Patents

Literature

4204 results about "Cold resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermoplastic elastomer composition, process for the preparation there of, hose made by using the composition, and process for the production thereof

InactiveUS6179008B1Improvement of hose flexibilityLow production costSynthetic resin layered productsFlexible pipesElastomerVulcanization

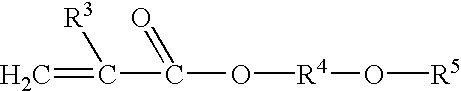

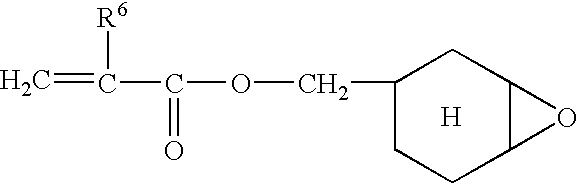

A thermoplastic elastomer composition which, when used for the inner tube and / or outer cover of a hose, can improve the hose flexibility at an ordinary temperature and low temperature, oil resistance, and cold resistance and can reduce the production costs since it does not require a vulcanization step and a hose having said properties using this elastomer composition for its inner tube and / or outer cover and a process and apparatus for the production thereof.

Owner:YOKOHAMA RUBBER CO LTD

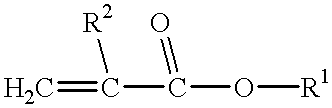

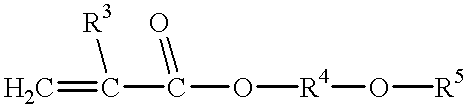

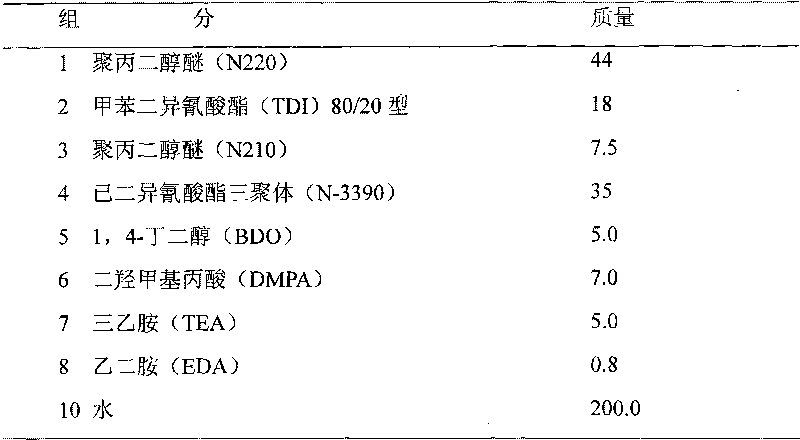

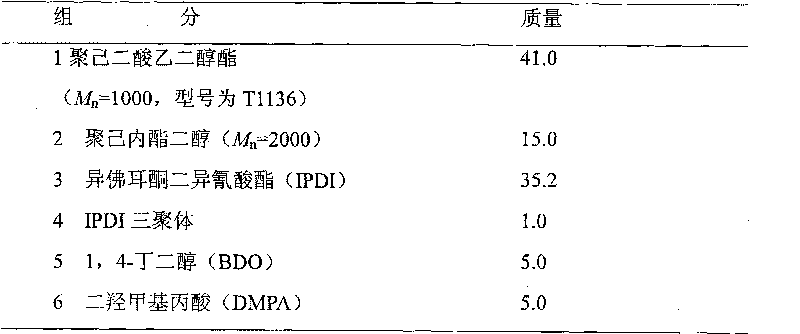

Preparation method and application of modified polyurethane aqueous dispersions of polyisocyanate curing agents

InactiveCN101696262ASimple processEasy to operatePolyurea/polyurethane coatingsLeather surface finishingPolyesterSolvent

The invention discloses a preparation method and application of modified polyurethane aqueous dispersions of polyisocyanate curing agents. The preparation method comprises the following steps of: carrying out prepolymerization reaction by using polyester polyol, vulcabond monomer and a polyisocyanate curing agent; reacting with a hydrophilic chain-extending agent and a micro-molecule chain-extending agent to obtain polyurethane prepolymer containing hydrophilic groups (carboxyl or sulfonic groups) and isocyanate(NCO)-terminated groups; neutralizing the polymer into salt, and then dispersing the salt into water; and preparing the modified polyurethane aqueous dispersions of the polyisocyanate curing agents by the chain extending of a polyamine chain-extending agent. The modified polyurethane aqueous dispersions of the polyisocyanate curing agents have self-crosslinking function at room temperature, and the self-crosslinking density is over 85%. Compared with non-modified polyurethane aqueous dispersions prepared under the same condition, the modified polyurethane aqueous dispersions have superior film forming property, water resistance, alcohol resistance, pollution resistance, cold resistance, dry / wet rubbing resistance and chemical solvent resistance; and coating films have especially high drying speed, high hardness increment speed and high final hardness.

Owner:SOUTH CHINA UNIV OF TECH

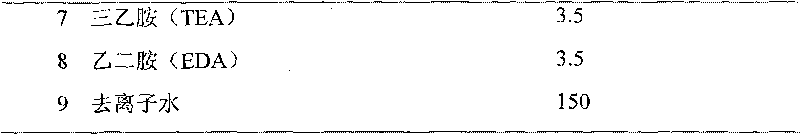

Organic matter decomposing inoculant, and preparation method and application thereof

ActiveCN102212494APromote growthEfficient decompositionBio-organic fraction processingFungiDiseaseAdditive ingredient

The invention discloses an organic matter decomposing inoculant, and a preparation method and application thereof. The organic matter decomposing inoculant comprises the following ingredients in part by weight: 10 to 20 parts of aspergillus niger microbial inoculum, 10 to 20 parts of lactobacillus plantarum microbial inoculum, 20 to 30 parts of saccharomyces cerevisiae microbial inoculum and 40 to 60 parts of bacillus subtilis microbial inoculum. The organic matter decomposing inoculant mainly comprises various microbial floras with mutual promotion and mutual synergy effects. The organic matter decomposing inoculant can decompose various organic matters quickly, can effectively kill germs, ova and weed seeds in the decomposed raw materials, can reduce diseases, weed and insect pests, andcan remove water and odor. The organic matter decomposing inoculant can stimulate growth and development of crops, can improve disease resistance, drought resistance and cold resistance, can increasesoil nutrients, can improve the soil structure, and can increase the utilization ratio of chemical fertilizer. The organic matter decomposing inoculant can be used directly and can also be used for producing commercial organic fertilizer, biological organic fertilizer, organic and inorganic complex fertilizer, biological organic and inorganic complex fertilizer and the like.

Owner:BEIJING SHIJI WANYEYUAN BIOENG TECHCO

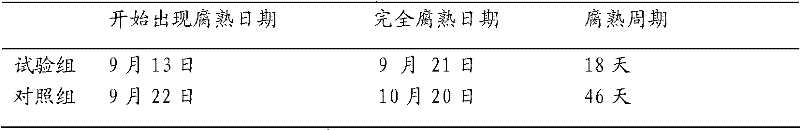

Waterproof cold resistant heatproof flame-retardant polychloroethylene insulation material

ActiveCN101481480AGood effectExcellent resistance to low temperature embrittlementPlastic/resin/waxes insulatorsInsulated cablesHeat resistancePlasticizer

The invention provides a waterproof cold resistance temperature resistance inflaming retarding polyvinyl chloride insulating material, which comprises the following components according to the parts by weight mixture ratio: 100 of polyvinyl chloride resin, 20-70 of thermal stability plasticizer, 1-7 of cold tolerance plasticizer, 5-15 of modifier, 3-9 of stabilizing agent, 4-30 of flame retardant, 5-70 of filling agent, and 0.5-3.5 of lubricant. The insulating material has excellent waterproof performance, temperature resistant cold resistance and insulating performance, also has good soft performance and good processing performance.

