Patents

Literature

101results about How to "Keep the feel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Weak solvent aliphatic polyurethane resin for synthetic leather and preparation method thereof

The invention relates to the technical field of materials for synthetic leather, in particular to weak solvent aliphatic polyurethane resin for synthetic leather and a preparation method thereof. The weak solvent aliphatic polyurethane resin for synthetic leather is prepared from the following components by weight percent: 2-30 percent of aliphatic diisocyanate compound, 5-40 percent of polyester or polyether polyalcohol compound, 0-10 percent of micromolecule polyol chain extender, 0.1-13 percent of micromolecule polyamine chain extender, 0.01-1.0 percent of catalyst, 0.05-5.0 percent of assistant and 45-85 percent of organic mild solvent. The invention also discloses the preparation method of the weak solvent aliphatic polyurethane resin for synthetic leather. By adopting the technical scheme, the polyurethane resin with different solid contents, different viscosities and different modulus can by synthesized, the requirement of the synthetic leather is satisfied, and the synthetic leather product with high temperature resistance, cold resistance, anti-sticking performance and better external tensility of pigment can be prepared.

Owner:ZHEJIANG SUNLIGHT MATERIAL TECH CO LTD

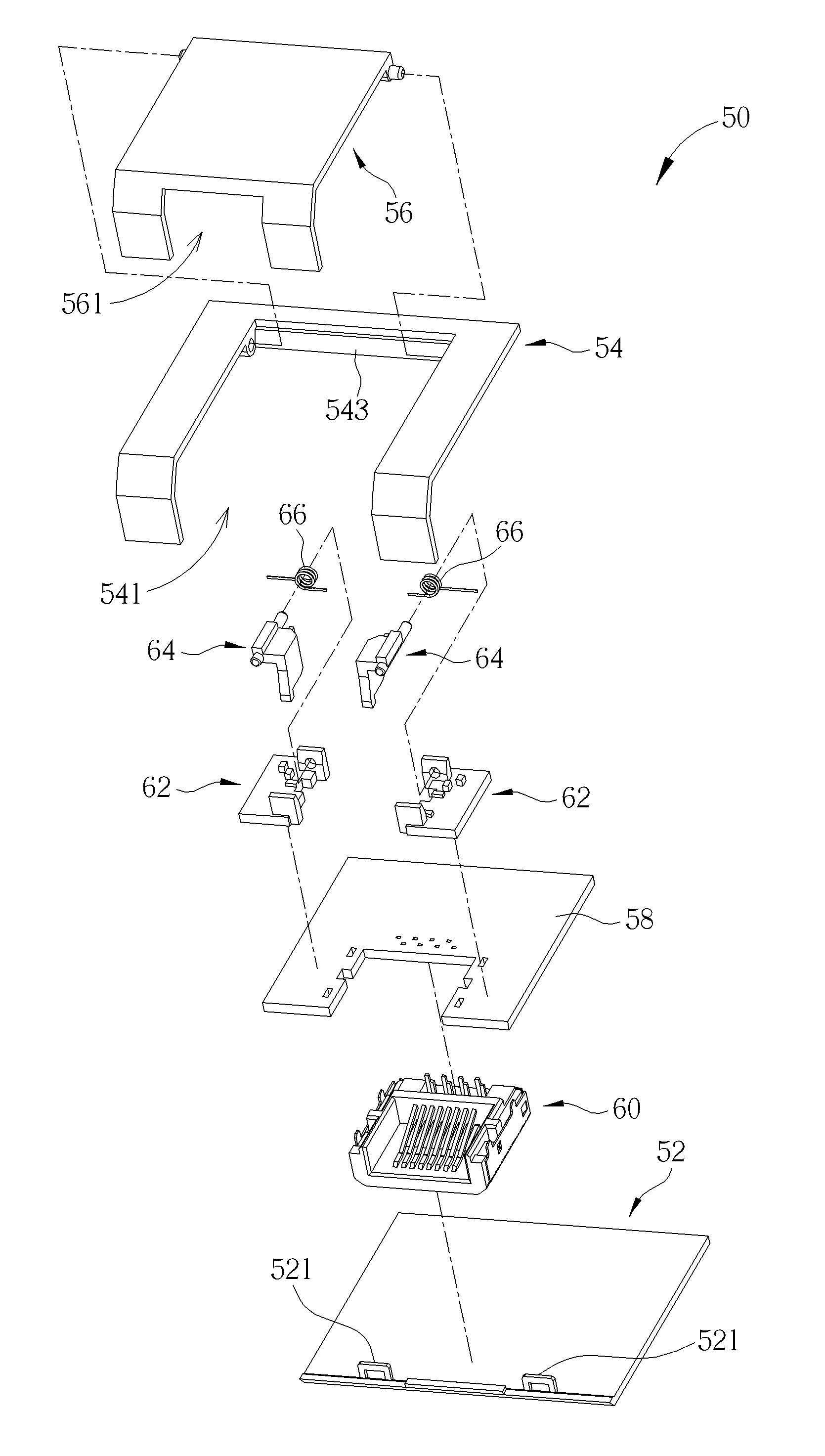

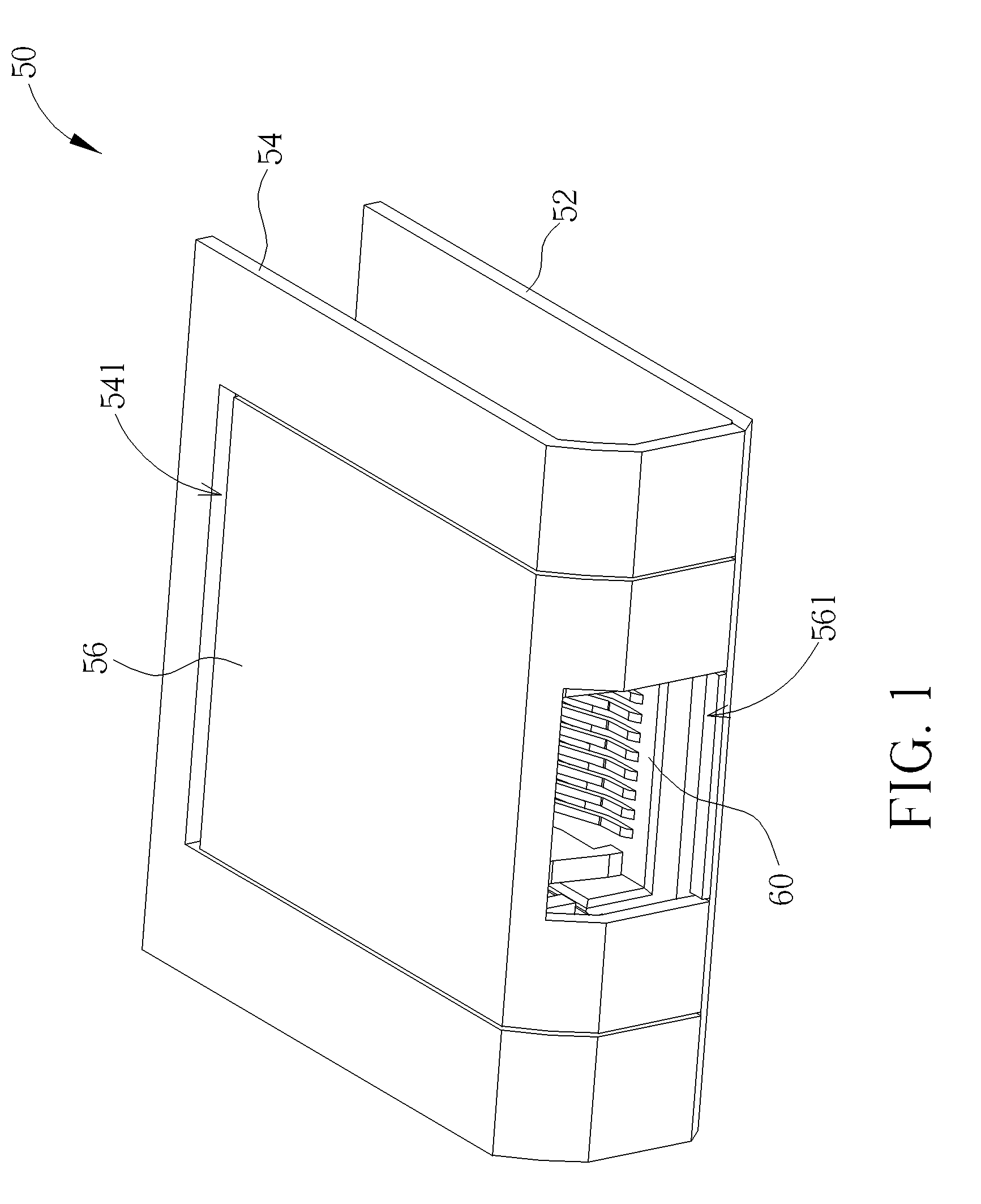

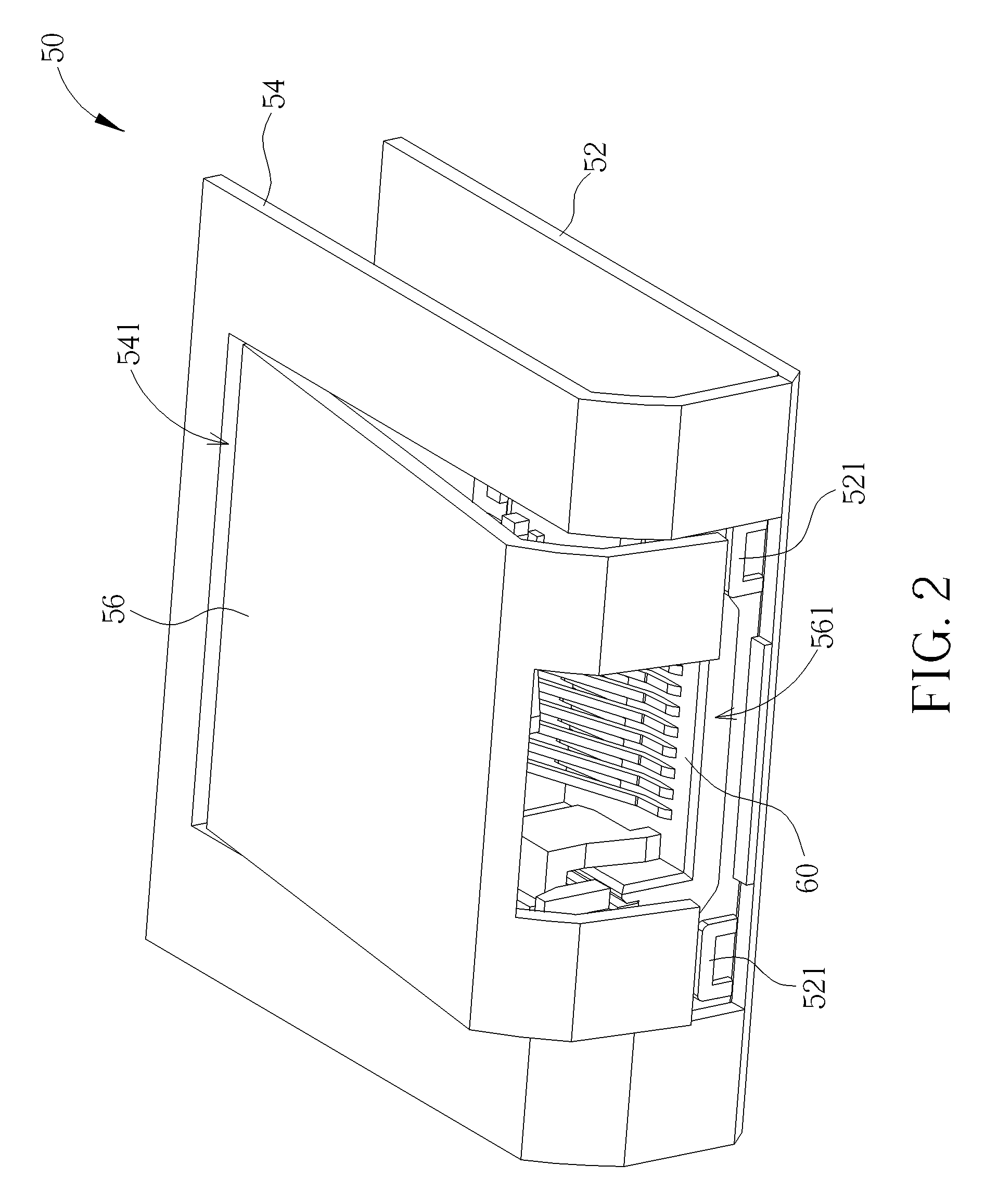

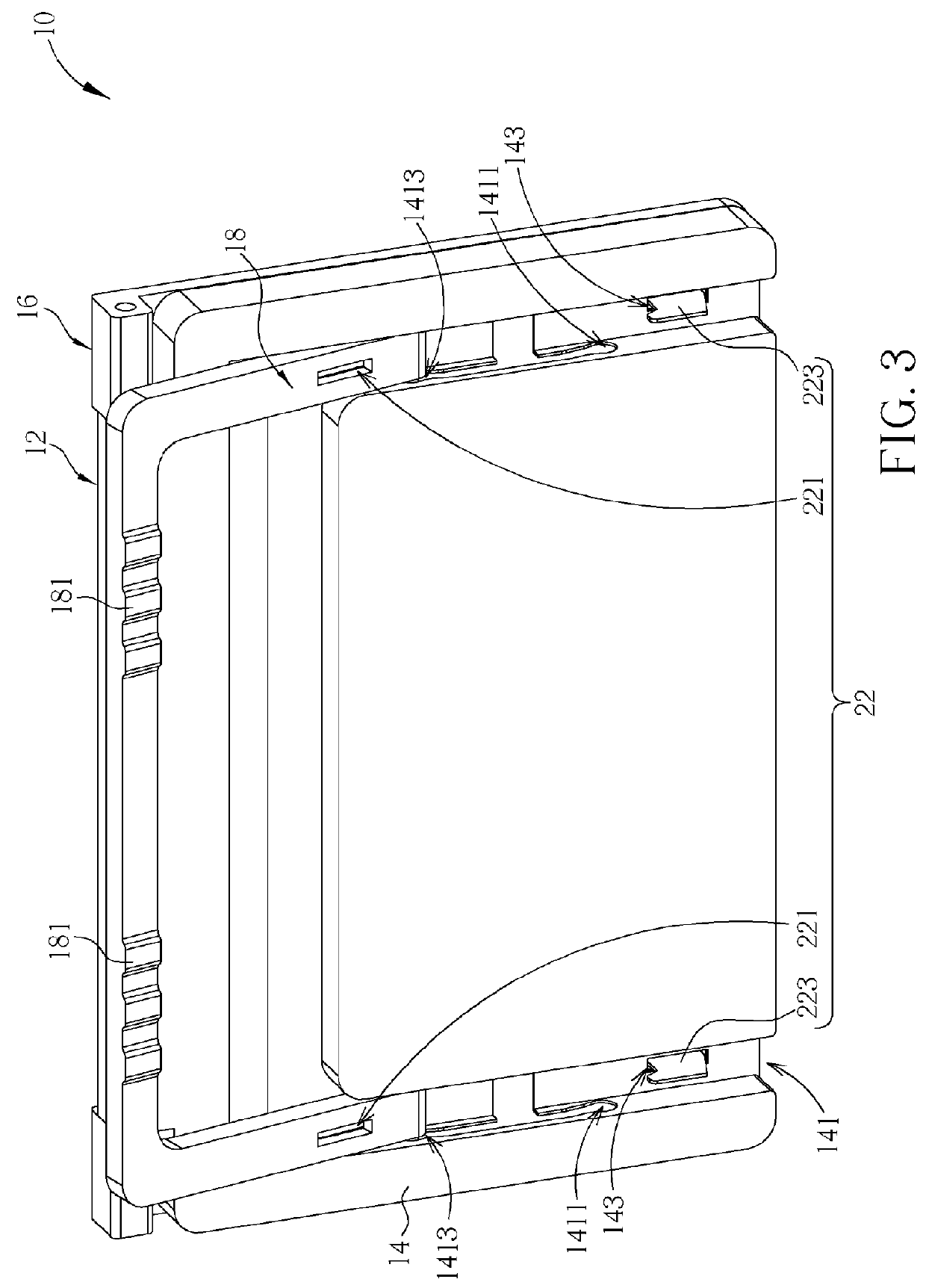

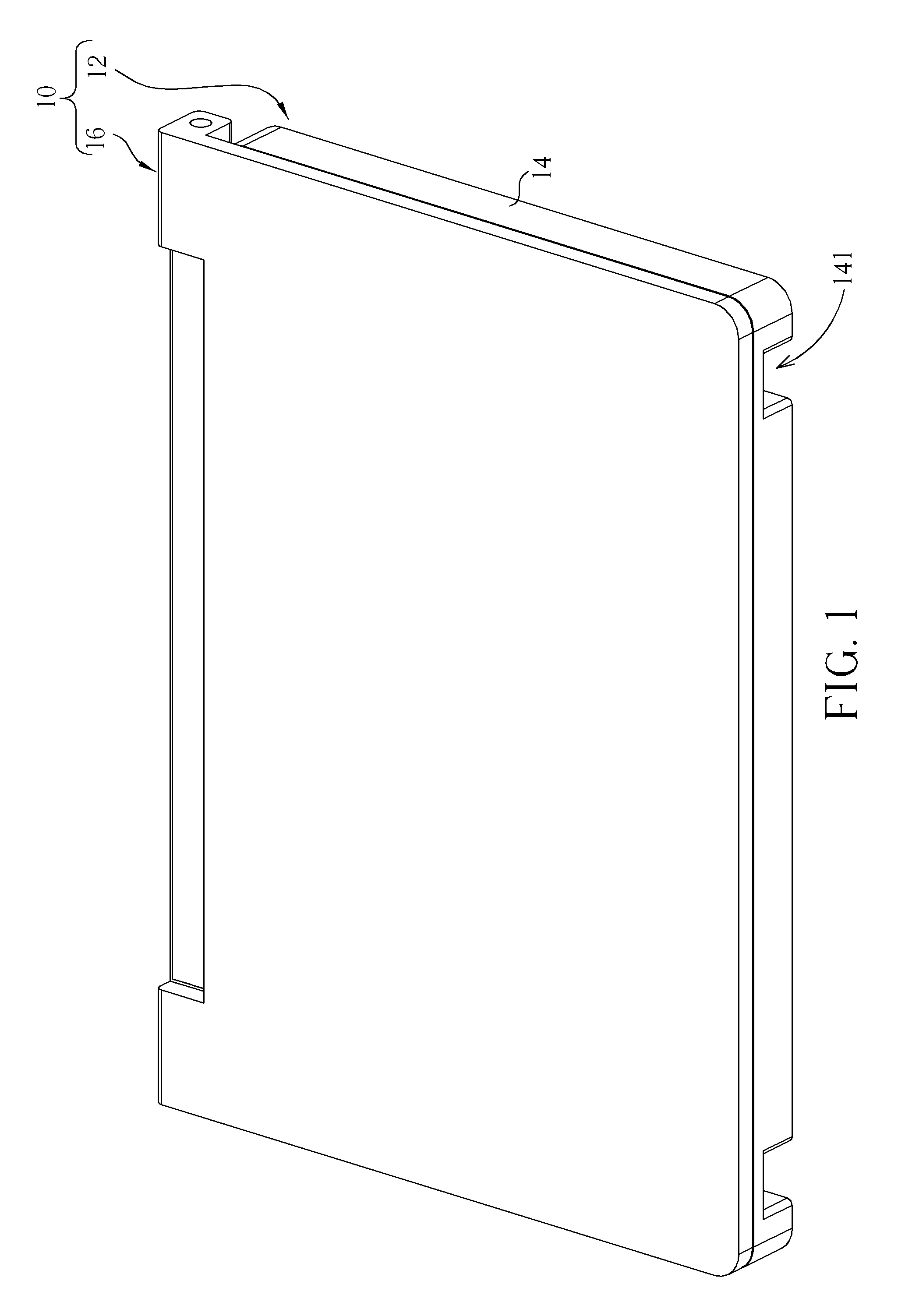

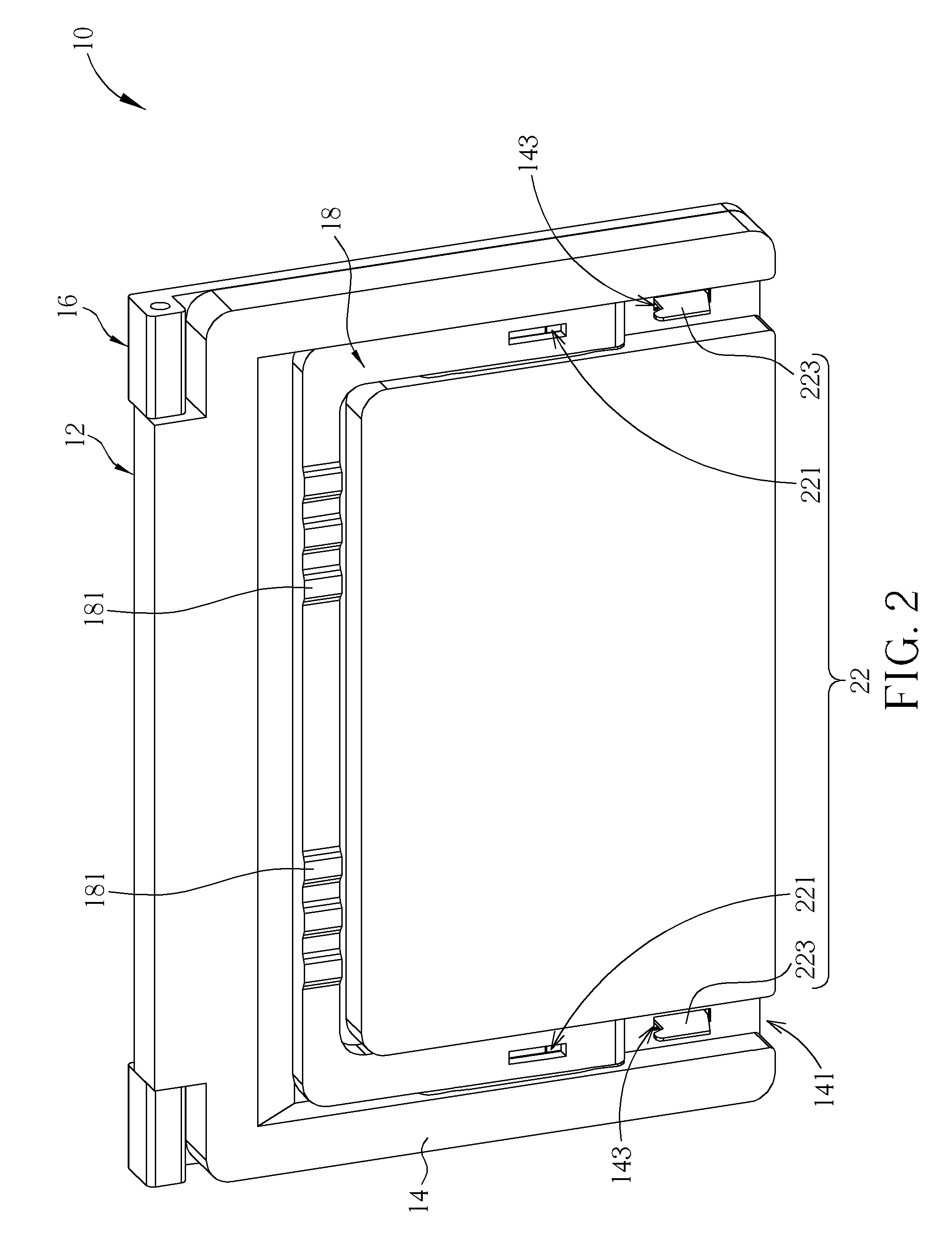

Connector mechanism

ActiveUS8758032B2Avoid separationIncrease the height of the structureTwo-part coupling devicesLive contact access preventionFastener

Owner:WISTRON CORP

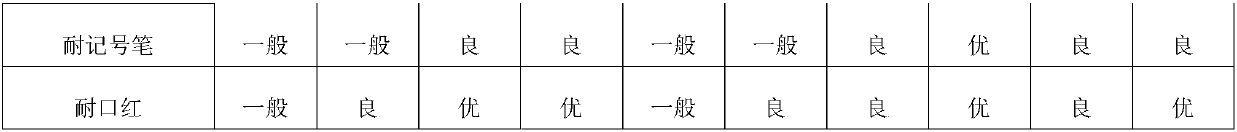

Pretreatment agents for acidic hair dyes

InactiveUS20040045099A1Good effectImprove abilitiesCosmetic preparationsHair removalHair dyesCationic polymerization

Pretreatment agents for hair colorings with acid dye comprising at least one cationic polymer selected from the group consisting of polymers having amino groups and polymers having quaternary ammonium groups. The pretreatment agents for hair colorings with acid dye are used for improving coloring ability and color fastness of hair colorings with acid dye.

