Nickel-based alloy radial-forging structure control method

A technology of nickel-based alloy and control method, which is applied in the field of metallurgy, can solve the problems of forging impermeability, radial forging structure mixed crystals, etc., and achieve the effect of forging impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

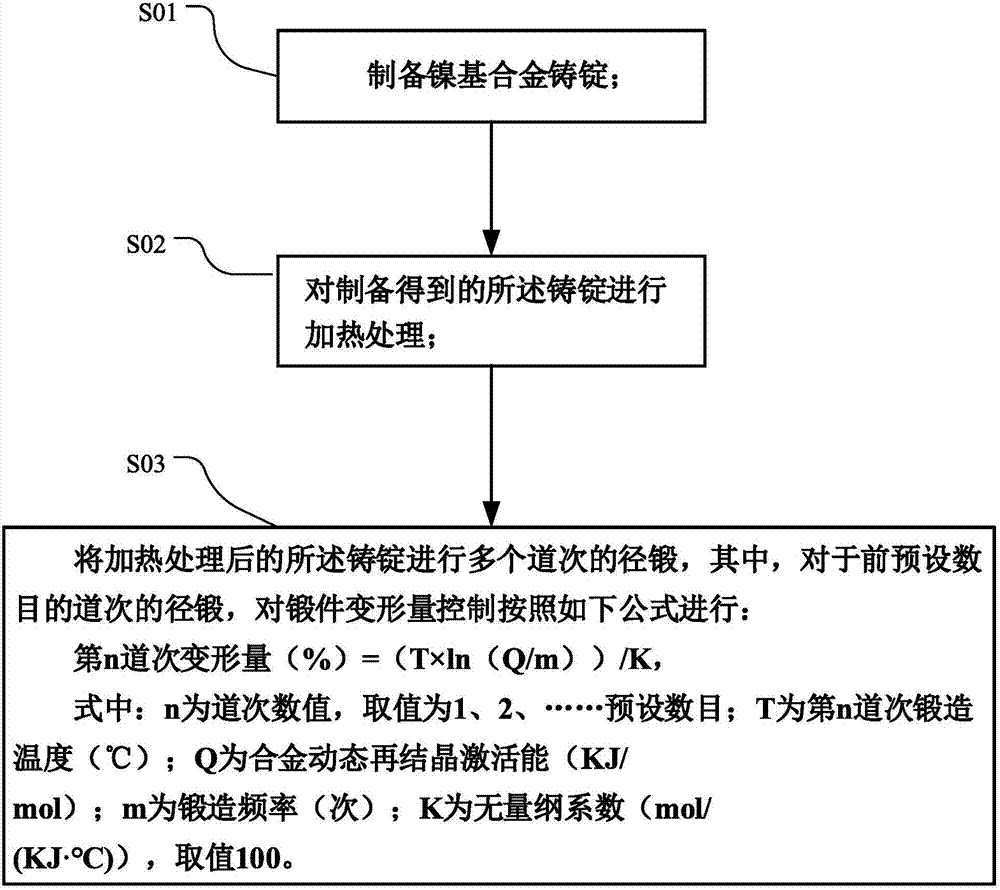

[0030] In this embodiment, the nickel-based alloy diameter forging structure control method includes the following steps:

[0031] S01), preparing nickel-based alloy ingot;

[0032] Specifically, the VIM+ESR process, that is, the vacuum induction smelting + electroslag remelting process is used to prepare nickel-based alloy ingots. Of course, the VIM+VAR process can also be used, that is, vacuum induction smelting + vacuum self-consumption to prepare nickel-based alloy ingots. In this embodiment, the diameter of the prepared nickel-based alloy ingot is φ360 mm, that is, the initial size of the ingot is φ360 mm. The mass percentage distribution ratio of the main components of the ingot is: Ni base, 22% Cr, 12% Co, 9% Mo, 1.2% Al, 0.44% Ti.

[0033] S02), heat-treating the prepared ingot;

[0034] Specifically, the ingot is put into a heating furnace to be heated to a preset temperature, and kept at the preset temperature for a preset period of time. In this embodiment, the ...

Embodiment 2

[0054] In this embodiment, the nickel-based alloy diameter forging structure control method includes the following steps:

[0055] S01), preparing nickel-based alloy ingot;

[0056] Specifically, the VIM+ESR process, that is, the vacuum induction smelting + electroslag remelting process is used to prepare nickel-based alloy ingots. Of course, the VIM+VAR process can also be used to prepare nickel-based alloy ingots, that is, vacuum induction smelting + vacuum self-consumption process. In this embodiment, the diameter of the prepared nickel-based alloy ingot is φ360 mm, that is, the initial size of the ingot is φ360 mm. The mass percentage distribution ratio of the main components of the ingot is: Ni base, 22% Cr, 9% Mo, 5% Nb, 0.2% Ti.

[0057] S02), heat-treating the prepared ingot;

[0058] Specifically, the ingot is put into a heating furnace to be heated to a preset temperature, and kept at the preset temperature for a preset period of time. In this embodiment, the pre...

Embodiment 3

[0078] In this embodiment, the nickel-based alloy diameter forging structure control method includes the following steps:

[0079] S01), preparing nickel-based alloy ingot;

[0080] Specifically, the VIM+ESR process, that is, the vacuum induction smelting + electroslag remelting process is used to prepare nickel-based alloy ingots. Of course, the VIM+VAR process can also be used to prepare nickel-based alloy ingots, that is, vacuum induction smelting + vacuum self-consumption process. In this embodiment, the diameter of the prepared nickel-based alloy ingot is φ360 mm, that is, the initial size of the ingot is φ360 mm. The mass percentage distribution ratio of the main components of the ingot is: Ni base, 25% Cr, 20% Co, 0.5% Mo, 1.5% Nb, 1.3% Ti, 1.3% Al.

[0081] S02), heat-treating the prepared ingot;

[0082] Specifically, the ingot is put into a heating furnace to be heated to a preset temperature, and kept at the preset temperature for a preset period of time. In thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com