Owner:ZHENG WEI TECH SHEN ZHEN LTD

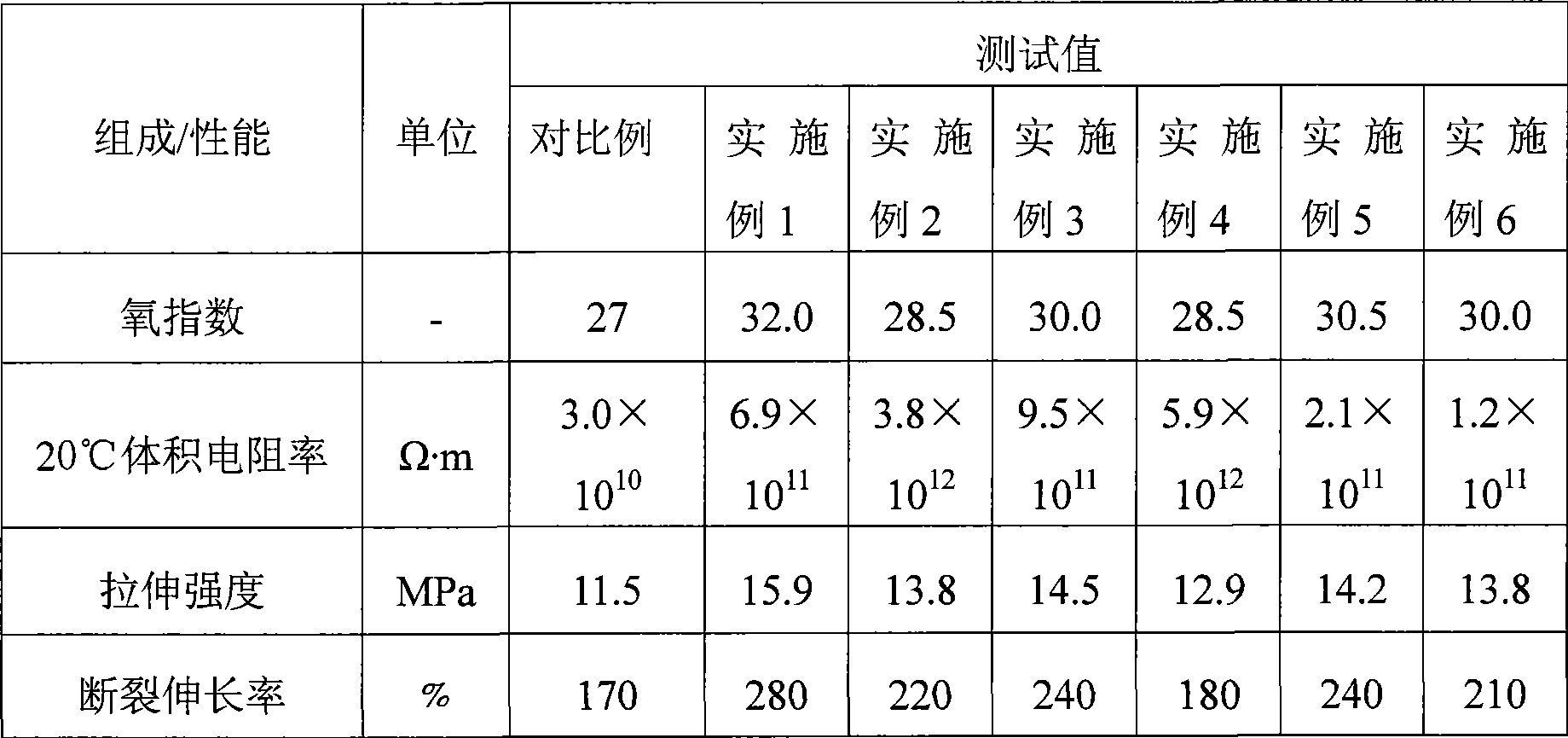

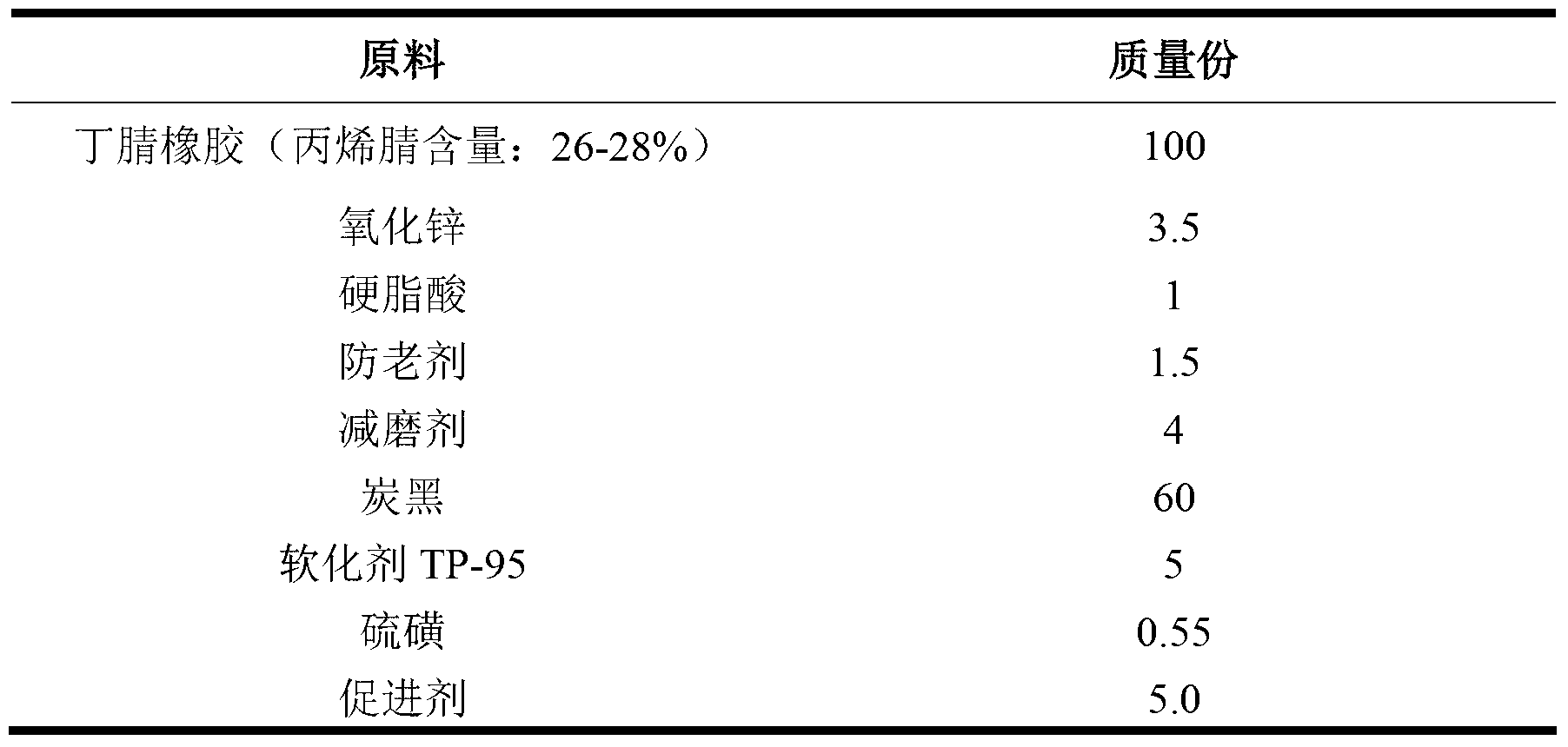

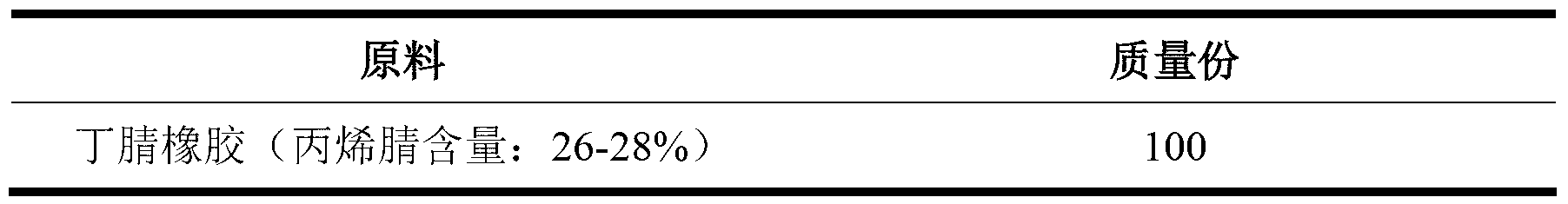

Cold-resistant wear-resistant nitrile rubber sealing material and preparation method thereof