Owner:MANDOM CORP

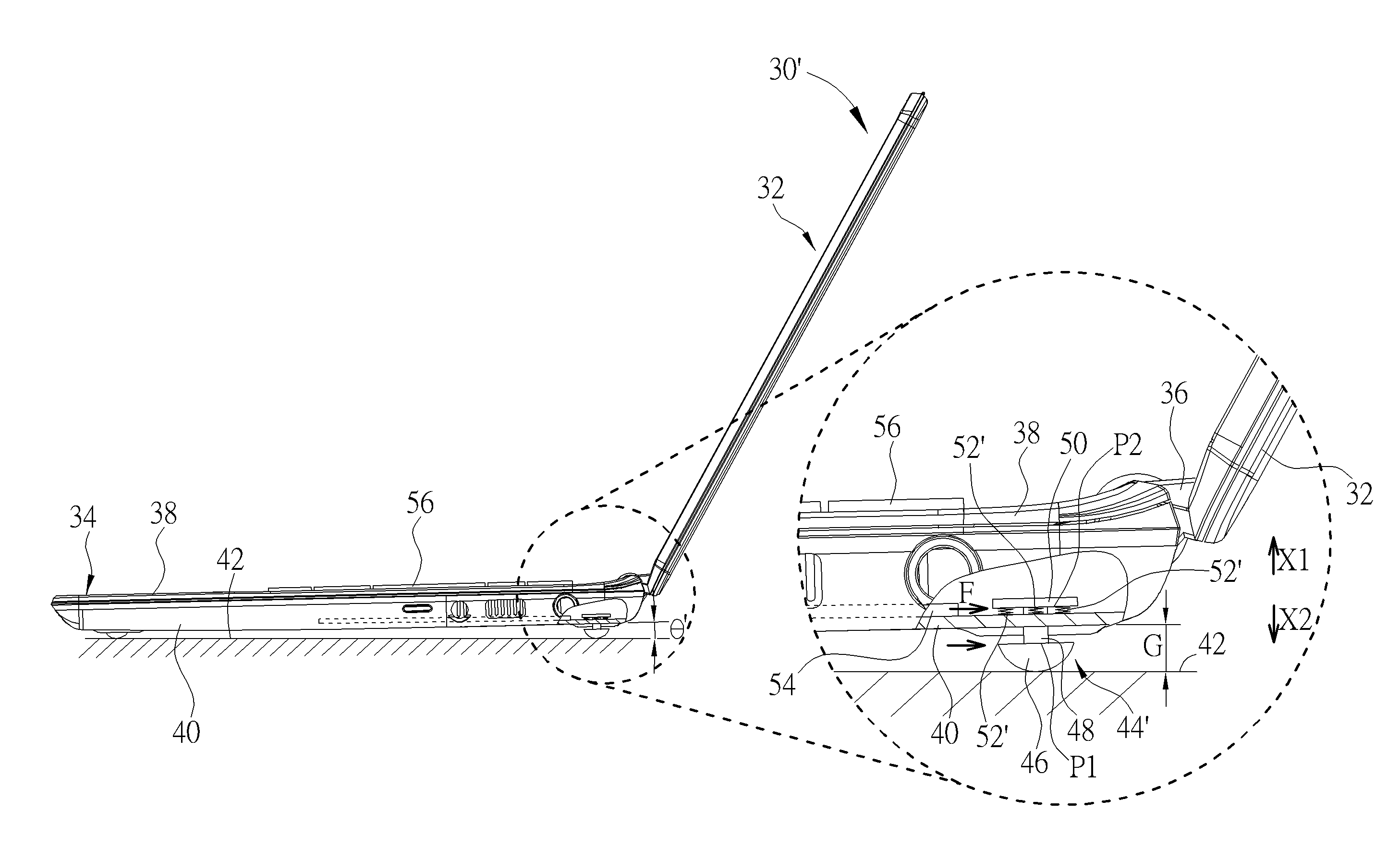

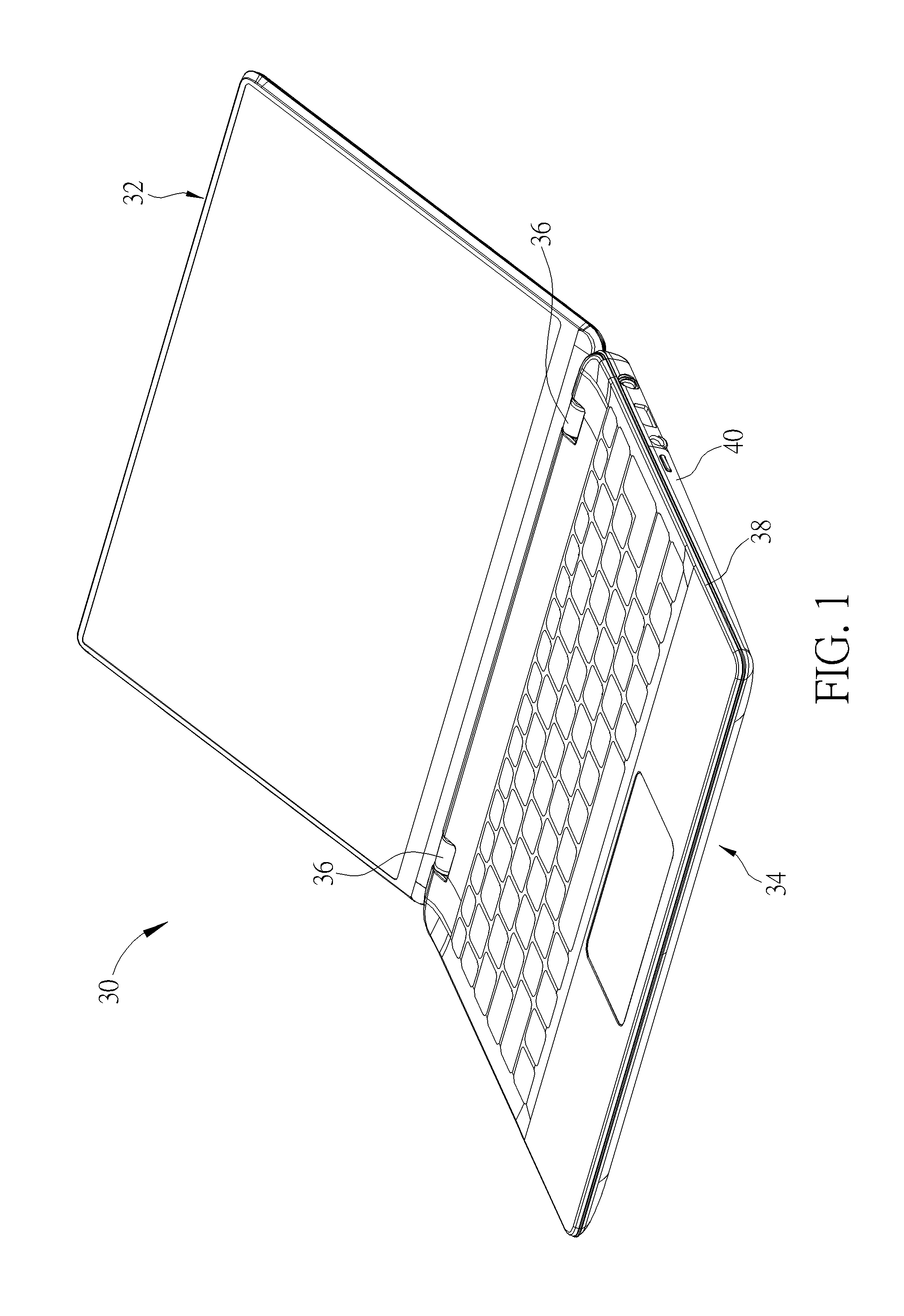

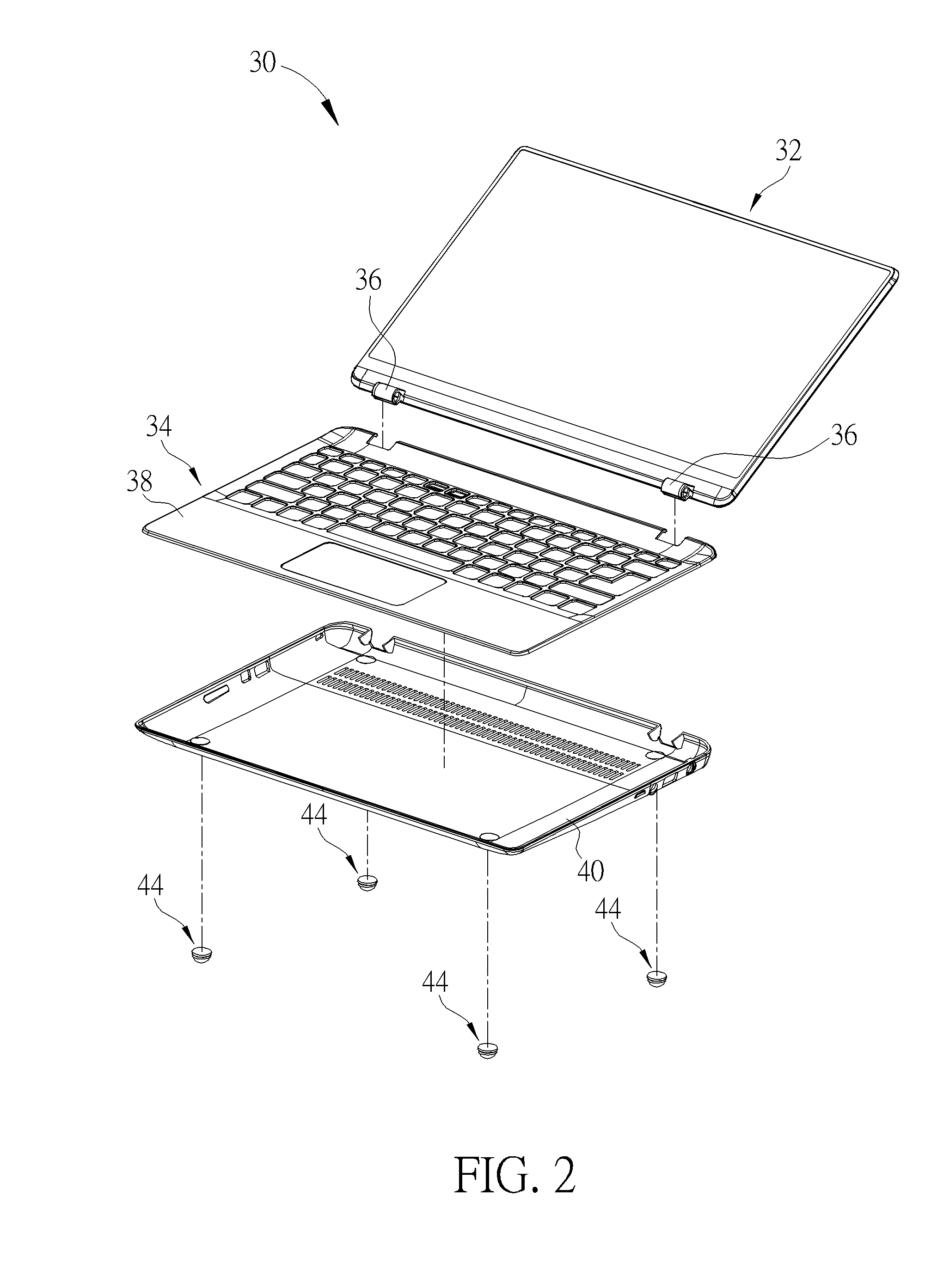

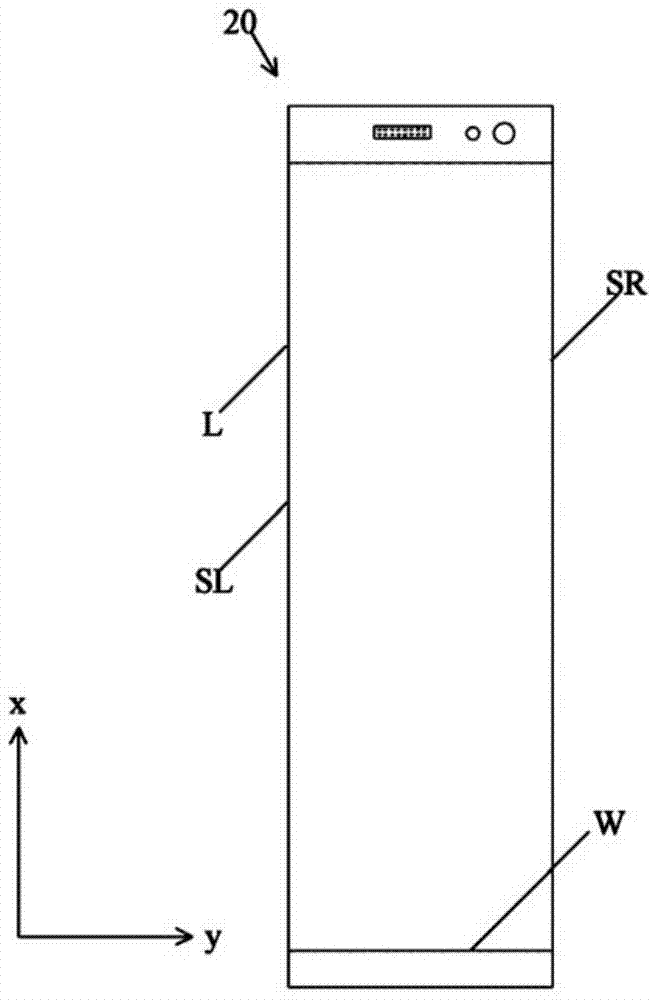

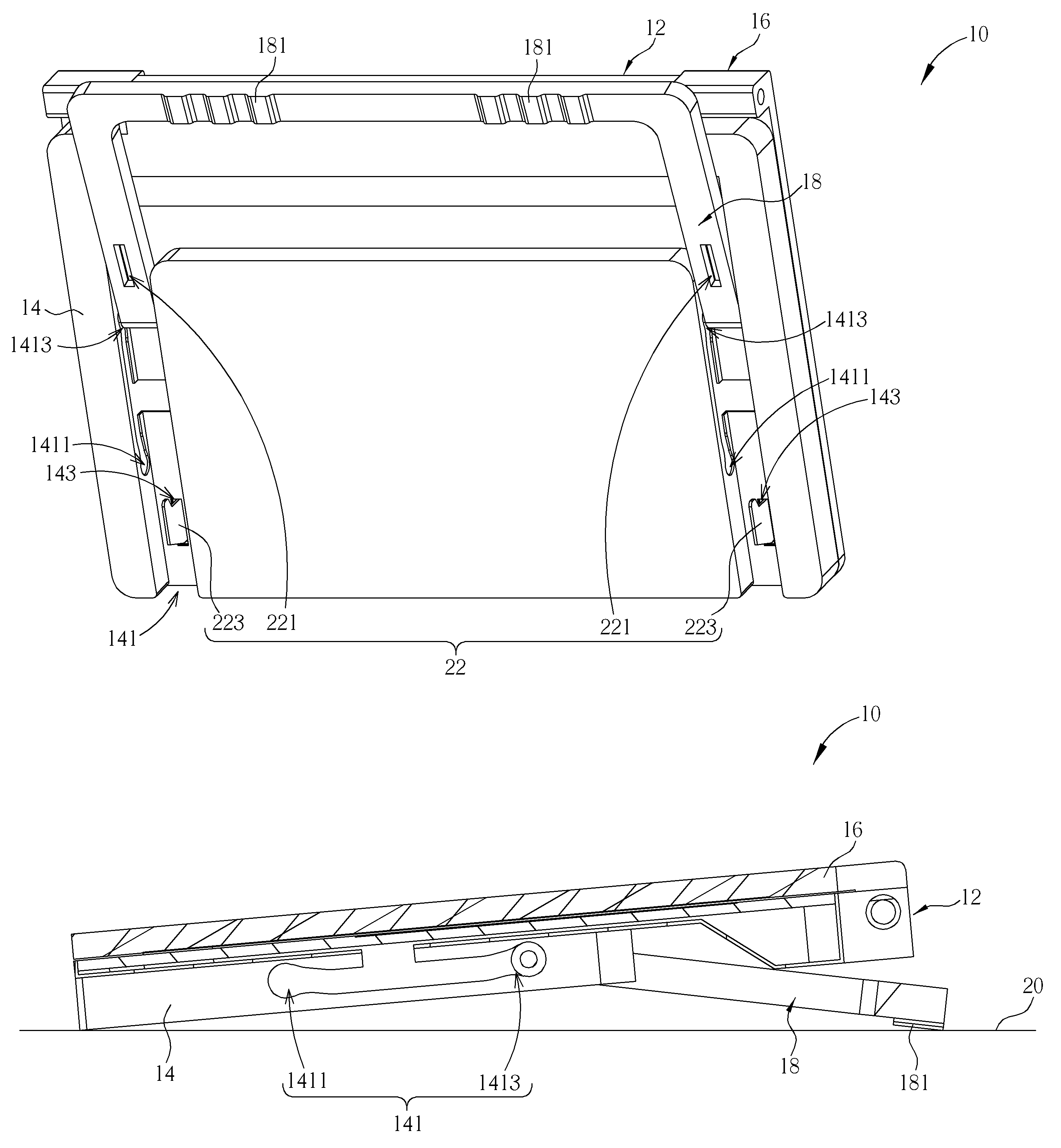

Foot cushion mechanism and electronic device therewith

ActiveUS20150016057A1DistanceIncrease distanceDetails for portable computersElectrical apparatus contructional detailsMemory effectFoot cushion

A foot cushion mechanism with lifting function is disclosed. The foot cushion mechanism includes a foot cushion member, a holding base and at least one shape memory material member. The foot cushion member is installed on a housing and abuts against a supporting surface. The holding base and the foot cushion member are respectively installed on opposite sides of the housing. The at least one shape memory material member selectively connects the housing and the holding base or connects the holding base and the foot cushion member. The at least one shape memory material member deforms when being heated due to a shape memory effect, and the housing is driven by the shape memory effect to move away from the foot cushion member such that a distance between the housing and the supporting surface is increased.

