Patents

Literature

146results about "Sulfur-dioxide/sulfurous-acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

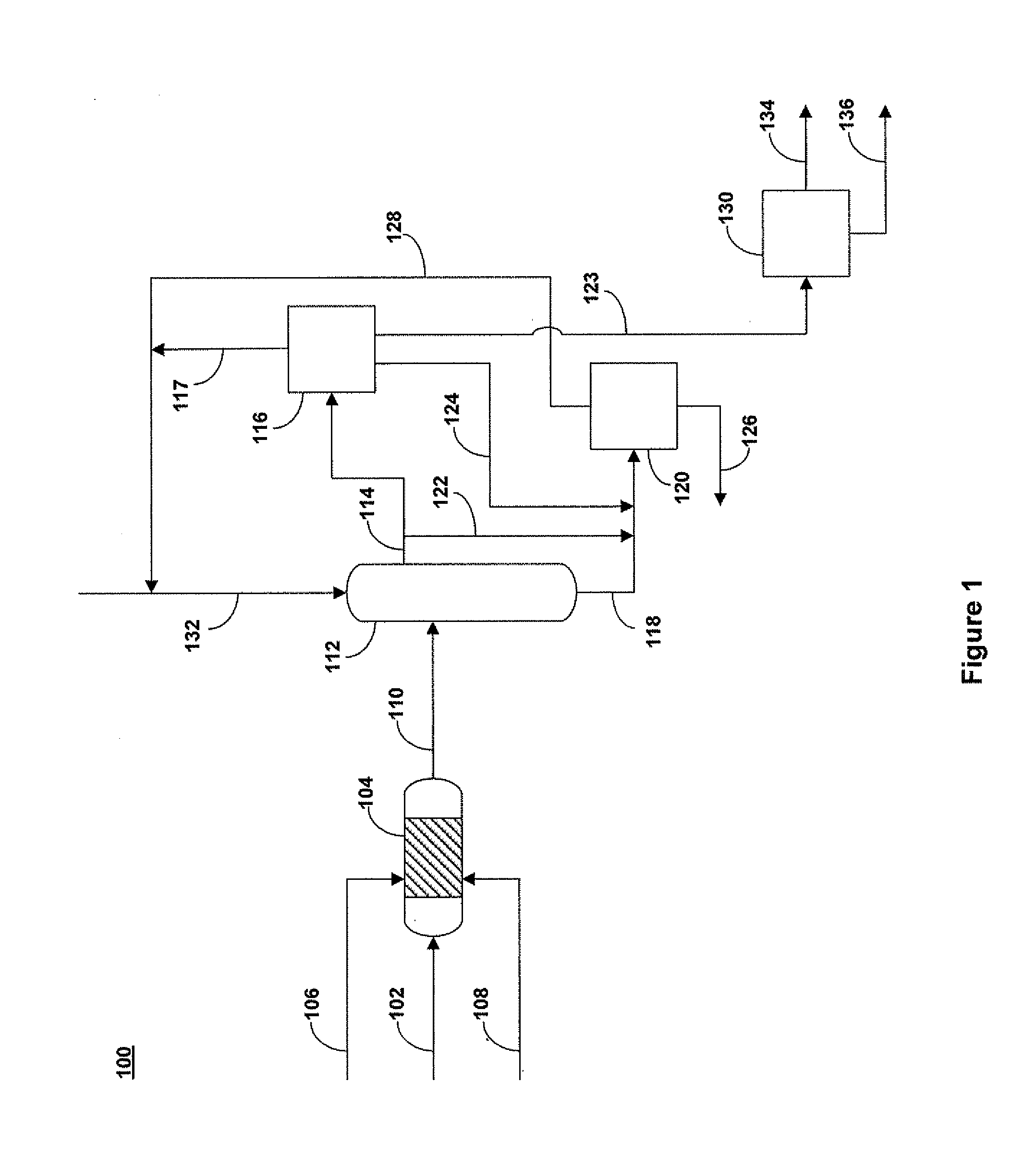

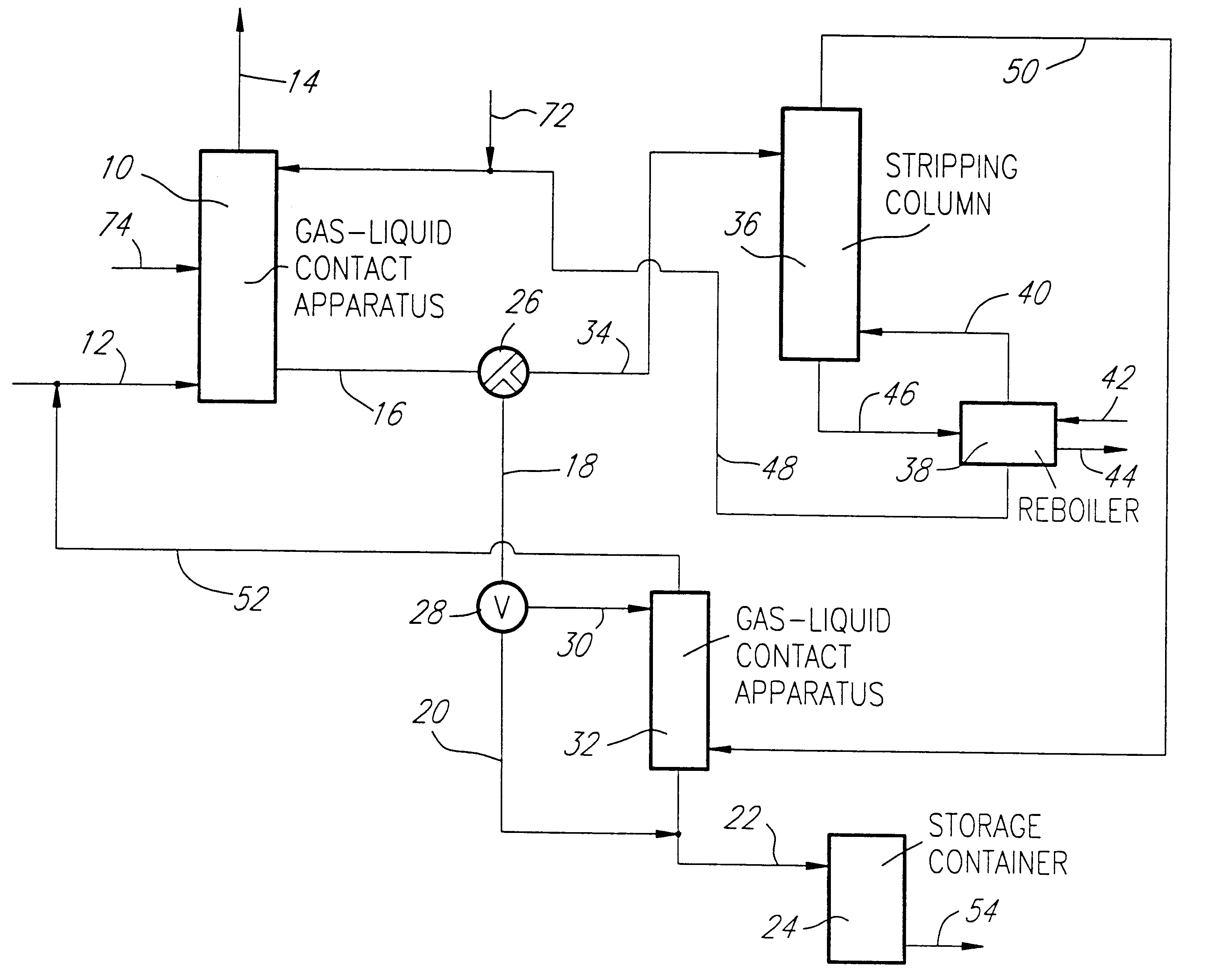

Regenerative recovery of sulfur dioxide from effluent gases

ActiveUS20120107209A1Improve energy efficiencySpeed up the processGas treatmentSulfur-dioxide/sulfurous-acidOrganic acidSulfate

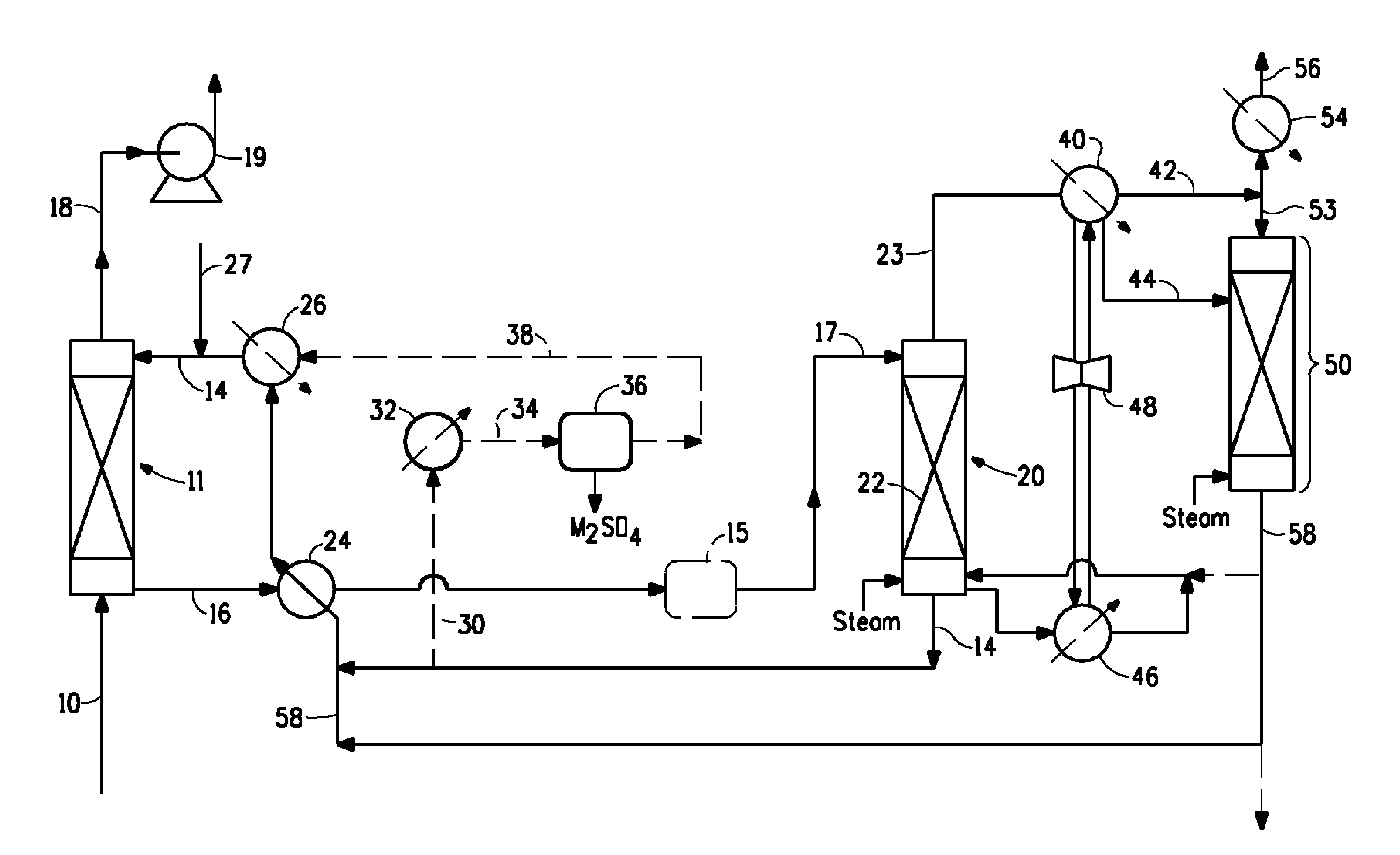

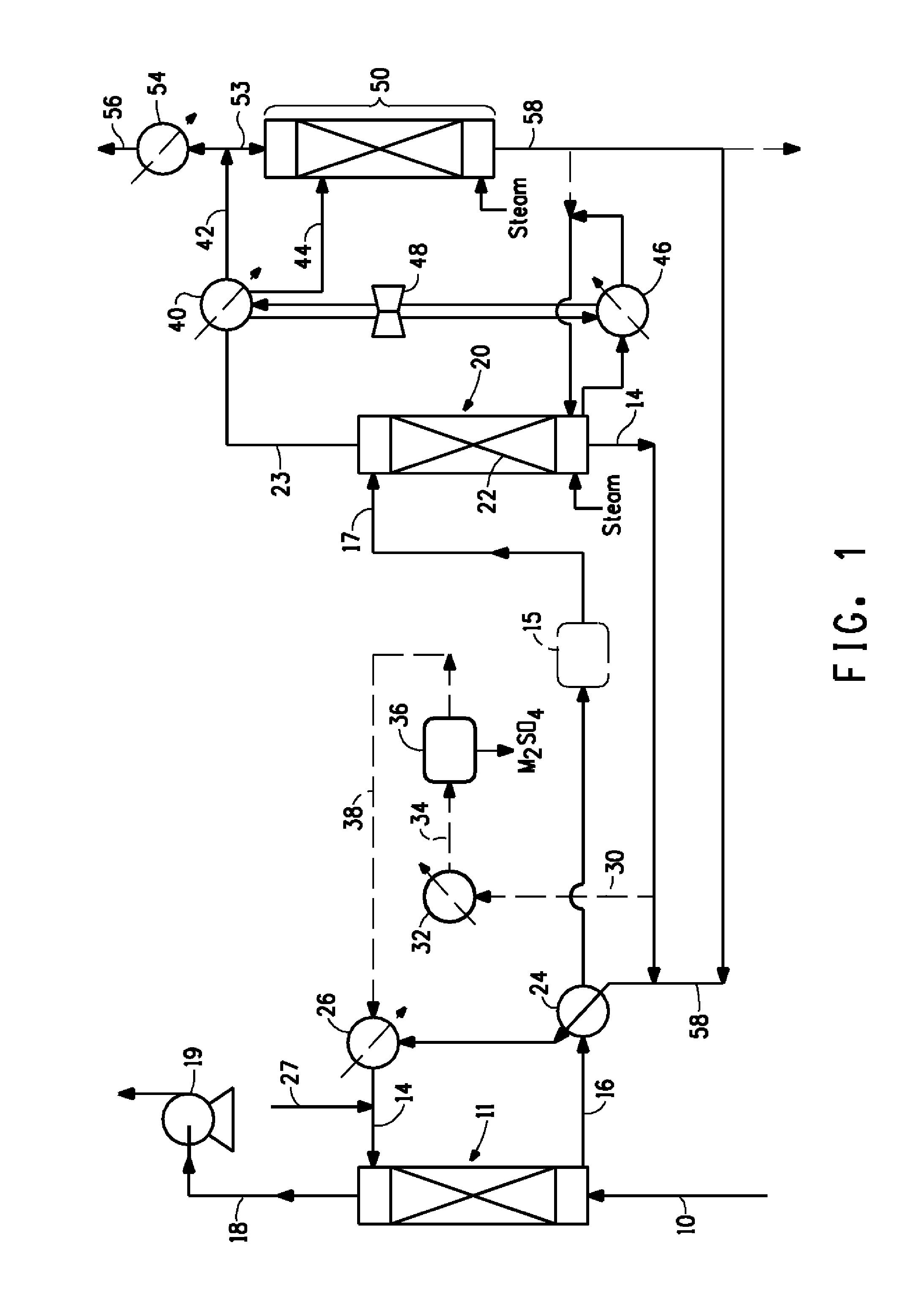

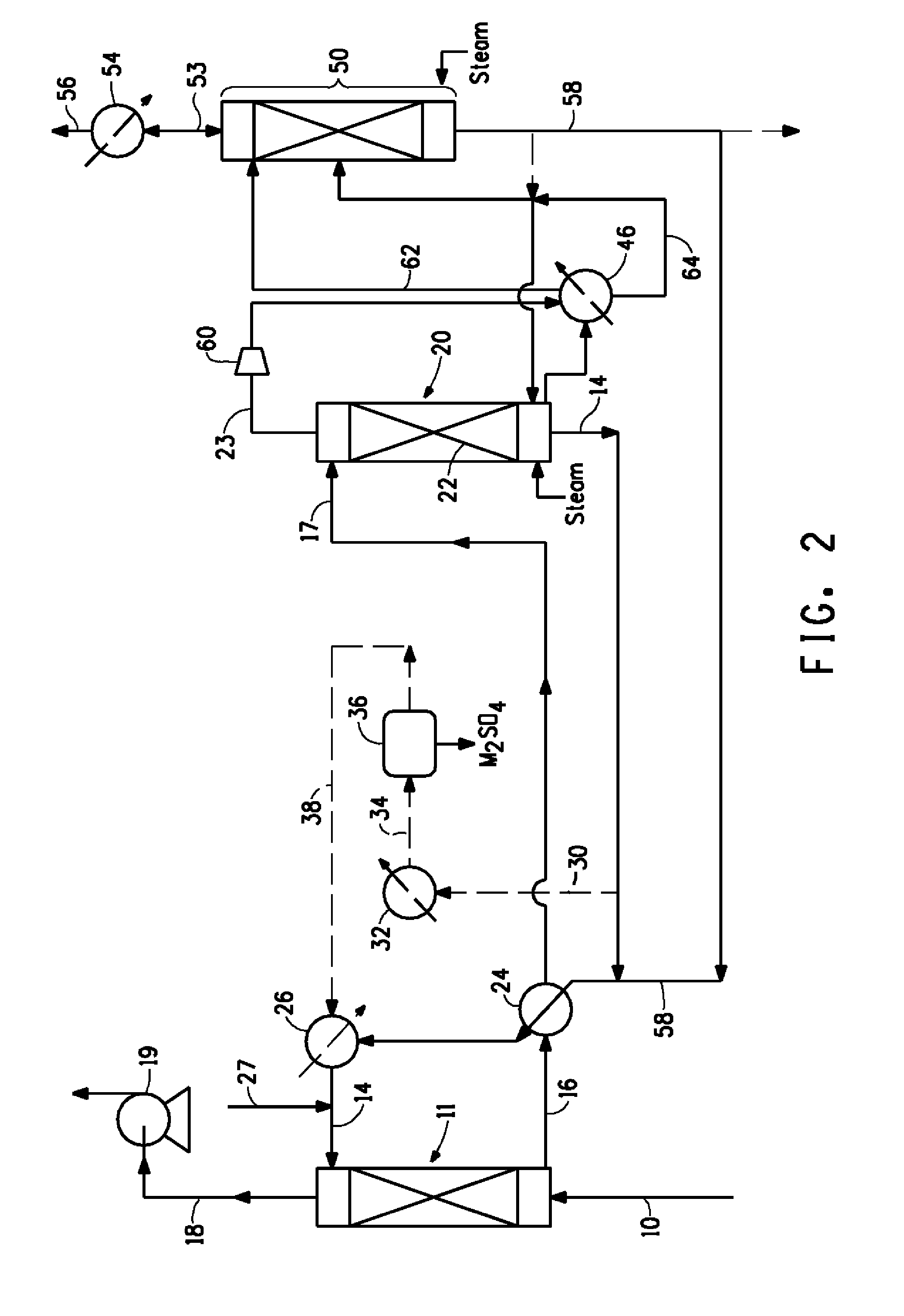

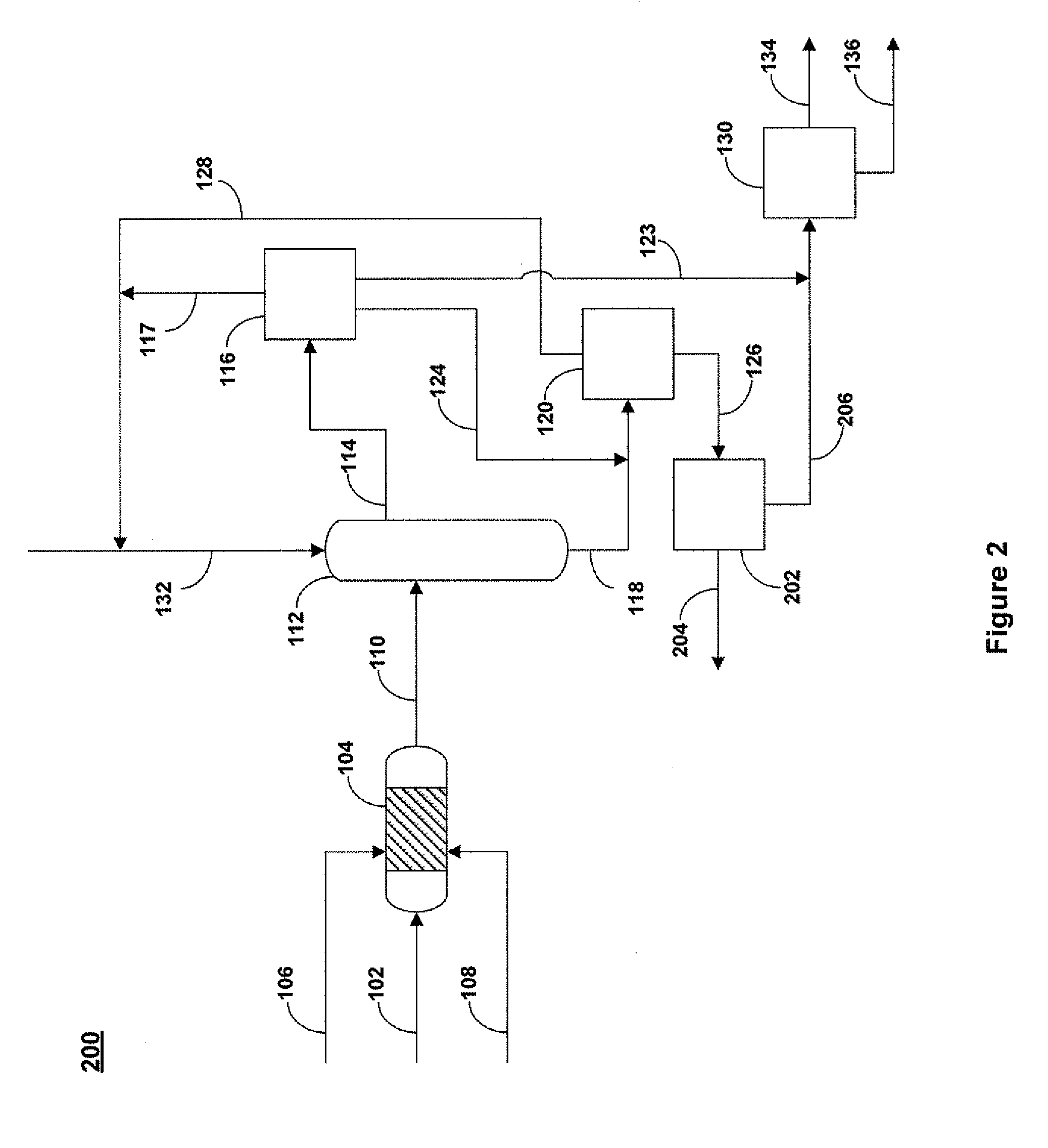

This invention relates to processes for selective removal of contaminants from effluent gases. A sulfur dioxide absorption / desorption process for selective removal and recovery of sulfur dioxide from effluent gases utilizes a buffered aqueous absorption solution comprising weak inorganic or organic acids or salts thereof, to selectively absorb sulfur dioxide from the effluent gas. Absorbed sulfur dioxide is subsequently stripped to regenerate the absorption solution and produce a sulfur dioxide-enriched gas. A process for simultaneous removal of sulfur dioxide and nitrogen oxides (NOx) from effluent gases and recovery of sulfur dioxide utilizes a buffered aqueous absorption solution including a metal chelate to absorb sulfur dioxide and NOx from the gas and subsequently reducing absorbed NOx to form nitrogen. A process to control sulfate salt contaminant concentration in the absorption solution involves partial crystallization and removal of sulfate salt crystals.

Owner:MECS

Maximizing regulatory credits in controlling air pollution

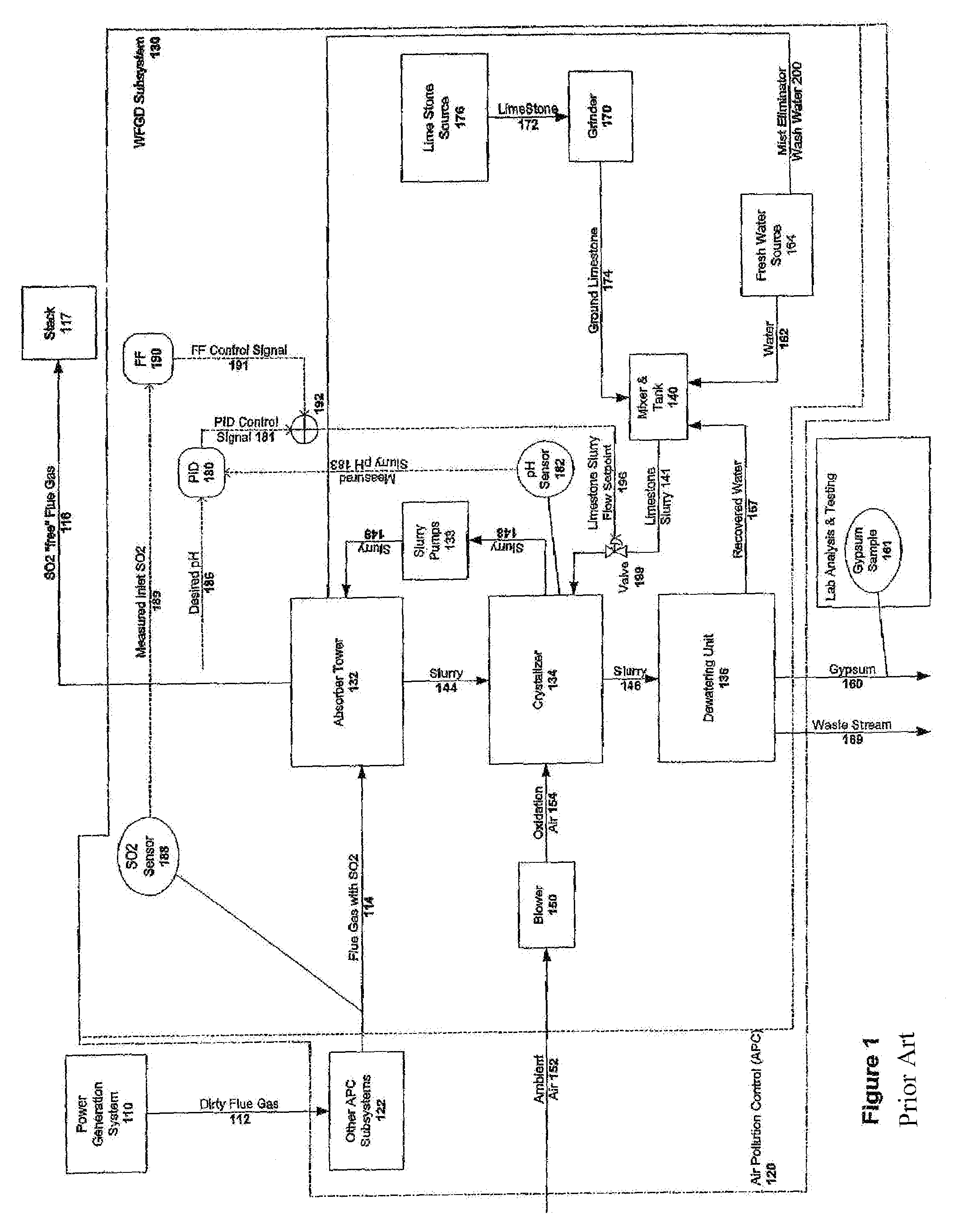

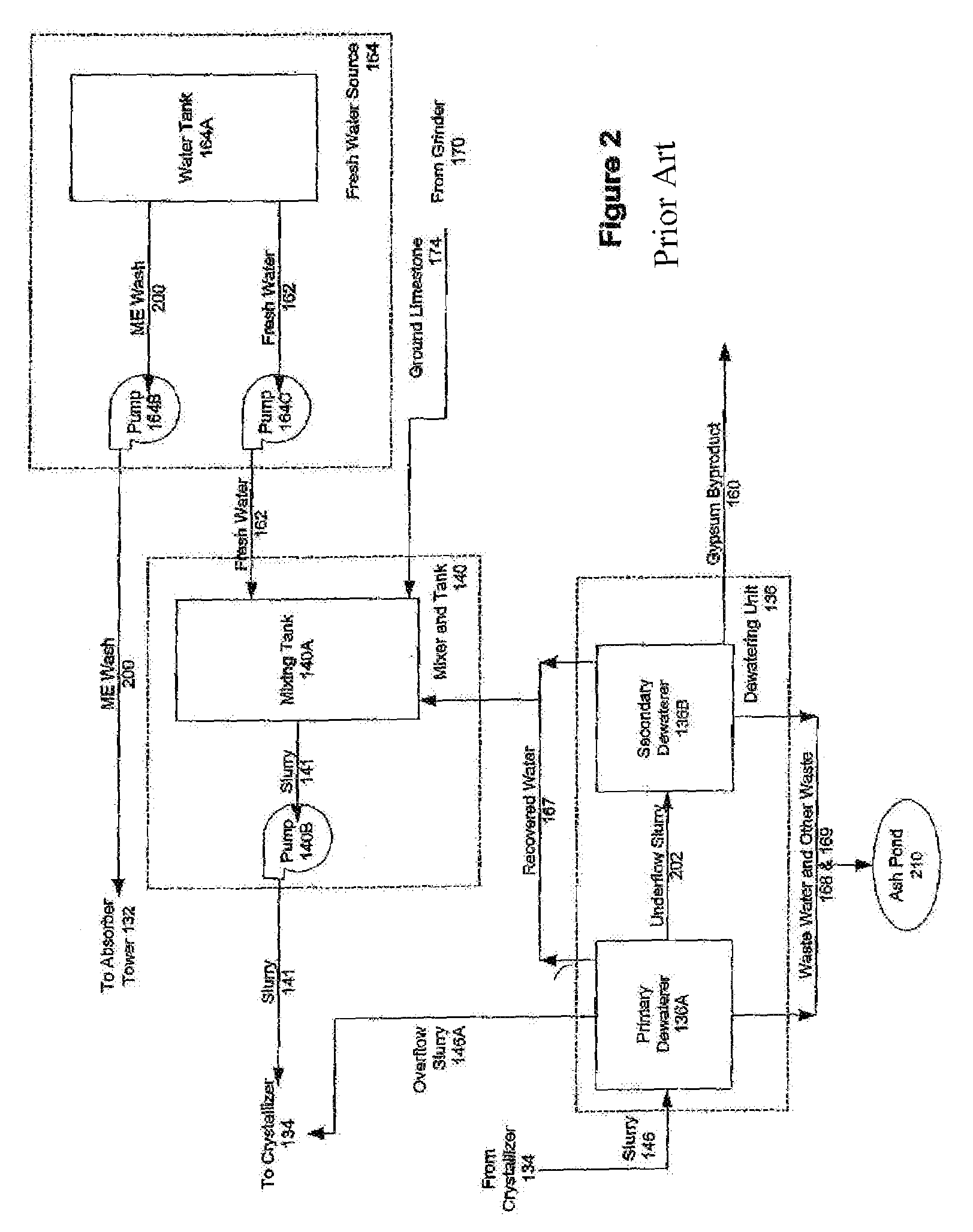

ActiveUS7323036B2Value maximizationCombination devicesAuxillary pretreatmentData controlControl system

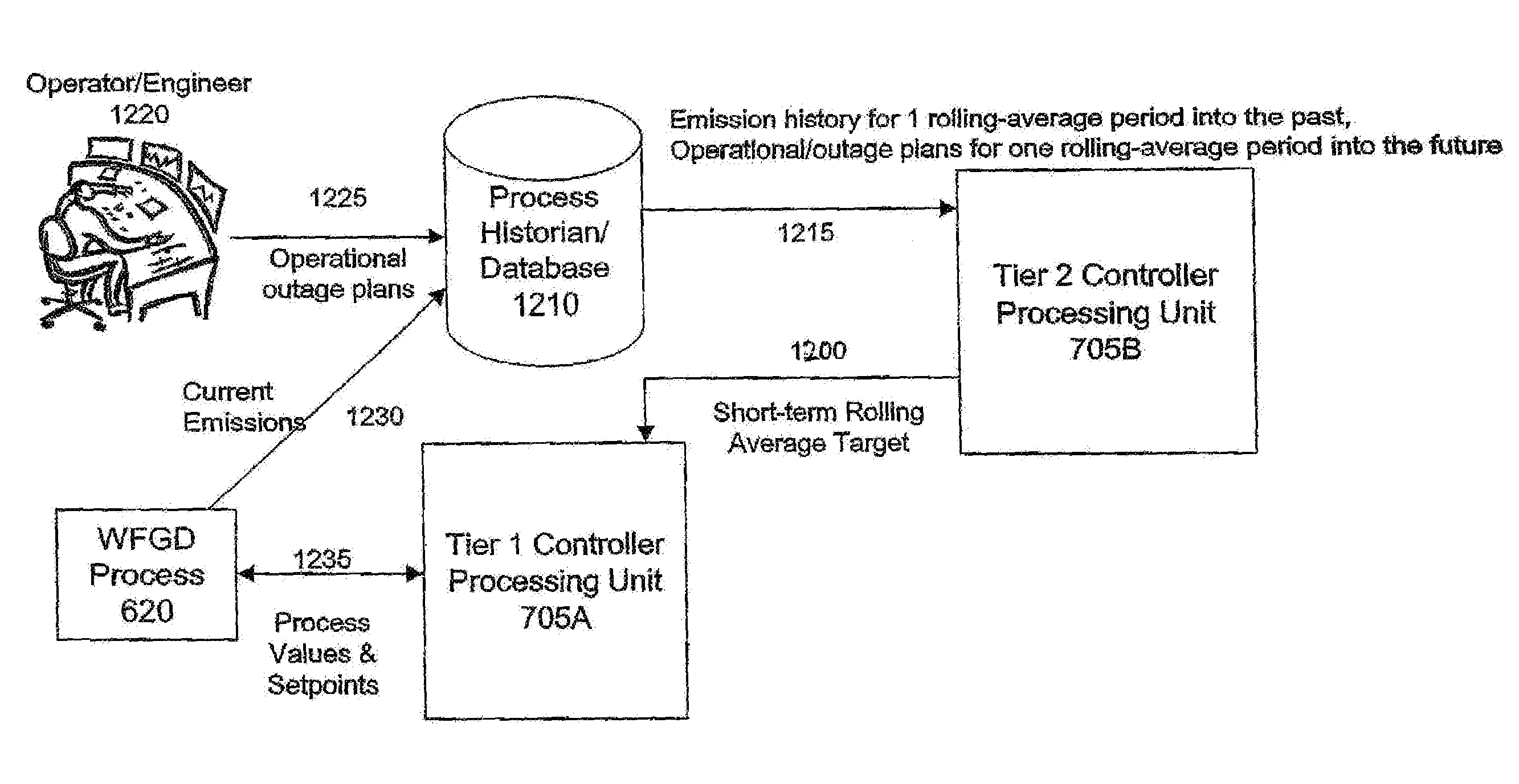

A controller directs the operation of an air pollution control (APC) system having one or more controllable operating parameters and a defined operating limit representing a regulatory limit on an allowed amount of pollutant to be emitted by the APC system. An interface receives data representing a value of a regulatory credit available for emitting less of the pollutant than the regulatory limit on the allowed amount of pollutant. A control processor (i) determines a target set point for each of at least one of the one or more controllable operating parameters, which will maximize the regulatory credits earned, based on the received data and (ii) to directs control of each of the at least one controllable operating parameter based on the determined target set point for that parameter.

