Patents

Literature

40 results about "Recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Recovery is a process by which deformed grains can reduce their stored energy by the removal or rearrangement of defects in their crystal structure. These defects, primarily dislocations, are introduced by plastic deformation of the material and act to increase the yield strength of a material. Since recovery reduces the dislocation density the process is normally accompanied by a reduction in a materials strength and a simultaneous increase in the ductility. As a result, recovery may be considered beneficial or detrimental depending on the circumstances. Recovery is related to the similar process of recrystallization and grain growth, each of them being stages of annealing. Recovery competes with recrystallization, as both are driven by the stored energy, but is also thought to be a necessary prerequisite for the nucleation of recrystallized grains. It is so called because there is a recovery of the electrical conductivity due to a reduction in dislocations. This creates defect-free channels, giving electrons an increased mean-free path.

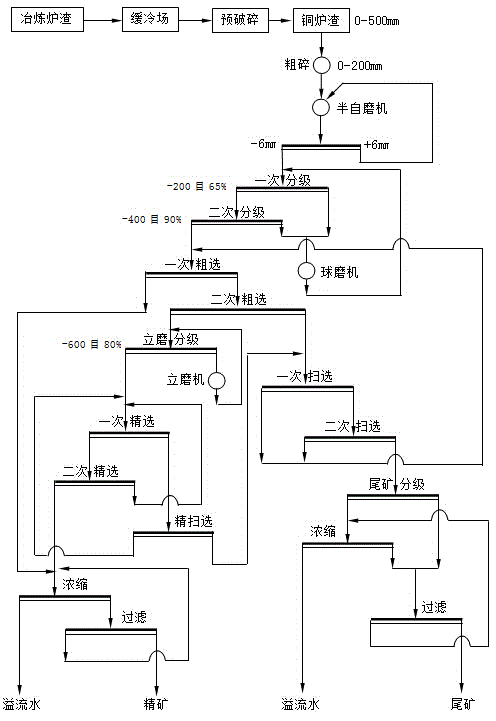

Copper furnace slag mineral processing process

InactiveCN104399573AExtend slow cooling timeIncrease collisionFlotationGrain treatmentsSlagEngineering

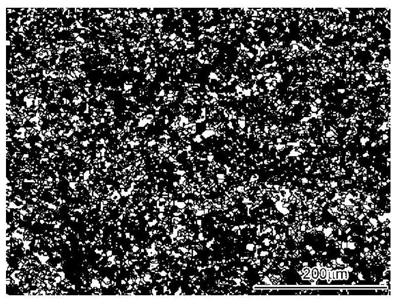

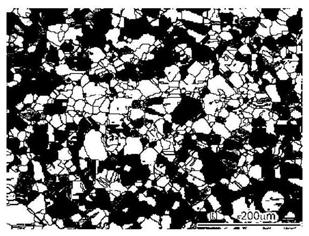

The present invention provides a copper furnace slag mineral processing process. According to the copper furnace slag mineral processing process, the slow cooling mode adopts centralized natural slow cooling for 12 h and spraying slow cooling for 60 h so as to prolong the slow cooling time of the slag ladle at a temperature of 1000-1250 DEG C, increase the opportunity of collision and growth of the copper matte particles, and easily achieve the crystallization development of the copper crystal, such that the recovery rate of the subsequent flotation operation is easily increased; the disseminated grain size of the copper sulfides in the furnace slag is fine, and for complete dissociation of the useful minerals, the stirring mill is adopted to carry out mineral grinding, ie., the crude concentrate is graded with a cyclone device, the setting sand after the grading is subjected to mineral grinding by adopting the stirring mill, the overflow after the grading is subjected to fine selection twice by adopting the flotation column, and the selected concentrate is directly adopted as the final concentrate, wherein the tailings being subjected to the one fine selection through the flotation column is sorted by adopting the flotation machine, and the tailings being subjected to the double fine selection through the flotation column cyclically returns. According to the present invention, the flotation machine, flotation column and vertical stirring mill combined process combining the machine, the column and the mill is adopted, such that the useful minerals with various particle sizes are easily recovered, and the metal recovery rate is efficiently increased.

Owner:广西金川有色金属有限公司

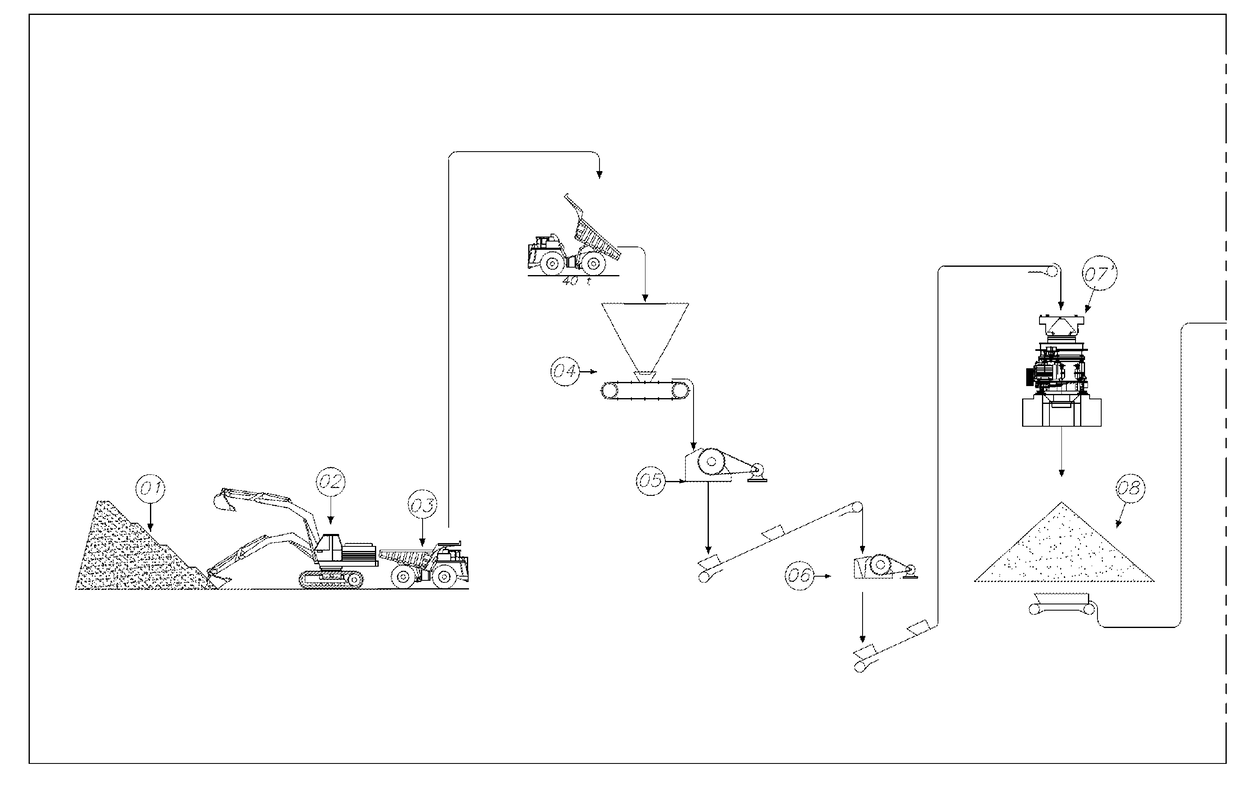

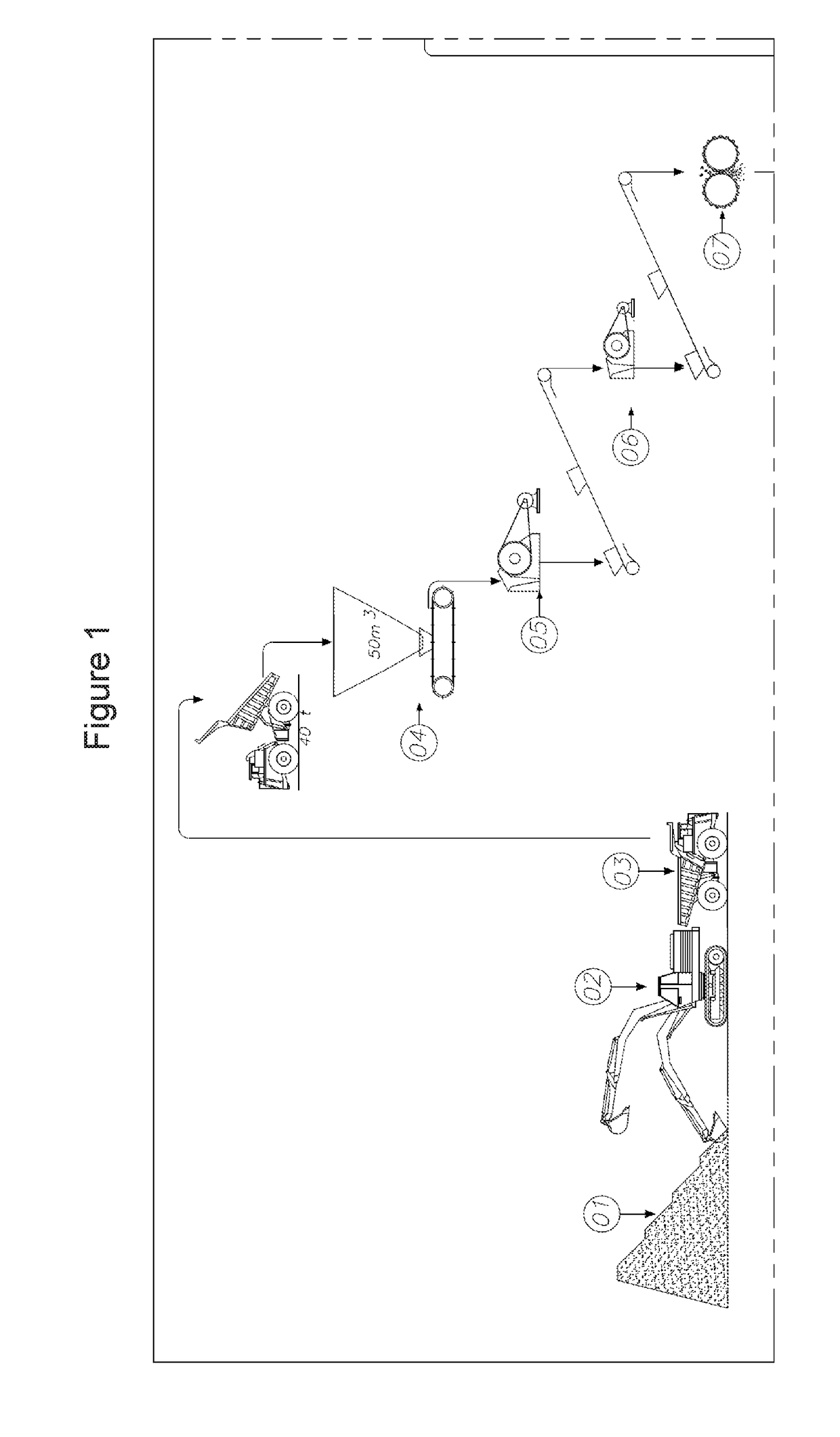

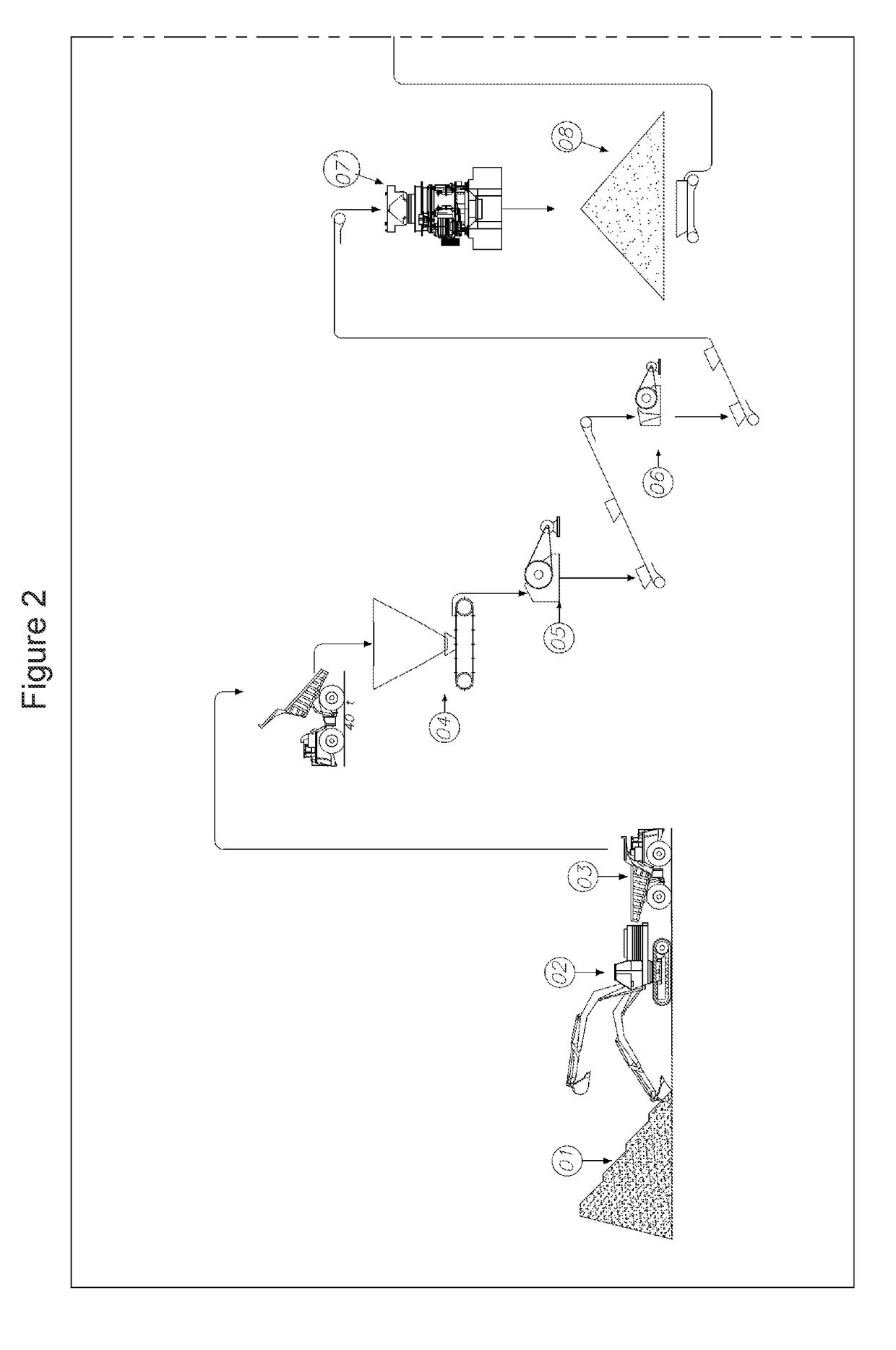

System and process for dry recovery of iron oxide fines from iron bearing compacted and semicompacted rocks

ActiveUS20180036803A1Gas current separationHigh gradient magnetic separatorsAir classifierUltimate tensile strength

The present invention relates to a system and a process for dry recovery of iron oxide fines from iron bearing compact and semicompact rocks that comprise primary (5), secondary (6) and tertiary (7, 7′) crushing means for preliminarily reducing the granulometry of ores containing the iron oxide fines in compact and semicompact rocks; means for finely grinding (10, 10′, 21) iron oxide minerals reduced through primary (5), secondary (6) and tertiary (7, 7′) crushing, provided with a dynamic air classifier (3.5, 4.6, 5.4); means of static air classification (11, 12, 13) arranged in series for intermediate granulometric cuts and bag filters (14) for retaining fine fraction; and means of magnetic separation (15, 16, 17), through magnetic rolls (71, 72, 73) arranged in cascade at a variable leaning angle, and formed by high and / or low magnetic intensity magnets,

Owner:VALE LIMITED

Treatment technology of anti-ash-deposition and anti-wear alloy material of waste heat recovery pipeline

InactiveCN105755316AImprove wear resistanceImprove corrosion resistancePressure inorganic powder coatingRare-earth elementAlloy

The invention discloses a treatment technology of an anti-ash-deposition and anti-wear alloy material of a waste heat recovery pipeline.An alloy blank is selected, vacuum arc remelting or electro slag remelting is adopted, the smelting temperature ranges from 3,050 DEG C to 3,100 DGE C, the alloy blank is prepared from, by mass, 11.3%-14.4% of Al, 14.6%-17.5% of Mg, 1.25%-1.5% of Fe, 0.40%-0.7% of Si, 0.01%-0.10% of Cu, 1.5%-1.7% of Mn, 1.4%-2.0% of Zn, 0.10%-0.25% of Zr, 1.10%-3.12% of rare earth elements, smaller than 0.015% of impurity content and the balance Ti; the rare earth elements comprise, by weight, 15%-18% of Gd, 3%-5% of Pr, 7%-9% of Dy, 12.5%-12.8% of Ac, 15%-20% of Nd, 11%-13% of Sm and the balance La.According to the treatment technology of the anti-ash-deposition and anti-wear alloy material of the waste heat recovery pipeline, wear resistance and corrosion resistance of tubing can be greatly improved, the tubing adapts to the severe environment, the service life of the tubing is prolonged, a large amount of ash deposits is prevented from splashing, a large number of resources are saved, and the cost is reduced.

Owner:JIANGSU JINYUAN TENGFENG HEAT EXCHANGE EQUIP CO LTD

Method for manufacturing pipeline assembly from shape memory alloy

ActiveCN108723110AHigh material strengthIncreased strength and recoveryExtrusion diesShearing deformationCrystallite

The invention relates to a method for manufacturing a pipeline assembly from shape memory alloy. The method adopts an equal-diameter bending extrusion mould to form an equal-diameter bending extrusionmethod for processing the shape memory alloy; the method can realize large shearing deformation of a test sample under relatively low load and relatively load stress in case of not changing the crosssection area of the material; in a deforming process, crystalline grains are greatly refined by processing and hardening, dynamic recovery and re-crystallizing of block materials; and finally, a sub-microcrystal or nano structure is finally formed, so that the material strength is improved; and according to the research, the strength and the recovery rate of iron-based shape memory alloy can be remarkably improved by ECAP deformed refined crystalline grains. Therefore, the method belongs to the technical field of metal material refining.

