Method for preparing gemini long-chain alkyl benzene sulfonate oil displacement agents

A technology of long-chain alkylbenzene sulfonate and oil-displacing agent is applied in the field of preparation of gemini long-chain alkylbenzene bissulfonate oil-displacing agent, and can solve the problems of complex process, low product selectivity, many side reactions, etc. problem, to achieve the effect of single structure, simple process and few reaction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Add distilled water and N,N-dimethylformamide mixed solvent 100mL in a four-necked flask equipped with a reflux condenser, a thermometer and a dropping funnel, then add 0.05mol iron powder and 0.005mol copper powder in sequence, gradually Raise the temperature to 30°C for 10 minutes;

[0023] (2) Add 0.004mol cuprous chloride after ripening, stir until cuprous chloride dissolves completely;

[0024] (3) be warmed up to 70 DEG C again, then dropwise add 0.1mol dodecylbenzyl chloride, drip quickly;

[0025] (4) The temperature is controlled at 90°C for 20 hours, and the reaction is stopped;

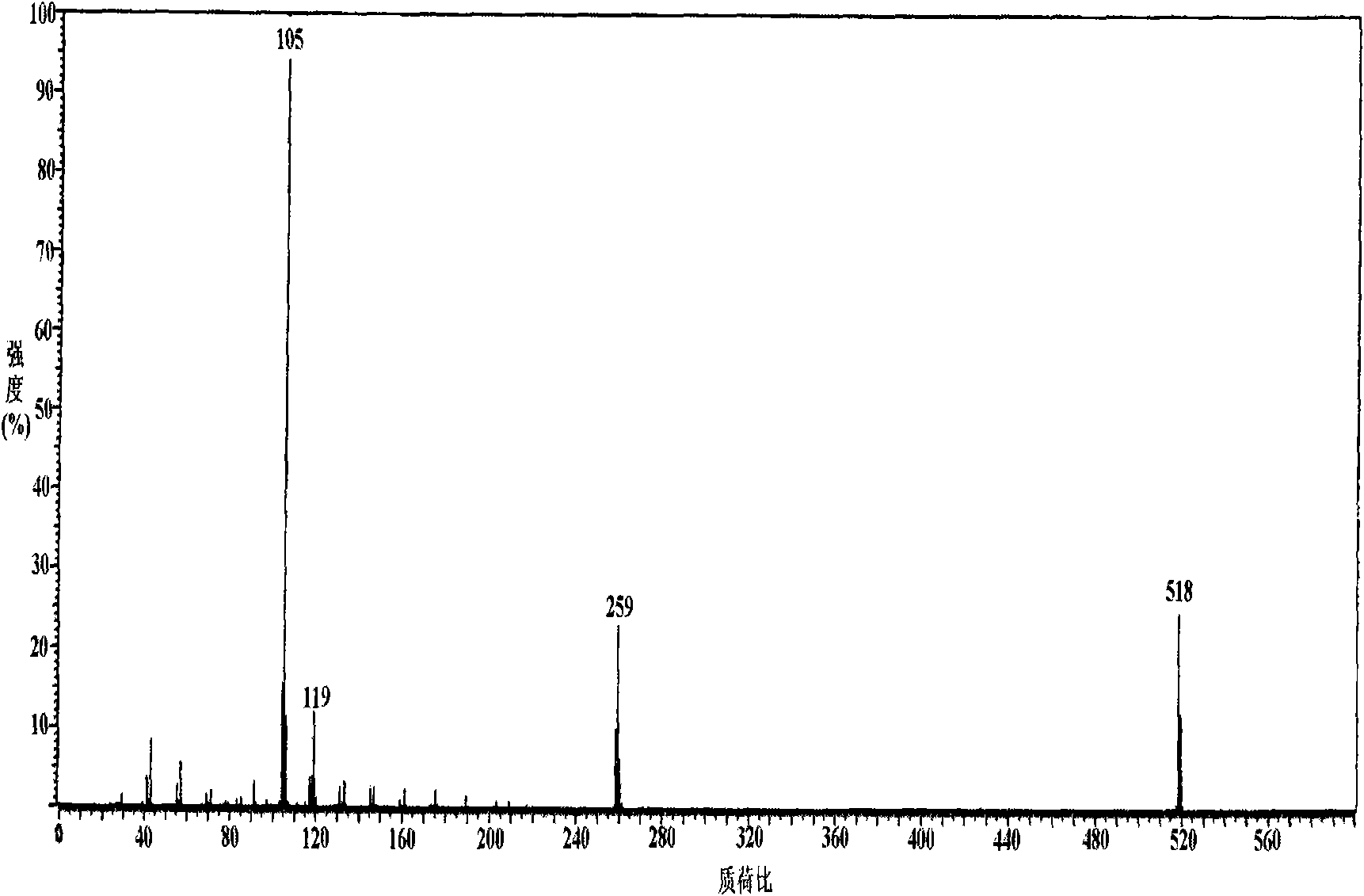

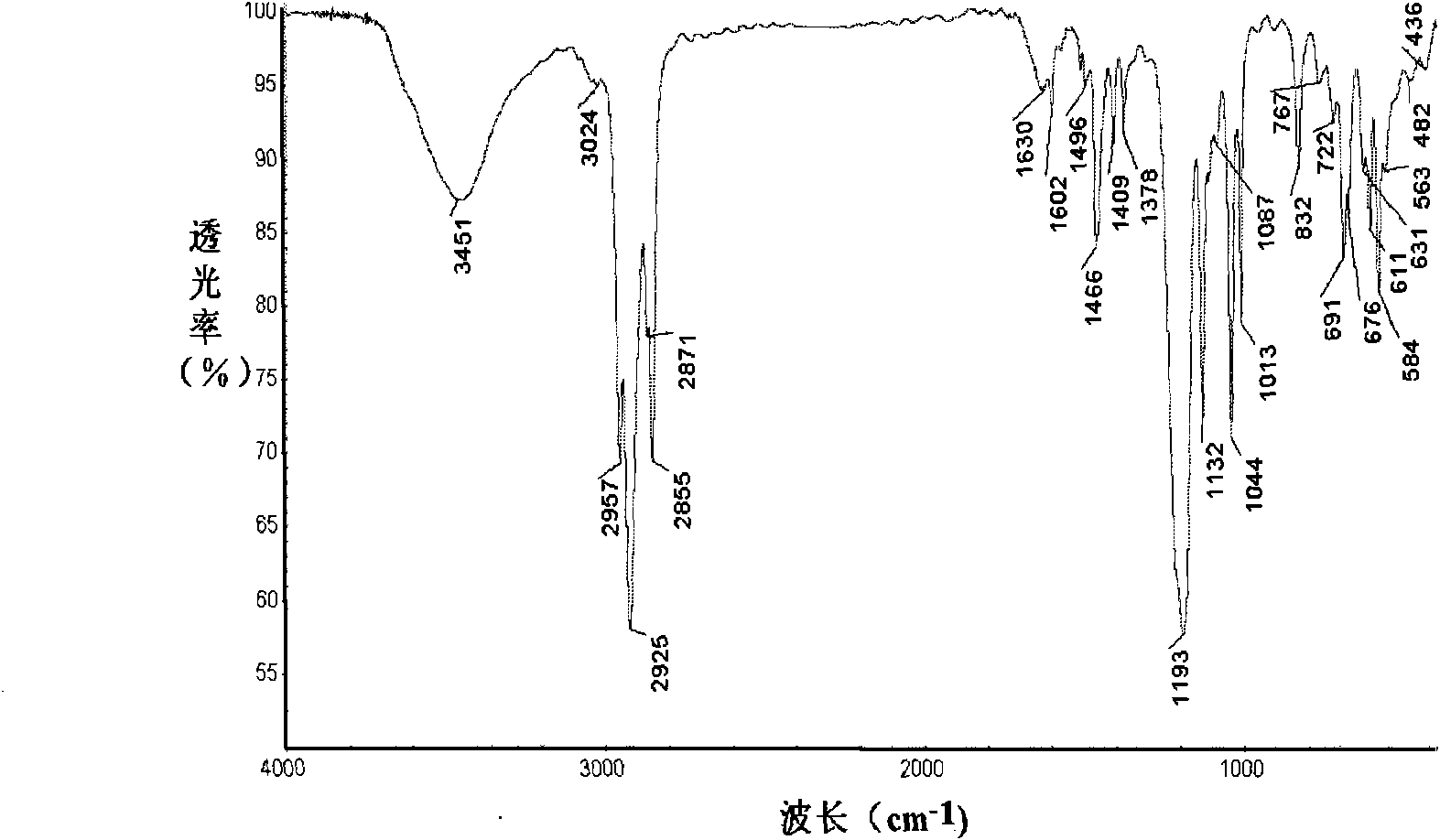

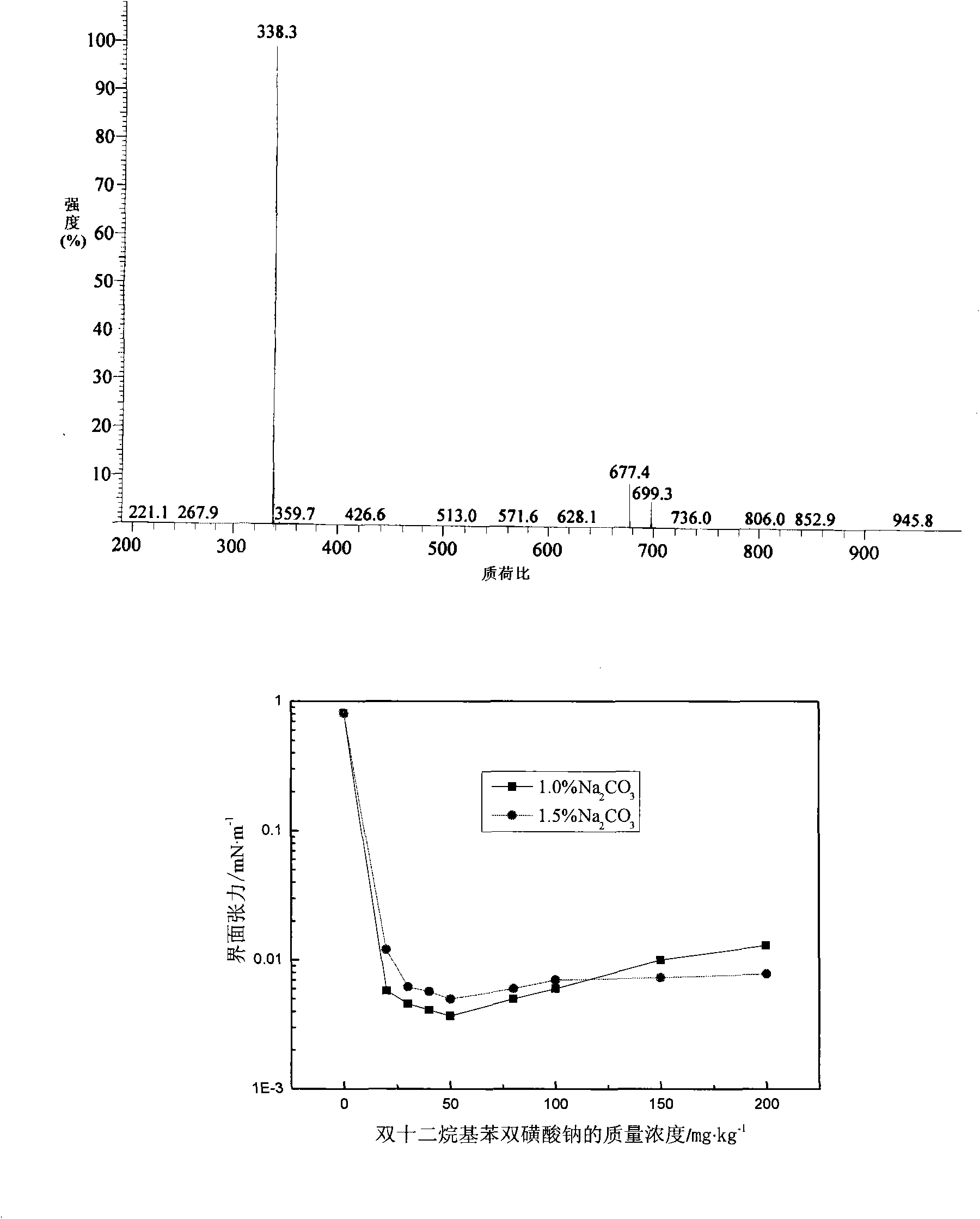

[0026] (5) Filter the reaction solution while it is hot, dilute the filtrate with petroleum ether and place it in a separatory funnel, take the organic layer and remove the petroleum ether by rotary evaporation to obtain the intermediate product 1,-2-bis(4,4'-dodeca Alkyl-1-phenyl)ethane, its electrospray mass spectrum (ESI-MS) see figure 1 , in the mass spectrum, the mass-to-...

Embodiment 2

[0033] The same operation as in Example 1, only the dodecylbenzyl chloride in Example 1 is replaced by hexadecylbenzyl chloride, and 30% sodium hydroxide is changed into 30% ammonia water to obtain dihexadecane Crude ammonium diphenylethane disulfonate.

Embodiment 3

[0035] The same operation as in Example 1, except that the dodecylbenzyl chloride in Example 1 was replaced with tetradecylbenzyl chloride, can obtain the ditetradecyl disulfonate sodium diphenylethane crude product.

[0036]In the foregoing examples, the instruments and reagents used are: Infrared Analyzer, Magana-IR 560E.S.PV., Nicolet Company, USA; Chromatography and Mass Spectrometry Instrument, Japan SHIMADZUGCMS-QP2010; POWEREACH JJ2000A Spinning Drop Interfacial Tensiometer, Shanghai Zhongchen Co., Ltd.; dodecylbenzyl chloride, homemade; tetradecylbenzyl chloride, homemade; hexadecylbenzyl chloride, homemade; reduced iron powder, analytically pure, Beijing Yili Fine Chemicals Co., Ltd. Company; cuprous chloride, analytically pure, Beijing Chemical Reagent Company; N, N-dimethylformamide, analytically pure, Beijing Yili Fine Chemicals Co., Ltd.; copper powder, analytically pure, Beijing Chemical Reagent Company; smoke Sulfuric acid, analytically pure, Beijing Chemical Pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com