Owner:GENERAL ELECTRIC TECH GMBH

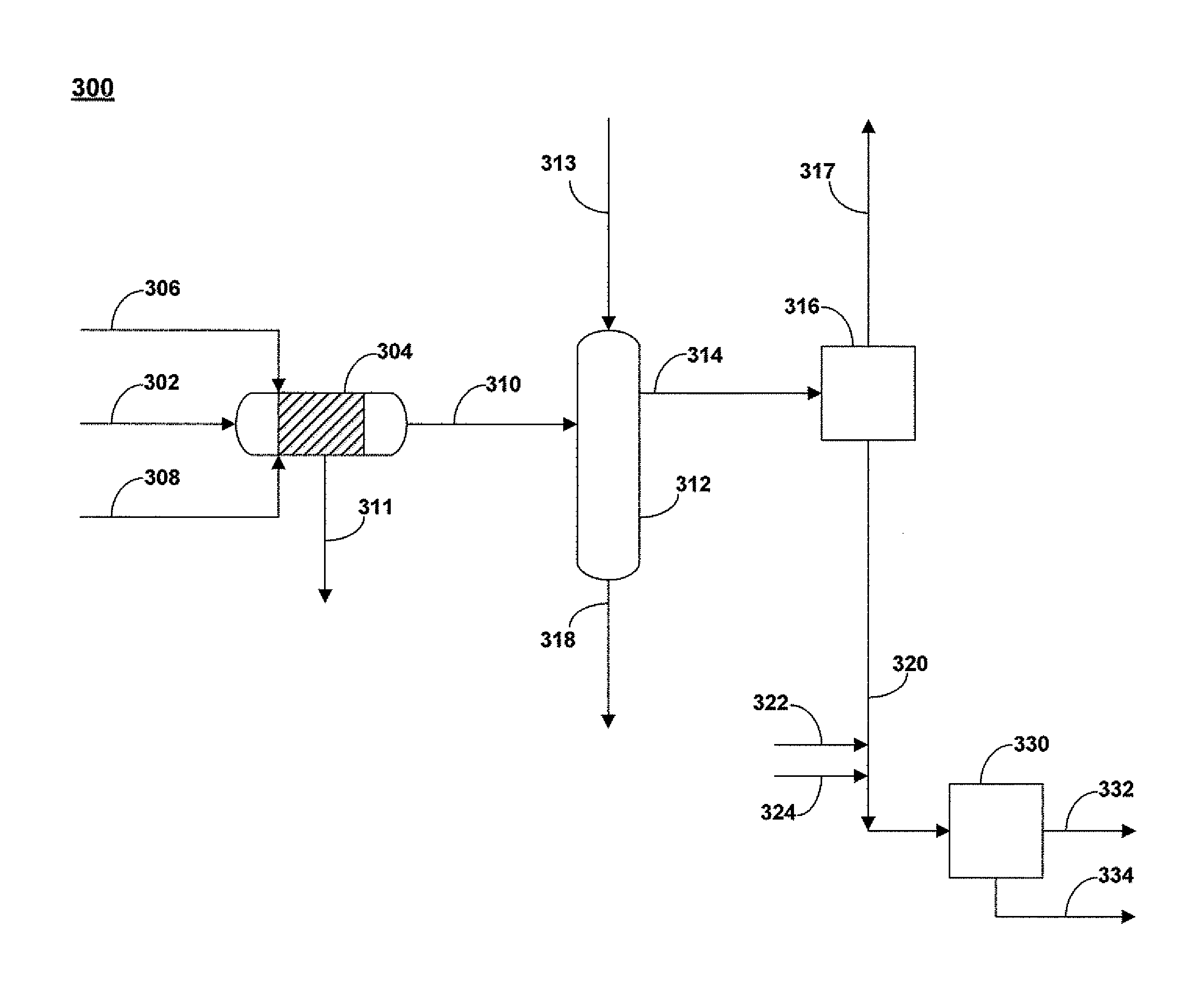

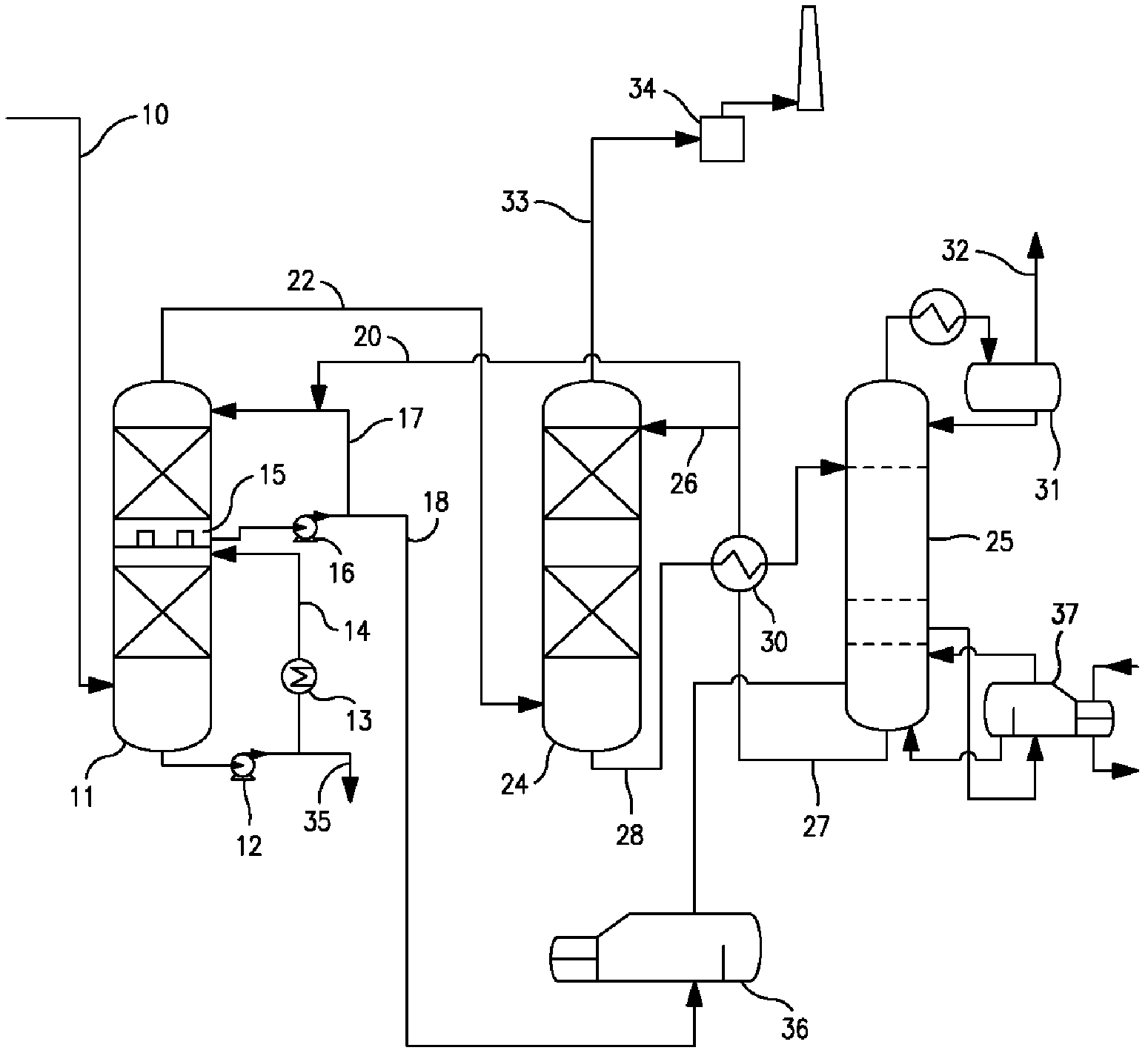

Process for Oxidative Desulfurization and Sulfone Disposal Using Solvent Deasphalting

ActiveUS20120055843A1High purityWorking-up pitch/asphalt/bitumen by selective extractionSulfur-dioxide/sulfurous-acidSulfurSolvent

A method and apparatus for upgrading a hydrocarbon feedstock is provided. The method includes the steps of (a) supplying a hydrocarbon feedstock to an oxidation reactor, wherein the hydrocarbon feedstock is oxidized in the presence of a catalyst under conditions sufficient to selectively oxidize sulfur compounds present in the hydrocarbon feedstock; (c) separating the hydrocarbons and the oxidized sulfur compounds by solvent extraction; (d) collecting a residue stream that includes the oxidized sulfur compounds; and (e) supplying the residue stream to a deasphalting unit.

Owner:SAUDI ARABIAN OIL CO

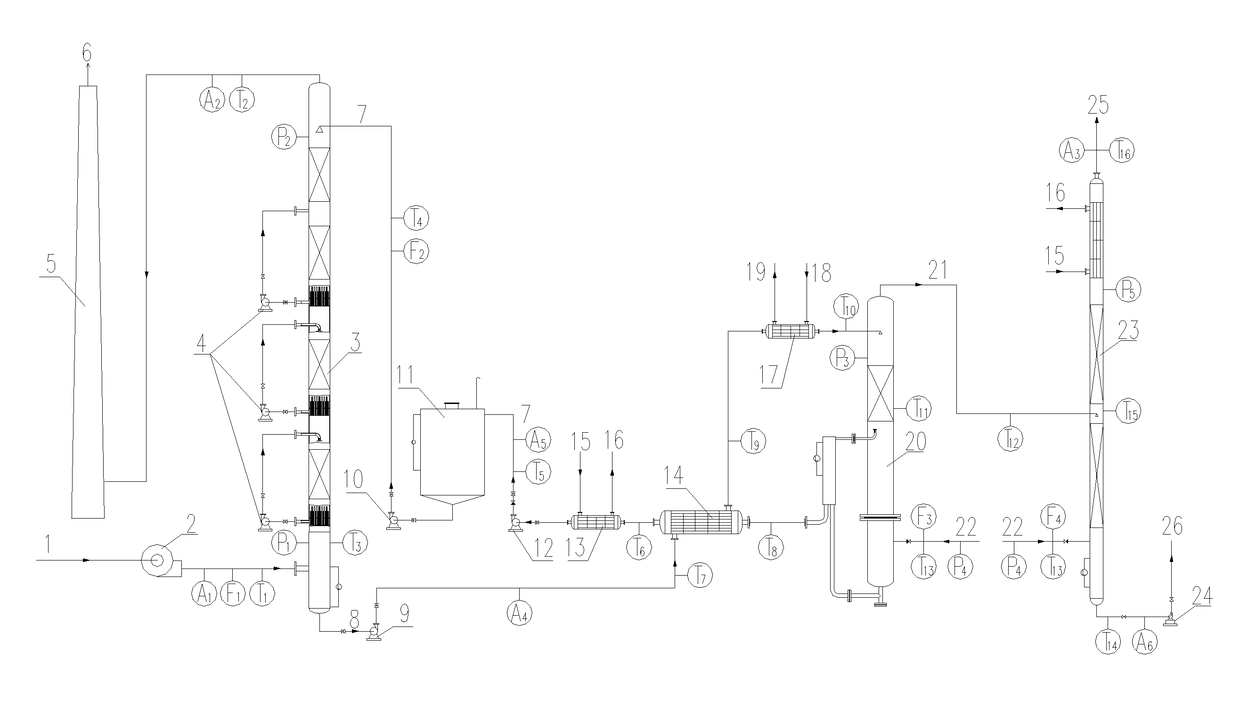

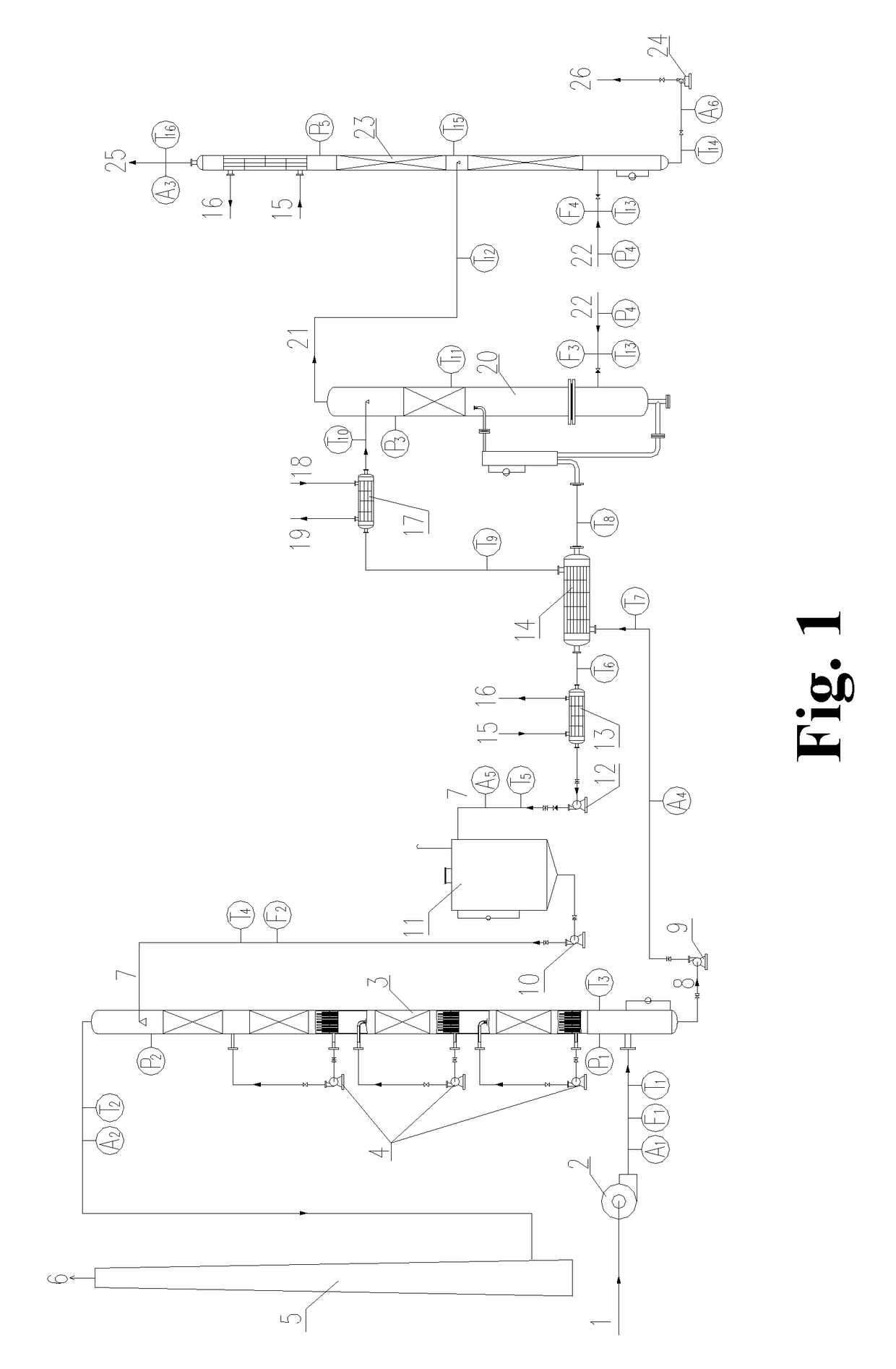

Process and device for desulphurization and denitration of flue gas

ActiveUS20170197180A1Promote circulationIncrease volumeGas treatmentNitrogen compoundsFiberSulfur dioxide

The invention discloses a process and device for desulfurization-denitration of a flue gas. A desulfurization-denitration solution is used in an absorption tower to absorb sulfur dioxide and / or nitrogen oxides from the flue gas or various combustion tail (waste) gases. The desulfurization-denitration solution with absorbed sulfur dioxide and / or nitrogen oxides releases the sulfur dioxide and / or nitrogen oxides by heating and / or gas stripping and / or vacuum regeneration in a regeneration tower. The released sulfur dioxide and / or nitrogen oxides are further concentrated into a sulfur dioxide and / or nitrogen oxide product with a higher purity in a concentration tower. The regenerated desulfurization-denitration solution is recycled for use. The process and device have a wide range of industrial applications, and can be used for desulfurization and / or denitration of flue gases, incineration gases, coke-oven gases, synthetic waste gases from dyestuff plants, pollutant gases discharged from chemical fiber plants and other industrial raw material gases or waste gases containing SOx.

Owner:WEI XIONGHUI +1

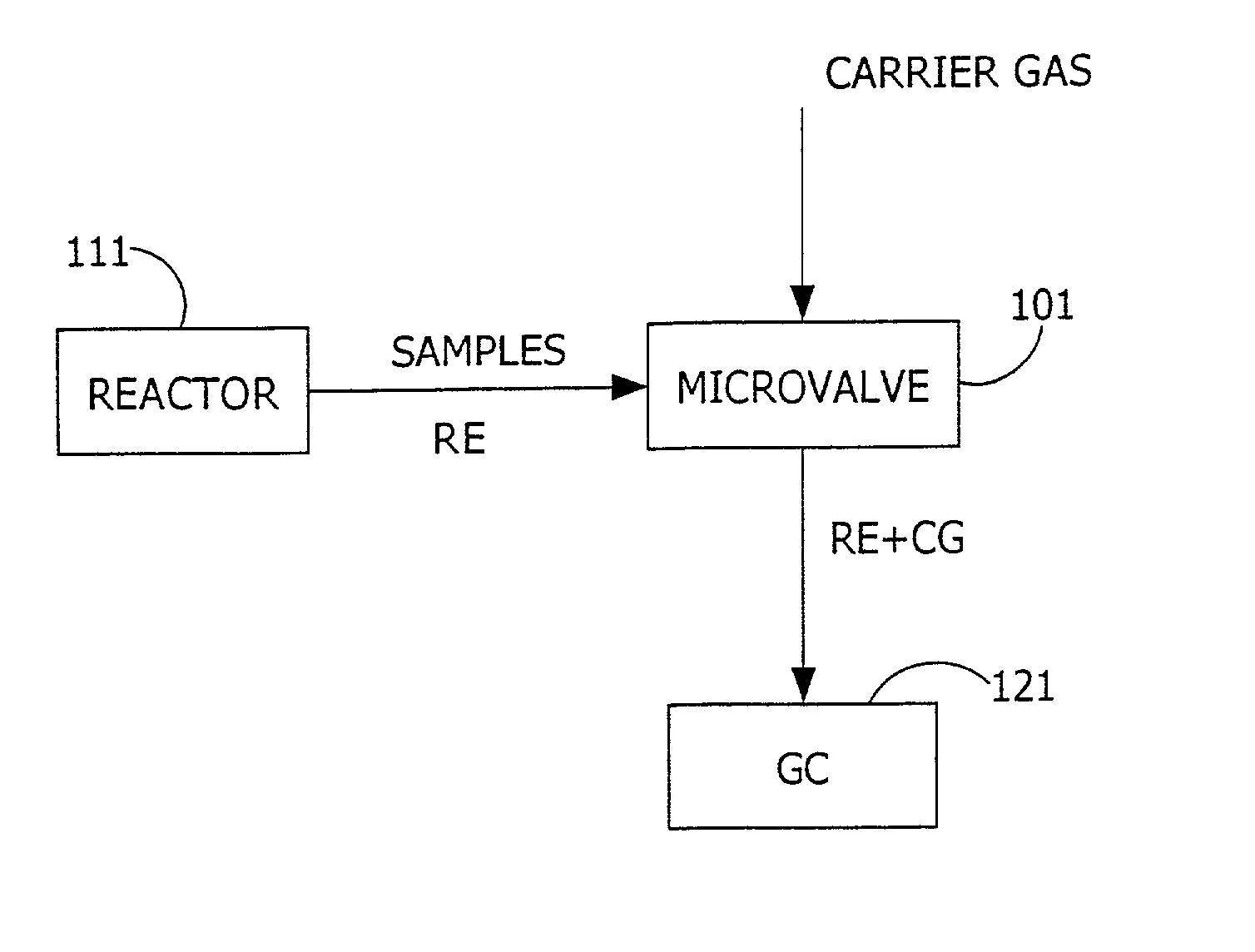

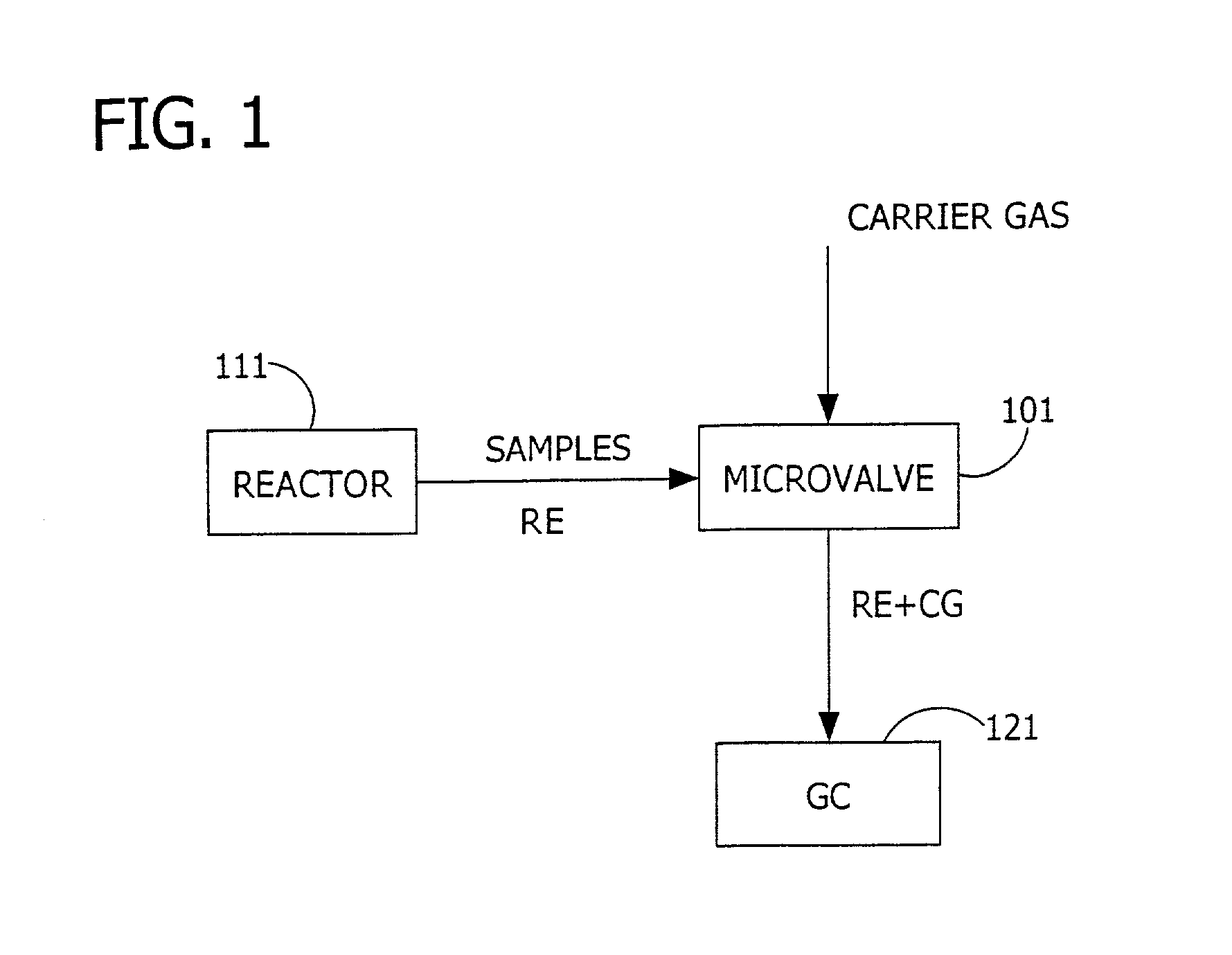

Gas chromatograph injection valve

A novel gas injection valve for injecting discrete charges of gas into a mobile phase or carrier stream is provided. Injection valves of the invention comprise a plurality of microvalves capable of receiving gas at different pressures and emitting discrete charges of gas at approximately the same pressure. The invention further provides for parallel injection valve arrays capable of injecting multiple samples substantially simultaneously and a method of injecting discrete gas samples at a controlled pressure to a high-resolution gas chromatograph.

Owner:SYMYX TECHNOLOGIES +1

Silicon carbides, silicon carbide based sorbents, and uses thereof

Methods of making silicon carbide comprise providing at least one organosilicon precursor material, hydrolyzing the organosilicon in a solution comprising water and an acid catalyst, providing a surfactant to the solution, forming a gel by adding a base to the solution, and heating the gel at a temperature and for a time sufficient to produce silicon carbide.

Owner:THE OHIO STATES UNIV

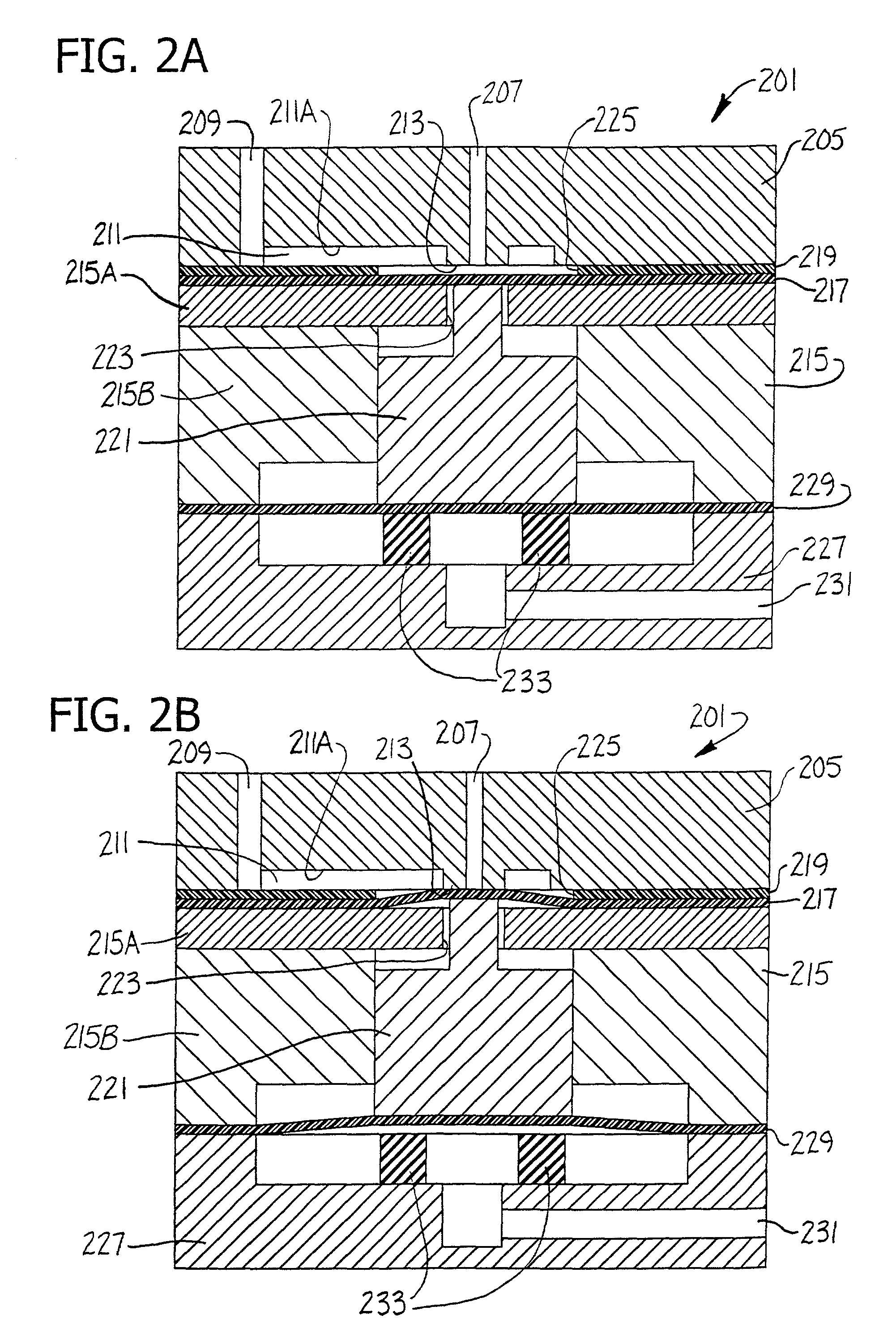

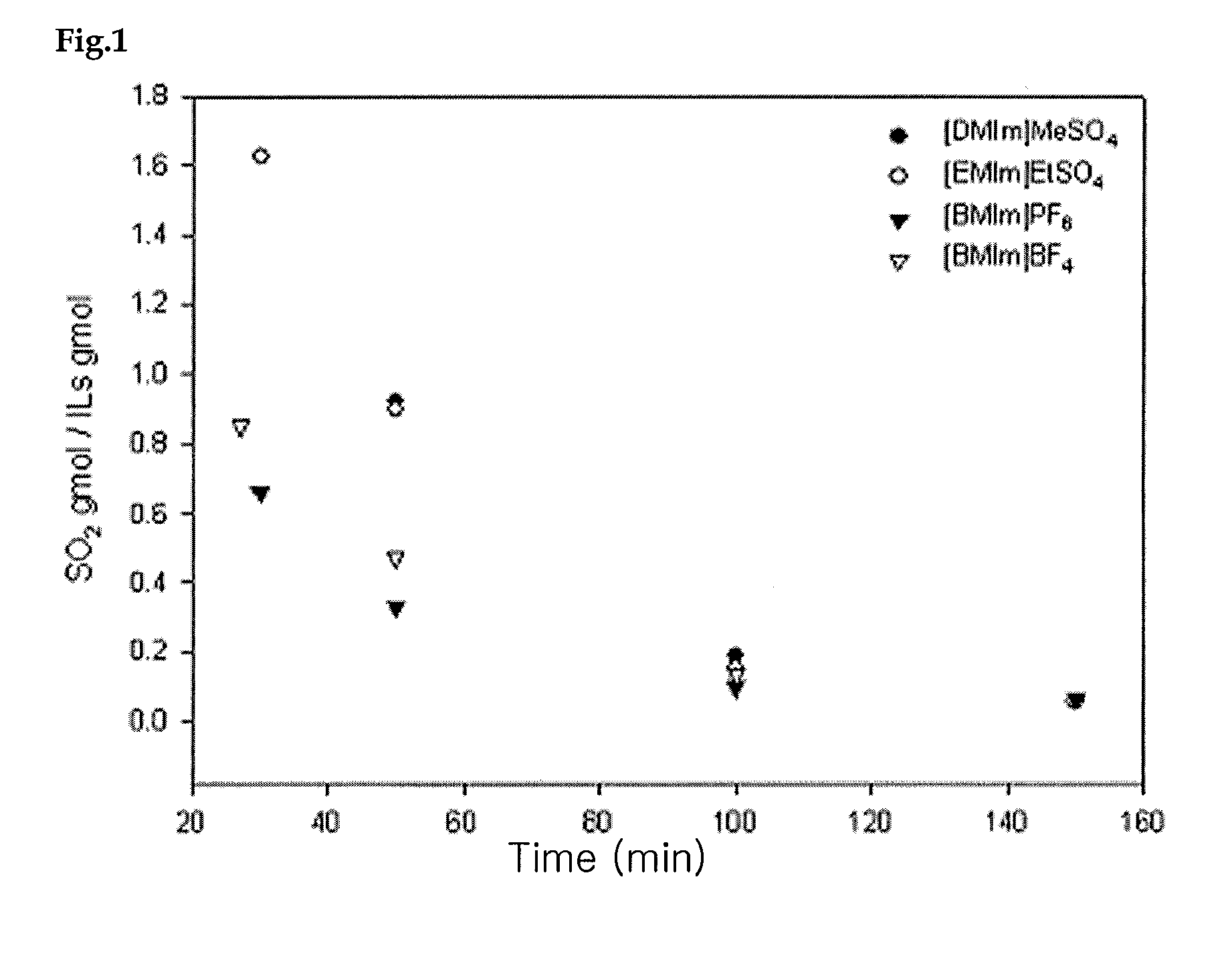

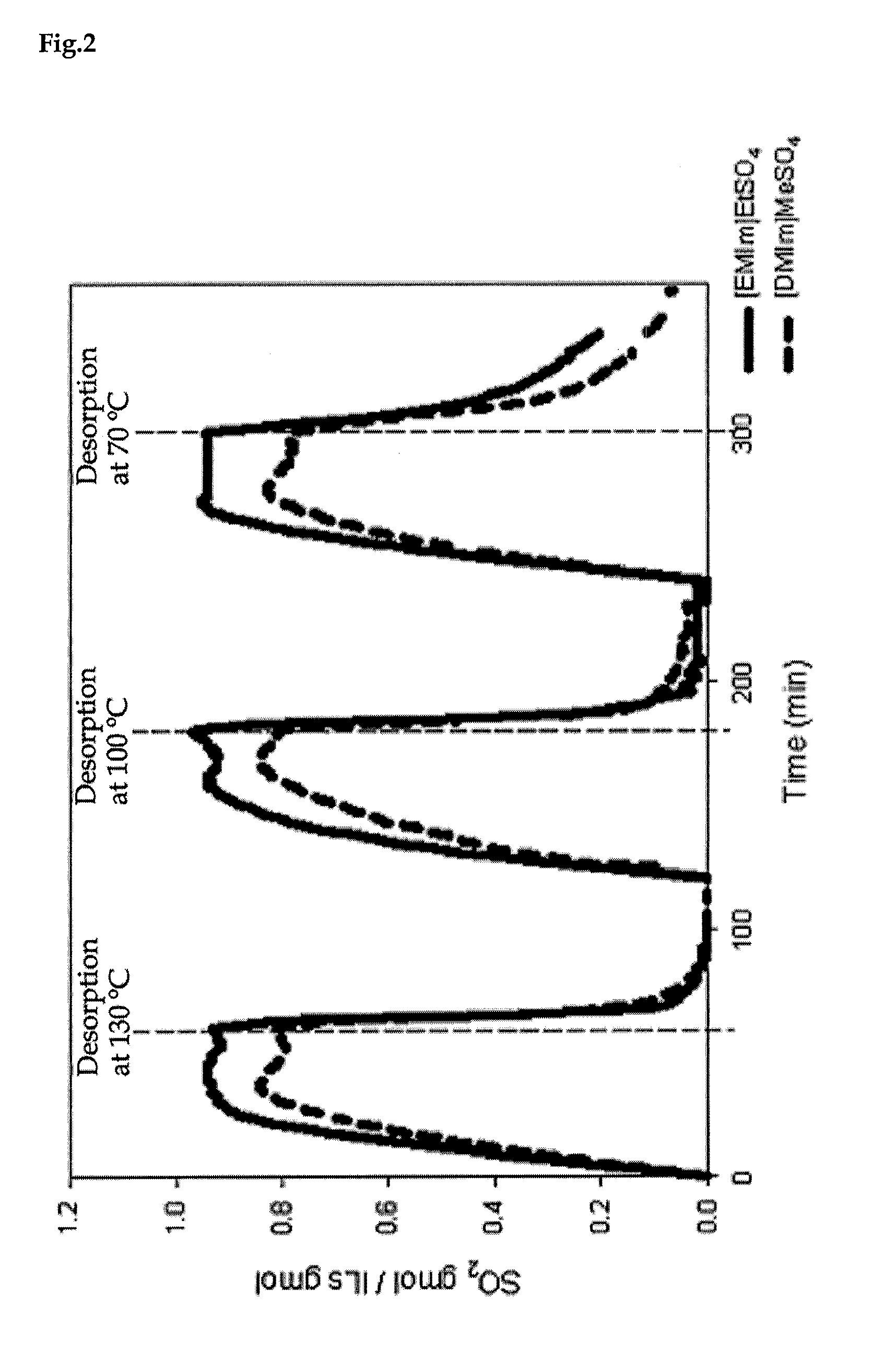

Method for separation and recycle of pure sulfur dioxide from a gaseous mixture in is cycle with ionic liquids

InactiveUS20100015040A1Improve processing efficiencyGood chemical stabilityChlorine/hydrogen-chlorideOxygen/ozone/oxide/hydroxidePhysical chemistryIonic liquid

The present invention relates to a method for separation and recycling of pure sulfur dioxide from a gaseous mixture in the IS cycle. More specifically, the present invention relates to a method for separation and recycling of pure sulfur dioxide from a gaseous mixture in the IS cycle using an ionic liquid under a specific condition. When compared with the conventional amine-based absorbent, the use of the ionic liquid enables continuous absorption and stripping of SO2 even at high temperature, and enables a reversible absorption of SO2 without loss, decomposition or degradation of a solvent due to good chemical stability, thereby enabling separation and recycling of pure SO2 from a gaseous mixture in the IS cycle.

