Patents

Literature

97 results about "Dibutyltin oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dibutyltin oxide, or dibutyloxotin, is an organotin compound with the chemical formula (C₄H₉)₂SnO. It is a colorless solid that, when pure, is insoluble in organic solvents. It is used as a reagent and a catalyst.

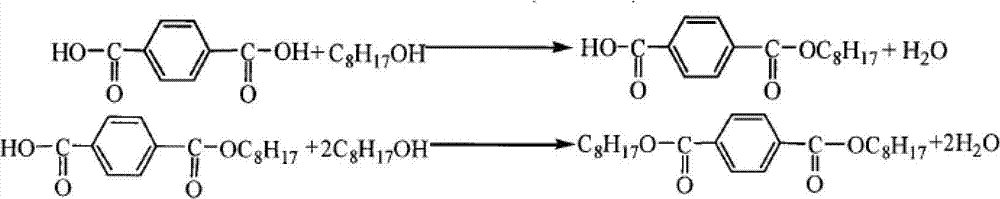

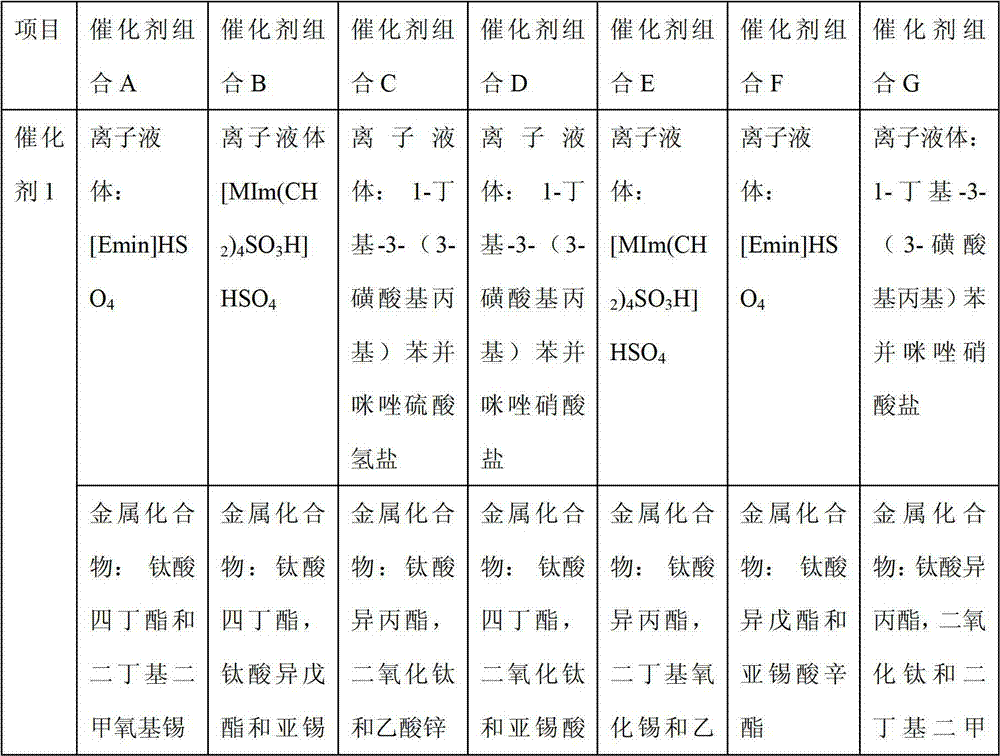

Preparation method of dioctyl terephthalate and used catalyst

InactiveCN102824929AIncrease contact areaShrink wellOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsDibutyltin oxideTitanium metal

The invention provides a catalyst for use in synthesis of dioctyl terephthalate and a method for preparing dioctyl terephthalate by applying the catalyst. The catalyst consists of a catalyst 1 and a catalyst 2, wherein the catalyst 1 consists of an ionic liquid and a metal compound; the catalyst 2 consists of a titanium metal compound and other metal compound; the positive ion of the ionic liquid are an imidazole ion or a benzimidazole ion; the negative ion of the ionic liquid is a bisulfate ion; or the positive ion of the ionic liquid is a benzimidazole ion or an imidazole ion with one or two sulfonic acid radicals; the titanium metal compound is selected from at least one compound of tetrabutyl titanate, isopentyl ester titanate, isopropyl titanate or titanium dioxide; and the other compound is selected from at least one compound of dibutyldimethoxytin, dibutyltin oxide, monooctyl ester stannite, zinc acetate and cobalt acetate. Due to the adoption of the technical scheme provided by the invention, the cost can be reduced, the reaction speed is increased, energy consumption is lowered, and the quality of an obtained product is high.

Owner:FOSHAN GAOMING XIONGYE CHEM

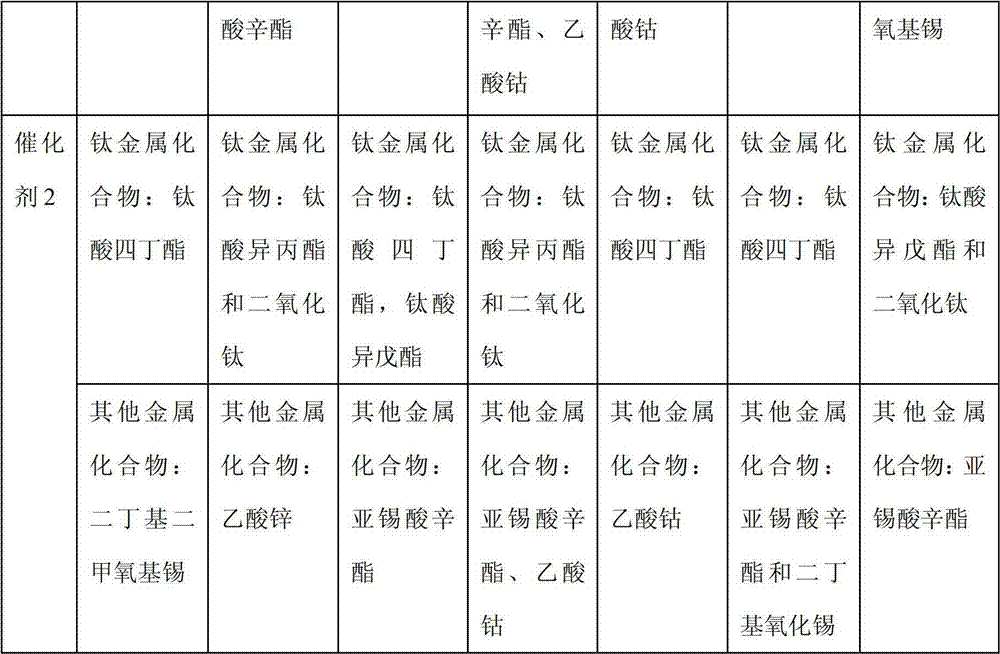

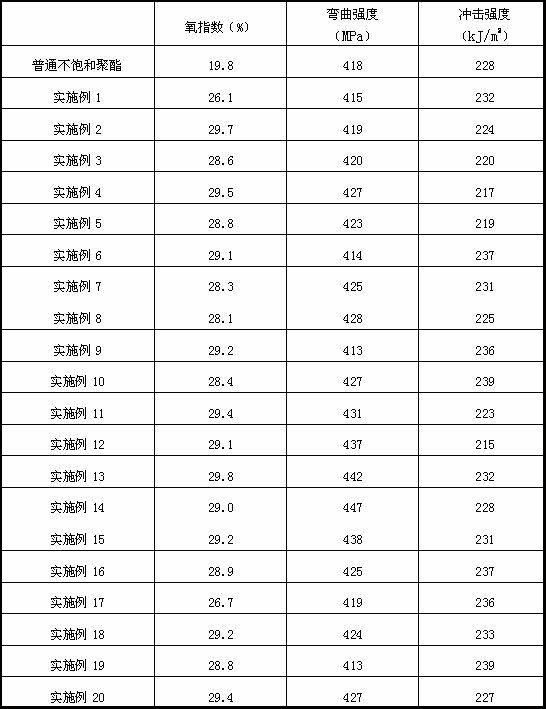

Method for synthesizing reactive halogen-free flame-retardant unsaturated polyester resin

The invention discloses a method for synthesizing reactive halogen-free flame-retardant unsaturated polyester resin. The method is characterized by taking dihydric alcohol, dibasic acid or dibasic acid anhydride, reactive phosphorus flame retardants such as 2- carboxyethyl (phenyl) phosphinic acid and phenyl hydroxymethyl phosphinic acid, and reactive silicon flame retardants such as dihydroxy diphenyl silane and dihydroxy dimethyl silane as basic materials, conducting esterification and polycondensation under the conditions of catalysts such as dibutyltin oxide and sodium acetate, and then adding diluent, thus preparing the halogen-free flame-retardant unsaturated polyester resin. The resin prepared by the method is especially applicable to the production of unsaturated polyester resin moulding compounds, glass fiber reinforced plastics and electrical plastic products, can meet the requirements of products on flame retarding and lightweight and has good properties.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

