Patents

Literature

258 results about "Dynamic recrystallization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

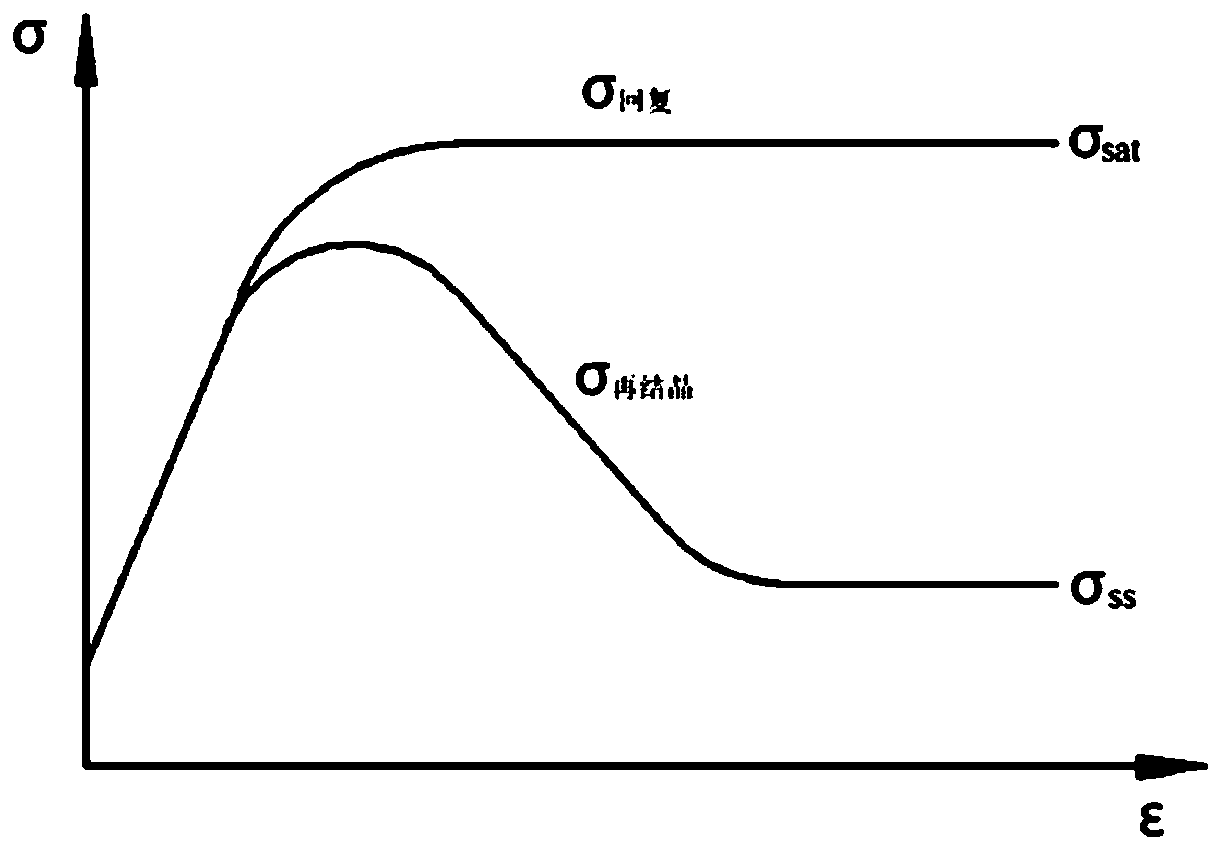

Dynamic recrystallization (DRX) is a type of recrystallization process, found within the fields of metallurgy and geology. In dynamic recrystallization, as opposed to static recrystallization, the nucleation and growth of new grains occurs during deformation rather than afterwards as part of a separate heat treatment.

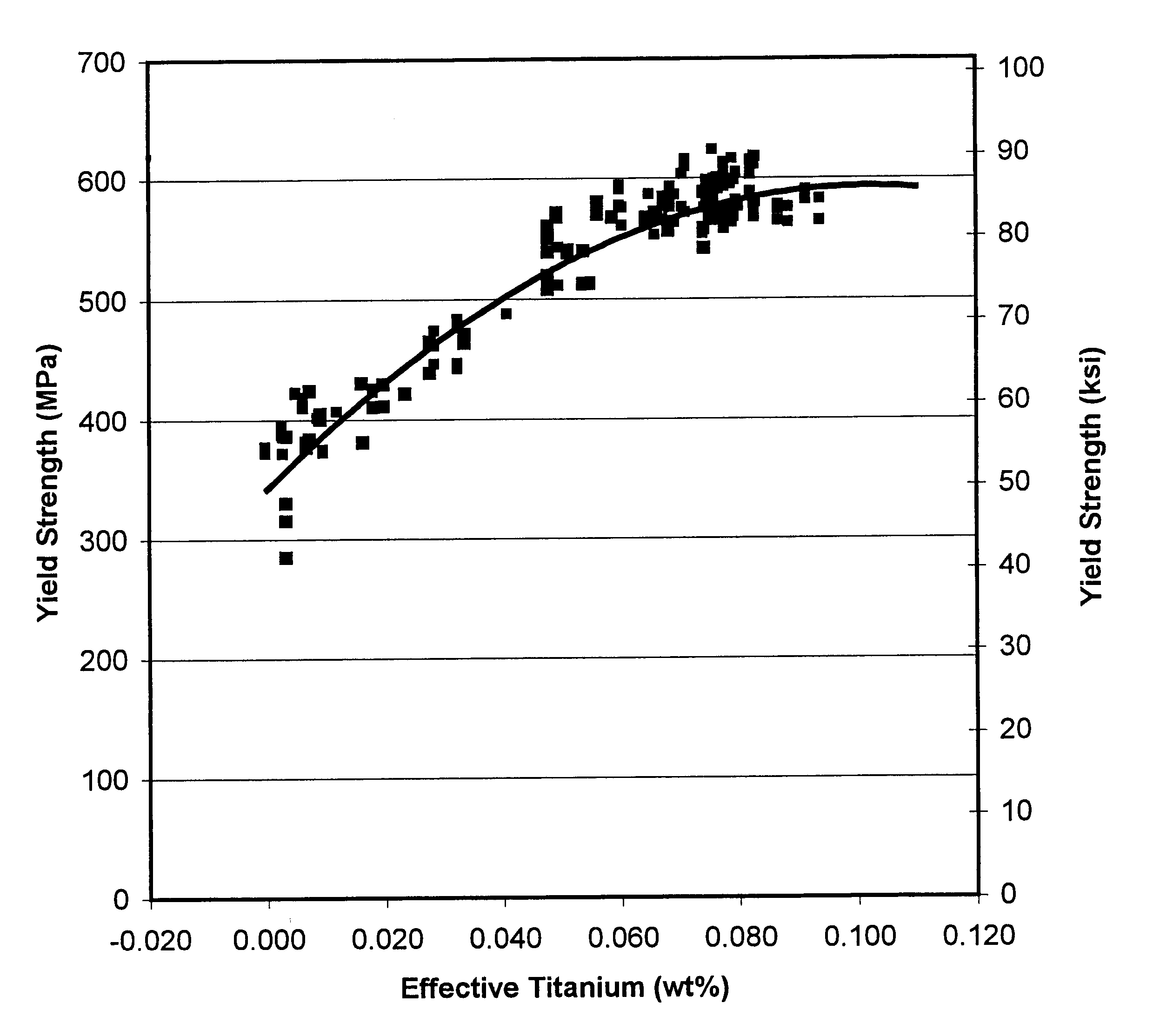

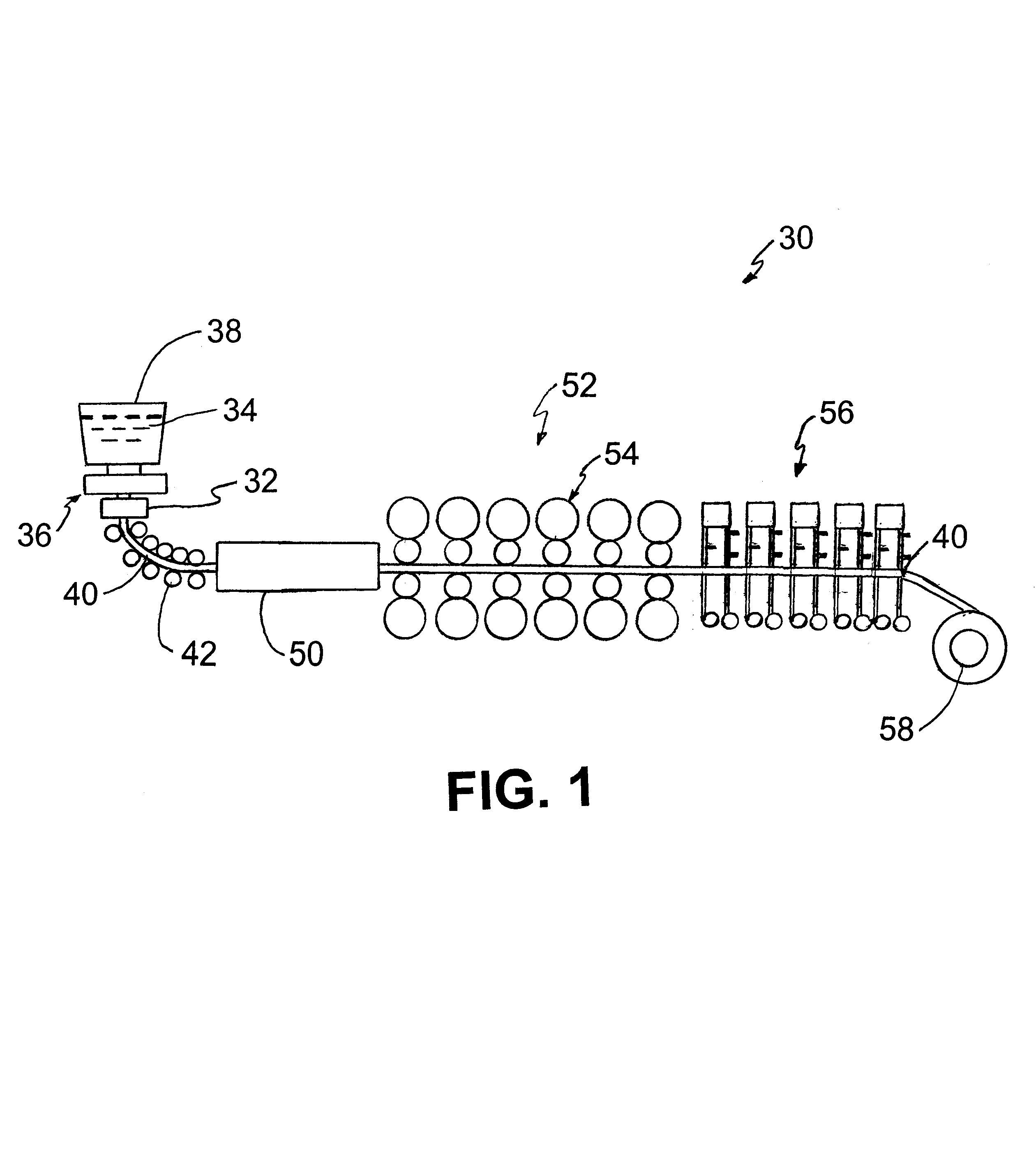

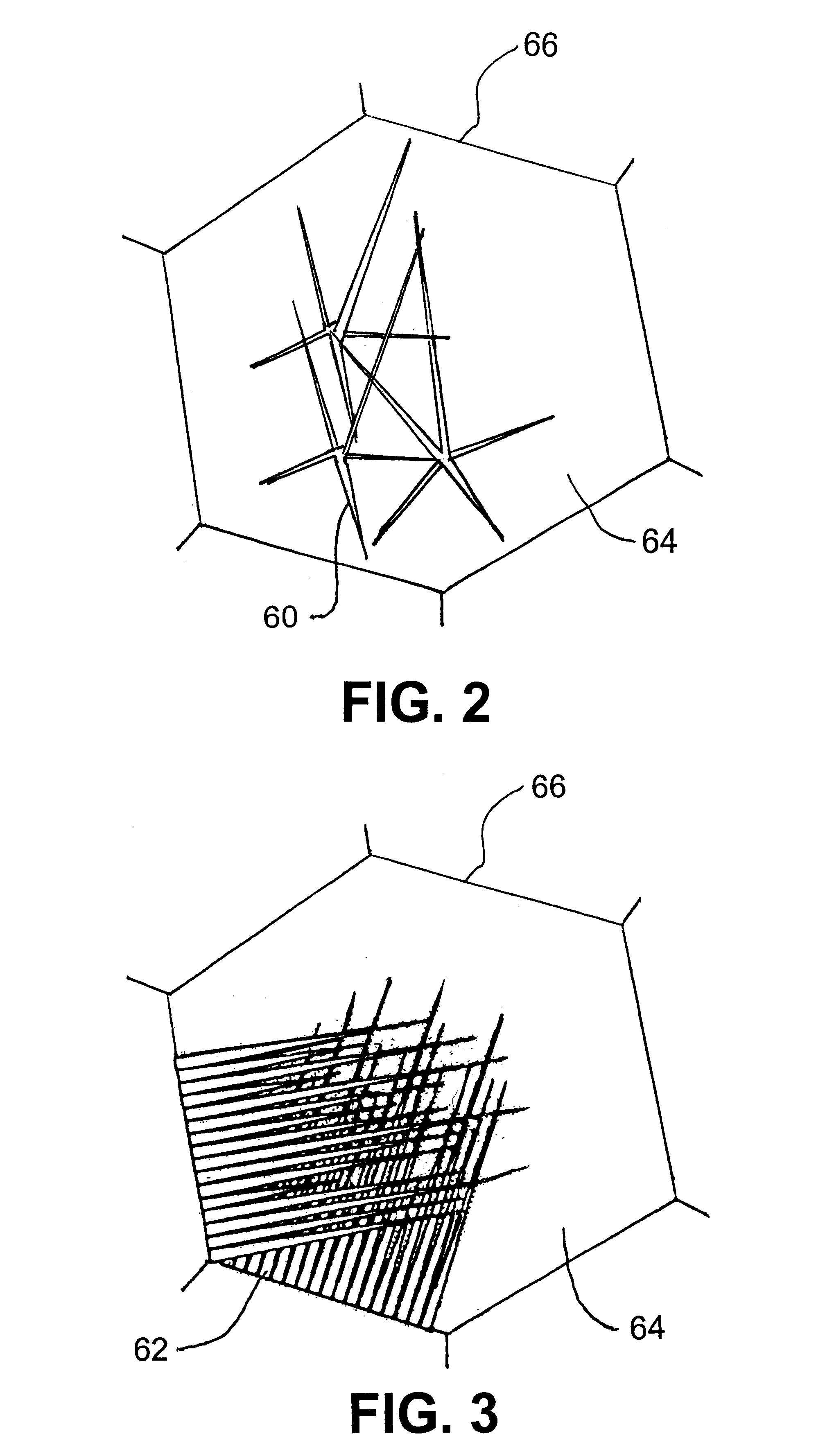

Method for producing titanium-bearing microalloyed high-strength low-alloy steel

A composition and method of making a high-strength low-alloy hot-rolled steel sheet, strip, or plate bearing titanium as the principal or only microalloy strengthening element. The steel is substantially ferritic and has a microstructure that is at least 20% acicular ferrite. The steel has a minimum yield strength of at least 345 MPa (50 ksi) and even over 621 MPa (90 ksi) adding titanium as the lone microalloy element for strengthening, with elongation of 15% and more. Addition of vanadium, niobium, or a combination thereof can result in yield strengths exceeding 621 MPa (90 ksi). Effective titanium content, being the content of titanium in the steel not in the form of nitrides, oxides, or sulfides, is in the range of 0.01 to 0.12% by weight. The manufacturing process includes continuously casting a thin slab and reducing the slab thickness using thermomechanical controlled processing, including dynamic recrystallization controlled rolling.

Owner:NUCOR CORP

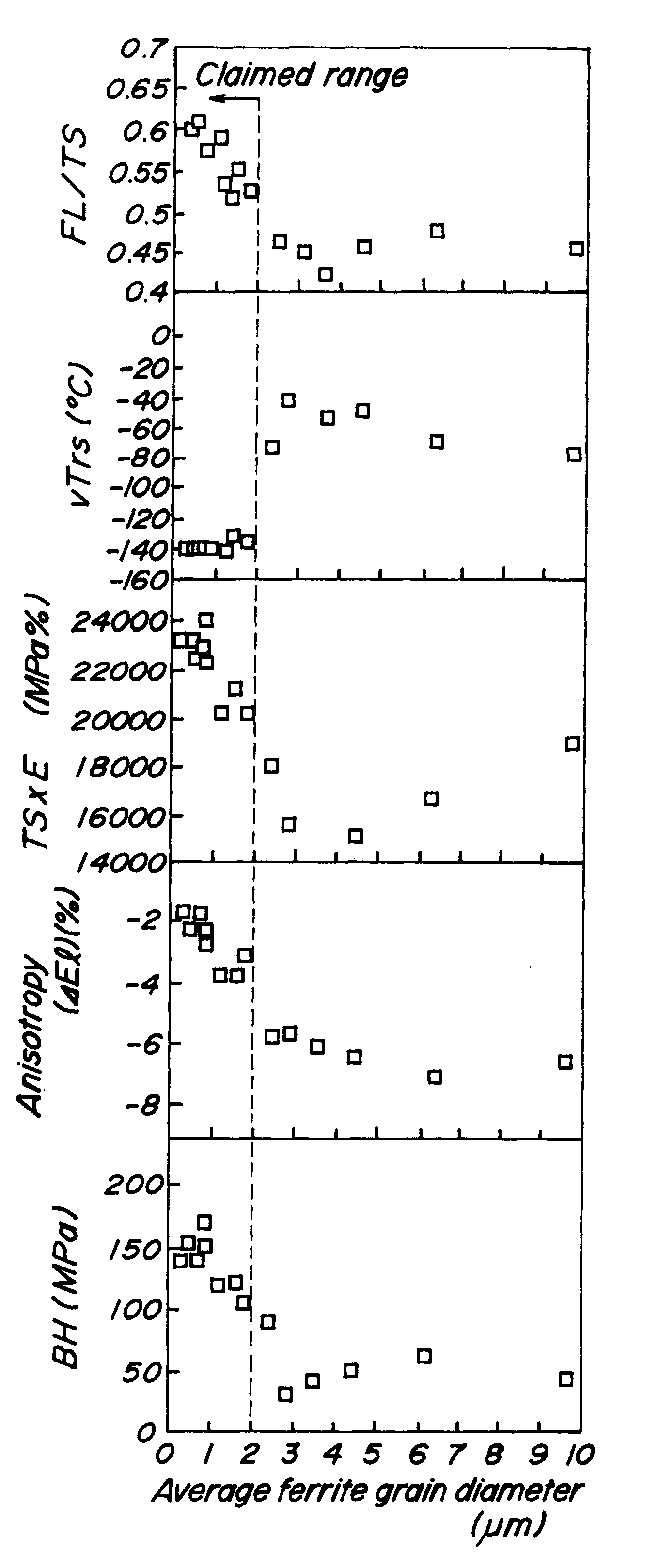

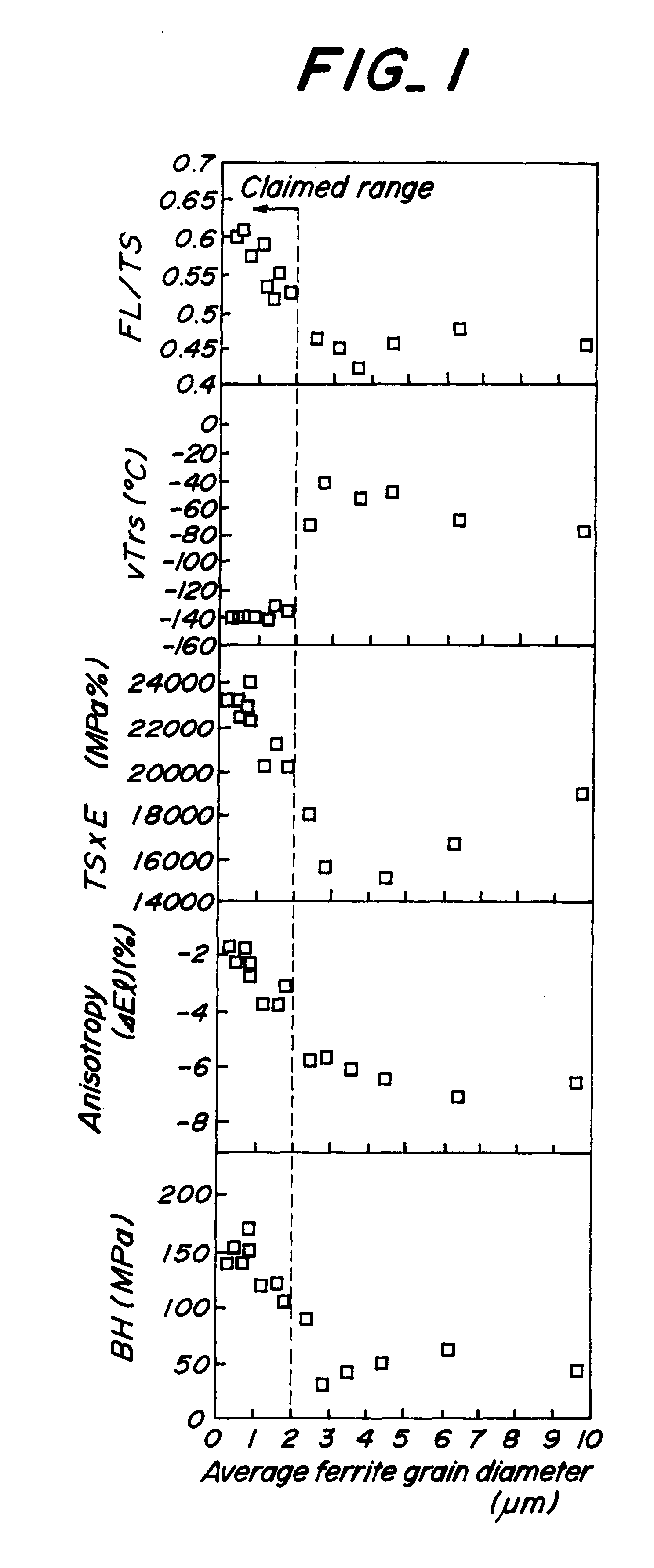

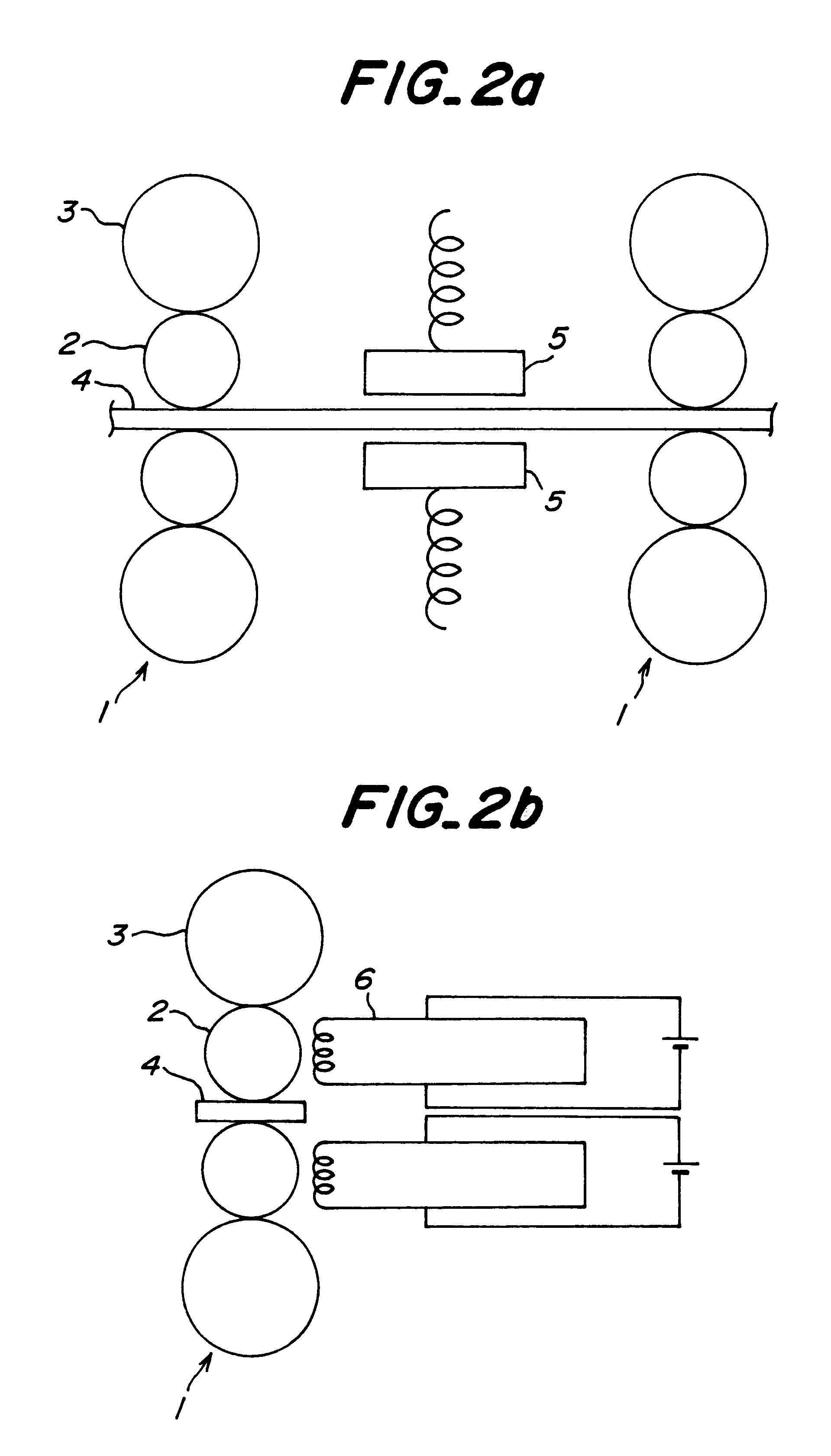

Hot rolled steel plate to be processed having hyper fine particles, method of manufacturing the same, and method of manufacturing cold rolled steel plate

A hot rolled steel sheet with improved formability and producing method therefor, which can be easily produced with general hot strip mills, having less anisotropy of mechanical properties and final ferrite grain diameter of less than 2 mum that could not be achieved by the prior art. The hot rolled steel sheet comprises a ferrite phase as a primary phase, and has an average ferrite grain diameter of less than 2 mum, with the ferrite grains having an aspect ratio of less than 1.5. The hot rolled steel sheet is obtained by carried out a reduction process under a dynamic recrystallization conditions through reduction passes of not less than 5 stands in the hot finish rolling.