Owner:KOREA INST OF SCI & TECH

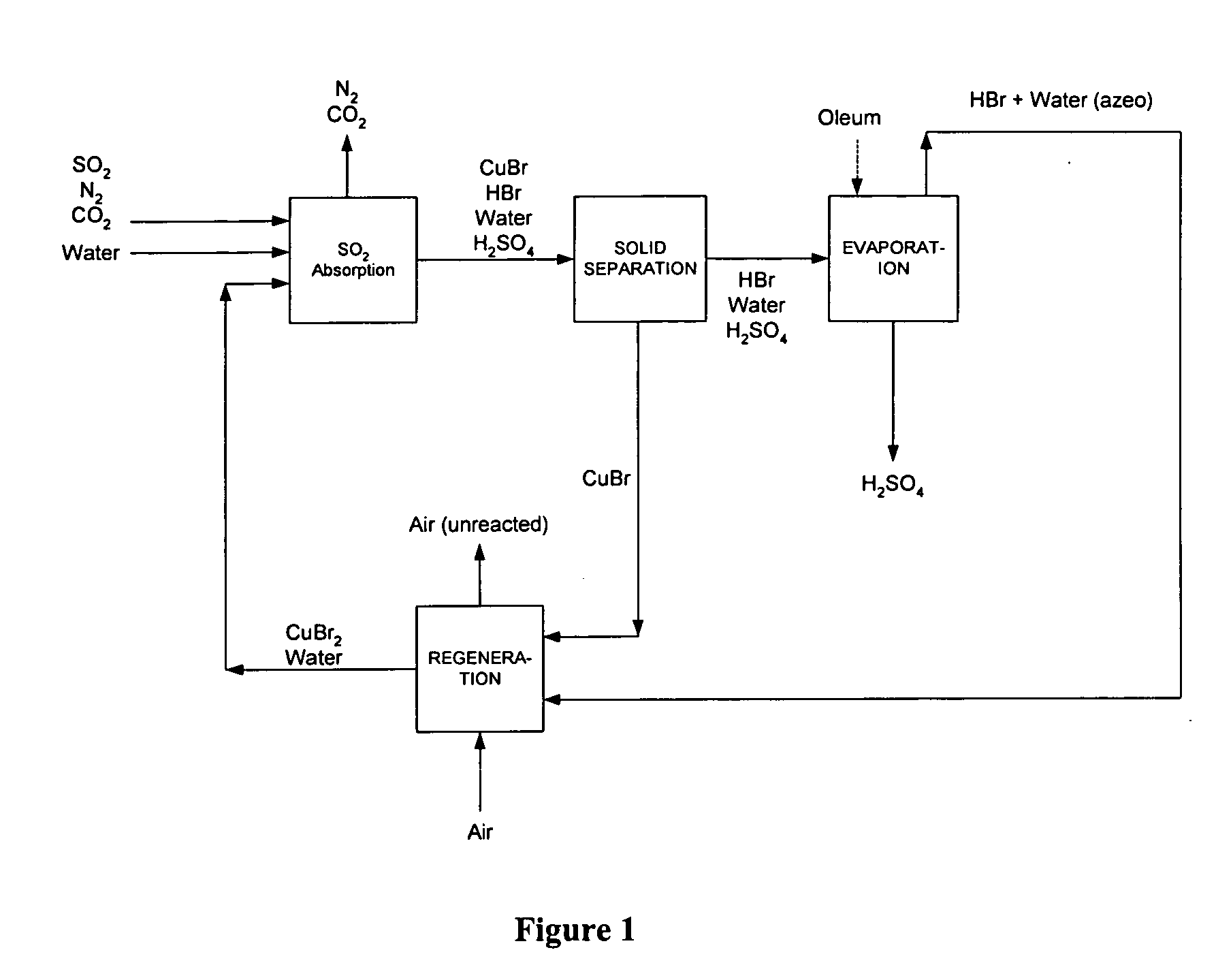

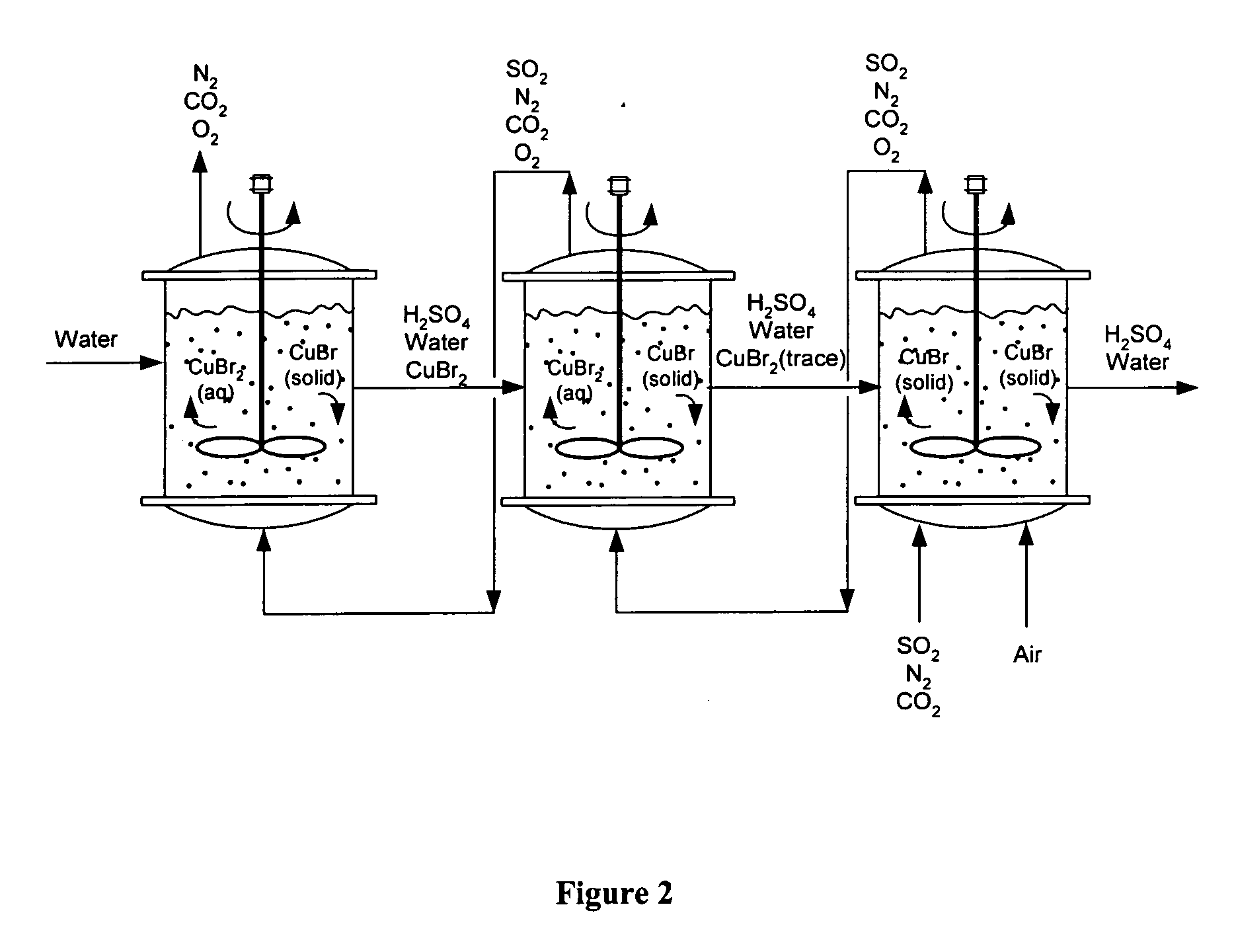

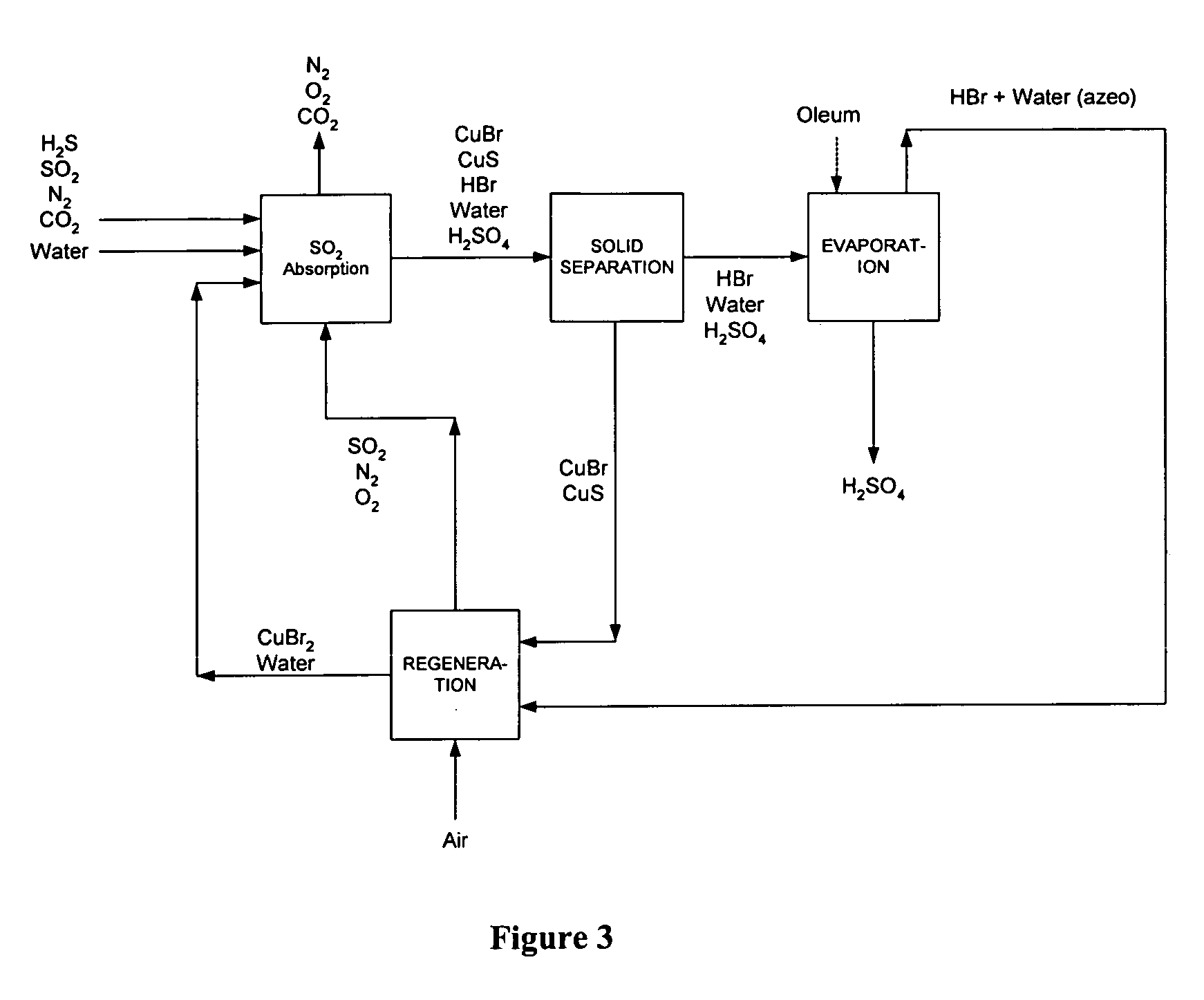

Process of gas treatment to remove pollutants

InactiveUS20070196255A1Dispersed particle filtrationSulfur-dioxide/sulfurous-acidOxidation stateOxidizing agent

A process for the removal of a pollutant from a gas is provided that includes contacting a gas comprising a pollutant with a cataloreactant wherein the cataloreactant reacts with the pollutant and wherein an oxidation state of the cataloreactant is reduced. The cataloreactant may be regenerated with an oxidizing agent.

Owner:REACTION 35 LLC

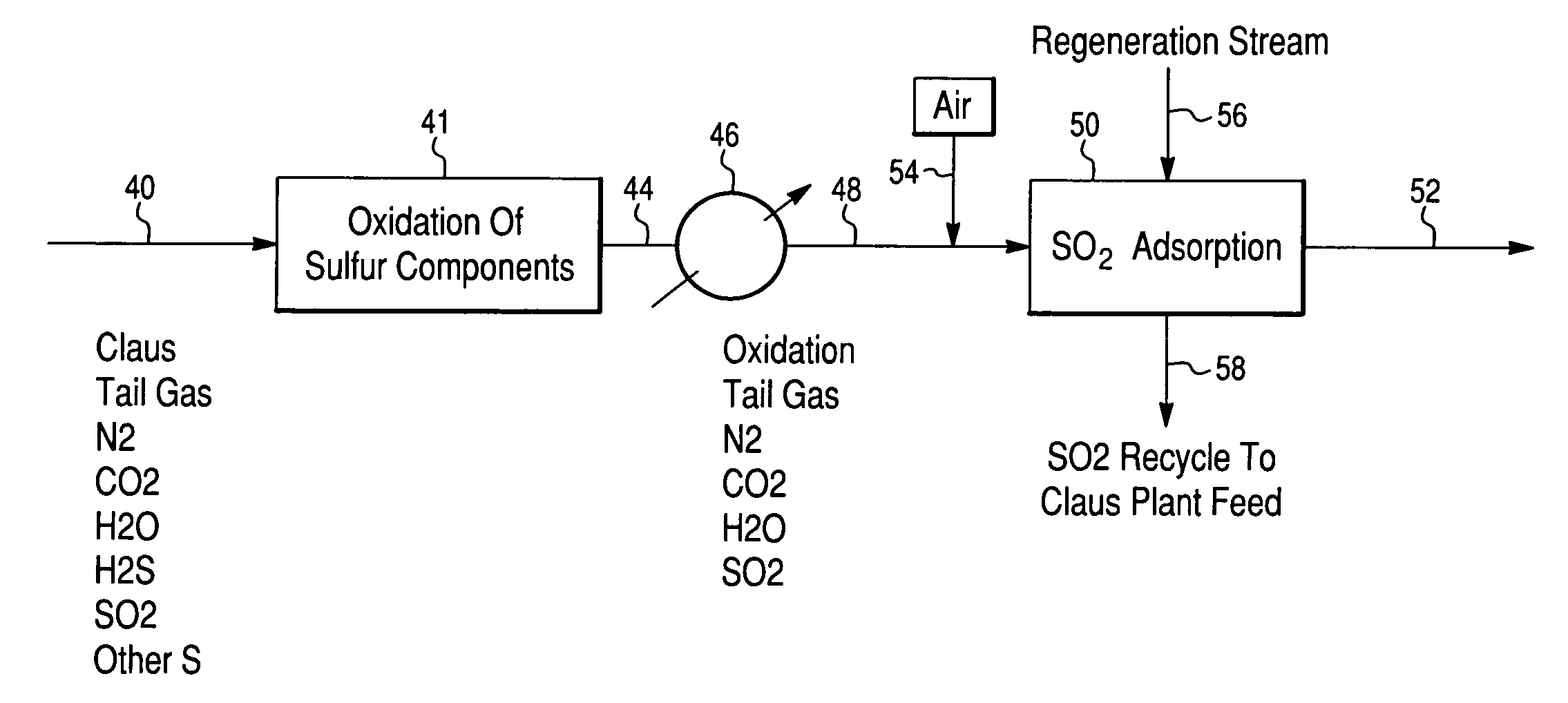

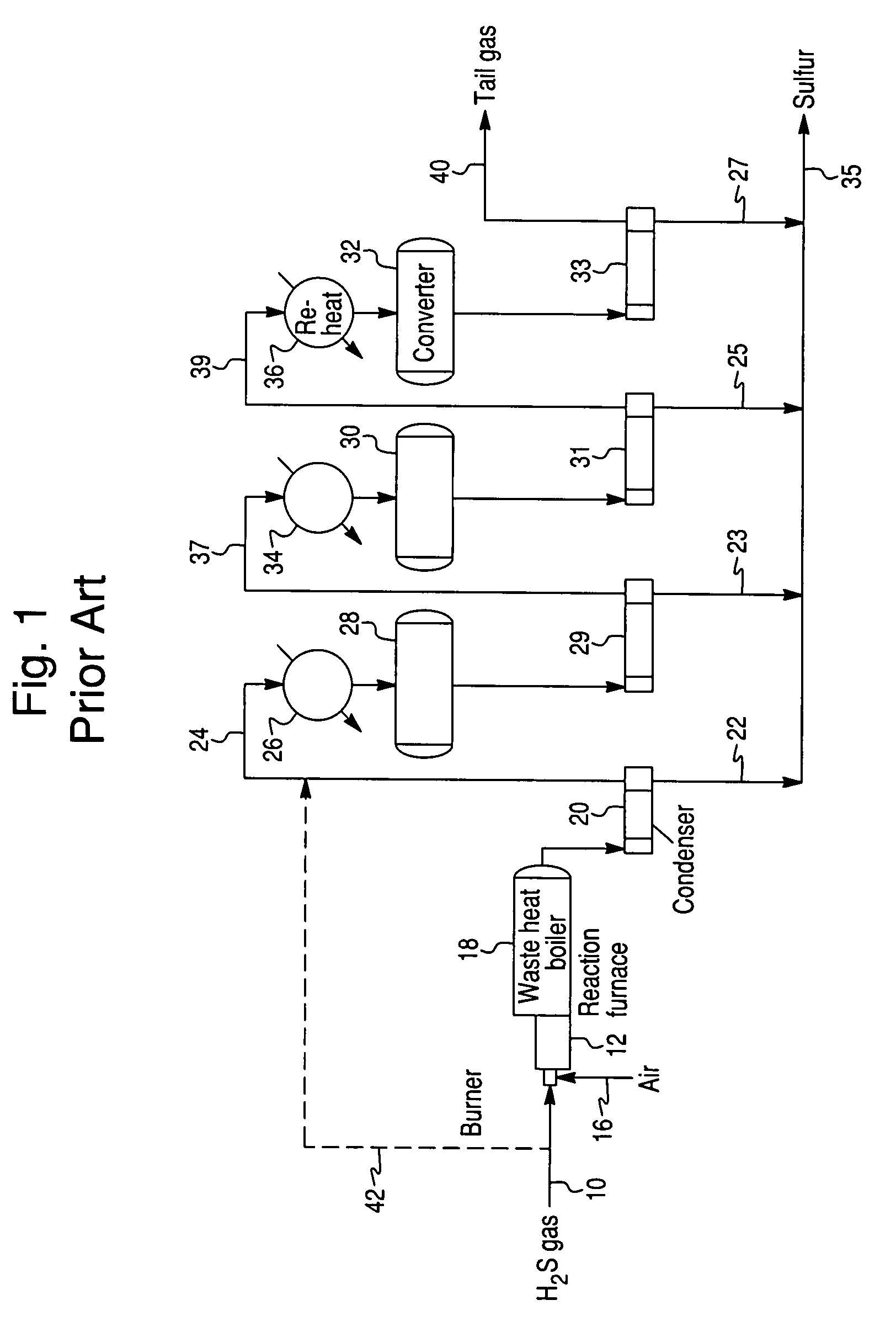

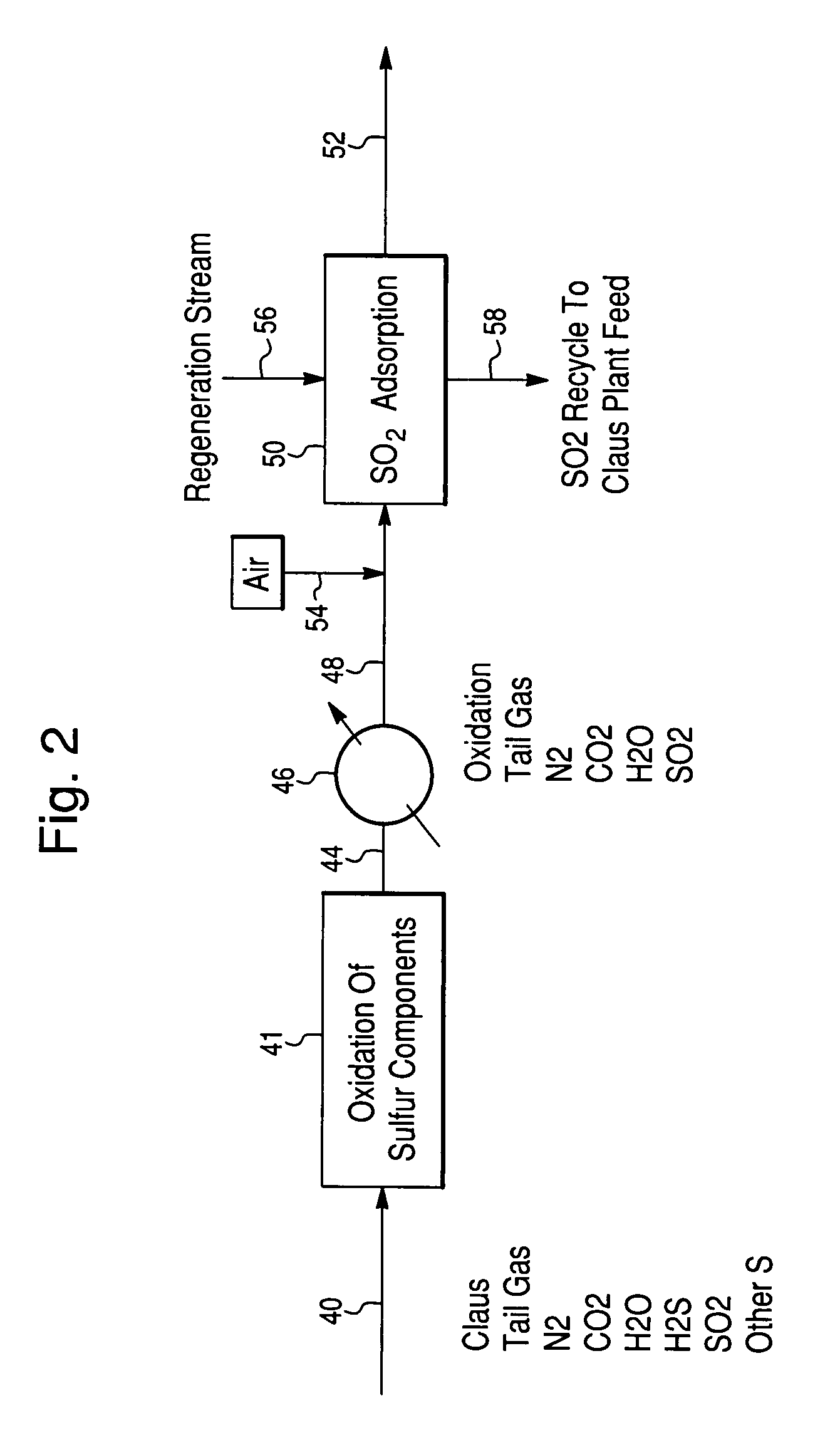

Process for the recovery of sulfur from Claus tail gas streams

Recovering sulfur from a gas stream containing hydrogen sulfide by oxidizing the gas stream to convert the hydrogen sulfide in the gas stream to sulfur oxide, and thus form a sulfur oxide enriched gas stream. The sulfur oxide enriched gas stream is contacted with a solid, sulfation resistant adsorbent bed at relatively low temperatures to extract the sulfur oxides and retain them as sulfur compounds, thus forming a sulfur oxide depleted gas stream. The adsorbent bed is then contacted with an inert or reducing gas stream to reduce the retained sulfur compounds to sulfur and / or sulfur dioxide and thereby form an enriched sulfur and / or sulfur dioxide bearing stream. The elemental sulfur is recovered and / or the sulfur dioxide bearing stream may be recycled to the Claus unit for further conversion.

Owner:ENGELHARD CORP

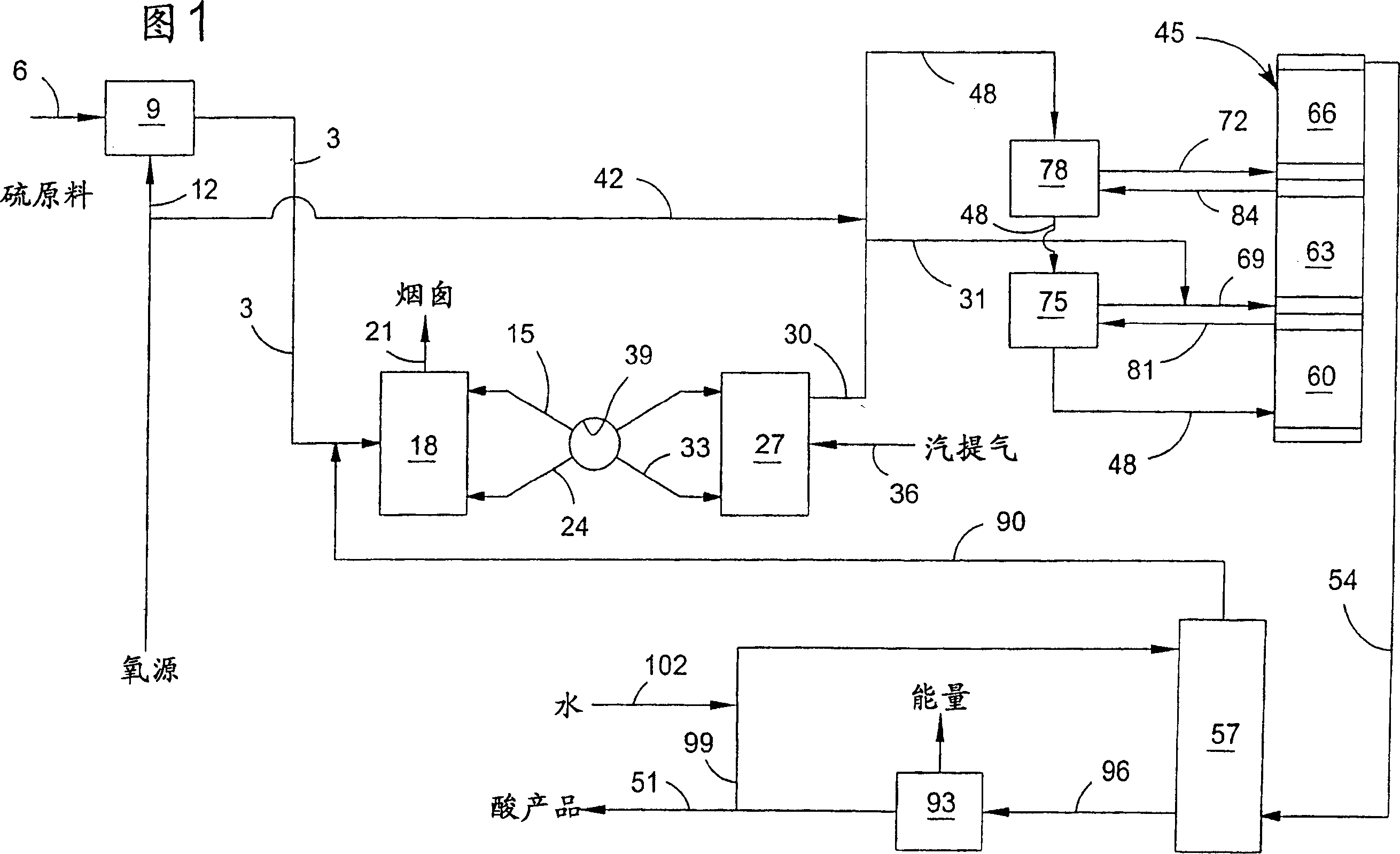

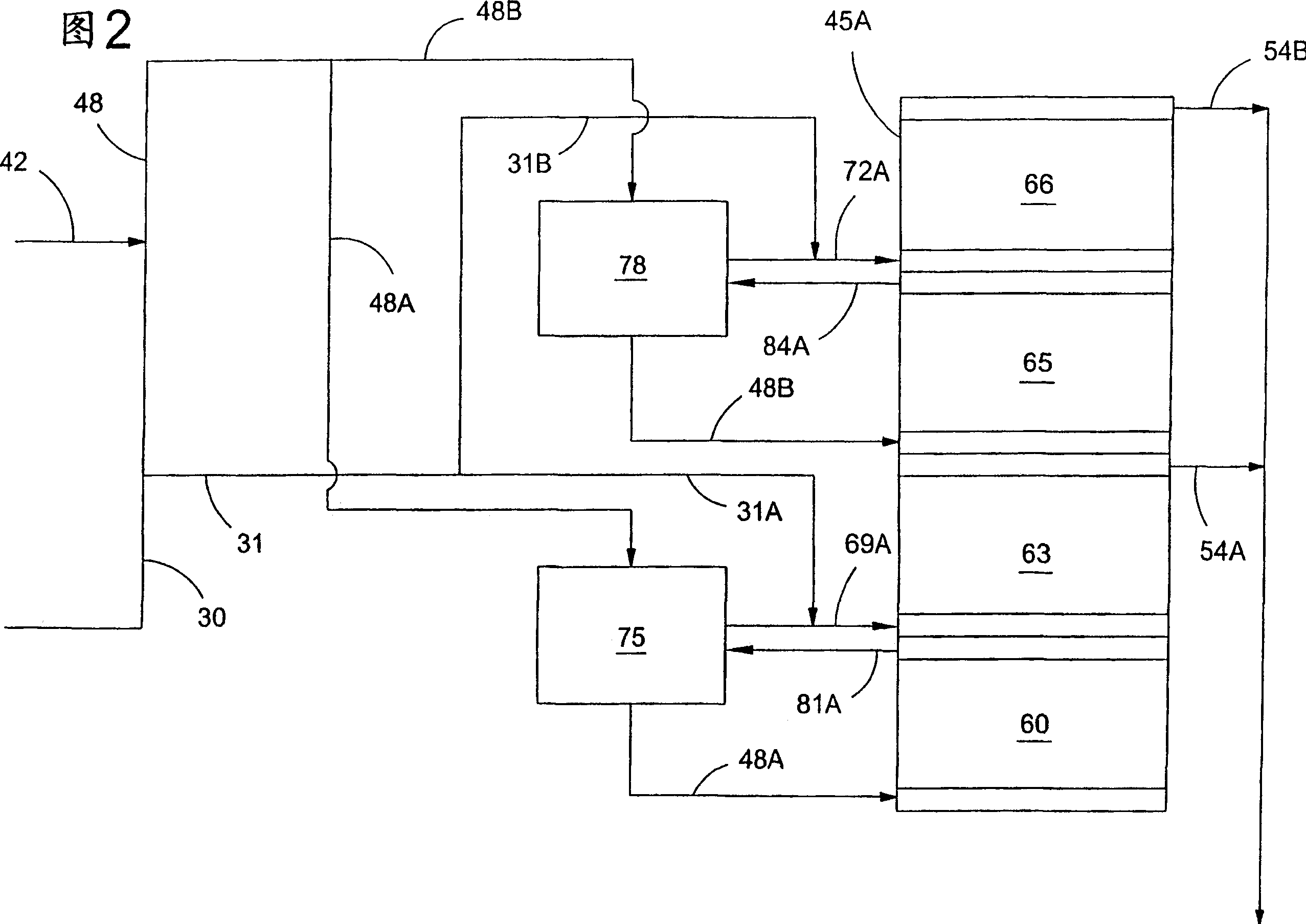

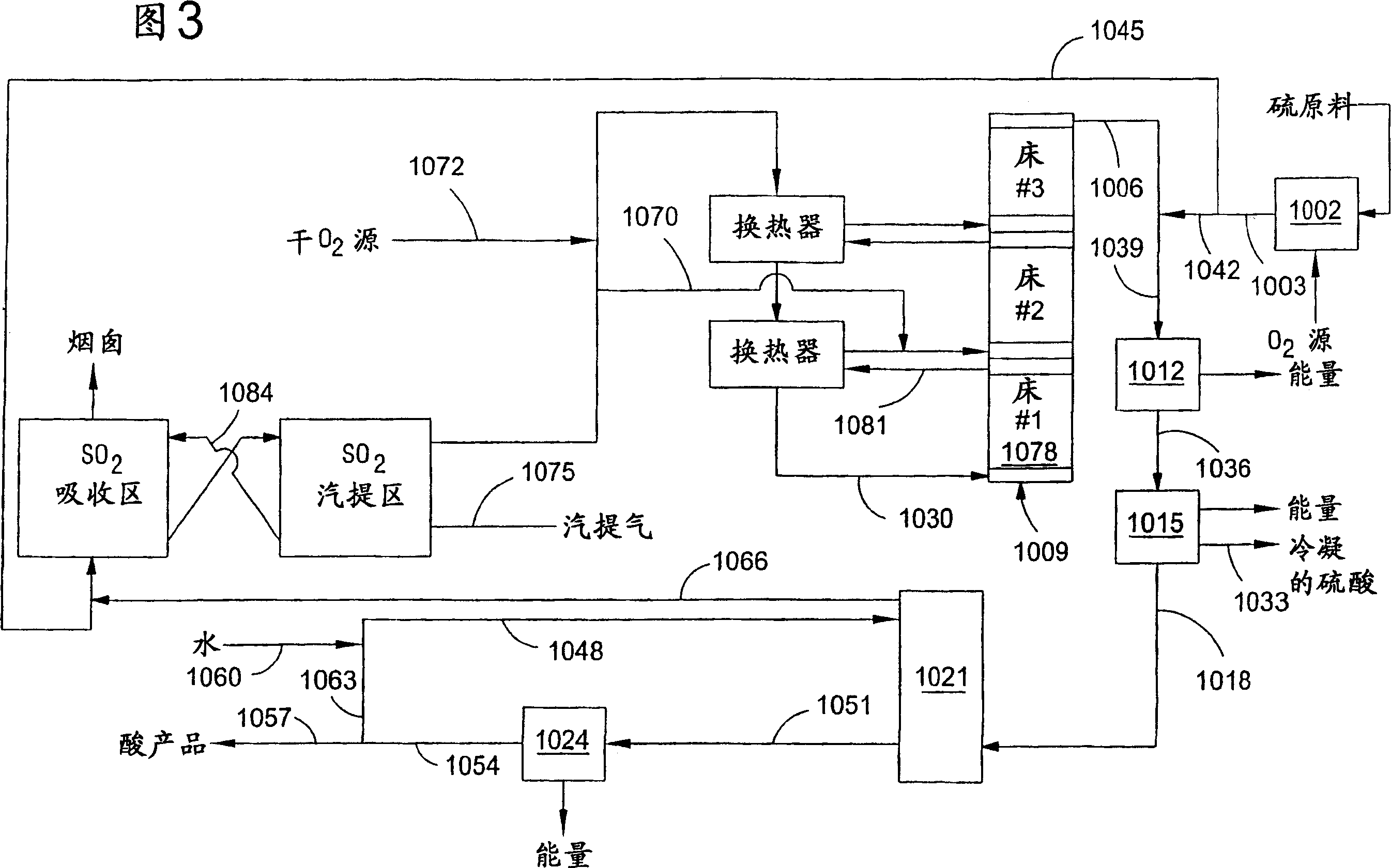

Method for making sulfur trioxide, sulfuric acid, and oleum from sulfur dioxide

A first portion of the converter feed gas comprising a SO 2 -enriched stripping gas is formed. Passing the converter feed through a plurality of catalyst beds in series to form a reformed gas comprising SO3 and residual SO2, the plurality comprising at least 2 and no more than 4 catalyst beds. The second portion of the SO2-enriched gas is introduced into at least one catalyst bed downstream of the most upstream catalyst bed of the plurality of catalyst beds to increase the SO2 concentration in the gas fed to the downstream bed. The invention also relates to a process for the production of sulfuric acid and / or oleum from a feed gas comprising SO2. The SO2-enriched stripping gas is passed through multiple series-connected catalyst beds to form a reformed gas comprising SO3 and residual SO2. mixing the reformed gas with water vapor to form a product acid gas comprising: (a) sulfuric acid from the gas phase reaction between SO3 from the oxidation product gas and water vapor, thereby generating gas phase heat of sulfuric acid formation; (b) SO3 ; and (c) SO2. Thermal energy is recovered from gas phase sulfuric acid generation heat by heat transfer from the product acid gas to steam or feed water in an indirect heat exchanger. The cooled product acid gas is then contacted with sulfuric acid liquid in the SO3 absorption zone to form additional sulfuric acid and / or oleum and SO3-depleted gas containing SO2.

