

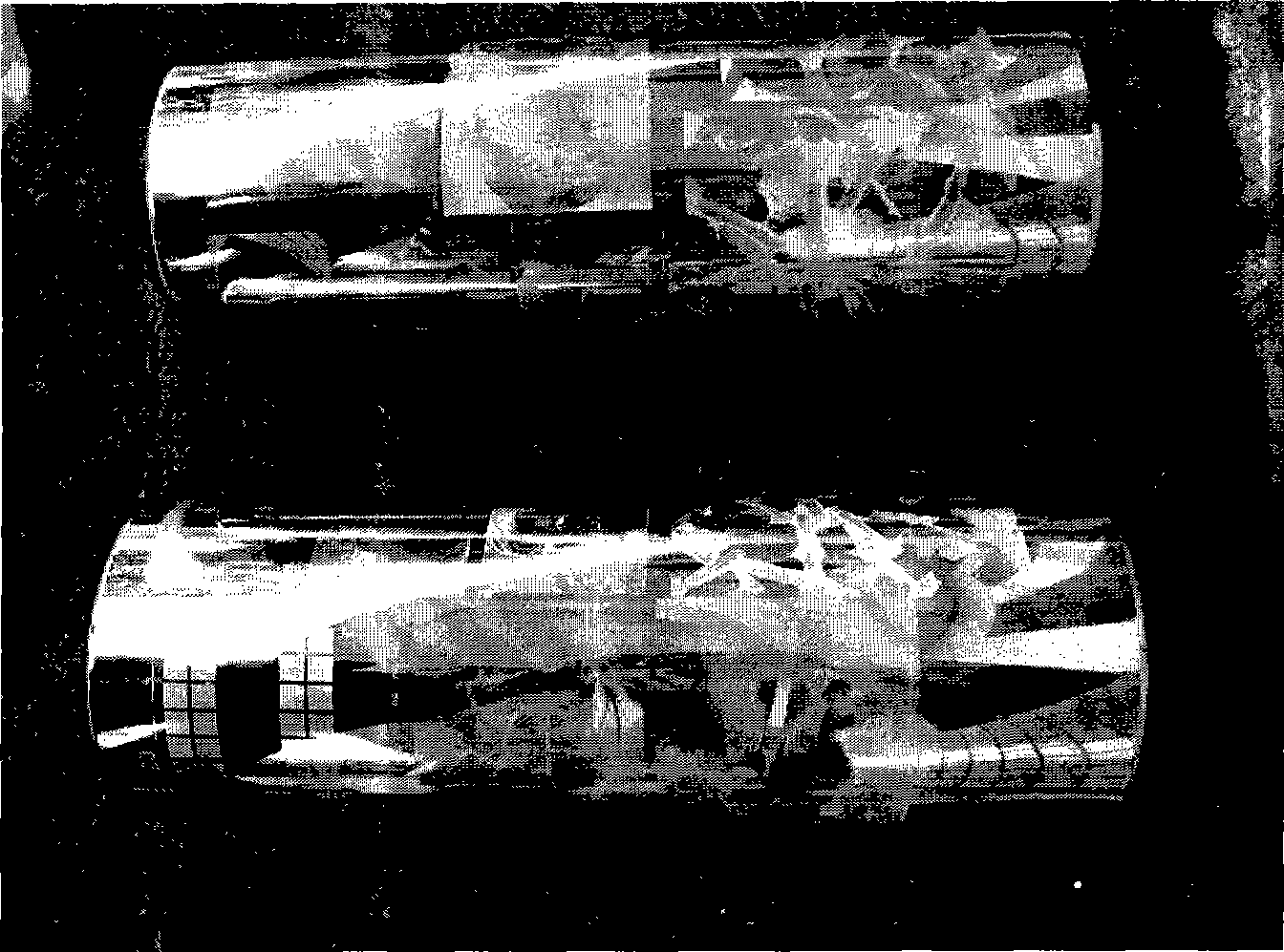

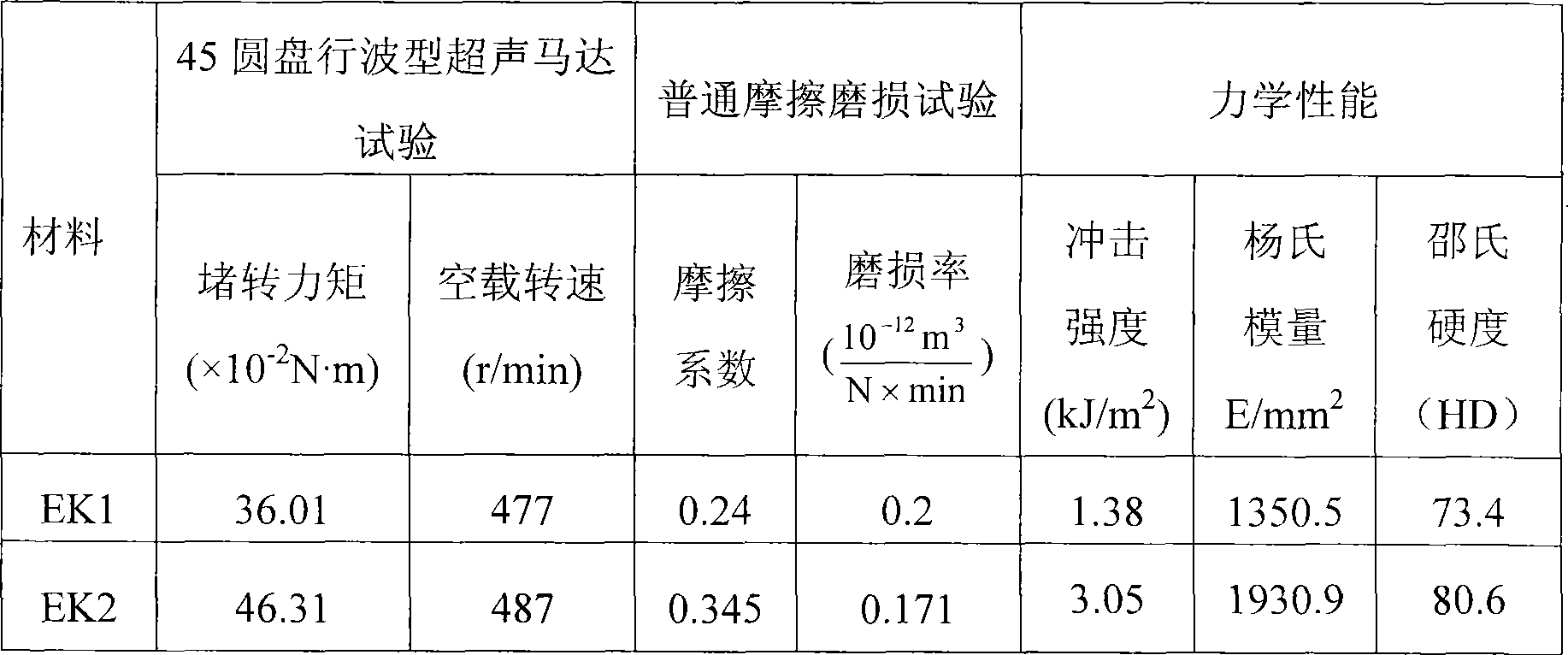

Temperature-resistant resin modified polyphenyl ester ternary alloy ultrasonic motor friction material

The invention discloses a ternary alloy hyperacoustic motor frictional material of the fire resistance resin modified polyphenyl ester, which solves the low friction coefficient problem, the low impact strength problem, the low abradability problem and the bad processability problem of the prior hyperacoustic motor. The invention is made by 5-25% politef, 5-20% fire resistant resin and the rest polyphenyl, which can also add one or a plurality of 10-35% fortifying fiber, 1-15% metal powder and 1-15% ceramic powder. The invention keeps all the advantages of the present polyphenyl ester plastic alloy hyperacoustic motor frictional material, which is provided with the high friction coefficient, the good abradability, the low noise, the high hardness and the high impact strength.

Owner:HARBIN INST OF TECH

Nickel cobalt boron ternary alloys

Disclosed are methods of electroplating a nickel cobalt boron alloy involving providing an electroplating bath comprising ionic nickel, ionic cobalt, ionic boron, and at least one brightener; and applying a current to the electroplating bath whereby a nickel cobalt boron alloy forms.