Owner:KAWASAKI STEEL CORP

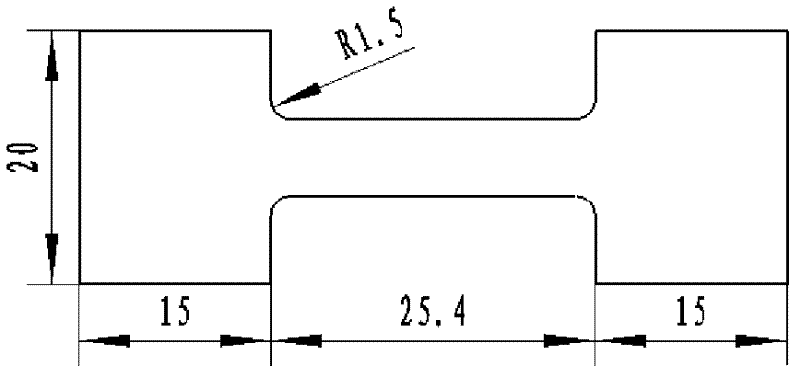

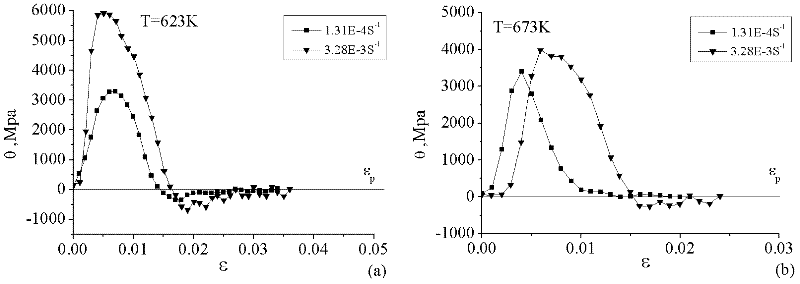

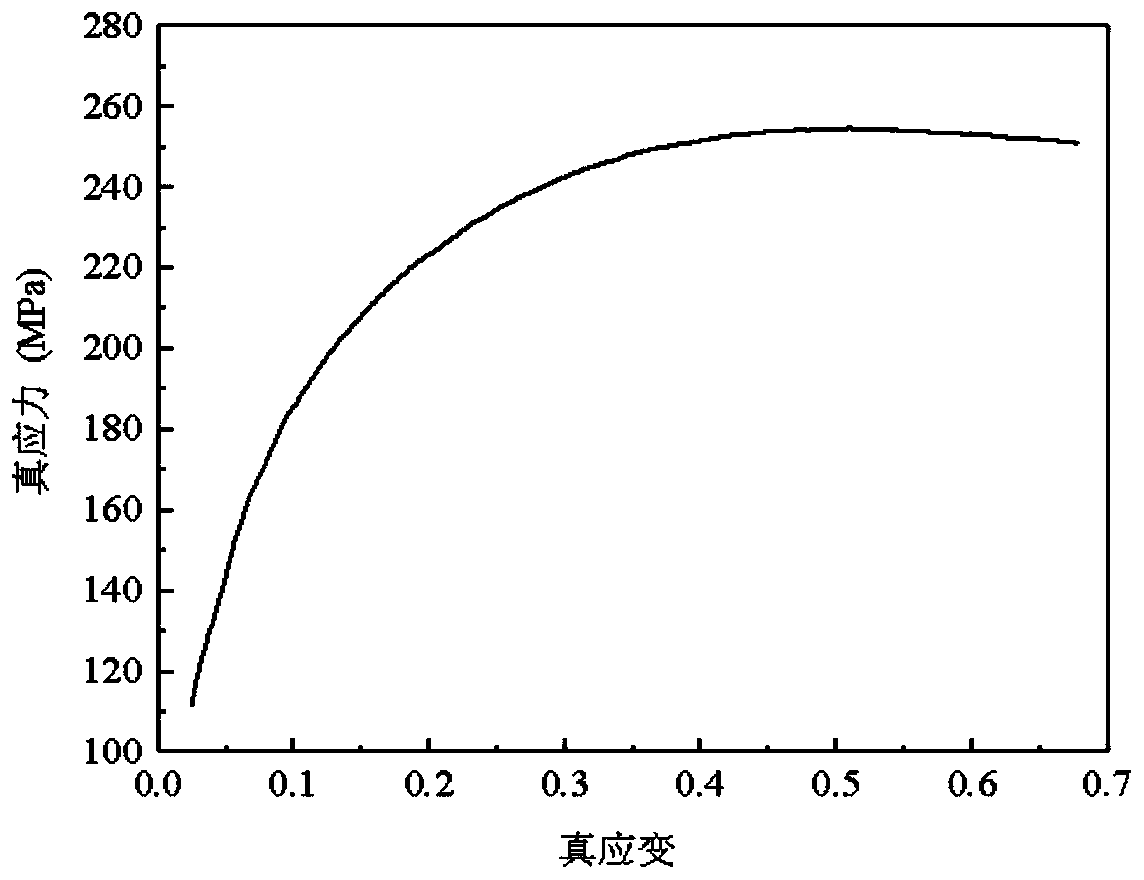

Method for establishing aluminium alloy dynamic recrystallization model by using true stress-true strain curve

InactiveCN102519801AMaterial strength using tensile/compressive forcesMathematical modelStress–strain curve

The invention discloses a method for establishing an aluminium alloy dynamic recrystallization model by using a true stress-true strain curve, belonging to the field of analyzing of material microstructures. The method comprises the following steps of: obtaining a hardening rate of a material by adopting the true stress-true strain curve obtained through a high-temperature tensile test, determining peak value strain, peak value stress and steady-state stress under different conditions by analyzing the change of the hardening rate, and establishing a peak value strain and critical strain mathematical model and a dynamic recrystallization volume fraction according to an empirical formula. The method disclosed by the invention overcomes the disadvantages of being lagging, time-consuming, incomplete and imprecise by using a metallographic method to research the recrystallization behaviour of the material. After being combined with finite element software, the method is capable of quantitatively analyzing the change condition of the dynamic recrystallization volume fraction of aluminium alloy.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

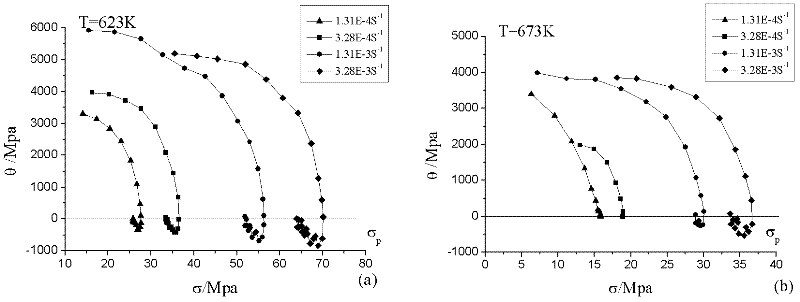

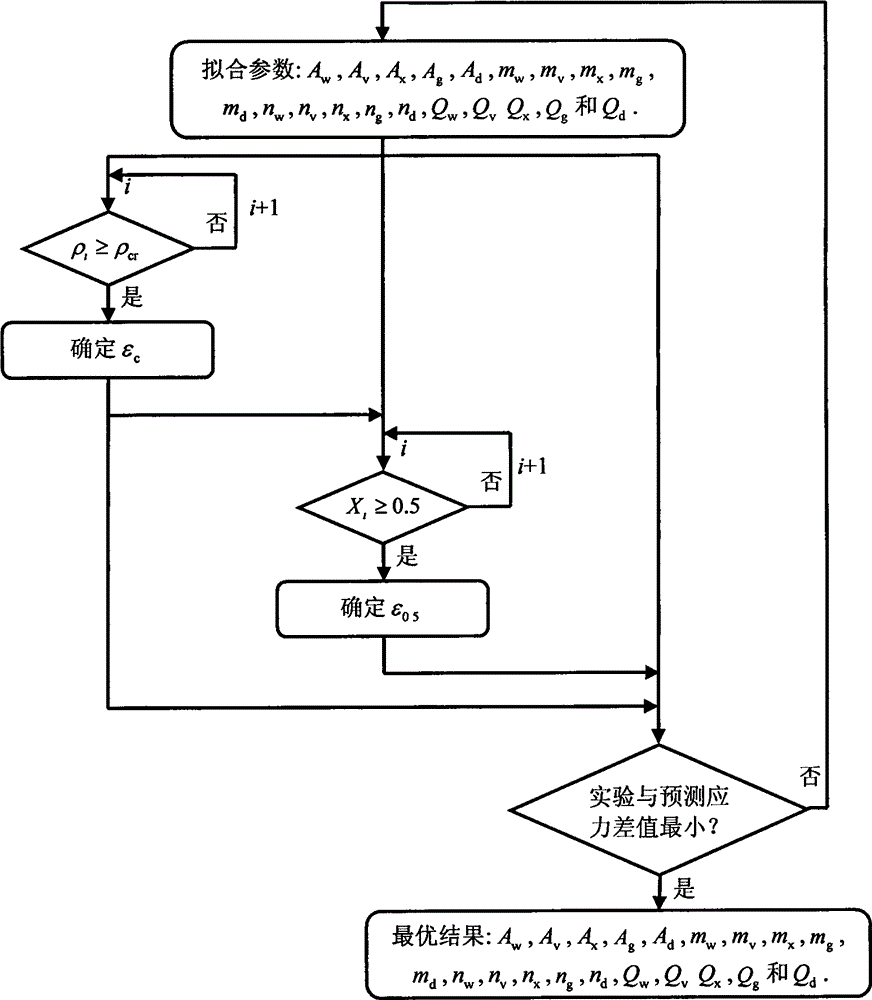

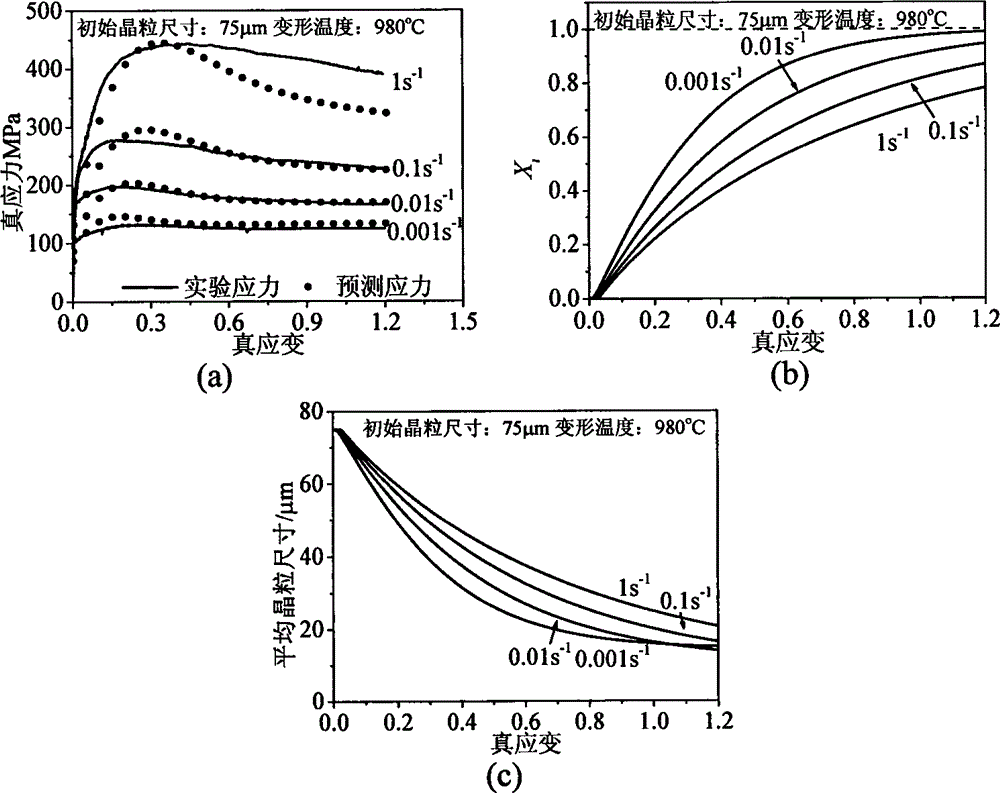

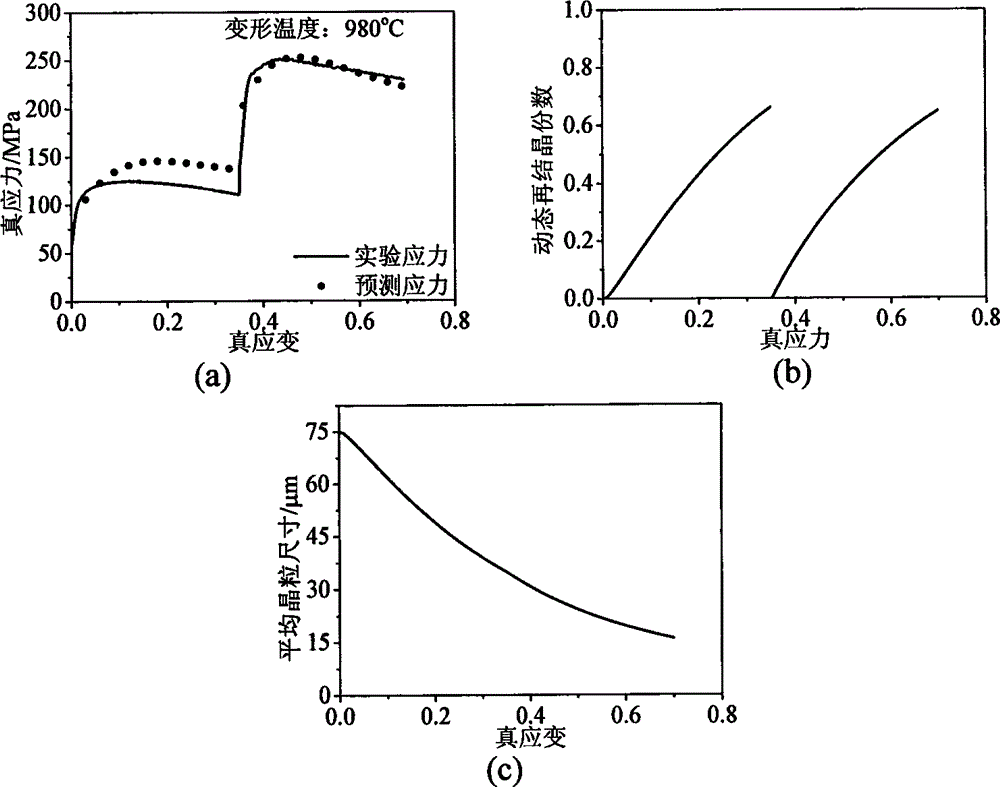

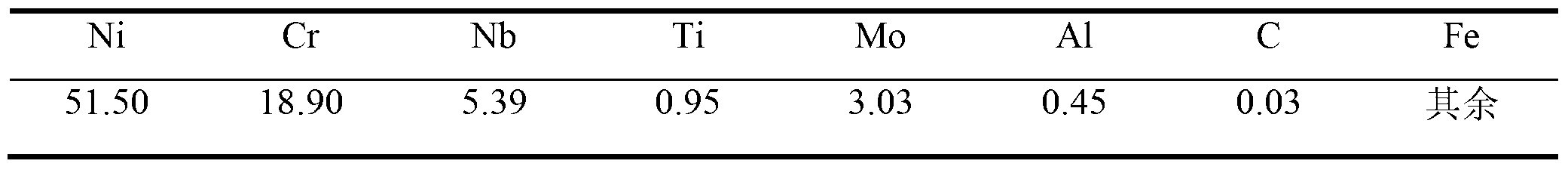

Method for predicting nickel base alloy high temperature flow stress and dynamic recrystallization behavior

The invention discloses a method for predicting nickel base alloy high temperature flow stress and a dynamic recrystallization behavior. The method comprises the following steps: 1 obtaining true stress-true strain data of nickel base alloy by means of high temperature compression tests; 2 establishing a unified constructive model for predicting the nickel base alloy high temperature flow stress and the dynamic recrystallization behavior; 3 utilizing the numerical value difference principle, writing an iterative accumulation algorithm program, inserting numerical value simulation software, and by combining the true stress-true strain data of the nickel base alloy, determining material parameters of the unified constructive model for predicting the nickel base alloy high temperature flow stress and the dynamic recrystallization behavior; 4 predicting the nickel base alloy high temperature flow stress and the dynamic recrystallization behavior under the constant temperature and constant strain rate condition as well as under the variable temperature and variable strain rate condition. By means of the method, the nickel base alloy high temperature flow stress and the dynamic recrystallization behavior under the constant temperature and constant strain rate condition as well as under the variable temperature and variable strain rate condition can be predicted rapidly and accurately, and important technical guidance significance for formulating the nickel base alloy hot working process reasonably is achieved.