Owner:MONSANTO CO (MONSANTO CY)

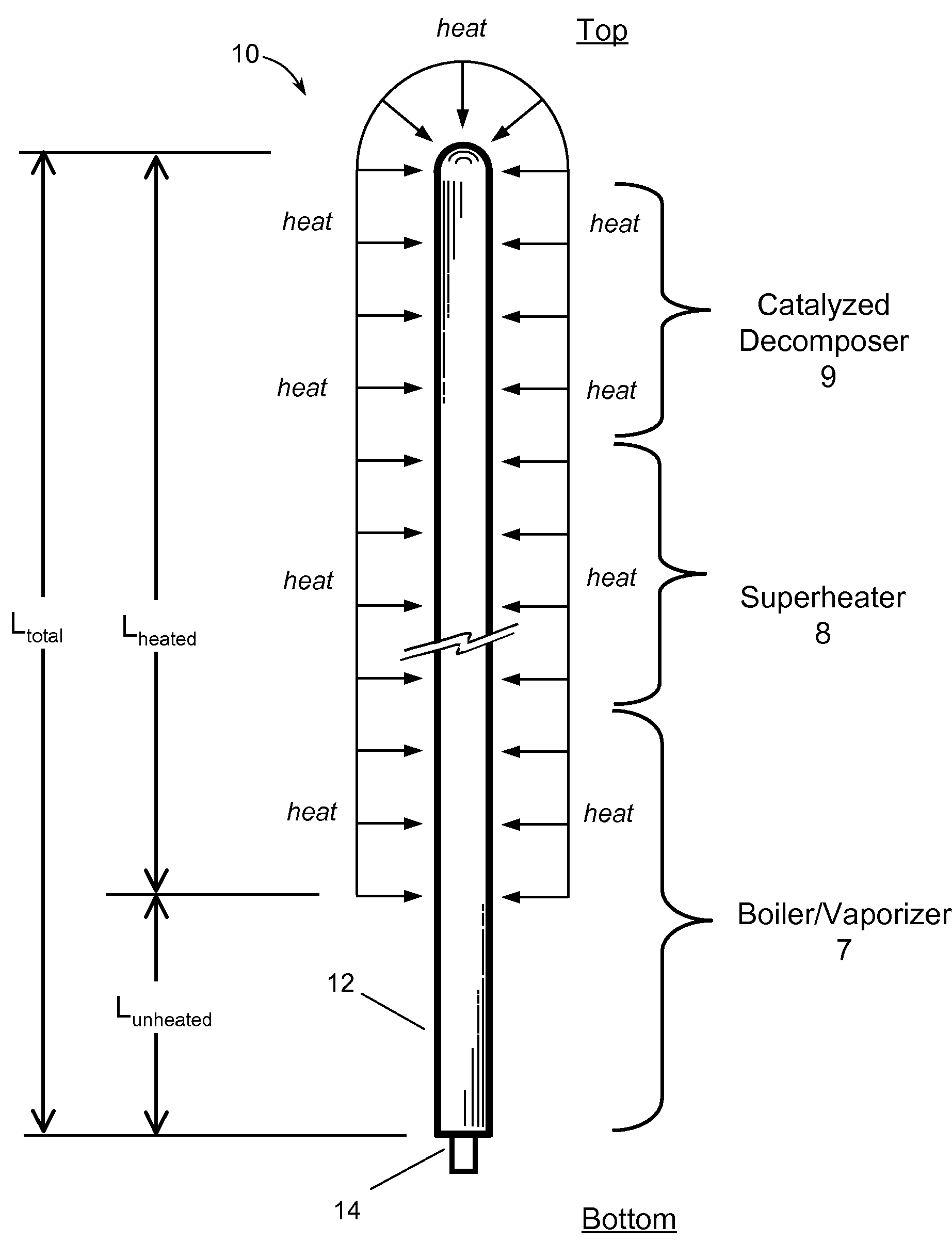

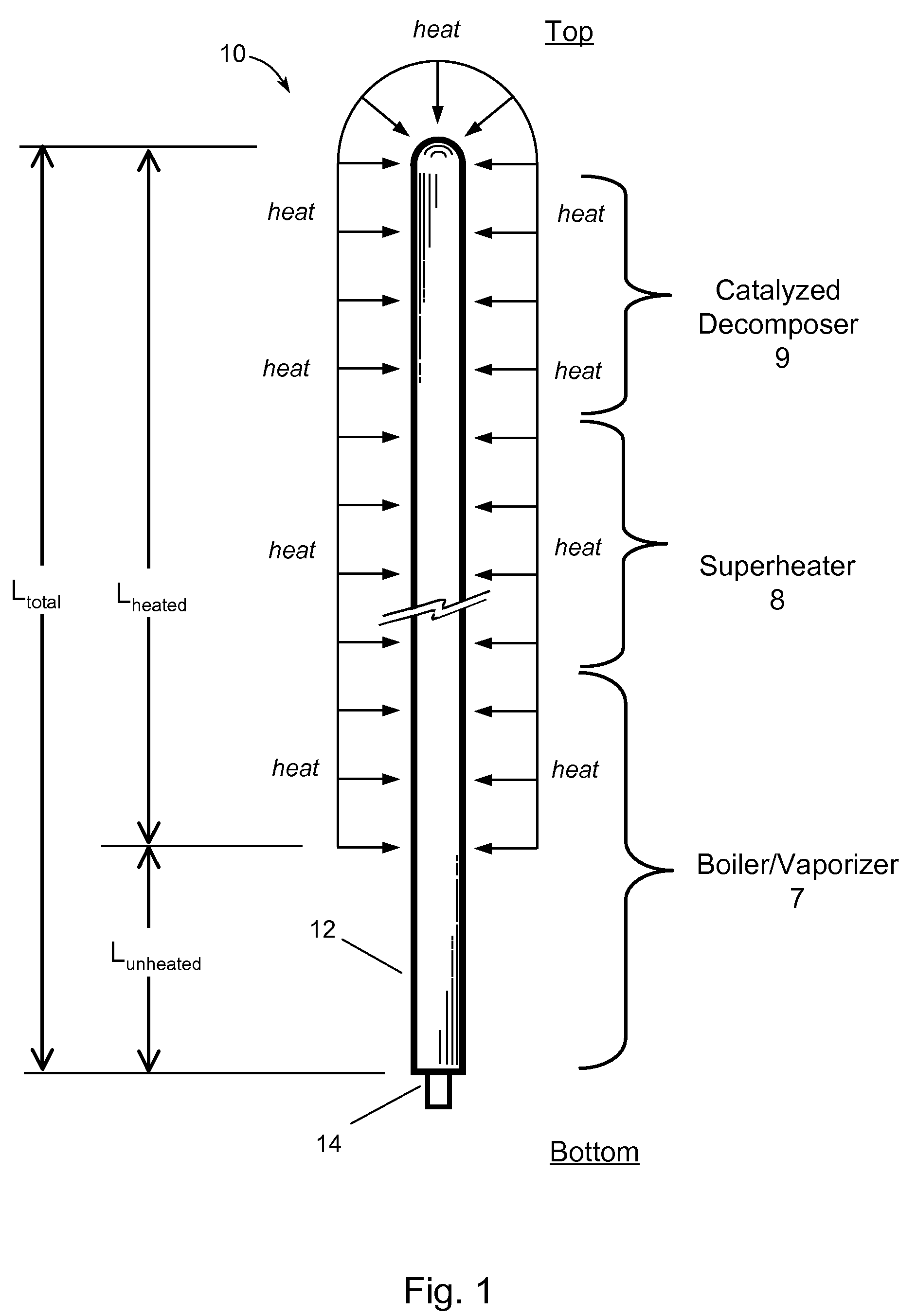

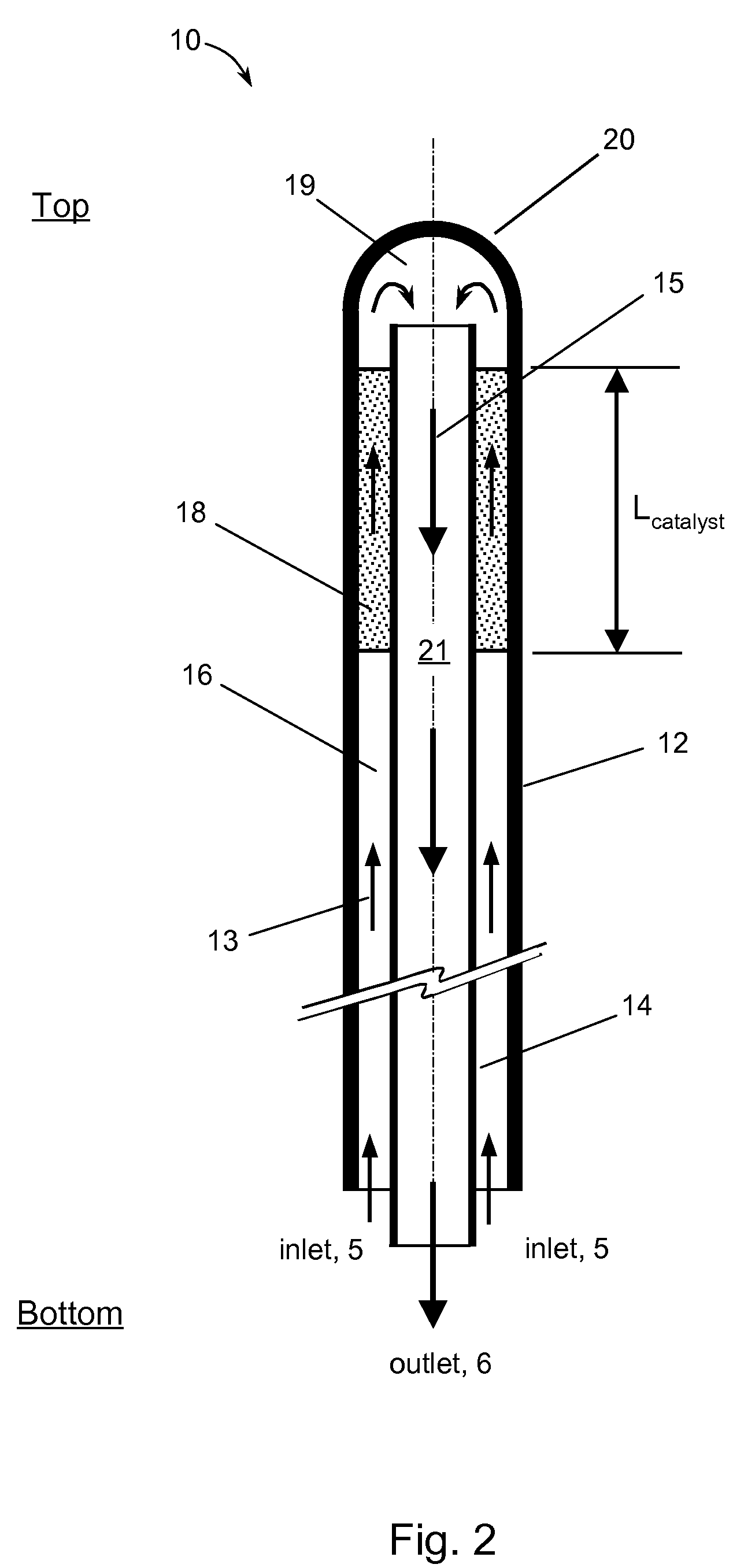

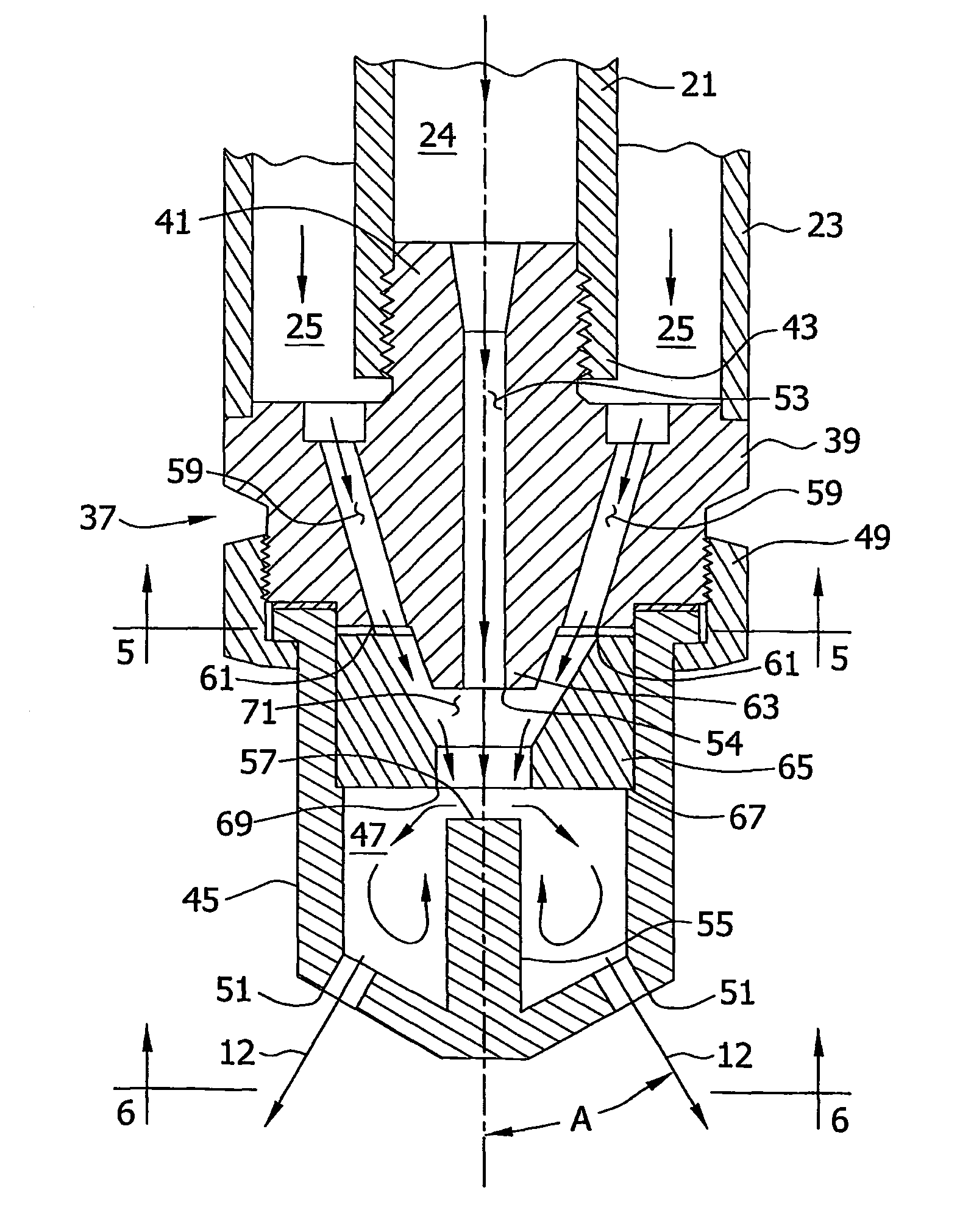

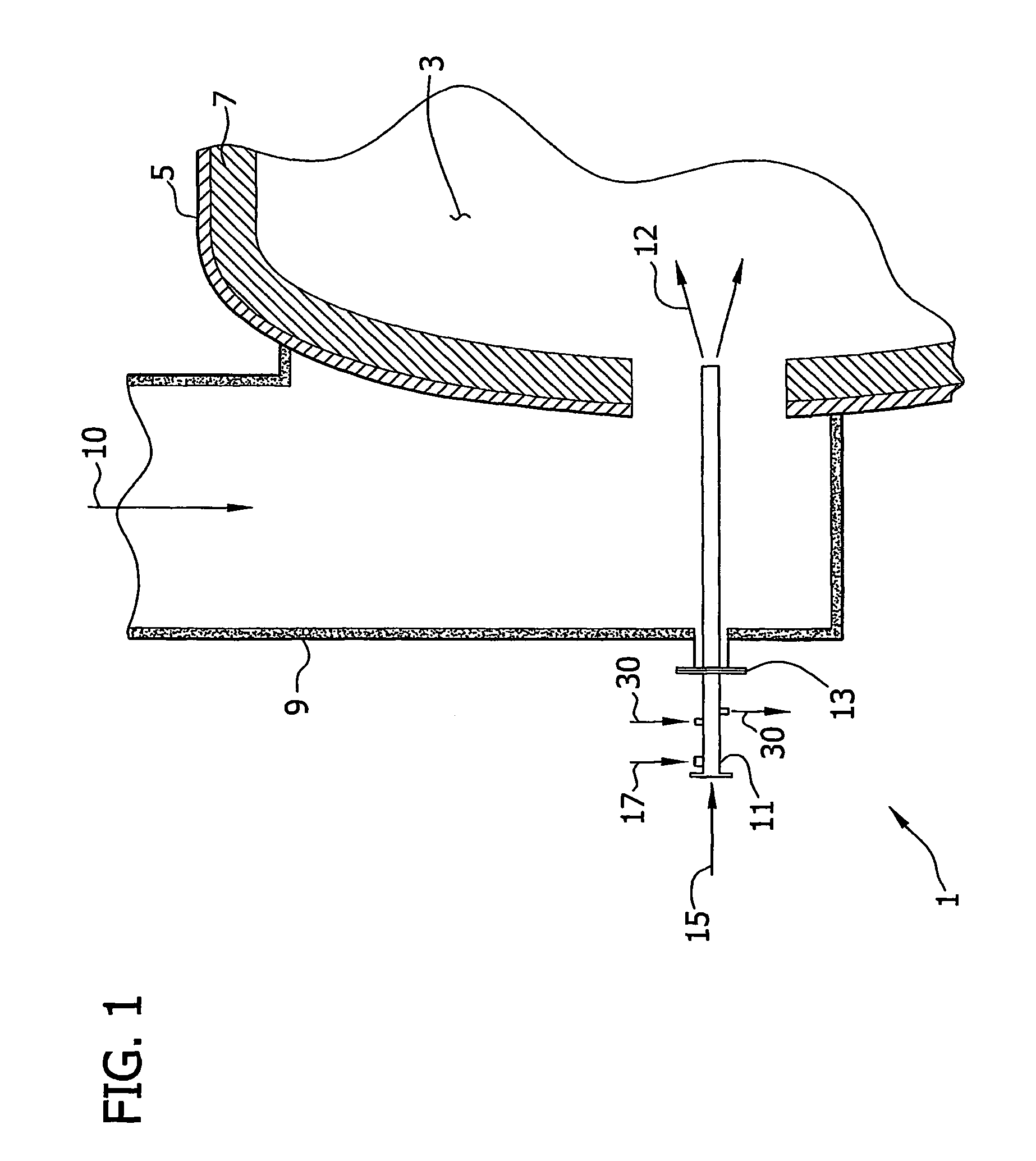

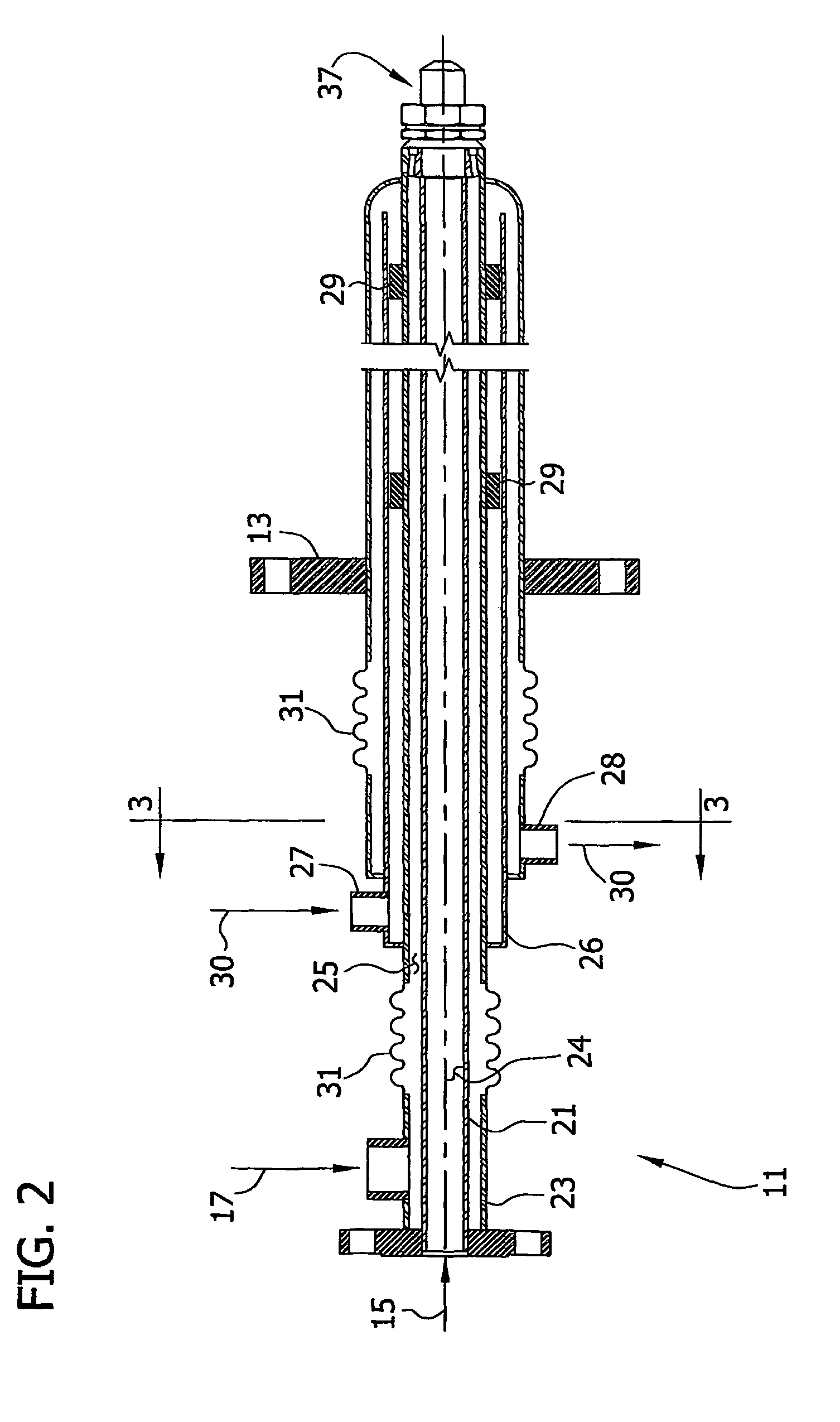

Integrated boiler, superheater, and decomposer for sulfuric acid decomposition

ActiveUS7645437B1Increase recuperation efficiencyHighly corrosive environmentHydrogenGaseous chemical processesWater useCounter flow

A method and apparatus, constructed of ceramics and other corrosion resistant materials, for decomposing sulfuric acid into sulfur dioxide, oxygen and water using an integrated boiler, superheater, and decomposer unit comprising a bayonet-type, dual-tube, counter-flow heat exchanger with a catalytic insert and a central baffle to increase recuperation efficiency.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

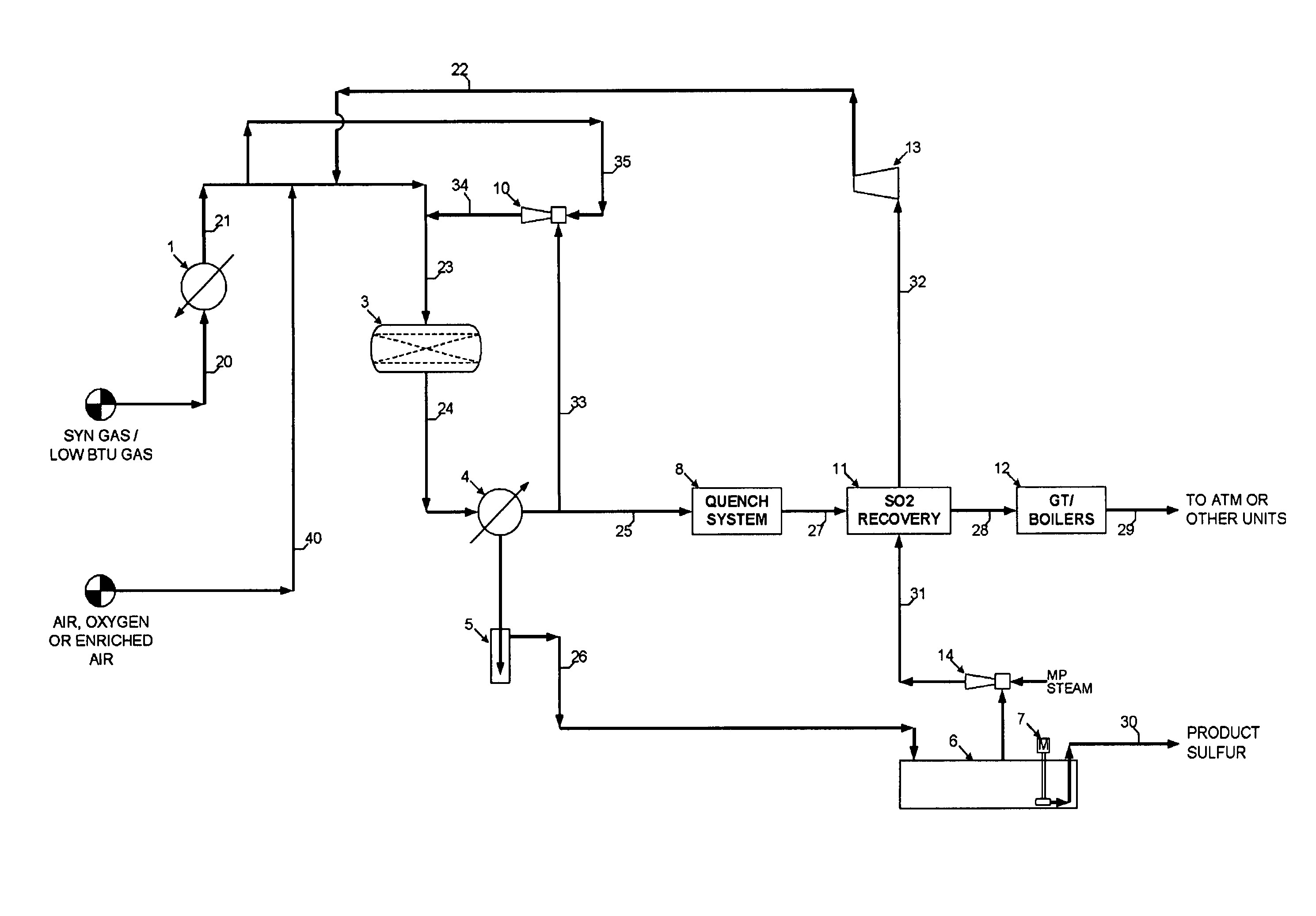

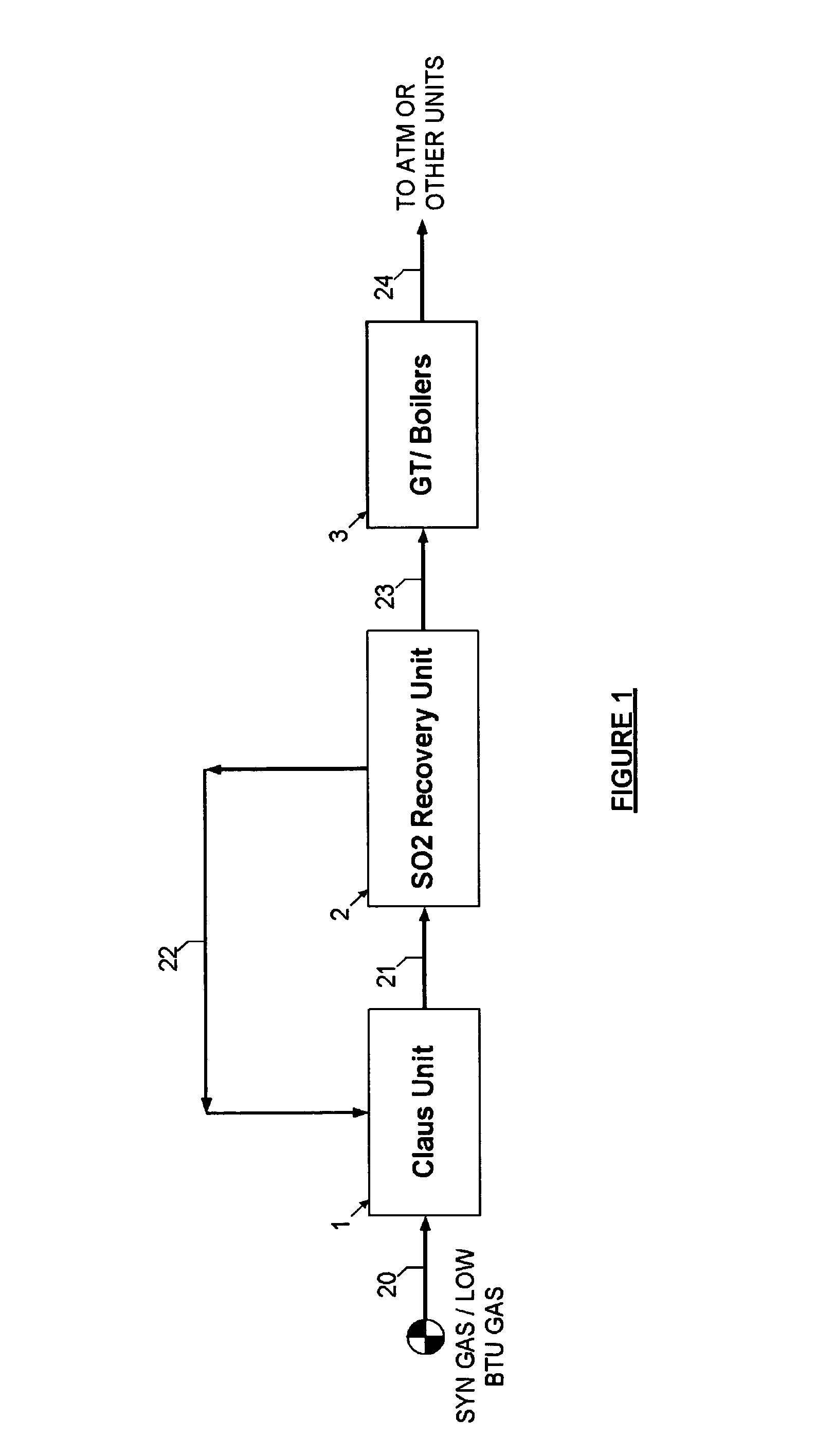

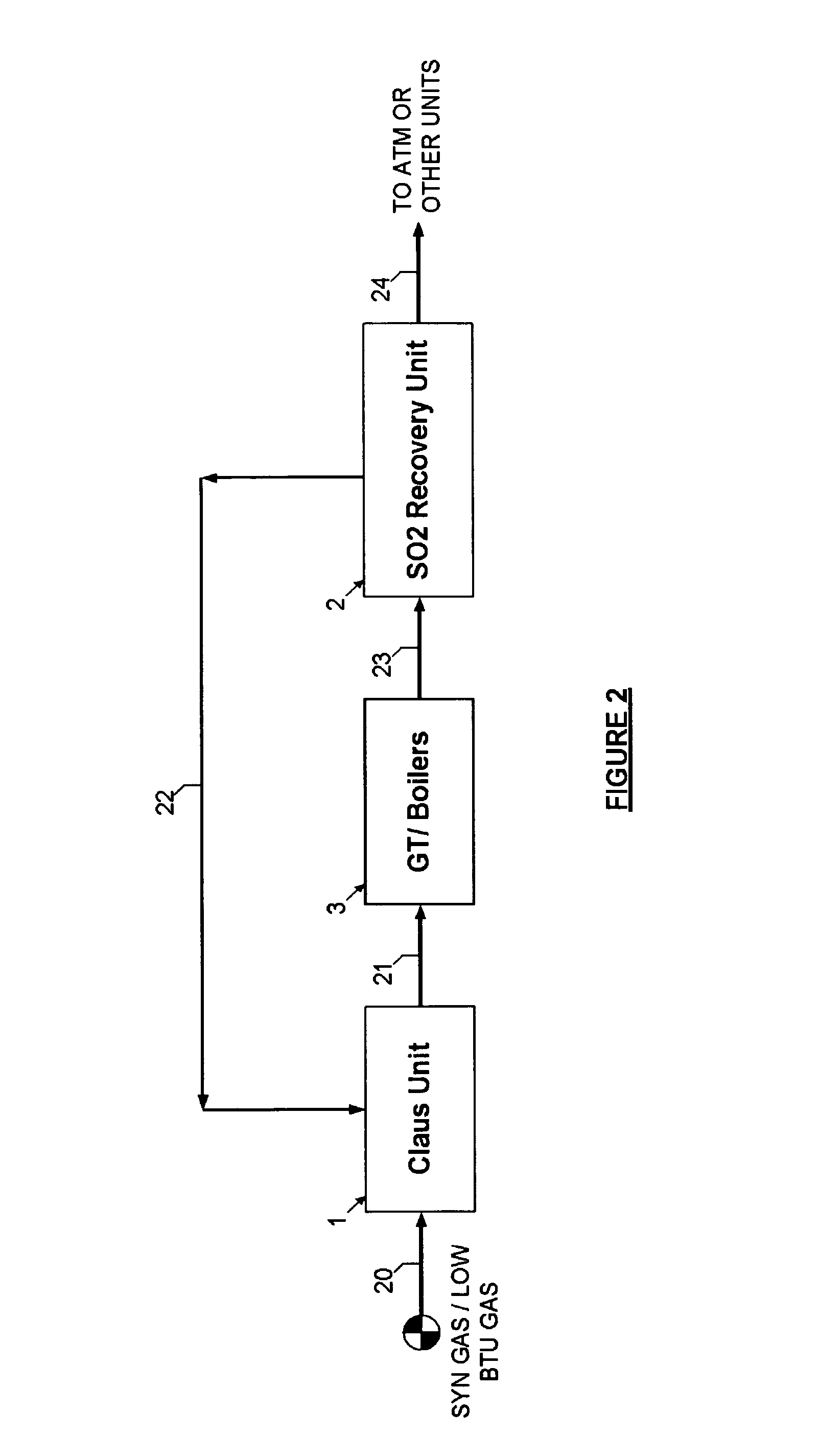

Integrated sulfur recovery methods in power plants and low BTU gas fields

ActiveUS8440160B1Weaken energyReasonable operationSulfur-dioxide/sulfurous-acidChemical industrySyngasRecovery method

This disclosure relates generally to processes for the production of elemental sulfur from Syngas, in the power plant, or Low BTU Gas fields and more particularly to processes the mixture of the 100% syngas or low BTU stream with the 100% SO2 recycle gas; with an additional stream comprising oxygen such as air, oxygen-enriched air, or substantially pure oxygen is added to the SO2 recycle stream prior entering the Claus reactor for producing elemental sulfur. The combination of innovation schemes comprises the sulfur recovery unit, the SO2 recovery unit and the gas turbines or boilers to promote a cost effective options by reducing the number of steps in an efficient manner and to achieve near 100% sulfur recovery with significant cost and energy saving. The SO2 gas is recycled from the SO2 recovery unit to the sulfur recovery unit by using one of the regenerable solvent.