ActiveCN103289150ACompatibility is reasonableImprove wear resistanceOther chemical processesPolymer scienceNitrile rubber

The invention discloses a cold-resistant wear-resistant nitrile rubber sealing material which comprises the following raw materials of: by weight, 100 parts of nitrile rubber, 3.5-8 parts of zinc oxide, 1 part of stearic acid, 1.5-3.5 parts of an antioxidant, 0.5-4.0 parts of an antifriction agent, 60-115 parts of carbon black, 2-10 parts of TP-95, 0.3-1.0 parts of a vulcanizing agent and 3.0-5.5 parts of an accelerant. A preparation method of the nitrile rubber sealing material comprises the steps of plasticating the nitrile rubber, adding the zinc oxide, the stearic acid, the antioxidant and the antifriction agent to carry out mixing, adding 1 / 2 of the carbon black to continue mixing after last mixing, then adding the residual carbon black and TP-95 to continue mixing, discharging glue stock and refining the glue stock with turning, obtaining a segment of rubber compound and placing the segment of the rubber compound, adding the rubber compound to a rubber covered roll of an open mill, adding the accelerant to carry out mixing, milling and packaging in a triangular bag, adjusting thickness and discharging material sheets. The nitrile rubber sealing material provided by the invention has better cold resistance and wear resistance.

Owner:GUANGZHOU JST SEALS TECH

Preparation method for aviation kerosene

The invention relates to a new synthesis route of a liquid branched paraffin fuel, the method adopts a lignocellulose based platform compound as a raw material and is completely independent of fossil energy. The liquid fuel obtained by the method can be used as an aviation kerosene (or diesel) substitute or as an additive to increase the cetane number and cold resistance of fuel. The method provided by the invention includes two steps of: 1) under the promotion of a base catalyst, subjecting a lignocellulose based furfural compound (including furfural, methylfurfural or 5 hydroxymethylfurfural) and branched chain keto (including methyl isobutyl ketone, and mesityl oxide, etc.) to aldol condensation reaction so as to synthesize an oxygen-containing organic compound with a carbon chain length of 9-16; and 2) conducting hydrodeoxygenation on the aldol condensation product generated in step1 to obtain biomass aviation kerosene branched hydrocarbon with a carbon chain length of 9-16, higher energy density, stability and low freezing point.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Technique for extracting active component of Enteromorpha prolifera and method for preparing Enteromorpha prolifera seaweed fertilizer

ActiveCN101485343AHigh extraction rateEfficient use ofBiocideAlkali orthophosphate fertiliserSolubilityPhosphate

The invention provides effective technology for extracting active ingredients of Entermorpha and a method for preparing an Entermorpha alga fertilizer. The method is characterized by comprising: taking the Entermorpha as a raw material, effectively extracting the active ingredients of the Entermorpha through technical processes such as pretreatment of raw materials, leaching, neutralization, concentration and combination, taking an extracting solution as a base fluid, combining the extracting solution with at least one composition of humic acid, urea, potassium dihydrogen phosphate, potassiumsulfate, monoammonium phosphate and microelement, and preparing the high-activity Entermorpha alga fertilizer. The Entermorpha alga fertilizer is rich in active substances of algae, not only can strengthen photosynthesis of crops, increase the yield of the crops and improve the product quality but also can strengthen the cold resistance, the drought resistance, the stress resistance and the disease resistance of the crops, promote earliness of the crops and increase the fertile flower percentage and the fertile fruit percentage, has lower production cost, good solubility and safe use, is friendly and harmless to human beings, domestic animals and the natural environment, and is a novel environment-friendly fertilizer suitable for modern agriculture.

Owner:青岛海大生物集团股份有限公司

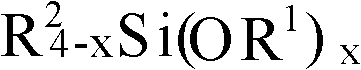

Weak solvent aliphatic polyurethane resin for synthetic leather and preparation method thereof

The invention relates to the technical field of materials for synthetic leather, in particular to weak solvent aliphatic polyurethane resin for synthetic leather and a preparation method thereof. The weak solvent aliphatic polyurethane resin for synthetic leather is prepared from the following components by weight percent: 2-30 percent of aliphatic diisocyanate compound, 5-40 percent of polyester or polyether polyalcohol compound, 0-10 percent of micromolecule polyol chain extender, 0.1-13 percent of micromolecule polyamine chain extender, 0.01-1.0 percent of catalyst, 0.05-5.0 percent of assistant and 45-85 percent of organic mild solvent. The invention also discloses the preparation method of the weak solvent aliphatic polyurethane resin for synthetic leather. By adopting the technical scheme, the polyurethane resin with different solid contents, different viscosities and different modulus can by synthesized, the requirement of the synthetic leather is satisfied, and the synthetic leather product with high temperature resistance, cold resistance, anti-sticking performance and better external tensility of pigment can be prepared.

Owner:ZHEJIANG SUNLIGHT MATERIAL TECH CO LTD

Thermoplastic elastomer composition and process of production thereof and hose using thermoplastic elastomer composition and process of production thereof

InactiveUS6526859B1Increase flexibilityLow production costFlexible pipesCoatingsElastomerVulcanization

A thermoplastic elastomer composition which, when used for the inner tube and / or outer cover of a hose, can improve the hose flexibility at an ordinary temperature and low temperature, oil resistance, and cold resistance and can reduce the production costs since it does not require a vulcanization step and a hose having said properties using this elastomer composition for its inner tube and / or outer cover and a process and apparatus for the production thereof.

Owner:THE YOKOHAMA RUBBER CO LTD

Waterproof moisture permeation polyurethane paint used for textiles and preparation method

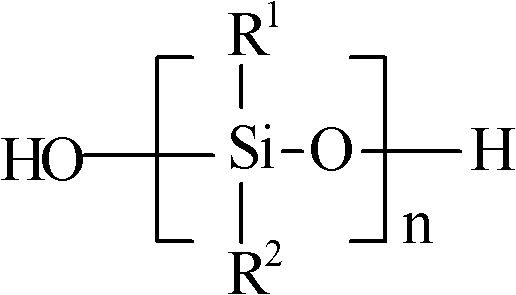

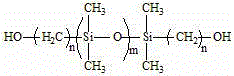

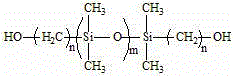

The invention relates to waterproof moisture permeation polyurethane paint used for textiles and a preparation method. The waterproof moisture permeation polyurethane paint is prepared from methyl diphenylene diisocyanate, toluene di-isocyanate, polyether glycol (with the molecular weight of 2000), linear dihydroxylated alkylsiloxane (with the molecular weight of 1000), polyester dihydric alcohol (with the molecular weight of 2000), trimethylolpropane, chain extending agents, sealing compounds, dibutyl tin laurate and solvents through the processes of pre-polymerization reaction, chain extension reaction and sealing reaction. The production process is simple, and the products have the advantages of self-crosslinking effect, soft hand feeling, good cold resistance performance, high moisture permeation performance, high water pressure resistance and little reduction after water pressure resistance washing.

Owner:郯城丰润粮机配件有限公司

Production method for seaweed bio-composite organic liquid fertilizer

ActiveCN102731176AReduce manufacturing costAvoid high temperatureOrganic fertilisersWater useCompound organic

The present invention relates to a production method for a seaweed bio-composite organic liquid fertilizer. The method comprises the following steps: carrying out crushing grinding on fresh kelps; adding the crushed kelp slurry to a fermentation tank, and adding water; adjusting the pH value to 6.8-8.8, adding a composite enzyme and a microbial fermentation bacteria agent, uniformly stirring, and heating to a temperature of 25-60 DEG C, wherein the thermal insulation fermentation time is at least 85 hours; and filtering, and adding an acid production bacterial agent to obtain the seaweed bio-composite organic liquid fertilizer. According to the present invention, the water used in the method adopting the fresh kelps as the raw material to produce the product is saved by 90% compared with the method adopting the dried kelp raw material to produce the product; the energy is saved by 40% by adopting solar heating and thermal insulation fermentation production, the production cost can be reduced by 25%, and characteristics of energy saving, water saving, low carbon and environmental protection are provided; the seaweed bio-composite organic liquid fertilizer of the present invention has effects of combination of organic fertilizer, inorganic fertilizer, microbial fertilizer, and medium and trace element fertilizer, rapid acting, long lasting time, synergy, fertilizer retention, water retention, cold resistance, insect repelling, disease resistance, soil improving, and the like.

