A method for measuring static recrystallization volume fraction of materials

A technology of static recrystallization and volume fraction, applied in the direction of material crystallization, material thermal analysis, material analysis, etc., can solve the problems of unspecified double-pass deformation conditions, pass deformation, systematic error, accidental error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

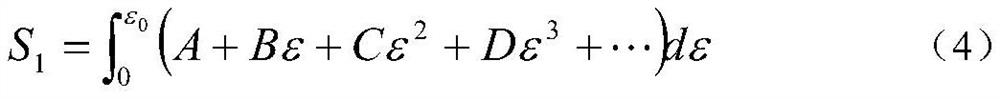

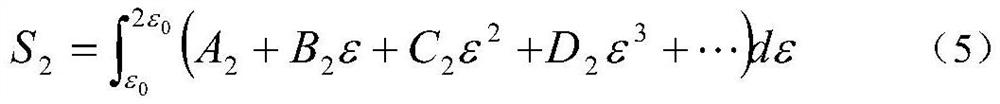

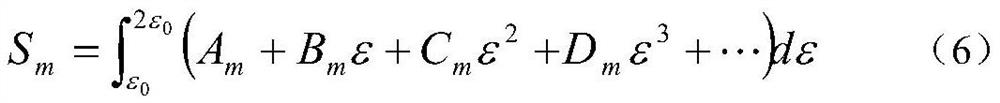

Method used

Image

Examples

Embodiment Construction

[0033] The specific embodiment of the present invention is:

[0034] 1. Select a low-carbon micro-alloy steel as the material to be tested, and use a thermal simulation testing machine to conduct a set of single-pass compression tests. The test process for the sample is to heat the sample at 20°C / s to 1150°C and hold it for 5 minutes. Then cool to 850°C and 950°C at a speed of 5°C / s, and carry out compression deformation after holding at this temperature for 1 minute, the deformation amount is 70%, and the strain rate is 5S -1 ; Collect the stress and strain data in the test process to obtain the stress-strain curve;

[0035] Data fitting and differential operations are performed on the single-pass stress-strain curves obtained by deformation at 850°C and 950°C to obtain the relationship curve between the work hardening rate and the corresponding stress. It can be seen from the curve that at 950°C The inflection point of the curve during deformation indicates that dynamic rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com