Owner:江苏华晨气缸套股份有限公司

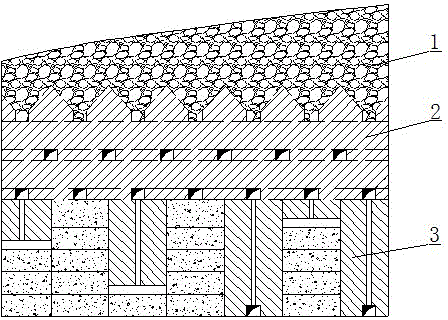

Method for transition from non-pillar sublevel caving method to upward horizontal cut-and-fill method

InactiveCN103557029AMake the transitionHigh recovery rateMaterial fill-upVegetationEcological environment

The invention relates to a method for transition from a non-pillar sublevel caving method to an upward horizontal cut-and-fill method. The technical scheme is as follows: in a section close to and below a caved area (1) of a mining area, the section is divided into an isolation zone (2) and a recovery area (3), the upper part of the section is the isolation zone (2), and the lower part of the section is the recovery area (3). The section is exploited in such a sequence that the recovery area is exploited before the isolation zone (2) is exploited. An exploitation method of the section is as follows: the upward horizontal cut-and-fill method is adopted for the recovery area (3), and the non-pillar sublevel caving method is adopted for the isolation zone (2). The thickness of the isolation zone (2) is one or two times of the sublevel height of the non-pillar sublevel caving method. The isolation zone (2) is exploited after final setting of a filling body of the recovery area (3). The method has the characteristics that the loss ratio of ore can be reduced, the dilution rate can be reduced, the surface vegetation and the ecological environment can be protected, atmospheric conditions of a stope can be improved, and the recovery is simple.

Owner:WUHAN UNIV OF SCI & TECH

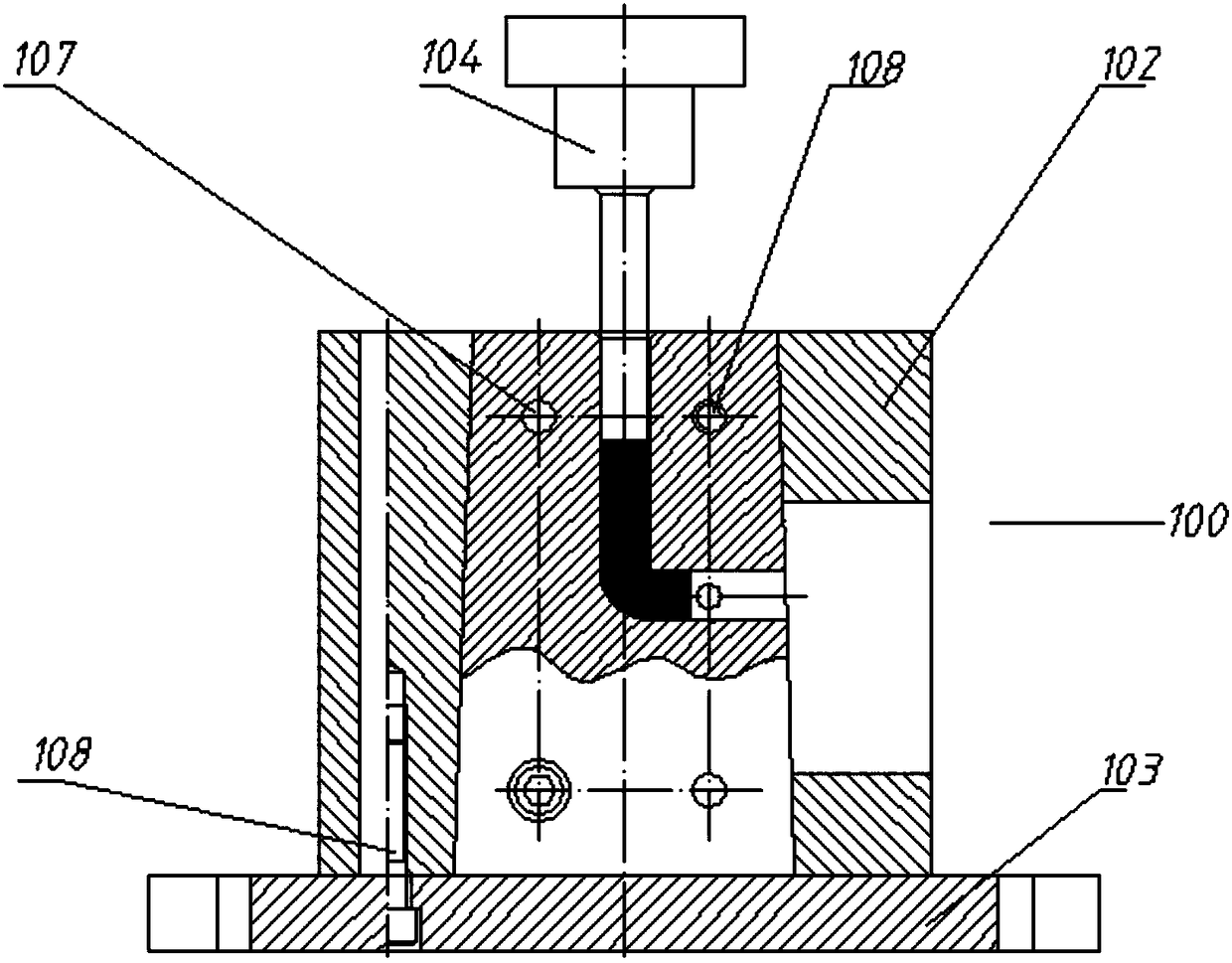

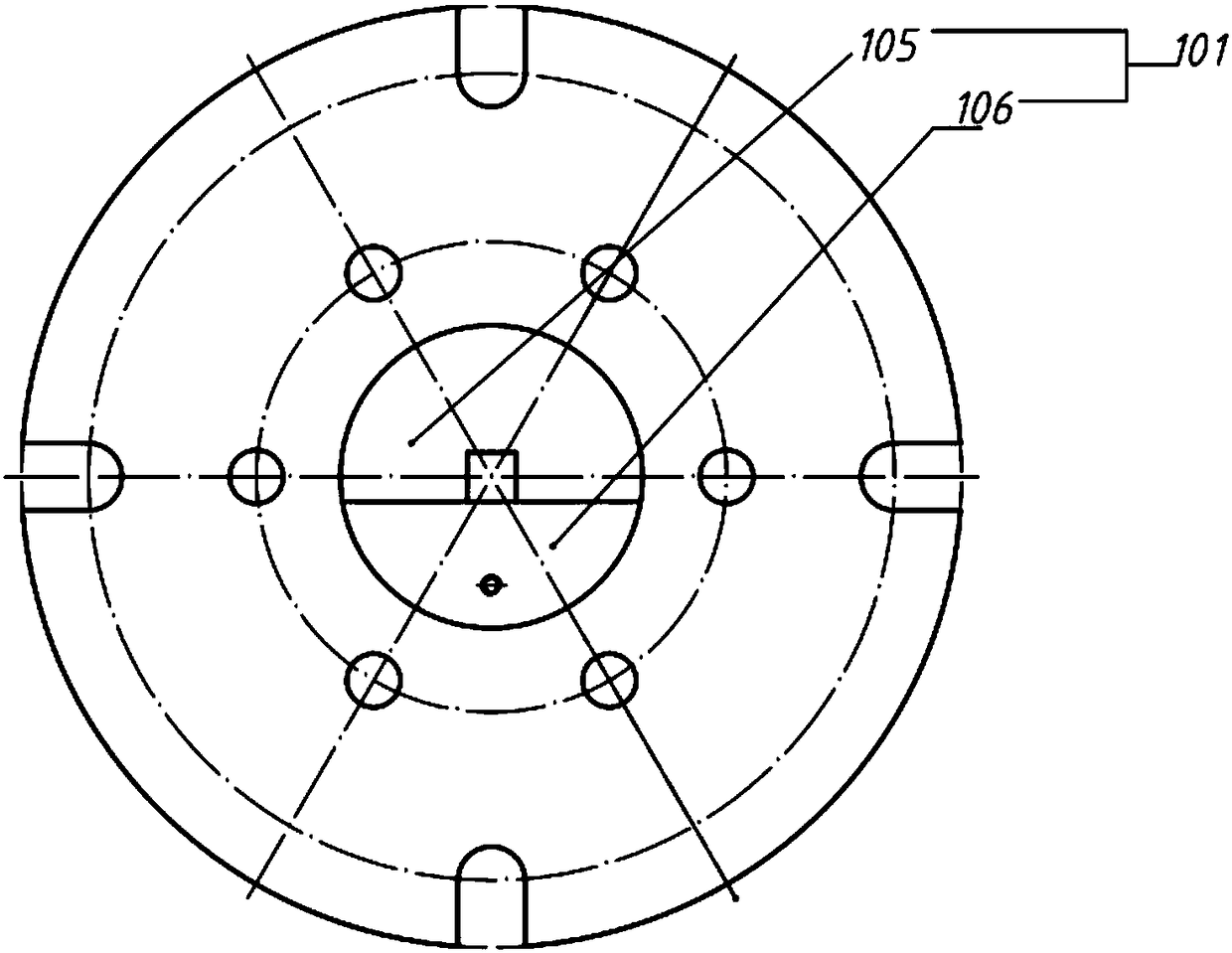

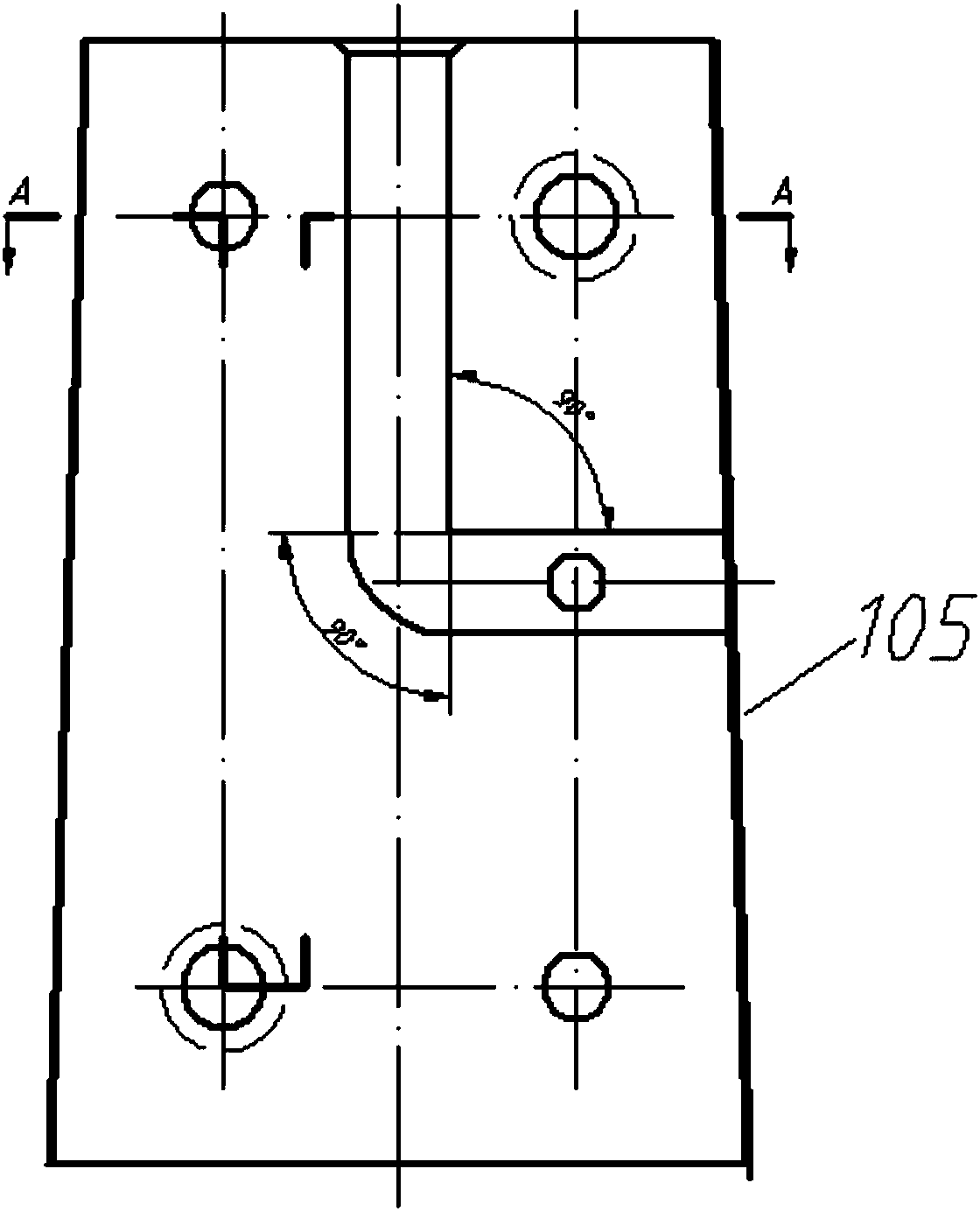

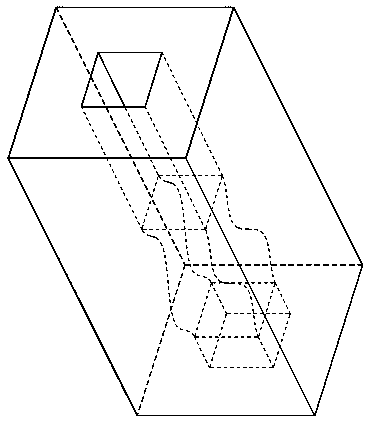

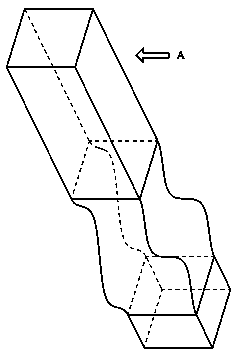

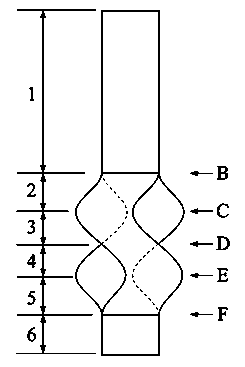

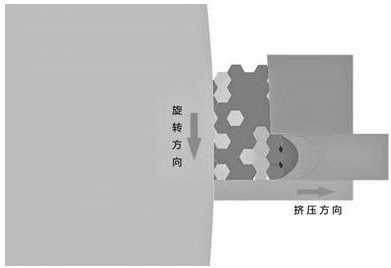

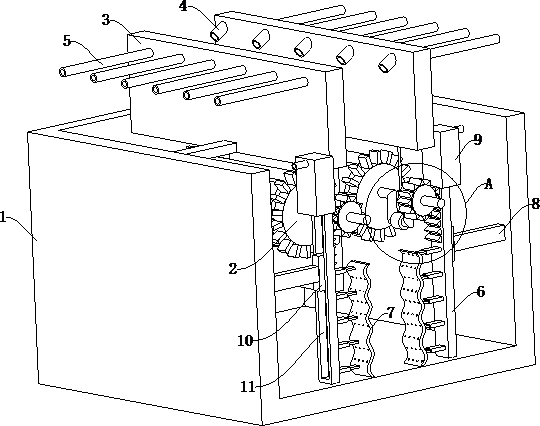

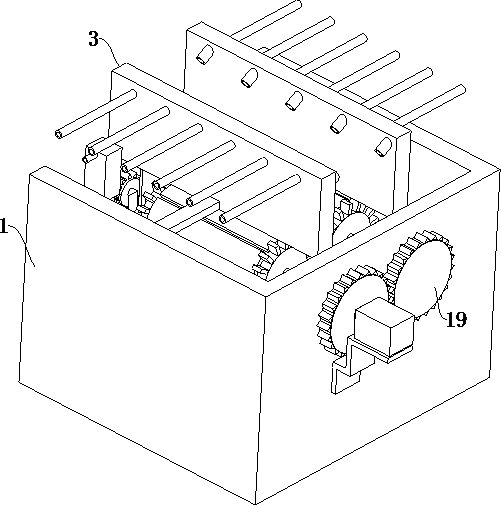

Equal-channel shear extrusion mold and molding method

InactiveCN104384225AAchieve shear crushingSuppression of microscopic defectsExtrusion diesMetallic materialsShearing deformation

The invention discloses an equal-channel shear extrusion mold and a molding method, and belongs to the technical field of metal material extrusion and molding. The mold is externally of a cuboid structure and is internally provided with a mold cavity, wherein the mold cavity is divided into an entrance section, a shear deformation section I, a shear deformation recovery section I, a shear deformation section II, a shear deformation recovery section II and an exit section. A blank is subjected to dramatic shear strain under the effect of shear strain, so that crystals are shorn and crushed, and the effect of refining the crystals is realized; meanwhile, the blank is limited by the extrusion mold cavity, and is in an intense pressure stress state, and the deformation degrees among the blank crystals in the pressure stress state are difficult, and the development of various original microdefects of a deformation body can be inhibited; the multi-pass shear extrusion can be carried out, and the final superfine crystal blanks with the uniform deformation can be molded; the shapes and the sizes before and after the deformation are not changed, the repeated multi-pass extrusion deformation can be realized, and the plastic deformation of the blank can be improved obviously.