Owner:WISTRON CORP

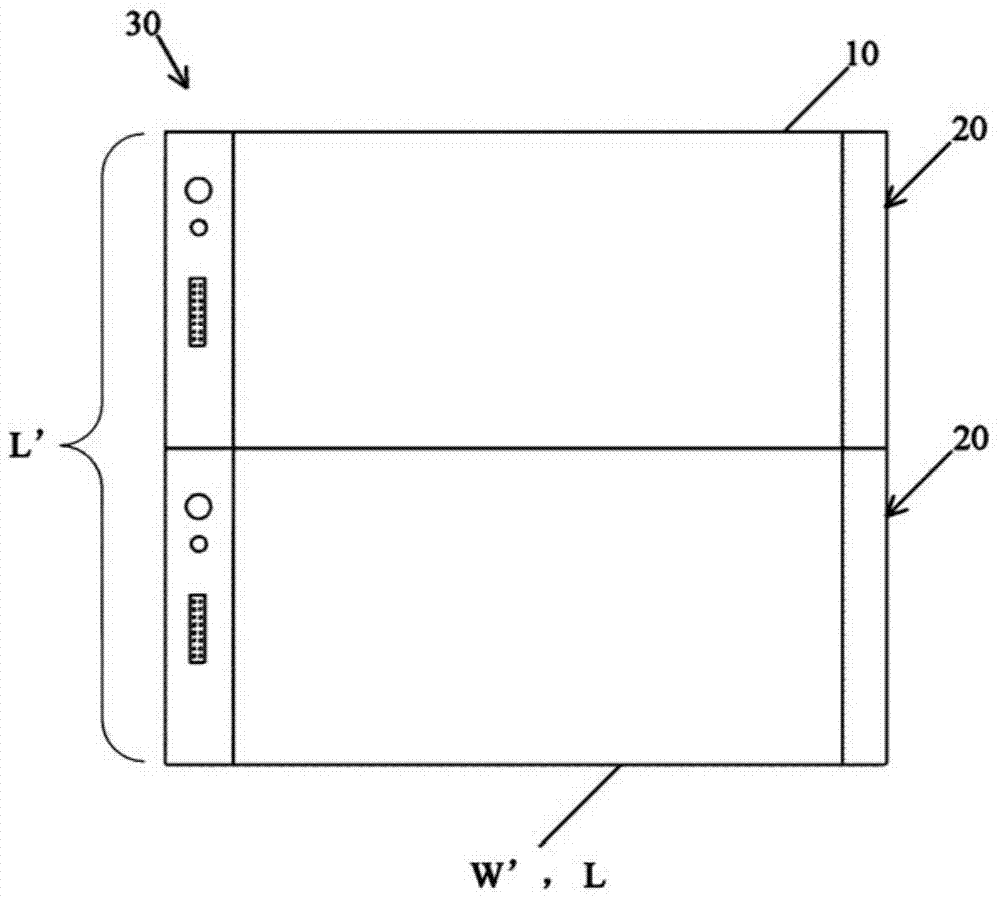

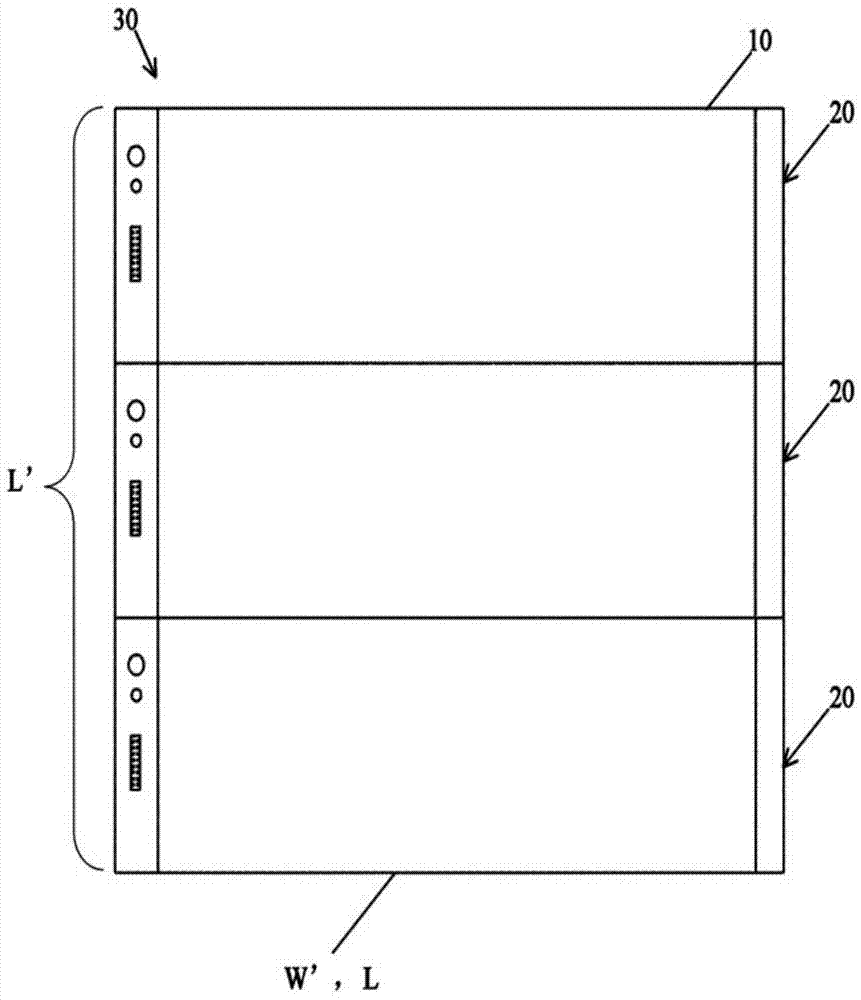

Mobile terminal and combined terminal device

ActiveCN104717330ARemove black borderKeep the feelTelephone set constructionsEngineeringTerminal server

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +1

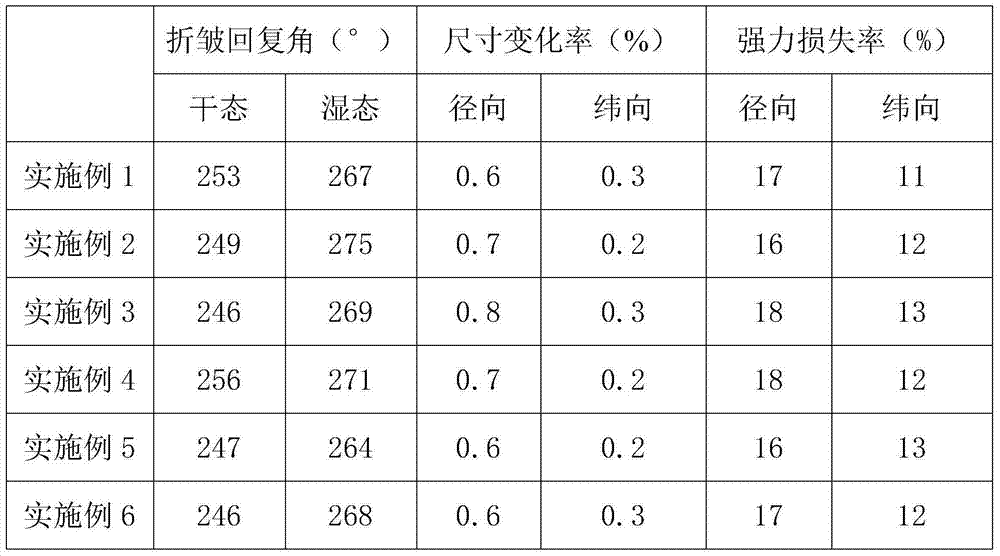

Soybean fiber fabric lousiness-pilling-resistance finishing method

InactiveCN1776085AImproved anti-pilling propertiesIncreased durabilityFibre treatmentFiberMethacrylate

This invention discloses a fuzzing-pilling resisting finishing method for soybean fiber fabric. It makes grafting modification to soybean fiber fabric, finishes by resin finishing agent. The monomer for grafting modification is diacritic acid or methacrylate of diatomic alcohol or with other active group, the finishing agent is organic silicon modified polyacrylate dispersion or modified polyurethane like finishing agent. Said invention has fine washing resistance and no formaldehyde in process agent.