Owner:WEIHAI SHIDAI MARINE BIOTECH

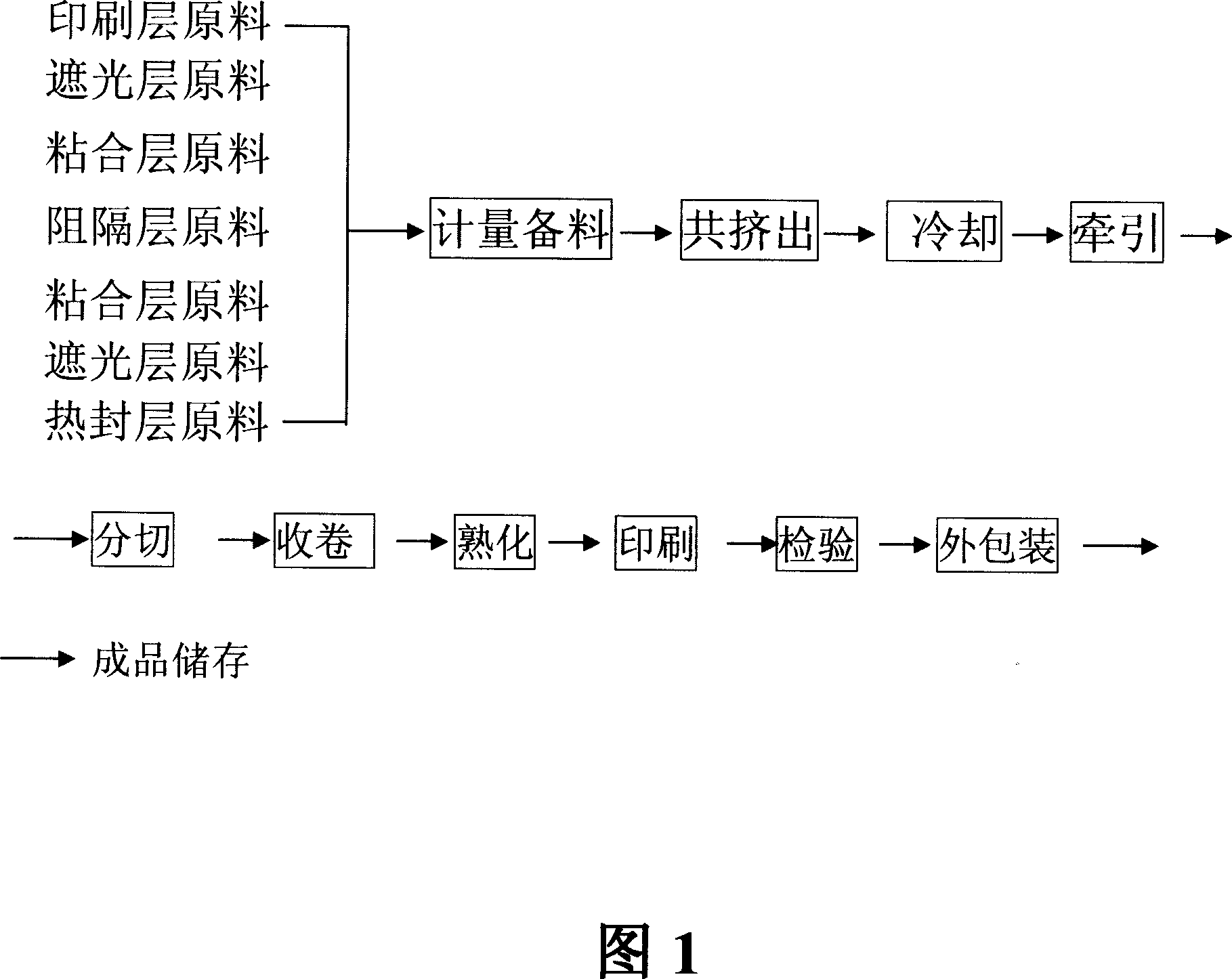

Seven-layer co-extrusion high-isolating packaging film

The seven layer high obstruct packing film includes the first printing layer made of LLDPE, LDPE and FSU; the second shading layer made of white color, LLDPE and LDPE; the third adhering layer of adhesive Tie; the fourth obstructing layer comprising EVOH; the fifth adhering layer of adhesive Tie; the sixth shading layer made of black color, LLDPE and LDPE; and the seventh thermal sealing layer made of LLDP, LDPE and FSU. The present invention possesses the advantages of non-toxicity, high humidity resistance, high oxygen resistance, high heat resistance, high flexibility, high cold resistance and high thermal sealing strength, and is used in packing milk without need of adding preservative and being cold stored.

Owner:郭瑞林

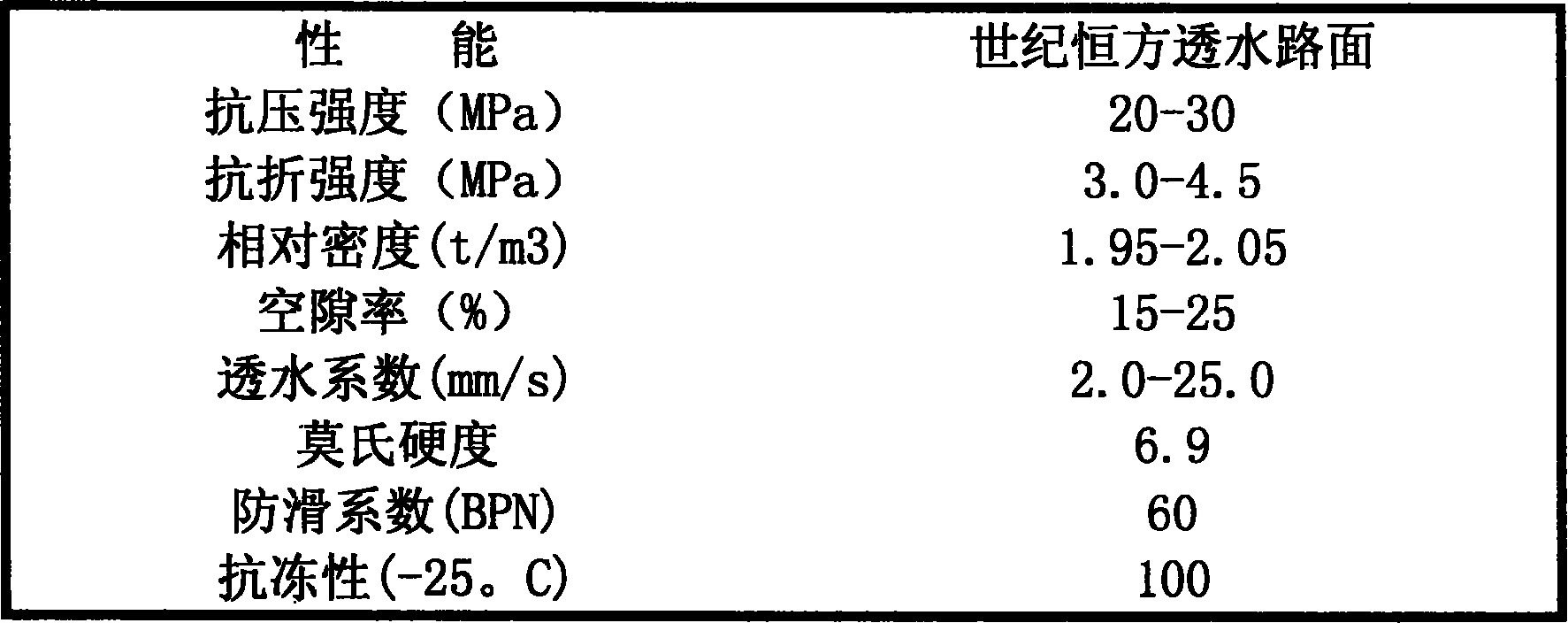

Water permeable concrete and manufacturing method thereof

InactiveCN101190833AQuality improvementHigh strengthSolid waste managementWater storageWeather resistance

The invention discloses a pervious concrete and is characterized in that the pervious concrete is made by mixing cement, aggregate, water, water reducer agent and adhesive evenly; and the cement, the aggregate, the water, the water reducer agent and the adhesive are mixed in different weight proportions of 1-1.2 to 5.5-8.5 to 0.2-0.5 to 0.01-0.2 to 0.01-0.2. The invention can solve the natural ecology problems of hardened ground in cities, atmospheric circulation as well as soil and water moisture retention, thereby forming a high-quality natural ecology environment and maintaining urban ecological balance. The pervious concrete consists of two pervious surface courses and two macadam bases in different particles so as to provide a water storage structure which can store the water until the water penetrates into the soil; meanwhile, the invention can be made into building block, which can be provided with different decorative patterns and colors on the surface, and has the advantages of artistic quality, water permeability, good water retention, skid resistance, high strength, cold resistance and weather resistance, etc.