Owner:TAIYUAN UNIV OF TECH

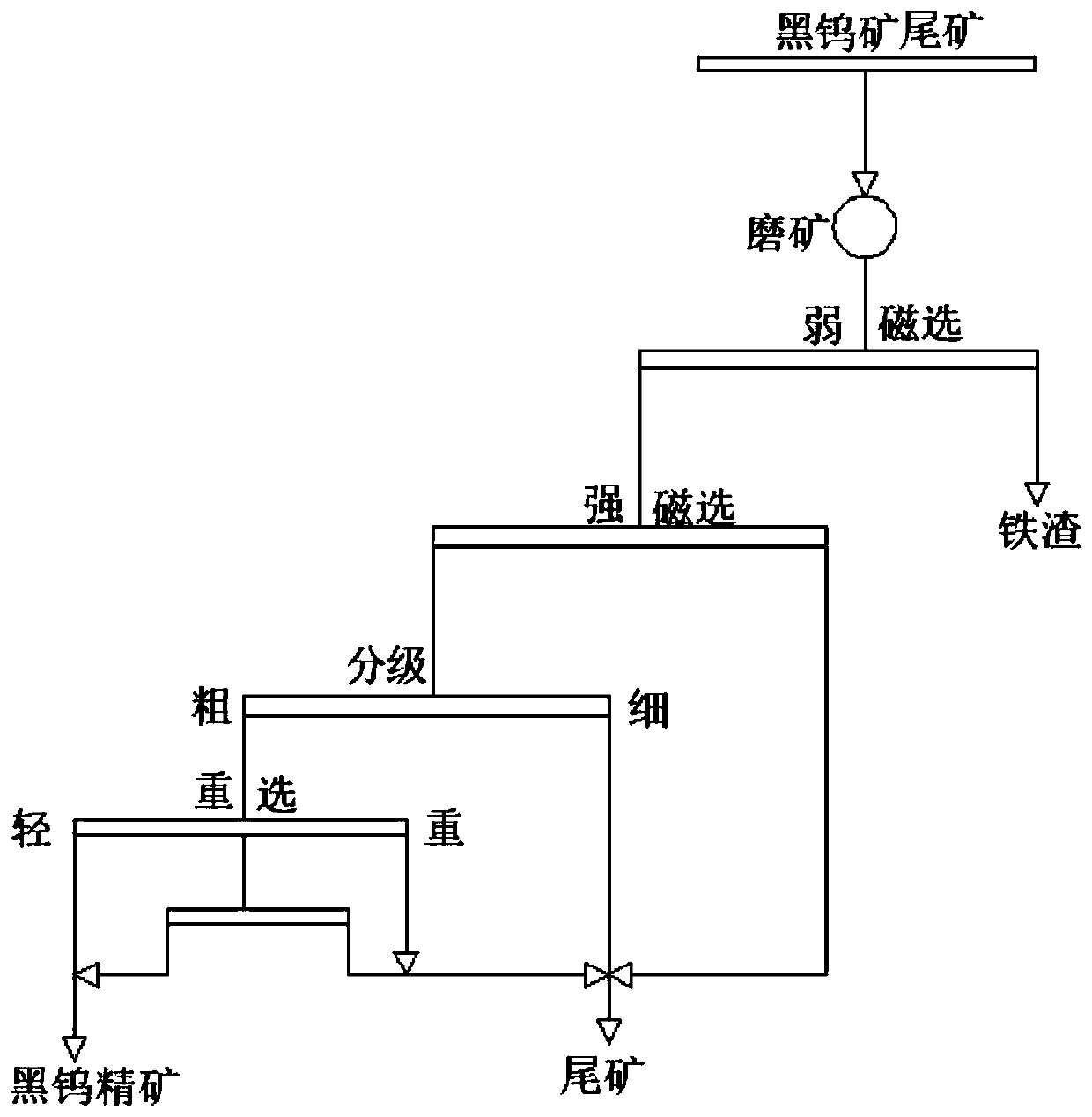

Beneficiation method for recovering wolframite from tailings

InactiveCN110813517AImprove qualityAvoid pollutionMagnetic separationWet separationEngineeringChemical agent

The invention relates to a beneficiation method for recovering wolframite from tailings, and belongs to the technical field of beneficiation recovery. The beneficiation method for recovering wolframite from tailings comprises the steps: (1) grinding wolframite tailings until the -0.075mm content is 70-90%; (2) performing magnetic separation on the materials obtained in the step (1) under the magnetic field intensity of 0.1-0.2T to obtain weak magnetic concentrate and weak magnetic tailings; (3) performing magnetic separation on the weak magnetic tailings obtained in the step (2) under the magnetic field intensity of 0.8-1.4T to obtain strong magnetic concentrate and non-magnetic tailings; (4) classifying the strong magnetic concentrate obtained in the step (3) into two grades of +0.051-0.075 mm, and -0.051-0.075 mm, and taking the coarse fraction therein; and (5) carrying out gravity separation on the materials obtained in the step (4), firstly carrying out roughing separation to obtain roughed concentrate, roughed middlings and roughed tailings, carrying out scavenging separation, wherein the feeding raw materials are the roughed middlings to obtain scavenged concentrate and scavenged tailings, and combining the roughed concentrate with the scavenged concentrate to obtain gravity separation wolframite concentrate. According to the beneficiation method for recovering wolframitefrom tailings, a flotation process which can be adopted in conventional wolframite beneficiation recovery is avoided, any chemical agent does not need to be added, and secondary pollution to the environment is avoided.

Owner:CHANGCHUN GOLD RES INST

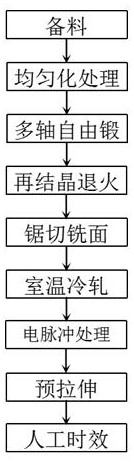

Production process for improving comprehensive performance of aluminum alloy plate

The invention discloses a production process for improving the comprehensive performance of an aluminum alloy plate. The production process comprises the following technological processes of material preparation, homogenization treatment, multi-axis free forging, recrystallization annealing, saw cutting and face milling, room temperature cold rolling, electric pulse treatment, pre-stretching and artificial aging. The production process is convenient to operate, crushing and dissolving of a coarse residual phase and uniform refining of the grain size are effectively promoted by carrying out large plastic deformation multi-axis free forging cogging and recrystallization annealing on a square ingot subjected to grading homogenization treatment, and the anisotropy of the formed plate is obviously reduced. Then room-temperature cold rolling and pre-stretching treatment are conducted on the formed alloy plate, and more defects such as dislocation and vacancy are introduced into an alloy structure; and secondly, electric pulse treatment and artificial aging processes are introduced, so that rapid, sufficient and uniform precipitation of a precipitated phase in the aging process of the alloy can be effectively promoted, it is guaranteed that the alloy obtains higher strength and hardness after heat treatment, and rapid recovery and recrystallization at the grain boundary of the alloy are promoted.

Owner:JIANGSU RIGID BUILDING MATERIALS TECH CO LTD

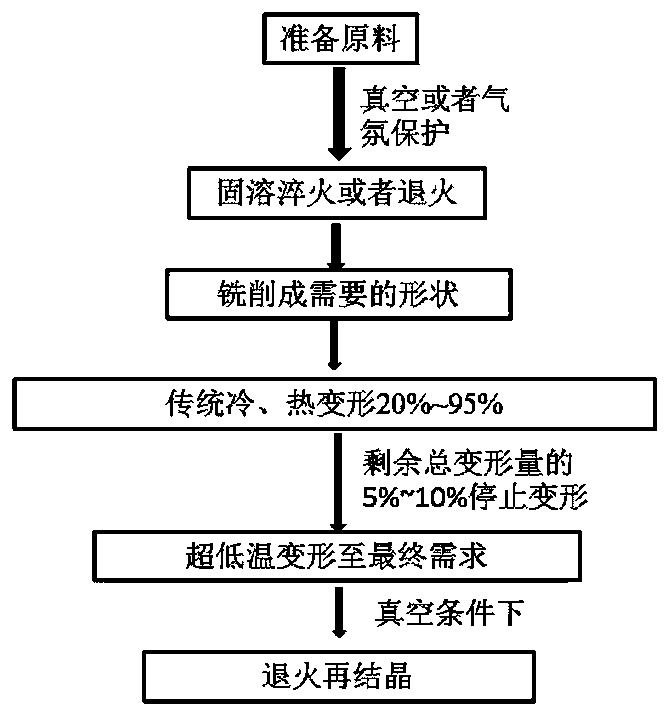

Method for rapidly refining metastable austenite grain structure

ActiveCN111139347AReduced Diffusion Migration AbilityReduce the ability of atomic diffusion and migrationMetallic materialsSS - Stainless steel

The invention relates to the field of metal material processing, in particular to a method for rapidly refining a metastable austenite grain structure. The method can realize metastable austenite grain refinement and rapidly improve the mechanical property and the processing deformation characteristic of original steel, and belongs to the field of metal material processing. According to the method, through the low-temperature effect of the ultralow-temperature environment, the atomic diffusion migration capacity in the material is obviously reduced, and the deformation heat generated in the rolling deformation process is rapidly consumed, so that the occurrence of dynamic recovery or recrystallization in the rolling process is effectively inhibited, the structure is remarkably refined, meanwhile, deformation defects such as dislocation, dislocation cells / walls and substructures are continuously accumulated to reach high density, and meanwhile, the metastable austenitic stainless steelcan be more rapidly converted into martensite through the low-temperature effect, the grain structure of the martensite is finer, annealing treatment is conducted through fine martensite grains, and finally austenite structure with refined grains is obtained.

Owner:河南盾刀智能科技有限公司

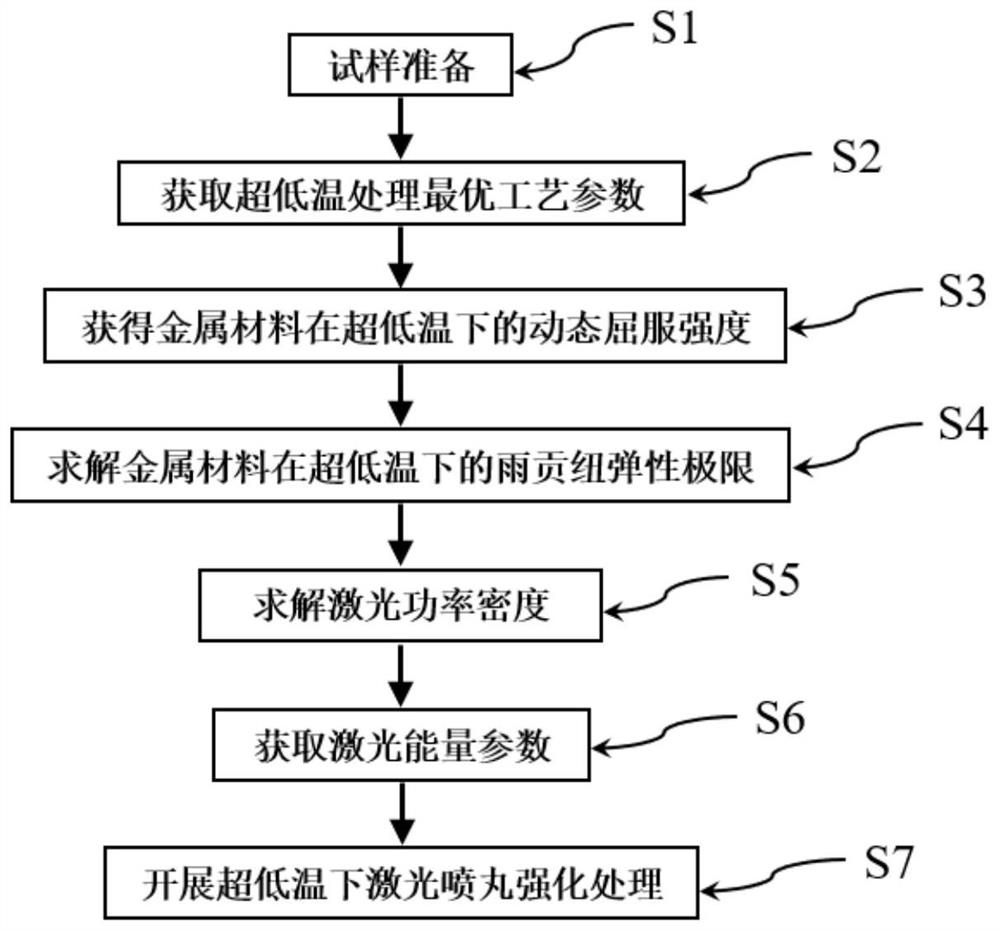

Method for strengthening vibration fatigue performance of metal material by laser peening and ultralow temperature coupling

PendingCN112877536AIncreased metal damping capacityImprove toughnessMetallic materialsLaser power density

The invention discloses a method for strengthening vibration fatigue performance of a metal material by laser peening and ultralow temperature coupling, and relates to the technical field of laser machining and surface strengthening of the metal material. The method mainly comprises the following steps of (1) preparing a sample; (2) acquiring optimal technological parameters of ultralow-temperature treatment; (3) obtaining the dynamic yield strength of the metal material at the ultralow temperature; (4) solving the hugoniot elastic limit of the metal material at the ultralow temperature; (5) solving the laser power density; (6) acquiring laser energy parameters; and (7) carrying out laser peening strengthening treatment at the ultralow temperature. According to the method, the dynamic recovery and annihilation inhibition effects of the ultralow temperature are utilized, so that the dislocation density is improved; by adopting the coupling effect of the ultralow temperature and the ultrahigh strain rate, the dislocation slippage is inhibited, and the nanometer deformation twin crystal nucleation driving force is improved; and the damping capacity and fracture toughness of the metal material are improved by utilizing the interaction between dislocation and nanometer deformation twin crystals, so that the vibration fatigue resistance is remarkably improved.

Owner:CHANGZHOU UNIV

High-quality aluminum alloy for semiconductor and preparation method of high-quality aluminum alloy

The invention relates to a preparation method of a high-quality aluminum alloy for a semiconductor. The preparation method comprises the following steps of: step 1, obtaining an aluminum alloy cast ingot by adopting a semi-continuous casting process; 2, homogenizing the aluminum alloy cast ingot by adopting a multi-stage homogenizing heat treatment process; 3, carrying out cryogenic treatment on the homogenized aluminum alloy cast ingot; 4, after the cryogenic treatment, subjecting the aluminum alloy cast ingot to low-forging-frequency, high-forging-ratio and intermediate stress relief annealing iterative forging; and 5, sequentially carrying out high-temperature short-time solid solution treatment, finishing and low-temperature long-time aging treatment on the forged piece obtained in thestep 4 to obtain the high-quality aluminum alloy for the semiconductor. By means of the method, dynamic recovery, dynamic recrystallization and sub-dynamic recrystallization of an alloy structure inthe forging deformation process are well restrained, the grain refinement effect on the structure is remarkable, the performance is excellent, the plasticity level is better, and the machining performance is excellent.

Owner:宁波锦越新材料有限公司

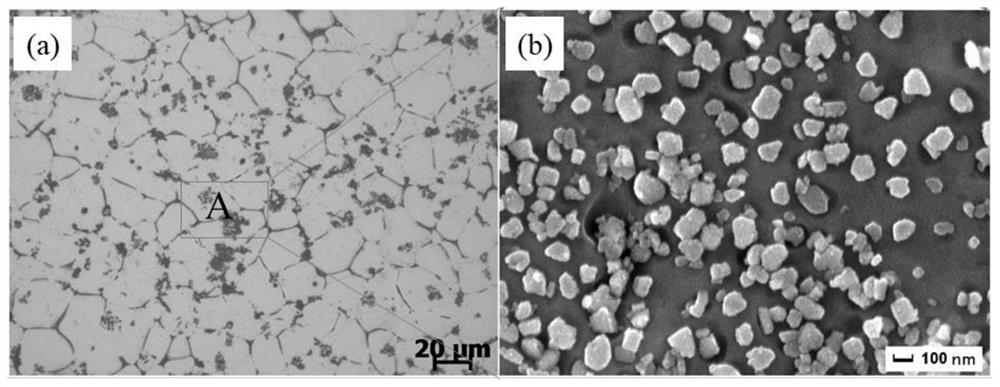

High-strength high-toughness weldable in-situ nano-reinforced rare earth aluminum alloy and preparation method thereof

The invention relates to an aluminum alloy material, in particular to a high-strength high-toughness weldable in-situ nano-reinforced rare earth aluminum alloy and a preparation method thereof. According to the high-strength high-toughness weldable in-situ nano-reinforced rare earth aluminum alloy and the preparation method, in-situ nano ceramic particles and rare earth elements are simultaneously introduced into the Al-Zn-Mg alloy, and therefore crystal grains can be effectively refined, the strength and toughness of the alloy are remarkably improved, the recrystallization temperature of the alloy can be remarkably improved through the rare earth nano precipitated phase and the in-situ nano particles which are distributed in the crystal / grain boundary, dynamic recovery is effectively inhibited, redissolution of alloy elements is reduced, and the weldability of the alloy is improved.

Owner:JIANGSU UNIV

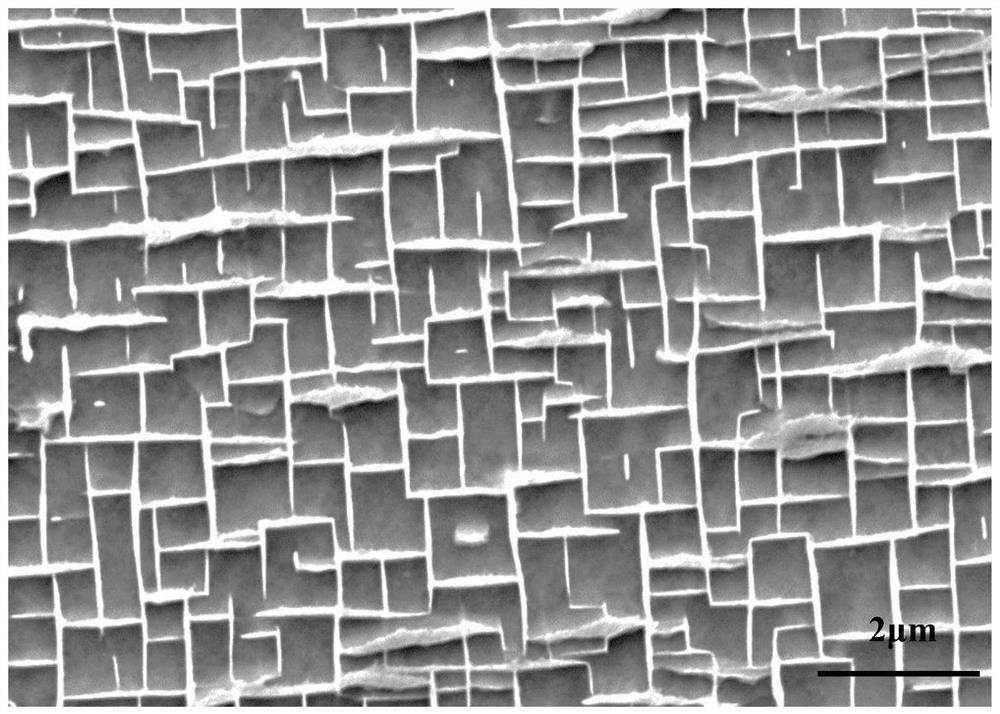

Anti-recrystallization method in repair process of turbine blade after service

ActiveCN113699347AInhibition of recrystallizationReduce dislocation densityFurnace typesHeat treatment process controlSolution treatmentTurbine blade

The invention belongs to the technical field of turbine blade repair treatment, and provides an anti-recrystallization method in the repair process of a turbine blade after service. The recrystallization behavior of the turbine blade in the repairing process after service is mainly caused by the fact that after the alloy is subjected to the high-temperature and high-load service process, the alloy structure degenerates, and a large number of dislocation structures generated due to high-temperature creep deformation are contained in the alloy structure. And when the turbine blade is in a recovery heat treatment process higher than the recrystallization temperature after service, dislocation rearrangement forms a large-angle grain boundary, and the large-angle grain boundary rapidly migrates to finally form recrystallized grains. According to the method, one-step anti-recrystallization heat treatment is carried out before solution treatment, a large number of dislocation existing in the alloy is pre-recovered, the dislocation density is reduced, and therefore recrystallization of the alloy in the subsequent heat treatment process is inhibited.

