Patents

Literature

604results about How to "Save production cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

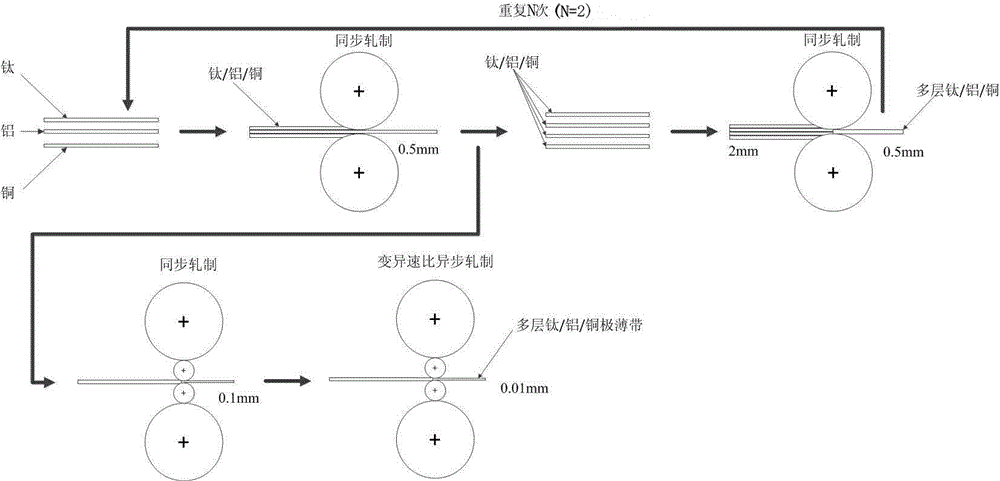

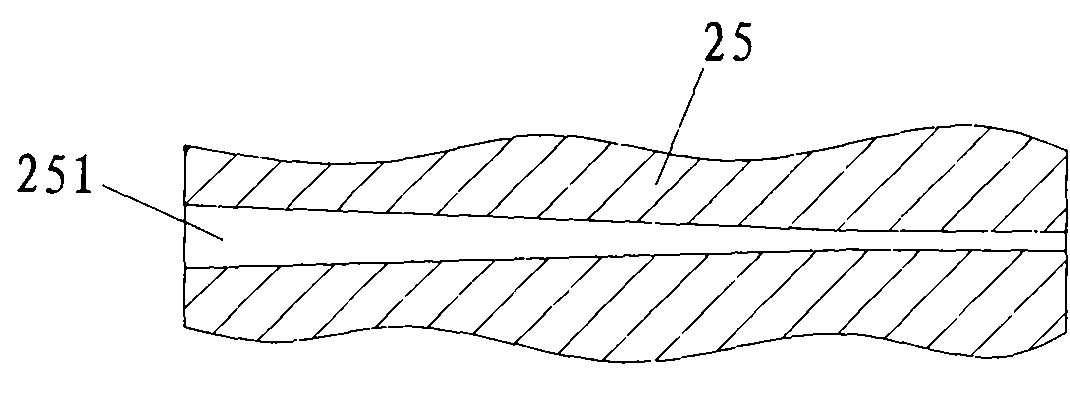

Preparation method for multilayer dissimilar metal composite ultra-thin strip

ActiveCN105170652AWide range of choicesEliminate intermediate heating processMetal rolling arrangementsRoll speed control deviceThinningMetal

The invention provides a preparation method for a multilayer dissimilar metal composite ultra-thin strip. The preparation method includes the process steps that (1) different metal materials are synchronously cold-rolled for first thinning; (2) metal thin strips are polished and cleaned; (3) the upper surfaces and lower surfaces of two or more metal thin strips are closely attached; (4) two-roll synchronous cold rolling is conducted on dissimilar metal combined strips; (5) the upper surfaces and lower surfaces of 2-10 dissimilar metal thin strips subjected to preliminary combination are closely attached and then the procedures of the step (1) to the step (4) are repeated 2-10 times; (6) reversible four-roll synchronous cold rolling is conducted on a multilayer dissimilar metal composite thin strip; and (7) reversible four-roll asynchronous cold rolling is conducted on the multilayer dissimilar metal composite thin strip, and the multilayer dissimilar metal composite ultra-thin strip with the thickness being 0.01 mm-0.02 mm is obtained. According to the method, the selection range of the metal materials is wide, the requirement for equipment capacity is low, and the surface quality of the ultra-thin strip can be improved remarkably; besides, production resources are saved, production cost is reduced, and the method is suitable for large-scale industrial production.

Owner:NORTHEASTERN UNIV

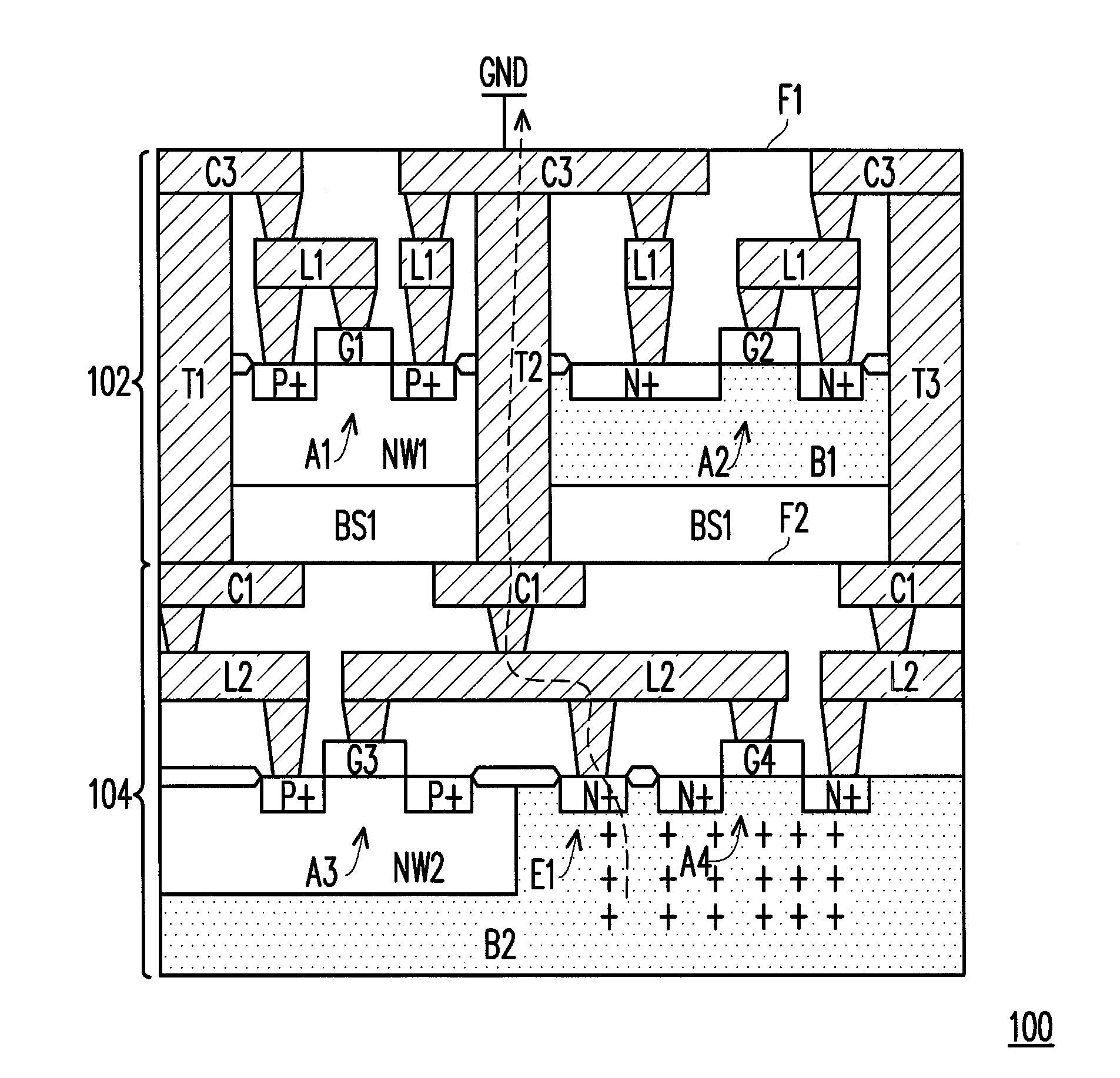

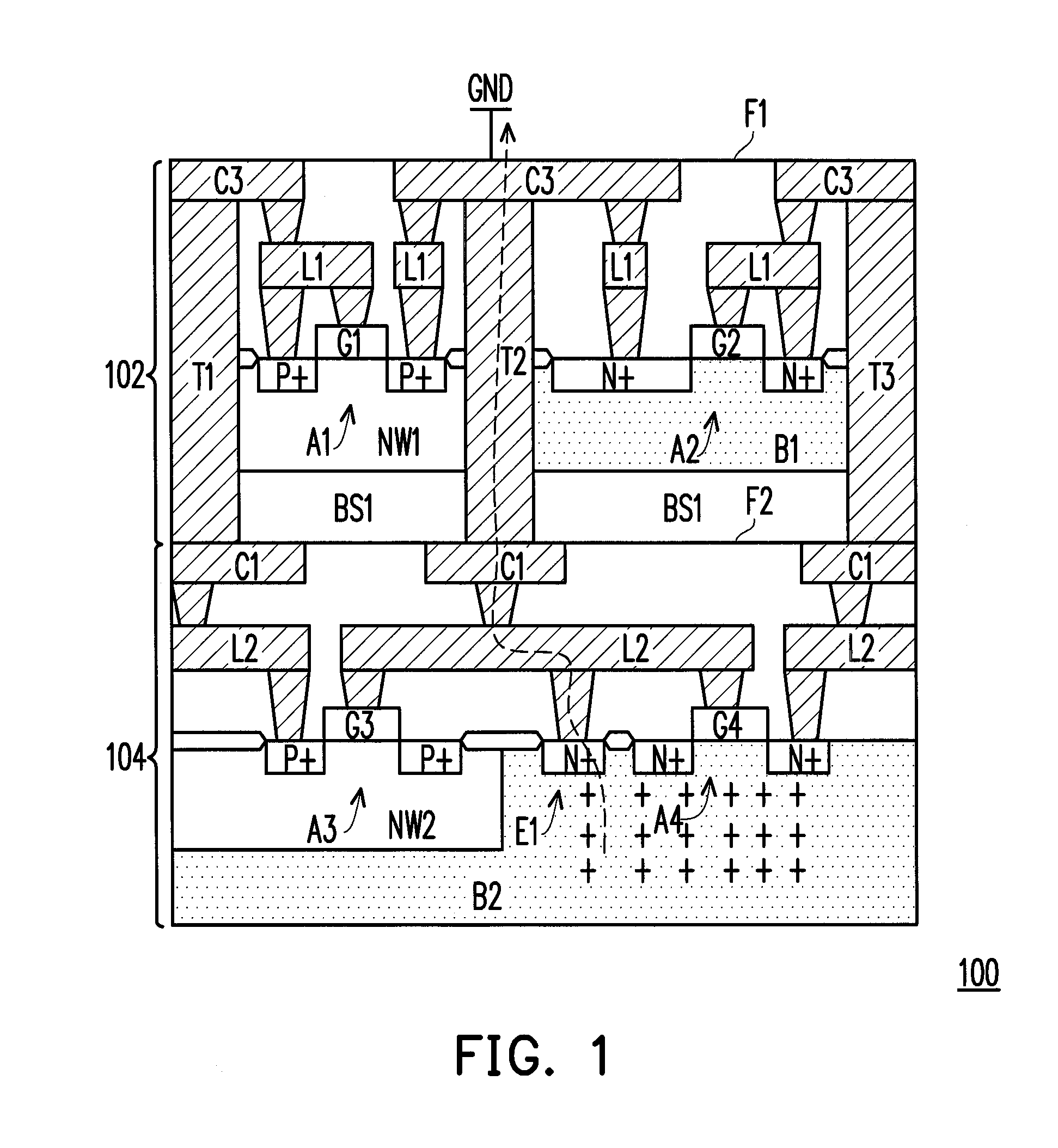

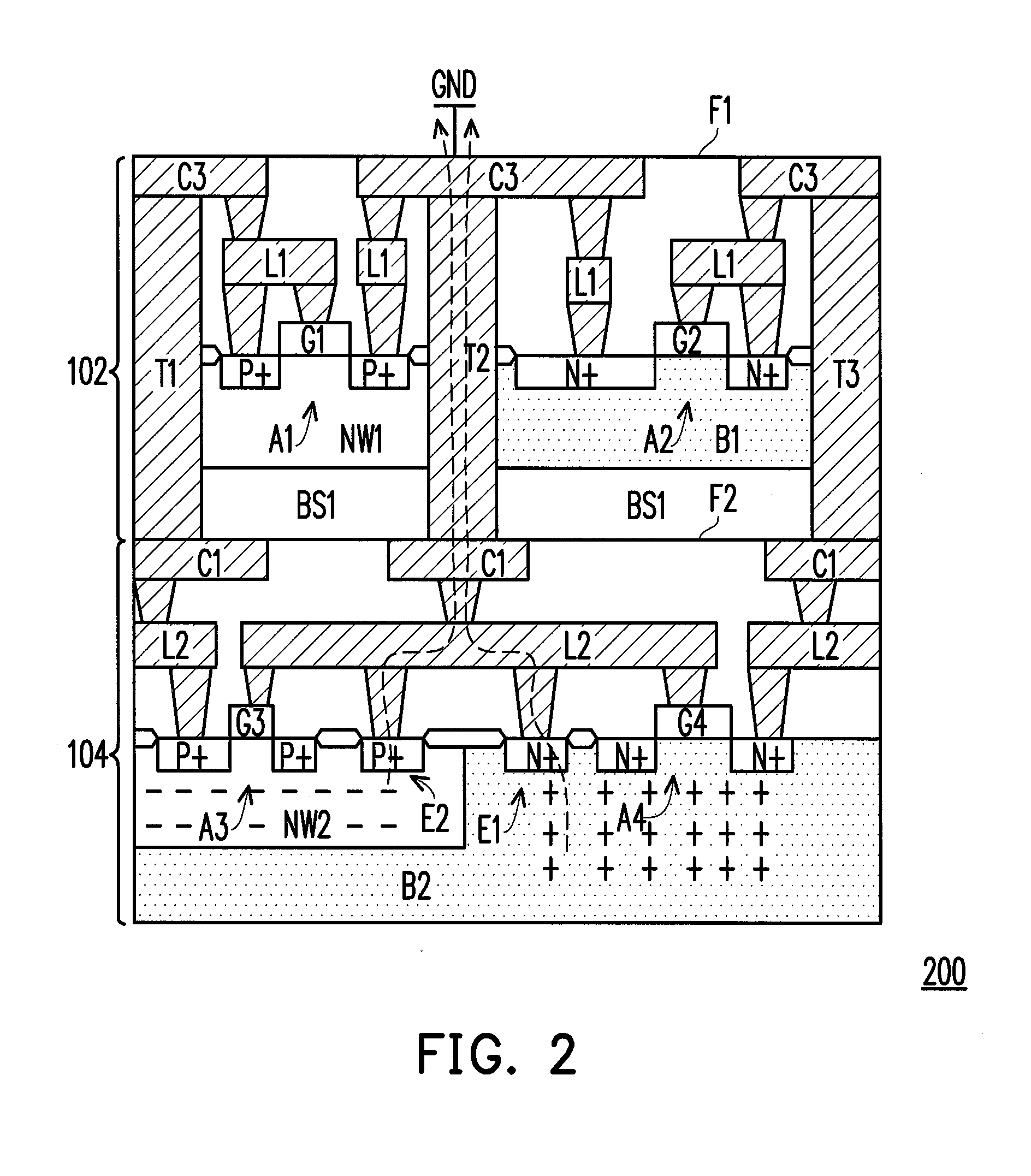

ESD protection structure for 3D IC

InactiveUS20120153437A1Reduce manufacturing costEffective ESD protectionSemiconductor/solid-state device detailsSolid-state devicesEngineeringActive layer

An electrostatic discharge (ESD) protection structure for a 3D IC is provided. The ESD protection structure includes a first active layer, a through-silicon via (TSV) device and a second active layer. The TSV is disposed in the first active layer, and the second active layer is stacked with the first active layer. The second active layer includes a substrate and an ESD protection device, wherein the ESD protection device having a doping area embedded in the substrate, and the ESD protection device electrically connects the TSV device.

Owner:NAT CHIAO TUNG UNIV

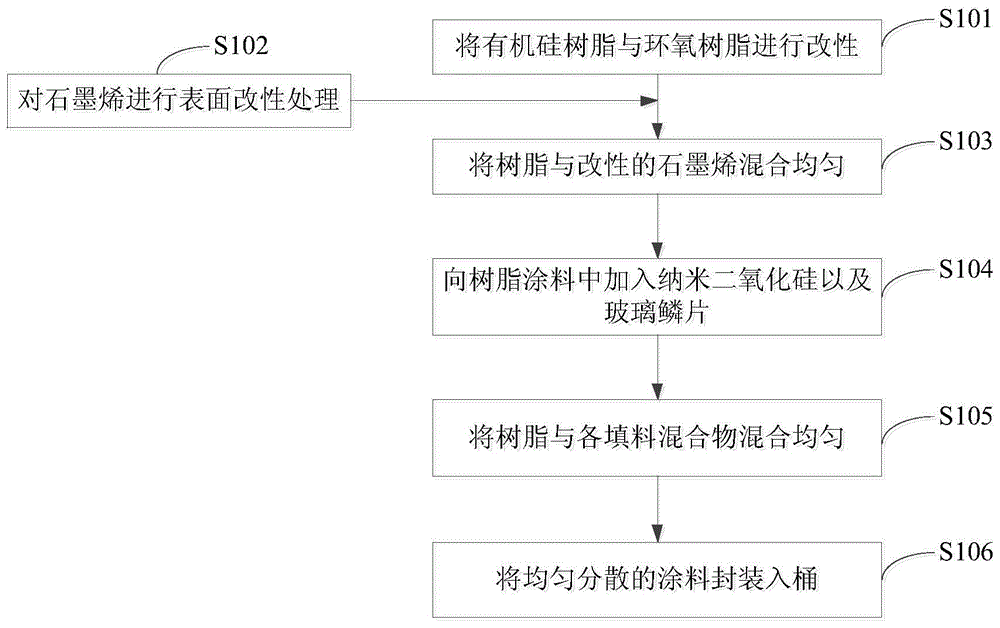

Novel abrasion-resistant, anti-corrosion and anti-static coating and preparation method thereof

InactiveCN105219219AEffectively dissipate static electricityEffective anti-electromagnetic interference capabilityAnti-corrosive paintsEpoxy resin coatingsCarbon nanotubeSilicon dioxide

The invention relates to a novel highly-abrasion-resistant, anti-corrosion and anti-static coating and a preparation method thereof. The coating comprises basic thermosetting resin and a filler, wherein the basic thermosetting resin is modified resin for coatings; the filler is formed through blending and combining one or more of a carbon nano tube, carbon black, graphite, graphene, nano aluminum powder and conductive mica powder with one or more of quartz sand, glass flake, nano silicon dioxide, nano-molybdenum disulfide, aluminium oxide and modified montmorillonite. The coating is directly smeared or sprayed on the surface of a metal outer shell of electronic and electrical equipment, the equipment can be effectively prevented from being corroded by the environment for a long time, and the influence of pad points and electromagnetic interference on the safe, normal and stable use of the equipment is prevented.

Owner:HUZHOU ELECTRIC POWER SUPPLY CO OF STATE GRID ZHEJIANG ELECTRIC POWER CO LTD +1

Universal nutrient solution for soilless culture leafy vegetables

InactiveCN102557807AIncrease productionSave labor costFertilizer mixturesNutrient solutionCopper sulfate

The invention provides a universal nutrient solution for soilless culture leafy vegetables and belongs to the technical field of soilless culture. A formula is as follows: 1 ton of water contains 600-700g of potassium nitrate, 400-500g of magnesium sulfate, 150-200g of ammonium dihydrogen phosphate, 800-900g of calcium nitrate, 20-60g of chelated iron, 2-3g of borax, 1.5-2.0g of manganese sulfate, 0.3-0.5g of zinc sulfate, 0.1-0.2g of copper sulfate and 0.01-0.05g of ammonium molybdate. Aiming at the special leafy vegetable nutrient solution for the current soilless culture, the nutrient solution provided by the invention has the characteristics of wide application, good culture effect and high yield, and the problem of mixed soilless culture of multiple varieties of leafy vegetables is solved. The nutrient solution provided by the invention is suitable for soilless culture of multiple varieties of leafy vegetables; and by using the nutrient solution, the yield is improved by more than 10%, and the effective management of a regional multiple-variety leafy vegetable mixing culture system in an agricultural sightseeing garden is achieved.

Owner:彭常安

Dry type manufacturing method of animal specimen

InactiveCN1971663AImprove qualityAdequate perfusionDead animal preservationEducational modelsHigh concentrationGlycerol

The invention relates to a dry type making method for animal specimen that includes six steps: collecting material, reshaping antisepsis fix and tube cavity cast, alcohol dewatering fix, glycerol process, turpentine impregnation and air drying, material repairing tinction preservation or seal up for keeping. Thereinto, in step 1, the animal material is bleed and killed via health quarantine, in step 2, potting it with the formalin with colorless glycerin and phenol or alcohol solution, in step 3, controlling the concentration of every step and fixed time, in step 4, marinating it with glycerol moisture absorption soften liquid, and transfer it from low concentration to high concentration of glycerin, and the time is prolonged gradually, in step 5, treating it with turpentine continually, in step 6, printing it. The invention improves the present technique, the quality of specimen is improved greatly, and that can keep the original state of material, the color and the luster. The dried specimen is sanitation without peculiar smell, and good at handle and quality.

