Patents

Literature

56356results about "Soldering auxillary devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

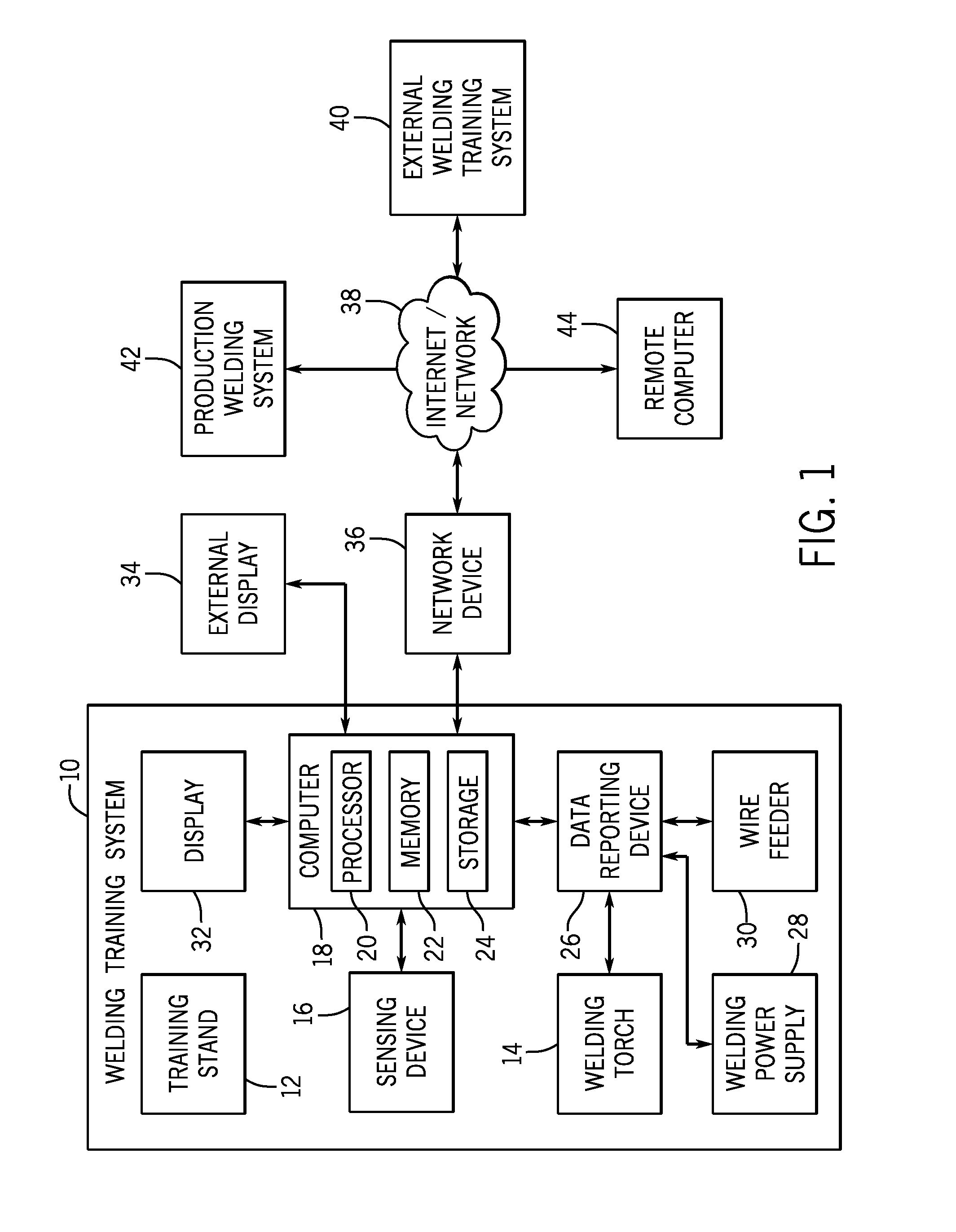

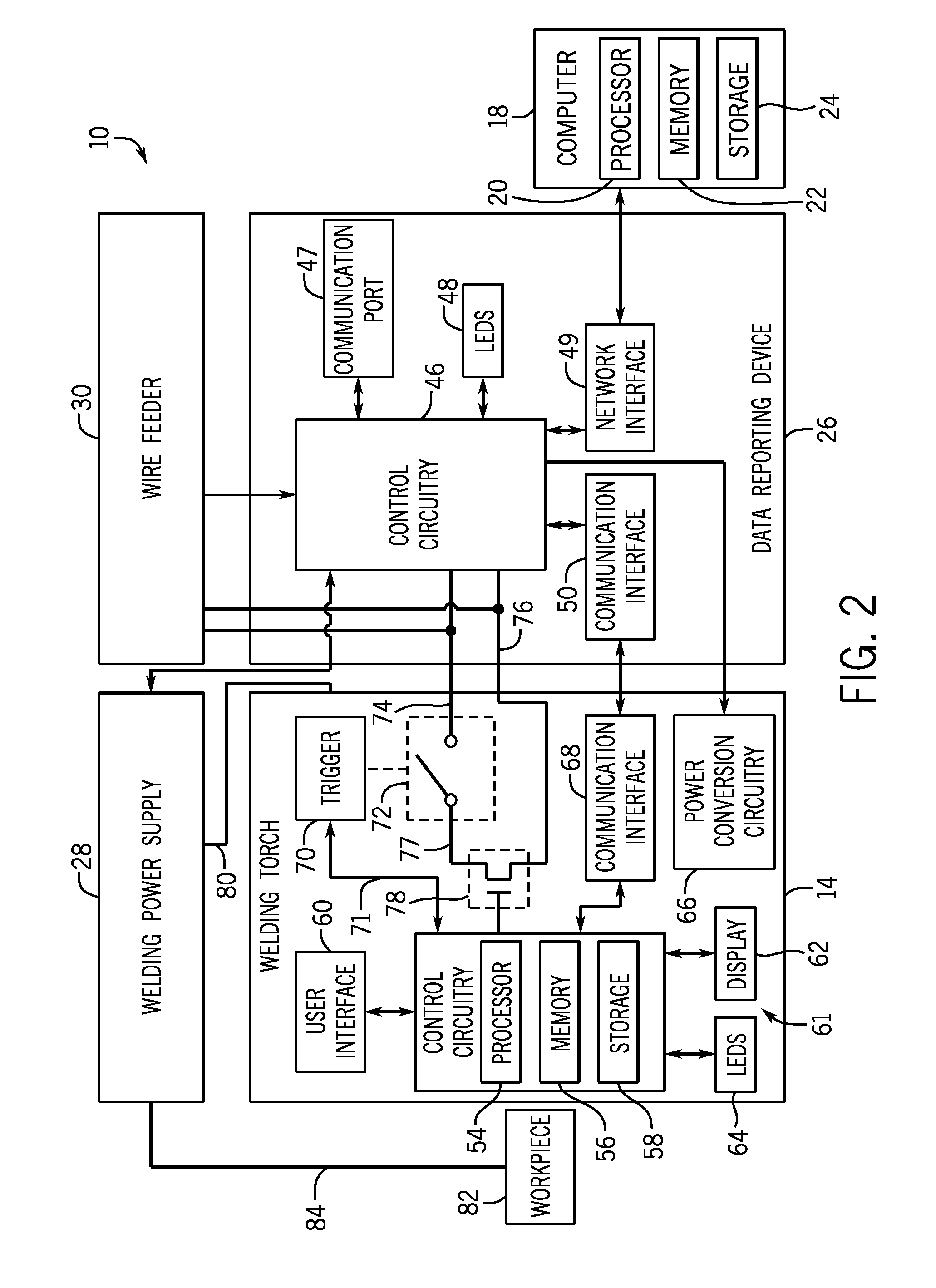

Welding training system

ActiveUS20090298024A1Fast learningProgramme controlWelding/cutting auxillary devicesEngineeringOperator - device

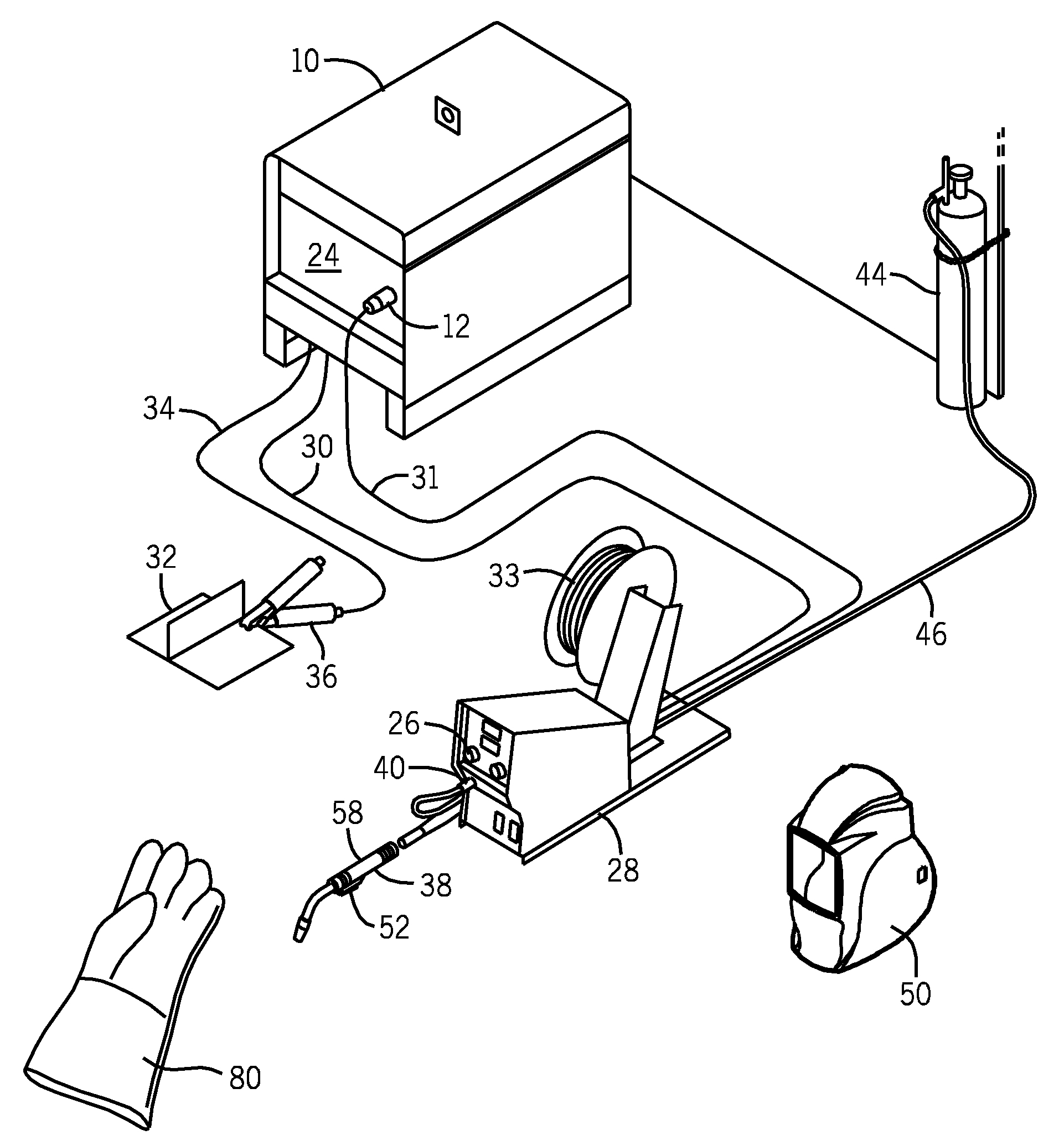

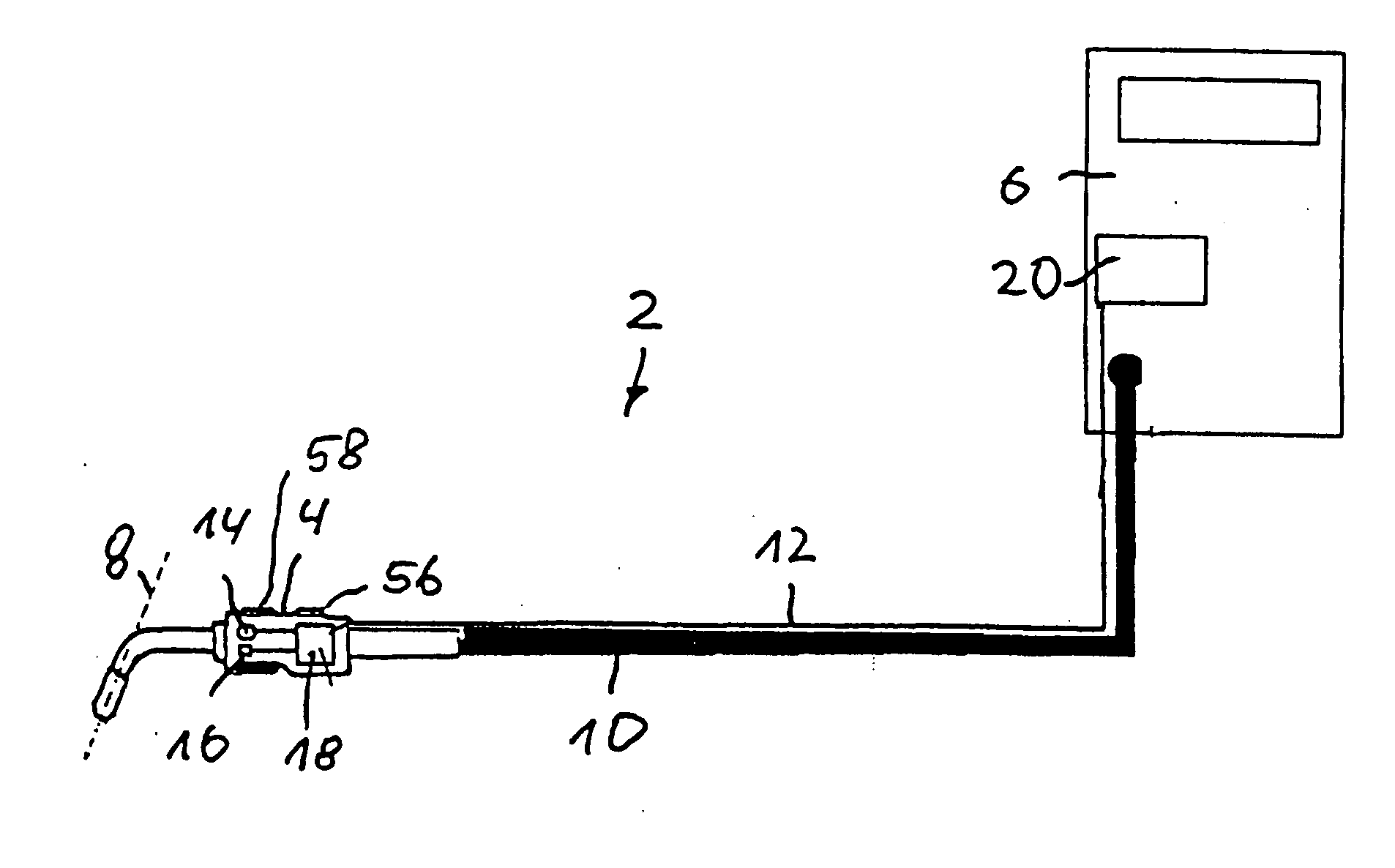

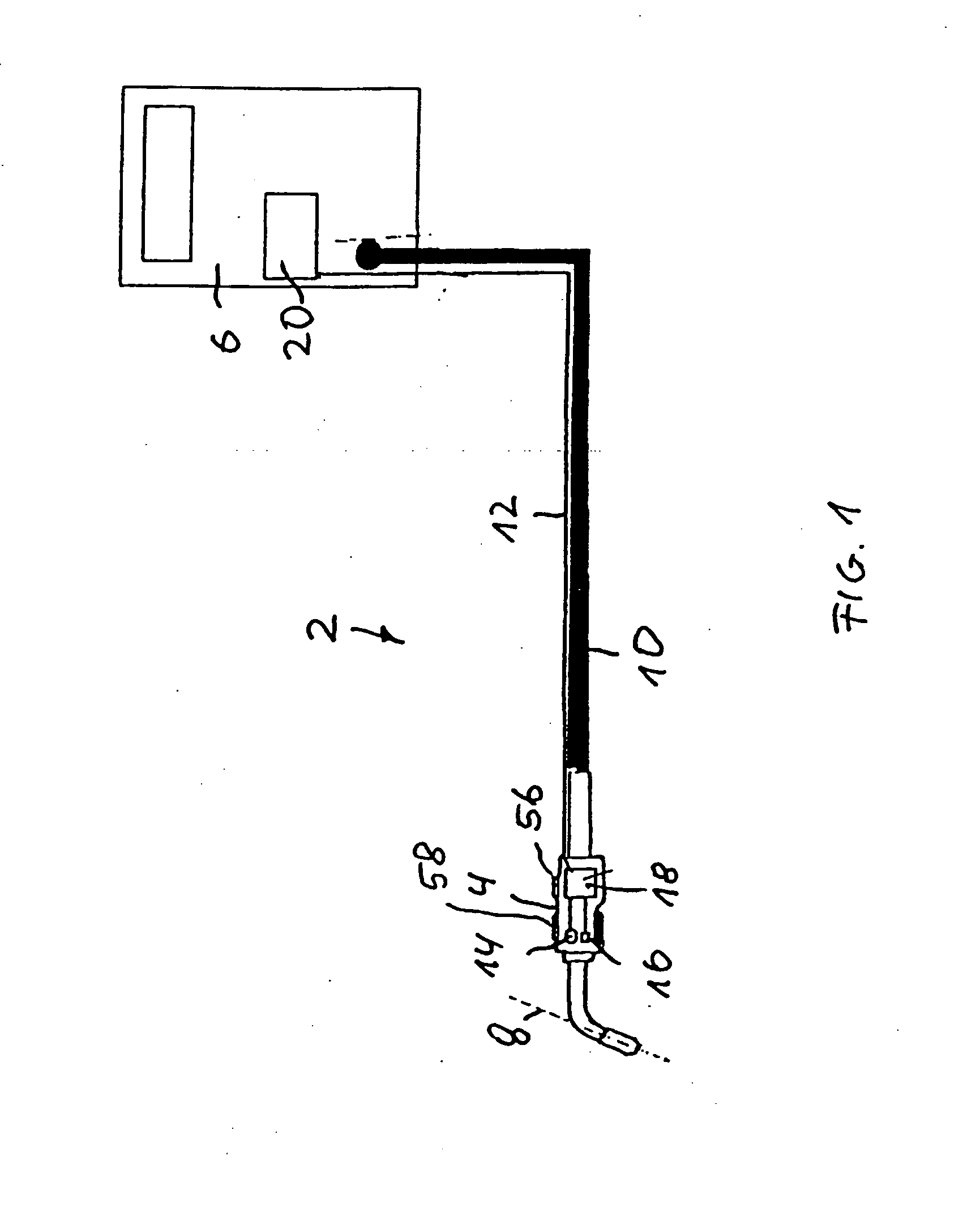

A welding training system includes one or more welding operator device which provides positional feedback relevant to a quality weld. The positional feedback is analyzed and, when the positional feedback is outside of a predetermined range, a signal is provided to the welding operator. In one embodiment, tactile feedback is provided in a welding gun.