Owner:上海恒方防腐工程有限公司

Method for increasing yield of plums

The invention relates to a method for planting plums. The method is suitable for the popularization and development of plum planting areas in south of Sichuan areas. The detailed technical scheme is provided emphatically from aspects of planting, tree pruning, soil and fertilizer management, the prevention and control of plant diseases and insect pests and the like by the integrated management and cultivation of seedlings of plum trees and adult trees. The method has the advantages that 1, field planting is performed according to the standard, namely 40 to 45 plants are subjected to field planting in soil per mu by a method for purifying the plums and a method for increasing the yield, and the planting number is neither more nor less; 2, yield and efficiency are high, namely the yield of a single plant of 7-age trees reached 40 to 60 kilograms in 2011; 3, benefits can be achieved for multiple times by performing field planting once, and the tree age is 30 to 35 years; and 4, cold resistance is improved. By the technology, in a chasmogamous period, the cold resistance and a fruit-bearing rate can be ensured under the condition of low-temperature overcast and rainy weather, so the plums which are stably yielded are obtained.

Owner:GAO COUNTY SIHEYUAN AGRI TECH

Room-temperature cured phenyl silicon resin conformal coating

The invention discloses a room-temperature cured phenyl silicon resin conformal coating which comprises components A) a segmented copolymer of phenyl silicon resin and linear polyorganosiloxane or methyl phenyl silicon resin and linear polyorganosiloxane, B) alkoxy silane, C) a silane coupling agent containing amino or epoxy group, D) an organic titanium compound, E) organic phosphate flame retardant synergist, and (F) an organic hydrocarbon solvent or low molecular weight siloxane, wherein the organic hydrocarbon solvent is one or multiple of methylbenzene, dimethylbenzene, petroleum ether, cyclohexane and normal heptane; and the low molecular weight siloxane is a mixture of octamethyl-trisiloxan, octamethyl cyclotetrasiloxane or methyl cyclosiloxane. A product produced by the cured resin conformal coating of the invention has the advantages of very high transparency, good elasticity, tough and wearable surfaces as well as excellent high / low temperature performance, waterproofing, heat resistance, cold resistance, weathering resistance, ultraviolet ray resistance, medium resistance, irradiation resistance, flame retarding and the like.

Owner:MIANYANG WELLS ELECTRONICS MATERIAIS

Preparation method for airtight liner material and raw material formula of airtight liner material

The invention relates to airtight materials and provides a preparation method for an airtight liner material and a raw material formula of the airtight liner material. The raw material formula involves, by weight, 100 parts of branched polyethylene, 30-100 parts of carbon black, 2-10 parts of peroxide crosslinking agents, 1-10 parts of zinc oxide, 0.1-1 part of lubricants and 0.3-1 part of accelerants. The branched polyethylene serves as a principal raw material of the airtight liner material, and raw material cost is lower than that of butyl rubber; the glass-transition temperature is low, cold endurance is good, and the phenomenon of low-temperature hardening is unlikely to occur; no unsaturated double bonds exist in the molecular structure, and ageing-resistant performance is excellent; mobility is good, and the dispersion effect of filler is good; the airtight liner material has the same air tightness as the butyl rubber and is better than the butyl rubber in abrasive resistance and rebound resilience.

Owner:ZHEJIANG UNIV

Toughened cold-resistant transparent modified polypropylene material and preparation

The invention provides a toughening cold-resistant transparent modified polypropylene material and a preparation method. The material is mainly made from the following components in parts by weight: 60-90 parts of homogeneous polypropylene, 10-30 parts of a toughening agent, 0.1-0.4 part of an alpha-nucleation agent, 0.1-0.4 part of a beta-nucleation agent and 0.2-0.4 part of an antioxidant. The material is added with propylene made from alpha-olefin with the same refractive index as polypropylene and a semi-crystalline polymer of the alpha-olefin as the toughening agent, thus the material can reduce effect on transparence of the polypropylene material and realize cold resistance and toughening of the polypropylene, and can be used together with an alpha-crystallographic form nucleating agent after compounding with a beta-crystallographic form nucleating agent to control proportions of polypropylene alpha-crystallographic form to polypropylene beta-crystallographic form, thus improving transparence of the polypropylene, compensating rigidity at room temperature and heat deformation temperature of the polypropylene and finally realizing development of the toughening cold-resistant transparent modified polypropylene.

Owner:浙江富丽新材料有限公司

Fertilizer with release-controlled function for strengthening root and inhibiting growth

InactiveCN1699302APromote growthAvoid injuryFertiliser formsFertilizer mixturesVegetationGrowth plant

The invention provides a fertilizer with release-controlled function for strengthening root and inhibiting growth, which comprises the components of (by weight ratio) nourishing substance 15-40, plant growth retardant 0.05-5, plant growth accelerator 0.05-5, controlled release carrier 50-84. The fertilizer has the functions of delaying vegetation, dwarfing the strains, accelerating tillering, root generating, reinforcing cold resistance, drought resistance, and minimizing soil residual quantity of growth regulator.

Owner:SICHUAN SANHE SLOPE TECH CO LTD

Organic water soluble fertilizer

The invention relates to an organic water soluble fertilizer, which belongs to a novel, efficient and organic hyperconcentration chelate fertilizer and is prepared from plant source organic matters, potassium humate, citric acid, amino acid, vitamin, monosaccharide, fructose, dextrose, polysaccharide, potassium sodium tartrate, zinc sulfate, copper sulfate, manganese sulfate, boracic acid, ammonium molybdate, ethanediol, monoammonium phosphate, monopotassium phosphate, phosphoric acid and the like through the processes of acidification, chelation and concentration. The organic water soluble fertilizer is suitable for being used for all plants in modes of leaf surface spray application, root filling, seed soaking, flushing application, drip irrigation and spray irrigation. The product is nontoxic and does not have hormone or residue, the crop growth and development can be regulated in a balanced way, the metabolism and the photosynthesis of the plants can be promoted, the aging of the plants can be delayed, the quality is improved, the yield is increased, and certain drought resistance, cold resistance and disease resistance effects are realized. 20 percent to 40 percent of soil fertilizer consumption can be reduced through using the organic water soluble fertilizer for many times, and the yield of the crops can be increased by about 10 to 40 percent.

Owner:GUANGXI PENSHIBAO

Method for producing real leather intimating polyurethane synthetic leather

InactiveCN101748613AReduce demandSmoothPattern makingSynthetic resin layered productsPolyesterSlurry

The invention discloses a method for producing real leather intimating polyurethane synthetic leather, which comprises the following steps: firstly, preparing a wet synthetic leather semi-finished product; secondly, coating a polyurethane finishing agent on the surface of the wet synthetic leather semi-finished product to perform printing surface treatment; thirdly, sticking a release paper pattern transferred polyurethane film to the surface of the printed wet synthetic leather semi-finished product, wherein raw materials in polyurethane slurry comprise polyester-polyether-polycarbon copolymerized polyurethane resin, cracking resin, dimethyl formamide, down powder, wet wax sensitive toner and solvent pigment; and finally, performing kneading treatment. The polyurethane synthetic leather has frosting effect on the surface, smooth handfeel, color change when pushing the surface by hand and strong third dimension of patterns, has good physical properties such as scratch resistance, cold resistance, hydrolysis resistance and the like, and can replace real leather in many aspects so as to reduce the requirement for furs, protect the nature and keep ecological balance.