Owner:TASKEM

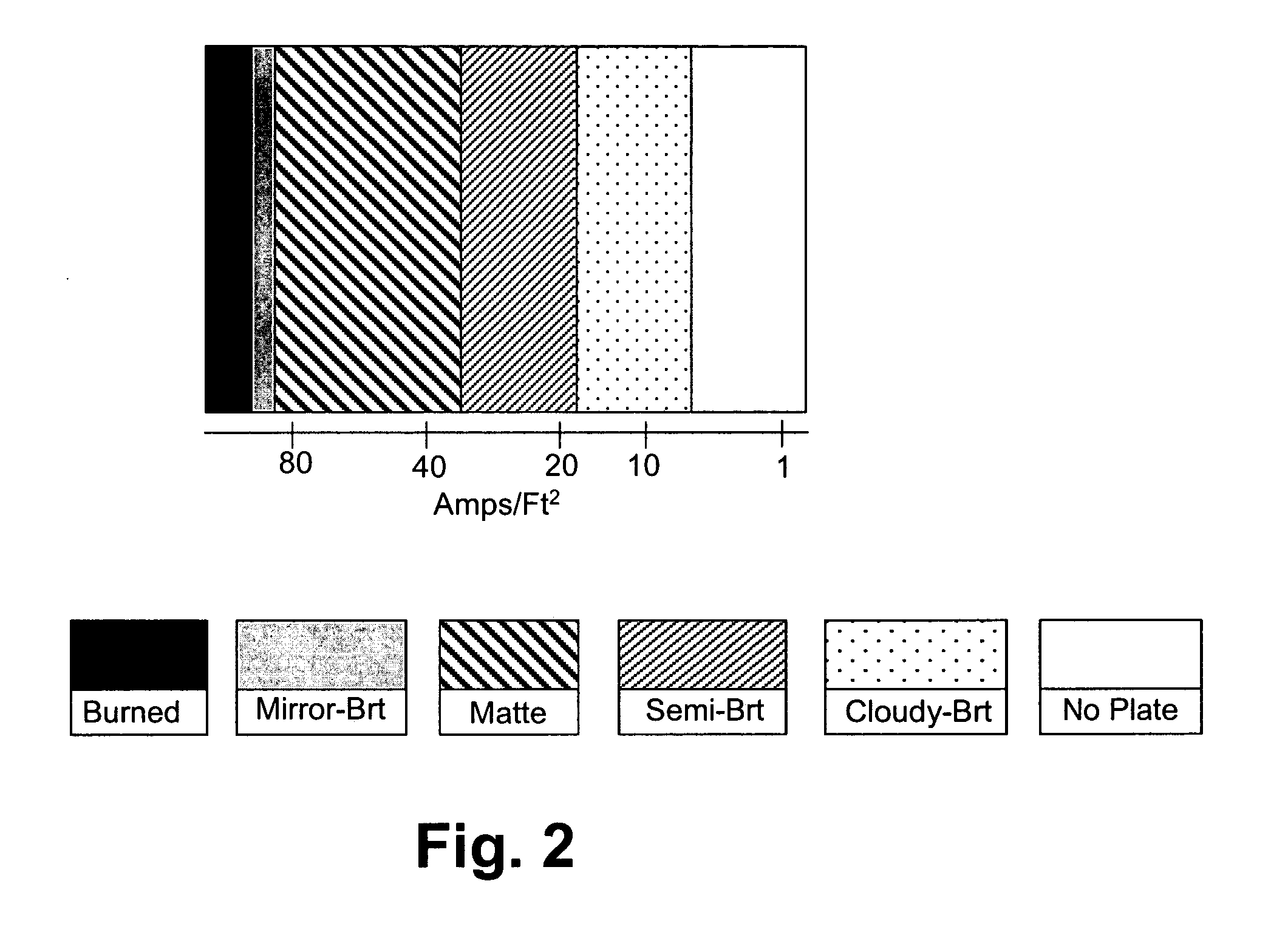

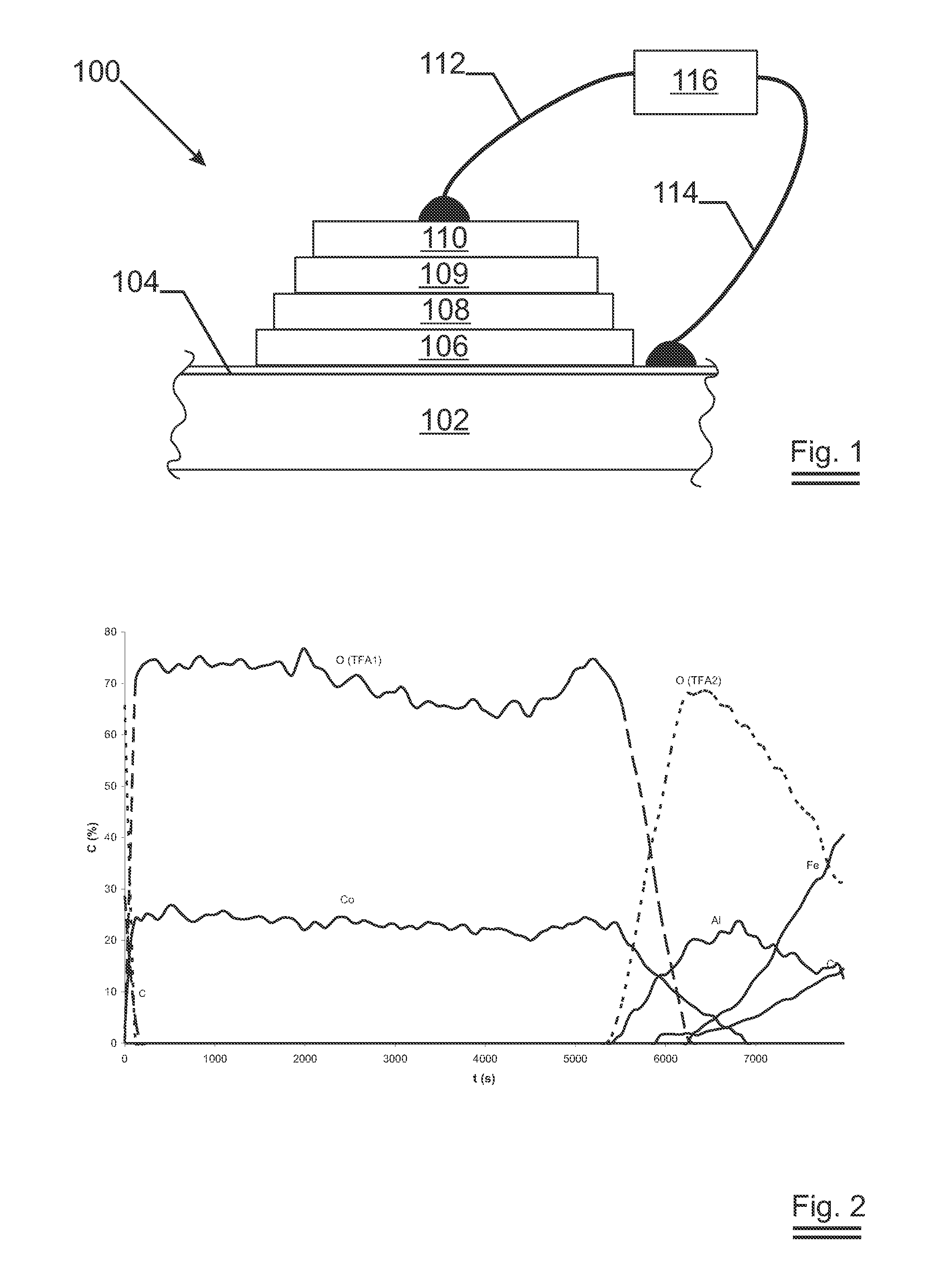

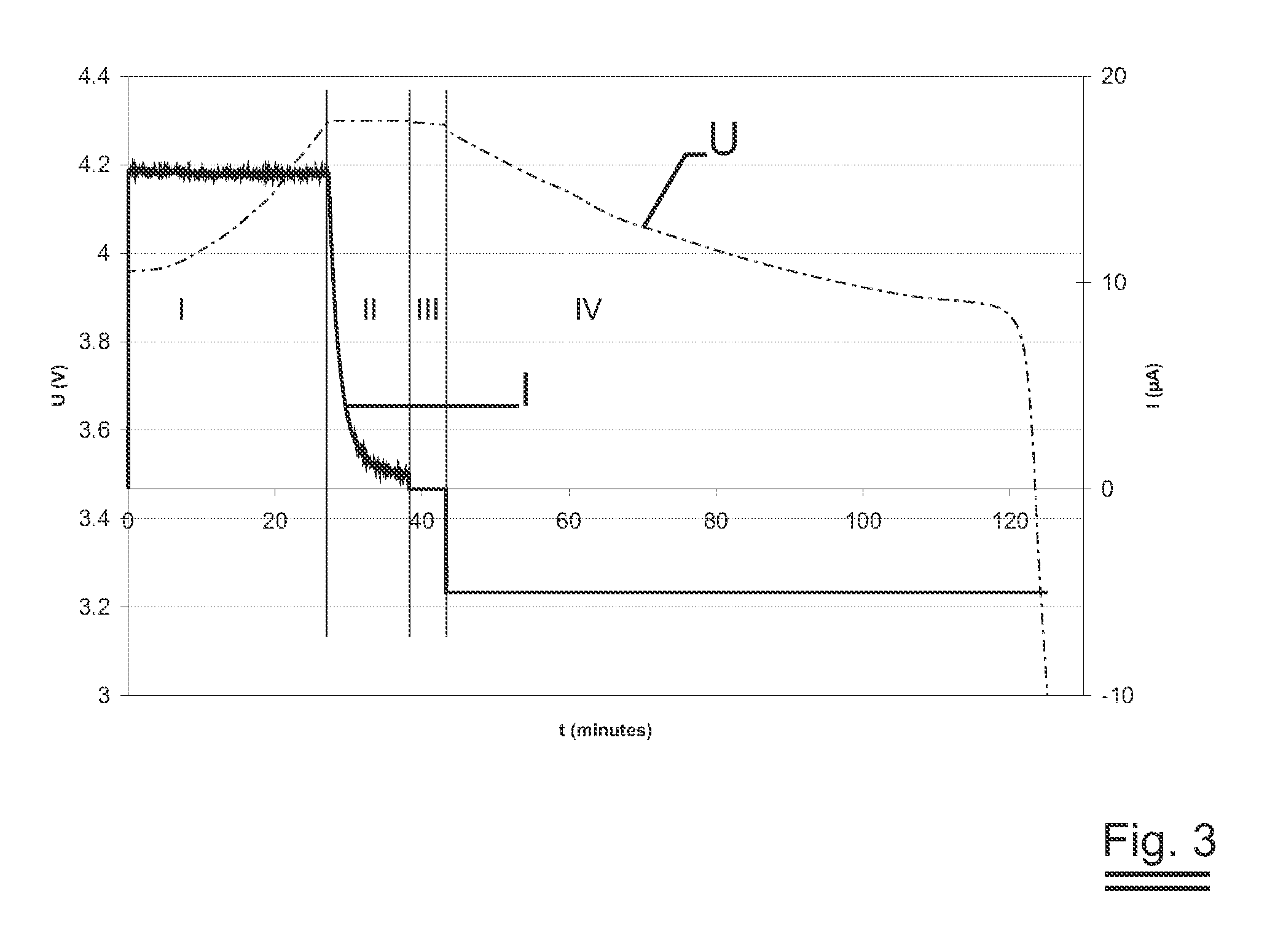

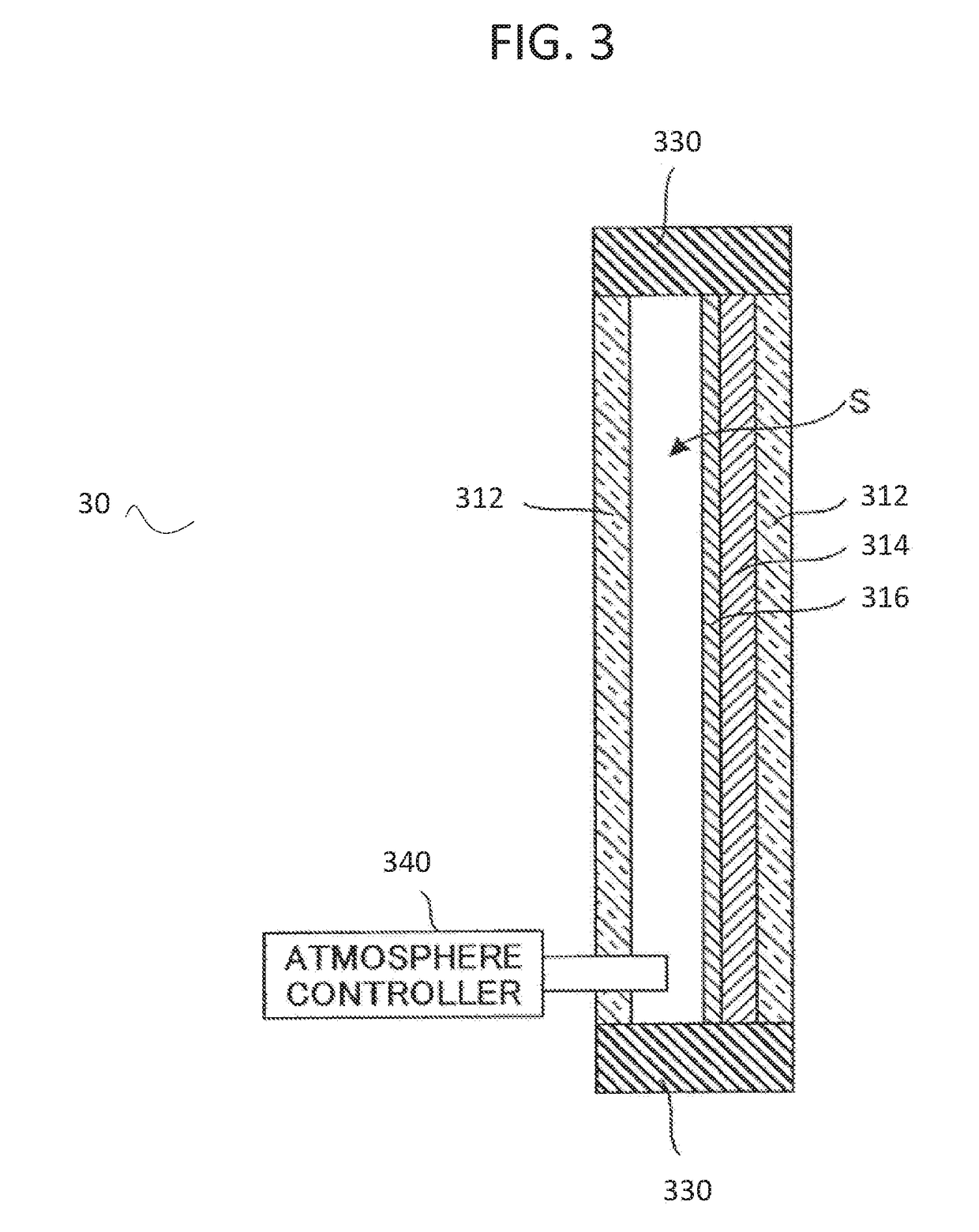

Substrate for lithium thin film battery

InactiveUS20100104942A1Easy to keepAvoid lostAlkaline accumulatorsActive material electrodesAll solid stateOxygen

When attempting to make a lithium ion-switching device such as a high-efficiency, all-solid state, thin film battery the choice of carrier substrate is all important. As such a substrate must withstand a high temperature under an oxidising atmosphere to crystallise certain layers making up the device, the substrate should not oxidise thereby ruling out most metals. The invention now describes a class of ternary alloys of which the oxidation rate is limited and that are useable to produce thin film batteries on. At least one element with a high affinity to oxygen (Al, Mg, Zn or Si) is present in the alloy. The other two metallic elements reduce the growth of the oxide of this first element. In addition the thus formed oxide scale turns out to be an effective barrier to lithium. Surprisingly, the scale shows nanoscopic voids that allow for sufficient electrical contact with the device layers, thereby eliminating the need for a separate current collector. As the ternary alloy can be made in a flexible foil, it can advantageously be used in a roll-to-roll process.

