Laser shock welding device with shock angle continuously adjustable under vacuum environment

A technology of laser shock and welding equipment, which is applied in the direction of laser welding equipment, auxiliary equipment, welding equipment, etc., to achieve the effect of improving welding performance, reducing manufacturing, and continuously and accurately adjusting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

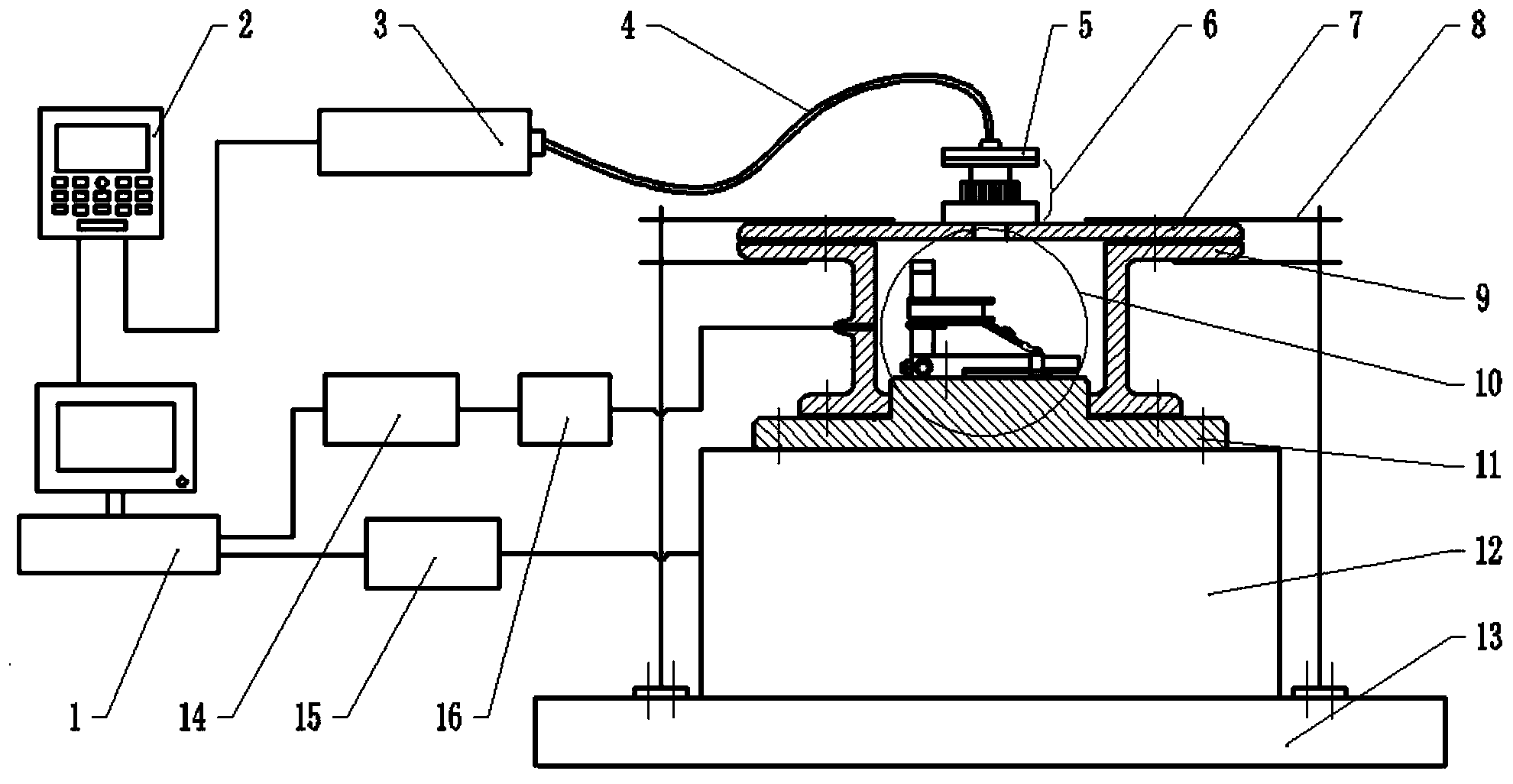