Owner:SUZHOU UNIV

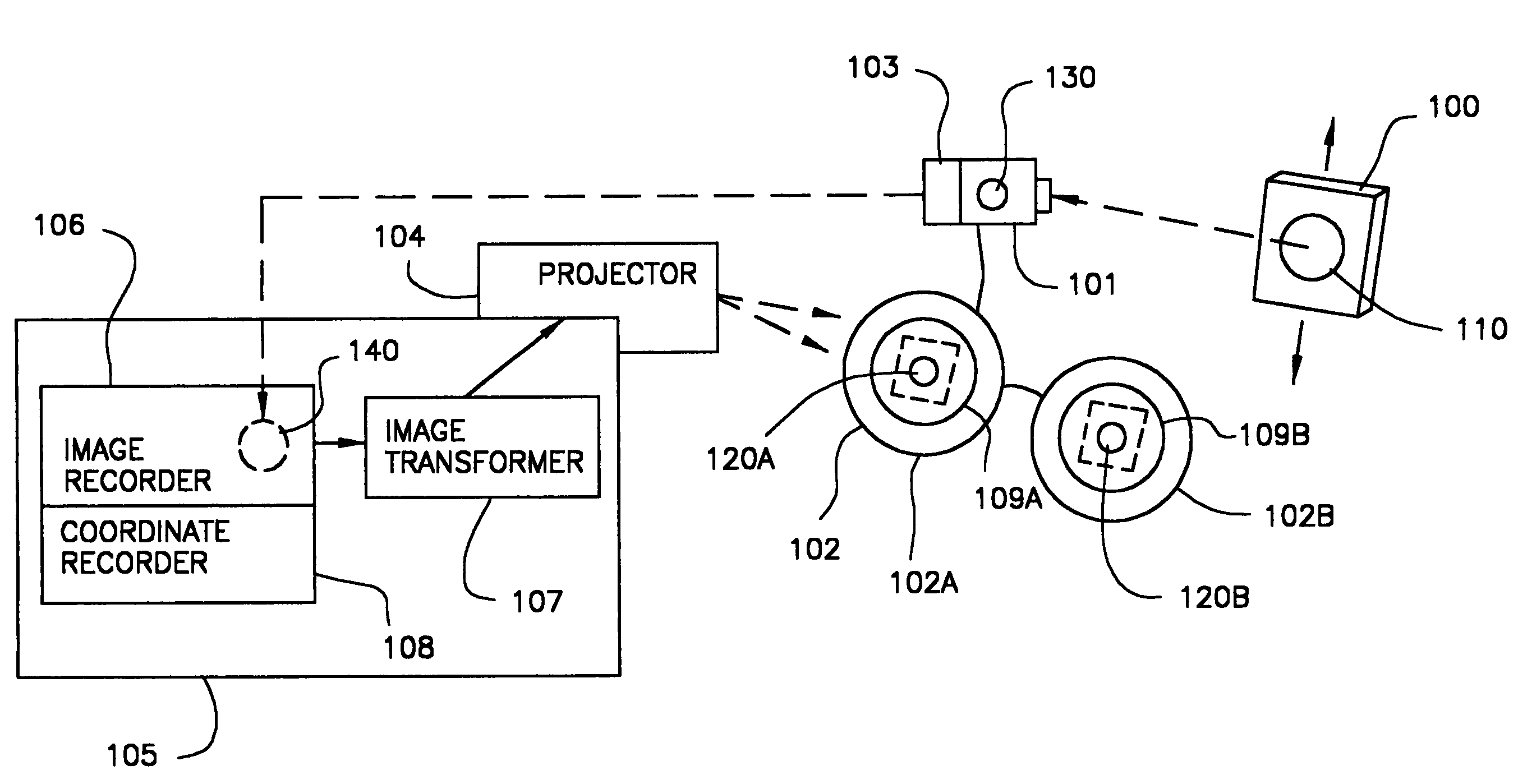

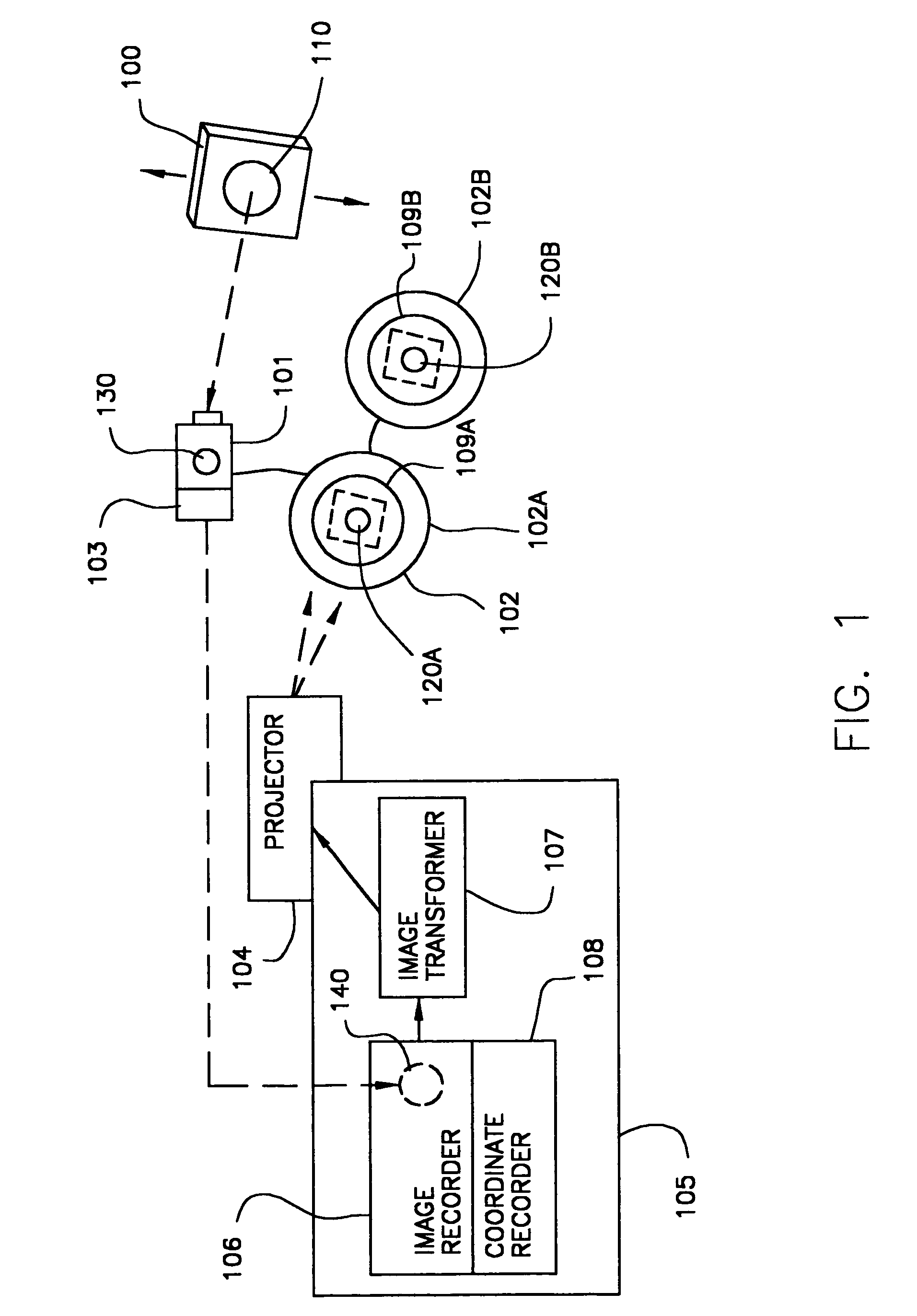

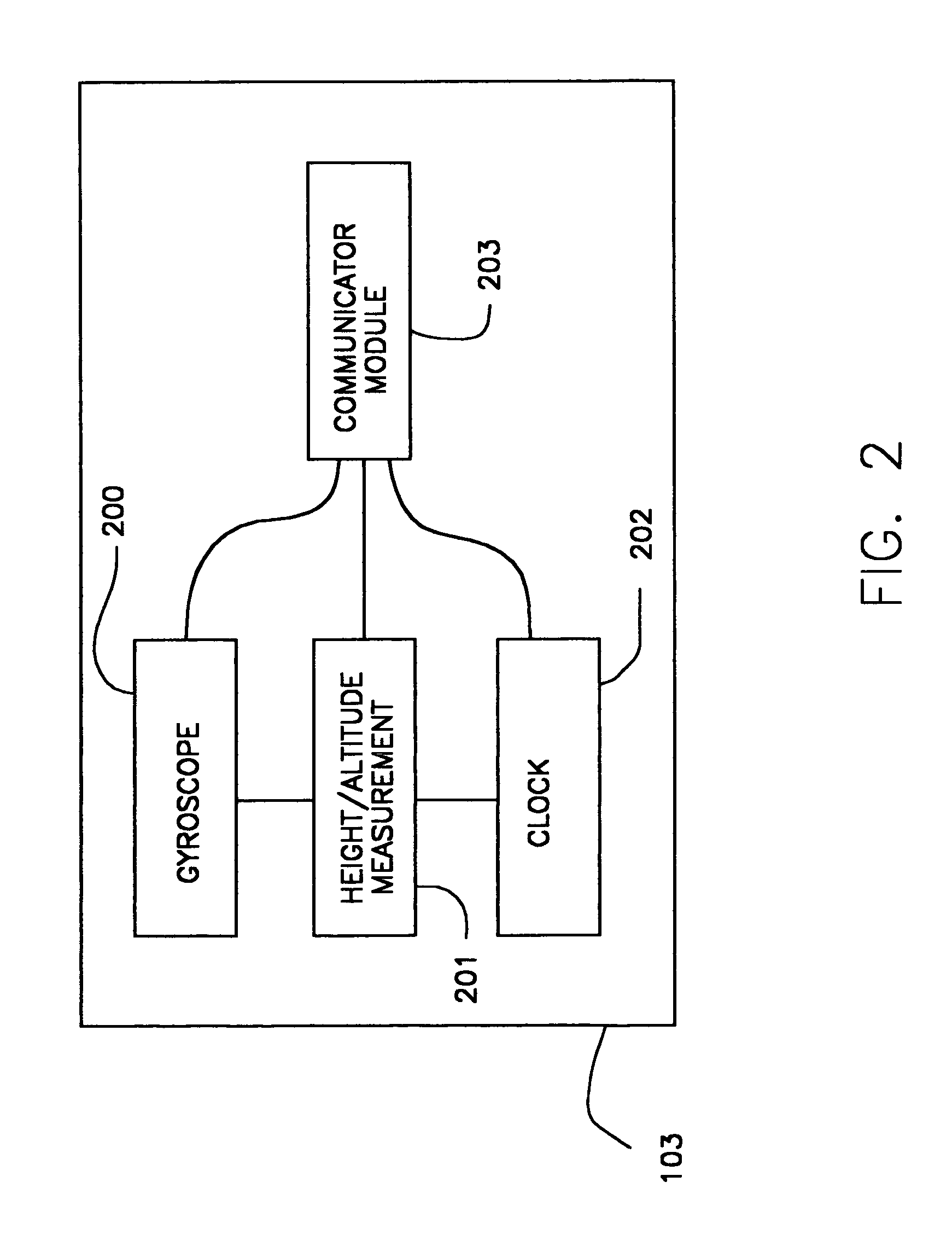

Method, apparatus and program storage device for image position stabilizer

ActiveUS7474335B2Without getting sick or frustratedKeep the feelTelevision system detailsColor television detailsDiseaseComputer graphics (images)

Apparatus, and associated methods, for stabilizing an image. The apparatus includes an aiming device to be aimed at a moving image, a transforming device which transforms the image into a non-moving image; and a displaying device which displays the non-moving image. The apparatus and methods are of particular benefit, for example, to individuals with Parkinson's disease and / or individuals attempting to work on a laptop computer or read a book while travelling via airplane, boat, train or road vehicle.

Owner:HULU

Noniron finishing method of silk fabric

InactiveCN104762821AGood shrink resistanceGuaranteed feelBiochemical fibre treatmentAnimal fibresWarm waterEngineering

The invention discloses a noniron finishing method of a silk fabric. The noniron finishing method particularly comprises the following steps: moistening and rinsing the silk fabric with warm water twice, refining and expanding the silk fabric by using a biological enzyme, after rinsing with warm water, padding the expanded silk fabric in a wash and wear finisher containing silk fibroin, citric acid and chitosan quaternary ammonium salt, then predrying the silk fabric, tentering at constant temperature, baking at high temperature, washing with water and drying, and pressing-packaging to obtain the noniron finished silk fabric. According to the noniron finishing method, a biological enzyme technology is combined with a padding technology, the silk fabric is subjected to noniron finishing by using the silk fibroin, the citric acid and the chitosan quaternary ammonium salt, so that the noniron finishing method has the advantages of simple and effective, environmental-friendly and biological effects. The silk fabric prepared by adopting the noniron finishing method reaches a noniron degree, and has a good crease-resisting and deformation-resisting capabilities; the dyeing performance of the fabric is improved; the handfeel, the style and the mechanical property of the fabric are reserved, and thus the noniron finishing method is an ideal noniron finishing method of the silk fabric.

Owner:SUZHOU WILDER IND & TRADE

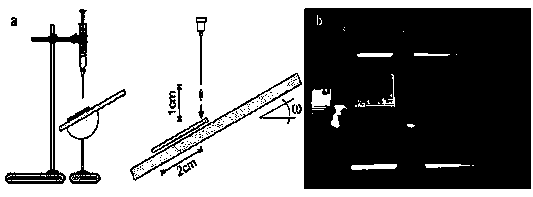

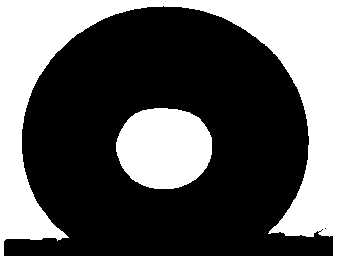

Preparation and application of organic silicon polymer super-hydrophobic textile finishing agent

InactiveCN109518468AEasy to prepareSimple preparation processLiquid repellent fibresGrip property fibresFiberPolymer science

The invention discloses an organic silicon polymer super-hydrophobic textile finishing agent. The organic silicon polymer super-hydrophobic textile finishing agent is prepared by adding organic silicon and organic silane into an alkaline alcohol-water solution and carrying out hydrolytic condensation. The organic silicon polymer super-hydrophobic textile finishing agent contains a hydrophobic group and a coupling group; and in dip-coating and high-temperature curing processes, the coupling group can be chemically bonded with fibers of a textile and the hydrophobic group has a super-hydrophobiceffect. The textile is dipped and coated in an organic silicon textile finishing agent solution which is diluted for 5 to 10 times for 2 to 10min and then is cured at 80 to 180 DEG C for 2 to 10min to obtain the super-hydrophobic textile. The super-hydrophobic textile disclosed by the invention has the advantages of excellent super-hydrophobic performance, washing resistance and the like and canbe used for constructing various super-hydrophobic textiles; and the textile does not need to be pre-treated, so that a preparation technology is extremely simplified, and properties including intrinsic mechanical strength, flexibility, luster, hand feeling and the like are kept.

Owner:山东鑫纳超疏新材料有限公司 +1

Antistatic agent for silk fabrics

The invention discloses an antistatic agent for silk fabrics. The antistatic agent comprises, by weight, 56 parts of dimetyl terephthalate, 18 parts of phenol, 50 parts of maleic anhydride, 16 parts of tetrabutyl titanate, 22 parts of glycol, 18 parts of tetrabutyl titanate, 18 parts of cyclohexanone, 10 parts of powdered steatile and 12 parts of zinc acetate. The product prepared by the invention has a simple production technology and low production cost; silk fabrics treated by the antistatic agent can keep original flexibility and handle, has good antistatic effect and is water washing resistant, safe and harmless.

Owner:SUZHOU KAQITE TEXTILE

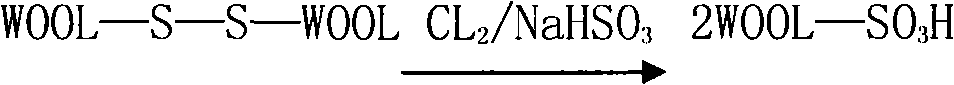

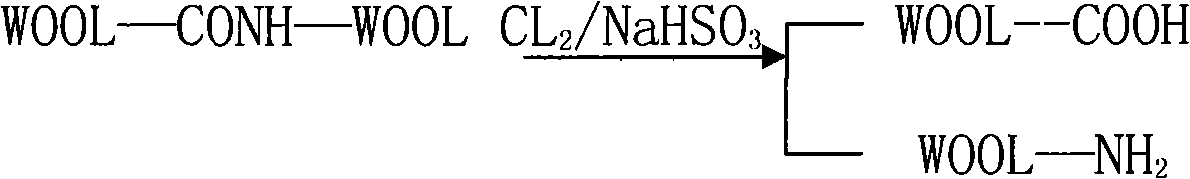

Preparation method of vintage woolen fabric and clothes

InactiveCN101642290AKeep the feelMaintain propertiesSucessive textile treatmentsBiochemical fibre treatmentWoolDyeing

The invention relates to a preparation method of vintage woolen fabric and clothes. A top dyeing product comprises the following processing steps: top dyeing, spinning, weaving, fabric preliminary finishing, chlorination pretreatment, clothes making, clothes washing, clothes pressing and finished product obtaining, or a piece dyeing product comprises the following processing steps: grey fabric prewashing, chloridization treatment, dyeing, drying, clothes making, clothes washing, clothes pressing and finished product obtaining, or garment dyeing comprises the following processing steps: grey fabric clothes making-chloridization treatment, clothes dyeing, clothes washing, clothes pressing and finished product obtaining. The invention has the advantages that woolen fabrics have a vintage effect after being washed and the original hand feeling is kept.