Owner:CYMBET CORP

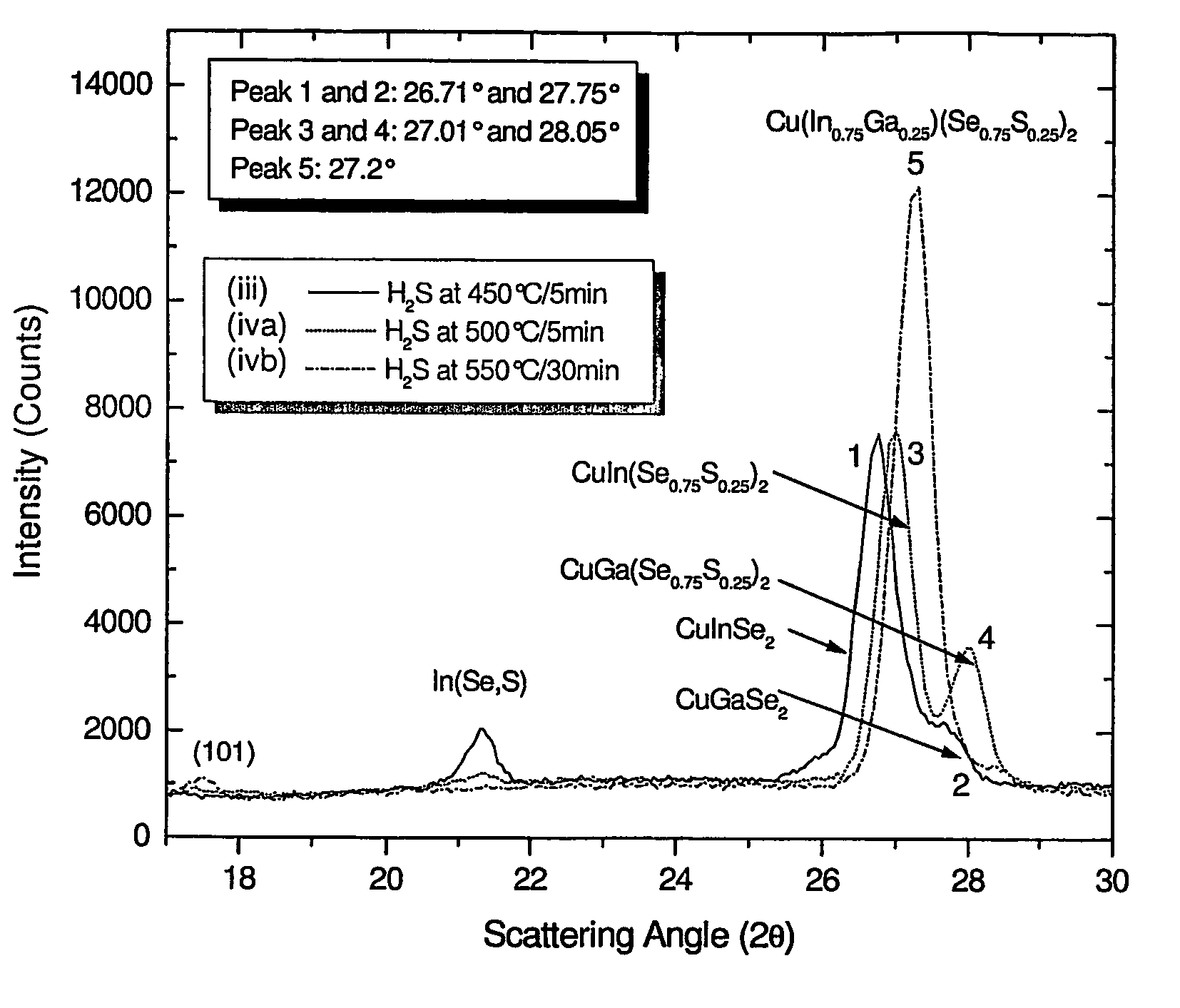

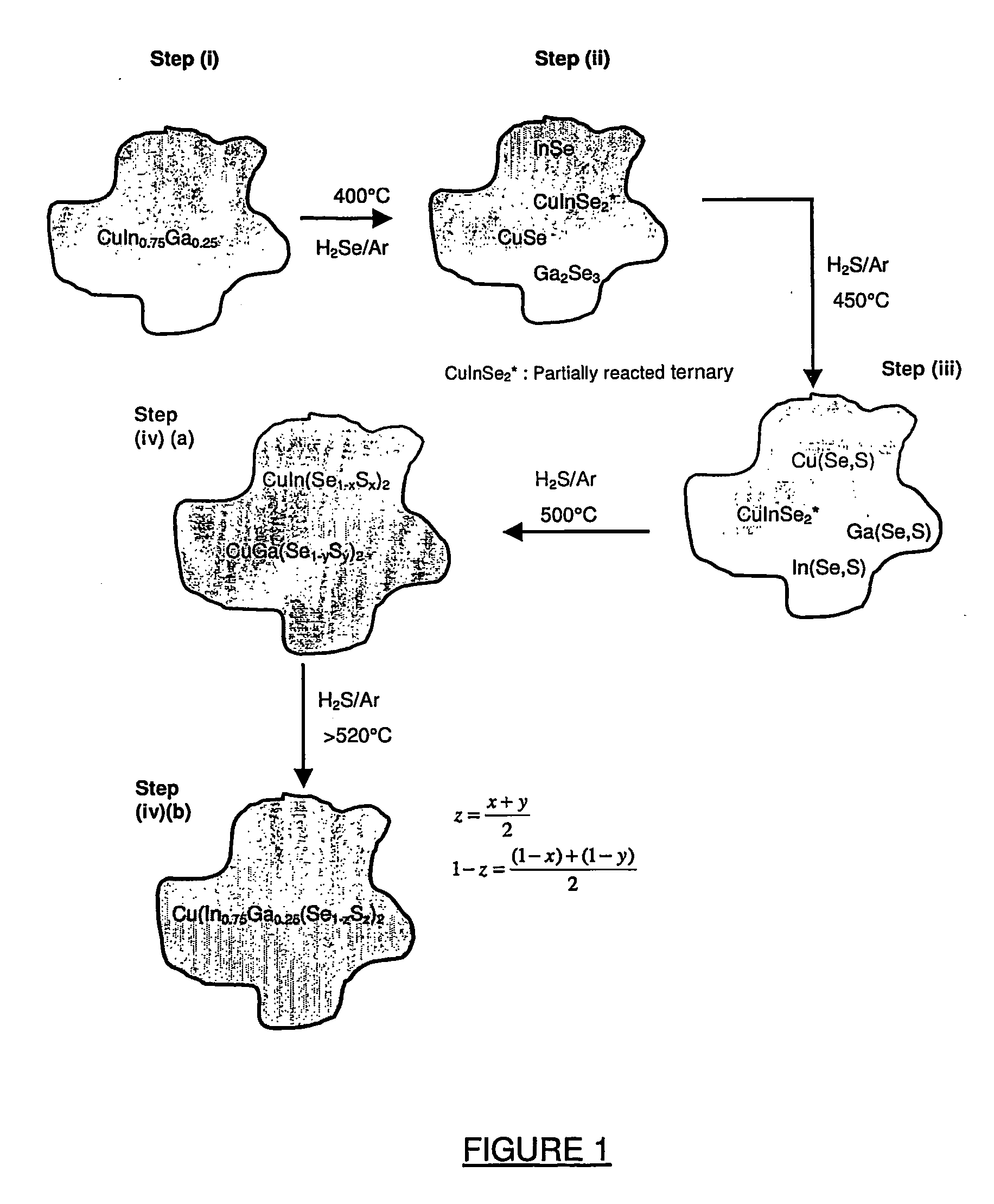

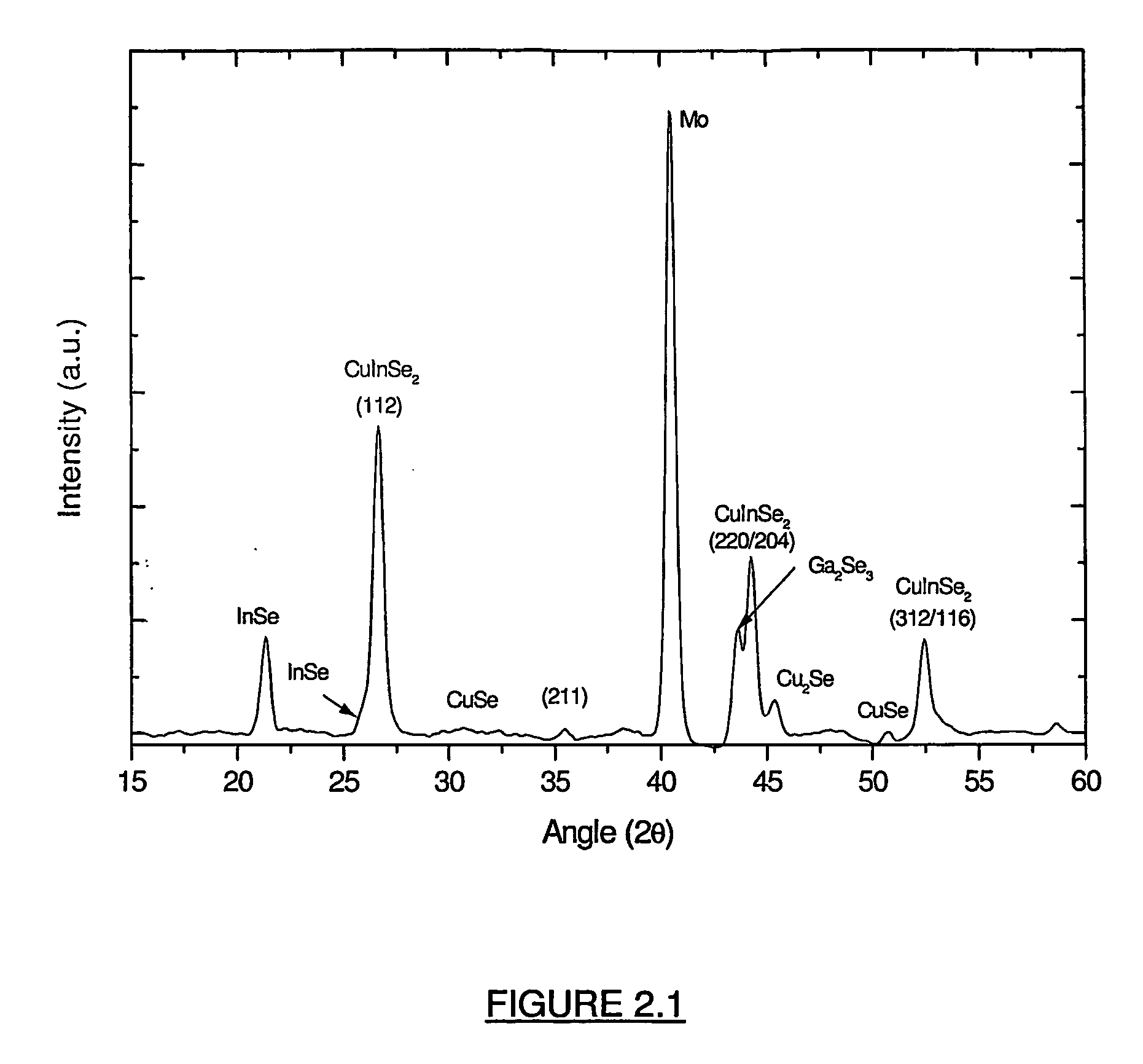

Method for the preparation of group ib-iiia-via quaternary or higher alloy semiconductor films

InactiveUS20070004078A1Final product manufactureSemiconductor/solid-state device manufacturingBinary alloyQuaternary

This invention relates to a method for producing group IB-IIA-VIA quaternary or higher alloy semiconductor films wherein the method comprises the steps of (i) providing a metal film comprising a mixture of group IB and group IIIA metals; (ii) heat treating the metal film in the presence of a source of a first group VIA element (said first group VIA element hereinafter being referred to as VIA1) under conditions to form a first film comprising a mixture of at least one binary alloy selected from the group consisting of a group IB-VIA1 alloy and a group IIIA-VIA1 alloy and at least one group IB-IIIA-VIA1 ternary alloy (iii) optionally heat treating the first film in the presence of a source of a second group VIA element (said second group VI element hereinafter being referred to as VIA2) under conditions to convert the first film into a second film comprising at least one alloy selected from the group consisting of a group IB-VIA1-VIA2 alloy and a group IIIA-VIA1-VIA2 alloy; and the at least one group IB-III-VIA1 ternary alloy of step (ii); (iv) heat treating either the first film or second film to form a group IB-IIIA-VIA quaternary or higher alloy semiconductor film.

Owner:JOHANNESBURG UNIV OF

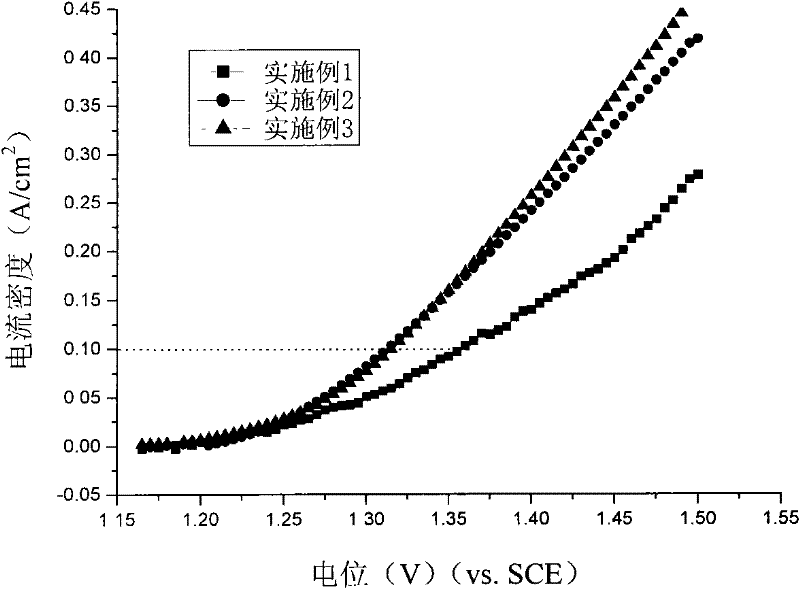

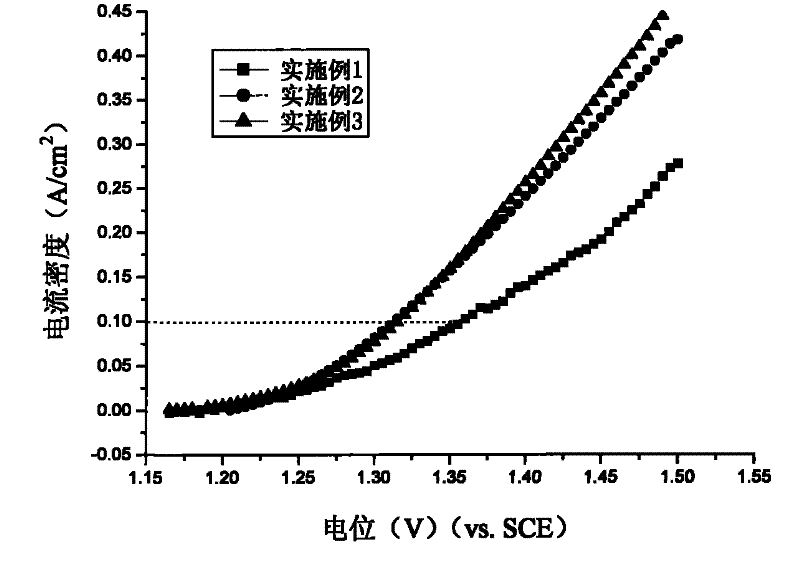

Amorphous plating layer with high hydrogen evolution catalytic activity and preparation method thereof

InactiveCN102127776AImprove utilization efficiencyLower cell voltageEnergy inputElectrodesElectricityElectrolysis

The invention relates to an amorphous plating layer with high hydrogen evolution catalytic activity and a preparation method thereof, relating to components, a structure and a preparation method of an amorphous plating layer. The amorphous plating layer is mainly characterized by containing ternary alloys, i.e., Ni, Mo and Co, the appearance of the plating layer presents silver white, the surface of the plating layer is smooth and fine, and the plating layer is of an amorphous structure. The amorphous plating layer is electrically deposited on a metal substrate with an electro-deposition method, the adopted plating solution comprises the following components of: 40-80g / L of NiSO4.6H2O, 10-40 g / L of NaMoO4.2H2O, 1-10g / L of CoSO4.7H2O, 10-60g / L of C6H5Na3O7.2H2O and 60-120g / L of Na2CO3. The amorphous plating layer provided by the invention has higher hydrogen evolution catalytic activity and can be used for hydrogen evolution electrodes in chlor-alkali industry, a brine electrolysis process, solar brine electrolysis hydrogen production, electrochemical hydrogen production and other systems.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