Owner:CENT SOUTH UNIV

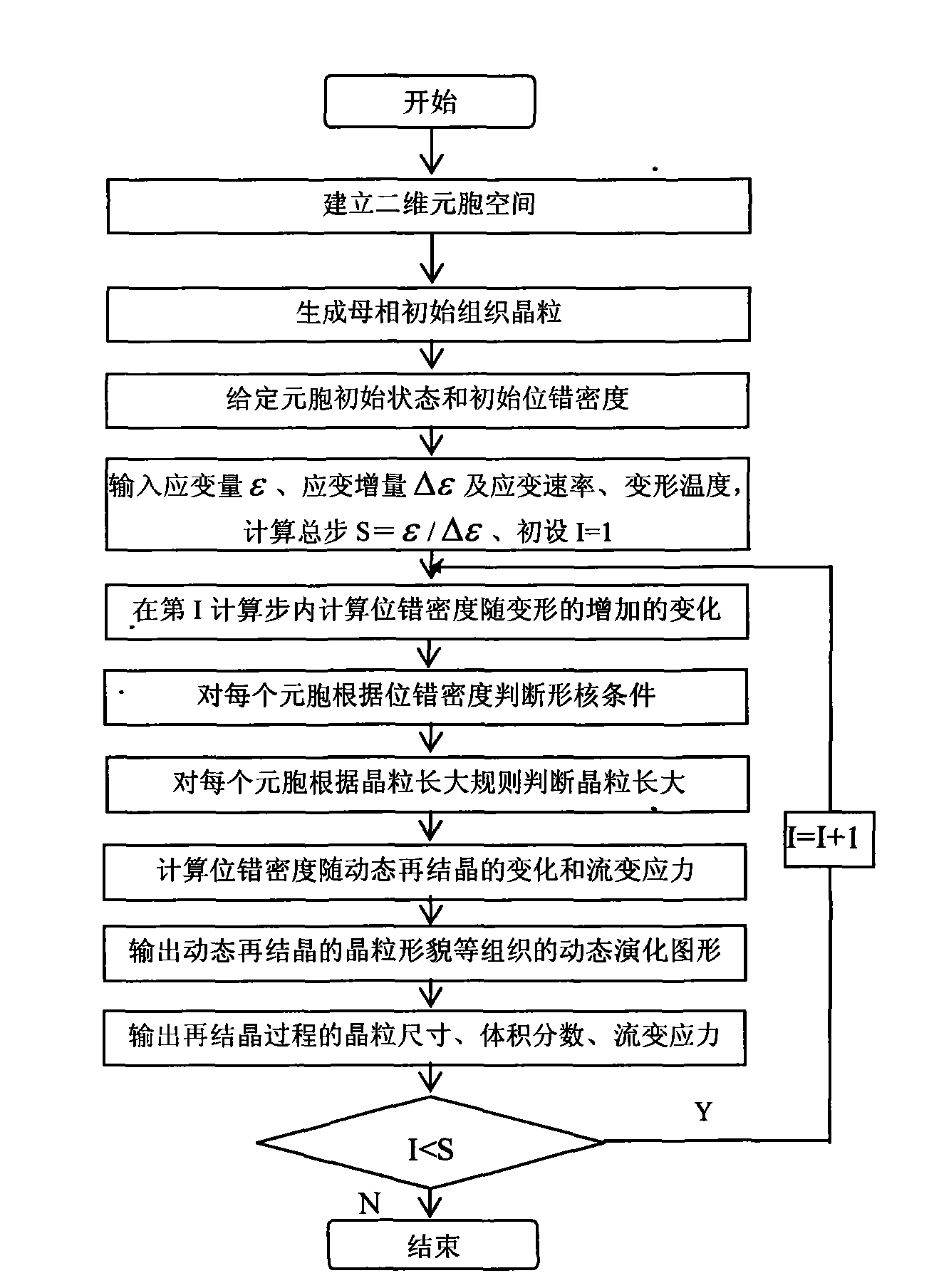

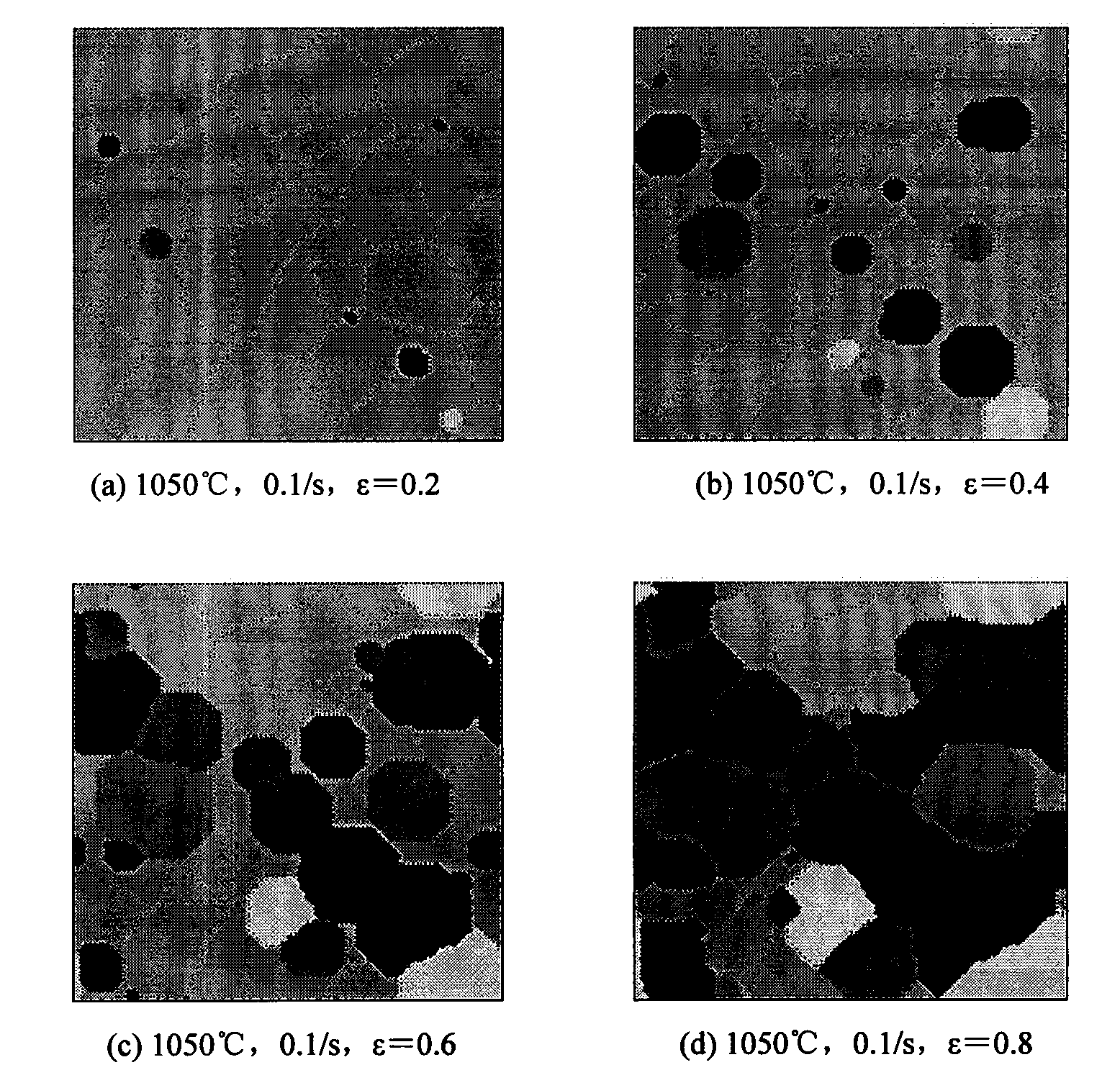

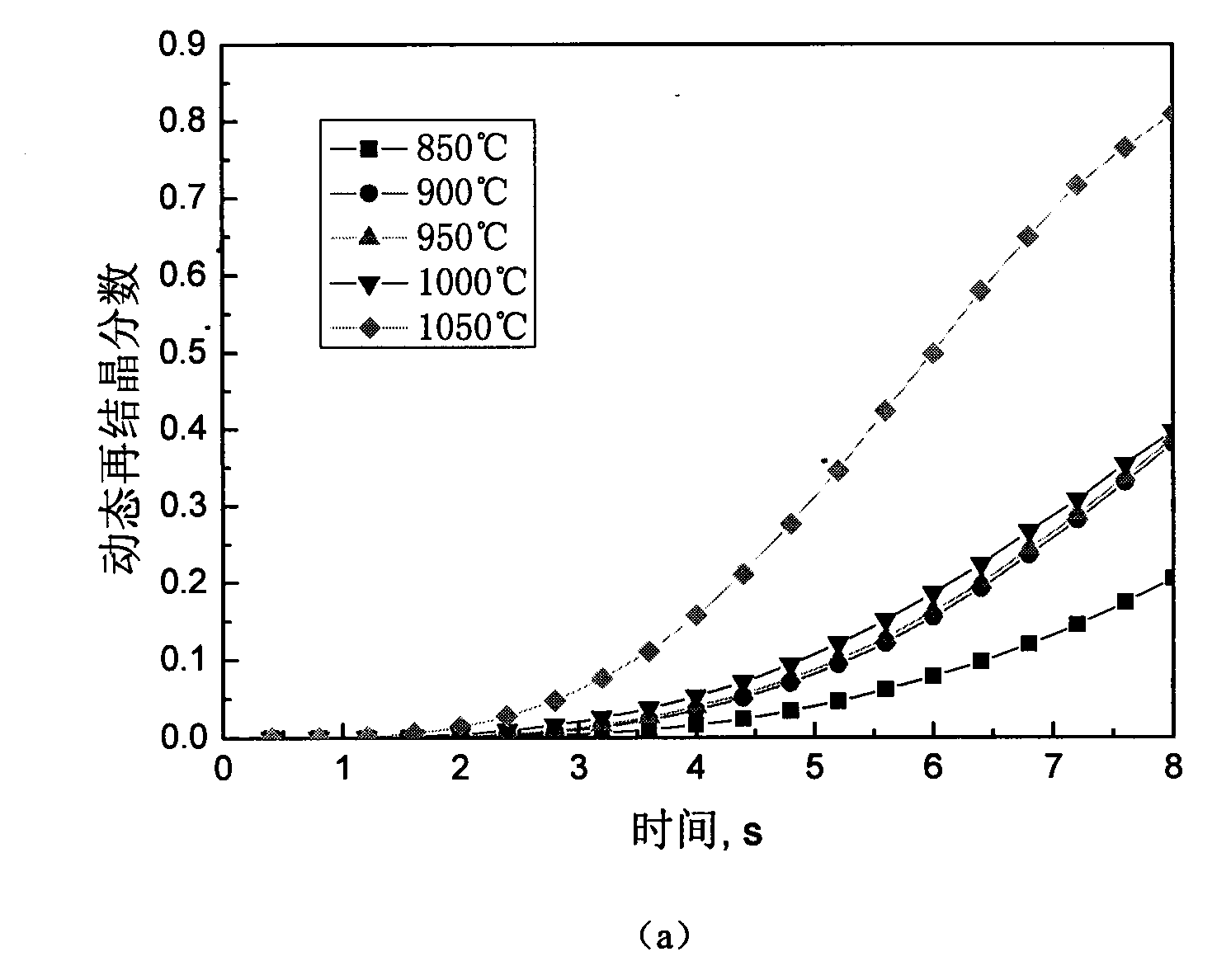

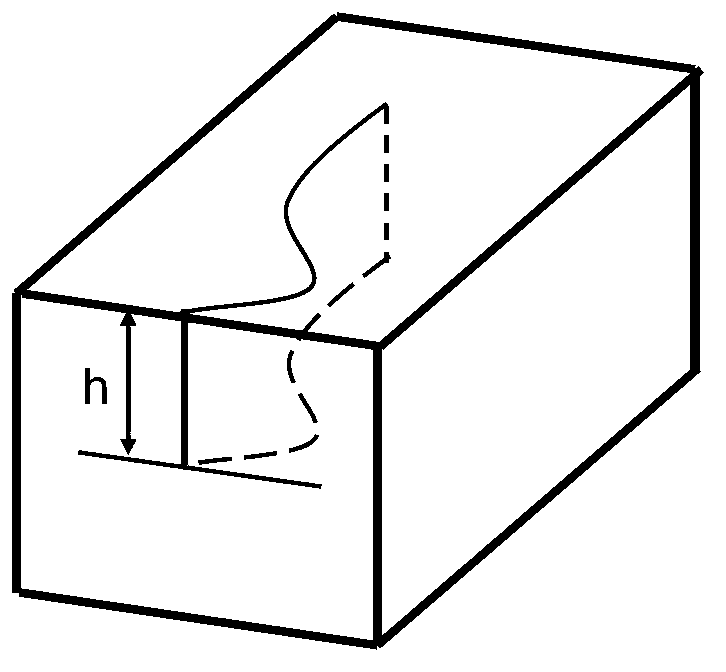

Method for predicting structure evolution of austenite dynamic recrystallization in thermal deformation of plate-strip steel

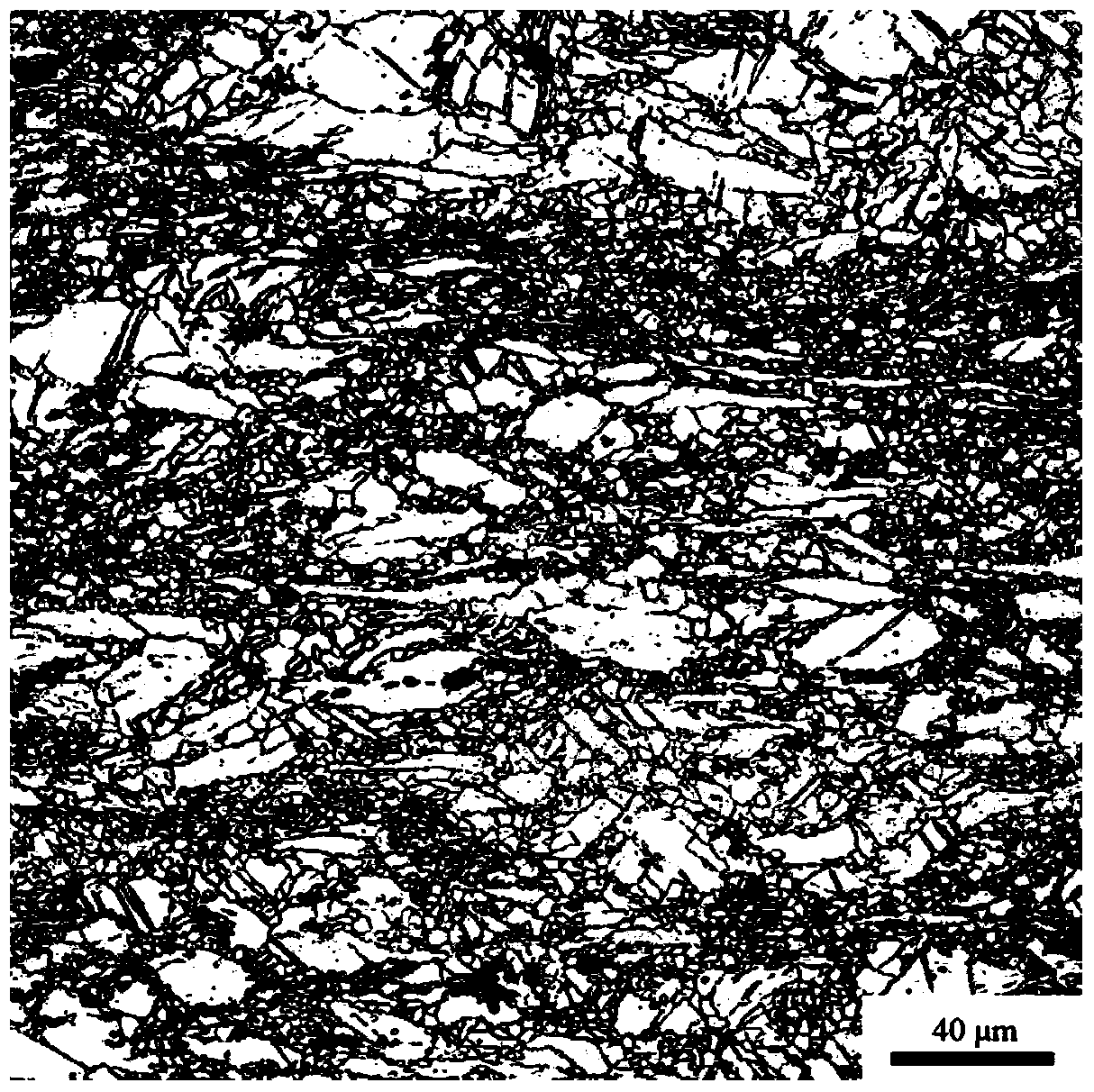

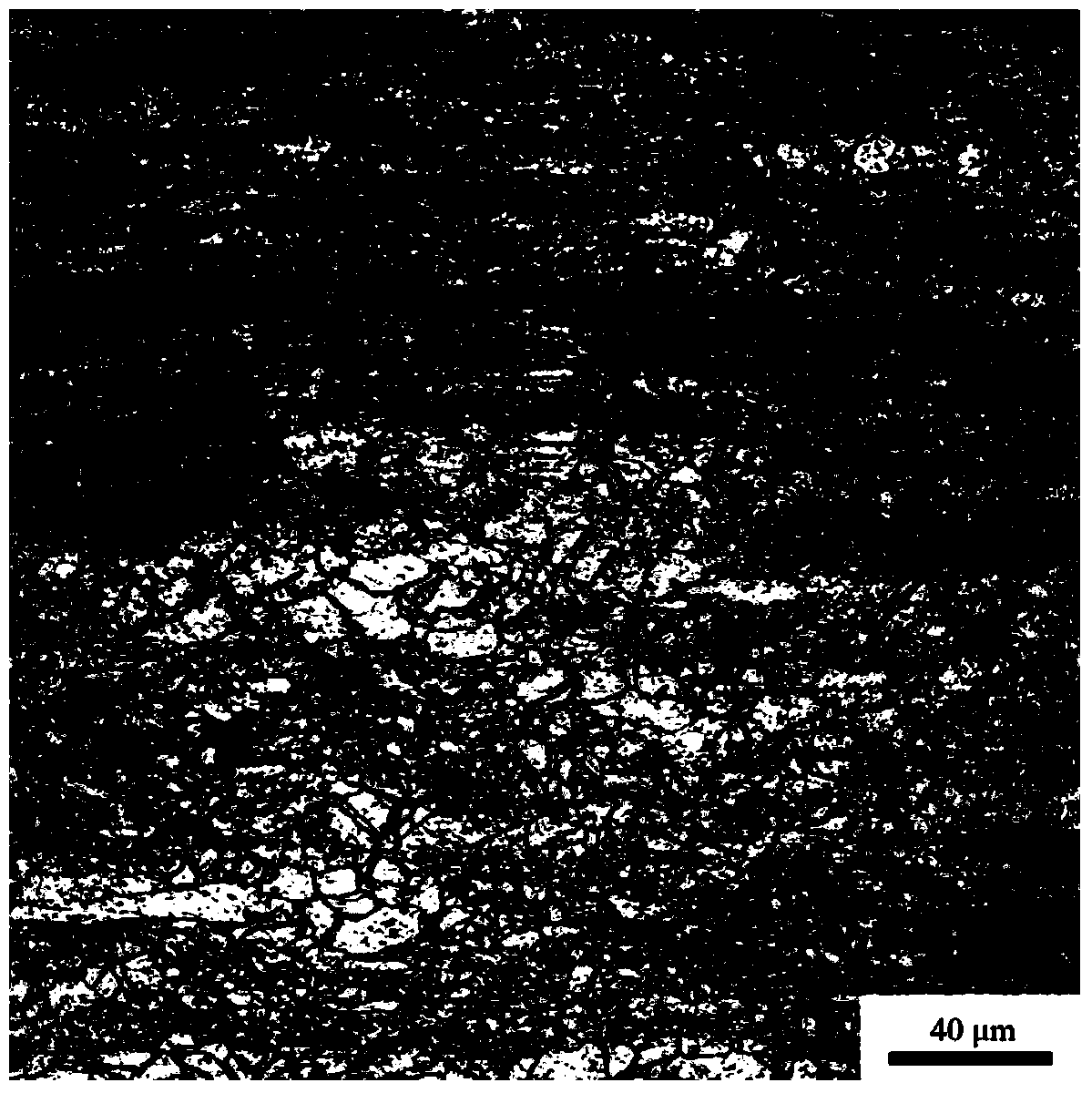

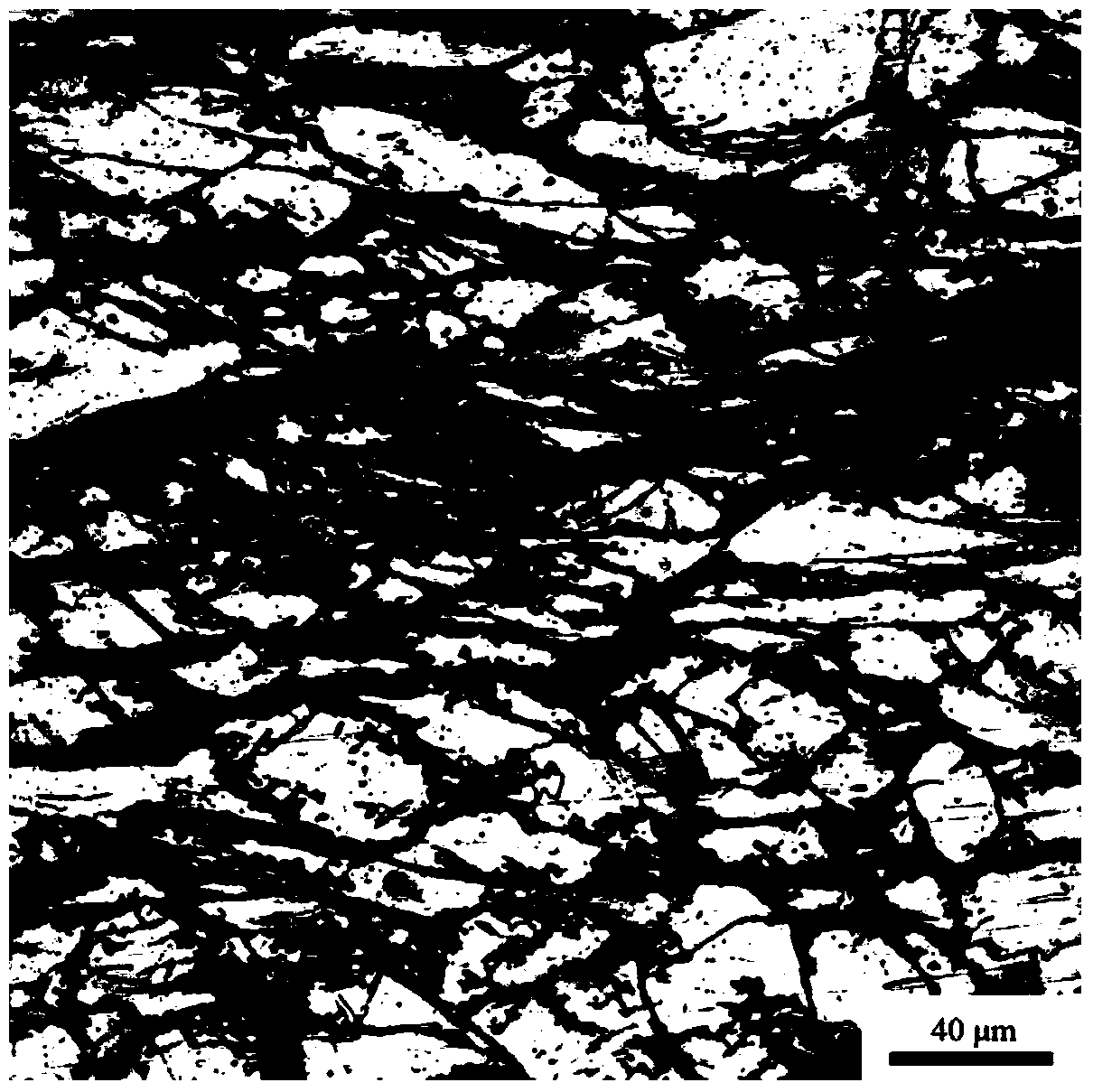

InactiveCN101591729AAccelerate development cycleQuantitativeHeat treatment process controlFlow stressCellular automation

The invention relates to a method for predicting structure evolution of austenite dynamic recrystallization in thermal deformation of plate-strip steel, which belongs to the technical field of steel rolling. The method achieves the predictions of the transformed fraction, the grain size, the grain morphology and the flow stress of dynamic recrystallization by establishing a dynamic recrystallization physical metallurgical model and a dynamic recrystallization cellular automation model. The method achieves the reproduction of the structure evolution of a metal forming process by a computer, not only can save the experimental cost, but also can accelerate the development cycle of a new type of steel. The developed method for predicting the structure evolution of the austenite dynamic recrystallization in the thermal deformation of the plate-strip steel achieves the quantitative, precise and visual descriptions of the grain morphology, the volume fraction and the grain size of the recrystallization process, and can obtain important parameters of the flow stress and the like, thus the method is significant in further analyzing the evolution law of microstructures.

Owner:NORTHEASTERN UNIV

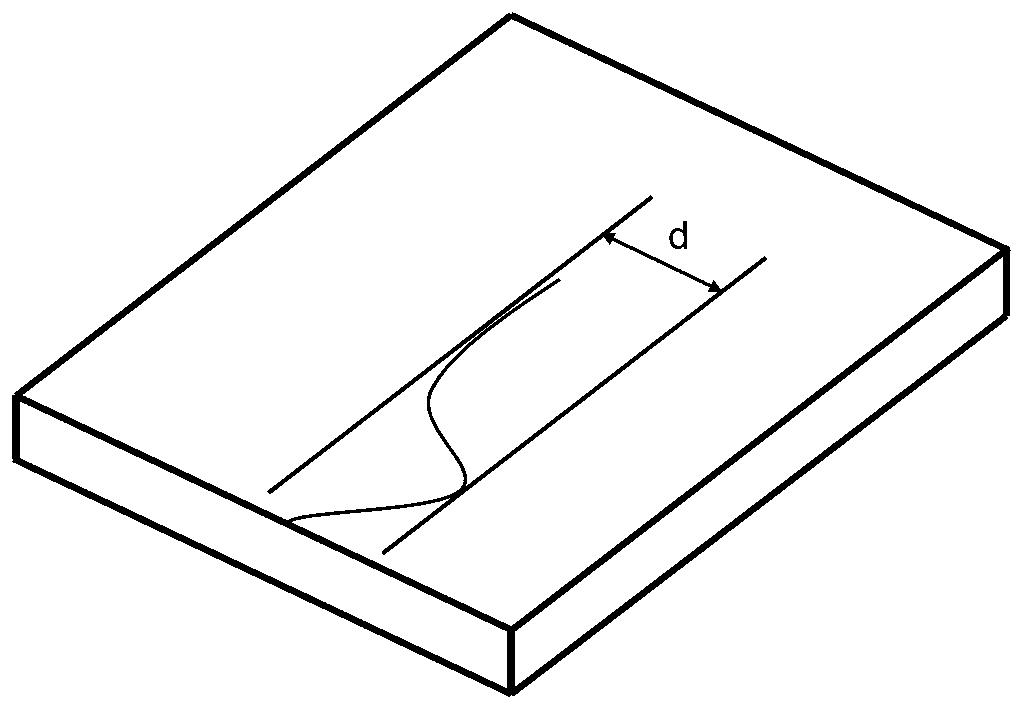

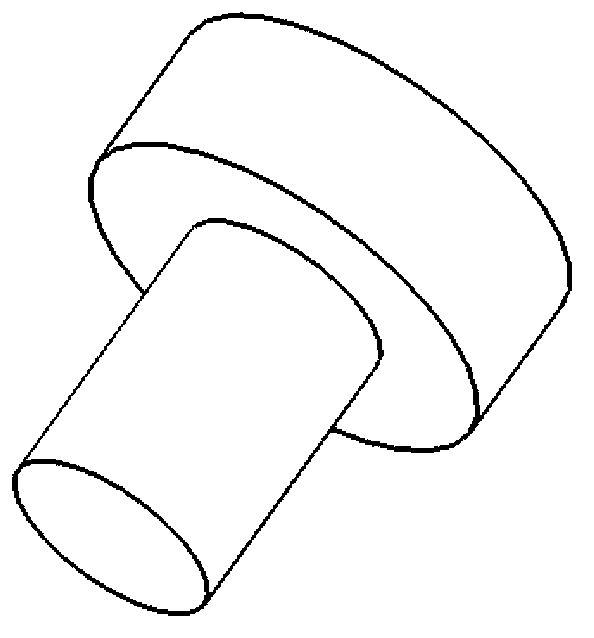

Stirring-friction-based crack repair method

InactiveCN103212778AReduce distortionReduce stressNon-electric welding apparatusUltimate tensile strengthAstronautics

The invention relates to a stirring-friction-based crack repair method which mainly is used for solving the problems in the prior art that the repair cost is high, the repair quality is poor and cracks appear repeatedly. The method is applied to the repair of surface cracks and through cracks of plate-shell metal structures, so as to enable cracked workpieces to meet reuse requirements. The method comprises the following specific steps of designing and manufacturing a friction repair tool according to the position and size of a crack, a material to be repaired, structural characteristics and the like; and realizing the friction between a shaft shoulder and the surface of the material to be repaired through the rotation of the repair tool so as to enable metal of a repair area to reach a thermoplastic state under the action of frictional heat, and realizing the flowing transfer and dynamic recrystallization of thermoplastic metal around the crack by using the rotating and upsetting action of the shaft shoulder of the repair tool, thereby realizing the filling repair of the crack. The method has the advantages that the method is simple, the damage to base metal is little, the quick, equal-strength and in-situ repair of engineering cracks can be realized, and the repair process is economical and environment-friendly. The method can be applied to the crack repair in fields, such as aeronautics and astronautics, shipbuilding, automobiles and rail transportation and has broad application prospects.

