Patents

Literature

629 results about "Technological system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Component based software system

ActiveUS20100325606A1Model driven codeRequirement analysisCOLA (software architecture)Customer requirements

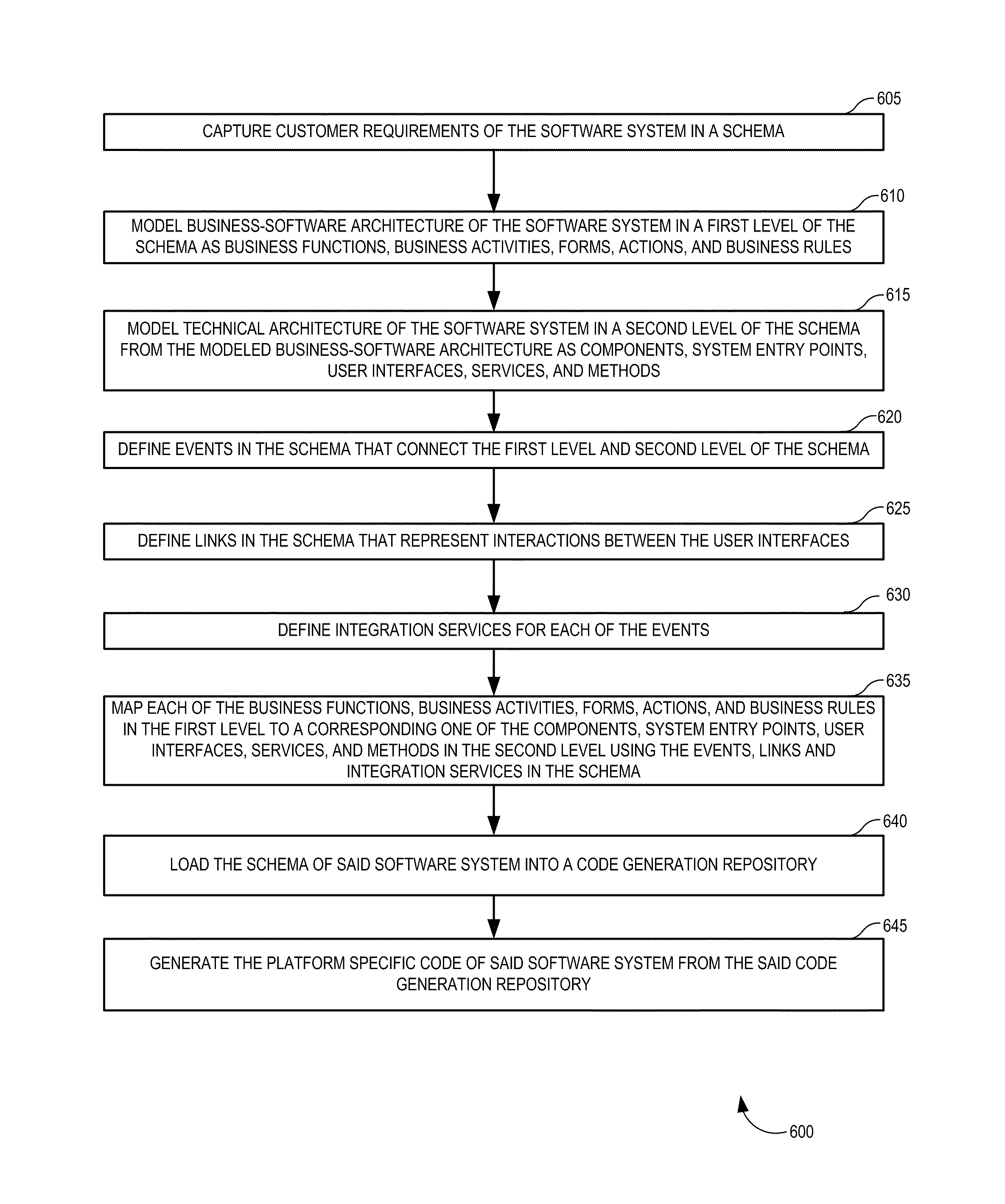

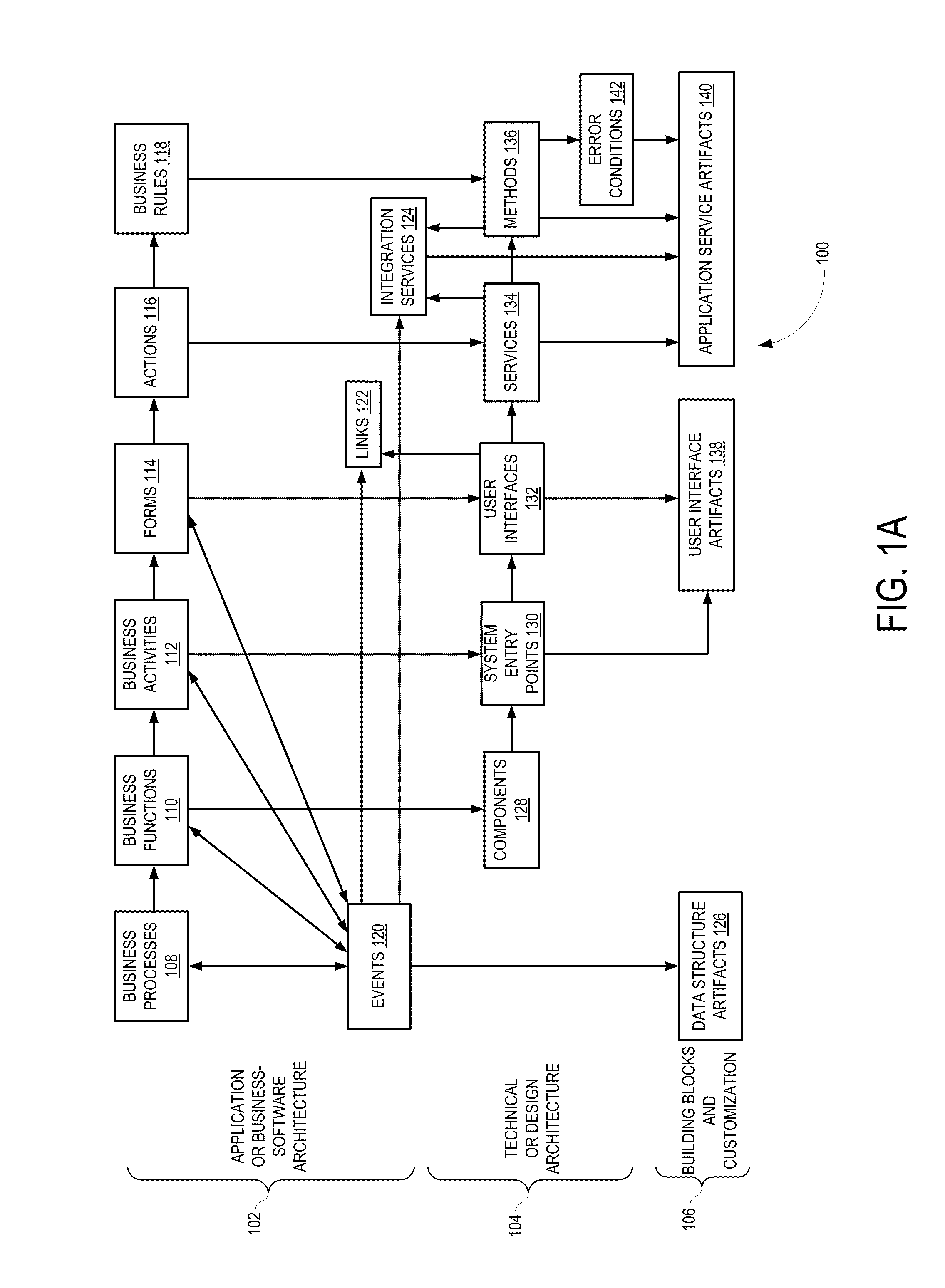

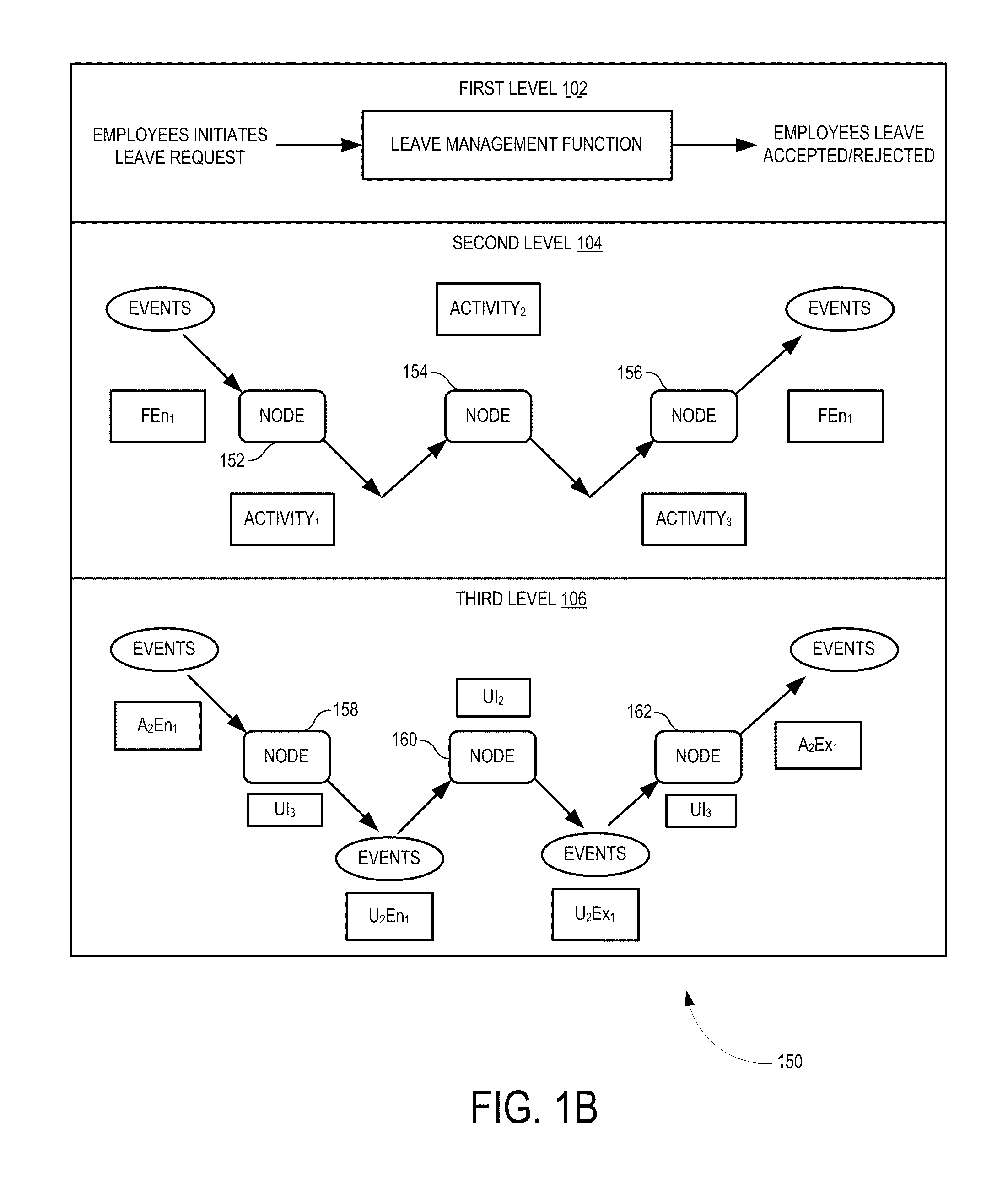

A computer implemented model-driven method to generate platform specific code for a user interface is disclosed. In one embodiment, the method includes, capturing customer requirements of the software component in a schema, modeling business-software architecture of the software component in a first level of the schema, modeling technical architecture of the software system from the modeled business-software architecture in a second level of the schema, defining events in the schema that connect the first level and the second level of the schema, defining links in the schema that represent interactions between the user interfaces, defining integration services in the schema for each of the events, mapping each element in the first level to a corresponding one of the elements in the second level using the events, links, and integration services in the schema, loading the schema of the software component into a code generation repository.

Owner:RAMCO SYSTEMS

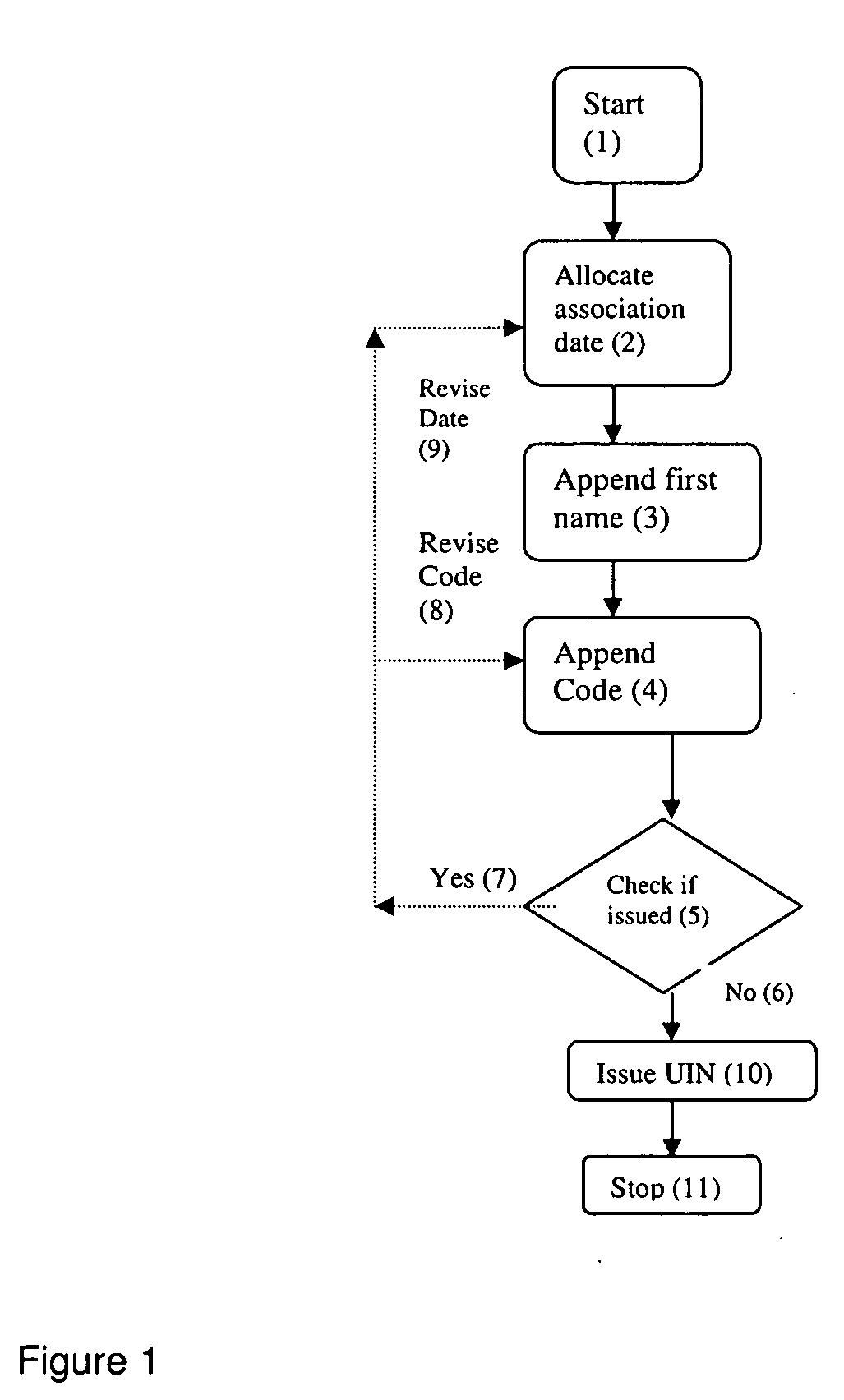

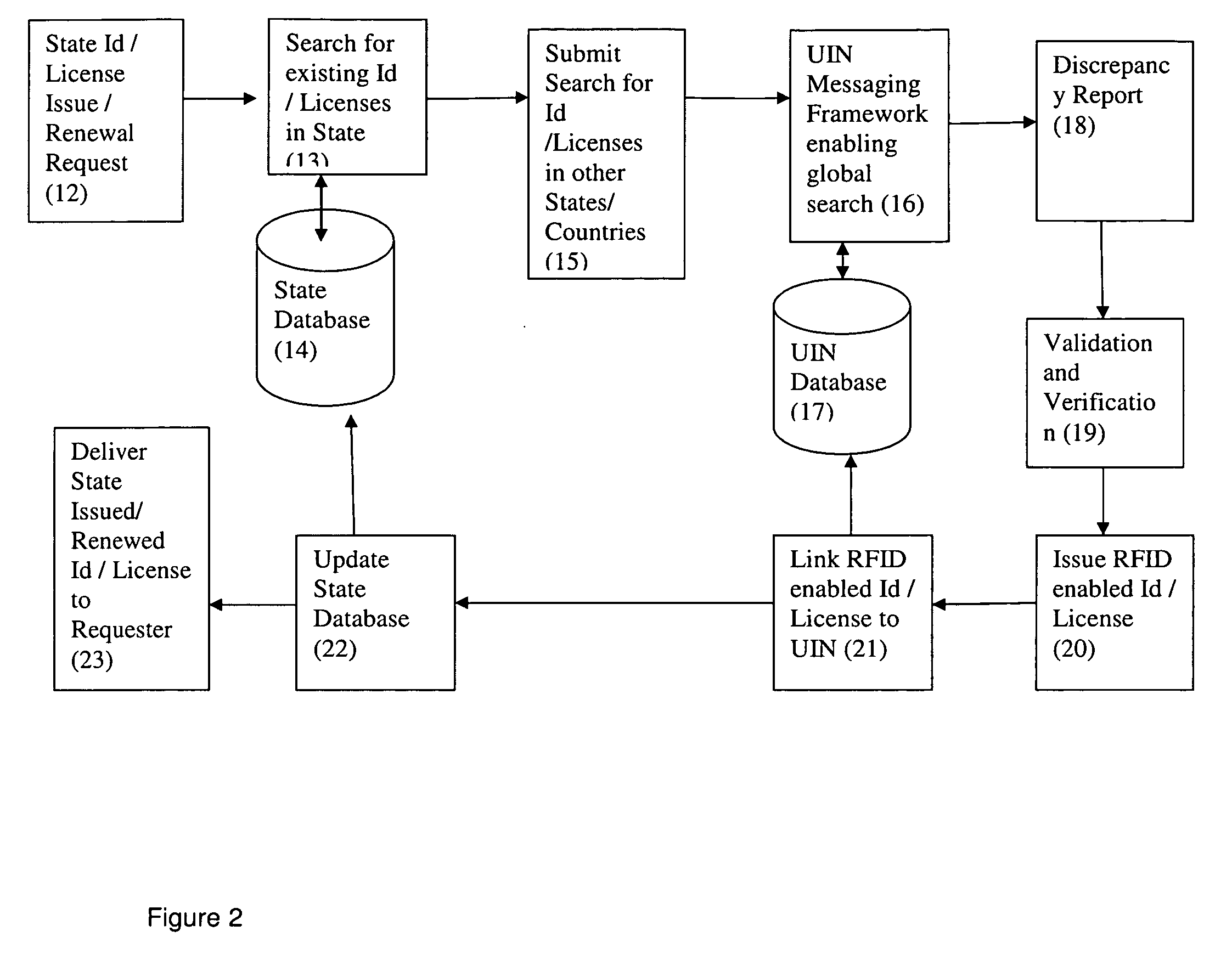

System and method for universal identity verification of biological humans

InactiveUS20090224889A1Rapid diagnosisQuick treatmentLocal control/monitoringTelemedicineCredit cardMedical treatment

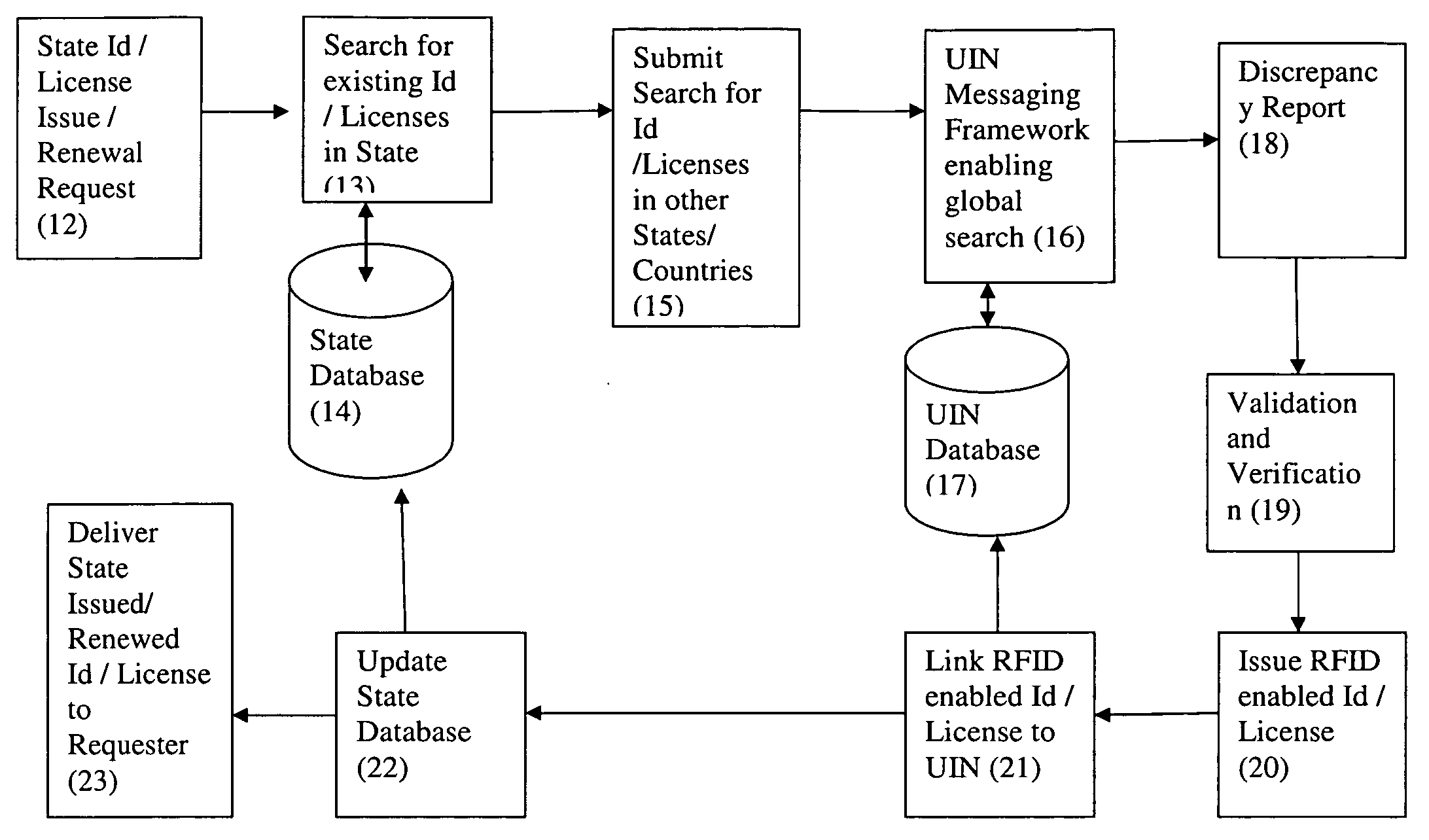

A system and method to generate a Universal Identification Number (UIN) for every human being on the planet, and its RFID application to uniquely verify the identity, and apparatus for biosensor integrated device receiving GPS or cellular signals to determine location, and transmitting data through radio signals to identify, track, monitor, and rescue humans. UIN database comprising of public, health, and confidential data, protects privacy by hiding the sensitive information and providing the required information only to authorized agencies on ‘need to know’ basis, like medical emergency data to authorized hospitals for advance preparedness to save lives or to law enforcement agencies when authorized under specific circumstances. UIN secures credit, debit and ATM card transactions through additional code verification and fulfills a pending need for technological system to eliminate child abduction, identity fraud, credit card theft, terrorism, and helps in saving lives of people.