Owner:JIANGSU SUNSHINE +1

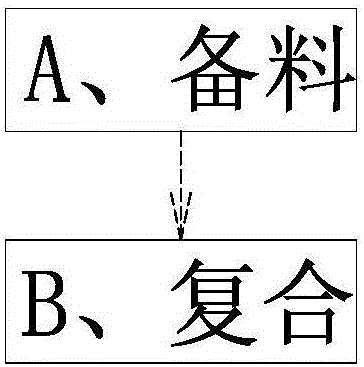

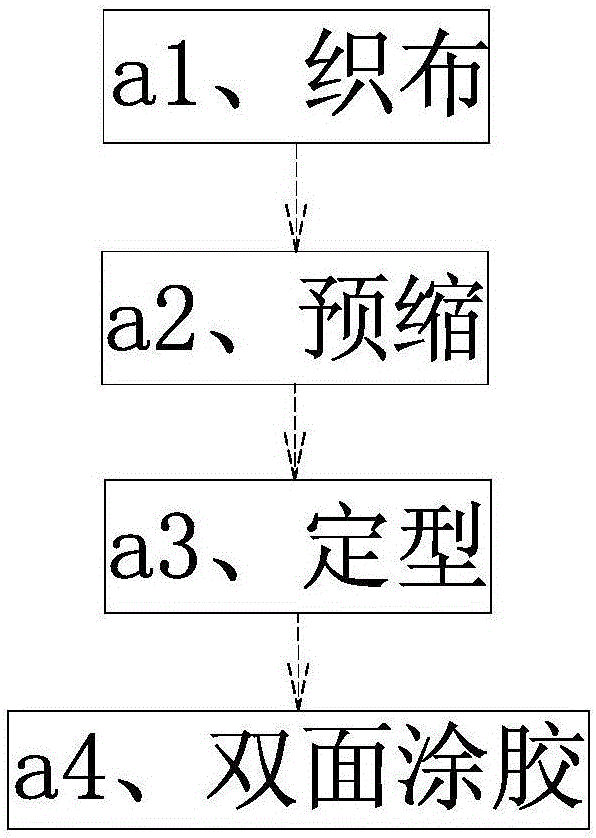

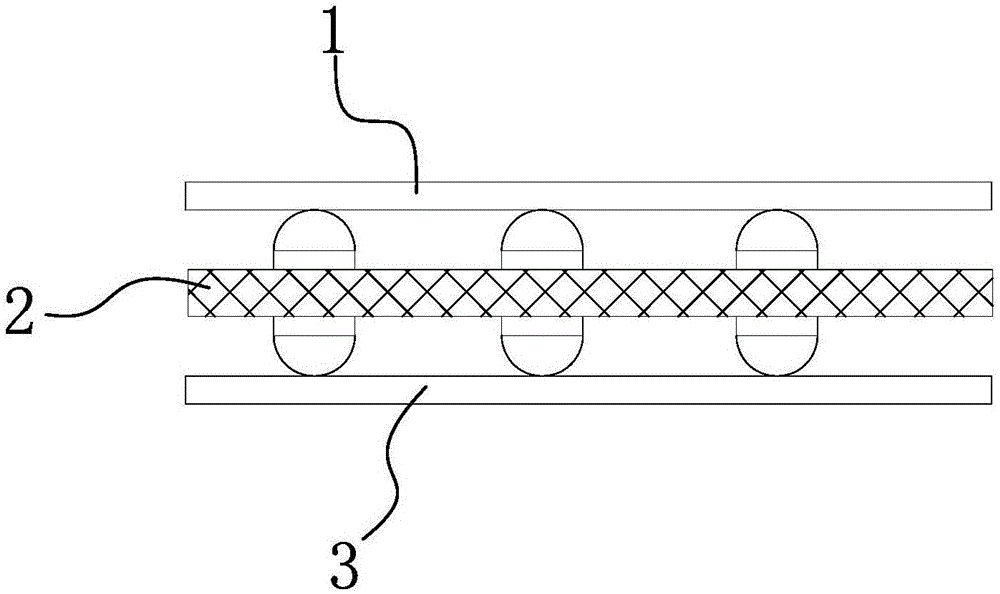

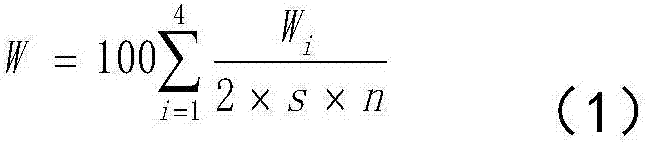

Three-layer composite two-sided knitted fabric and production process thereof

ActiveCN106218055AComposite process is simpleIncrease elasticitySynthetic resin layered productsCellulosic plastic layered productsMaterials preparationEngineering

The invention belongs to the technical field of garment fabrics, and particularly relates a three-layer composite two-sided knitted fabric and a production process thereof. The three-layer composite two-sided knitted fabric and the production process solve the problems of high plate hardness, low elasticity and the like in the prior art. The production process of the three-layer composite two-sided knitted fabric comprises the following steps of A, material preparation and B, compounding. The three-layer composite two-sided knitted fabric is processed and formed by the production process. The three-layer composite two-sided knitted fabric and the production process have the advantages that the process is simple; the elasticity, the bulkiness and the softness of the product can be greatly improved.

Owner:CPL NEW MATERIAL TECH CO LTD

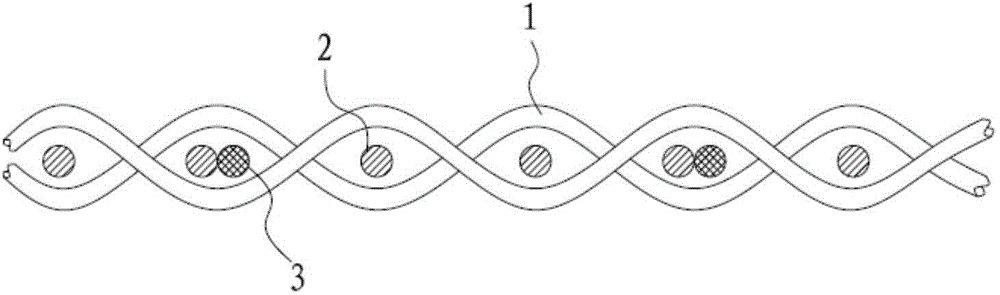

Polyester Chenille yarn and textile technology and application of polyester Chenille yarn

The invention provides a textile technology of polyester Chenille yarn. The textile technology comprises the steps that firstly, low-melting-point hot-melting binder fibers and polyester fibers are blended, and center yarn is prepared; secondly, decoration yarn is sandwiched between the center yarn for spinning through twisting, and a semi-finished product of the polyester Chenille yarn is obtained, wherein the decoration yarn is made of polyester fibers; thirdly, the semi-finished product of the polyester Chenille yarn is heated at the temperature of 0-200 DEGC, and the polyester Chenille yarn is obtained. According to the polyester Chenille yarn, the center yarn is prepared in the mode that the low-melting-point hot-melting binder fibers and the polyester fibers are blended, the polyester fibers are used as the decoration yarn, and after heat treatment, the low-melting-point hot-melting binder fiber skin layer is melted while the central layer is not changed, so that point-like bonding structures are formed between the fibers, the binding power of the fibers is increased, the slippage phenomena of the fibers are reduced, and the picking-resistant effect is good. The polyester Chenille fabric prepared from the yarn is not prone to picking, and the original hand feeling and style are maintained; meanwhile, the textile technology is simple and easy to implement, no auxiliary equipment is needed, and the cost is low.

Owner:三问家居股份有限公司

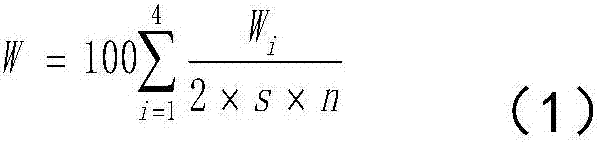

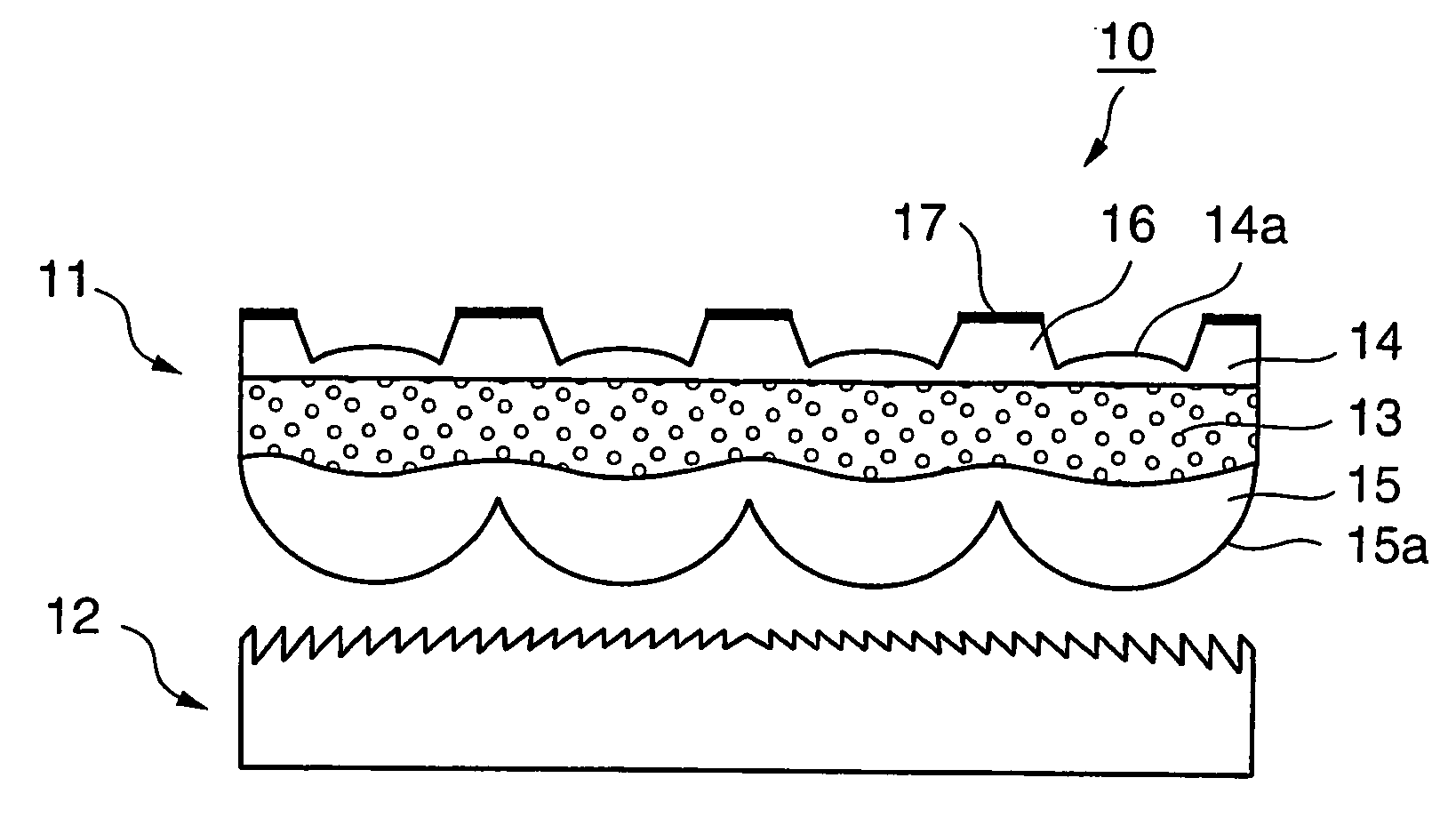

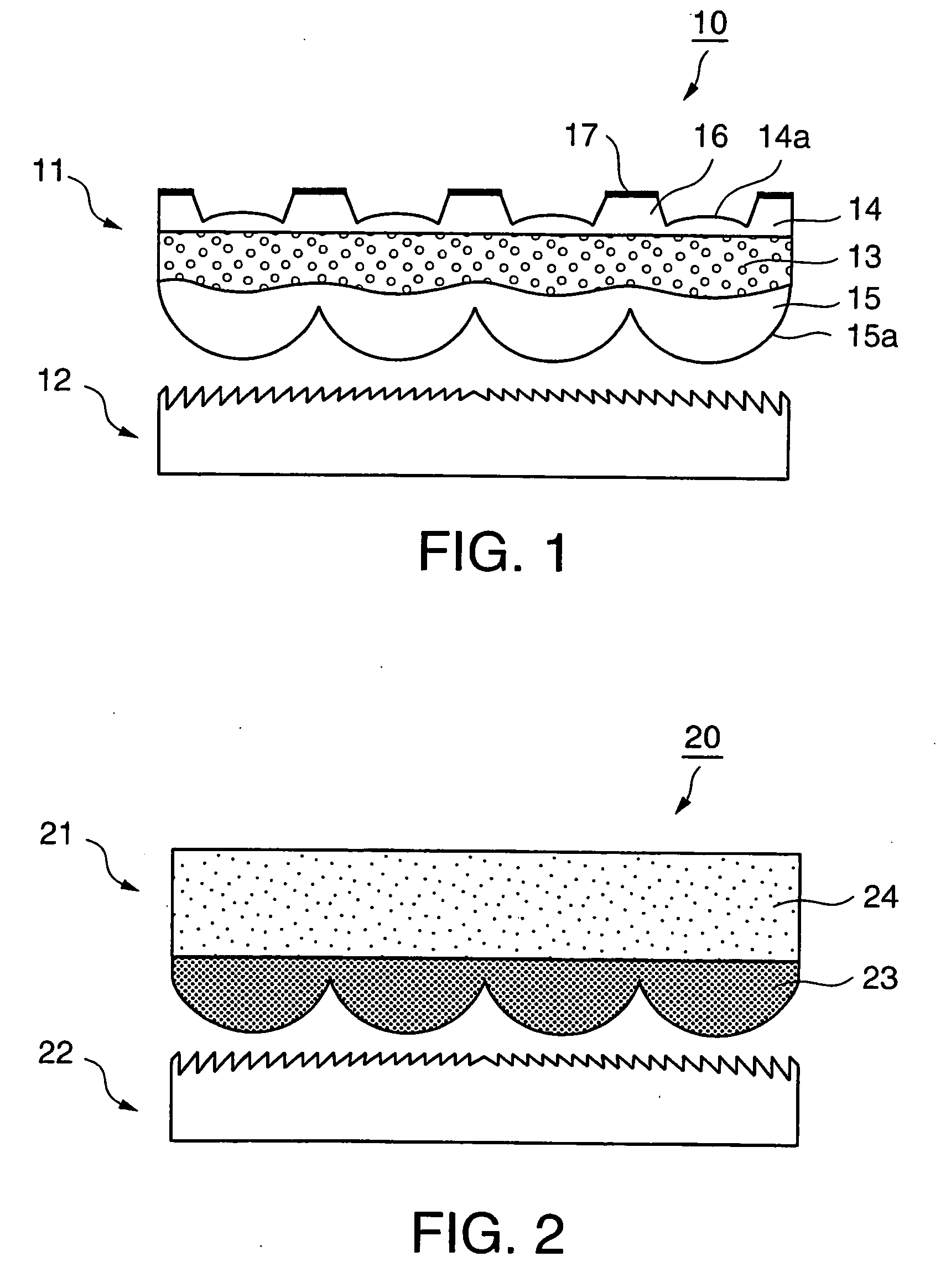

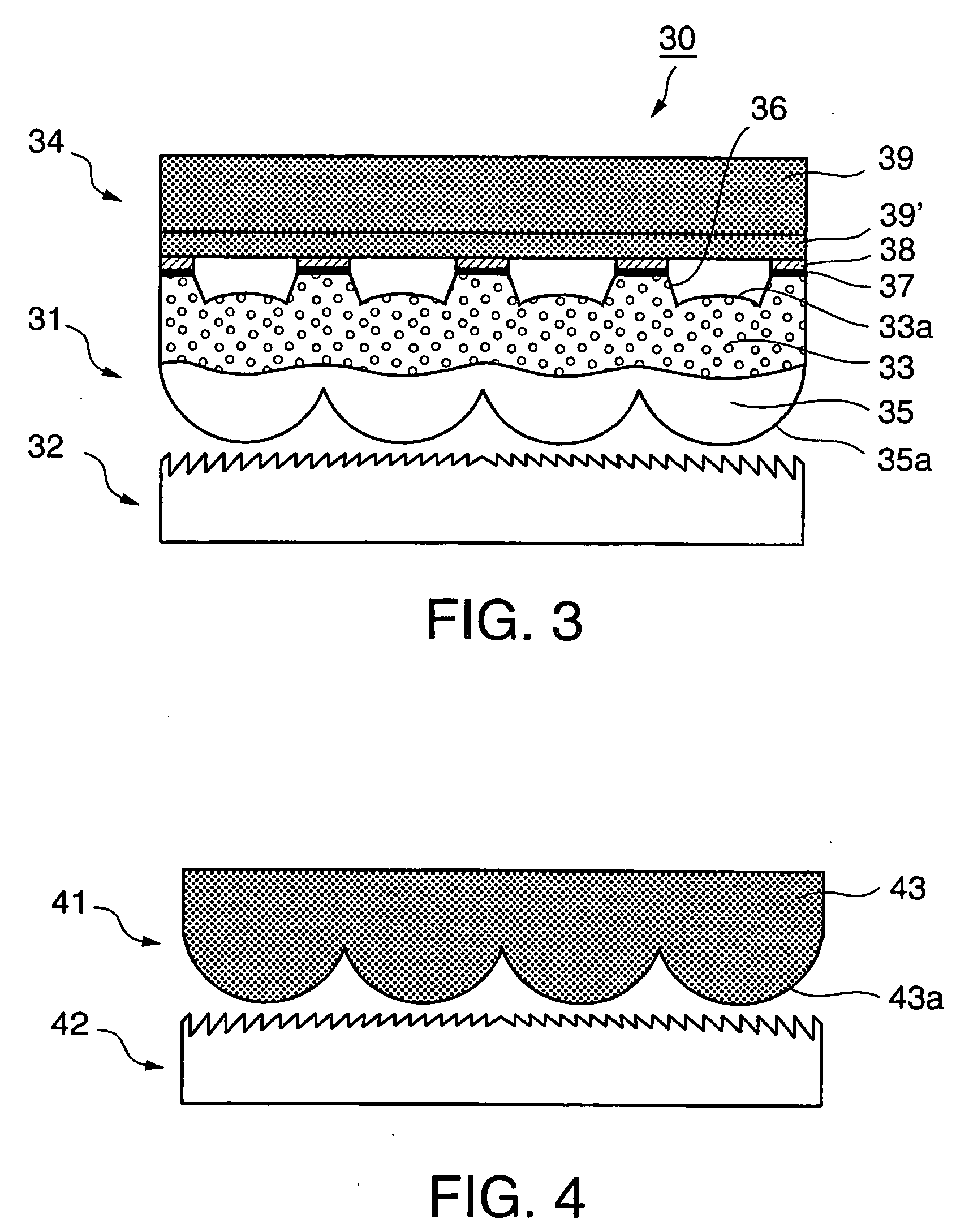

Transmission type screen

InactiveUS20060001975A1Prevent image degradationKeep the feelProjectorsLensFresnel lensImaging quality

There is provided a transmission type screen that can suppress deterioration of image quality due to glare distortion of external light and the like that occurs on a screen surface while keeping a feeling (a glossy feeling of an image) as if a CRT-TV is directly viewed. The transmission type screen 10 is arranged by combining a plurality of screen members (for example, a lenticular lens sheet 11 and a Fresnel lens sheet 12), which realize various optical functions such as transmission, diffusion, condensing and the like of light, with each other. A smooth surface having a surface roughness Ra of 0 μm≦Ra≦0.5 μm is formed on the viewer side surface of a nearest-to-viewer side screen member (for example, the lenticular lens sheet 11) of the plurality of screen members, as well as the amount of warping D of the nearest-to-viewer side screen member (for example, the lenticular lens sheet 11) is −10 mm≦D≦15 mm.