Owner:SHENYANG AEROSPACE UNIVERSITY

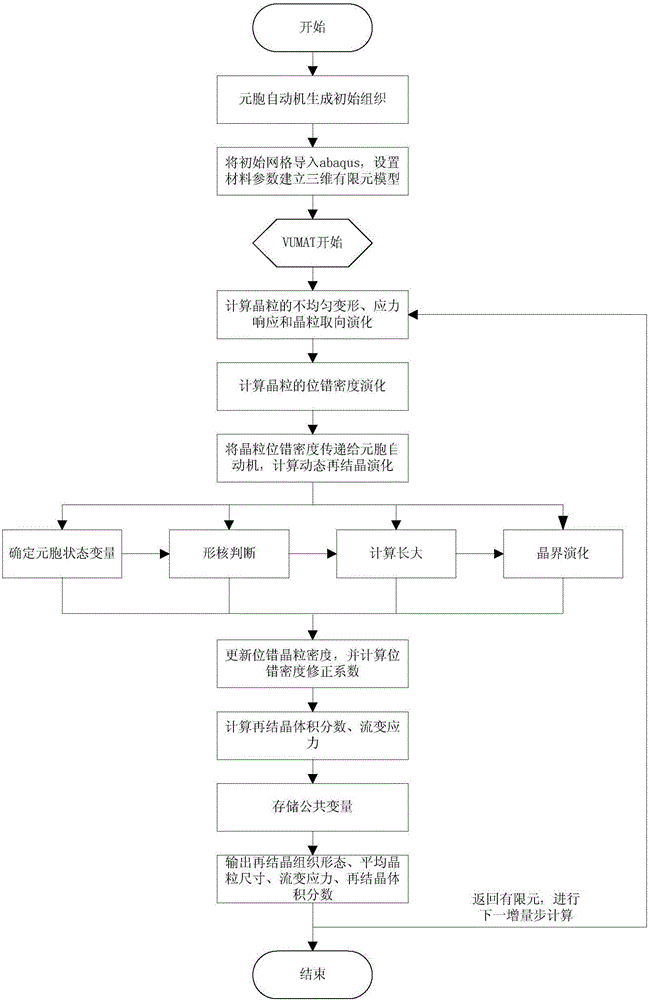

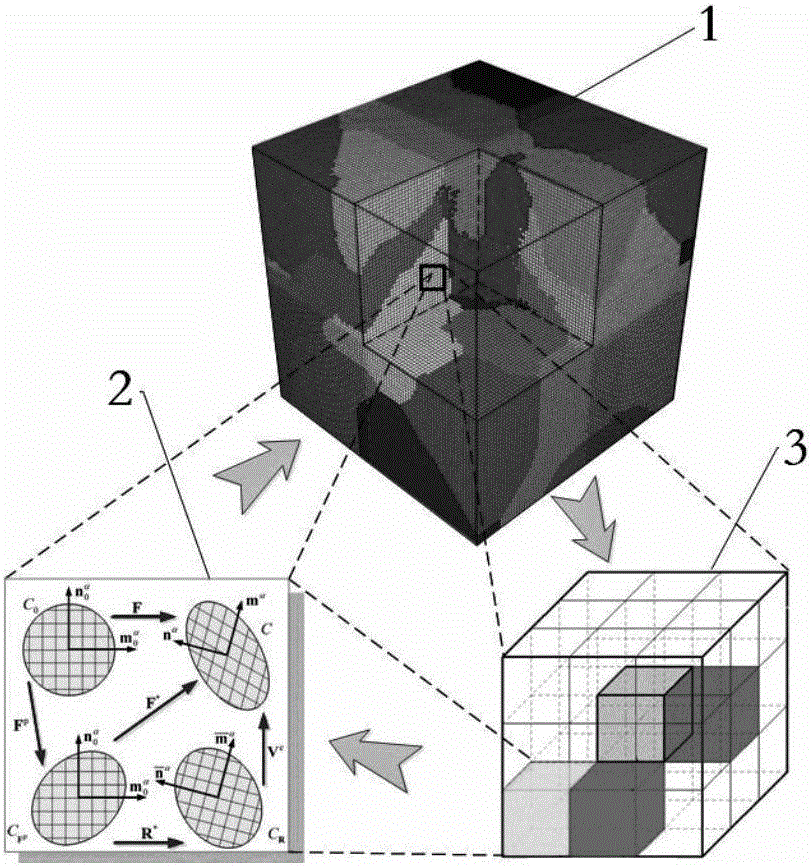

Method for predicting coupling responses of isothermal forming and dynamic recrystallization evolution of titanium alloys

ActiveCN106202675AAchieving Unified PredictionTightly deformedDesign optimisation/simulationSpecial data processing applicationsCrystallization kineticsTitanium alloy

The invention provides a method for predicting coupling responses of isothermal forming and dynamic recrystallization evolution of titanium alloys. Grain stress responses, intercrystalline non-uniform deformation and non-uniform dislocation density caused by intercrystalline non-uniform deformation are obtained in an isothermal forming process of the titanium alloys and are adopted as variables and transmitted to a cellular automaton, dynamic recrystallization evolution of the grain size under the condition of non-uniform size deformation is obtained, and dynamic recrystallization nucleation and grown structure morphology as well as grain boundary evolution and updated dislocation density which are caused by the dynamic recrystallization nucleation and grown structure morphology are obtained. The obtained grain and grain boundary information including dynamic recrystallization nucleation and growth as well as the dislocation density is returned to a crystal plasticity finite element method, dislocation gliding resistance of each grain unit is updated, so that subsequent deformation of the titanium alloys is influenced, and the stress responses of the grain size are calculated according to the constitutive relation. The method realizes synchronous prediction of non-uniform deformation of the grain size in isothermal forming of the titanium alloys, dynamic recrystallization structure morphology evolution, recrystallized grain size evaluation, recrystallization kinetics, deformable bodies and grain flow stress.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Prediction method for microstructure evolution law of 20CrMnTiH steel in thermal deformation process

ActiveCN105373683AForming Quality ControlImprove forming qualityDesign optimisation/simulationSpecial data processing applicationsAustenite grainThermoforming

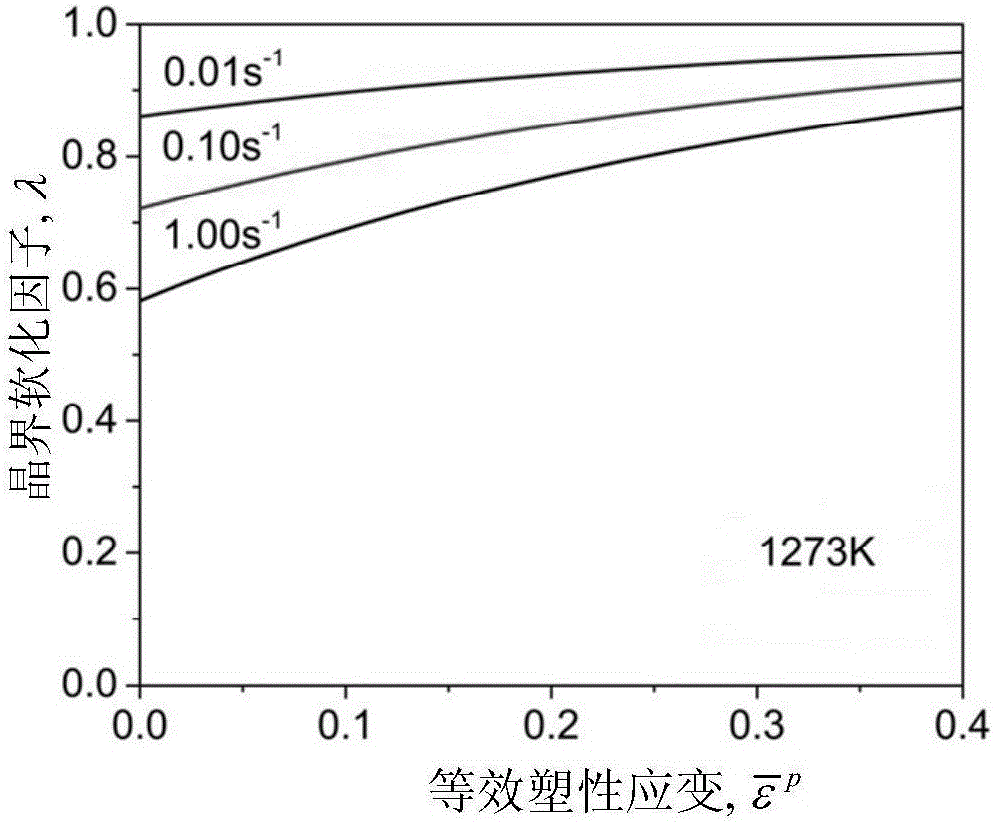

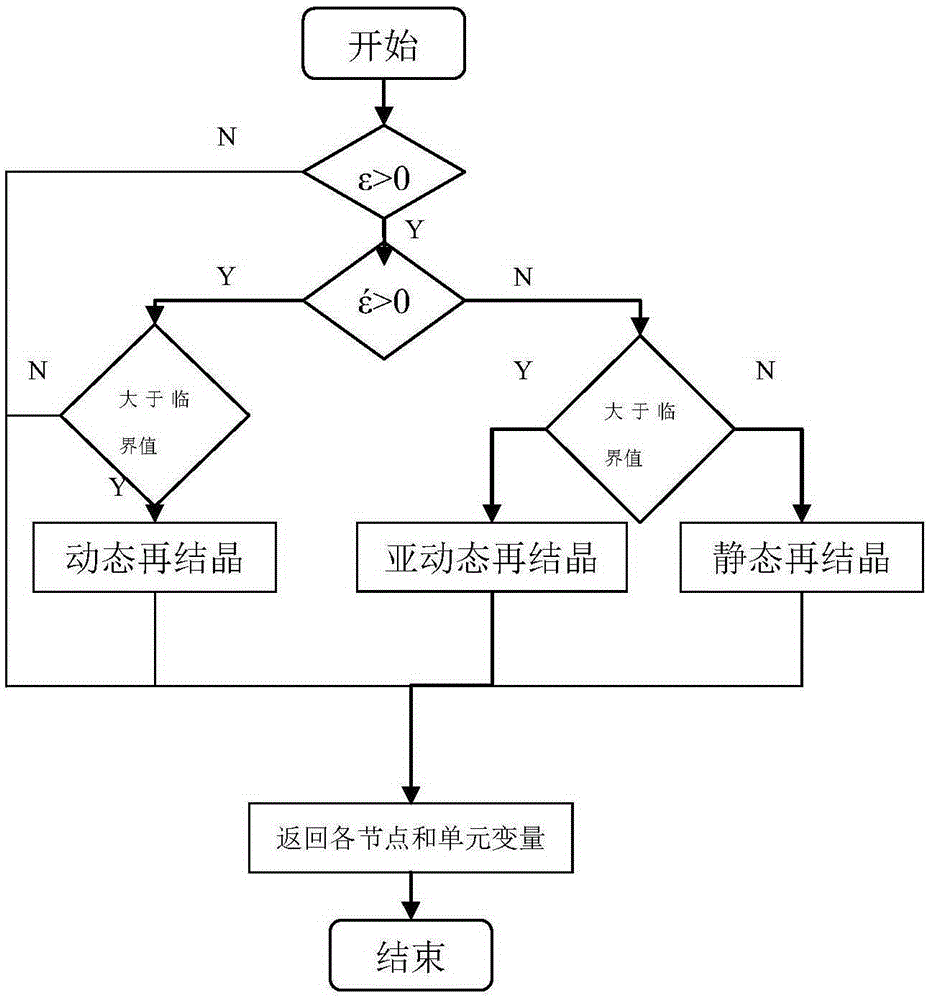

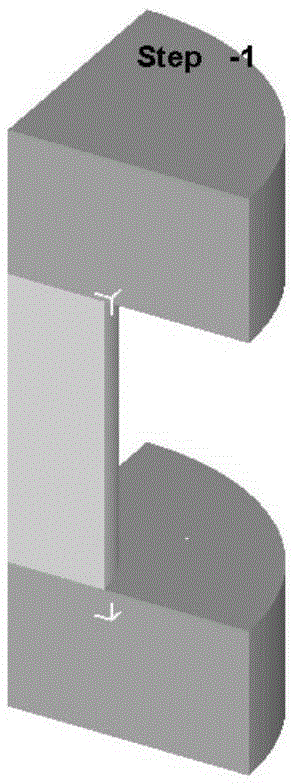

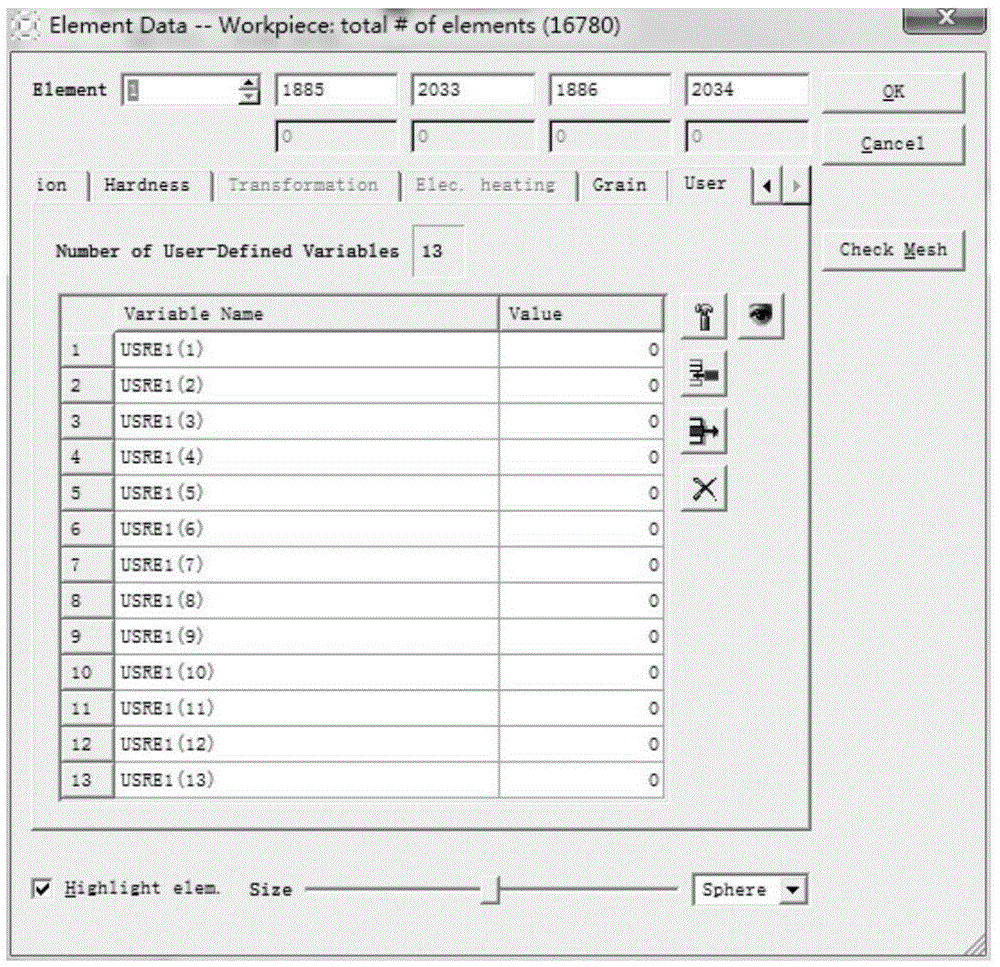

The invention discloses a prediction method for a microstructure evolution law of 20CrMnTiH steel in a thermal deformation process. According to the method, a Deform-3D based secondary development microstructure simulation module is combined with the thermal deformation process; a mathematic model of a microstructure evolution mechanism of the 20CrMnTiH steel is obtained by a physical experiment; dynamic recrystallization, static recrystallization, meta dynamic recrystallization and austenite grain growth microstructure analysis and simulation modules for a material are compiled by adopting an Absoft Pro Fortran language; and microstructure distribution of a thermal deformation workpiece in different process conditions is calculated by calling the microstructure modules, and macroscopic field quantity such as a temperature field, an equivalent stress-strain field and a microstructure mutual influence law in the thermal deformation process is analyzed to realize prediction of the microstructure distribution and evolution law of the 20CrMnTiH steel in the thermal deformation process, thereby providing technical bases for setting and optimizing thermoforming process parameters of 20CrMnTiH steel products in actual production, and providing theoretic bases for obtaining high mechanical performance of the material by controlling deformation conditions in a thermal precision forming process.

Owner:WUHAN UNIV OF TECH

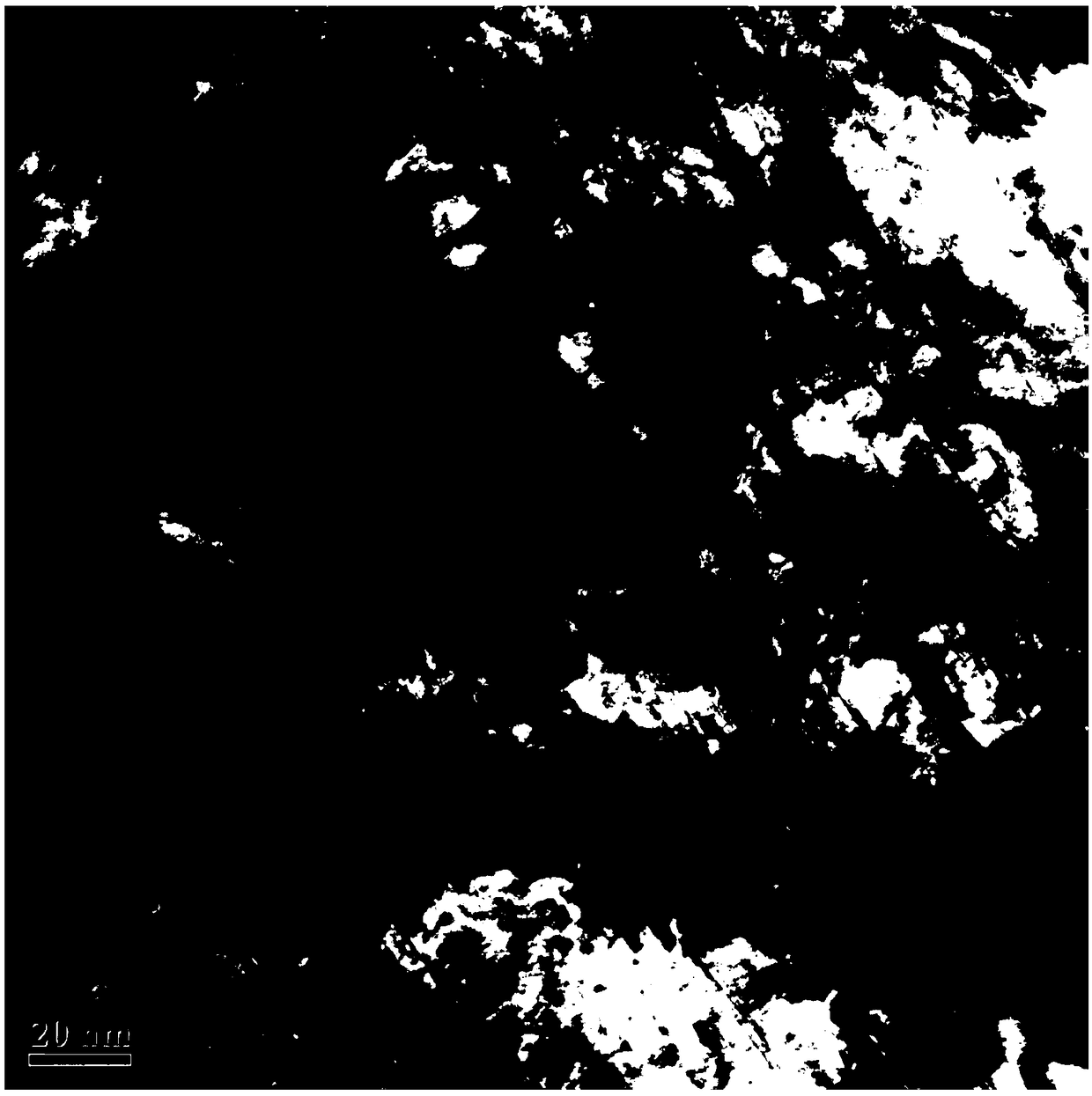

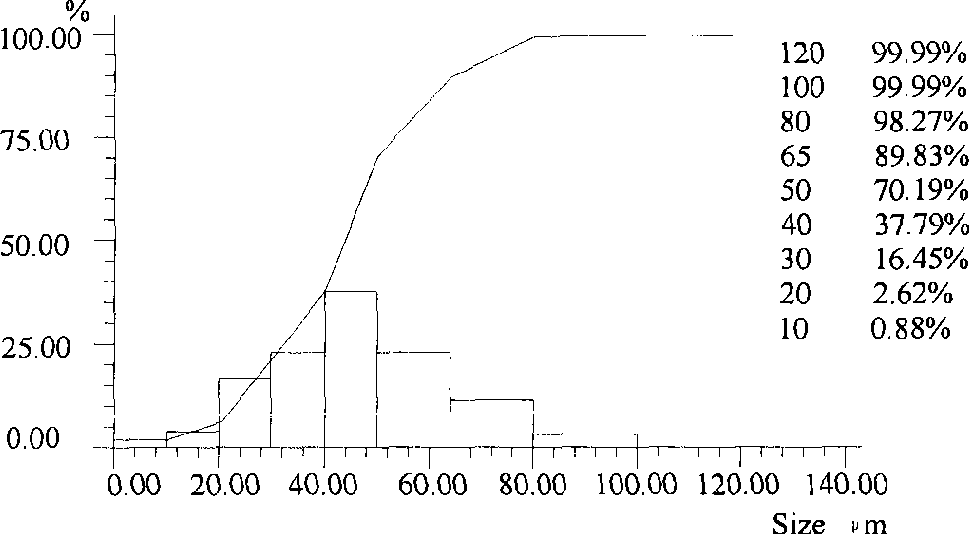

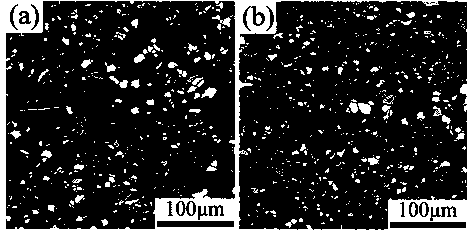

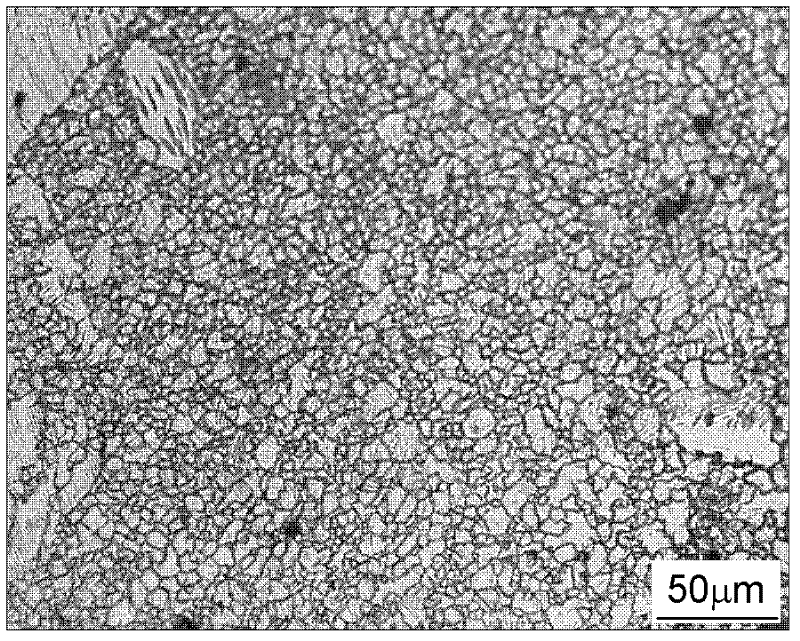

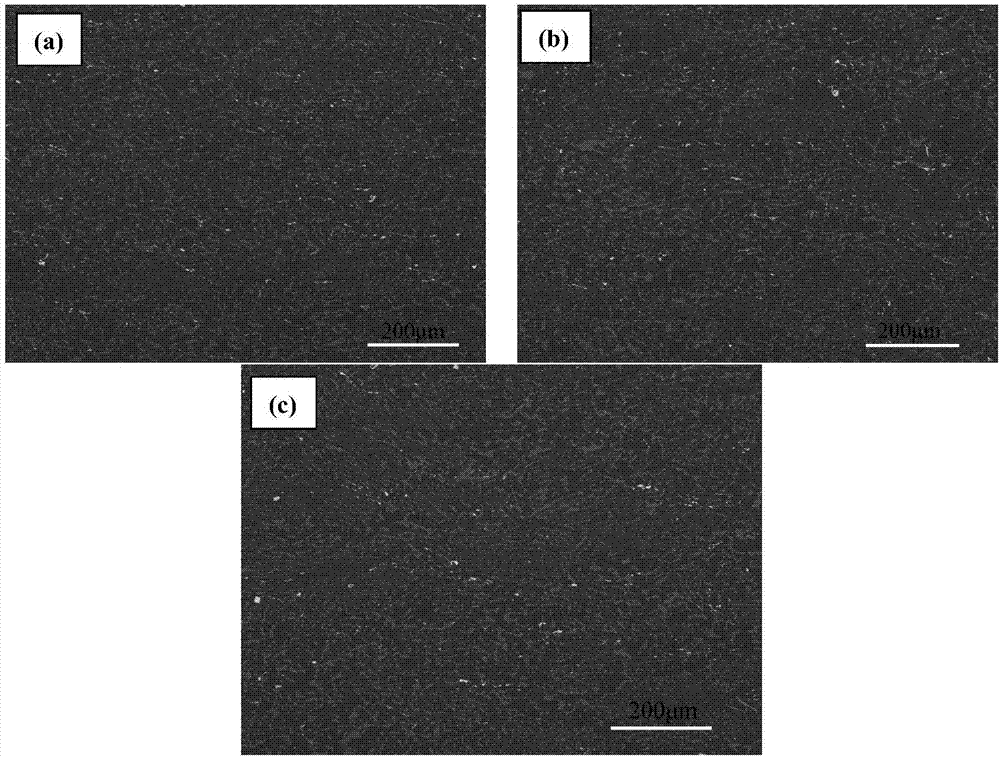

Preparation method of ultra-pure aluminum ultrafine grain sputtering target

InactiveCN101638760AIncrease the amount of deformationVacuum evaporation coatingSputtering coatingSputteringMaterials processing