Owner:AGGARWAL ABHINAV +2

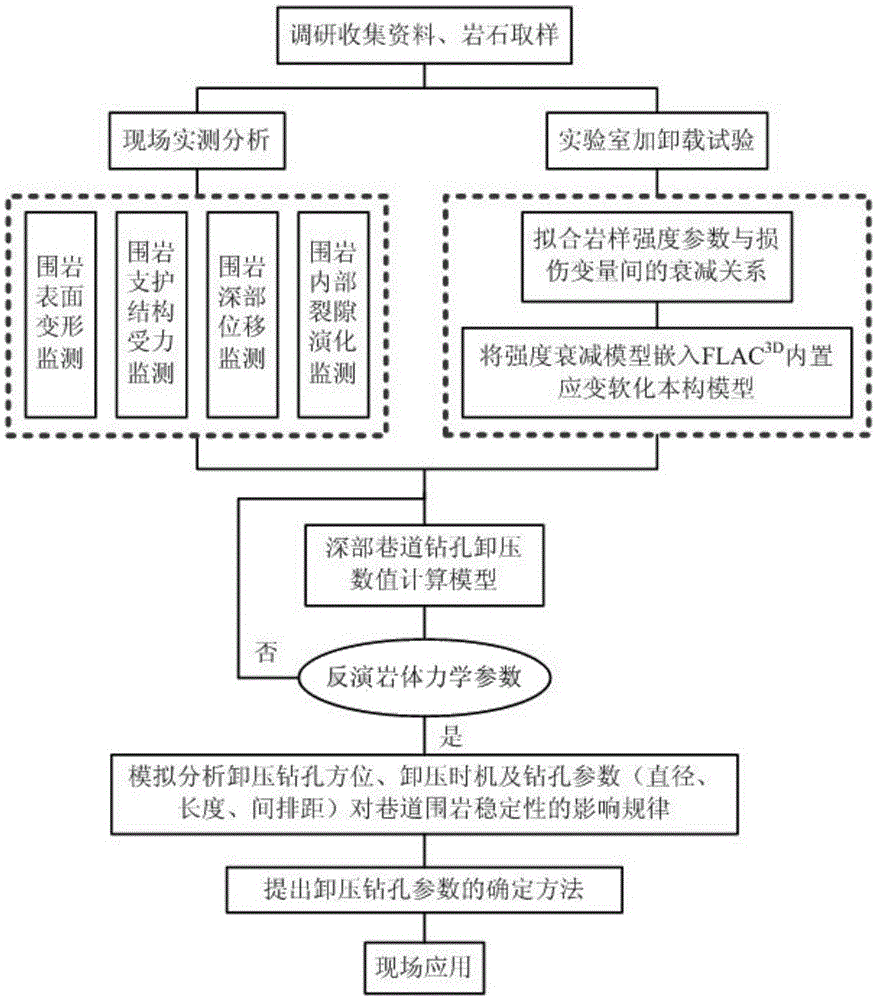

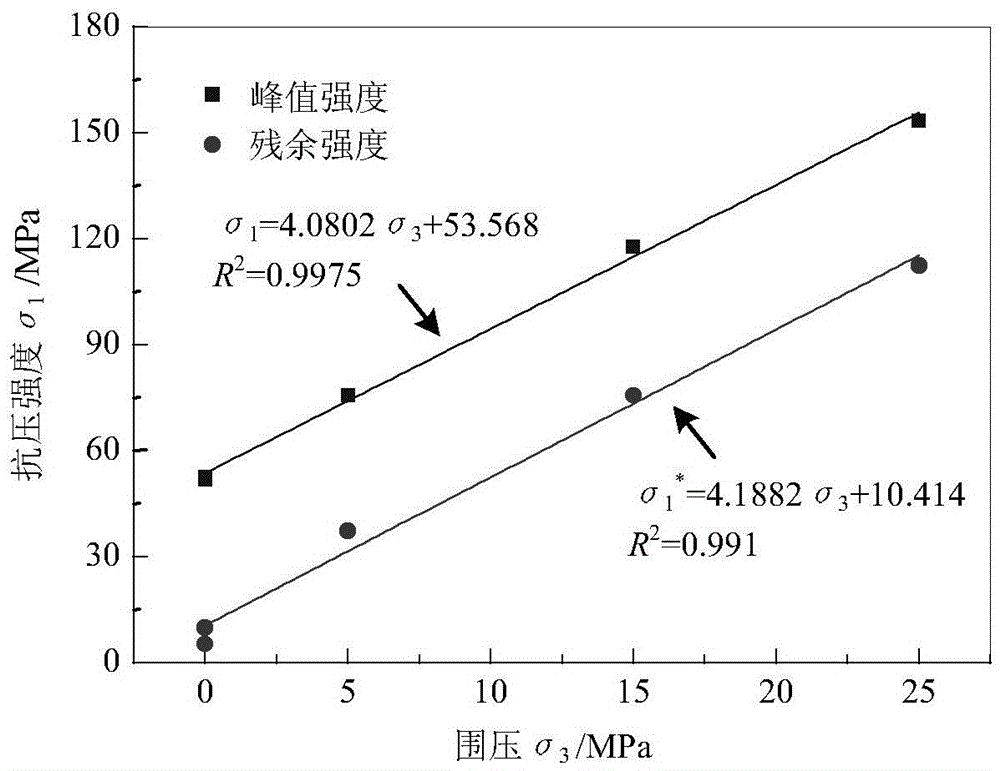

Numerical simulation determination method of deep high-stress roadway drilling pressure relief parameter

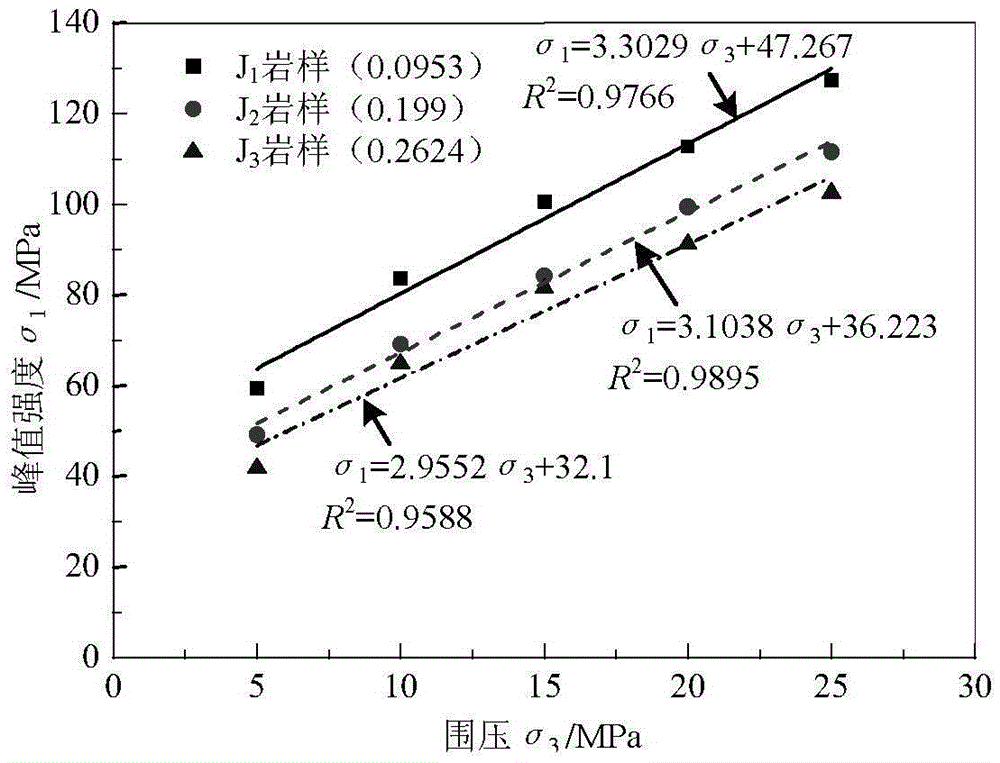

ActiveCN105631102AGood pressure relief effectStrong innovation significanceGeometric CADSpecial data processing applicationsModel parametersHigh stress

The invention discloses a numerical simulation determination method of a deep high-stress roadway drilling pressure relief parameter. Before simulation is carried out, a test roadway surrounding rock sample is firstly subjected to a loading and unloading test in a laboratory, an attenuation relationship between a rock sample strength parameter and a damage variable is obtained by fitting and is embedded into a FLAC<3D> (Fast Lagrangian Analysis of Continua) built-in strain softening constitutive model, and an actual measurement mine pressure expression law of a test roadway is taken as a known characteristic value to carry out inversion on the numerical calculation model parameter of a rock mass. A deep roadway drilling pressure relief numerical calculation model is established to simulate and analyze the influence law of a pressure relief drilling orientation, pressure relief opportunity and drilling parameters (diameter, length and inter-row spacing) on the stability of roadway surrounding rock, and a determination method of each factor which affects a pressure relief effect is put forward, and a drilling pressure relief technology system is perfected. The numerical simulation determination method considers the mutual action relationship of a pressure relief degree and the stability of the surrounding rock while pressure relief drilling parameters are determined, and the designed pressure relief drilling can perform a maximum pressure relief effect on a premise that the stability of the surrounding rock is guaranteed. The method is simple and exhibits high application value.

Owner:HENAN POLYTECHNIC UNIV

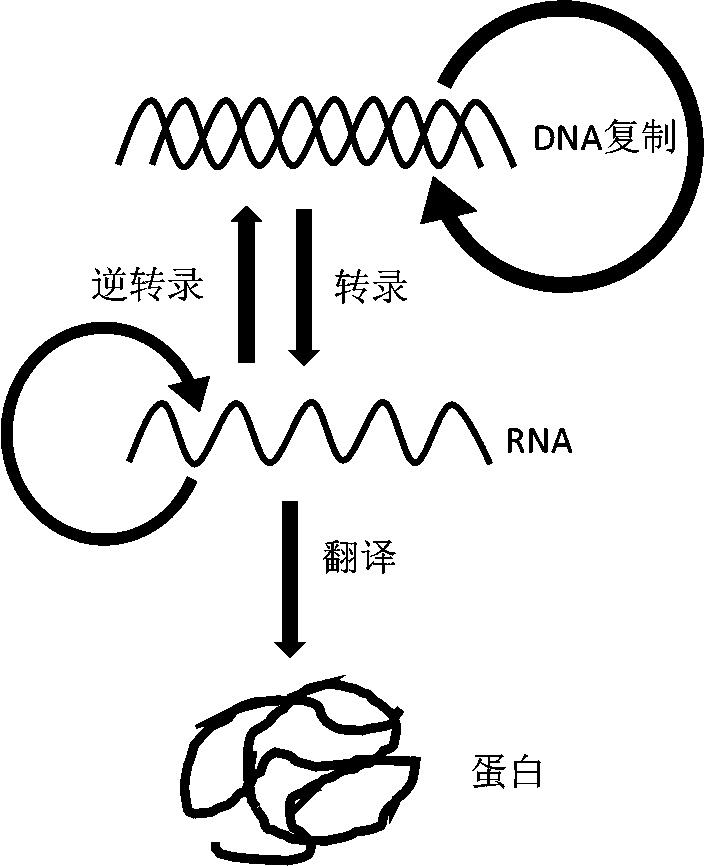

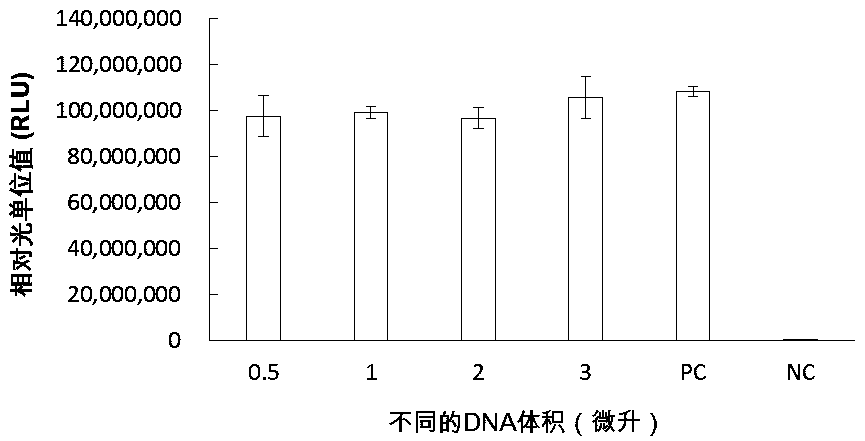

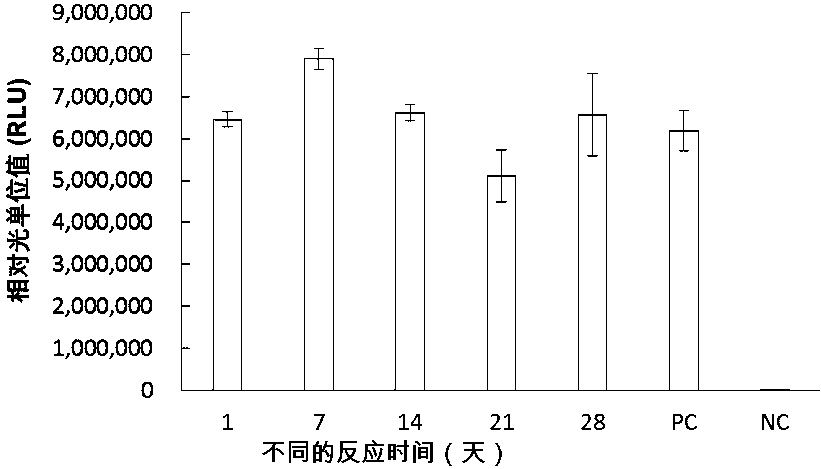

Synthesis system, preparation, kit and preparation method of in-vitro DNA-to-Protein (D2P)

The invention provides a theoretical design and technical design of cell-free protein synthesis for DNA replication, transcription and translation coupling, a preparation, a kit and a preparation method. Specifically, with the application of the in-vitro cell-free synthesis system provided by the invention, complex protein can be synthesized, and moreover, DNA and mRNA can be synthesized; and effective, high-throughput and quite convenient protein synthesis can be completed with the use of a DNA template by a minute quantity (nanogram-microgram).

Owner:KANGMA SHANGHAI BIOTECH LTD

Smoke desulfurization and denitrification integration method and special device thereof

InactiveCN103212281AIncrease the amount of dissolutionIncrease oxidation rateDispersed particle separationAir quality improvementLiquid wasteNitric oxide

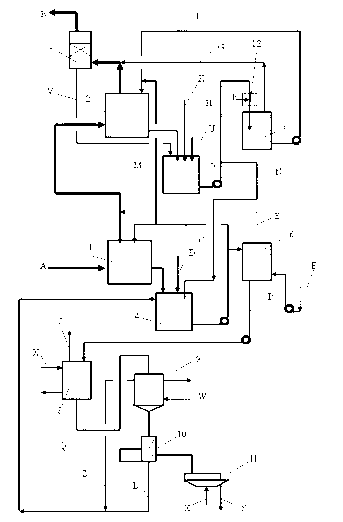

The invention discloses a smoke desulfurization and denitrification integration method and a special device thereof. The method is characterized in that a wet-method process is used in one technological system to simultaneously remove sulfur dioxide and nitrogen oxide in the smoke; an ammonium method is used for desulfurization, ammonia water is also used as a desulfurizer of the sulfur dioxide and a neutralizing agent for byproduct nitric acid produced in the denitrification process; an oxidization reduction method is used for the denitrification, a desulfurization byproduct ammonium sulfite or ammonium bisulfite is used as a reducing agent, urea is used as a reducing agent, a quinine-contained hydroxyl compound is used as a catalyst, air is blown into the denitrification circulating liquid so as to provide the dissolving oxygen and the oxidant for the oxidization reaction of the nitrogen oxide; a byproduct ammonium nitrate of the denitrification reaction is placed into the desulfurization liquid so as to recycle the nitrogen ammonium; and ammonia nitrogen chemical fertilizer ammonium sulfate and ammonium nitrate are recycled, and the entire technological flow is free from discharging sulfur-contained or ammonia nitrogen-contained waste liquid out of the system. Due to the adoption of the method, the integration of the desulfurization and the denitrification can be realized, the device is miniaturized, and no waste liquid is discharged in the technological process.