Owner:RAMESHNI MAHIN +1

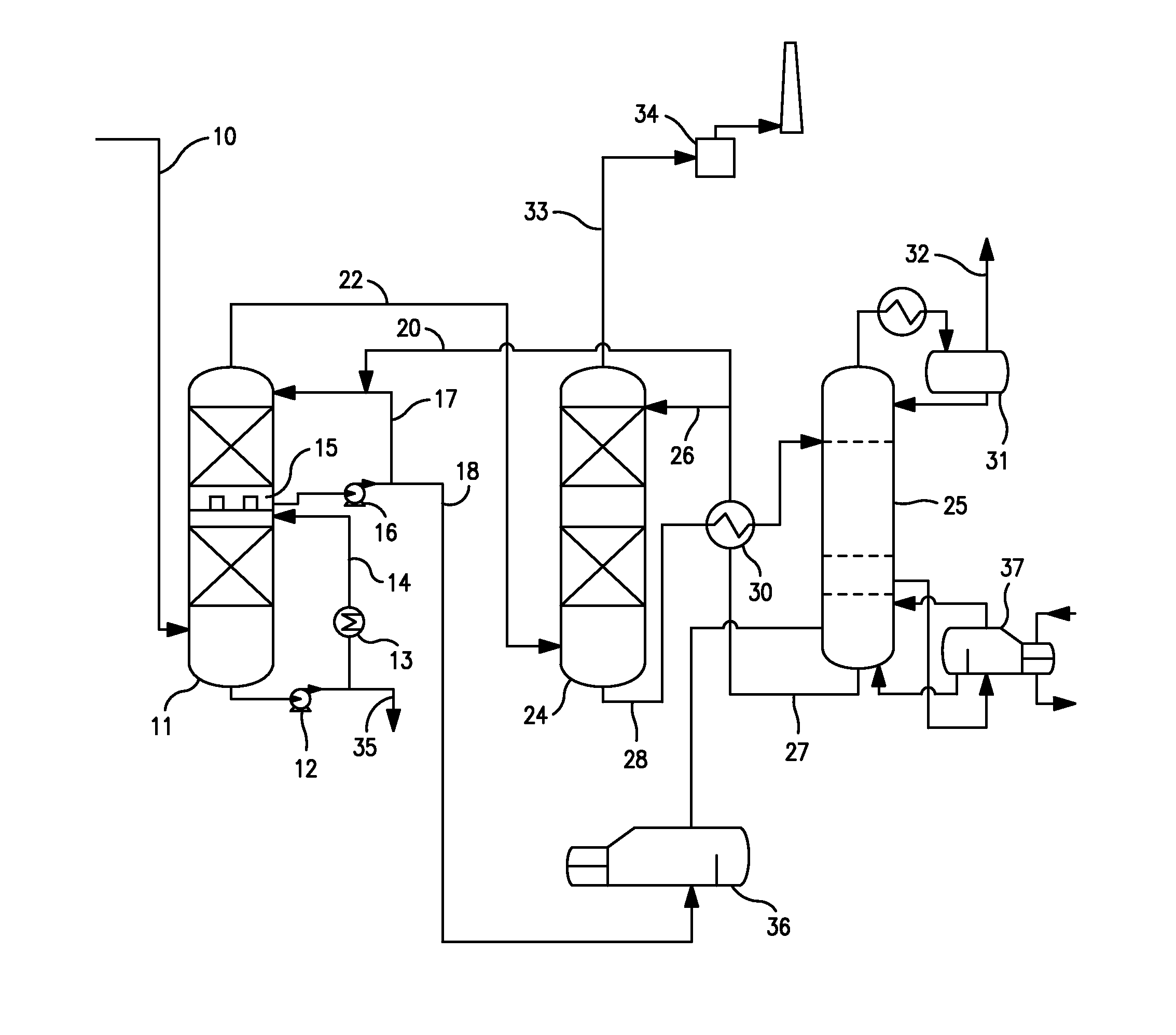

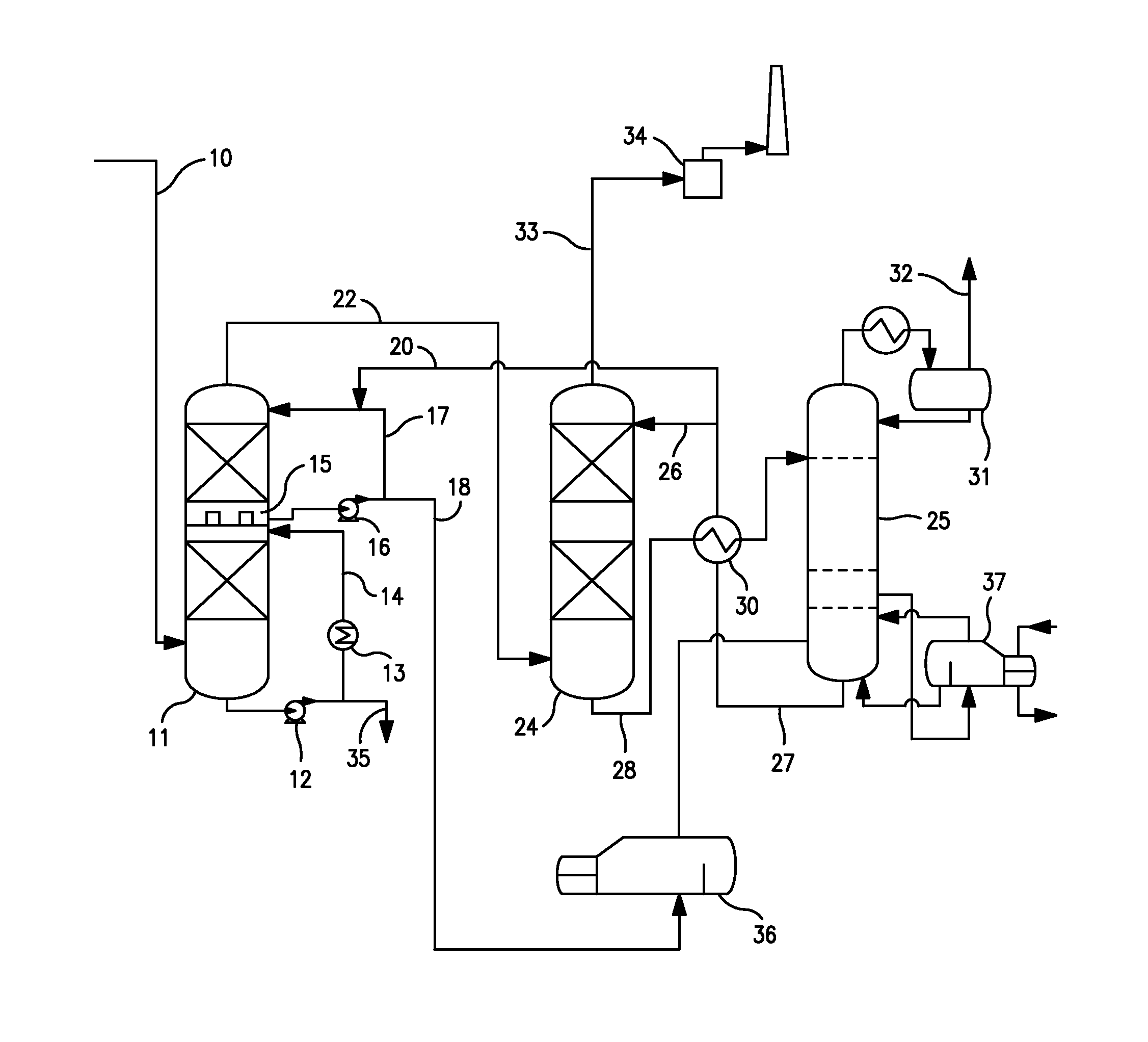

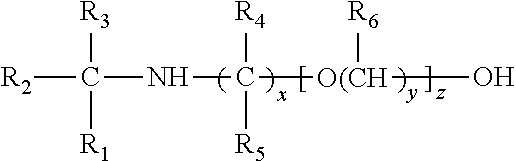

Sulfur recovery plant tail gas treatment process

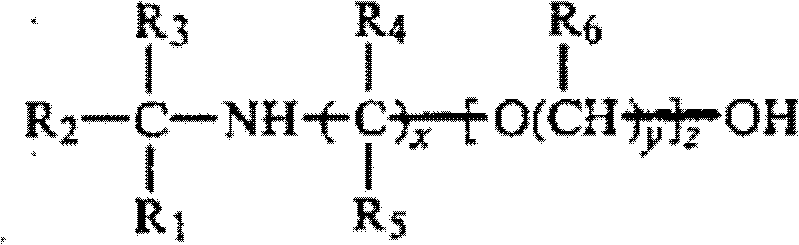

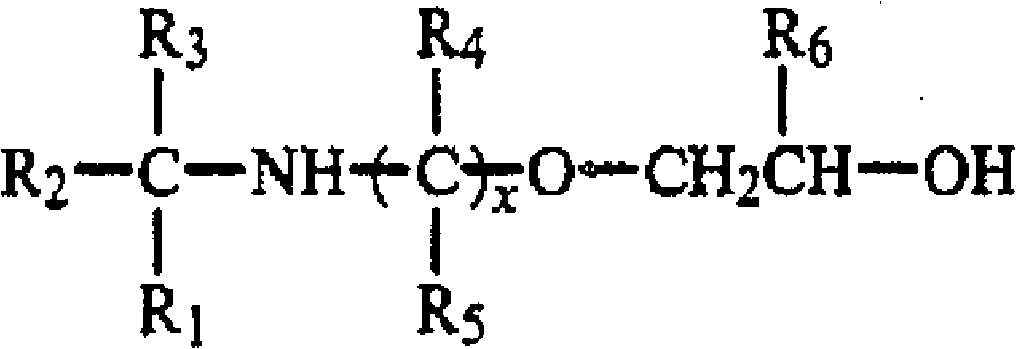

ActiveUS20110008229A1Low investment costNo regretsGas treatmentLiquid degasificationAlcoholChemical measurement

A process for the removal of hydrogen sulfide from a gas stream in which the gas stream is first passed through a Claus unit operating at a sub-stoichiometric ratio (H2S:SO2) of greater than 2:1 to produce a tail gas stream comprising less than 2000 vppm SO2. This tail gas stream is then treated to increase the sulfur recovery to at least 99.5% by first directly cooling the tail gas stream by contact with water as a coolant, followed by contacting the gas stream with a circulating stream of a dilute, absorbent solution of a severely sterically hindered secondary aminoether alcohol to further cool the gas stream, and then removing the H2S from the stream using a stronger absorbent solution of a severely sterically hindered secondary aminoether alcohol.

Owner:EXXON RES & ENG CO

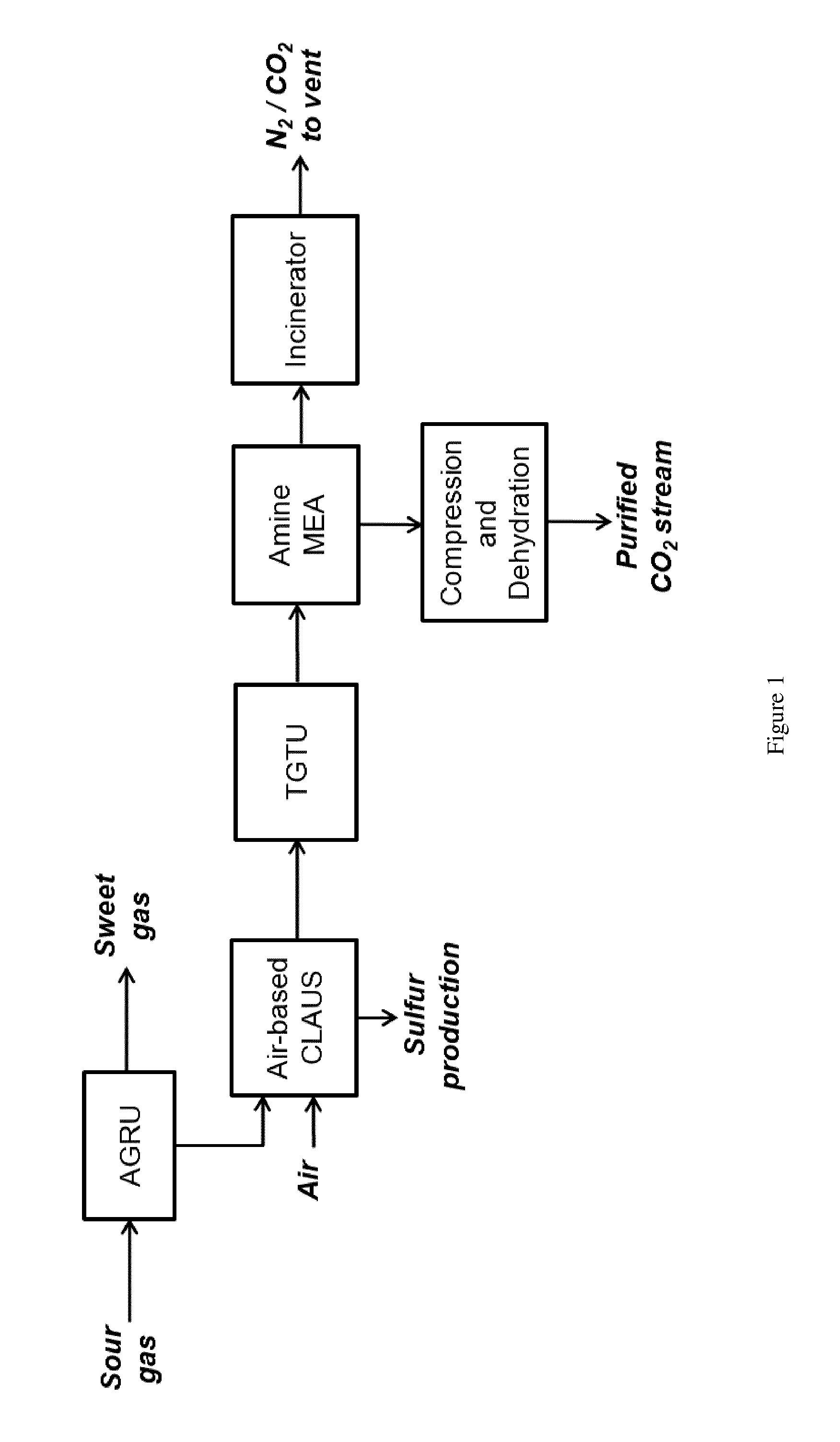

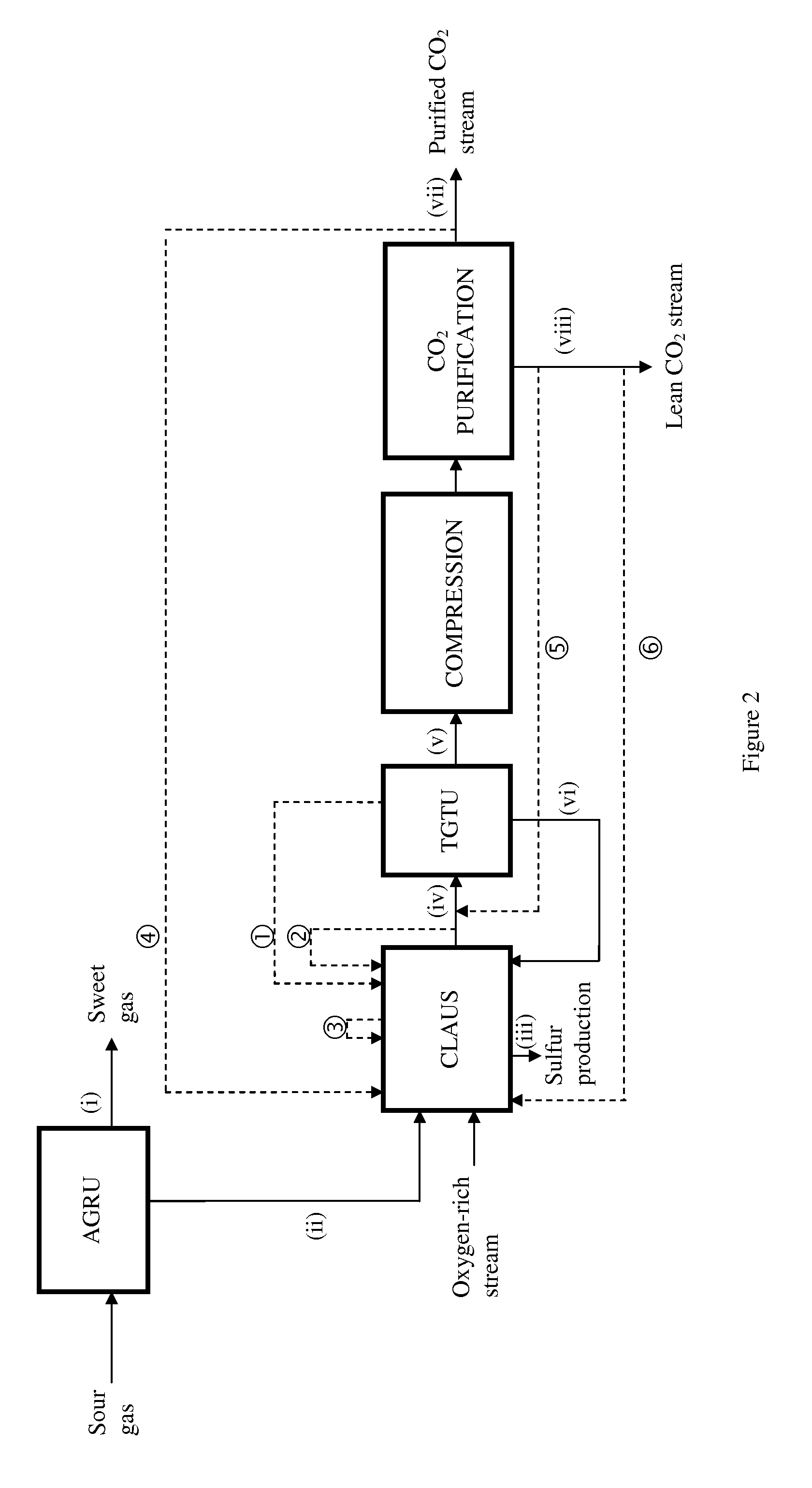

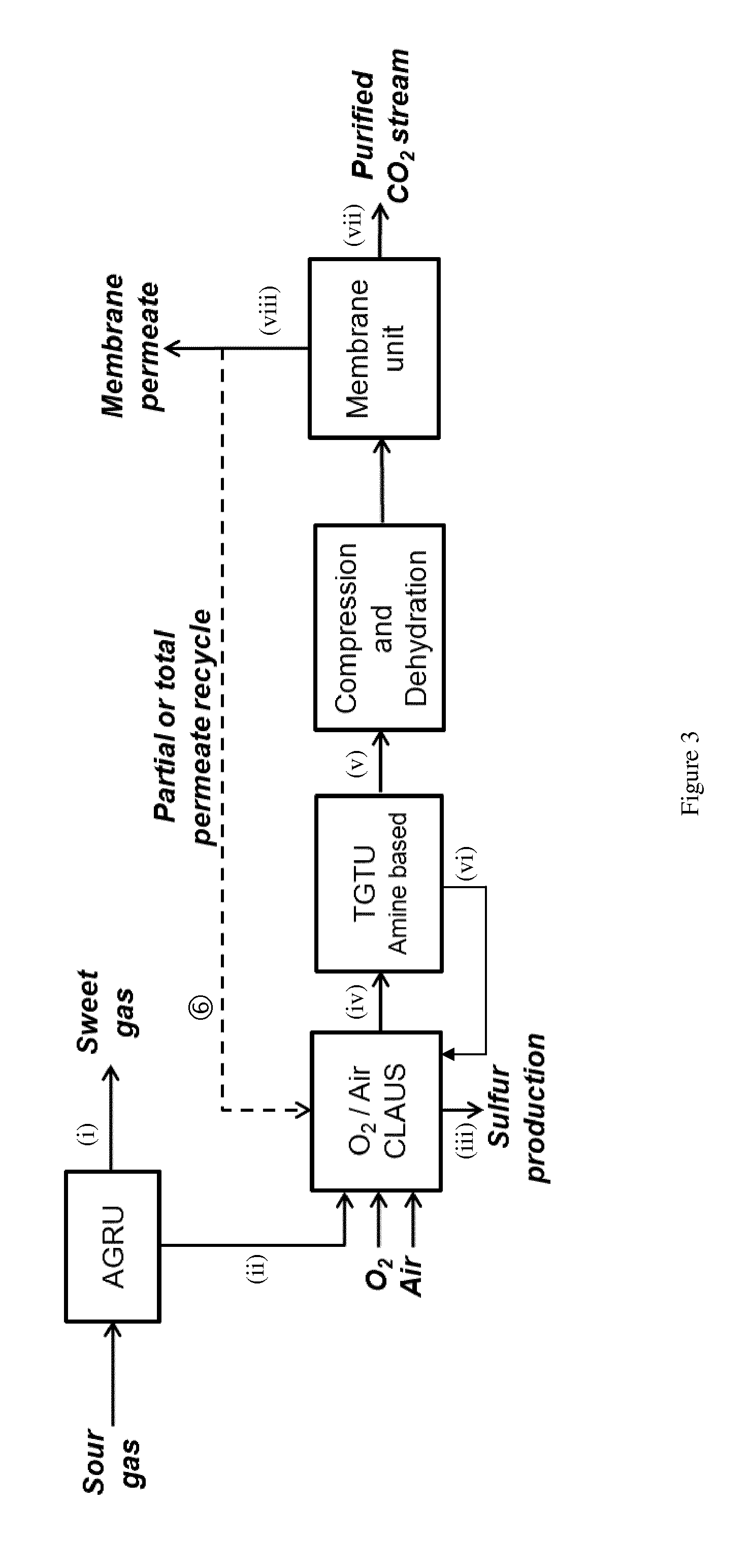

Integrated process for native co2 recovery from a sour gas comprising h2s and co2

The invention relates to a method for treating a hydrocarbon feed gas stream containing CO2 and H2S to recover a purified CO2 gas stream (vii), comprising: a. Separating said feed gas stream into a sweetened gas stream (i), and an acid gas stream (ii); b. Introducing stream (ii) into a Claus unit wherein an oxygen-rich stream is used as a combustive agent in the Claus furnace, thereby recovering a liquid stream of elemental sulfur (iii) and a tail gas stream (iv); c. Introducing the stream (iv) into a Tail Gas Treatment Unit (TGTU) thereby separating said tail gas stream into a CO2 enriched gas stream (v), and a stream enriched in sulfur compounds (vi); d. Compressing stream (v) exiting the TGTU; e. Passing the compressed CO2 enriched gas through a CO2 purification unit thereby recovering a purified CO2 gas stream (vii), and the device for carrying out said method.

Owner:TOTAL PUTEAUX FR +1

Safe storage and transportation of sulfur dioxide

The invention relates to a method of confining sulfur dioxide for storage or transportation under safe conditions. The method of the invention comprises the steps of (a) contacting a sulfur dioxide-containing gas stream with an absorbing medium comprising water and a water-soluble amine absorbent having at least one amine group with a pKa value greater than about 7 and at least one other amine group with a pKa value less than about 6.5 so that the at least one amine group with a pKa value greater than about 7 irreversibly absorbs sulfur dioxide in salt form rendering the amine absorbent non-volatile and the at least one other amine group with a pKa value less than about 6.5 reversibly absorbs sulfur dioxide, to thereby saturate the absorbing medium with sulfur dioxide against a partial pressure of sulfur dioxide of no more than about 1 atmosphere at 25° C.; and (b) charging the absorbing medium saturated with sulfur dioxide obtained in step (a) into a container for storage or transportation.

Owner:SHELL OIL CO

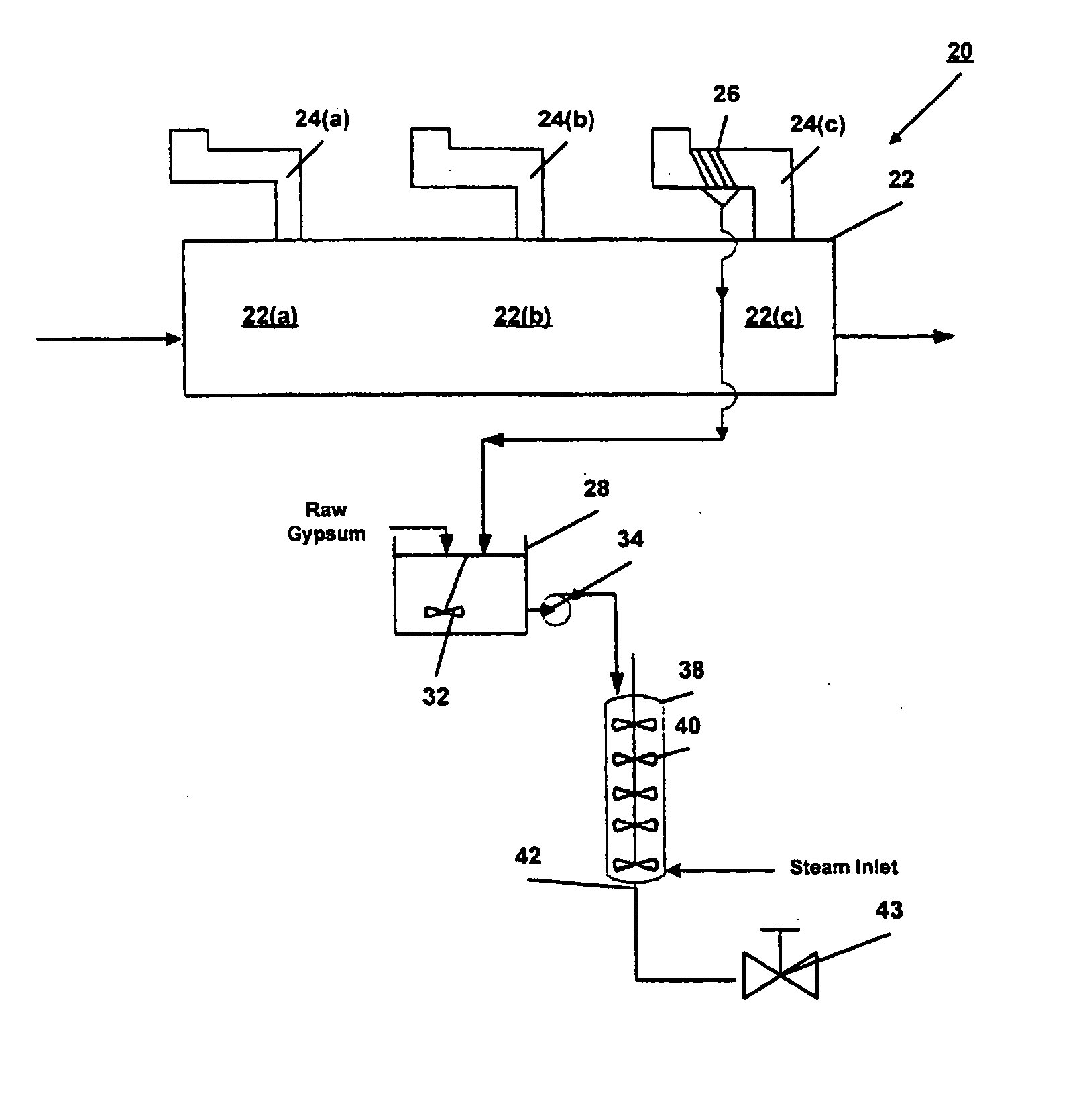

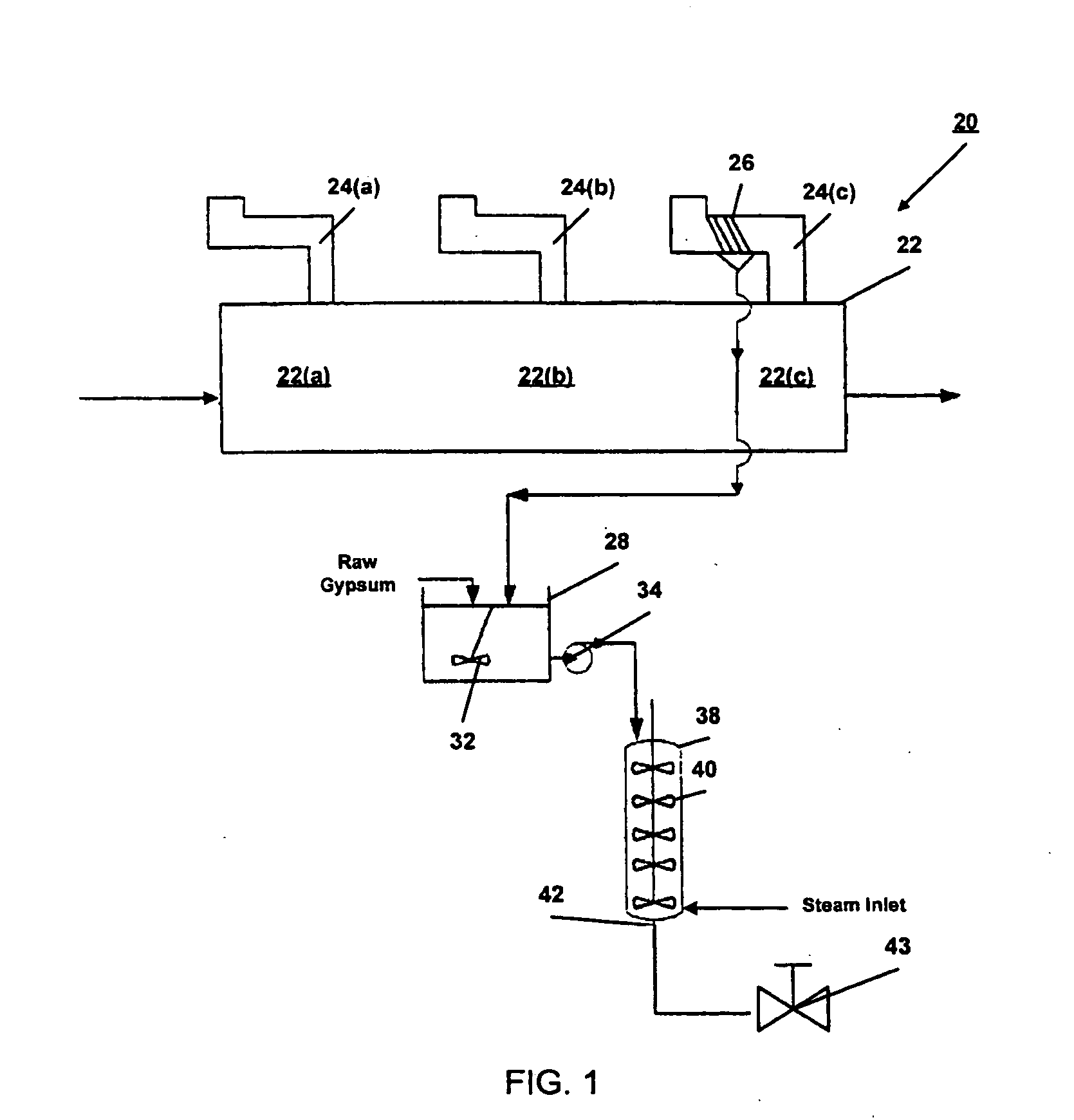

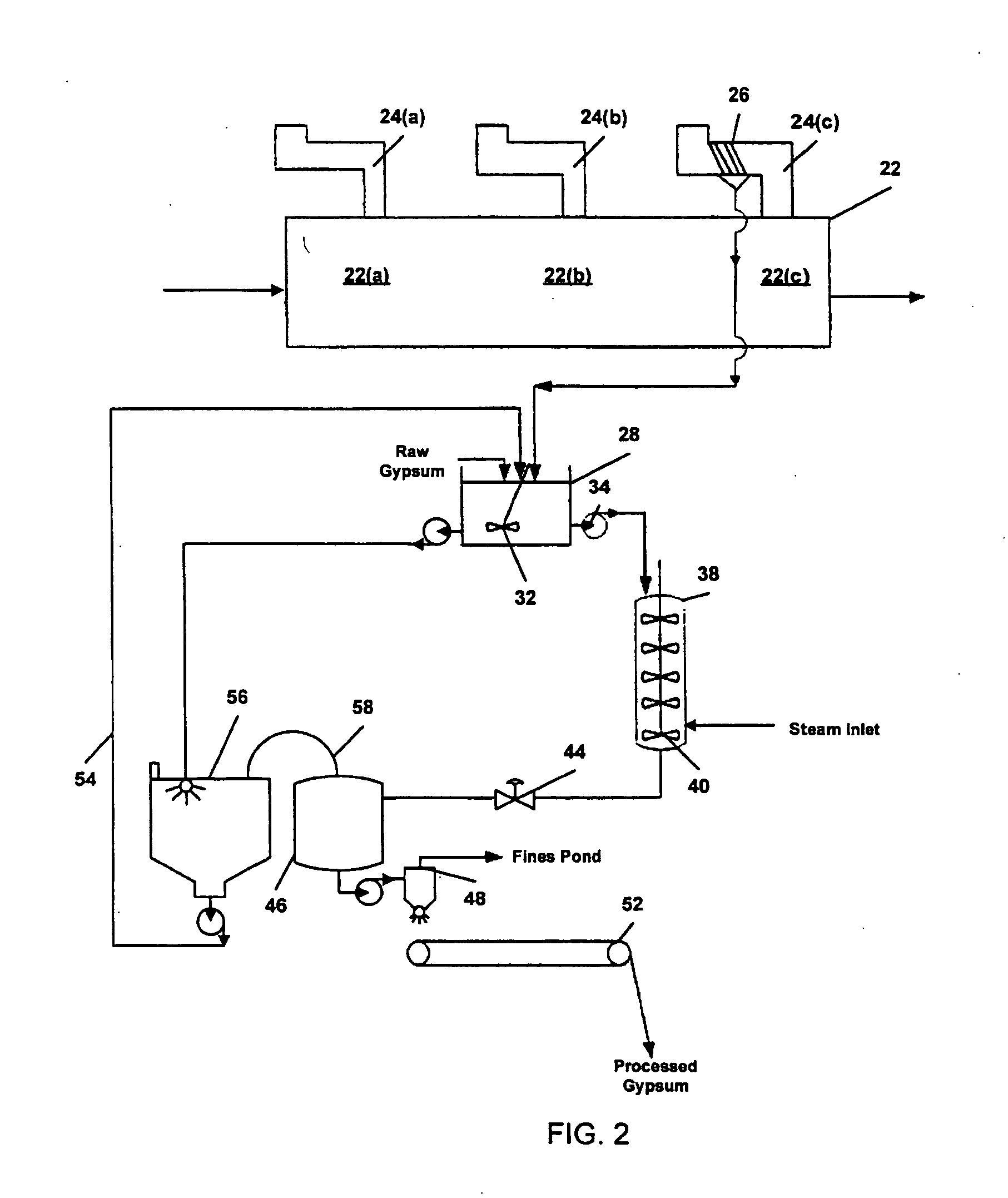

System and method for the production of alpha type gypsum using heat recovery

The present invention relates to a system and associated method for the production of gypsum in manufacturing plant. More specifically, the invention relates to the production of alpha-type gypsum in a gypsum board manufacturing plant. The system yields increased efficiencies by capturing heat given off during processing steps and using that heat to reduce the energy needed for calcination. The invention finds particular application in the production alpha-type gypsum. The present invention is described in greater detail hereinafter in conjunction with the following specific embodiments.