Owner:ANHUI ANLI MATERIAL TECH

Seed coating agent for raising cold resistance of super sweet corn seed

InactiveCN1973630AImprove germination rateImprove germination indexBiocideAnimal repellantsPhosphateAdditive ingredient

The present invention discloses one kind of seed coating agent for raising cold resistance of super sweet corn seed. The seed coating agent is mixture of cold resisting components including dimethyl sulfoxide 0.5-5 wt% and praline 0.005-1 wt%; nutritious components including glucose 0.1-2 wt%, vitamin C 0.01-0.5 wt%, amino acid 0.5-7 wt%, zinc sulfate 0.05-0.5 wt% and potassium dihydrogen phosphate 0.05-0.9 wt%; plant growth regulator including gibberellin 0.004-0.025 wt% and naphthylacetic acid 0.01-0.35 wt%; one or two pesticides 0.3-8 wt%; germicide 5-15 wt%; filming including agent chitosan 0.15-2 wt% and gum Arabic 1-8 wt%; penetrant alcohol 2-10 wt%; red pigment as warning color 0.5-1.5 wt% and water for the rest. The present invention can raise the cold resistance of super sweet corn seed, prevent and control diseases and pests, regulate the growth of super sweet corn seed and increase yield.

Owner:ZHEJIANG UNIV

High cold resistance polyvinyl chloride cable material and preparation method thereof

InactiveCN101260214AEasy to useExpand the usable rangeInsulated cablesInsulated conductorsPolyvinyl chlorideEngineering

The invention provides a polyvinyl chloride (PVC) cable material used in gelid state (minus 50 DEG C to minus 70 DEG C) and a preparation method of the cable material. During use, the cable material does not split and can be bent normally, thereby greatly increasing the application range of products. Moreover, the cable material is made from the following raw materials in portions by weight: PVC of 80 to 100 portions, dioctyl phthalate of 20 to 40 portions, dioctyl sebacate of 60 to 80 portions, dioctyl butane dicarboxylic acid of 4 to 8 portions, light activated calcium carbonate of 20 to 40 portions, lubricant of 1 to 3 portions , Ca-Zn composite stabilizer of 4 to 8 portions, antioxidant 1010 of 1 to 4 portions, frost resisting agent K175C of 0.5 to 5 portions and nitrile butadiene rubber of 20 to 50 portions.

Owner:WUXI DONGTIAN CABLE

Polypropylene material filled with inorganic mineral powder, and its preparation method and application

InactiveCN102206376AExcellent resistance to folding fatigueImprove cold resistanceFlexural modulusMicrosphere

The invention discloses a polypropylene material filled with inorganic mineral powder, and its preparation method and application. The polypropylene material comprises, by weight, 43 to 90% of polypropylene, 0 to 1% of a heat stabilizer, 0 to 1% of a lubricant, 0 to 15% of a flexibilizer and 10 to 40% of an inorganic mineral powder filler, wherein the inorganic mineral powder filler is one selected from the group consisting of calcium carbonate, powdered steatile, kaolin, mica, wollastonite, glass microballoons, ceramic microspheres and barium sulfate or a mixture of the above-mentioned materials. When used as a material for hinges, the polypropylene material filled with inorganic mineral powder in the invention has excellent folding resistance which is similar to that of a pure polypropylene material, good fatigue durability and comprehensive mechanical properties, outstanding cold resistance and high thermal deformation temperature, wherein tensile strength is no less than 30 MPa, flexural modulus is no less than 2000 MPa, the thermal deformation temperature is no less than 110 DEG C; the material can be used for a long time at a temperature of from -35 to 85 DEG C and can be used to prepare hinge materials which have requirements for high heat resistance and cold resistance.

Owner:SHANGHAI KINGFA SCI & TECH

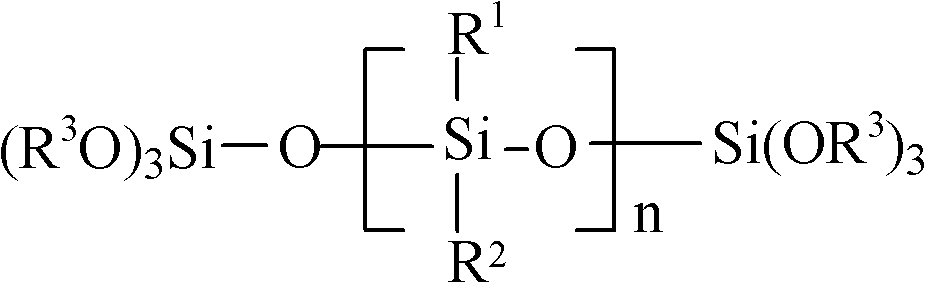

Organic silicon modified waterborne polyurethane leather coating agent and preparation method

InactiveCN104356342AMake up for the defects of poor mechanical propertiesImprove water resistancePolyurea/polyurethane coatingsLeather surface finishingSolventCastor oil

The invention discloses an organic silicon modified waterborne polyurethane leather coating agent which comprises the following raw materials in parts by weight: 30-50 parts of polyether polyol, 10-30 parts of isocyanate, 1-8 parts of castor oil, 0.1-11 parts of end hydroxyalkyl polydimethylsiloxane, 0.01-1 part of a catalyst, 1-10 parts of a hydrophilic chain extender, 5-25 parts of an organic solvent, 1-5 parts of a salt-forming agent, 1-3 parts of a small-molecule chain extender and 120-250 parts of deionized water. Correspondingly, the invention further provides a method for preparing the organic silicon modified waterborne polyurethane leather coating agent. By adopting the organic silicon modified waterborne polyurethane leather coating agent, properties such as the water resistance, the cold resistance, the solvent resistance and the surface property of synthesized waterborne polyurethane are all remarkably improved, the process is simple, the operation is convenient, the prepared emulsion is uniform and stable, no sediment is generated in the water dispersion and storage process, a coating film is transparent and bright, and the application prospect in leather coating is wide.