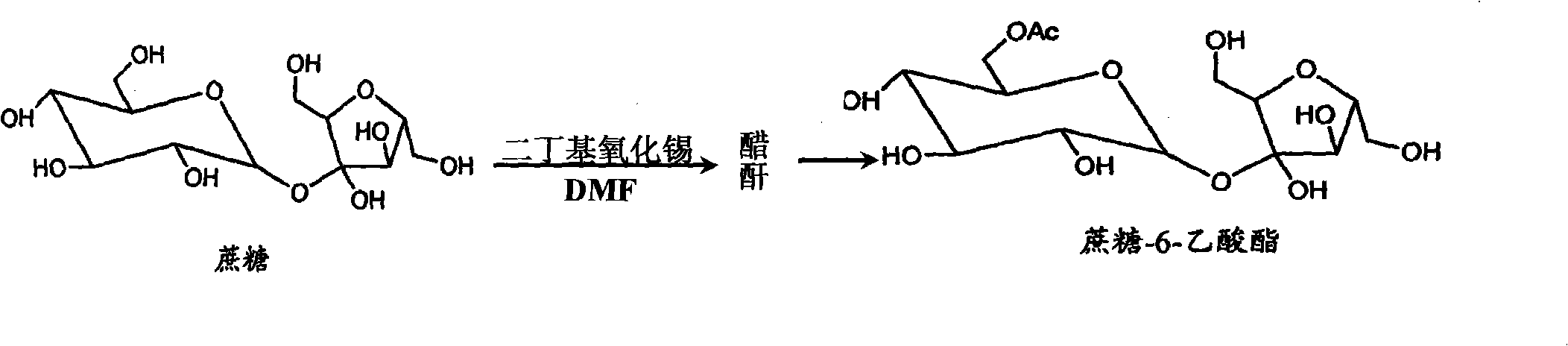

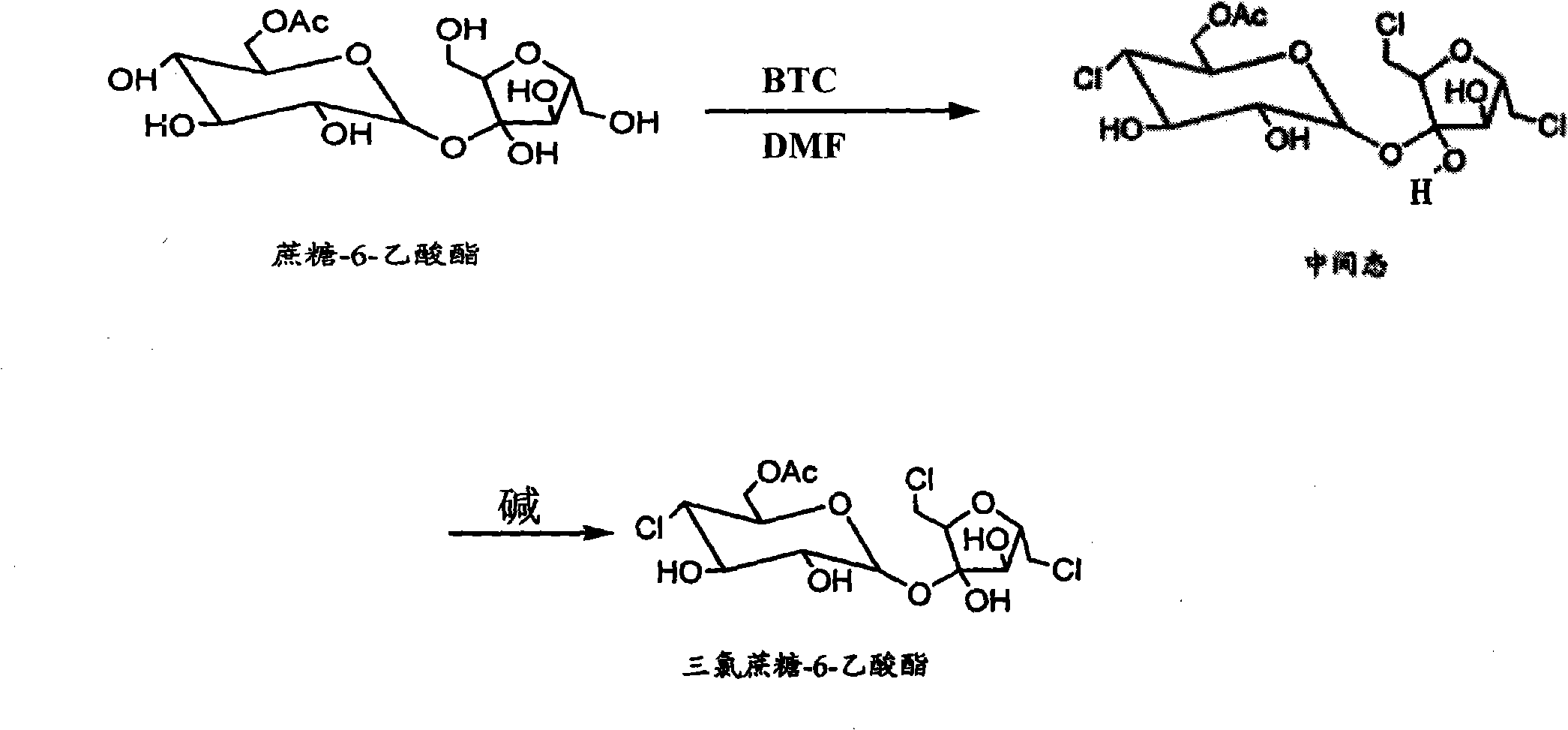

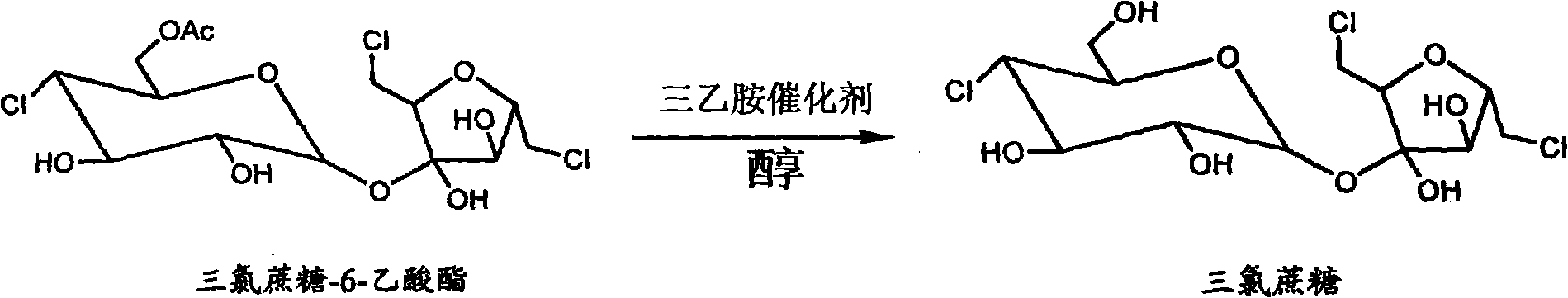

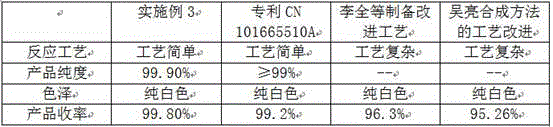

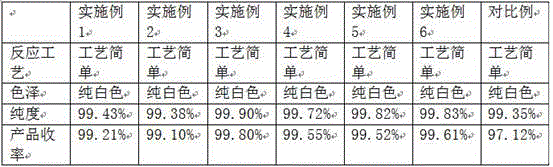

Synthetic method for sucralose

InactiveCN102167712ASolve protection problemsHigh yieldSugar derivativesSugar derivatives preparationAcetic acidTrans esterification

The invention belongs to the field of a synthetic method and especially relates to the field of the synthetic method for a sucralose. The synthetic method for the sucralose is characterized in that the method comprises an esterification reaction, a chlorination reaction and a deacetylation reaction of sucralose-6-acetate. The method of the invention successively solves a problem of 6-hydroxy-group protection, that is to say, dibutyltin oxide is utilized to selectively protect other functional groups near the 6-hydroxy-group and the dibutyltin oxide is retrieved after the 6-hydroxy-group is esterified. The method is ingenious and allows little loss of the dibutyltin oxide during recovery, thereby greatly reducing cost. A domestic leading technology of trans-esterification is adopted for final removal of 6-ester. Crystallization is mild, color of finished products is as white as snow, purity of the products is usually more than 99% and yield is 35 to 40%.