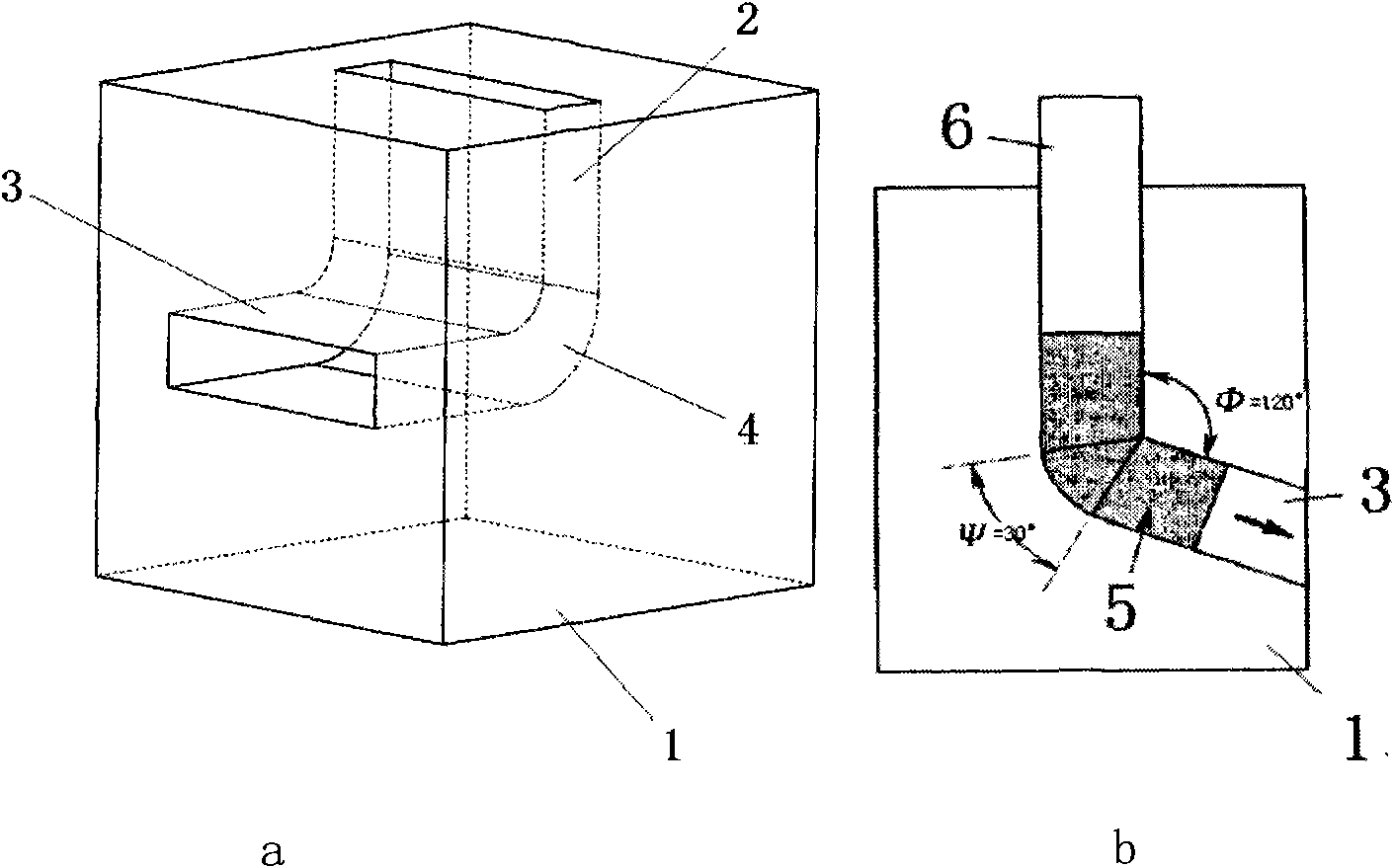

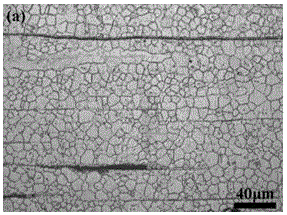

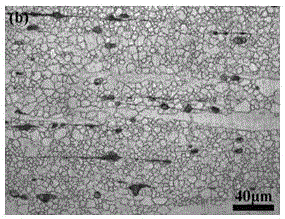

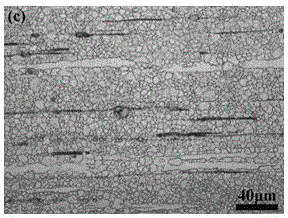

The invention discloses a preparation method of ultra-pure aluminum ultrafine grain sputtering target, belonging to the technical field of metal material processing. The preparation method comprises:putting an ultra-pure aluminum board into an equal channel angular extruding module for extrusion for 3-15 passes; performing deep undercooled processing to extruded ultra-pure aluminum board in liquid nitrogen at the deep undercooled temperature of minus 80 to minus 10 DEG C; rolling the deep undercooled ultra-pure aluminum board for 3-15 passes. The invention combines equal channel pressing, deep undercooled processing and rolling to fully utilize the characteristic of large extruded deformation amount so as to greatly improve the deformation amount of the ultra-pure aluminum board. The invention utilizes dynamic recrystallization in the deep undercooled inhabitation rolling process and utilizes vertical rolling to change fibroid grain tissue produced by extrusion, and finally, grain shape changes to be even and small as well as easy to be equiaxial.

Owner:SHANGHAI JIAO TONG UNIV

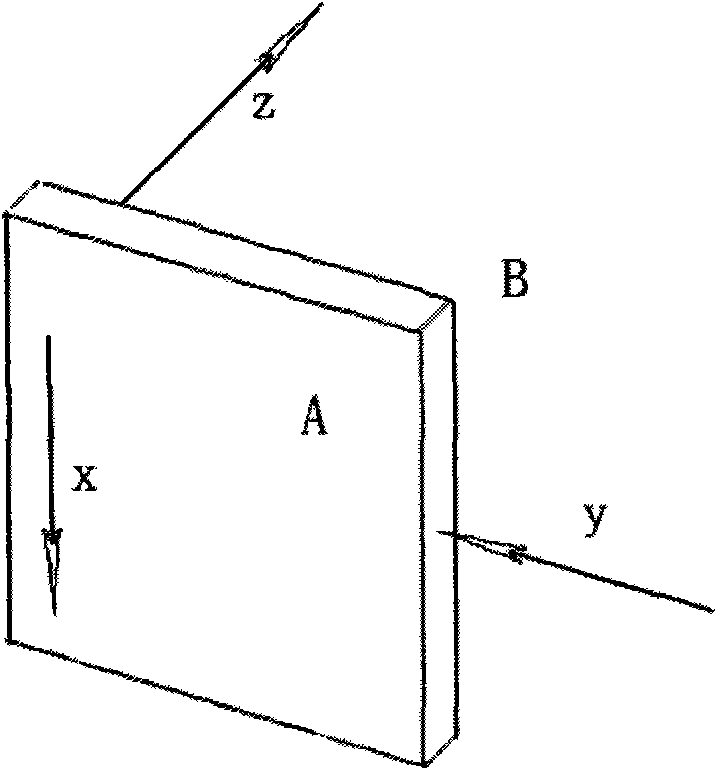

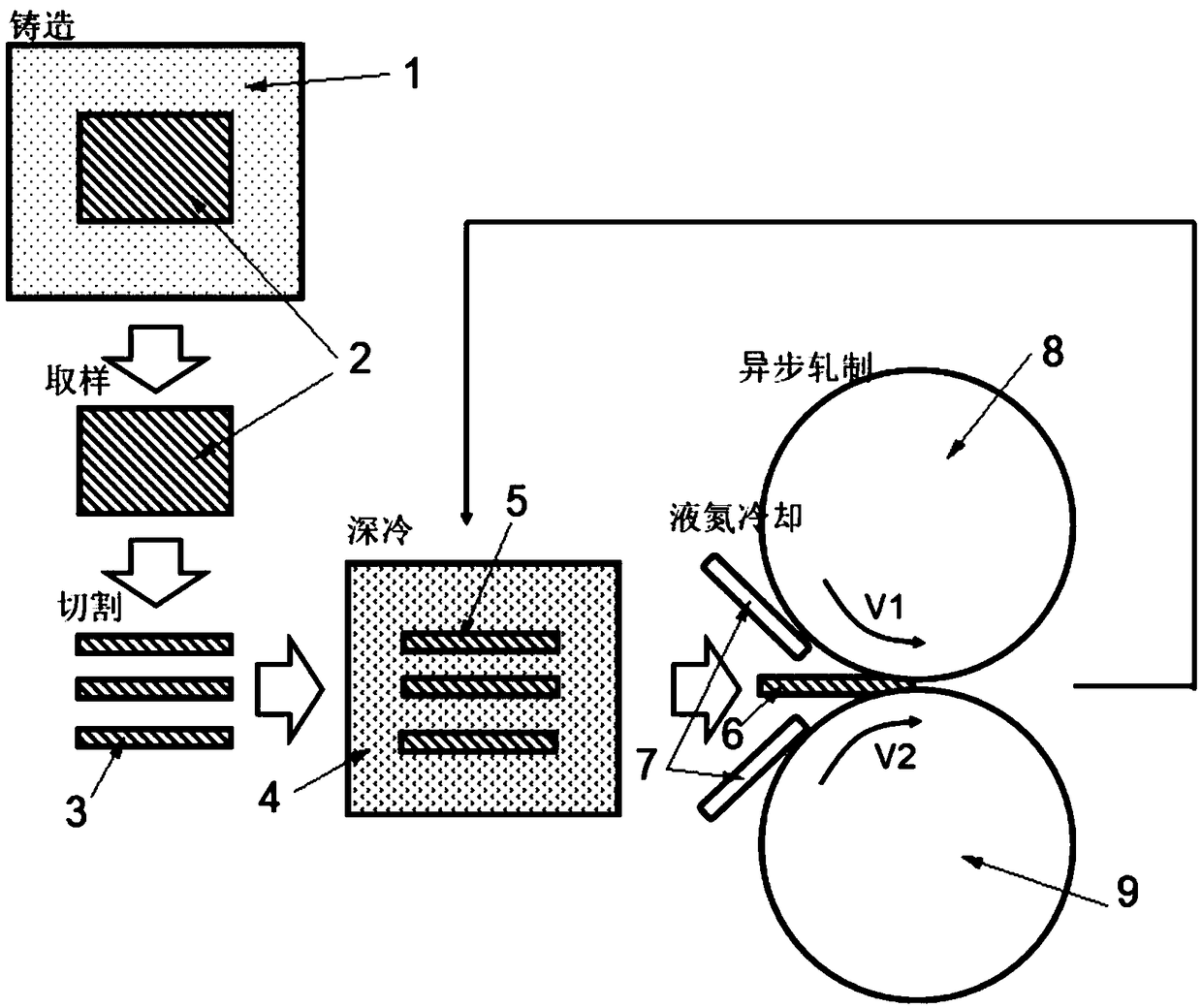

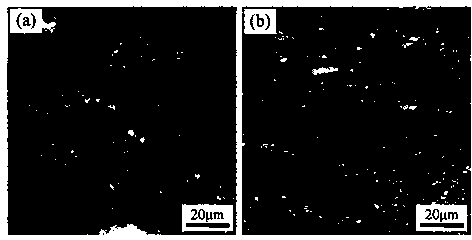

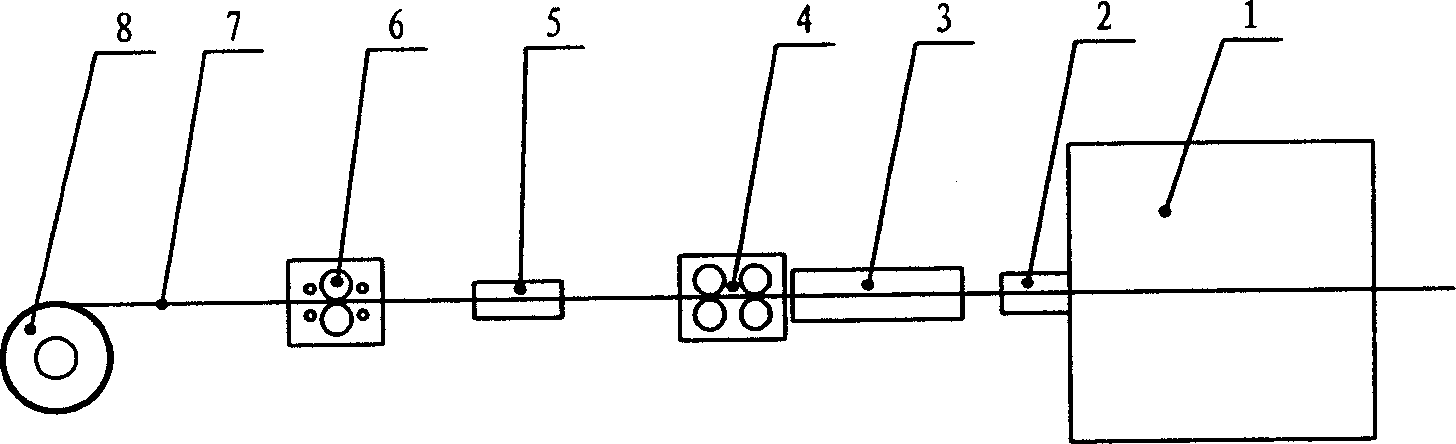

Copious cooling asymmetrical rolling method for preparing entropy alloy foil in high-performance CrCoNi

A copious cooling asymmetrical rolling method for preparing an entropy alloy foil in high-performance CrCoNi comprises the following steps: cutting a CrCoNi alloy bar or plate into sheets; carrying out copious cooling treatment in a copious cooling box at the temperature of minus 190 DEG C to minus 150 DEG C; cooling rolls by using a liquid nitrogen spray gun; carrying out copious cooling asymmetrical rolling on samples after copious cooling; maintaining liquid nitrogen in an asymmetrical rolling process to cool the rolls; cooling the rolled materials in the copious cooling box; and repeatingthe fourth step and the fifth step until the reduction rate of rolled pieces exceeds 85%-95% and the thickness of the foil is 200 mu m-6 mu m. CrCoNi alloy has good plastic deformation capacity underthe condition of ultra-low temperature, dynamic recrystallization behavior of the grain size of a material in a large plastic deformation process is inhibited by ultra-low temperature to reduce the grain size, the thickness of the material is reduced by twisting rolling deformation in a rolled piece deformation region in the asymmetrical rolling process, thus, entropy CrCoNi alloy foil is produced, the strength and plasticity of the material are improved effectively, and thus, the prepared medium-entropy CrCoNi foil has high toughness.

Owner:CENT SOUTH UNIV +1

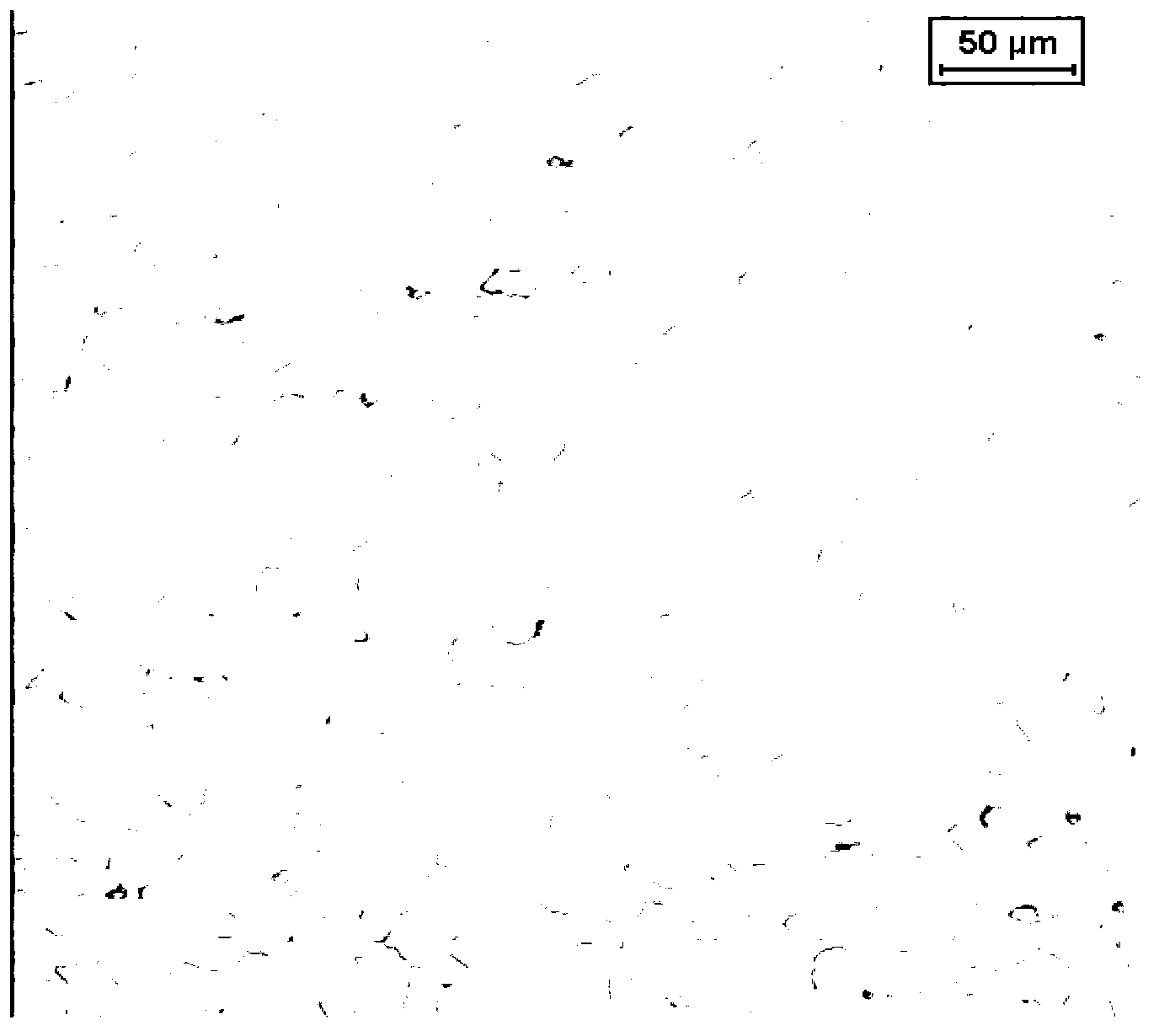

Method for preparing niobium sputtering target

ActiveCN101660130AFast film formationSame orientationVacuum evaporation coatingSputtering coatingNiobiumIngot

The invention relates to a method for preparing niobium sputtering target, which is characterized in that the preparation process sequentially comprises the steps: (1) extruding a niobium ingot with the diameter of 300-330mm to be a niobium rod with the diameter of 100-150mm at the temperature of 900-1100 DEG C, and controlling the extrusion ratio to be more than 7; (2) after heating the niobium rod to be 500-700 DEG C for homeothermy, and upsetting and reshaping the niobium rod to be a plate blank by an air hammer, wherein controlling the processing rate of the previous two times of upsettingto be more than or equal to 30%; (3) carrying out intermediate annealing on the plate blank with the annealing temperature of 900-1100 DEG C and the heat preservation time of 1-2h; (4) after annealing, rolling the plate blank, and controlling the single processing rate of the previous two times of upsetting to be more than 35% and the subsequent rolling processing rate to be more than 20%; and (5) annealing the rolled finished product. The method adopts high temperature extrusion with high processing rate, so as to lead the niobium rod to have dynamic recrystallization when in the extruding process and ensure the crystalline grains to be fully ground, so that the difference between the sizes of the crystalline grains at the core part and the edge of a cast ingot can be reduced, the orientation of the crystalline grains can be ensured to be consistent, and more than 70% (111) type texture can be obtained.

Owner:西安诺博尔稀贵金属材料股份有限公司

Method for producing wear-resisting hot-rolling steel plate by using furnace rolling machine and steel plate prepared by the same method

InactiveCN101186960AHigh strengthUniform tissueRoll mill control devicesHeat treatment process controlWear resistantAlloy

The invention discloses a production process of using a steckel mill to produce wear-resistant steels and produced steel plates thereof. Selected components of the invention are that C<=0.30%, Mn<= 2.5%, P <= 0.015%, S <= 0.005% and Si <= 2.2%. Continuous casting slab of alloys which includes Cr, Mo, Nb, V and the like (Cr <= 1.3%, Mo <= 0.9%, Nb <= 0.05%, V <= 1.0%) is moderately added. The invention employs warm loading and delivery. Steel plates of medium thickness are flatly rolled on the steckel mill with the employment of TMCP + off-line tempering processes, thin steel plates utilize coil rolling + cooling control + off-line tempering processes, and the uniformity, thinning and intensification of tissue are realized by controlling dynamic recrystallization and meta-dynamic recrystallization in the rough rolling stage, strain accumulation and relaxation process in the finely rolling stage, cooling rate within the range of producing lower bainite, and final cooling temperature between the formation temperature of lower bainite and the formation temperature of martensite by employing the off-line low tempering temperature which is equal to or less than 350 DEG C(<= 350 DEG C), thereby ensuring high-intensity, high ductility and abrasion resistant combination property of the steel plates.

