Patents

Literature

2433 results about "Phosphorous acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phosphorous acid, is the compound described by the formula H₃PO₃. This acid is diprotic (readily ionizes two protons), not triprotic as might be suggested by this formula. Phosphorous acid is an intermediate in the preparation of other phosphorus compounds. Organic derivatives of phosphorous acid, compounds with the formula RPO₃H₂, are called phosphonic acids.

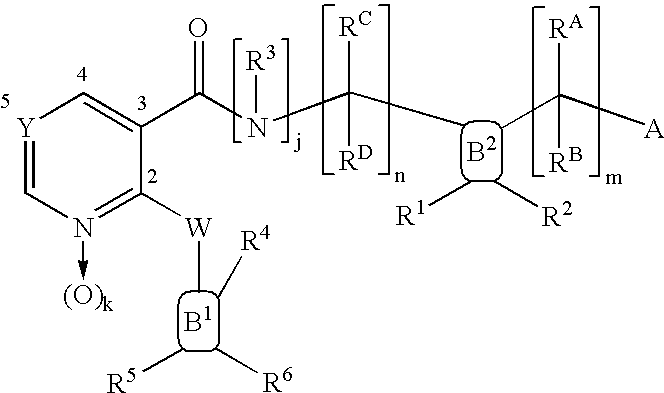

Nicotinamide acids, amides, and their mimetics active as inhibitors of PDE4 isozymes

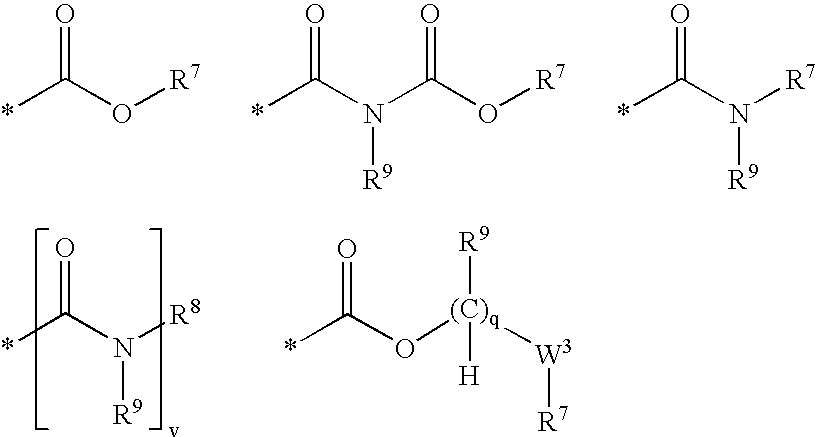

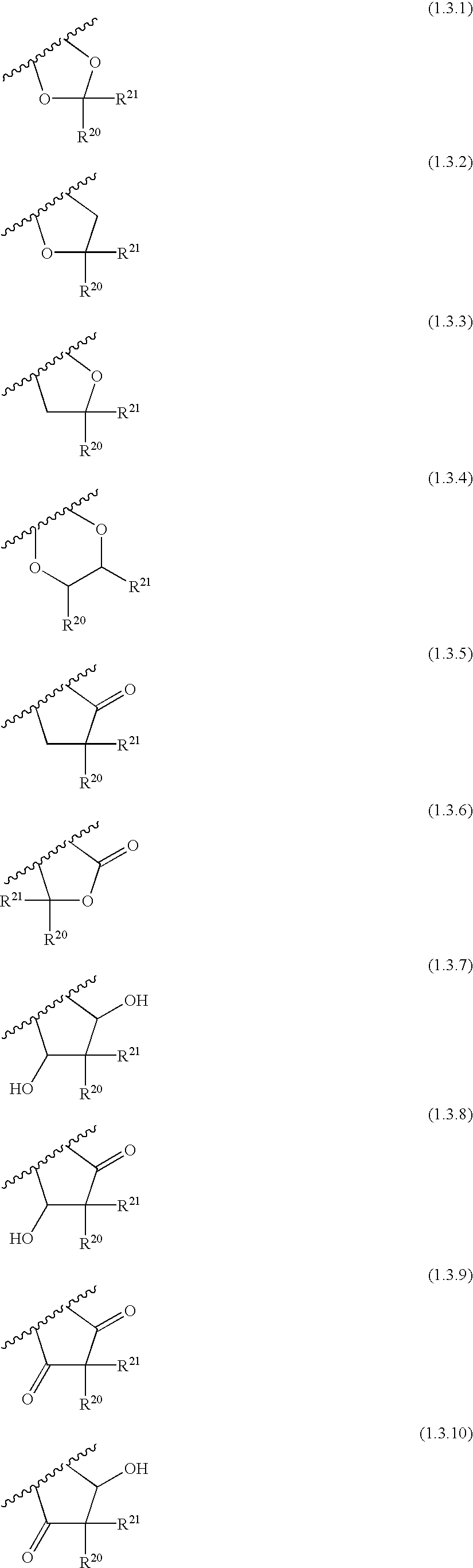

Compounds useful as inhibitors of PDE4 in the treatment of diseases regulated by the activation and degranulation of eosinophils, especially asthma, chronic bronchitis, and chronic obstructuive pulmonary disease, of the formula: wherein j is 0 or 1, k is 0 or 1, m is 0, 1, or 2; n is 1 or 2; A is selected from the partial Formulas: where q is 1, 2, or 3, W3 is -O-; -N(R9)-; or -OC(=O)-; R7 is selected from -H; -(C1-C6) alkyl, -(C2-C6) alkenyl, or -(C2-C6) alkynyl substituted by 0 to 3 substituents R10; -(CH2)u-(C3-C7) cycloalkyl where u is 0, 1 or 2, substituted by 0 to 3 R10; and phenyl or benzyl substituted by 0 to 3 R14; R8 is tetrazol-5-yl; 1,2,4-triazol-3-yl; 1,2,4-triazol-3-on-5-yl; 1,2,3-triazol-5-yl; imidazol-2-yl; imidazol-4-yl; imidazolidin-2-on-4-yl; 1,3,4-oxadiazolyl; 1,3,4-oxadiazol-2-on-5-yl; 1,2,4-oxadiazol-3-yl; 1,2,4-oxadiazol-5-on-3-yl; 1,2,4-oxadiazol-5-yl; 1,2,4-oxadiazol-3-on-5-yl; 1,2,5-thiadiazolyl; 1,3,4-thiadiazolyl; morpholinyl; parathiazinyl; oxazolyl; isoxazolyl; thiazolyl; isothiazolyl; pyrrolyl; pyrazolyl; succinimidyl; glutarimidyl; pyrrolidonyl; 2-piperidonyl; 2-pyridonyl; 4-pyridonyl; pyridazin-3-onyl; pyridyl; pyrimidinyl; pyrazinyl; pyridazinyl; indolyl; indolinyl; isoindolinyl; benzo[b]furanyl; 2,3-dihydrobenzofuranyl; 1,3-dihydroisobenzofuranyl; 2H-1-benzopyranyl; 2-H-chromenyl; chromanyl; benzothienyl; 1H-indazolyl; benzimidazolyl; benzoxazolyl; benzisoxazolyl; benzothiazolyl; benzotriazolyl; benzotriazinyl; phthalazinyl; 1,8-naphthyridinyl; quinolinyl; isoquinolinyl; quinazolinyl; quinoxalinyl; pyrazolo[3,4-d]pyrimidinyl; pyrimido[4,5-d]pyrimidinyl; imidazo[1,2-a]pyridinyl; pyridopyridinyl; pteridinyl; or 1H-purinyl; or A is selected from phosphorous and sulfur acid groups; W is -O-; -S(=O)t-, where t is 0, 1, or 2; or -N(R3)-; Y is =C(R1a)-, or -[N<custom-character file="US20020111495A1-20020815-P00900.TIF" wi="20" he="20" id="custom-character-00001" / >(O)k] where k is 0 or 1; R4, R5 and R6 are (1) -H; provided that R5 and R6 are not both -H at the same time, -F; -Cl; -(C2-C4) alkynyl; -R16; -OR16; -S(=O)pR16; -C(=O)R16, -C(=O)OR16, -C(=O)OR<highlight><sup

Owner:PFIZER INC

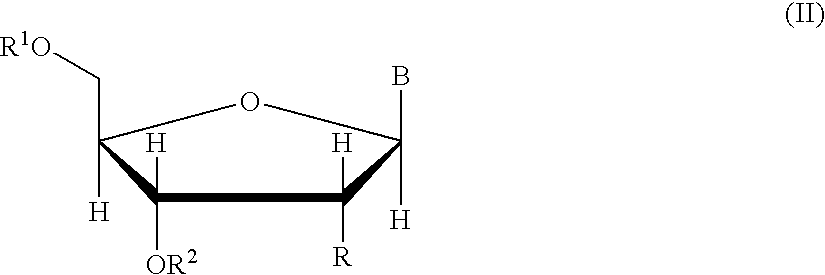

Methods of synthesizing oligonucleotides using carbonate protecting groups and alpha-effect nucleophile deprotection

The invention provides methods for synthesizing oligonucleotides using nucleoside monomers having carbonate protected hydroxyl groups that are deprotected with α-effect nucleophiles. The α-effect nucleophile irreversibly cleave the carbonate protecting groups while simultaneously oxidizing the internucleotide phosphite triester linkage to a phosphodiester linkage. The procedure may be carried out in aqueous solution at neutral to mildly basic pH. The method eliminates the need for separate deprotection and oxidation steps, and, since the use of acid to remove protecting groups is unnecessary, acid-induced depurination is avoided. Fluorescent or other readily detectable carbonate protecting groups can be used, enabling monitoring of individual reaction steps during oligonucleotide synthesis. The invention is particularly useful in the highly parallel, microscale synthesis of oligonucleotides.