Owner:李罡

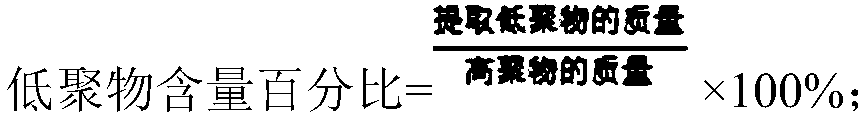

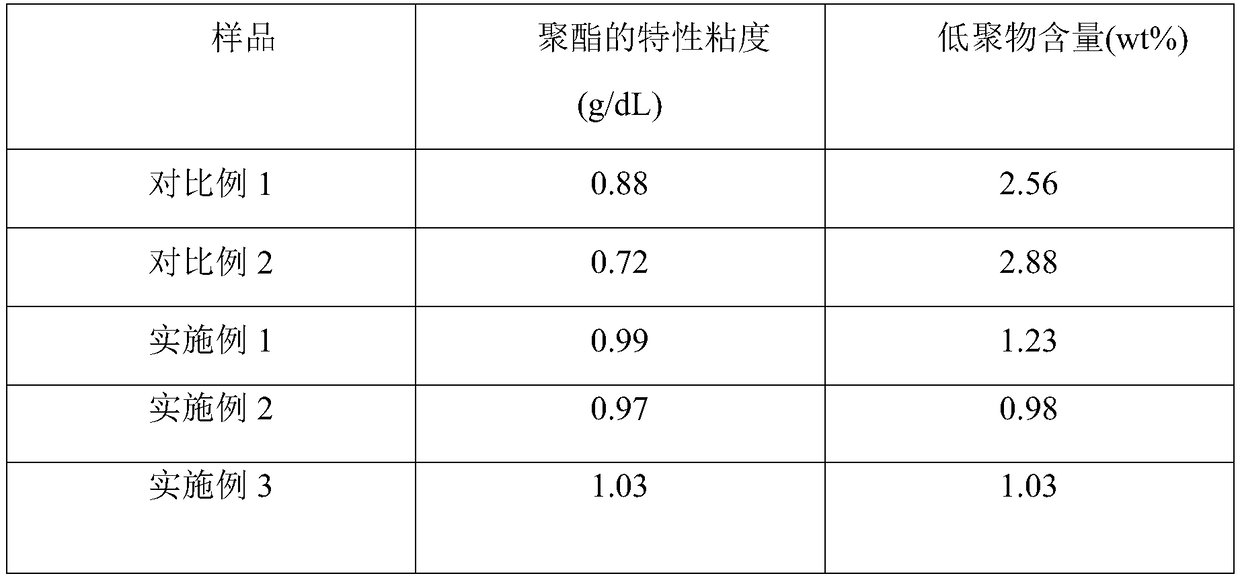

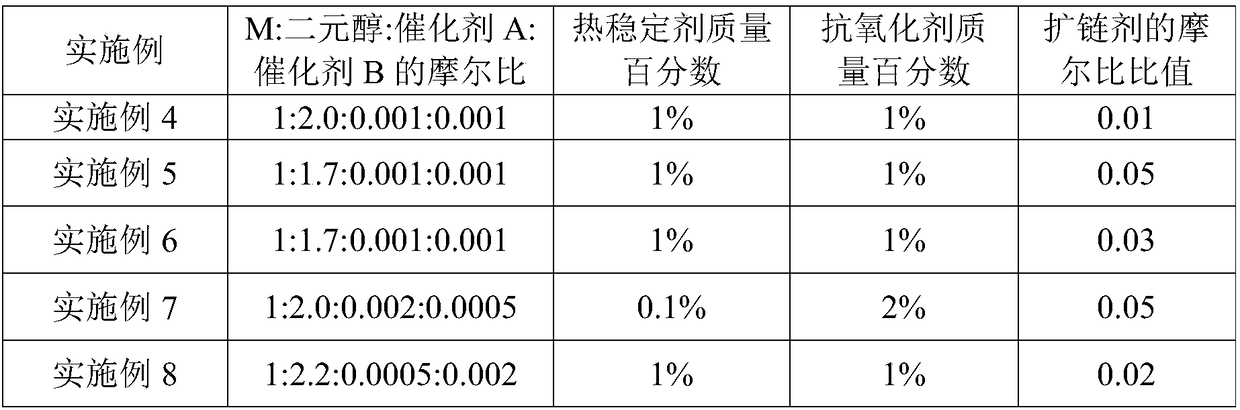

Polyester with low oligomer content and preparation method of polyester

The invention relates to a polyester with low oligomer content and a preparation method of the polyester. The method comprises the following steps: carrying out an esterification reaction and a first-stage condensation polymerization reaction on M and dihydric alcohol in the presence of a catalyst A; carrying out a second-stage condensation polymerization reaction; adding a catalyst B and carryingout a third-stage condensation polymerization reaction; and finally, adding a chain extender for carrying out a chain extension reaction, thereby obtaining the polyester with low oligomer content, wherein M is dicarboxylic acid or binary alkyl carboxylate; the catalyst A is a titanium catalyst, an antimony catalyst or metal acetate, the catalyst B is more than one of aluminum isopropoxide, dibutyl tin oxide, monobutyltin oxide, stannous octoate and stannous 2-ethyl caproate, and the oligomer content in the prepared polyester is less than 1.5wt%. The method disclosed by the invention is simplein operation, and the prepared product is low in oligomer content and has excellent popularization value.

Owner:DONGHUA UNIV

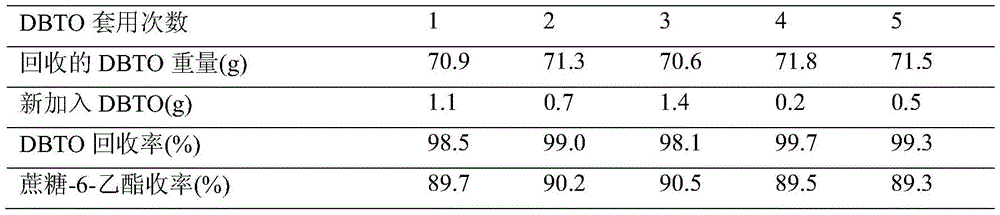

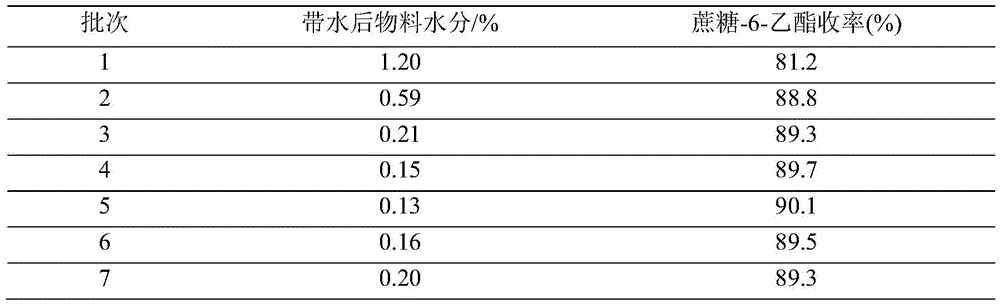

Method of recycling and reusing of dibutyltin oxide in process of cane sugars manufacturing cane suger-6-ethyl ester

InactiveCN103130843AEliminates the drying stepAvoid safety hazardsEsterified saccharide compoundsTin organic compoundsSucroseDibutyltin oxide

The invention relates to a method of recycling and reusing of dibutyltin oxide in the process of cane sugars manufacturing cane suger-6-ethyl ester. The method of recycling and reusing of the dibutyltin oxide in the process of the cane sugars manufacturing the cane suger-6-ethyl ester comprises the following steps: (1), carrying out the cane sugars manufacturing the cane suger-6-ethyl ester; (2), recycling cyclochexane liquor which contains the dibutyltin oxide; (3), using the recycled and obtained dibutyltin oxide with a moisture percentage of 10%-20% for the step (1) of manufacturing the cane suger-6-ethyl ester. The method of recycling and reusing of the dibutyltin oxide in the process of the cane sugars manufacturing the cane suger-6-ethyl ester is concise, operation is easy, and the obtained dibutyltin oxide which contains water can be directly used for manufacturing the cane suger-6-ethyl ester again. A step of drying the dibutyltin oxide can be saved. Under conditions of not affecting yields generally, production cost is reduced. Safe hidden dangers which exist in the process of drying and dewatering the dibutyltin oxide are completely prevented. The method of recycling and reusing of the dibutyltin oxide in process of the cane sugars manufacturing the cane suger-6-ethyl ester can be suitable for industrial production.

Owner:LIYANG WEIXIN CHEM

Oil-proof high-and low-temperature resistant cable

InactiveCN105694236AImprove heat resistanceImprove corrosion resistanceInsulated cablesInsulated conductorsDibutyltin oxideRare earth

The invention discloses a high-low temperature and oil-resistant cable, which comprises a wire, a high-temperature-resistant insulating layer covering the wire, a shielding layer covering the high-temperature-resistant insulating layer, and a protective layer covering the shielding layer; Parts include: EPDM rubber 60-80, silicone rubber 20-40, modified sepiolite 15-25, modified silica 15-25, ferric oxide 1-3, tributyl citrate 15 -25, epoxy soybean oil 20-30, microencapsulated red phosphorus 10-20, nano magnesium hydroxide 10-30, Si69 0.5-2.5, sulfur 1-2, dicumyl peroxide 0.5-1, isocyanide Triallyl Urate 0.5-0.8, Stearic Acid 0.2-0.5, Zinc Oxide 0.2-0.4, Dibutyltin Oxide 2-3, Rare Earth Stabilizer 1-2, Antiaging Agent 264 0.1-0.3, Antiaging Agent 4010 0.2- 0.4, paraffin 3-5.