Owner:ILLINOIS TOOL WORKS INC

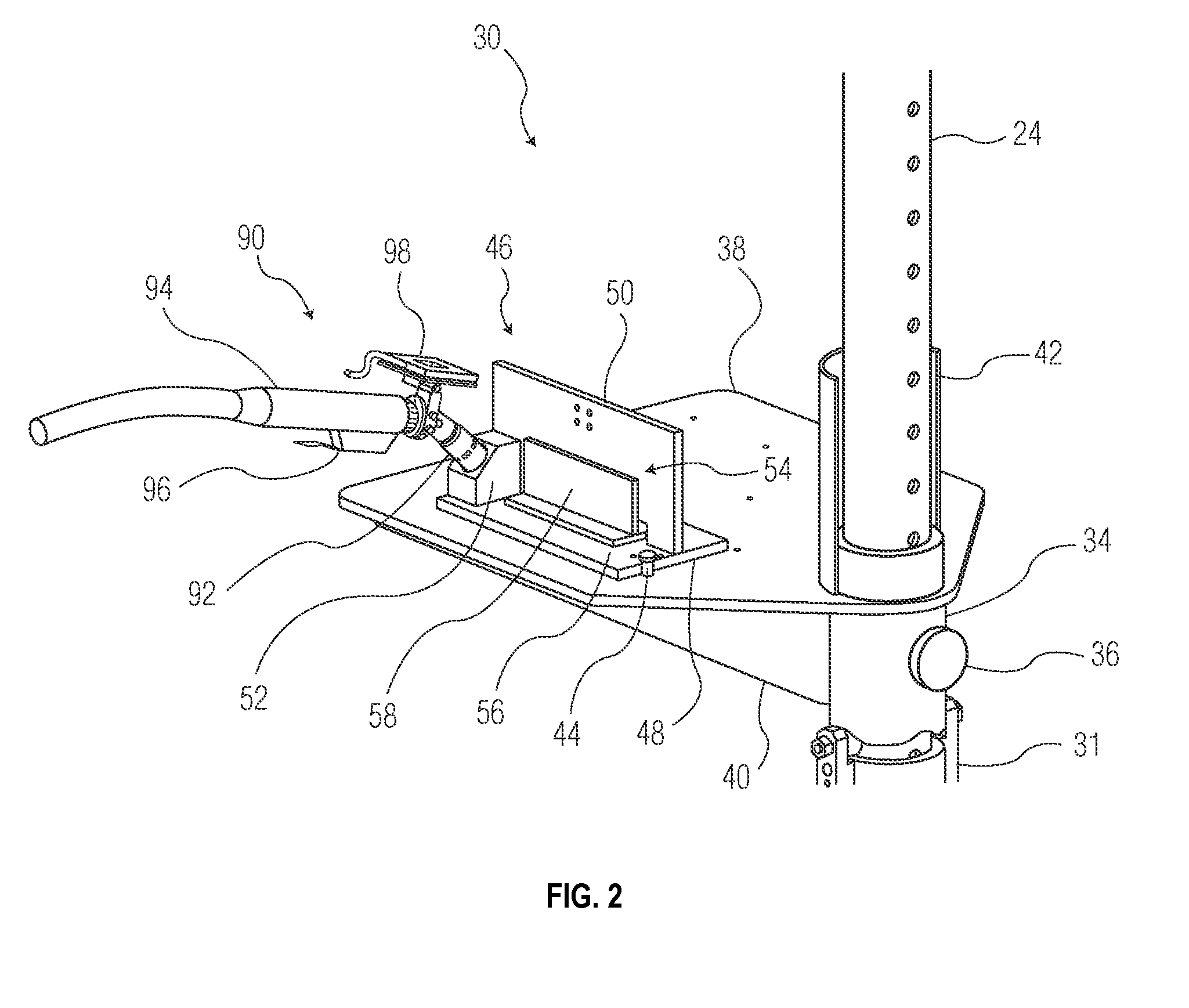

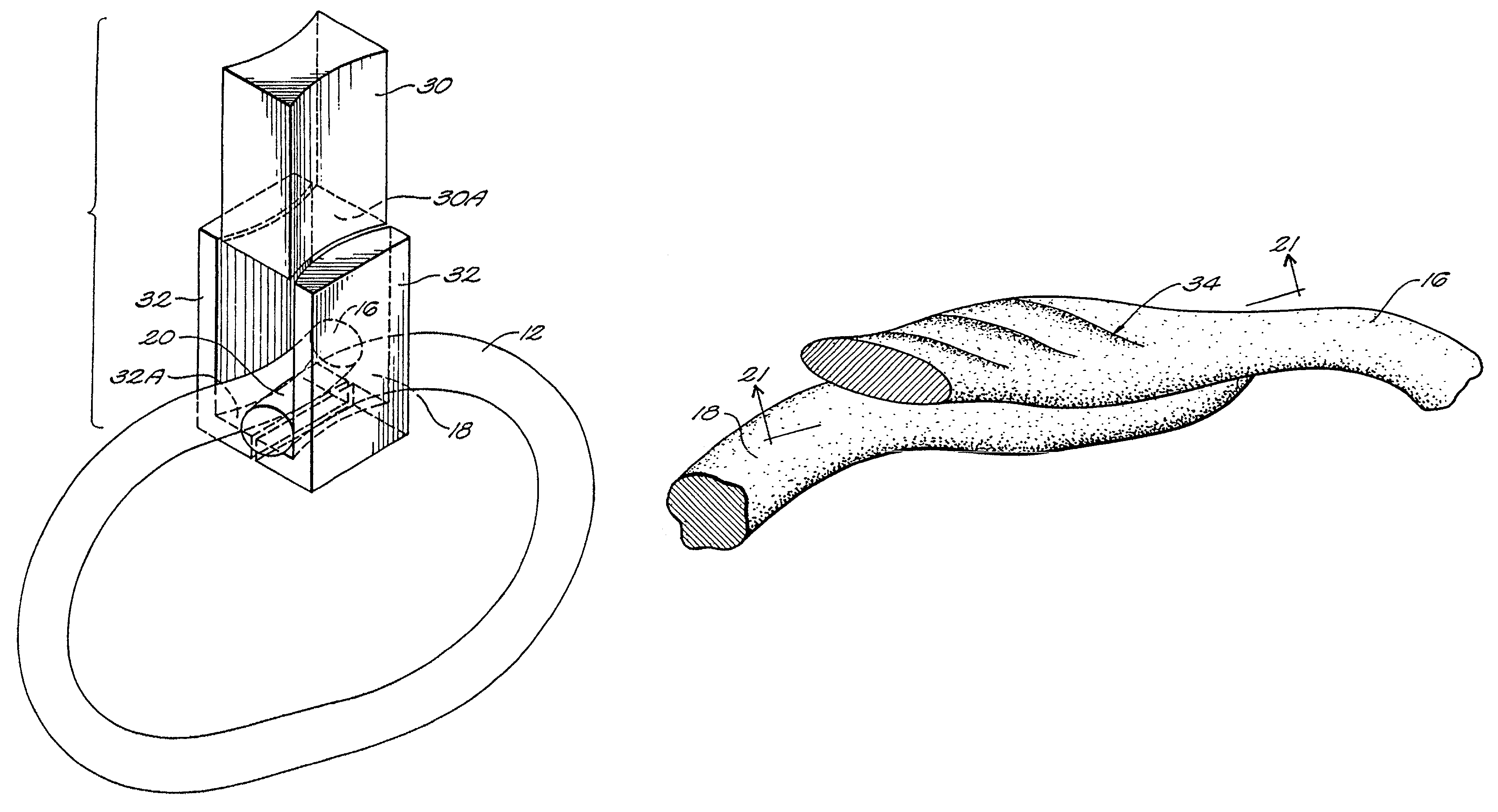

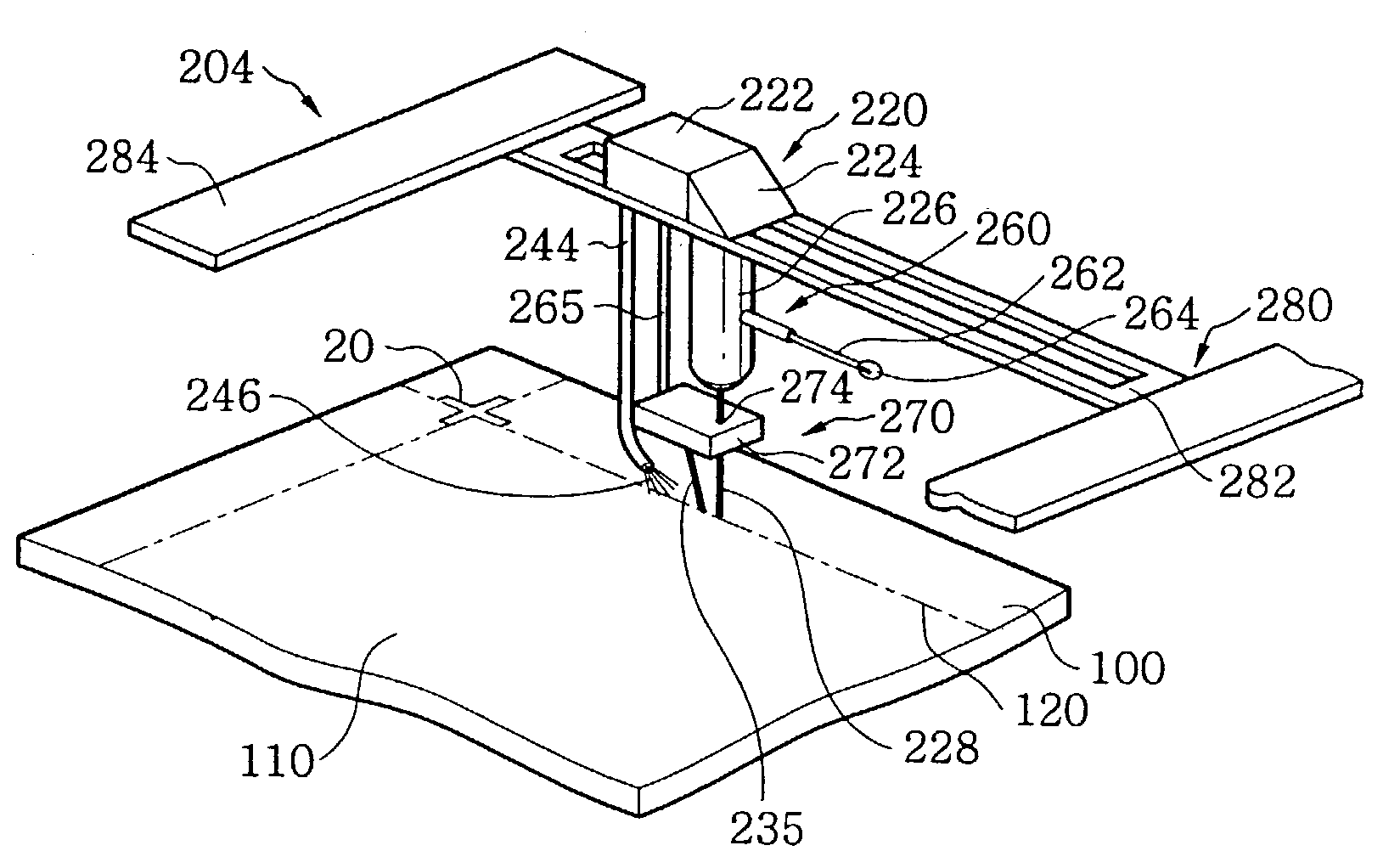

Welding training system

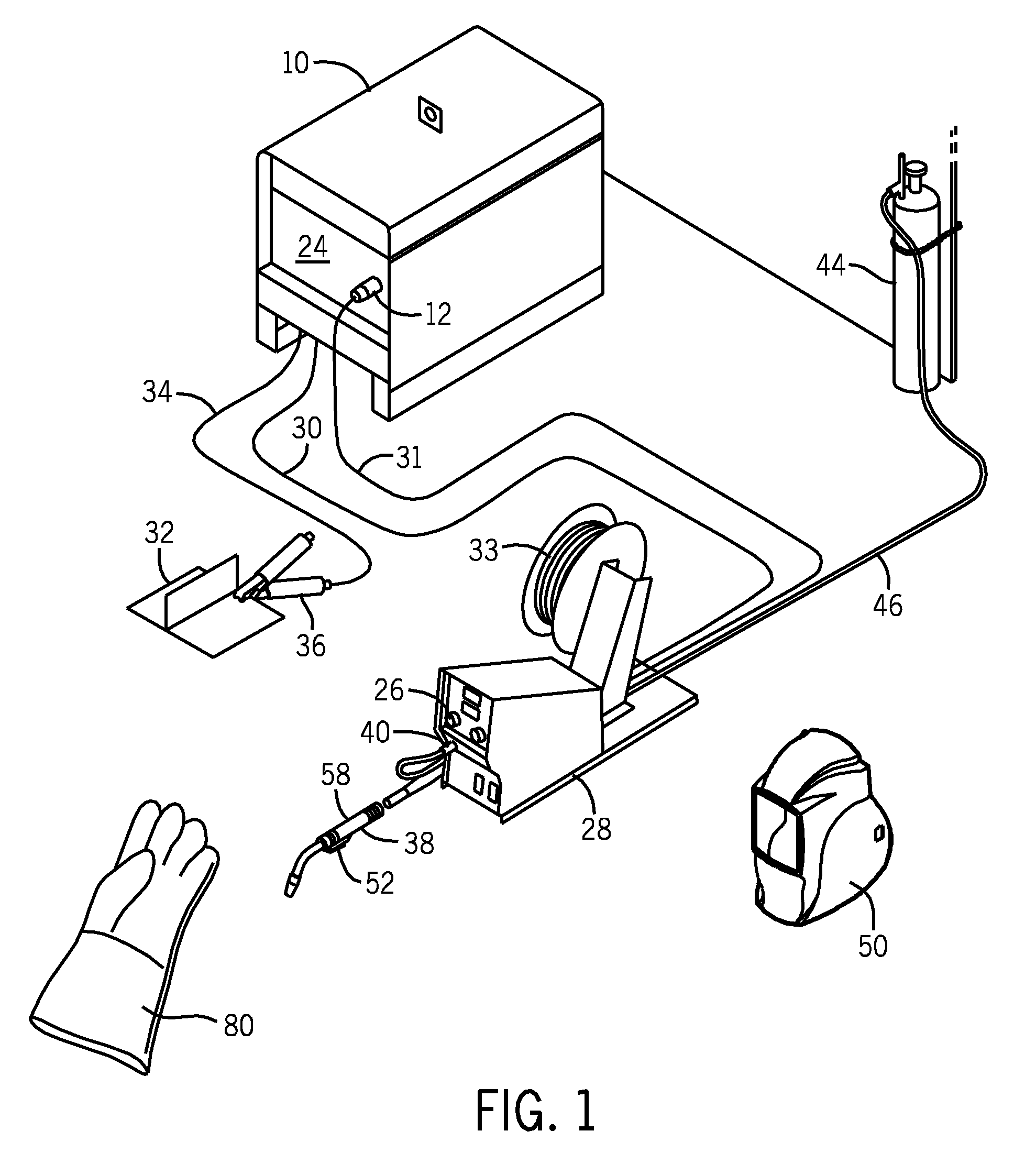

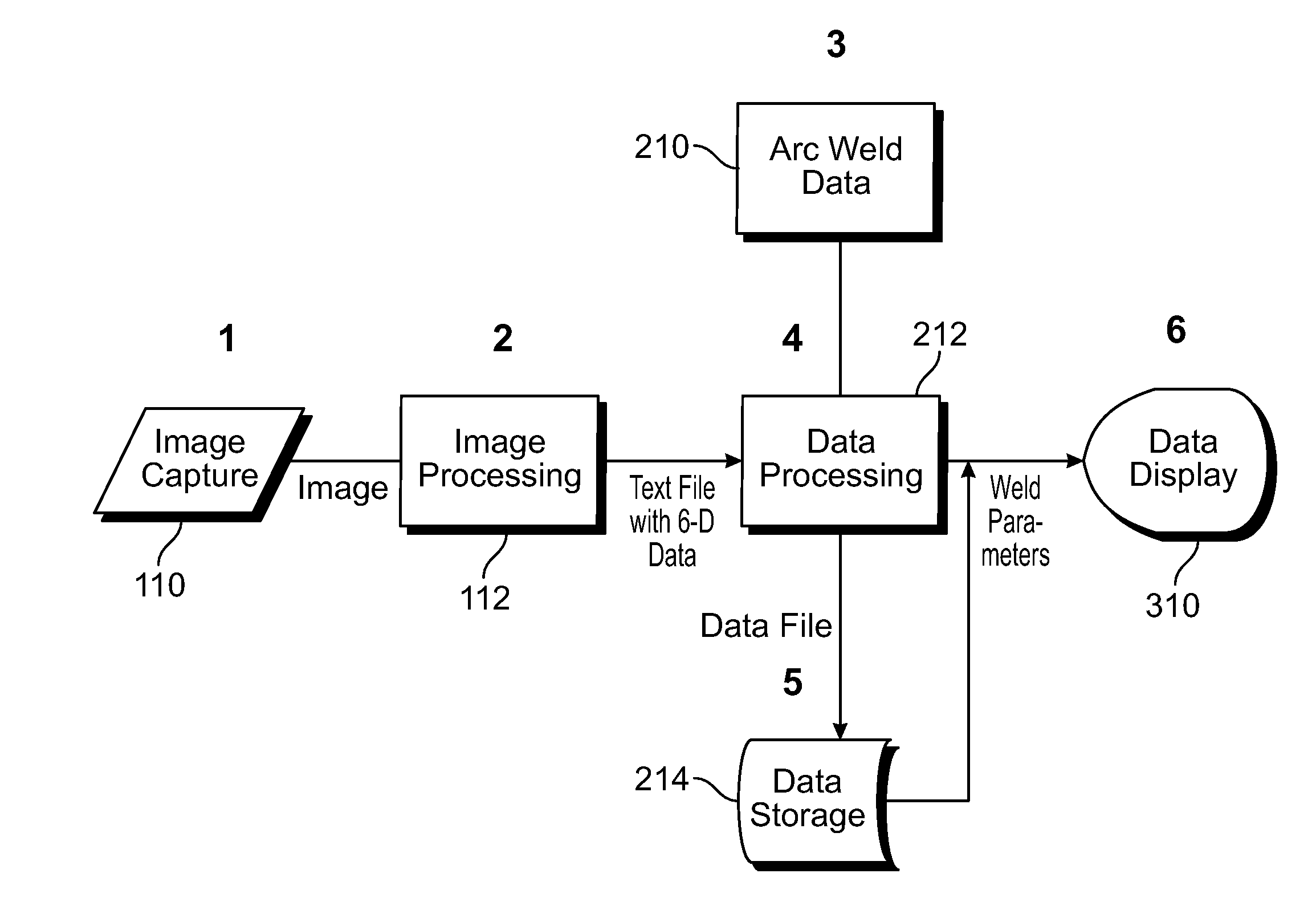

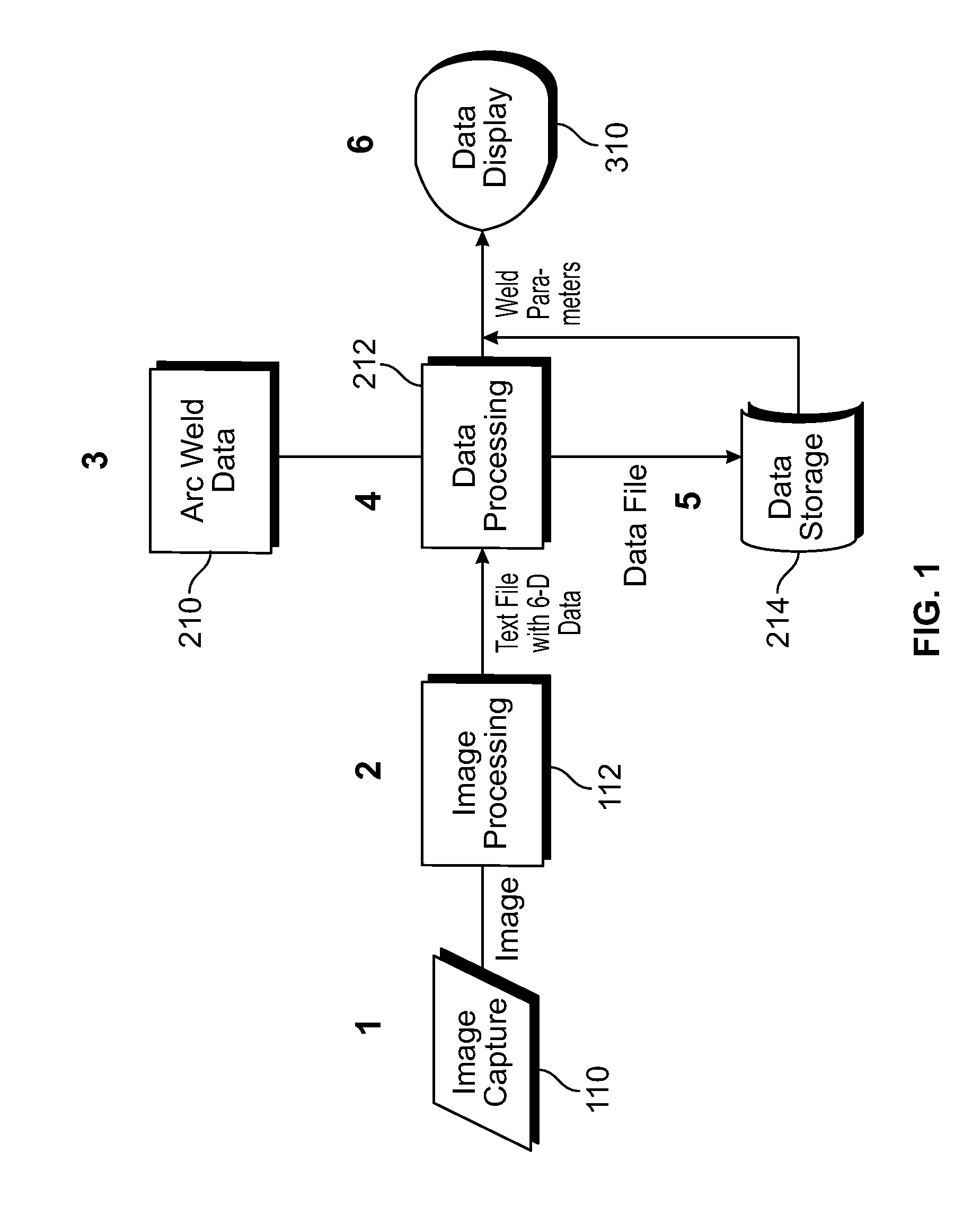

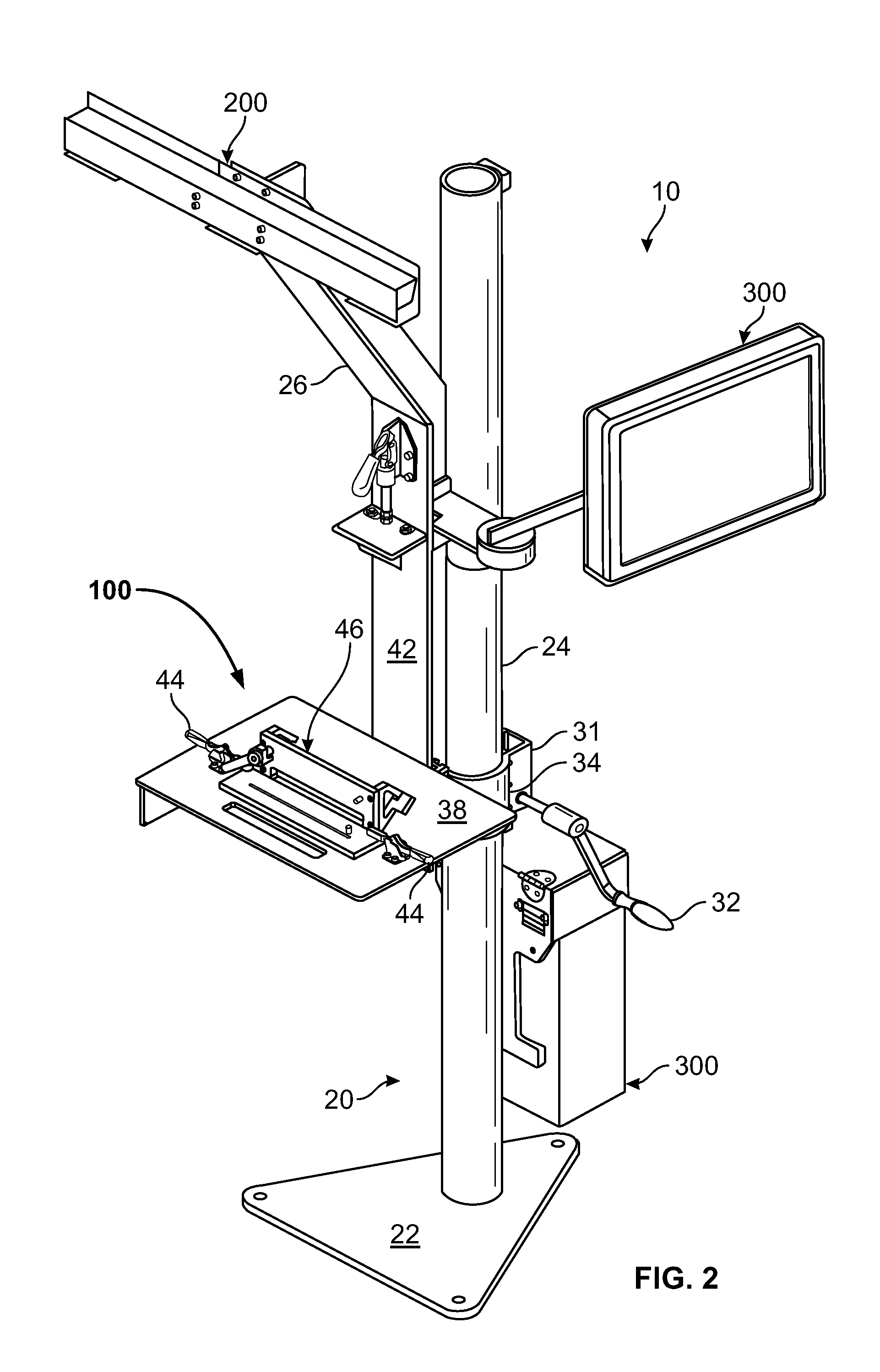

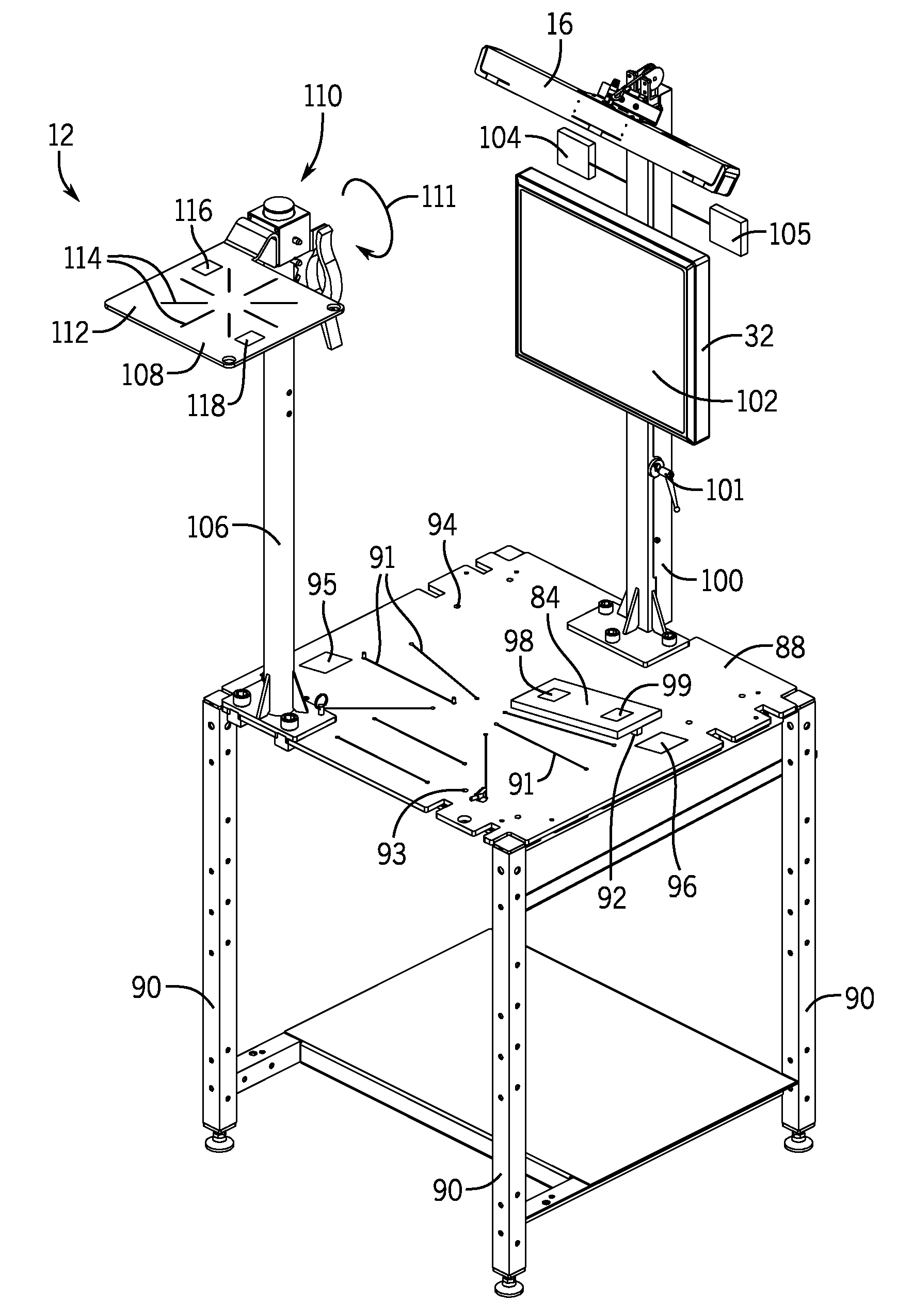

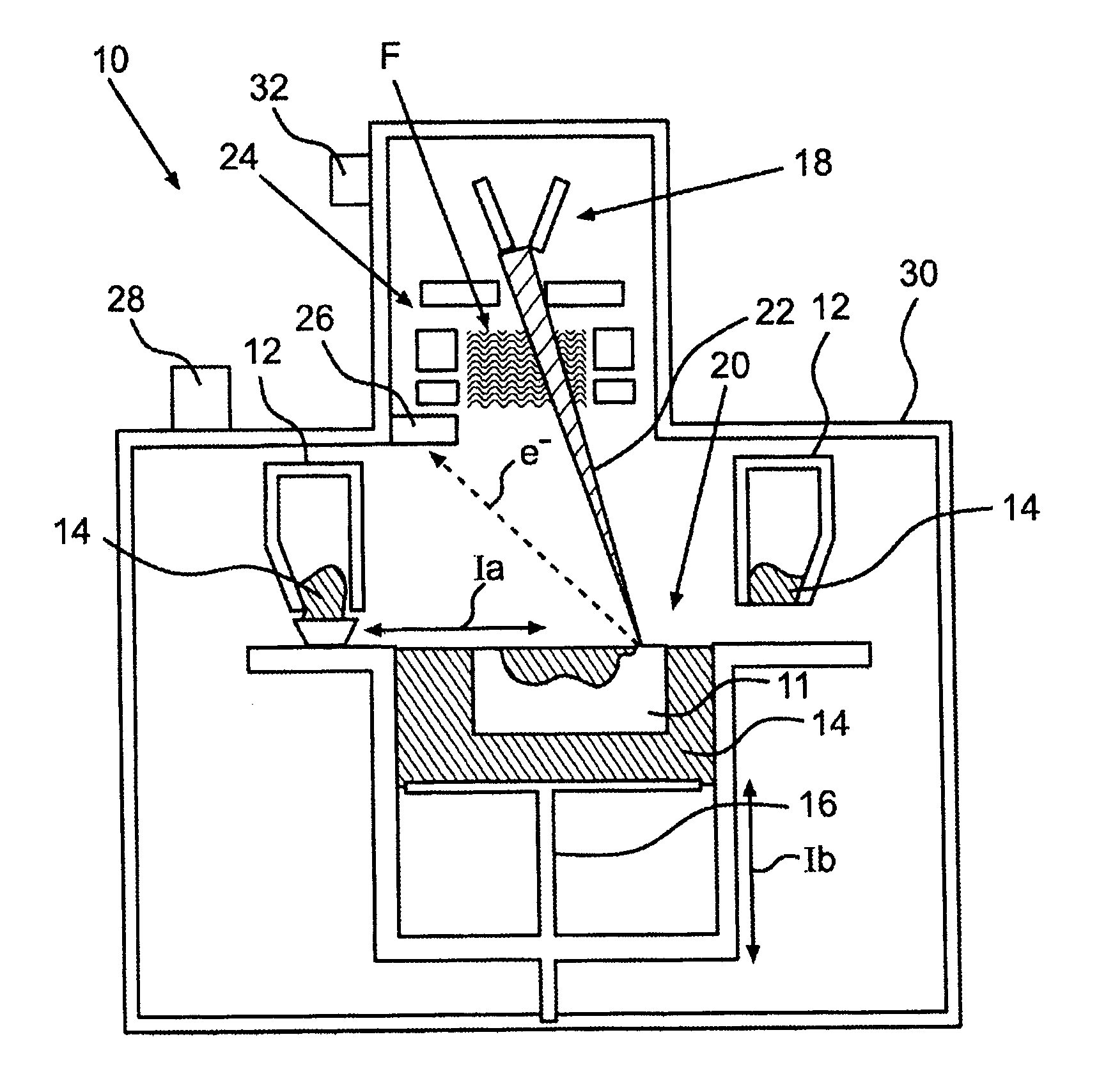

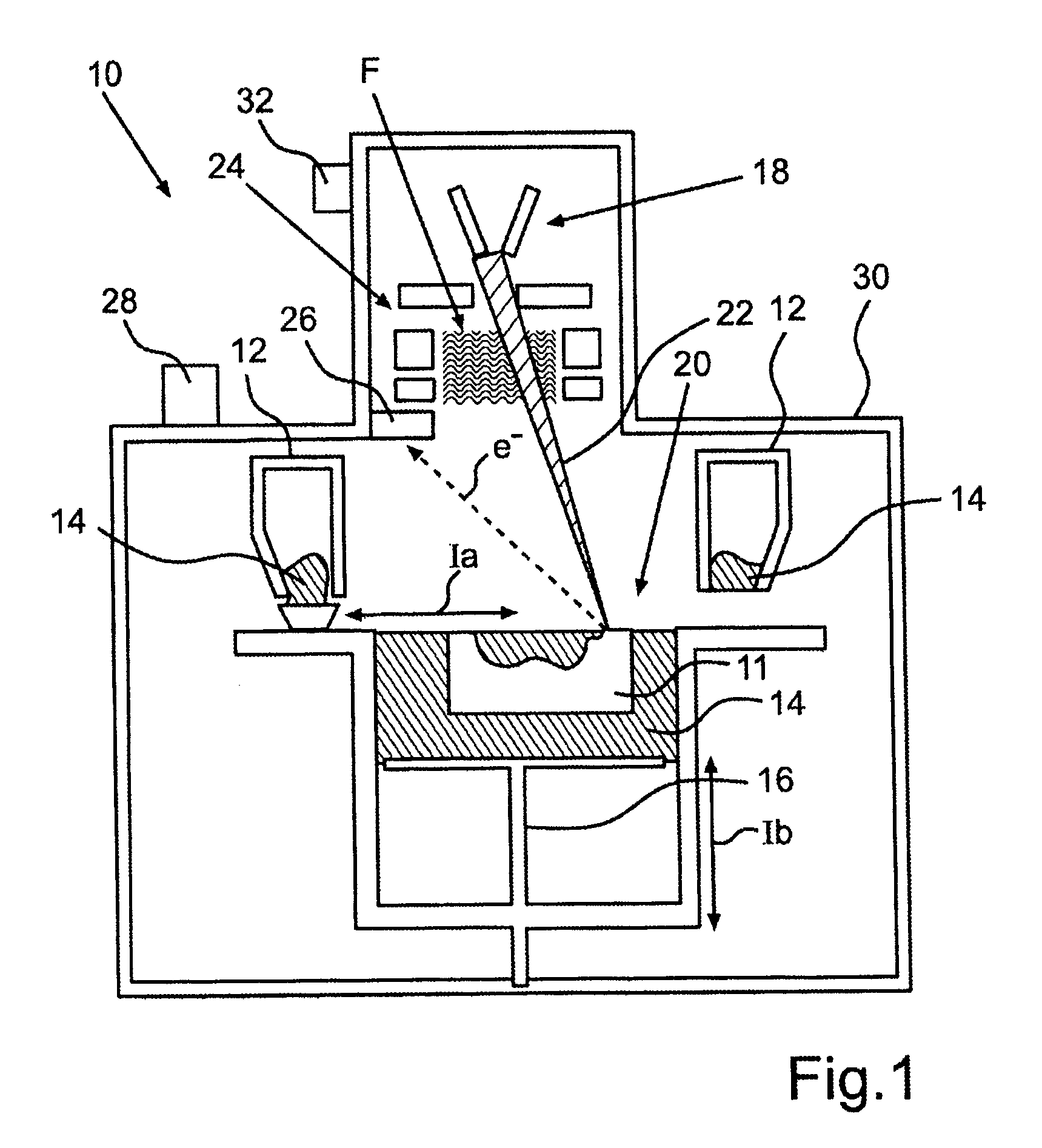

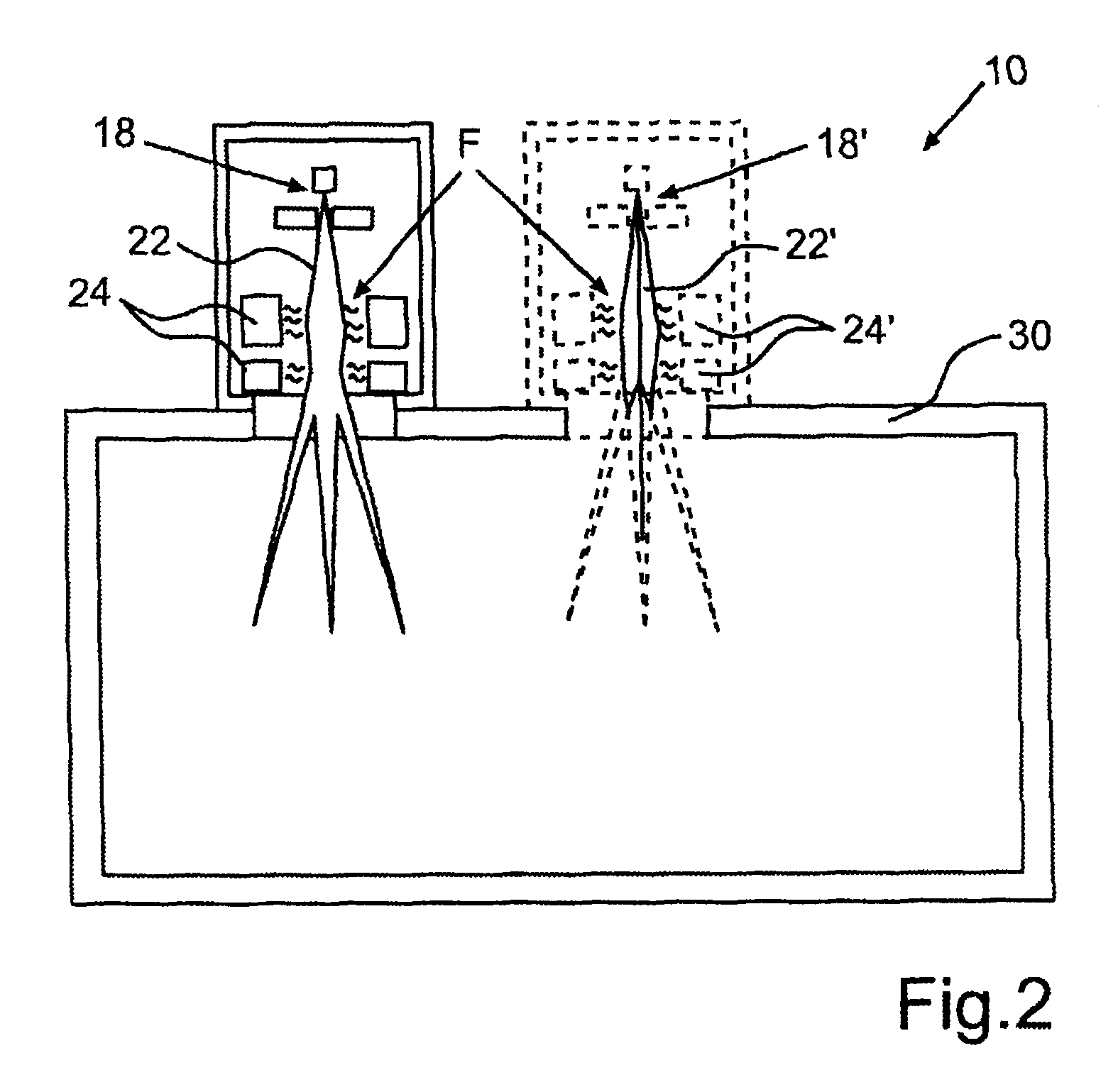

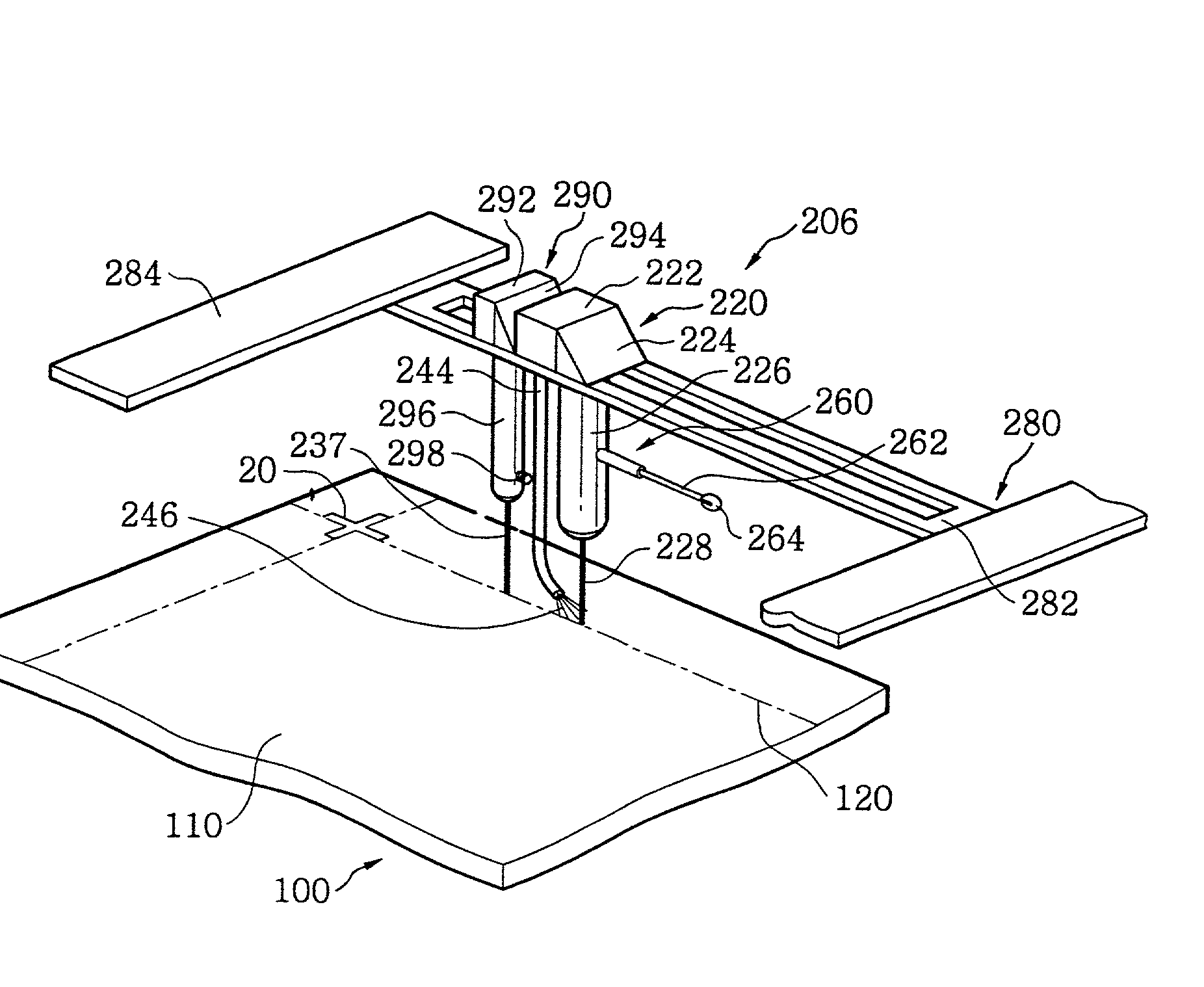

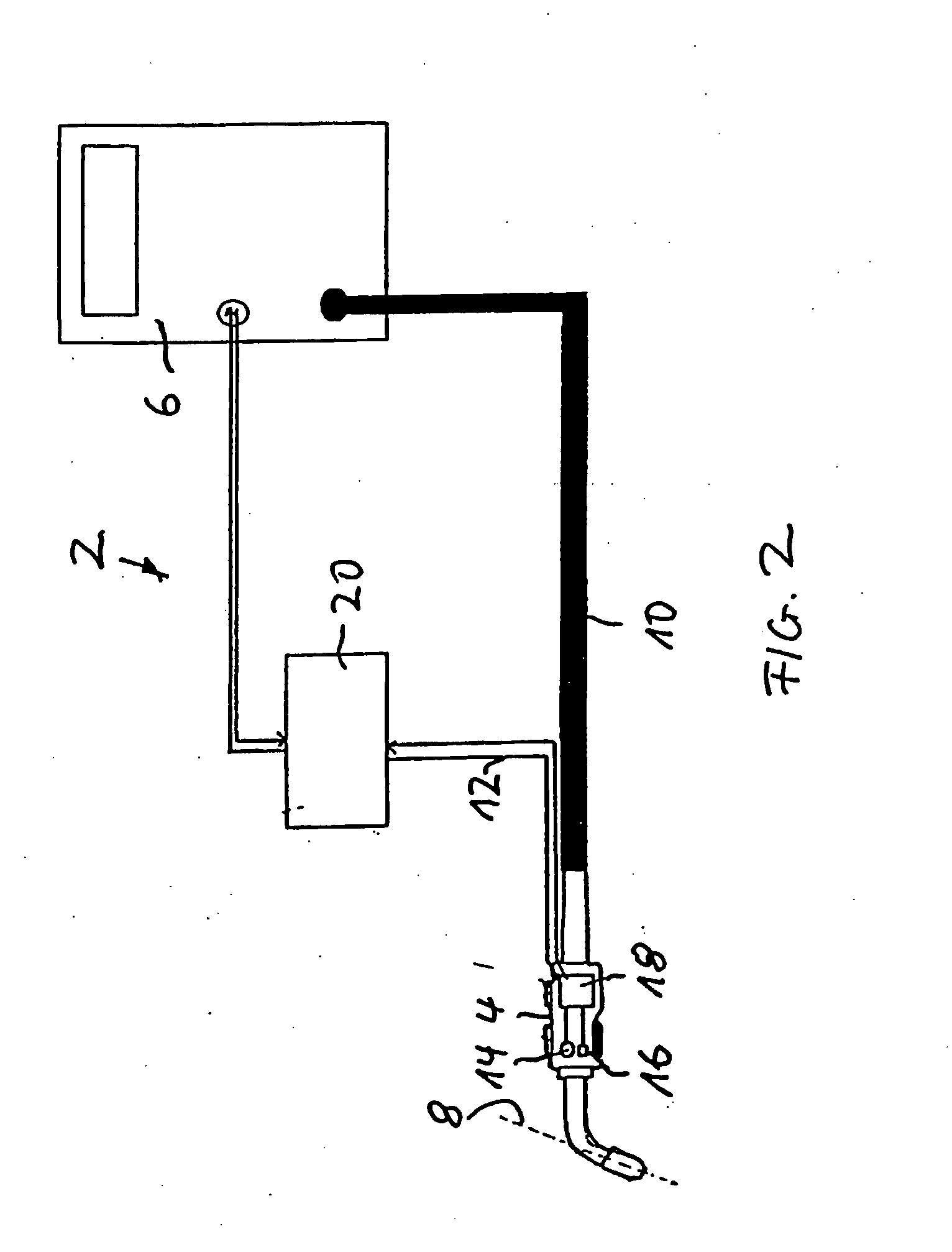

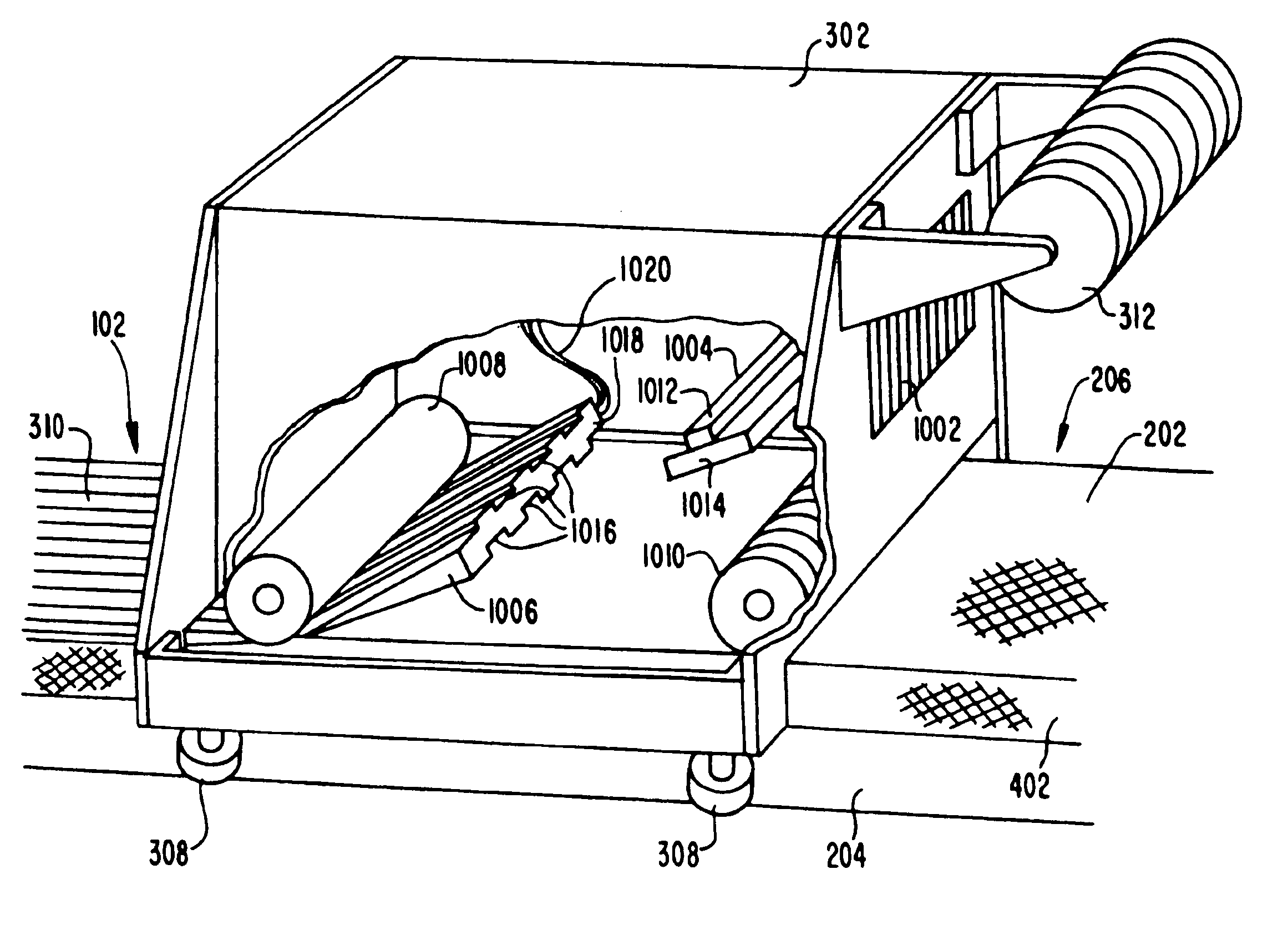

ActiveUS20110117527A1Clear visionUseful feedbackWelding/cutting auxillary devicesAuxillary welding devicesSimulationDerived Data

A system for training welders that includes a data generating component, a data capturing component and a data processing and visualization component. The data generating component operates in real time and derives data from an actual manually-executed weld and further includes a weld process-specific jig, a calibration block positioned on the jig, wherein the geometric configuration of the calibration block is specific to a particular type of weld joint, a weld coupon positioned on the welding process-specific jig adjacent to the calibration block, a welding gun for use by a trainee, wherein the welding gun is operative to form the weld; and at least one target mounted on the welding gun that is recognized by the data processing and visualization component for providing multidimensional position and orientation feedback to the trainee.

Owner:LINCOLN GLOBAL INC

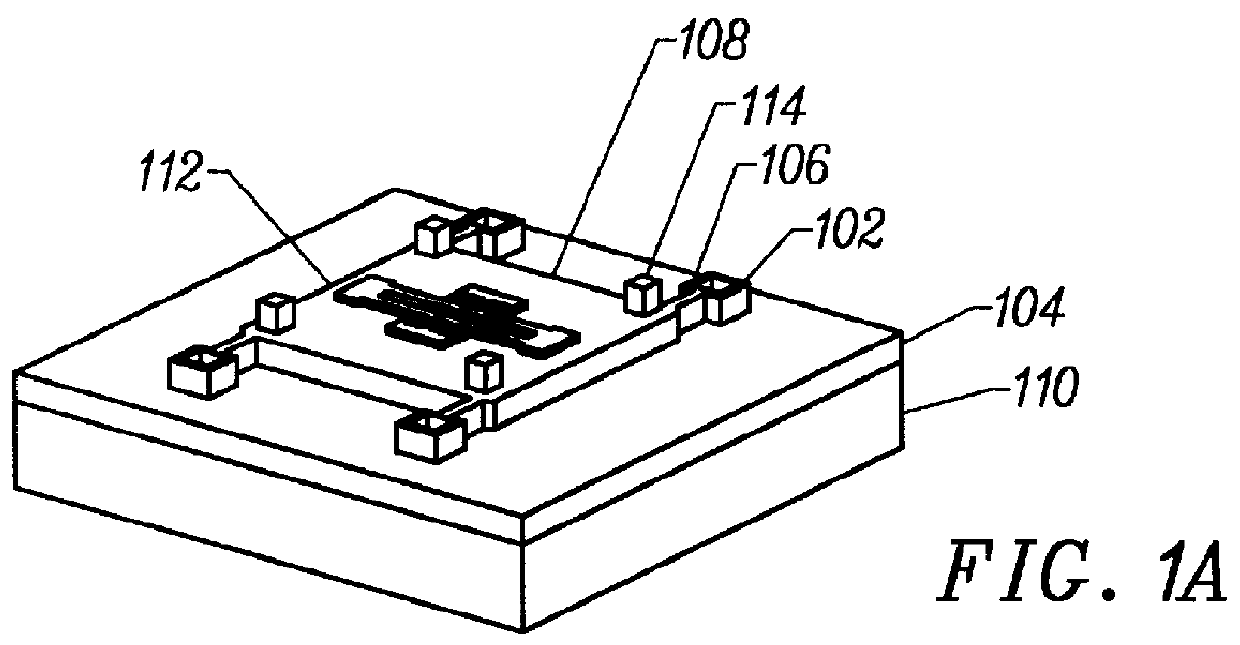

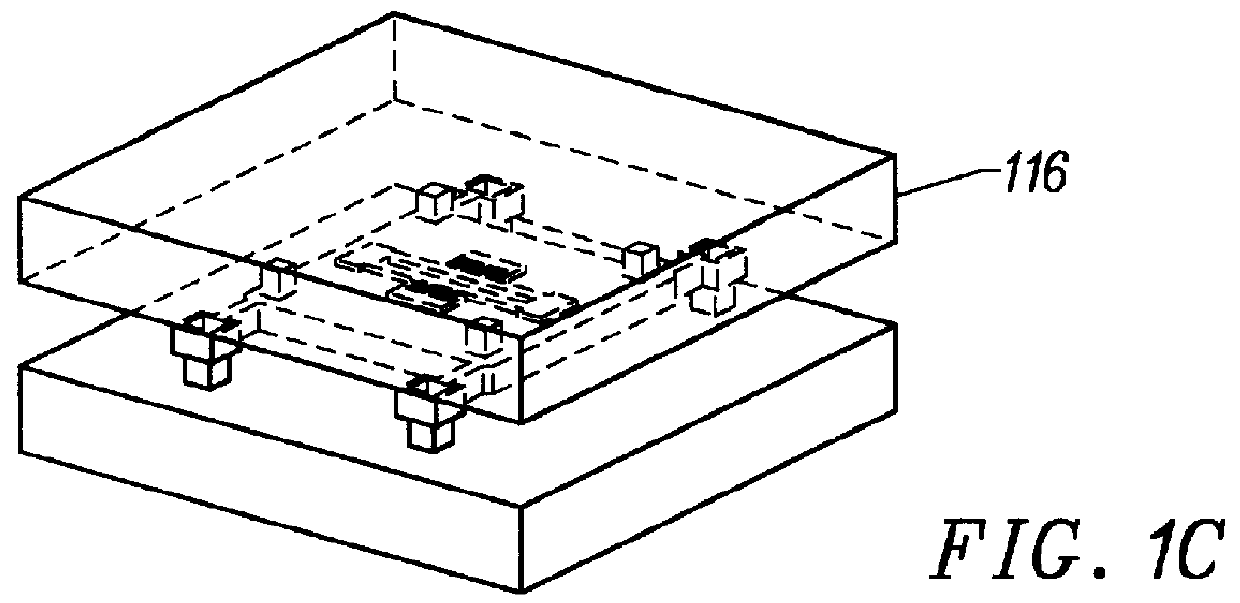

Wafer-to-wafer transfer of microstructures using break-away tethers

InactiveUS6142358AReduce tensionSemiconductor/solid-state device detailsWelding/cutting auxillary devicesOptoelectronicsMicrostructure

Break-away tethers to secure electronic, mechanical, optical, or other microstructures, during release from one substrate and transfer to another. Microstructures are fabricated with integrated tethers attaching them to a first substrate. The structures are undercut by etching and contacted and bonded to a second substrate. First and second substrates are separated, breaking the tethers.