Owner:AGILENT TECH INC +1

High temperature glass fiber insulation

Owner:GLASS

Industrial process for the synthesis of 17a-acetoxy-11ss-[4-(n,n-dimethyl-amino)- phenyl]-19-norpregna-4,9-diene-3,20-dione and new intermediates of the process

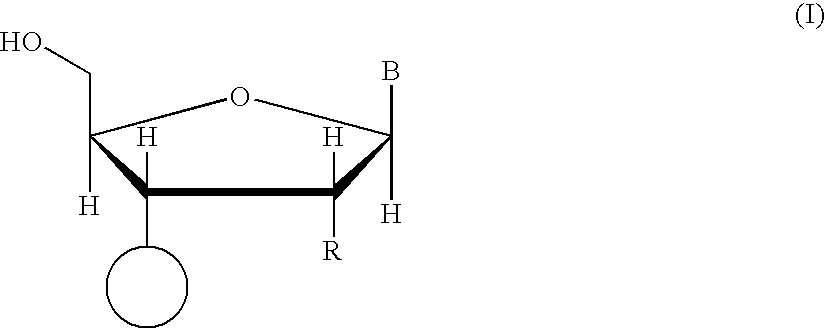

The present invention relates to a new industrial process for the synthesis of solvate- free 17a-acetoxy-11ss-[4-(N,N-dimethyl-amino)-phenyl]-19-norpregna-4,9-diene-3,20-dione [CDB -2914] of formula (I) which is a strong antiprogestogene and antiglucocorticoid agent. The invention also relates to compounds of formula (VII) and (VIII) used as intermediates in the process. The process according to the invention is the following: i) 3-(ethylene-dioxy)-estra-5(10),9(11)-diene-17-one of formula (X) is reacted with potassium acetilyde formed in situ in dry tetrahydrofuran by known method, ii) the obtained 3-(ethylene-dioxy)-17a-ethynyl-17ss-hydroxy-estra-5(10),9(11)-diene of formula (IX) is reacted with phenylsulfenyl chloride in dichloromethane in the presence of triethylamine and acetic acid, iii) the obtained isomeric mixture of 3-(ethylene-dioxy)-21-(phenyl-sulfinyl)-19-norpregna-5(10),9(11),17(20),20-tetraene of formula (VIII) is reacted first with sodium methoxide in methanol, then with trimethyl phosphite, iv) the obtained 3-(ethylene-dioxy)-17a-hydroxy-20-methoxy-19-norpregna-5(10),9(11),20-triene of formula (VII) is reacted with hydrogen chloride in methanol, then v) the obtained 3-(ethylene-dioxy)-17a-hydroxy-19-norpregna-5(10),9(11l); -diene-20- one of formula (VI) is reacted with ethylene glycol hi dichloromethane in the presence of trimethyl orthoformate and p-toluenesulfonic acid by known method, vi) the obtained 3,3,20,20-bis(ethylene-dioxy)-17a-hydroxy-19-norpregna- 5(10),9(11)-diene of formula (V) is reacted with hydrogen peroxide in a mixture of pyridine and dichloromethane in the presence of hexachloroacetone by known method, vii) the obtained 3,3,20,20-bis(ethylene-dioxy)-17a-hydroxy-5,10-epoxy-19-norpregn-9(11)-ene of formula (IV), containing approximately a 1:1 mixture of 5a,10a- and 5ss,10ss-epoxides, is isolated from the solution and reacted with a Grignard reagent obtained from 4-bromo-N,N-dimethyl-aniline in tetrahydrofuran.

Owner:RICHTER GEDEON NYRT

Method for recycling titanium dioxide in waste SCR (Selective Catalytic Reduction) denitration catalyst

ActiveCN103130265AQuality assuranceAvoid overdoseTitanium dioxideChemical recyclingSolubilityPhosphorous acid

The invention relates to a method for recycling titanium dioxide in a waste SCR (Selective Catalytic Reduction) denitration catalyst. The method comprises the following steps of: firstly removing dust from the waste denitration catalyst, pulverizing, then adding concentrated sulfuric acid so as to carry out acid hydrolysis on the waste denitration catalyst to obtain a concentrated titanyl sulfate solution, and adding water for dilution; adding a non-ionic emulsifier serving as a flocculating agent and a sulfonate surface active agent or a polycarboxylate surface active agent as a coagulant aid, and adding water-solubility methyl silicone oil; pumping into a plate-and-frame filter press for filter pressing, carrying out vacuum concentration on filtrate, then heating to 90 DEG C to 98 DEG C, and maintaining for 5.5 hours so as to hydrolyze the filtrate; cooling a hydrolysis product to 40 DEG C, and carrying out vacuum filtration so as to sediment out metatitanic acid; rinsing with sand-filtered water and deionized water, and adding potassium carbonate or phosphorous acid to obtain metatitanic acid filter cakes; and drying the filter cakes, calcining at 500-800 DEG C, and then pulverizing to obtain a titanium dioxide finished product. The method has the advantages of being capable of reducing disposal amount of the waste denitration catalyst, recycling the waste denitration catalyst and reducing the production cost of the waste denitration catalyst.