Owner:DAI NIPPON PRINTING CO LTD

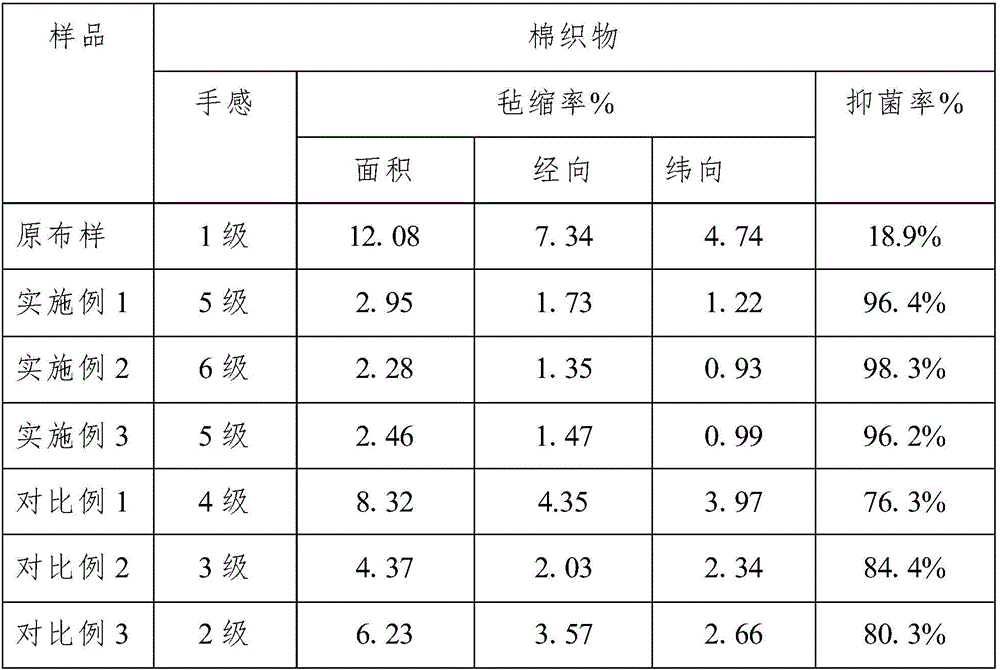

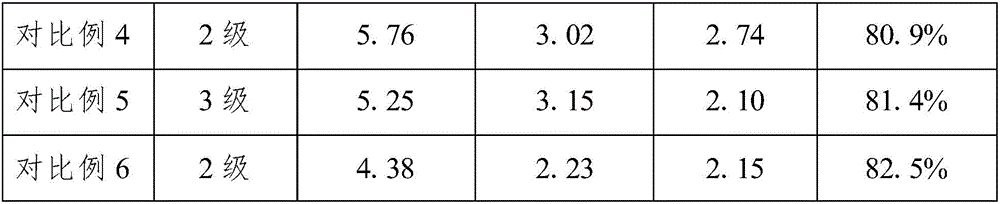

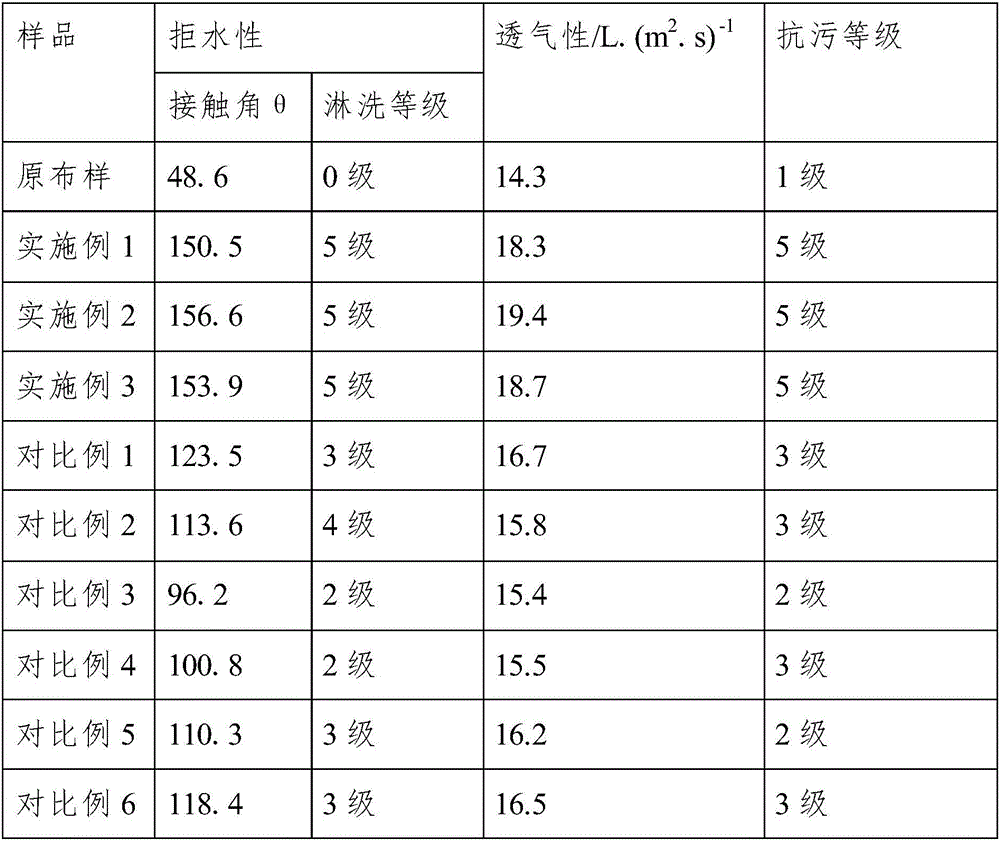

Fluoride-free water-repellent antifouling finishing agent and preparation method and application thereof

ActiveCN106012543AEasy to makeLow costStain/soil resistant fibresBiochemical fibre treatmentFluorideCHITOSAN OLIGOSACCHARIDE

The invention belongs to the field of textile finishing agents, and particularly relates to a fluoride-free water-repellent antifouling finishing agent and a preparation method and application thereof. The finishing agent comprises a system A and a system B, the weight ratio of the system A to the system B is 1:(0.6-0.8), the system A is prepared from 0.3%-3% of chitosan oligosaccharide, 1%-10% of waterborne polyurethane and the balance water, and the system B is modified nanosilicon dioxide sol. According to the fluoride-free water-repellent antifouling finishing agent, a textile finished through the finishing agent has the super-water-repellent and antifouling effects, meanwhile, the good hand feeling and breathability of the textile can be kept, the excellent antibacterial property and shrink-proofing property are achieved, and a preparation process of the finishing agent is easy to operate and suitable for application and popularization.

Owner:JIANGSU NEW REBA TECH CO LTD

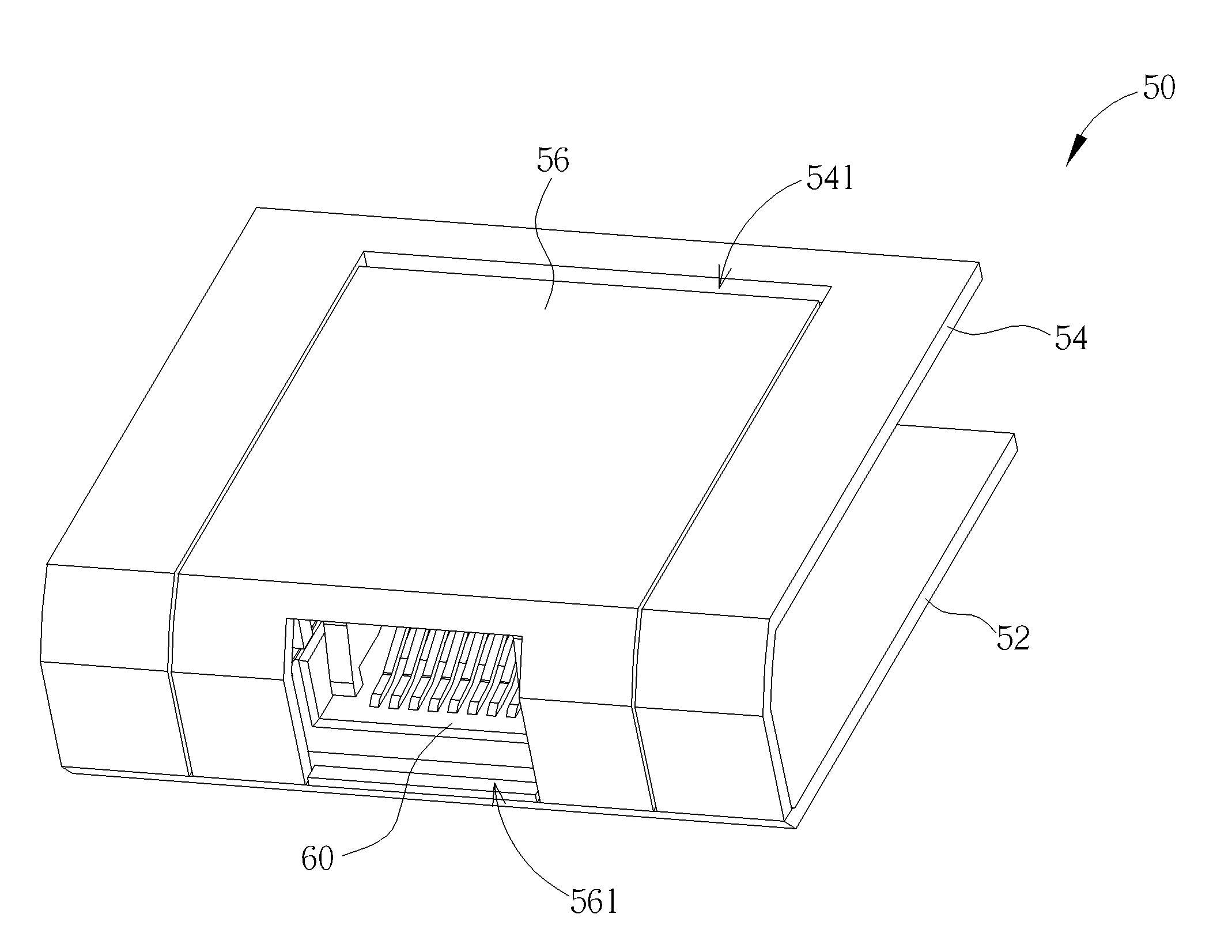

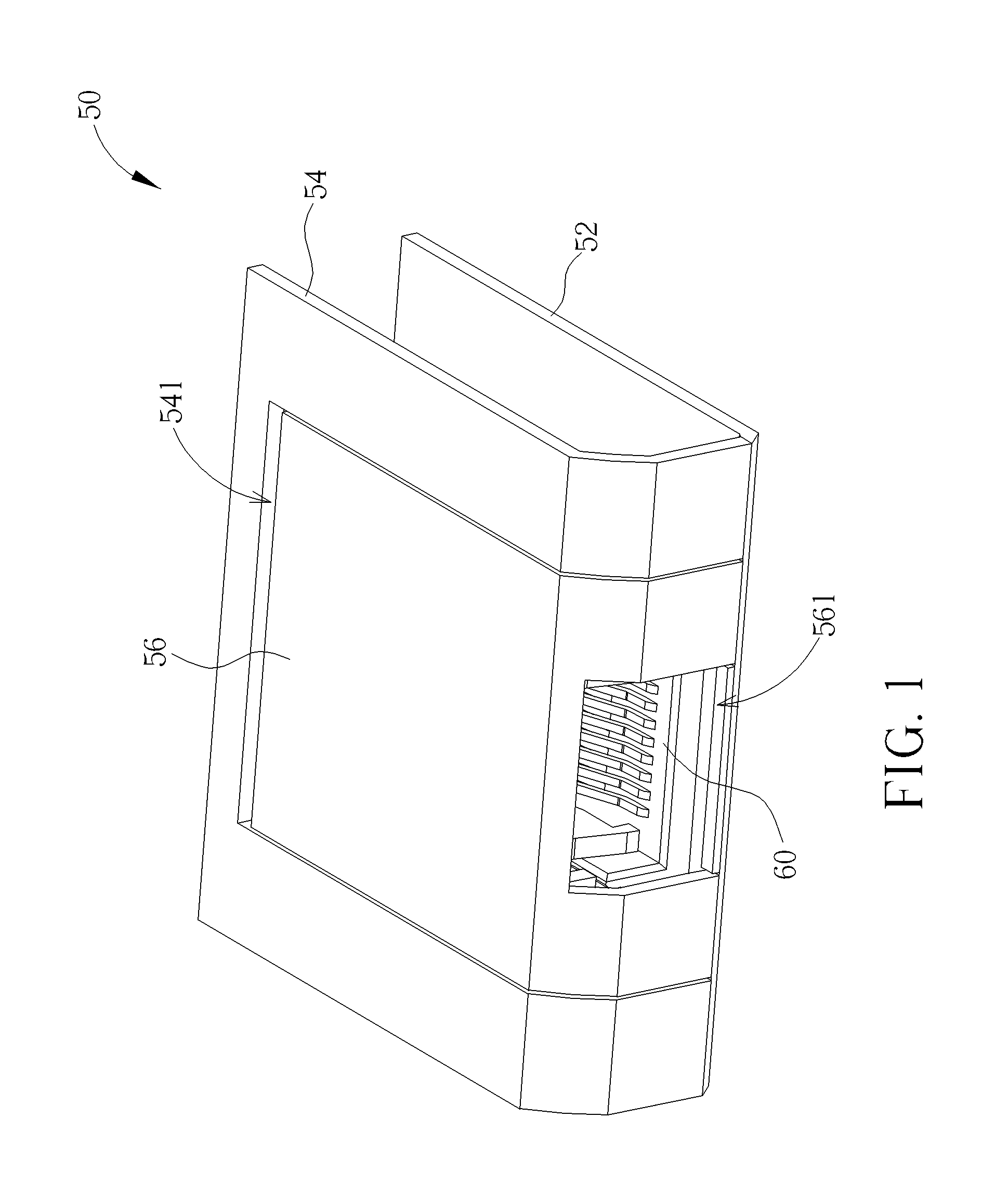

Connector mechanism

ActiveUS20130231010A1Avoid separationIncrease the height of the structureCoupling device detailsTwo-part coupling devicesEngineeringFastener

A connector mechanism includes a first casing, a second casing, a rotary cover, a circuit board, a socket, a base, a rotary fastener and a resilient component. The rotary cover is connected to the second casing in a rotable manner. The rotary fastener is pivoted to the base. The rotary fastener is pressed by the rotary cover when the rotary cover rotates to a close position. The rotary fastener fastens a plug when the rotary cover rotates to an open position so as not to press the rotary fastener and when the plug is inserted into the socket. The resilient component is connected to the rotary fastener for driving the rotary fastener to fasten the plug when the rotary cover rotates to the open position.

Owner:WISTRON CORP

Method for bleaching fibrous articles

InactiveCN1673443AAvoid embrittlementPrevent hardeningNon-surface-active detergent compositionsBleaching apparatusFiberOxidizing agent

In a method for bleaching fibrous articles by impregnating the fibrous articles with oxidizing or reducing agent solutions and irradiating the impregnated fibrous articles with ultraviolet or visible light, the oxidizing or reducing agent solutions are re-added one or more times to the fibrous articles while they are being irradiated with ultraviolet or visible light.

Owner:NAT INST OF ADVANCED IND SCI & TECH +1

Anti-static agent for cloth

The invention relates to an anti-static agent for cloth. The anti-static agent is prepared from the following raw materials including ethoxy alkylamine, polyethylene glycol diglycidyl ether, tetrabutyl titanate, surfactants, zinc acetate, glycol, glycerin, lauryl ether, octadecyl imidazoline, alkyl quaternary ammonium salts, isopropanol, linear alkylbenzene sulfonate, fatty alcohol-polyoxyethyleneether, sodium stearate, alkenyl sulphonate, white soap powder, phenol salicylate, epoxy resin, phenol, cyclohexanone, xylene and dibutyltin oxide. The anti-static agent has the beneficial effects that (1) the cost is low; a textile product can maintain the original flexibility and hand feeling after being treated by the anti-static agent; the anti-static effect is good; water washing resistance and heat resistance are good; meanwhile, meanwhile, the influence on the hand feel of the textile is small; no injury is caused on the skin; (2) the long-effect maintenance can be realized; the anti-static agent can be used for cloth and can also be widely applicable to various rubber and plastic products.