Owner:BEIHANG UNIV

Smelting method for high-purity low-oxygen recovery sputtering target material

InactiveCN110923641AReduce oxygen contentImprove use valueVacuum evaporation coatingSputtering coatingSputteringIngot casting

The invention discloses a smelting method for a high-purity low-oxygen recovery sputtering target material. The smelting method comprises the following specific steps: 1) a recovered target material and high-purity low-oxygen metal crystals / powder are detected and analyzed; 2) the number of layers of the recovered target materials after a bin is fully paved with the recovered target materials is calculated according to the calculated dosage ratio, the bin length and the length of the recovered target material; 3) the high-purity low-oxygen metal crystal / powder is uniformly mixed and is pressedinto a block; 4) the recycled target material and the block body are stacked and fully pave the bin; and 5) the stacked recycled target materials and blocks are put into an electron beam smelting furnace for smelting and ingot casting. According to the method, the oxygen content of the recovered target remelting cast ingot is effectively reduced, the metal impurity content is balanced, cast ingotcomponents are distributed uniformly and stably and meet the requirements of industries such as semiconductors, the utilization value of the recovered target material is improved, and the productivity of high-purity metal is improved; moreover, the adopted equipment is existing equipment, extra investment is not needed, the cost is low, and the operation is simple.

Owner:成都建极微波技术有限公司

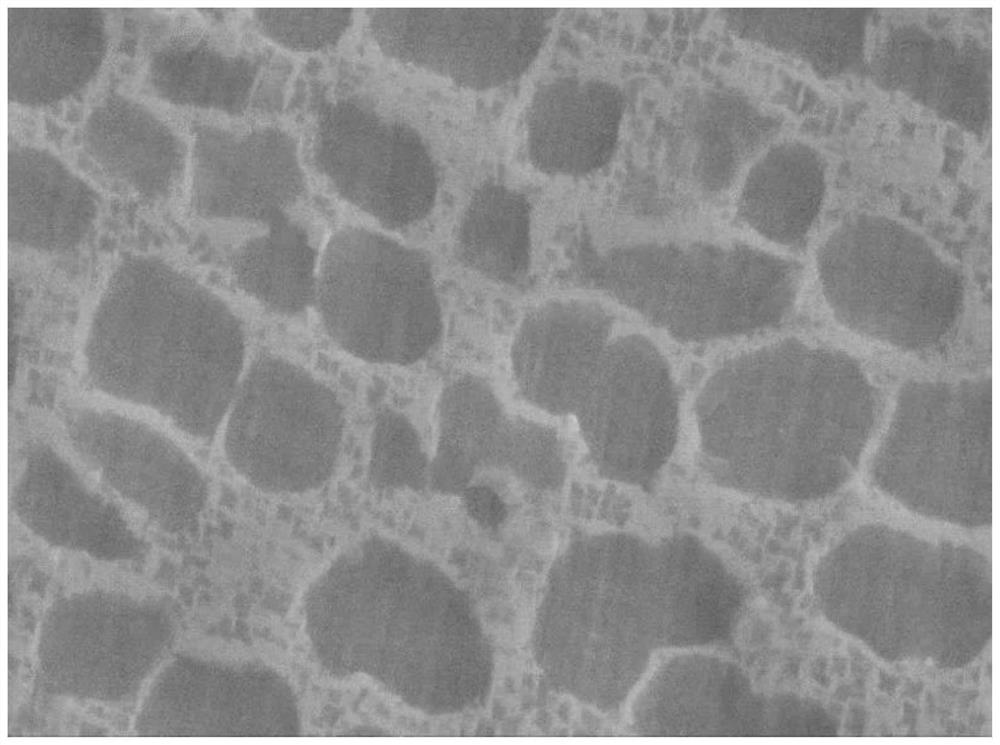

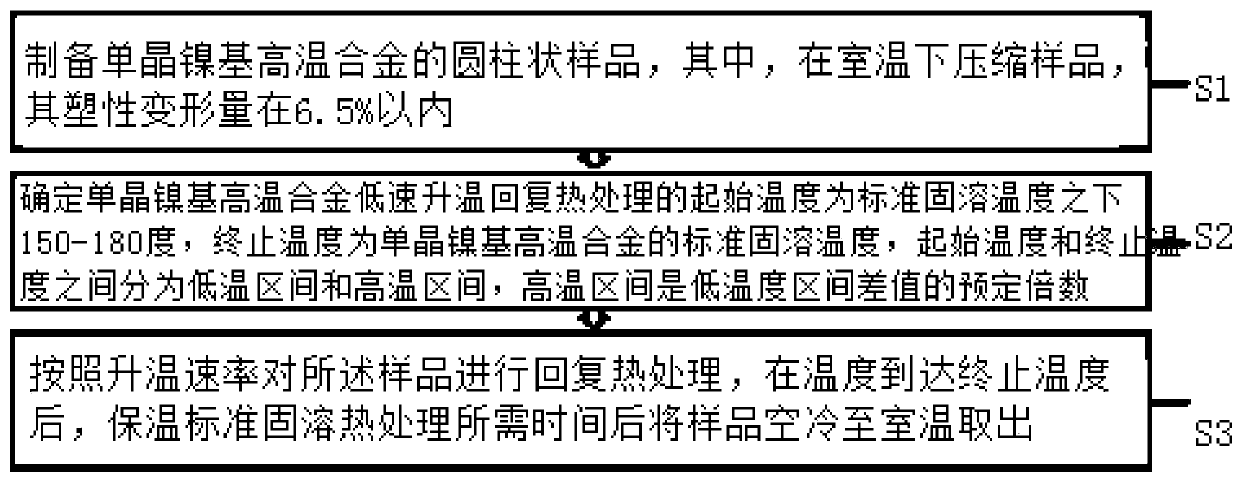

Heat treatment method single-crystal nickel-based high-temperature alloy after cold deformation

ActiveCN110760770AReduce deformation energy storageEnough timeFurnace typesHeat treatment furnacesScanning electron microscopeSingle crystal

The invention discloses a heat treatment method a single-crystal nickel-based high-temperature alloy after cold deformation. The method comprises the following steps that a cylindrical sample of the single-crystal nickel-based high-temperature alloy is prepared, wherein the sample is compressed at room temperature, the plastic deformation ainstall of the single-crystal nickel-based high-temperature alloy is 6.5% or within, and the starting temperature of the low-speed heating recovery heat treatment of the single-crystal nickel-based high-temperature alloy is determined to be 150-180 DEG C below a standard solid solution temperature, the termination temperature is the standard solid solution temperature of the single-crystal nickel-based high-temperature, the part between the starting temperature and the termination temperature is divided into a low temperature interval and a high temperature interval, the temperature difference value of the high temperature interval is a predeterminedmultiple of the temperature difference value of the low temperature interval, the sample is subjected to the recovery heat treatment according to the temperature rise rate, after the temperature reaches the termination temperature, the sample is air cooled to room temperature and taken out after the time required for the solid solution heat treatment, and the taken-out sample is subjected to microscopic tissue morphology characterization by using a scanning electron microscope to detect the size and shape of the precipitated reinforced phase gamma' phase in the sample and determine the occurrence of no recrystallization texture.

Owner:XI AN JIAOTONG UNIV

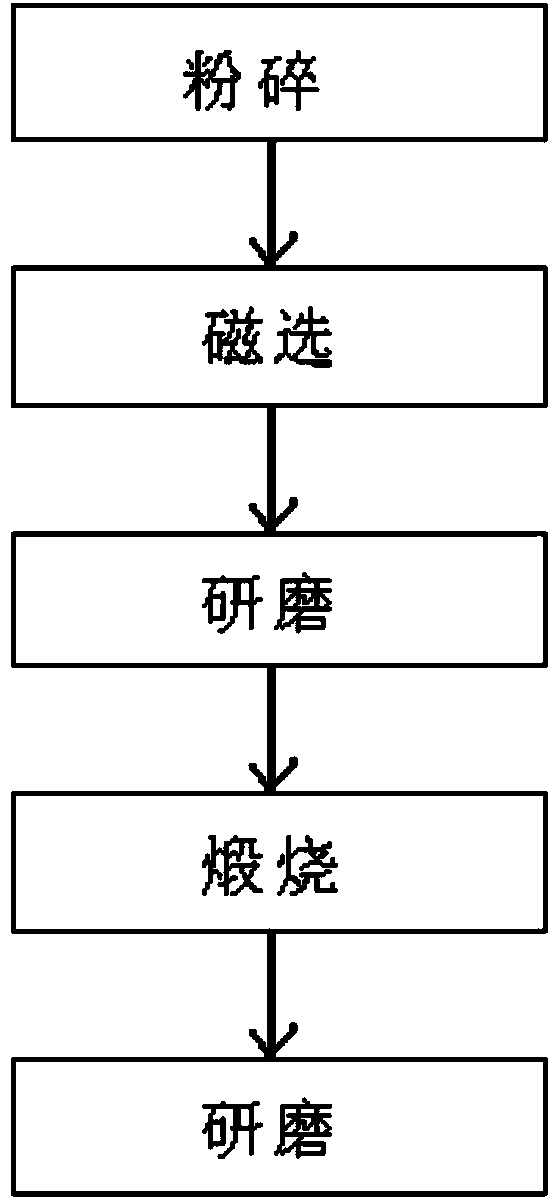

Low-grade magnesite selective dissociation equipment and method

The invention provides a low-grade magnesite selective dissociation method. The method comprises the following steps: (1) crushing the low-grade magnesite to be particles with size of 1-10mm; (2) placing the magnesite crushed in the step (1) in a magnetic separator for magnetic separation under the magnetic field intensity of 2-5T; (3) grinding the magnesite obtained in the step (2) into powder with size less than 200 meshes and the mass content more than 60%, sieving by a 200-mesh screen, thus obtaining screen underflows; (4) calcining the magnesite obtained in the step (3) at 600-900 DEG C for 40-180min to obtain light roasting powder; and (5) grinding the light roasting powder obtained in the step (4) into powder with size less than 200 meshes and the mass content of more than 97%, sieving by a 200-mesh screen, thus obtaining screen underflows which are high-grade magnesite concentrate. The low-grade magnesite selective dissociation method has scientific and reasonable steps, and solves the problems that the magnesium oxide recovery rate is low and environment pollution is caused easily in the prior art.

Owner:营口东吉科技(集团)有限公司

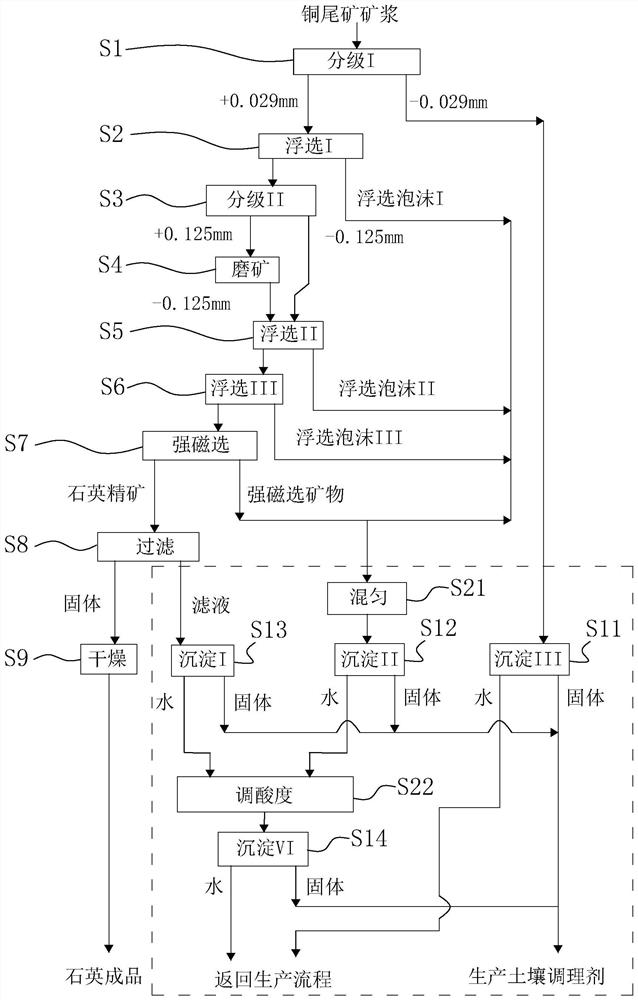

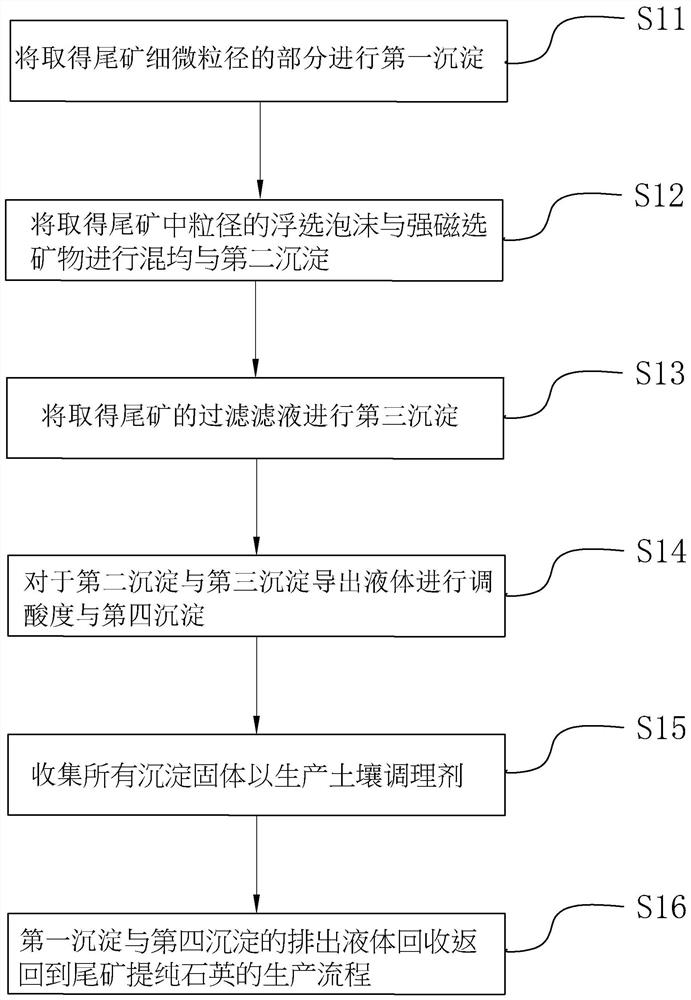

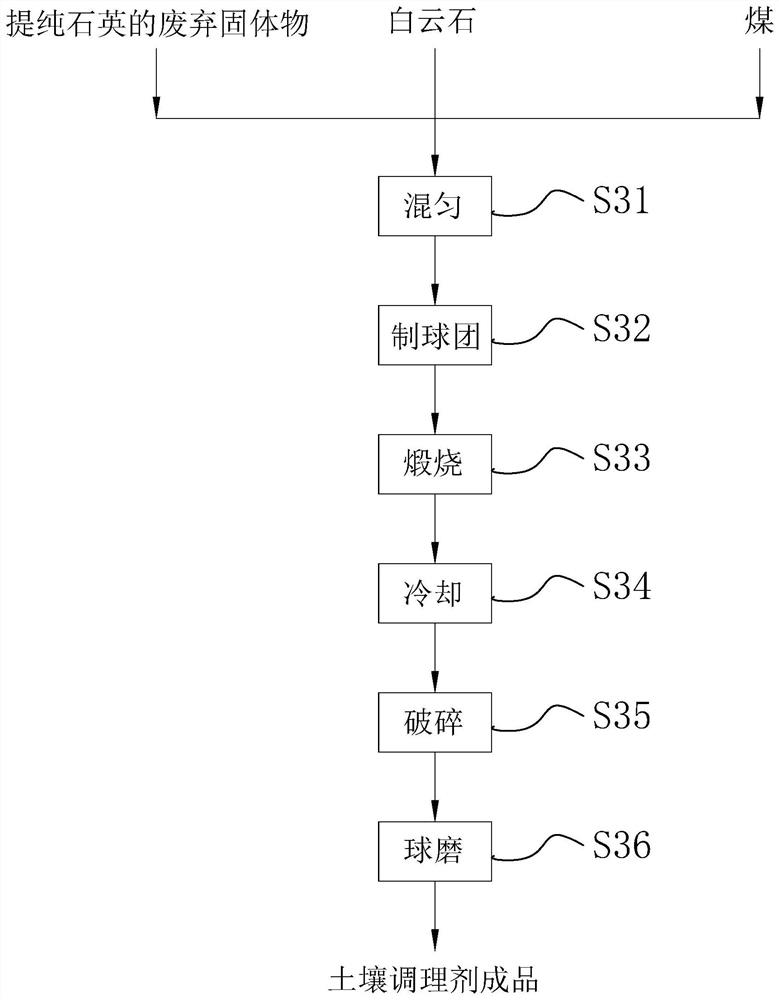

Method and device for purifying quartz in non-ferrous metal tailings

InactiveCN112090576AAchieving zero waste solidsReduce dosageWet separationChemical reactionSilicon oxide

The invention relates to a method and a device for purifying quartz in non-ferrous metal tailings. The method comprises the following steps of setting a flotation particle size lower limit and a flotation particle size upper limit; carrying out different treatment to ensure that tailings with ultra-fine particle size do not participate in a flotation process and a grinding process; separating tailings with ultra-coarse particle size, and carrying out individual grinding; carrying out a pre-flotation process before only grinding the tailings with ultra-coarse particle size; separating out non-quartz impurities; and then combining the ground tailings with the separated tailings with proper particle sizes, and carrying out post-flotation, high-intensity magnetic separation and filtration to finally obtain a quartz concentrate finished product with the silicon oxide purity of 90% or above. The method and the device have the effects that the quartz with standard inner particle siz is purified from the non-ferrous metal tailings, and heating and chemical reaction are not needed. And on the other hand, a non-trunk recovery process can be performed in the quartz purification process to produce a soil conditioner, thereby implementing the effects of no waste and zero wastewater discharge.