Owner:江苏万德环保科技有限公司

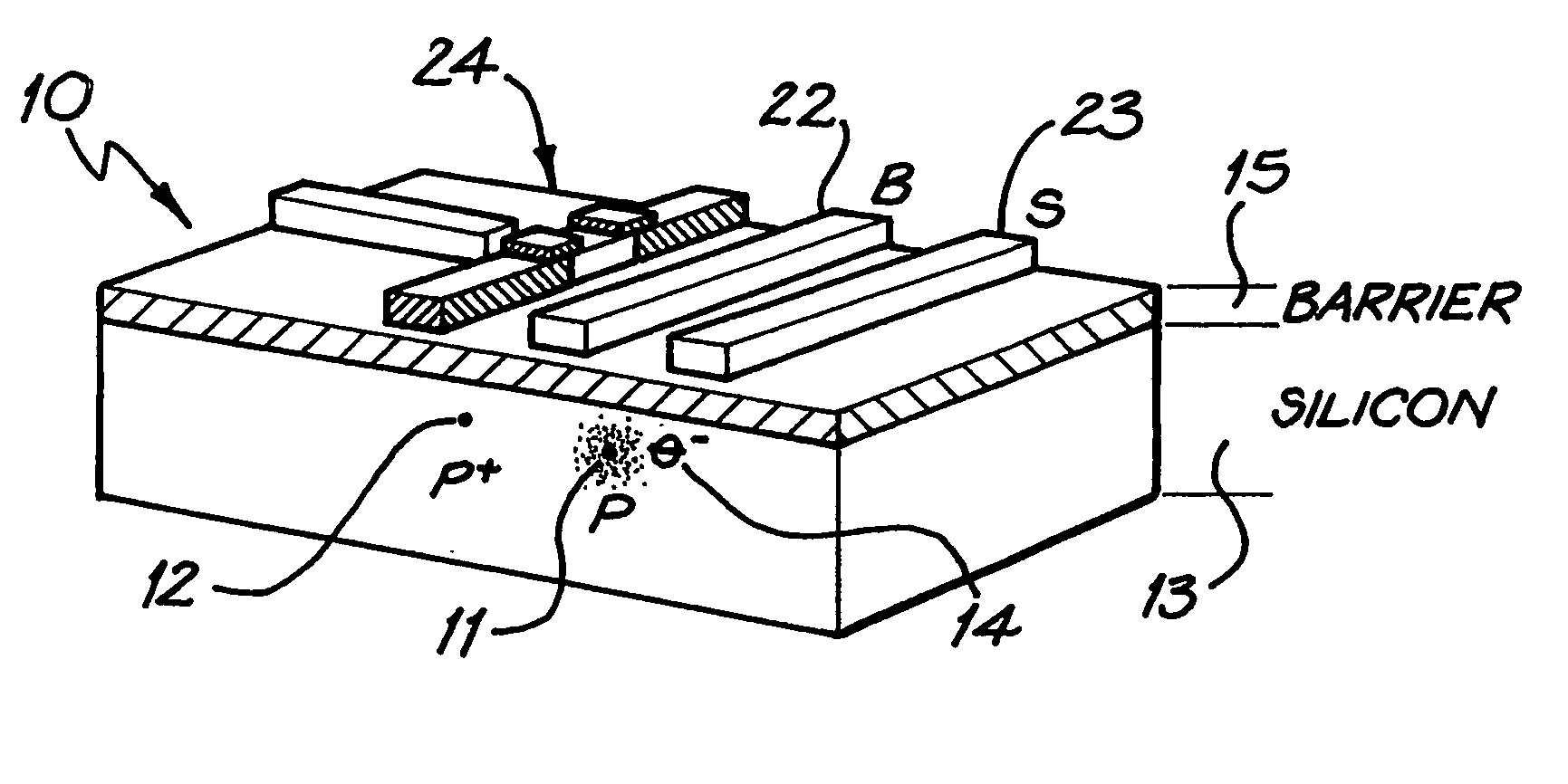

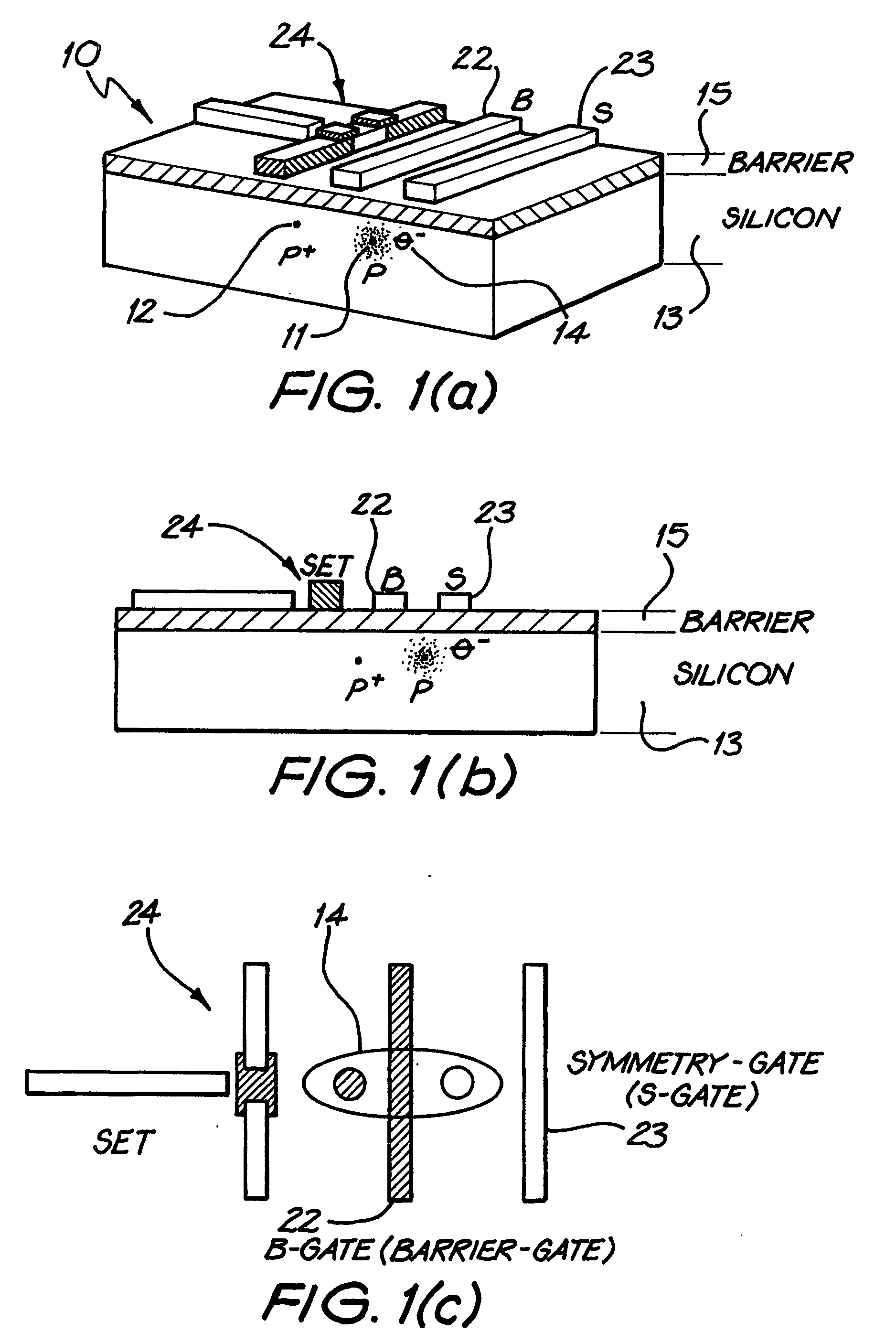

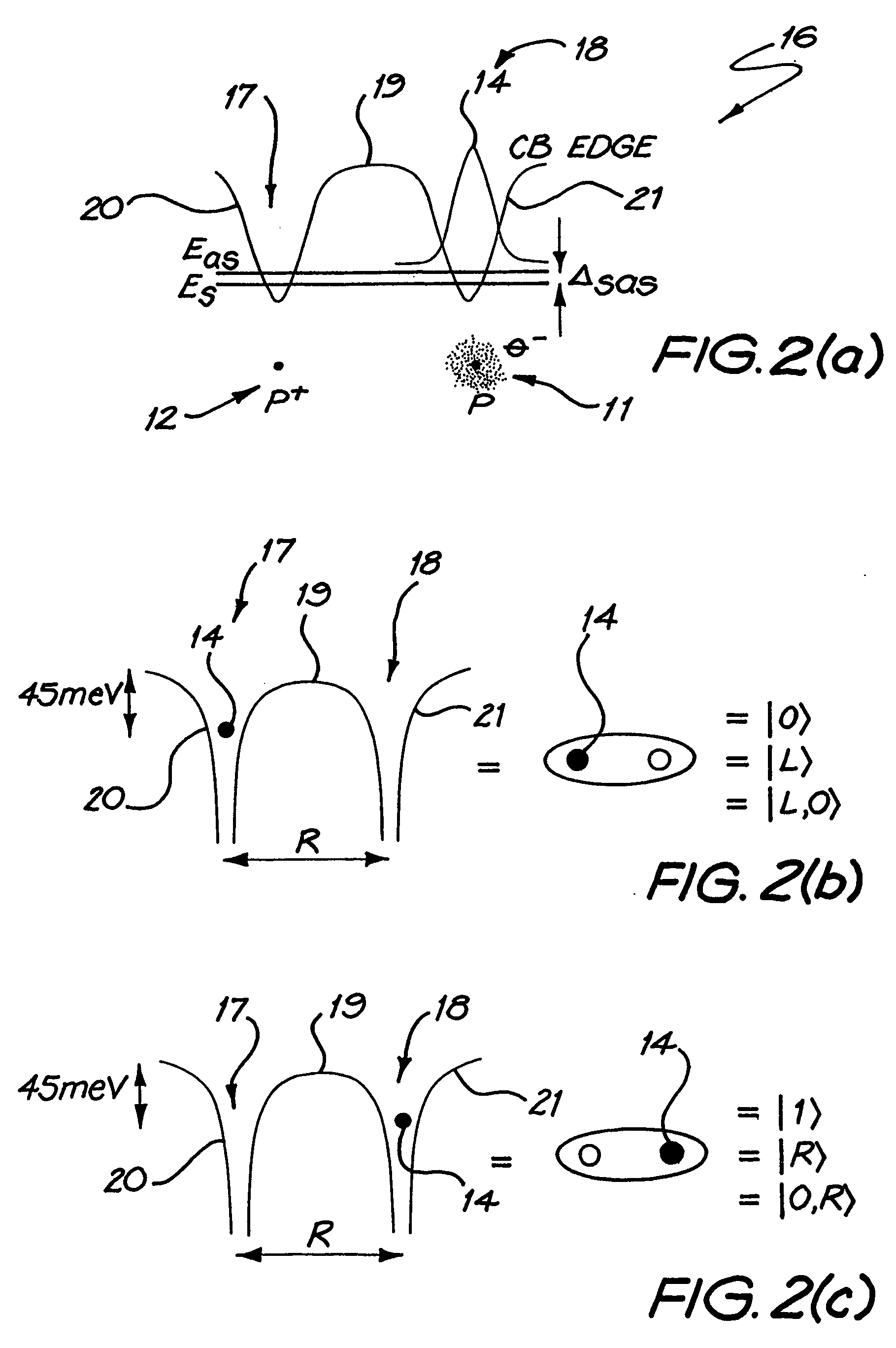

Solid state charge qubit device

ActiveUS20060151775A1Minimize couplingNanofabrication considerably easierQuantum computersNanoinformaticsPhosphorous acidDouble-well potential

Ionisation of one of a pair of dopant atoms (11, 12) in a substrate (13) creates a double well potential, and a charge qubit is realised by the location of one or more electrons or holes (14) within this potential. The dopant atoms may comprise phosphorous atoms, located in a silicon substrate. A solid state quantum computer may be formed using a plurality of pairs of dopant atoms (11, 12), corresponding gate electrodes (22, 23), and read-out devices comprising single electron transistors (24).

