Method for making sulfur trioxide, sulfuric acid, and oleum from sulfur dioxide

A technology of sulfuric acid and catalytic converters, applied in the fields of sulfur dioxide/sulfurous acid, chemical instruments and methods, inorganic chemistry, etc., which can solve the problems of limited capacity of SO2 emission equipment, low conversion rate, increased system investment and operating costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0117] This example further illustrates and explains the invention. However, the invention should not be construed as limited to any details of this example.

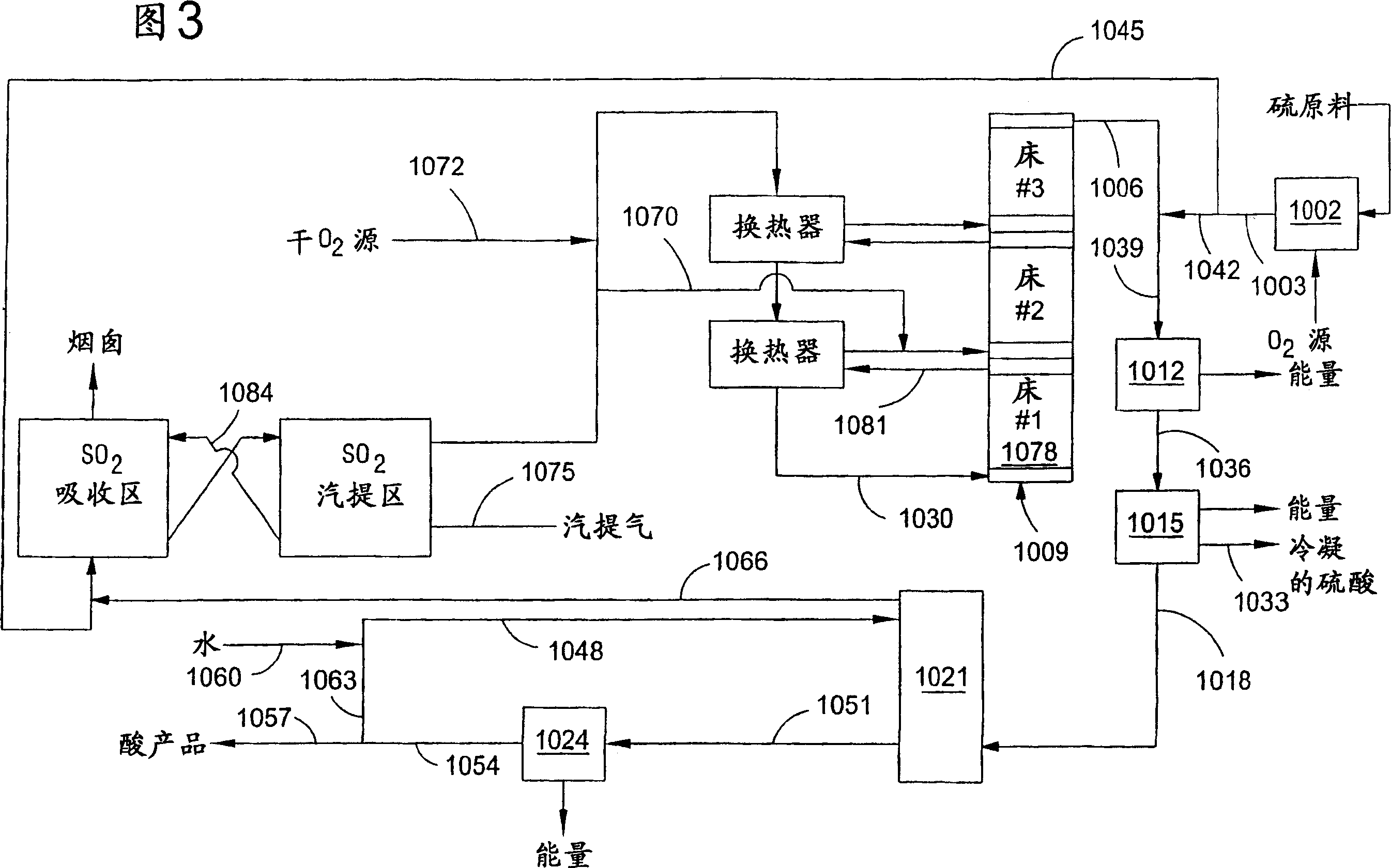

[0118] The performance of the system shown in Figure 4 was evaluated using a computer model. In the sulfur burner 2006 by burning sulfur 2009 in the presence of dry air 2012 to form 2 , about 2mol%O 2 and about 79 mol% N 2 The feed gas 2003. The feed gas 2003 (at a temperature of about 1538°C when leaving the sulfur burner 2006) is cooled to about 548°C in the waste heat boiler 2002. In the indirect heat exchanger 2015 (ie Monplex TM , Monsanto Environ-Chem Systems, Inc., St.Louis, MO, USA) from feed gas 2004 to supply SO 2 Heat transfer to the gas 2024 of the oxidation catalytic converter 2021 further cools the feed gas 2004 to about 337°C. Finally, the feed gas 2024 is cooled to about 204° C. in another indirect heat exchanger 2023 that utilizes the heat of the feed gas 2024 to generate steam.

[0119] The coo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com