Owner:FOSHAN CENT FOR FUNCTIONAL POLYMER MATERIALS & FINE CHEM

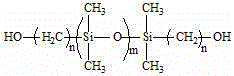

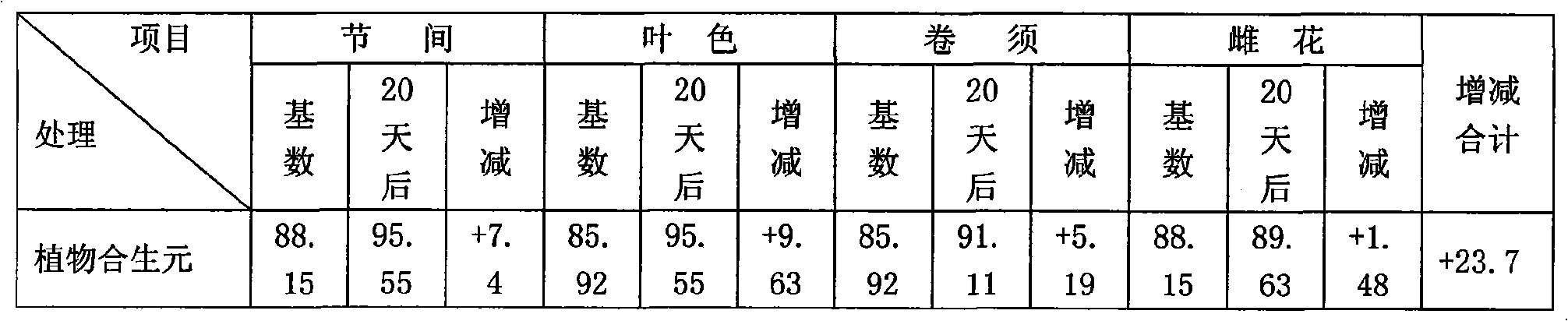

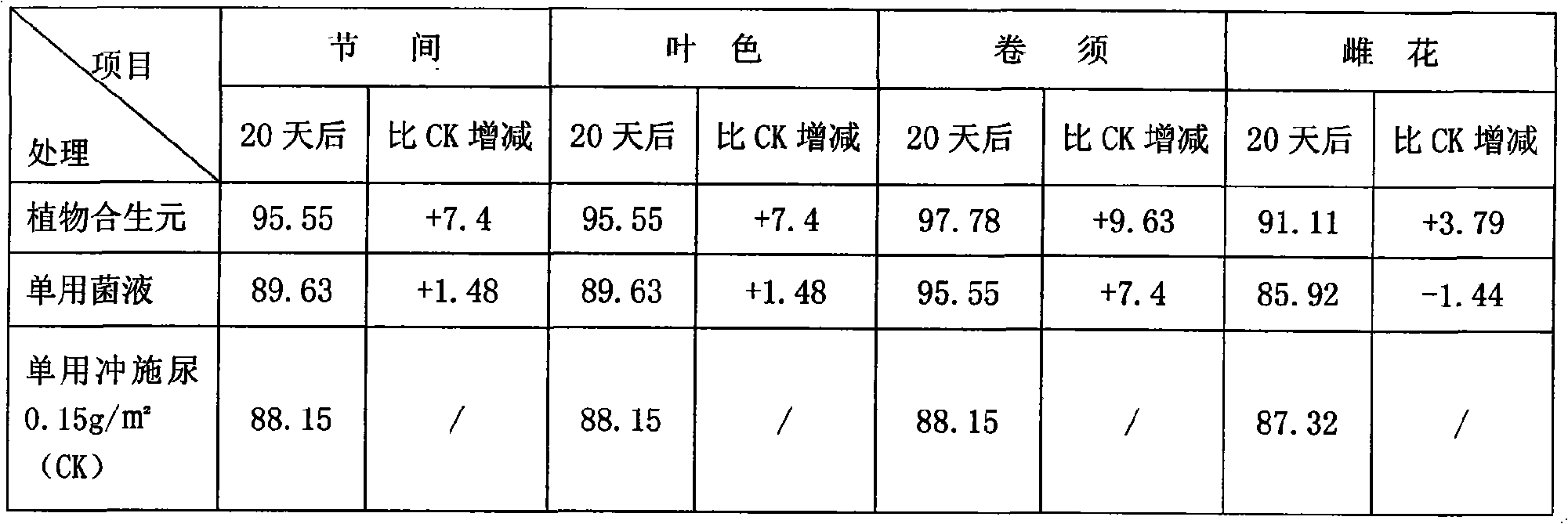

Microbial fertilizer-plant synbiotic composition preparation and method for preparing symbiotic preparation

ActiveCN101591199AThe effect of increasing production is obviousStable growthBacteriaMicroorganism based processesContinuous croppingPlant roots

The invention discloses a microbial fertilizer-plant synbiotic composition preparation and a method for preparing the synbiotic preparation. In the composition preparation, the plant synbiotic consists of probiotics, prebiotics and stabilizer; and bacillus forms zymotic fluid. The method for preparing the synbiotic preparation comprises the following steps: fermenting the probiotics; regulating bacteria amount; and preparing and homogenizing to obtain the product. Azotobacter, pralidoxime iodide and potassium bacteria in the preparation can increase soil nutrition, improve the fertilizer utilization rate and soil granule structures, promote the air permeability, water-retaining property and drainage, and overcome the defect of sunlight greenhouse continuous cropping; oligosaccharide prebiotics in the preparation can stimulate crops to improve resistance to pathogenic microorganisms, and promotes permanent planting and proliferation of the probiotics; the preparation can inhibit toxicity generated by bacteria, start self immunity system, eliminate diseases and remove evils, reduce bactericidal pesticide, has cold resistance, heat resistance, drought resistance, waterlogging resistance, saline and alkaline resistance, fertilizer damage resistance, chemical damage resistance and nutrition imbalance resistance, can promote plant root elongation and good development of capillary roots, and promote blooming and fruit yielding.

Owner:渭南德龙生物科技有限公司

Silicon rubber shrinkable tube and preparation method thereof

The invention discloses a silicon rubber shrinkable tube and a preparation method thereof. In order to solve the problems that the conventional shrinkable tube has low high-temperature resistance, oil resistance and solvent resistance and cannot meet the requirements on high oil resistance and solvent resistance in automobiles, high-speed trains, military project, space flight and other industries, the invention provides a silicon rubber shrinkable tube, which mainly comprises the materials of silicon rubber, shrinkable resin, a reinforcing agent, a cross-linking agent, silicone oil and optional zinc stearate. Meanwhile, the invention also provides a method for preparing the shrinkable tube from the materials. The provided silicon rubber shrinkable tube has high stability and high heat resistance and cold resistance, and can be applied to electric and electronic industrial places with higher requirements on heat resistance, cold resistance and insulation property.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL

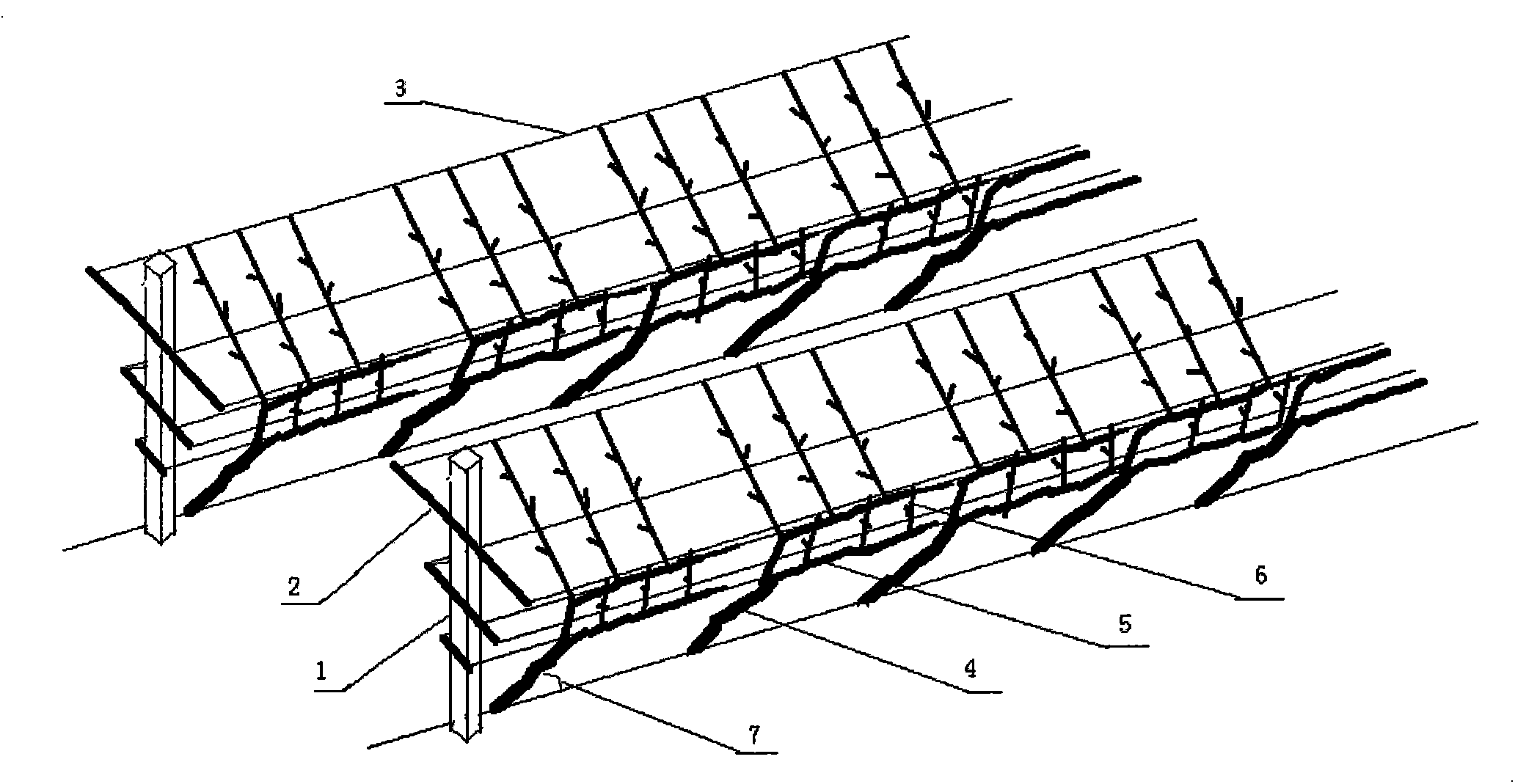

Trellis viticulture method suitable for alpine region

InactiveCN103907499AEasy to get on and off the shelvesAccurately control outputCultivating equipmentsViticultureEngineering