Owner:RGT UNIV OF CALIFORNIA

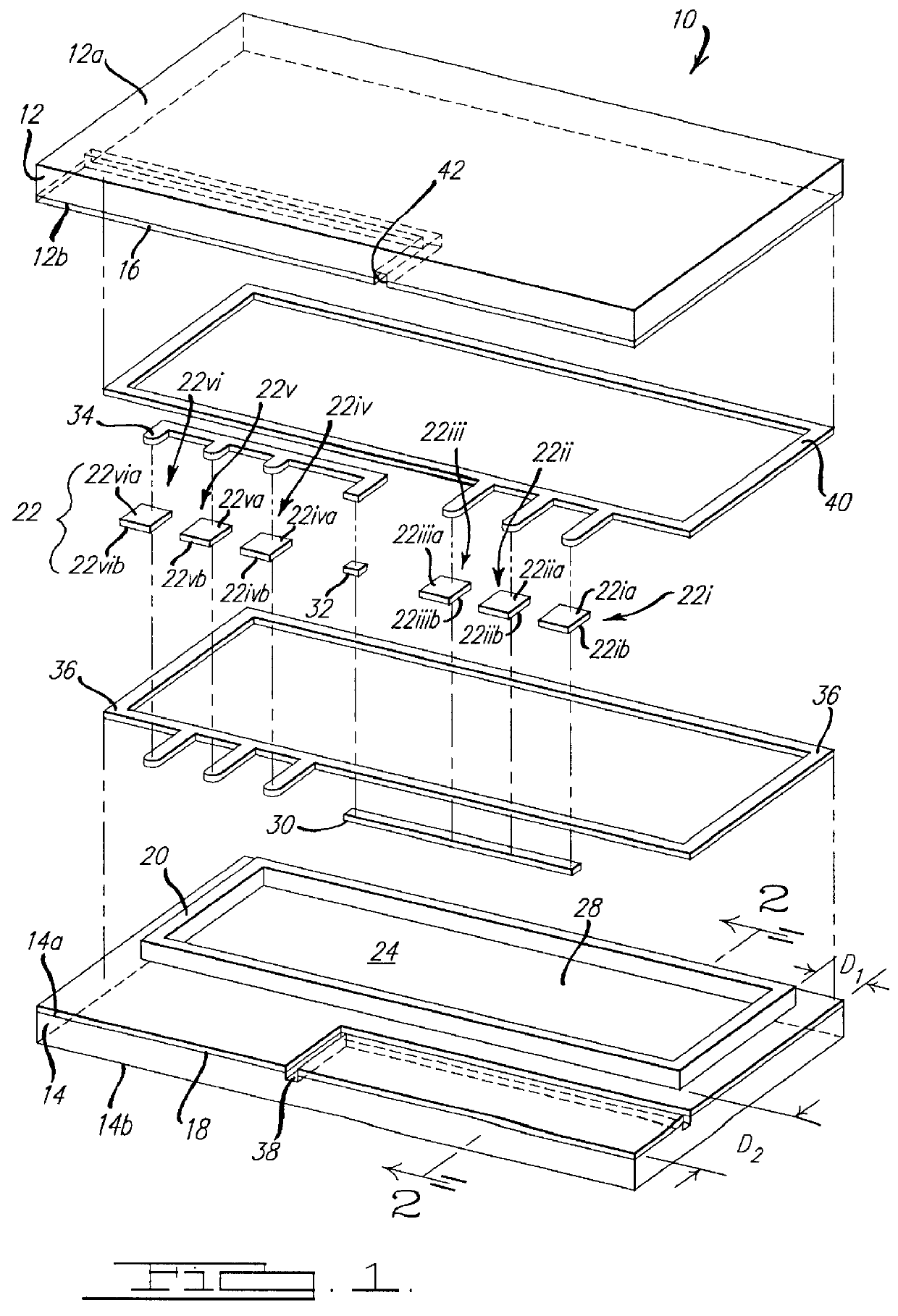

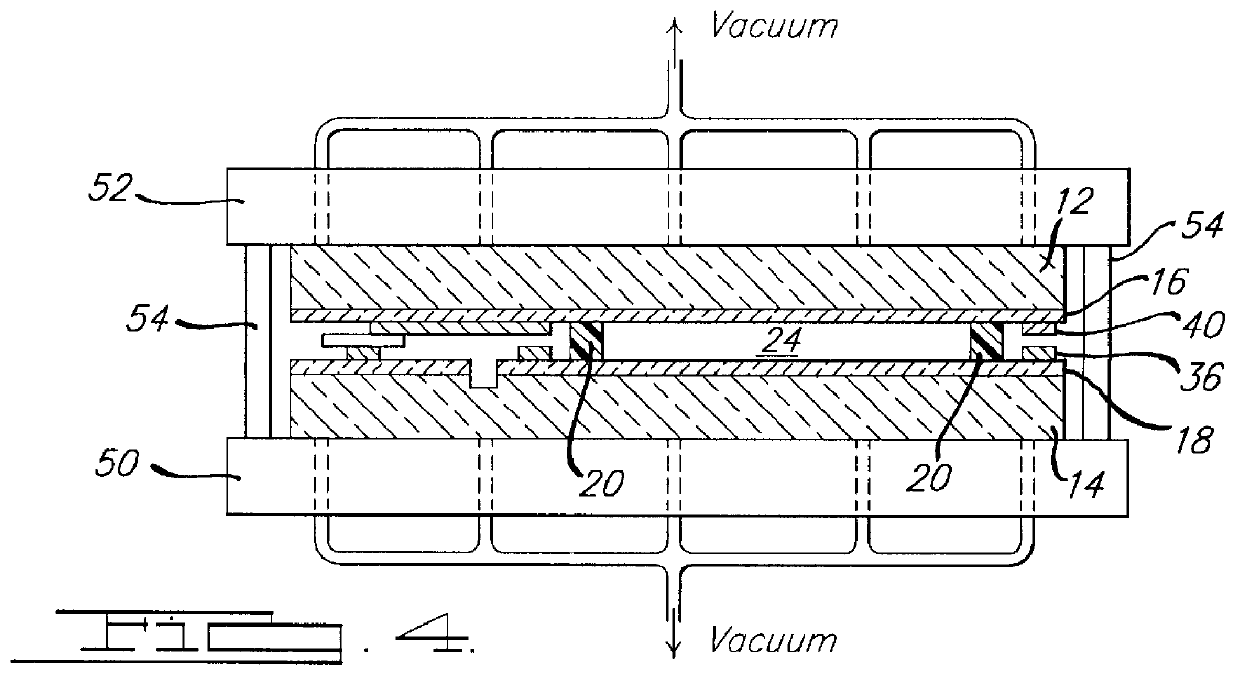

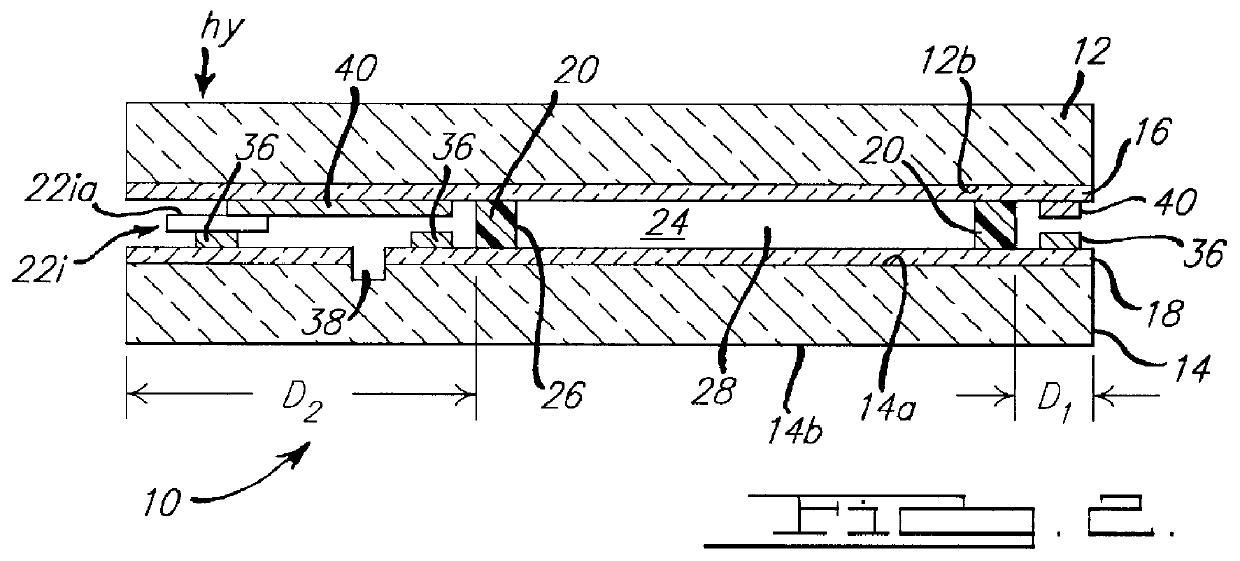

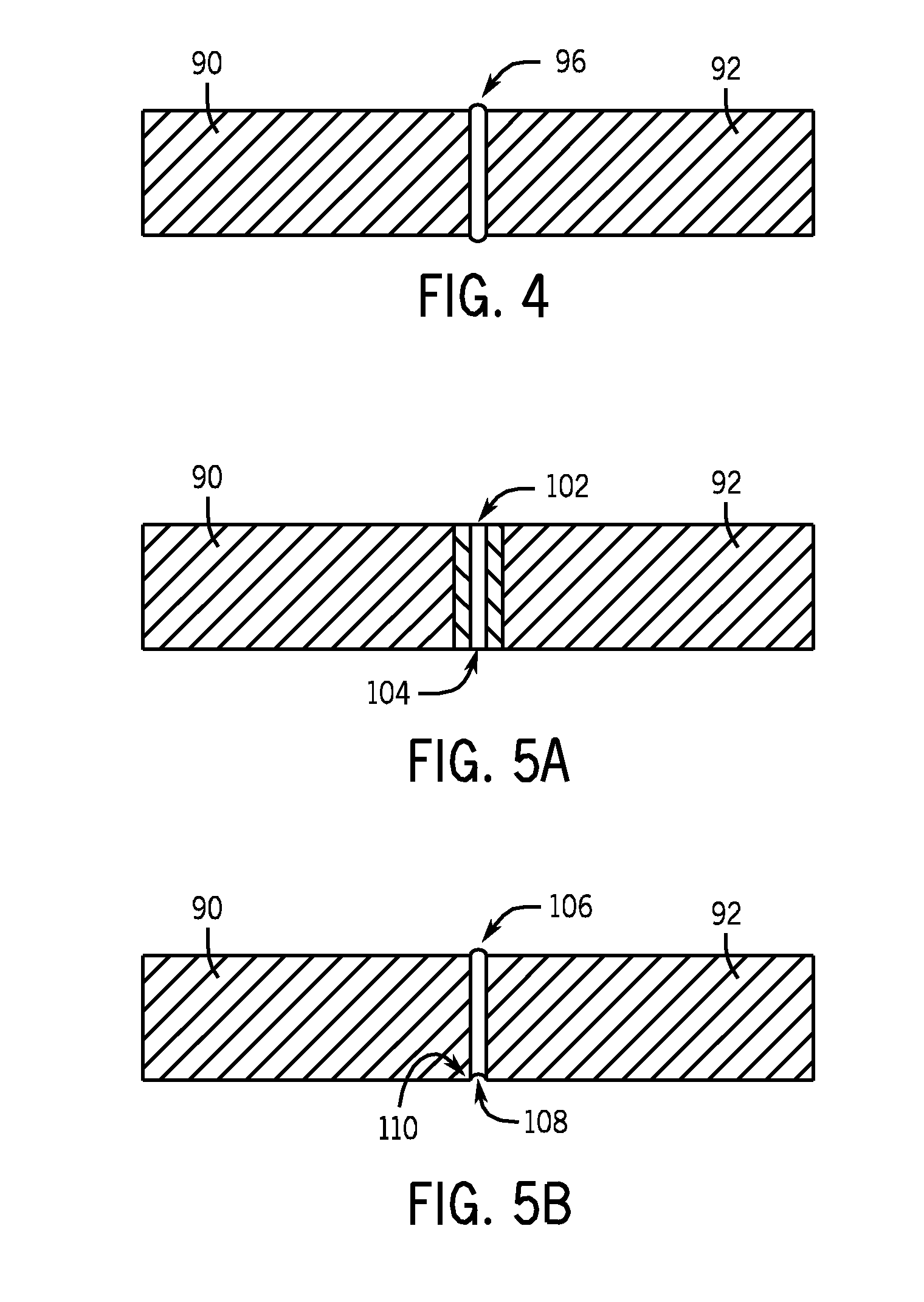

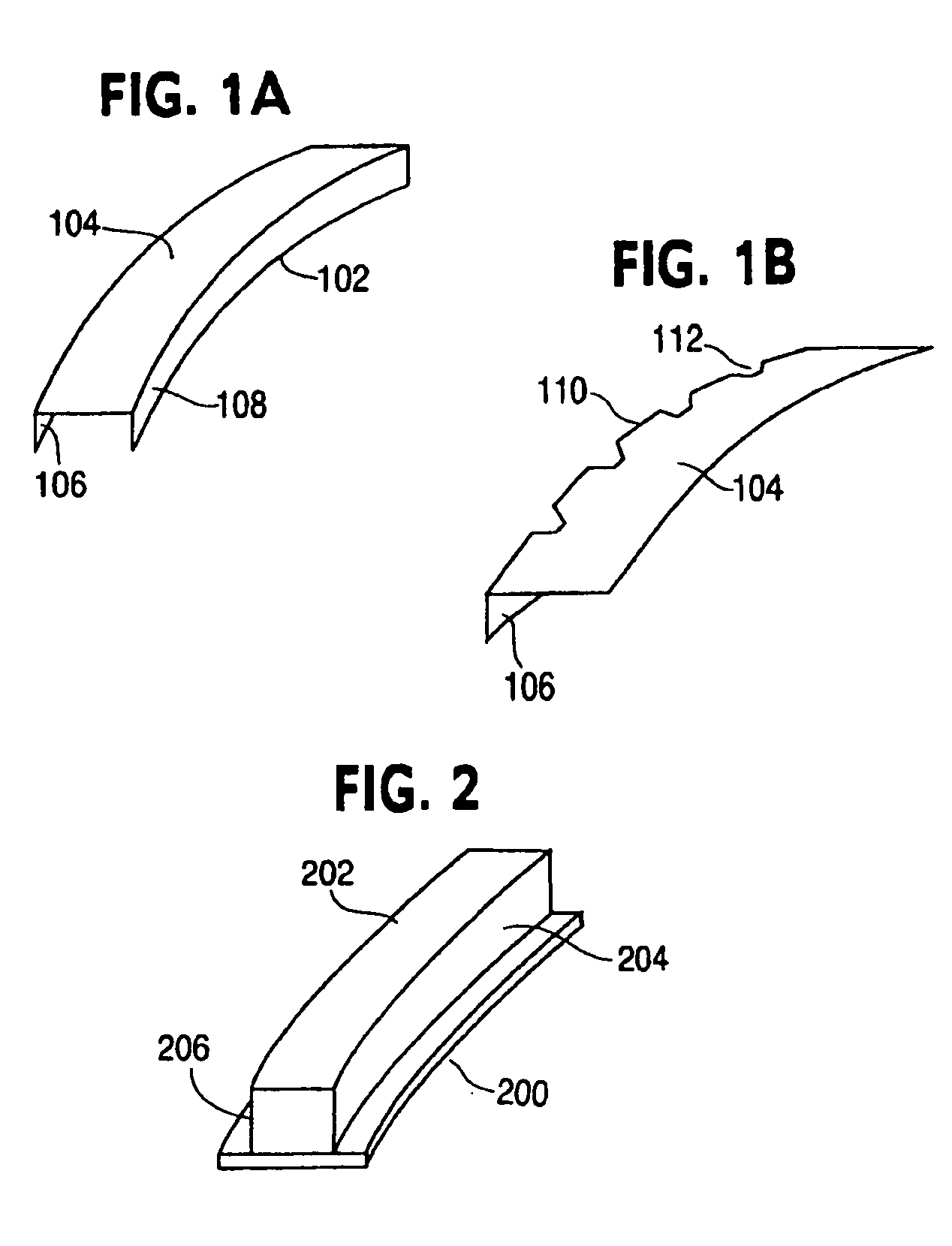

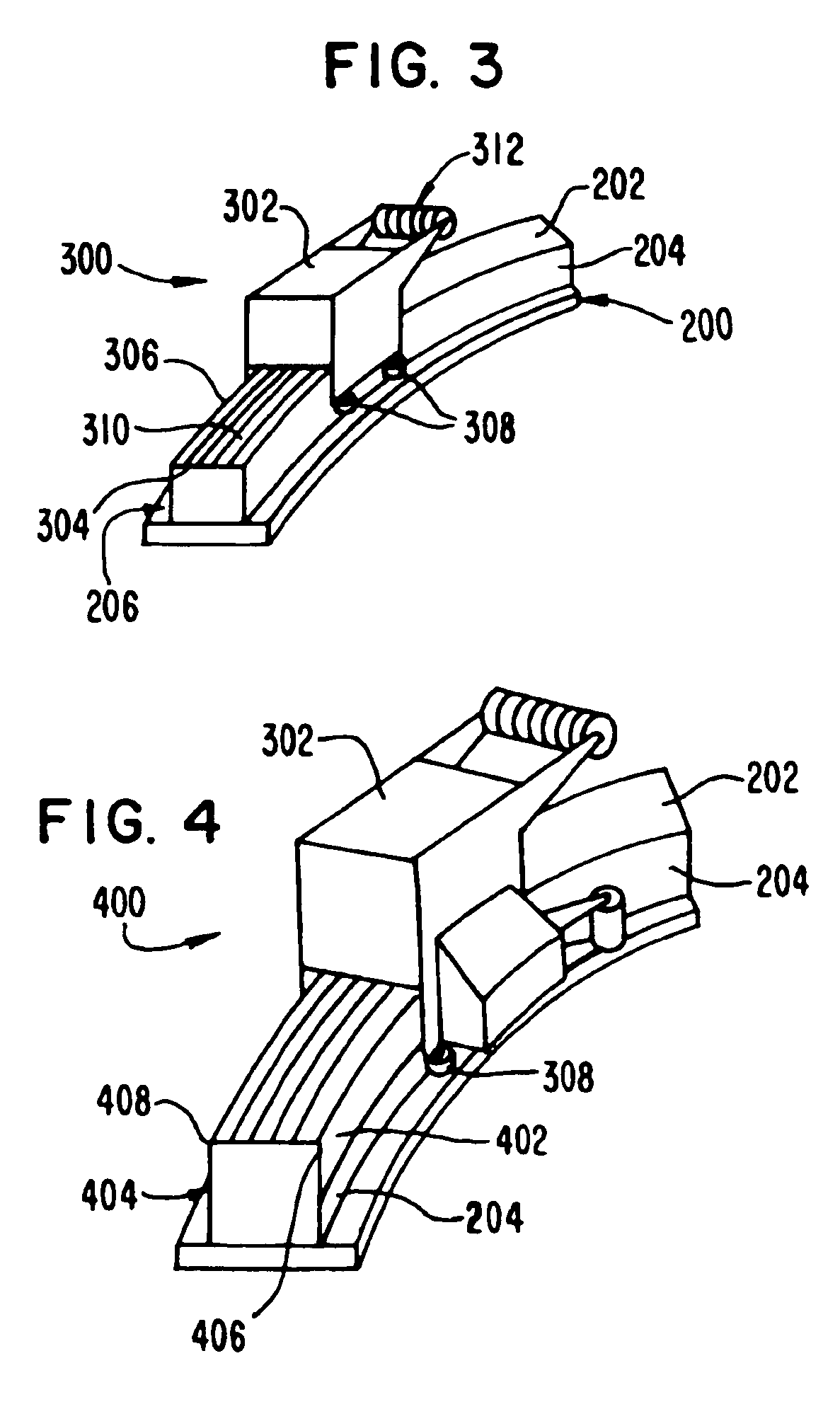

Electro-optic window incorporating a discrete photovoltaic device and apparatus for making same

InactiveUS6045643ALimited amountSimple designStatic indicating devicesWelding/cutting auxillary devicesElectricityResistor

An electro-optic window is provided which is powered solely by at least one discrete photovoltaic cell within an electro-optic window. The electro-optic window has front and back spaced-apart glass elements sealably bonded together in a spaced-apart relationship and defining a chamber filled with an electro-optic material. The front glass element has a transparent conductive layer on the face of the front glass element confronting the rear glass element and the rear glass element has a transparent conductive layer on the face confronting the front glass element. The seal is generally disposed along the perimeter of three edges of both glass elements and some distance in from the remaining (fourth) edge. The photovoltaic assembly is electrically connected to the two transparent conductive layers and is placed on the outer perimeter along this fourth edge with the photon-absorbing side of all the photovoltaic cells within the photovoltaic assembly facing in one direction ("out" the window). When light impinges on the photovoltaic cell a current is created which darkens the electro-optic material in proportion to the amount of impinging light. By choosing the relative area of the photovoltaic assembly to produce the correct current for the electro-optically active window area, the darkening of the electro-optic portion can be directly and accurately controlled without the need for any circuit, wires or shorting resistors. In addition, an apparatus for making an electro-optic window having two members capable of securing and holding two glass elements in a spaced-apart and parallel relationship is provided. The glass elements may be secured by vacuum-applying members or simple clips. The glass elements may be held in a spaced-apart and parallel relationship by a hydraulic mechanism or by simple spacers placed between the securing members.

Owner:GENTEX CORP

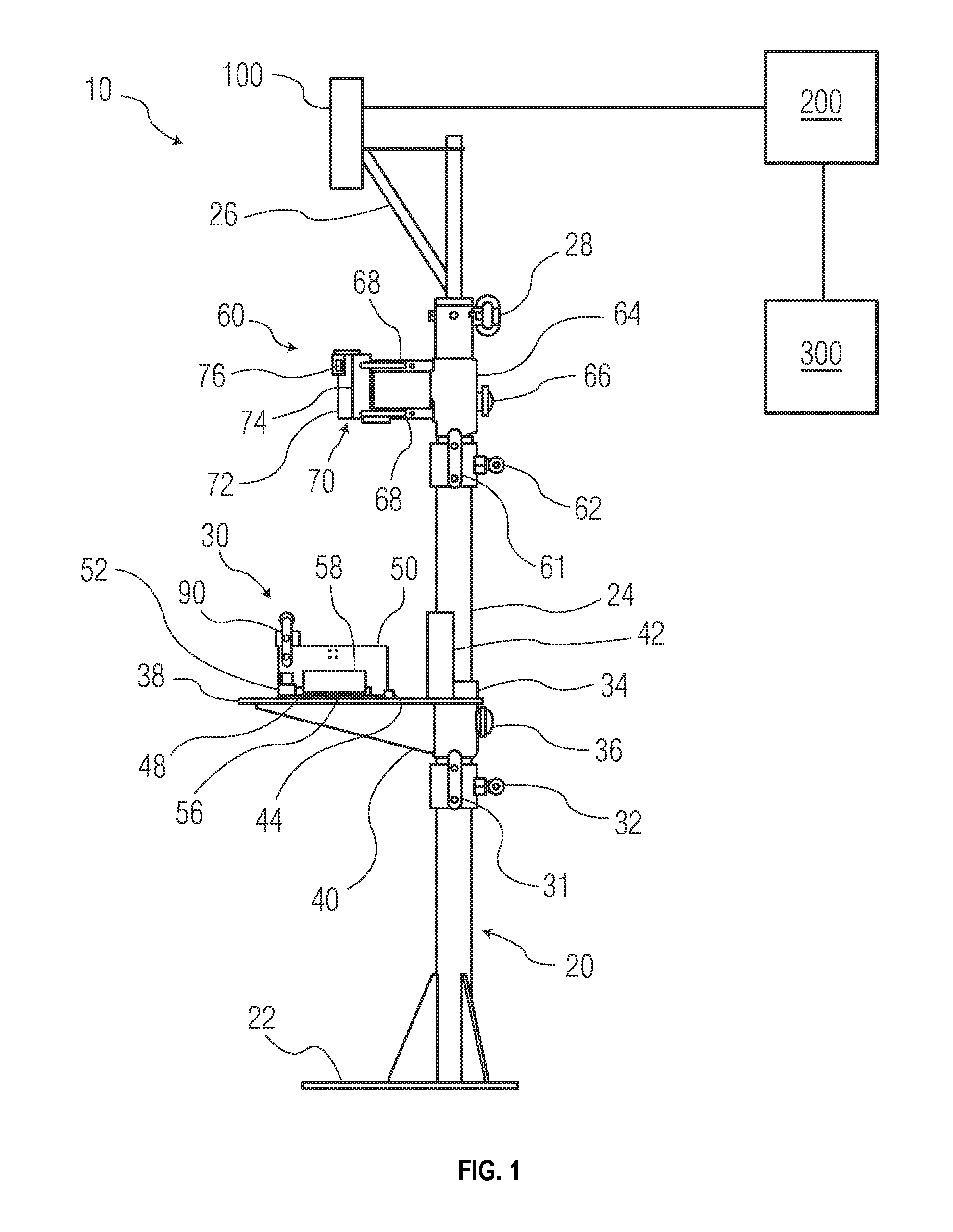

System for characterizing manual welding operations

ActiveUS20120298640A1Improve image signal-to-noise ratioImprove signal-to-noise ratioWelding/cutting auxillary devicesAuxillary welding devicesImage systemWelding

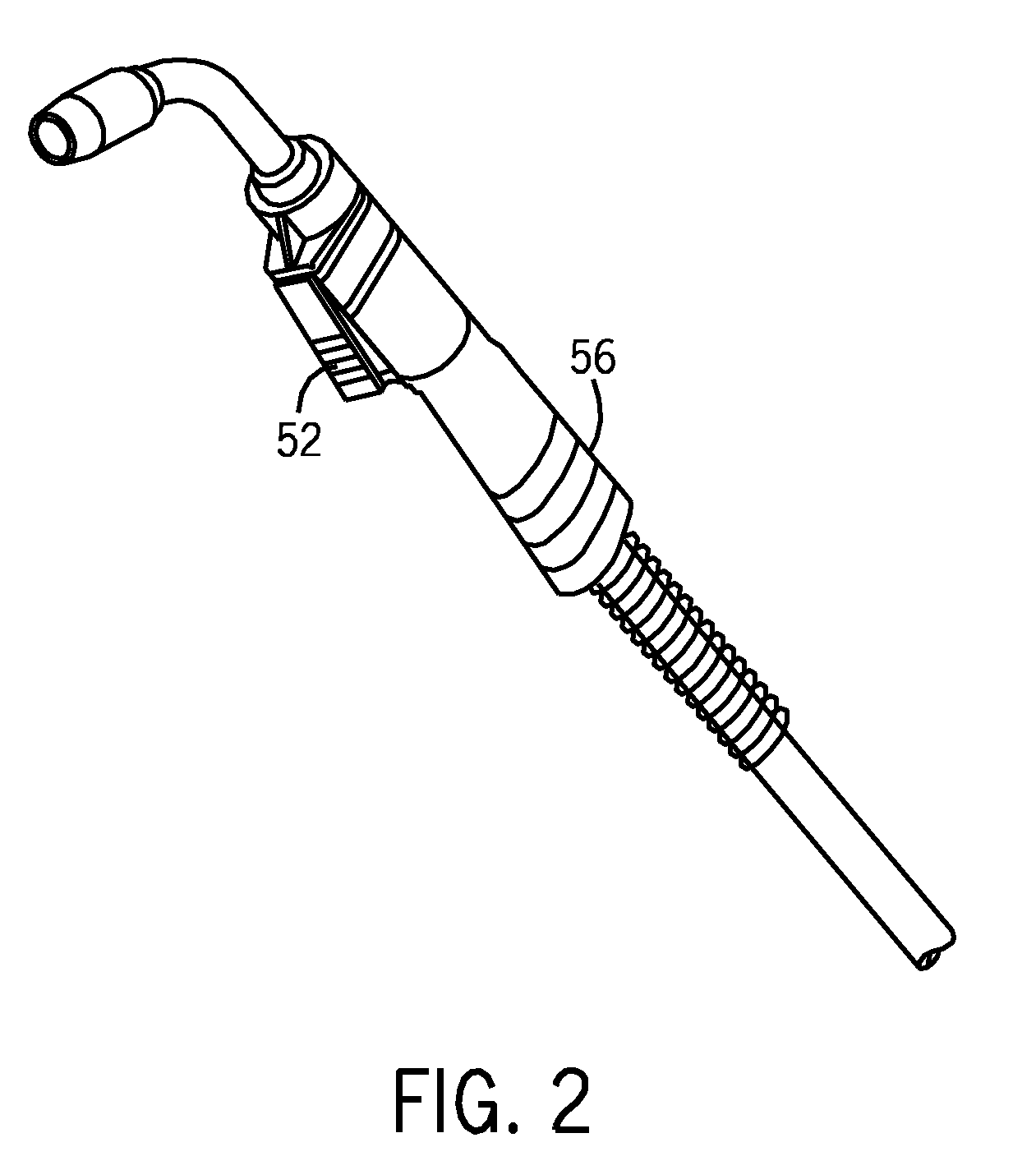

A system for characterizing manual welding exercises and providing valuable training to welders that includes components for generating, capturing, and processing data. The data generating component further includes a fixture, workpiece, at least one calibration devices each having at least two point markers integral therewith, and a welding tool. The data capturing component further includes an imaging system for capturing images of the point markers and the data processing component is operative to receive information from the data capturing component and perform various position and orientation calculations.

Owner:LINCOLN GLOBAL INC

Data storage and analysis for a welding training system

ActiveUS20140272838A1Restrict trainingWelding/cutting auxillary devicesAuxillary welding devicesDisplay deviceEngineering

A welding training system includes a camera configured to capture video data corresponding to a welding training operation. The welding training system also includes a storage device configured to store the video data, and to store welding parameter data corresponding to the welding training operation. The welding training system includes a welding training software configured to retrieve the video data from the storage device, to retrieve the welding parameter data from the storage device, to synchronize the video data with the welding parameter data, and to provide the synchronized video and welding parameter data to a display device.

Owner:ILLINOIS TOOL WORKS INC

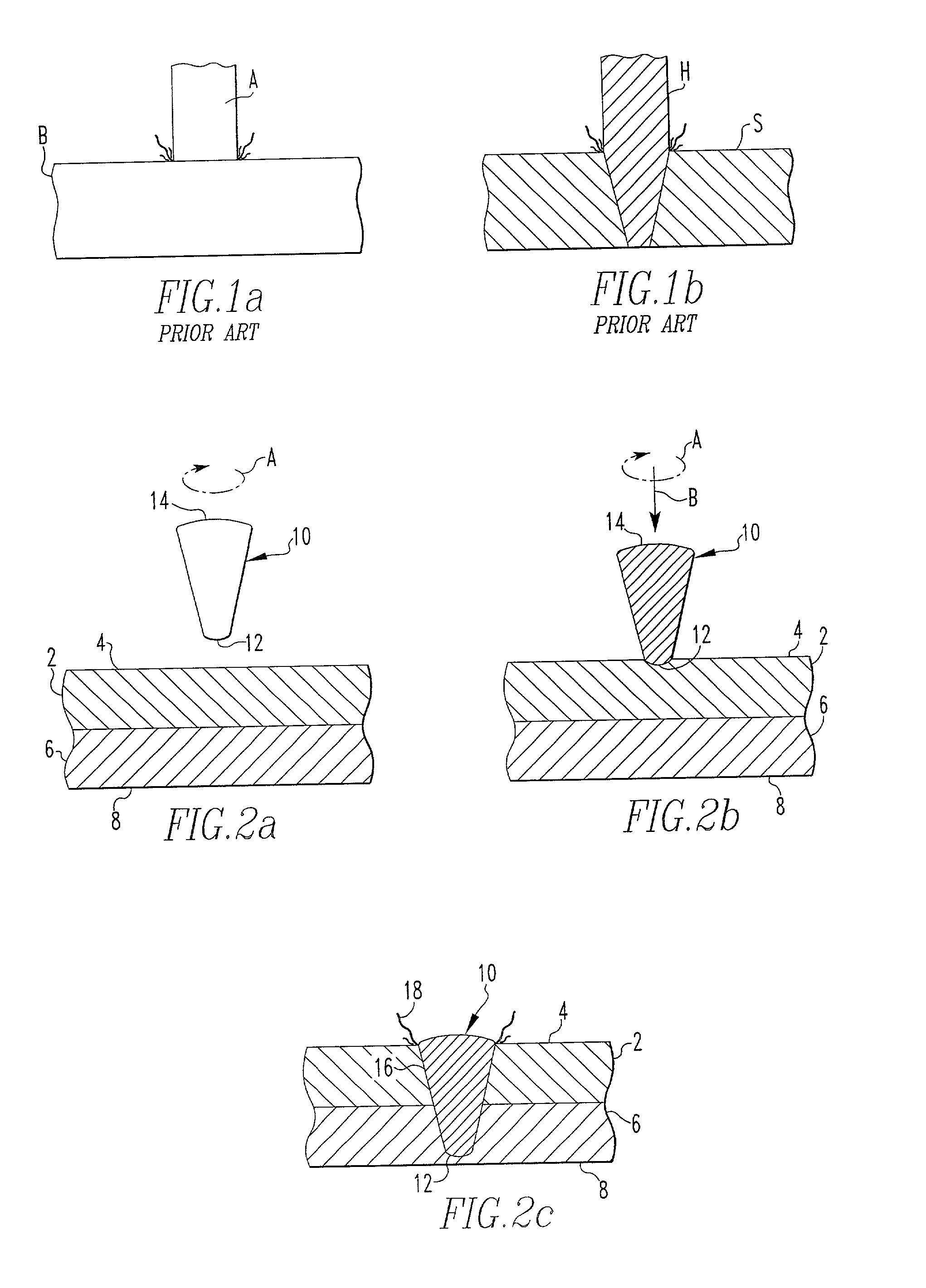

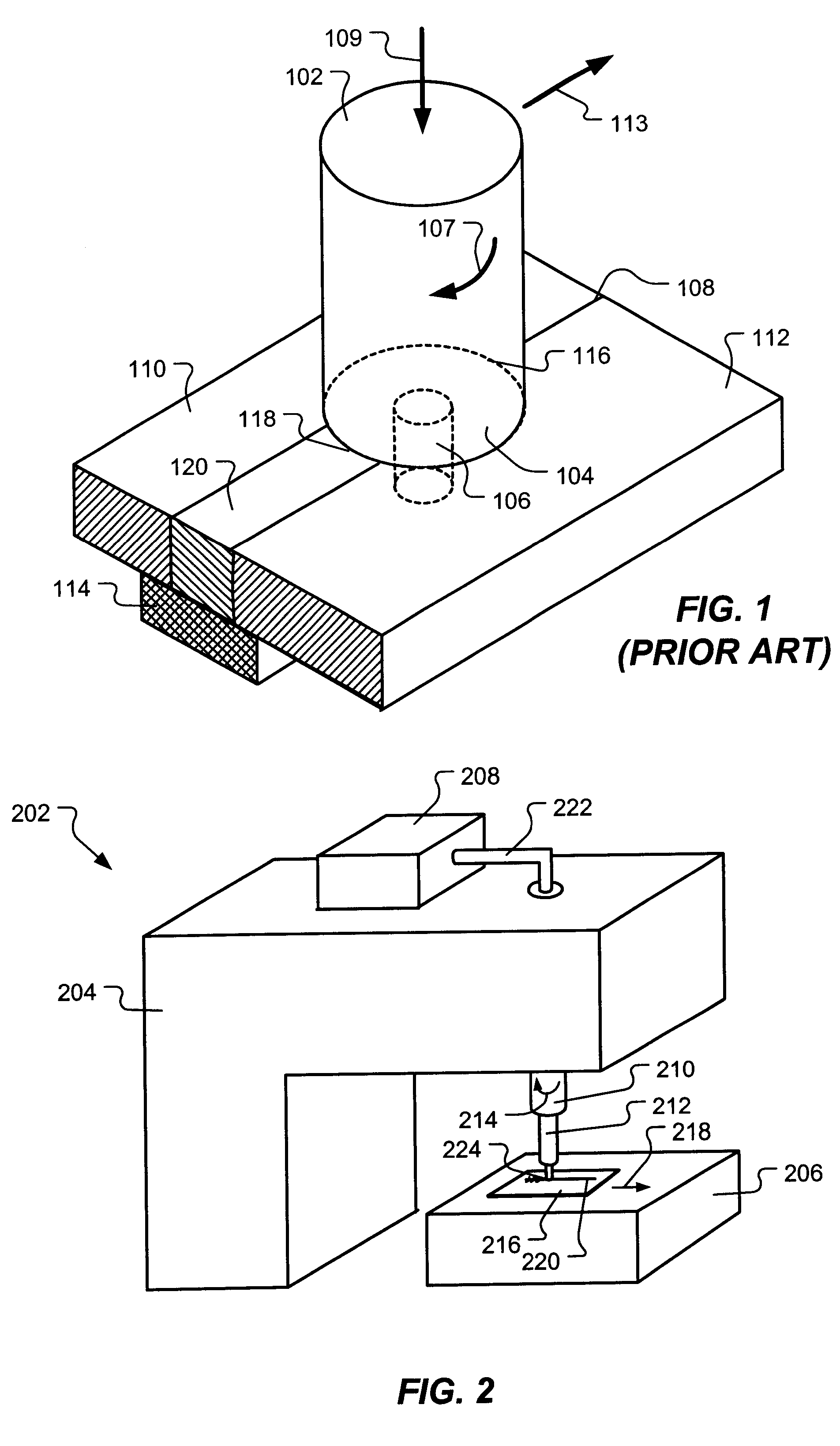

Friction plunge riveting

InactiveUS20020125297A1Welding/cutting auxillary devicesAuxillary welding devicesFriction weldingHardness

A method of joining a pair of metal components with a rivet having a hardness that is substantially similar to at least one of the metal components. The metal components are stack upon each other and the rivet is rotated and simultaneously plunged in the metal components under pressure to friction weld and metallurgically bond the rivet to the metal components.

Owner:ARCONIC INC

Method and device for producing a component

InactiveUS20130055568A1High build rateSpeed up preparationTurbinesAdditive manufacturing apparatusMetallurgyLayer thickness

A method for manufacturing a component, in particular a component of a turbine or a compressor, in which at least these steps are carried out: application in layers of at least one powdered component material to a component platform in the area of a buildup and joining zone; melting and / or sintering locally in layers of the component material by supplying energy with the aid of at least one electron beam in the area of the buildup and joining zone; lowering of the component platform in layers by a predefined layer thickness; and repeating steps a) through c) until completion of the component. During the manufacturing, electrons emitted due to the interaction of the electron beam with the component material are detected, after which material information, characterizing the topography of the melted and / or sintered component material, is ascertained on the basis of the emitted electrons. Alternatively or additionally, the component material is melted and / or sintered by at least two, preferably at least four electron beams.