Owner:JIANGSU ZHONGXIAN GRP CO LTD

Micromirror array

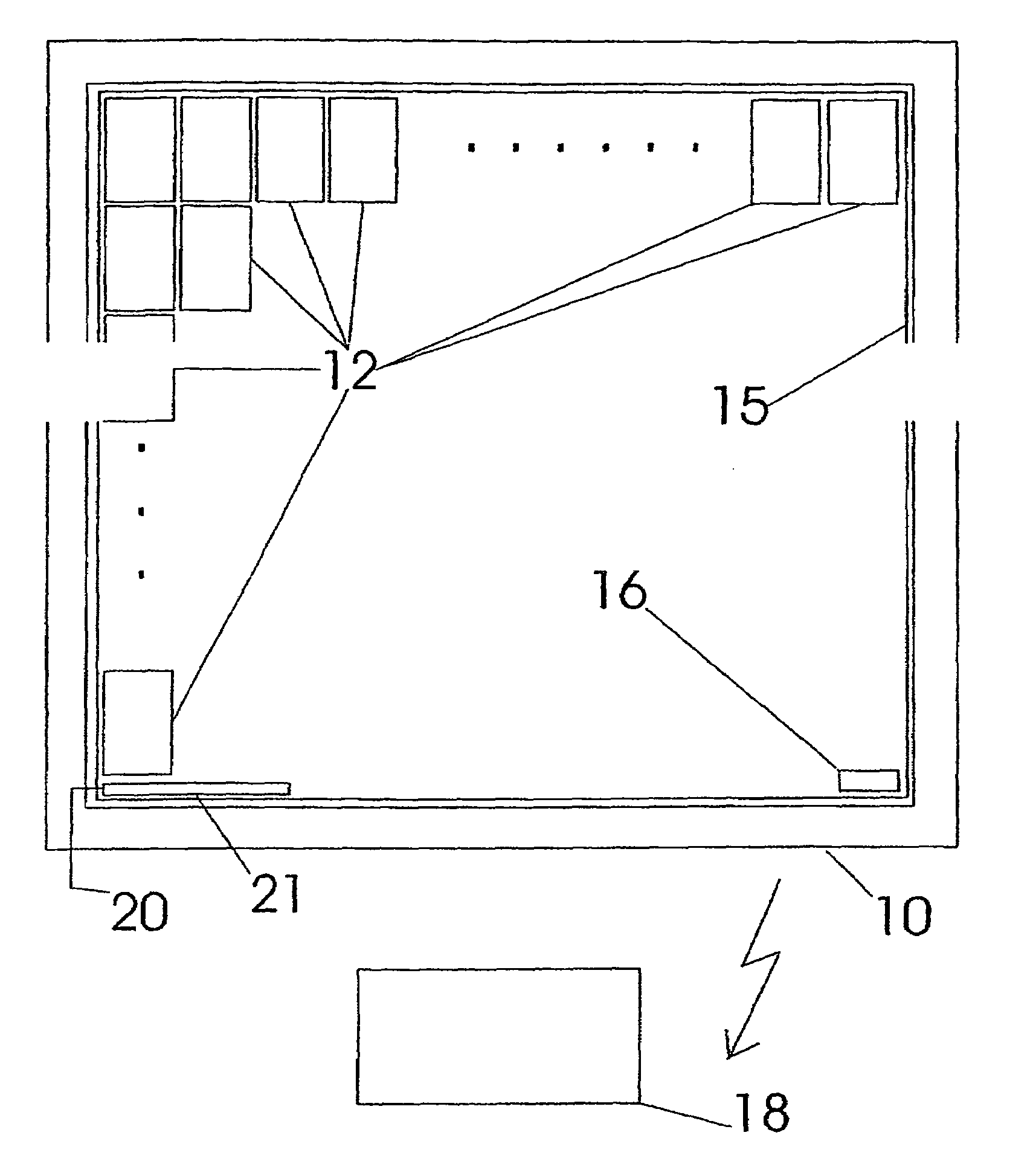

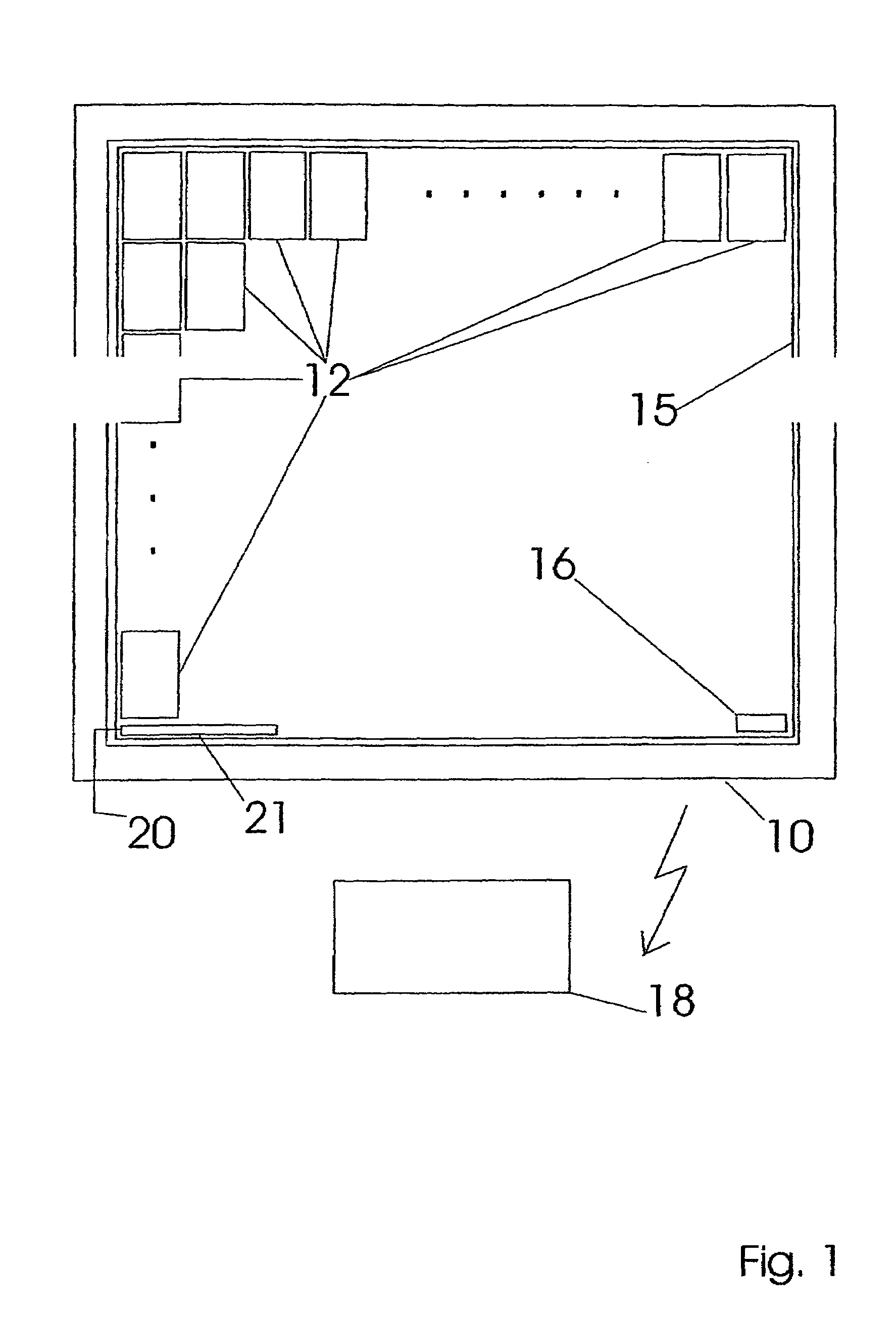

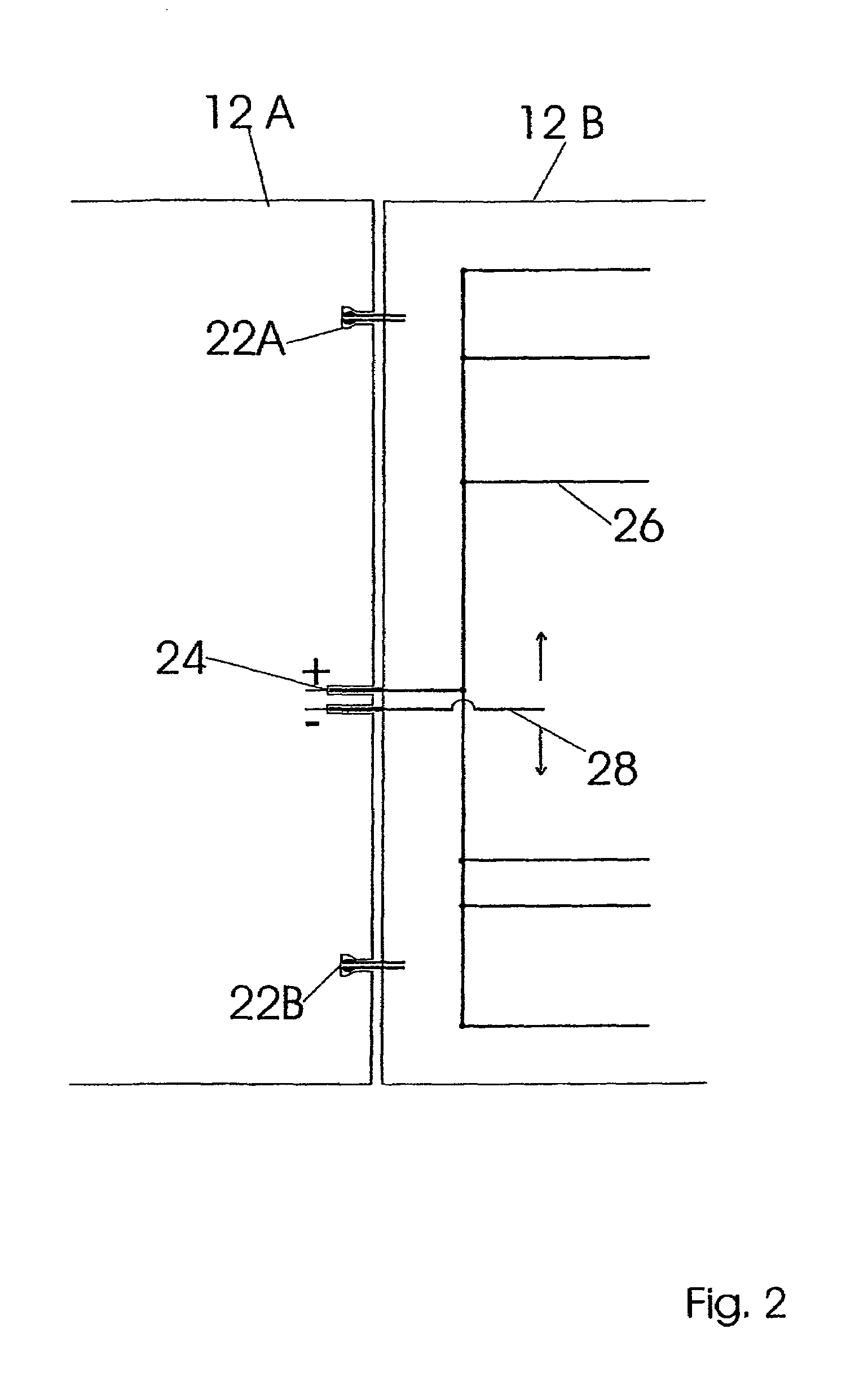

ActiveUS7677742B2Easy to produceLess effortSolar heating energyDoor/window protective devicesElectronic systemsTechnological system

The invention relates to a microstructured technological system and, in particular, micromirror arrangements. The aim of the invention is to produce facade elements for buildings having large areas in square centimetres and above, at reduced cost. The entire micromirror arrangement can be produced as a flat, architectonically useable structural element in a modularly replicable manner. According to the invention, the control electronic system, which contains the logics which are controlled as mirror elements, is arranged in the centre of a control device at a specific, remote distance from which an addressing network is used to control the individual mirror elements or modules. Said addressing network is already integrated into the flat modules during production and to a large degree, in the form of printed lines. As a result, the necessity of incorporating silicon-based chip technology into the facade elements, which is expensive, is no longer necessary. Also, essentially less expensive materials than highly pure silicon are used in the production of the micromirror arrangements. Production costs, which are at least in the same size order as other, traditional, high quality façade elements, result therefrom.

Owner:WAITZ VON ESCHEN FRIEDRICH +4

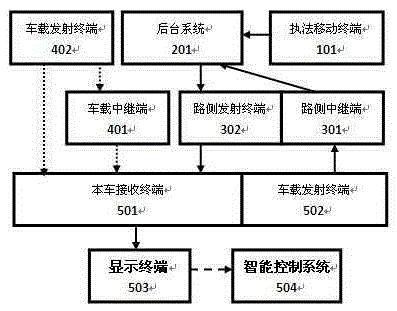

Intelligent early warning method for surrounding vehicle with abnormal driving state

InactiveCN105303890ALow costSuitable for unified mandatory promotion and popularizationAnti-collision systemsData synchronizationState parameter

The invention discloses an intelligent early warning method for a surrounding vehicle with an abnormal driving state. Vehicle driving state parameters are read via a roadside relay end or a vehicle-mounted reading end, the data are simultaneously submitted to a backstage system or a vehicle-mounted processing system, the backstage system or the vehicle-mounted processing system tracks or marks a vehicle driving electronic trajectory, vehicle instant state parameters comprise a driving speed, a driving direction and an inter-road position instant state, whether the vehicle driving state is abnormal is judged, or after the abnormal type is further confirmed, vehicle abnormal state warning information is sent to the vehicle. As the widely-used RFID technology is adopted, the cost is lower, the application is more convenient, and the method can be forced to be promoted by the government in a unified mode; according to the technology system for intelligent warning, judging and recognizing the abnormal driving vehicle, the surrounding other driving vehicles are warned instantly, effective and reasonable avoidance measures are adopted, and traffic safety accidents can be prevented from happening; and a special global meaning is provided for ensuring safe vehicle driving.

Owner:CHONGQING ZHITAO INFORMATION TECH CENT

Method for identifying and evaluating cold resistance of bamboo

InactiveCN101852757ASolve the problem of cold resistance identificationMaterial analysis by observing effect on chemical indicatorMicrobiological testing/measurementQuick FreezePeroxidase

The invention relates to a technology system applicable to identification and evaluation of cold resistance of isolated parts of different bamboo varieties, in particular to a method for identifying and evaluating the cold resistance of bamboos. The method for identifying and evaluating the cold resistance of the bamboos is characterized by comprising the following steps of: a) taking a twig of the same bamboo age and with a length of 30 centimeters as a reference; b) quick-freezing a part of processed leaves in liquid nitrogen for 30 minutes and then storing the leaves into a refrigerator at the temperature of 80 DEG C below zero and the like. The method for identifying and evaluating the cold resistance of the bamboos is characterized by: a) conductivity determination; b) determination of soluble sugar content; c) determination of soluble protein content; d) malondialdehyde (MDA) determination; e) praline determination; f) determination of activities of superoxide dismutase (SOD); and g) determination of activities of peroxidase (POD).

Owner:胡尚连

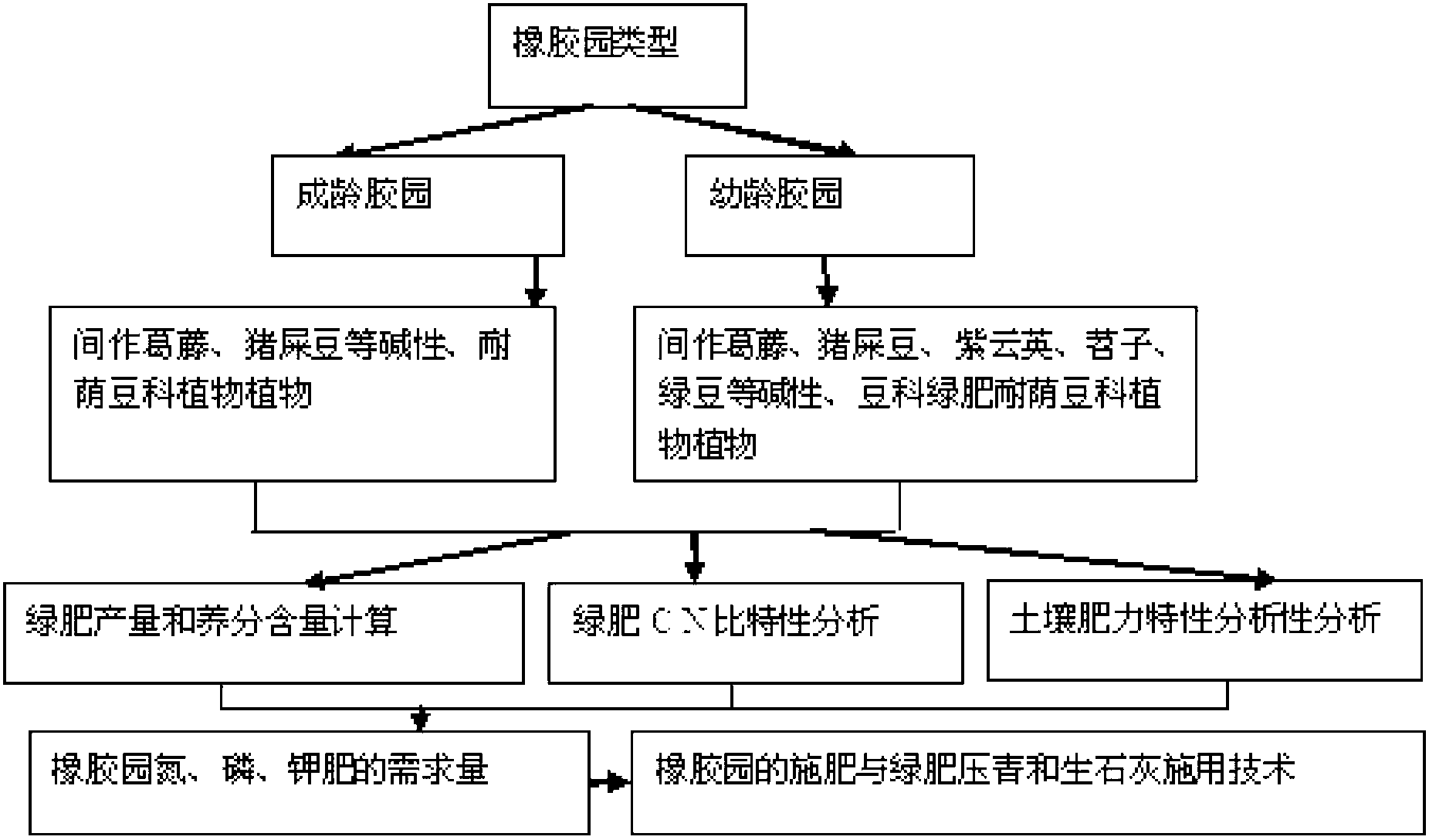

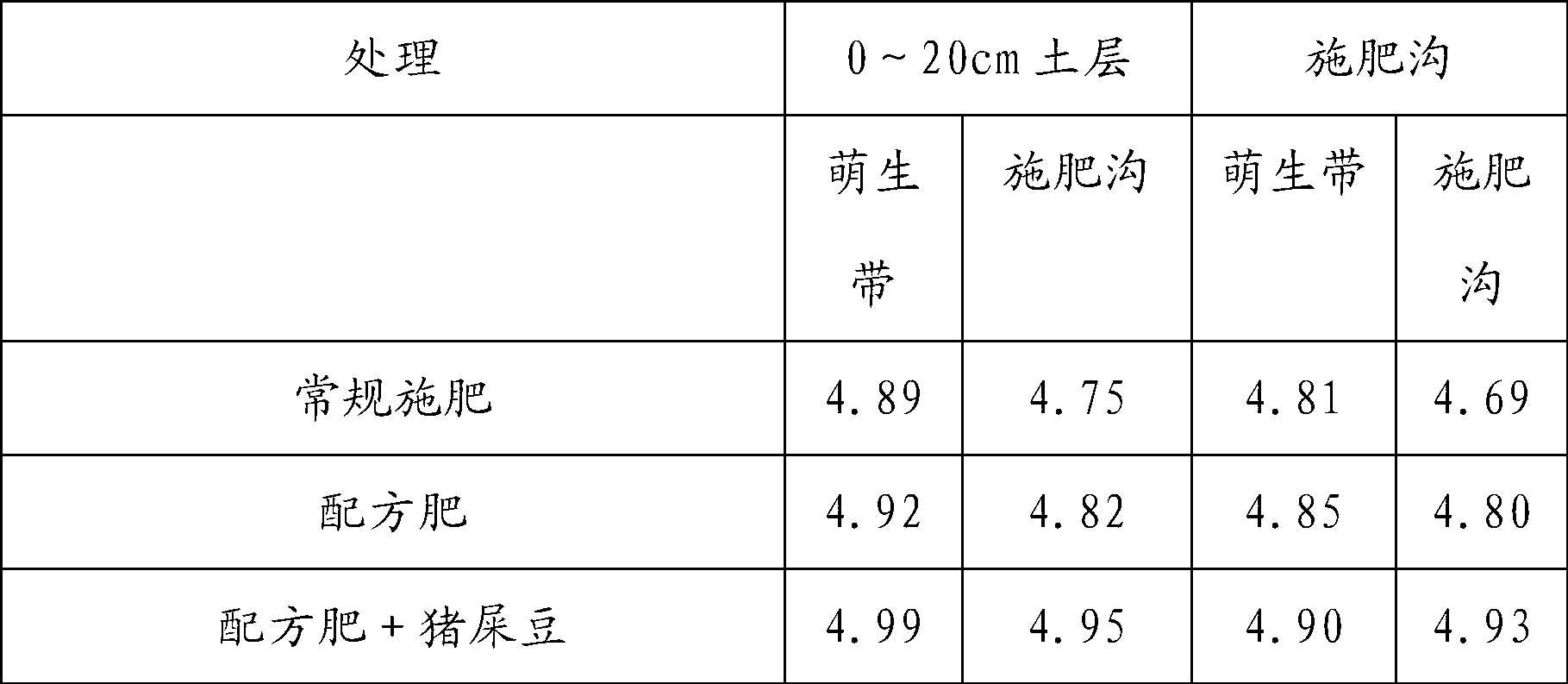

Acidified soil improvement method for rubber plantation

ActiveCN103069947AIncrease contentImprove acidified soilSeed coating/dressingHorticultureGreen manureBiology

The invention discloses an acidified soil improvement method for a rubber plantation. The method comprises the following steps of: 1, selecting sowing time and green manure variety; 2, planting green manure, i.e., A, performing seed dressing by using symbiotic matching root nodule bacteria and phosphorus fertilizer before plantation of leguminous green manure; and 3, harvesting and burying the green manure, i.e., burying the harvested green manure in a dressing furrow and performing combined application of lime as a corrosion promoter in a burying process. The method aims at serious acidification of soil of the rubber plantation; meanwhile, no systematic control technology system is available at present; and the leguminous green manure with higher acid resistance and shading resistance is selected and used and application of microbial manure, DCD (dicyandiamide), the lime and the like is combined according to farm operation time process such as rubber plantation soil fertilization and winter management, so that the pH (Potential of Hydrogen) of the soil and contents of soil organic matter and the like of the rubber plantation are improved, thereby improving the acidified soil of the rubber plantation.