Owner:王荣林

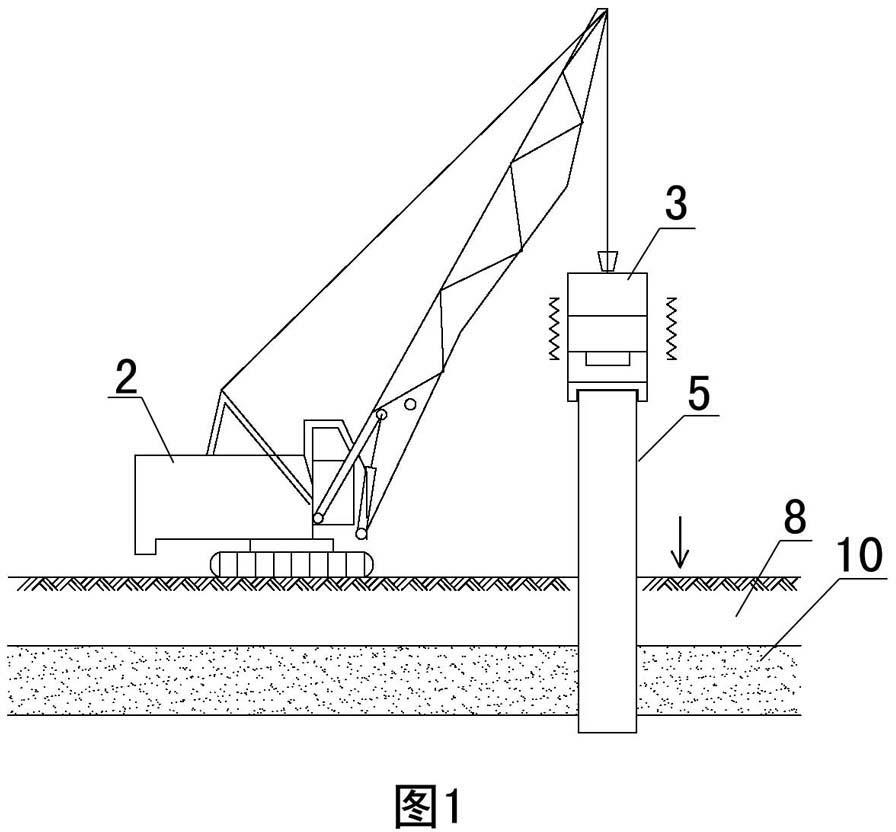

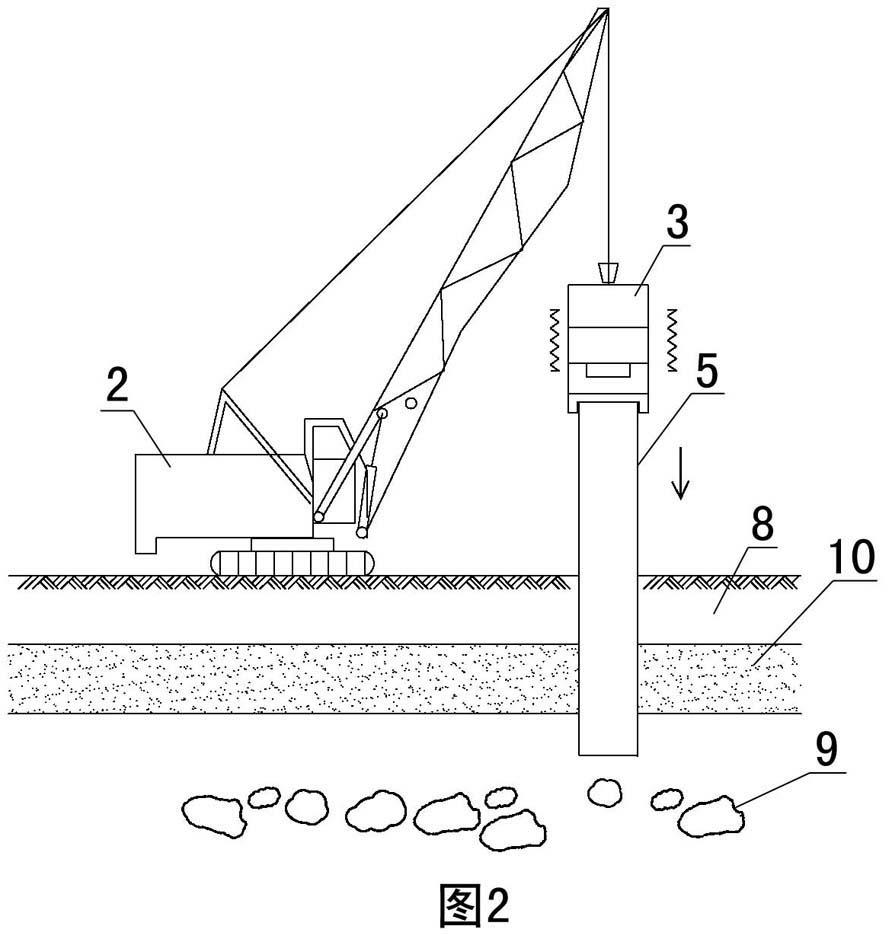

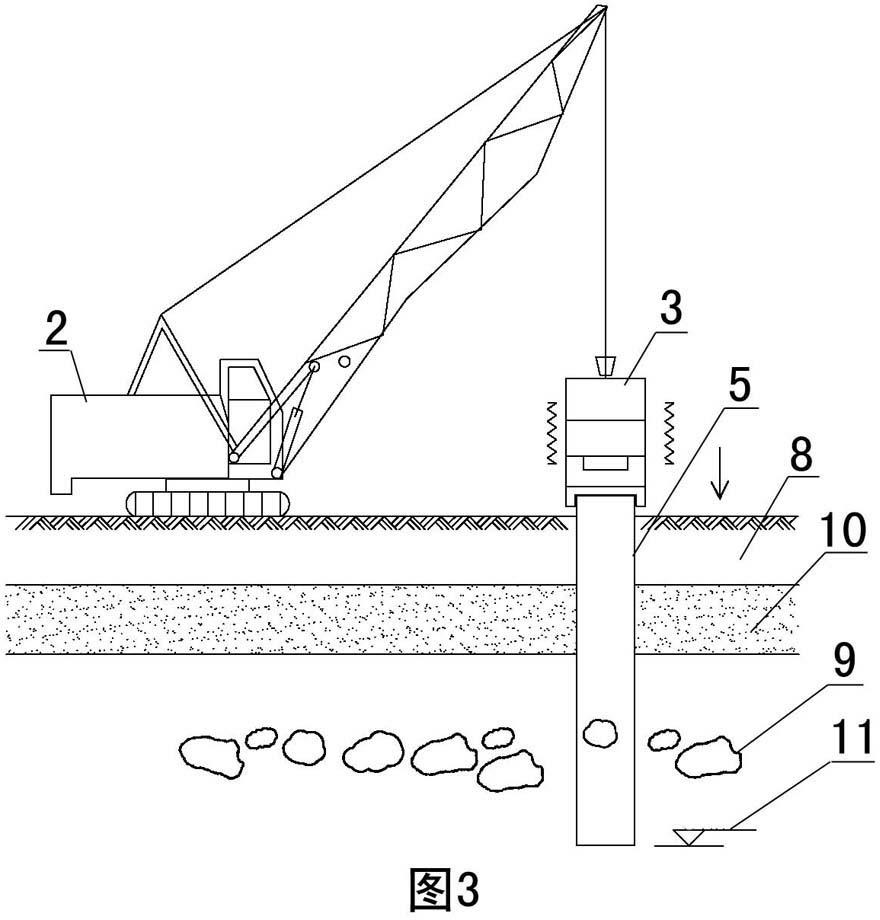

Rotary-digging combined pile-forming construction method in complicated geological conditions

InactiveCN102644275AEnsure safetySolve the technical problems of easy reamingBulkheads/pilesSlagRebar

The invention provides a rotary-digging combined pile-forming construction method in complicated geological conditions. The method comprising the following steps of: firstly, positioning a pile foundation; secondly, positioning a steel protecting barrel; thirdly, sinking the steel protecting barrel; fourthly, when the steel protecting barrel penetrates through a boulder layer without encountering the boulder, sinking the steel protecting barrel to the design elevation by using a vibration hammer; fifthly, starting a rotary digging and drilling machine to perform rotary digging and drilling at the inner side of the steel protecting barrel; sixthly, hoisting an impacting and catching hammer by a hoist, and downwards hammering and impacting the boulder by the impacting and catching hammer; seventhly, starting the rotary digging and drilling machine to continuously perform rotary digging and drilling to the design elevation; eighthly, fishing slag from the bottom of a hole; ninthly, checking and accepting a final hole; tenthly, aligning the skeleton of a steel reinforcement cage to the opening of the hole and slowly hoisting into the hole by the hoist; eleventhly, secondly cleaning the bottom; twelfthly, concreting; and thirteenthly, after primarily setting the concrete, lifting up the steel protecting barrel by the hoist. The method has the advantages of high safety and reliability, strong stratum adaptability and high construction progress and is suitable for the pile foundation engineering in cities with complicated geological conditions.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

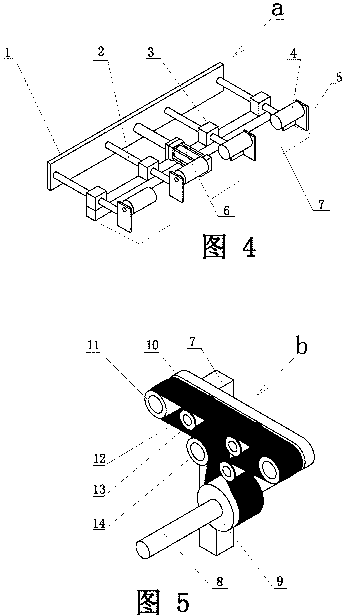

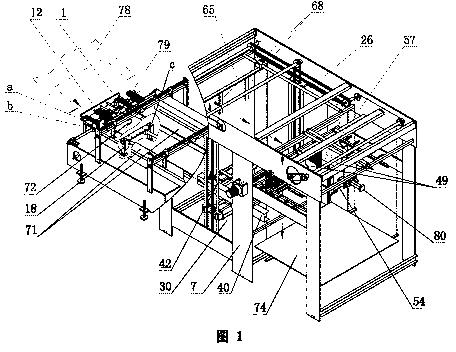

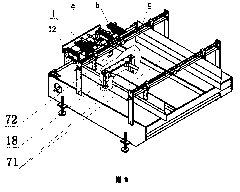

Automatic paper lamination stacking machine

The invention discloses an automatic paper lamination stacking machine which comprises a rack, wherein a paper lifting plate and a paper conveying belt are arranged in the rack; the paper conveying belt is arranged in front of the paper lifting plate; the upper plane of the paper conveying belt is lower than the upper end surface of the paper lifting plate; a paper support plate is arranged in front of the paper conveying belt; a movable paper pushing arm is arranged at the corresponding position of the paper support plate; a counting sensor is arranged in the rack at the end of the paper support plate close to the paper conveying belt and electrically connected with a control device of the machine; a lifting device is arranged on the rack and is in transmission connection with a turnover frame; a paper holding arm and a paper blocking arm are arranged on the turnover frame; a paper moving plate capable of sliding along the horizontal direction and a movable stacking paper support plate capable of going up and down in the vertical direction are mounted on the rack; the paper moving plate is located at the top of the lifting device; the movable stacking paper support plate is arranged in front of the paper moving plate; a stacking transition platform is arranged between the movable stacking paper support plate and the lifting device; a paper aligning plate is also arranged on the rack; and the paper aligning plate is located above the movable stacking paper support plate. The automatic paper lamination stacking machine disclosed by the invention has the advantages of high production efficiency and good stacking quality.

Owner:YANCHENG HONGJING MACHINERY SCI & TECH CO LTD

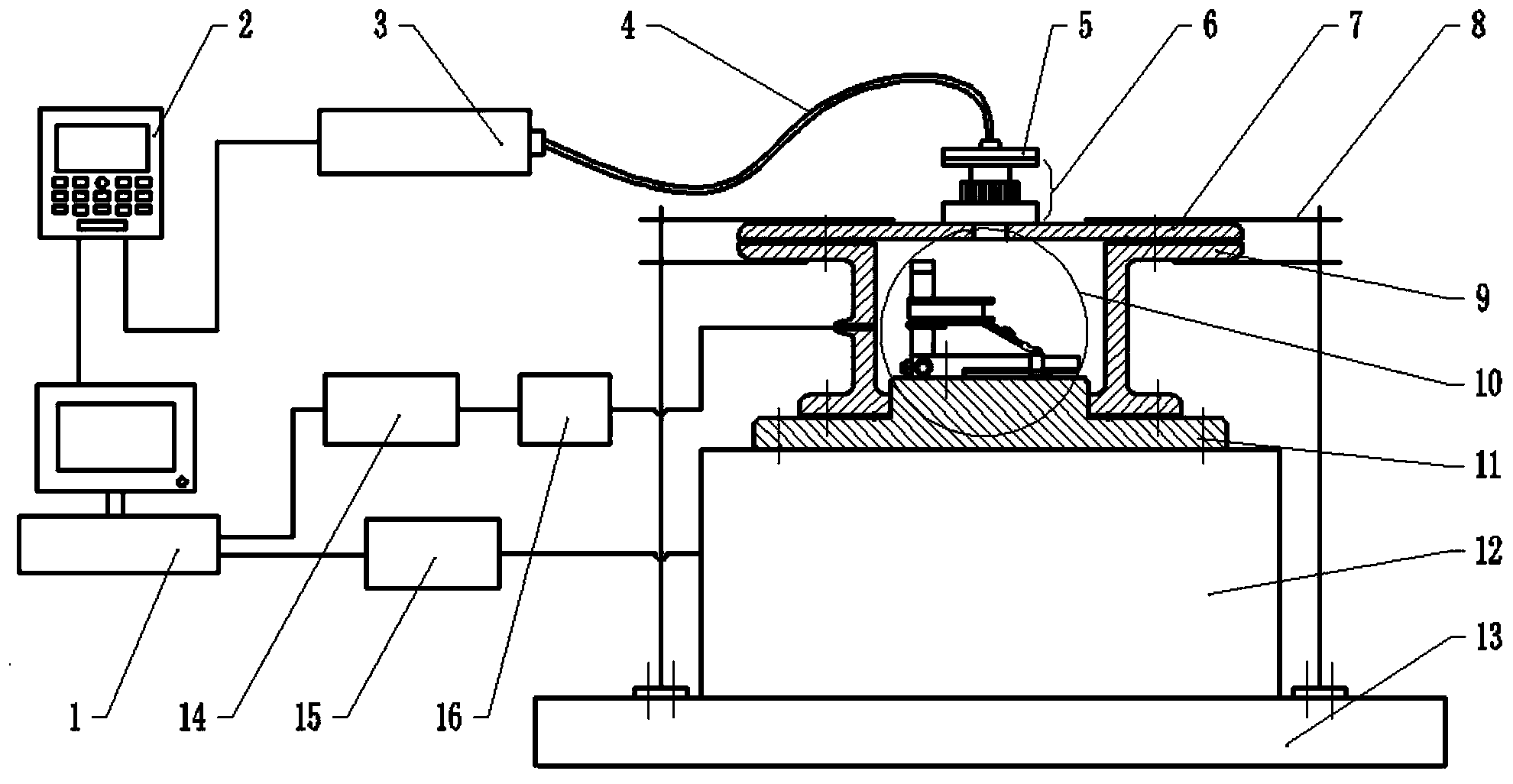

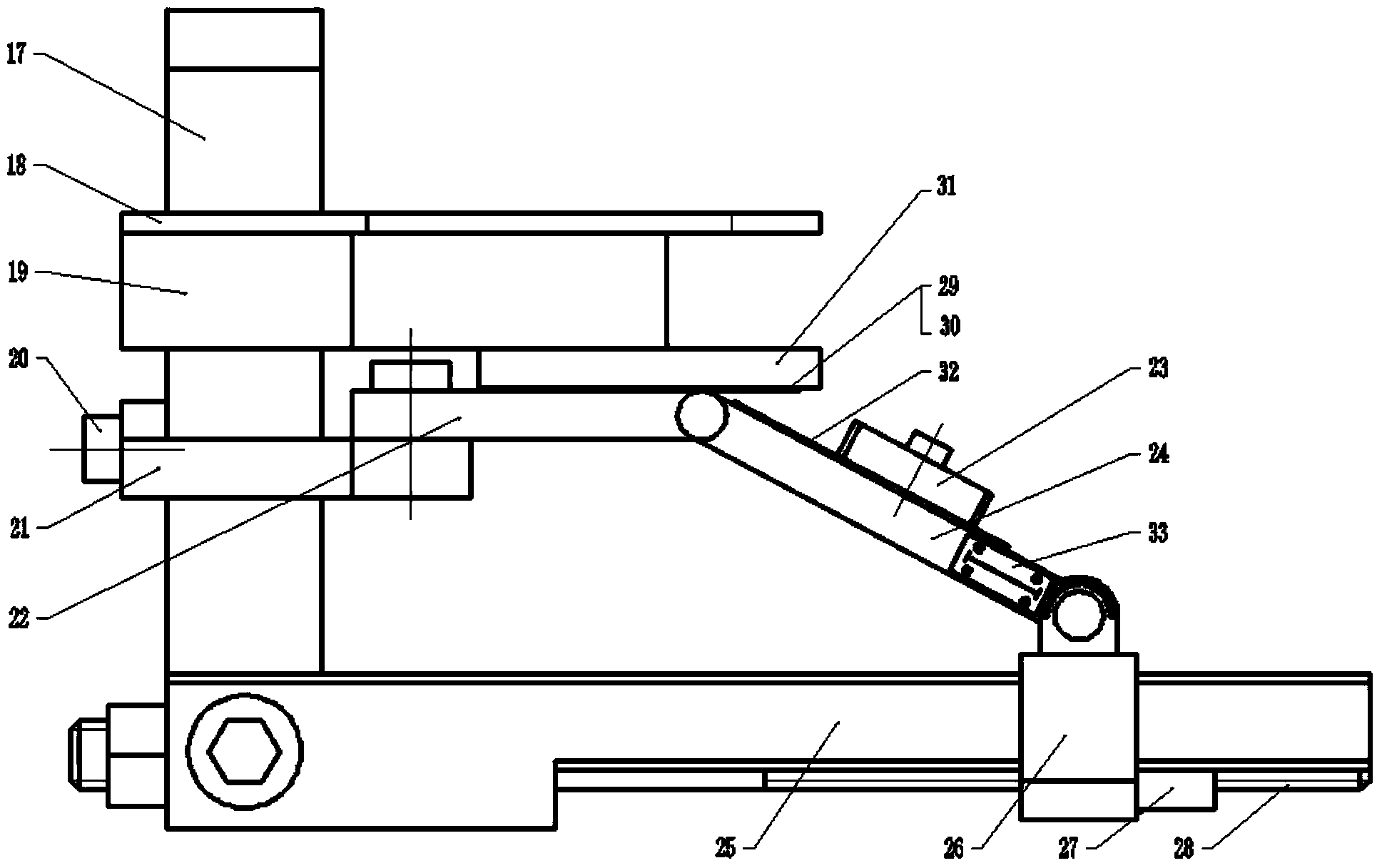

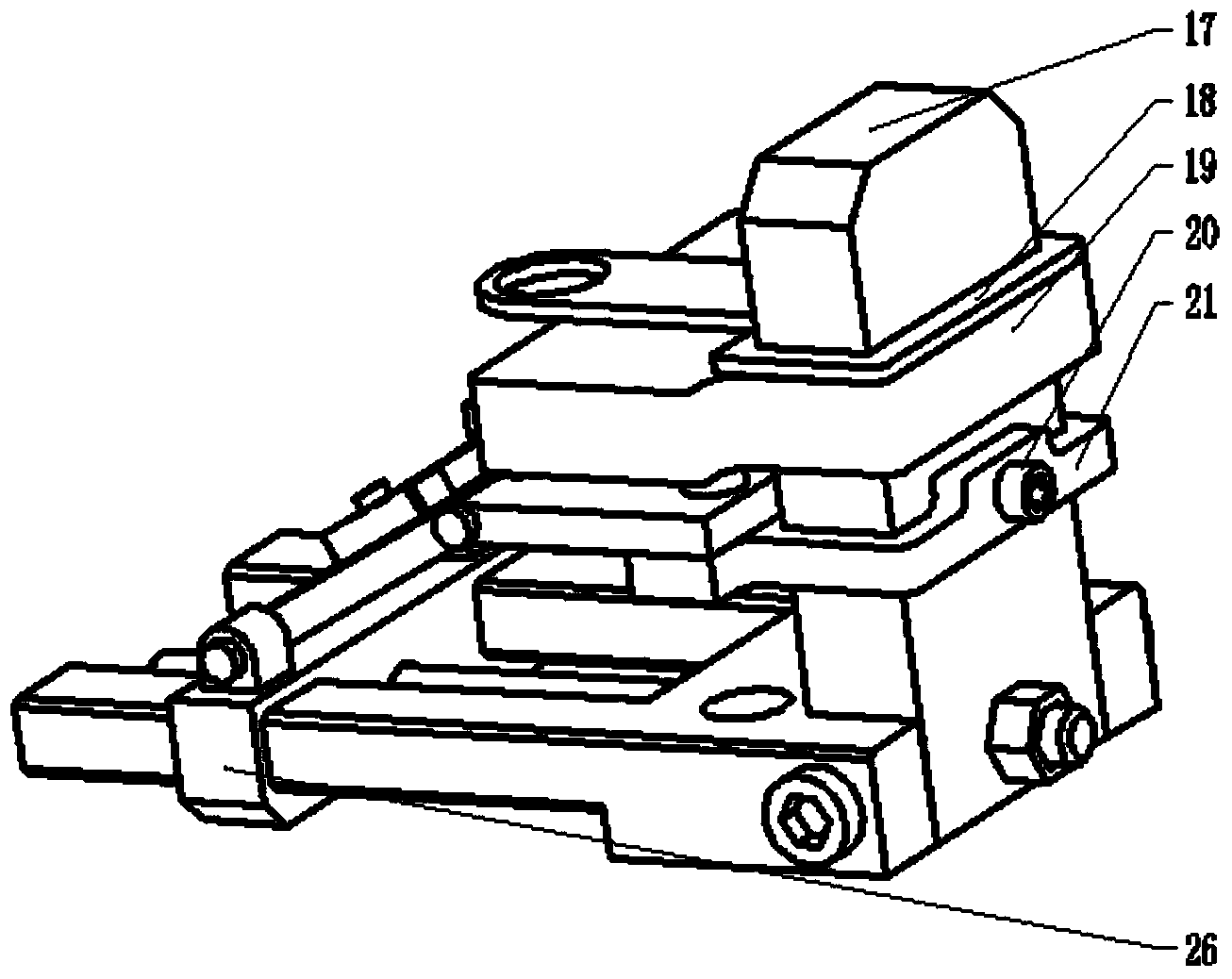

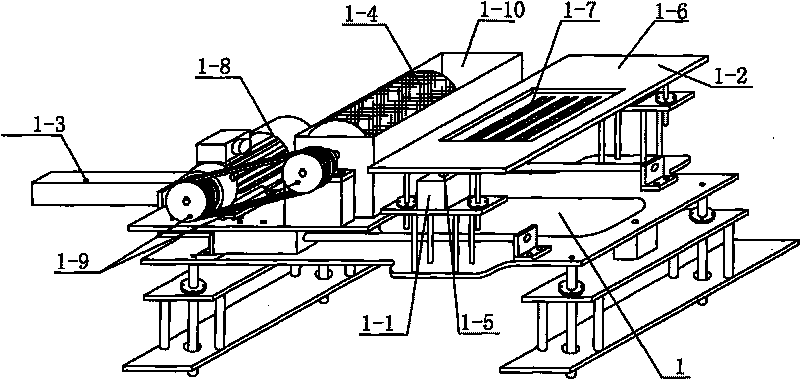

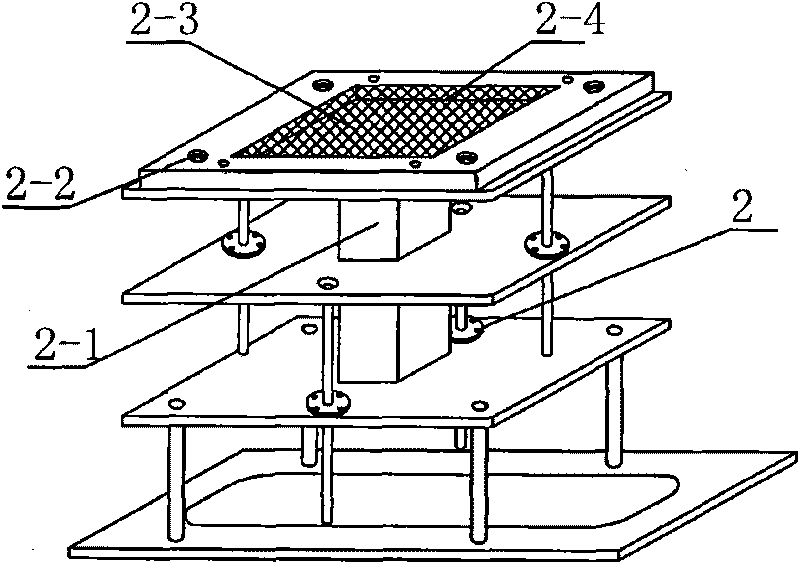

Laser shock welding device with shock angle continuously adjustable under vacuum environment

InactiveCN103722291AReduce productionFacilitates verification of the impact of laser shock welding on qualityWelding/cutting auxillary devicesAuxillary welding devicesComputer control systemEngineering

The invention provides a laser shock welding device with the shock angle continuously adjustable under a vacuum environment. The device comprises a computer control system, a laser generating system, a vacuum system and a clamp, wherein the clamp is located in a vacuum chamber and fixed on the bottom surface of the vacuum chamber, the clamp comprises a horizontal working platform with the vertical position adjustable and an inclined working platform with the inclining angle adjustable, the laser generating system is connected with the vacuum chamber through a light path, and the laser generating system and the vacuum system are both connected with the computer control system. According to the device, continuous adjustment of the shock angle is achieved during laser shock welding, resistance of the atmosphere to an ultra-thin composite plate material under the high-speed shock condition is eliminated, and welding performance is effectively improved.