Owner:GLOBAL BEAM TECH +1

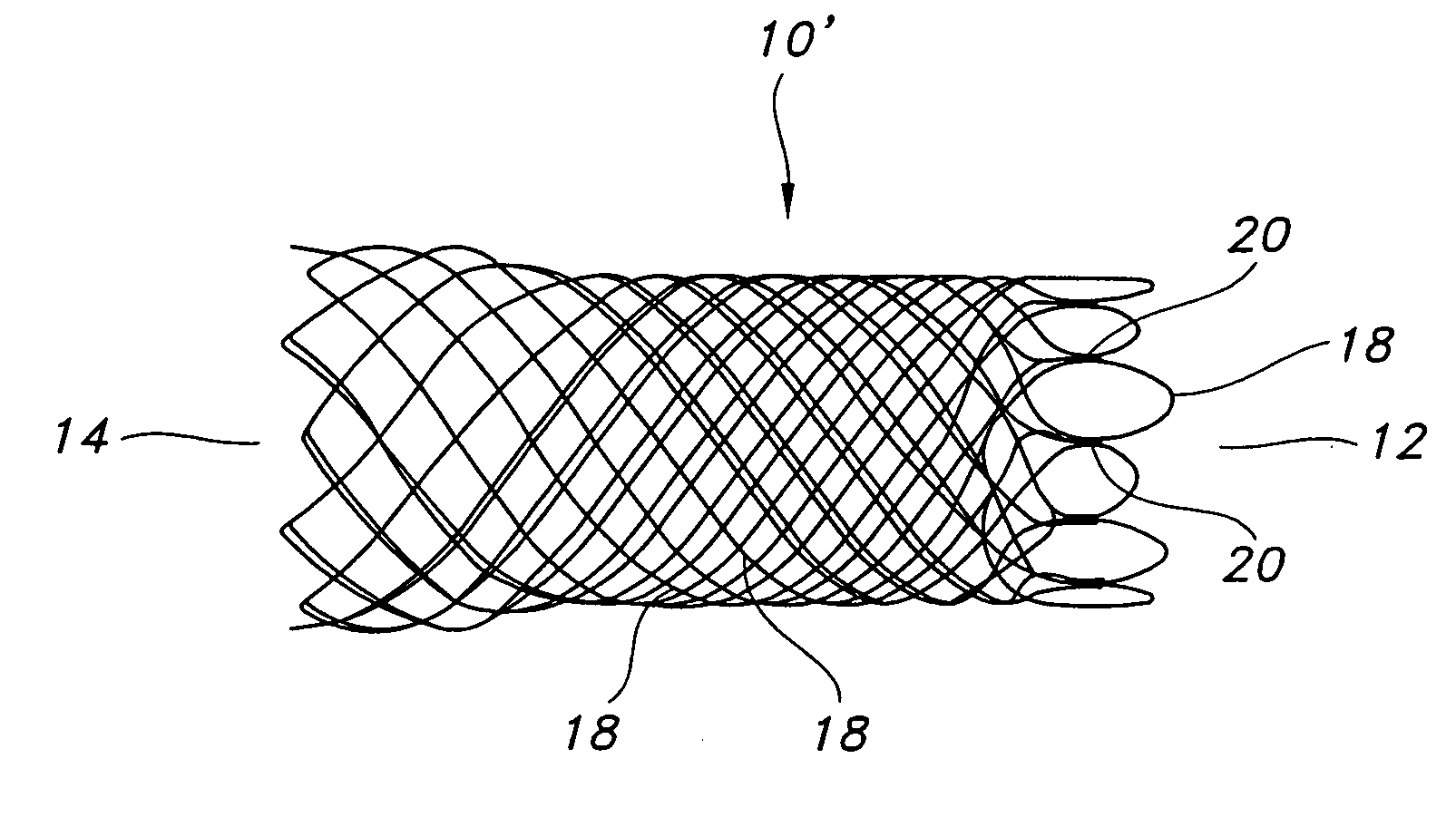

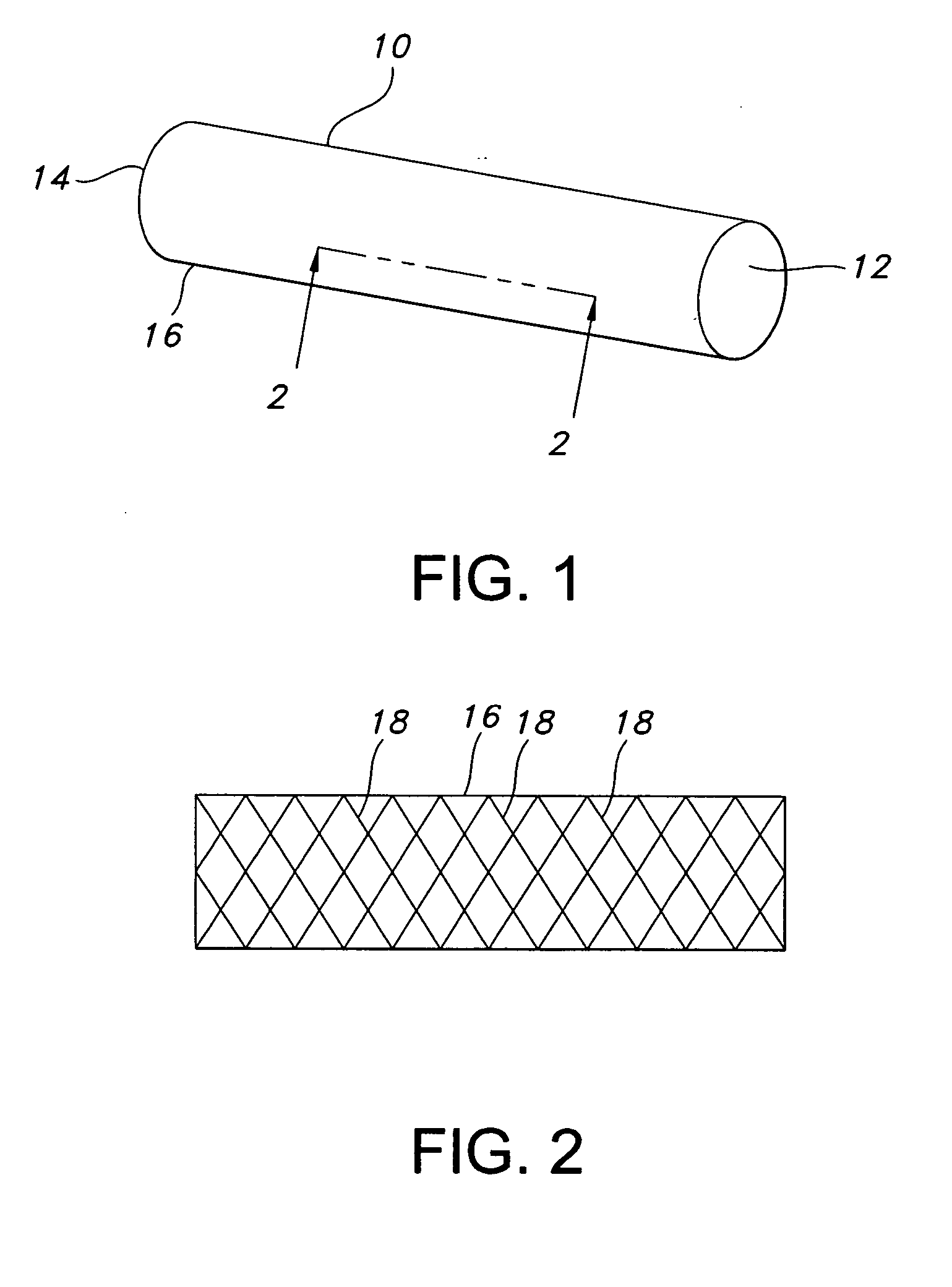

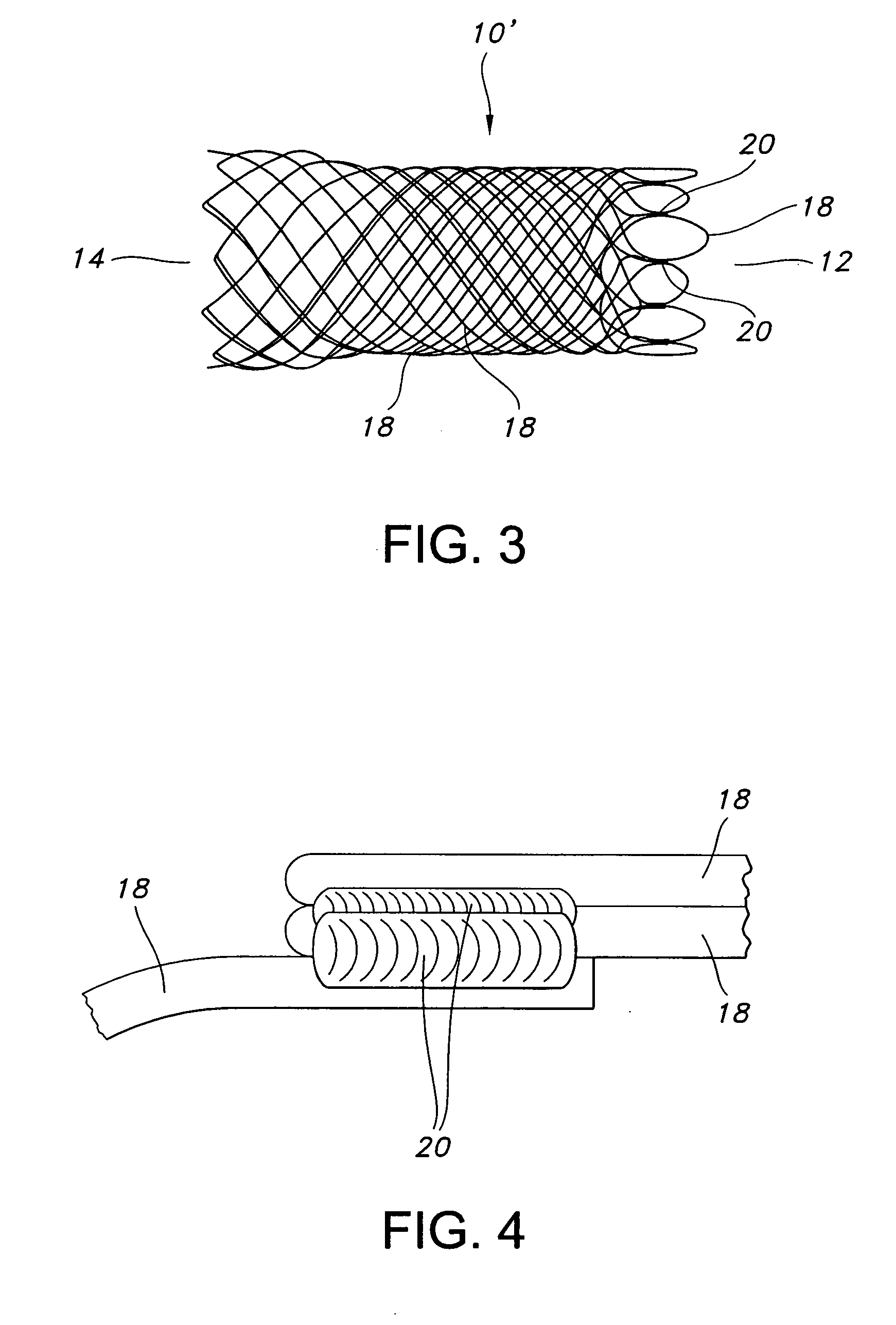

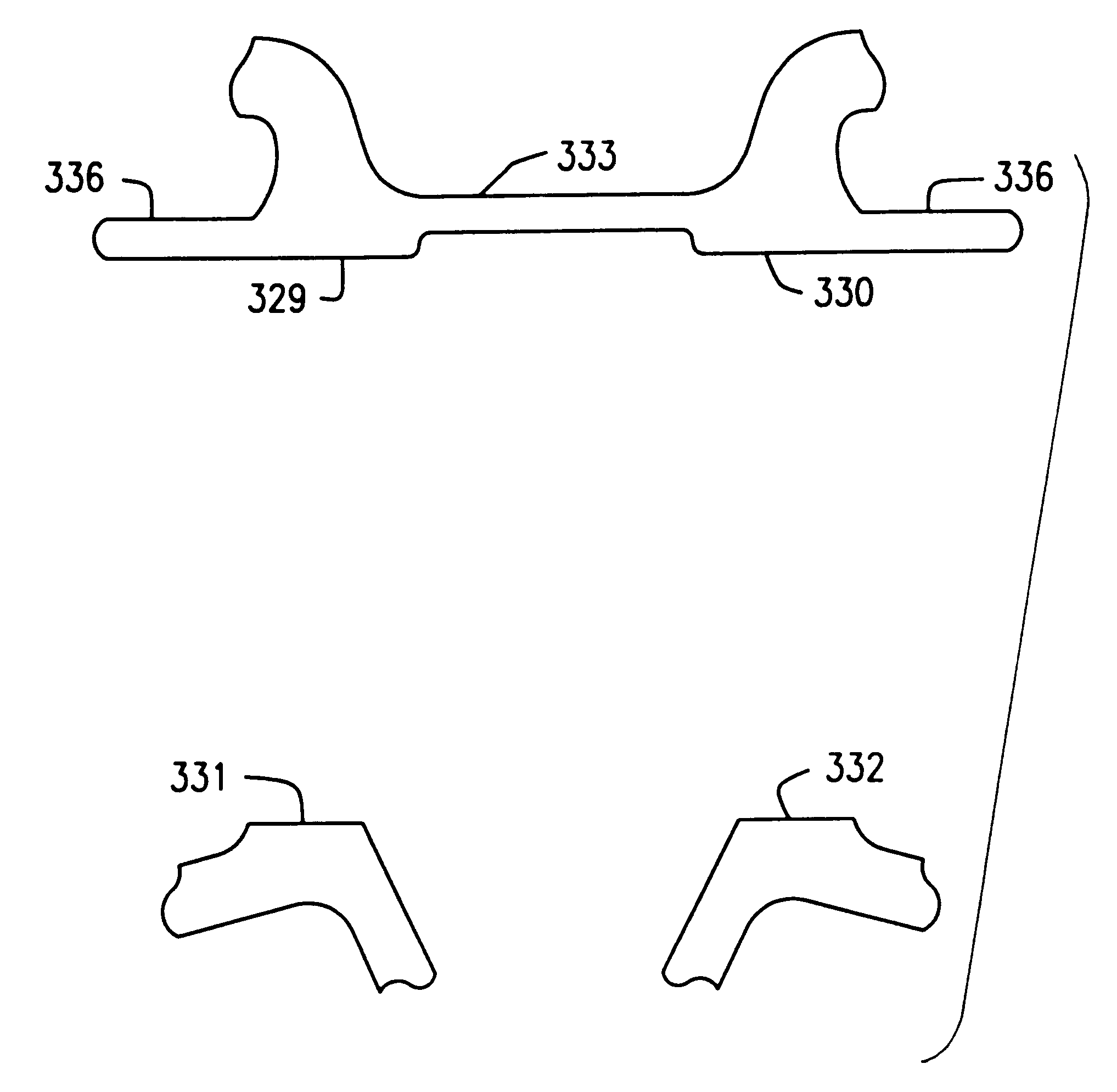

Method for reducing stent weld profiles and a stent having reduced weld

InactiveUS20050256563A1Easy to captureEasy to grabOrnamental textile articlesWelding/cutting auxillary devicesWire rodInsertion stent

A method for making an implantable stent includes the steps of (i) providing a plurality of elongate stent wires; (ii) forming said wires into a hollow tubular structure having opposed first and second open ends; (iii) terminating said wires at the second end; (iv) aligning the wires at the second end into a plurality of mated adjacent wires to define a plurality of abutting regions; (v) welding the mated adjacent wires to one and the other at the abutting regions to define a plurality of welds; and optionally (vi) chemically or electro-chemically removing a portion of the welds. The method may further include the steps of (a) extending at least one of the mated stent wires to provide an extended stent wire; (b) looping the extended stent wire so the extended end abuts a proximal pair of stent wires; and (c) welding the extended and looped wire to the proximal pair of wires. The step of looping may include the forming of the wire into a equilaterally arched loop having an apex, but not having other sharp bends.

Owner:BOSTON SCI SCIMED INC

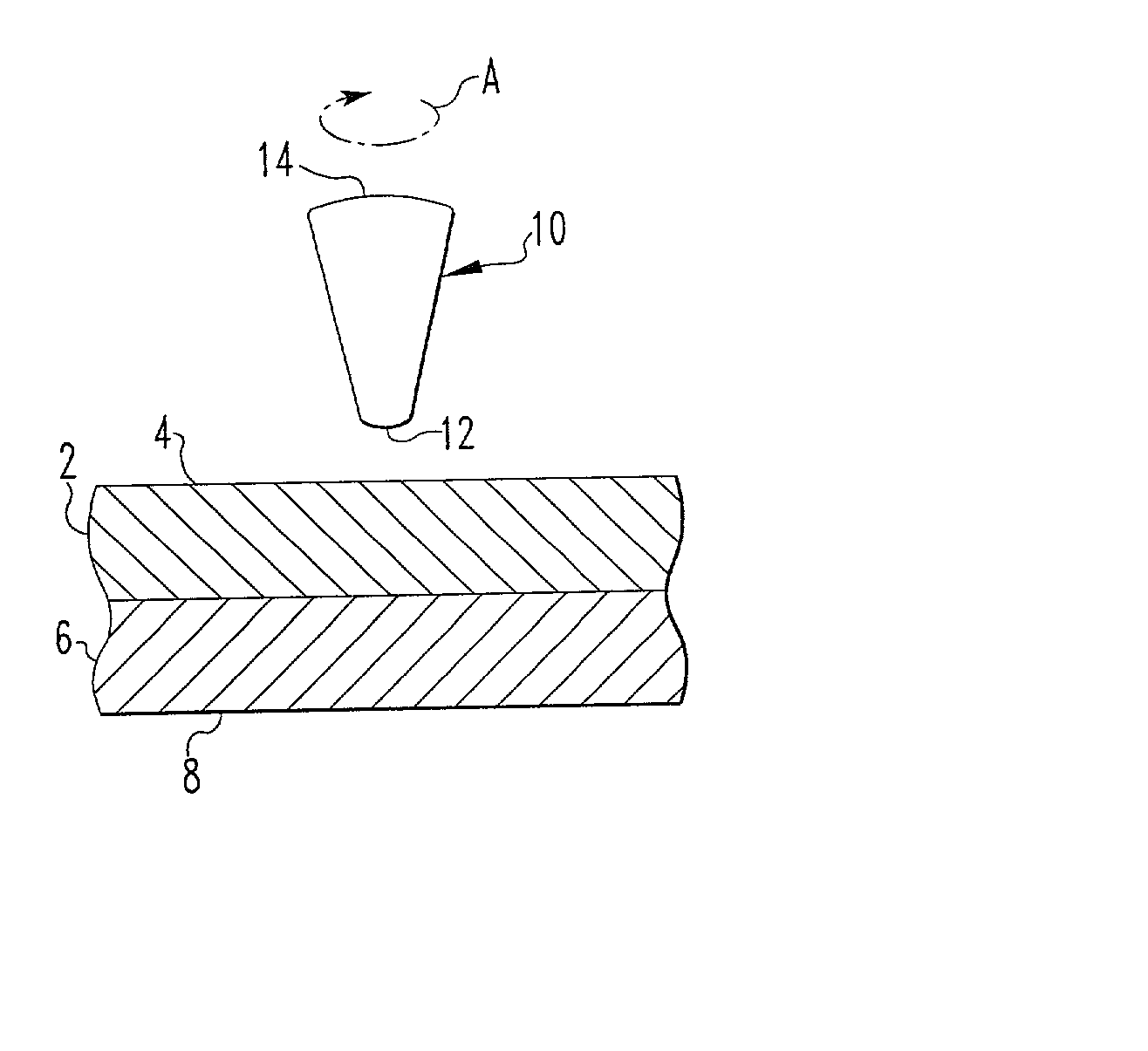

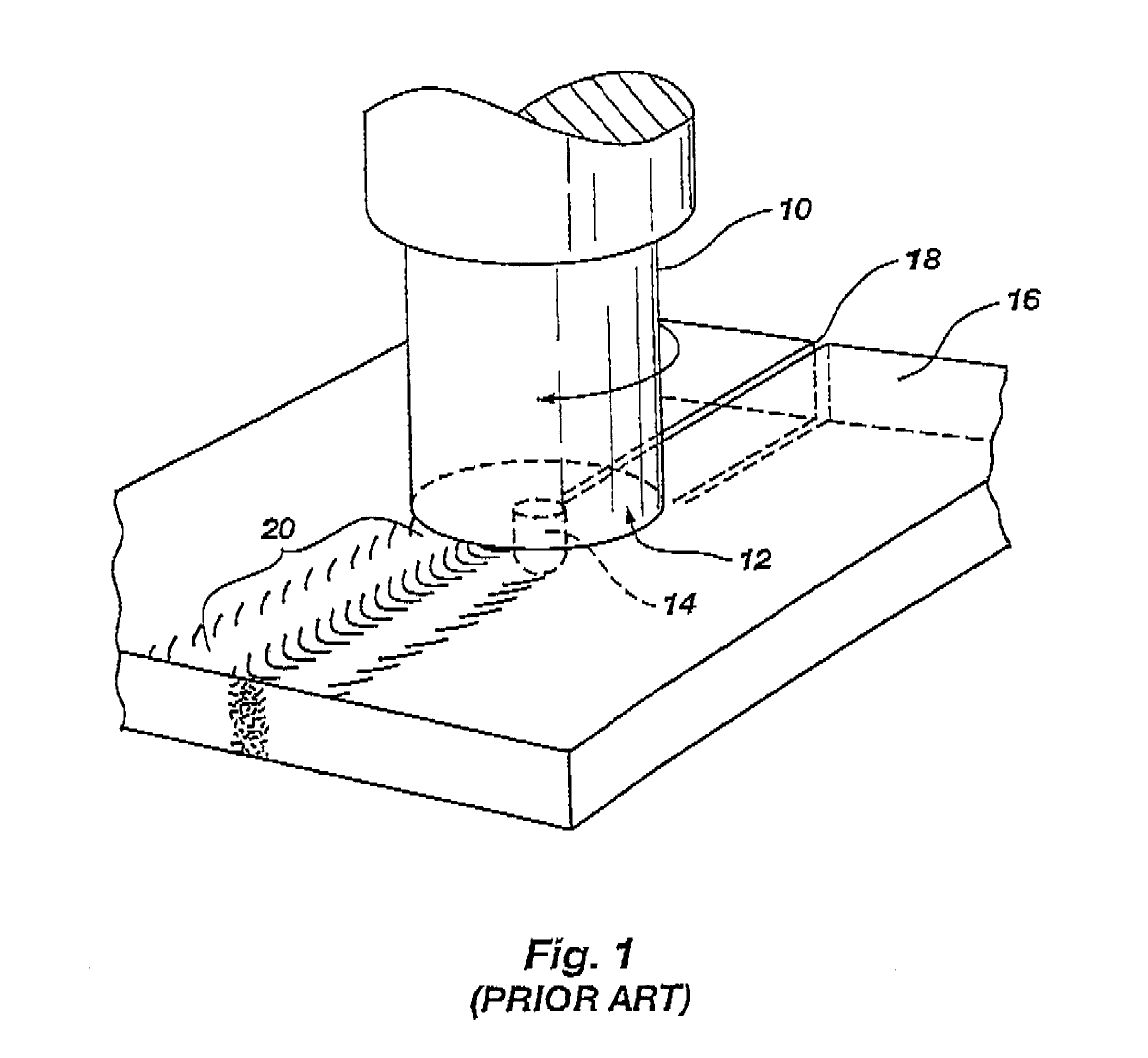

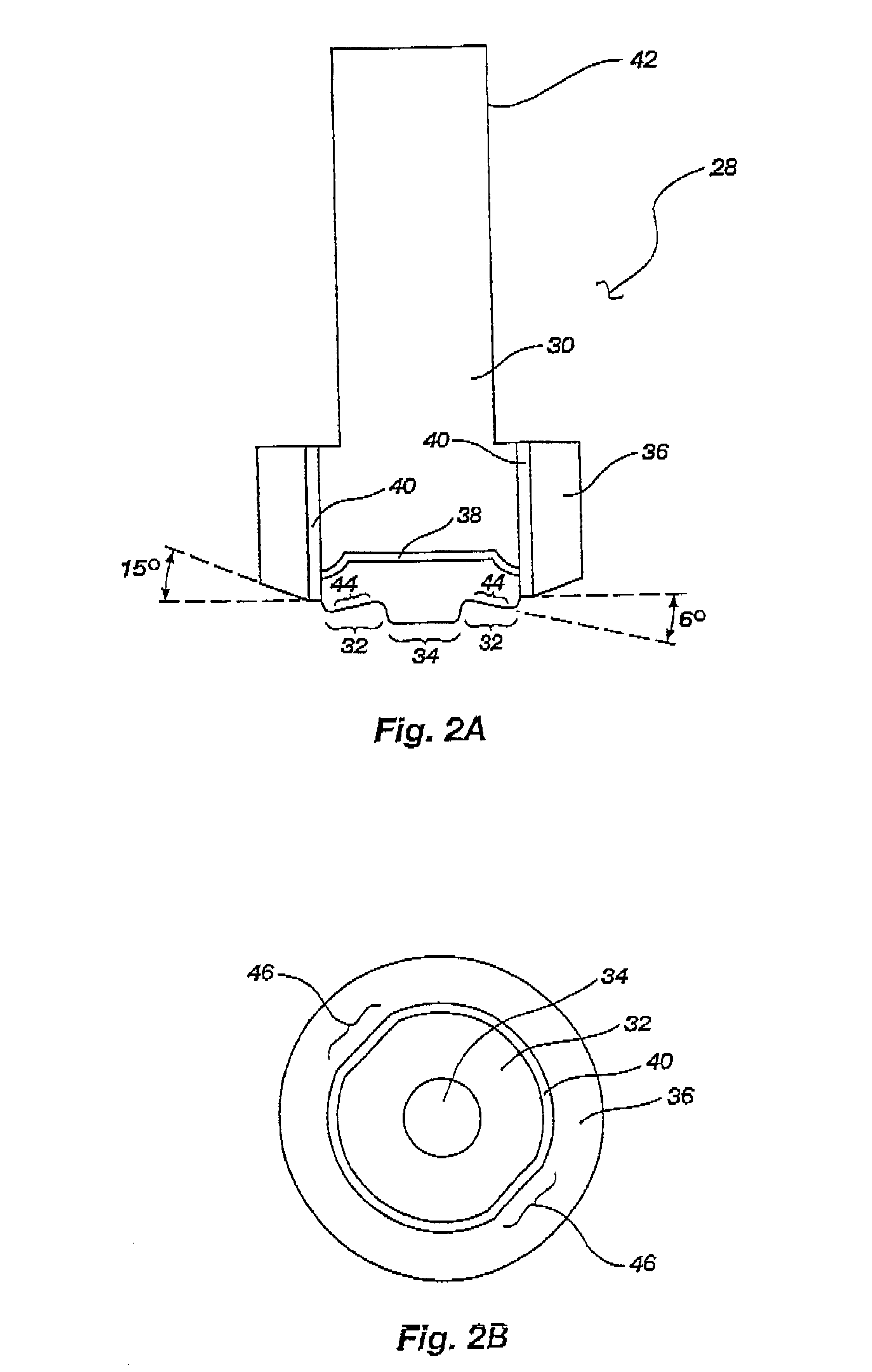

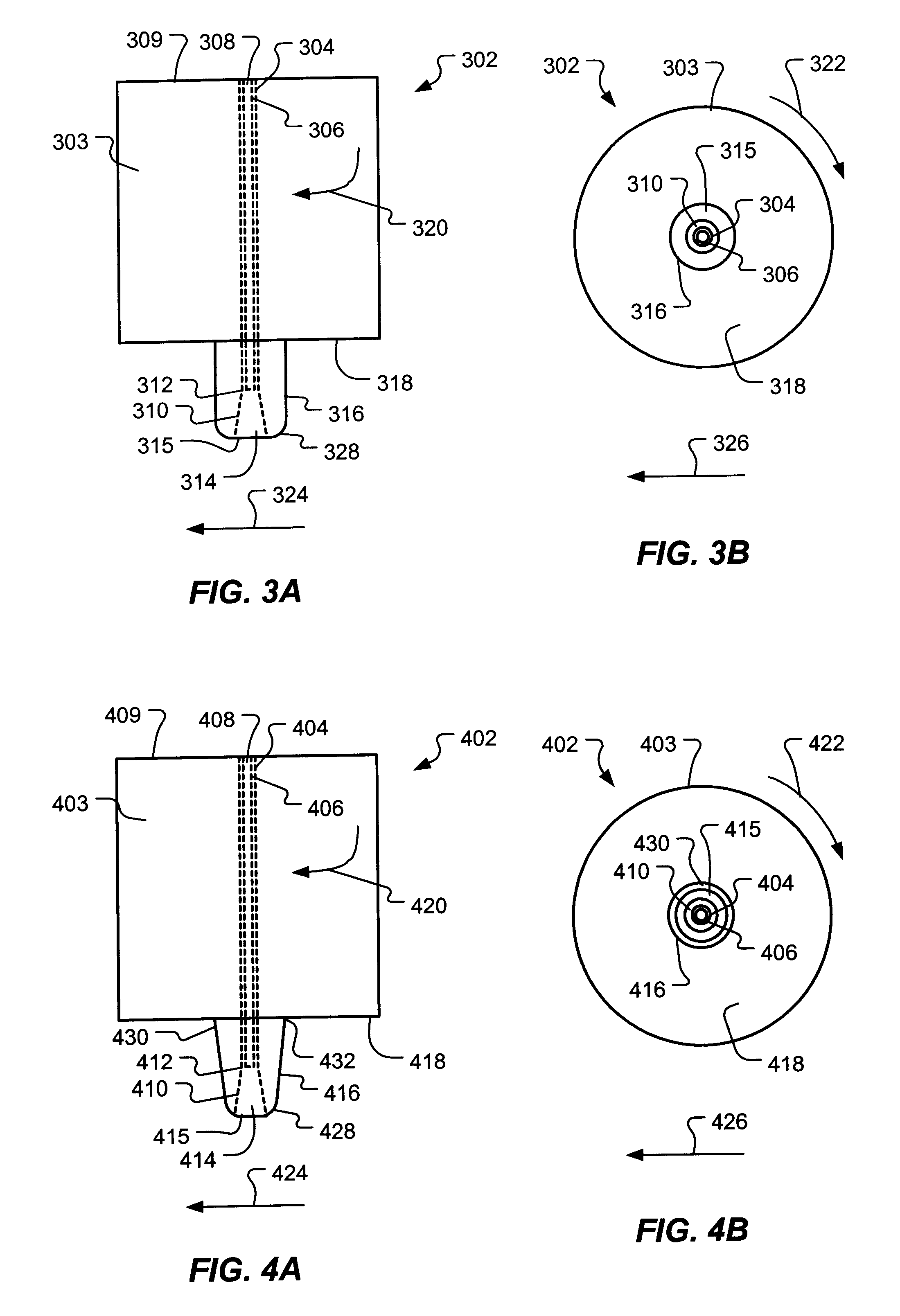

Friction stir welding using a superabrasive tool

InactiveUS6648206B2Improve wear characteristicsReduced tool wearWelding/cutting auxillary devicesVacuum evaporation coatingHeat flowEngineering

A probe for friction stir welding MMCs, ferrous alloys, non-ferrous alloys, and superalloys, as well as non-ferrous alloys, the probe including a shank, a shoulder, and a pin disposed through the shoulder and into the shank, wherein the pin and the shoulder at least include a coating comprised of a superabrasive material, the pin and shoulder being designed to reduce stress risers, disposing a collar around a portion of the shoulder and the shank to thereby prevent movement of the shoulder relative to the shank, and incorporating thermal management by providing a thermal flow barrier between the shoulder and the shank, and between the collar and the tool.

Owner:BRIGHAM YOUNG UNIV +1

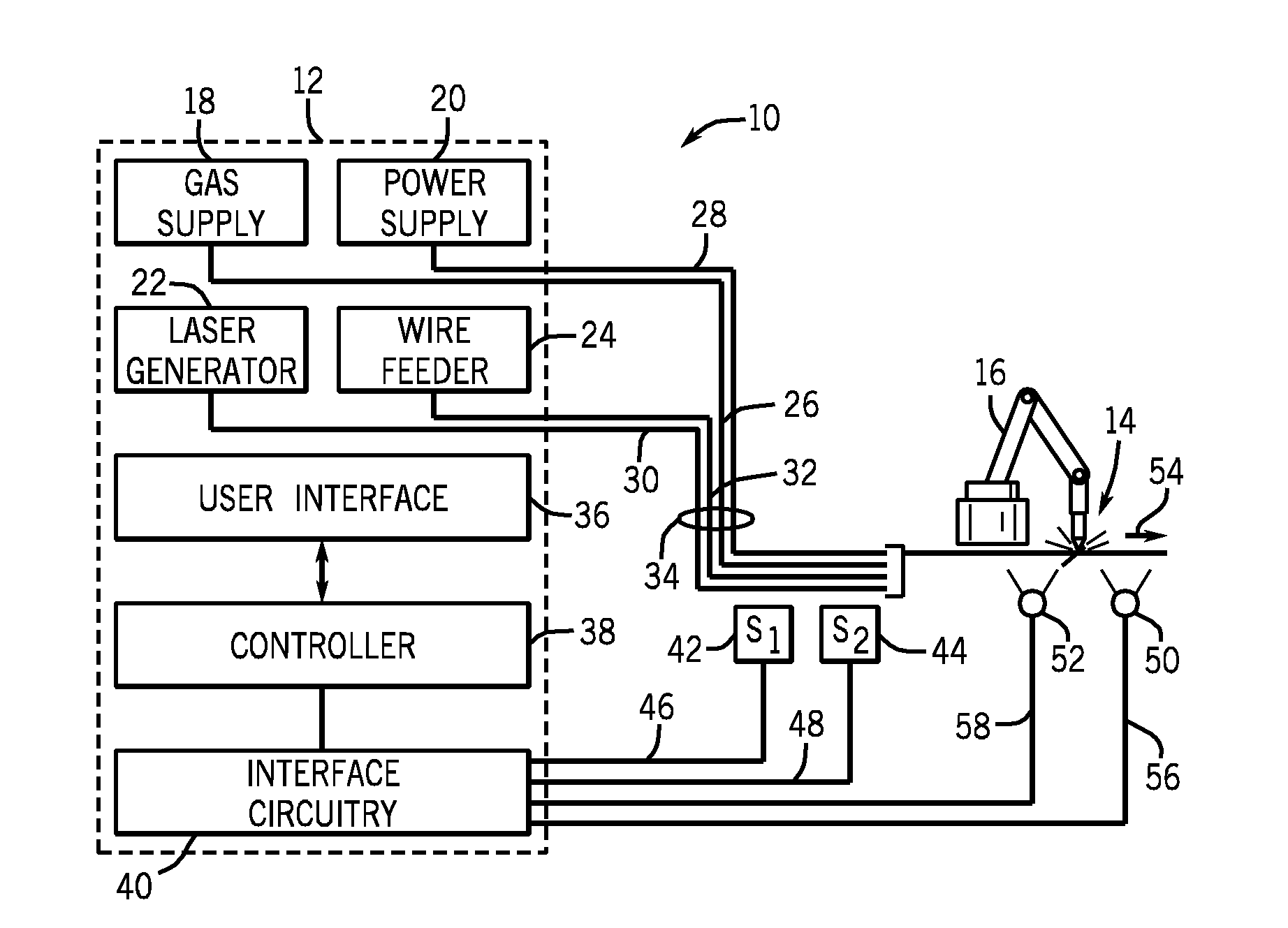

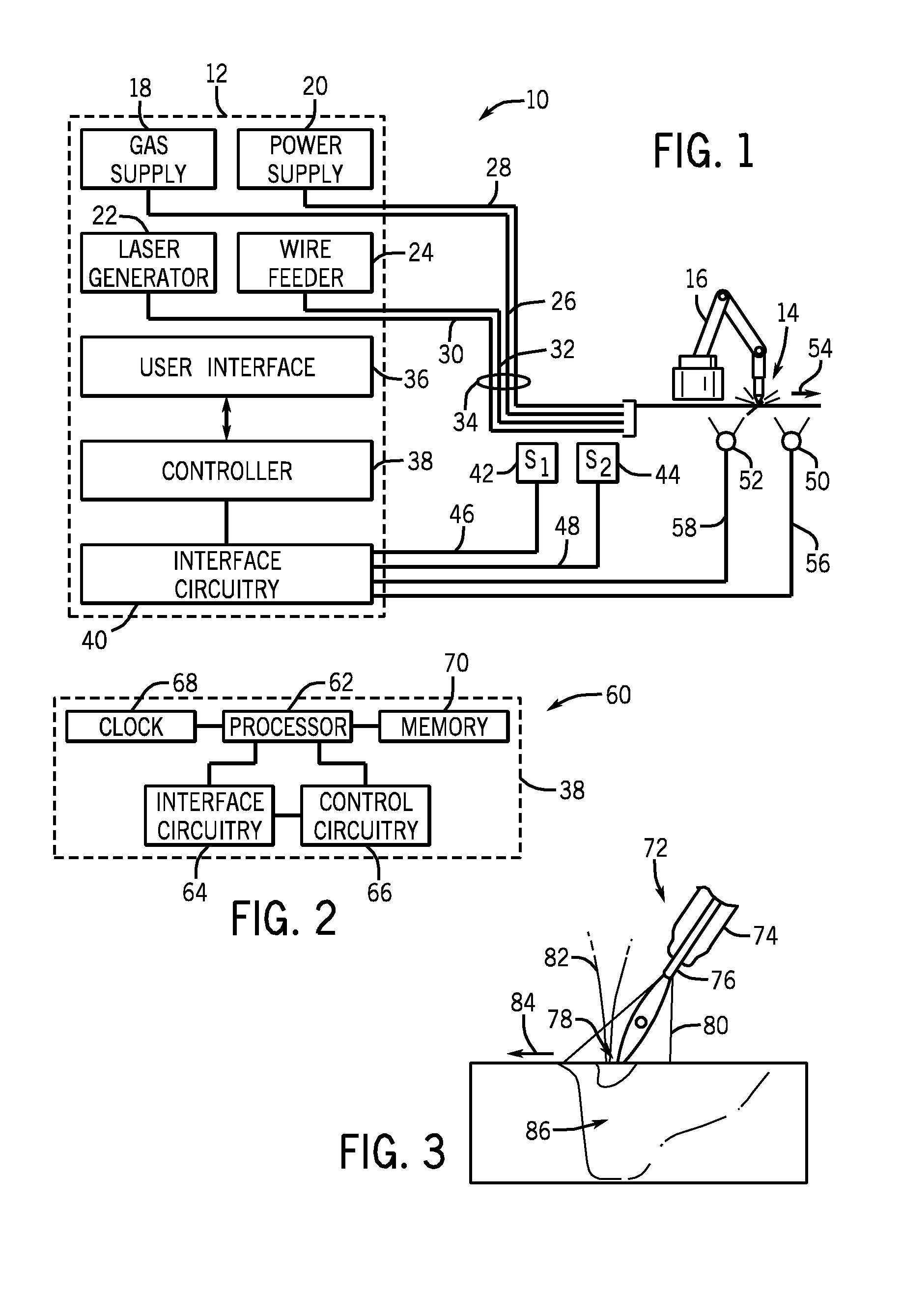

Weld defect detection systems and methods for laser hybrid welding

ActiveUS20100314362A1Welding/cutting auxillary devicesArc welding apparatusLaser-hybrid weldingPower flow

Laser hybrid welding systems adapted to identify and / or fix a weld defect occurring during a laser hybrid welding process are provided. Embodiments of the laser hybrid welding system may include one or more devices that provide feedback to a controller regarding one or more weld parameters. One embodiment of the laser hybrid welding system includes sensors that are adapted to measure the weld voltage and / or amperage during the welding process and transmit the acquired data to the controller for processing. Another embodiment of the laser hybrid welding system includes a lead camera and a lag camera that film an area directly in front of the weld location and directly behind the weld location.