Owner:深圳市考拉生态科技有限公司

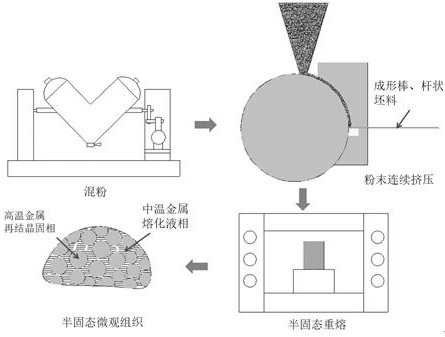

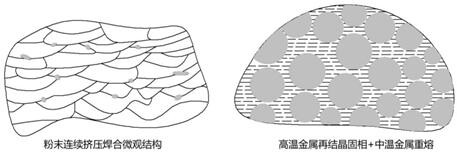

Method for preparing alloy semi-solid thixotropic blank by continuously extruding elementary substance mixed powder

ActiveCN113000842AReduce manufacturing costShorten the production cycleIncreasing energy efficiencySolid structureSemi solid

The invention discloses a method for preparing an alloy semi-solid thixotropic blank by continuously extruding elementary substance mixed powder, and belongs to the technical field of material processing. According to the method, two or more kinds of elementary substance mixed powder is evenly mixed and conveyed into a groove of a continuous extrusion wheel, the powder in a female die is crushed, rubbed, extruded and welded to form a block material after passing through the female die, the block material is cut out according to the equal volume of a target part, heat preservation is carried out for a certain time near the melting point of low-melting-point elementary substance metal, the low-melting-point powder begins to melt, recovery recrystallization occurs in a welding area of the high-melting-point powder, and a semi-solid structure with a high-melting-point solid phase as a framework and a low-melting-point liquid phase distributed between is formed. According to the method, metal powder continuous extrusion and a strain-induced melting activation method are combined, the short-process and batch semi-solid alloy blank making method is achieved, the semi-solid thixotropic temperature of the alloy can be reduced, and energy consumption and the cost of a tool mold are reduced.

Owner:KUNMING UNIV OF SCI & TECH

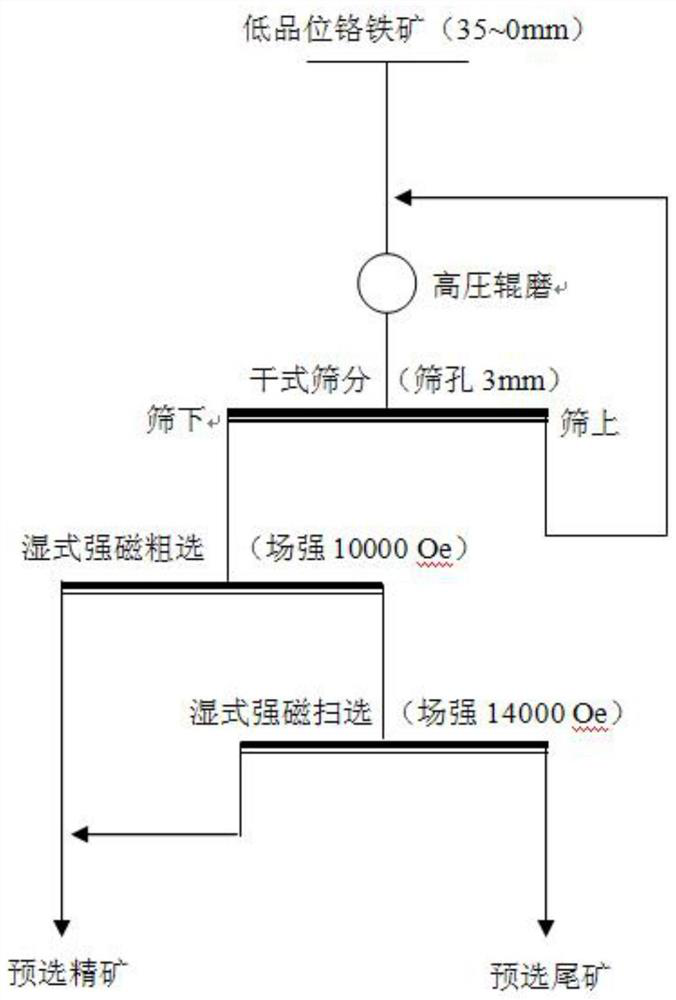

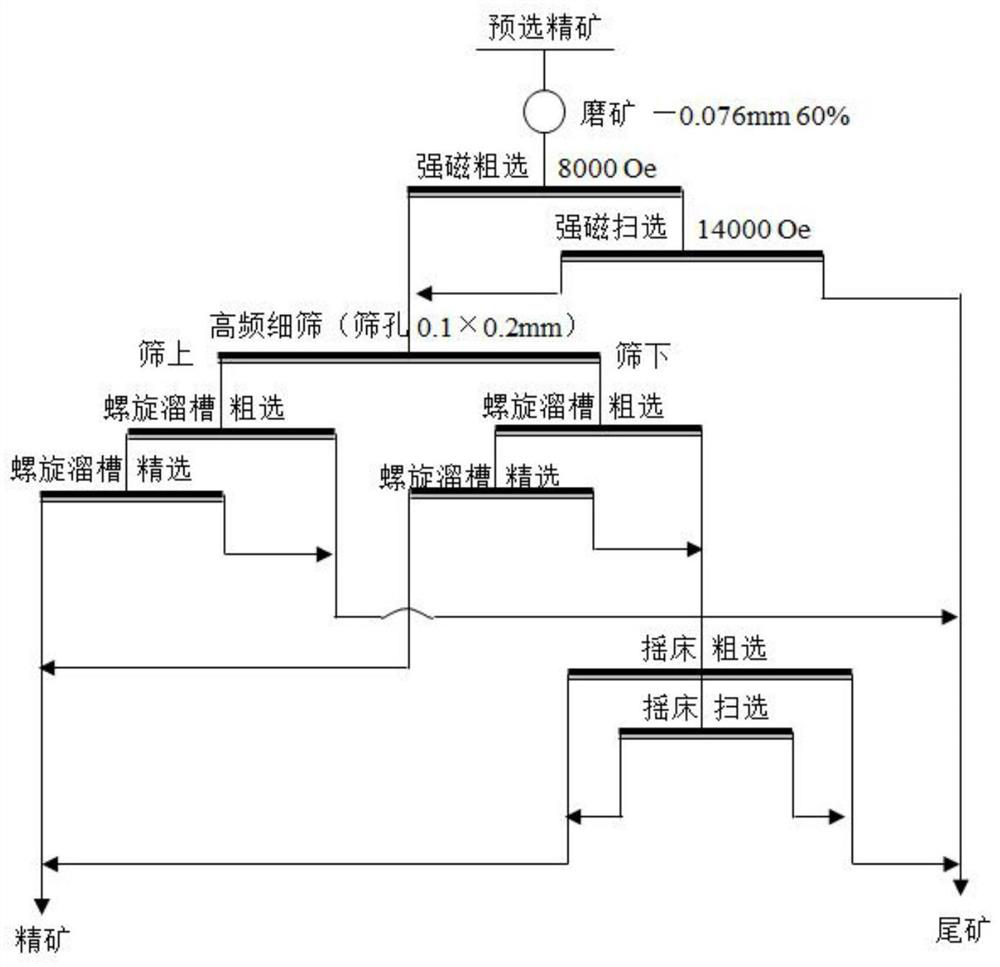

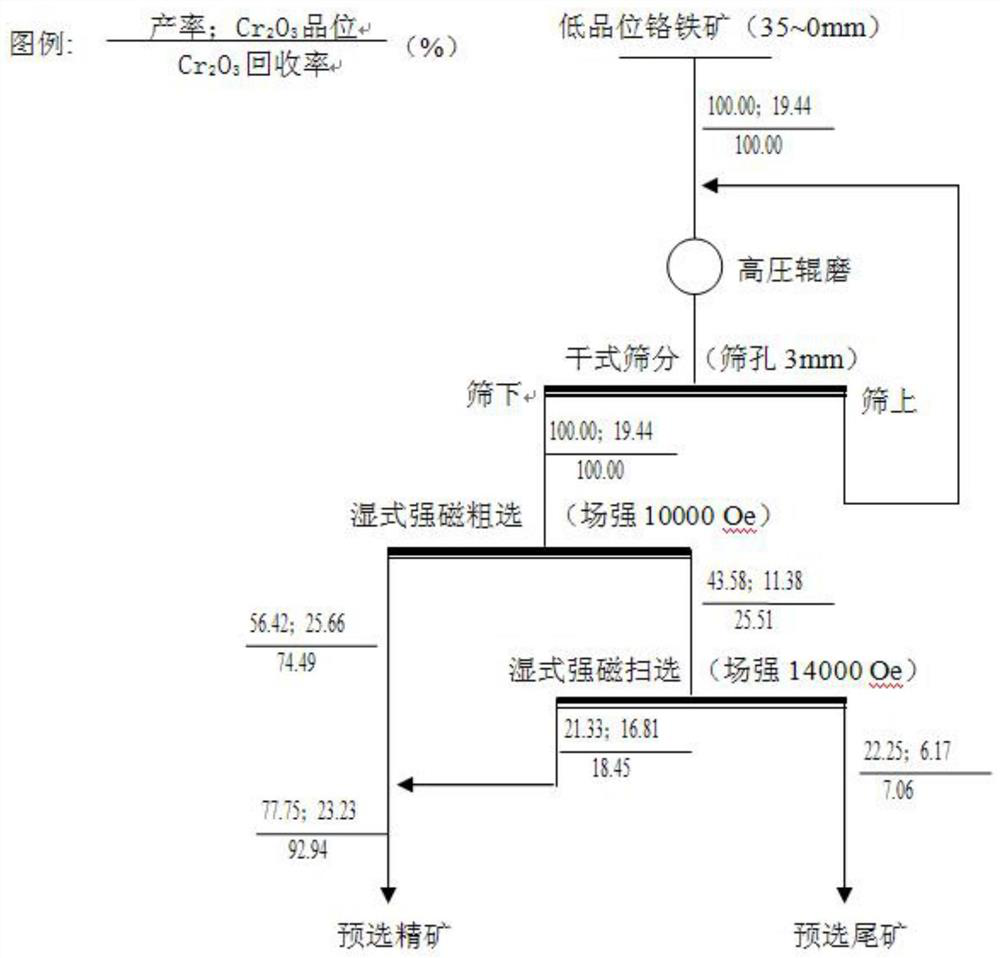

Beneficiation method for stepped recovery and segmented tailing discarding of low-grade chromite

ActiveCN113941433AReflect the concept of energy-saving mineral processingEasy to handleSolid separationMechanical material recoveryIndustrial engineeringChromium

The invention discloses a beneficiation method for stepped recovery and segmented tailing discarding of low-grade chromite, and the technological process of high-pressure roller grinding, coarse grain wet-type strong magnetic pre-concentration, ore grinding, wet-type strong magnetic tailing discarding, strong magnetic concentrate thickness grading, spiral chute refining and middling table re-concentration is researched and developed. A high pressure roller mill is adopted as ultrafine crushing equipment, and has the characteristics of large crushing ratio, low energy consumption, high product fine fraction content and the like; and the pre-selected tailings can be sold as building material products due to relatively large granularity. According to the beneficiation method for the stepped recovery and segmented tailing discarding of the low-grade chromite provided by the invention, a wet-type strong magnetic one-roughing and one-sweeping pre-selection process is adopted, so that the treatment granularity is fine, the adaptability is high, the tailing discarding yield is high, and the metal loss rate is low. The low-grade chromite with the Cr2O3 grade being 19.44% is treated through the method, the chromium concentrate with the Cr2O3 grade being 43.87% and the Cr2O3 recovery rate being 67.28% can be obtained, and the method has the advantages of being large in system treatment capacity, large in coarse grain tailing discarding yield, high in adaptability, capable of saving energy and environmentally friendly.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +2

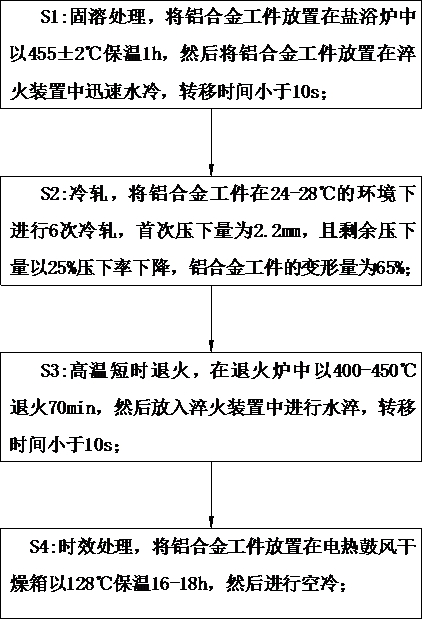

Heat treatment method for deformation of high-toughness aluminum alloy

ActiveCN114717492AHeating up fastPrevent oxidationFurnace typesProcess efficiency improvementUltimate tensile strengthToughness

The invention belongs to the technical field of aluminum alloy heat treatment, and discloses a heat treatment method for deformation of a high-toughness aluminum alloy. Comprising the following steps: preserving the heat of an aluminum alloy workpiece at 455 + / -2 DEG C for 1 hour, and quickly cooling in a quenching device; cold rolling is conducted for 6 times in the environment of 24-28 DEG C, the first rolling reduction is 2.2 mm, and the remaining rolling reduction is reduced by 25%; annealing at 400-450 DEG C for 70 minutes, and then carrying out water quenching; and keeping the temperature at 128 DEG C for 16-18 hours, and then carrying out air cooling. According to the method, the recrystallization nucleation rate of the deformed alloy is remarkably increased through high-temperature annealing, rapid recovery and recrystallization of the alloy occur, coarsening growth of a precipitated phase can be inhibited through short-time heat preservation, recrystallization grains can be inhibited from growing, then a high-supersaturation-degree fine grain structure is obtained, finally aging treatment is conducted, a large number of solute atoms are precipitated, and therefore the high-supersaturation-degree fine grain structure is obtained. The strength of the alloy is further improved, and the plasticity and toughness of the alloy are remarkably improved through good matching of a fine grain structure and a precipitated phase.