Owner:RUBBER RES INST CHINESE ACADEMY OF TROPICAL AGRI SCI

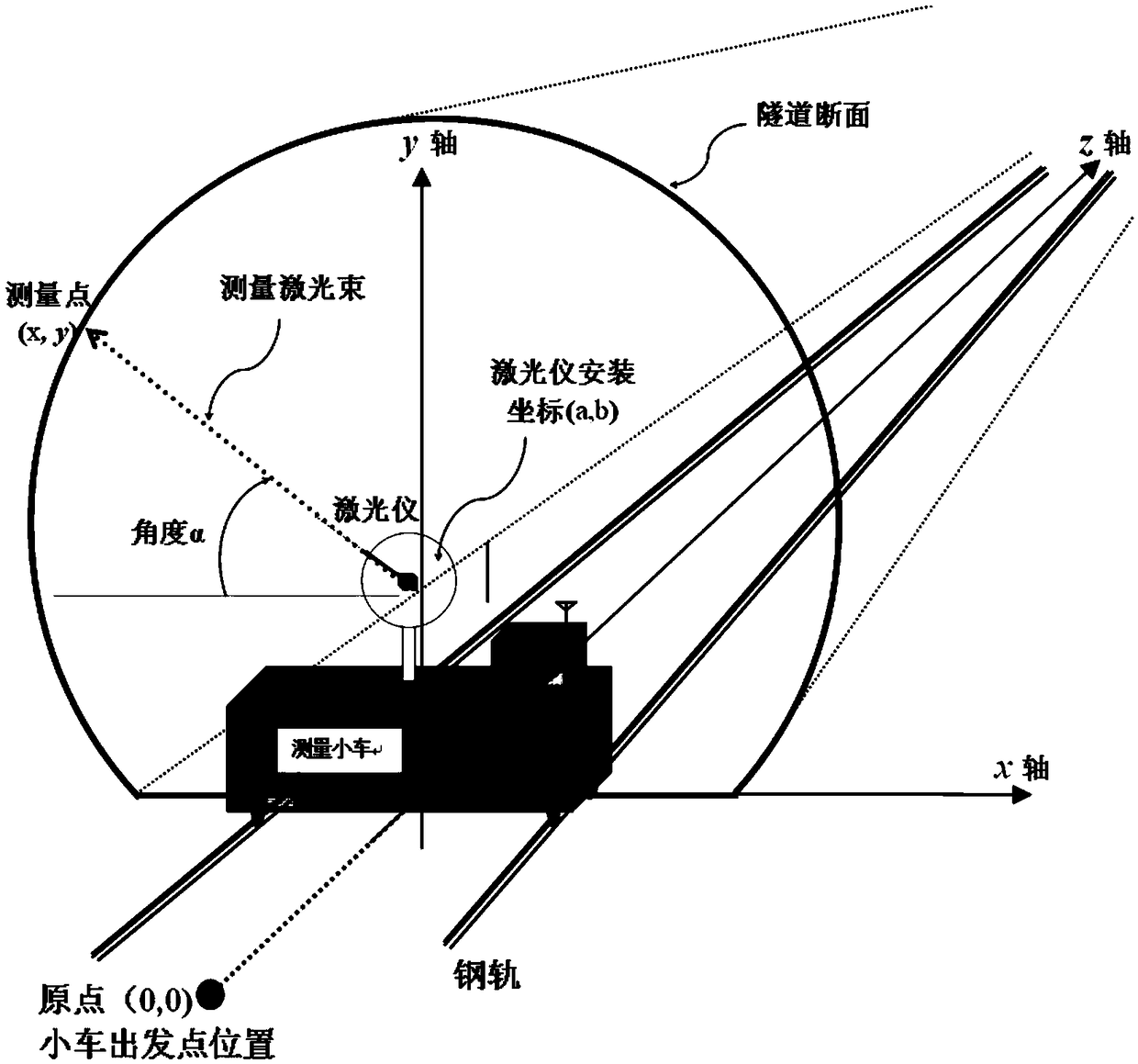

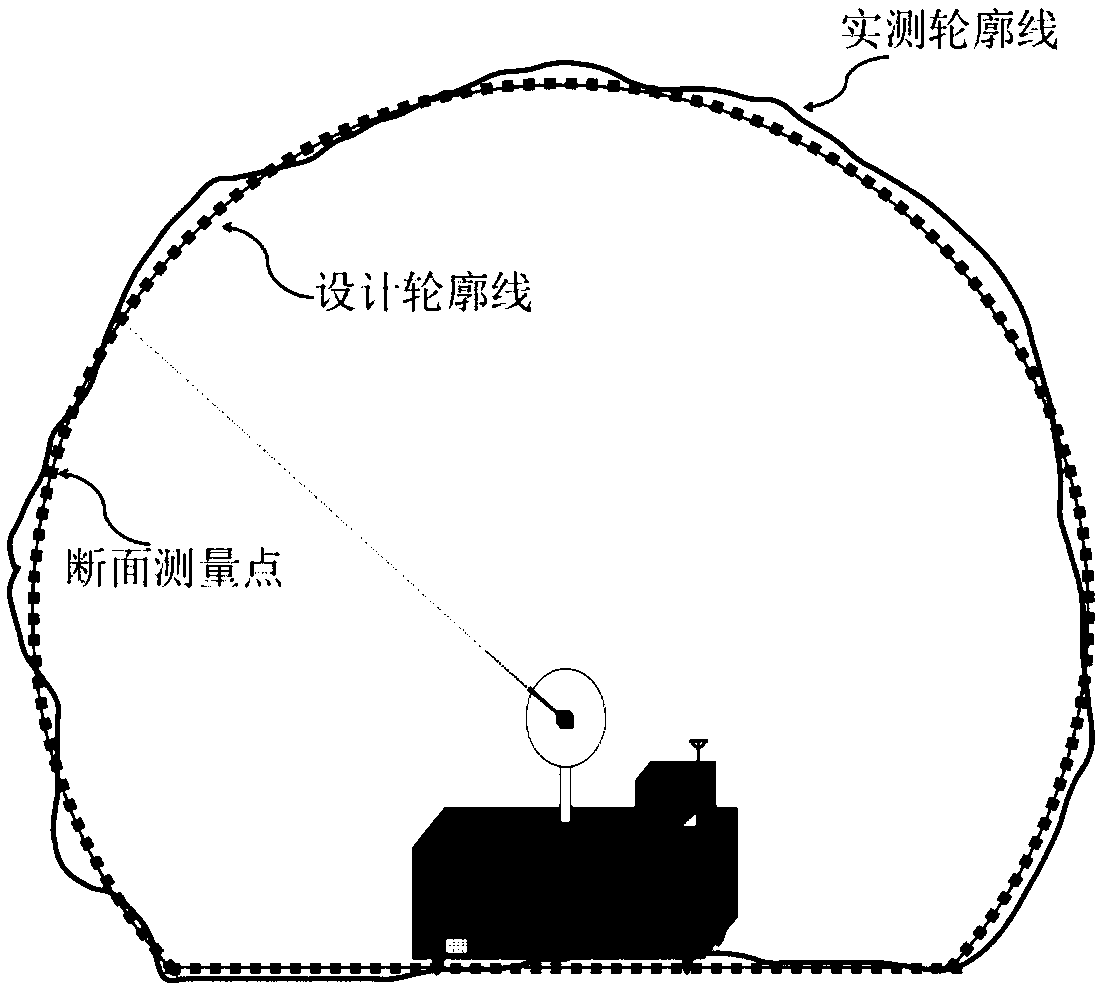

Vehicle-mounted measurement device of three-dimensional deformation monitoring of subway tunnels based on reference transmission

PendingCN108917638ATimely warningHigh precisionTransmission systemsUsing optical meansMeasurement deviceReliability design

The invention belongs to the technical field of three-dimensional detection of subway tunnels, and discloses a vehicle-mounted measurement device of three-dimensional deformation monitoring of subwaytunnels based on reference transmission. A rotatable laser distance measurement system for high-speed distance measurement and angle measurement is integrated by a laser range finder, an inclination angle sensor, a high-precision turn table and a PLC controller together; a tunnel section outline is measured in a discrete multi-point mode; meanwhile, in combination with a photoelectric encoder installed on a distance measurement wheel at the bottom of a tunnel detection vehicle, a fixed displacement amount of the detection vehicle between a starting position and a travelling position on an axial direction of the tunnel is obtained, a program is triggered, and the detected data of the specific position in the tunnel are transmitted to an upper computer by a wireless communicator. The vehicle-mounted measurement device disclosed by the invention makes breakthroughs in the practical technical innovation of the online monitoring of the tunnel structure safety, lays a foundation for forminga technical system for the reliability design, analysis, test and evaluation of rail transit facilities, and has practicality in many fields.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

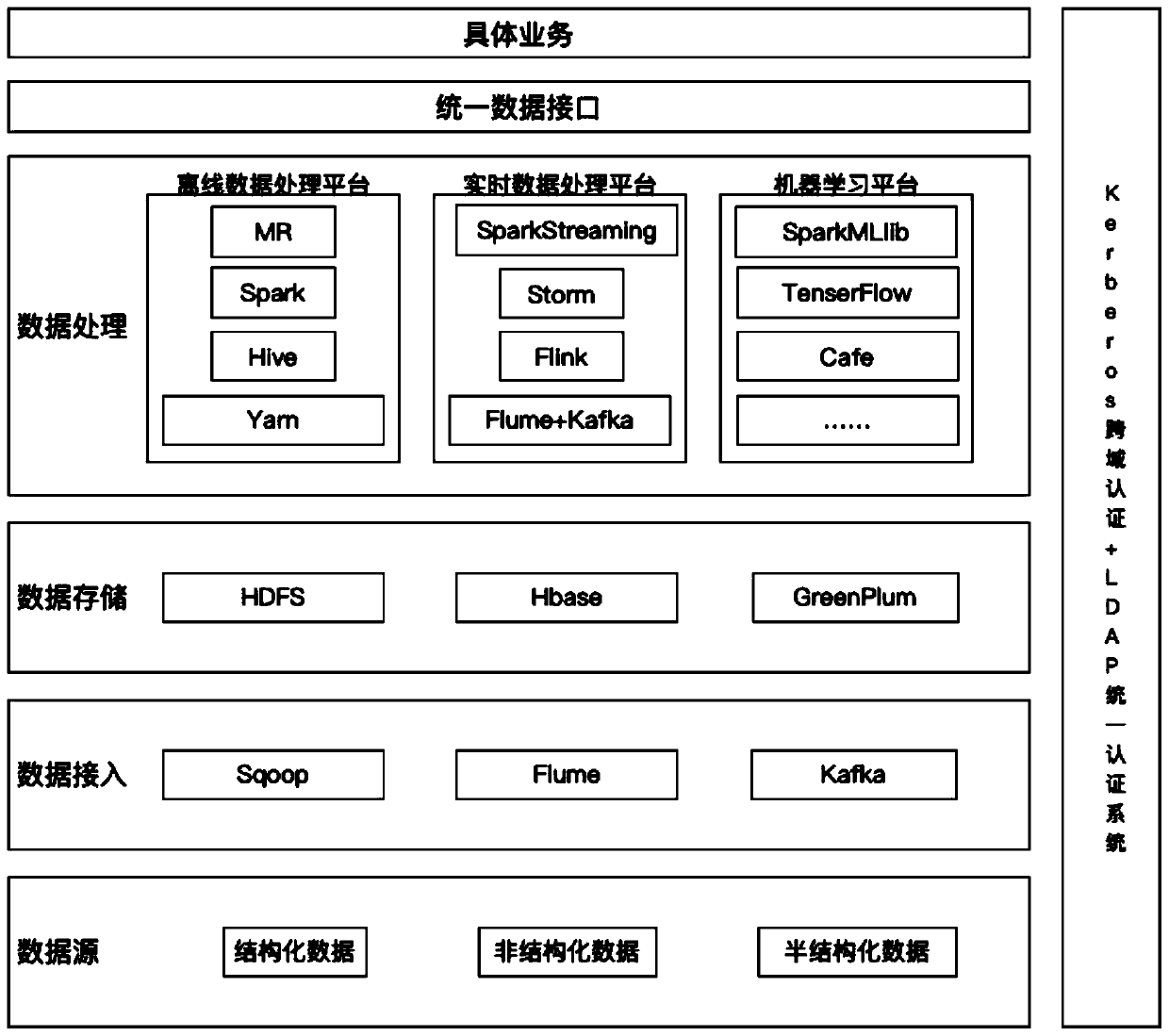

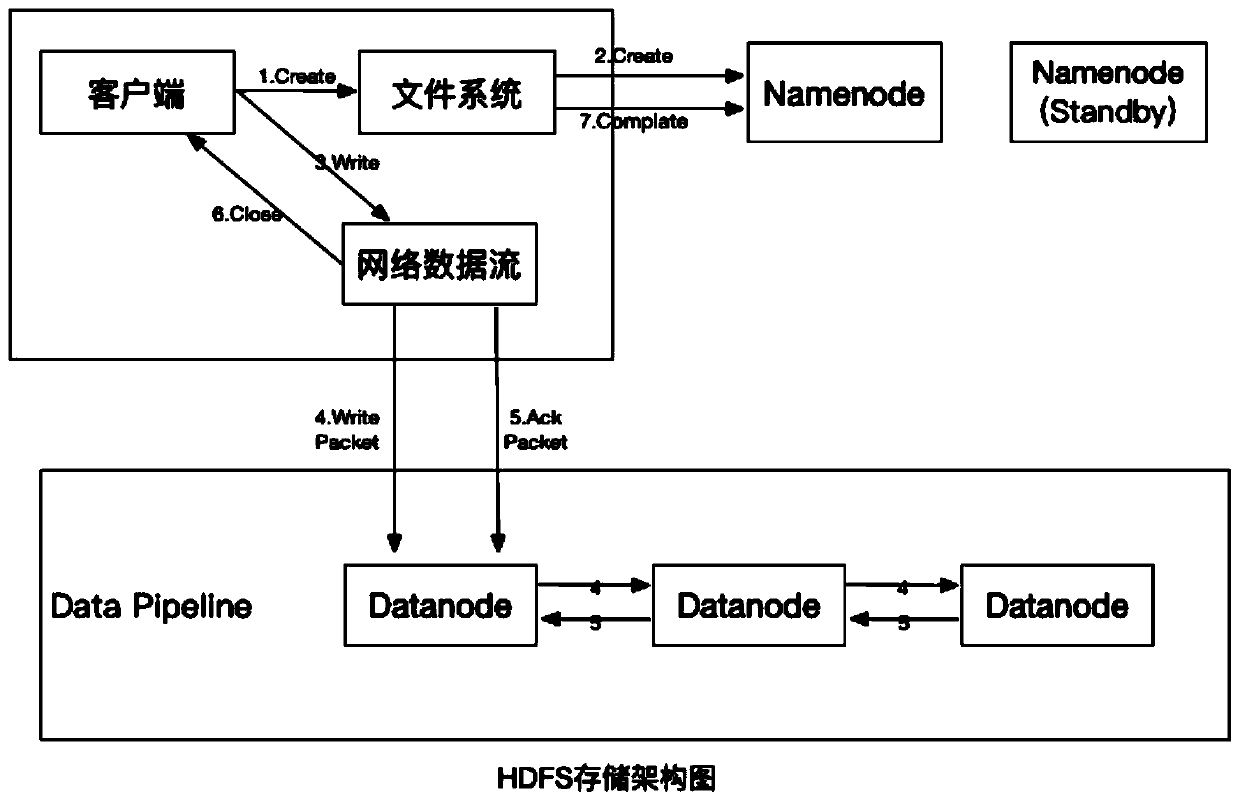

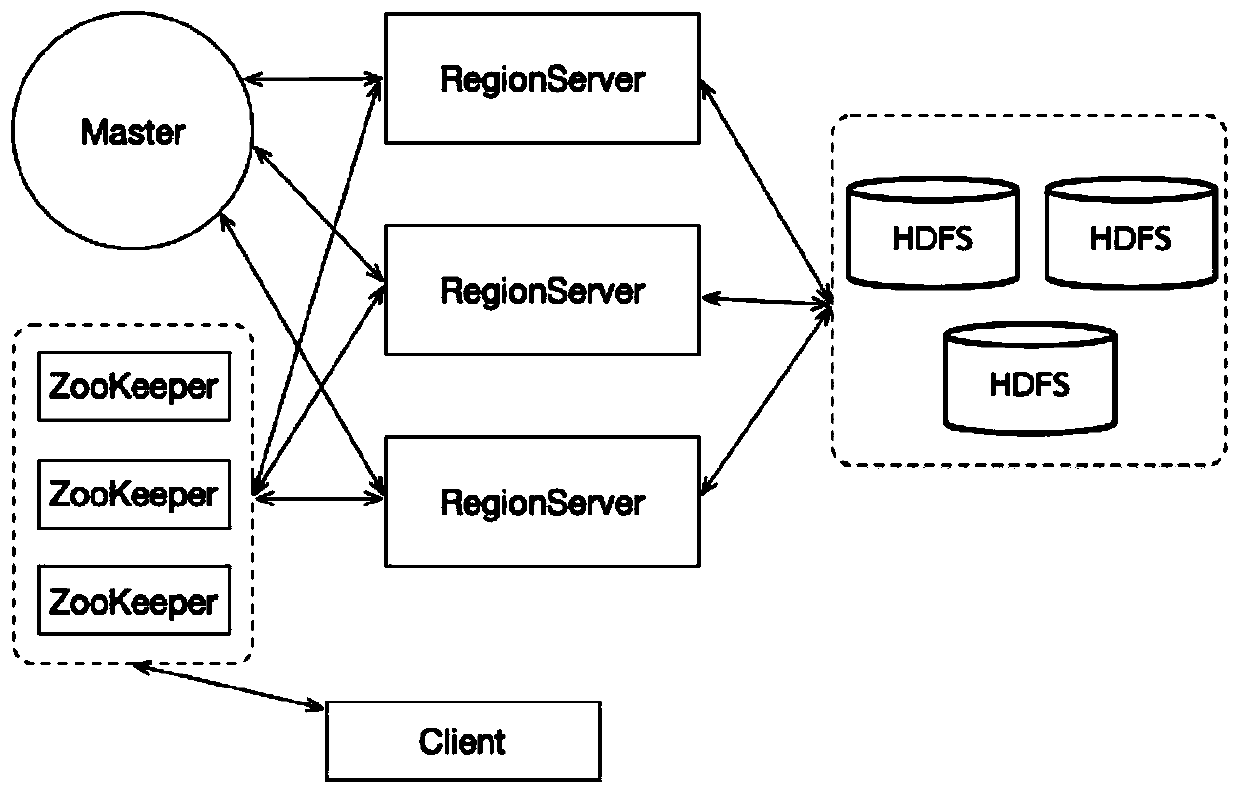

An enterprise-level big data platform architecture

InactiveCN109840253ADatabase queryingDatabase distribution/replicationData platformEnterprise computing

The invention relates to enterprise-level big data platform architecture, and aims to improve standardization and efficiency of big data processing, extraction, storage and data mining of enterprisesin actual production at low cost. The big data platform can run on expandable common hardware based on Hadoop, Spark, Hive, Hbase and other Apache open source projects, and a complete big data technical system is constructed and comprises a data storage platform, an offline computing platform, a real-time computing platform and a machine learning platform. And enterprise computing tasks under various complex conditions can be met. The platform further comprises a set of complete data processing standards such as data storage, data quality supervision and ETL process standards, and strategy schemes such as core data protection and data authority control so as to ensure data quality normalization and data asset safety.

Owner:BEIJING UNIV OF TECH

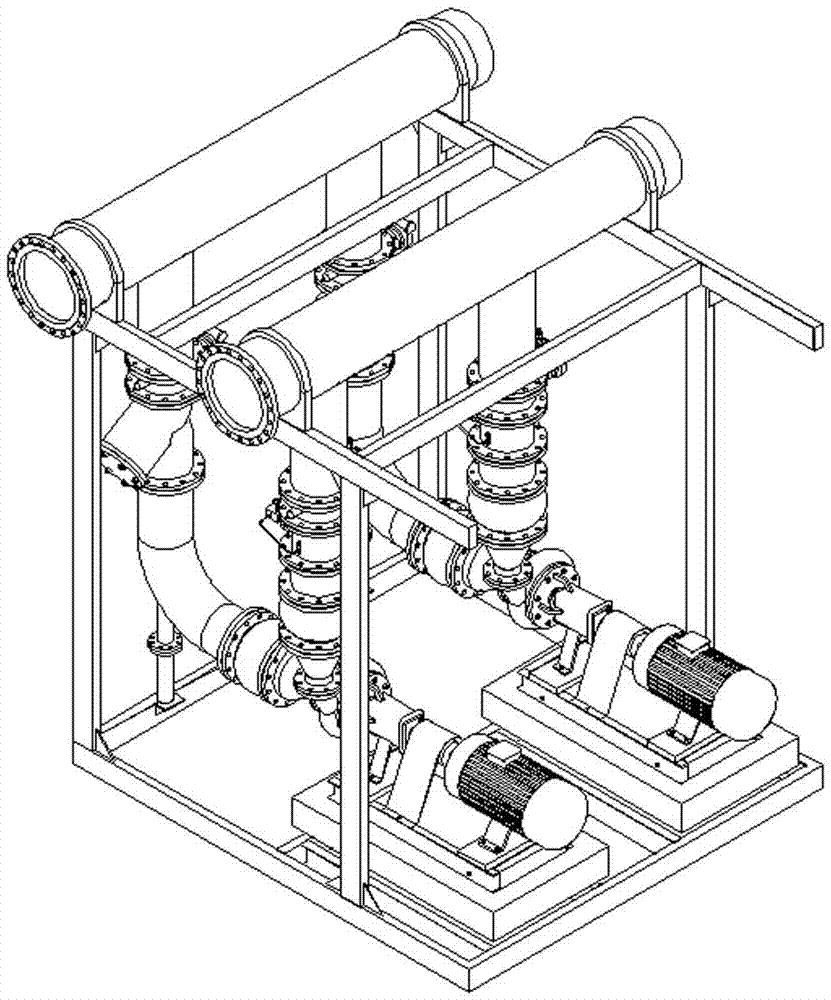

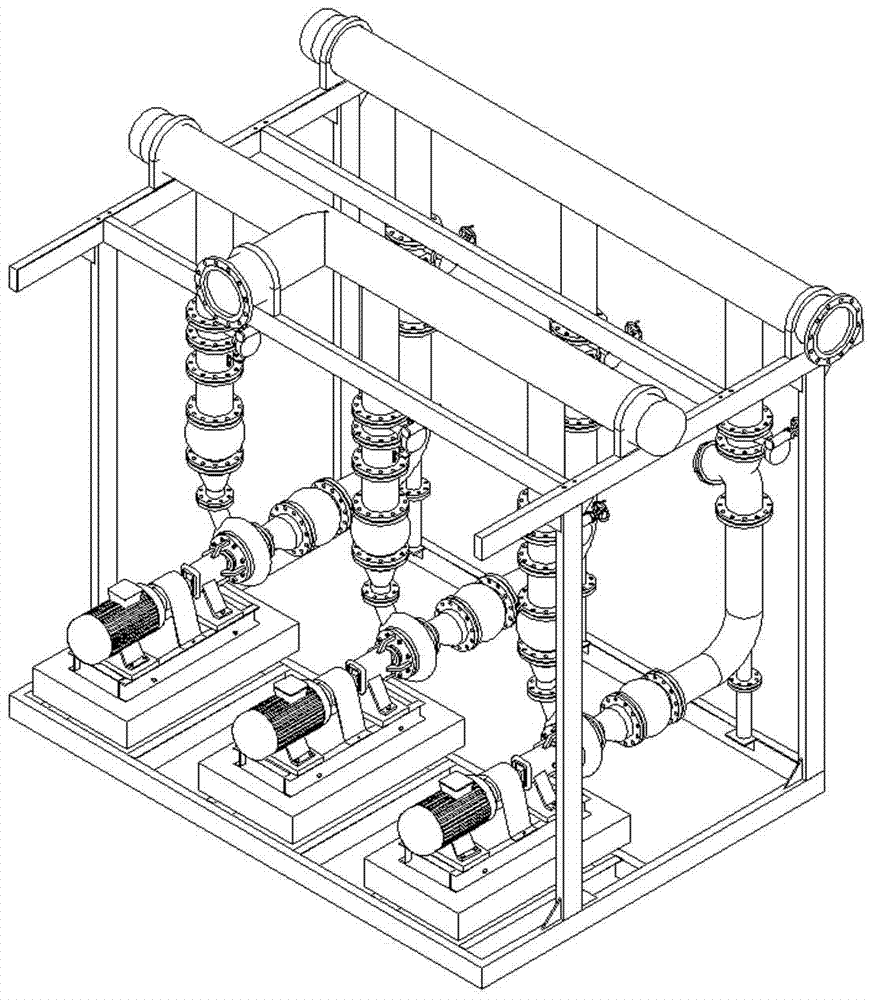

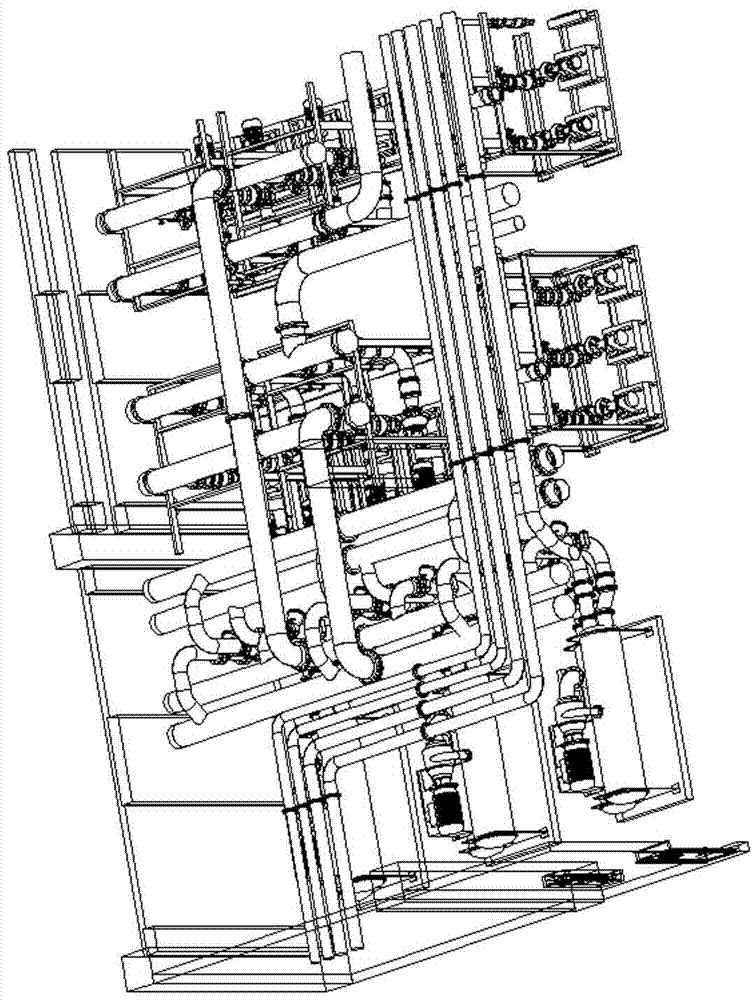

BIDA integral engineering technology system

InactiveCN107542161AEfficient transportImprove transportation efficiencyBuilding constructionsTechnological systemResource saving