Owner:繁昌县菲德通讯材料设计有限公司

Ultrafine dibutyltin oxide and preparation method thereof

ActiveCN106008588AFine and uniform particlesLow concentration of soluble ionsTin organic compoundsElectrophoresisDibutyltin dichloride

The invention relates to an ultrafine dibutyltin oxide and a preparation method thereof, and belongs to the technical field of preparation of ultrafine powder catalysts. The preparation method concretely comprises the following steps: 1, heating dibutyltin dichloride to a certain temperature in order to liquefy dibutyltin dichloride , and introducing the liquefied dibutyltin dichloride to an atomizer; 2, starting the atomizer to atomize the liquid dibutyltin dichloride ; 3, spraying atomized dibutyltin dichloride flow into a reaction kettle equipped with an alkali liquid, fully mixing the flow with the alkali liquid, and carrying out a primary reaction; 4, separating the obtained liquid after the primary reaction ends, adding the alkali liquid, carrying out a secondary reaction, and carrying out a tertiary reaction; and 5, washing a material obtained in step 4 with water, centrifuging the washed material, carrying out vacuum drying, discharging the dried material, and weighing the discharged material to obtain the required ultrafine dibutyltin oxide product. Ultrafine dibutyltin oxide synthesized through the method is fine and uniform, has high purity, and can be used as an electrophoresis paint catalyst.

Owner:云南锡业锡化工材料有限责任公司

Method for recycling organic tin in sucralose production

ActiveCN105111246AThe generation of solutionImprove the on-site environmentEsterified saccharide compoundsSugar derivativesRecovery methodSucrose

The invention relates to a method for recycling organic tin in sucralose production. The method includes sucralose esterification reaction, dibutyltin oxide serves as a catalyst to take participate in the reaction to generate a sucrose-6-ester midbody, after a midbody solution is extracted through cyclohexane, organic tin acetic ester is dissolved in an extractant cyclohexane phase, a cyclohexane phase is extracted out, and cyclohexane is obtained through evaporation by means of a distillation still. The method is characterized by including the following steps that a, boiled cooling water is cooled to 50 DEG C, then pure water is added for stirring and washing, and stirring is carried out for one hour; b, bottom water is separated out, residues in the still are recycled organic tin acetic ester, and the residues are returned to an esterification reactor to take participate in the esterification reaction and be used repeatedly. The method has the advantages that the organic tin acetic ester is not degreased or dried and can be directly recycled and used repeatedly, so that zero emission is achieved, production cost is reduced, waste water generated in the organic tin recycling process is eliminated to the largest extent, production efficiency is greatly improved, and economic benefits are remarkable.

Owner:ANHUI JINGHE IND

Preparation process of dibutyltin oxide

InactiveCN105801619ASolve the phenomenon of clumpingImprove conversion rateTin organic compoundsDibutyltin oxideChloride

The invention relates to a preparation process of dibutyltin oxide. According to the preparation process, dibutyltin chloride and sodium hydroxide are taken as raw materials and subjected to a synthesis reaction under the action of a surfactant, finally, centrifugal water washing, vacuum drying and smashing are performed, and a finished product, namely, dibutyltin oxide, is prepared; the surfactant used in the synthesis process is one of n-heptane, toluene and ethanol, and a sodium hydroxide solution is added twice in the reaction process. The preparation process of dibutyltin oxide has the advantages that the synthesis raw materials and the reaction process are simple, little waste is discharged, and the production cost is saved; the reaction is controllable, the operation is simple and convenient, the product purification process is simple, and the product is high in purity and good in color; the surfactant can be completely separated from the product and recycled; the conversion rate of the raw material dibutyltin chloride can reach 99.80%.

Owner:JIANGSU XINLU CHEM NEW MATERIAL

Method of preparing polyvinyl wood-plastic composite with cotton stalks

The invention discloses a method of preparing polyvinyl wood-plastic composite with cotton stalks. The method comprises the following steps: soaking cotton stalks in a sodium hydroxide aqueous solution to alkalify the cotton stalks, washing the alkalified cotton stalks with distilled water, drying the washed cotton stalks, and smashing the dried cotton stalks to obtain cotton stalk powder; weighing and taking raw materials according to the mass ratio of cotton stalk powder to medium density polyethylene to azobisisobutyronitrile to dibutyltin oxide to silicone oil to chlorinated paraffin to dibasic lead phthalate being (20-60):(20-50):(0.05-1.8):(0.02-1.5):(15-20):(1-7):(0.5-4.0); stirring the mixed raw materials at a high speed to obtain mixed materials; performing reactive extrusion in a double-screw extruder to obtain extruded materials; pressing a mold containing the extruded materials on a press vulcanizer to obtain the polyvinyl wood-plastic composite. The method is easy to operate, and the prepared polyvinyl wood-plastic composite is nontoxic, environment-friendly, good in comprehensive performance and wide in application prospect.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

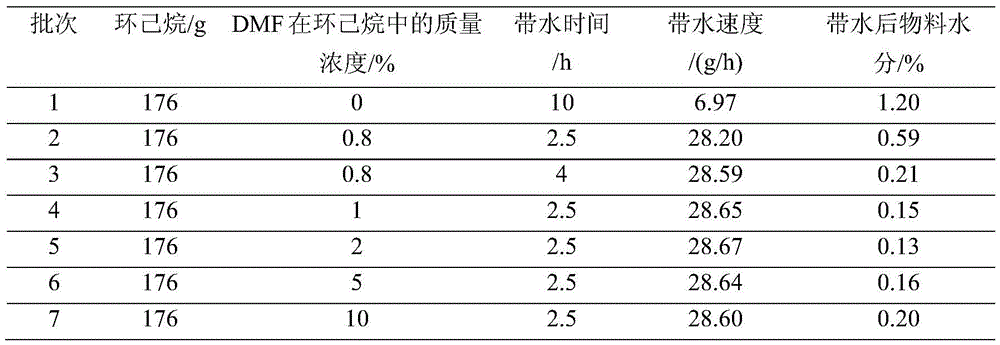

Treatment method of dibutyltin oxide and application of treatment method to synthesis of cane sugar-6-ethyl ester

ActiveCN105601665AAvoid breakingNot easy to loseEsterified saccharide compoundsTin organic compoundsSucroseDibutyltin oxide

The invention discloses a treatment method of dibutyltin oxide and application of the treatment method to synthesis of cane sugar-6-ethyl ester. The treatment method comprises the steps of adding the water-containing dibutyltin oxide to nonpolar solvent containing DMF, and heating the mixture for azeotropic water removal, so that low-water-content dibutyltin oxide is obtained after the process is ended. The mass percentage of water in the low-water-content dibutyltin oxide is 0.6% and below. The treatment method is safe, easy to operate and good in dehydration effect, the dibutyltin oxide is not prone to damage and loss in the recycling process, the recycling rate is high, purity is high, the method can be directly applied to production of cane sugar-6-ethyl ester, meanwhile, harm and potential safety hazards caused to human bodies and the environment in the dibutyltin oxide shifting process are avoided, and the treatment method is quite suitable for industrialized production.

Owner:ZHEJIANG NHU CO LTD

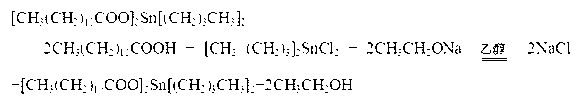

Synthesis method of dibutyltin dilaurate

InactiveCN102838631AEliminate the step of hydrolysisNothing producedTin organic compoundsOrganic synthesisDibutyltin oxide

The invention discloses a synthesis method of dibutyltin dilaurate, belonging to the field of organic synthesis. The synthesis method comprises the following steps of: 1, adding lauric acid, dibutyltin dichloride and ethanol into a reactor with a condenser pipe, heating and stirring mixed solution in the reactor, dropping sodium ethoxide-ethanol solution when temperature reaches 50-60DEG C; 2, after the sodium ethoxide-ethanol solution is completely dropped, maintaining the temperature, turning on a cooling water tap after reaction, starting to vacuumize, evaporating ethanol solvent, and stopping vacuumizing and heating when the temperature of the mixed solution in the reactor again reaches 70DEG C and no liquid is distilled off; and 3, conducting separation. By adopting the method of evenly mixing the dibutyltin dichloride instead of dibutyltin oxide with the lauric acid and then dropping sodium ethoxide-ethanol solution to prepare the dibutyltin dilaurate, the step of hydrolyzing dibutyltin dichloride in caustic soda solution is omitted, toxic dust and wastewater are not produced, the environmental and personal health is promoted and water resources are saved.