Owner:NEWSOUTH INNOVATIONS PTY LTD

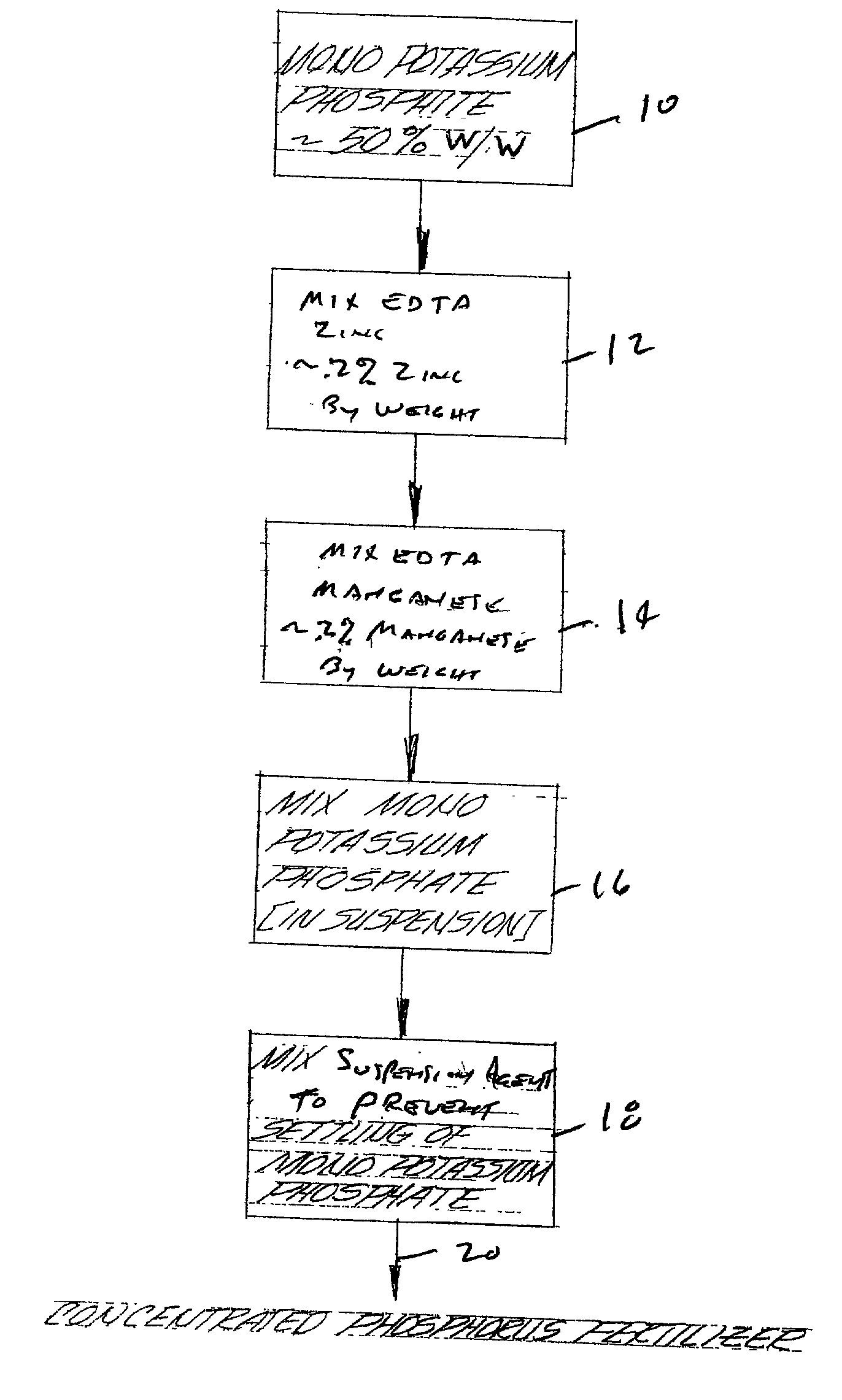

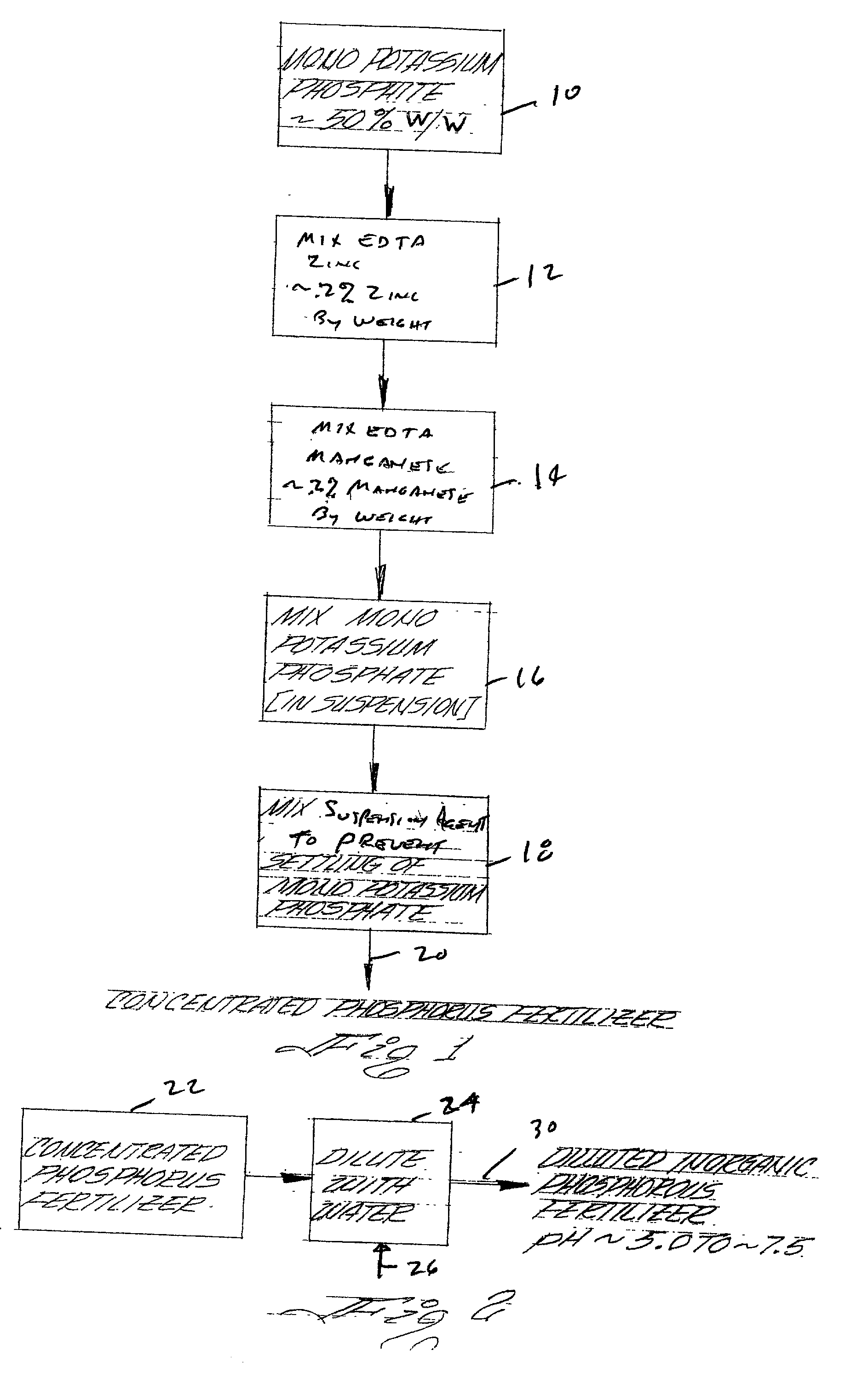

Concentrated phosphorus fertilizer

InactiveUS20020129632A1Easy to diluteImproving phosphorus uptakeAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPhosphorous acidSalt content

A concentrated fluid phosphorus fertilizer is shown. In the preferred embodiment, the concentrated fluid phosphorus fertilizer is an aqueous suspension fertilizer composition. The composition comprises one or more phosphorus-containing acids or salts thereof selected from the group consisting of phosphoric acid, polyphosphoric acid, phosphorous acid, polyphosphorous acid, hypophosphorous acid and polyhypophosphorous acid, and salts thereof. A suspension agent maintains undissolved solids in substantially homogeneous suspension wherein the suspension has a total acid and salt content of about 50% w / w to about 80% w / w. The concentrated fluid phosphorus fertilizer is a stable suspension and when diluted with water a substantially fully soluble fertilizer having acceptable pH for phosphorus uptake is formed. Methods for improving the phosphorus uptake and improving the growth rate of plants is also shown.

Owner:INTERFARM

Method for forming ultrahigh-voltage anode foil for aluminum electrolytic capacitors

ActiveCN102610390AImprove compactnessIncrease costSurface reaction electrolytic coatingCapacitor electrodesConvertersPhosphorous acid

The invention relates to the production of electronic components, and discloses a method for forming anode foil for electrolytic capacitors. The ultrahigh-voltage anode foil is formed through six stages, wherein from the stage 1 to stage 5, each stage has a formation tank, and in the stage 6, three formation tanks are connected in parallel; and an acid fluid mixture containing a boric acid, a citric acid or an azelaic acid (the electric conductance and pH value thereof are adjusted by using carbon-containing inorganic salts) and ammonium hypophosphite or sodium monophosphate for improving the boiled performance of an oxidation film is filled in each formation tank. Correspondingly, the processing step is also adjusted, and the produced anode foil not only can be applied to the fields and industries of aerospace and automotive frequency converters and industrial frequency converters and the like meeting the ultrahigh voltage requirements on a withstand voltage of 700-1200V, but also is dense in oxidation film surface, high in specific volume and short in boosting time.

Owner:新疆金泰新材料技术股份有限公司

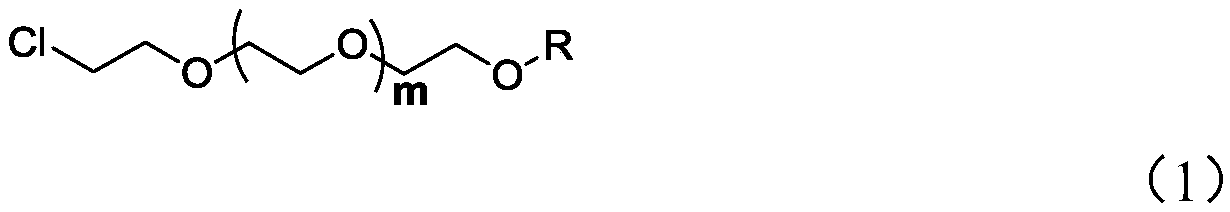

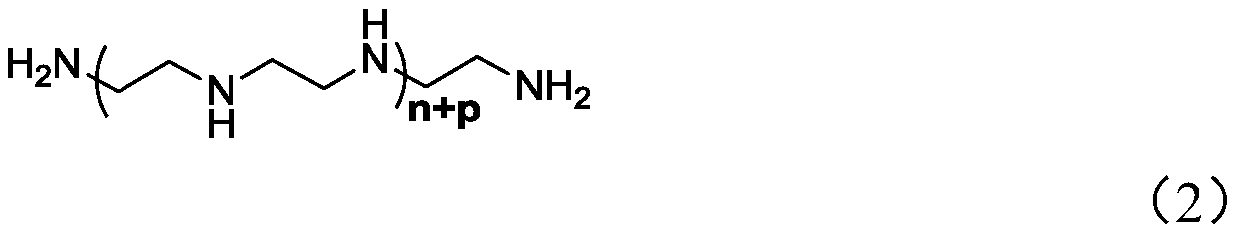

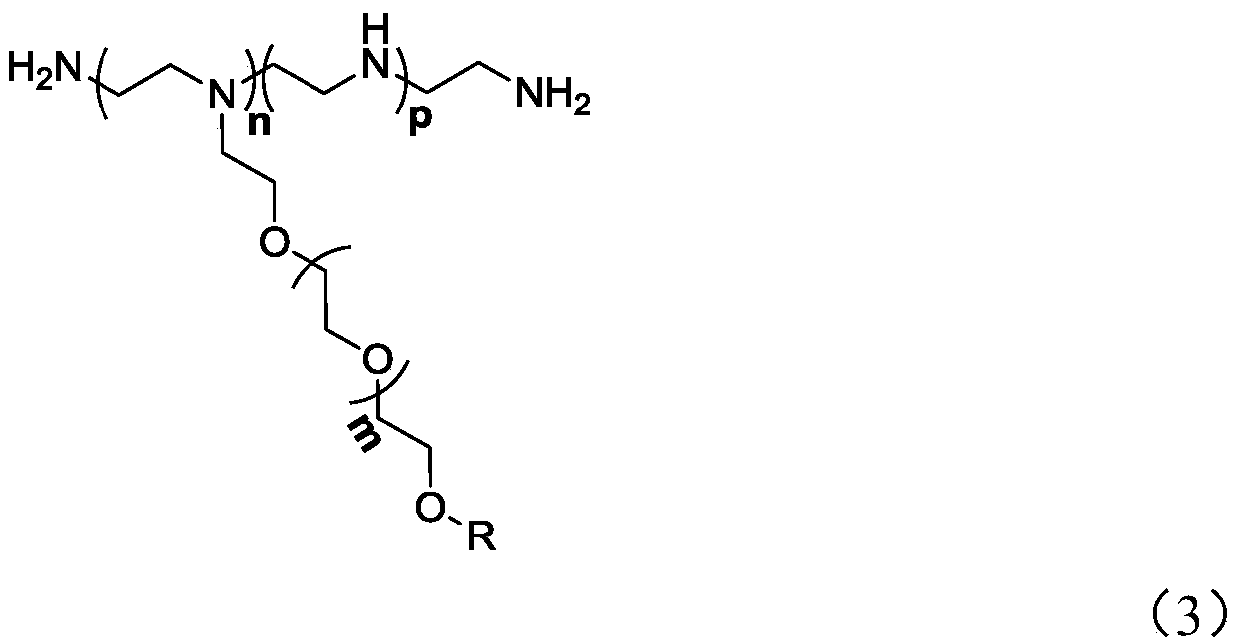

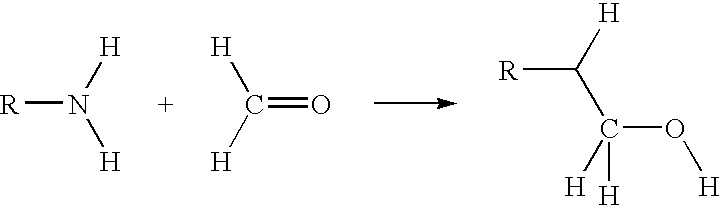

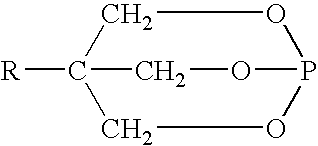

Phosphorous acid concrete super plasticizer with polyethyleneimine structure as well as preparation method and application thereof

The invention provides a new phosphorous acid concrete super plasticizer with a polyethyleneimine structure as well as a preparation method and an application thereof. The phosphorous acid concrete super plasticizer with a polyethyleneimine structure can effectively improve the concrete fluidity, and the preparation method is simple and effective. The preparation method comprises the following steps: a) making chloro-substituted polyether react with polyethyleneimine so that a part of amino groups H of the polyethyleneimine are substituted to obtain polyethyleneimine with a polyoxyethylene ether branch structure, wherein the molar ratio of the chloro-substituted polyether to the imino groups contained in the polyethyleneimine is 1:(3-8); and b) performing phosphorylation of the remaining amino groups H of the polyethyleneimine with a polyoxyethylene ether branch structure to obtain the phosphorous acid concrete super plasticizer with a polyethyleneimine structure.