Owner:CERTAINTEED GYPSUM INC

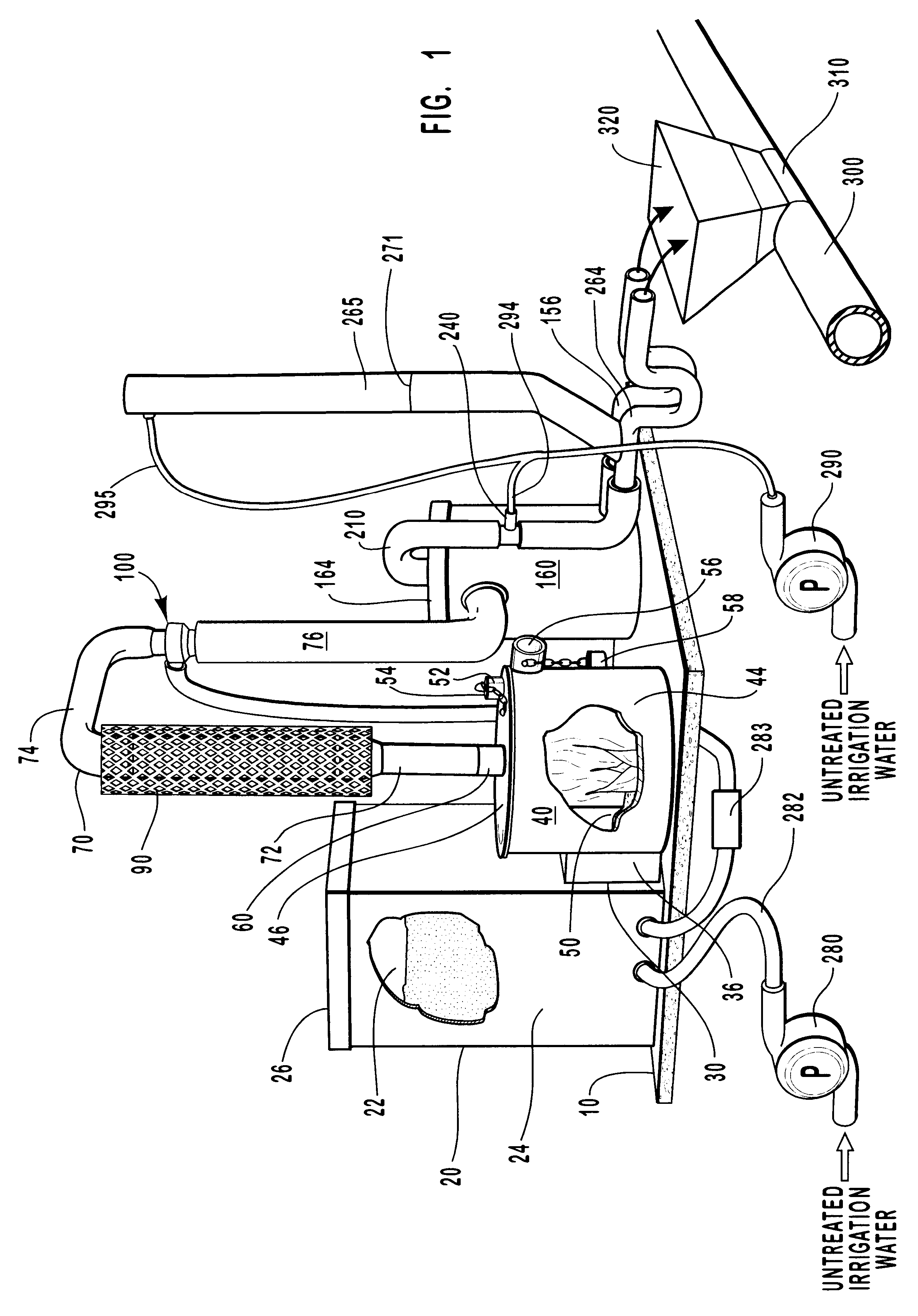

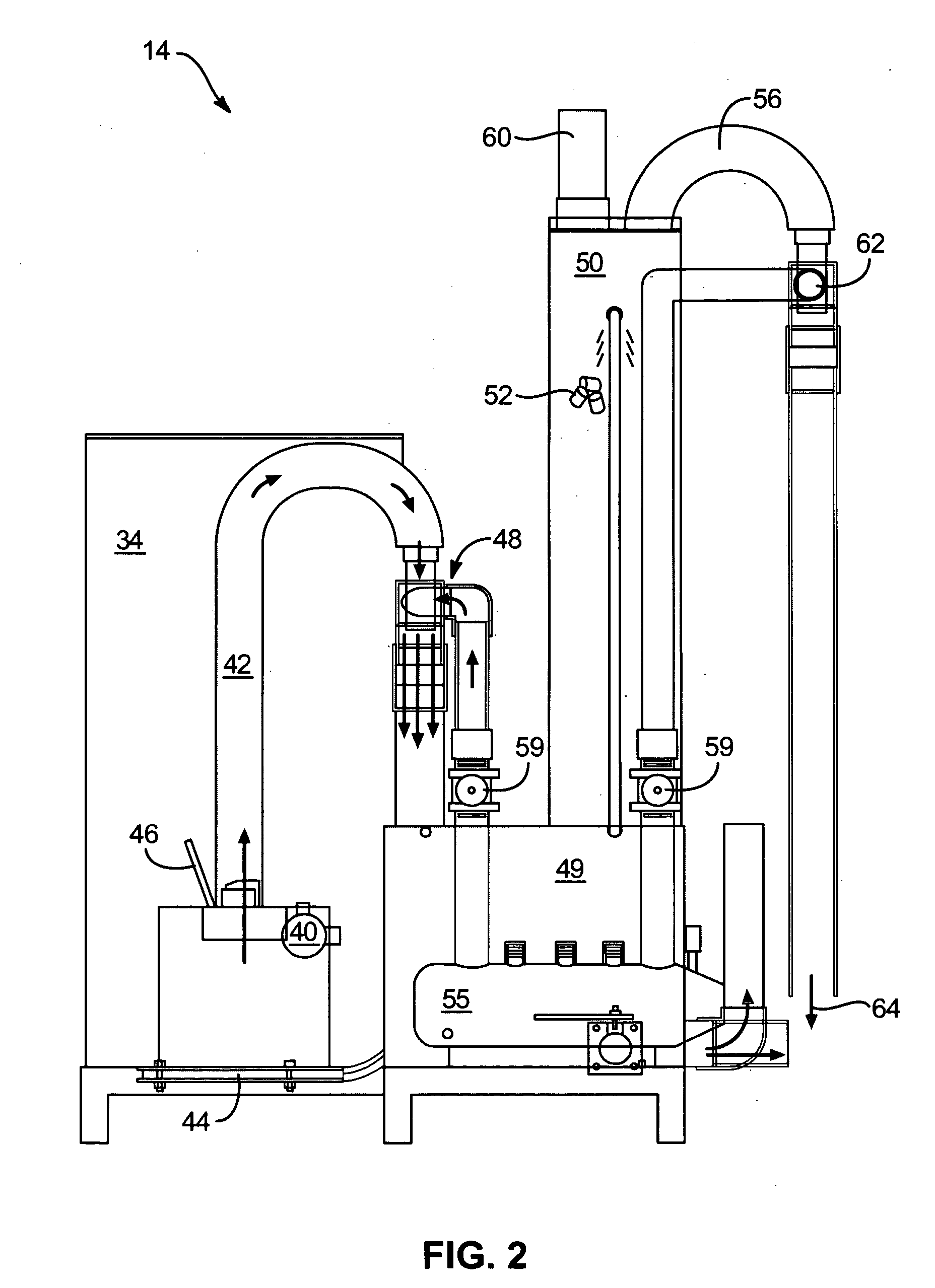

Method and apparatus for introducing sulphur dioxide into aqueous solutions

InactiveUS6689326B1Improve alkaline irrigation waterImprove usabilitySulfur-dioxide/sulfurous-acidSulfur-trioxide/sulfuric-acidSulfurTower

This invention presents a sulphurous acid generator which employs a combination of novel blending, contact and mixing mechanisms which injects sulphur gases into aqueous solution or which maximize the efficiency and duration of contact between sulphur dioxide gas and water or aqueous solution to form sulphurous acid in an open nonpressurized system, without employing a countercurrent absorption tower. The present invention also incorporates a novel high temperature concrete for use in constructing portions of the present invention.

Owner:SWEETWATER LICENSE HLDG

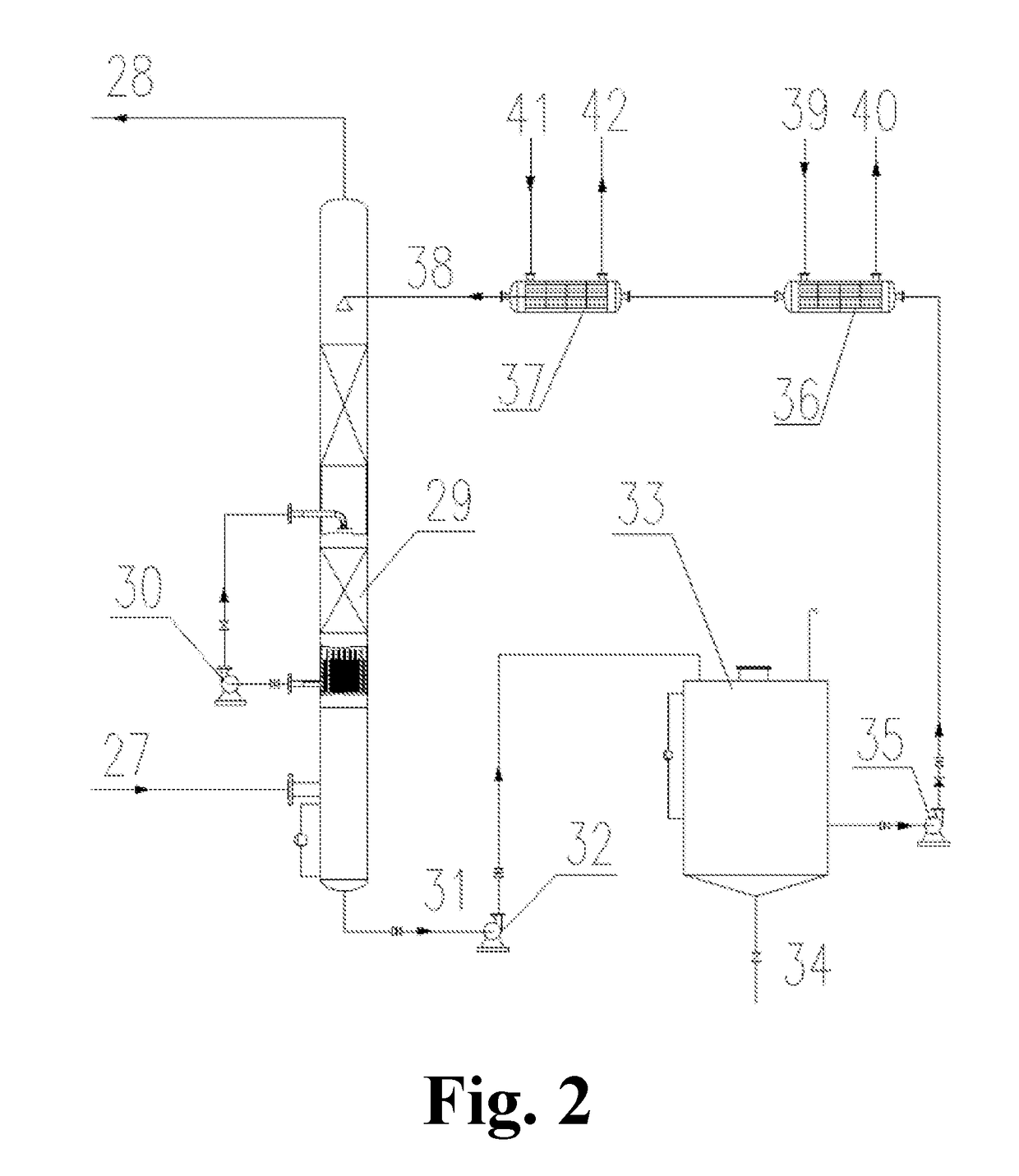

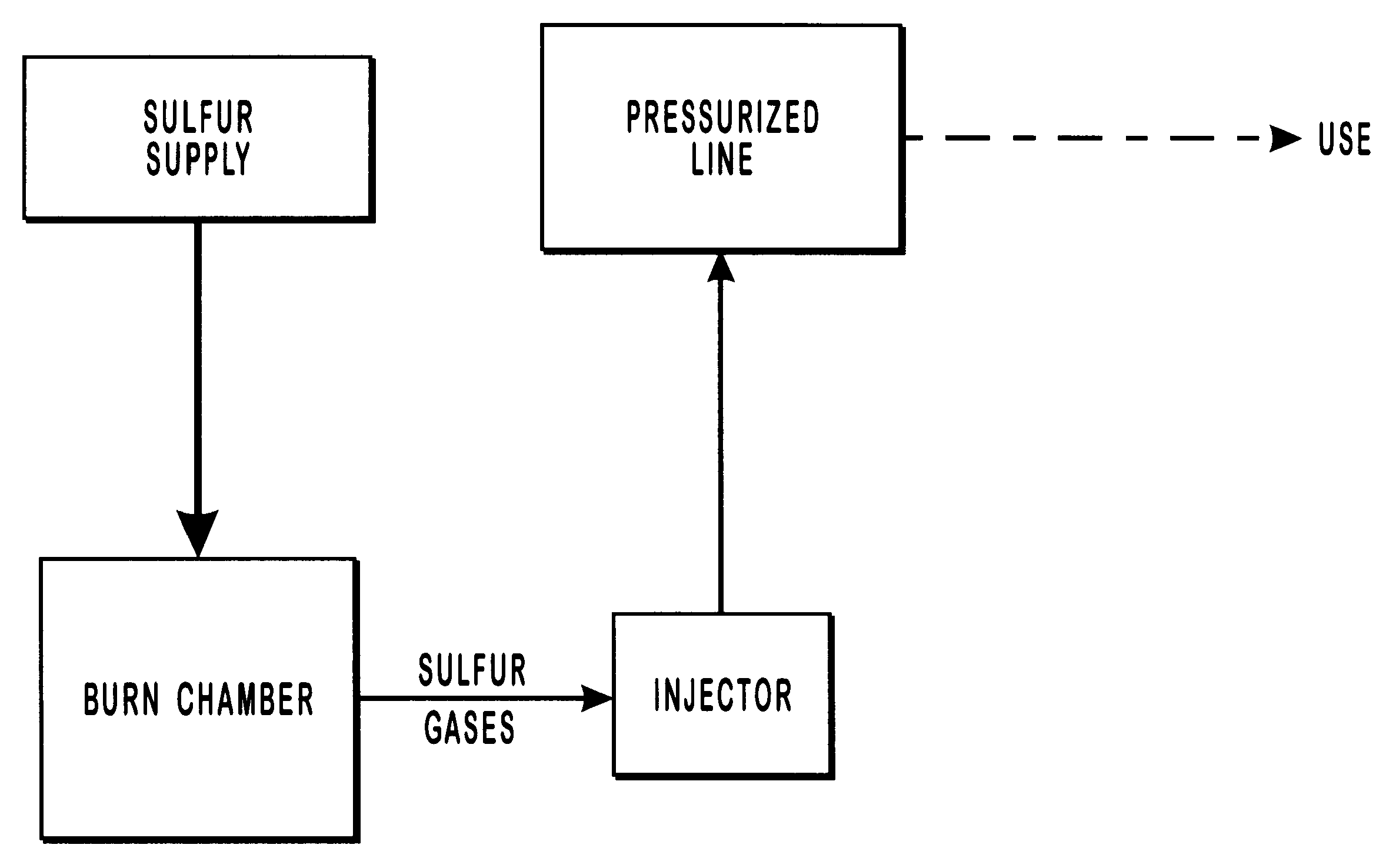

Alkylated waste acid cracking technology adopting sulphur as fuel

InactiveCN105480953AAvoid emissionsEmission reductionSulfur-dioxide/sulfurous-acidEnergy inputCombustionLiquid gas

The invention discloses an alkylated waste acid cracking technology adopting sulphur as fuel and especially a production technology of sulfuric acid by alkylated waste acid cracking in high-temperature environment generated by sulphur combustion. The technology comprises the following steps: cracking the waste sulfuric acid in high-temperature environment, recovering the heat from an exhaust-heat boiler, performing closed acid scrubbing and purifying, transforming for two times, absorbing for two times, absorbing the tail gas and so on, so that qualified sulfuric acid product is produced. Compared with commonly used gaseous fuels, such as the natural gas, the liquefied gas and the like, the fuel sulphur can be transformed into the product in the alkylated cracking technology, so that the device operation cost is greatly reduced; dilute acid efflux caused by H2O generated by gaseous fuel combustion is avoided, so that new waste discharge is thereby avoided; moreover, the alkylated waste acid cracking technology also reduces CO2 discharge generated by gaseous fuel combustion.

Owner:CHINA PETROLEUM & CHEM CORP +1

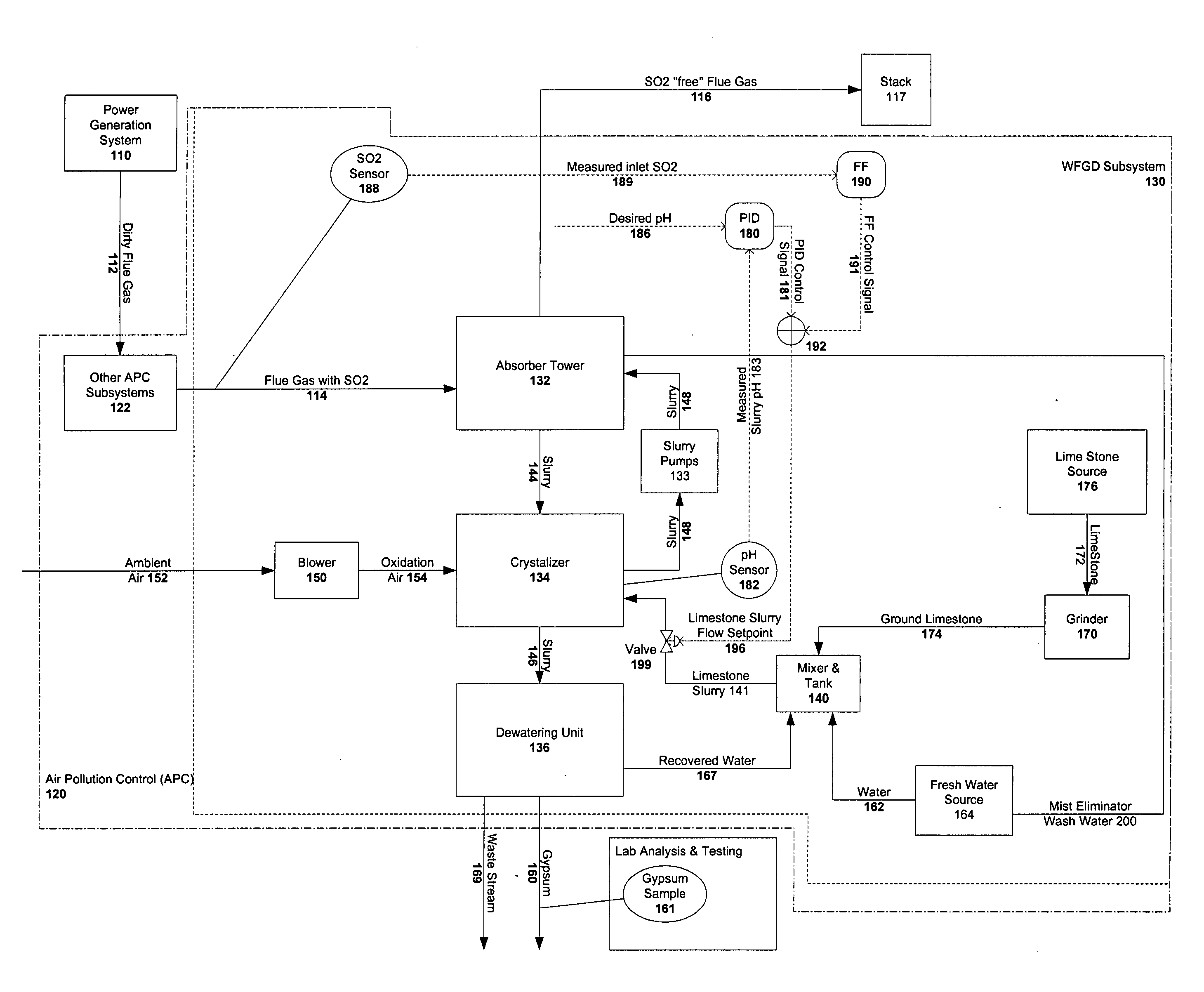

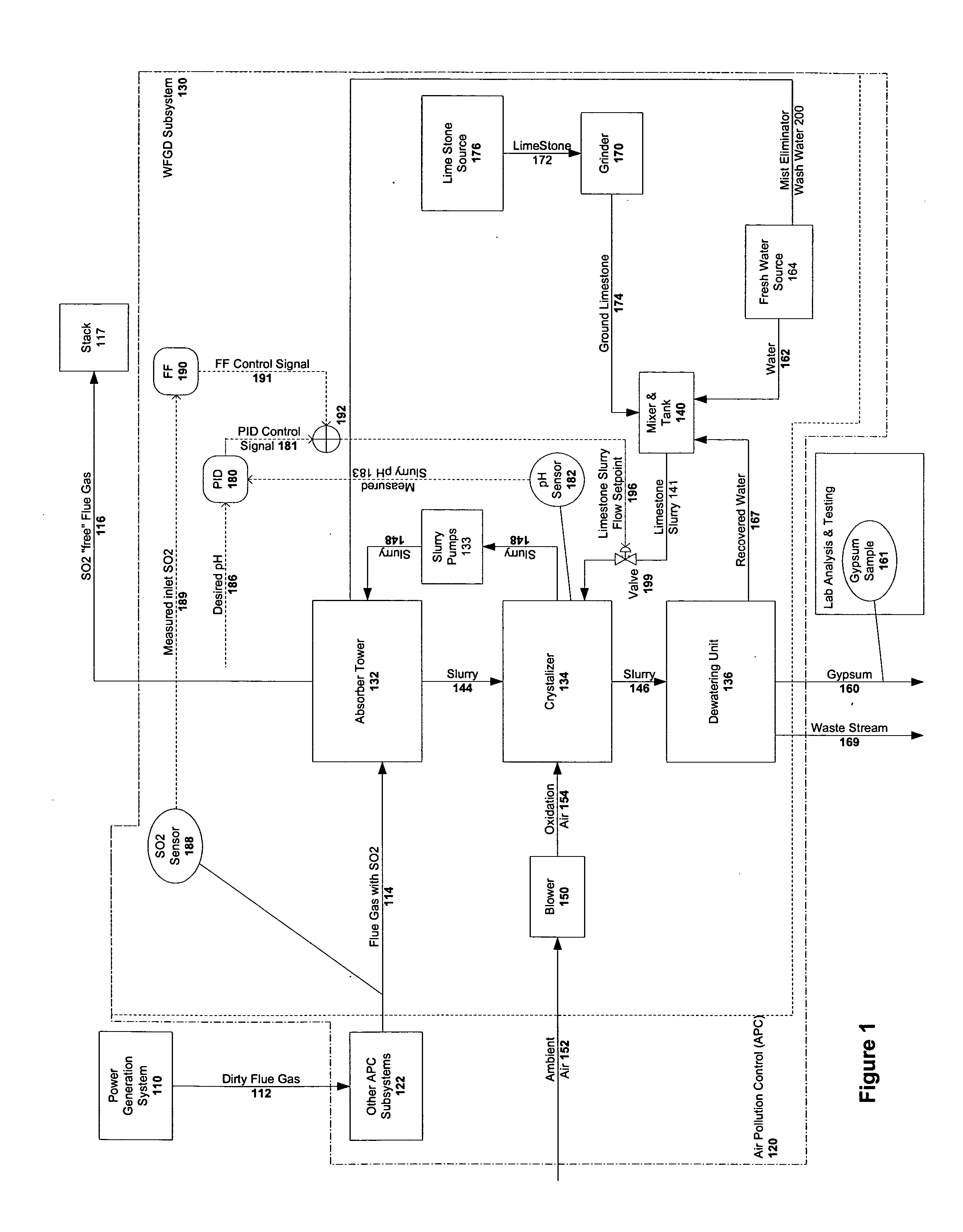

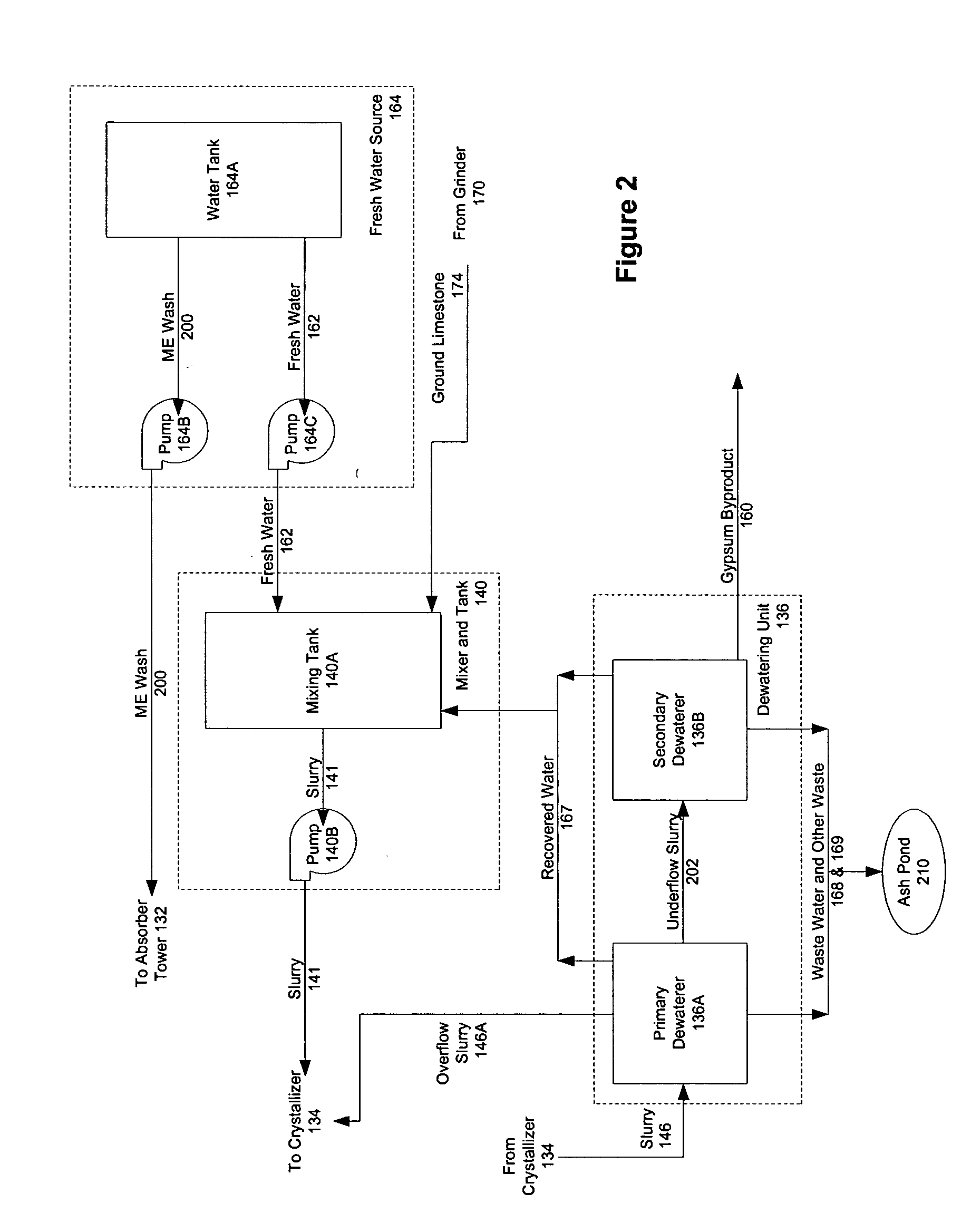

Maximizing regulatory credits in controlling air pollution

ActiveUS20060042461A1Reduce oxidationReduce removalCombination devicesAuxillary pretreatmentEngineeringAir pollution

A controller directs the operation of an air pollution control (APC) system having one or more controllable operating parameters and a defined operating limit representing a regulatory limit on an allowed amount of pollutant to be emitted by the APC system. An interface receives data representing a value of a regulatory credit available for emitting less of the pollutant than the regulatory limit on the allowed amount of pollutant. A control processor (i) determines a target set point for each of at least one of the one or more controllable operating parameters, which will maximize the regulatory credits earned, based on the received data and (ii) to directs control of each of the at least one controllable operating parameter based on the determined target set point for that parameter.

Owner:GENERAL ELECTRIC TECH GMBH

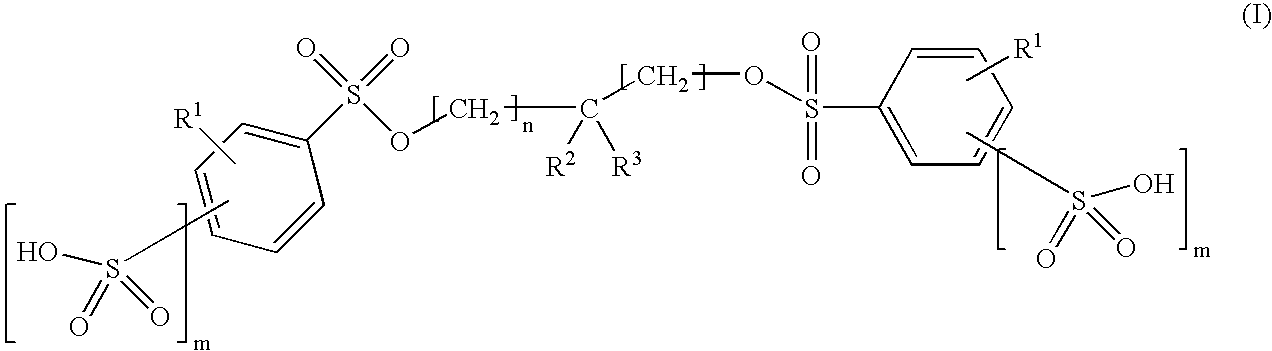

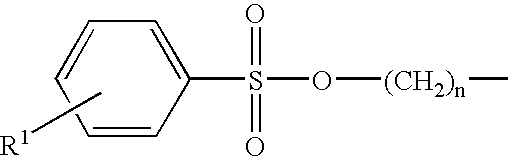

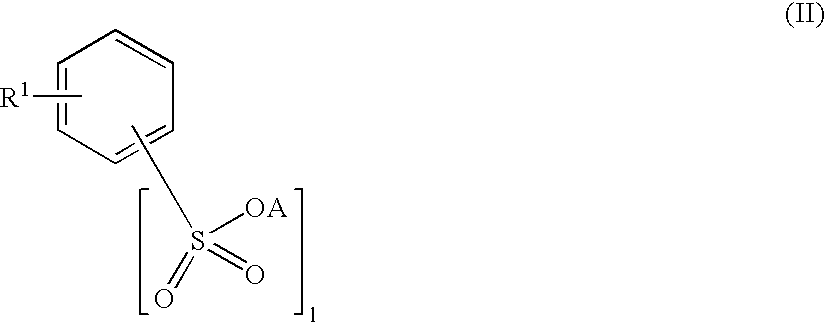

Inhibition of catalytically active impurities in polycarbonate by the melt transesterification process

ActiveUS7250483B2DisadvantagePrevent particle and metal cation and deficiencyCombination devicesSulfur-dioxide/sulfurous-acidTransesterificationPolycarbonate

An improvement to the melt transesterification process for the preparation of polycarbonate is disclosed. The improvement entails adding to the process between its medium viscosity reactor and a high viscosity reactor at least one bridged ester of organic sulphur-containing acid.

