Anticorrosive wearable electrodeposit clad layer of Ni-W-P ternary alloy and manufacturing technique and electroplate liquid thereof

A ternary alloy, anti-corrosion and wear-resistant technology, applied in the field of electrochemistry and metal surface treatment, can solve the problems of heavy equipment corrosion, poor coating performance, Ni-W-P alloy electroplating is not widely used in production, etc. Less corrosion, less damage to equipment and human body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] ① Plating solution configuration

[0028] Add clear water into the electroplating tank, heat to 50°C-60°C, then add 0.09mol / L sodium tungstate, 0.14mol / L sodium citrate, and 0.1mol / L citric acid, and stir to dissolve. Then add nickel sulfate 0.08mol / L, phosphorous acid 0.24mol / L, boric acid 0.48mol / L, stir to dissolve, adjust the pH value to 7.0 with ammonia water and sodium hydroxide, add water to make up to volume, and finally heat the solution to 75°C Then you can try plating.

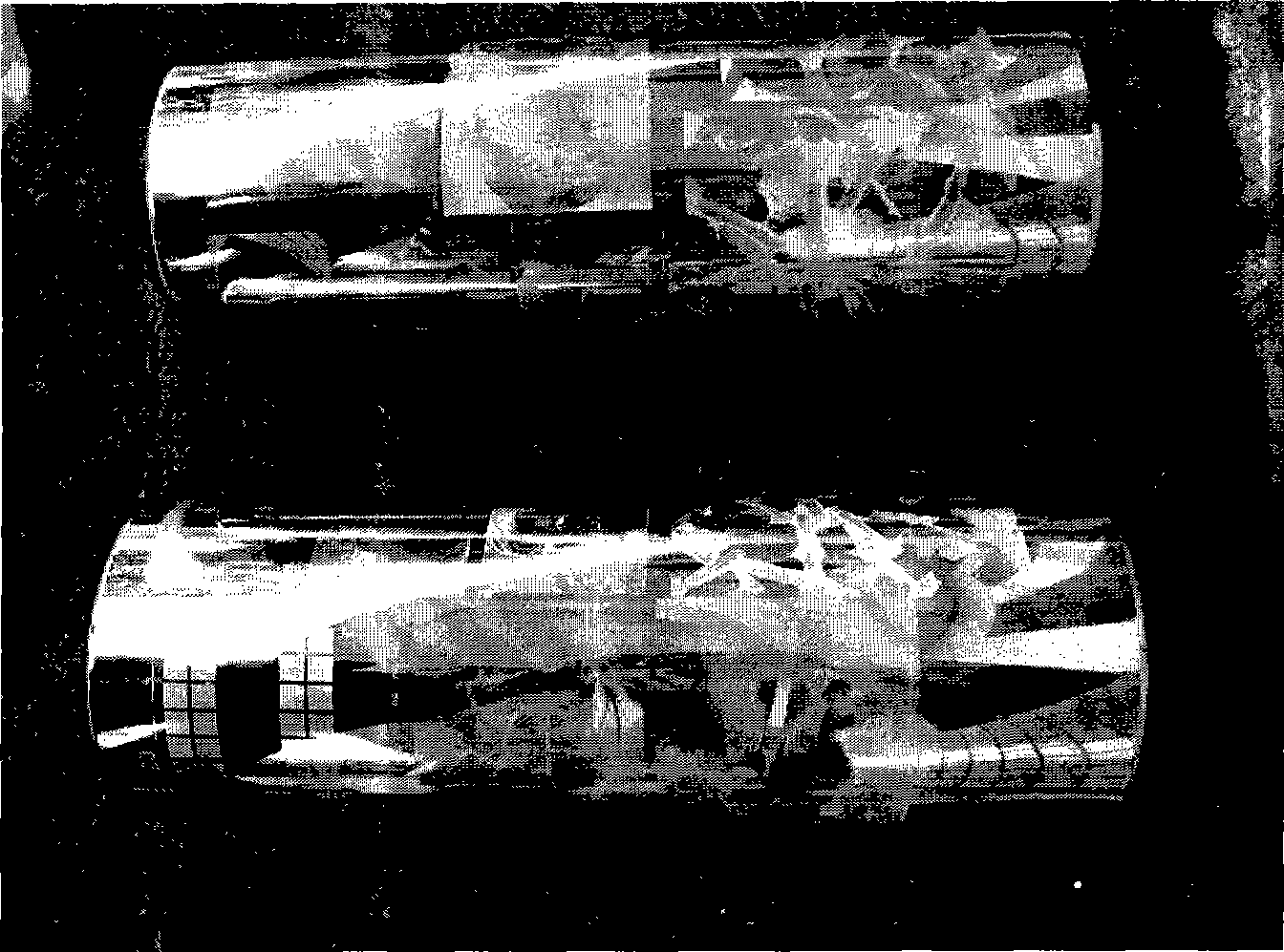

[0029] ② Pretreatment of the workpiece

[0030] The workpiece material is low carbon steel, which has been derusted, degreased and activated.