The invention provides a BIDA integral engineering technology system, and belongs to the technical field of construction engineering. According to the technical system, a BIM model is used, refined family library building according to a construction sample, BIM model building for deep design, prefabricated processing segmentation and grouping, processing detailed diagram drawing, factory prefabrication processing, field assembly and debugging and acceptance check are performed. The BIM technology is used in the whole process for guiding the application. The technical system is favorable for engineering construction efficiency improvement and labor release. Through the standardized design, preassembled part factorized production and mechanical construction, the construction period is greatly shortened; in addition, the construction people number is reduced to a great degree; the work productivity is improved; the labor cost is reduced; and the energy source saving, resource saving and environment pollution reduction are facilitated. The engineering quality and construction safety improvement is facilitated; and the industrialization level improvement is facilitated.

Owner:THE FIRST COMPARY OF CHINA EIGHTH ENG BUREAU LTD

Low-cost slagging and dephosphorizing technique for high-phosphorus molten iron through converter smelting

ActiveCN105671237ALow costIncreased (MgO) contentManufacturing convertersProcess efficiency improvementAlkalinitySlag

The invention discloses a low-cost slagging and dephosphorizing technique for high-phosphorus molten iron through converter smelting. The slagging and dephosphorizing technique comprises the steps of slag remaining and splashing, primary charging, primary blowing, turning down and deslagging, secondary feeding, secondary blowing, and terminal control and steel tapping, all final slag is reserved for slag splashing after steel tapping, and the steps are repeated circularly. The obtained final slag comprises, 35-48% of CaO, 8-14% of MgO, 8-13% of SiO2, 10.20-18.50% of TFe, and 2.50-5.60% of P2O5, and the alkalinity is 2.5-6. By the adoption of the slagging and dephosphorizing technique, smelting of the high-phosphorus molten iron is integrally optimized; materials, such as high-cost slagging agents, magnesite pellets and light-burned magnesian limestone, are partially or completely replaced by low-cost and environment-friendly sintered and returned mines and raw magnesian limestone, and a corresponding technological system is set; and the extra heat is balanced while smooth dephosphorizing is guaranteed, the slag oxidation, the P2O5 content and the final slag MgO content are improved, the slagging cost is reduced by over 8 yuan / t while a furnace lining is protected and the dephosphorizing effect is achieved, the furnace age is prolonged from 12000 times to 15000 times, and the application value and popularization value are high.

Owner:WUKUN STEEL

Chemical bulk stack dipping process for gold-containing tailing ore without pelletizing

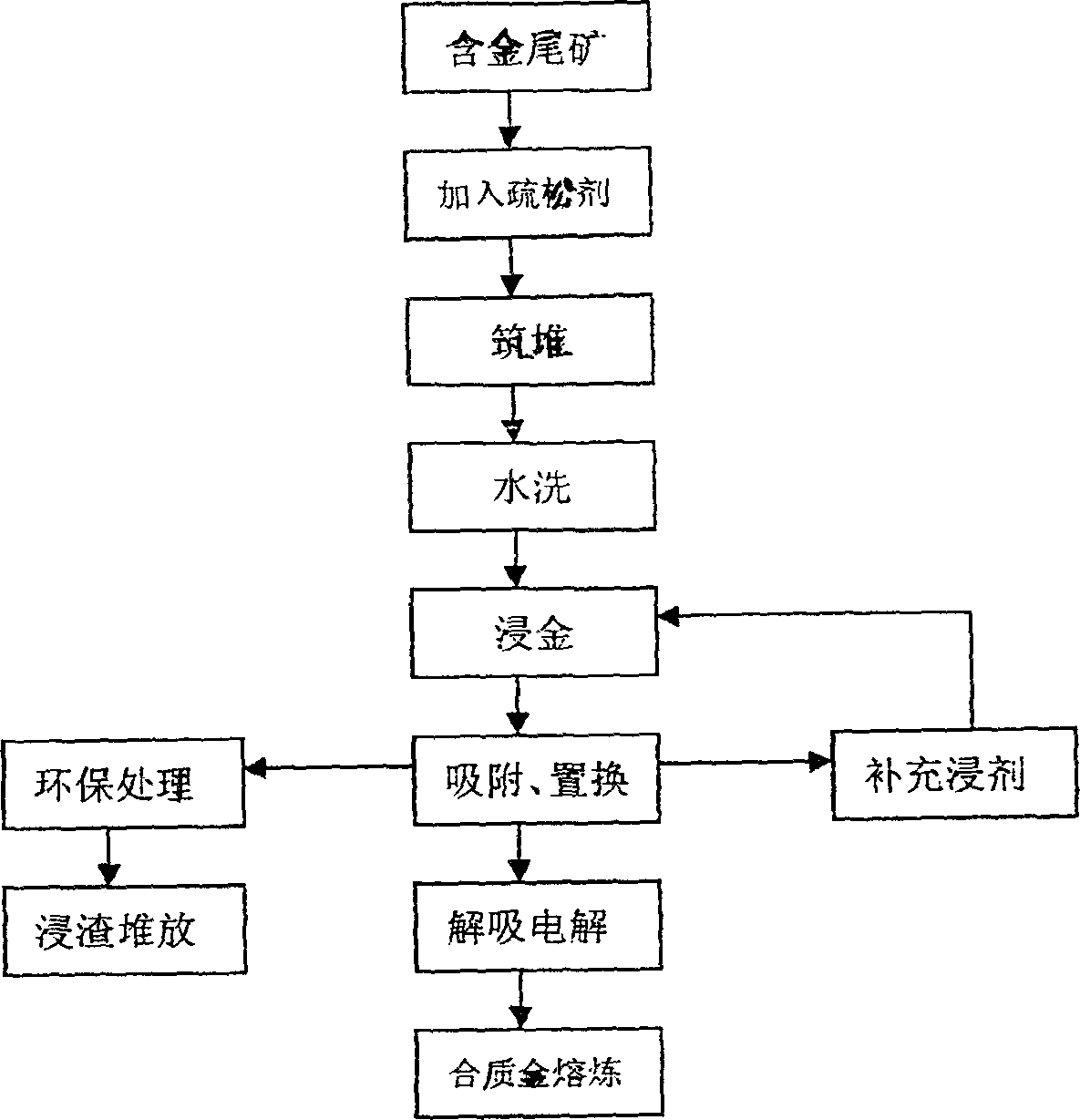

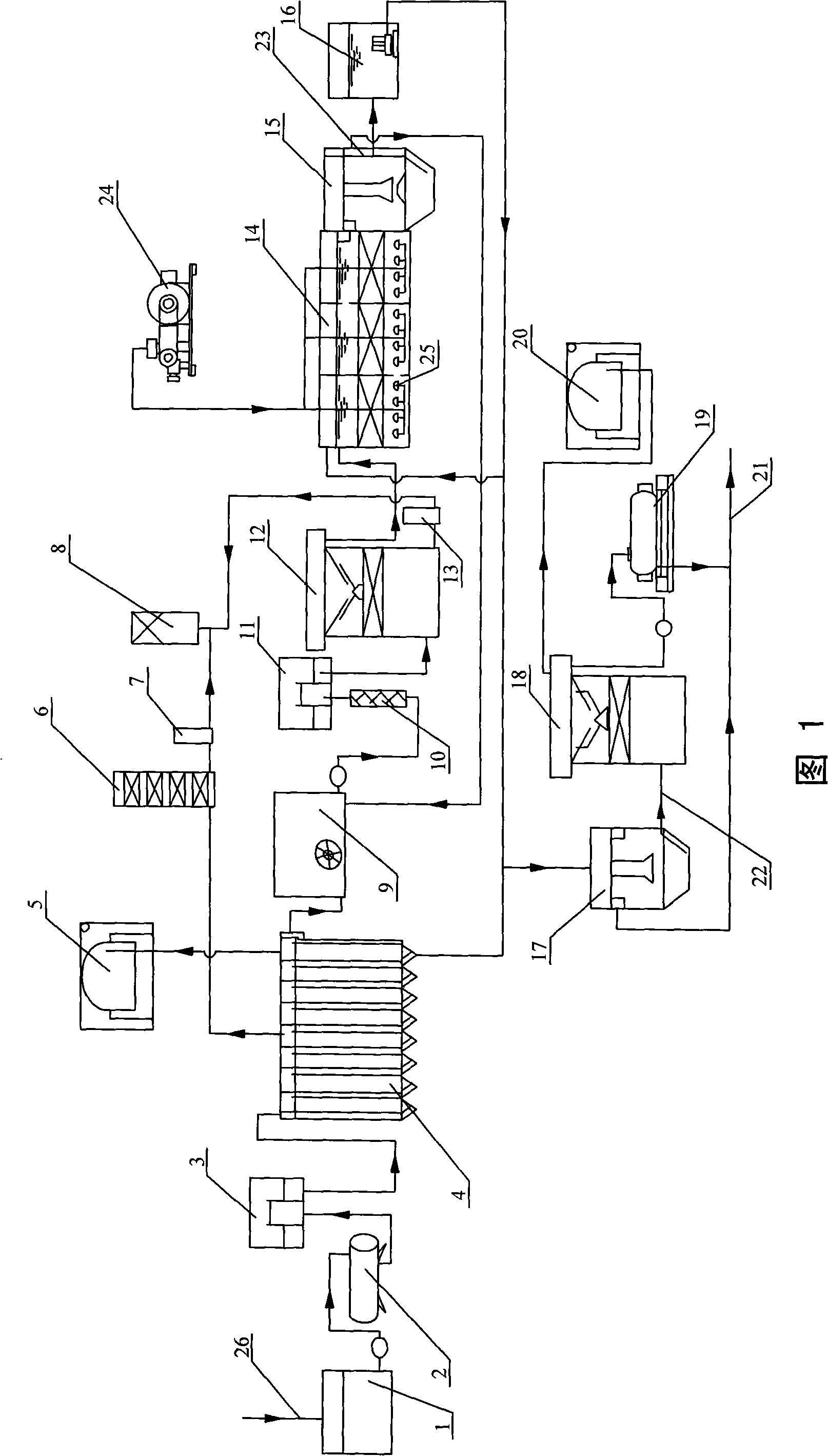

InactiveCN1554785AOvercome the disadvantages of large investment scaleLess investmentProcess efficiency improvementTechnological systemMaterials science

The technological process of extracting gold from tailing containing gold includes preparing material, stacking tailing, laying the liquid soaking system, leaching out gold, recovering gold, treating leached dregs and other technological steps. In the step of preparing material, the present invention solves the seepage problem in chemical loosening mode, rather than physical mode. Compared with traditional gold extracting technique, the present invention has the advantages of simple technological process, low production cost, high gold recovering rate, wide application range and good environment protecting effect.

Owner:王金祥

Technological system and method for removing carbon, nitrogen and sulphur in waste water synchronously

ActiveCN101302069AImprove processing efficiencySimple processDispersed particle separationSulfur preparation/purificationProcess systemsGas phase

The invention provides a process system and a method for synchronously removing carbon, nitrogen and sulfur in wastewater, relating to a device and a method for treating the wastewater. The process system solves the defects of complicated process, high operating cost, low processing efficiency and difficult elemental sulfur separation in the prior art for removing the carbon, the nitrogen and the sulfur in the wastewater. In the process system, an outlet of a carbon-nitrogen-sulfur synchronous removal device is communicated with an inlet of a nitrifying reactor; and an outlet of the nitrifying reactor is communicated with an inlet of a sedimentation tank. The method comprises the following steps of: transforming organic substances, sulfate and ammonia nitrogen in the wastewater into carbon dioxide, elemental sulfur and nitrogen respectively; transforming H2S and NH3 metabolized in gas phase into the elemental sulfur and the nitrogen; and degrading sludge generated in the growth of microorganisms. The method has the advantages of high processing efficiency, no secondary pollution, simple process, low operating cost, completely recycled elemental sulfur and so on; and the process system also has the advantages of occupied area conservation and convenient operation.

Owner:HARBIN INST OF TECH +1

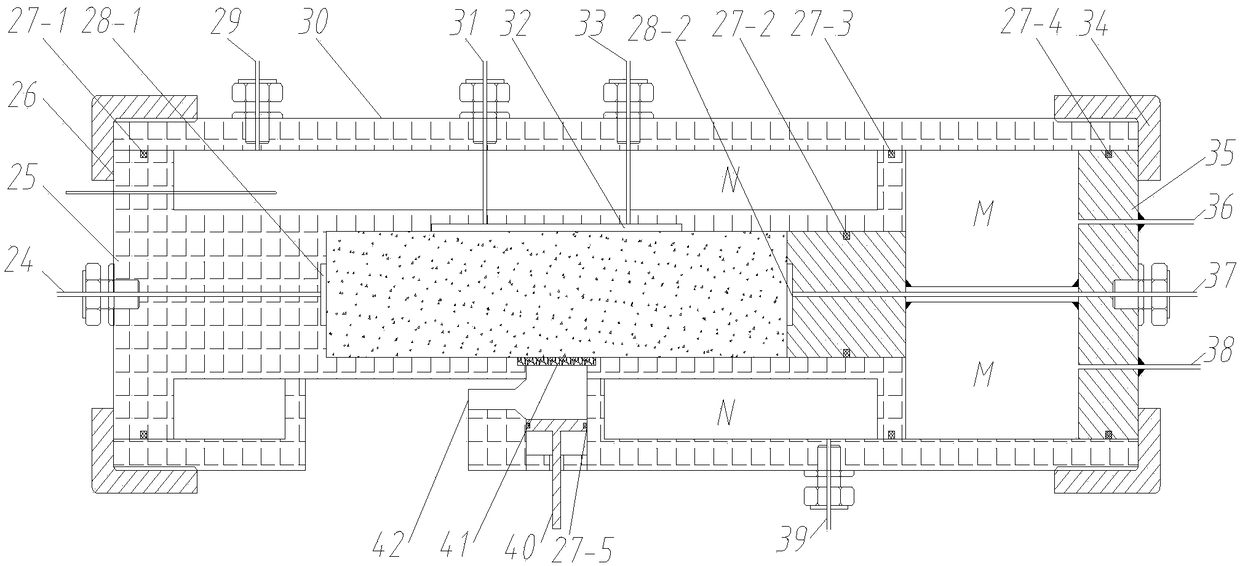

Heavy-pitch ultra-thick coalbed fully-mechanized caving mining three-dimensional similar material simulation test bed

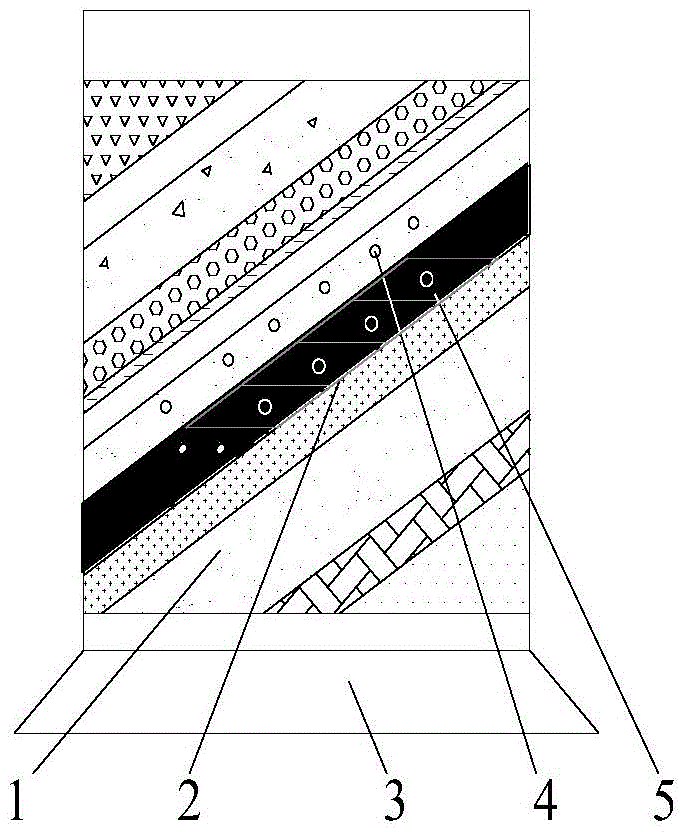

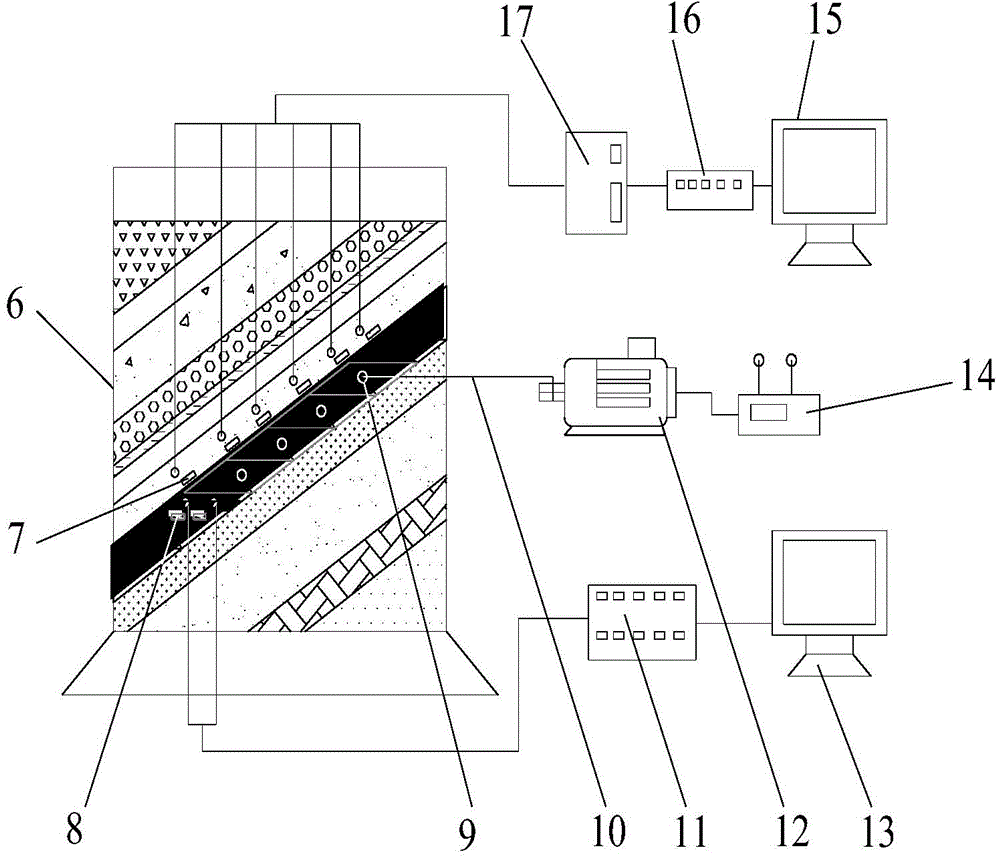

ActiveCN104931674AHelp with simulationHelpful for analysisEarth material testingTechnological systemThree-dimensional space

The invention discloses a heavy-pitch ultra-thick coalbed fully-mechanized caving mining three-dimensional similar material simulation test bed, which solves the problems in the prior art that the two-dimensional similar material for heavy-pitch ultra-thick coalbed is poor in similarity and accuracy. The test bed comprises a test box body, a coalbed mining simulation system, an acoustic transmitting and monitoring system and a stress monitoring system, the coalbed mining simulation system comprises a peristaltic motor and a controller, the peristaltic motor is connected with a metal lock ring on the tail part of a cylindrical medium simulation material in a test box body, a parallelogram jack is respectively formed in a left baffle plate and a right baffle plate of the test box body. By adopting the heavy-pitch ultra-thick coalbed fully-mechanized caving mining three-dimensional similar material simulation test bed, the simulation in a three-dimensional space form can be carried out and is closer to the real situation of the engineering, the moving rule of a overlying strata in the heavy-pitch ultra-thick coalbed fully-mechanized caving mining process, the pressure release rule of a coalbed soleplate and the surface mining settlement rule can be obtained, and theoretical support can be provided for establishing a heavy-pitch ultra-thick coalbed fully-mechanized caving mining technical system.