Owner:JIANGSU SOBUTE NEW MATERIALS

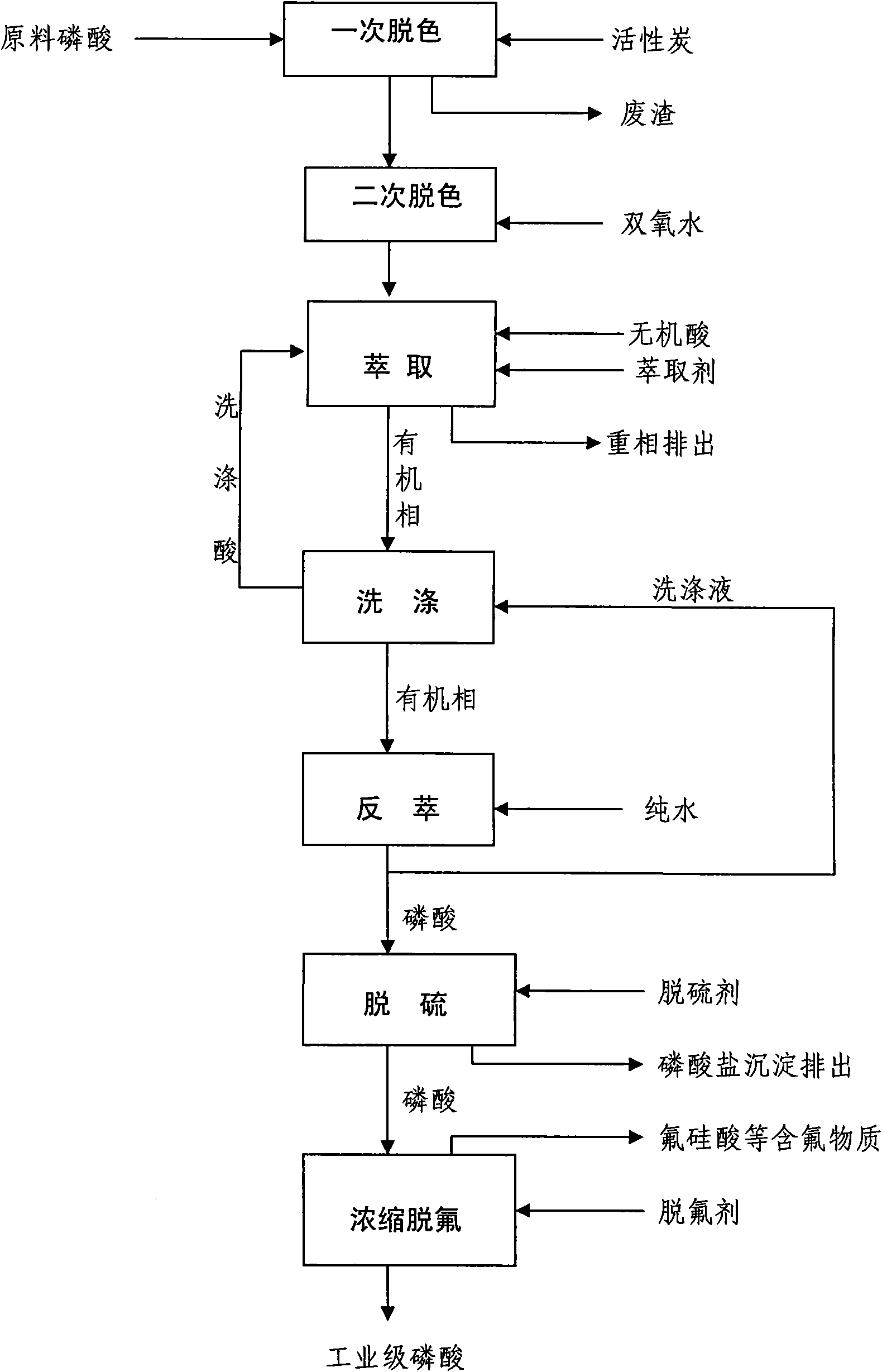

Method for extracting and purifying wet-process phosphorous acid to produce industrial-grade phosphorous acid

ActiveCN101857216AIncreased concentration of hydrogen ionsHigh partition coefficientPhosphorus compoundsPhosphorous acidSulfate radicals

The invention discloses a method for extracting and purifying wet-process phosphorous acid to produce industrial-grade phosphorous acid, which comprises the following steps: step 1, decoloration: utilizing active carbon and hydrogen peroxide to decolorize the phosphorous in two steps; step 2, extraction: utilizing extracting agent to extract phosphorous; step 3, washing: utilizing cleaning solution to washing organic phase; step 4, backextraction: utilizing pure water to extract the phosphorous acid in the organic phase; step 5, desulphurization: utilizing desulphurization agent to remove sulfate radical in the phosphorous acid; and step 6, concentration: improving the concentration of phosphorous acid, defluoridating through vacuum concentration to obtain the industrial-grade phosphorous acid. The method has the advantages that: (1) segmented decoloration is adopted, so the pretreatment process is simplified; (2) the used turntable tower is stable, the continuity is strong, and the maintenance expense is low; (3) sulfuric acid is compensated from the middle part of the extraction tower, so the yield of the industrial product is improved, the extraction rate can reach more than 95 percent, and the yield of the industrial product can reach more than 90 percent; (4) a plate-type heat exchanger is adopted, so the land occupation area is small; and (5) and the side-product barium sulfate is washed and dried to be used as an industrial product.

Owner:GUIZHOU CHANHEN CHEM CO LTD

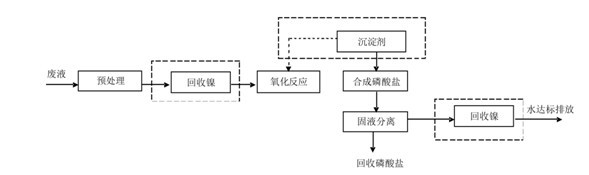

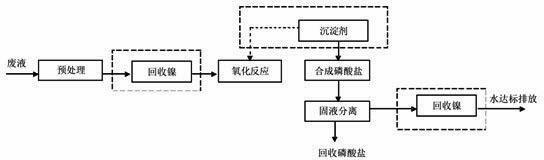

Method for degrading organic pollutant and recycling phosphate in chemical nickel-plating waste liquid

InactiveCN102616961AReduce phosphorus contentRemove completelyPhosphatesWaste water treatment from metallurgical processPhosphorous acidLiquid waste

The invention discloses a method for degrading organic pollutant and recycling phosphate in chemical nickel-plating waste liquid, which belongs to the technical field of environment-friendly waste water treatment and resource recycle. The method conducts oxidation degradation of organic pollutant in waste water through the oxidation technology, simultaneously oxidizes hypophosphorous acid radical and phosphorous acid radical in waste water into orthophosphate radical and recycles phosphate and nickel by enabling the orthophosphate radical and nonmetal or metal ions to be precipitated. The method achieves resource recycle while treating waste water and has good environment benefits and economical benefits and wide application prospect.

Owner:李朝林

Lubricating oil composition for refrigerators

ActiveUS20100133463A1Improve compatibilityLow global warming potentialHeat-exchange elementsAdditivesPhosphorous acidScavenger

A lubricating oil composition for refrigerators including (A) a base oil containing as a main component a polyol ester compound obtained from a polyhydric alcohol selected from among pentaerythritol, dipentaerythritol, trimethylolpropane and neopentyl glycol and a C4 to C20 aliphatic monocarboxylic acid, (B) a phosphorus-based additive comprised of a phosphoric acid triester and / or a phosphorous acid triester, and (C) at least one acid scavenger selected from among glycidyl esters, glycidyl ethers and α-olefin oxides.The lubricating oil composition is applicable to such refrigerators that use a refrigerant having a specific structure, such as an unsaturated fluorinated hydrocarbon compound, and being usable in current car air conditioner systems, and has excellent compatibility with the refrigerant, good sealing properties, capability of imparting a low coefficient of friction to sliding members and, yet, excellent stability.

Owner:IDEMITSU KOSAN CO LTD

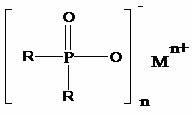

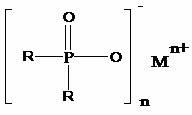

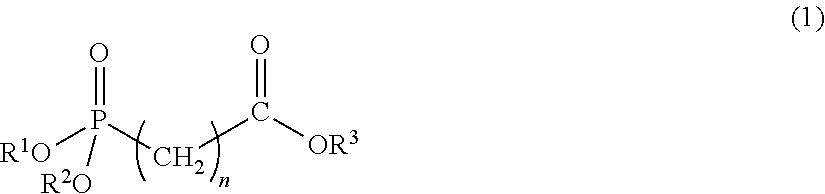

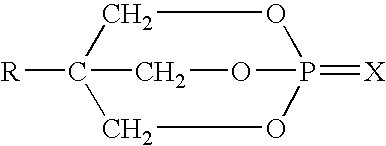

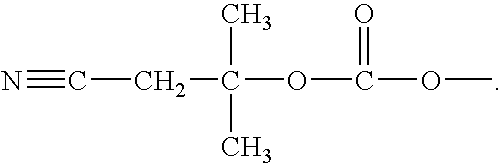

Preparation method of dialkyl hypophosphite

InactiveCN102050835AHigh purityAvoid it happening againGroup 5/15 element organic compoundsPhosphorous acidOrganic solvent

The invention discloses a preparation method of dialkyl hypophosphite. The structure of the dialkyl hypophosphite is disclosed as a Formula (I). The preparation method of the dialkyl hypophosphite comprises the following steps: preparing a Grignard reagent from alkylogen, magnesium powder and organic solvent, preparing dialkyl phosphorus oxide from the Grignard reagent and diethylester phosphite,carrying out reaction on the dialkyl phosphorus oxide and an oxidant, acidifying to obtain a dialkyl phosphinic acid solution, and carrying out reaction on the dialkyl phosphinic acid solution and a metal salt to obtain the corresponding dialkyl hypophosphite. The preparation method of dialkyl hypophosphite has the advantages of high yield and simple synthesis technique, is convenient to operate,greatly lowers the production cost, simplifies the production equipment and enhances the safety of the production process.(I).

