Method for extracting and purifying wet-process phosphorous acid to produce industrial-grade phosphorous acid

A wet-process phosphoric acid, industrial-grade technology, applied in the field of phosphoric acid, can solve the problems of unsatisfactory purification product yield and production cost, insufficient utilization of sulfur, cost reduction and environmental protection, etc., to improve element utilization rate and small footprint. , the continuous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 20ktP of Guizhou Chuanheng Chemical Co., Ltd. 2 o 5 / a industrial grade phosphoric acid production plant

[0037] Raw material concentrated phosphoric acid 296t (kind), the indicators are as follows:

[0038] P 2 o 5 %

SO 3 %

F%

Fe%

Ca%

Mg%

As%

Exterior

proportion

40.5

2.4

0.9

0.15

0.6

0.8

0.0024

yellow liquid phase

1.46

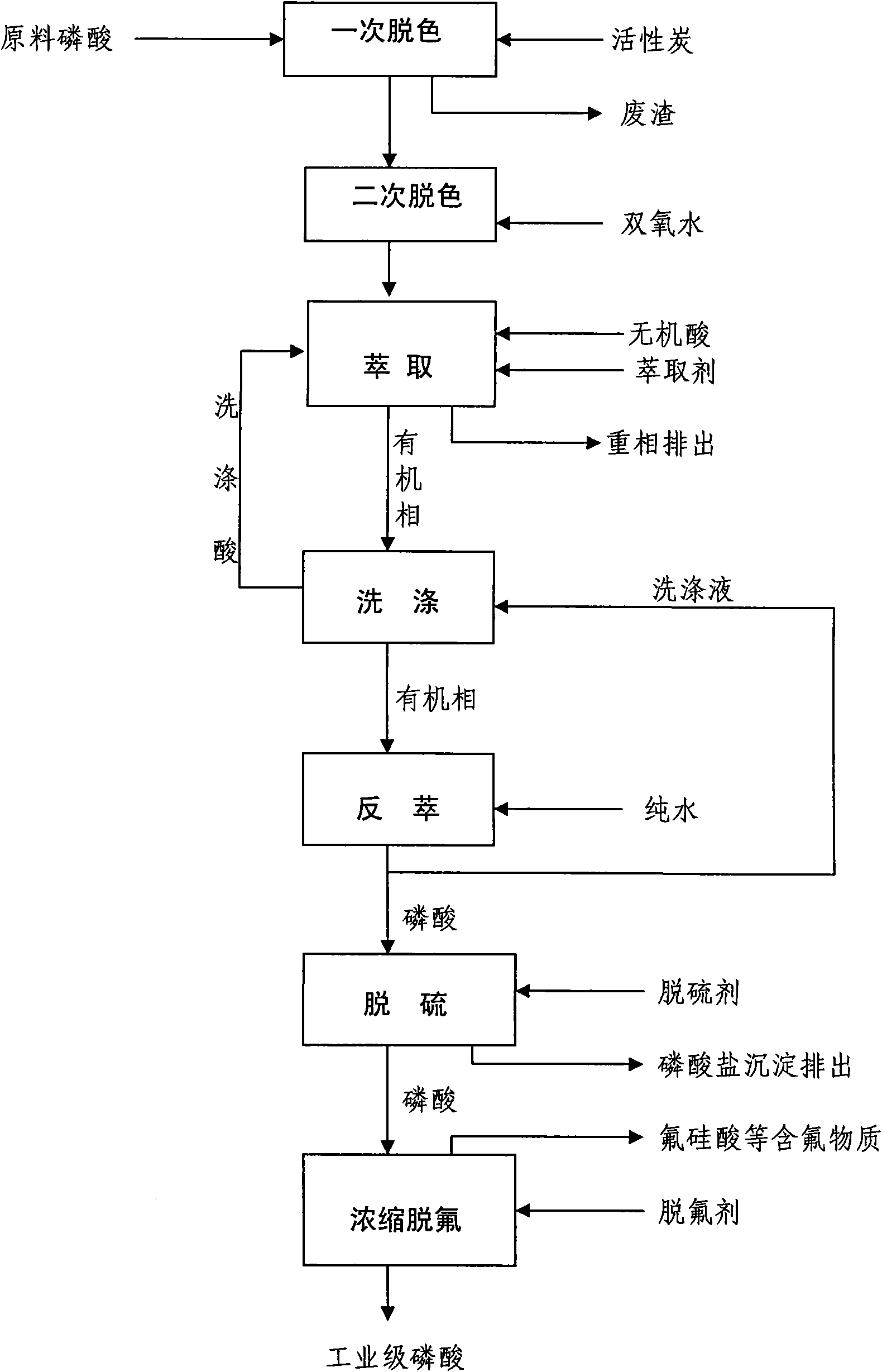

[0039] The steps to produce industrial-grade phosphoric acid are: primary decolorization, separation, secondary decolorization, extraction, washing, stripping, desulfurization, concentration and defluorination.

[0040] (1) Decolorization: Phosphoric acid from the wet system, the temperature is 72 ° C, measured at 5m 3 The flow rate of / h is added to the decolorization reaction tank, and 5.9t of wood powdery activated carbon is added in an amount of 146kg / h (2.0% of phosphoric acid weight), the reaction temperature is 65°C to 72°C, the stirring int...

Embodiment 2

[0050] Production device is the same as embodiment 1, raw material concentrated phosphoric acid 310t (kind), index is as follows:

[0051] P 2 o 5 %

SO 3 %

F%

Fe%

Ca%

Mg%

As%

Exterior

proportion

58

4.5

0.4

0.22

0.05

1.4

0.0020

yellow liquid phase

1.78

[0052] The production steps are: primary decolorization, separation, secondary decolorization, extraction, washing, stripping, desulfurization, concentration and defluorination.

[0053] (1) Decolorization: the wet concentrated phosphoric acid in the previous section, the temperature is 80°C, and the temperature is 5m 3 The flow rate of / h is metered into the decolorization reaction tank, and 4.7t of coal-based powdered activated carbon is added in an amount of 135kg / h (1.5% of the phosphoric acid weight), the reaction temperature is 78°C, the stirring intensity is 6m / s, and the continuous reaction residence time is 1h. The ac...

Embodiment 3

[0063] Production device is the same as embodiment 1, raw material concentrated phosphoric acid 580.7t (kind), index is as follows:

[0064] P 2 o 5 %

SO 3 %

F%

Fe%

Ca%

Mg%

As%

Exterior

proportion

52.01

4.4

0.7

0.2

0.1

1.1

0.0024

yellow liquid phase

1.64

[0065] The production steps are: primary decolorization, separation, secondary decolorization, extraction, washing, stripping, desulfurization, concentration and defluorination.

[0066] (1) Decolorization: Phosphoric acid from the wet concentration system, temperature 67°C, at 5m 3 The flow rate per hour is measured and added to the decolorization reaction tank, and 5.8t of powdered activated carbon from shells is added at an amount of 82kg / h (1.0% of the phosphoric acid weight), the reaction temperature is 62 ° C ~ 67 ° C, the stirring intensity is 4 m / s, continuous reaction 1h, use the filter pump to transport to the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com