Owner:SHANDONG UNIV OF SCI & TECH

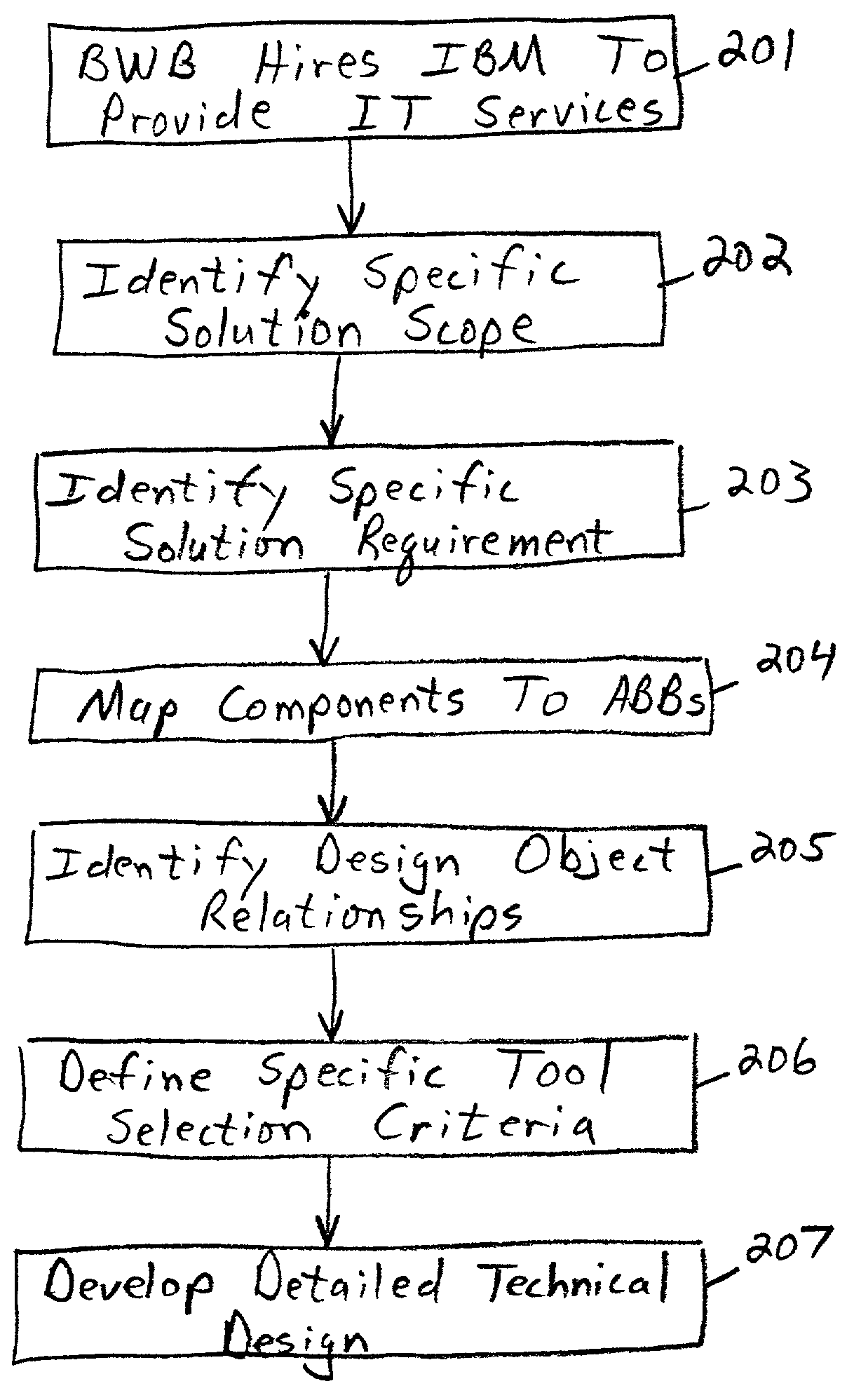

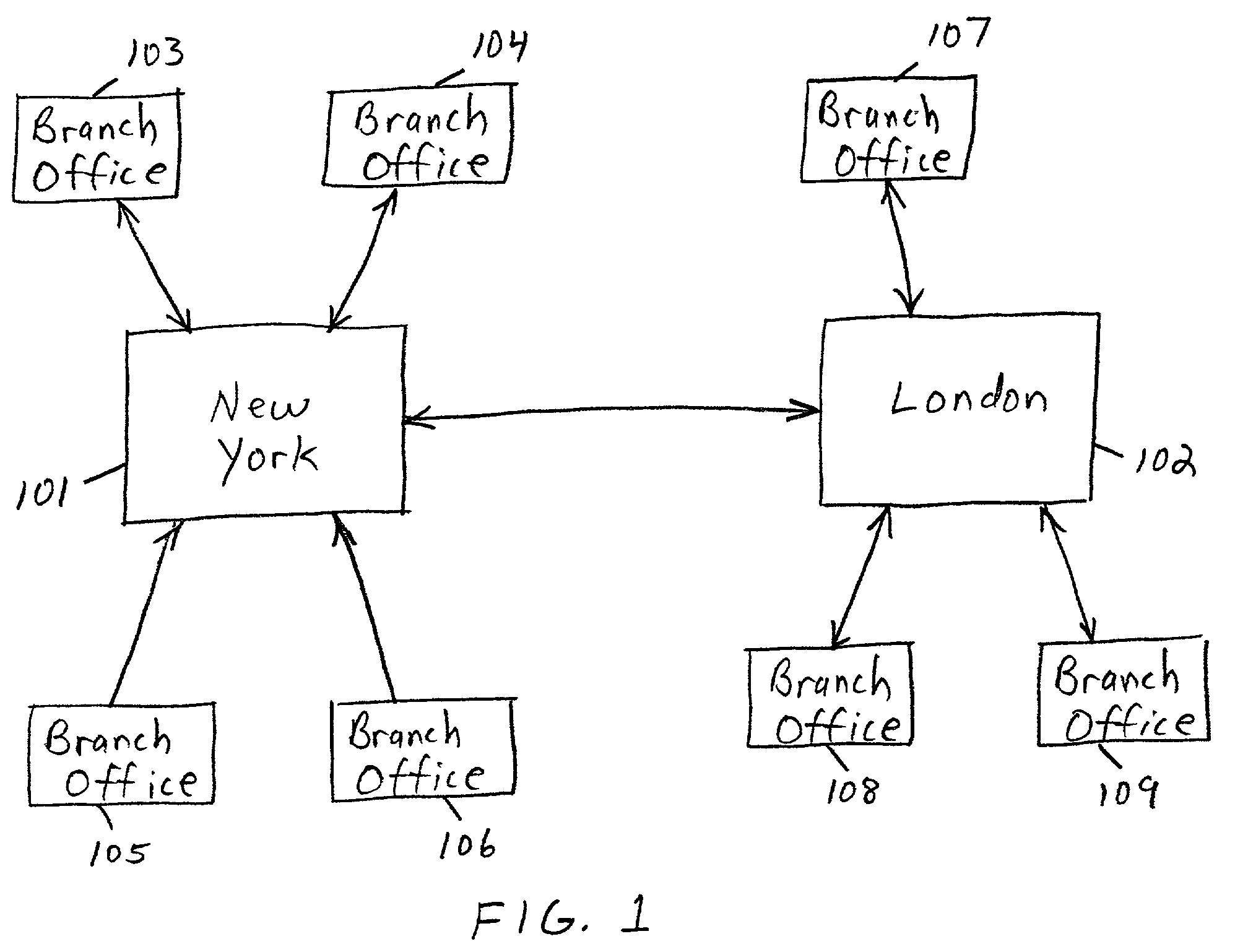

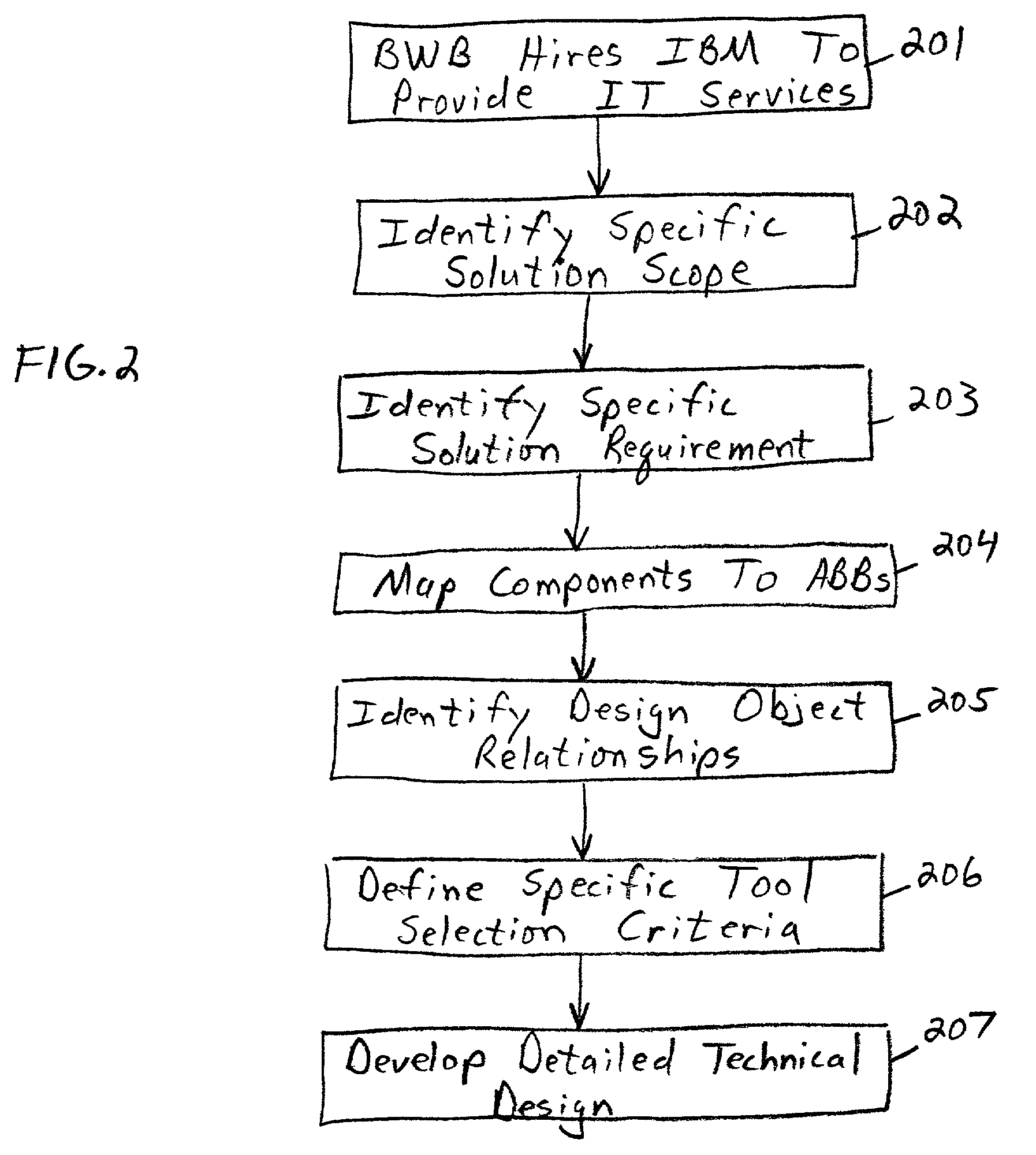

Enterprise service delivery technical architecture

InactiveUS7487079B2Enhance the imageMultiple digital computer combinationsOffice automationSystems managementTechnological system

Owner:INT BUSINESS MASCH CORP

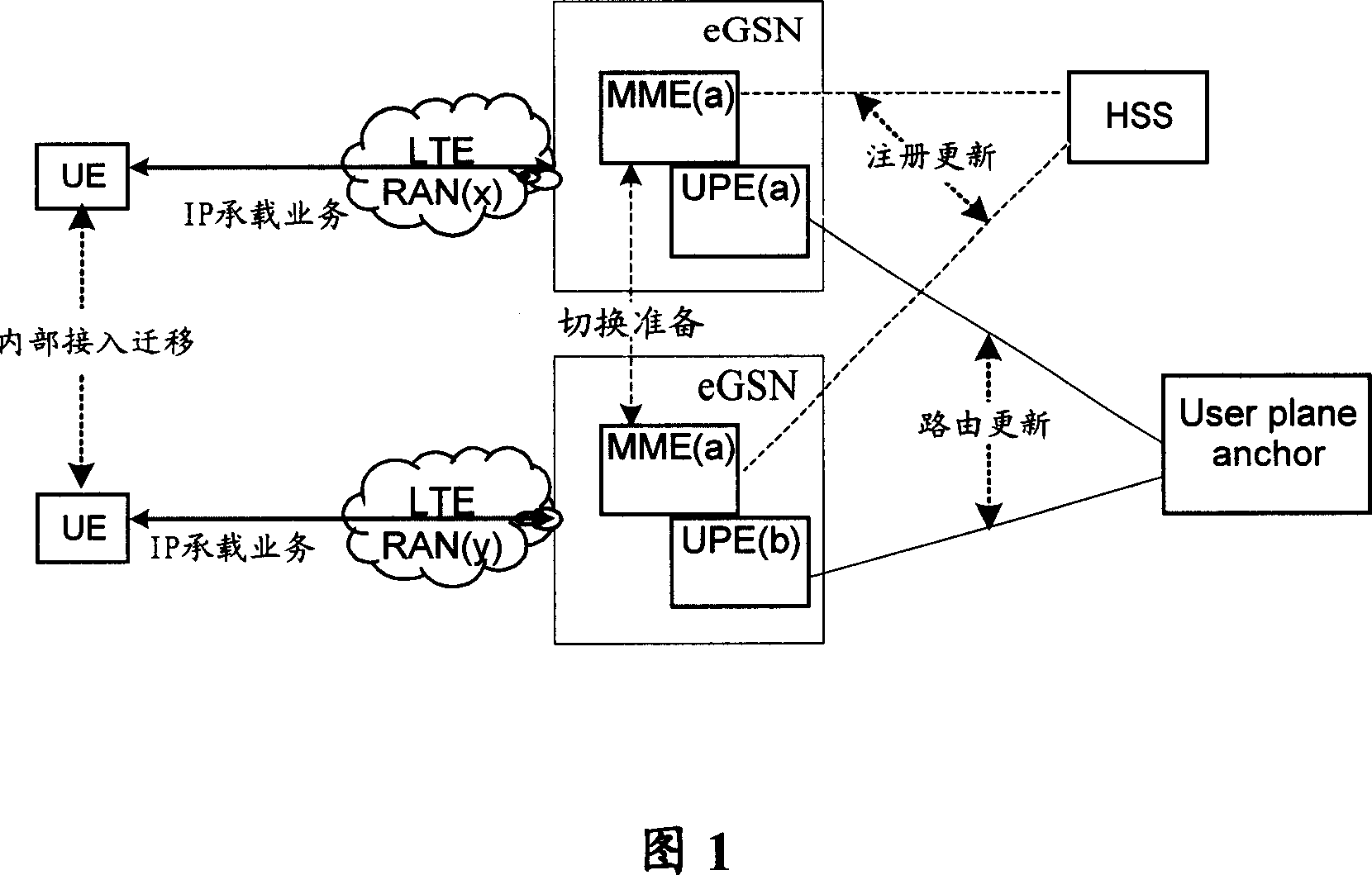

Resident, call method for teminal at multi-radio access technology public overlay area

InactiveCN101047948ADoes not increase the number of registration updatesReduce paging volumeAssess restrictionRadio/inductive link selection arrangementsRadio access technologyTelecommunications

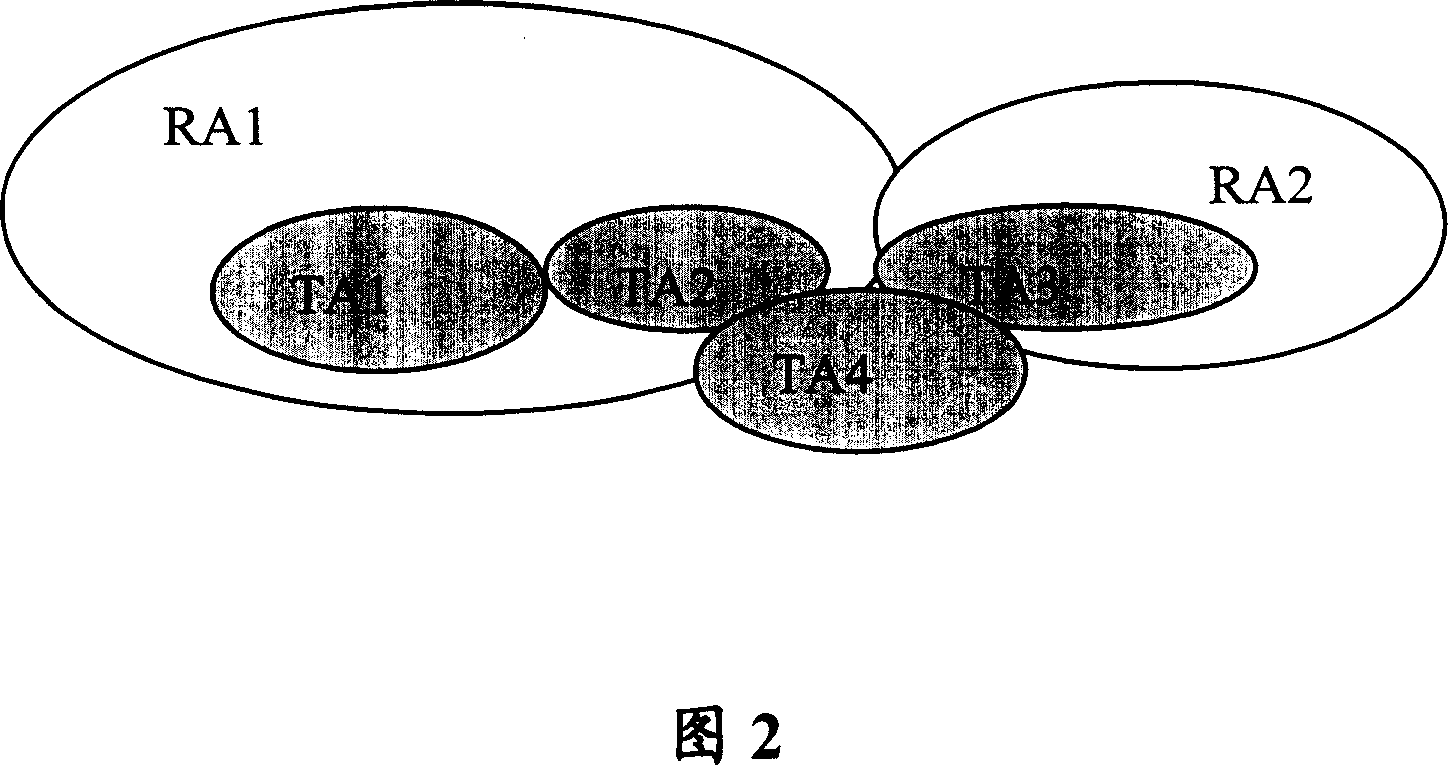

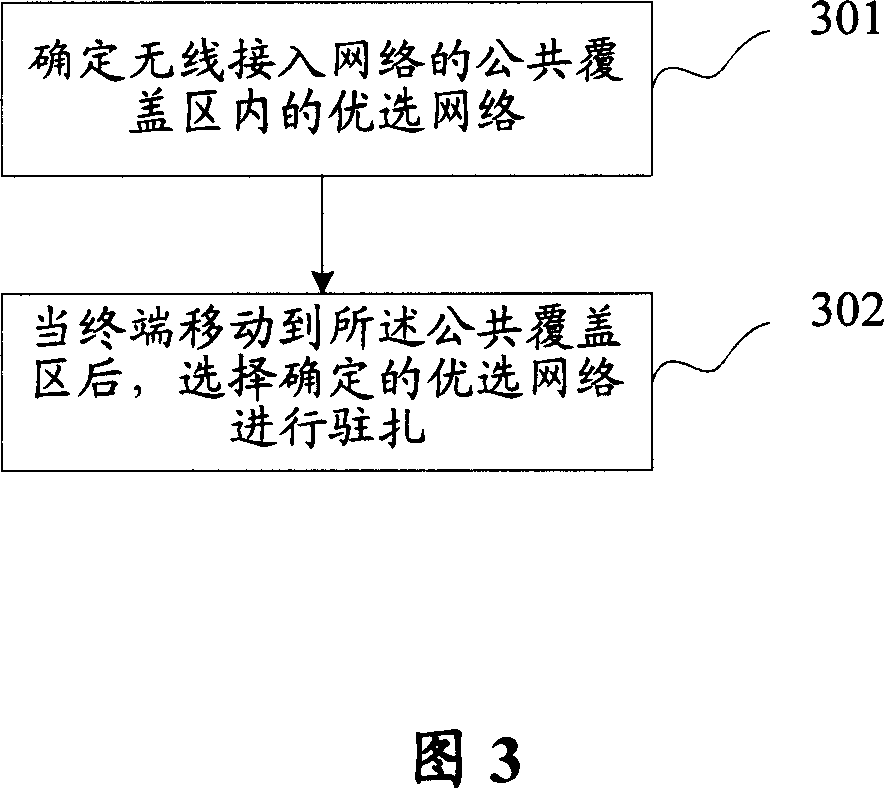

This invention discloses a stationing method for terminals in multi-radio access technology public cover regions by determining a prior network in a public covery region of a radio access network and selecting a determined option network for stationing when the terminal moves to said public covery region. This invention also discloses a bp method for terminals at multi-radio access technology public covery region, in which, when a network side beeps a public covery region to the down-line of the terminal, it beeps in the prior network only, in this way, it can optimize network beep when multi-kind of different radio access technological systems coexist.