Owner:沧州威达化工股份有限公司

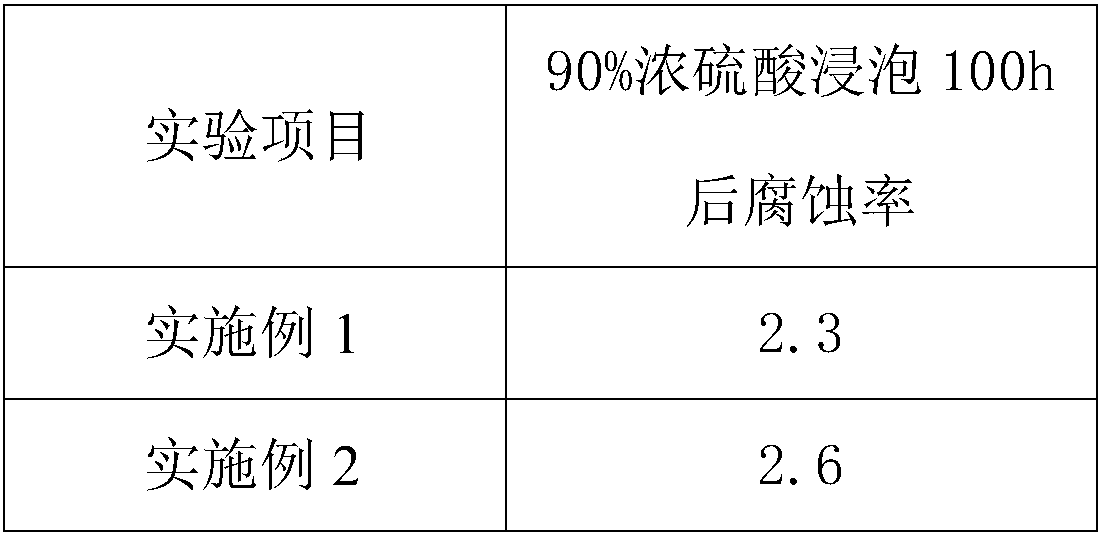

Corrosion resistant unsaturated polyester resin and preparation method thereof

The invention discloses a corrosion resistant unsaturated polyester resin, and belongs to the technical field of preparation of resins. The corrosion resistant unsaturated polyester resin comprises the following raw materials: unsaturated polyester resin, organic silicon resin, trimethyl phosphate, alkide resin, dicyclopentadiene, dibutyltin oxide, isophthalic anhydride, triiso-tricyanurate ester,polycarbonate, cobalt iso-octoate, cobalt cyclopentanecarboxylate, hexafluorobutyl methacrylate, methyl ethyl ketone peroxide, oleic acid, dibutyltin oxide, hexafluorobutyl methacrylate, trihydroxymethyl propane diallyl ether, castor oil, precipitated barium sulphate, glass flake, cellulose acetate, zinc acetate, a silane coupling agent KH-560, and a corrosion resistant modified auxiliary, and the corrosion resistant unsaturated polyester resin is prepared by the steps of preparing a matrix, preparing a modified material, mixing the matrix and the modified material, etc. The prepared unsaturated polyester resin has an excellent property of corrosion resistance.

Owner:定远汇利化工有限公司

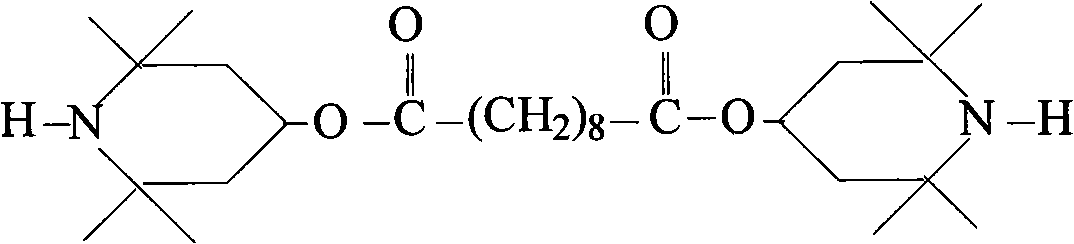

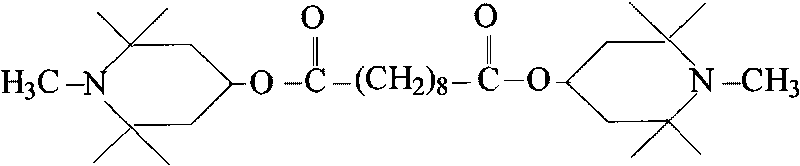

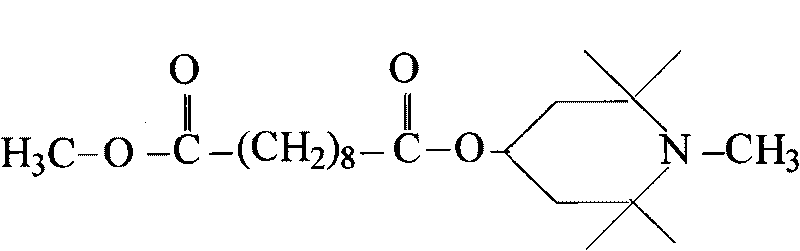

Light stabilizer bis(2,2,6,6-tetramethyl-4-piperidinyl)sebacate and preparation method thereof

InactiveCN101665457AReduce pollutionEasy to separate and purifyOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsDibutyltin oxideDIETHYL SEBACATE

The invention discloses a light stabilizer bis(2,2,6,6-tetramethyl-4-piperidinyl)sebacate and a preparation method thereof. Dimethyl sebacate and 2,2,6,6-tetramethyl-4-hydroxypiperidine are taken as raw materials, and then the raw materials react in the presence of catalyst to prepare bis(2,2,6,6-tetramethyl-4-piperidinyl)sebacate. The invention uses dimethyl sebacate and 2,2,6,6-tetramethyl-4-hydroxypiperidine as the raw materials to synthesize the bis(2,2,6,6-tetramethyl-4-piperidinyl)sebacate and adopts dibutyltin oxide as the catalyst, and thereby the separation and purification process issimplified, the reaction time is short, and the product yield is as high as more than 97 percent; the obtained product has high purity, reduced energy consumption, little environmental pollution andlow cost, and therefore, the invention is an ideal process for realizing industrial production.

Owner:南通惠康国际企业有限公司

Resin for toner binder and toner composition

InactiveUS7049041B2Good low temperature fixabilityPreventing Image Quality DeteriorationDevelopersDiketoneDibutyltin oxide

The present invention provides a toner binder for developing electrostatic charge images,which binder comprises a polycondensate polyester resin,said polyester resin being a product formed in the presence of at least one titanium-containing catalyst (A) selected from the group consisting of a titanium halides (A1), a titanium diketone enolate (A2), a titanium carboxylate (A3), a titanyl carboxylate (A4), and a titanyl carboxylate salt (A5).Furthermore, the present invention provides a toner binder for developing electrostatic charge images,which binder comprises a polycondensate polyester resin,said polyester resin being a product formed in the presence of at least one tin-containing catalyst (B) selected from the group consisting of dioctyltin oxide (B1), monobutyltin oxide (B2), and dibutyltin oxide (B3), with the content of tributyltin compounds in (B3) being not more than 250 ppm.

Owner:SANYO CHEM IND LTD

Preparation method of composite cellulose acetate membrane

ActiveCN105148746AEasy to degradeExtended service lifeSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisFiberAcetic anhydride

The invention discloses a preparation method of a composite cellulose acetate membrane, and belongs to the technical field of membrane preparation. The preparation method comprises the steps of extracting bamboo fibers; mixing the bamboo fibers, glacial acetic acid and acetic anhydride to obtain a mixture I; in the acetylating process, adding tetrakis triphenylphosphine palladium into the mixture I to obtain a mixture II, carrying out primary modification on the mixture II, then mixing the modified mixture with dibutyltin oxide to obtain dibutyltin dilaurate which is loaded onto cellulose acetate; and complexing dibutyltin dilaurate and added dissociative nickel due to the effect of tetrakis triphenylphosphine palladium to finally obtain the composite cellulose acetate membrane which has a corrosion resistant effect and an acid and alkali resistant effect and is difficult to degrade. Through the powerful proving, the prepared composite cellulose acetate membrane can be used for processing oily sewage without any chemical reagent, and the oil catching rate can reach 98.8% and above.

Owner:JIANGSU LONGMEM ENVIRONMENTAL TECH CO LTD

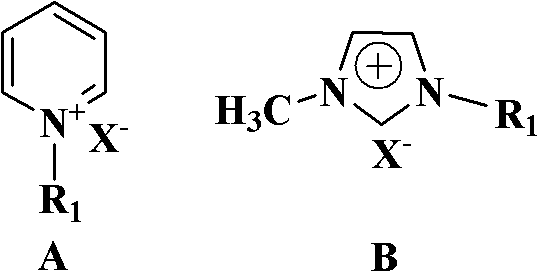

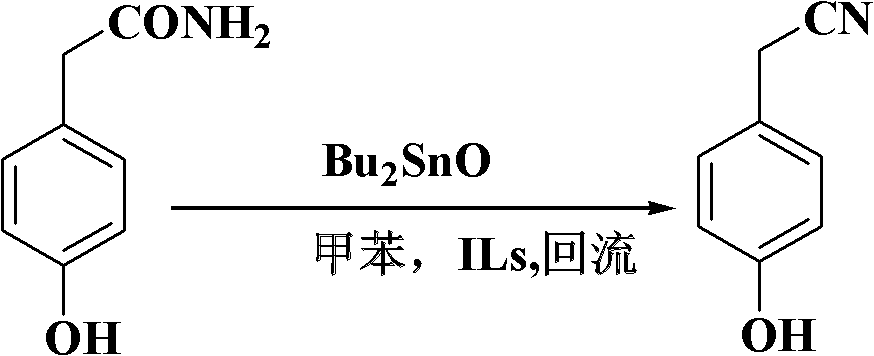

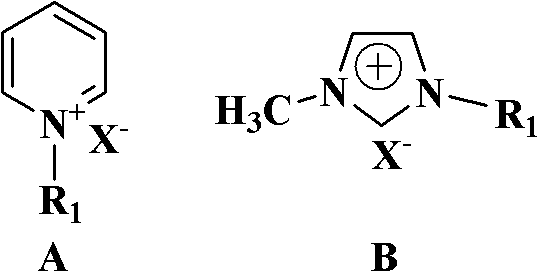

Preparation method of hydroxybenzyl cyanide

InactiveCN102675148AMild reaction conditionsNo pollution in the processPreparation by carboxylic acid amide dehydrationBulk chemical productionChemical synthesisChlorobenzene