The invention discloses a trellis viticulture method suitable for an alpine region. When a vineyard is built in a viny region, 'Y'-shaped double trellises 180cm in height are built, three cross rods with the lengths of 20cm, 50cm and 100cm respectively from bottom to top are arranged at positions 60cm, 100cm and 180cm of each vertical column respectively, bracing lines are designed at two ends of each cross rod and jointly form leaf curtains of the 'Y'-shaped double trellises with lower bracing lines, grades are all led to the trellises in a way that single trunks are led to the trellises in 30-degree inclination along the row directions, double main vines extend to the front plant along the row direction to meet the front plant at a position 60cm of each bracing line, and a young sprout on each main vine is led to be bound to one side of the corresponding main vine perpendicularly along the row direction. Owing to the trellis viticulture method suitable for the alpine region, yield can be precisely controlled, mechanical management is facilitated, convenience in getting grapes on and off the trellis is achieved, overwintering and cold resistance are facilitated, and the method is extensive in practicability.

Owner:XINJIANG ACADEMY OF AGRI & RECLAMATION SCI

Coal gangue-fly ash-sludge substrate and mycorrhiza technology for restoring ecology of mining area

InactiveCN101920261AOvercome poor water holding capacityOvercoming low fertilityContaminated soil reclamationBiological sludge treatmentSurface layerSludge

The invention relates to a coal gangue-fly ash-sludge substrate and a mycorrhiza technology for restoring ecology of a mining area. The invention belongs to the technical field of environmental protection, and relates to an ecology restoring technology, in particular to a method for restoring the ecology of an abandoned coal mine area. The method for restoring the abandoned coal mine area by the mycorrhiza technology of the invention adopts a composite substrate prepared by mixing fly ash, coal gangue and sludge, and comprises the following steps: a, preparing an inoculant; b, preparing a basic plant material; c, carrying out inoculating mycorrhiza treatment on the plant by the inoculant obtained in the step a; d, analyzing the physicochemical property of the abandoned coal mine area, and carrying out mixed treatment to form the composite substrate; and e, sowing seeds on the composite substrate surface layer of the treated abandoned coal mine area. The method of the invention can improve the adaptability of plants to the complex adverse environment of the abandoned coal mine area, wherein the adaptability comprises stronger nutrient acquisition capability and cold resistance, thereby fully utilizing waste and sludge in the mining area, and solving the source problem of other soil for melioration in the mining area.

Owner:CHINA UNIV OF MINING & TECH

Cable sheath material for coal mine

ActiveCN101538380AImprove stabilityEasy to useInsulated cablesInsulated conductorsPolymer sciencePolyvinyl chloride

The invention discloses a cable sheath material for a coal mine, which is characterized by comprising the following raw materials for preparing effective constituents according to the parts by weight: 70-100 of butyronitrile-polyvinyl chloride compound, 10-30 of neoprene, 30-60 of white carbon black, 2-8 of magnesium oxide, 20-60 of aluminum hydroxide, 30-60 of chlorcosane, 2-6 of accelerant CZ, 3-8 of zinc oxide, 1-5 of stearic acid, 3-8 of age inhibitor, 4-15 of diantimony trioxide, 2-7 of titanium pigment and 3-9 of vulcanizing agent. The cable sheath material for the coal mine has better performance of stink resistance, cold resistance, flame resistance, oil resistance, ageing resistance, and the like and has good elasticity, high tensile strength, good tear resistance, good extrusion performance and low cost.

Owner:阳谷新太平洋电缆有限公司

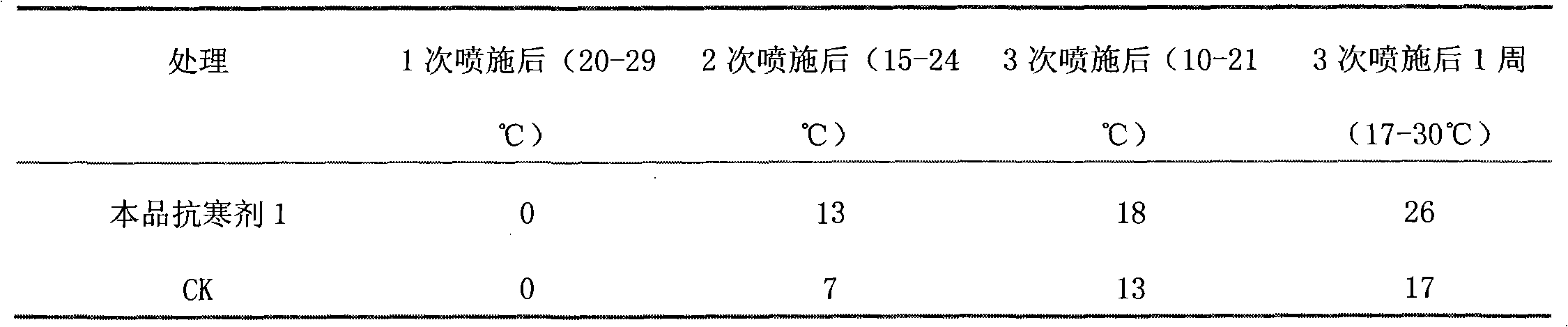

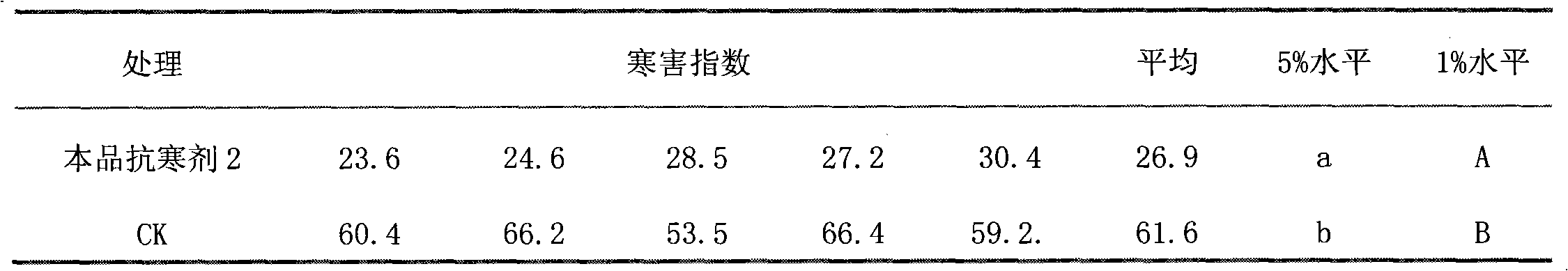

Chitosan oligosaccharide composite with cold-resistant function and application of composite

ActiveCN102144637APromote photosynthesisTo promote metabolismBiocidePlant growth regulatorsNormal growthPotassium

The invention discloses a chitosan oligosaccharide composite with cold-resistant function, which is aqueous solution, wherein the mass concentration of the chitosan oligosaccharide is 5%-10%, other auxiliary active constituents include at least one of phosphorus, potassium, calcium, boron, molybdenum, zinc, salicylic acid and betaine, and the content of the auxiliary active constituents is 0.5%-30% of the total mass concentration of the composite. Before the flowering period and the young fruit period of fruit trees, the time of young seedling of melon and fruit, vegetables and flowers, and the cold sensitive period of the winter growth of greenhouse crops, the composite is diluted by 1000 times with water to be sprayed on the leaves of the plants for 2-3 times; the chitosan oligosaccharide composite used in the invention has the function of promoting photosynthesis of the crops, improving activation performance of various enzymes and promoting metabolism of carbohydrates; and the chitosan oligosaccharide composite is used for inducing the crops to improve stress resistance and inducing the crops to improve cold resistance, so that the crops can get through the low-temperature cold harmful period, and regular development and yield of the crops are ensured.

Owner:HAINAN ZHENGYE ZHONGNONG HIGH TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com