Owner:ILLINOIS TOOL WORKS INC

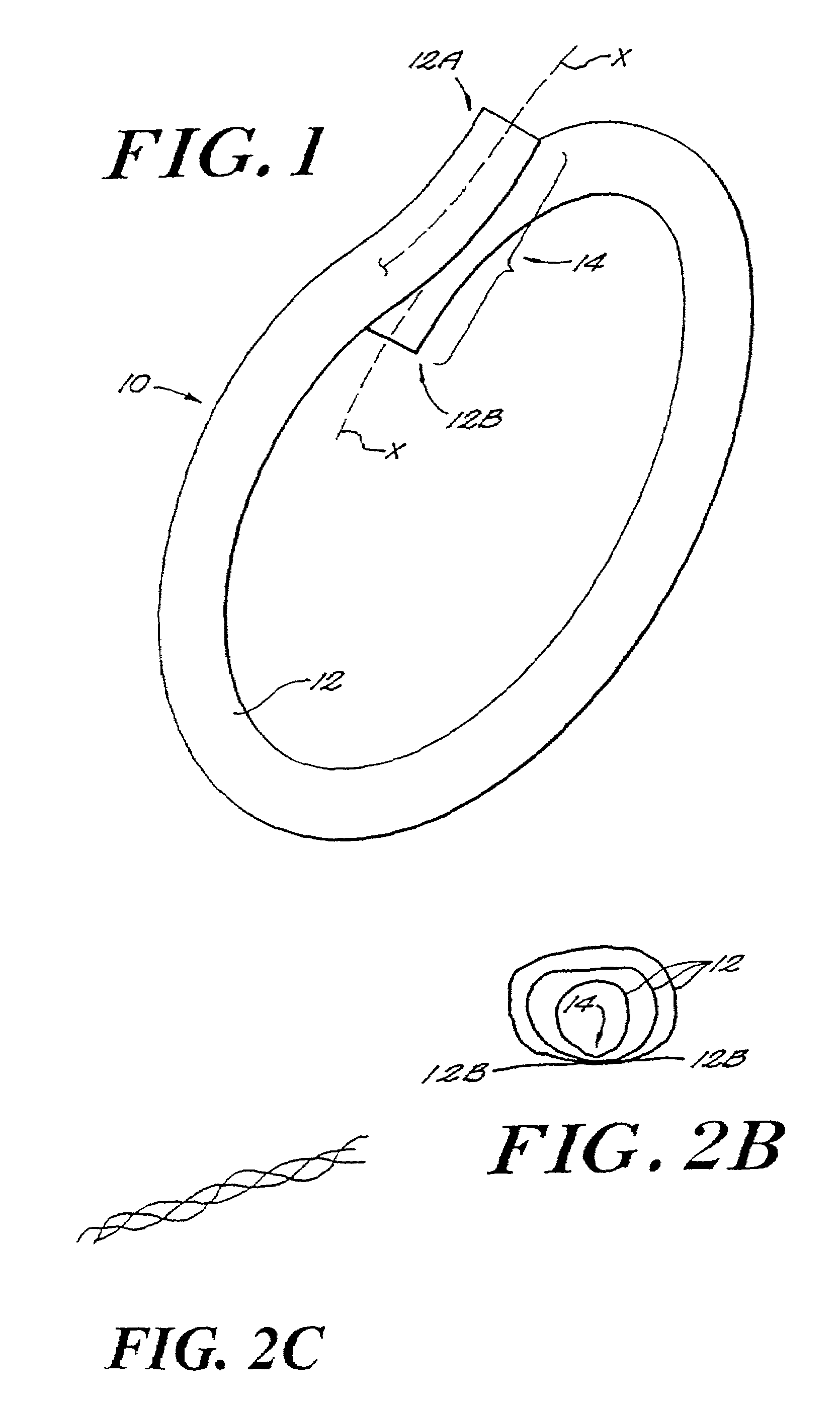

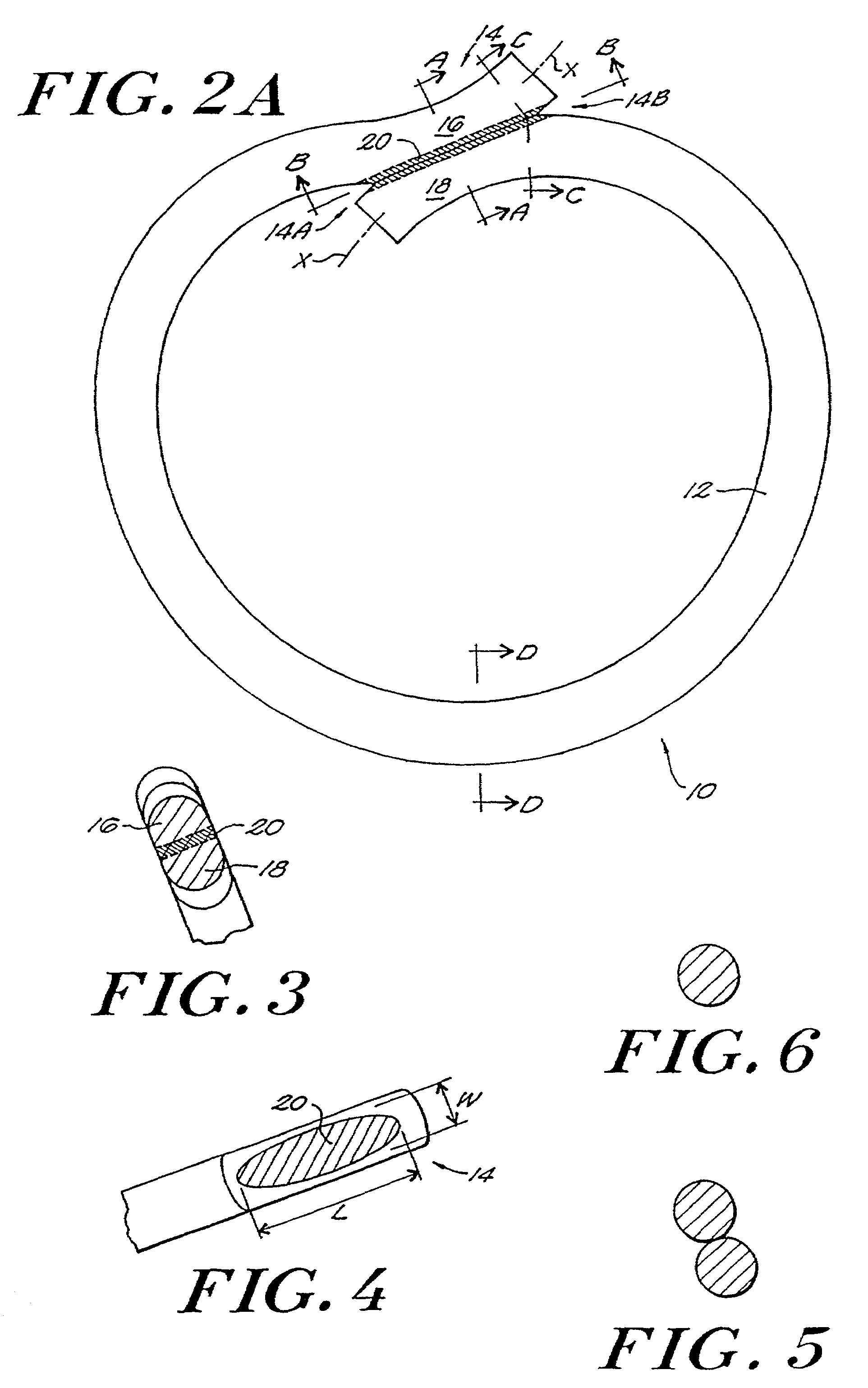

Fused loop of filamentous material and apparatus for making same

InactiveUS7090111B2Maximize joint strengthSuture equipmentsSurgical needlesSurface patternUltrasonic welding

A welding apparatus that includes a first member having a first suture-contacting surface, a second member having a second suture-contacting surface, and a device for moving the first member relative to the second member to define a gap between the respective suture-contacting surfaces. The first member is capable of vibrating and delivering mechanical energy at ultrasonic frequencies. The second member is stationary relative to the first member. A fixture element is adapted to receive and maintain two or more segments of a material to be welded in a predetermined alignment in the gap between the first and second surfaces of the first and second members during a welding operation. According to another aspect of the invention, an ultrasonic welding apparatus includes first and second members with patterned first and second suture-contacting surfaces. The patterned surfaces can be complementary or non-complementary and the surface patterns on each member may vary in either a periodic or a non-periodic manner.

Owner:TORNIER INC

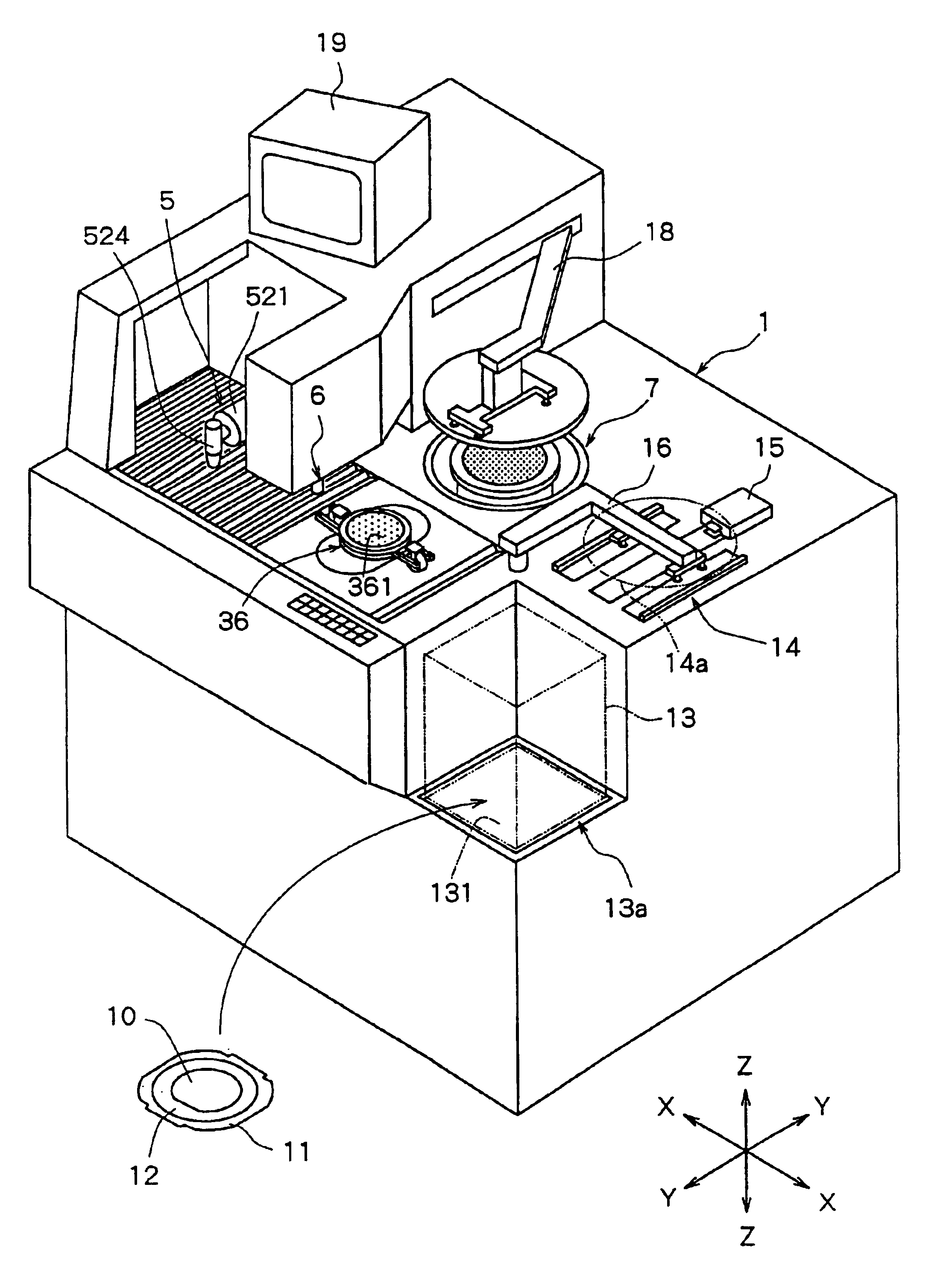

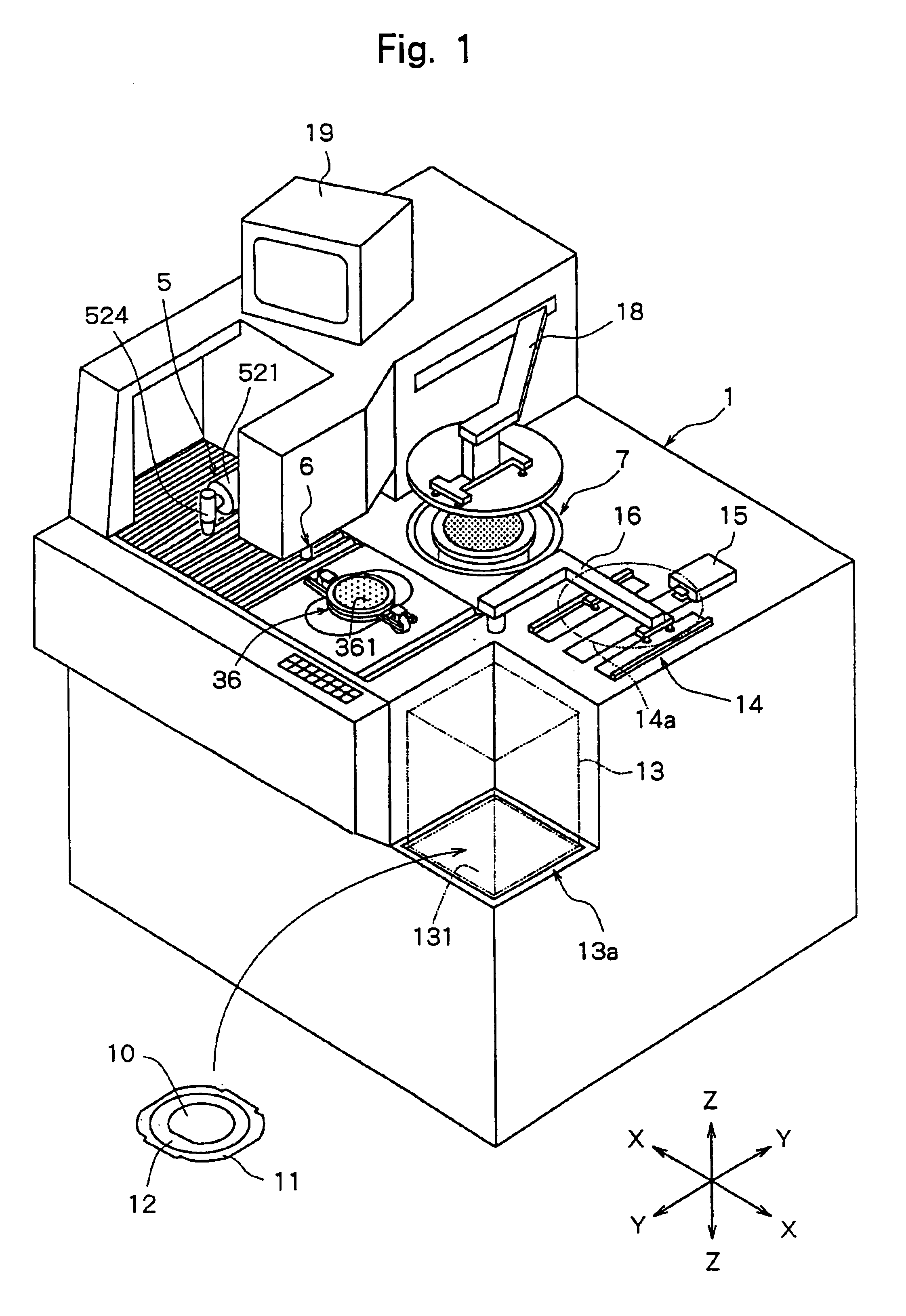

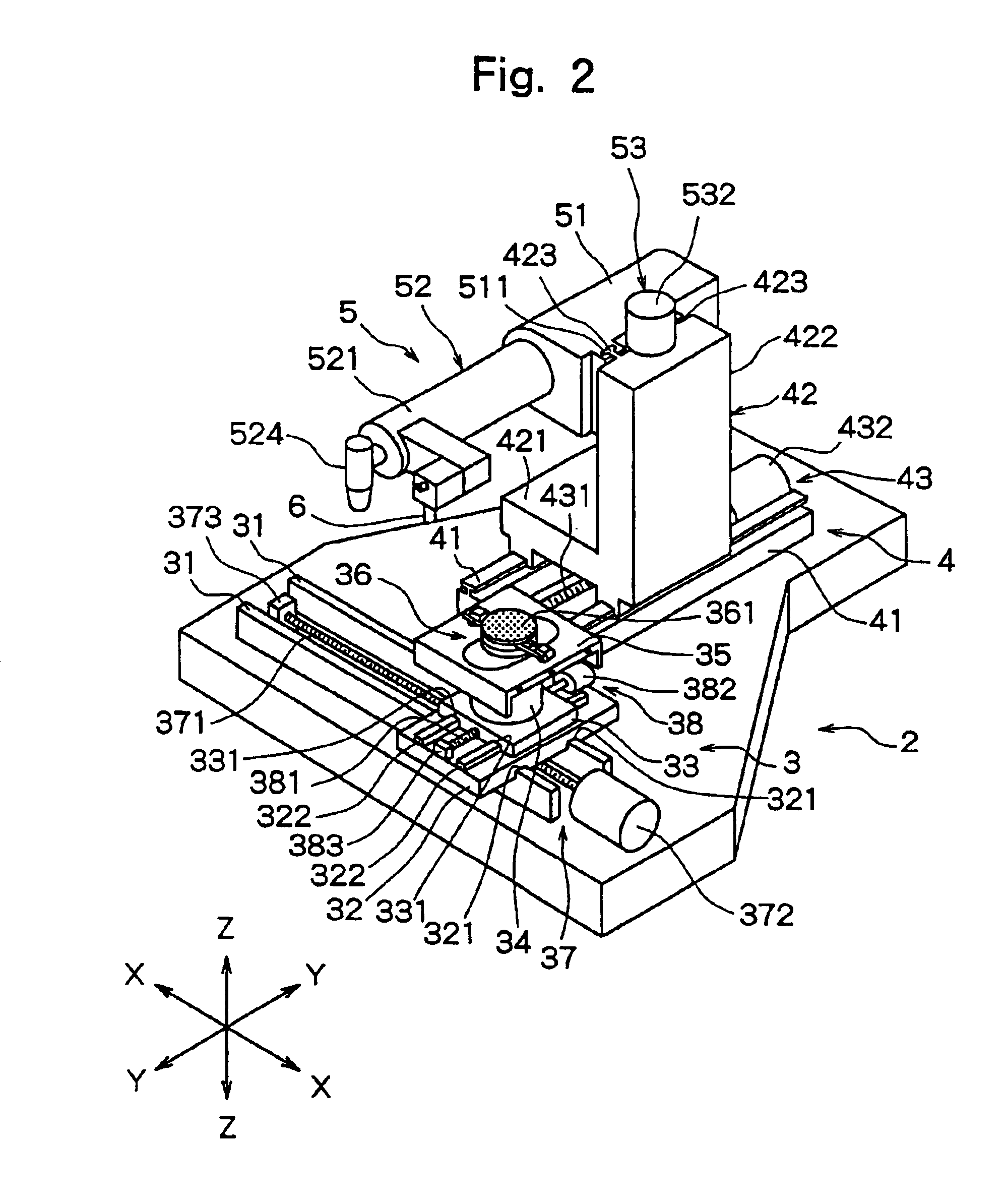

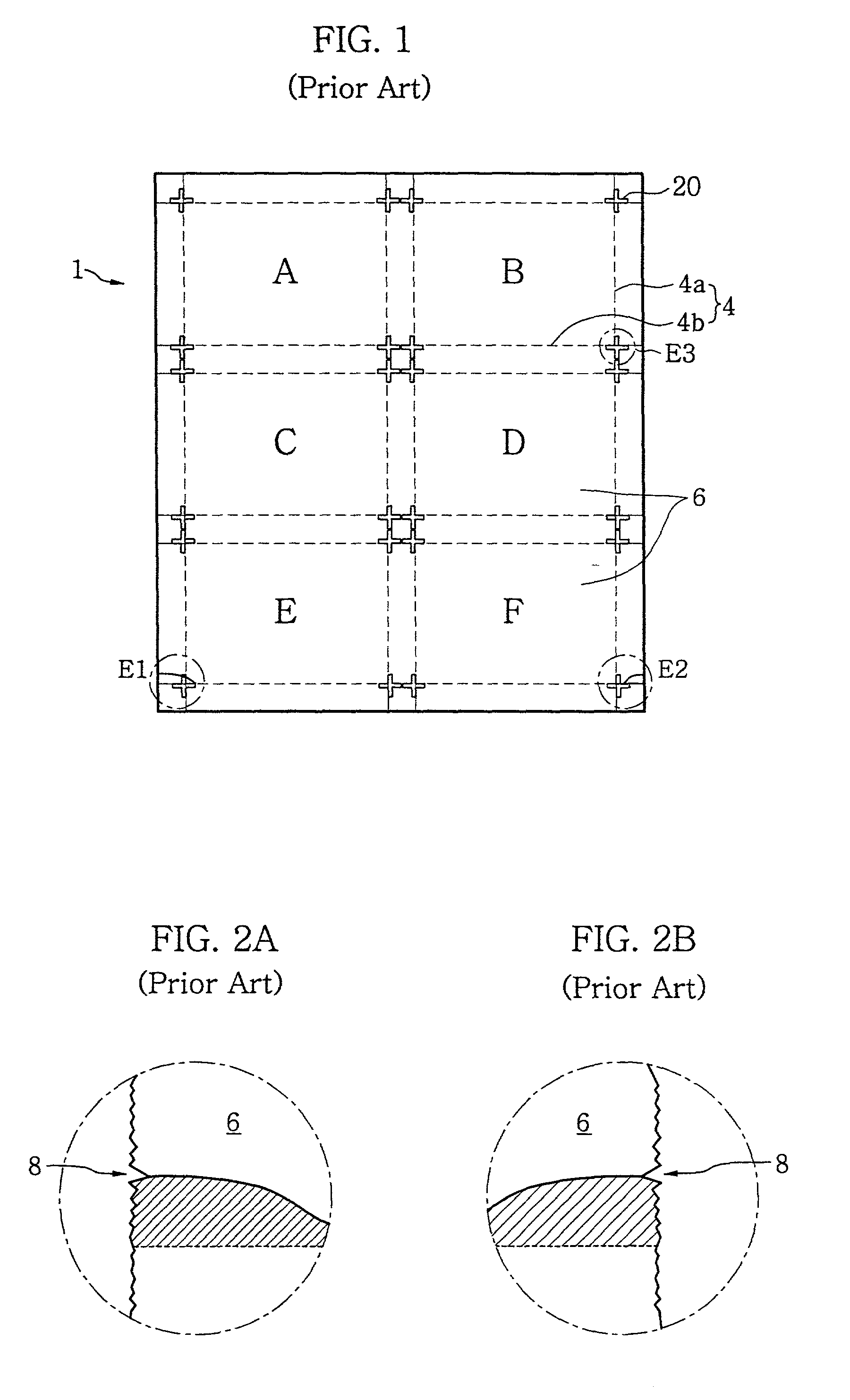

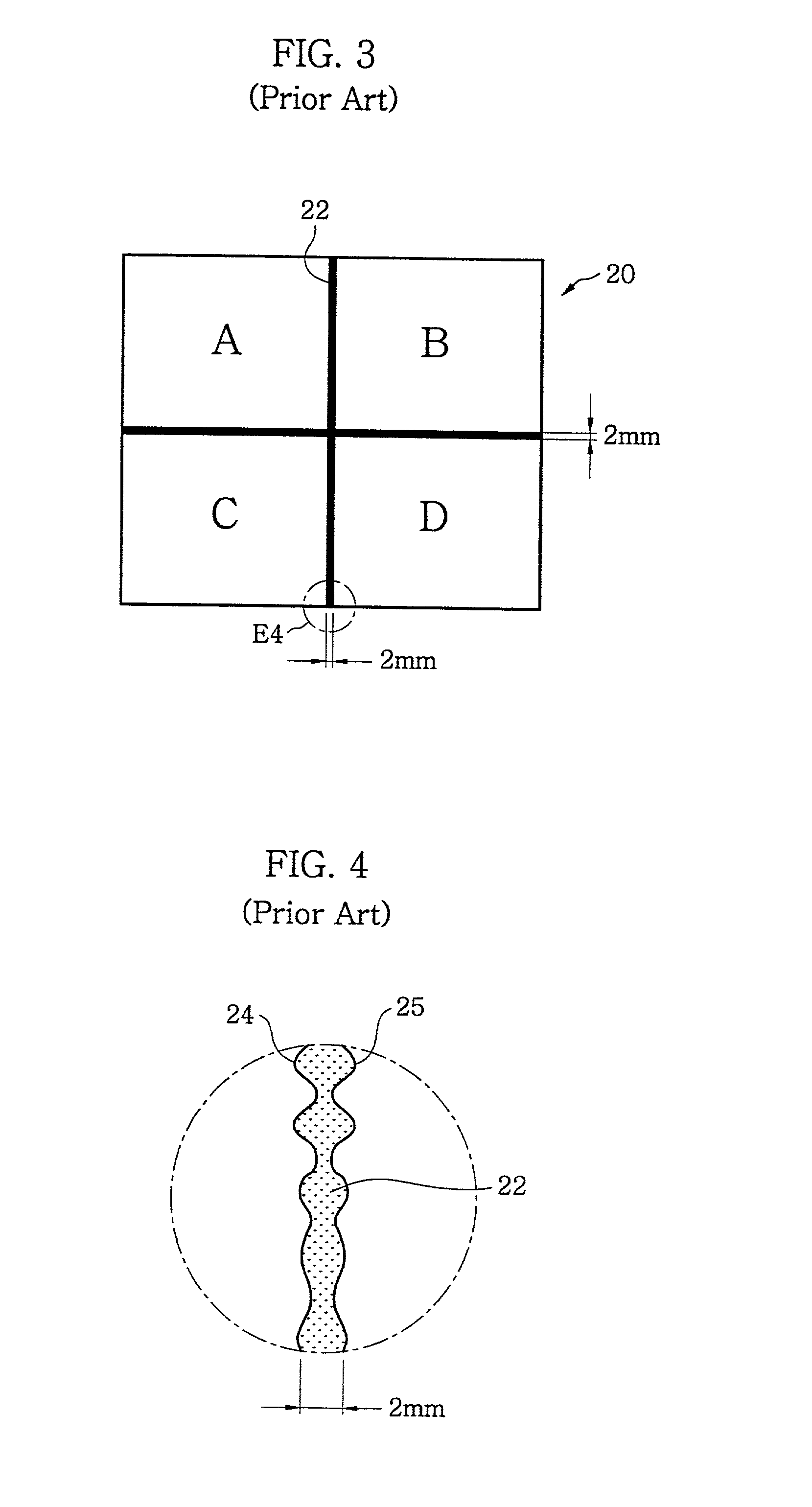

Laser beam processing machine

ActiveUS6998571B2Welding/cutting auxillary devicesSemiconductor/solid-state device manufacturingTectorial membraneLaser beam machining

A laser beam processing machine comprising a chuck table for holding a workpiece and a laser beam application means for applying a laser beam to the workpiece held on the chuck table, wherein the machine further comprises a protective film forming means for forming a protective film on the to-be-processed surface of the workpiece before laser beam processing.

Owner:DISCO CORP

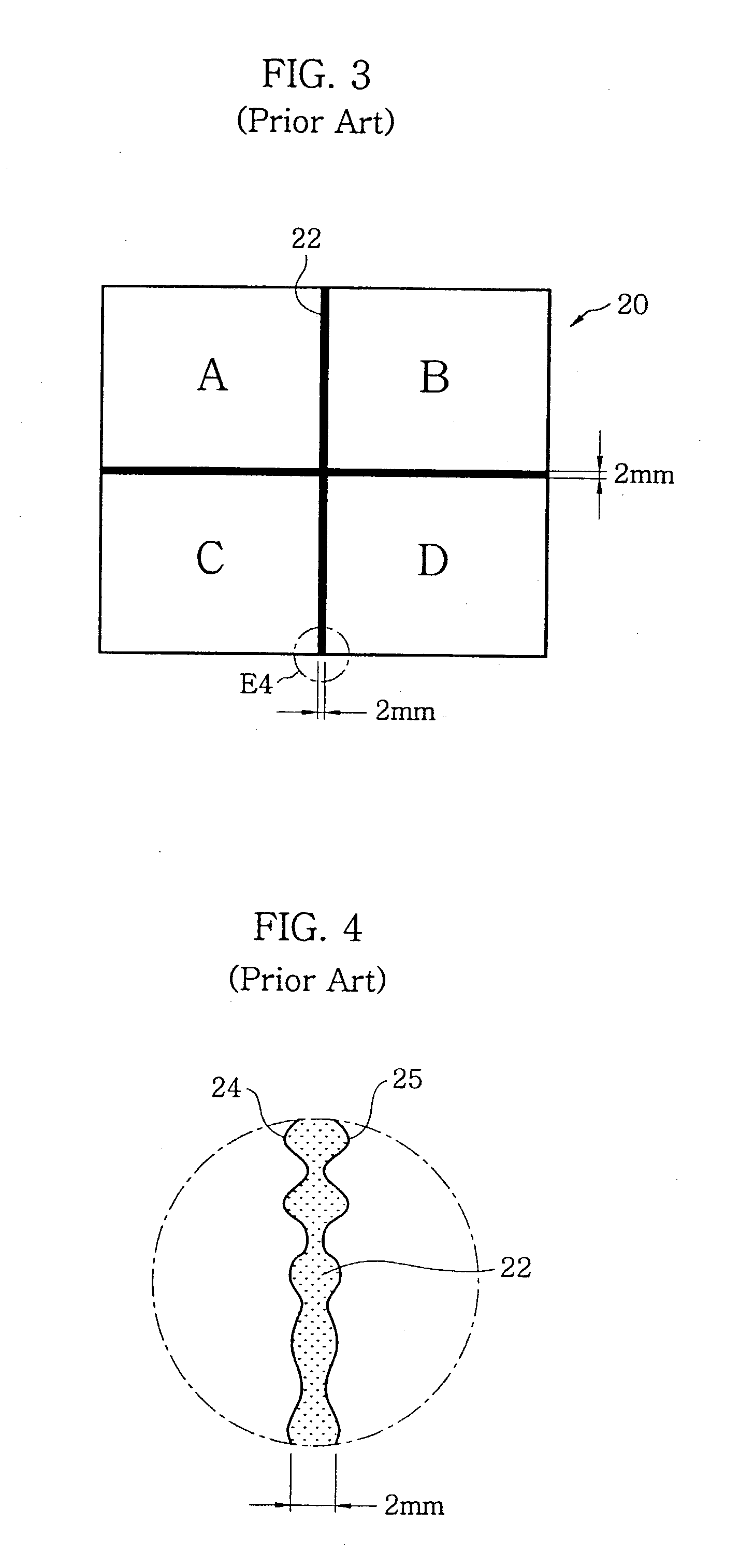

Laser cutting apparatus and method

The present invention disclose a laser cutter for cutting an object being cut such as a two glasses-attached panel for LCD using a laser beam. The laser cutter includes a laser unit for irradiating a laser beam with a specific wavelength along a marked cutting line of the object, a pre-scriber for forming a pre-cut groove at starting edge of the marked cutting line, and a cooling unit for cooling the cutting line which said laser beam has been irradiated.

Owner:SAMSUNG DISPLAY CO LTD

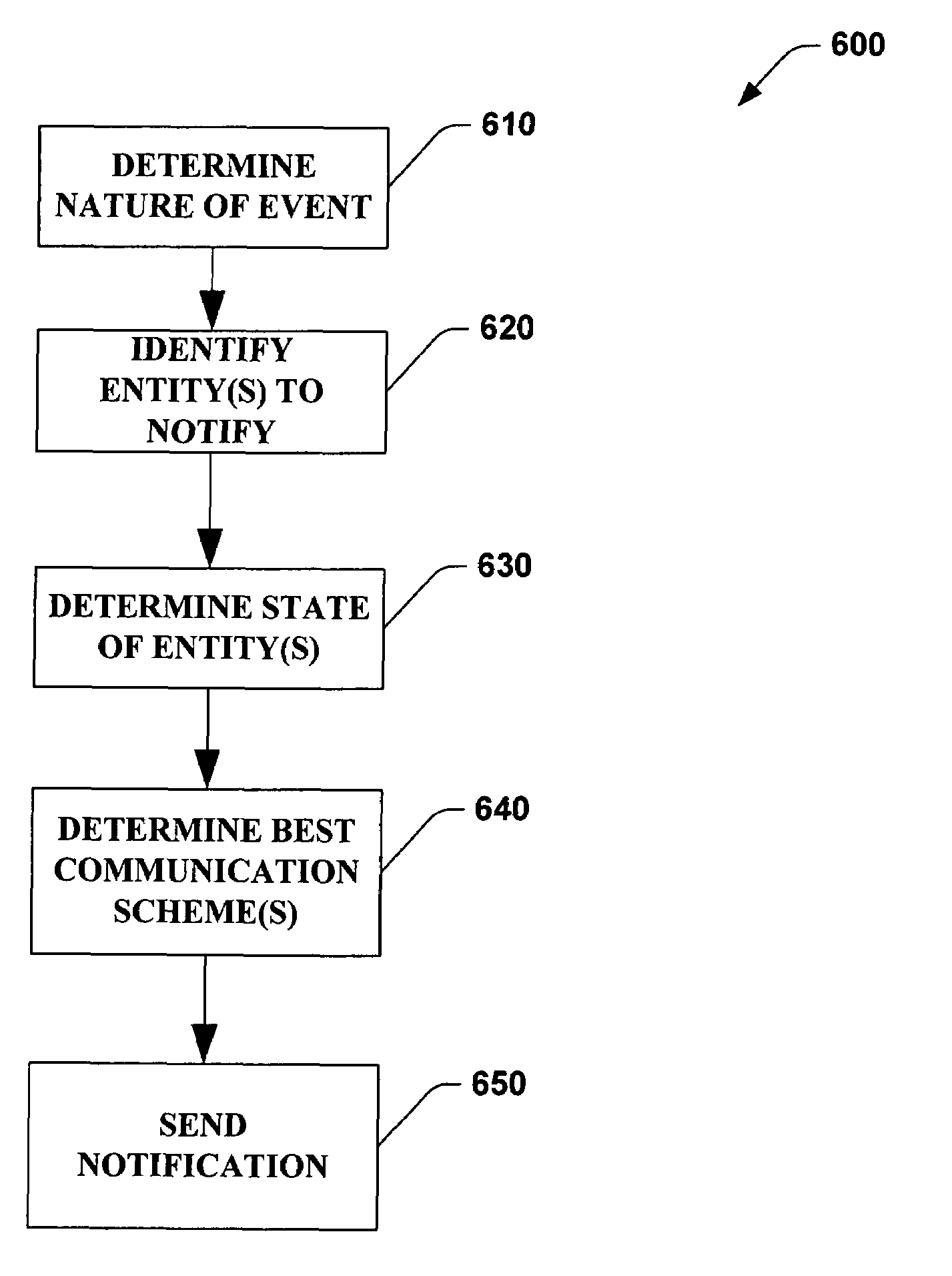

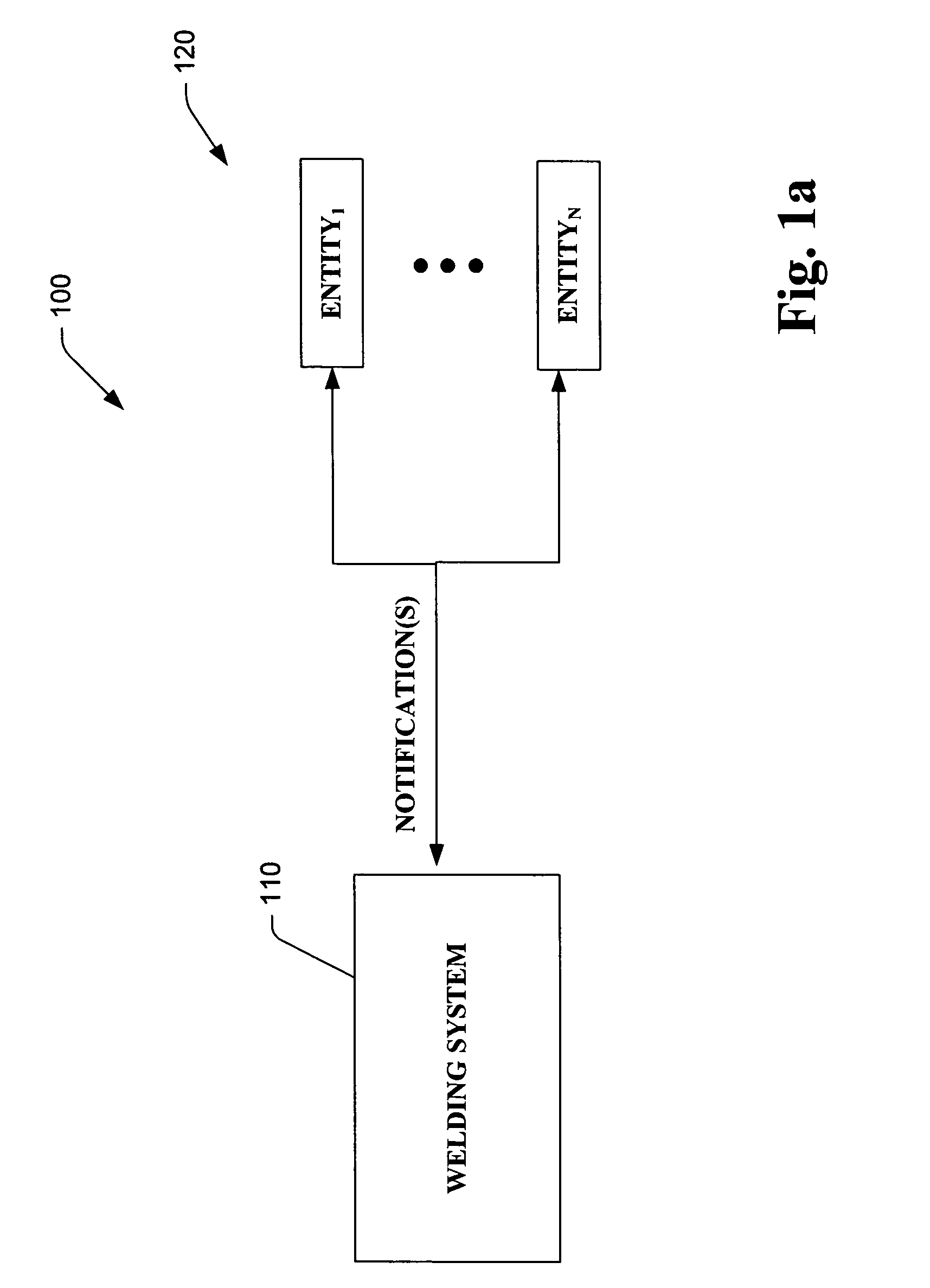

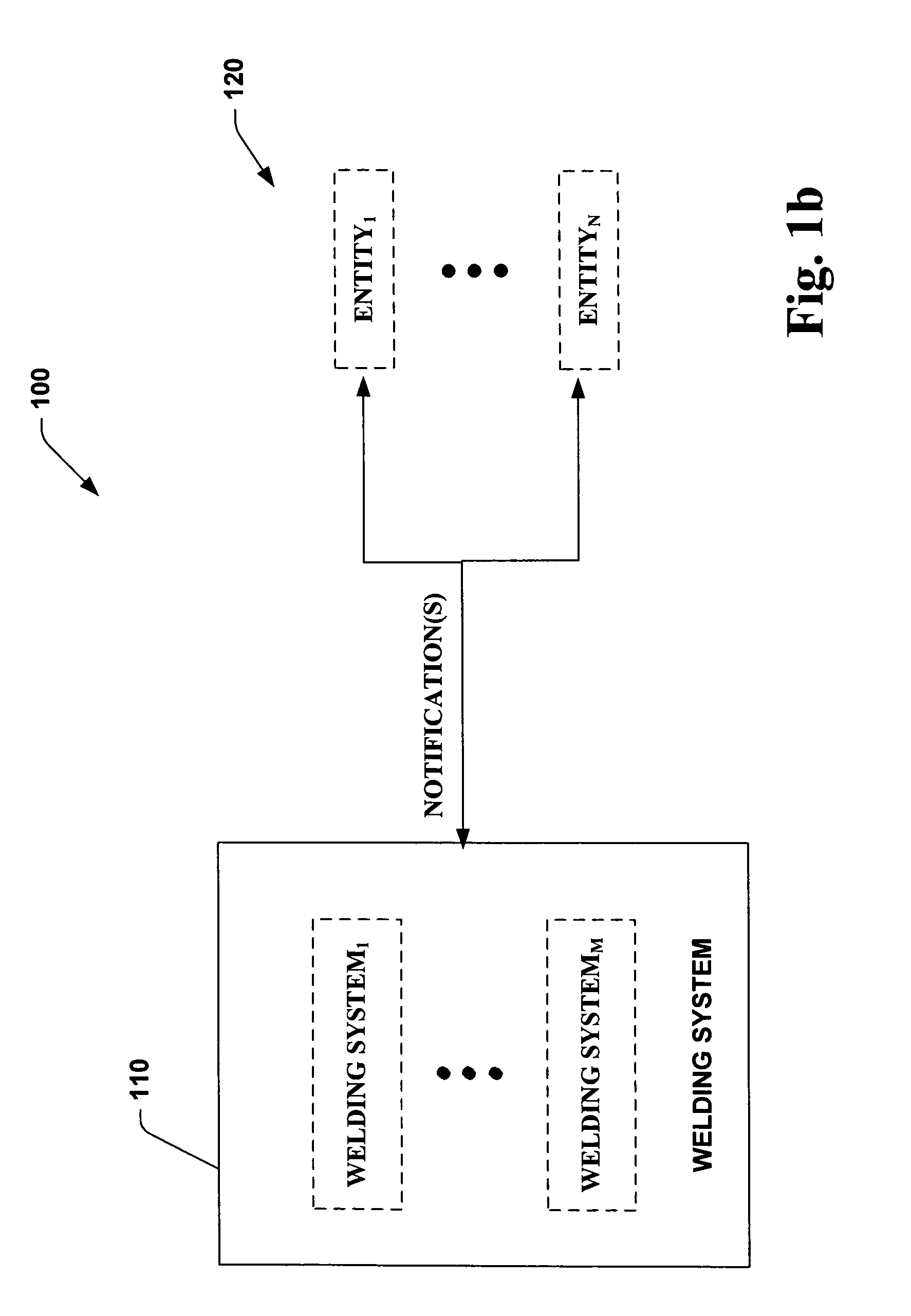

System and method providing automated welding notification

InactiveUS7375304B2Welding/cutting auxillary devicesTelephonic communicationGraphicsDiagnostic Radiology Modality

The present invention relates to a system and method that provide for automated notification to entities (e.g., individuals, groups of individuals, computers, systems . . . ) of welding system related information. The invention provides for determination of events and / or conditions that warrant automatic notification thereof to relevant entities. The notifications are conveyed via a most appropriate subset of available communication modes available. The system identifies most appropriate entities to receive the notification about the event, and optionally determines or infers state of the entities and conveys the notification via a communication mode (e.g., text, audio, graphical, video, combination thereof . . . ) and modality (e.g., wireless, Ethernet, cable, optical, telephone, e-mail, voicemail, pager, ghosting, instant messaging . . . ) that is most suitable given context / state of the event and entities.