Owner:JIANGSU UNIV

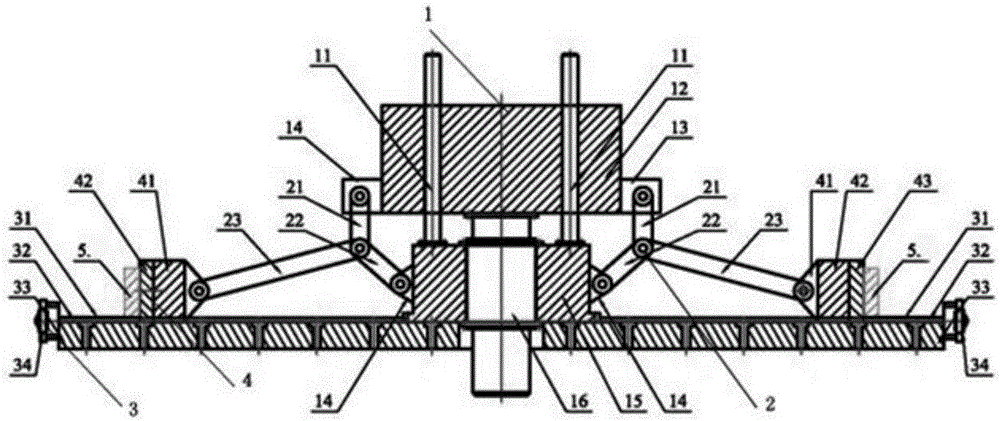

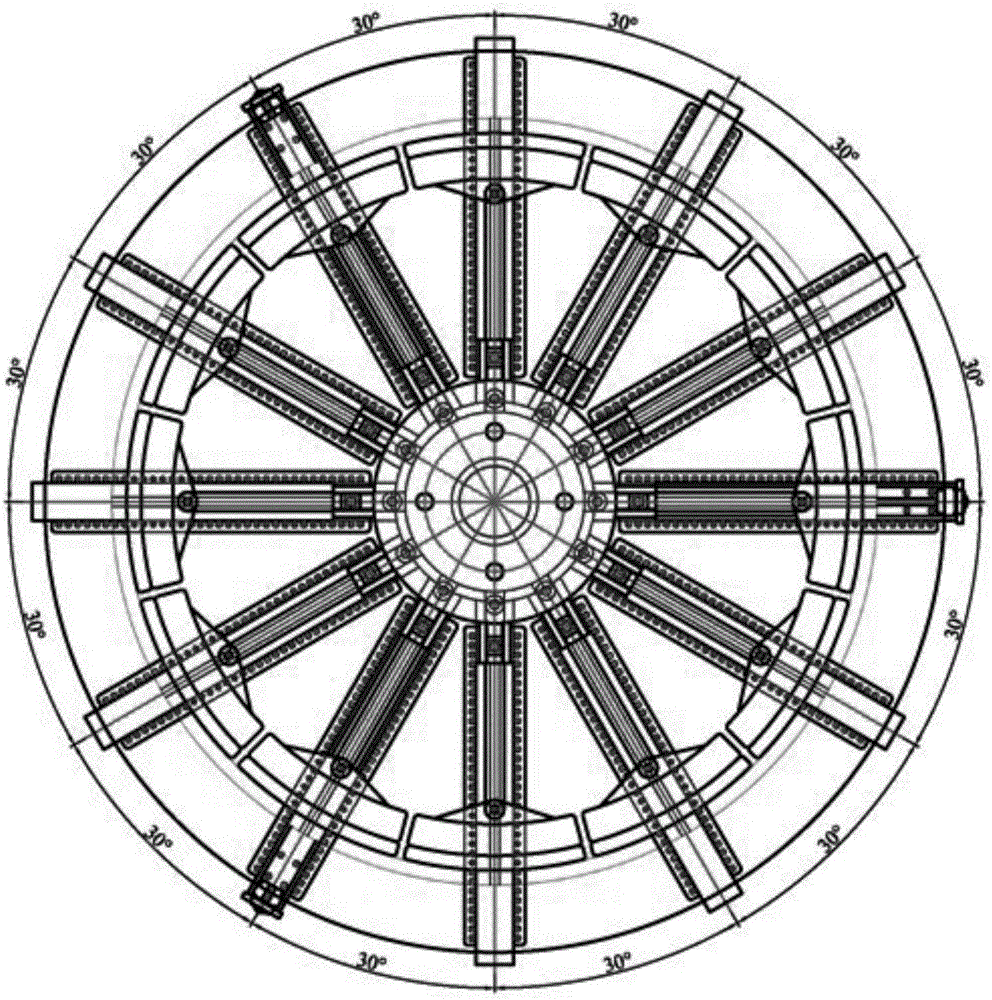

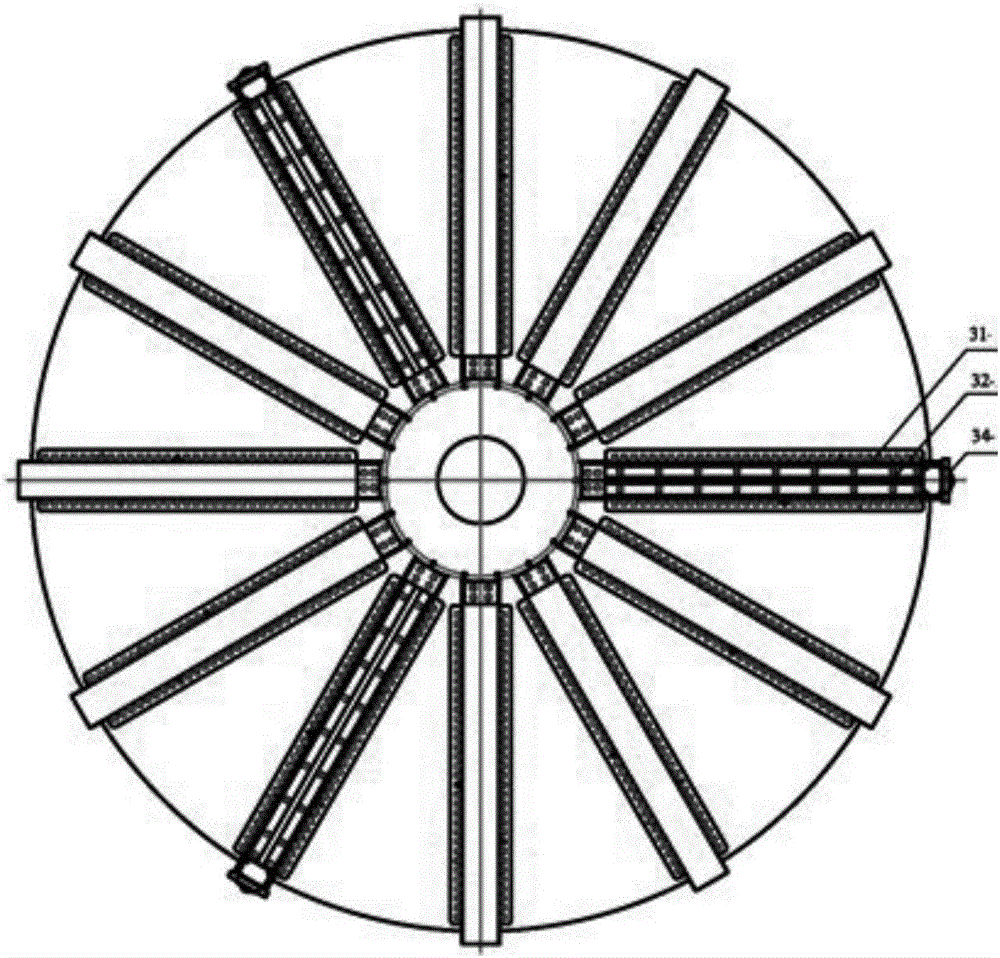

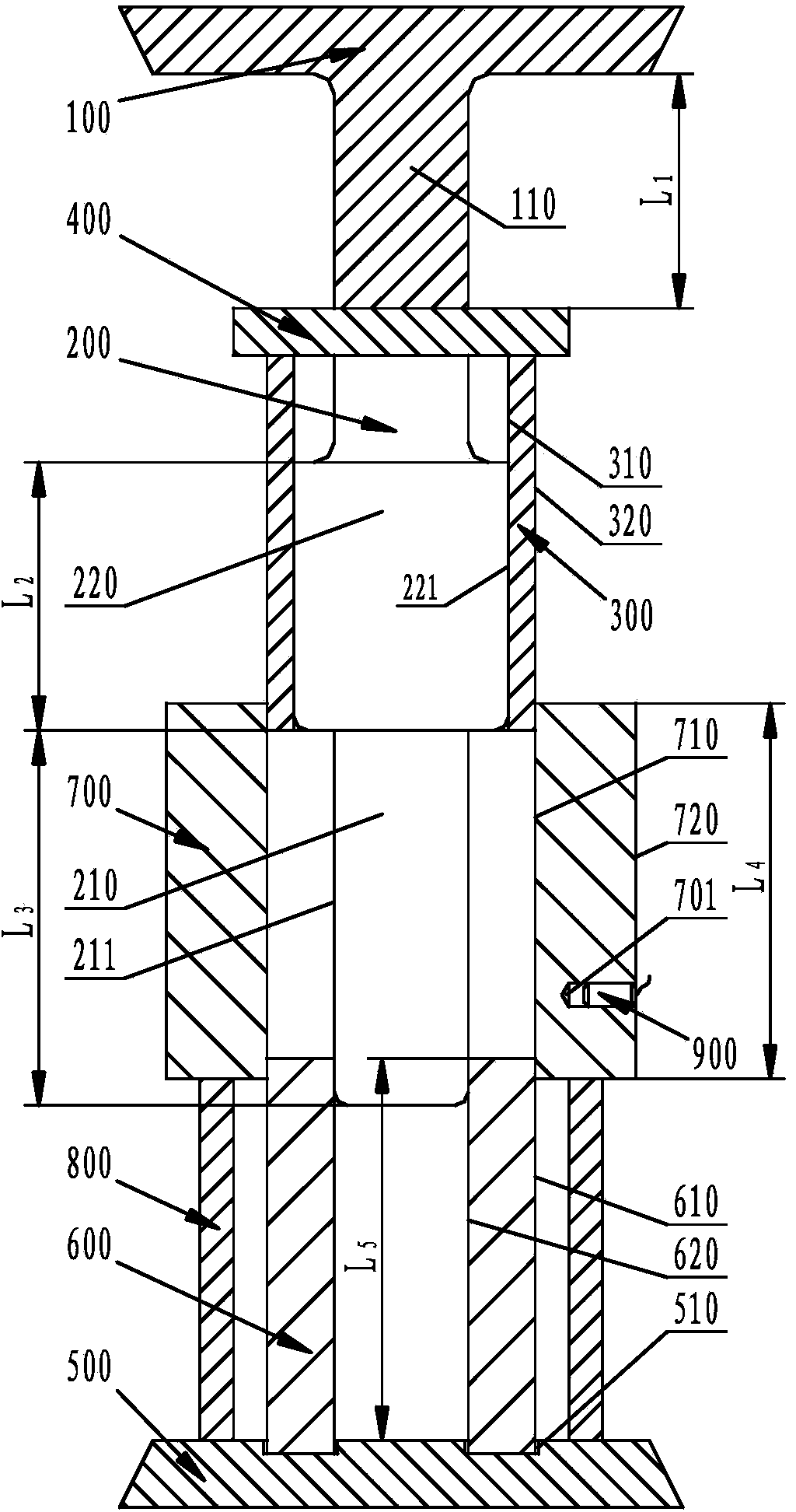

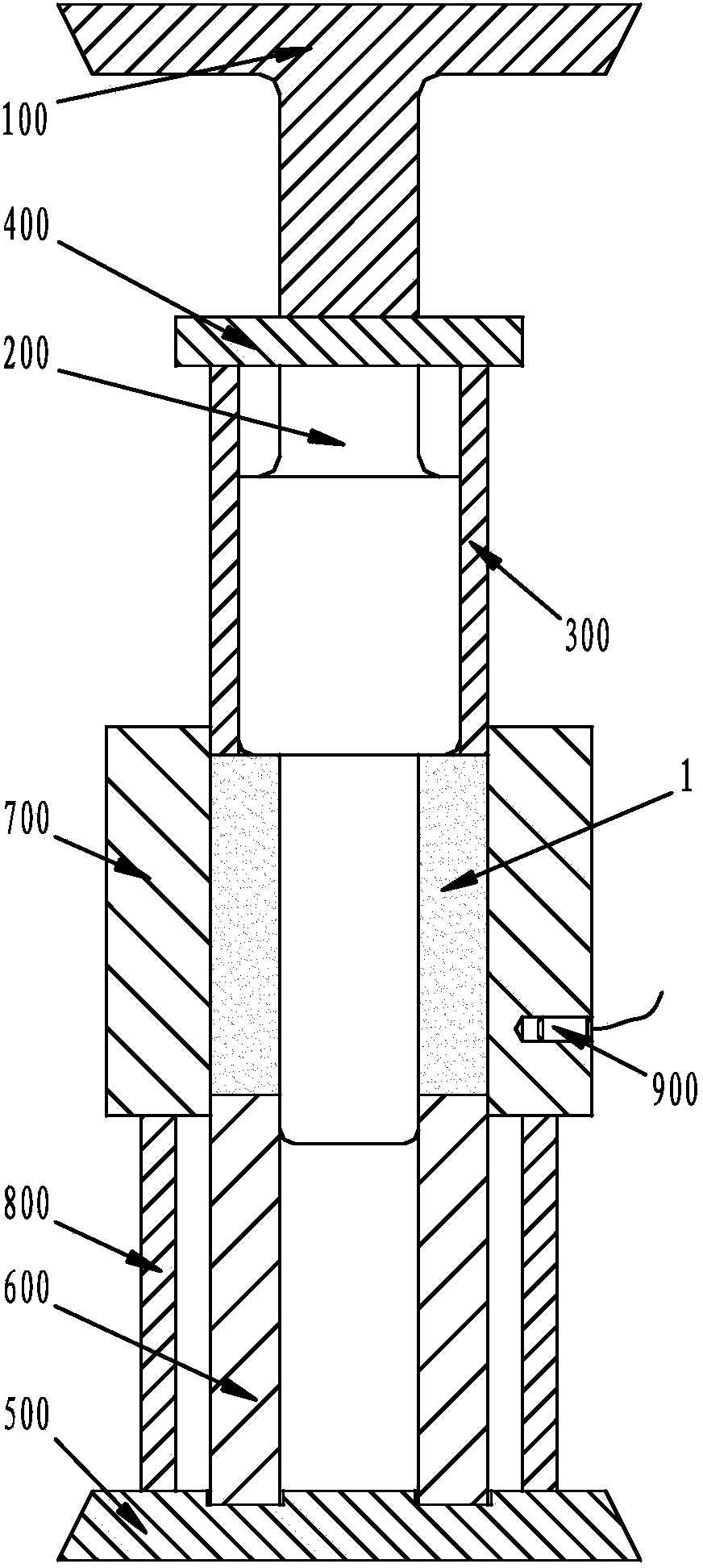

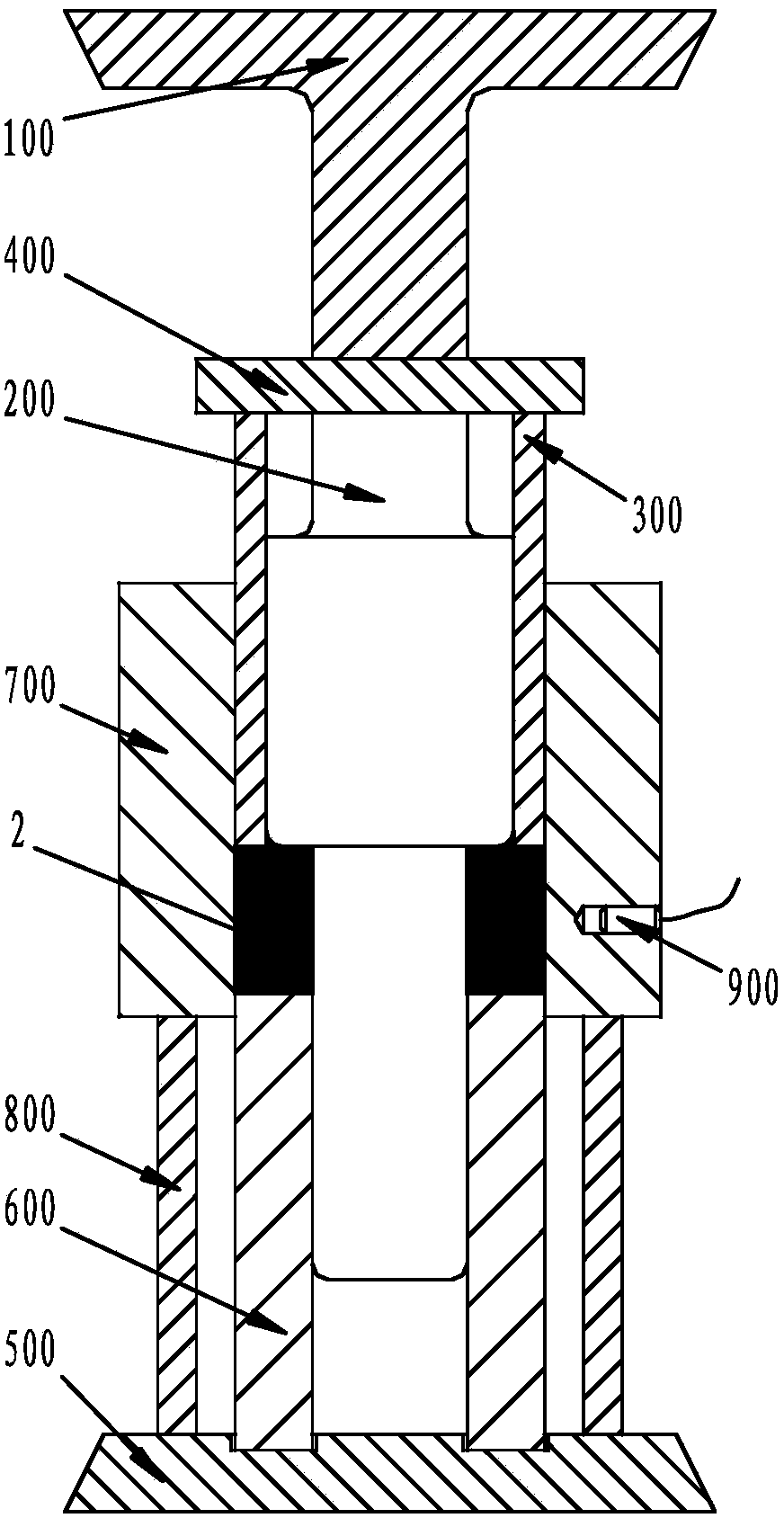

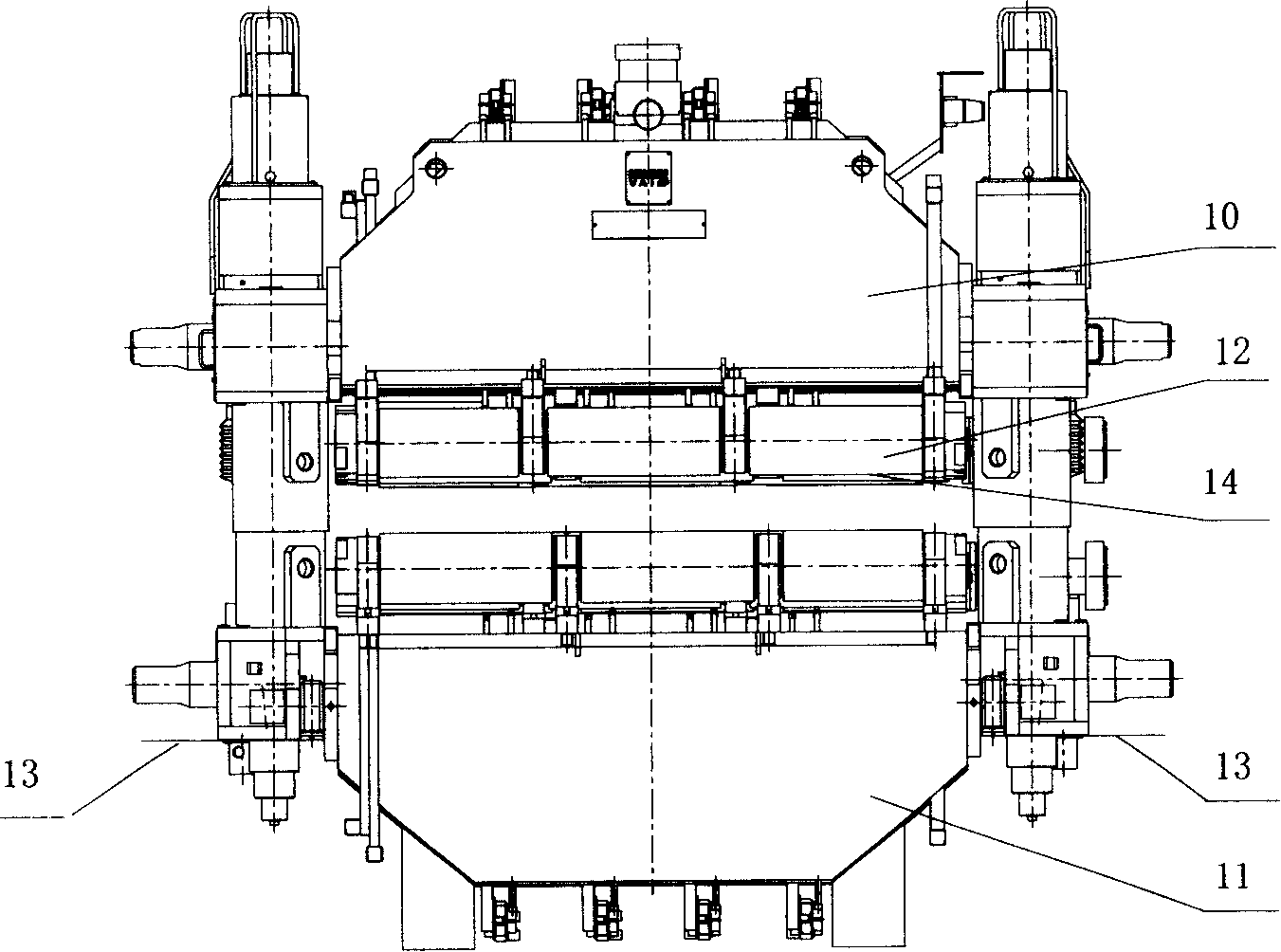

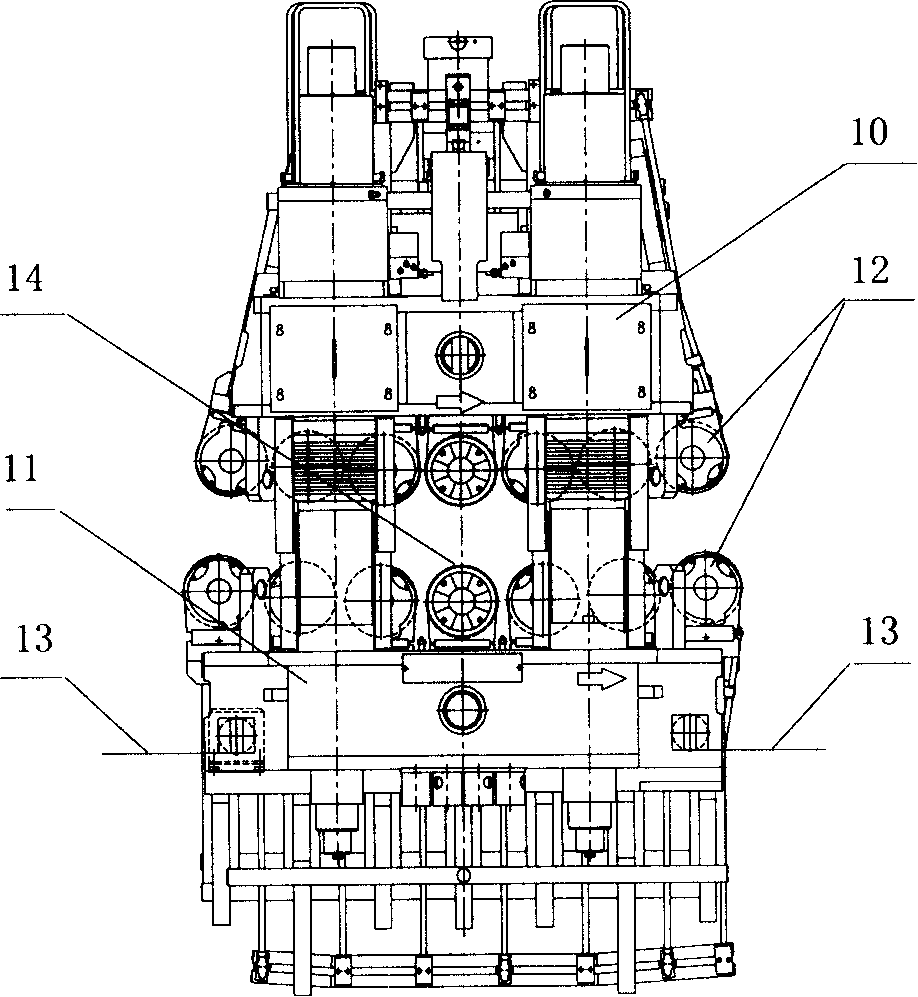

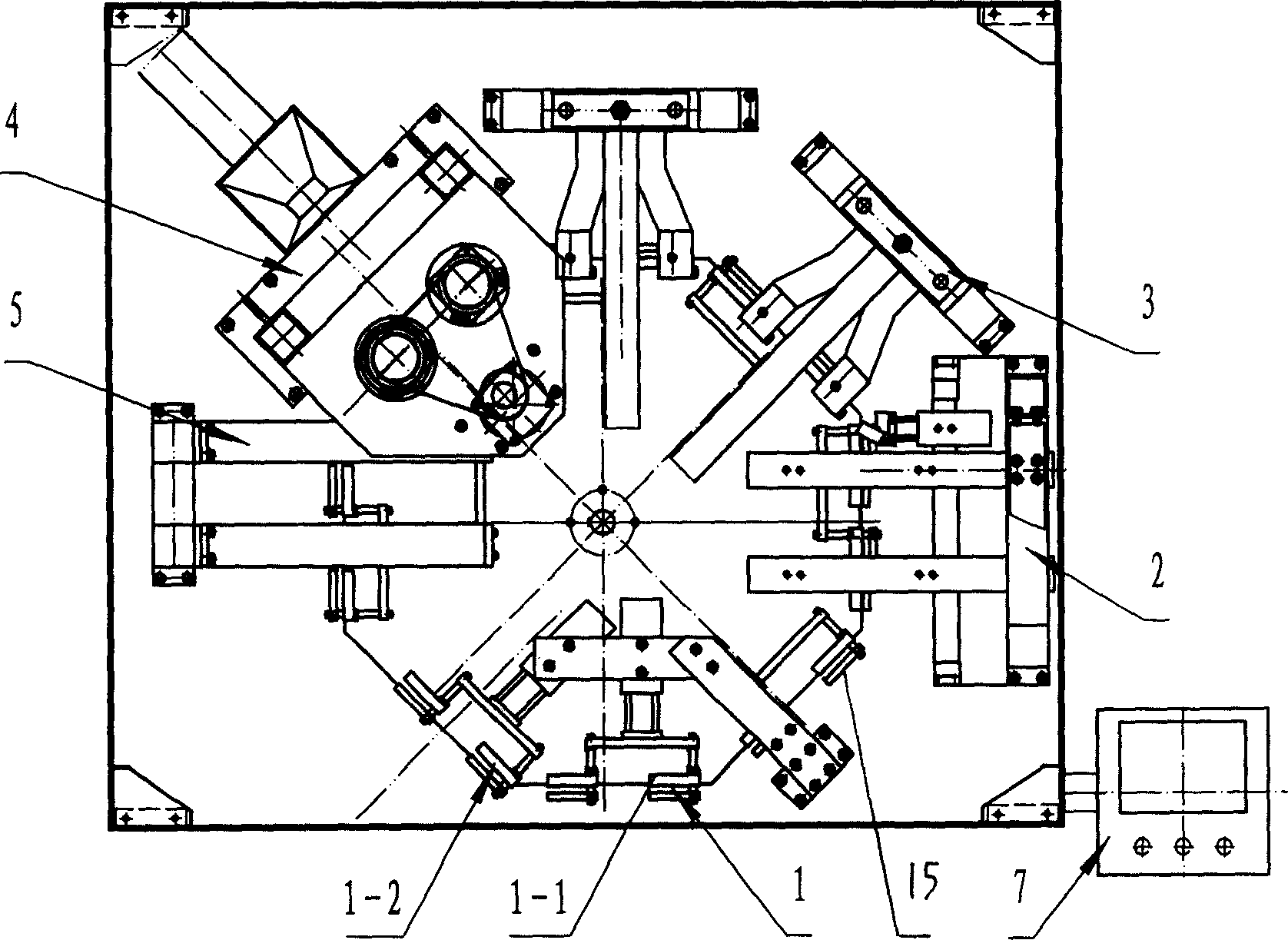

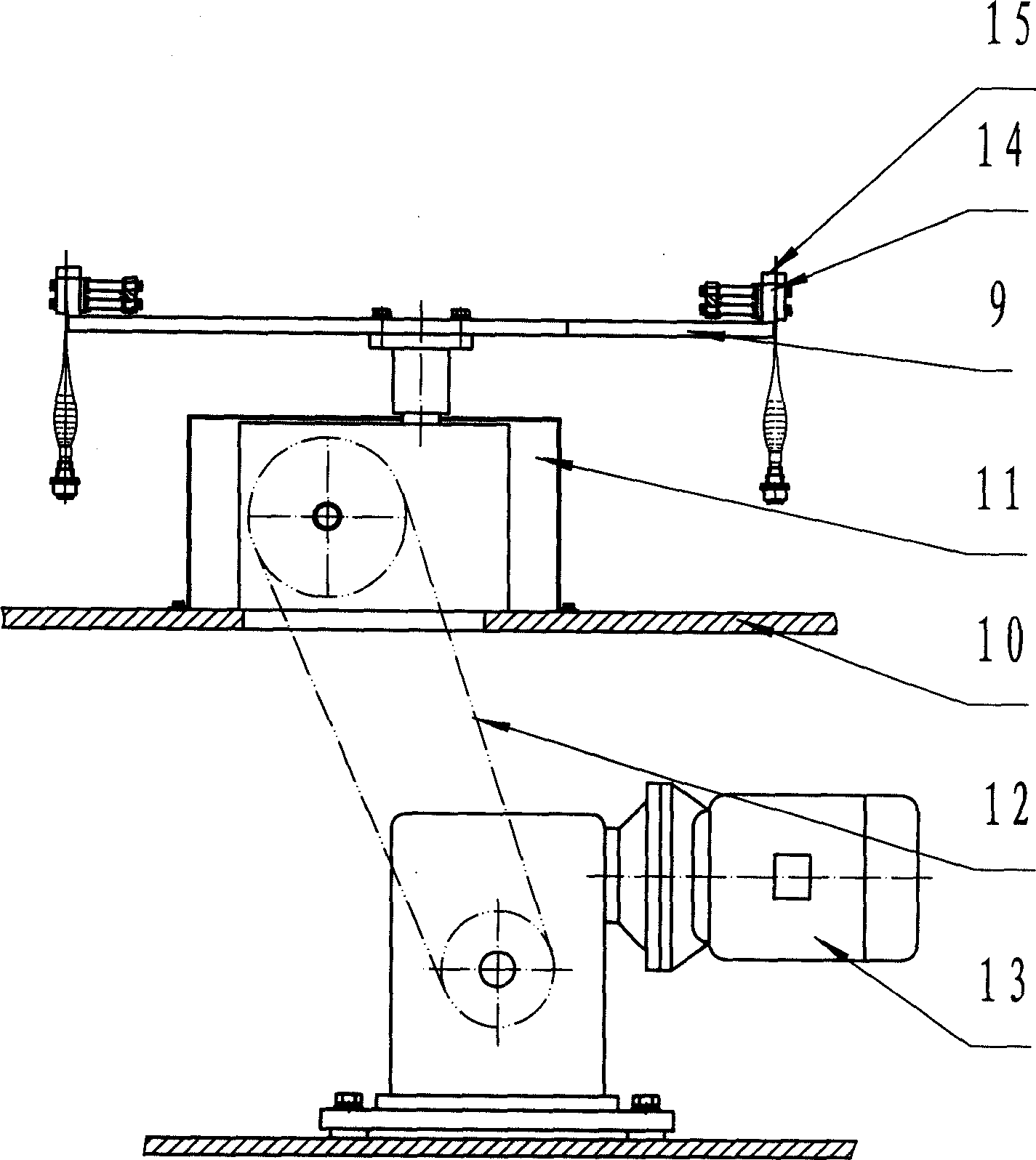

Mechanical expanding machine for large-diameter ring piece

ActiveCN106216538AEasy to useMeet the needs of expanding forceShaping toolsHydraulic cylinderEngineering

The invention discloses a mechanical expanding machine for a large-diameter ring piece. The mechanical expanding machine for the large-diameter ring piece comprises a piston cylinder, a supporting disk, a fixed workbench and a sliding block. The fixed workbench is arranged at the center of the upper surface of the supporting disk. The piston cylinder is installed in the fixed workbench and is connected with the lower end face of the fixed workbench through a piston rod. At least two hinged rod force amplifying devices are evenly arranged in the circumferential direction of the fixed workbench. Sectioned male dies corresponding to the hinged rod force amplifying devices are evenly distributed on the supporting disk in the circumferential direction of the fixed workbench. The bottom of each sectioned male die is provided with a guide groove, and each sectioned male die slides in a radial guide rail on the supporting disk under the action of the corresponding hinged rod force amplifying device. According to the mechanical expanding machine for the large-diameter ring piece, a hinged rod force amplifying mechanism is adopted, force exerted by the hydraulic cylinder on the sliding block is amplified, and therefore the mechanical expanding machine can obtain large output force. The mechanical expanding machine for the large-diameter ring piece is particularly suitable for expanding of the large-diameter ring piece with the diameter larger than 5 m. In addition, the hinged rod force amplifying mechanism is convenient to use and maintain, accessories of the hinged rod force amplifying mechanism are convenient to replace, and the production and manufacturing cost of the hinged rod force amplifying mechanism is low.

Owner:CENT SOUTH UNIV

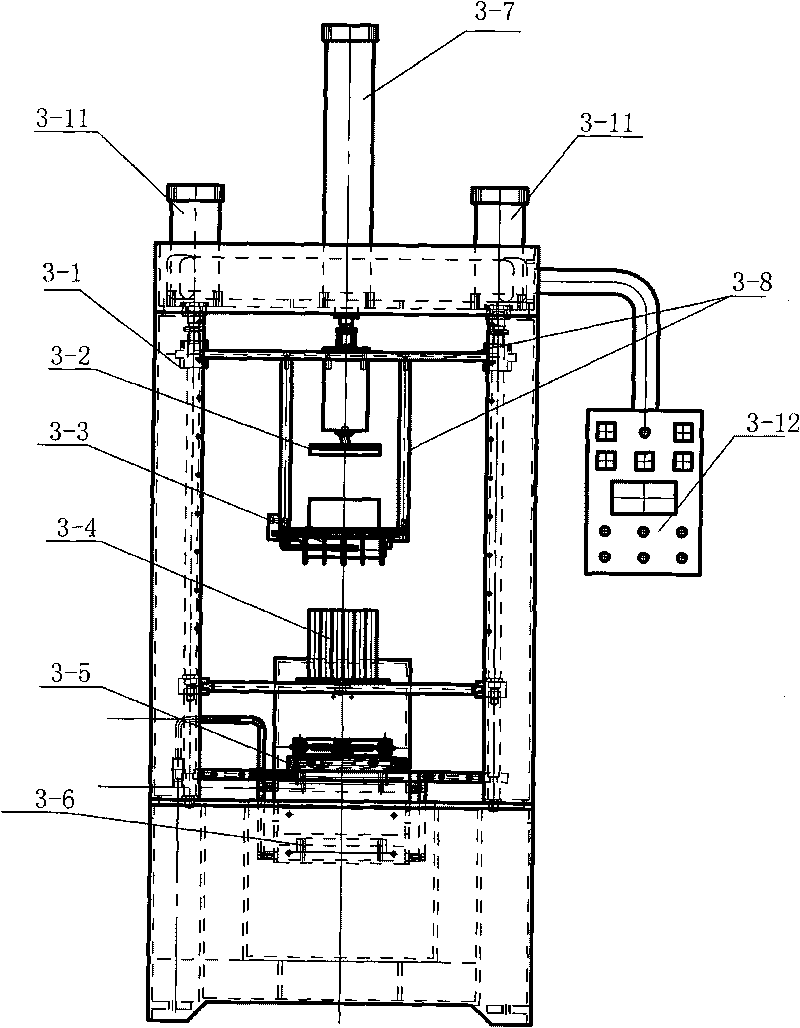

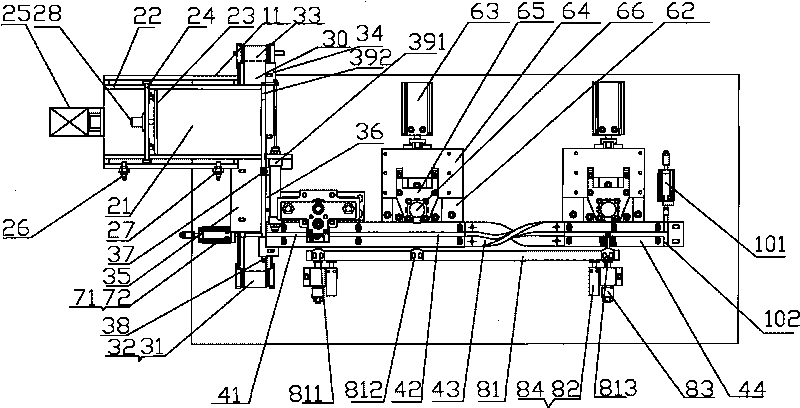

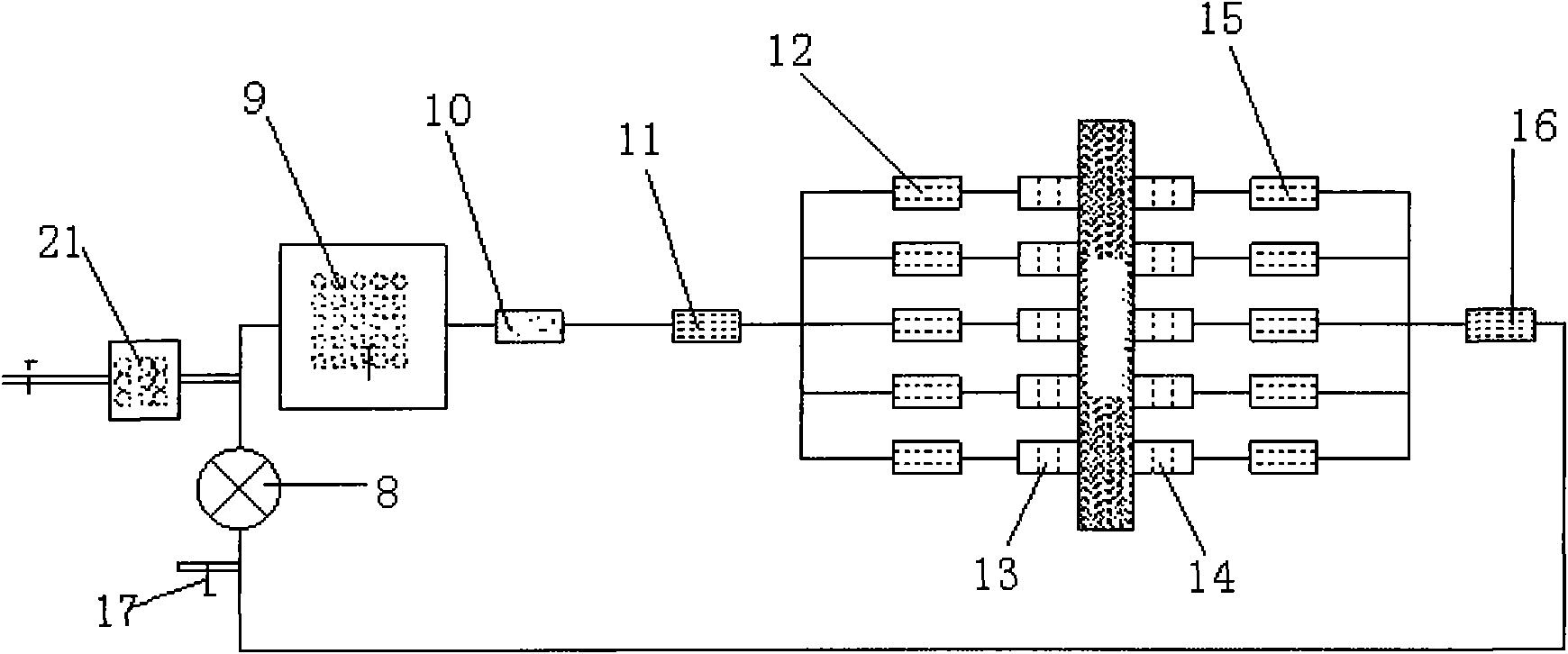

Cast-welding production device of accumulator and production process thereof