Owner:GUANGZHOU KINGSKY MATERIAL

Preparation method of Li2FeSiO4 cathode material used for controlling Fe3P

InactiveCN101734675ALow costWide variety of sourcesCell electrodesAlkali metal silicatesPhosphorous acidWater baths

The invention relates to a preparation method of Li2FeSiO4 cathode material used for controlling Fe3P. The technical scheme comprises the following steps: weighting lithium salt or hydrate of lithium salt, ferrous salt or hydrate of ferrous salt, silicon compound and phosphorous acid or aqueous solution of phosphorous acid according to a molar ratio of the reactants that Li<+>:Fe<2+>:Si:H3PO3=0.95-1.10:0.95-1.10:0.70-0.999:0.001-0.429, mixing the reactants, then adding carbon-containing compound which accounts for 1wt%-20wt% of anhydrous reactants and wet grinding medium which accounts for 0.10-10 times of anhydrous reactants by volume, mixing with a ball mill, heating with water bath, mixing with a ball mill again, heating and drying in vacuum, and then using the two-stage sintering process or temperature programmed two-stage sintering process to prepare Li2FeSiO4 with controllable Fe3P under inert atmosphere or weak reduction atmosphere. The material prepared by the method of the invention has better discharge performance, the discharge capacity is significantly increased in 2.9V zone and the cycle performance is good under 0.3C current.

Owner:FUJIAN NORMAL UNIV

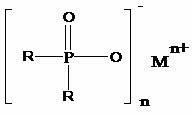

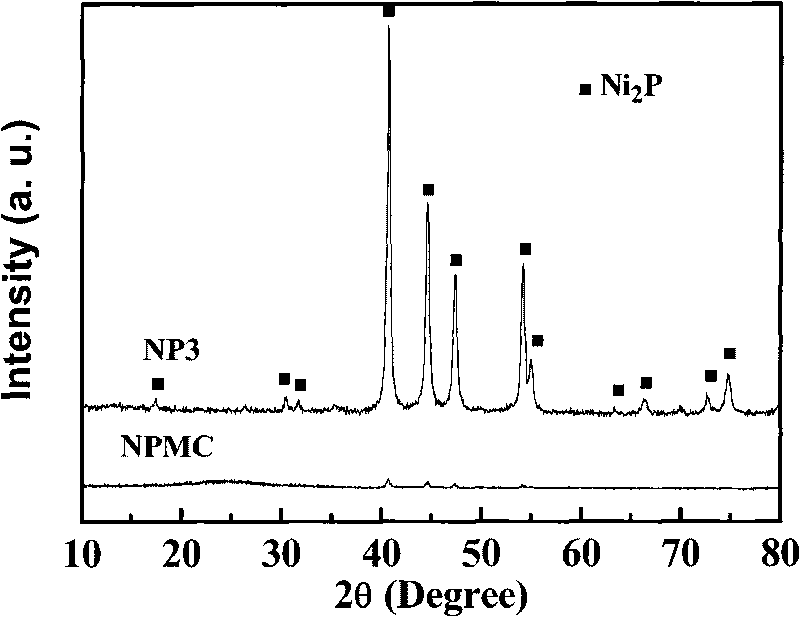

Preparation method of nickel phosphide

InactiveCN101734633ASolve the problem of sulfur poisoningIncrease investmentPhosphidesDispersityPhosphorous acid

On the premise of deep hydrodesulfurization, the main problem in diesel fuel's hydrotreatment is to rid the refractory sulfide and hydrogenate polycyclic aromatic hydrocarbon. Loaded nickel phosphide catalyst demonstrates higher hydrodesulfurization activity and better activity stability. However, the traditional nickel phosphide catalyst is prepared by temperature programming of nickel phosphide, so that dispersion degree of active components is low. In the invention, through solid-phase reaction between phosphorous acid ions and nickel ions, bulk phase and loaded nickel phosphide catalyst with higher active component dispersion degree and fine catalytic activity are obtained at low temperature. The invention is applicable to diesel oil hydroprocessing.

Owner:NANJING UNIV

Method for treating metallic surfaces

InactiveUS6572983B2Improve corrosion resistanceEasy to processPretreated surfacesEfficient propulsion technologiesWater dispersiblePhosphate ion

A method of treating a metallic surface which comprises treating a metal-coated steel panel with a nonchromate metallic surface treating agent containing, in each liter thereof, (a-1) a silane coupling agent and / or a hydrolytic condensation product thereof, (a-2) water-dispersible silica in a proportion, and (a-3) a zirconium compound and / or a titanium compound, drying the treated steel panel and coating it with an anticorrosion coating agent containing, in each liter of an aqueous resin solution or dispersion, (b-1) a silane coupling agent and / or a hydrolytic condensation product thereof, (b-2) water-dispersible silica and (b-3) at least one phosphorus-containing ion selected from among phosphate ion, phosphite ion and hypophosphite ion.

Owner:NIPPON PAINT CO LTD

Method for mfg of anode foil of aluminium electrolytic capacitor

InactiveCN1484259ALarge capacityReduce leakage currentAnodisationElectrolytic capacitorsPhosphorous acidCapacitance

This invention relates to a method for manufacturing electrode foils of aluminium electrolytic condensers including pure water boiling, formation, depolarization and reformation in which, the formation liquid electrolyte includes one of solutions of mineral acid containing boric acid or phosphoric acid or organic acid with oxalic acid or their saline material characterizing in adding soppm~5000ppm hypophosphorous acid, phosphorous acid, or their saline materials as the active material added by 100ppm~10000ppm citric acid, tartaric acid or their saline material as the complexant suppressing solution of the foil to reduce attenuation of capacitance.

Owner:深圳市东阳光化成箔股份有限公司

Preparation and application methods of selective laser sintering polypropylene powdery material

The invention relates to the technical field of high molecular materials and particularly relates to preparation and application methods of a selective laser sintering polypropylene powdery material. The method comprises the following steps: obtaining polypropylene powder by a freeze grinding method; grading and collecting by an airflow screening machine, selecting polypropylene powder with the granularity in a range of 200-800 meshes and returning coarse materials which do not meet the fineness requirement to a stock bin and continuously smashing; and adding 100 parts of polypropylene powder, 0.1-1 part of graphite powder, 0.01-0.5 part of antioxidant and 0.5-6 parts of metallic soap salt and uniformly mixing in a high speed mixer, wherein the granularity of the graphite powder is 1000-5000 meshes and the antioxidant is a compound antioxidant consisting of phenols and phosphonate or thioester in a weight ratio of 1:1. The polypropylene powder prepared by the invention has excellent sintering performance and the SLS (Selective Laser Sintering) formed piece prepared by the polypropylene powder has high mechanical property and dimensional precision.

Owner:GUANGDONG SILVER AGE SCI & TECH CO LTD

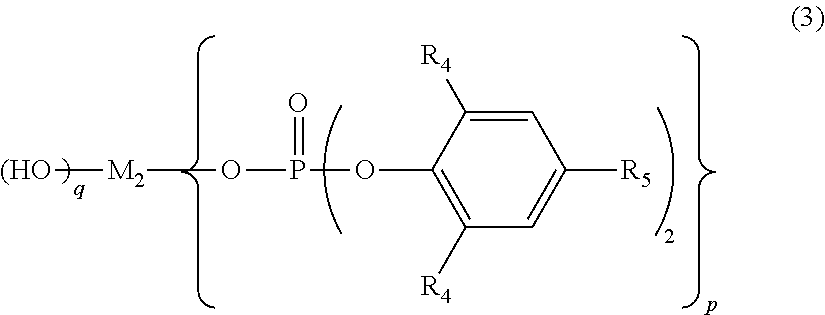

Polylactic acid composition and molded article thereof

InactiveUS20110263762A1Improve thermal stabilityReduce heatGroup 5/15 element organic compoundsPhosphorous acidPolymer science

A composition comprising polylactic acid and having excellent heat stability, especially moist heat stability, and a molded article thereof.The composition comprises 100 parts by weight of a resin component (component A) which is composed of 5 to 100 wt % of polylactic acid (component A-α) and 95 to 0 wt % of a thermoplastic resin (component A-β), 0.001 to 5 parts by weight of a phosphono-fatty acid ester (component B), 0.01 to 5 parts by weight of a phosphate metal salt (component C), 0.001 to 2 parts by weight of at least one antioxidant (component D) selected from the group consisting of a phosphite-based compound, a phosphonite-based compound, a hindered phenol-based compound and a thioether-based compound, and 0.001 to 10 parts by weight of an end-sealing agent (component E).