The invention belongs to the field of organic chemical synthesis and particularly relates to a preparation method of hydroxybenzyl cyanide. The preparation method of the hydroxybenzyl cyanide comprises the following steps: taking P-hydroxyphenylacetamide as a raw material and carrying out dehydration reaction on the P-hydroxyphenylacetamide in an organic solvent under the condition that dibutyltin oxide and an ion liquid compound exist to obtain the hydroxybenzyl cyanide, wherein the organic solvent selects from toluene, ethylbenzene, isopropylbenzene, n-butyl benzene, benzene, nitrobenzene, chlorobenzene and mixture thereof. In the preparation method, the hydroxybenzyl cyanide is prepared through taking the P-hydroxyphenylacetamide as the raw material, the dibutyltin oxide as a dewatering agent, the ion liquid compound as a catalyst, and the toluene and the like as a solvent and a dehydrating agent. The preparation method has the characteristics of mild reaction condition, no pollution and high yield; the dibutyltin oxide and the ion liquid can be recycled for above 10 times, and the yield is basically kept unchanged.

Owner:JIAXING UNIV

Preparation method of dibutyltin oxide catalyzed sucrose-6-acetate single solvent

InactiveCN107011394AEsterified saccharide compoundsSugar derivativesResource consumptionDibutyltin oxide

The invention relates to a preparation method of dibutyltin oxide catalyzed sucrose-6-acetate. The preparation method is characterized by including: using dibutyltin oxide as the catalyst and trace diacetyl distannoxane as the cosolvent to prepare the sucrose-6-acetate single solvent in a single DMF solvent, and using a simple heating, alkali washing and neutralizing method to recycle the dibutyltin oxide. The preparation method has the advantages that the method is high in sucrose-6-acetate yield, low in resource consumption and high in operability in industrial production, the prepared sucrose-6-acetate is good in quality, and the catalyst recycling method is simple.

Owner:林洪

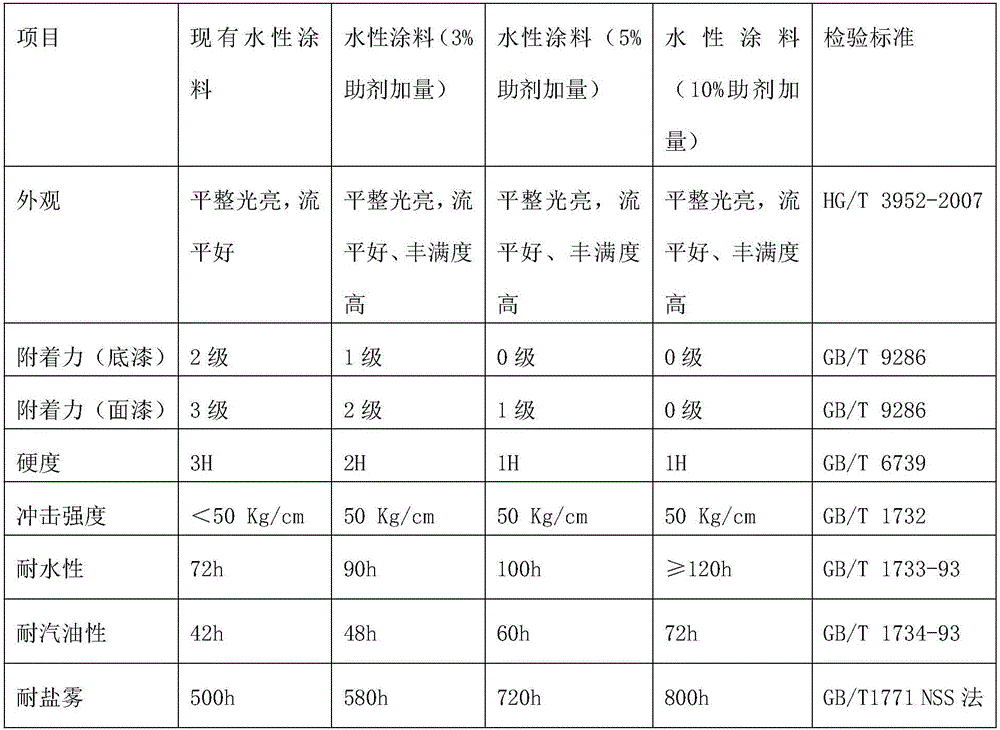

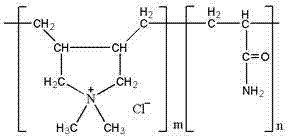

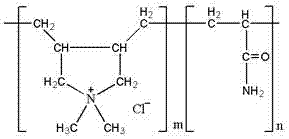

Waterborne polyester resin and preparation method as well as functional auxiliary agent based on waterborne polyester resin

InactiveCN106750225ALower average functionalityGood adhesion between layersAnti-corrosive paintsSolubilityFunctional monomer

The invention provides waterborne polyester resin. The waterborne polyester resin is prepared from the following raw materials in parts by weight: 15 to 18 parts of trimethylol propane, 25 to 30 parts of neopentyl glycol, 18 to 22 parts of m-phthalic acid-5-sodium sulfonate, 25 to 30 parts of adipic acid, 5 to 8 parts of hexahydro-phthalic acid, 12 to 15 parts of 2-butoxy ethanol, 8 to 10 parts of sec-butyl alcohol, 0.05 to 0.08 part of dibutyltin oxide and 8 to 10 parts of dimethylethanolamine. The waterborne polyester resin mainly comprises a cyclic binary acid emulsified group monomer introduced with a non-benzene ring, so that the water solubility is improved; meanwhile, a waterborne functional monomer, namely the m-phthalic acid-5-sodium sulfonate, is directly introduced into a main chain to obtain the waterborne polyester resin; the invention further provides a production method of the waterborne polyester resin and a functional auxiliary agent based on the waterborne polyester resin.

Owner:HAOLISEN CHEM TECH (JIANGSU) CO LTD

Preparation method of high-purity dibutyltin oxide

The invention relates to a preparation method of high-purity dibutyltin oxide. The preparation method comprises the steps of carrying out synthetic reaction on the raw materials including dibutyltin oxide and alkali in a heterogeneous system of an organic solvent and a water solution, and finally carrying out centrifugation and drying, so as to obtain a dibutyltin oxide finished product. The product prepared by virtue of the preparation method is high in purity; the organic solvent and a surfactant are respectively used as a solvent and an extraction medium in a preparation process, and dibutyltin oxide particles generated by alkalization reaction are rapidly transferred into an organic phase by virtue of an absorption effect of the surfactant in the alkalization reaction process, so that the product is separated from water rich in chloride ions; the organic phase containing dibutyltin oxide is collected through layering separation, toluene is recycled through distillation, and then high-purity dibutyltin oxide is prepared; the content of the chloride ions in the product is effectively controlled to be less than or equal to 50ppm, so that the industrial water pollution is reduced.

Owner:JIANGSU FEITUO INTERFACE ENG TECH CO LTD

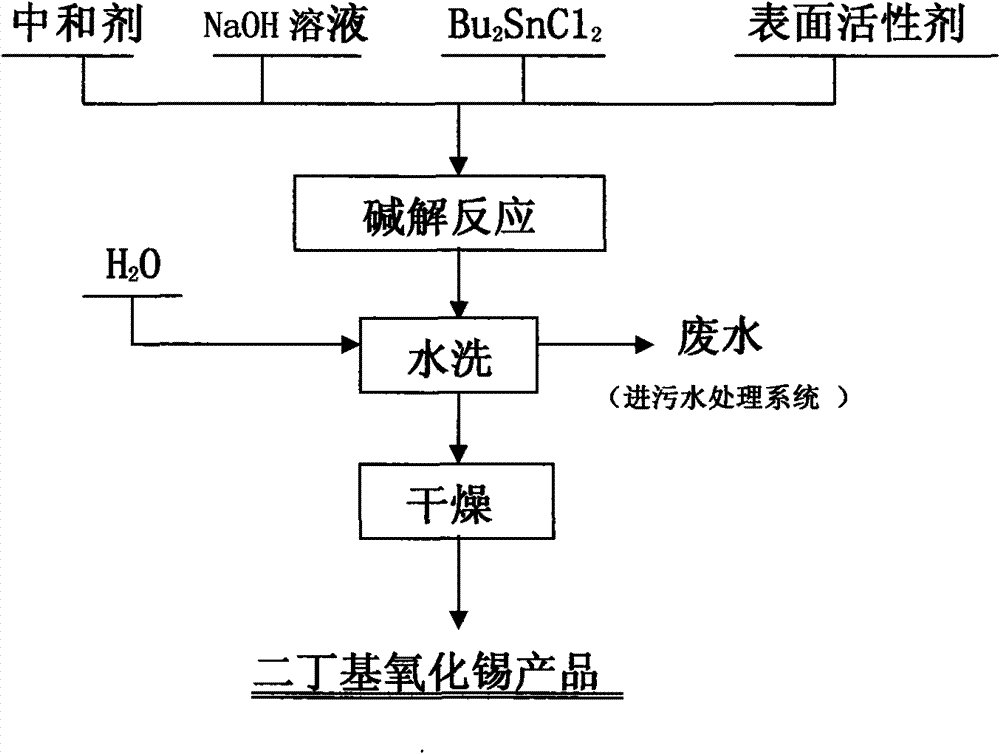

Preparation method of granular dibutyltin oxide

ActiveCN101665510BReduce operating intensityIncrease production capacityTin organic compoundsDibutyltin oxideDibutyltin dichloride