The invention provides a cast-welding production device of an accumulator and a production process thereof, belonging to accumulator industry. The technical scheme is characterized in that the production device comprises a brushing device, a steeping device and a cast-welding mainframe; the brushing device and the steeping device are connected with each other sequentially by a battery conveying line; and the brushing device comprises a brushing mainboard with an ejector cylinder and a steel wire brush with a brushing cylinder. The cast-welding production device and the production process have the following advantages that the cast-welding machine adopts a mode of closed production, has special smoke gas exhausting system and higher automation degree, only needs a worker to carry out simple transporting operation, greatly reduces the environmental pollution and the harm to human body, has regular and attractive cast-welding appearance and extremely low reject rate and welding repair rate, and leads the worker to not need technical requirements, thus greatly saving cost for manufacturers, improving output and increasing production value.

Owner:FUJIAN JIANYANG YAHENG MACHINERY MFG

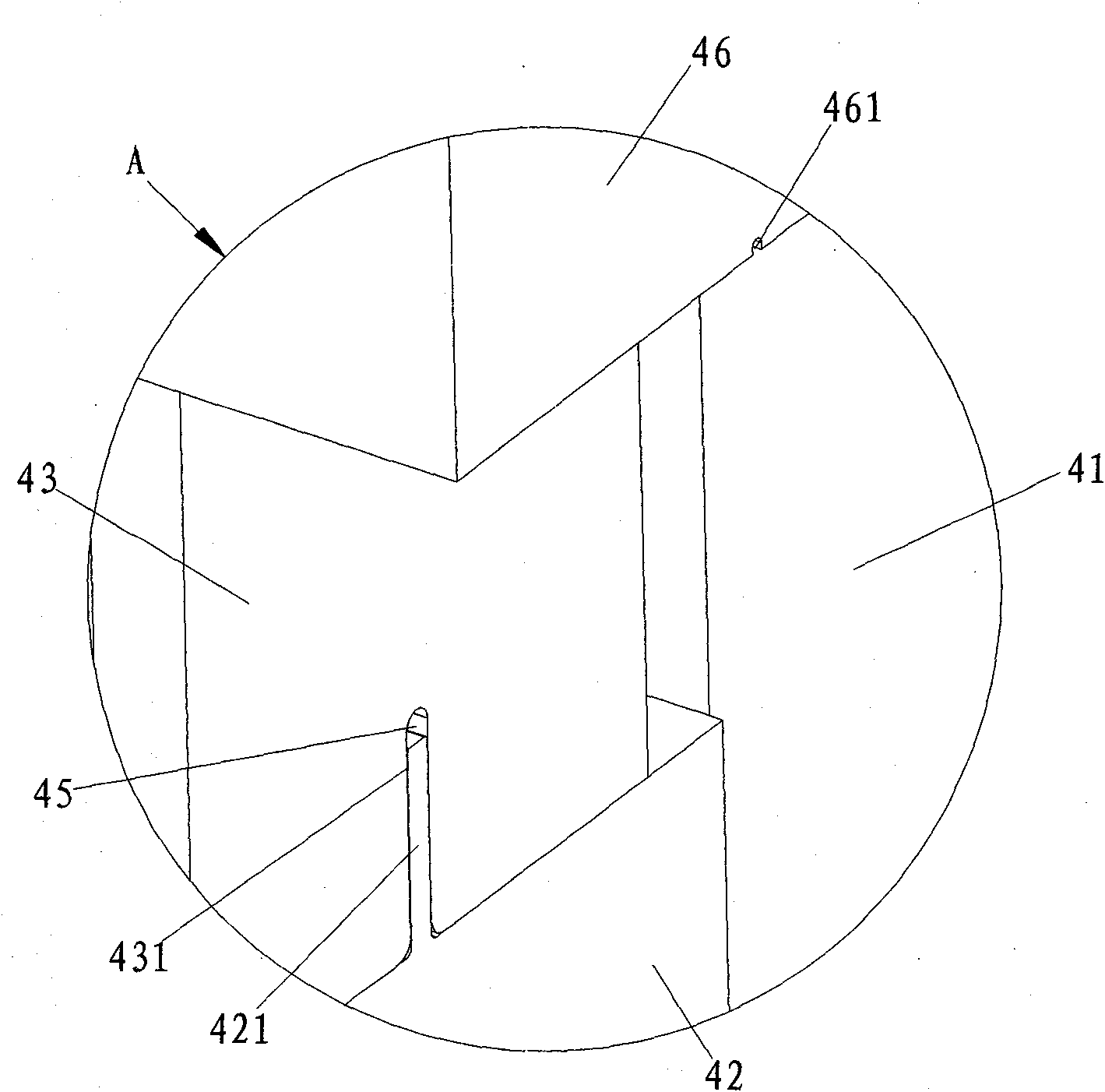

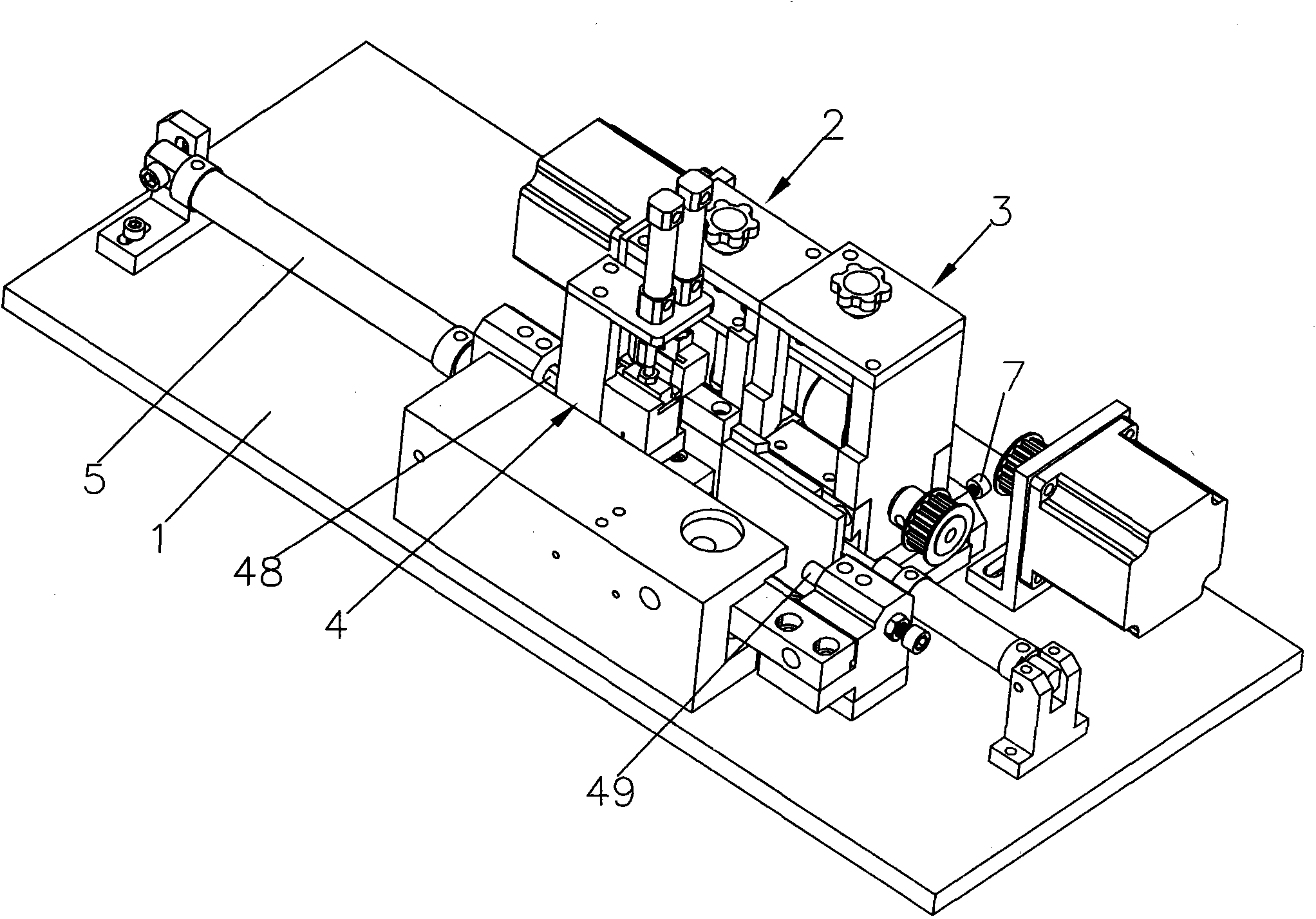

Automatic sleeve penetrating device

InactiveCN102059487AImprove work efficiencyLabor savingWelding/cutting auxillary devicesAuxillary welding devicesCopper wireEngineering

The invention relates to the technical field of copper foil spot welders, in particular to an automatic sleeve penetrating device. The device comprises a welding bench, wherein a sleeve penetrating device, a copper wire penetrating device, a sleeve clamping device, a sleeve moving cylinder and a linear slide are arranged on the welding bench; the sleeve clamping device is connected with the linear slide in a sliding manner; the output end of the sleeve moving cylinder is connected with the sleeve clamping device; sleeves are conveyed into the sleeve clamping device and are clamped by the sleeve clamping device; the sleeve clamping device clamping the sleeves is pushed to the copper wire penetrating device by the sleeve moving cylinder and then copper wires are conveyed to be penetrated into the sleeves clamped by the sleeve clamping device, thus completing sleeve penetrating; the device can automatically penetrate the sleeves by utilizing the mechanism structure, can automatically penetrate the sleeves on the copper wires accurately, has high working efficiency and saves labor, production cost and processing time. Besides, a sleeve stepping motor controls conveying of the sleeves through driving, the length of the sleeves can be arbitrarily adjusted and the control is accurate.