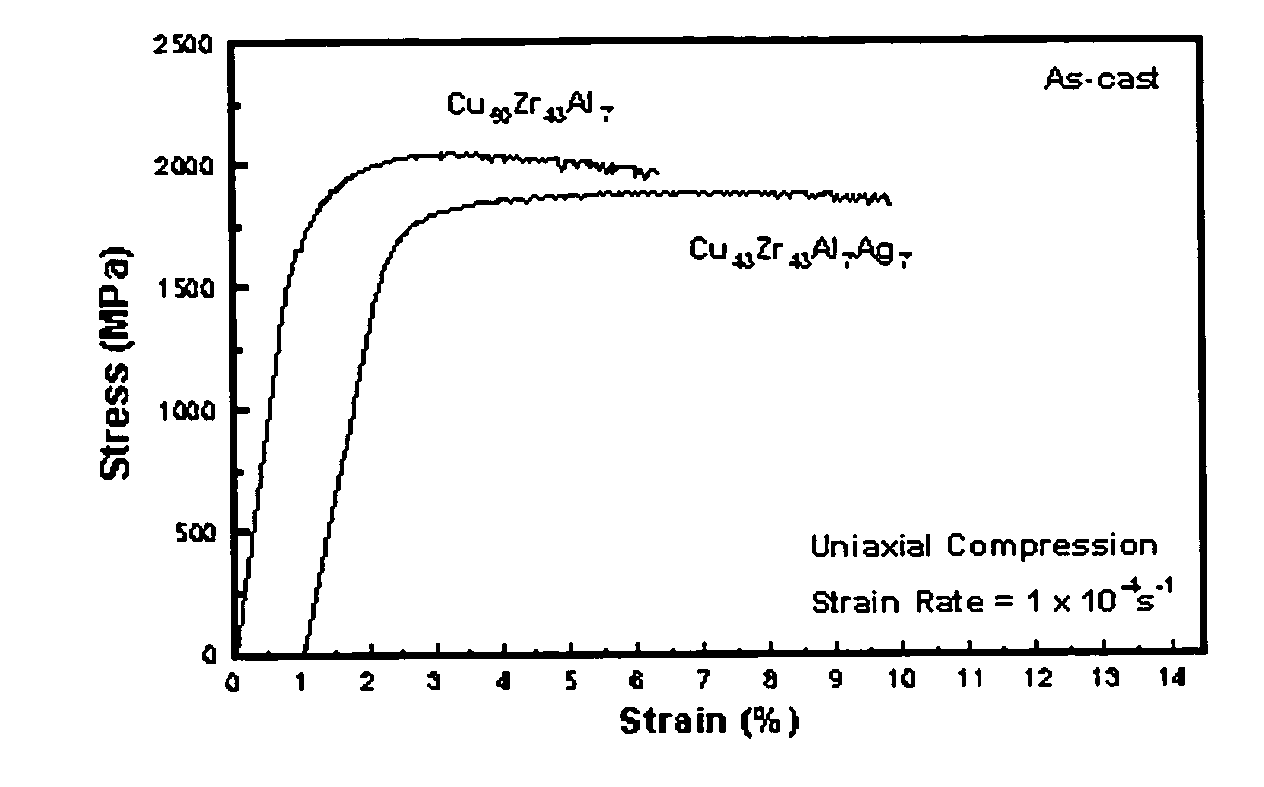

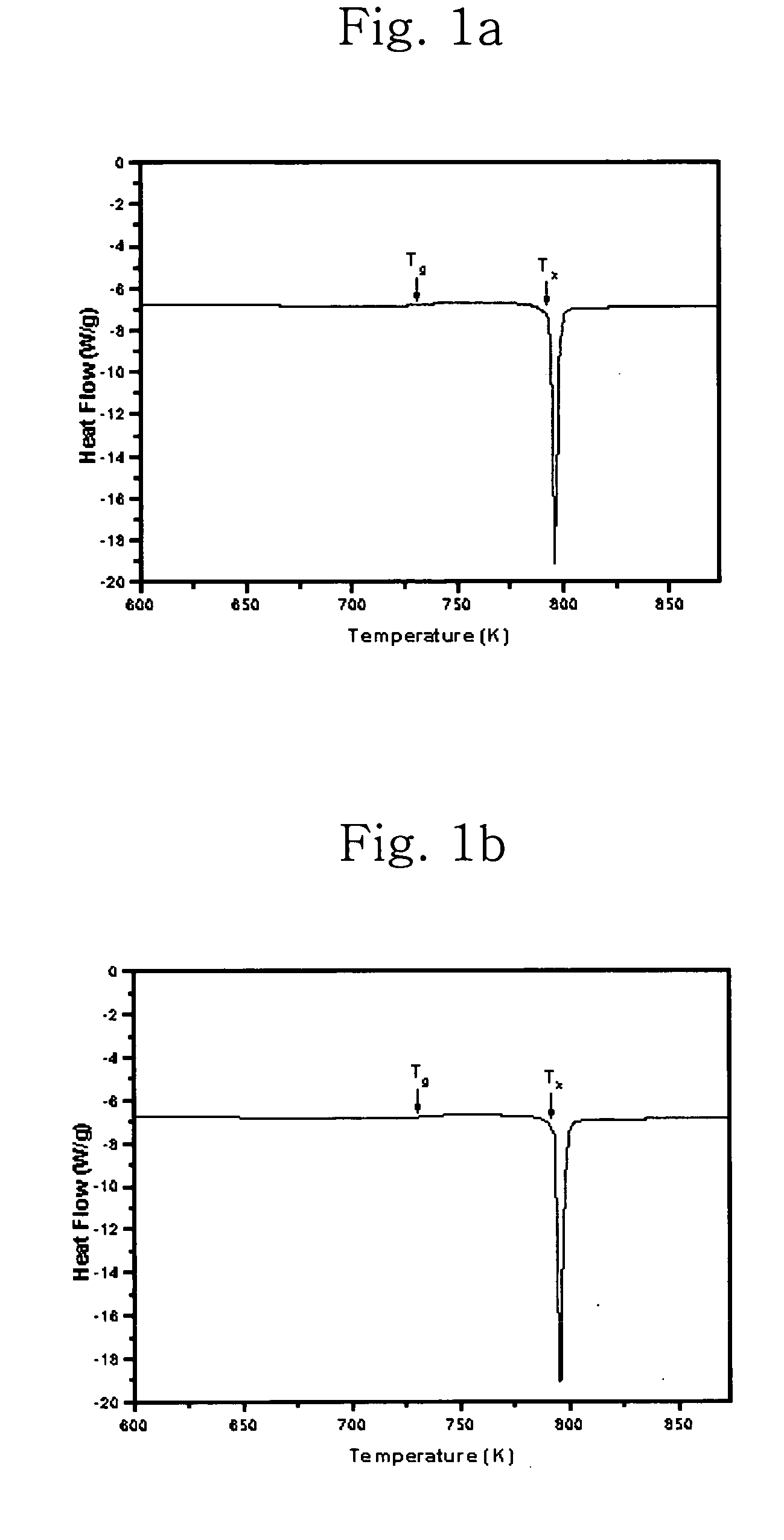

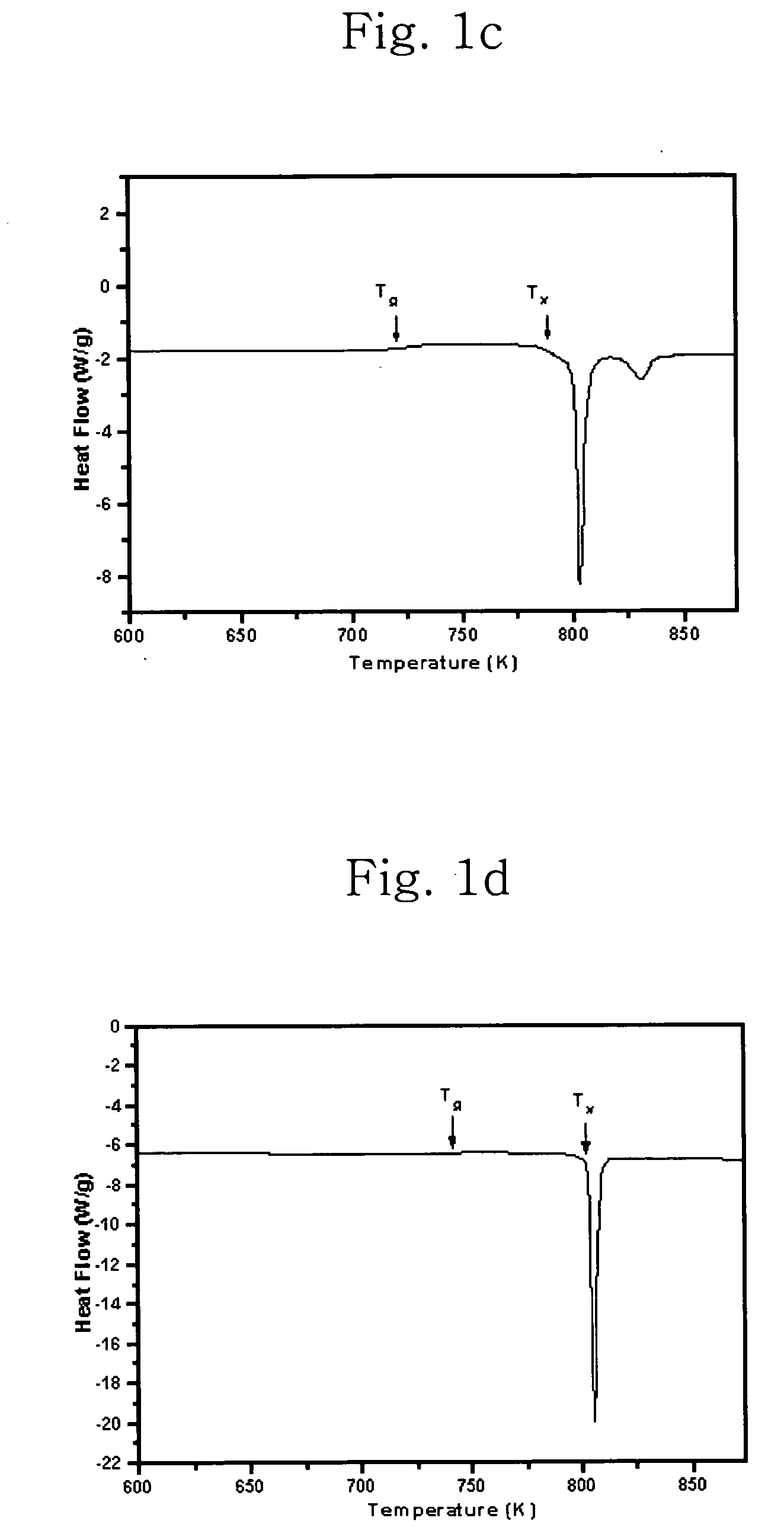

Cu-based amorphous alloy composition

InactiveUS20050211340A1Improve efficiencyGood molding effectMagnetic materialsSkate-boardsChemical compositionMetal

The present invention relates to a Cu-based amorphous alloy composition having a chemical composition represented by the following general formula, by atomic %: Cu100-a-b-c-dZraAlb(M1)c(M2)d, where a, b, c and d satisfy the formulas of 36≦a≦49, 1≦b≦10, 0≦c≦10, and 0≦d≦5, respectively, and c and d are not zero at the same time, and M1, the 4th element added to a ternary alloy of Cu—Zr—Al, is one metal element selected from the group consisting of Nb, Ti, Be and Ag, and M2, the 5th element added to the ternary alloy of the Cu—Zr—Al, is one amphoteric element or non-metal element selected from the group consisting of Sn and Si.

Owner:KOREA INST OF SCI & TECH

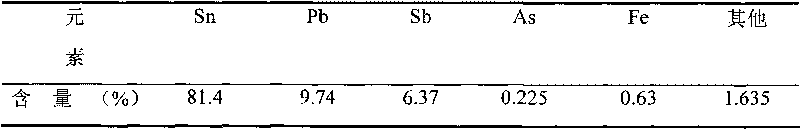

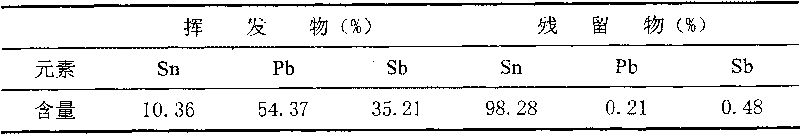

Method for separating ternary alloy of lead, tin and stibium

InactiveCN101696475AEasy to separateSimplify the refining processProcess efficiency improvementBoiling pointLiquid state

The invention relates to a method for separating a ternary alloy of lead, tin and stibium, which adopts a vacuum distillation method to treat the ternary alloy of lead, tin and stibium, wherein the distillation temperature is controlled at 900 to 1,200 DEG C, the distillation time is 40 to 60min and the vacuum degree is 5 to 15 Pa. The three components in the alloy are distilled in one step, then the tin of a high boiling point is kept in a liquid state, and the lead and the stibium of a low boiling point are volatilized from the alloy in a gas state so as to be separated from the liquid tin. The method can reduce the content of the lead and the stibium in the lead to be less than 1 percent, and the recovery rates of the lead, tin and stibium are over 98 percent.