The invention relates to a preparation method of an organotin product, in particular to a preparation method of granular dibutyltin oxide, belonging to the field of the chemical engineer. The method comprises the following steps: adding sodium hydroxide solution, neutralizer and surfactant in a reaction tank, heating the mixture to the initial temperature of the alkaline hydrolysis reaction, then dropwise adding dibutyltin dichloride solution while controlling the adding speed to 15-25kg / min, then performing the alkaline hydrolysis reaction under the temperature of the alkaline hydrolysis reaction to obtain dibutyltin oxide and finally obtaining the pure white granular dibutyltin oxide through water washing, filtrating and vacuum drying. The invention is characterized by high efficiency, controllable reaction and high purity and yield, the prepared product is granular, the purity of the prepared dibutyltin oxide is not less than 99%, and the yield of dibutyltin oxide which is synthesized by adopting dibutyltin dichloride as starting raw material is not less than 98%.

Owner:云南锡业锡化工材料有限责任公司

Light stabilizer and production method thereof

InactiveCN101712772AReduce pollutionEasy to separate and purifyOrganic chemistryDibutyltin oxideDIMETHYL SEBACATE

The invention discloses a light stabilizer-292 and a production method thereof. The light stabilizer-292 is prepared by taking dimethylbenzene, dimethyl sebacate and 1,2,2,6,6-pentamethyl-4-hydroxypiperidine as raw materialls and reacting in the presence of a catalyst. According to the method, the dimethylbenzene, the dimethyl sebacate and the 1,2,2,6,6-pentamethyl-4-hydroxypiperidine are used as the raw materials to synthesize the light stabilizer-292, and the dibutyltin oxide catalyst is adopted, so the method has the advantages of simplifying separation and purification processes, having short reaction time and high product yield, ensuring that the yield of products reaches over 96 percent, reducing energy consumption, and having less environmental pollution and low cost, which is an ideal process for realizing industrialized production.

Owner:南通惠康国际贸易有限公司

Modified unsaturated polyester resin with low viscosity and corrosion resistance and preparation method of modified unsaturated polyester resin

InactiveCN106519135AImprove corrosion resistanceImprove water resistanceMethacrylateCellulose acetate

The invention discloses modified unsaturated polyester resin with low viscosity and corrosion resistance. The modified unsaturated polyester resin is prepared from raw materials as follows: maleic anhydride, diethylene glycol, dicyclopentadiene, m-phthalic anhydride, terephthalic acid, ethylene glycol, propylene glycol, rosin, phloroglucinol, hydroquinone, styrene, dibutyltin oxide, zinc acetate, cellulose acetate, tetrabutyl titanate, cobalt iso-octoate, cobalt cyclopentanecarboxylate, methyl ethyl ketone peroxide and hexafluorobutyl methacrylate. The invention further provides a preparation method of the modified unsaturated polyester resin with low viscosity and corrosion resistance. The modified unsaturated polyester resin prepared with the method has excellent corrosion resistance and low viscosity.

Owner:滁州常源新材料有限公司

Alkenyl succinic anhydride, and preparation method and application thereof

ActiveCN106316997AThe synthesis process is simpleShort reaction timeOrganic chemistryDibutyltin oxideChloride

The invention discloses a preparation method of alkenyl succinic anhydride. The preparation method comprises the following steps: carrying out a reaction on alpha-olefin, maleic anhydride and a catalyst at 140-240 DEG C under 0.3-0.5 Mpa for 5-10 h, and purifying the above obtained reaction product to obtain the alkenyl succinic anhydride, wherein the catalyst is selected from at least one of monobutyltin oxide, dibutyltin oxide, dibutyltin oxide chloride, dibutyltin dilaurate and dibutyltin diacetate, the particle size of the catalyst is 3-5 [mu]m, and the catalyst can be cyclically used. The alkenyl succinic anhydride is mainly used as a raw material for papermaking sizing agents. The preparation method has the advantages of simplicity, short reaction time and high efficiency.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

High-temperature-resistant and impact-resistant cable material

InactiveCN106084781AGood high and low temperature resistanceImprove corrosion resistanceRubber insulatorsDibutyltin oxideTemperature resistance

The invention discloses a high-temperature-resistant and impact-resistant cable material. The high-temperature-resistant and impact-resistant cable material is prepared from, by weight, 70-90 parts of silicone rubber, 30-40 parts of modified polyurethane, 20-30 parts of kaolin, 40-60 parts of organized montmorillonoid, 2-4 parts of tributyl citrate, 30-40 parts of aluminum hydroxide, 8-10 parts of zinc borate, 0.8-1.5 parts of 2,5-dimethyl-2,5-di(tert-butylperoxy)hexane, 0.1-0.2 part of sulphur, 0.1-0.3 part of an accelerant BZ, 3-5 parts of dibutyltin oxide and 3-5 parts of paraffin oil. The high-temperature-resistant and impact-resistant cable material is high in impact resistance, high temperature resistance and mechanical property.

Owner:ANHUI HAIRONG CABLE

Method for continuously preparing and supplementing organic tin catalyst in sucralose production

InactiveCN111574572ASave installation costSave production costEsterified saccharide compoundsSugar derivativesAcetic anhydridePtru catalyst

The invention relates to a method for continuously preparing and supplementing an organic tin catalyst in sucralose production. The method comprises the following steps of pumping a cyclohexane phasecontaining organic tin acetate recovered after acylation in the previous batch into a distillation kettle, and supplementing 1-5% of dibutyltin oxide according to the amount of the organic tin acetateadded before esterification, and heating to a certain temperature, keeping the temperature, performing reacting, distilling under reduced pressure to remove the solvent after the reaction, and reusing the prepared organic tin acetate in the sucralose production process. According to the method, the acylation reaction of the dibutyltin oxide is carried out by fully utilizing the acetic anhydride remained in the cyclohexane extraction phase recovered in the previous batch in the production, so that the production device and the production cost of the sucralose catalyst are saved, the process issimplified, the production efficiency is greatly improved, the working intensity of operators is reduced, the pollution is reduced, and the environment is protected. The utilization rate of residualraw material is increased by using a novel process, so that the reaction efficiency and the material utilization rate are optimized in the whole production process, and the economic benefit of an enterprise is obviously increased.

Owner:ANHUI JINGHE IND

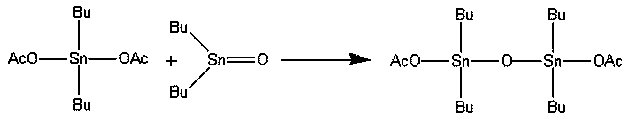

Preparation method of catalyst organotin acetate in sucralose production

InactiveCN111592564AImprove the on-site environmentReduce manufacturing costTin organic compoundsSugar derivativesPtru catalystDibutyltin oxide

The invention relates to a preparation method of a catalyst organotin acetate (DSDA) in sucralose production. The method comprises the following steps: directly reacting dibutyltin diacetate and dibutyltin oxide at a certain temperature to obtain organotin acetate (DSDA), and distilling the reacted material under reduced pressure to remove impurities, thereby obtaining the organotin acetate (DSDA)which can be used in sucralose esterification reaction. The method is simple and smooth in process, and can basically realize one-step implementation. And under the same equipment condition, the production efficiency is greatly improved. The problems of solvent volatilization and high energy consumption in the prior art are solved, and the solvent and steam consumption is reduced; and the environment is protected, the working intensity of field operators is greatly reduced, and the working environment is improved.

Owner:ANHUI JINGHE IND

PVC (polyvinyl chloride) wood-plastic composite added with shell powder

InactiveCN105086254AReduce frictional heatHigh mechanical strengthEnvironmental resistanceBenzoyl peroxide

The invention discloses a PVC (polyvinyl chloride) wood-plastic composite added with shell powder. The PVC wood-plastic composite added with the shell powder is prepared from the following raw materials in part by weight: 30-40 parts of wood powder, 10-20 parts of butyl acrylate, 0.02-0.03 part of benzoyl peroxide, 0.01-0.02 part of N, N-dimethylaniline, 3-4 parts of polyethylene wax, 1-1.2 parts of dilauryl thiodipropionate, 1.5-2 parts of calcium stearate, 95-100 parts of polyvinyl chloride, 2-3 parts of AC foaming agents, 1-2 parts of cell regulator ACR530, 6-8 parts of chlorinated polyethylene, 1-2 parts of dibutyltin oxide, 4-5 parts of shell powder, 3-4 parts of nitrile rubber powder and 0.2-0.4 part of silane coupling agents kh570. By the PVC wood-plastic composite added with the shell powder, the problem of material processing is solved. The PVC wood-plastic composite is good in processability and attractive in appearance; added ingredients are biological and environment-friendly; the cost is low; various properties are excellent; and the PVC wood-plastic composite is worthy of being popularized.