Owner:谢奎胜 +1

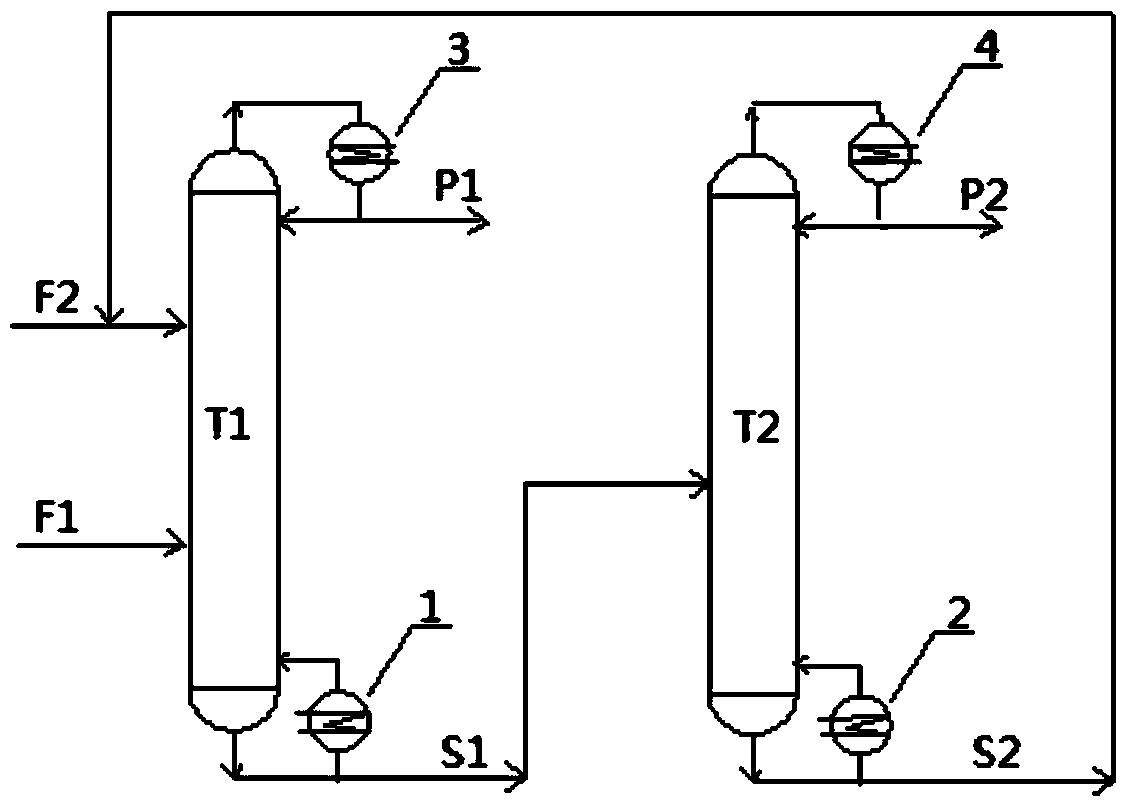

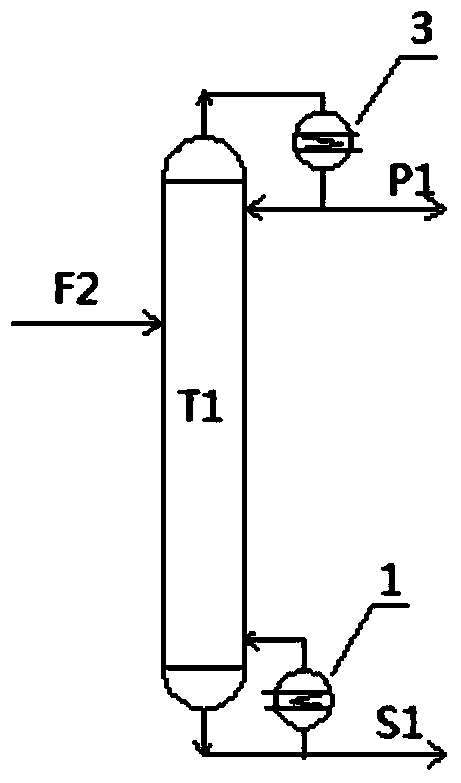

Method for separating isopropanol-water compound

InactiveCN103467246AIncrease relative volatilityEfficient separationOrganic compound preparationHydroxy compound preparationOrganic solventExtractive distillation

The invention provides a method for separating a isopropanol-water compound, which comprises the following steps: adopting an isopropanol-water compound in any proportion as a raw material, taking ionic liquid or a double solvent composed of ionic liquid and an organic solvent as an extraction agent, and extracting isopropanol and water in sequence after the raw material goes through an extractive distillation stage and an extraction agent recycle stage, wherein the extraction agent is used circularly after being extracted in the recycle stage. The method has the advantages that the energy consumption is low, environment pollution can be avoided, the product purity is high, the industrialization is facilitated, the equipment cost is low, and the economic benefit is good.

Owner:TIANJIN CLEANTECH TECH

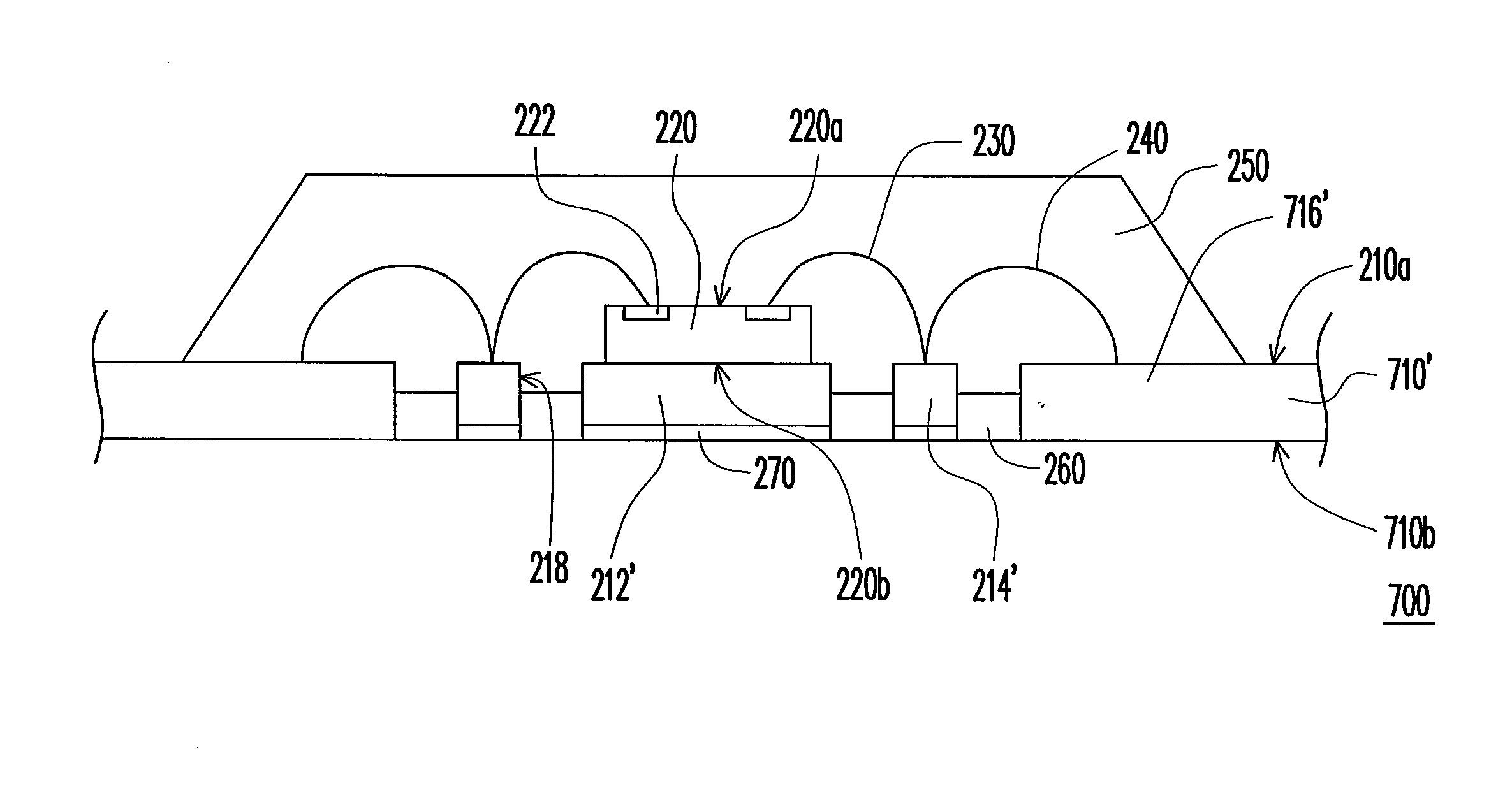

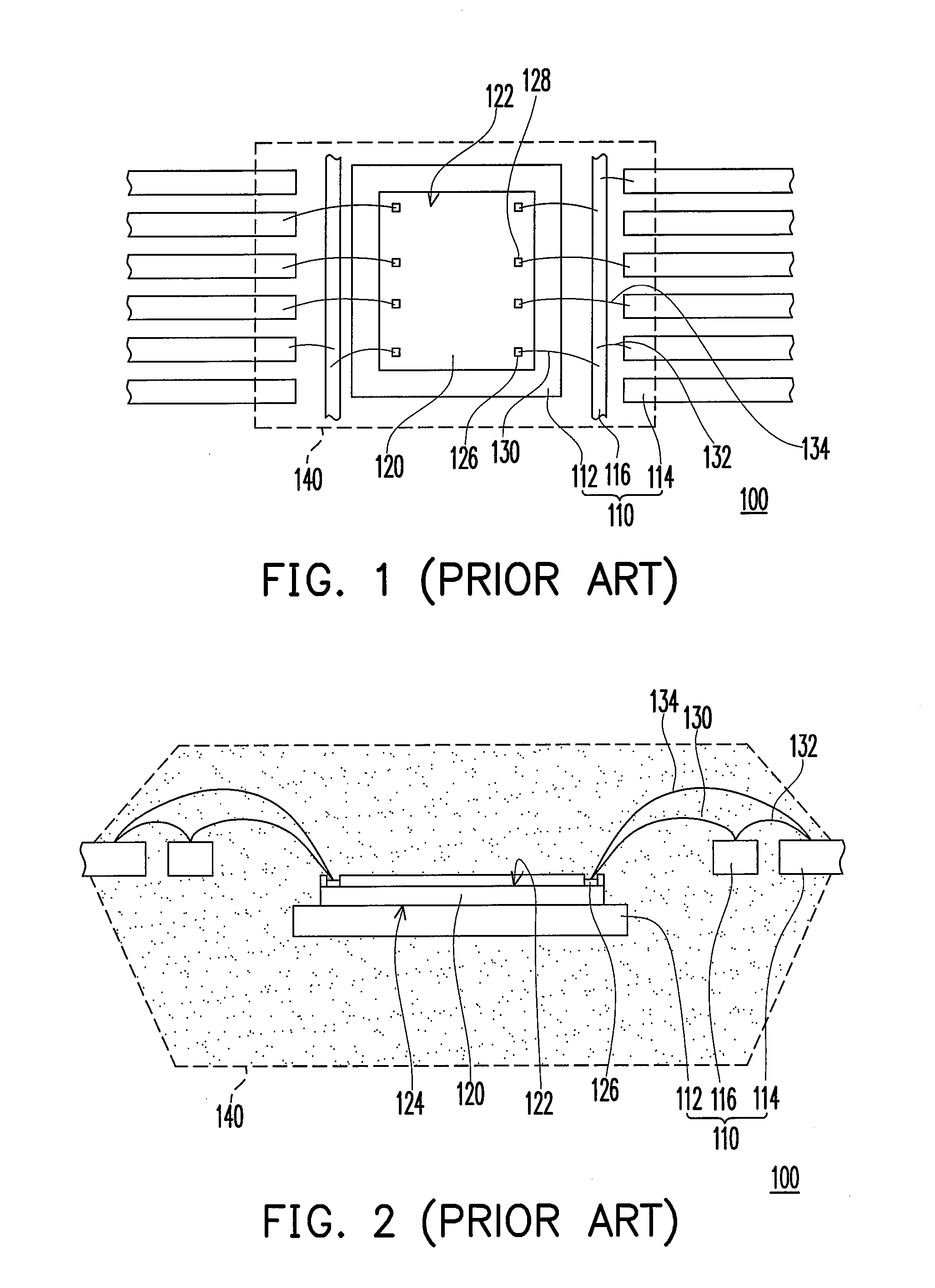

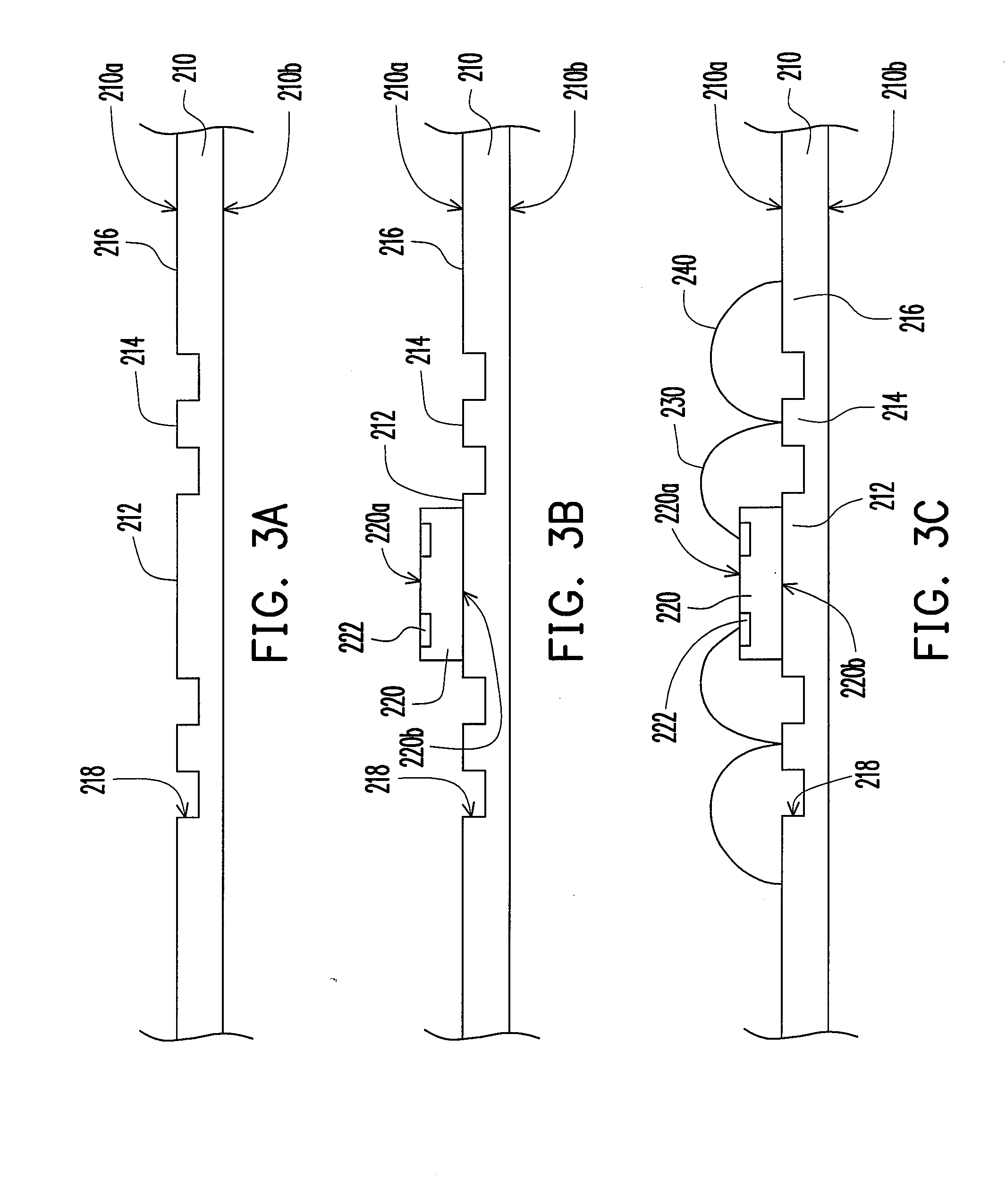

Chip package structure and method of fabricating the same

InactiveUS20080191324A1Reduce packaging costsSave production costSemiconductor/solid-state device detailsSolid-state devicesMetal sheetEngineering

A method of fabricating a chip package structure includes the steps of providing a metal thin plate having a first protrusion part, a second protrusion part and a plurality of third protrusion parts. A chip is then disposed on the metal thin plate and a plurality of bonding wires is formed to electrically connect the chip to the second protrusion part and connect the second protrusion part to the third protrusion parts. Next, an upper encapsulant and a lower encapsulant are formed on an upper surface and a lower surface of the metal thin plate, respectively. Thereafter, an etching mask is formed on the lower surface and exposes the connections among the protrusion parts. Finally, the metal thin plate is etched, such that the first protrusion part, the second protrusion part and the third protrusion parts form a die pad, a bus bar and leads of a lead frame, respectively.

Owner:CHIPMOS TECH INC

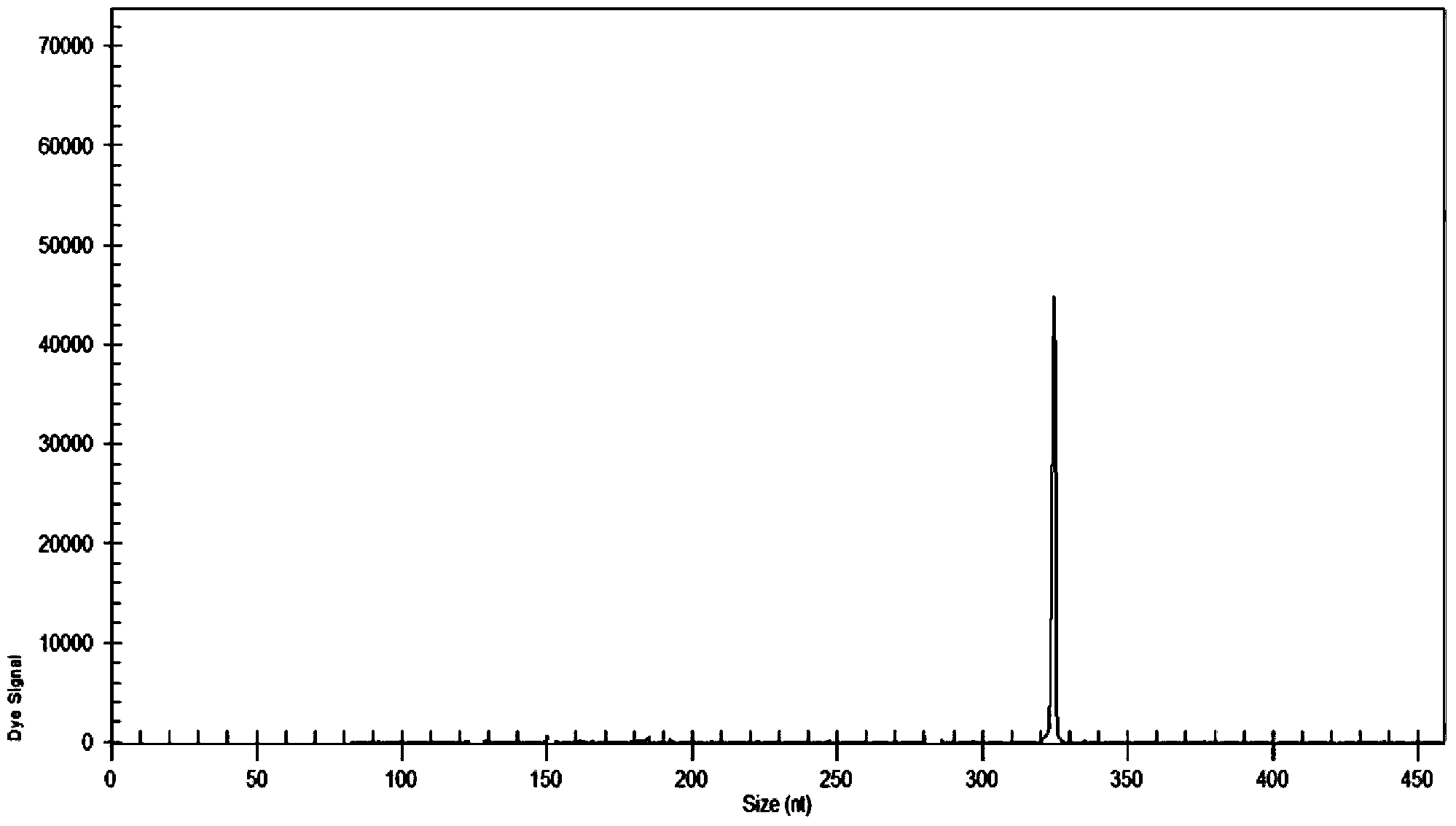

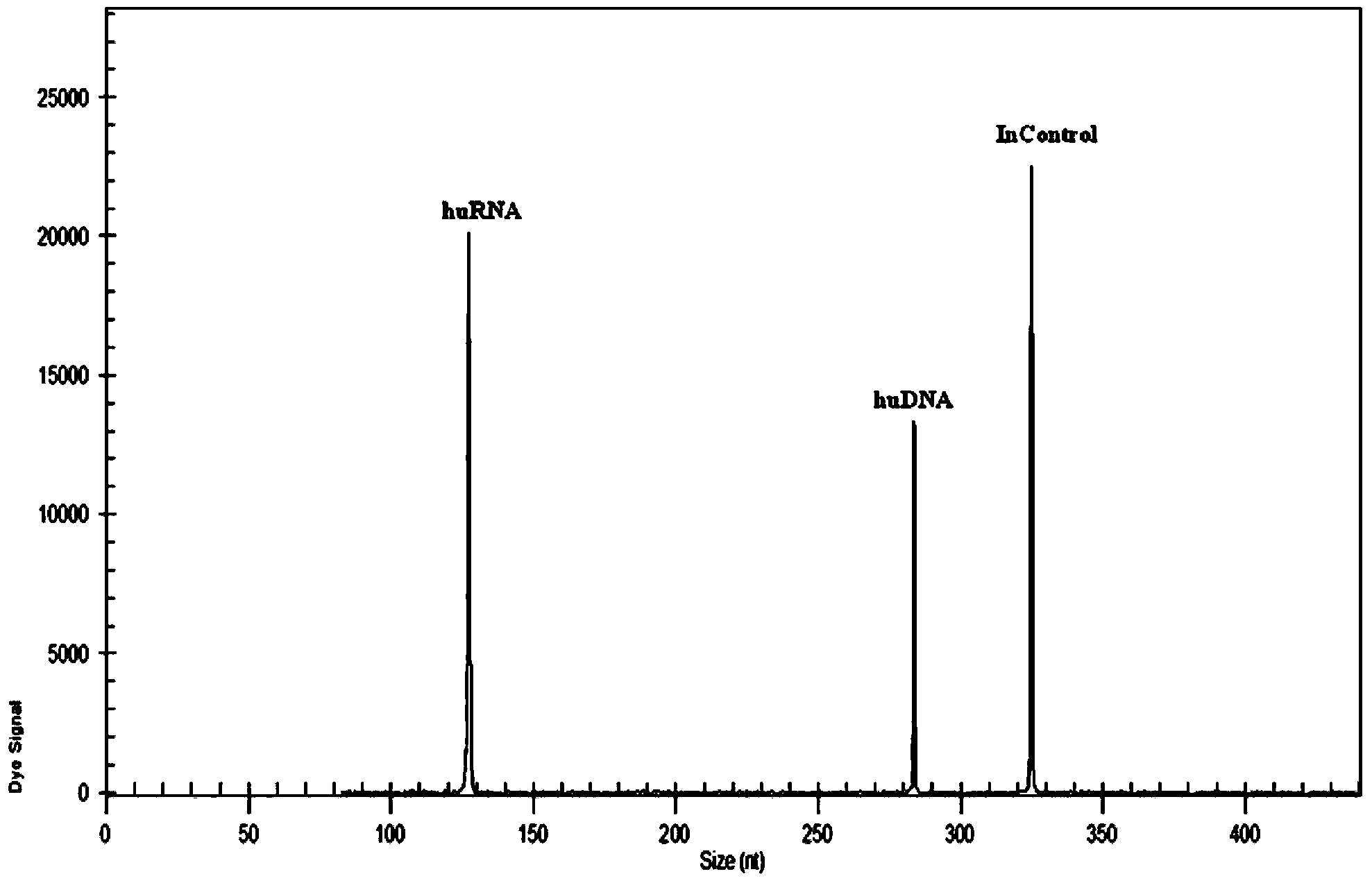

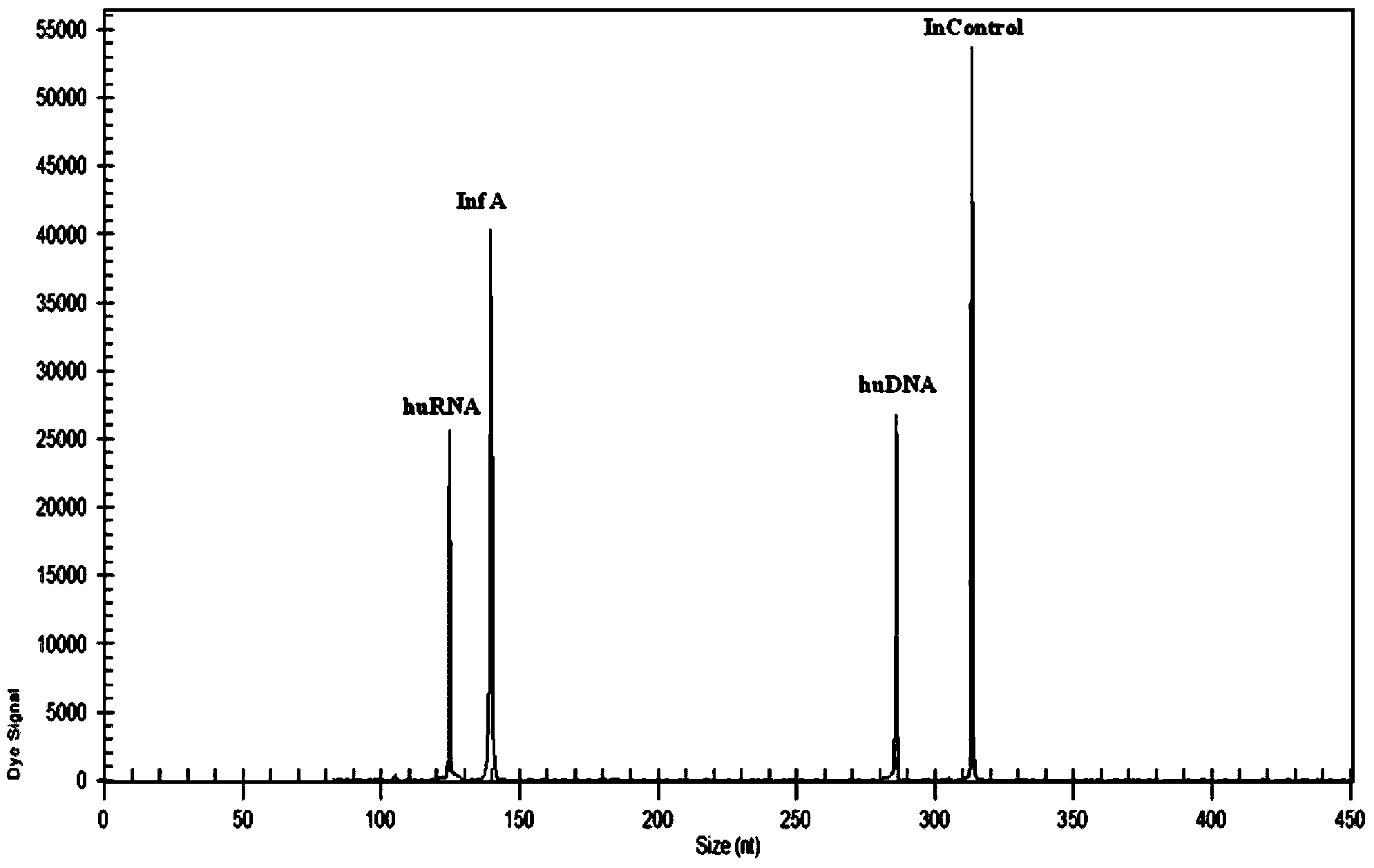

Method for simultaneously detecting twelve kinds of common respiratory viruses

InactiveCN104342503ASave production costSave testing costMicrobiological testing/measurementMicroorganism based processesMultiplexInfluenza virus C

The invention discloses a method for simultaneously detecting twelve kinds of common respiratory viruses. According to the method, primers and probes are designed according to gene conservative areas of the twelve kinds of common respiratory viruses, namely influenza A virus, influenza B virus, influenza C virus, parainfluenza virus type 1, parainfluenza virus type 2, parainfluenza virus type 3, rhinovirus, Bocavirus, adenovirus, coronavirus, metapneumovirus and respiratory syncytial virus, nucleic acid fragments of samples to be measured are extracted for amplifying, and finally, the samples are separated by using a capillary electrophoresis method. The method disclosed by the invention has the advantages of low required sample size, high sensitivity and accuracy, good specificity and low cost; the defects that the conventional single tube multiplex fluorescence PCR (Polymerase Chain Reaction) detection primers are difficult to design, and multicolor fluorescence mutually intervenes and is not easy to part are overcome, the defects that a chip detection method is tedious in operation, high in detection cost and the like are also overcome, and a new method is provided for screening the respiratory viruses.