Owner:HUAWEI TECH CO LTD

Water supplement and algae control method for large-scale shallow lake water bloom agglomeration water area

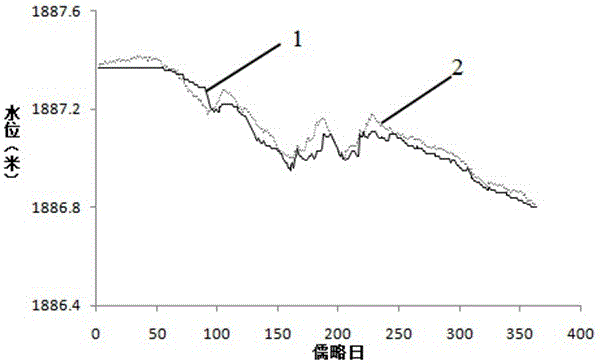

InactiveCN105973207AQuick resultsGood continuityGeneral water supply conservationOpen water surveyWater qualityDynamic monitoring

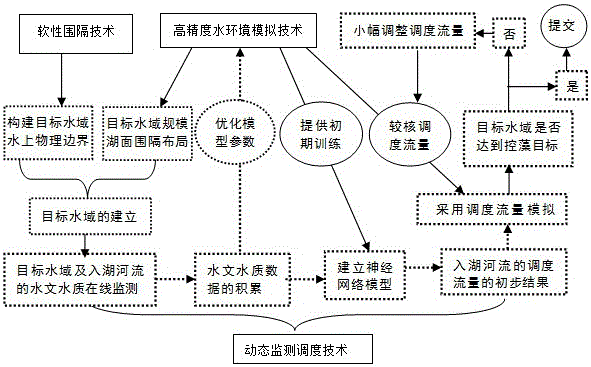

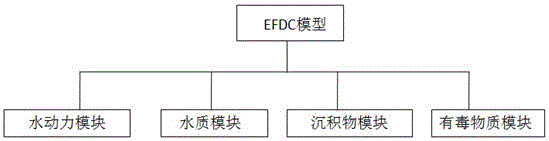

The invention discloses a water supplement and algae control method for a large-scale shallow lake water bloom agglomeration water area. The method utilizes a water environment simulation technology, a soft enclosure technology and a dynamic monitoring and scheduling technology and comprises building a lake water environment analogy model, constructing soft enclosure engineering to form a desired water area, carrying out on-line monitoring on the desired water area, building a space-time high precision water environment analogy model of the desired water area, constructing a water quality neural network model and building a flow scheduling system of a water supplement river. The method is a systematic and quantitative technical system which utilizes a river flowing into lake to supply water for a large-scale shallow lake water bloom agglomeration water area so that algal density is controlled. The method builds a defined quantification relationship between supplement water amount and quality and water quality response of a desired water area so that quantitative water environment in the water resource scheduling system is realized, and the problem that the existing water diversion-based alga control engineering measures cannot form a quantitative technical solution so that alga control effects are uncertain or unconspicuous is solved.

Owner:云南省环境科学研究院(中国昆明高原湖泊国际研究中心)

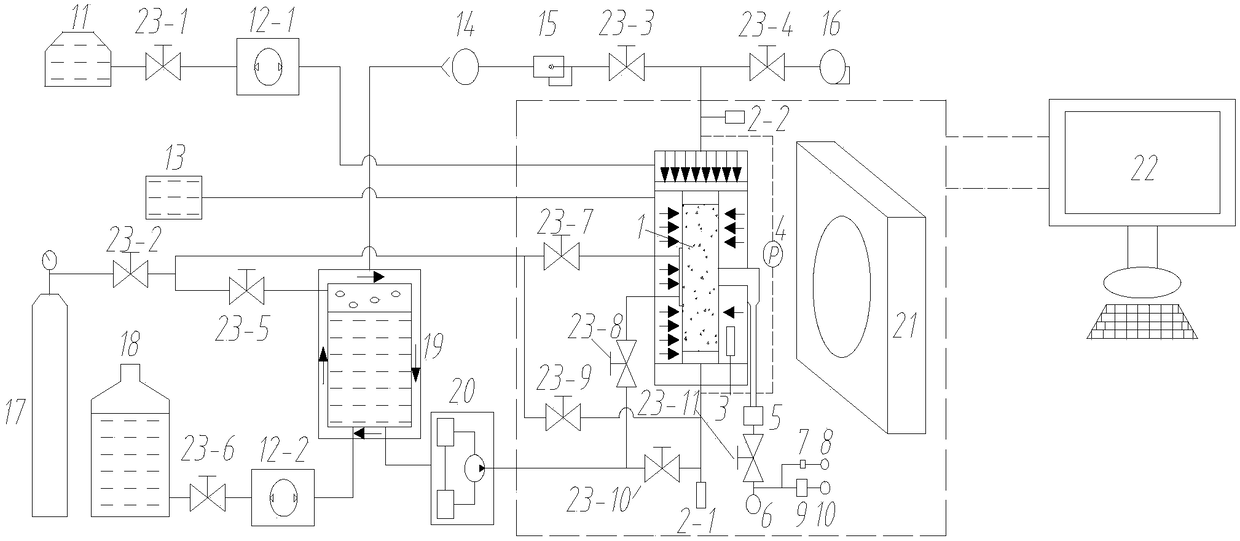

Hydrate sediment flow solid output measuring device combining X-CT technology and measuring method

ActiveCN109254137AImprove gas production efficiencyImprove the pressure reduction mining technology systemEarth material testingPermeability measurementsX-ray

The invention discloses a hydrate sediment flow solid output measuring device combining an X-CT technology and a measuring method. The measuring device comprises an X-ray penetration type reaction kettle, an X-CT scanning analysis system, a vacuum system, a temperature and pressure control system, a hydrate sample preparation system, a sand production monitoring system and a permeability measuringsystem, wherein through integrated application of a sand production-seepage system under the micro-scale multi-factor coupling effect, the coupling relationship of a reservoir structure and physicalspace-time evolution and flow solid output under the multi-factor collaborative action can be quantitatively described, different hydrate generation modes can be selected according to the experiment requirements, different hydrate occurrence states in natural sediments can be simulated and studied, and the device and the method can be used for researching the space-time evolution characteristics of a sediment pore structure under the hydrate convergence and divergence and effective stress conditions and an influence rule of the space-time evolution characteristics on sediment flow solid output, so that the theoretical bottleneck of the hydrate reservoir structure and a physical evolution and flow solid output mechanism in a hydrate production process is broken through, and the device and the method have important engineering significance to deeply understand a depressurizing production law of the South China Sea, practically improve the biogas production efficiency and perfect a depressurizing production technology system.

Owner:QINGDAO INST OF MARINE GEOLOGY

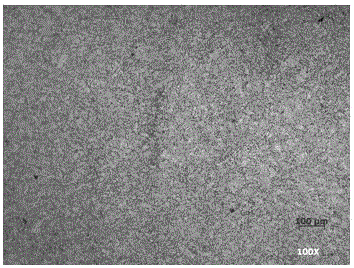

Super-thick high-strength lamellar-tearing-resistant Q500D-Z35 hydroelectric generating set steel plate and manufacturing method thereof

The invention relates to a super-thick high-strength lamellar-tearing-resistant Q500D-Z35 steel plate and meanwhile further relates to a manufacturing method of the steel plate. The steel plate meets the quality requirements of steel plates for manufacturing a large or a super-large hydropower station generator set. An appropriate amount of carbon and alloy elements are compounded; the problems of the quenching degree and hardenability of a steel plate are solved; reasonable quenching equipment and a reasonable hardening and tempering technological system are combined; the microstructure of the steel plate can achieve reasonable compounding of granular bainite, polygonal ferrite and tempered sorbite of proper morphology; and it is guaranteed that base metal of the steel plate and performance achieved after welding stress-elimination treatment can meet the using requirements. Through appropriate ingot type selection and the strict and reasonable steel-making technology, steel ingot casting technology, steel ingot forging technology and steel plate rolling technology, it is guaranteed that the required thickness and piece weight requirements for the steel plate are met; and under the conditions of high thickness and high piece weight, the excellent macrostructure is achieved, and thus the core quality and lamellar-tearing resistance of the steel plate and uniformity of the whole plate are guaranteed.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

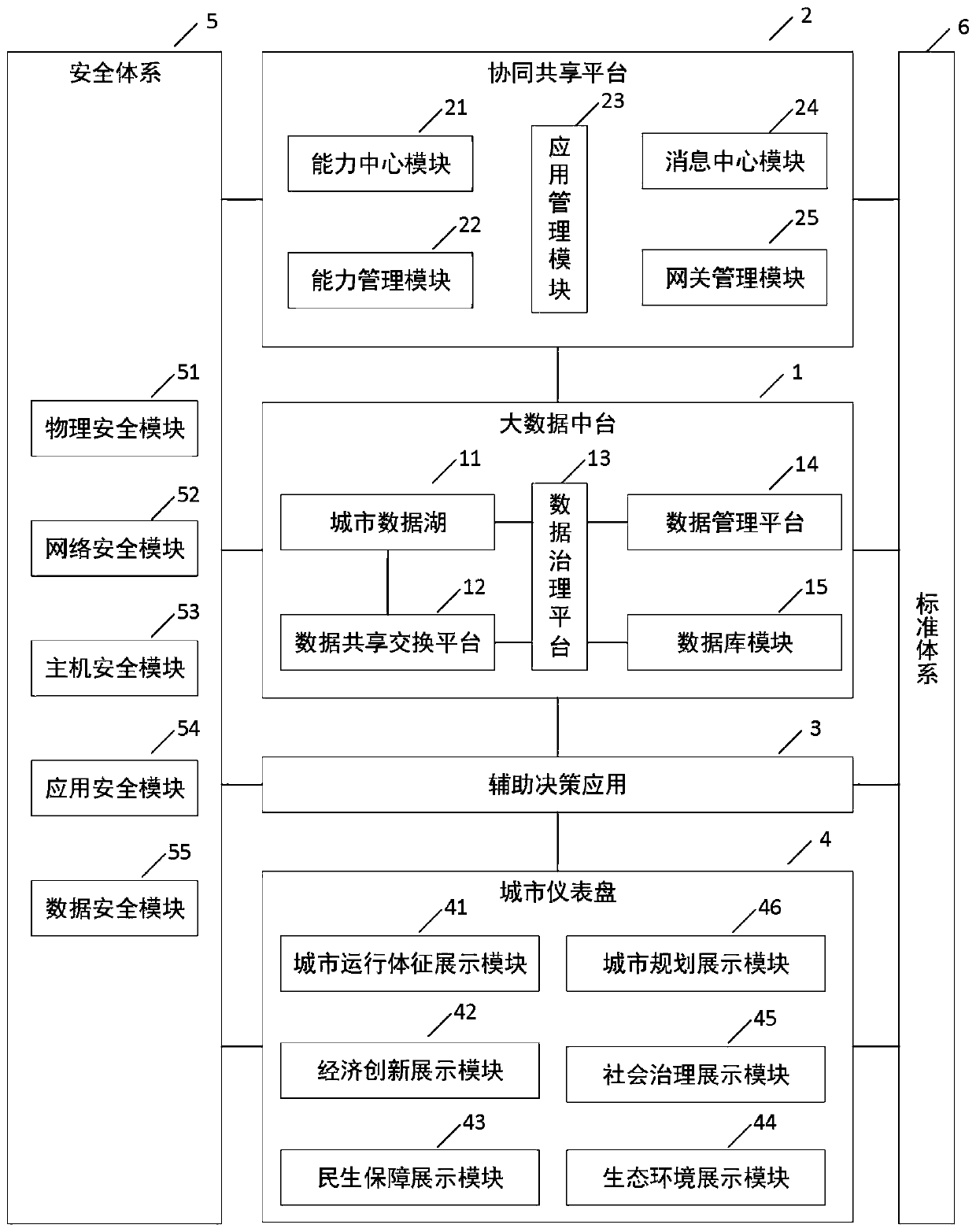

Smart city big data management system

PendingCN111209269AAchieve self-regulationAchieve perceptionDigital data information retrievalOffice automationEngineeringUrban management

The invention provides a smart city big data management system, and relates to the technical field of smart cities, and the system comprises: a big data center station which is used for collecting city big data provided by city infrastructures, carrying out the preprocessing of the city big data to obtain preprocessed big data, and storing the preprocessed big data to form a city brain database; acollaborative sharing platform which is used for carrying out capacity encapsulation and protocol adaptation on the capacity components, abstracting the capacity components into atomic energy, and providing services to the outside through an open communication interface so as to support business applications of different technical systems to call and interact with the preprocessed big data; and an auxiliary decision application which is used for carrying out artificial intelligence analysis according to a pre-generated adaptive decision analysis engine set and the preprocessed big data, and displaying an analysis result to an urban manager through an urban instrument panel so as to monitor an urban operation state in real time and provide technical support for decision making of the urbanmanager. According to the invention, the city can self-discover problems to the greatest extent and assist in solving the problems.

Owner:INESA ELECTRON

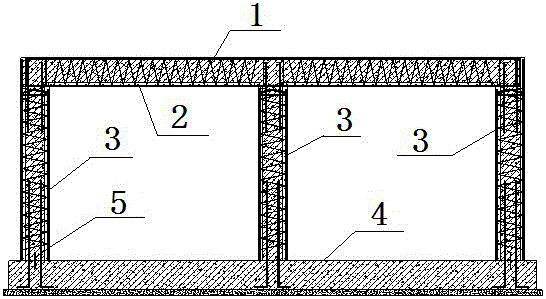

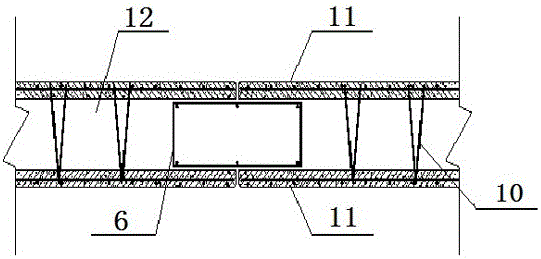

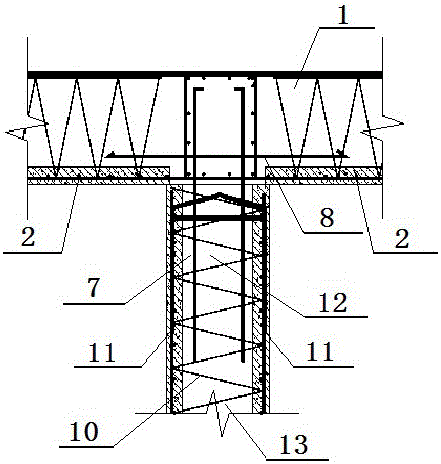

Superimposed assembled type underground pipe gallery system and construction and manufacturing process

InactiveCN105862916AOutstanding FeaturesHighlight significant effectArtificial islandsUnderwater structuresTechnological systemTechnology system

The invention provides a superimposed assembled type underground pipe gallery system and a construction and manufacturing process. A bottom plate is a cast-in-place bottom plate on an underground pipe gallery cushion layer, side walls and a middle wall body are prefabricated sandwich superimposed walls, a top plate is a prefabricated superimposed plate, and the bottom plate, the side walls and the middle wall body and the top plate are connected into an overall underground pipe gallery in a cast-in-place mode. According to the novel underground pipe gallery technology system, part is subjected to prefabrication in a factory, part is subjected to on-site superimposed cast-in-place, advantages of prefabrication in the factory and on-site cast-in-place are fully played, defects and disadvantages of prefabrication in the factory and on-site cast-in-place are overcome, particularly defects that a traditional superimposed pipe gallery is low in production efficiency and small in transport quantity are overcome, on-site template-free construction is achieved, environmentally friendliness and energy conservation are achieved, efficiency is high, and excellent waterproof performance is achieved.