Owner:ANHUI BEIMA TECH CO LTD

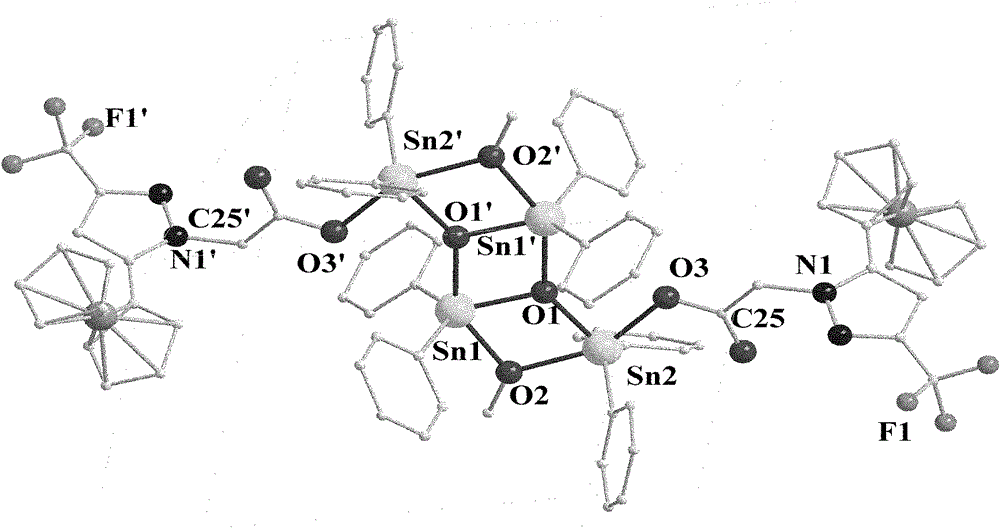

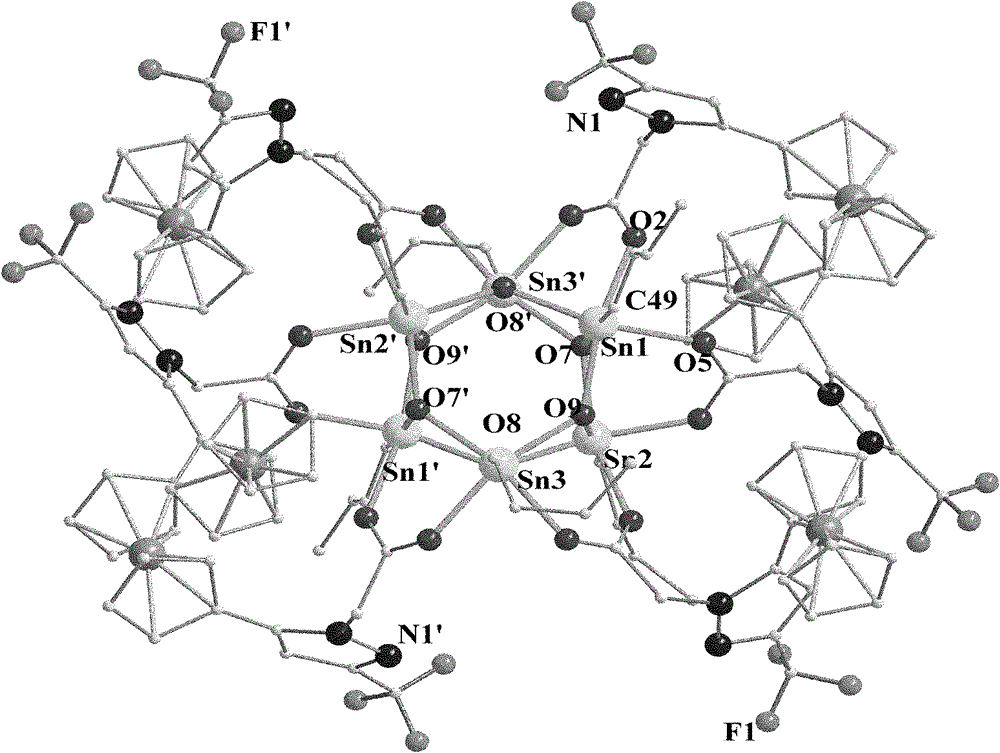

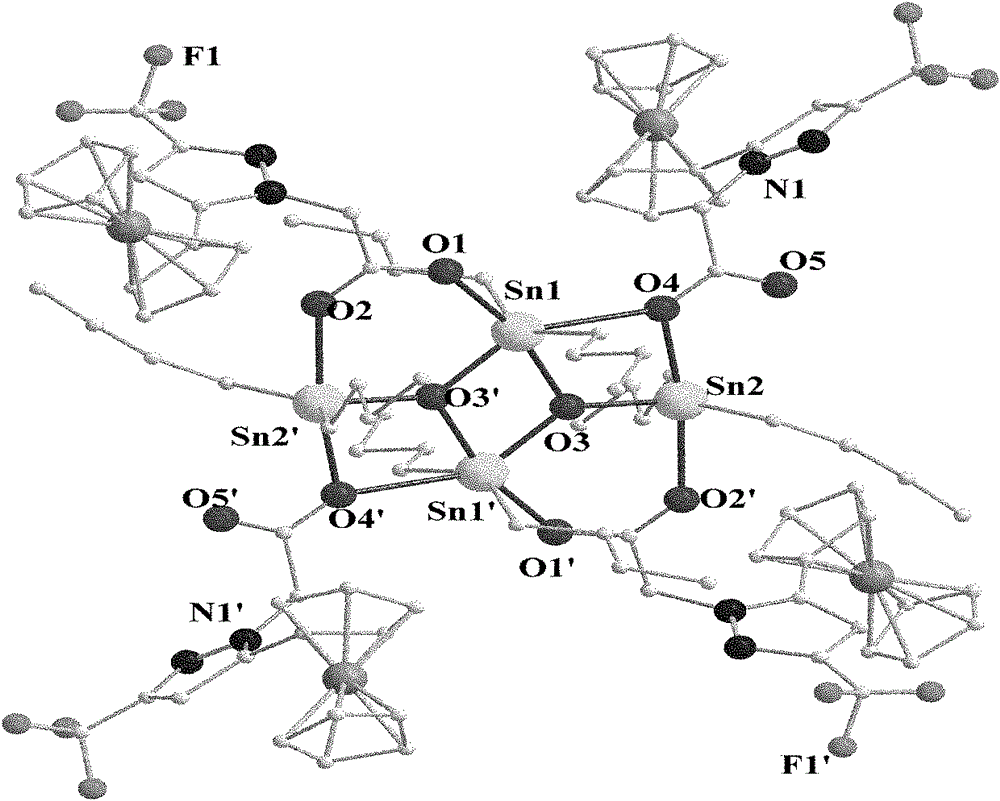

Organotin-oxygen cluster containing ferrocene pyrazole and application of cluster

InactiveCN102093431BImprove biological activityLow toxicityTin organic compoundsAntineoplastic agentsDibutyltin oxideCoordination complex

The invention provides an organotin-oxygen cluster containing ferrocene pyrazole. The cluster is characterized in that the complexes with the following chemical formulas are prepared from a ligand 3-trifluoromethyl-5-ferrocene pyrazole acetic acid (LCOOH) and monobutyltin oxide, dibutyltin oxide and triphenyltin hydroxide respectively: [BuSnO(OOCL)]6, [Ph4Sn2O(OCH3)(OOCL)]2 and [Bu4Sn2O(OOCL)2]2.The cluster has inhibiting effects on human lung cancer cells (A549), hepatoma cells (HepG2) and mouse melanoma (B16-F10) and the inhibiting effects are obviously superior to the inhibiting effects of the control drugs 5-fluorouracil and cisplatin, so the cluster can be applied to preparing the anti-tumor drugs.

Owner:ANHUI UNIVERSITY

Low-shrink resin for mould pressing technology

The invention relates to low-shrink resin for a mould pressing technology. The low-shrink resin is prepared from the following components: 15-25% of ethylene glycol, 10-20% of propylene glycol, 55-65%of adipic acid, 5-15% of maleic anhydride and 0.002-0.005% of dibutyltin oxide; a preparation method of the low-shrink resin comprises the following steps: (1) sequentially putting the ethylene glycol, propylene glycol, adipic acid, maleic anhydride and dibutyltin oxide into a reaction kettle; (2) reacting for 48h; measuring the center control acid value at 50+ / -2; cooling to 180 DEG C; discharging and diluting through a dilution kettle connected with the reaction kettle. The low-shrink resin provided by the invention has good compatibility with matrix resin and also can meet the needs of themould pressing technology.

Owner:宜兴市兴合树脂有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com