Owner:FUJIAN INT TRAVEL HEALTH CARE CENT +1

Forming method and die of anisotropic annular magnet

InactiveCN103894607AIncrease productivitySave production costInductances/transformers/magnets manufactureEngineeringInert gas

The invention provides a die of an anisotropic annular magnet. The die comprises an upper die body and a lower die body; the upper die body comprises an upper annular punch and an upper die core punch arranged inside the upper annular punch, the top of the upper annular punch and the top of the upper die core punch are provided with a base plate, and an upper base is arranged above the base plate; the lower die body comprises a female die supporting ring and a lower annular punch arranged in the female die supporting ring, the female die supporting ring and the lower annular punch are arranged on a lower base, and an annular female die is arranged above the female die supporting ring; the outer wall of the upper annular punch is matched with the inner wall of the annular female die, and the outer wall of a die core of the upper die core punch is matched with the inner wall of the lower annular punch. The invention further provides a forming method of the anisotropic annular magnet. The method comprises the steps that a cavity formed by the upper die core punch, the upper annular punch and the annular female die of the die is filled with magnetic powder, then a hot-pressing technology and a hot deformation technology are conducted in a vacuum or inert gas environment, and the anisotropic annular magnet is processed and formed. By means of the method and the die, the hot-pressing technology and the hot deformation technology are conducted continuously, and production efficiency is high.

Owner:SHANGHAI JIAO TONG UNIV

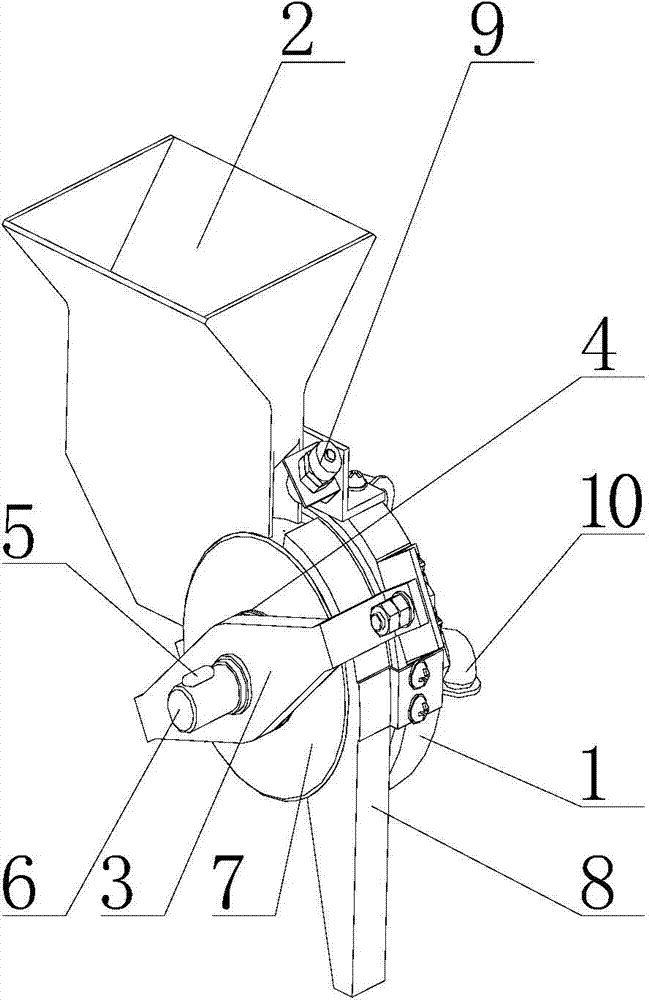

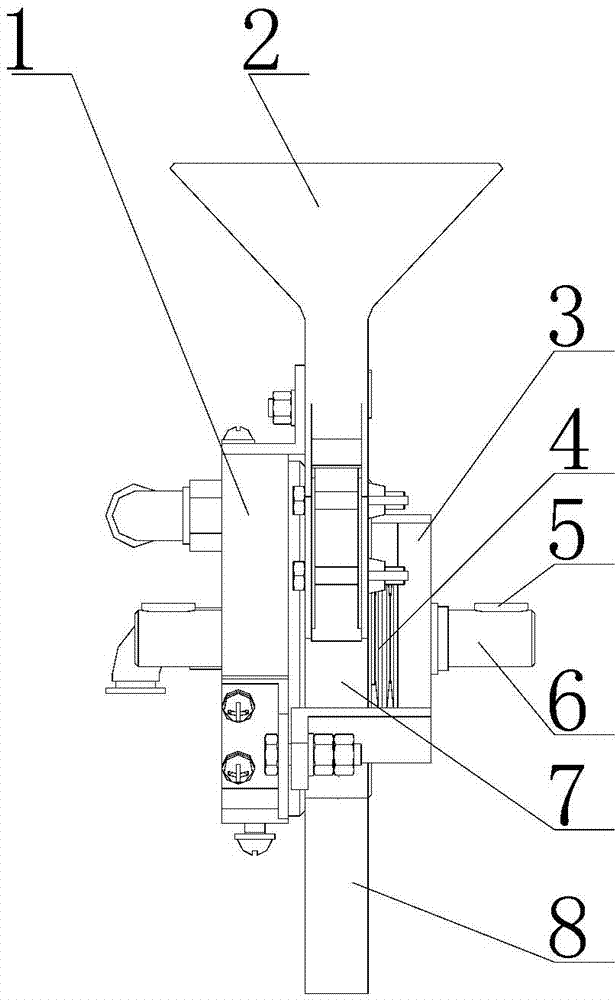

Precision seed-metering device and precision seed-metering device group for direct sowing of small-granular seeds

ActiveCN104756651AFlexible line spacing adjustmentEnable direct seedingAgriculture gas emission reductionSeed depositing seeder partsPositive pressureEngineering

The invention relates to a precision seed-metering device and a precision seed-metering device group for direct sowing of small-granular seeds. The precision seed-metering device includes: a fixed gas distribution plate fixed on a rack and a seed plate fixedly sleeving a shaft. The fixed gas distribution plate separately sleeves the shaft. The seed plate is arranged closely to the fixed gas distribution plate. The fixed gas distribution plate is provided with a negative pressure chamber and a positive pressure chamber. An end surface, which faces to the fixed gas distribution plate, of the seed plate is provided with a plurality of vent holes arranged in the peripheral direction uniformly. The side surface of the periphery of the seed plate is provided with a plurality of seed-discharging suction holes which are arranged in the peripheral direction uniformly to form a circle. The number of the vent holes is equal to that of the seed-discharging suction holes and each vent hole is communicated with each corresponding seed-discharging suction hole. The vent holes are rotated with the rotation of the seed plate, wherein one vent hole is communicated with the positive pressure chamber for discharging seeds while the other partial vent holes are communicated with the negative pressure chamber for sucking the seeds. The precision seed-metering device can achieve direct sowing and precision sowing of small-granular seeds, can be used for single-row sowing and multiple-row sowing and belongs to the field of design of agricultural machinery.

Owner:SOUTH CHINA AGRI UNIV

SEBS thermoplastic high-elasticity earphone cord coating special-purpose material and preparation method thereof

ActiveCN103194032AIncrease elasticityImprove stabilityPlastic/resin/waxes insulatorsAging resistancePlasticizer

The invention belongs to the technical field of thermoplastic materials and relates to a SEBS thermoplastic high-elasticity earphone cord coating special-purpose material. The SEBS thermoplastic high-elasticity earphone cord coating special-purpose material comprises, by weight, 30.0 to 60.0% of a SEBS rubber resin, 10.0 to 35.0% of a softening plasticizer, 5.0 to 20.0% of a modifier, 10.0 to 35.0% of a polypropylene resin, 0.3 to 1.5% of an anti-oxidant, 0.3 to 1.5% of a light stabilizer, 0.3 to 1.5% of a metal deactivator and 0.3 to 1.5% of a processing assistant. Compared with the prior art, the SEBS thermoplastic high-elasticity earphone cord coating special-purpose material has an optimized formula, has good stability, good aging resistance, high elasticity, yellowing resistance, copper toxicity resistance, high tensile strength and a silky and elegant handle, and can be processed and molded easily. In addition, the invention also discloses a preparation method of the SEBS thermoplastic high-elasticity earphone cord coating special-purpose material.

Owner:DONGGUAN JISU PLASTIC TECH

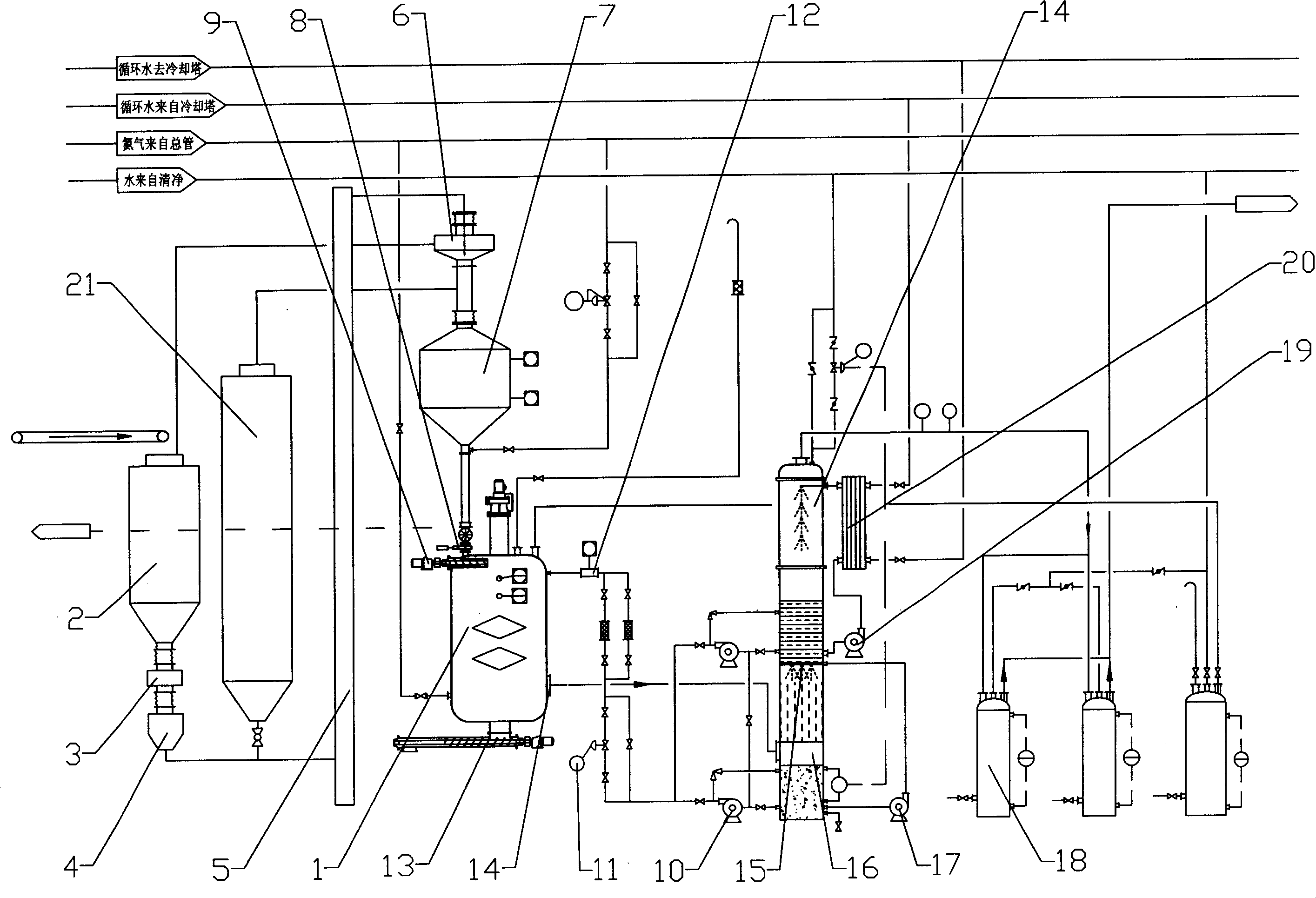

Technique for producing acetylene gas by dry method

ActiveCN101100617AReduce pollutionSave waterOrganic chemistryGenerators with non-automatic water feedGas phaseSlag

A process for producing ethyne by dry method is carried out by: mixing water with calcium acetylide powder in proportion of 1.1-1.9:1, and spraying water on calcium acetylide powders in ethyne generator and hydrolyzing to generate ethyne. Calcium acetylide rate at outlet of residual slag machine is 99.5-99.85 wt%, ethyne recovery rate reaches to 98.5 wt%, water content of calcium acetylide slag is 4-12 wt%, reactive temperature is set between 87-93 deg.C and water content is 75%. It's safe, continuous, simplified and cheap.

Owner:SHANDONG XINLONG TECH

Crystallization method of abamectin Bla

The present invention relates to a crystallization method of abamectin B 1a. Said method includes the following steps: using crystallization solvent n-butanol to stir and dissolve primary crude powder of abamectin B 1a at 75-100deg.C to saturation, filtering while the saturated solution is hot to obtain clear hot-saturated solution; slowly cooling said solution to that when the supersaturation degree is 1-3, adding crystal seeds, constant stirring for 20-60min, its stirring speed is 120-300rpm, and cooling to make crystallization, fitering crystal slurry or centrifugally-separating said crystal slurry, washing crystal and drying so as to obtain the invented abamectin B 1a.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

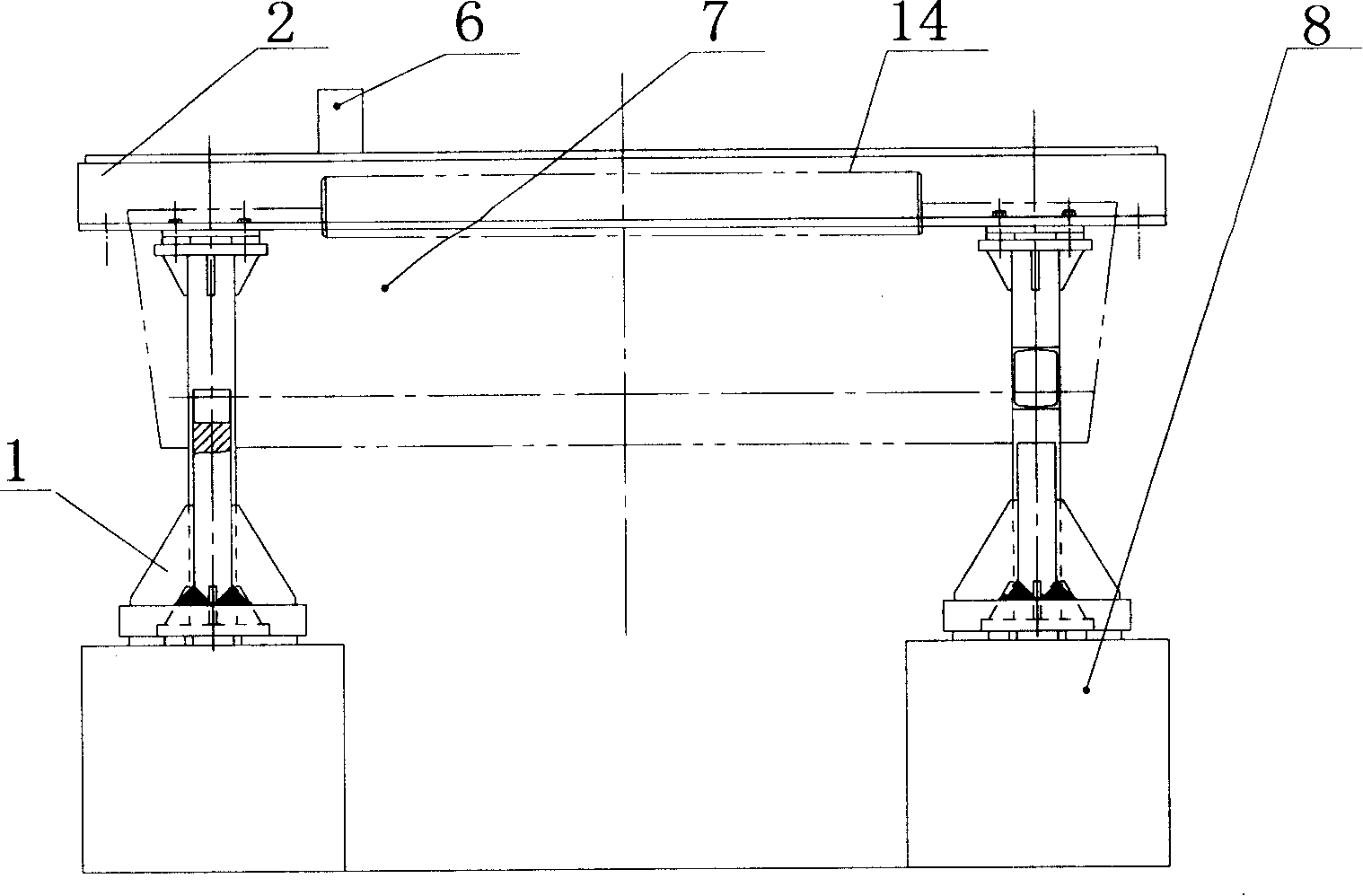

Continuous casting machine sector section centering measurement method

InactiveCN101210809AHigh measurement accuracyLow costMechanical clearance measurementsHeight/levelling measurementMeasurement deviceMicrometer

The invention discloses a method for central position control of fan-shaped sections in a continuous caster. The method comprises the following steps of: suspending a work piece to be test on a shaft supporter and a plane supporter on a test platform, installing four equal-altitude upright columns in the periphery of the test work piece, measuring the altitudes of the equal-altitude upright columns and reference plane of the test work piece by using a laser measurement device, installing two equal-altitude cross beams on the equal-altitude upright columns, measuring the altitudes of the equal-altitude cross beams by using the laser measurement device, placing a straight ruler on the equal-altitude cross beams, moving the straight ruler to each roll surface, and measuring the distance between each roll surface and the straight ruler by using an inside micrometer. The invention has the advantages of easy operation, high measurement accuracy, low cost and short measurement time.

Owner:SHANGHAI JIANSHE LUQIAO MASCH CO LTD

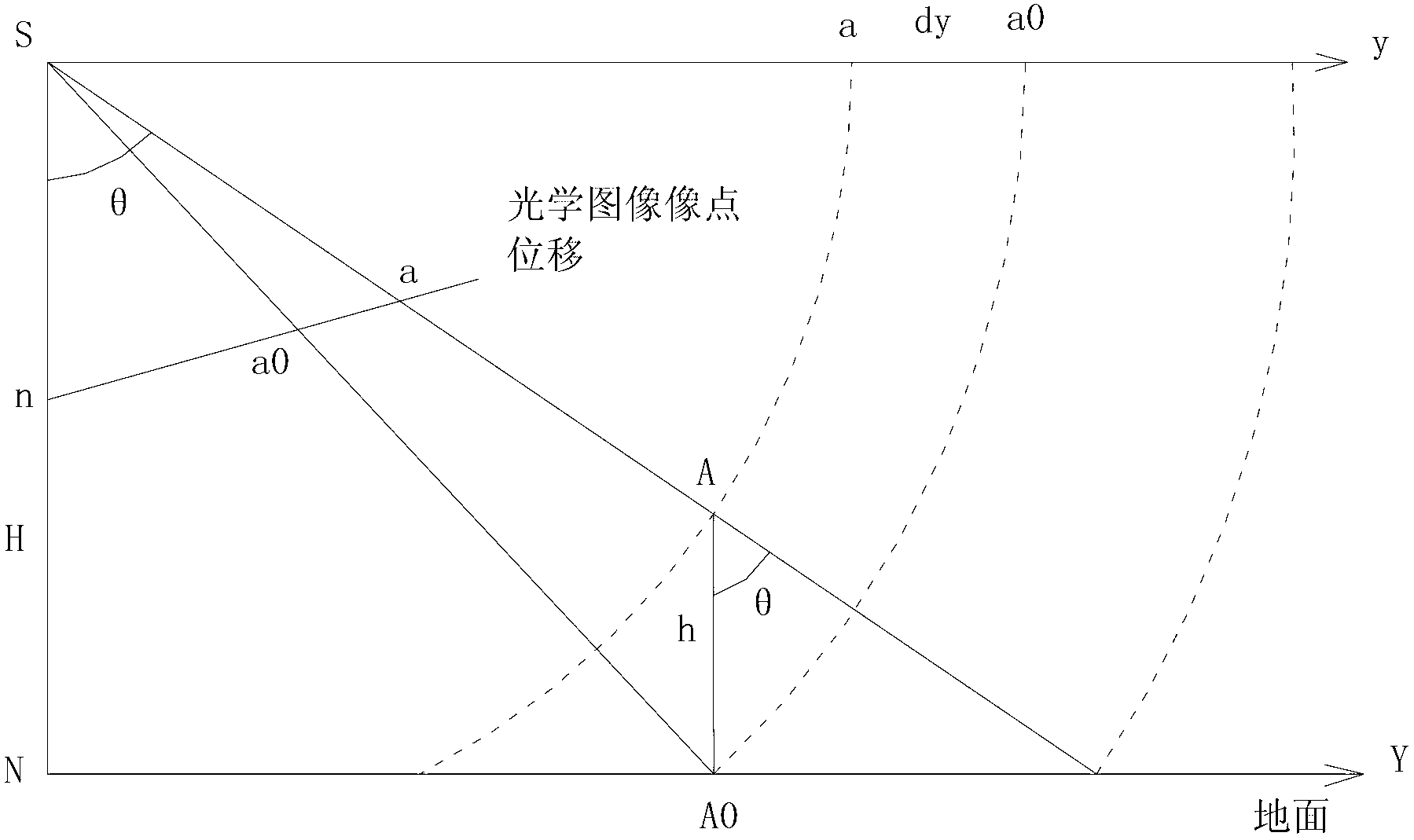

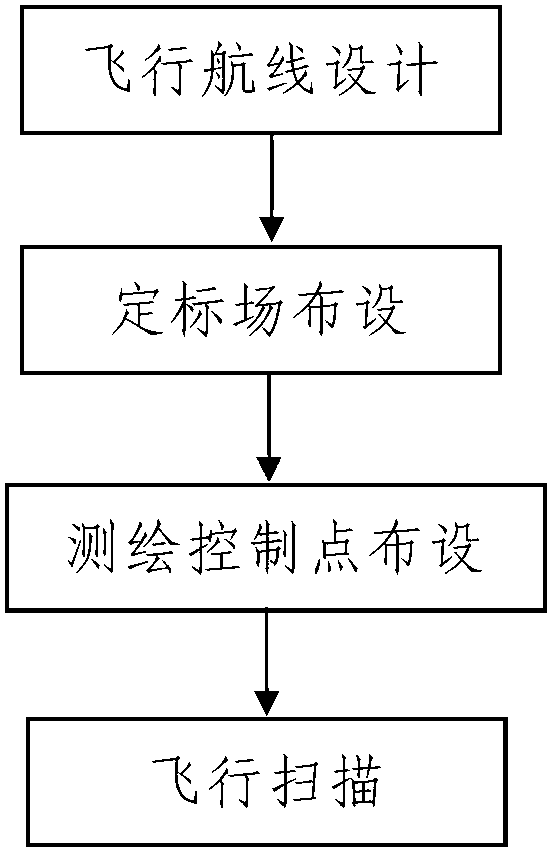

Ground control and measurement stationing method based on onboard interferometric synthetic aperture radar (InSAR)

InactiveCN102707284AThe method steps are simpleEasy to operateRadio wave reradiation/reflectionTerrainInterferometric synthetic aperture radar

The invention discloses a ground control and measurement stationing method based on an onboard interferometric synthetic aperture radar (InSAR). The method comprises the following steps of: 1, designing a flight line, namely determining a range of a region to be plotted according to pre-collected information of a detection region terrain and designing the number N of sorties required to fly and the flight line of each sortie according to the determined range of the region to be plotted and flight parameters during plotting; 2, arranging calibration fields, namely arranging one or two calibration fields for radiating and geometrically calibrating an onboard InSAR system inside or outside the detection region; 3, stationing plotting control points; and 4, scanning flight, namely after the N sorties fly in the calibration fields and the detection region, acquiring InSAR measurement data in the region to be plotted. By the method, the steps are rational in design, the use operation is simple, and the using effect is good; and the shortcoming that the onboard InSAR terrain plotting control and measurement cannot be instructed according to the technical rule of the conventional optical system is overcome.