Owner:COVESTRO DEUTSCHLAND AG

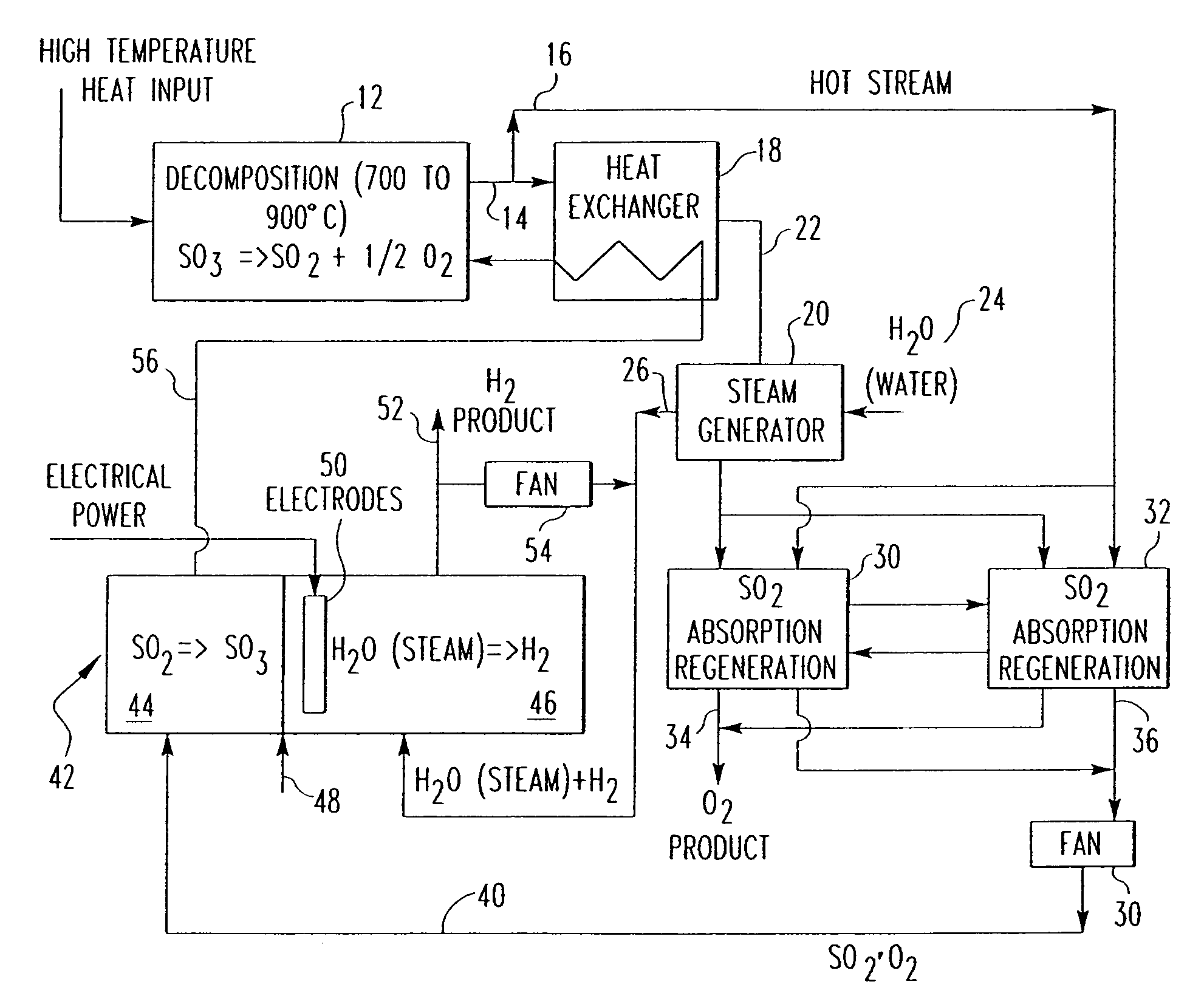

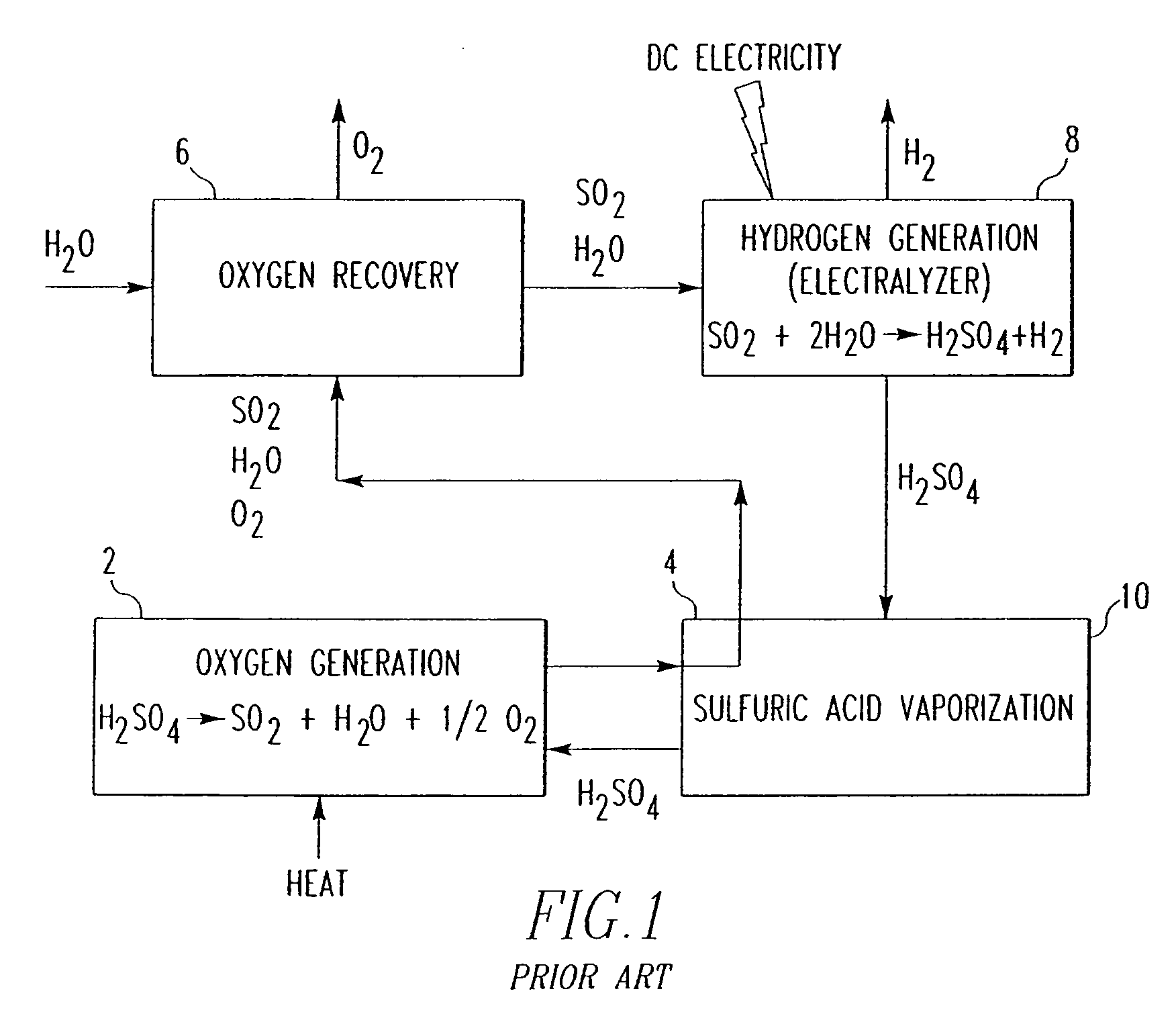

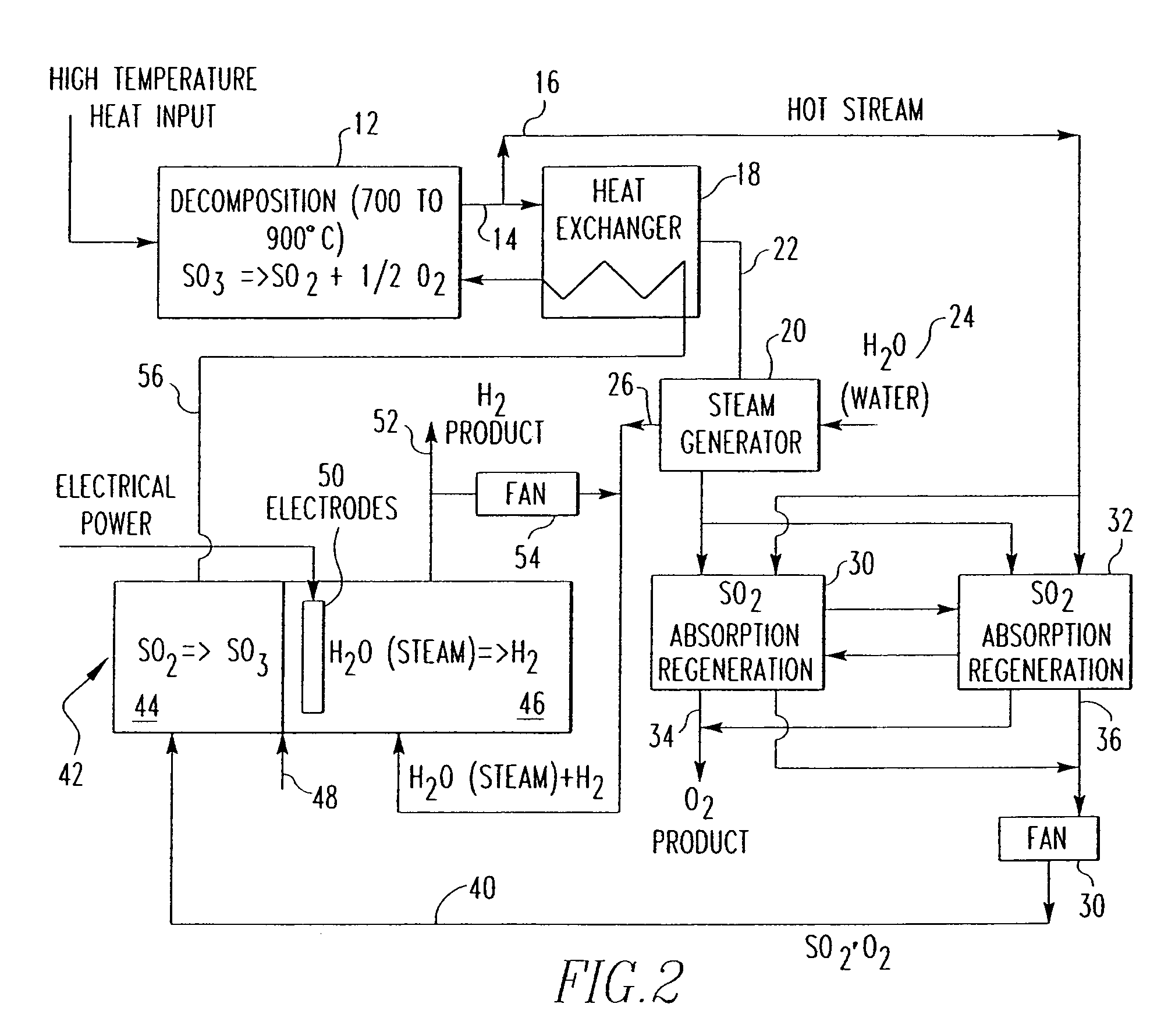

Gas phase electrolyzer process for producing hydrogen

The invention provides a method for a sulfur based hydrogen production cycle wherein the sulfur products are maintained in a gaseous state throughout the cycle. The cycle includes a decomposition of a gaseous phase sulfur trioxide to sulfur dioxide and water in a decomposition reactor and an oxidation of gaseous sulfur trioxide with H2O in an electrolyzer to form sulfur trioxide and hydrogen. Costs are reduced by elimination of energy costs previous necessary to convert the sulfuric products from liquid to gas and back again and by extending the lifespan of decomposition catalysts through the elimination of water in an SO2 / SO3 stream.

Owner:WESTINGHOUSE ELECTRIC CORP

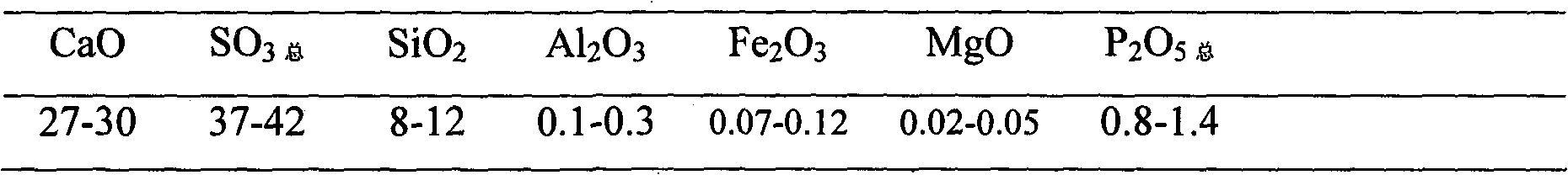

Method for reducing ardealite decomposition temperature

InactiveCN101357773ANo secondary pollutionSimple processSulfur-dioxide/sulfurous-acidCalcium/strontium/barium oxides/hydroxidesChemical treatmentVulcanization

The invention relates to a method for decreasing the decomposition temperature of phosphogypsum and belongs to the technical field of phosphate chemical treatment. The invention respectively adopts gaseous reducing agents of CO and H2S and powder of solid reducing agents such as fly ash and coal gangue as well as the gas-solid, solid-solid complex reducing agents as admixtures and adds the admixtures into the phosphogypsum to decompose and control the double-atmosphere reaction, thus achieving the purposes that the decomposition temperature of the phosphogypsum is decreased, and the high decomposition ratios and vulcanization rate are ensured, and the decomposition temperature of the phosphogypsum is caused to be less than or equal to 1000 DEG C, and the decomposition rate is caused to be more than or equal to 95 percent and the resource SO2 can be stably recovered.

Owner:KUNMING UNIV OF SCI & TECH

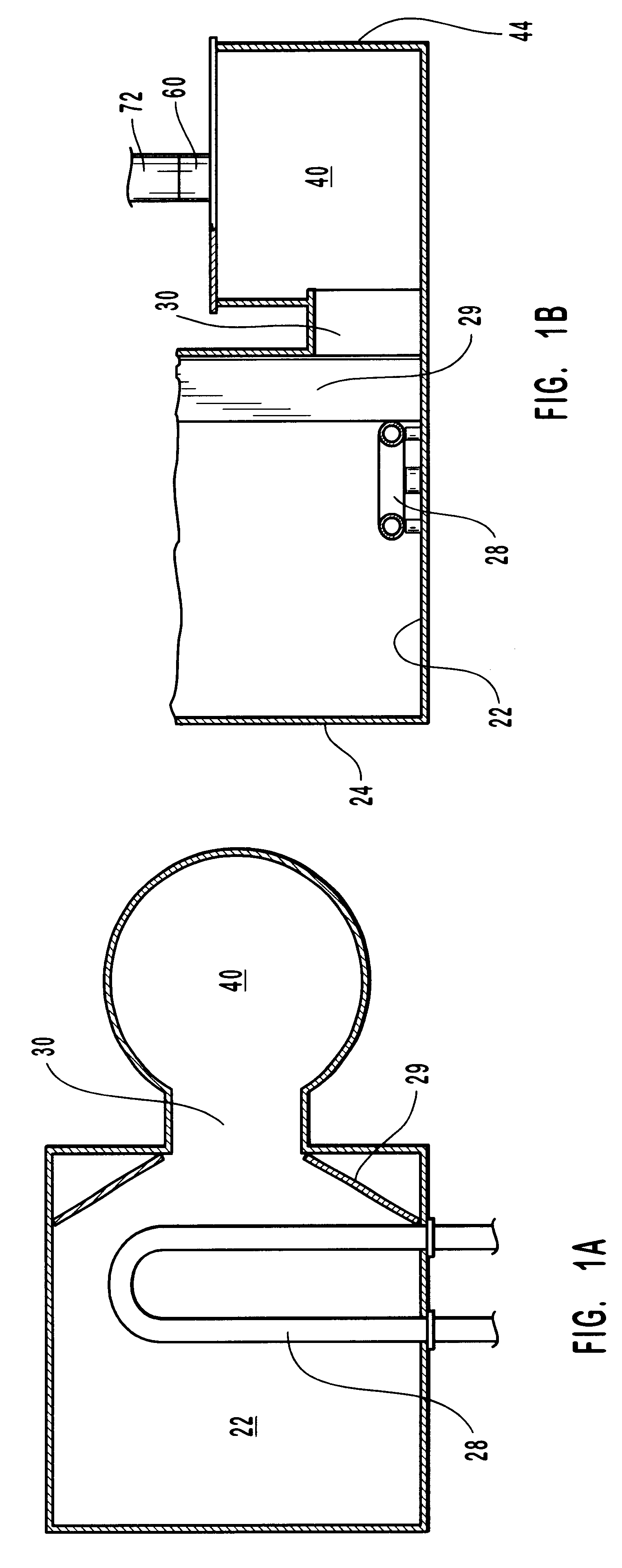

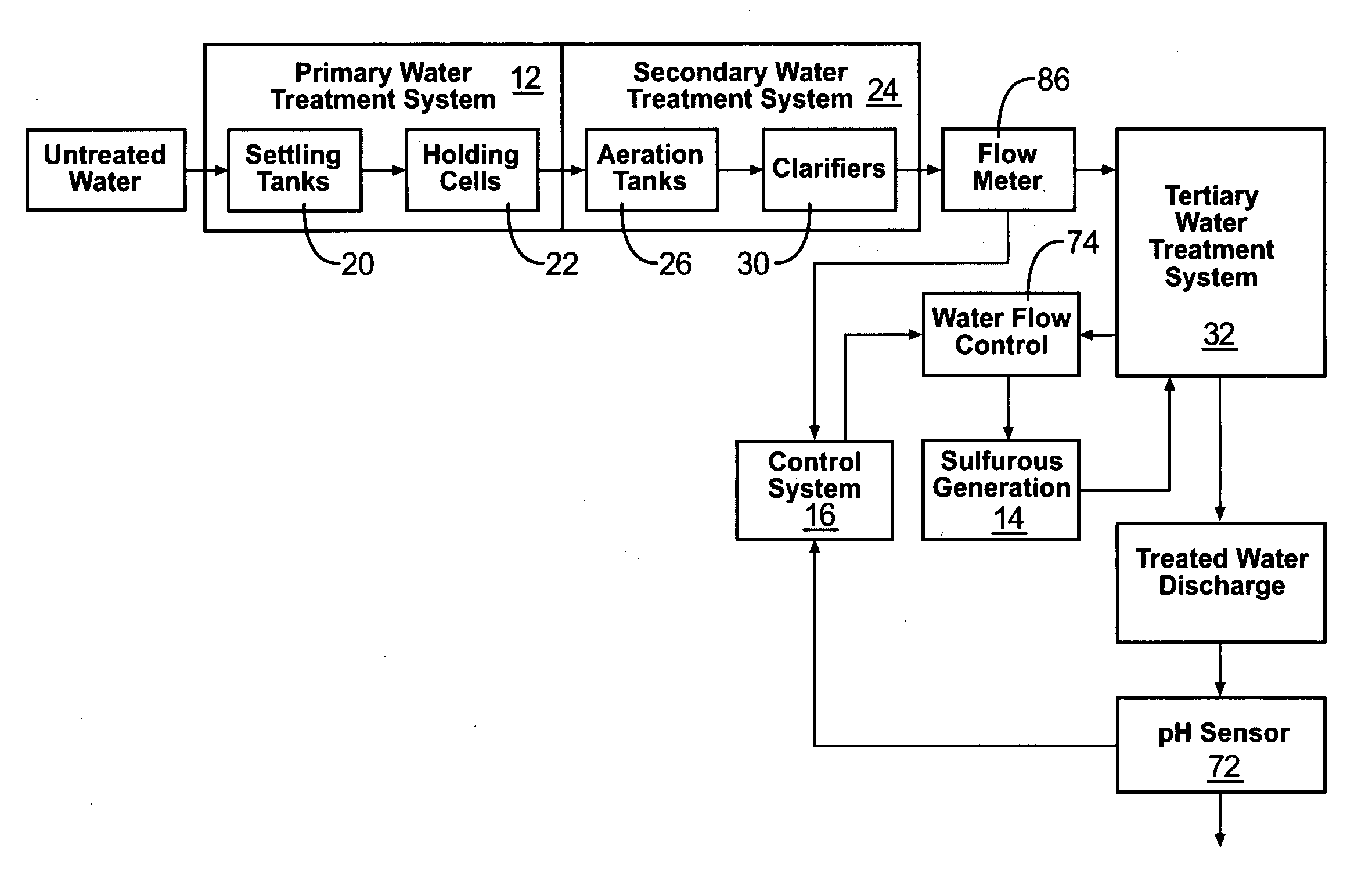

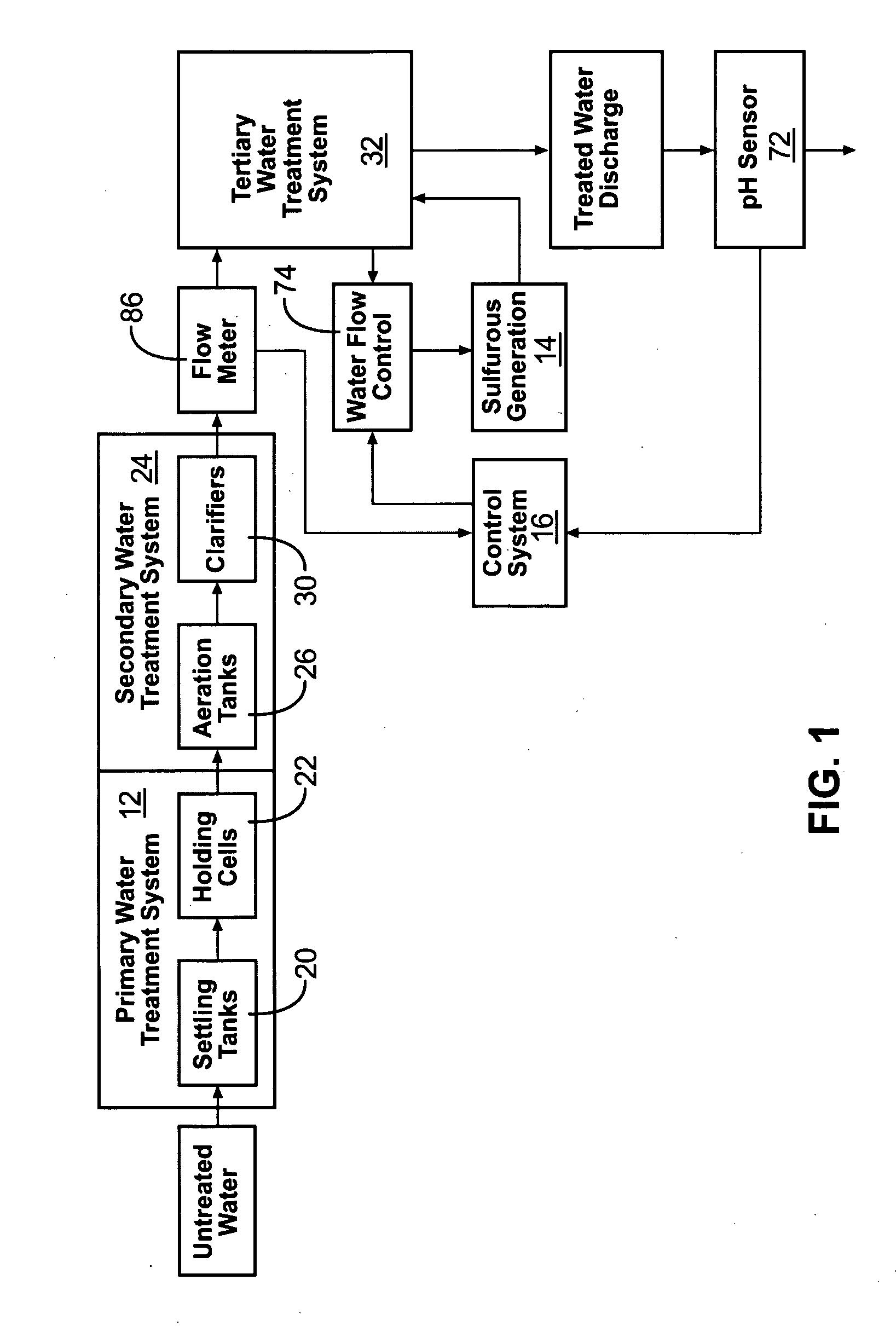

Wastewater treatment system

InactiveUS20050011820A1Sulfur-dioxide/sulfurous-acidIon-exchanger regenerationCombustionWater treatment system

A water treatment system for treating water. The water treatment system includes a primary water treatment station and a solid-based sulfurous generator downstream from the primary water treatment station for producing aqueous sulfurous acid for further treatment of the water. In one embodiment, the solid-based sulfurous generator includes a hydraulic air inlet shut off valve safety system for automatically reducing the combustion air to the sulfurous generator when water is not delivered to the solid-based sulfurous generator. Also, in one embodiment, the water treatment system includes a control system that monitors the pH of the treated water to control the water flow rate through the solid-based sulfurous generator to achieve the desired concentration of sulfurous acid in the water being treated.

Owner:S02 SOLUTIONS

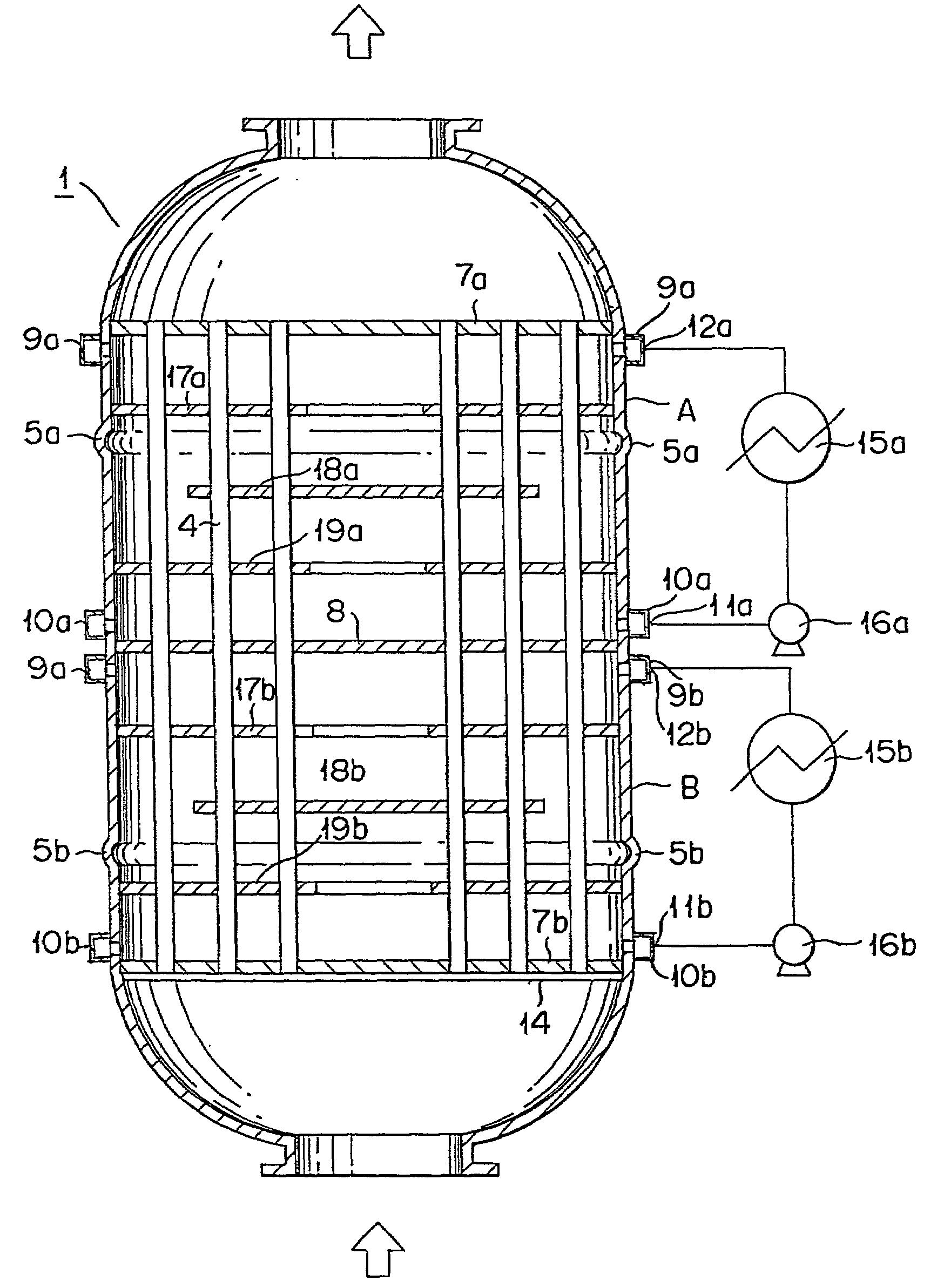

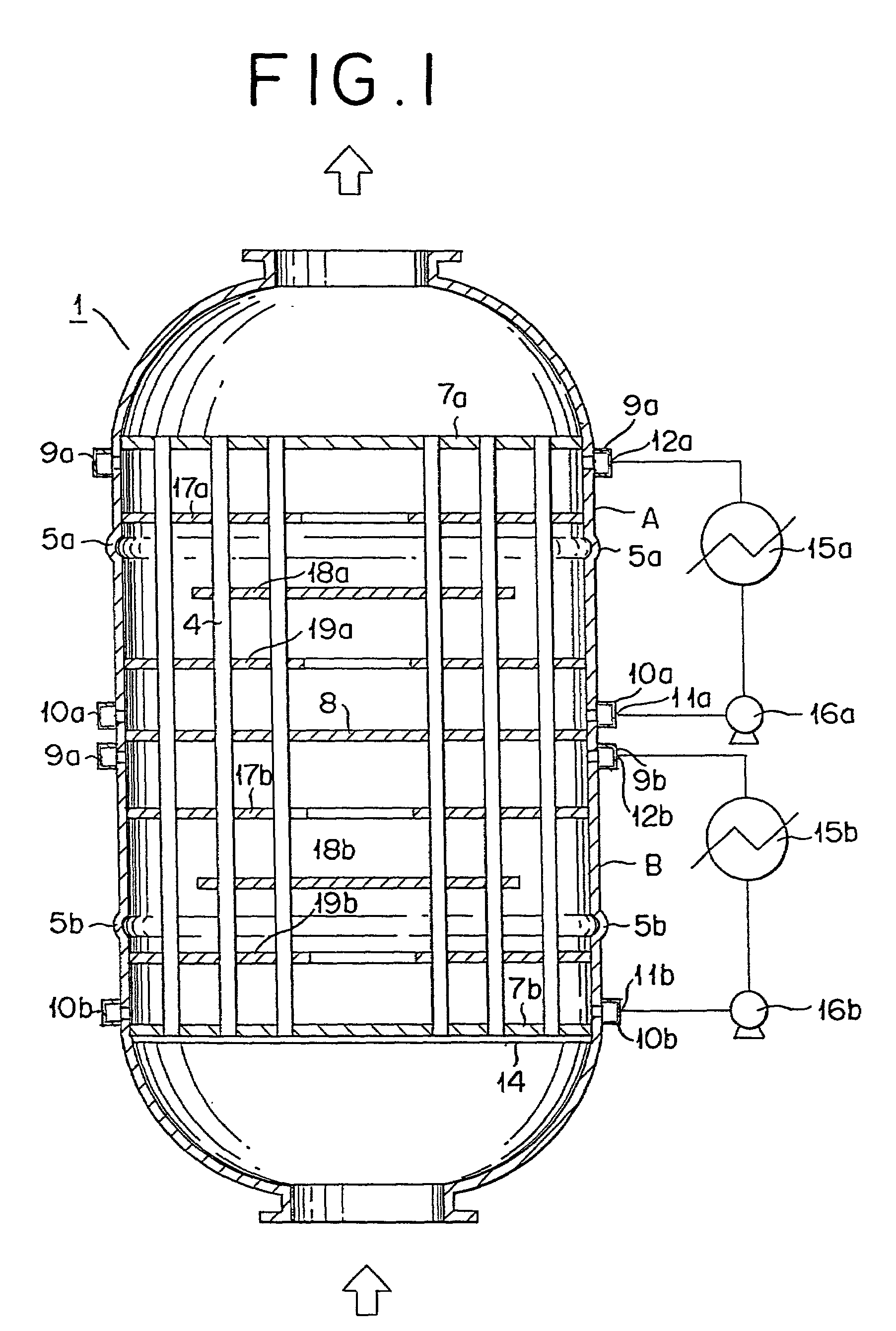

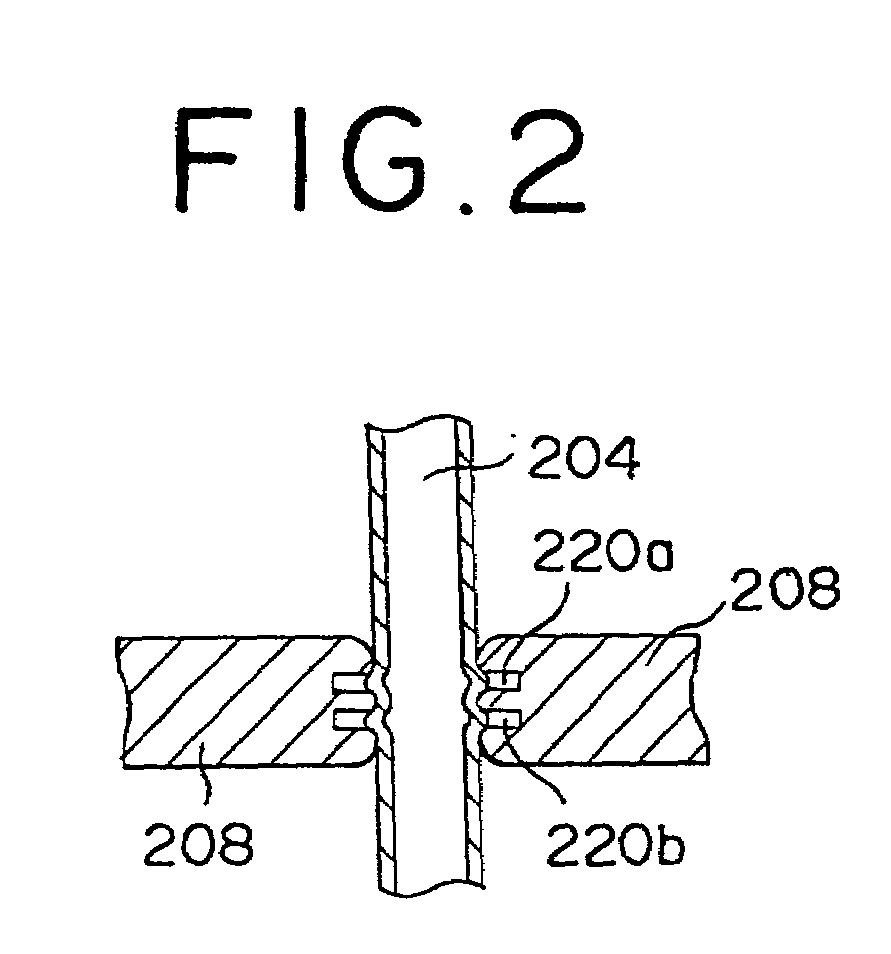

Reactor for catalytic gas phase oxidation

InactiveUS6994833B1Easy to controlEasy maintenanceSulfur-dioxide/sulfurous-acidOrganic chemistry methodsReaction tubeEngineering

In a shell-and-tube type reactor, the leakage between the upper and lower chambers is substantially decreased by tightly fitting the reaction tubes to the shield. The present invention provides a reactor for use in catalytic gas phase oxidation characterized by expanding reaction tubes to at least one groove formed in the reaction tube-fixing part of an intermediate tube sheet to form a shield, thereby forming plural of chambers with the intermediate tube sheet, and forming an expansion joint around the periphery of each of the chambers.