Owner:南通雨奇金属制品有限公司

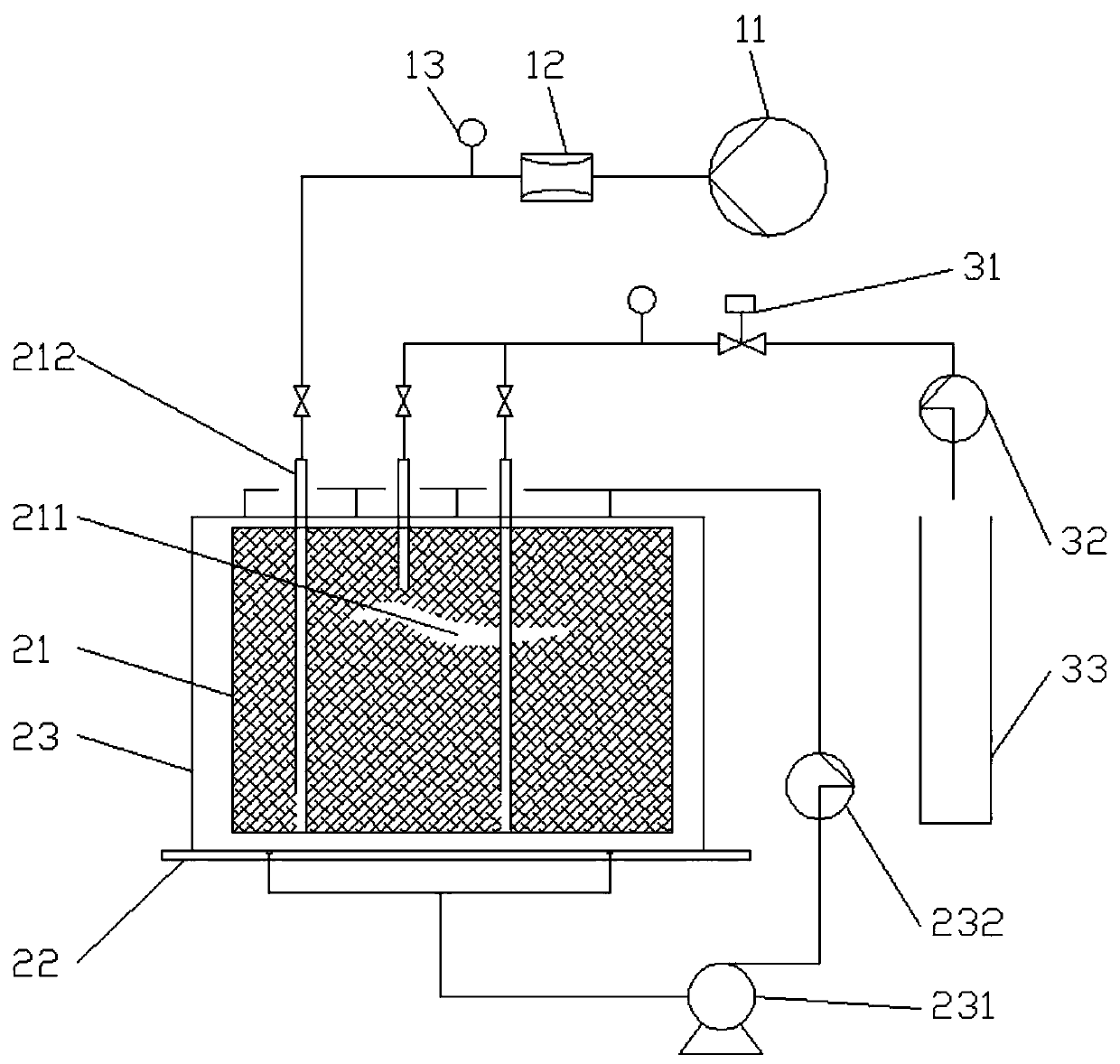

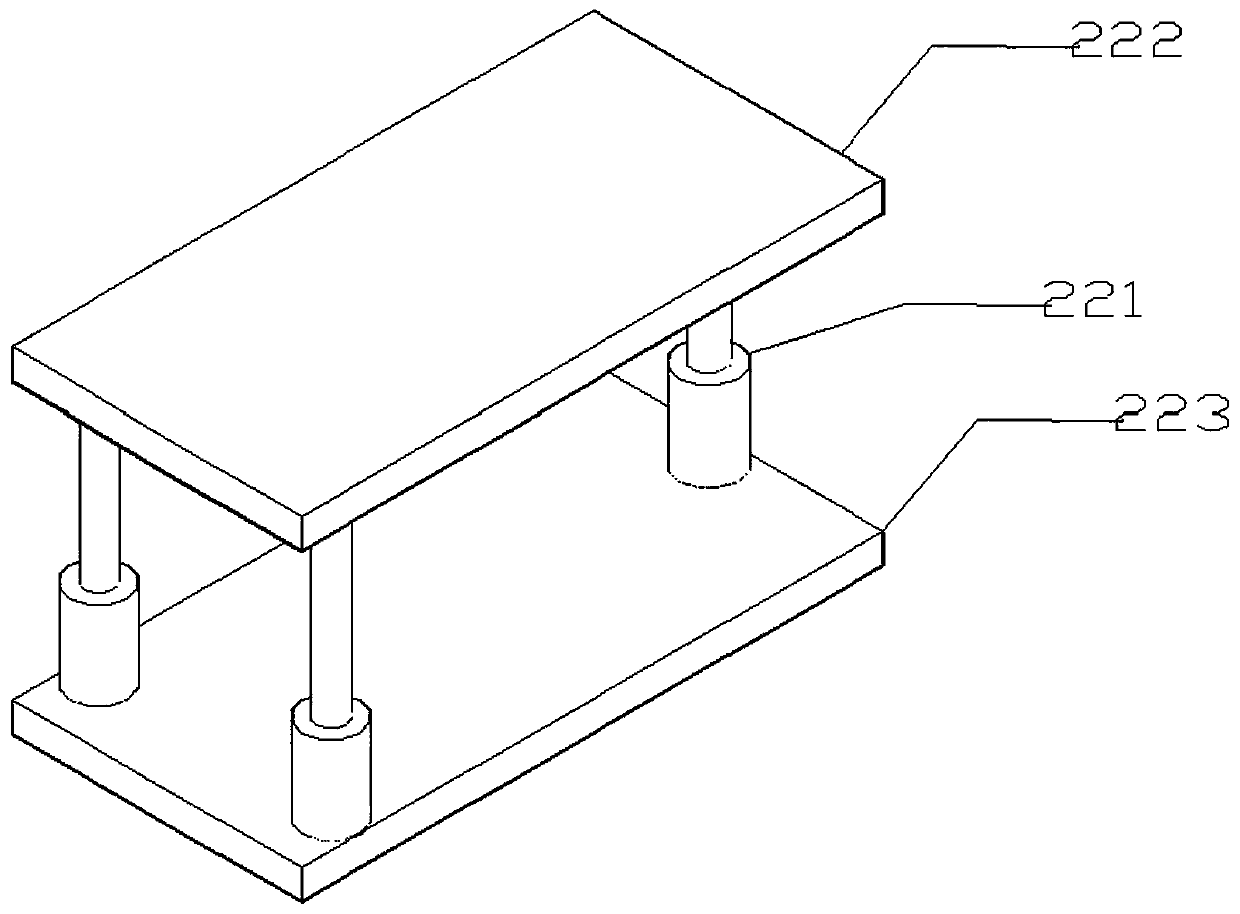

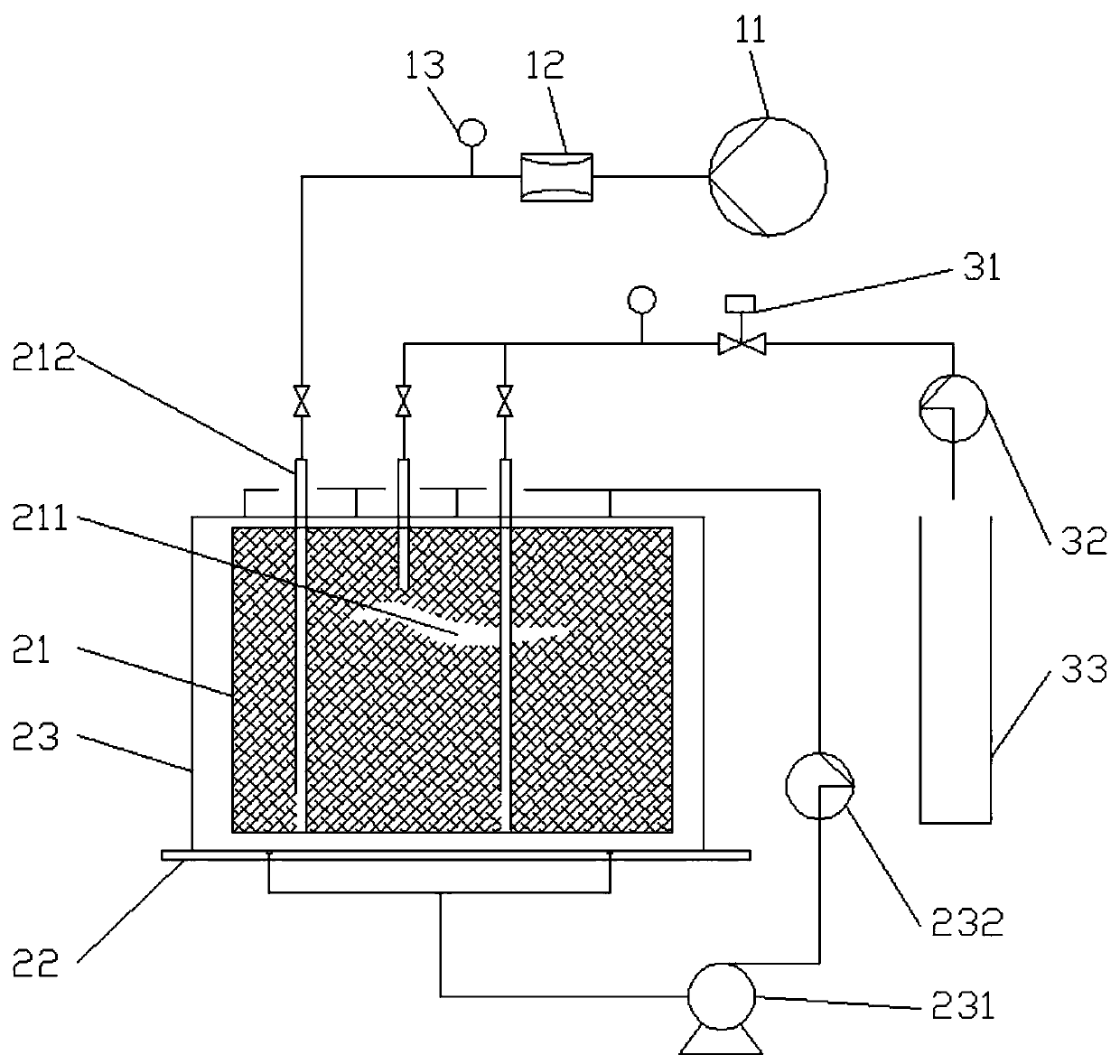

Experimental device for evaluating influence of interlayer and injection-production point on recovery ratio of thick-layer oil reservoir

The invention discloses an experimental device for evaluating influence of interlayer and injection-production point on recovery ratio of thick-layer oil reservoir. The experimental device comprises an injection part, a sand filling model part and a displacement product metering part which are connected in sequence, the sand filling model part comprises a sand filling box and an inclinable supporting frame, the sand filling box is filled with quartz sand, a low-permeability block is buried in the quartz sand, and the displacement product metering part is connected with the sand filling box, for simulating an interlayer; at least three simulation wellbores are further inserted into the sand filling box, the well bottom of one simulation wellbore is located above the low-permeability block,the well bottoms of the other two simulation wellbores are located below the low-permeability block, at least one simulation wellbore penetrates through the low-permeability block, during experiment,simulated wellbore can be optionally selected as injection well and production well, the influence of different displacement positions on the recovery ratio can be simulated; and the sand filling boxis located on the inclinable supporting frame, so that the inclination angle of the sand filling box can be adjusted, and the influence of interlayers with different inclination angles on the recoveryefficiency is simulated.

Owner:SOUTHWEST PETROLEUM UNIV

Preparation method of alloy mold with heat resistance stability and impact resistance

The invention belongs to the technical field of alloy mold preparation, and particularly relates to a preparation method of an alloy mold with heat resistance stability and impact resistance. The preparation method comprises the steps of alloy matching, smelting, forging and annealing, H2-H2O atmosphere treatment and nanocrystallization treatment. Compared with the prior art, the preparation method has the following beneficial effects that the comprehensive service performance and service behavior of an alloy material can be improved through treatment in the H2-H2O atmosphere; under the low temperature condition, through small-grain-size steel shot impacting, dynamic recovery and recrystallization happen to an obtained nanolayer in the forming process; hardness distribution of the cross section metallographic structure and hardness distribution from the surface to a matrix are in changes of gradient, and the surface layer hardness reaches up to 3 times of the matrix or above; the heatresistance and corrosion resistance of an obtained product are both improved; the special use requirements of large loads and the long service life under the high temperature environment can be met; the service life of the mold can be prolonged; in the whole preparation process, conditions are easy to control; the thickness of a nitride effective infiltrated layer is remarkably increased; and thepreparation method is suitable for being popularized.

Owner:蚌埠市华鼎机械科技有限公司

Preparation method for reducing hot shrinkage rate of Cu-Ni-Si alloy

PendingCN113249666ALow heat shrinkageHigh strengthFurnace typesMetal rolling arrangementsSilicon alloyStress relaxation

The invention relates to new materials, belongs to the non-ferrous metal processing industry, and particularly relates to a preparation method for reducing the hot shrinkage rate of a Cu-Ni-Si alloy. According to the method, the hot shrinkage rate of the Cu-Ni-Si alloy is reduced so as to meet the requirements for materials applied to high-angle lead frames and image electronic components. The preparation method for reducing the hot shrinkage rate of the Cu-Ni-Si alloy comprises the process steps of semi-continuous ingot casting, ingot heating, hot rolling, first solution treatment, surface milling, first cold rolling, edge cutting, first aging annealing, cleaning, second cold rolling, second solution annealing, third cold rolling, third aging annealing, cleaning, fourth cold rolling, cleaning, withdrawal and straightening and slitting in sequence. According to the method, technical treatment is carried out on the basis of a traditional process, on the premise of ensuring the properties of high strength, high elasticity, medium conductivity, low stress relaxation and the like of the material, different solid solution plus aging heat treatment plus cold rolling plus finishing treatment processes are adopted, the density change in recovery and recrystallization is controlled, and the hot shrinkage rate of the product is reduced.

Owner:TAIYUAN JIN XI CHUNLEI COPPER CO LTD

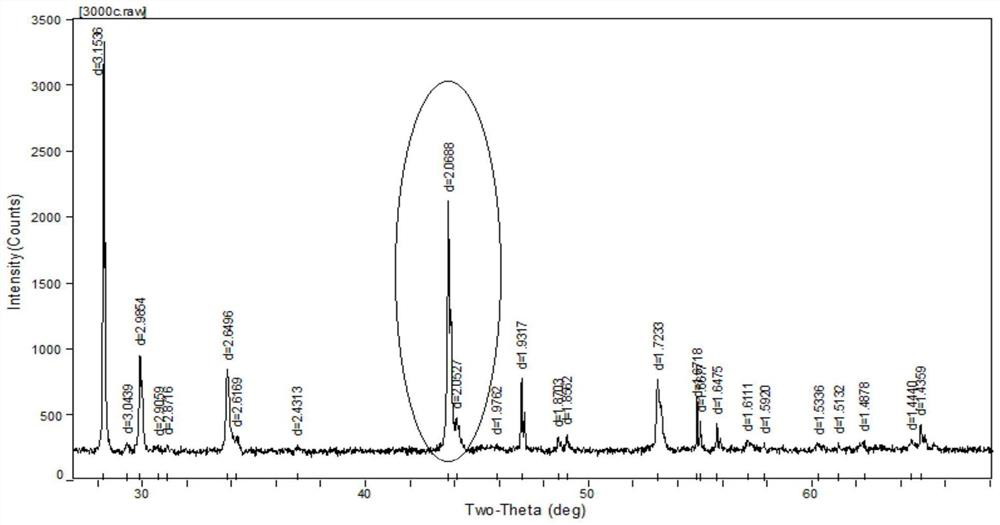

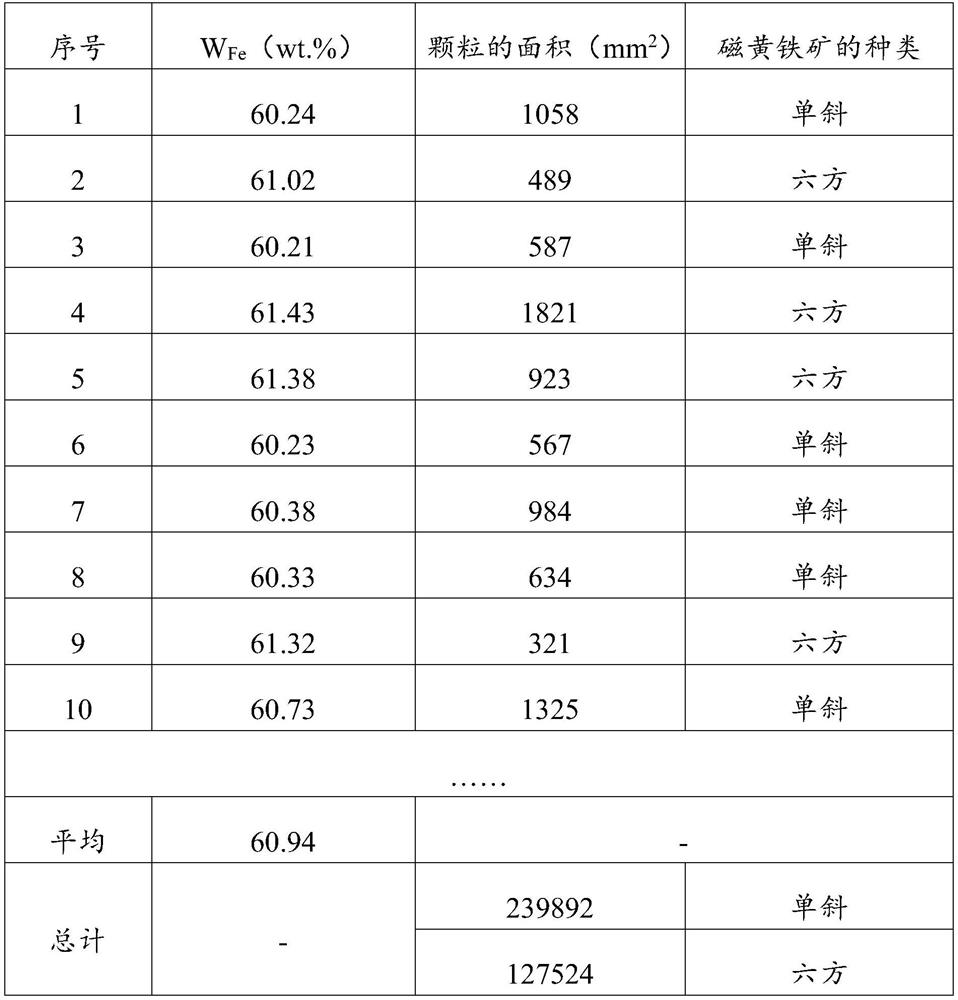

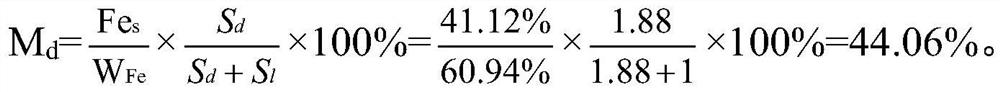

Prediction method for yield and recovery rate of pyrrhotite and application thereof

PendingCN114708926AReduce forecast errorImprove accuracyMolecular entity identificationForecastingCrystal structureComputational physics

The invention relates to the technical field of mineral processing, in particular to a prediction method for the yield and recovery rate of pyrrhotite and application of the prediction method. The prediction method comprises the following steps: judging the crystal structure type of pyrrhotite in to-be-treated ore, and calculating the content Md of monoclinic pyrrhotite and / or the content M1 of hexagonal pyrrhotite in the to-be-predicted ore; counting the number of monoclinic pyrrhotite and / or hexagonal pyrrhotite particles in the to-be-predicted ore in different particle size ranges, counting the maximum particle size value and the minimum particle size value in each particle size range, and then calculating a variable D according to the counting result; the content Kd of monoclinic pyrrhotite with the particle size smaller than 0.02 mm and / or the content K1 of hexagonal pyrrhotite with the particle size smaller than 0.02 mm in the to-be-predicted ore are / is calculated; and respectively calculating the maximum yield and the maximum recovery rate of the pyrrhotite. The error of the theoretical maximum yield and the theoretical maximum recovery rate calculated by the prediction method is small.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