Owner:KUNMING UNIV OF SCI & TECH +1

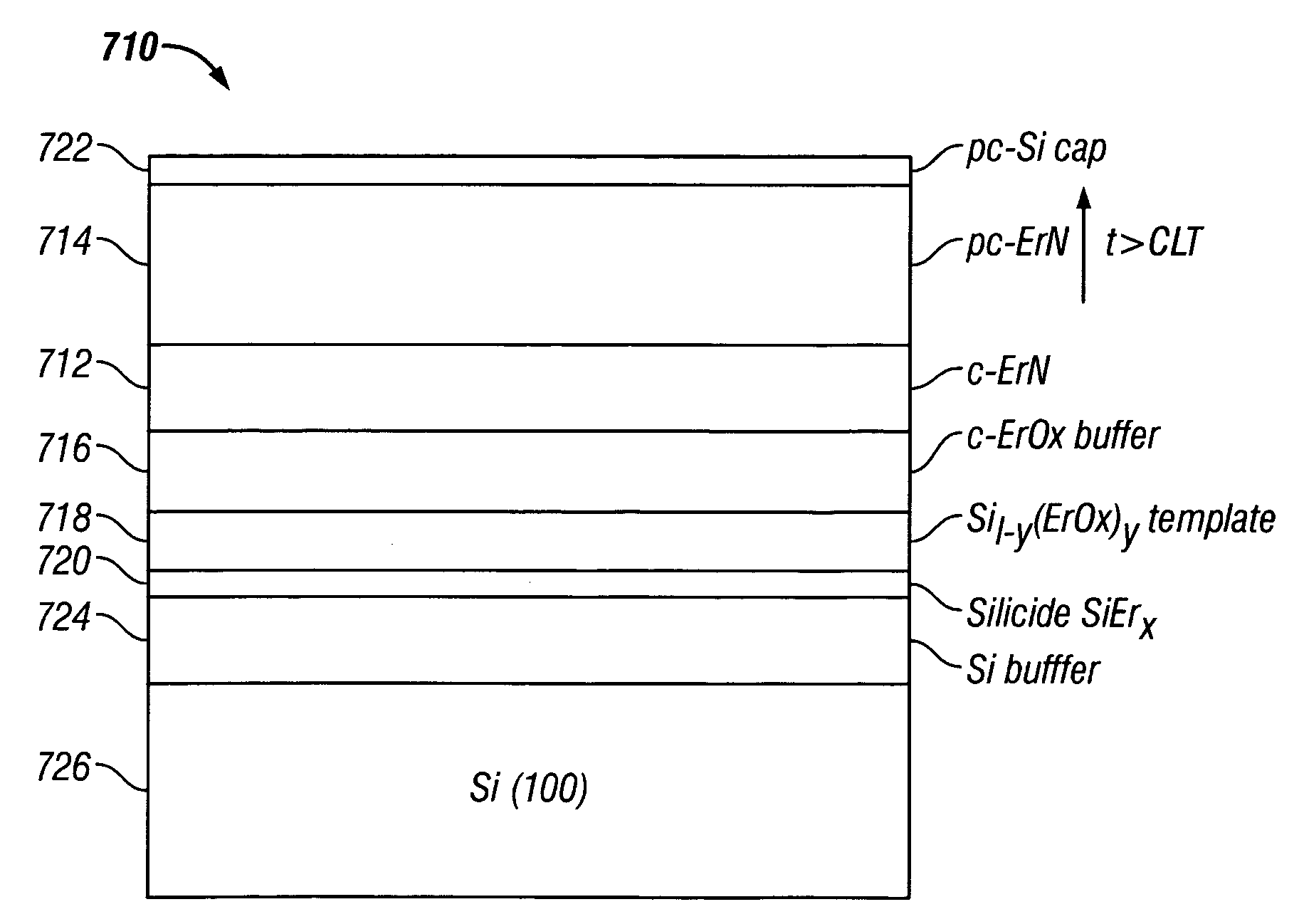

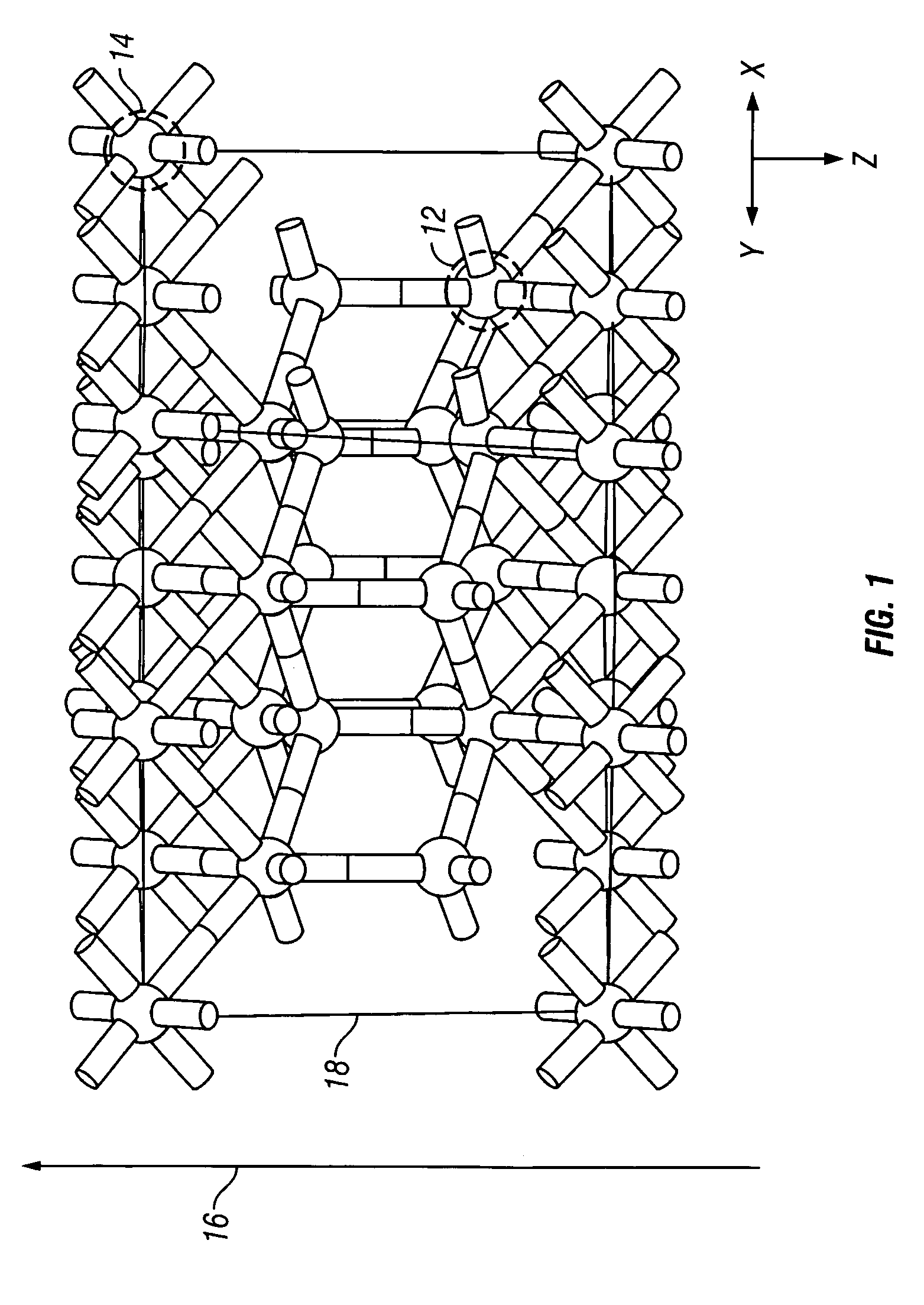

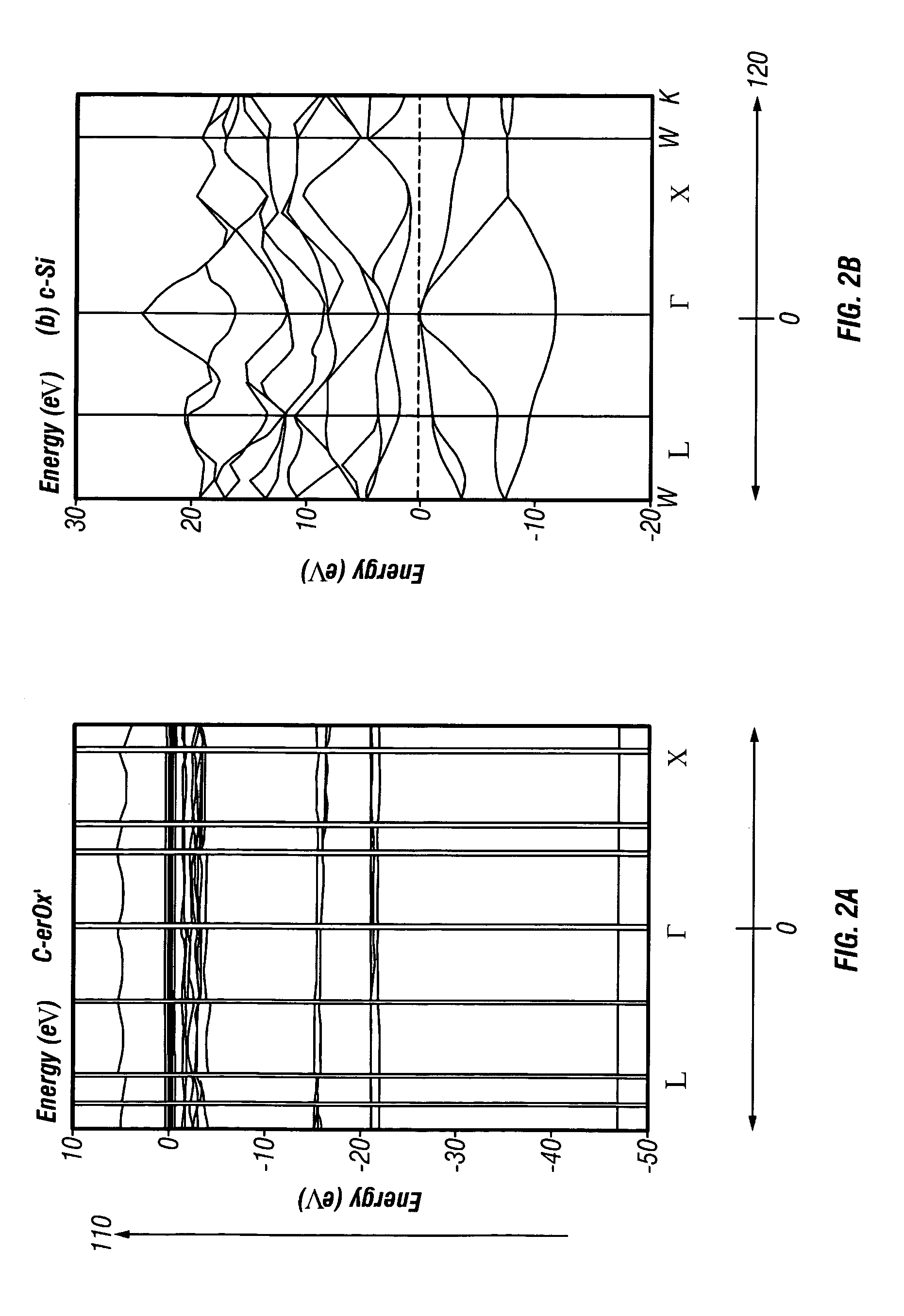

Rare earth-oxides, rare earth-nitrides, rare earth-phosphides and ternary alloys with silicon

InactiveUS7273657B2Quality improvementLaser detailsSemiconductor/solid-state device detailsRare earthOpto electronic