[0031] ③ Plating

[0032] After the workpiece is pretreated, it is placed in the electroplating tank, and the current density is 70mA / cm 2 Under electroplating, time 1.5h. After plating, rinse and blow dry.

[0033] ④ Hydrogen removal

[0034] The plated workpiece was kept at 200°C for 2h.

[0035] ⑤ inspection

[0036] First check whether th...

Embodiment 2

[0046] ① Plating solution configuration

[0047] First add clear water to the electroplating tank, heat to 50°C-60°C, then add 0.09mol / L sodium tungstate, 0.14mol / L sodium citrate, and 0.1mol / L citric acid, and stir to dissolve. Then add nickel sulfate 0.08mol / L, phosphorous acid 0.12mol / L, stir to dissolve, use ammonia water and sodium hydroxide to adjust the pH value to 6.5, add water to make up the volume, and finally heat the solution to 75°C before trial plating.

[0048] ② Pretreatment of the workpiece

[0049] The workpiece material is low carbon steel, which has been derusted, degreased and activated.

[0050] ③ Plating

[0051] After the workpiece is pretreated, it is placed in the electroplating tank. At a current density of 70mA / cm 2 Under electroplating, time 1.5h. After plating, rinse and blow dry.

[0052] ④ Hydrogen removal

[0053] The plated workpiece was kept at 200°C for 2h.