Owner:LINCOLN GLOBAL INC

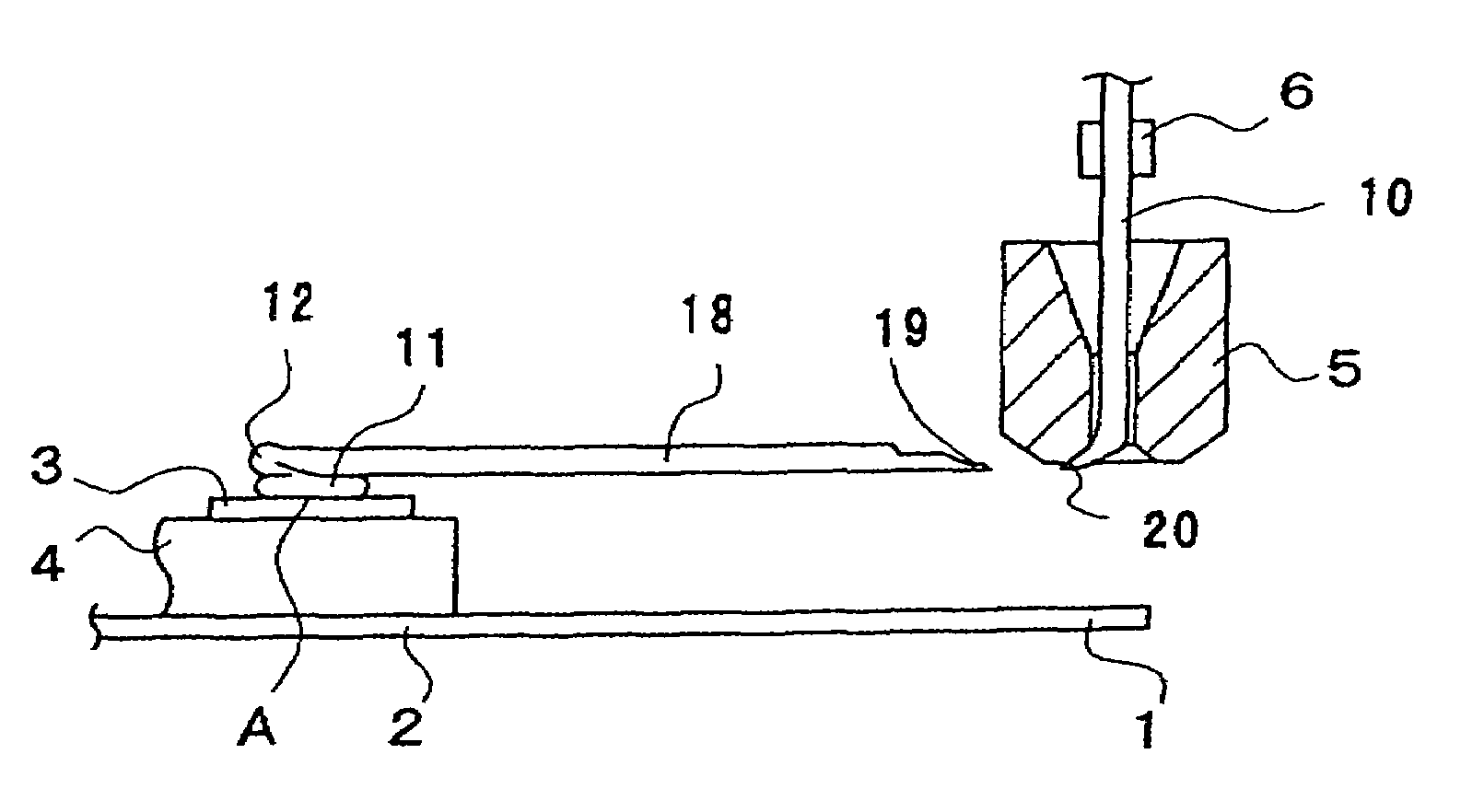

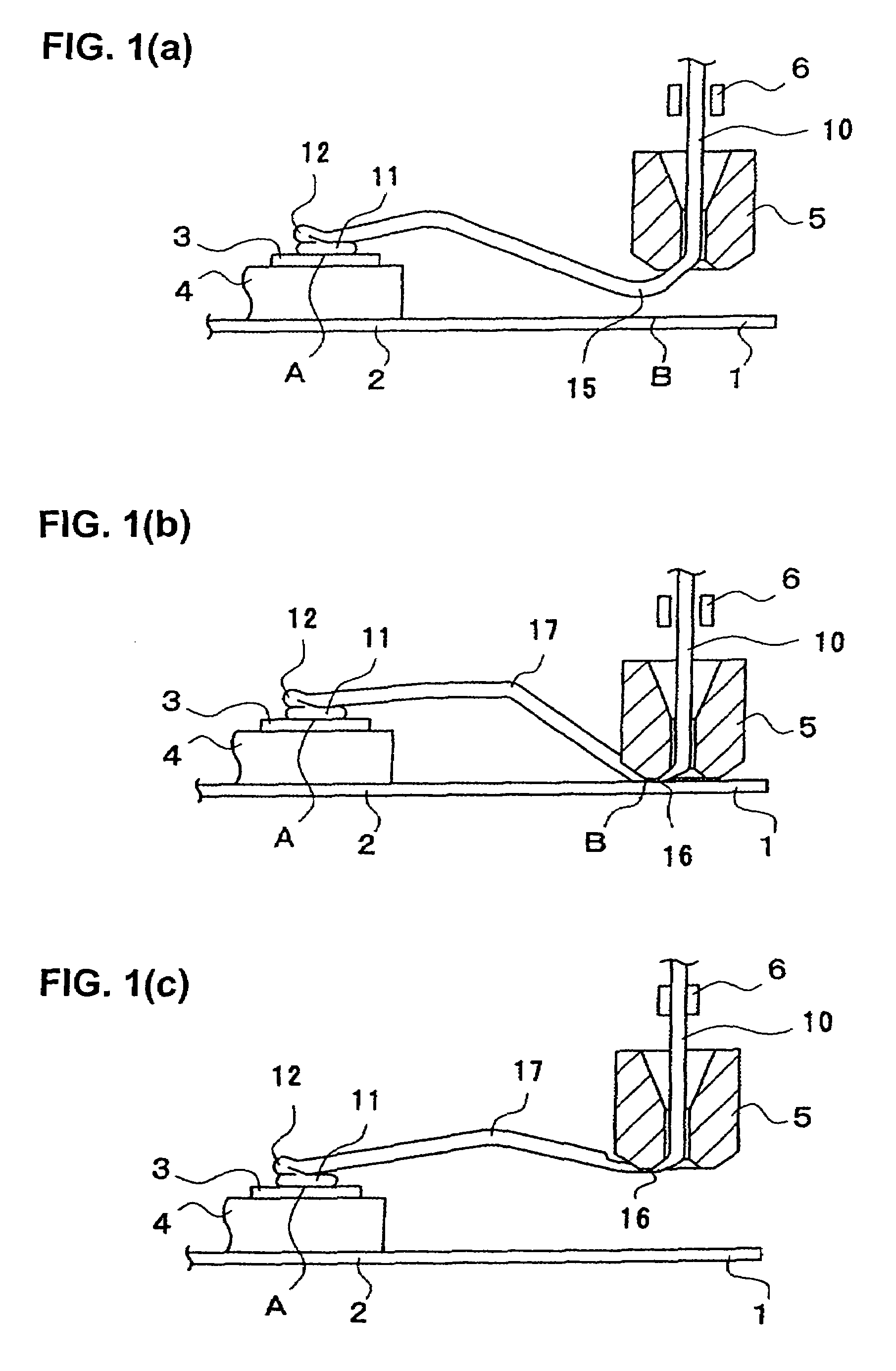

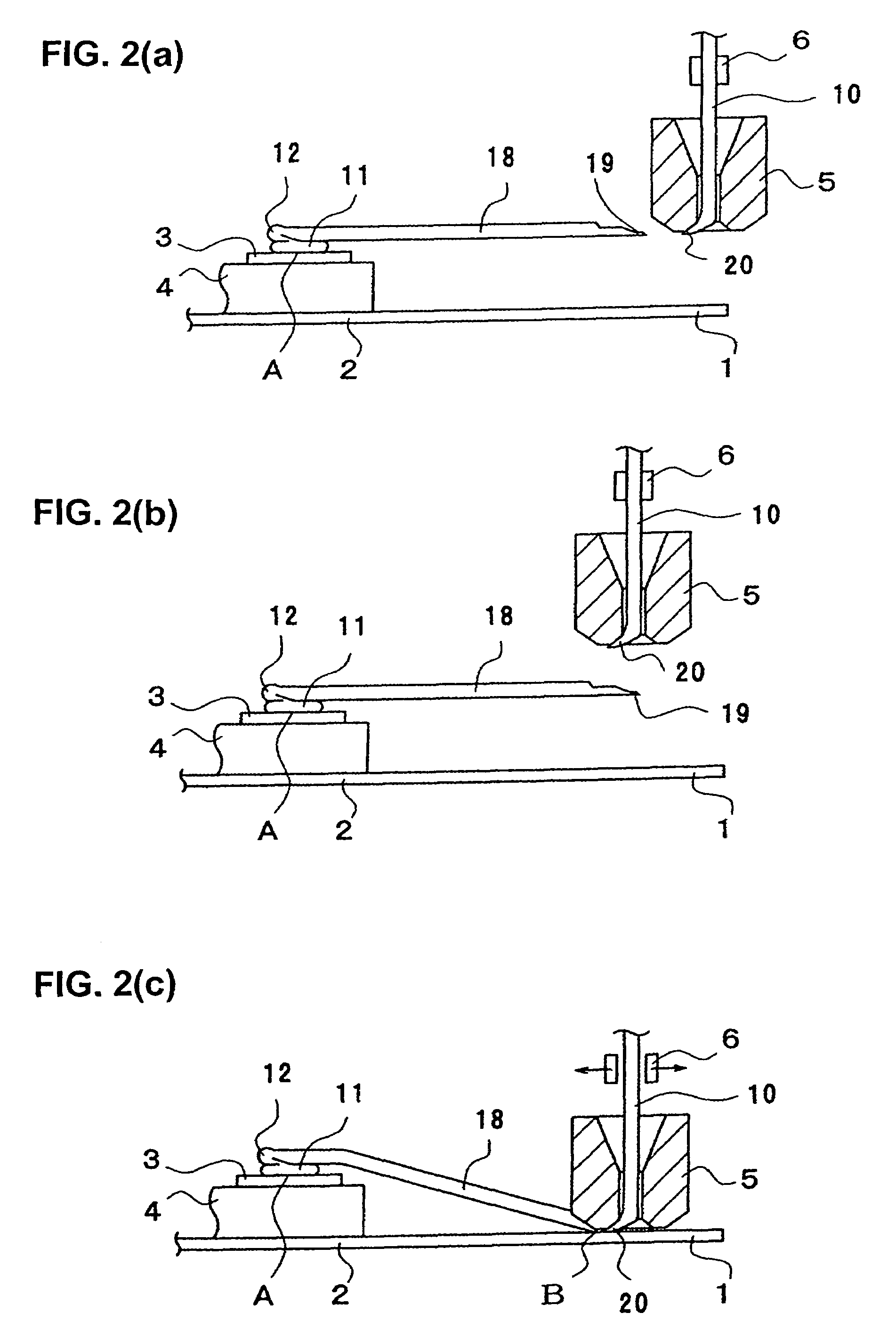

Wire bonding method

InactiveUS7621436B2Inhibit swellingImprove straightnessSolid-state devicesWelding/cutting auxillary devicesEngineeringWire bonding

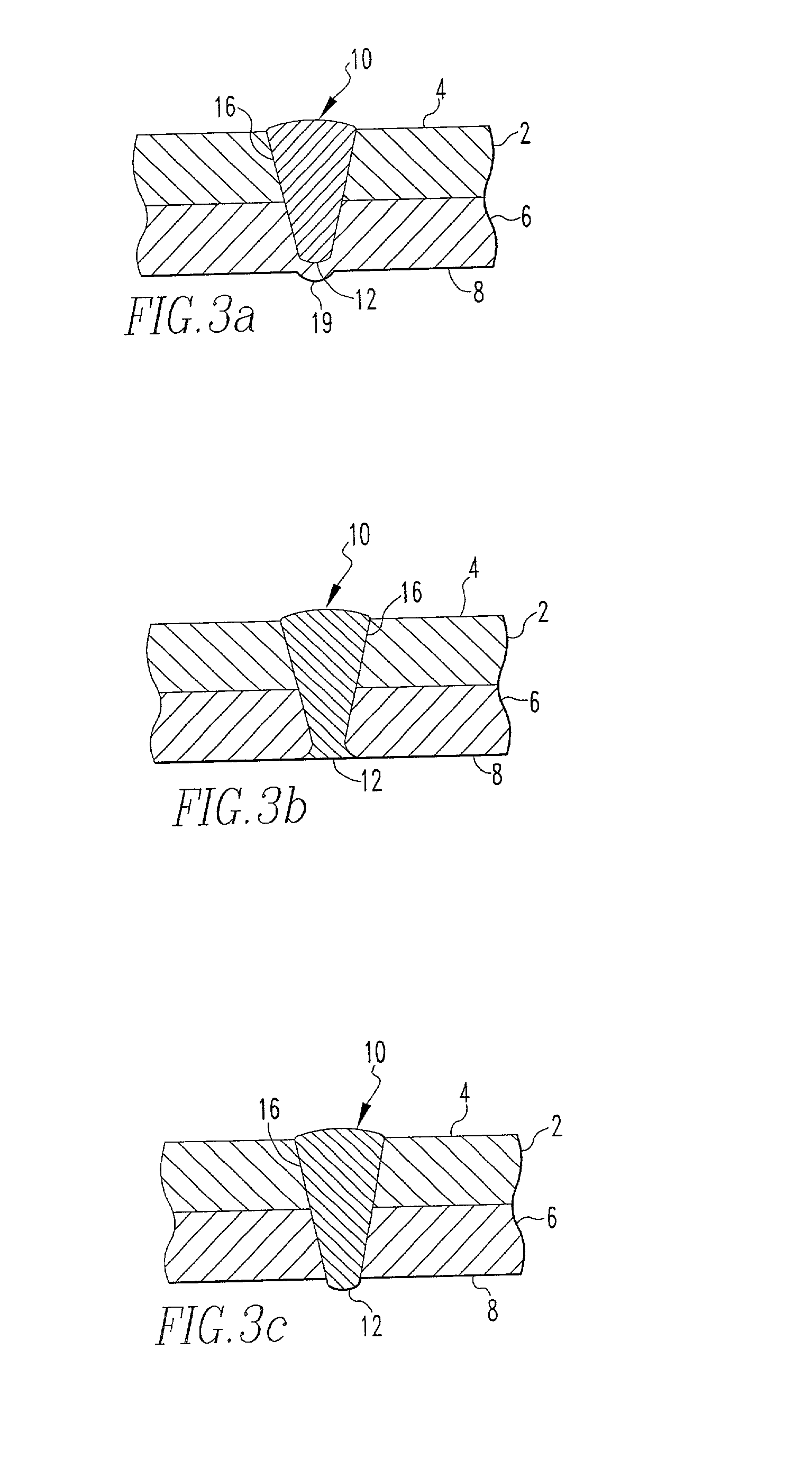

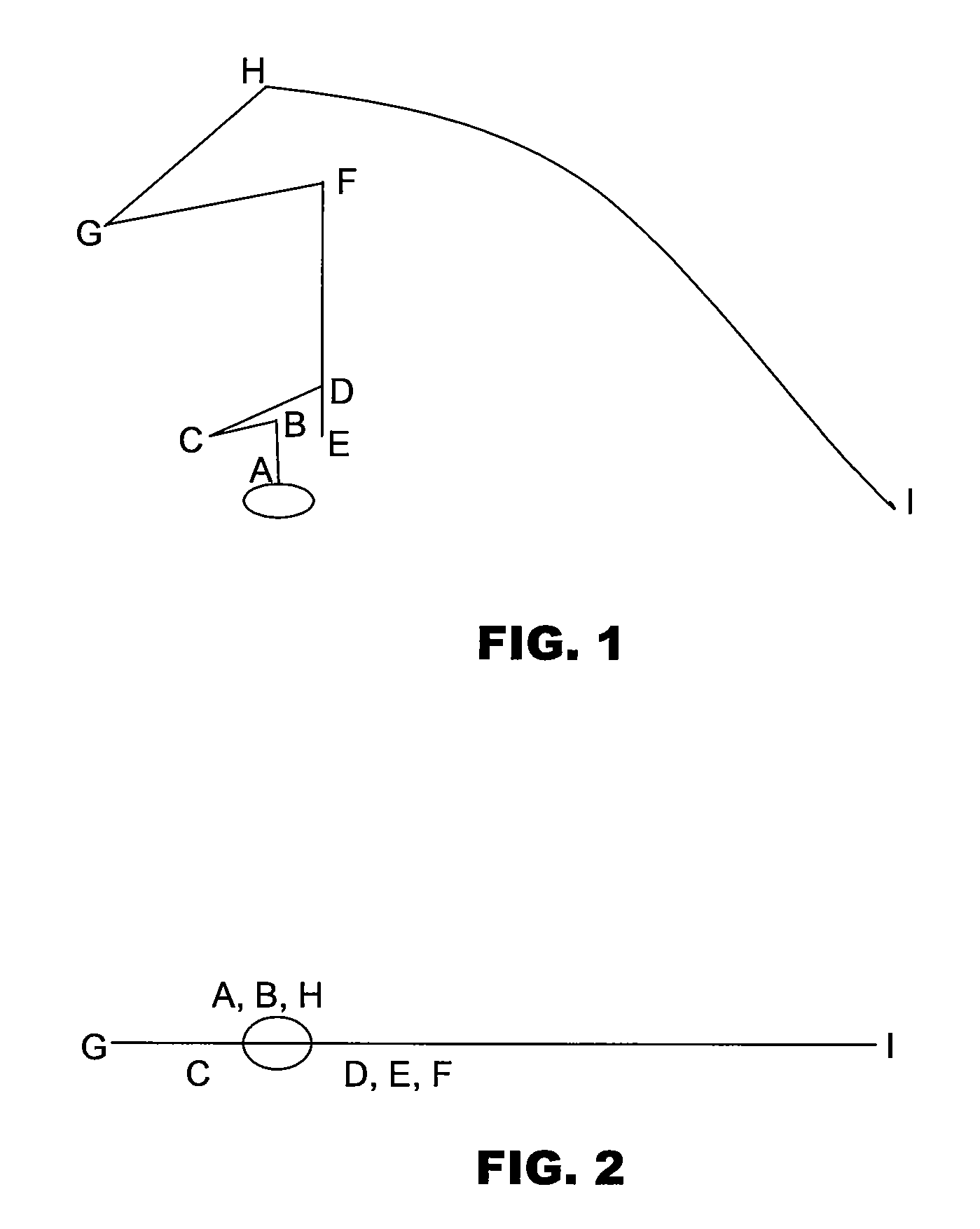

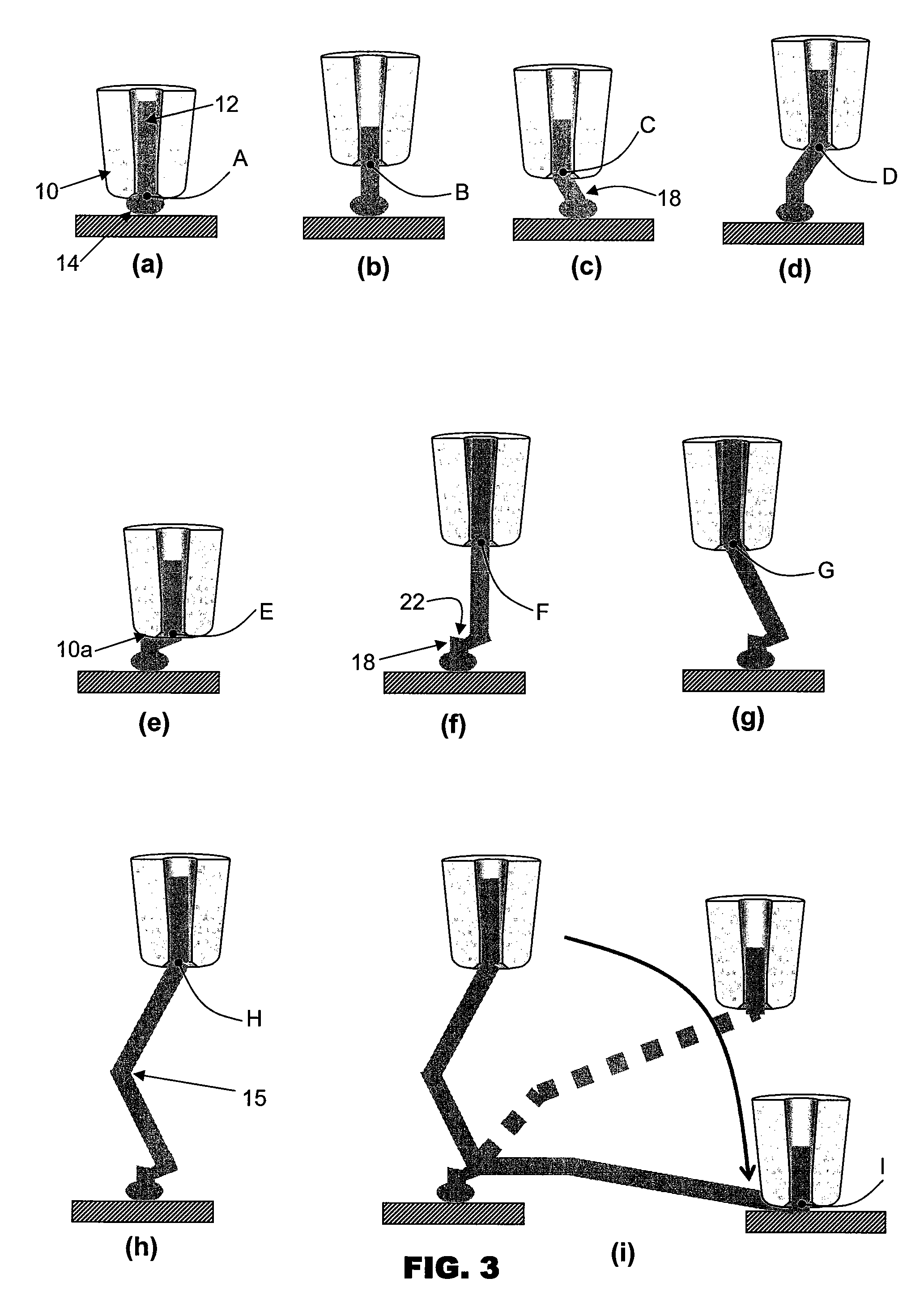

A wire bonding method including the steps of: descending a capillary 5 from above an external lead 1 to press a wire 10 to such an extent that the wire is not completely connected to the external lead 1, thus forming a thin part 16 in the wire; next ascending the capillary 5 and the thin part 16 to substantially the same height as a first bonding point A, then moving the capillary 5 in a direction away from the first bonding point A, thus making a linear wire portion 18 and then cutting the wire at the thin part 16; then connecting the end 19 (thin part) of the linear wire portion 18 and the wire tip end 20 at the lower end of the capillary 5 are connected to the external lead 1; and then separating the wire tip end 20 from the external lead 1.

Owner:SHINKAWA CO LTD

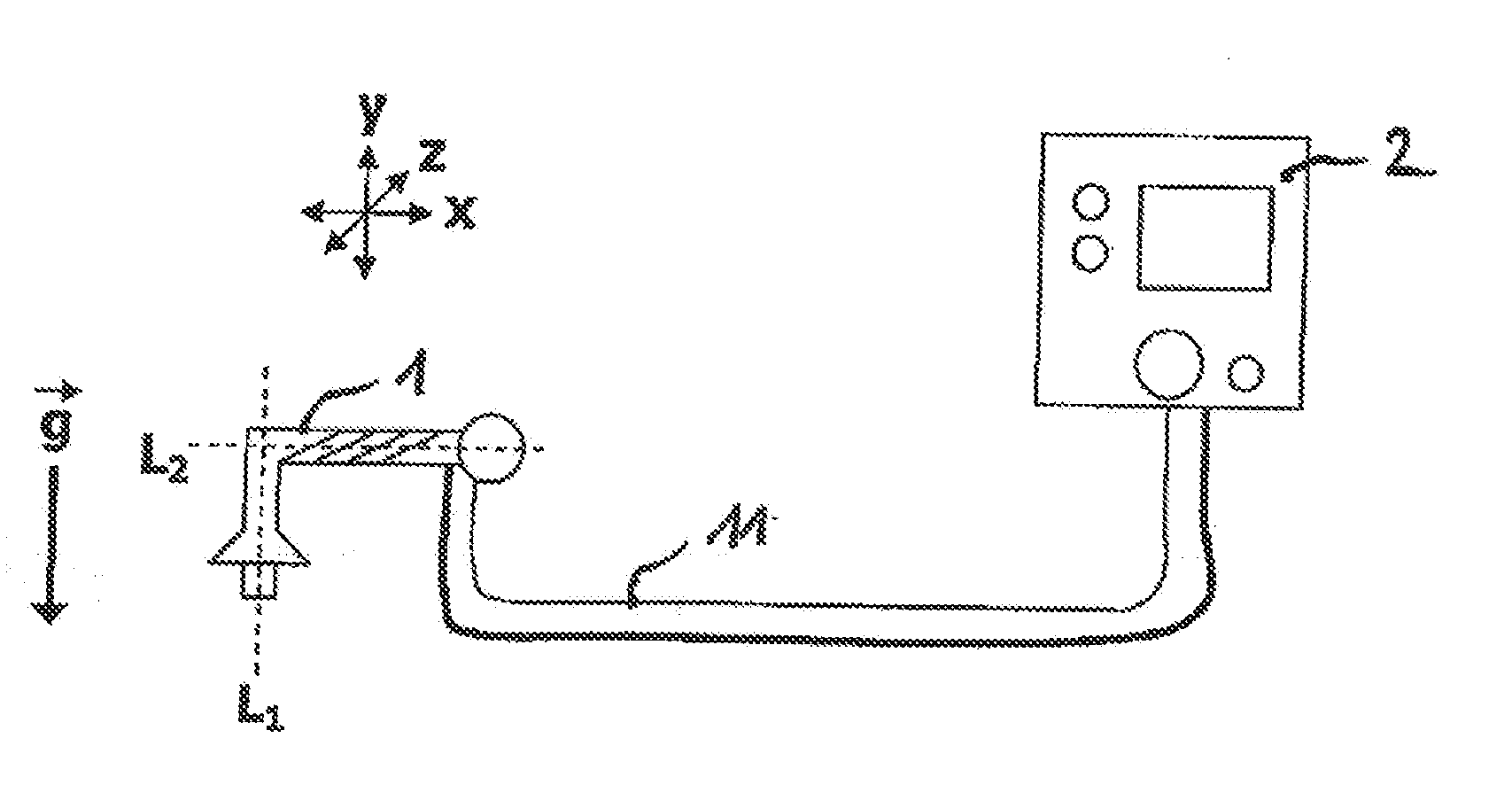

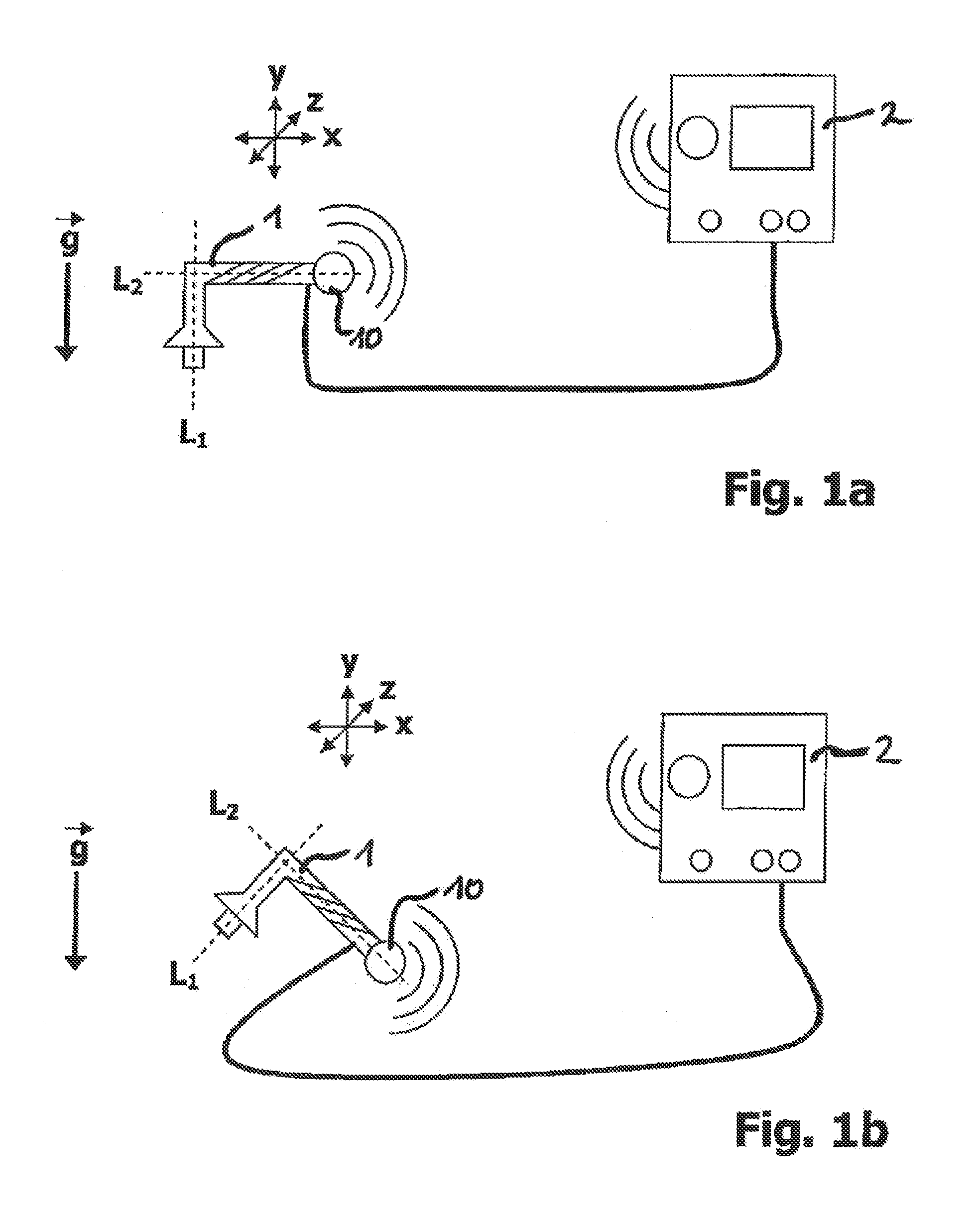

Device for carrying out a joint, separation, or suface treatment process, particularly a welding process

InactiveUS20070187378A1Easy and comfortable to operateImprove welding qualityWelding/cutting auxillary devicesArc welding apparatusEngineeringSoldering process

Owner:DRITTE PATENTPORTFOLIO BET GMBH & CO KG

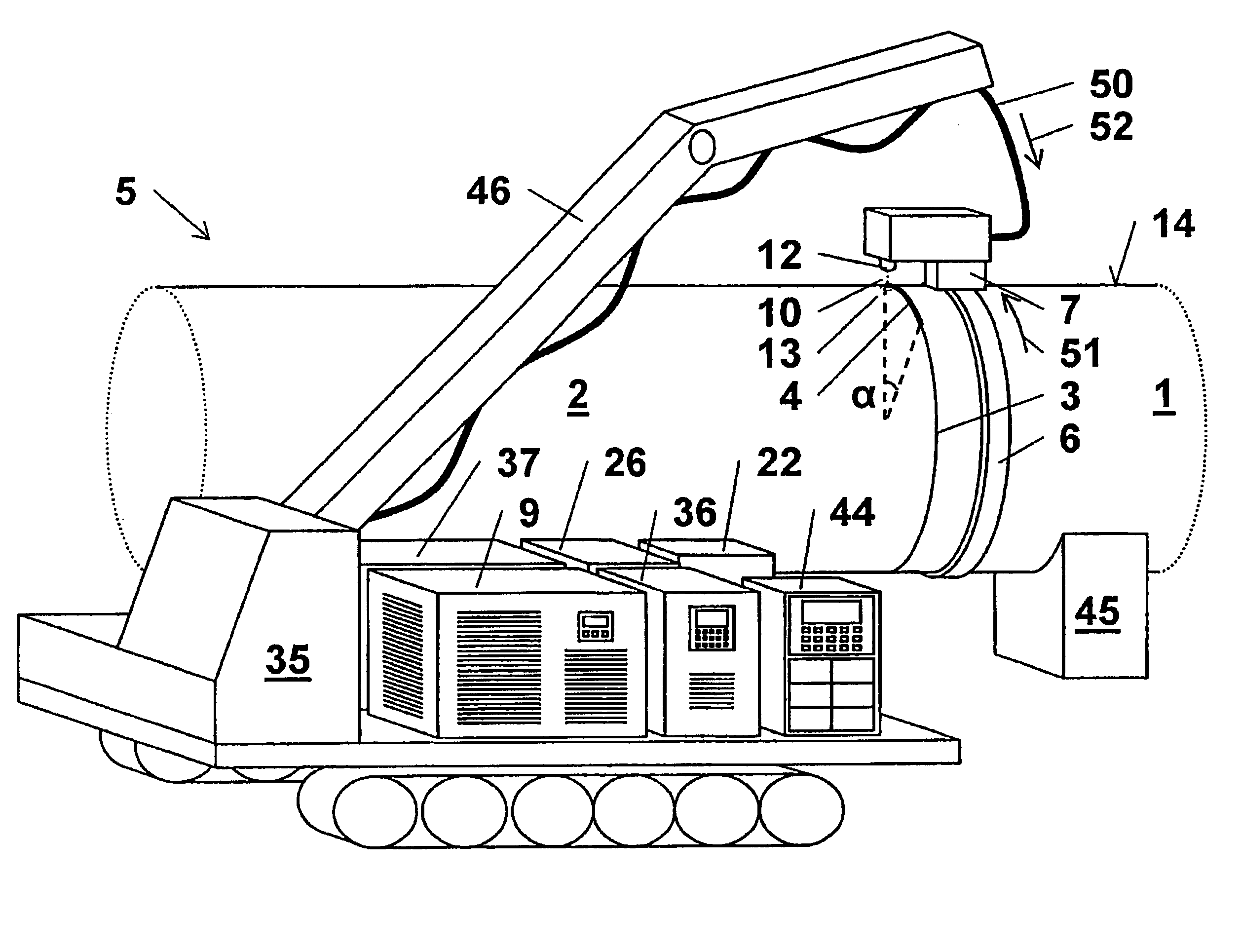

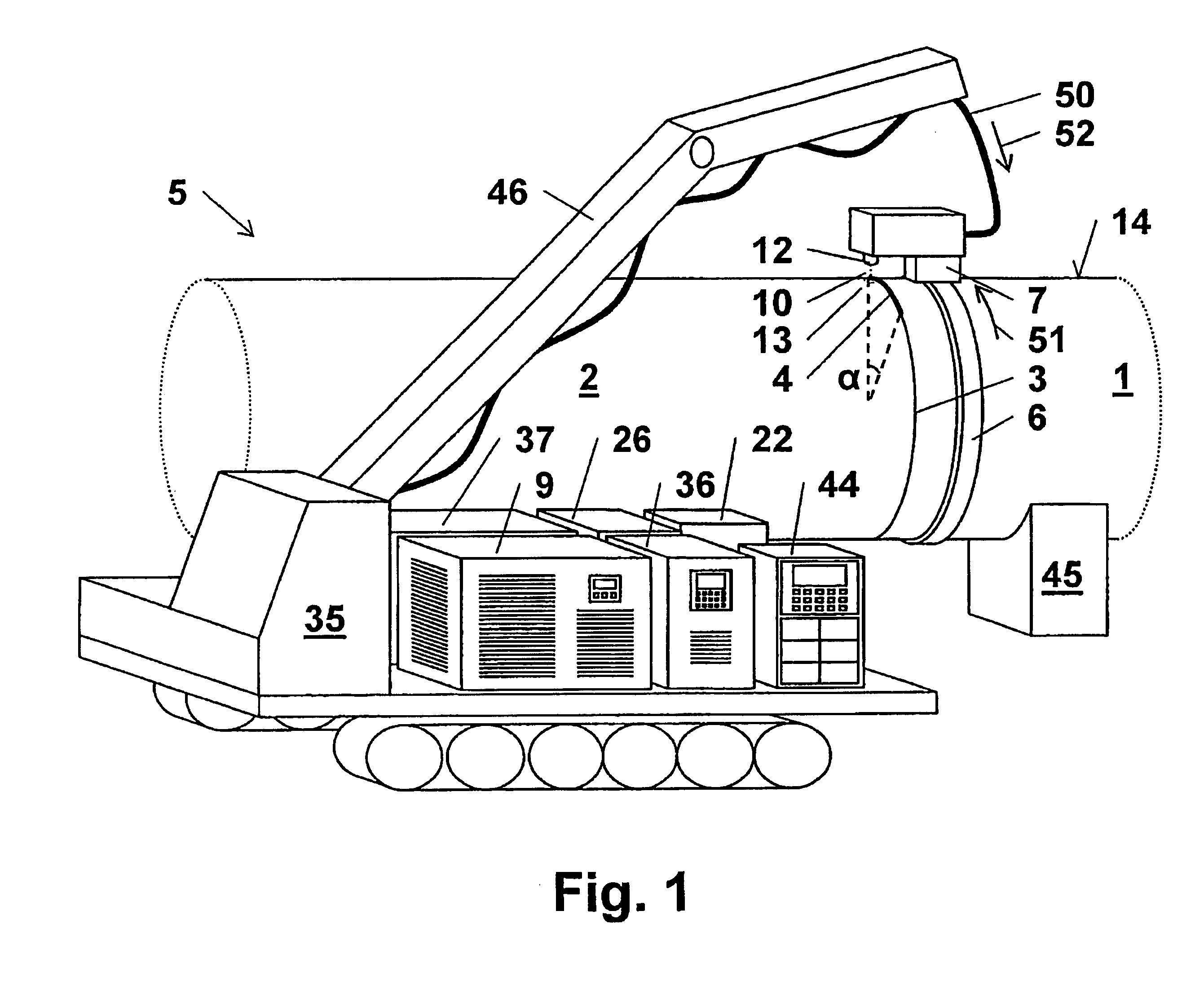

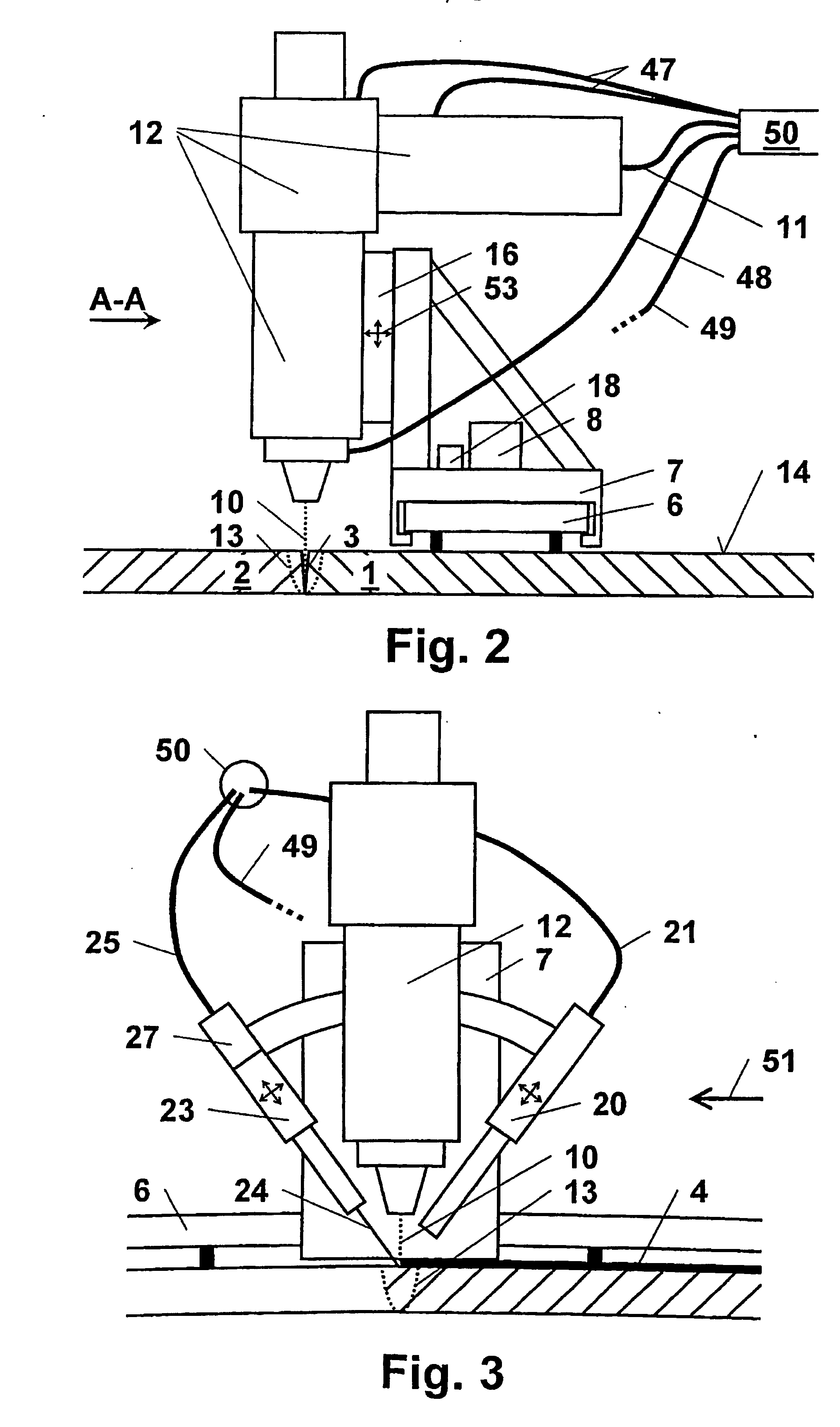

Orbital welding device for pipeline construction

InactiveUS20070119829A1Increase production speedArc welding apparatusLaser beam welding apparatusLight guideBeam source

The invention relates to an orbital welding device for mobile use in order to join a first pipe (1) and a second pipe end (2) along a circumferential joint (3) by at least one weld seam (4), particularly for producing a pipeline (5) to be placed on land. The inventive device includes a guide ring (6), which can be oriented toward the first pipe end (1) and the circumferential joint (3), and an orbital carriage (7) that can be motor-displaced along the guide ring (6) via an advancing device (8). On the orbital carriage (7), a laser welding head (12) for directing a laser beam (10) into a laser welding zone (13) is mounted in a manner that enables it to be oriented toward the circumferential joint (3) whereby enabling the production of the weld seam (4) along the circumferential joint (3) by displacing the orbital carriage (7). The laser beam (10) is produced by a high-power fiber laser beam source (9) located, in particular, on a mobile transport vehicle (35) while being situated at a distance from the orbital carriage (7), is guided by light guide (11) passing through a tube bundle (50) to the orbital carriage (7) and then supplied to the welding head (12). A significant advantage of the invention resides in the fact that the joining of two pipe ends by only one single welding process during a short period of time is made possible in the field with autonomous operation.