Owner:TEIJIN KASEK KK +1

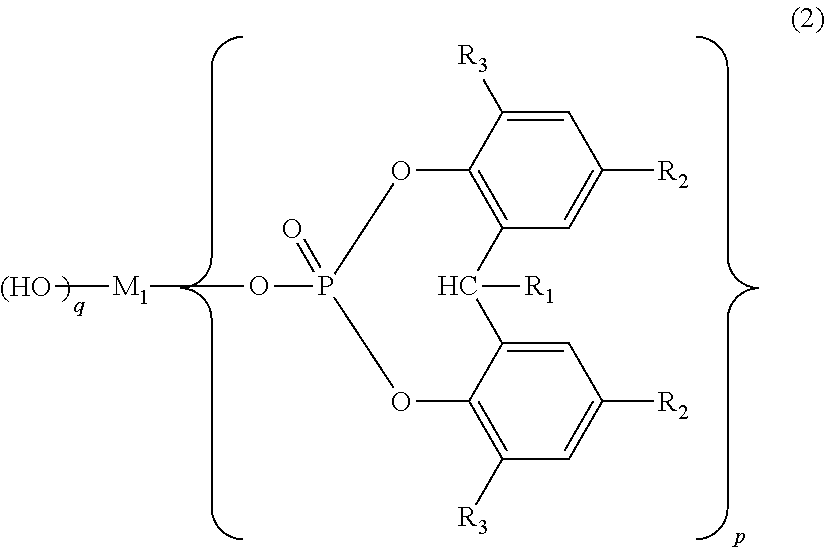

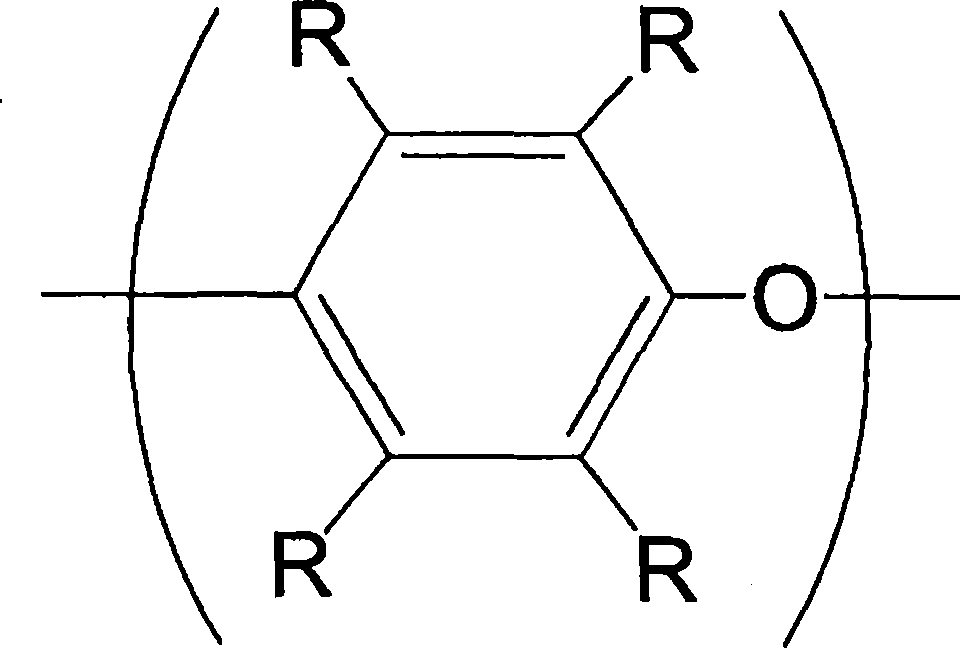

Polyamide-polyphenylene ether resin composition

ActiveCN101163746AExcellent retention stabilitySimplify moisture managementElastomerPhosphoric Acid Esters

A resin composition characterized by containing polyamide (A), polyphenylene ether (B), elastomer (C) and phosphorus compound (D) selected from among phosphoric acids, phosphorous acids, hypophosphorous acids, metal phosphates, metal phosphites, metal hypophosphites and phosphoric esters wherein per 100 mass% of the sum of components (A) to (D), phosphorus element is contained in an amount of 1 to 35 ppm. Further, there is provided a molding of the resin composition. Application can be found in a wide spectrum of fields, such as electrical / electronic parts, OA parts, vehicle parts and mechanical parts. In particular, suitable application can be found in exterior parts of automobile, etc. wherein large moldings are required.

Owner:ASAHI KASEI KK

Polyamide composition

ActiveUS20060142443A1Aluminium compoundsPlastic/resin/waxes insulatorsPhosphorous acidPhosphoric Acid Esters

A polyamide composition has (a) a polyamide, (b) at least one phosphorus compound selected from the group consisting of phosphoric acids, phosphorous acids, hypophosphorous acids, metal phosphates, metal phosphites, metal hypophosphites, phosphoric esters, and phosphorous esters, and (c) a soluble metal aluminate compound represented by the general formula (M2O)x(Al2O3)y (wherein X+Y=1 and M is a Group 1 metal of the Periodic Table), wherein the molar ratio of polyvalent metal to monovalent metal in the composition (polyvalent metal / monovalent metal) is from 0.25 to 1.0.

Owner:ASAHI KASEI CHEM CORP

Packing leather cup rubber for hydraulic mount and preparation method thereof

The invention discloses packing leather cup rubber for hydraulic mount. The packing leather cup rubber is prepared from the following raw materials in parts by weight: 30-40 parts of nitrile rubber, 20-30 parts of isoprene rubber, 20-40 parts of ethylene propylene terpolymer 5962 (LANXESS Deutschland), 10-15 parts of fluorosilicone rubber, 3-5 parts of natural rubber, 20-30 parts of high abrasion furnace black N330, 10-15 parts of modified white carbon black, 3-4 parts of antimony trioxide, 8-10 parts of modified wood ash, 4-6 parts of attapulgite, 4-6 parts of meerschaum, 9-11 parts of modified iron tailing slag powder, 0.5-1 part of stearic acid, 0.5-1 part of vulcanizing agent TMT, 0.2-0.4 part of accelerant DM, 0.3-0.6 part of accelerant BZ, 1-2 parts of calcium stearate, 2-4 parts of zinc oxide, 0.2-0.4 part of ferrocene, 1-2 parts of polyethylene wax, 1-2 parts of triphenyl phosphite, 1-2 parts of anti-aging agent RD, 2-3 parts of vinyl-tris(beta-methoxyethoxy)silane and 16-18 parts of butyl epoxy oleate. The rubber disclosed by the invention has excellent ozone resistance, excellent low temperature resistance and heat resistance and is large in operating temperature range and environment-friendly in process, so that the rubber can be used for preparing various packing materials.

Owner:WUHU HENGKUN AUTO PARTS

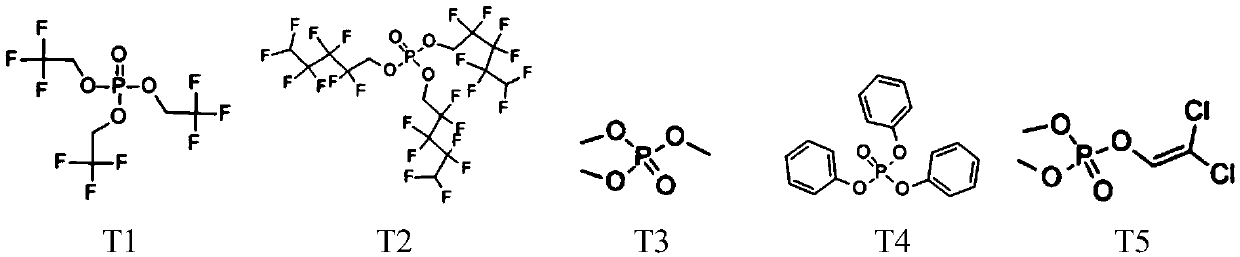

Silicon carbon lithium ion battery electrolyte and silicon carbon lithium ion battery using same

InactiveCN109546218AAvoid breakingImprove cycle performanceSecondary cellsOrganic electrolytesPhosphateSulfate

A silicon carbon lithium ion battery electrolyte and a silicon carbon lithium ion battery using the same belong to the field of lithium ion battery materials. The electrolyte comprises a film-formingadditive accounting for 8% to 15% by weight of the total weight of the electrolyte. The film-forming additive comprises a phosphate ester / phosphite ester compound, fluoroethylene carbonate (FEC), ethylene sulfate (DTD) and lithium difluorophosphate (LiPO2F2). The electrolyte has excellent cycle performance. The phosphate ester / phosphite ester compound has chemical structural formulas shown by theformulas (I) and (II) which are described in the specifications.

Owner:ZHUHAI COSMX BATTERY CO LTD

Acid-methylol compound reaction products for flame resistance

InactiveUS20040039085A1Promotes even distributionSuppress aciditySpecial tyresPhosphorous acidAdhesive

This invention relates to novel flame retardants (FR) resulting from the reaction of (a) or (b) with (c) where (a) is a compound containing at least one amine group and with at least one sixteenth of the amine molecules having at least one methylol bond, (b) is a phenol with at least one sixteenth of the phenol molecules having at least one methylol bond, and (c) is a mineral acid, organic acid, and organo-phosphorous acid, or a mixture thereof and optionally adding a polyhydric compound and / or optionally adding formaldehyde to the acid. These compositions are for use in general flame retardant applications such as coatings, adhesives, and articles made of polymeric materials. The FR mechanism by which these compounds generally perform as an FR agent is intumescence but the field of this invention is not restricted to that mechanism. Some of the compounds have substantial intumescence and others have very little intumescence but still are flame retardants.

Owner:KASOWSHI ROBERT VALENTINE +1

Preparation method of full biodegradation film

The invention discloses a preparation method of a full biodegradation film, which takes poly adipic acid / polybutylene terephthalate (PBAT) and starch as base materials, poly-epsilon carpolaction (PCL), epoxidized soybean oil (ESO), and phosphorous acid dialkyl ester as plasticizers, and montmorillonoid or calcium carbonate, talcum powder and the like as inorganic fillers. The method comprises the steps that modification and pelleting are performed in a twin screw; modified resin is added to a film blowing machine for film blowing; and the full biodegradation film can be obtained finally. The full biodegradation film produced by the method is better in physical characteristic, can be directly prepared into a film bag, and can serve as a daily-used packaging film, a waistcoat bag, a food packaging bag and the like; the preparation method of the full biodegradation film is simple in technology, and easy to control, and is suitable for industrial mass production; the film bag produced by the method is high in strength, can be biodegraded fully after use, and is easy to dispose; and environmental pollution is reduced.

Owner:DONGGUAN XINHAI ENVIRONMENT PROTECTION MATERIAL

Preparation method of titanium series catalyst for polyester

The invention discloses a preparing method of titanium-system catalyst of polyester, which is characterized by the following: reacting titanic acid ester and 2-hydroxy carboxylic compound and organic phosphonic acid compound; making the product react with at least one phosphorus compound of phosphoric acid, phosphorous acid, hypophosphorous acid, phosphate ester or phosphite ester; fitting for polyester industry.