[0054] ⑤ inspection

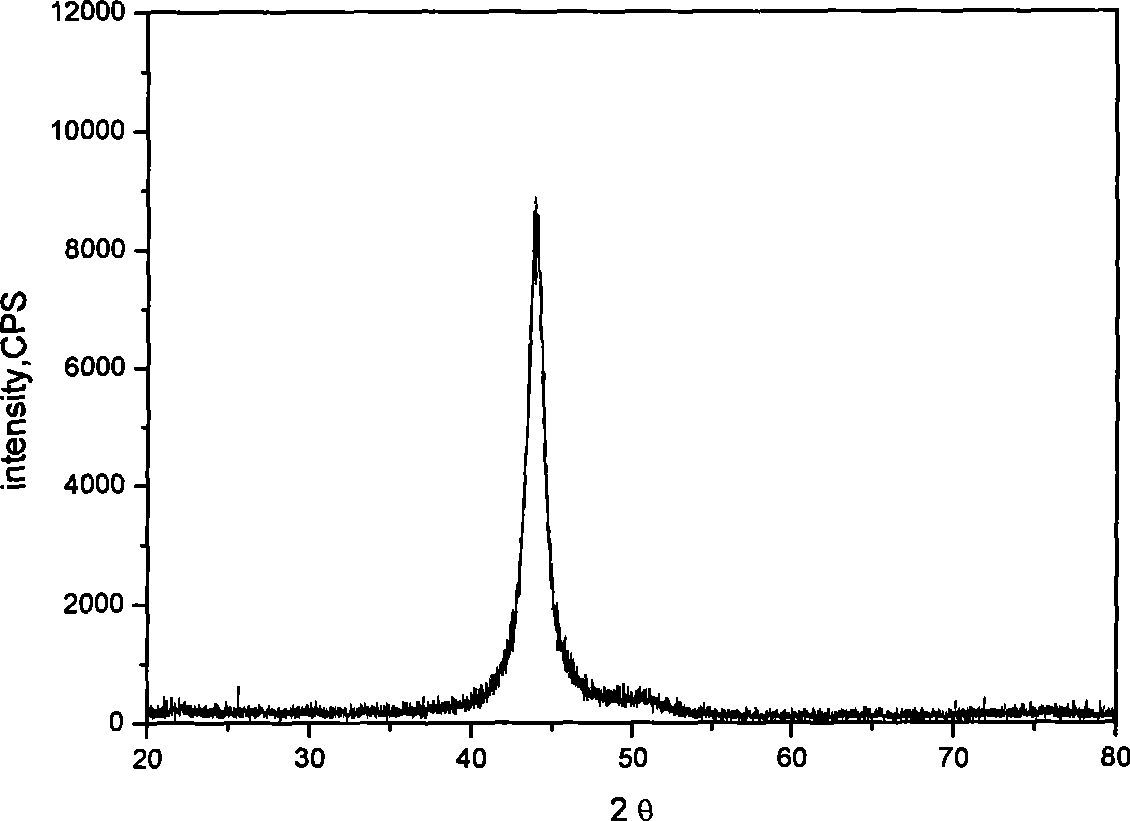

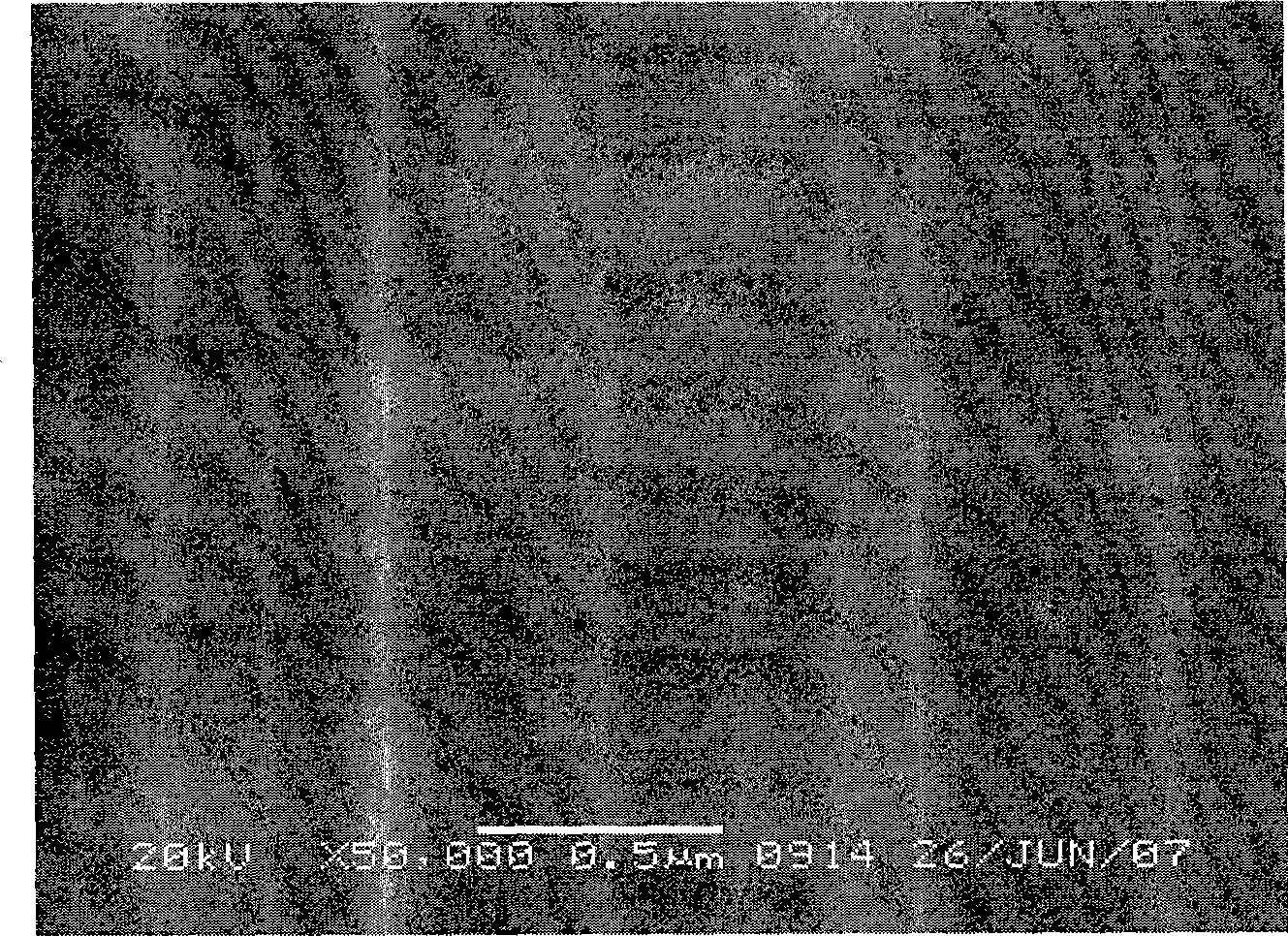

[0055] The composition of the Ni-W-P coating obtained...

Embodiment 3

[0057] ① Plating solution configuration is the same as Example 1

[0058] ② Pretreatment of the workpiece

[0059] The workpiece material is brass, which has been derusted, degreased and activated.

[0060] ③ Plating

[0061] After the workpiece is pretreated, it is placed in the electroplating tank. Electroplating current density 70mA / cm 2 Under electroplating, time 1.5h. After plating, rinse and blow dry.

[0062] ④ Hydrogen removal

[0063] The finished workpiece is de-insulated at 200°C for 2 hours.

[0064] ⑤ inspection

[0065] The coating obtained in this embodiment is bright and dense, and has good bonding force, corrosion resistance and wear resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com