Owner:IQE

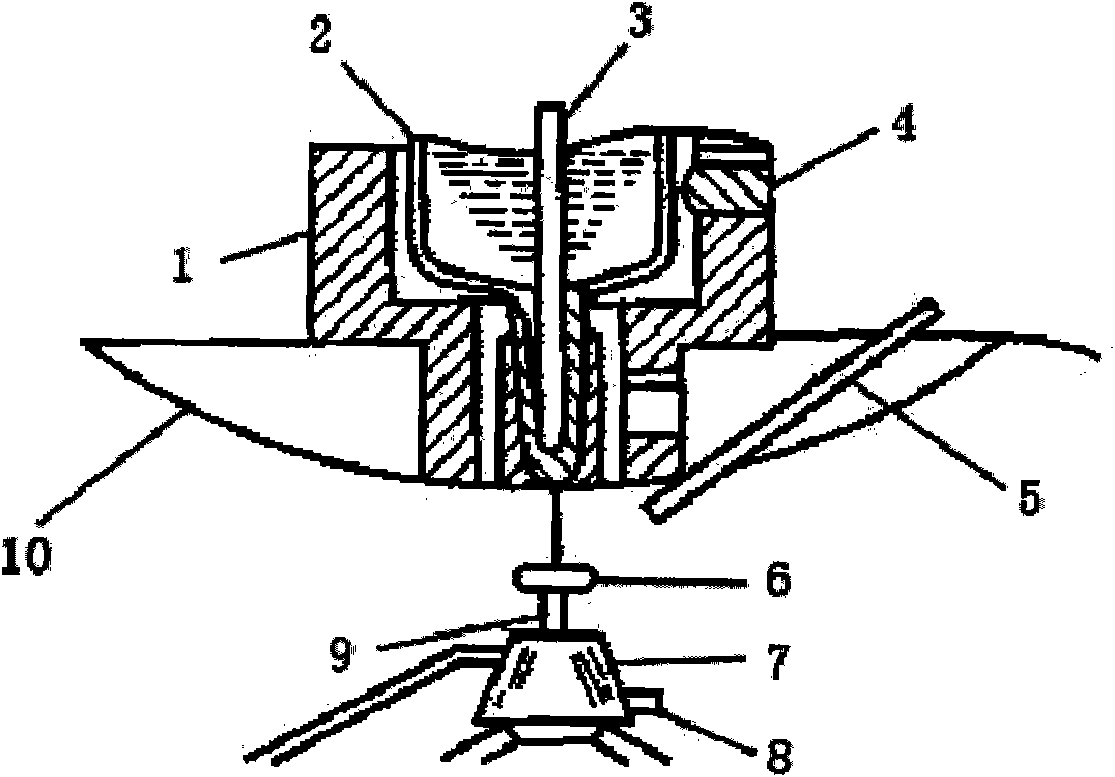

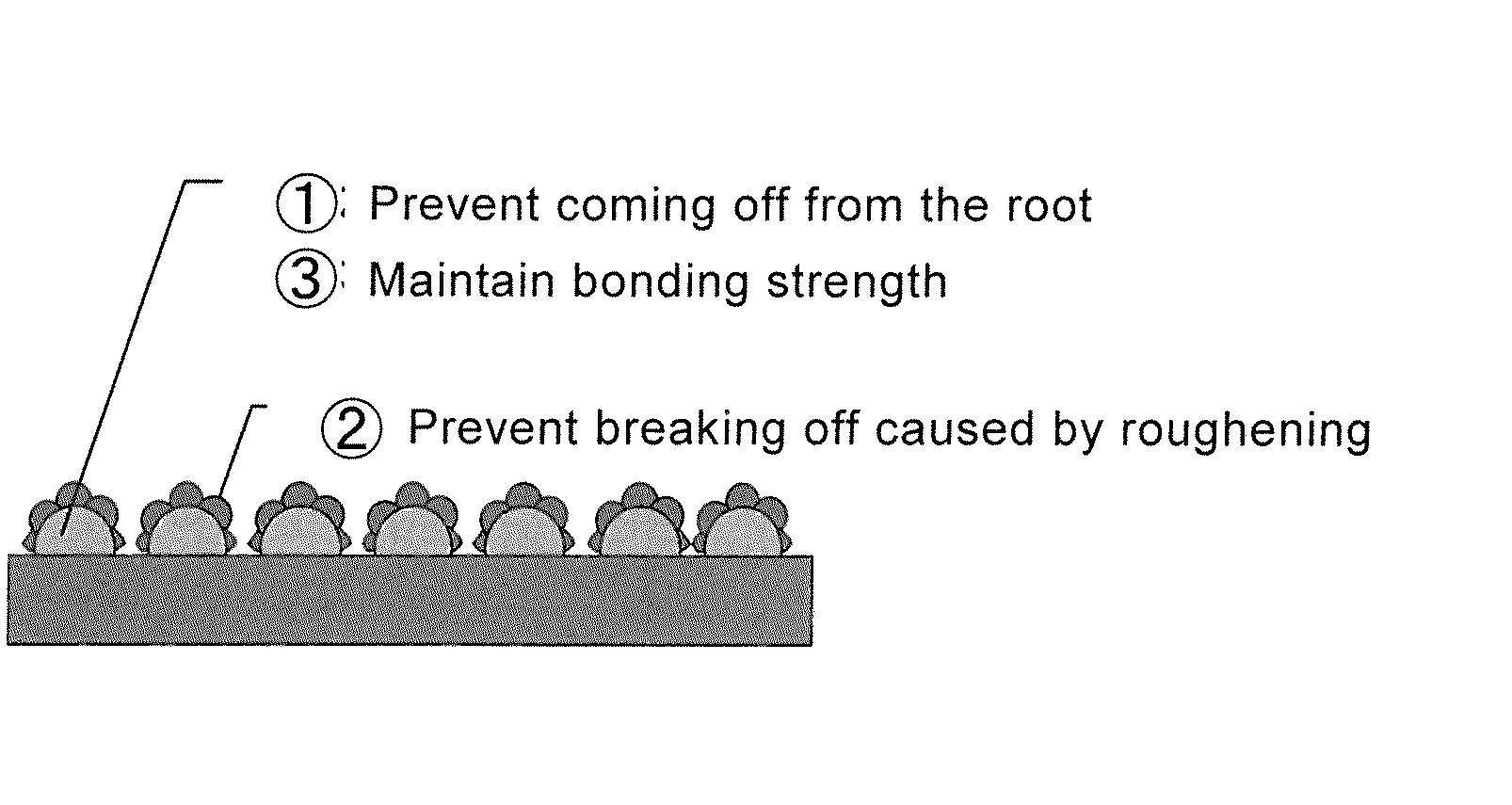

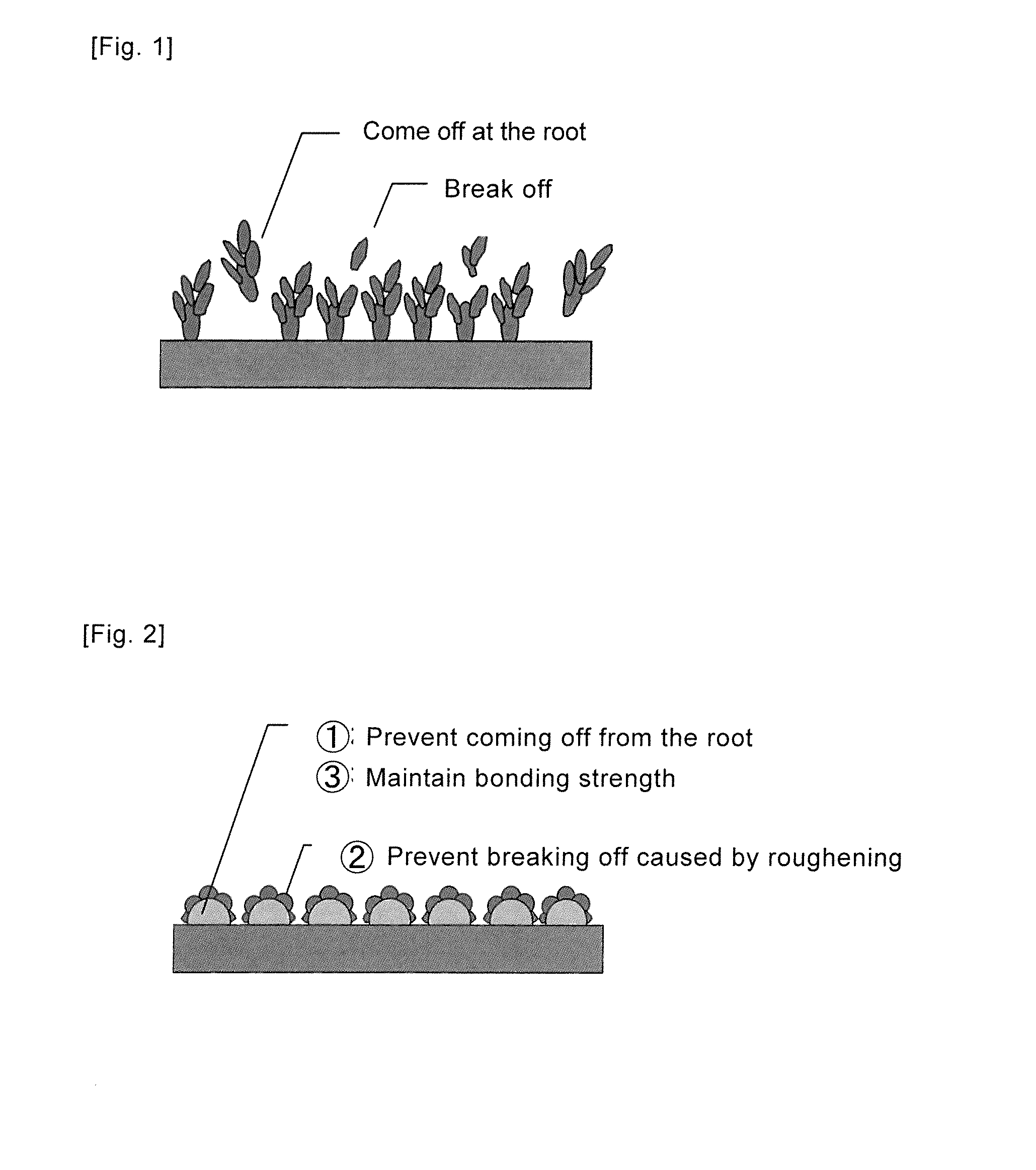

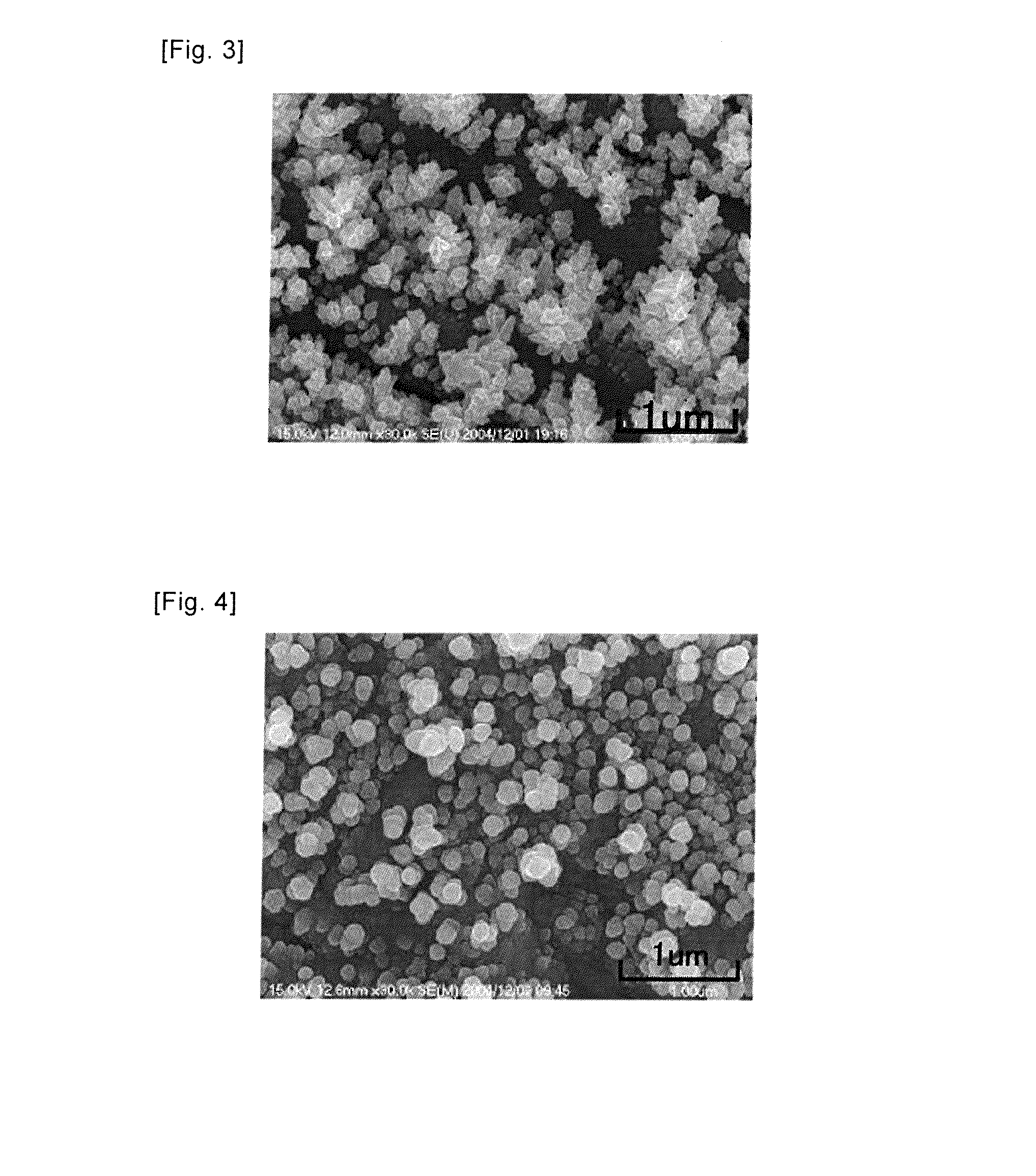

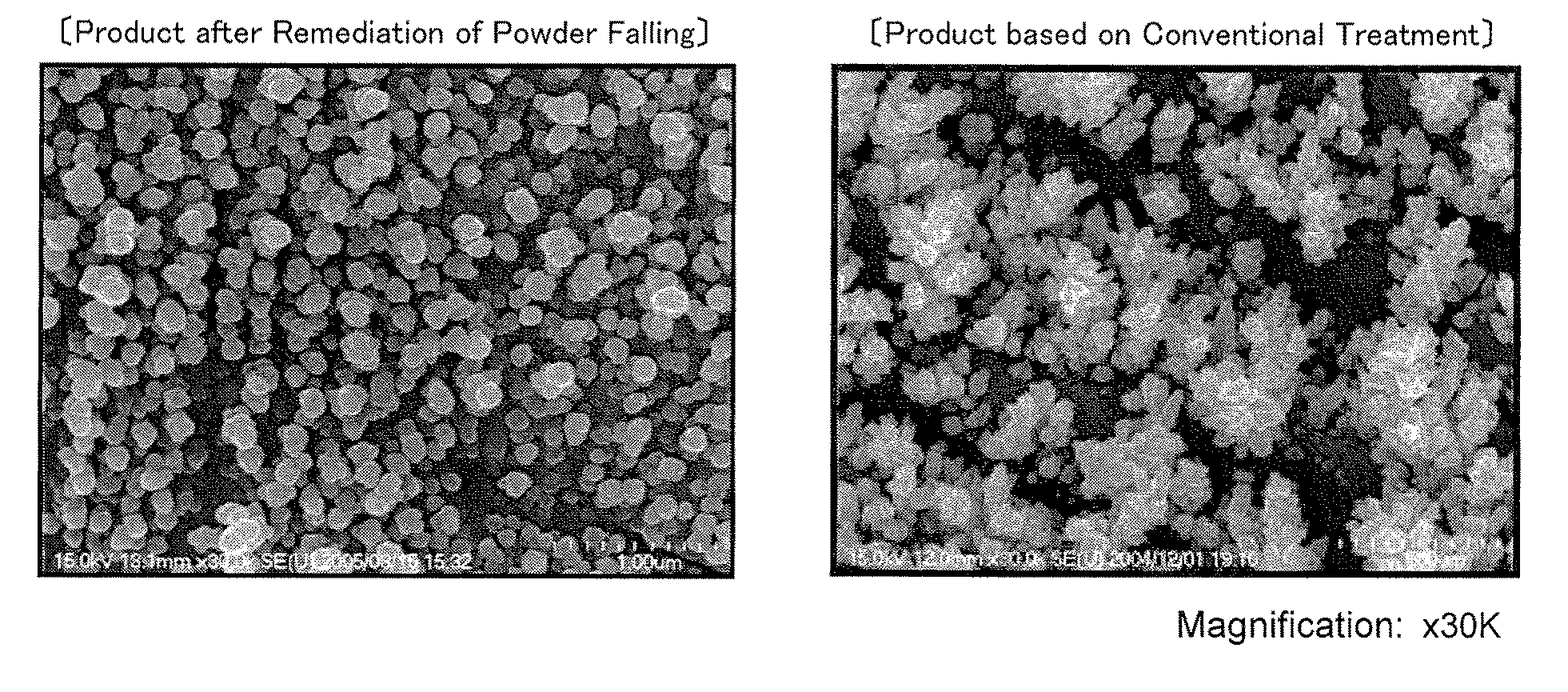

Copper Foil for Printed Circuit

ActiveUS20130011690A1High peel strengthImprove heat resistanceInsulating substrate metal adhesion improvementElectrolytic inorganic material coatingCopper foilTernary alloy

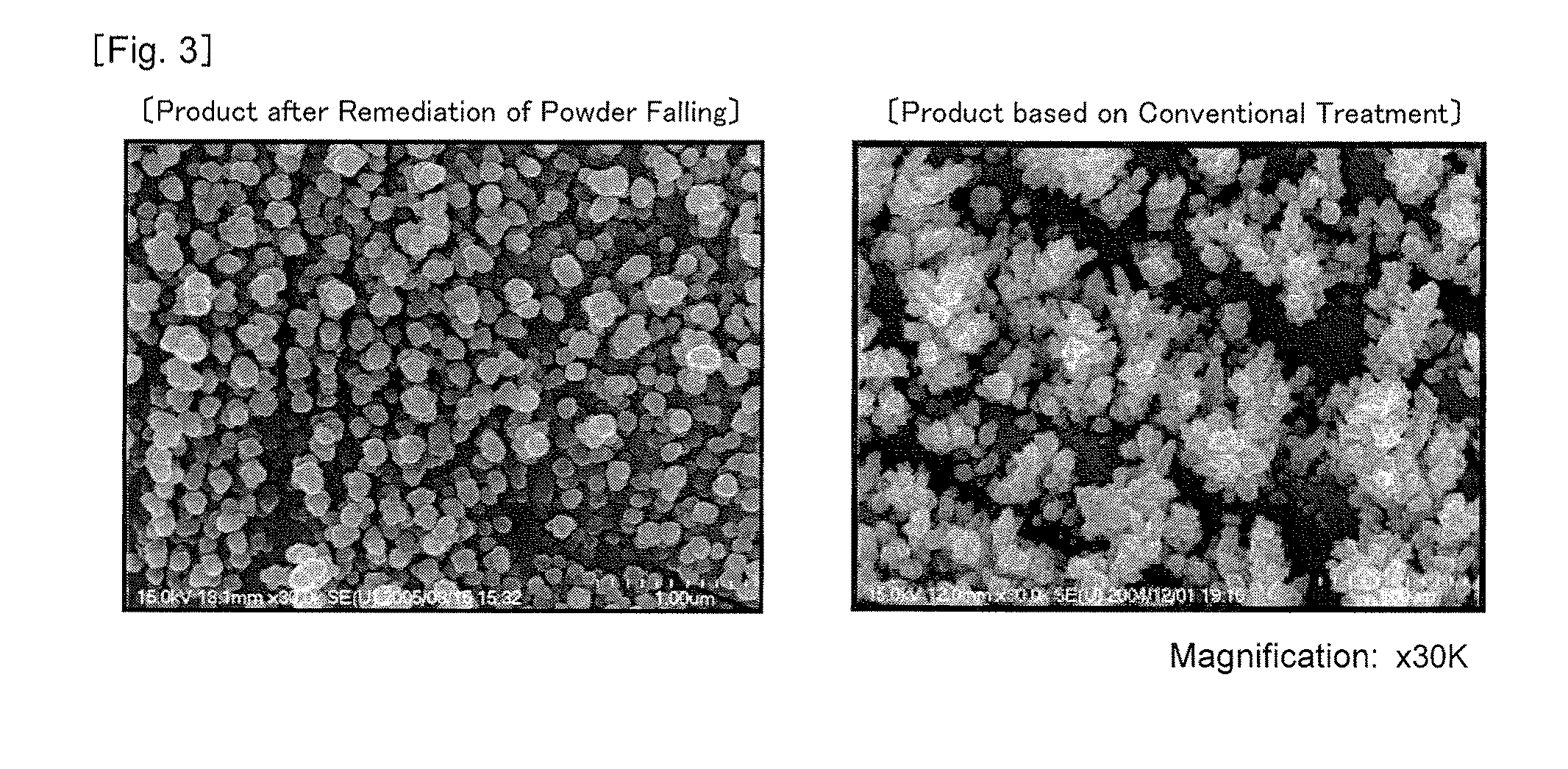

Disclosed is a copper foil for printed circuits prepared by forming a primary particle layer of copper on a surface of a copper foil, and then forming a secondary particle layer based on ternary alloy composed of copper, cobalt and nickel on the primary particle layer; in which the average particle size of the primary particle layer is 0.25 to 0.45 μm, and the average particle size of the secondary particles layer based on ternary alloy composed of copper, cobalt and nickel is 0.05 to 0.25 μm. Provided is a copper foil for printed circuits, in which powder fall from the copper foil can be reduced and the peeling strength and heat resistance can be improved by forming a primary particle layer of copper on a surface of a copper foil, and then forming a secondary particle layer based on copper-cobalt-nickel alloy plating on the primary particle layer.

Owner:JX NIPPON MINING& METALS CORP

Rare earth-oxides, rare earth-nitrides, rare earth-phosphides and ternary alloys with silicon

InactiveUS20050156155A1Quality improvementLaser detailsSemiconductor/solid-state device detailsRare earthOpto electronic

Atomic layer epitaxy (ALE) is applied to the fabrication of new forms of rare-earth oxides, rare-earth nitrides and rare-earth phosphides. Further, ternary compounds composed of binary (rare-earth oxides, rare-earth nitrides and rare-earth phosphides) mixed with silicon and or germanium to form compound semiconductors of the formula RE-(O, N, P)—(Si,Ge) are also disclosed, where RE=at least one selection from group of rare-earth metals, O=oxygen, N=nitrogen, P=phosphorus, Si=silicon and Ge=germanium. The presented ALE growth technique and material system can be applied to silicon electronics, opto-electronic, magneto-electronics and magneto-optics devices.