Owner:VIETZ

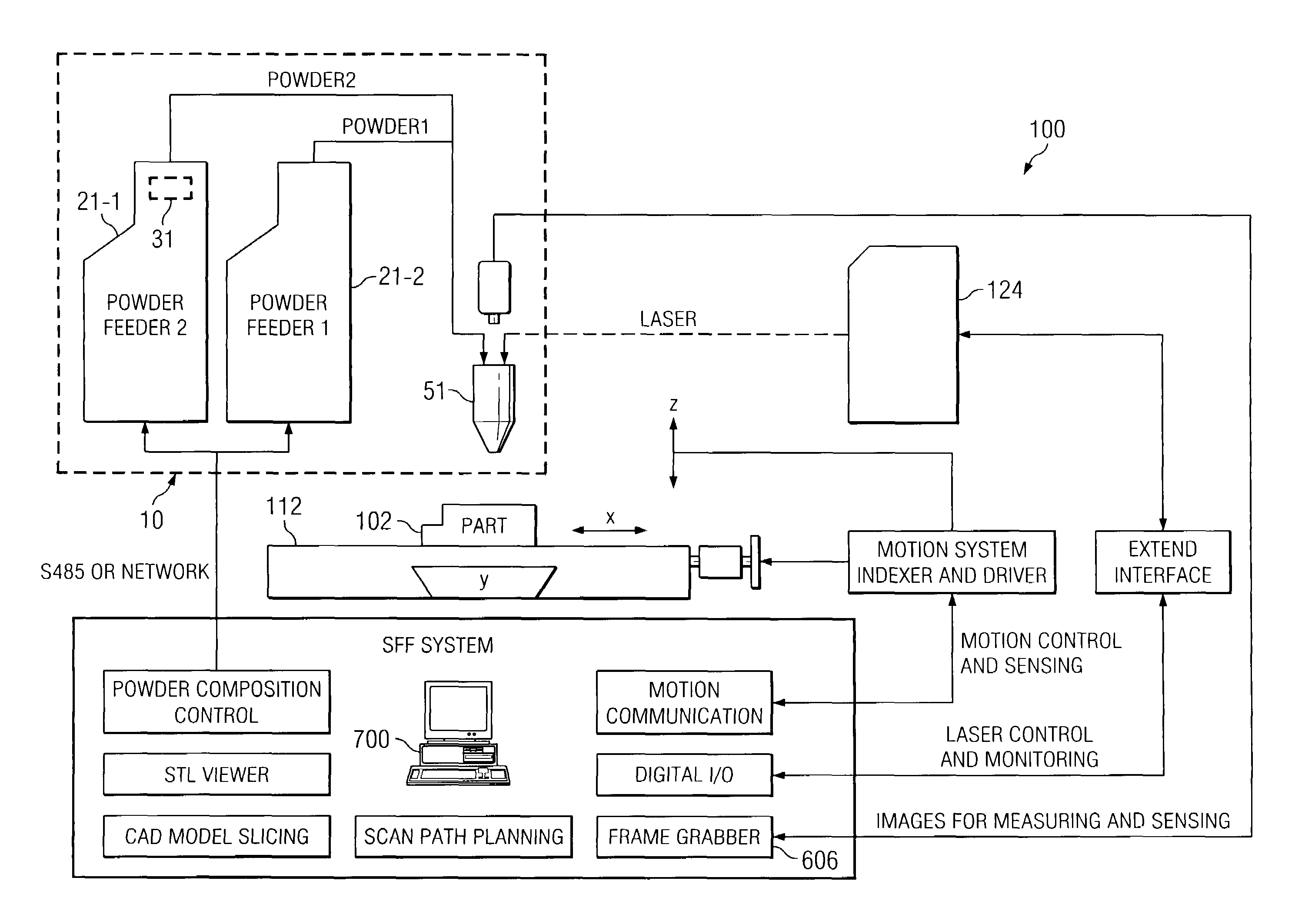

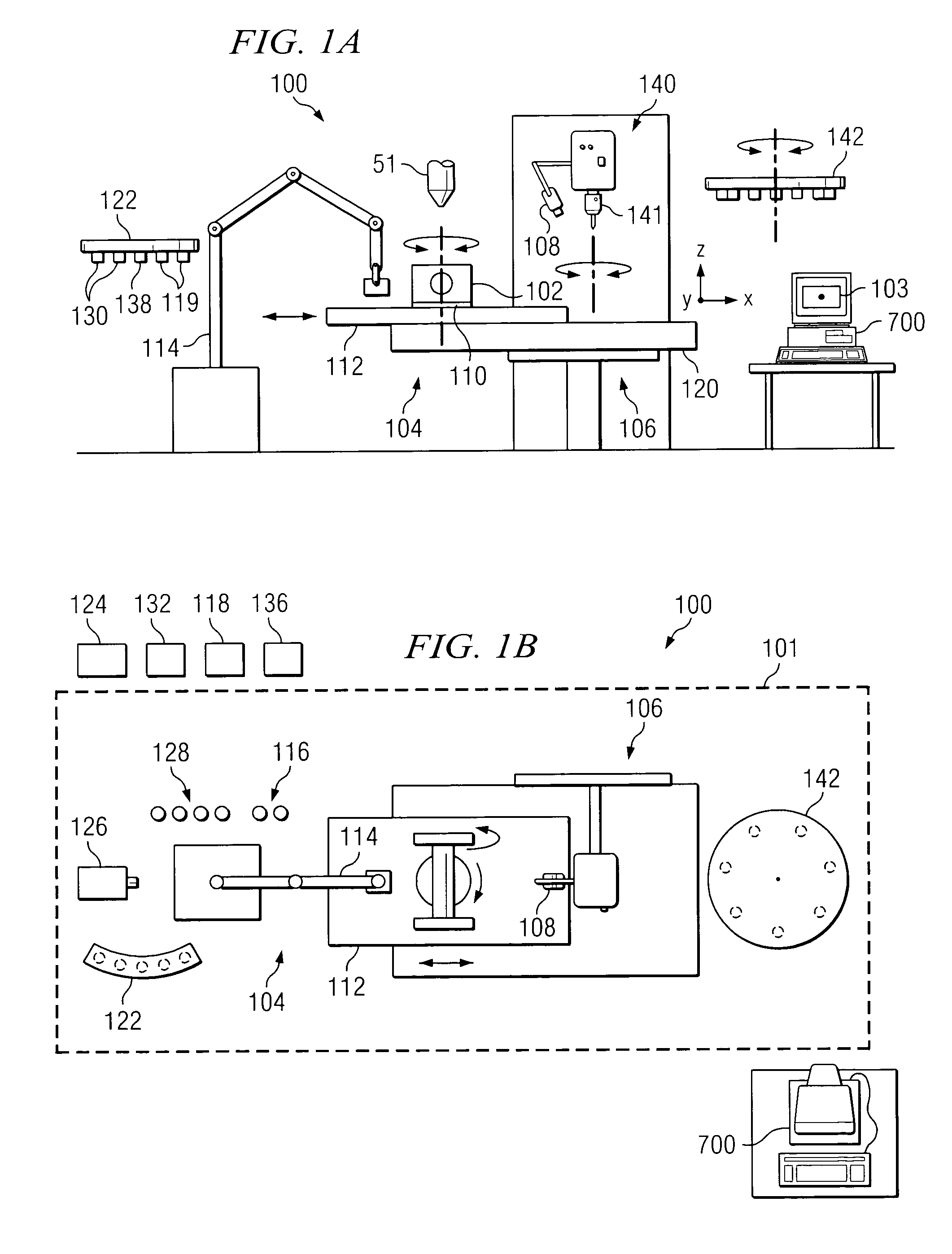

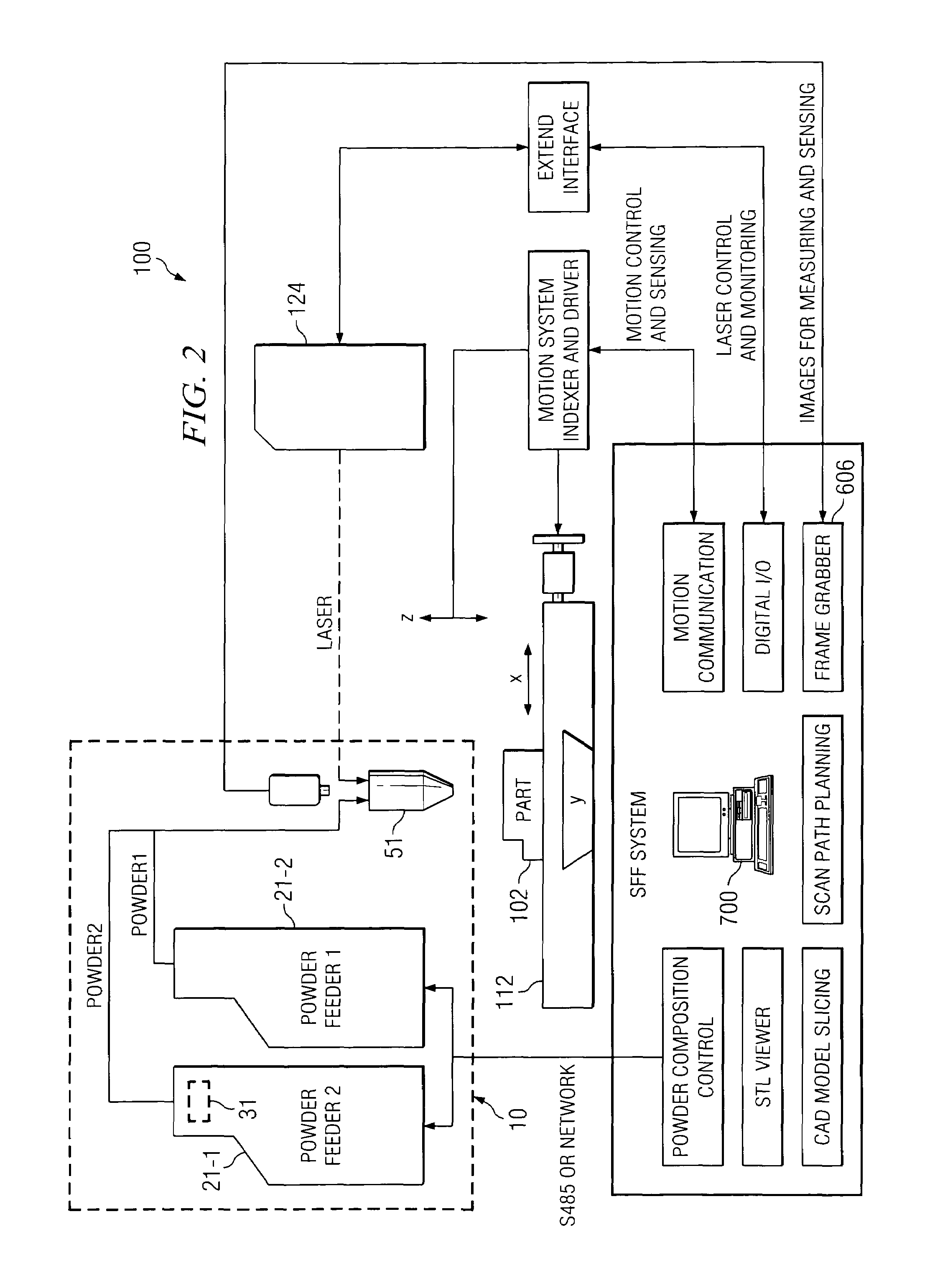

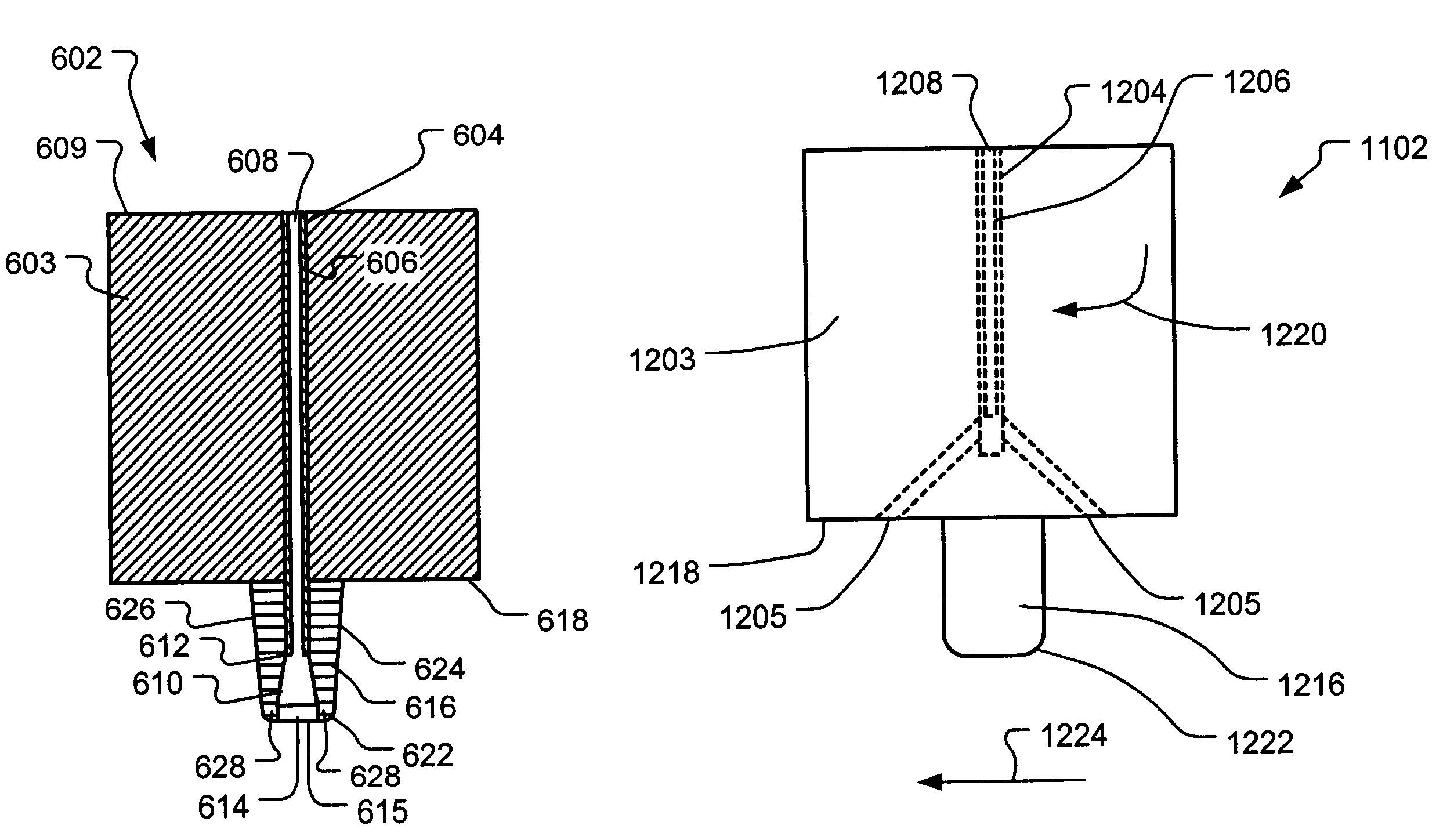

Powder delivery system and method

ActiveUS7045738B1High geometric accuracyEasy to controlWelding/cutting auxillary devicesArc welding apparatusMechanical engineeringDelivery system

A powder delivery system for a laser-based additive manufacturing process includes a hopper adapted to contain a powder and continuously feed the powder through an output of the hopper, a rotatable disk having a top surface that is substantially flat, the top surface adapted to receive the powder continuously fed through the output of the hopper, the top surface being disposed below the output of the hopper by a prescribed gap, and a vacuum powder removal device operable to remove the powder from the top surface via a vacuum.

Owner:SOUTHERN METHODIST UNIVERSITY

Apparatus and method for friction stir welding using filler material

InactiveUS6543671B2Welding/cutting auxillary devicesAuxillary welding devicesFilling materialsEngineering

Owner:LOCKHEED MARTIN CORP

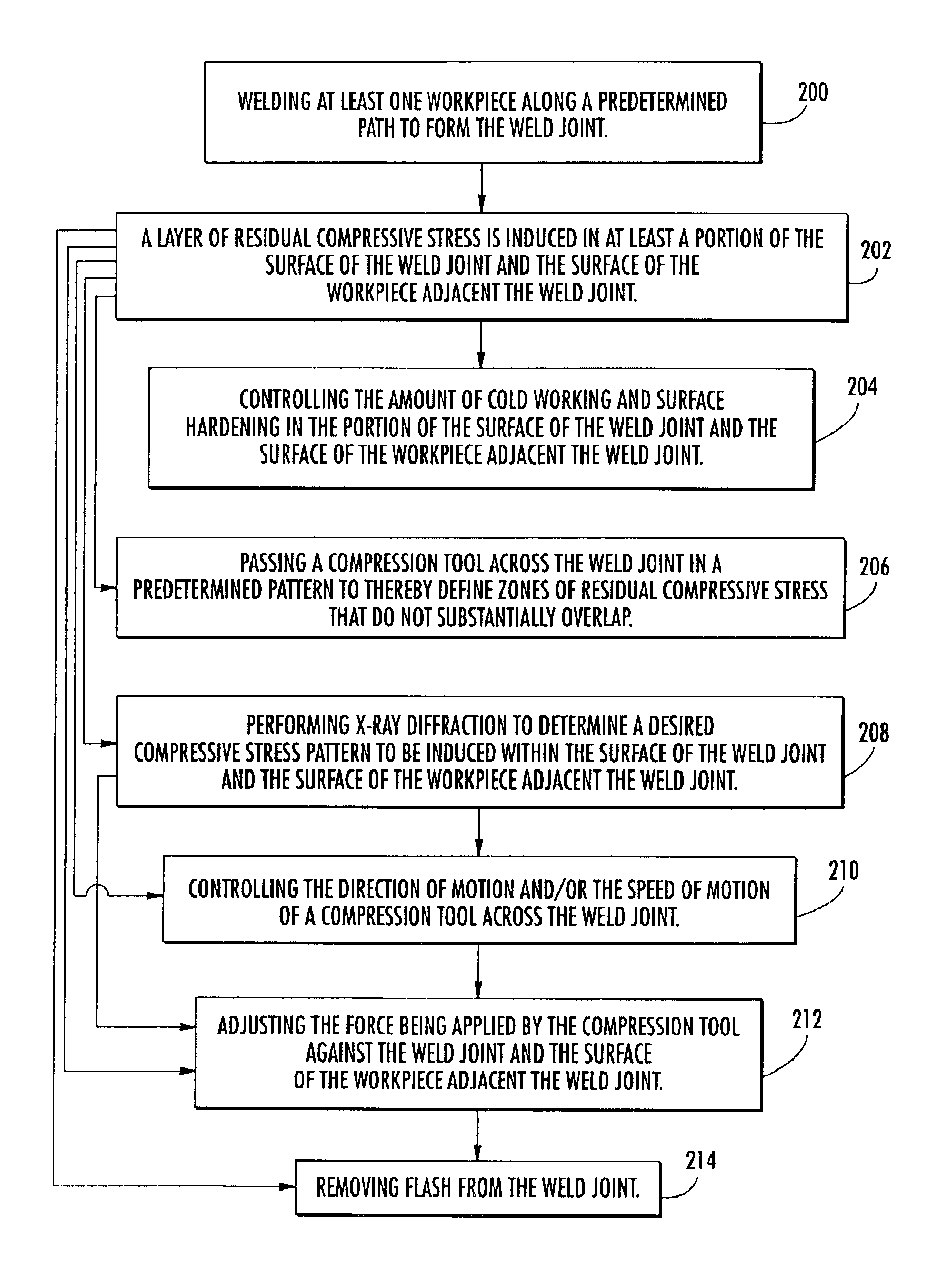

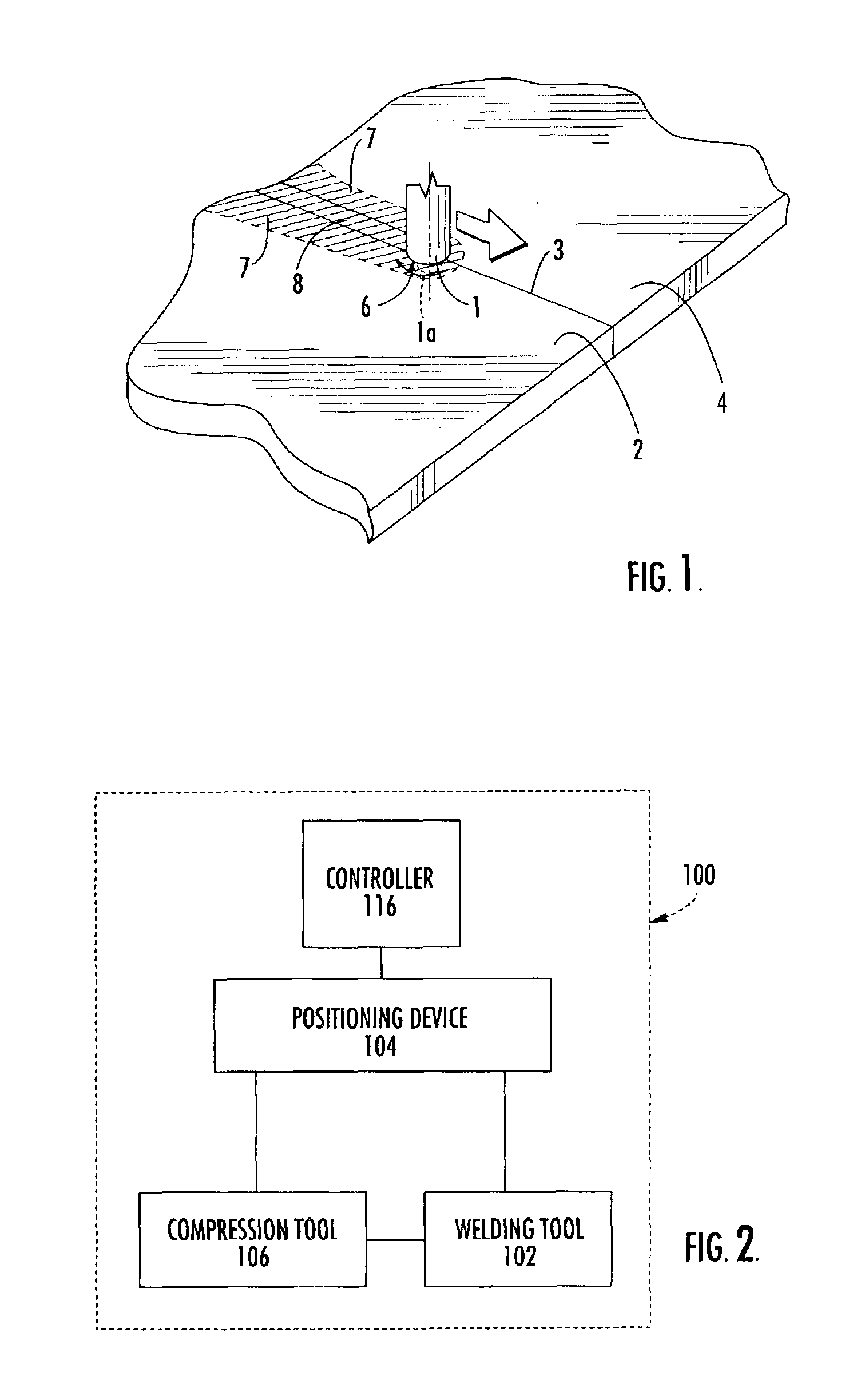

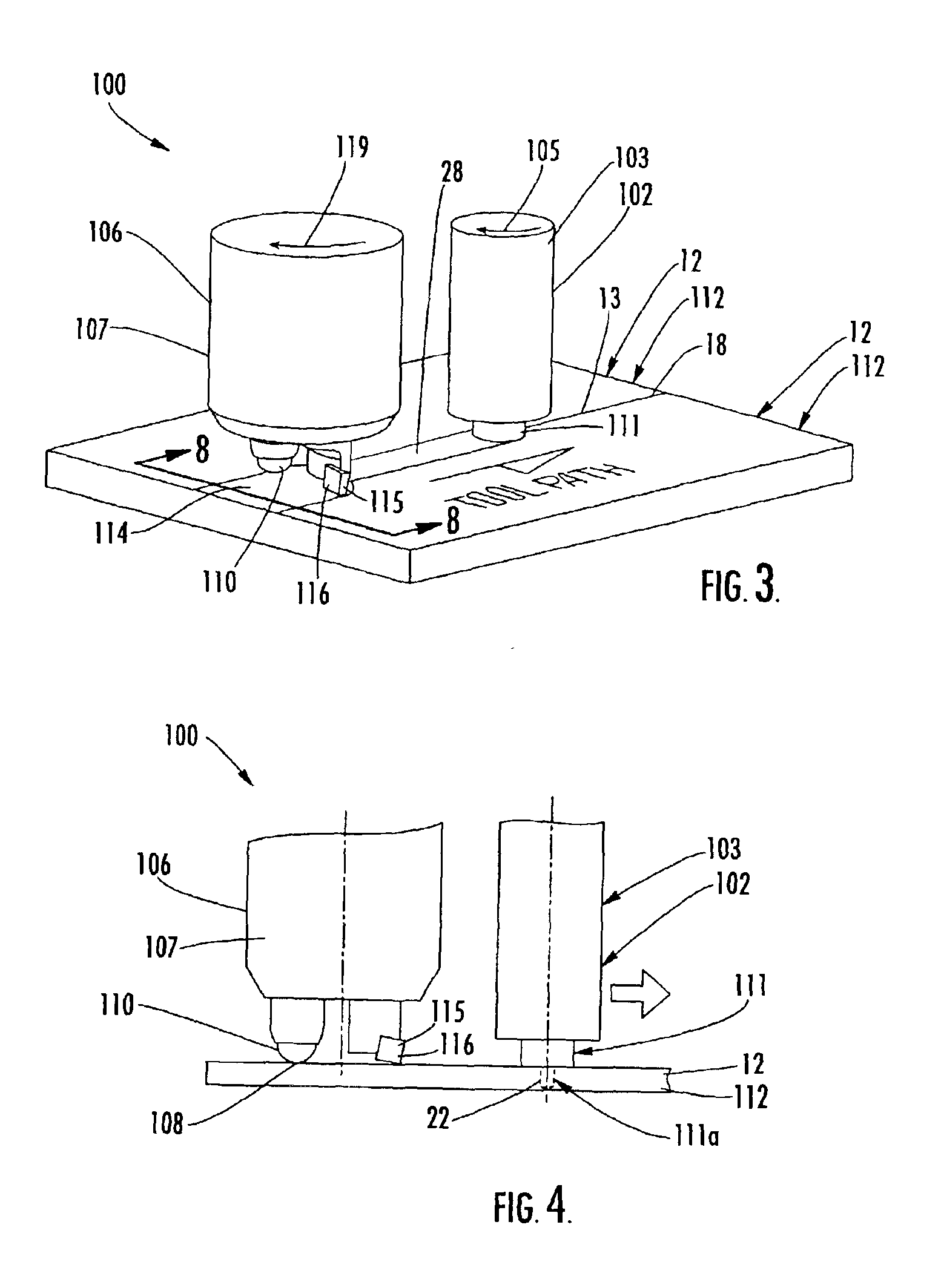

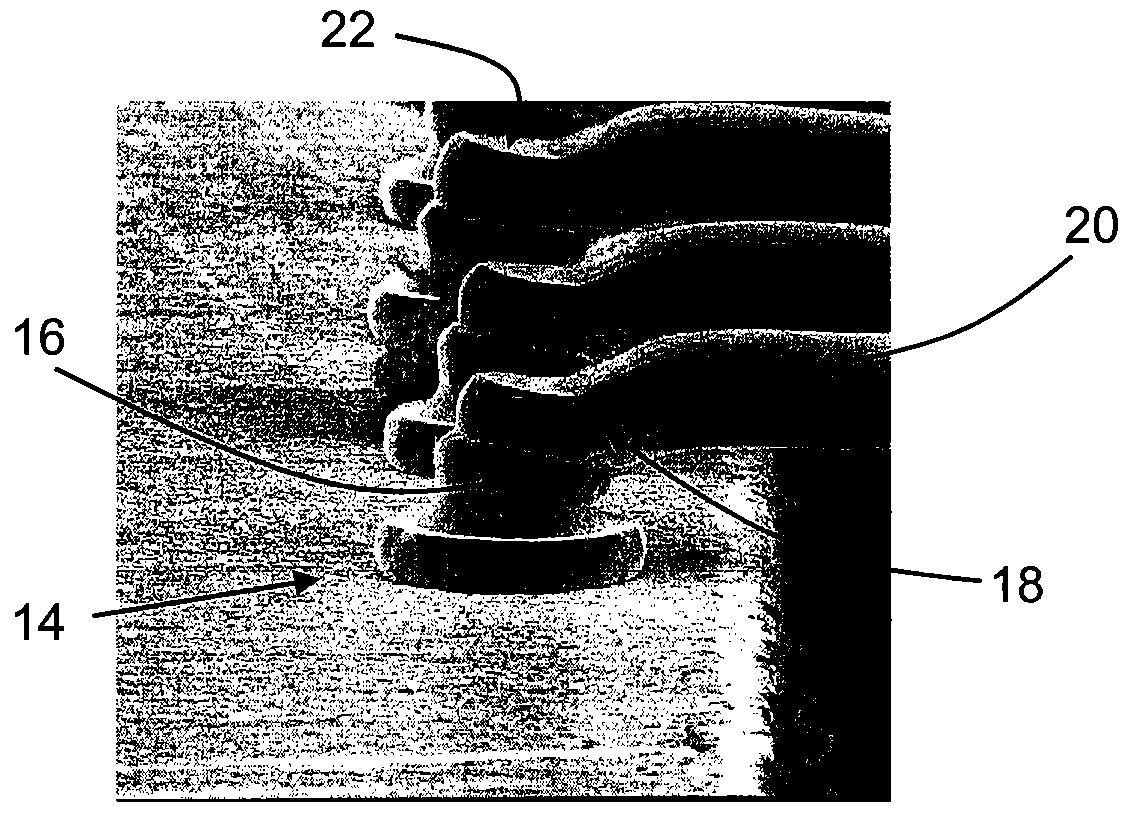

Apparatus and method for forming weld joints having compressive residual stress patterns

InactiveUS6926970B2Improve material propertiesHigh surface finishWelding/cutting auxillary devicesBurnishing machinesUltimate tensile strengthMechanical engineering

The welding apparatus and associated method are provided. The welding apparatus includes a welding tool for forming a weld joint along the surface of at least one workpiece. The welding apparatus also includes a compression tool for selectively inducing a layer of residual compressive stress in at least a portion of the surface of the weld joint and the surface of the at least one workpiece to thereby improve the material properties of the workpiece, including corrosion resistance and fatigue strength.

Owner:SURFACE TECH HLDG +1

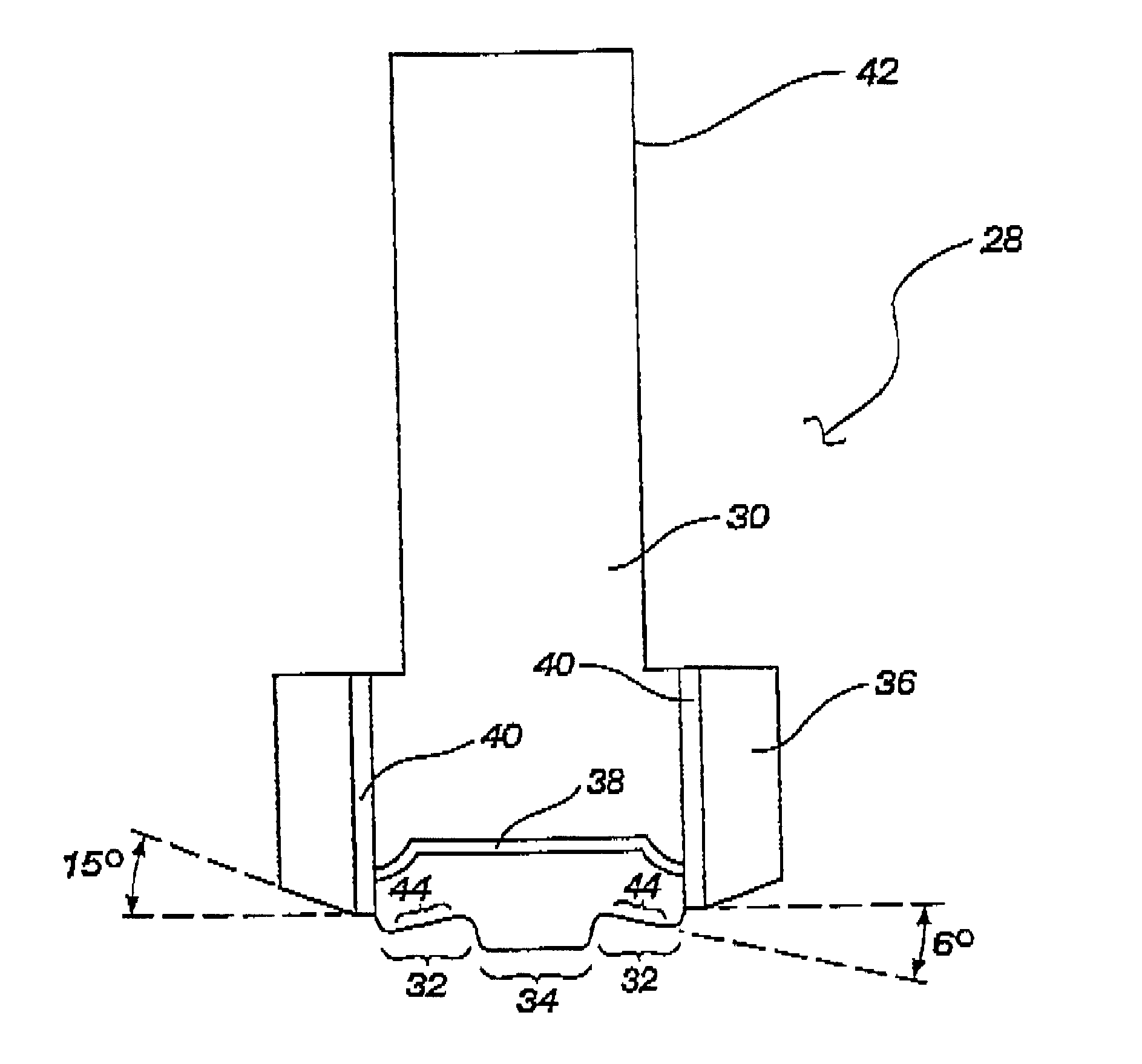

Method for filling insulated glass units with insulating gas

An apparatus and method for replacing air with an insulating gas during manufacture of an insulated glass article having two parallel panes and a peripheral spacer between the panes. The apparatus includes an upright first platen, a second platen confronting the first platen, a mechanism for moving at least one of the platens toward and away from the other platen, and a peripheral resilient seal positioned to define a sealed enclosure between the platens. The apparatus may further include a conveyer for conveying a partially assembled insulating glass article between the platens, an exhaust mechanism for drawing gas from the enclosure, and an intake mechanism for introducing insulating gas to the enclosure. One method of the invention involves filling such an insulated glass article and measuring the thickness of the article to detect bulging or cupping.