Owner:NANJING IRON & STEEL CO LTD +1

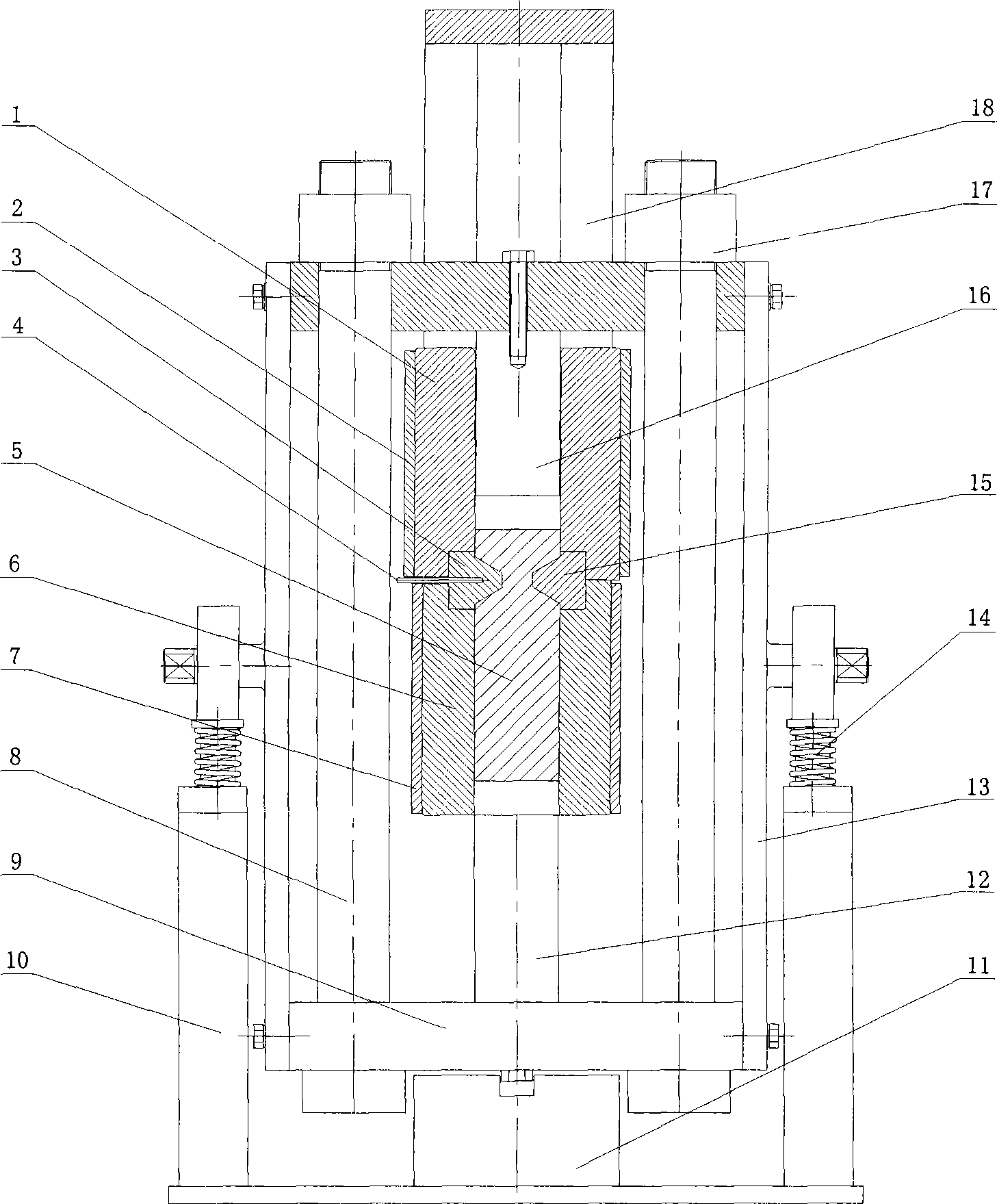

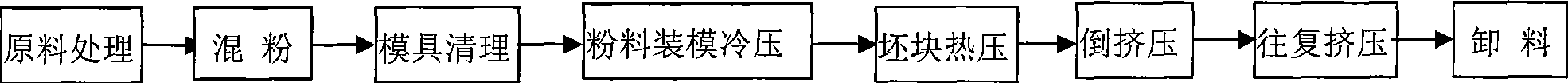

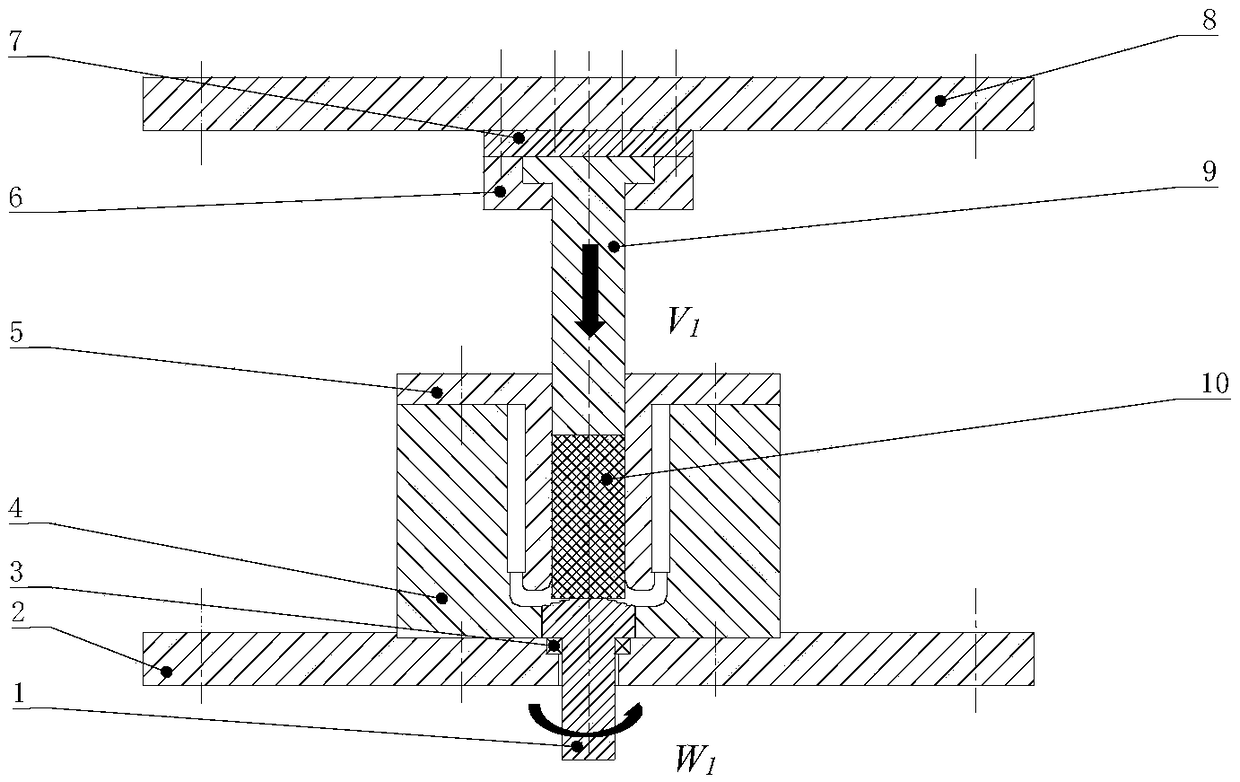

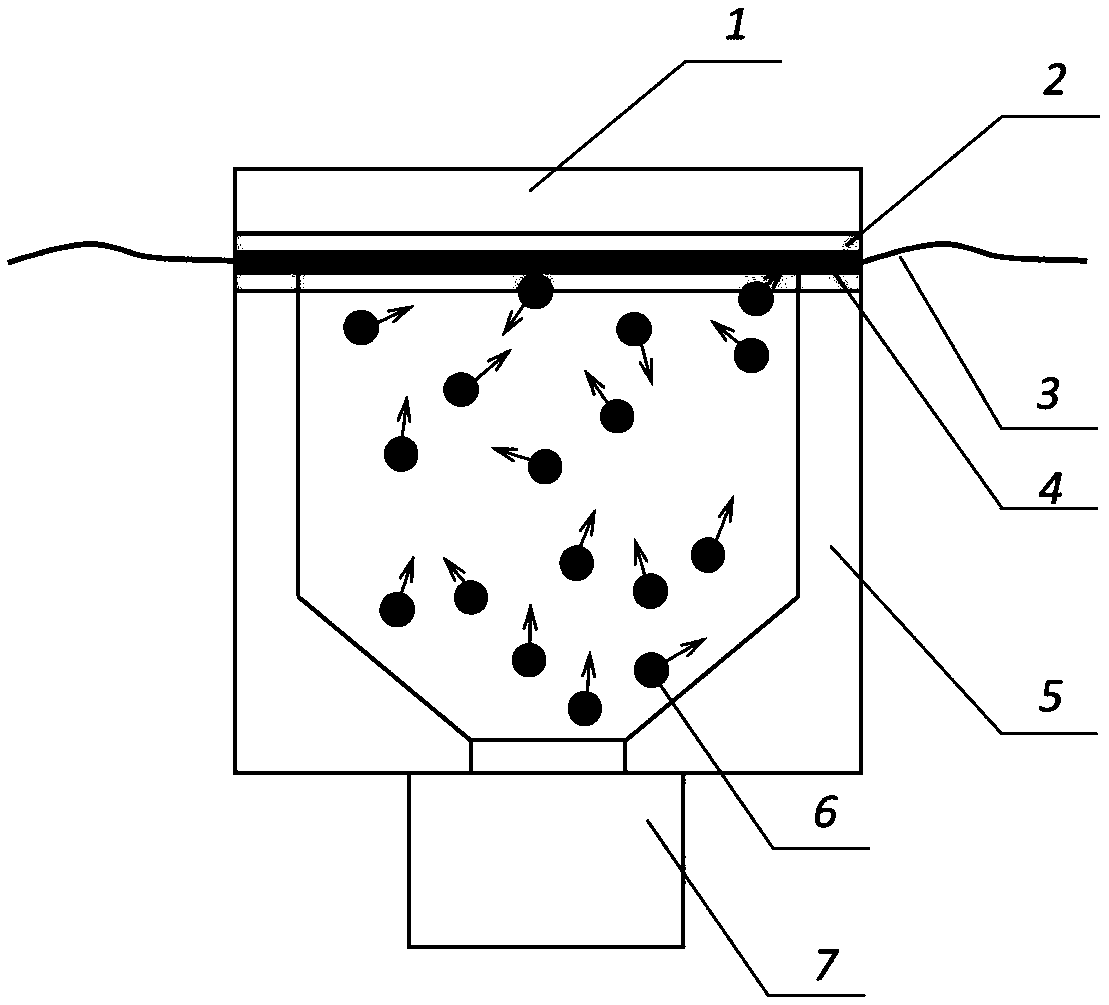

Technique and apparatus for preparing particle reinforced aluminum-based composite material by reciprocating type extrusion

The invention relates to a process and a device for preparing a particle-reinforced aluminum-matrix composite by means of utilizing reciprocating extrusion. The device comprises an extrusion barrel, an extrusion barrel heating member, a semi-ring-shaped cavity die, a temperature control thermocouple, a die connection guiding rod, a die connection turning beam, a die turning mechanism support, an extrusion cushion, a male die, a die turning connecting beam, a die turning mechanism elastic supporting member, a die connection guiding rod nut and a U-shaped extrusion rod. When the device is used, a die connecting device and a die turning mechanism are used for realizing the equivalent volumes of an extruded material and a mould cavity and for performing repeated extrusion and upsetting by alternately applying pressures in different directions to the two ends of the extruded material so as to cause the material to be kneaded. The extruded material can generate strong plastic deformation and simultaneously undergo dynamic recrystallization so that the interface of the extruded powder material is fully welded together. Due to the dynamic recrystallization, newly-generated crystals are remarkably thinned, and the isotropic fine-grain aluminum-matrix composite is obtained.

Owner:HENAN POLYTECHNIC UNIV

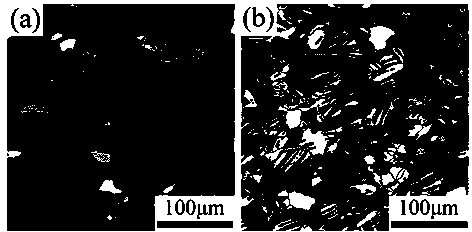

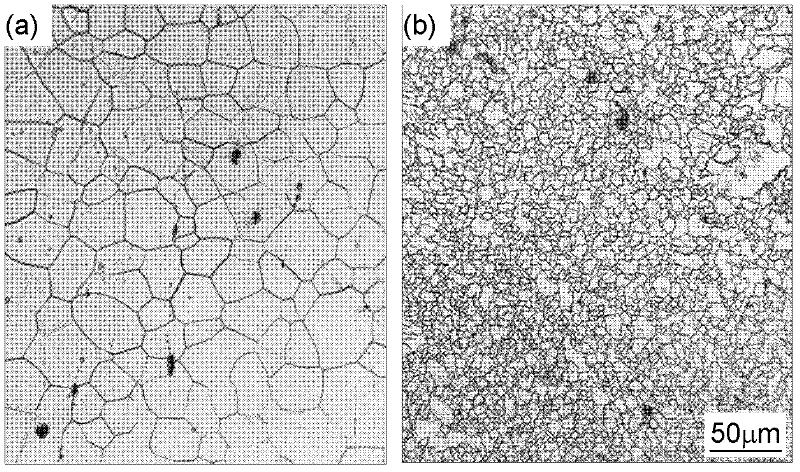

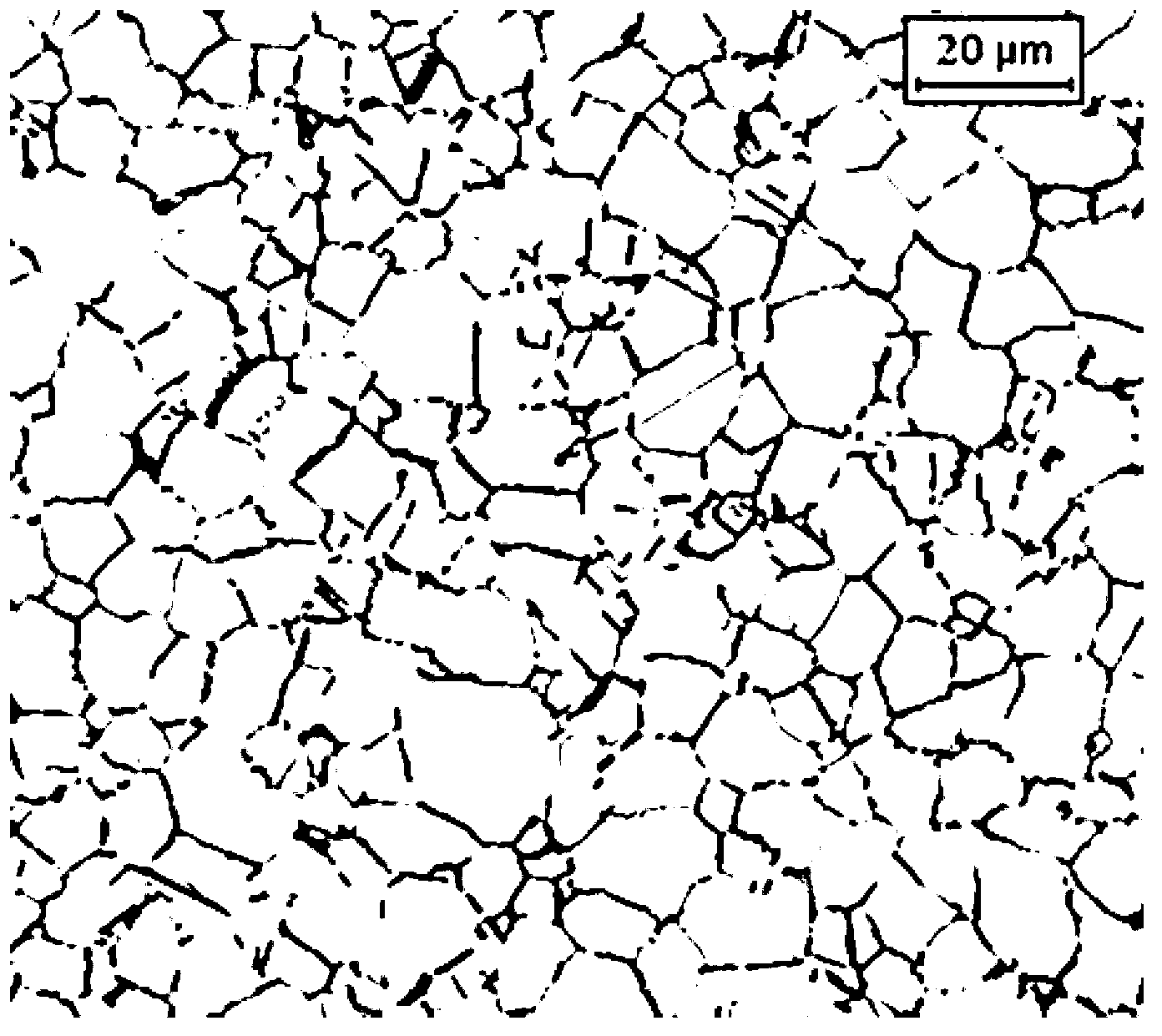

Method for refining magnesium alloy crystal grains

The invention discloses a method for refining magnesium alloy crystal grains, belonging to the technical field of plastic processing of nonferrous metals. According to the method, a magnesium alloy is easily subjected to twin dynamic recrystallization in a low-temperature thermal deformation process by virtue of the processes of twin crystal presetting, low-temperature annealing and low-temperature thermal deformation, and nucleation of new crystal grains is promoted by means of interaction of twin crystals as well as interreaction between the twin crystals and moving dislocation; twin crystal resetting can provide preferred nucleation points, including twin crystal boundaries, boundaries between twin crystals as well as boundaries between twin crystals and crystal boundaries, for dynamic recrystallization in order to accelerate a dynamic recrystallization process and realize refining of crystal grains. The method has the advantages of simple production equipment and low cost, is easy to implement and can be put into mass production.

Owner:TAIYUAN UNIV OF TECH

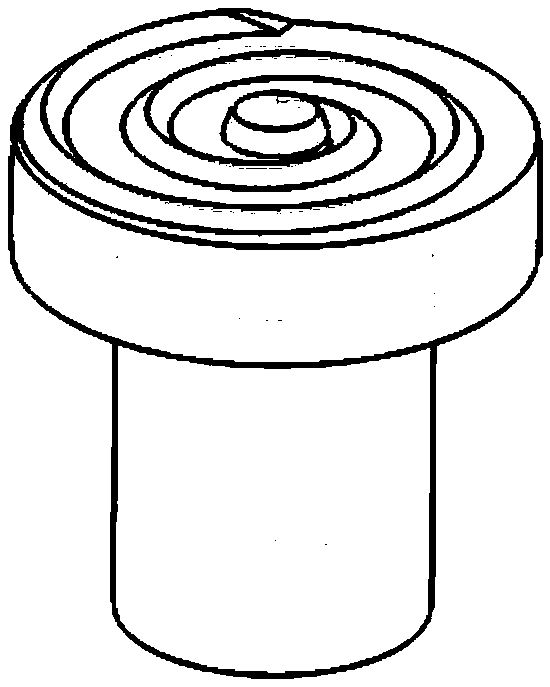

Torsion-extrusion composite strong-plastic forming method and technological device

The invention provides a torsion-extrusion composite strong-plastic forming method and a technological device, and belongs to the technical field of metal plastic processing. The method combines the advantages of high-pressure torsion fine crystal and extrusion forming, the blank is simultaneously subjected to high-pressure torsion and extrusion, the metal at the lower end of the blank is violently sheared, so that crystal grains are mechanically broken, meanwhile, the temperature rise generated by plastic work and friction power enables the dynamic recrystallization to be refined and the metal plasticity is improved; a large extrusion force is applied to enable the metal to generate plastic flow, and then a high-performance component is obtained through corner deformation in a cavity of aprocess device, and accurate control of property forming and shape forming of the technological process is achieved; and the process device mainly comprises a male mould, a combined female mould, a rolling bearing and a rotary head with a special shape. According to the method and the device, crystal grain refining capacity is strong, the crystal grain growth caused by the heating link of the blank can be avoided by shortening the heating process.

Owner:UNIV OF SCI & TECH BEIJING

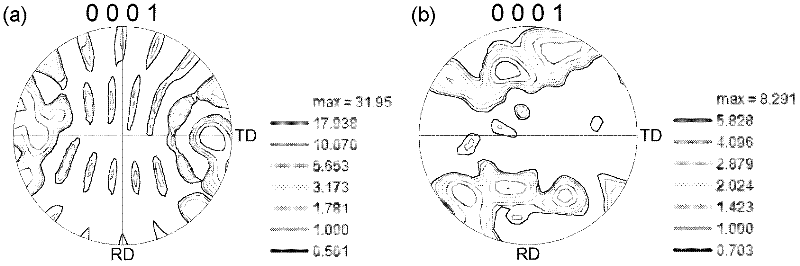

Method for weakening cardinal plane texture of magnesium alloy plate strip

InactiveCN102409273AImprove ductilityGood subsequent processing performanceCrystal twinningUltimate tensile strength

The invention relates to a method for weakening the cardinal plane texture of a magnesium alloy plate strip, which comprises the following steps of: placing the magnesium alloy plate strip between corrugated rollers, carrying out alternative rolling for many times under the temperature of 300-550 DEG C, straightening, and water quenching, or carrying out multi-channel one-way or alternative rolling for many times under the temperature of 150-300 DEG C, straightening, carrying out static recrystallization, and annealing; carrying out corrugated rolling at the temperature of over 300 DEG C, andincreasing along with the channel, wherein each flat surface which is vertical to normal direction of the plate strip is respectively applied with shearing force in different directions; inducing dynamic recrystallization, so that the orientation distribution of grains in the plate strip is randomized, and the strength of the cardinal plane texture is reduced; and carrying out corrugated rolling under the temperature of below 300 DEG C, wherein at the position in the plate strip, especially, the position where the repeated wave bending deformation is the most serious, a large amount of twin crystals are produced to enable the grain orientation to deflect, and further, the initial texture is weakened. The invention has the advantages that the process design is reasonable, the equipment is easy to manufacture, the operation process is easy to realize, the defects of the normal plastic deformation and difficulty in weakening of the texture in annealing of the magnesium alloy are overcome, and the efficiency is high. The method is suitable for the large scale of industrial production.

Owner:CENT SOUTH UNIV

Method for determining Avrami mathematical model coefficient of metal dynamic recrystallization volume fraction

PendingCN110245382AReduce consumptionSimple calculationDesign optimisation/simulationSpecial data processing applicationsMathematical modelStress–strain curve

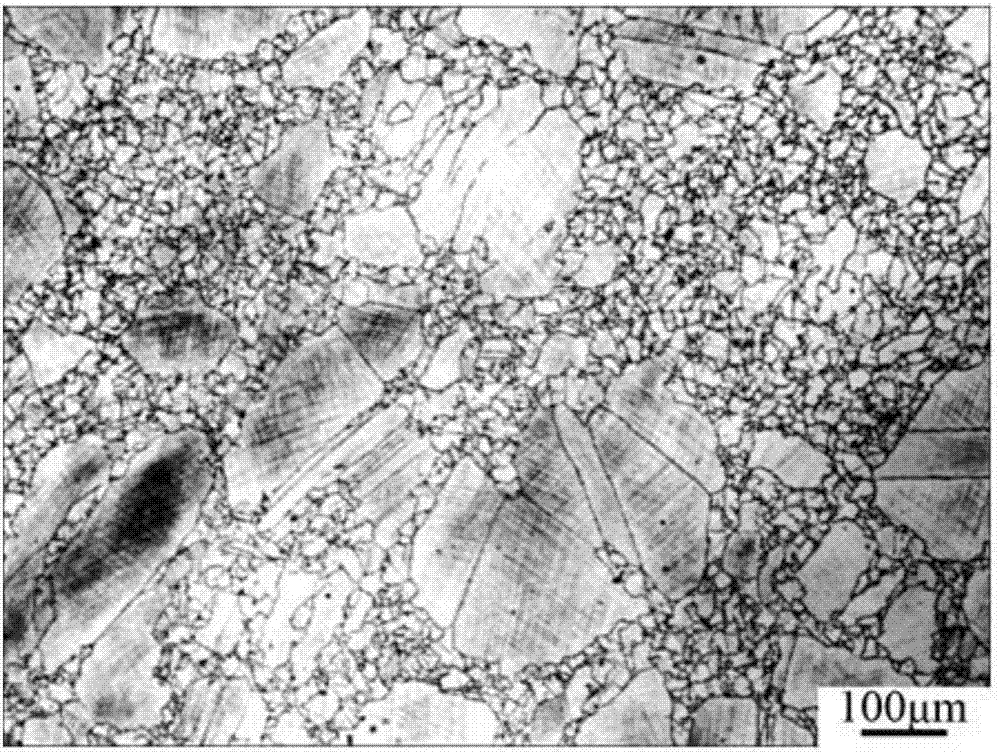

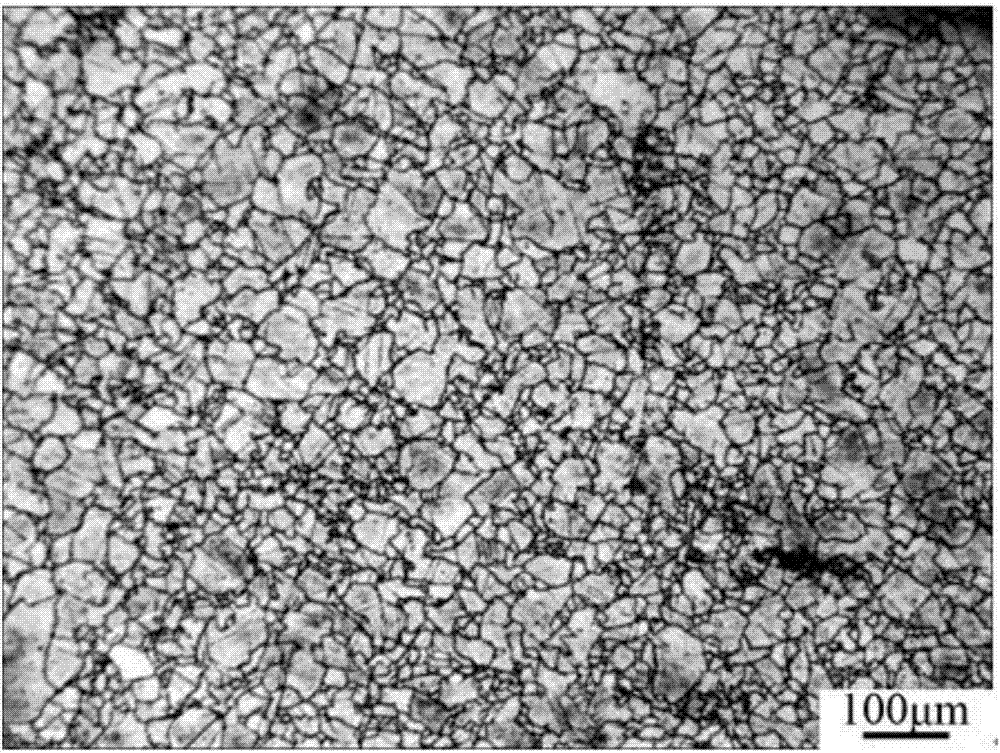

The invention provides a method for determining an Avrami mathematical model coefficient of a metal dynamic recrystallization volume fraction, and the method comprises the following steps: 1, obtaining a stress-strain curve of a material, carrying out water quenching treatment on a sample after the sample is deformed, observing a metallographic structure in the sample, and measuring the recrystallization volume fraction; 2, determining critical strain epsilon c of dynamic recrystallization; 3, determining a return curve; 4, calculating a curve of the volume fraction of the dynamic recrystallization along with the strain; and 5, solving coefficients m and epsilon * of the Avrami mathematical model according to the curve obtained in the step 4. According to the method, only the recrystallization volume fraction in the sample after deformation is measured, the recrystallization volume fraction of the sample in the deformation process is not needed, an equation is directly used for obtaining the curve of the recrystallization volume fraction changing along with strain, and steady-state stress epsilon ss does not need to participate in calculation; compared with the existing method, the method provided by the invention has the advantages of less parameters required in the calculation process, low workload and less sample consumption, and is suitable for popularization.