Owner:XIAN MEIHANG INFORMATION IND

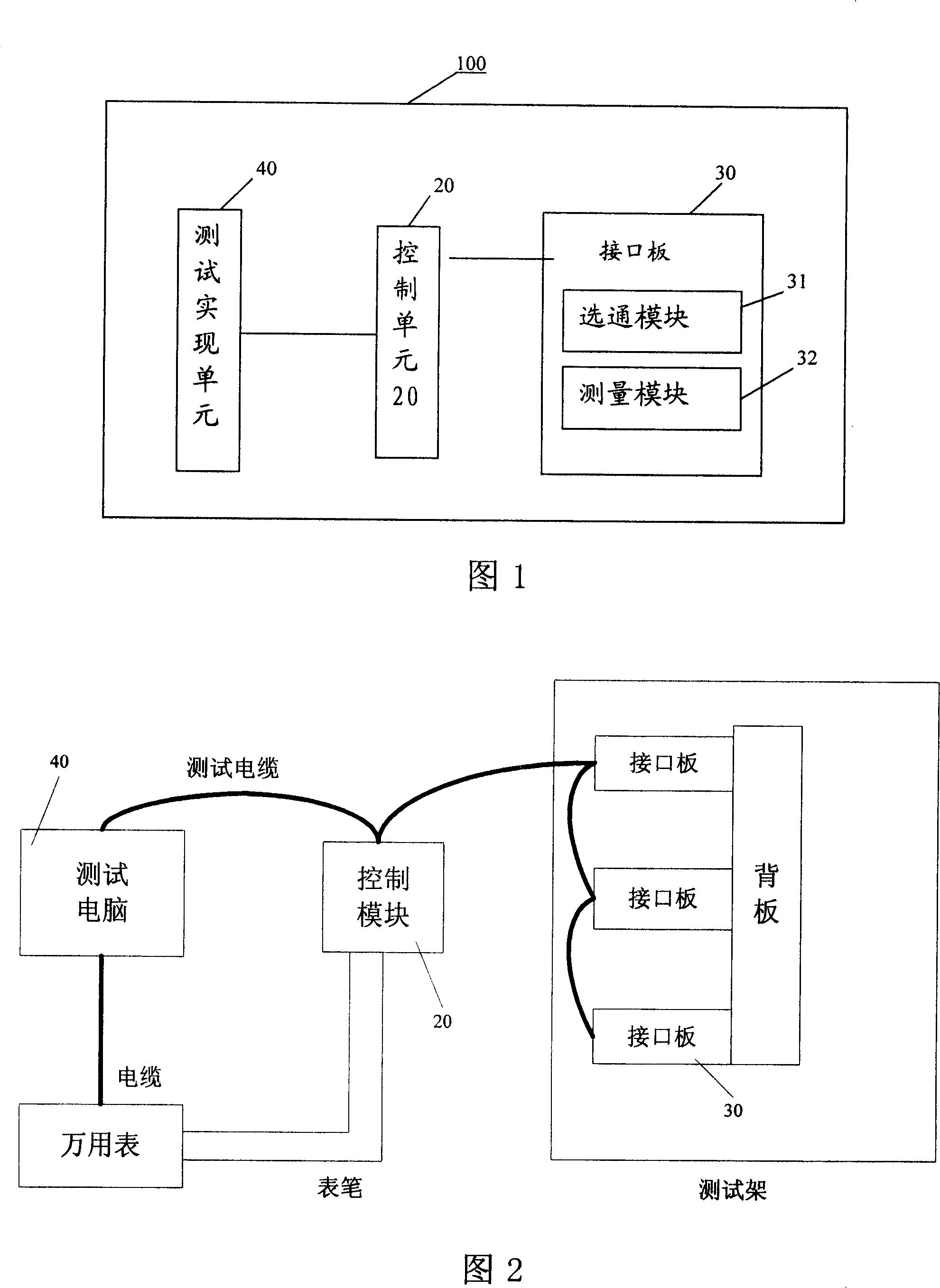

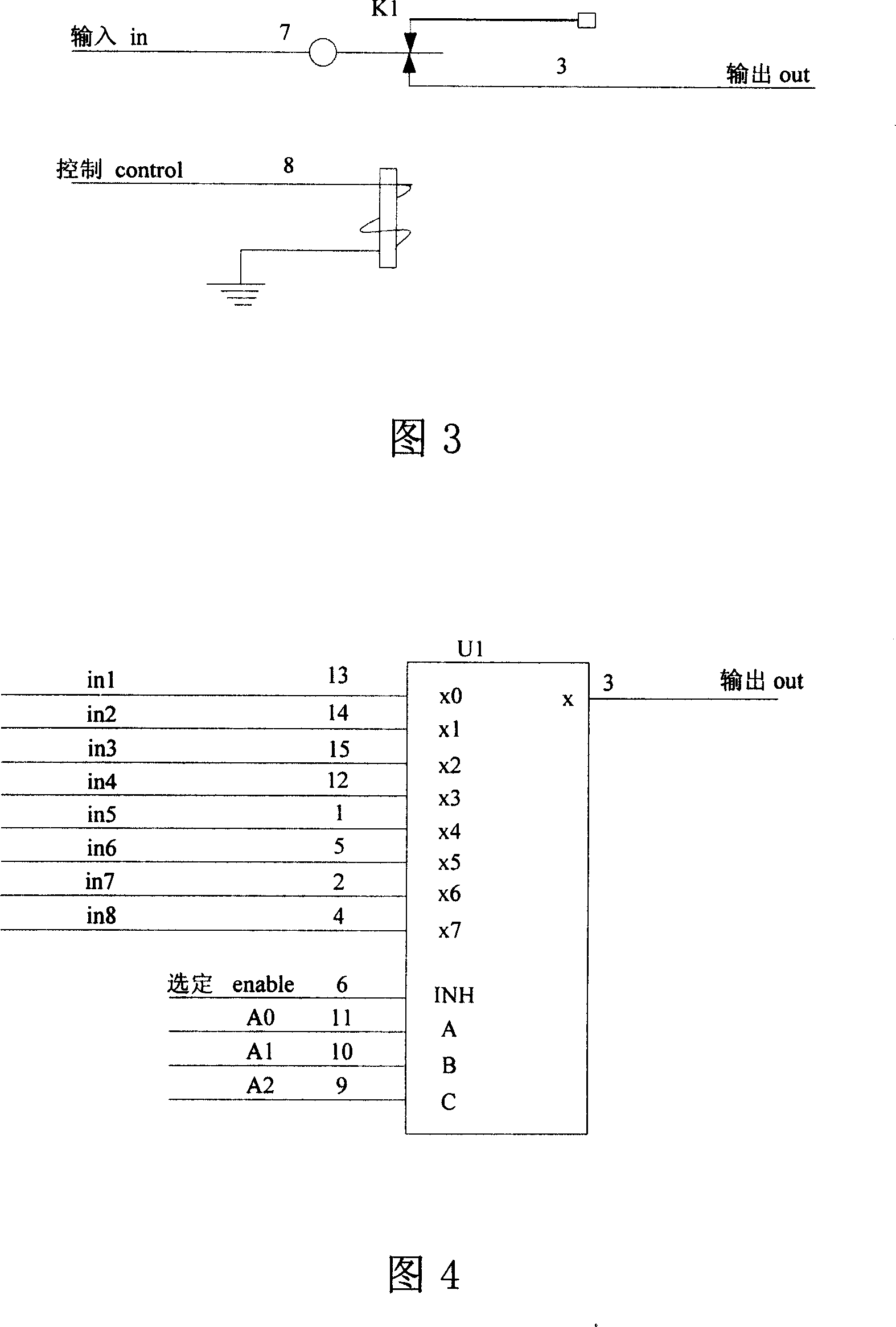

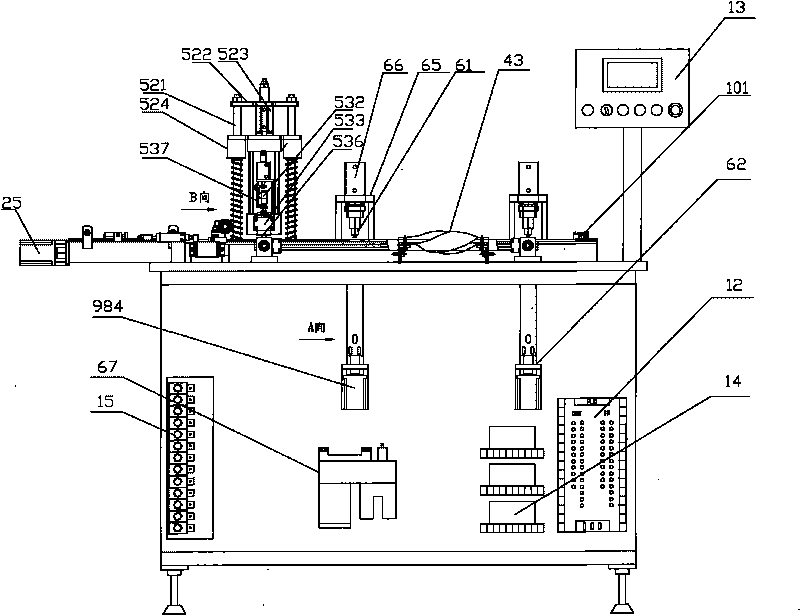

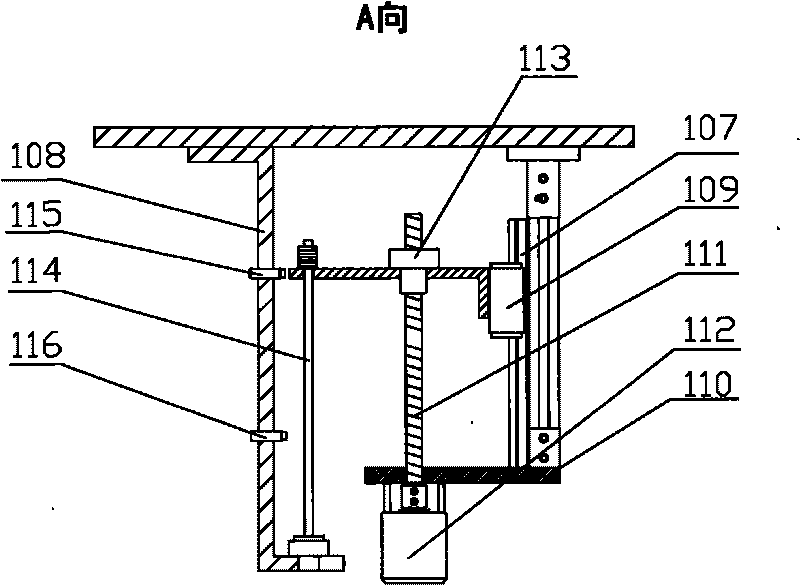

Rear-panel testing system

InactiveCN1982903AReduce design costReduce processing costsElectronic circuit testingHigh volume manufacturingEngineering

A test system of back plate is prepared as using test realization unit to operate test program, connecting interface plate to said back plate, setting control unit between said test realization unit and said interface plate and using said control unit to control interface plate to carry out test operation on said back plate.

Owner:HUAWEI TECH CO LTD

Preparation method of multifunctional yarn containing silver fibers

InactiveCN101985786ASignificant progressSolve the problem that it is easy to fall off and affect the subsequent production processYarnFiberYarn

The invention provides a preparation method of a multifunctional yarn containing silver fibers. The multifunctional yarn containing silver fibers is prepared by the following fiber materials by weight percent: 8-15% of nano silver fibers, 10-20% of nano carbon fiber and the balance of other fibers, wherein the other fibers refer to any one or more of Tencel fibers, modal fibers, outlast, moisture absorption fibers and fine denier fibers; the nano silver fiber is prepared by adding nano silver the weight ratio of which is 0.2-2% and the particle size of which is 18-150nm in a polypropylene solution and interlacing into a net structure through a multipoint high pressure jet mode, and the monofilament length of the nano silver fiber is 20-30mm; the monofilament length of the nano carbon fiber is 25-35mm, and the nano carbon content thereof is 1-3%; and the other fibers are discontinuous short fibers. By special treatment and collocation of raw materials as well as adjustment and improvement of the preparation method, the requirements of the existing production equipment for producing top grade textiles can be met.

Owner:山东昊龙集团有限公司

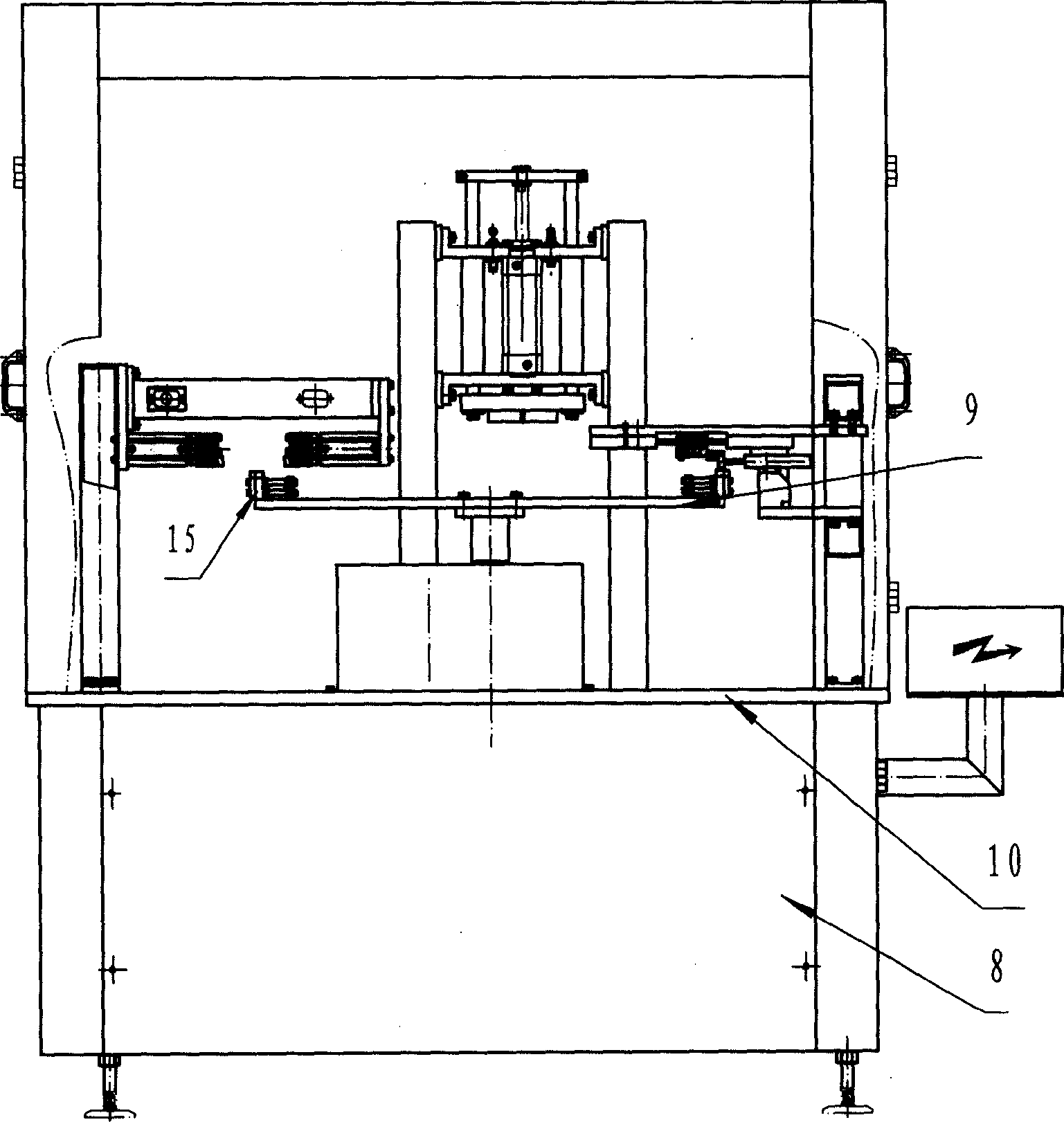

Full-automatic miniature bearing greasing gland method and device thereof

InactiveCN101718307AReduce processing timeSave energyBearing componentsMechanical engineeringSurface processing

The invention discloses a full-automatic miniature bearing greasing gland method and a device thereof; a miniature bearing to be processed is transported to a material arrangement device by a feeding device, so as to obtain the sequence of only one group of miniature bearings to be processed, and the miniature bearings are axially arrayed in parallel one by one, and then the miniature bearings to be processed are pushed in a material conveying channel one by one by a material pushing device and carry out greasing processing and single-surface gland processing by sequentially passing through the greasing device and the gland device on the material conveying channel, and then, the miniature bearings to be processed, which carry out single-surface processing, are turned with 180 degrees through a closed distorted material channel on the material conveying channel, and finally, the gland device is adopted again to carry out glad processing of a processing surface without a gland of the miniature bearings to be processed; therefore, the invention adopts a full-automatic mode to carry out greasing gland processing of the miniature bearings, every procedure is carried out automatically, the production efficiency is greatly improved, and the working efficiency is improved 10-15 times compared with the original manual operation.

Owner:南通山口精工机电有限公司

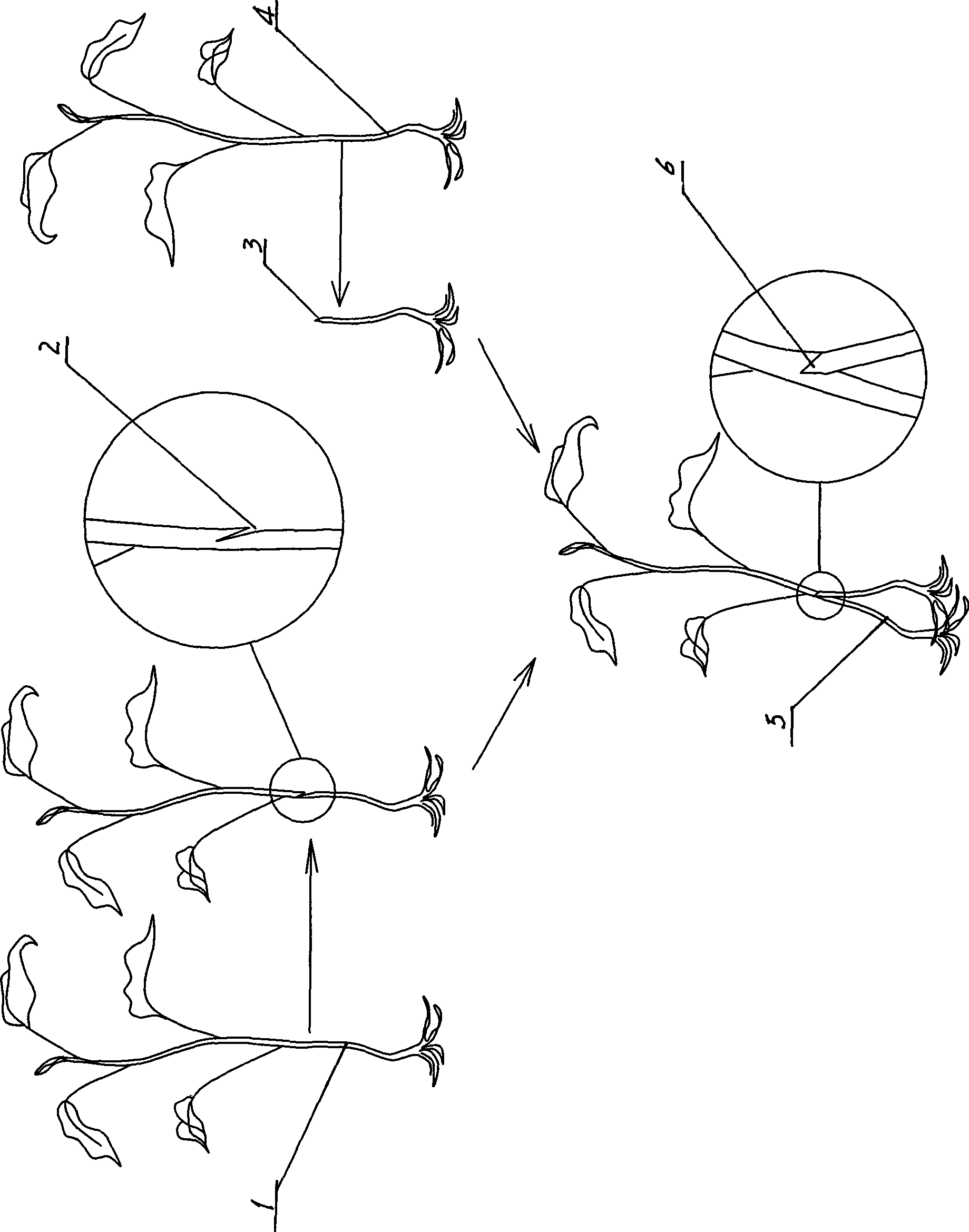

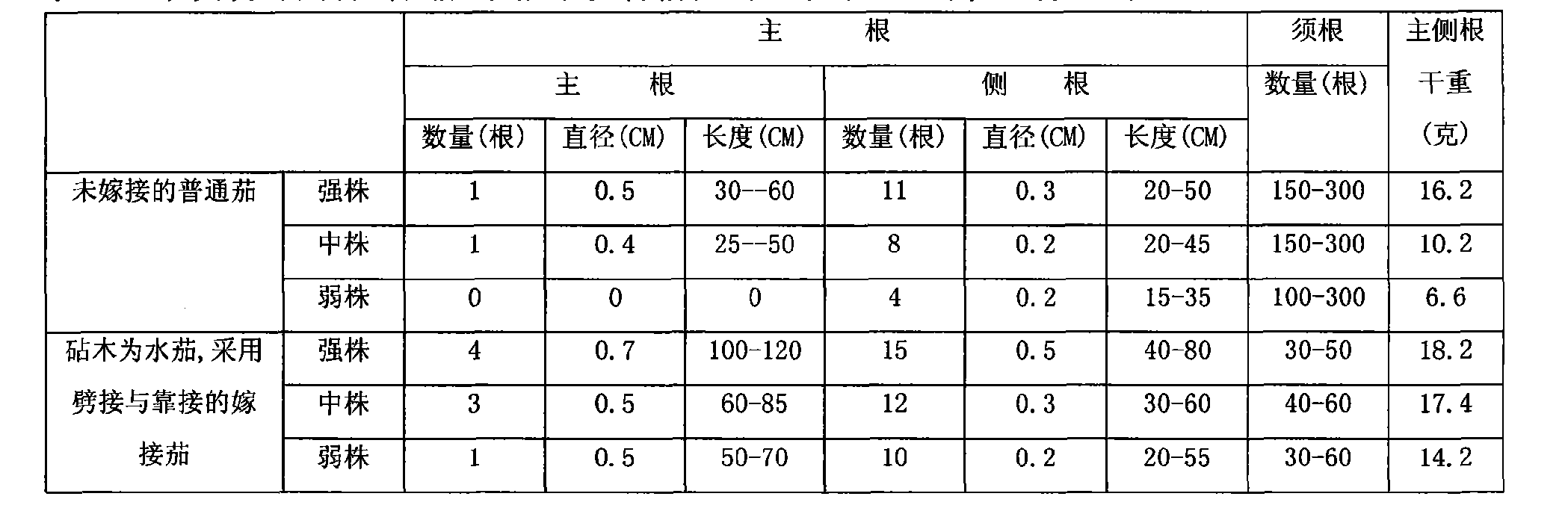

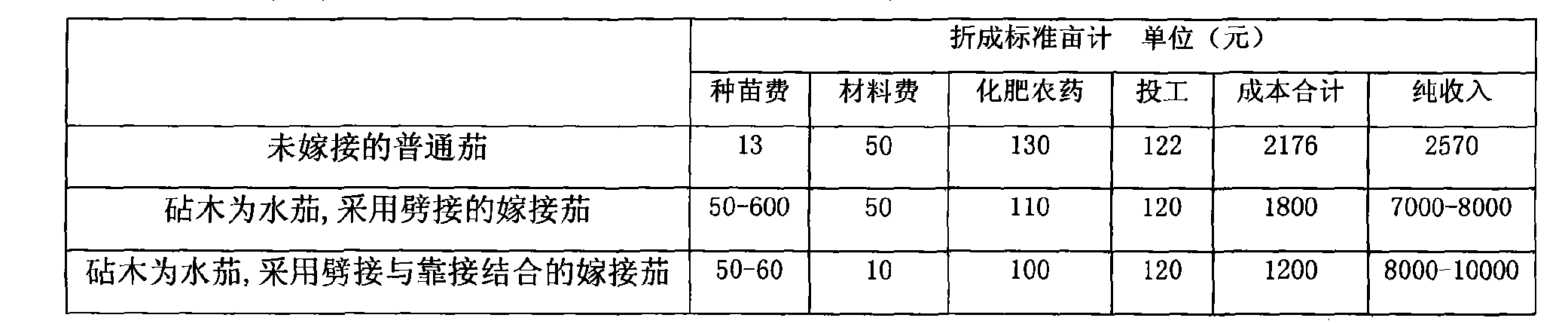

High output and good quality aubergine graft and transplantation technique in different seasons