Owner:CARDINAL CG

Wire bonding method for forming low-loop profiles

ActiveUS7780064B2Reduce the overall heightAvoid disadvantagesCooking-vessel materialsSemiconductor/solid-state device detailsLead bondingEngineering

Owner:ASM TECH SINGAPORE PTE LTD

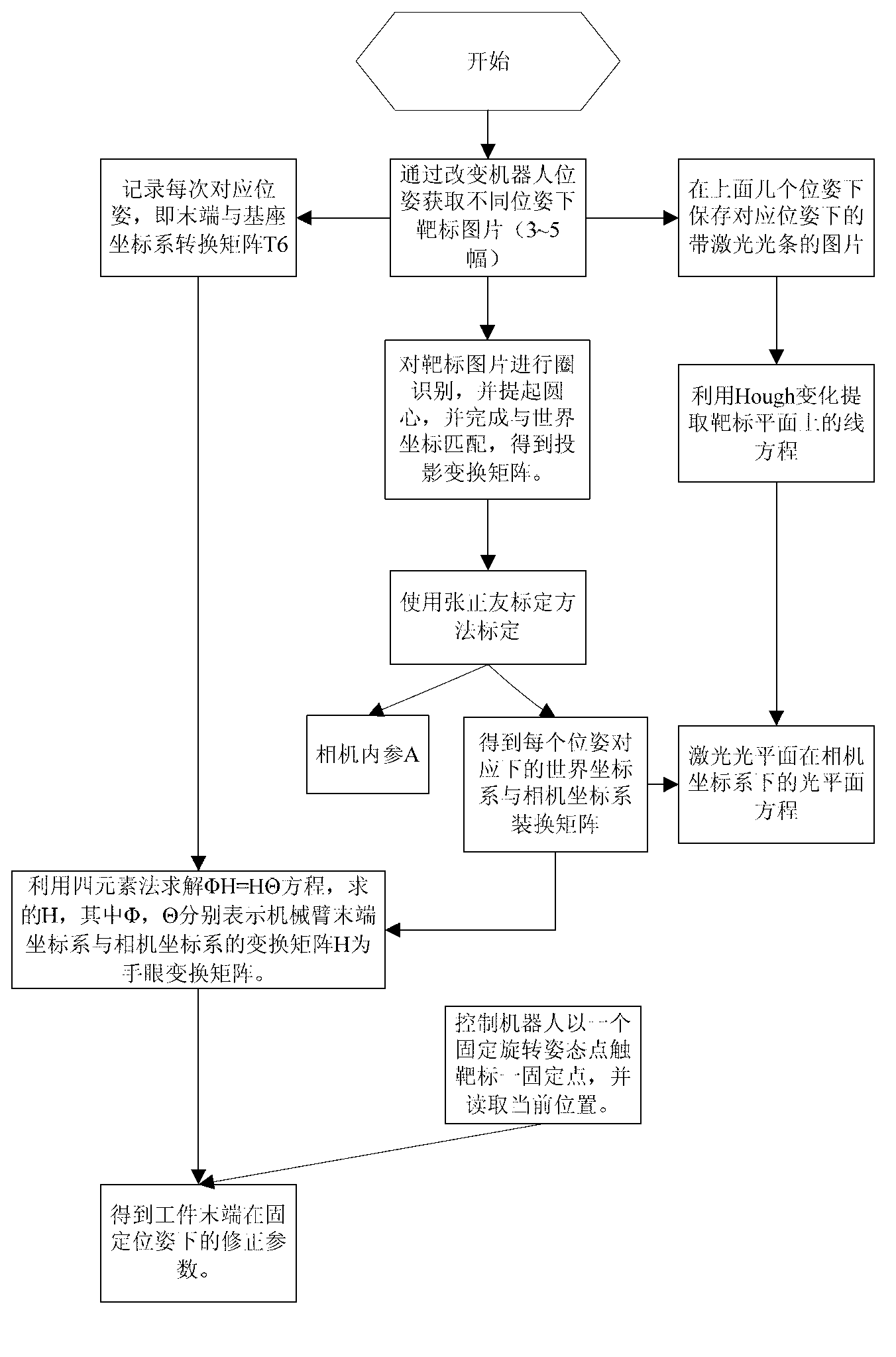

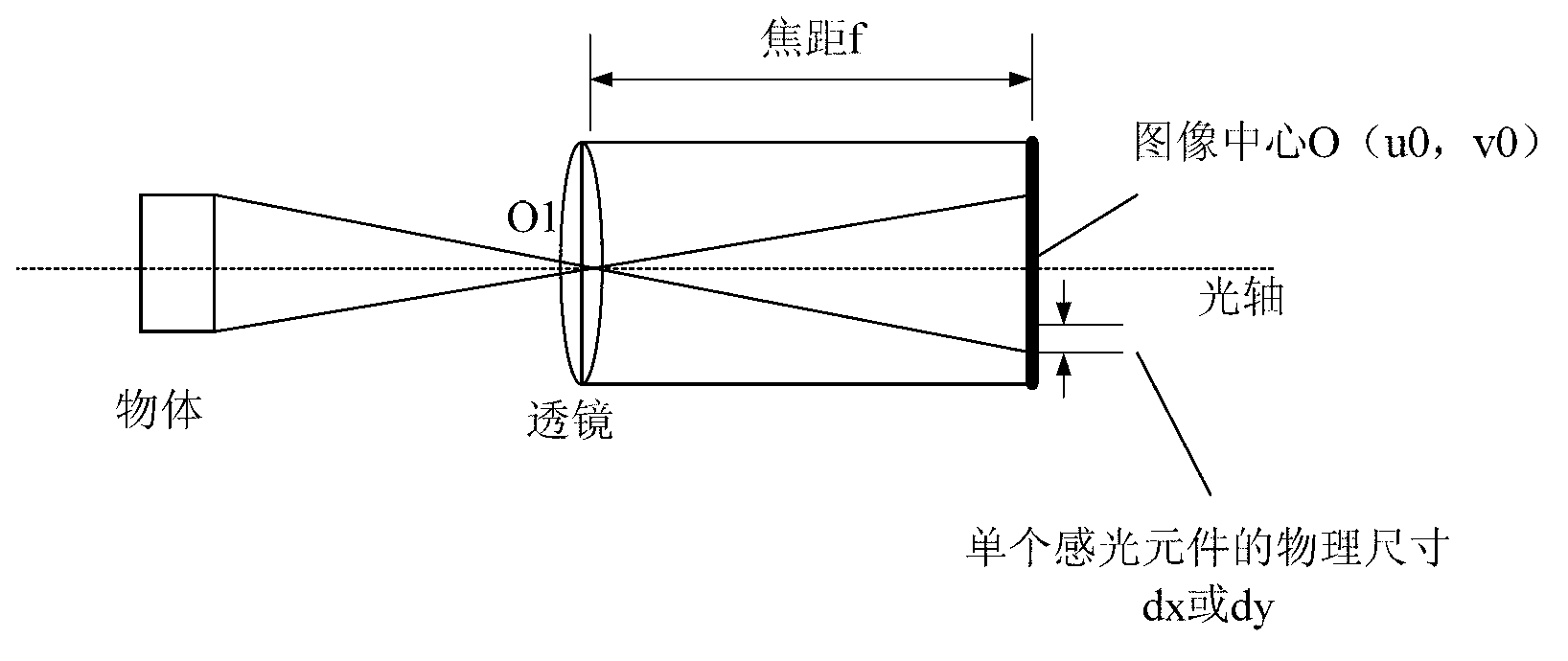

Systematic calibration method of welding robot guided by line structured light vision sensor

ActiveCN102794763AImprove tracking accuracyIncrease flexibilityProgramme-controlled manipulatorWelding/cutting auxillary devicesQuaternionEngineering

The invention relates to a systematic calibration method of a welding robot guided by a line structured light vision sensor, which comprises the following steps: firstly, controlling a mechanical arm to change pose, obtaining a round target image through a camera, accomplishing the matching of the round target image and a world coordinate, and then obtaining an internal parameter matrix and an external parameter matrix RT of the camera; secondly, solving a line equation of a line laser bar by Hough transformation, and using the external parameter matrix RT obtained in the first step to obtain a plane equation of the plane of the line laser bar under a coordinate system of the camera; thirdly, calculating to obtain a transformation matrix of a tail end coordinate system of the mechanical arm and a base coordinate system of the mechanical arm by utilizing a quaternion method; and fourthly, calculating a coordinate value of a tail end point of a welding workpiece under the coordinate of the mechanical arm, and then calculating an offset value of the workpiece in the pose combined with the pose of the mechanical arm. The systematic calibration method of the welding robot guided by the line structured light vision sensor is flexible, simple and fast, and is high in precision and generality, good in stability and timeliness and small in calculation amount.

Owner:JIANGNAN UNIV +1

Composite structural element fabricating device and method

ActiveUS20070029038A1Easy to produceAdhesive processes with surface pretreatmentWelding/cutting auxillary devicesEngineeringMechanical engineering

To fabricate a composite item, a device places a composite ply on a curved form at about 0° relative to a longitudinal axis of the form. The form includes a web surface and a cap surface. The device includes a web compaction roller and a set of guides. The web compaction roller compacts a composite material upon the web surface and generate a web ply. The set of guide rollers urges against the cap surface. The compaction roller is directed along the form by the guide rollers.

Owner:THE BOEING CO

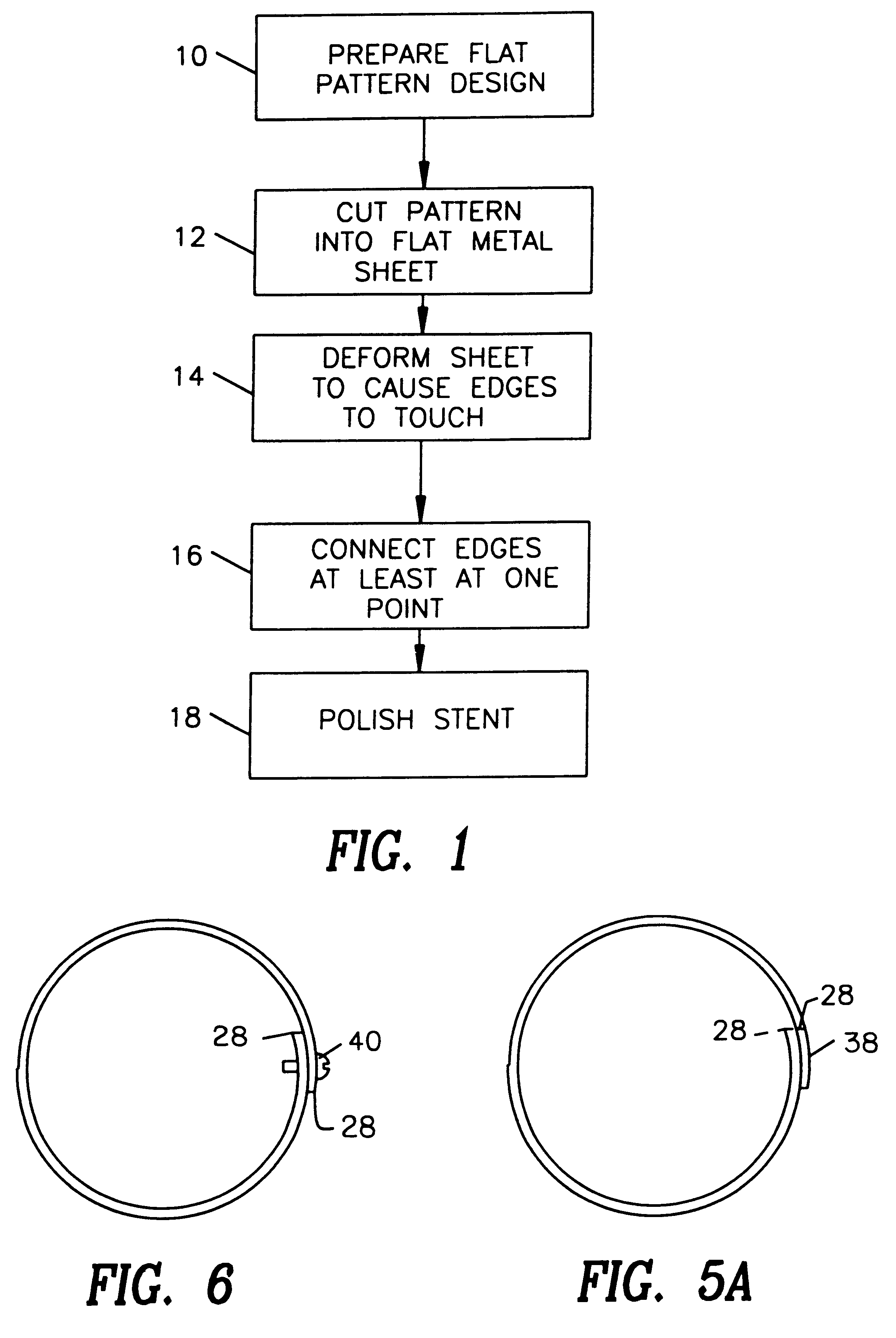

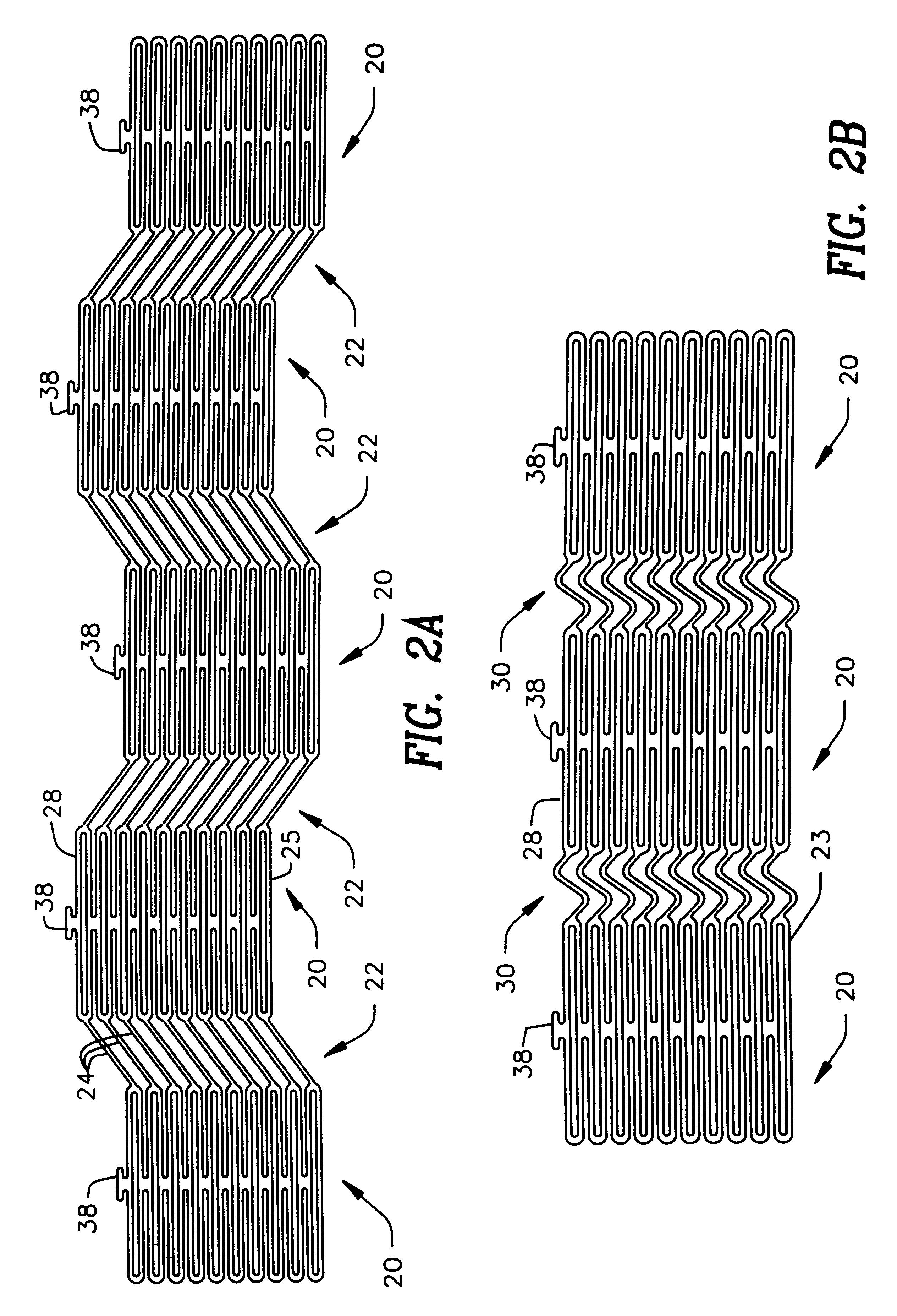

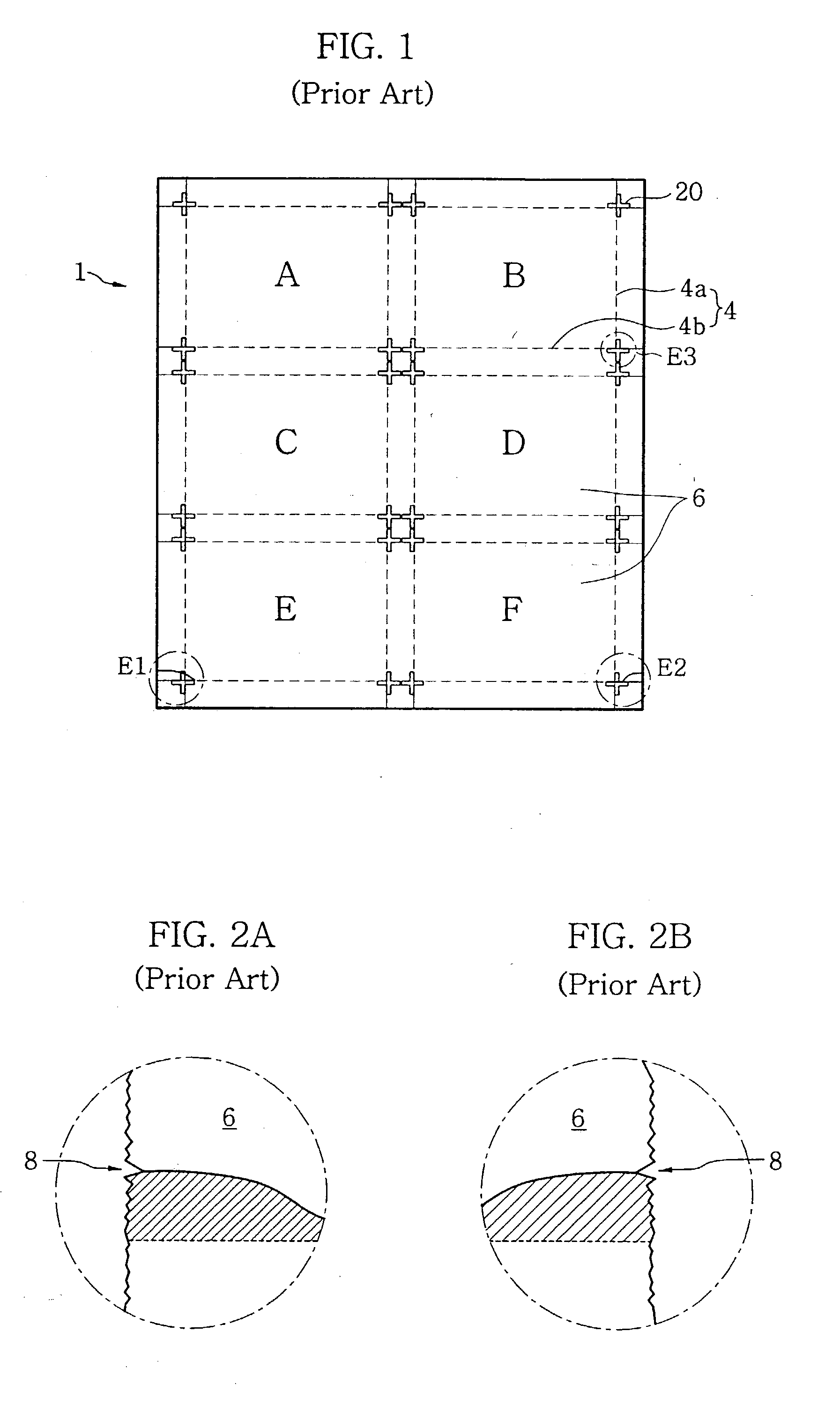

Stent

A stent and a method for fabricating the stent are disclosed. The stent has an originally flat pattern and connection points where the sides of the flat pattern are joined. The method includes the steps of a) cutting a stent pattern into a flat piece of metal thereby to produce a metal pattern, b) deforming the metal pattern so as to cause two opposing sides to meet, and c) joining the two opposing sides at least at one point. Substantially no portion of the stent projects into the lumen of the stent when the stent is expanded against the internal wall of a blood vessel.

Owner:MEDINOL LTD

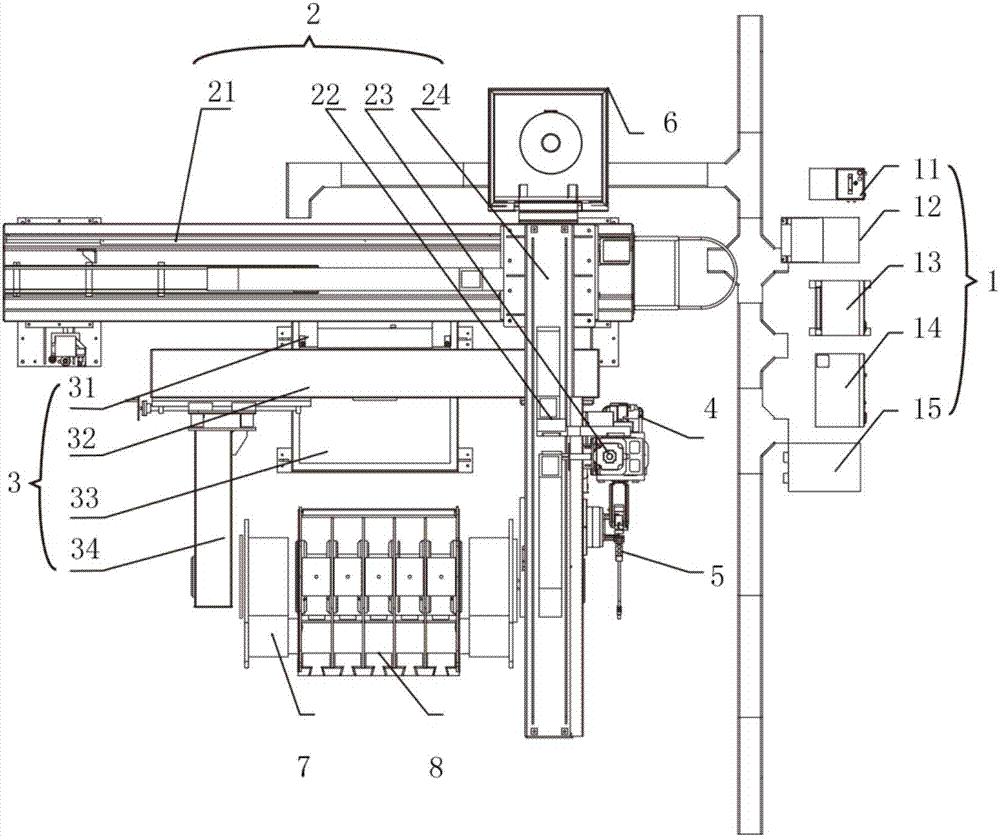

Welding robot device for welding of plunger pump power end shell

PendingCN107234358AGuarantee quality and efficiencyGuaranteed welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesFillet weldControl system

The invention provides a welding robot device for welding of a plunger pump power end shell. The welding robot device for welding of the plunger pump power end shell comprises a controlling system, a portal frame X-Y-Z coordinate system, a welding system, a space positioner and a tool clamp. The tool clamp is used for clamping the plunger pump power end shell, and a plunger pump shell can be one-time clamped; all welding joints of the plunger pump shell can be positionally changed to a flat welding position or a flat fillet welding position through the space positioner; a welding mechanical arm is connected with a coordinate Z-axis in the portal frame X-Y-Z coordinate system, and welding of welding joints in the different positions can be finished; and synchronized driving of the welding mechanical arm, a coordinate X-axis, a coordinate Y-axis, the coordinate Z-axis and the space positioner can be realized, so that continuity during the welding process is guaranteed, and welding quality and welding efficiency are ensured.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

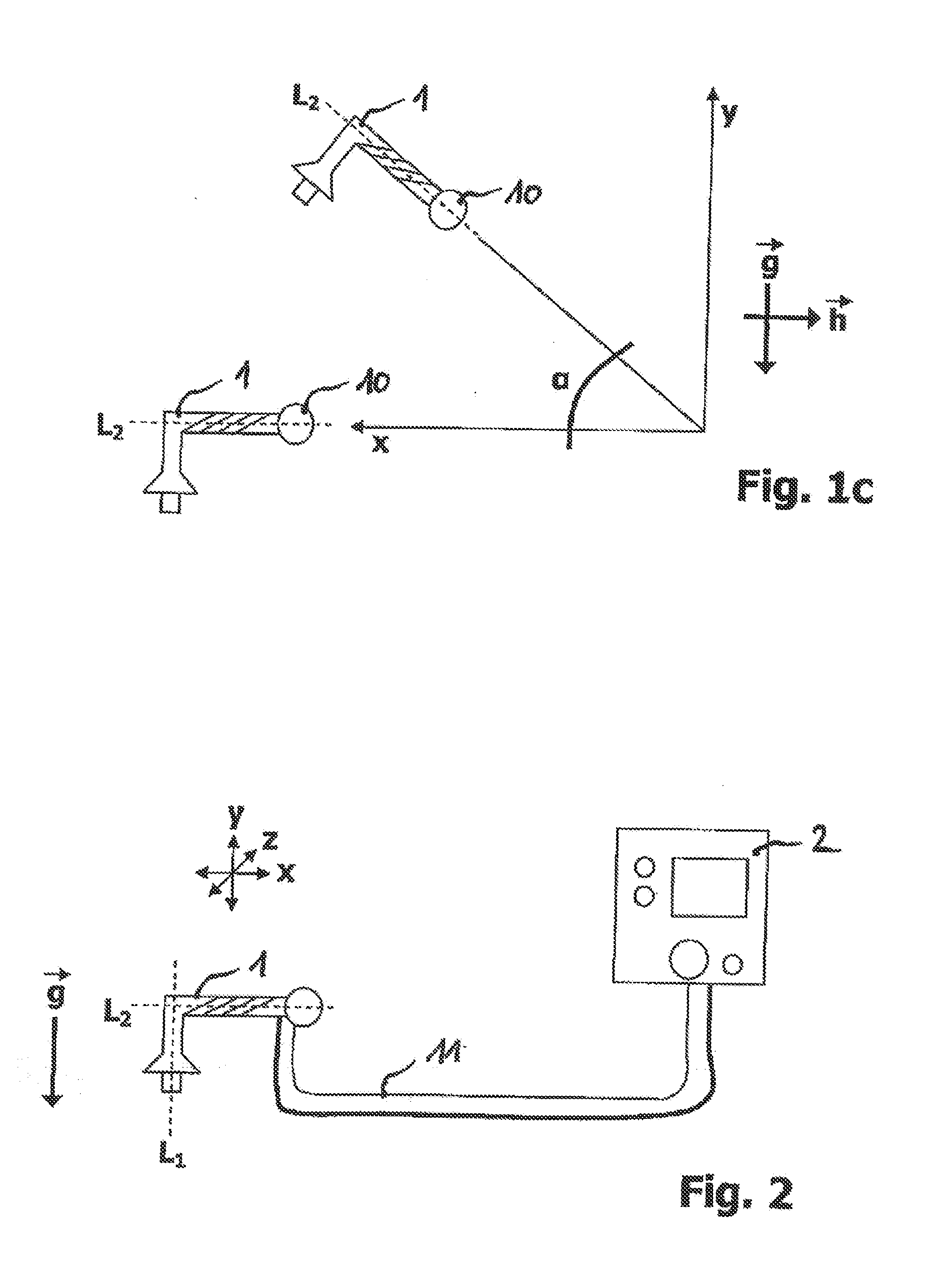

Method for determining a position change of a tool and the tool and the tool control unit

InactiveUS20130081293A1Increase flexibilityFlexibilityAutomatic control devicesWelding/cutting auxillary devicesEngineeringControl unit

A method for determining a position change of a handheld tool in space includes: alignment of an initial tool position with a reference position to determine at least a first position vector of the tool, at least one component of the first position vector being determined by measurement of a component of the gravitational acceleration in the direction of a predetermined axis of the tool;establishing a modification of the tool position during an actual position change by determining at least one angular discrepancy of a second position vector of at least one temporally preceding position vector, at least one component of the second position vector being determined after the position change by measuring the component of the gravitational acceleration in the direction of the predetermined axis of the tool; and providing information relating to the orientation of the tool established from the at least one angular discrepancy.

Owner:DRITTE PATENTPORTFOLIO BET GMBH & CO KG

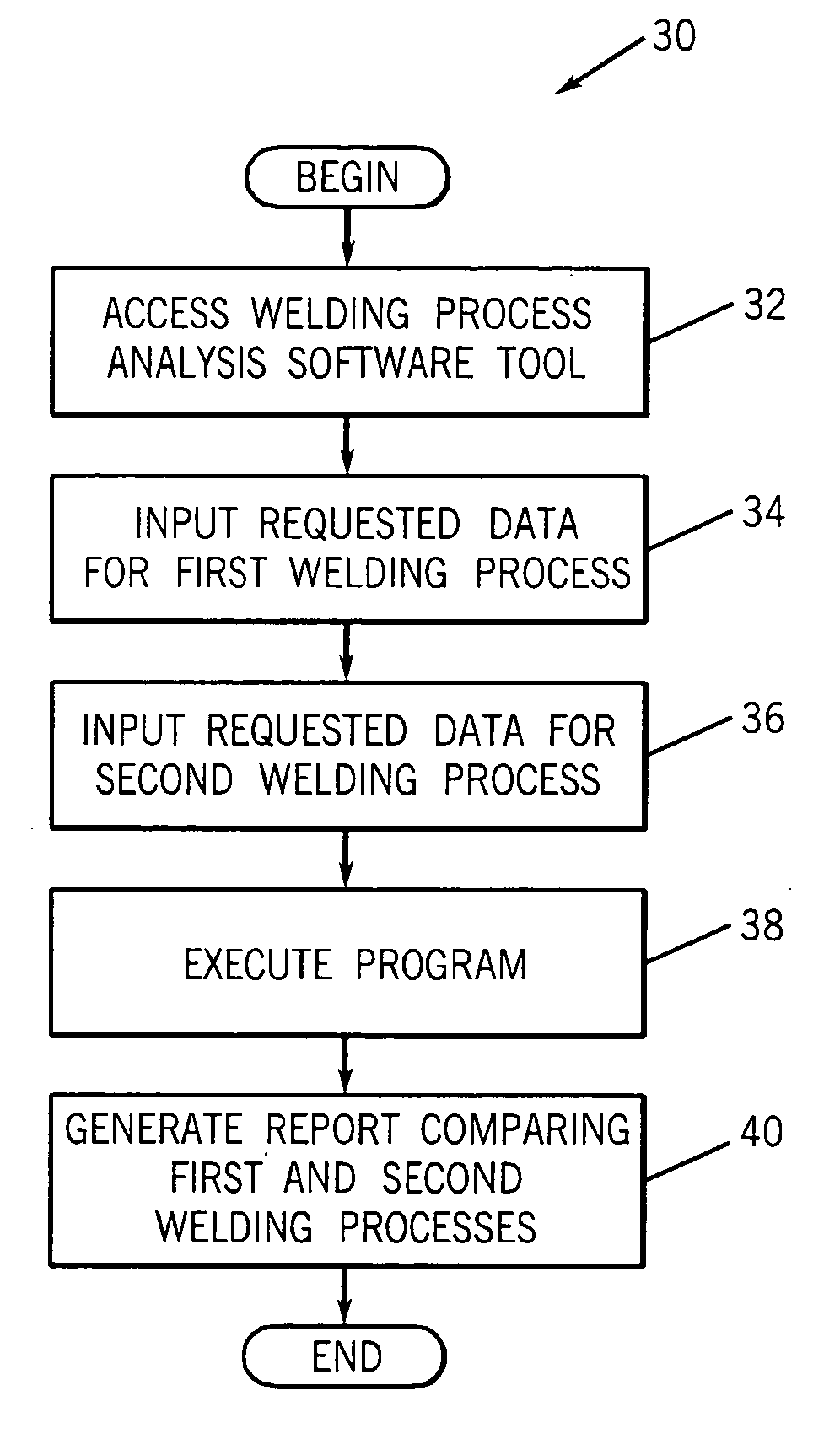

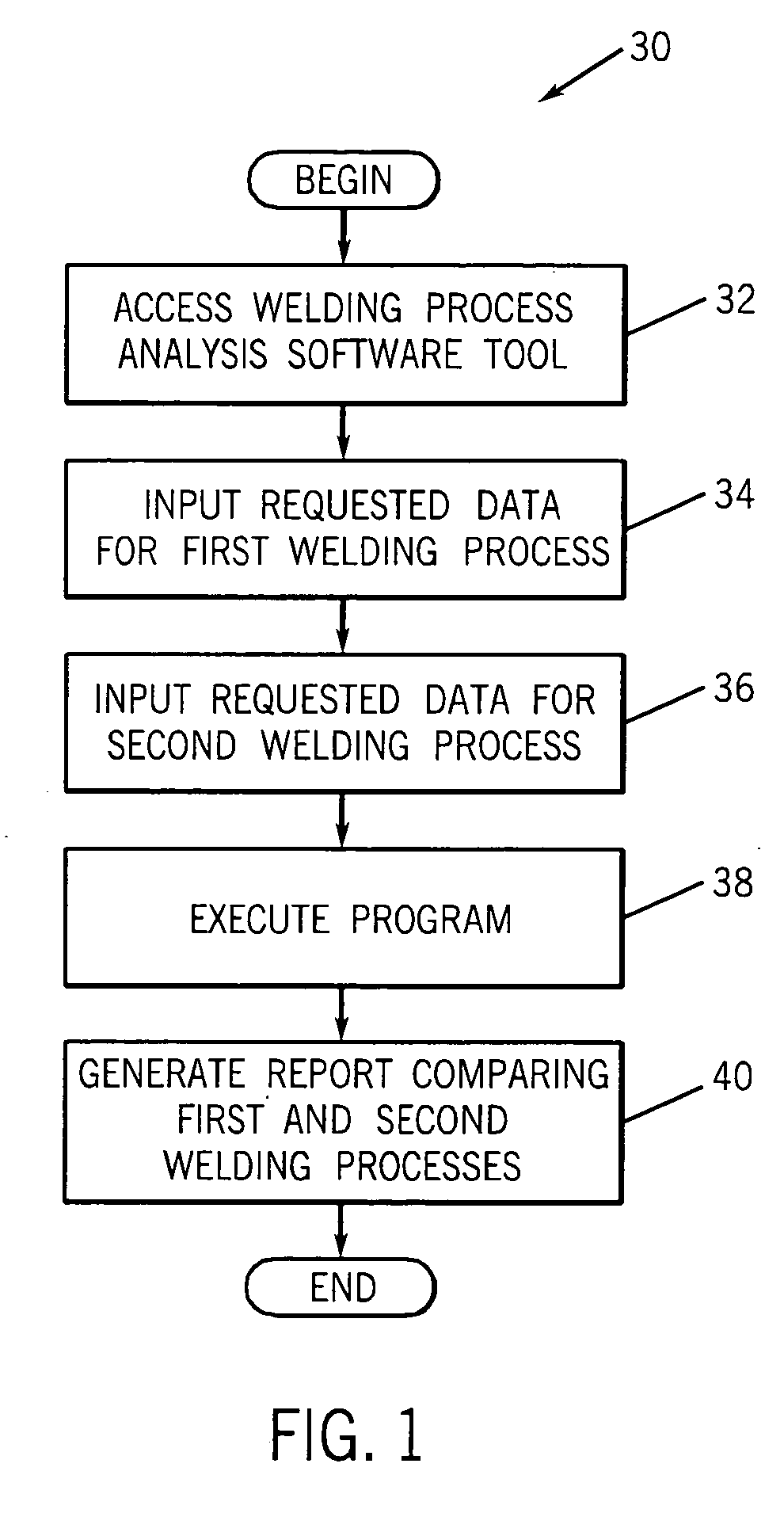

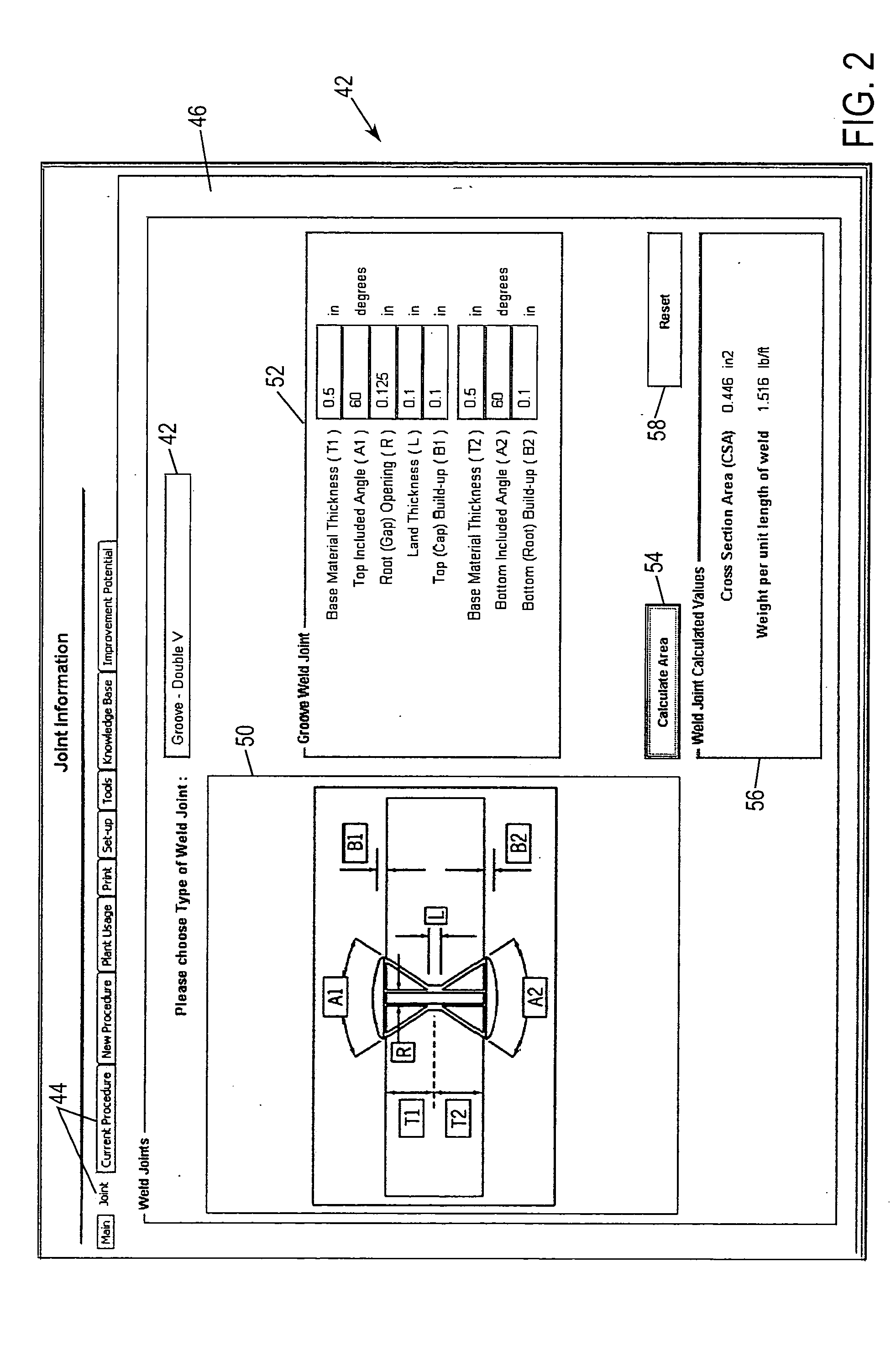

System and method for processing welding data

ActiveUS7194447B2Welding/cutting auxillary devicesDigital computer detailsCycle timeIndustrial engineering

A system and method for evaluating the use of a welding process for welding a weld joint. The method comprises providing a user with requests for data to enable a processor-based system to establish various attributes of welding a specific weld joint using a specific welding process. The various attributes may include the cost of welding the weld joint using the welding process. The various attributes may include the cycle time for welding the weld joint using the welding process. The system comprises a program operable to direct the processor-based system to request data from a user and to process the requested data received from the user to enable a processor-based system to establish various attributes of welding a specific weld joint using a specific welding process.

Owner:HOBART BROS

Laser cutting apparatus and method

The present invention disclose a laser cutter for cutting an object being cut such as a two glasses-attached panel for LCD using a laser beam. The laser cutter includes a laser unit for irradiating a laser beam with a specific wavelength along a marked cutting line of the object, a pre-scriber for forming a pre-cut groove at starting edge of the marked cutting line, and a cooling unit for cooling the cutting line which said laser beam has been irradiated.

Owner:SAMSUNG DISPLAY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com