A method for mass production of low-iron quartz dry sand

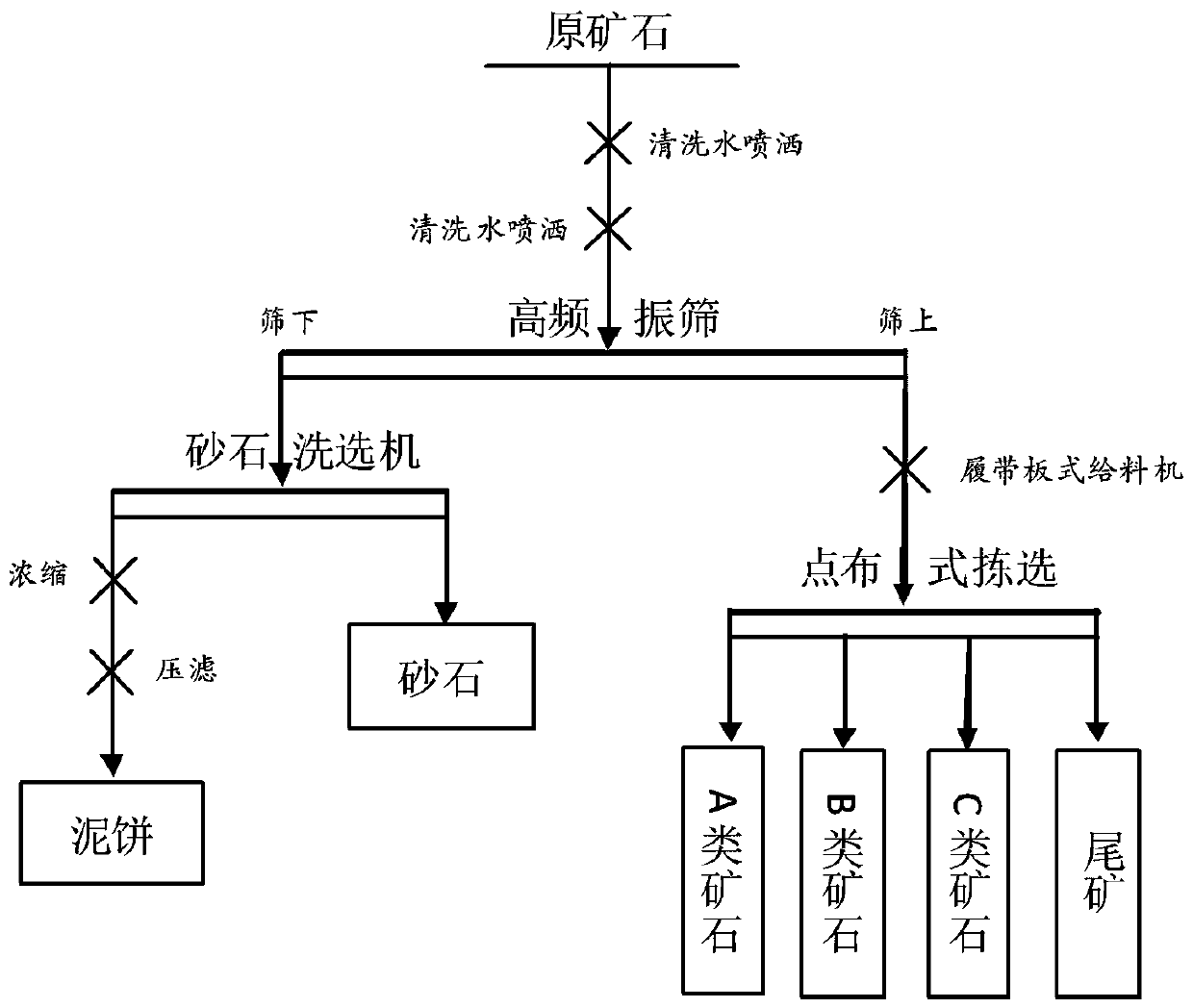

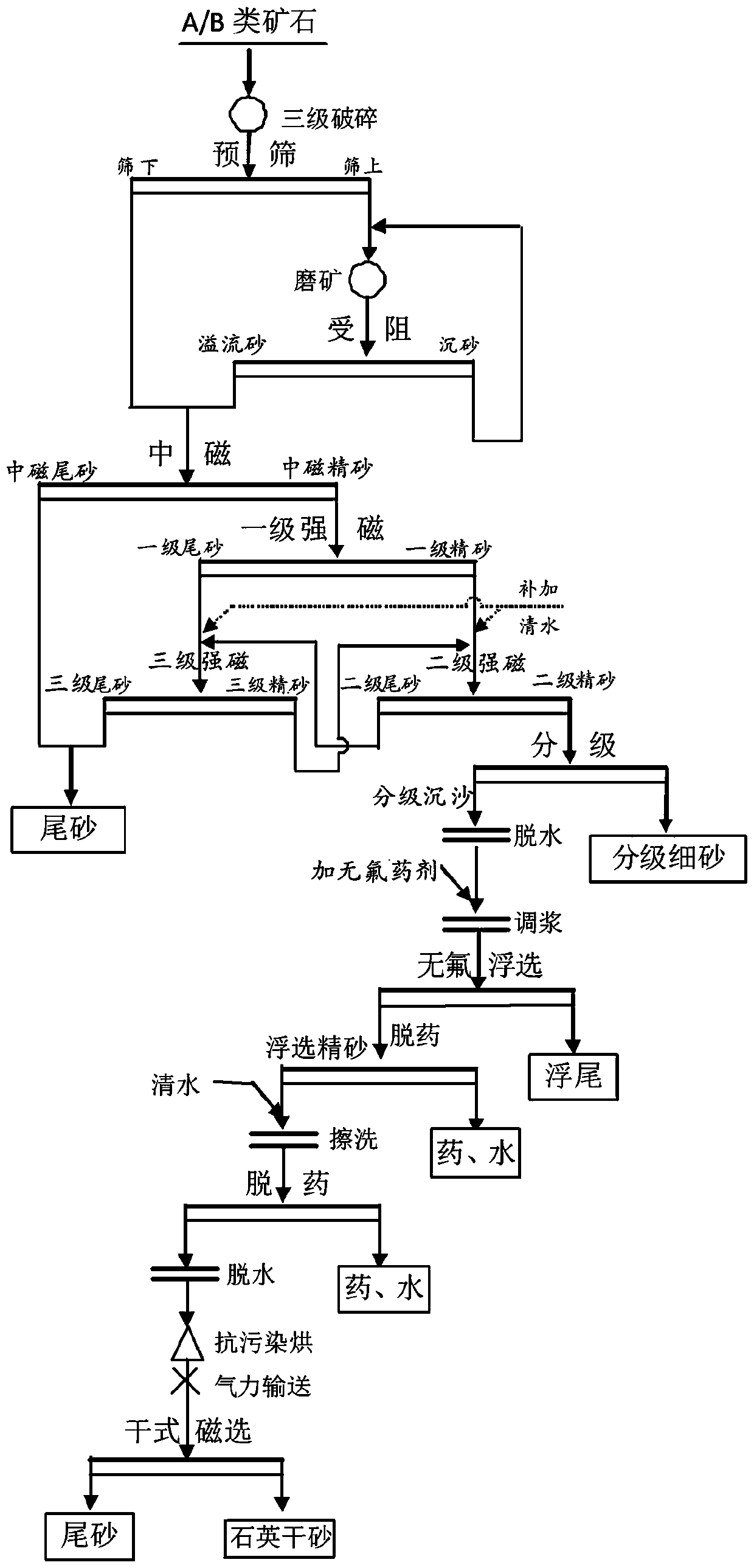

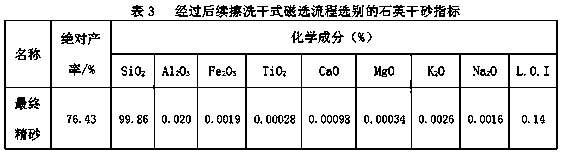

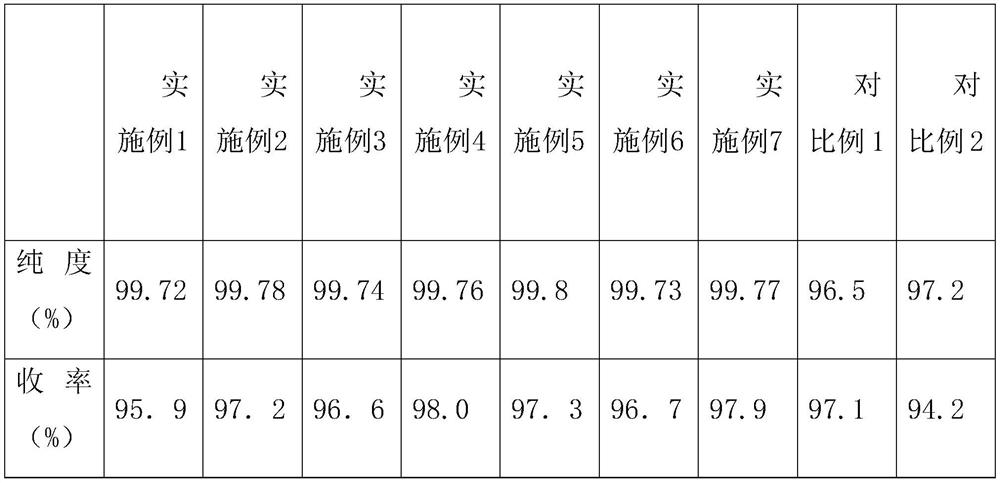

ActiveCN109110767BReduce entrainmentRealize cleaner productionSilicaWet separationSilenesMagnetic separation

The invention relates to a method for mass production of low-iron quartz dry sand. A track point distribution type artificial sorting system selects the raw ore to obtain type A / B / C ores and tailings;the type A / B ores are subjected to three-level crushing, grinding and blocking process in order to control the coarse particles, and then are sorted by the layered dilution and the multi-level magnetic separation joint recovery technology, namely that most impurities such as mechanical iron in the ores are sorted at a high concentration; through layered supplement of clear water and large-proportion dilution of the pulp concentration, the magnetic ores are thoroughly dispersed and picked out by strong-magnetism magnetic separation; in graded sand setting, by adopting a novel anion-cation collector as a flotation reagent and optimizing the parameters of the fluoride-free flotation technology, the Fe2O3 index of the fine sand of the type A and B ores is controlled to 30ppm or less; the floatation fine sand is scrubbed by a proper amount of water to meet the requirement of low halogenation; then through dehydration, anti-pollution drying and dry magnetic separation, an aim of 30ppm low-iron quartz dry sand of a silica raw material for preparing optical glass, crystal items and electronic-grade silica powder is achieved finally.

Owner:凯盛石英材料(黄山)有限公司 +1

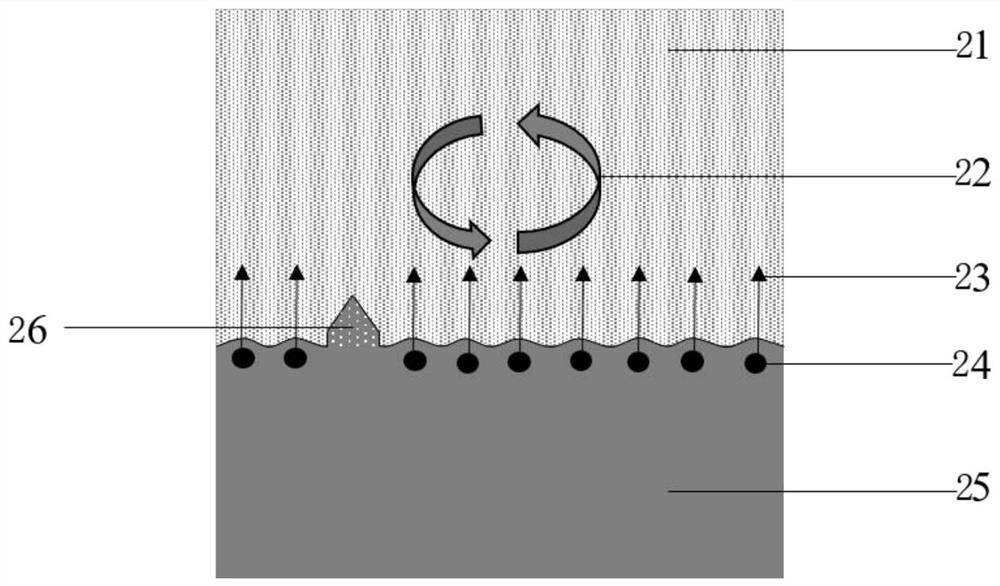

A method for separation and purification of durene based on bubble fractional crystallization and distillation

ActiveCN108383678BReduce transfer resistanceImprove clearanceDistillation purification/separationHydrocarbonsTemperature controlPurification methods

The invention provides a durene separation and purification method based on stepped bubble crystallization and distillation. The method is characterized by comprising the following steps: adding a durene-containing material into a crystallizer, introducing small nitrogen bubbles from bottom to top, cooling to a temperature of 10-15 DEG C below zero, then cooling to a temperature of 25-30 DEG C below zero, performing crystallization treatment, introducing the small nitrogen bubbles from top to bottom, and filtering the crystallized and settled crystal through a tilting porous screen so as to obtain coarse durene; heating and melting the coarse durene, introducing the small nitrogen bubbles from bottom to top, raising the temperature to 190 DEG C, continuously raising the temperature to 196-198 DEG C, maintaining the temperature, and performing condensation recovery on steam, thereby obtaining the separated and purified durene. According to the method disclosed by the invention, crystallization and evaporation of the durene can be accelerated by utilizing a bubble technique, and along with an accurate temperature control technology, on the basis of reducing the energy consumption, the durene separation and purification efficiency can be obviously improved. The method is simple, high-efficiency, high in controllability and suitable for industrial production.

Owner:连云港鹏辰特种新材料有限公司

A method for measuring static recrystallization volume fraction of materials

ActiveCN110702727BAccurate measurementAccurately build mathematical modelsMaterial crystallisationUsing mechanical meansThermodynamicsStrain energy

The invention discloses a method for measuring the static recrystallization volume fraction of a material. A group of single-pass compression tests are performed using a thermal simulation testing machine to obtain a stress-strain curve, and data fitting and differential operations are performed to obtain the work hardening rate and the corresponding The relationship curve between stresses, and the critical strain ε at which dynamic recrystallization occurs can be judged from the inflection point in the curve c ; A group of double-pass compression tests are carried out using a thermal simulation testing machine, the total deformation of the double-pass is less than that of the single-pass, and the deformation of each pass in the double-pass compression test ε 0 are less than the critical strain ε of dynamic recrystallization determined by the single-pass compression test c ; Use polynomials to fit the stress-strain curves in single pass and double pass respectively, and perform integral operations respectively to obtain the corresponding strain energy; finally calculate the static recrystallization volume fraction. The invention considers the influence of recovery and dynamic recrystallization on the static recrystallization volume fraction, and can more accurately measure the austenite static recrystallization volume fraction of iron and steel materials.

Owner:ANGANG STEEL CO LTD

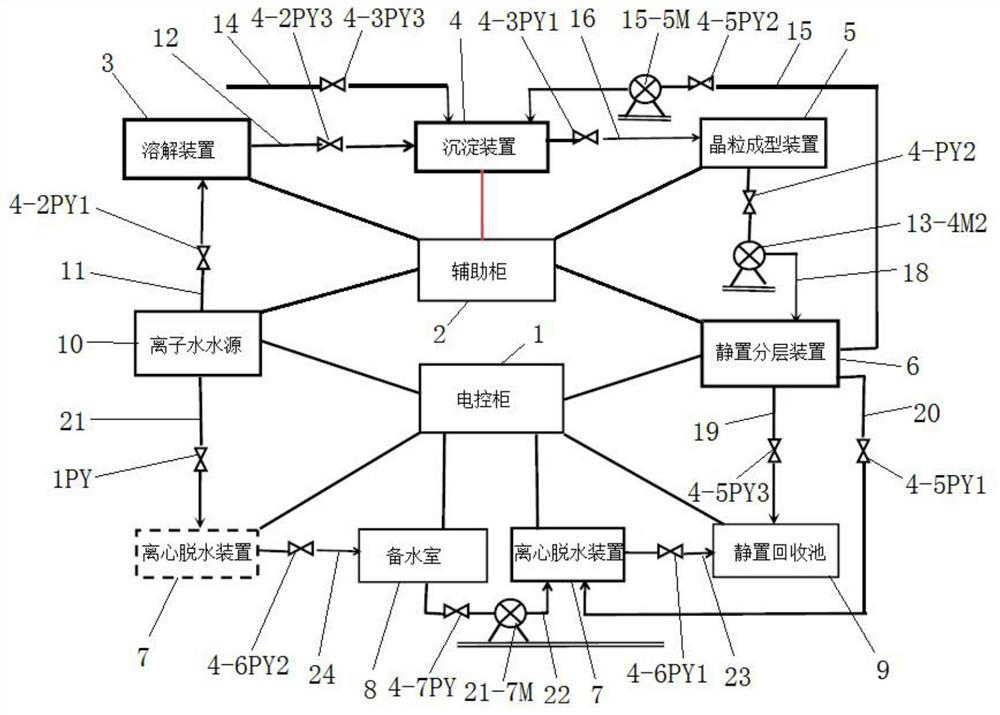

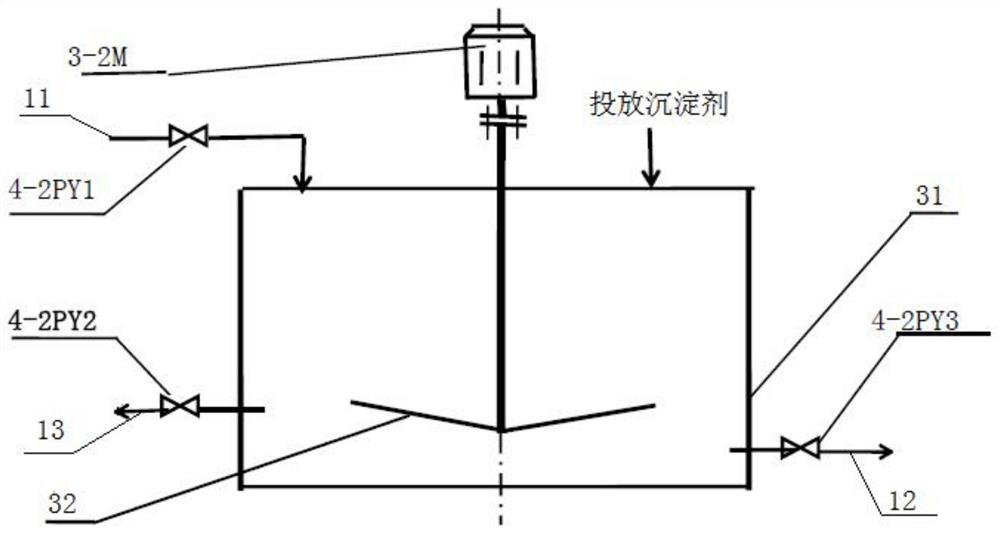

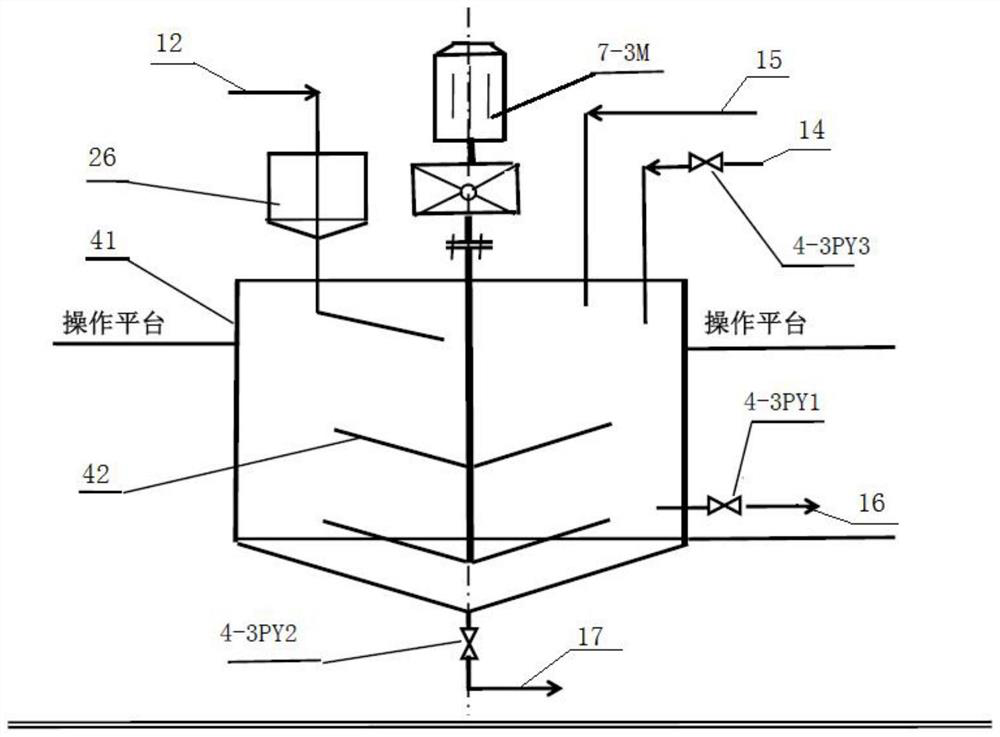

Precipitation system and precipitation method of rare earth compound

PendingCN111974033AGrowth coordinationEasy to settleSedimentation separationProcess efficiency improvementControl systemResource recovery

The invention discloses a precipitation system and precipitation method of a rare earth compound, and relates to the technical field of rare earth resource recovery. The precipitation system comprisesa dissolving device, a precipitation device, a crystal grain forming device, a standing layering device, a centrifugal dewatering device, a water preparation chamber, a standing recovery pool and a control system. By adding an independent crystal grain forming process, high-quality precipitation is facilitated, washing and filtering are easy, washing of chlorine radicals of the rare earth compound is facilitated, and the quality is stabilized; feeding and crystal nucleus growth are more coordinated, an emulsification phenomenon is effectively solved, and meanwhile, a crystal nucleus materialcan be automatically returned according to a process requirement; the water preparation chamber is arranged for linkage control of secondary washing, so that water is saved, and the defect of large washing water consumption is overcome; electric control is reasonable, dewatering and washing are linked, and operation is convenient; and the whole production process is continuous and smooth, the operation is more simplified, the cost is saved, the energy consumption is reduced, the labor productivity is improved, and the yield is obviously improved.