InactiveCN101379929AIncrease vitalityStrong resistance to pests and diseasesHorticultureDiseaseVitality

The invention relates to a technology for grafting and transplanting of a high-yield and high-quality anti-seasonal eggplant, which comprises the following steps: (1) a common eggplant is taken as a graft and Solanum torvum is taken as a rootstock; (2) the seeds of the Solanum torvum are used for raising seedlings in July, and the seeds of the eggplant are used for raising seedlings in August; when the seedlings of the Solanum torvum grow 7-9 true leaves and the seedlings of the eggplant grow 4-5 true leaves, the seedlings are taken out; (3) a growing point which is 60-80mm from the root of Solanum torvum is cut off, and the end of the rootstock is cut into a wedge shape; the eggplant seedling is cut into a bevel opening at the eggplant seedling 60-80mm above a cotyledon from bottom to top, and the wedge-shaped end of the rootstock is inserted into the bevel opening of the graft with cortex aligned, and then the graft opening is bound up and fixed to form a two-root seedling; (4) the two-root seedling is transplanted into a field while grafting; after 10-15 days upon transplanting, when the wounds of the rootstock and the graft heal, the graft root is cut from the bottom of the graft opening with only the root of the rootstock left. The technology can cause the anti-seasonal eggplants planted in autumn and winter to have more strong vitality and the ability against diseases and insect pests; in addition, the eggplant planted by the technology has high yield and high quality, the seedling raising method is simple, the grafting seedling rate is high, thus the technology can realize transplanting seedlings into the field while grafting, which reduces the land, labor labor and production cost required by seed bed management.

Owner:梅清林

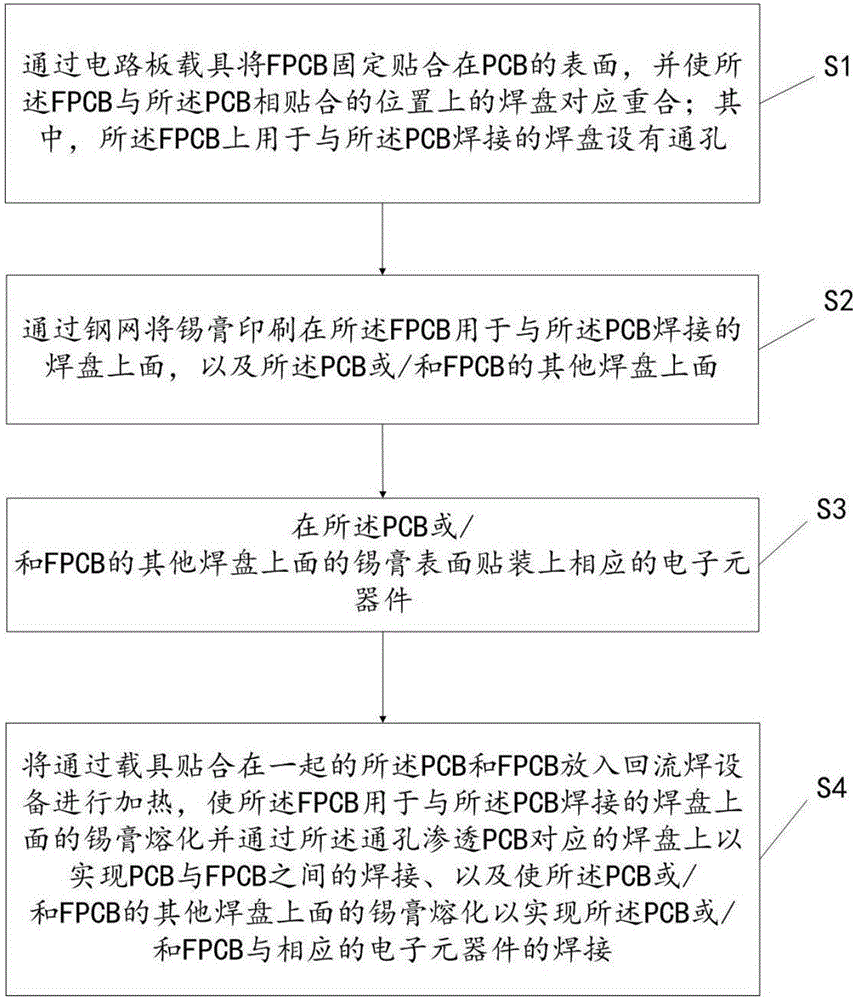

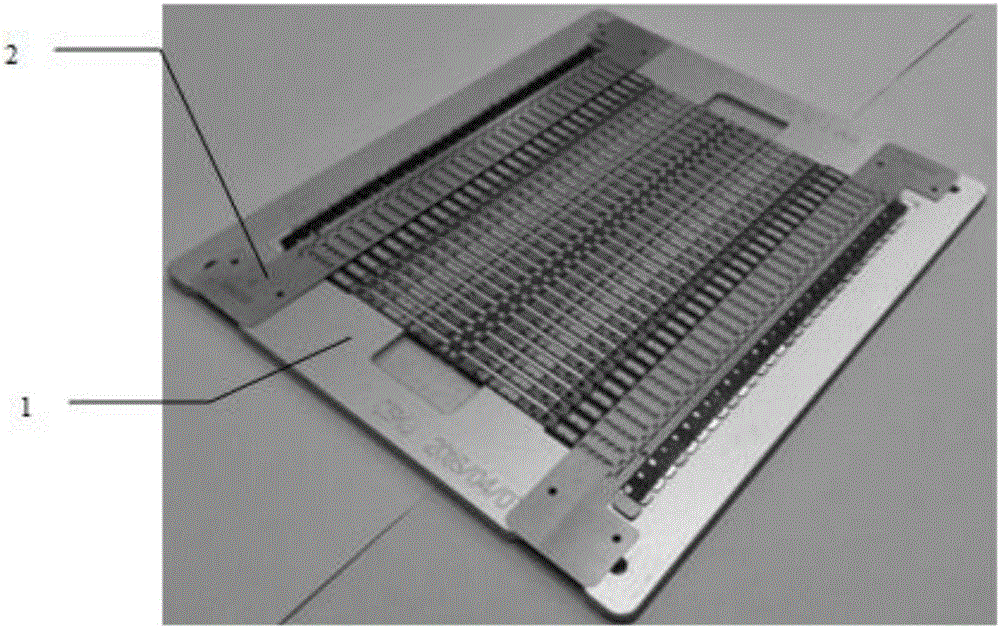

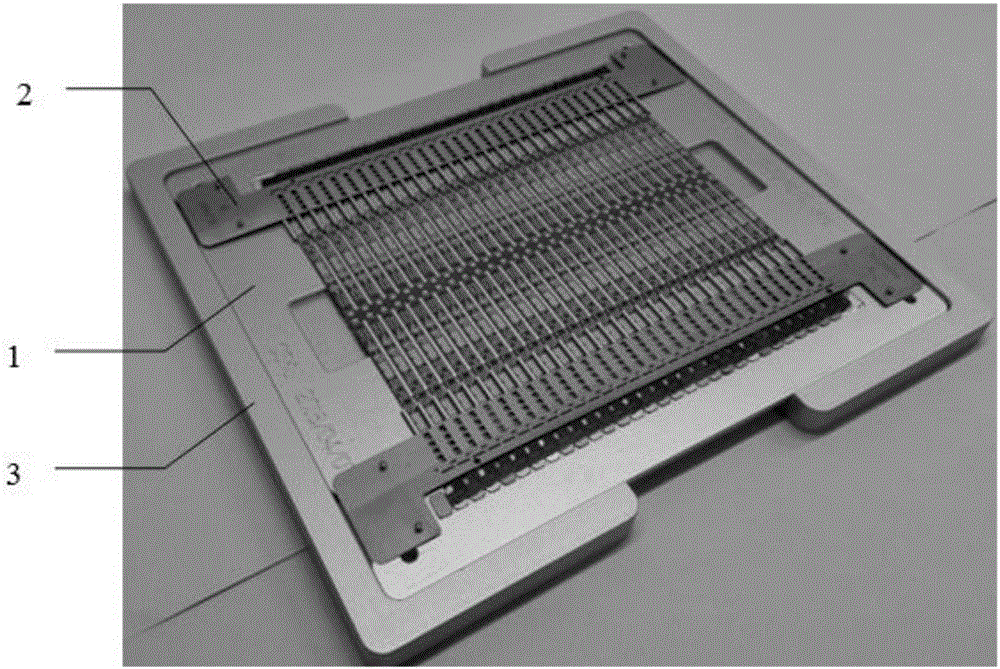

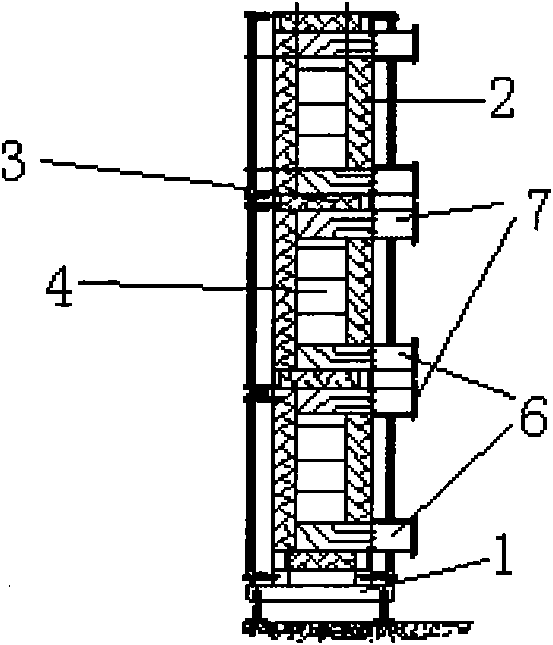

Welding structure and welding method for PCB and FPCB

ActiveCN106304688AIncrease productivityImprove qualityPrinted circuit assemblingMetallurgical bondingElectronic componentTin

The invention discloses a welding method for a PCB and an FPCB. The welding method comprises the following steps of S1, enabling the FPCB to be fixedly attached to the surface of the PCB through a circuit board carrier, and enabling bonding pads in the attached position to be aligned and attached; S2, printing tin paste on the bonding pads of the attached FPCB and PCB through a steel net; S3, mounting electronic components on the corresponding bonding pads; and S4, putting the PCB and the FPCB which are attached together through the carrier into reflow soldering equipment to be heated to realize the welding of the PCB and the FPCB and the welding of the corresponding electronic components at the same time. The invention discloses a welding structure for the FCB and the FPCB. The welding between the FCB and the FPCB realized by the welding method and the welding structure has the advantages of high production efficiency, capability of reducing cost, and stable welding quality.

Owner:广州明美新能源股份有限公司

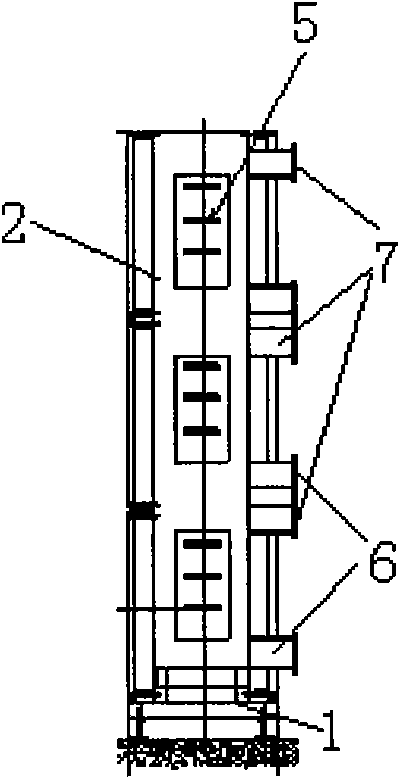

Pre-oxidation furnace

The invention discloses a pre-oxidation furnace, which comprises a furnace frame on which a furnace body is fixed; the inside of the furnace body is fixed with horizontally arranged clapboards which divide a furnace retort in the furnace body into a plurality of layers of mutually independent furnace chambers; a front end face and a rear end face which are opposite on each layer of furnace chamberare respectively provided with a yarn inlet and a yarn outlet; opposite side walls of each layer of the furnace chamber are provided with an air inlet and an air outlet; the pre-oxidation furnace comprises a fan; and an air outlet of the fan is communicated with the air inlet of each layer of the furnace chamber through an air intake system, while an air inlet is communicated with the air outletof each layer of the furnace chamber through an air outlet system. The pre-oxidation furnace has simple structure, and solves the problems of the prior pre-oxidation equipment in aspects of temperature uniformity, an oxygen content control system and a spontaneous precursor combustion phenomenon, and an effective space of a hearth is fully utilized, so equipment and production cost is saved, and the economic production of carbon fibers is feasible.

Owner:HEFEI RISINE HEATEK

Method for cultivating edible fungi and medicinal fungi by utilizing fresh fungi grass

ActiveCN101699967ASave on energy costsSave production costHorticultureBiotechnologyAdditive ingredient

The invention discloses a method for cultivating edible fungi and medicinal fungi by utilizing fresh fungi grass, belonging to the technical field of biological resource fungi grass cultivation. The invention comprises the following steps: harvesting Jujun grass, pennisetum sinese roxb and napiergrass with machines, utilizing a fungi grass grinder to directly grind the fresh grass into particles, preparing nutrient medium according to a weight ratio, taking the ingredient as raw materials according to the above weight ratio, mixing evenly, bagging or bottling to carry out cultivation of edible fungi and medicinal fungi. In the invention, fresh grass is directly used for cultivating edible fungi and medicinal fungi, thus not only reducing procedures like drying and the like, but also greatly saving consumption of energy, reducing the investment of edible fungi and medicinal fungi cultivated by fungi grass, reducing production technology, increasing the nutrient components directly utilized by plants, thus being an important innovative revolution in the cultivation methods of edible fungi and medicinal fungi currently.

Owner:FUJIAN ZHENGYUAN JUNCAO INT COOP CO LTD

Intermittent rotary non-PVC large infusion soft-bag solid drug filling machine

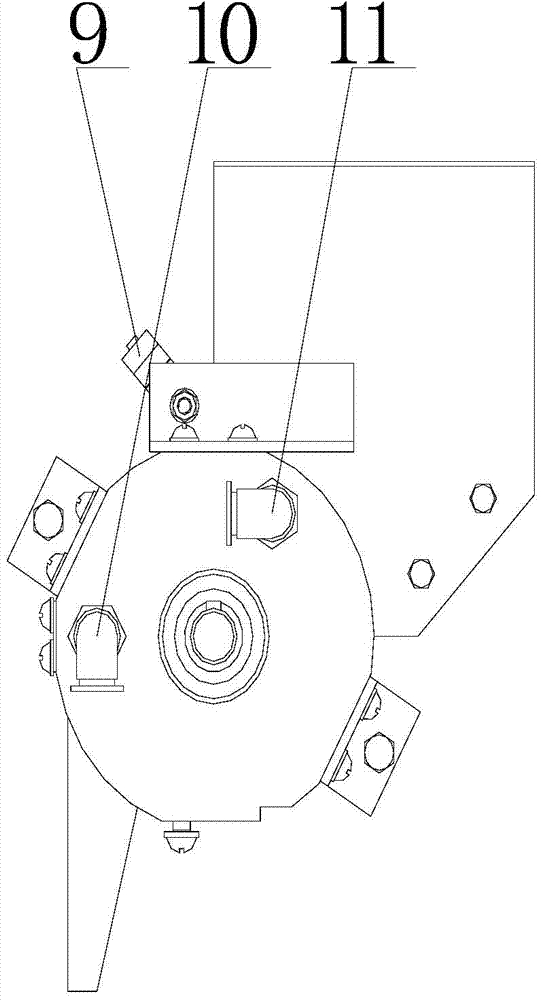

ActiveCN1743232AChange the way the medicine is dispensedChange middle linkPharmaceutical product form changeWrapper supporting apparatusNitrogenEngineering

The solid medicine filling machine comprises power drive component, central dial, take-in and take-out component, bag-cutting part, part for filling clean air, part for filling nitrogen, thermal sealing part, rack and electric control cabinet. The parts above are set on the side of the center dial that connects with the power drive component and are supported by the rack to layout in turn. Around the central dial is fitted with a bag holder for hanging infusion bag.

Owner:HUNAN CHINASUN PHARMA MASCH CO LTD

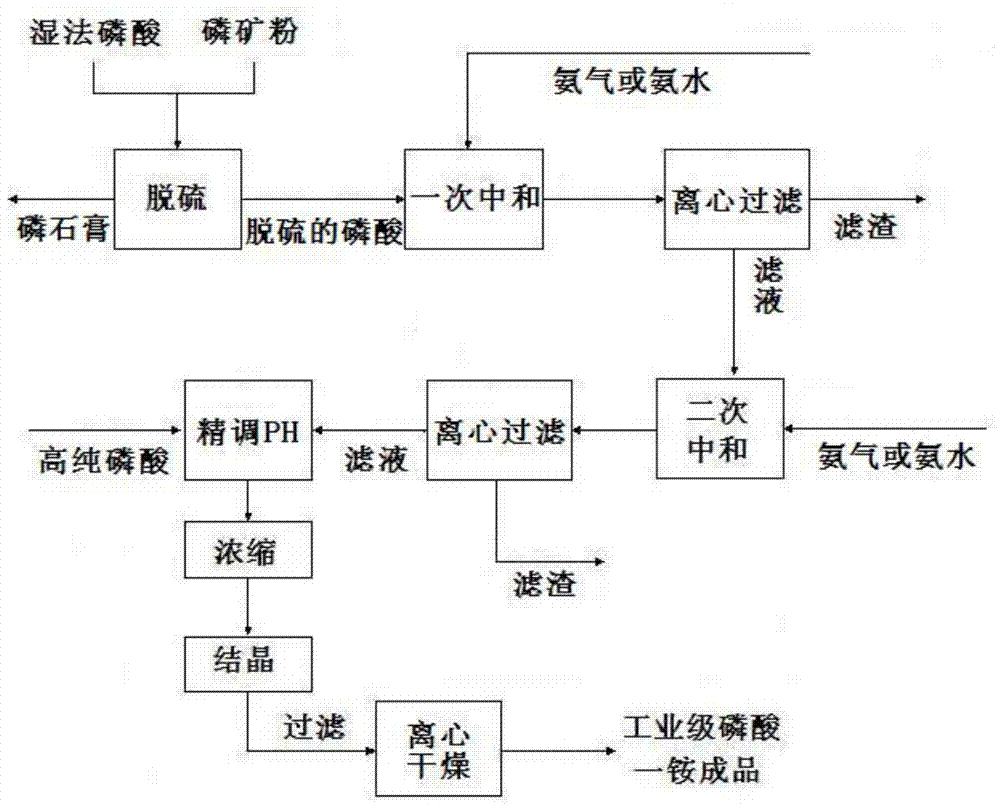

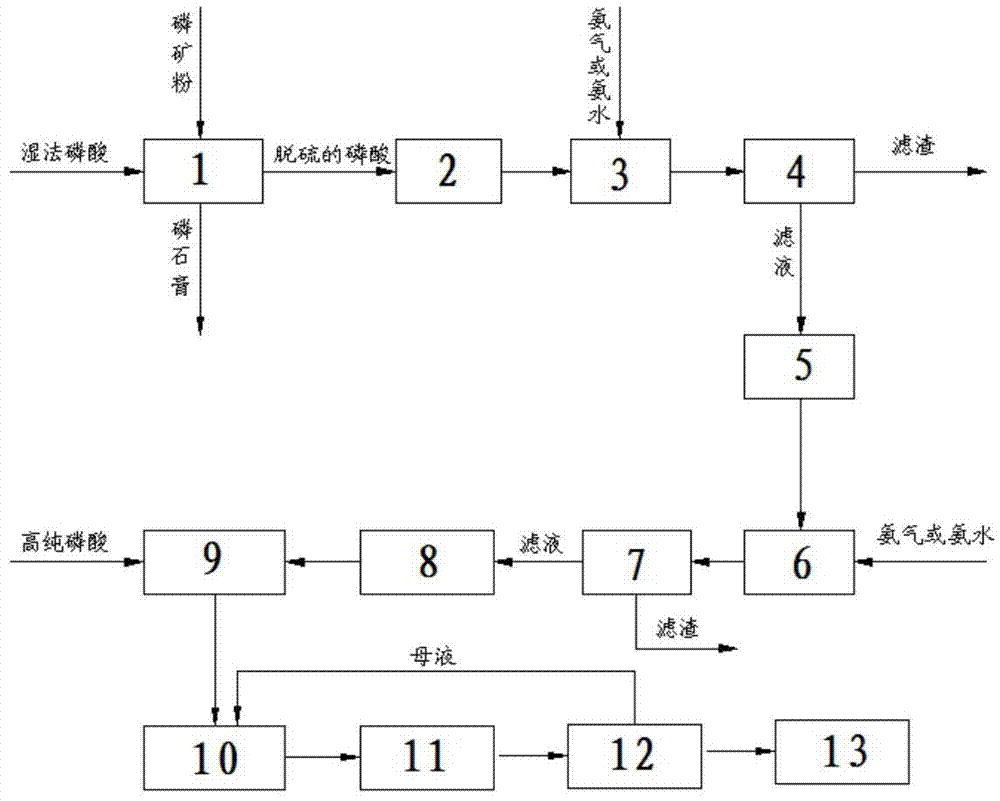

Method for producing industrial grade monoammonium phosphate through combination of wet process phosphoric acid and high-purity phosphoric acid

The invention discloses a method for producing industrial grade monoammonium phosphate through combination of wet process phosphoric acid and high-purity phosphoric acid. The method comprises the steps of performing neutralization reaction for two times on filtrate and ammonia gas or ammonia water to obtain ammonium phosphate slurry, wherein the filtrate is obtained by performing desulfurization reaction on phosphate rock powder and wet process phosphoric acid; performing concentration, crystallization and drying by using filtrate which is obtained by adjusting the pH value with high-purity phosphoric acid to obtain an industrial grade monoammonium phosphate product; removing most of impurity ions when the pH value is neutralized to 4.0-5.0 by the first neutralization reaction, then performing the second neutralization reaction to remove impurities in the wet process phosphoric acid, finely adjusting the pH value to 3.9-4.4 by using the high-purity phosphoric acid, and performing concentration and crystallization to obtain the industrial grade monoammonium phosphate. The method disclosed by the invention reduces the production cost and energy consumption and is environment-friendly and pollution-free; the obtained product is stable in quality, the process flow is short, the device construction investment is saved, the needed operators are less, the energy consumption is reduced, the pollution is reduced, and the quality of monoammonium phosphate is ensured through effective impurity removal, so that the method has a very good economic benefit.

Owner:GUIZHOU KAILIN GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com