Owner:NIPPON SHOKUBAI CO LTD

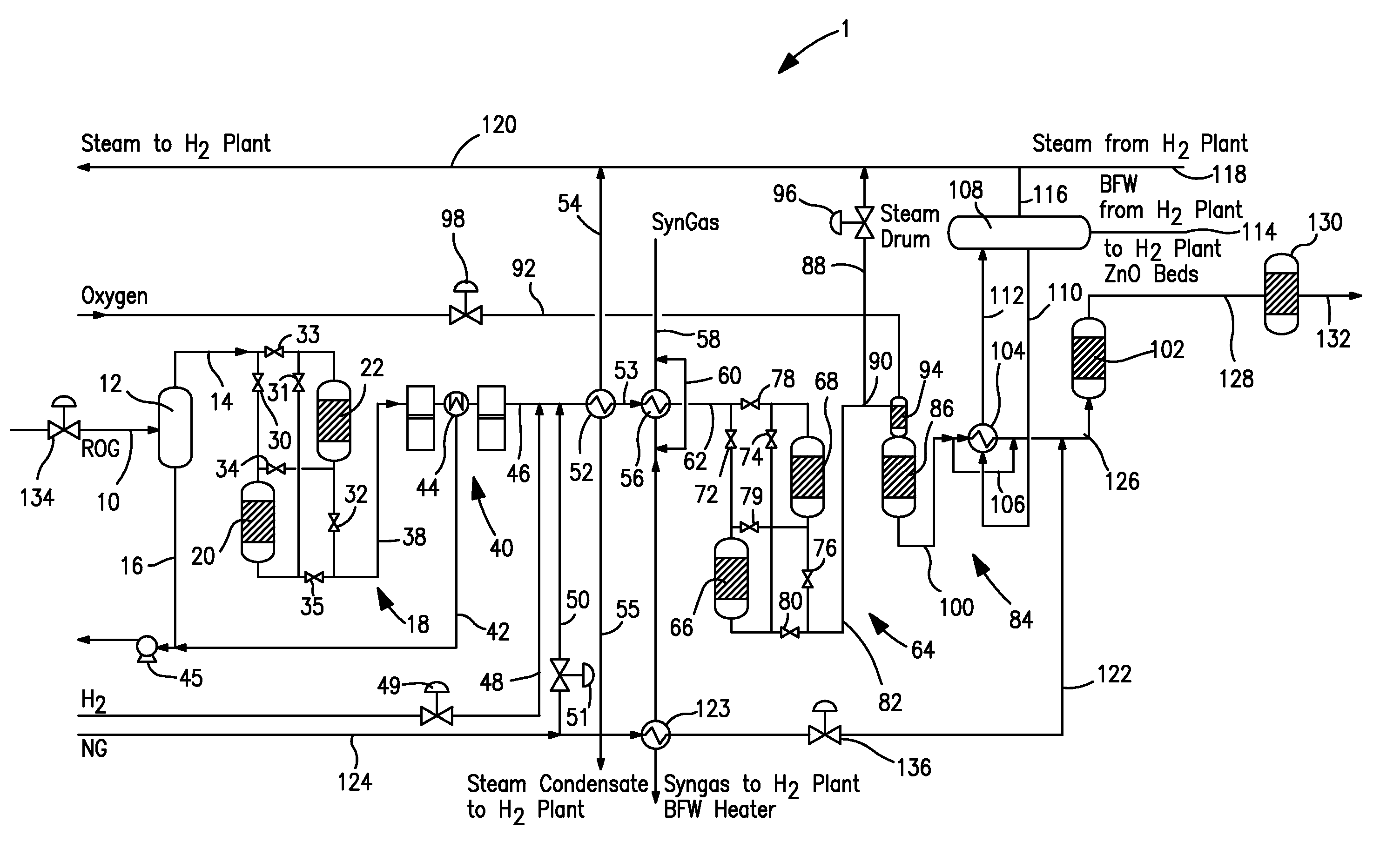

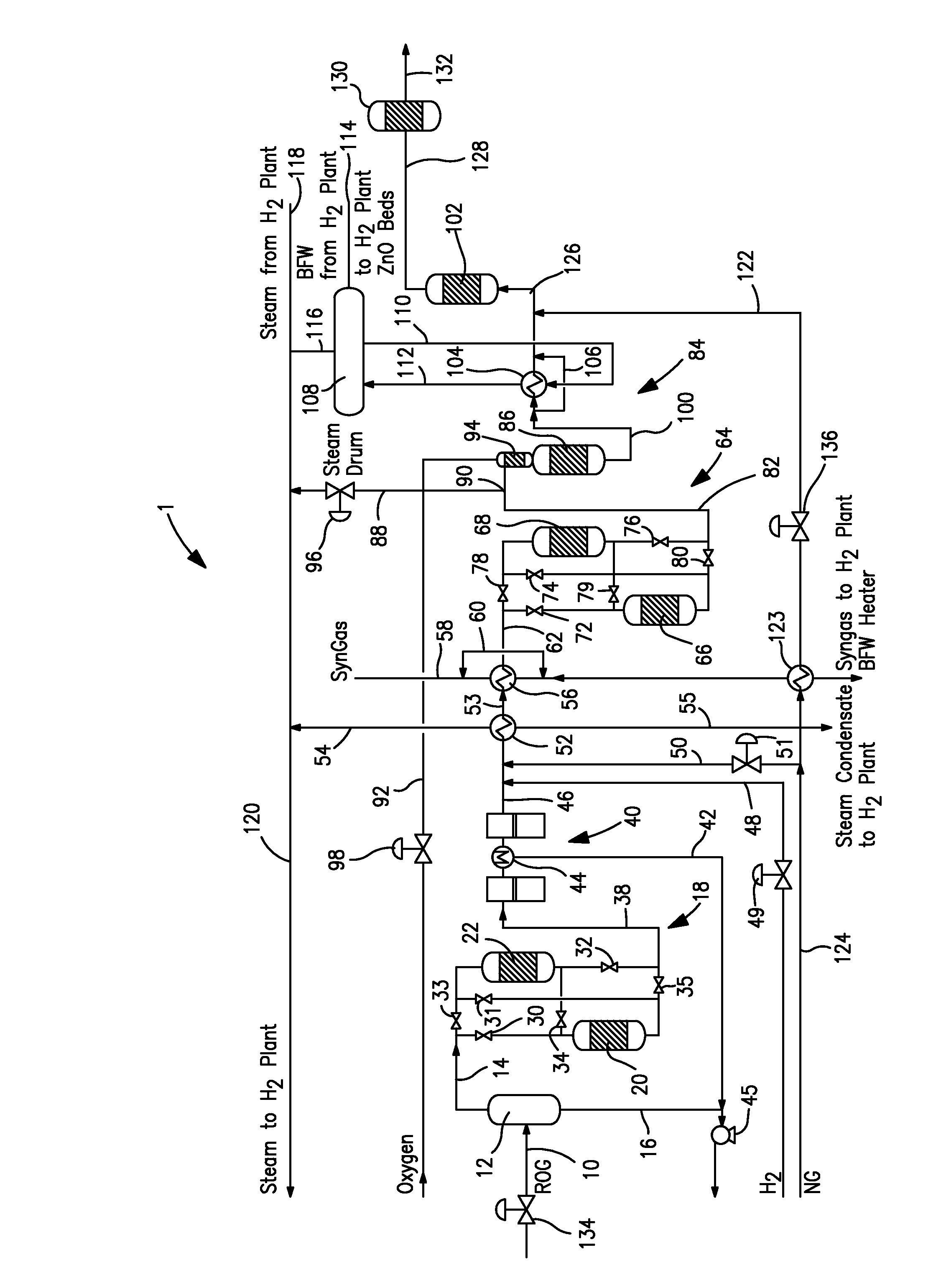

Hydrocarbon treatment method and apparatus

InactiveUS20110034745A1Improve responseReduce the amount requiredTreatment with plural serial cracking stages onlySulfur-dioxide/sulfurous-acidMethane reformerSulfur

The present invention provides a method and apparatus for producing a treated hydrocarbon containing stream for use as a feed to a steam methane reformer of a hydrogen plant. In accordance with such method, amounts of olefins and organic sulfur species within an untreated feed are decreased in a reactor that is operated in either a hydrogenation mode to hydrogenate the olefins into saturated hydrocarbons or a pre-reforming mode in which hydrocarbon containing two or more carbon atoms including the olefins are reacted with oxygen and steam to form saturated hydrocarbons, methane, additional hydrogen and carbon monoxide. The reactor is configured and operates at a sufficiently high space velocity that olefin and organic species slip occurs that is further treated in a hydrotreater. The reactor contains a catalyst capable of promoting both hydrogenation and oxidation reactions and the hydrotreater contains a catalyst that is capable of only promoting hydrogenation reactions.

Owner:PRAXAIR TECH INC

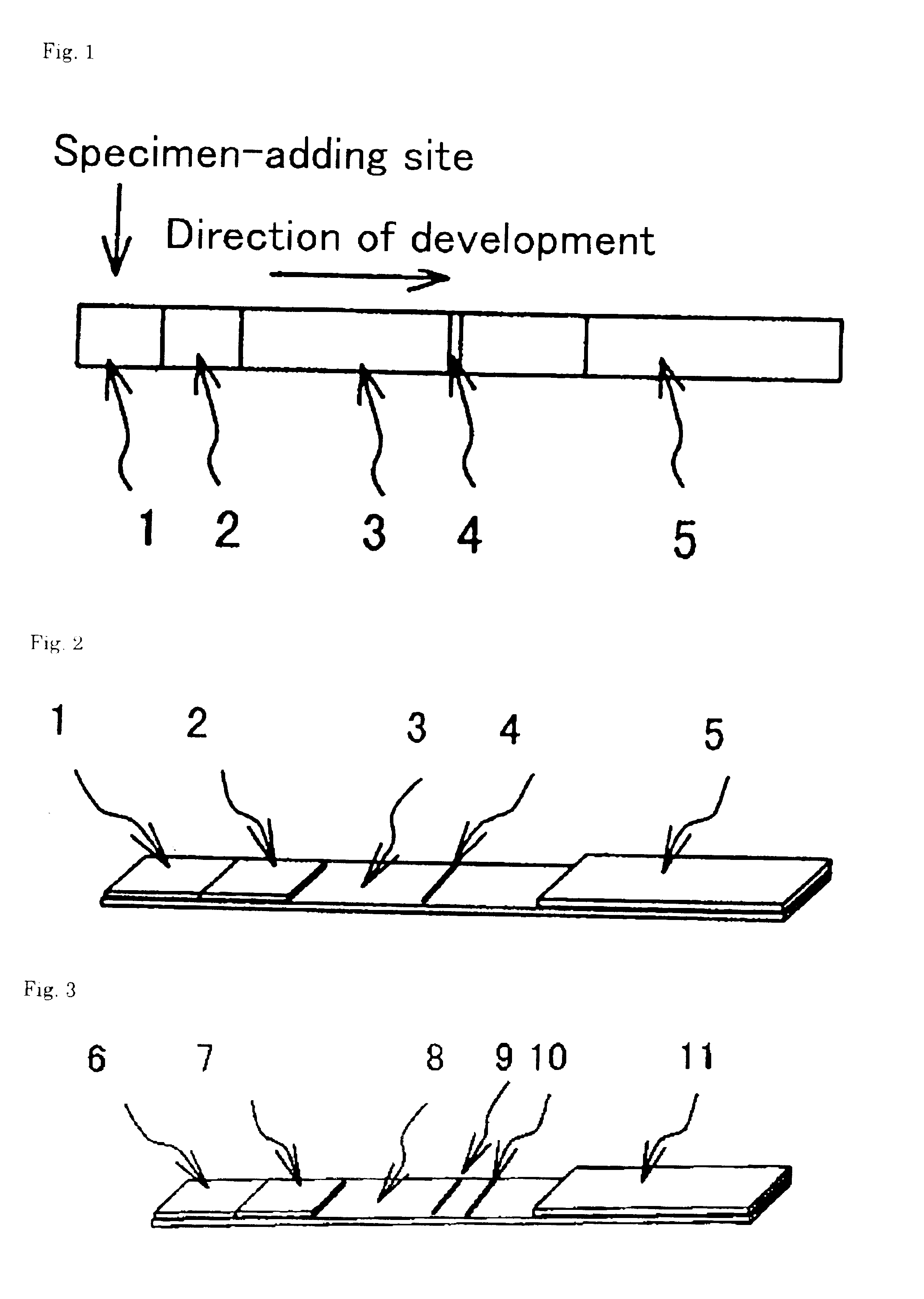

Method for diagnosing nephropathy

Means of conveniently examining nephropathy; and a method of assaying substance(s) in association with nephropathy (for example, podocalyxin and / or nephrin) in the urine to be used in the above means. The above assay method can be provided by releasing proteins in association with nephropathy, which exist on the surface of podocytes, from the cell surface and thus assaying the substances existing on the cell surface and / or free substances contained in the urine.

Owner:DENKA SEIKEN CO LTD +1

Sulfur recovery plant tail gas treatment process

ActiveCN102481515ALow investment costEasy to handleGas treatmentSulfur-dioxide/sulfurous-acidAlcoholCoolant

A process for the removal of hydrogen sulfide from a gas stream in which the gas stream is first passed through a Claus unit operating at a sub-stoichiometric ratio (H2S: SO2) of greater than 2:1 to produce a tail gas stream comprising less than 2000 vppm SO2. This tail gas stream is then treated to increase the sulfur recovery to at least 99.5% by first directly cooling the tail gas stream by contact with water as a coolant, followed by contacting the gas stream with a circulating stream of a dilute, absorbent solution of a severely sterically hindered secondary aminoether alcohol to further cool the gas stream, and then removing the H2S from the stream using a stronger absorbent solution of a severely sterically hindered secondary aminoether alcohol.

Owner:EXXON RES & ENG CO

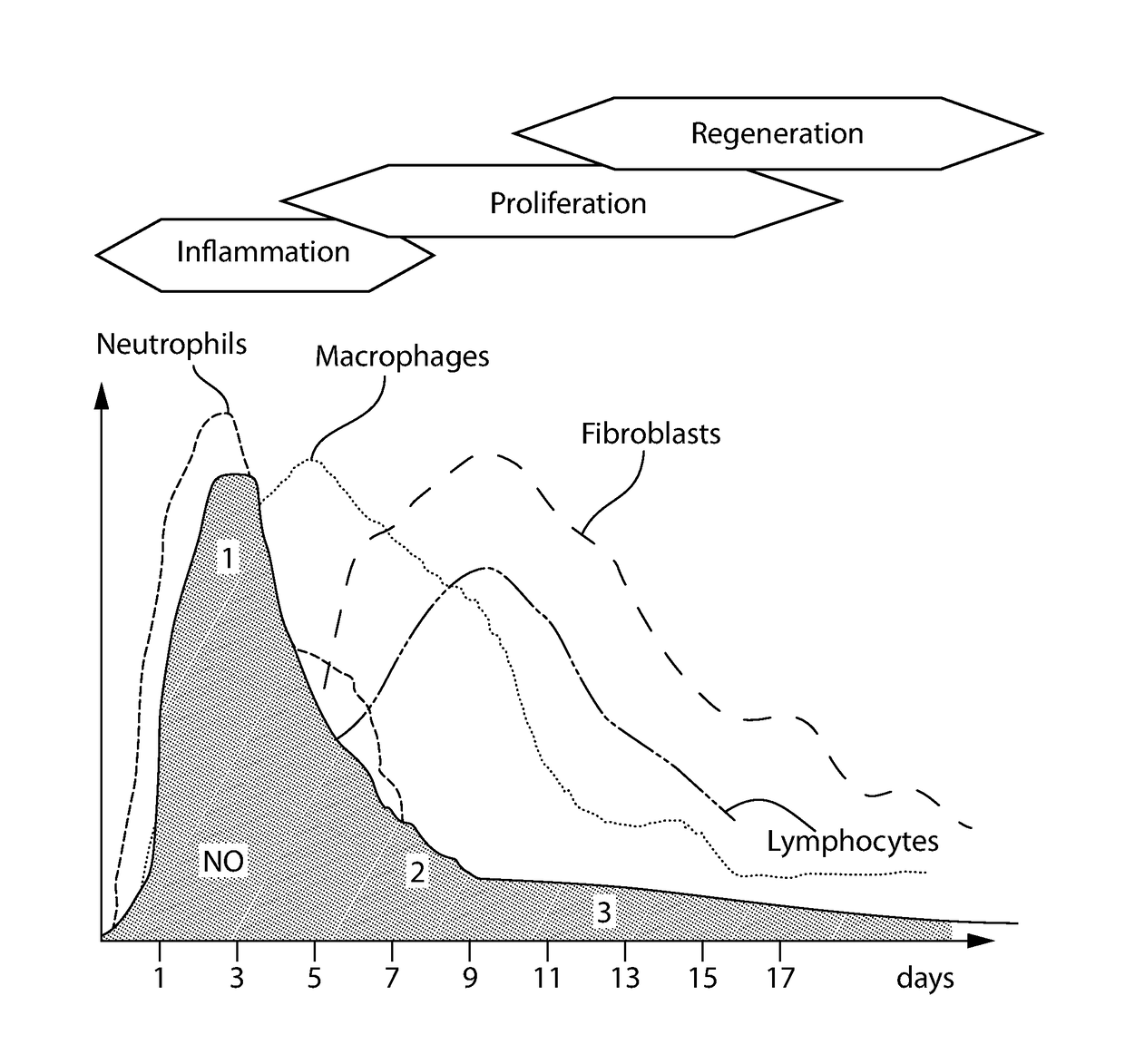

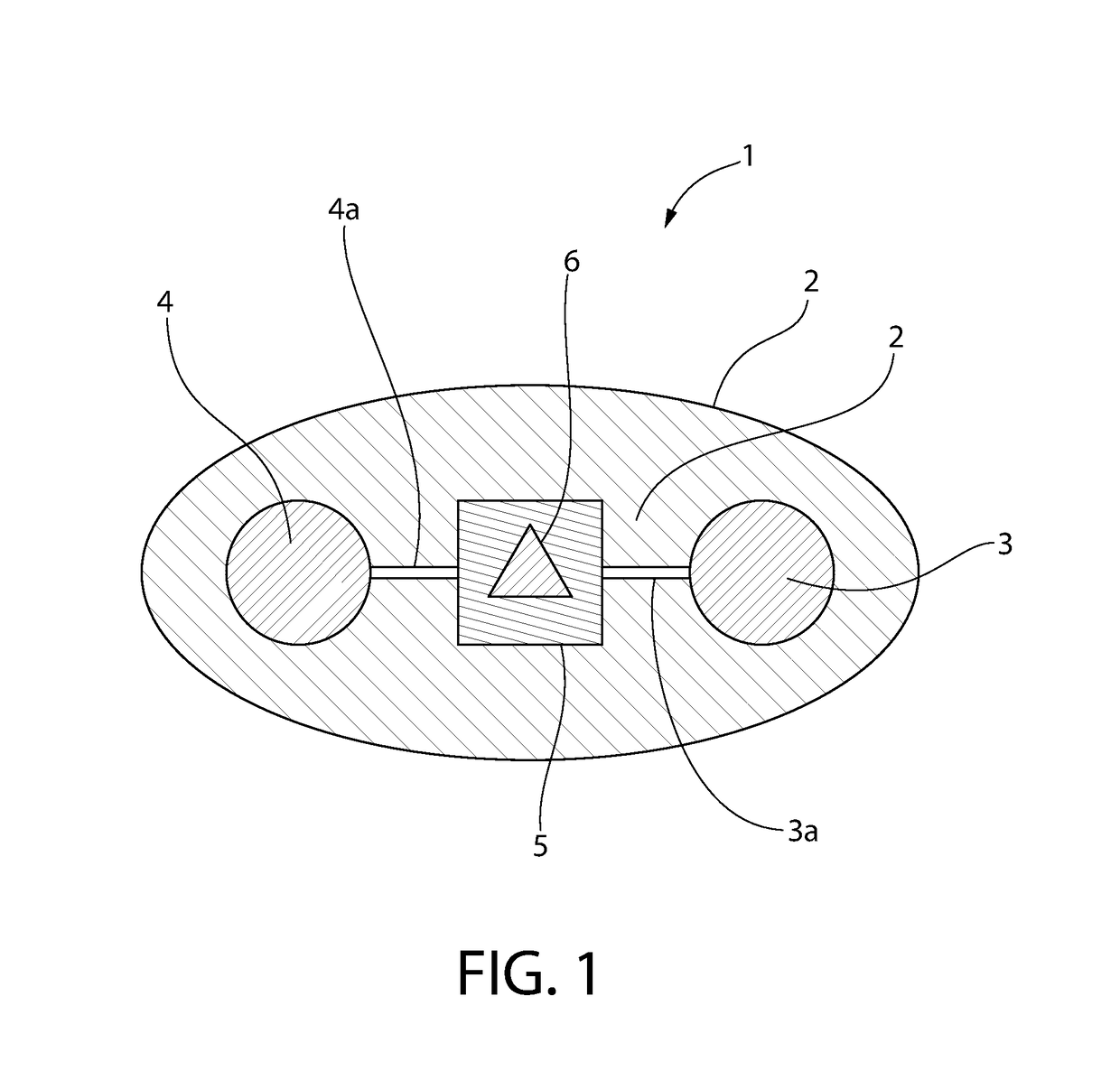

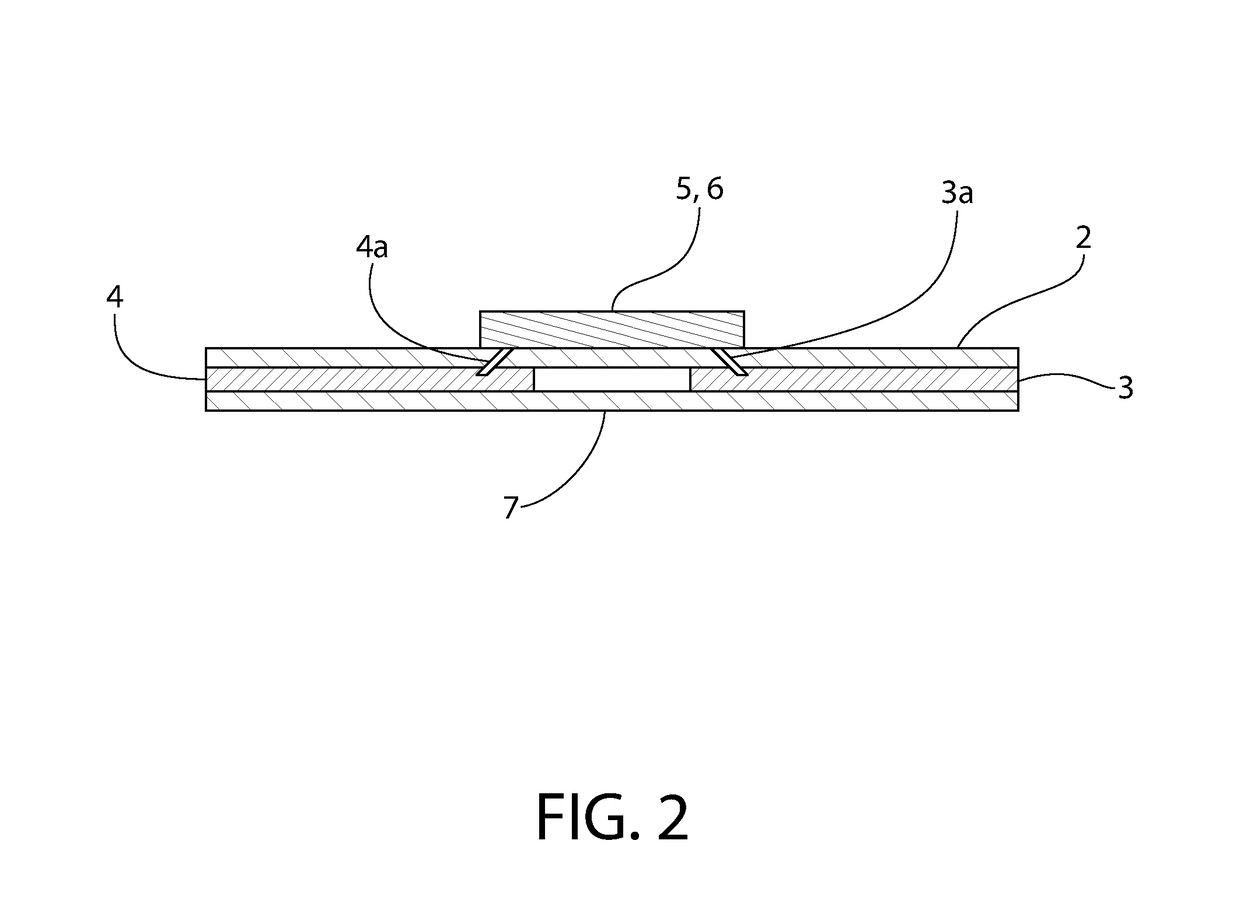

Electrochemical gasotransmitter generating compositions and methods of using same and dressings and treatment systems incorporating same

ActiveUS20180221210A1Reduced pressure tissuePromote growthNon-adhesive dressingsSulfur-dioxide/sulfurous-acidDiseaseElectrolysis

Disclosed are compositions that comprise an organic electrochemical mediator and a gasotransmitter salt which converts into a gasotransmitter via electron transfer. Also disclosed are bandages and wound dressings comprising the subject gasotransmitters, and methods of making a gasotransmitters, comprising exposing the compositions to a voltage sufficient to reduce the water soluble organic mediator. Further disclosed are methods of treating a variety of trauma and disease states by applying a therapeutically effective amount of at least one gasotransmitter thereto, and methods of generating an effective dose of the gasotransmitter generated from electrolytic reaction involving the gasotransmitter-generating compositions.

Owner:NOXSANO INC

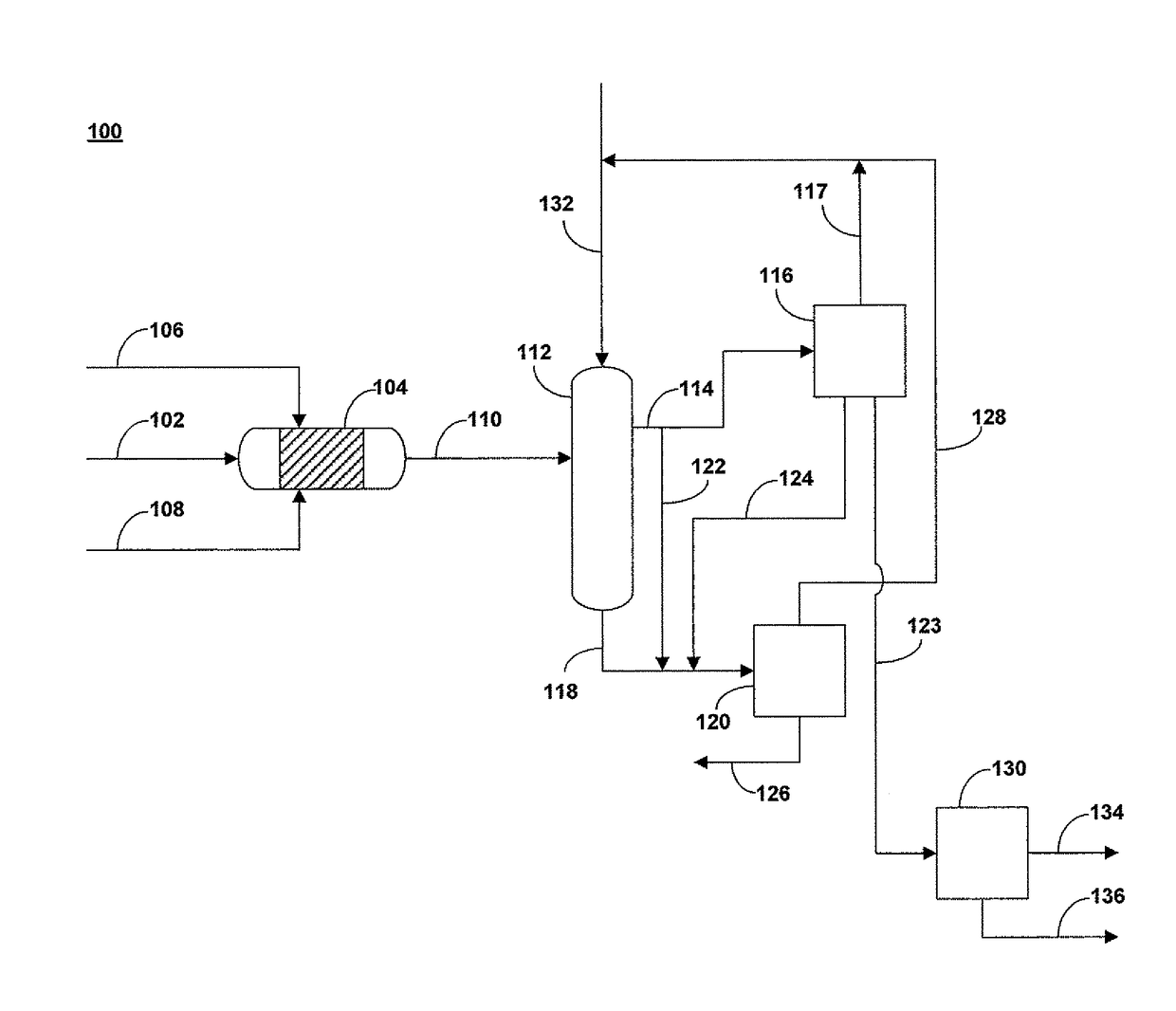

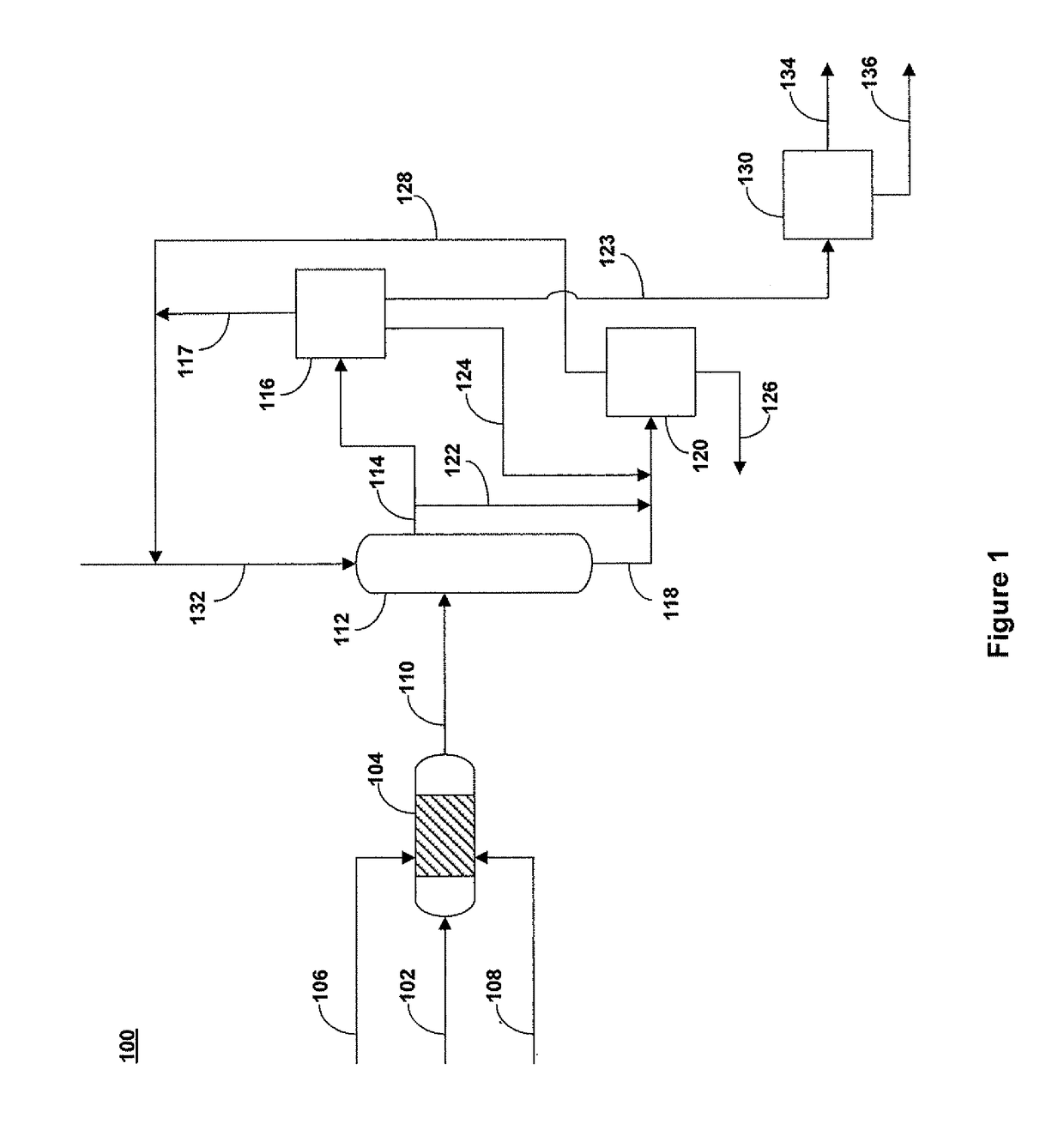

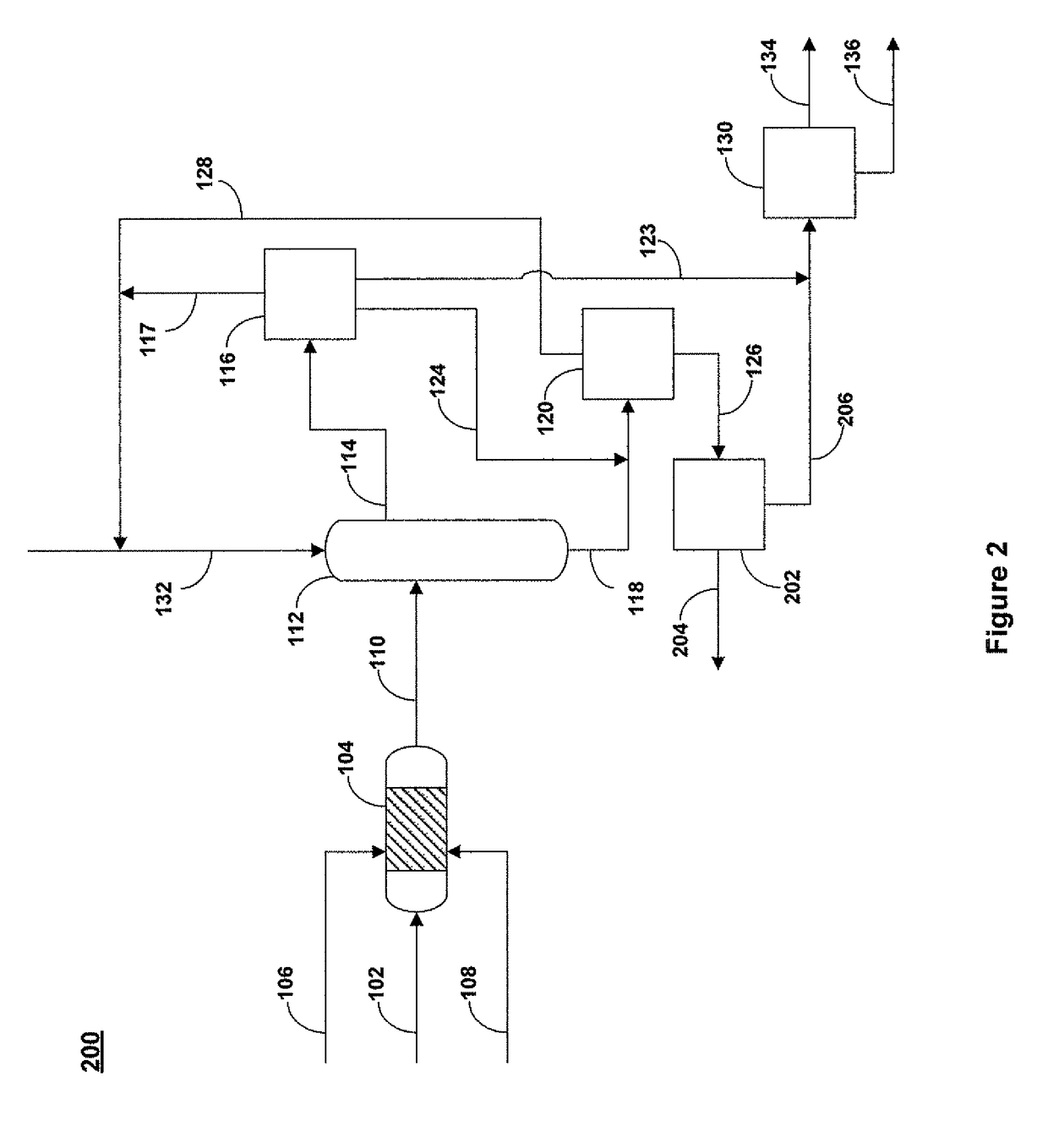

Process for oxidative desulfurization and sulfone disposal using solvent deasphalting

ActiveUS9598647B2Working-up pitch/asphalt/bitumen by selective extractionSulfur-dioxide/sulfurous-acidSulfurSolvent

A method and apparatus for upgrading a hydrocarbon feedstock is provided. The method includes the steps of (a) supplying a hydrocarbon feedstock to an oxidation reactor, wherein the hydrocarbon feedstock is oxidized in the presence of a catalyst under conditions sufficient to selectively oxidize sulfur compounds present in the hydrocarbon feedstock; (c) separating the hydrocarbons and the oxidized sulfur compounds by solvent extraction; (d) collecting a residue stream that includes the oxidized sulfur compounds; and (e) supplying the residue stream to a deasphalting unit.

Owner:SAUDI ARABIAN OIL CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com