Owner:CHANGSHA BROAD HOMES IND GRP CO LED

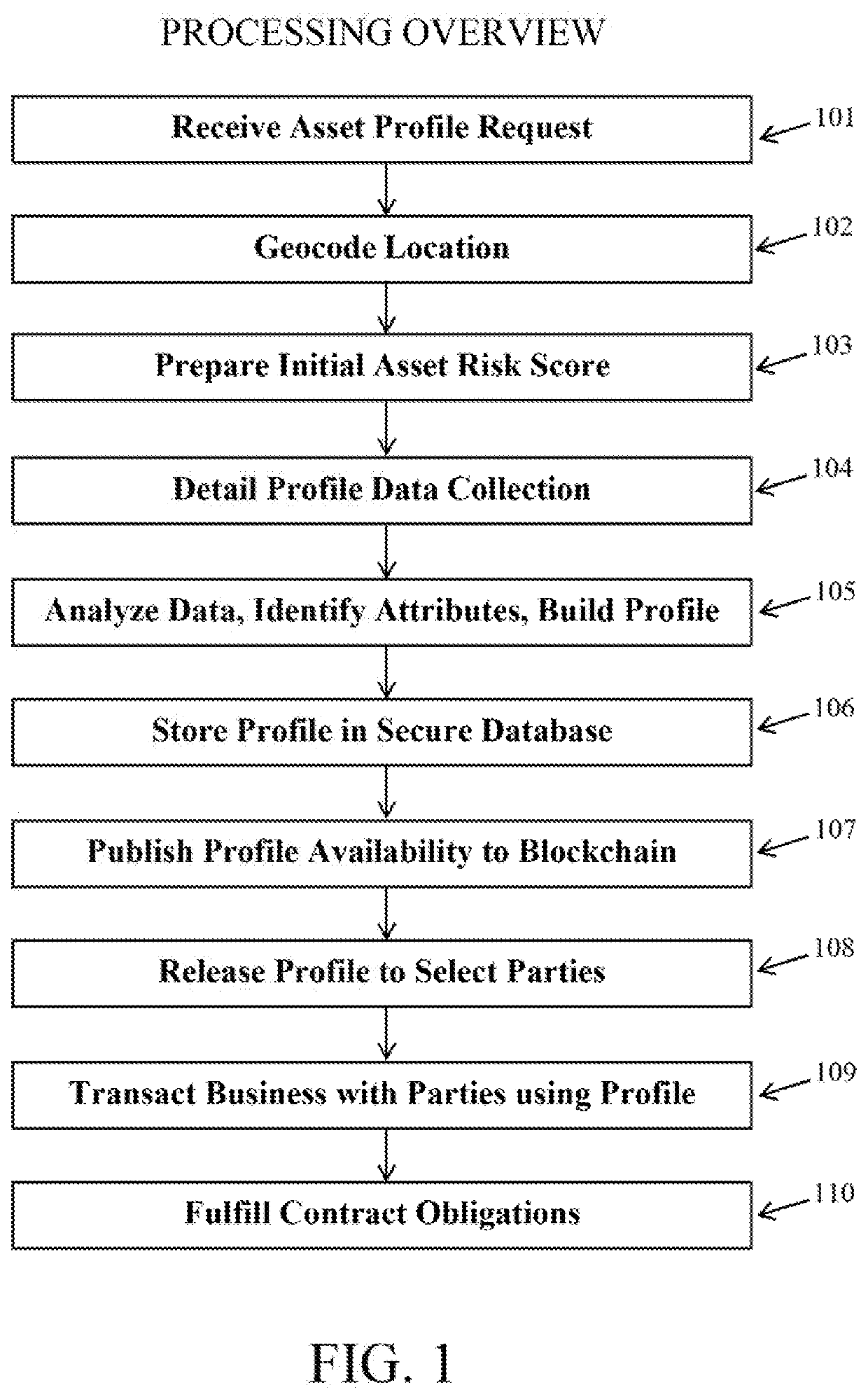

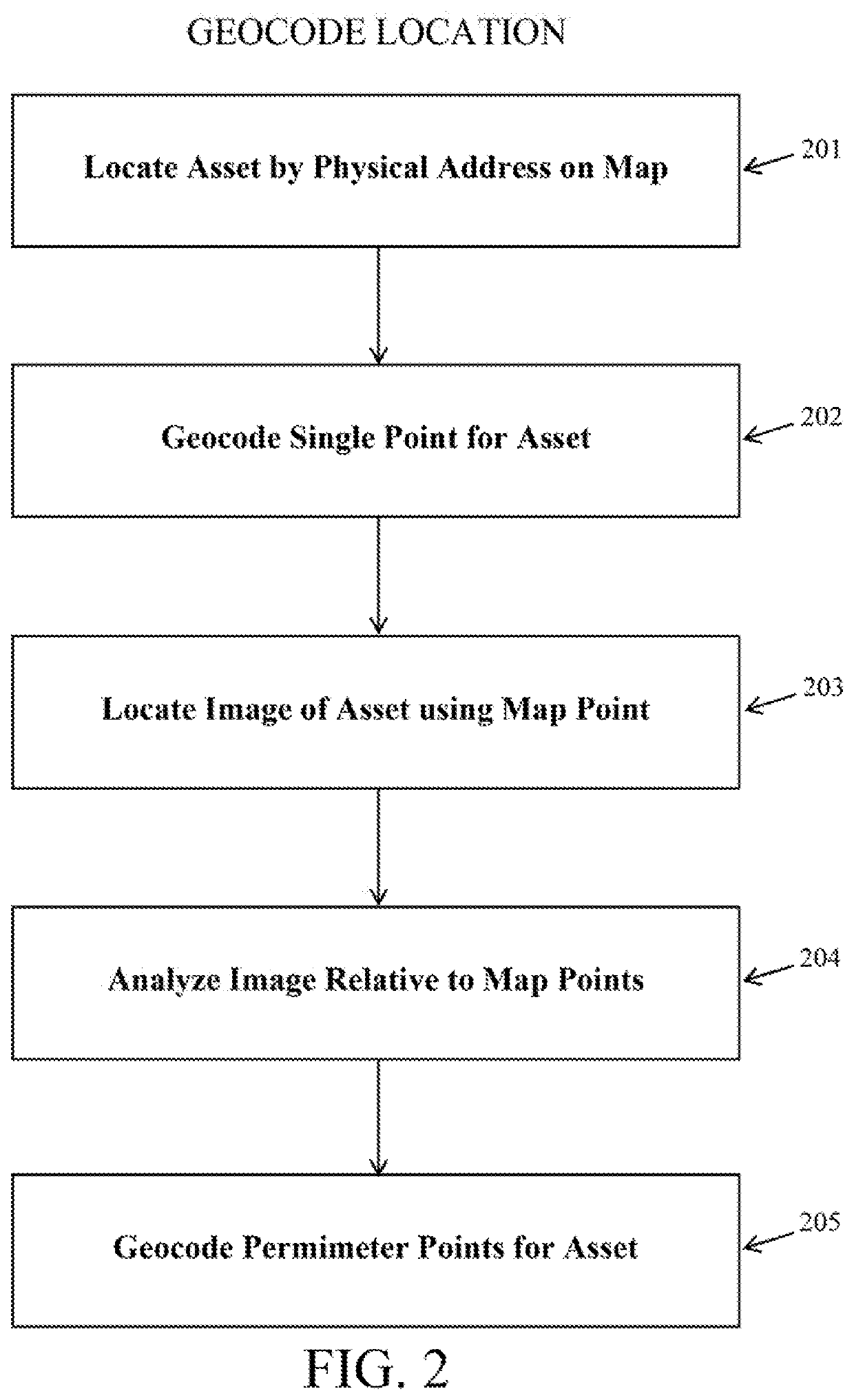

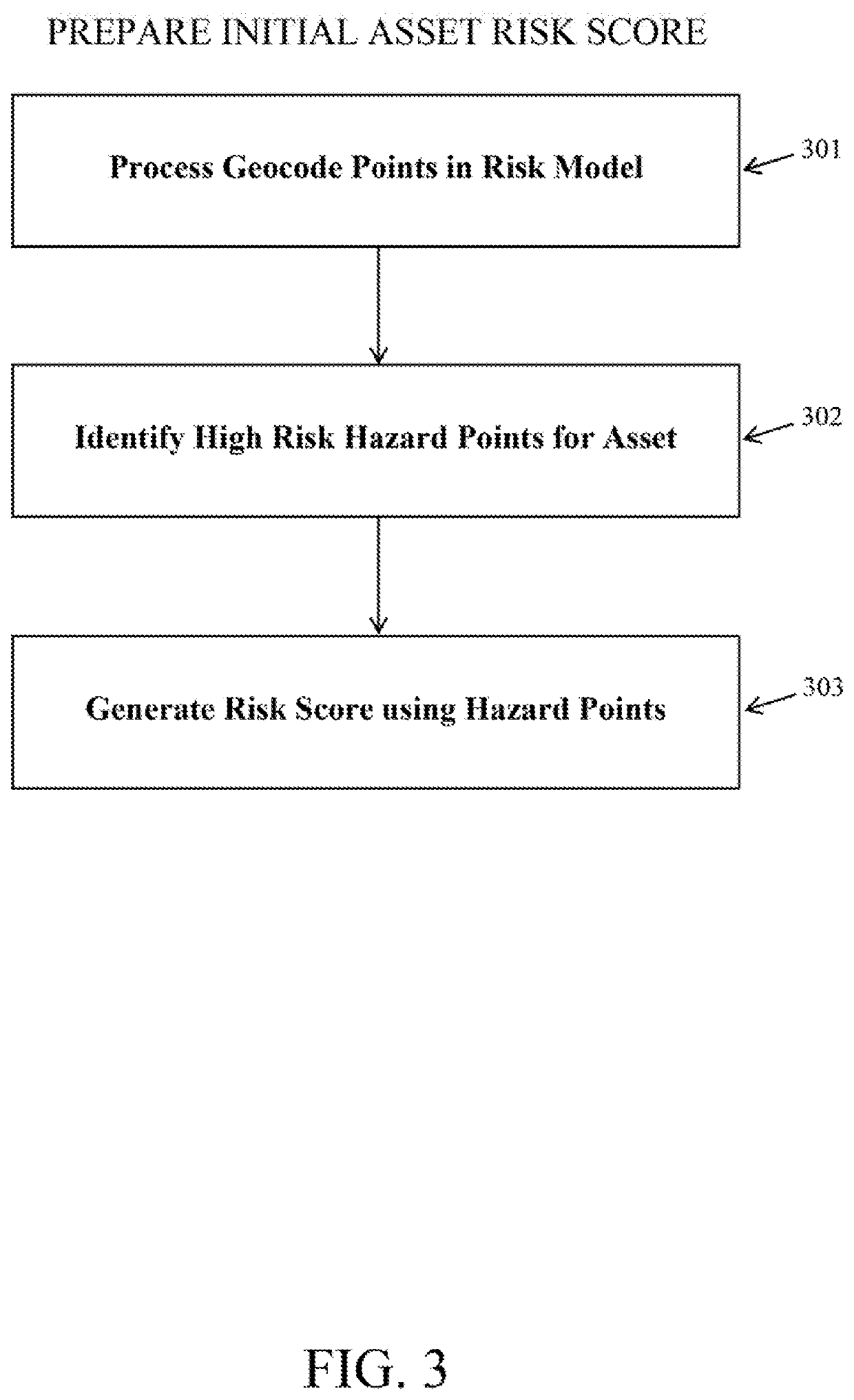

Method and System Configured for Risk Asset Data Collection

InactiveUS20200167870A1Accurate understandingFinanceEncryption apparatus with shift registers/memoriesAnalysis dataTechnological system

Various technological systems and methods are provided related to risk asset analysis, data capture and generating and executing agreements. In one embodiment, for example, a method and system configured for assisting with risk asset data collection is provided. In one implementation, for example, the method and system are configured for accurately collecting detailed information on assets which are subject to risk, including the accurate and unambiguous collection of financial terms of any agreements associated with those assets that all parties have a common and invariable understanding and record of the terms.

Owner:INSURDATA CORP

New cultivation technology for preventing and controlling banana fusarium wilt

InactiveCN101878726AReduce the incidence of Fusarium wiltEasy to operateCultivating equipmentsPlant protectionDiseaseChinese Chive

The invention relates to a novel cultivation technology for preventing and controlling banana fusarium wilt, which is characterized in that mixed planting of banana and Chinese chive is adopted and root exudate or residue putrilage of Chinese chive is used for inhibiting fusarium oxysporum f. sp. Cubense. The cultivation technology for preventing and controlling banana fusarium wilt by taking Chinese chive as a core comprises crop rotation and intercropping. The technology has low incidence for whether plantain or banana (Musa AAA Group Cavendish), even no disease, and is suitable for application in a large area.

Owner:POMOLOGY RES INST GUANGDONG ACADEMY OF AGRI SCI +1

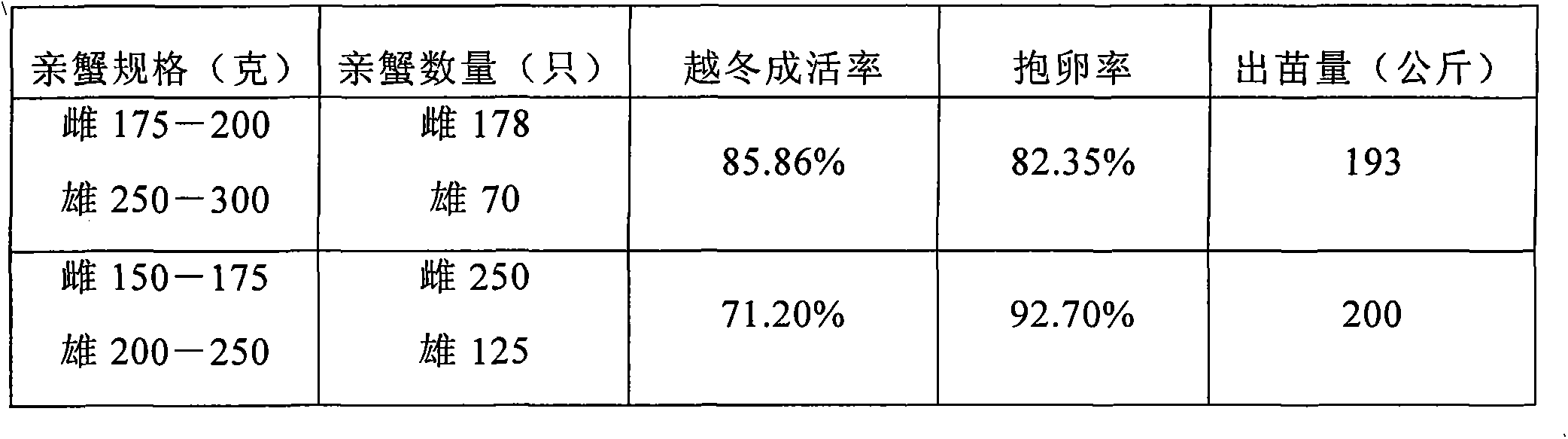

Method for ecological breeding of large Chinese mitten crabs in pond

ActiveCN103314904AImprove the survival rate of overwinteringIncrease egg fertilization rateClimate change adaptationPisciculture and aquariaTechnological systemReproductive ecology

The invention discloses a technology for ecological breeding of large Chinese mitten crabs (female crabs 150g and male crabs more than 200g) in a pond. The method comprises the steps of (1) selection and transportation of the large parent crabs, (2) mating of the parent crabs, (3) over-wintering fatting and management of the parent crabs, (4) catching and temporary breeding of egg-carrying crabs, (5) cage hanging and distribution of the egg-carrying crabs, (6) food organism culture, (7) zoea cultivation, (8) megalopa desalting. The technology for ecological breeding of the large Chinese mitten crabs in the pond is developed for emphasizing to improve the over-wintering survival rate and the egg-carrying rate of the large parent crabs and the survival rate of the egg-carrying crabs according to features of reproductive biology and reproductive ecology of the Chinese mitten crabs on a basis of in-pond ecological breeding work of large parent crabs. Technical practices of an inventor for nearly a year proves that unprecedented success on the in-pond ecological breeding of the large parent crabs is achieved, an in-pond ecological breeding technical system of the large parent crabs is established, and profound influence is made in the Chinese mitten crab breeding industry of our country.

Owner:SHANGHAI OCEAN UNIV

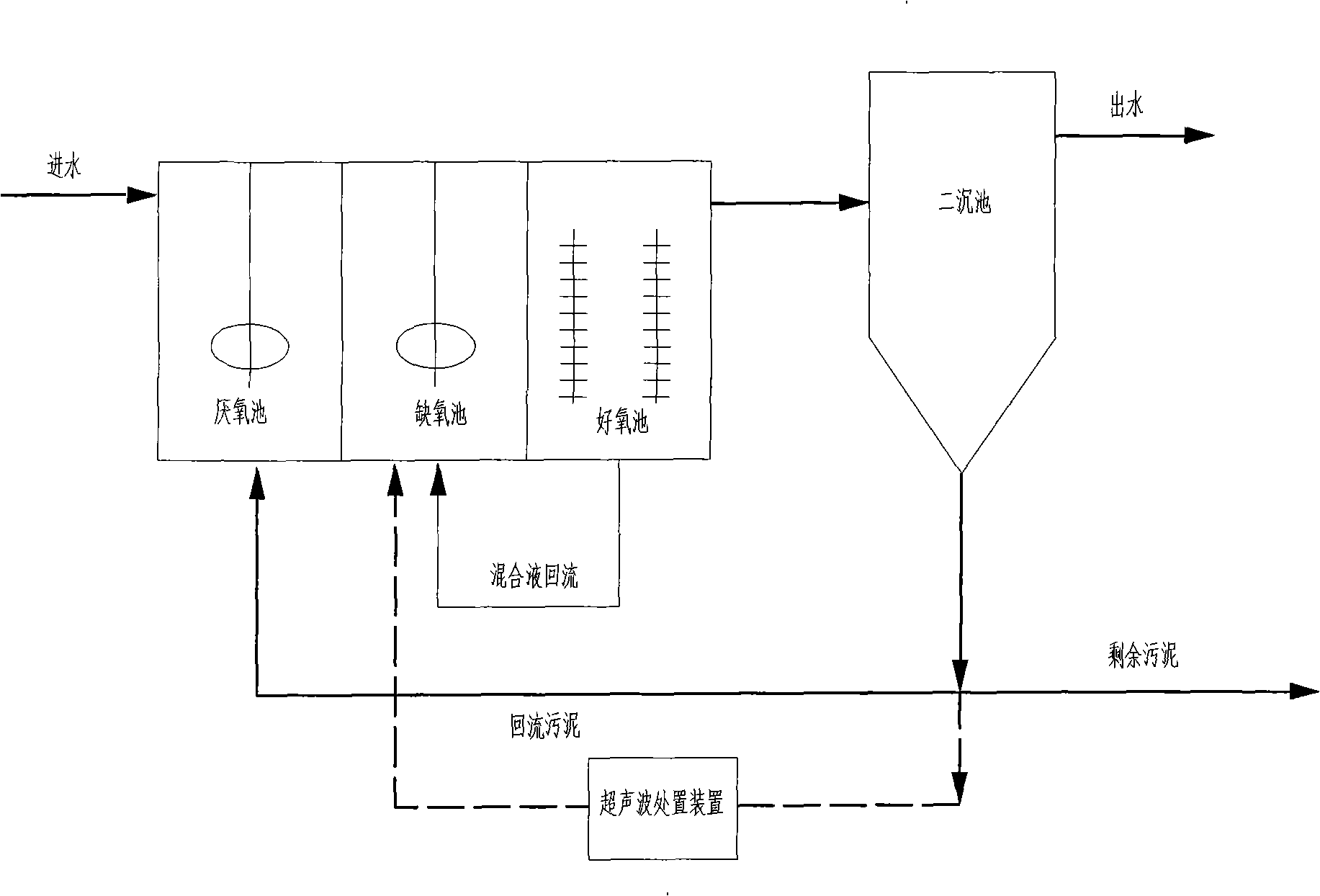

Improved process of activated sludge and biological film composite type A2/O

InactiveCN101348304AImprove the effect of nitrogen and phosphorus removalReduce the impactWater/sewage treatment with mechanical oscillationsTreatment with aerobic and anaerobic processesSolubilityActivated sludge

The invention relates to an improved process for activated sludge and biomembrane composite A<2>O. The improved process consists of three stages of processes, i.e. an anaerobic stage, an anoxic stage and an aerobic stage, and is characterized in that a ciliary biological packing material is added in an aerobic reactor; an ultrasonic treatment device is adopted to carry out cavitated decomposition for residual sludge inside a secondary settling tank so as to form organic substance with liquid solubility; moreover, the sludge is returned to the front end of an anoxic reactor. The improved process adopts the ciliary biological packing material to fix a great amount of nitrifying bacteria of long generation reproduction time, thereby improving the speed of nitration reaction and reducing the influence on nitrifying flora caused by sludge age change; the ultrasonic treatment device is adopted to treat residual sludge, thereby making use of efficient useful substances contained in the residual sludge; meanwhile, the improved process solves the problem of insufficient carbon source during A<2>O technological process, and maintains better denitrogenation and dephosphorization effects for an A<2>O technological system at the same time.

Owner:中钢集团武汉安全环保研究院有限公司

Third nickel-base high-temperature single crystal alloy in low cost

ActiveCN1966750AGood heat and corrosion resistanceImprove durabilitySingle crystal superalloySingle crystal

The invention belong to the field of nickel-based monocrystal superalloy, specifically a kind of low-cost third generation nickel-based monocrystal superalloy, which is mainly used for producing units bearing high stress under high temperature such as impeller blade in aero-motor. The chemical components of the alloy are (wt.%): Cr 2-4%,Co 11-13%,W 5-7%,Mo 0.5-2%,Re 3- 5%,Al 5-7%,Ta 6-10%,Hf 0.05-0.2%,and Ni as balance. The invention adopts vacuum induction melting for smelting, first smelting mother alloy with chemical components meeting the requirement, growing to monocrystal units. The following technological system for heating treatment is carried out before using: 1300DEG C / 8h,A.C.+1305DEG C / 15h,A.C.+1310DEG C / 8h, A.C.+1315DEG C / 24h,A.C.+1180DEG C / 4h,A.C.+870DEG C / 24h,A.C.. The alloy of the invention has the advantages of excellent persistence correspondent to that of third generation monocrystal superalloy CMSX-10, little Re content, low cost and good causticity resistance.

Owner:辽宁红银金属有限公司

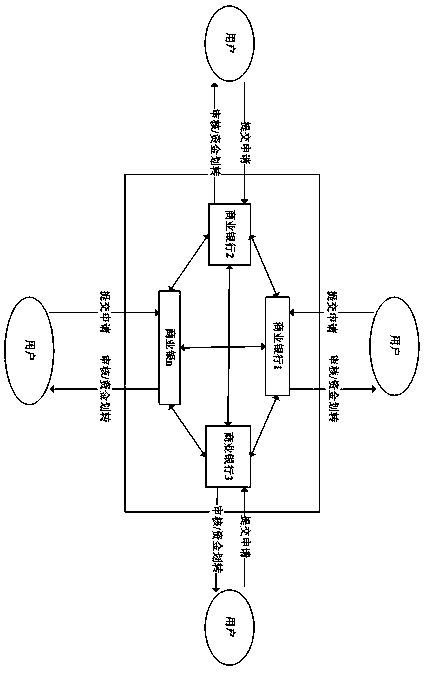

An online cross-border transfer payment method for users between commercial banks based on a block chain

ActiveCN109741045AGuaranteed operational safetyReduced traceabilityFinanceProtocol authorisationDigital currencyTechnological system

The invention discloses an online cross-border transfer payment method for users between commercial banks based on a block chain. A traditional cross-border transfer payment technology system betweencommercial banks and an emerging virtual digital encryption currency cross-border transfer payment technology system based on a block chain technology are fused. Certain national legal currencies areused as intermediary currencies. Medium currency is used as a carrier for value conversion between different countries of currency. Value conversion between different countries of currency is realizedby using the smart contract. Compared with the prior art, the method has the advantages that the virtual digital currency is replaced, point-to-point transmission of cross-border payment between commercial banks is realized by the aid of an alliance chain in a block chain technical system on the basis of existing financial supervision of cross-border payment of the commercial banks, and the technical scheme has the technical characteristics of controllability, anonymity and traceability so as to meet financial supervision requirements between the international and the regions.

Owner:丁庆洋

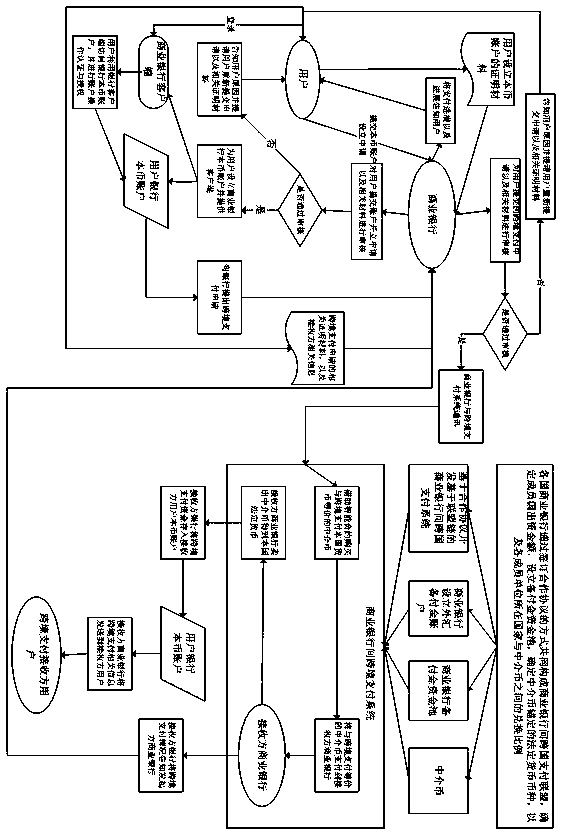

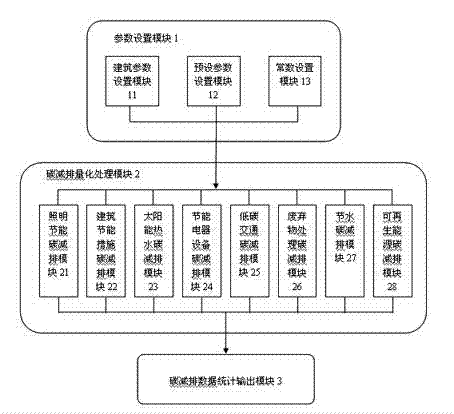

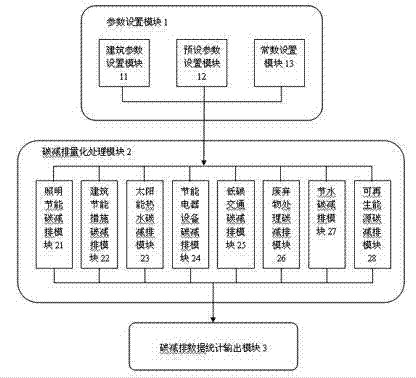

Quantizing system and computing method of carbon dioxide emission reduction quantity based on building

InactiveCN102243685AAchieve integrationImplement classificationSpecial data processing applicationsWater savingLight energy

The invention discloses a quantizing system and a computing method of carbon dioxide emission reduction quantity based on a building. A carbon dioxide emission reduction mode which can be implemented in the operating period of the building is divided into eight modes, namely lighting energy-saving carbon emission reduction, building energy-saving measure carbon emission reduction, solar hot water carbon emission reduction, energy-saving electric equipment carbon emission reduction, low-carbon traffic carbon emission reduction, waste disposal carbon emission reduction, water saving carbon emission reduction and renewable energy source carbon emission reduction. By directly quantizing the carbon emission reduction of the eight carbon dioxide emission reduction modes, the carbon dioxide emission reduction total quantity in the operating period of the building and the carbon dioxide emission reduction quantity of unit area are obtained finally. For the situation that the conventional building carbon emission reduction is subjected to qualitative analysis and not subjected to quantitative computation, the quantitativity of a low-carbon technology is realized by unifiedly converting different design effects of the low-carbon technology to the carbon dioxide emission reduction quantity of the building, so the popularization of a low-carbon technical system in reforming of a new building and the existing building is more facilitated.

Owner:翎零碳建筑科技(上海)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com