Owner:ANHUI HONGYUAN NONWOVEN FABRIC

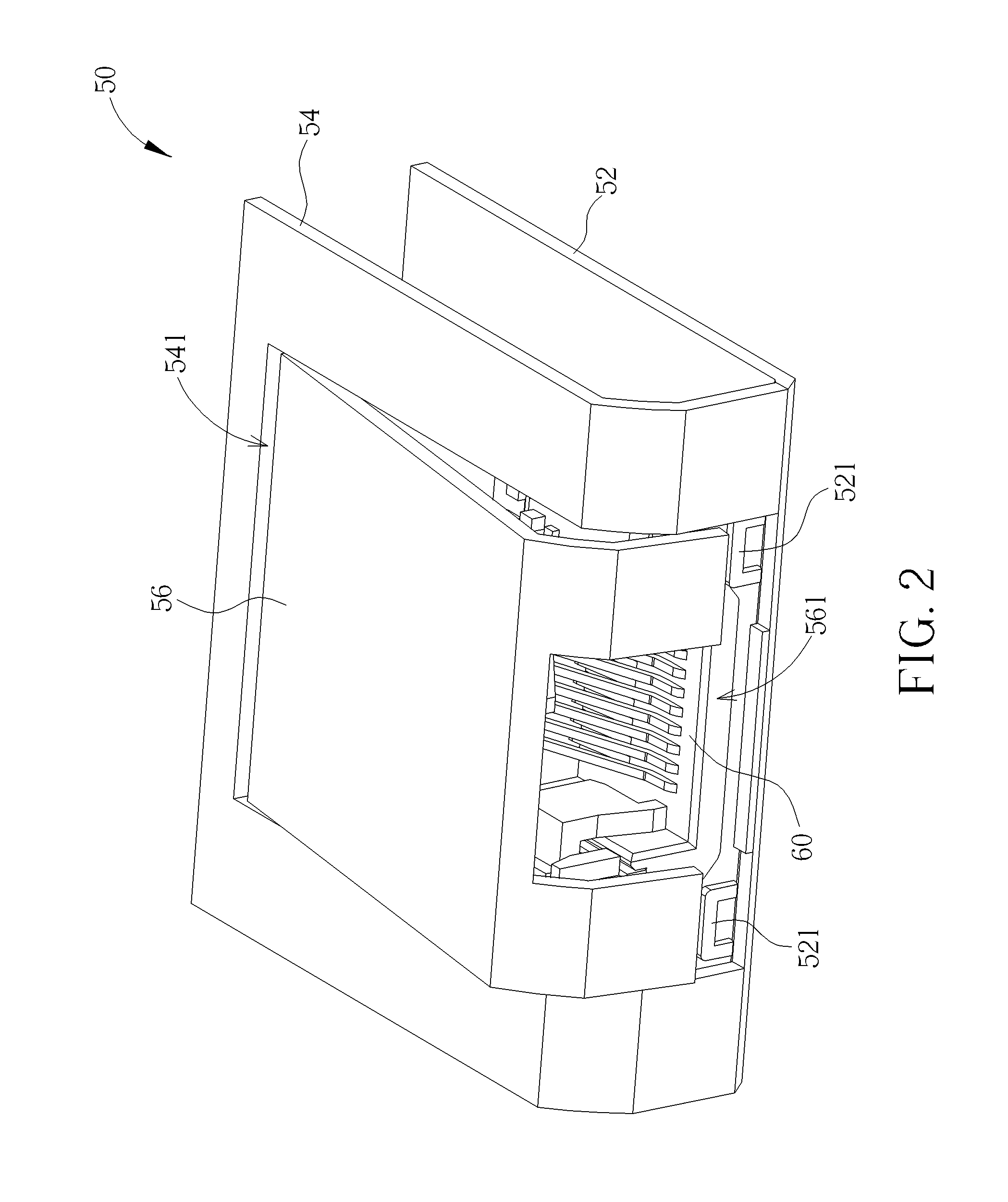

Portable computer with a heat dissipating stand

ActiveUS20120176742A1Reduce extra spaceKeep aesthetic feelingInput/output for user-computer interactionCathode-ray tube indicatorsComputer moduleComputer engineering

A portable computer includes a host module having a host housing. A slot is formed on the host housing, and the slot includes a first fixing end and a second fixing end. The portable computer further includes a display module pivoted to the host module, and a heat dissipating stand installed inside the slot on the host housing in a slidable manner. When an end of the heat dissipating stand is fixed on the first fixing end of the slot, the heat dissipating stand is contained inside the slot completely. When the end of the heat dissipating stand is fixed on the second fixing end of the slot, the other end of the heat dissipating stand protrudes out of the slot and is disposed under the host housing so as to lift the host module.

Owner:WISTRON CORP

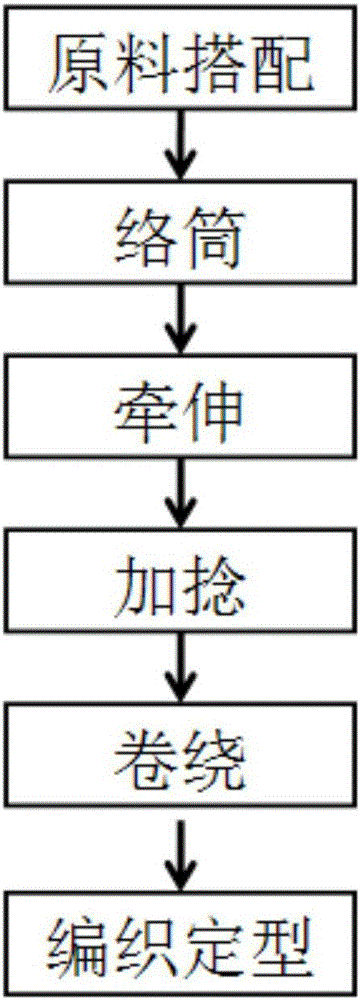

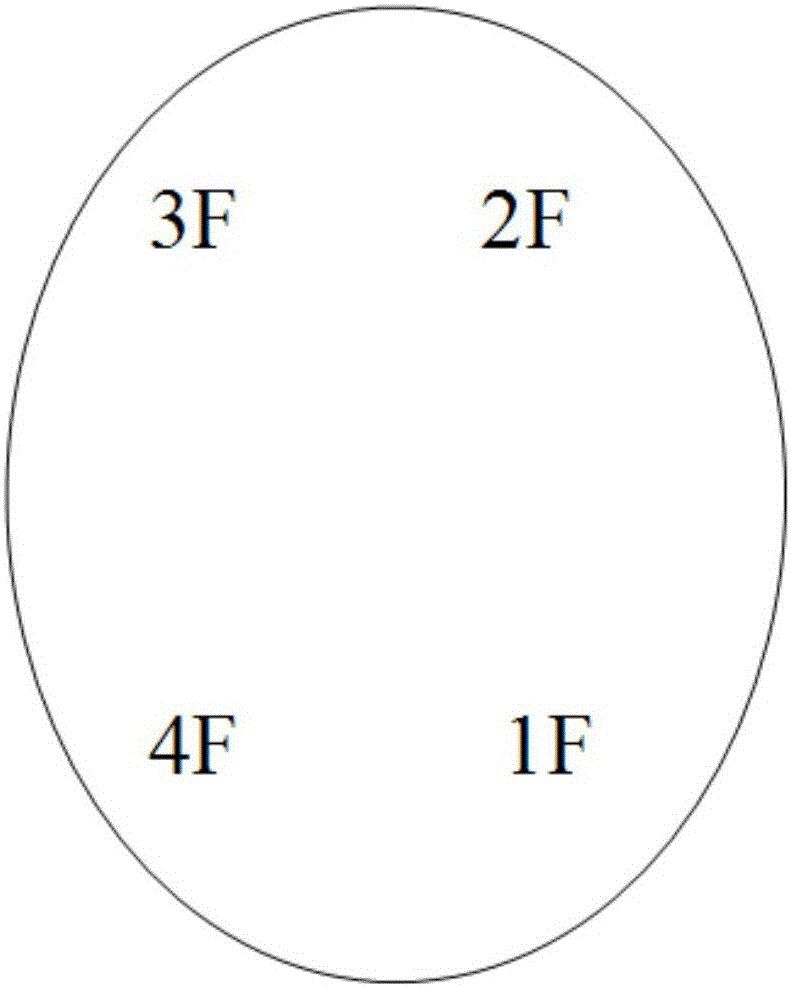

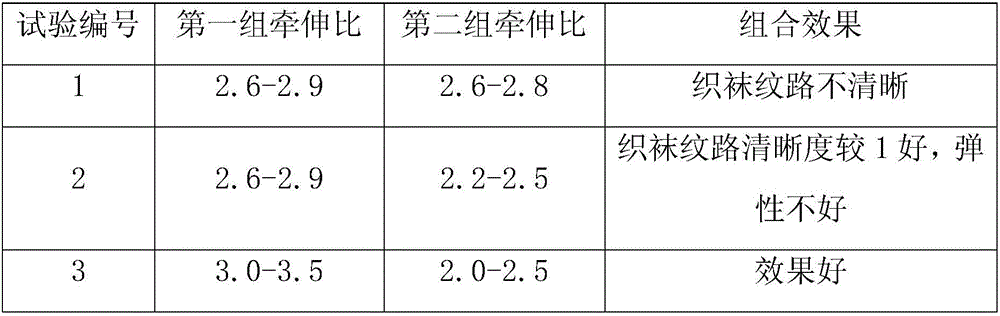

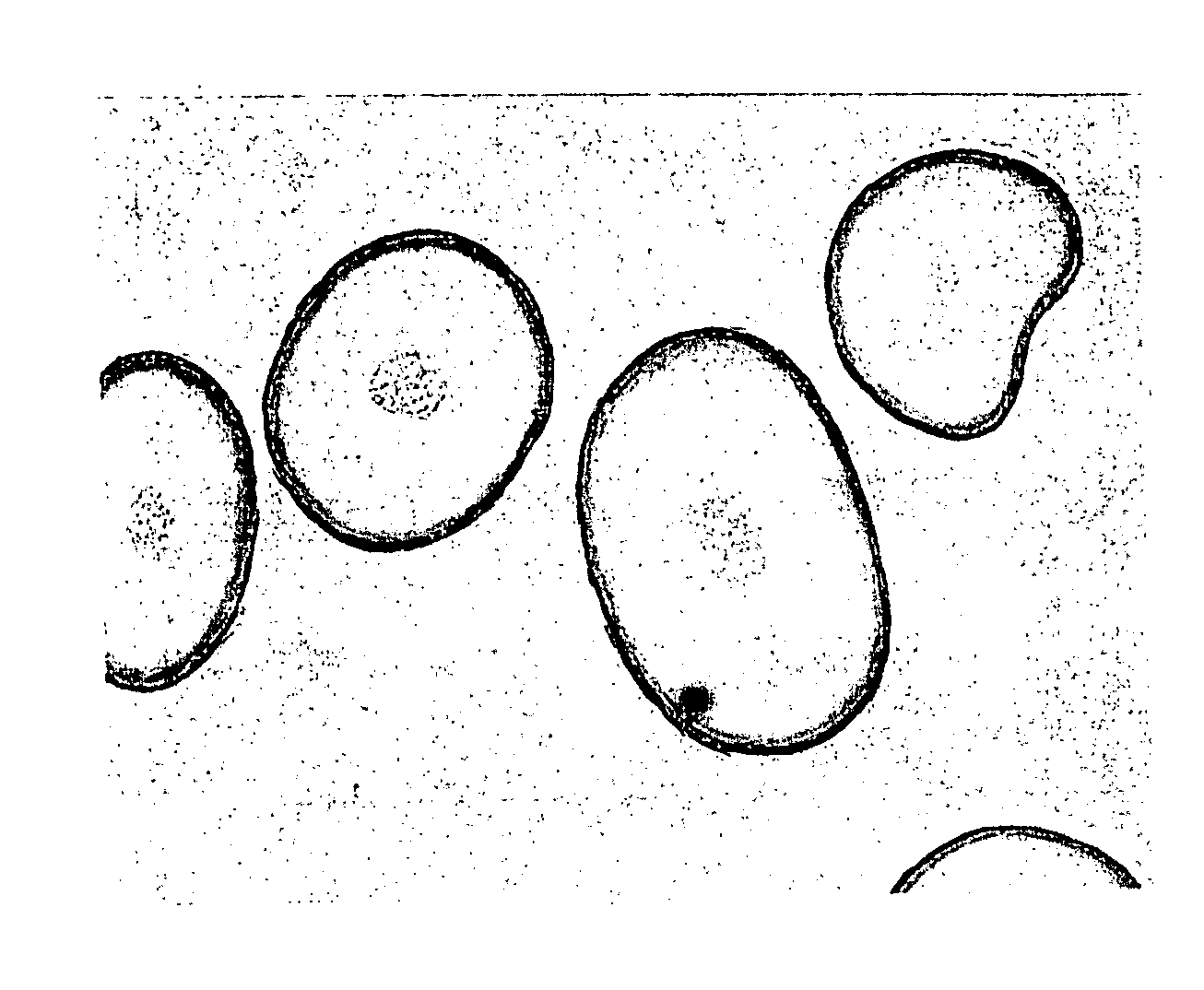

Production technology of uniformly-knitted transparent four-way silk stocking wrapping yarn

ActiveCN106120066AHighlight strong and weak collocationImprove uniformityDrafting machinesDyeing processYarnManufacturing technology

The invention discloses a production technology of uniformly-knitted transparent four-way silk stocking wrapping yarn. Silk stockings are matched with wrapping yarn of two different raw materials and technologies. The silk stocking manufacturing technology sequentially comprises raw material matching, spooling, drafting, twisting, winding, knitting and forming. According to the raw material matching step, the method for matching spandex of different thicknesses, the uniformity of silk stockings can be improved, and the silk stocking clarity can be improved; according to the drafting step, thick spandex high drafting and thin spandex low drafting are matched to be adopted as raw materials, the high and low strength matching of the two materials is obvious due to the matching of the two technologies, and the knitted silk stockings can achieve the best effect.

Owner:LUSHAN HUAMEI COVERED YARN CO LTD

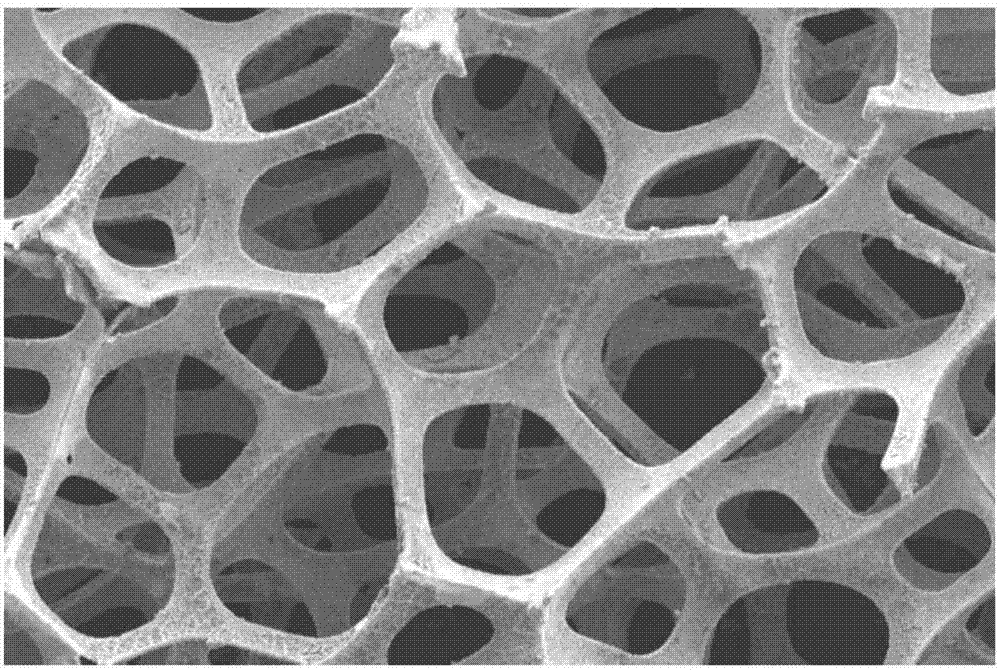

Hard and soft integrated electronic product shell and preparation method thereof

ActiveCN106879197AImprove bindingNot easy to disengageClosed casingsDomestic articlesElastomerPolymer science

The invention provides a hard and soft integrated electronic product shell, comprising a rigid part formed by foamed metal and a flexible part formed by a polymer elastomer, wherein the foamed metal is fixedly connected with the polymer elastomer. According to the electronic product shell provided by the invention, a rigid framework is provided by using the foamed metal, and excellent rigidity can be achieved; and meanwhile, the polymer elastomer and the foamed metal are fixedly connected and are inserted to each other to form the locking force, and thus the metal and the elastomer are combined very firmly and cannot easily disconnect; and moreover, the appearance of the shell can be an integrated elastomer, and thus the consistency between the appearance effect and the hand feeling can be maintained.

Owner:LENOVO (BEIJING) CO LTD

Pretreatment agents for acidic hair dyes

InactiveUS7037347B2Improve abilitiesImprove fastnessCosmetic preparationsHair removalHair dyesCationic polymerization

Pretreatment agents for hair colorings with acid dye comprising at least one cationic polymer selected from the group consisting of polymers having amino groups and polymers having quaternary ammonium groups. The pretreatment agents for hair colorings with acid dye are used for improving coloring ability and color fastness of hair colorings with acid dye.