Owner:BENGANG STEEL PLATES

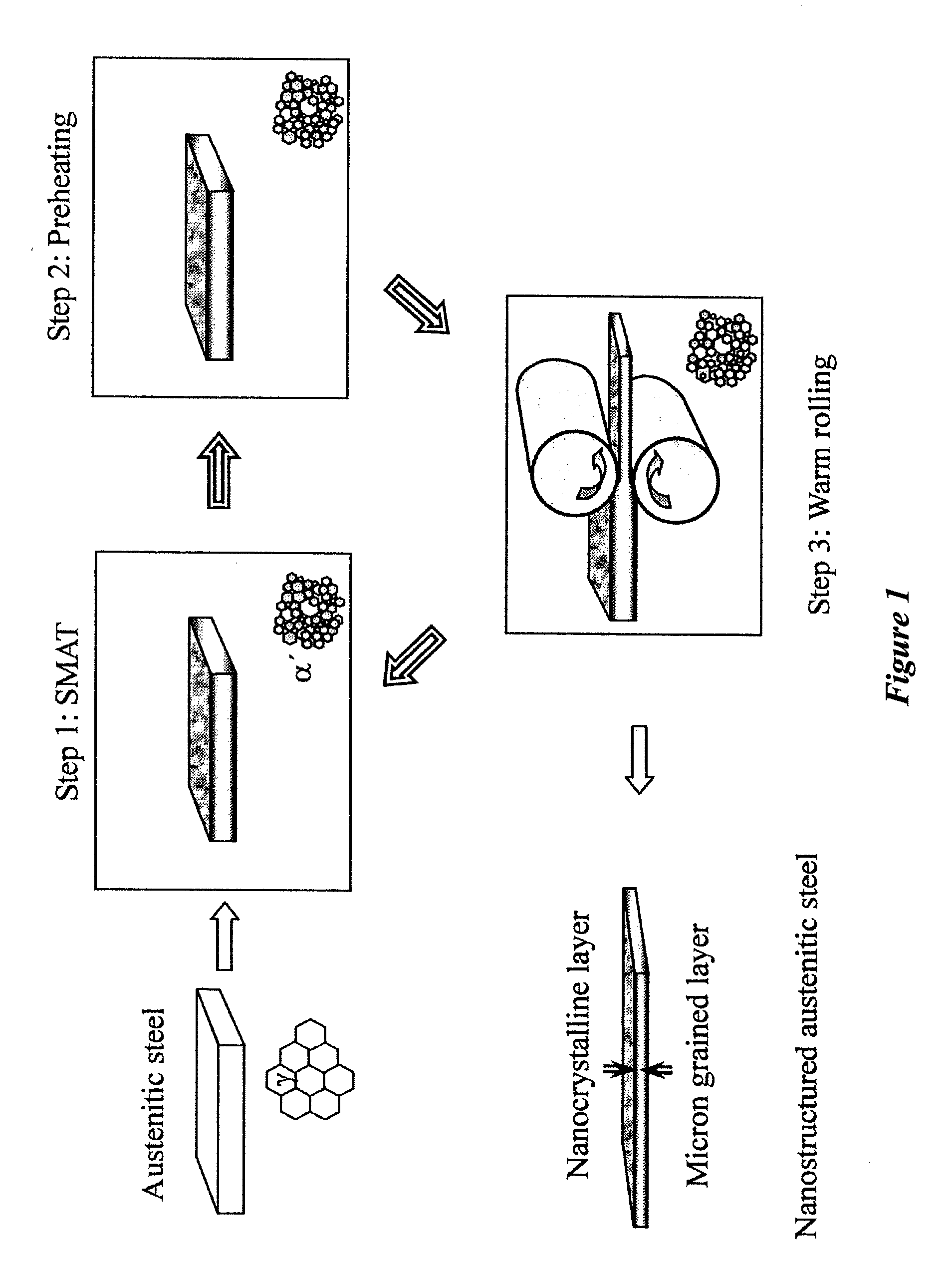

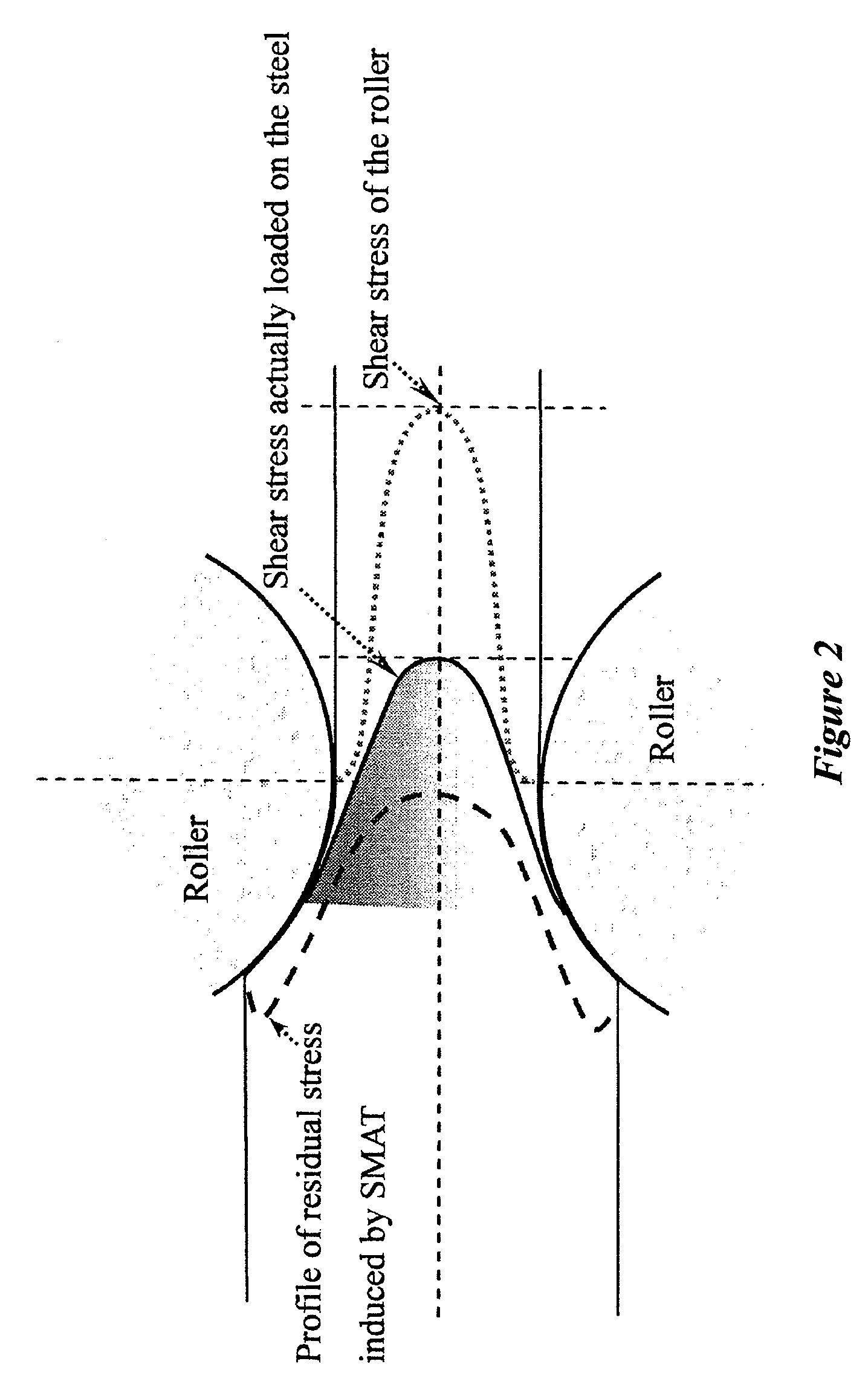

Nanostructured austenitic steel and method of making nanostructured austenitic steel

ActiveUS20100101686A1High strengthSignificant ductilityMaterial nanotechnologyFurnace typesMetallurgyNanostructure

A method for producing a nanostructured austenitic sheet by consecutive martensite and austenite phase (γ / α′) transformations, in which the coarse grained austenite sheet transforms to nanocrystalline martensite by strain-induced transformation, and then generates reverse transformation to nanostructured austenite by warm rolling due to dynamic recrystallization.

Owner:THE HONG KONG POLYTECHNIC UNIV

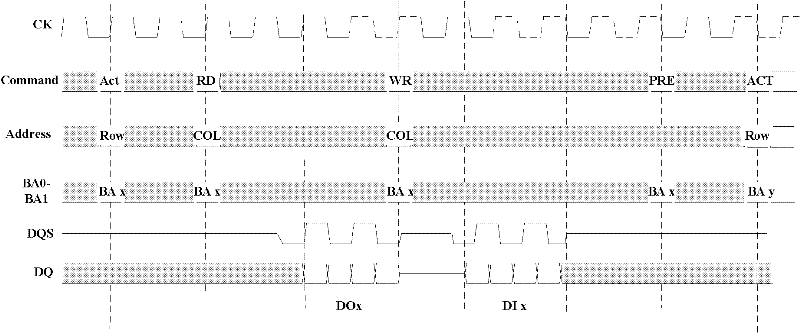

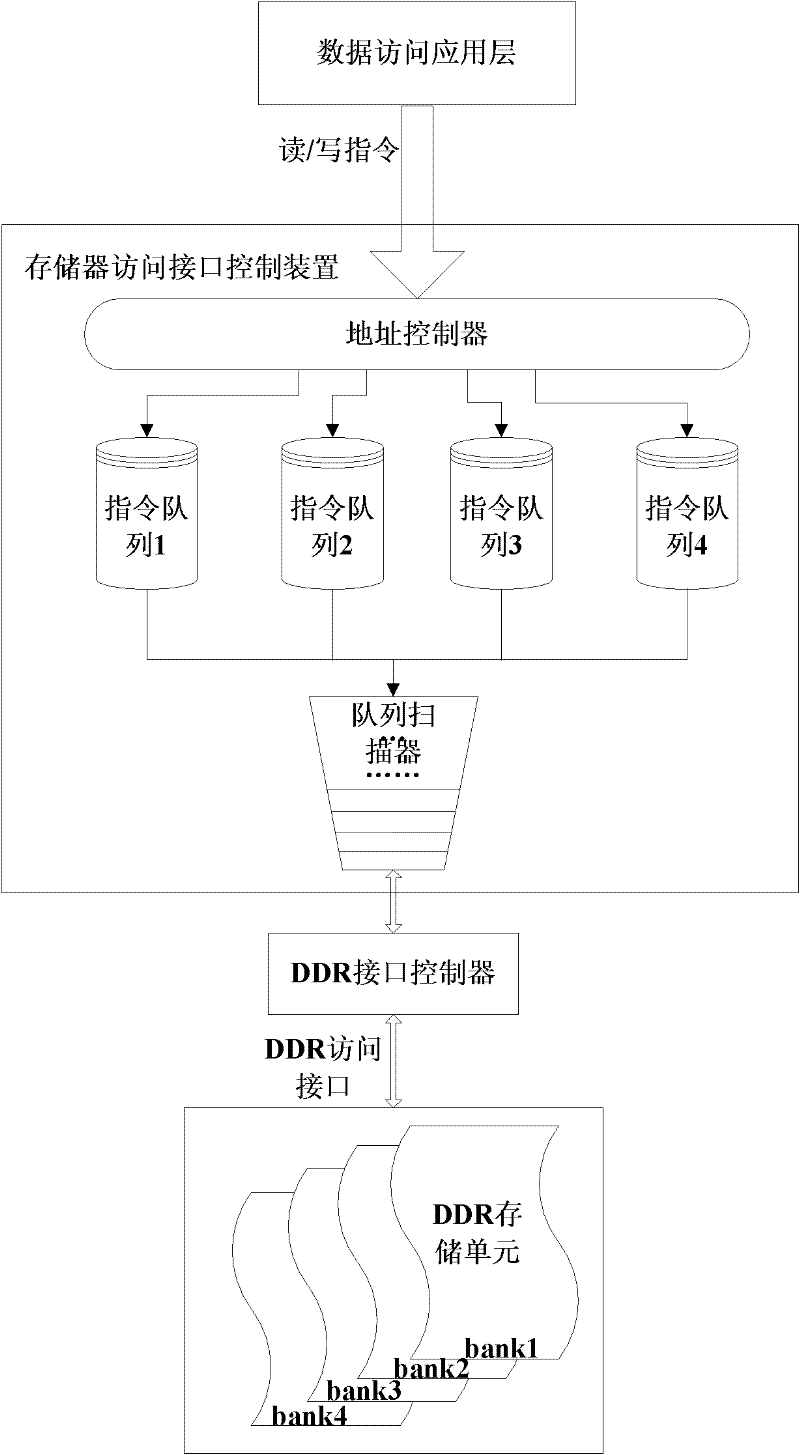

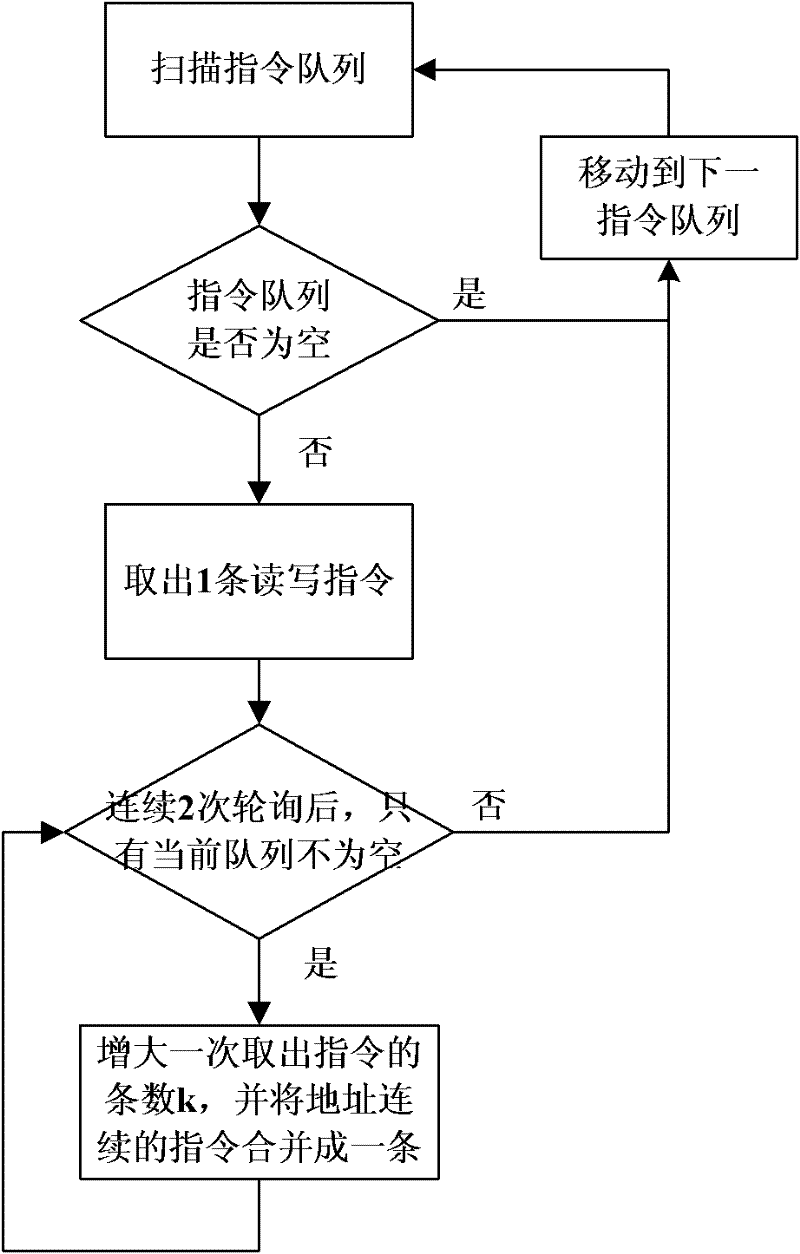

Memory interface access control method and device

ActiveCN102541769AIncrease throughput bandwidthImprove access efficiencyMemory adressing/allocation/relocationProgram controlMemory interfaceAddress control

The invention discloses a memory interface access control method and device. The device comprises an address controller, an instruction queue and an instruction queue scanner which are sequentially connected, wherein the address controller is connected with a data storage application layer, the instruction queue scanner is connected with an interface controller of a memory, the address controller is used for respectively mapping an instruction sent by the data storage application layer into different spaces of the memory and sending read write instructions of different spaces into corresponding instruction queues; each instruction queue is used for caching received read write instructions; and the queue scanner is used for sequentially reading the read write instructions from each instruction queue and sending the read write instructions into the interface controller of the memory. By adopting the memory interface access control method and device disclosed by the invention, throughput width of a DDRX (discontinuous dynamic recrystallization) memory can be effectively improved, the same effect can be realized on a read operation and a write operation, and access efficiency of the memory can be improved, thus overall performance of equipment is enhanced.

Owner:ZTE CORP

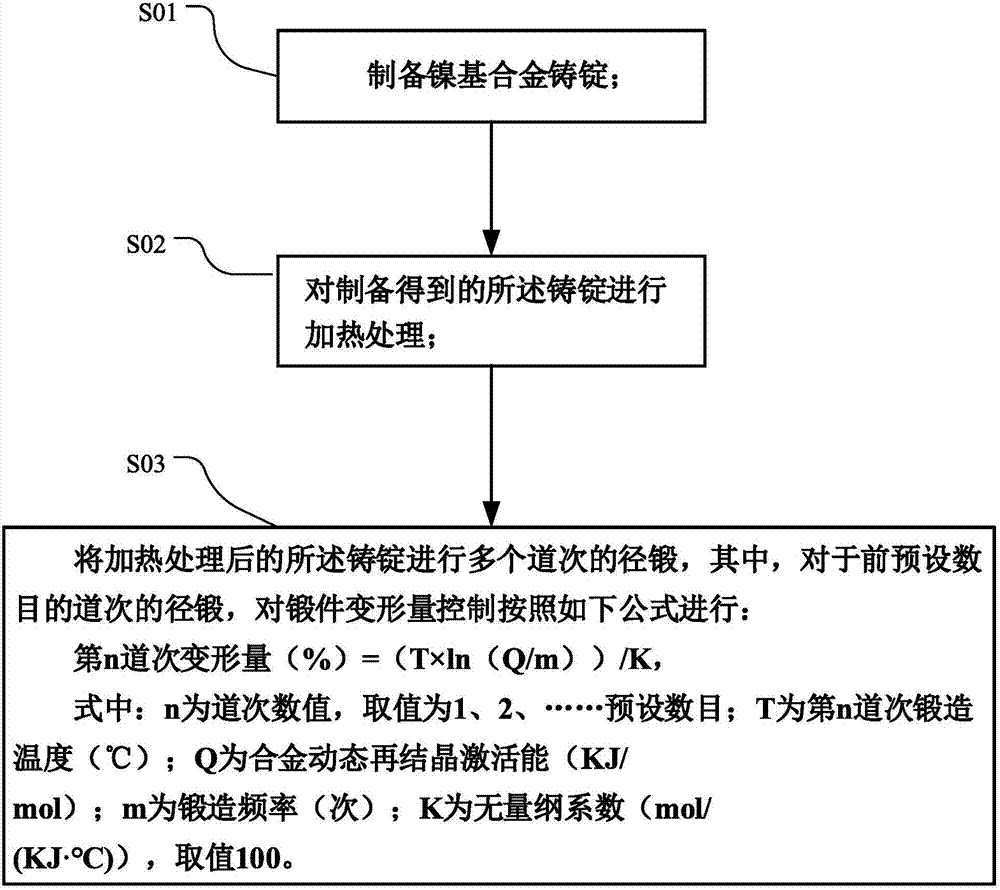

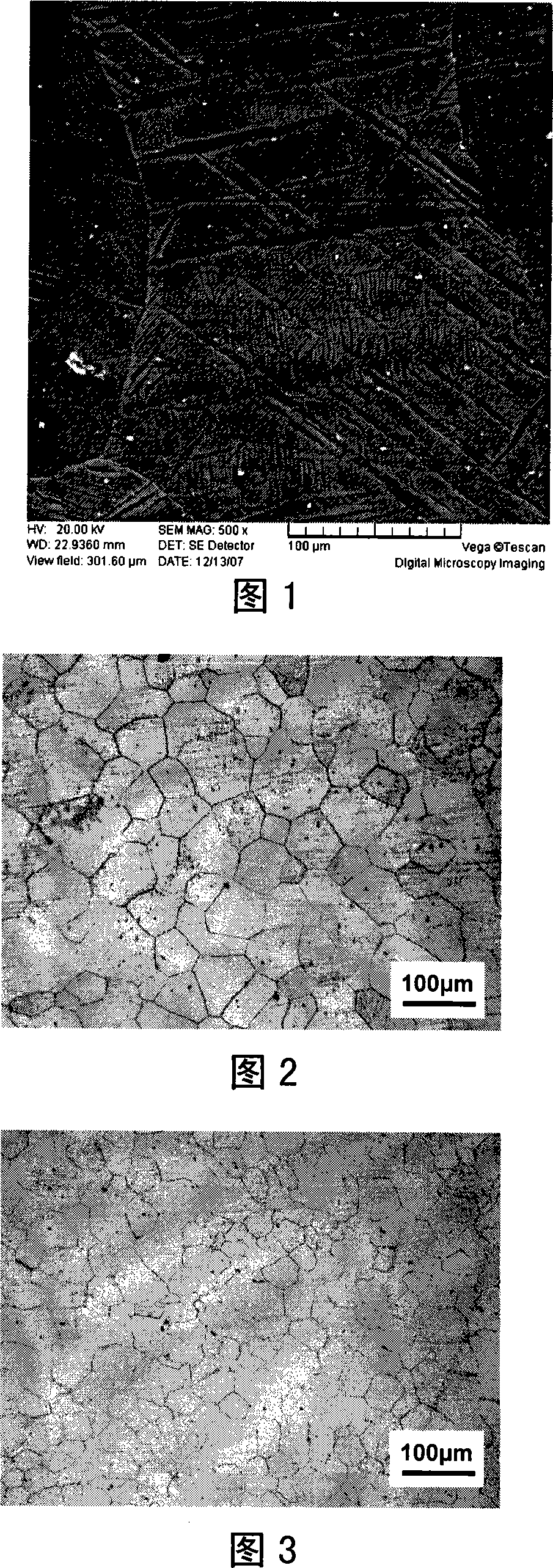

Nickel-based alloy radial-forging structure control method

The invention discloses a nickel-based alloy radial-forging structure control method. The nickel-based alloy radial-forging structure control method comprises the following steps that a), a nickel-based alloy casting ingot is manufactured; b), the manufactured casting ingot is heated; c), the heated casting ingot is subjected to multiple passes of radial forging, wherein for radial forging of passes of a preset number, control on deformation of a forged workpiece is performed according to the following format: deformation of the nth pass (%) is equal to (T multiplied by ln)(Q / m)) / K; in the format, n is the value of the pass and can be 1, 2 and other preset numbers; T is forging temperature (DEG C) of the nth pass; Q is alloy dynamic recrystallization activating energy (KJ / mol); m is forging frequency (times); and K is a nondimensional coefficient (mol / (KJ.DEG C)), and is 100. According to the nickel-based alloy radial-forging structure control method, effective control for a nickel-based alloy radial forging in a forging process can be realized, and therefore, by utilizing the nickel-based alloy radial-forging structure control method, a deformation technological system can be rapidly formulated according to features of different steel types, so that problems of insufficient forging, crystal doping in the radial forging and the like are solved.

Owner:太原钢铁(集团)有限公司

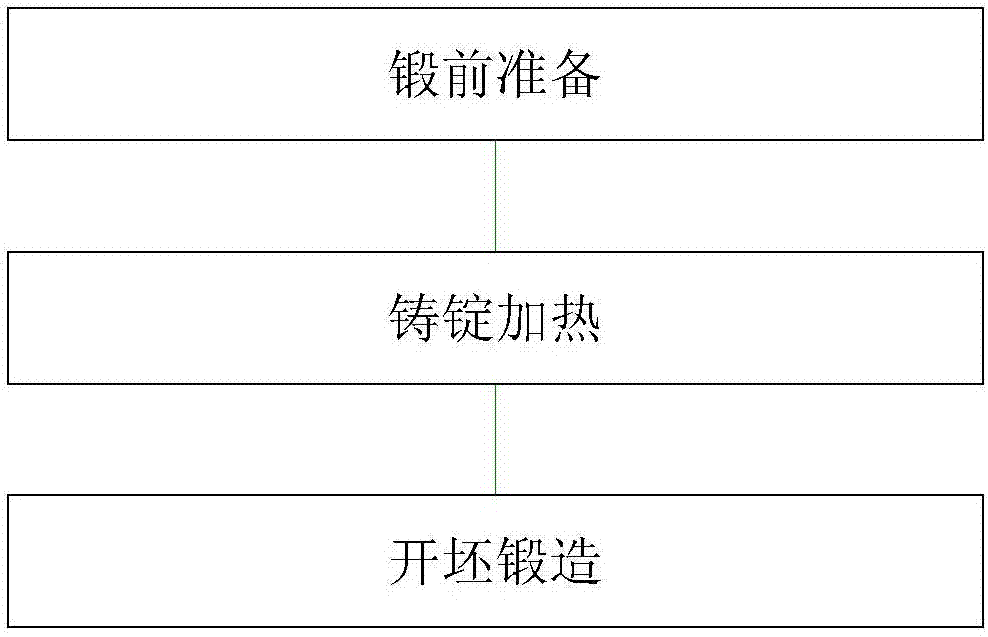

Cogging method for Ti2AlNb-based alloy ingot

ActiveCN104148562ALow Steady State Deformation ResistanceGood process plasticityMetal-working apparatusFiberWire cutting

The invention discloses a cogging method for a Ti2AlNb-based alloy ingot. The cogging method comprises the steps that the Ti2AlNb-based alloy ingot is loaded on a wire cutting machine and manufactured into a Phi290*280mm bar; the Ti2AlNb-based alloy ingot is sleeved with alumina silicate fibers, placed into a high-temperature heating furnace to be heated to 1150 DEG C and then placed on a press after the temperature is kept for 80 minutes, and repeated upsetting and drawing are performed at the strain rate of 0.01S-1; the ingot is drawn out to 350mm after first fire, upset to 350mm after second fire, drawn out to 350mm after third fire, upset to 270mm after fourth fire and drawn out to 350mm after fifth fire, and air cooling is performed. The ingot is returned to the furnace to be heated to 1150 DEG C and the temperature is kept for 40 minutes for each fire, and the final forging temperature of each fire is guaranteed to be equal to or larger than 1050 DEG C. According to the method, the steady state deformation resistance of the Ti2AlNb-based alloy ingot is reduced in a fully dynamic recrystallization state, the technological plasticity is improved, cracking is prevented, a cast structure is smashed completely, and a uniform and dense forge structure is obtained.

Owner:GUIZHOU ANDA AVIATION FORGING +1

Method for rolling high-ductility and high-scalability Mg-Al series magnesium alloy plates

InactiveCN104259201AEnhanced ability to recover and recrystallizeImprove plasticityTemperature control deviceTension/compression control deviceDynamic recrystallizationSingle pass

The invention relates to a magnesium alloy processing method, in particular to a method for rolling high-ductility and high-scalability Mg-Al series magnesium alloy plates. The method comprises the steps of milling, heating and heat preservation of a plate, heating and heat preservation of a roller, rolling and cooling, wherein the rolling speed is 10-100 m / min; the rolling reduction of each time of rolling is 45%-80%. As the high-speed single-pass big-dependent-variable rolling is adopted for inducing obvious dynamic recrystallization, fully fine equiaxed grains are generated, and accordingly, the magnesium alloy plates of which the ductility and the scalability are greatly improved are acquired. Besides, as the annealing process is omitted, the manufacturing cost is greatly lowered, and the method is more suitable for large-scale industrial production.