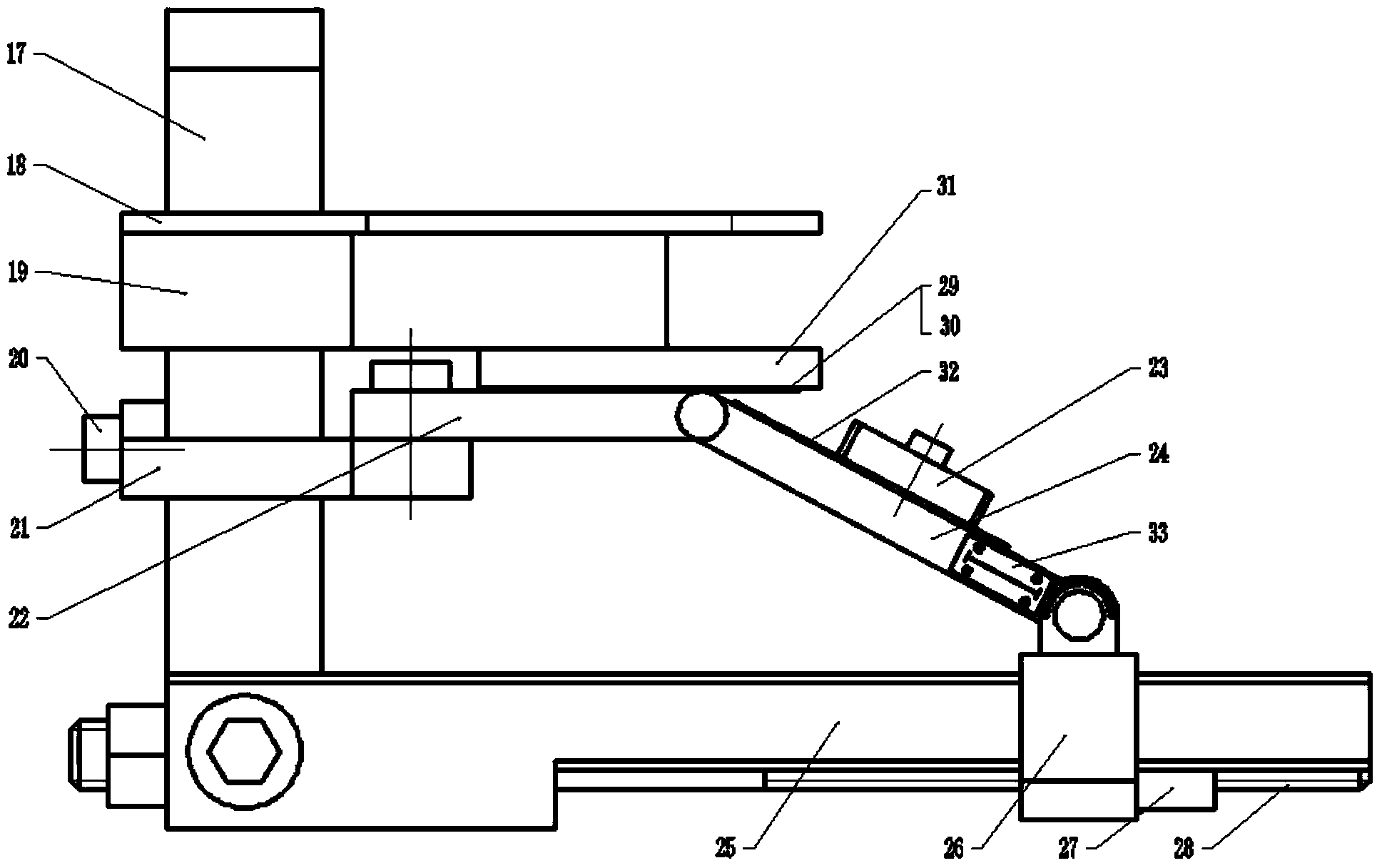

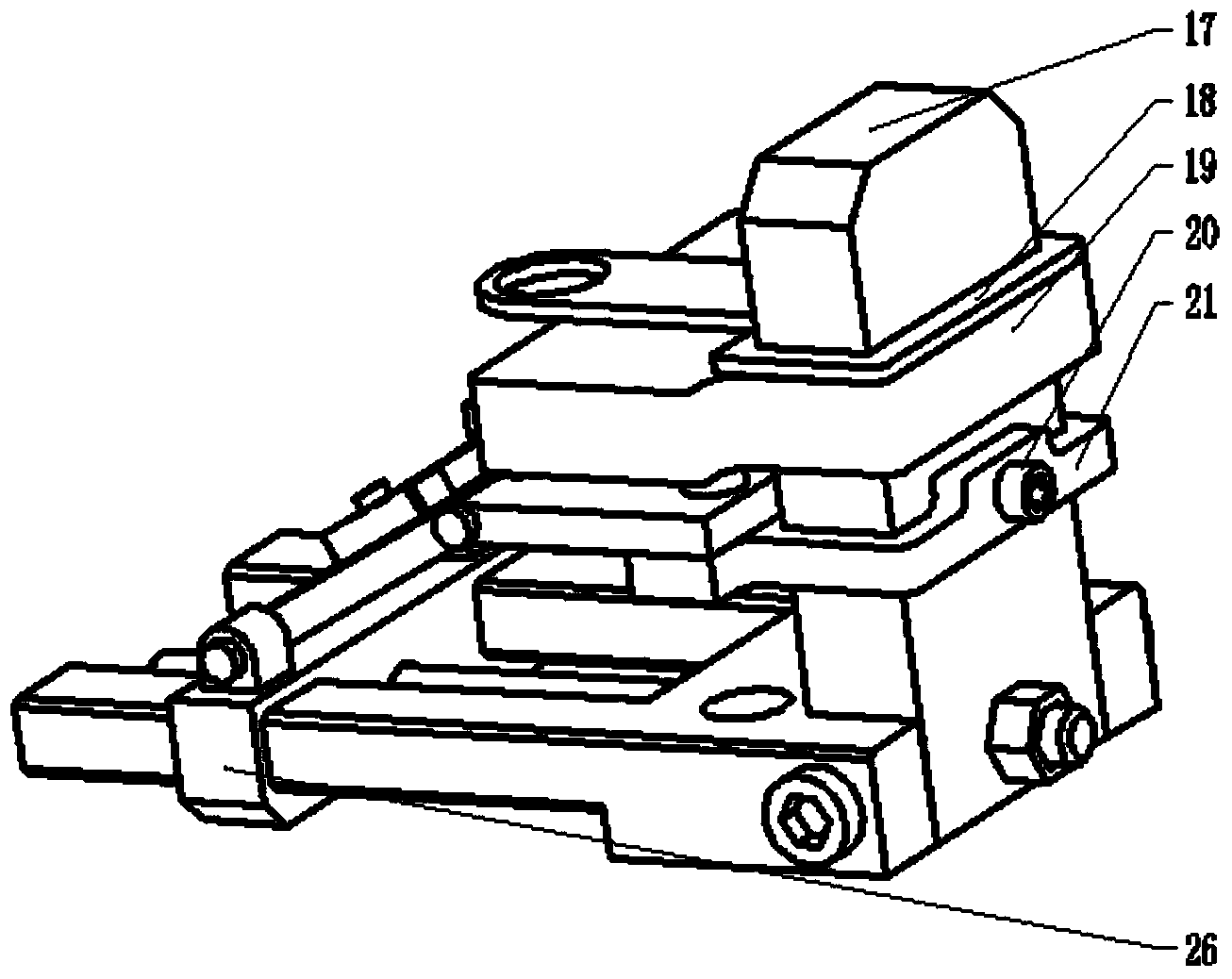

[0031] figure 1 Shown is an embodiment of the laser shock welding device with continuously adjustable shock angle in vacuum environment according to the present invention. The laser shock welding device with continuously adjustable shock angle in a vacuum environment includes a computer control system 1 , a laser generating system, a focusing lens barrel 6 , a vacuum system and a fixture 10 .

[0032]The vacuum system provides a vacuum environment for the laser shock welding device, eliminates the resistance of atmospheric pressure to the ultra-thin doubler plate material under high-speed impact conditions, and improves welding performance. The vacuum system includes a vacuum pump controller 14, a vacuum pump 16, and a vacuum chamber. The vacuum pump controller 14 is ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com