Owner:MANDOM CORP

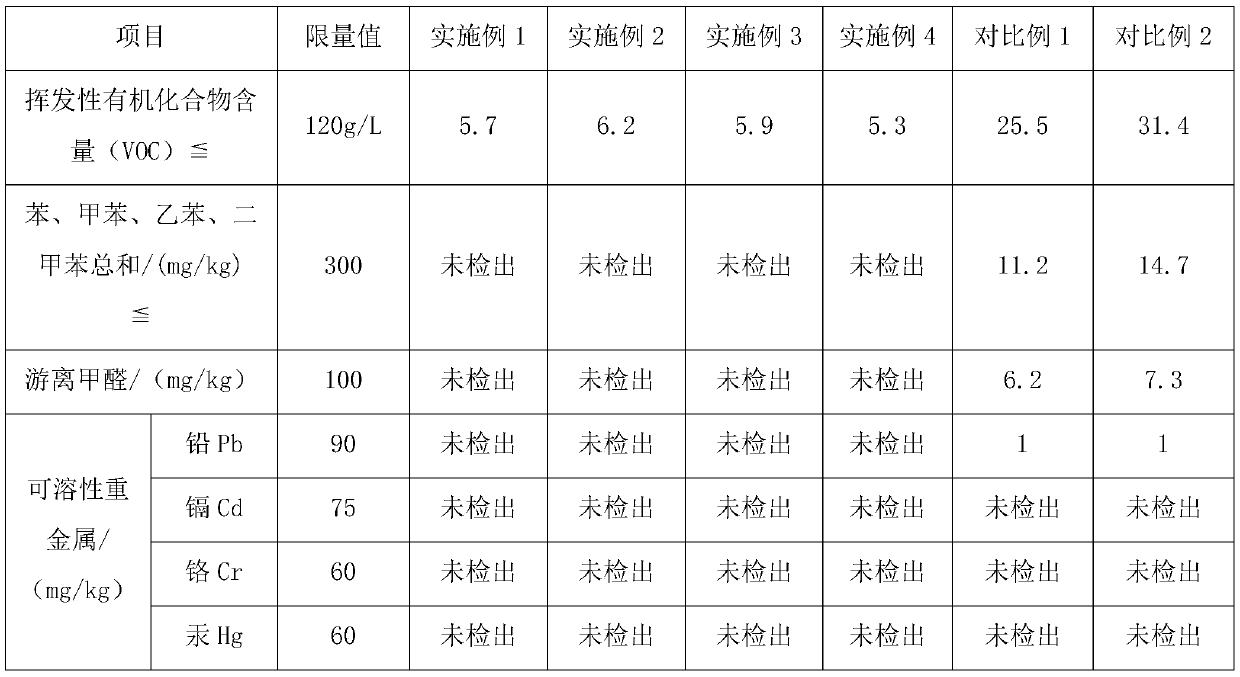

Finish coat and preparation method thereof

InactiveCN110128888AEquivalent performancePromote environmental protectionAntifouling/underwater paintsPaints with biocidesCelluloseEmulsion

The invention relates to the technical field of coatings, in particular to a finishing coat and a preparation method thereof. The finishing coat comprises the following raw materials in parts by weight: 15-20 parts of film-forming emulsion, 0.8-1.2 parts of film-forming auxiliary agent, 5-10 parts of hydrophobic agent, 1.5-2.3 parts of cellulose ether thickening agent, 0.2-0.8 part of preservativeand 60-80 parts of water, wherein the hydrophobic agent is hydrophobic agent LC-808 produced by Shandong Lugong. The finish paint has good waterproof, stain-proof, waterproof and other properties, can be used for repairing wall surfaces and protecting paints such as true stone paint, and has better environmental protection.

Owner:河南方众环保科技有限公司

Portable computer with a heat dissipating stand

ActiveUS8508938B2Keep the feelEnhanced convectionInput/output for user-computer interactionCathode-ray tube indicatorsComputer moduleComputer engineering

Owner:WISTRON CORP

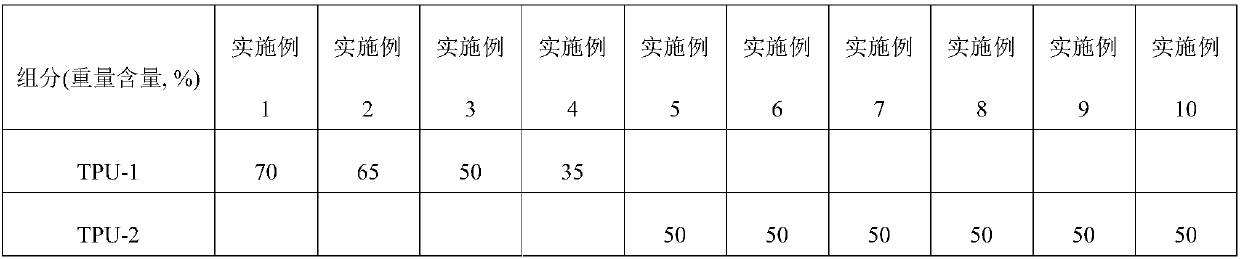

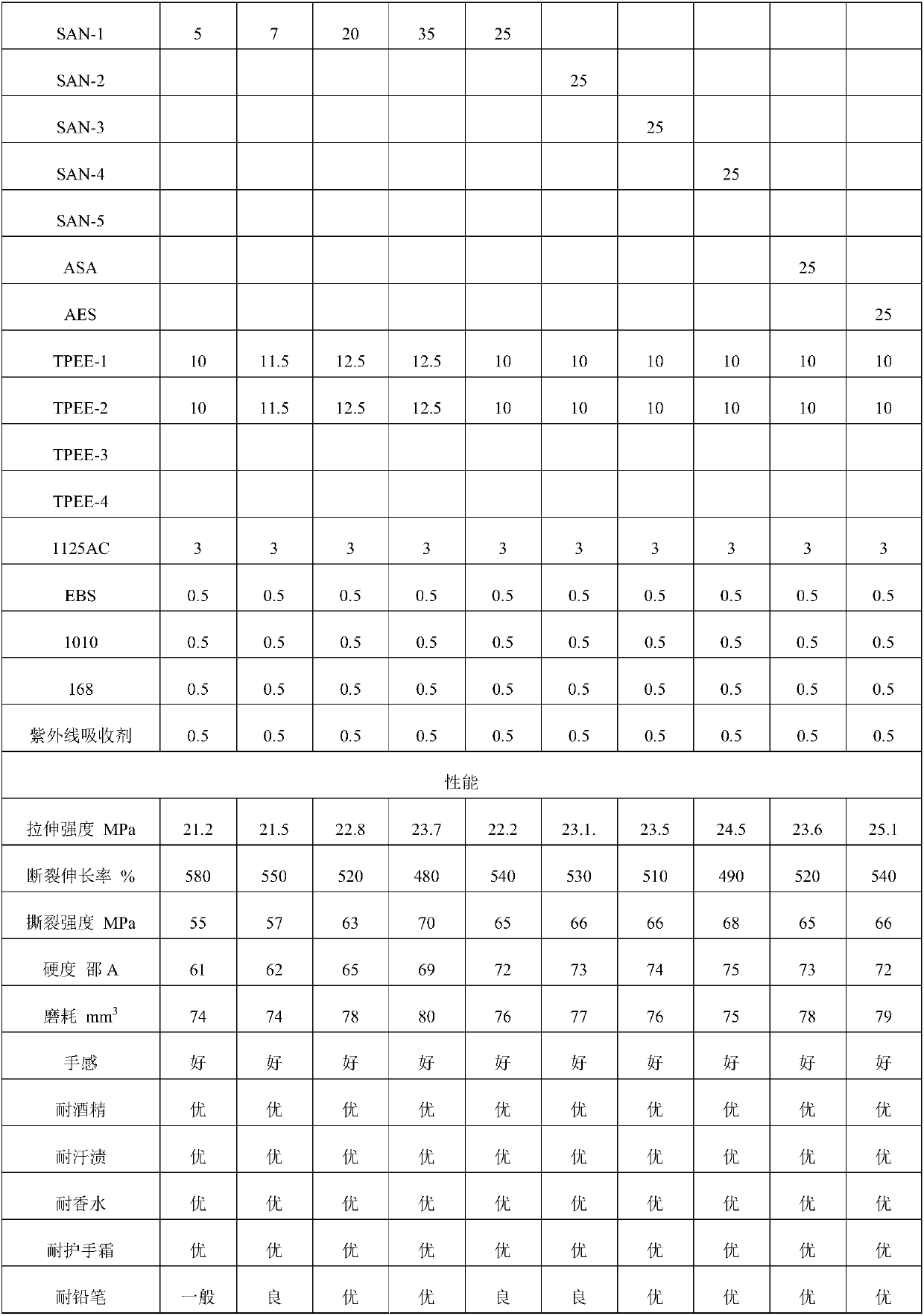

Stain-resistant elastomer compound and preparation method and application thereof

ActiveCN107903618AHigh retention performanceImprove adsorption capacityBraceletsWrist-watch strapsPolyesterCompound s

The invention belongs to the technical field of elastomer material modification and provides a stain-resistant elastomer compound and a preparation method and application thereof. The elastomer compound is prepared from, by weight, 30-70wt% of thermoplastic polyurethane elastomer, 5-40wt% of thermoplastic polyester elastomer and 5-40wt% of acrylonitrile comonomer containing thermoplastic copolymer, wherein the total weight percentage of all components is 100wt%. The preparation method includes: premixing all components to obtain a premixed material, and adopting a double-screw extruder for extrusion granulating of the premixed material to obtain the elastomer compound. Stain resistance of the elastomer compound prepared according to the method is remarkably improved while TPU (thermoplastic polyurethane) elasticity, abrasion resistance and hand feeling are kept.

Owner:WANHUA CHEM GRP CO LTD

Ultraviolet-resistant agent for viscose/cotton fabric

The invention discloses an ultraviolet-resistant agent for a viscose / cotton fabric. The ultraviolet-resistant agent for a viscose / cotton fabric comprises: by weight, 88 parts of epoxy resin, 18 parts of phenol, 36 parts of titanium isopropoxide, 42 parts of a salicylic acid ester, 22 parts of glycol, 36 parts of diphenol propane and 28 parts of dimethylbenzene. The ultraviolet-resistant agent for a viscose / cotton fabric has a simple production technology and a low production cost. After being treated by the ultraviolet-resistant agent, a viscose / cotton fabric can retain original flexibility and a handle. The ultraviolet-resistant agent for a viscose / cotton fabric has the characteristics of good ultraviolet resistance effect, washing resistance, safety and no harm.

Owner:SUZHOU KAQITE TEXTILE

Novel antibacterial finishing agent for textiles

The invention discloses a novel antibacterial finishing agent for textiles. The novel antibacterial finishing agent is prepared from the following components in parts by weight: 10-15 parts of polyoxyethylene ether, 1-5 parts of sodium alginate, 1-5 parts of sodium tripolyphosphate, 2-6 parts of potassium oxalate, 20-30 parts of ethanol, 7-12 parts of linear alkyl benzene sulphonic acid, 3-9 parts of ethoxylated linear chain primary alcohol, 6-15 parts of alkyl glycoside, 3-7 parts of polyvinylpyrrolidone, 2-6 parts of potassium xylene sulfonate, 5-10 parts of musk ambrette, 10-15 parts of polyethylene glycol octylphenol ether, 5-8 parts of isooctyl palmitate and 70-80 parts of de-ionized water. The product prepared by the invention is simple in production process and low in production cost; and the textiles can keep original flexibility and hand feeling after being treated by the finishing agent, have excellent effect, can resist water washing and are safe and harmless. A test shows that the antibacterial and mold-proof finishing agent for the textiles, disclosed by the invention, has very good antibacterial effect on a plurality of types of bacteria.

Owner:HUZHOU LIHUA YUJIE UNION TEXTILE

Antistatic agent for cotton fabrics

The invention discloses an antistatic agent for cotton fabrics. The antistatic agent provided by the invention is made from the following ingredients of: by weight, 78 parts of epoxy resin, 36 parts of tetrabutoxy titan, 22 parts of ethylene glycol, 18 parts of tetrabutyl titanate, 18 parts of cyclohexanone, 28 parts of dimethylbenzene, 10 parts of powdered steatile and 12 parts of aziridine. The product prepared in the invention has advantages of simple production technology and low manufacturing cost. After processed by the antistatic agent provided by the invention, cotton fabrics can maintain original flexibility and hand feeling, has an excellent antistatic effect, and is water resistant, safe and harmless.

Owner:SUZHOU KAQITE TEXTILE

Polyurethane resin preparation method

The invention relates to the technical field of materials for synthetic leather, in particular to a polyurethane resin preparation method. The method includes the steps: 1) increasing the temperature of 145 parts of polyneopentanediol adipate with the molecular weight of 2000 to 100 DEG C, performing vacuum dehydration for about 1h and cooling to 50 DEG C; 2) adding 150 parts of methylbenzene, 251 parts of IPDI (isophorone diisocyanate) and 5 parts of organic bismuth catalysts into a reactor with stirring uniformly, increasing the temperature to 90 DEG C and reacting for 2h; 3) adding 46 parts of 1,6-hexanediol to continue reaction for 2h at the temperature of 90 DEG C; 4) cooling to 50 DEG C, adding 100 parts of methylbenzene, 100 parts of normal butanol and 100 parts of isopropyl alcohol with stirring uniformly, slowly tackifying with 53 parts of isophorone diamine, and stopping adding the isophorone diamine when the viscosity is increased to 150000cps; and 5) continuing to stir for 30 minutes and cooling to 30 DEG C to discharge so that weak-solvent aliphatic polyurethane resin with 50% of solid content and 220kgf / cm<2> of modulus is obtained.

Owner:ZHEJIANG SUNLIGHT MATERIAL TECH CO LTD

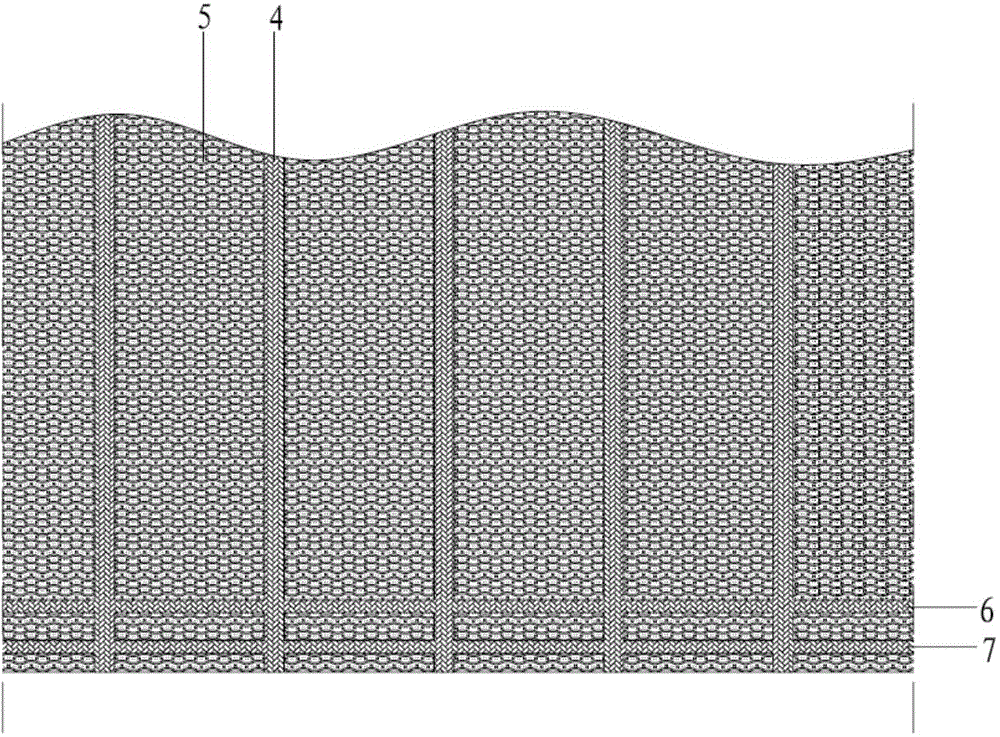

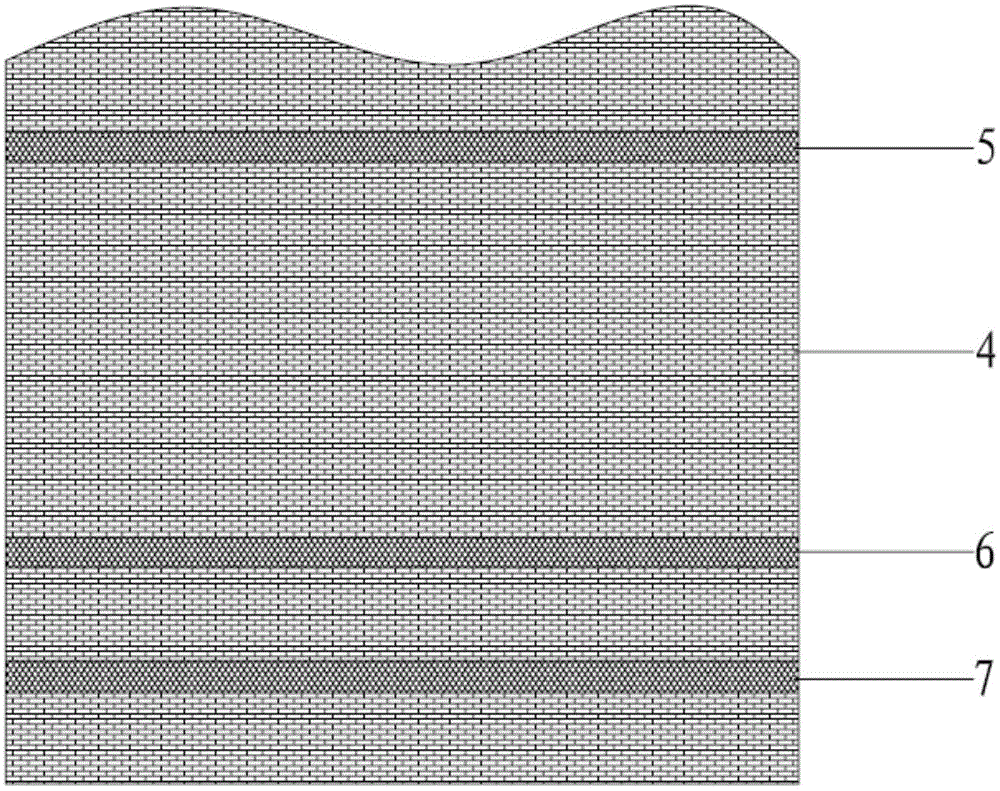

Fabric and curtain interwoven with hot-melt yarn

The invention discloses fabric interwoven with hot-melt yarn. The fabric comprises warp and weft which are interwoven, wherein full hot-melt yarn is arranged in the warp or the weft at intervals. The invention further discloses a curtain interwoven with the hot-melt yarn. The curtain is formed by weaving the warp and the weft and comprises thick fabric sections and thin fabric sections which are distributed at intervals in the weft direction, and full hot-melt yarn is arranged in the warp or the weft at intervals. By the aid of the hot-melt yarn interwoven with the fabric weave at intervals, good hand feeling and softness are kept while the fabric hardness is improved. After the fabric is applied to the folding curtain, the thick fabric sections are thicker, the smoothness of the curtain in the vertical direction is kept, the thin fabric sections are soft, and the curtain is convenient to fold and unfold.

Owner:绍兴游龙窗饰有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com