Owner:CHONGQING UNIV

Deformation magnesium alloy with high yield ratio and high-ductility

The invention discloses a wrought magnesium alloy with high yield tensile ratio and high plasticity, wherein the percentage by weight of each component of the alloy comprises zinc 1.0%-2.0%, zirconium 0.1%-0.6%, rare earth erbium 0.1%-0.8%, and others are magnesium and unavoidable impurities. Erbium and impurity element, magnesium and oxygen which is rolled alloy liquid in alloy are combined to form small and dispersed precipitation phase which effectively purifies alloy, promotes dynamic recrystallization in the process of thermal deformation, and blocks recrystallized grain to grow. Zinc plays a solution strength effect in alloy. The wrought magnesium alloy of the invention not only has high yield tensile ratio, but also has excellent plasticity, when the yield tensile is not less than traditional commercial wrought magnesium alloy ZK60 with high intensity, the wrought magnesium alloy of the invention greatly improves the plasticity of magnesium alloy, which fully mines application potential of material.

Owner:CHONGQING UNIV

High-plasticity magnesium alloy and preparation method thereof

The invention discloses a high-plasticity magnesium alloy and a preparation method thereof. The magnesium alloy comprises the following components in percentage by mass: 3-4% of Zn, 0.1-0.6% of Ca, 0.05-0.8% of Mn, and the balance of Mg and inevitable impurities. Ca and Mn are added in a magnesium zinc alloy to prominently refine alloy grains; in hot extrusion process, the dynamic recrystallization can be promoted to stop growth of recrystallized grains, so that the strength and the plasticity of the alloy are synchronously improved, the base surface texture of the alloy can be prominently weakened, and the plasticity of the alloy is improved; in addition, through separation of a second phase and dispersion and separation of nanoscale Mn particles, the strength of the alloy can be effectively improved; the magnesium alloy is high in plasticity; and the component-optimized alloy can reach the ductility of 25-29.8%, the yield strength of 160-205 MPa and the tensile strength of 270-289 MPa.

Owner:CHONGQING UNIV

Casting-milling process method for manufacturing copper and copper alloy band

InactiveCN1730181AIncrease the elongation factorReduce energy consumptionWork treatment devicesMetal rolling arrangementsNitrogen gasDynamic recrystallization

The invention relates to a processing method for copper and copper alloy strip, which pertains to sheet metal strip casting, heat-rolling and machining technology. Specifically, the invention adopts continuous casting, hot rolling, thermomechanical treatment and machining principle and subjects band of horizontal continuous casting and downward continuous casting to heat preservation and samming, rapidly cooling after directly hot-rolling, on-line surface milling and rolling to built-up coil. Rolling is operated under the condition of exceeding recrystallization temperature and nitrogen protection. In the rolling, dynamic recrystallization of band structure takes place. The invention provides photo-quality and high-accuracy blank for cold rolling of end product.

Owner:JIANGSU XINGRONG HI TECH

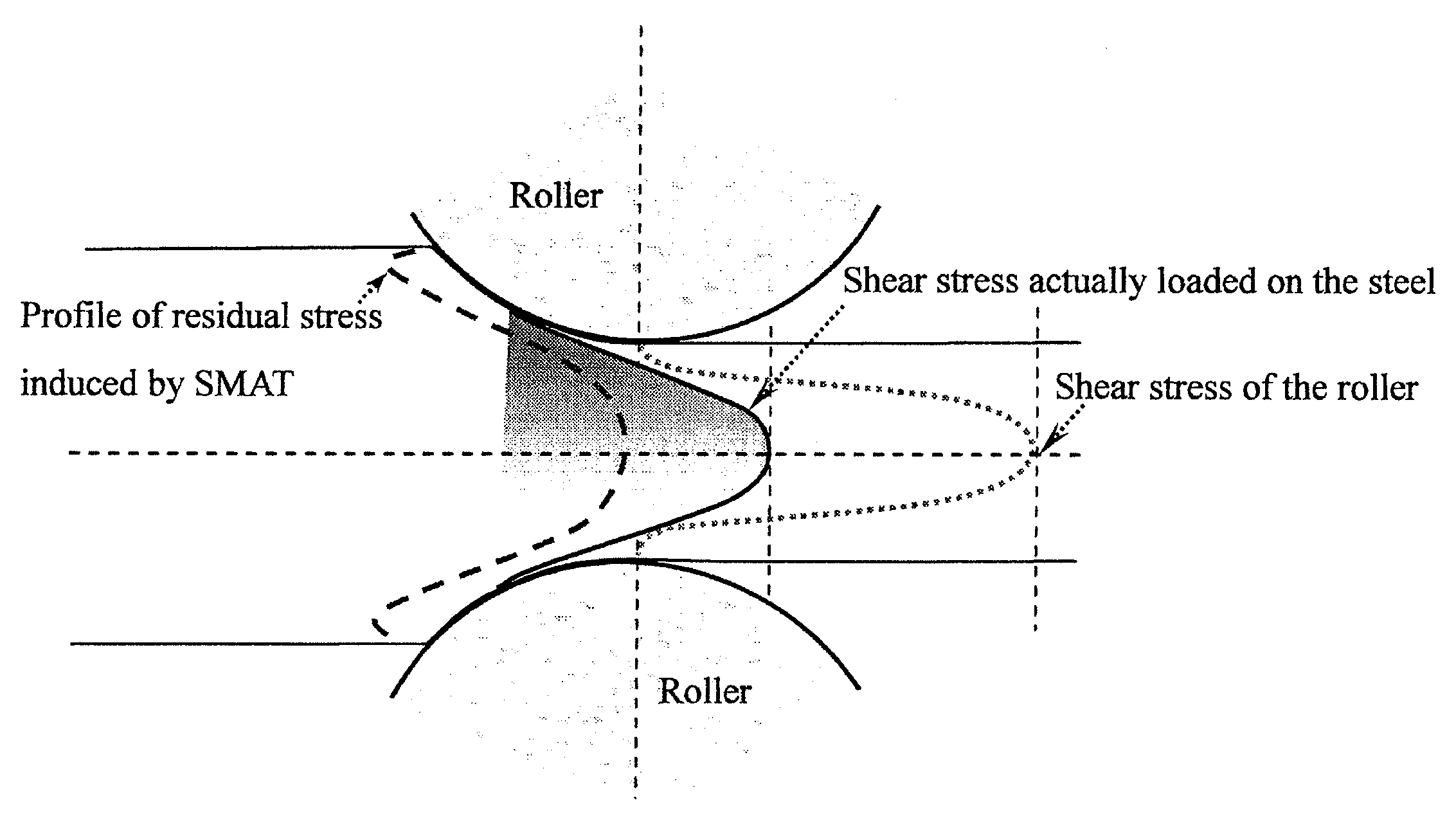

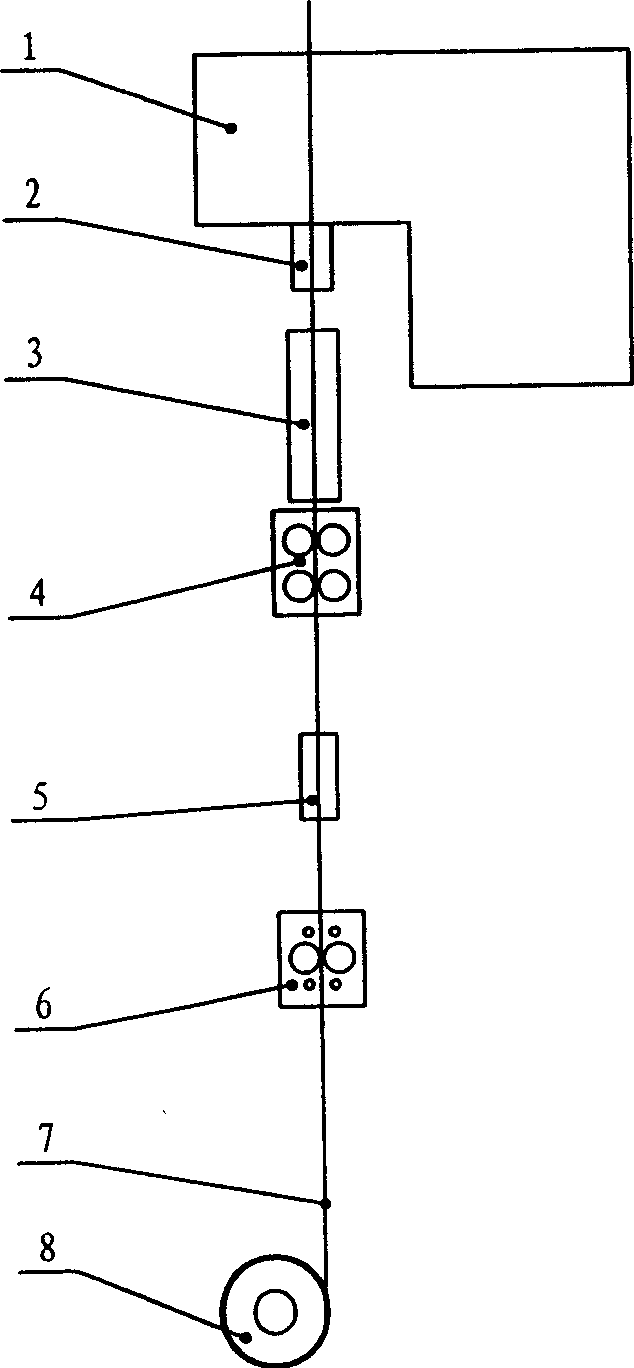

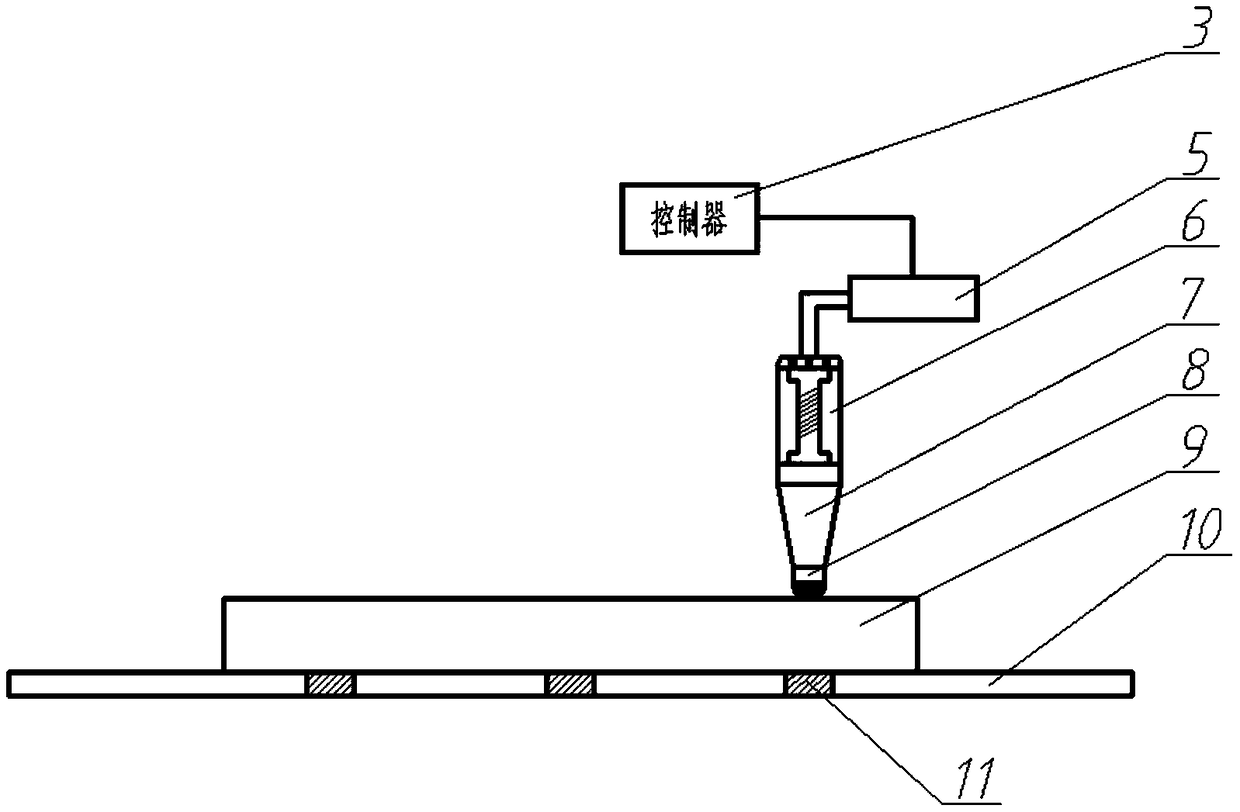

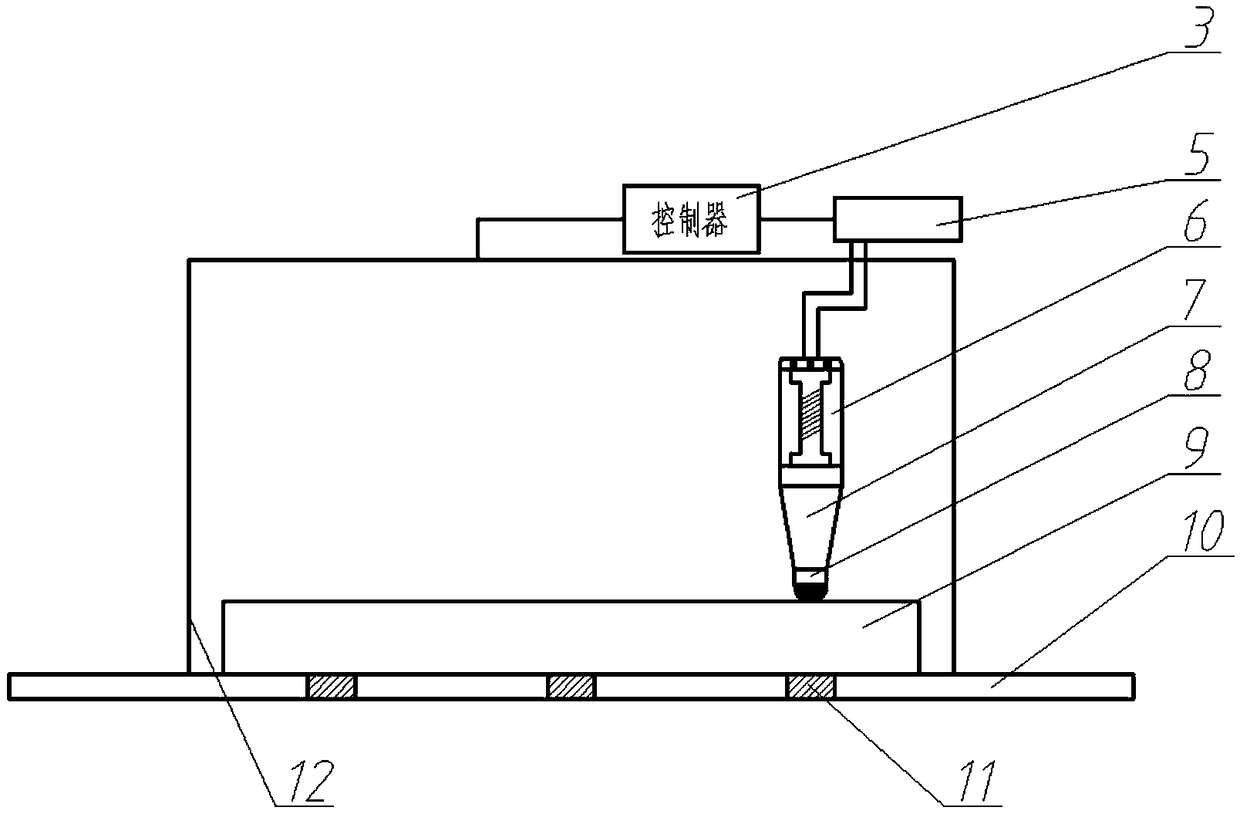

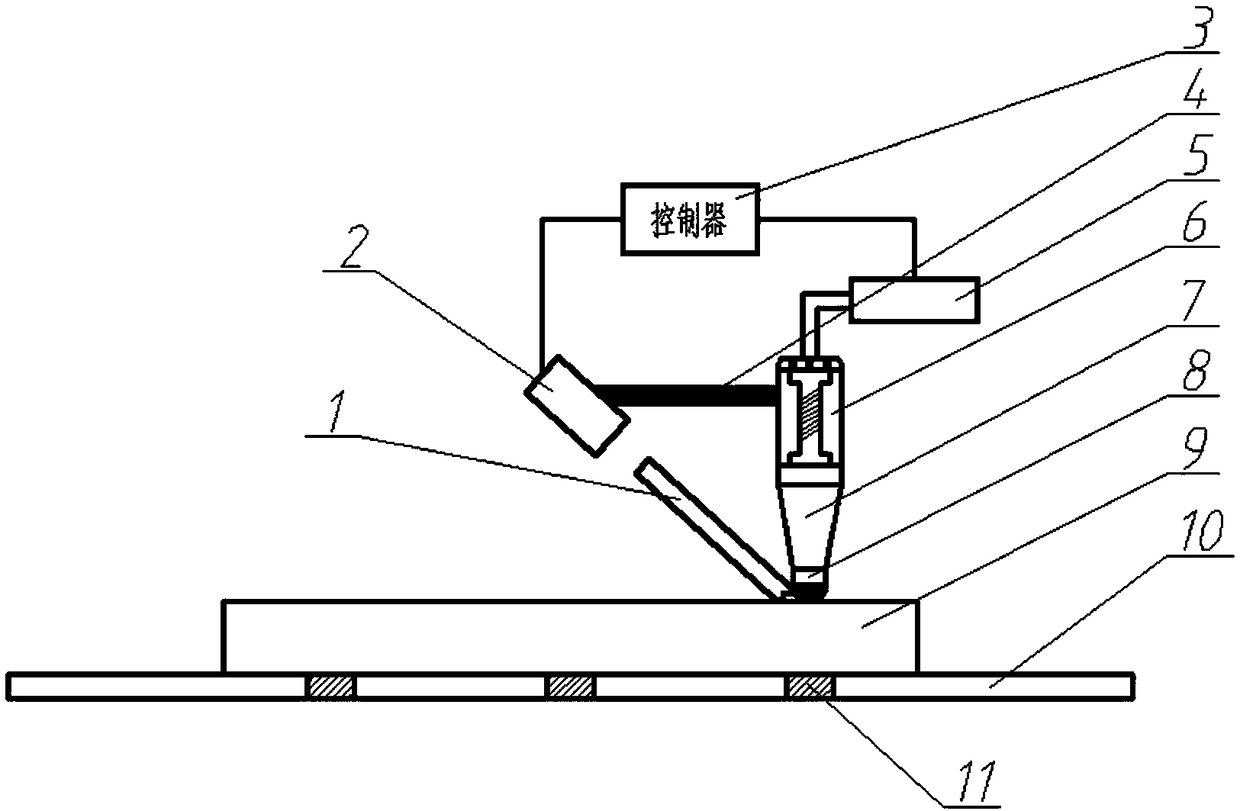

Method for laser-assisted ultrasonic rolling for surface modification

InactiveCN109158831AAvoid heating large areasInhibit grain coarseningMetal working apparatusLaser assistedLaser beams

The invention relates to the field of ultrasonic rolling machining, and specifically relates to a method for laser-assisted ultrasonic rolling for surface modification. The method comprises the following steps: carrying out local heating on the surface of a metal workpiece by virtue of a continuous laser beam to reach a dynamic recrystallization temperature of the metal workpiece at first; and then immediately carrying out ultrasonic rolling treatment on the same position by virtue of an ultrasonic rolling device, and completing the surface modification for the workpiece along a previously-planned path and through the same operation step.

Owner:JIANGSU UNIV

Cogging and forging method of TiAl alloy

ActiveCN107952922AImprove uniformityThere will be no double belly phenomenonHeating/cooling devicesDiameter ratioDynamic recrystallization

The invention discloses a cogging and forging method of a TiAl alloy. Lamellas in an original structure are subjected to crushing and balling by controlling technological parameters of the deformationtemperature, the pressing machine screwdown rate, the deformation and the like. Meanwhile a phenomenon of meta-dynamic recrystallization occurring in the post-forging heat preservation process is sufficiently utilized, a forged disc is subjected to heat preservation after forging is conducted, energy stored by the forged disc in the forging process is sufficiently transformed into driving force needed by the structure in the meta-dynamic recrystallization process, so that the structure uniformity is good, and the forged disc with the structure being even and fine is obtained. According to thecogging and forging method of the TiAl alloy, when a height-diameter ratio (h:d) of a cast ingot is larger than (2:1), a double bulging phenomenon cannot happen compared with a traditional method that cogging and forging are conducted in the axial direction of the cast ingot, therefore the height-diameter ratio (h:d) of the cast ingot cannot be limited to be smaller than or equal to (2:1), cogging and forging can be conducted on TiAl alloy cast ingots with various height-diameter ratios, and therefore the cogging and forging cost is saved.

Owner:重庆两航金属材料有限公司

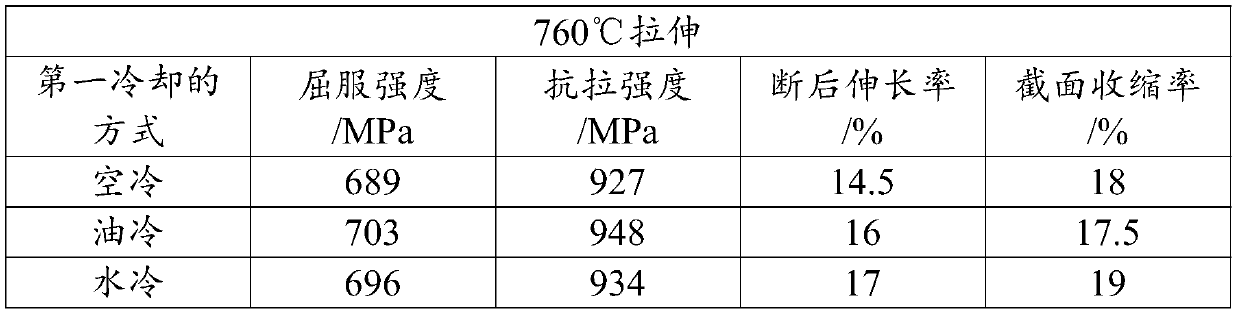

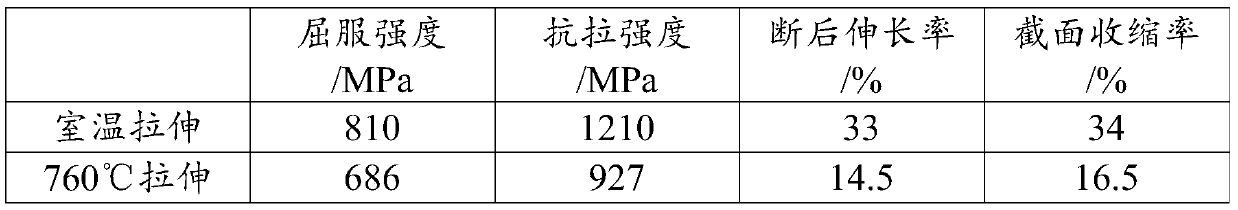

Production method of fine-grain high-strength GH4169 alloy by hot rolling

The invention discloses a production method of a fine-grain high-strength GH4169 alloy by hot rolling, belongs to the technical field of production techniques of high-temperature alloy rods for aerospace. According to the method, a roughly rolled blank is subjected to a conventional production process, including heating, rolling, cooling and the like, to produce the hot rolled rod of which the diameter is 20-45mm. The technical key is to implement grain refinement and grain size control by controlling the rolling speed of the continuous hot rolling set (controlling the dynamic and sub-dynamic recrystallization of the rolling process), and to shorten the alloy heating and holding time through an on-line solution treatment technique by inducing the second phase precipitation with deformation, thereby achieving the goals of inhibiting grain growth and solution strengthening. The method lowers the manufacturing cost of the high-temperature alloy hot rolled rod, enhances the strength indexes of the alloy, and provides a new technique for producing the hot rolled high-temperature alloy for aerospace.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Heat treatment method of GH4780 alloy forging

ActiveCN110484841AHigh strengthImprove plasticityBlade accessoriesStatorsSmelting processUltimate tensile strength

The invention provides a heat treatment method of a GH 4780 alloy forging, and relates to the technical field of alloy manufacturing. The method comprises the following step: carrying out solution heat treatment on the GH 4780 alloy forging, wherein the temperature of the solution heat treatment is 1020-1170 DEG C. The GH 4780 alloy forging subjected to heat treatment not only can effectively eliminate the segregation of alloy elements such as Ti, Al and Cr in the smelting process and eliminate metallurgical defects such as cavities, but also can break columnar crystals and promote dynamic recrystallization, thereby refining the crystal grains and improving the strength and plasticity of the alloy forging.

Owner:BEIJING CISRI GAONA TECH +3

Method of assistance of resistance heating in surface mechanical grinding to form gradient nanostructure

InactiveCN109457092ANo pollution in the processImprove thermal efficiencyProcess efficiency improvementElectrical resistance and conductanceSurface engineering

The invention relates to the technical field of surface engineering technology and laser processing, in particular to a method of assistance of resistance heating in surface mechanical grinding to form a gradient nanostructure. A workpiece resistance heating method is adopted to heat a metallic workpiece, the temperature is controlled within the dynamic recrystallization temperature range, and after heating, the surface mechanical grinding treatment process is immediately adopted to carry out large-area intensification on the metallic workpiece to obtain the gradient nanostructure with a higher degree.

Owner:INST OF LASER & OPTOELECTRONICS INTELLIGENT MFG WENZHOU UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com