Owner:IQE

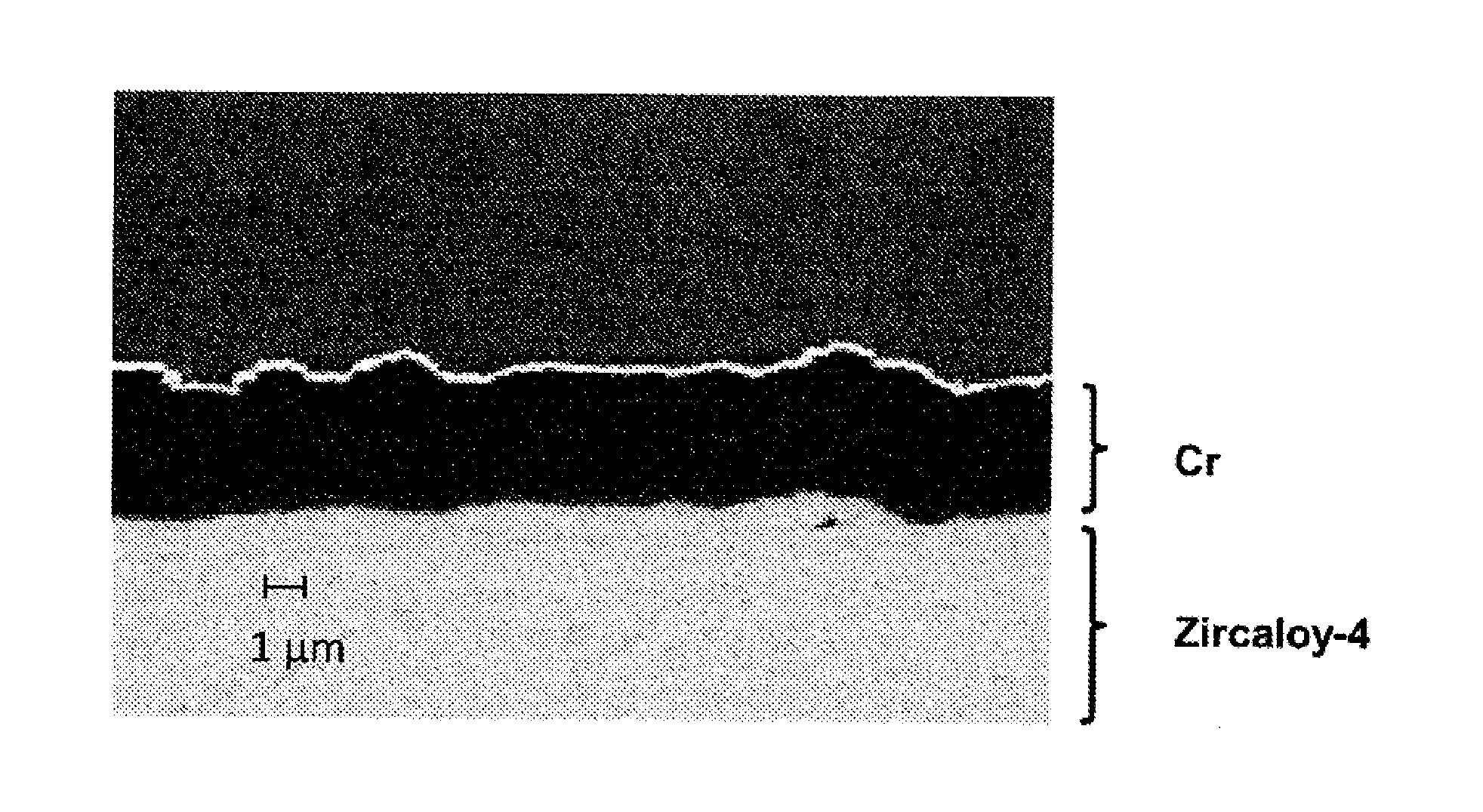

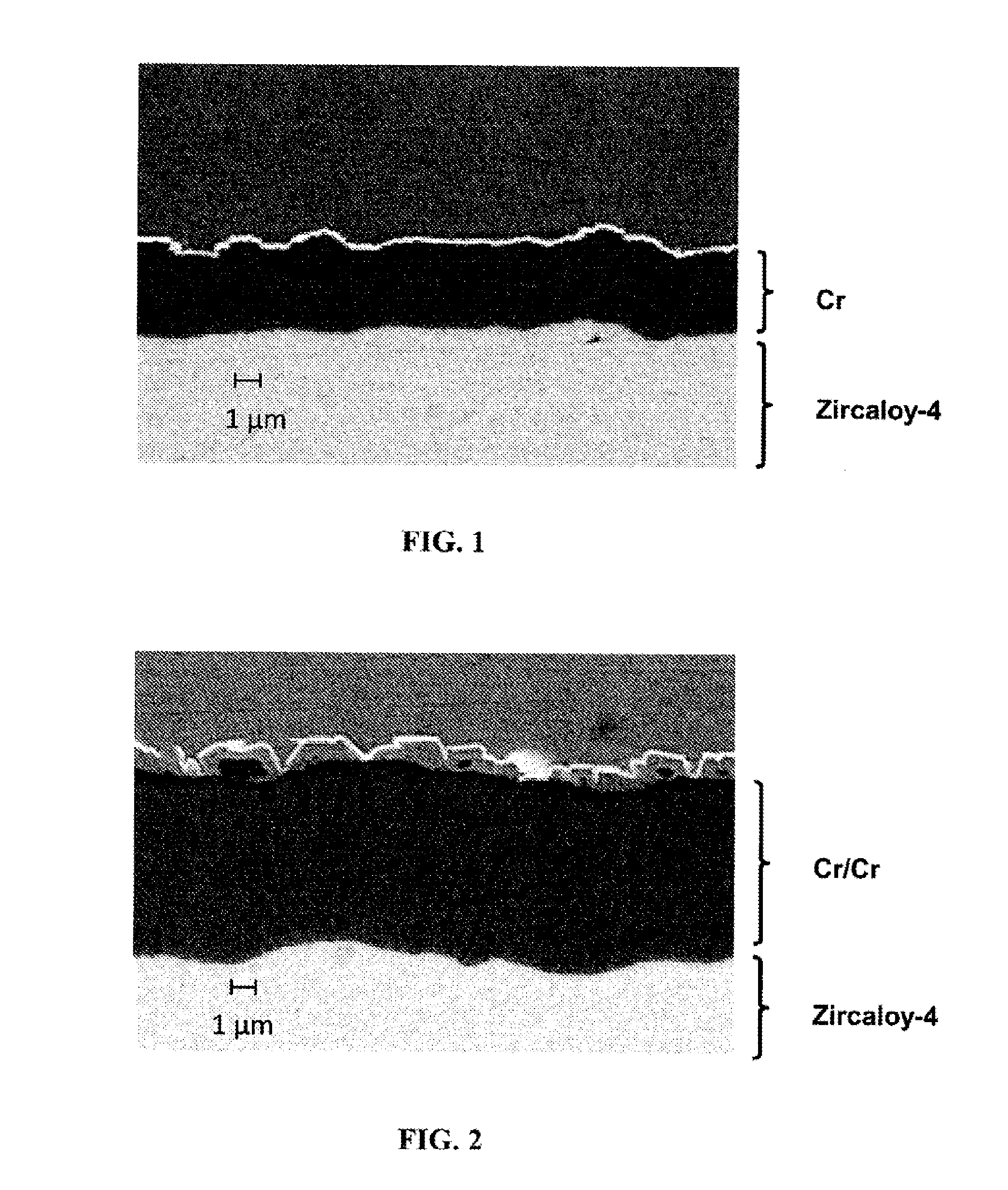

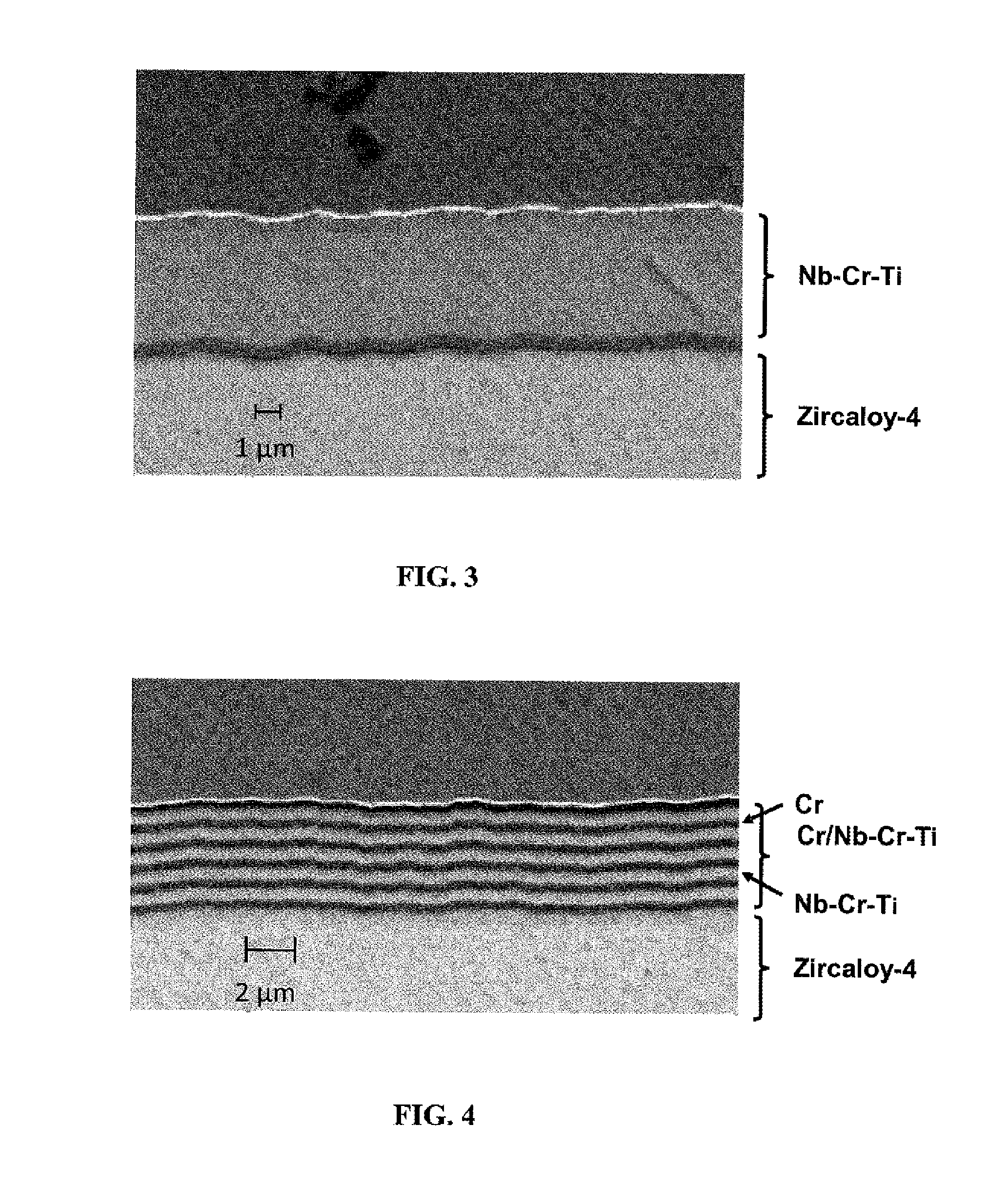

Multilayer material resistant to oxidation in a nuclear environment

ActiveUS20150050521A1Improve the immunityPromote oxidationFuel elementsNuclear energy generationNuclear reactorMetal

Multilayer material comprising a zirconium-based substrate covered with a multilayer coating, the multilayer coating comprising metallic layers composed of identical or different substances chosen from chromium, a chromium alloy or a ternary alloy of the Nb—Cr—Ti system. Such a material has improved resistance to oxidation in accident conditions of a nuclear reactor. The invention also relates to a multilayer coating, a part composed wholly or partly of the multilayer material or of the multilayer coating, as well as the method for manufacturing the multilayer material such as for example a magnetron cathodic sputtering process.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