Owner:中稀天马新材料科技股份有限公司

Method for preparing high-purity silicon by recovering diamond wire cutting silicon powder through electric field coupling directional solidification technology

PendingCN114875484AEnhanced convectionGuaranteed stabilityPolycrystalline material growthSingle crystal growth detailsSilicon solar cellIngot

The invention discloses a method for preparing high-purity silicon by recovering diamond wire cutting silicon powder through an electric field coupling directional solidification technology, which comprises the following steps: grinding a diamond wire cutting silicon powder waste material, preparing a solution from HF, H2O and C2H5OH in a ratio of 1: 3: 1, pickling, centrifugally drying, and briquetting; the silicon powder block is subjected to vacuum induction melting, after heat preservation is finished, an electric field is introduced in the solidification process, the temperature gradient at the solid-liquid cross section is controlled, some protruding parts at the solid-liquid interface are remelted, the stability of the solid-liquid interface is kept, growth of dendrites is restrained, and the yield in the recovery process is remarkably increased. The introduction of the electric field can promote the convection of the silicon liquid, can ensure the uniformity of impurities and temperature in the silicon liquid, enables the segregation effect of the impurities in the solidification process to be more obvious, further improves the purity of the silicon ingot, and improves the purity of the recovered silicon to 5N. According to the technology, environmental pollution caused by the silicon powder waste can be prevented, silicon resources can be reused, and the industrial cost of the crystalline silicon solar cell industry is further saved.

Owner:DALIAN UNIV OF TECH

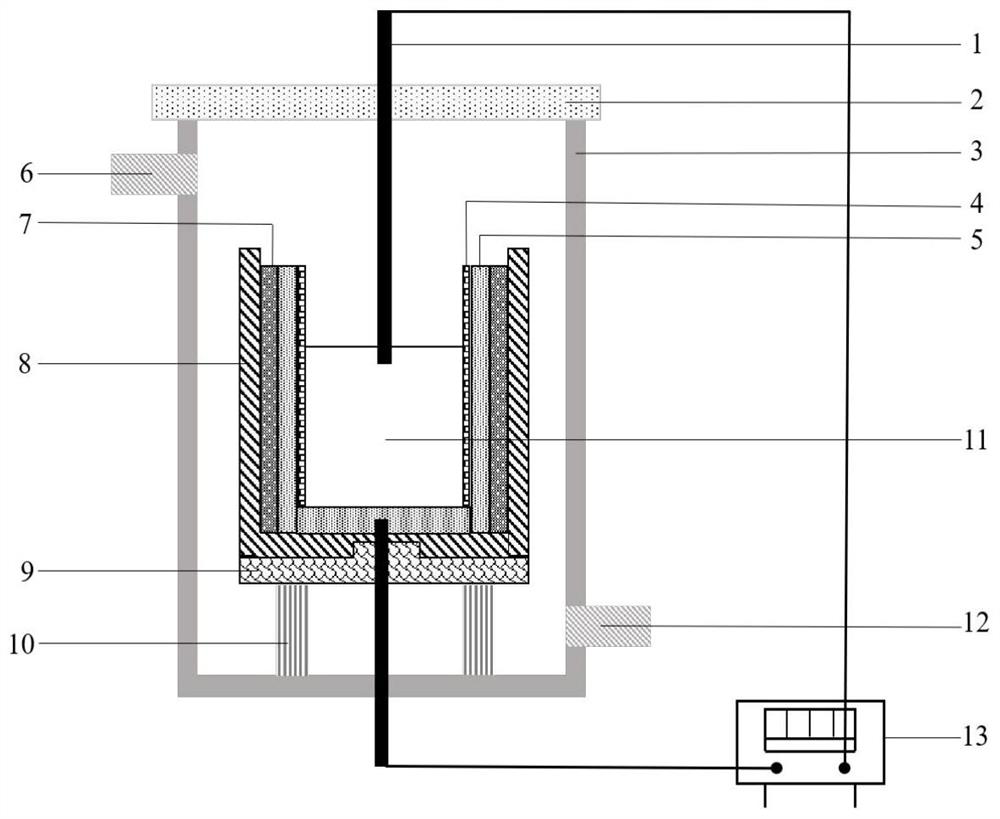

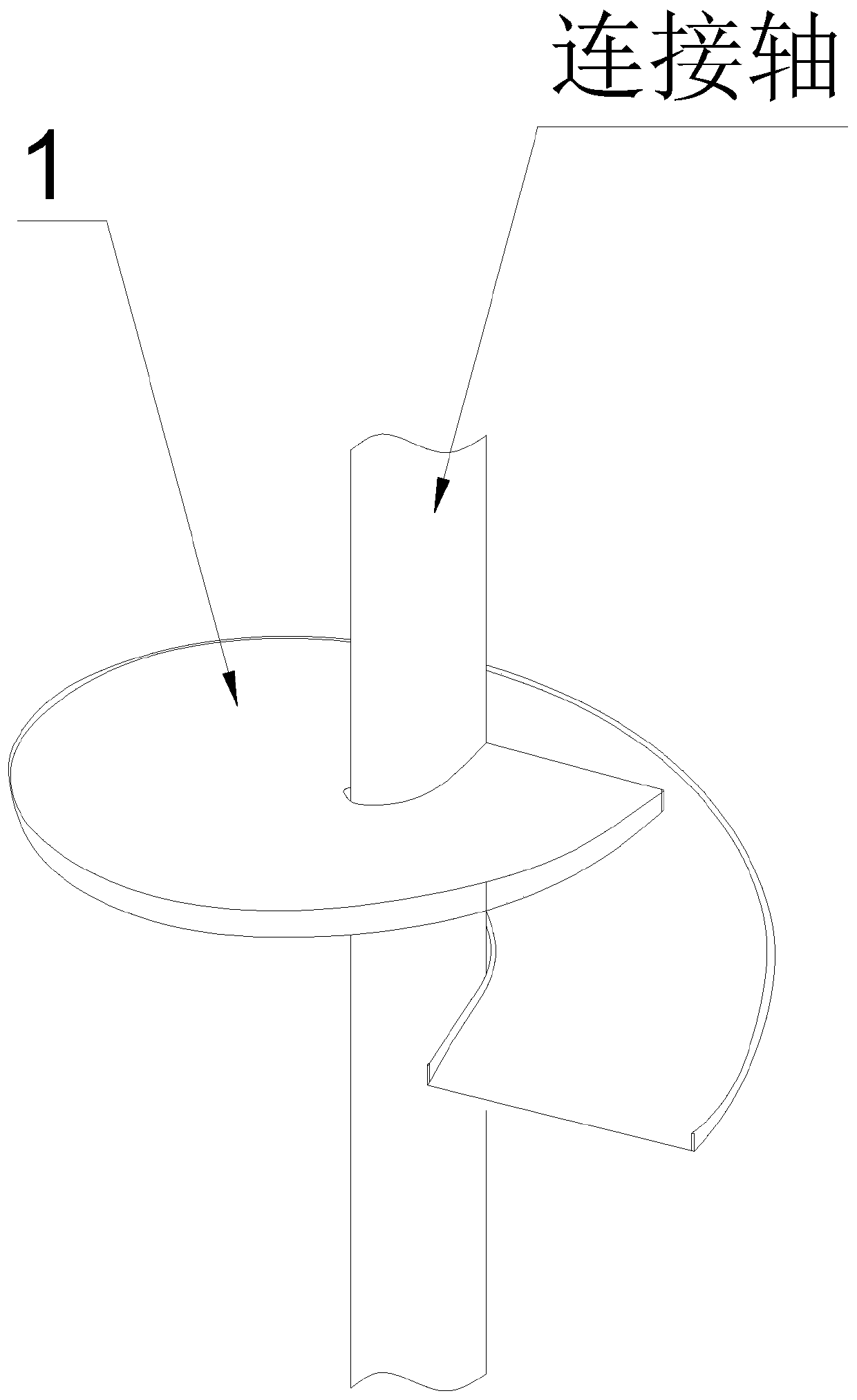

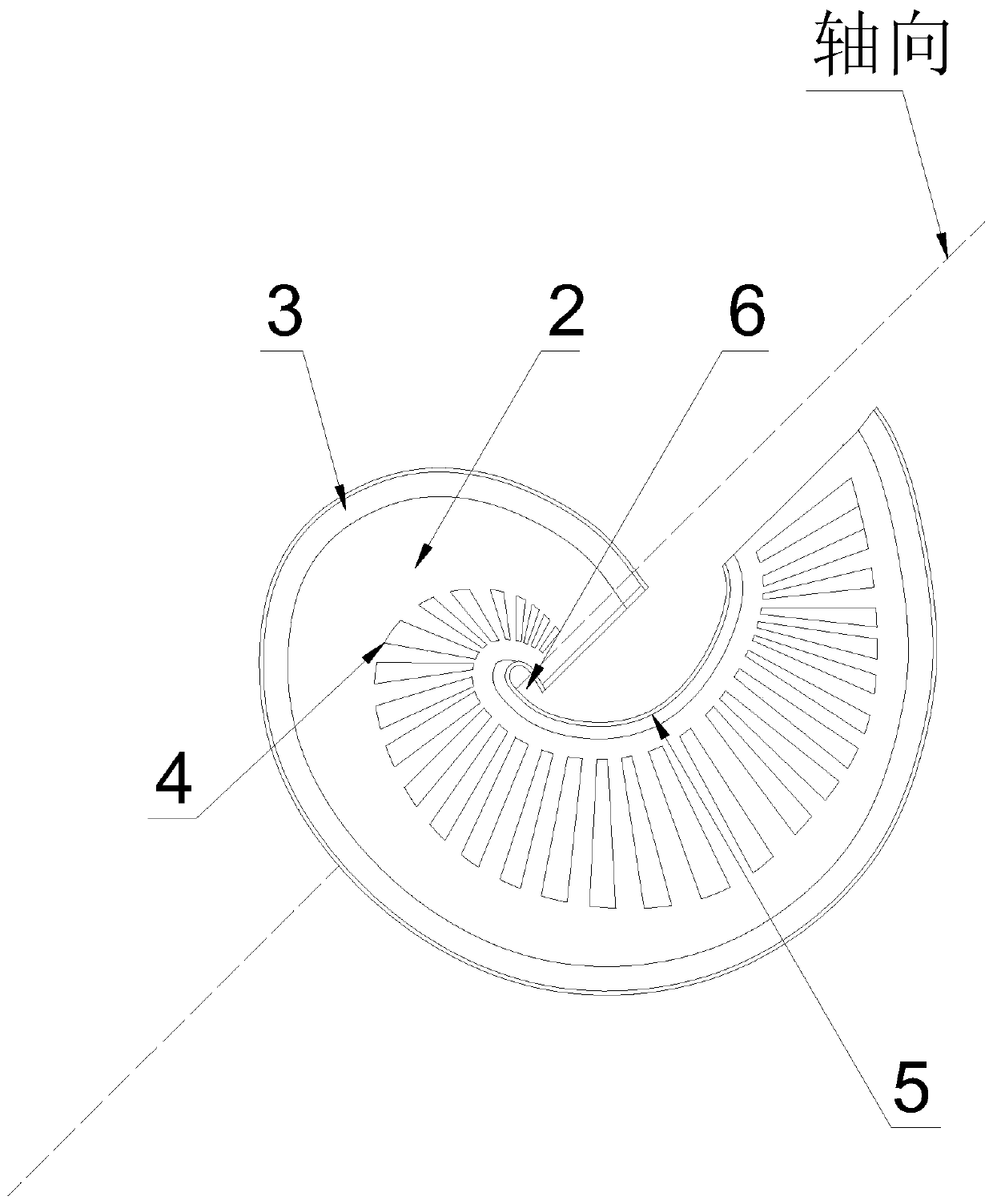

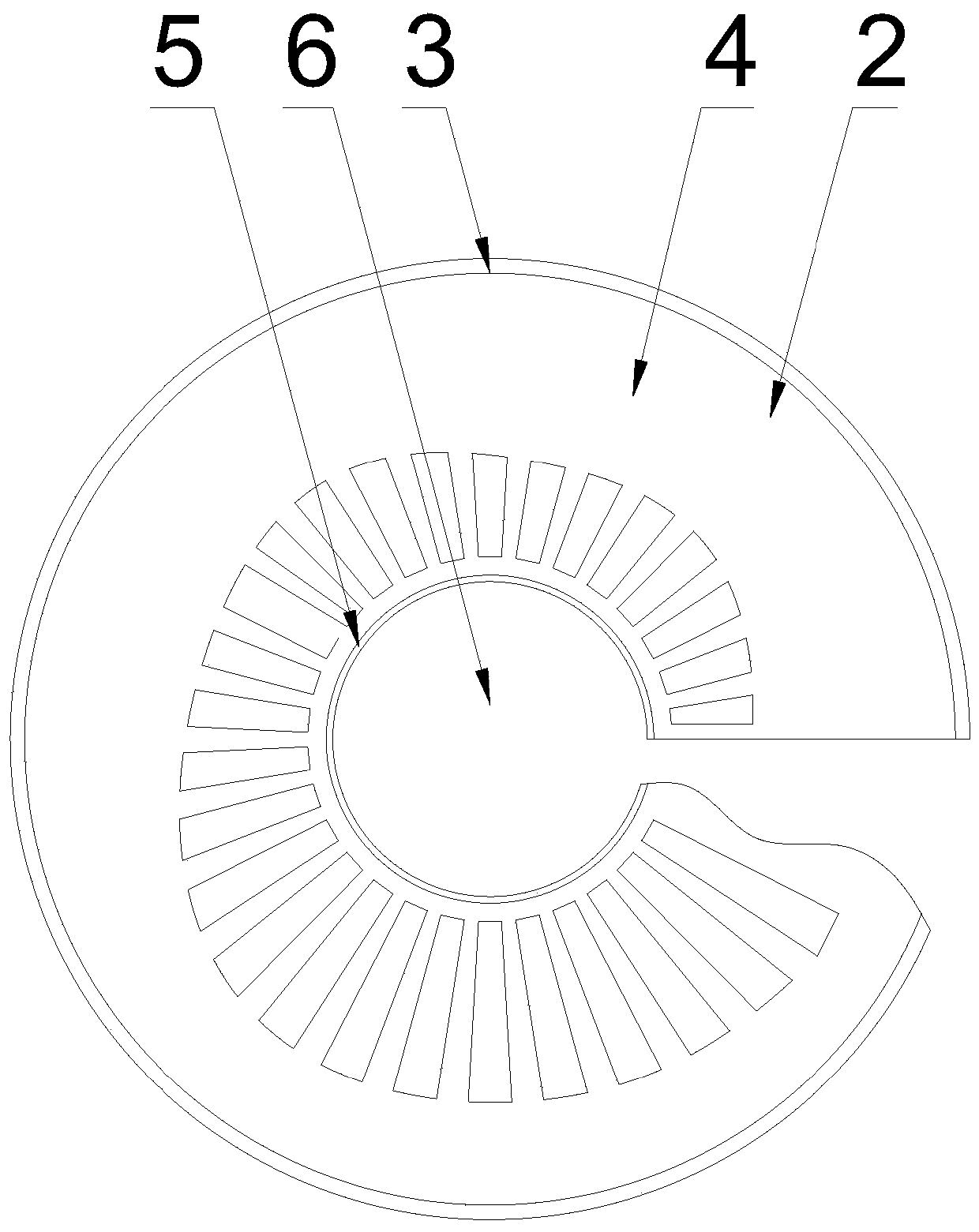

Recovery device for fine particle weak-magnetic minerals

PendingCN110871139AHigh and stable magnetic fieldImprove working precisionMagnetic separationWet separationEngineeringMechanical engineering

The invention discloses a recovery device for fine particle weak-magnetic minerals. The recovery device comprises a plurality of spiral chutes spirally arranged from top to bottom; an installation groove matched and connected with a connecting shaft is arranged in the middle of the spiral chutes; the spiral chutes comprise a bottom plate; an outer baffle is arranged on the periphery of the spiralchutes; an inner baffle is arranged on the inner periphery of the spiral chutes; the outer baffle and the inner baffle are both vertically connected with the bottom plate; on each spiral chute, a plurality of magnetic strips are arranged at the bottom of the bottom plate at equal intervals and are gradually shortened from top to bottom; and the bottom plate is gradually inclined upwards along thedirection from the center of the spiral chutes to the edge direction. The recovery device for fine particle weak-magnetic minerals is widely applied in the separation of weak-magnetic minerals such aschromite, manganese ore, hematite, limonite and ilmenite, and in recycle of the fine particle weak-magnetic minerals from waste residues; the magnetic strips adopt high-quality neodymium-iron-boron materials, has high and stable magnetic field strength, and can recycle weak-magnetic minerals with granularity of 0.005 mm; and the working accuracy and efficiency are improved, and the quality is ensured.

Owner:成都市宏智达科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com