Owner:CHINA PETROLEUM & CHEM CORP +1

Clean reclaiming process for byproduct chloromethane of glyphosate acid

InactiveCN1629112ARealize cleaner productionEasy to operateGroup 5/15 element organic compoundsHalogenated hydrocarbon separation/purificationPhosphorous acidForeign matter

The discharged exhaust gas during the glyphosate acid production process through phosphorous acid alkyl acid includes 20-90% of methyl chloride, methanol, formaldehyde dimethyl acetal, water, hydrogen chloride and other foreign matter, by solvent absorption of foreign matter, condensation impurity or charging part of the foreign matter such as methanol, formaldehyde dimethyl acetal into hydrochloride-containing liquid and converting it into methyl chloride, high purity of methyl chloride can be obtained. The process not only solves the problem of environmental pollution in the glyphosate acid production, the production cost can also be lowered substantially.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

Process for producing 4-amino-1-hydroxybutylidene-1,1-bisphosphonic acid and its trihydrated monosodium salt

InactiveUS6573401B1Easy to adaptHigh yieldGroup 5/15 element organic compoundsRecord information storagePhosphorous acidHydrolysis

The invention relates to a process for the preparation of 4-amino-1-hydroxybutylidene-1,1-bisphosphonic acid and of the trihydrated monosodium salt thereof, consisting of reacting 4-aminobutyric acid with a phosphonation mixture formed by phosphorous acid and methanesulfonic anhydride and thereafter hydrolyzing the product of said reaction and isolating the products by adjustment of the pH.

Owner:MEDICHEM

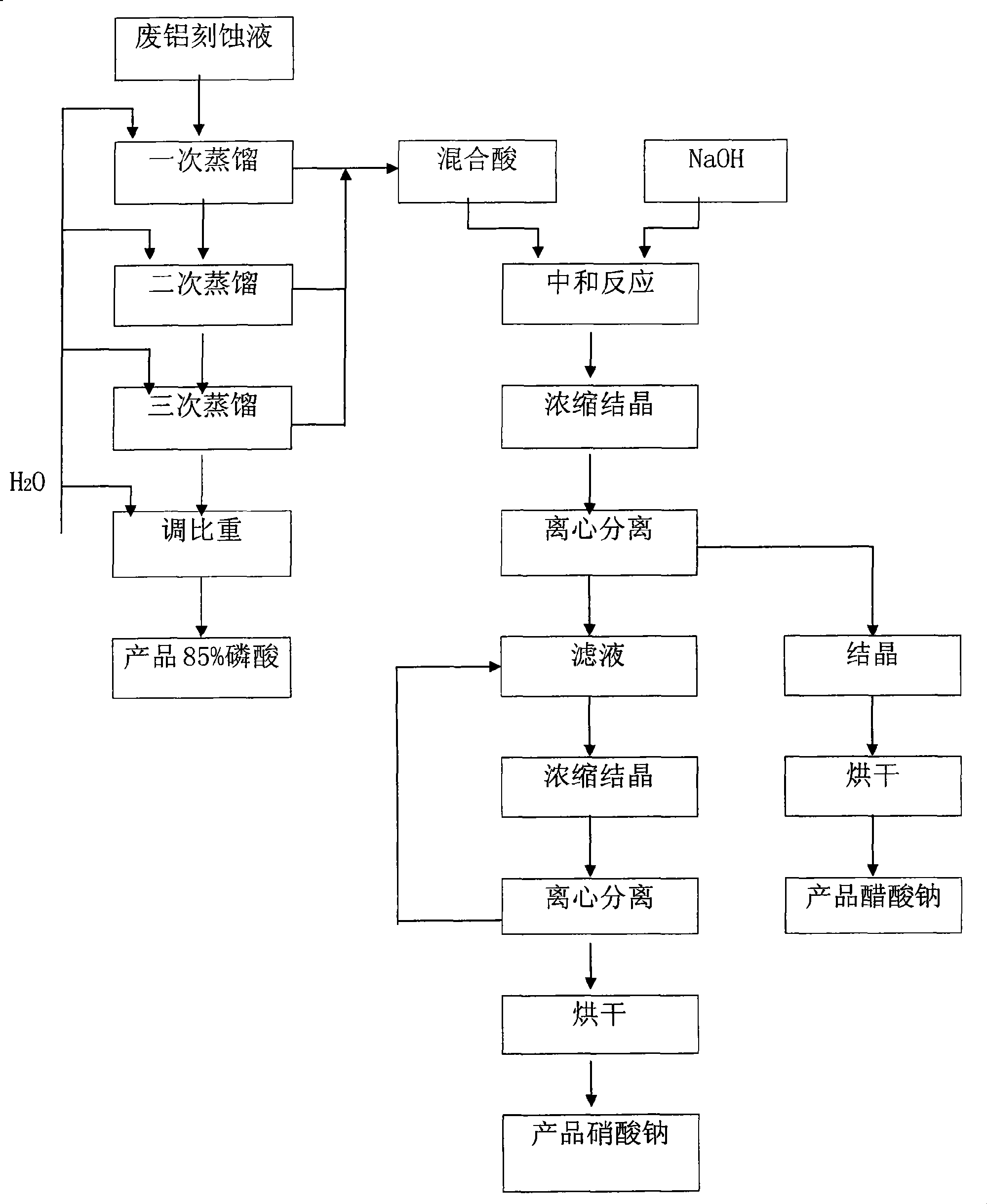

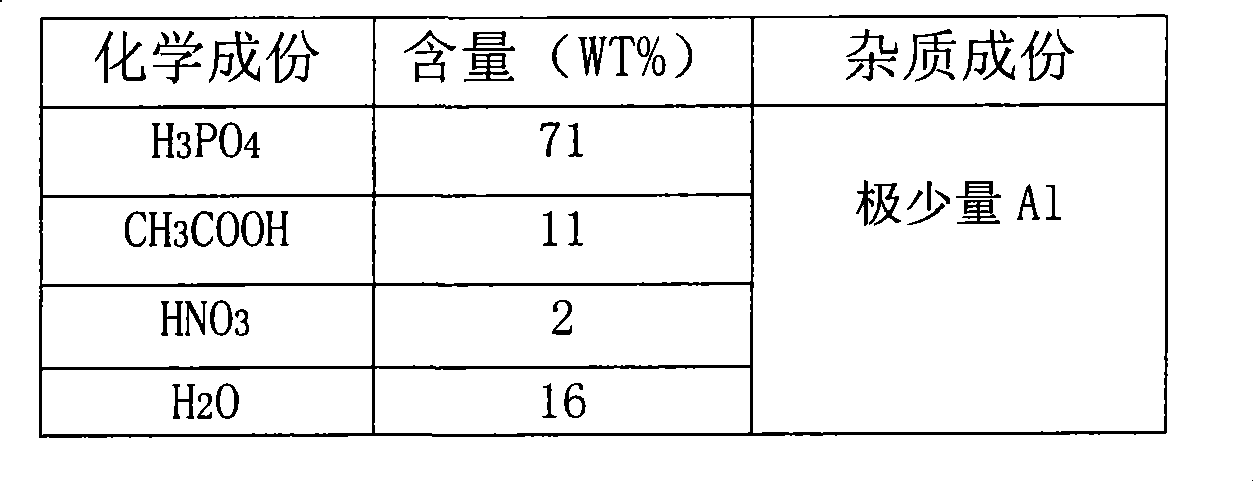

Comprehensive utilization process for waste aluminum etching solution

ActiveCN101439849AIncrease production capacityExtend your lifeAlkali metal nitrate preparationCarboxylic acid salt preparationPhosphorous acidSodium acetate

The invention relates to a comprehensive utilization process for a waste aluminum etching solution. The process utilizes the characteristic that the boiling point and the volatility of phosphorous acid are greatly different from those of nitric acid and acetic acid to separate the phosphorous acid from the nitric acid and the acetic acid by adopting a distillation method, then filters the phosphorous acid after the distillation separation to remove mechanical impurities, and then adds distilled water to adjust the specific gravity to obtain 85 percent industrial phosphorous acid; a mixed acid of the nitric acid and the acetic acid obtained by the distillation is placed into a stainless steel reaction kettle, sodium hydroxide is added into the mixed acid to react under the stirring, then a purified reaction liquid is concentrated, crystallized, and separated to obtain a filtrate and crystals; and the crystals are dried to obtain a product, namely sodium acetate, and then the filtrate is concentrated, crystallized, separated, and dried to obtain a product, namely sodium nitrate. The process can recover and utilize a mixed acid waste liquid containing a plurality of acids, and obtain a plurality of novel chemical raw materials from the mixed acid waste liquid.

Owner:孟庆深

Method for preparing functionalization polyolefin resin

The preparation process of functional polyolefin resin includes electronic beam or gamma-ray pre-irradiation treatment of functional polyolefin resin; mechanical mixing of polyolefin resin after pre-treatment, functional monomer and electron donor reagent; and reacting extrusion for the polyolefin resin in molten state and functional monomer to produce grafting reaction. The polyolefin resin includes polyethylene, polypropylene, ethylene-propylene copolymer, ethylene-styrene copolymer, polystyrene, etc; the functional monomer is unsaturated organic acid or its derivative with amino group, isocyanate, hydroxyl group or other reactive functional group; and the electron donor reagent includes electron-rich compound with P, N, S or O element, p-benzoquinone, triphenyl phosphite, triphenyl phosphate, etc.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Industrial process for the synthesis of 17a-acetoxy-11ss-[4-(n,n-dimethyl-amino)- phenyl]-19-norpregna-4,9-diene-3,20-dione and new intermediates of the process Industrial process for the synthesis of 17a-acetoxy-11ss-[4-(n,n-dimethyl-amino)- phenyl]-19-norpregna-4,9-diene-3,20-dione and new intermediates of the process](https://images-eureka.patsnap.com/patent_img/9a66d1cf-4b54-4dee-bae5-7e40fd7cdedf/A200780021915E00221.PNG)

![Industrial process for the synthesis of 17a-acetoxy-11ss-[4-(n,n-dimethyl-amino)- phenyl]-19-norpregna-4,9-diene-3,20-dione and new intermediates of the process Industrial process for the synthesis of 17a-acetoxy-11ss-[4-(n,n-dimethyl-amino)- phenyl]-19-norpregna-4,9-diene-3,20-dione and new intermediates of the process](https://images-eureka.patsnap.com/patent_img/9a66d1cf-4b54-4dee-bae5-7e40fd7cdedf/A200780021915E00231.PNG)

![Industrial process for the synthesis of 17a-acetoxy-11ss-[4-(n,n-dimethyl-amino)- phenyl]-19-norpregna-4,9-diene-3,20-dione and new intermediates of the process Industrial process for the synthesis of 17a-acetoxy-11ss-[4-(n,n-dimethyl-amino)- phenyl]-19-norpregna-4,9-diene-3,20-dione and new intermediates of the process](https://images-eureka.patsnap.com/patent_img/9a66d1cf-4b54-4dee-bae5-7e40fd7cdedf/A200780021915E00232.PNG)