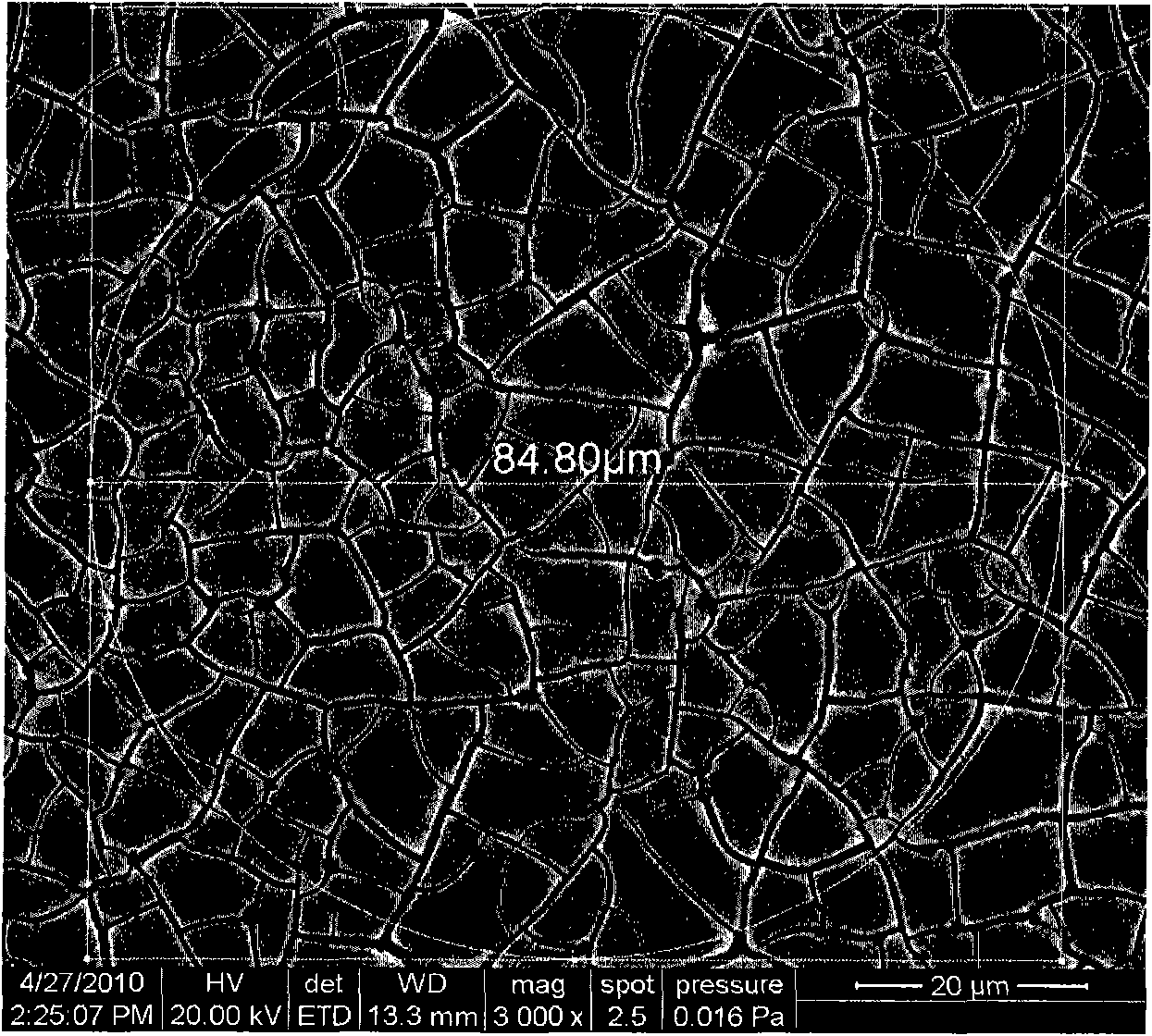

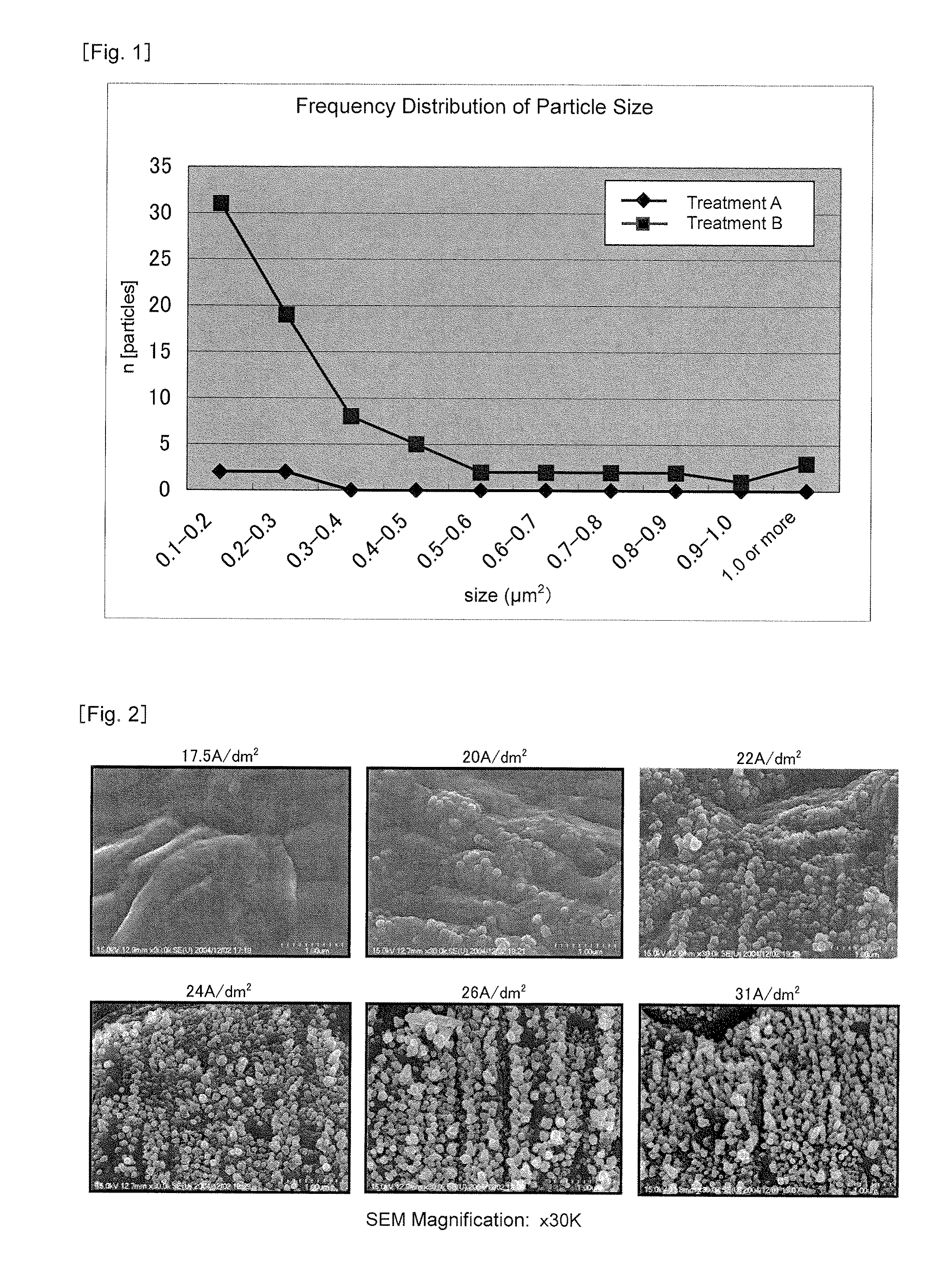

Copper Foil for Printed Circuit

ActiveUS20110262764A1Small sizeEasy to integrateThermometers using material expansion/contactionPrinted circuit aspectsCobalt nickel alloyCopper foil

Provided is a copper foil for a printed circuit with an electrodeposited ternary-alloy layer composed of copper, cobalt and nickel formed on a surface of the copper foil, wherein the electrodeposited layer comprises dendritic particles grown on the copper foil surface, and the entire surface of the copper foil is covered with particles having an area as seen from above the copper foil surface of 0.1 to 0.5 μm2 at a density of 1000 particles / 10000 μm2 or less, particles exceeding 0.5 μm2 at a density of 100 particles / 10000 μm2 or less, and particles less than 0.1 μm2 as the remainder. Roughening particles formed dendritically in a roughening treatment based on copper-cobalt-nickel alloy plating are inhibited from shedding from the copper foil surface, and the phenomenon known as powder falling and uneven treatment are thereby inhibited.

Owner:JX NIPPON MINING & METALS CORP

Rare earth-oxides, rare earth-nitrides, rare earth-phosphides and ternary alloys with silicon

Atomic layer epitaxy (ALE) is applied to the fabrication of new forms of rare-earth oxides, rare-earth nitrides and rare-earth phosphides. Further, ternary compounds composed of binary (rare-earth oxides, rare-earth nitrides and rare-earth phosphides) mixed with silicon and or germanium to form compound semiconductors of the formula RE-(O, N, P)—(Si,Ge) are also disclosed, where RE=at least one selection from group of rare-earth metals, O=oxygen, N=nitrogen, P=phosphorus, Si=silicon and Ge=germanium. The presented ALE growth technique and material system can be applied to silicon electronics, opto-electronic, magneto-electronics and magneto-optics devices.

Owner:IQE

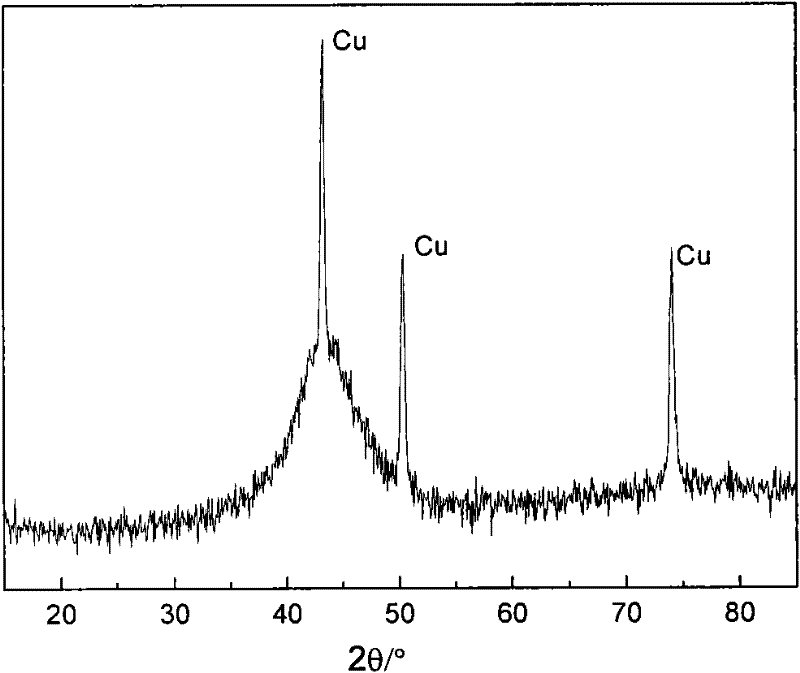

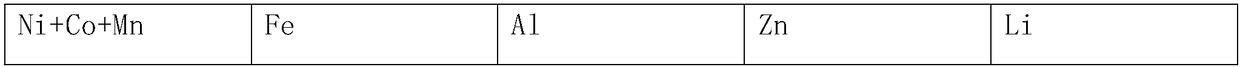

Waste Ni-Co-Mn lithium manganate positive electrode material recycling method

ActiveCN108539309APrevent oxidationHigh recovery rateCell electrodesWaste accumulators reclaimingAluminium hydroxideManganese

The invention discloses a waste Ni-Co-Mn lithium manganate positive electrode material recycling method. The waste Ni-Co-Mn lithium manganate positive electrode material recycling method comprises dismantling waste Ni-Co-Mn lithium manganate batteries, crushing positive electrode sheets, sieving and reducing crushed materials through hydrogen in a reducing furnace; washing reduced materials in hotpurified water to obtain washing solution and washed residues, inletting carbon dioxide into the washing solution to obtain lithium hydrogen carbonate solution and aluminum hydroxide precipitates, calcining the aluminum hydroxide precipitates to obtain ultrafine aluminum oxide, and pyrolyzing the lithium hydrogen carbonate solution to obtain battery-level lithium carbonate; adding the washed residues into hydrazine hydrate solution, then adding and stirring in sodium hydroxide for reaction, filtering the mixture to obtain a second filter liquor and second filtered residues, vacuum-drying thesecond filtered residues inside a vacuum drying oven, screening and magnetically-separating dried materials to obtain Ni-Co-Mn ternary alloy powder, or directly dissolving the dried materials in acidto obtain Ni-Co-Mn ternary mixed solution. The waste Ni-Co-Mn lithium manganate positive electrode material recycling method is low in cost, capable of achieving separation and recycling of all components, and high in recycling rate and value added of products.

Owner:中锂能新能源科技(烟台)有限公司

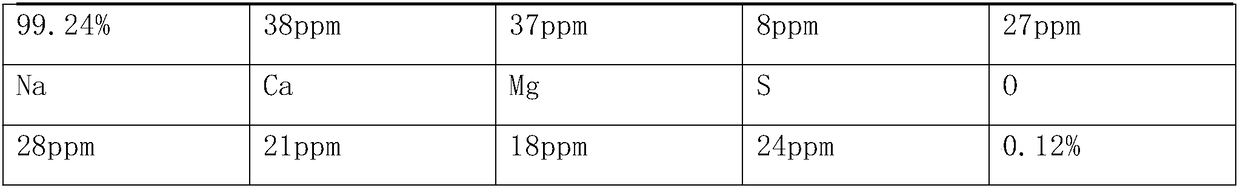

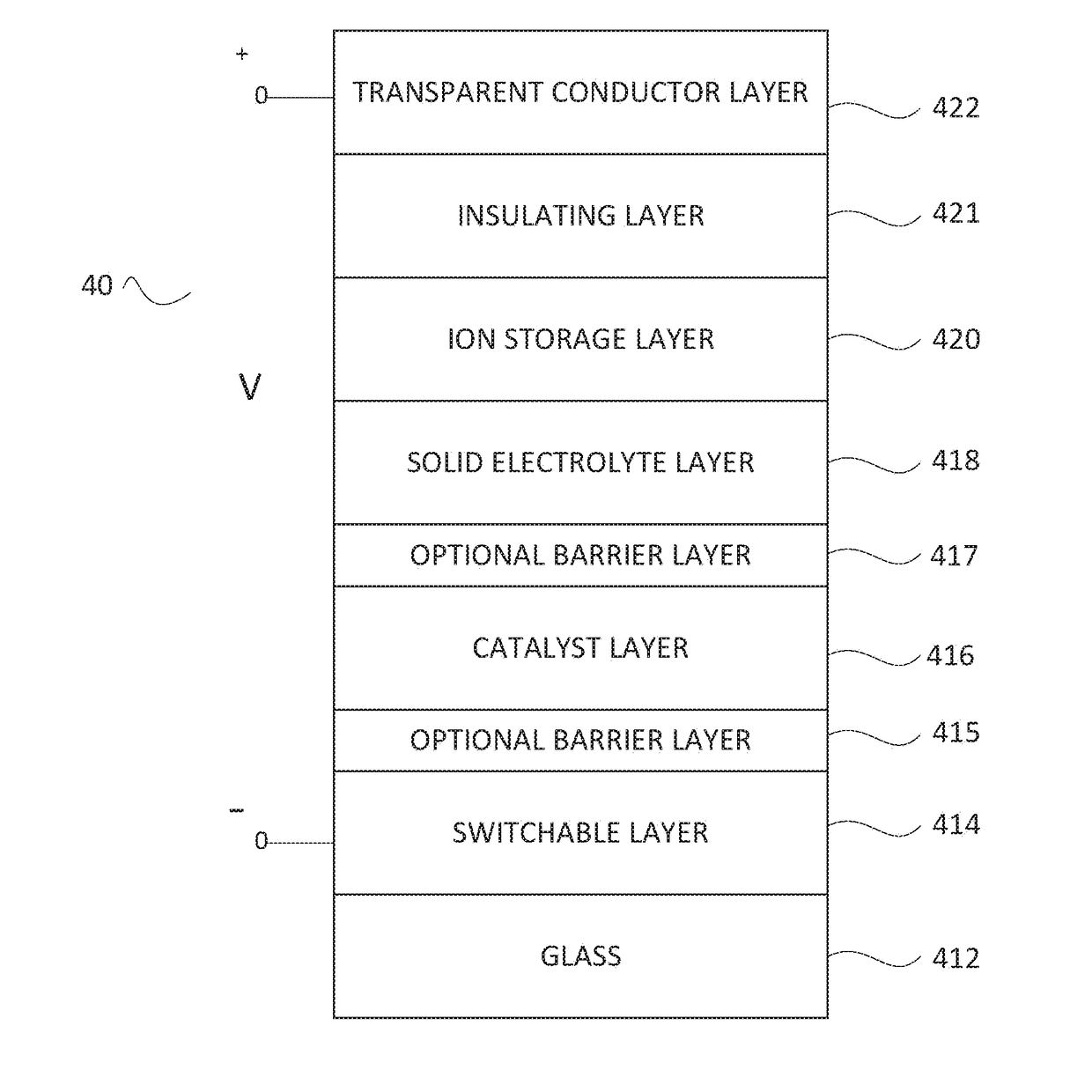

Switchable hydride smart window and the methods for procuding the same

A switchable hydride smart window solid thin film coating having variable opacity and the methods for producing the same is described. The coating includes the following layers deposited on substrate such as glass: a switchable layer, an optional barrier layer, a catalyst layer, an optional barrier layer, a solid electrode, an ion storage layer, an optional insulating layer and a transparent conductor layer. The switchable layer is preferably formed of a magnesium alloy and ore preferable, a ternary alloy of magnesium along with two additional rare earth metals such as yttrium (Y) and Titanium (Ti), i.e., MgYTi.

Owner:CARDINAL CG

Super-tough PC (polycarbonate)/PBT (Polybutylece Terephthalate)/PET (Polyethylene Glycol Terephthalate) alloy and preparation method thereof

InactiveCN102061076AOvercoming difficult processing characteristicsImprove mechanical propertiesGlycidyl methacrylateAntioxidant

The invention relates to a super-tough PC (polycarbonate) / PBT (Polybutylece Terephthalate) / PET (Polyethylene Glycol Terephthalate) alloy and a preparation method thereof. The alloy comprises the following components in percentage by weight: 35-65% of PC, 10-40% of PBT, 10-40% of PET, 4-8% of toughening compatilizer, 0.4-1% of antioxidant and 0.4-1% of processing agent, wherein the toughening compatilizer is an ethylene-methyl acrylate copolymer and / or an ethylene-methyl acrylate-glycidyl methacrylate copolymer. The preparation method comprises the following steps of: drying raw materials; then sufficiently mixing; co-mixing; extruding and pelletizing. Compared with the PC / PBT alloy, the PC / PBT / PET ternary alloy has remarkable advantages in the aspects of rigidity, toughness, heat resistant temperature and size stability, has higher cost performance and greatly improved toughness, and is the alloy with excellent comprehensive performance and high cost performance.

Owner:SHENZHEN FUHENG PLASTICS PIGMENT

Aluminum alloy automobile hub casting process

The invention discloses an aluminum alloy automobile hub casting process which comprises the following steps: a, metal melting: smelting an Al-Si-Mg ternary alloy aluminum material into an alloy liquid; and b, casting: adopting low-pressure casting, controlling a casting temperature at 600-700 DEG C, mould-filling pressure to 0.02-0.03MPa, mould-filling time to 7-9 seconds, freezing and pressure-maintaining pressure to 0.05-0.06MPa, pressure-maintaining time to 8-10 minutes, and de-molding after releasing pressure and cooling. In this way, the aluminum alloy automobile hub casting process is simple and easy to control; the Al-Si-Mg ternary alloy aluminum material which is self-formulated is adopted for low-pressure casting and forming, so that the alloy liquidity is good, the linear shrinkage is small, and hot cracking tendency is avoided, and therefore, the cast automobile hub has relatively high strength, good plasticity and high impact toughness; and a casting piece is good in surface quality, and follow-up mechanical processing is not required.

Owner:SUZHOU HUACHONG PRECISION MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com